Patents

Literature

1190 results about "Short cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A short period cycles is a cycle length shorter than 21 days. If you can seem to go for 21 days without having a period, then you may have a shortened menstruation cycle. It is widely believed that a normal cycle is 28 day long.

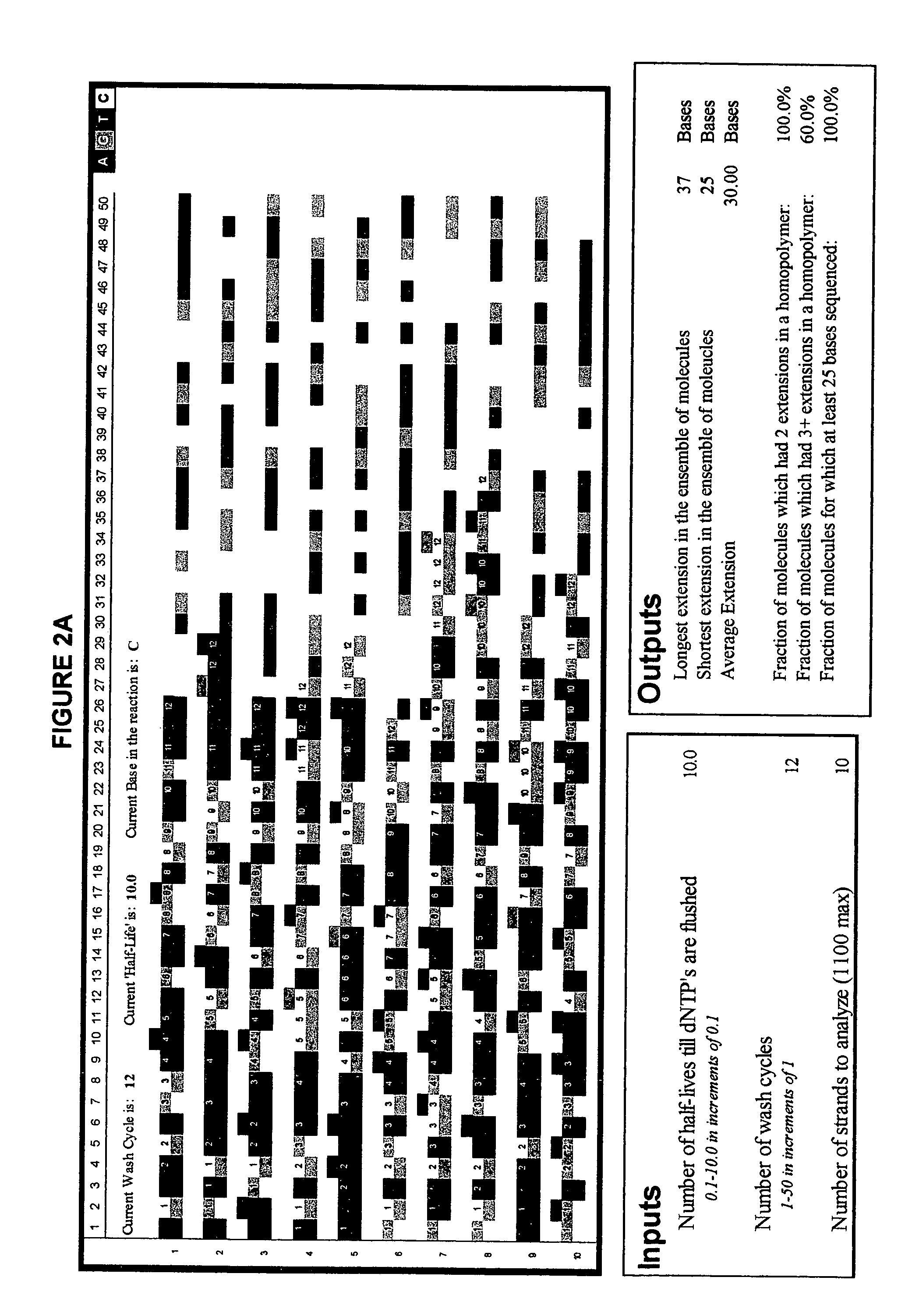

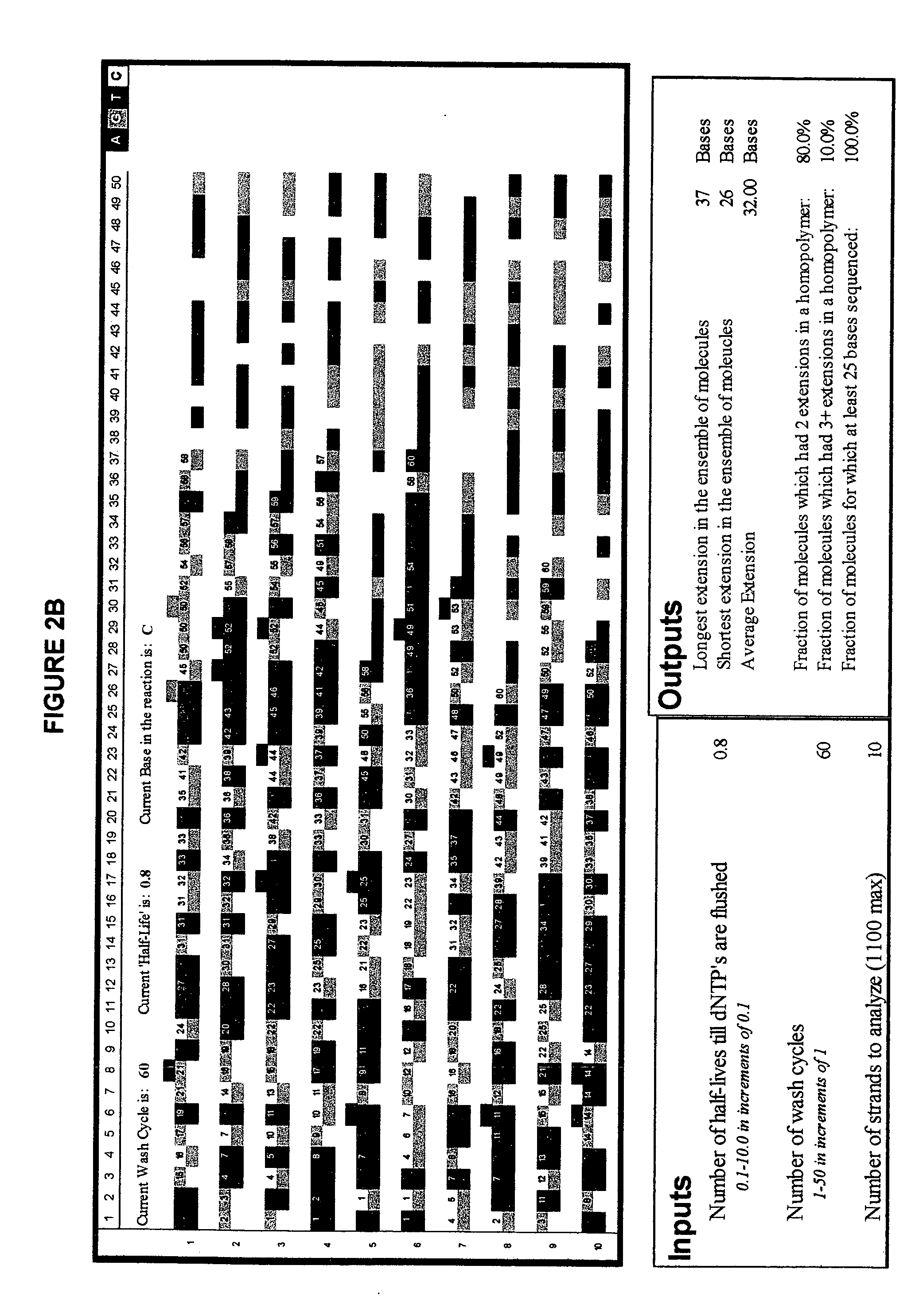

Short cycle methods for sequencing polynucleotides

InactiveUS7169560B2Increase resolution and reliabilityHigh throughput single molecule sequencingSugar derivativesMicrobiological testing/measurementPolynucleotideComputational biology

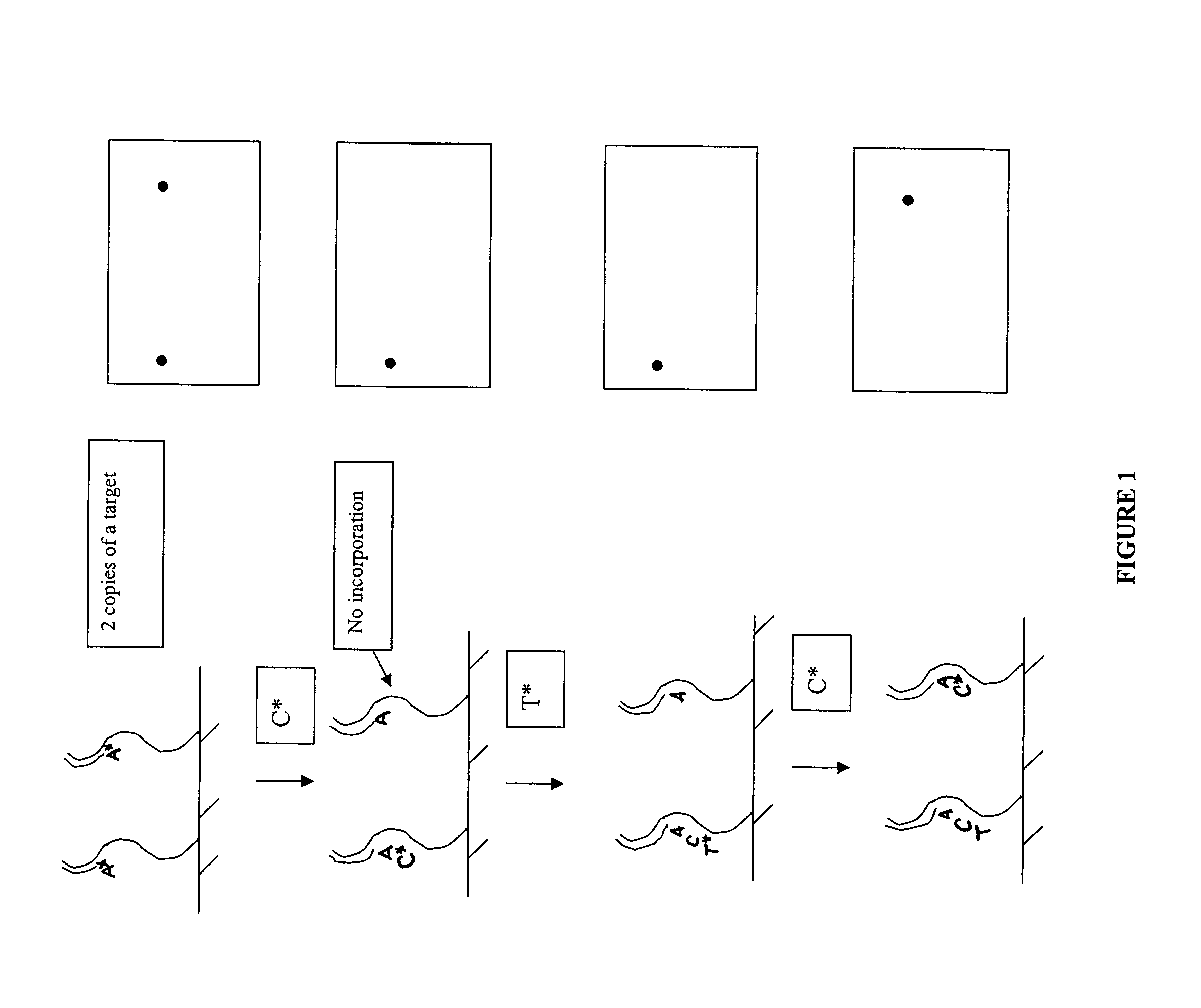

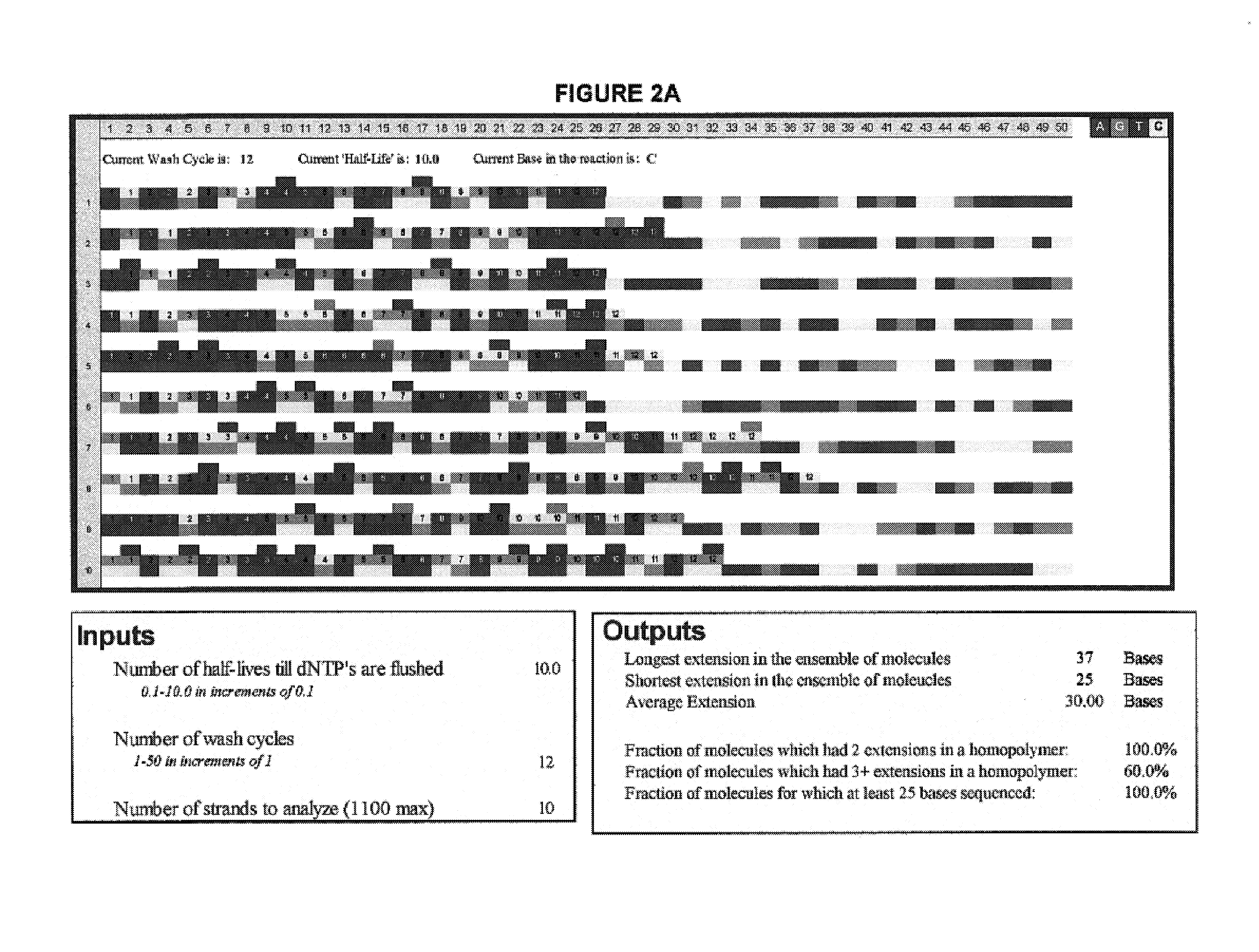

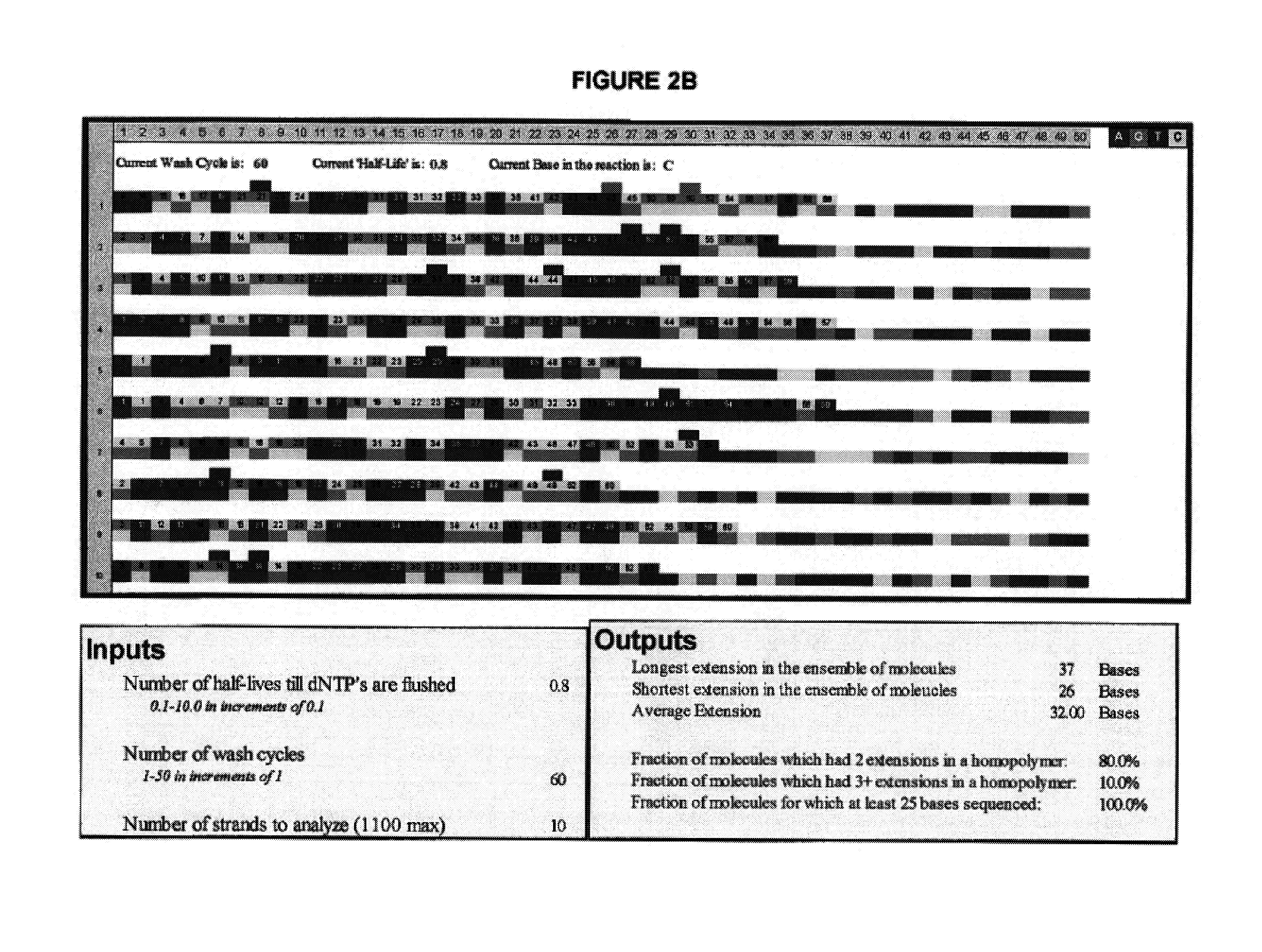

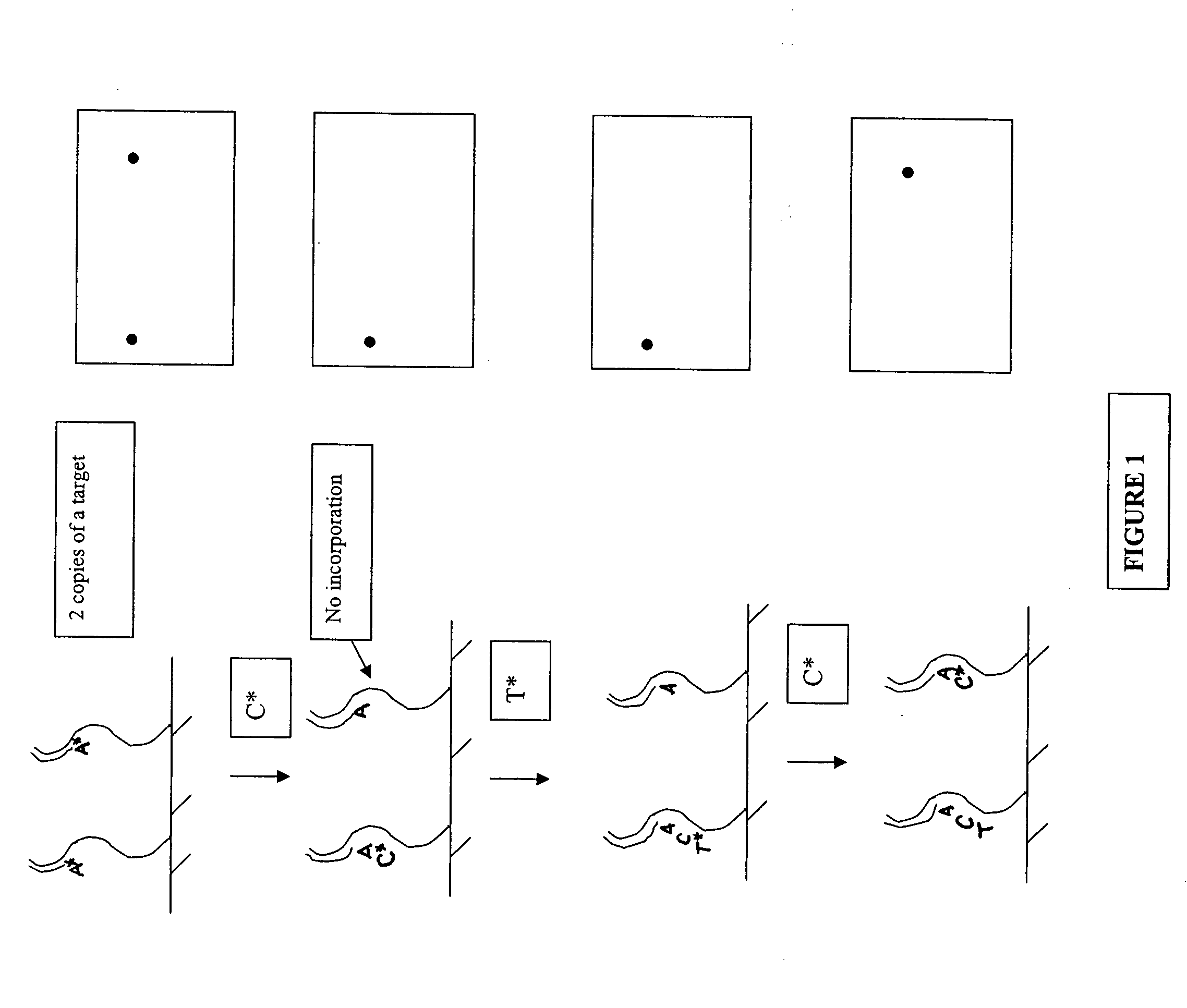

The invention provides methods for sequencing a polynucleotide comprising stopping an extension cycle in a sequence by synthesis reaction before the reaction has run to near or full completion.

Owner:FLUIDIGM CORP

Short cycle methods for sequencing polynucleotides

InactiveUS20050100932A1High throughput single molecule sequencingImprove resolutionSugar derivativesMicrobiological testing/measurementPolynucleotideComputational biology

The invention provides methods for sequencing a polynucleotide comprising stopping an extension cycle in a sequence by synthesis reaction before the reaction has run to near or full completion.

Owner:FLUIDIGM CORP

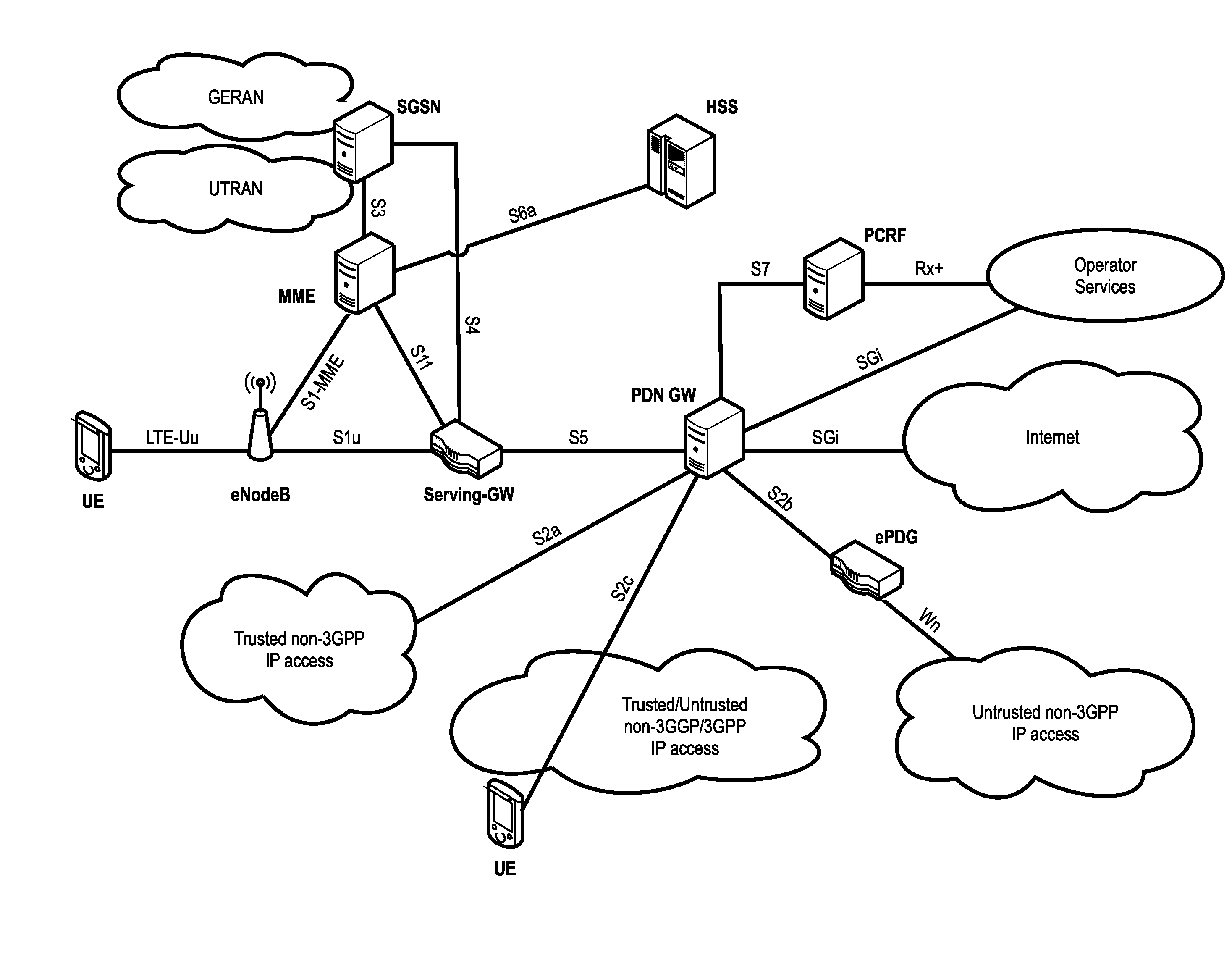

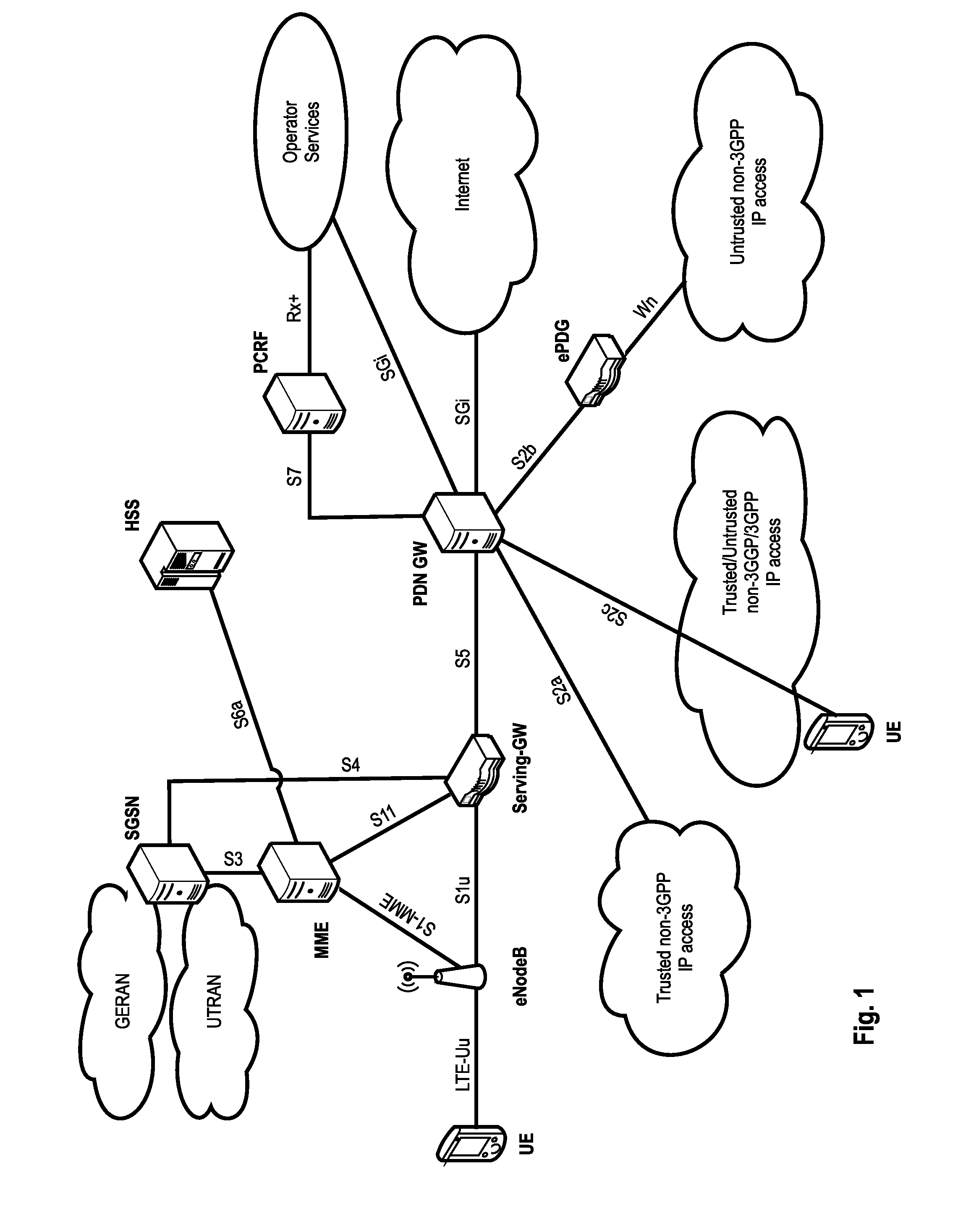

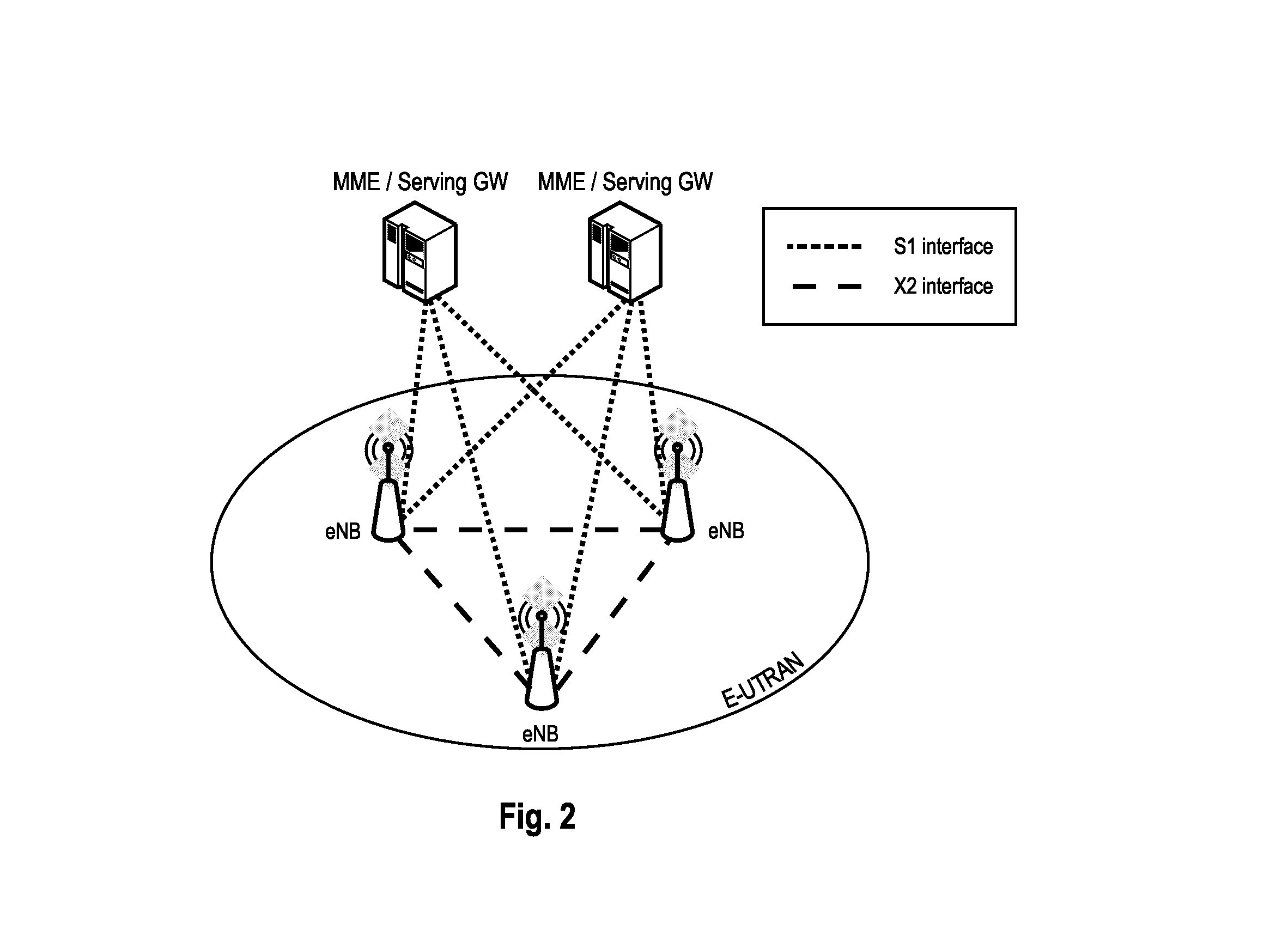

Discontinuous reception operation with additional wake-up opportunities

ActiveUS20150003311A1Short response timeMinimal impactPower managementTransmission systemsLongest cycleShort length

The invention relates to methods for improving the DRX operation of a UE by introducing an additional DRX wake-up cycle, which runs in parallel to the short and / or long DRX cycle. The DRX wake-up cycle defines time intervals after which the UE starts monitoring the PDCCH for a wake-up duration of time; the UE does not perform any other operation during the wake-up duration apart from monitoring the PDCCH. The time intervals of the wake-up cycle between the wake-up durations are preferably shorter than the one of the DRX long cycle, and may have the same or a shorter length than the ones of the DRX short cycle. The wake-up duration may be as long as the on-duration of the DRX short / long cycle, or may be preferably much shorter, such as only one or a few subframes.

Owner:APPLE INC

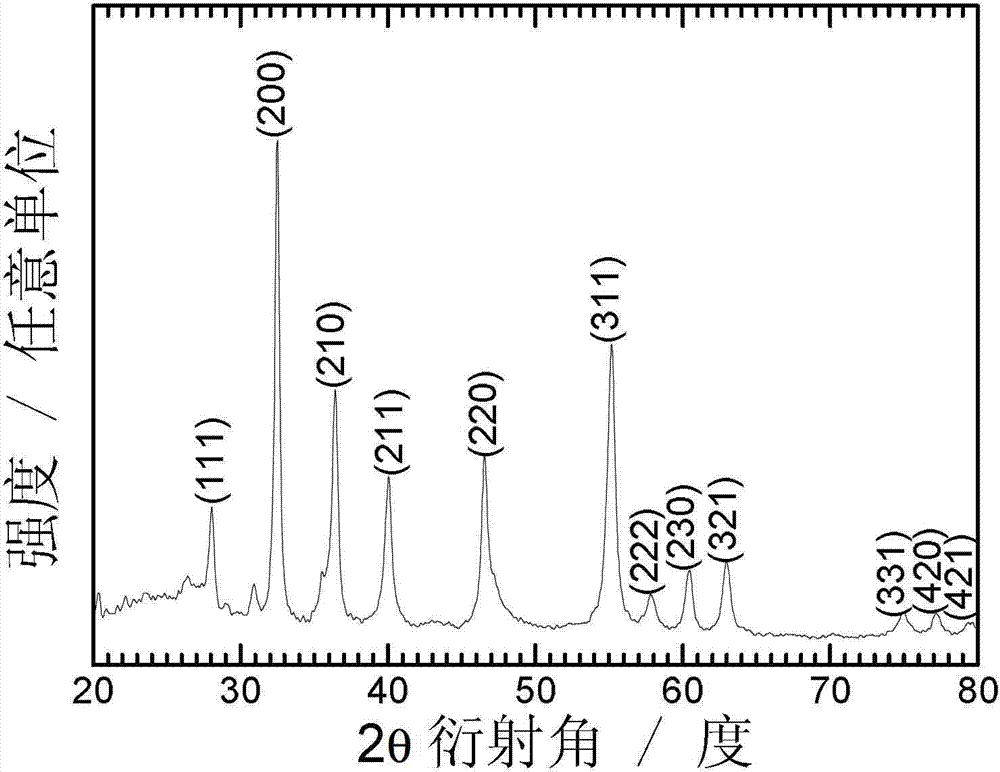

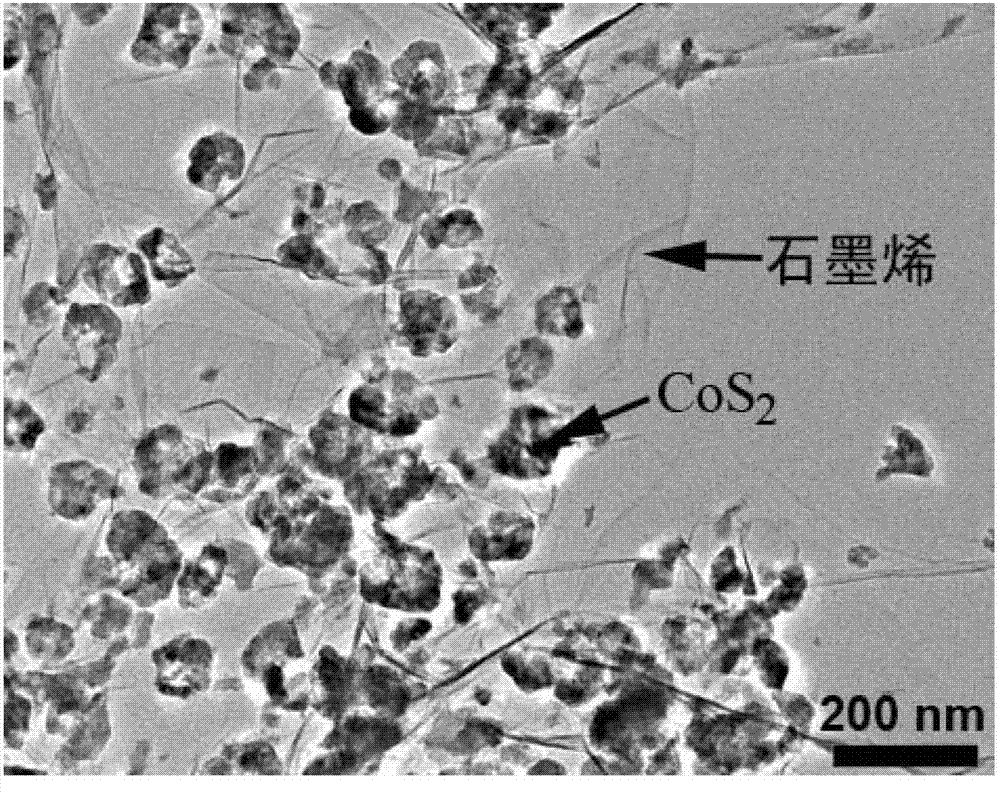

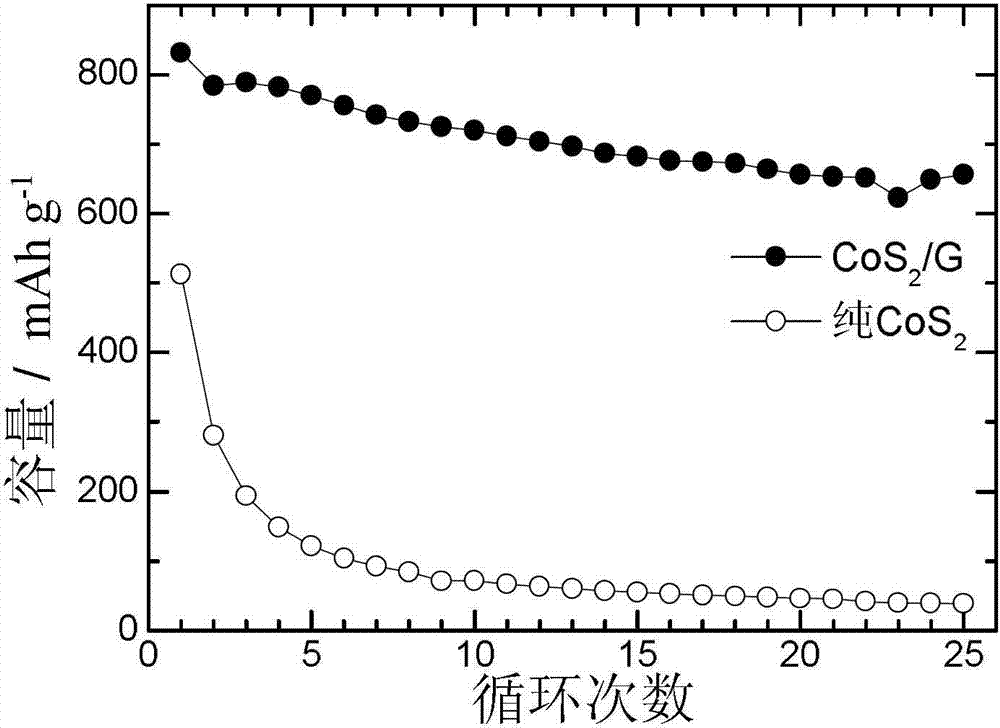

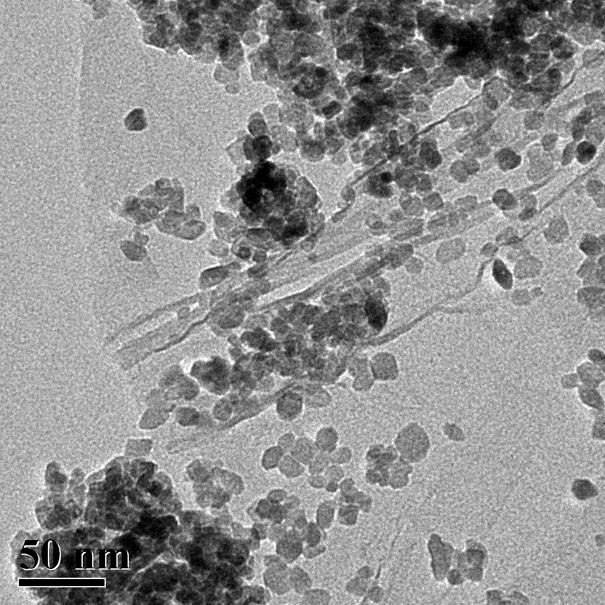

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

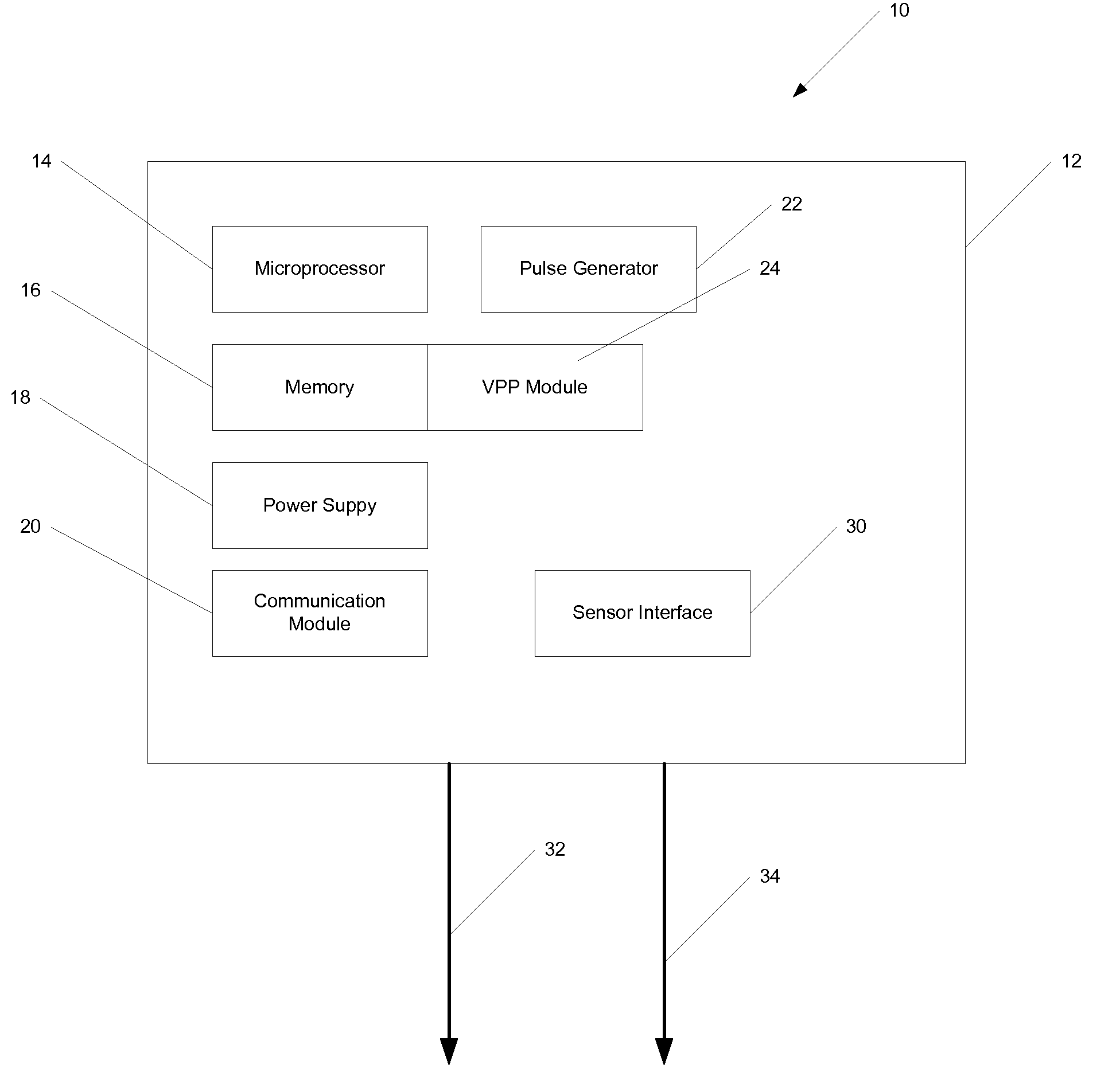

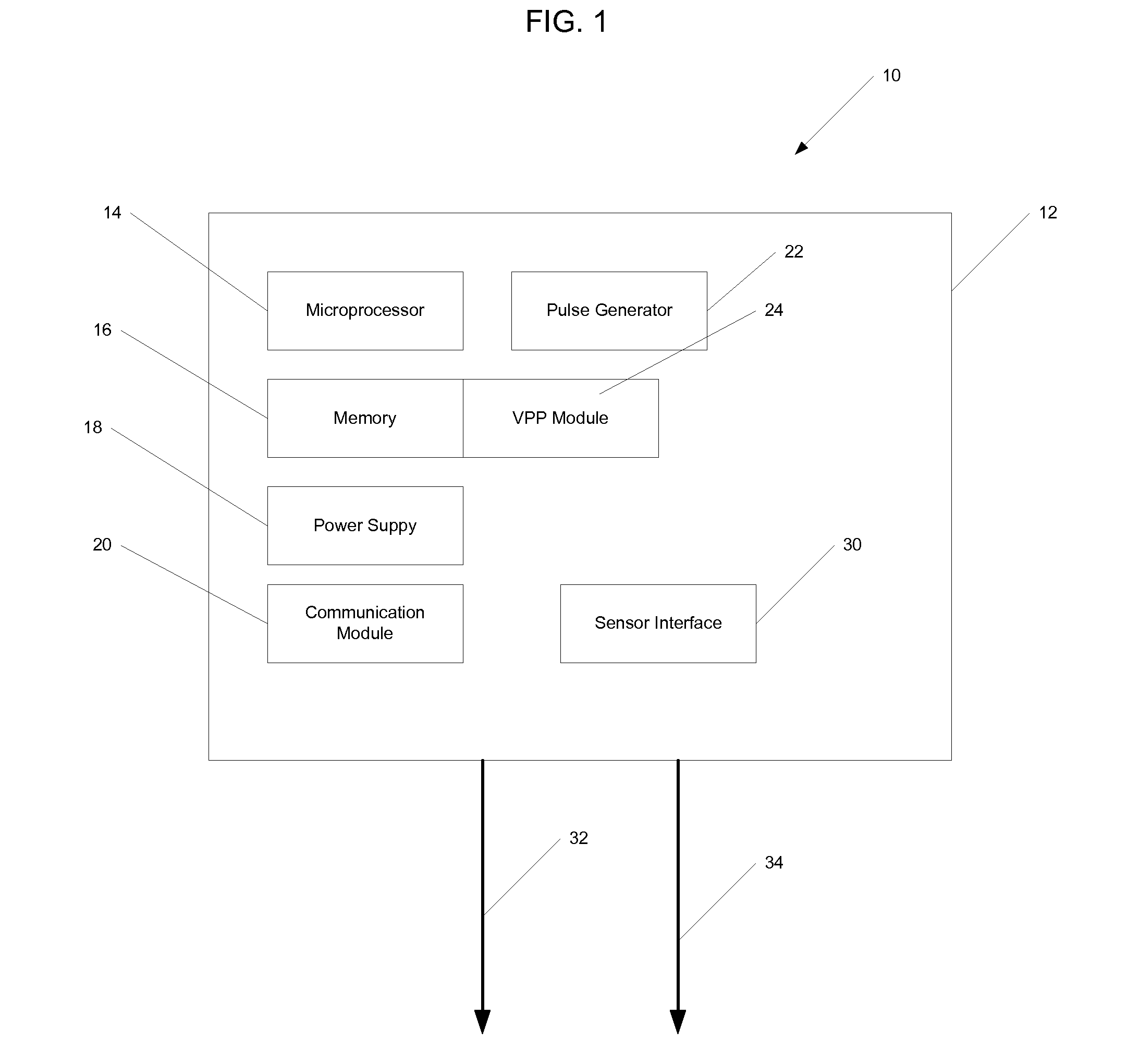

System and Method for Promoting Intrinsic Conduction Through Atrial Timing

An atrial based pacing protocol promotes intrinsic conduction. An entire cardiac cycle is monitored for ventricular activity and permitted to lapse with ventricular activity. Ventricular pacing is available in a cardiac cycle immediately subsequent to such a skipped beat. When monitoring for intrinsic ventricular events, an event is expected within a given window. If no such event is detected, the cardiac cycle in truncated, leading to a shorter cycle that is devoid of ventricular activity. The subsequent cycle has a high likelihood of a ventricular sensed event and a greater than normal AV interval is provided prior to pacing.

Owner:MEDTRONIC INC

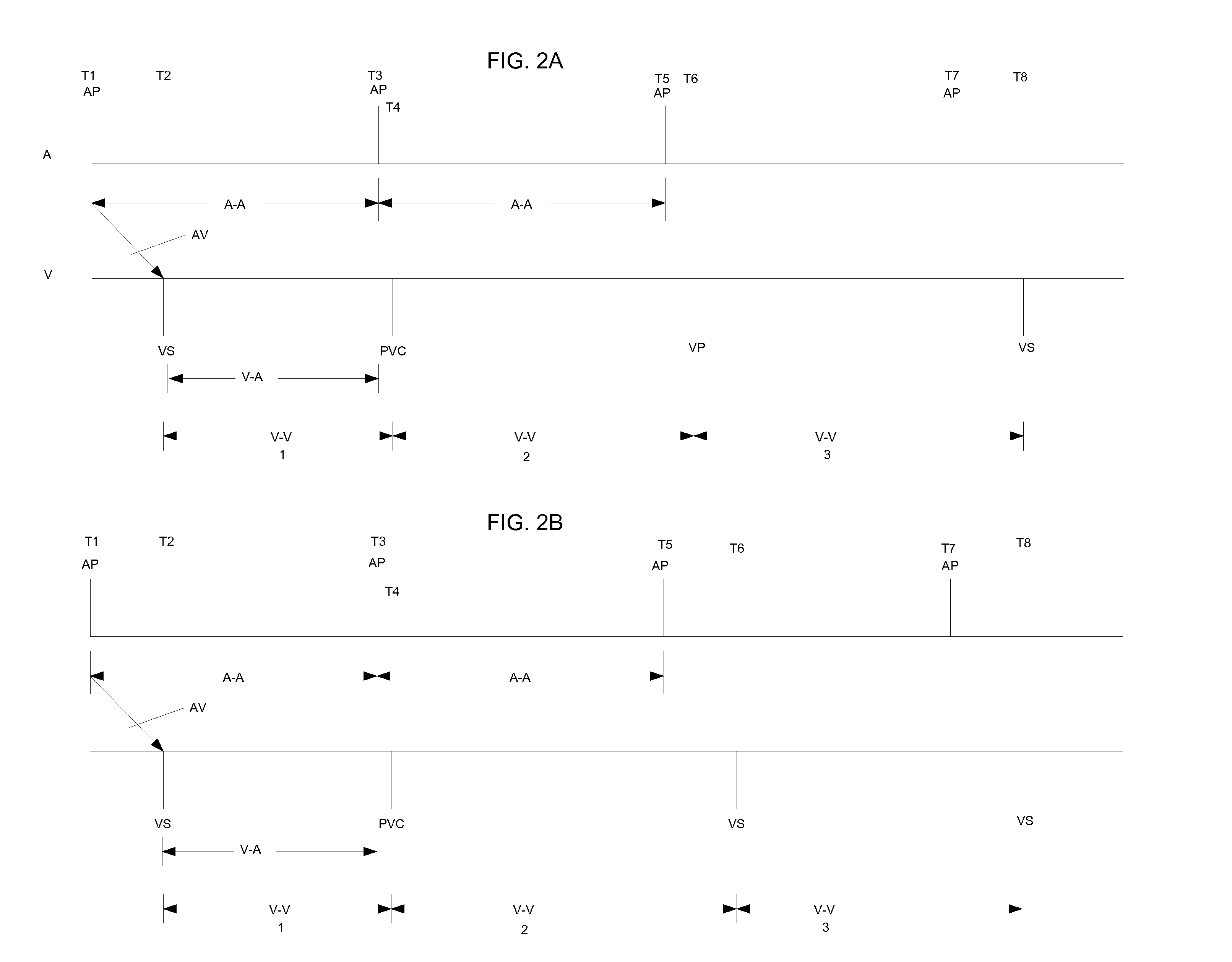

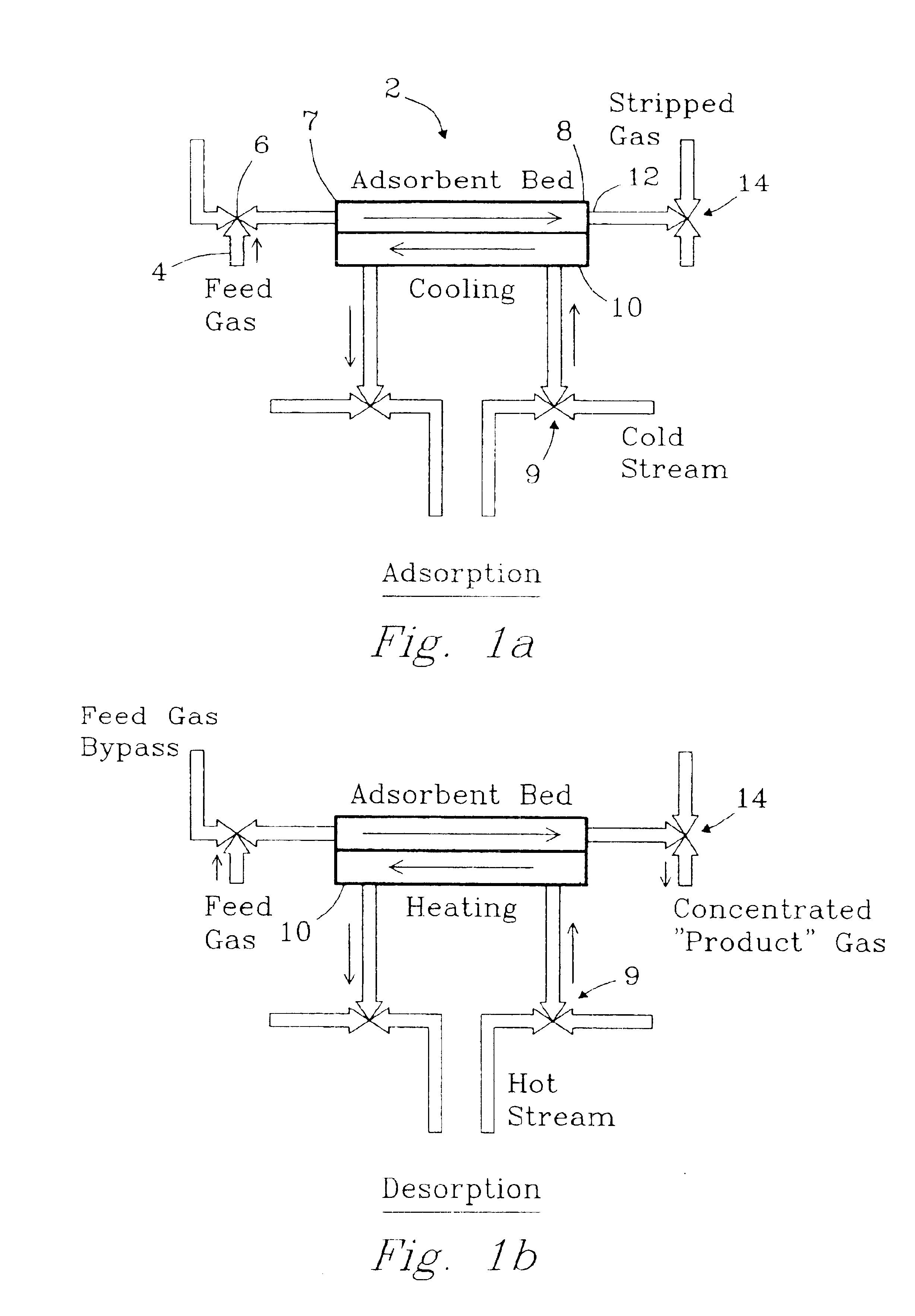

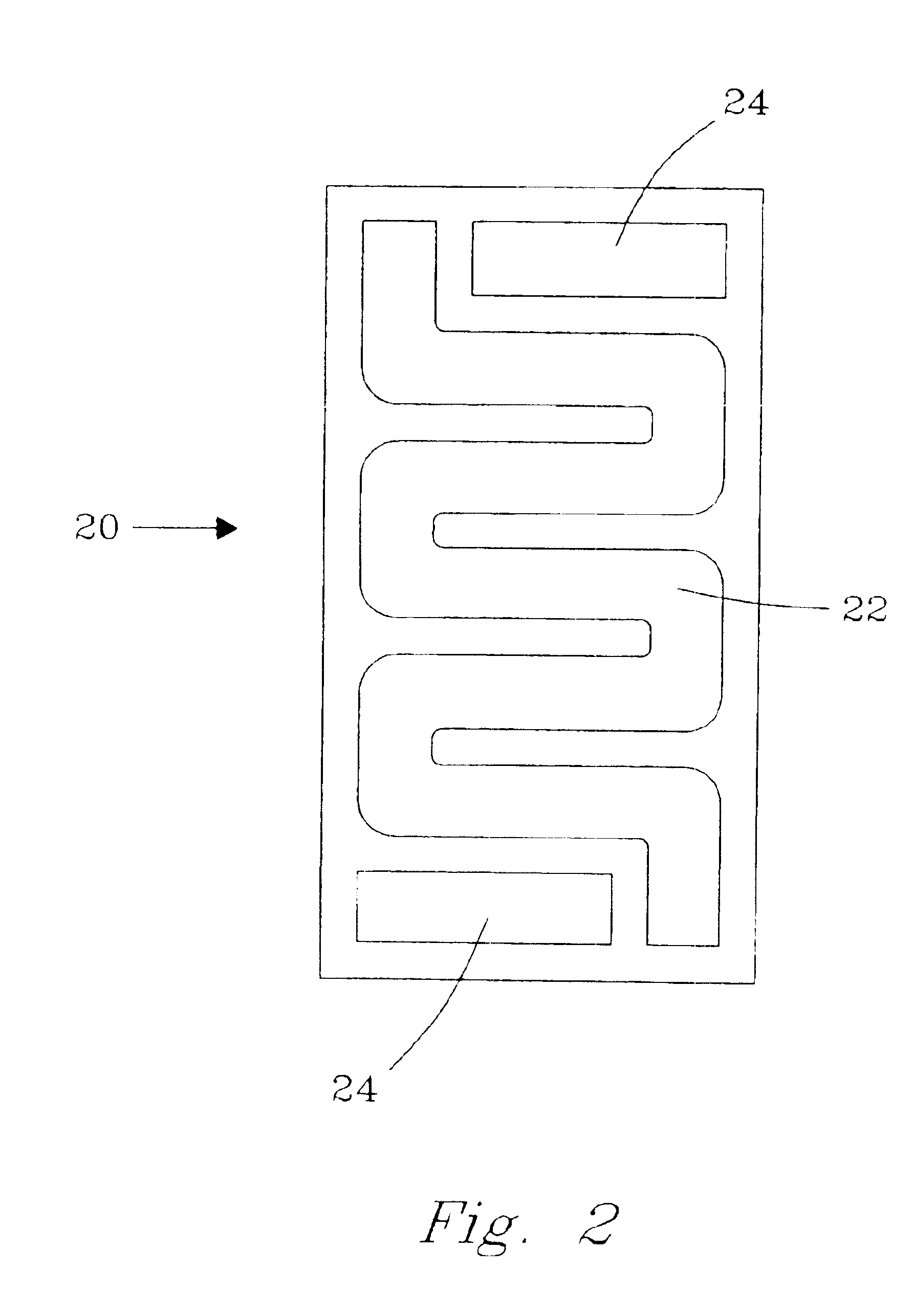

Apparatus for thermal swing adsorption and thermally-enhanced pressure swing adsorption

The present invention provides compact adsorption systems that are capable of rapid temperature swings and rapid cycling. Novel methods of thermal swing adsorption and thermally-enhanced pressure swing adsorption are also described. In some aspects of the invention, a gas is passed through the adsorbent thus allowing heat exchangers to be very close to all portions of the adsorbent and utilize less space. In another aspect, the adsorption media is selectively heated, thus reducing energy costs. Methods and systems for gas adsorption / desorption having improved energy efficiency with capability of short cycle times are also described. Advantages of the invention include the ability to use (typically) 30-100 times less adsorbent compared to conventional systems.

Owner:BATTELLE MEMORIAL INST

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

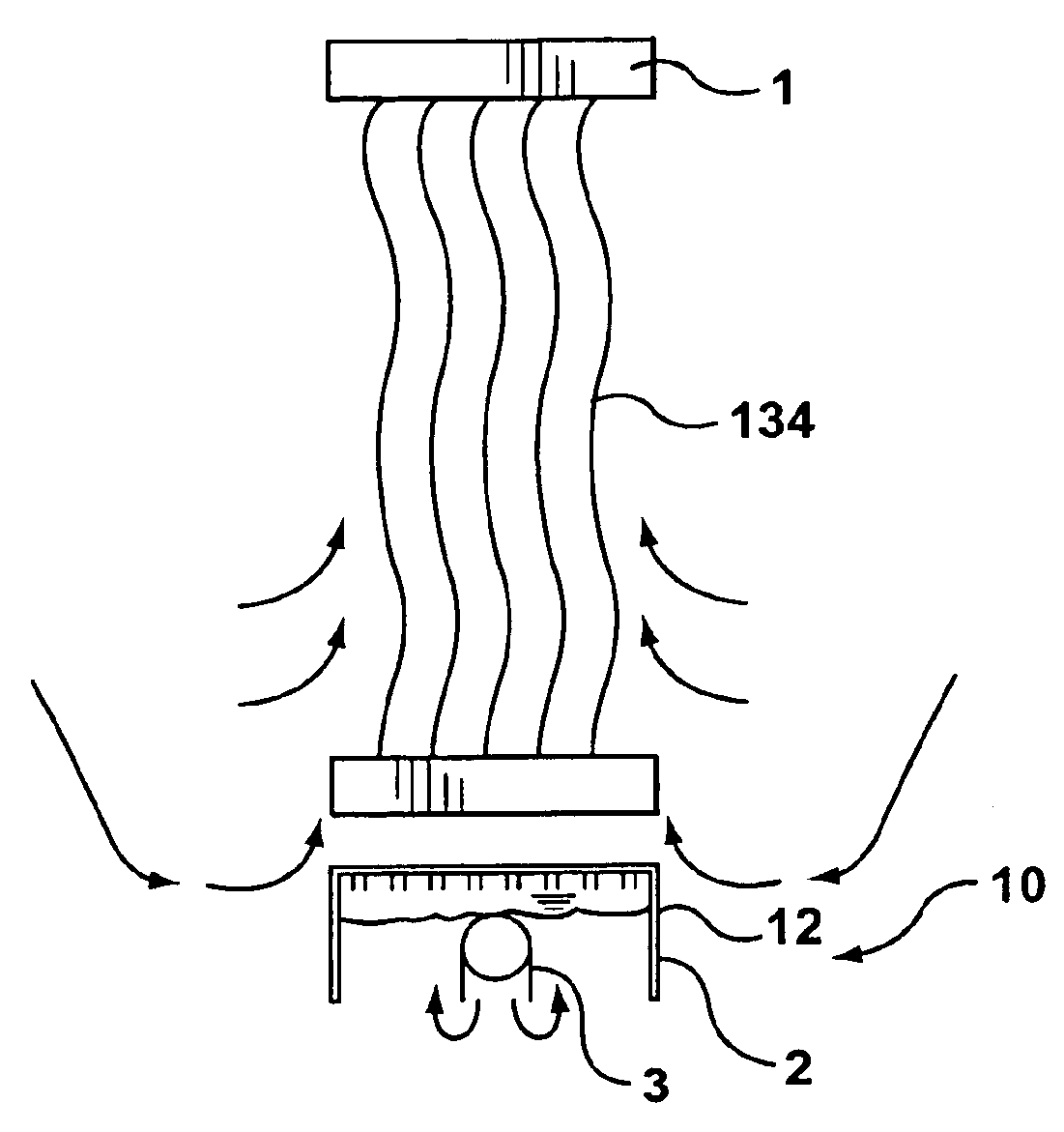

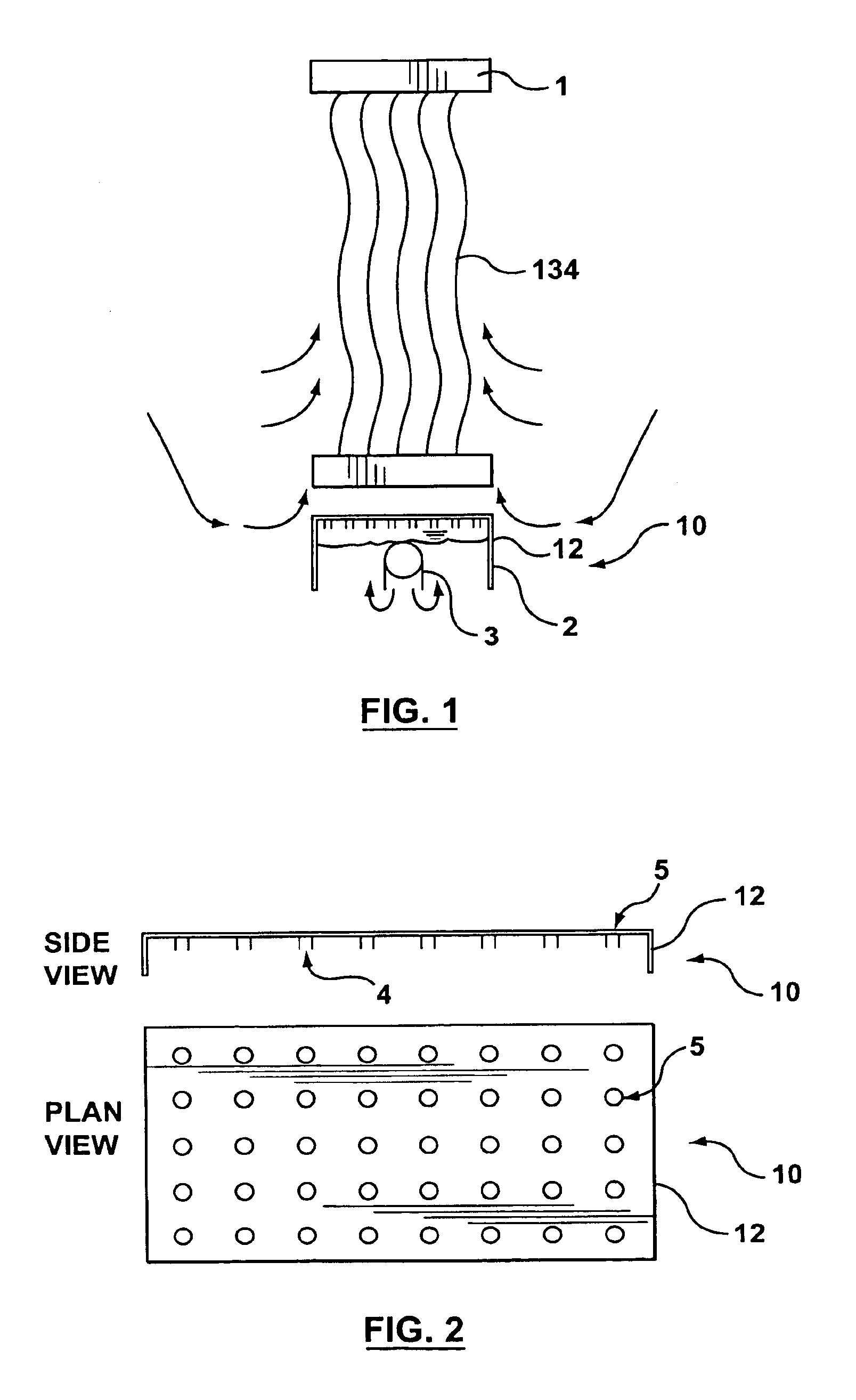

Inverted air box aerator and aeration method for immersed membrane

InactiveUS6863823B2Reduce air volumeLower the volumeTreatment using aerobic processesIon-exchanger regenerationFiltrationAir space

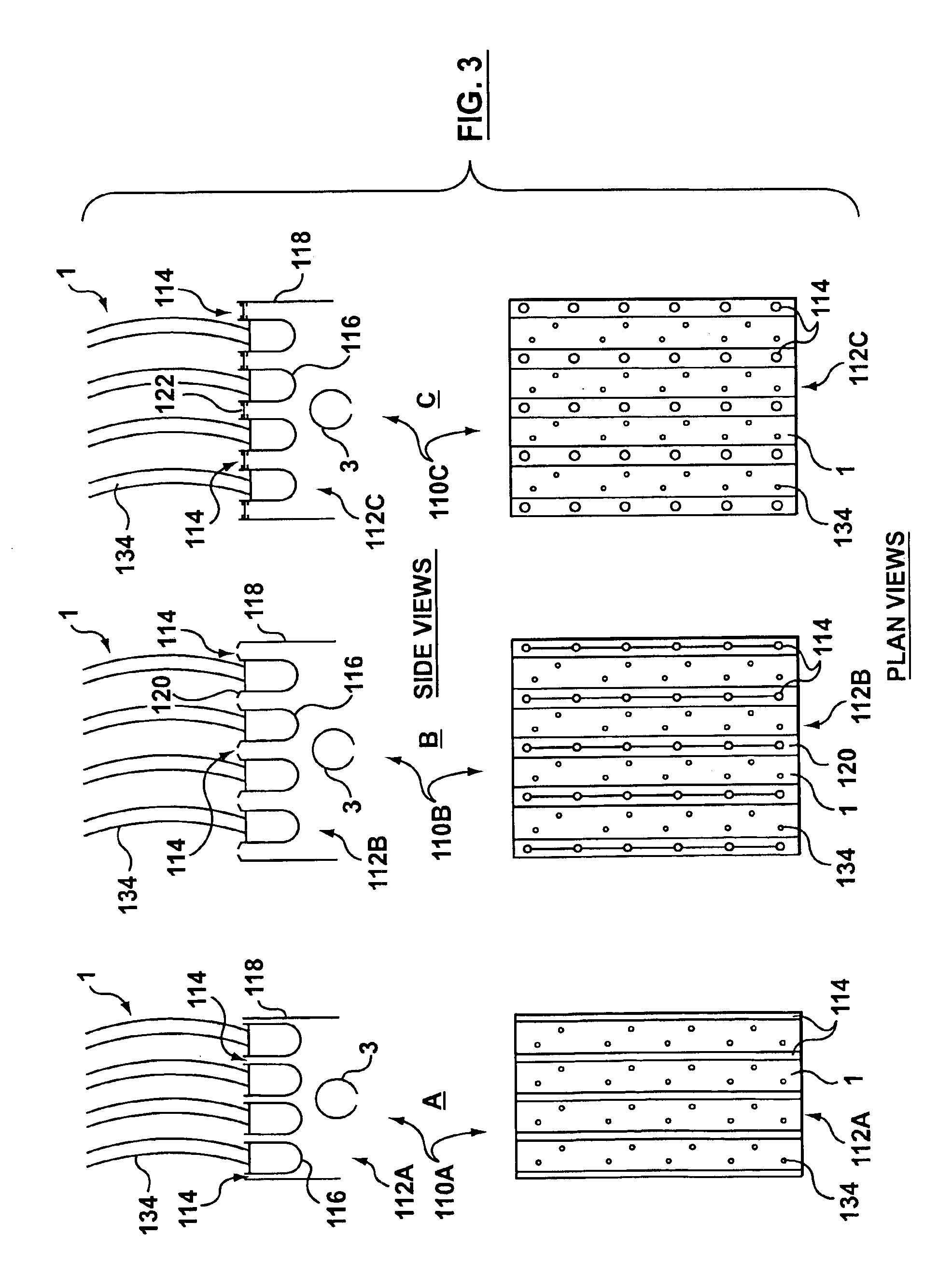

An aerator for immersed filtering membranes has an aerator shell with openings for discharging bubbles from its upper surface and a shape capable of temporarily containing a volume of air in fluid communication with the openings. The shell is open to tank water below it and located so that discharged bubbles will rise through an assembly of the filtering membranes. The shell may be wholly or partially made of parts of the assemblies of filtering membranes. A supply of air is provided to the air space in the aerators alternating between a high flow rate and a low flow rate in short cycles of between about 10 seconds and 100 seconds. A filtration system has an inlet for adding substrate and an outlet for retentate are located so as to create a horizontal flow of substrate through the tank. Membrane assemblies are located within the horizontal flow of substrate. Aerators as described above are provided and operated as described above.

Owner:ZENON TECH PARTNERSHIP

Method for avoiding unnecessary excessive stay of short cycle in discontinuous reception mechanism

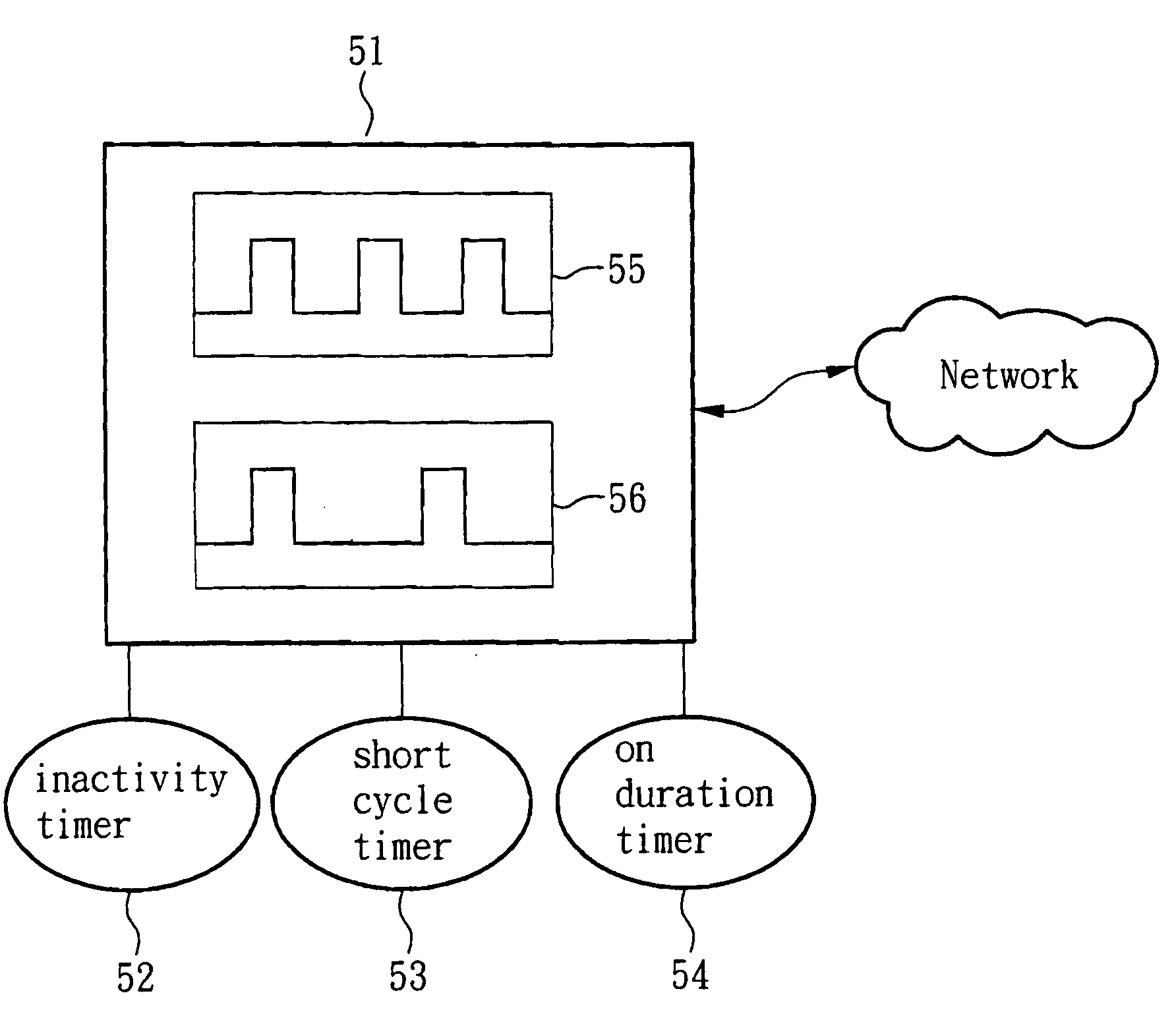

ActiveUS20090238105A1Avoiding unnecessary excessive stayAvoiding unnecessary excessive stay of short cyclePower managementTransmission systemsTimerEmbedded system

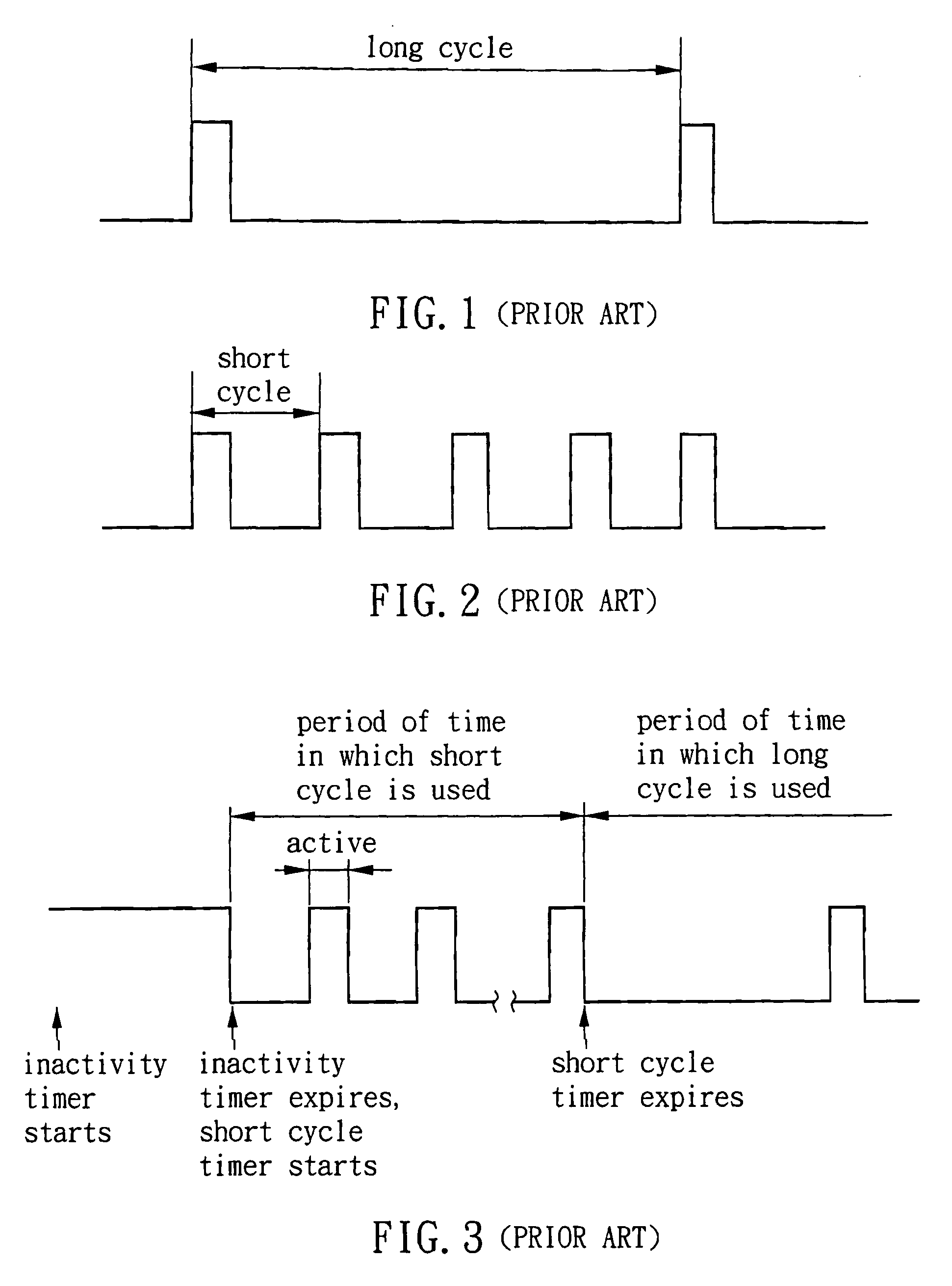

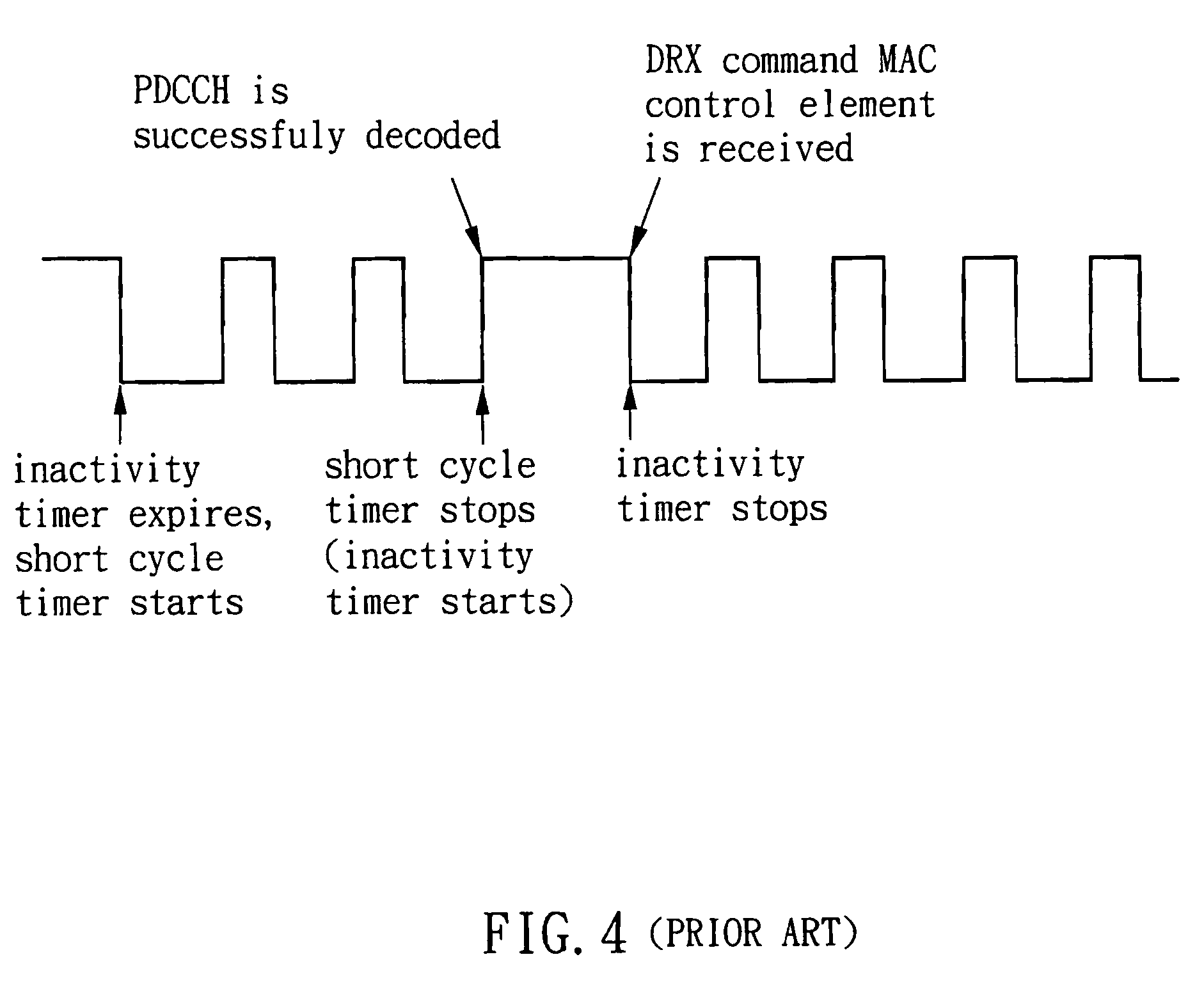

A method for avoiding unnecessary excessive stay of short cycle in discontinuous reception mechanism begins by using the short cycle while the short cycle timer is running. Then, it determines whether the inactivity timer expires or not and whether the short cycle timer expires or not. If the inactivity timer expires but the short cycle timer does not expire, the short cycle is used. If the short cycle timer expires but the inactivity timer does not expire, the long cycle is used. If the inactivity timer and the short cycle timer expire at the same time, either the short cycle or the long cycle is selected for use.

Owner:HFI INNOVATION INC

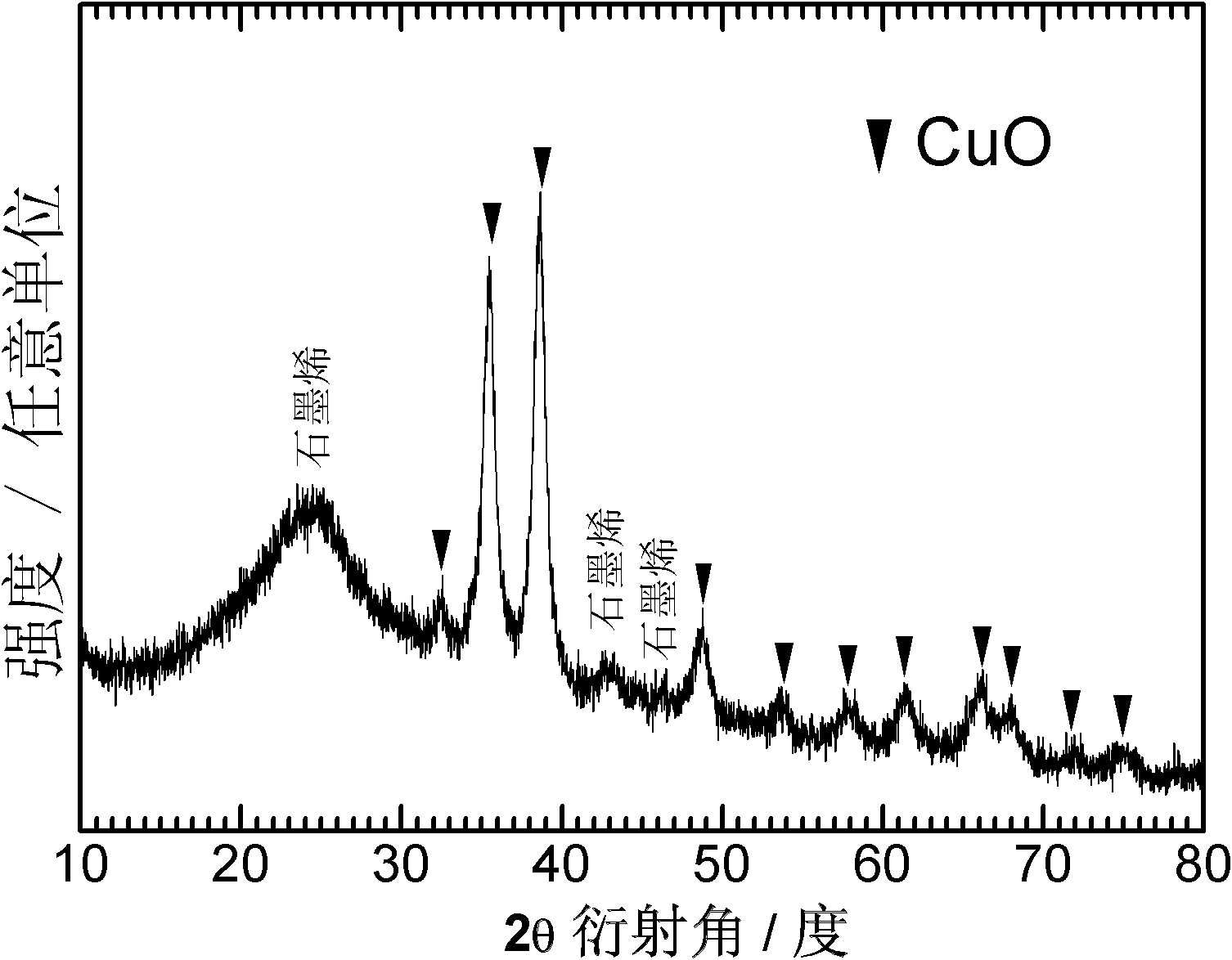

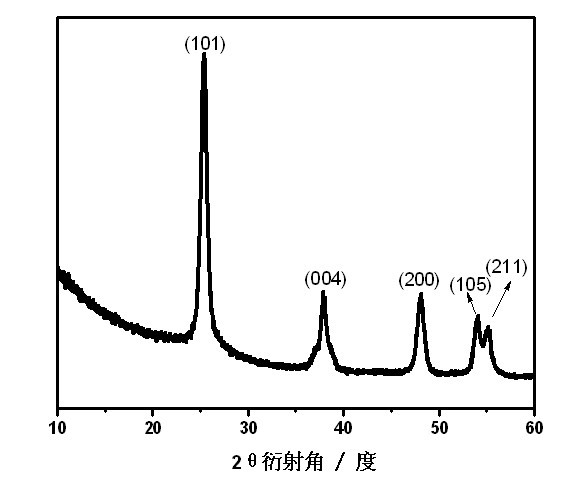

Transition metal oxide/ graphene composite material and preparation method thereof

The invention discloses a transition metal oxide / graphene composite material, which consists of a nanometer transition metal oxide and graphene, wherein the transition metal oxide is MnO, Fe2O3, Cr2O3, Cu2O, CuO or V2O5. Because of the dispersing and loading effects of the graphene, the transition metal oxide in the composite material can be distributed uniformly and is small in particle size, and the stability and the cyclical stability of the transition metal oxide in the process of charging and discharging can be effectively improved. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple process, low cost, short cycle, low energy consumption and the like, and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

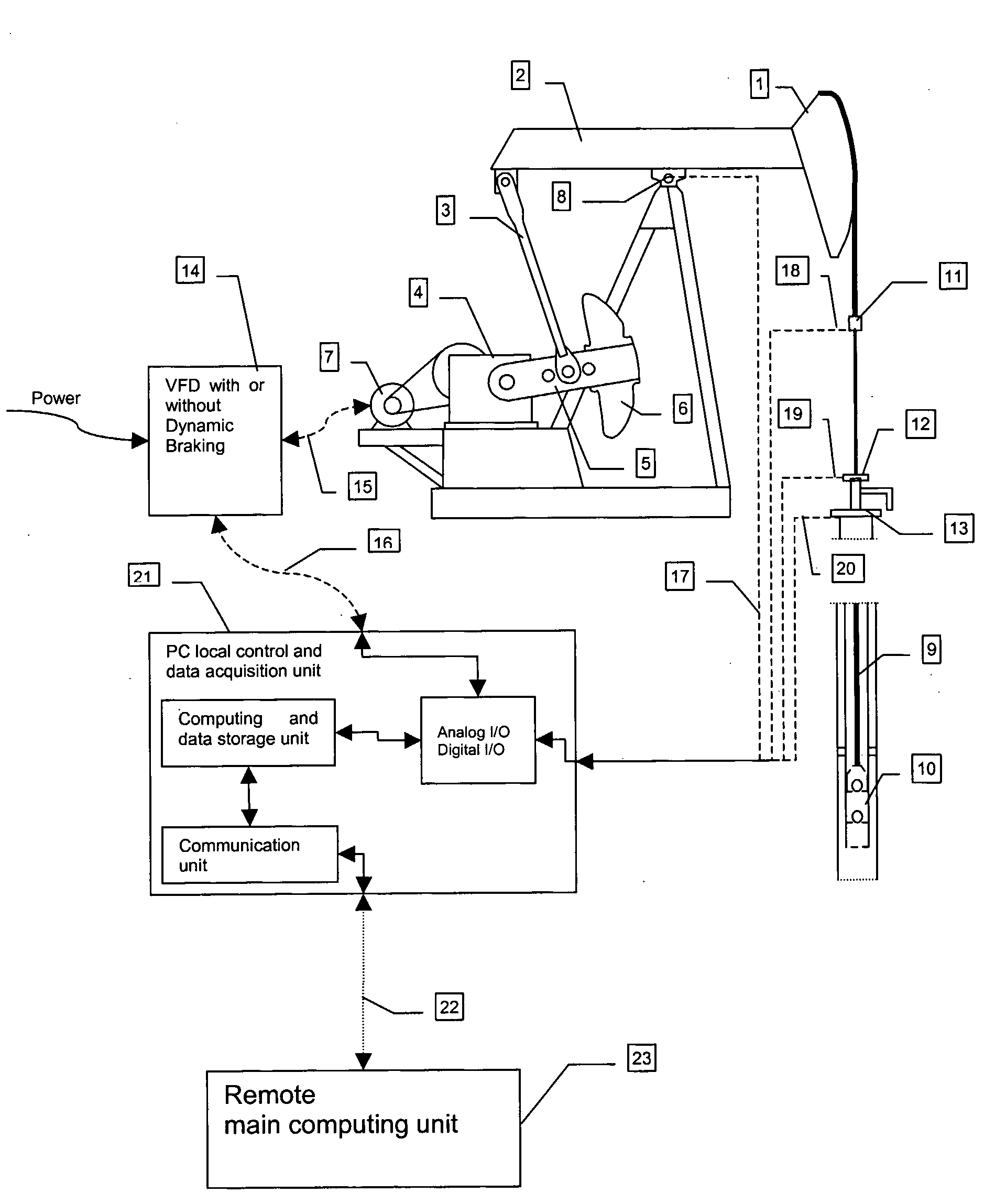

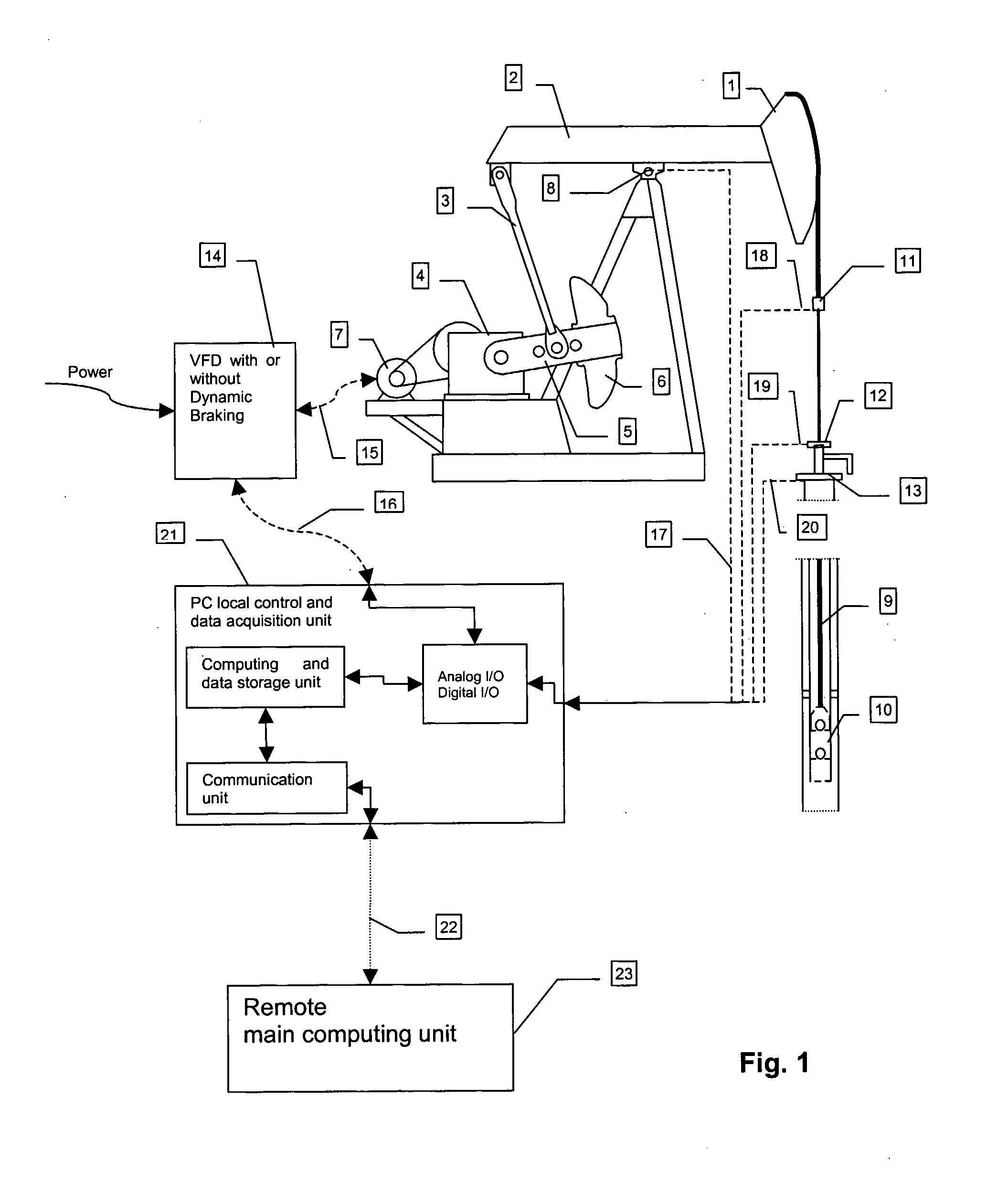

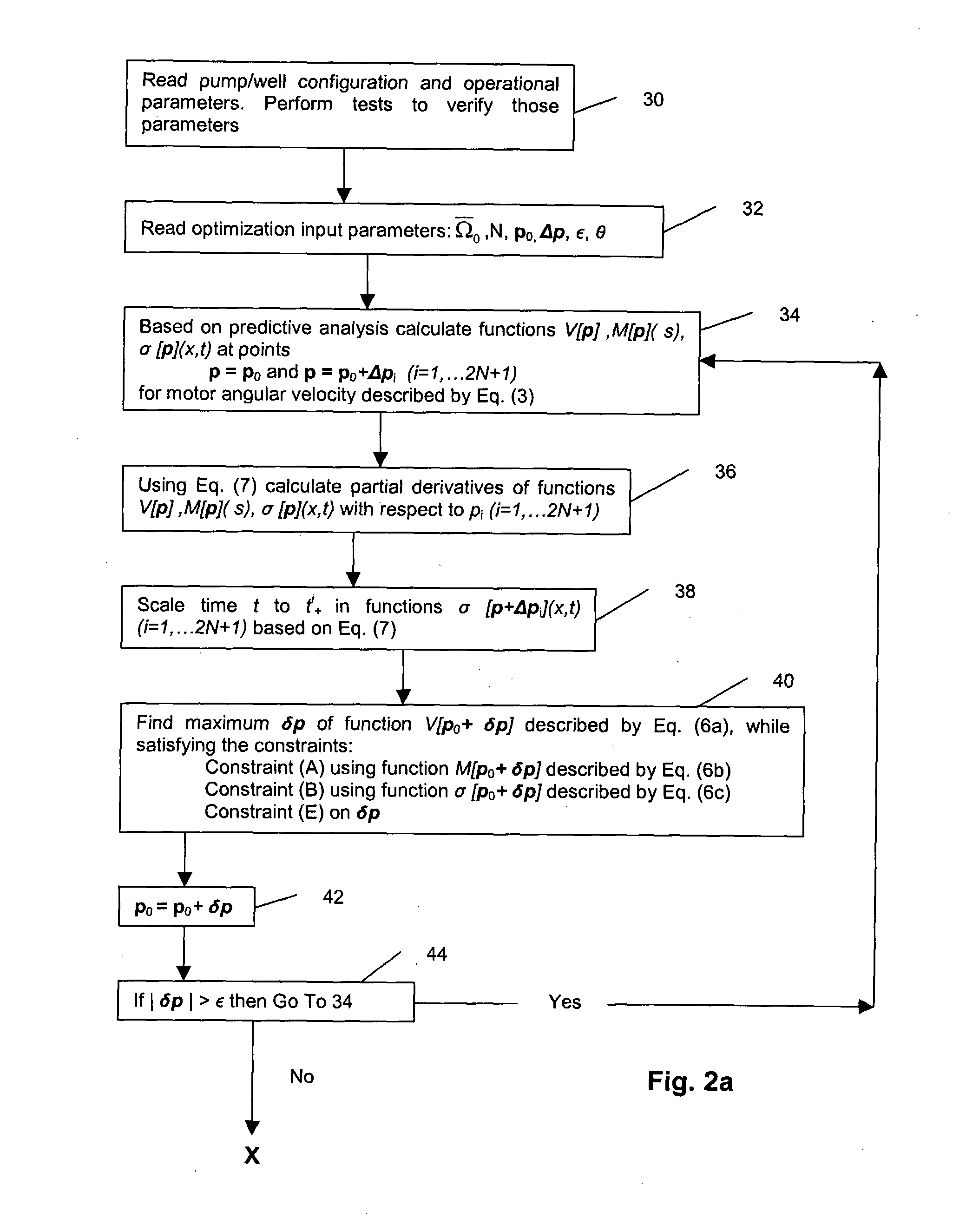

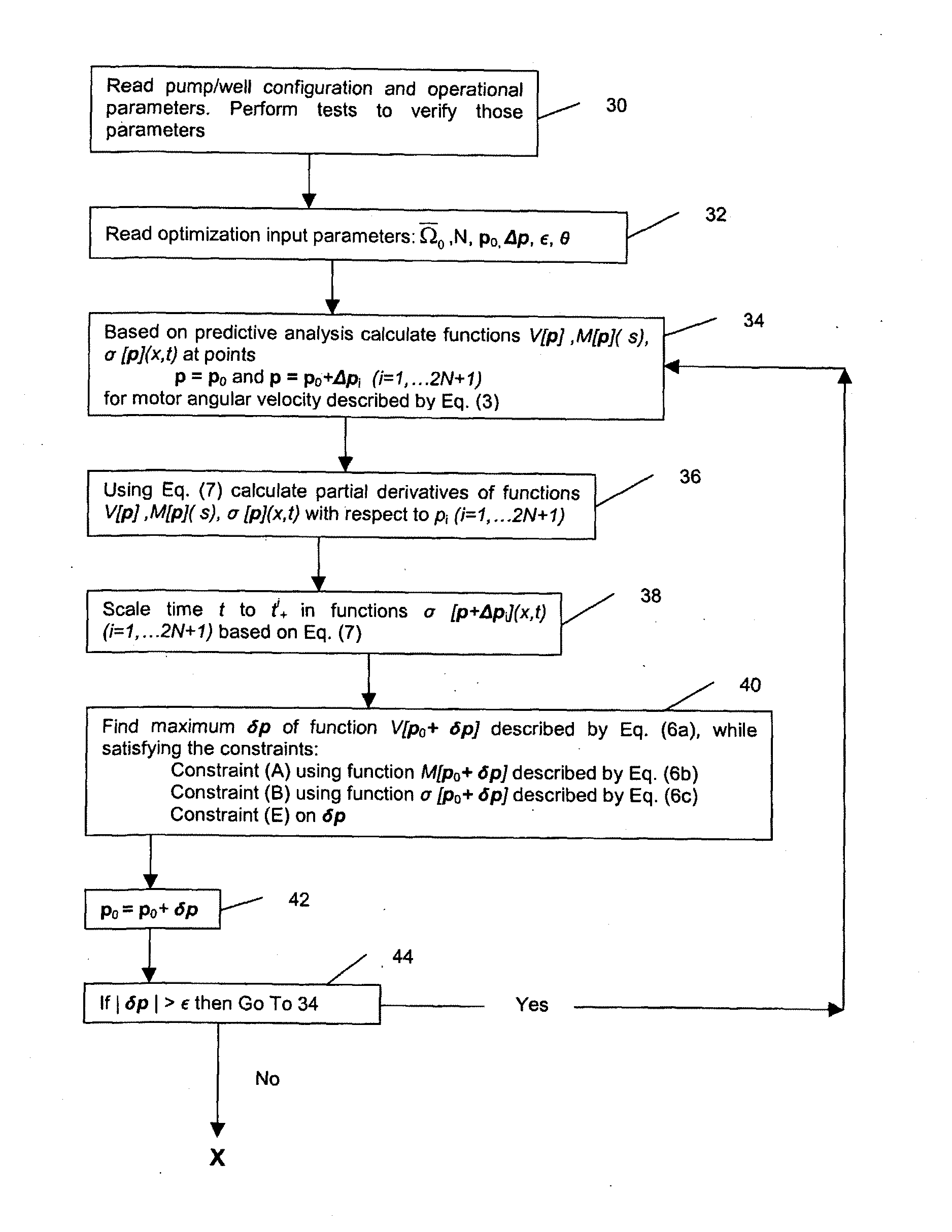

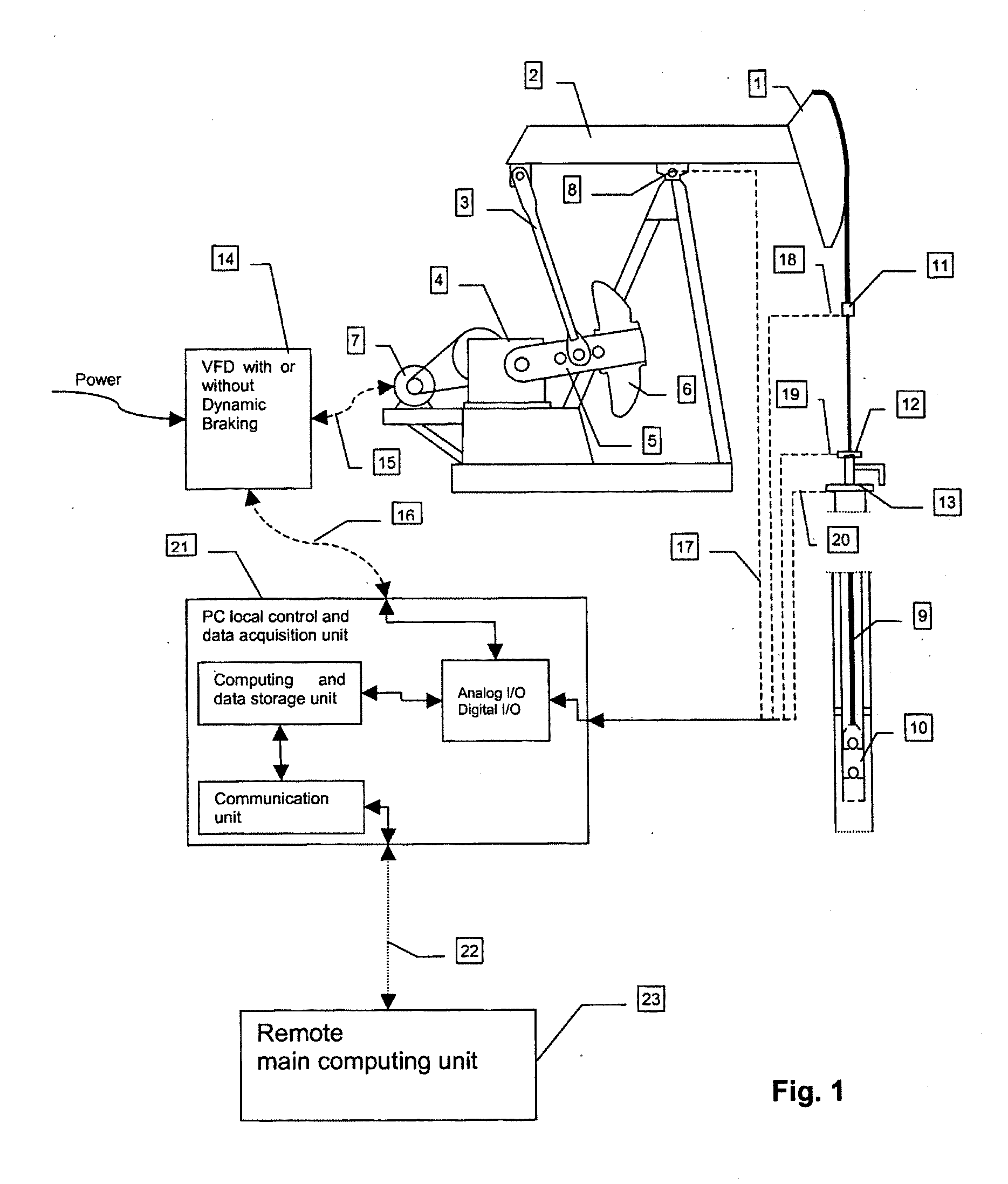

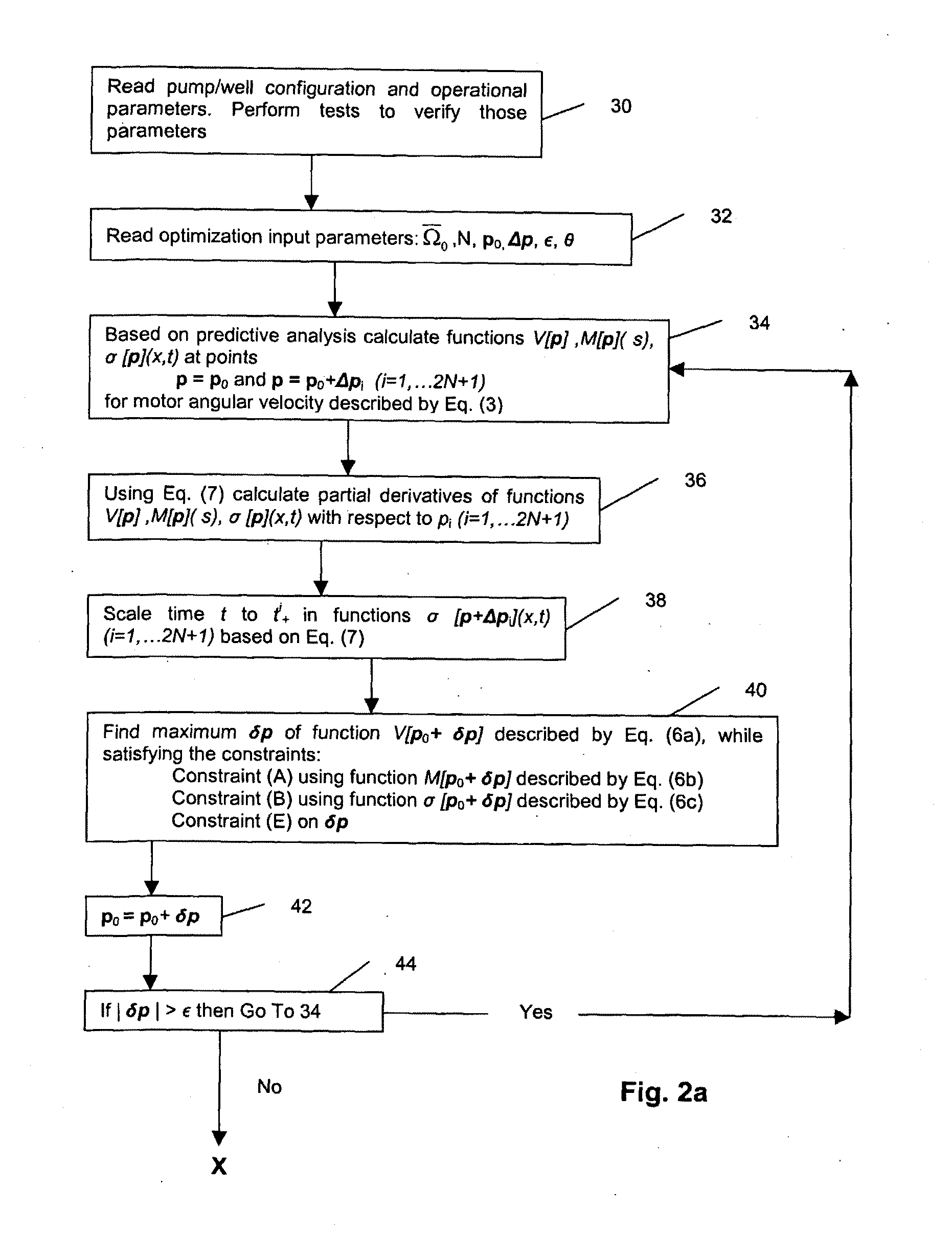

Method and System for Optimizing Downhole Fluid Production

InactiveUS20080240930A1Maximize oil productionReduce operating costsFluid parameterSurveyEngineeringUltimate tensile strength

A method and system for pumping unit with an elastic rod system is applied to maximize fluid production. The maximum stroke of the pump and the shortest cycle time are calculated based on all static and dynamic properties of downhole and surface components without a limitation to angular speed of the prime mover. Limitations of structural and fatigue strength are incorporated into the optimization calculation to ensure safe operation while maximizing pumped volume and minimizing energy consumption. Calculated optimal prime mover speed is applied to the sucker rod pump by means of beam pumping, long stroke or hydraulic pumping unit by controlling velocity, acceleration and torque of the electric prime mover or by controlling pressure and flow rate in hydraulically actuated sucker rod pumping system.

Owner:PUMPWELL SOLUTIONS

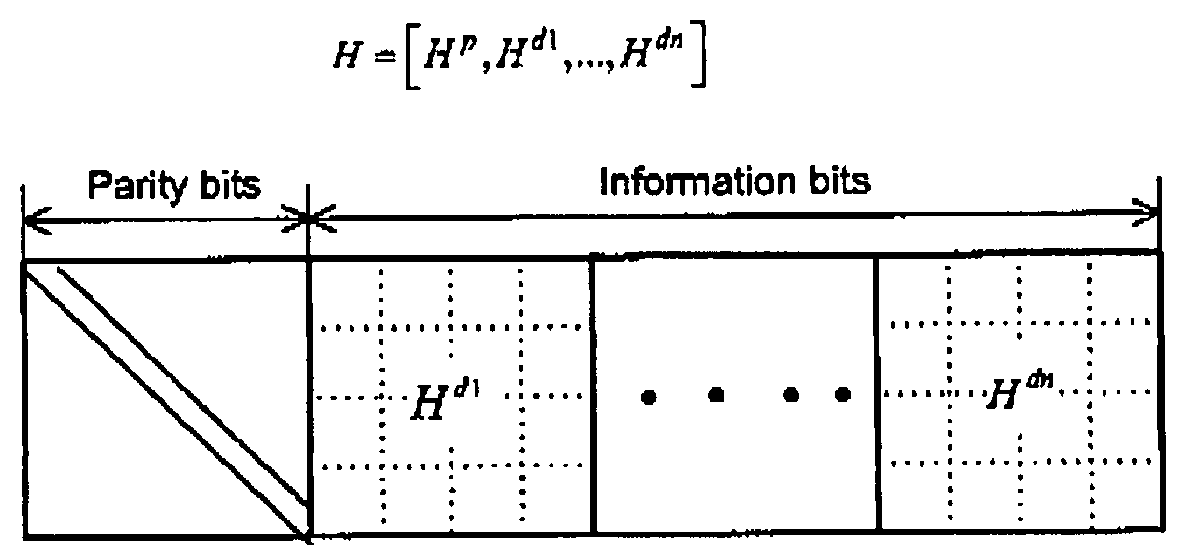

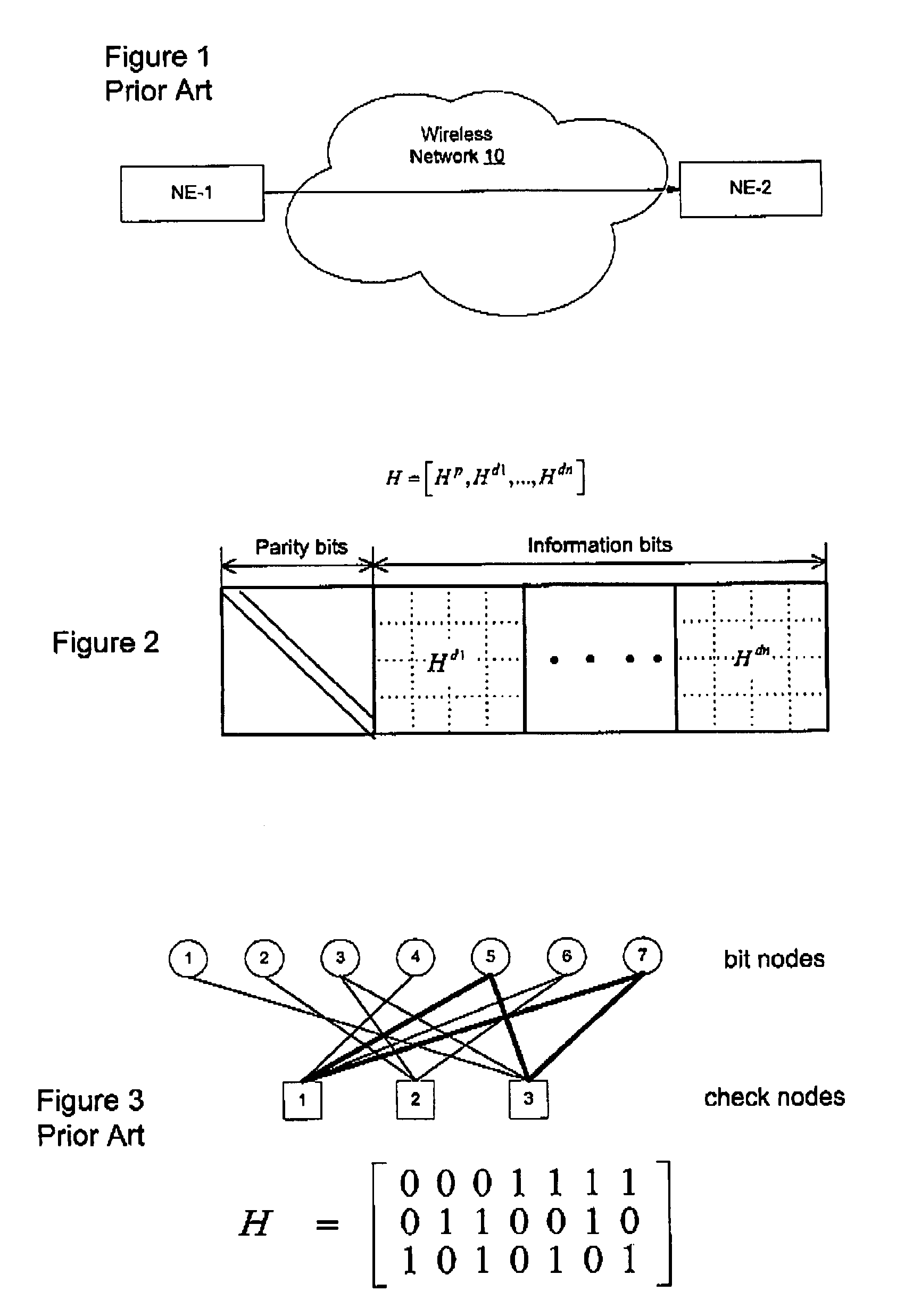

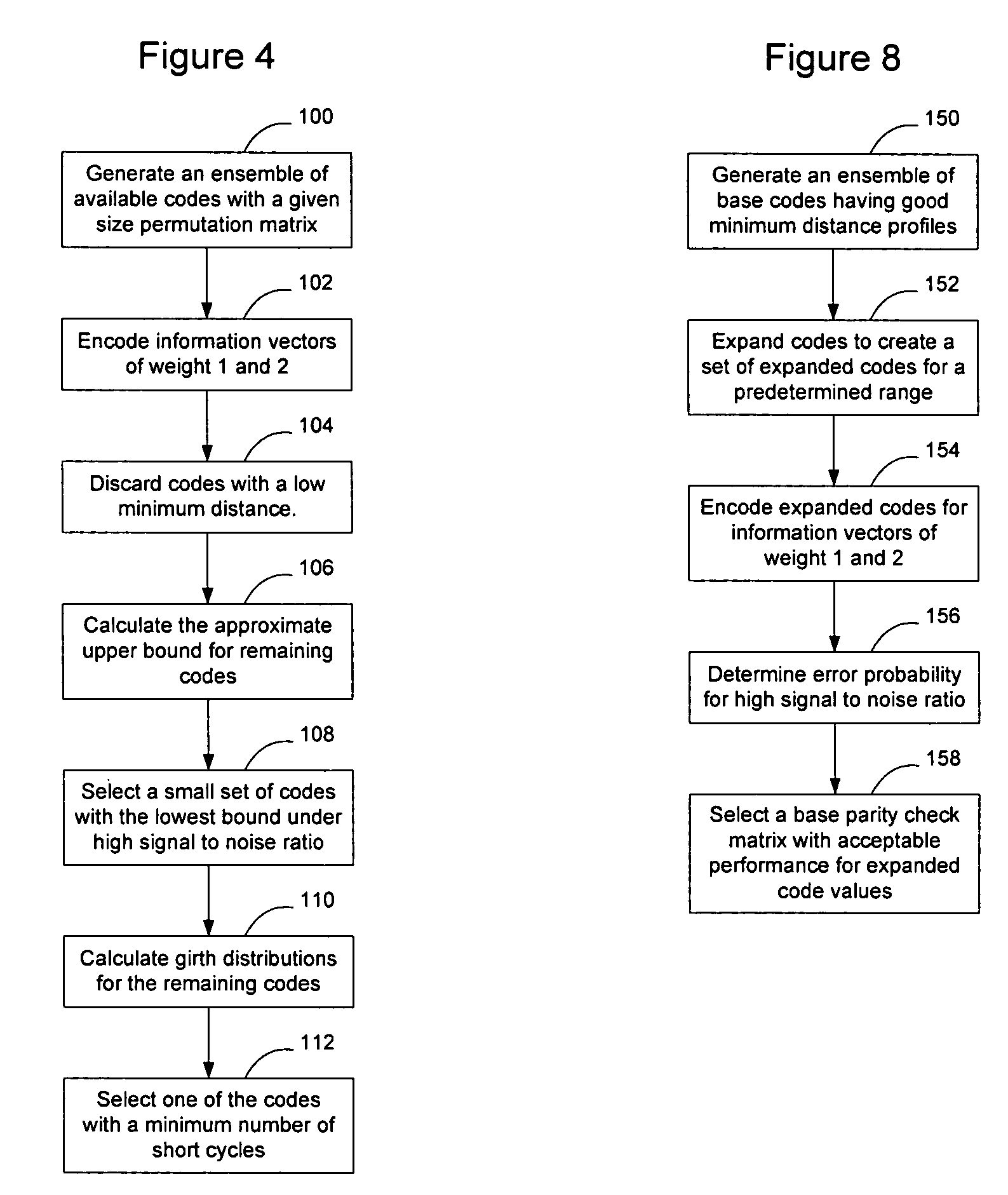

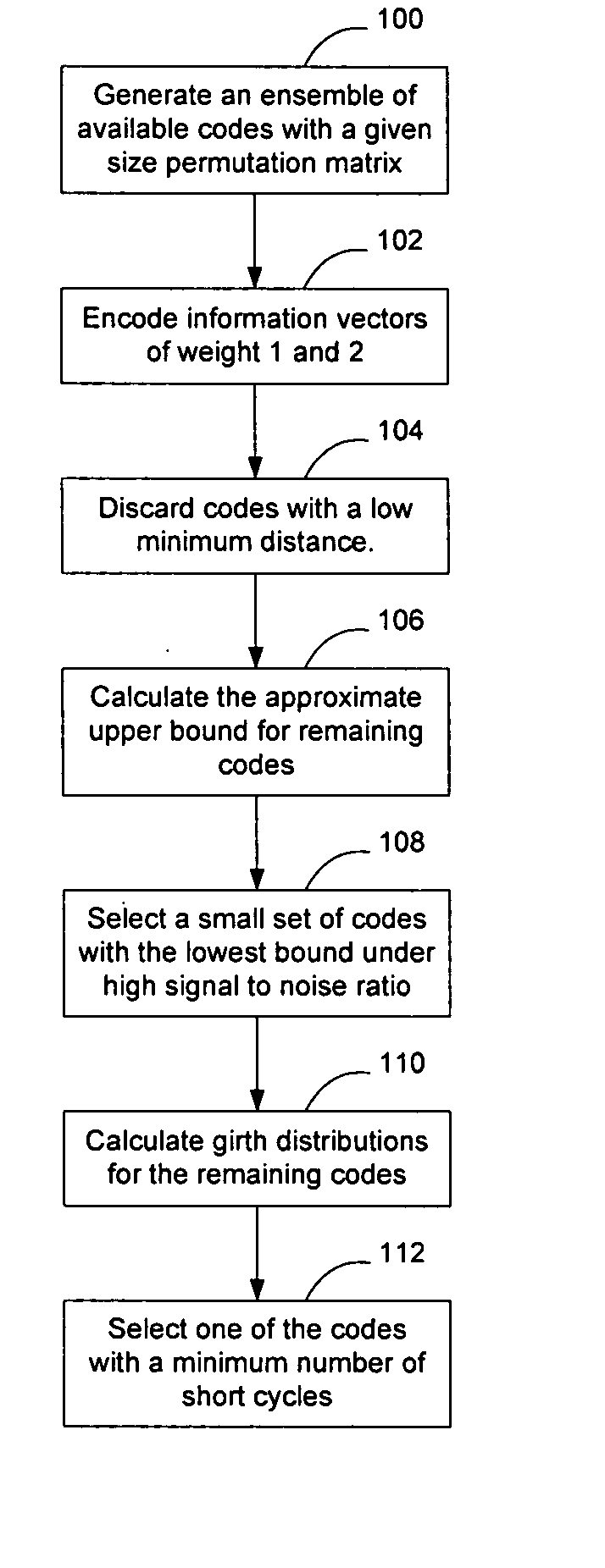

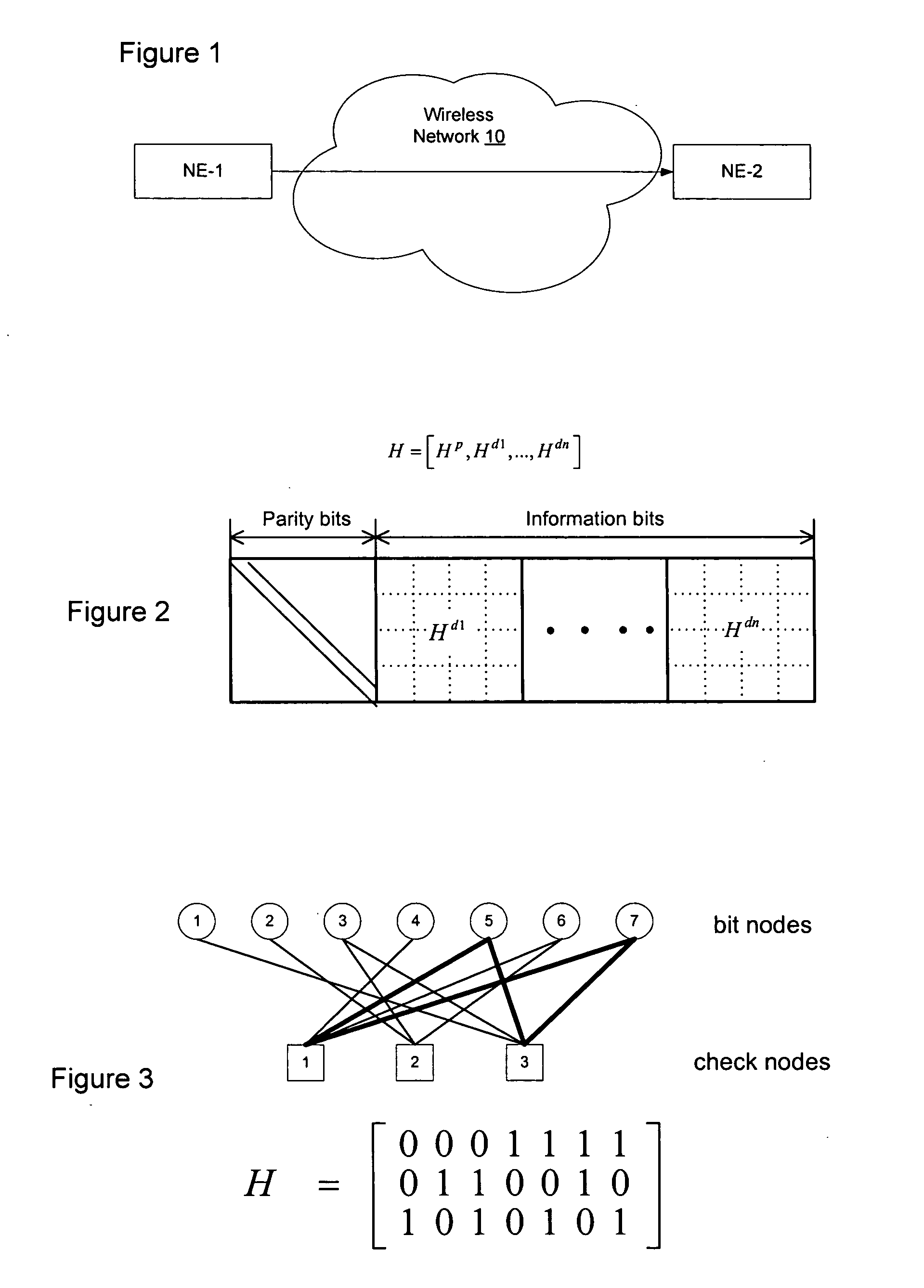

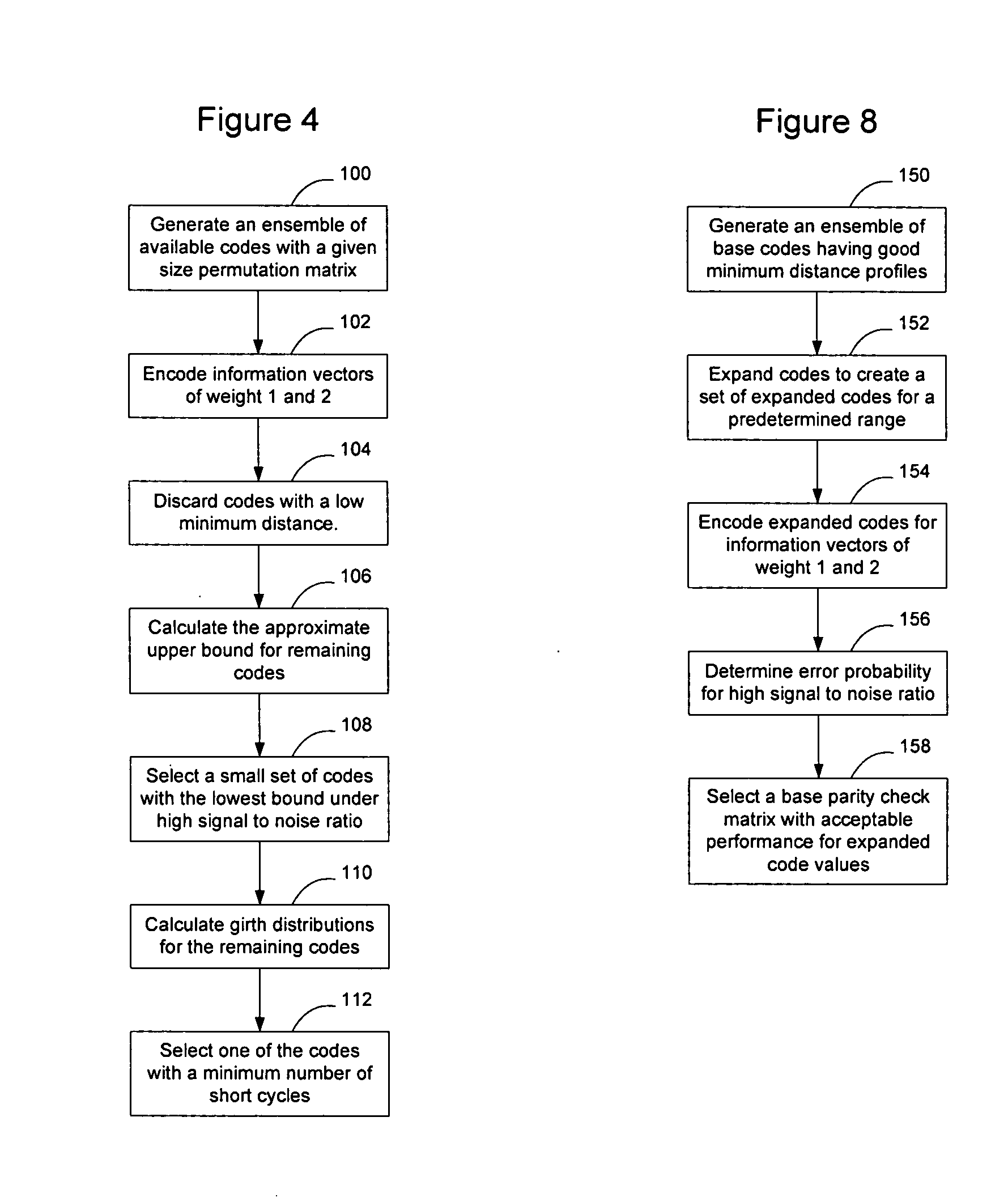

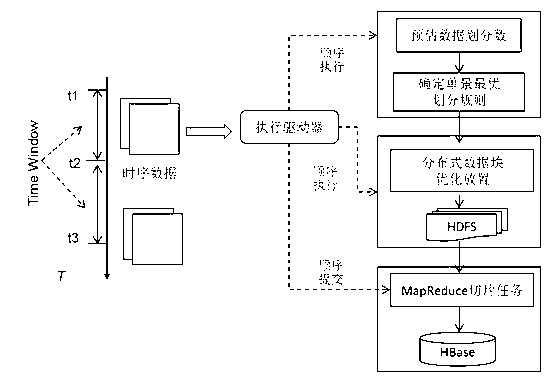

Algebraic low-density parity check code design for variable block sizes and code rates

InactiveUS7260763B2Readily implemented in hardwareHigher code rate parityError detection/correctionError correction/detection using multiple parity bitsVariable-length codeSignal-to-noise ratio (imaging)

A higher code rate Low-Density Parity Check (LDPC) matrix may be designed by concatenating additional matrices to a π-rotation parity check matrix. The concatenated matrix may be selected such that the resultant LDPC matrix exhibits good expansion characteristics to enable the LDPC matrix to be used with variable block length codes. The codes may be designed by generating an ensemble of available codes, encoding them with information vectors of weight 1 and 2 and discarding codes with a low minimum distance. The approximate upper bounds for the remaining codes are then calculated and a small set of codes with the lowest bound under high signal to noise ratio is selected. The girth distributions for the remaining codes are then calculated and the code that has the minimum number of short cycles is selected. The selected code is concatenated to the original π-rotation parity check matrix.

Owner:MICROSOFT TECH LICENSING LLC

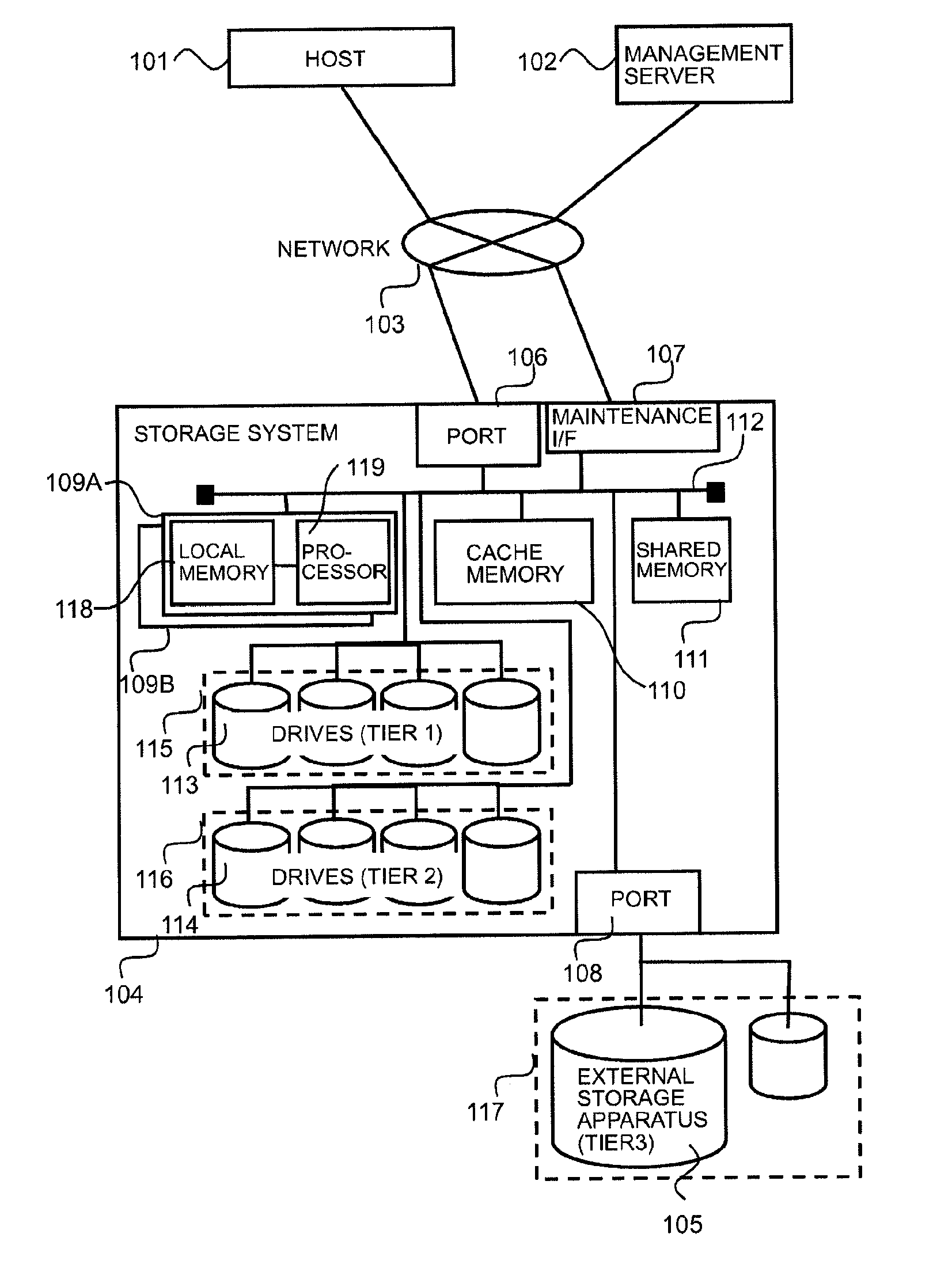

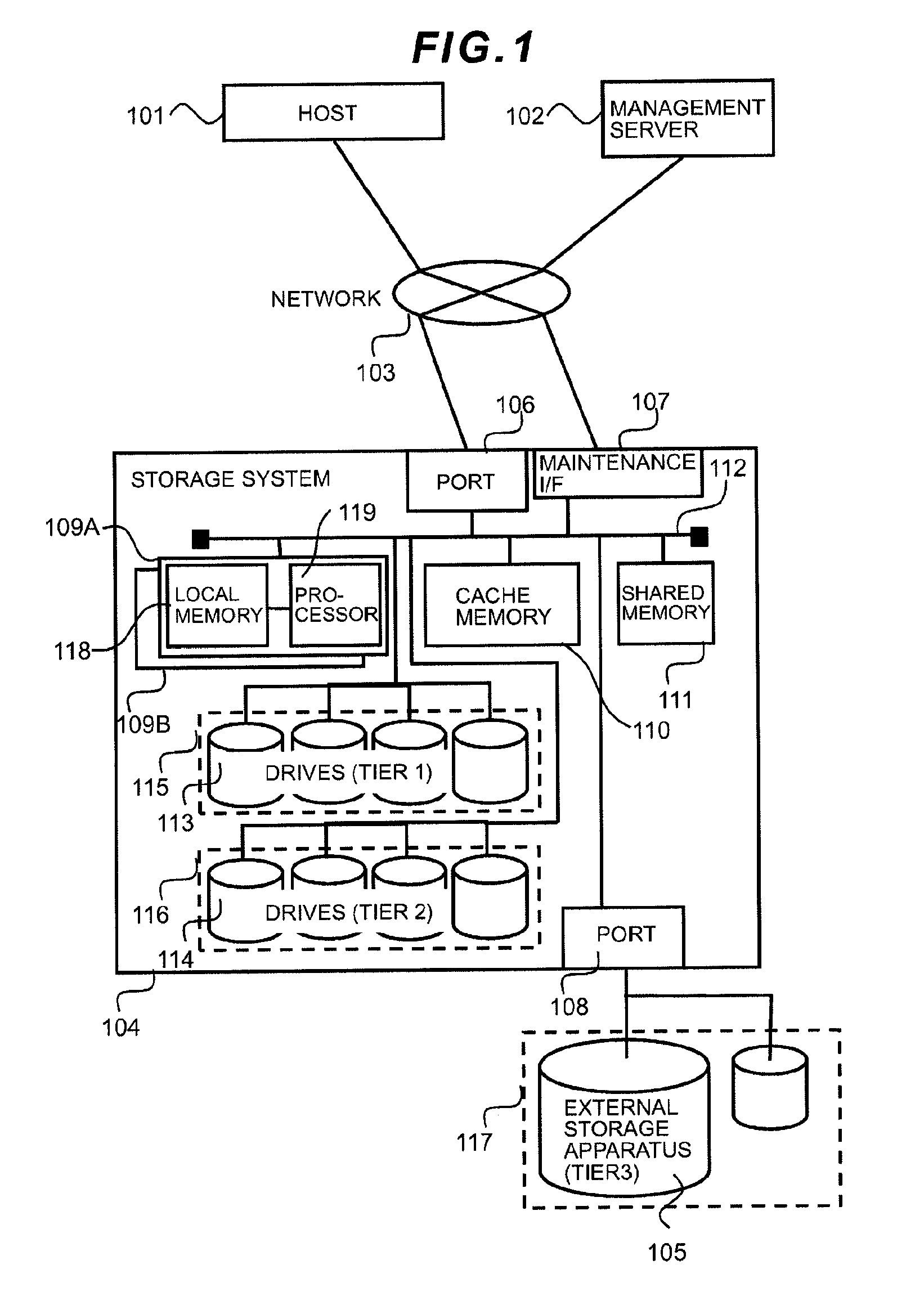

Storage system and storage area allocation method

ActiveUS20120246386A1Improve performanceMemory adressing/allocation/relocationInput/output processes for data processingViewpointsMonitoring system

If a monitor measurement cycle is set as a long cycle, promotion in a short cycle cannot be performed; and even if the number of I / Os is very large in response to fluctuations of the number of I / Os in several minutes to several hours of normal work, pages will be promoted after waiting for several weeks. As a result, I / Os which could have normally accepted by an upper tier will be accepted by a lower tier, which results in a problem of worsening the performance efficiency. A monitoring system capable of preventing demotion due to temporary reduction of the number of I / Os for specific pages from a viewpoint of a long cycle and enabling prompt promotion in response to an increase of the number of U / Os for 3the specific pages is realized.A load index value defined from a viewpoint of a long cycle and a load index value defined from a viewpoint of a short cycle are updated based on the number of I / Os which is counted cyclically for each storage area. Promotion and demotion are implemented based on a value(s) calculated from these load index values.

Owner:HITACHI LTD

Highly effective straw decomposition composite flora

The invention relates to a biotechnology dealing agricultural discard stem with an highly effective stem decomposing composite bacterial, which dissolves the problem of single species of applying microbiological bacterial, weak breaking up, low total degradability rate of cellulose, long developmental cycle. The composite bacterial comprises the following parts: yellow archespore wool bacterium leather bacterial, mushroom bacterial, haci trichoderma, green trichoderma, coninic trichoderma, aspergillus niger, bacillus subtilis, feed bacillus, bacillus megaterium, candida, distillery yeast, food-yeast, brown sphere azotobacter, thermoactinomyces, and so on. The composite bacterial can overall degrade lignin, cellulose, hemicellulose and other organic material in the stem, has a more than 80% degrading rate, a 10-15 days short cycle, keeps a long time for providing a solid bacteria.

Owner:韩农

Method and system for optimizing downhole fluid production

ActiveUS20130151216A1Maximize productionReduce operating costsFluid parameterConstructionsEngineeringCycle time

A method and system for pumping unit with an elastic rod system is applied to maximize fluid production. The maximum stroke of the pump and the shortest cycle time are calculated based on all static and dynamic properties of downhole and surface components without a limitation to angular speed of the prime mover. Limitations of structural and fatigue strength are incorporated into the optimization calculation to ensure safe operation while maximizing pumped volume and minimizing energy consumption. Calculated optimal prime mover speed is applied to the sucker rod pump by means of beam pumping, long stroke or hydraulic pumping unit by controlling velocity, acceleration and torque of the electric prime mover or by controlling pressure and flow rate in hydraulically actuated sucker rod pumping system.

Owner:AMBYINT INC

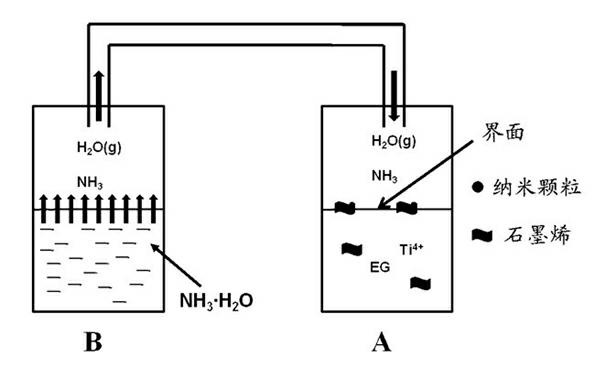

Preparation method of nitrogen doped graphene/ metal oxide nanometer composite material

ActiveCN102602917ASimple processLess investmentMaterial nanotechnologyCarbon compoundsNitrogenNitrogen doped graphene

The invention discloses a preparation method of a nitrogen doped graphene / metal oxide nanometer composite material. The preparation method comprises the following steps of: weighing graphene and metal salt the cation of which is trivalent or quadrivalent to be added in a dispersant, and then carrying out ultrasonic dispersion to obtain mixed liquor; (2), reacting the mixed liquor obtained in the step (1) with alkaline air on a gas-liquid interface for 3-12hours at the temperature of 60-200 DEG C, cooling, centrifuging, washing a precipitate and drying to obtain powder; and (3) introducing the alkaline air or a mixed gas of the alkaline air and inert gas, maintaining the powder to be at the constant temperature of 600-900 DEG C for 2-6 hours, and cooling to room temperature to obtain the nitrogen doped graphene / metal oxide nanometer composite material. According to the invention, the conductibility and interface action of the composite material obtained by the method provided by the invention are improved due to the doping of nitrogen; and the method provided by the invention has the advantages of simple process, cheap cost, high productive rate, short cycle and the like, and is environment-friendly, and can be suitable for industrialization large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Algebraic low-density parity check code design for variable block sizes and code rates

InactiveUS20050204253A1Increase heightReadily implemented in hardwareError detection/correctionError correction/detection using multiple parity bitsVariable-length codeSignal-to-noise ratio (imaging)

A higher code rate Low-Density Parity Check (LDPC) matrix may be designed by concatenating additional matrices to a π-rotation parity check matrix. The concatenated matrix may be selected such that the resultant LDPC matrix exhibits good expansion characteristics to enable the LDPC matrix to be used with variable block length codes. The codes may be designed by generating an ensemble of available codes, encoding them with information vectors of weight 1 and 2 and discarding codes with a low minimum distance. The approximate upper bounds for the remaining codes are then calculated and a small set of codes with the lowest bound under high signal to noise ratio is selected. The girth distributions for the remaining codes are then calculated and the code that has the minimum number of short cycles is selected. The selected code is concatenated to the original v-rotation parity check matrix.

Owner:MICROSOFT TECH LICENSING LLC

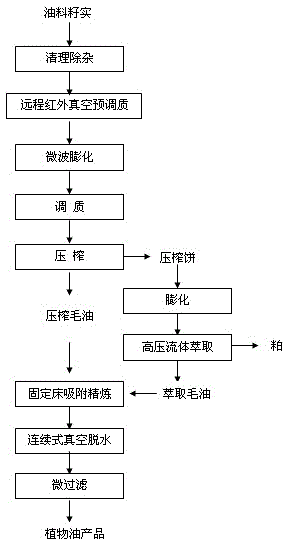

Physical method for preparing vegetable oil

ActiveCN103333738AAvoid damageFast and efficient remote infrared vacuum preconditioningFatty-oils/fats refiningFatty-oils/fats productionOil and greaseVegetable oil

The invention relates to a physical method for preparing vegetable oil. The method comprises the following process steps of: cleaning, remote infrared vacuum pre-tempering, microwave puffing, tempering, pressing, puffing, high-pressure fluid extraction, fixed bed adsorption refining, continuous vacuum dehydration and finally micro-filtering. The remote infrared vacuum pre-tempering and microwave puffing pre-processing method is fast and high-efficient and is suitable for industrial production. Press cake puffing and high-pressure fluid extraction are combined so that the problem of oil extraction of cold-pressing cakes is effectively solved, and meanwhile residual oil of the cold-pressing cakes is effectively reduced. The fixed bed adsorption refining method is simply and conveniently operated and has the advantages of short cycle, low energy consumption, low oil refining loss, high grease quality and the like. The whole process has the advantages of simplicity and convenience in operation, no solvent residue, low energy consumption, small neutral oil loss, high product quality and the like, an environment-friendly effect is achieved, and the method can be widely suitable for different kinds of oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

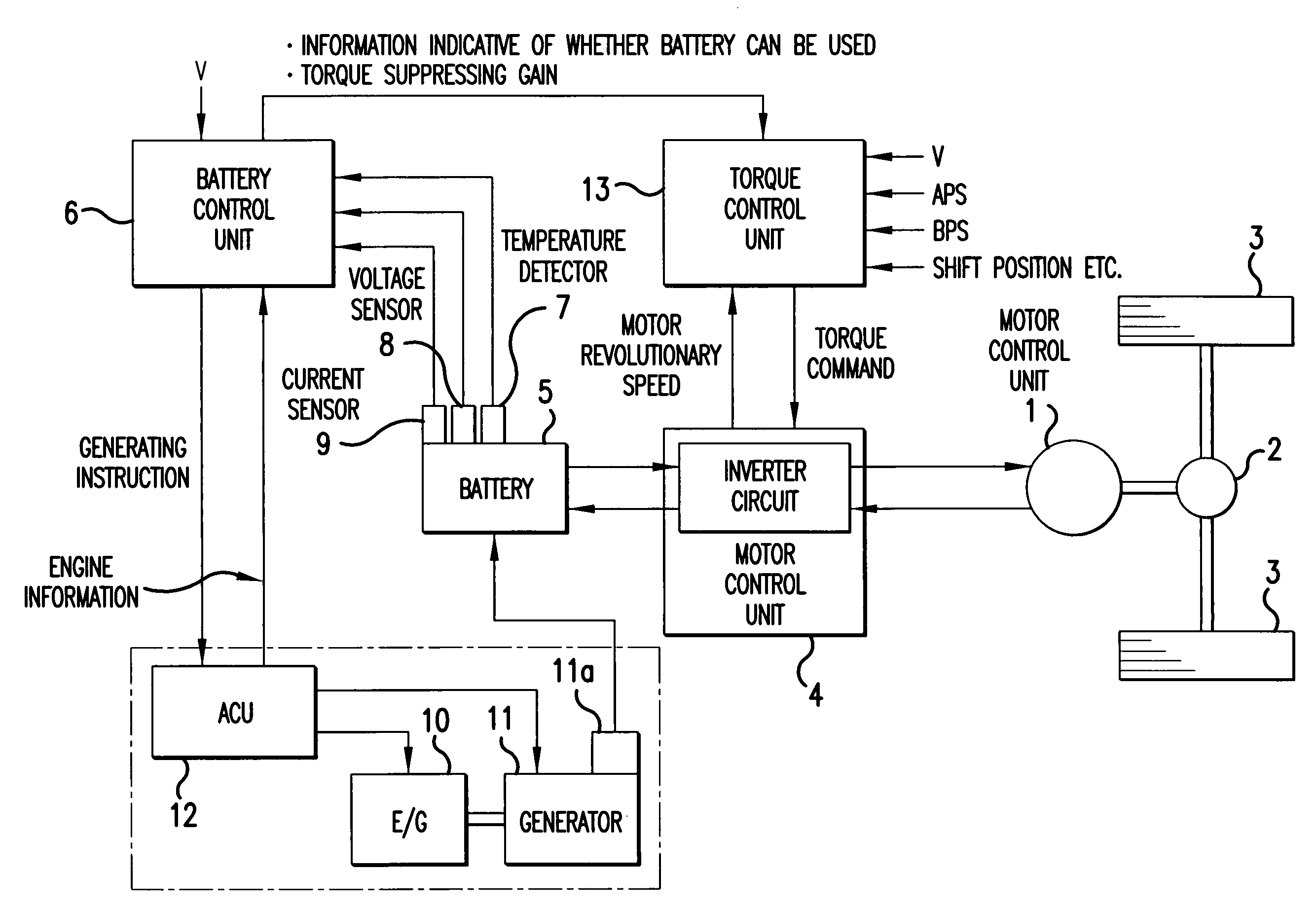

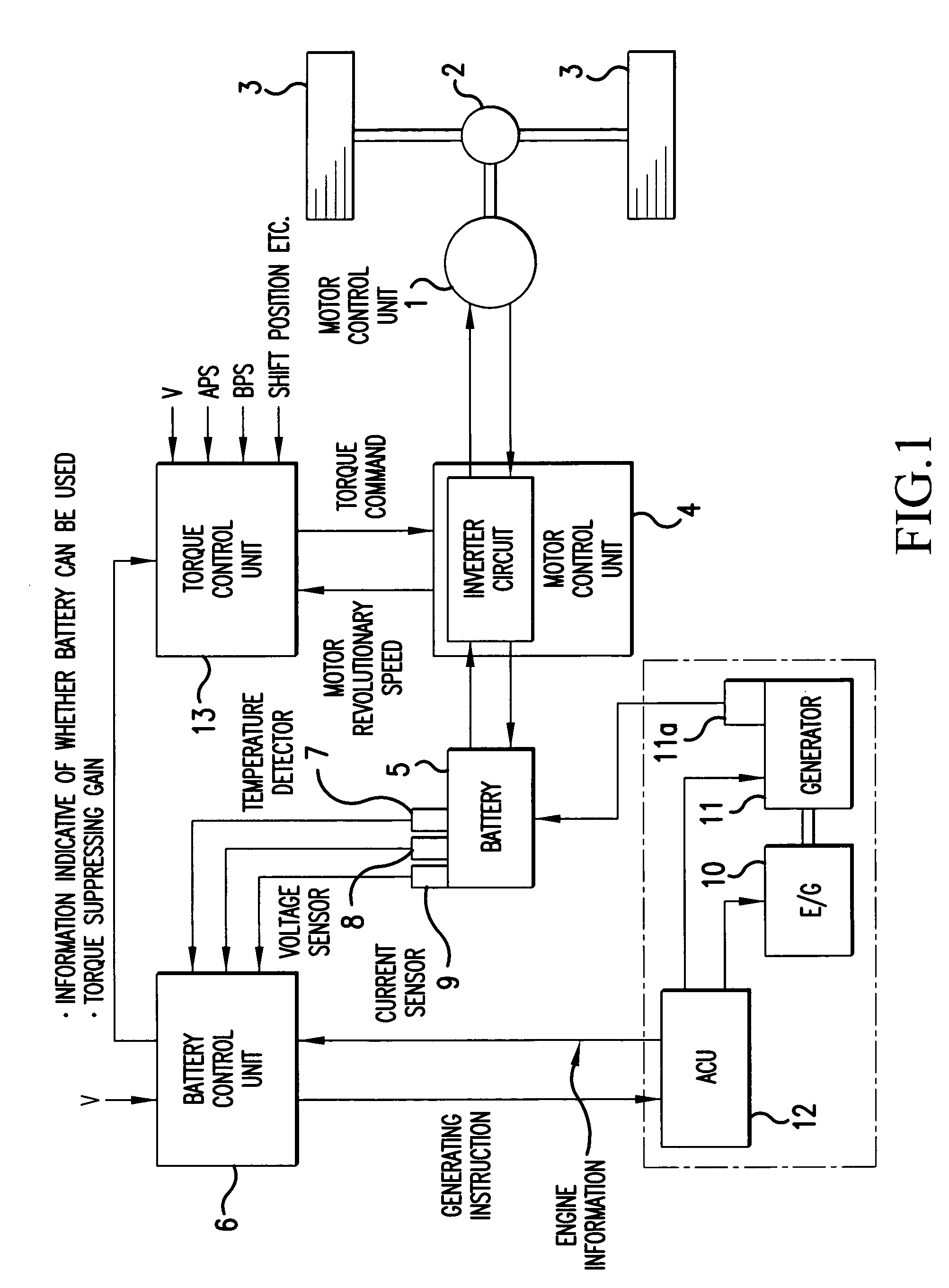

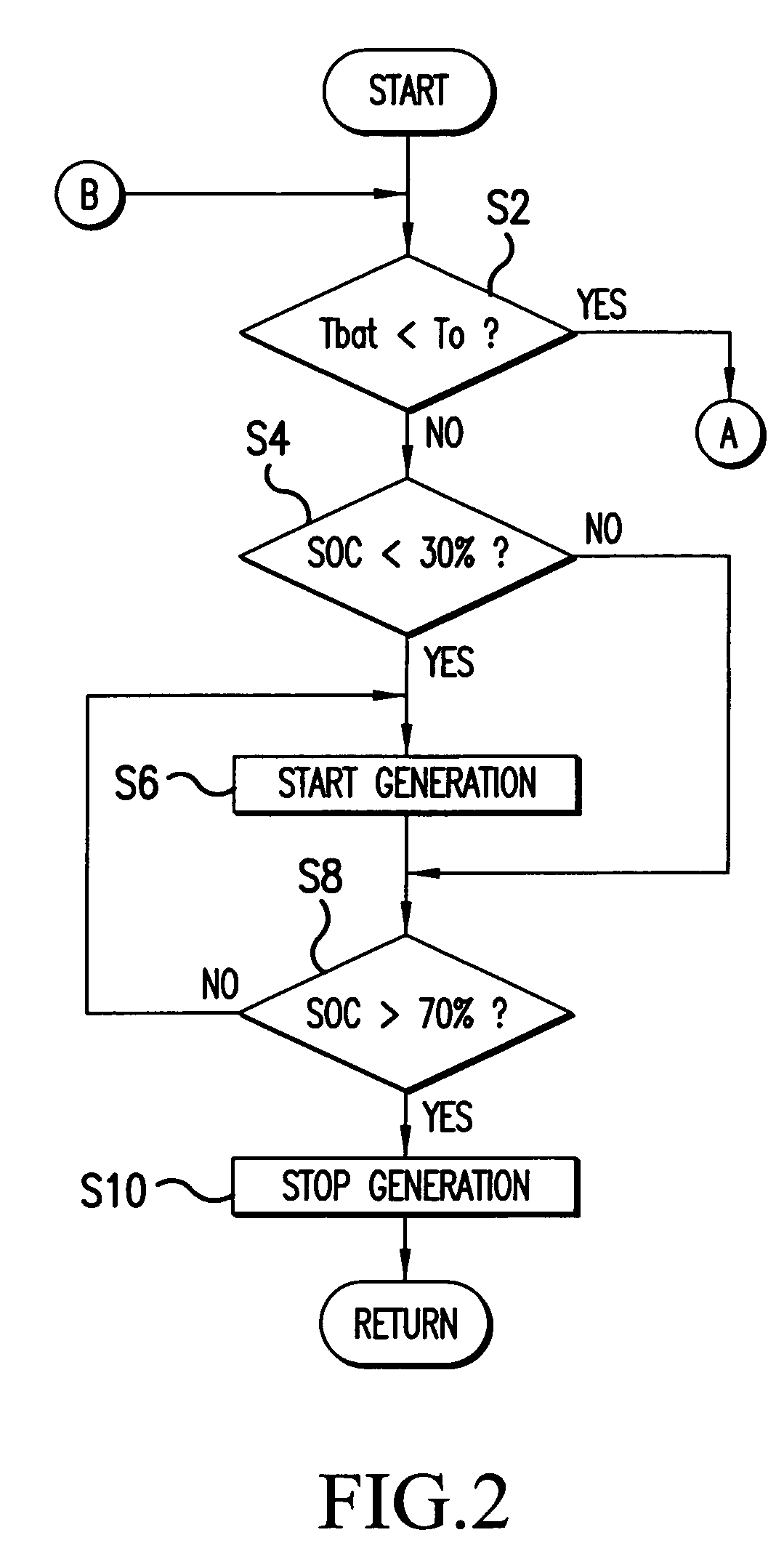

Battery control apparatus

InactiveUS7015676B2Increase in battery temperatureIncrease temperatureHybrid vehiclesBatteries circuit arrangementsState of chargeEngineering

There is provided a battery control apparatus that, when the battery temperature is low, repeats the charge and discharge of a battery on a short cycle such that the state of charge (SOC) of the battery lies in the range of 30 to 40% if the present SOC is less than 50%, and repeats the charge and discharge of the battery on a short cycle such that the SOC lies in the range of 50 to 60% if the present SOC is equal to or greater than 50%, thus increasing the temperature of the battery. Therefore, it is possible to increase the battery temperature in an efficient manner, and to prevent the available input-output power of the battery from being reduced due to a decrease in the battery temperature.

Owner:MITSUBISHI MOTORS CORP

Direct light-curing fabrication method of hollow blade ceramic cast

The invention relates to a method for directly making a hollow blade ceramic mold based on a photo-curing process. The method is as follows: firstly, ceramic powder and pre-mix liquid are evenly mixed so as to make ceramic slurry; secondly, according to a hollow blade model, a hollow blade mold model containing a gating system is obtained, and the ceramic slurry is directly made into a ceramic mold biscuit on a photo-curing forming machine according to the hollow blade mold model; then, the ceramic mold biscuit is dewatered to obtain a dry ceramic mold; finally, the dry ceramic mold is placed in a high-temperature baking furnace so as to carry out degreasing and sintering, thereby making the hollow blade ceramic mold. The ceramic mold can be used in the casting of a hollow blade, and replaces a multi-layer ceramic shell and core manufacturing process adopted in the prior investment casting. The method does not need the processes of investment pattern making, slurry coating and sand spreading adopted in the prior process, and has the characteristics of simple process, short cycle, low cost and quick returns, etc.

Owner:XI AN JIAOTONG UNIV

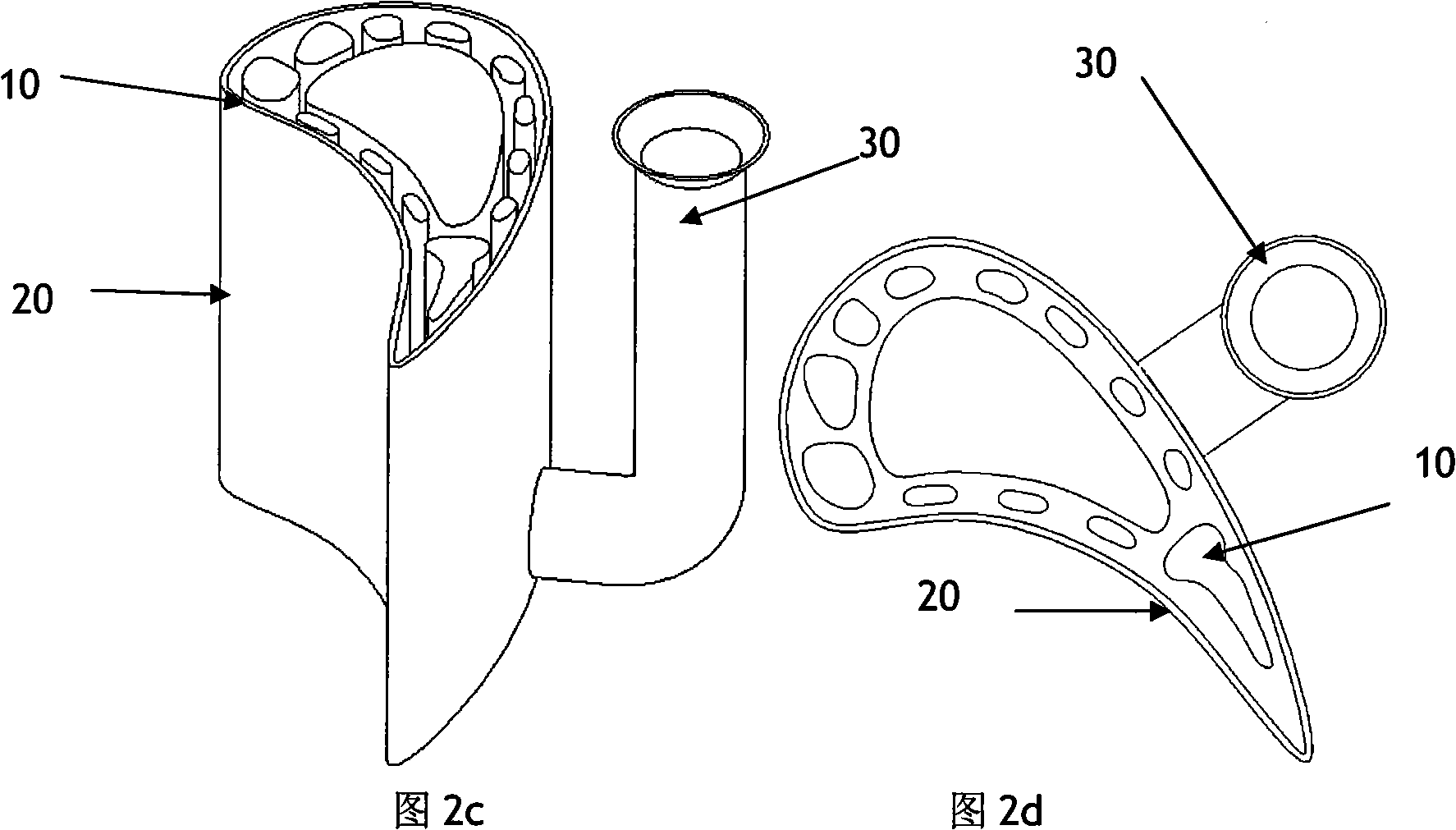

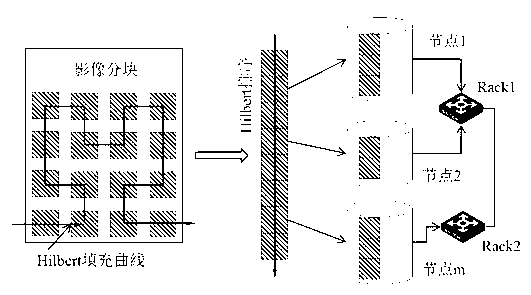

Method for automatic caching construction of massive timing sequence remote-sensing images in cloud environment

Provided is a method for automatic caching construction of massive timing sequence remote-sensing images in a cloud environment. The method for automatic caching construction of the massive timing sequence remote-sensing images in the cloud environment comprises the steps of carrying out data optimization partition on sub-scene data which are received newly in a fixed time interval aiming at imaging caching construction characteristics in the Hadoop cloud environment, carrying out single-scene or multi-scene data caching calculation, wherein a scene is of a data-block particle size, influencing task scheduling of caching slices through optimizing placement of data blocks in the cloud environment, and thus achieving an automatic caching construction process through a plurality of continuous small-batch MapReduce tasks in time in a condition that time sequence images continuously reach. The method for automatic caching construction of the massive timing sequence remote-sensing images in the cloud environment exerts the characteristic of data localization calculation of MapReduce as far as possible through a plurality of optimizing strategies, can carry out rapid construction and update of various caching services of time sequence reaching remote-sensing data in a short cycle by using scalable cloud computing capacity provided by Hadoop, is applicable to remote-sensing images with different space temporal resolutions and different data sources, and has good universality.

Owner:WUHAN UNIV

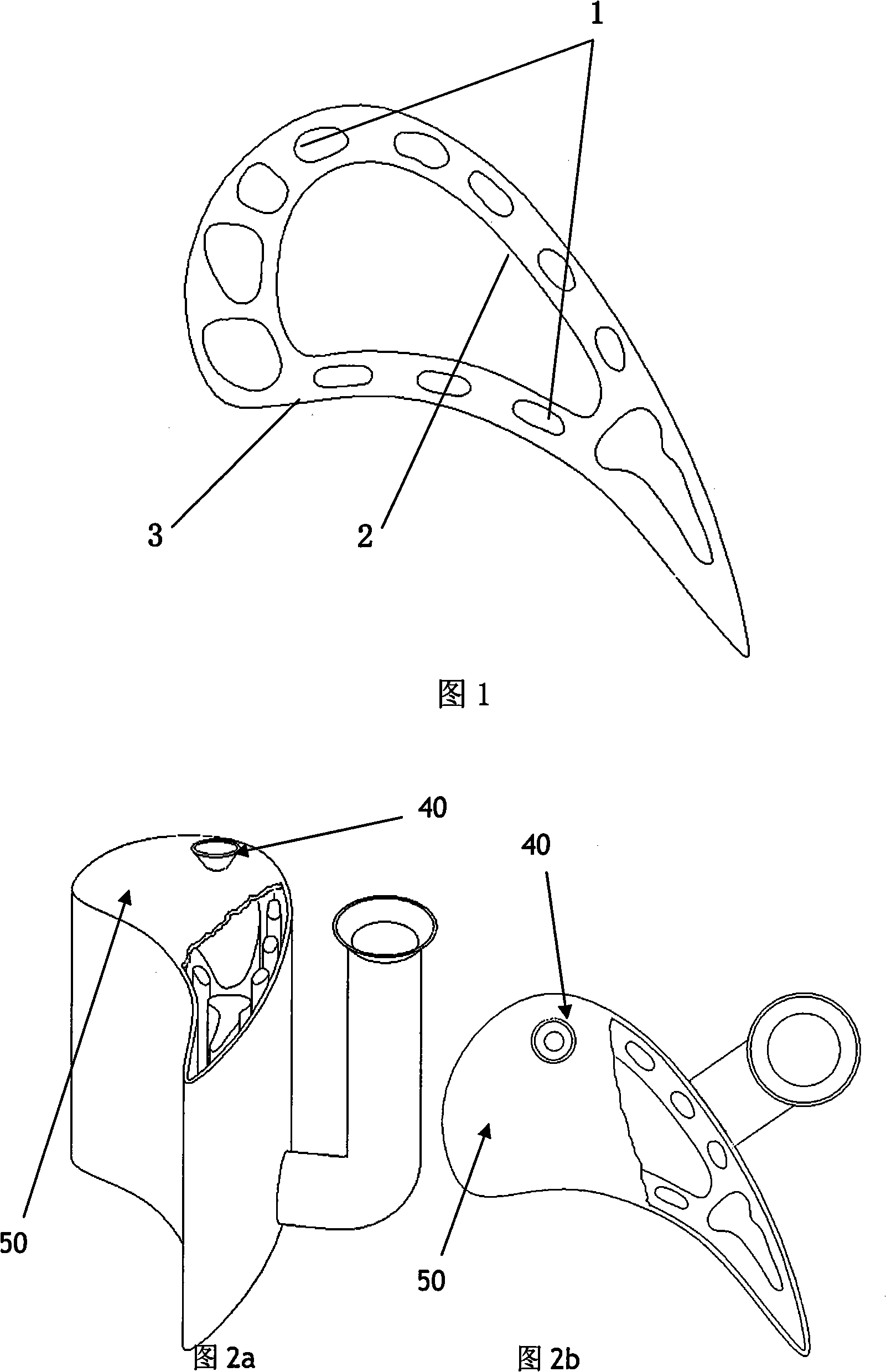

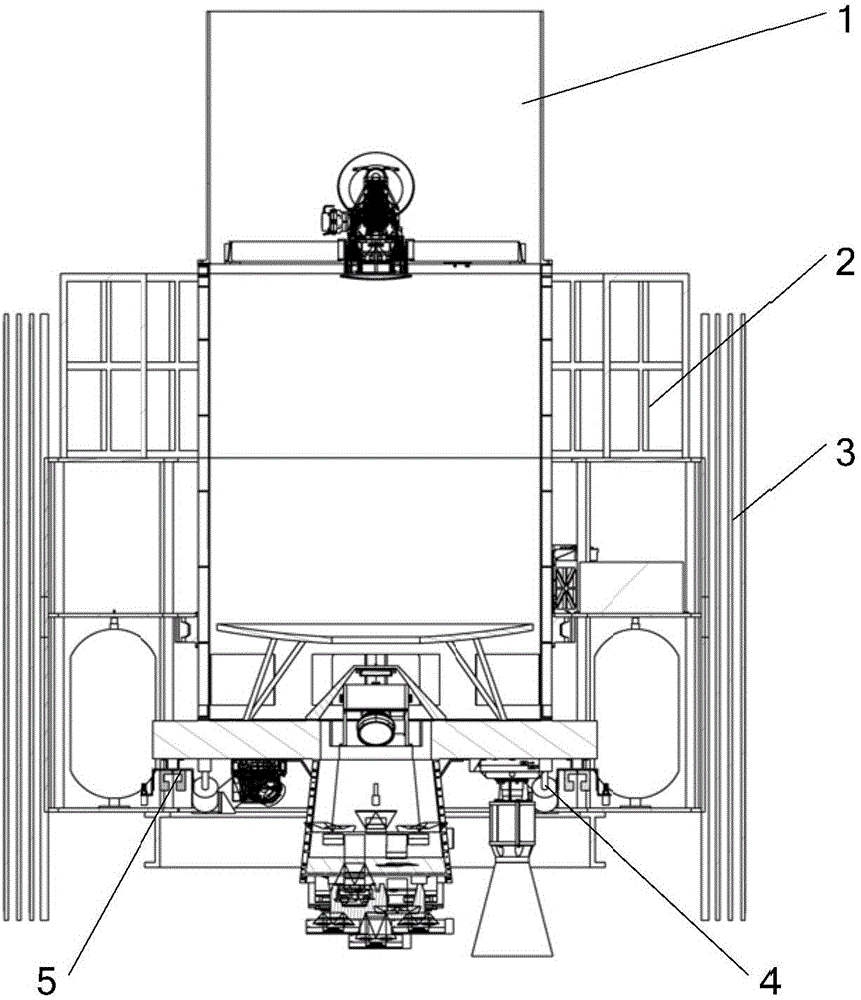

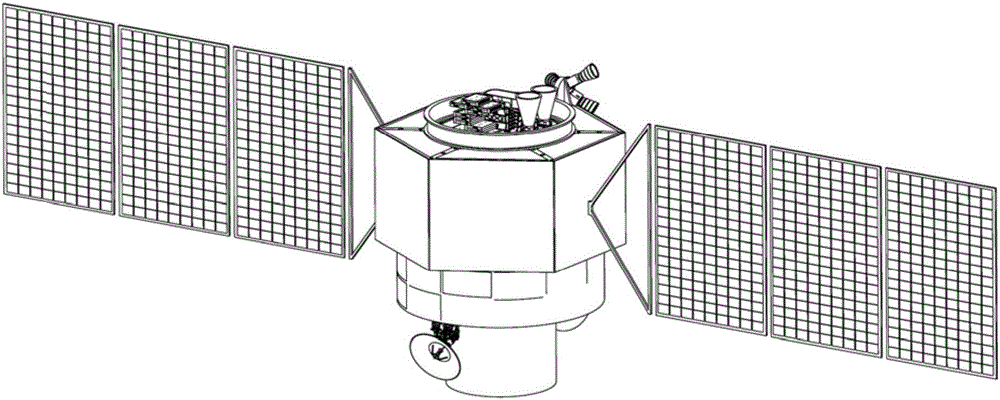

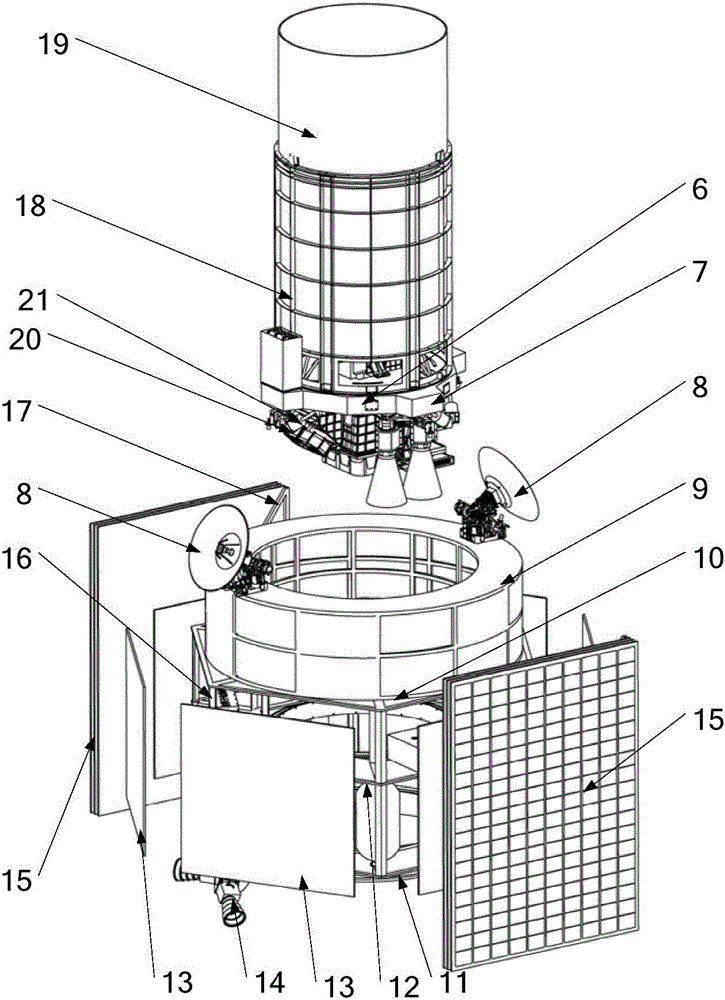

Embedded satellite configuration

InactiveCN106742063AReduce feature sizeReduce the inertia of the whole starCosmonautic power supply systemsArtificial satellitesSpace environmentSolar cell

The invention provides an embedded satellite configuration. The embedded satellite configuration comprises a platform cabin, a loading cabin, a docking locking-unlocking mechanism, a non-contact magnetic suspension direct force control mechanism and a solar cell array. The platform cabin is in a hollow annular structure; the loading cabin is arranged in the platform cabin; the docking locking-unlocking mechanism and the non-contact magnetic suspension direct force control mechanism are arranged between the platform cabin and the loading cabin respectively; the solar cell array is arranged on the side of the platform cabin. Ultrahigh-precision ultrahigh-stability control requirements of satellites are met, quality characteristics and agile mobility performances of the satellites are improved, a loading space environment is improved, and influences of platform disturbance and thermal cycling on satellite loading are reduced. According to a design conception of non-contact split design and centralized control, the embedded satellite configuration has advantages of structural configuration compactness, high control precision, high environmental adaptability, low development risk, short cycle and simplicity and feasibility in integration and final assembly.

Owner:SHANGHAI SATELLITE ENG INST

Lithium-ion power battery electrolyte for high/low temperature environment

InactiveCN104810551AImprove high temperature performanceImprove discharge characteristicsSecondary cellsImidePower battery

The invention discloses a lithium-ion power battery electrolyte for a high / low temperature environment. The electrolyte comprises a lithium salt, an organic solvent and a negative electrode film forming additive. The lithium salt is a mixture of lithium hexafluorophosphate and lithium dis(trifluoromethanesulfonyl)imide or a mixture of lithium hexafluorophosphate and lithium difluoro(oxalato)borate. The organic solvent is a mixture of a carbonic ester solvent and a carboxylate solvent and a volume ratio of the carbonic ester solvent to the carboxylate solvent is 7-9: 1-3. Through modification of the lithium salt, the organic solvent and the film forming additive, charging-discharging, cycle and storage performances of the lithium-ion battery under condition of high / low temperature are obtained, and the problem that the existing lithium-ion power battery electrolyte has a low charging-discharging capacity, a short cycle life and poor storage performances in a high / low temperature environment is solved.

Owner:WANXIANG 123 CO LTD +2

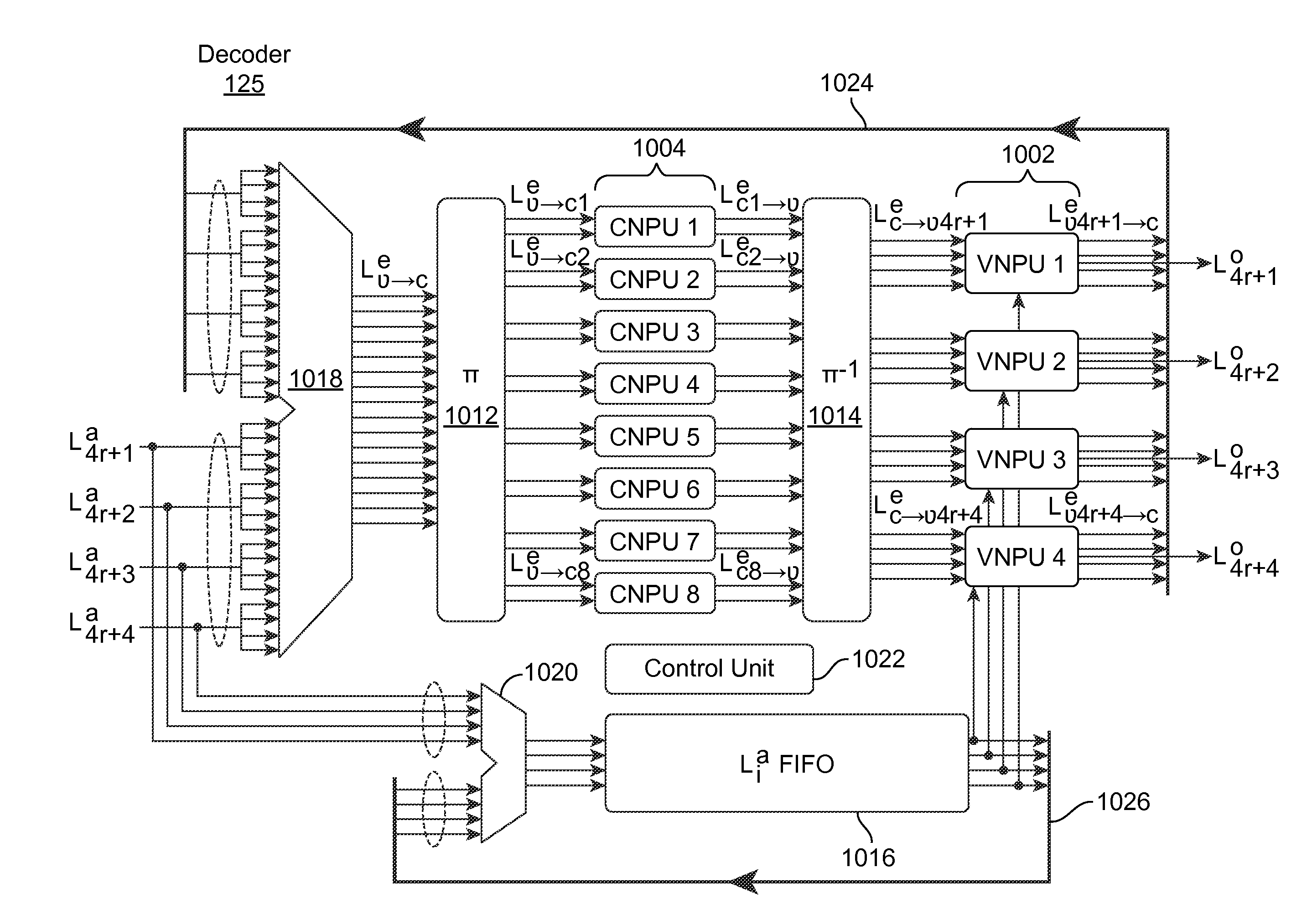

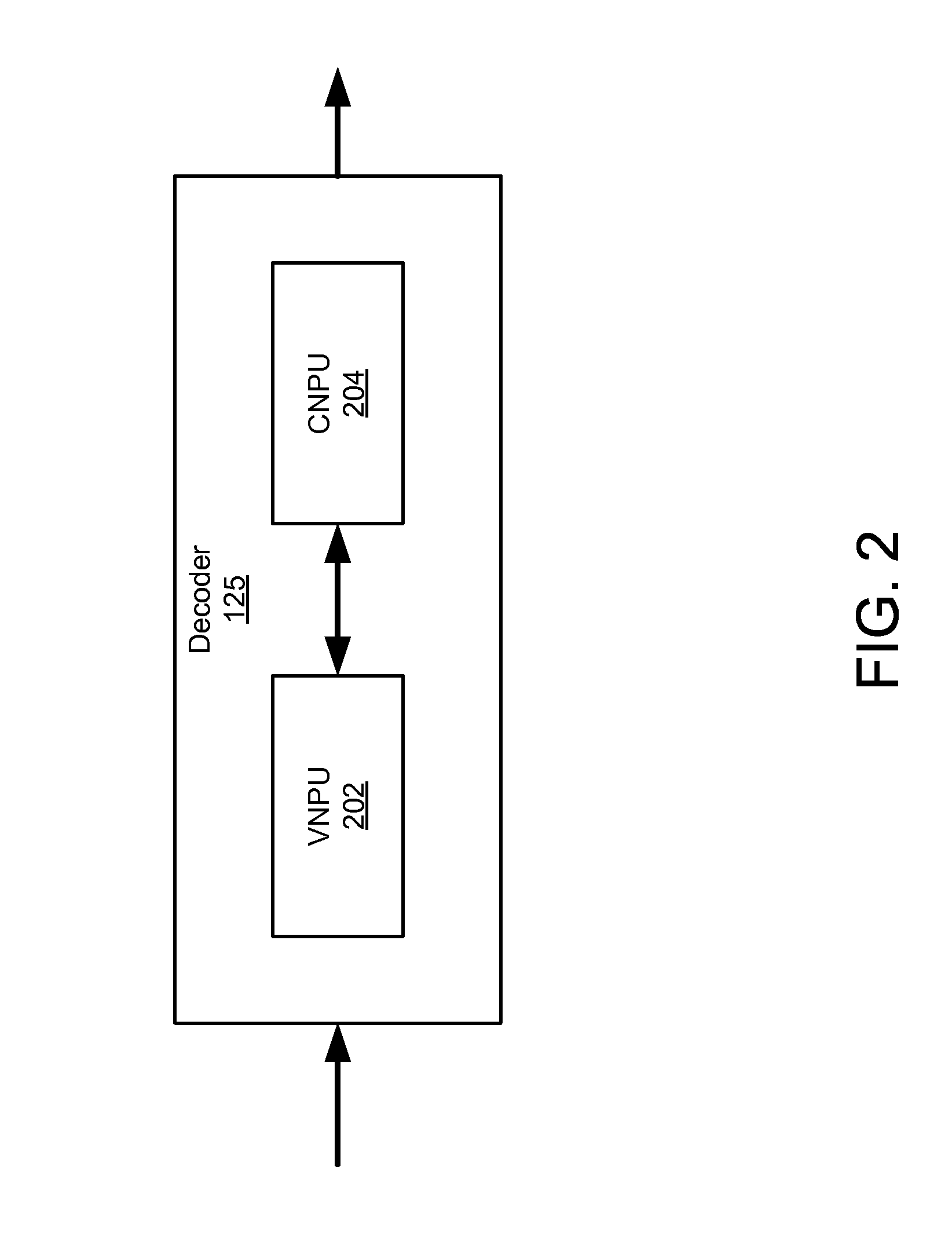

Non-Concatenated FEC Codes for Ultra-High Speed Optical Transport Networks

ActiveUS20120221914A1Improves decoding processAvoid delayError preventionChecking code calculationsUltra high speedParallel computing

A decoder performs forward error correction based on quasi-cyclic regular column-partition low density parity check codes. A method for designing the parity check matrix reduces the number of short-cycles of the matrix to increase performance. An adaptive quantization post-processing technique further improves performance by eliminating error floors associated with the decoding. A parallel decoder architecture performs iterative decoding using a parallel pipelined architecture.

Owner:MARVELL ASIA PTE LTD

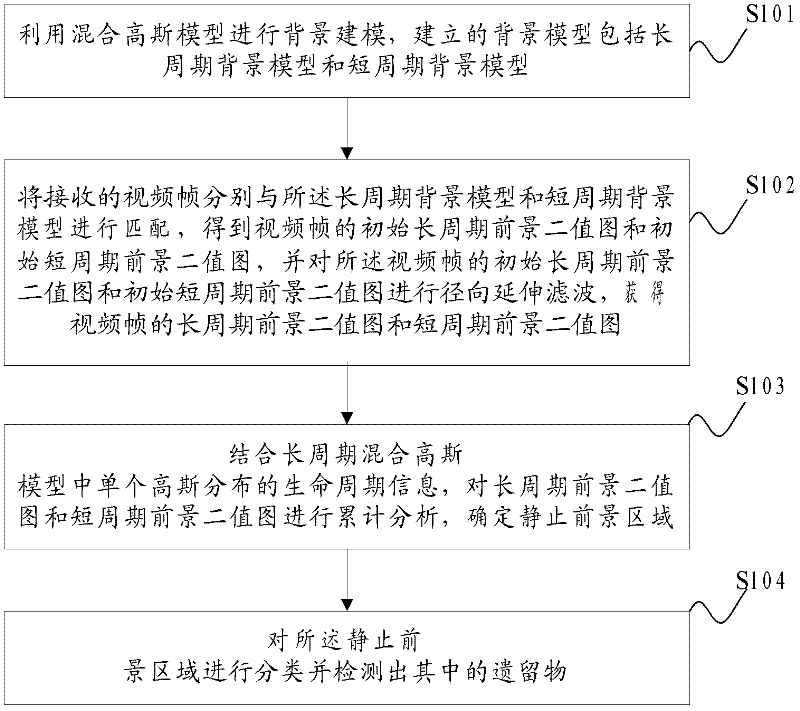

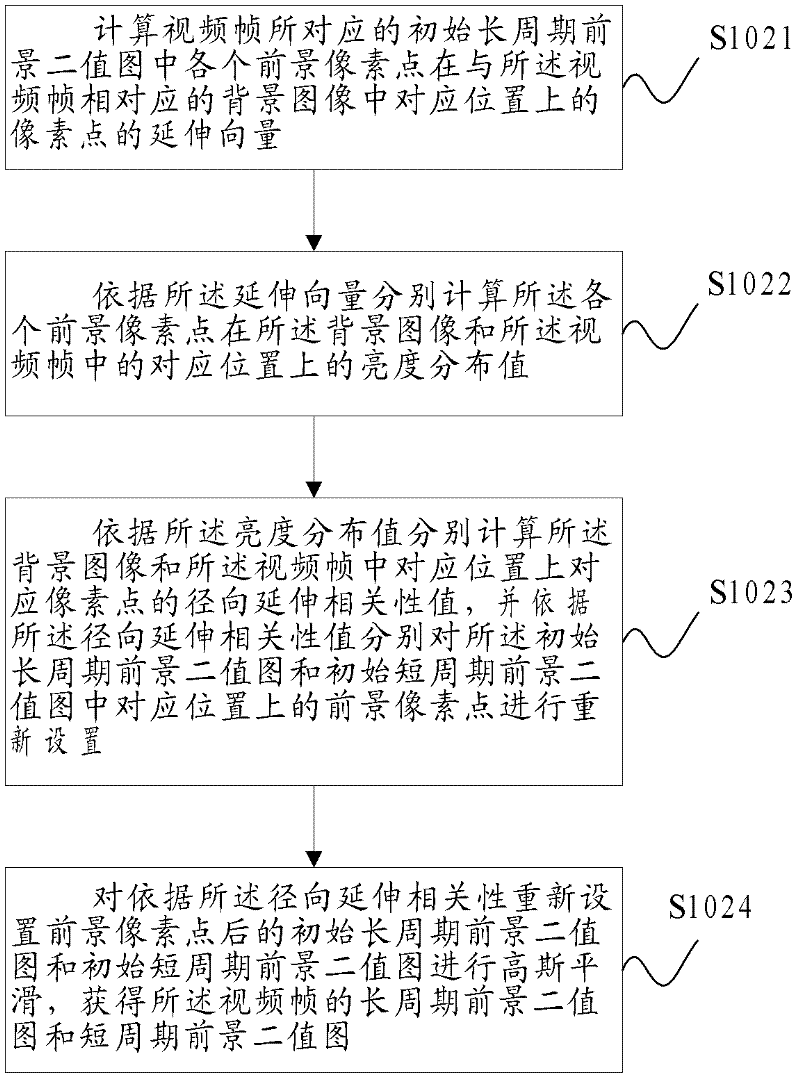

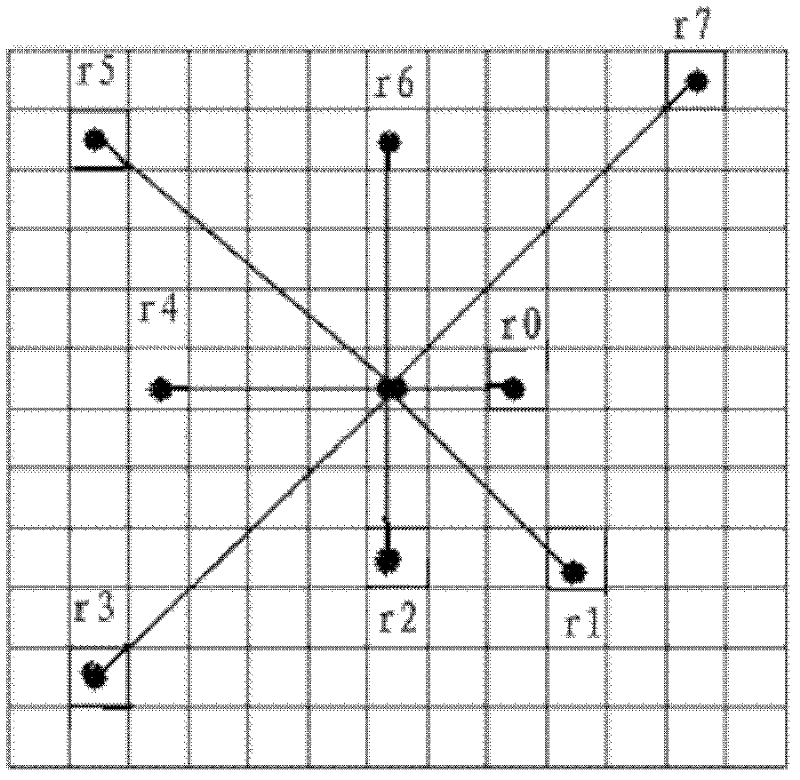

Remnant object detection method and device

ActiveCN102509075AImprove detection accuracyReduce false detection rateCharacter and pattern recognitionClosed circuit television systemsObject detectionLongest cycle

Owner:CRSC COMM & INFORMATION GRP CO LTD

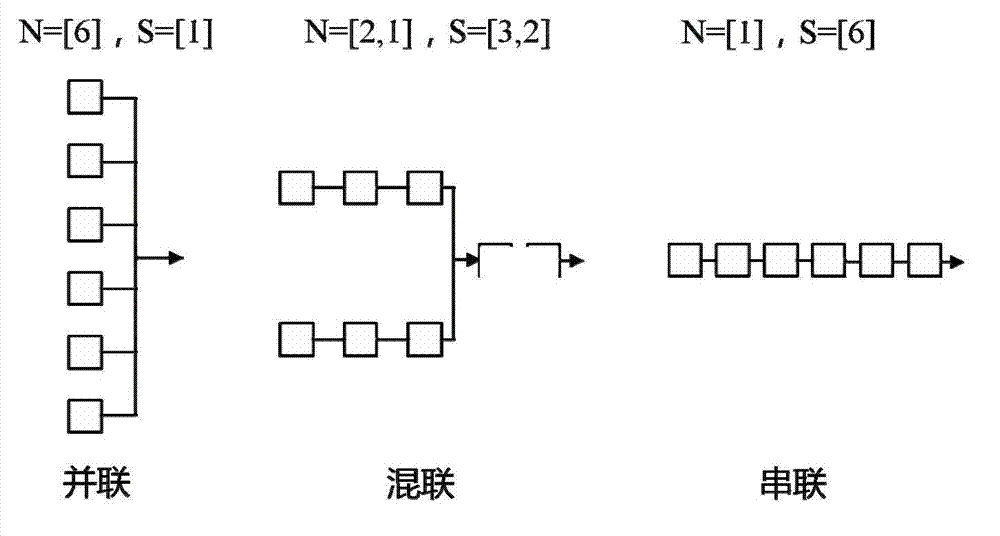

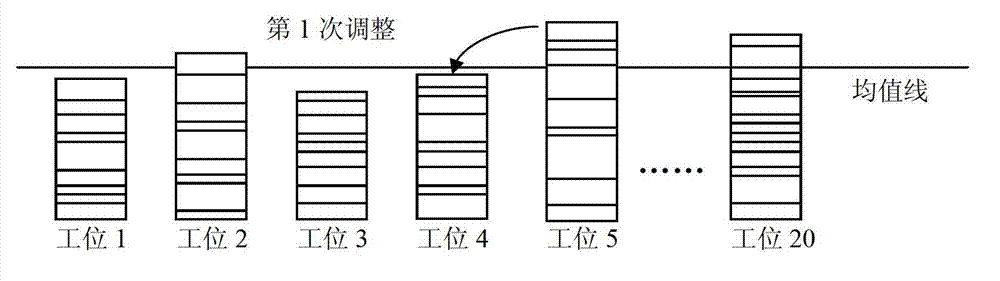

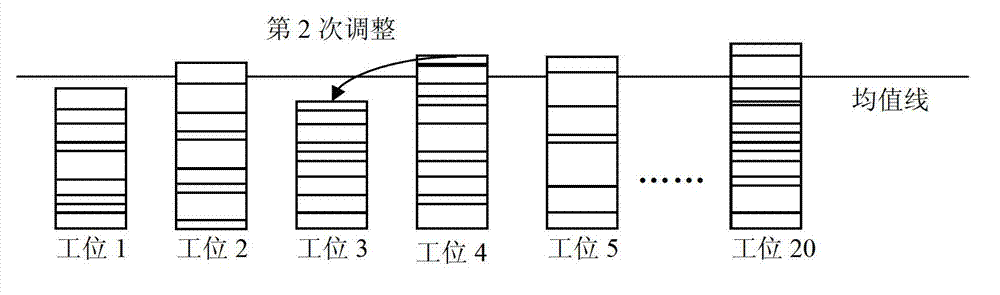

Optimal design method for production line layout

ActiveCN103049801AReduce the impact of volatilityIncrease production capacityForecastingProduction lineTotal investment

The invention relates to the field of engineering manufacture, in particular to an optimal design method for production line layout. The technical problem that the influence of production fluctuation on production efficiency cannot be reduced by the conventional method so as to reduce enterprise benefits is solved. According to the scheme, the optimal design method for new production line layout mainly comprises the following steps of: acquiring the labor house data of original sub-procedures; generating functional segments and a station number by adopting a line balancing planning method, so that the cycle time of a single line in each functional segment is shortest; when total investment C is determined, finding all N and S combinations consistent with a constraint condition by using an enumeration method; calculating the cycle time of each functional segment; calculating the overall cycle time of each [N, S] scheme; and performing calculation according to the steps, and when the total investment C is determined, determining a scheme with the shortest cycle time in all the [N, S] schemes as a target scheme. The method can be used for the design of the new production line layout and the modification of the conventional production line layout.

Owner:四川长虹智能制造技术有限公司

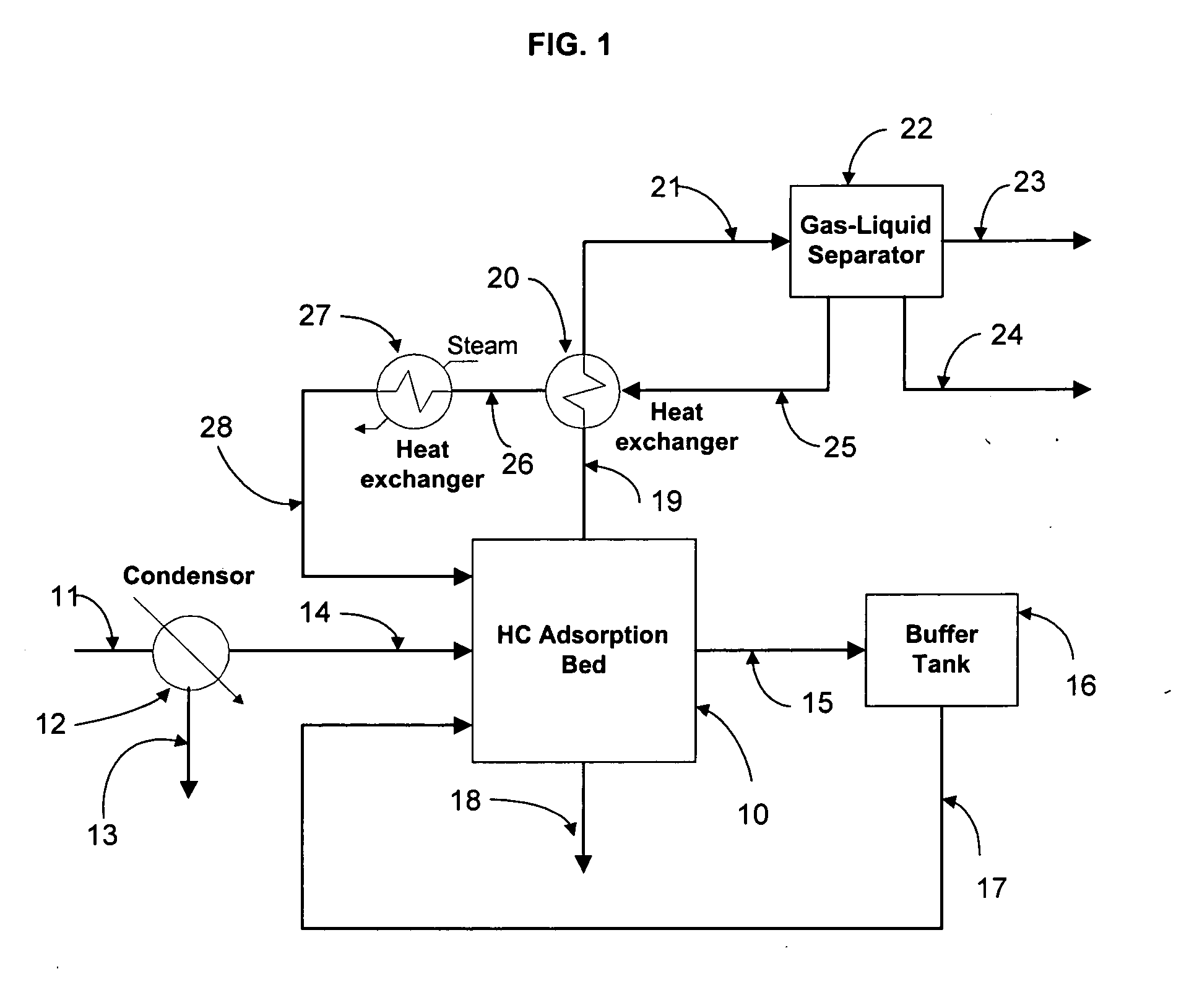

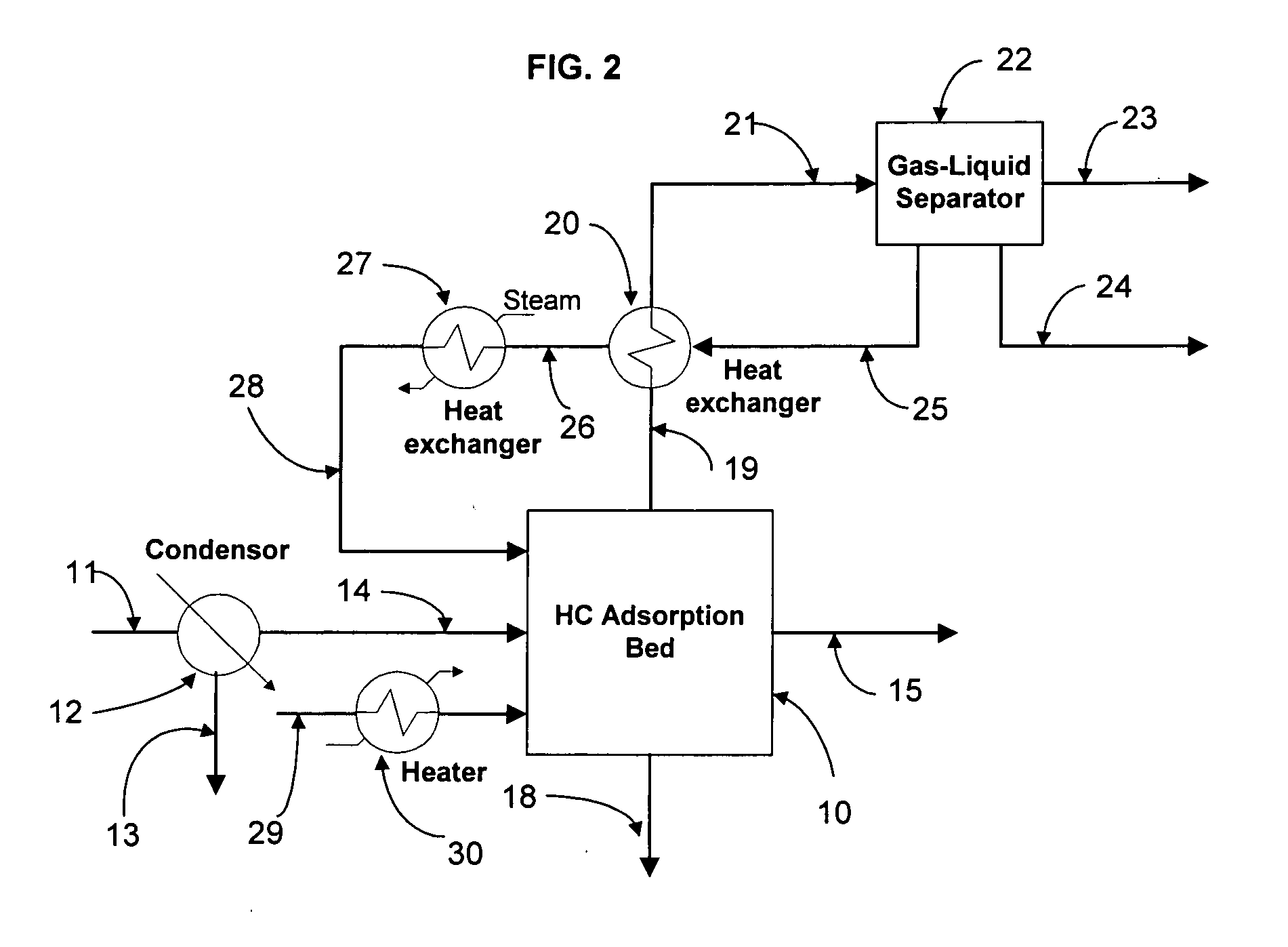

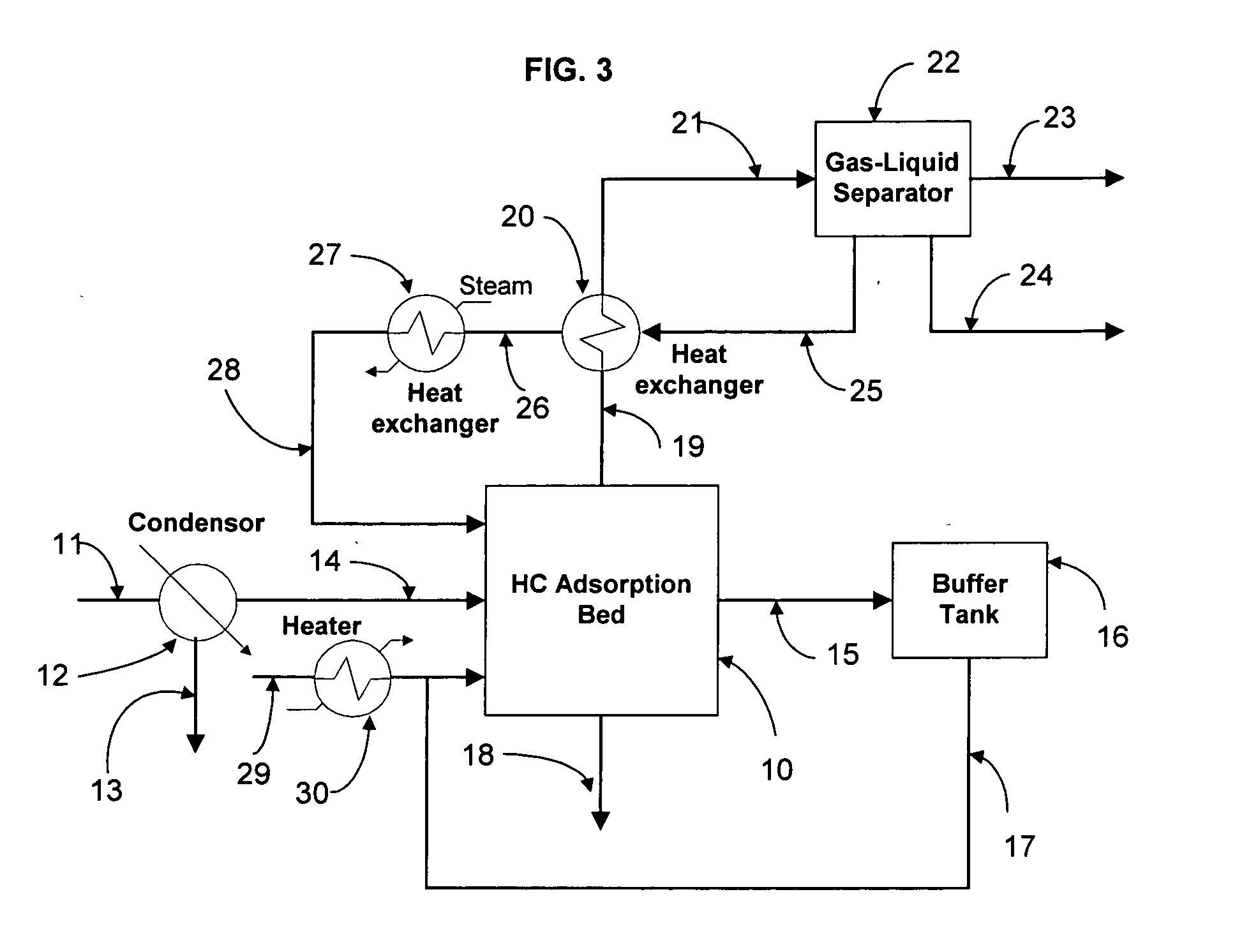

Hydrocarbon separation process

InactiveUS20050203327A1Lowering capitalReduce operating expensesMemory architecture accessing/allocationGas treatmentAlkaneSorbent

The present invention provides for a process of separating hydrocarbons such as short chain paraffins and olefins from non-hydrocarbon gases using short-cycle time concentration swing adsorption processes. The hydrocarbons are adsorbed from the gaseous stream on highly siliceous nanoporous materials, e.g., such as of aluminum-deficient faujasite-type zeolites, by way of a pressure, vacuum or temperature swing adsorption, then desorbed from the adsorbent in the presence of steam. Optionally, the steam is desorbed from the adsorbent through the use of air or inert gas or a recycle of the waste gas effluent. The invention also provides for a new method of preparing novel shapes such as beads and monolithic structures of the highly sileceous nanoporous materials.

Owner:BOC GRP INC

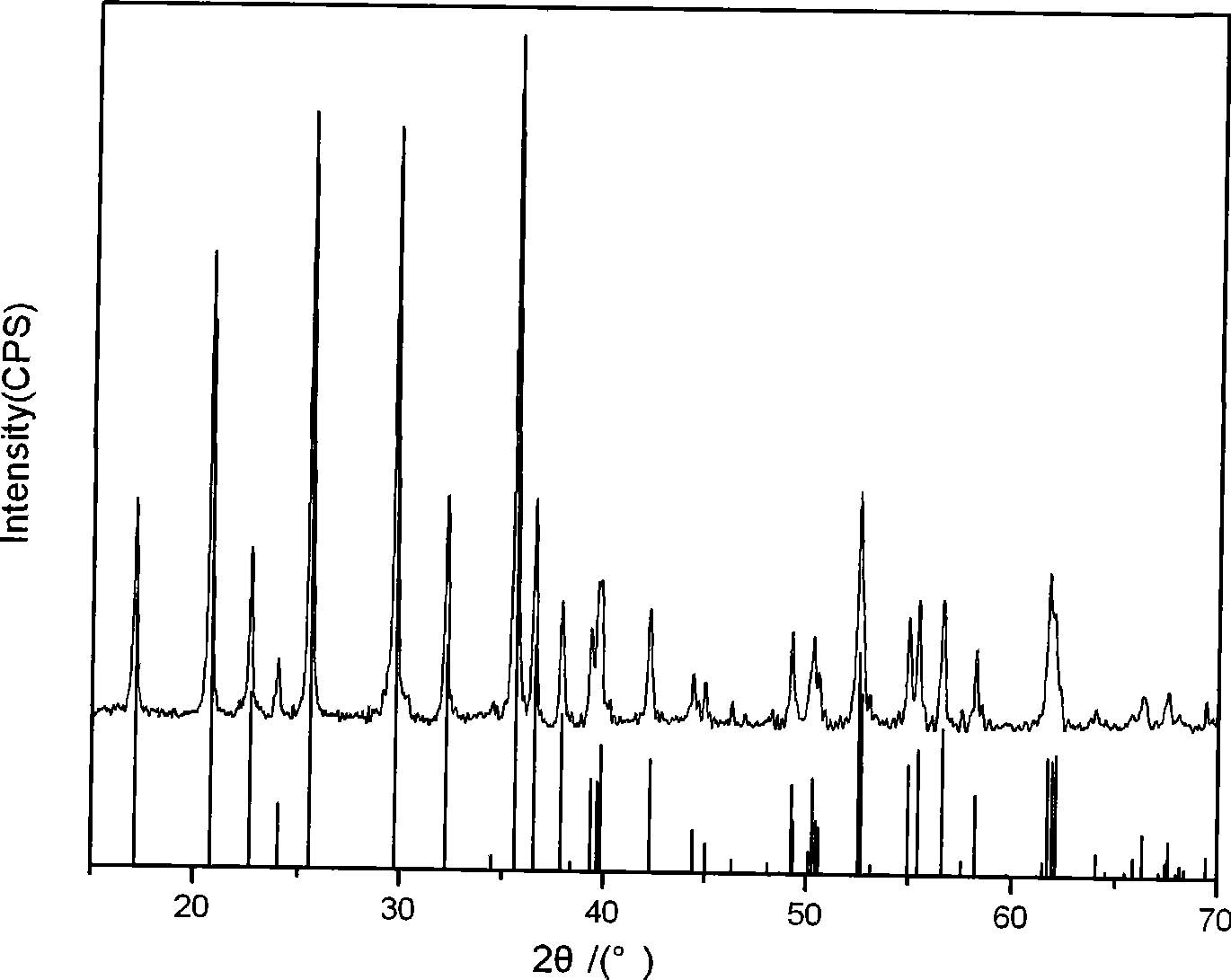

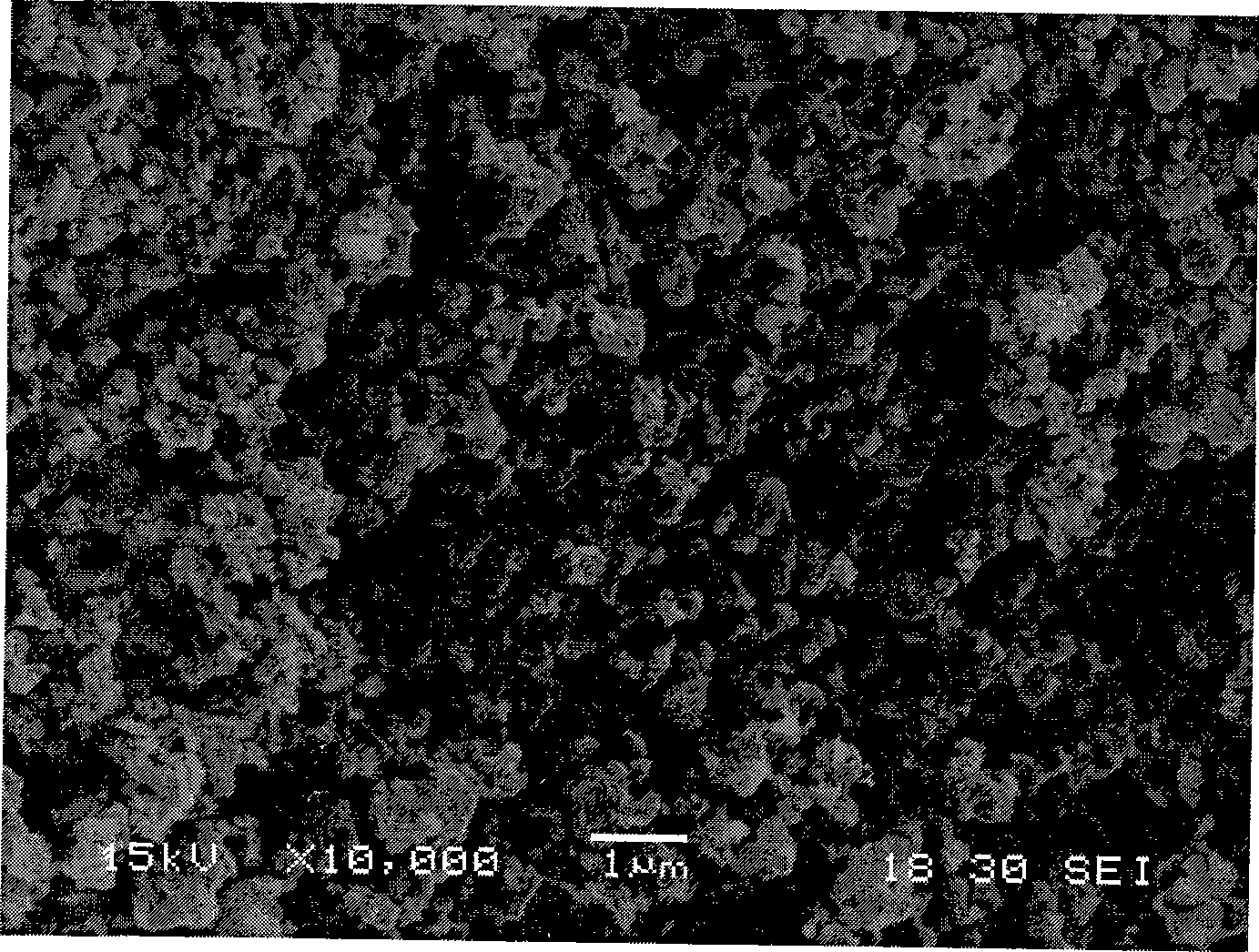

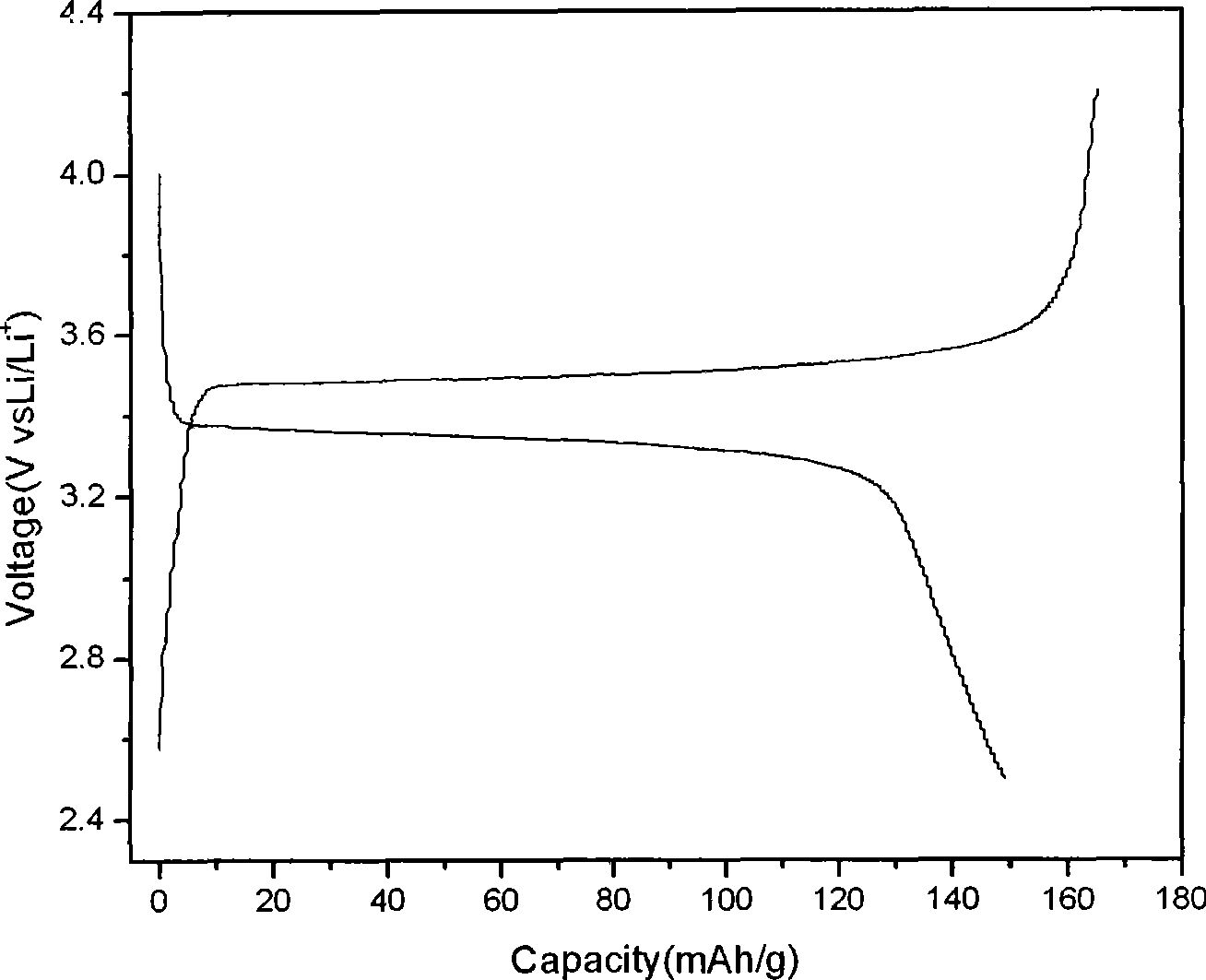

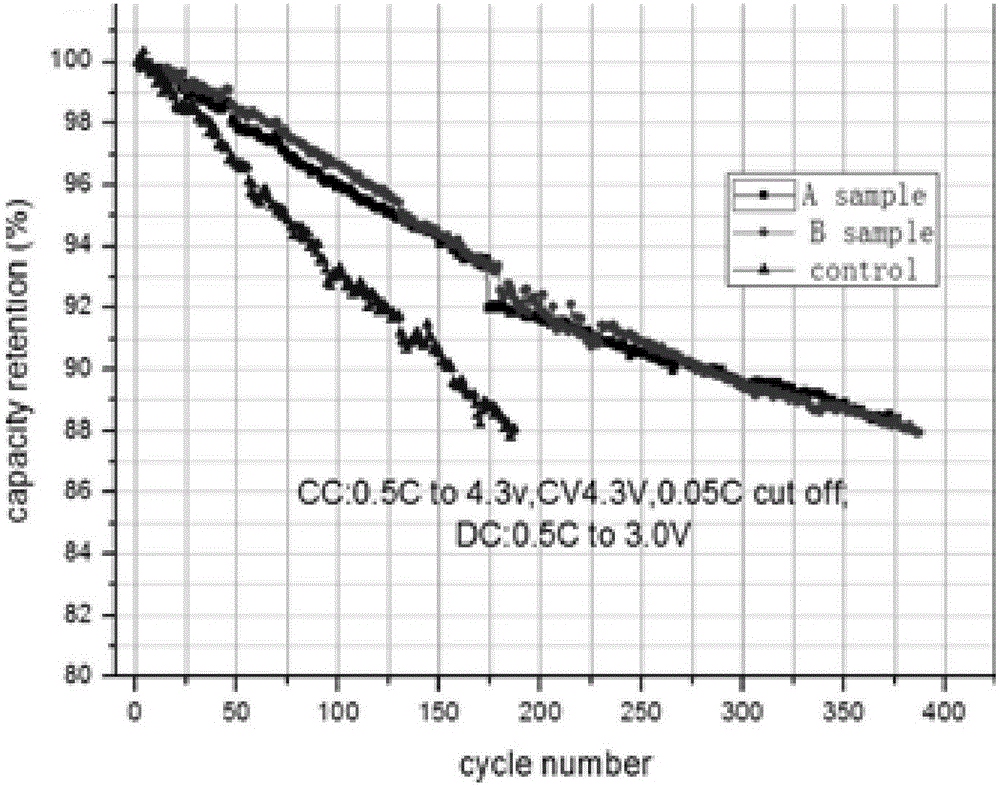

A novel preparation method for LiFePO4/C composite positive pole material

InactiveCN101504979AUniform particle distributionImprove cycle stabilityElectrode manufacturing processesPhosphorus compoundsPhosphoniumEvaporation

The invention discloses a LiFePO4 / C composite anode material and a method for preparing the same, and in particular relates to a method for preparing a lithium ion buttery anode material. The LiFePO4 / C composite anode material is synthesized by a liquid phase evaporation drying method, and the method comprises the following steps: firstly, according to a stoichiometric ratio, weighing certain amount of lithium source compounds, iron source compounds and phosphonium source compounds to prepare mixed solution with certain concentration, and adding right amount of carbon sources; secondly, synthesizing a precursor by controlling the reaction temperature, the stirring speed and the ultrasonic dispersion; thirdly, drying and grinding the precursor; and finally, processing the precursor powder at a temperature of between 500 and 800 DEG C for 2 to 15 hours, and cooling the product to room temperature to obtain the LiFePO4 / C composite anode material. The method has the advantages of easy control, low energy consumption, short cycle, lithium source saving, low cost and the like; and the LiFePO4 / C composite anode material prepared by the method has the characteristics of high purity, small particle size, even distribution of particles, good electrochemical performance and the like.

Owner:SHANGHAI HUAMING HI TECH GRP +1

High-specific-capacity silicon-based negative electrode composite binder and preparation method for negative plate containing same

ActiveCN106058259ASolve the technical problem of short cycle lifeCell electrodesSecondary cellsButadiene-styrene rubberPolymerization

The invention discloses a high-specific-capacity silicon-based negative electrode composite binder and a preparation method for a negative plate containing the same, belonging to the field of binders for batteries. The high-specific-capacity silicon-based negative electrode composite binder comprises 5 to 50 wt% of carboxymethylcellulose sodium, 5 to 30 wt% of polyacrylic acid and 20 to 90 wt% of styrene-butadiene rubber. The preparation method for the negative plate comprises the following steps: binder preparation; addition of a conductive agent; addition of a main material; sieving; coating; high temperature polymerization; rolling; and punching. The composite binder provided by the invention can overcome the technical problem of short cycle life of a battery caused by immense volume changes of a conventional silicon-based negative electrode material during intercalation and deintercalation of lithium ions.

Owner:WANXIANG 123 CO LTD

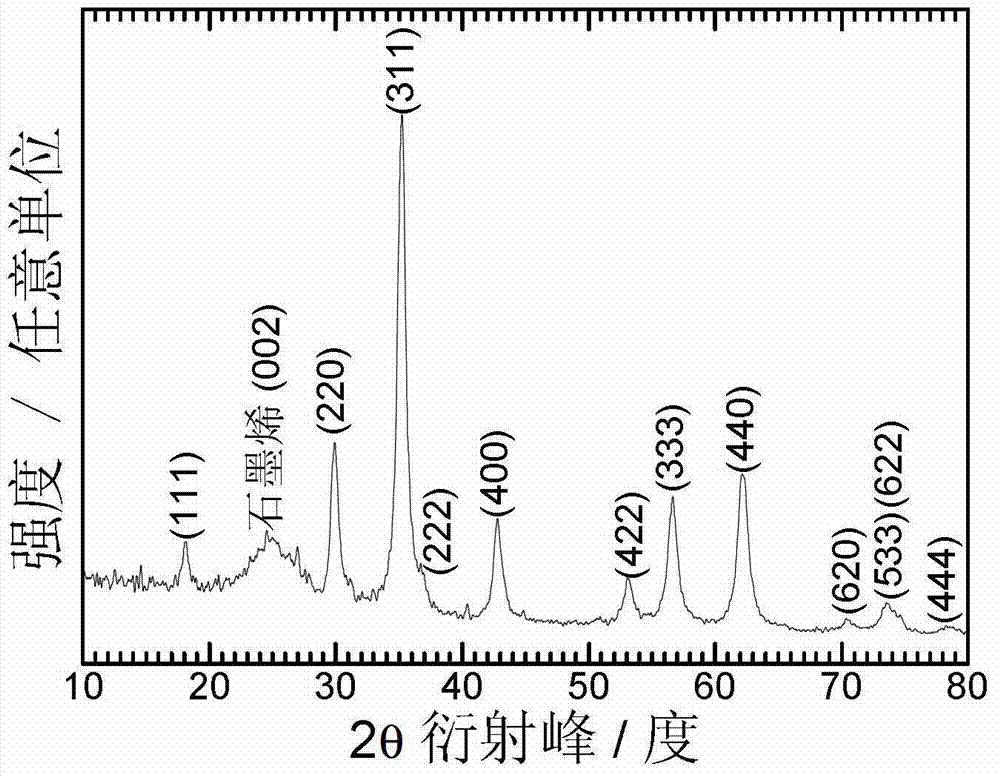

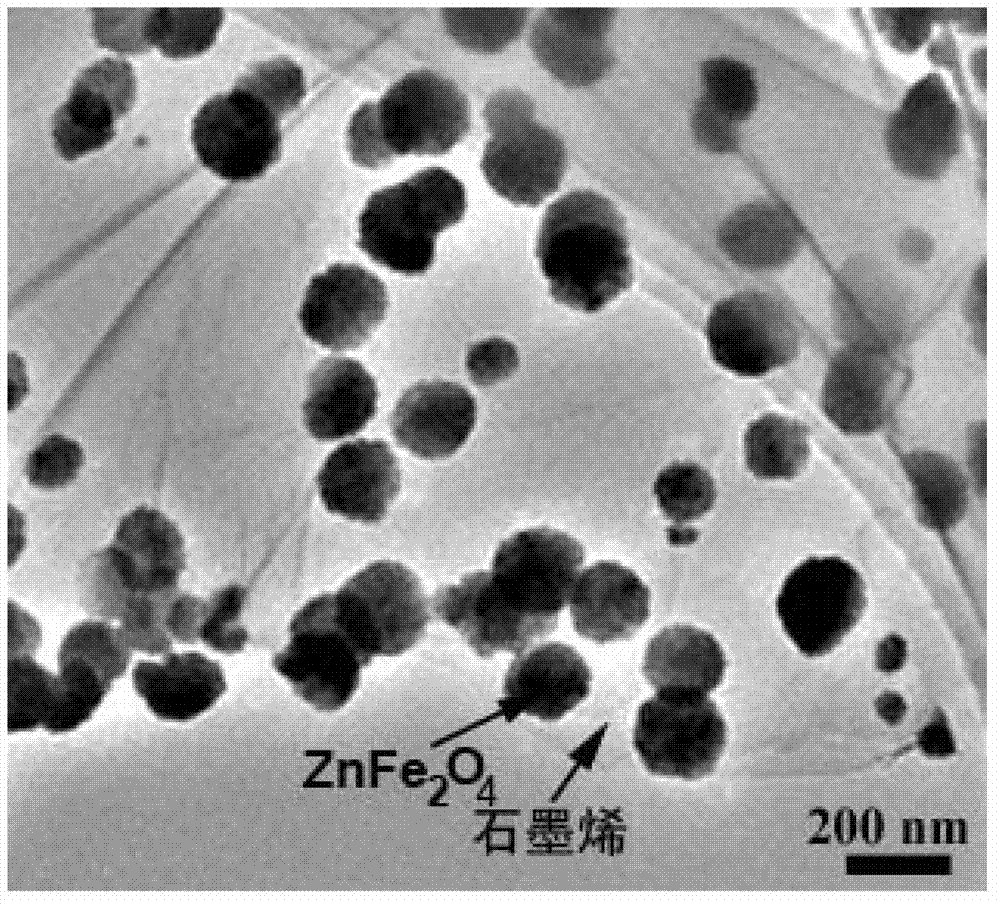

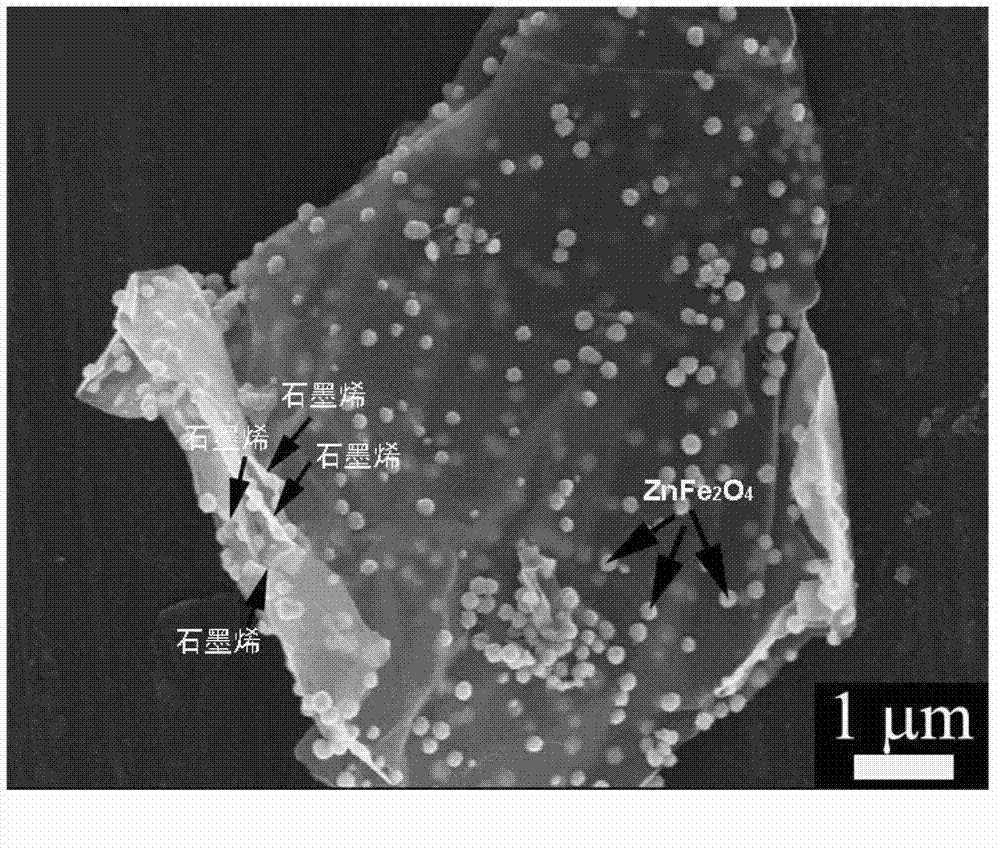

Zinc-base complex oxide/graphene composite material, and preparation method and application thereof

InactiveCN102760873AImprove electrochemical stabilityImprove cycle stabilityCell electrodesLoop stabilityZinc

The invention discloses a zinc-base complex oxide / graphene composite material which is in a laminated structure and is composed of a nano zinc-base complex oxide and graphene, wherein the general formula of the zinc-base complex oxide is ZnM2O4, and M is Mn, Co, Fe or Cr. Under the dispersion and loading actions of the graphene, the zinc-base complex oxide can be distributed uniformly and have small particle size to form a laminated structure, the stability and loop stability of the zinc-base complex oxide in the charging / discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com