Patents

Literature

610results about How to "Uniform particle distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

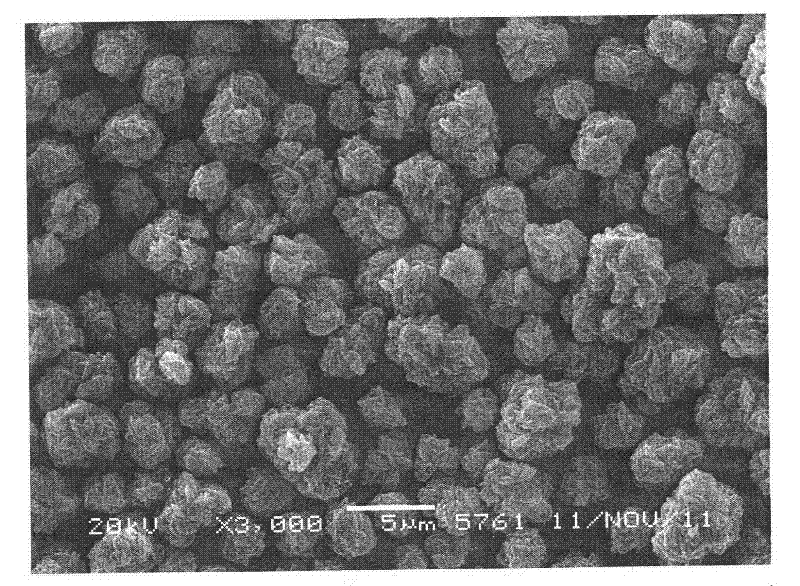

Preparation method for nickel-manganese-cobalt anode material of lithium ion battery

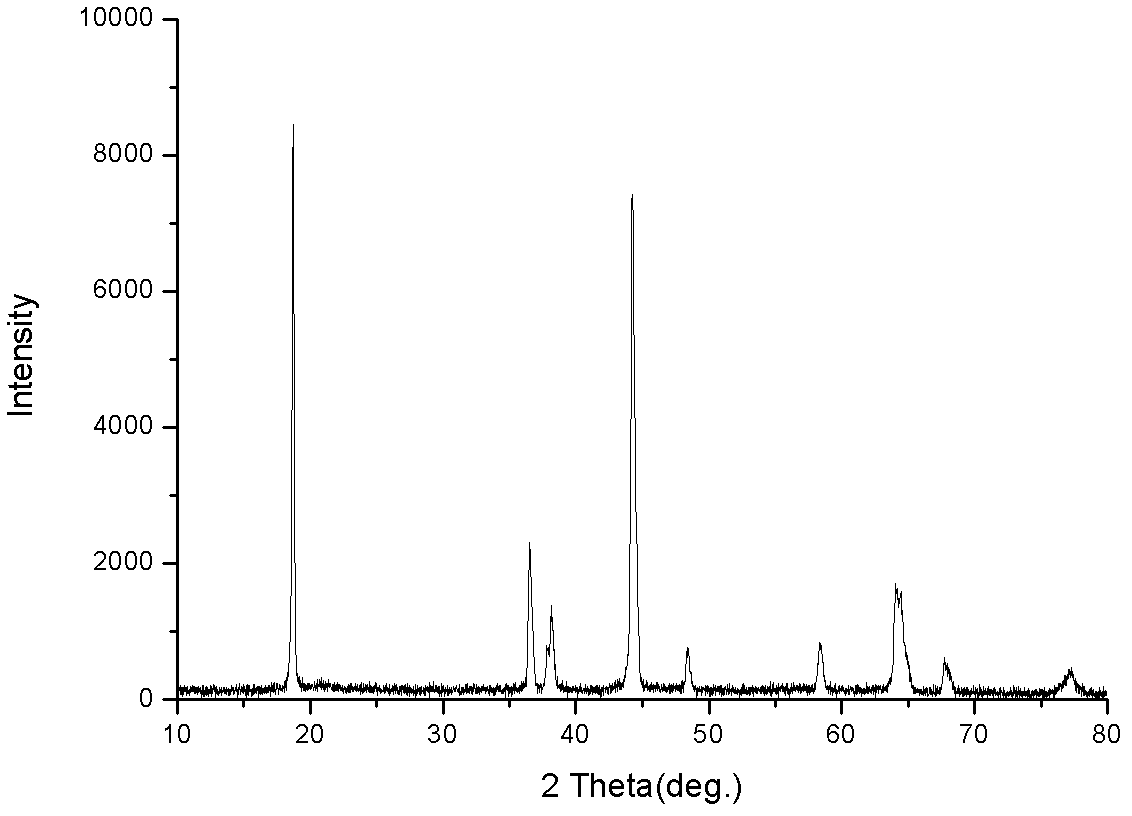

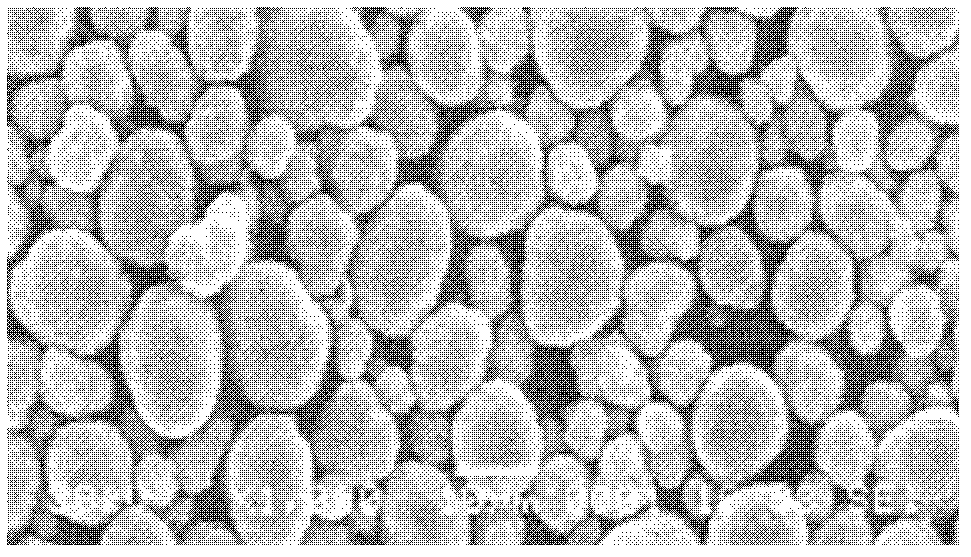

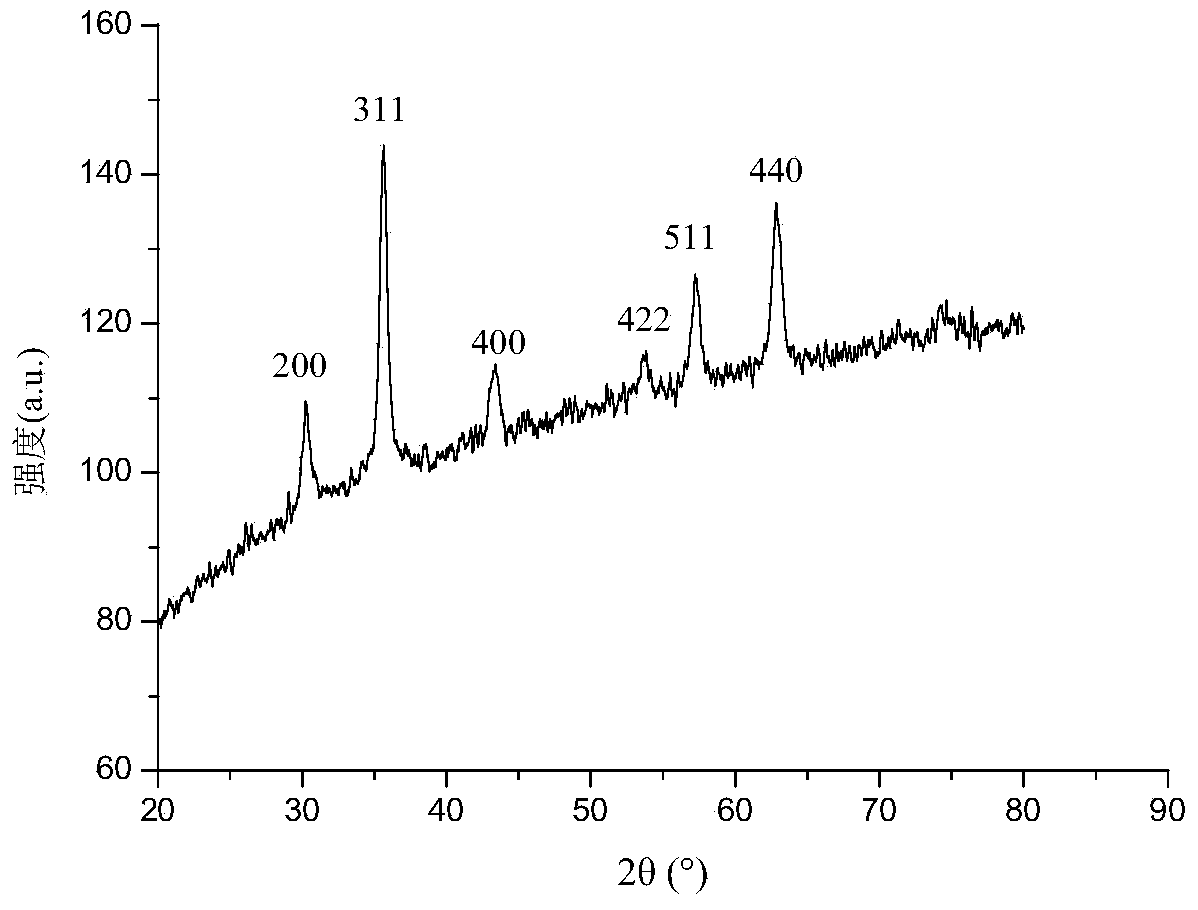

InactiveCN102306765AImprove discharge capacityImprove cycle performanceCell electrodesManganeseLithium compound

The present invention relates to a preparation method for a nickel-manganese-cobalt anode material of a lithium ion battery. According to the present invention, in the presence of nitrogen atmosphere, a mixed solution containing nickel iron, manganese iron and cobalt ion reacts with a precipitating agent, then processes of aging, washing, drying and the like are performed to obtain a nickel-manganese-cobalt hydroxide precursor, the synthesized precursor material has spherical morphology, ideal particle size distribution and high tap density; the precursor, a lithium compound and a doped compound are mixed, then the sintering processing is performed for twice to prepare the nickel-manganese-cobalt three-element composite anode material. The method has characteristics of simple synthesis process, easy process controlling, low energy consumption, high efficiency and low cost, and is applicable for the industrial production; the prepared precursor material has characteristics of spherical morphology, uniform particle distribution and high tap density; the discharge capacity of the battery is improved through doping the metals; the cycle performance of the battery is stable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

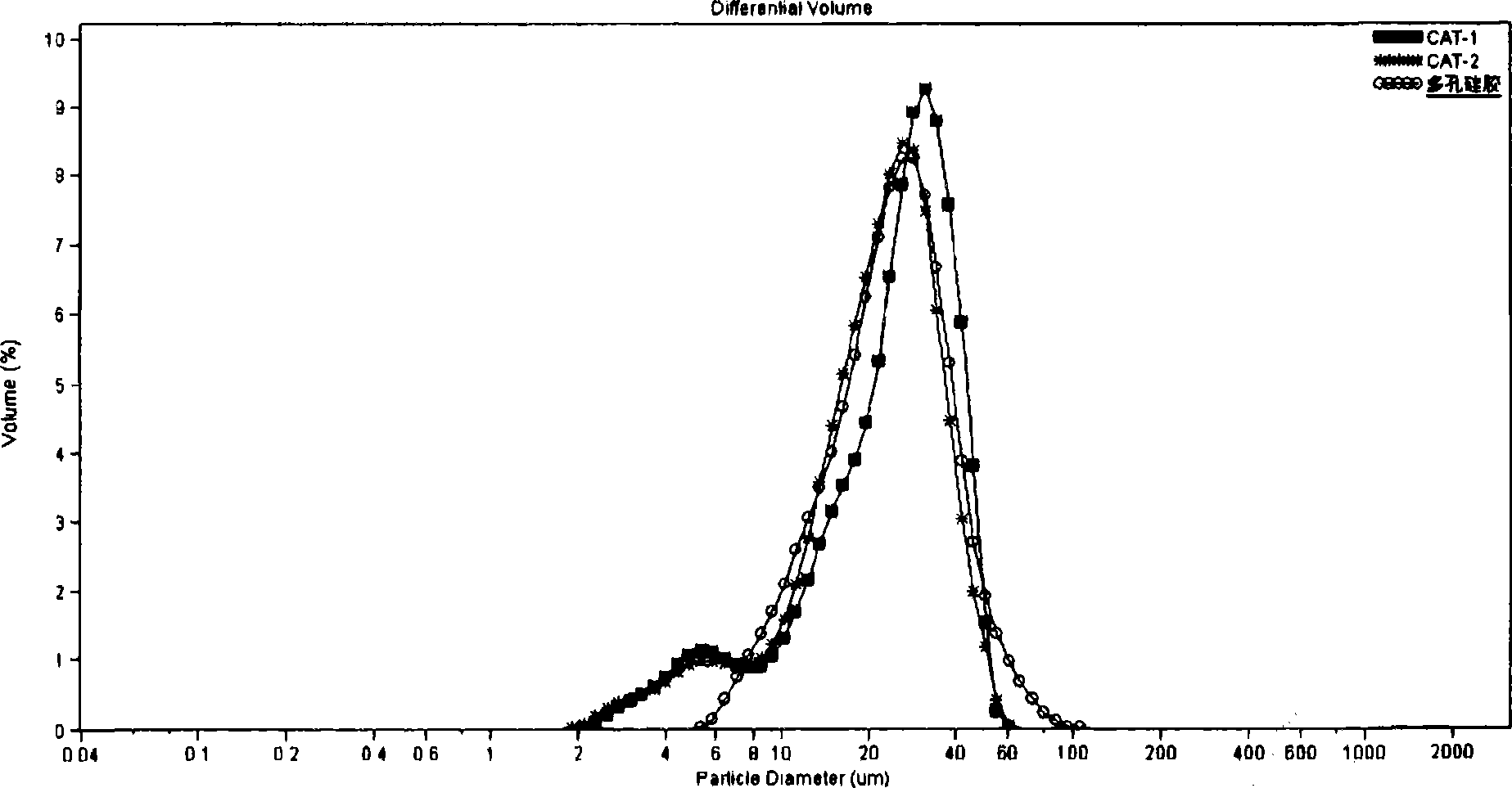

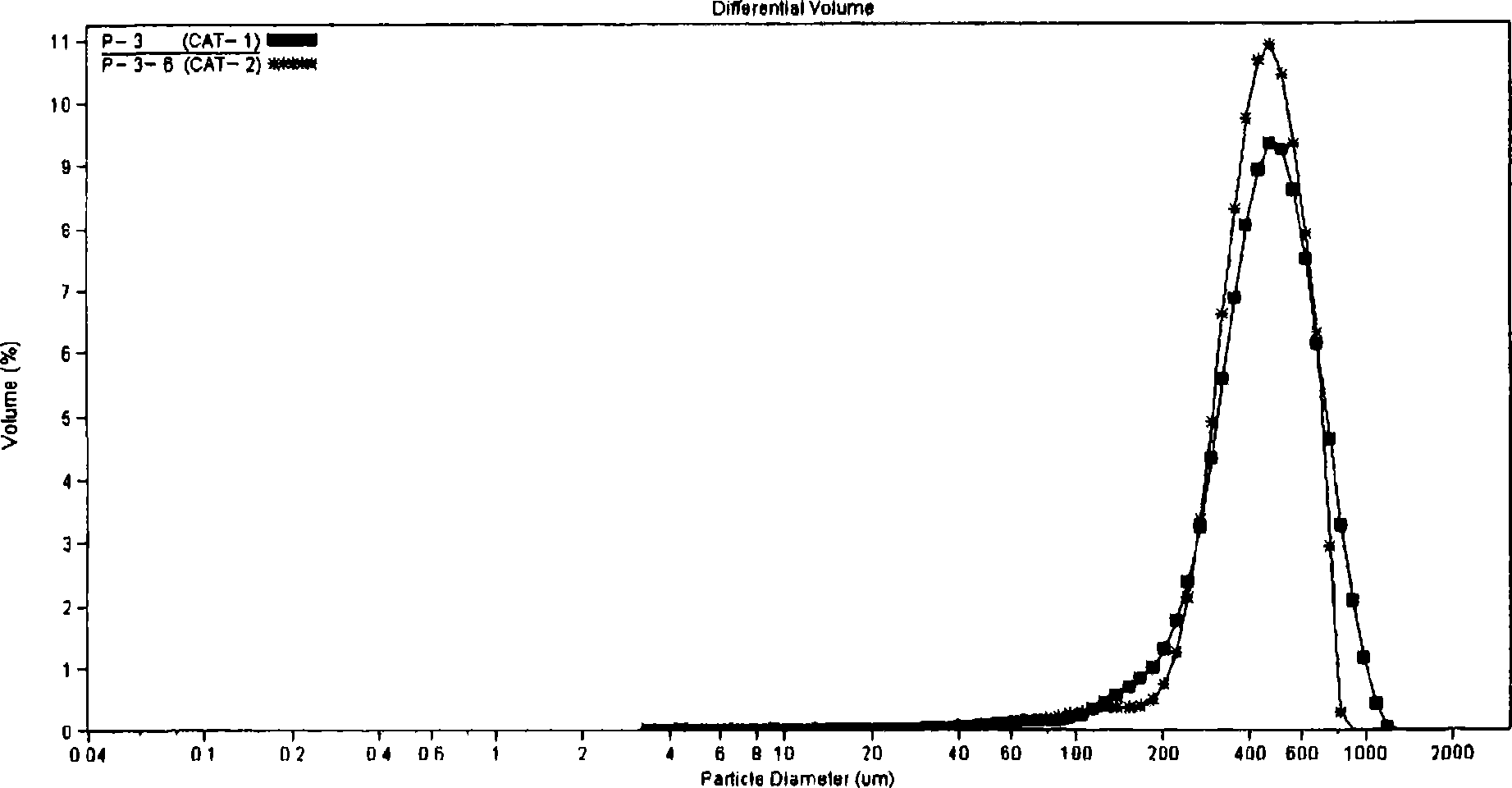

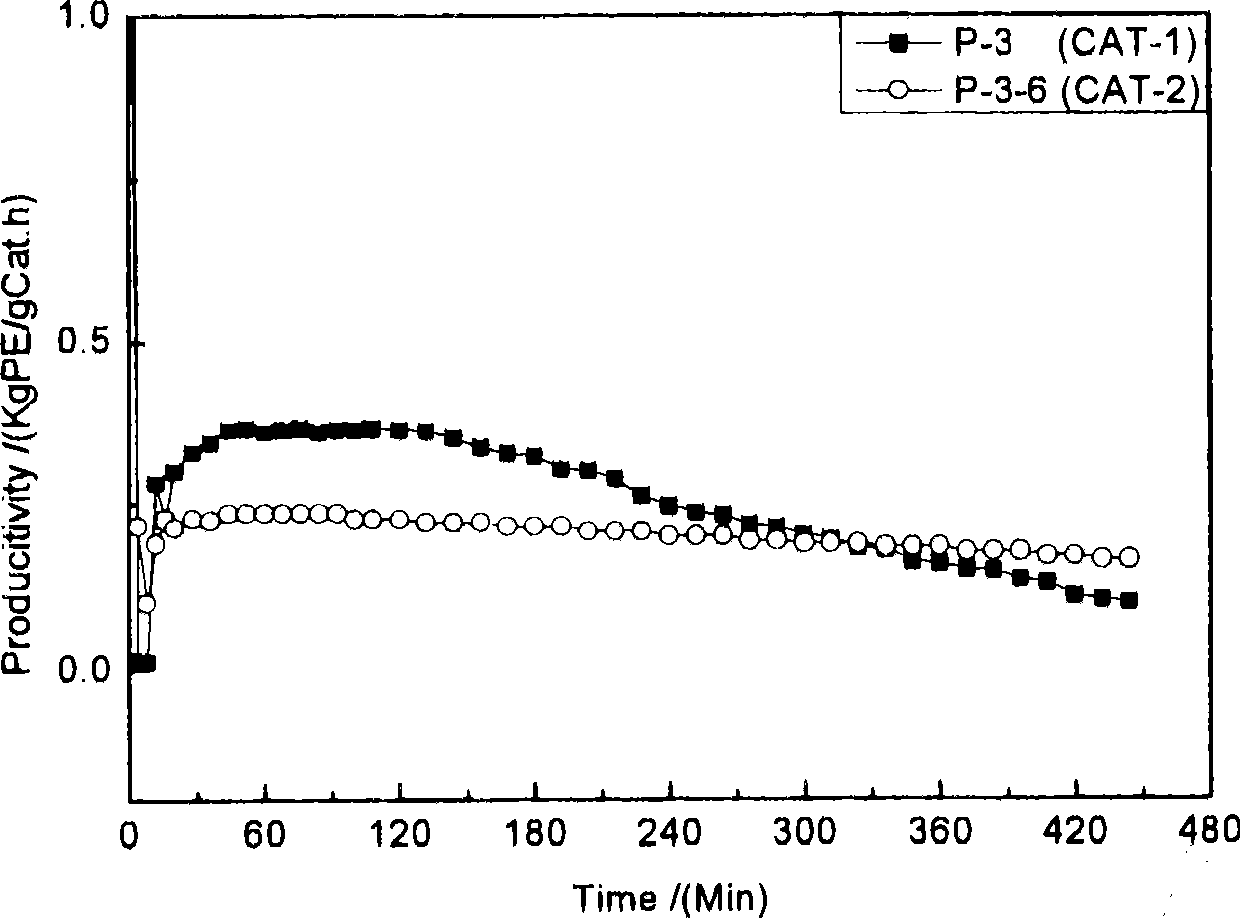

Load type catalyst, load type non-metallocene catalyst and preparations thereof

ActiveCN101412765AAdapt to polymerization activity requirementsHigh and adjustable polymerization activityChemical treatmentEthylene Homopolymers

The invention relates to a method for preparing a supported catalyst by supporting a chemical treatment agent on a composite carrier formed by a magnesium compound and a porous carrier, and a method for preparing the supported non-metallocene catalyst by further supporting a supported non-metallocene complex on the supported catalyst. The invention also relates to the supported catalyst and the supported non-metallocene catalyst which are prepared through the methods respectively. The range of polymerization activities of the catalysts is flexible and adjustable. When the catalysts are adopted for catalytic polymerization of ethylene and so on, an ethylene homopolymer / copolymer with high bulk density and evenly-distributed polymer particles can be prepared. Moreover, the catalysts have longer life of the polymerization activities and relatively stable polymerization kinetics curves.

Owner:SINOPEC YANGZI PETROCHEM

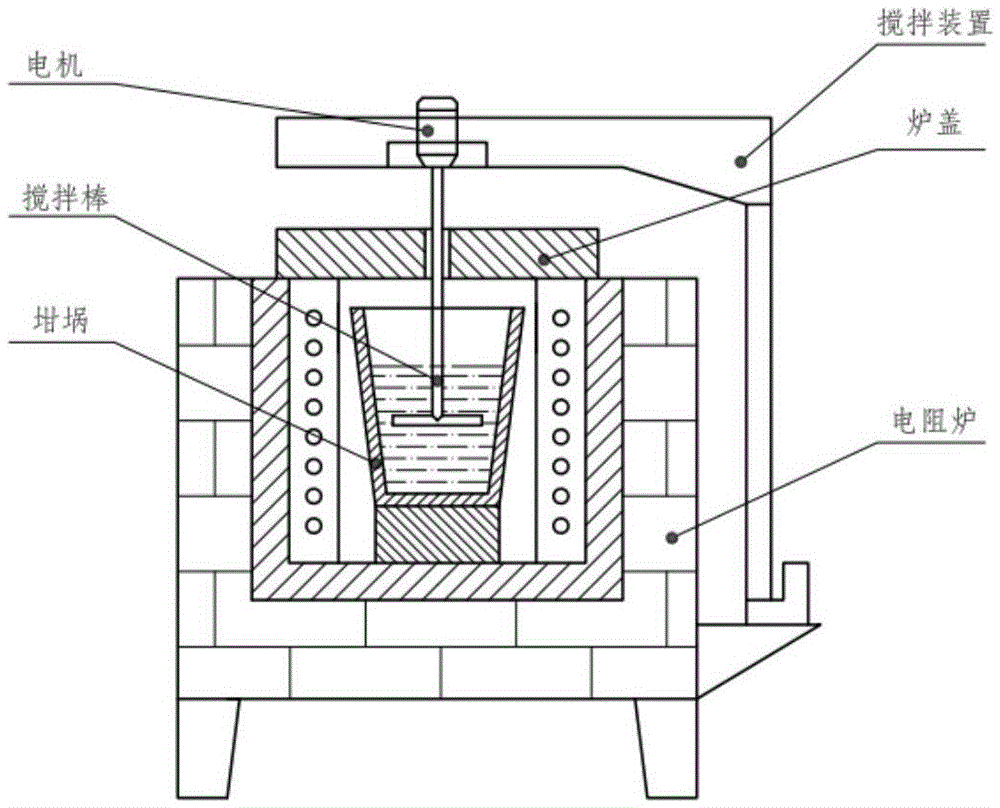

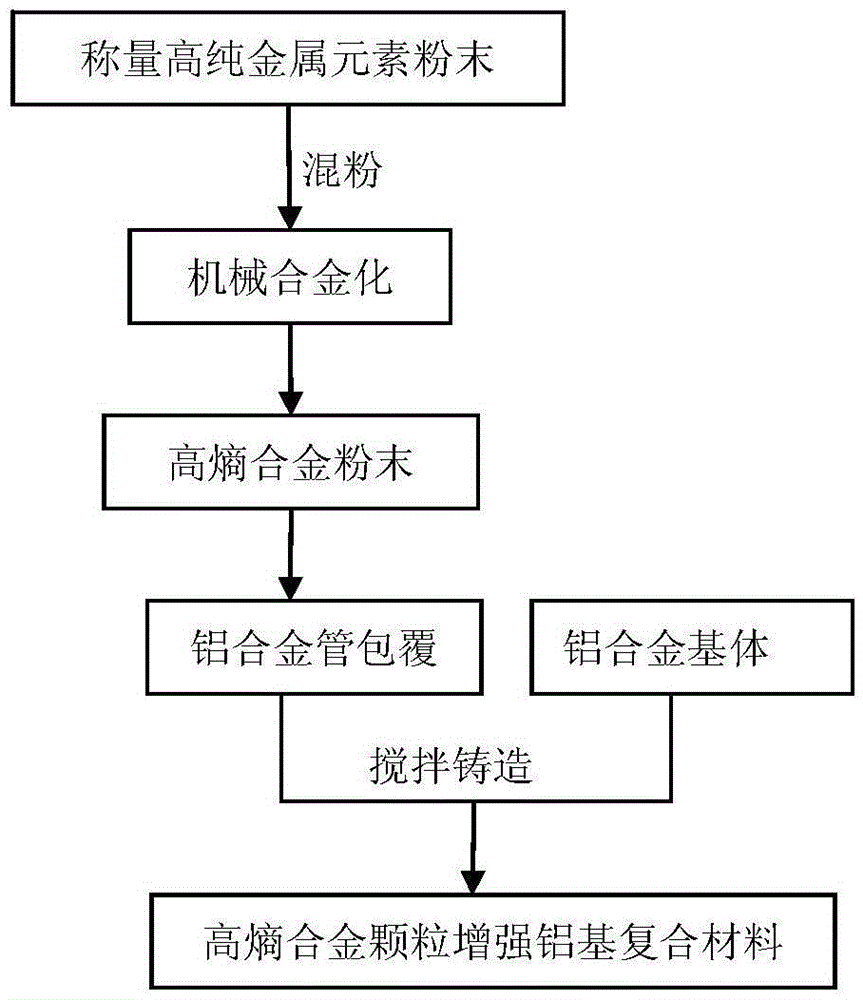

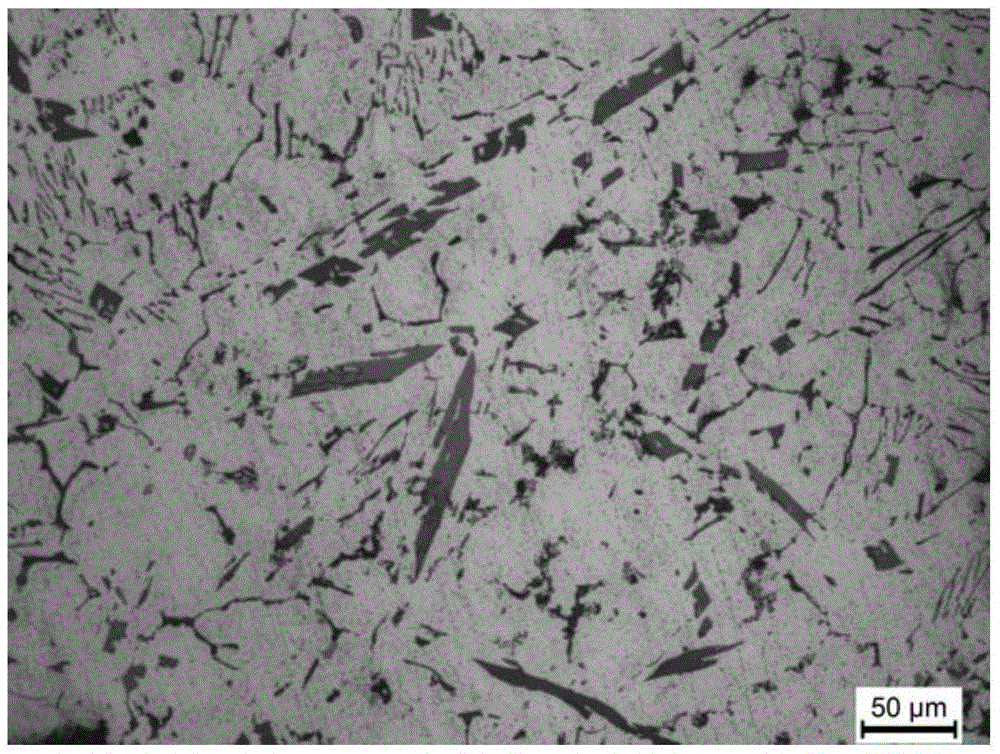

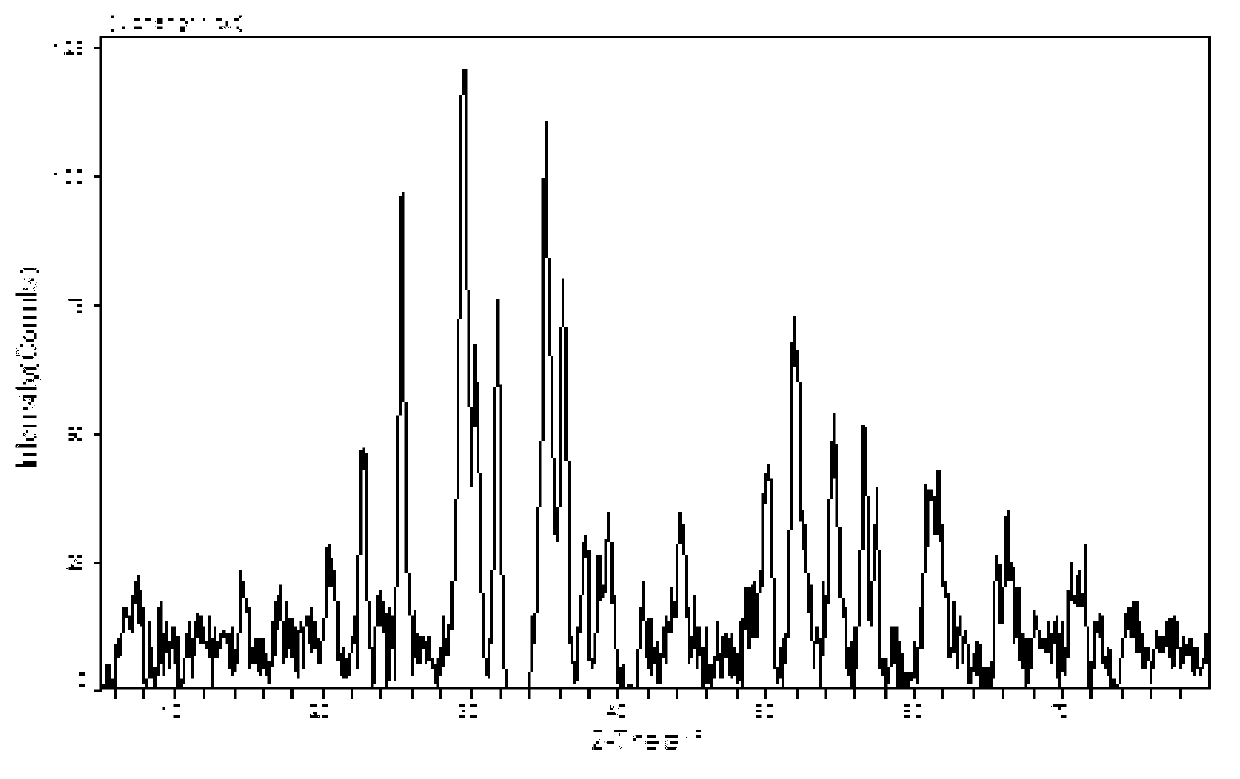

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

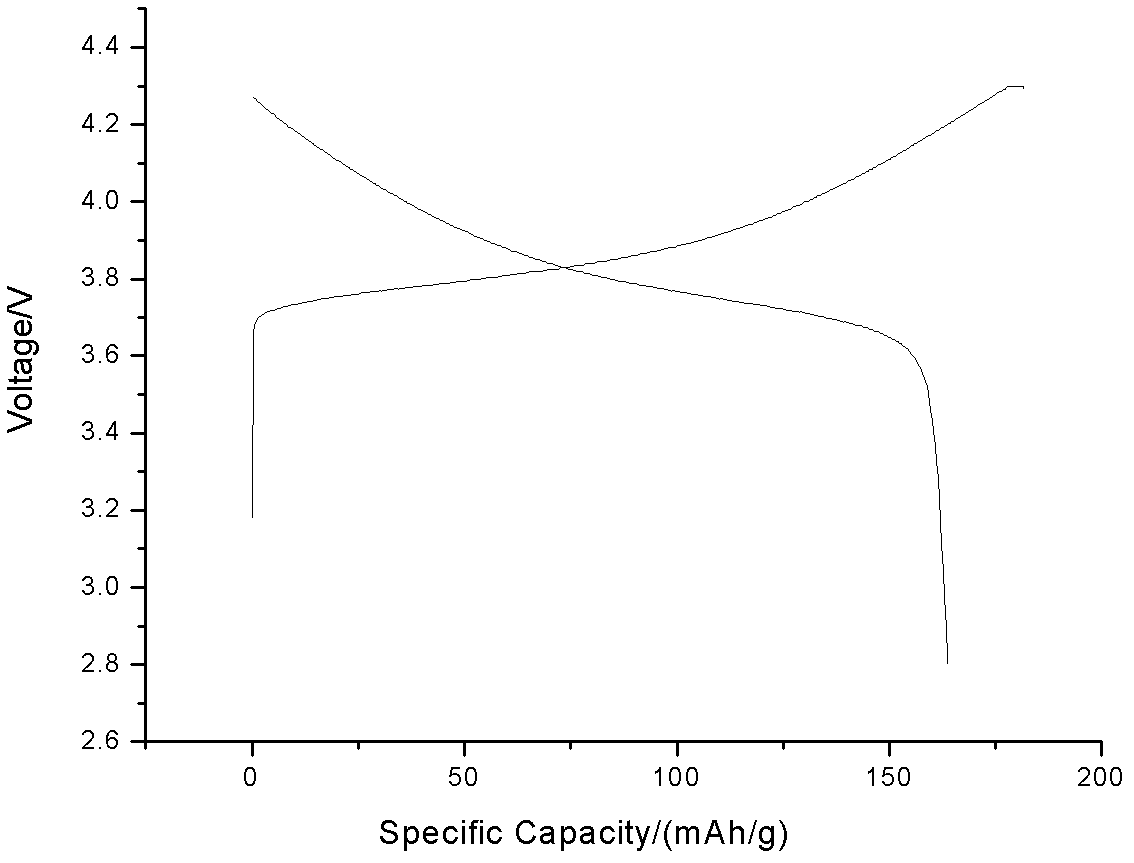

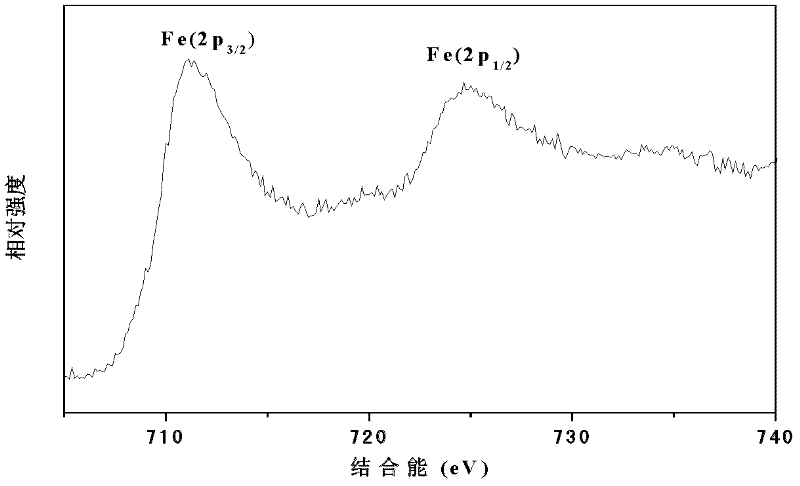

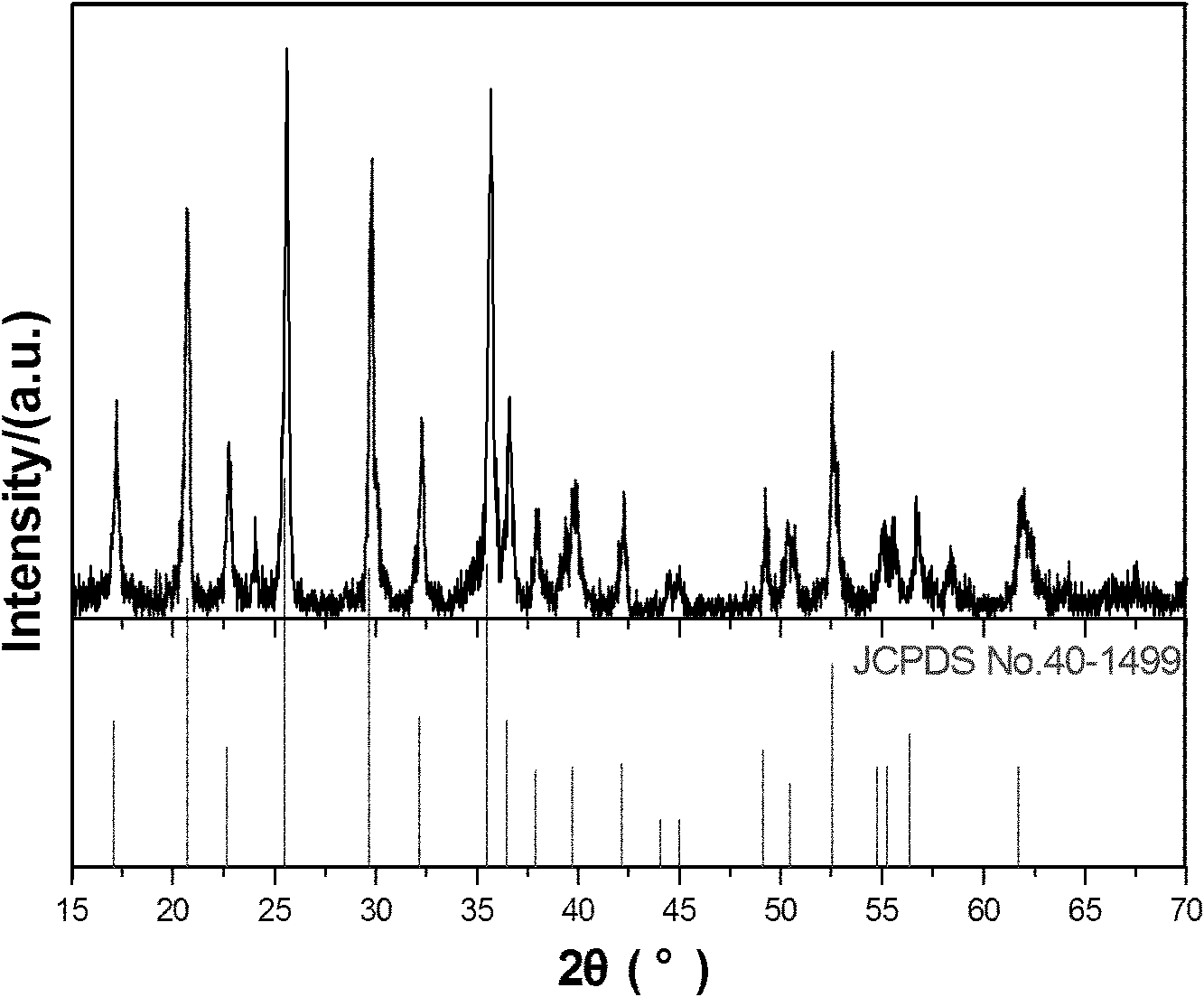

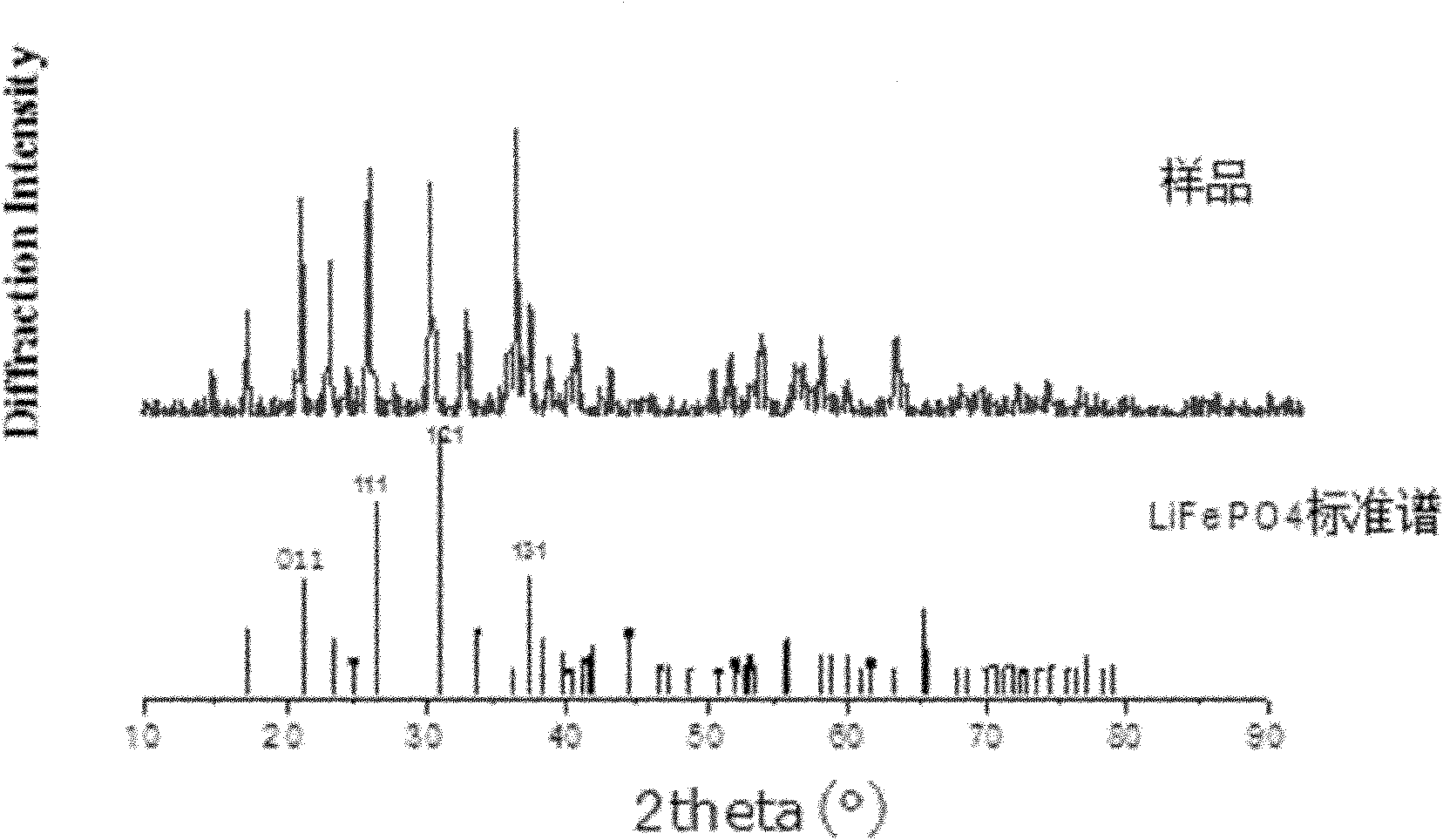

High-performance lithium iron phosphate cathode material and preparation method of lithium iron phosphate cathode material

The invention relates to a cathode material lithium iron phosphate for a lithium ion cell and a preparation method of lithium iron phosphate. The preparation method comprises the following steps: synthesizing a lithium iron phosphate cathode material through a hydrothermal method by taking a ferric iron salt as an iron source and a nanocrystalline metal oxide as a doped source, subsequently mixing lithium iron phosphate with organic acid or sugars, and sintering at high temperature to obtain the high-performance lithium iron phosphate cathode material coated by carbon. According to the preparation method disclosed by the invention, the ferric iron salt with low price is used as the raw material, so that the cost is saved; and the nanoscale metal oxide is used as the doping element, so that a crystal nucleus is provided for hydrothermal crystallization and the implementation of the reaction is accelerated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

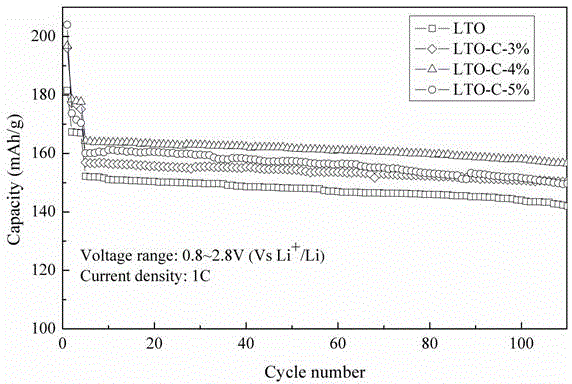

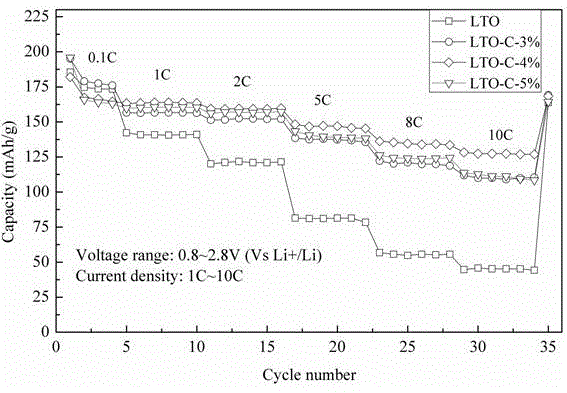

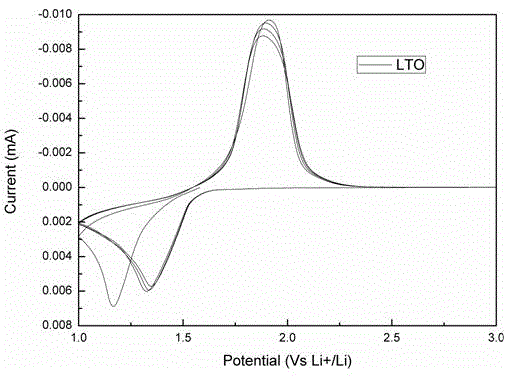

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

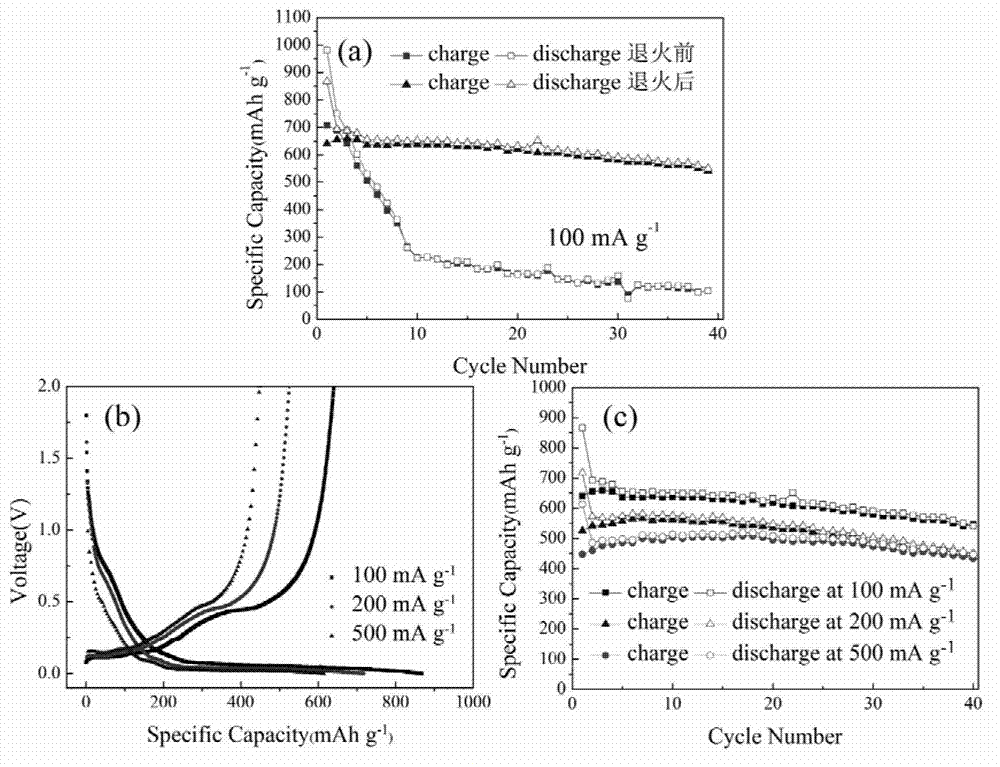

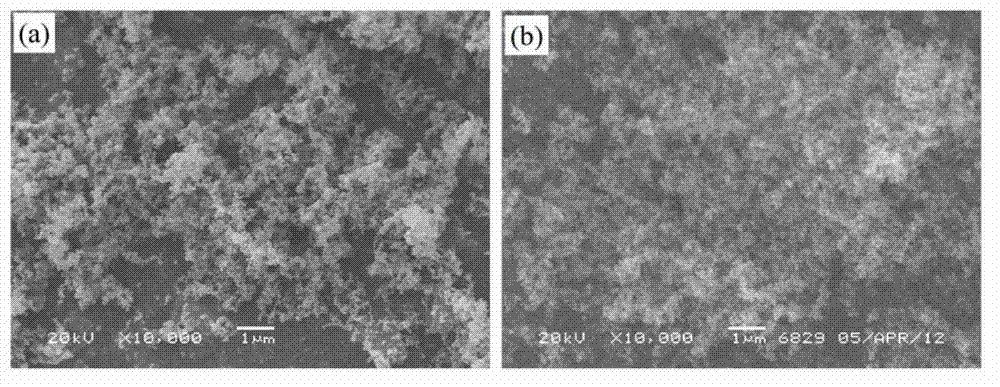

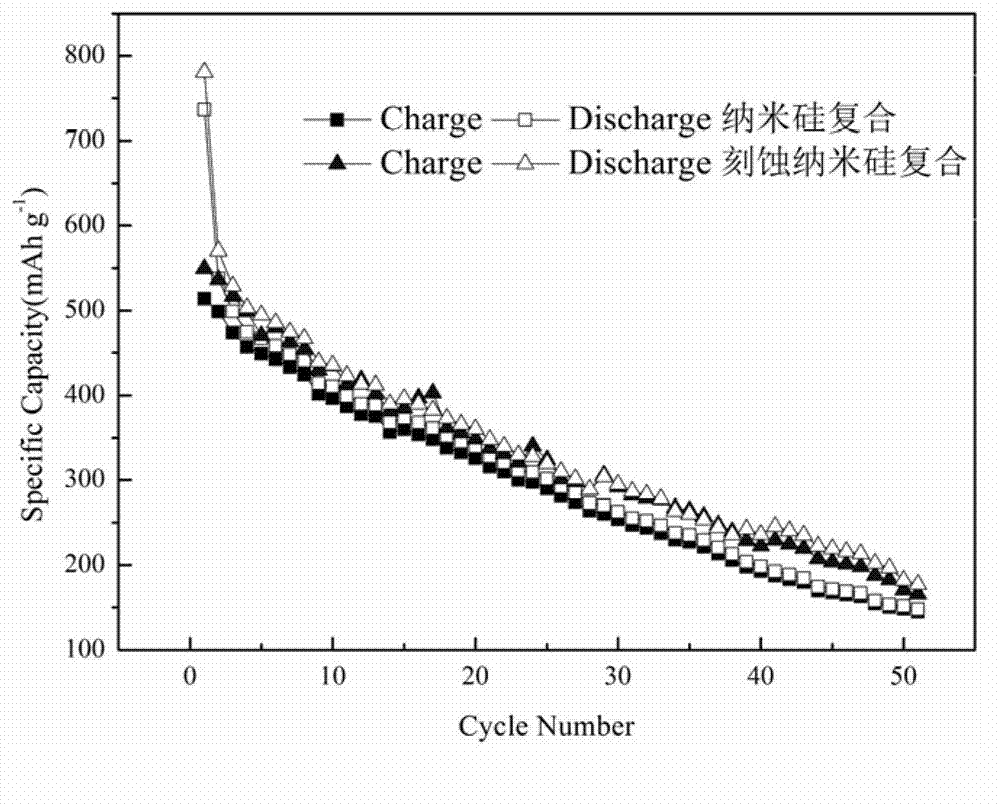

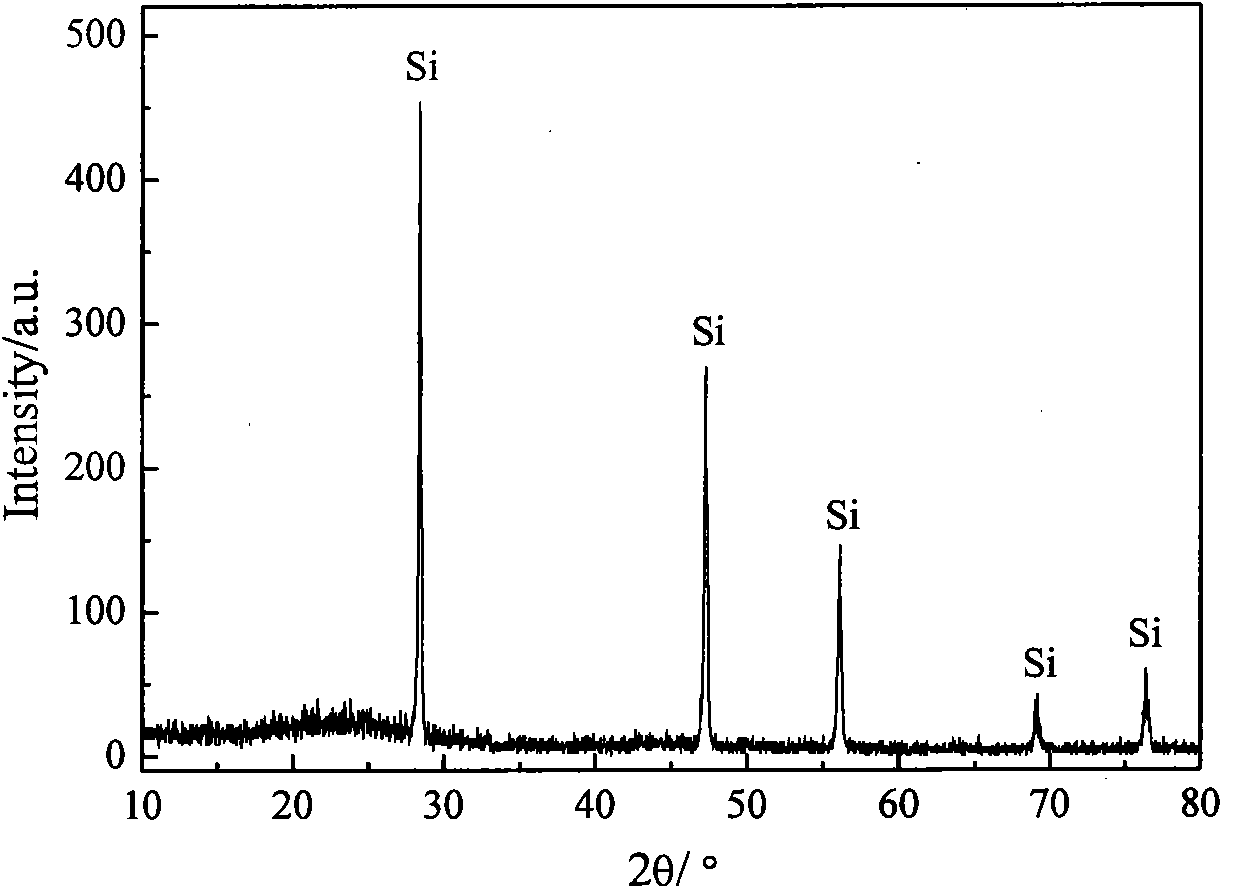

Method for preparing Si/C composite cathode material of lithium ion battery

ActiveCN103078092AUniform particle distributionExcellent performanceCell electrodesSolventCarbon source

The invention discloses a method for preparing a Si / C composite cathode material of a lithium ion battery. The method is characterized in that through a liquid phase solidification-high temperature pyrolysis-low temperature treatment combined method, the Si / C composite cathode material having good cycling stability and good rate capability is prepared. Concretely, the method comprises the following steps of uniformly dispersing a silicon source (before or after etching) and graphite in an appropriate solvent in the presence of a second-type additive with control of a temperature to obtain a solid precursor after the solvent is volatilized completely, transferring the solid precursor into a protective atmosphere, carrying out pyrolysis at a high temperature so that the carbon source is pyrolyzed into amorphous carbon and forms a coating layer, carrying out furnace cooling to obtain the Si / C composite cathode material, uniformly mixing the Si / C composite cathode material, a conductive agent and a binder, coating the mixture on a pole piece, carrying out drying, carrying out low-temperature treatment, and carrying out an electrochemical performance test. The method is simple and feasible and has a high practical degree. The Si / C composite cathode material prepared by the method has a high capacity and good cycling stability and a good rate capability after the low-temperature treatment.

Owner:CENT SOUTH UNIV

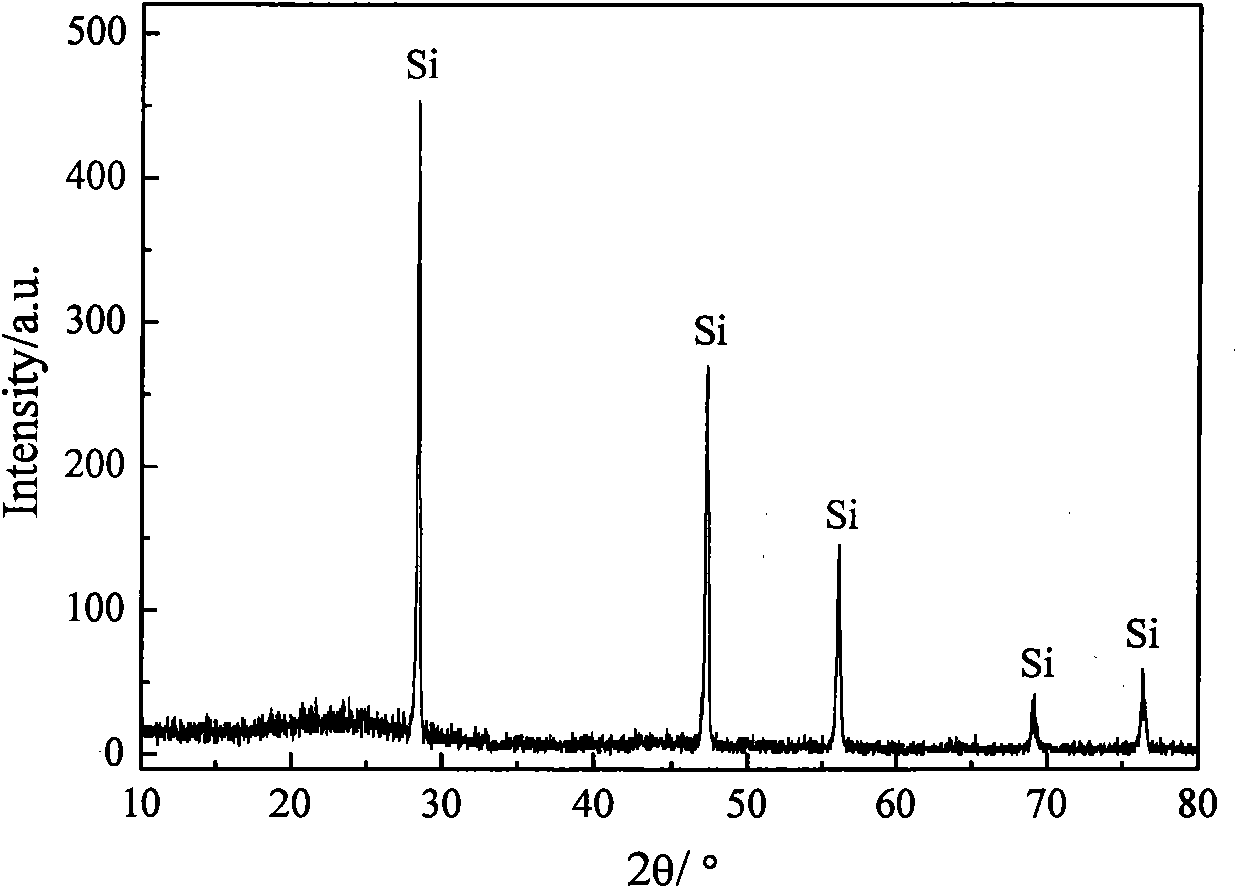

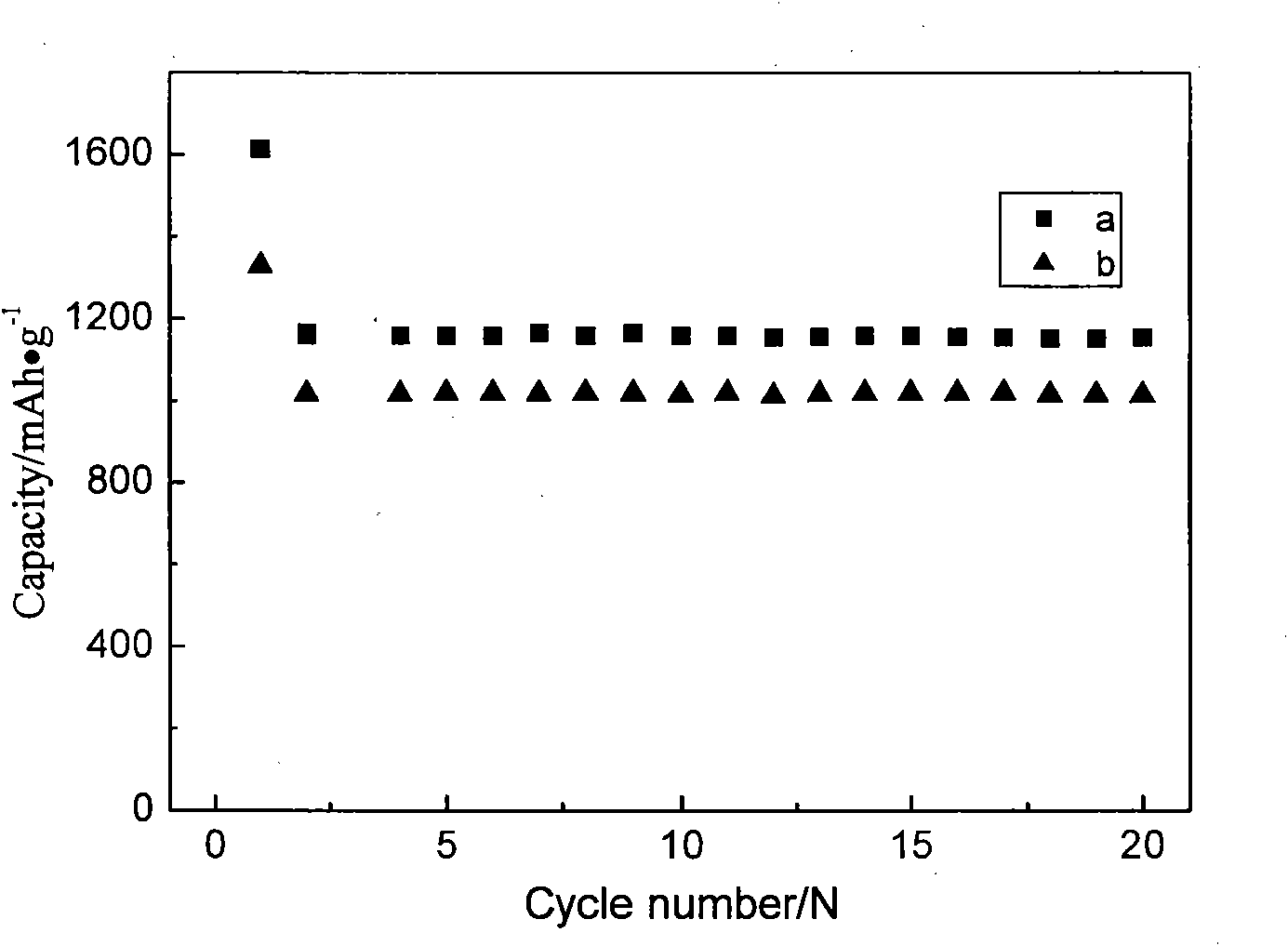

Method for preparing silicon-carbon cathode material of lithium ion battery

The invention provides a method for preparing a silicon-carbon cathode material of a lithium ion battery. The silicon-carbon cathode material prepared by the method has the advantages of high capacity and good cyclical stability. The preparation method of the invention comprises the following steps of: putting phenol monomers and aldehyde monomers into a solvent to carry out hydrolyzation to synthesize a porous precursor with high specific surface, then adding nano silicon powder into the porous precursor and effectively making the nano silicon powder uniformly dispersed in the synthesized porous precursor with high specific surface by using specific cavatition oscillation of ultrasonic to finally synthesize a porous macromolecular resin-coated silicon precursor with high specific surface so as to make the volume effect greatly weakened and make cycle performance excellent; and then drying the obtained precursor and roasting the dried precursor in protective atmosphere at a specific temperature to finally obtain the silicon-carbon cathode material. The preparation method of the invention has the advantages of simple process, short flow and small equipment investment. The prepared silicon-carbon anode material of the lithium ion battery has uniformly distributed particles and excellent electrochemical performance.

Owner:CHERY AUTOMOBILE CO LTD

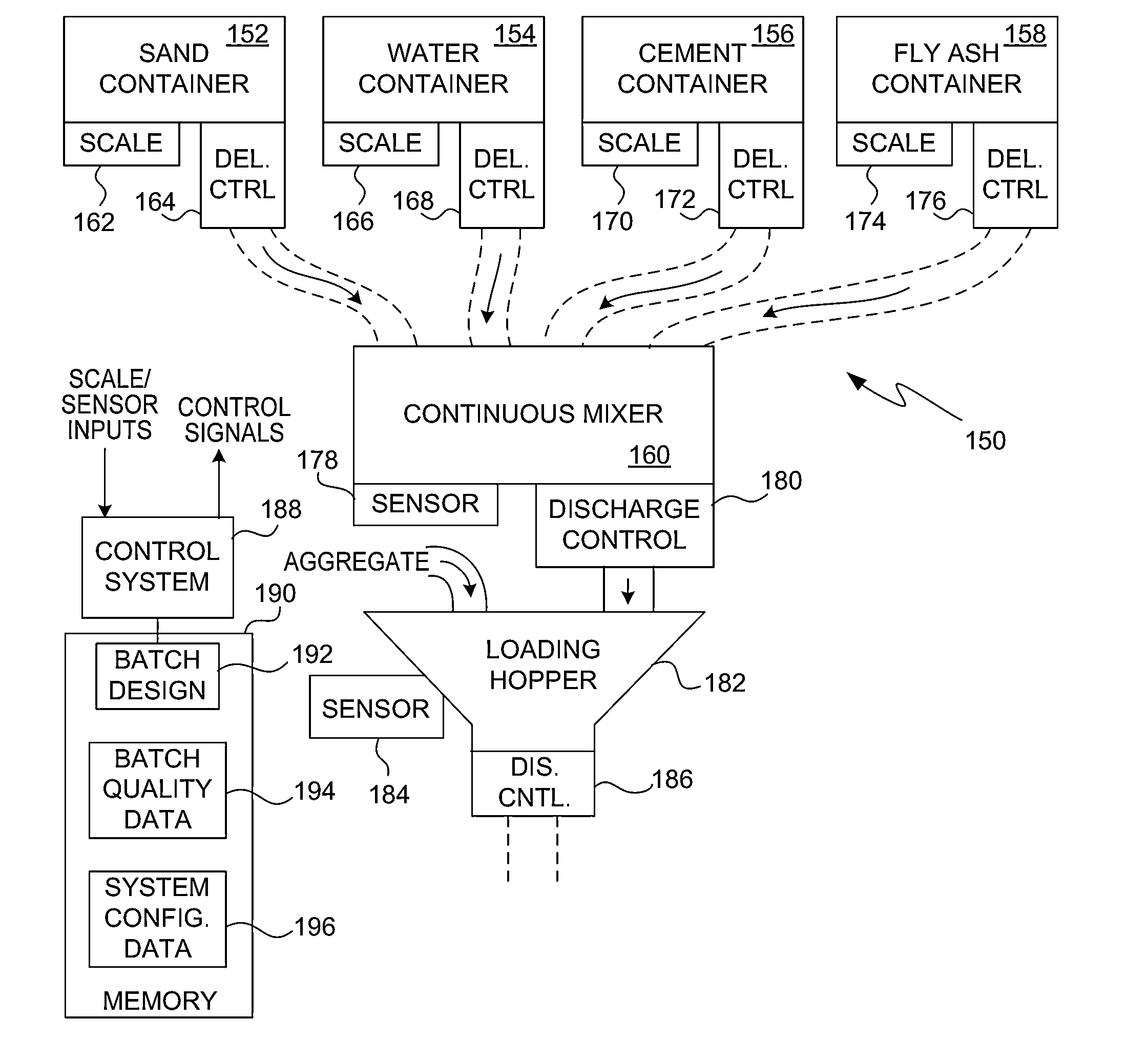

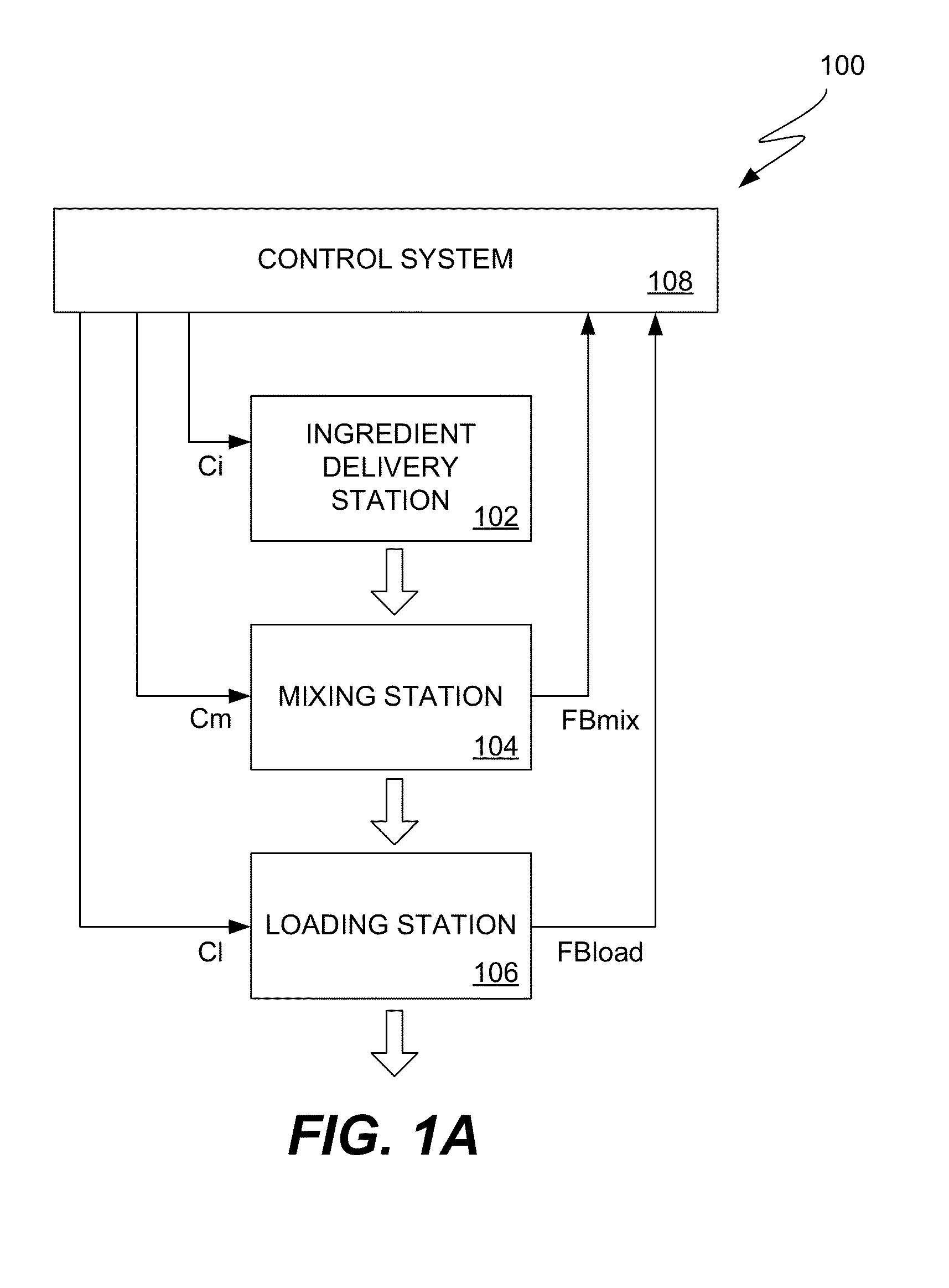

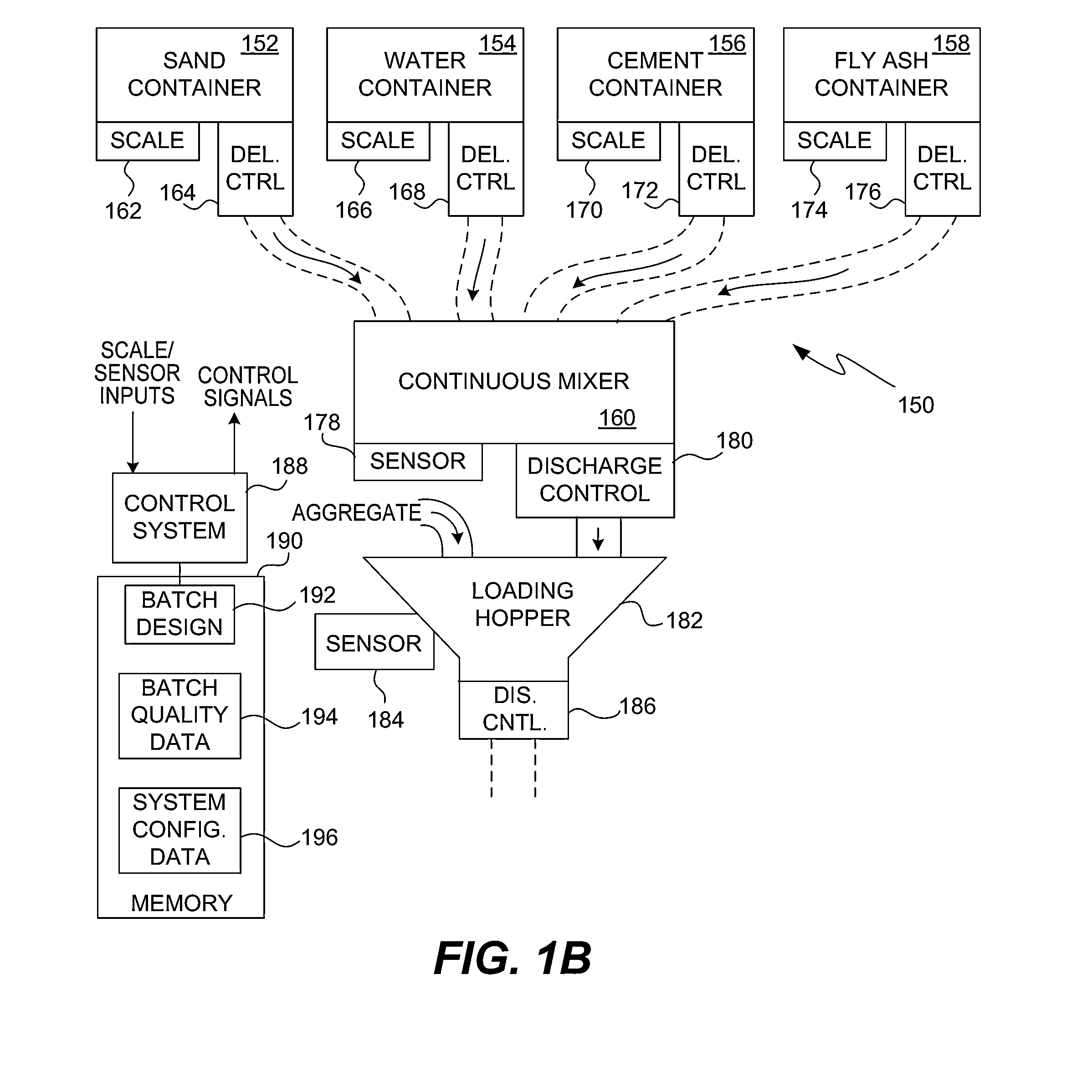

Feedback Controlled Concrete Production

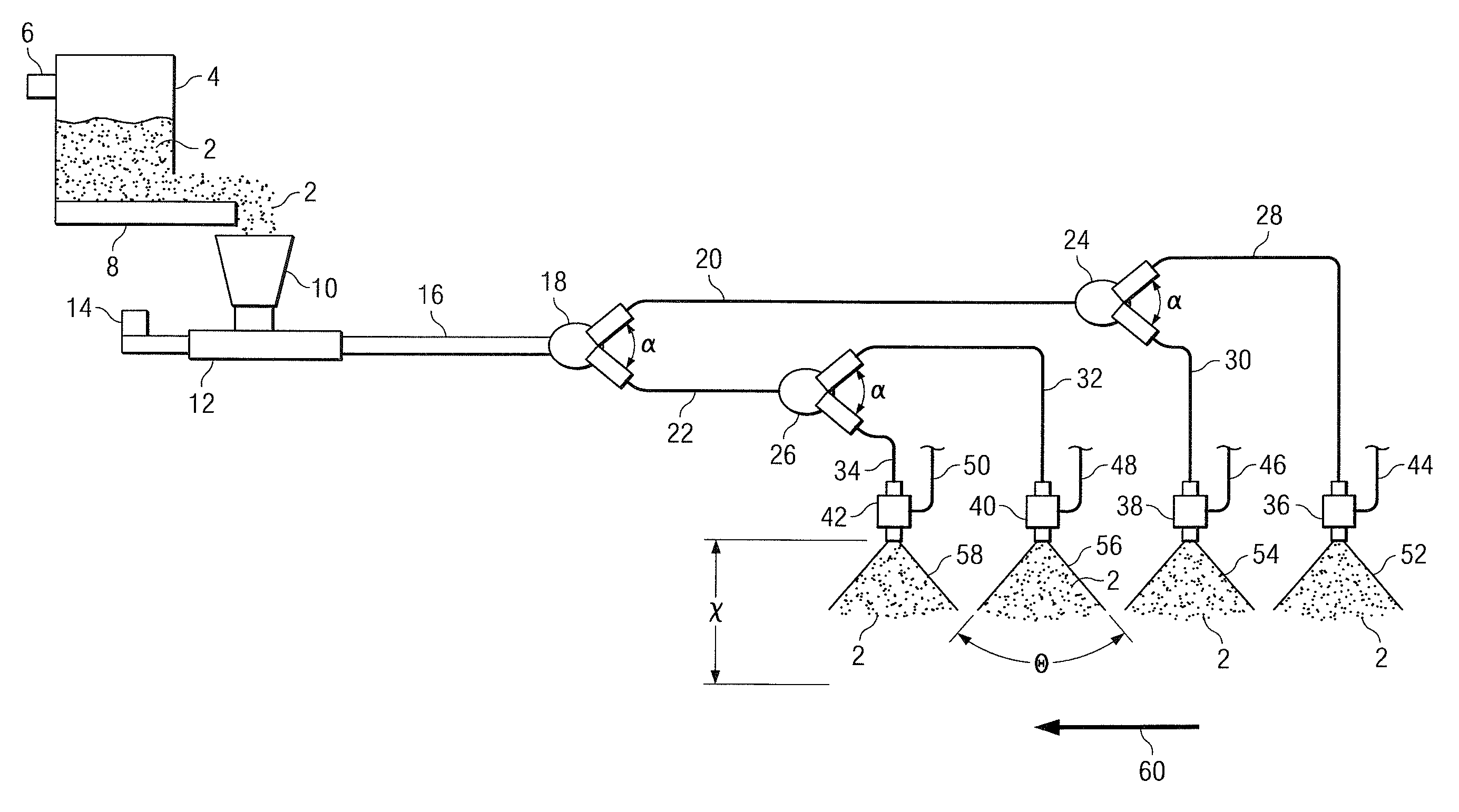

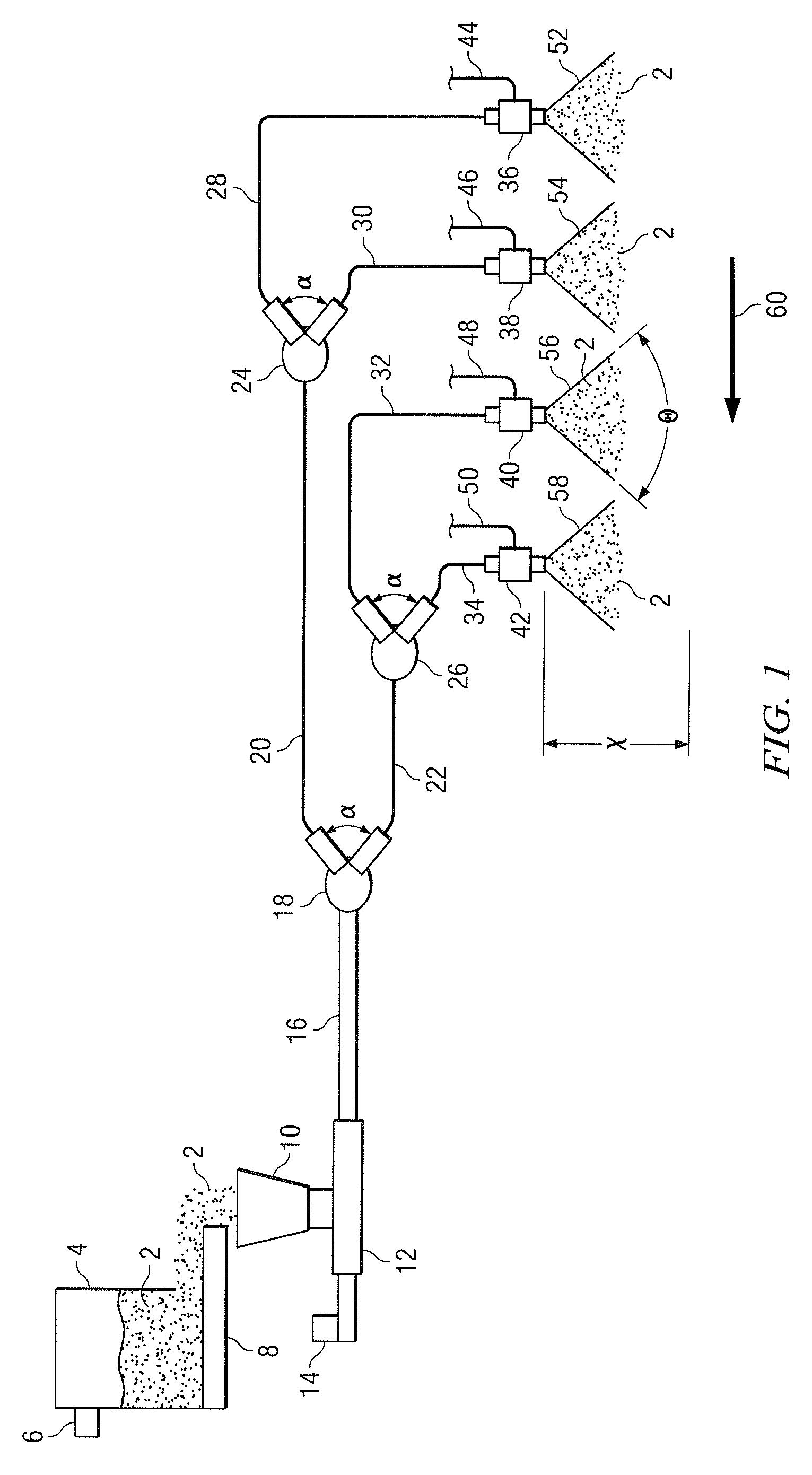

ActiveUS20140355372A1Easy loadingEfficient productionRotary stirring mixersMixing operation control apparatusControl systemStructural engineering

Techniques or processes for efficiently producing concrete using dynamic feedback are disclosed. A concrete plant can use a control system to manage concrete production based on the dynamic feedback. The dynamic feedback can control mixing of concrete ingredients so as to yield uniform particle distribution for the concrete ingredients. The dynamic feedback can also avoid overflow situations as well as yield improved loading of the resulting concrete into a concrete transport vehicle (e.g., concrete truck).

Owner:BLACK MELVIN L +1

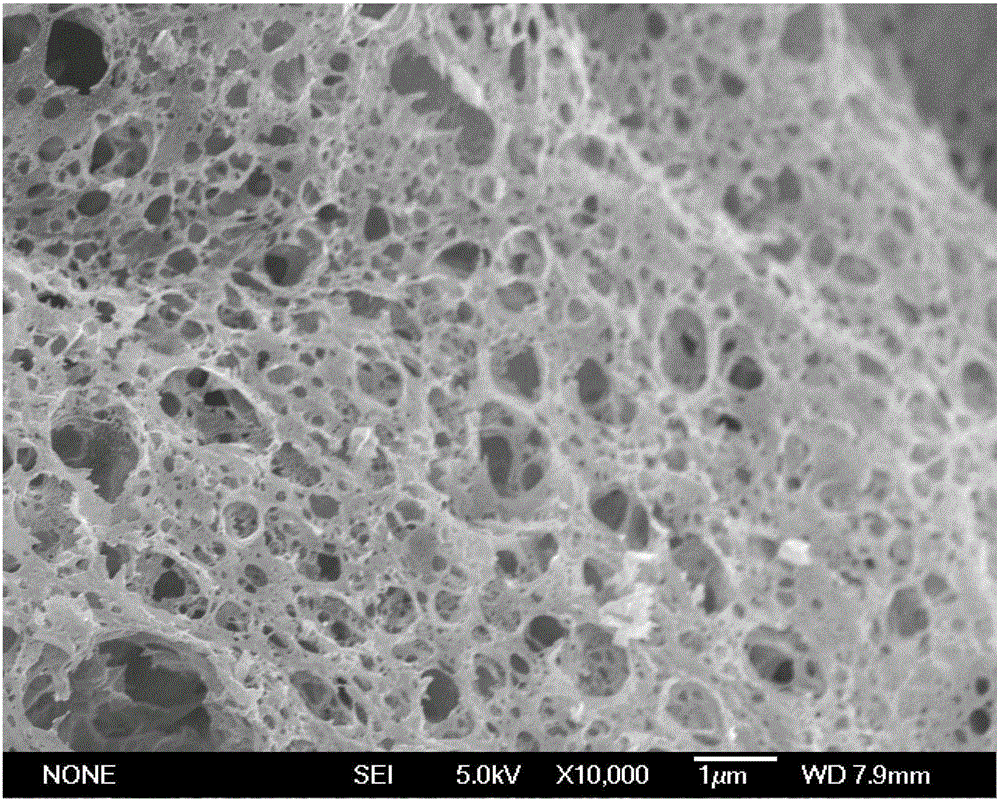

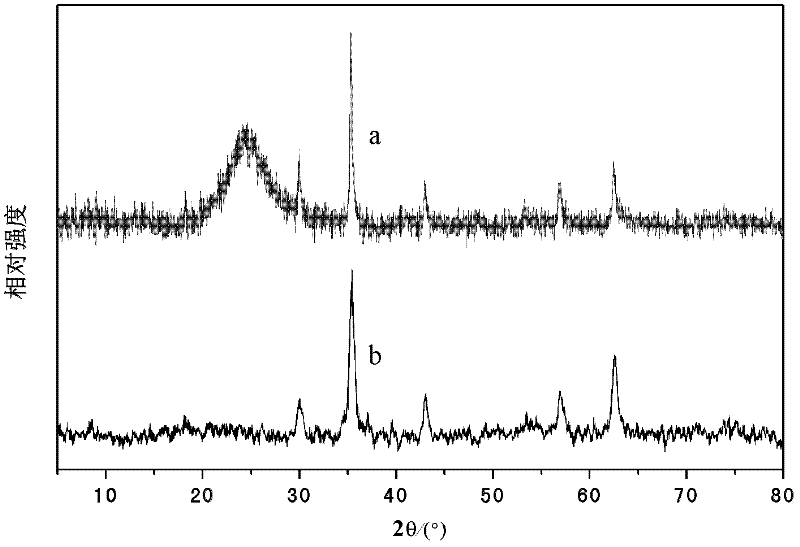

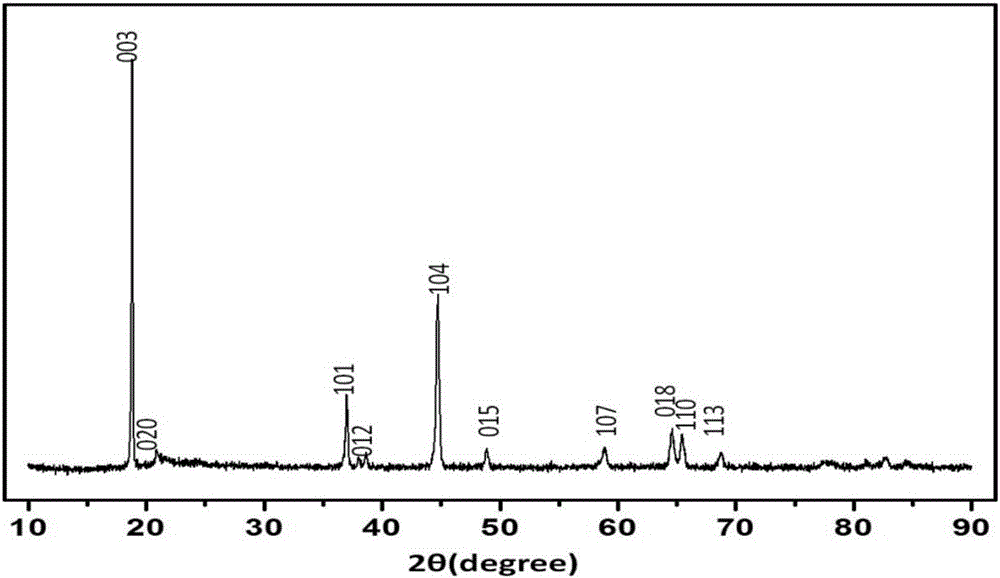

Lithium-rich manganese-based anode material and method for manufacturing same

ActiveCN102916169AImprove featuresUniform structureCell electrodesSecondary cellsPtru catalystActive agent

The invention discloses a lithium-rich manganese-based anode material and a method for manufacturing the same. The method includes steps of (a), providing mixed solution containing lithium compounds, nickel compounds and manganese compounds, optional titanium compounds, optional iron compounds, optional cobalt compounds or an optional combination of the titanium compounds, the ion compounds and the cobalt compounds; (b), adding complexing agents, catalysts and surfactants into the mixed solution to form pre-coagulated substances; and (c), calcining the pre-coagulated substances to obtain the lithium-rich manganese-based anode material Li[LixNiaMnbM1-a-b-x]O2 or a combination of lithium-rich manganese-based anode materials. The complexing agents, the catalysts and the surfactants are used for forming the pre-coagulated substances, the complexing agents contain resorcinol and formaldehyde, in the molecular formula of the lithium-rich manganese-based anode material, the M represents Ti, Fe, Co or a combination of the Ti, the Fe and the Co, the x is larger than 0 and is smaller than or equal to 0.4, the a is larger than 0 and is smaller than or equal to 0.5, the b is larger than or equal to 0.33 and smaller than or equal to 0.6, and a result of 1-a-b-x is larger than or equal to 0. The lithium-rich manganese-based anode material is of a multi-channel porous structure, is small in grain size, uniform in grain distribution, advanced in porosity and stable in electrochemical performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

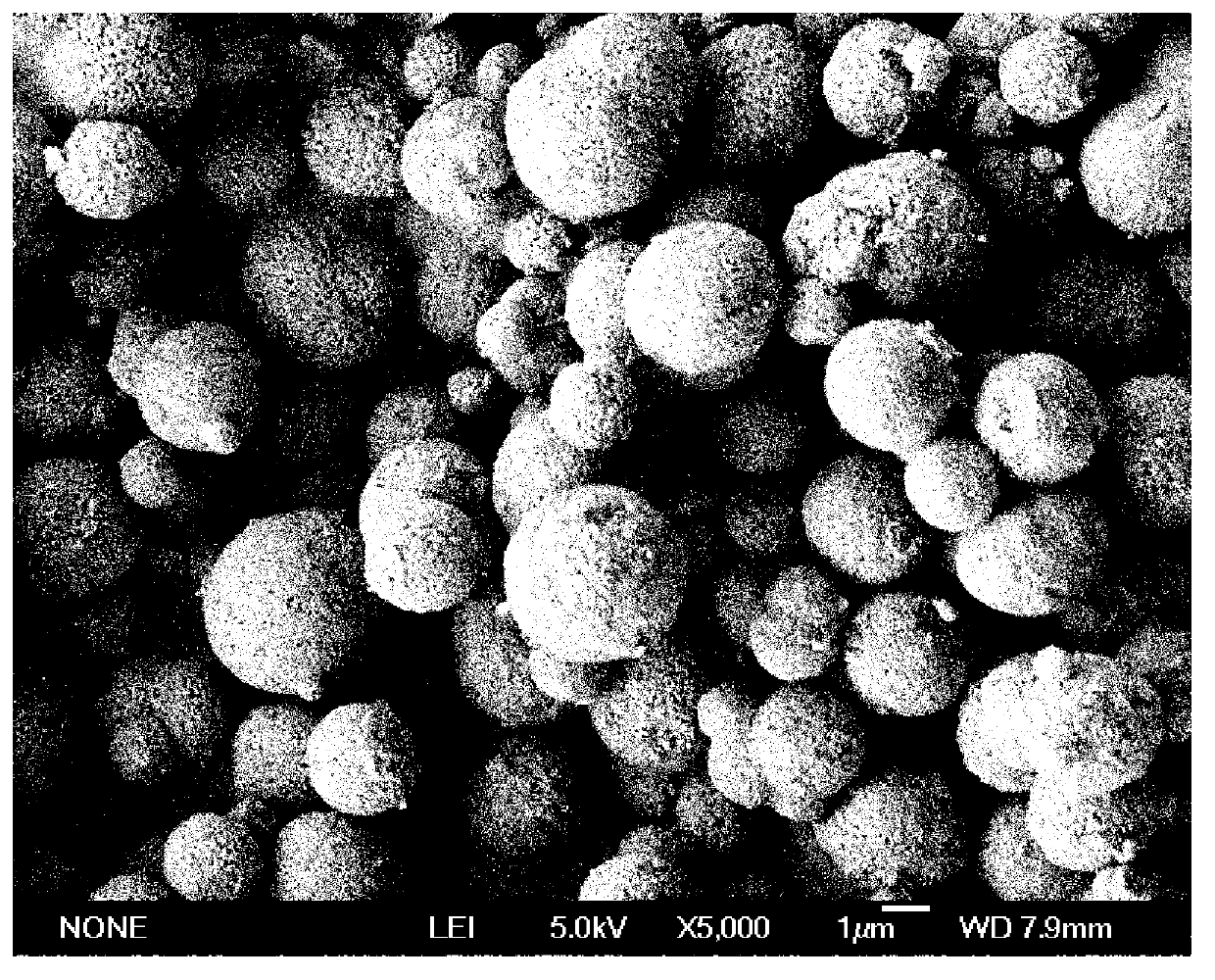

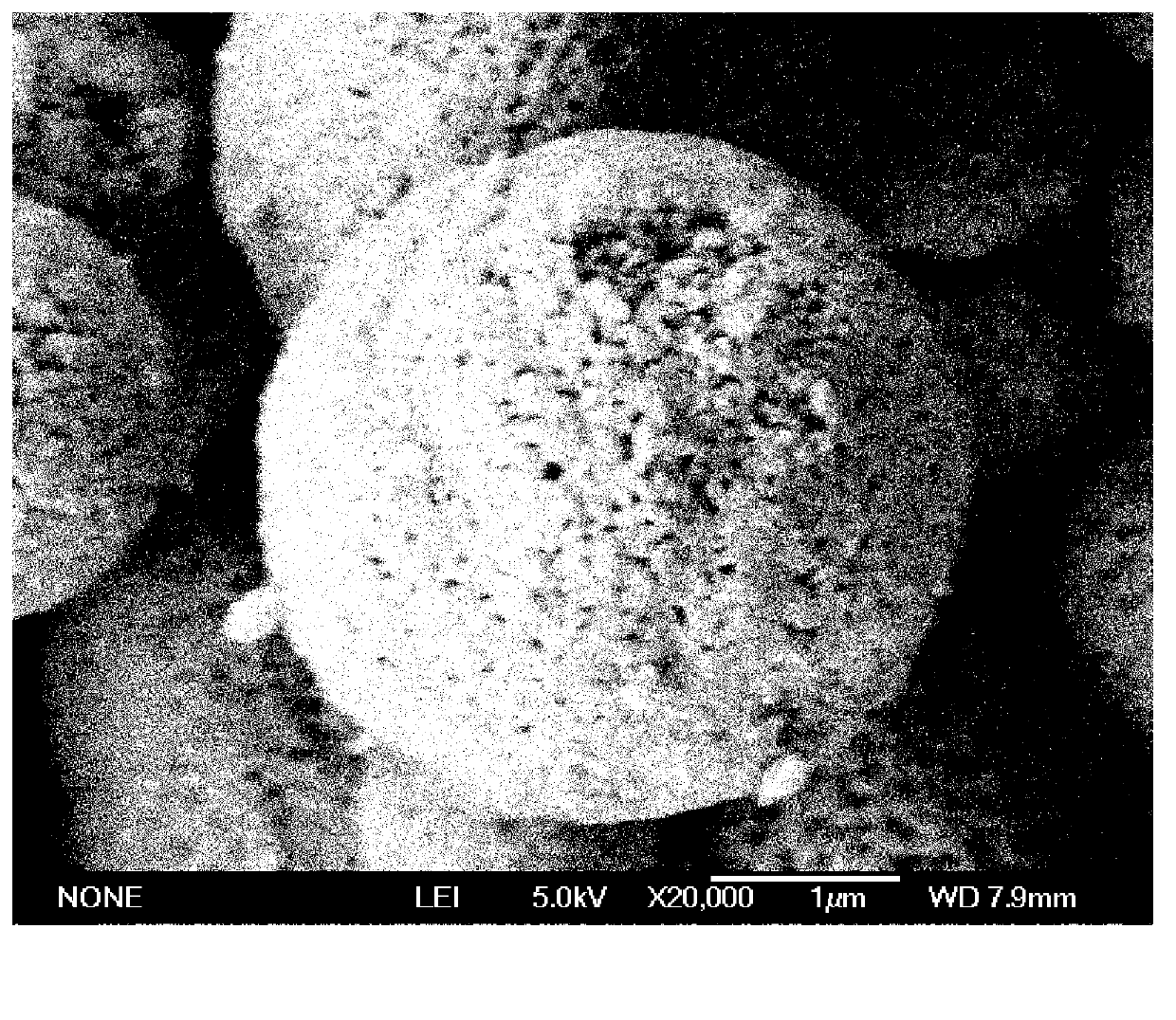

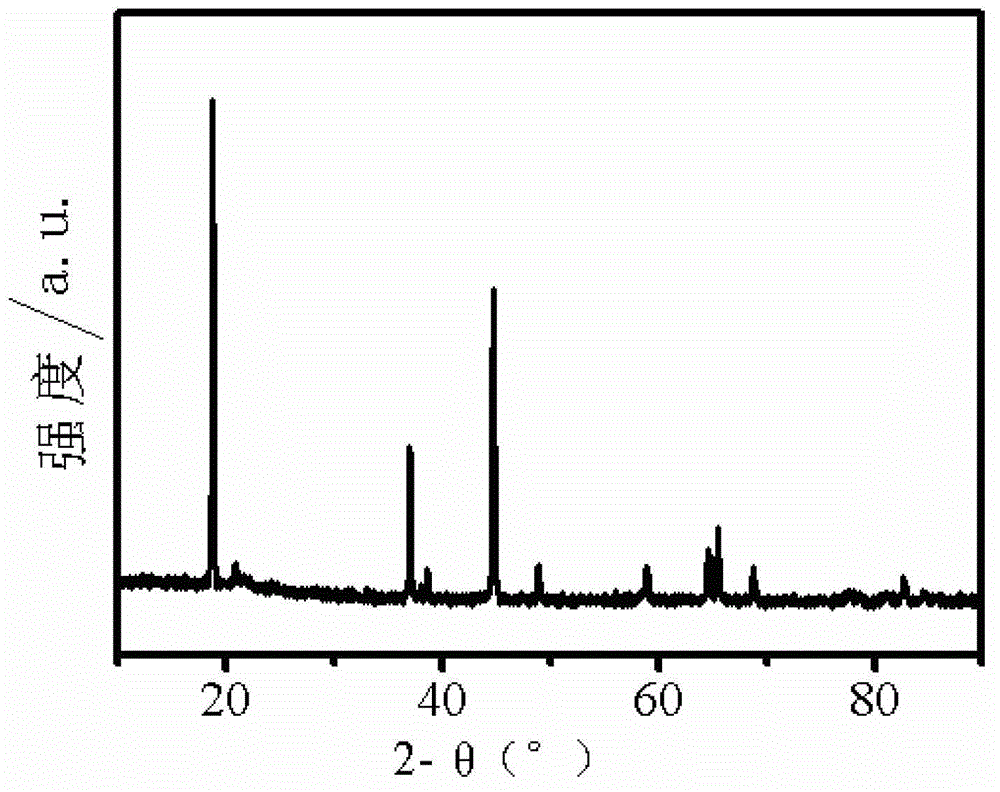

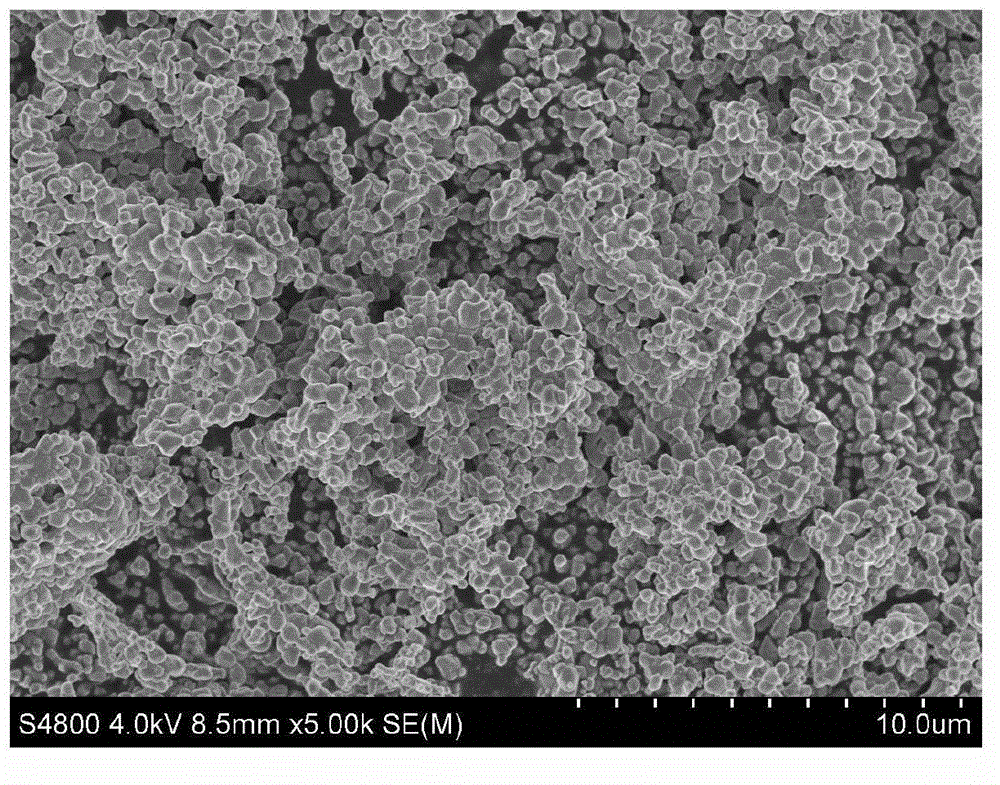

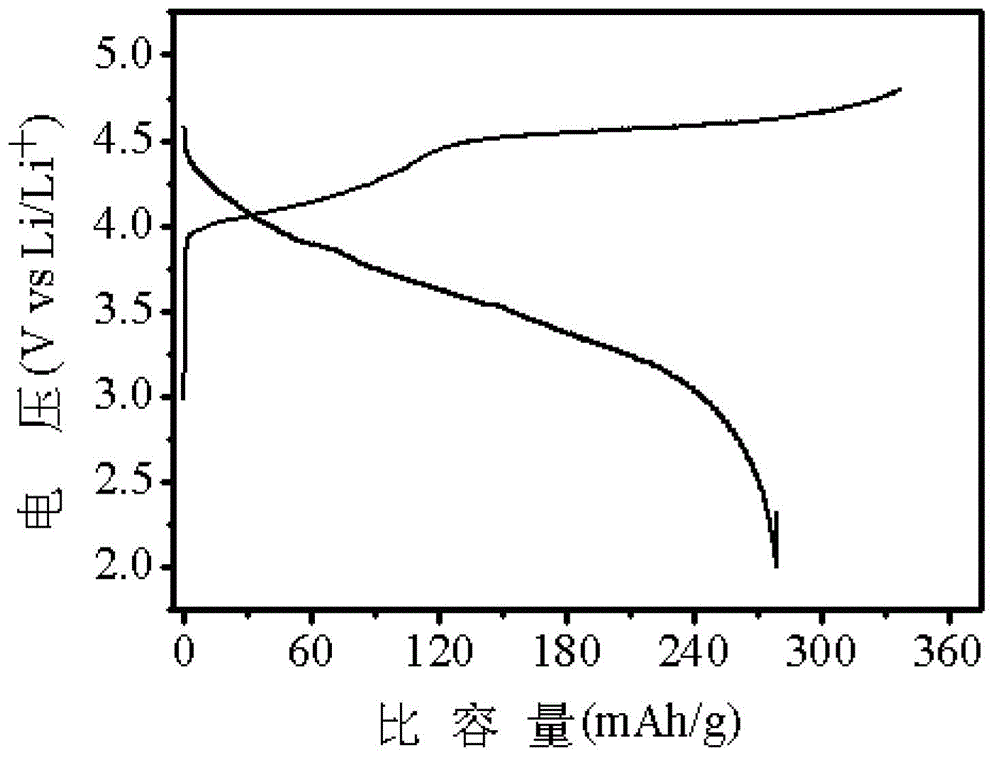

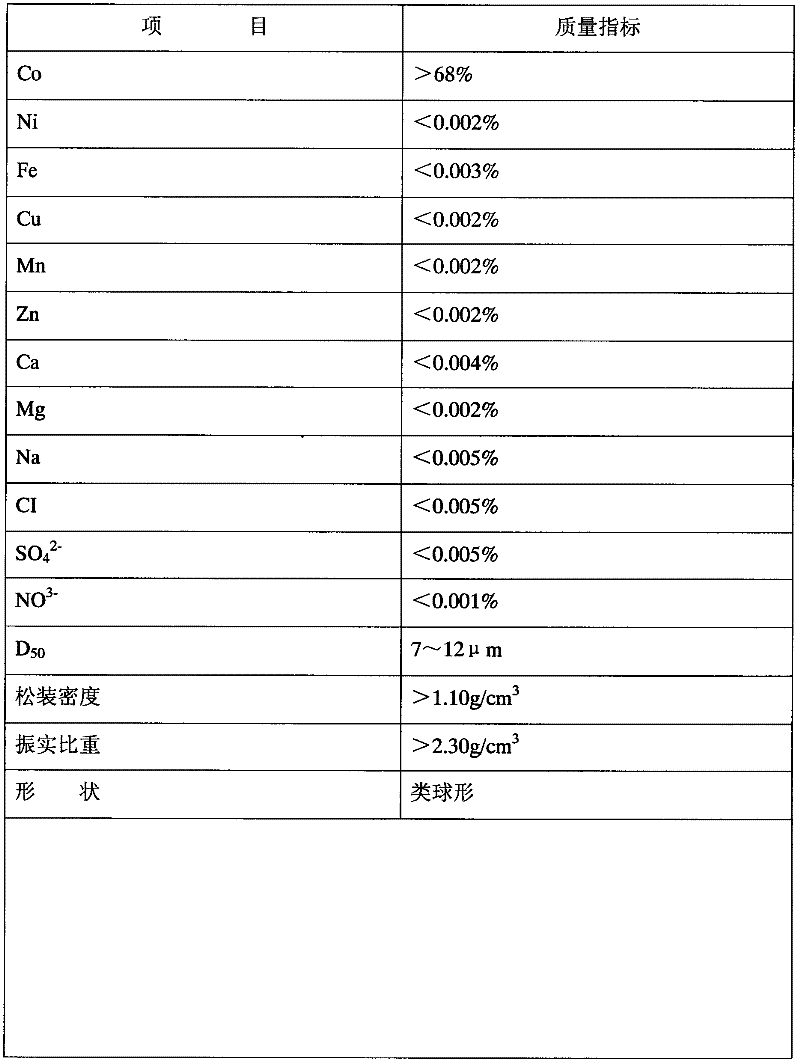

Method for producing hydroxy cobalt oxide

InactiveCN102689933AThe production process is easy to controlImprove product qualityCobalt oxides/hydroxidesEthylene diamineReaction temperature

The invention discloses a method for producing hydroxy cobalt oxide, comprising the following steps of: firstly, preparing a cobaltous sulfate solution with cobalt content of 75-85g / l; adjusting a pH value of the solution to be 3.0-4.5; adding EDTA (Ethylene Diamine Tetraacetic Acid) into the solution according to the proportion of cobalt to EDTA of 100:(1-3); preparing sodium hydroxide solution with alkali concentration of 7-9mol; performing cocurrent flow on two solutions and flowing into a reaction groove; introducing the air for performing synthetic reaction; controlling the reaction temperature to be between 50 and 70 and a pH value to be between 10.0 and 12.0 for reacting for 15-25 hours; flowing into an aging groove for aging for 50-60 minutes; and finally, filtering, washing and slurrying to prepare a hydroxy cobalt oxide solid product. According to the method, the production process is controllable, particles of the product are uniformly distributed with good consistency, the shape is spherical and the product has good dispersibility; and the production process is free of ammonia nitrogen pollution, so that continuous production is realized, and the equipment utilization rate and the production efficiency are improved.

Owner:湖南红太阳电源新材料股份有限公司

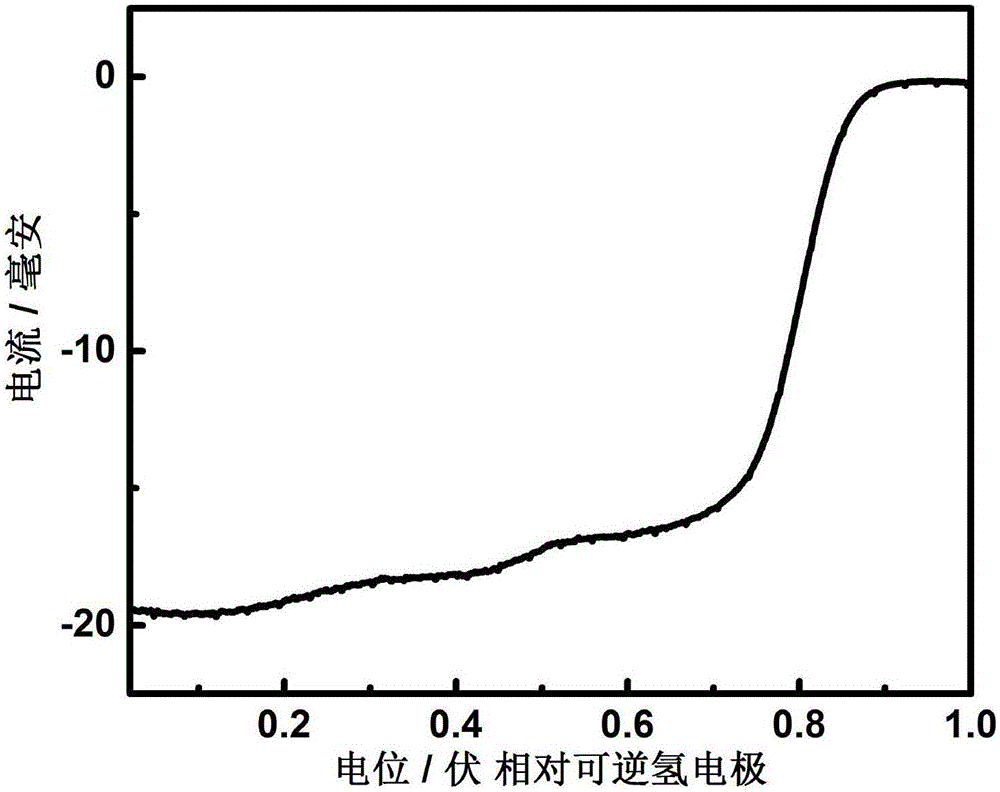

Nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and preparation method thereof

ActiveCN105879895ASimple processGood repeatabilityMaterial nanotechnologyPhysical/chemical process catalystsMetal oxide nanoparticlesPorous carbon

The invention relates to nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and a preparation method thereof. The catalyst is made by embedding metal and metal oxide nanoparticles into nitrogen-doped porous carbon nanosheets or supporting them to the surfaces of the nitrogen-doped porous carbon nanosheets; the preparation method comprises: 1), synthesizing a polymerizable ionic liquid monomer; 2), reacting the obtained ionic liquid with a metal salt precursor, and drying to obtain an intermediate product, solid powder; 3), placing the obtained solid powder in a magnetic boat, placing in a tubular furnace fitted with a quartz tube, charging an inertial gas at a certain flow rate, heating to 600-1000 DEG, holding the temperature for 0.5-5 h, and naturally cooling to room temperature to obtain the catalyst. The poly-ionic liquid is used as the precursor, metal supporting capacity is high, the cost is low, oxygen reduction and oxygen evolution catalytic activity is high, the prepared product has stable performance, and the preparation method is simple and is easy to scale up and industrially apply.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing biomedical amorphous nano calcium phosphate

InactiveCN1488574AHigh reactivityUniform particle distributionBone implantPhosphorus compoundsCalcium biphosphateAqueous solution

The invention discloses a manufacturing method for amorphous nano calcium phosphate in medical field. The method uses phosphor-contained compound and calcium-contained compound as raw materials, uses polymer as stabilizer, carries on reaction under 0í½20íµ in water solution and produces into amorphous calcium phosphate.

Owner:ZHEJIANG UNIV

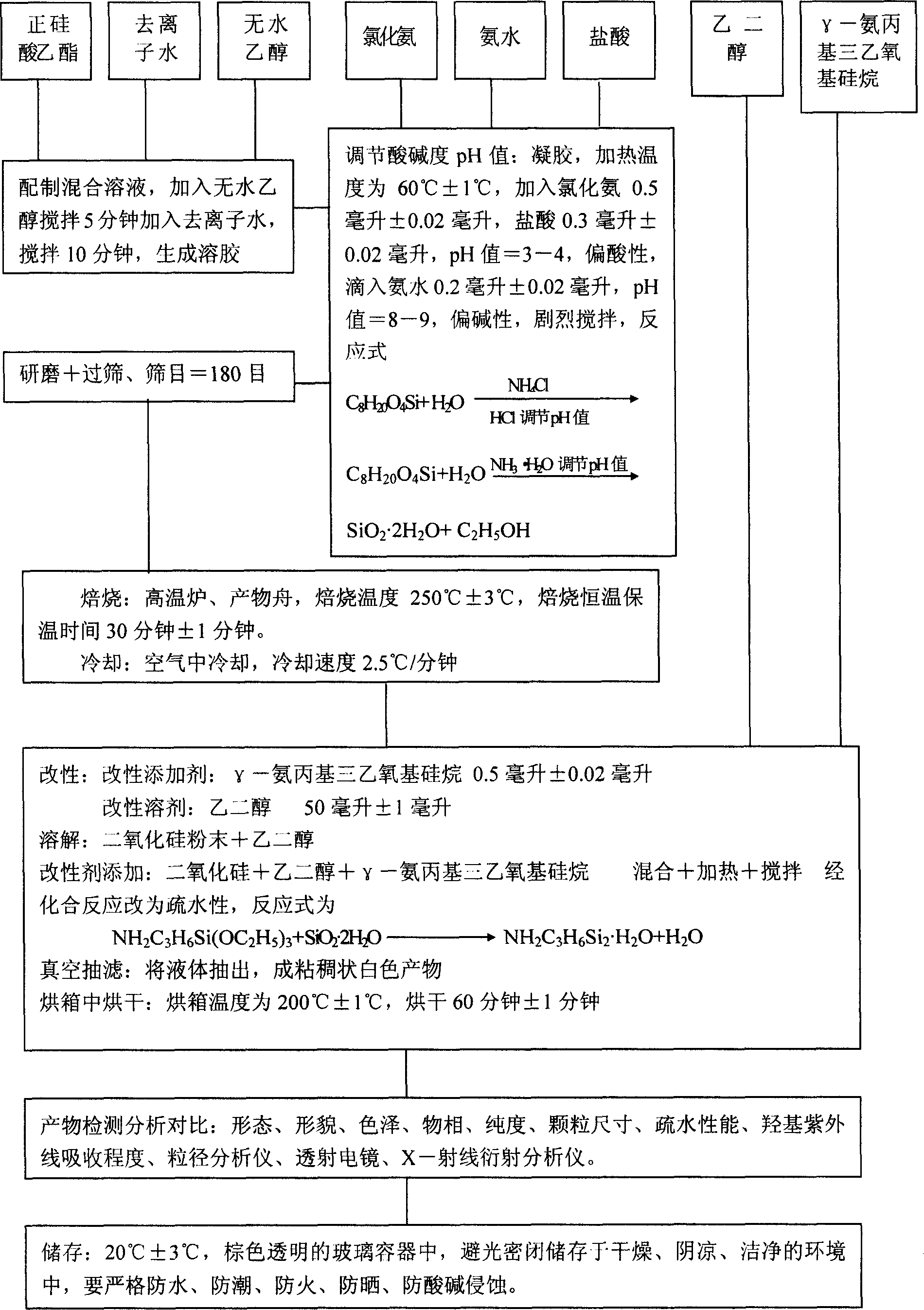

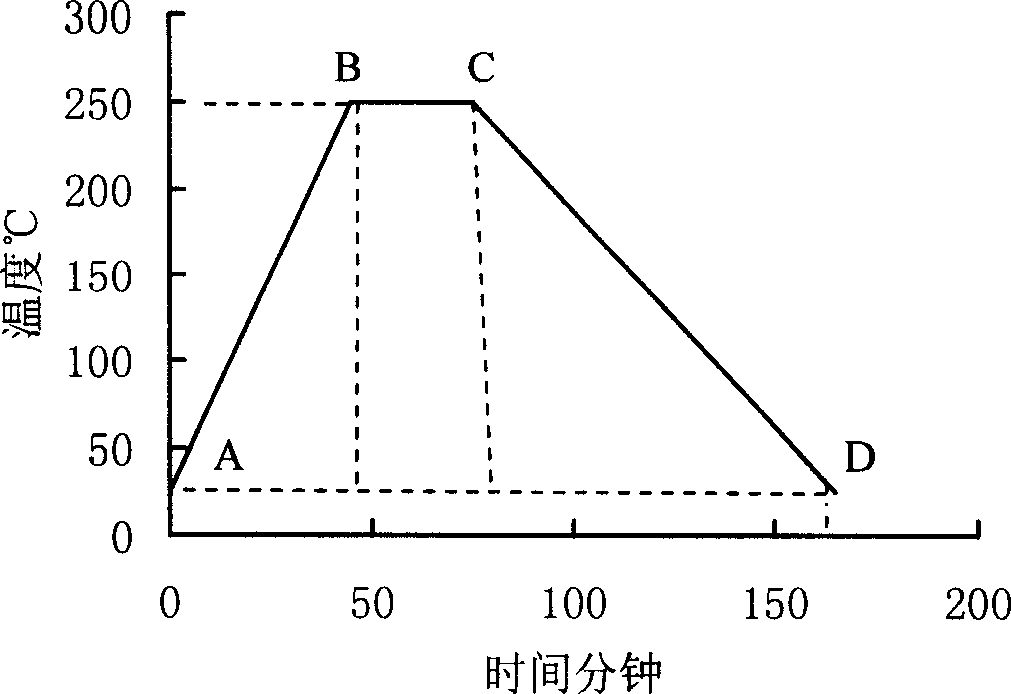

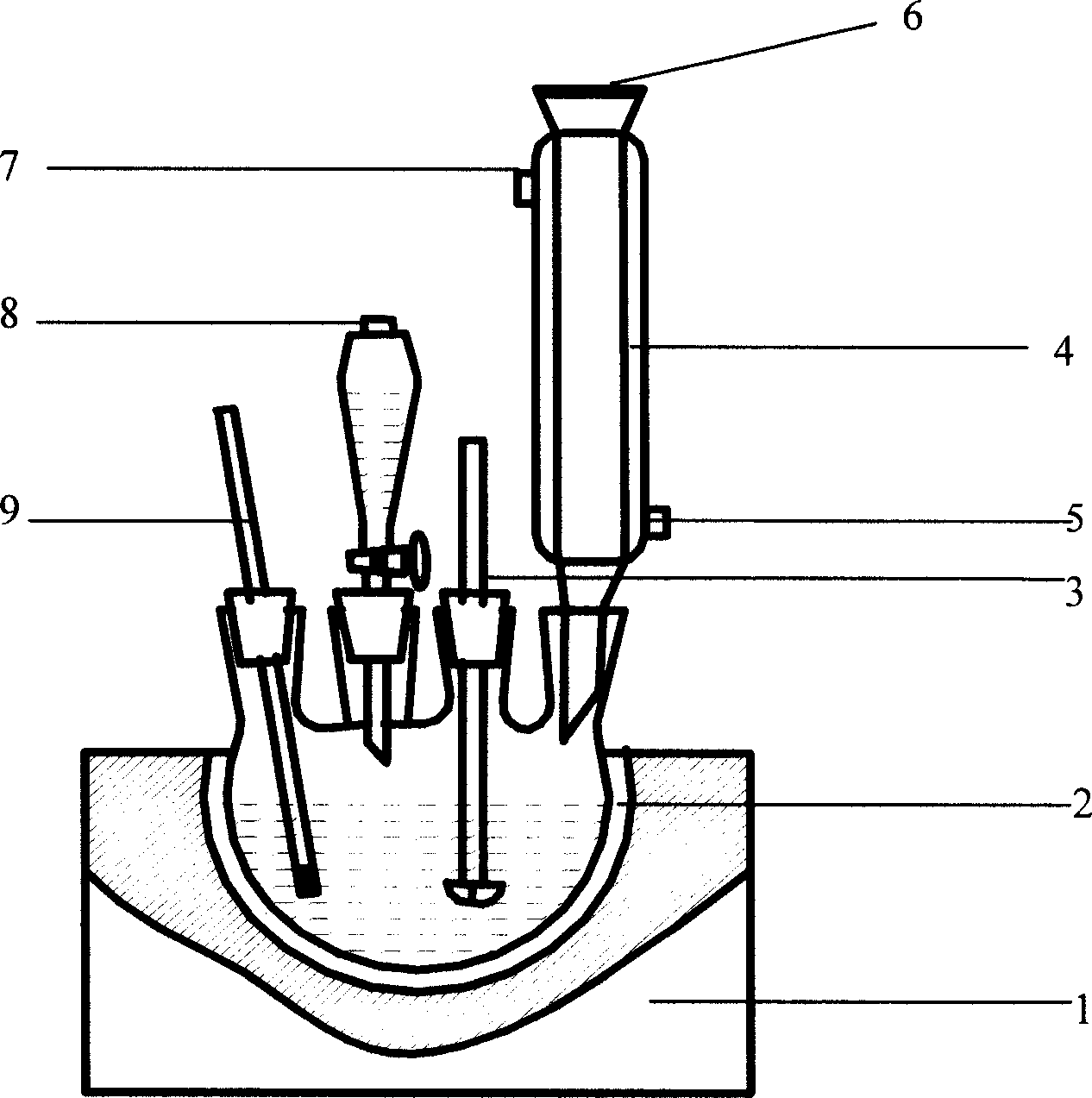

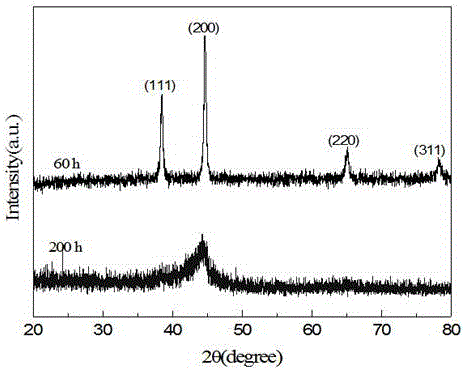

Method for preparing super fine hydrophobic silicon dioxide

InactiveCN1757598AHigh purityUniform particle distributionSilicon oxidesCooking & bakingPolymer science

A process for preparing the superfine hydrophobic SiO2 includes such steps as proportionally mixing ethyl n-silicate, ammonium chloride, de-ionized water, absolute alcohol, hydrochloric acid, ammonia water, gamma-aminopropyltriethoxy silane and ethanediol, preparing sol, preparing gel, baking, grinding, sieving, calcining, cooling, hydrophobic modifying, reaction, filter, baking and examining.

Owner:TAIYUAN UNIV OF TECH

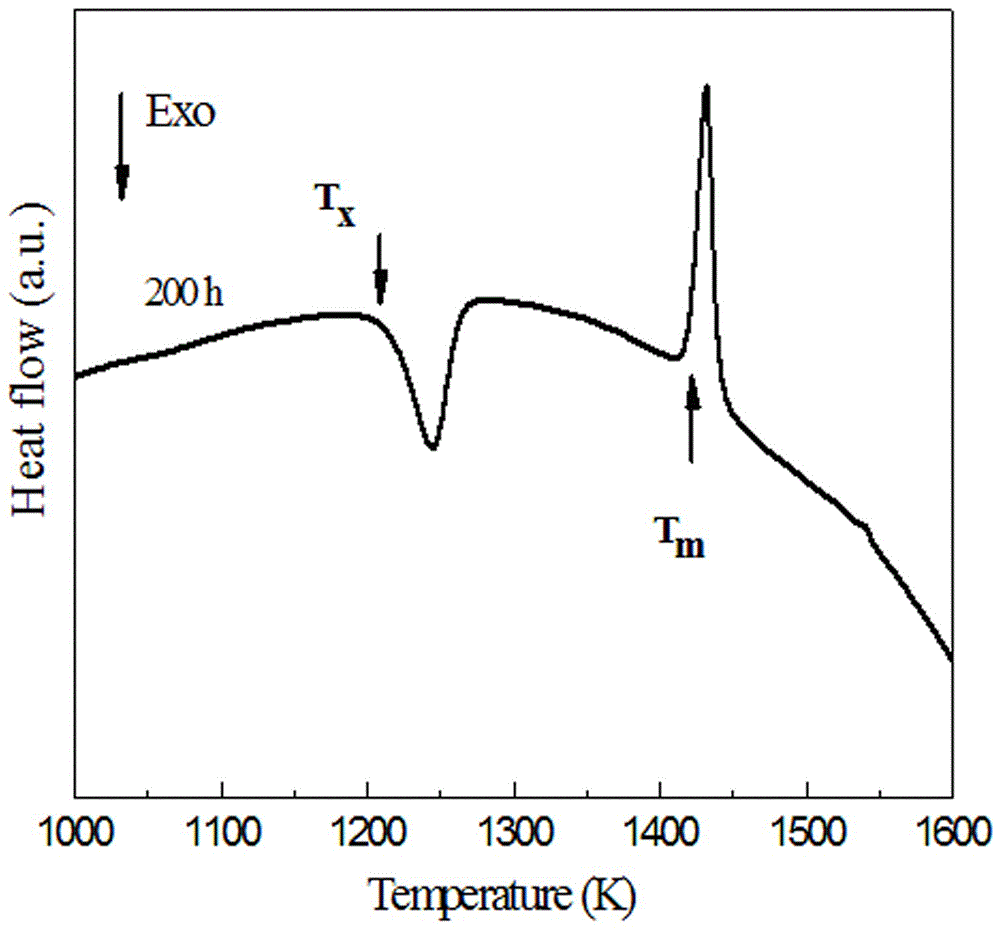

Amorphous alloy reinforced aluminum matrix composite and preparation method thereof

InactiveCN105803236AUniform particle distributionImprove density and hardnessAluminum matrix compositesMechanical properties of carbon nanotubes

The invention discloses an amorphous alloy reinforced aluminum matrix composite and a preparation method thereof. The composite takes an aluminum matrix amorphous alloy as a reinforcement and takes an aluminum alloy as a matrix, and the aluminum matrix amorphous alloy is uniformly dispersed in the aluminum alloy. The preparation method is simple to operate, the temperature of a preparation process is low, and the composite can be prepared through a simple hot-pressed sintering process. The interface bonding strength of the aluminum matrix amorphous alloy and the aluminum alloy matrix is high, the interface state is good, and aluminum matrix amorphous alloy particles are uniformly distributed in the matrix and not easy to aggregate, so that the prepared composite is high in density and good in mechanical property, that is, the strength and the hardness are high.

Owner:UNIV OF JINAN

Method for preparing loaded nano titanium dioxide photocatalysis film

InactiveCN1634653AHigh catalytic activityImprove photocatalytic activityCatalyst activation/preparationChemical reactionTitanic acid

This invention relates to a sol to gel method to process load nanometer titania effective light catalyzer thin film process method, which belongs to light catalyzer materials chemical technique field and comprises the following steps: using the pure titanic acid butonate and absolute ethyl alcohol, aminoethyl alcohol, water, poly-glycol 600 as materials; getting transparent stable light yellow titania sol through common temperature chemical reaction; then adopting the dipping and lifting method to load titania thin film on metal wire surface; finally burning in Muffle furnace under temperature of 450íµ to 550íµ to get the light catalyzer thin film.

Owner:SHANGHAI UNIV

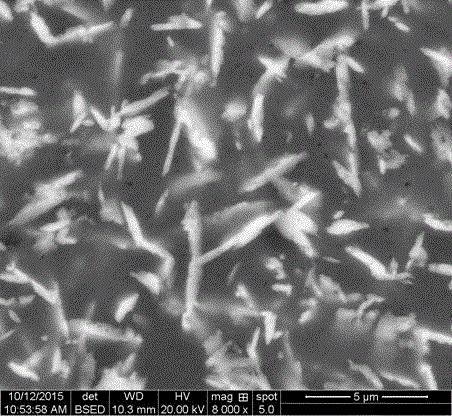

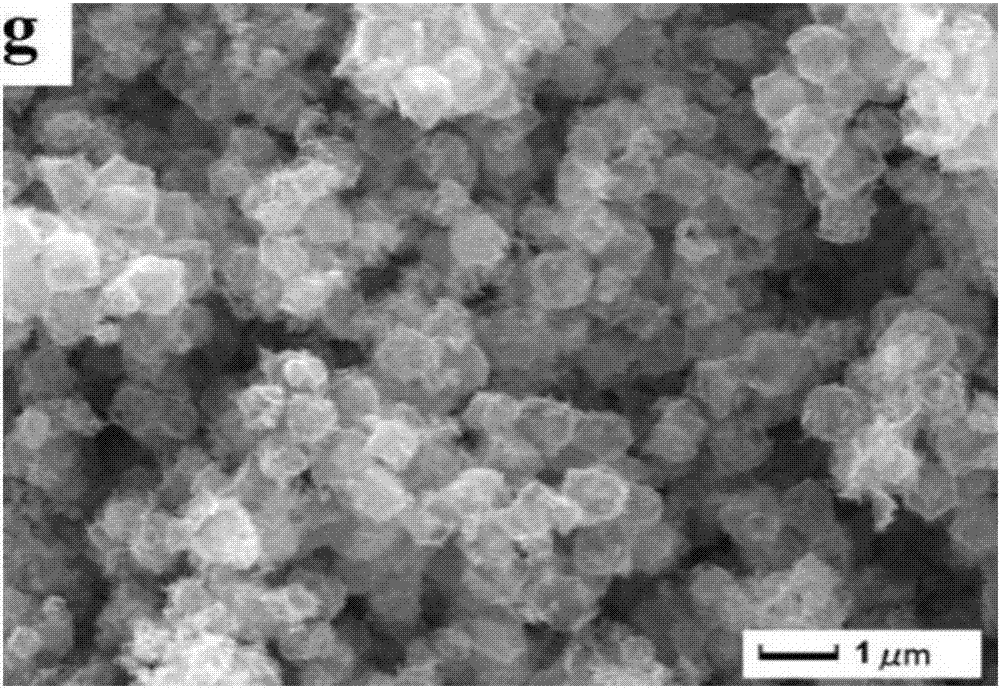

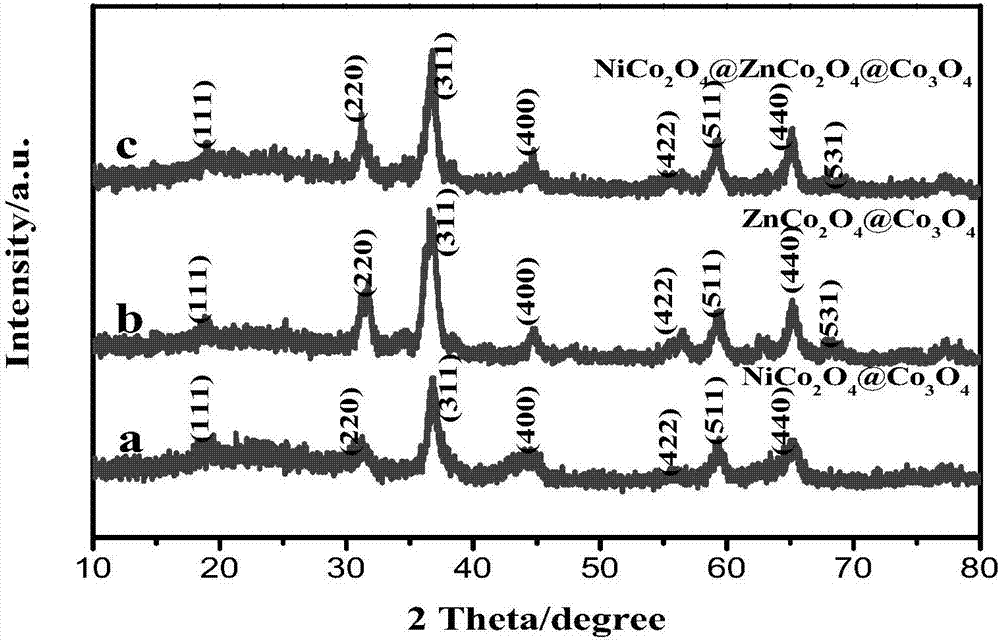

Method for preparing polynary nano-cage composite material

InactiveCN107487790AOperating conditions are easy to controlSimple equipmentHybrid capacitor electrodesCobalt compoundsSolventChemistry

The invention belongs to the technical field of metal-organic framework materials, and relates to a method for preparing a polynary nano-cage composite material by using a zeolitic imidazolate framework as a template. The method comprises the following steps: synthesizing a ZIF-67 framework through a solvothermal technology by using methanol as a solvent, and synthesizing a hydroxide precursor from nickel nitrate and zinc nitrate by adjusting a mass ratio of the zinc nitrate to the nickel nitrate; and sequentially centrifuging, washing, drying and calcining the hydroxide precursor to obtain the nano-cage composite material. The method has the advantages of simple process, low price, easiness in control, and low cost, and the prepared product is a nano-cage composite material having a non-spherical hollow structure, and has the advantages of large specific surface area, high crystallinity, good morphology, and easiness in realization of industrialization.

Owner:JIANGSU UNIV

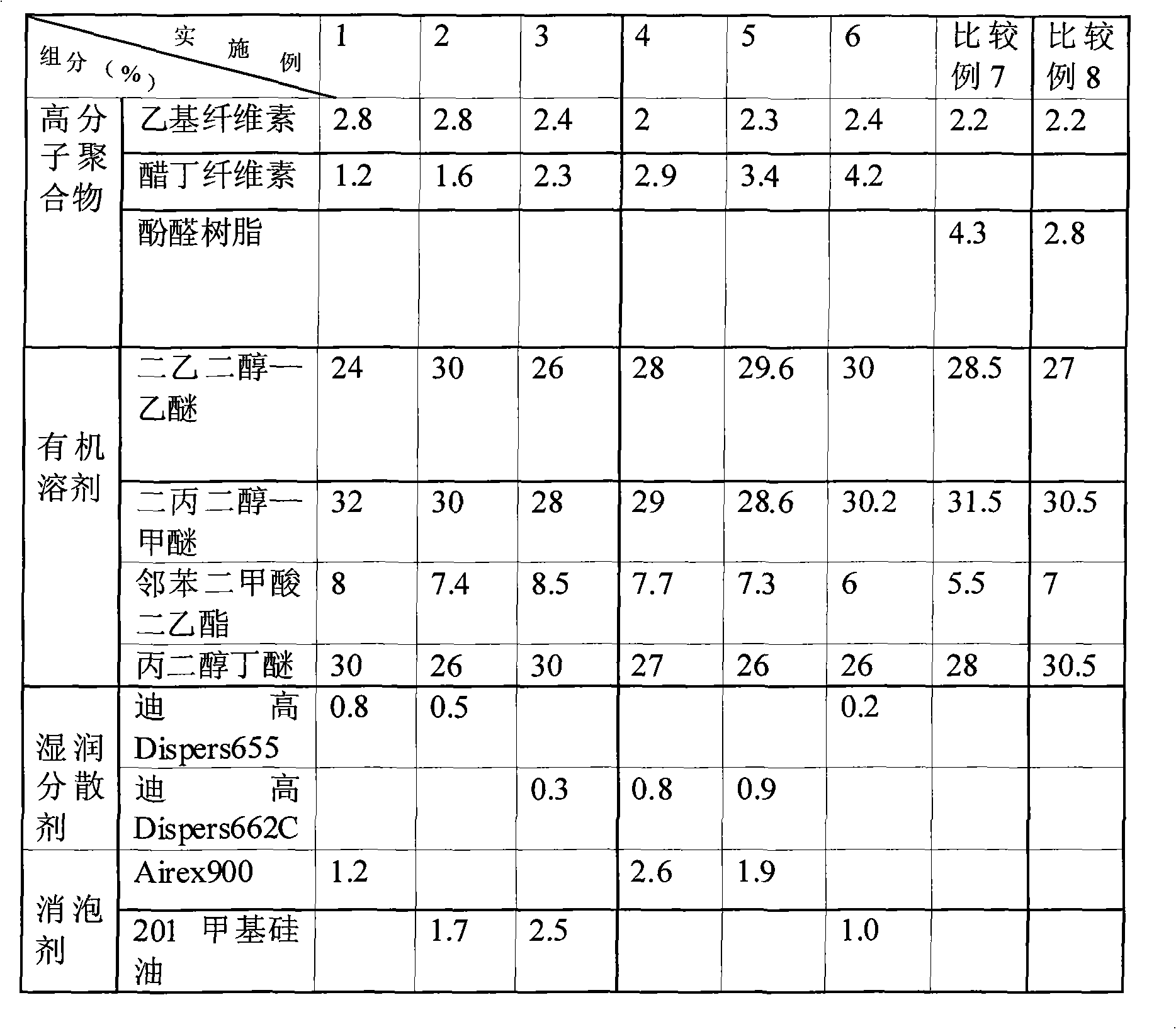

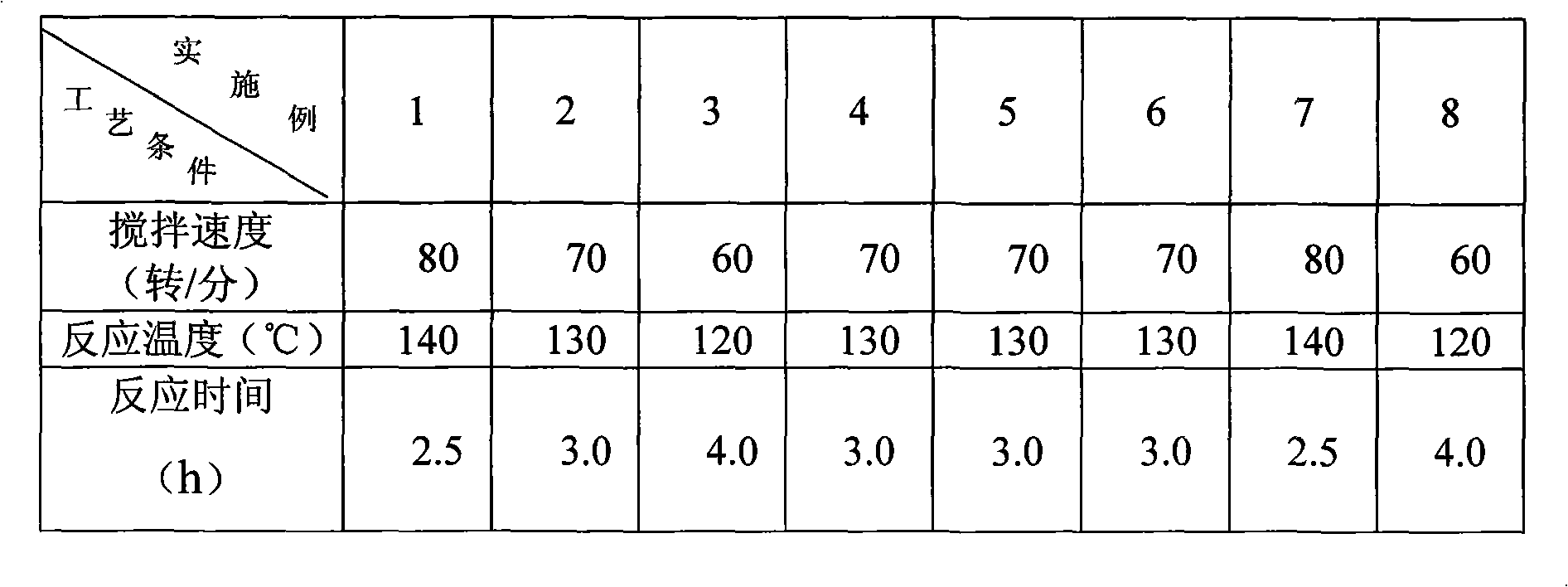

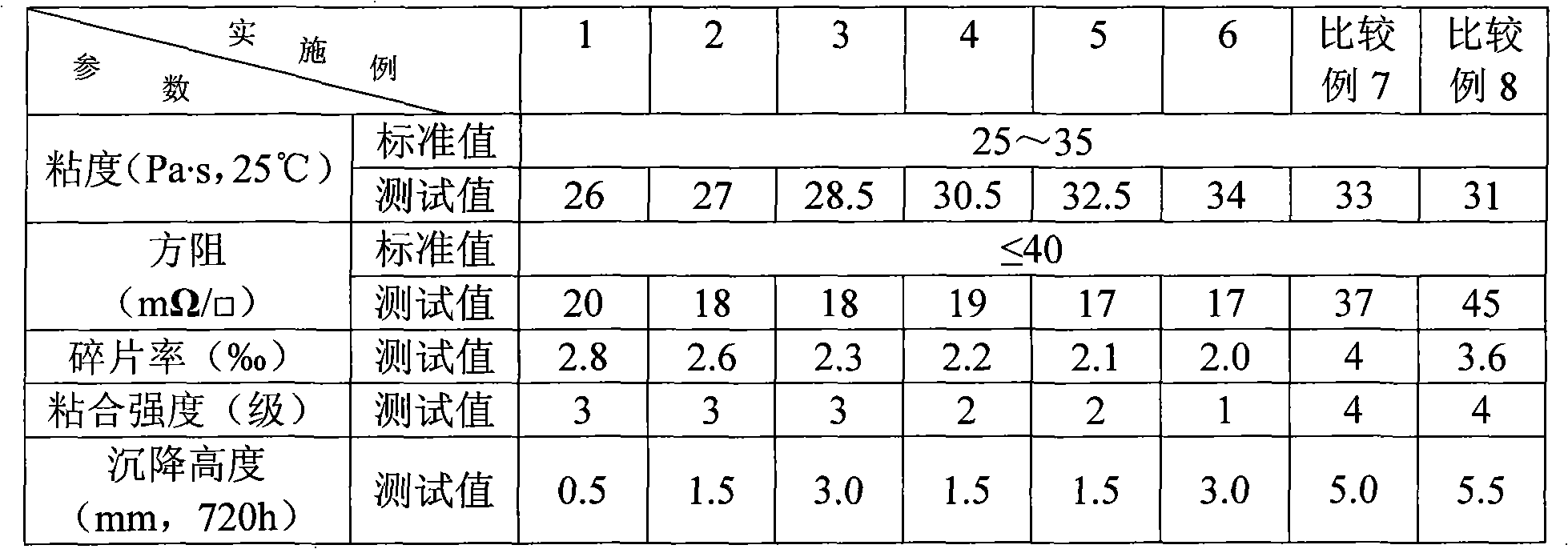

Organic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555394AReduce stressReduce Fragmentation RateFinal product manufactureCellulose adhesivesAluminum Oxide PasteChemistry

The invention provides organic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The organic adhesive comprises the following components by the weight part: 23% of ethyl cellulose, 1% to 5% of cellulose acetate butyrate, 88% to 94% of organic solvent, 0.2% to 1% of wetting dispersant and 1% to 3% of defoamer with the total amount being 100%. The preparation method comprises the following steps: putting the components into a reaction kettle; heating the components up to the temperature of 120 to 140 DEG C while stirring at the speed of 60 to 80 RPM and holding at a constant temperature for 2 to 4 hours to ensure that the components in the reaction kettle can be evenly stirred and subjected to complete reaction; and cooling the reactant and filtering the reactant with mesh to obtain the final product of the organic adhesive. The aluminum paste prepared from the organic adhesive has the advantages that the dispersibility or the suspensibility thereof is high, the aluminum paste does not laminate or precipitate after long-time storage and the aluminum paste can be uniformly coated so that the solid powder in the dried aluminum powder has the advantages of high adhesive strength and low stress generated on silicon chips.

Owner:WUXI RUXING TECH DEV +1

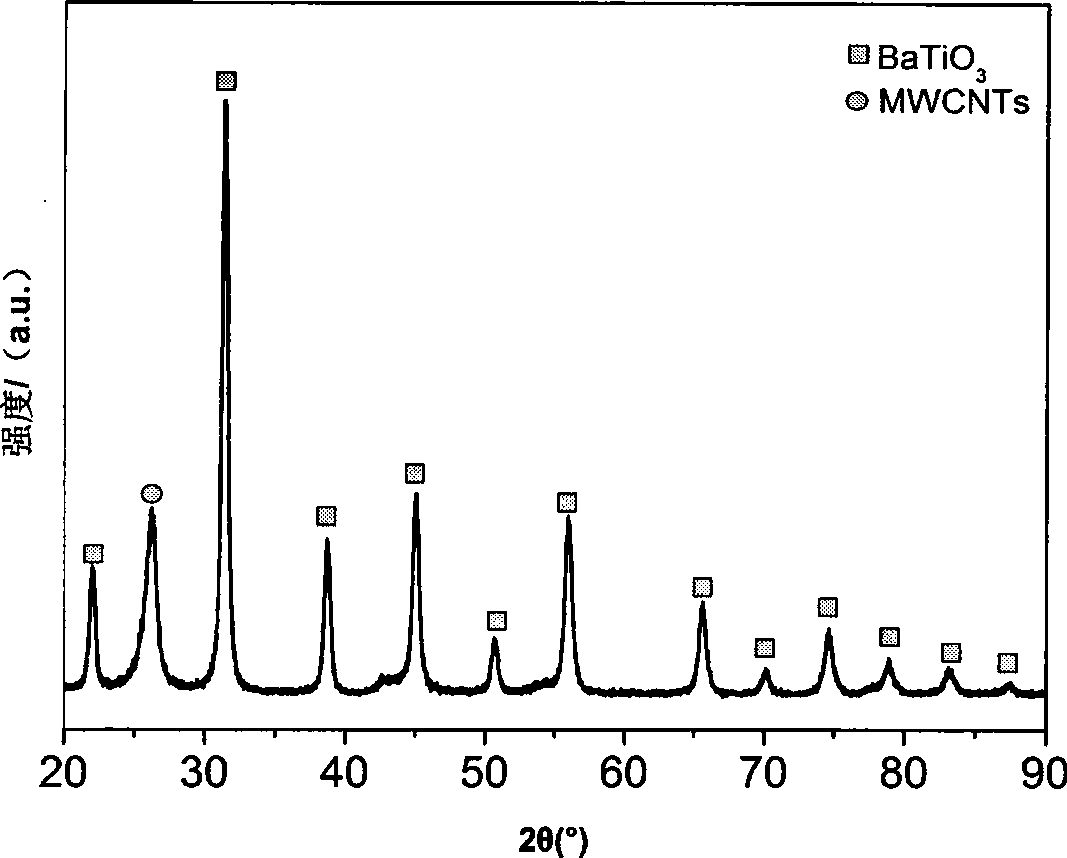

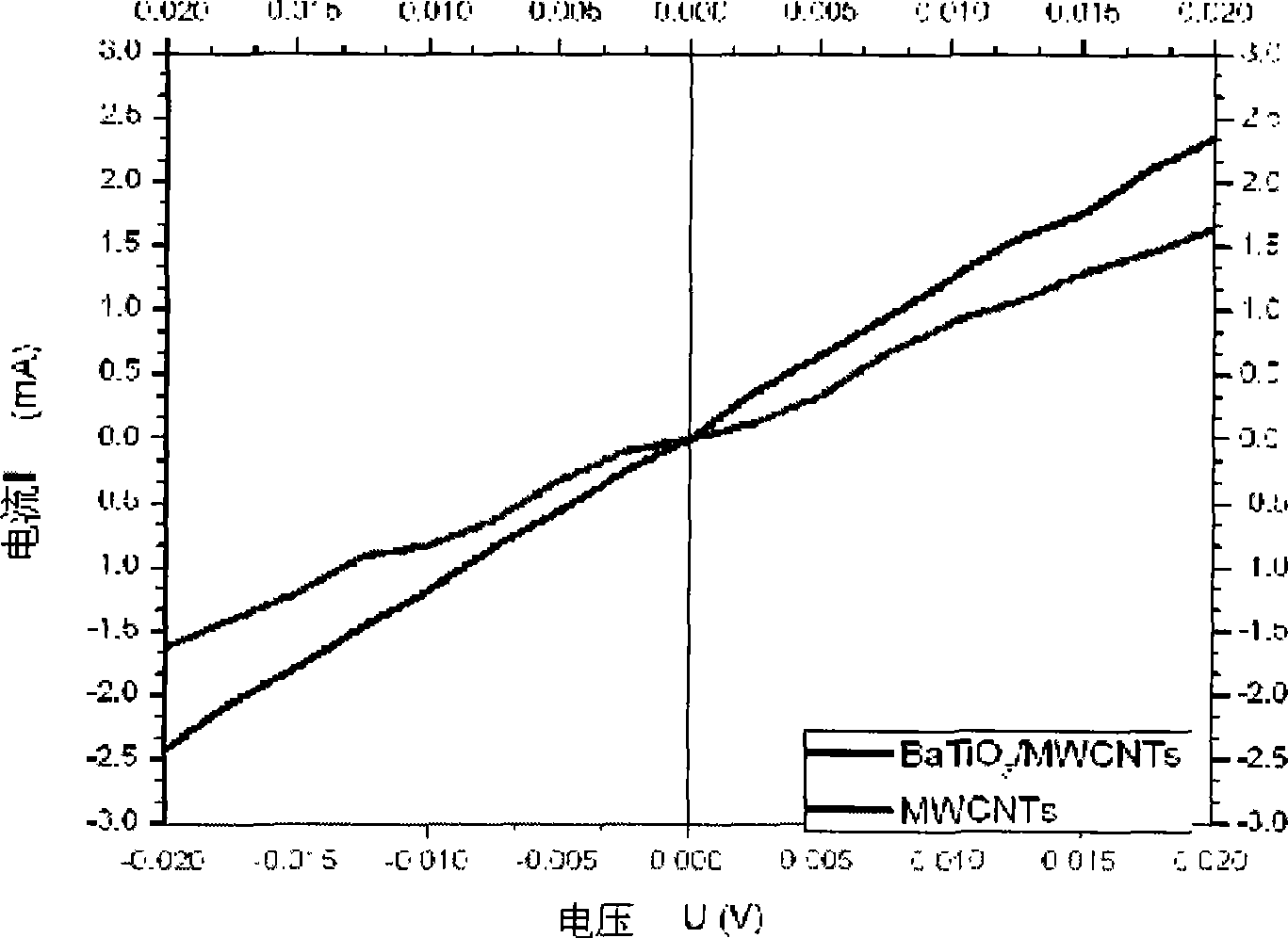

Method for preparing BaTiO3 / multi-wall carbon nano-tube (MWCNTs) nano composite material

InactiveCN101475161AImprove conductivitySmall particlesTitanium compoundsBarium titanatePolyethylene glycol

The invention relates to a method for preparing a BaTiO3 / MWCNTs nano composite material, which comprises the following steps: using MWCNTs, barium acetate, sodium hydrate and tetrabutyl titanate as initial raw materials, using deionized water, ethylene diamine and ethanolamine as solvents, adopting concentrated nitric acid to modify the surface of the MWCNTs, using a tetrabutyl titanate hydrolysis product as a titanium source, adding a dispersant, namely polyethylene glycol and plasmosan into the mixture, and adopting a solvent hot method to obtain the BaTiO3 / MWCNTs nano composite material. By changing the proportion of the MWCNTs, the barium acetate and the tetrabutyl titanate, the BaTiO3 / MWCNTs nano composite material with different compositions can be obtained. The prepared BaTiO3 / MWCNTs nano composite material has good electric conductivity, the synthesis process and the production equipment are simple, and industrialized production is easy to realize.

Owner:DONGHUA UNIV

Emulsion water of finishing agent for textile containing fluorin

The present invention relates to a fabric finishing agent water emulsion, in particular, it relates to a fabric finishing agent water emulsion containing acrylic perfluoroalkyl ester. Its composition includes (by wt%) 10-40% of comonomer mixture formed from at least (methyl) acrylic perfluoroalkyl ester and (methyl) acrylic straight chain alkyl ester, 10-20% of solvent, 30-70% of deionic water, 1.0-5.0% of emulsifier and small quantity of molecular weight regulating agent.

Owner:JUHUA GRP

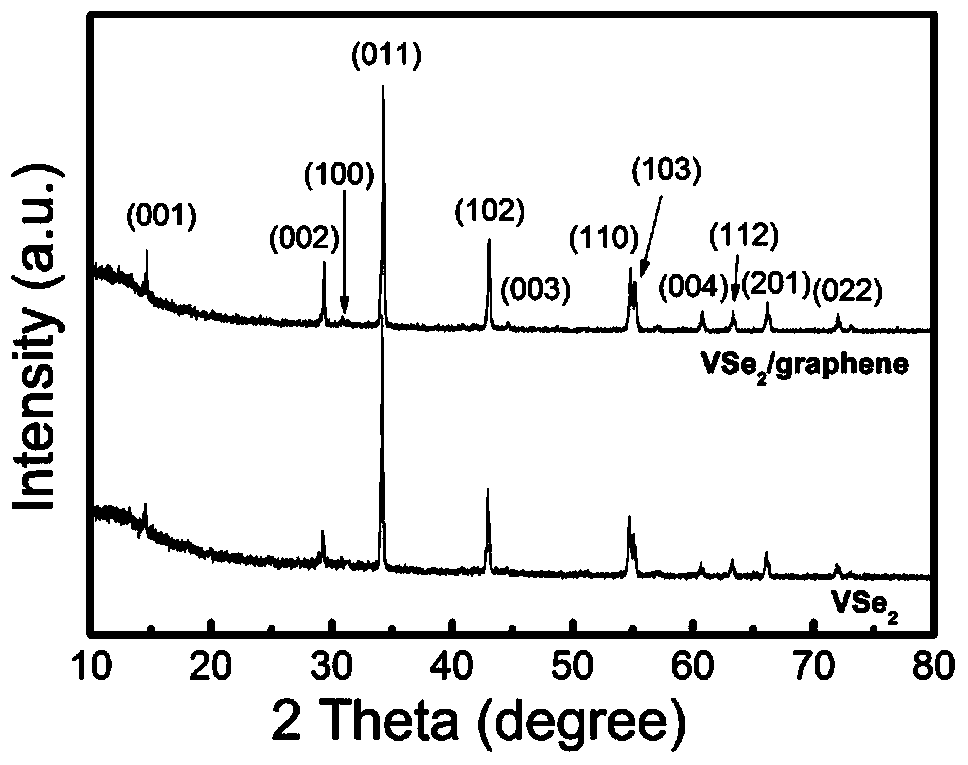

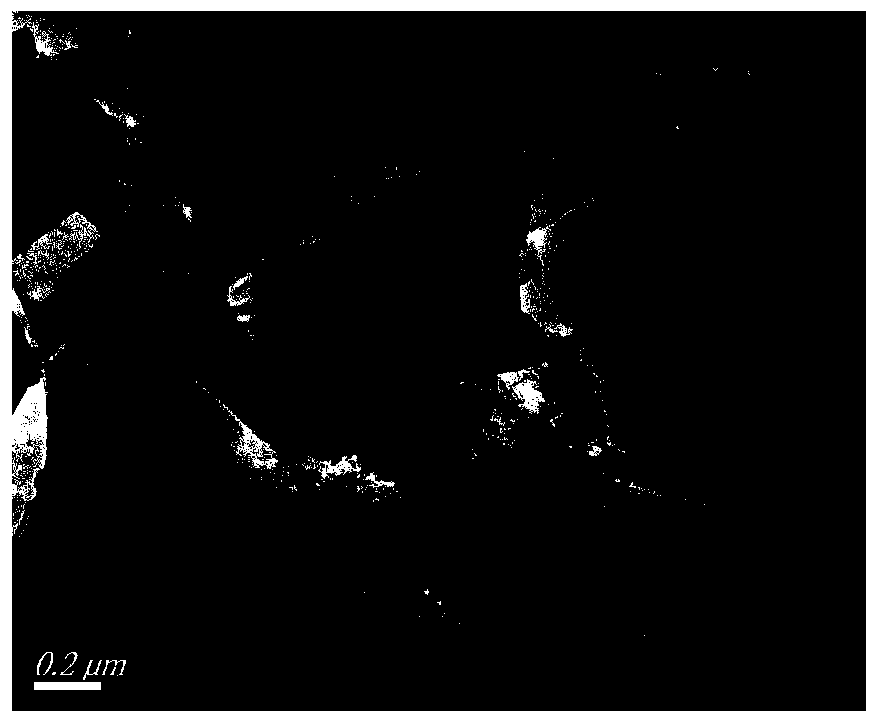

Vanadium selenide/carbon-based composite material, preparation method of material, and negative electrode of lithium ion battery

ActiveCN104051733AUniform particle distributionSmall particle sizeSecondary cellsNon-aqueous electrolyte accumulator electrodesHexagonal crystal systemHigh rate

The invention provides a vanadium selenide / carbon-based composite material, a preparation method of the material, and a negative electrode of a lithium ion battery. Vanadium selenide in the vanadium selenide / carbon-based composite material is of a hexagonal crystal system and is deposited on the surface of a carbon-based material, or the surfaces of vanadium selenide particles are at least partially coated with the carbon-based material to form vanadium selenide / carbon particles of a core shell-like structure; the vanadium selenide / carbon particles are connected through carbon nets to obtain the high conductivity. In the negative electrode of the power lithium ion battery, prepared from the vanadium selenide / carbon-based composite material provided by the invention, since selenide with the relatively large specific capacity is combined with the carbon-based material, the negative electrode has the characteristics of large capacity, high rate and high cyclic stability. Therefore, the negative electrode made of the composite material has the relatively large capacity, relatively long service life and relatively low price when applied to the lithium ion battery.

Owner:JIANGSU UNIV

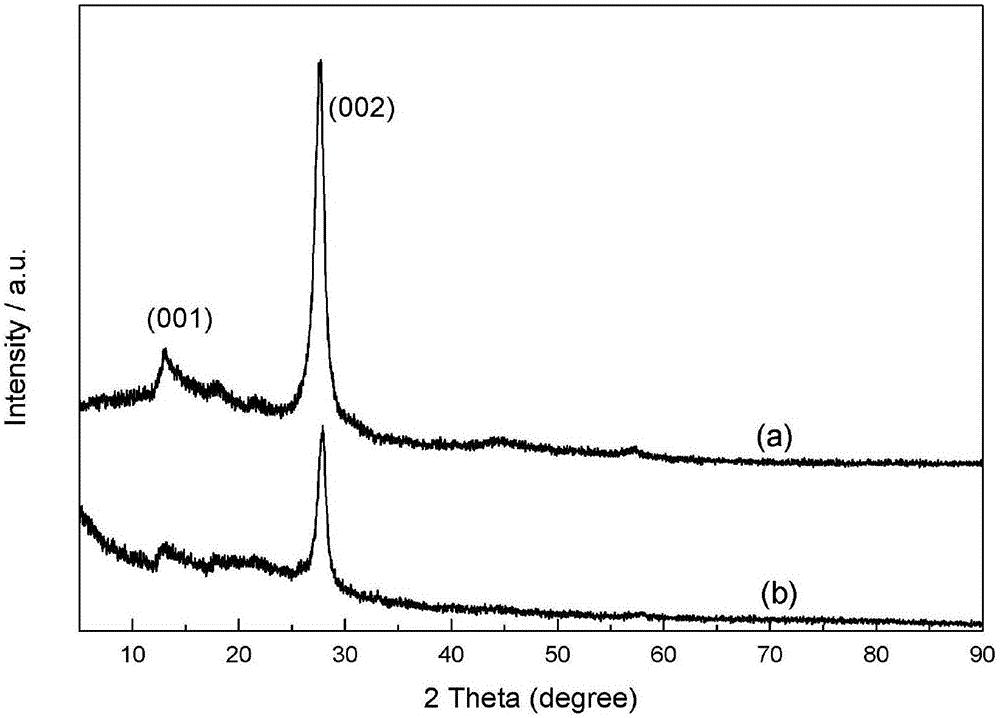

G-C3N4 nanosheet with monodisperse structure and preparation method of g-C3N4 nanosheet

InactiveCN106629638AUniform particle distributionNo agglomerationMaterial nanotechnologyNitrogen and non-metal compoundsMicro nanoDispersity

The invention relates to the technical fields of micro-nano structures and photocatalysis, in particular to a g-C3N4 nanosheet with a monodisperse structure and a preparation method of the g-C3N4 nanosheet. The size of the g-C3N4 nanosheet with the monodisperse structure is 10 to 50nm; particles are uniformly distributed, so that the agglomeration phenomenon is avoided. The g-C3N4 nanosheet is prepared by a secondary calcination method under the condition of water vapor atmosphere, is mild in preparation conditions and can be prepared in macroscopic quantity; the g-C3N4 nanosheet with the monodisperse structure is large in specific surface area and good in dispersity, has higher reactive sites, and can be effectively applied to photocatalytic degradation of organic matters and production of hydrogen by water photodecomposition.

Owner:HEFEI UNIV OF TECH

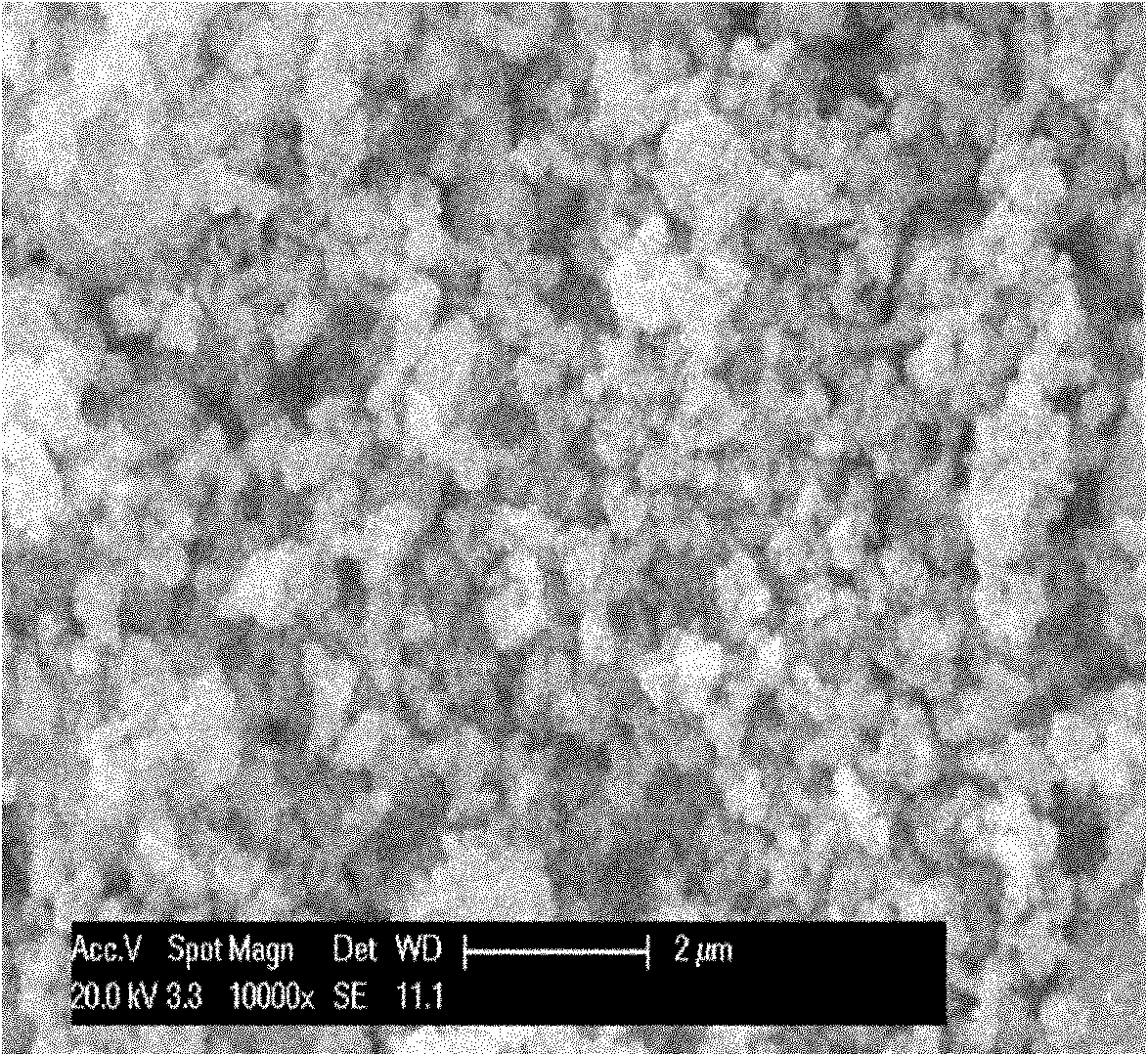

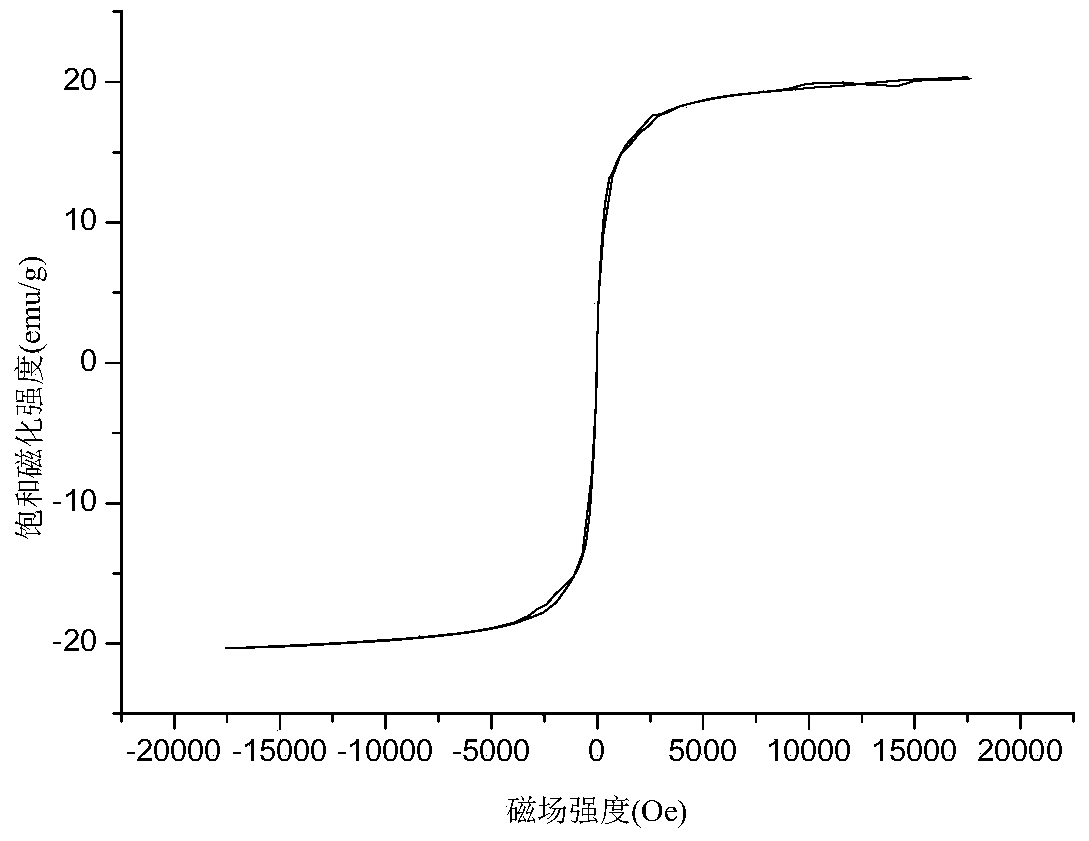

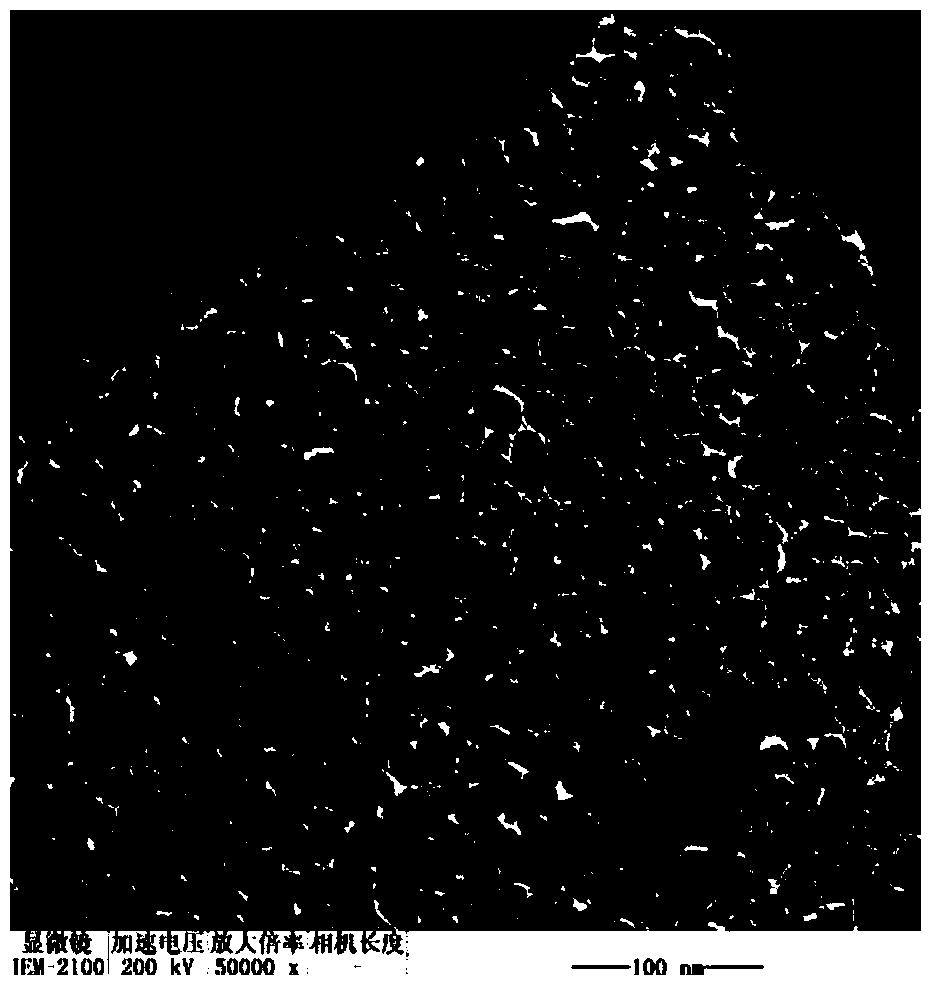

Preparation method of magnetic-functionalized graphene composite material

InactiveCN102583336AHas superparamagnetic propertiesImprove conductivityCarbon compoundsInorganic material magnetismEthylenediamineMagnetization

The invention provides a preparation method of a magnetic-functionalized graphene composite material, and relates to preparation of a graphene composite material. According to the invention, the preparation method is simple, the raw material is easily obtained, and the industrial production is easy; the prepared magnetic-functionalized graphene composite material has superparamagnetic property and is higher in saturated magnetization; and the graphene carrier is good in conductivity, and loaded ferroferric oxide nano particles are uniformly distributed, are small and are good in crystallizability. The preparation method comprises the following steps of: matching ethanediamine and water into a mixed solvent, then ultrasonically dispersing graphite oxide and iron acetylacetonate in the mixed solvent, and obtaining ethanediamine / dispersion of the graphite oxide and the iron acetylacetonate; transferring the ethanediamine / dispersion of the graphite oxide and the iron acetylacetonate into a reactor lined with polytetrafluoroethylene for reaction and obtaining solid products; and cleaning the solid products, collecting the products with a magnet, drying and obtaining the magnetic-functionalized graphene composite material.

Owner:XIAMEN FUNANO NEW MATERIAL TECH COMPANY

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

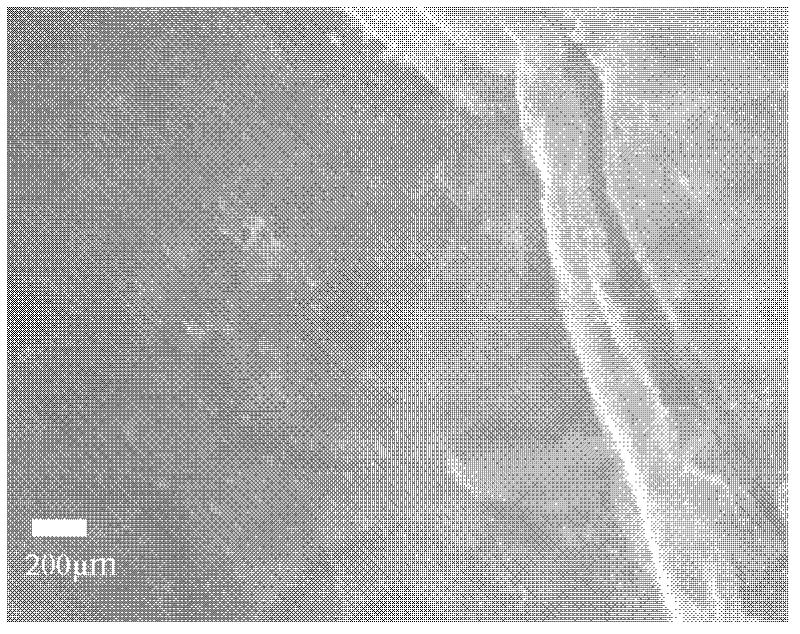

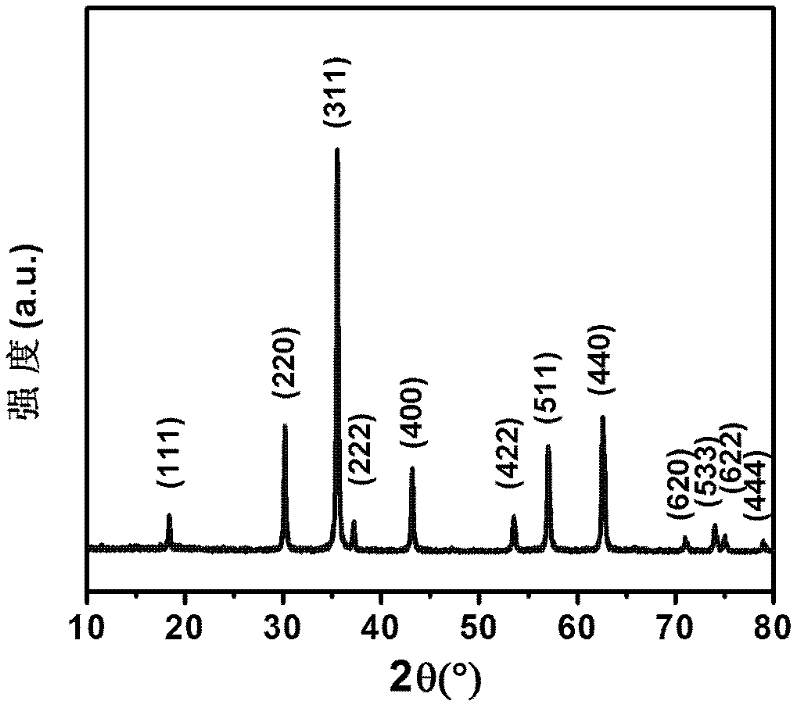

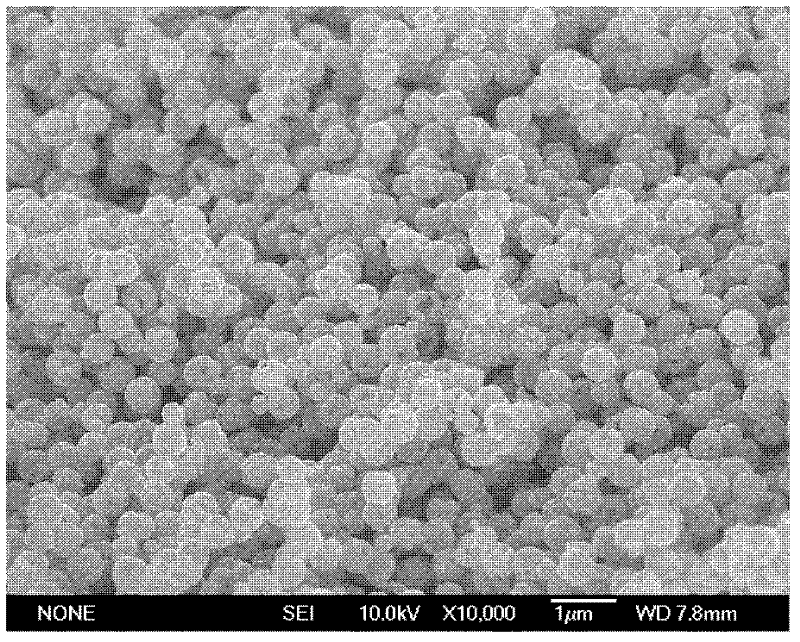

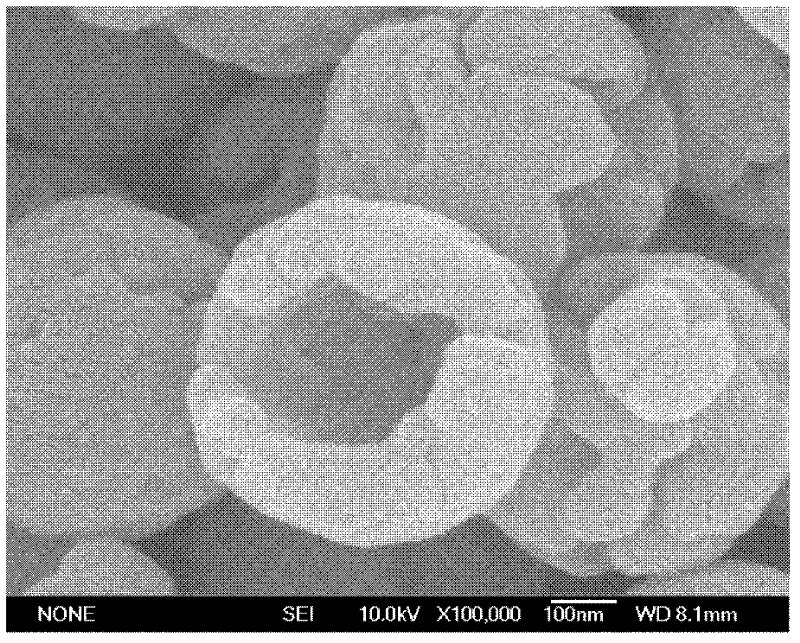

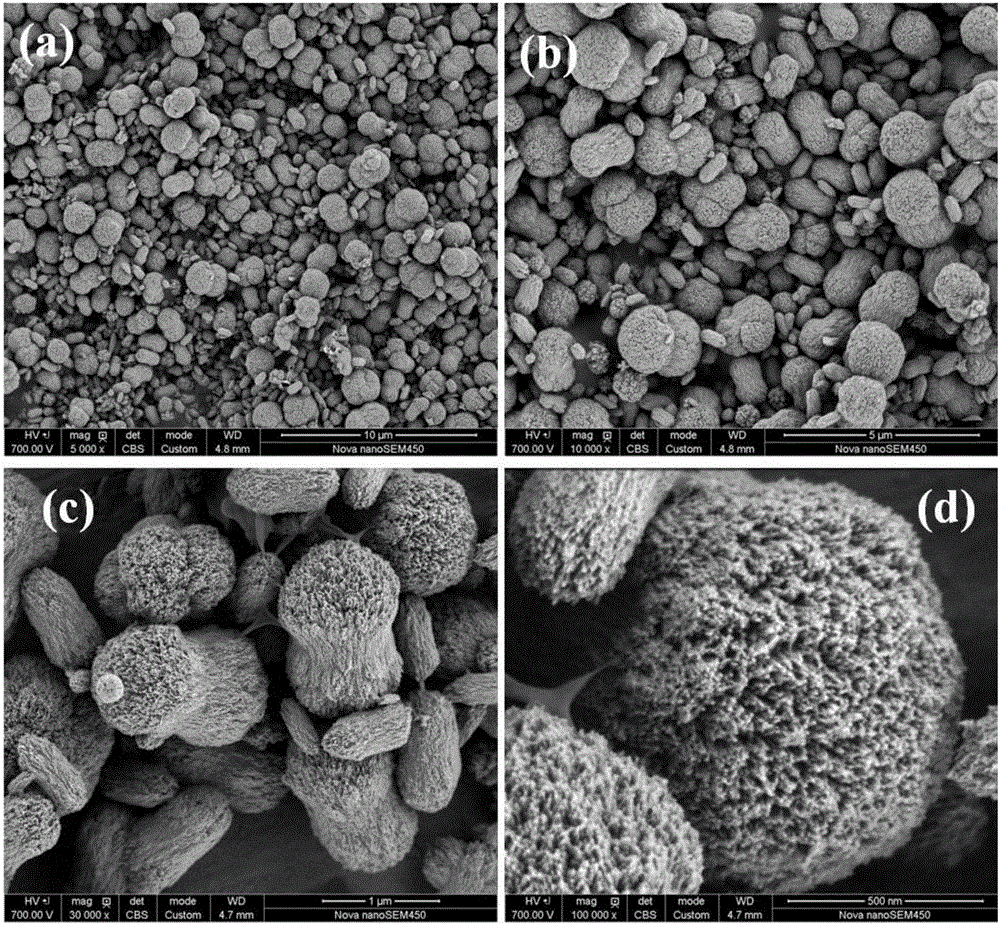

Spherical ferrate having hollow structure and preparation method thereof

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Cold water dispersion type xanthophyll micro-capsule and its preparing method

InactiveCN101219125AUniform particlesUniform particle distributionHydroxy compound active ingredientsAntinoxious agentsSolubilityWater dispersible

The invention discloses a cool water dispersible lutein microcapsule. The lutein microcapsule comprises lutein powder used as core material, modified starch and natural colloid used as wall material, and appropriate amount of emulsifier added, which are mixed and added with proper amount of water, heated and stirred, and then filtered and spray dried to obtain the lutein microcapsule. The invention has easy material acquiring, can be applied to food or pharmaceutical industry, and has good safety without using organic solvents thus the nature of the lutein is well kept. In the invention, the core material and the wall material are mixed directly in one step, and emulsified by controlling the temperature; the lutein liquid is embedded into semi-permeable or hermetic solid microcapsule powder by adopting spay drying. The obtained microcapsule powder has good water-solubility, high stability and encapsulation rate.

Owner:云南博浩清亮生物科技有限公司

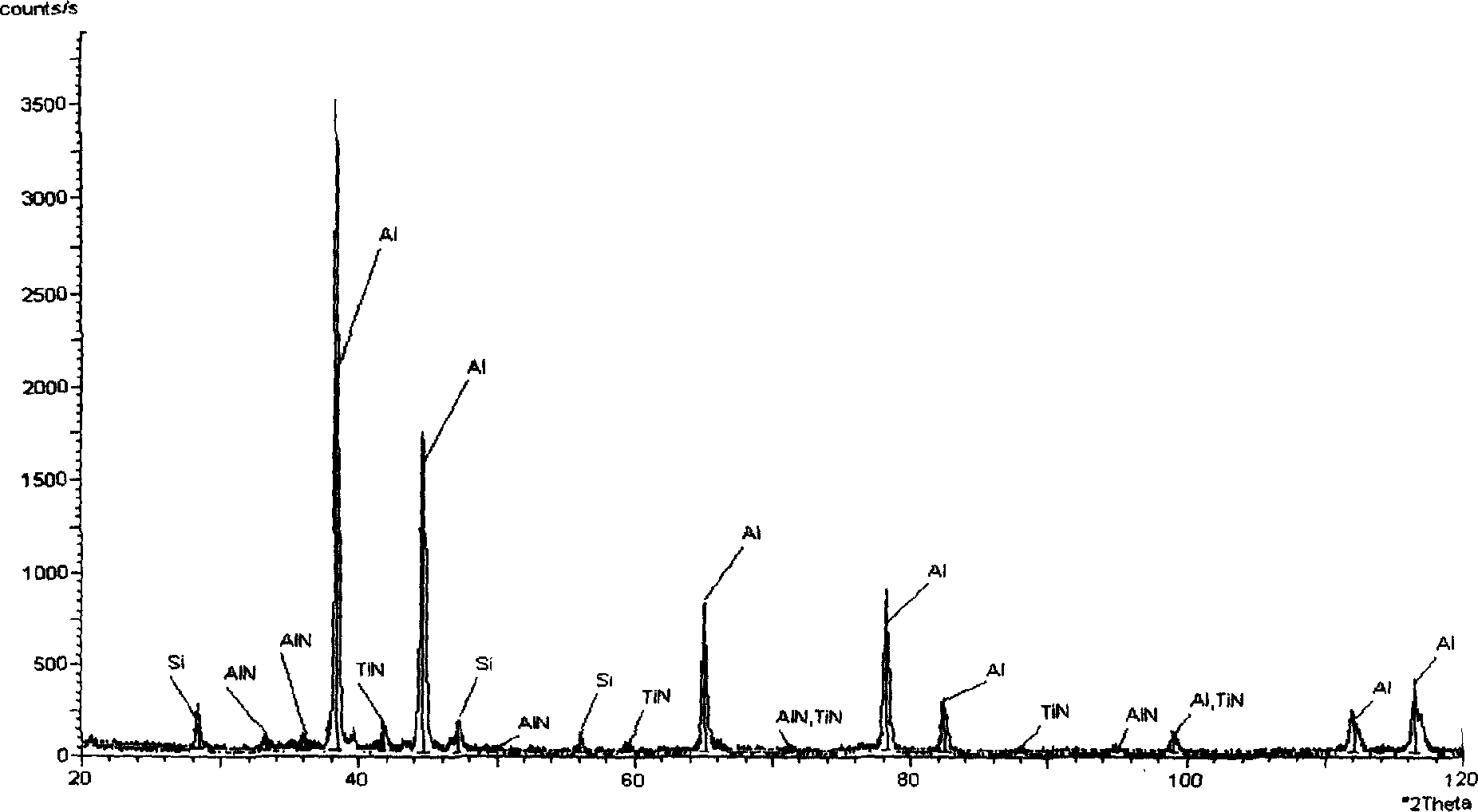

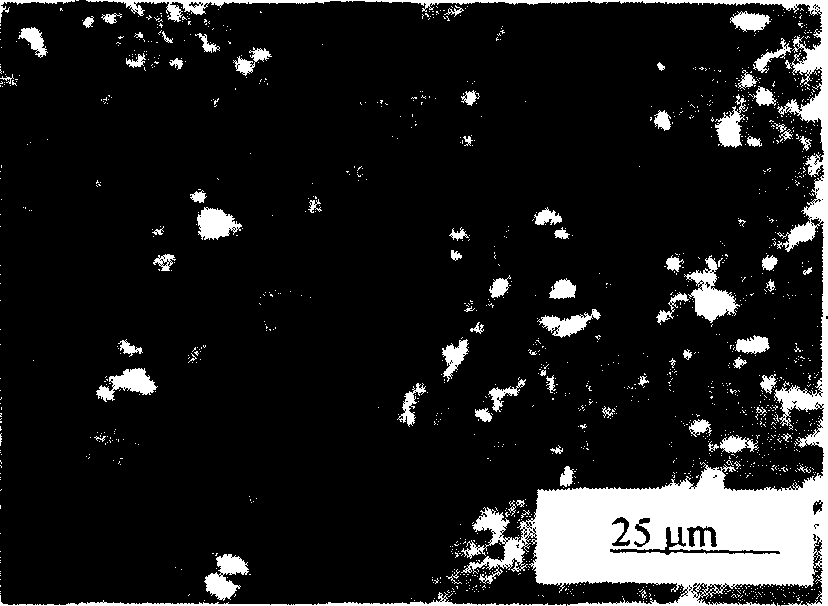

Ceramic granule reinforced aluminium-base composite material and its preparing method

This invention is a ceramic grain reinforcing Al-base compound material and its preparation method, and relates to a Al-base alloy. Its components are: 2.5-15% TiN, 2.4-10%AIN, 4-6.5%Si, 0.5-1.5%Cu, 0.3-0.5%Mg, 0-0.8%Ni, 0-0.5%Ti, and the rest is Al, and the percentages are weight percentages; the preparation method adopts melt blending founding method, and the technique flow is: material matching-melting base body-adding reinforcing grains-melting-modifying treatment-pouring-heat treatment, and the size reinforcing grains is in the range of 5-10 mum, and the vacuum degree of the vacuum furnace is 1.3-1.6X10 to the power -3 Pa, the temperature is 670-800deg.C, the modifying agent is 1-18g / Kg compound material containing 1-6% Na nanometer Al alloy powder; the Al-base compound material of this invention has light weight, high modulus number, high intension, good heat-fast and wearable performances, and the preparation cost is low, the technique is simple and it can be industrially produced.

Owner:HEBEI UNIV OF TECH

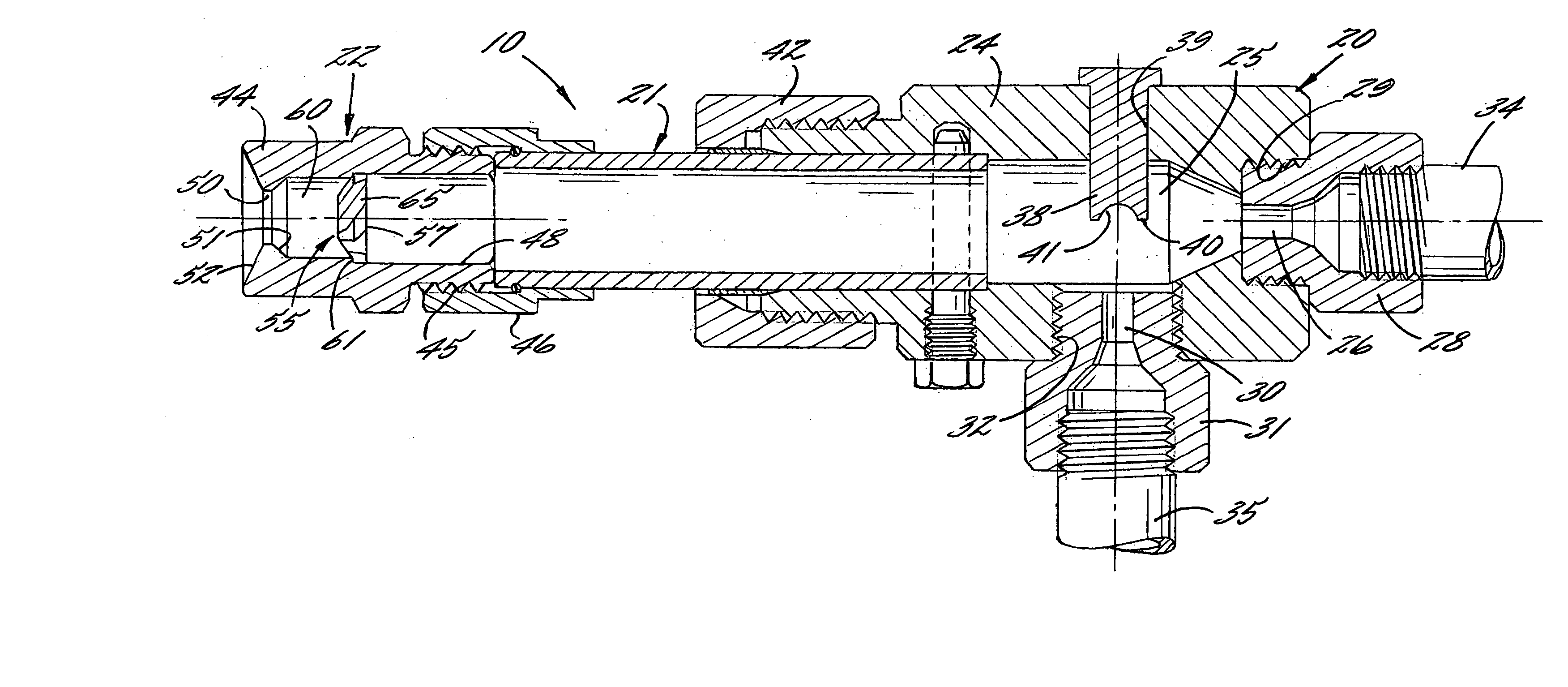

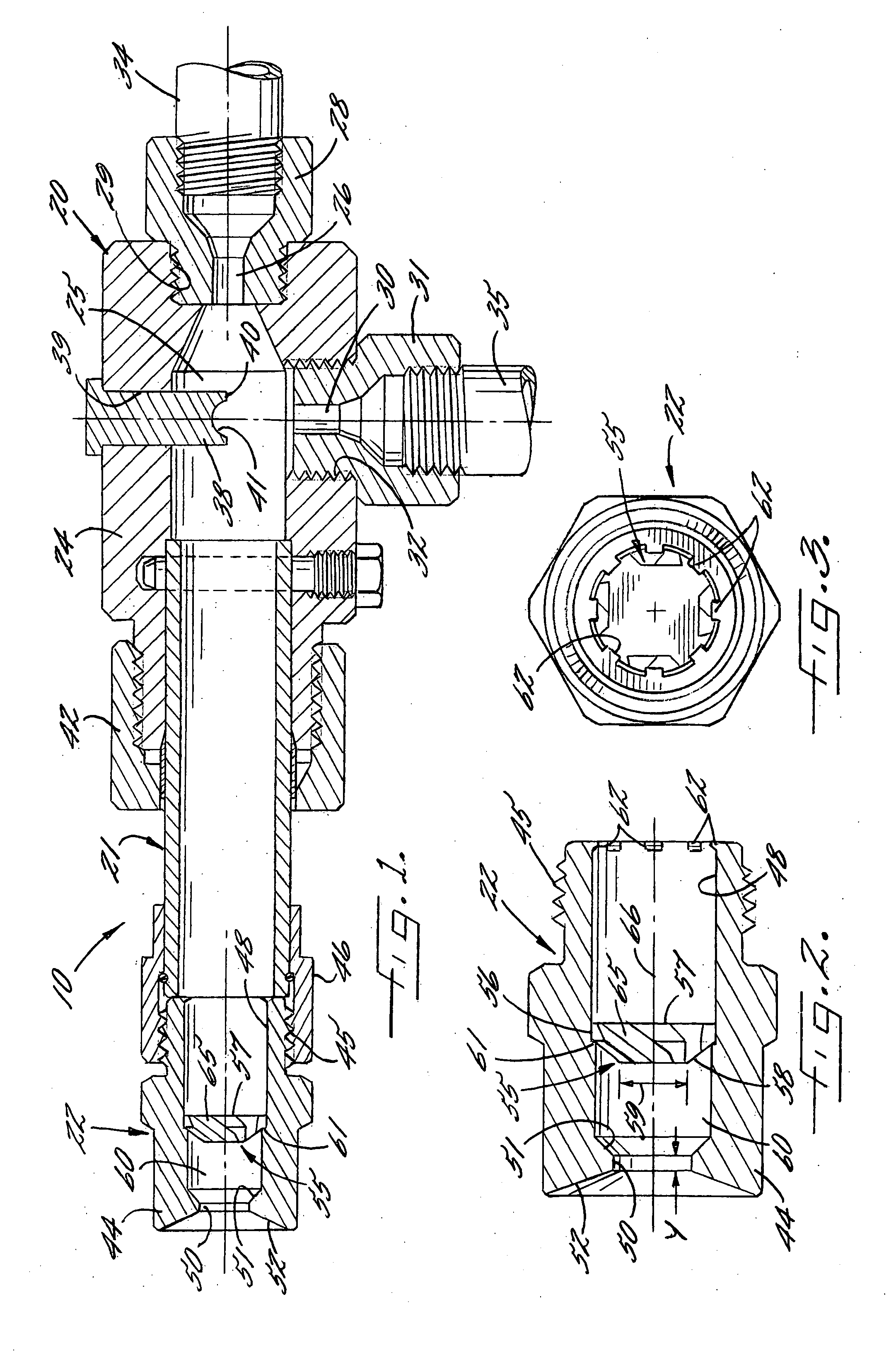

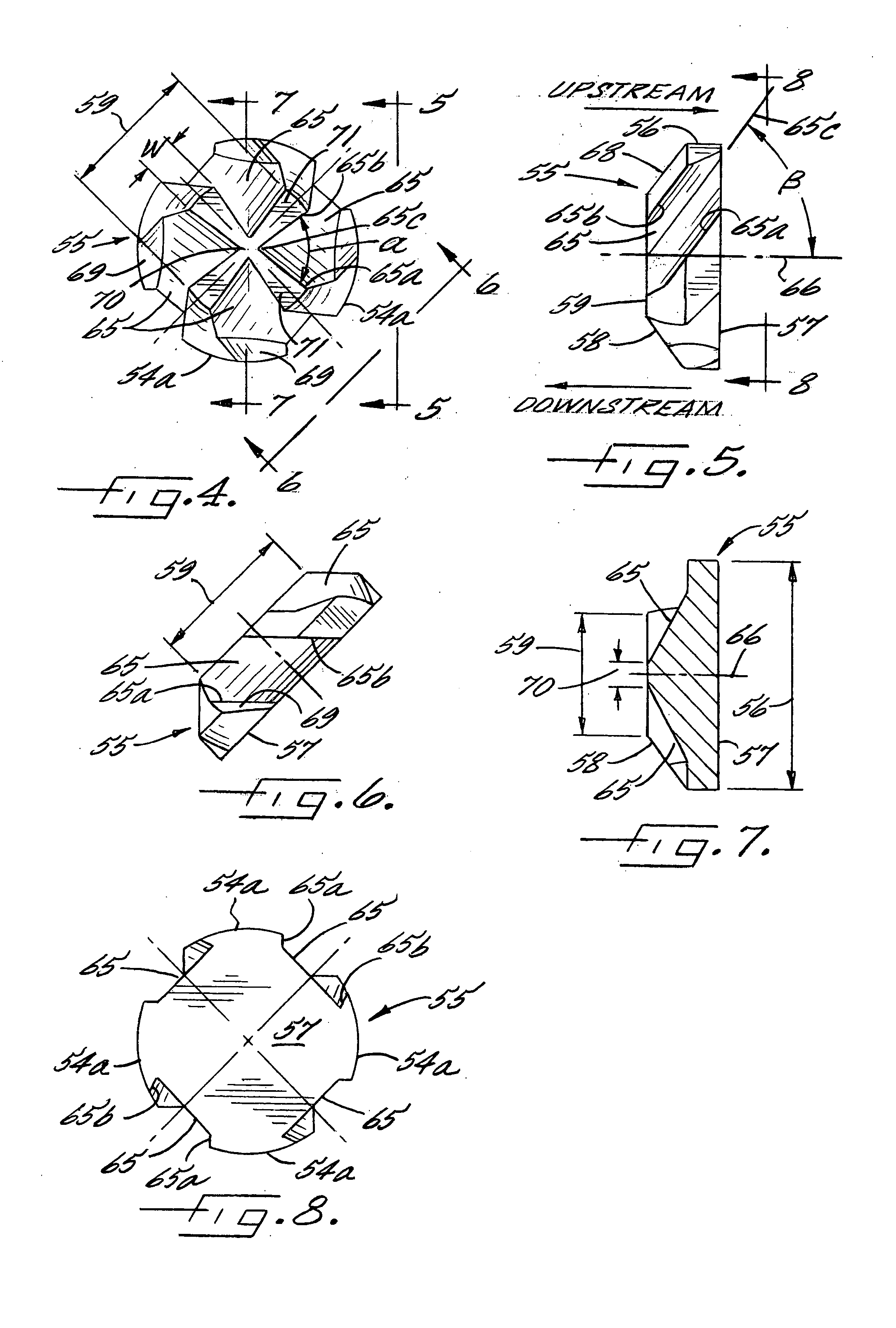

Full cone air assisted spray nozzle for continuous metal casting cooling

ActiveUS20070290073A1Uniform particle distributionImprove particle distributionSpray nozzlesLiquid spraying apparatusMixing chamberNozzle

A full cone liquid spray nozzle is provided. The spray nozzle includes a nozzle body having a discharge orifice at a downstream end and an inlet at an upstream end for connection to a liquid supply. A liquid flow passageway extends through the nozzle body communicating between the inlet and the discharge orifice. A vane is disposed in the liquid flow passageway upstream of the discharge orifice. The vane has a plurality of V-shaped passageways therein. Each V-shaped passageway extends inward at an angle with respect to a longitudinal axis of the vane between an upstream face and downstream face of the vane. A whirl and mixing chamber defined by the liquid flow passageway is arranged between the vane and the discharge orifice.

Owner:SPRAYING SYST

Preparation method for perfluor polyether oil-based magnetic liquid

InactiveCN103680798AExtended application environmentEasy to useMagnetic liquidsOrganic/organic-metallic materials magnetismHigh energyMagnetization

The invention discloses a preparation method for a perfluor polyether oil-based magnetic liquid. The magnetic liquid is formed by bare Fe[3]O[4] magnetic nano-particles, a perfluor polyether carboxylic acid surface active agent and a perfluor polyether oil-based carrier liquid in a prepared mode. The bare Fe[3]O[4] nano-particles with the average particle diameter of 10 nanometers are firstly prepared by the adoption of a chemical coprecipitation method; the perfluor polyether carboxylic acid surface active agent is then adopted for modifying the bare Fe[3]O[4] nano-particles; finally, the modified Fe[3]O[4] magnetic nano-particles and the perfluor polyether oil-based carrier liquid are blended through a high-energy ball milling or ultrasonic shaking method to form the uniform and stable perfluor polyether oil-based magnetic liquid, and the saturation magnetization of the perfluor polyether oil-based magnetic liquid is 14-600 Gs. The magnetic liquid has the excellent special performance of resisting to chemical corrosion, high temperature, low temperature resistance and radiation and never burning, can work stably for a long time at the temperature of 40 DEG C below zero-200 DEG C at the pH value of 1-14, and is particularly suitable for space stations, aeronautics and astronautics and other military industry fields.

Owner:BEIJING JIAOTONG UNIV

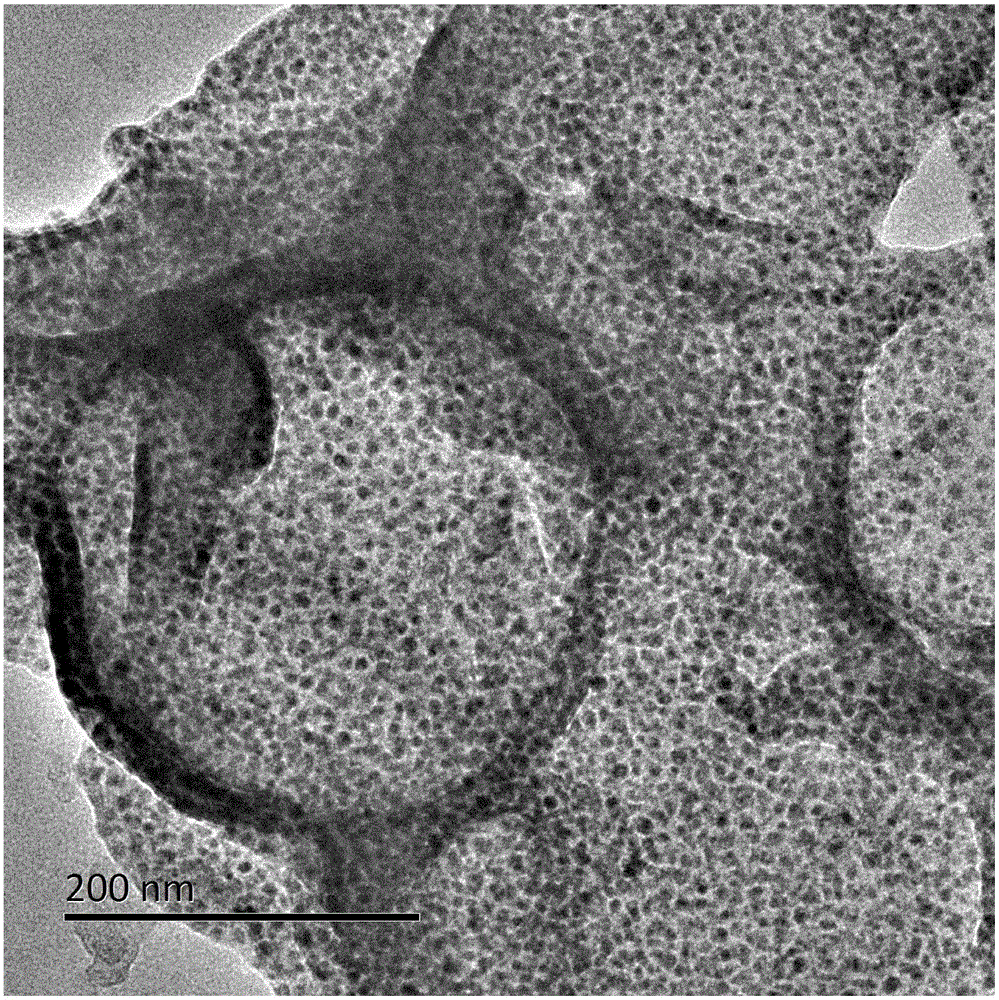

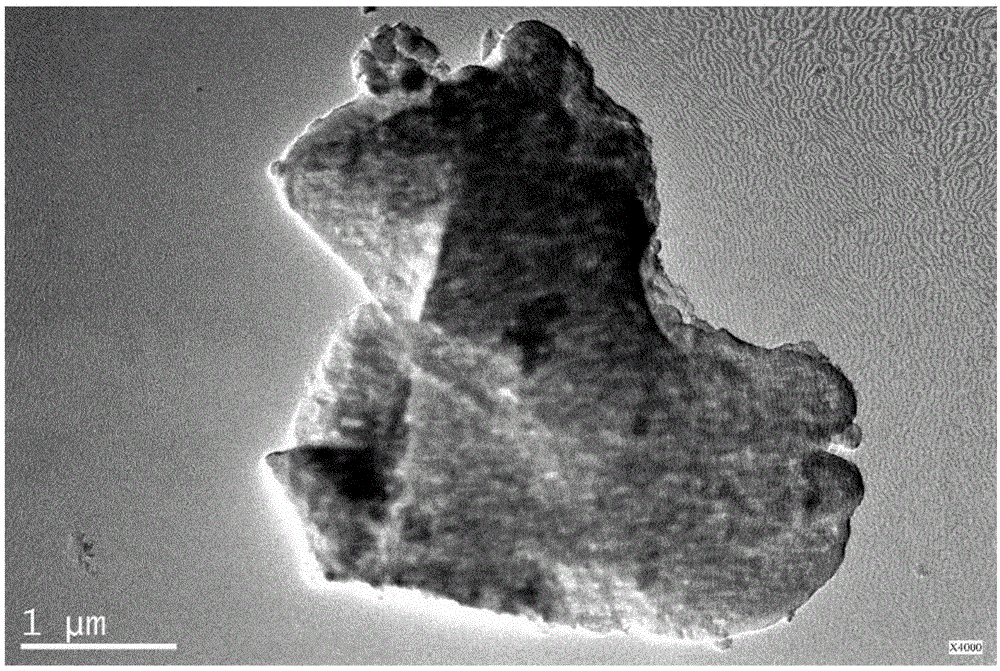

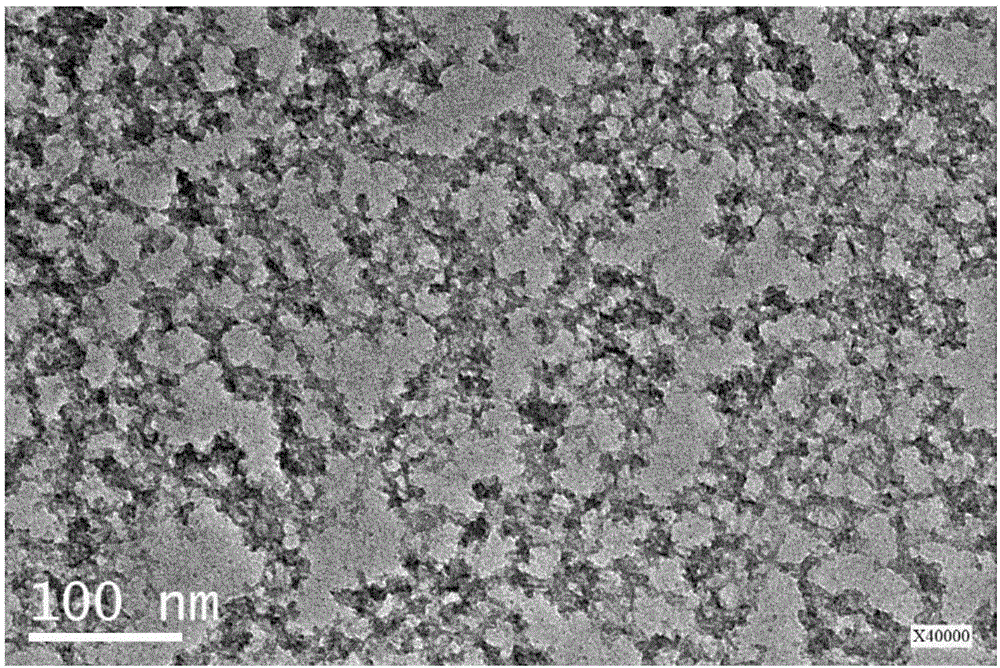

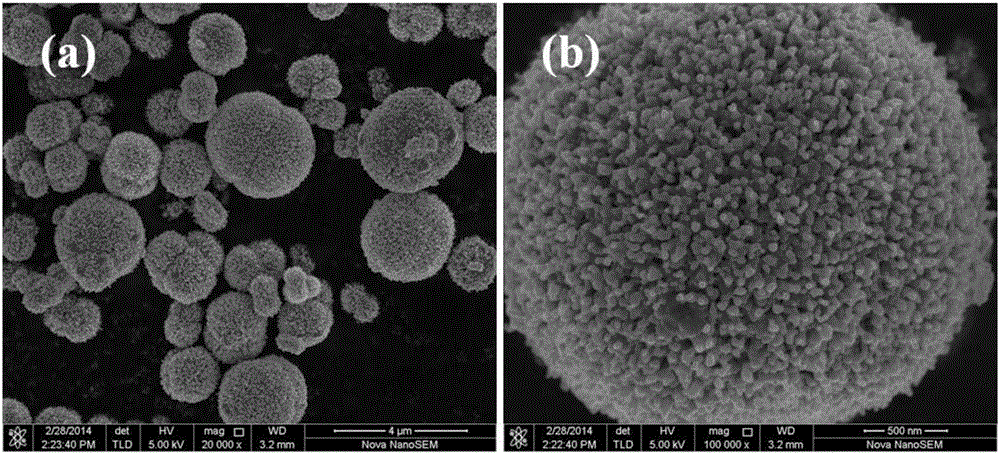

Lithium-rich manganese-based cathode material precursor, cathode material and preparation method thereof

ActiveCN106564967AAccelerates and intensifies the mass transfer processWell mixedMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to the field of electrode material preparation and relates to a lithium-rich manganese-based cathode material precursor, a cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing metal salts (manganese salt, cobalt salt and nickel salt) and a surfactant and water, and dissolving to obtain a metal salt solution; putting a precipitant in water, stirring and dissolving to obtain a precipitant solution; carrying out liquid-liquid coprecipitation reaction on the metal salt solution and the precipitant solution in a hypergravity field reactor, filtering, cleaning, and carrying out vacuum drying so as to obtain a precursor; mixing the precursor and lithium salt and then calcining so as to obtain the lithium-rich manganese-based cathode material. By the coprecipitation method based on the hypergravity technology, the lithium-rich manganese-based cathode material precursor with primary particle being below 100 nm and secondary particle being 1-10 microns is rapidly prepared, and furthermore the prepared cathode material has advantages of uniform component distribution and particle size distribution, small granularity and high activity. Initial irreversible capacity can be reduced, and cycle performance of a lithium ion secondary battery can be enhanced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

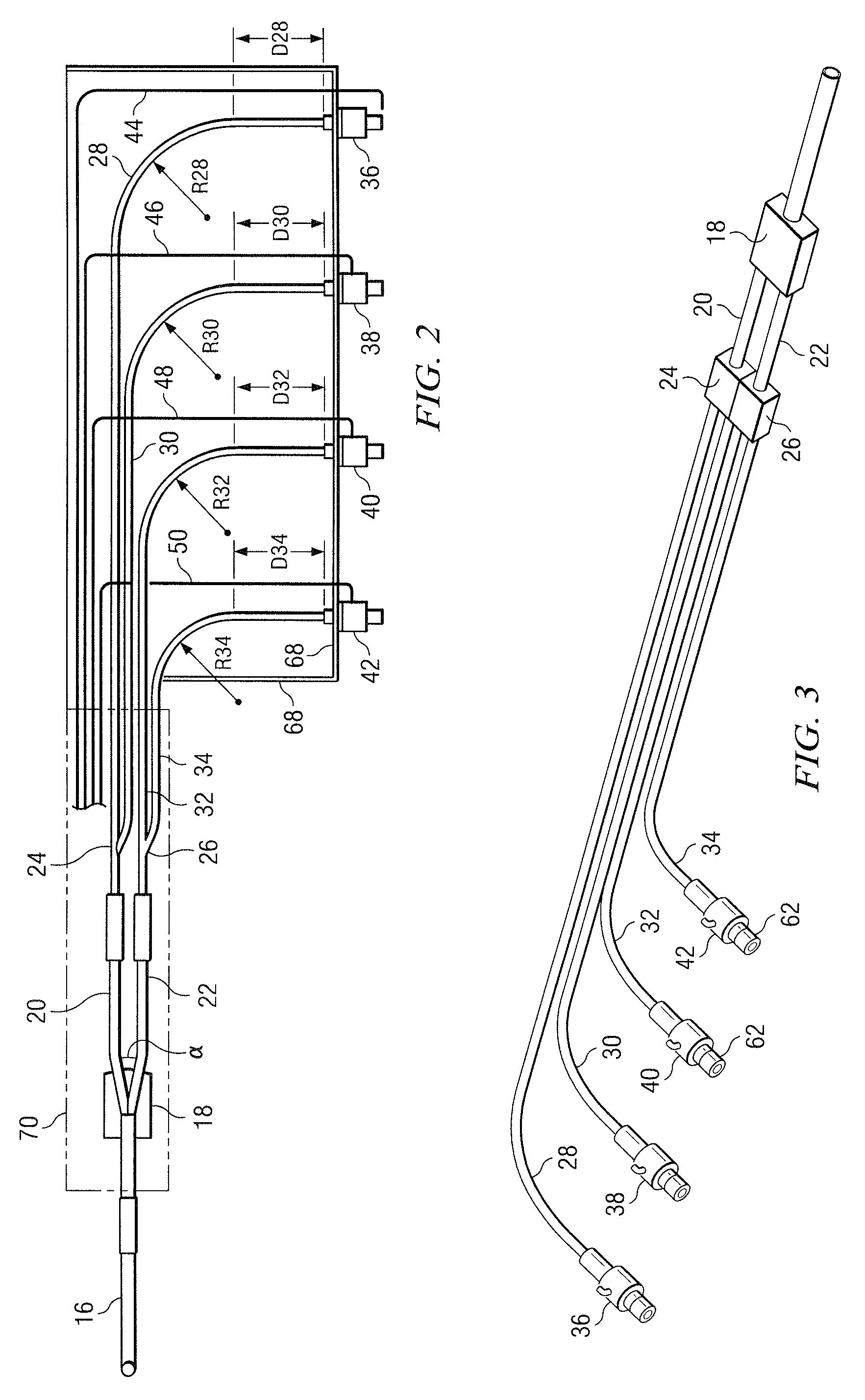

Pneumatic seasoning system

InactiveUS7827929B2Uniform particle distributionPromotes superior adhesion and implantationLiquid surface applicatorsConfectioneryEngineeringRotating drum

A pneumatic seasoning system and method utilizing a rotating drum for seasoning, a funnel-fed pneumatic eductor, line splitters, and a plurality of specially-designed swirl-inducing nozzle spools for inducing a broad and even seasoning plume. In a preferred embodiment, a pneumatic seasoning system transports seasoning from a seasoning hopper to food items within a rotating drum using a combination of an eductor and four in-line vacuum generators, which vacuum generators operate on compressed air. Each vacuum generator comprises a distributing nozzle roughly shaped like a collared spool, wherein compressed air is supplied to the annular region defined between the spool and its collar, and said compressed air exits through swirl ports distributed about the circumference of the spool exit. Each swirl port preferably has a pitch angle of 15° and a yaw angle of 15°.

Owner:FRITO LAY NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com