Patents

Literature

555results about How to "Improve interfacial bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

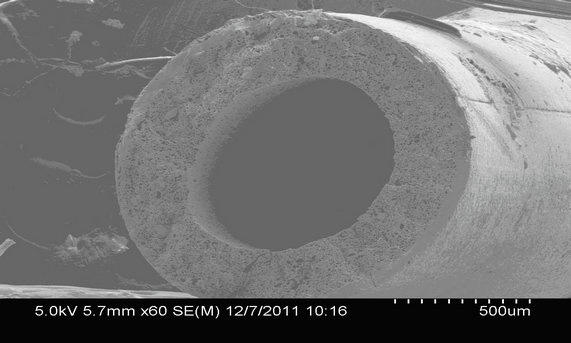

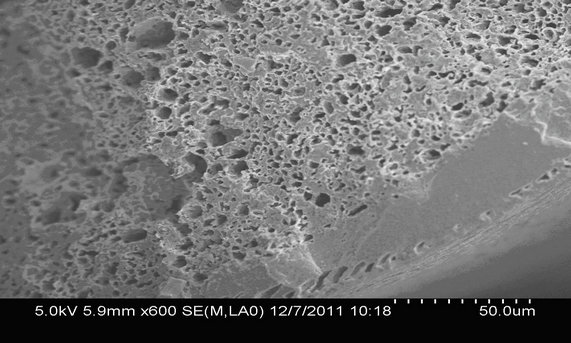

Preparation method for homogeneously-enhanced polyvinylidene fluoride hollow fiber membrane

ActiveCN102600733AImprove hydrophilicityImprove interfacial bond strengthMembranesSemi-permeable membranesPolymer scienceSpinning

Owner:TIANJIN POLYTECHNIC UNIV

Temp, resisting type carbon fibre emulsion sizing agent and its preparation process and application

The heat resisting emulsion sizing agent for carbon fiber consists of main sizing agent and assistant in 1-5 wt% of the main sizing agent. The main sizing agent is mixture of thermoplastic polyimide resin and glycidol ether type epoxy resin in the weight ratio of 50-90 to 10-50; and the assistant includes emulsifier, wetting agent and defoaming agent in the weight ratio of 10-80 to 10-80 to 10. The present invention has the advantages of low cost, stable performance, convenient use and no environmental pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Ultra-high-strength buoyancy material and preparation method thereof

InactiveCN101824206AHigh compressive strengthMeet the needs of deepwater engineering applicationsUnderwater equipmentEpoxyMicrosphere

The invention discloses a method for preparing an ultra-high-strength buoyancy material. The method comprises the following steps of: a, adding 100 mass parts of epoxy resin, 25 to 35 mass parts of diluent and 5 to 10 mass parts of toughening agent into an autoclave, vigorously and uniformly mixing the mixture at the temperature of 60 to 75 DEG C, adding 4 to 8 mass parts of curing agent into themixture and uniformly mixing the mixture to obtain a high-strength epoxy resin; b, adding 18 to 44 mass parts of hollow microspheres pretreated by a silane coupling agent into 56 to 82 mass parts of the high-strength epoxy resin obtained in the step a and slowly and uniformly mixing the mixture; and standing, placing the mixture in a vacuum drying chamber for removing the air bubbles from the mixture and then casting the mixture in a mold for curing molding. The prepared ultra-high-strength buoyancy material has a density of 0.65 to 0.83g / cm<3> and compressive strength of up to 60 to 93MPa, and is suitable for a deepwater environment as deep as 6,000 to 9,000m.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

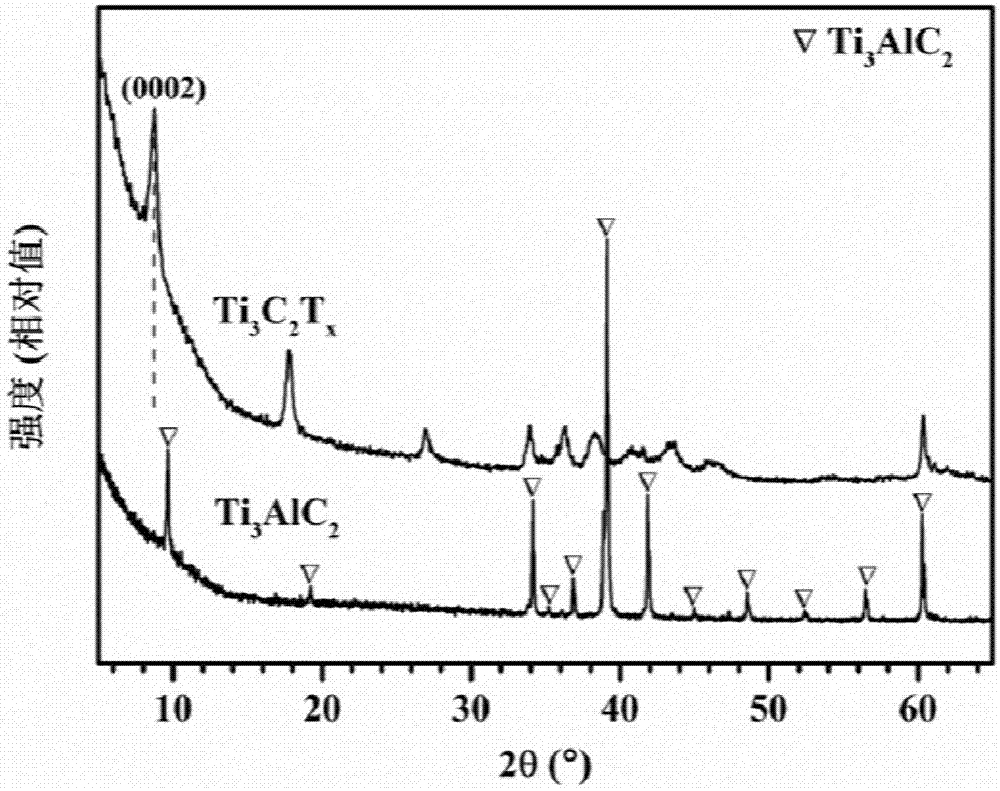

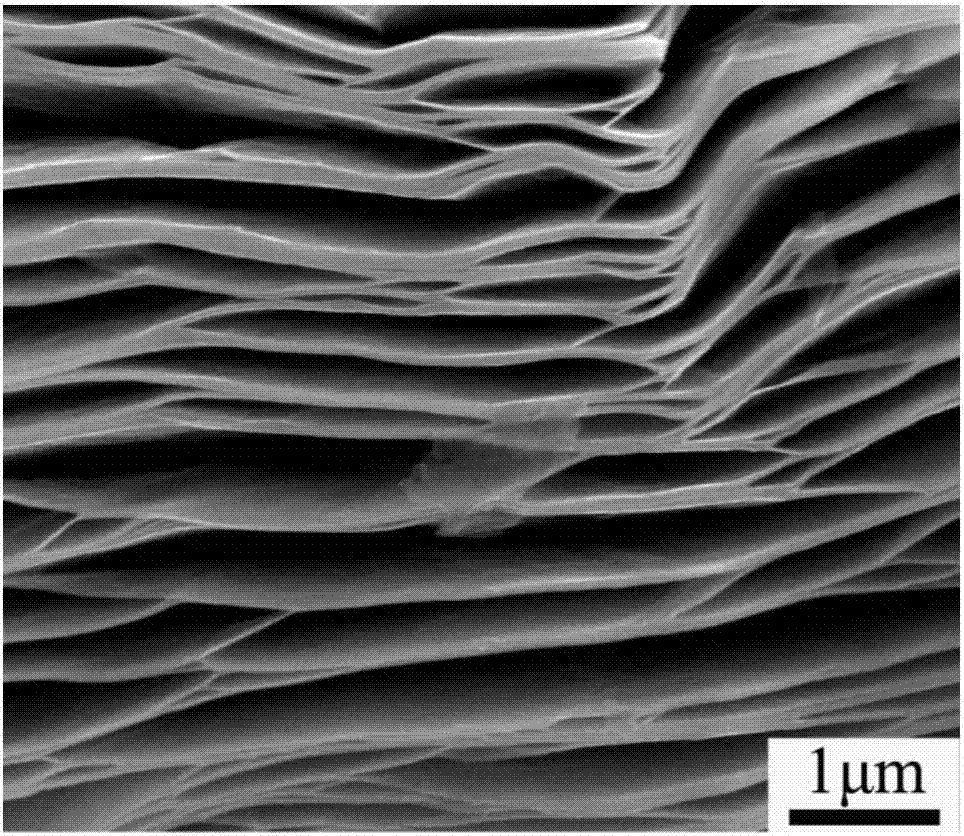

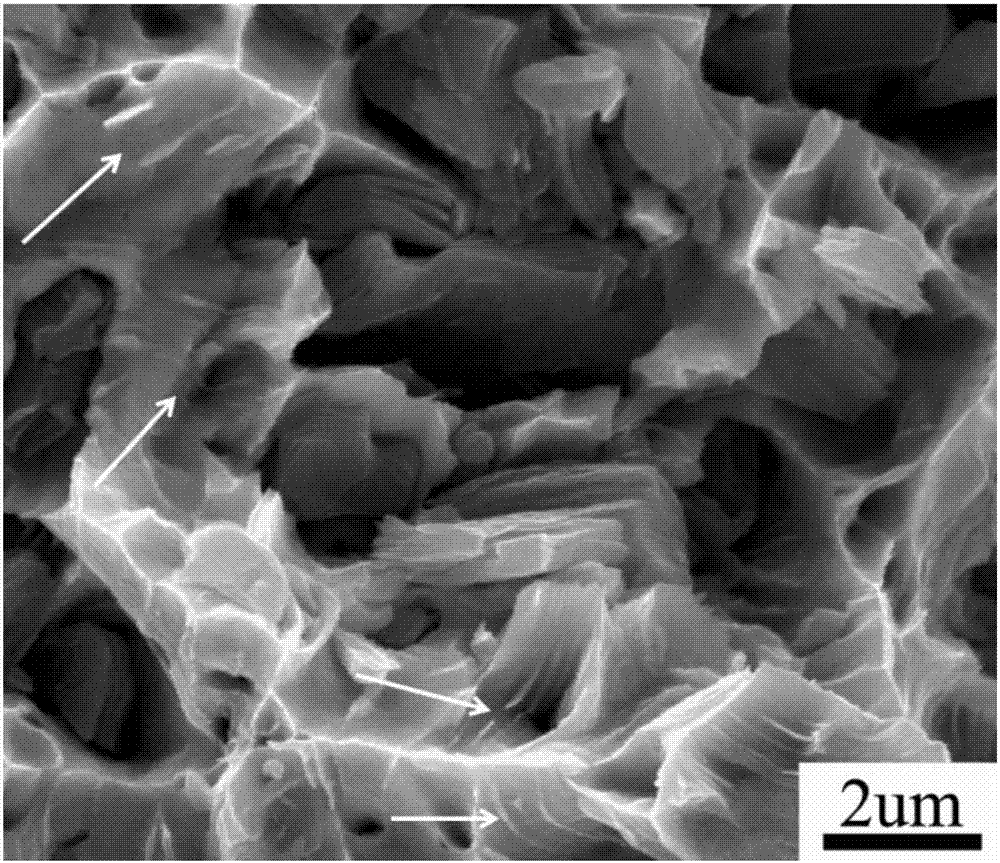

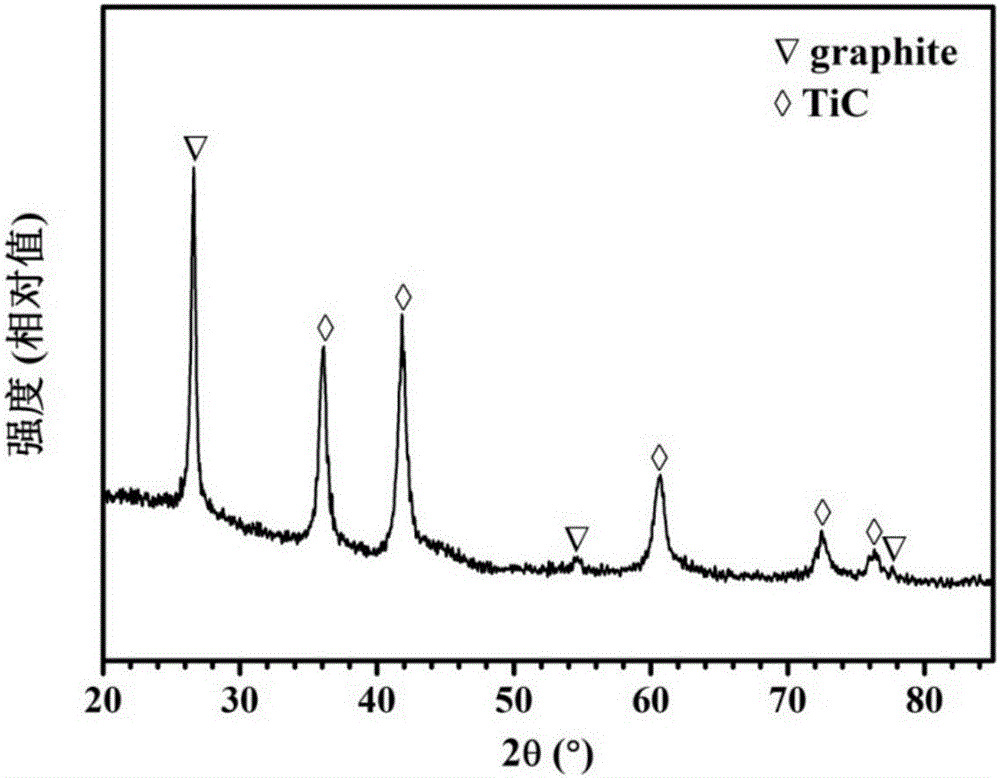

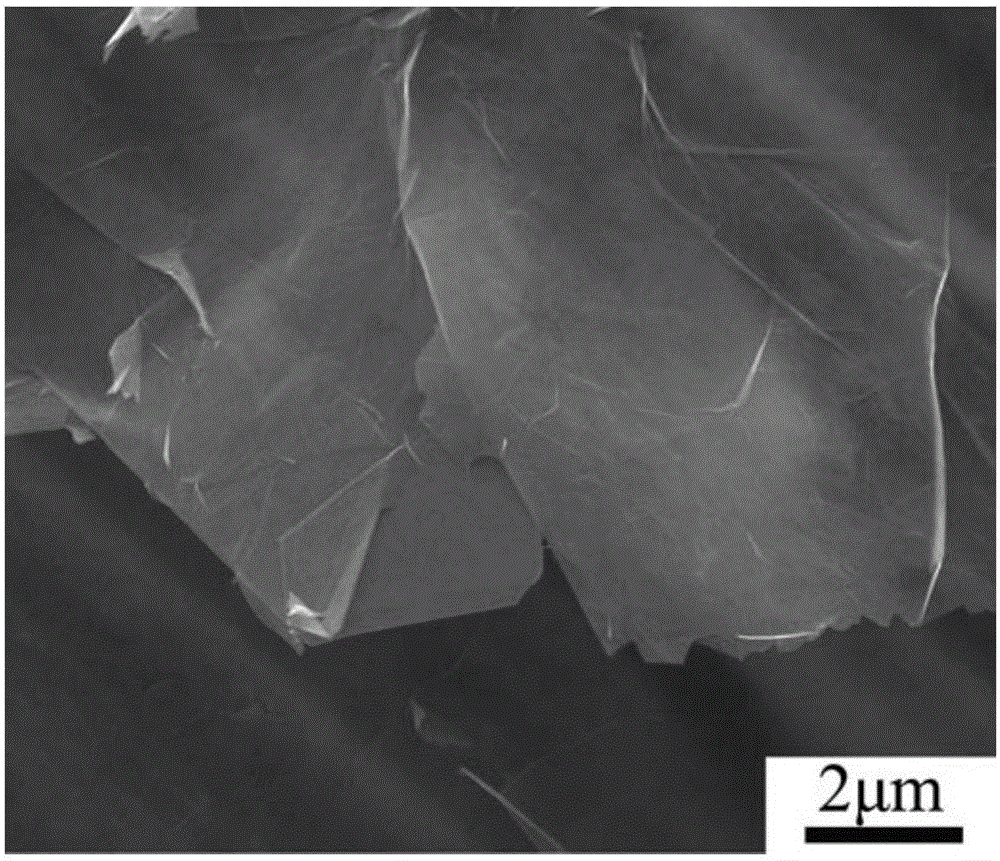

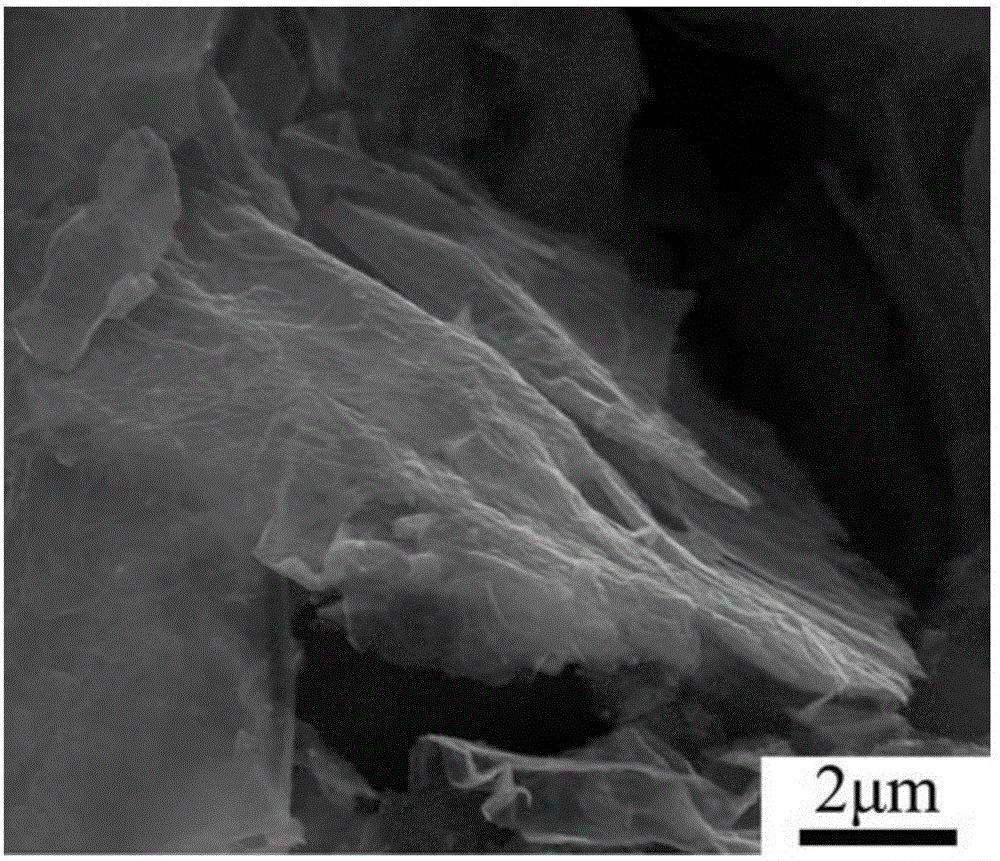

Two-dimensional slice material enhanced metal-based composite

The invention provides a two-dimensional slice material enhanced metal-based composite. According to the composite, metal is adopted as a base body, two-dimensional transition metal carbide or carbonitride, namely, MXenes is adopted as a reinforced phase, and MXenes particles are evenly dispersed in metal base body particles. Due to the fact that the MXenes material comprises a hollow carbon position and tends to metallicity, the metal base body has good wettability, and the interface bonding strength of the metal-based composite can be effectively improved. Therefore, the mechanical performance, wear resistance and other performance of the metal-based composite are enhanced. Meanwhile, the electronic coupling effect of the MXenes material and a metal base body interface is better, and the problem that in the prior art, the mechanical performance and corrosion resistance of the metal-based composite are improved through the reinforced phase, and meanwhile the heat conducting and electrical conducting performance of the metal-based composite is reduced can be avoided.

Owner:SHANGHAI UNIV +1

High-performance 3D printing supply alloy material

InactiveCN103804862AImprove impact performanceImprove the disadvantage of poor temperature resistanceGlycidyl methacrylateAcrylonitrile

The invention provides a high-performance 3D (Three Dimensional) printing supply alloy material. The high-performance 3D printing supply alloy material comprises, in parts by weight, 20.0-50.0 parts of polylactic acid, 50.0-80.0 parts of high impact polystyrene, 0.1-5.0 parts of compatilizer and 0.2-3.0 parts of auxiliaries, wherein the compatilizer comprises one or more than two, matched with each other in use, of a maleic anhydride grafted high polymer, a terpolymer copolymerized with styrene, acrylonitrile and glycidyl methacrylate (SAG), and a terpolymer copolymerized with methyl methacrylate, butadiene and a styrol copolymer (MBS). The high-performance 3D printing supply alloy plastics prepared from the high-performance 3D printing supply alloy material are non-toxic, low-carbon and environment-friendly, low in alloy material cost, excellent in combination properties, and very high in economic value and wide in market prospect.

Owner:芜湖瀚博电子科技有限公司

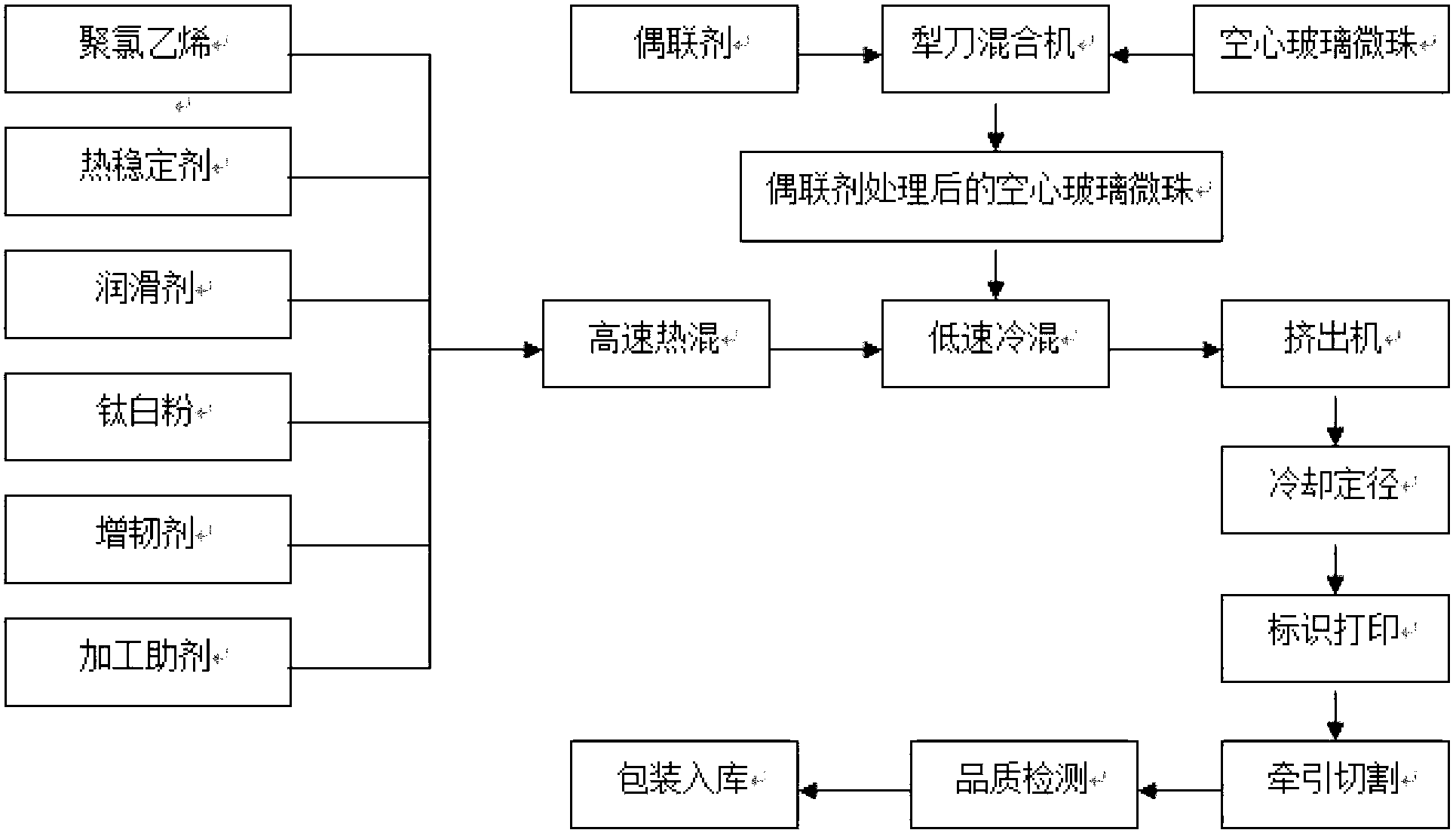

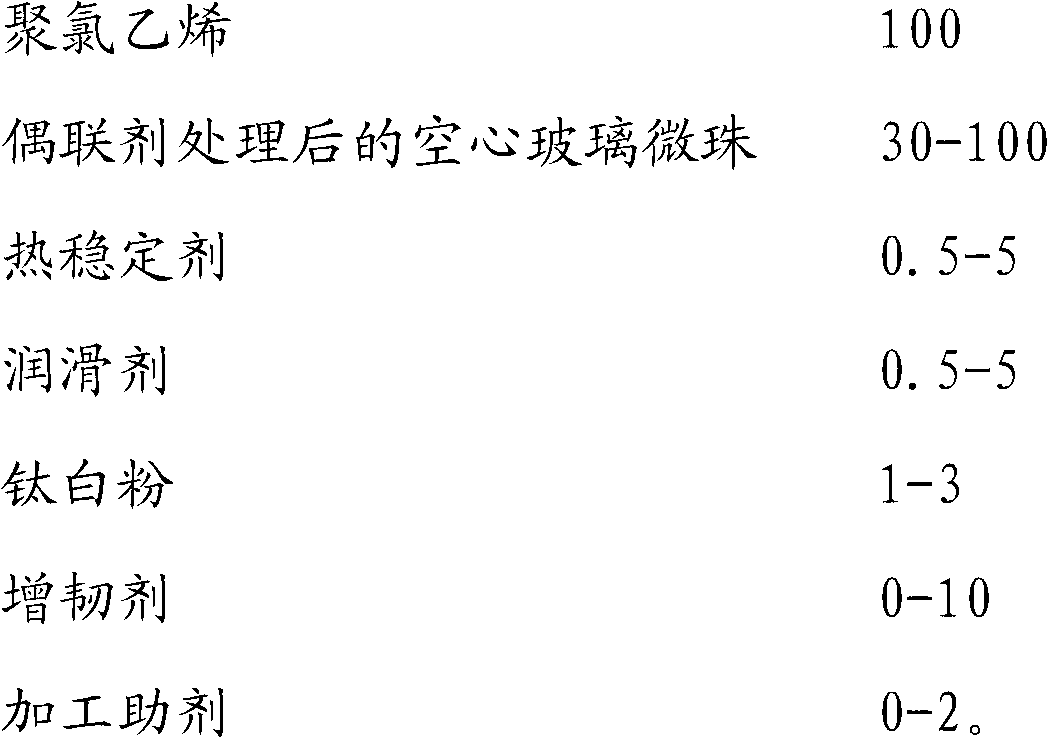

Polyvinyl chloride drain pipe and preparation method thereof

The invention discloses a polyvinyl chloride drain pipe and a preparation method thereof. The polyvinyl chloride drain pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 30 to 100 parts of hollow glass microsphere processed by coupling agent, 0.5 to 5 parts of thermal stabilizer, 0.5 to 5 parts of lubricating agent, 1 to 3 parts of titanium dioxide, 0 to 10 parts of flexibilizer and 0 to 2 parts of processing agent. The method adopts the mode of plastic modifying, creatively introduces the hollow glass microsphere for filling, effectively improves the product toughness on the basis that the product rigidity is guaranteed, simultaneously effectively reducing noises through a hollow structure, greatly reduces the product density, reduces the product weight, and can also reduce the product cost.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +1

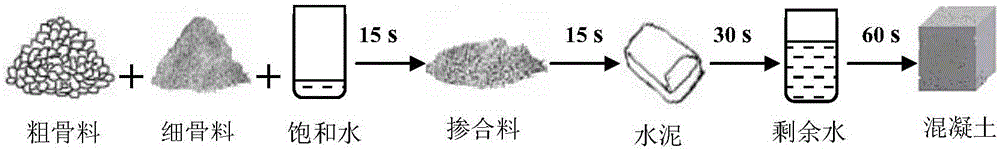

In-situ reinforcement method of recycled aggregate

InactiveCN105130299AReduce intensityReduced durabilitySolid waste managementCompressive strengthUltimate tensile strength

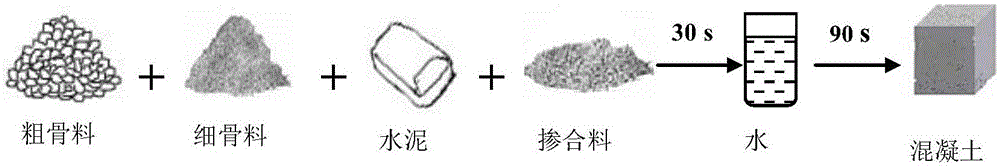

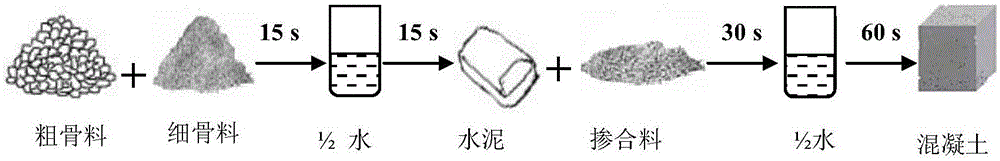

The invention discloses an in-situ reinforcement method of a recycled aggregate; the method comprises that concrete containing the recycled aggregate is stirred and mixed and subjected to in-situ reinforcement, wherein the concrete comprises raw materials of an admixture, cement, a coarse aggregate, a fine aggregate and water. The method is characterized by comprising the steps: firstly, stirring all the admixture and half of the mass of water for 10-20 s, then adding all the coarse aggregate and all the fine aggregate, stirring for 10-20 s, next adding all the cement, stirring for 20-40 s, finally adding the remaining half of the water, continuing to stir for 30-60 s, and thus obtaining the in-situ reinforced recycled aggregate concrete mixture. The recycled aggregate concrete prepared by the process can achieve in-situ reinforcement of the recycled aggregate, and the compressive strength of the recycled aggregate concrete can be effectively improved.

Owner:ZHEJIANG UNIV OF TECH

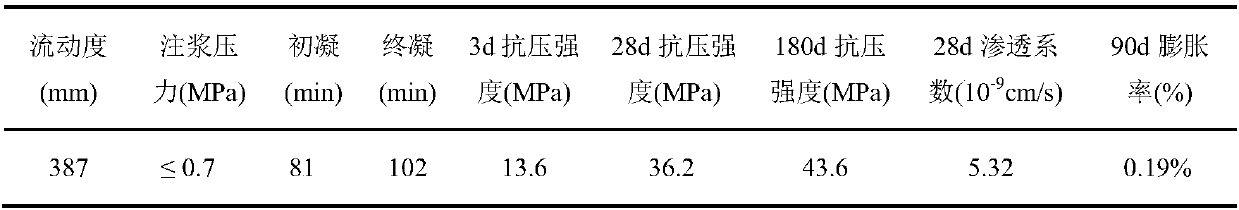

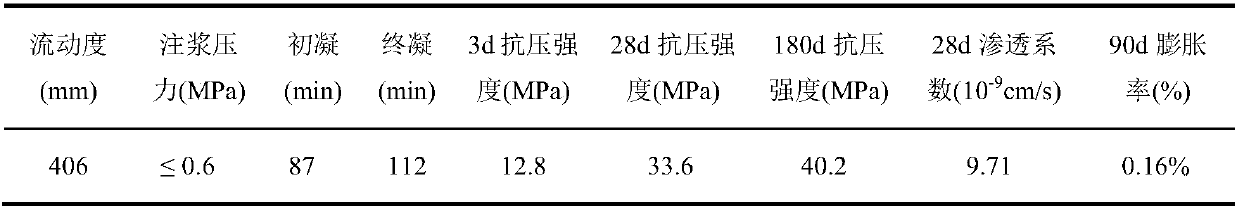

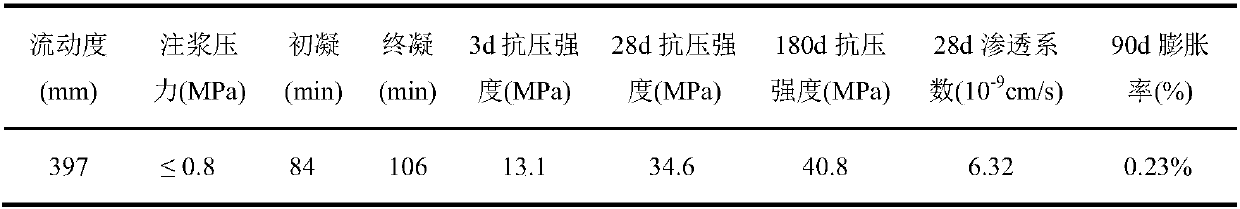

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Metal-matrix composite material and preparation method thereof

InactiveCN105861866AImprove interfacial bond strengthModulation of interfacial binding strengthCvd grapheneBlock layer

The invention provides a metal matrix composite material, which uses metal as a matrix and uses graphene modified on the surface of carbide as a reinforcement. Due to the surface modification of the carbide, the interface bonding strength between the metal matrix and the graphene can be adjusted. For example, when the chemical affinity between graphene and the metal matrix is too strong and an excessive reaction occurs, resulting in an excessively strong interface bond, the carbide can be used as a diffusion barrier to avoid the overreaction and weaken the interface bond; When the interfacial affinity is weak, the carbide can be used as a transition layer to promote interfacial wetting and improve interfacial bonding force.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

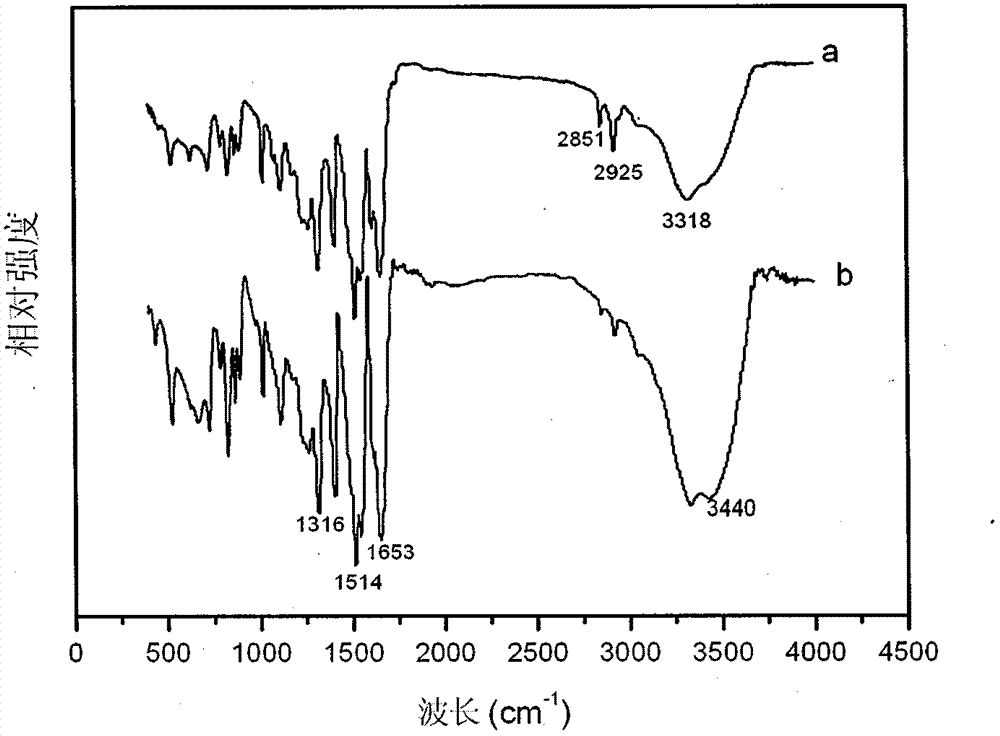

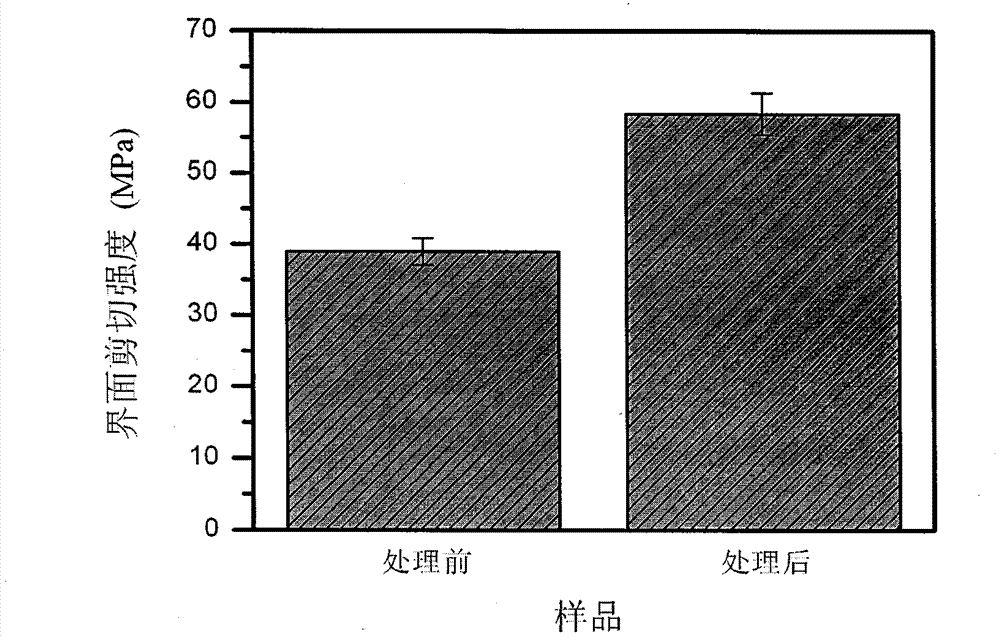

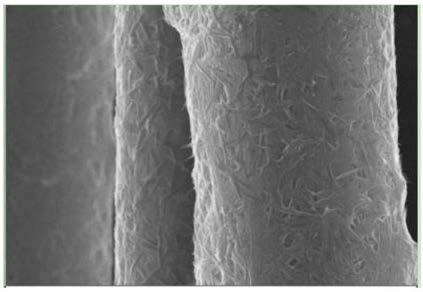

Method for improving surface activity of aramid fiber

InactiveCN103031708AImprove surface activityImprove interfacial bond strengthFibre typesFiber-reinforced compositeBiological activation

The invention discloses a method for improving the surface activity of aramid fiber. The method comprises the following steps of: (1) immersing the aramid fiber in acetone, heating and boiling for 1 hour, further immersing into anhydrous ethanol, and heating and boiling for 1 hour; and then placing into deionized water for washing, and drying for 2 hours after the treatment; and (2) performing surface activation treatment on the aramid fiber: (a) preparing a hydrogen peroxide solution with the concentration of 20%-60%; (b) cutting the aramid fiber after pretreatment into samples of 20cm, and placing into the hydrogen peroxide solution for performing treatment at the temperature of 0 DEG C-80 DEG C for 30min-90min; (c) washing with the deionized water till the pH value of a washing solution is 7; and (d) drying after washing to obtain the aramid fiber with surface modification. The treatment method disclosed by the invention is simple, the interfacial binding strength of an aramid fiber-reinforced composite material can be greatly improved, the mechanical strength of the aramid fiber can be also kept unchanged, the equipment is simple, the operation is convenient, and the industrial continuous treatment is convenient to realize.

Owner:SHANDONG UNIV OF TECH

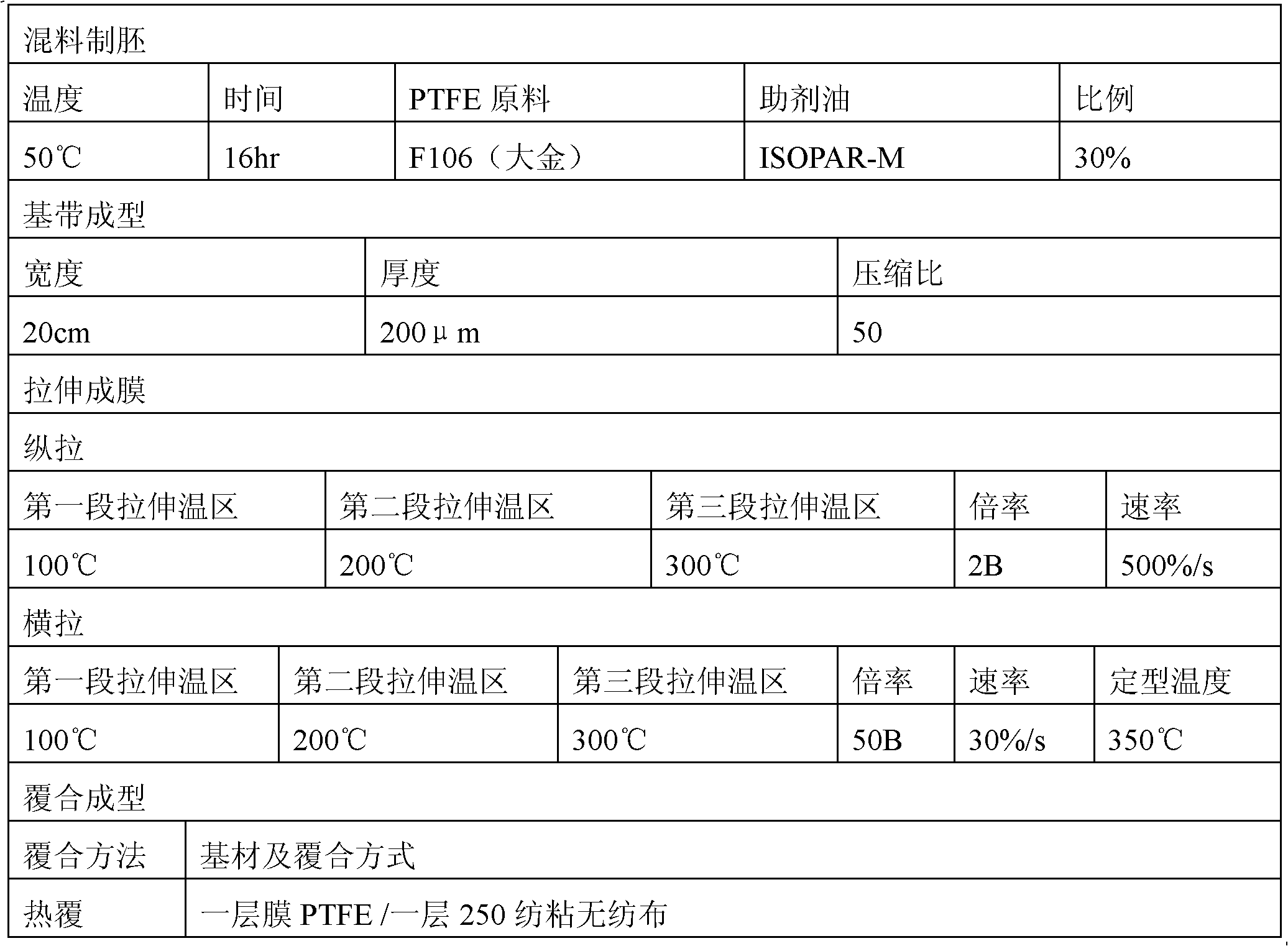

Preparation method of sub-high efficiency polytetrafluoroethylene (PTFE) micro-porous film and film lamination material

ActiveCN102658038AIncreasing the thicknessReduce resistanceSemi-permeable membranesWater processingUltimate tensile strength

The invention discloses a preparation method of a sub-high efficiency PTFE micro-porous film and a film lamination material. The preparation method comprises the following steps: 1, uniformly mixing auxiliary oil with PTFE, slaking in a constant temperature baking oven, and pre-pressing to form a cylindrical blank; 2, putting the cylindrical blank in an extruder, and preparing a base band through extruding, calendering and drying; 3, forming a film through two-step stretching, wherein the first step is characterized in that the base band is gradually vertically stretched through gradient heating, and the second step is characterized in that the vertically stretched base band is gradually transversely stretched through gradient heating, and is sintered and fixed to form the PTFE micro-porous film; and 4, laminating the PTFE micro-porous film and a base material through at least one of glue lamination and hot lamination to prepare the film lamination material. The PTFE micro-porous film and the film lamination material prepared in the invention have the excellent performances of low resistance, high interface strength, high tensile strength, high puncture strength and the like, and can be applied to the industrial dust removal field, the clothes field, the dust collector field, the liquid phase filter field, the water processing field and the like.

Owner:浙江净膜环保有限责任公司

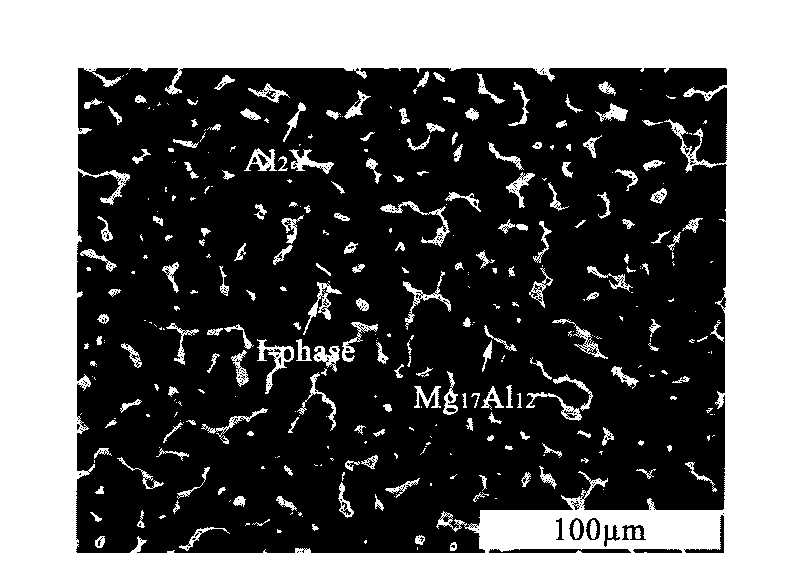

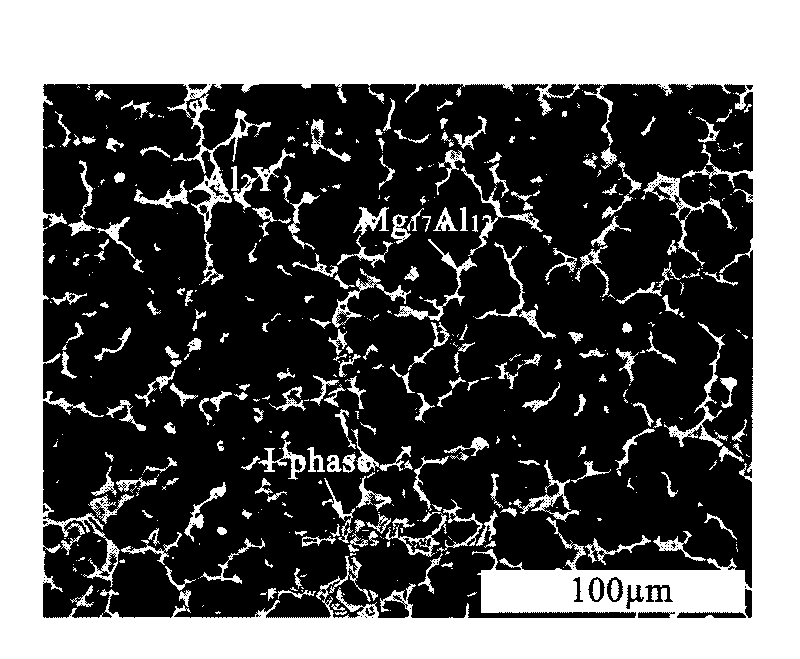

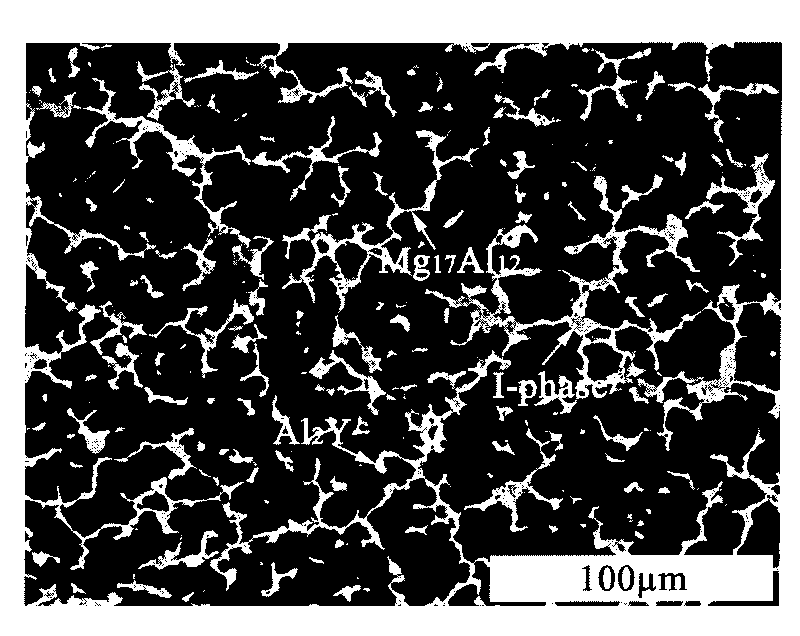

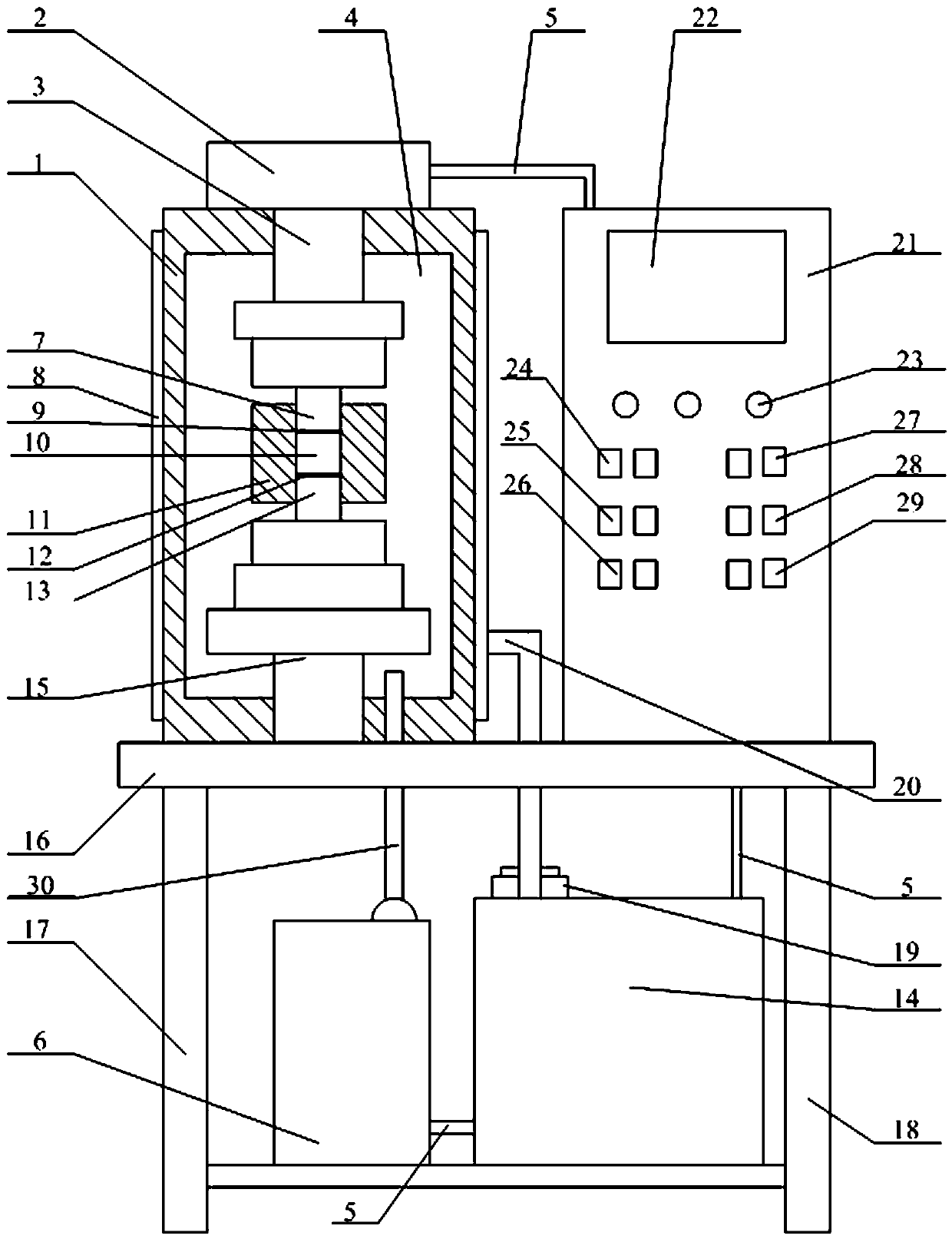

Quasicrystal reinforced magnesium alloy and semisolid preparation method thereof

InactiveCN101713042AImprove comprehensive mechanical propertiesSimple processInjection mouldingInterfacial bond

The invention discloses a quasicrystal reinforced Mg-Zn-Y-Al alloy and a semisolid preparation method thereof, belonging to the industrial magnesium alloy and the manufacturing field thereof. The quasicrystal reinforced magnesium alloy comprises the following components in percentage by weight: 4-15% of Zn, 0.5-3.5% of Y, 3-10% of Al and the balance of Mg. A hot extrusion method is adopted to extrude the Mg-Zn-Y-Al alloy into bars, and an electromagnetic induction heating device is adopted to heat the extrude bar into semisolid to carry out semisolid injection moulding. The fine texture of the quasicrystal reinforced Mg-Zn-Y-Al alloy of the invention contains fine quasicrystal reinforced phase which has favorable interfacial bond strength with a matrix so as to obviously improve the comprehensive mechanical properties of magnesium alloy. The semisolid preparation technology thereof is suitable for producing high-performance magnesium alloy parts with complex shape, is simple, has high yield, energy saving and environment protection, lowers cost and can be widely applied to industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

Polyving alcohol composite hydrogel and preparation method thereof

The invention relates to polyving alcohol composite hydrogel and a preparation method thereof. The polyving alcohol composite hydrogel is prepared from the following raw materials in parts by weight through cross-linking solidifying compounding of boric acid solution containing solidifier: 30 to 90 parts of polyving alcohol, 0.1 to 50 parts of sodium alginate, 0.1 to 20 parts of inorganic nanoparticles, 1 to 20 parts of elastomer material, 0.5 to 5 parts of coupling agent and 200 to 2000 parts of water, wherein the degree of polymerization of polyving alcohol is 400 to 3000, and the alcoholysis degree is 75 to 99 percent. The polarity elastomer material and the inorganic nanoparitcles which are processed through the coupling agent are compounded with the polyving alcohol, the mechanical strength and flexibility of the polyving alcohol hydrogel can be improved through the toughening effect of the elastomer material and the synergistic effect of the inorganic nanoparticles, so that the service life is prolonged, and the requirement of the real application on the mechanical performance can be met; the preparation method of the polyving alcohol composite hydrogel is simple in process, easy to operate and applicable to the mass production.

Owner:CHINA PETROCHEMICAL CORP +2

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

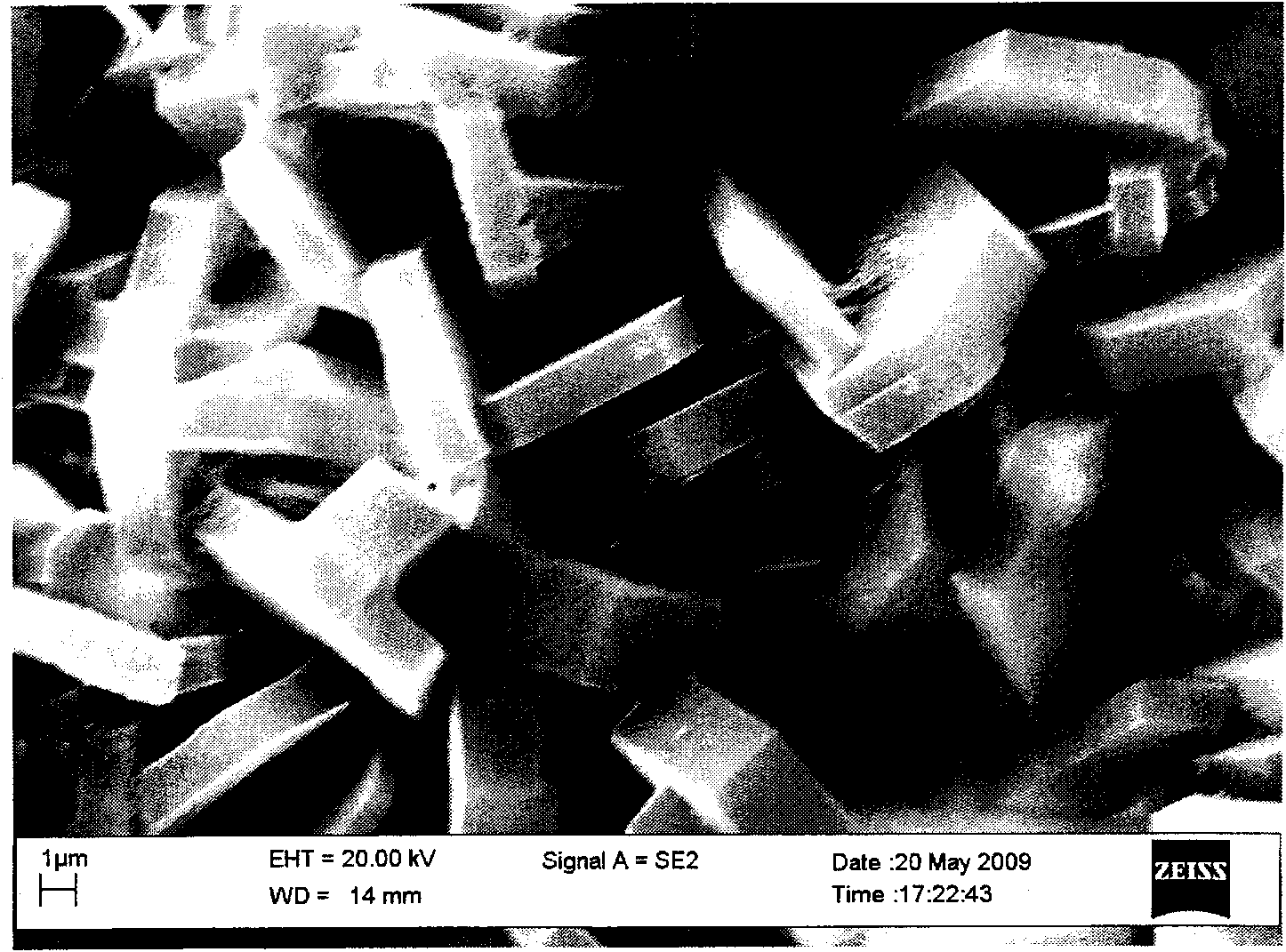

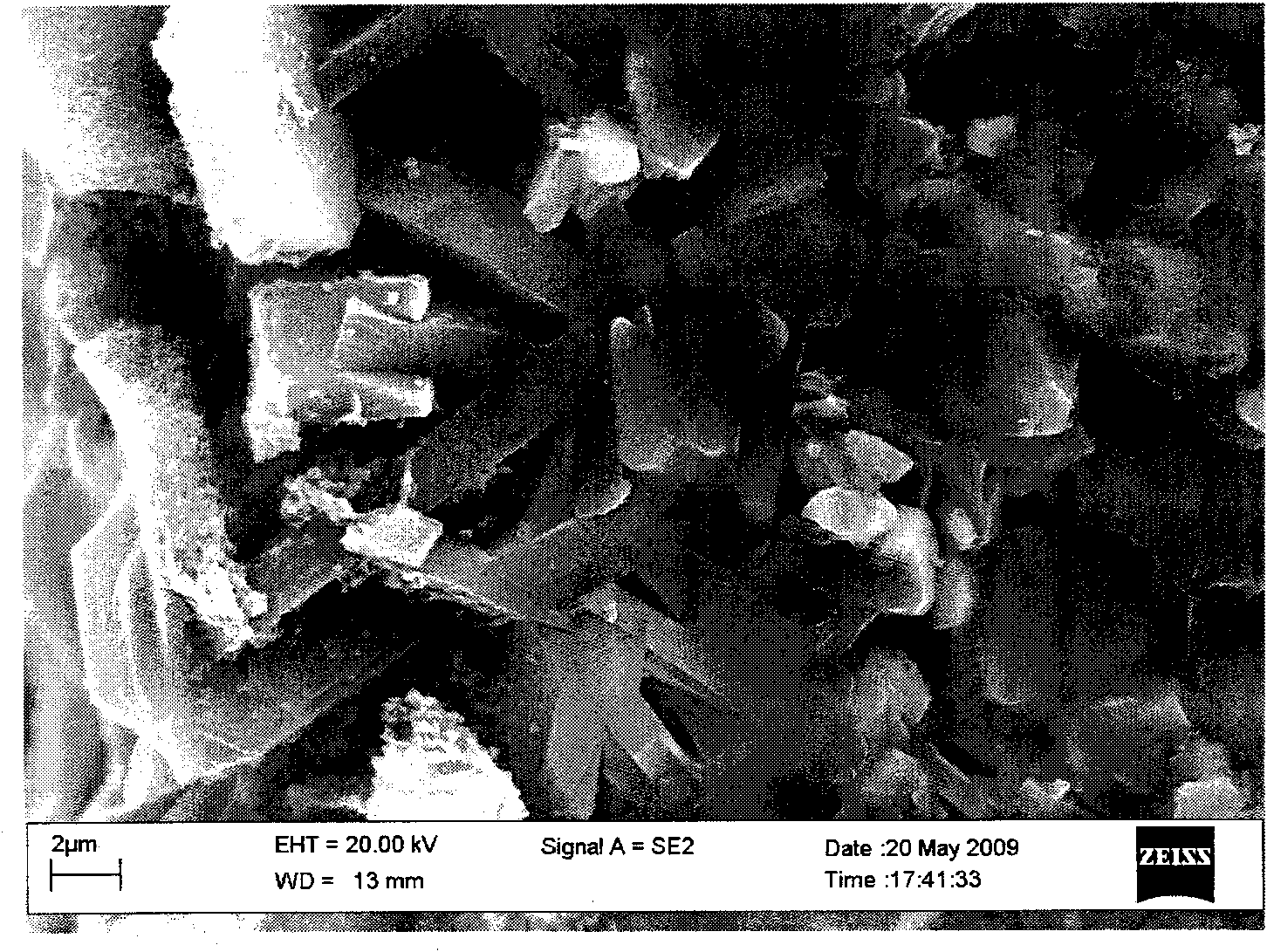

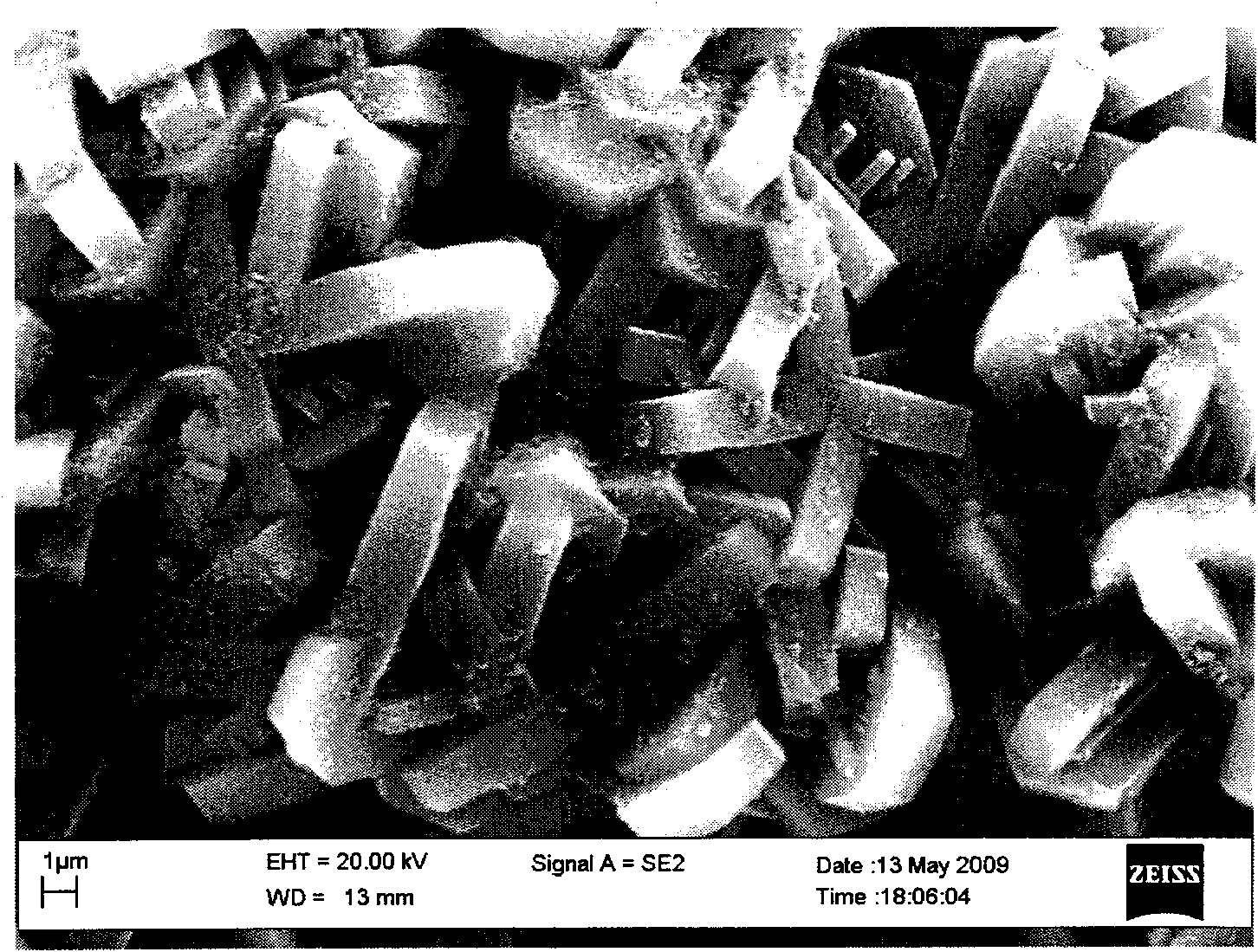

Porous zeolite molecular sieve coating material on surface of silicon carbide ceramics and preparation method thereof

ActiveCN101992126AIncrease profitEnhanced mass transferMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAmmonium hydroxide

The invention belongs to the field of catalysis of zeolite crystals, in particular to a porous zeolite molecular sieve coating material on a surface of silicon carbide ceramics and a preparation method thereof. The zeolite molecular sieve coating is uniformly loaded on the surface of a porous silicon carbide ceramics carrier, and the zeolite molecular sieve coating has a double-pore canal structure composed of micropores of zeolite molecular sieves and macropores formed by mutual overlapping of zeolite crystals. The preparation method comprises the following steps: coating a zeolite precursor sol layer on the surface of porous silicon carbide ceramics, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.1-1.0:29; and growing in a secondary growth solution, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.05-1.0:110. Micron-sized pore canals are formed among the zeolite crystals in the coating, thereby improving the utilization efficiency of the zeolite coating. At the same time, the method has the advantages of simple process and low energy consumption, and the prepared zeolite molecular sieve coating is uniformly loaded and stably combined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

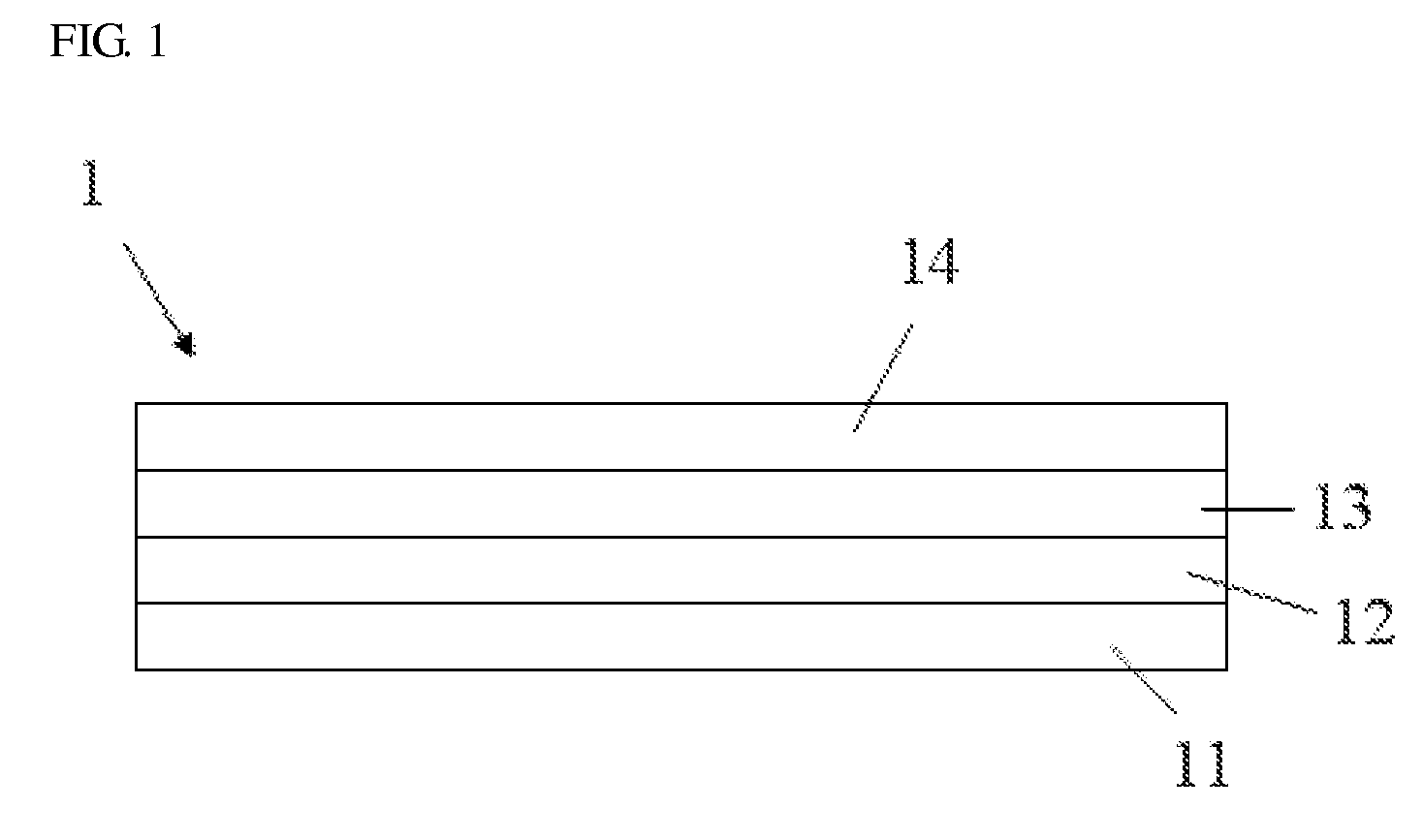

Liquid crystal film

ActiveUS20120212692A1Storage stability be excellentLow viscosityLiquid crystal compositionsSpecial surfacesPolarizerChemistry

A liquid crystal film, a method for manufacturing the same, a polarizing plate, and a liquid crystal display are provided. The liquid crystal film has excellent physical properties such as durability and an optical physical property so that it can be effectively used for various applications. In addition, the physical property of the liquid crystal film can be controlled according to desired purposes.

Owner:LG CHEM LTD

Preparation method of reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material and application

ActiveCN108660352AImprove shape deformation abilityPrevent oxidationShieldingAl powderElectrical resistance and conductance

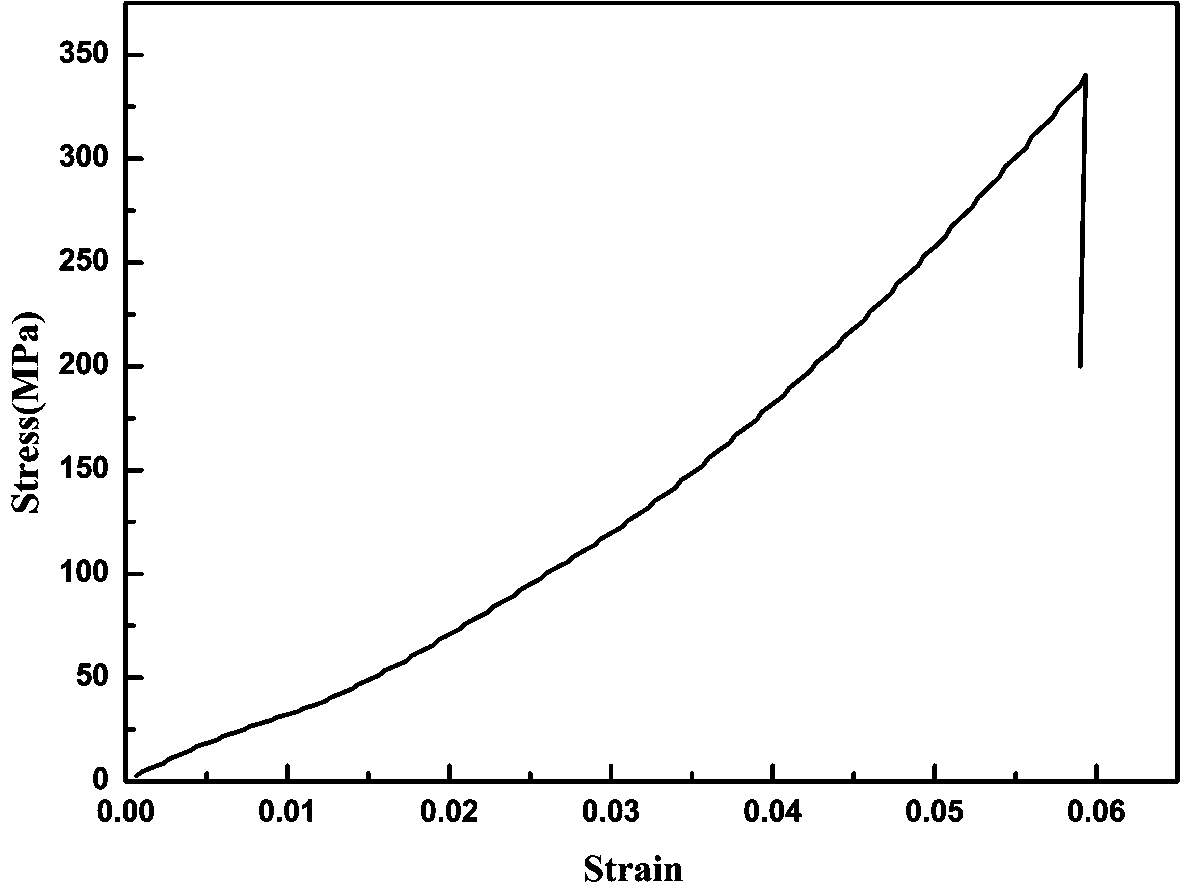

The invention belongs to the technical field of nonferrous metal alloy preparation, and in particular, relates to a preparation method of a reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material. The preparation method comprises the following steps: the ball milling and the mixing are performed on Al powder, Co powder, Cr powder, Fe powder and Ni powder according to a mole ratioof 1: 1: 1: 1: 2 to prepare AlCoCrFeNi2 high-entropy alloy powder; the ball milling and the mixing are performed on the AlCoCrFeNi2 high-entropy alloy powder, the Al powder and B4C powder according to a volume ratio of 6: 3: 1; a plasma discharge sintering technology is adopted to sinter under the conditions of vacuum, resistance heating and pressurization to prepare the reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material; B4C particles are uniformly distributed in a basal body; through adding of the Al powder, the plastic deformation capacity of the material can be further improved; the oxidation of the material can be effectively prevented in the vacuum environment; through plasma discharge quick sintering, the growth of grains in the material can be prevented; local high temperature is generated by particle tip discharge to improve the interface connecting strength of the material; the preparation method is advanced in process and precise and accurate in data;the compactness of the AlCoCrFeNi2 high-entropy alloy base neutron absorbing material can reach 98%; the hardness can reach HV0.5=563.3; and the tensile strength can reach 340 MPa.

Owner:TAIYUAN UNIV OF TECH

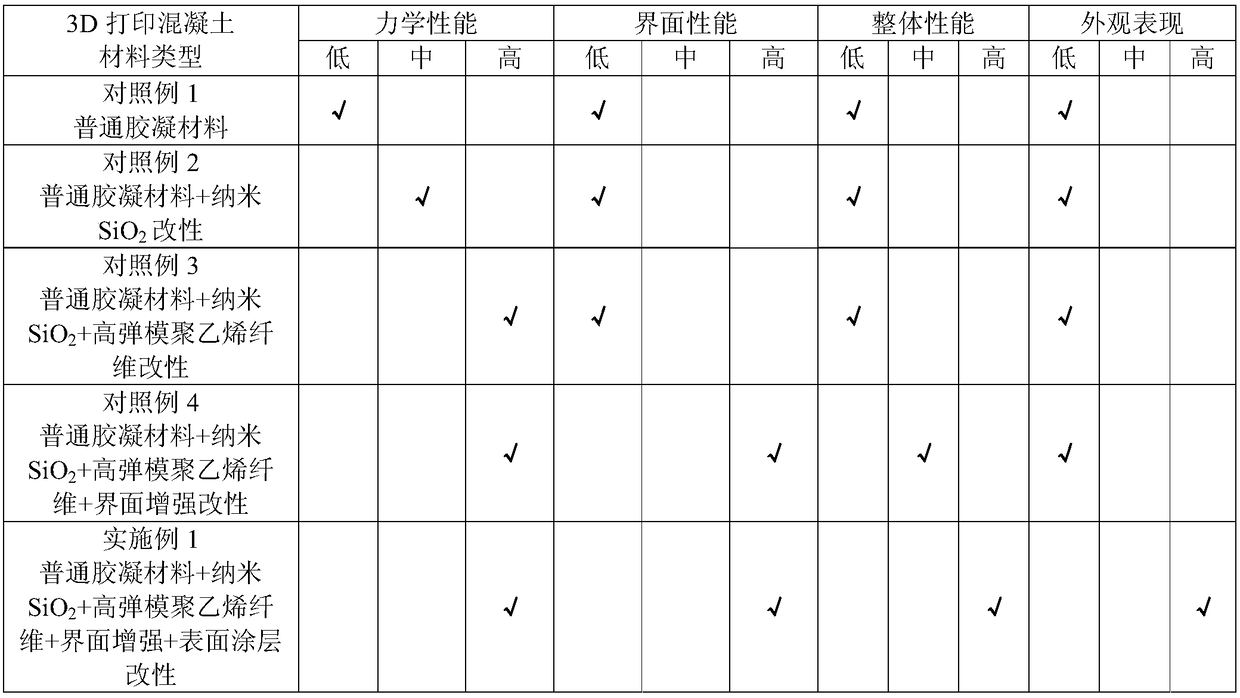

Concrete material for 3D printing, and preparation method thereof

ActiveCN109020369AImprove microscopic pore structureImprove plasticityAdditive manufacturing apparatusCeramic shaping apparatus3d printSocial benefits

The present invention provides a concrete material for 3D printing, and a preparation method thereof. The invention further provides the preparation method and an application of the concrete material.The invention further provides a concrete combination material for 3D printing, a concrete member, and a production method of the concrete member. A 3D printing concrete material system based on theconcept of material improvement, interface modification and overall reinforcement is formed, so the overall performances of the 3D printing concrete material and the produced member are improved, theconcrete material and the member have excellent mechanical properties and durability, the service life of the 3D printing material is prolonged, the concrete material is convenient to construct, the promotion of 3D printed concrete structures and buildings in practical engineering is promoted, and high engineering application values and high social benefits are achieved.

Owner:TONGJI UNIV

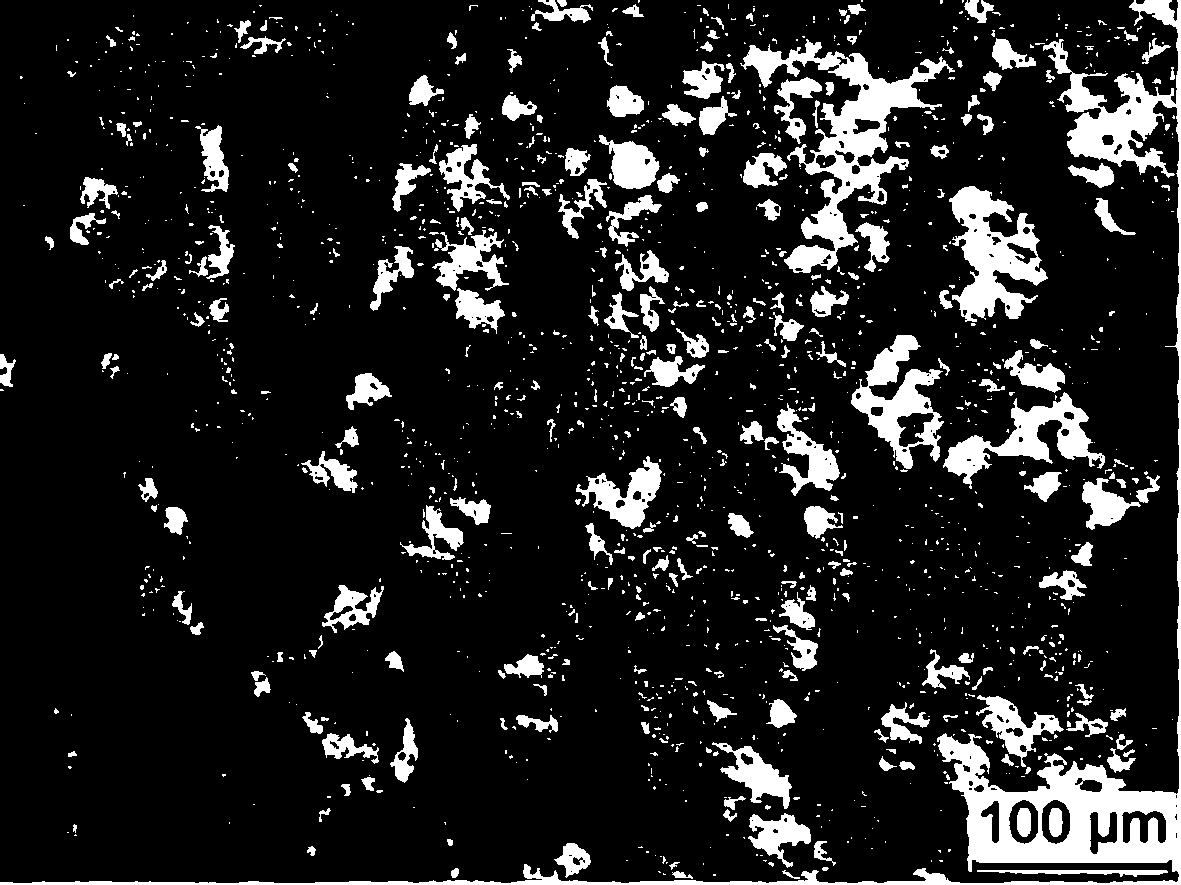

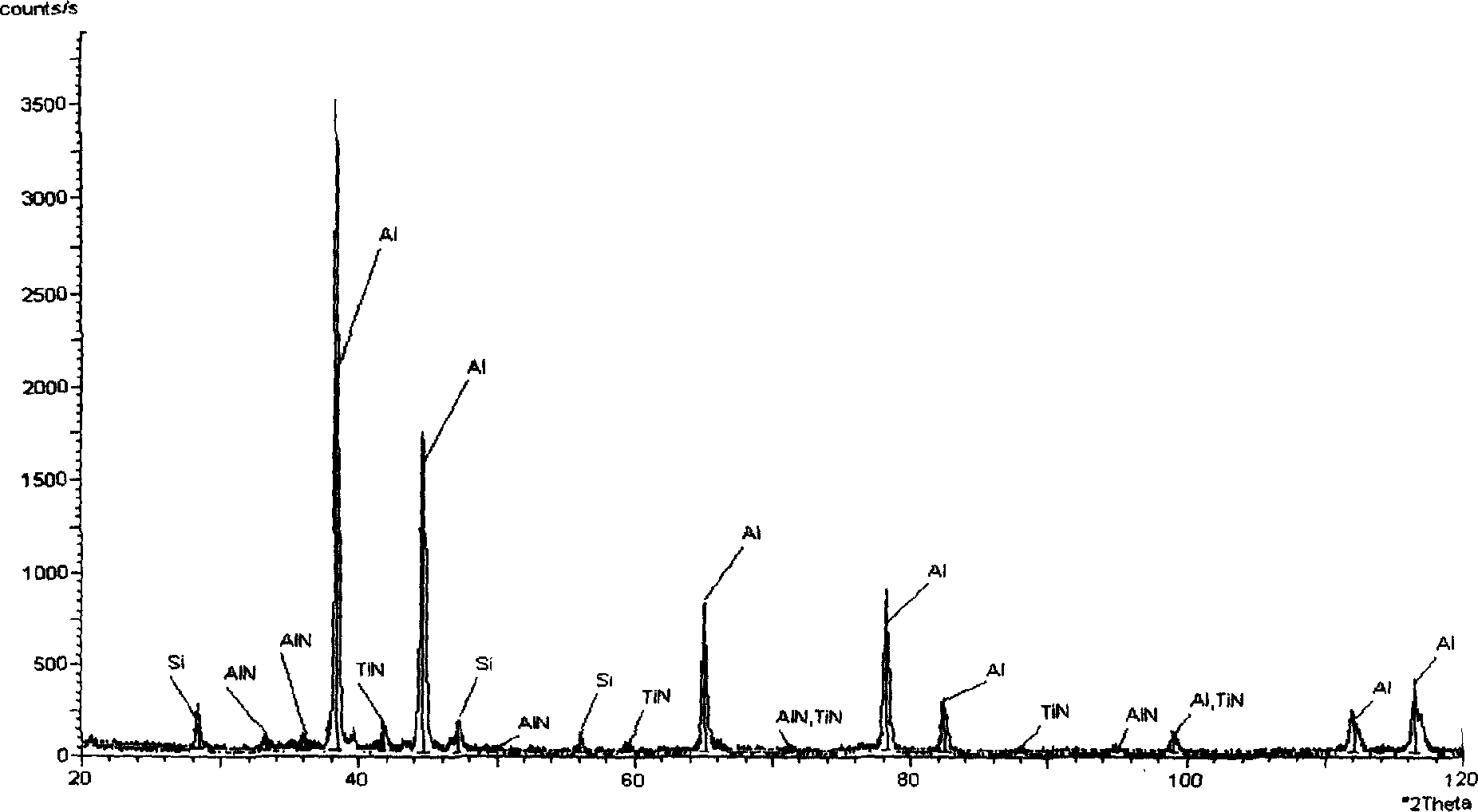

Ceramic granule reinforced aluminium-base composite material and its preparing method

This invention is a ceramic grain reinforcing Al-base compound material and its preparation method, and relates to a Al-base alloy. Its components are: 2.5-15% TiN, 2.4-10%AIN, 4-6.5%Si, 0.5-1.5%Cu, 0.3-0.5%Mg, 0-0.8%Ni, 0-0.5%Ti, and the rest is Al, and the percentages are weight percentages; the preparation method adopts melt blending founding method, and the technique flow is: material matching-melting base body-adding reinforcing grains-melting-modifying treatment-pouring-heat treatment, and the size reinforcing grains is in the range of 5-10 mum, and the vacuum degree of the vacuum furnace is 1.3-1.6X10 to the power -3 Pa, the temperature is 670-800deg.C, the modifying agent is 1-18g / Kg compound material containing 1-6% Na nanometer Al alloy powder; the Al-base compound material of this invention has light weight, high modulus number, high intension, good heat-fast and wearable performances, and the preparation cost is low, the technique is simple and it can be industrially produced.

Owner:HEBEI UNIV OF TECH

Method for preparing heat insulation anti-cracking raw soil bricks

The invention discloses a method for preparing heat insulation anti-cracking raw soil bricks. The method is characterized in that: calcined desulfurization gypsum, desulfurization ash, crop stalk powder, re-dispersible latex powder, surfactant, clay and water in a water-solid ratio of 0.3 to 0.5 are adopted in the method; and the bricks are prepared by adopting the steps of mixing, stirring, molding, curing and the like. The method effectively utilizes desulfurization wastes of a coal fired power plant and agricultural solid waste crop straws, has the advantages of low cost, good mechanical property and durability, good cracking resistance, thermo-technical performance and the like, is convenient for production and can be recycled.

Owner:CHONGQING UNIV

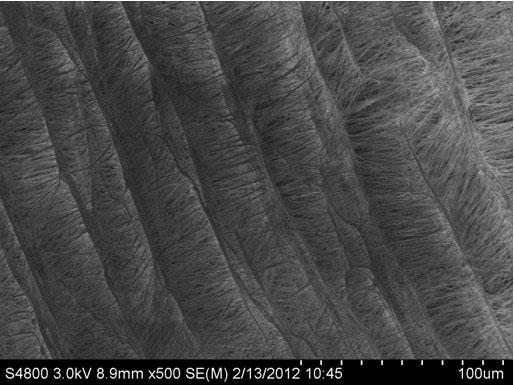

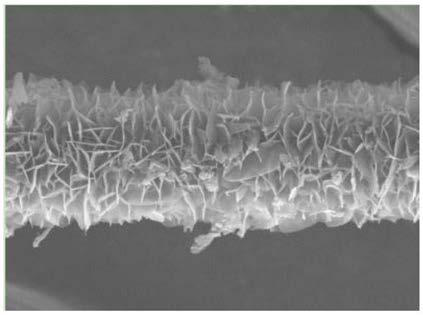

Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

InactiveCN103275282AThe surface is inertSmall specific surface areaPhysical treatmentInterlaminar shearResin matrix

The invention discloses a preparation method of an acrylic polymer grafted carbon fiber multi-scale reinforcement, relating to a carbon fiber reinforcement and a preparation method thereof. The preparation method comprises the following steps of: 1) performing oxidation treatment on a carbon fiber surface; 2) grafting a silane coupling agent to the carbon fiber surface after the oxidation treatment; 3) obtaining chain transfer agent grafted carbon fiber through a reaction between the carbon fiber surface grafted silane coupling agent and a chain transfer agent; and 4) initiating acrylic monomer grafting polymerization on the surface of the chain transfer agent grafted carbon fiber to finally obtain an acrylic polymer grafted carbon fiber multi-scale reinforcement. The method disclosed by the invention has the advantages that the roughness of the carbon fiber surface can be greatly improved, a great quantity of active functional groups can be introduced, the reaction activity of the carbon fiber surface is improved, the wettability and cohesiveness between the carbon fiber and a resin matrix are improved, and the interlaminar shear strength of an epoxy composite material is enhanced by 40-50%.

Owner:NANCHANG HANGKONG UNIVERSITY

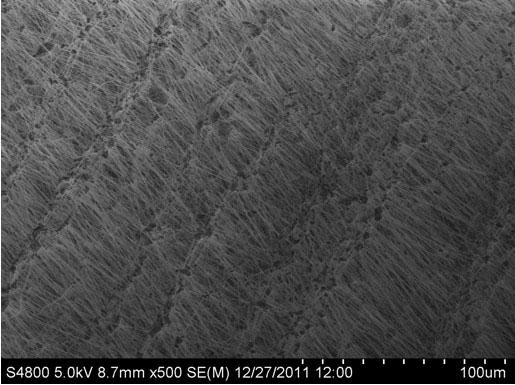

Preparation method of polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement

InactiveCN105778153AImprove surface roughnessHigh grafting rateCarbon fibresCarbon fibersSilsesquioxane

The invention relates to a preparation method of a polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement. The preparation method comprises the following steps of firstly, grafting a vinyl silane coupling agent onto the carbon fiber surface which is acidified by a hydrolysis method; then, generating a click reaction between introduced vinyl on the carbon fiber surface and sulfydryl on the sulfydryl polyhedral oligomeric silsesquioxane, so as to obtain the polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement. After the polyhedral oligomeric silsesquioxane is introduced onto the carbon fiber surface, the wettability between the carbon fiber and the resin is improved, and the interfacial strength between the carbon fiber and the resin is improved. The preparation method has the advantages that the process is simple, the reaction time is short, the byproduct has no toxicity, and the scaled production is favorably realized.

Owner:NANCHANG HANGKONG UNIVERSITY

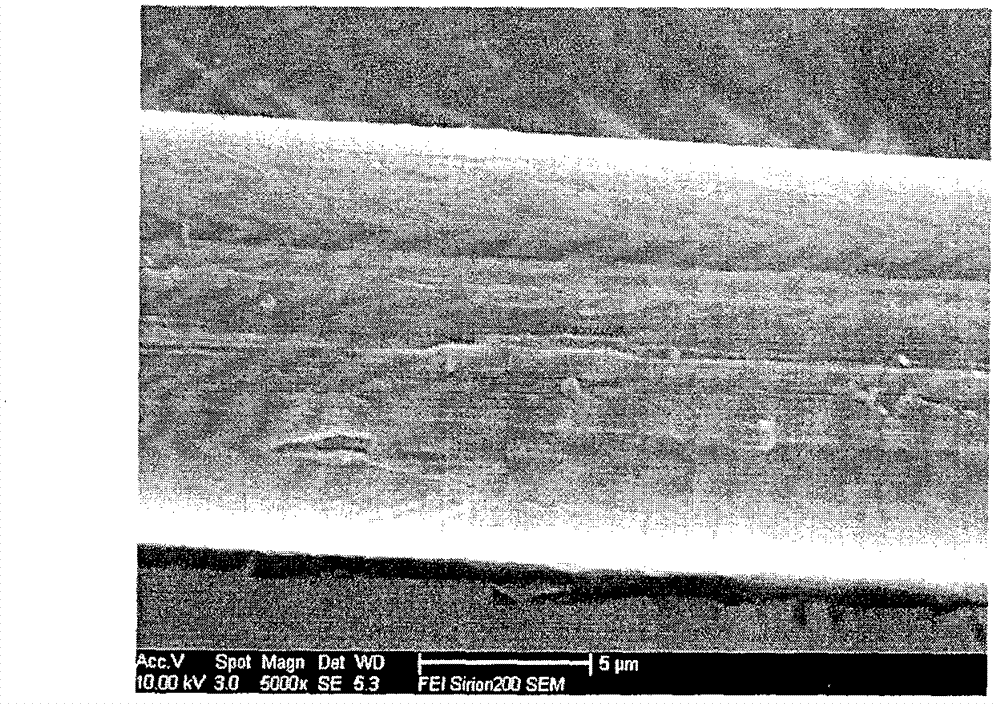

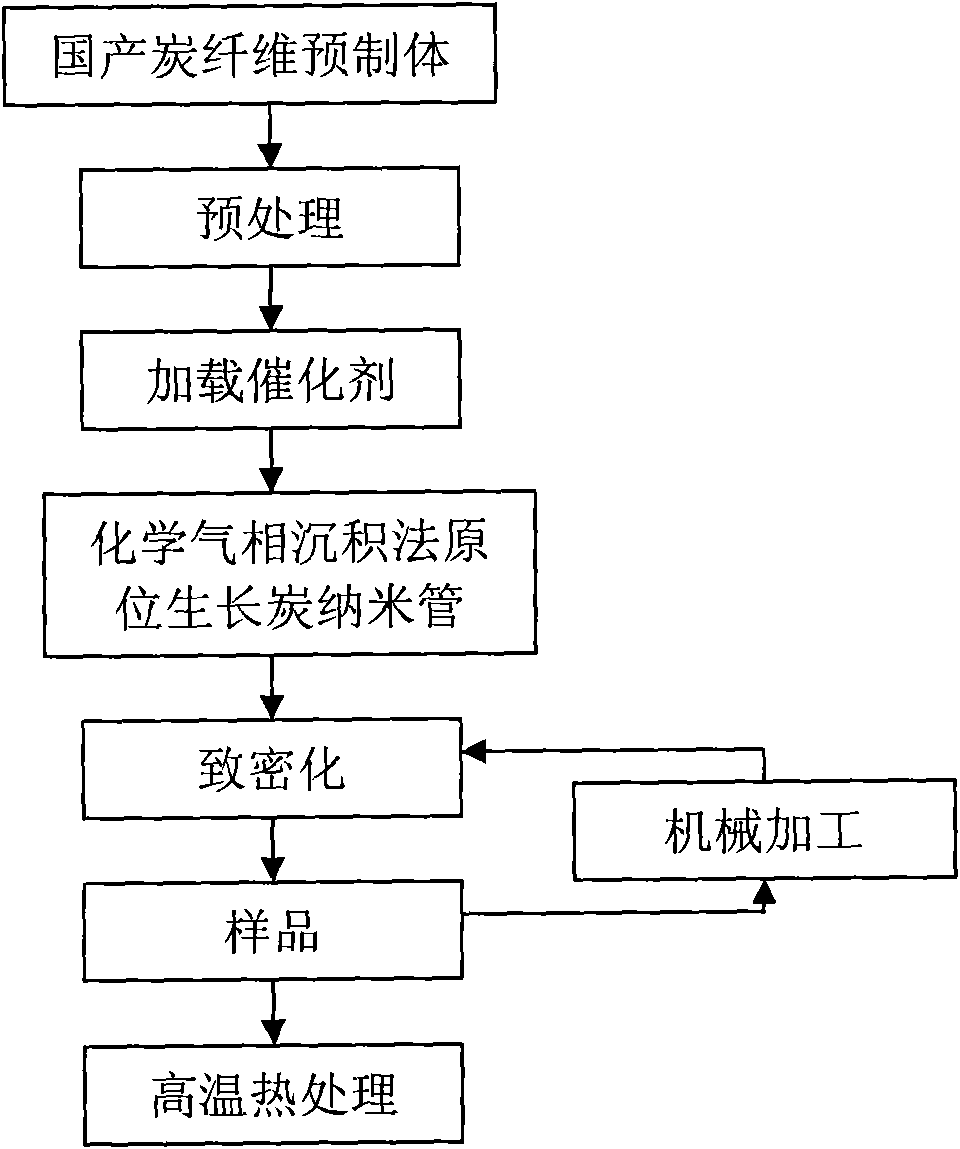

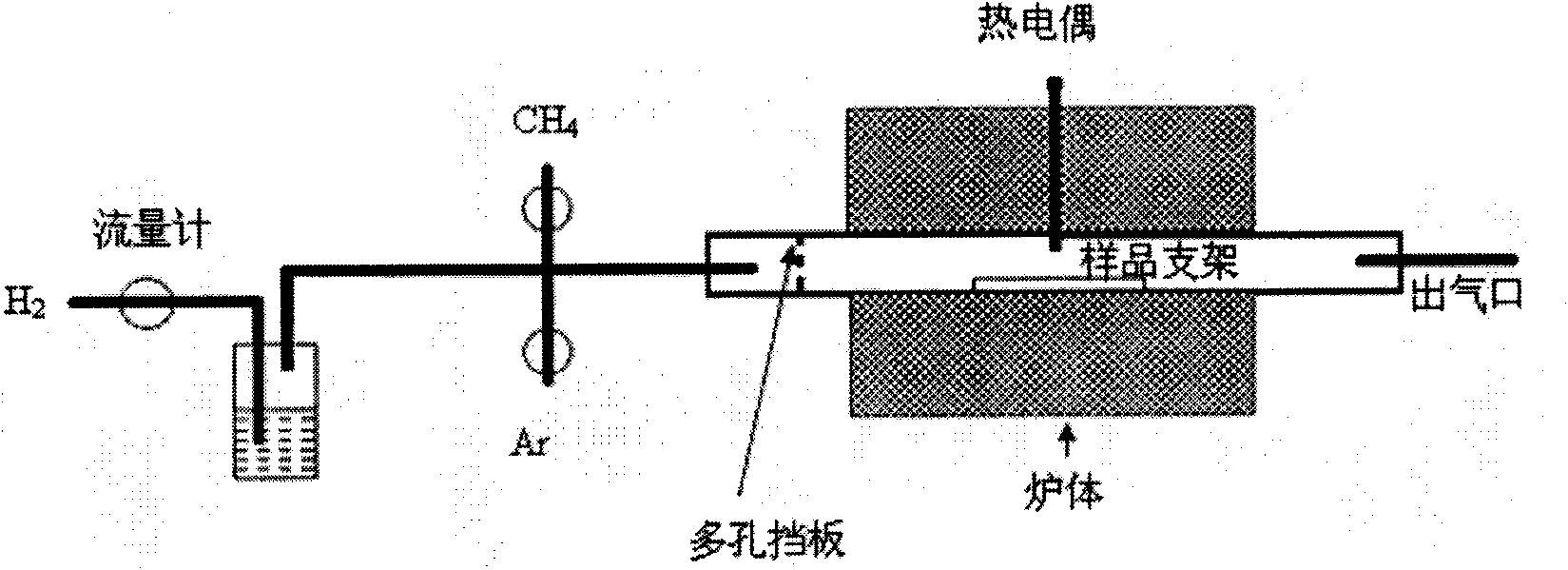

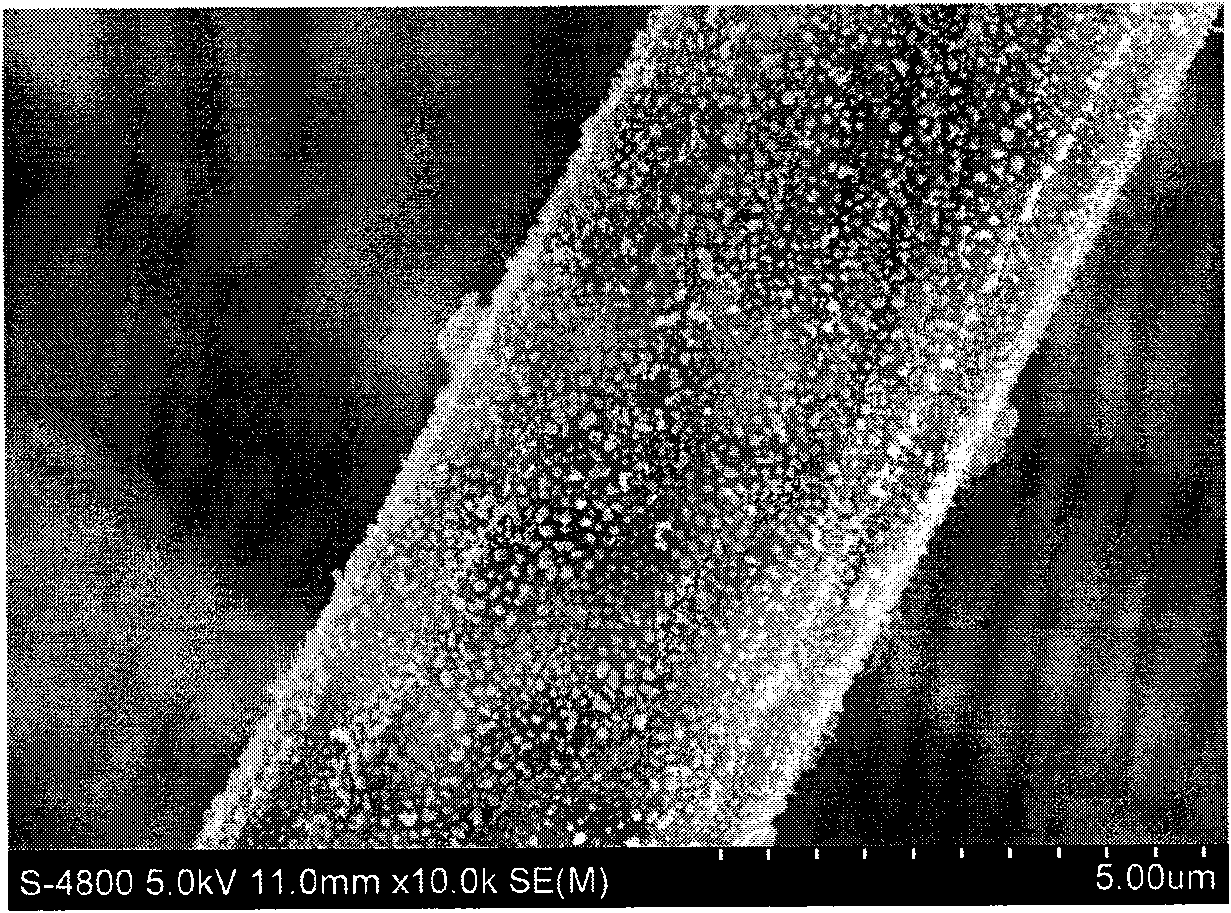

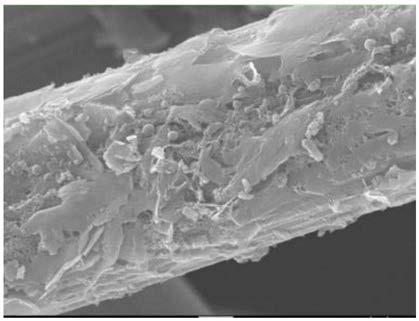

Method of carbon nanotube for modifying polyacrylonitrile-based carbon fiber interface produced in China

The invention provides a method of a carbon nanotube for modifying a polyacrylonitrile-based carbon fiber interface produced in China. The technology includes four parts: (1) surface treatment of thedomestic polyacrylonitrile-based carbon fiber: firstly treating and removing colloid on the surface of carbon fiber at the temperature of 600-800 DEG C and then using the mixed acid of nitric acid andsulfuric acid to remove the impurities on the surface of fiber; (2) preparation of domestic carbon fiber preform where the carbon nanotube grows in situ: firstly putting treated carbon fiber needle preform in the organic solution of catalyst precursor and then growing the carbon nanotube in situ in a chemical vapor deposition furnace; (3) densification of preform: adopting chemical vapor infiltration process to densify the preform and depositing the preform for 200-350h so that the density of the preform reaches 1.70-1.75g / cm<3>; and (4) high-temperature heat treatment: putting the material in a vacuum carbonization furnace, heating to the temperature of 2, 000-2, 300 DEG C at the heating rate of 30-50 DEG C / h under the protection of nitrogen, argon and other gases and preserving the heatfor 3-5h, and finally, the finished product is obtained.

Owner:BEIHANG UNIV

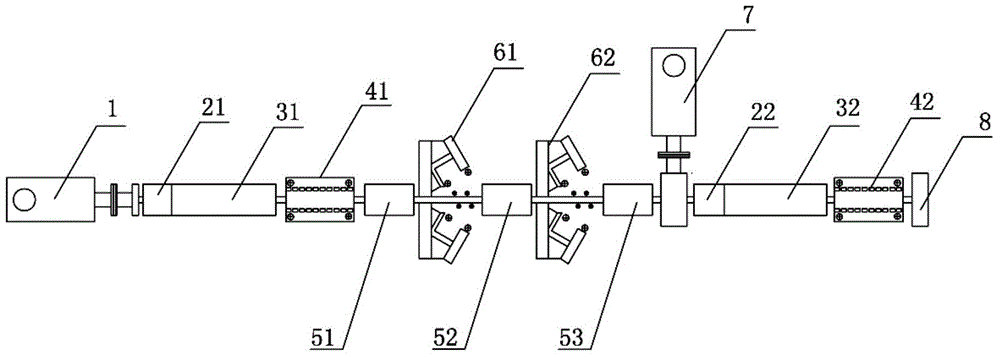

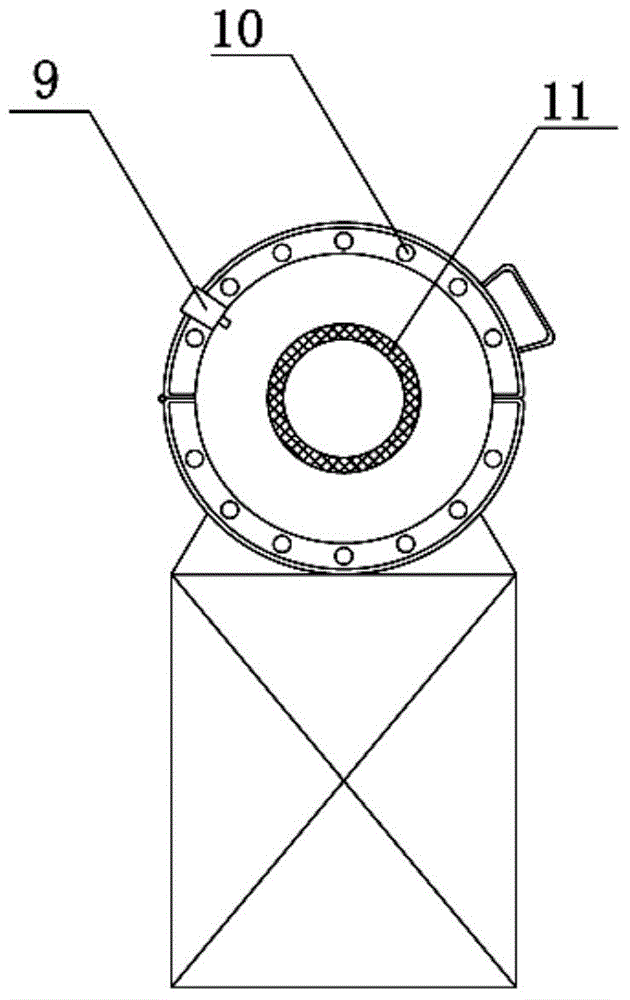

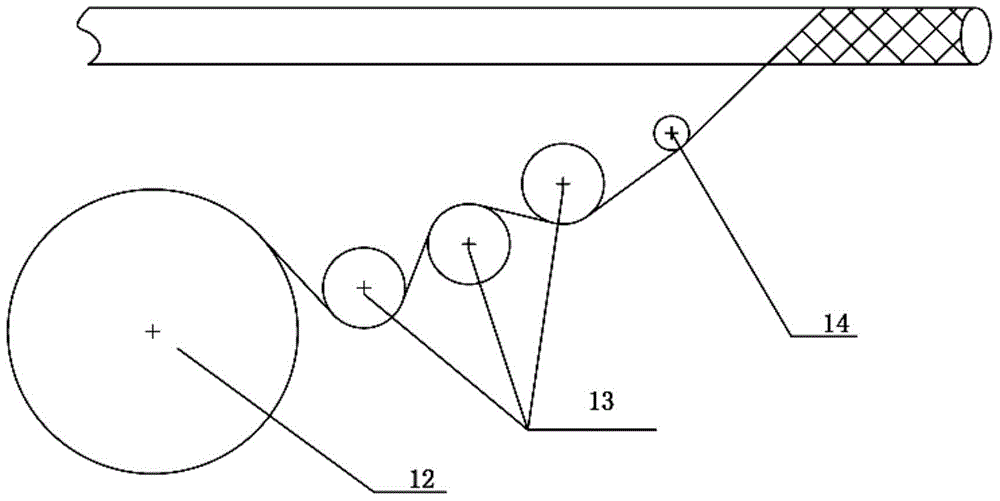

A production device for a thermoplastic wound reinforced plastic composite tube and a production method of the composite tube

ActiveCN104690933AReduce wall thicknessHigh strengthTubular articlesUltimate tensile strengthThermoplastic composites

The invention relates to a production method and a production device for a thermoplastic wound reinforced plastic composite tube. The production device comprises an inner tube extrusion module, a reinforcing layer winding module, an outer tube extrusion module and a cutting module from left to right in order, wherein the inner tube extrusion module is used for extruding an inner tube; the reinforcing layer winding module is used for winding and compositing a continuous fiber reinforced thermoplastic composite material around the inner tube so as to form a reinforcing layer; and the outer tube extrusion module is used for extruding an outer tube and composting the outer tube onto the surface of the reinforcing layer. A product produced by adoption of the method and the device is high in strength. The thickness of a plastic tube wall under same pressure conditions can be largely reduced, thus saving the cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Quick cold-patch repair method for asphalt pavement, and application thereof

InactiveCN103570334ANo wasteSimple construction equipmentRoads maintainenceMagnesium phosphateBitumen emulsion

The invention discloses a quick cold-patch repair material for an asphalt pavement, and application thereof. The material is prepared from the following components in parts by weight: 20-80 parts of magnesium phosphate cement, 5-20 parts of fine sand, 0-20 parts of medium sand, 0-50 parts of rubble with the grain size of 5-20 mm, 0-10 parts of emulsified asphalt, 0-10 parts of water-soluble polyurethane, 0-10 parts of rubber powder and 0-1 part of air entraining agent. The materials in parts by weight are uniformly stirred (1.5-2 min) in a stirrer and then poured in a damaged part of the cleared asphalt pavement, thereafter the damaged part is plastered, shaped and repaired, and then the asphalt pavement can be opened for traffic after 2-3 hours of maintenance. The quick cold-patch repair material disclosed by the invention adopts blending and pouring for molding in practical application, no heating is needed, the construction is convenient, the maintenance time is short, small influence is caused to traffic, and the mechanical property and the durability both satisfy the application requirement, so the quick cold-patch repair material is especially suitable for quick repair of pothole and crack-type damages of the asphalt pavement. The quick cold-patch repair material disclosed by the invention not only has a remarkable effect on damage repair aspect of the asphalt pavement but also can expand the application thereof to the field of cement concrete engineering and fields of damage repair of house buildings and old buildings, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

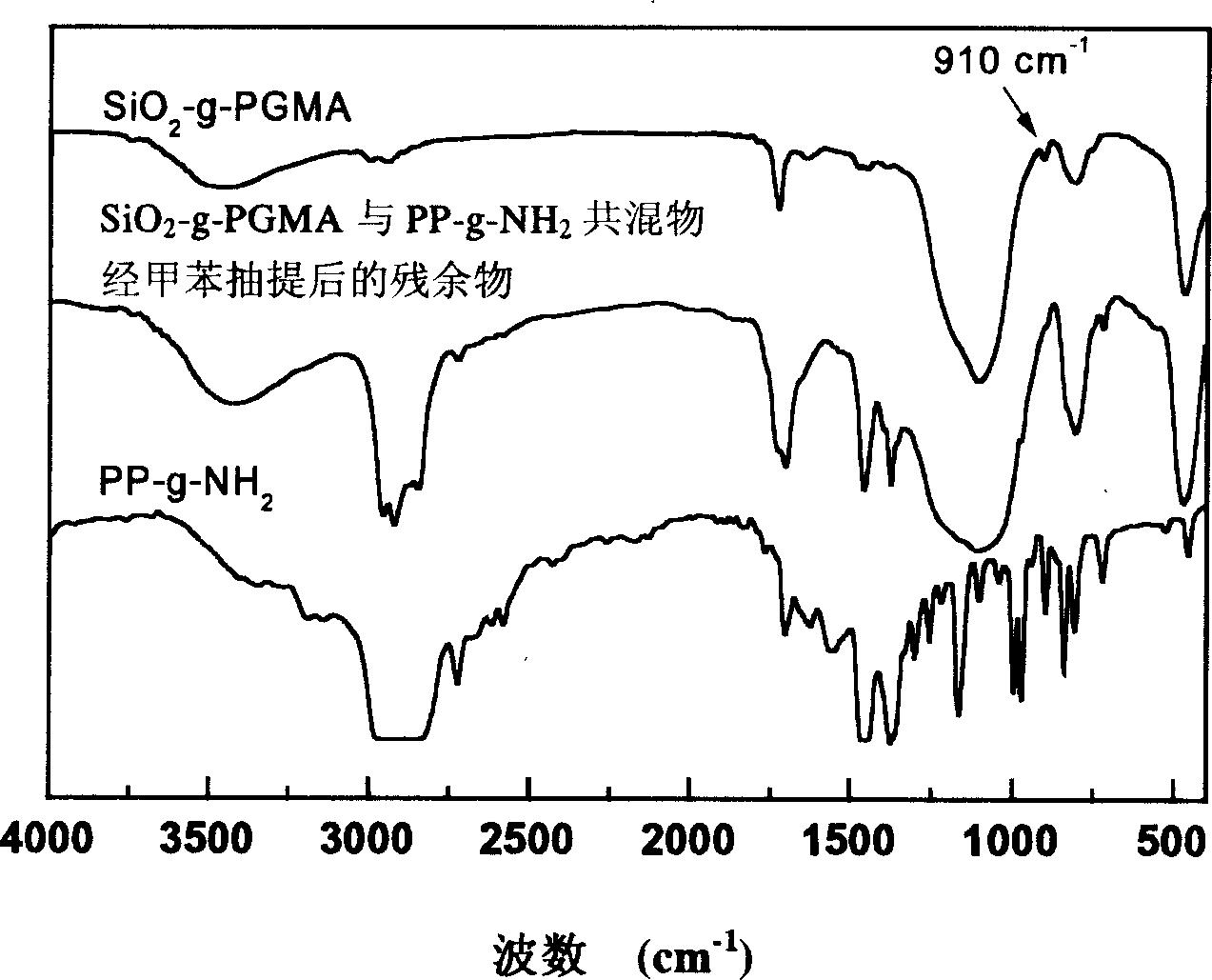

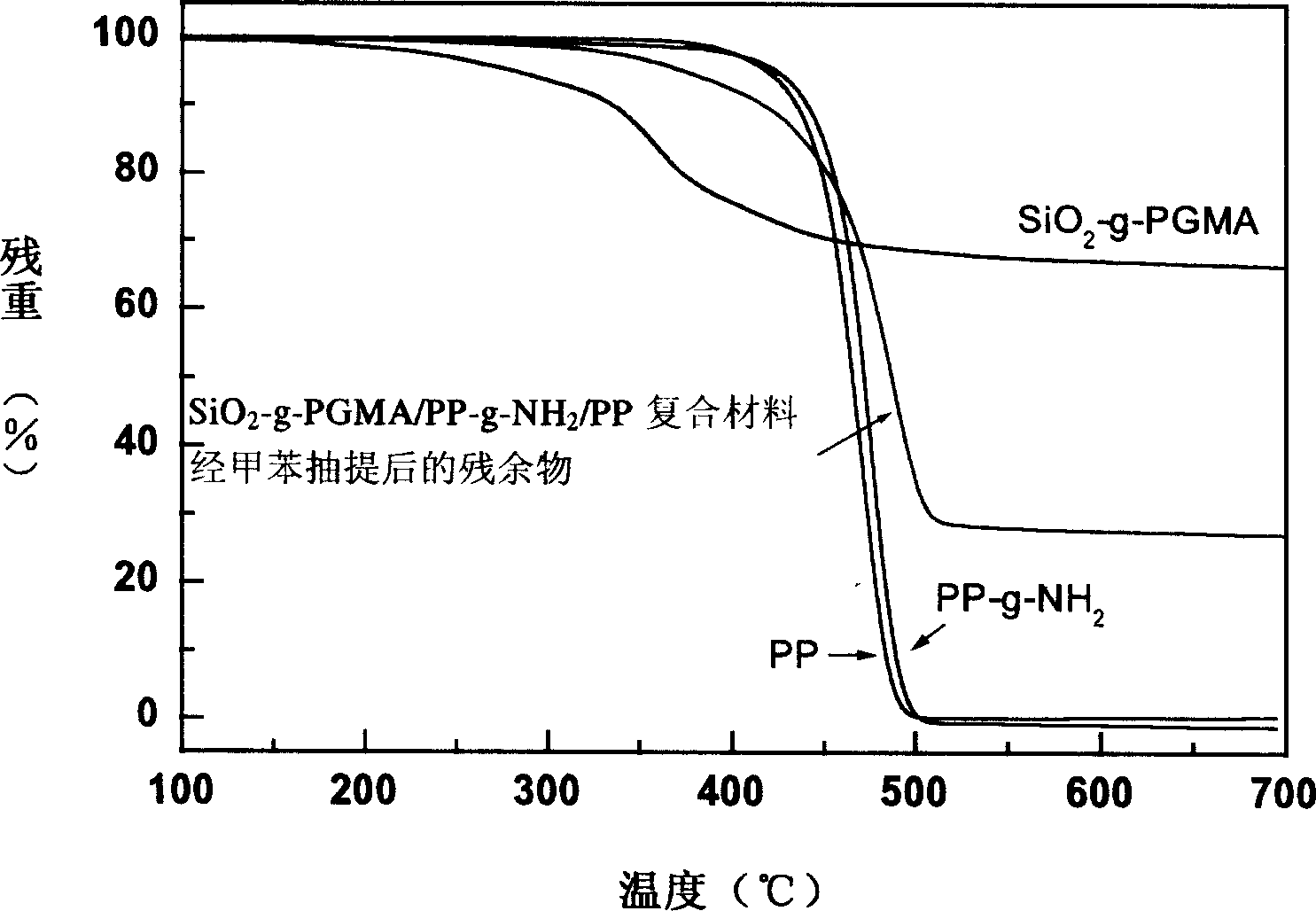

Reacting nano inorganic particle/polymer composite material

This invention discloses a kind of reactive inorganic nanoparticle / polymer composite materials which comprises 1~5wt% inorganic nanoparticles, 2.5~10wt% reactive compatilizers and 85~96.5wt% polymer matrix. In this invention, reactive compatilization technology is adopted, that is, inorganic nanoparticles react with polymer in situ during ordinary blending to produce grafted compounds, which greatly enhances the interfacial effect between inorganic nanoparticles and polymer matrix so that both the interfacial adhesion strength and the dispersion of inorganic nanoparticles in the matrix are greatly improved and mechanical properties of the prepared composite materials are effectively promoted. This invention requires no special apparatus or technique the composite materials with good comprehensive properties can be obtained with only common facilities.

Preparation method of concrete mixed with addition and aggregate

InactiveCN1994709AImprove interfacial bond strengthHigh compressive strengthMixing operation control apparatusCement mixing apparatusSlagCompressive strength

The invention relates to a method for producing concrete dipped with skeleton material, wherein said method comprises that: packing dipping material layer on the face of skeleton, to be mixed with cement and water, to obtain the mixture. And said mixture comprises: mineral slag, silicon powder, coal powder ash, and sinter China clay; the weigh ratio between mixture and cement is 1:1-9. The invention can reduce or eliminate the interface transition area, to improve the adhesive strength between skeleton and cement stone. And compared with common technique, the invention can improve 20-40% anti-compress strength.

Owner:ZHEJIANG UNIV OF TECH

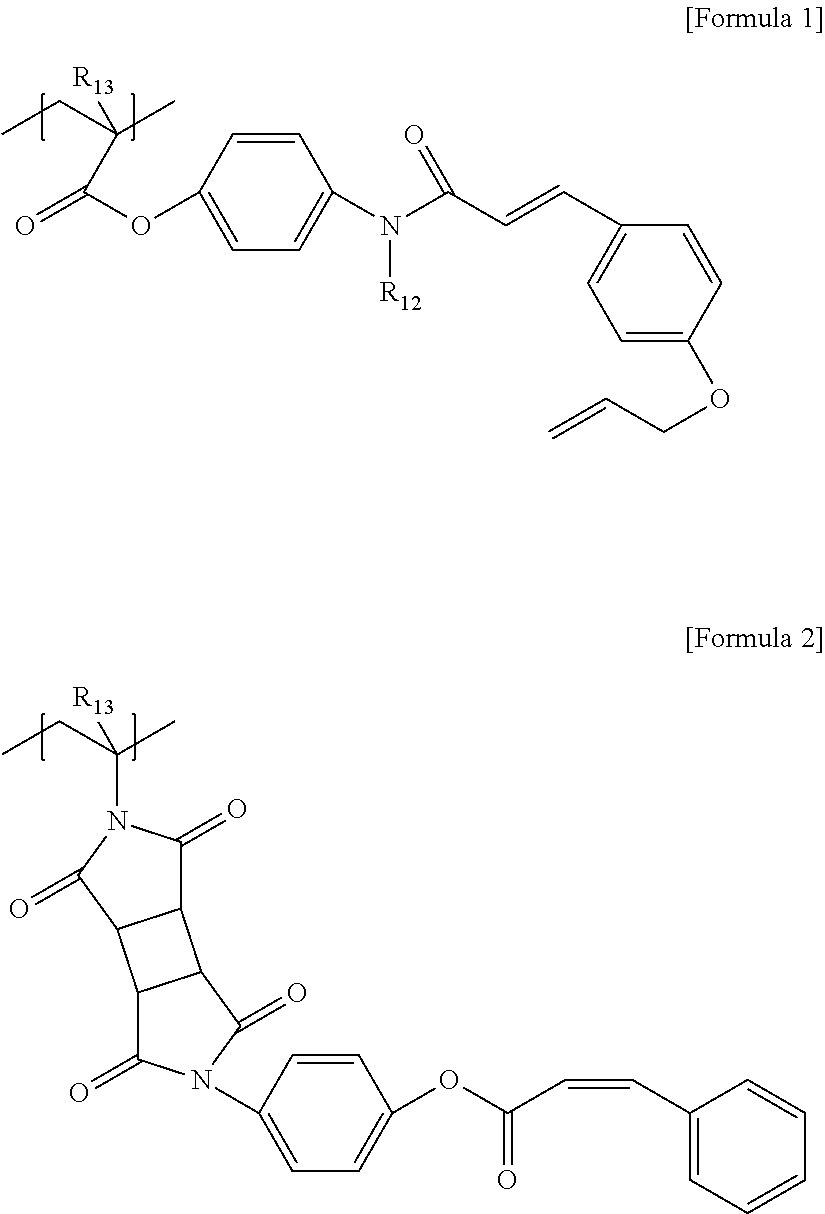

Method for modifying carbon fiber surface by assembly of aromatic fused ring molecules and preparation method of carbon fiber interface reinforced resin matrix composite

The invention provides a method for modifying a carbon fiber surface by assembly of aromatic fused ring molecules and belongs to the technical field of carbon fiber modification. The method comprisesthe following steps: aromatic fused ring dianhydride and diamine are subjected to imidization, and an aromatic fused ring imide molecule assembly liquid is obtained; carbon fibers are soaked in the aromatic fused ring imide molecule assembly liquid, the aromatic fused ring imide molecules are combined with the carbon fibers, and the carbon fibers with surfaces subjected to assembly modification are obtained. Chemical activity of the surfaces of the carbon fibers can be improved with the modification method. The invention further provides a preparation method of a carbon fiber interface reinforced resin matrix composite. The obtained carbon fibers with the surfaces subjected to assembly modification are compositely cured with resin, and the aromatic fused ring molecule assembly-modified carbon fiber interface reinforced resin matrix composite is obtained. The interface reinforced resin matrix composite obtained with the preparation method has good interfacial adhesion strength and interfacial shear strength.

Owner:BEIJING UNIV OF CHEM TECH

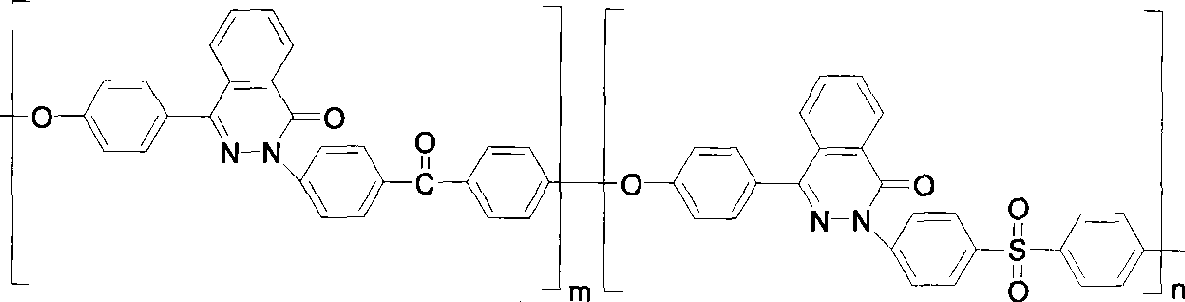

Interface modification method of poly(p-phenylene-benzobisoxazole) fiber-reinforced soluble polyaryl ether resin composite material

InactiveCN101445613AEnhanced interface bindingImprove adhesionPhysical treatmentFibre typesEpoxyFiber

The invention discloses an interface modification method of a poly(p-phenylene-benzobisoxazole) fiber-reinforced soluble polyaryl ether resin composite material, and the interface modification method belongs to the technical field of advanced composite materials. The interface modification method is characterized in that the interface modification method adopts the low-temperature plasma technology to graft epoxy resin and other thermosetting resins on an interface of poly(p-phenylene-benzobisoxazole) fiber and a soluble polyaryl ether resin matrix under the processing power of 10-400W, the processing time of 0.5-30min and the gas pressure of 1-1.01 multiplied by 10<5> Pa in a processing cavity, the content of the epoxy resin and other thermosetting resins by weight percentage is 1-50 percent, and the grafting time is 0.5-24 hours. The interface modification method has the advantages that the prepared composite material has excellent interface binding performance and mechanical performance and can better play the comprehensive performance of the composite material, meet the using requirements of high temperature resistant environments of aerospace, military and other fields and realize batch, continuous and large-scale industrial production.

Owner:DALIAN UNIV OF TECH

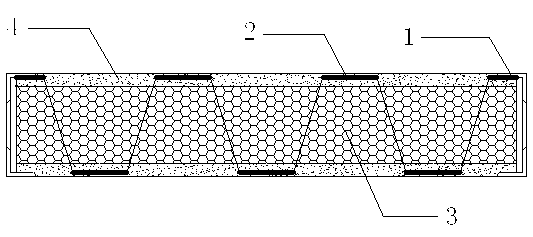

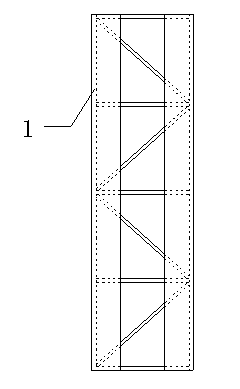

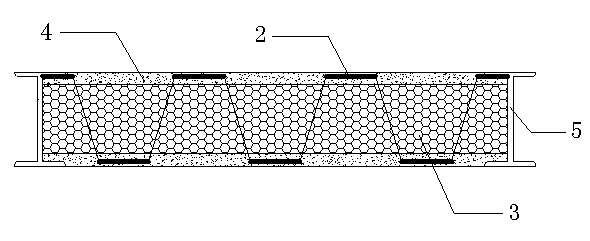

Compressed-steel sandwich combination wallboard

The invention discloses a compressed-steel sandwich combination wallboard comprising a lateral frame, compressed steel, a concrete or cement mortar face layer and core material, wherein the concrete or cement mortar face layer comprises an upper face layer and a lower face layer which are respectively connected with the lateral frame. The core material is arranged between the upper face layer and the lower face layer. The compressed steel is arranged in the combination wallboard and connected with the lateral frame or the concrete or cement mortar face layer. The compressed-steel sandwich combination wallboard integrates the characteristics of thin-wall compressed steel plate, such as good ductility and high strength, and the characteristics of lightweight core material, such as greenness and environmental protection. Due to the reasonable design of the cross section, the compressed-steel sandwich combination wallboard not only solves the problems of durability of steel products and the fire resistance of core materials and also fully uses the characteristics of each component. The compressed-steel sandwich combination wallboard not only can be used as the structure of the normal filling wallboard body, but also can be used as the shearing wall with high anti-seismic requirements, so that the compressed-steel sandwich combination wallboard is specially used as the shearing walls of high-rise buildings, filling walls of frame structures, outer walls of industrial workshops, and structures of other retaining wall.

Owner:JIANGSU SAITE STEEL STRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com