Patents

Literature

1463 results about "Thermoplastic composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer covered advanced polymer/wood composite structural member

InactiveUS6357197B1Corner/edge jointsMetal rolling stand detailsComposite constructionMoisture absorption

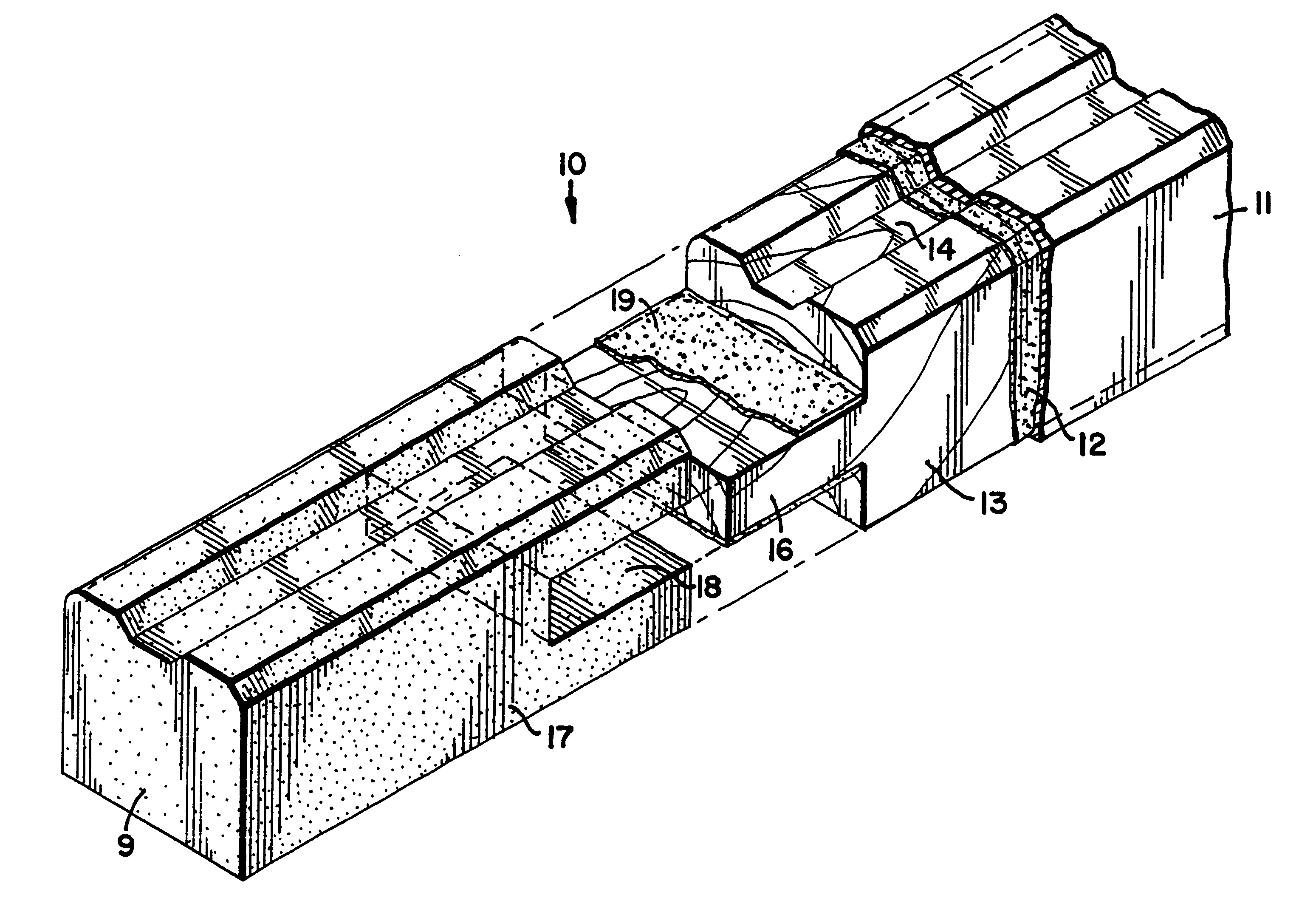

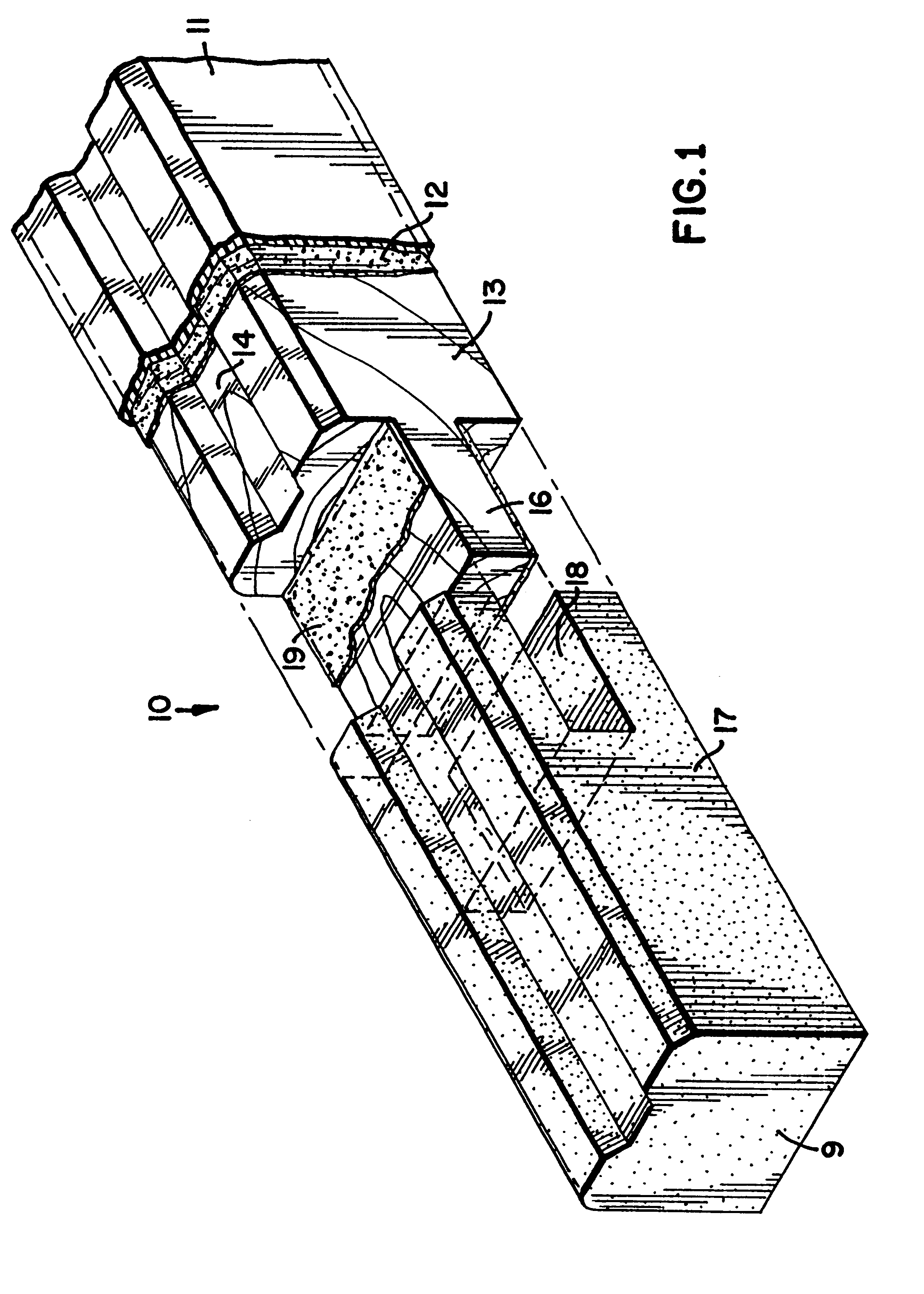

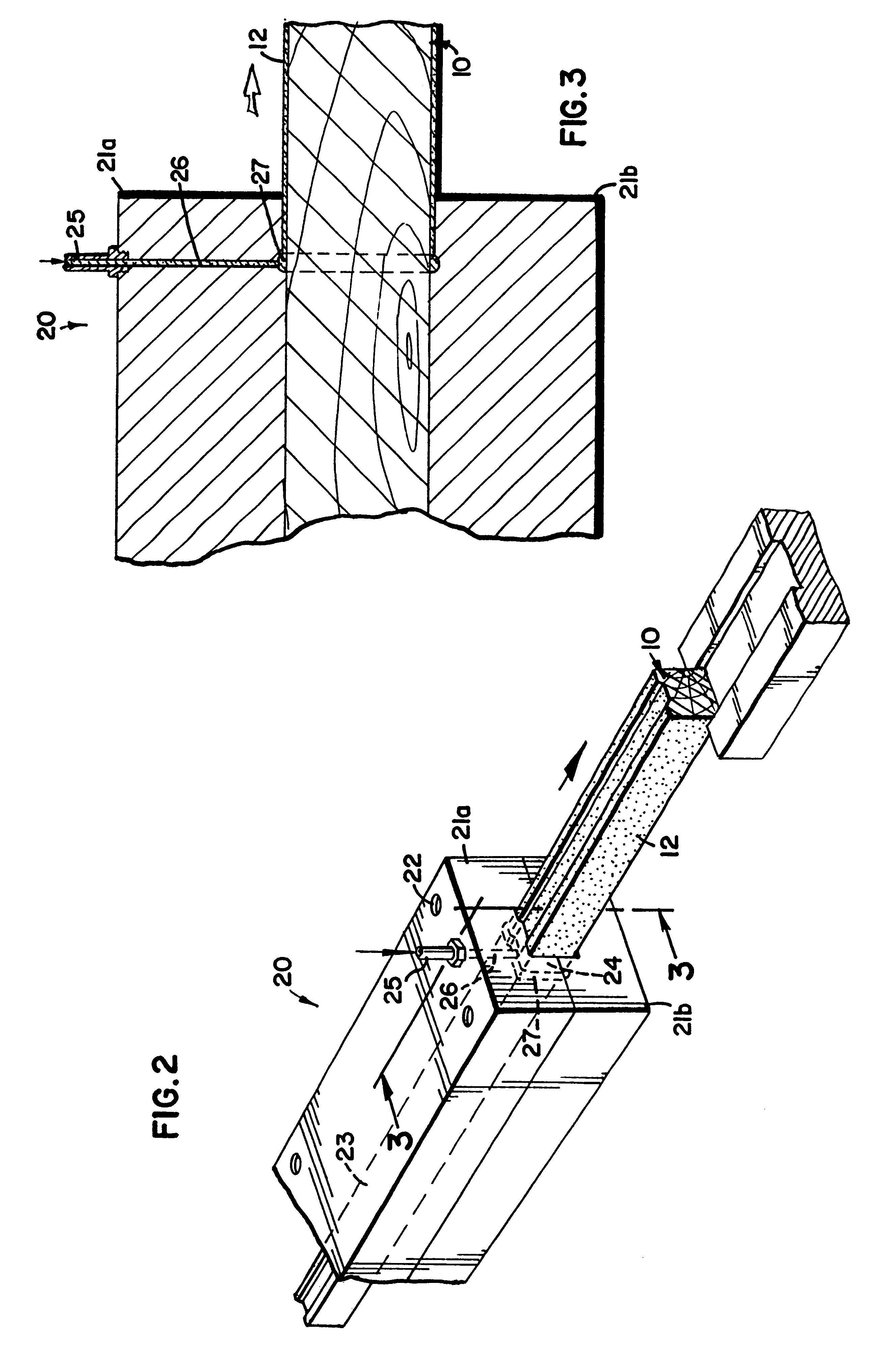

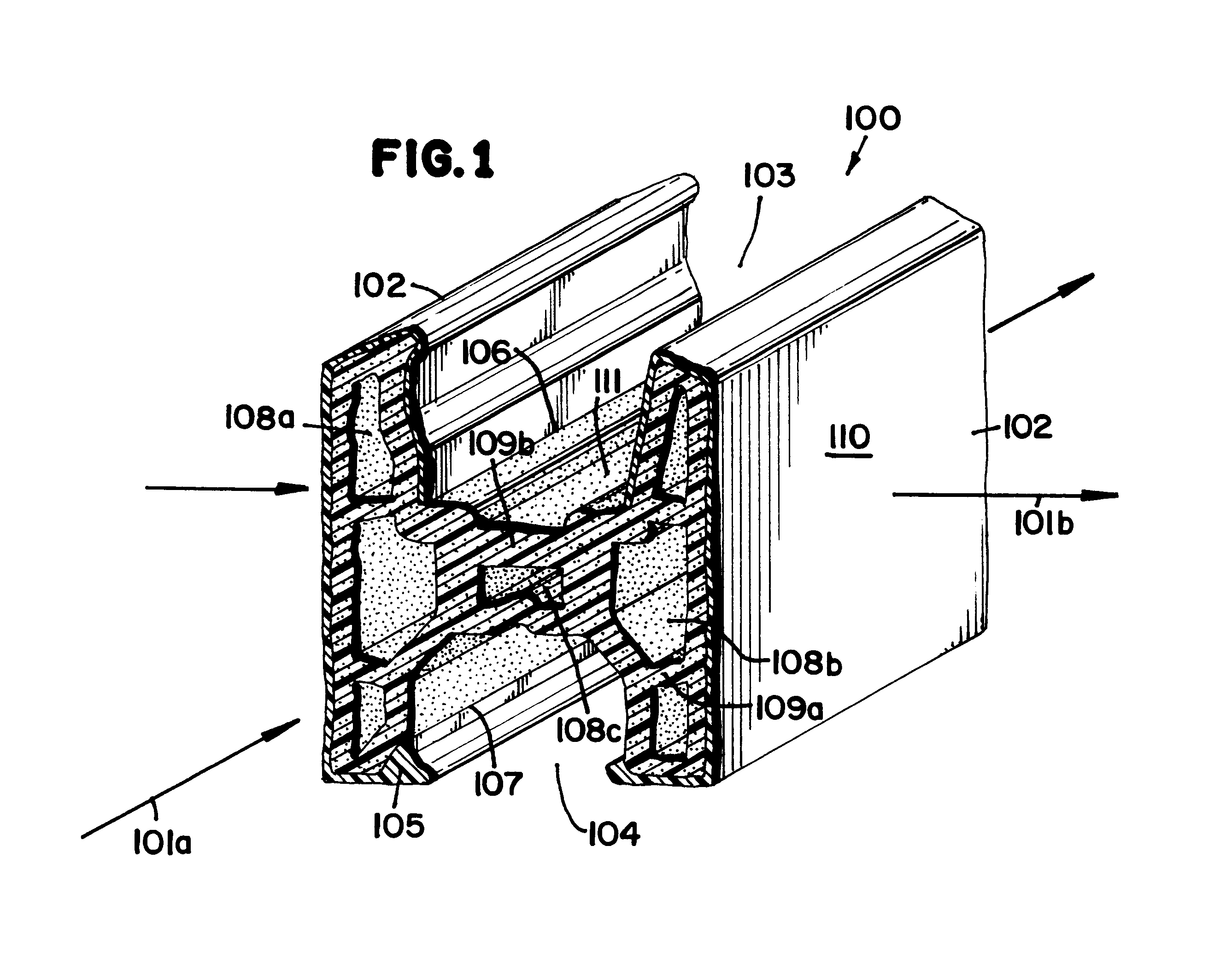

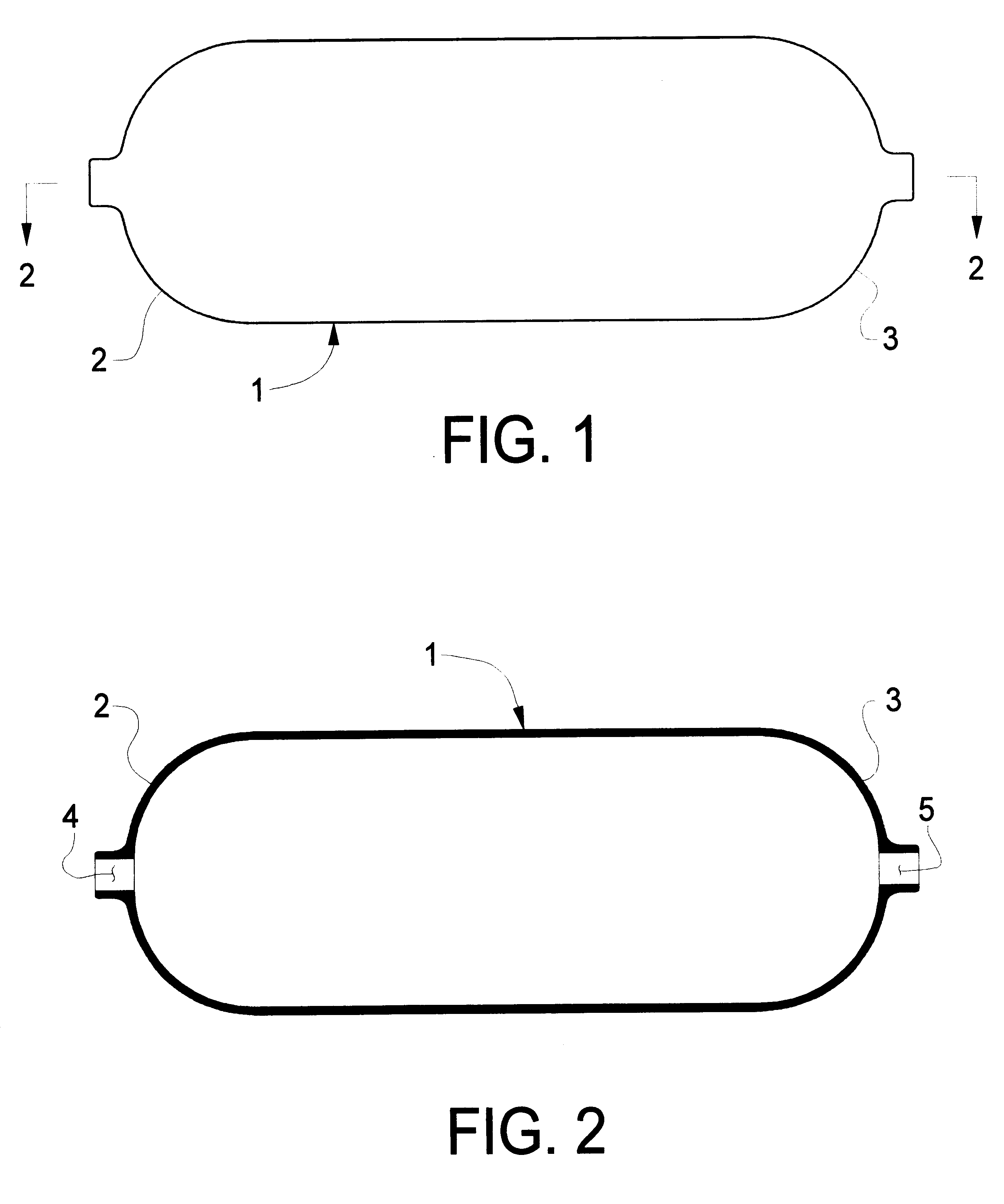

A composite structural member of the invention comprises a linear member having a first end and a second end attached to each end of the linear member as an end piece or end cap structure. Covering the composite member is a thermoplastic envelope preferably adherently bonded to the composite member. The end caps or end pieces are preferably thermoplastic materials typically thermoplastic composites comprising a thermoplastic resin and a fiber. Such a member is environmentally stable, resists moisture absorption, forms strong mitered joints and can be used in the assembly of fenestration products for commercial and residential real estate.

Owner:ANDERSEN CORPORATION

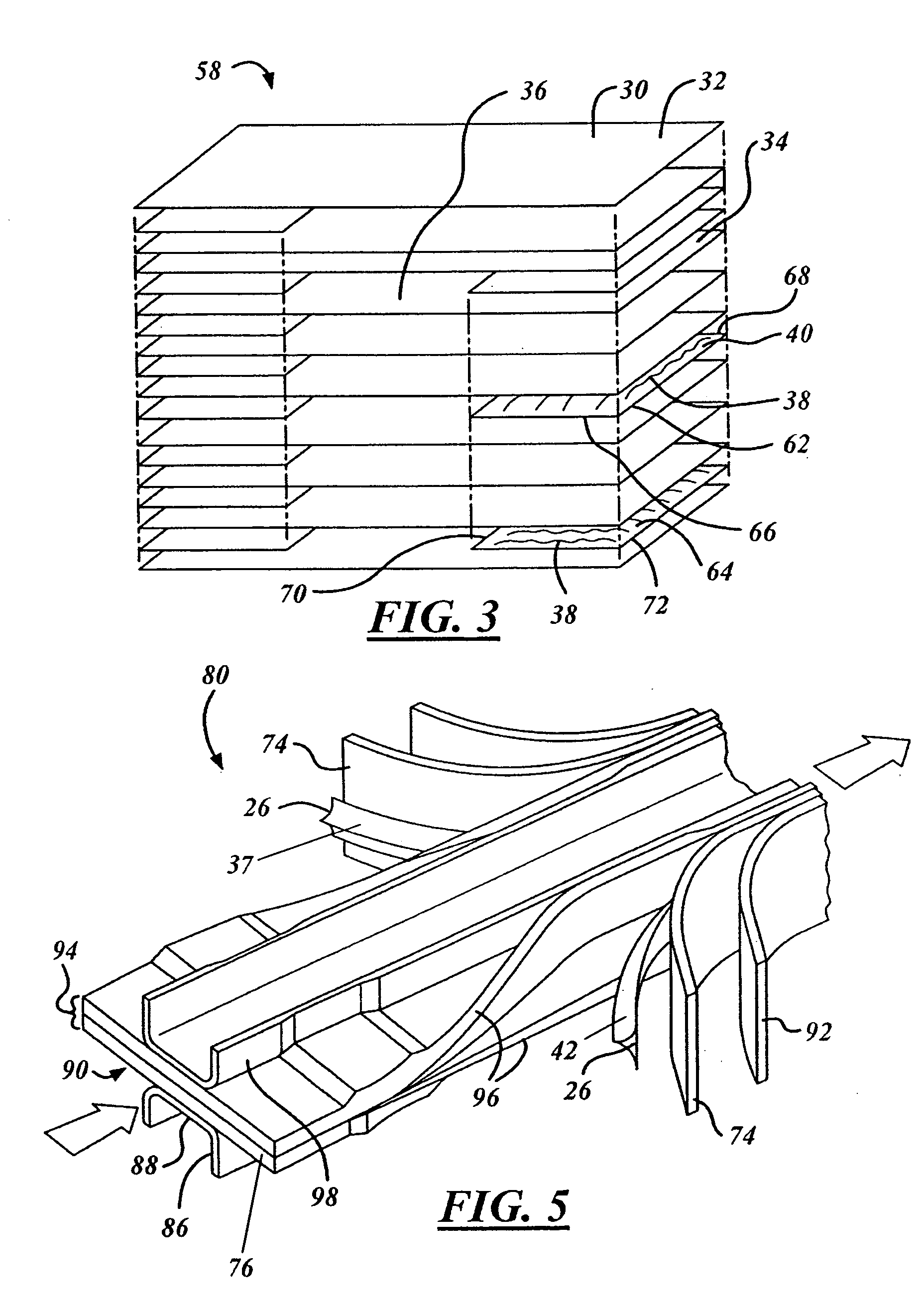

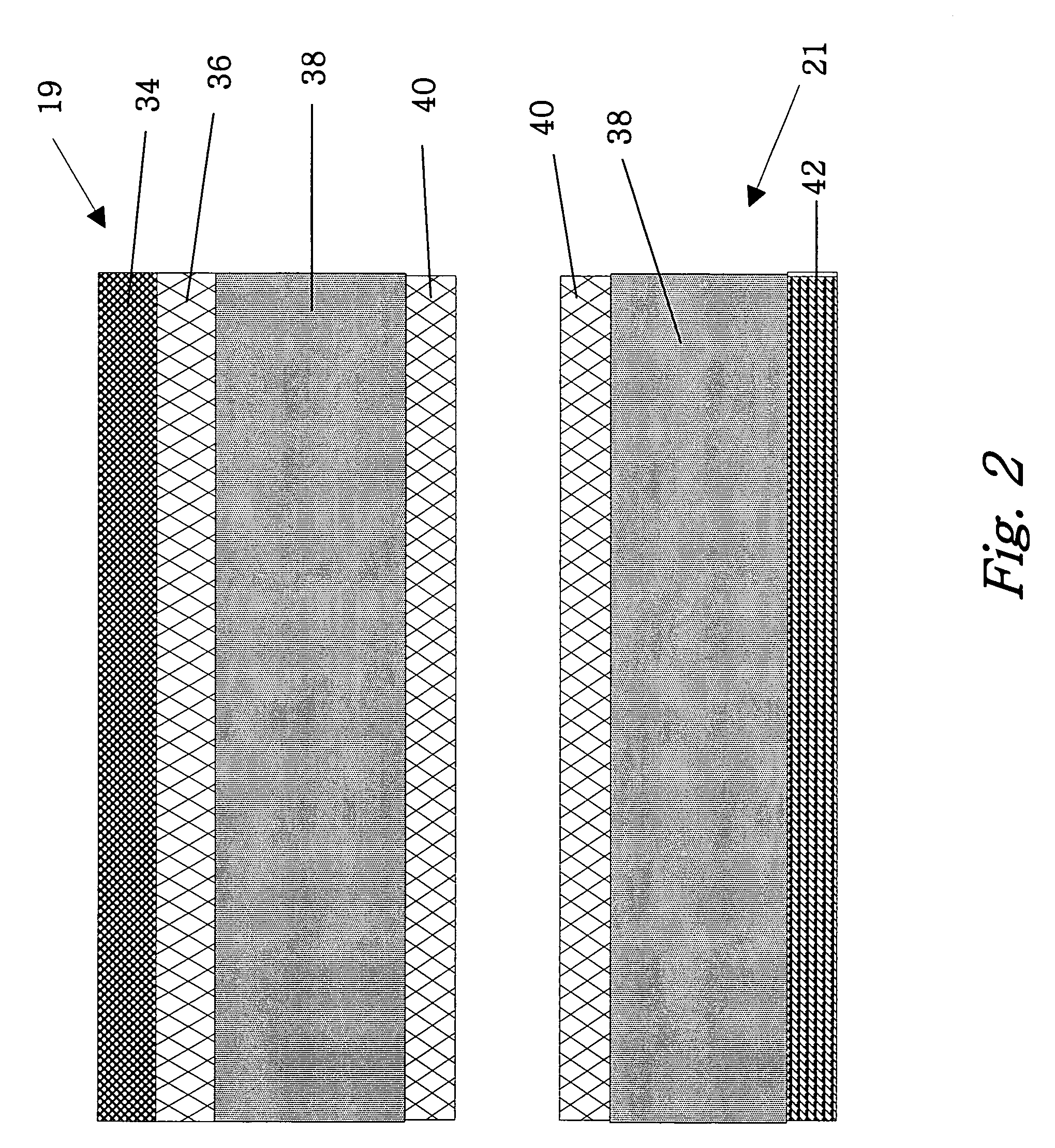

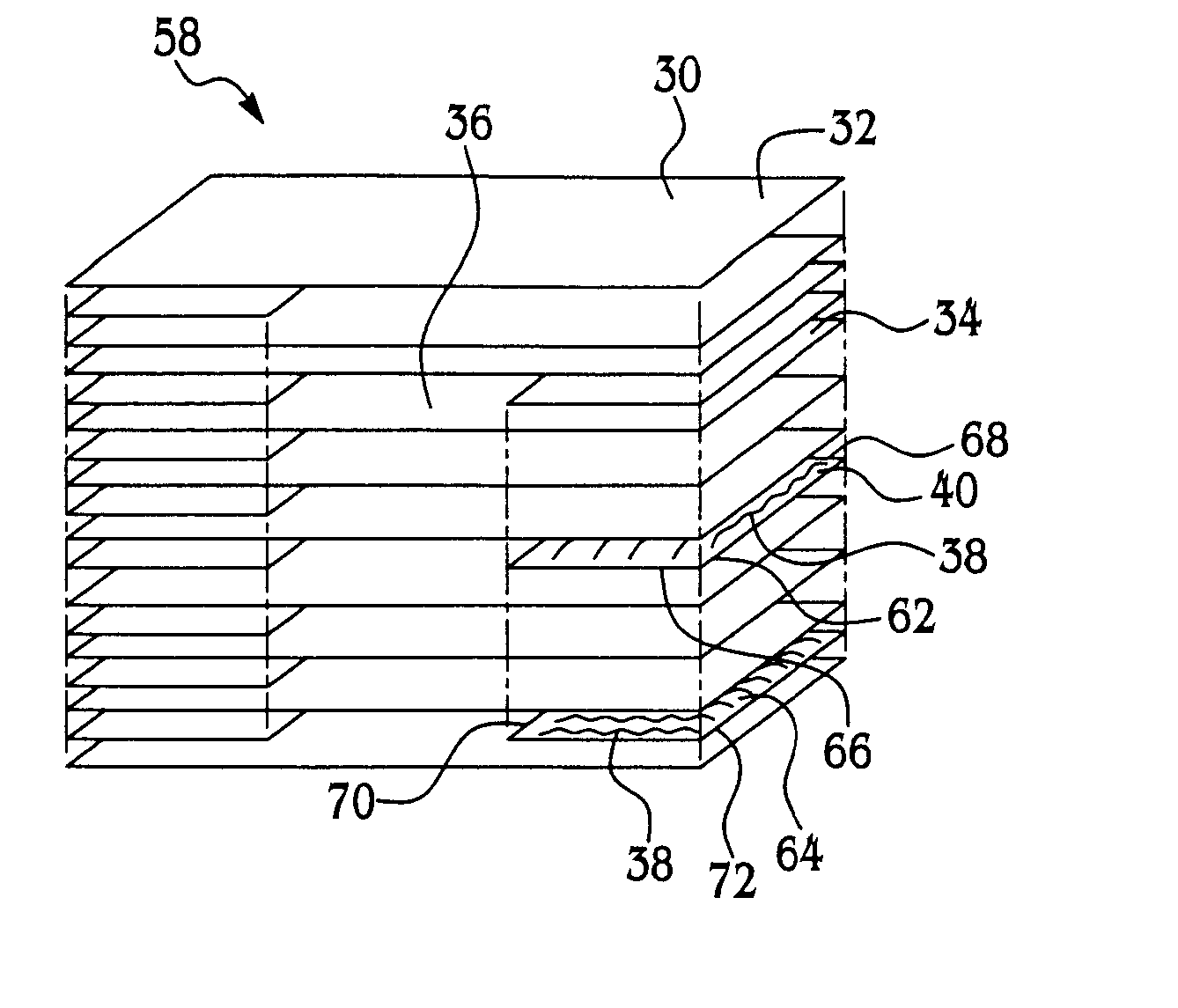

Composite panels

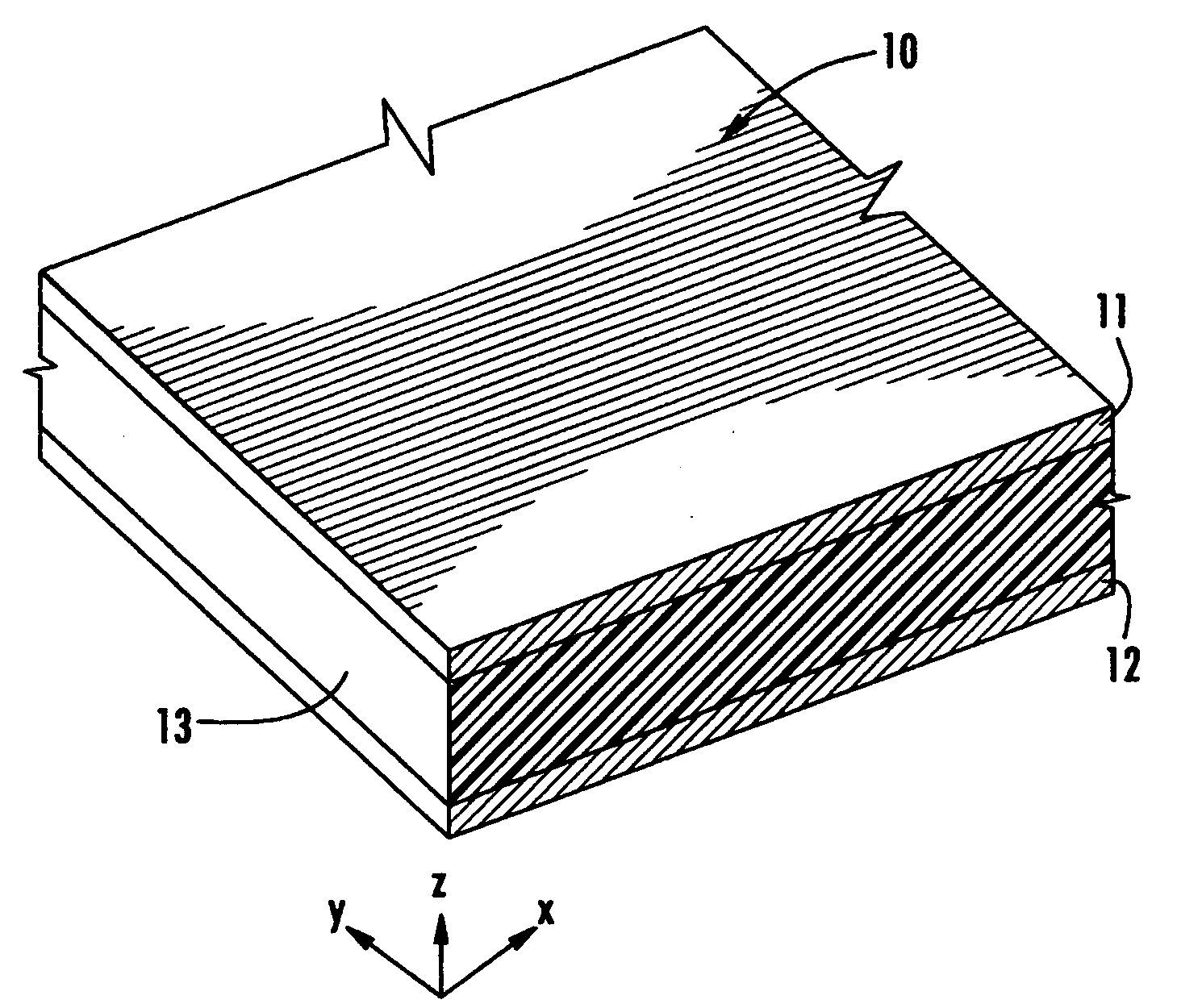

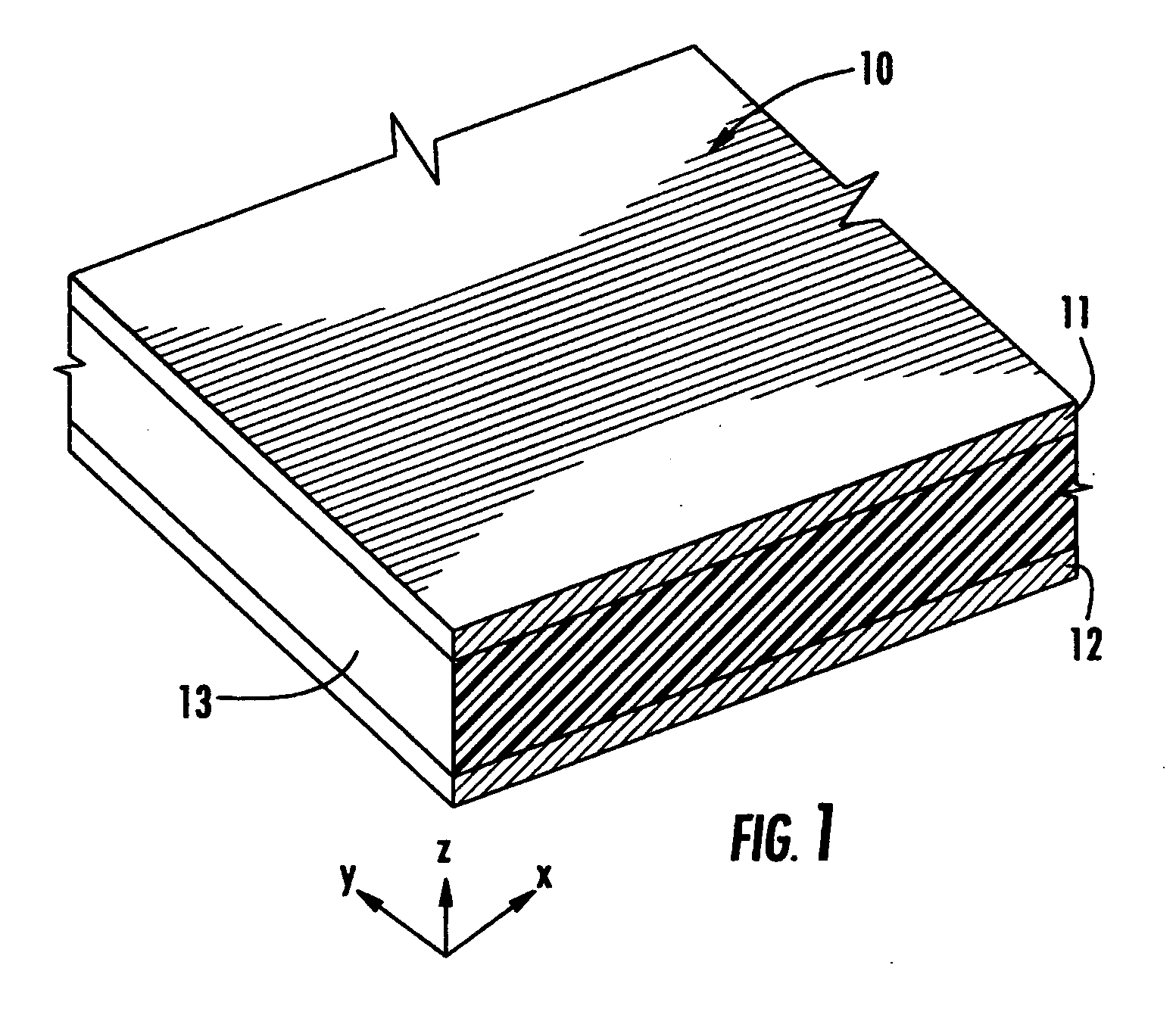

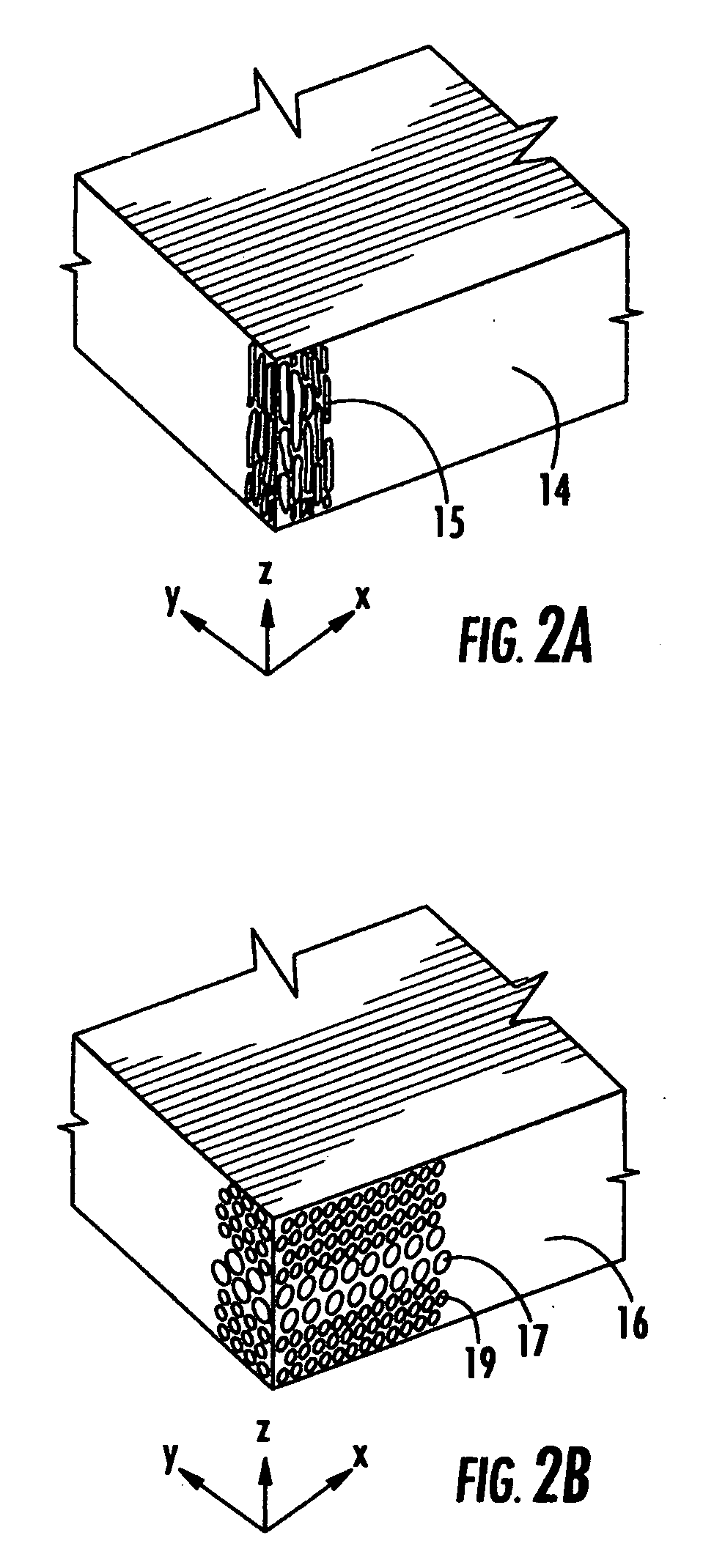

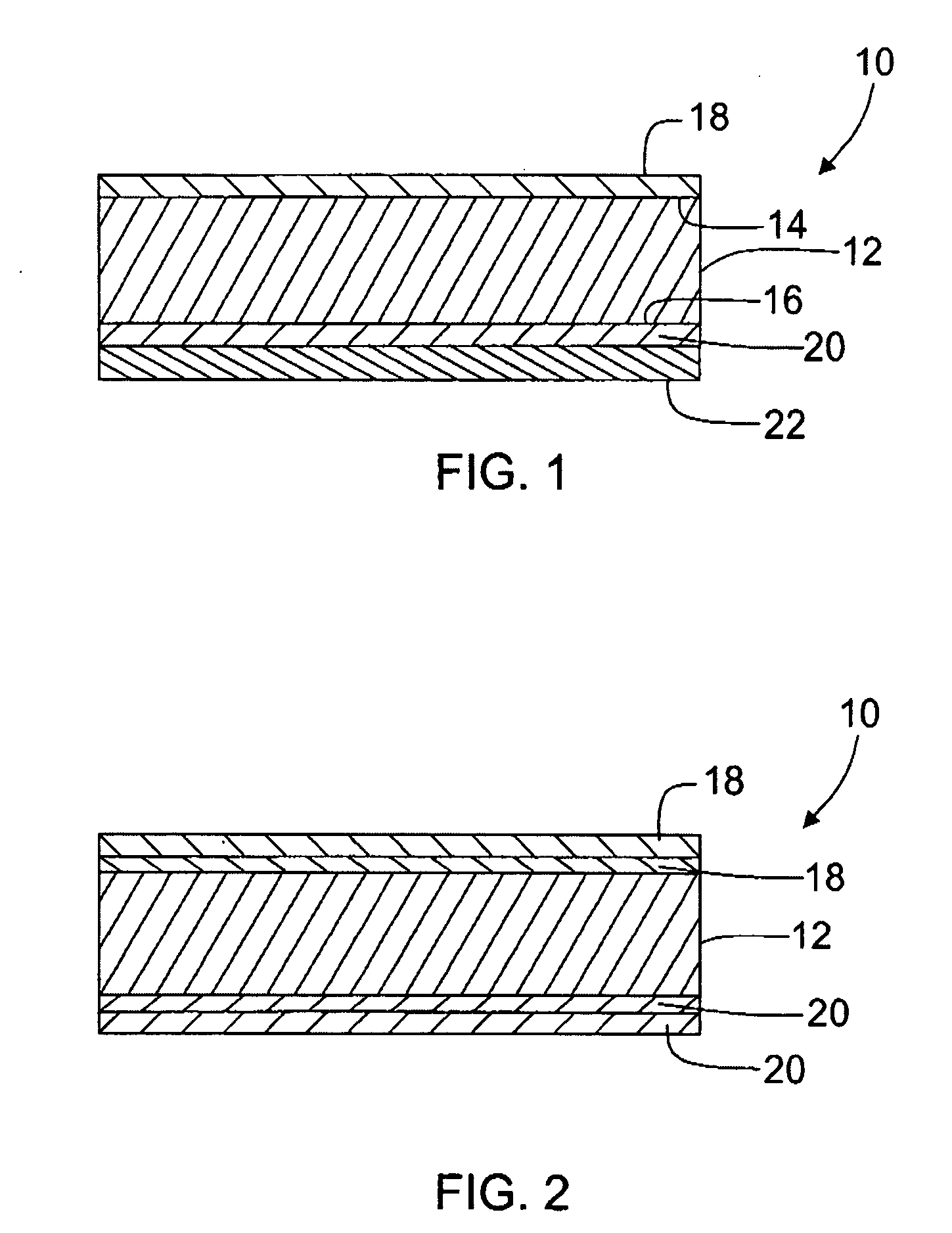

A composite panel consisting of outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic. The composite panel can be made by applying external heat and pressure to melt a skin of thermoplastic composite and an initial thickness of a thermoplastic core which has anisotropic properties causing the skin and core to fuse together followed by cooling the fused structure. The composite panel can be made by applying external heat and pressure to melt layers of a thermoplastic adhesive positioned between the outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic, so that the skins are bonded to the core by the melted layers of the thermoplastic adhesive followed by cooling the bonded structure.

Owner:EDWARDS CHRISTOPHER M

Method for manufacture of minimum porosity, wrinkle free composite parts

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

Fiber thermoset reinforced thermoplastic structural member

InactiveUS6106944AHigh strengthImprove mechanical propertiesLayered productsSpecial ornamental structuresYoung's modulusEngineering

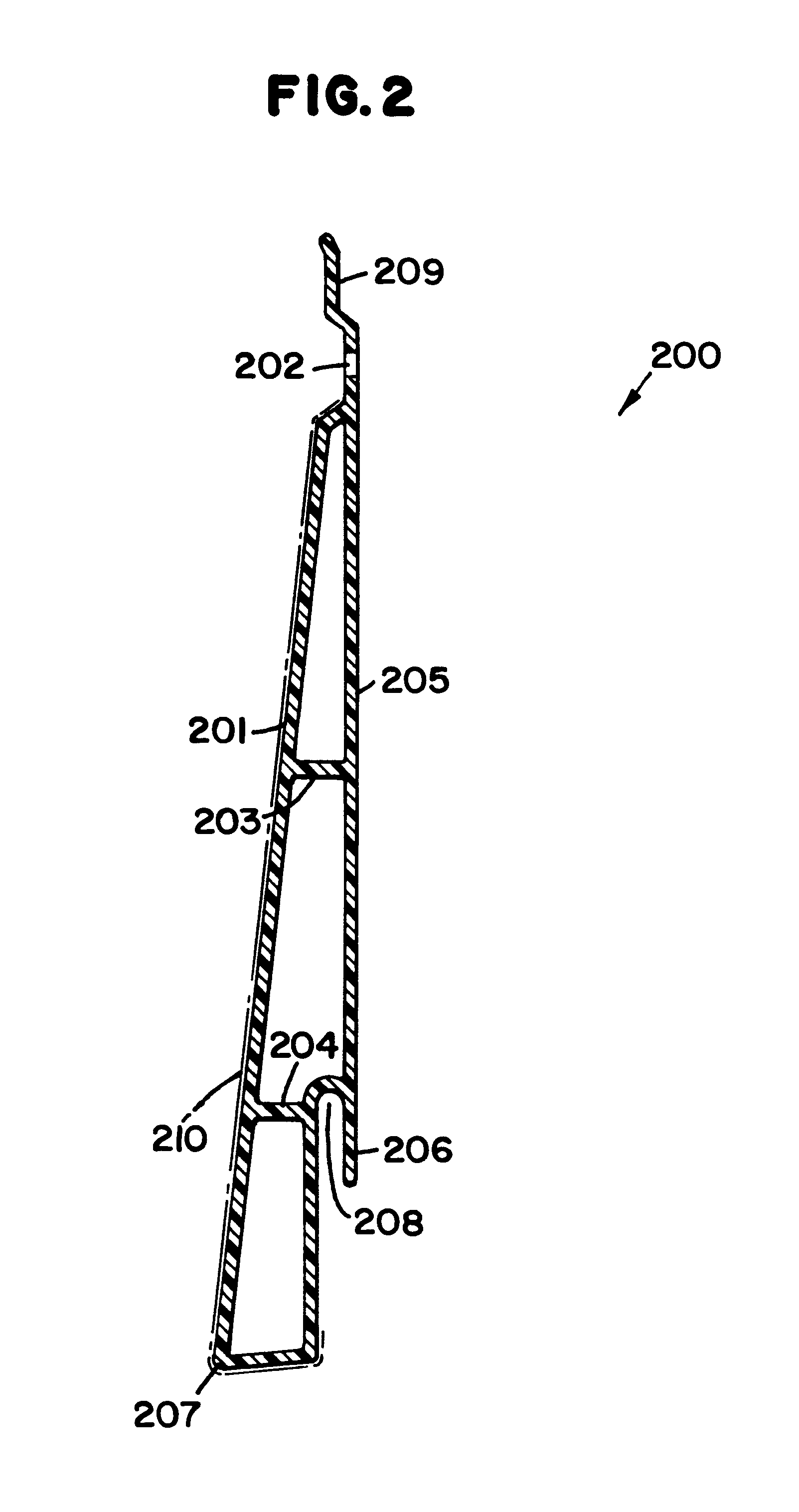

In the manufacture of a structural member comprising a thermoplastic composite core with an exterior reinforcing layer, the core member is initially extruded in the shape of a profile. The profile is then contacted with reinforcing fiber and resin to form the exterior reinforcing layer. The exterior thermosetting layer is cured to form a reinforcing layer. The structural member is preferably manufactured using a pultrusion method in which a tractor device is used to provide linear movement of the profile from the extrusion head to the exterior coating operation. The fiber-reinforced thermoset is coated on the entirety of the exterior of the profile or is applied only on a portion of the profile requiring reinforcement in a defined load-bearing direction. A preferred thermoplastic core comprises a polymer-fiber composite material. A structural member of the invention has significantly improved Young's modulus providing strength for applications such as telephone poles, electric poles, electric lighting poles, boat mast or keel applications, lumber replacements, structural members used in window and door manufacture, etc.

Owner:ANDERSEN CORPORATION

Polyolefin wood fiber composite

InactiveUS6265037B1Improve mechanical propertiesImproved chemicalConstruction materialCovering/liningsPolyolefinEngineering

An improved composite structural member comprising a complex profile structural member, made of a composite comprising a polypropylene polymer and a wood fiber. The material is useful in conventional construction applications. The complex profile, in the form of an extruded thermoplastic composite member can be used in residential and commercial structures as described. Preferably, the structural member is used in the manufacture of the fenestration components such as windows and doors. Such linear members are designed with specifically configured cross-sectional shapes to form structural elements in the fenestration units. Structural elements must possess sufficient strength, thermal stability and weatherability to permit the manufacture of a structurally sound window unit that can be easily installed into a rough opening but can maintain its attractive appearance and structural integrity over the life of the window unit often twenty years or more. The structural member comprises a hollow complex cross-section with at least one structural web or one fastener web formed within the component. The exterior of the extruded component has a visible capstock layer and is shaped and adapted for installation in rough openings. The exterior also contains shape and components capable of supporting the elements of the fenestration unit such as a window, sash or movable door unit. The improved polypropylene structural members have unique advantages and can be assembled in thermoplastic weld processes.

Owner:ANDERSEN CORPORATION

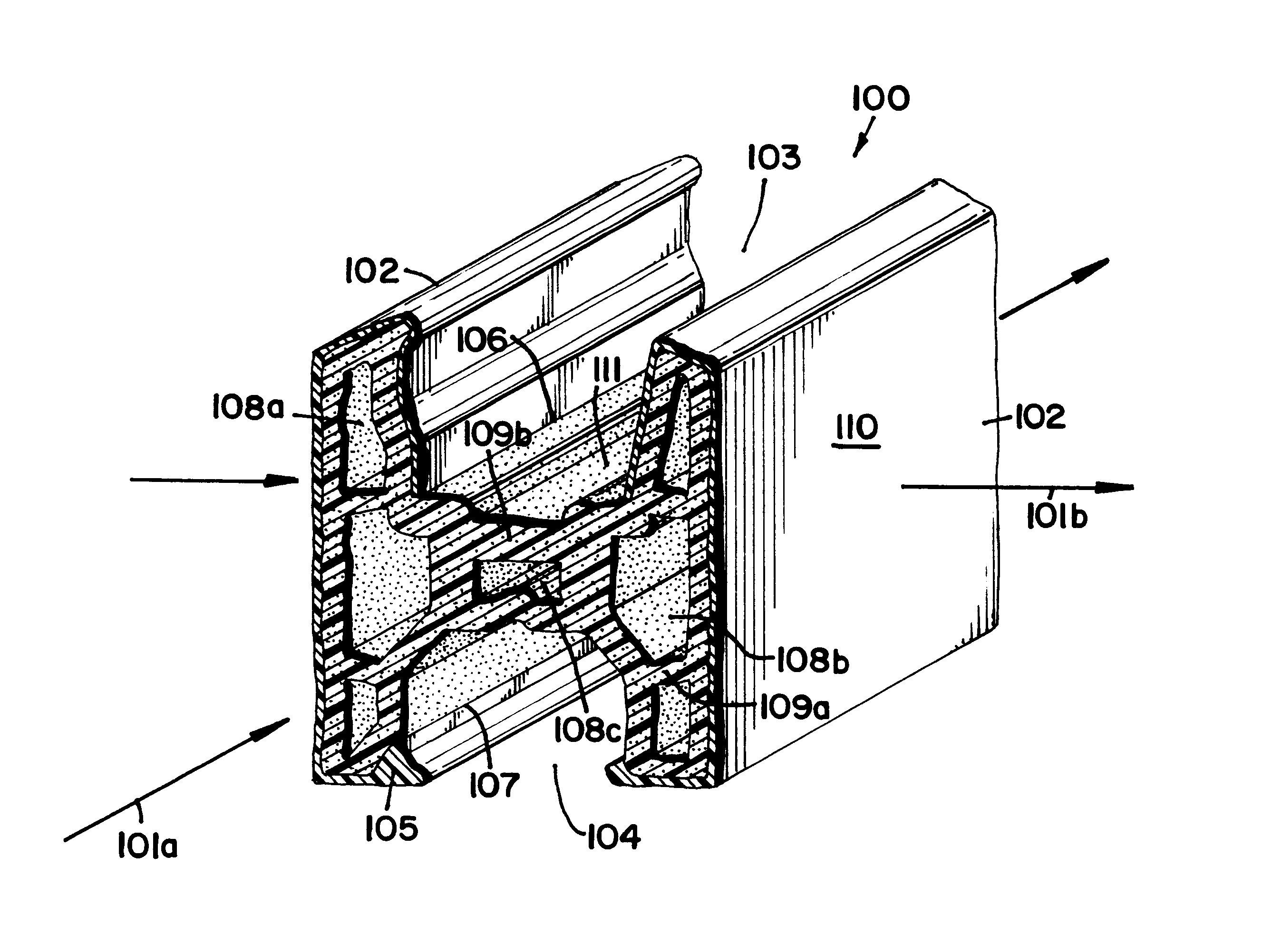

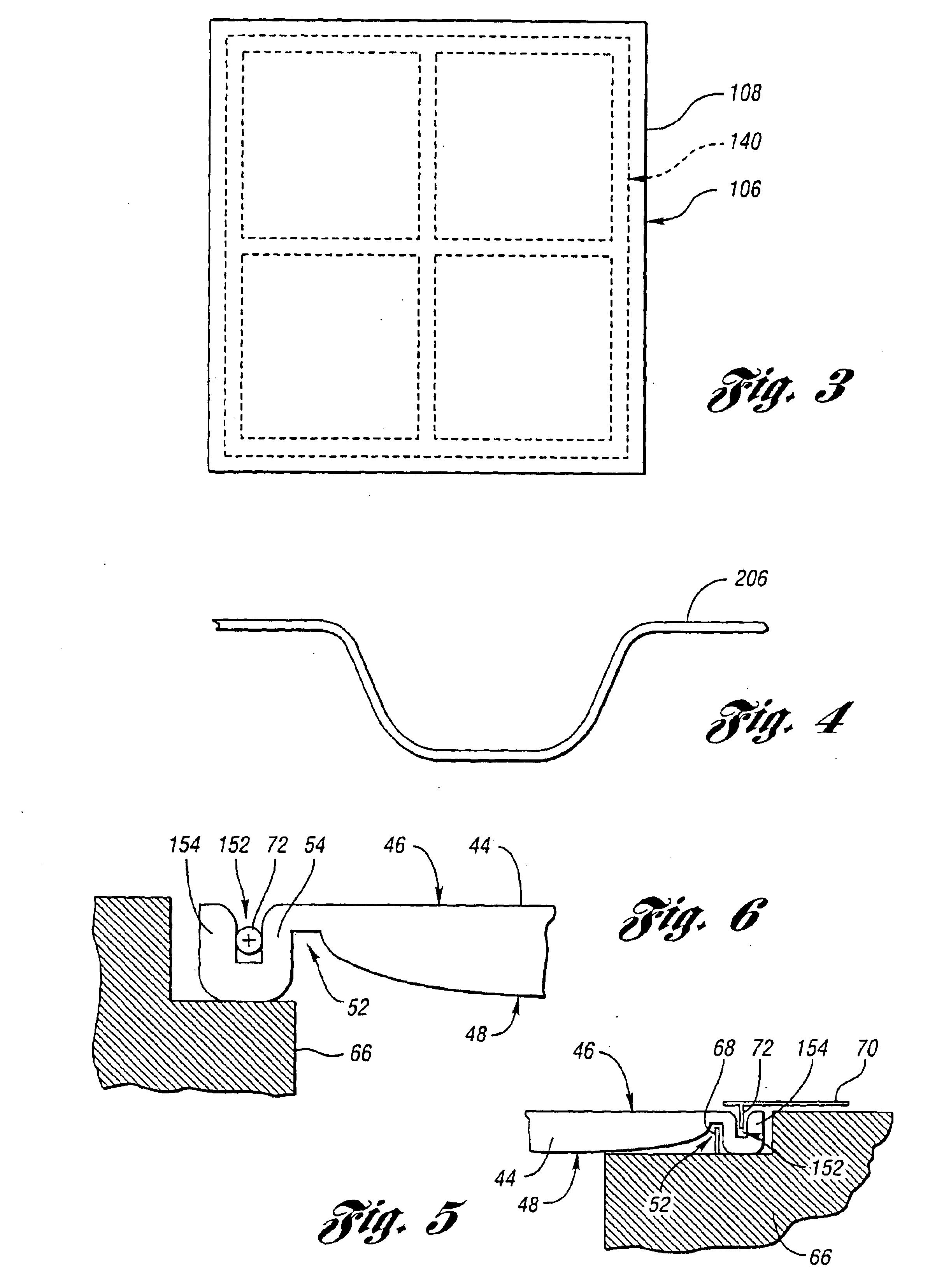

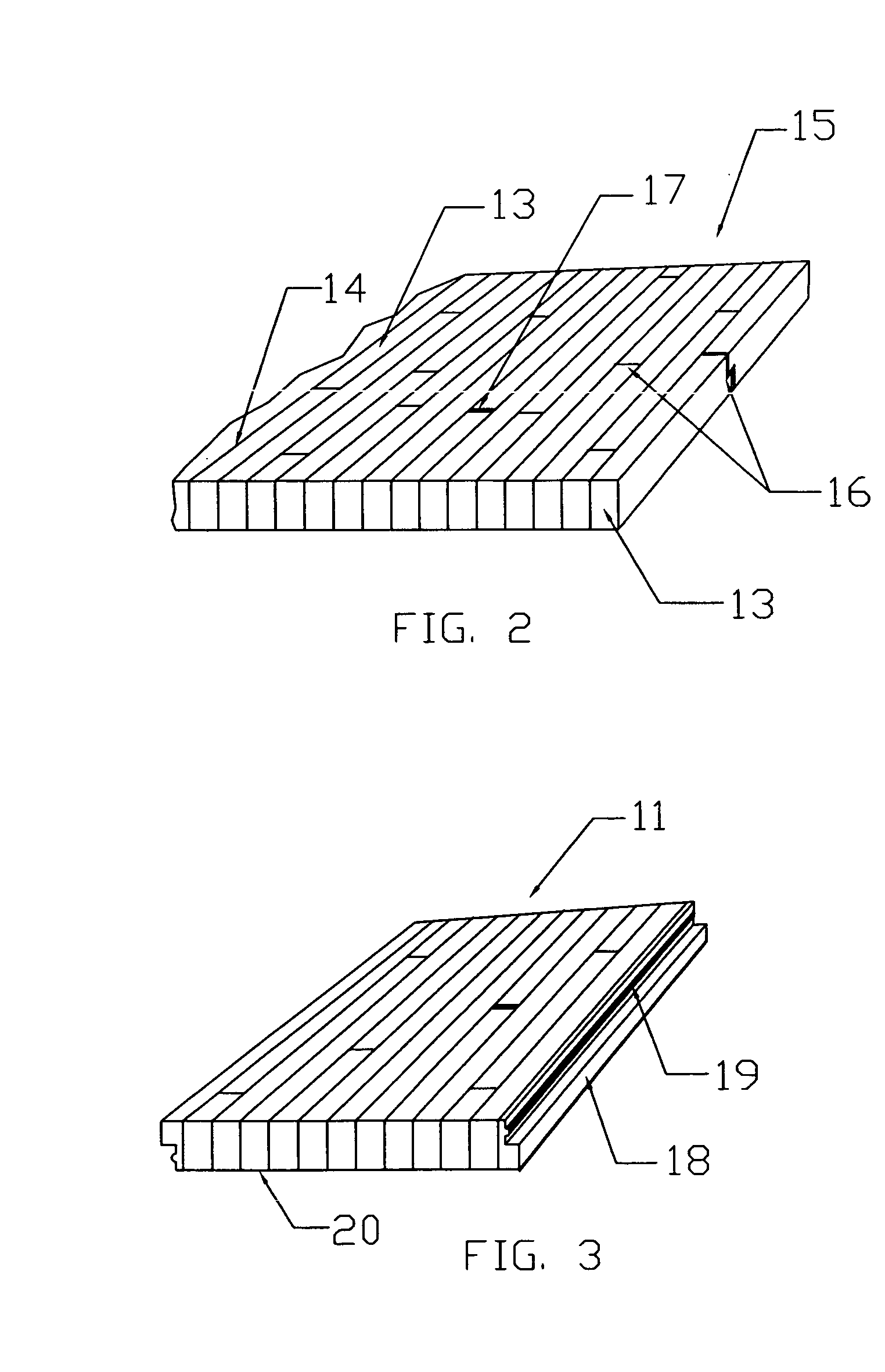

Reinforced composite vehicle load floor of the cellular core sandwich-type

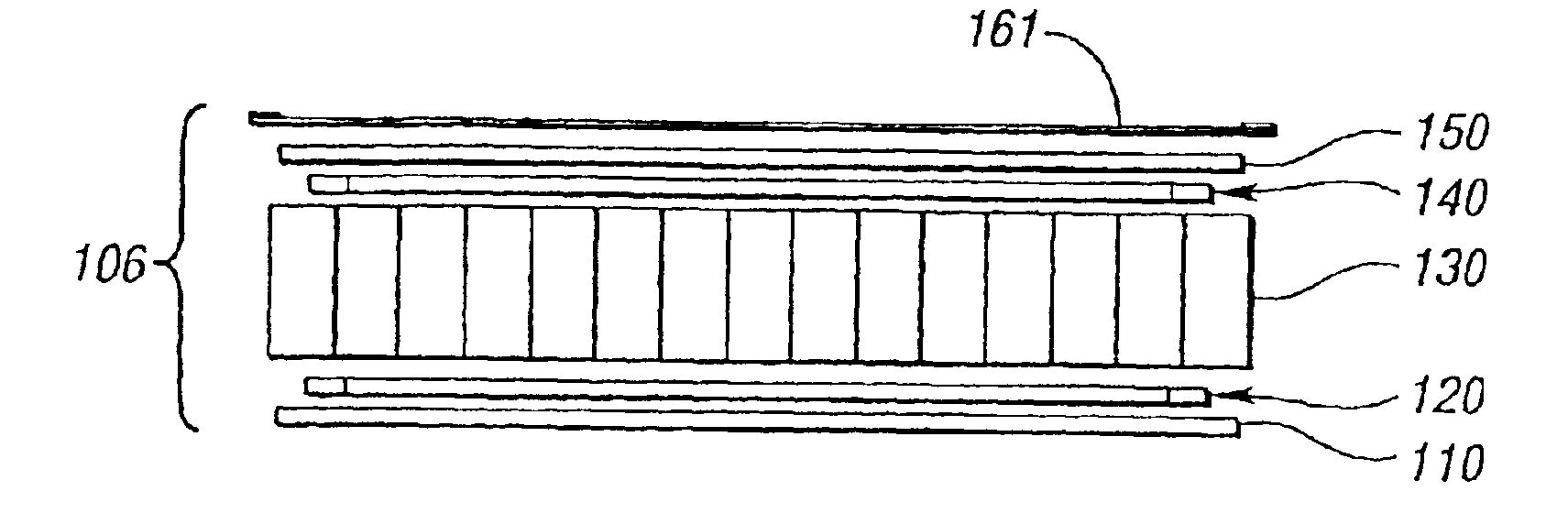

The invention relates to reinforced composite vehicle load floors of the sandwich-type having a cellular core. In a method for making a load floor of the invention, a stack is formed that is made up of: a load-bearing upper skin made of a reinforced thermoplastics material; an upper skeletal frame structure of reinforcing slats each of which is made of a reinforced thermoplastic composite or pultrusion; a cellular core made of a thermoplastic material; a lower skeletal frame structure of reinforcing slats each of which is also made of a reinforced thermoplastic composite or pultrusion; and a bottom skin made of a reinforced thermoplastic material. Each of the frame structures of reinforcing slats has a surface area that is smaller than the surface area of each of the skins. The frame structures of reinforcing slats are positioned symmetrically about a plane formed by the cellular core against the skins.

Owner:GLOBAL IP HLDG

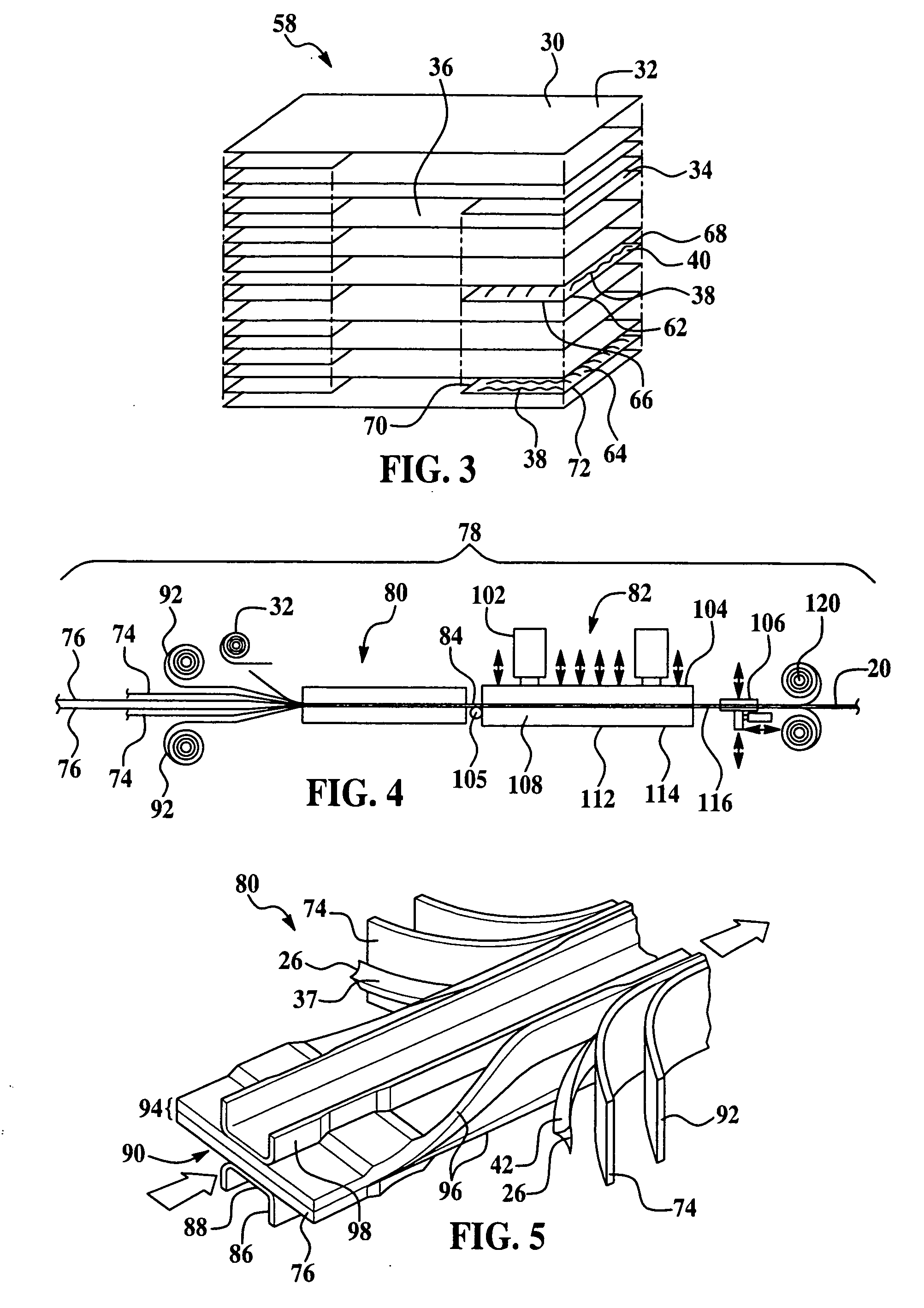

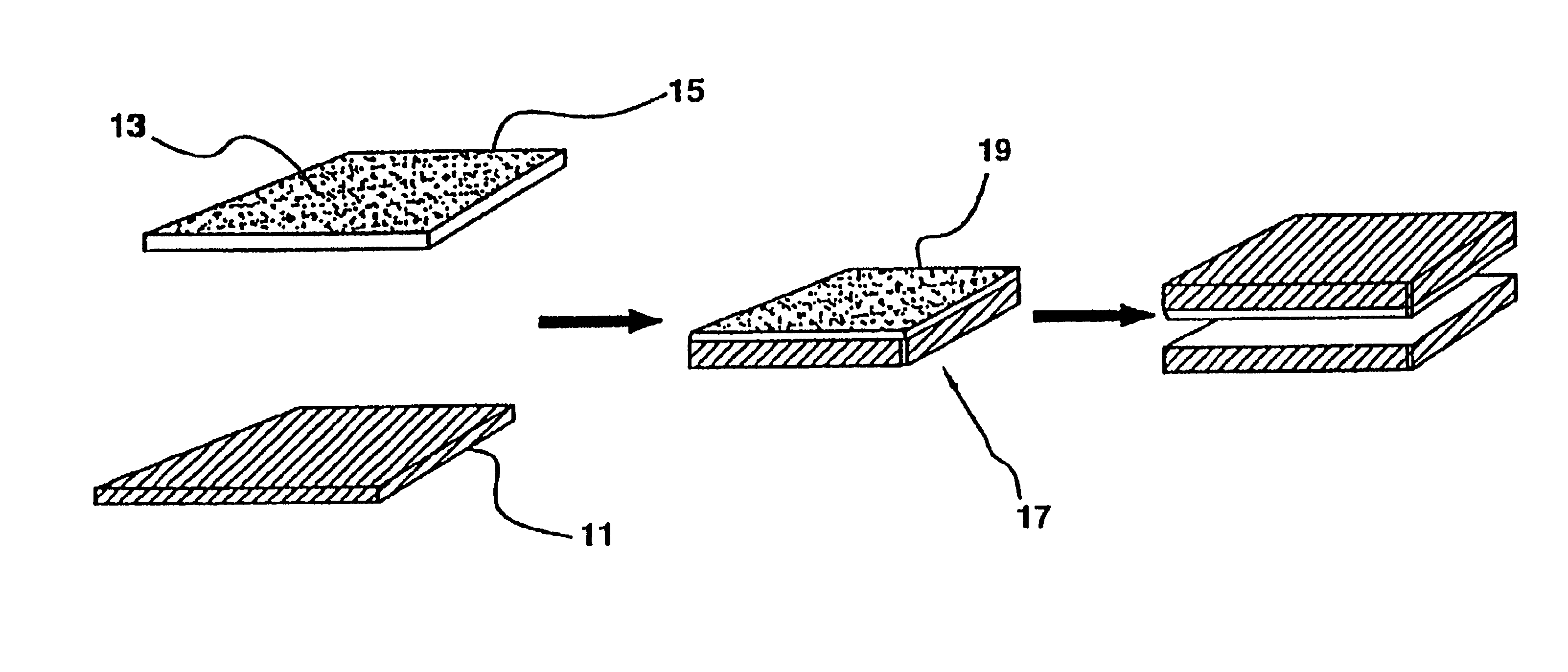

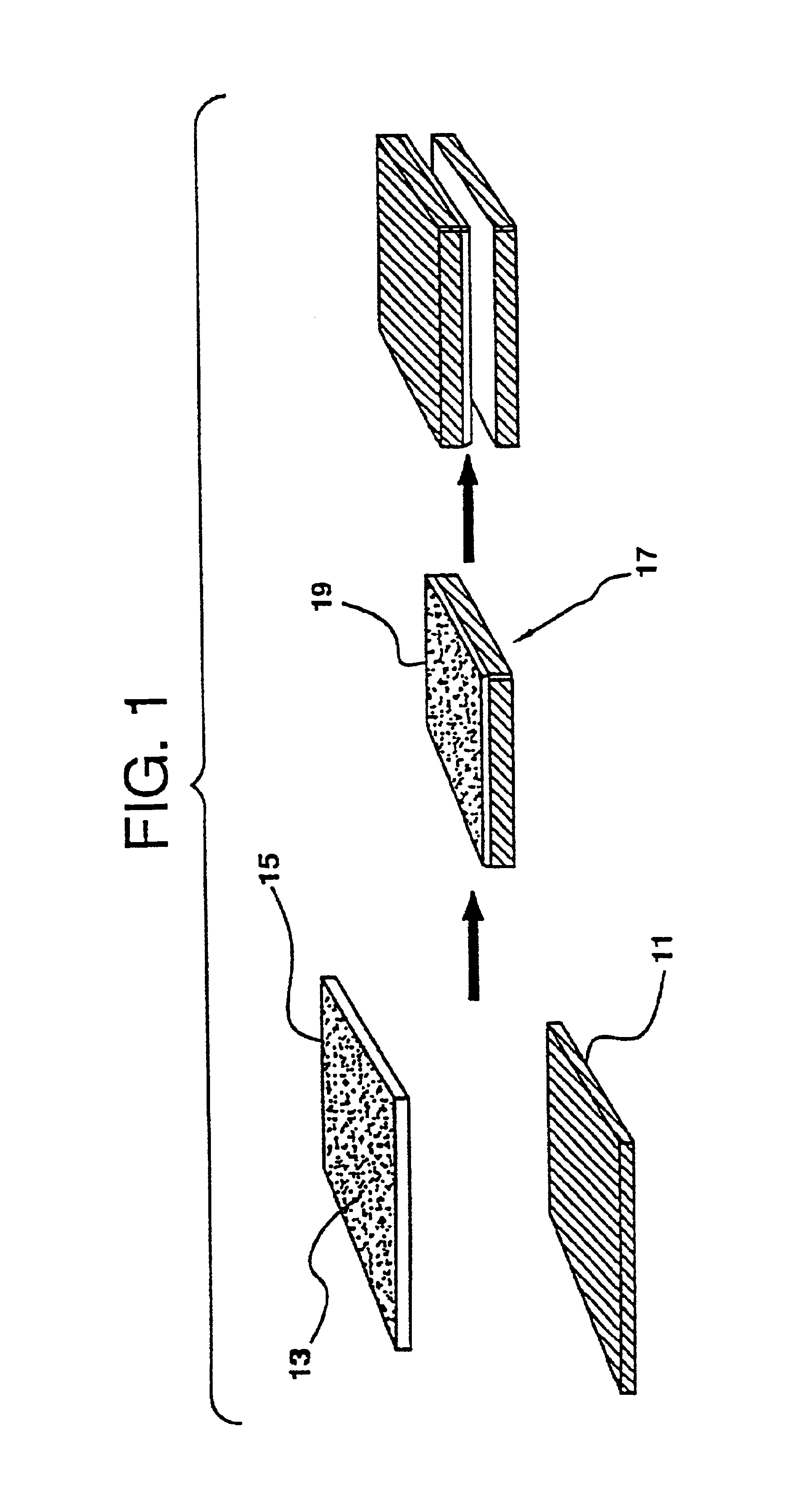

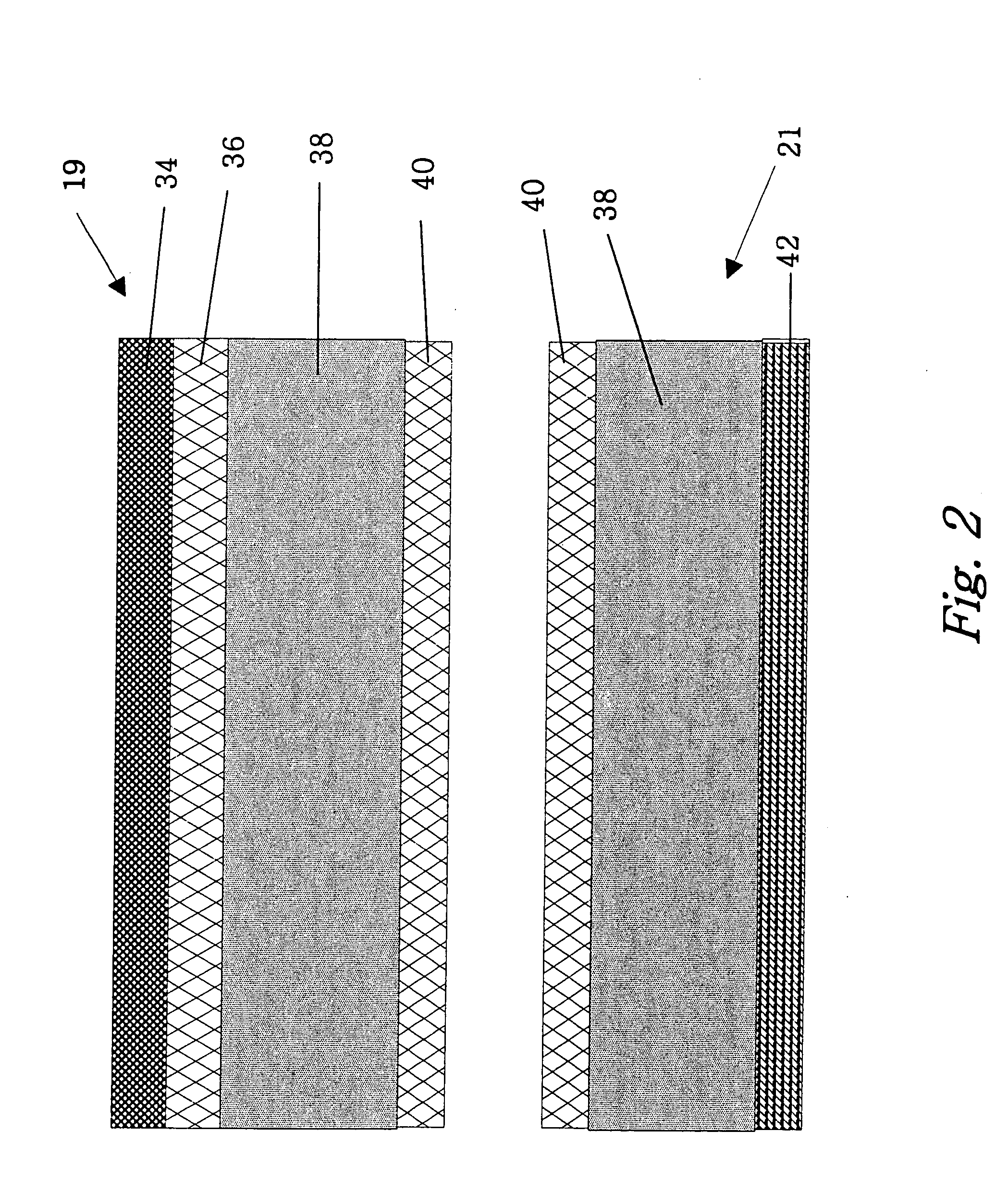

Thermoplastic composite material with improved smoke generation, heat release, and mechanical properties

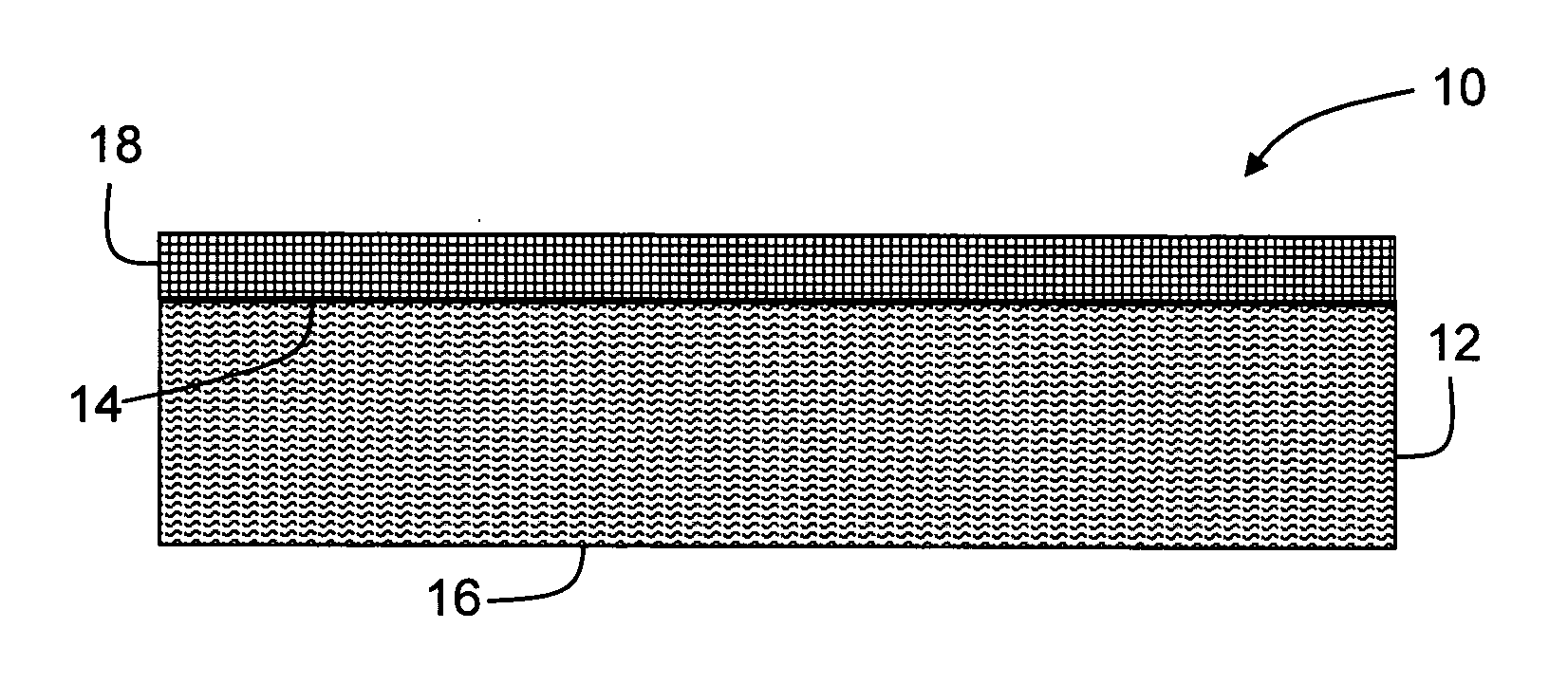

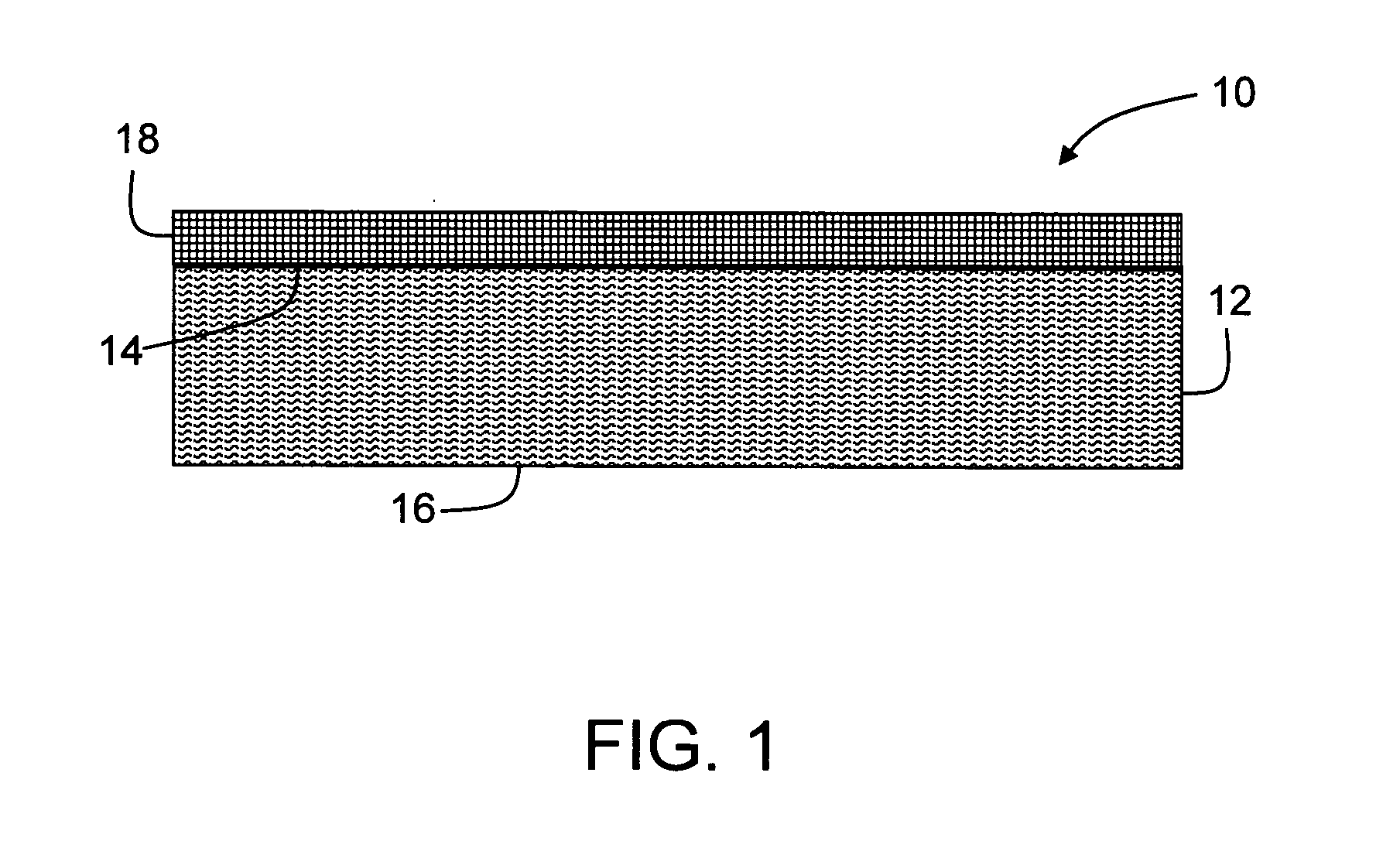

InactiveUS20100021718A1Reduce fiber contentSynthetic resin layered productsLaminationAviationVolumetric Mass Density

A fiber-reinforced thermoplastic composite material having an advantageous combination of smoke generation, heat release, and mechanical property characteristics. The composite generally comprises a fiber-reinforced thermoplastic core containing discontinuous reinforcing fibers bonded together with one or more thermoplastic resins. The core material may further comprise at least one first skin material applied to a first surface of the core and / or one or more second skin material applied to a second surface of the core material. The thermoplastic core material has a maximum smoke density Ds (4 minutes) of less than 200 as measured in accordance with ASTM E662, a maximum heat release (5 minutes) of less than 65 kW / m2 as measured in accordance with FAA Heat release test FAR 25.853 (a) Appendix F, Part IV (OSU 65 / 65), and an average total heat release (2 minutes) of less than 65 kW / m2 as measured in accordance with FAA Heat release test FAR 25.853 (a) Appendix F, Part IV (OSU 65 / 65). The invention is useful in the manufacture of articles for aircraft, automotive, railcar, locomotive, bus, marine, aerospace and construction in which the certain advantages may be provided over other materials utilized for such applications.

Owner:AZDEL INC

Anti-bacterial thermoplastic composite and preparation method thereof

The invention relates to an anti-bacterial thermoplastic composite, which comprises the following mixed components: 100 parts of thermoplastic by weight and 0.1-40 parts of composite antibacterial agent by weight, wherein the composite antibacterial agent comprises micronano inorganic / organic particles and guanidinesalt polymers which are coated on the surfaces of the micro / nano particles and / or embedded among pores and layers of the micronano particles; the weight ratio of the guanidinesalt polymers to the micro / nano particles is 1:1-1:50; and the micro / nano particles have at least a one-dimensional average size of 1nm-1000mum. The anti-bacterial thermoplastic composite is obtained by melting and mixing the components such as the thermoplastic, the composite antibacterial agent, and the like, therefore the antibacterial rate of the anti-bacterial thermoplastic composite is higher and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

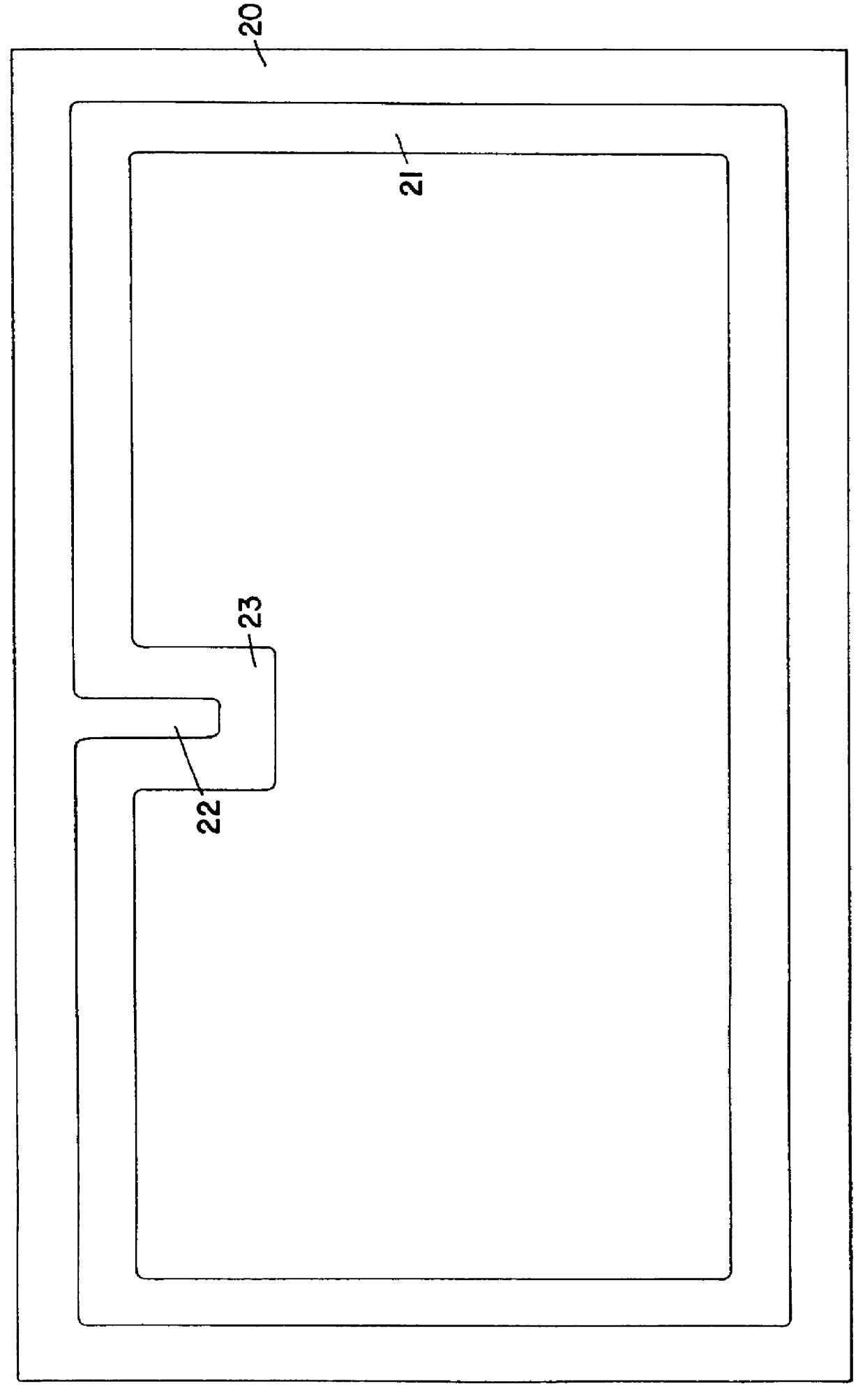

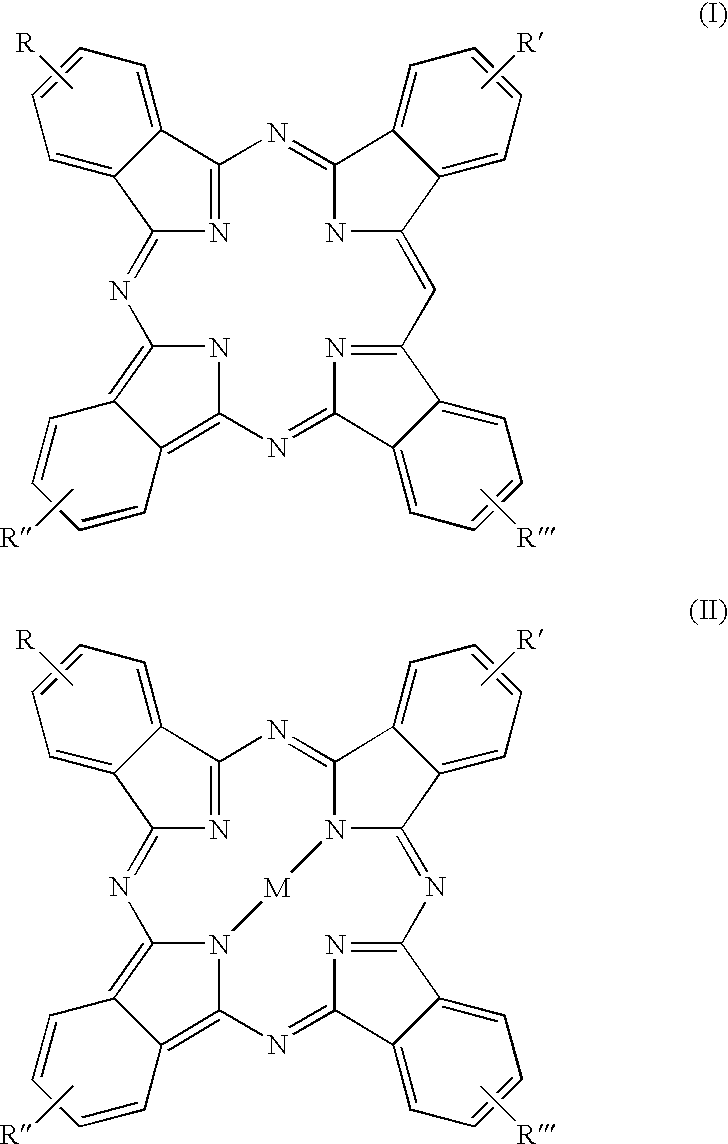

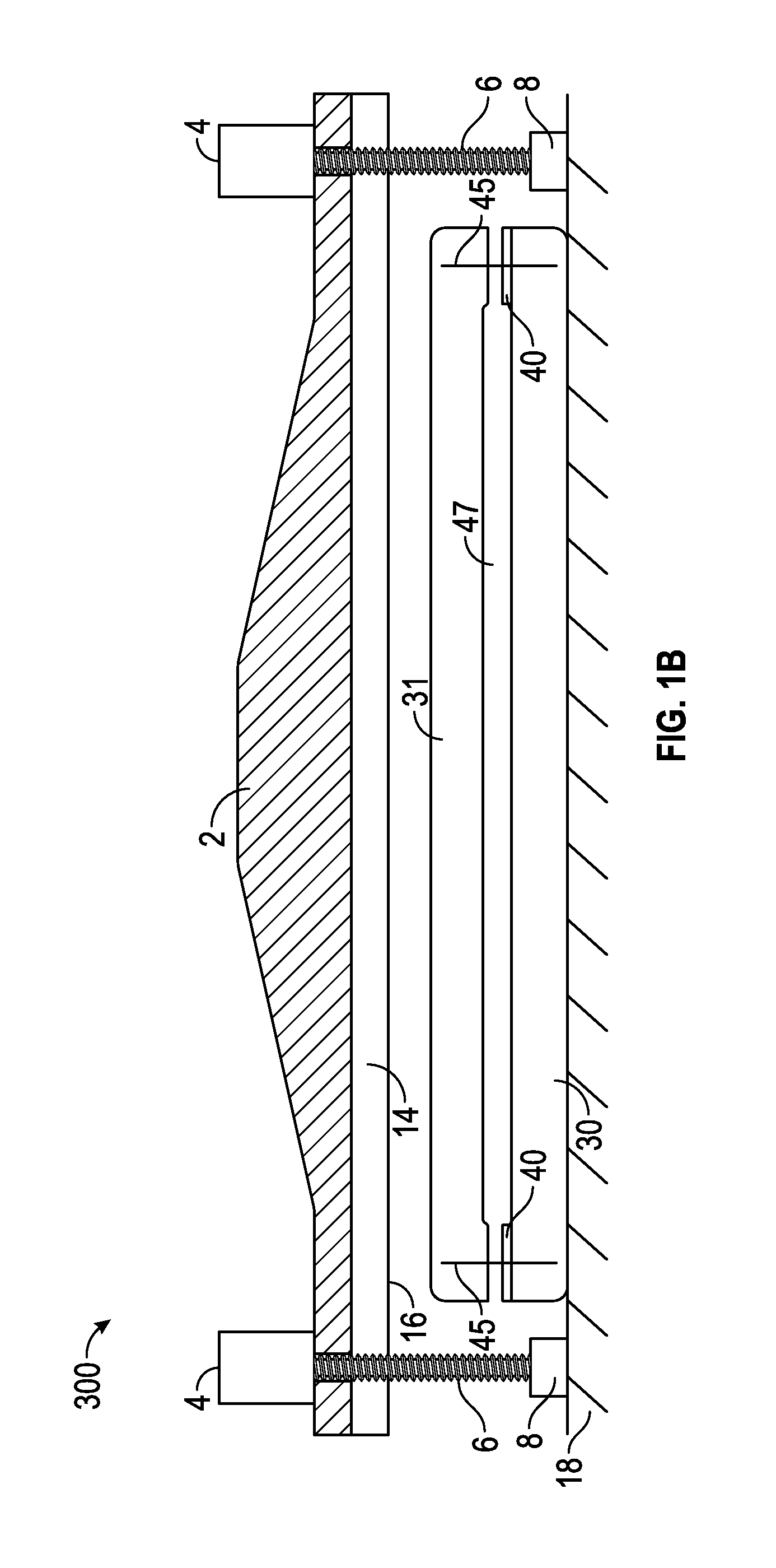

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

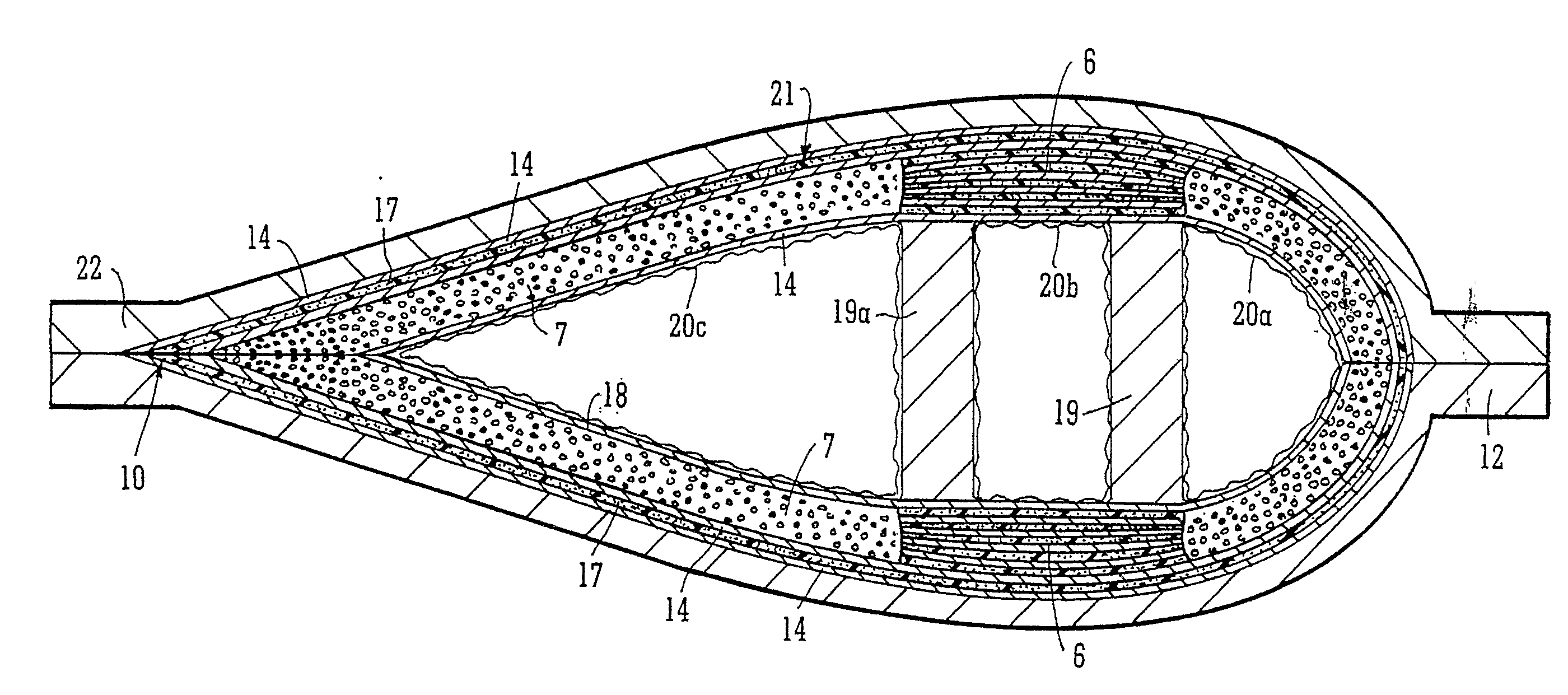

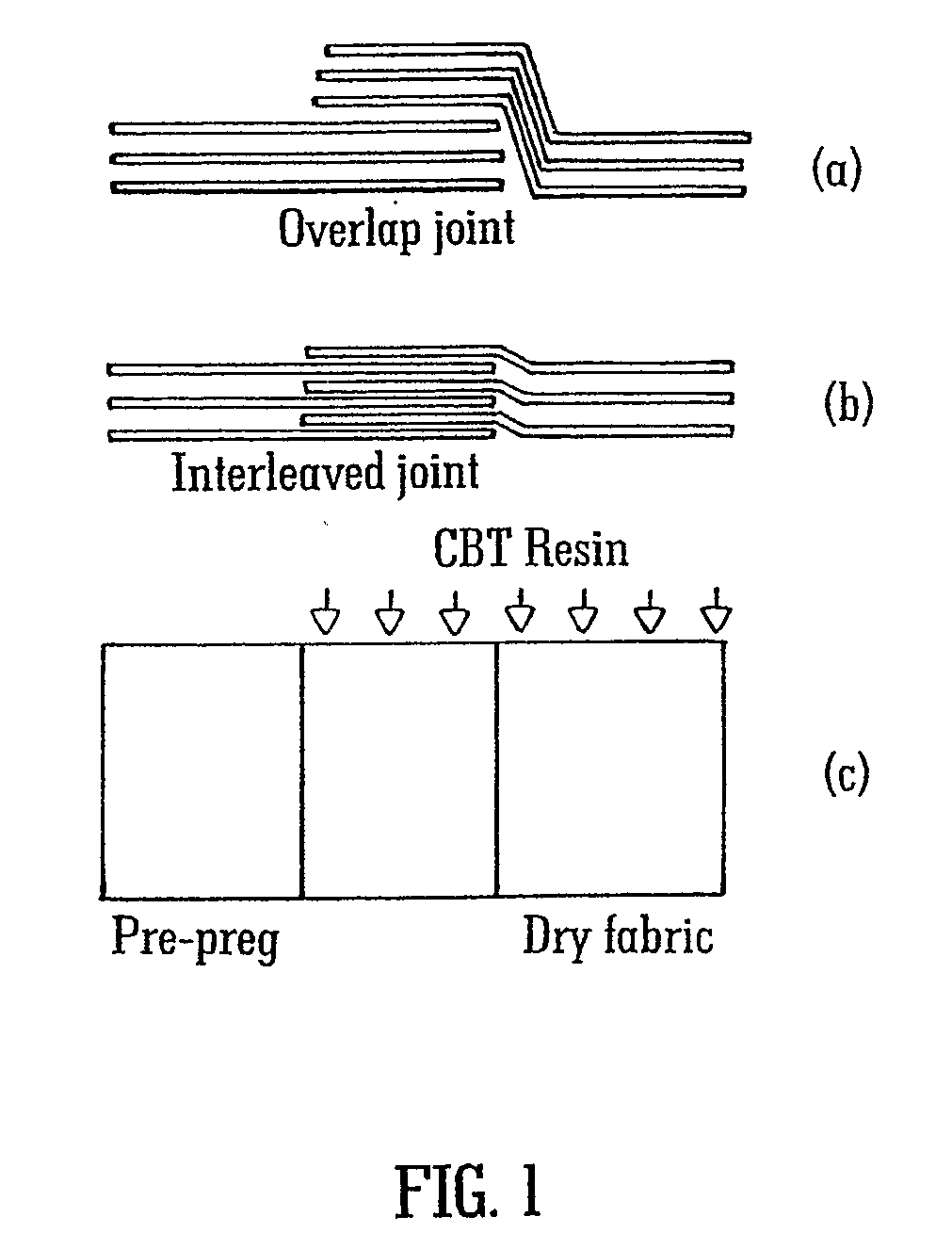

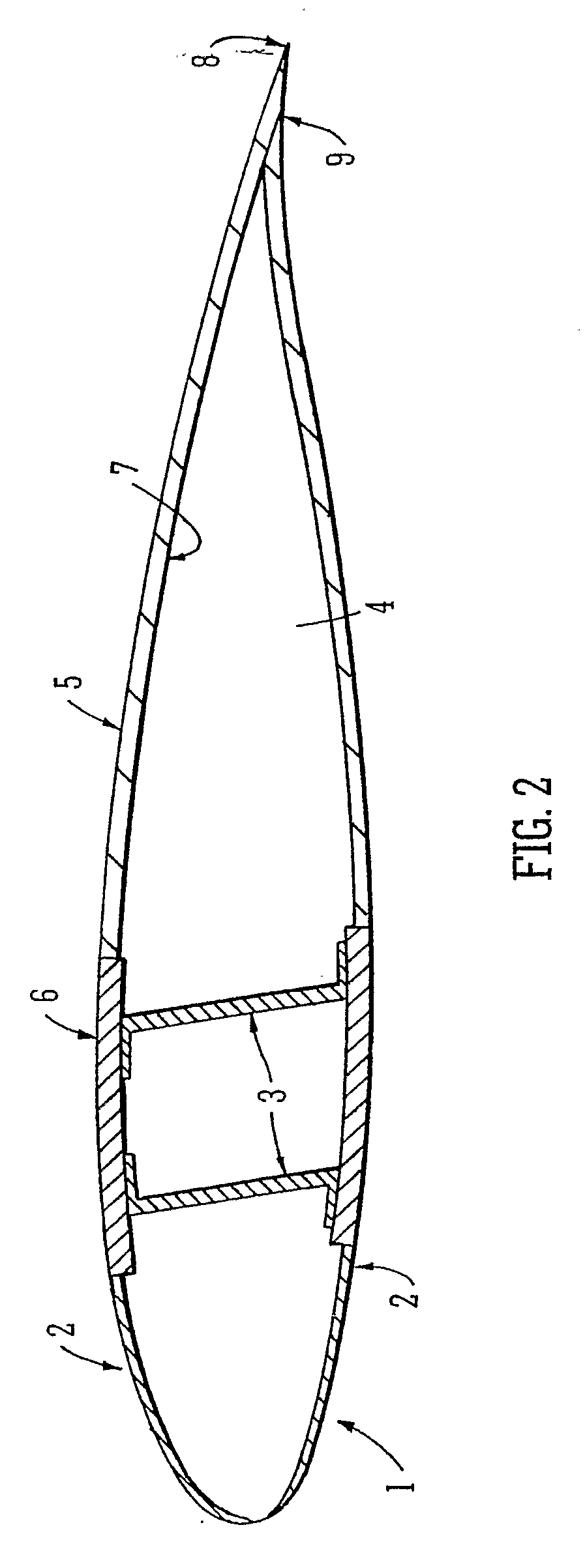

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

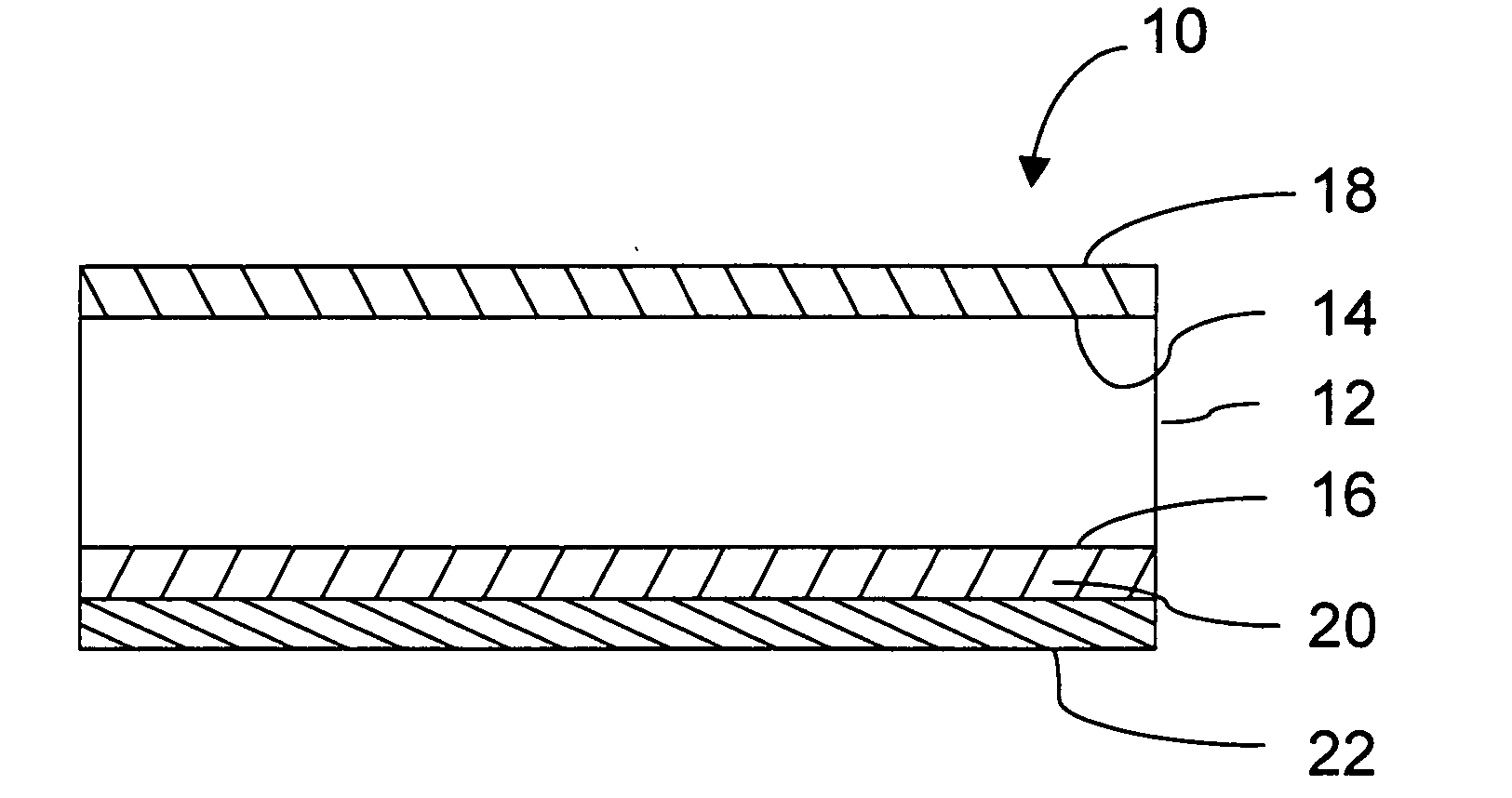

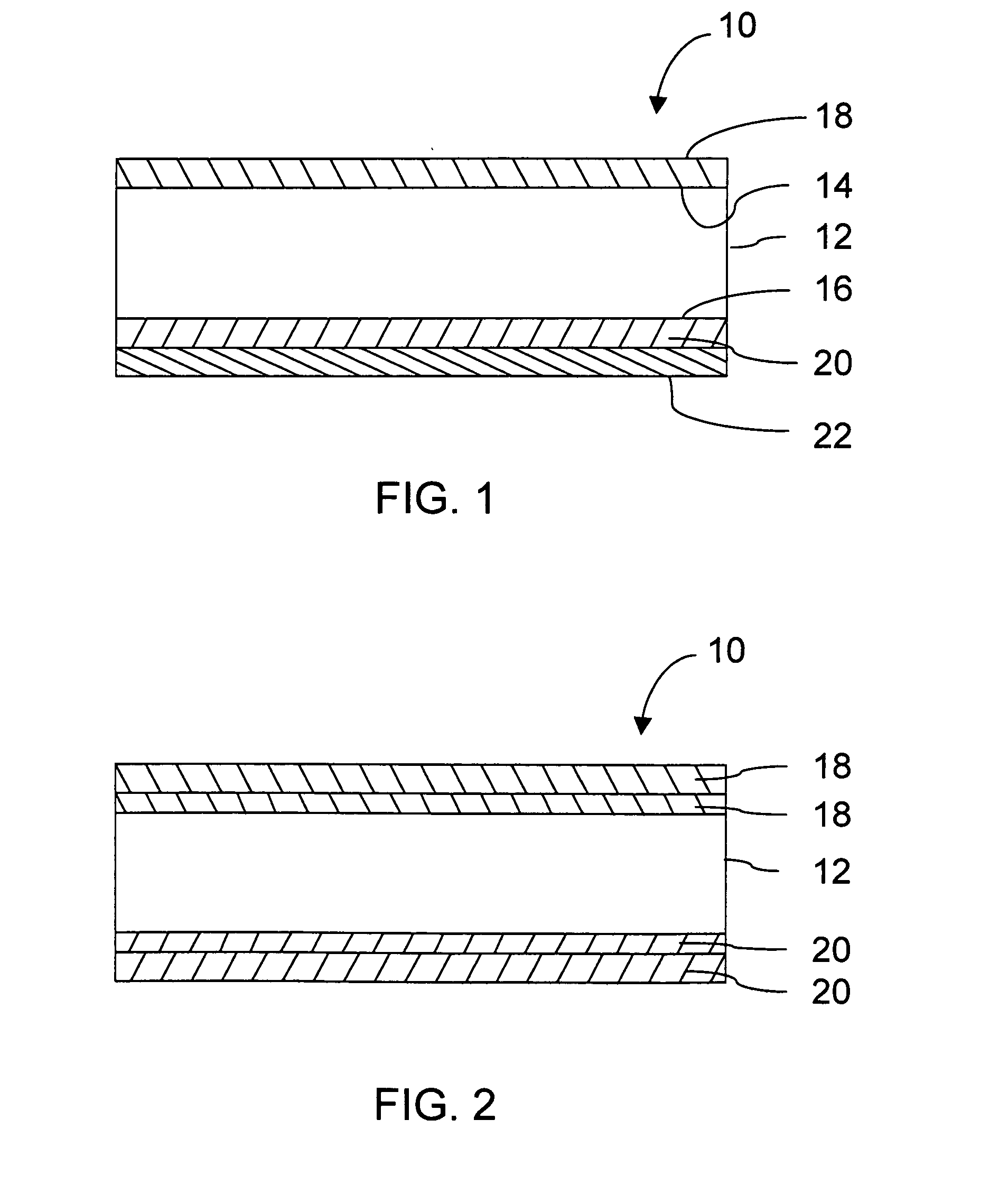

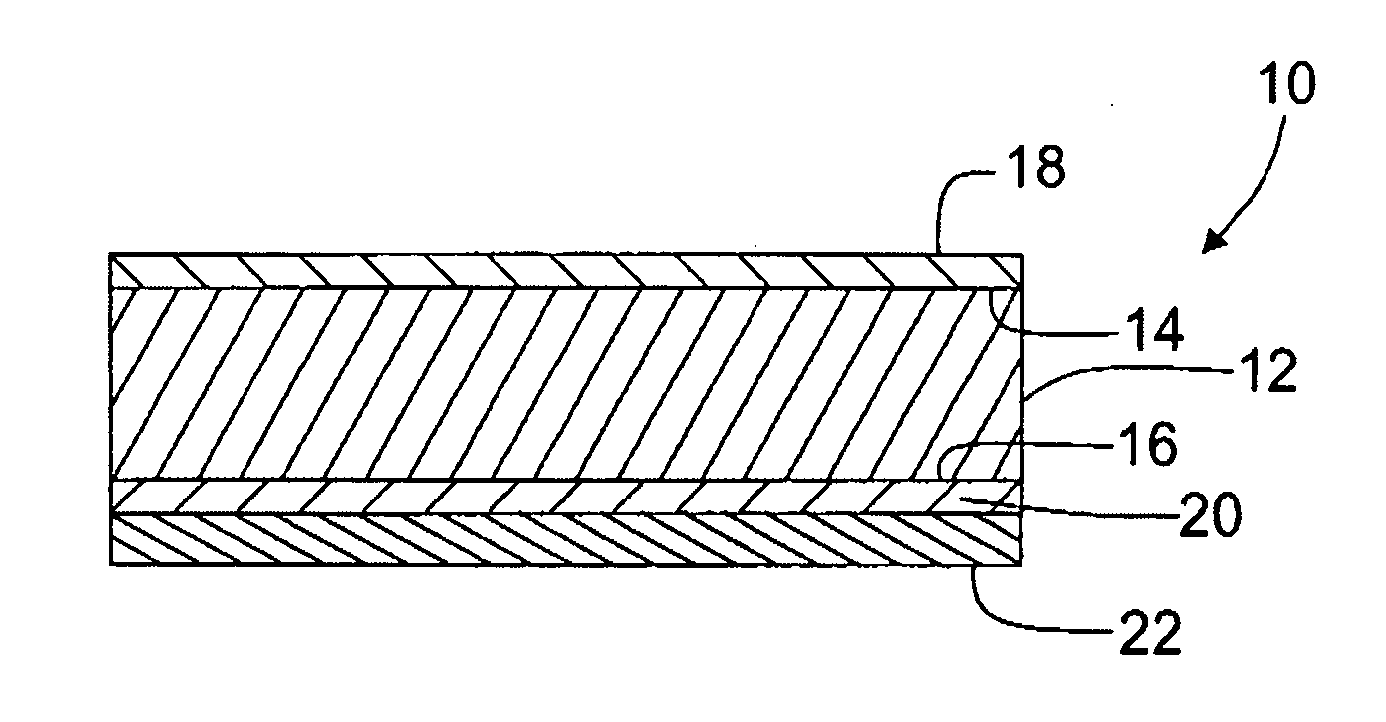

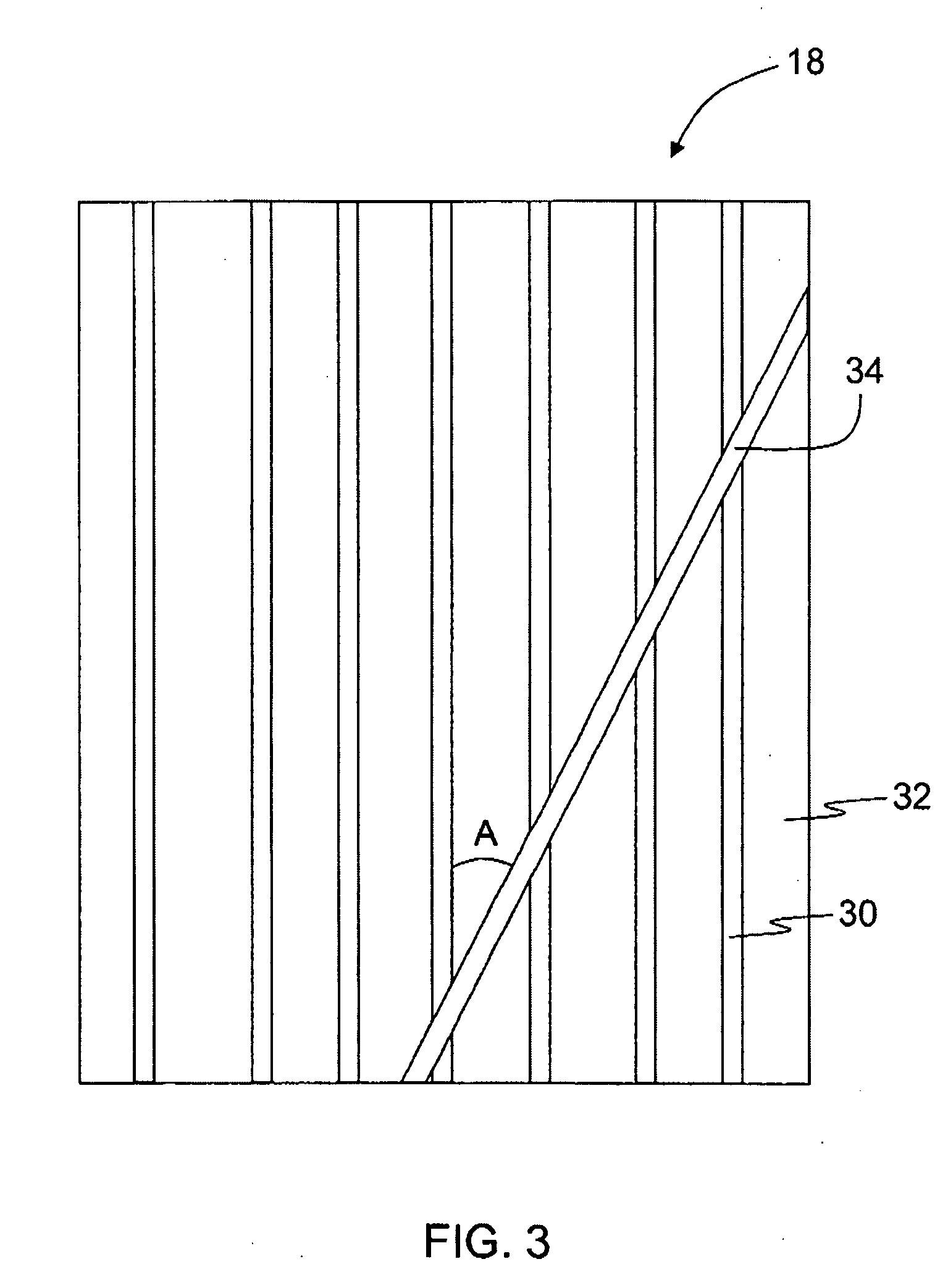

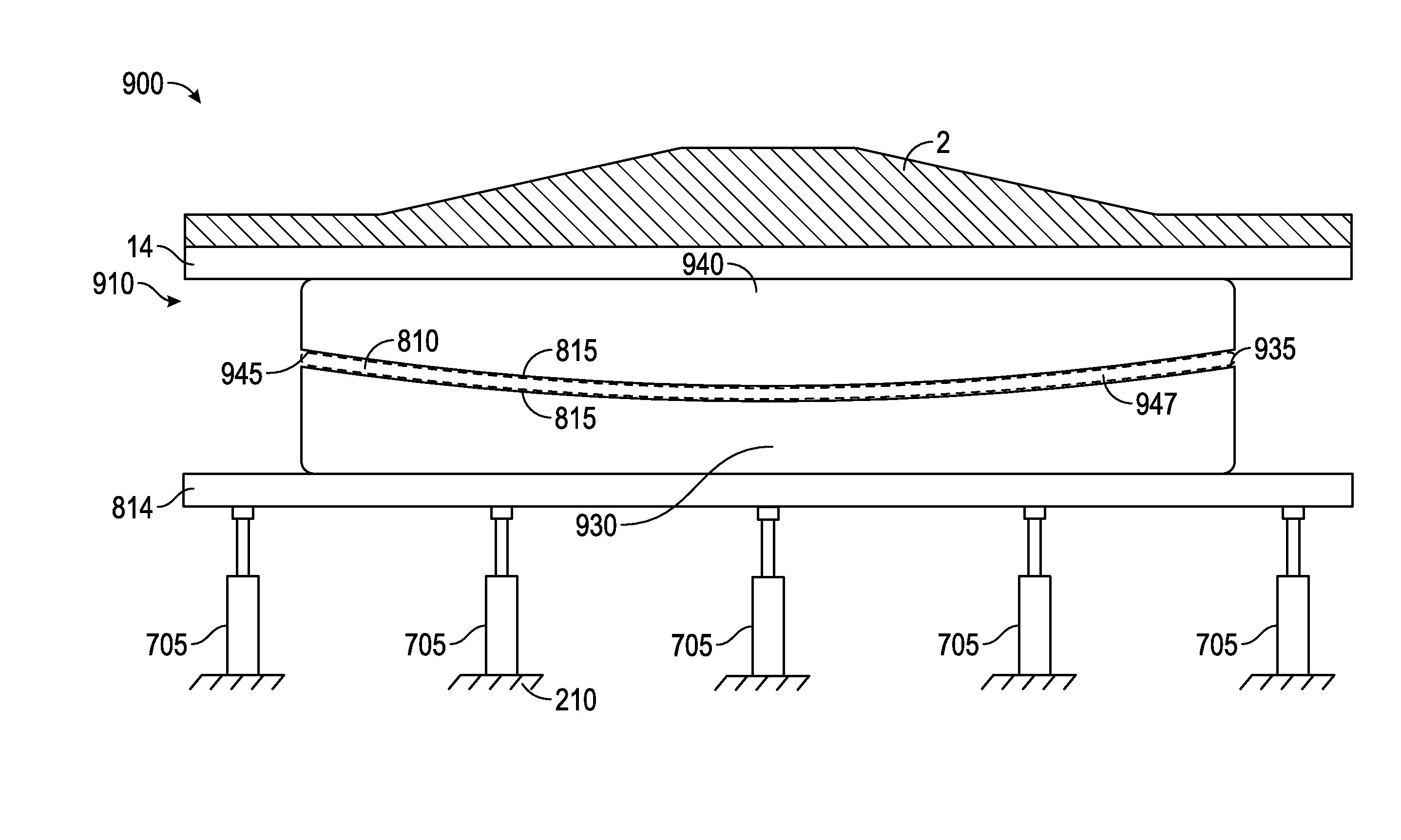

Lightweight thermoplastic composite including reinforcing skins

A lightweight fiber reinforced thermoplastic composite having an improved combination of surface roughness, flexural and shear characteristics. The composite generally comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin in which the core has a first surface and a second surface and at least one first skin applied to the first surface. The first skin comprises a plurality of fibers bonded together with a second thermoplastic resin, with the fibers in each first skin aligned in a unidirectional orientation within the first skin. The composite satisfies at least one of the conditions: an average surface roughness of the outer surface of the first skin is equal to or less than about 4.0 μm / 10 mm; the flexural modulus and strength are greater than about 10,000 MPa and greater than about 180 MPa, respectively; and the shear modulus and strength are greater than about 3,000 MPa and greater than about 100 MPa, respectively. In another embodiment, a fiber reinforced thermoplastic composite comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin, the core having a density of about 0.1 gm / cc to about 2.25 gm / cc and a porosity greater than about 0% by volume. The core has a first surface and a second surface and at least one first skin applied to the first surface, each of the first skins comprising fibers bonded together with a second thermoplastic resin. The first skin comprises a thermoplastic melt impregnated continuous fiber prepreg material, or commingled fiber rovings comprising reinforcing fibers and thermoplastic fibers, with the fibers in the first skin aligned in a unidirectional orientation within the first skin.

Owner:AZDEL INC

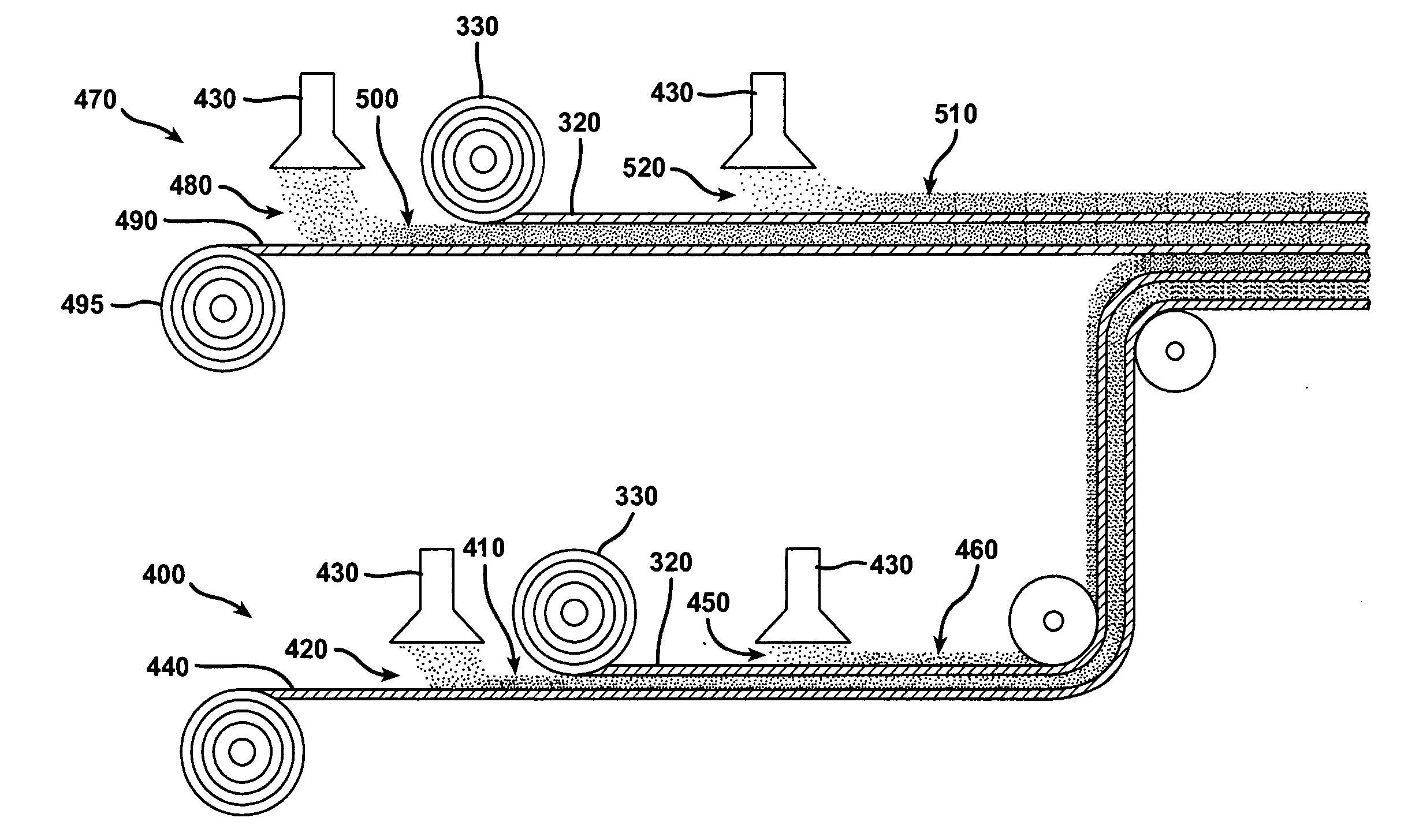

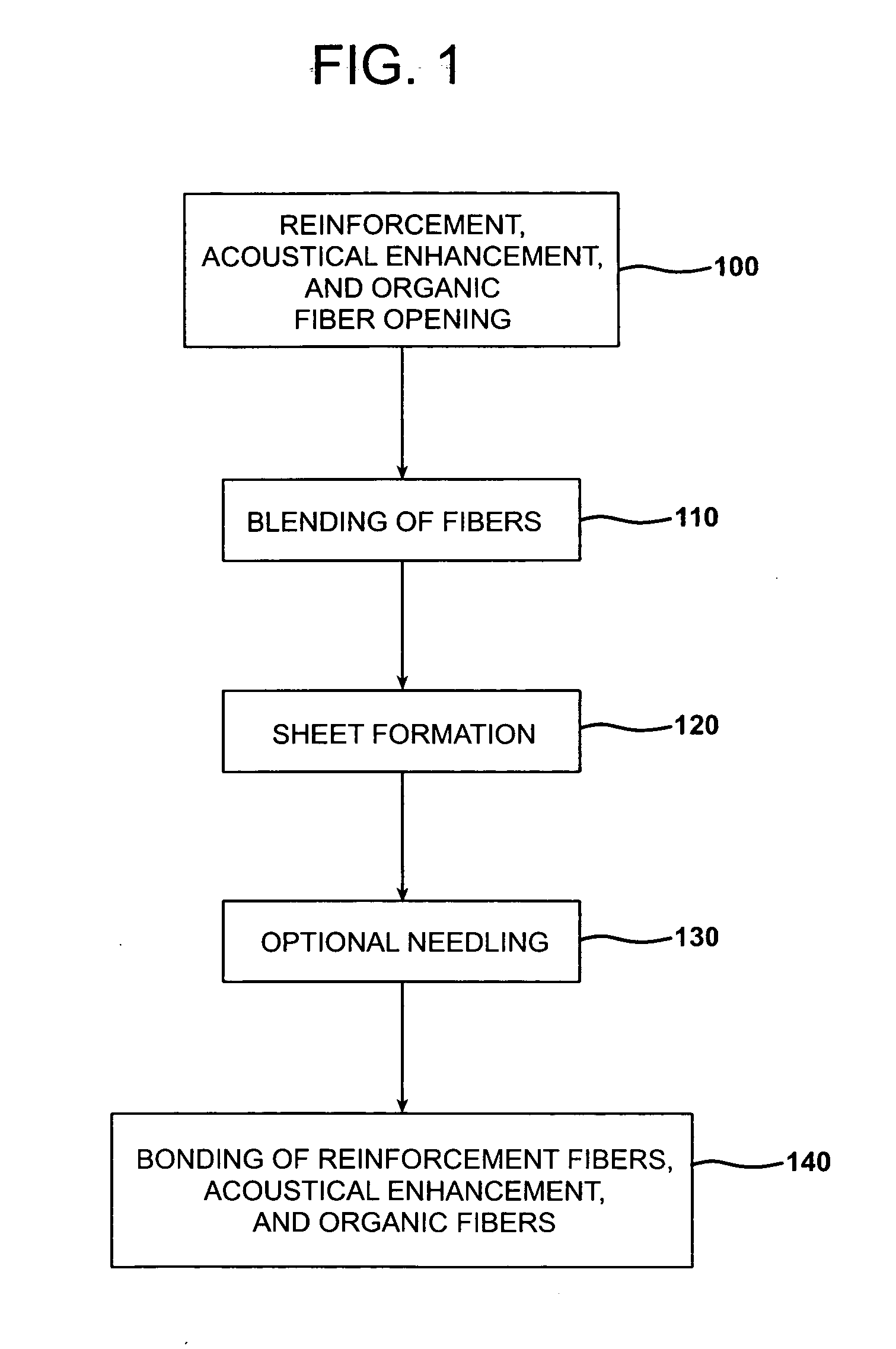

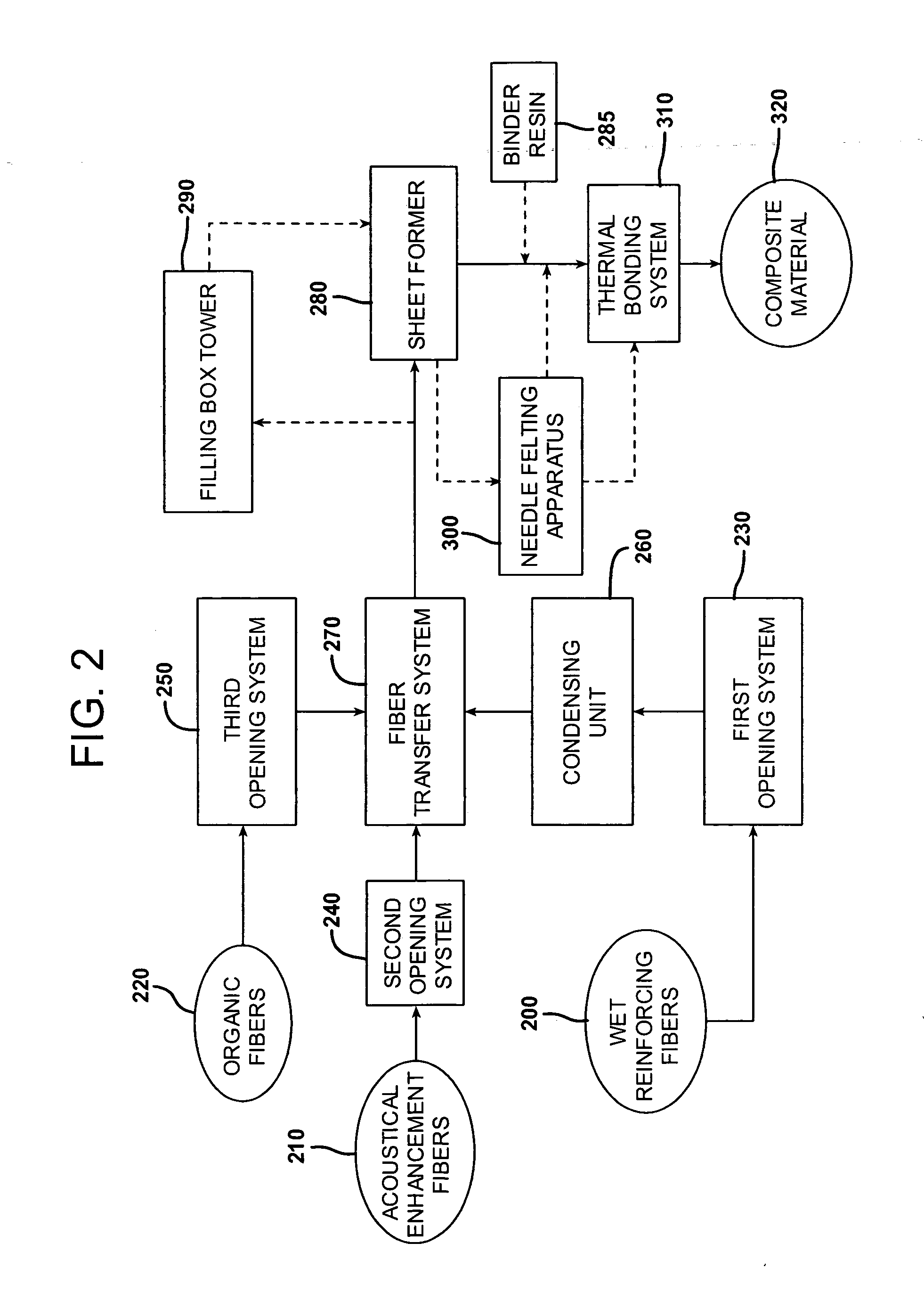

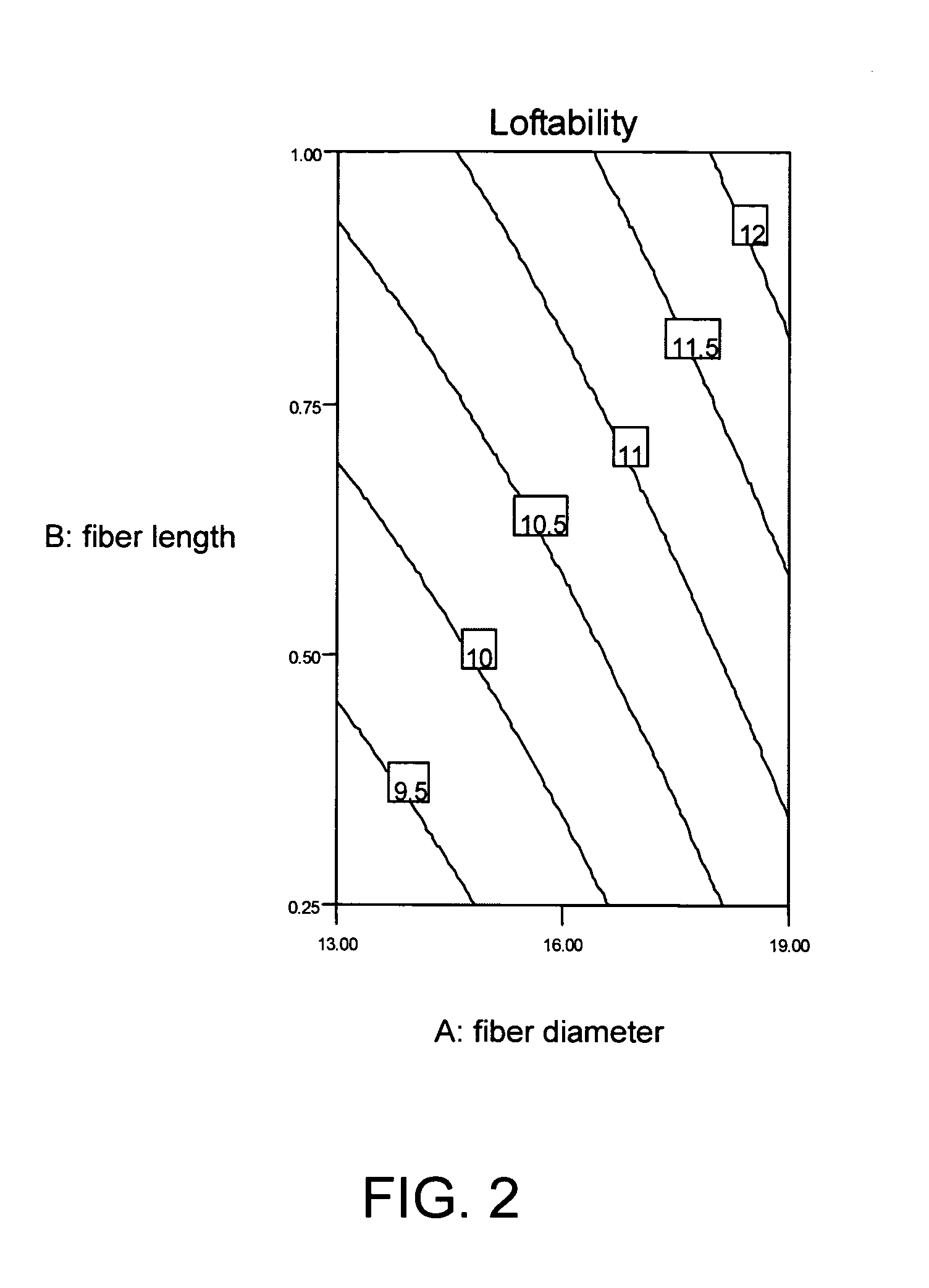

Thermoplastic composites with improved sound absorbing capabilities

InactiveUS20060137799A1Alter its performanceOptimization propertiesWood working apparatusBaby linensGlass fiberPolyethylene terephthalate

A composite material formed of reinforcement fibers, acoustical enhancing fibers such as polyethylene terephthalate (PET) fibers or modified polyethylene terephthalate fibers, and one or more organic fibers is provided. The acoustical enhancing fiber may be any fiber that provides increased or enhanced acoustical absorbance, particularly at low frequencies. The composite material may be formed by partially opening wet reinforcing fibers, acoustical enhancing fibers, and organic fibers, mixing the reinforcing, acoustical enhancement, and organic fibers, forming the fibers into a sheet, and bonding the fibers in the sheet. Preferably the reinforcing fibers are wet use chopped strand glass fibers. The composite material may be formed of a single layer of reinforcement, acoustical enhancement fibers, and organic fibers. Alternatively, the composite material may be a multi-layered composite in which the acoustical enhancement fibers are located in an acoustical layer laminated to a thermal layer formed of the organic fibers and reinforcement fibers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

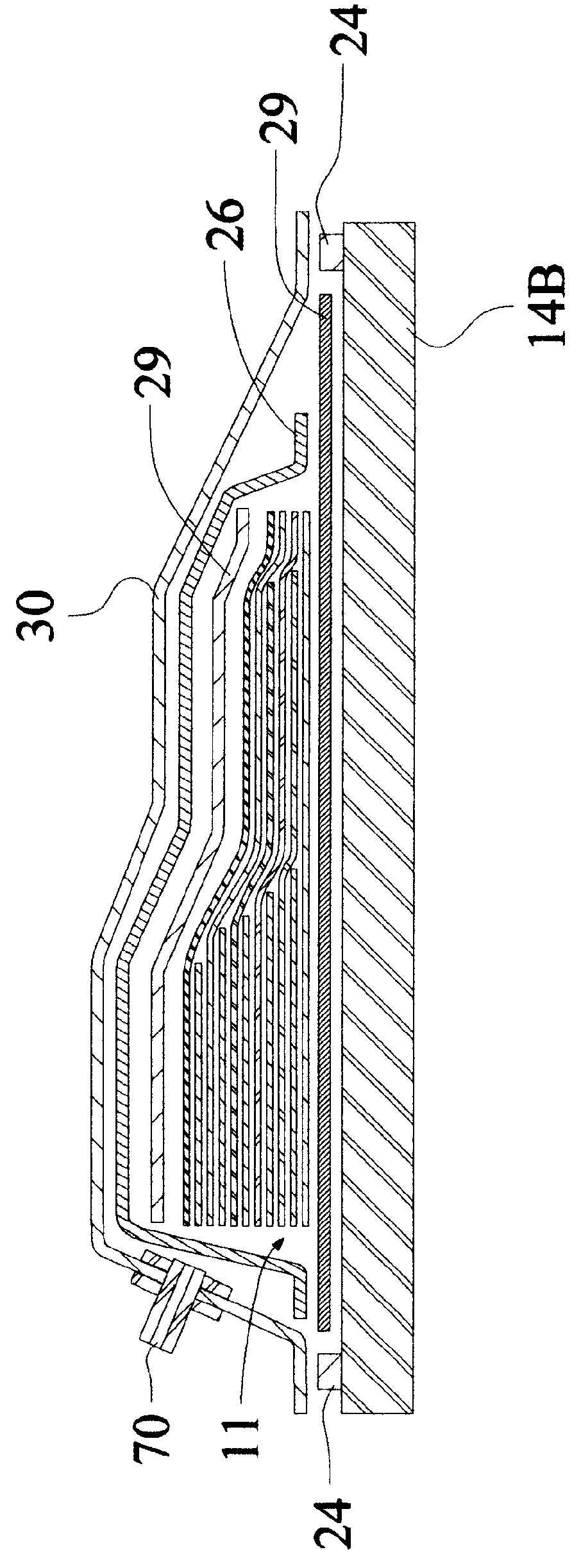

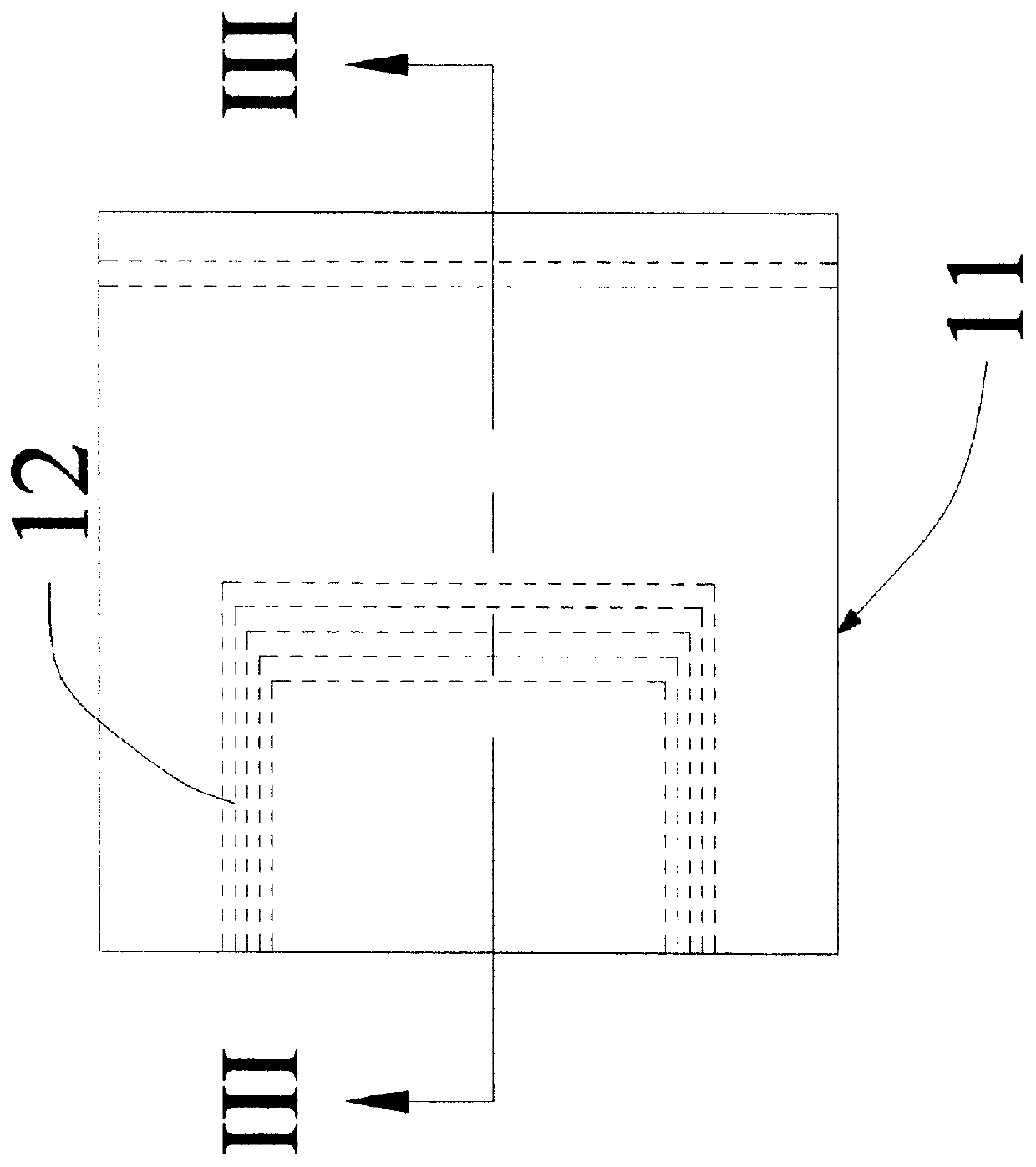

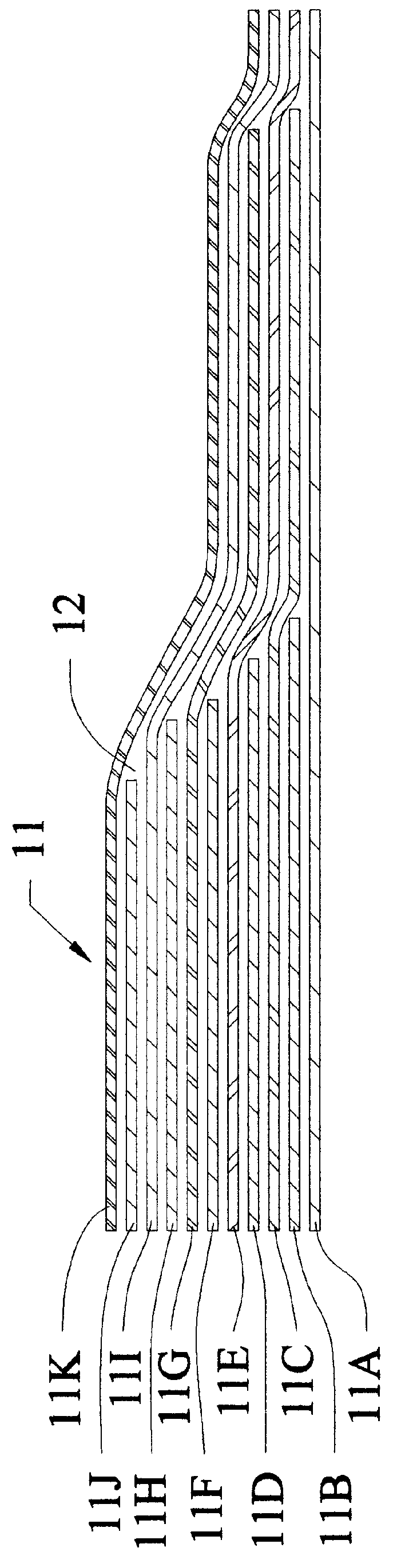

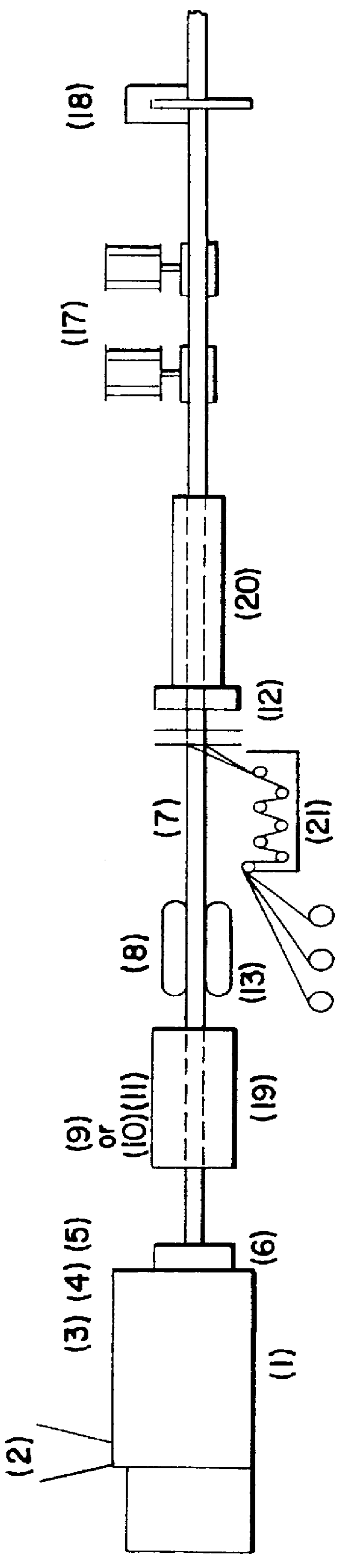

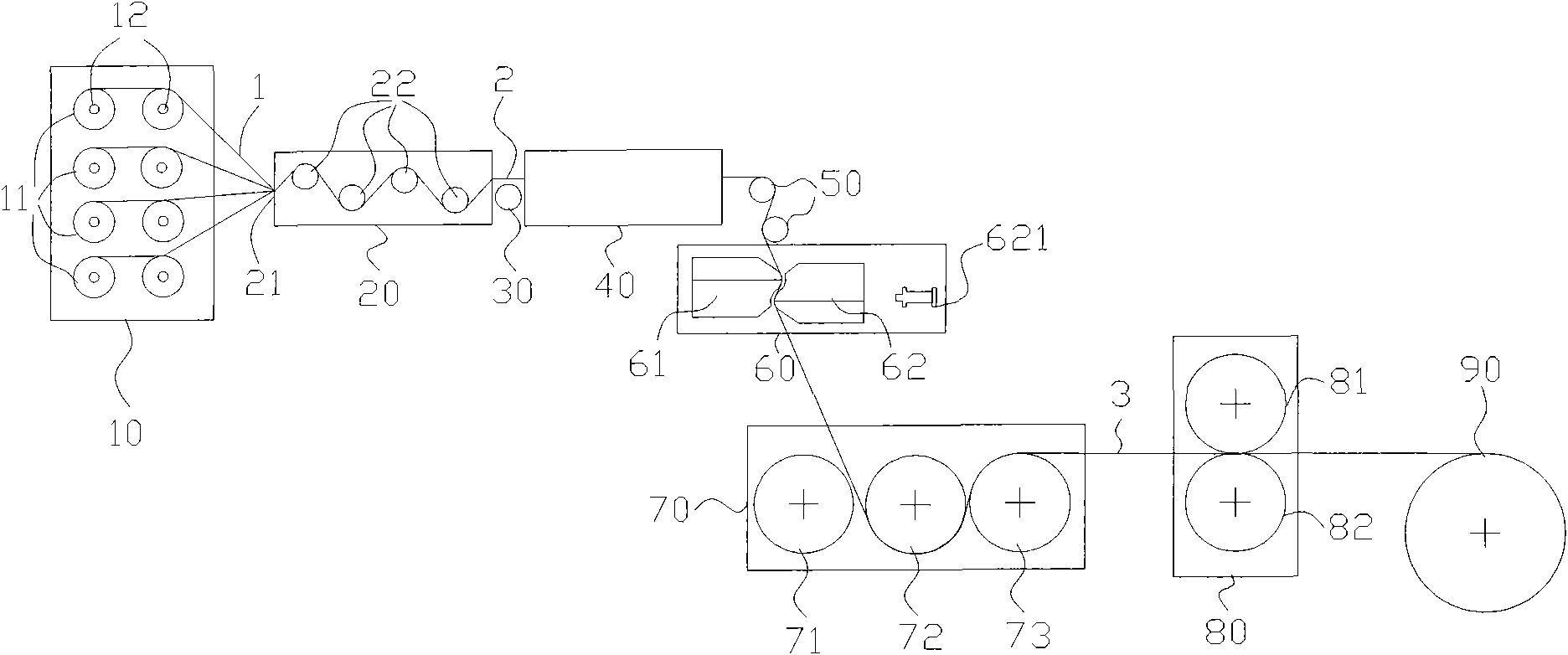

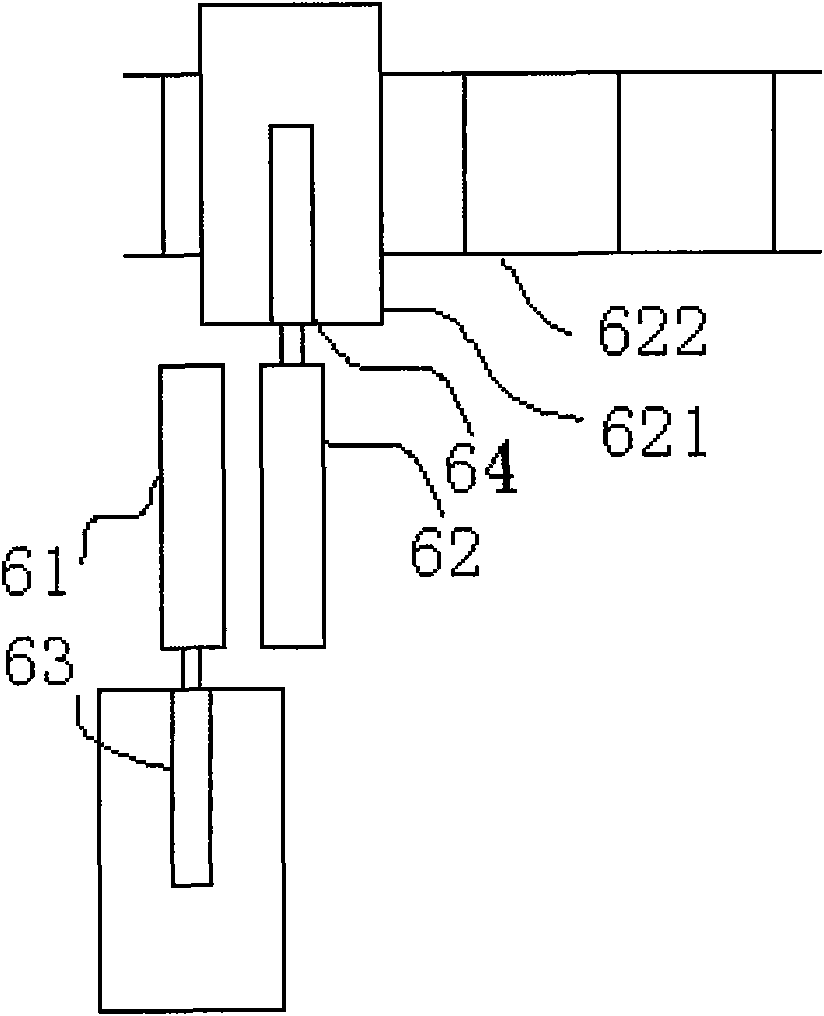

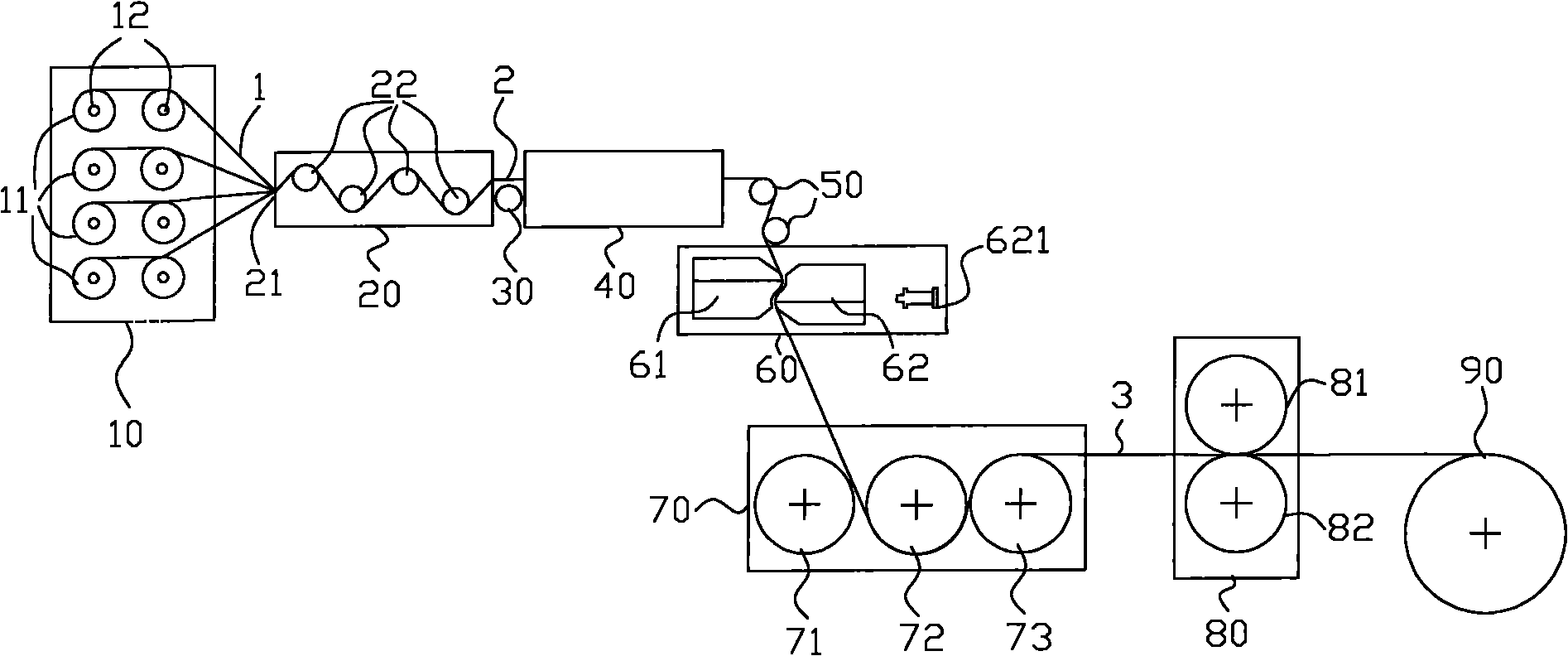

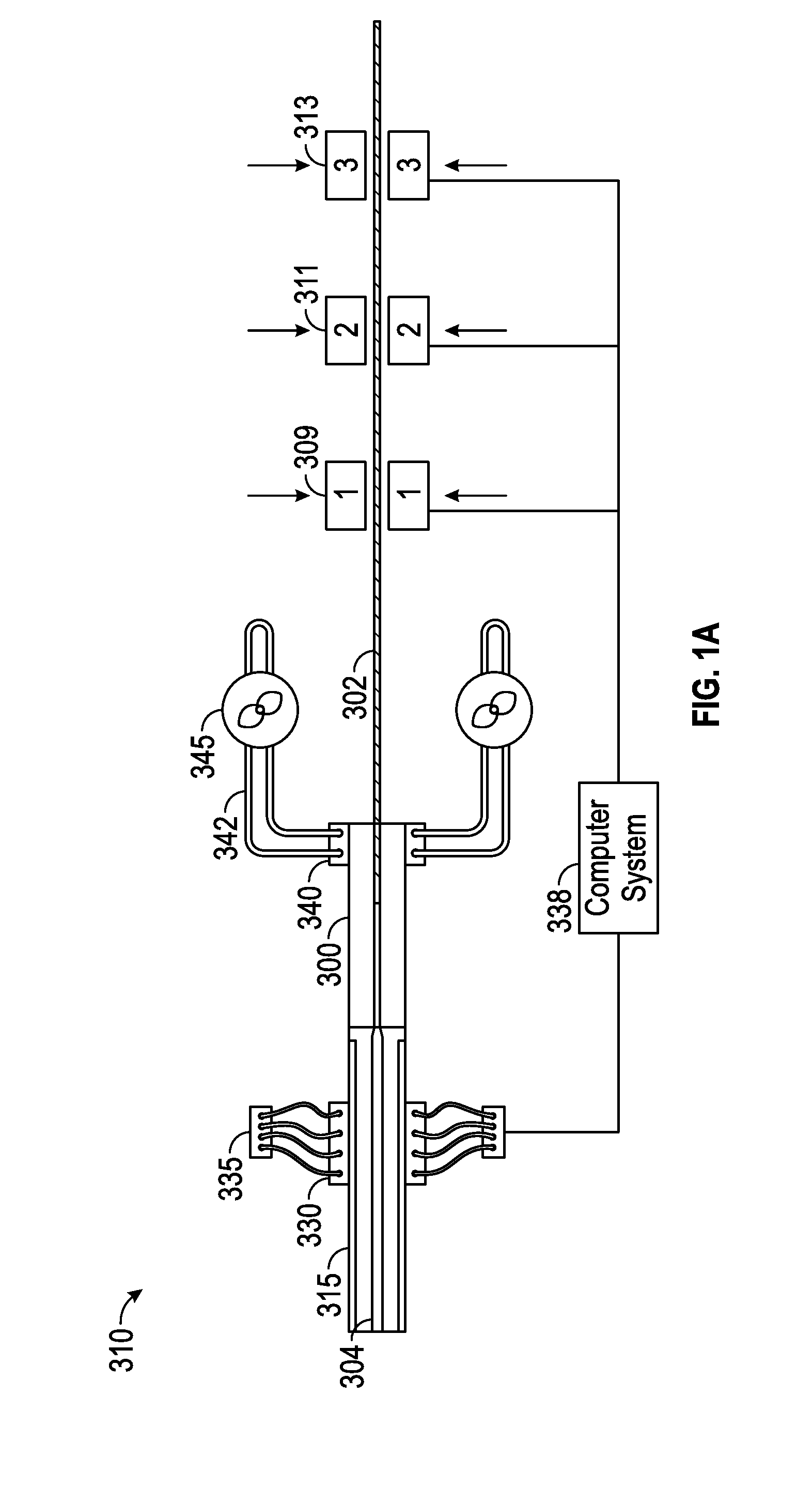

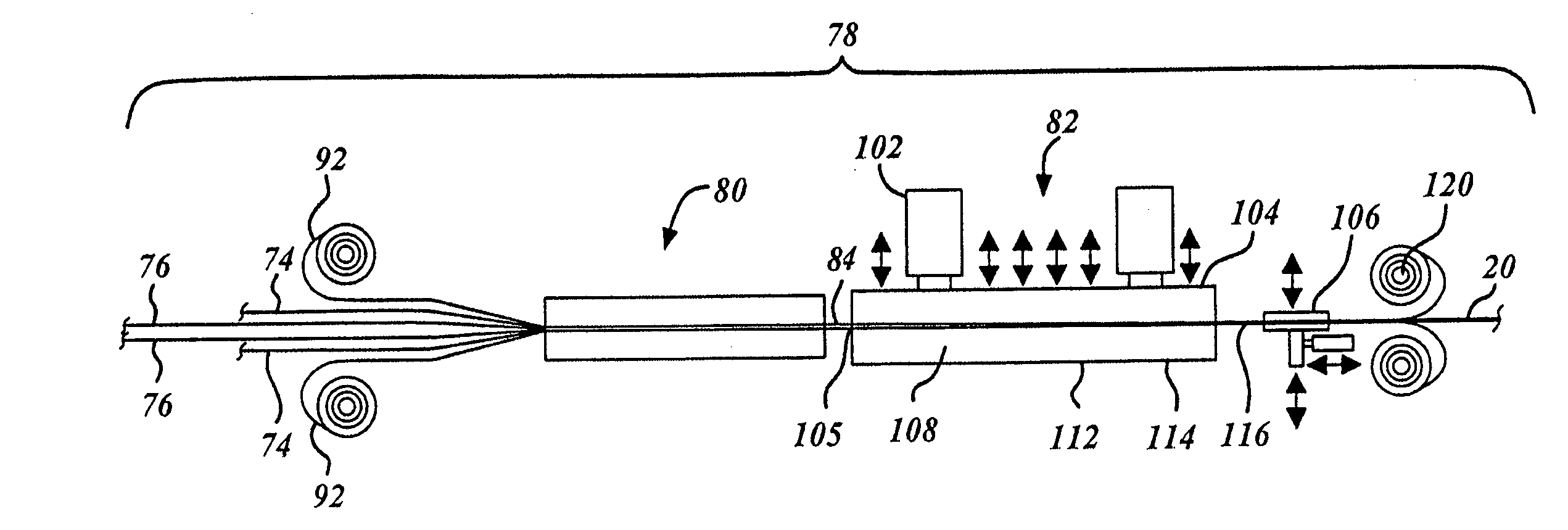

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Completely degraded plant powder modified thermoplastics composite material and preparation method thereof

ActiveCN101760037AHas physical and chemical propertiesEasy to processThermoplastic compositesPolypropylene

The invention discloses a completely degraded plant powder modified thermoplastics composite material and preparation method thereof, which consists of the components with the weight portions as follows: 100 portions of degradable thermoplastics resin, 1-400 portions of plant powder, 0.1-40 portions of dispersing agent, 0.5-60 portions of impact modifier, 0-40 portions of inorganic filler as well as 0.1-10 portions of stabilizing agent. The degraded thermoplastics resin has similar physiochemical performances with universal polyethylene and polypropylene, has excellent processing performances, and can be commixed with plant powder to prepare thermoplastics wood plastic composite materials. The obtained thermoplastics wood plastic composite materials can be completely degraded into carbon dioxide and water in natural environment under the effects of broadly existed microbes like germs, actinomycetes, etc. Compared with wood products, the composite material has the characteristics of good durability and dimensional stability, easy forming, small water absorbability, and corrosion resistance; compared with plastic, the composite material has the characteristics of low cost and high rigidity. The completely degraded plant powder modified thermoplastics composite material can be used for producing the shells of electric apparatuses like TV, sound, copier, printer, etc, and can also be applied on other workpieces used for injection.

Owner:GUANGDONG KINGFA TECH CO LTD +2

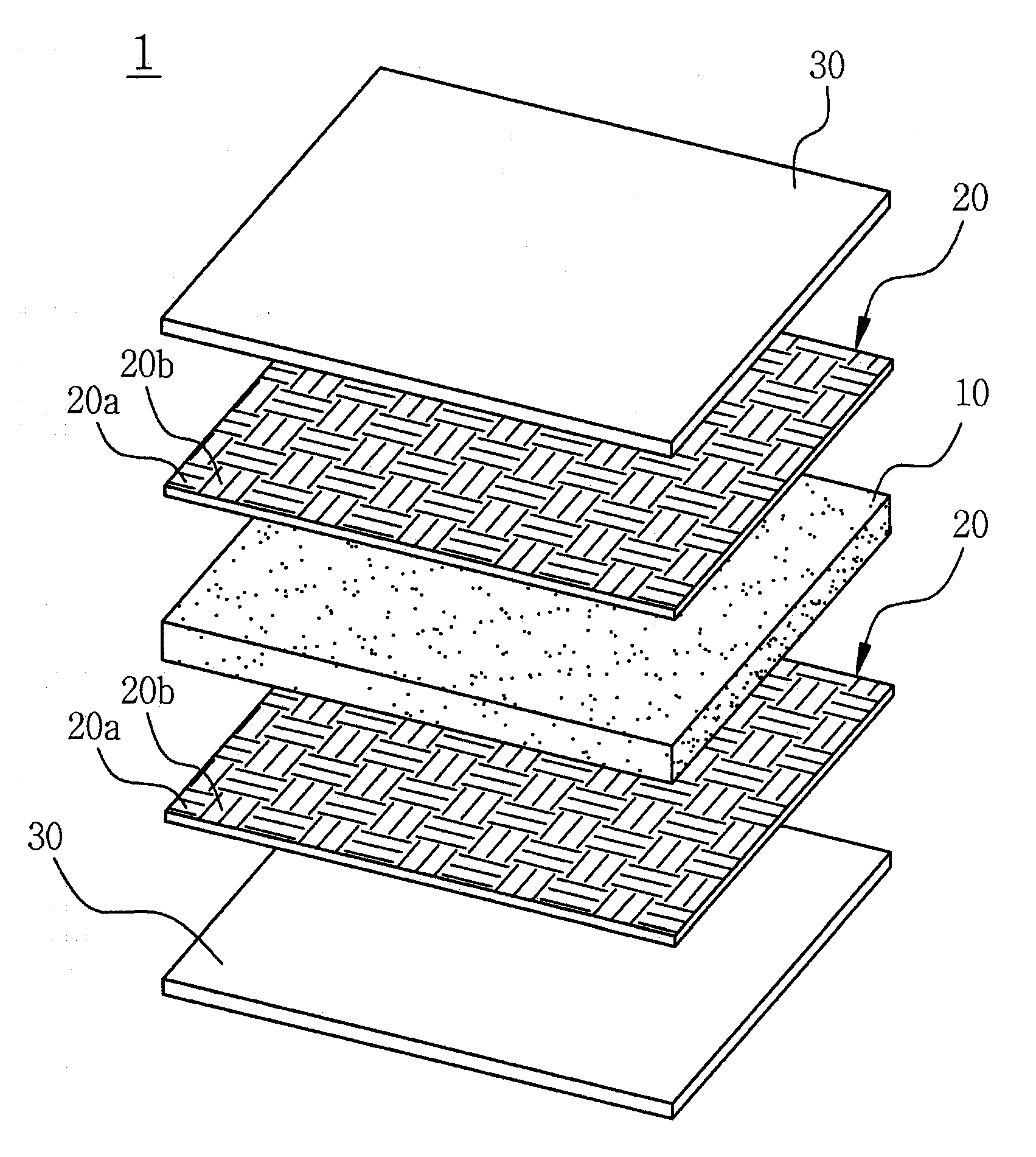

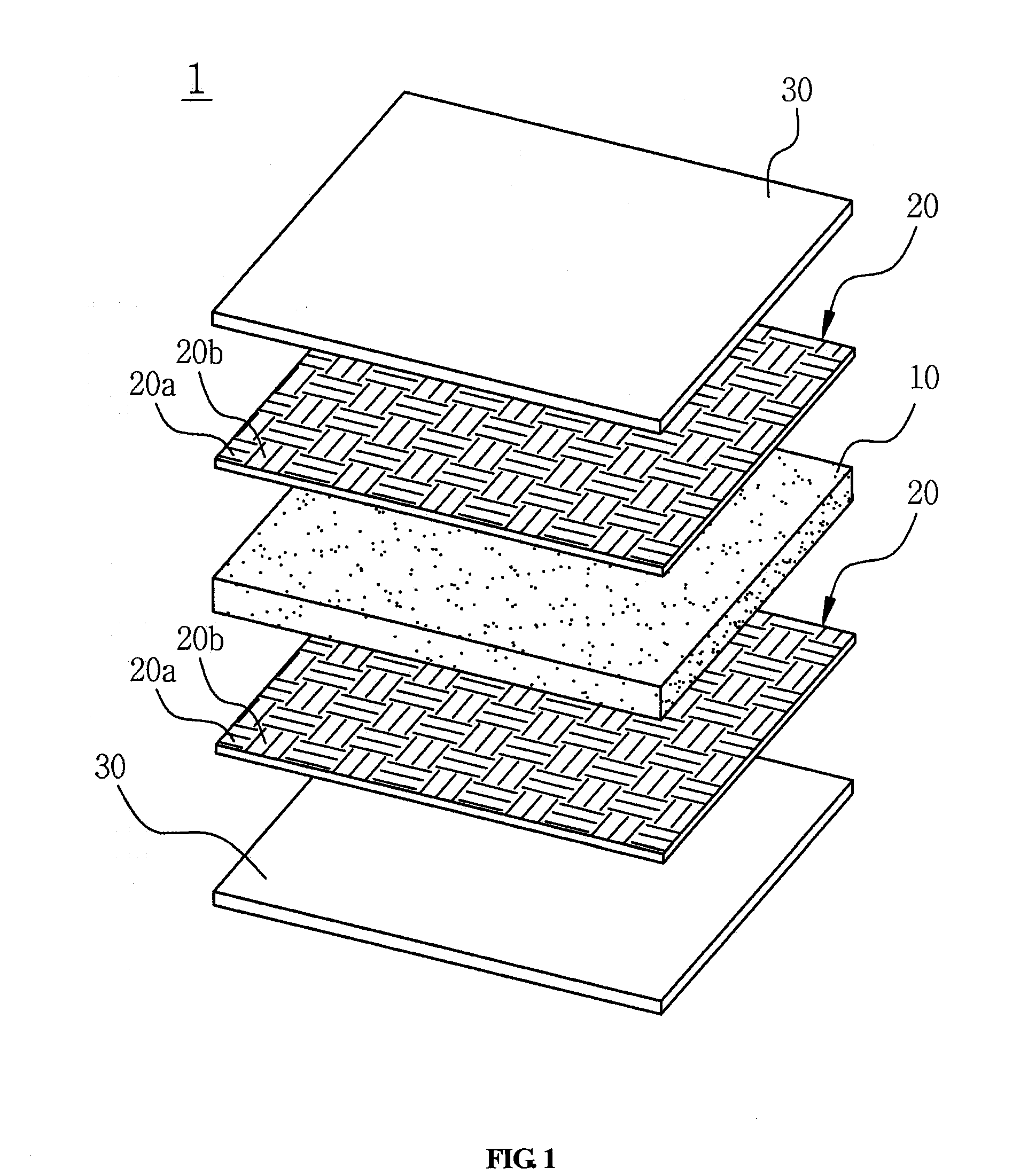

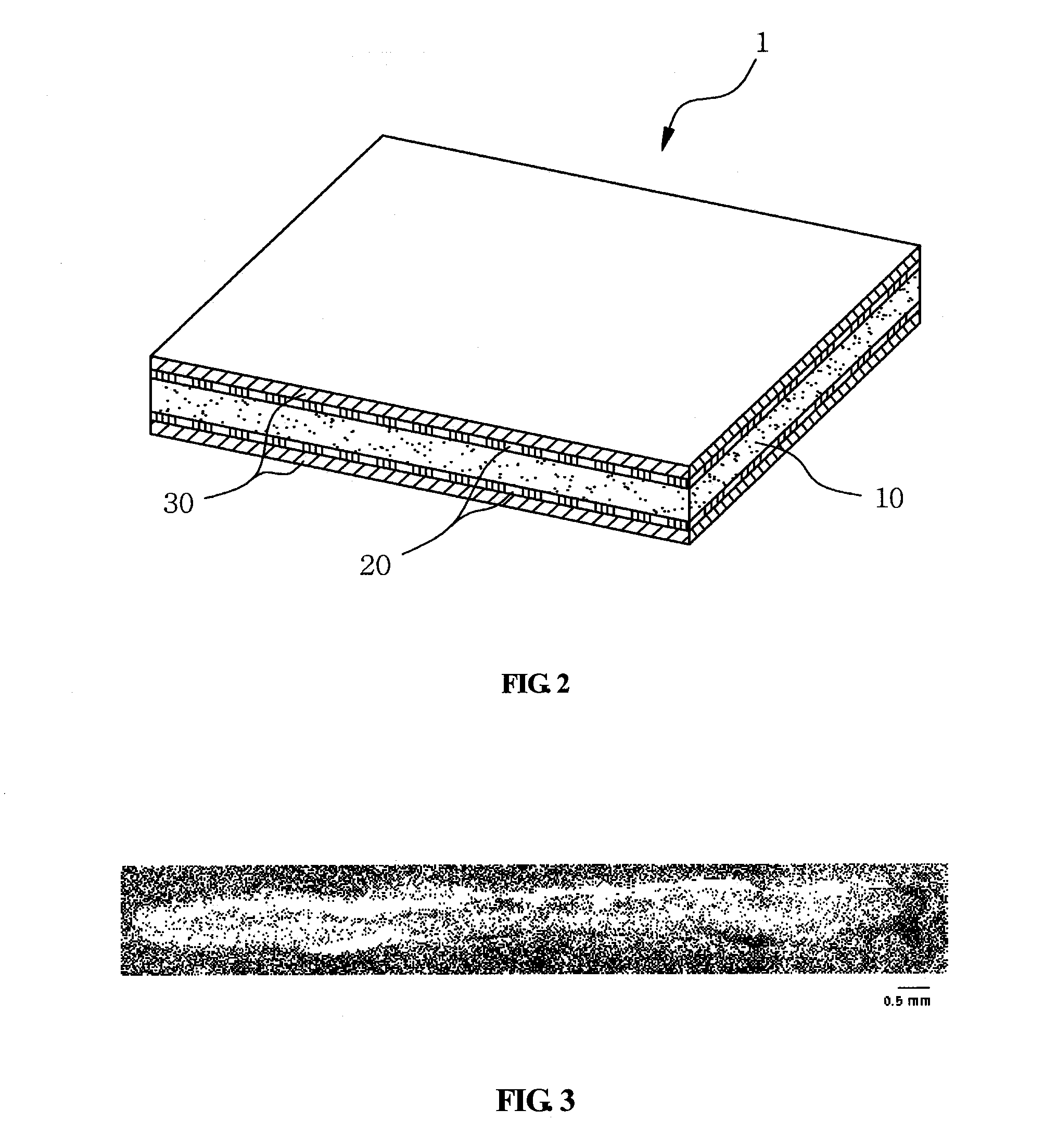

Thermoplastic Compound Plate-Shaped Material, Method For Manufacturing And Articles Manufactured Using The Same

InactiveUS20070202314A1Excellent in not mechanical propertySynthetic resin layered productsBuilding componentsFlexural strengthThermal expansion

The present invention relates to a recyclable thermoplastic composite sheet which is excellent in mechanical properties, such as bending strength, bending elastic modulus, impact strength and linear thermal expansion coefficient, and also in secondary processability, and suitable for molding into various structures, such as panels for use as building materials, and automobile parts, as well as a manufacturing method thereof and an article manufactured therefrom. The sheet comprises: a center layer of a thermoplastic composite material comprising 40% by weight of reinforcing fibers with an average length of 1-30 mm and 60% by weight of a thermoplastic resin containing an organic filler; and a continuous reinforcing fiber-impregnated prepreg layer laminated on at least one surface of the upper surface and lower surface of the center layer, the prepreg layer comprising 5-65% by weight of reinforcing fibers and 35-95% by weight of a thermoplastic resin containing a small amount of inorganic filler.

Owner:SAMBARK

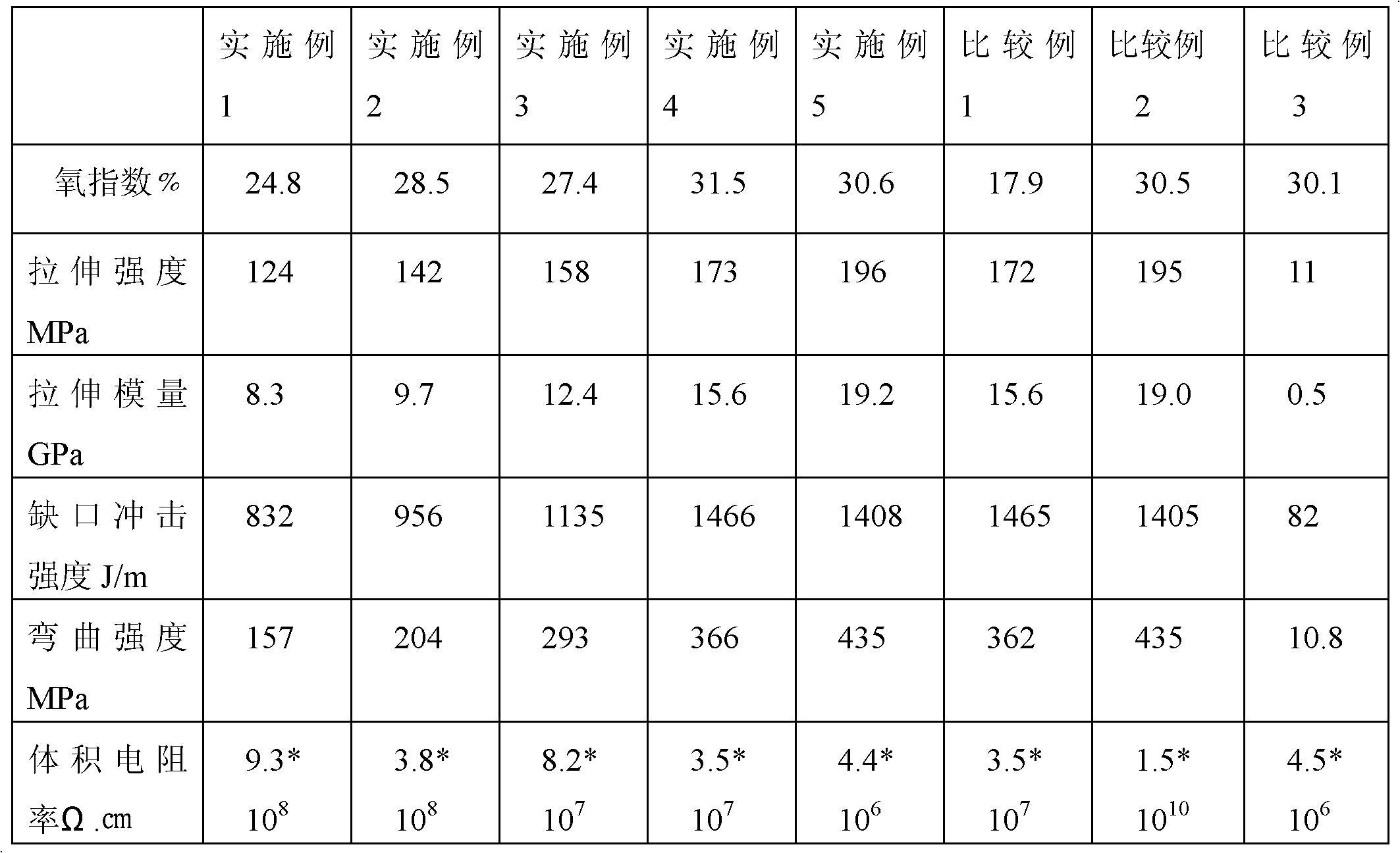

Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

The invention belongs to polymer modification technical field and processing technology field, and discloses a flame-retardant antistatic high-strength thermoplastic composite material and its preparation method. The material comprises (by weight share) 80-100 thermoplastic resin, 50-120 reinforcing fiber, 8-18 flame retardant, 0-5 flame retardant synergistic agent, 0.5-1.8 antistatic agent, 15-30 compatibilizer, 4-10 composite antioxidants, and 0-80 other additives. The invention also discloses the thermoplastic composite material preparation method. The inventive lame-retardant antistatic high-strength thermoplastic composite material has high tension and bending strength, high impact resistance property at low and high temperature, obvious antistatic property, high flame-retardant and fire proof performance. It can reach UL-94 V-O level standard.

Owner:杭州电力设备制造有限公司建德冠源成套电气制造分公司

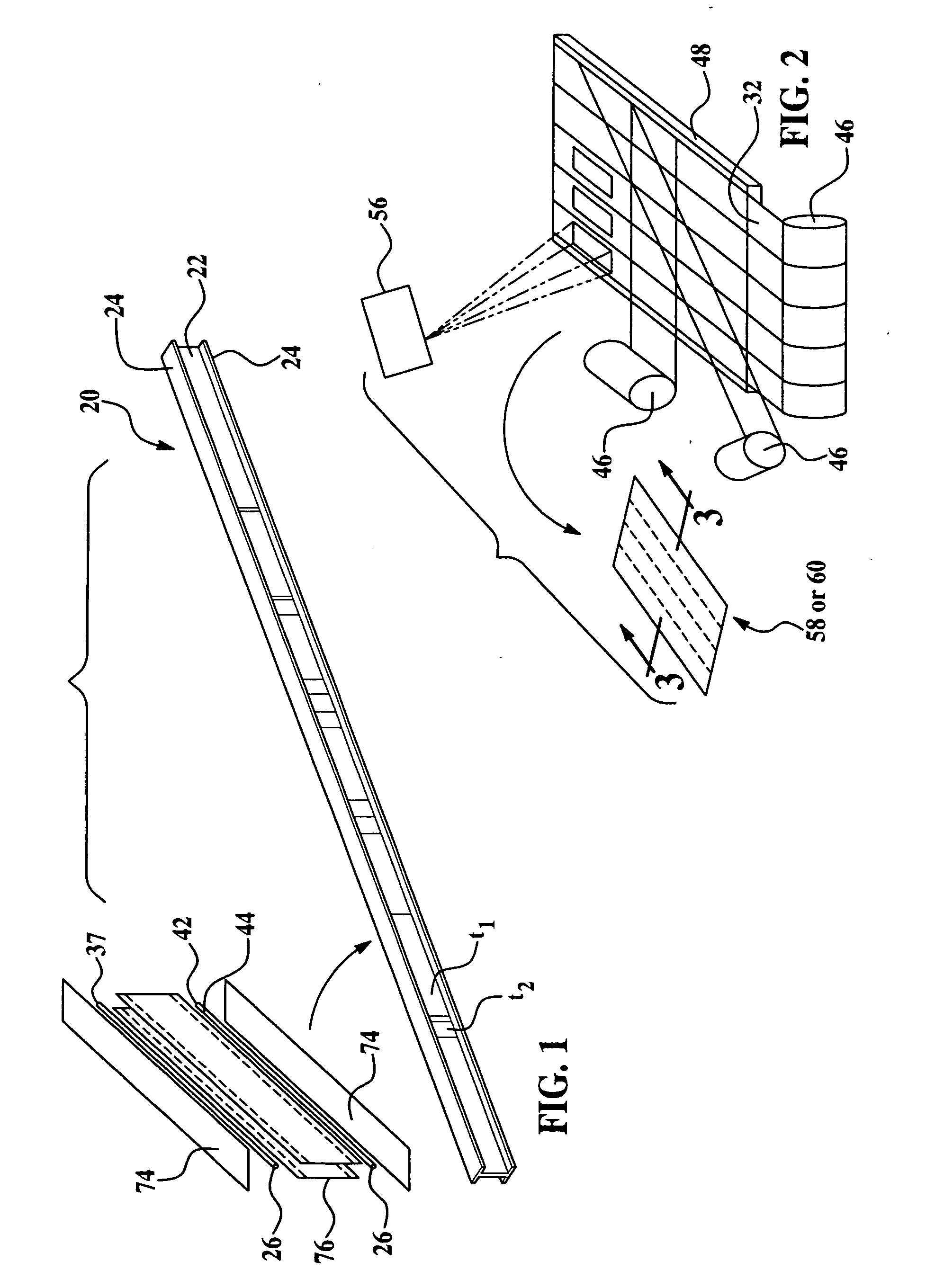

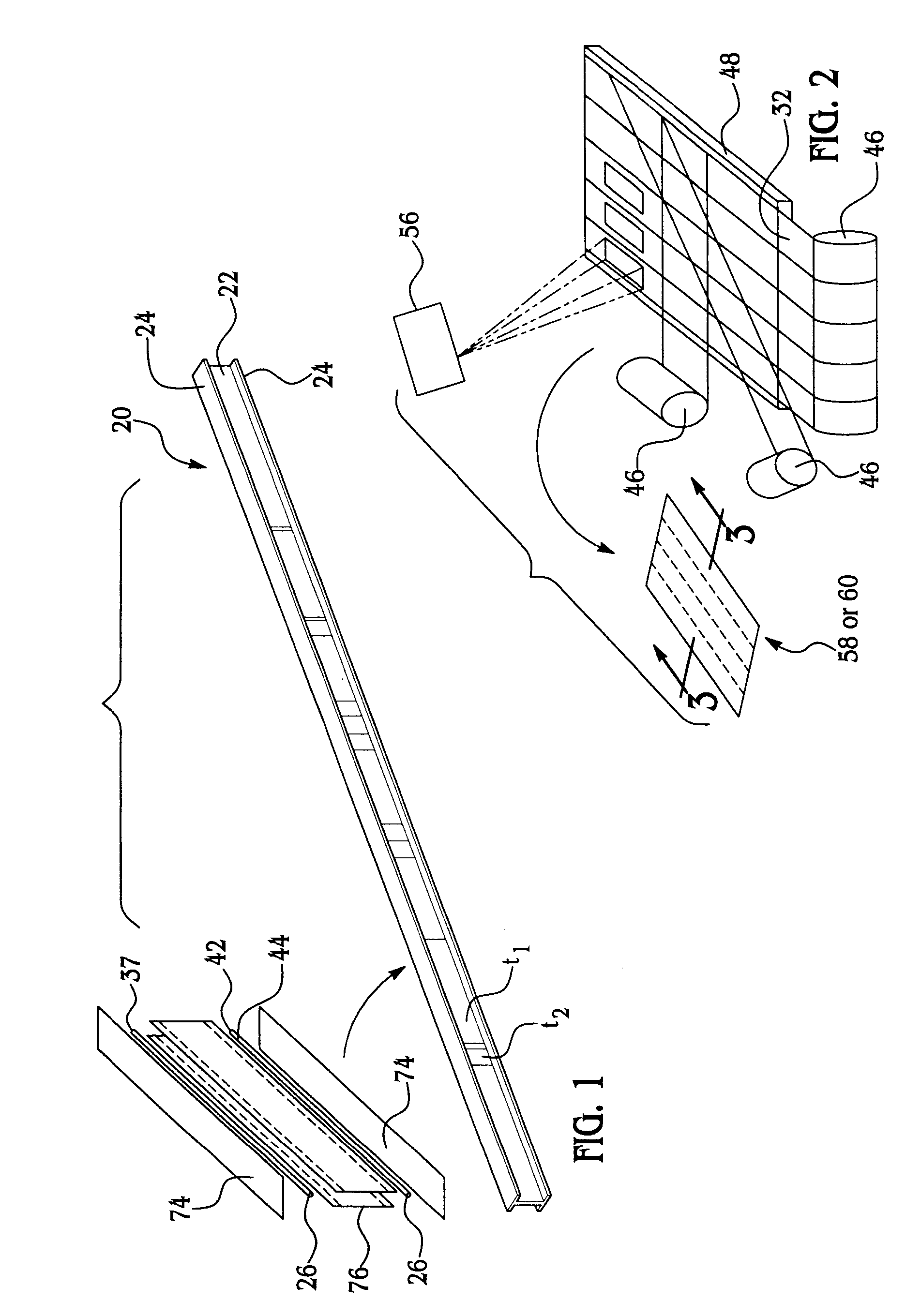

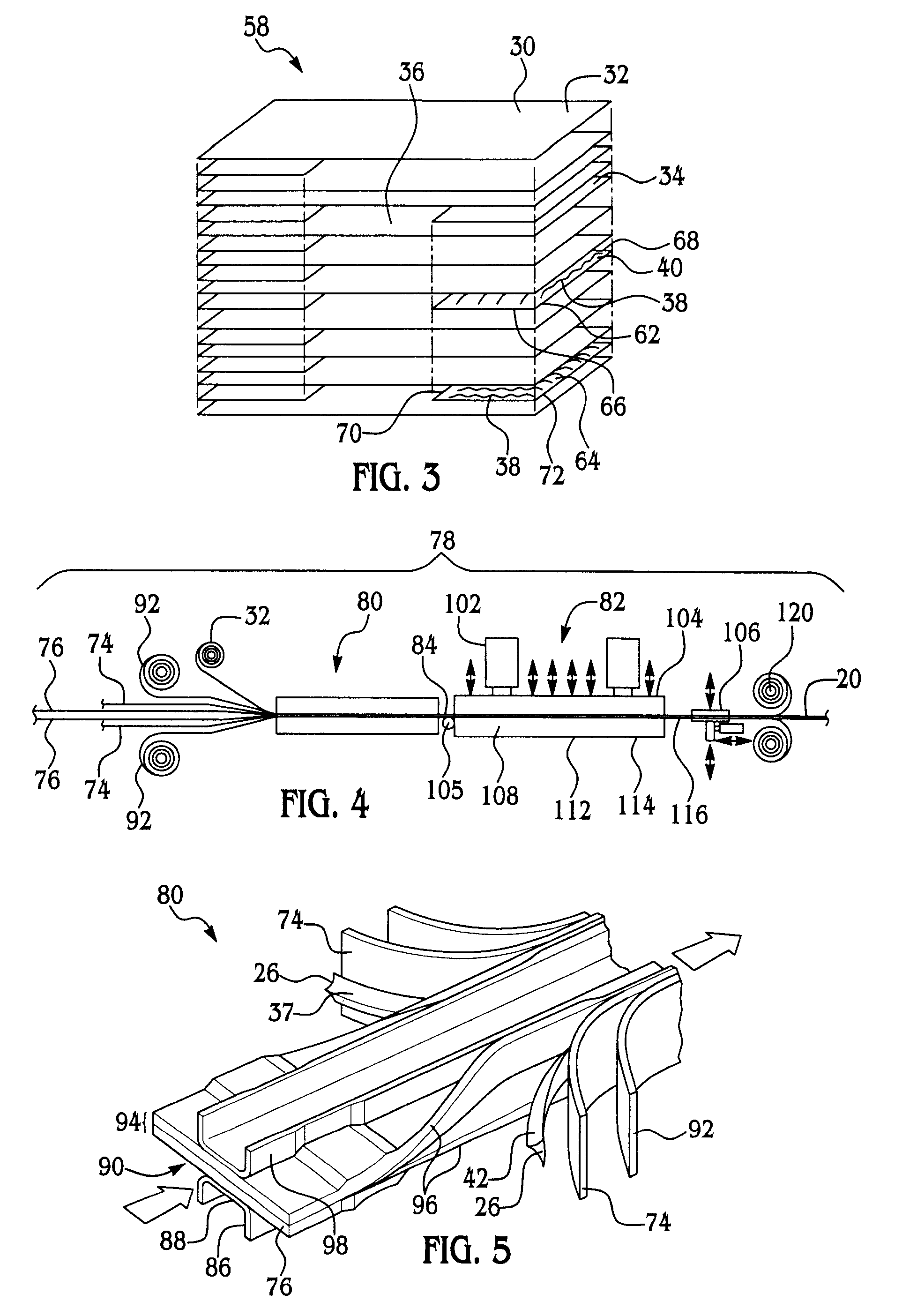

Method for fabricating curved thermoplastic composite parts

ActiveUS20070175575A1Mechanical working/deformationWood working apparatusEngineeringThermoplastic composites

A fabrication method of forming curved thermoplastic composite laminate parts with tailored and varying thickness in a continuous process. Automated equipment or hand lay-up are used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

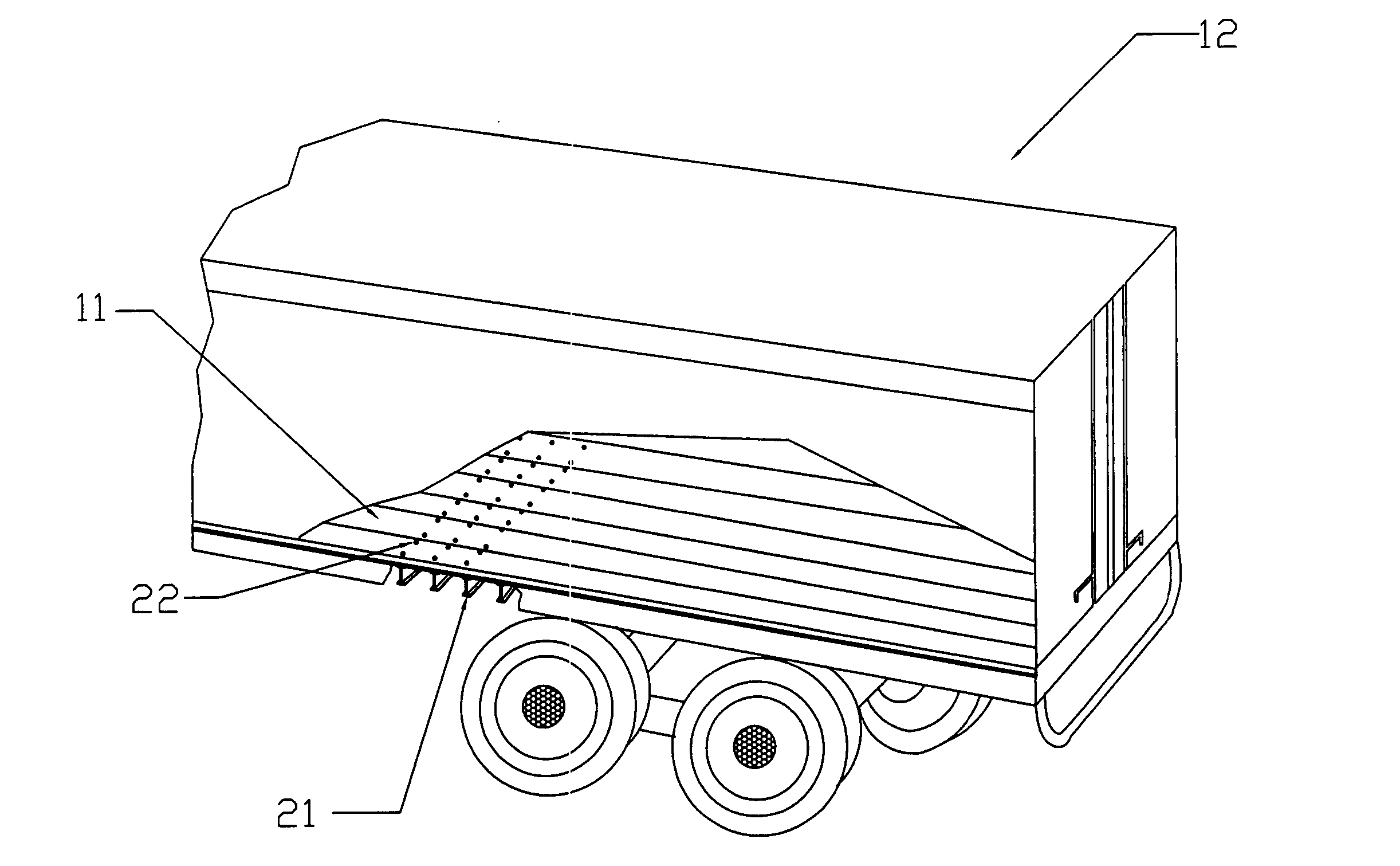

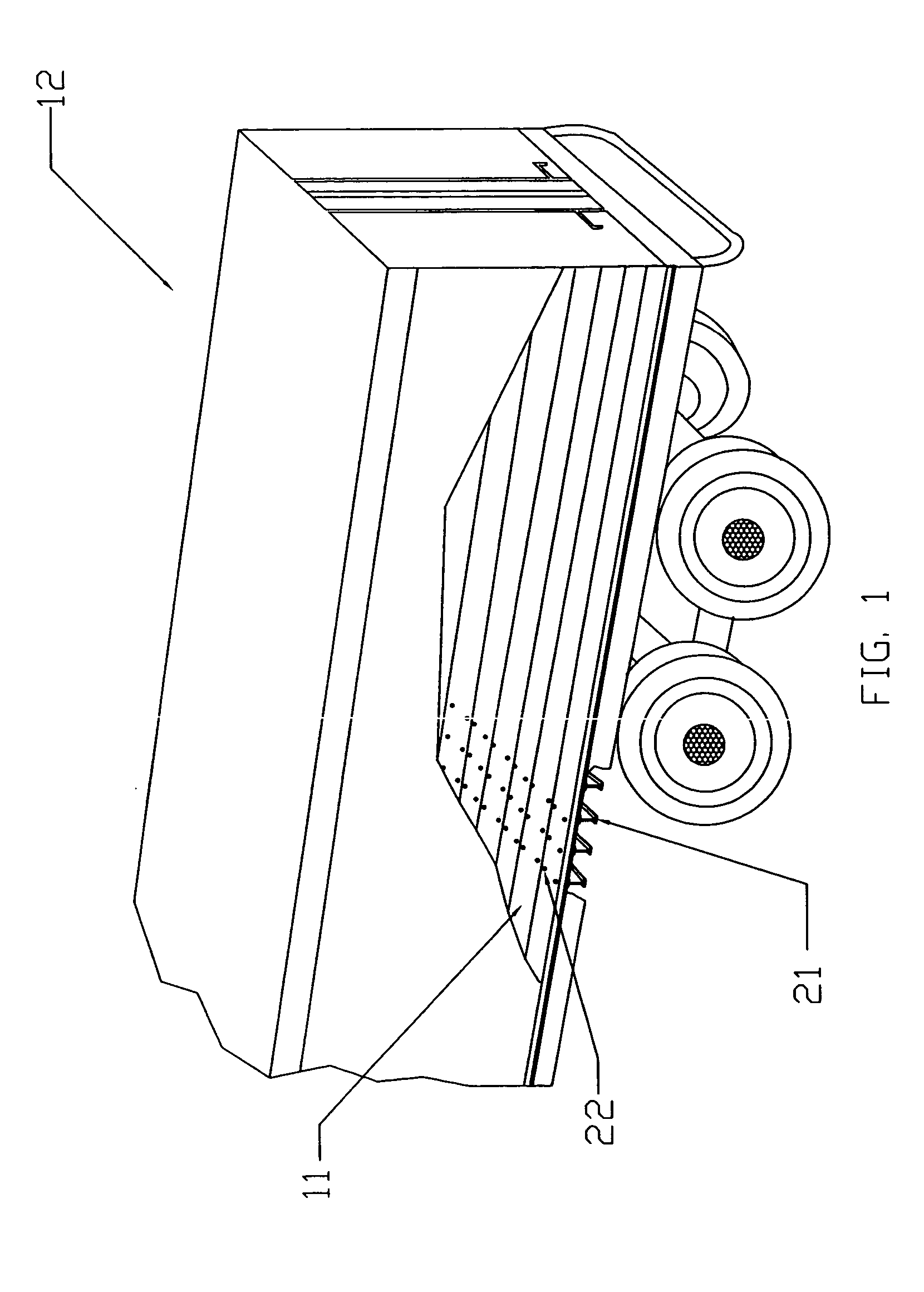

Durable wood-plastic composite flooring for trailers

InactiveUS20060179733A1Little and no structural defectLow costTreadsSynthetic resin layered productsEngineeringThermoplastic composites

A composite wood flooring system for a vehicular trailer floor comprising: a plurality of wood boards, each wood board comprising a top surface and a bottom surface opposite the top surface; and a filled thermoplastic composite layer comprising a thermoplastic polymer and a discontinuous filler, the thermoplastic layer being substantially bonded to the top surface of each wood board.

Owner:HAVCO WOOD PRODS

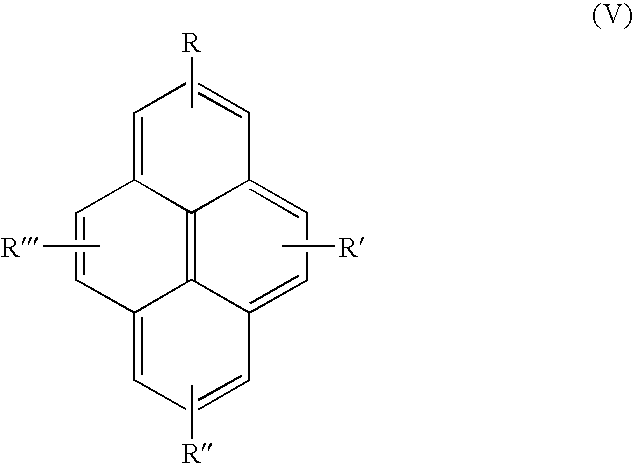

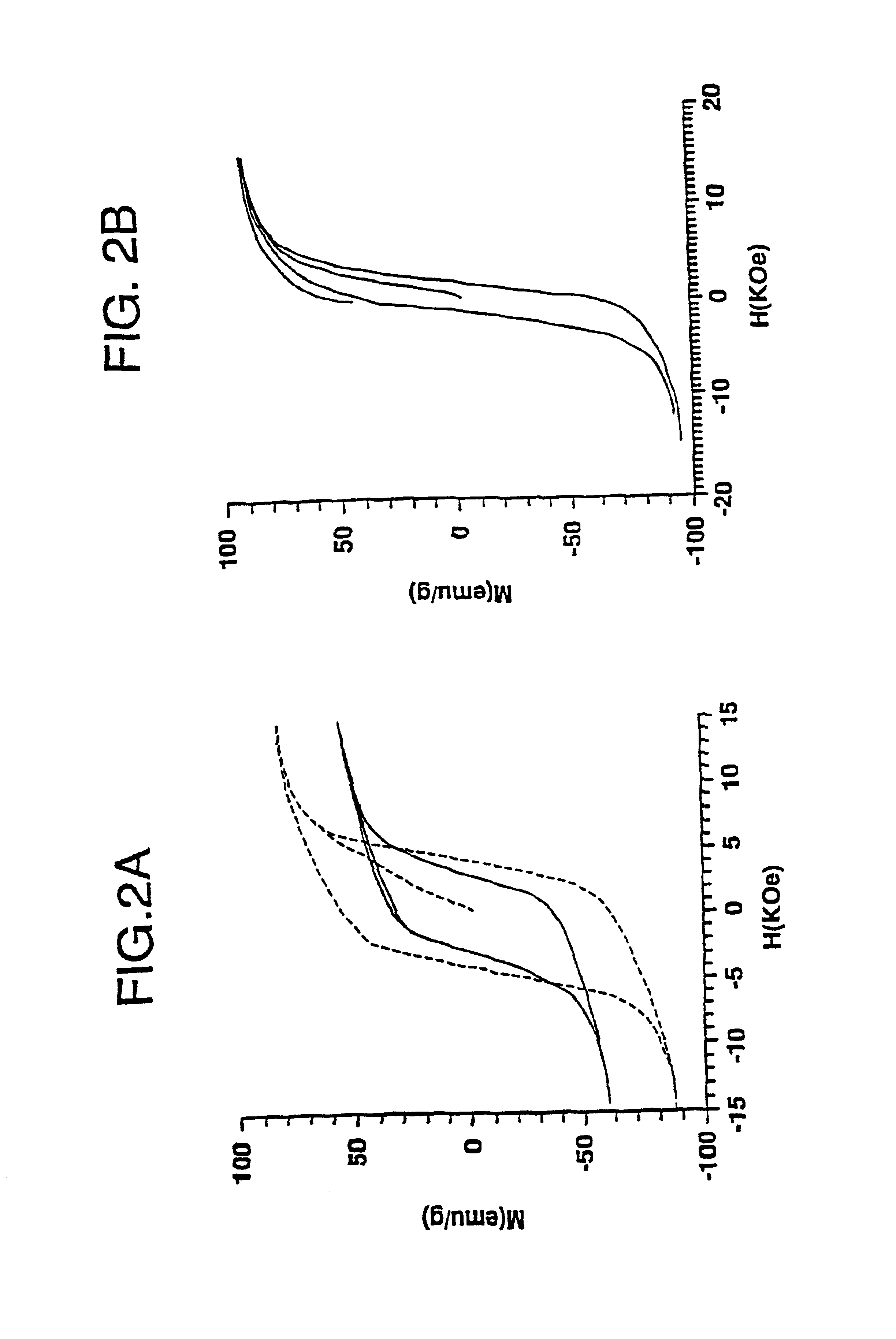

Conductive thermoplastic composites and methods of making

InactiveUS20040016912A1Improve conductivityImprove mechanical propertiesMaterial nanotechnologyConductive materialPolymer resinPolymer composites

A polymeric composite comprises a polymeric resin; an electrically conductive filler; and a polycyclic aromatic compound, in an amount effect to increase the electrical conductivity of the polymeric composition relative to the same composition without the polycyclic aromatic compound. The addition of the polycyclic aromatic compound in addition to a conductive filler imparts improved electrical and mechanical properties to the compositions.

Owner:SHPP GLOBAL TECH BV

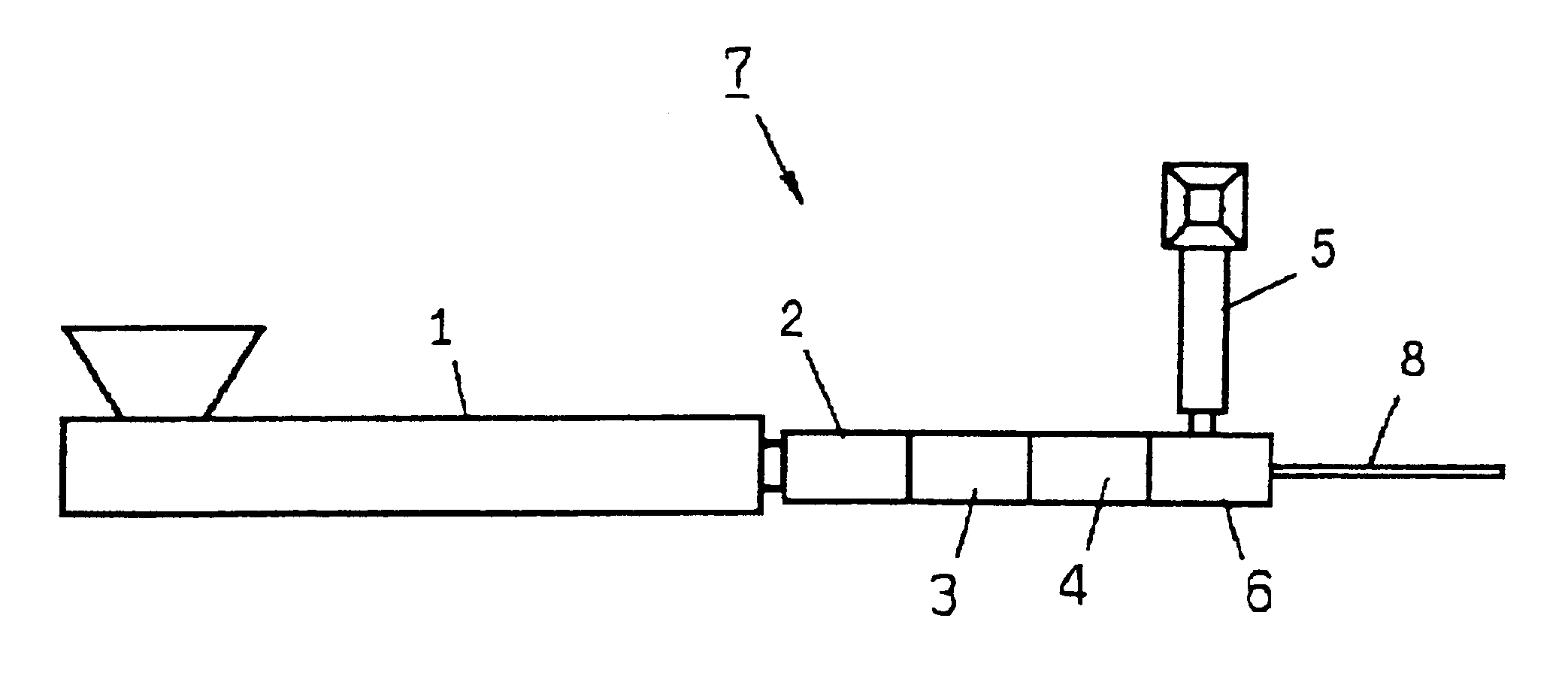

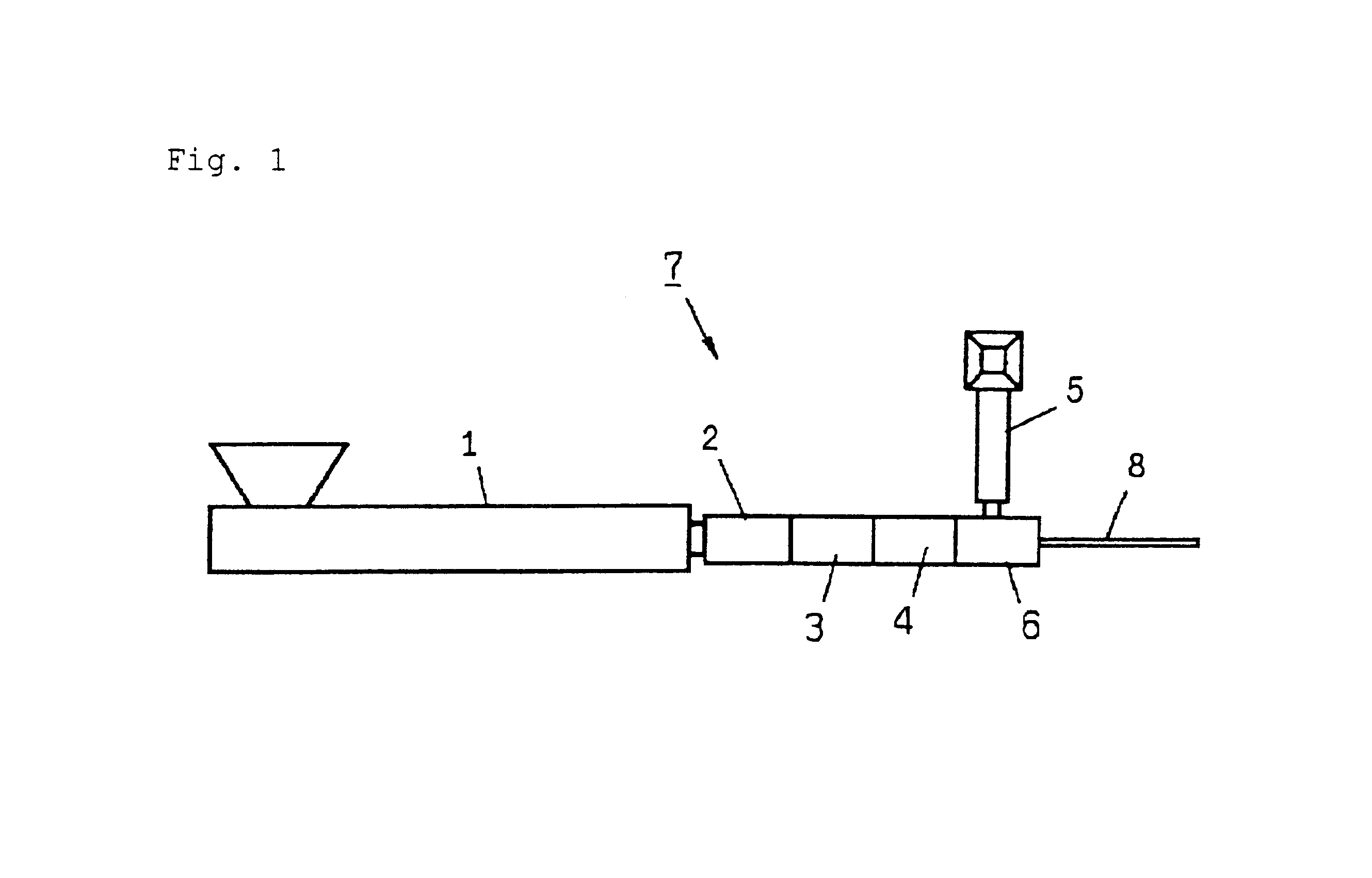

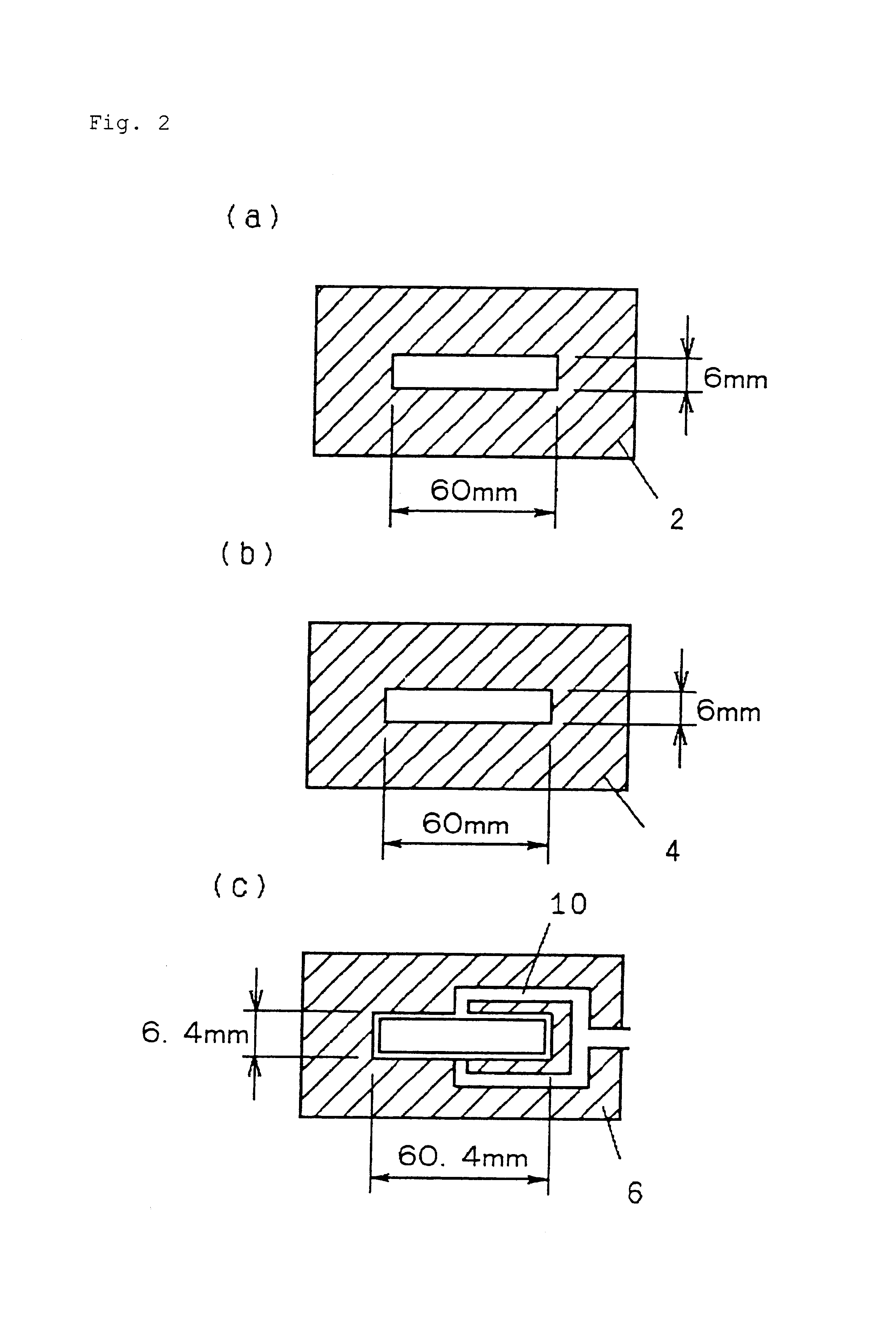

Molded article from thermoplastic composite material and method for producing the same

InactiveUS6716522B2No fading or discolorationIncreased durabilityHair accessoriesToupeesShell moldingThermoplastic composites

The present invention has for its object to provide a molded article of a thermoplastic composite material which is not only durable with little discoloration or fading even on prolonged outdoor exposure and is very satisfactory in physical properties and appearance qualities inclusive of wood-like texture but also has high productivity and good economics.The present invention is a method of producing a molded article of a thermoplastic composite material comprising extruding the thermoplastic composite material containing a thermoplastic resin and a vegetable filler, said vegetable filler content being 50 to 90 weight % of the total weight of said thermoplastic resin and said vegetable filler, wherein extrusion is carried out by means of an extrusion apparatus comprising at least an extruder, a hot shaping die, and a cooling die, said hot shaping die and cooling die being directly coupled.

Owner:SEKISUI CHEM CO LTD

Thermoplastic pultrusion die system and method

ActiveUS8747098B1High compression forceFacilitated releaseAdhesive processesConfectioneryNumerical controlEngineering

A thermoplastic pultrusion die system for pultruding a thermoplastic composite includes a first pultrusion die member with a curved, concave top surface; a second pultrusion die member with a curved, convex bottom surface; a curved die cavity gap formed between the a curved, concave top surface of the first pultrusion die member and the curved, convex bottom surface of the second pultrusion die member; a die cavity gap adjustment mechanism that imparts movement to at least one of the first pultrusion die member and the second pultrusion die member to vary the die cavity gap from closed to a specified location to open at a specified location; a pultrusion gripper mechanism having one or more grippers in series, and a computer numerical control (CNC) computer system controlling the die cavity gap adjustment mechanism.

Owner:EBERT COMPOSITES

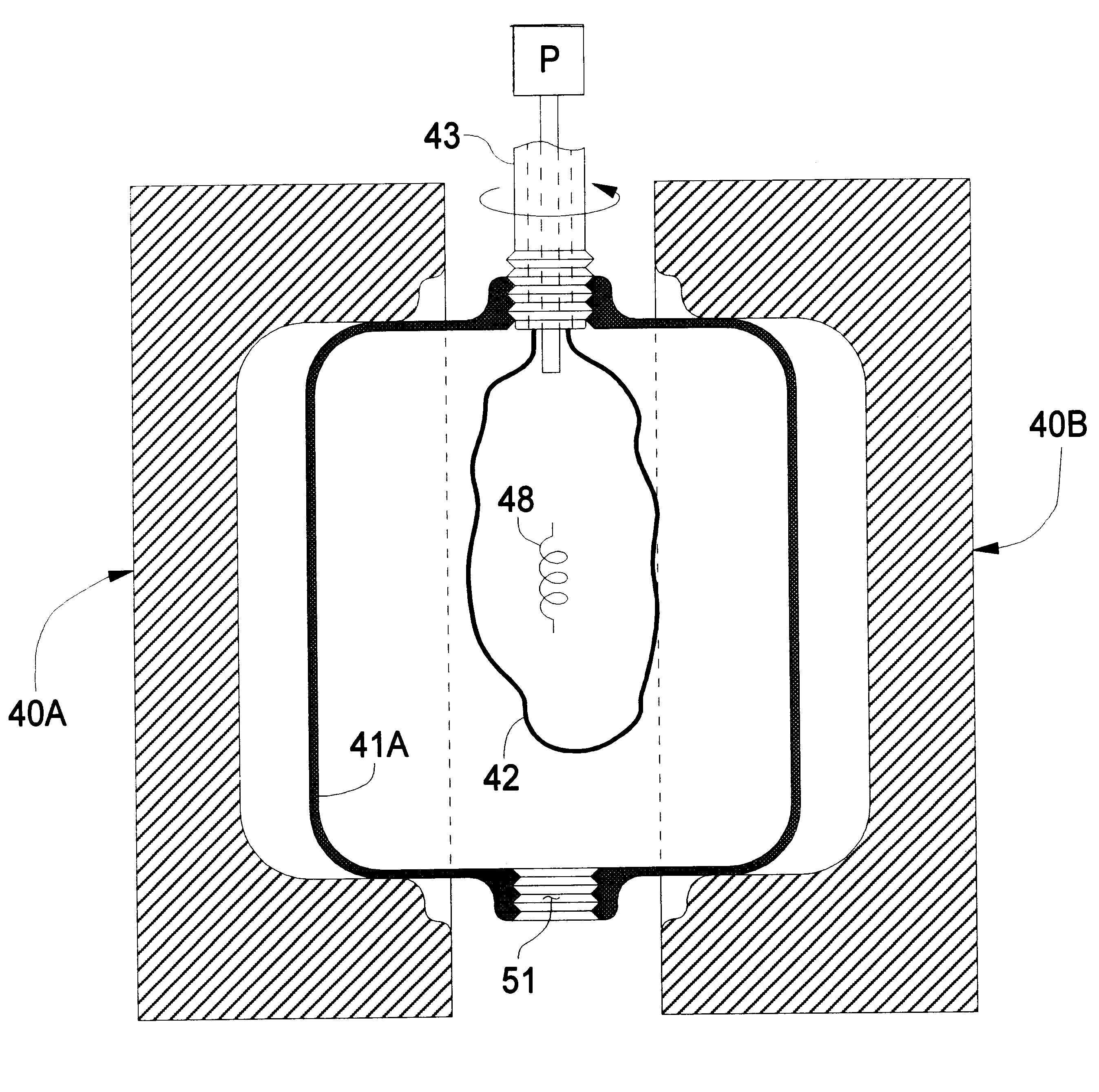

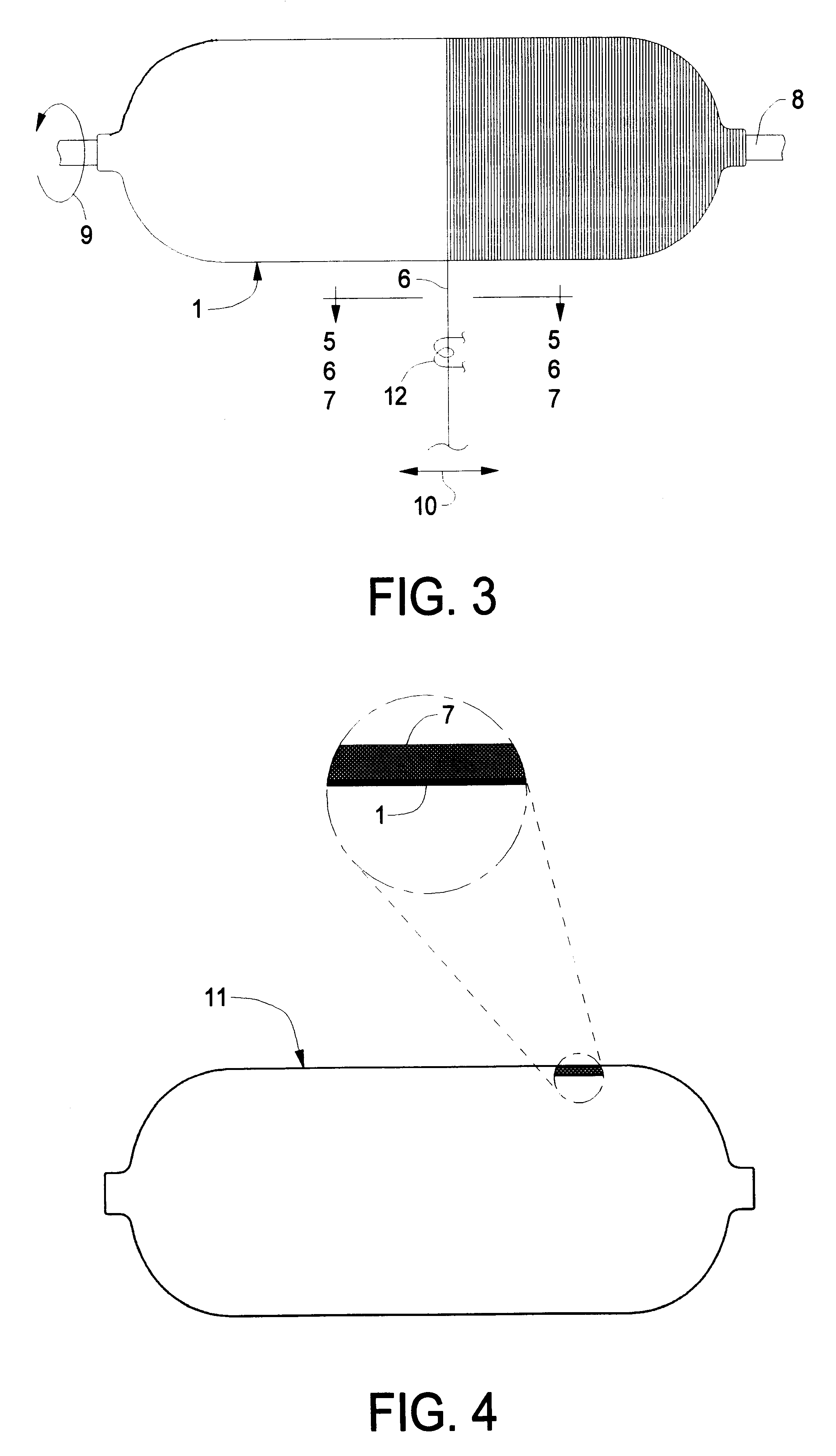

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

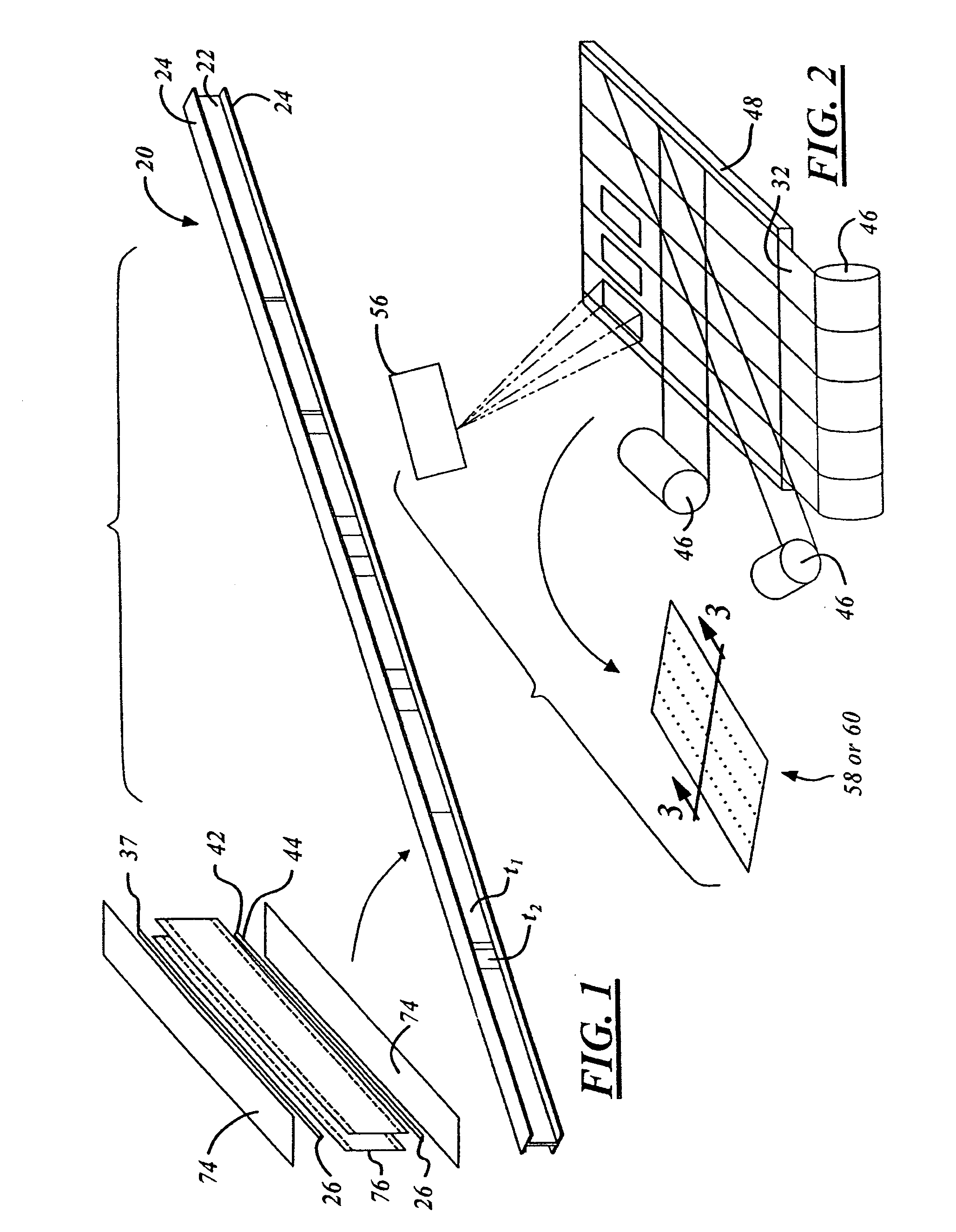

Novel fabrication process for thermoplastic composite parts

ActiveUS20070175571A1Mechanical working/deformationArtificial flowers and garlandsManufacturing technologyEngineering

A fabrication method of forming a thermoplastic composite laminate material with tailored and varying thickness in a continuous process. This process utilizes automated equipment or hand lay-up to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. The consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from these multiple ply stacks.

Owner:THE BOEING CO

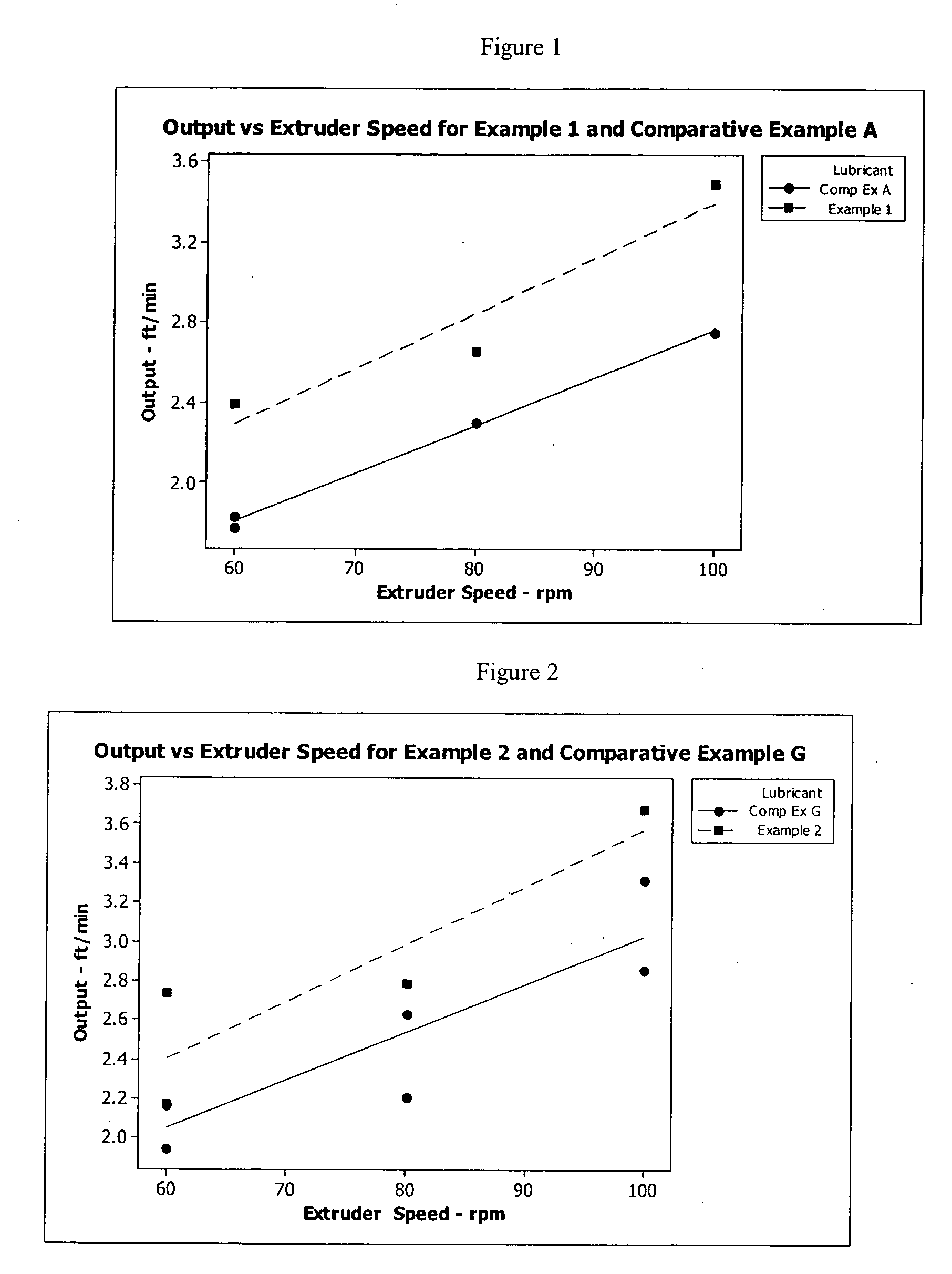

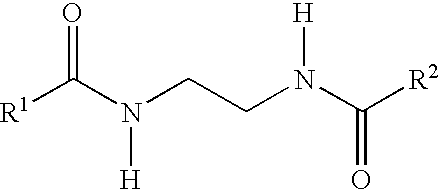

Cellulosic-thermoplastic composite and method of making the same

Provided is a composition comprising fatty acid bis-amide, inorganic particulate such as pumice, cellulosic particulate, thermoplastic and maleic anhydride grafted polyolefin. The combination of an ethylene bis-amide and a minor amount of pumice produces cellulosic-thermoplastic composite that has superior extrusion properties over conventional metal stearate / ethylene bis-stearamide (EBS) compositions such as improved flex strength and resistance to water absorption.

Owner:ADDIVANT USA

Fiber-reinforced thermoplastic composite material

InactiveUS20070196637A1Reduce basis weightMaximum flexural stiffnessSynthetic resin layered productsThin material handlingThermoplastic compositesBending stiffness

Owner:AZDEL INC

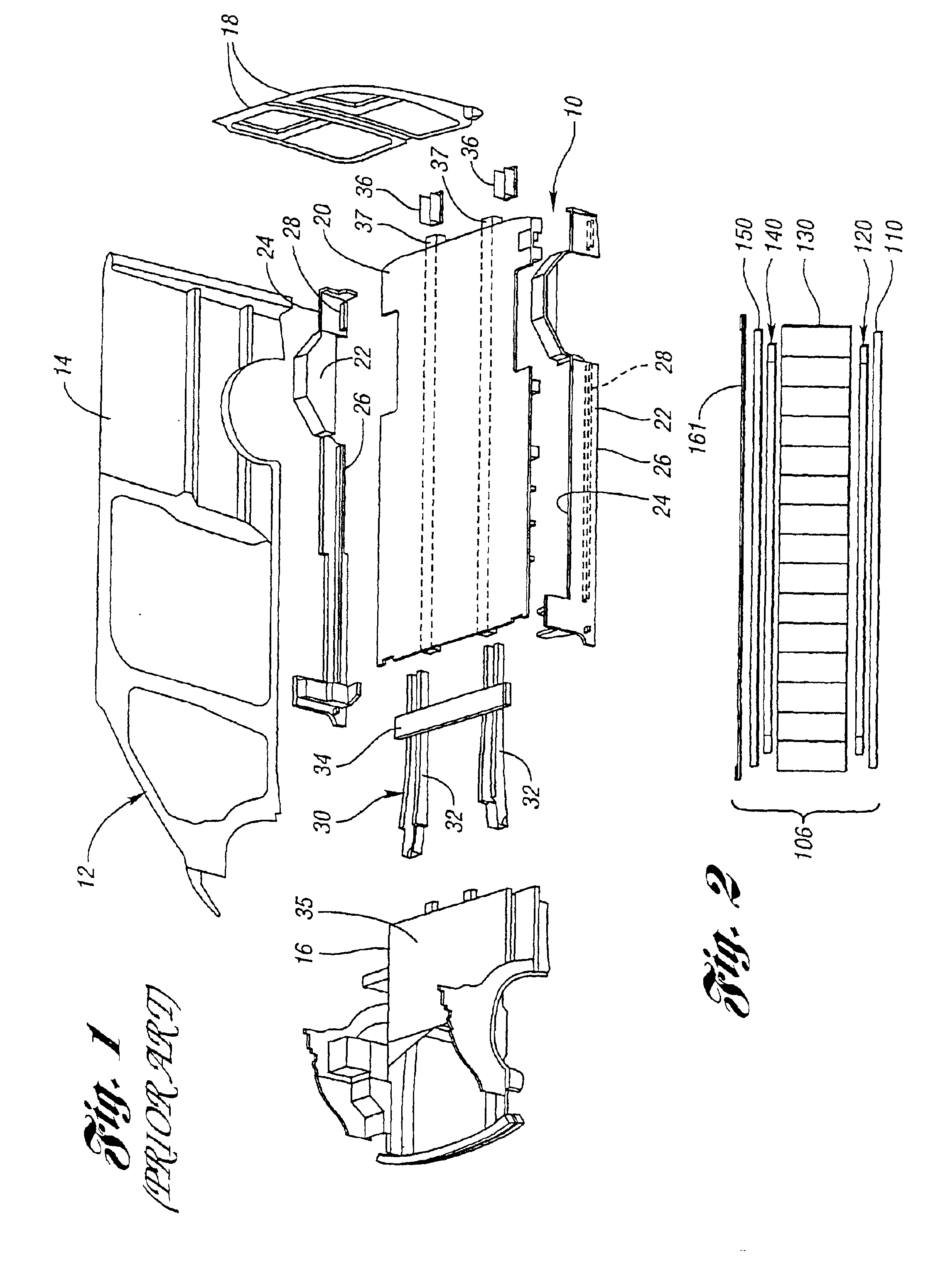

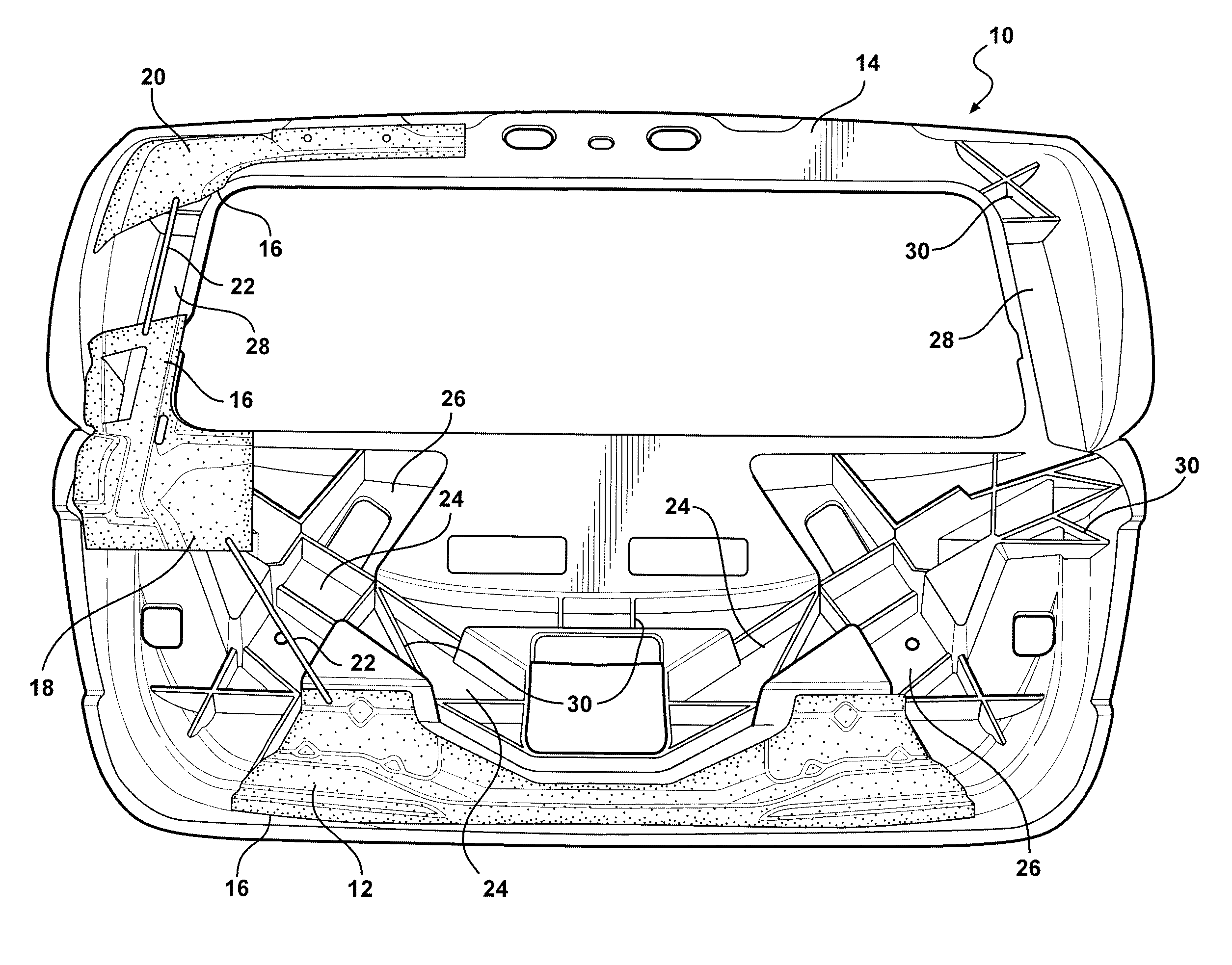

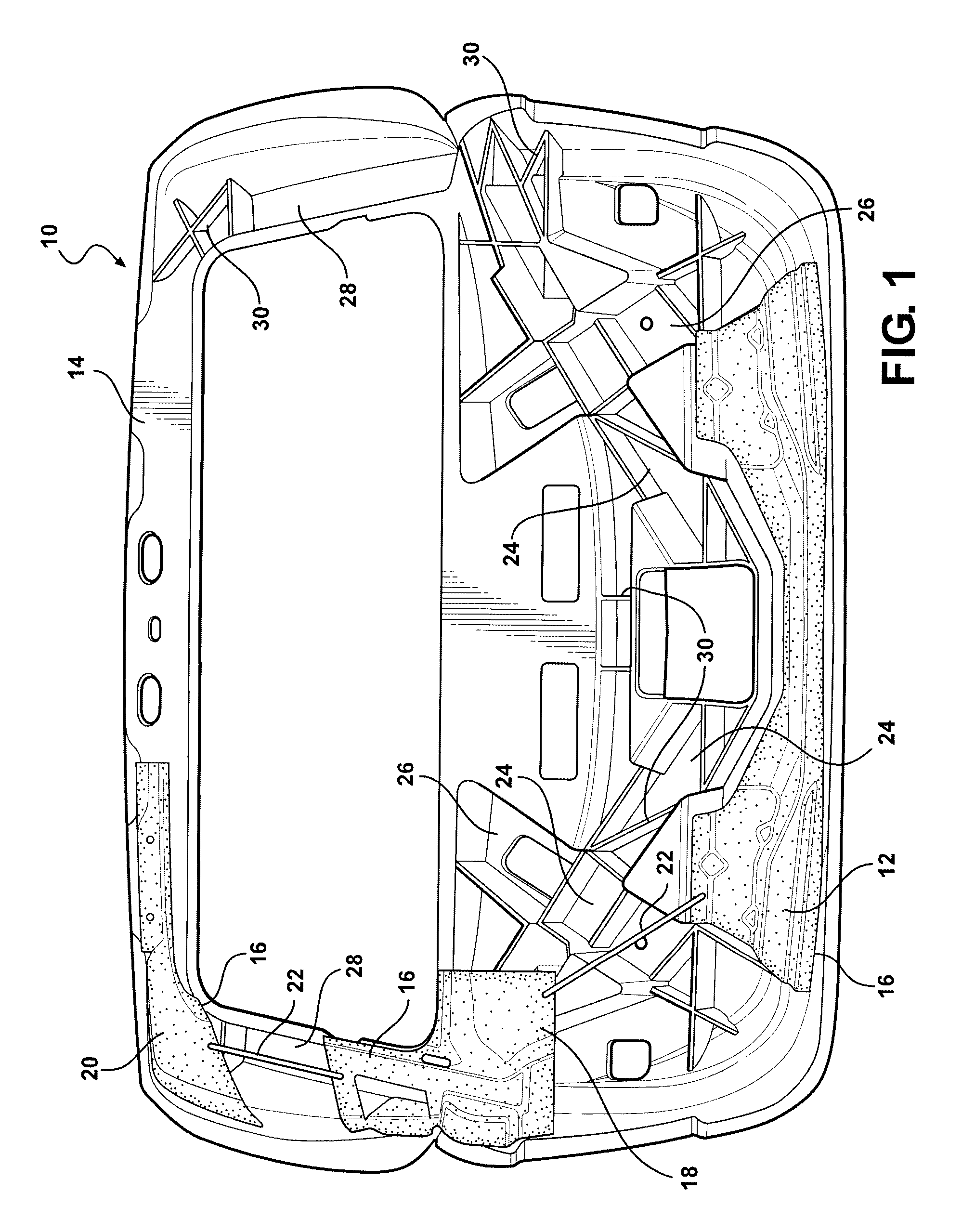

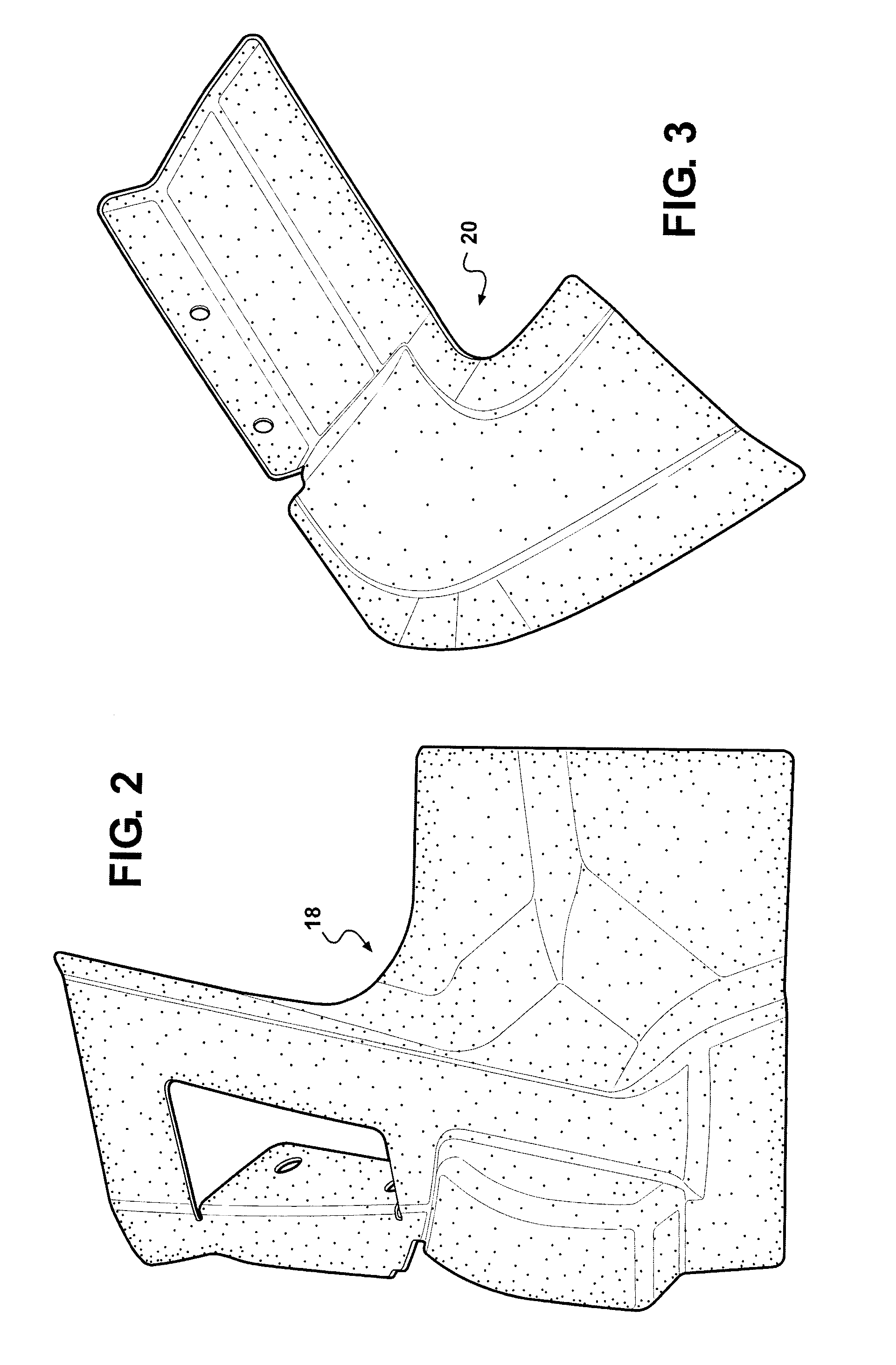

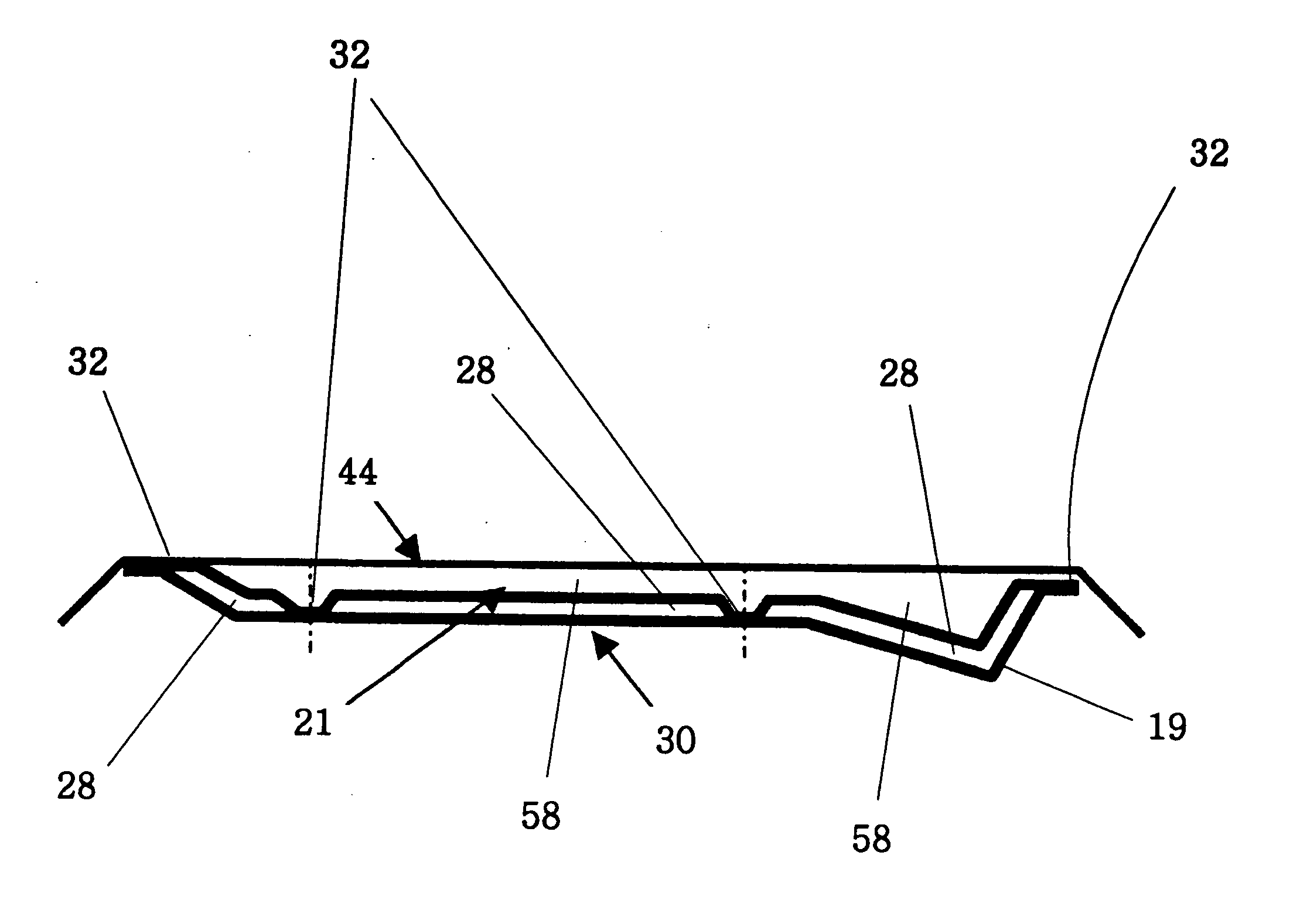

Composite Liftgate System

ActiveUS20110074179A1Reduce investmentImproving styling flexibilityVehicle seatsDashboardsEngineeringThermoplastic composites

The present invention is a thermoplastic composite liftgate system with reinforcements in key areas to allow the system to meet performance requirements, while lowering the tooling investment, lowering the system mass, and improving the styling flexibility. The present invention includes an inner panel and at least one bracket or reinforcement member connected to the inner panel such that when a force is applied to the bracket, the force is distributed to the inner panel.

Owner:MAGNA INTERNATIONAL INC

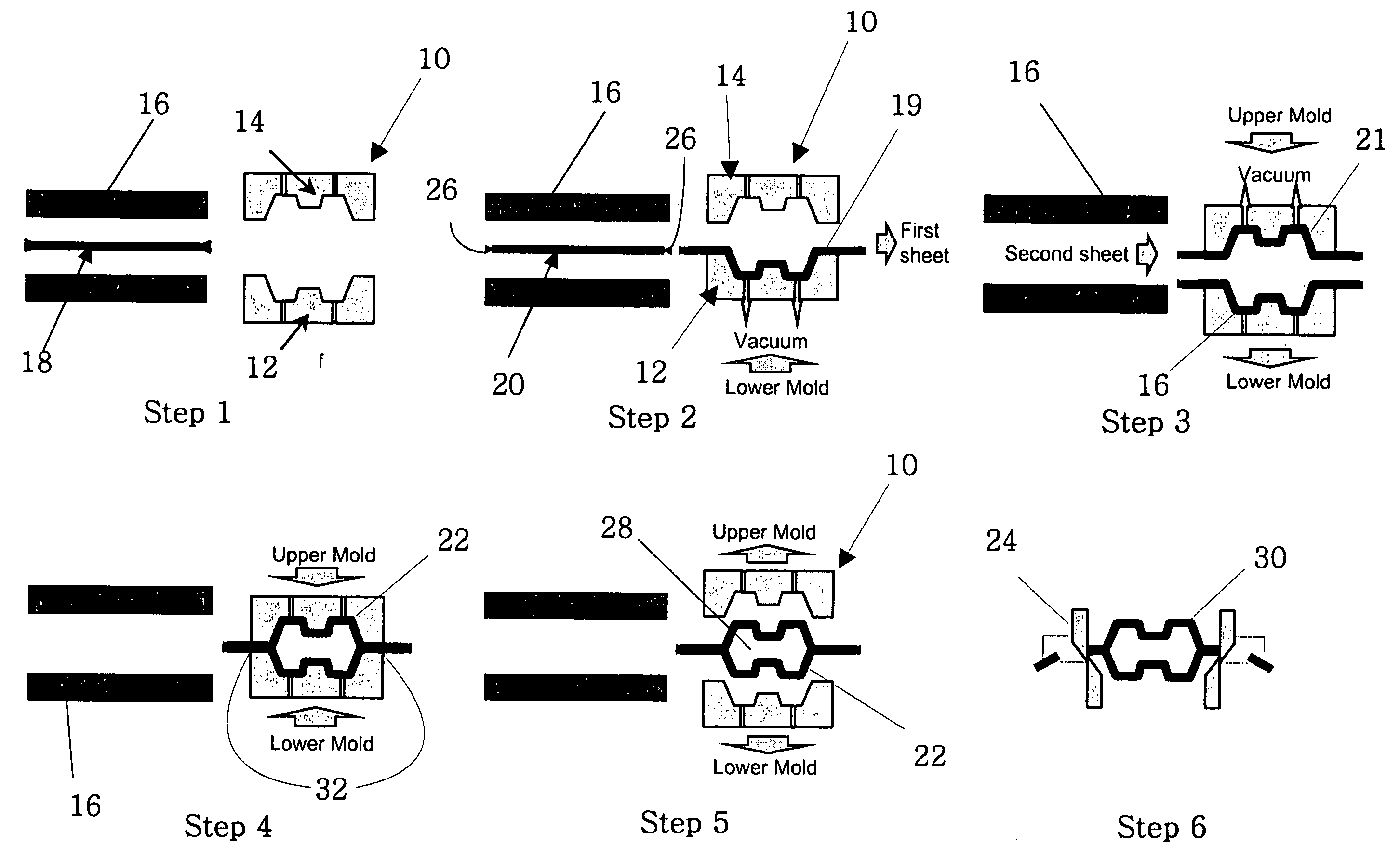

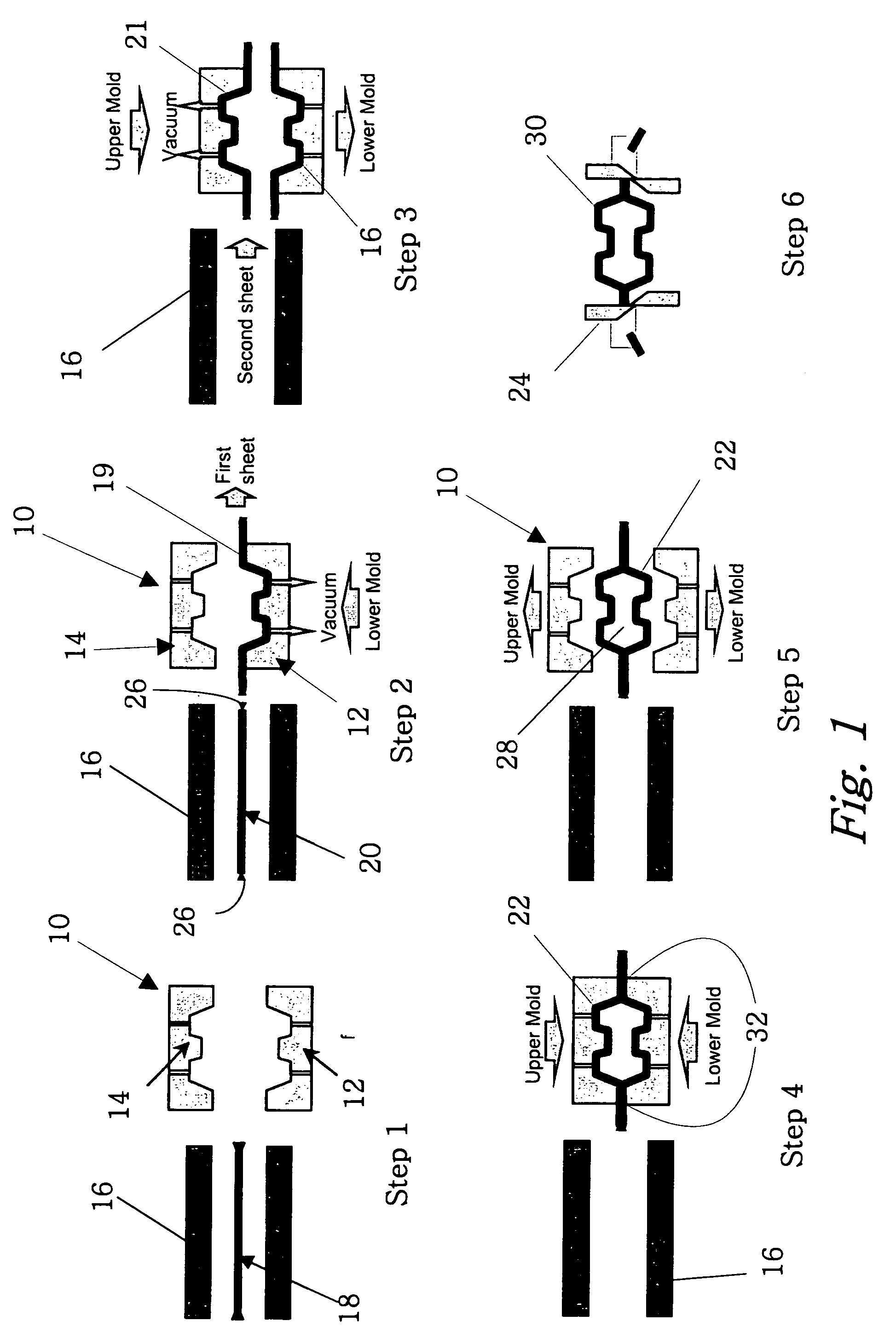

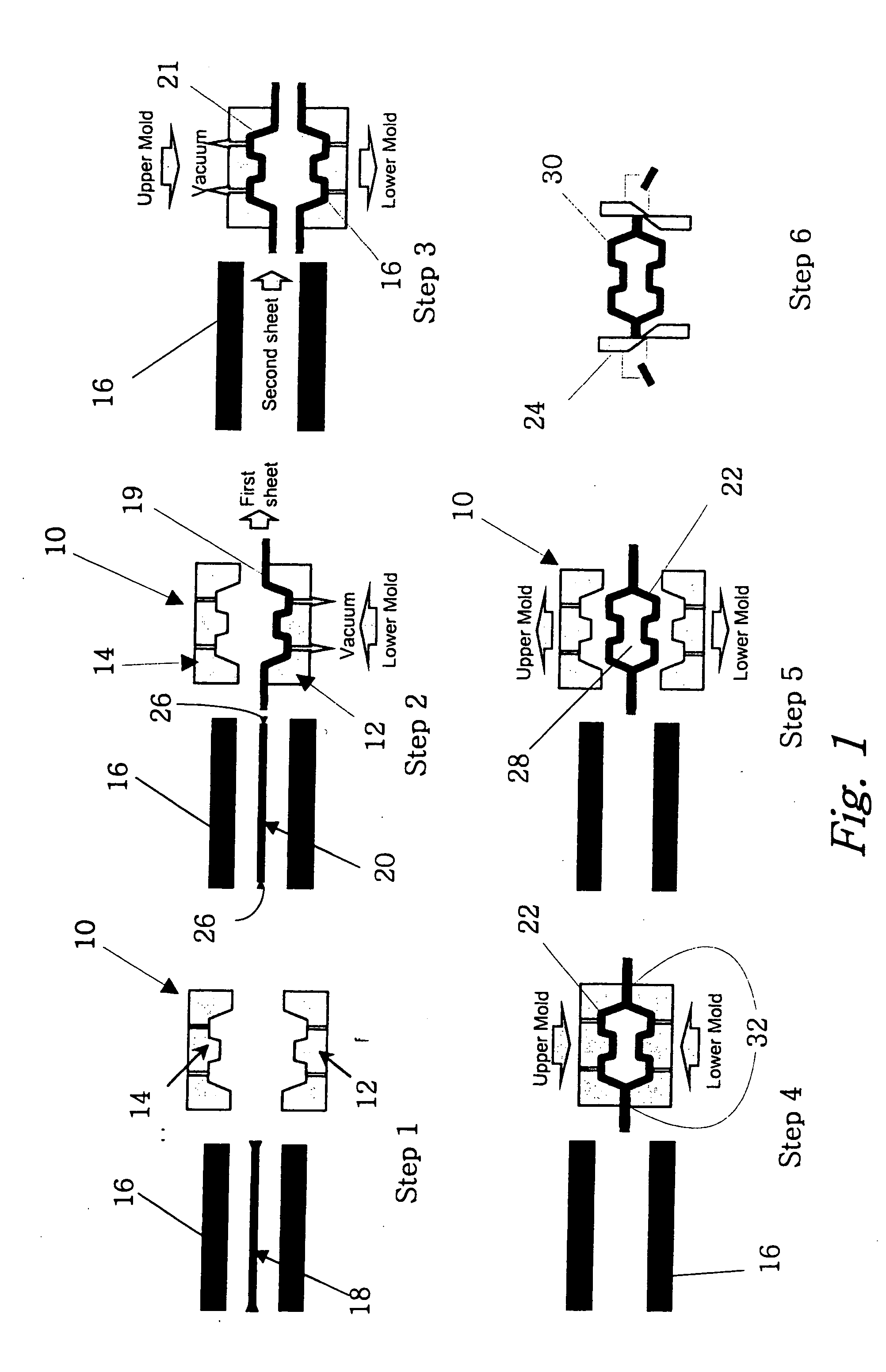

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

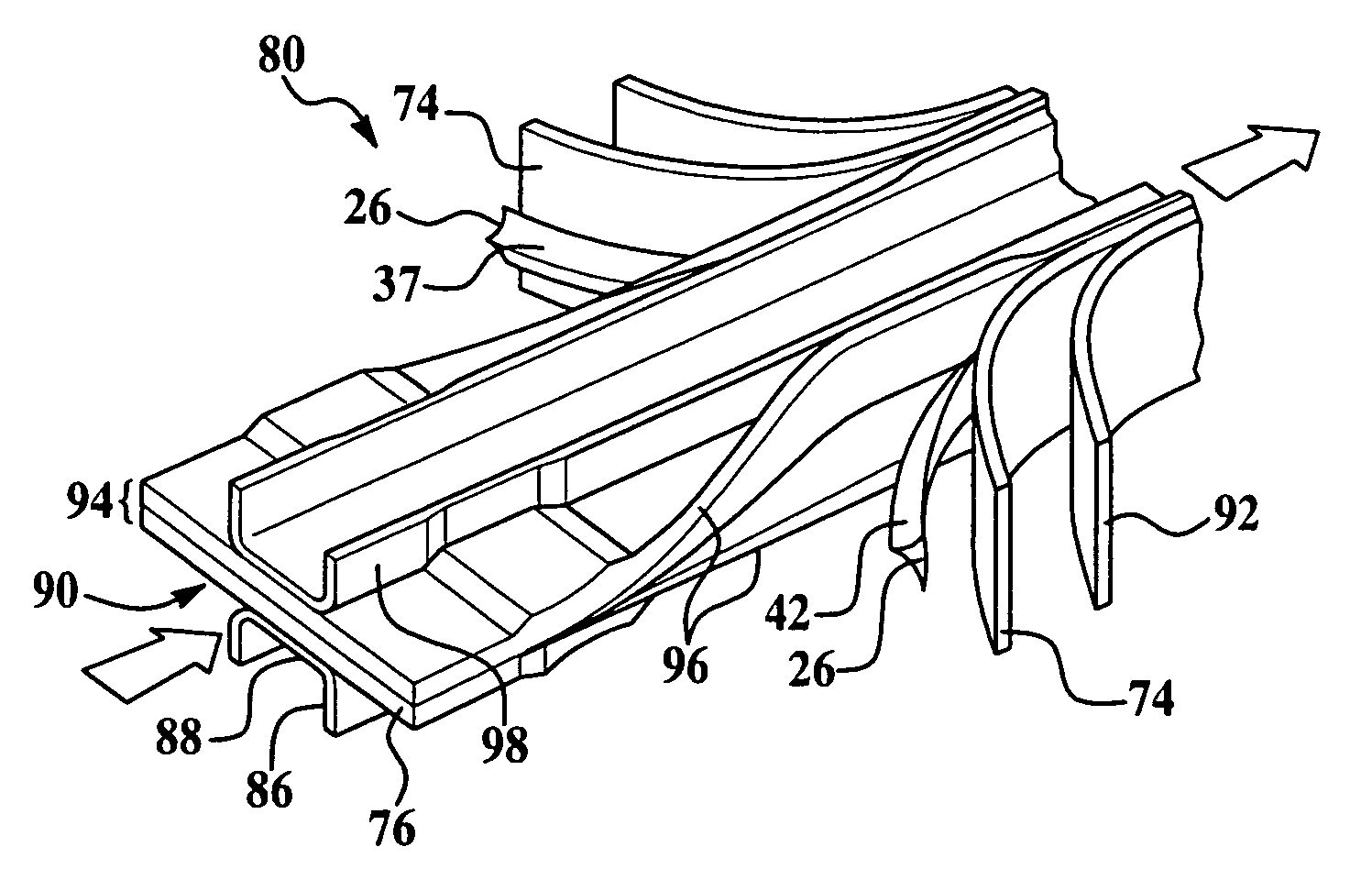

Continuous Fabrication of Parts Using In-Feed Spools of Fiber Reinforced Thermoplastic

ActiveUS20070175572A1Automate processingNeed can be reduced eliminatedWood veneer joiningBaby linensEngineeringVarying thickness

Thermoplastic composite laminate parts with tailored and varying thickness and / or curved sections are manufactured in a continuous process. Automated equipment or hand lay-up is used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Some or all of the plies may be continuously fed from spools of single or multiply ply material. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

Temperature-controlled induction heating of polymeric materials

Owner:TAS ACQUISITION CO

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com