Patents

Literature

5245 results about "Antistatic agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity. Static charge may be generated by the triboelectric effect or by a non-contact process using a high voltage power source. Static charge may be introduced on a surface as part of an in-mold label printing process.

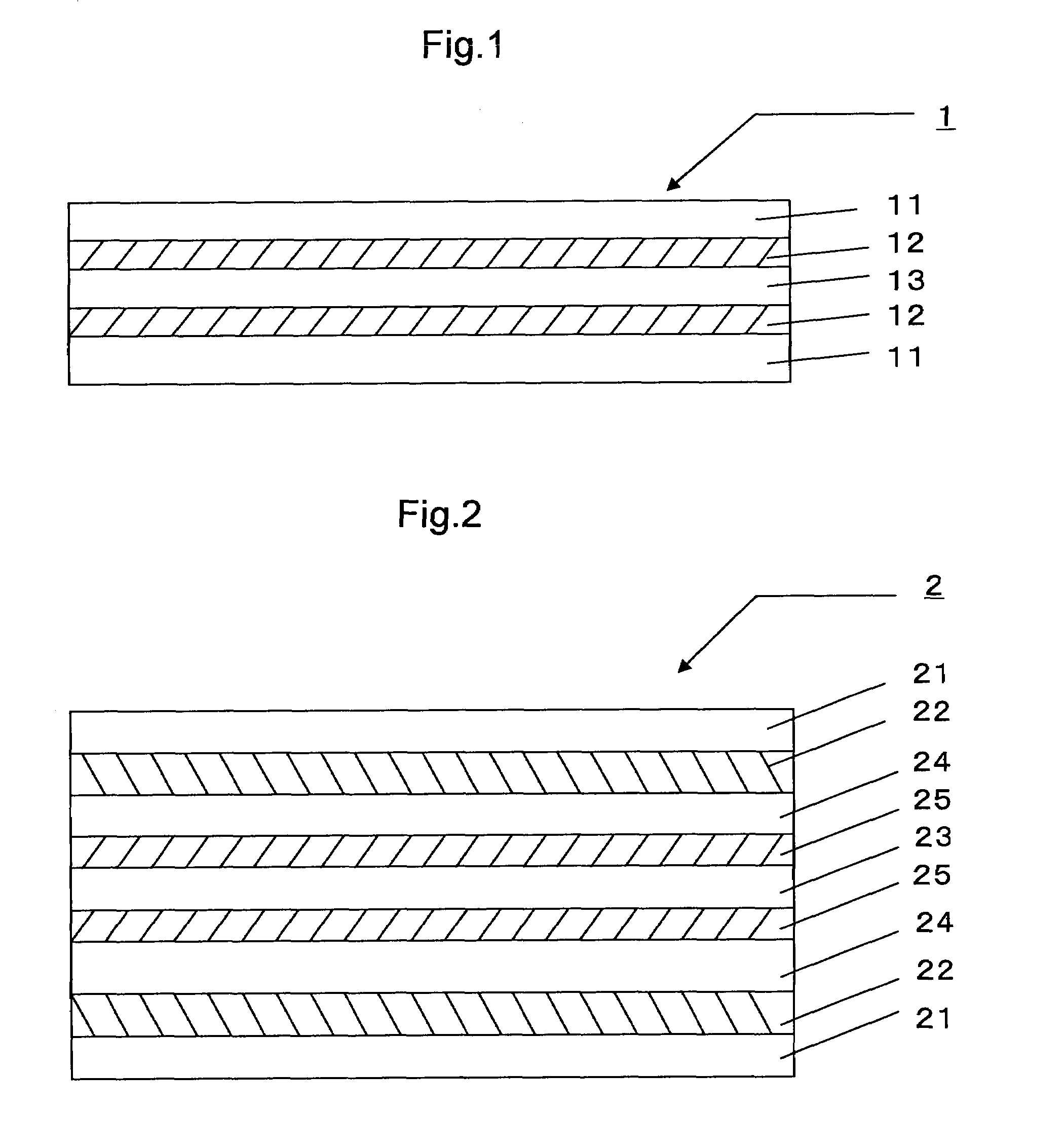

Multi-Layer Film Comprising a Barrier Layer and an Antistatic Layer

InactiveUS20100028637A1Guarantee capacityPrevent buildupSynthetic resin layered productsDomestic containersAntistatic agentEngineering

The invention relates to a multi-layer film comprising a barrier layer, a poorly extensible plastic layer, and an antistatic plastic layer arranged on the side of the barrier layer, opposing the poorly extensible plastic layer. According to the invention, either a layer of material that is generally recognised as safe in terms of food is arranged next to the antistatic plastic layer, opposing the barrier layer, said layer of material being between 5 and 20 μm thick, and the antistatic layer being approximately between 10 and 150 μm thick, or the antistatic plastic layer is embodied as a layer of material that is generally recognised as safe in terms of food, the antistatic plastic layer containing a plastic material that is generally recognised as safe in terms of food and an antistatic agent that is generally recognised as safe in terms of food.

Owner:SUNJUT DEUT

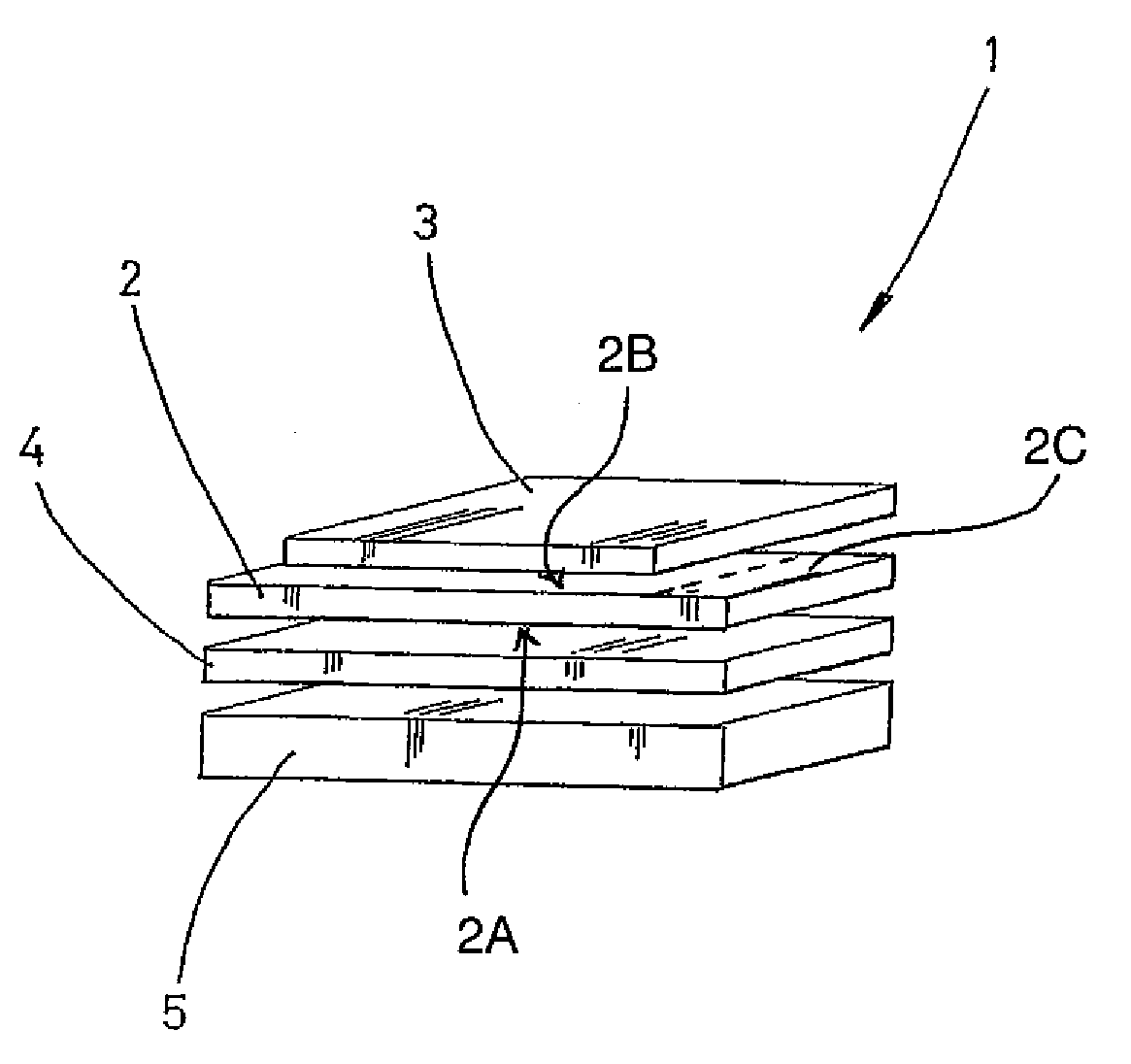

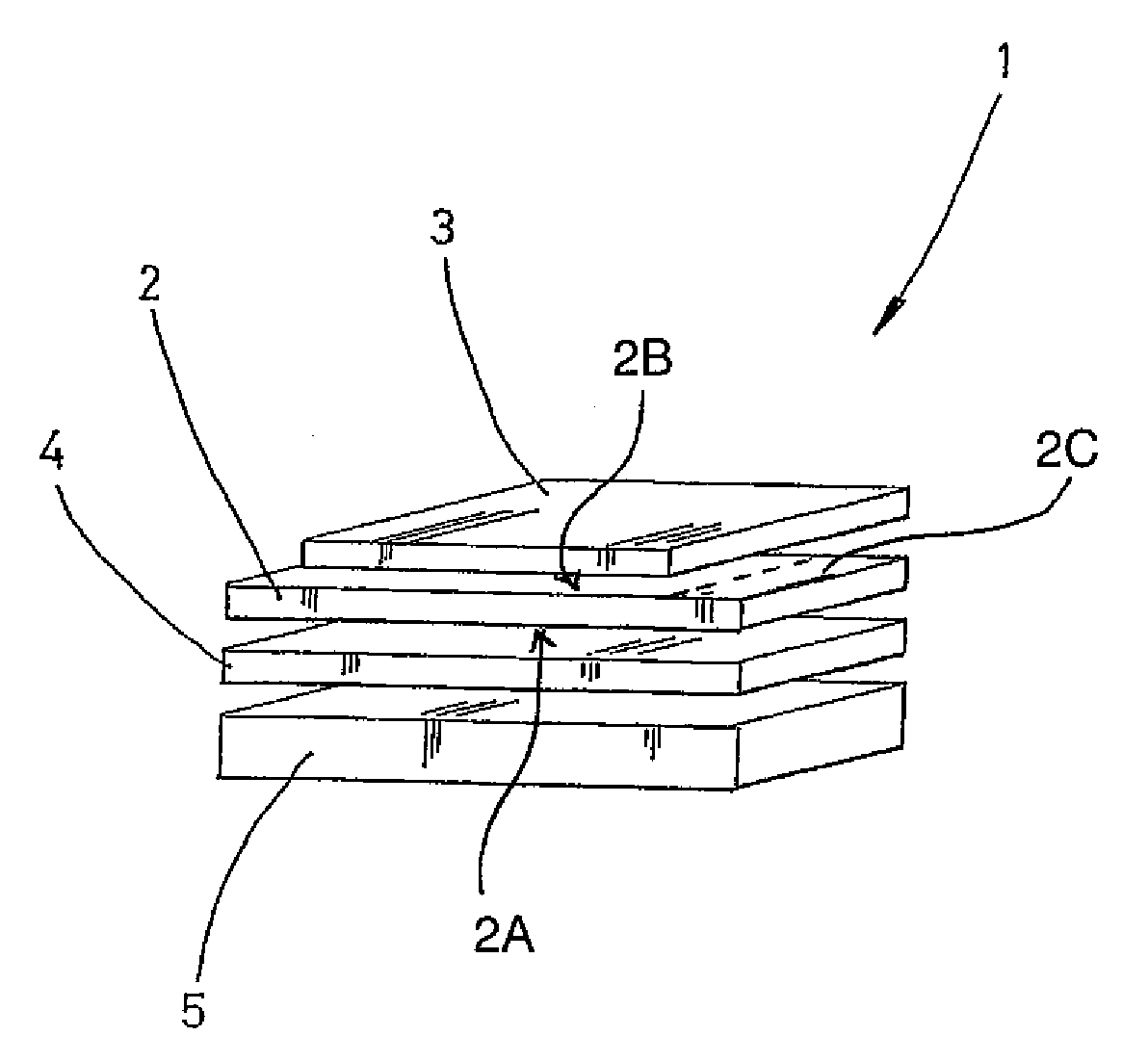

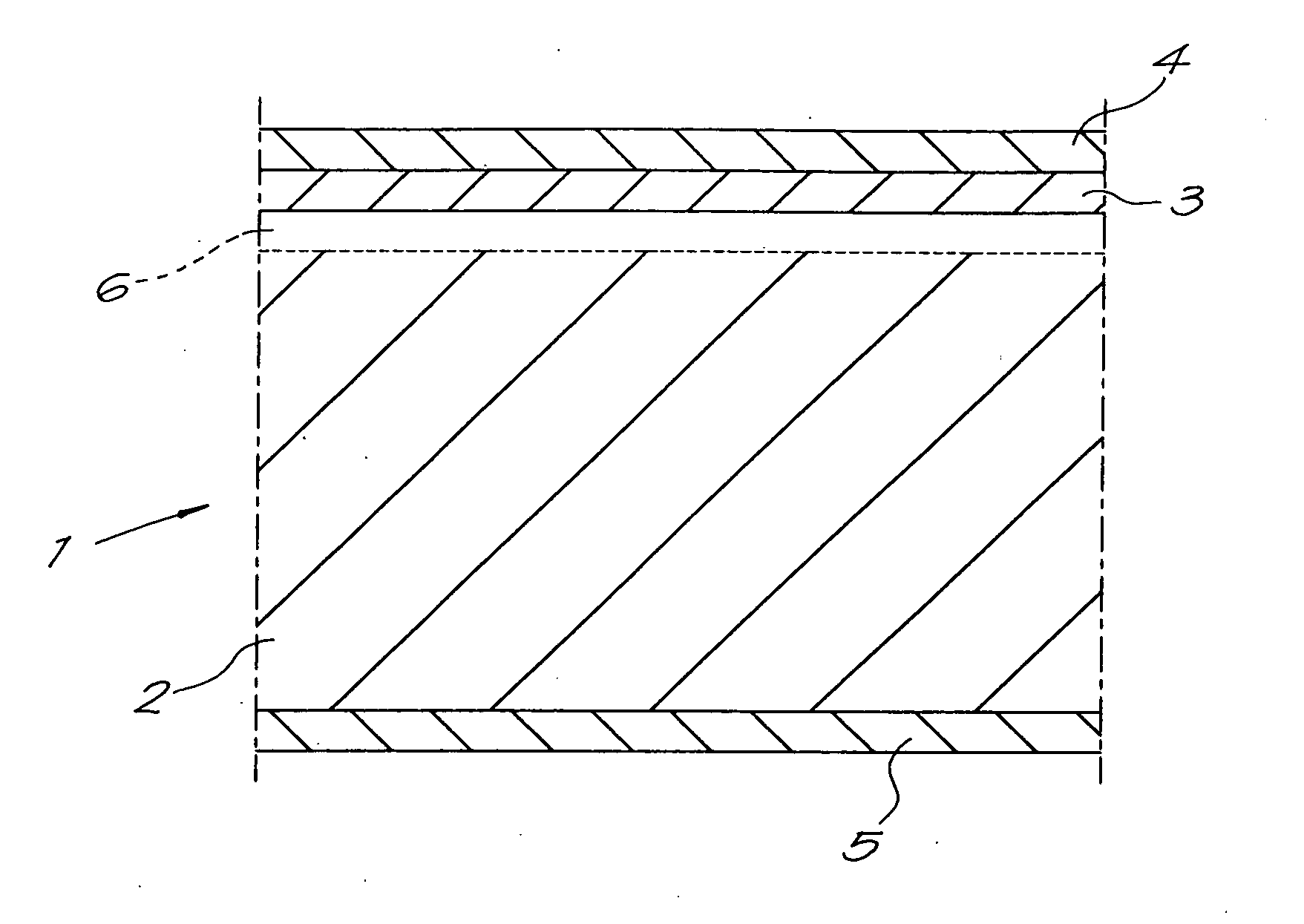

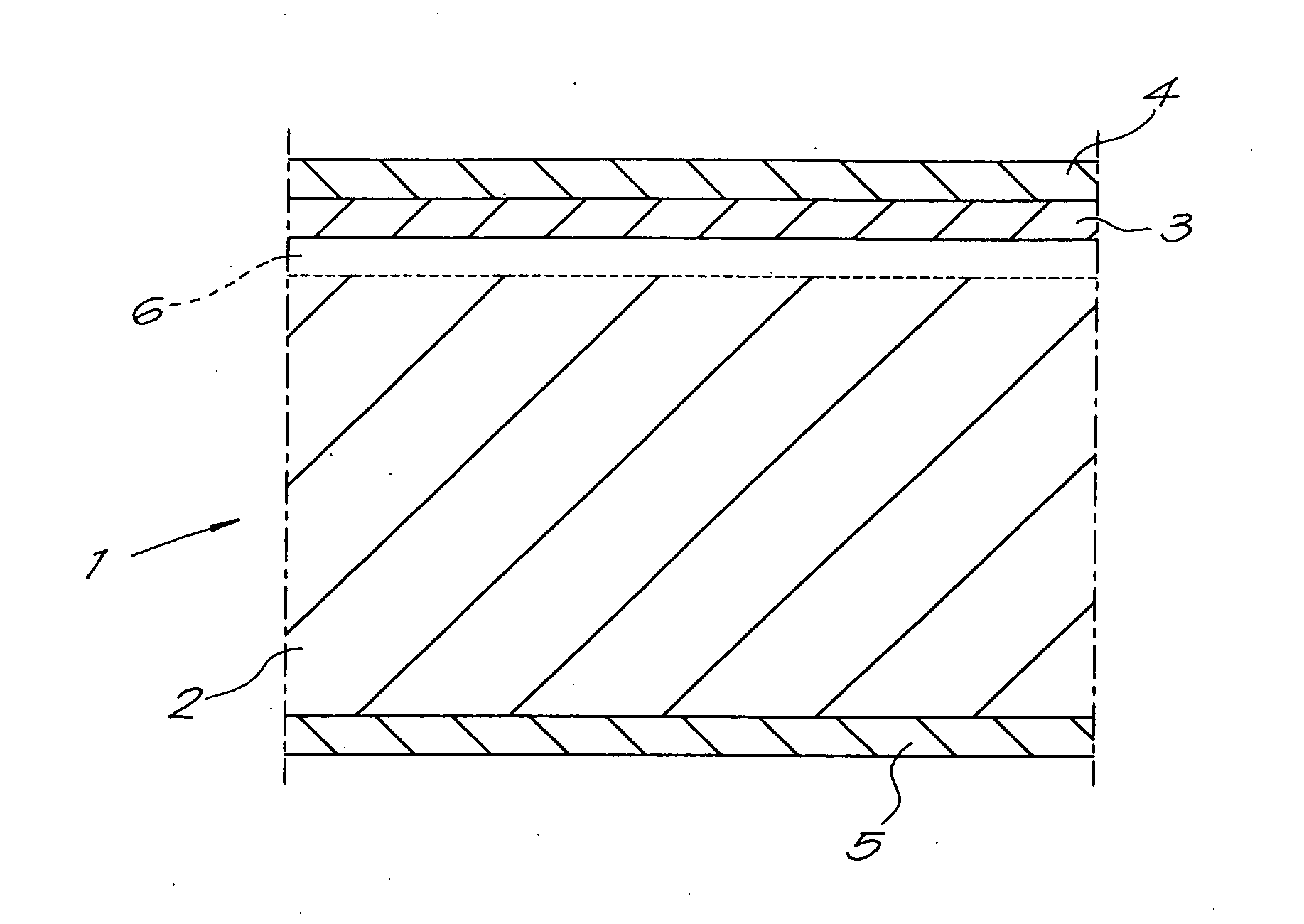

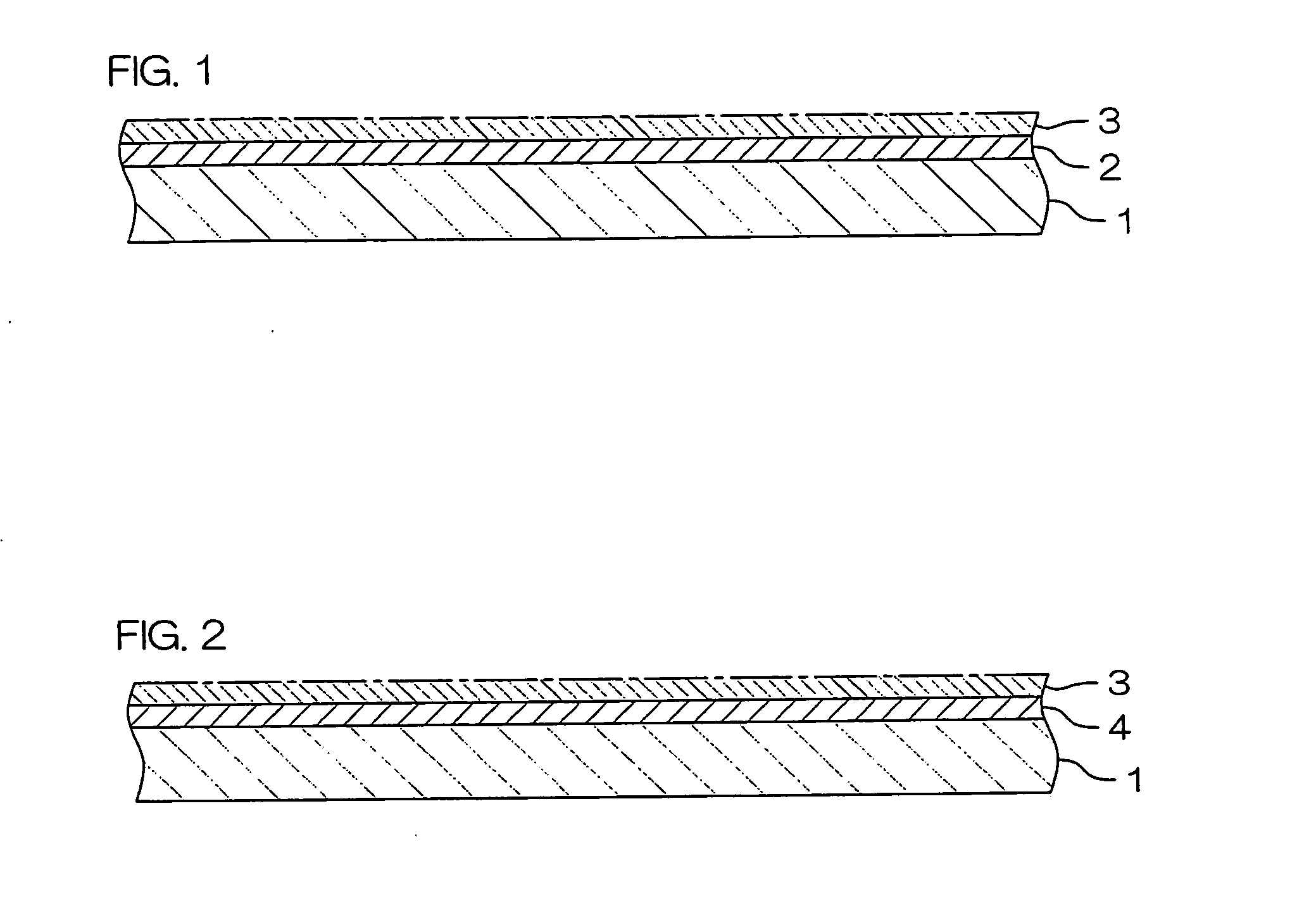

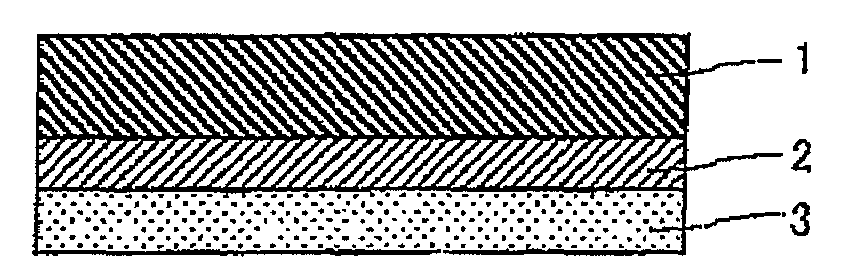

Antistatic layered panel and method of its manufacture

InactiveUS20060008630A1Simple and economic and durable mannerSynthetic resin layered productsPretreated surfacesAntistatic agentEngineering

The invention relates to an antistatic layered panel (1) including a substrate (2) and one or more layers (3, 4) on top of said substrate, said one or more layers comprising a decorative covering layer (3). At least one of the layers on top of said substrate comprises a synthetic resin and is consolidated by pressure with one or more of the other layers. The panel contains at least one antistatic agent evenly distributed in said synthetic resin over the surface of the panel. The invention relates also to methods of its manufacture and in particular to such antistatic laminated floor panels.

Owner:FLOORING IND LTD

Topical application of solid antimicrobials to carpet pile fibers during carpet manufacture

InactiveUS6641829B1Good light fastnessShampoo durabilityBiocideBiochemical fibre treatmentFiberLiquid medium

Carpeted floor covering articles comprising carpet pile fibers to which a topical antimicrobial application of solid particles has been applied either during or after product manufacture (such as part of a cleaning or treatment process) are provided. Such a topical treatment includes specific inorganic antimicrobial metal ion-based solid compounds, such as silver ion-exchange compounds, silver zeolites, and / or silver glasses, which may or may not be dispersed within a liquid medium for ease in handling and application. Such treatments also optionally include compositions of stain resistant agents, anti soil-redeposition compounds and liquids, surfactants, antistatic agents, and the like, to impart other characteristics to the target carpeted products. Such carpeted products thus exhibit excellent antimicrobial characteristics at both the surface of the carpet pile, as well as within the pile itself. Furthermore, it has been found that application of such solid metal-ion based antimicrobials permits the ability to increase antimicrobial activity for the target carpet product after vacuuming.

Owner:SAGE AUTOMOTIVE INTERIORS INC

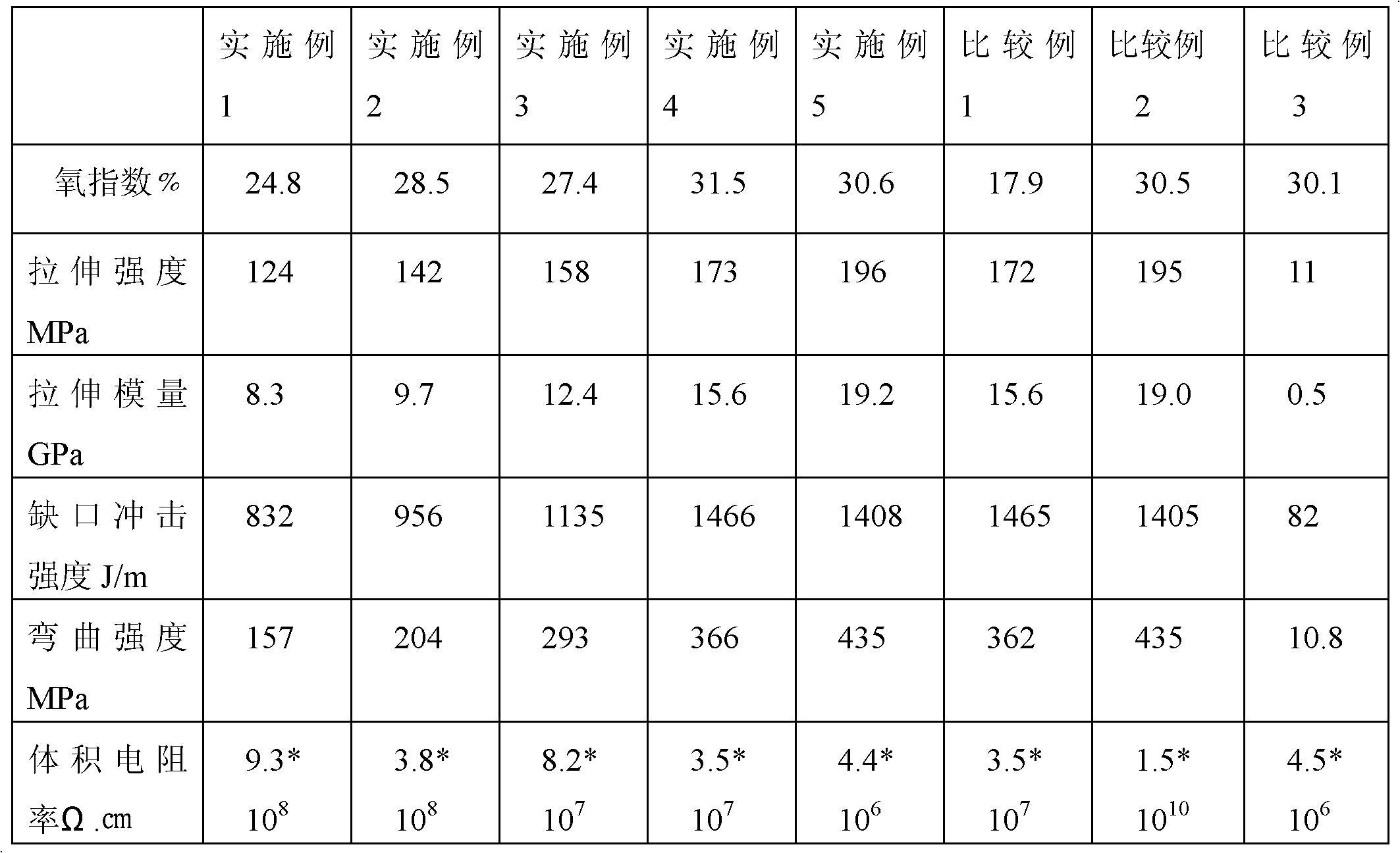

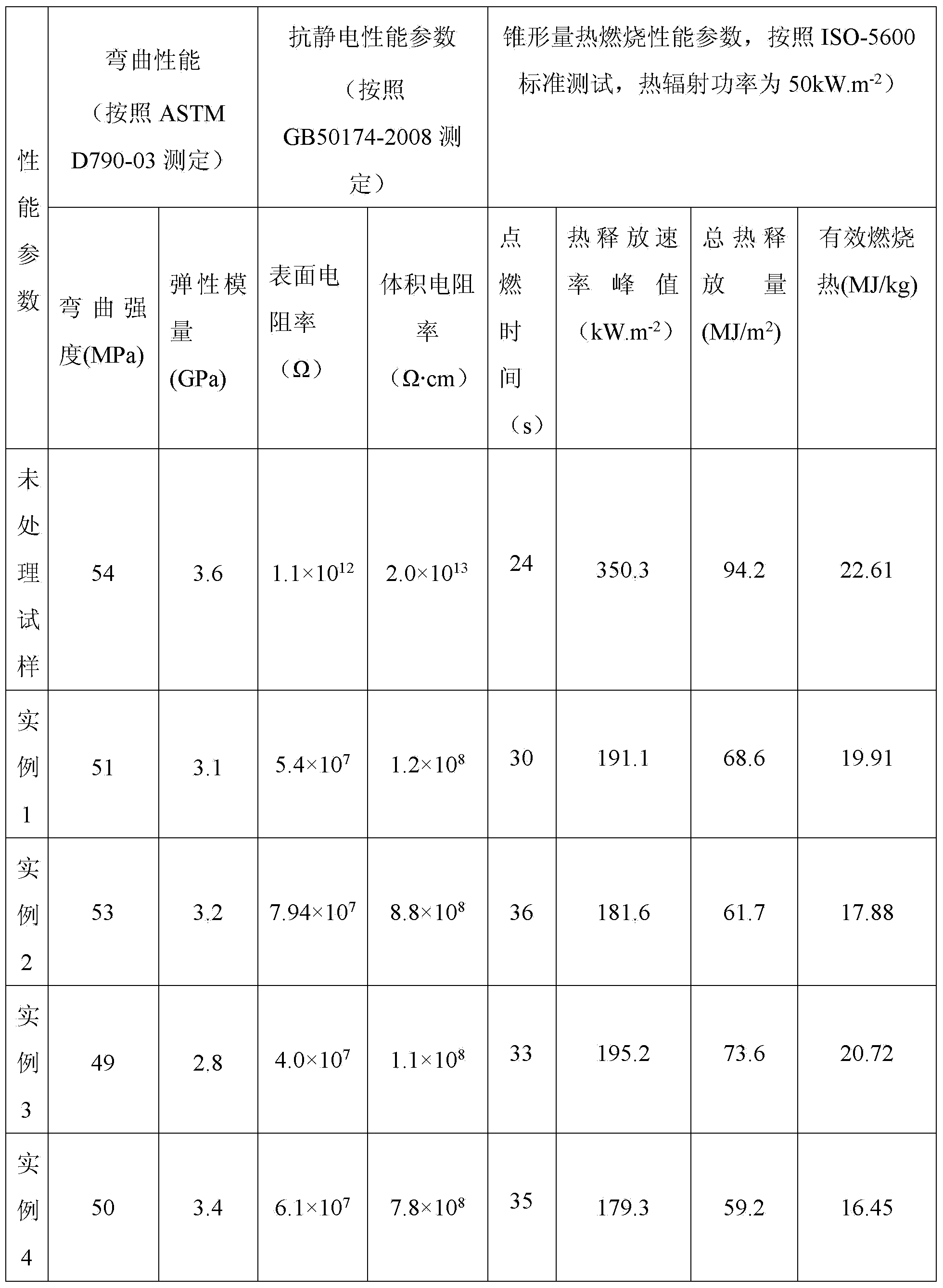

Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

The invention belongs to polymer modification technical field and processing technology field, and discloses a flame-retardant antistatic high-strength thermoplastic composite material and its preparation method. The material comprises (by weight share) 80-100 thermoplastic resin, 50-120 reinforcing fiber, 8-18 flame retardant, 0-5 flame retardant synergistic agent, 0.5-1.8 antistatic agent, 15-30 compatibilizer, 4-10 composite antioxidants, and 0-80 other additives. The invention also discloses the thermoplastic composite material preparation method. The inventive lame-retardant antistatic high-strength thermoplastic composite material has high tension and bending strength, high impact resistance property at low and high temperature, obvious antistatic property, high flame-retardant and fire proof performance. It can reach UL-94 V-O level standard.

Owner:杭州电力设备制造有限公司建德冠源成套电气制造分公司

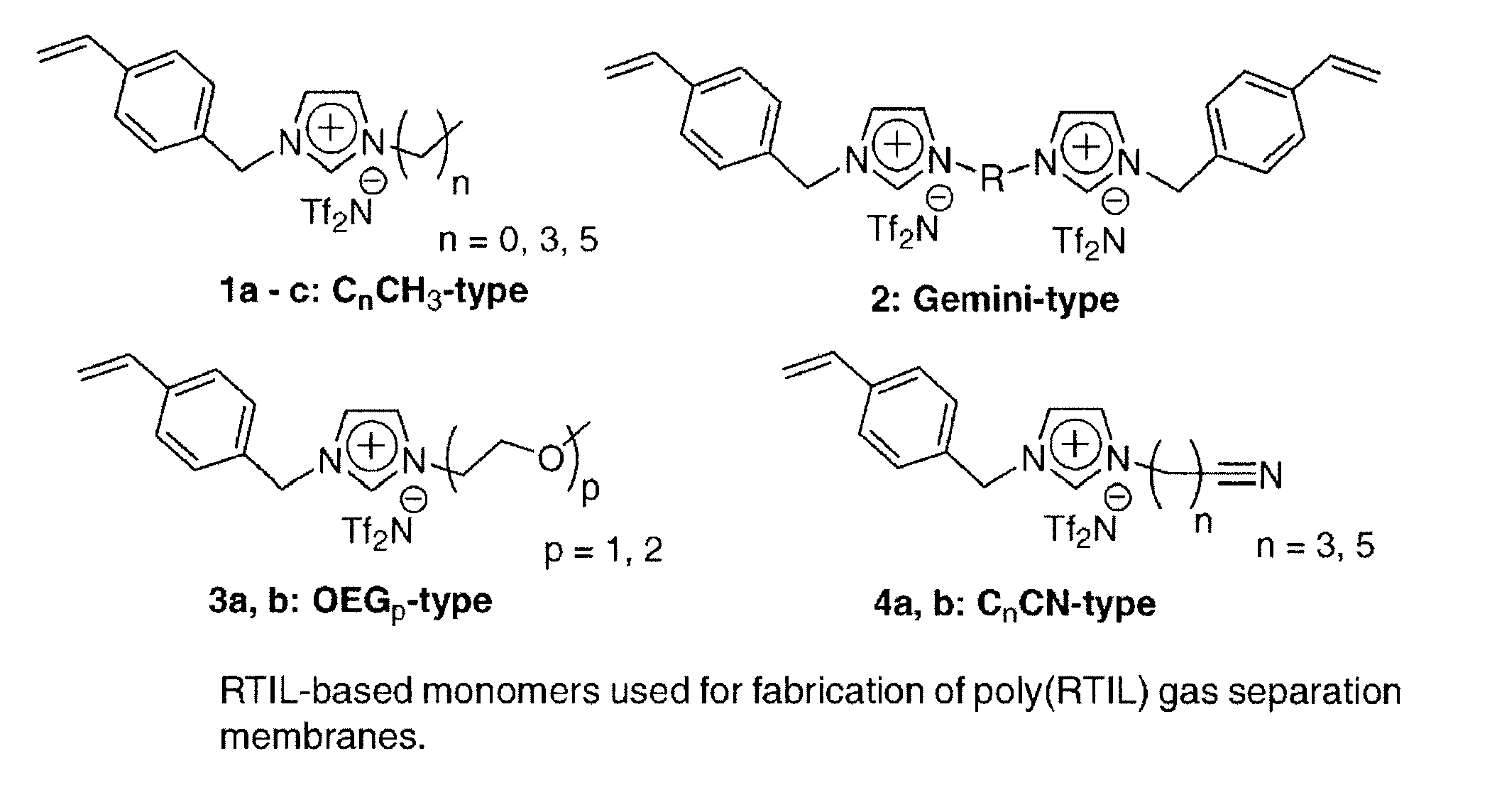

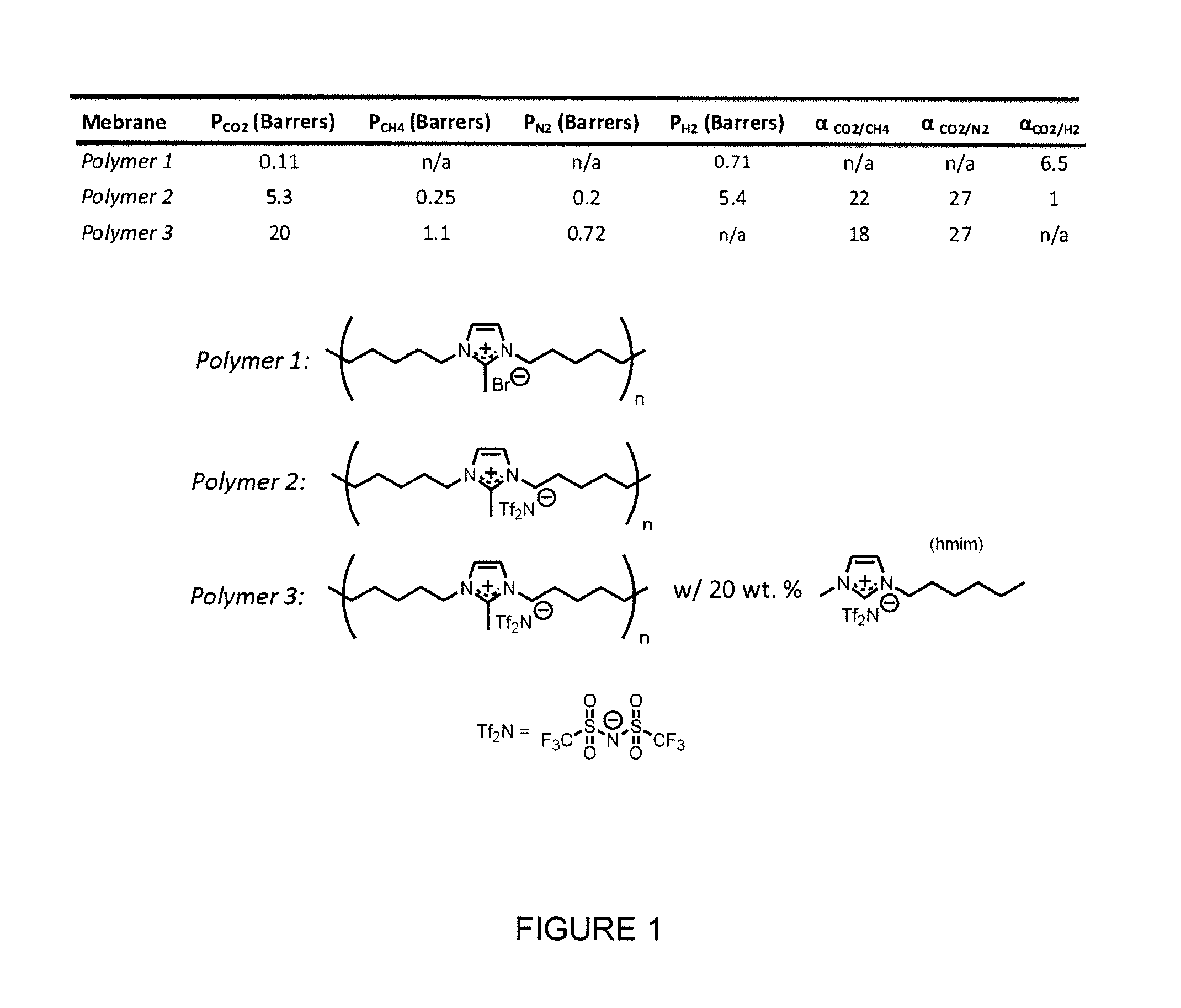

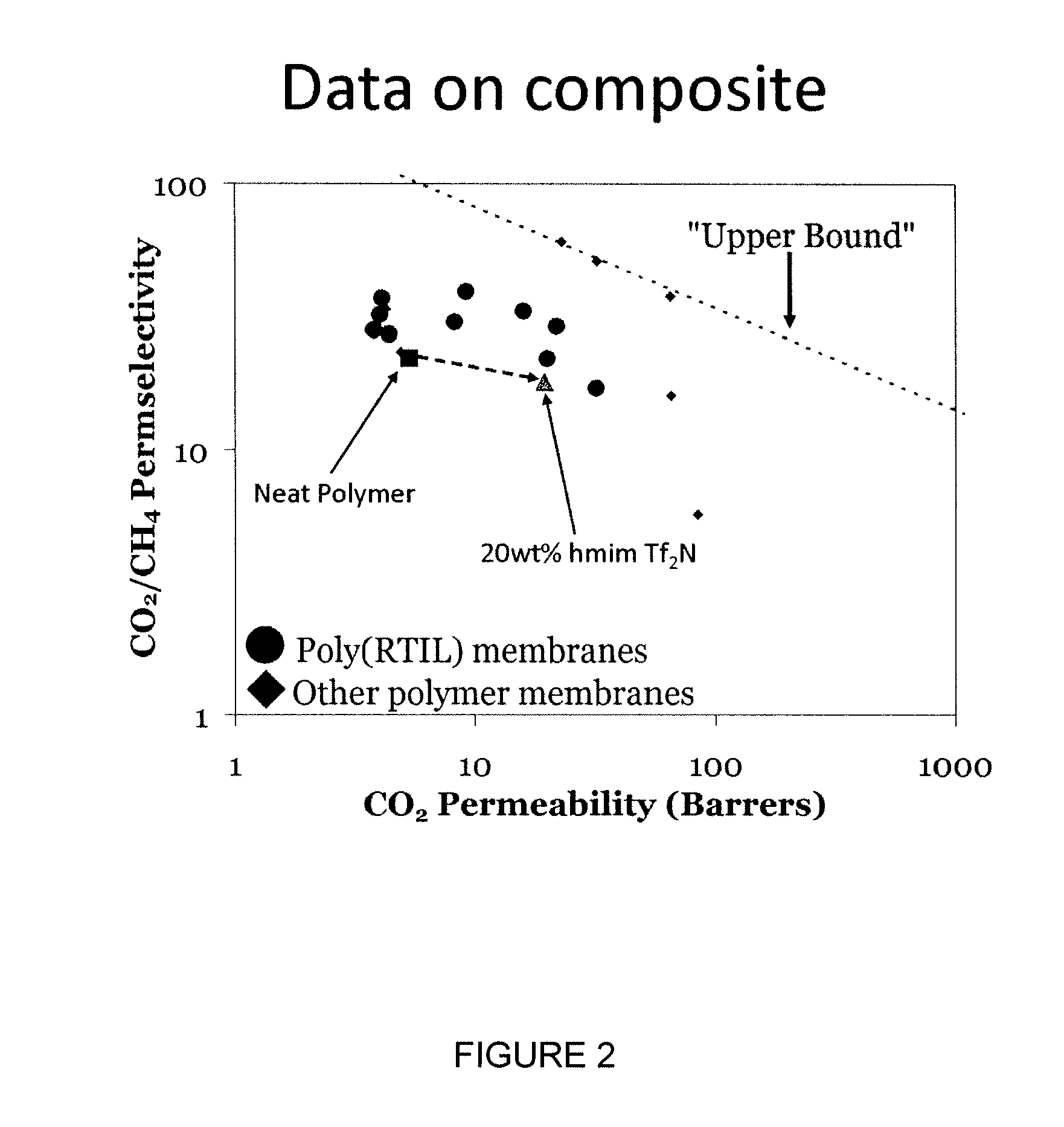

Imidazolium-based room-temperature ionic liquids, polymers, monomers, and membranes incorporating same

ActiveUS20120186446A1Low production costSimple chemistryLiquid crystal compositionsMethane captureAntistatic agentRoom temperature

The present invention provides gels, solutions, films, membranes, compositions, and other materials containing polymerized and / or non-polymerized room-temperature ionic liquids (RTILs). These materials are useful in catalysis, gas separation and as antistatic agents. The RTILs are preferably imidazolium-based RTILs which are optionally substituted, such as with one or more hydroxyl groups. Optionally, the materials of the present invention are composite materials comprising both polymerized and non-polymerized RTILs. The RTIL polymer is formed from polymerized RTIL cations typically synthesized as monomers and polymerized in the presence of the non-polymerized RTIL cations to provide a solid composite material. The non-polymerized RTIL cations are not covalently bound to the cationic polymer but remain as free cations within the composite material able to associate with charged subunits of the polymer. These composite materials are useful in catalysis, gas separation, and antistatic applications.

Owner:UNIV OF COLORADO THE REGENTS OF

Polyvinyl chloride antistatic dust-proof modified window section bar and producing method thereof

The invention discloses a kind of window PCE shaped material with antistatic and dustproof function and its manufacturing method. It raw materials are composes of PVC resin powder, antistatic agent, impact modifier, stabilizer, filler and processing aid in accordance with the weight ratio of 100:0.2-20:1-10:2-8:5-20:1-10. Then it heats and stirs the raw materials at a temperature of 100 ~ 130deg.C in the high-speed mixer, and then it slowly cools the mixture to room temperature and transfers the materials to the extruder, finally it achieves the shaped material through extrusion molding mold, vacuum cooling, traction and cutting.

Owner:LG HAUSYS TIANJIN

Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

ActiveCN104327530AAchieve flame retardant and antistatic effectImprove flame retardant performanceThermoplasticFiber

The invention discloses a flame-retardant and antistatic wood-plastic composite material and a preparation method thereof and relates to a wood-plastic composite material and a preparation method thereof. The invention aims at solving the problems of relatively poor flame retardance and relatively high cost of the existing antistatic wood-plastic composite material. The wood-plastic composite material is prepared from the following components in parts by weight: a lignocellulosic material, thermoplastic, a lubricant, an antistatic agent, a flame retardant, a coupling agent and an inorganic filler. The method comprises the following steps: 1) performing hot mixing on the lignocellulosic material, the thermoplastic and the lubricant to obtain a hot-mixed material; 2) putting the hot-mixed material into a cold mixing machine for cold mixing, and adding the weighed antistatic agent, the flame retardant, the coupling agent and the inorganic filler into the cold mixing machine for re-mixing when the temperature is lowered to 40-60 DEG C to obtain a premix; 3) putting the premix into a twin-screw extruder to perform melting, mixing and granulation; and 4) performing extrusion molding or thermoforming to prepare the flame-retardant and antistatic wood-plastic composite material. The flame-retardant and antistatic wood-plastic composite material is used in the fields of indoor buildings, decorations, decoration materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Polyolefin fibers and method for the production thereof

InactiveUS6811716B1Poor propertyPoor processabilityOther chemical processesFibre typesFiberPolyolefin

A method for producing hydrophobic polyolefin-containing fibers or filaments, in particular cardable staple fibers, using spin finishes applied after spinning and stretching, that comprise at least one water-insoluble ester of a mono-, di-, tri- or tetrahydric alcohol with a molecular weight not exceeding 500 and a branched or straight chain fatty acid with between 12 and 30 carbon atoms, e.g. a water-insoluble ester of ethylene or propylene glycol, glycerol, neopentyl glycol, trimethylolethane or trimethylolpropane and at least one saturated or unsaturated fatty acid residue having 12-24 carbons atoms, an anionic or nonionic antistatic agent preferably being applied after crimping; fibers produced by the method; and nonwovens produced from such fibers.

Owner:FIBERVISIONS LP

Halogen-free flame retardant antistatic PC/ABS alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof, belonging to the technical field of alloy materials. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention comprises the following components in parts by weight: 1-30 parts of ABS resin, 40-90 parts of PC resin, 8-20 parts of fire retardant, 1-10 parts of flexibilizer, 0.02-0.5 part of antistatic agent, 0.1-1 part of photo-thermal stabilizing agent and 0.1-1 part of processing agent. The invention also discloses a preparation method of the halogen-free flame retardant antistatic PC / ABS alloy material, which comprises the following steps of: mixing the 1-30 parts of ABS resin, the 40-90 parts of PC resin, the 8-20 parts of fire retardant, the 1-10 parts of flexibilizer, the 0.02-0.5 part of antistatic agent, the 0.1-1 part of photo-thermal stabilizing agent and the 0.1-1 part of processing agent, and then sending to a dual-screw extruder, mixing, extruding, staying, cooling, sized-dicing and obtaining a finished product of the halogen-free flame retardant antistatic PC / ABS alloy material. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention has the advantages of simple process, continuity, high production efficiency and stable quality.

Owner:HEFEI GENIUS NEW MATERIALS

Biaxially oriented polylactic acid-based resin films

InactiveUS7175917B2Synthetic resin layered productsCeramic shaping apparatusDynamic viscoelasticityAntistatic agent

The present invention provides a biaxially oriented film of a polylactic acid resin that is suitable for films for bags and packaging films for various windows, particularly films for outlook window envelopes. The film is biodegradable and, as films for outlook window envelopes, is superior in the coating adaptability for an antistatic agent, a lubricant and an antiblocking agent or the like and in the high-speed cutting property.The present invention discloses a biaxially oriented film of a polylactic acid resin comprising not less than 50% by weight of a polylactic acid resin, which has a storage modulus E′at 80° C. within the range from 10 MPa to 3,000 MPa, as determined by the test method for temperature dependency of dynamic viscoelasticity, in accordance with JIS K7198 (method A); a heat shrinkage of not higher than 10%, upon heating at 80° C. for 10 seconds; and a tear strength in the width direction (TD direction) of the film of 10 to 200 mN, as determined in accordance with JIS K7128 (method B).

Owner:ASAHI KASEI LIFE & LIVING CORP

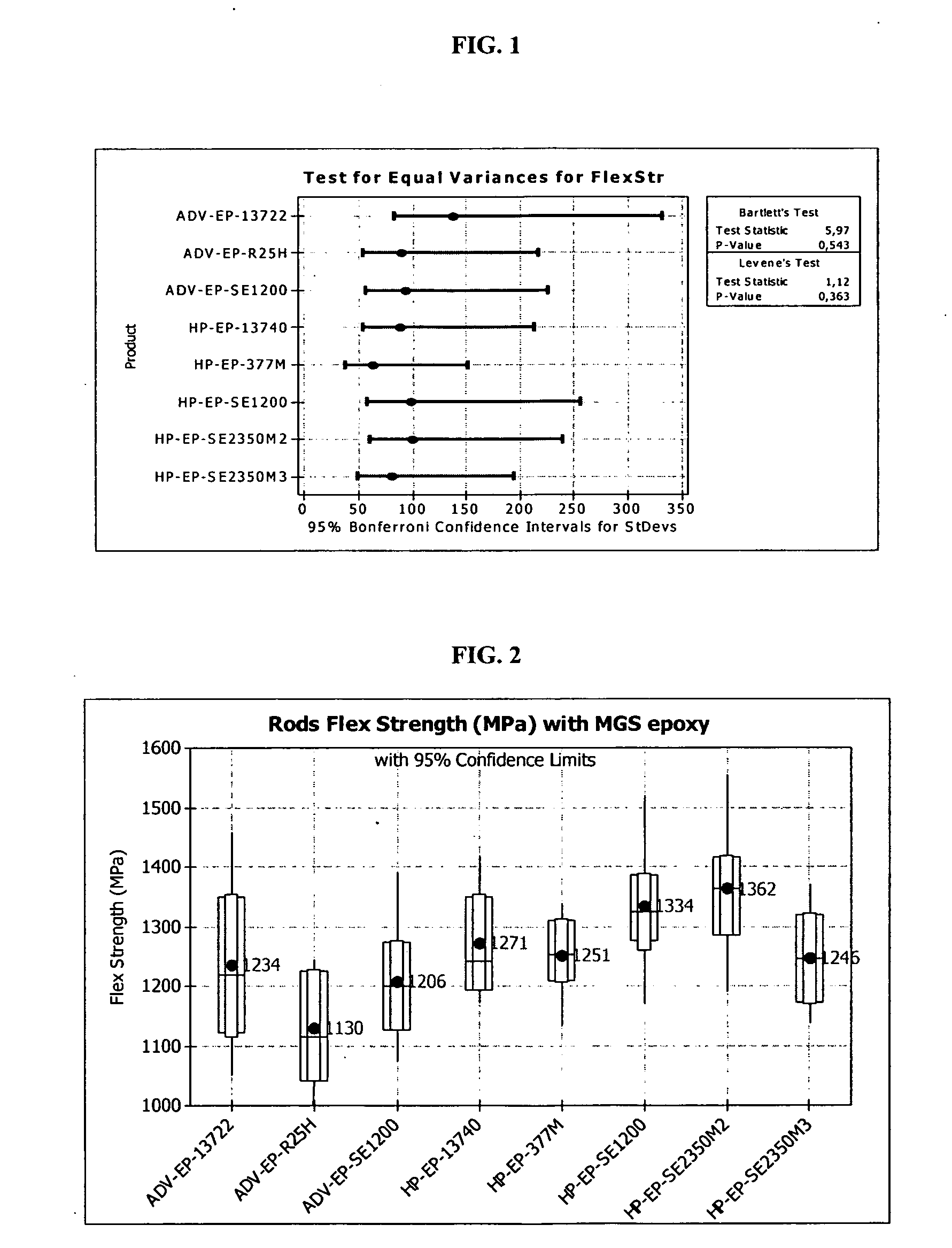

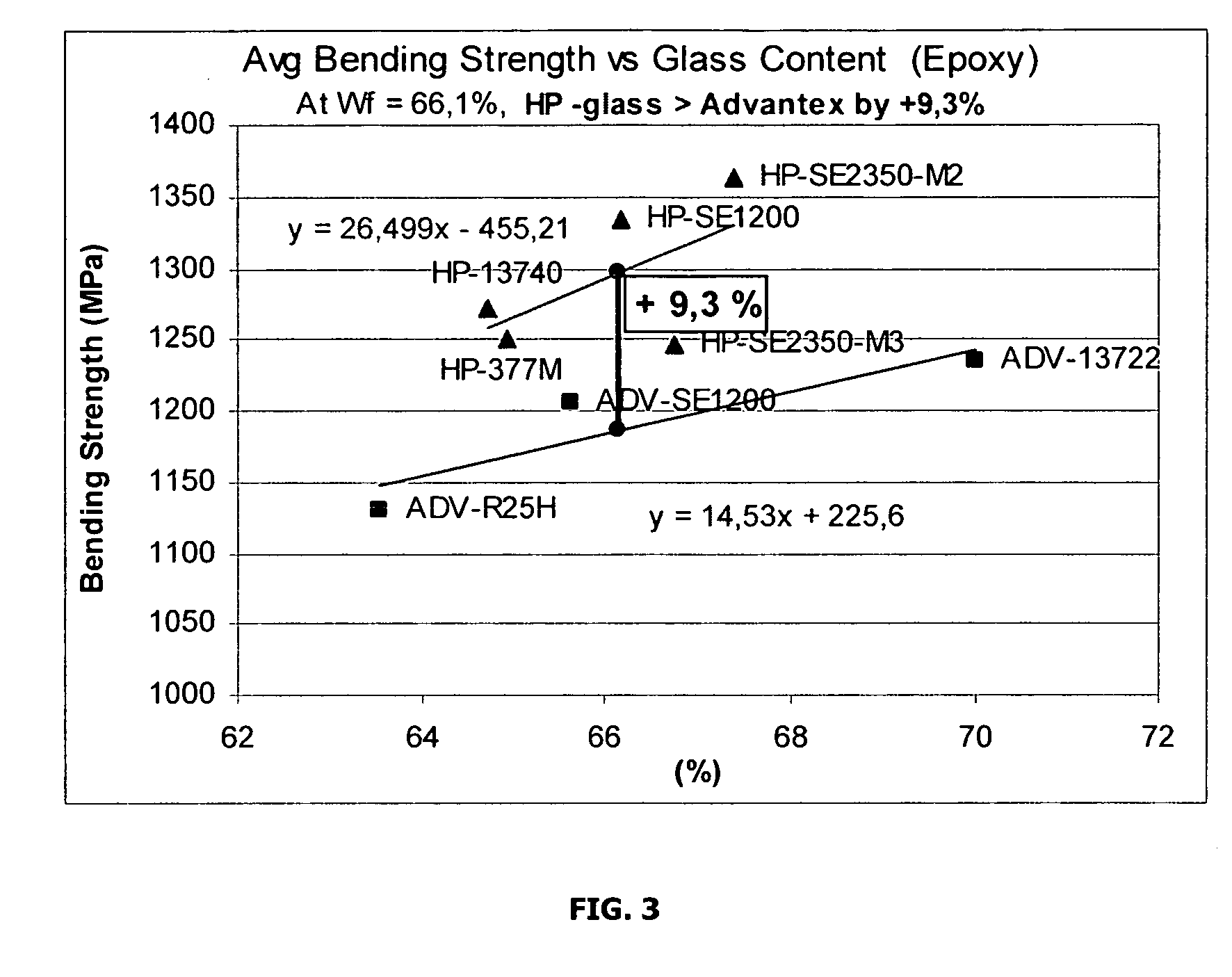

Sizing for high performance glass fibers and composite materials incorporating same

ActiveUS20060204763A1Reduces amount of boronProcess environmental protectionOther chemical processesFibre treatmentEpoxySilanes

A sizing composition containing an epoxy film former, a urethane film former, a silane package that includes an aminosilane coupling agent and an epoxy silane coupling agent, a cationic lubricant, a non-ionic lubricant, an antistatic agent, and at least one acid is provided. The epoxy resin emulsion includes a low molecular weight liquid epoxy resin and one or more surfactants. The epoxy resin preferably has an epoxy equivalent weight from 185-192. The sizing composition may optionally contain a methacryloxy silane. The sizing composition may be used to size glass fibers used in filament winding applications to form reinforced composite articles with improved mechanical properties, wet tensile properties, improved resistance to cracking, and improved processing characteristics.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

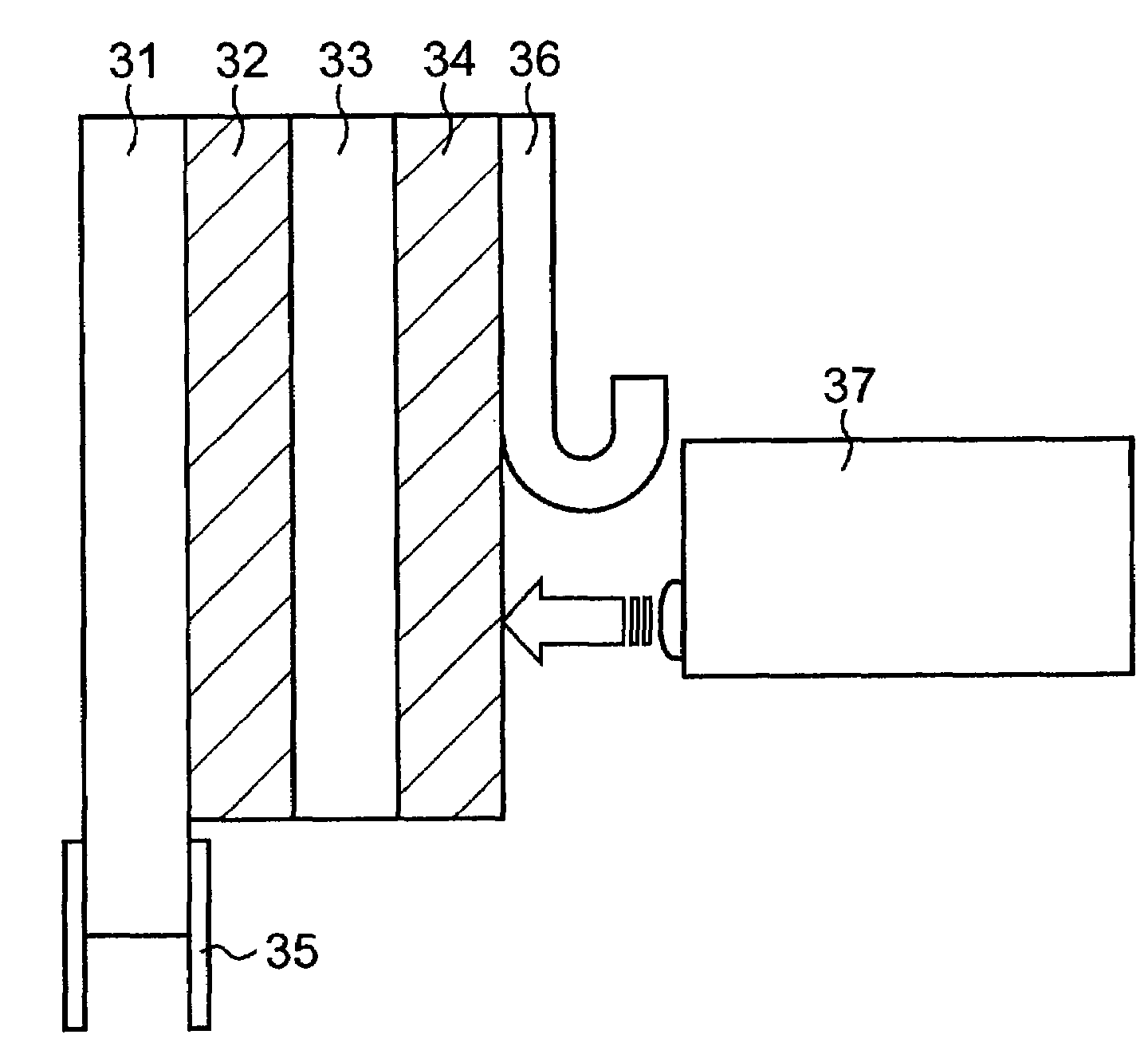

Adhesive film and image display device

InactiveUS20070031660A1Improve bindingImprove adhesionSynthetic resin layered productsLaminationAntistatic agentWater dispersible

An adhesive film prevents static charge on peeling generated when removed from an adherend and also improves adhesion between a base material and an adhesive layer, where an under coat layer containing an organometallic is formed on the base material and then an adhesive layer is formed on the base material. Alternatively, an adhesive film showing high adhesion with a glass substrate, and including an antistatic layer, which prevents static charge on peeling generated when the surface protective film is removed, and improves adhesion between a base material and an adhesive layer, where the adhesive film includes a base material, an adhesive layer made of a water dispersible adhesive including, and an antistatic layer, containing a water soluble or water dispersible conductive material, interposed between them, and the adhesive film is stuck onto an image display device.

Owner:NITTO DENKO CORP

Strengthening-toughening type antistatic antiflaming master batches and preparation method and application

InactiveCN101838418AImprove antistatic performanceImprove flame retardant performanceAntistatic agentProcedure Agents

The invention discloses strengthening-toughening type antistatic antiflaming master batches and a preparation method and application. The antistatic antiflaming master batches mainly comprise the following components of: a fire retardant, an antistatic agent, a processing aid and a carrier resin. The preparation method comprises the steps of: preparing the components in a formula ratio to obtain a mixture; plasticizing and mixing the mixture by using an internal mixer or a kneading machine first and then pelletizing by using a single screw extrusion machine to obtain the master batches; and or uniformly mixing the components by using a high mixing machine and then pelletizing the mixture by using a reciprocating type single screw extrusion machine to obtain the master batches. The antistatic antiflaming master batches not only have the antistatic and antiflaming function but also have the function of strengthening and toughening. The master batches are mainly used for plastic products, coal mine underground plastic pipes and top meshes which have high requirements on antistatic and antiflaming performance and strengthening and toughening performance, and can be used for gas transport pipelines and various plastic products of the electric appliances.

Owner:SHANXI DAXING NEW MATERIALS TECH

Damp-absorbing fast-drying and sweat-repelling fabric finishing agent, its preparing method and use

This invention relates to a method of making an absorbing moisture fast and the perspiration fabric finishing agent and its use. The fabric finishing agent including 20-60wt% fabric water affinity finishing agent or antistatic agent, 20-60wt% organosilicon softening agent, 0-20wt% water. Compares with the present technology, this invention's characteristic is as follows: it can enable the fabric to keep the moisture absorption, make the perspiration function fast, has the water affinity anti-static electricity performance, and the soft, smooth feel as well as comfortable when put on it.

Owner:SHANGHAI SAIBO CHEM

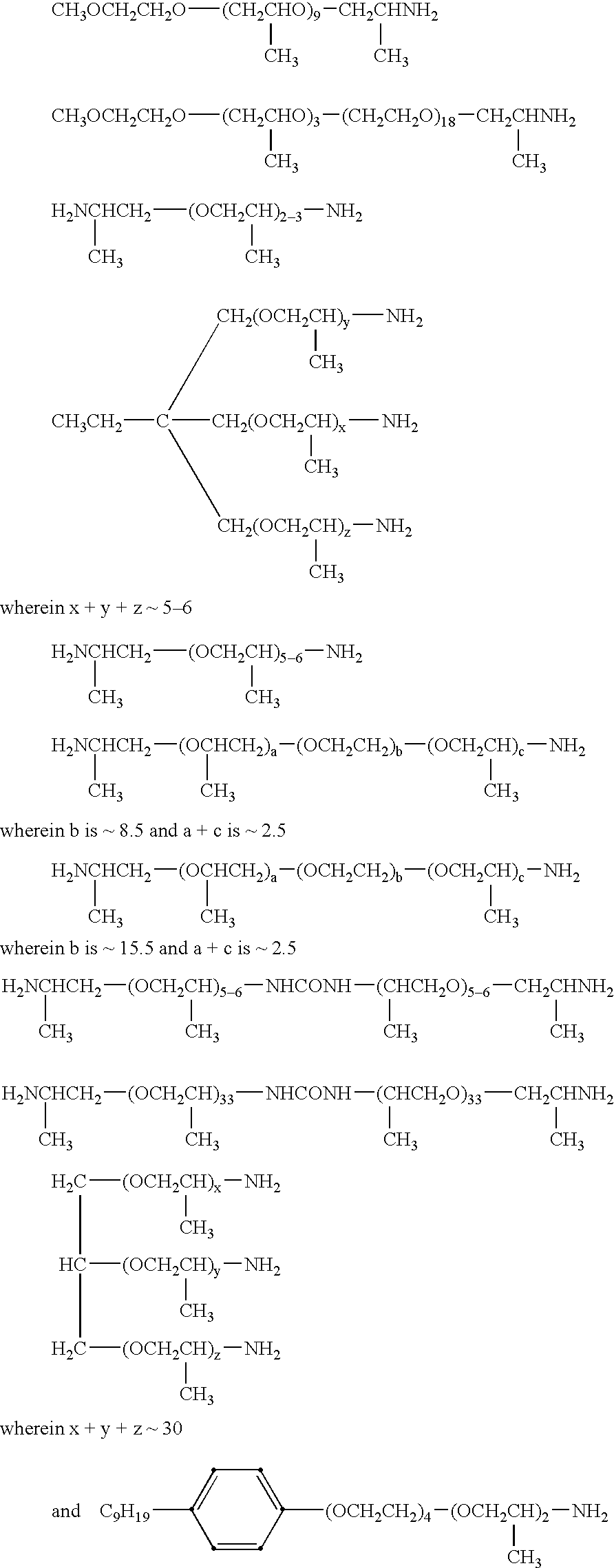

Optically clear and antistatic pressure sensitive adhesives

InactiveUS20070141329A1Natural rubber adhesivesNon-macromolecular adhesive additivesAntistatic agentPolymer chemistry

The present invention is directed to an antistatic pressure sensitive adhesive. The antistatic pressure sensitive adhesive comprises a pressure sensitive adhesive, and an antistatic agent comprising at least one organic salt. Certain embodiments of the antistatic pressure sensitive adhesive also have a luminous transmission of greater than about 89% according to ASTM D 1003-95. Additional embodiments of the antistatic pressure sensitive adhesive have a haze of less than about 5% according to ASTM D 1003-95, and in specific embodiments the haze is less than about 2% according to ASTM D 1003-95.

Owner:3M INNOVATIVE PROPERTIES CO

Special material for antistatic impact fire resistant polyethylene pipe

InactiveCN1657561AImprove antistatic performanceMeet the use requirementsTubular articlesPolymer scienceAntistatic agent

An antistatic, anti-impact and flame-retarded polyethene used for pipeline is proportionally prepared from high-density polyethene, antistatic agent, flame retarder, flame-retarded synergist, toughening agent, optical stabilizer and antioxidizing agent through mixing part of polyethene with others, extruding out to become particles, mixing with rest of polyethene, dual-screw extruding out, cooling, drying and cutting to become particles.

Owner:QINGDAO UNIV OF SCI & TECH

Basalt fiber surface modification impregnating compound and preparation method thereof

The invention discloses a basalt fiber surface modification impregnating compound and a preparation method thereof, and belongs to a basalt fiber impregnating compound. The impregnating compound comprises the following components in percentage by weight: 0.2-0.6% of organic silane coupling agent, 0.05-0.3% of pH (potential of hydrogen) conditioning agent, 3.0-10.0% of polyvinyl acetate emulsion, 0.2-2.0% of polyurethane emulsion, 0.5-3.0% of water-borne epoxy resin film forming matter, 1.0-5.0% of polyolefin emulsion, 0.1-1.0% of organic silicon emulsion, 0.1-1.0% of antistatic agent and the balance of water. The basalt fiber surface modification impregnating compound prepared according to the rated mass ratio is directly coated on the surface of basalt fiber in the basalt producing and wiredrawing process, and the surface modification is finished after the basalt fiber surface modification impregnating compound is dried, thereby being convenient to use. Meanwhile, the preparation method for the basalt fiber surface modification impregnating compound, which is disclosed by the invention, is simple, is suitable for industrial production and is easy for popularizing.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

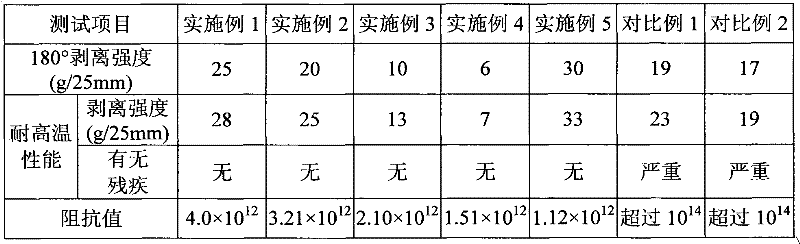

A kind of pressure-sensitive adhesive for PET protective film and preparation method thereof

ActiveCN102260478AAdaptableSlightly viscousFilm/foil adhesivesEster polymer adhesivesEthylene HomopolymersSolvent

The invention relates to a pressure-sensitive adhesive for a PET protective film and a preparation method thereof. The pressure-sensitive adhesive provided by the invention is made from the following raw materials of: by weight, 1-20 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 45 DEG C to 10 DEG C, 60-90 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 90 DEG C to minus 50 DEG C, 1-20 parts of a acrylic acid monomer containing functional groups, 0.01-15 parts of a cross-linking agent, 0.01-1 part of an initiator, 0.001-5 parts of a silane coupling agent, 0.001-5 parts of a plasticizer, 0.001-5 parts of an antistatic agent, and 70-100 parts of a solvent. The pressure-sensitive adhesive for the PET protective film in the invention has characteristics of strong adaptability to the PET basement film, microviscosity, repeelable performance, high temperature resistance and antistatic property, and can be widely applied in the production of the PET protective film. The invention also provides a preparation method ofthe above pressure-sensitive adhesive.

Owner:上海绘兰材料科技有限公司

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

Low-smoke FDY (Fully Drawn Yarn) oiling agent and preparation method thereof

The invention discloses a low-smoke FDY (Fully Drawn Yarn) oiling agent and a preparation method thereof. The low-smoke FDY oiling agent comprises the following materials in percentage by weight: 50-60% of emulsifying agent, 10-30% of smoothing agent, 6-10% of antistatic agent, 1-3% of beam concentrating agent, 9-11% of moisture, and 0.1-0.2% of preservative. The low-smoke FFY oiling agent provided by the invention has such functions of lubricating fiber, concentrating beam, preventing static electricity and the like in a production process of FDY, has the characteristics of reducing broken yarns, broken filaments, reducing dyeing and the like in a pre-spinning process, and further has the characteristics of reducing broken yarns, broken filaments, static electricity and the like in a post-processing (weaving) process, and is an important auxiliary ingredient which is essential in the production process of chemical fiber.

Owner:ZHEJIANG TIANSHENG HLDG GROUP

Antistatic Anti-glare film

InactiveUS20090142562A1Improve efficiencyLow costDiffusing elementsSynthetic resin layered productsAntistatic agentHigh humidity

An antistatic antiglare film that can remain antistatic and transparent even after a long time of use, particularly even after a long time of use at high temperature or high humidity. The antistatic antiglare film of the invention includes a transparent substrate film and an antiglare layer disposed thereon, the antiglare layer includes a polymeric antistatic agent, optically-transparent fine particles and a binder.

Owner:DAI NIPPON PRINTING CO LTD

High-precision non-water-based nano-diamond grinding fluid and preparation method and application thereof

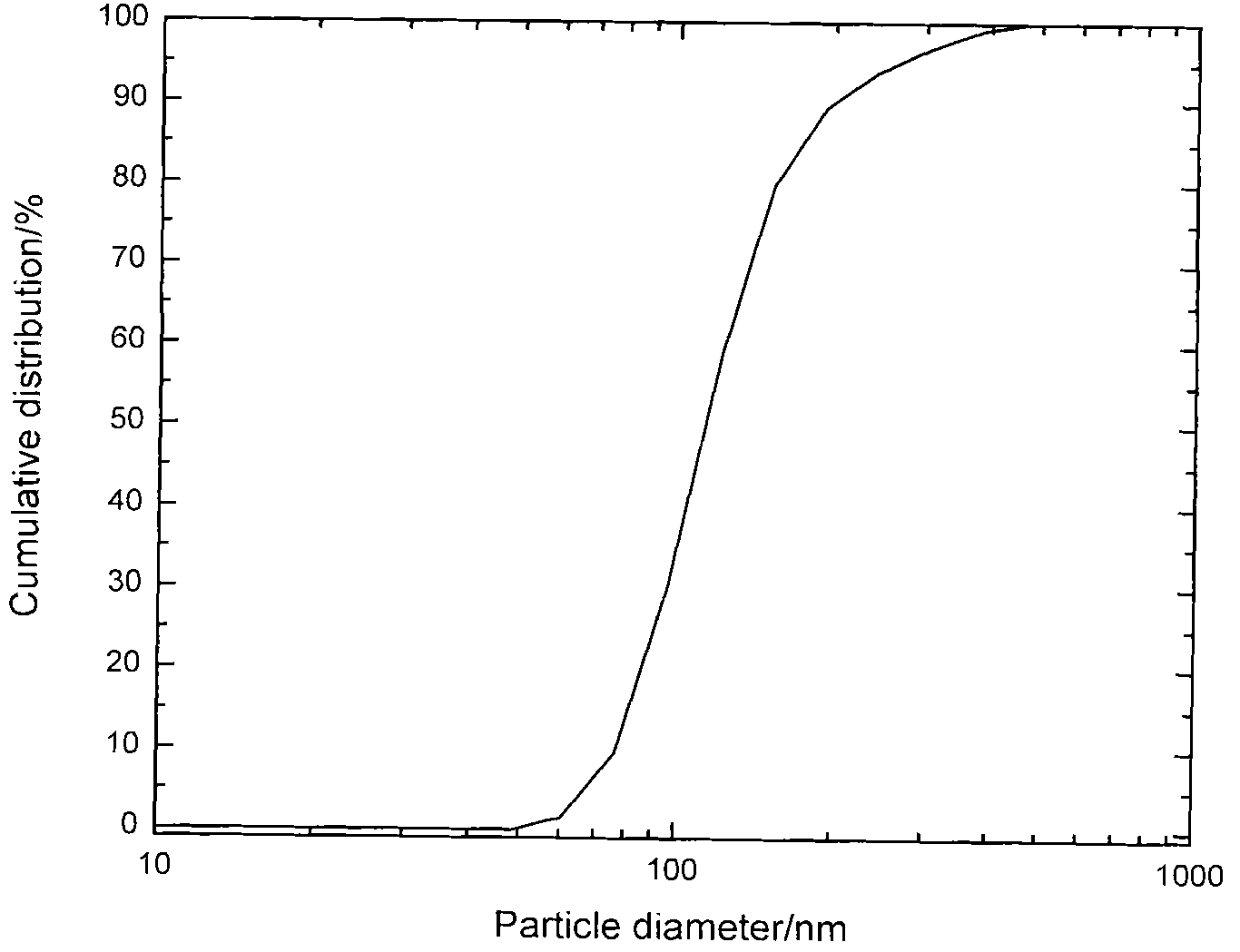

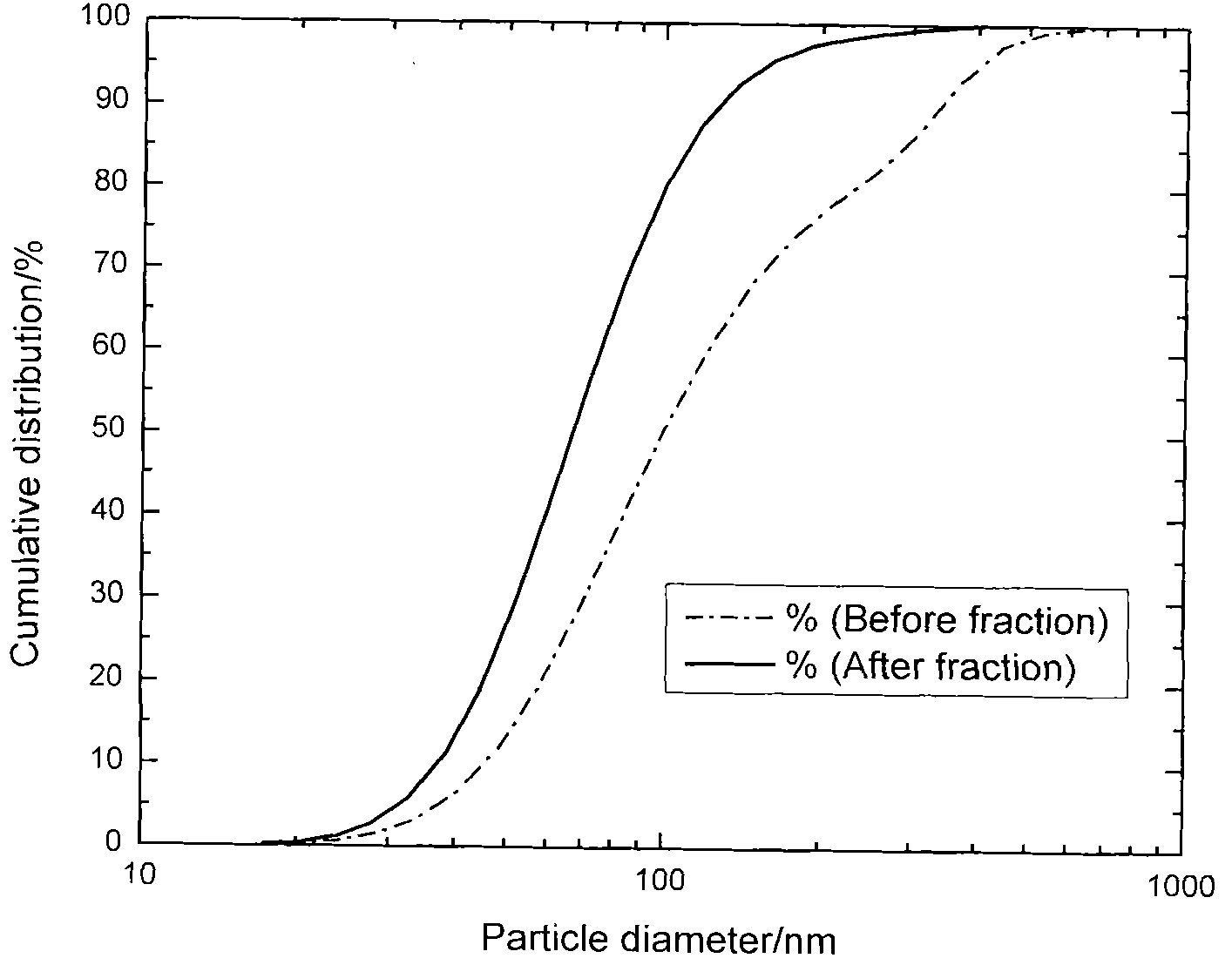

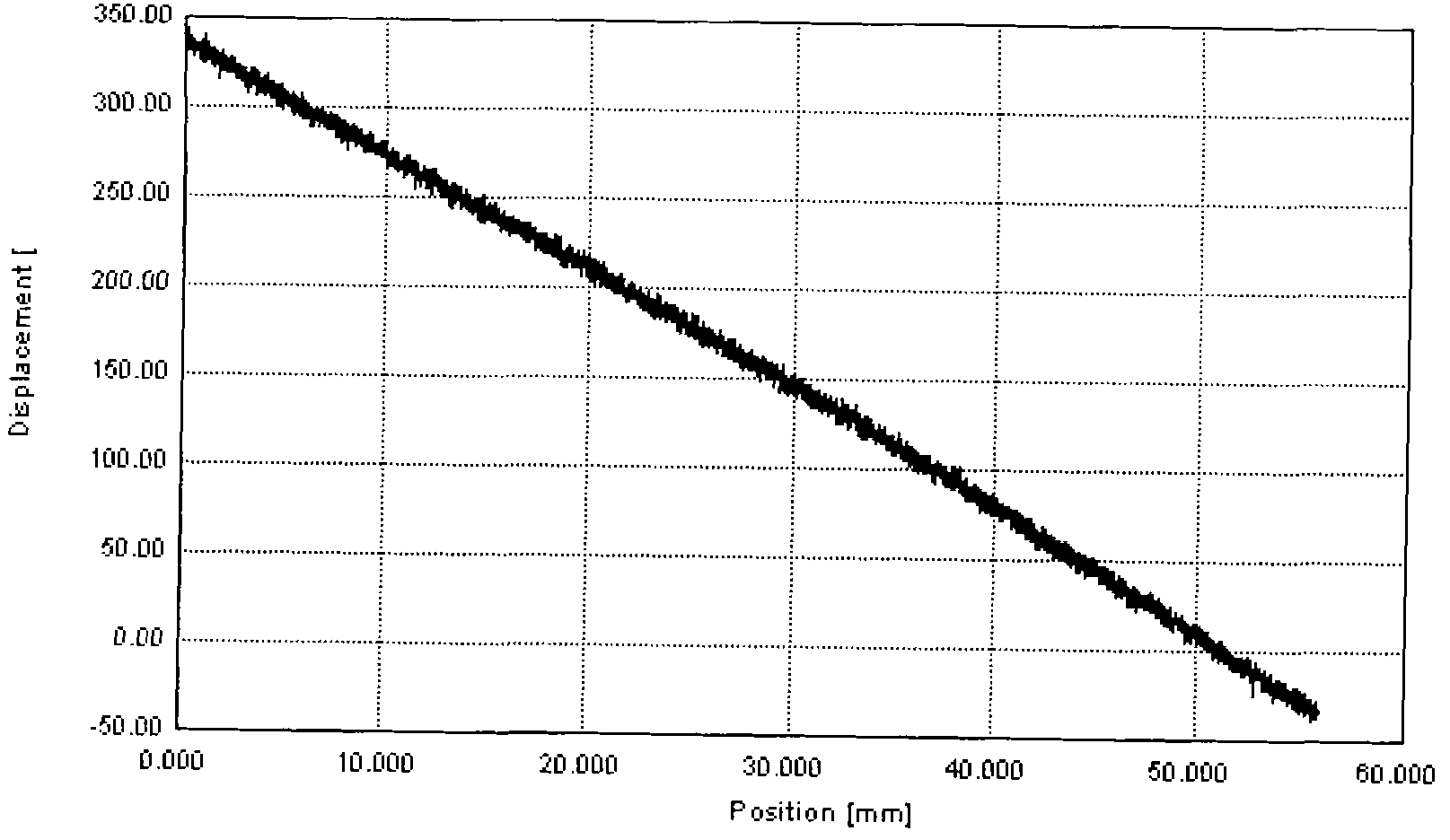

InactiveCN101831243AStrict control of particle size distributionTight control of particle morphologyPolishing compositions with abrasivesWater basedAlloy

The invention provides a high-precision non-water-based nano-diamond grinding fluid and a preparation method and application thereof. The high-precision non-water-based nano-diamond grinding fluid comprises main components of nano-diamond particles, a dispersion stabilizing agent, a suspension agent, a pH value regulator, an antistatic agent, an antioxidant, a dispersion medium and the like. In the invention, the particle size distribution is 130nm or smaller D50 particle size; the ratio of D10 to D50 is 50 percent or more; and the ratio of D90 to D50 is 200 percent or less. The preparation method comprises the following steps of: thinning diamond raw materials; carrying out modifying processing; deeply purifying; separating particle size; and finally mixing components according to a certain ratio. The invention has the advantages of completely eliminating deliquesce, hydrolization, chemical corrosion and electrochemical corrosion during the premise polishing and improving the polishing efficiency and the polishing quality to be maximum extent. The products have wide application to hard alloys, disk moulds, computer magnetic heads, computer disks, solar batteries and the like.

Owner:CHINA JILIANG UNIV

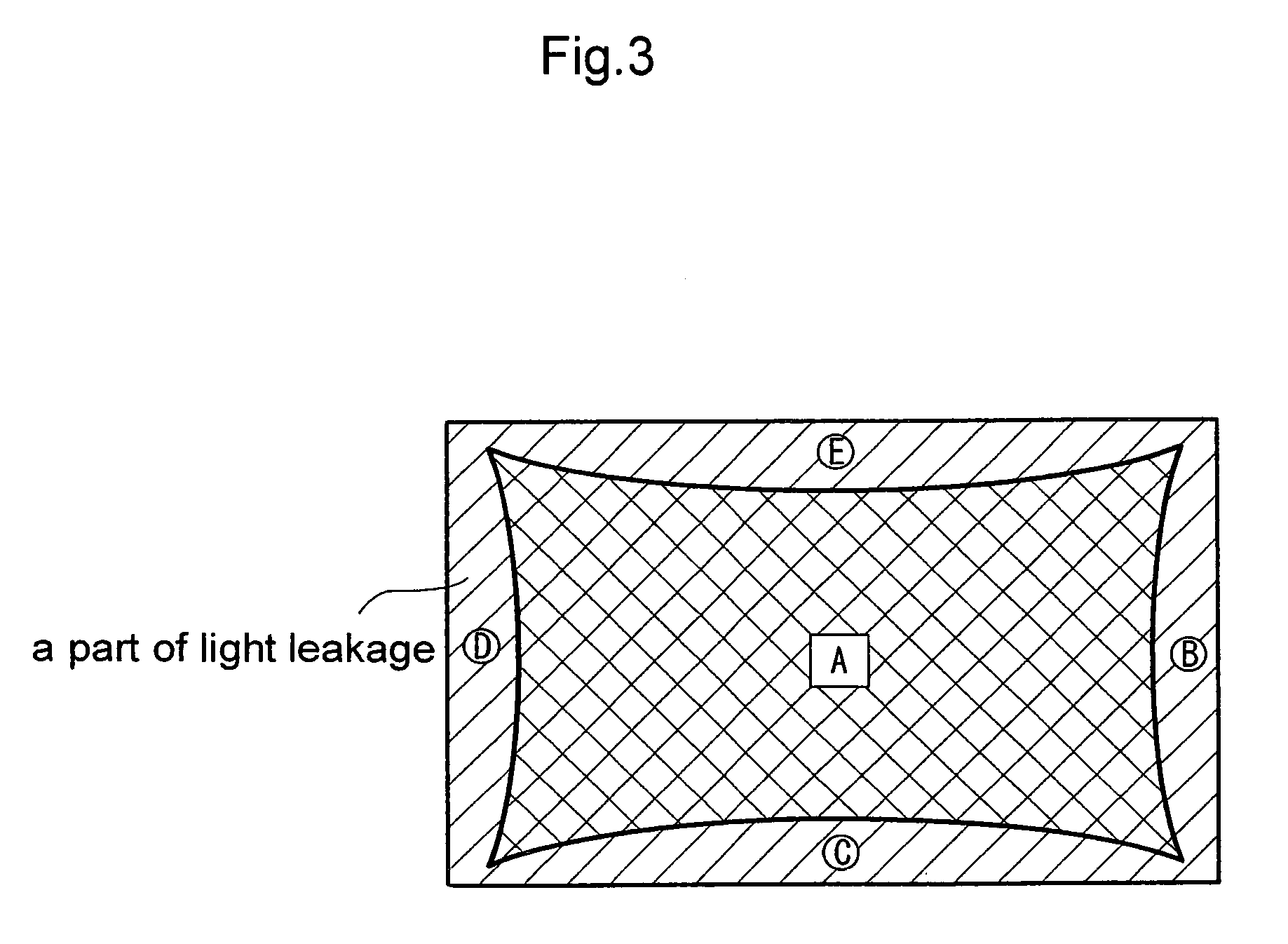

Pressure-sensitive adhesive for applying optically functional film, optically functional film and production process for the same

ActiveUS20080023132A1Increased durabilityLamination ancillary operationsNon-macromolecular adhesive additivesAntistatic agentHigh humidity

Provided is a pressure-sensitive adhesive for an optically functional film which can carry out adhesion with a good durability in adhesion of an optically functional film such as adhesion of a polarizing plate, particularly a polarizing plate integrated with a viewing angle expanding film and the like with a liquid crystal cell, adhesion of a polarizing plate with a retardation film, adhesion of a retardation film with a retardation film and adhesion of a retardation film with a liquid crystal cell and which has the characteristics that a liquid crystal display obtained therefrom is less liable to cause light leakage even under the environment of high temperature and high humidity and that static electricity is less liable to be produced when peeling off a release film from a pressure-sensitive adhesive layer.The pressure-sensitive adhesive for applying an optically functional film comprises a pressure-sensitive adhesive resin and an antistatic agent, wherein a storage elastic modulus (G′) at 23° C. is 0.3 MPa or more, and a charged voltage on the surface of a layer comprising the above pressure-sensitive adhesive which is measured 5 seconds later since peeling off a release film brought into contact with the above pressure-sensitive adhesive layer under the environment of 23° C. and a relative humidity of 50% is 1.0 kV or less.

Owner:LINTEC CORP

Antistatic Adhesive Optical Film and Image Display

ActiveUS20080118752A1Good effectMaintain good propertiesThin material handlingMetal layered productsOptical propertyAntistatic agent

The present invention aims at providing an antistatic pressure-sensitive adhesive optical film exhibiting excellent antistatic effect, optical properties, and water resistance and having excellent adhesion between the antistatic layer and the pressure-sensitive adhesive layer. An antistatic pressure-sensitive adhesive optical film, the optical film having an antistatic layer laminated on at least one side of the optical film, and a pressure-sensitive adhesive layer further laminated on the antistatic layer, wherein the antistatic layer comprises a conductive polymer and a sulfonic acid compound as raw material components, and the pressure-sensitive adhesive layer is formed of an acryl-based pressure-sensitive adhesive containing nitrogen.

Owner:NITTO DENKO CORP

Composite activated cement reinforced grinding aids containing polycarboxylic acid series and method for preparing the same

InactiveCN101182149AIncrease productionNon-irritatingCement productionAntistatic agentUltimate tensile strength

The invention relates to a cement reinforced grinding aid, containing polycarboxylic acid type composite activated cement reinforced grinding aid, which contains esterification catalyst, inhibitor, initiator, grinding aid, activator, strengthening agent, blending agent and chain transfer agent and contains no chlorine ion. The polycarboxylic acid type composite activated cement reinforced grinding aid is a neutral efficient composite cement additive, which is synthesized through the highly efficient magnetized, activated and composite technology. The invention is made though synthesizing inorganic reinforced components with optimized surfactant and antistatic agent and has the advantages of toxin-free, hazard-free, nonirritant, chlorine-free, flame retardant and non-corrosive. The product belongs to green produce. The used amount is 0.015-0.025 weight portions of cement, and the mill output per hour can be improved by 10-25 percent. The twenty eighth day strength of the cement can be increased by 4-8MPa. The strength is increased by 2-4MPa in three days.

Owner:李军

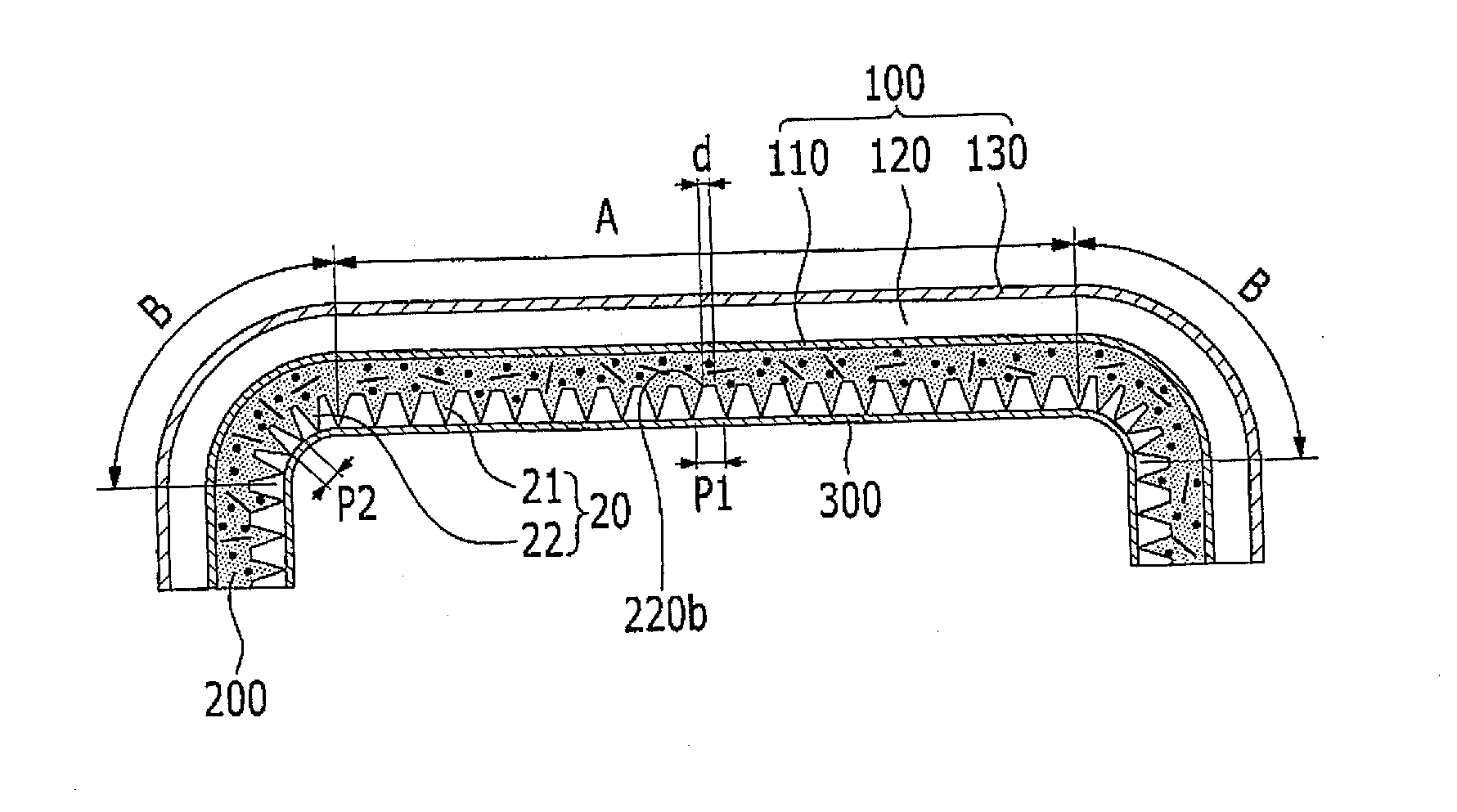

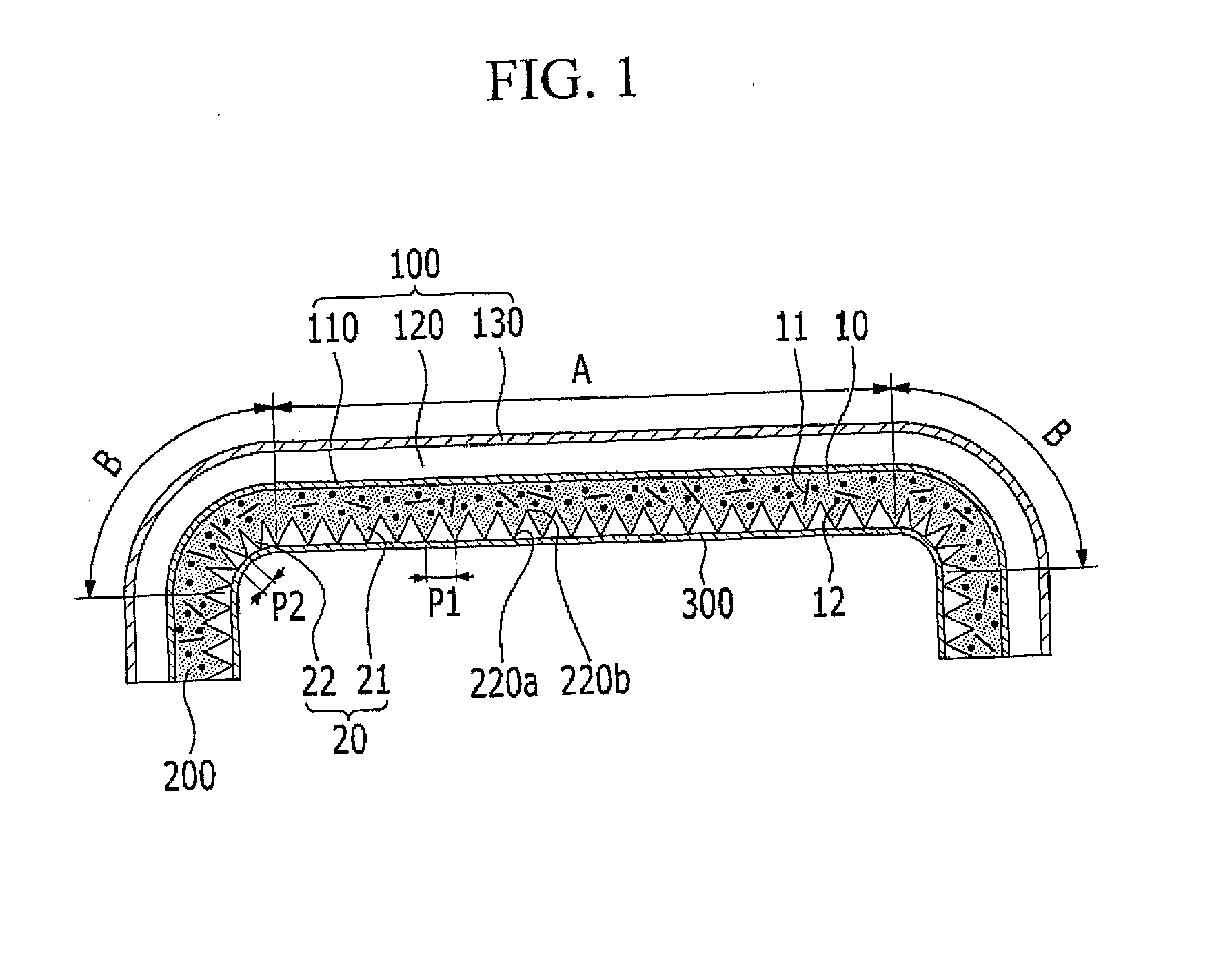

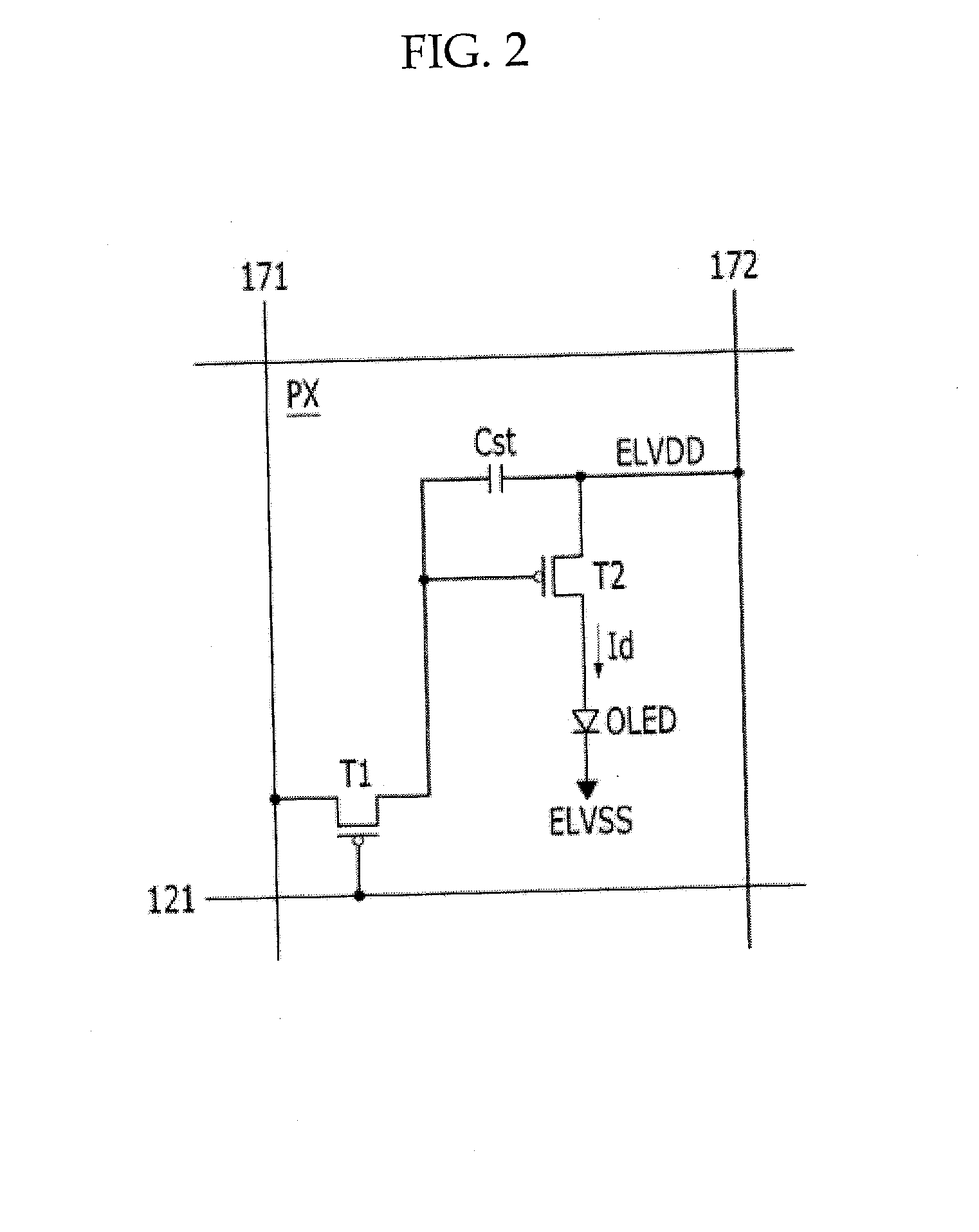

Organic light emitting diode display and manufacturing method thereof

ActiveUS20150102296A1Decreases bending intervalSelectively minimizing stressFinal product manufactureSolid-state devicesAntistatic agentPolymer resin

A organic light emitting diode display including an organic light emitting display panel displaying an image, and a lower passivation film attached to a bottom of the organic light emitting panel and including a polymer resin and an antistatic agent, wherein the lower passivation film includes a plurality of stress adjustment patterns disposed to be adjacent to each other wherein decreasing the bending interval between the bending stress adjustment patterns formed at the lower passivation film processed with the antistatic agent and attached at the position corresponding to the bending portion of the organic light emitting panel, thereby selectively minimizes the stress of the bending portion of the organic light emitting panel, therefore, asymmetry of strains of the bending portions of the organic light emitting display panel can be prevented to remove a picture abnormality, and static electricity may be prevented.

Owner:SAMSUNG DISPLAY CO LTD

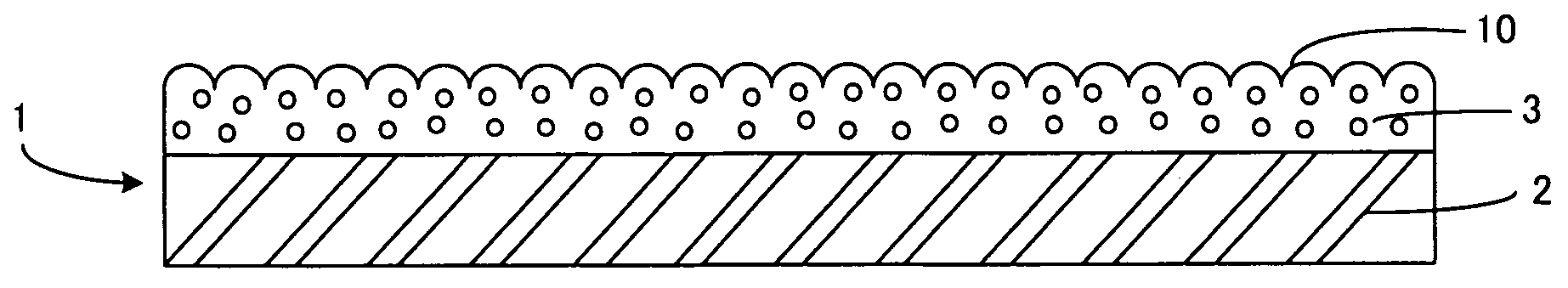

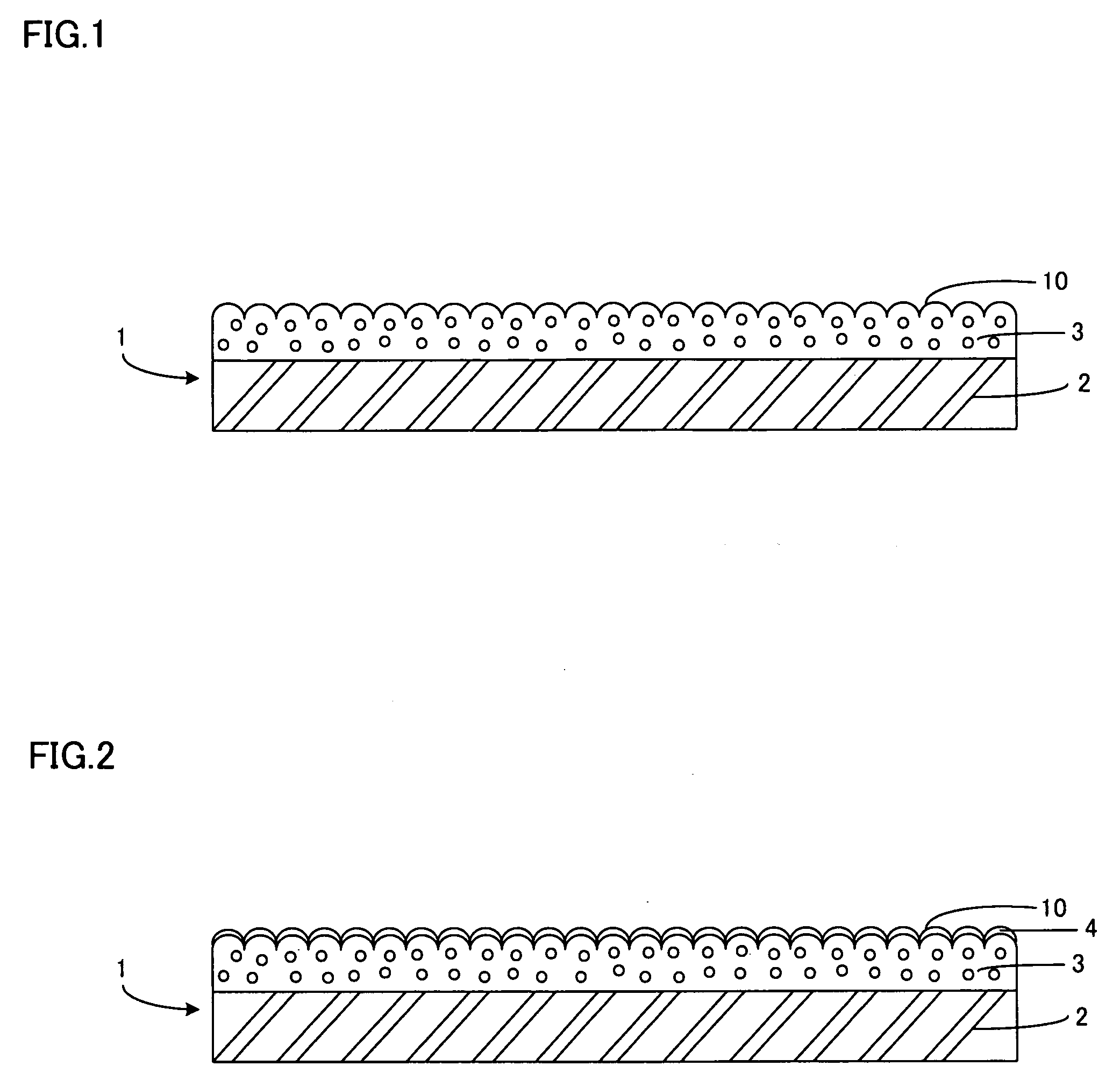

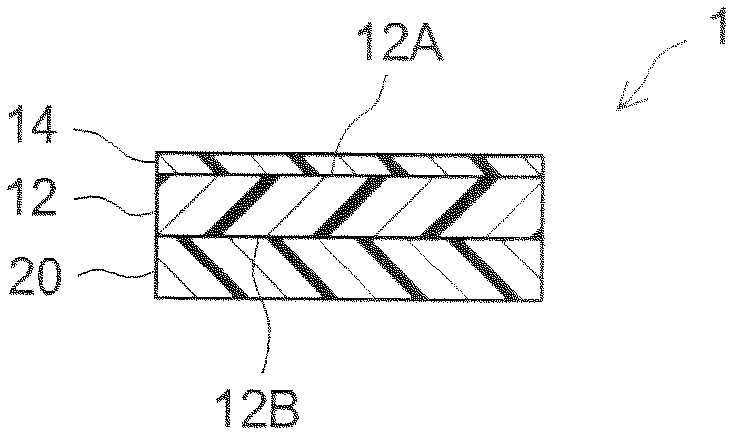

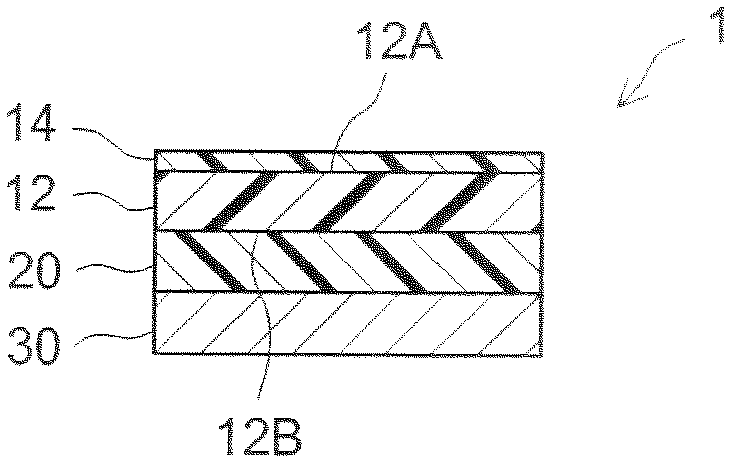

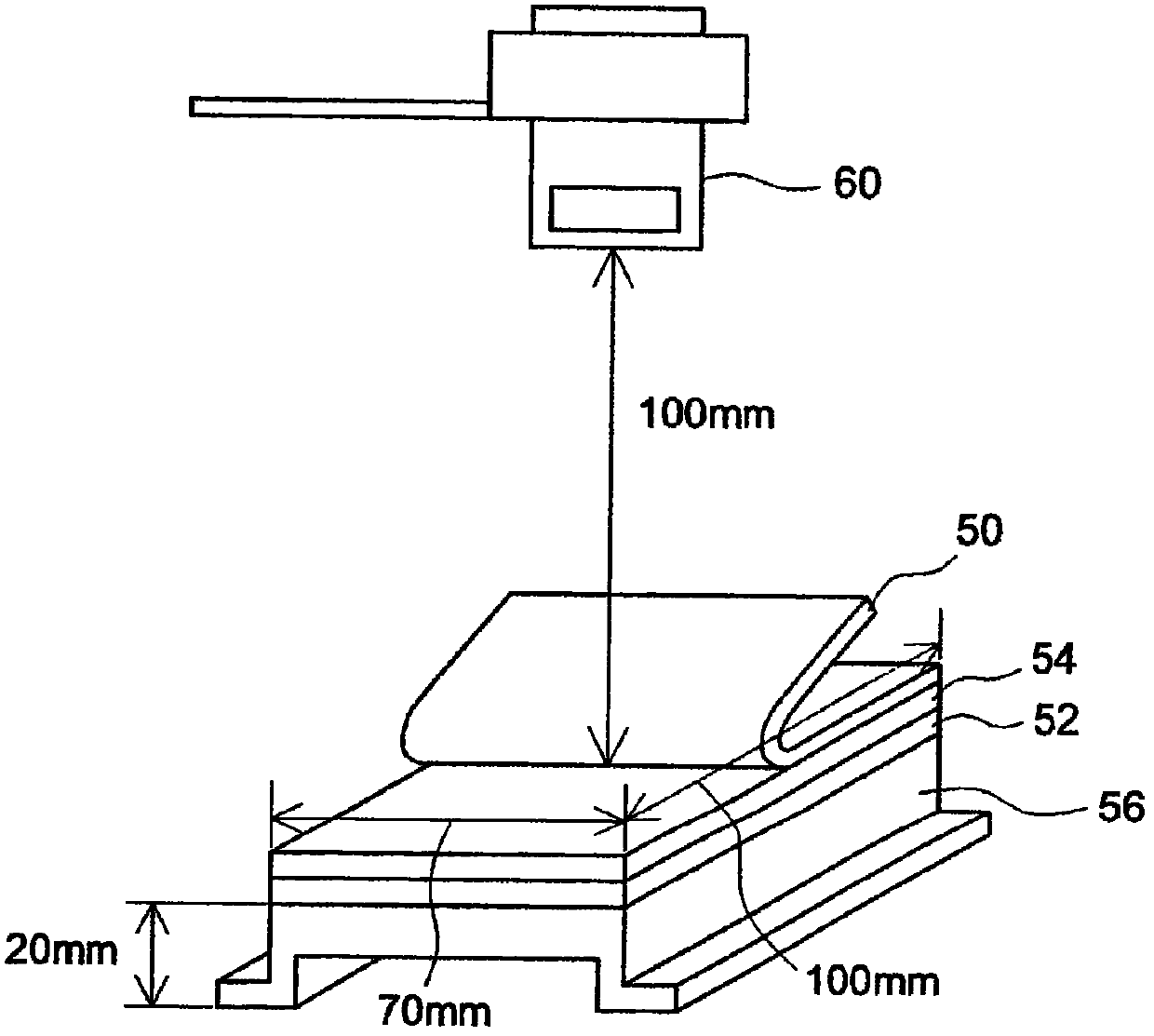

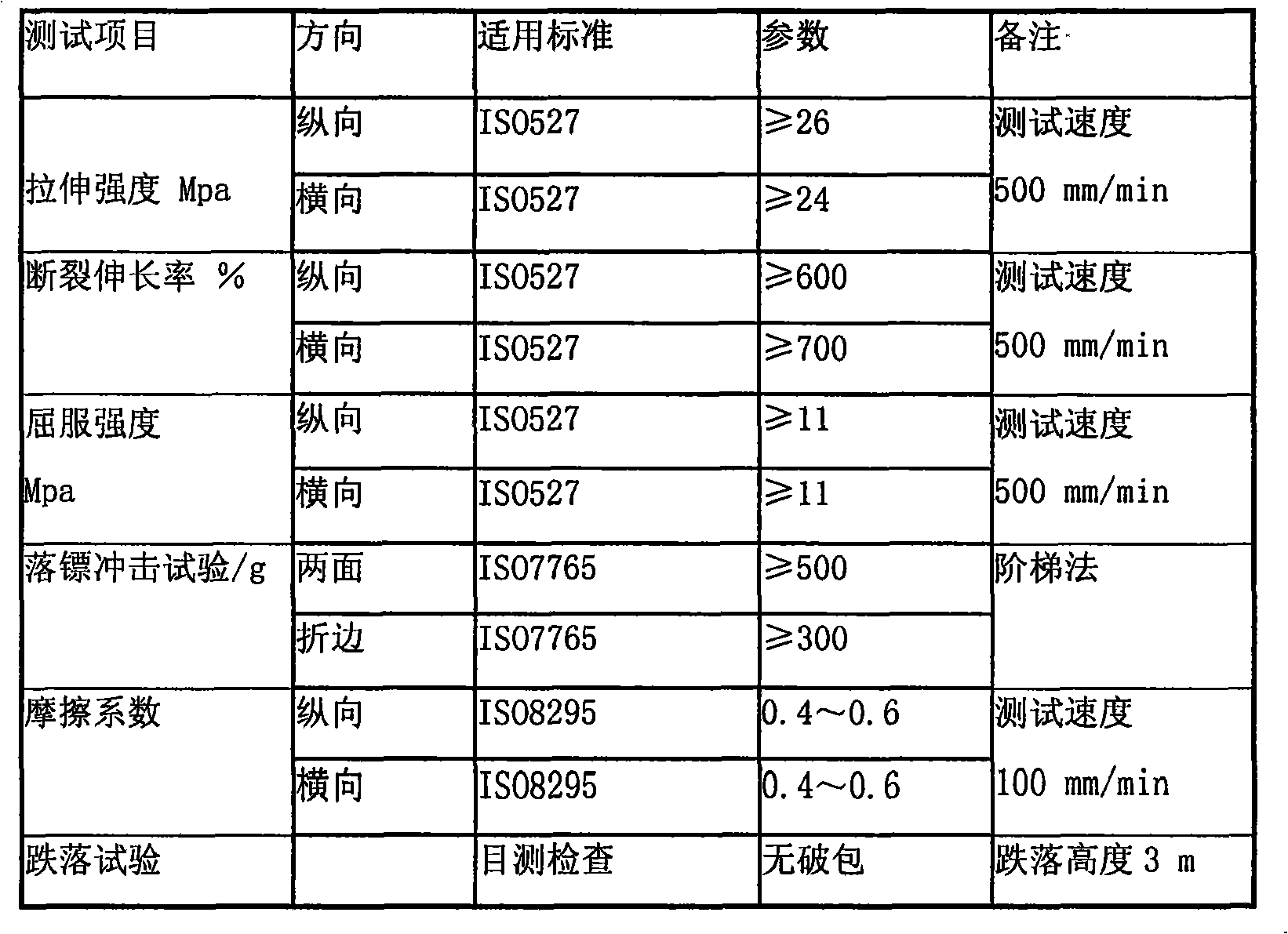

Adhesive sheet and surface protective film

A pressure-sensitive adhesive sheet 1 provided by the present invention is provided with a substrate film 12 comprising a transparent resin material, an antistatic layer 14 provided on a first side 12A thereof, and a pressure-sensitive adhesive layer 20 provided on a second side 12B thereof. The antistatic layer 14 contains an antistatic component (for example, an electroconductive polymer) and a binder resin, and has an average thickness Dave of 1 nm to less than 100 nm. The pressure-sensitive adhesive layer 20 contains an acrylic polymer as a base polymer and an ionic compound (such as an ionic liquid and alkaline metal salt) as an antistatic component.

Owner:NITTO DENKO CORP

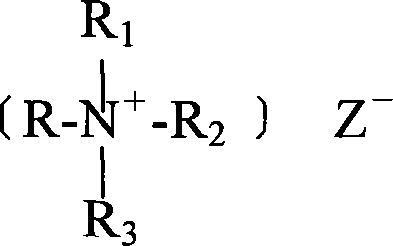

Antistatic polyester film and antistatic film laminate

InactiveUS6103368AIncrease resistanceIncrease productivityRecord carriersMagnetic materials for record carriersCarbon numberPolyester

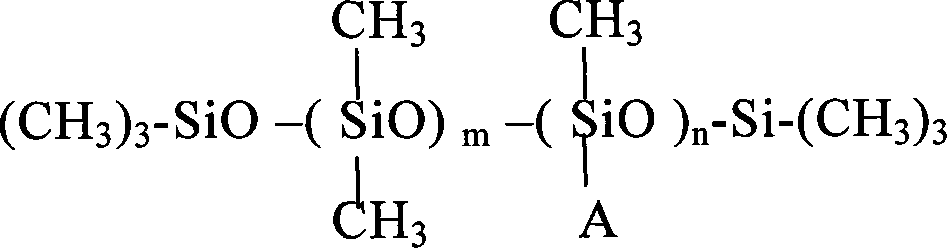

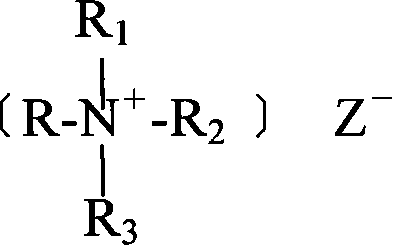

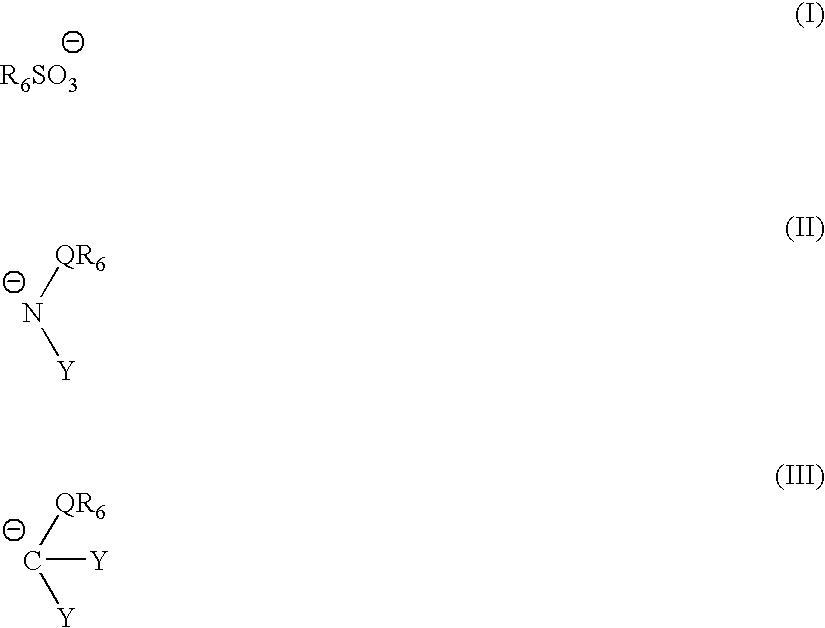

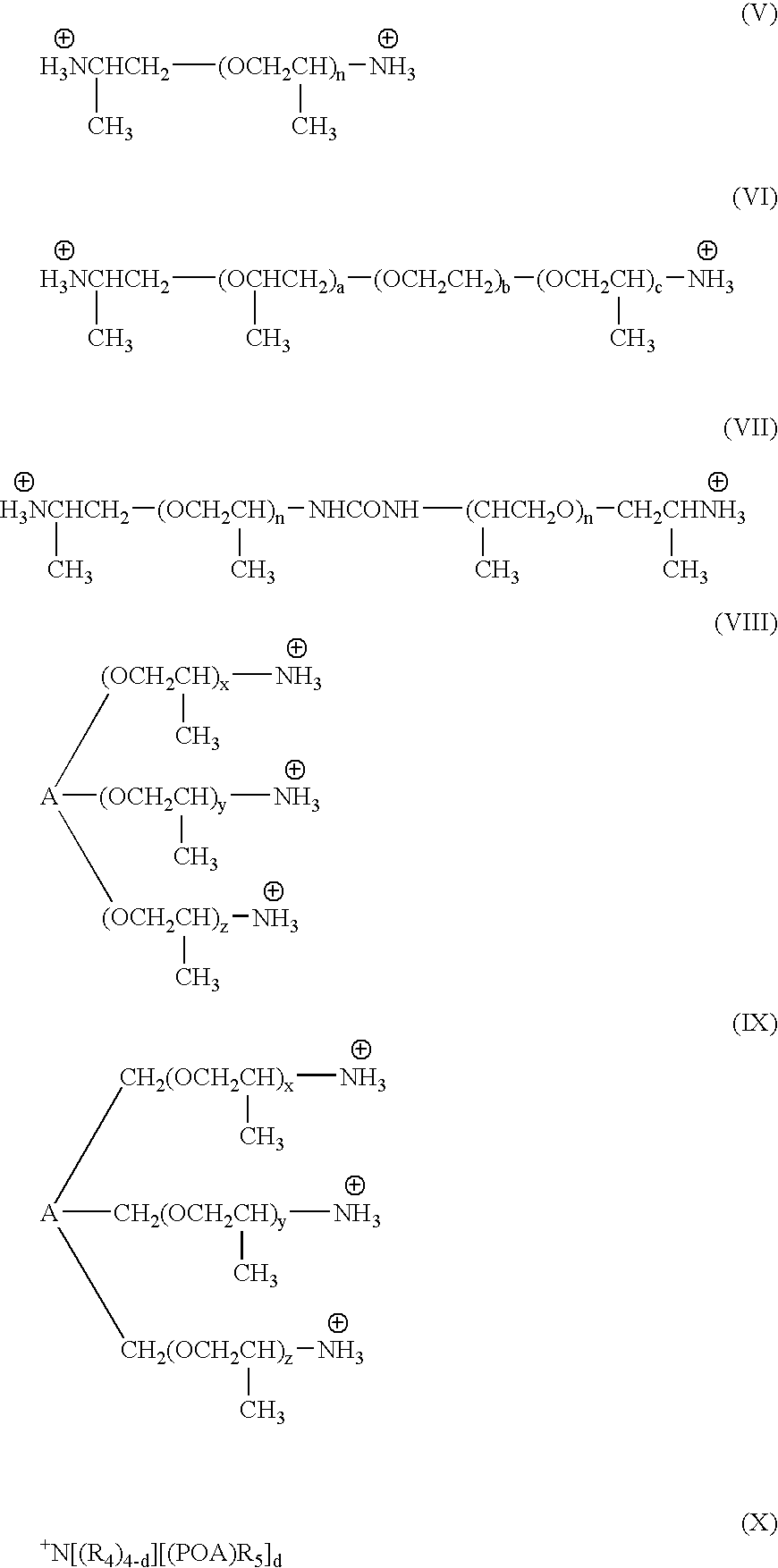

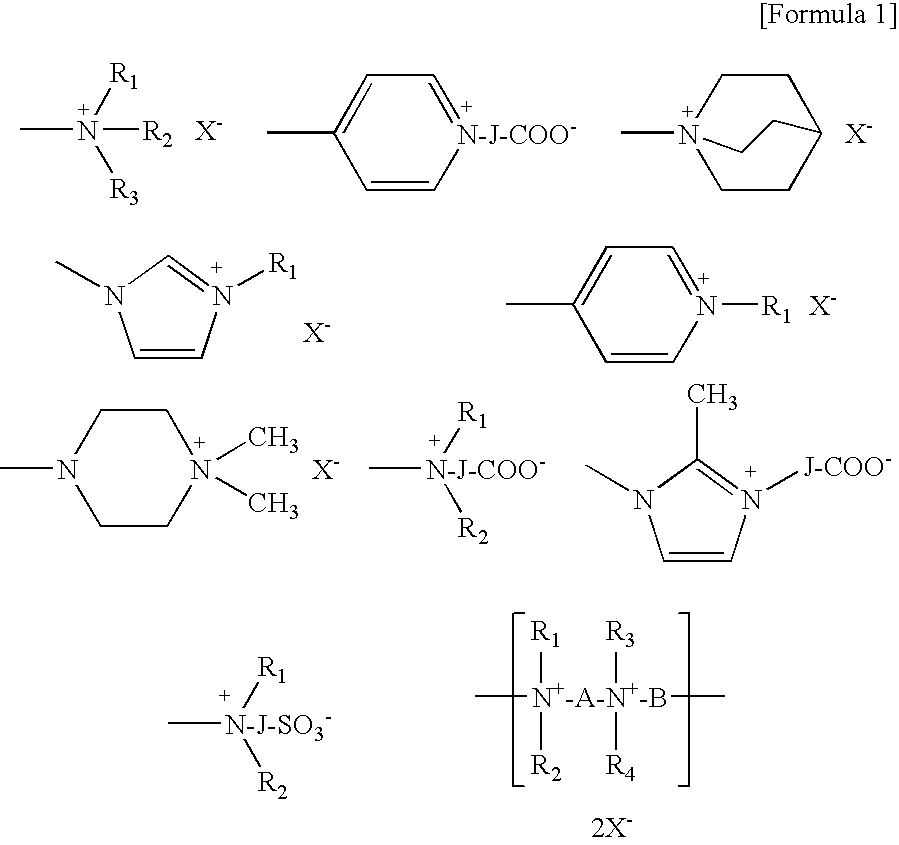

PCT No. PCT / JP97 / 02341 Sec. 371 Date Feb. 27, 1998 Sec. 102(e) Date Feb. 27, 1998 PCT Filed Jul. 7, 1997 PCT Pub. No. WO98 / 02308 PCT Pub. Date Jan. 22, 1998The present invention provides an antistatic polyester film having an antistatic layer formed of an antistatic agent (A) composed mainly of a polymer having a recurring unit of a structure expressed by the following formula (I) on at least one surface of a polyester film wherein R1 and R2 are each H or CH3, R3 is an alkylene group having a carbon number of 2 to 10, R4 and R5 are each a saturated hydrocarbon group having a carbon number of 1 to 5, R6 is an alkylene group having a carbon number of 2 to 5, n is a number of 0 to 40, m is a number of 1 to 40, and Y- is a halogen ion, a mono- or polyhalogenated alkyl ion, nitrate ion, sulfate ion, an alkylsulfate ion, sulfonate ion or an alkylsulfonate ion.

Owner:TEIJIN LTD

Flame-retardant polycarbonate resin composition and its injection moldings

InactiveUS6150443AImprove antistatic performanceImprove stabilityPlastic/resin/waxes insulatorsDomestic articlesElastomerAntistatic agent

Provided are a flame-retardant polycarbonate resin composition capable of being formed into moldings having good impact resistance, high strength and good thermal stability that are intrinsic to polycarbonate resins and having good antistatic properties and good flame retardancy, and also injection moldings of the composition. The composition comprises 100 parts by weight of a resin or resin mixture of (A) from 50 to 100% by weight of a polycarbonate resin and (B) from 0 to 50% by weight of a styrenic resin, from 1 to 50 parts by weight of (C) a flame retardant, and from 0.1 to 5 parts by weight of (D) an anionic antistatic agent, and has a sodium sulfate content of at most 0.05% by weight. Optionally, the composition may contain (F) a fluoro-olefinic resin, (G) a rubber-like elastomer, and (H) an inorganic filler.

Owner:IDEMITSU KOSAN CO LTD

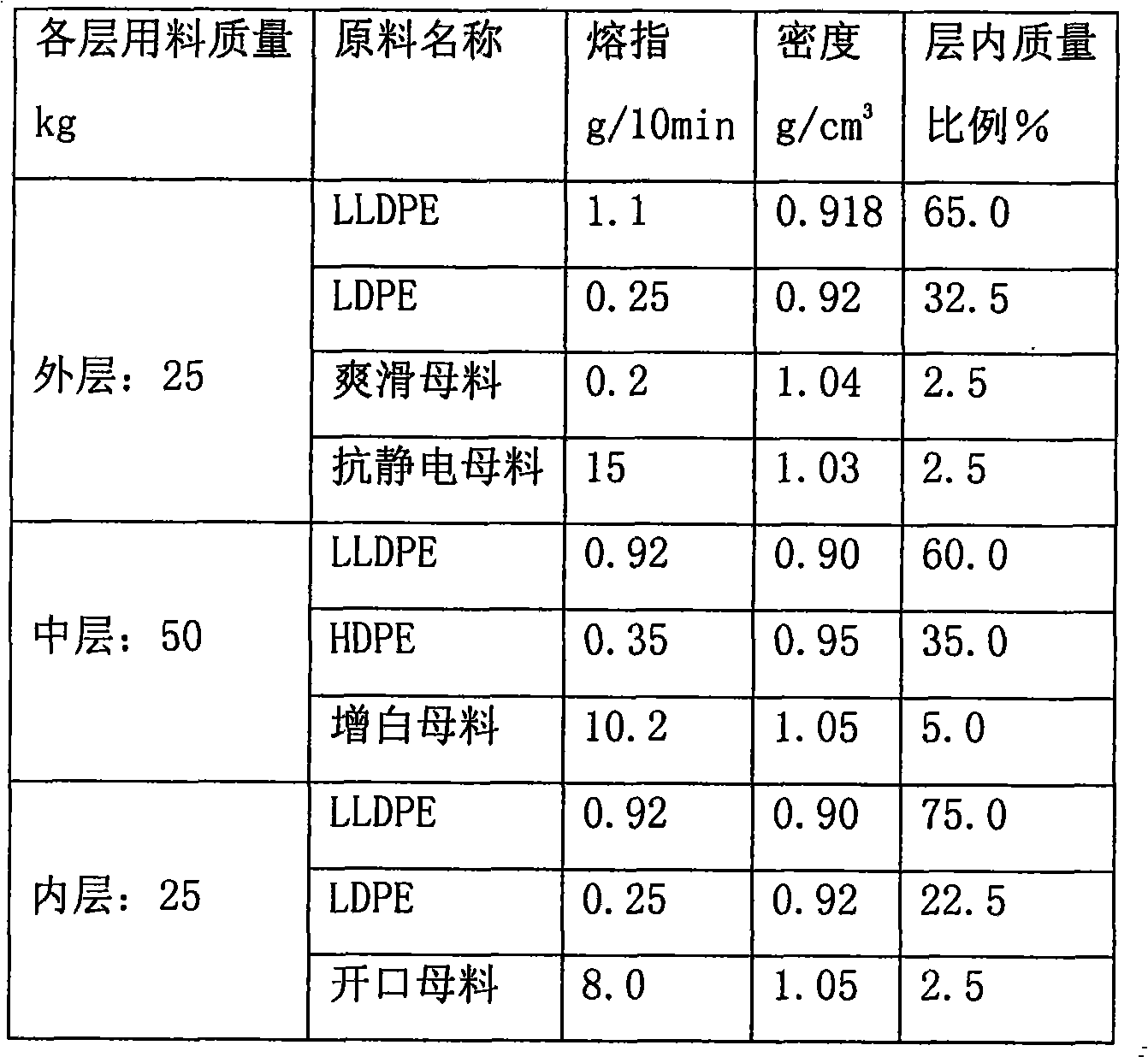

Polyethylene repackaging film material composition

ActiveCN101255249AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

A polyethylene heavy packaging film composite can be widely used for producing blisterpack, such as FFS package, large goods package, tray package and so on, which can effectively improve the all round performance of packaging film, and make the package of goods more beauty, firm, green and effective. The film composite comprises: linear low density polyethylene accounting for 60-80% of the sum of the material, low density polyethylene accounting for 5-25% of the sum of the material, metallocene linear low density polyethylene accounting for 10-30% of the sum of the material, additive accounting for 3-7% of the sum of the material. An automatic feed proportioning system feeds the material of three extruders to die head and the heavy packaging film combination is obtained after three-layer extruding and mixing. The additive is combination of one or several kinds of slippery agent, antistatic agent, antioxidant, opening agent, thermal stabilizer.

Owner:SINOPEC YANGZI PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com