Patents

Literature

890results about How to "Improve puncture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

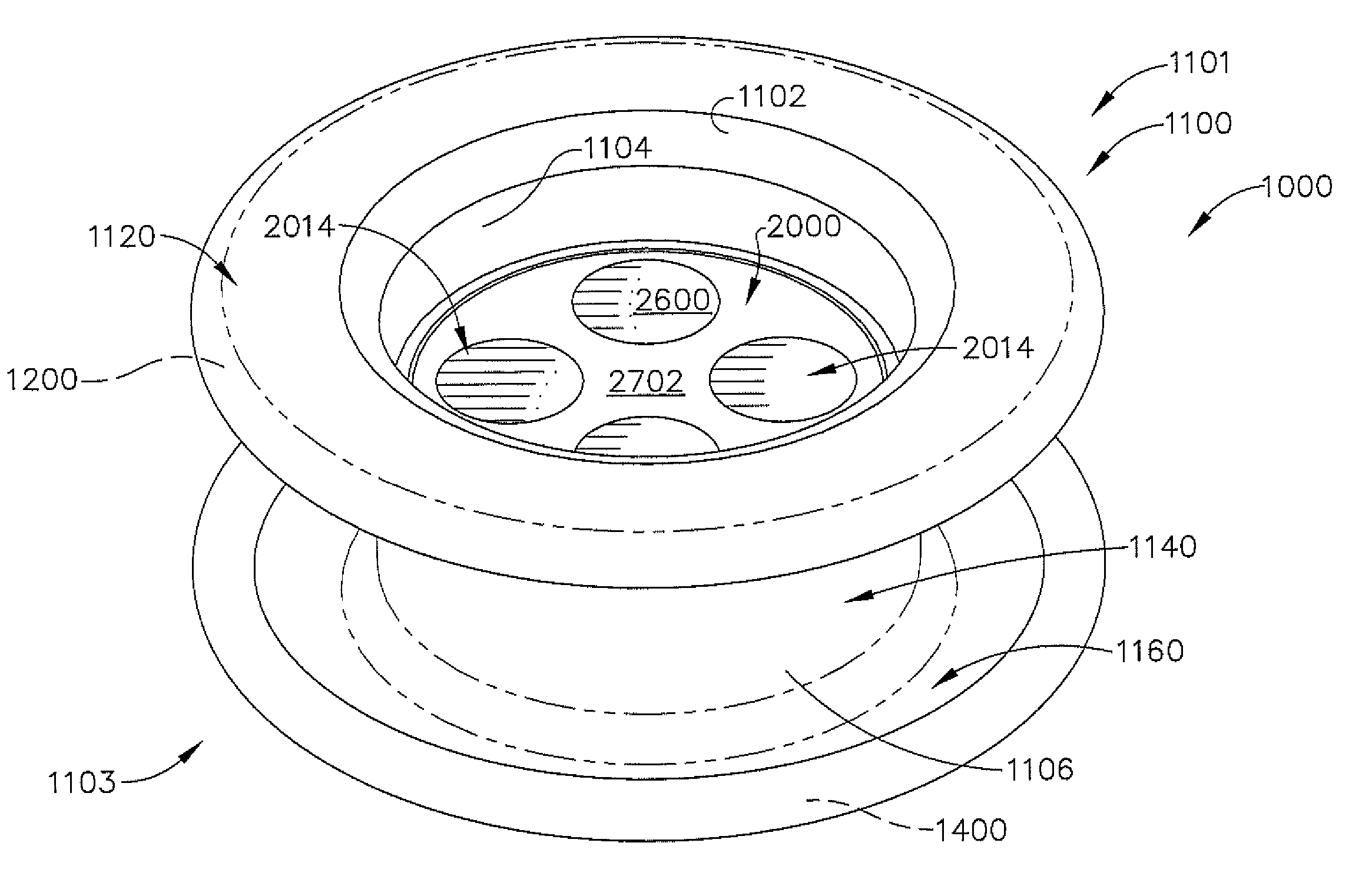

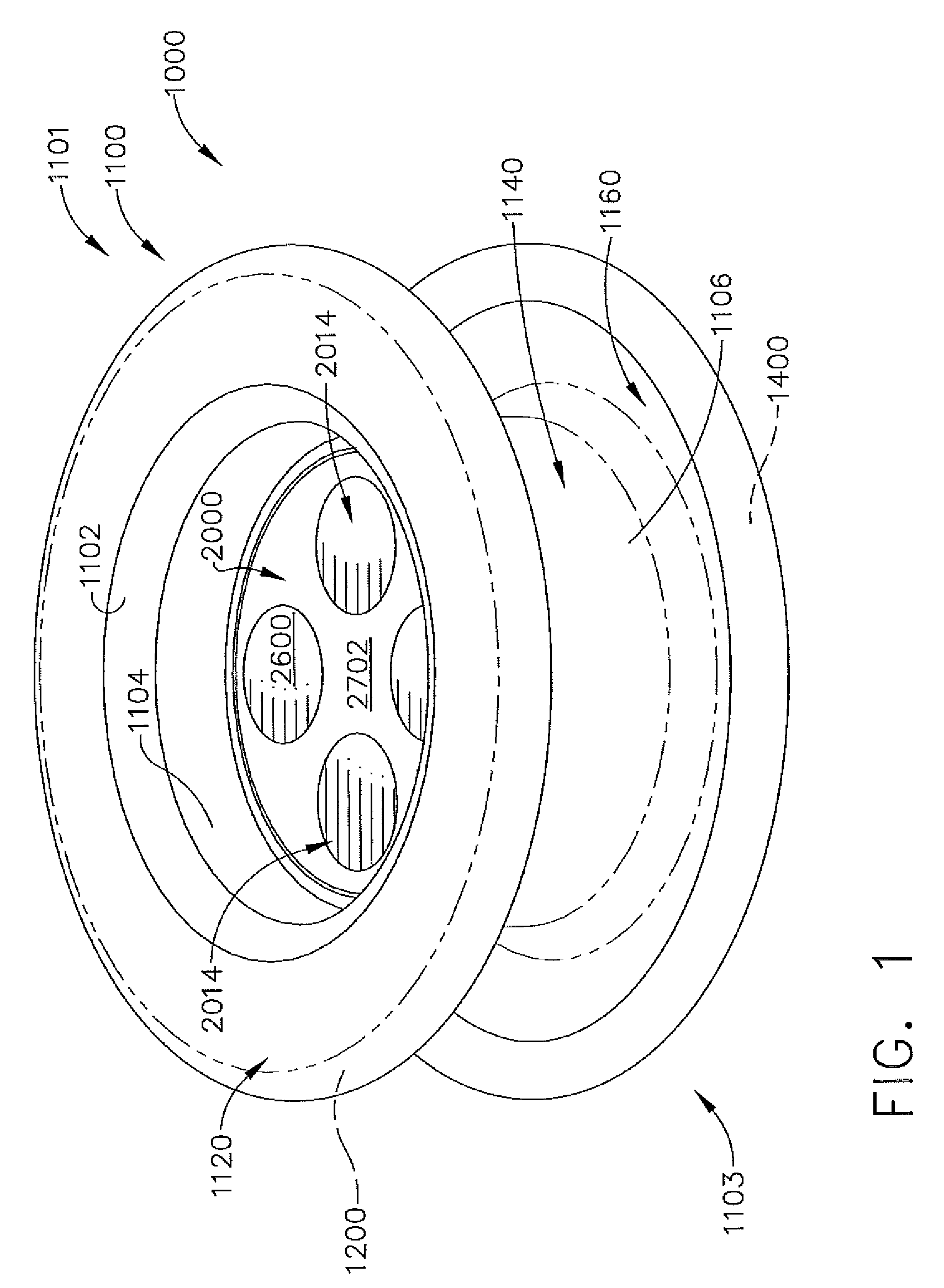

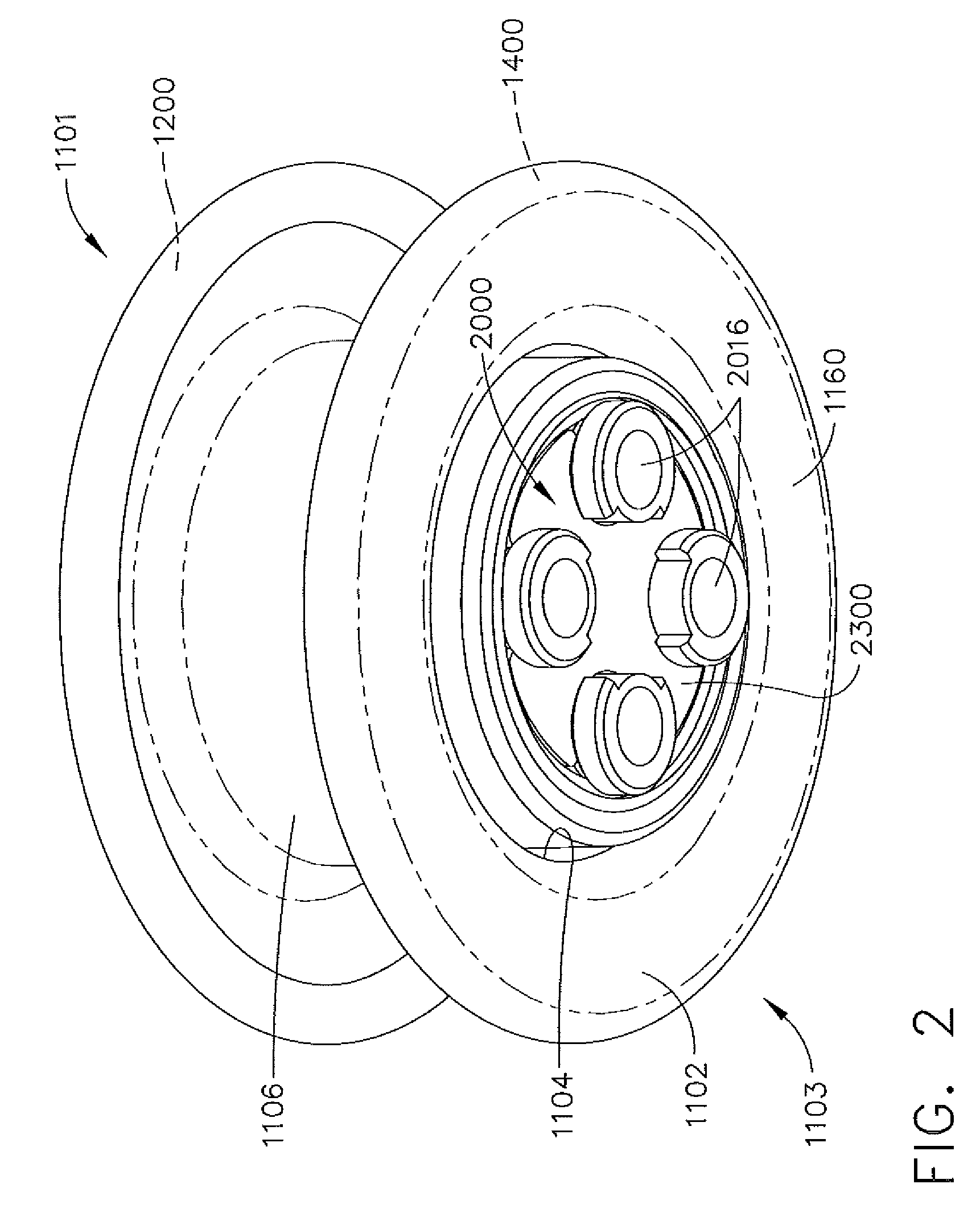

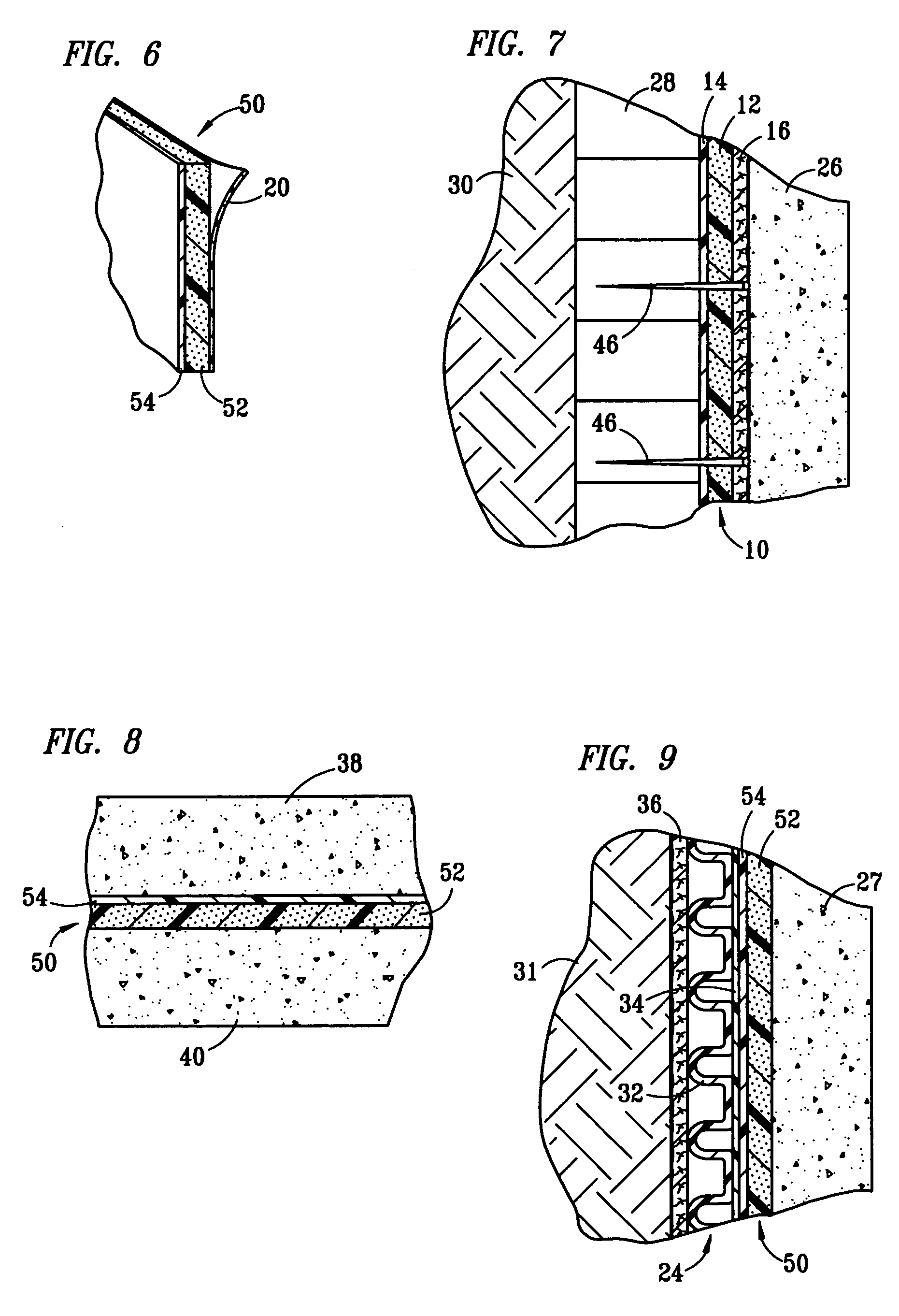

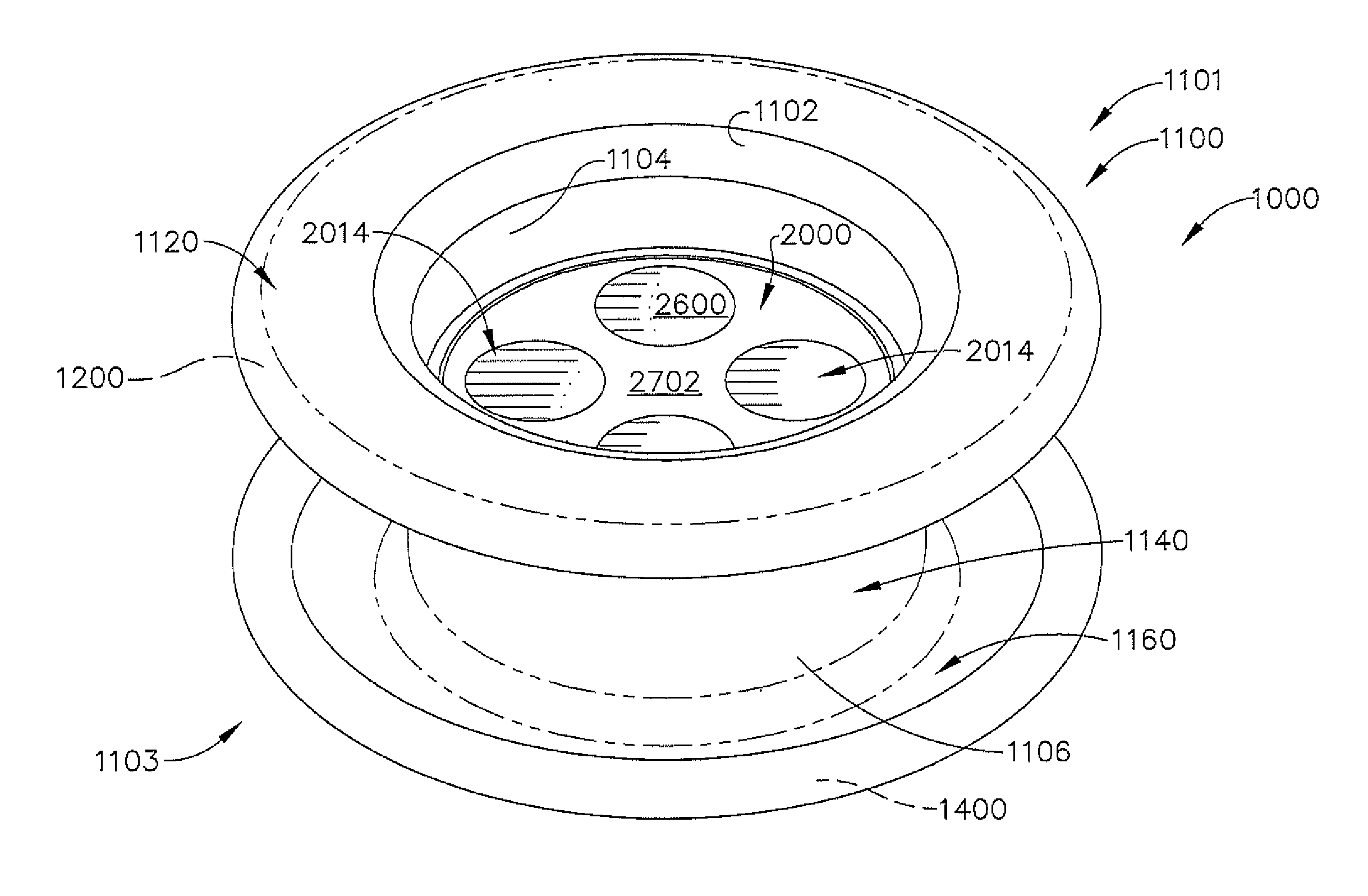

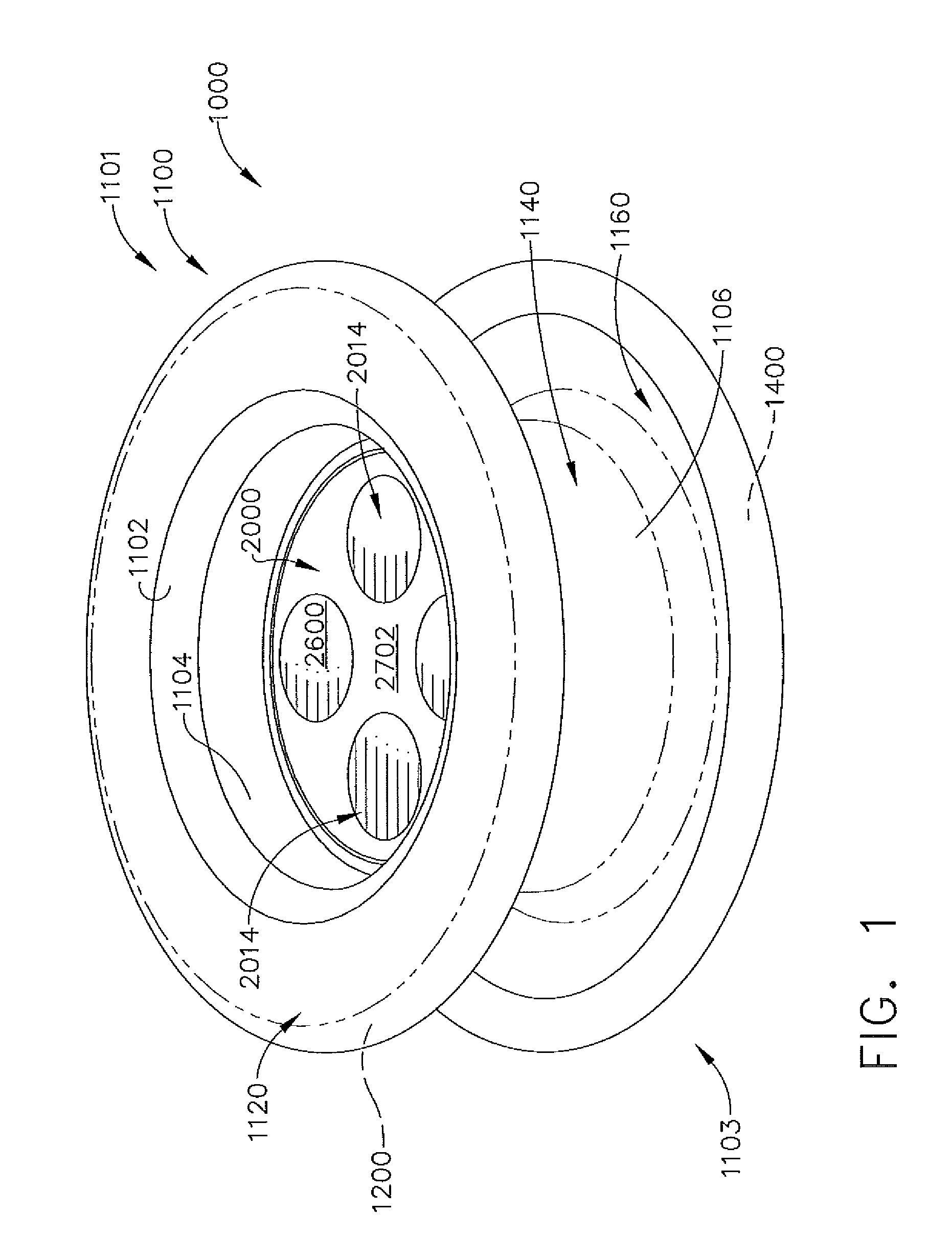

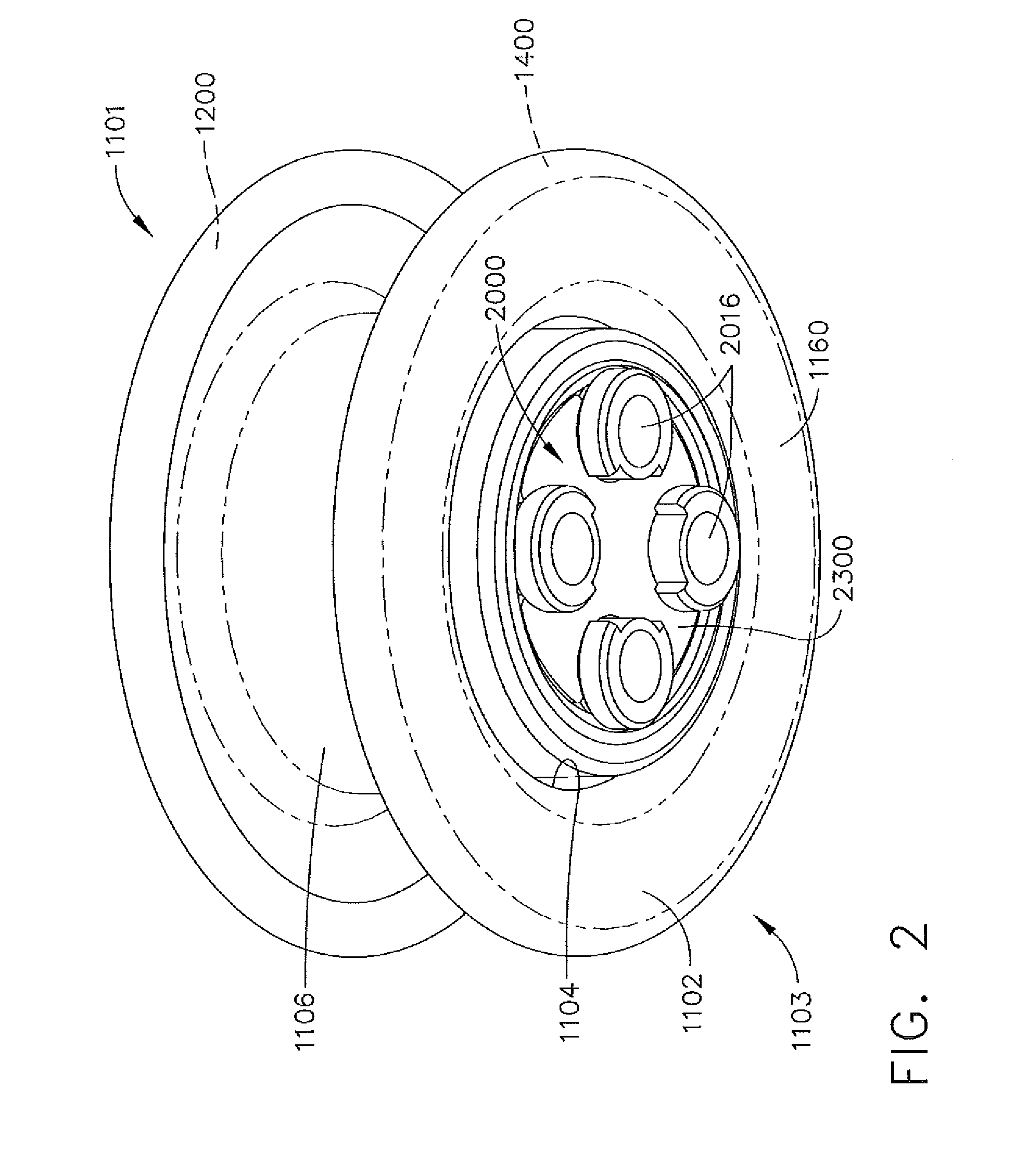

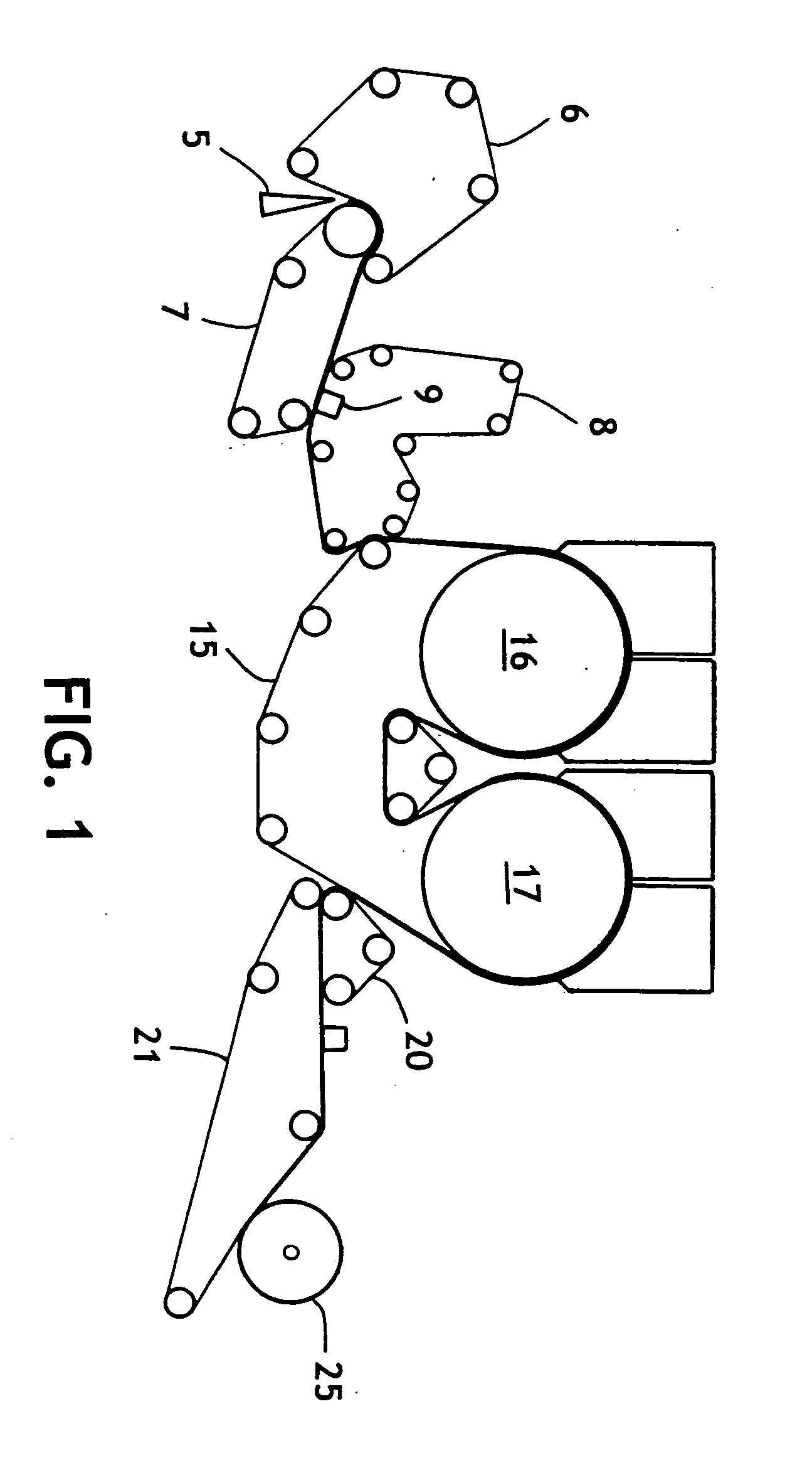

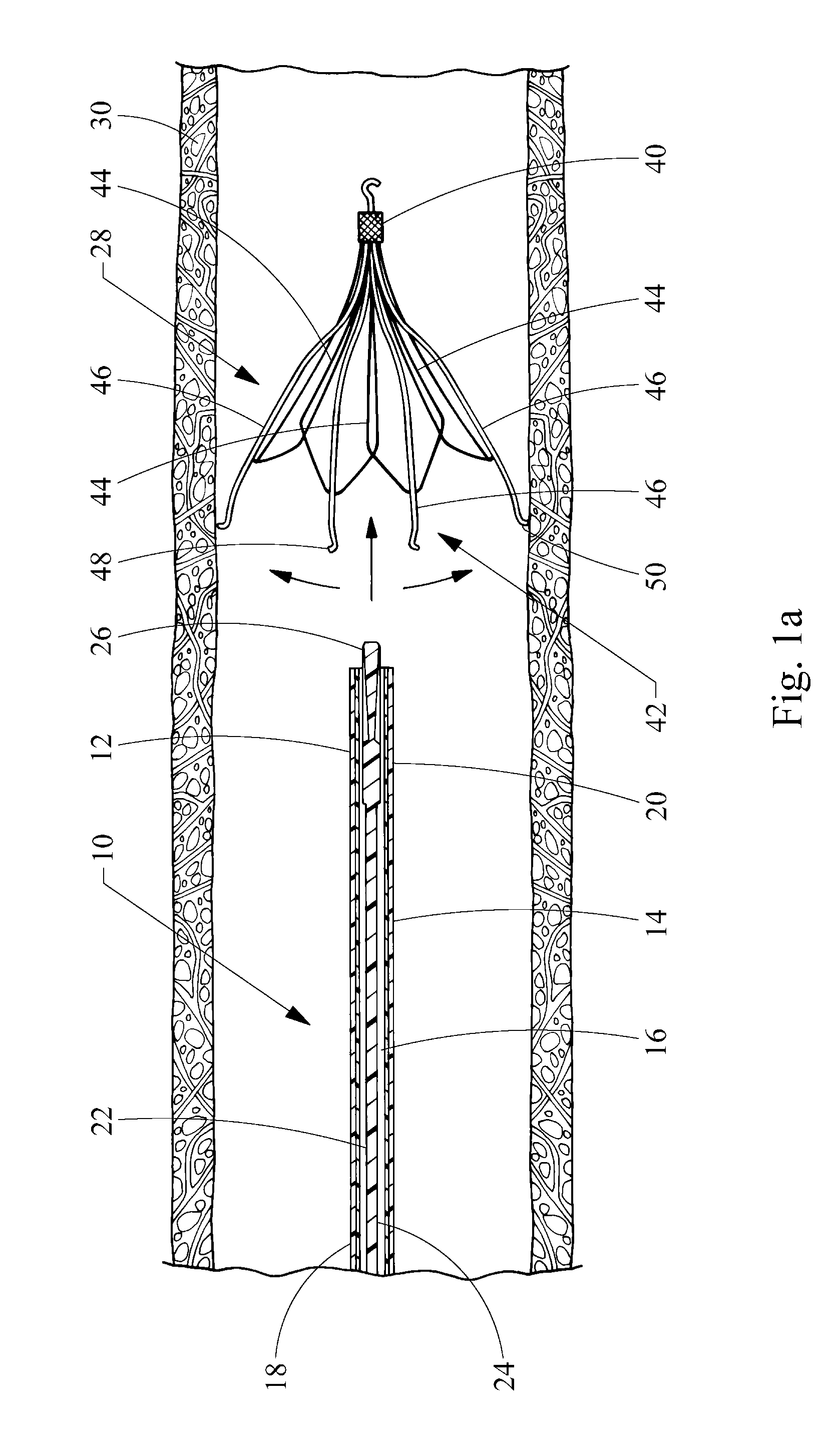

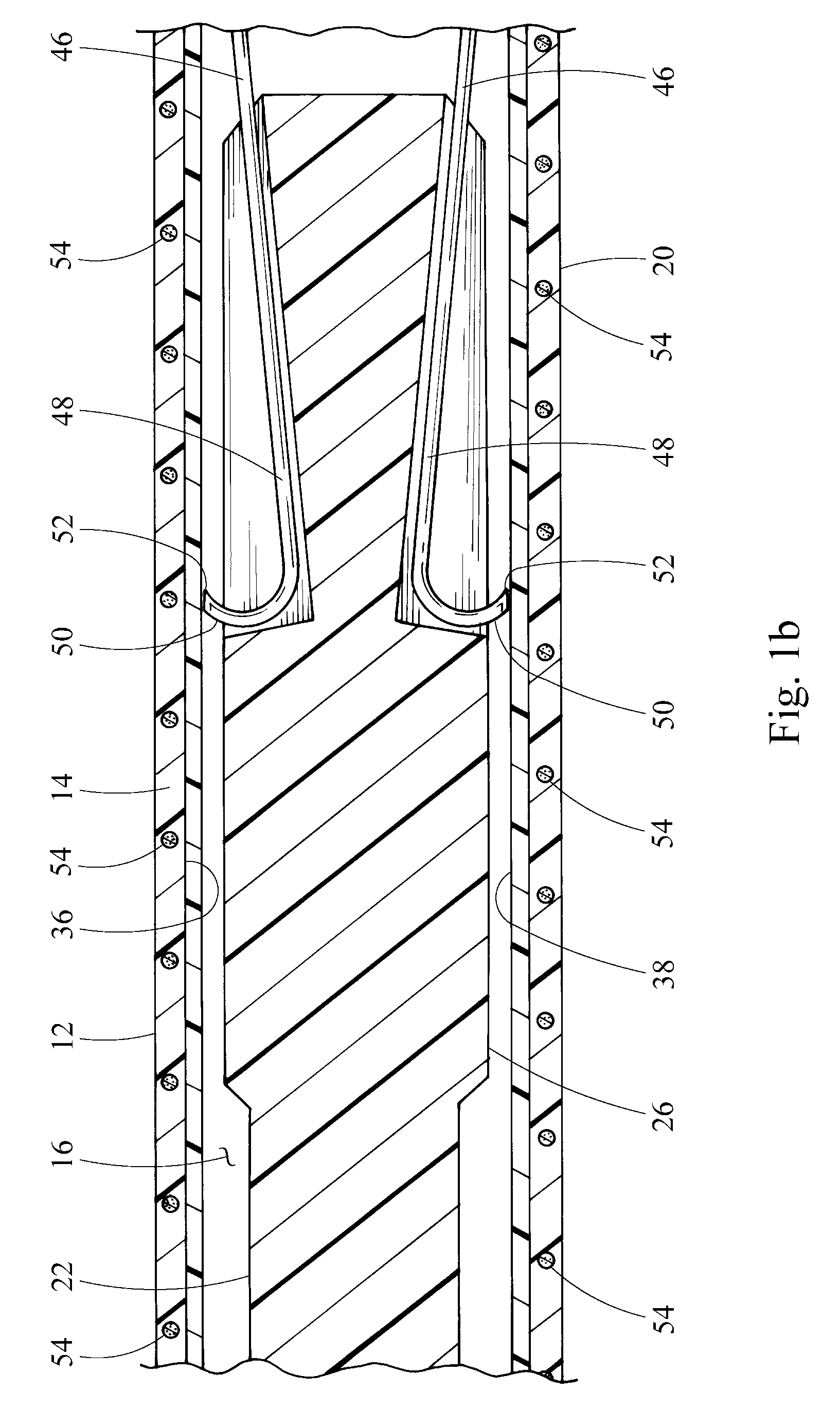

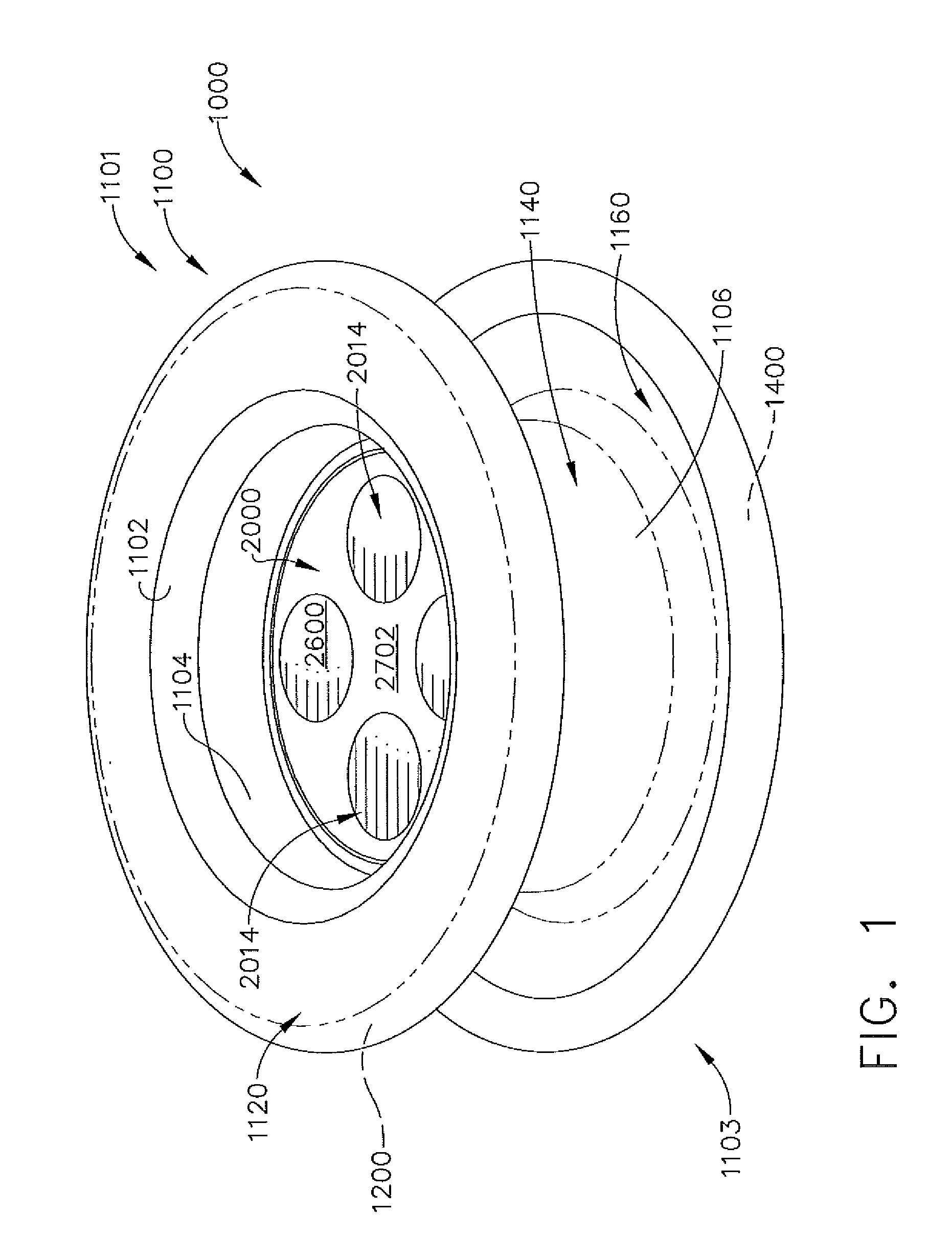

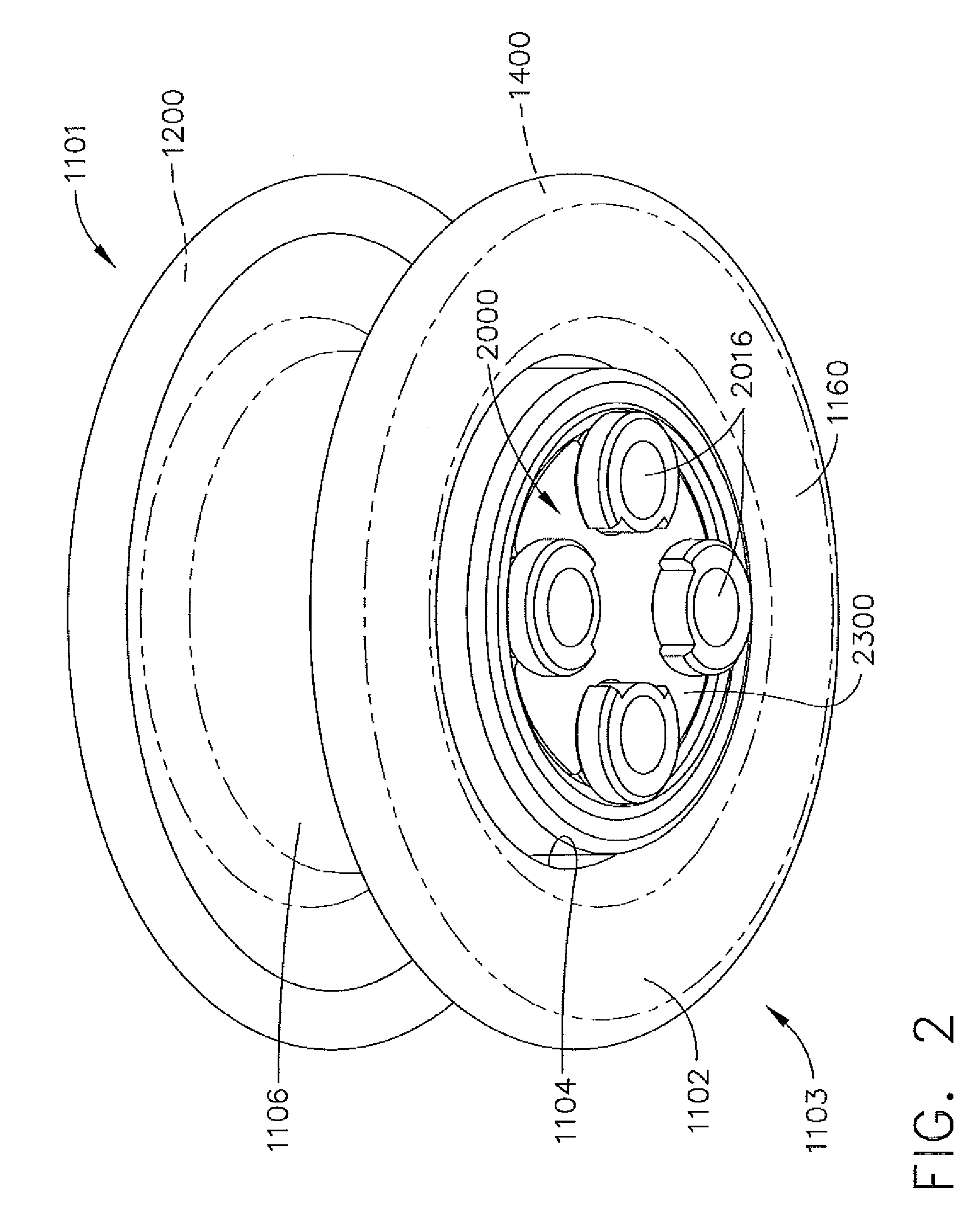

Access device with insert

ActiveUS8226553B2Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterMedical deviceBiomedical engineering

Various devices and methods are provided with respect to inserting multiple surgical instruments through a single surgical access device. A medical device including a flexible tissue retractor and a releasable insert having multiple instrument openings is disclosed. The insert can be in the form of an insert assembly including multiple components. A method of using the insert is also described.

Owner:CILAG GMBH INT

Heat-shrinkable polymeric films

InactiveUS6908687B2High and predictable and controlled shrinkage characteristicGood optical claritySynthetic resin layered productsSausage casingsOptical transparencyControl layer

The present invention relates to oriented or hot-blown shrink films which may be manufactured from by a number of processes. The oriented films may be manufactured by double bubble, LISIM, tape bubble, trapped bubble or tenter framing processes. The films of the present invention are useful as a shrink film to package and label a variety of products. The films exhibit a high degree of MD shrinkage in a very controlled and consistent manner while providing a number of other positive characteristics such as optical clarity, puncture and abrasion resistance, controlled gauge, and superior web winding and handling characteristics. The shrink control layers of the films of the present invention contain a modifier component selected from plastomers and / or metallocene catalyzed ethylene-propylene copolymers and blends thereof.

Owner:JINDAL INNOVATION CENT SRL

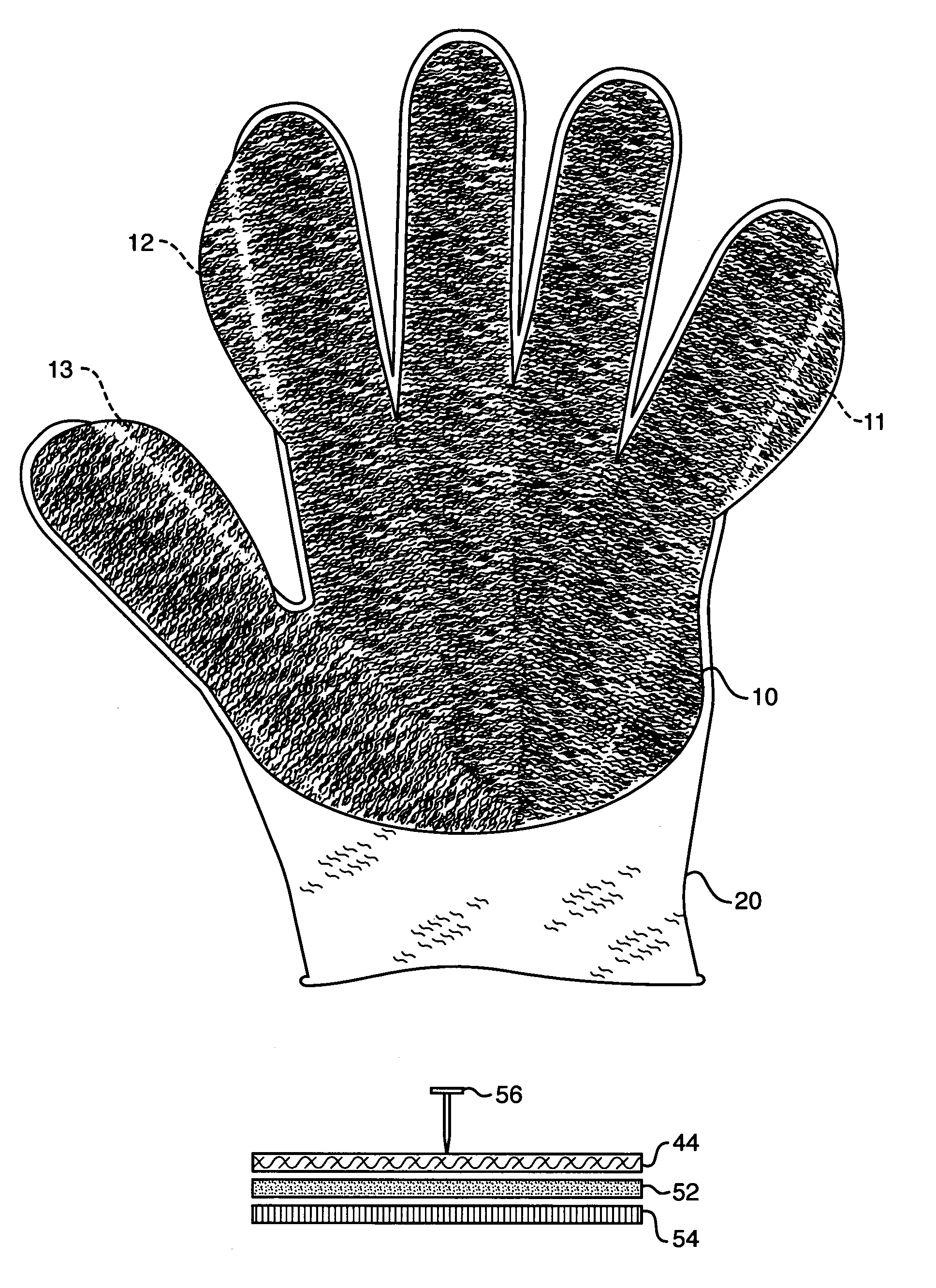

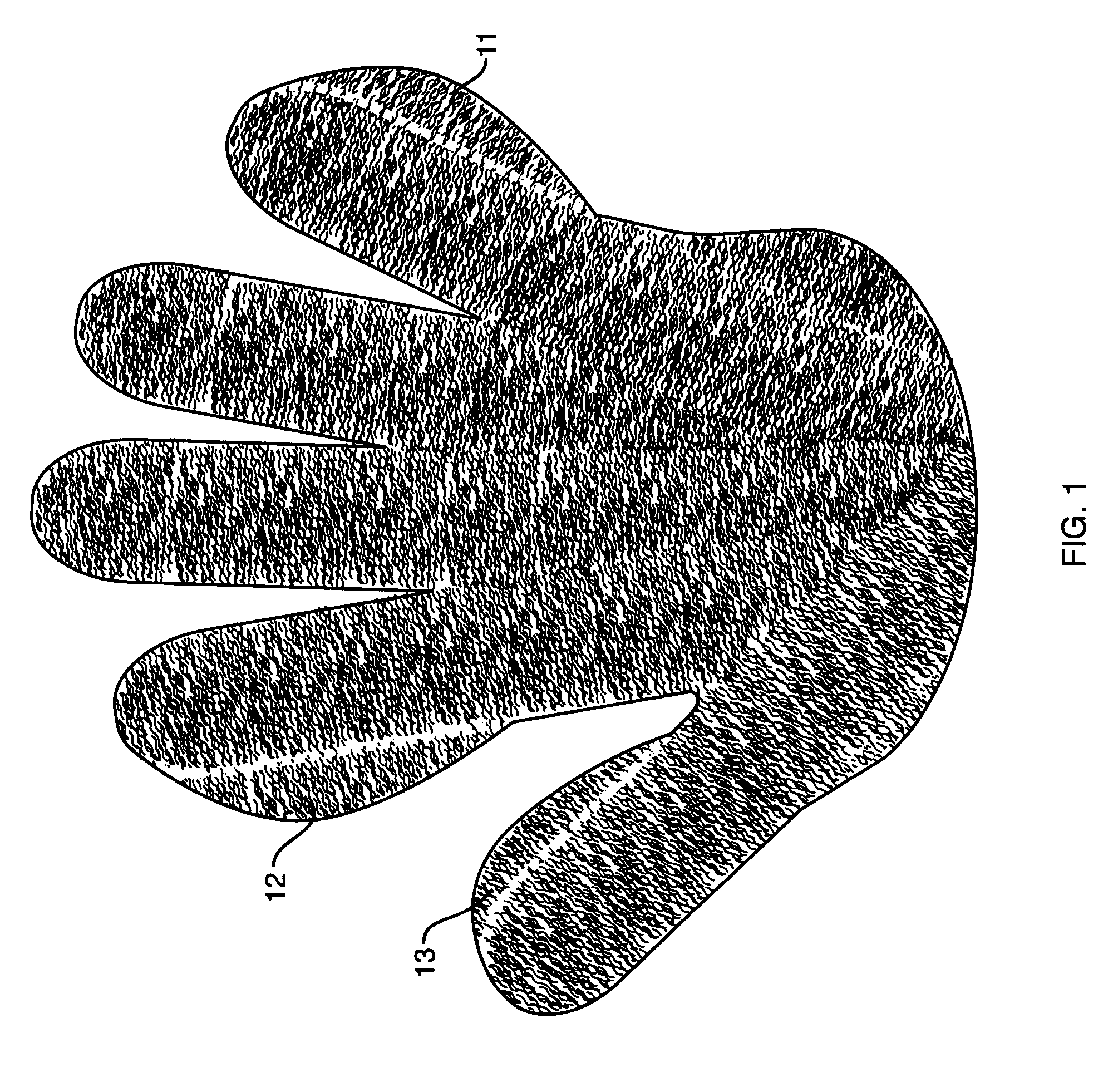

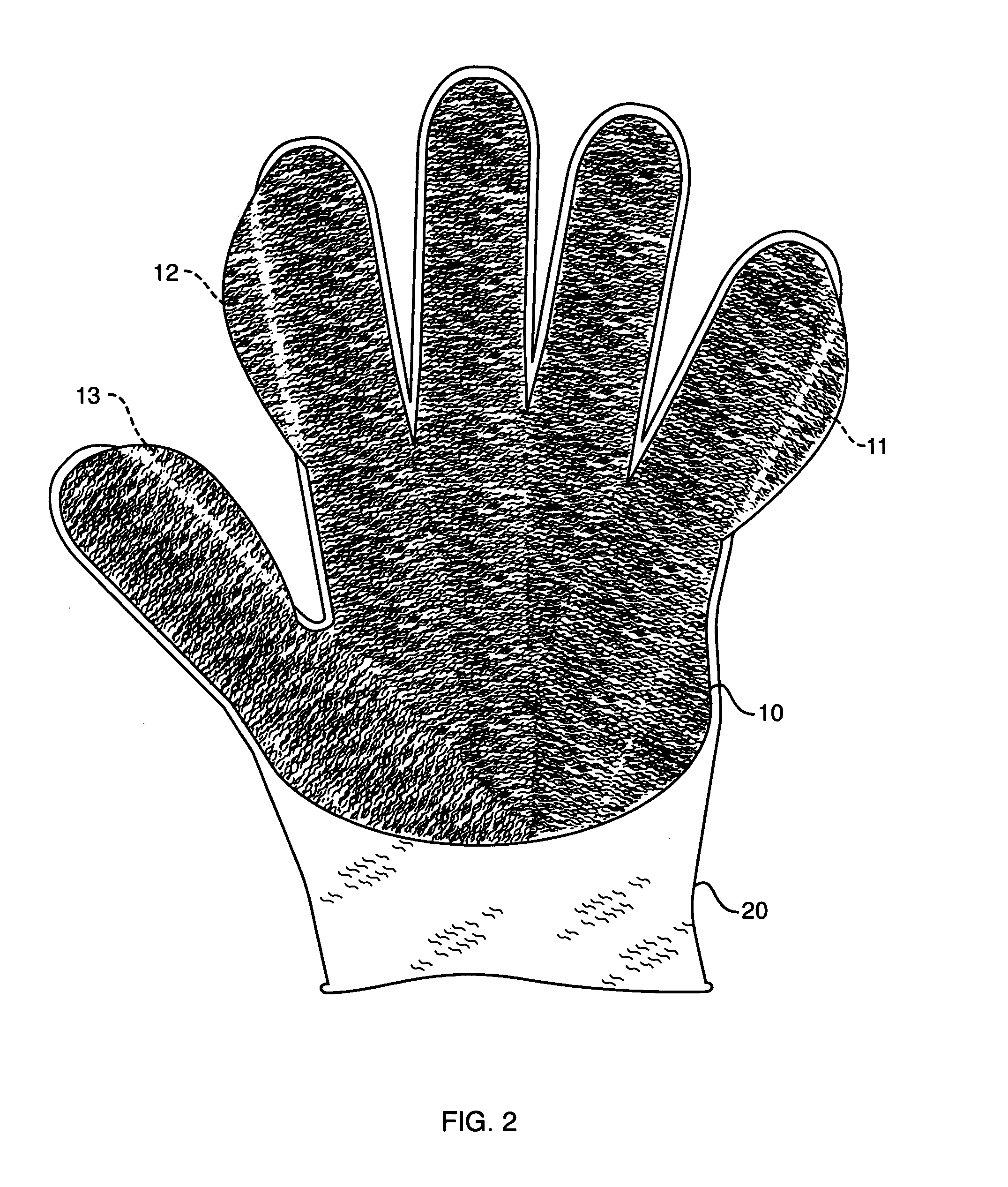

Protective garment and glove construction and method for making same

ActiveUS7007308B1High dexterityIncreasing overall composite puncture resistanceGlovesEye treatmentAdhesivePuncture resistance

A system of manufacturing to incorporate protective materials with high cut and puncture resistance into standard safety and apparel products including gloves, to create a highly effective and low cost system of producing safety garments while preserving the characteristics of the original garment. This includes attaching a cut and puncture resistant protective liner or multiple liners to the inside or outside of or within a garment such as a glove by means of adhesives or stitching. The liner may be a protective liner with cut resistance greater than 450 lbs per inch / thickness and / or puncture resistance greater than 50 lbs per inch / thickness depending on the application requirement for protection and dexterity.

Owner:WARWICK MILLS INC

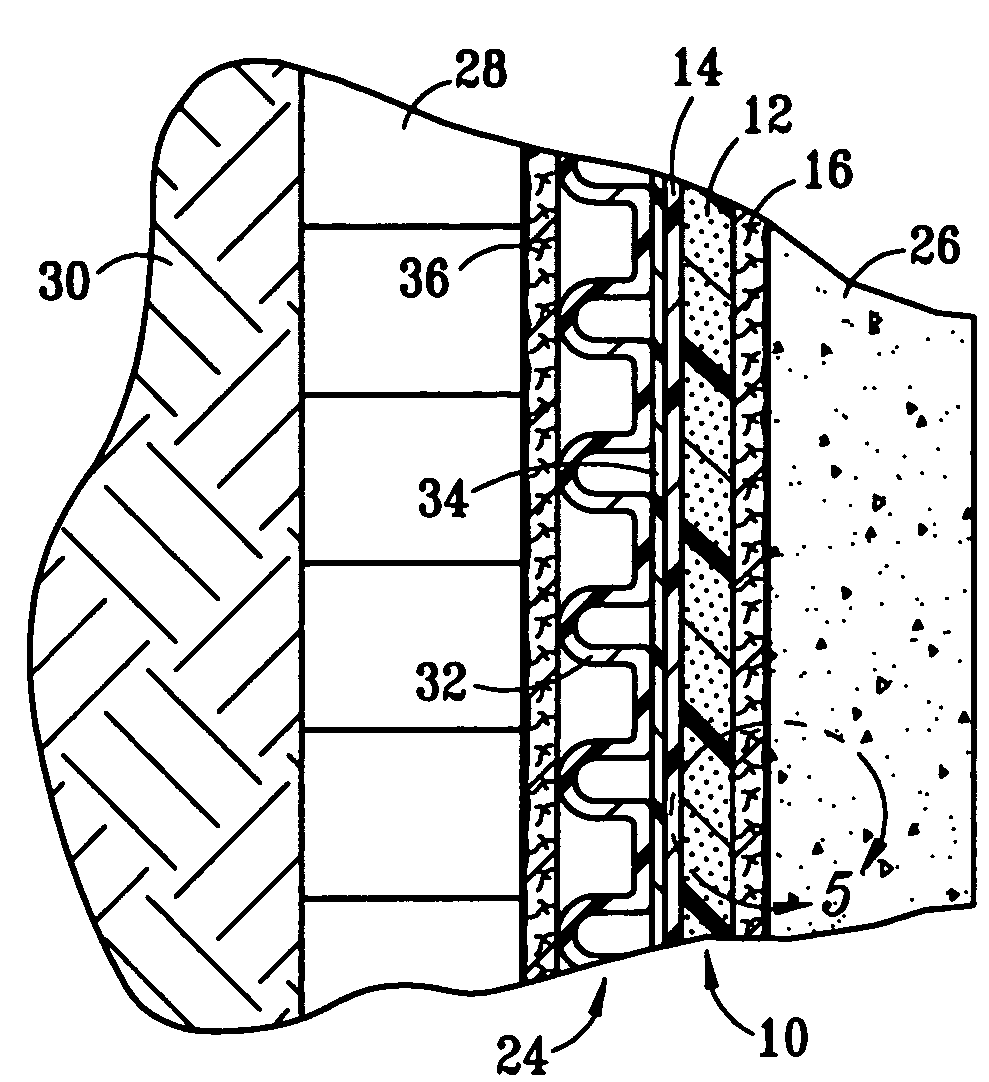

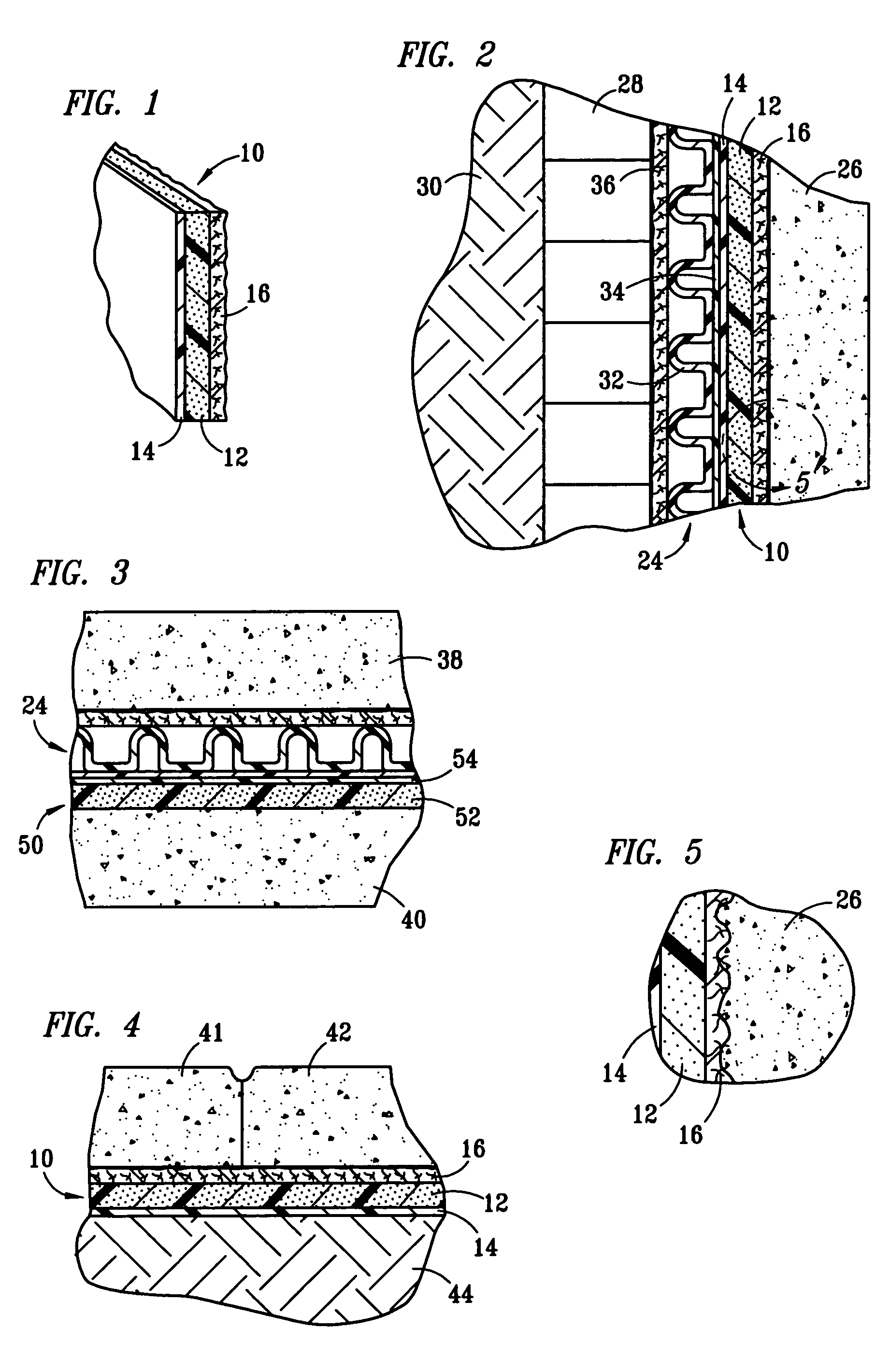

Stress-relieving barrier membrane for concrete slabs and foundation walls

ActiveUS7488523B1Relieve pressureReduce crack formationPaving reinforcementsIn situ pavingsStress relievingToxic material

A composite membrane comprising a layer of rubberized asphalt having a heavy duty plastic film layer continuously bonded to one side and, optionally, a layer of nonwoven geotextile continuously bonded to the other side. The membrane can be used in vertical or horizontal applications, and is particularly useful for its stress-relief properties that resist crack formation and propagation in concrete walls and slabs in addition to serving as a barrier to moisture, toxic substances and insects. An appropriate composite membrane of the invention can be advantageously utilized in positive side, blindside, underslab or split slab applications. The thickness of the composite membrane preferably ranges from about 30 mils to about 150 mils.

Owner:POLYGUARD PRODS

Access method with insert

ActiveUS8353824B2Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterAccess methodEngineering

Owner:CILAG GMBH INT

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

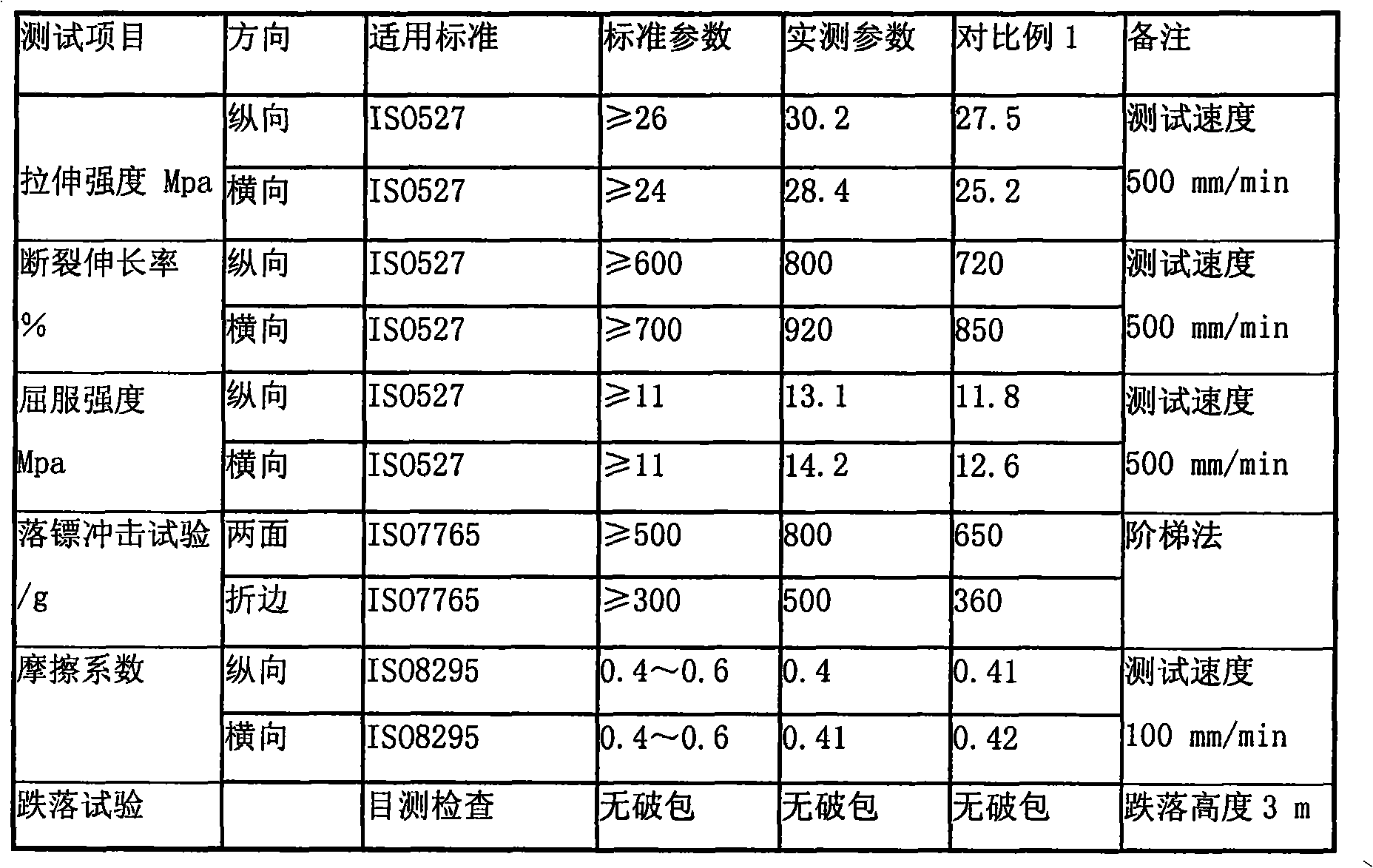

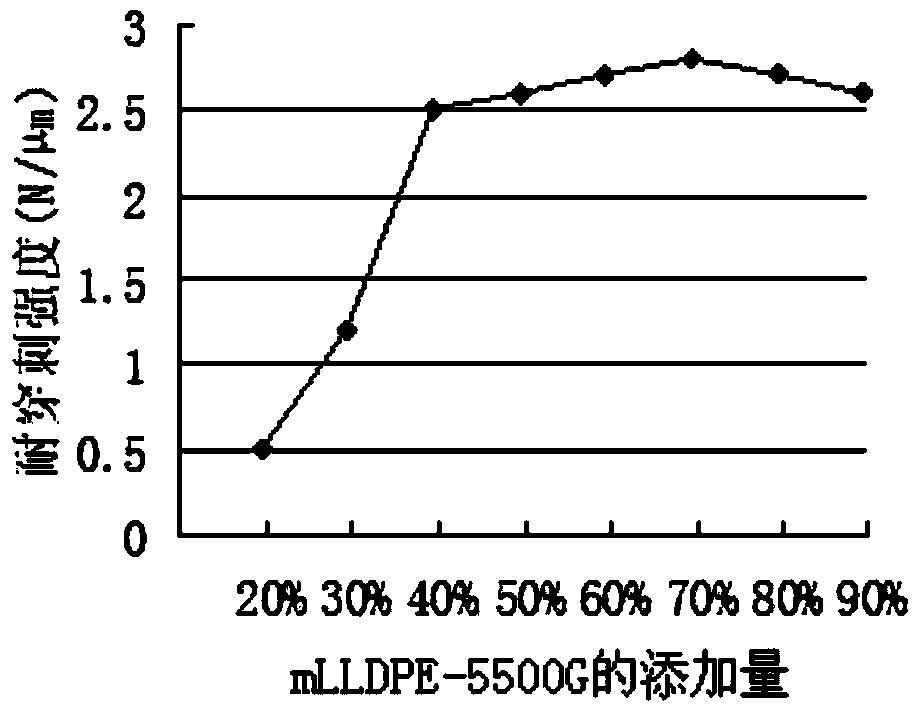

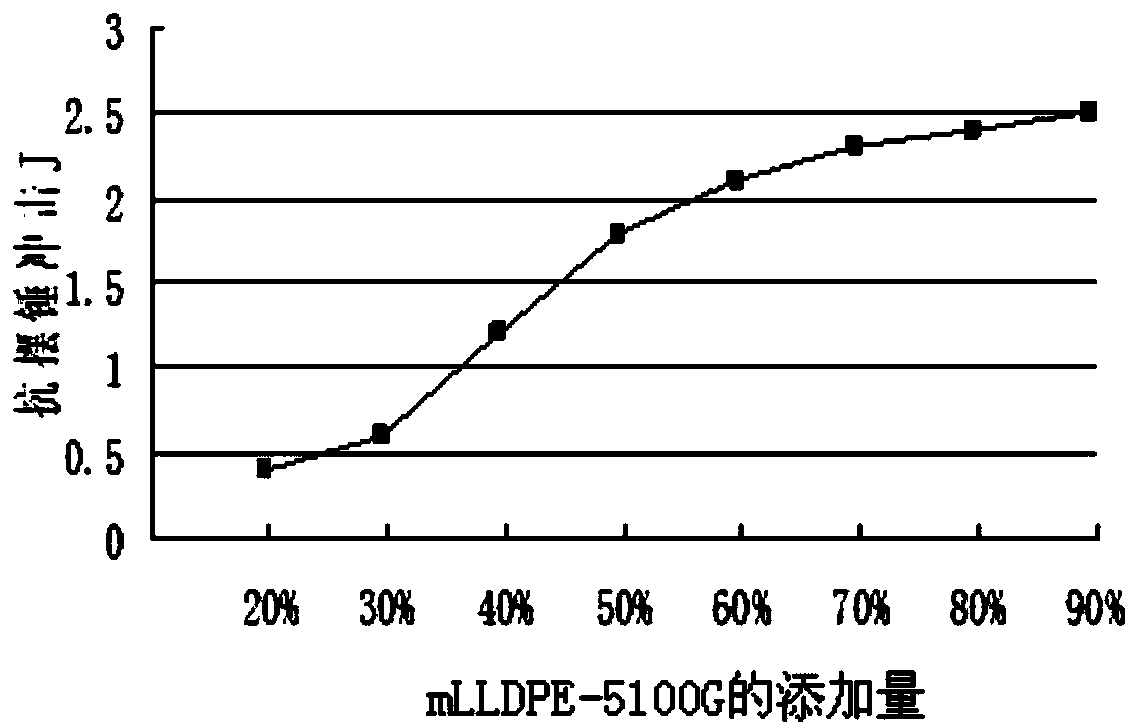

Polyethylene repackaging film material composition

ActiveCN101255249AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

A polyethylene heavy packaging film composite can be widely used for producing blisterpack, such as FFS package, large goods package, tray package and so on, which can effectively improve the all round performance of packaging film, and make the package of goods more beauty, firm, green and effective. The film composite comprises: linear low density polyethylene accounting for 60-80% of the sum of the material, low density polyethylene accounting for 5-25% of the sum of the material, metallocene linear low density polyethylene accounting for 10-30% of the sum of the material, additive accounting for 3-7% of the sum of the material. An automatic feed proportioning system feeds the material of three extruders to die head and the heavy packaging film combination is obtained after three-layer extruding and mixing. The additive is combination of one or several kinds of slippery agent, antistatic agent, antioxidant, opening agent, thermal stabilizer.

Owner:SINOPEC YANGZI PETROCHEM

Syringe needle coated with polyorganosiloxanes

InactiveUS6015398AImprove puncture resistanceReduce resistanceCatheterCoatingsSyringe needleDegree of polymerization

A needle which has decreased piercing resistance, which resistance does not increase by repeated piercing and of which a sterilizing means is not limited, is provided by the present invention. The needle is coated on its outside surface with a mixture of (1) a polyorganosiloxane having amino groups at both terminal ends reacted with an alkoxysilane having epoxy groups and (2) a non-reactive polyorganosiloxane which has a lower average degree of polymerization of its siloxane part than that of polyorganosiloxane (1).

Owner:NISSHO CORP

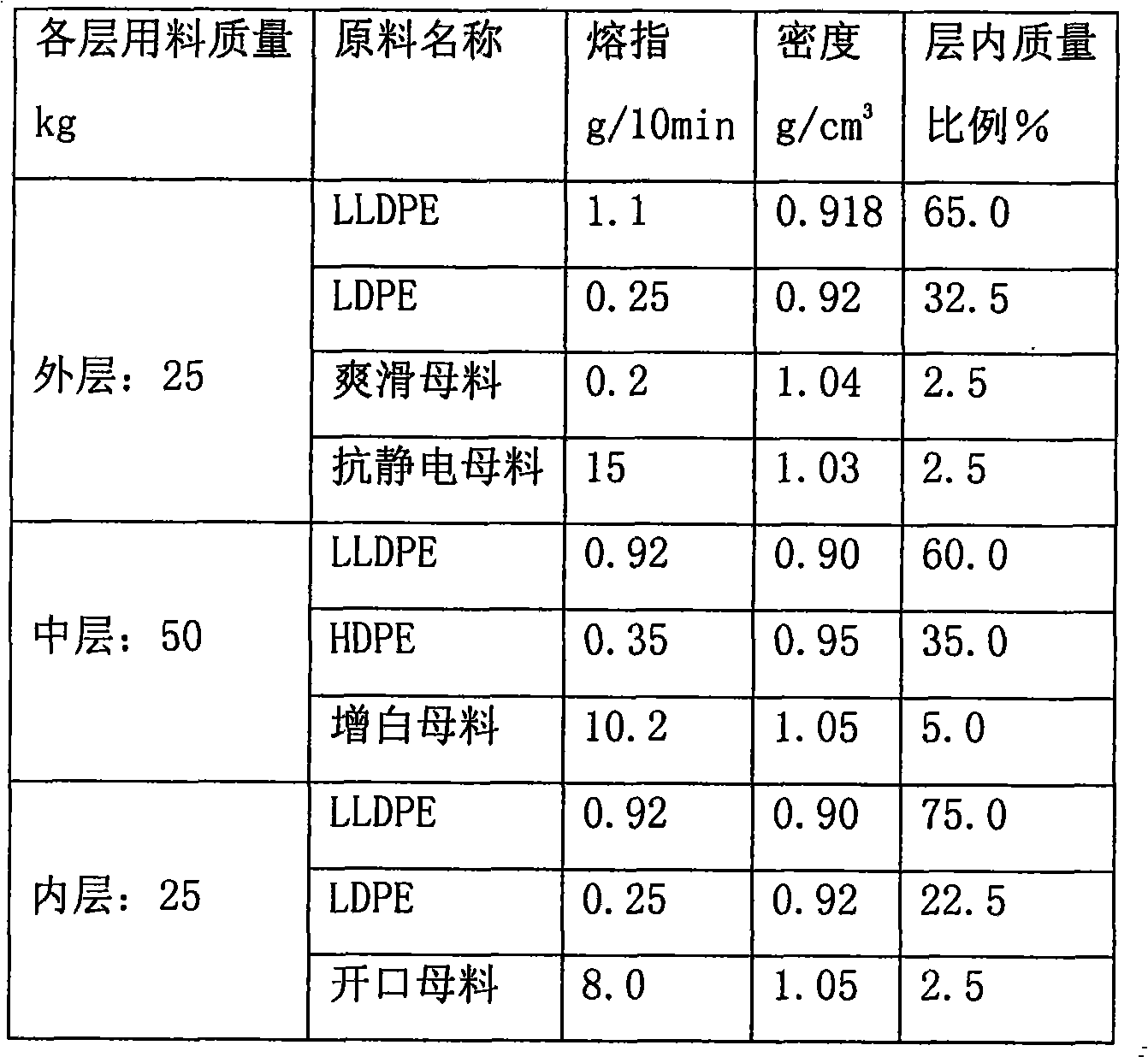

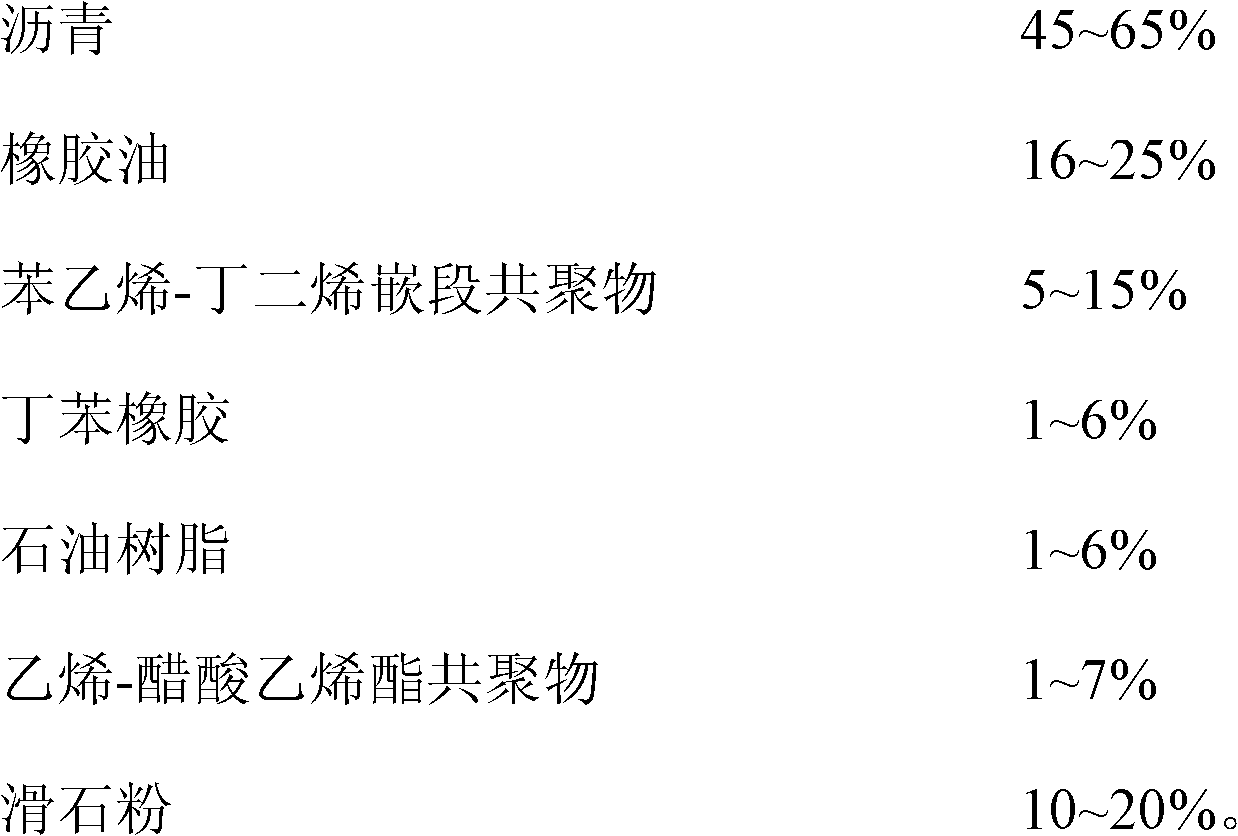

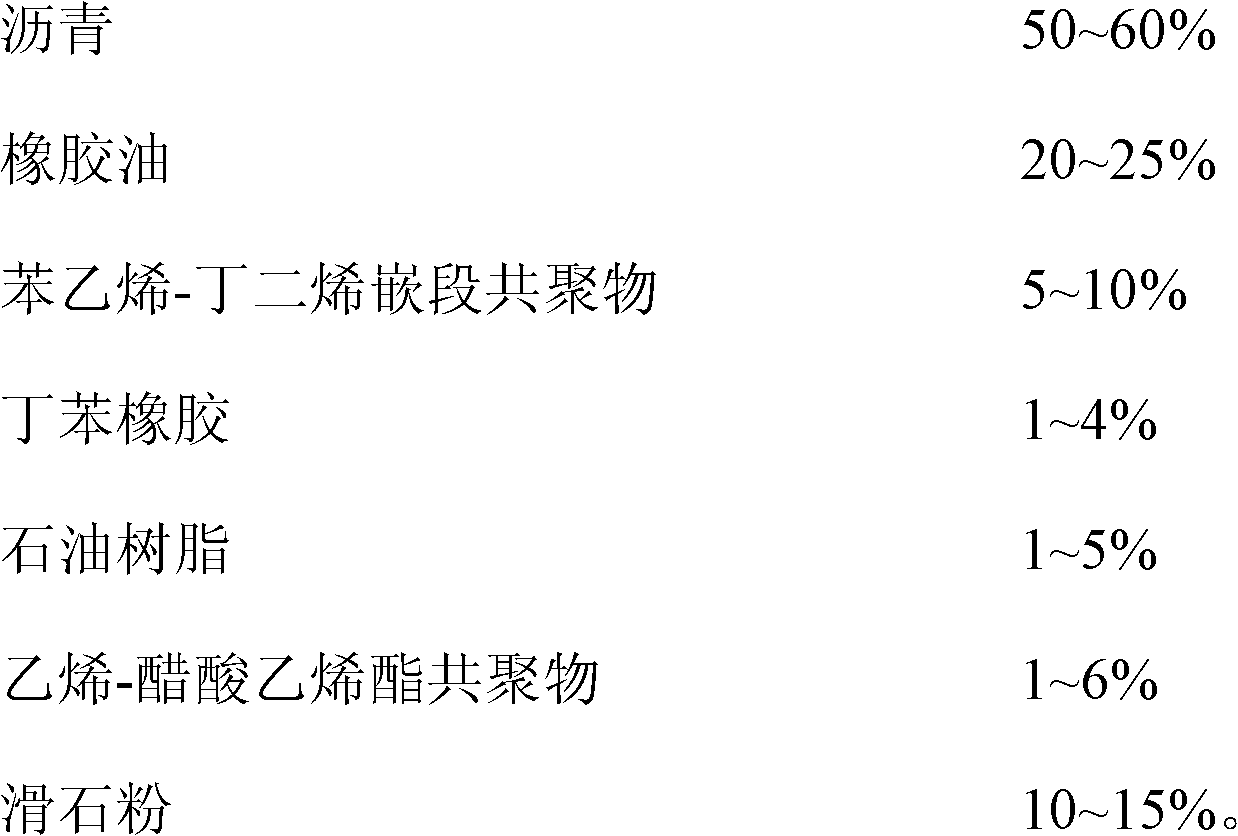

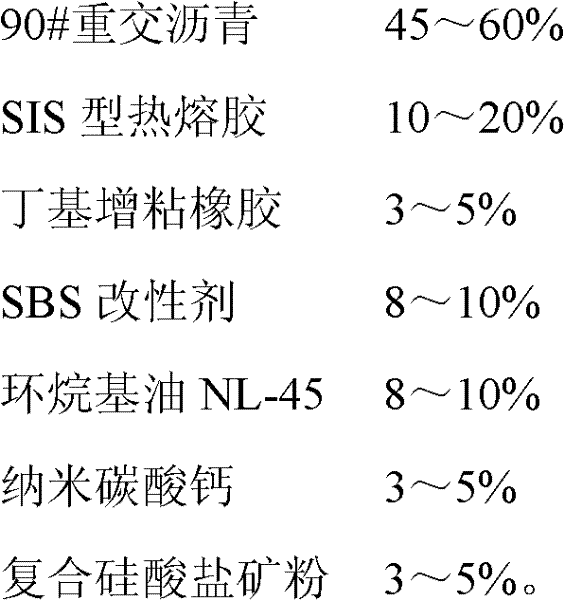

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

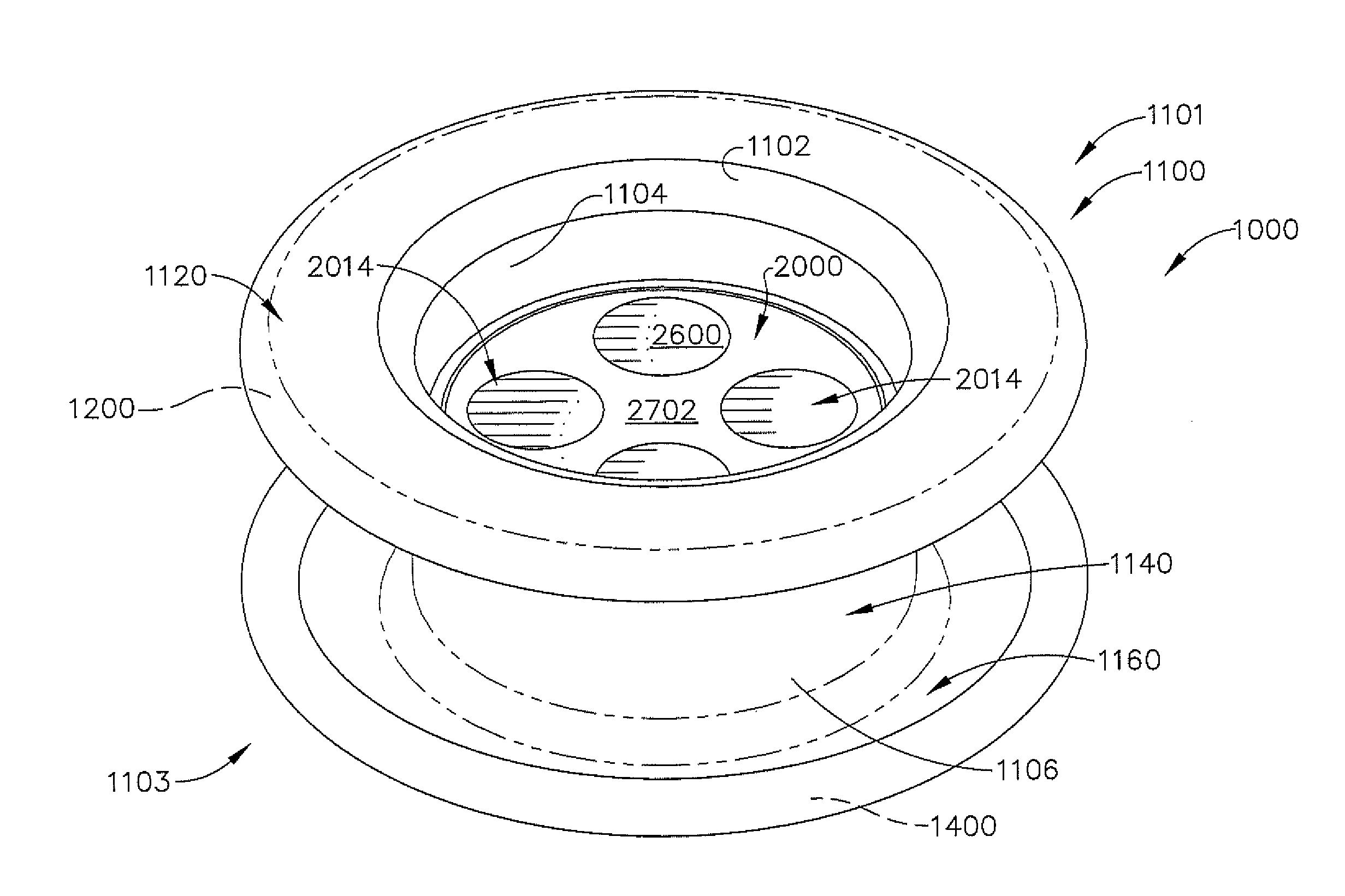

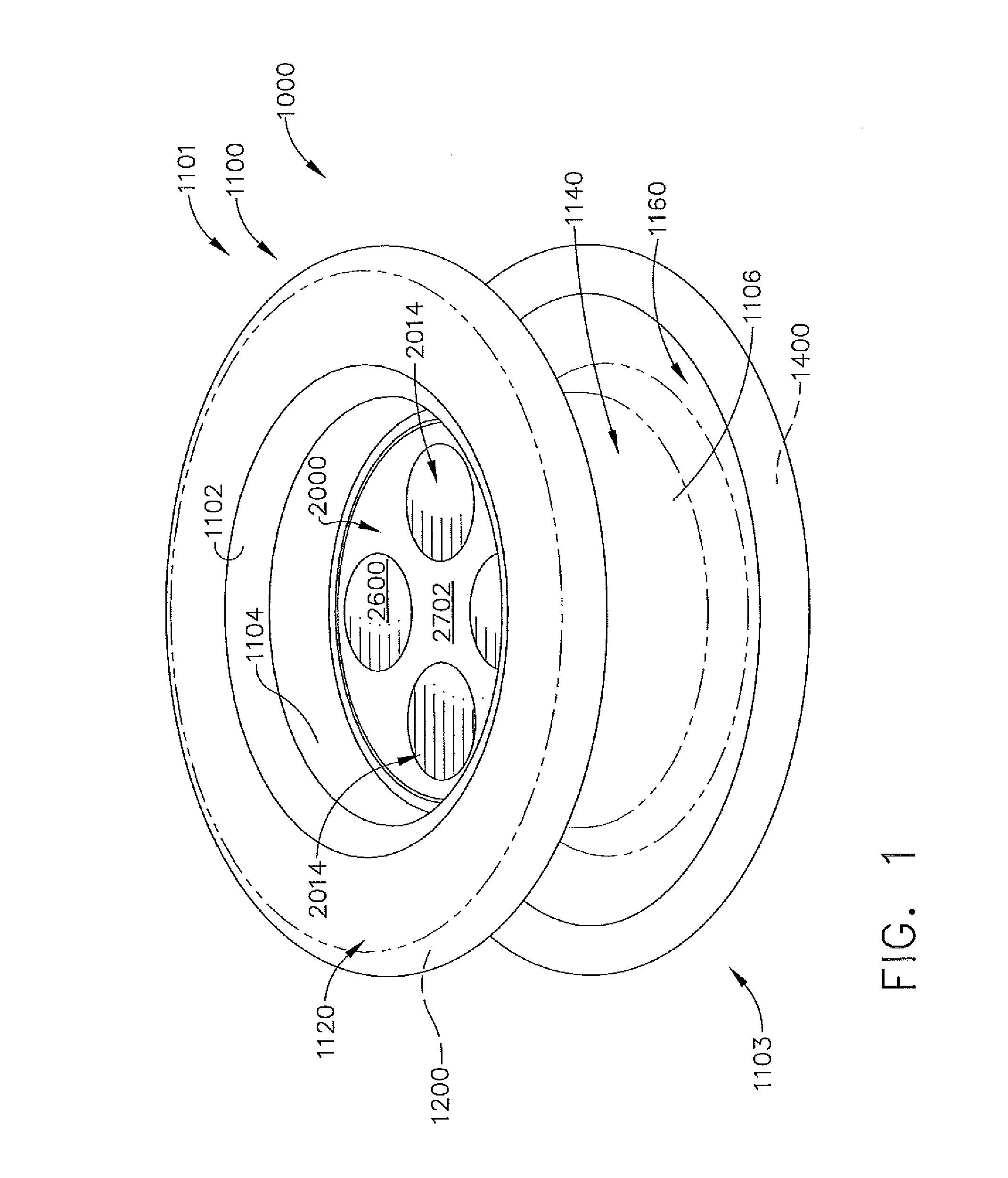

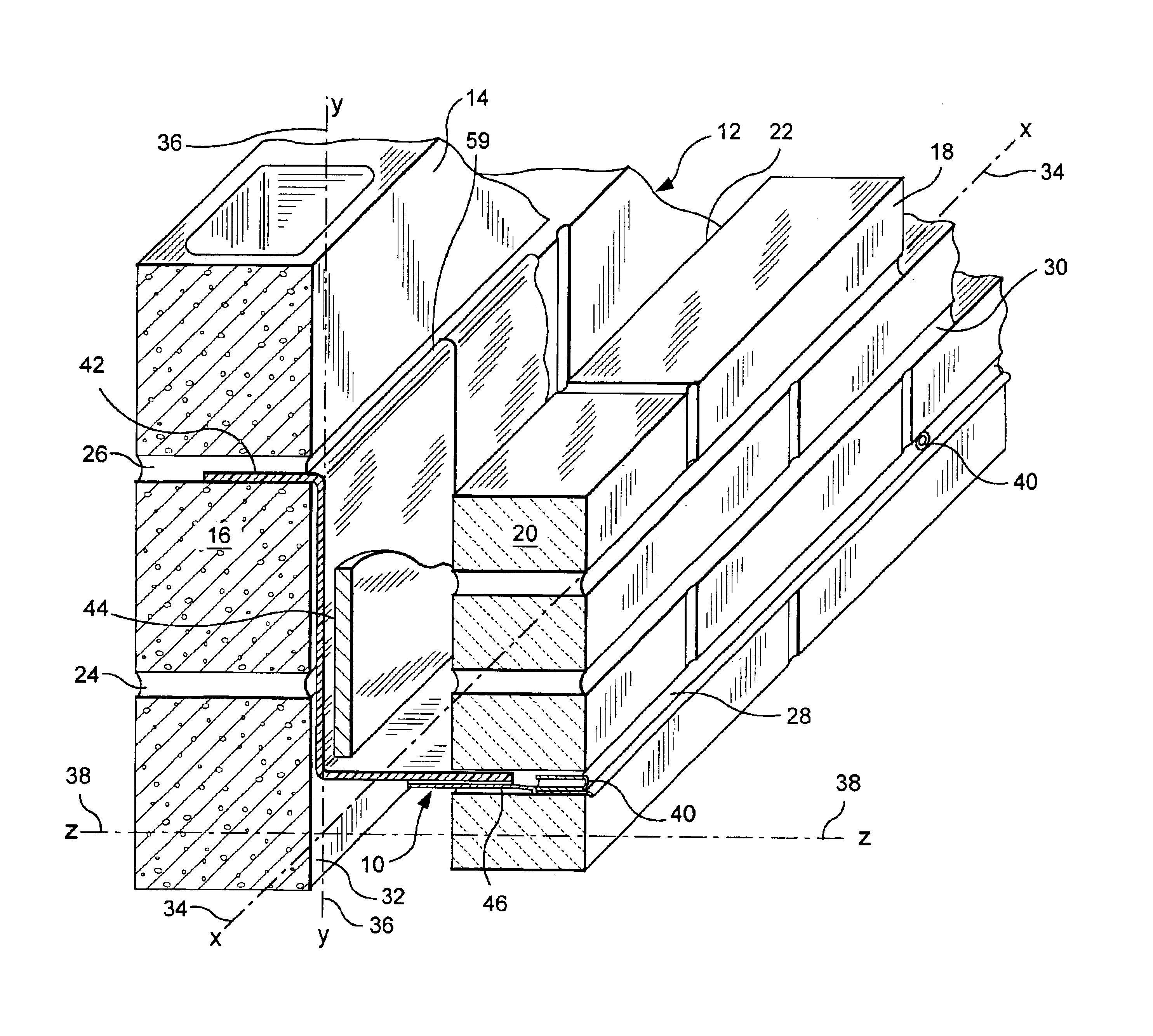

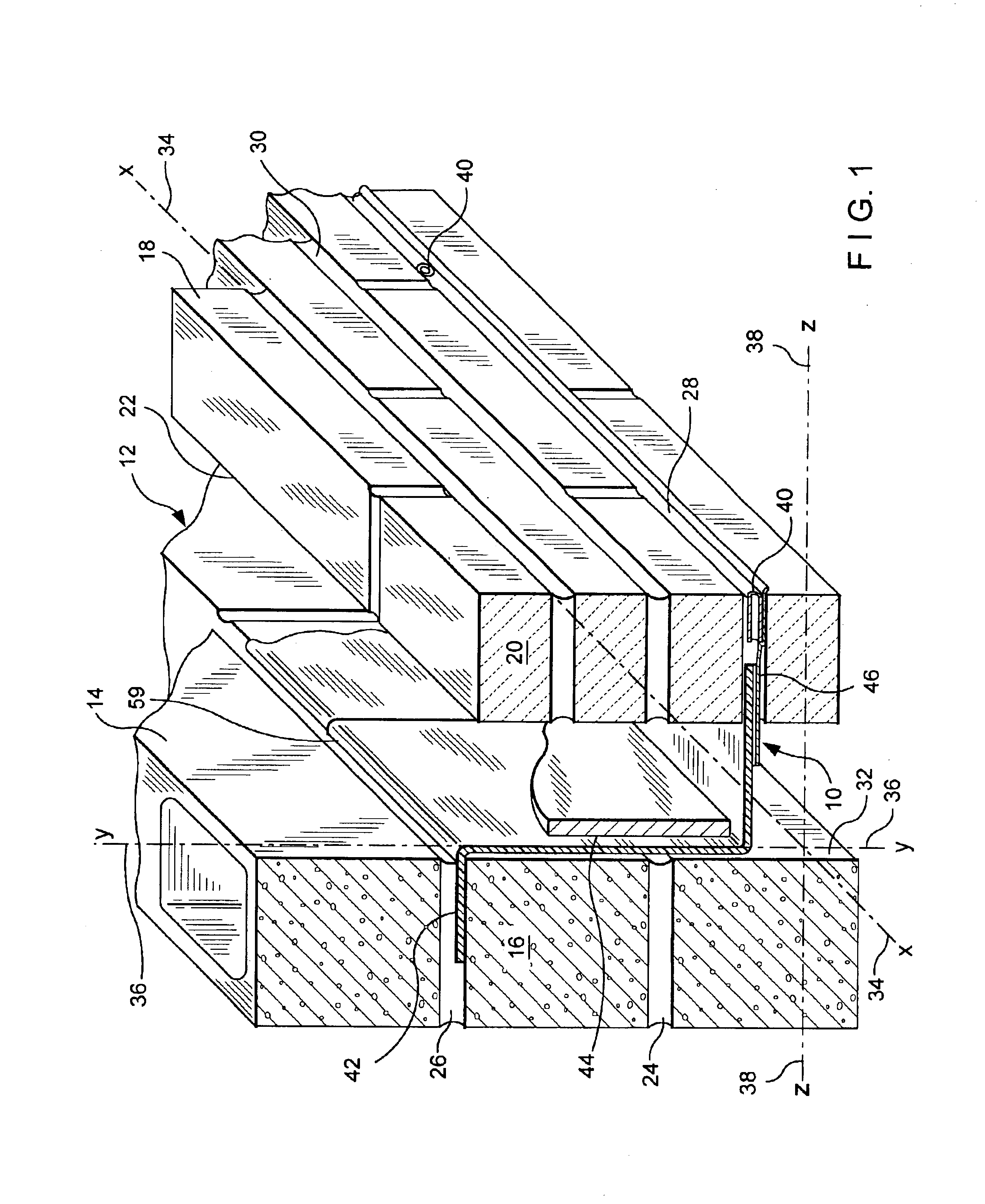

Access Device With Insert

ActiveUS20100249526A1Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterMedical deviceBiomedical engineering

Various devices and methods are provided with respect to inserting multiple surgical instruments through a single surgical access device. A medical device including a flexible tissue retractor and a releasable insert having multiple instrument openings is disclosed. The insert can be in the form of an insert assembly including multiple components. A method of using the insert is also described.

Owner:CILAG GMBH INT

High-separation multilayer joint-extrusion shrink film

InactiveCN102642359AImprove barrier propertiesIncrease oxygenFlexible coversWrappersSurface layerWater vapor

The invention discloses a high-separation multilayer joint-extrusion shrink film, which comprises an outer surface layer, a separation layer, a heat sealing layer and two bonding layers. The two bonding layers are respectively located between the separation layer and the outer surface layer and between the separation layer and the heat sealing layer, the separation layer is made of one of or a combination of two of ethylene vinyl alcohol (EVOH) resin, polyvinylidene chloride resin and modified polyamide resin, the thickness of the separation layer is 10%-45% of the total thickness, the thickness of the outer surface layer is 3%-5% of the total thickness, the thickness of the heat sealing layer is 25%-35% of the total thickness, the thickness of the bonding layers is 10%-30% of the total thickness, and the number of the separation layer is one or three. The outer surface layer of the film is made of high-melting-point resin to overcome the shortcoming that users are easy to burn during a using process of products, simultaneously oxygen and water vapor separation performance are good, the anti-puncturing effect and heat sealing strength are good, and the high-separation multilayer joint-extrusion shrink film can be suitable to vacuum shrink package of chilled pork, cheese products and seafood products.

Owner:张建岭

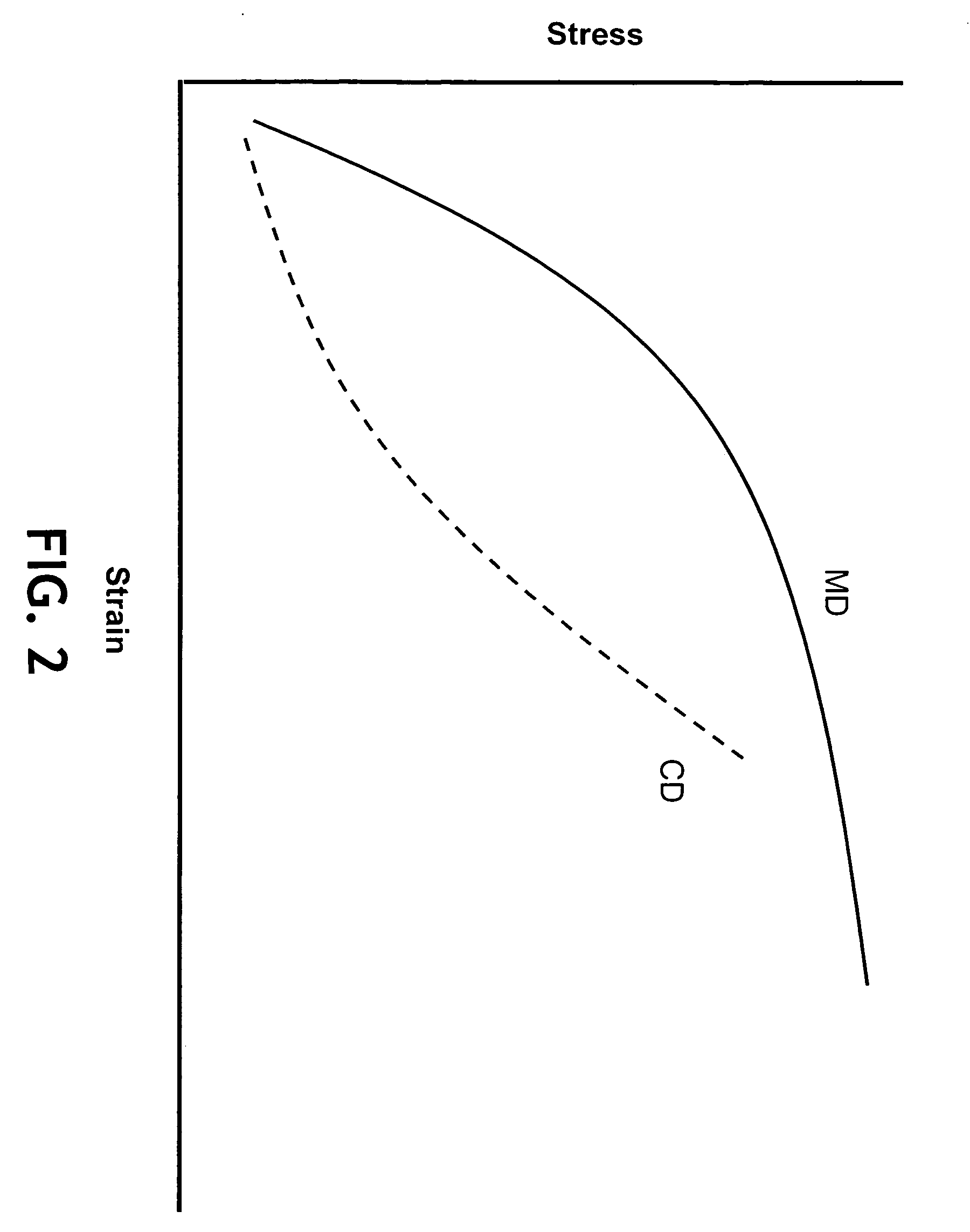

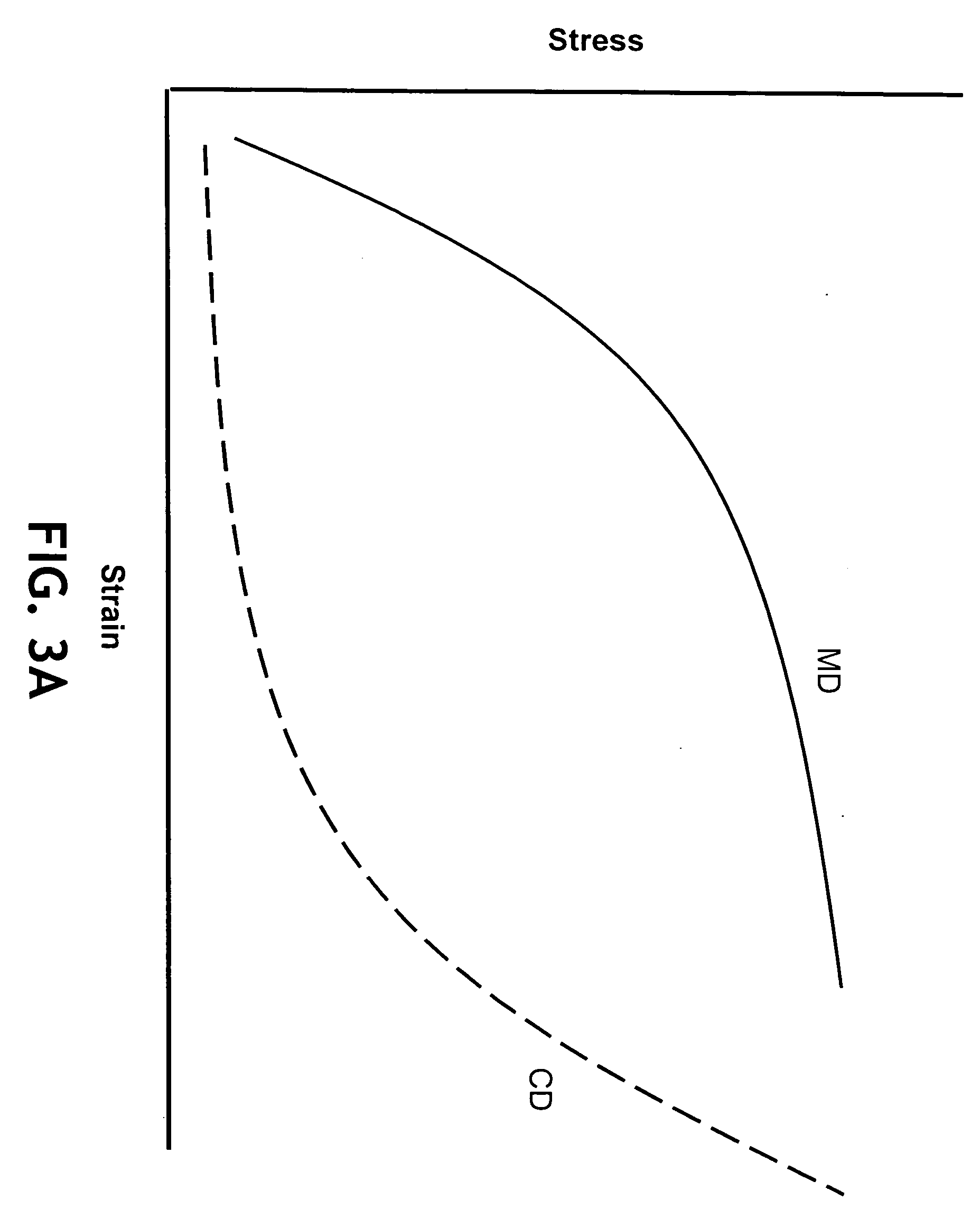

Tissue products having substantially equal machine direction and cross-machine direction mechanical properties

InactiveUS20050133175A1Improve puncture resistanceHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperPattern perceptionUltimate tensile strength

A tissue product having a combination of substantially equal tensile energy absorbed (TEA) in the machine direction and the cross-machine direction of the tissue sheet and a significant level of stretch in both directions provides improved perception of strength and resistance to “poke through” in use.

Owner:KIMBERLY-CLARK WORLDWIDE INC

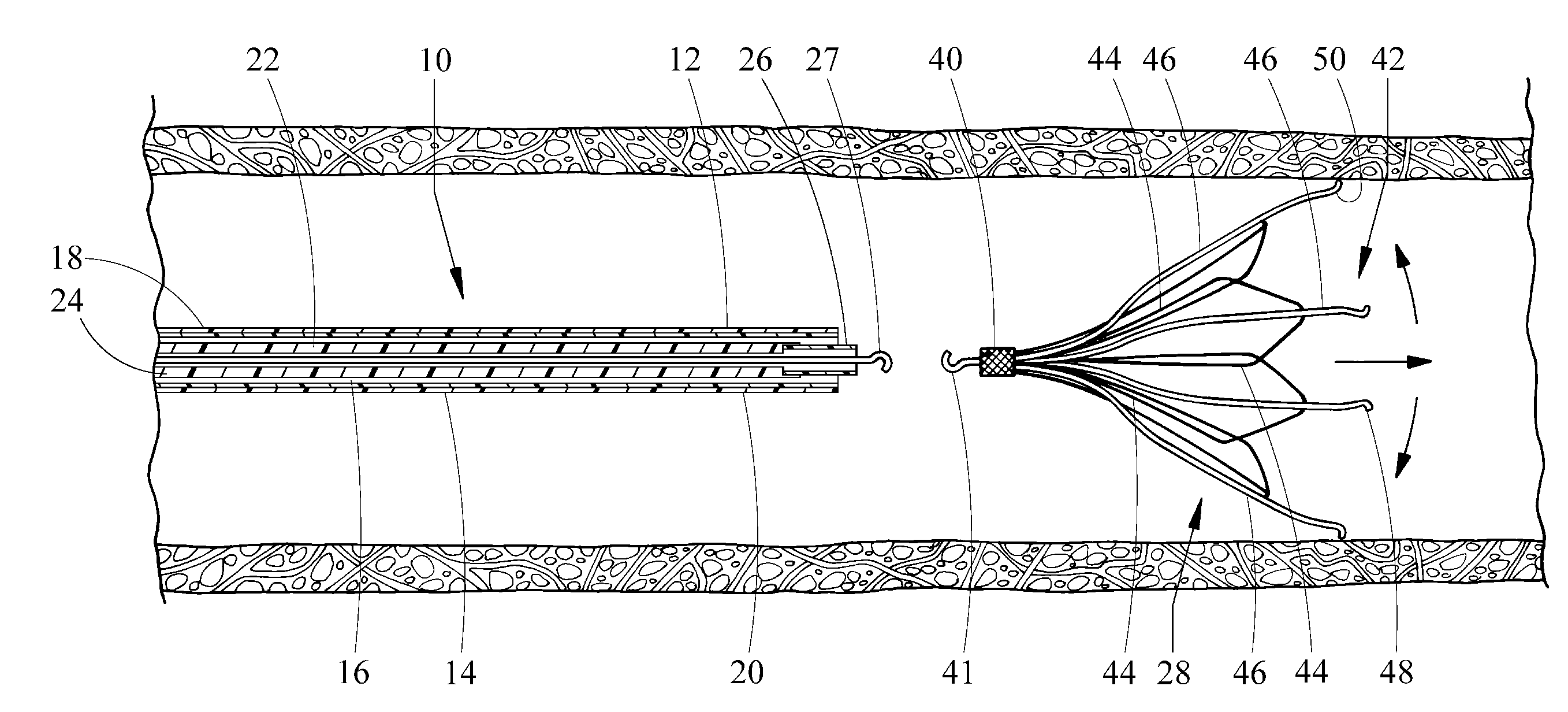

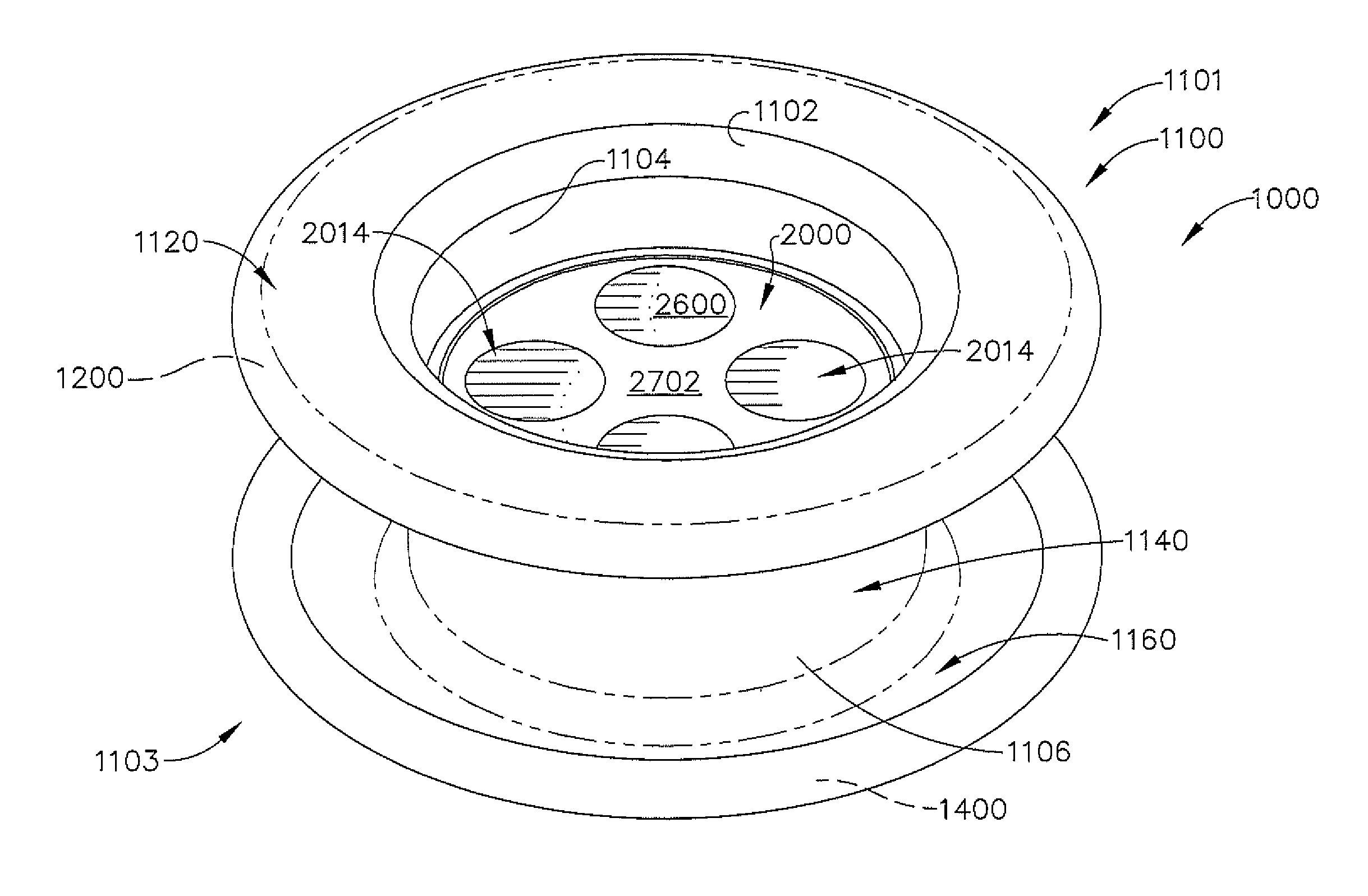

Puncture and abrasion resistant sheath

InactiveUS20080119867A1Excellent abrasion resistanceImprove puncture resistanceGuide needlesEar treatmentDistal portionPolyether ether ketone

A delivery apparatus for introducing an implant, such as a vena cava filter, for capturing emboli in a body vessel. The apparatus includes an outer sheath having a tubular wall defining a lumen formed therethrough and having a proximal end extending to a distal end. The tubular wall includes an inner surface and may also include optional reinforcing members. A radiopaque marker band is disposed about the inner surface adjacent the distal end, and a tubular liner is disposed along the inner surface. The tubular liner comprises at least one of polyimide, PEEK, and PVDF. An inner catheter is slidably disposed within the lumen of the outer sheath and has a distal portion configured to engage and deliver the implant through the distal end of the outer sheath in the body vessel.

Owner:COOK INC

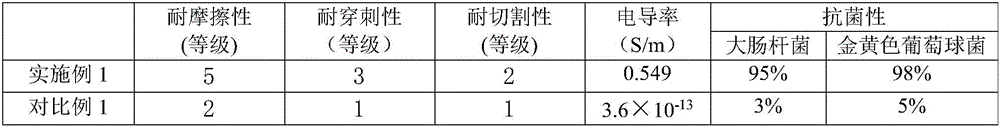

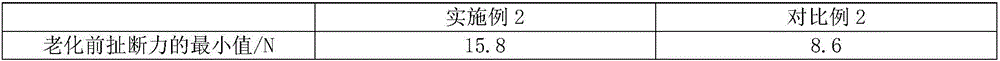

Graphene-latex functional high-strength protection glove and production method thereof

InactiveCN106065095AComfortable to wearImprove friction resistanceGlovesBulk chemical productionElectricityAviation

The invention discloses a graphene-latex functional high-strength protection glove and a production method thereof. The method comprises the following steps: (1) immersing a glove blank in a coagulating agent, immersing the glove blank in a graphene-latex composite liquid, and drying the immersed glove blank to obtain the glove; or (2) immersing the glove blank in the coagulating agent, drying the immersed glove blank, immersing the dried glove blank in the graphene-latex composite liquid, leaching the immersed glove blank, crimping the leached glove blank, drying the crimped glove blank, vulcanizing the dried glove blank, leaching the vulcanized glove blank, and drying the leached glove blank to obtain the glove. Compared with gloves in the prior art, the graphene-latex functional high-strength protection glove produced in the invention fully performs the advantages of high electricity conductivity, high strength, friction resistance and strong bacteriostasis of graphene, and has wide uses in the fields of the manufacturing industry, the medical industry, the chemical engineering industry and the space flight and aviation industry.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

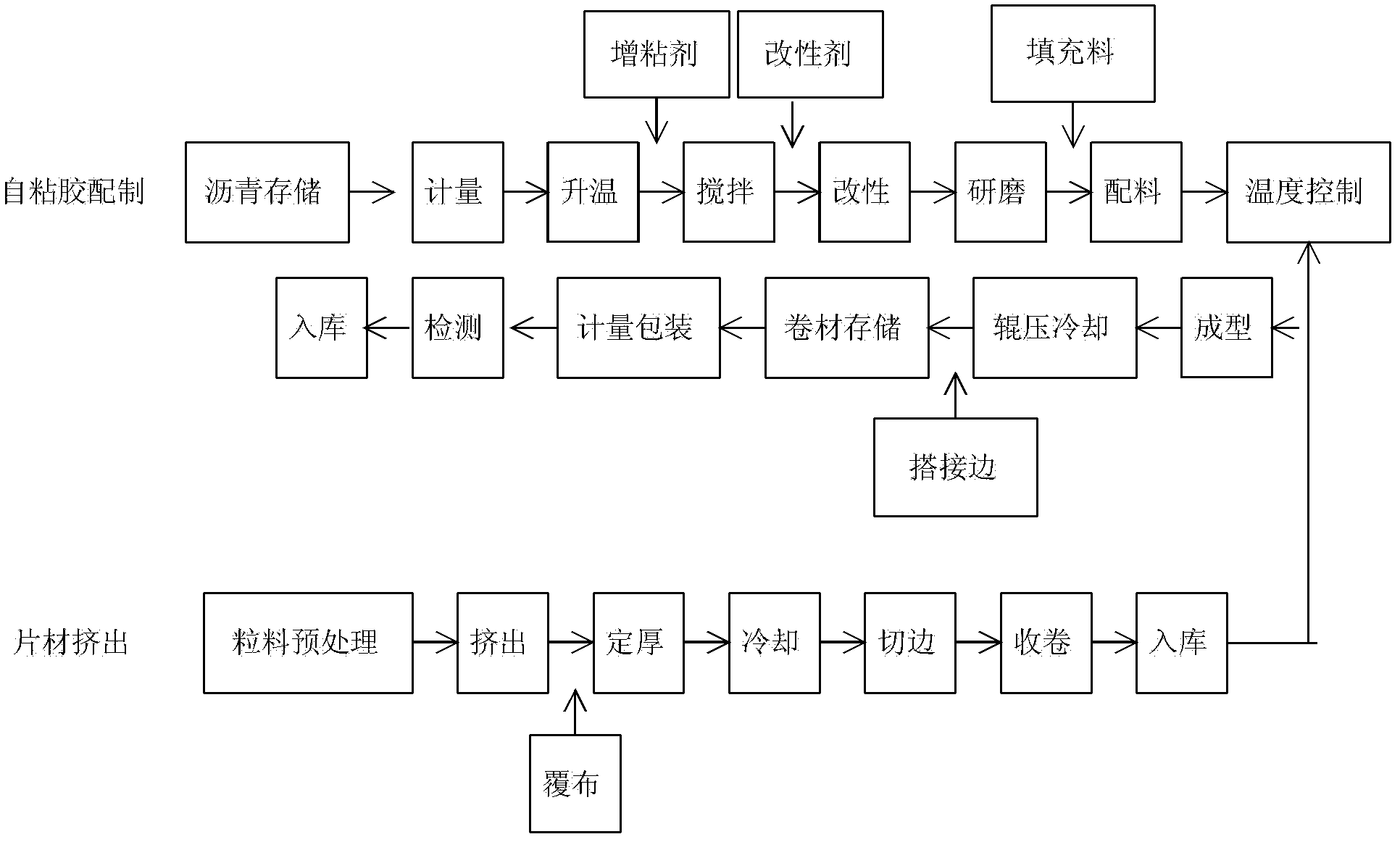

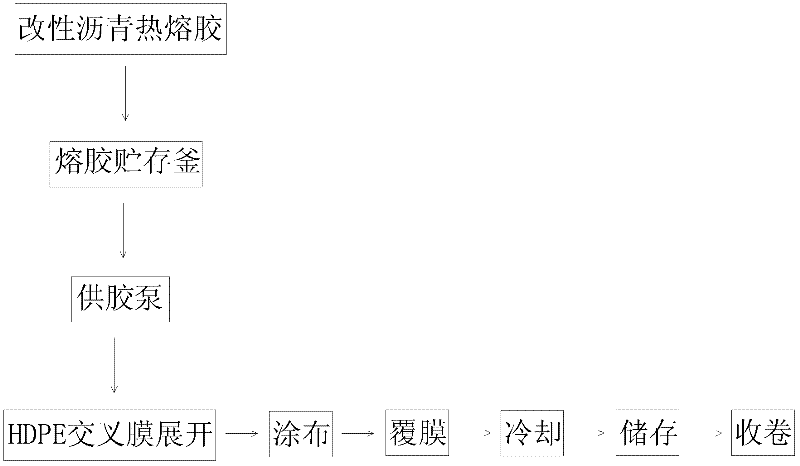

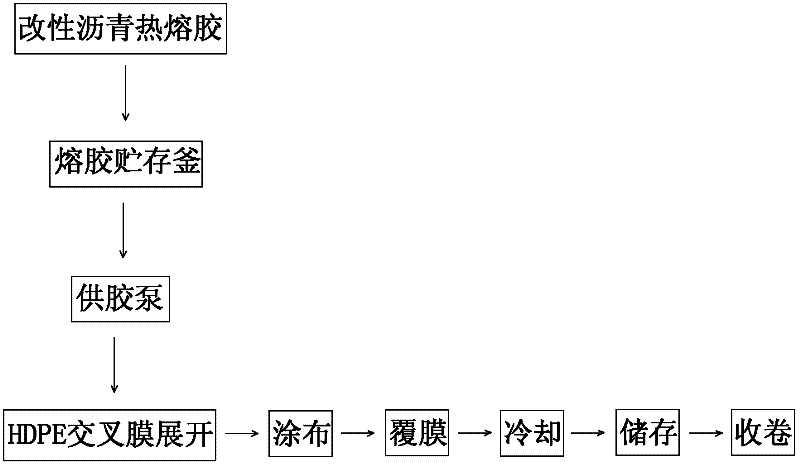

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

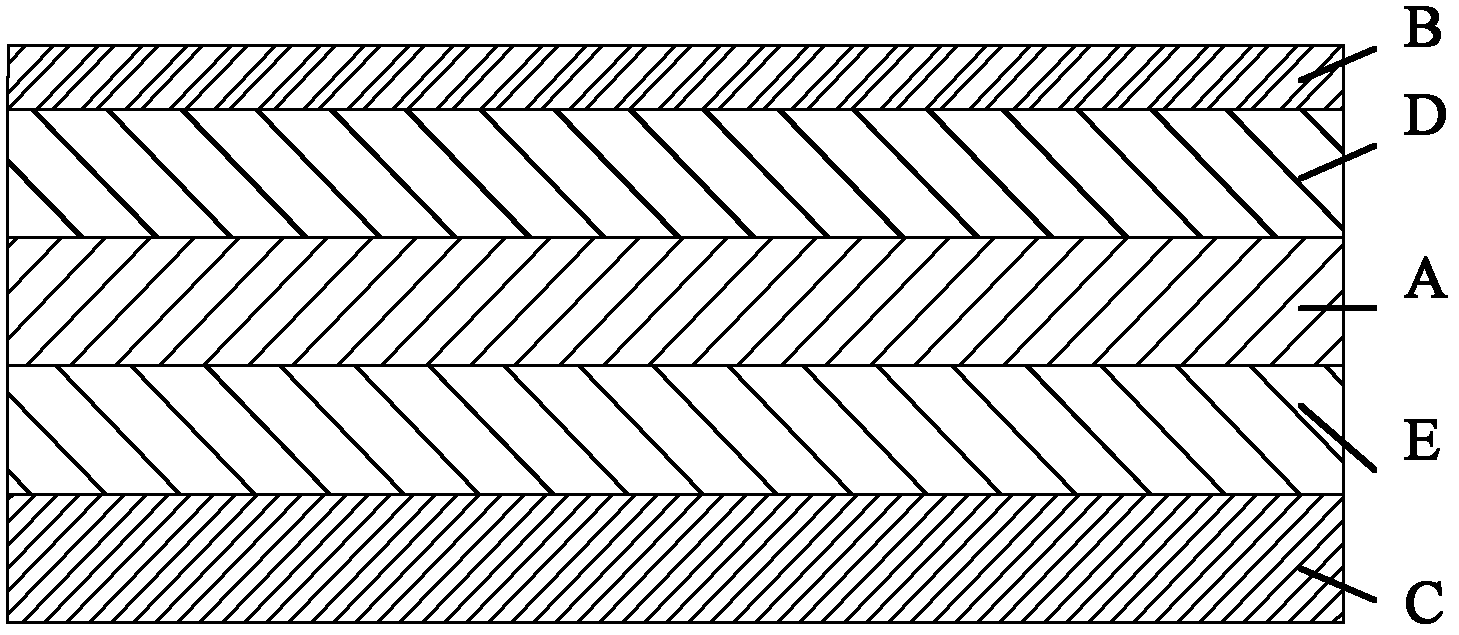

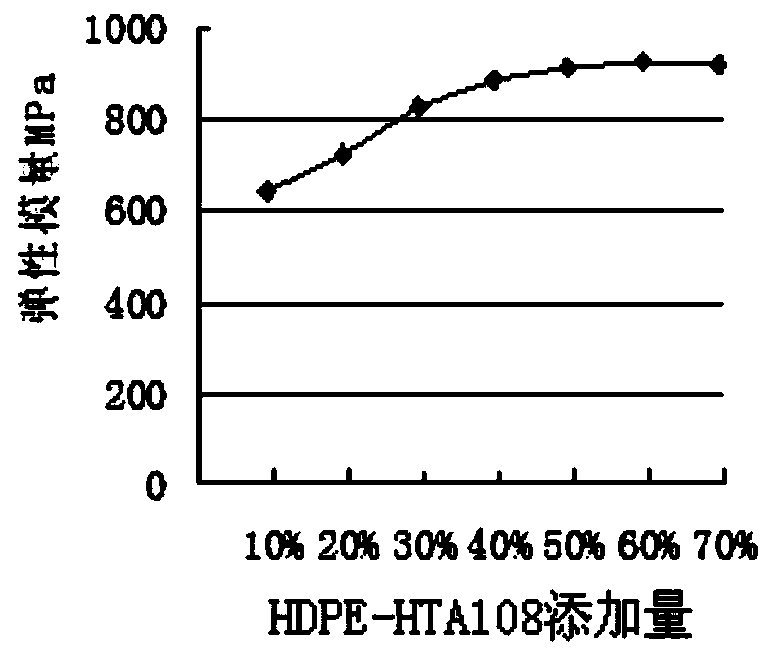

High-stiffness puncture-resistant low-friction coefficient composite film and preparation method thereof

ActiveCN103770422AImprove barrier propertiesMaintain flavor and qualityFlexible coversWrappersHigh-density polyethylenePuncture resistance

The invention belongs to the technical field of package materials, and in particular relates to a high-stiffness puncture-resistant low-friction coefficient composite film and a preparation method of the high-stiffness puncture-resistant low-friction coefficient composite film. The high-stiffness puncture-resistant low-friction coefficient PE thin film orderly comprises a composite layer, an intermediate layer and a heat-seal layer, the composite layer comprises low-density polyethylene, metallocene linear low density polyethylene and a processing agent; the intermediate layer comprises high-density polyethylene, metallocene linear low density polyethylene and a processing agent; and the heat-seal layer comprises low-density polyethylene, metallocene linear low density polyethylene and the like. The high-stiffness puncture-resistant low-friction coefficient composite film provided by the invention is high in barrier property and capable of well satisfying the quality-guaranteeing demand of content, and maintaining the quality and flavor of the content, so that the content has long expiration date. The puncture resistance is good so that objects such as sharp bone and fishbone can be packaged, the phenomenon that the bag is punctured has small possibility of occurring. The stiffness is high so that the packaged content can be directly distinguished clearly, and the shelf effect is good. The friction coefficient is low and stable so that the film has good equipment adaptation, and the package efficiency is improved.

Owner:HUANGSHAN NOVEL

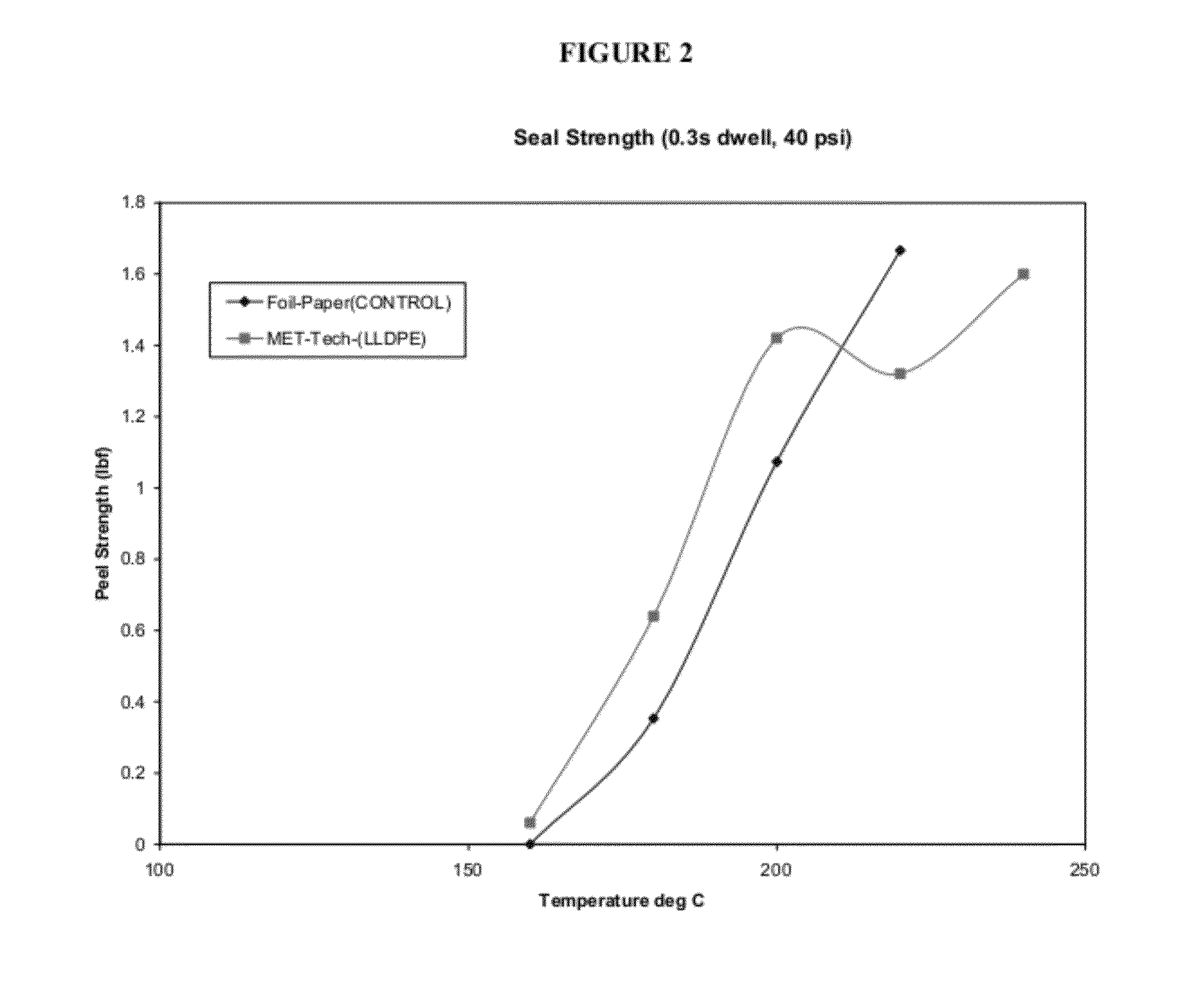

Laminate for packaging hygroscopic materials, pouches made therefrom, and method for manufacturing same

InactiveUS20120207954A1Good heat sealing performanceReduce water permeabilityBag making operationsFlexible containers manufacturePuncture resistancePolymer

The present invention provides a novel packaging laminate designed particularly for packaging highly hygroscopic, pelleted, flowable materials. It is a multilayer structure which incorporates a layer of heat-sealable polymeric material which has had a thin film of aluminum deposited onto it by vapour coating. This layer combined with a further effective barrier layer provides the low WVTR in the range required by such highly hygroscopic materials. This laminate can be used with additional structural layers of paper or plastic, to form bags that have the features of very low WVTR, excellent puncture resistance, and excellent heat sealability.

Owner:HOOD PACKAGING

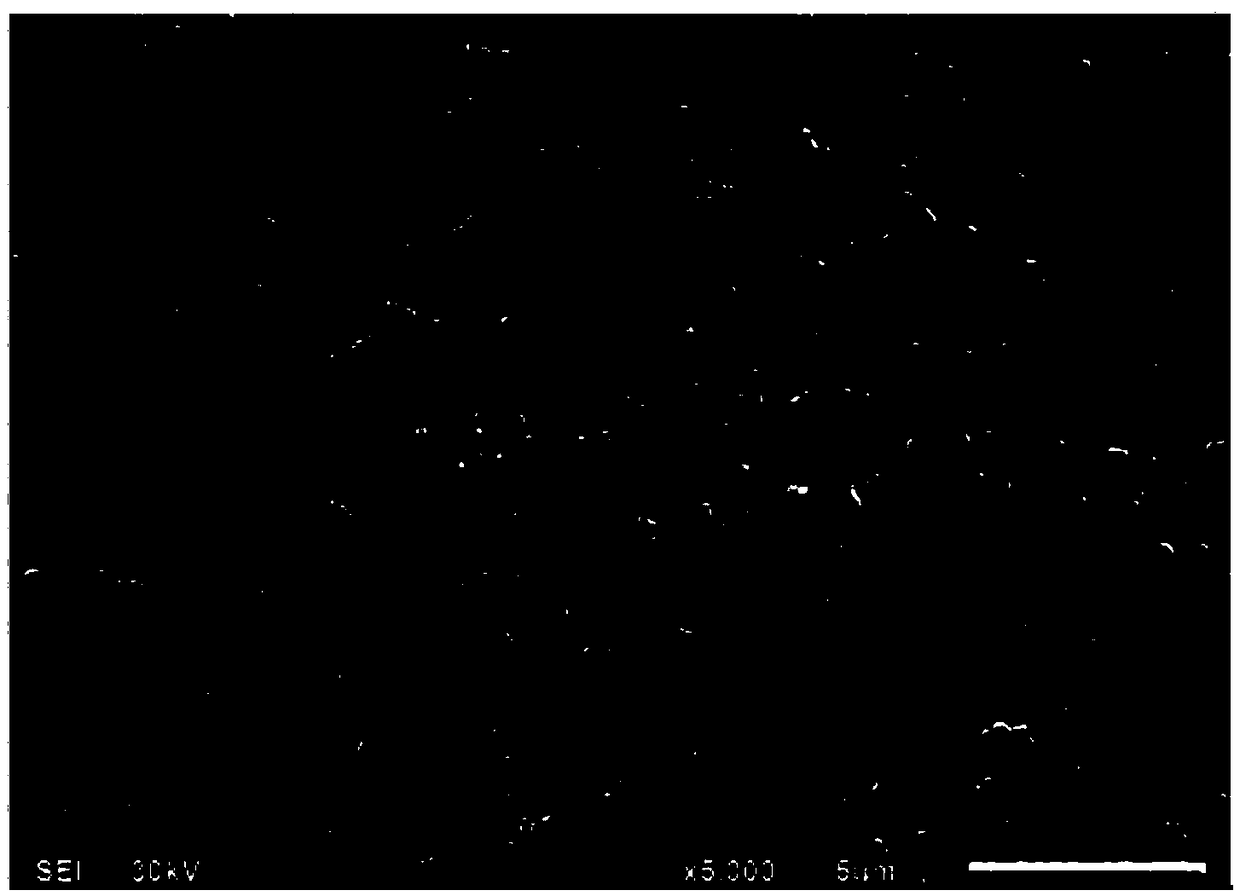

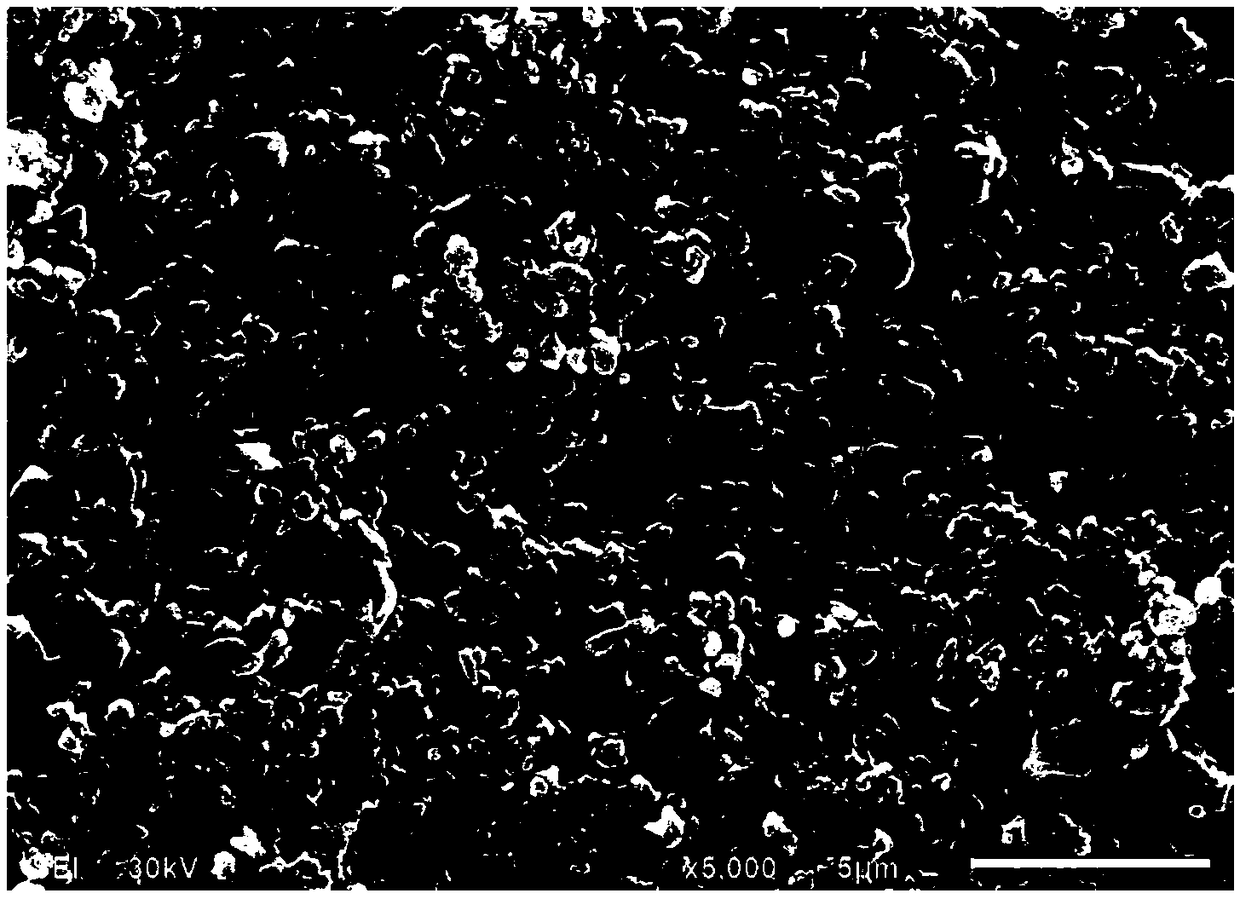

Tyre tread rubber composition used in hard mine area and production method of tyre tread rubber composition in hard mine area

ActiveCN102634089AGood dispersionImprove puncture resistanceSpecial tyresMicrocrystalline waxVulcanization

The invention relates to the technical field of rubber, in particular to a tyre tread rubber composition used in a hard mine area and a production method of the tread rubber composition in the hard mine area. The tyre tread rubber composition comprises the following materials by weight: 50-90 parts of styrene butadiene rubber, 10-50 parts of natural rubber, 45-55 parts of carbon black, 15-25 parts of white carbon black, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4.5 parts of silane coupling agent, 2-5 parts of cutting resistant resin, 10-20 parts of aromatic oil, 1-3 parts of antioxidant N-(1,3-dimethylbutyl)-N'-phenyl p-phenylenediamine, 1-2 parts of antioxidant 2, 2, 4-trimethyl-1,2-dihydroquinoline polymer, 1-3.5 parts of microcrystalline wax, 1-2 parts of sulfur, 1.0-2.0 parts of vulcanization accelerant N-tertiary butyl-2-benzothiazole sulfonamide, 0.5-1.0 parts of vulcanization accelerant N,N-diphenylguanidine and 0.1-0.3 parts of scorch retarder. The tyre tread rubber composition used in a hard mine area and the production method provided by the invention can obviously improve puncture resistant property, the chipping resistant property, the safety and the service life of a tyre in the hard mine area.

Owner:TRIANGLE TIRE

Reaction-type high-strength laminated film waterproof roll

InactiveCN102604553ASolve the problem of poor UV and weather resistanceNot easy to ageNon-macromolecular adhesive additivesUnderground chambersCross-linkAging resistance

The invention discloses a reaction-type high-strength laminated film waterproof roll which comprises a layer of high-strength cross laminated film (HDPE, high-density polyethylene) with thickness of 0.10-0.14mm and a layer of modified asphalt super glue which can react with cast-in-place concrete and is solidified together with the cast-in-place concrete. The waterproof roll can be chemically cross-linked and physically blended with concrete; under the effect of a coagent, a bonding layer can be continuously and permanently bonded with a base layer processing agent or the concrete poured on the bonding layer so as to completely prevent water from permeating into a clearance between the waterproof roll and the structure and form a skin-type net-shaped integer together with the base surface. Since the high-strength cross laminated film of special material HDPE has good tensile strength, breaking elongation rate and anti-puncture capability, the self-adhered waterproof roll of the high-strength cross film has the advantages of relatively good tensile strength, breaking elongation rate, anti-puncture capability and aging resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

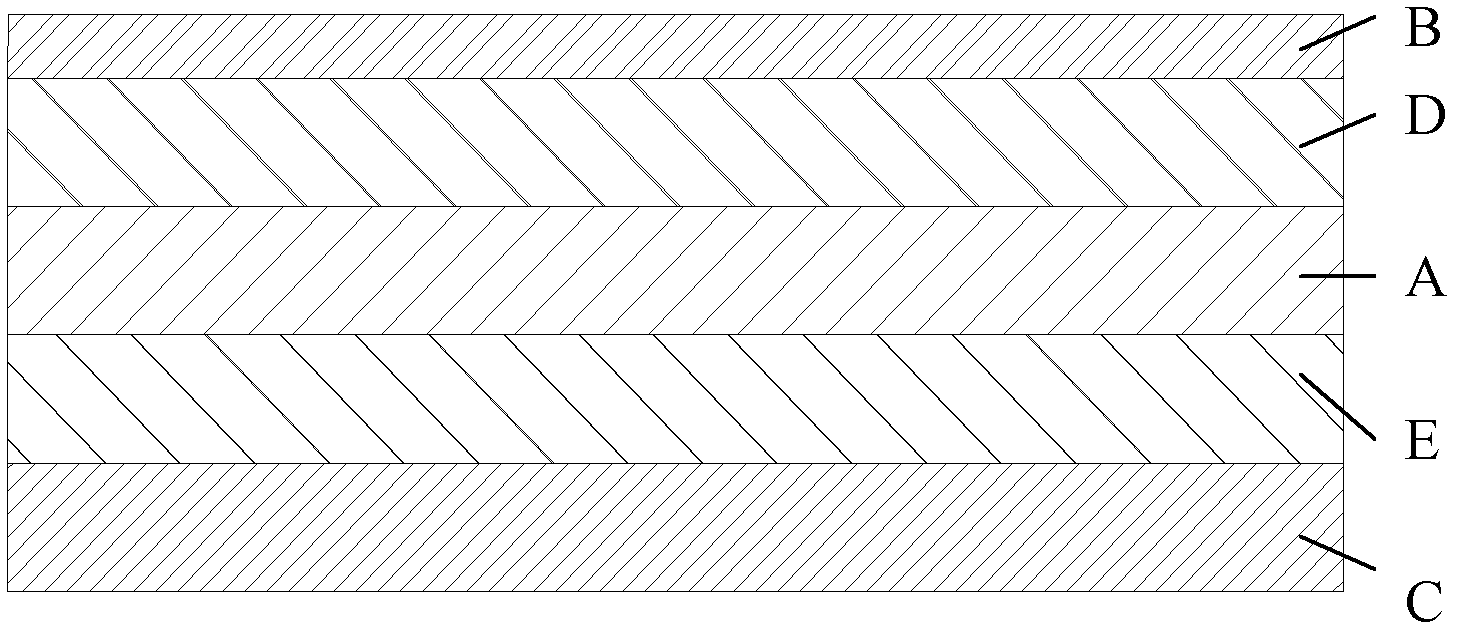

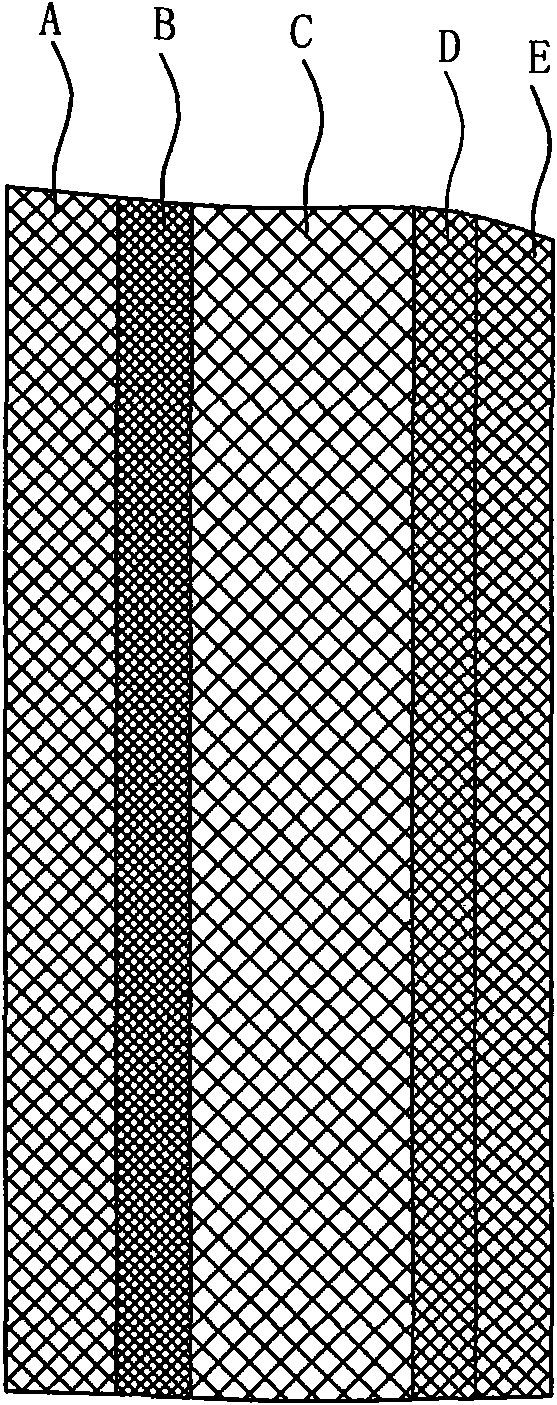

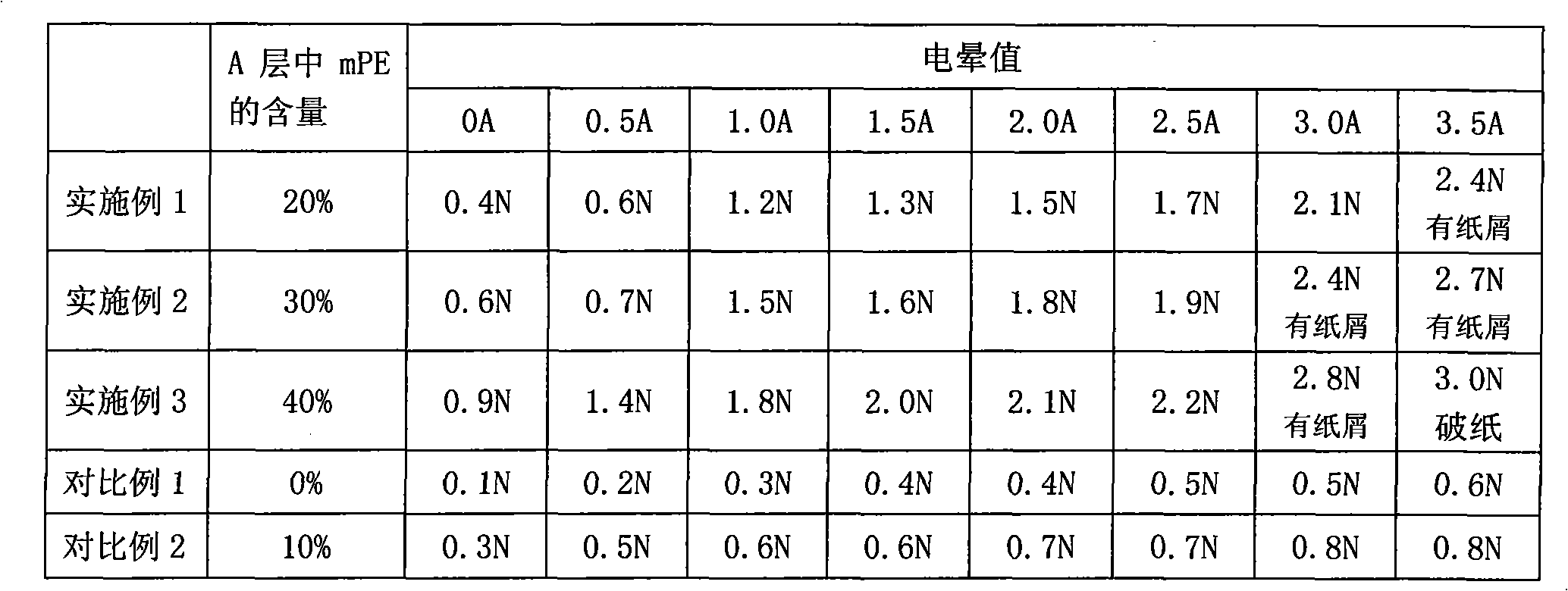

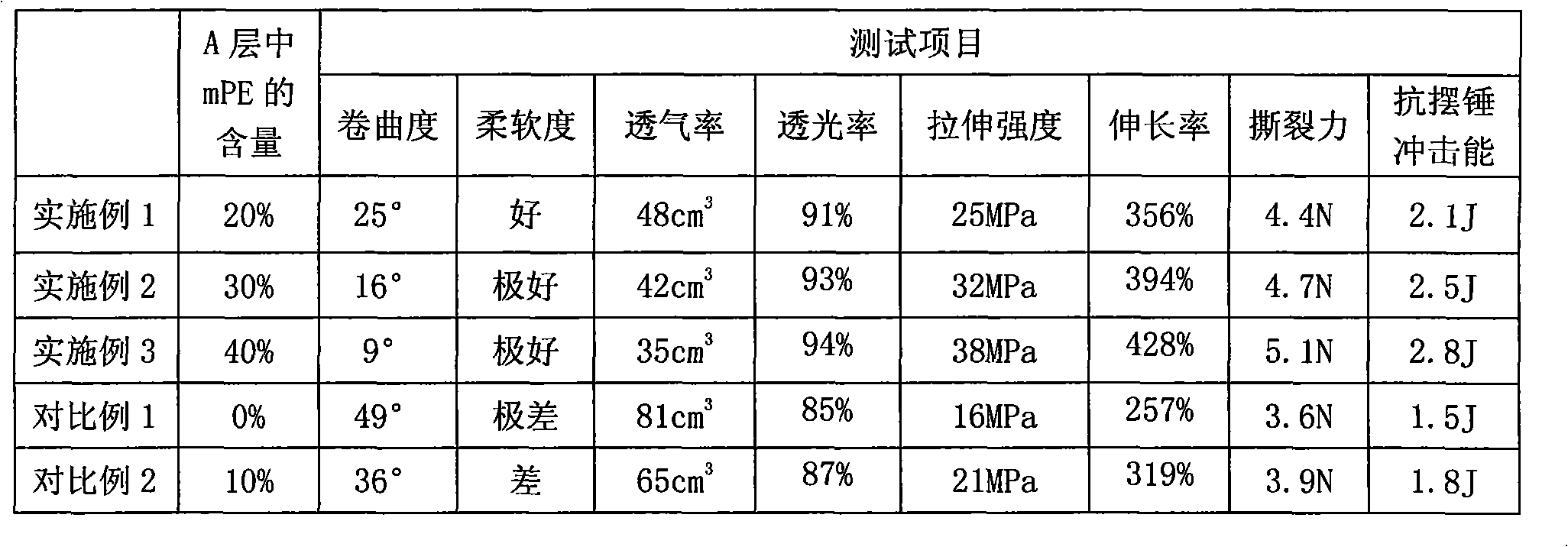

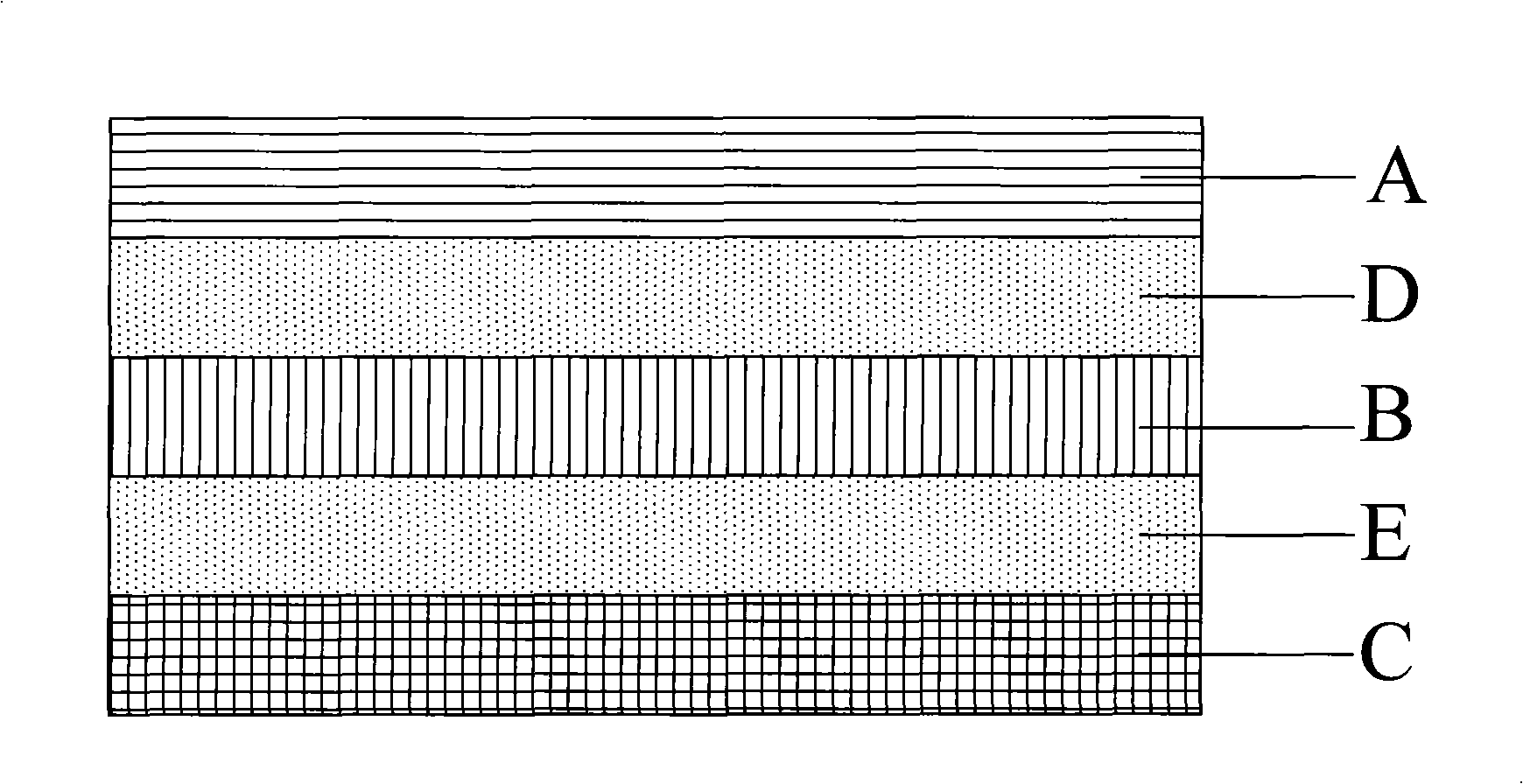

Film for suction plastic packaging of medical equipment and method for preparing same

InactiveCN101559854AGood heat sealing effectReduce production linksFlexible coversWrappersMaleic anhydrideMetal

The invention relates to a film for suction plastic packaging of medical equipment and a method for preparing the same. The film adopts a five-layer structure; the first layer is a heat seal layer A, of which the component is co-mixing resin of linear low-density polyethylene and metallocene catalytic polyethylene taking octene as a comonomer, wherein the content of the metallocene catalytic polyethylene in the co-mixing resin is 20 to 40 weight percent; the second layer is an inner layer B, of which the component is linear low-density polyethylene containing a hexene comonomer; the third layer is a core layer, of which the component is linear low-density polyethylene containing a butene comonomer; the fourth layer is a bonding layer D, of which the component is maleic anhydride grafted polyethylene; and the fifth layer is a weathering resistant layer E, of which the component is nylon 6 or 66. The preparation method comprises the following steps that: the bottom blowing water cooling type co-extrusion process or flow casting method is adopted, and the plastics is subjected to fusion and die inflation or flow casting, and quick cooling at water temperature of between 15 and 18 DEG C. The film and the preparation method have the advantages that: the method is simple; the products have merits of various resins; the film can be thermally sealed with the dialyzing paper without glum spreading; and moreover, the method and the film also have the advantages of low film thickness, good comprehensive property and reutilization.

Owner:NINGBO HUAFENG PACKAGE

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

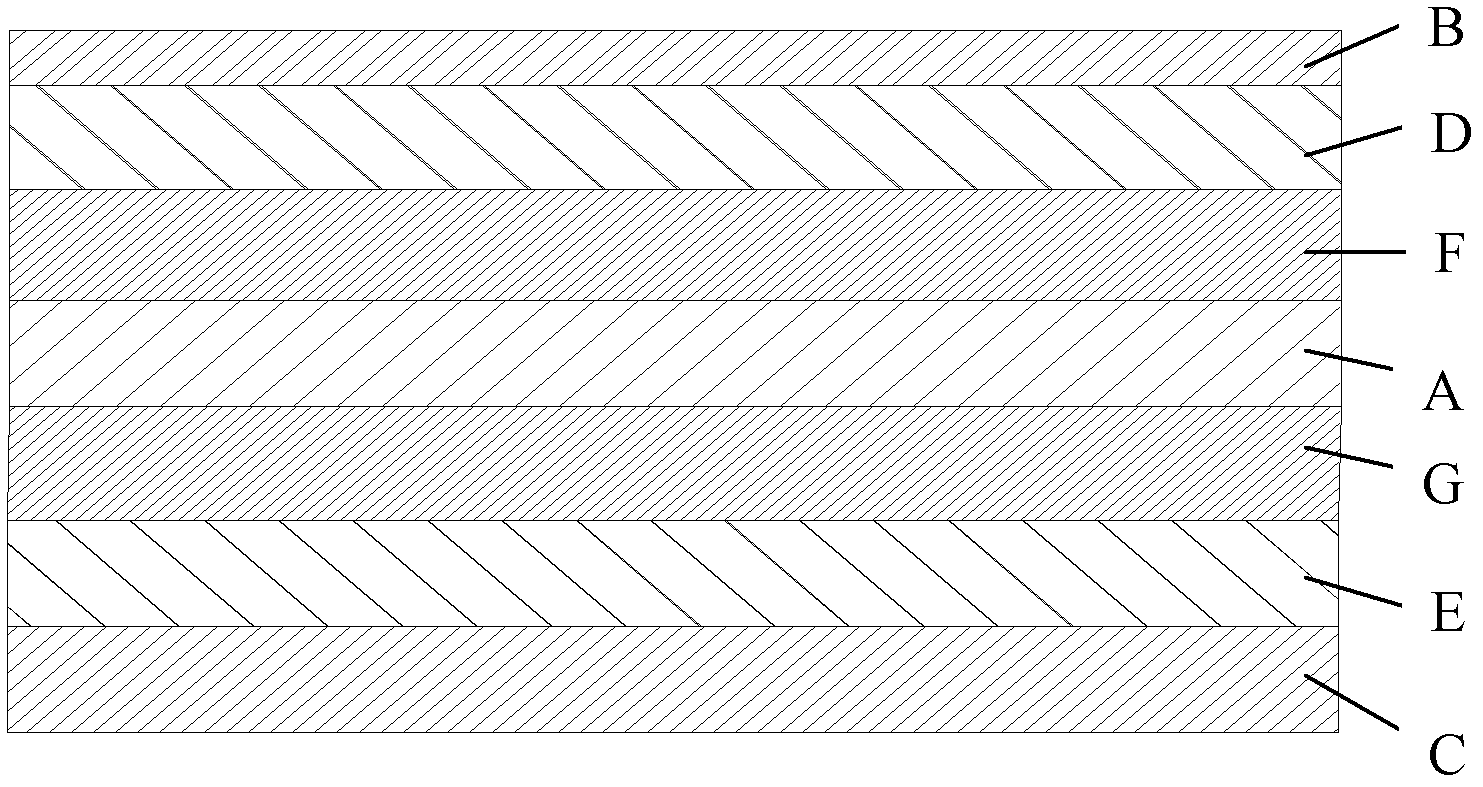

Multilayer coextruding pyrocondensation film

ActiveCN101306593AOvercoming low shrinkageOvercome barrierFlexible coversWrappersSurface layerCopolymer

2499. The invention provides a multilayer coextrusion heat shrinking film which comprises a surface layer, a sandwich layer and a heat-sealing layer. The surface layer and the heat-sealing layer are respectively bonded with the sandwich layer through a bonding layer; the sandwich layer comprises a mixture composed of 98Wt% of PVDC resin and 2Wt% of processing aid, wherein, the PVDC resin is a VDC-MA copolymer, the melting point is 150 DEG C, the density is 1.7g / cm<3>, and the processing aid is epoxidized soybean oil or other plasticizing agent systems. The proposal increases the shrinkage factor of the multilayer coextrusion heat shrinking film, and improves the barrier property; the multilayer coextrusion heat shrinking film has excellent heat sealing performance, and is widely applied to the vacuum shrink package.

Owner:SUZHOU TIPACK

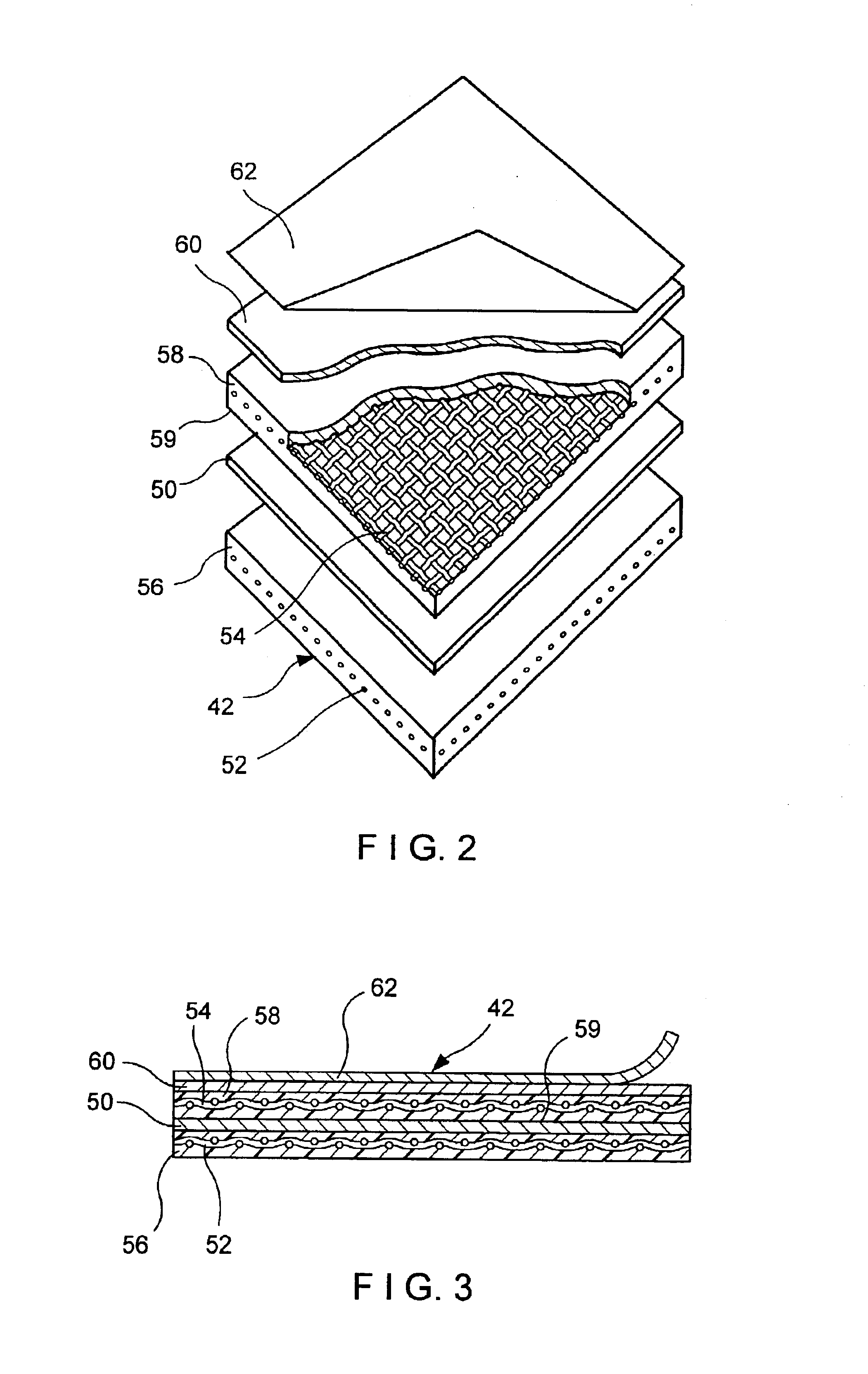

Metal foil/scrim flashings

InactiveUS6928780B1Improve puncture resistanceImprove tear resistanceRoof covering using slabs/sheetsConstruction materialMetal foilMetallurgy

A metal foil / scrim flashing laminate is disclosed, which laminate is for flashing cavity walls. The laminate has at least one layer of a modified polymeric coating which is disposed by roll coating onto the central metal foil. In all the embodiments, the metal foil lamina is sandwiched between either layers of the modified polymeric coating or between a coating layer and a hot melt adhesive layer. In application the laminates are used with a release paper to form a peel-and-stick product and is suitable for surface mounting. An embodiment of the metal foil / scrim flashing with adhesive is shown for field installation with sealants and mystics.

Owner:HOHMANN & BARNARD INC

Tyre

InactiveCN101450594AMaintain ice resistanceMaintain wet skid resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention discloses a tyre, which comprises (A) tread rubber, (B) tread basal rubber, (C) sidewall rubber, (D) rebate protective rubber, (E) carcass layer rubber, (F) lining layer rubber, (G) triangle rubber, (H) belted layer rubber, (I) air-tight layer rubber and (J) tyre bead steel wire rubber. The tyre components consist of rubber compositions, wherein the rubber compositions of the (A) tread rubber, the (B) tread basal rubber, the(C) sidewall rubber and the (D) rebate protective rubber adopt white carbon black and carbon black with high specific surface area as reinforcing fillers; and the rubber compositions of the (E) carcass layer rubber, the (F) lining layer rubber, the (G) triangle rubber, the (H) belted layer rubber, the (I) air-tight layer rubber and the (J) tyre bead steel wire rubber adopt white carbon black and carbon black with low specific surface area as reinforcing fillers. The tyre has the advantages of good puncture resistance and chunking resistance, low rolling resistance and heat generating performance, and greatly-reduced production cost. The full-steel giant engineering tyre is particularly suitable for an adverse road environment such as a large-scale mine yard.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Access Method With Insert

ActiveUS20110066001A1Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterAccess methodEngineering

Various devices and methods are provided with respect to inserting multiple surgical instruments through a single surgical access device. A medical device including a flexible tissue retractor and a releasable insert having multiple instrument openings is disclosed. The insert can be in the form of an insert assembly including multiple components. A method of using the insert is also described, and includes releasably positioning an insert having multiple instrument openings into the tissue retractor

Owner:CILAG GMBH INT

Three dimensional orthogonal woven fabric stab-resistant material and preparation method thereof

The invention relates to a three dimensional orthogonal woven fabric stab-resistant material and a preparation method thereof. The material comprises three dimensional orthogonal woven fabric and shear thickening fluid distributed at surface or interior of the woven fabric. The preparation method comprises the following steps: applying the shear thickening fluid onto the three dimensional orthogonal woven fabric and removing excess fluid after the shear thickening fluid has infiltrated the woven fabric; taking out the woven fabric for drying at room temperature and removing ethanol so as to obtain the three dimensional orthogonal woven fabric stab-resistant material. The three dimensional orthogonal woven fabric stab-resistant material provided in the invention not only has the advantages of good flexibility, lightweight and comfortableness as a flexible stab-resistant material does, but also has greatly improved stab-resistance.

Owner:DONGHUA UNIV

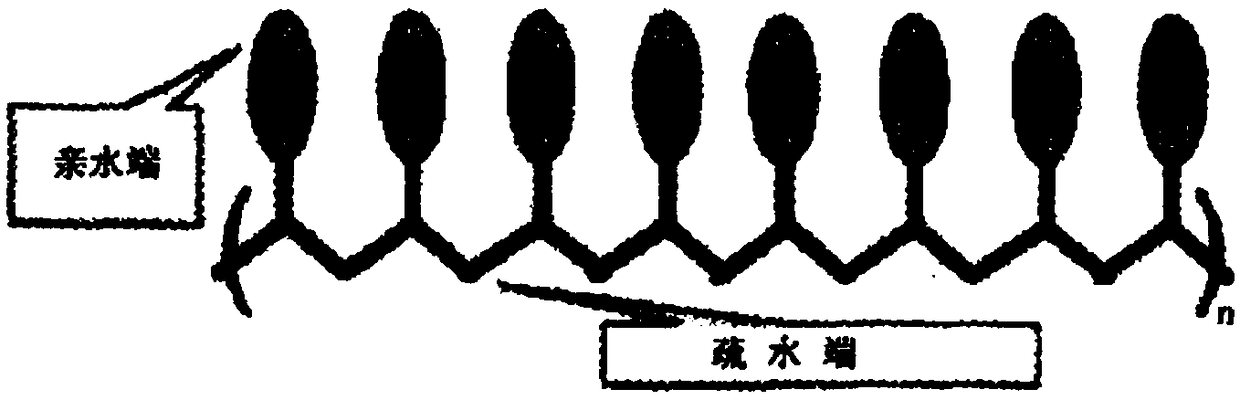

Ceramic slurry, ceramic composite diaphragm and lithium ion battery

InactiveCN109449354AEvenly dispersedNo settlementSecondary cellsCell component detailsCeramic compositeCeramic coating

The invention relates to the technical field of lithium ion battery diaphragm preparation, and discloses ceramic slurry, a ceramic composite diaphragm and a lithium ion battery. The slurry comprises deionized water, ceramic particles, a thickening agent, a binder, a dispersing agent and a wetting agent, wherein the dispersing agent is an amphiphilic high-molecular compound with a comb structure. The ceramic composite diaphragm prepared from the slurry is high in thermal stability, puncture resistance and liquid absorption capacity, and the ceramic coating is not easy to fall off in an electrolyte when being used in the lithium ion battery, so that the cycling life of the battery can be prolonged, and the consistency of cells and the safety of the battery can be improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

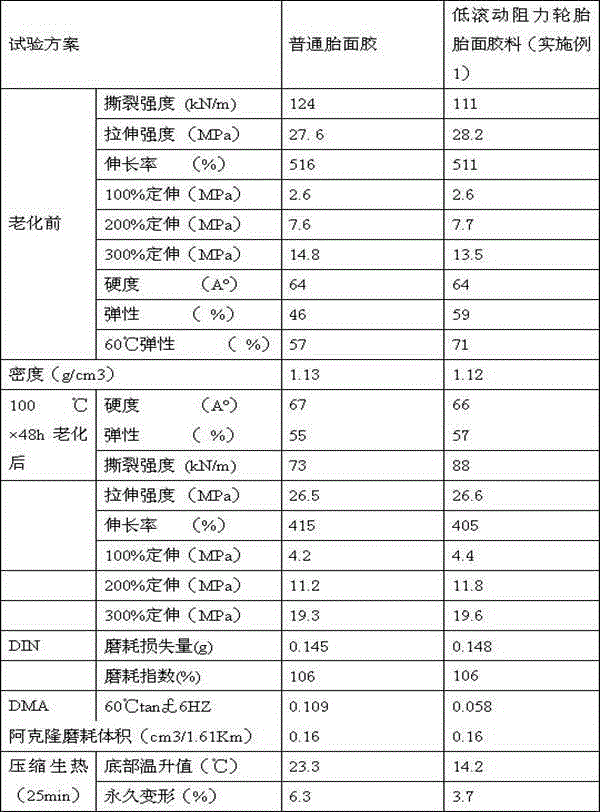

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Novel lead-acid storage battery clapboard and preparation method thereof

The invention discloses a novel lead-acid storage battery clapboard, which belongs to the technical field of storage batteries. The novel lead acid storage battery clapboard consists of the following raw materials in part by weight: 38 to 41 parts of superfine glass cellucotton, 7 to 10 parts of bicomponent organic fiber, 0.5 to 0.6 part of sulfuric acid, and 0.1 to 0.2 part of wet strength agent; and the novel lead acid storage battery clapboard is prepared through the processes of pulping, processing and conveying of sizing materials, paper-making from paper pulp for the clapboard, drying by a drying box, reeling, clapboard processing and the like. The lead-acid storage battery clapboard has the advantages of high porosity, low resistance, high wet strength and good anti-puncture capability, and compared with a pure glass fiber clapboard, the wet strength is improved by nearly 70 percent, the anti-puncture capability is improved by about 45 percent, and the wet resilience force is improved by 5 to 11 percent.

Owner:YIHECHENG GRP CO LTD

Abrasion and pierce proof low-resistance tire rubber compound and preparation method thereof

The invention discloses an abrasion and pierce proof low-resistance tire rubber compound and a preparation method thereof. The abrasion and pierce proof low-resistance tire rubber compound comprises, by weight, 40-70 parts of natural rubber SIR20, 10-15 parts of cis-polybutadiene rubber, 3-5 parts of styrene butadiene rubber SBR1500, 5-6 parts of N234 high-structure medium super abrasion furnace black, 5-6 parts of white carbon black, 1-1.5 parts of a silane coupling agent Si-69, 1-1.5 parts of polyethylene glycol, 0.5-1.0 part of toluene diisocyanate, 0.5-1.0 part of stannous chloride, 0.5-1.0 part of hydroxy-terminated polybutadiene, 1-1.5 parts of softening plasticizer aromatic oil, 1-2 parts of stearic acid, 2-3 parts of an antioxidant, 1-1.5 parts of tackifier 204 resin, 1-1.5 parts of a homogenizing agent UB4000, 0.5-1.0 part of zinc oxide, 1-1.5 parts of sulfur, 0.5-1.0 part of an XY900 anti-reversion agent, 1-1.5 parts of a promoter TBBS and 0.5-1.0 part of an anti-fatigue agent G-108. The tire rubber compound obtained in the invention has the advantages of good compatibility, abrasion proofing, pierce proofing, low resistance, fatigue proofing, ageing proofing, deformation proofing and wide application prospect.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com