Patents

Literature

115results about How to "Good overall performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

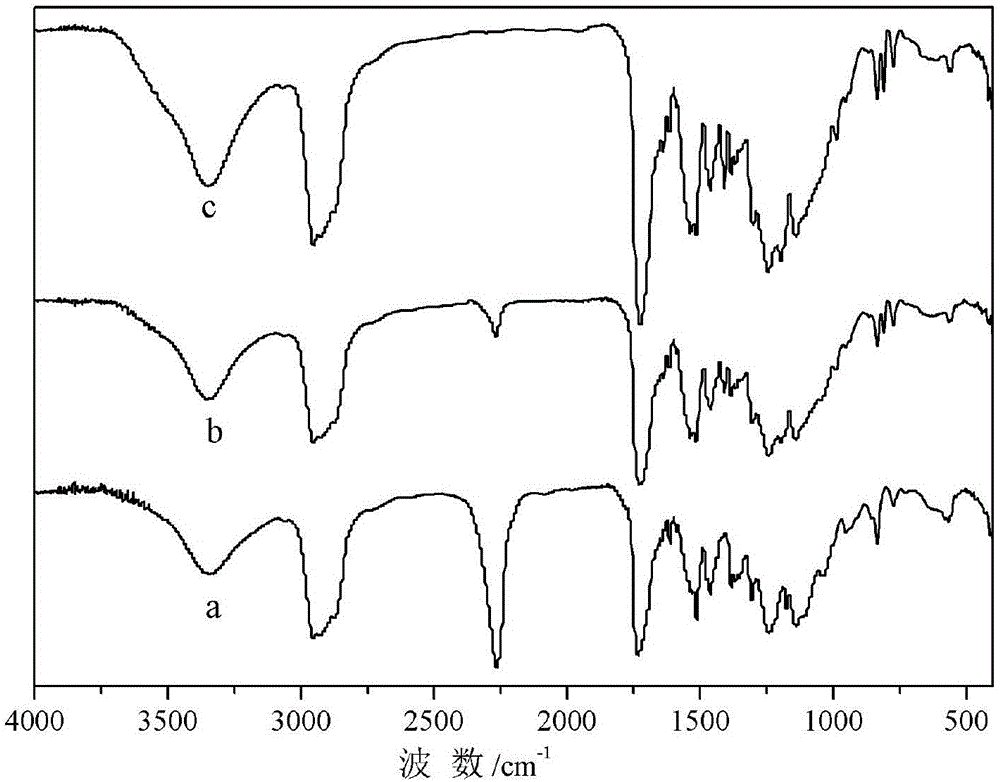

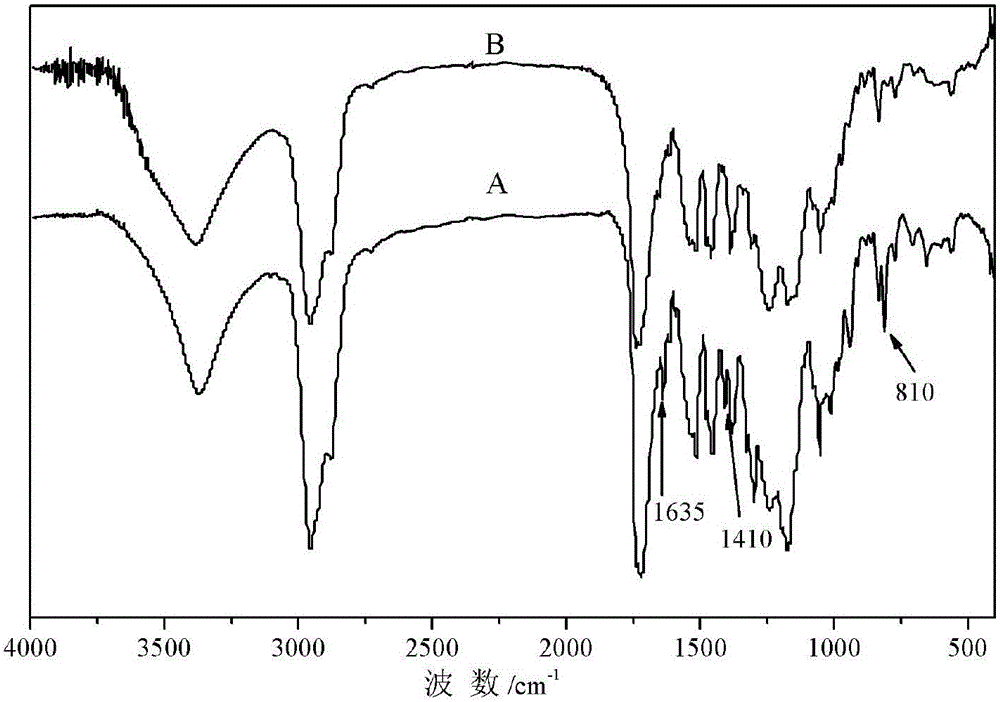

Multielement functional modified polymer binder for lithium ion battery and application of binder in electrochemical energy storage device

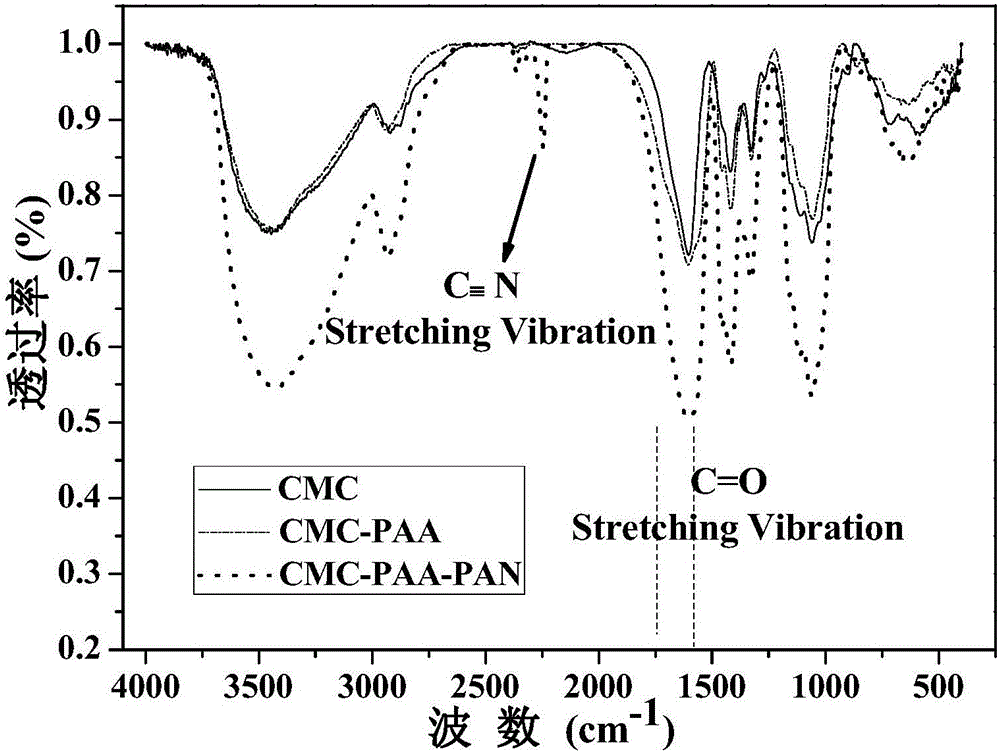

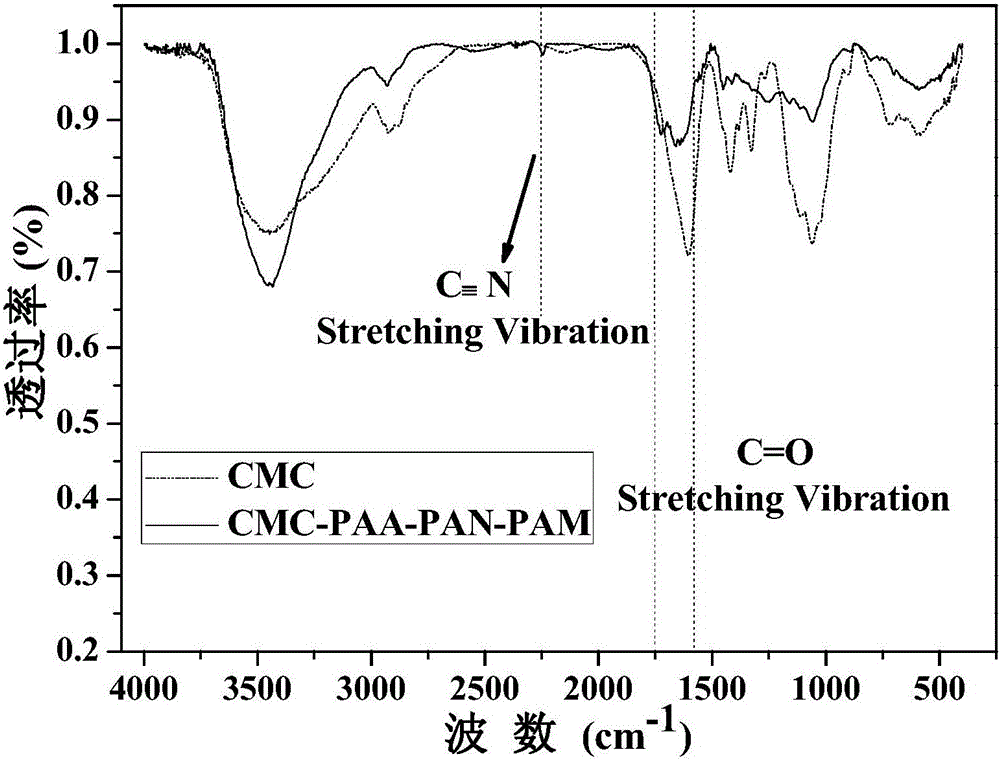

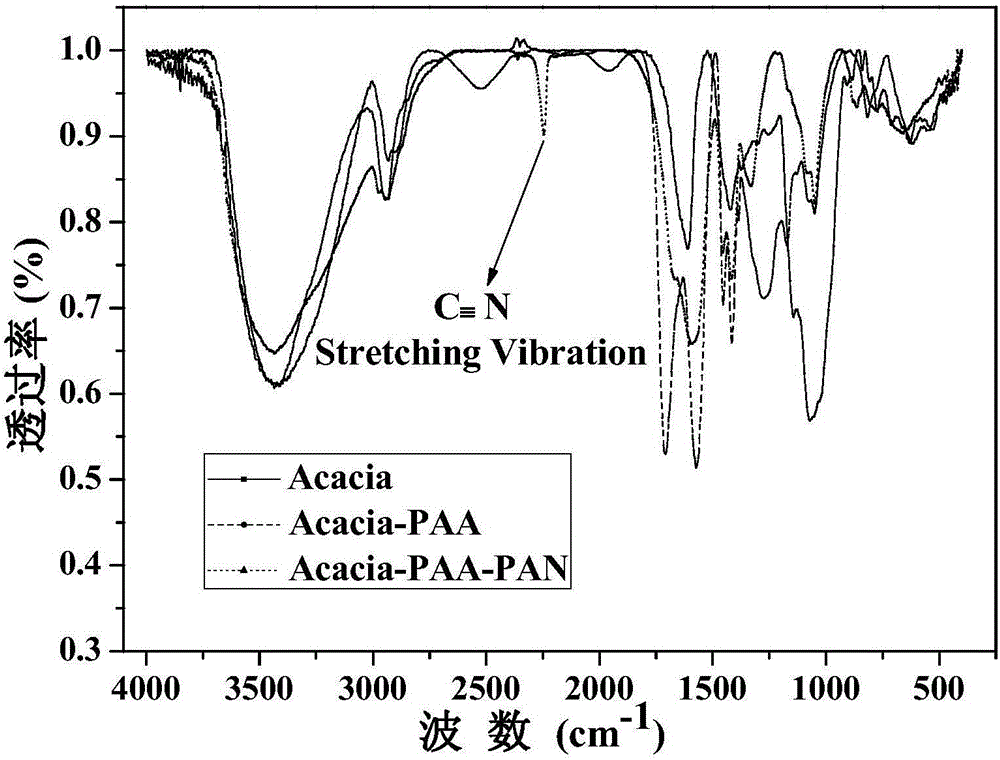

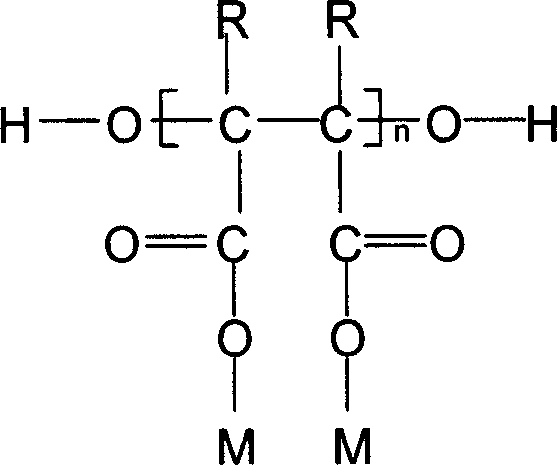

ActiveCN105914377AStable and uniform qualityGood overall performanceCyclodextrin adhesivesCellulose derivative adhesivesBiomassAddition reaction

The invention discloses a multielement functional modified binder for a polymer lithium ion battery. The binder takes a biomass polymer or a synthetic polymer as the substrate, takes a hydrophilic monomer and an oleophilic monomer as the functional modified monomer; and then the binder is prepared through a free radical graft copolymerization reaction or a Michael addition reaction in a modification manner. The binder has a multi-branch structured three-dimensional space network body, so that more active sites in contact with the electrode active material can be provided, and the uniformity and the smoothness of the electrode slurry in film-forming can be improved; the peeling strength of the active materials and the conductive agent on the metal substrate is reinforced; and meanwhile, the binder is excellent in elasticity and binding force, can be applied to water / organic solvent and can be applied to the positive electrode and negative electrode of the lithium ion battery; the conduction of electrons / ions in the charging-discharging process can be promoted; the electrochemical interface impedance of the pole piece is lowered; the high rate capacity and the cycling stability of the positive electrode material and the negative electrode material of the lithium battery are relatively improved; in addition, the synthetic raw material is wide in source, so that the cost can be obviously lowered; and therefore, the binder has a wide market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

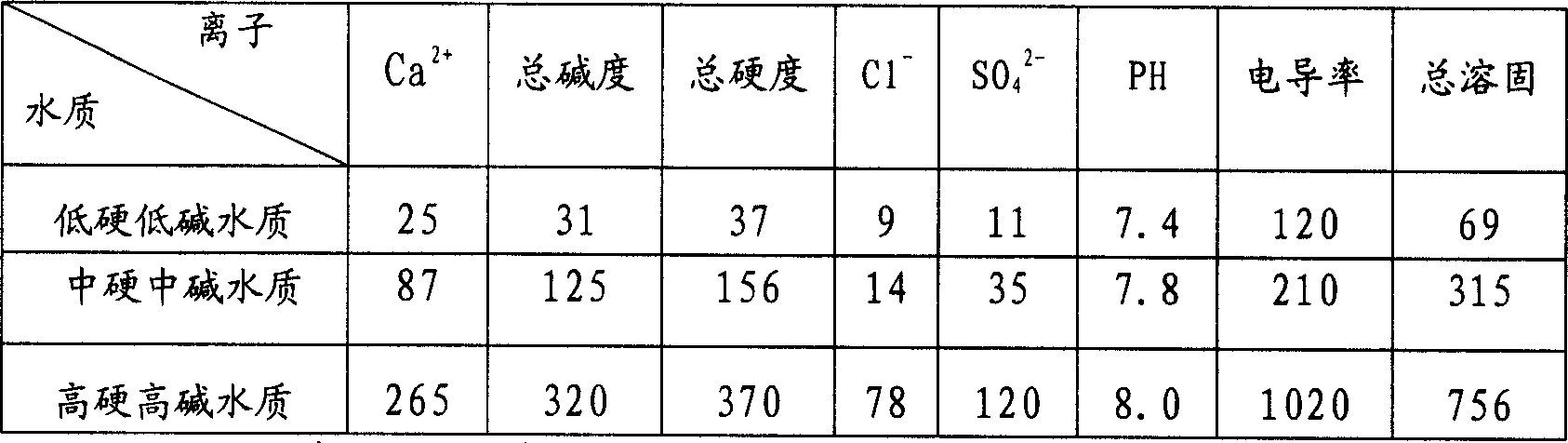

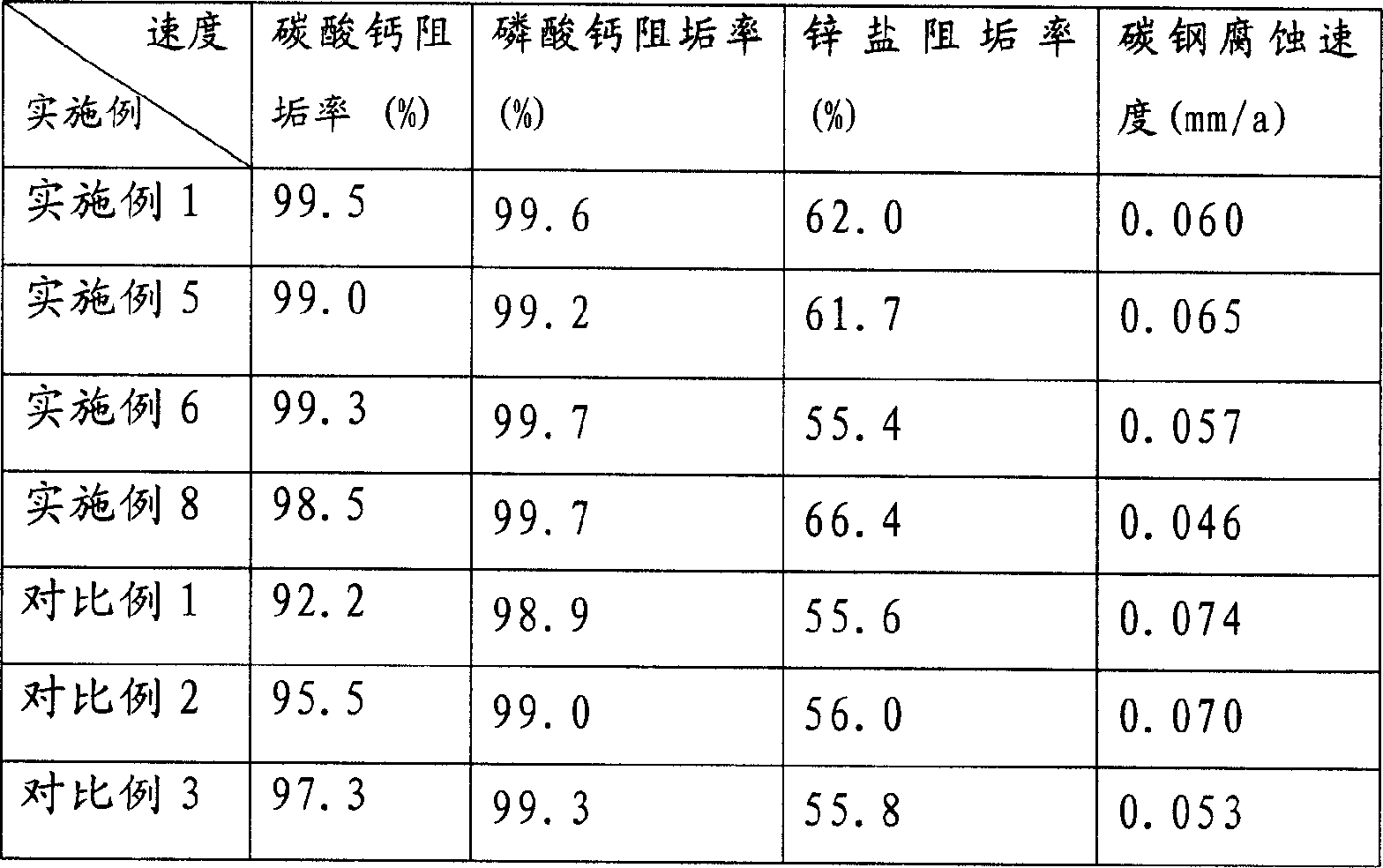

Composite scale-proof corrosion inbibitor containing poly epoxy succinic acid and its use

ActiveCN1616361AGood overall performanceExcellent corrosion inhibition performanceScale removal and water softeningCalcium EDTACorrosion inhibitor

The present invention relates to a kind of composite antiscale corrosion inhibitor containing polyepoxy succinic acid. The composite antiscale corrosion inhibitor includes two kinds of organic phosphonic acid and polyepoxy succinic acid, and may contain zinc salt and copper corrosion inhibitor, if necessary. The composite antiscale corrosion inhibitor is suitable for processing circular cooling water and can make the calcium hardness reach 1200 mg / L.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

High-strength 6xxx aluminum alloy for mobile phone parts and machining method thereof

InactiveCN105296811AOptimize processing technologyGood overall performanceMachining processForced air cooling

The invention relates to a high-strength 6xxx aluminum alloy for mobile phone parts and a machining method thereof. The high-strength 6xxx aluminum alloy comprises, by weight, 0.6-1.3% of Mg, 0.6-1.3% of Si, 0.1-1.0% of Cu, 0.1-1.2% of Mn, 0.10-0.5% of Cr, 0-0.25% of Zr, 0-0.20% of Ti, 0-0.50% of Zn, 0-0.40% of Fe, and the balance Al and inevitable impurities. The machining process of the high-strength 6xxx aluminum alloy comprises the steps that firstly, cast ingots are subjected to homogenizing heat treatment and then subjected to forced air cooling, and then the cast ingots are extruded after being preheated; and secondly, the cast ingots are subjected to on-line water hardening, straightening and artificial aging. According to the high-strength 6xxx aluminum alloy for the mobile phone parts and the machining method thereof, on the basis of guaranteeing the anodic oxidization property of the alloy, the strength of the alloy is improved; the aluminum alloy is an ideal material for manufacturing external parts of electronic products and has wide market application prospects.

Owner:苏州有色金属研究院有限公司

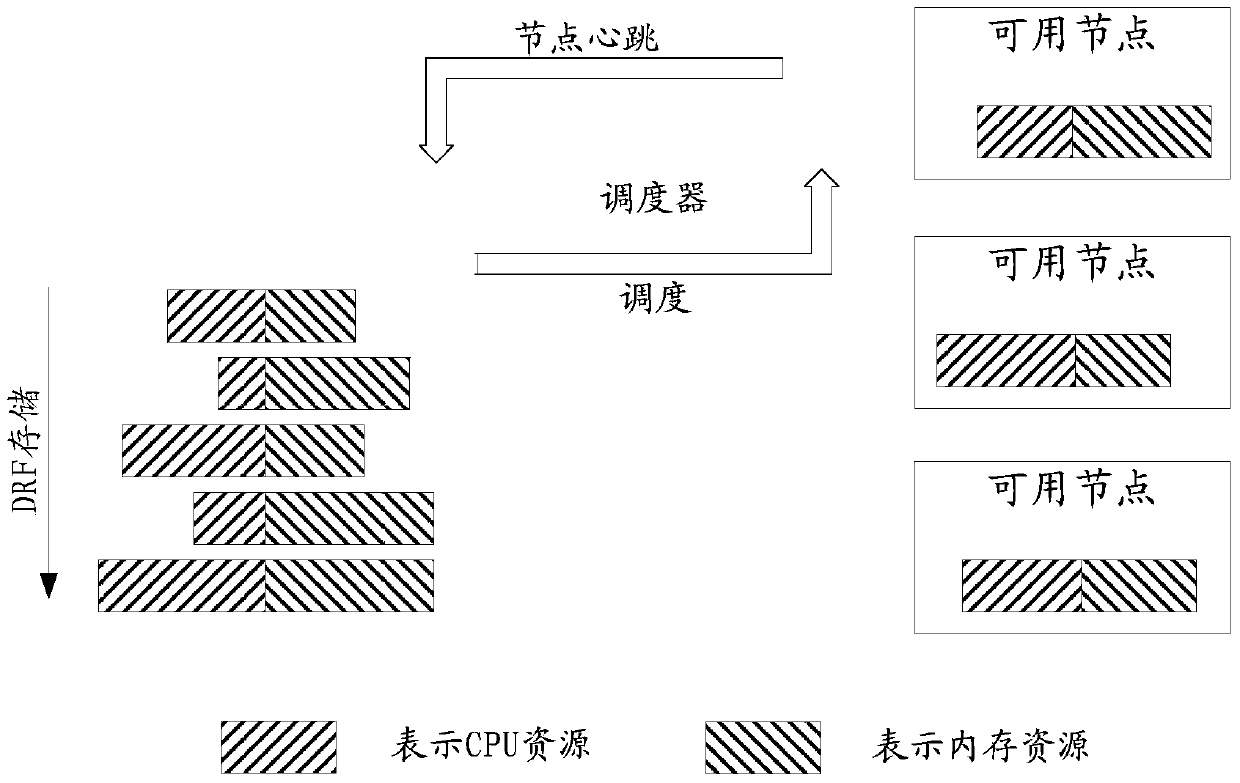

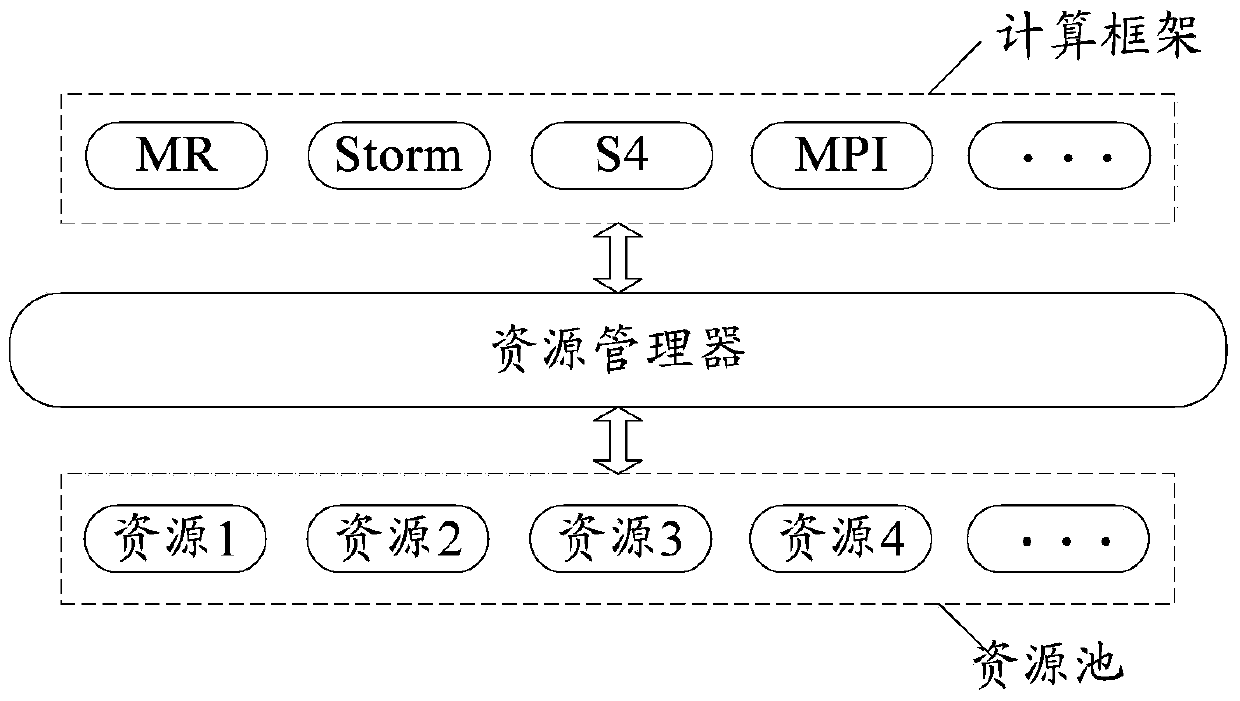

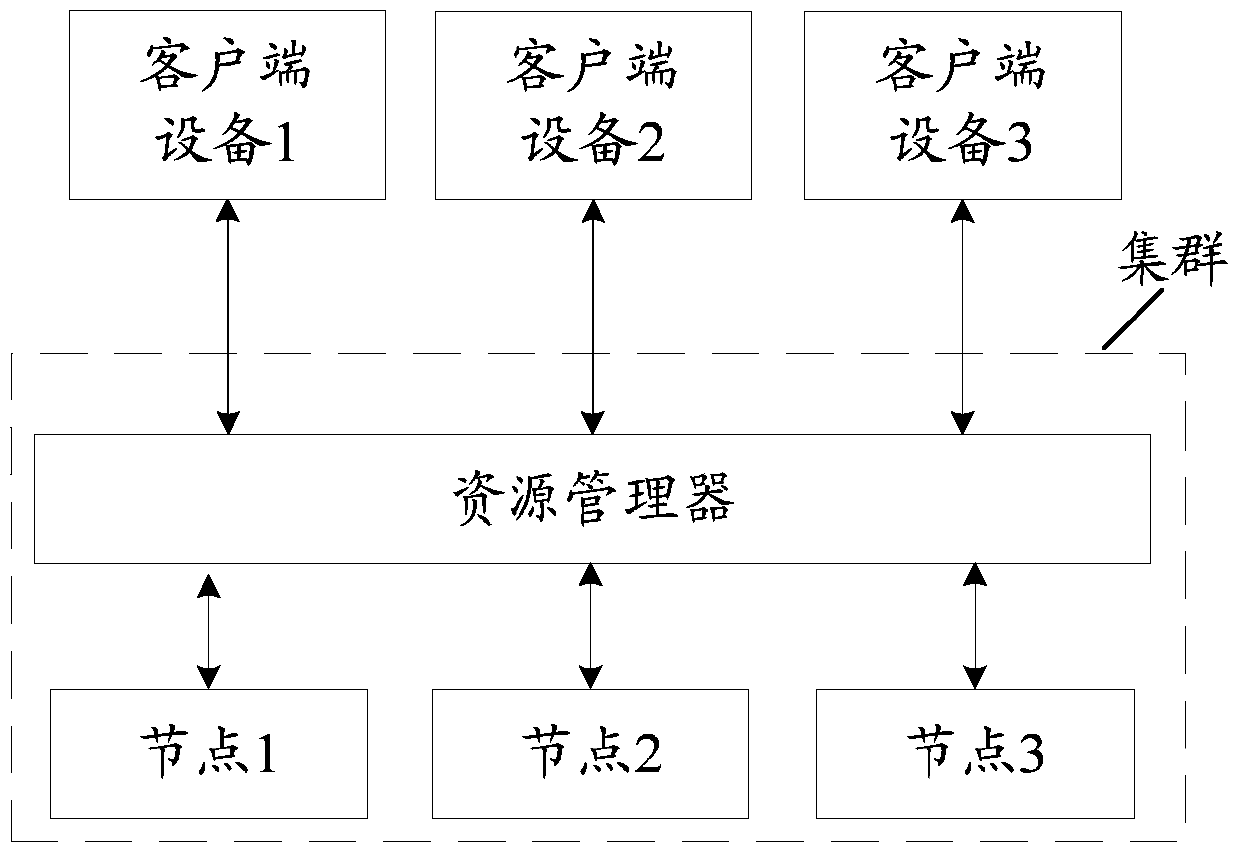

Resource distribution method and explorer

ActiveCN107045456AWide applicabilityGood overall performanceResource allocationResource managementResource utilization

The embodiment of the invention provides a resource distribution method and an explorer. The method is used for increasing the resource utilization rate and / or improving the execution efficiency of user jobs. The method comprises the steps that a job submitted by a client device is received, and the job is divided into multiple tasks, wherein a corresponding resource demand quantity is configured for each of the tasks; running time of each task is estimated; a first distribution position form of the tasks is determined according to the resource demand quantity and the running time of each task in combination with a preset scheduling strategy, wherein the first distribution position form is used for indicating distribution of the tasks on runnable computing nodes among multiple computing nodes, and the scheduling strategy comprises at least one of a resource utilization rate preference strategy and an efficiency preference strategy; and the tasks are distributed to the runnable computing nodes of the tasks according to the first distribution position form. The method is suitable for the high-performance cluster field.

Owner:HONOR DEVICE CO LTD

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

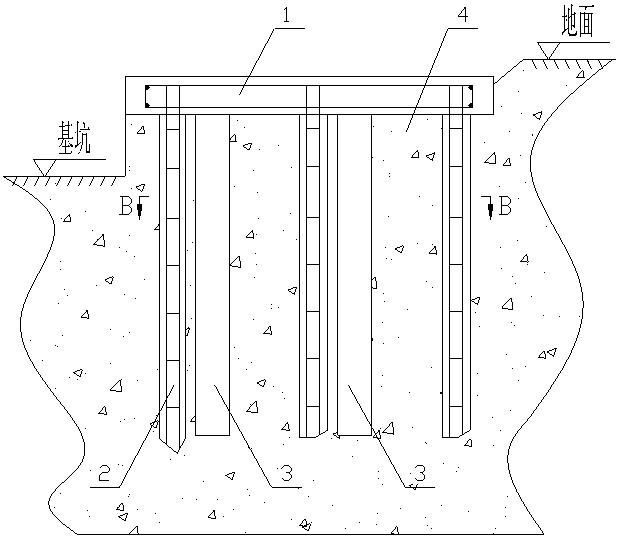

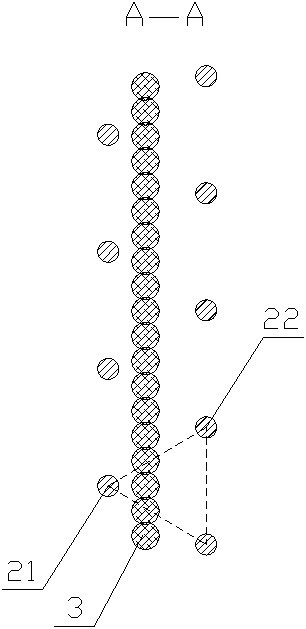

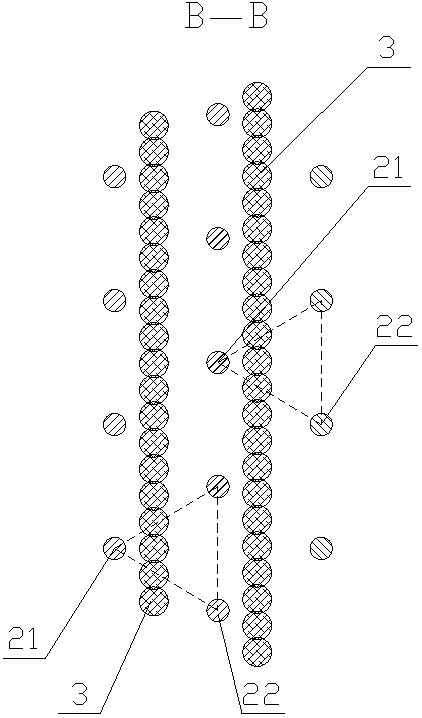

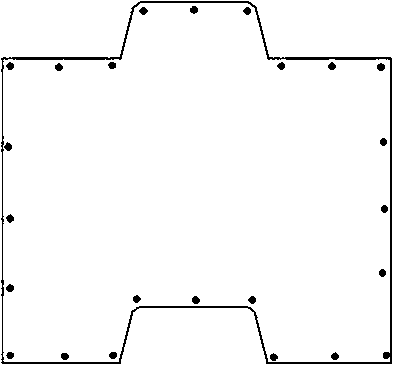

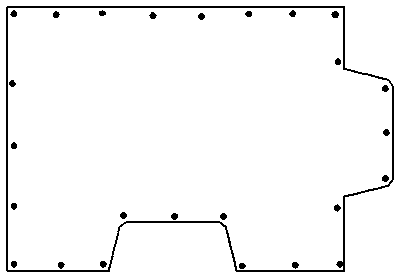

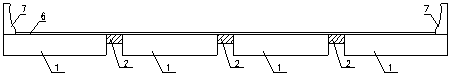

Multi-row mini-pile enclosing structure for blocking soil and construction process

ActiveCN102605792AGood overall performanceIncreased bending stiffnessExcavationsDrill holeEnvironmental geology

The invention relates to the field of foundation bases and discloses a multi-row mini-pile enclosing structure for blocking soil and a construction process. The multi-row mini-pile enclosing structure for blocking soil comprises a top beam (2) and more than two rows of mini piles (2), the mini piles (2) comprise front-row piles (21) and rear-row piles (22), cement stirring piles (3) are arranged between the front-row piles and the rear-row piles (22), and the top ends of the mini piles (2) are connected together by the top beam (1). The construction process comprises the steps of digging grooves, positioning pile heads, drilling, grouting, casting and the like. The multi-row piles have the advantages that the whole performance is good, the anti-bending rigidity is high, the lateral deformation of a foundation pit and the surface subsidence of the periphery of the foundation pit can be effectively controlled by an inner support or an anti-pulling anchor rod, the construction time can be saved well and the construction cost is reduced.

Owner:ZHEJIANG SCI-TECH UNIV

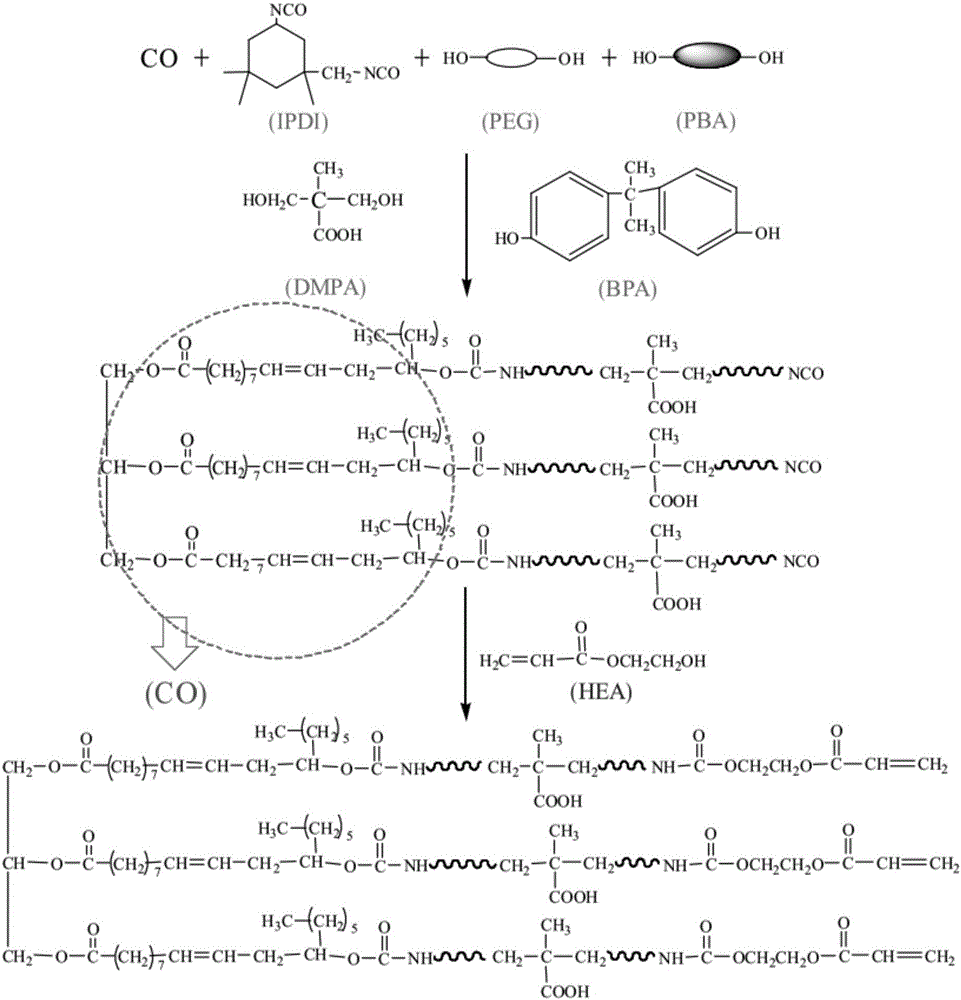

Castor oil-based UV-cured polyurethane acrylate and preparation method and application thereof

The invention belongs to the field of UV-cured high molecular materials, and particularly discloses castor oil-based UV-cured polyurethane acrylate and a preparation method and application thereof. The method comprises the steps that dihydric alcohol and castor oil are subjected to decompression dehydration, a mixture of diisocyanate and a catalyst is added, a reaction is conducted for 2 h-3 h, a N,N-dimethyl formamide and acetone mixed solution dissolving with bisphenol A and 2,2-dimethylolpropionic acid is added, and an intermediate product is obtained; a mixture of hydroxyalkyl methacrylate or hydroxyalkyl acrylate and a polymerization inhibitor is added under stirring, a reaction is conducted for 2 h-3 h, and castor oil-based UV-cured polyurethane acrylate is obtained. According to castor oil-based UV-cured polyurethane acrylate and the preparation method and application thereof, the castor oil serves as a polyurethane raw material, and positive reference values for relieving pressure of petrochemical engineering, widening application of natural oil products and increasing the added value of the natural oil products are achieved; due to the fact that the castor oil is introduced, and bisphenol A has a high insulating property, prepared castor oil-based UV-cured polyurethane acrylate has a good low-temperature property, hydrolysis resistance and a good electrical insulating property.

Owner:GUANGDONG LANYANG SCI & TECH

High-performance organosilicone sealant for photovoltaic (PV) module and preparation method thereof

ActiveCN102181264AGood overall performanceExtend the service lifeNon-macromolecular adhesive additivesOther chemical processesOrganosiliconTetra

The invention relates to a sealant, and in particular relates to a high-performance organosilicone sealant for a photovoltaic (PV) module. The high-performance organosilicone sealant for the PV module comprises the following components in parts by weight: 100 parts of (alpha, omega) dihydroxyl polydimethylsiloxane, 50-200 parts of super-fine reinforcing powder, 10-100 parts of functional powder adjuvant, 3-8 parts of methyltris (methylethylketoxime) silane, 1-4 parts of vinyltris(methylethylketoximino)silane, 1-3 parts of tetra-(methylethylketoxime)silane, 5-20 parts of fumed silica, 0.2-3 parts of 3-aminopropyltriethoxysilane, 0.2-4 parts of gamma-glycidoxy propyl trimethoxy silane and 0.05-0.5 part of organosilicon condensation reaction catalyst. The organosilicone sealant has the advantage of good comprehensive performances and can help prolong the service life of solar products.

Owner:兆舜科技(广东)有限公司

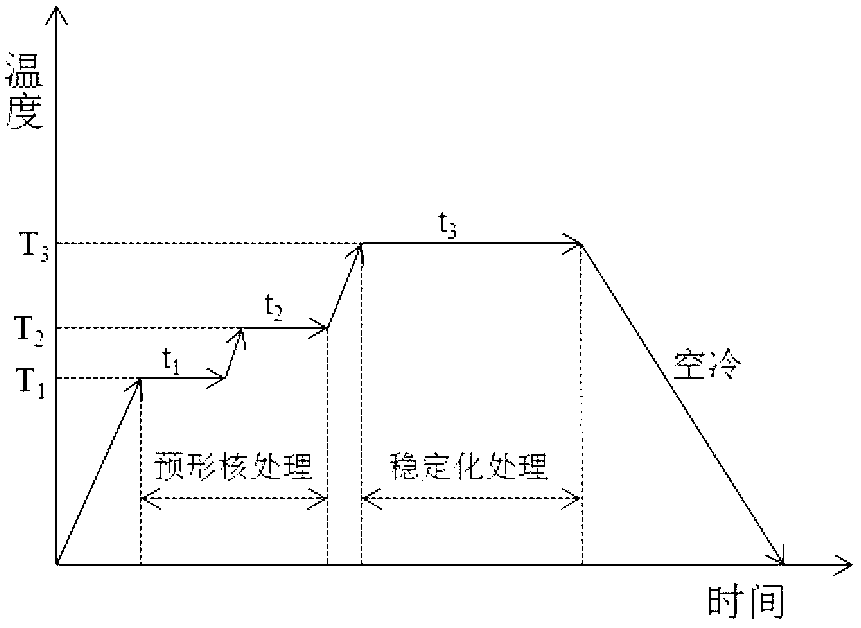

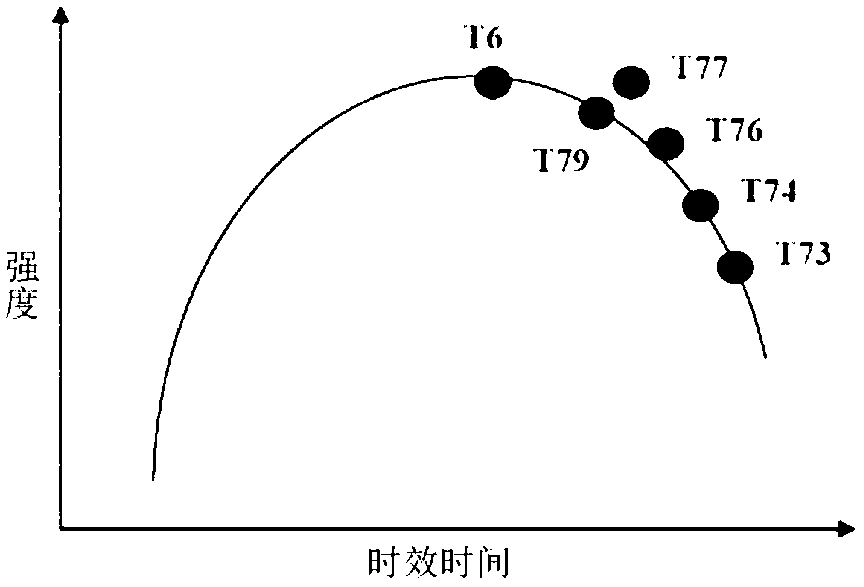

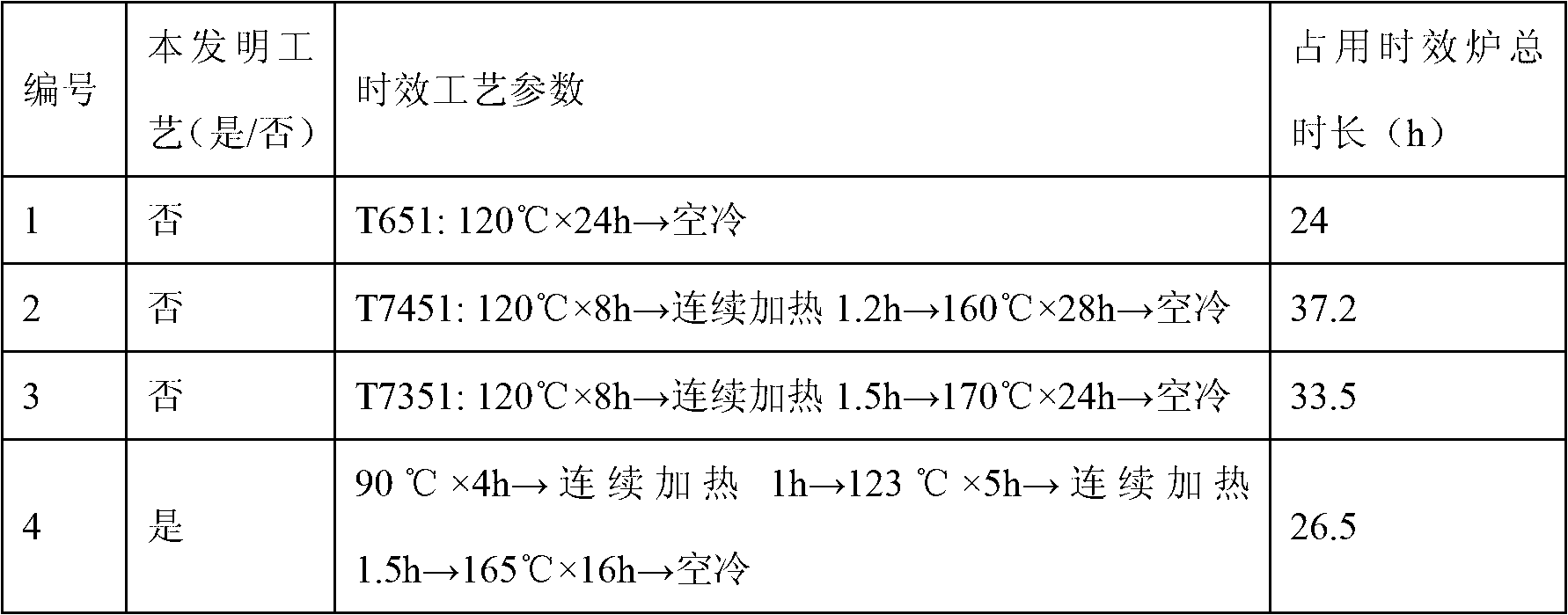

Improved 7000 series aluminum alloy double-stage overaging heat treatment technology

ActiveCN102796974AGood overall performanceGood corrosion resistance and fracture toughnessDouble stageCorrosion

The invention discloses an improved 7000 series aluminum alloy double-stage overaging heat treatment technology, the method divides the preaging in a low temperature zone into a low temperature phase and a high temperature phase orderly for performing pre-nucleation treatment, and then is continuously heated to a high-temperature region for final stabilizing aging treatment. The two phases preaging technical scheme that the low temperature is first and the high temperature is second is employed by aiming the defects and disadvantages of the heat treatment technology of 7000 series aluminum alloy double-stage overaging (T73, T74, T76 and T79), simultaneously, the technical scheme of high-temperature region aging treatment which is completely different from a T7x double-stage overaging technology is employed, the cooperation of an intra-grain precipitate phase and a grain boundary precipitated phase can be realized. Compared with a traditional T73, T74, T76 and T79 double-stage overaging system, the heat treatment technology can obviously enhance the corrosion resisting performance and the fracture toughness property of the 7000 series aluminum alloy under the prerequisite that equivalent strength level is kept, the total insulation time of aging treatment is reduced, and the production efficiency is increased.

Owner:GRIMAT ENG INST CO LTD

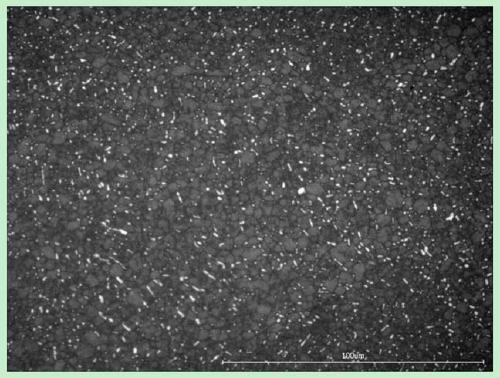

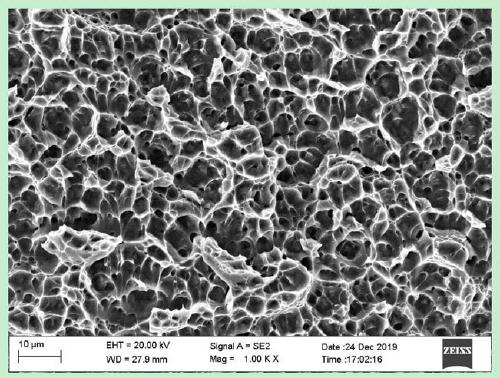

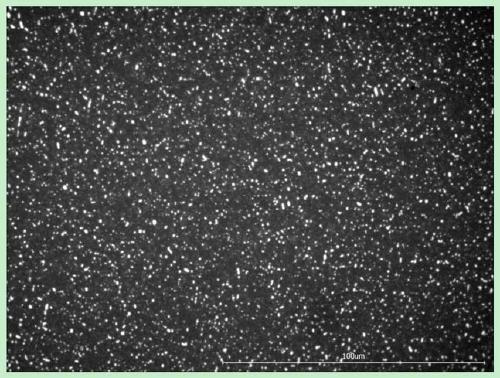

Chinese fir chip-based supercapacitor electrode, preparation method and supercapacitor

ActiveCN109192525AGood overall performanceHigh specific capacitanceHybrid capacitor electrodesCapacitanceHigh energy

A Chinese fir-based electrode material for supercapacitor is prepared from carbonized chip Chinese fir through activation treatment including CO2 activation, wherein the CO2 activation treatment comprises CO2 activation in CO2 flowing atmosphere at 650 DEG C-850 DEG C for 8-12 hours, the activated chips are polished to a thickness of 0.4-1.2 mm sheet. CO2, alkali and acid are sequentially activated to carbonize that cross-cut Chinese fir slices. Through a series of activation treatments, carbon wood chips have more micro-and nano-pores, and their specific surface area is increased to 613.2 m2g-1. By using these wafers as electrodes, symmetrical supercapacitors with excellent comprehensive performance, high specific capacitance and high energy density are fabricated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Microgrid multi-objective economic dispatching method and device considering demand side response

ActiveCN109658012AGood overall performanceSatisfactory Scheduling StrategyResourcesTie lineSearch algorithm

The invention provides a multi-objective economic dispatching method and device for micro-grid which takes the demand side response, and includes economic dispatching modeling, algorithm programming and simulation calculation. Under the premise of considering the economy, environmental protection, high efficiency and safety of microgrid operation, the economic dispatching model has the lowest integrated operating cost, optimal demand side response and microgrid and large distributed power supply in the microgrid. The minimum power fluctuation of the grid tie line is the objective function; thealgorithm programming uses Monte Carlo simulation, multi-target crowd search algorithm and fuzzy membership function to solve the established model; the simulation calculation uses the known initialconditions and other information to A specific microgrid system performs simulation calculations and visualizes the results. The invention achieves the technical effect of improving the comprehensiveperformance of multi-objective economic dispatch.

Owner:WUHAN UNIV OF TECH

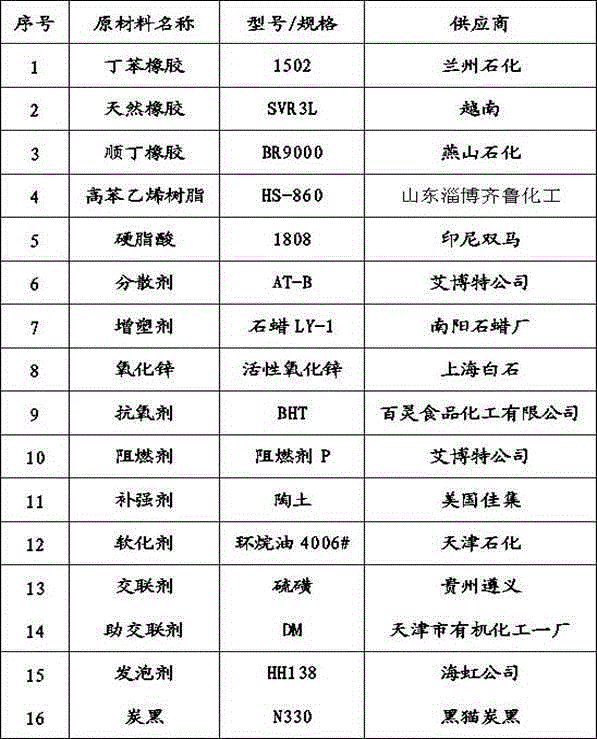

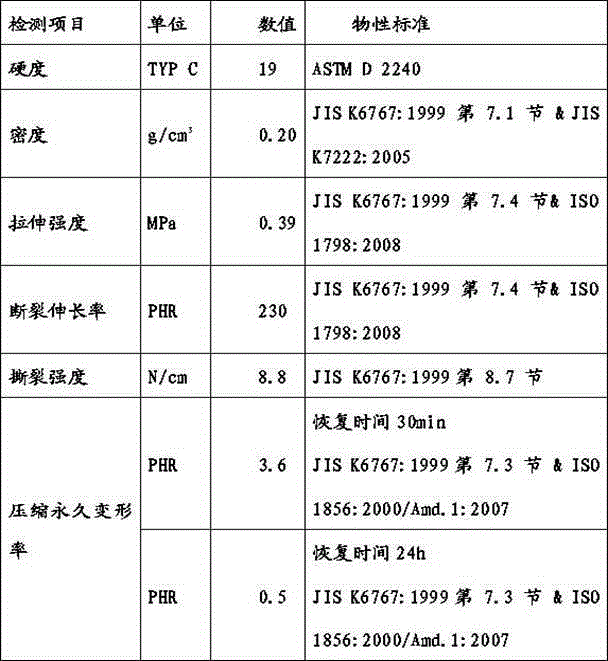

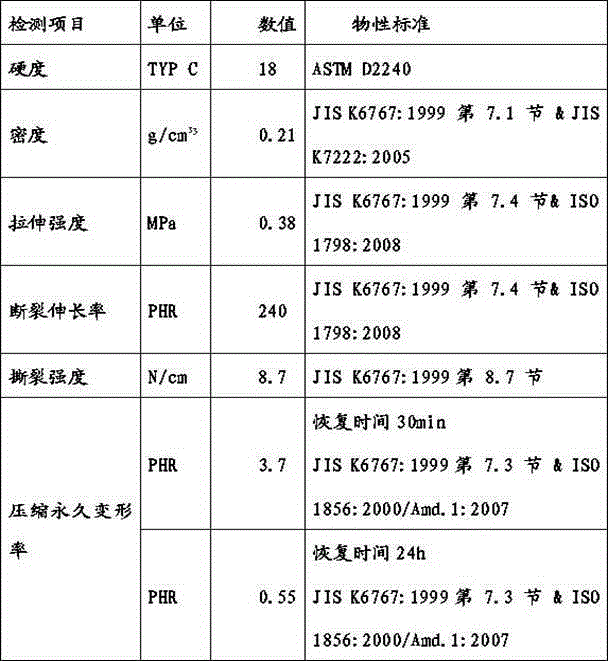

Closed-cell two-step foamed material prepared from styrene butadiene rubber, natural rubber, butadiene rubber and high styrene resin, and preparation method of closed-cell two-step foamed material

The invention relates to the technical field of foam materials and provides a closed-cell two-step foamed material prepared from styrene butadiene rubber, natural rubber, butadiene rubber and high styrene resin, and a preparation method of the closed-cell two-step foamed material. The closed-cell two-step foamed material retains the relatively good elasticity, wear resistance, fracturing resistance and slippery resistance of the styrene butadiene rubber; the addition of the natural rubber improves the rebound resilience, elongation, tensile strength and tear strength of the material; the cold resistance, wear resistance and elasticity of the material are particularly excellent and heat generated under live load is less due to the addition of butadiene rubber; the use of the high styrene resin improves the mechanical rigidity, hardness and stiffness of products, and makes up the cold flow property of the butadiene rubber at normal temperature. The produced product is remarkable in properties such as cold resistance (the lowest temperature reaches -100 DEG C), embossing and the like, and is free of toxicity, odorless and pollution. During the preparation, firstly, the natural rubber is masticated separately, and the high styrene resin and the natural rubber are blended in a ratio of 1:1; and then the two premixed rubbers are blended with styrene butadiene rubber and butadiene rubber, and the process of rolling and standing is carried out, so that the difficulty that the three types of rubber resins are poor in compatibility is overcome.

Owner:YIBAO FUJIAN POLYMER MATERIALS

Method for producing wax with co-cracking of multiple plastics and resins

InactiveCN101402697AGood overall performanceSimple production operationPlastic recyclingDistortionWax

The invention discloses a method for preparing wax from multiple plastic resins by copyrolysis. Raw material of polyolefin is put into a reaction kettle; the reaction kettle is vacuumized and then filled with nitrogen until the pressure reaches 100kPa; raw material in the kettle is heated by a method of oil-bath or infrared ray until the raw material comes to a total fusion; the temperature is controlled between 300 DEG C to 450 DEG C and maintained constant for 0.5 hour to 10 hours; heating is stopped, the temperature is reduced below 200 DEG C and the raw material which is the wax is discharged; and the performance of the product is tested. The method has the advantages of high heat distortion point, high rigidity, high tenacity, lubricating property, wet fastness and the like; and the method also has simple production operation and wide application.

Owner:上海五将化工科技有限公司

Near-beta ultrahigh-strength titanium alloy with tensile strength of more than 1450 MPa and preparation method thereof

The invention provides a near-beta ultrahigh-strength titanium alloy with the tensile strength of more than 1450 MPa. The volume fraction of a primary alpha phase in the near-beta ultrahigh-strength titanium alloy is 15-30%, and a secondary alpha phase is uniformly distributed on a beta matrix. The preparation method comprises the following steps: (1) determining a main component system of the novel ultrahigh-strength titanium alloy; (2) measuring the beta transformation temperature, performing cogging forging above the beta transformation temperature of a titanium alloy cast ingot, and then gradually reducing the forging temperature to below the beta transformation temperature for repeated upsetting-drawing forging; (3) setting the temperature of the finish forging process below the betatransition temperature to obtain an ultrahigh-strength titanium alloy forging stock; and (4) carrying out solid solution treatment and double aging strengthening treatment on the ultrahigh-strength titanium alloy forging stock in a hot working state to obtain the near-beta ultrahigh-strength titanium alloy with the tensile strength of more than 1450 MPa. The strength of the ultrahigh-strength titanium alloy is more than 1450 MPa, and simultaneously, the requirements for comprehensive performance such as good plasticity, good toughness and the like can be met.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

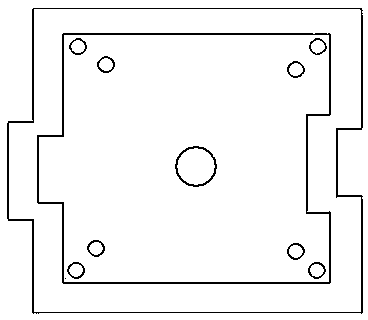

Concave-convex support-engaged water-stopping pile

InactiveCN104164868AGood overall performanceImprove support strengthBulkheads/pilesPile capShock resistance

The invention discloses a concave-convex support-engaged water-stopping pile. The concave-convex support-engaged water-stopping pile comprises a pile body and a pile tip. The pile tip is provided with anchor bars and construction bars. The pile body comprises an upper pile section, a middle pile section and a lower pile section. The top of the upper pile section is provided with a pile cap and construction bars. The lower end of the upper pile section is provided with anchor bars. The upper end of the middle pile section is provided with threaded anchor holes. The lower end of the middle pile section is provided with anchor bars. The upper end of the lower pile section is provided with threaded anchor holes. The lower end of the lower pile section is provided with the pile tip. The two sides of the concave-convex support-engaged water-stopping pile are respectively of a concave-convex shape. The concave-convex support-engaged water-stopping pile has the advantages that the bars are evenly distributed through a long-line pedestal to tension stress overall, the two sides of the support-engaged water-stopping pile are respectively of the concave-convex shape, and spiral stirrups are distributed on the two sides of the support-engaged water-stopping pile; as a result, production on the long-line pedestal can be carried out, labor and efforts are saved, the environment is protected, the productivity is high, product quality is good, the pile can form a tall and straight appearance beneficially, and the beauty and shock resistance are both good; the pile is especially suitable for stopping water in ports, wharfs and deep foundation pits, high in bearing capacity and resistant to collision.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Antibacterial biological nano packaging film and preparation method thereof

InactiveCN105907063AGood mechanical properties and barrier propertiesGood overall performanceZinc Acetate DihydrateCarbon nanofiber

The invention provides an antibacterial biological nano packaging film and a preparation method thereof. The packaging film is prepared from the following raw materials in parts by weight: L-polylactic acid, gelatin, polyhydroxybutyrate, esterification-modified nano cellulose, nano medical stone powder, nano cerium oxide, nano copper powder, carbon nano fibers, nano kaolin, gliadin, fucosan sulfate, natamycin, alangiym root powder, glycyrrhizic acid, zinc acetate, vitamin E, sodium alginate, polyethyleneglycol 500 and dioctyl phthalate. By using various existing appropriate nano materials according to the proper proportioning, the prepared packaging film product has the advantages of favorable antibacterial property, favorable mechanical properties, favorable barrier property and favorable comprehensive properties, and can satisfy the application requirements in the field of packaging films.

Owner:苏州倍力特物流设备有限公司

Squeeze casting preparation method for magnalium automobile engine support

The invention relates to a squeeze casting preparation method for a magnalium automobile engine support. Magnalium comprises the following raw material components by weight percent: 3.5-5.5% of Si, 1-2.5% of Fe, 0.5-2% of Ti, 0.15-0.25% of Cu, 0.01-0.05% of Mn, 10.2-15.5% of Mg, less than 0.1% of Zn, less than 0.05% of Ni, less than 0.05% of Pb, less than 0.05% of Sn and the balance of Al, wherein Fe / Ti is more than 1 and less than 2. The squeeze casting preparation method comprises the following steps: preheating the raw material components at 320-345 DEG C, and then, adding into a heated crucible melting furnace; and continually heating to 500-600 DEG C, then pumping in argon, after that, heating to 760-780 DEG C, transferring into a crane ladle, performing heat preservation, refining, casting, and then conducting solution and aging strengthening to obtain the automobile engine support with superior mechanical property. The prepared automobile engine support has the tensile strength of 320 MPa or above and the yield strength of 100-110 MPa.

Owner:过冬

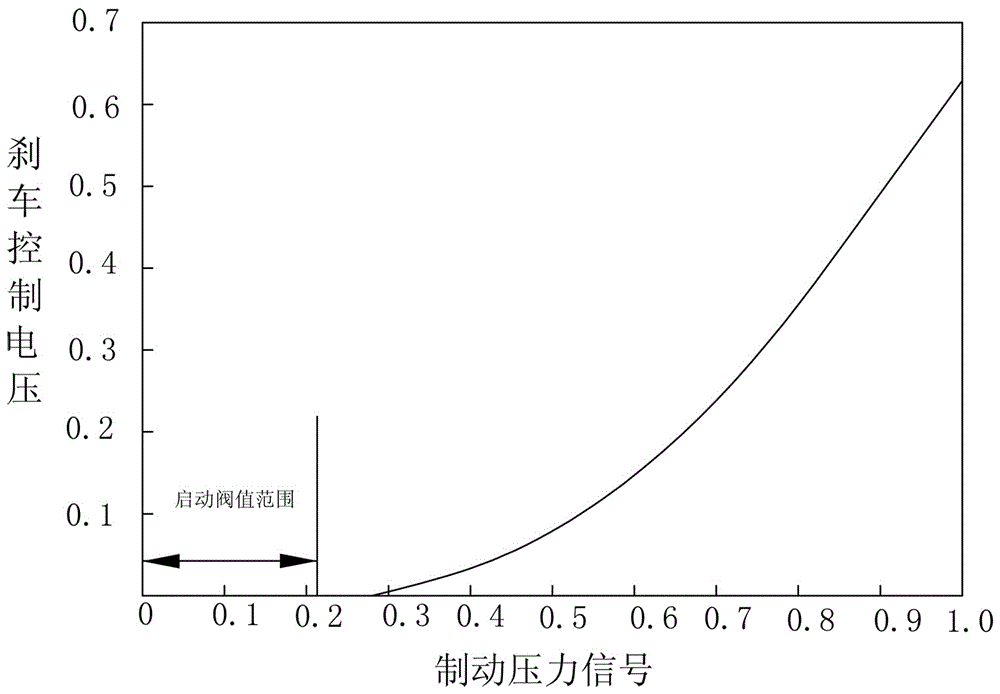

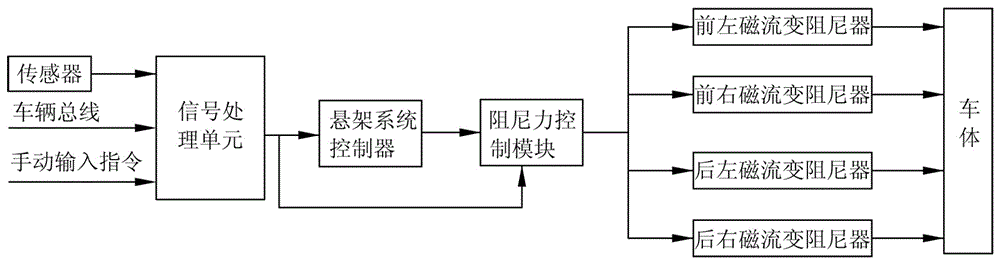

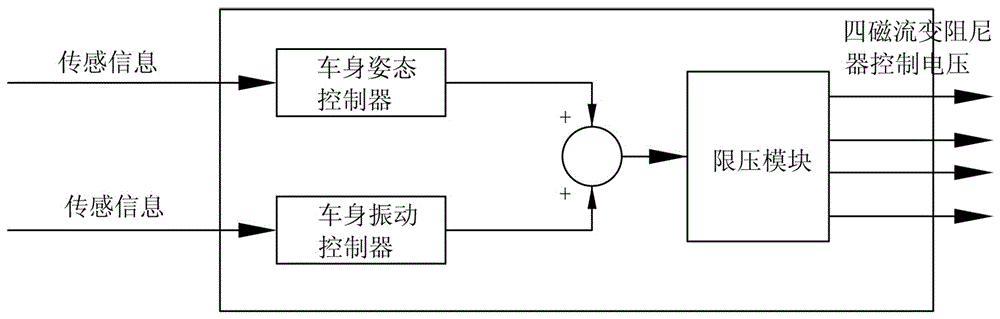

Control device and control method of summing-mode vehicle magnetorheological suspension system

InactiveCN105922836AGood overall performanceDriving safetyResilient suspensionsElectric/fluid circuitAttitude controlEngineering

The invention discloses a control device and a control method of a summing-mode vehicle magnetorheological suspension system. The control device comprises a signal processing unit, a suspension system controller, a damping force control module and a plurality of magnetorheological dampers. The control device and the control method have the advantages that a vehicle body posture control algorithm and a vehicle body vibration control algorithm are operated in real time, results of the two control algorithms are taken into consideration comprehensively, and accordingly, better comprehensive performance is achieved; vehicle handling stability is focused, and vehicle driving is safe.

Owner:陈超

Preparation method of aluminium alloy rod for electric bicycle frame pipe

The invention discloses a preparation method of an aluminium alloy rod for electric bicycle frame pipes, which is characterized in that the aluminium alloy comprises the following components by weight: 2-3% of Si, 2-5% of Mg, 0.5-1% of Zn, 0.2-1% of Mn, 0.3-0.7% of Cu, and the balance of Al and inevitable impurities; the preparation method comprises the following steps: (1) melting the ingots and intermediate alloy according to the weight ratios respectively; (2) injecting Ar-Cl2 mixed gas into a melting furnace, refining at a temperature of 710-730 DEG C for 8 min-10 min to obtain aluminium alloy melt; (3) adding an aluminium titanium boron grain refiner with the stream so as to allow the elements in the aluminium titanium boron grain refiner to uniformly melt in the alloy melt; (4) casting at a casting temperature of 720 DEG C-730 DEG C and with a casting speed of 45 mm / min-55 mm / min to obtain the aluminium alloy rod.

Owner:JIANGSU GREENHUB TECH

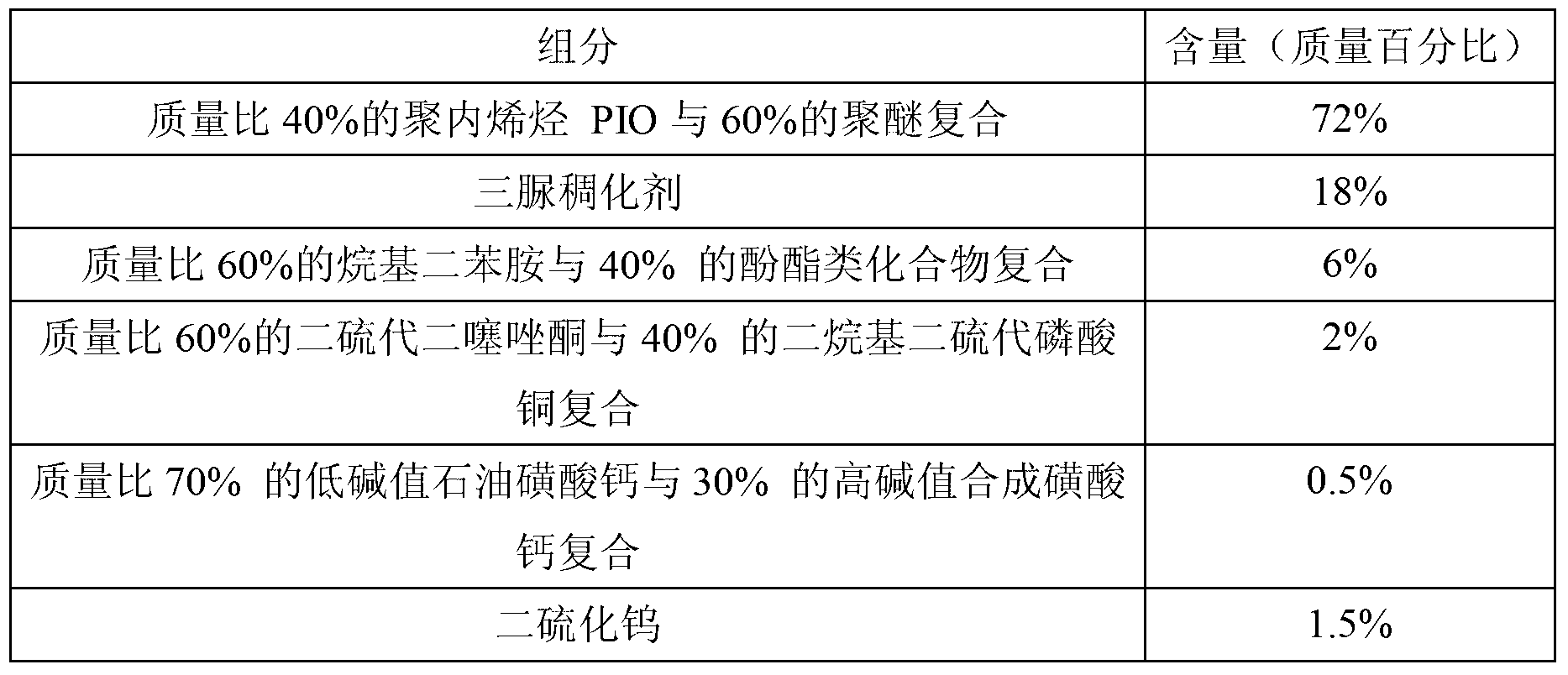

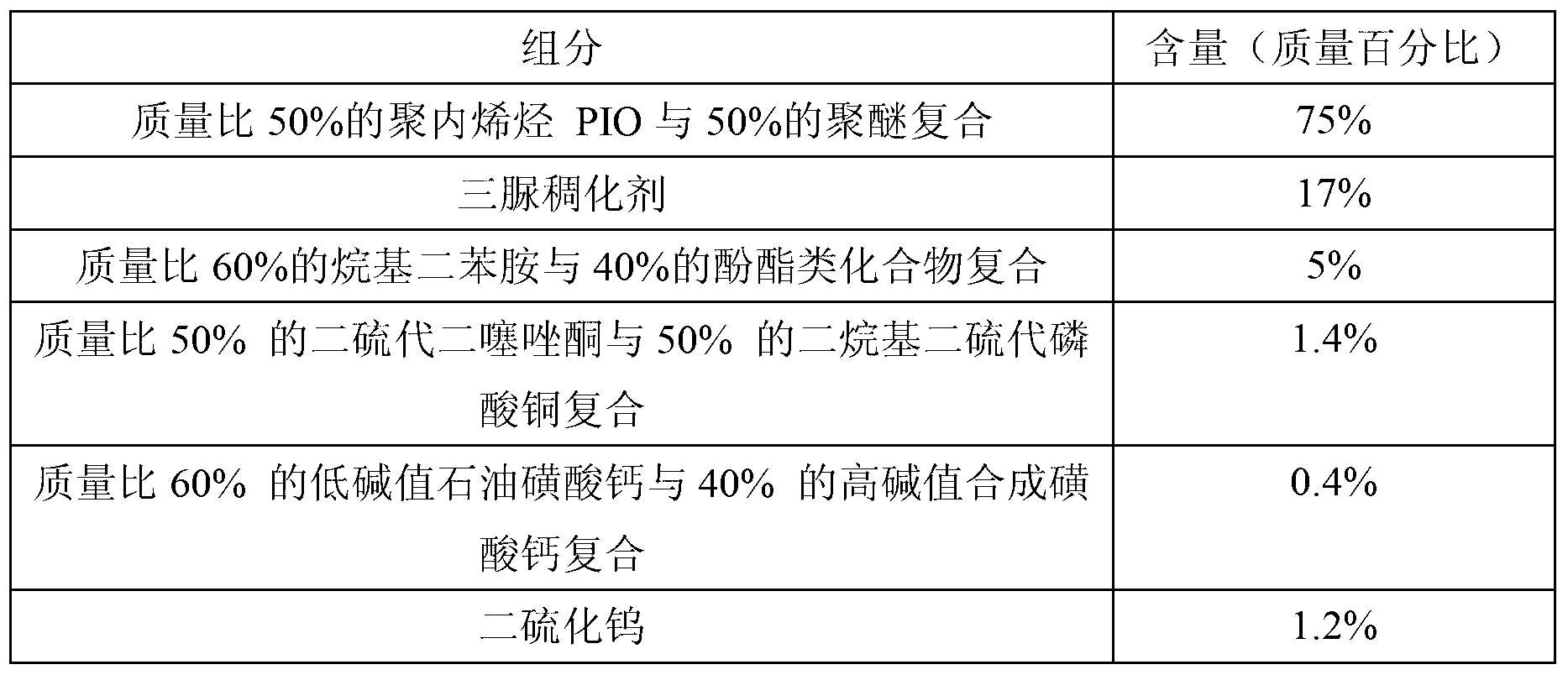

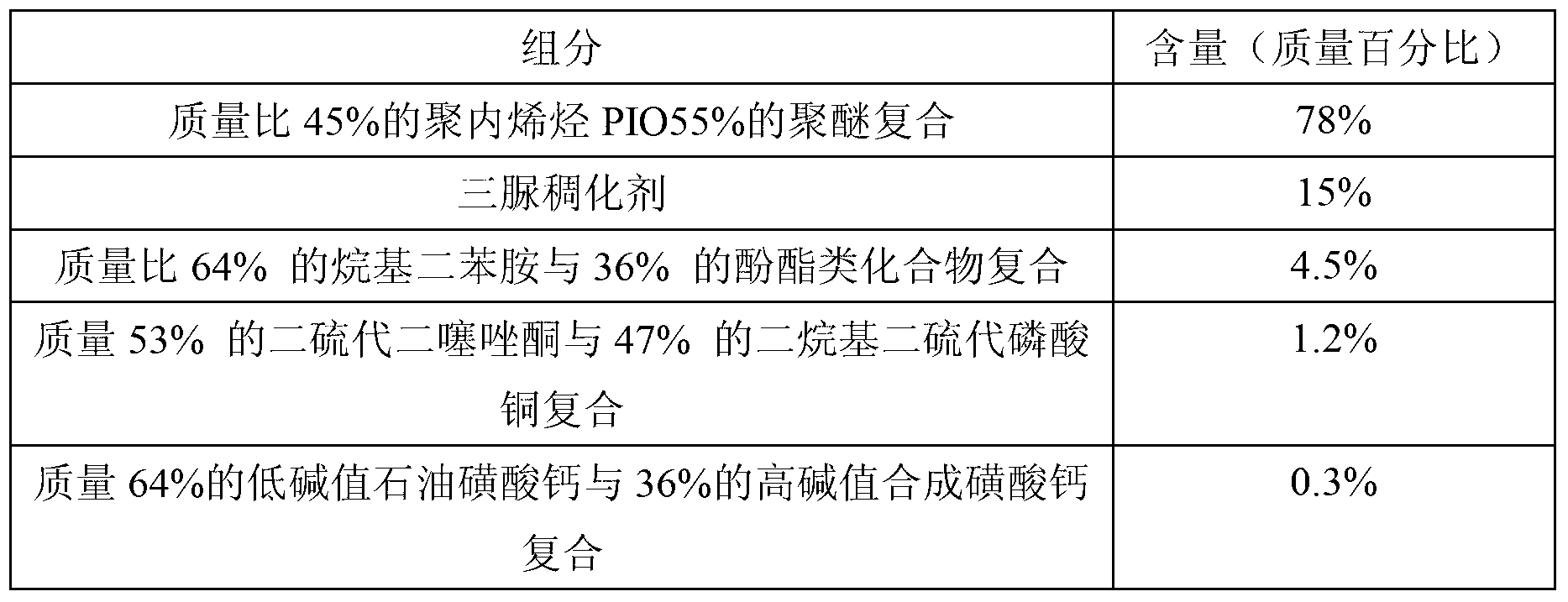

Heat-resistant grease

ActiveCN103265998AGood overall performanceGood high and low temperature performance and lubricating performanceLubricant compositionCarrying capacityFrictional coefficient

The invention discloses heat-resistant grease. The heat-resistant grease is characterized by comprising the following ingredients by mass percent: 70-80% of base oil, 20-12% of thickening agent, and 10-8% of other additives, wherein polyinternalolefin (PIO) is compounded with polyether to serve as the base oil of the heat-resistant grease, and a triuret thickener is utilized. The heat-resistant grease composition disclosed by the invention is good in overall performance, has good high-and-low temperature performance and lubricating property, excellent high temperature and oxidation stability, long high-temperature service life, excellent extreme pressure property and wear resistance, low frictional coefficient, strong carrying capacity, excellent mechanical stability and water resistance, high oil film strength, and excellent anti-rust and anti-corrosion performances and biodegradability, is suitable for lubricating and sealing of a bearing, a valve and a friction component which run under bad work conditions such as extreme high temperature, heavy load, and humid and polluted conditions, and can provide the maximal anti-wear, anti-rust and anti-corrosion protection.

Owner:GUANGXI UNIV

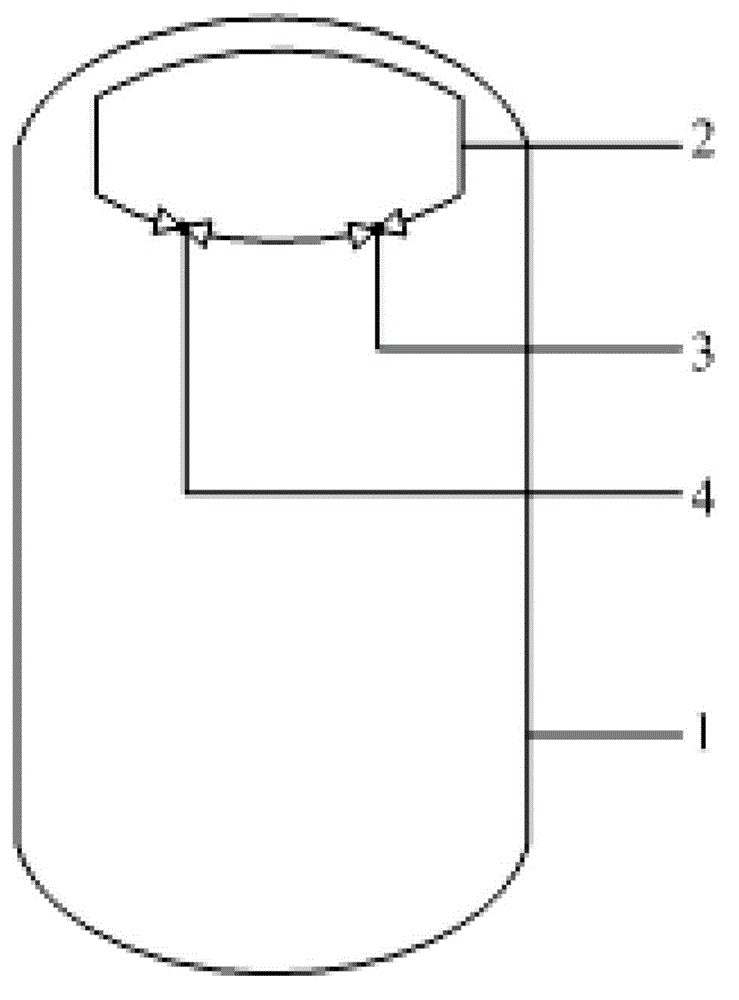

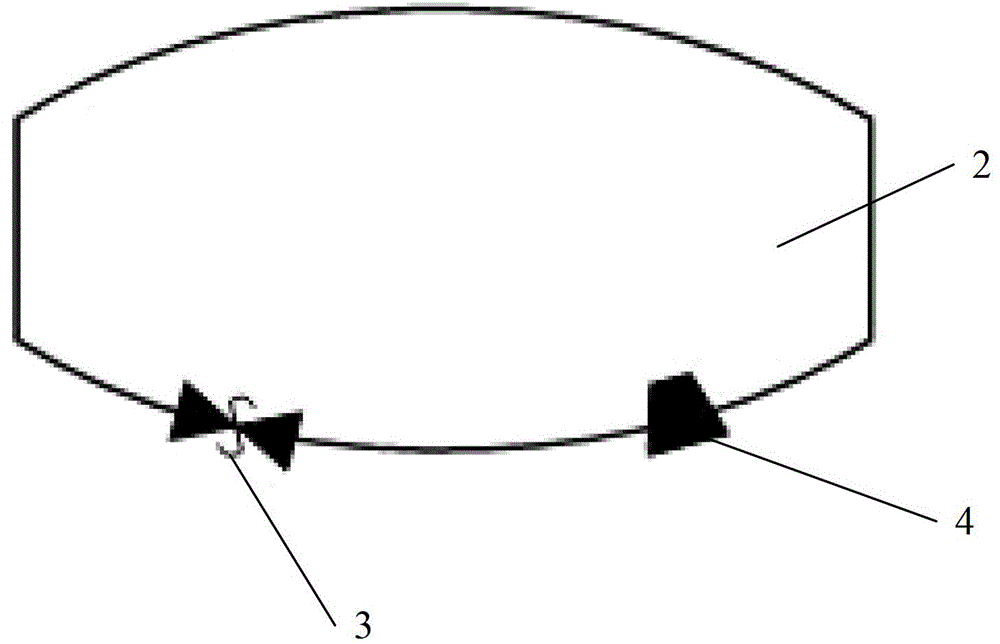

Temperature-pressure dual-control explosion suppression device and petrochemical industry safety reaction device

ActiveCN102940940AGood overall performanceImprove securityFire rescueChemical/physical/physico-chemical processesPetrochemicalInstrumentation

The invention provides a temperature-pressure dual-control explosion suppression device, comprising an explosion suppression storage tank, a pressure control trigger, and a temperature control trigger, wherein the pressure control trigger and the temperature control trigger are arranged on the explosion suppression storage tank. According to the invention, the device has good whole performance, can realize dual explosion suppression control of pressure and temperature, increases the safety of the reaction device; the physical temperature control trigger has the advantages of low cost, good stability, low failure rate, etc., and the explosion accidents of devices that only use pressure to conduct explosion suppression caused by malfunctions of electric control apparatus, fault of decompression valve, etc. are eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic silicon rubber water-proof paint special for sheet metal roofing and method for preparing same

InactiveCN101333412AStrong adhesionGood overall performanceLiquid surface applicatorsAntifouling/underwater paintsChemistryEmulsion

The invention relates to a special metal roofing organo-silicone rubber waterproof paint and a preparation method thereof. The paint is prepared from water, organo-silicone rubber emulsion, sodium lauryl benzenesulfate emulsion, phthalic acid, emulsifier, dispersant, sodium chloride, vinyl acetate, isooctyl alcohol, bentonite, heavy calcium carbonate, aedelforsite, ferric oxide, nano silicon dioxide, pigment and defoamer. The paint is nontoxic and tasteless and is ultraviolet radiation resistant, ageing resistant, waterproof, anticorrosion, thermally insulated, environment-friendly and energy-saving; therefore, the paint is suitable for metal roofing of workshops and factories, and the paint has special waterproofing effect as for important waterproofing complicated roofs.

Owner:青州市利达防水材料有限公司

Bacteriostatic coating and preparation method thereof

InactiveCN104497766AWide range of applicationsGood overall performanceAntifouling/underwater paintsPaints with biocidesChitinDefoaming Agents

The invention discloses a bacteriostatic coating and a preparation method thereof, and belongs to the coating field; the bacteriostatic coating comprises the following components by weight: 25-45 parts of a polyacrylate emulsion, 15-20 parts of a polyurethane emulsion, 6-15 parts of nano alumina, 5-10 parts of a talcum powder, 5-10 parts of a dispersing agent, 5-10 parts of an adsorbent, 7-15 parts of a curing agent, 2-15 parts of chitin, 4-10 parts of a thixotropic agent, 3-8 parts of a thickening agent, 2-8 parts of a defoaming agent, and 22-25 parts of deionized water. The bacteriostatic coating has the achieved beneficial effects that the formaldehyde release amount of the bacteriostatic coating is 0 g / L, a TVOC value is 0 g / L, and the coating also has waterproof and bacteriostatic effects, the application range is wider, and a coating film has better comprehensive performance.

Owner:张明

Production method for aluminum alloy bicycle frame pipe for electric bicycle

The invention discloses a production method for an aluminum alloy bicycle frame pipe for an electric bicycle. The aluminum alloy comprises, by weight, 2-3% of Si, 2-5% of Mg, 0.5-1% of Zn, 0.2-1% of Mn, 0.3-0.7% of Cu, and the balance of Al and other inevitable impurities. The production method comprises the following steps: (1) smelting the aluminum alloy according to the components and casting into a bar; (2) carrying out a homogenizing annealing treatment; (3) discharging the bar from a furnace after carrying out the homogenizing annealing treatment, cooling to a room temperature, then placing the bar in a heating furnace to heat to the temperature of 430-450 DEG C, and holding the temperature for 3 hours; concurrently heating an extrusion mold to the temperature of 350-380 DEG C, and heating an extrusion material cylinder to the temperature of 350-380 DEG C; (4) placing the heated aluminum alloy bar into an extruder to extrude into the bicycle frame pipe profile, wherein the extrusion speed is 2-7 m / min.

Owner:徐艳

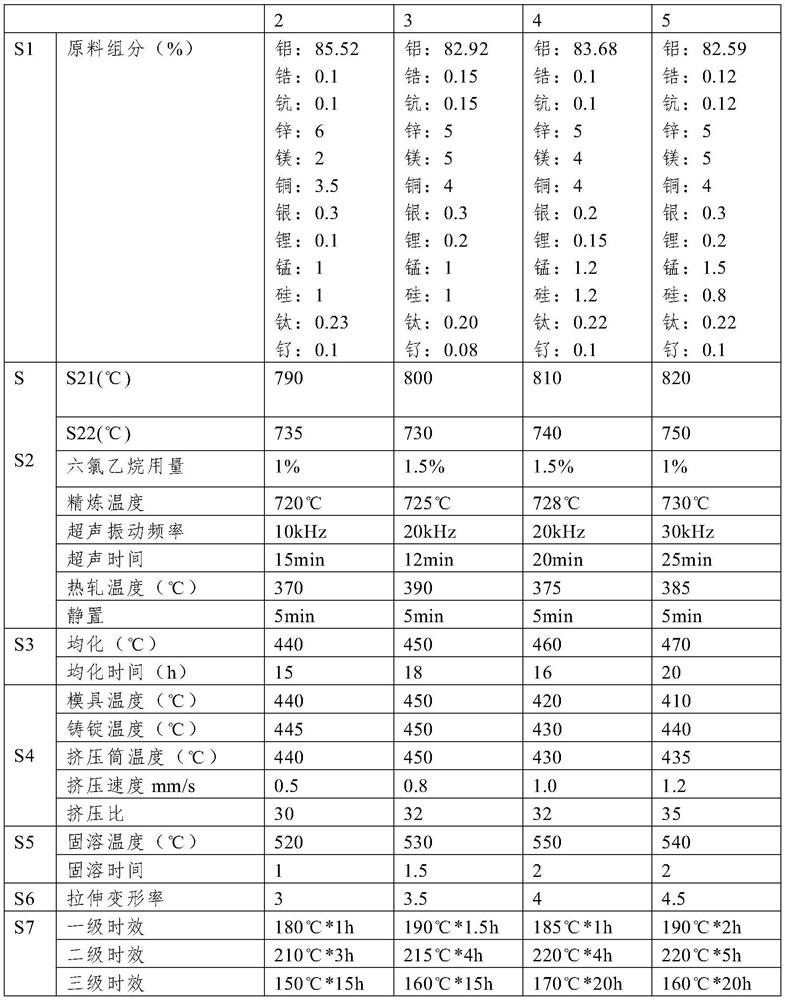

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

Method for assembled integral type reinforced concrete slab bridge

The invention discloses a method for an assembled integral type reinforced concrete slab bridge. An integral slab bridge is divided into slab blocks with the same width in the transverse direction, namely the direction perpendicular to the driving direction, then the slab blocks are prefabricated, the prefabricated slab blocks are connected through wet joints, the width of each prefabricated slab block is the difference of the width of a driveway and the width of each wet joint, connecting reinforcing steel bars are embedded at the position, corresponding to each wet joint, of the side face of each prefabricated slab block, the embedded connecting reinforcing steel bars are bound and connected, then cement concrete is poured, accordingly, an assembled integral type reinforced concrete slab is manufactured, and finally bridge deck pavement is carried out on the manufactured assembled integral type reinforced concrete slab, anti-collision guardrails are installed on both sides of a bridge deck in the longitudinal direction, namely the driving direction, thus, the assembled integral type reinforced concrete slab bridge is manufactured. The method for the assembled integral type reinforced concrete slab bridge has the advantages of being high in speed of the prefabricated assembly type construction method, low in cost and good in stress performance of the integral slab bridge. The manufactured slab is good in performance, can effectively avoid the occurrence of the condition that a single slab is stressed, saves cost of later maintenance and reinforcement and ensures construction quality.

Owner:苏州三木知识产权服务有限公司

Method for preparing diphenolic propane diglycidol ether

InactiveCN1935767AGood overall performanceLow costEther preparation by compound dehydrationChemistryDiglycidyl ether

The invention discloses a diphenol propane diglycerol ether preparing method, comprising the steps of: mxing diphenol propane, diphenol propane by-products and epoxy chloropropane, and adding in benzyl triethyl ammonium chloride water solution as catalyst, making etherification reaction at 75-125 deg.C for 0.5-10 h, dropping in sodium hydroxide water solution and blending, and keeping; eliminating water and epoxy chloropropane and obtaining a mixture containing diphenol propane diglycerol ether; adding in toluene to extract to remove sodium chloride from the mixture. And it has better synthetic performance of product and low cost and recycles the wastes.

Owner:蓝星安迪苏股份有限公司

Light-transmission and heat-insulation membrane and manufacturing method thereof

InactiveCN103496202AEnhanced anti-reflectionGood overall performanceSynthetic resin layered productsVacuum evaporation coatingReflectivityChemistry

The invention provides a light-transmission and heat-insulation membrane and a manufacturing method thereof. The light-transmission and heat-insulation membrane is a durable electrostatic-clinging heat-insulation membrane which has excellent light transmission and high infrared and ultraviolet reflectivity and is prepared by simple processes. The manufacturing method comprises that various function layers are overlaid on a substrate layer.

Owner:HANGZHOU ZEAL SCI & TECH

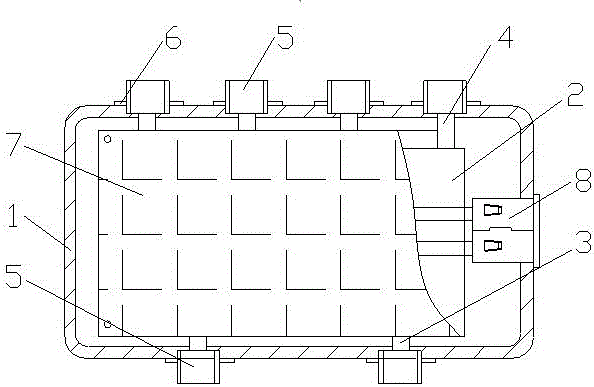

Conductor shunt

ActiveCN106602370AGood overall performanceEasy maintenanceVehicle connectorsCouplings bases/casesElectric vehicleElectricity

The invention provides a conductor shunt. A circuit for realizing shunting of electrical signals of a main wiring harness and a shunting wiring harness is arranged on a PCB. Incoming line conductive tubes and outgoing line conductive tubes are connected with the PCB and are electrified; and plugging holes are formed in the incoming line conductive tubes and the outgoing line conductive tubes. Mounting holes communicated with the plugging holes are formed in a sealed housing; and internal threads are arranged in the mounting holes. Guiding elements are provided with via holes matching the main wiring harness and the shunting wiring harness and an interference fit is formed; and external threads matching the internal threads of the mounting holes are arranged at the peripheral of the guiding elements. When the guiding elements and the mounting holes are connected, conductors of the main wiring harness or the shunting wiring harness can be inserted into the corresponding plugging holes. According to the conductor shunt, routing can be carried out directly on the circuit board, so that the assembling time can be saved and the production efficiency can be improved; and because of the waterproof and dustproof effects of the conductor shunt, overhaul can be realized conveniently. When the conductor shunt is in use, the interference by an external environment can be avoided; and the service life of the conductor shunt is long and the excellent performance of the electric vehicle can be guaranteed.

Owner:江西众达泰科技有限公司

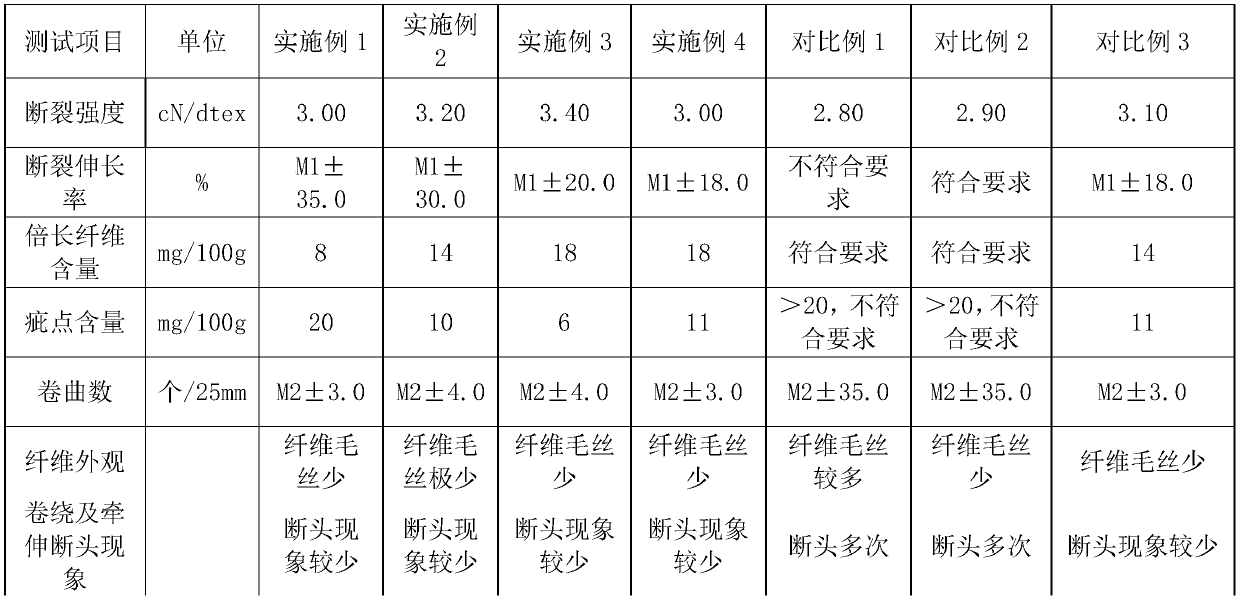

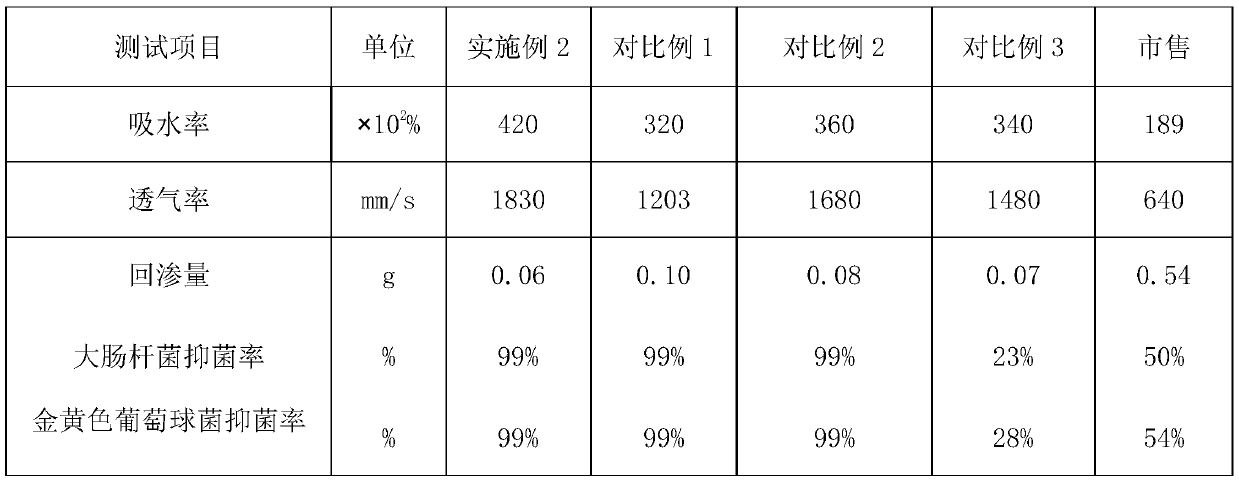

Antibacterial composite short fiber and preparation method thereof

InactiveCN110565203ALow rewetGood overall performanceFilament/thread formingConjugated synthetic polymer artificial filamentsSuper absorbentSodium polyacrylate

The invention discloses an antibacterial composite short fiber and a preparation method thereof. The PP / PE composite short fiber is composed of a core layer and an outer layer; the core layer and theouter layer are concentric circles; the core layer is prepared from, by mass, 40-50 parts of polypropylene, 5-9 parts of an ethylene-propylene copolymer, 4-6 parts of a propylene block copolymer, 8-9parts of starch-acrylic acid super-absorbent resin, 2-3 parts of titanium dioxide and 4-8 parts of zinc oxide; the outer layer is prepared from, by weight, 20-30 parts of linear low-density polyethylene, 20-30 parts of high-density polyethylene, 20-30 parts of antibacterial polyethylene particles, 10-15 parts of methyl-methacrylate-grafted modified polyethylene, 10-12 parts of ethylene-grafted methyl methacrylate and 12-17 parts of sodium polyacrylate super-absorbent resin. The PP / PE composite short fiber has the following advantages that the short fiber has few curls and defects, and preparedproducts have a small back infiltration amount after absorbing water, excellent air permeability, an excellent bacteriostatic effect and excellent comprehensive performance.

Owner:嘉兴市新丰特种纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com