Improved 7000 series aluminum alloy double-stage overaging heat treatment technology

An aluminum alloy, overaging technology, applied to the heat treatment of 7000 series (Al-Zn-Mg-Cu series) aluminum alloys, the improved 7000 series aluminum alloy double-stage overaging heat treatment process, which can solve the problem of low production efficiency and poor operation Difficulty, long process flow, etc., to achieve high production efficiency, good overall performance matching, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

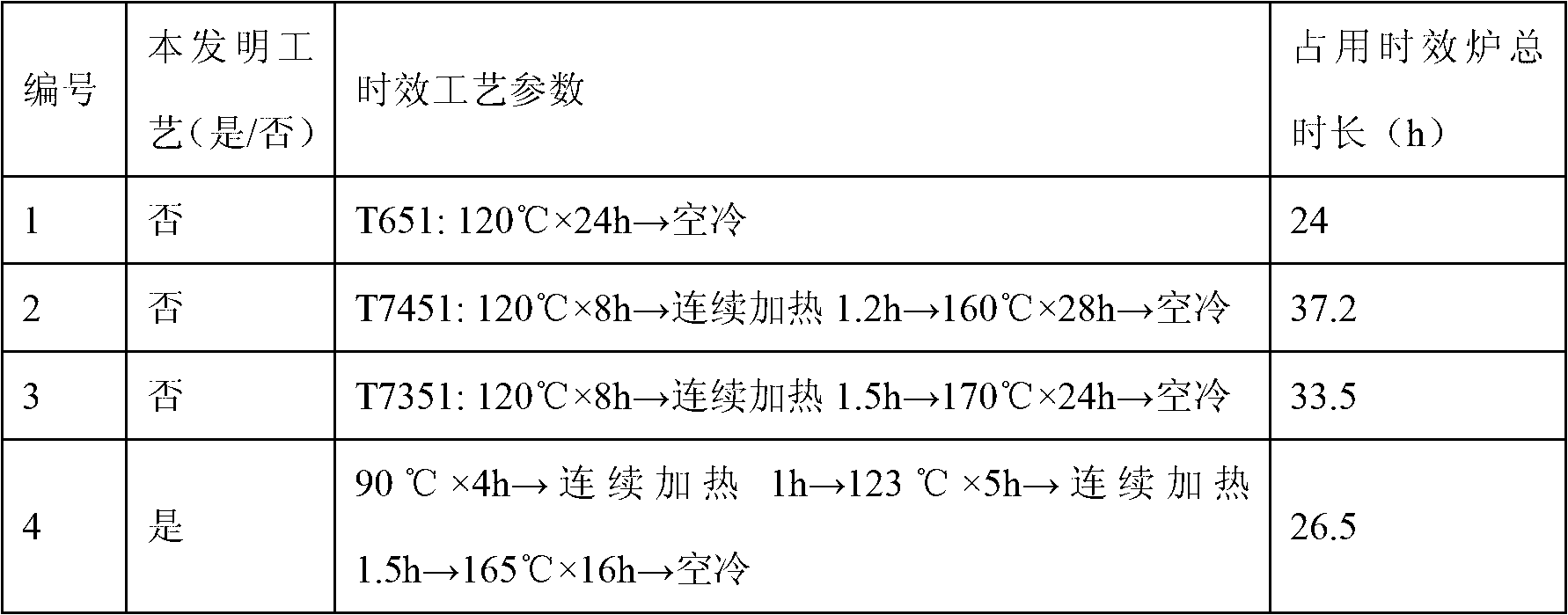

[0028] Al-6.5Zn-2.3Mg-2.1Cu-0.12Zr alloy is configured, and a solution quenched state with a thickness of 40mm is obtained through smelting, semi-continuous casting, homogenization annealing, rolling, solution quenching, pre-stretching and other processes ( T351 state) plates, block samples were cut from the plates for aging treatment tests of different schemes, and the aging process schemes are shown in Table 1. According to relevant test standards, the tensile mechanical properties, electrical conductivity, fracture toughness, and exfoliation corrosion properties of samples with different aging treatments were tested, and the results are shown in Table 2.

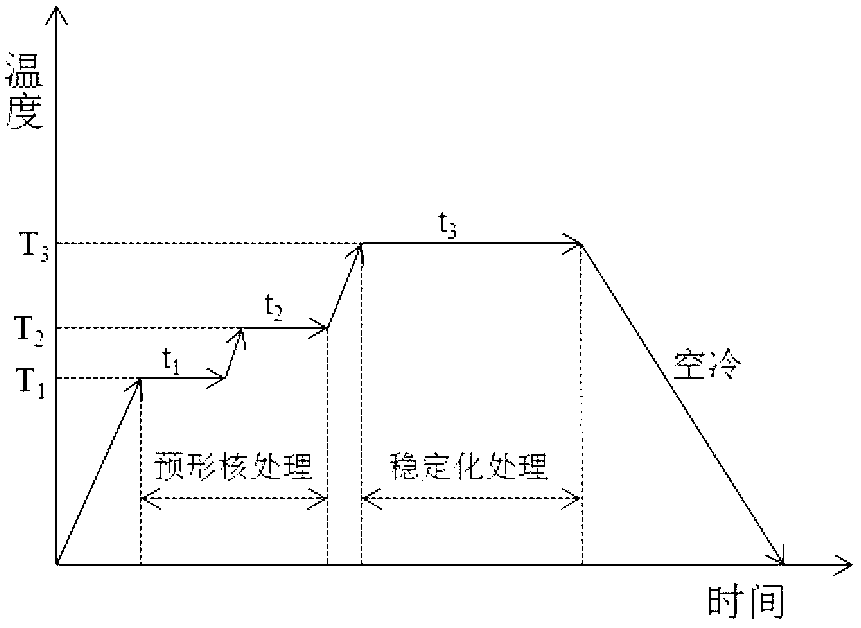

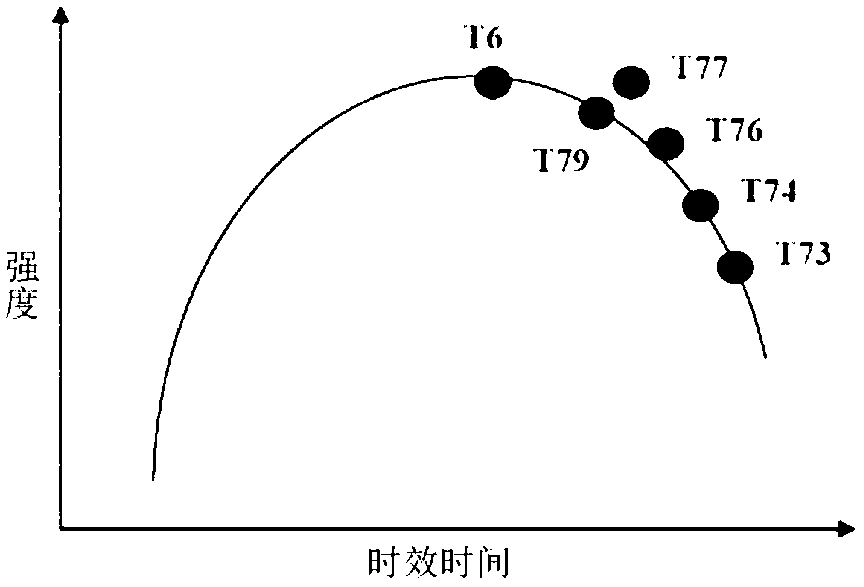

[0029] An improved 7000 series aluminum alloy double-stage overaging heat treatment process, the method mainly includes the following process steps as figure 1 As shown, the range of its main parameters: (1) The pre-aging in the low temperature zone includes two stages of aging and heat preservation process, that is, at T...

Embodiment 2

[0043] Configure Al-6.2Zn-2.8Mg-1.6Cu-0.16Cr-0.31Mn alloy, through melting, semi-continuous casting, homogenization annealing, rolling, solution quenching, pre-stretching and other processes to obtain a thickness of 40mm solution quenching The thick plate in state (T351 state) is used to carry out aging treatment tests of different schemes, and the aging process scheme and its properties are shown in Table 3. According to the relevant test standards, the tensile mechanical properties, electrical conductivity, stress corrosion resistance, exfoliation corrosion properties, and fracture toughness of the samples with different aging treatments were tested. The results are shown in Table 4.

[0044] table 3

[0045]

[0046] Table 4

[0047]

[0048]

[0049] From the performance test results in Examples 1 and 2 (Table 2 and Table 4), it can be seen that whether it is Al-6.5Zn-2.3Mg-2.1Cu-0.12Zr alloy T351 plate or Al-6.2Zn-2.8Mg-1.6 Cu-0.16Cr-0.31Mn alloy T351 plate, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com