Light-transmission and heat-insulation membrane and manufacturing method thereof

A manufacturing method and heat insulation film technology, applied in chemical instruments and methods, ion implantation plating, coating, etc., can solve problems such as blocking and reduction of brightness in the interior space of commercial buildings, and achieve increased deposition rate, heat insulation effect and Excellent light transmittance and high shielding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

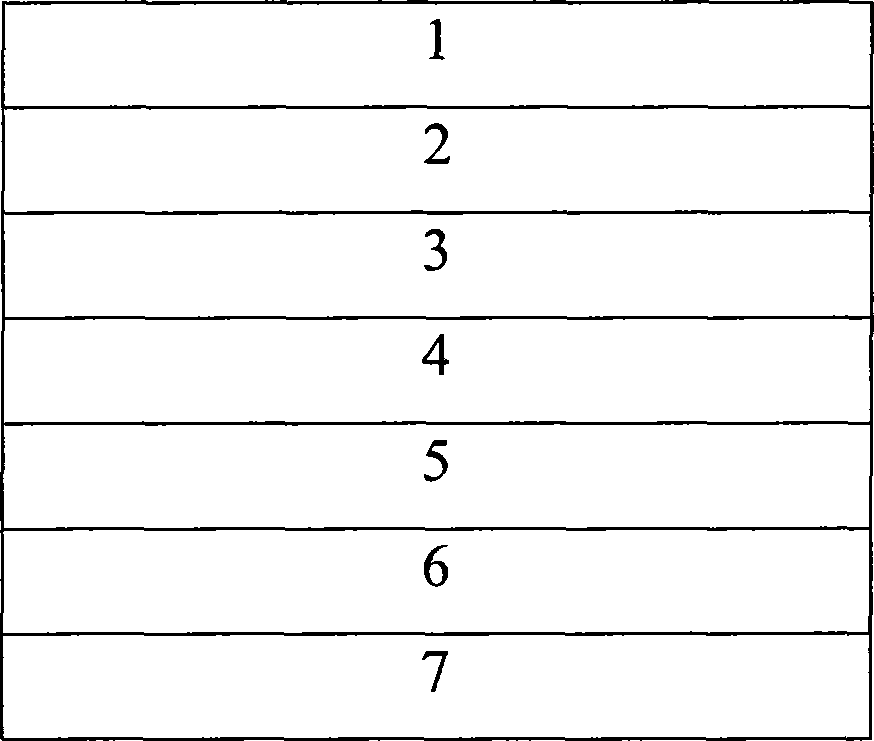

[0050] To manufacture light-transmitting and heat-insulating film, the steps are as follows:

[0051] (1) Provide the substrate, which is a carbon fiber film;

[0052] (2) Physical vapor deposition (PVD) is used to deposit a titanium layer on the surface of the substrate. The deposition temperature is 80°C and the deposition time is 1h. During the deposition process, a vertical direction control electric field is applied to the deposition surface so that the titanium layer grains arranged in vertical strips;

[0053] (3) Depositing a titanium nitride layer on the surface of the titanium layer by a physical vapor deposition process;

[0054] (4) drying the semi-finished product obtained in step (3), the drying temperature is 80°C, and the drying time is 2-3h;

[0055] (5) Depositing a nickel oxide coating layer on the titanium nitride layer by using a bias magnetron sputtering method;

[0056] (6) drying the semi-finished product obtained in step (5), the drying temperature ...

Embodiment 2

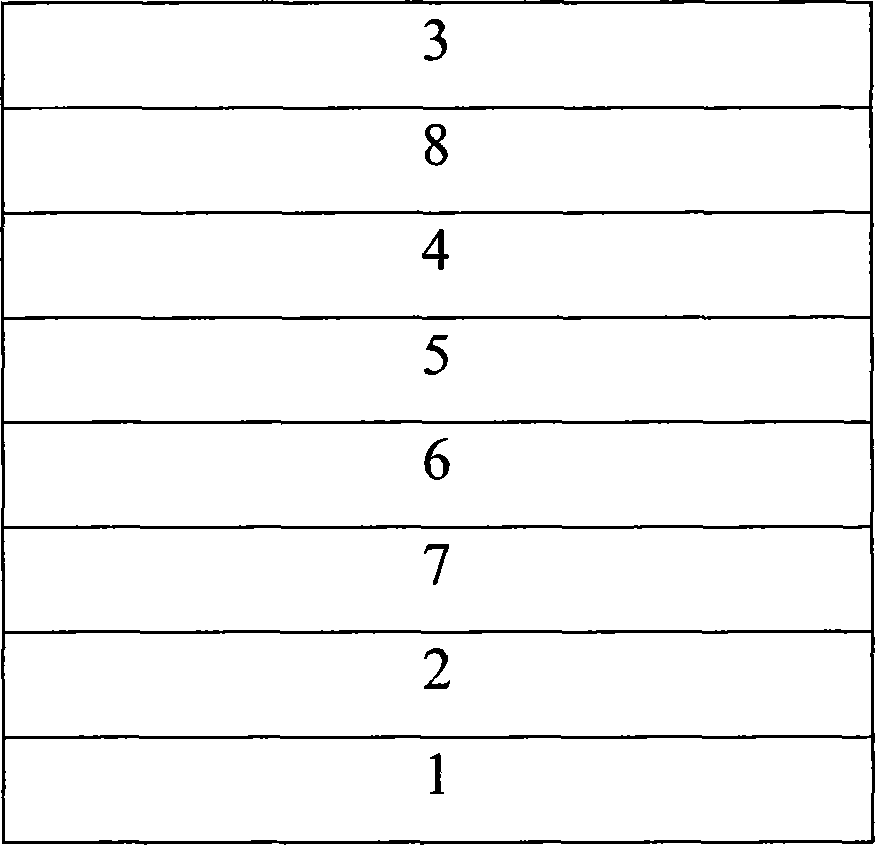

[0064] To manufacture light-transmitting and heat-insulating film, the steps are as follows:

[0065] (1) Provide the substrate, which is a carbon fiber film;

[0066] (2) Physical vapor deposition (PVD) is used to deposit a titanium layer on the surface of the substrate. The deposition temperature is 80°C and the deposition time is 1h. During the deposition process, a vertical direction control electric field is applied to the deposition surface so that the titanium layer grains arranged in vertical strips;

[0067] (3) Depositing a titanium nitride layer on the surface of the titanium layer by a physical vapor deposition process;

[0068] (4) drying the semi-finished product obtained in step (3), the drying temperature is 80°C, and the drying time is 2-3h;

[0069] (5) Depositing a nickel oxide coating layer on the titanium nitride layer by using a bias magnetron sputtering method;

[0070] (6) drying the semi-finished product obtained in step (5), the drying temperature ...

Embodiment 3

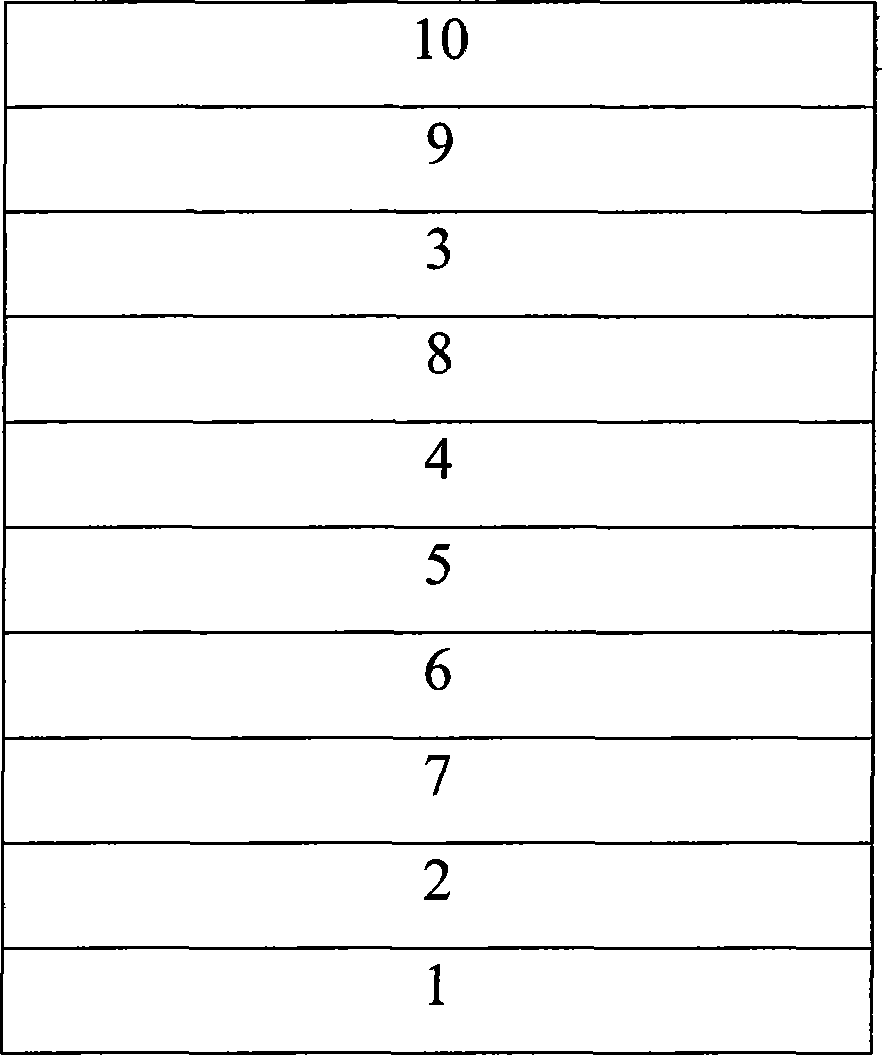

[0079] To manufacture light-transmitting and heat-insulating film, the steps are as follows:

[0080] (1) Provide the substrate, which is a carbon fiber film;

[0081] (2) Physical vapor deposition (PVD) is used to deposit a titanium layer on the surface of the substrate. The deposition temperature is 100°C and the deposition time is 1h. During the deposition process, a vertical direction control electric field is applied to the deposition surface so that the titanium layer grains arranged in vertical strips;

[0082] (3) Depositing a titanium nitride layer on the surface of the titanium layer by a physical vapor deposition process;

[0083] (4) drying the semi-finished product obtained in step (3), the drying temperature is 100° C., and the drying time is 3 hours;

[0084] (5) Depositing a nickel oxide coating layer on the titanium nitride layer by using a bias magnetron sputtering method;

[0085] (6) drying the semi-finished product obtained in step (5), the drying tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com