Patents

Literature

43368 results about "Thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

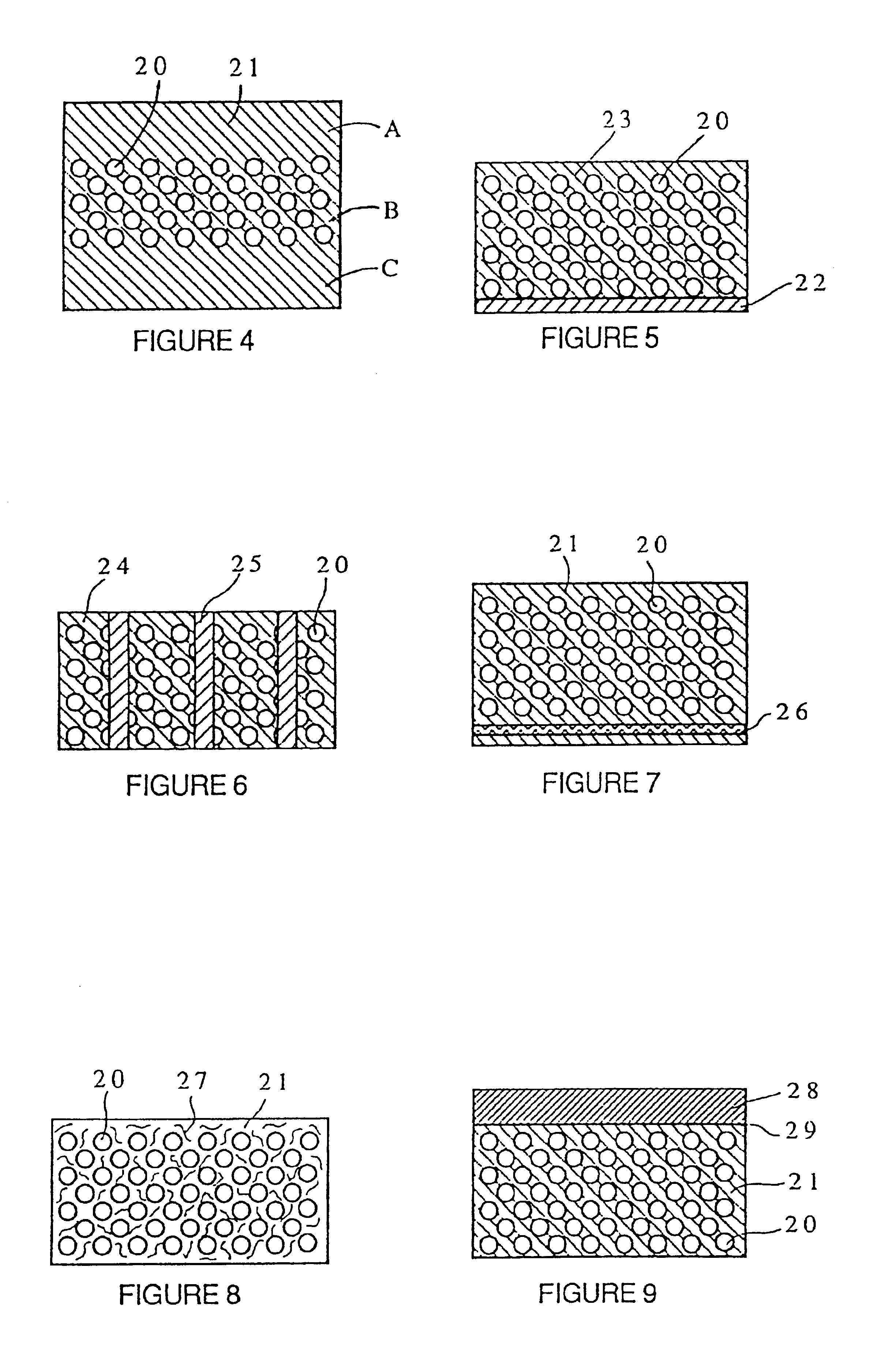

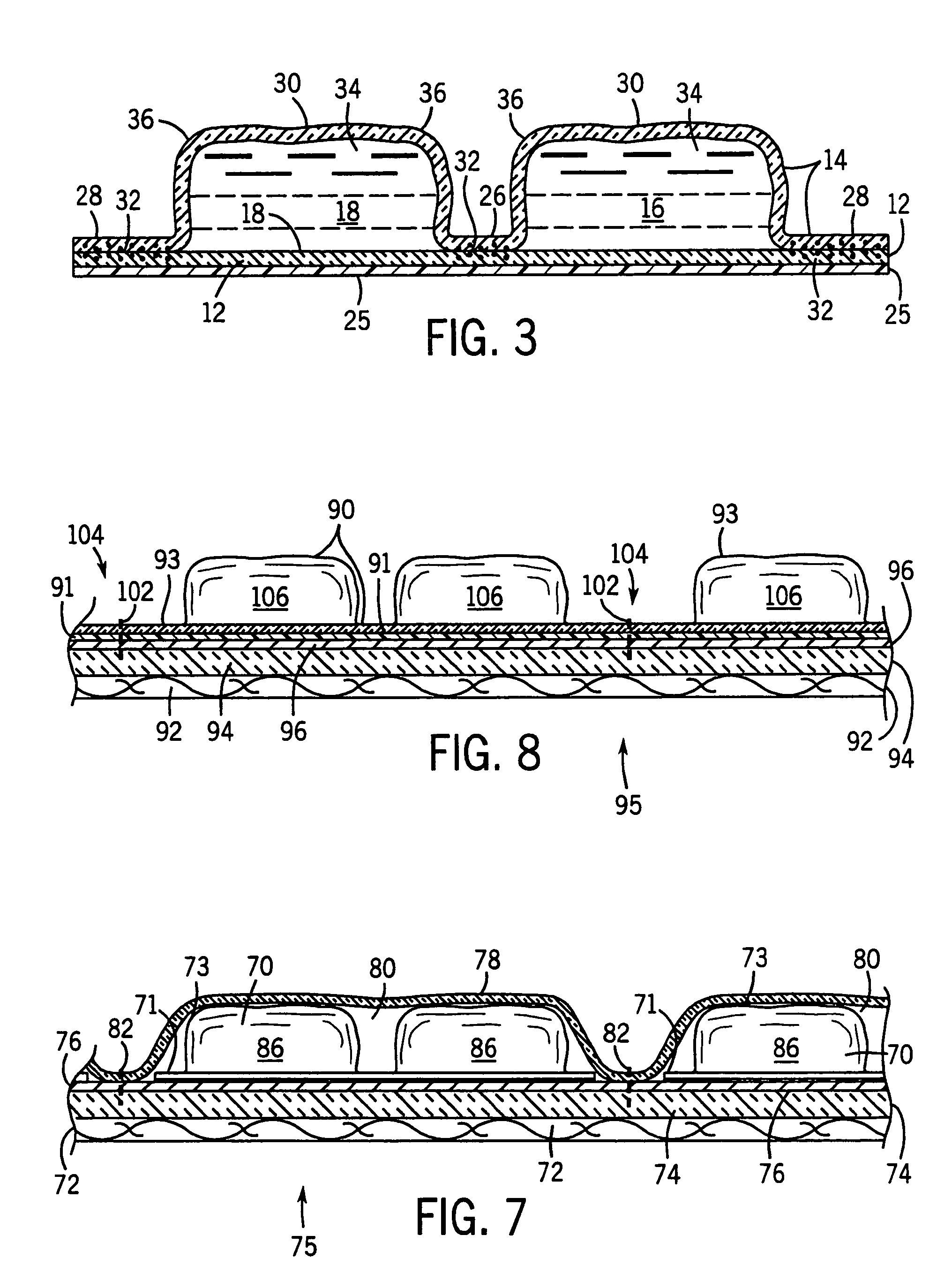

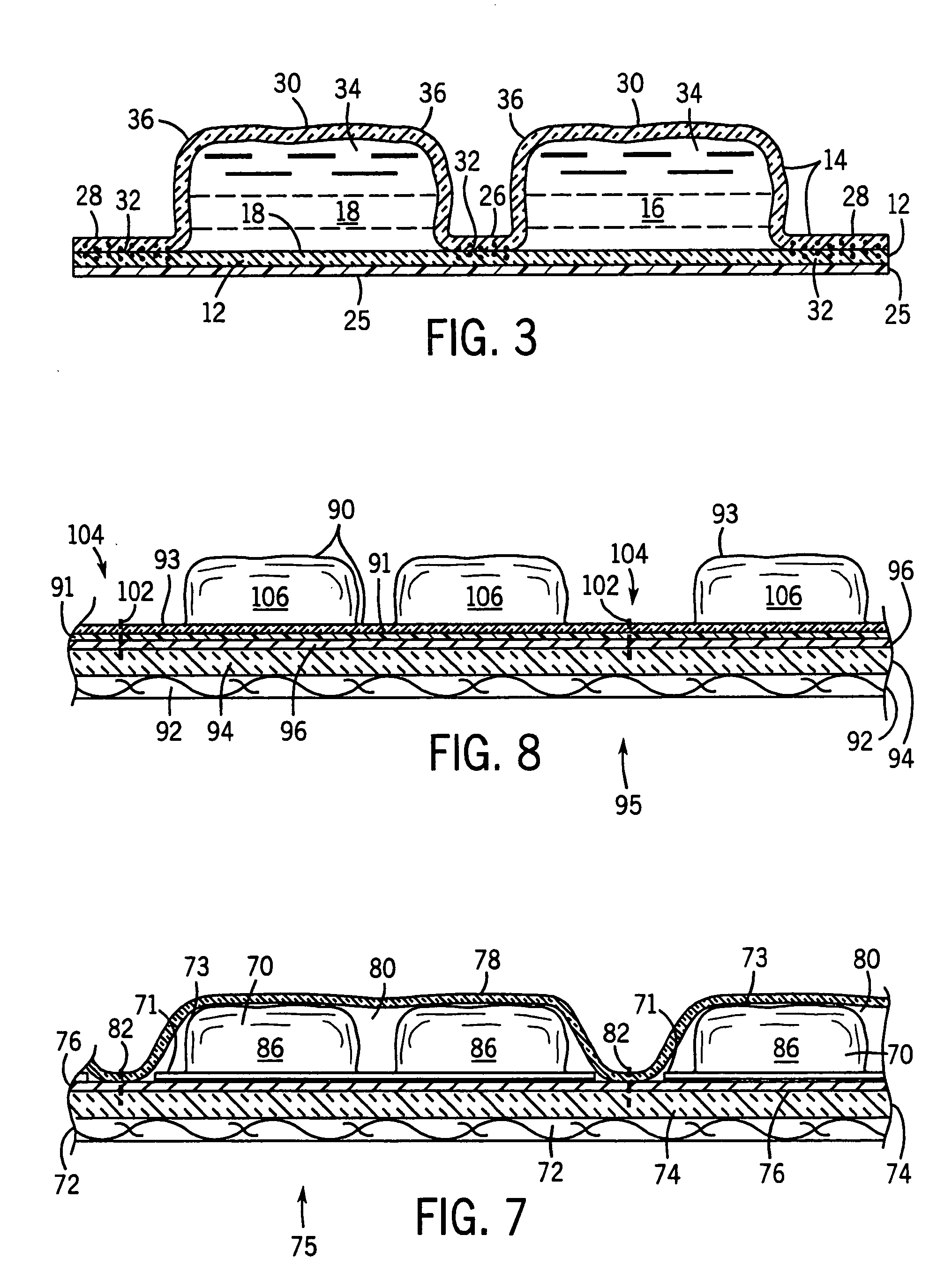

Phase change material thermal capacitor clothing

InactiveUS6855410B2Good thermal controlFast regenerationExothermal chemical reaction heat productionNatural cellulose pulp/paperSOCKSThermal insulation

An apparatus and method for metabolic cooling and insulation of a user in a cold environment. In its preferred embodiment the apparatus is a highly flexible composite material having a flexible matrix containing a phase change thermal storage material. The apparatus can be made to heat or cool the body or to act as a thermal buffer to protect the wearer from changing environmental conditions. The apparatus may also include an external thermal insulation layer and / or an internal thermal control layer to regulate the rate of heat exchange between the composite and the skin of the wearer. Other embodiments of the apparatus also provide 1) a path for evaporation or direct absorption of perspiration from the skin of the wearer for improved comfort and thermal control, 2) heat conductive pathways within the material for thermal equalization, 3) surface treatments for improved absorption or rejection of heat by the material, and 4) means for quickly regenerating the thermal storage capacity for reuse of the material. Applications of the composite materials are also described which take advantage of the composite's thermal characteristics. The examples described include a diver's wet suit, ski boot liners, thermal socks, gloves and a face mask for cold weather activities, and a metabolic heating or cooling blanket useful for treating hypothermia or fever patients in a medical setting and therapeutic heating or cooling orthopedic joint supports.

Owner:BUCKLEY THERESA M

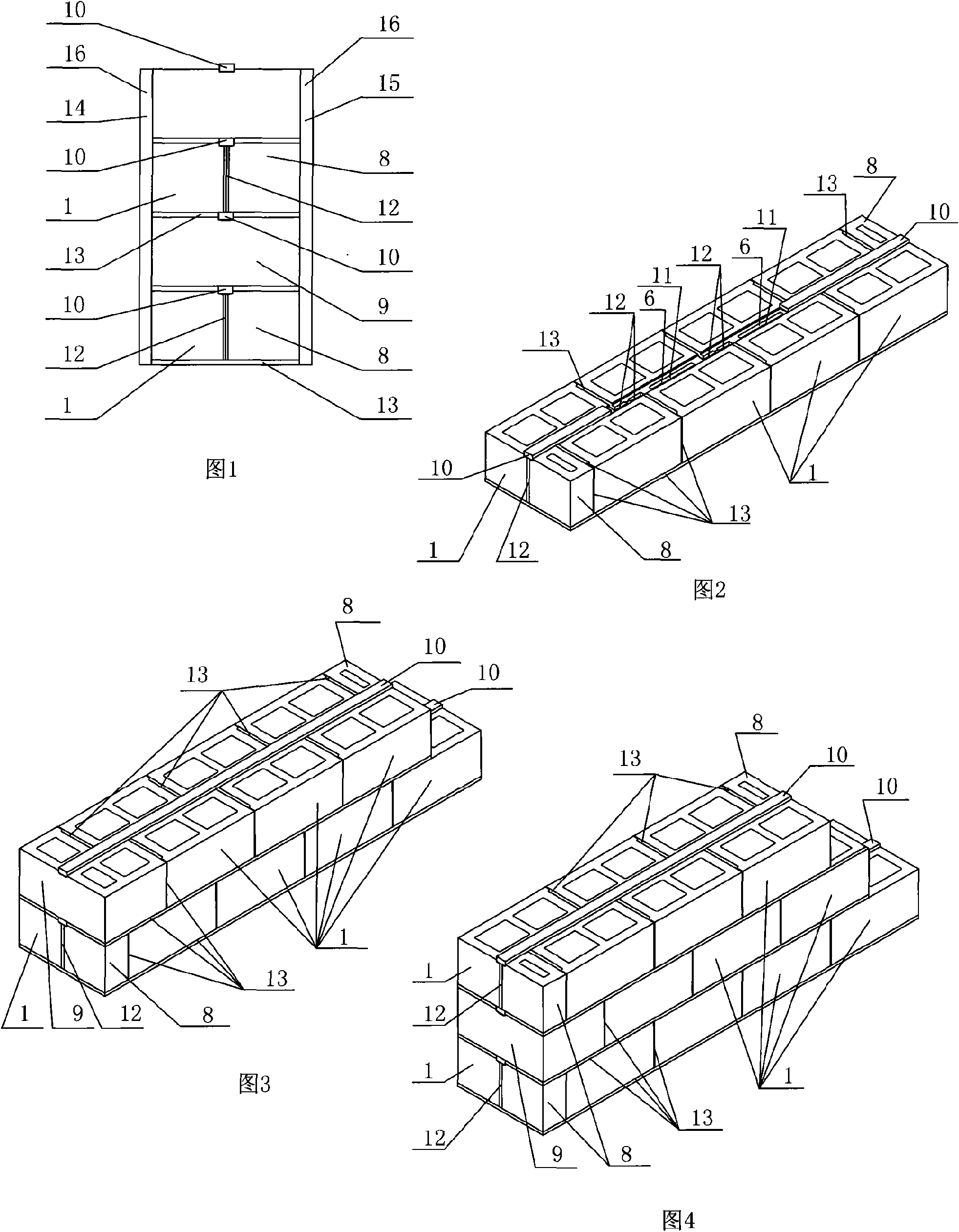

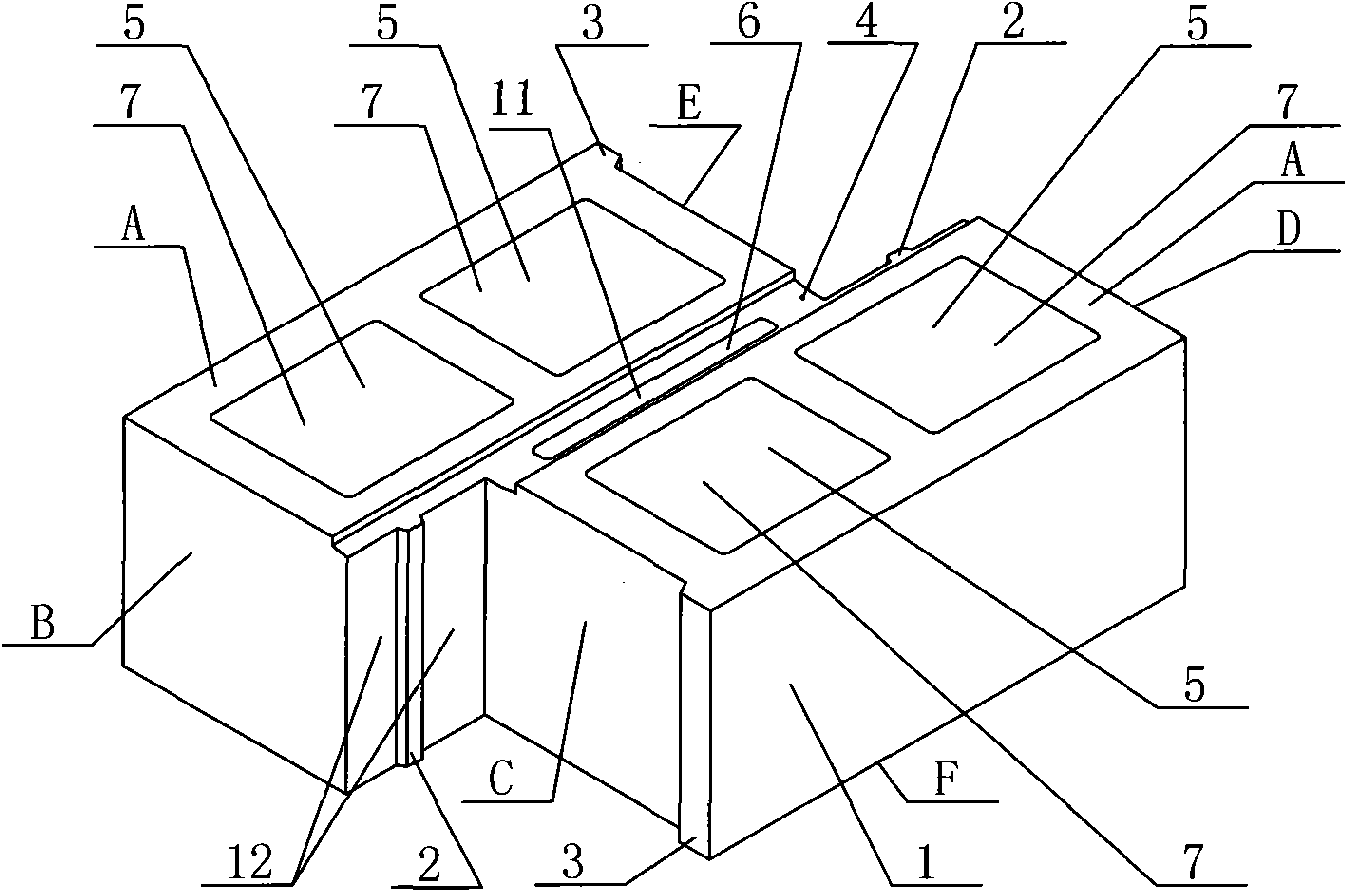

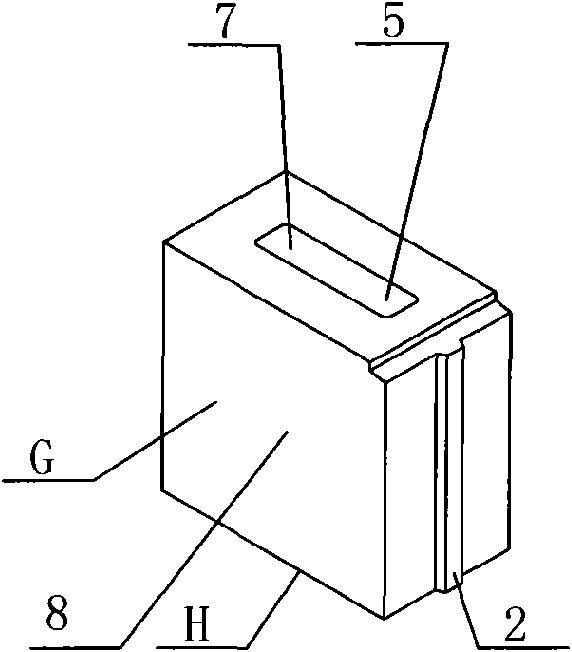

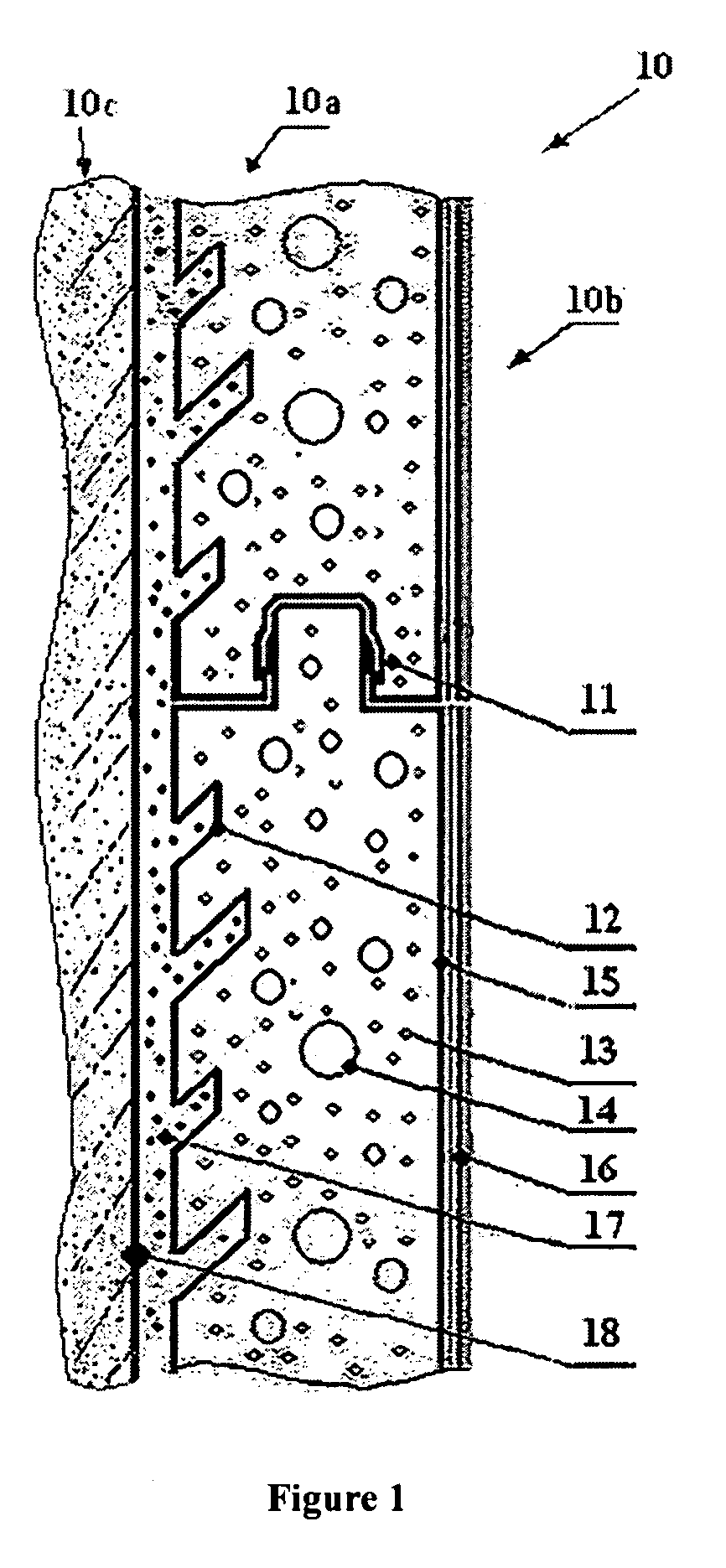

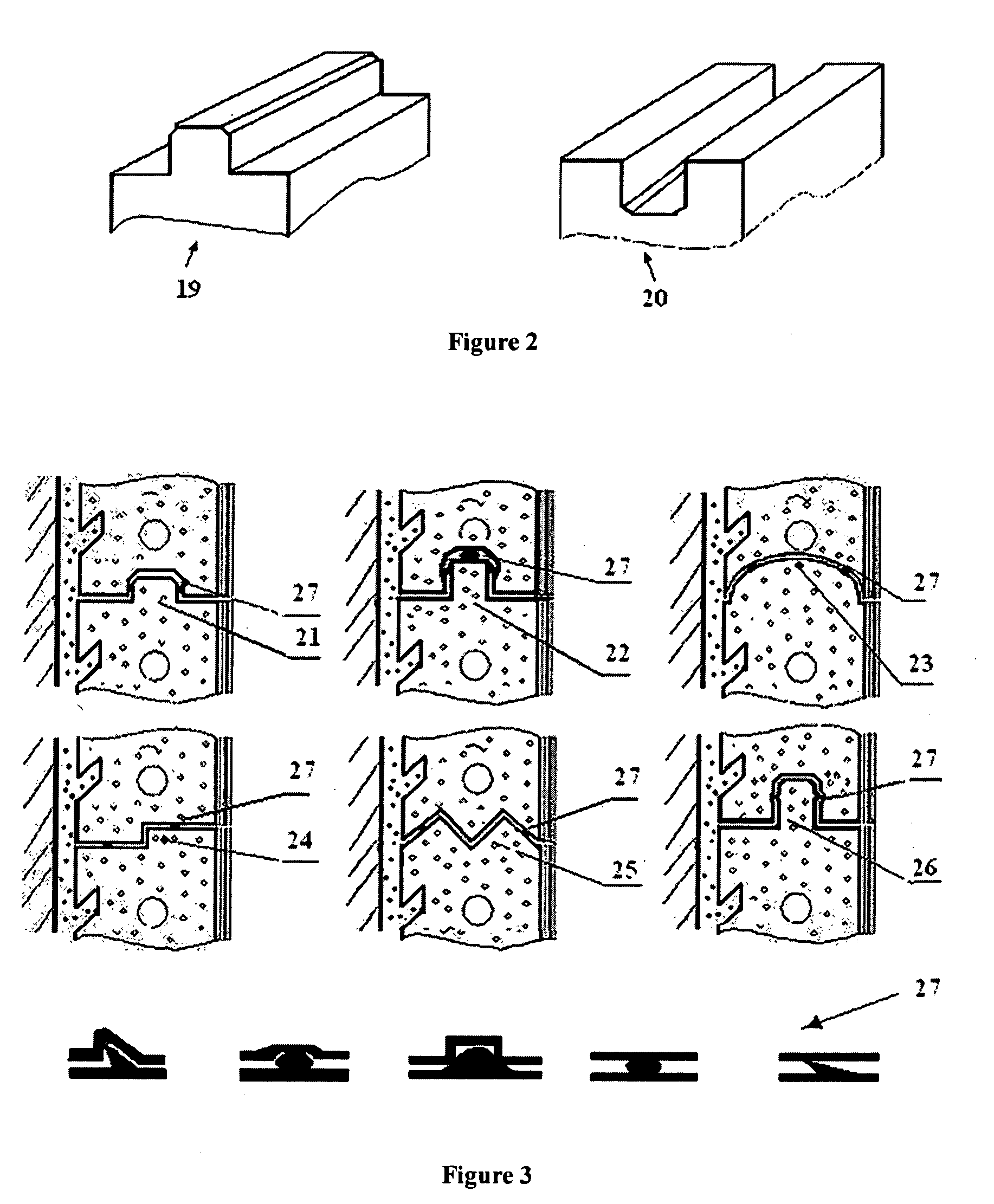

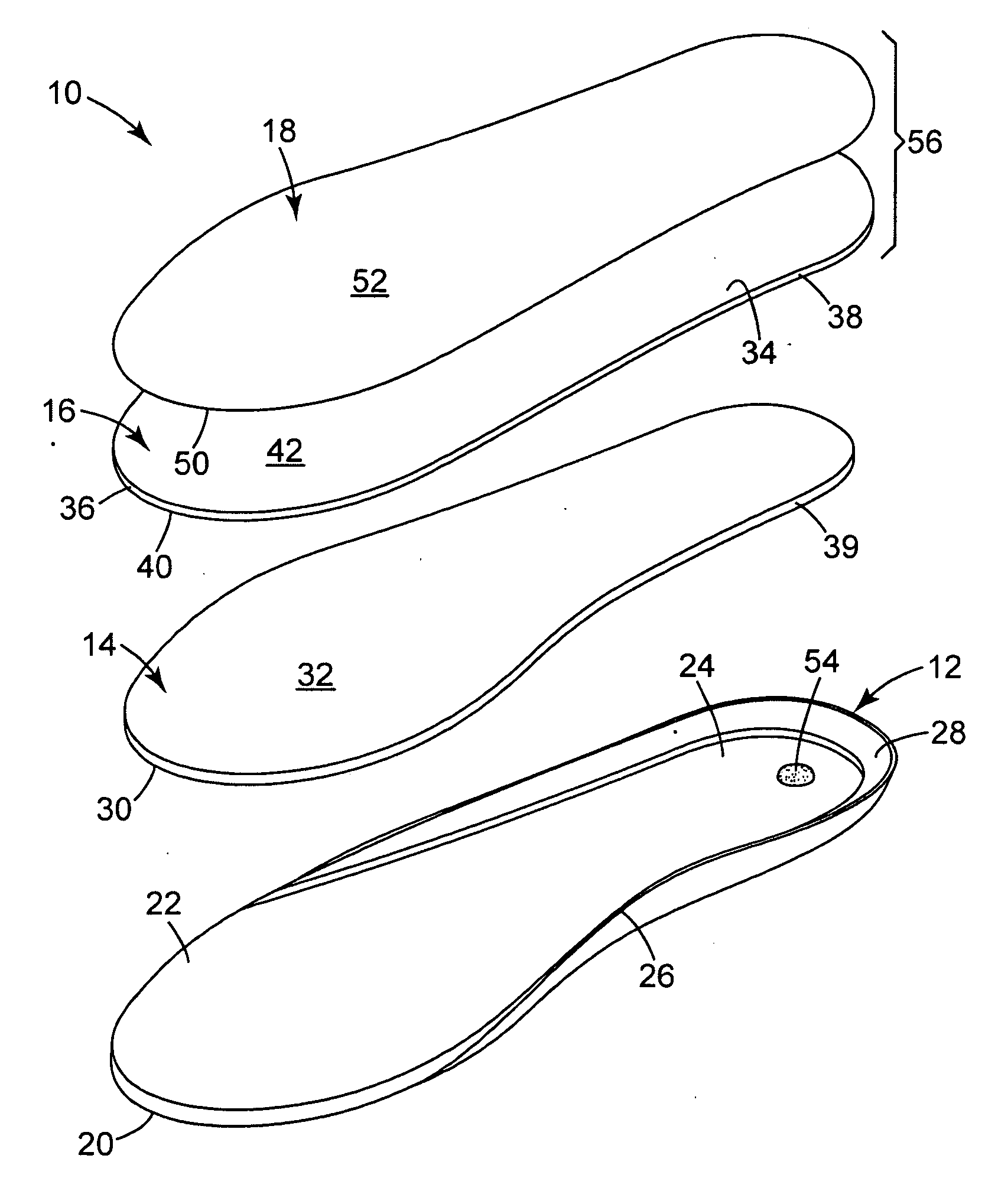

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

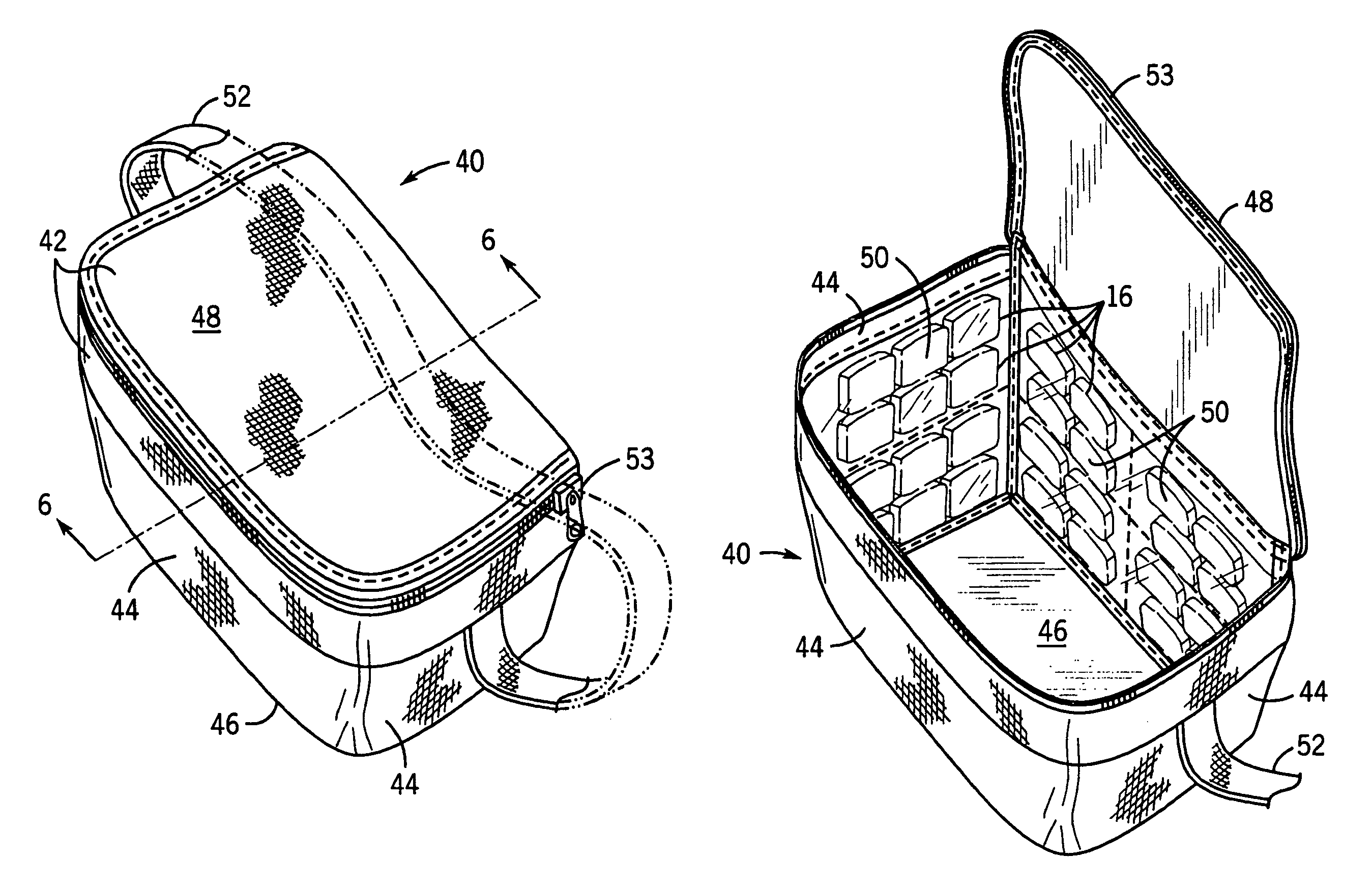

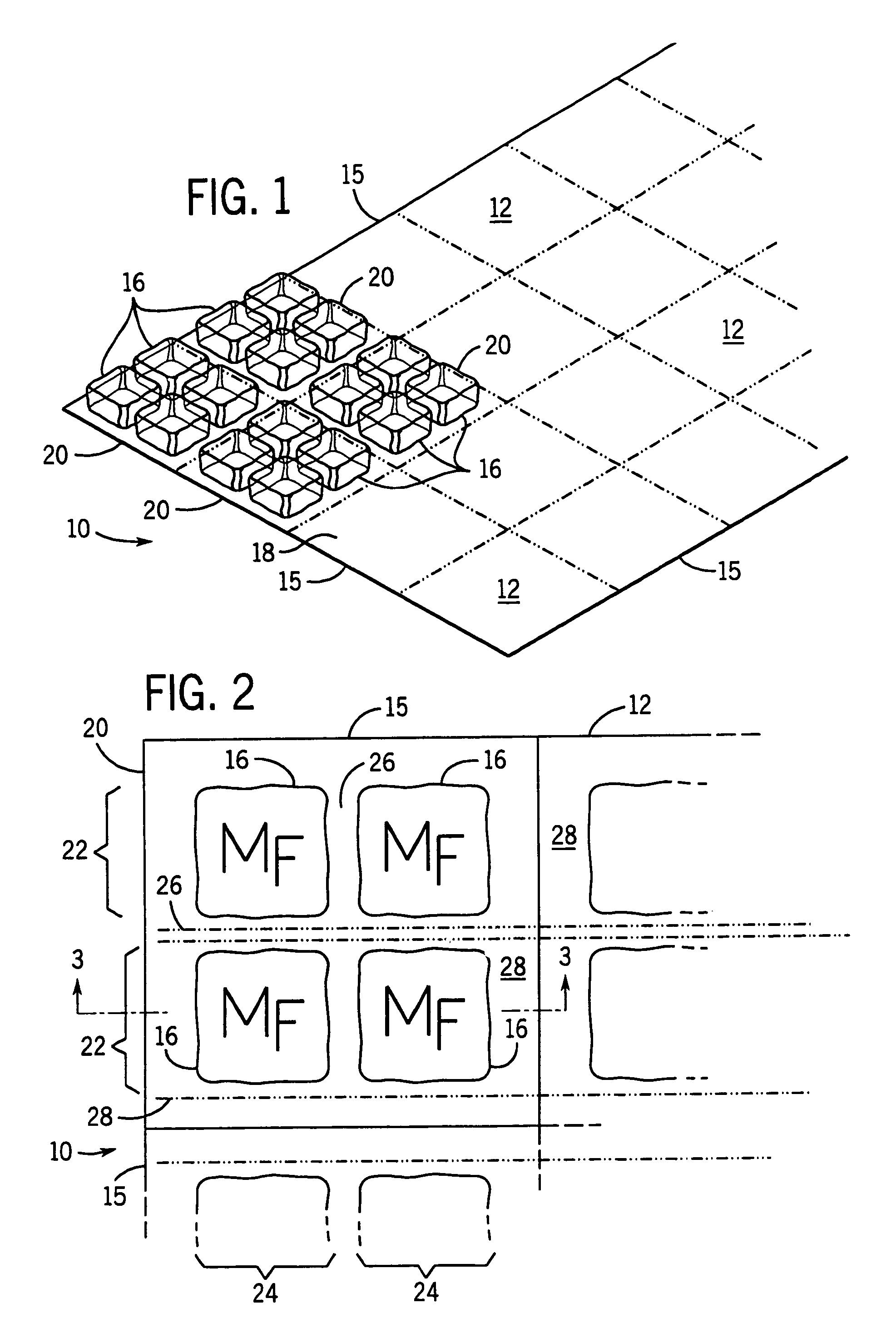

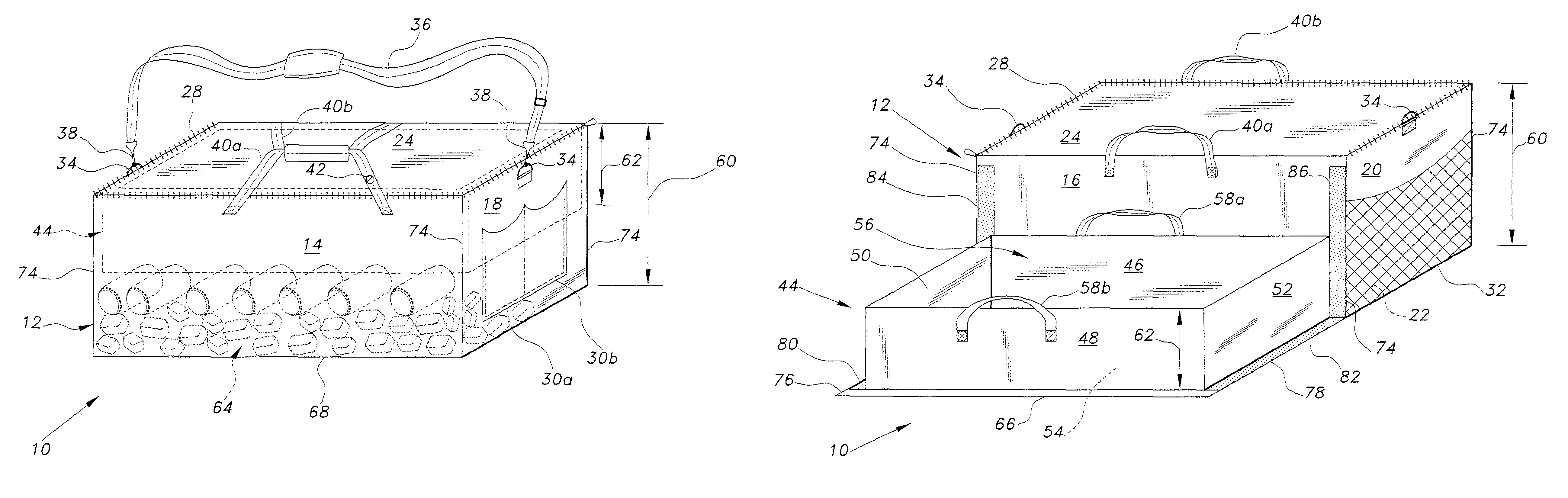

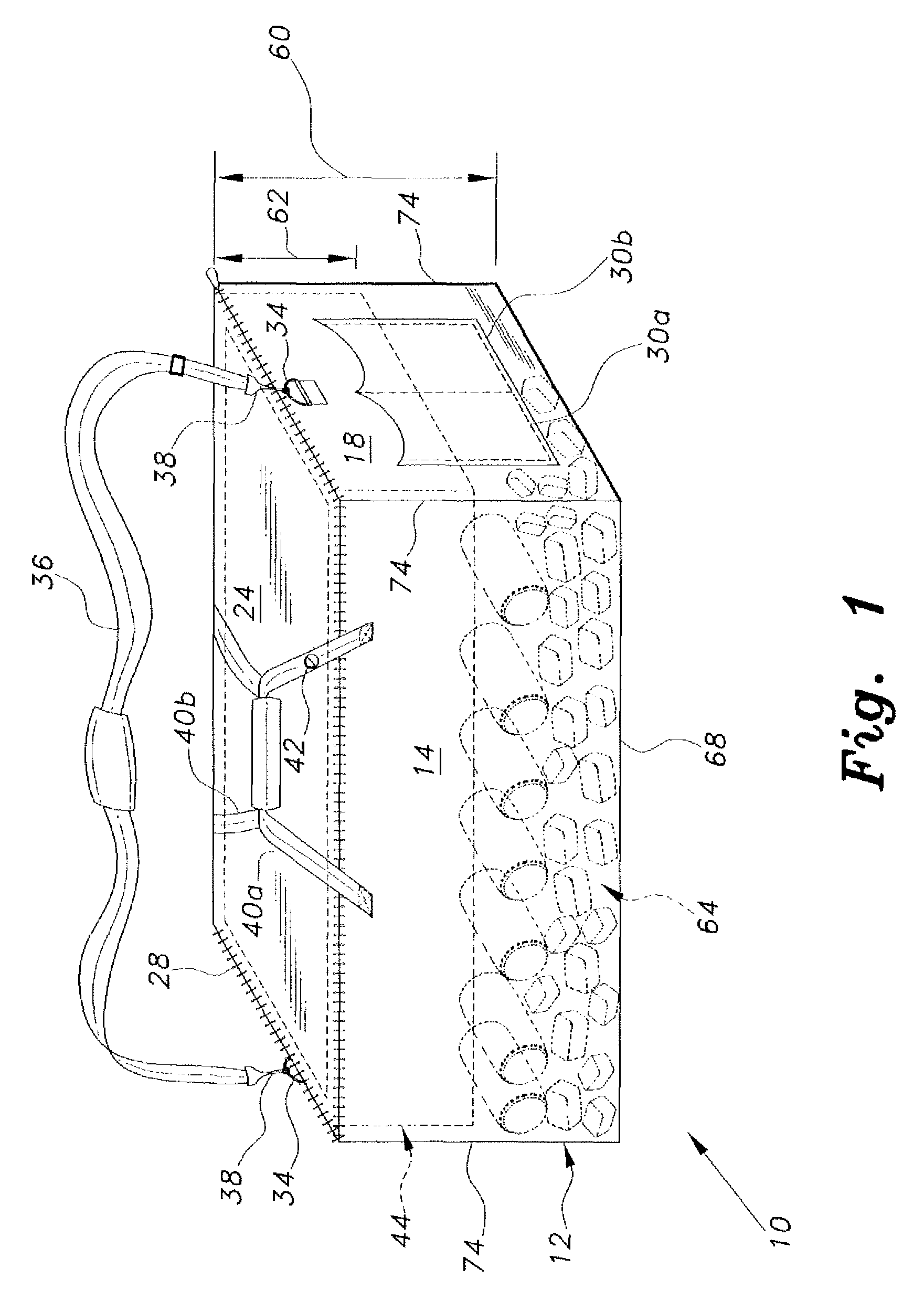

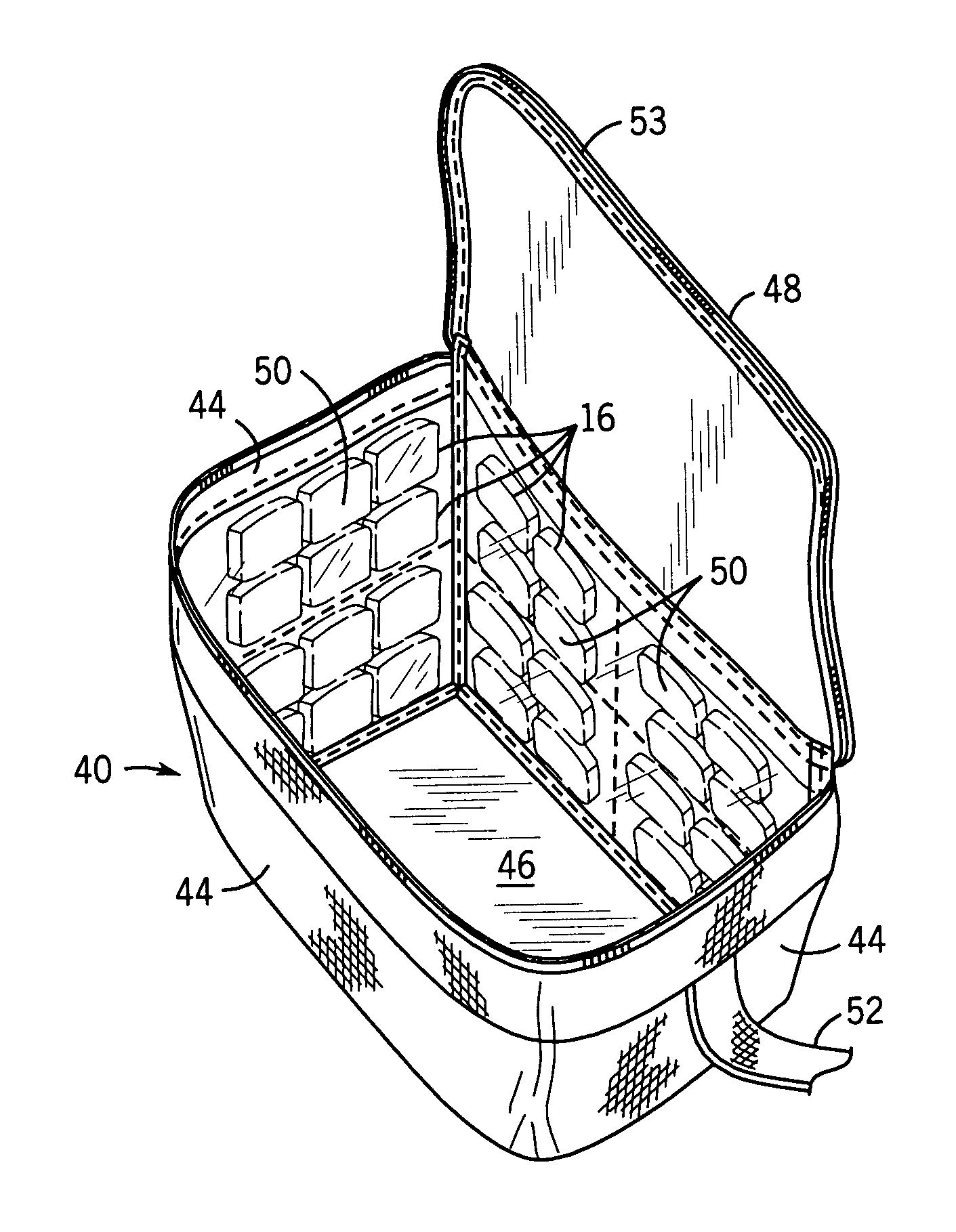

Portable cooler with built-in refrigerant cubes

ActiveUS7730739B2Effective mergerEasy to storeLighting and heating apparatusIce productionThermal insulationCooling effect

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or by being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler. The cooler may include a hinged top and bottom that can be folded flat for allowing the cooler to assume a compact configuration during storage or freezing of the refrigerant cubes.

Owner:FUCHS MARK D

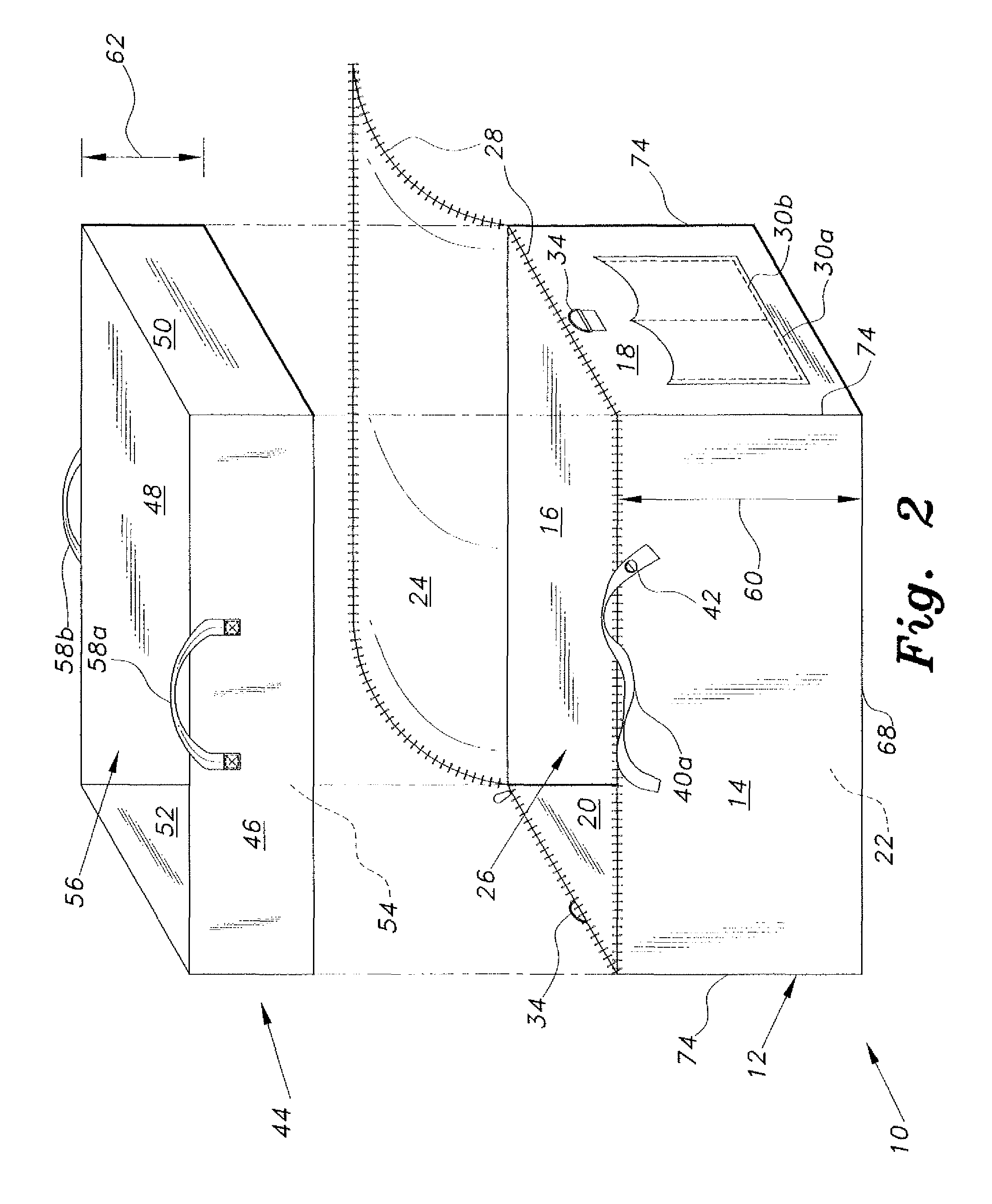

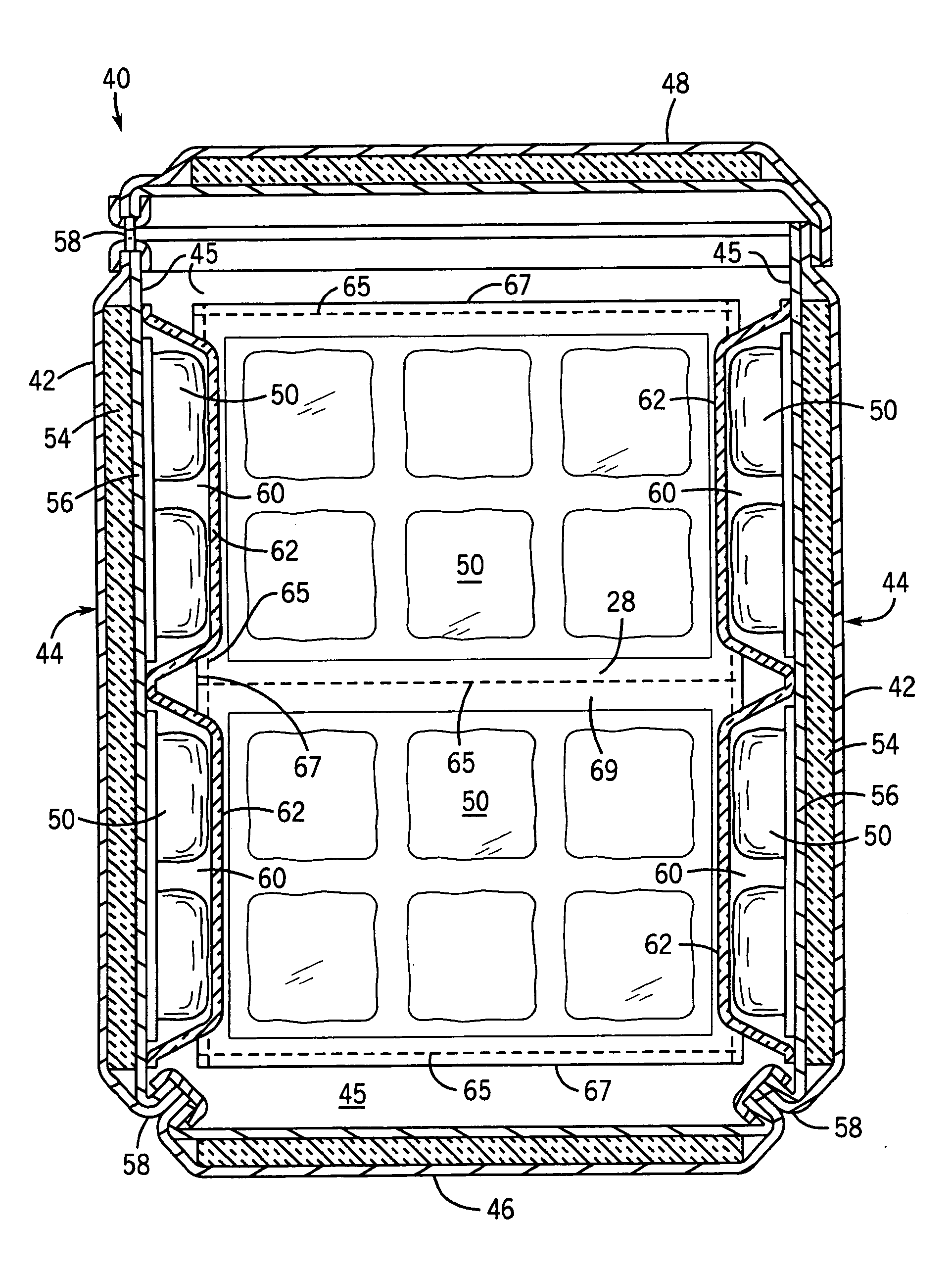

Insulated container and insert

ActiveUS8622235B2Improve insulation efficiencyImprove sealingLighting and heating apparatusClimate change adaptationThermal insulationEngineering

The insulated container and insert are formed of relatively soft and flexible panels having relatively thick cores of thermal insulation captured between thin impervious sheets. The outer container has a closable top, and the insert has an open top. The insert is about half the height of the outer container, allowing ice or other cooling material, beverage cans and / or bottles, etc., to be placed in the bottom of the outer container with the insert resting thereon for the carriage of food therein. As the outer bottom surface of the insert will be moist from contact with ice or the like therebelow, the outer container includes a drop down panel that may be lowered for placement of the insert thereon to preclude contamination of the bottom of the insert with loose sand or the like. Additional carrying handles and straps are provided, as well as outer pockets on the outer container.

Owner:SUCHECKI GLEN R

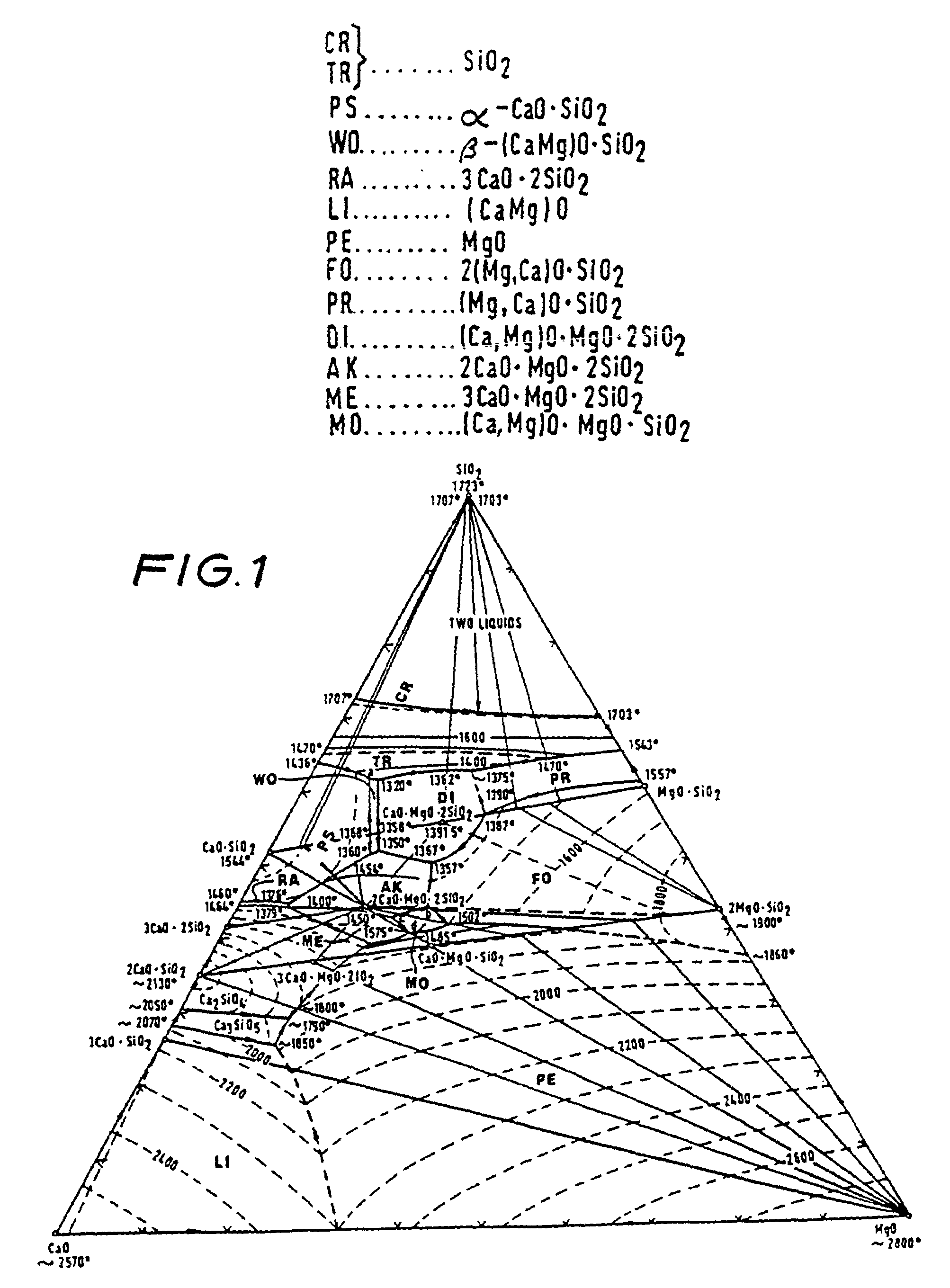

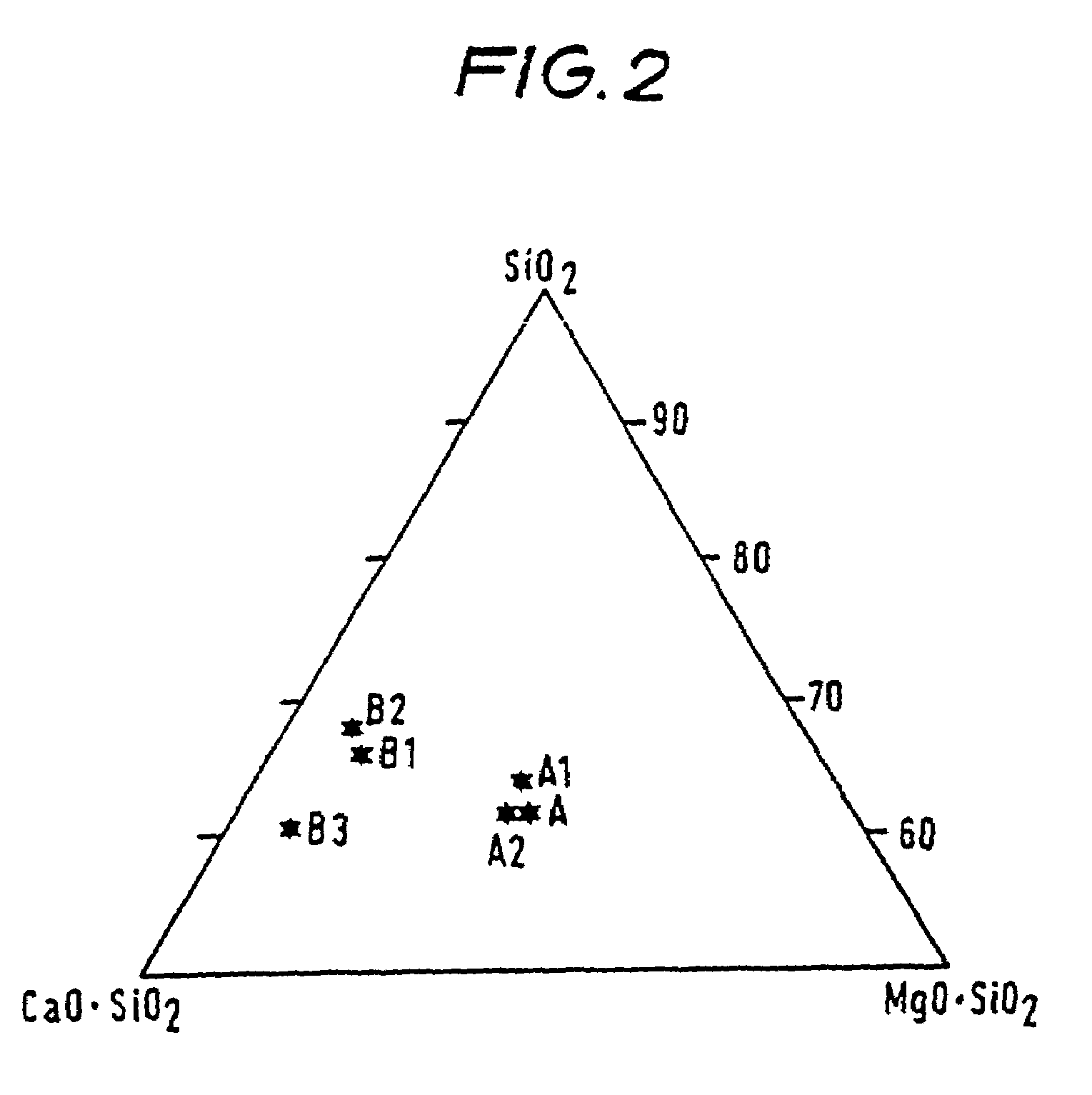

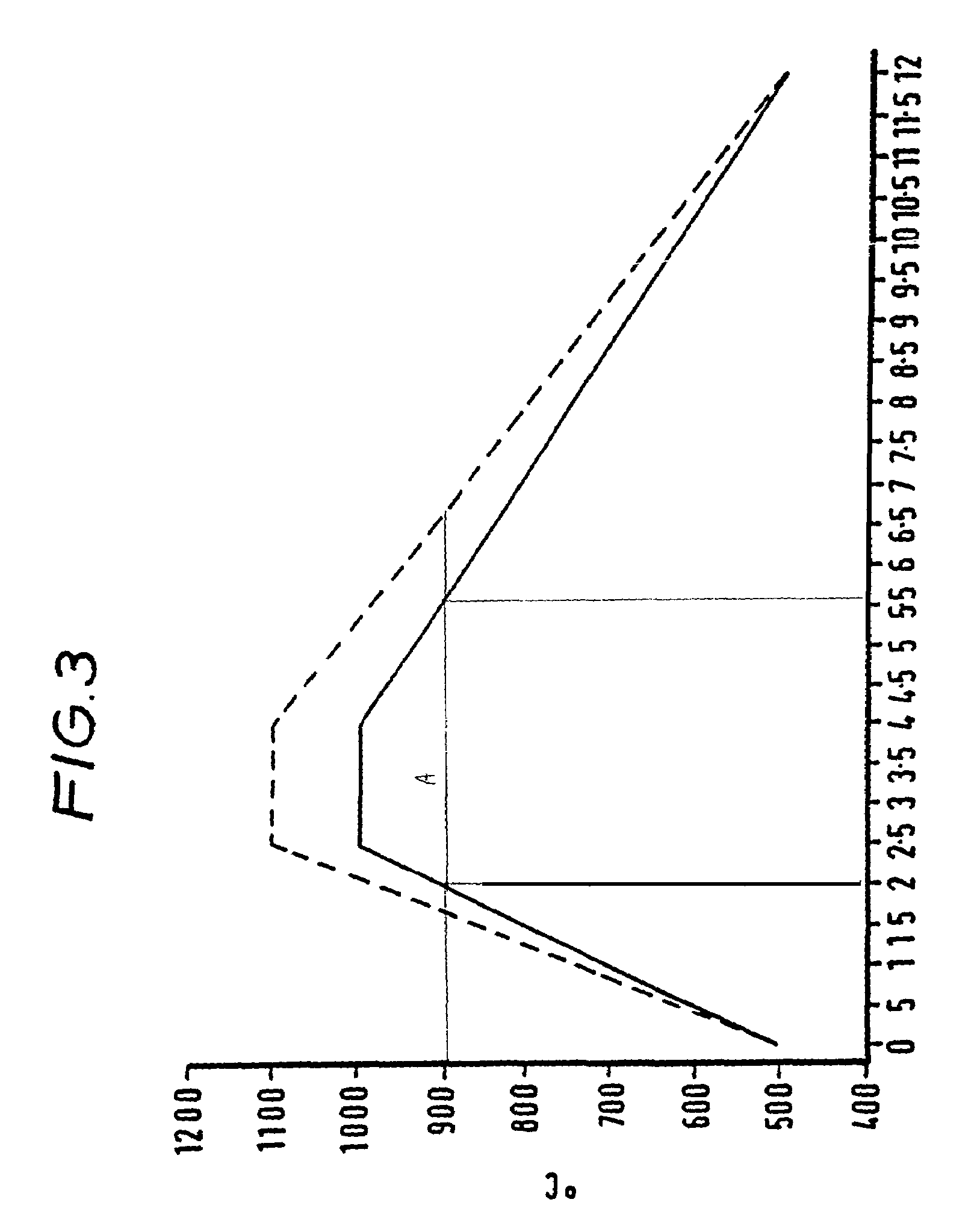

Saline soluble inorganic fibers

A method for insulating an article requiring resistance against repeated exposure to temperatures exceeding 900° C. uses saline soluble, non-metallic, amorphous, inorganic oxide, refractory fibrous materials as thermal insulation. The compositions that can be used for that purpose include vitreous fibers based on SiO2, CaO, MgO, and optionally, A2O3.

Owner:THE MORGAN CRUCIBLE CO PLC

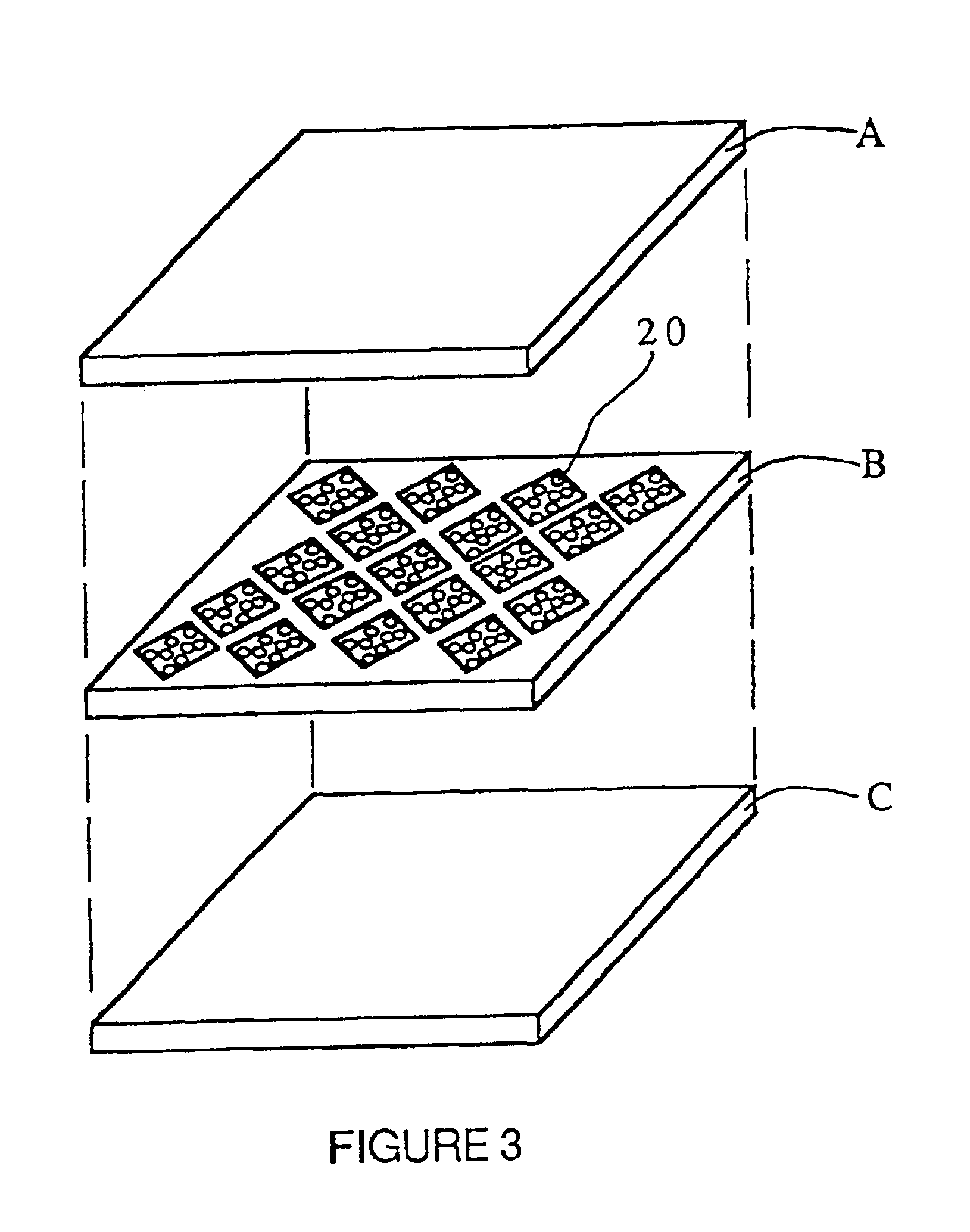

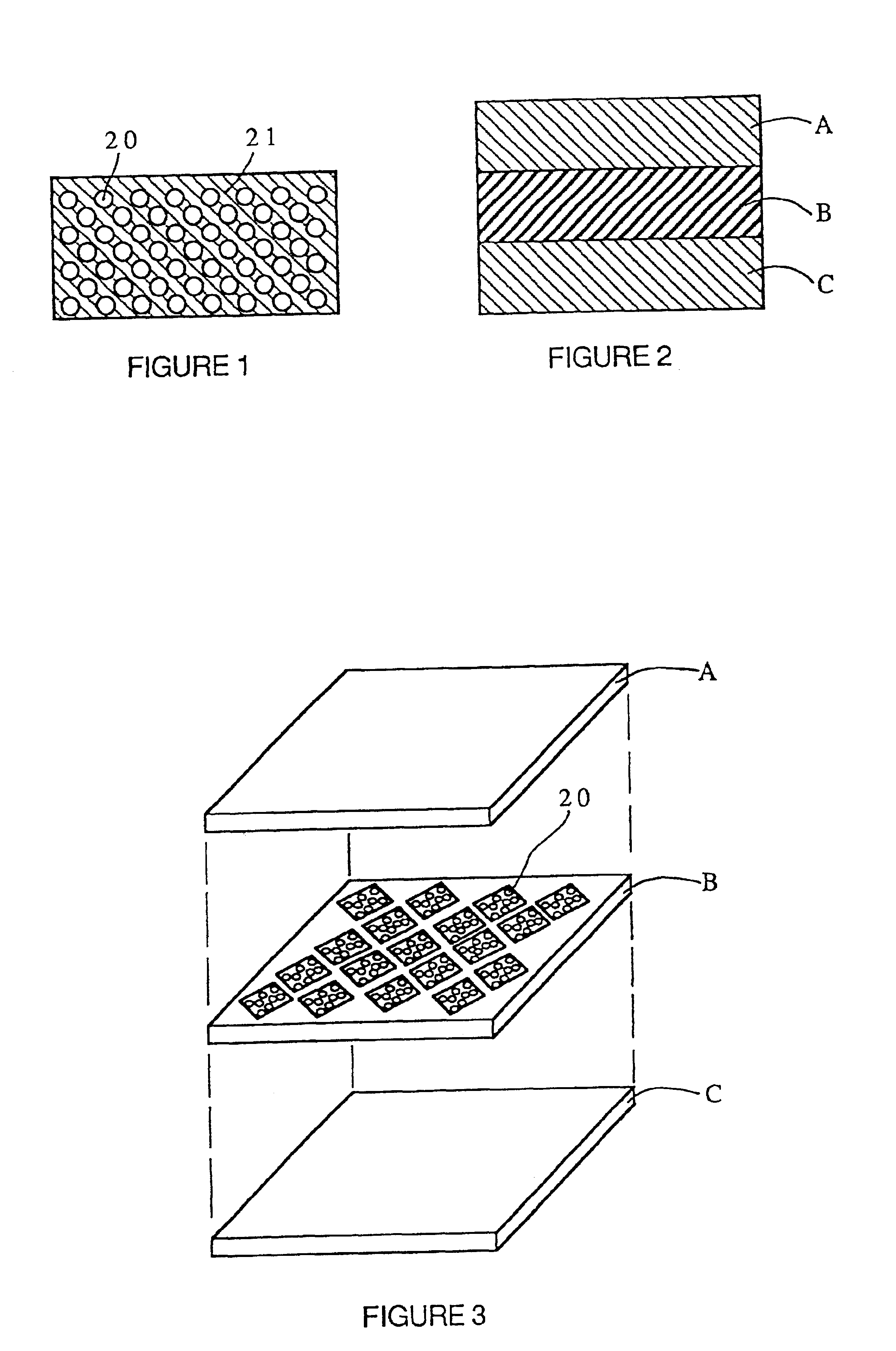

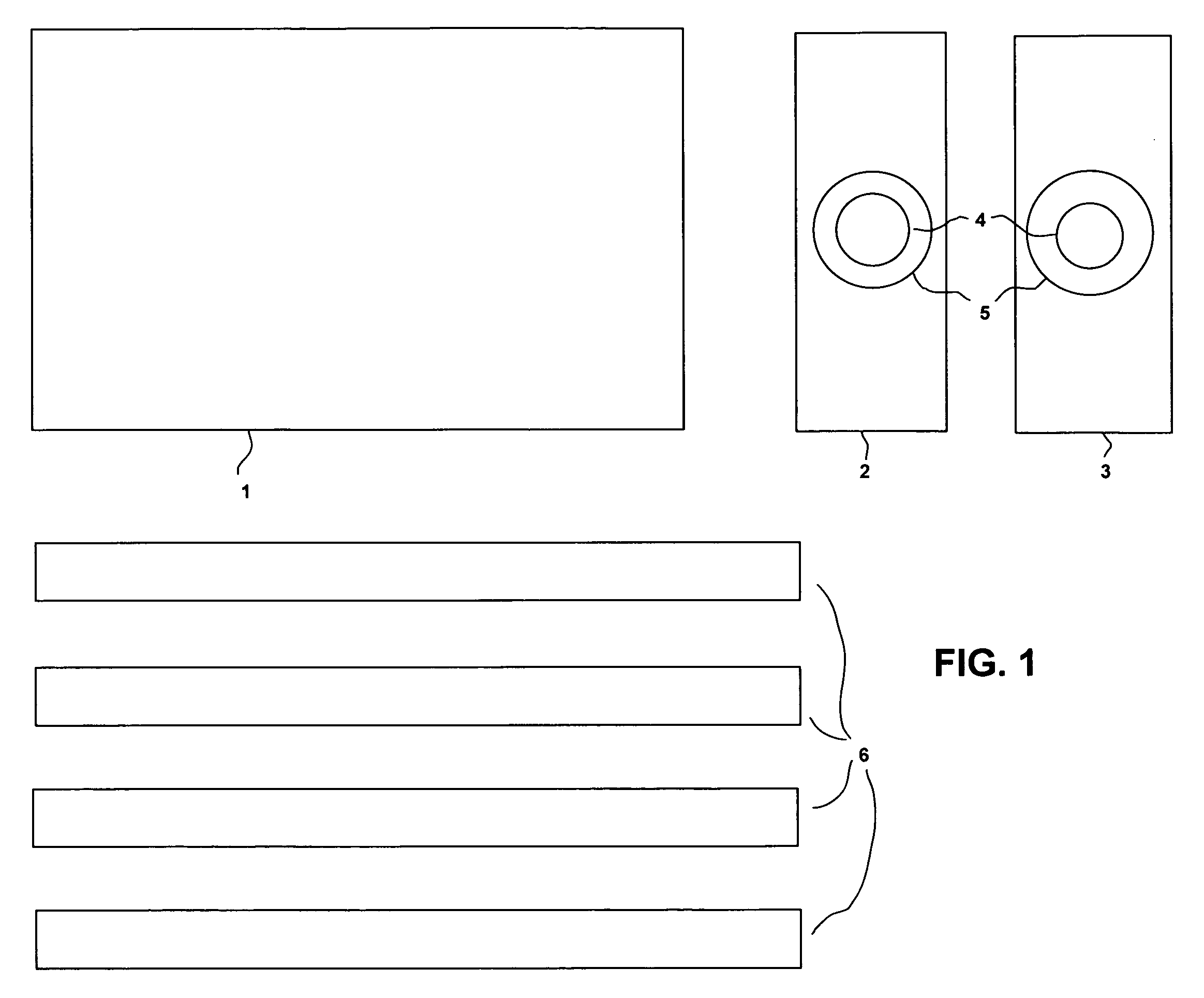

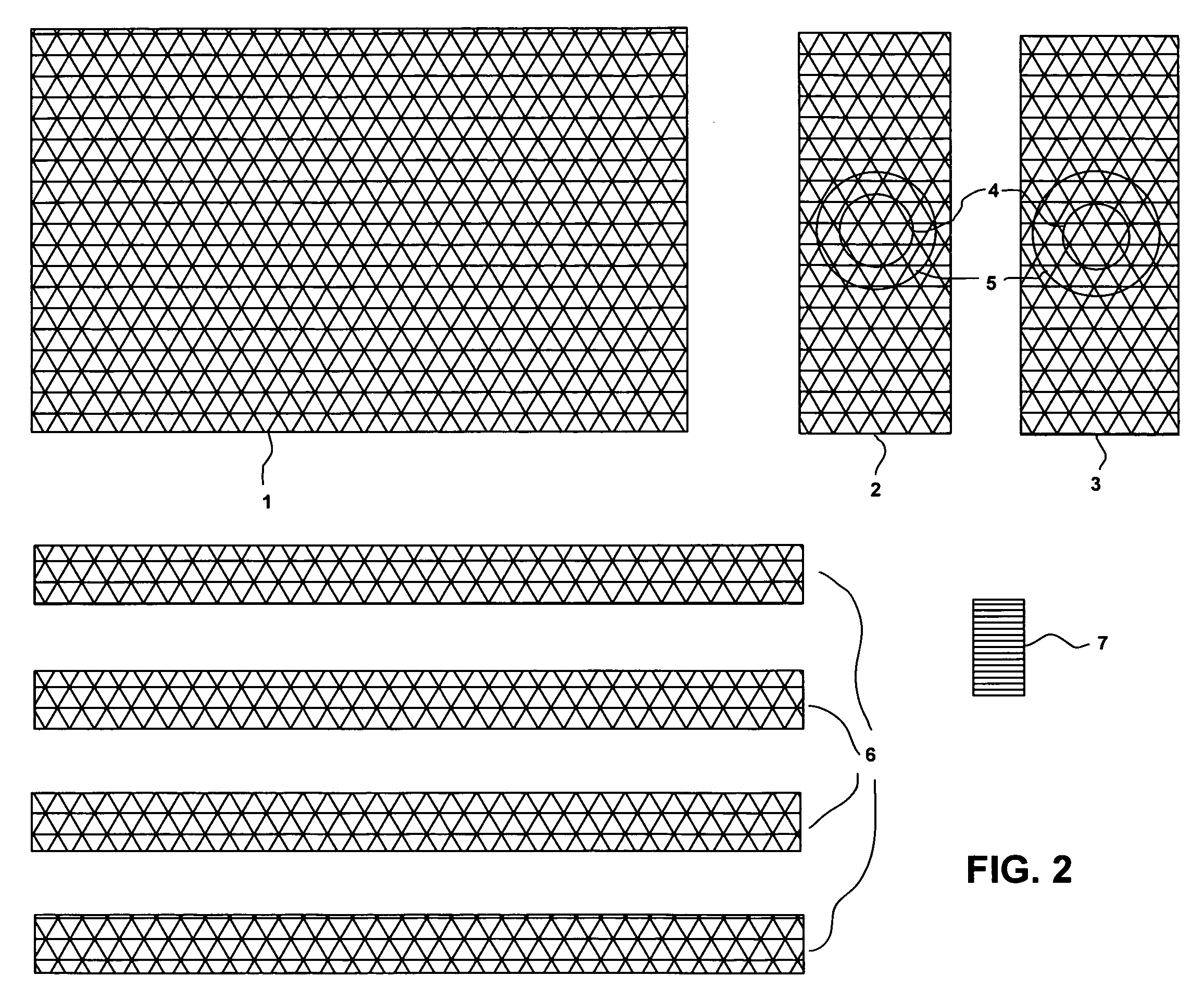

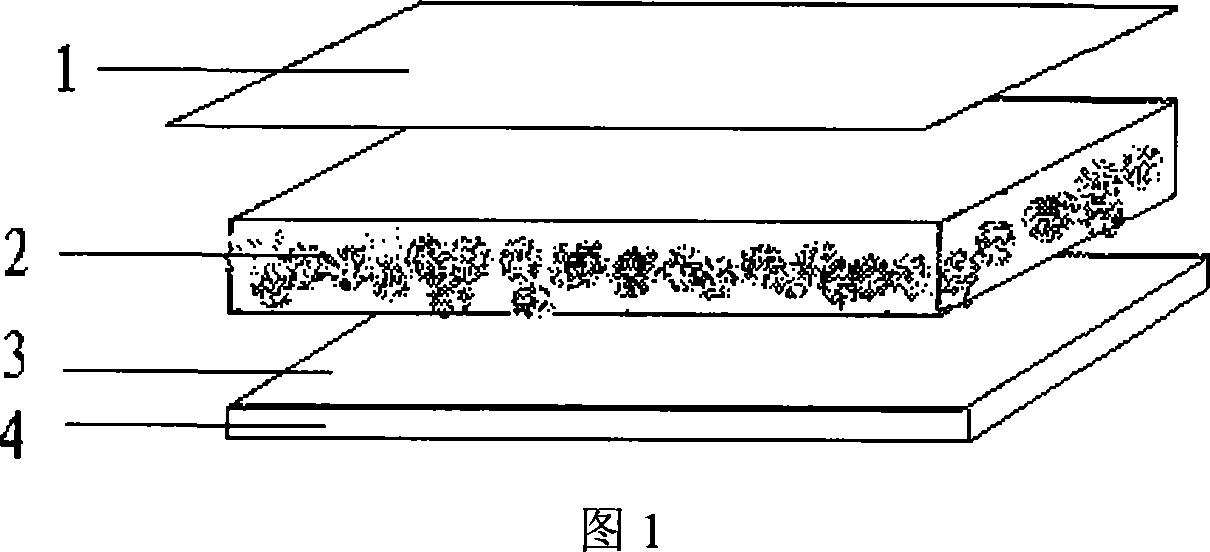

Substrate and the application

InactiveUS20090308001A1Reducing global warmingImprove energy efficiencyPhotovoltaic supportsSolar heating energyThermal energyThermal insulation

This invention relates to a substrate and the application. In particular, this invention discloses a substrate which has at least one contact structure at least on one side and at least one contact structure at least on one surface of the substrate. The substrate includes a thermal insulation material comprising at least two materials selecting from a thermal energy reflecting material, a homogeneous foam material, a heterogeneous foam material, a skin material, a skeleton structured material, an electromagnetic wave shielding material. The substrate may be used to construct various articles with different features of energy saving, decoration and protection as well as simple installation for various applications.

Owner:WU SHAOBING

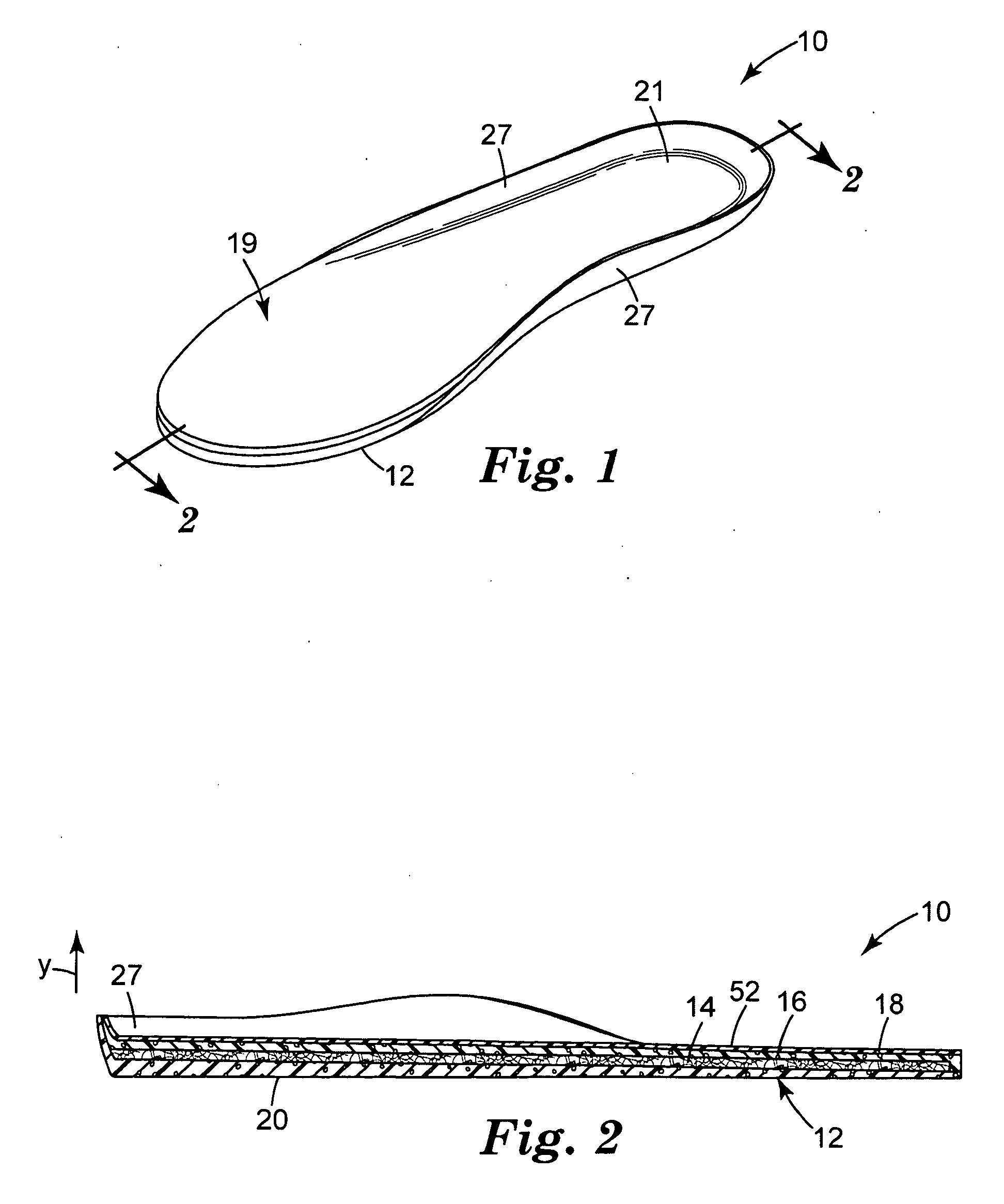

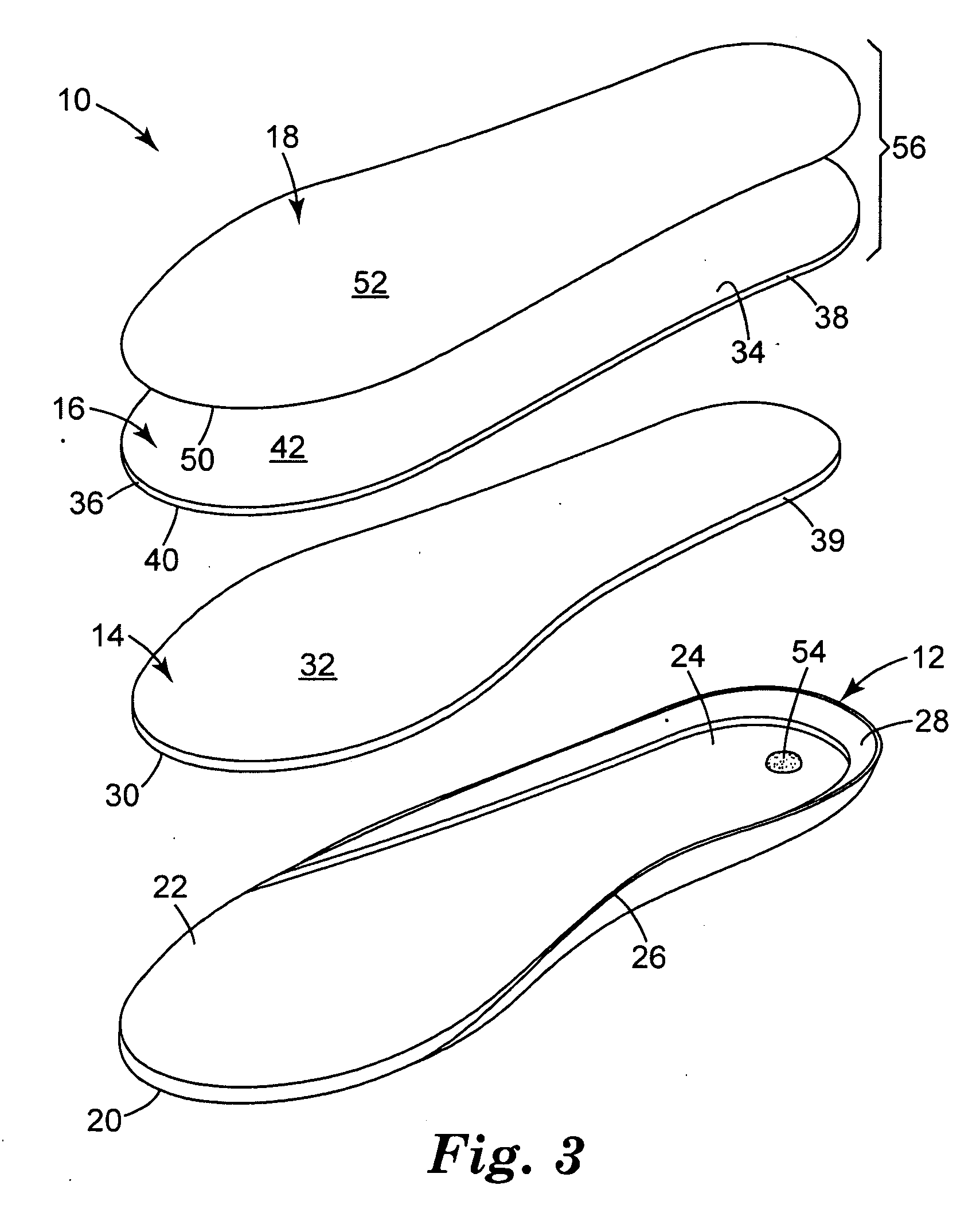

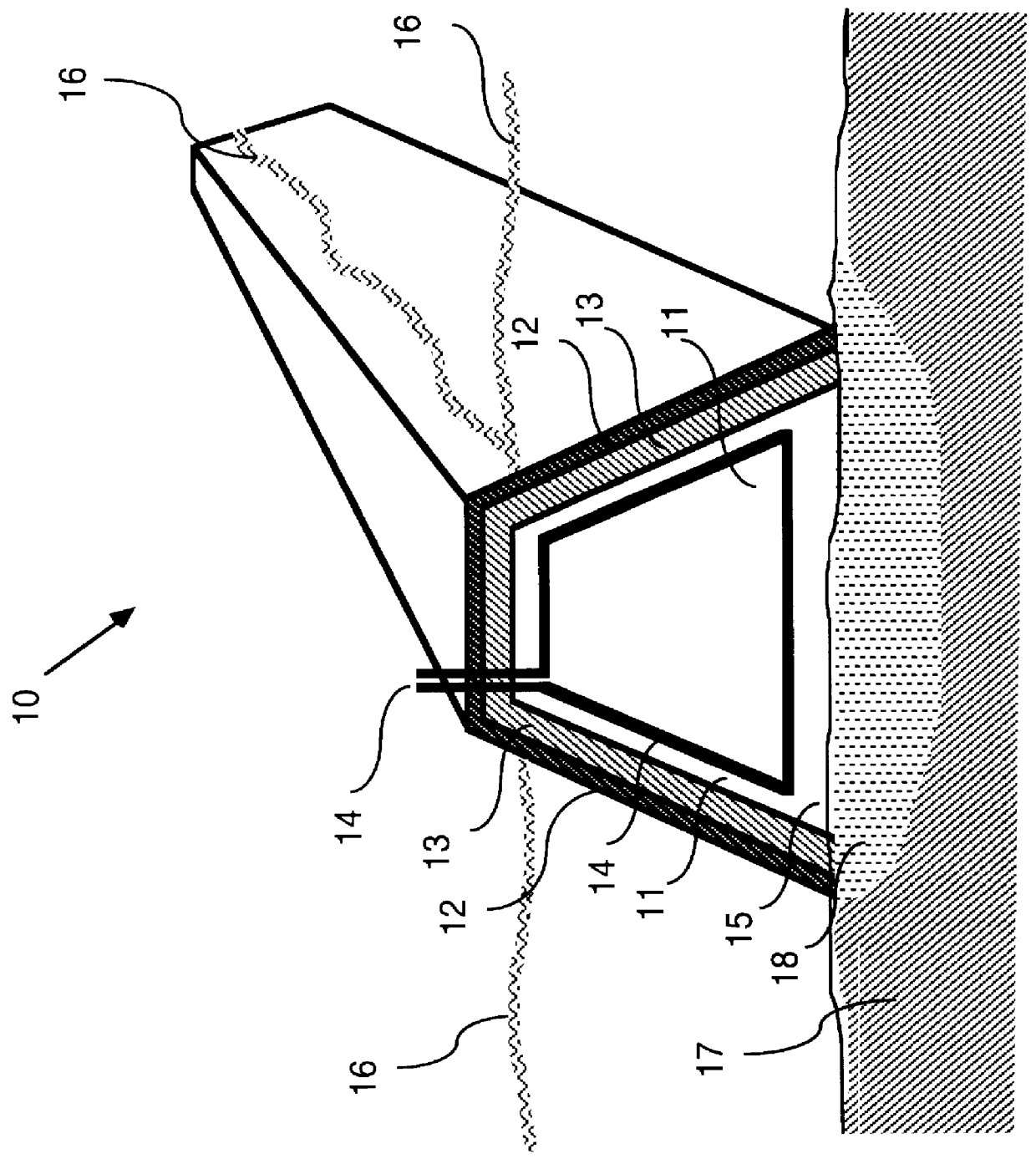

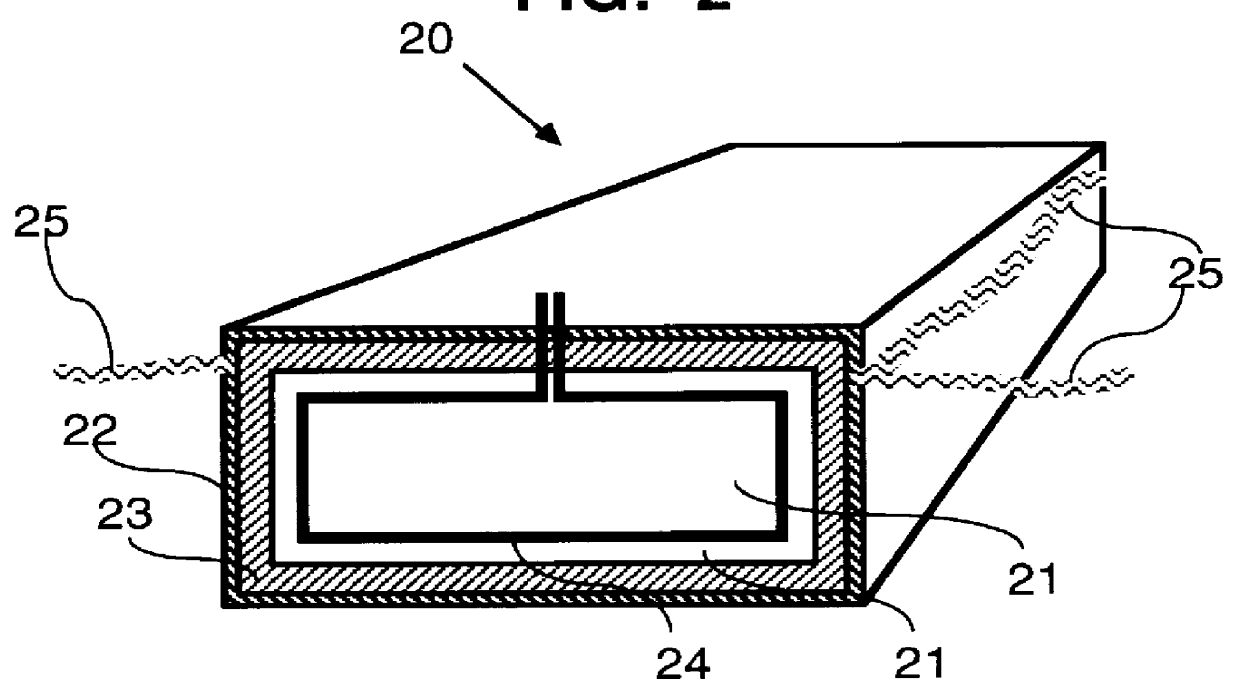

Molded insulated shoe footbed and method of making an insulated footbed

A shoe footbed 10 made by first molding a shape-retaining layer 12 into a contoured condition. After the shape-retaining layer 12 has been molded, a layer of thermal insulation 14 is placed on top of the molded layer 12. A conforming layer 16 and a fabric top layer 18 may be placed over the thermal insulation 14 and the shape-retaining layer 12. The inventive method of manufacture is particularly suited for making insulated footbeds that contain nonwoven webs of polymeric microfiber because damage to the fibrous web from heat and compression may be avoided.

Owner:3M INNOVATIVE PROPERTIES CO

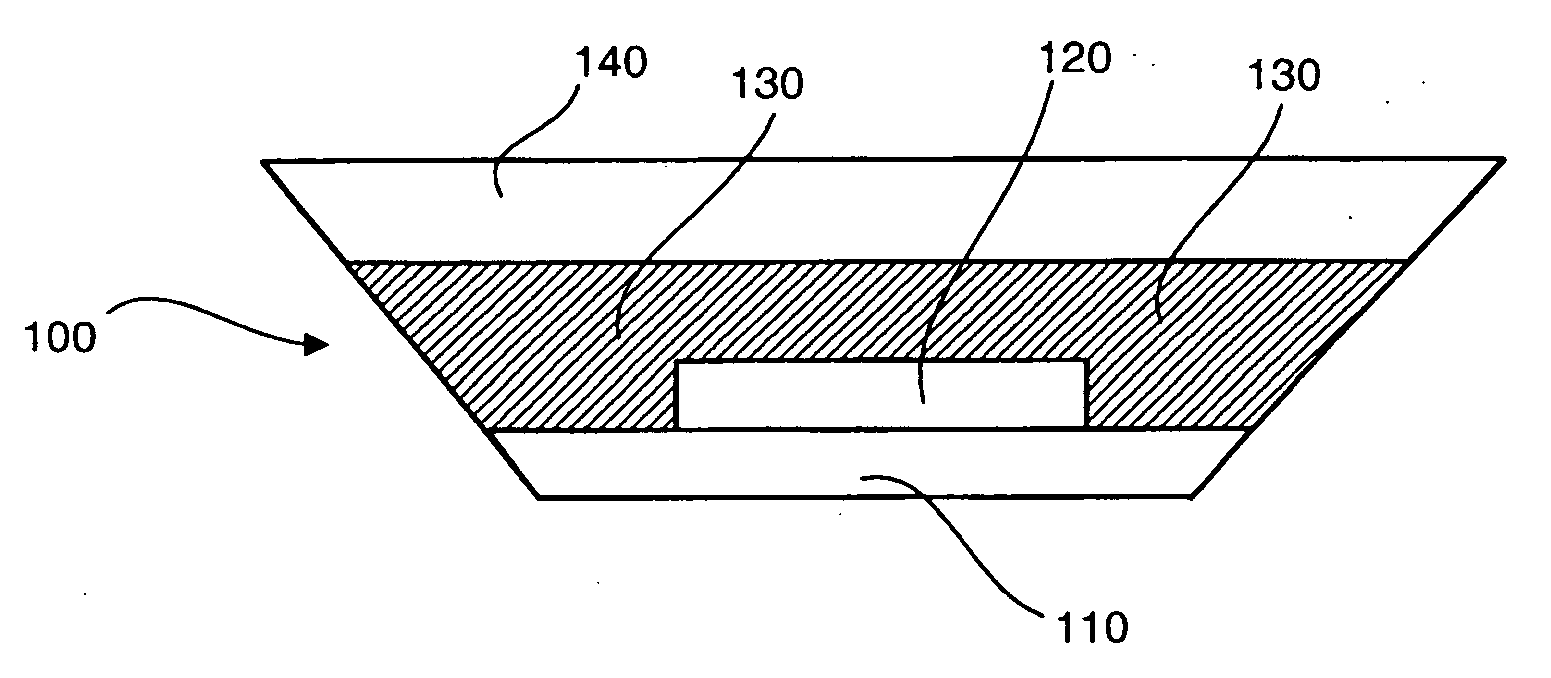

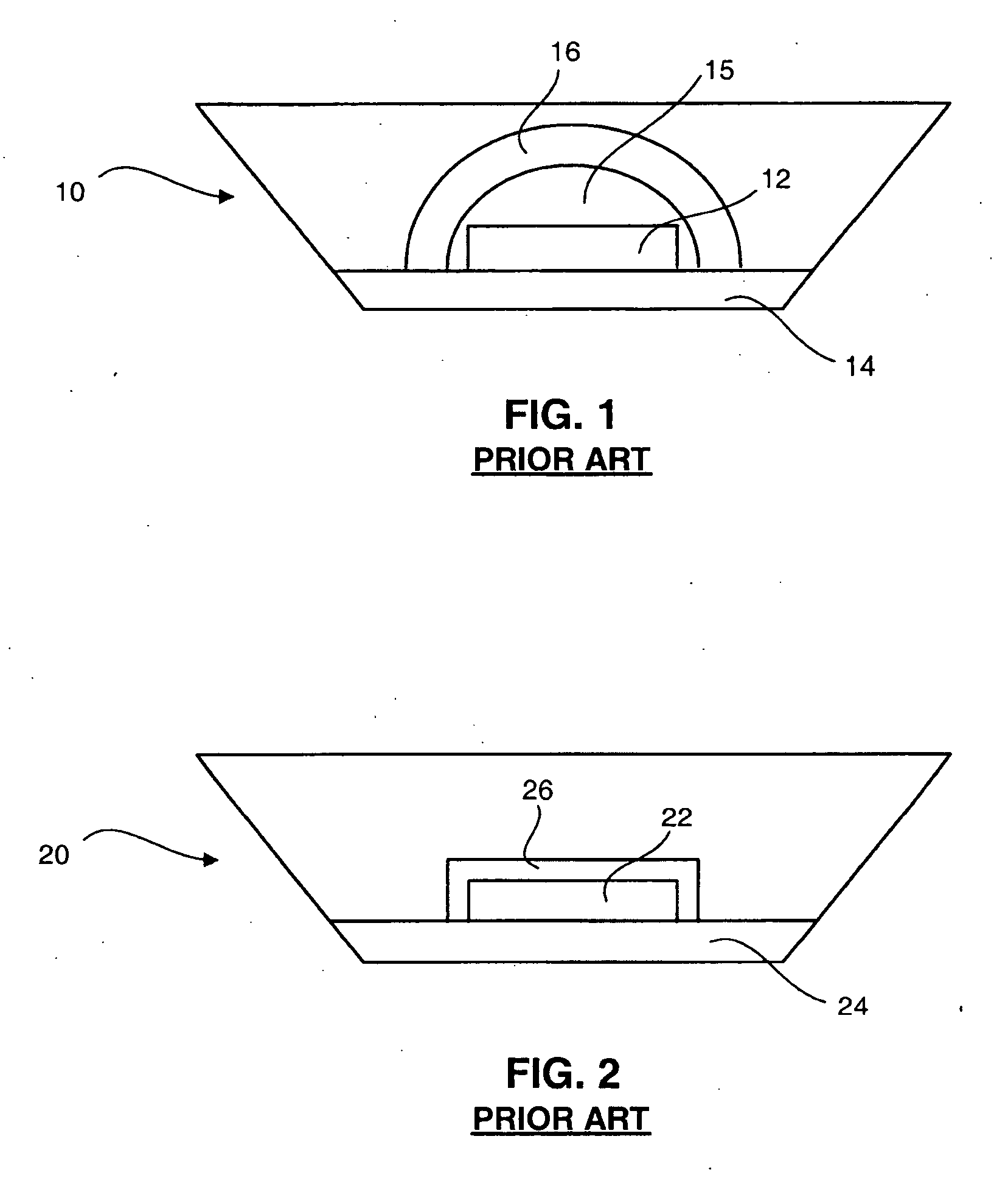

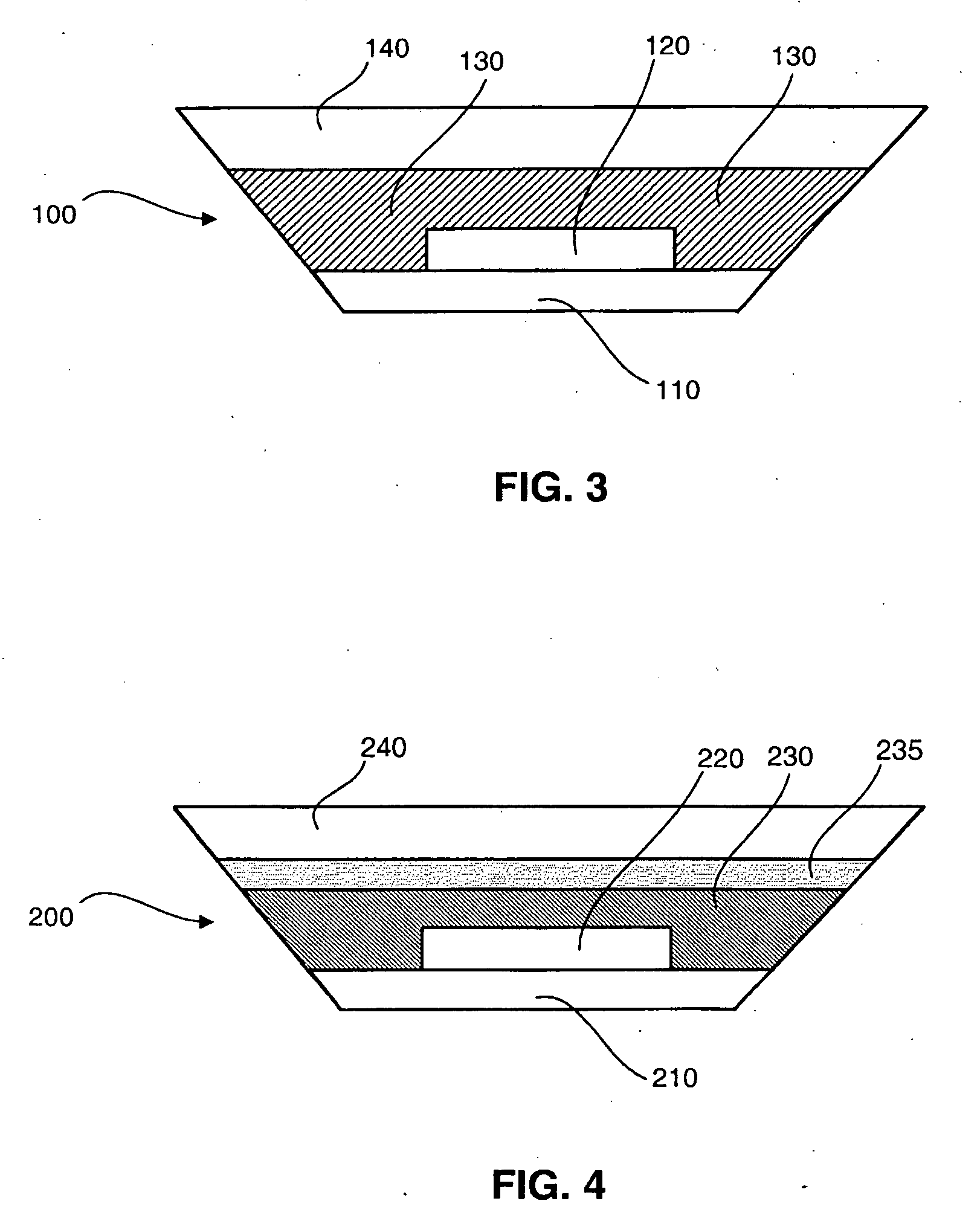

Light emitting device with a thermal insulating and refractive index matching material

ActiveUS20060091788A1Reduce heat transferPrevent thermal degradationDischarge tube luminescnet screensLamp detailsThermal insulationPhosphor

A light emitting device has a light emitting diode (LED) encapsulated by an encapsulant member. The encapsulant member includes a luminescent material, such as a phosphor, and a thermal insulating material. The thermal insulating material effectively insulates the luminescent material from the heat generated by the LED. A thermal conducting material is desirably placed in thermal contact with a back side of the LED to assist heat dissipation. The encapsulant member may be formed in two separate layers with the luminescent material forming a luminescent layer, and the thermal insulating material forming a thermal insulation layer disposed between the luminescent layer and the LED.

Owner:LED ENGIN

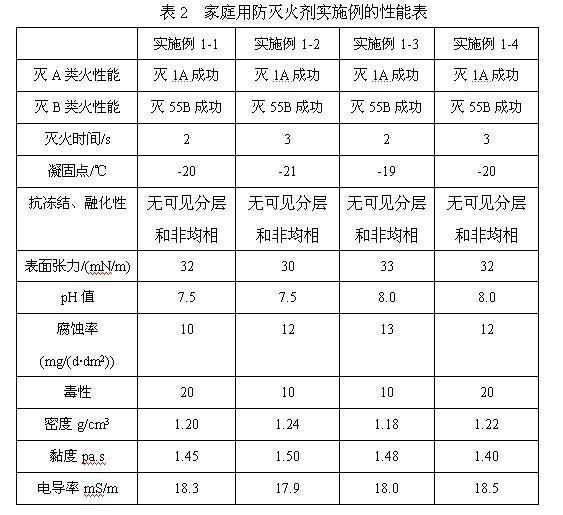

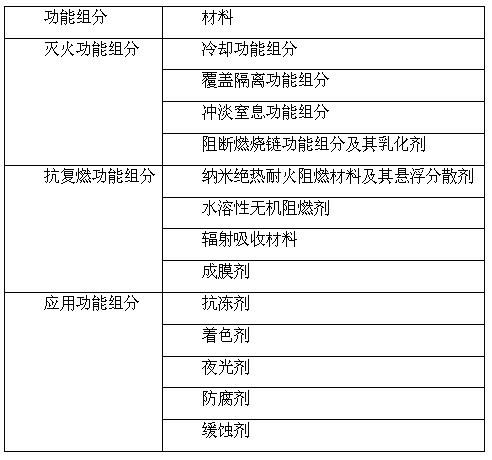

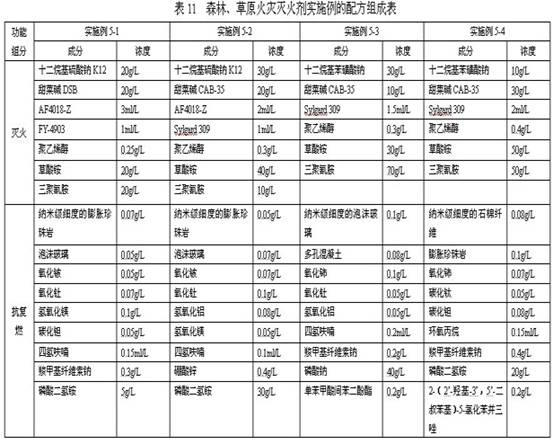

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

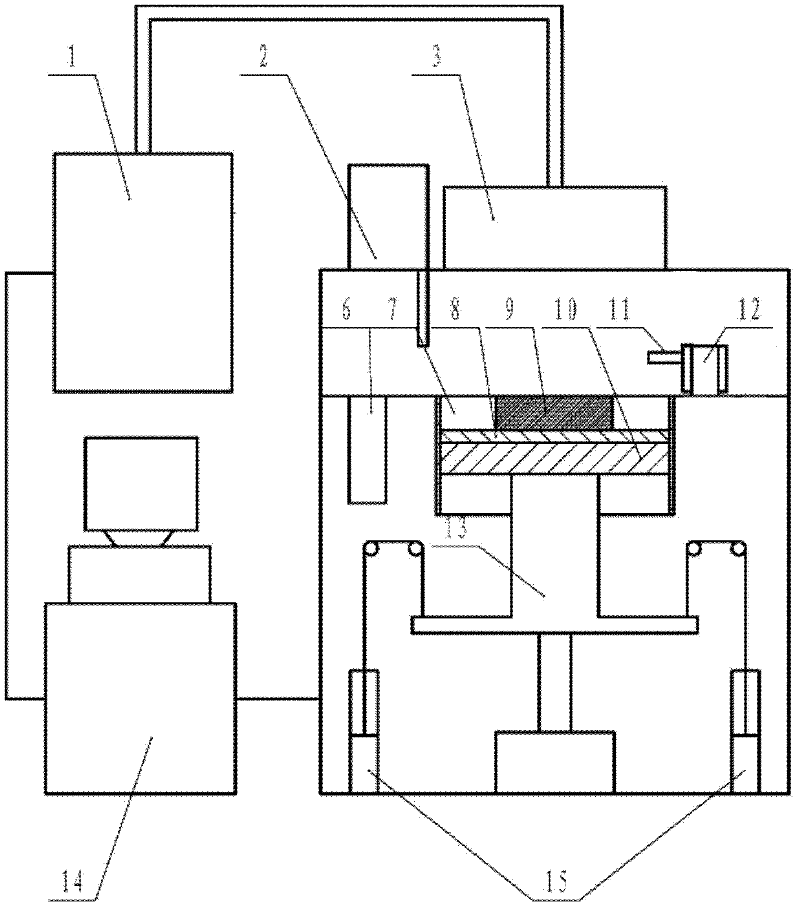

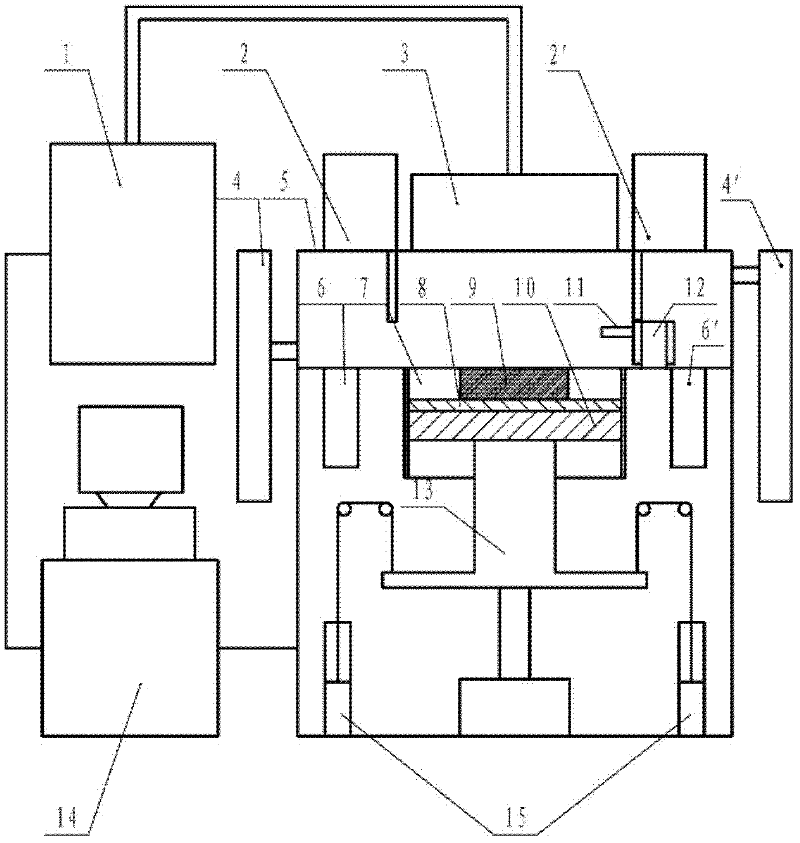

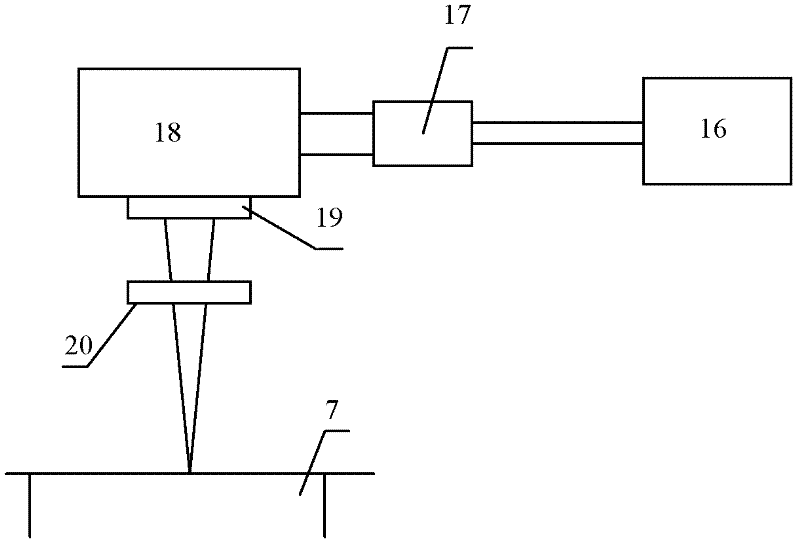

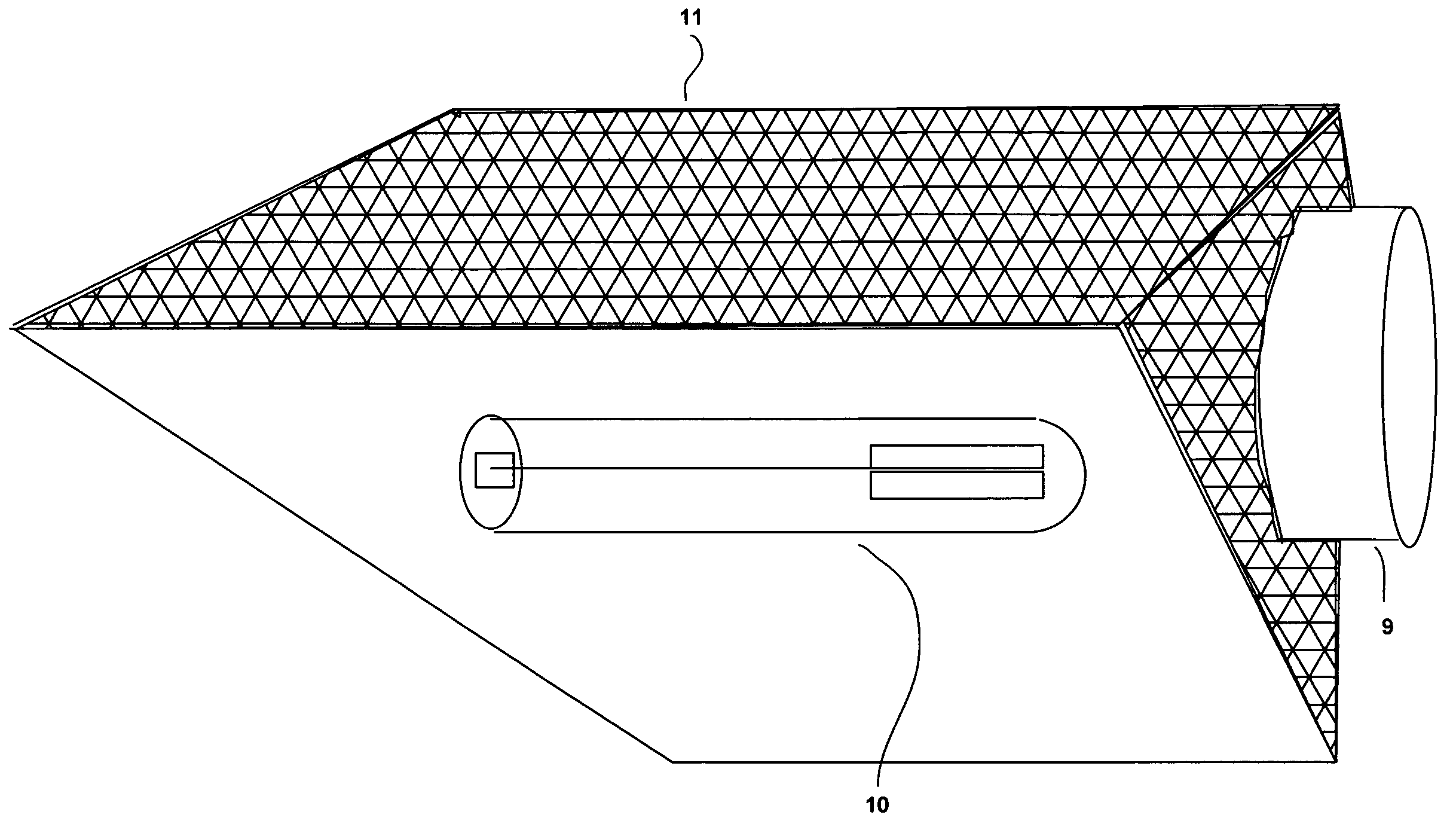

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

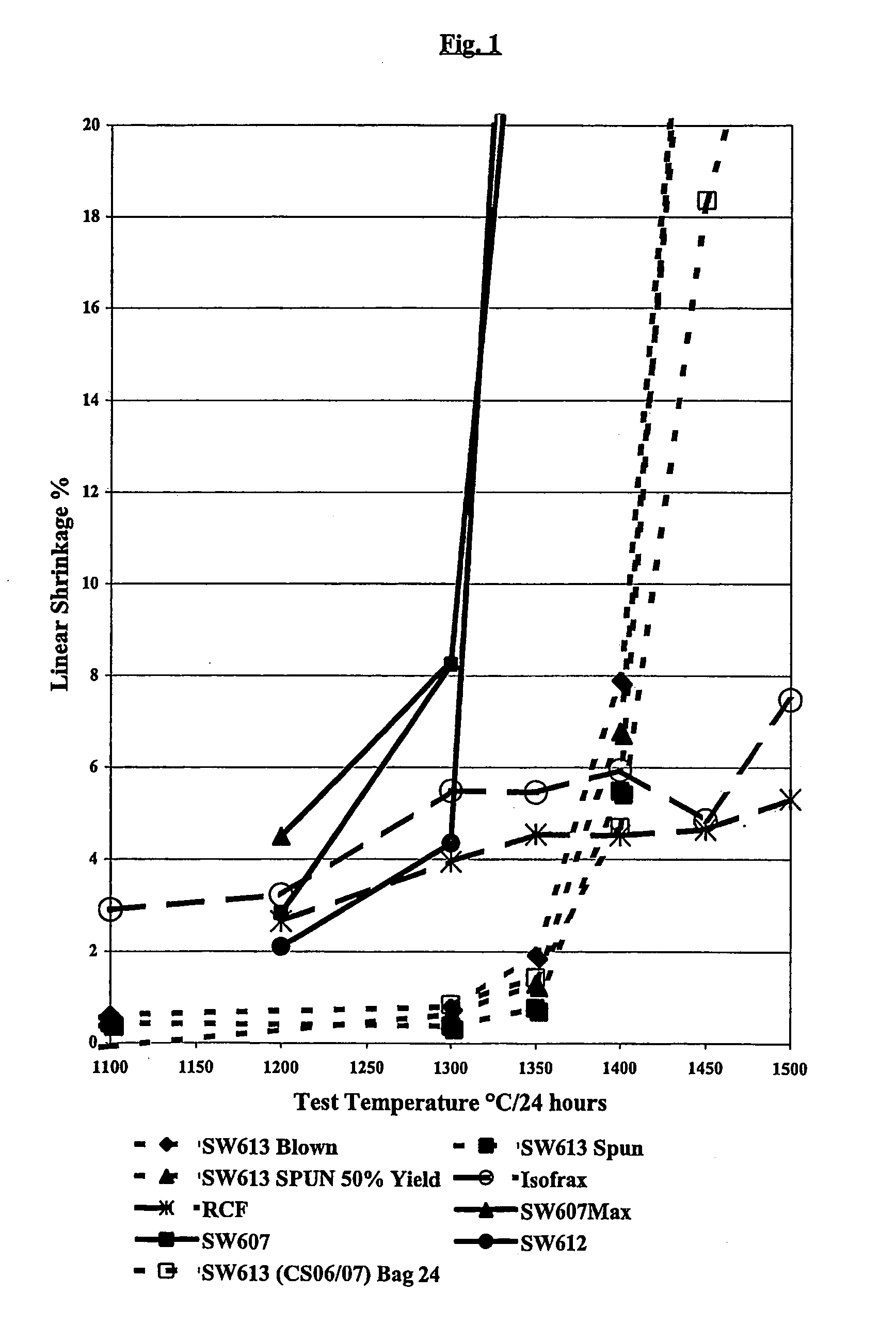

Saline soluble inorganic fibres

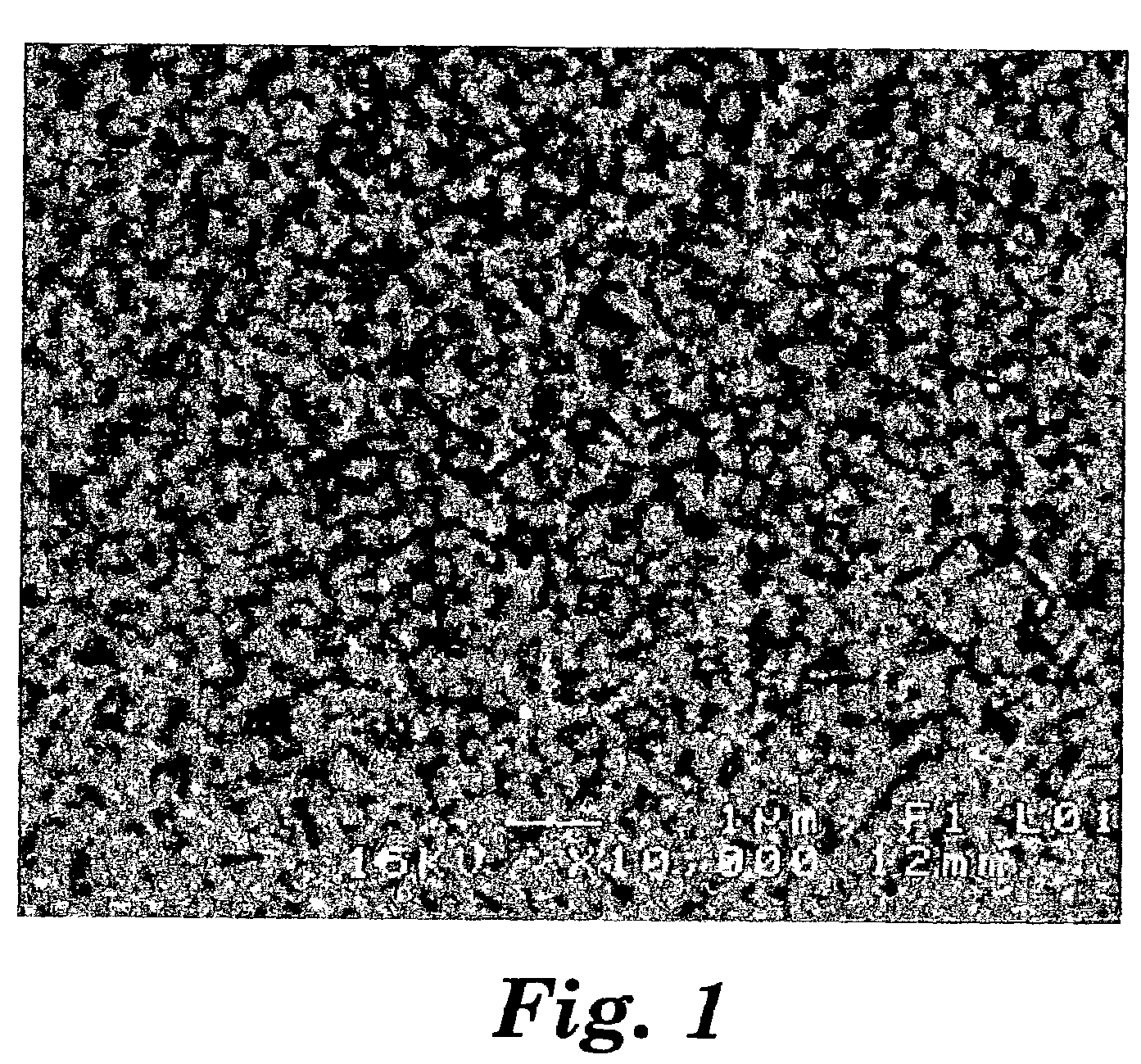

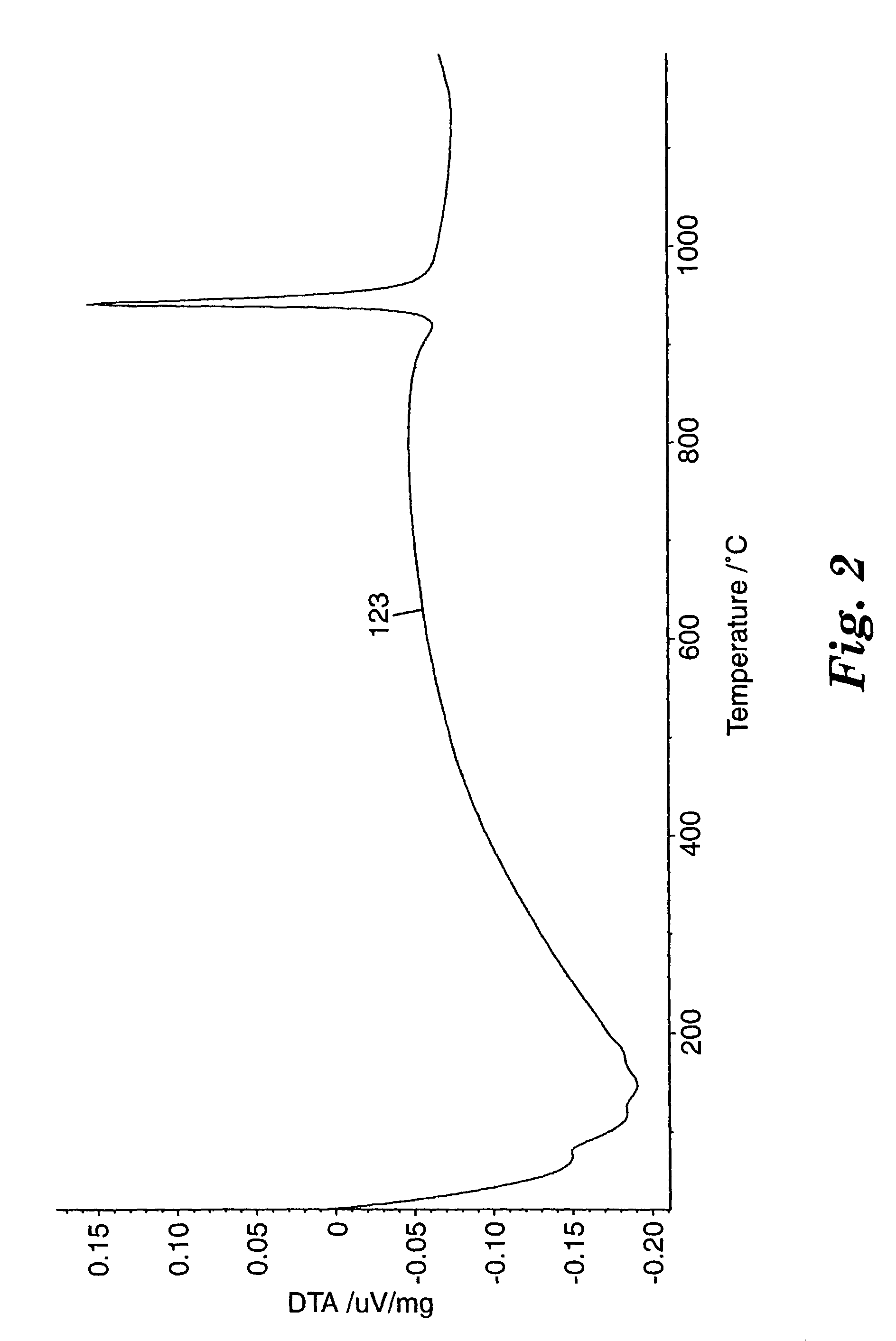

InactiveUS7153796B2Improve fiber qualityMinimise reduction is solubilityInorganic material artificial filamentsHeat proofingFiberThermal insulation

Thermal insulation is provided for use in applications requiring continuous resistance to temperatures of 1260° C. without reaction with alumino-silicate firebricks, the insulation comprises fibers having a composition in wt %65%<SiO2<86%MgO<10%14%<CaO<28%Al2O3<2%ZrO2<3%B2O3<5%P2O5<5%72%<SiO2+ZrO2+B2O3+5*P2O5 95%<SiO2+CaO+MgO+Al2O3+ZrO2+B2O3+P2O5 Addition of elements selected from the group Sc, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y or mixtures thereof improves fiber quality and the strength of blankets made from the fibers.

Owner:THE MORGAN CRUCIBLE CO PLC

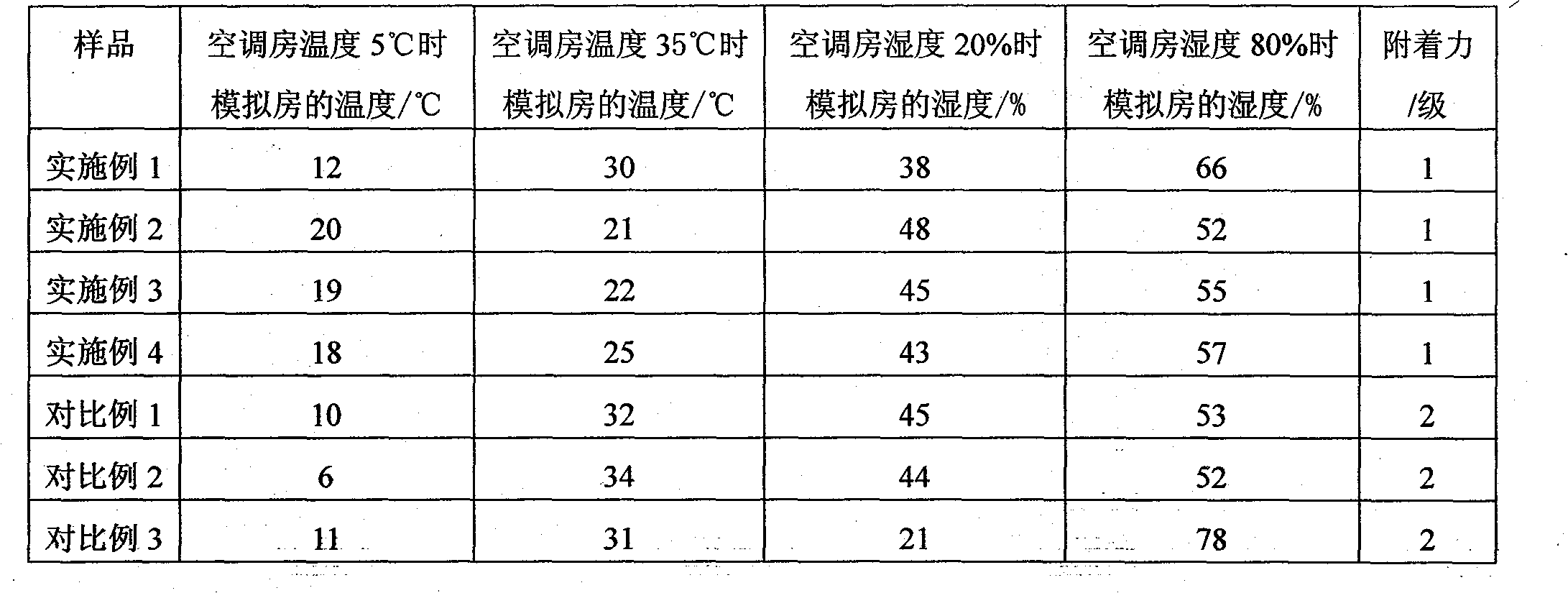

Temperature adjusting humidity adjusting coating and preparation method thereof

InactiveCN103159437ALower room temperatureTurn up the room temperatureEnvironmental resistanceThermal insulation

The invention relates to temperature adjusting humidity adjusting coating and a preparation method thereof. The temperature adjusting and humidity adjusting coating comprises thermal insulation undercoat, phase transition energy storage intermediate coat and heat conduction humidity adjusting finish. The undercoat insulates heat, and the phase transition energy storage intermediate coat transmits indoor energy through the finish and stores energy through the phase transition, and thereby effectively adjusting indoor temperature. The phase transition energy storage intermediate coat and the humidity adjusting function of the finish impart the whole coating temperature adjusting and humidity adjusting function. In addition, the temperature adjusting and humidity adjusting coating has the advantages of being fireproof, waterproof, antifouling, mechanical, capable of eliminating peculiar smell, sterilizing, insulating heat, removing sound, protecting environment and the like. The temperature adjusting and humidity adjusting coating is applicable to various kinds of constructional coating.

Owner:LUNAN RES INST OF COAL CHEM

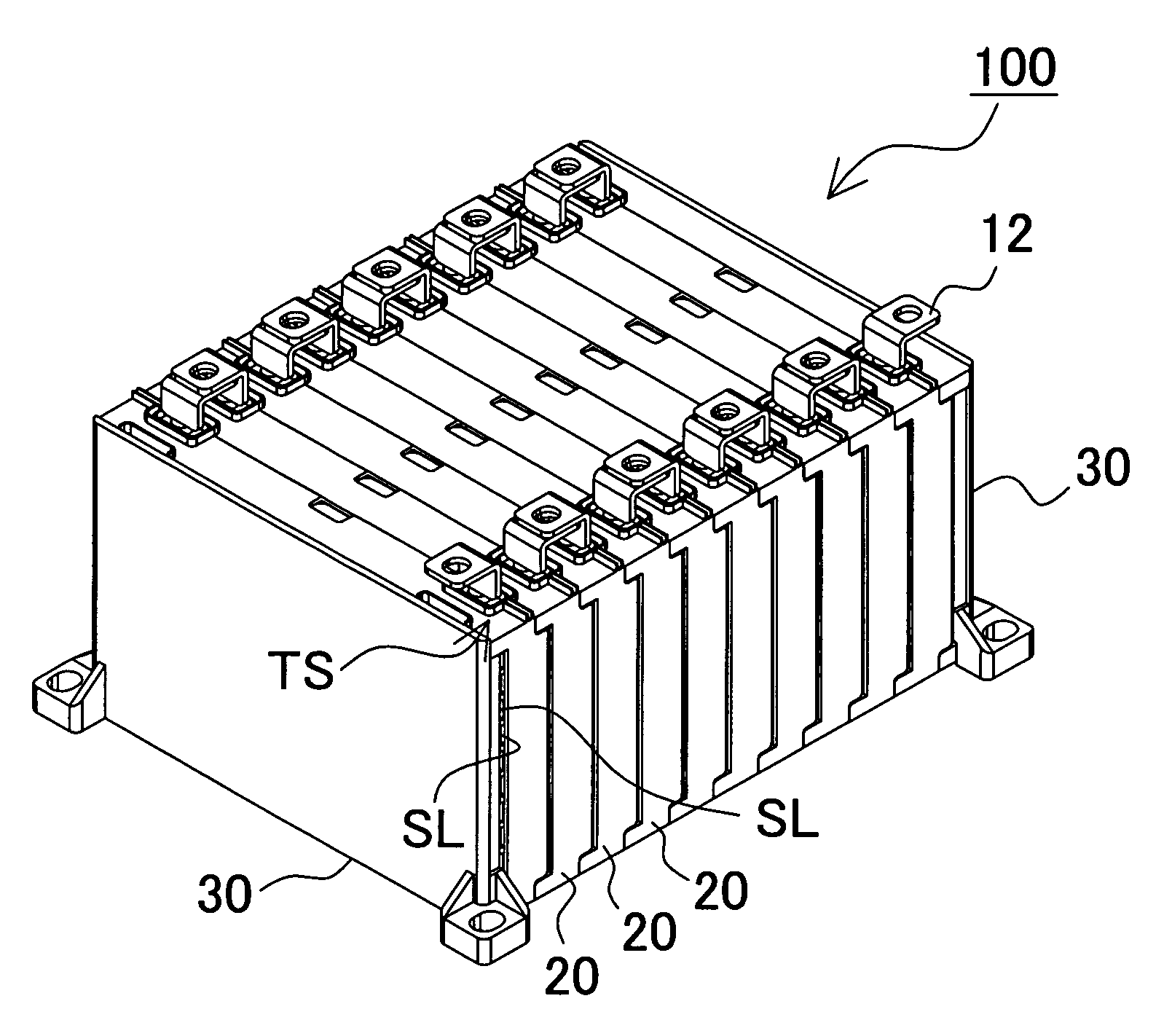

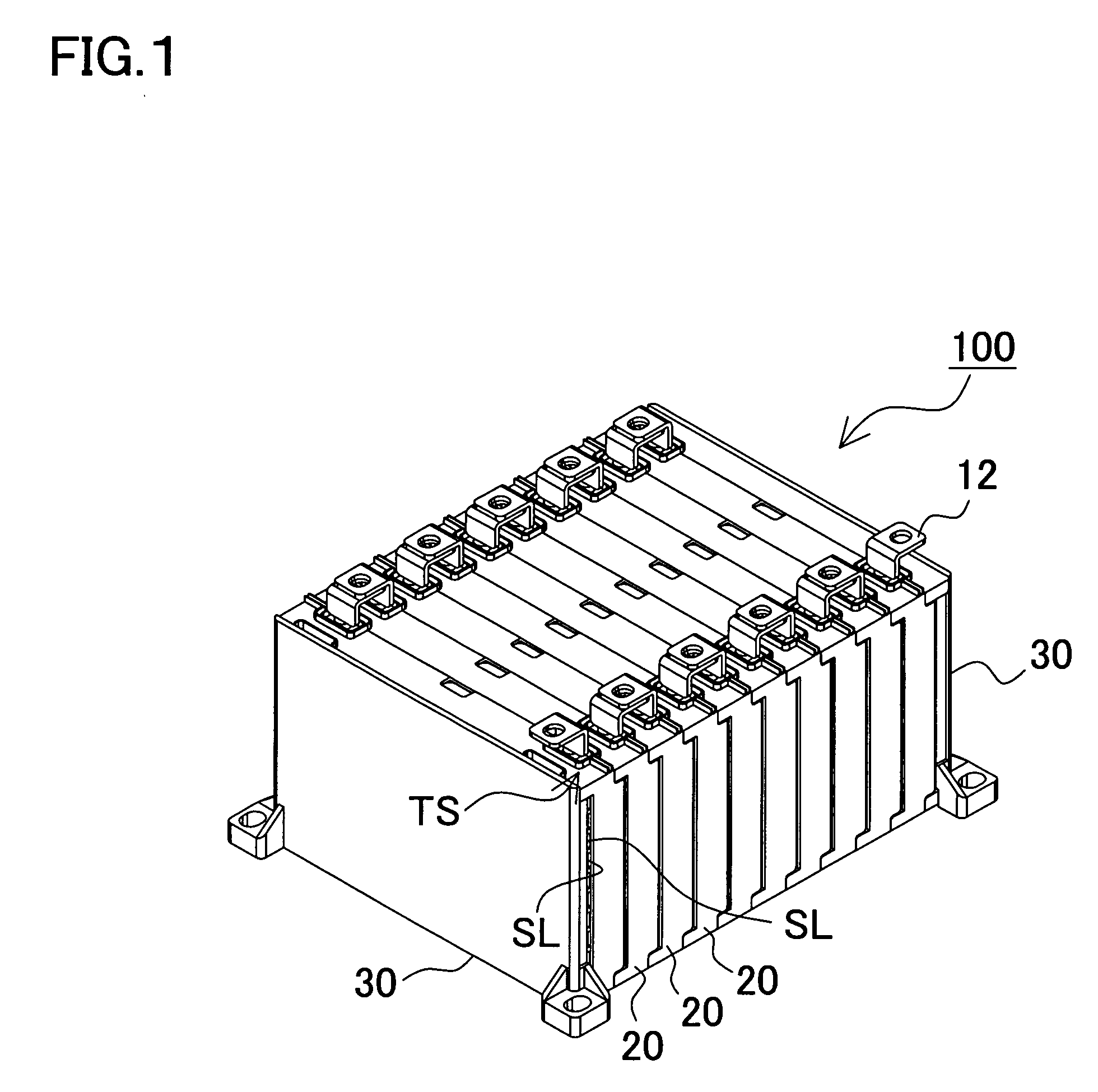

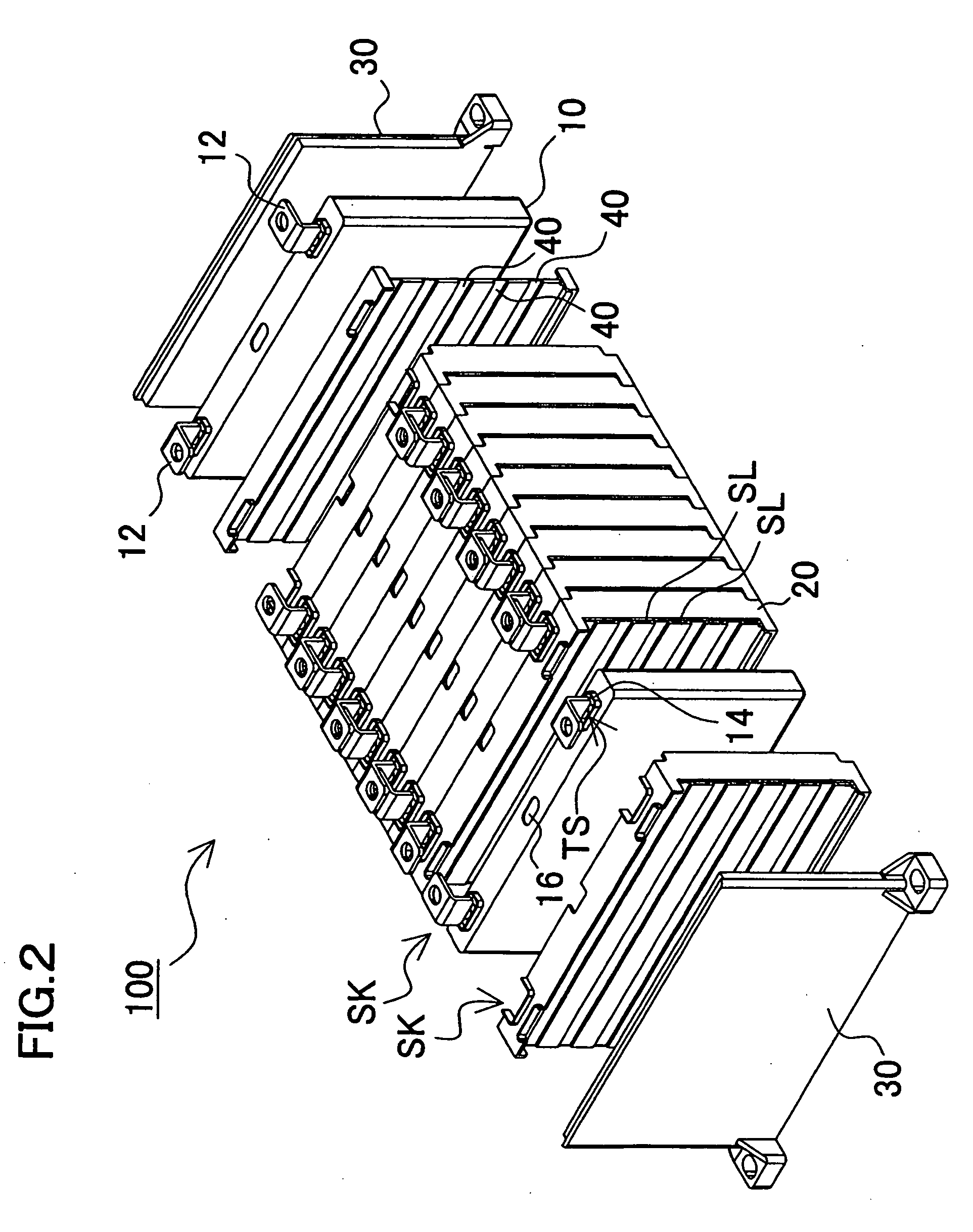

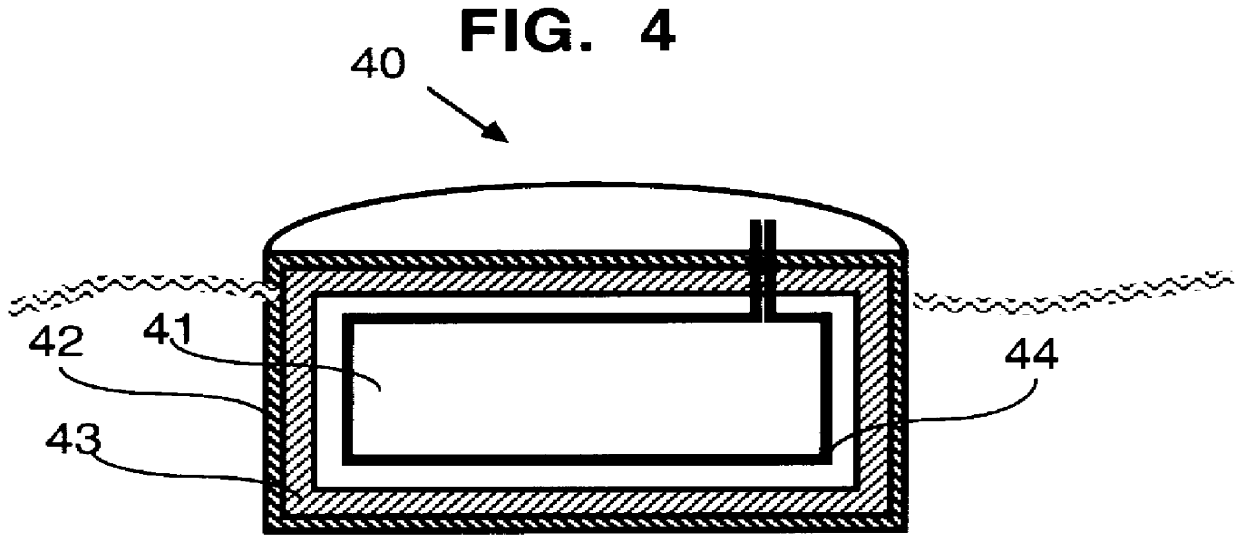

Battery pack

In a battery pack having a plurality of battery cells 10 connected in series and / or parallel, the battery pack is provided with a plurality of battery cells 10 each encased in a rectangular external case, and a plurality of separators 20 with electrical and heat insulating properties covering the outside of each battery cell external case excluding electrode terminals 12. Each separator 20 is disposed to intervene between adjacent battery cells 10 putting the external cases of those battery cells 10 in contact with both sides of the separator 20. With the external case of each battery cell 10 covered by separators 20 while exposing electrode terminals 12, those electrode terminals 12 are connected together. As a result, excluding required regions, battery cells 10 can be enclosed and unintended events such as short circuits can be effectively prevented.

Owner:SANYO ELECTRIC CO LTD

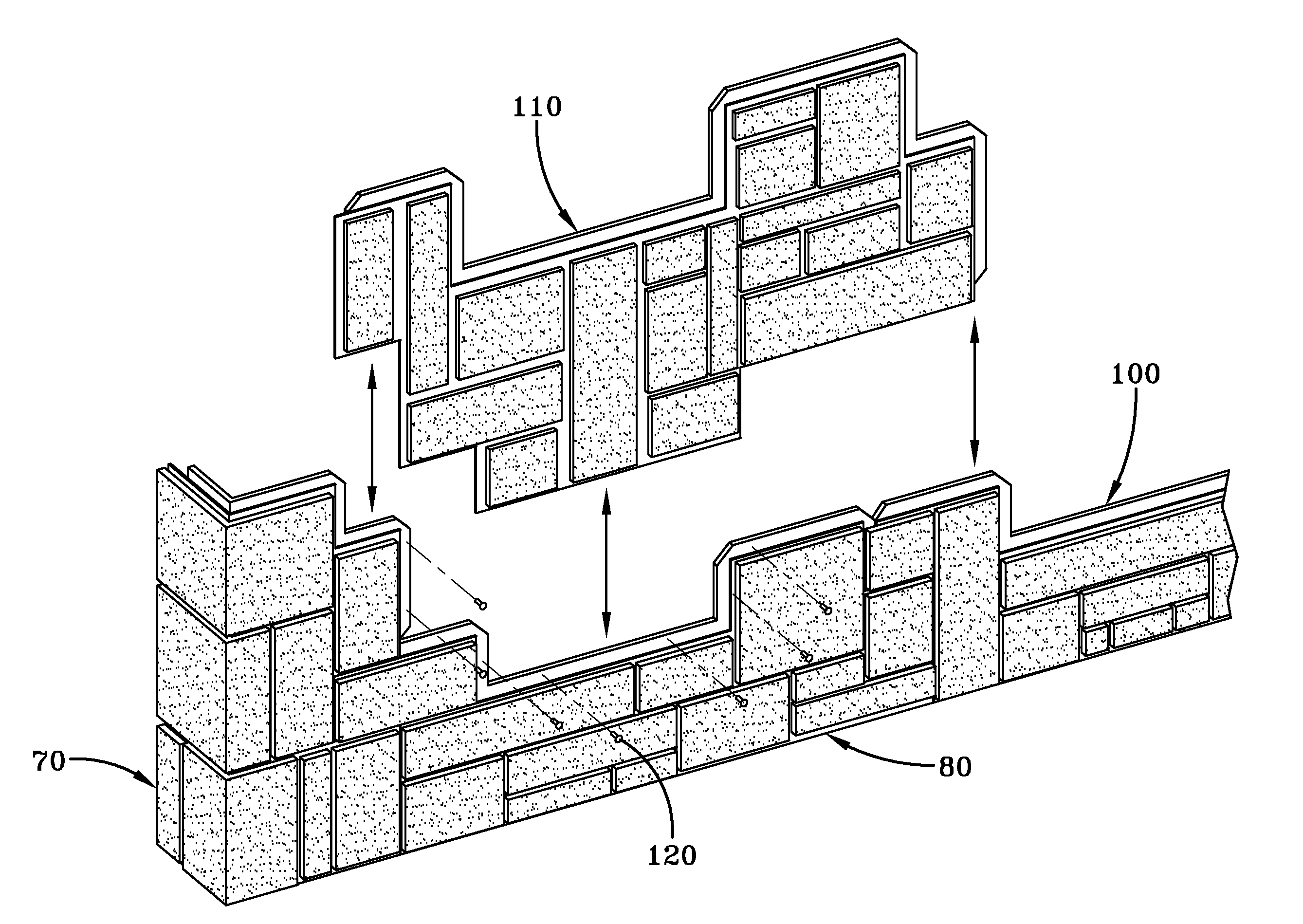

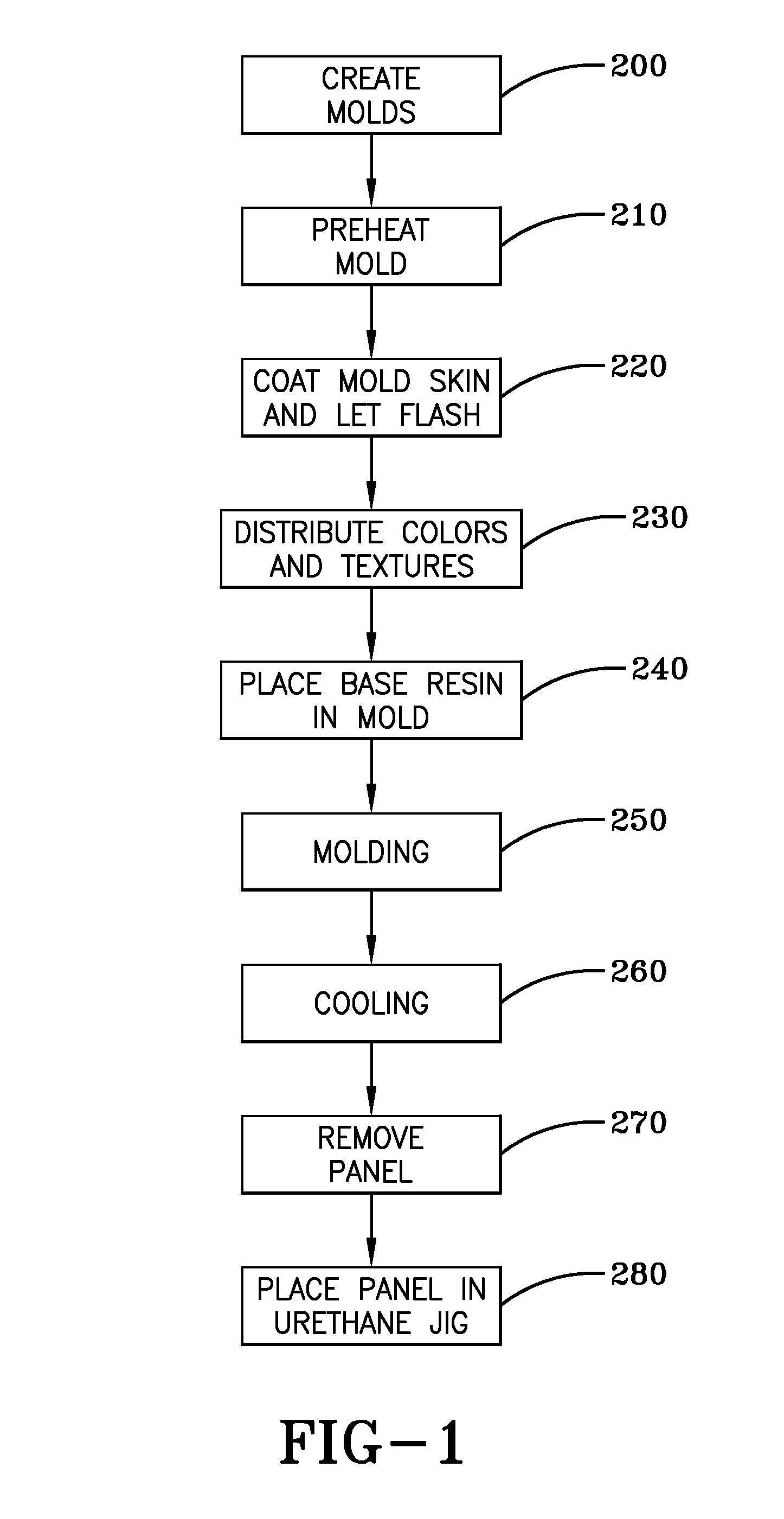

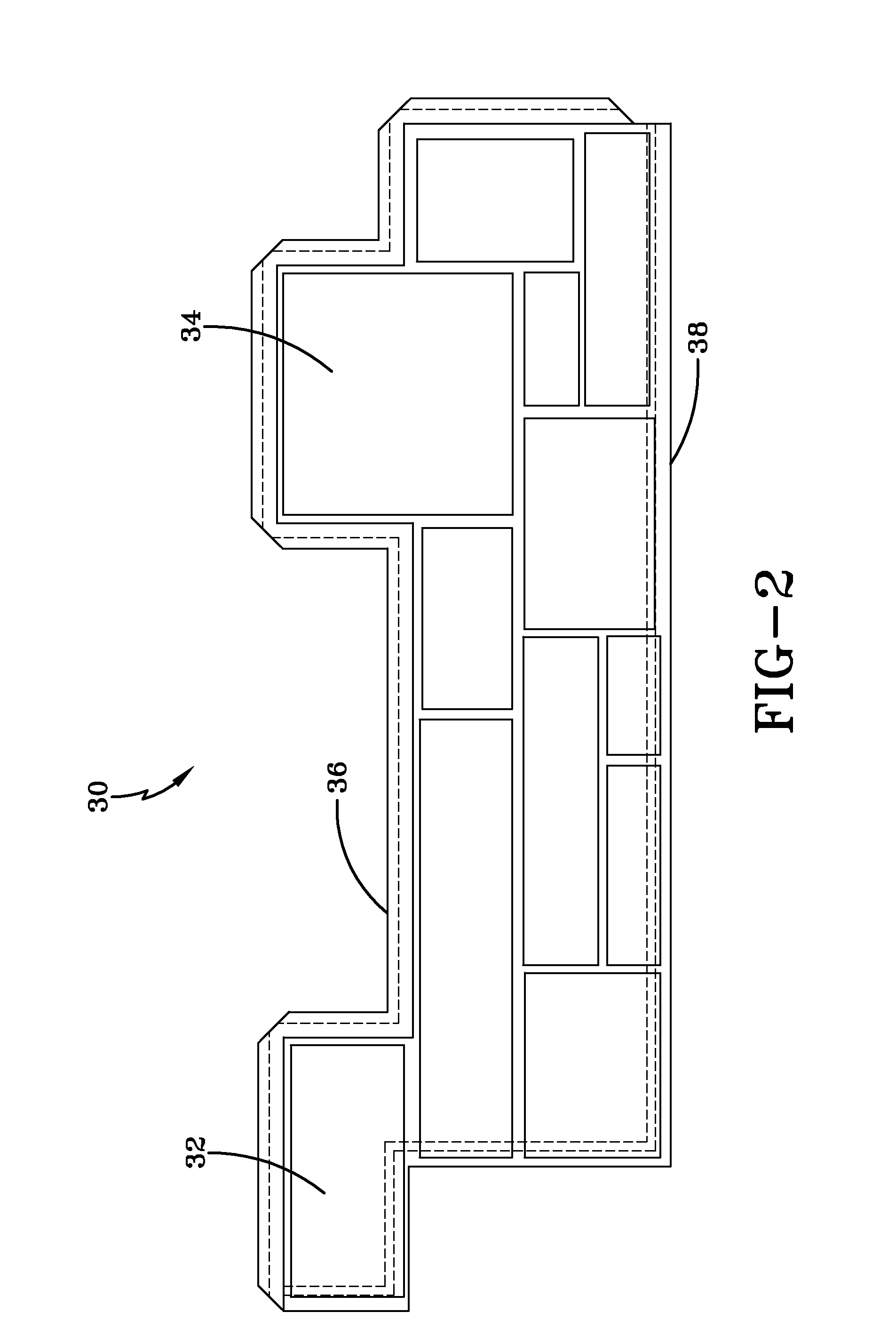

Foaming of simulated stone structures

InactiveUS20090056257A1Improve insulation performanceImprove sound insulationConstruction materialCovering/liningsBrickThermal insulation

Simulated stone, masonry, and brick textured products such as siding having a foam backing or with the hollow parts injected with foam or molded with foam in one or more steps, obtained when specially selected materials are properly admixed and formed via molding techniques. The foam backing is applied to the product in either a one or two step process. The foam backing may be used on panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearance of conventional building and construction materials including, but not limited to, stone, brick, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. The foam backing provides improves thermal insulation, improved sound reduction, improved rigidity, and improved dimensional stability. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

Ice composite bodies

InactiveUS6099208AHigh purityEfficiency sometimes variesArtificial islandsDrilling rodsThermal insulationEngineering

PCT No. PCT / IE97 / 00002 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Jan. 10, 1997 PCT Pub. No. WO97 / 25483 PCT Pub. Date Jul. 17, 1997An ice composite body has an inner ice core covered by a protective outer armor layer. Thermal insulation is provided between the inner core and the outer armor layer. Refrigeration is accomplished by a system of conduits for refrigerant are located within the body. The insulation and the refrigeration are adapted to maintain the ice core in a frozen condition relative to the ambient temperature. The base of the body cavity can be in direct contact with the water bed such that the ice core is freeze bonded to an advancing ice front in the water bed. The ice composite body provides structures of equal or greater strength than equivalent structures using conventional materials.

Owner:MCALISTER PADRAIG

Method for preparing silicon dioxide silica aerogel composite material by drying in atmosphere pressure

InactiveCN101318659ALow thermal conductivityIncrease added valueSilicaThermal insulationPipeline transport

The invention discloses a method for preparing a silicon dioxide aerogel composite material at the condition of normal pressure and drying, which comprises the steps as following: (1) silicon dioxide sol and a reinforcing material are compounded and placed statically to form plural gel, and then ageing treatment is carried out to the plural gel; (2) a modifying agent is used for the hydrophobic modification of the aged plural gel, and then ambient pressure drying is carried out for the modified plural gel to obtain the silicon dioxide aerogel composite material at the condition of normal pressure and drying. The silicon dioxide aerogel composite material prepared by the method of the invention has extremely low coefficient of heat conductivity, which greatly increases the added value of the reinforcing materials such as corpus fibrosum, the product can be widely applied to thermal insulation and sound insulation of buildings, thermal insulation and sound insulation in the industrial pipeline transportation, and the like, and expands the application field of silicon dioxide and the corpus fibrosum.

Owner:绍兴纳诺气凝胶新材料研发中心有限公司 +2

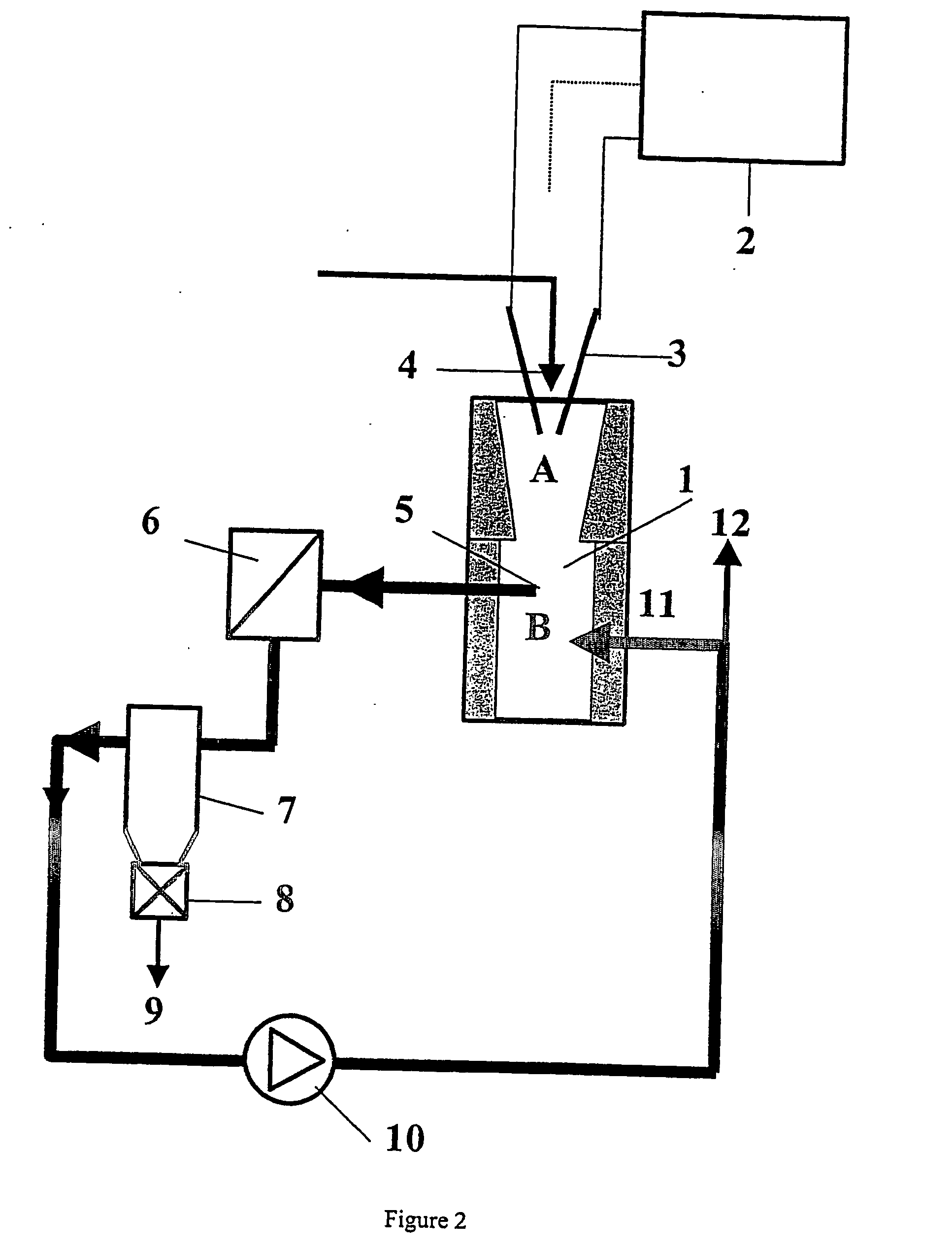

Method and apparatus for insulating hydroponic lamps

InactiveUS7722228B2Reduce heat dissipationClimate change adaptationLighting heating/cooling arrangementsThermal insulationEngineering

A kit and process for retrofitting hydroponic lamp hoods with thermal insulation, and an apparatus for a thermally insulated hydroponic light hood.

Owner:BROER PAUL ERNEST

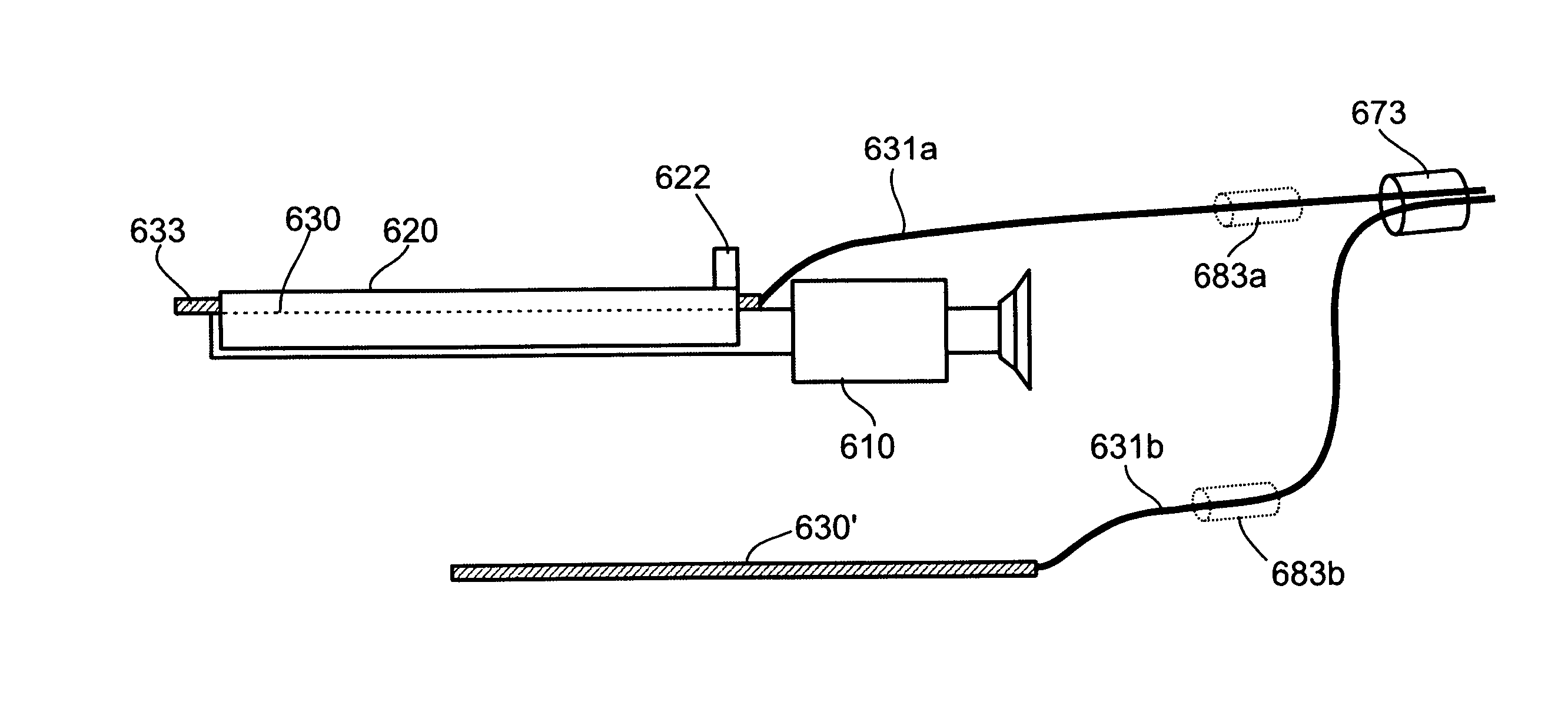

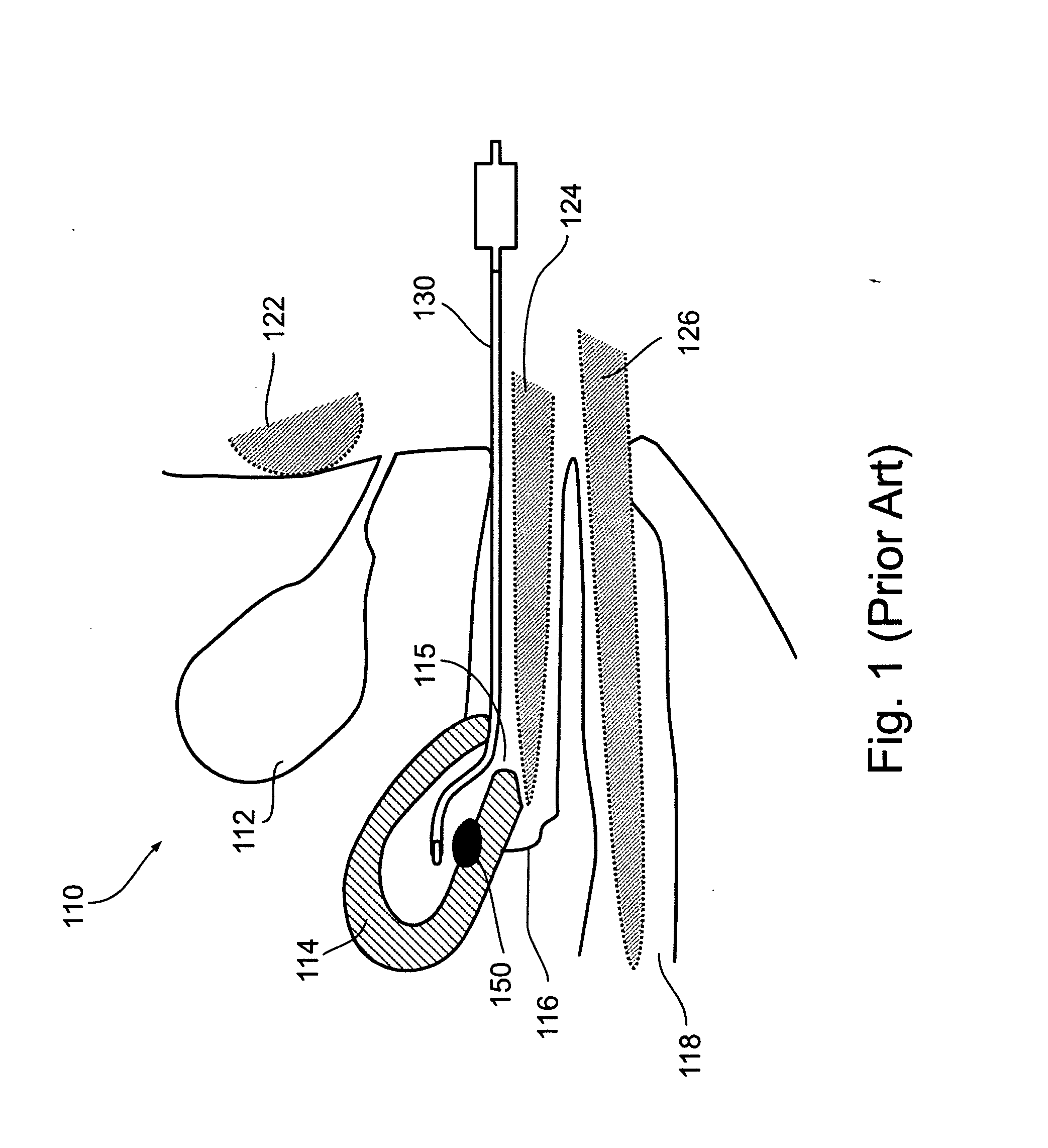

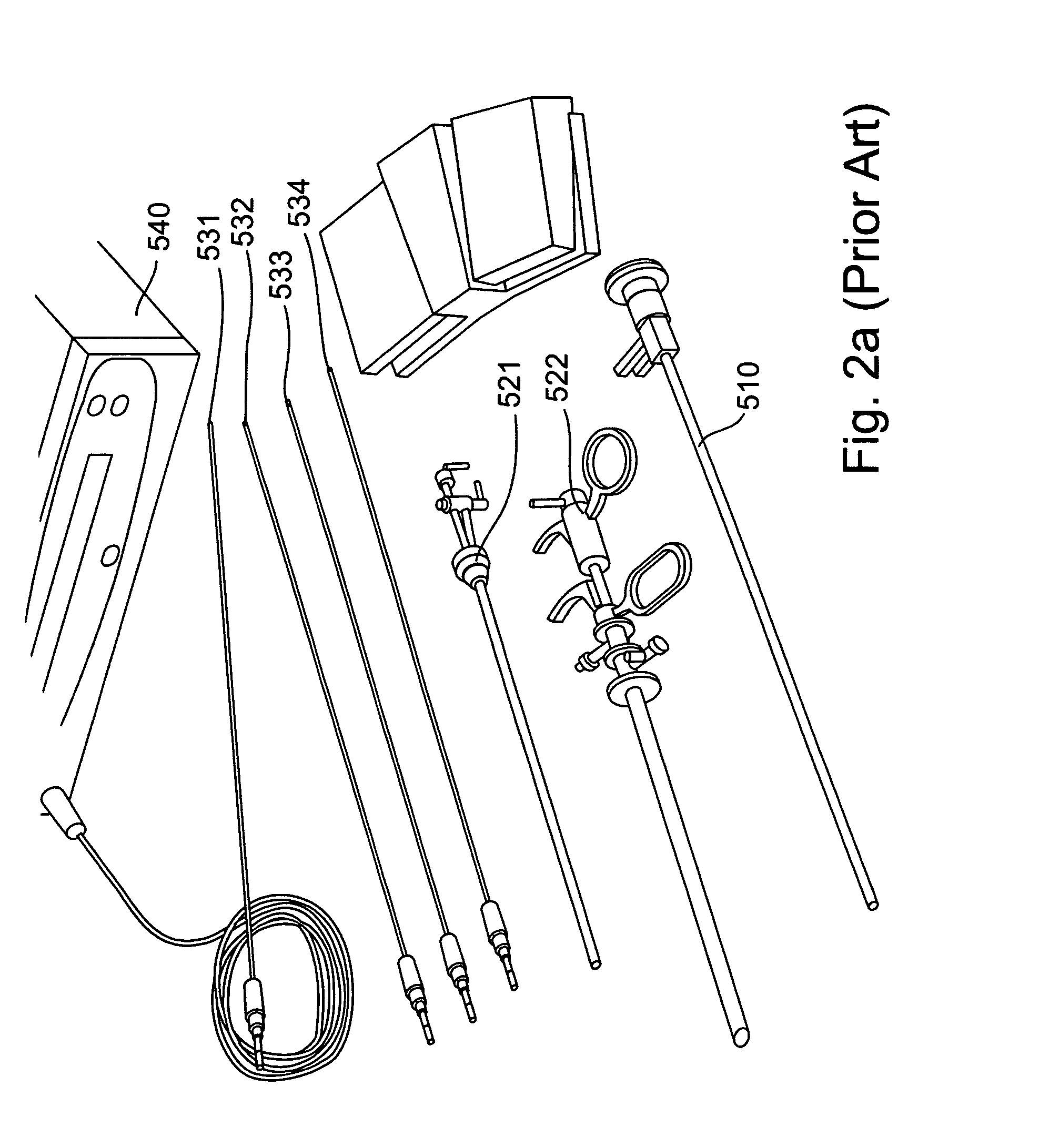

Apparatus and method for thermal ablation of uterine fibroids

InactiveUS20070088247A1Improve mobilityProtection from damageCannulasEndoscopesThermal insulationCervix

The present invention relates to apparatus and methods for thermally ablating uterine fibroids. More particularly, the present invention relates to a conduit having a plurality of channels for delivering a plurality of thermal ablation probes to an organic target such as a uterine fibroid, the probes being delivered in such configuration and orientation as to enable efficient and thorough ablation of the fibroid. In a preferred embodiment, the conduit is formed as a sleeve having a large central lumen sized to accommodate a hysteroscope, channels sized to accommodate cryoprobes are used as thermal ablation probes, and comprises thermal insulation materials serving to protect the cervix from damage by cold. The present invention further relates to bent cryoprobes usable in conjunction with such a conduit and designed to exit therefrom in a desired configuration useful for ablating a large fibroid.

Owner:GALIL MEDICAL

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

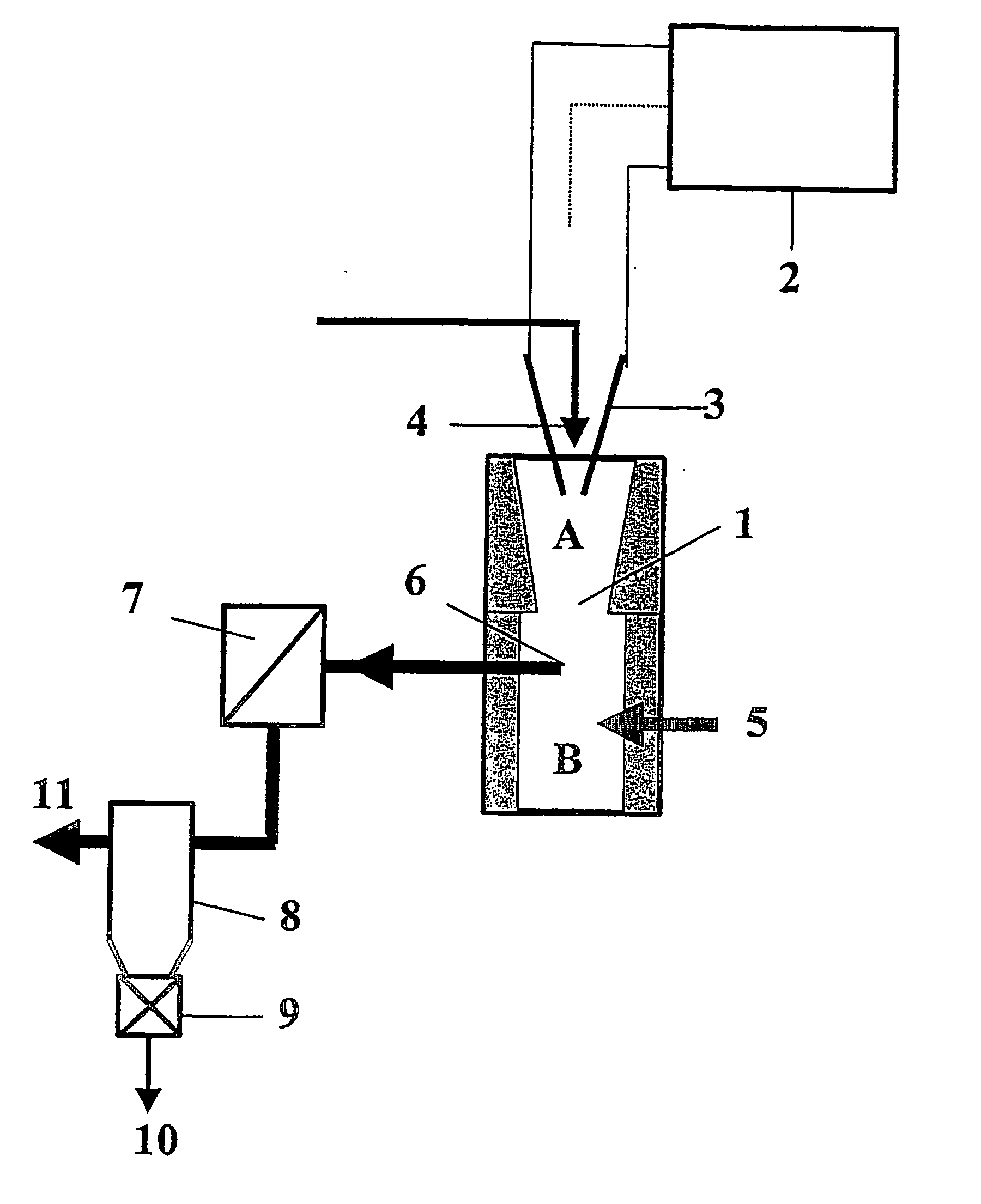

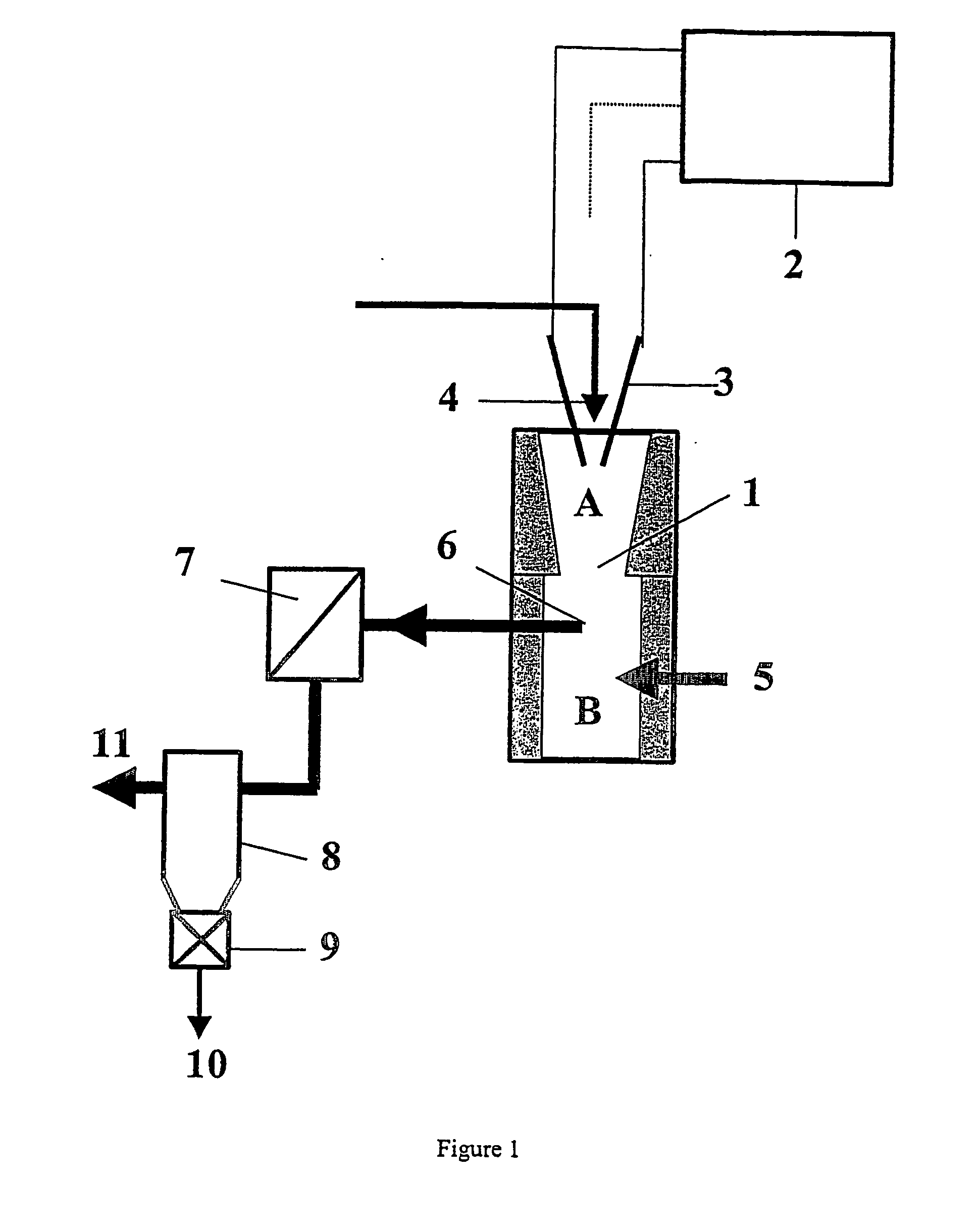

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

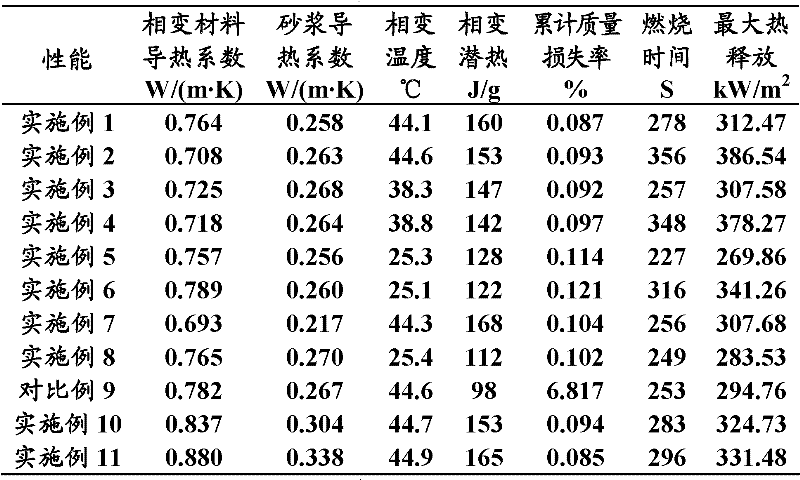

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

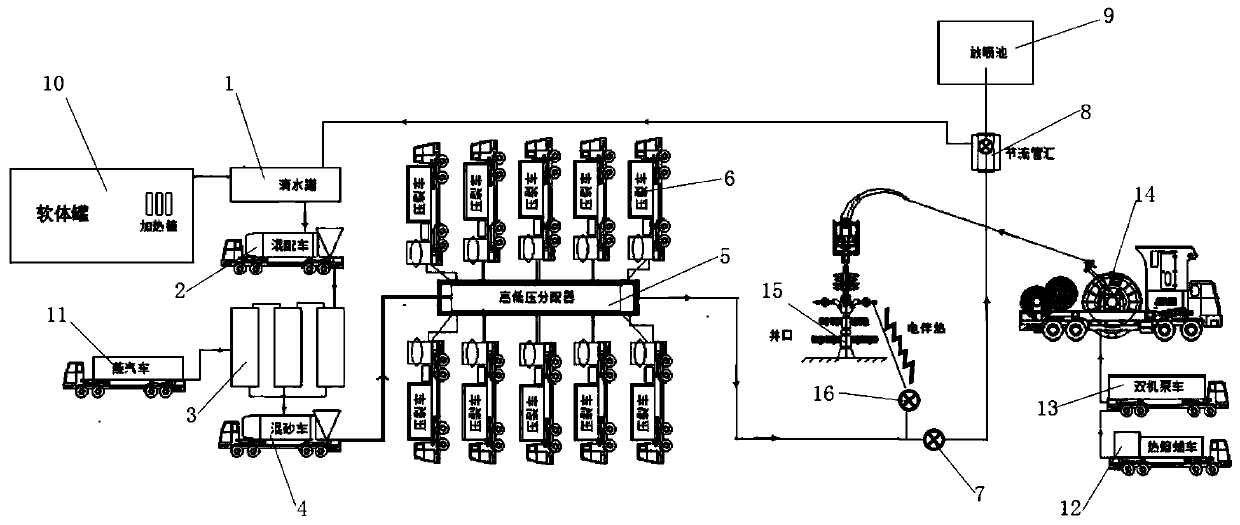

Fracturing system with antifreezing performance

The invention discloses a fracturing system with the antifreezing performance. The fracturing system comprises a first branch and a second branch, wherein the first branch comprises a clear water tank, a mixing truck, a buffer tank, a sand blender, a fracturing device, a first cock and a throttle manifold connected in sequence; the outlet of the throttle manifold enters the clear water tank through backflow, to form a closed circulating system; the second branch comprises a hot melting wax truck, a dual-machine pump truck, a coiled tubing and a wellhead; the hot melting wax truck, the dual-machine pump truck and the coiled tubing are sequentially connected; the coiled tubing penetrates through the wellhead to enter the shaft bottom; the wellhead in the second branch is connected with the inlet end of the first cock in the first branch through a high-pressure pipeline; and the high pressure pipeline is provided with a second cock close to the inlet end of the first cock. The fracturingsystem has the following beneficial effects: during the construction process, a steamer is adopted to fully swell guanidine gum; and when construction is not carried out, all pipelines are adopted torealize antifreezing and thermal insulation in a circulating manner to avoid pipeline dismantling.

Owner:JEREH ENERGY SERVICES

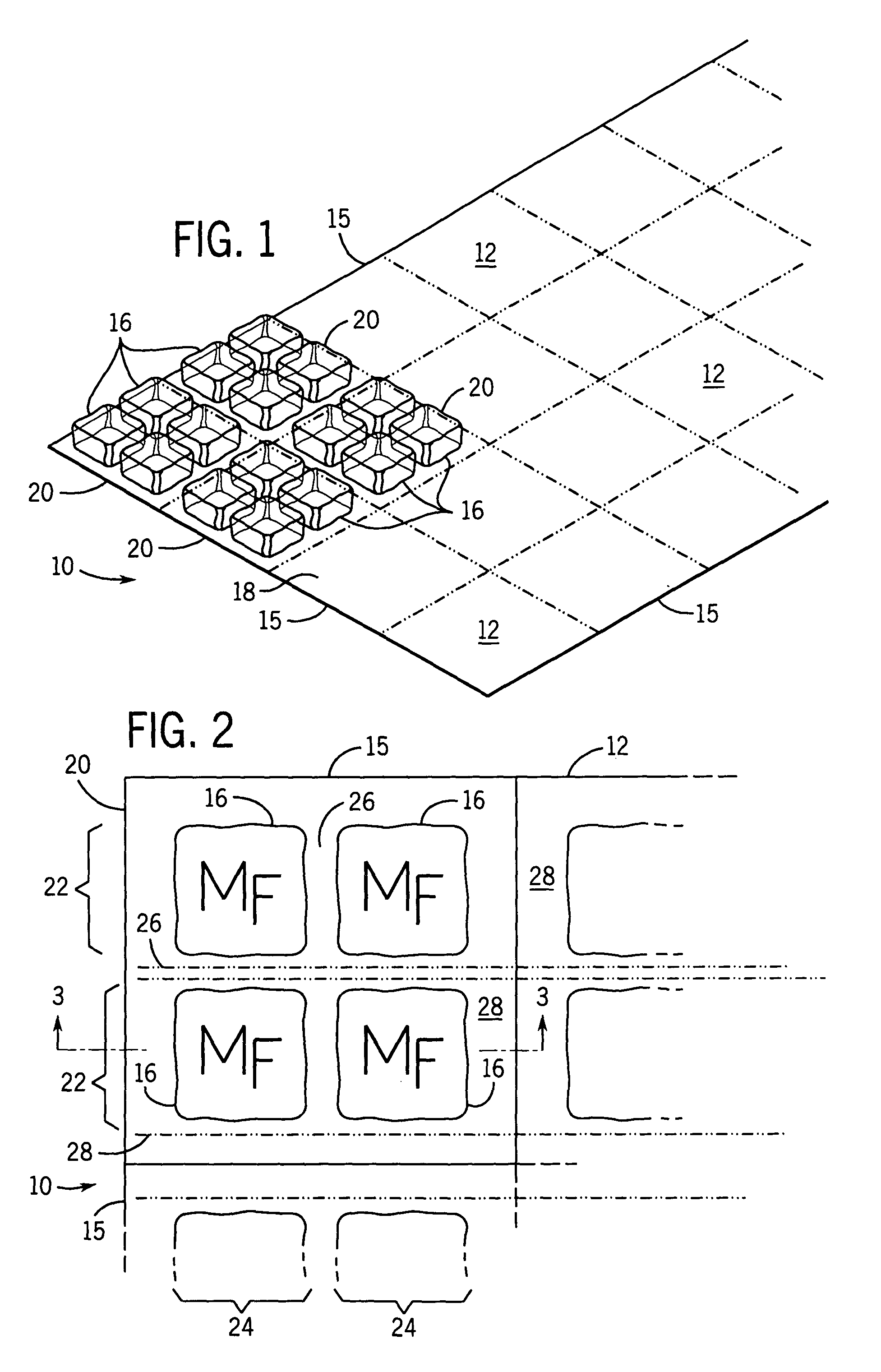

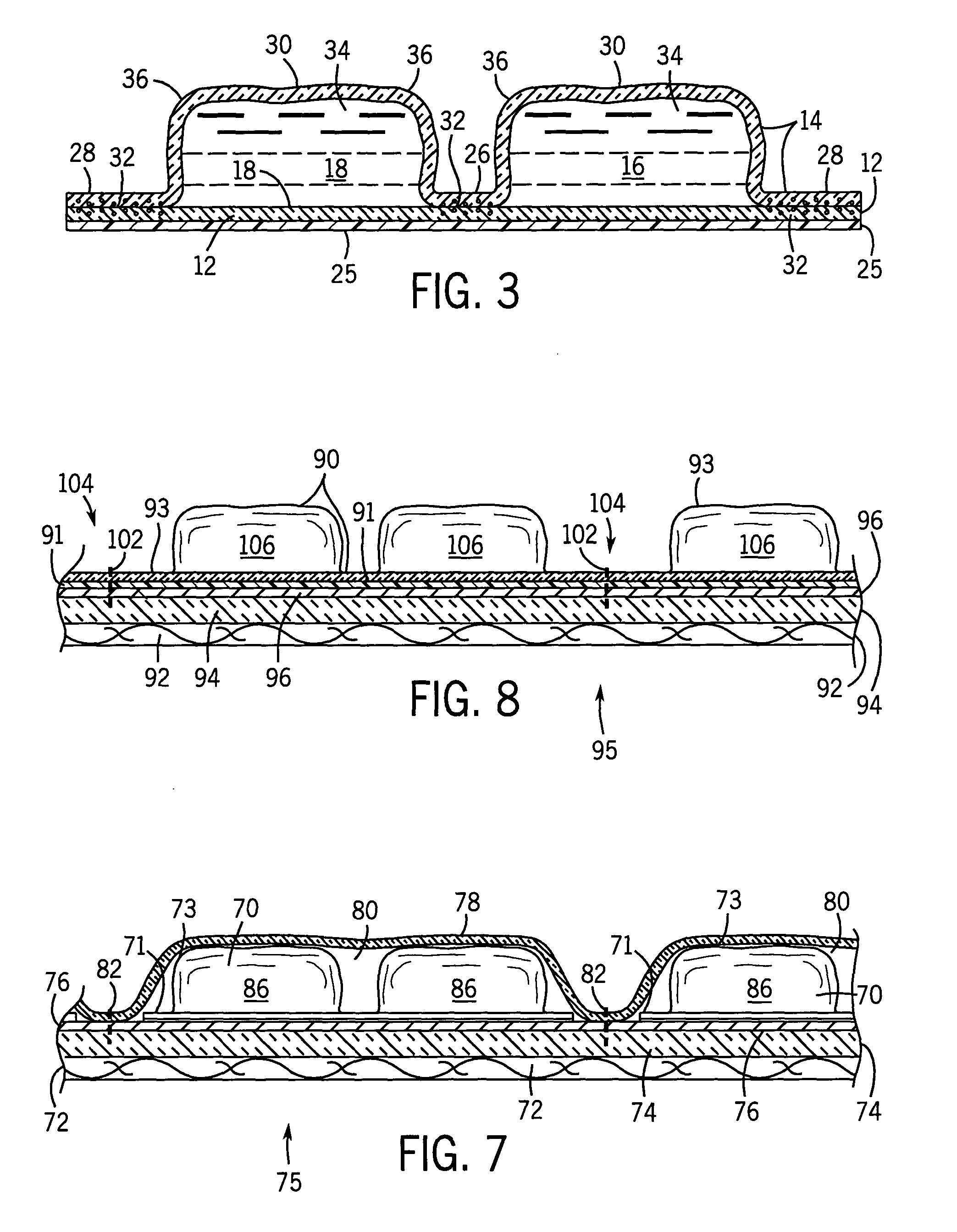

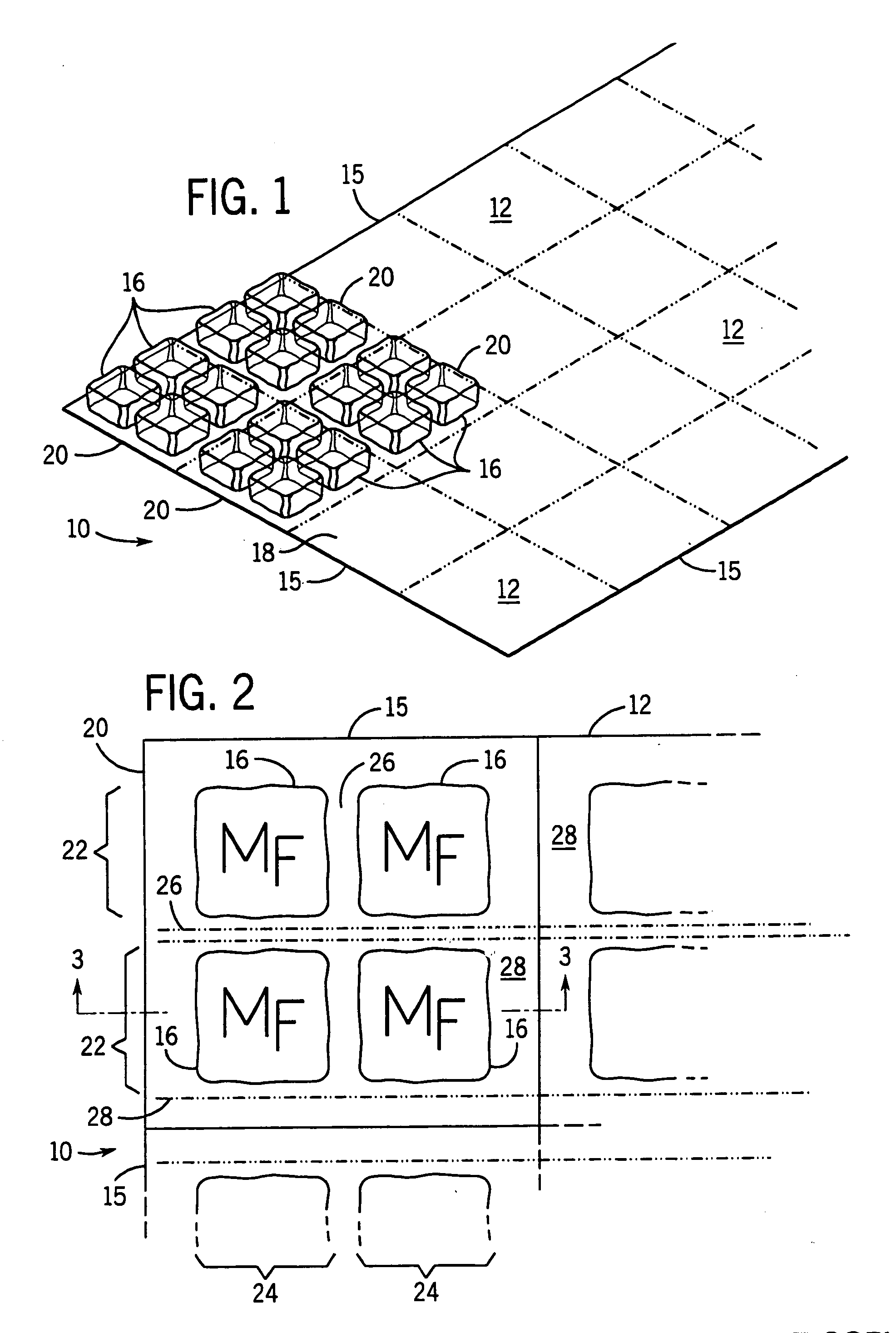

Portable cooler including ice sheet having refrigerant cubes

InactiveUS6925834B2Effective mergerLighting and heating apparatusIce productionThermal insulationEngineering

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or be being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler.

Owner:FUCHS MARK D

Portable cooler with built-in refrigerant cubes

ActiveUS20050183446A1Easy to storeSpace minimizationLighting and heating apparatusIce productionThermal insulationCooling effect

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or by being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler. The cooler may include a hinged top and bottom that can be folded flat for allowing the cooler to assume a compact configuration during storage or freezing of the refrigerant cubes.

Owner:FUCHS MARK D

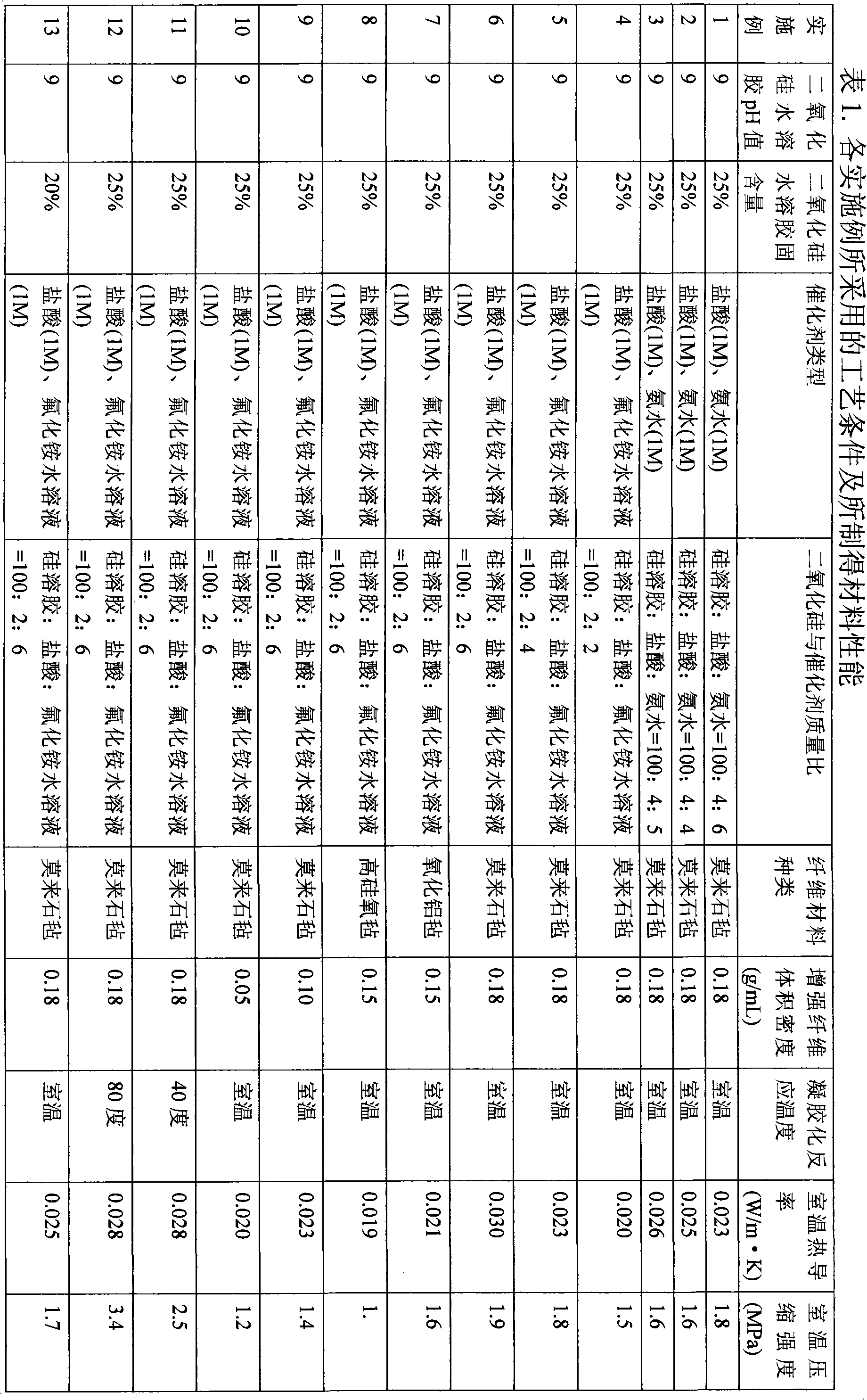

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

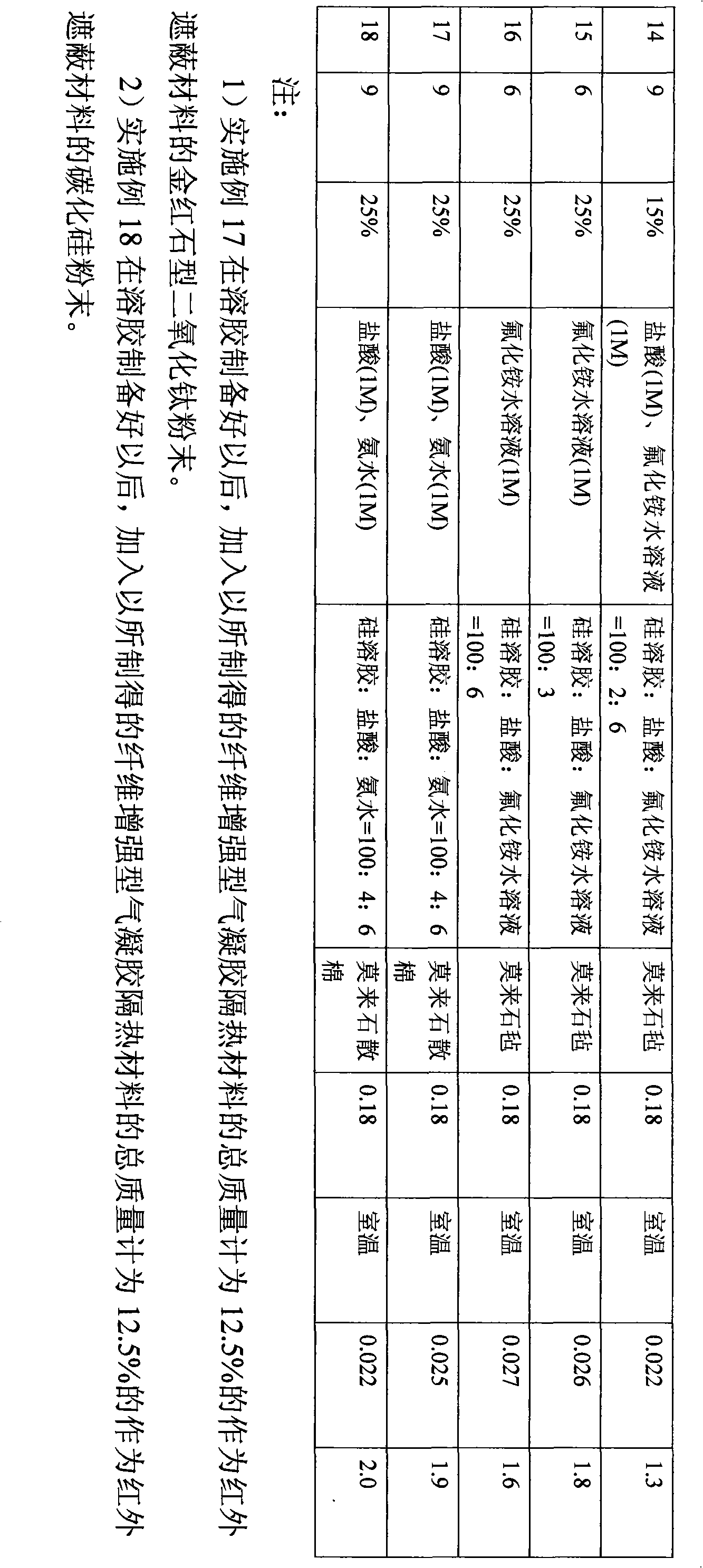

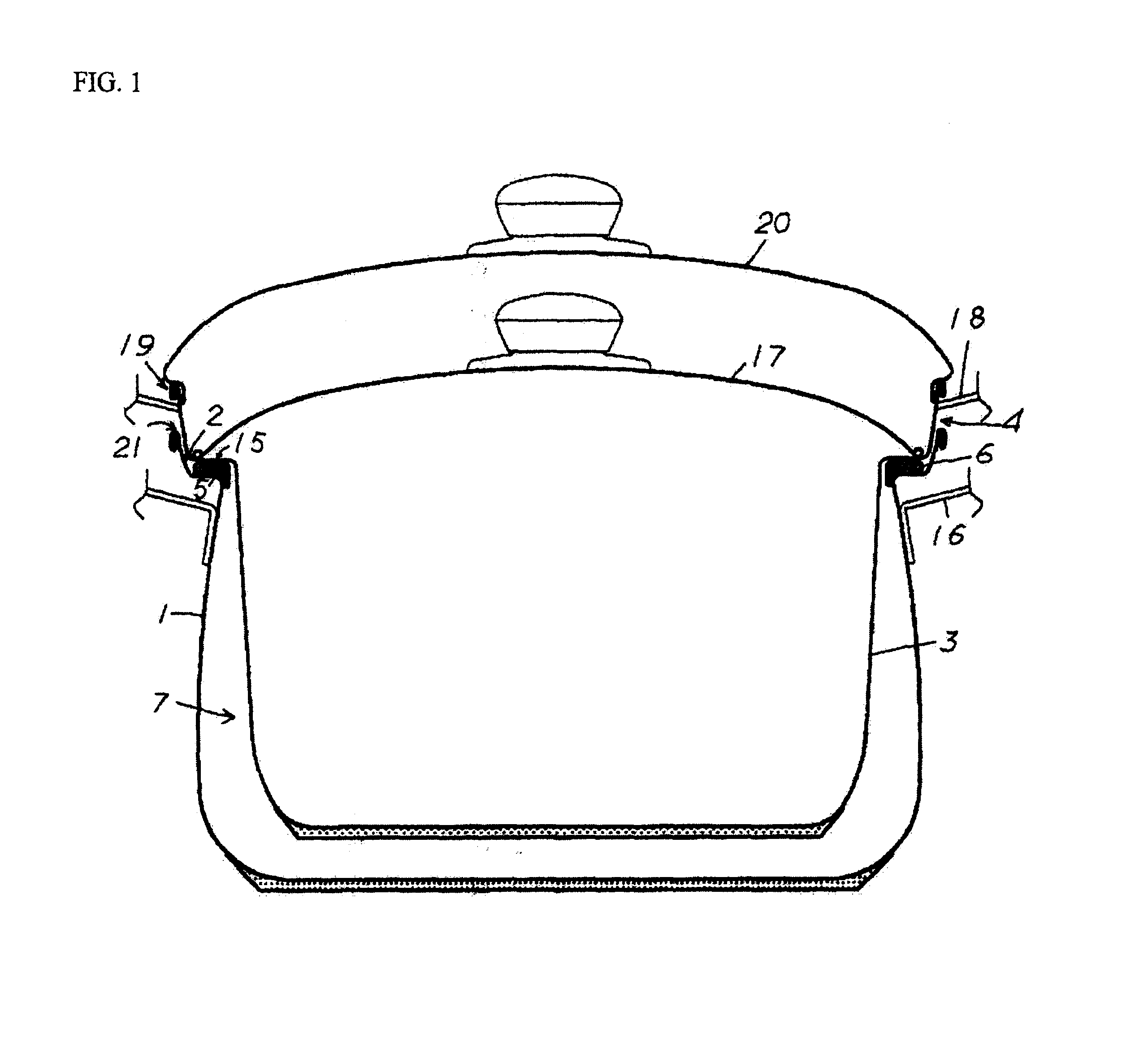

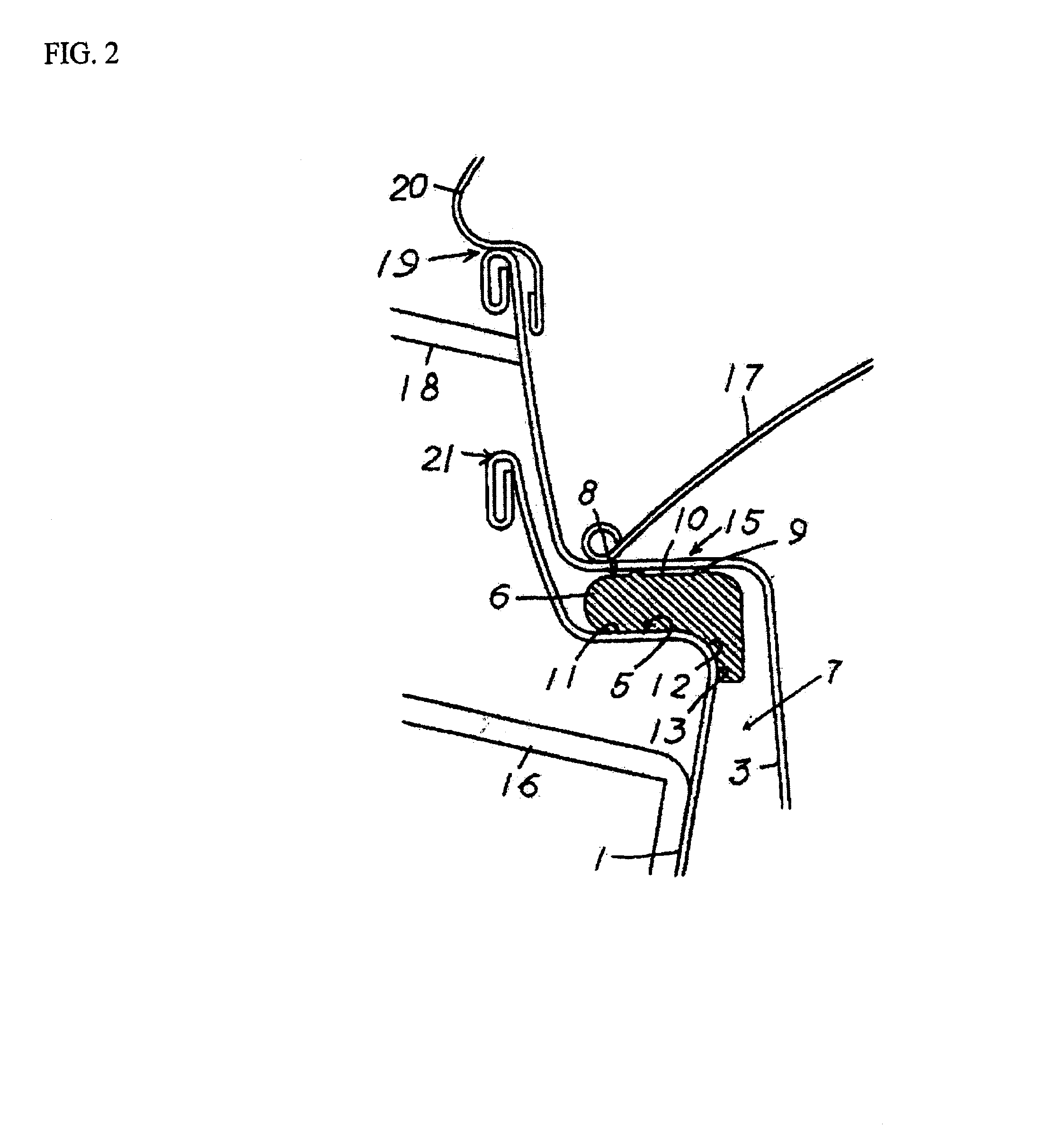

Thermally insulated pot

InactiveUS7086326B2Improve insulation effectImprove sealingWater heating stoves/rangesStove/ranges for heating waterThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

Polyurethane composite thermal insulation board, manufacturing method and application of the same

InactiveCN101220614AImprove thermal insulation performanceImprove fire and flame retardant performanceCovering/liningsLaminationProduction lineAlcohol

The invention provides a polyurethane compound heated board and a manufacturing method and application, which relates to a heated board and supplies a polyurethane compound heated board that has good heat-insulating effect, high fire-fighting and flame-retardant performance, convenient using performance and high constructing efficiency and the manufacturing method and the application. The invention includes a polyurethane rigid foam insulating layer, a bonding layer and an inorganic material composite board; the bonding layer is arranged between the polyurethane rigid foam insulating layer and the inorganic material composite board; the thickness of the polyurethane rigid foam insulating layer is 20-80mm and the thickness of the inorganic material composite plate is 3-10mm. The inorganic material composite board can be continuously produced for further use; an adhesive treatment agent is coated on the inorganic material composite board; polyhydric alcohol combination material and isocyanate combination material are added into the continuous production line for mixed foaming and curing to obtain the polyurethane compound heated board; the mass ratio of the polyhydric alcohol combination material and the isocyanate is 100:95-160.

Owner:厦门高特高新材料有限公司

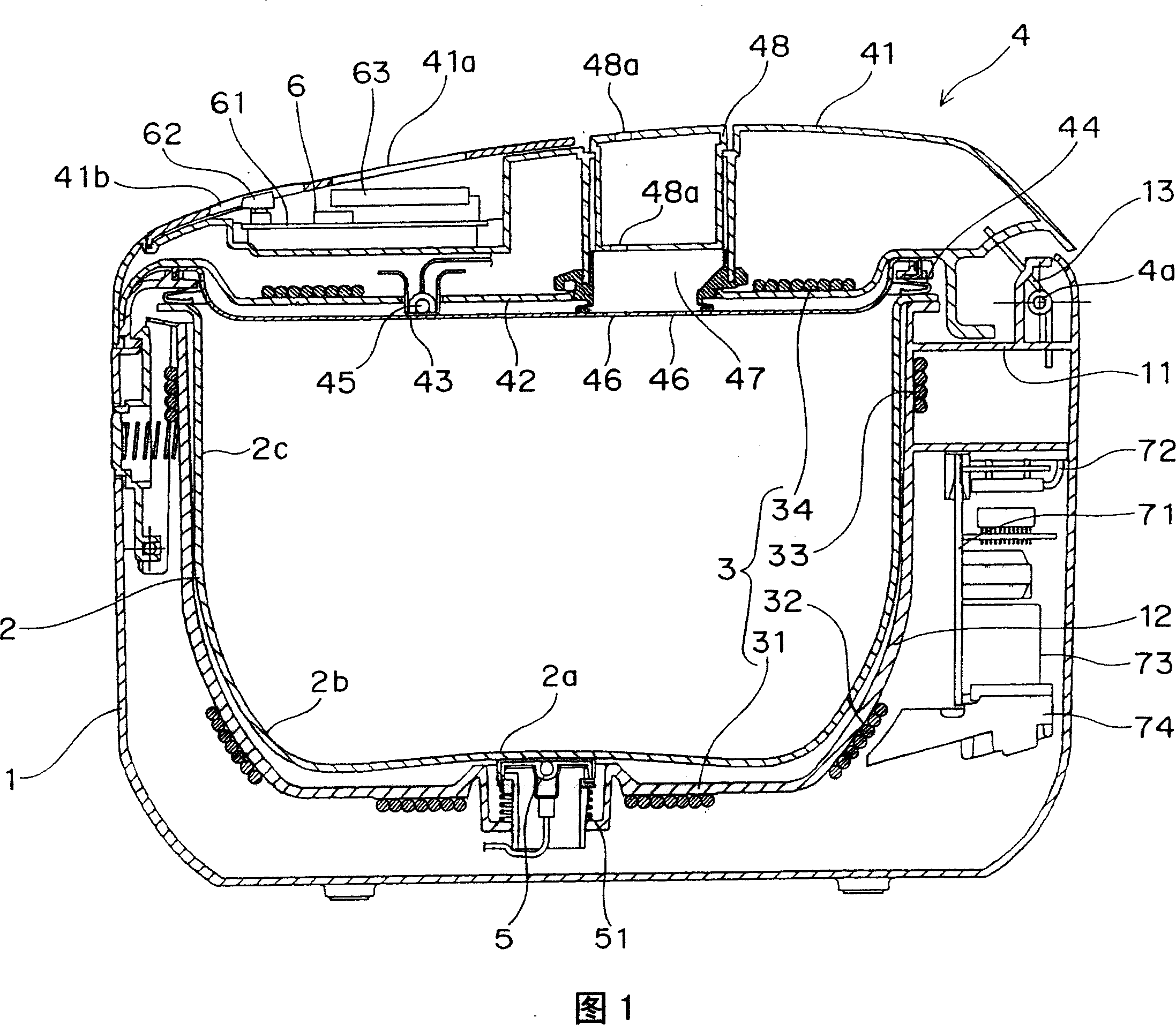

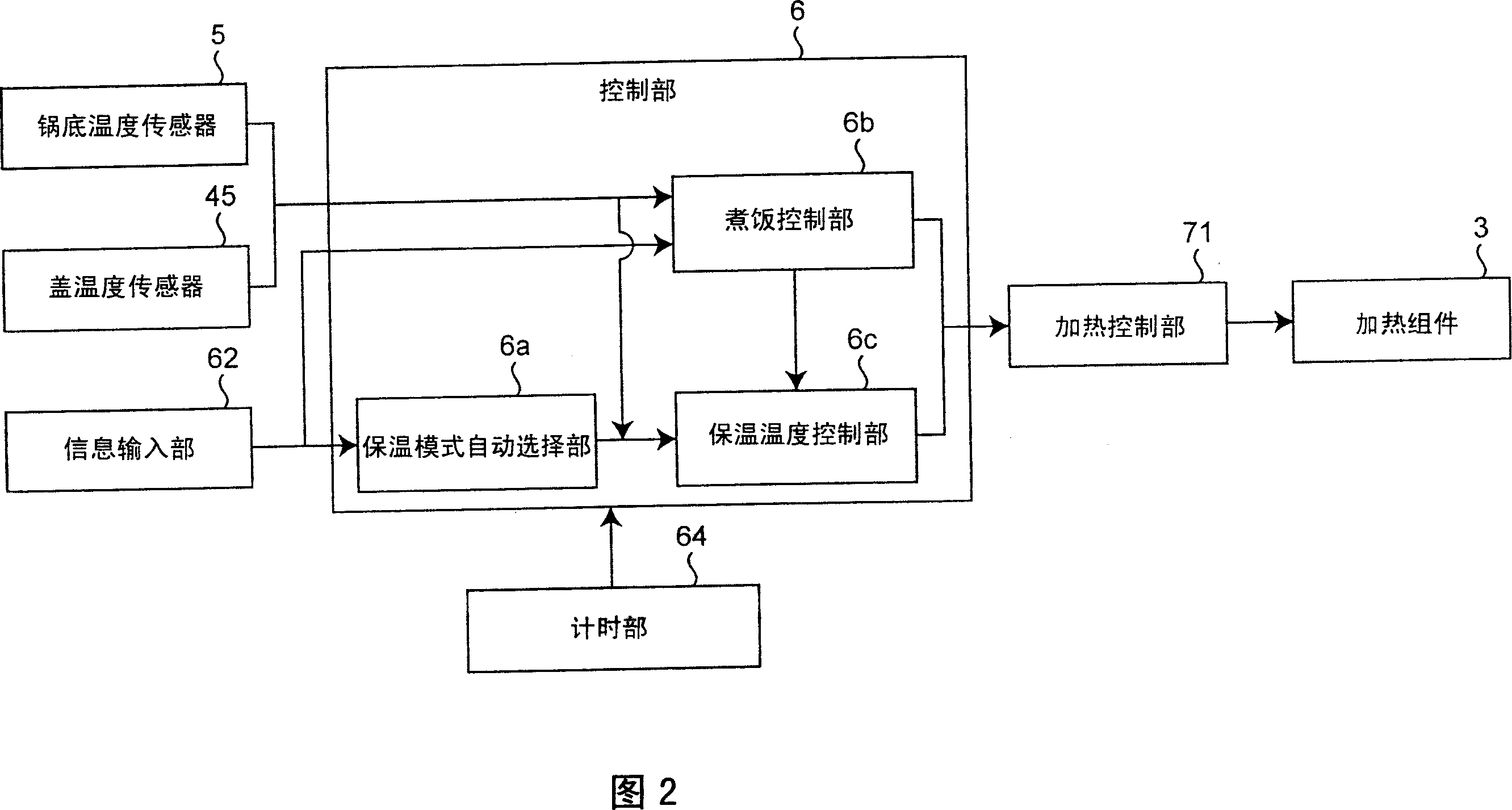

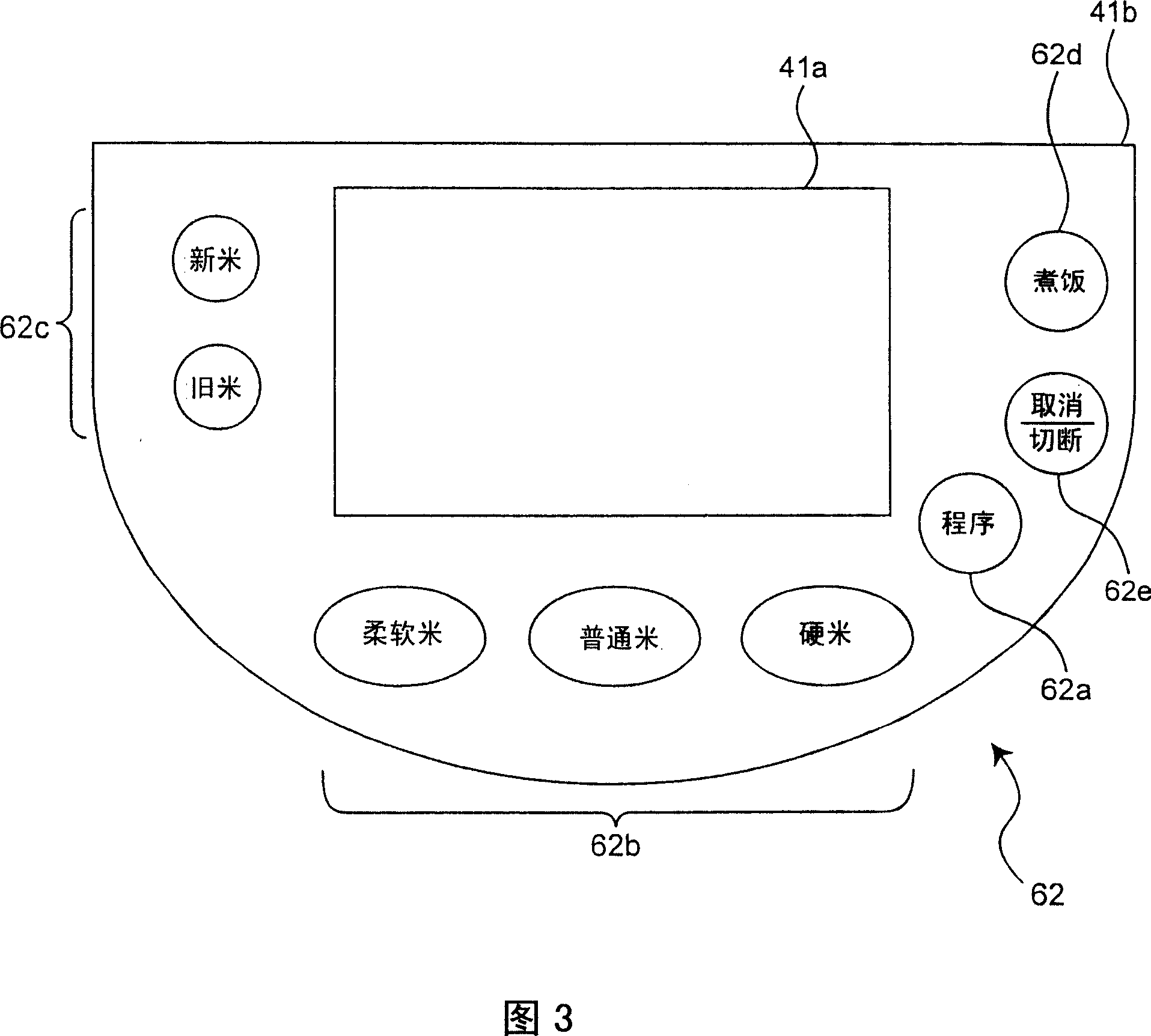

Electric cooker

ActiveCN101023842AReduce the burden onReduce rotBoiling over preventionCooking insertsTemperature controlThermal insulation

The invention provides an electric cooker capable of relieving the burden of user and more effectively depressing the decay of rice and deterioration of edible flavour induced by heat preservation. The electric cooker comprises boiler holding rice inside the electric cooker body; cover easily openned and closed for covering the peristome of upside of the cooker; heating arrangement for heating the pan bottom; cooker temperature test sensor for detecting temperature; heat control section for controlling the heating action of heating arrangement of the pan bottom; cook information input part for inputting the cook information related with cooking rice; automatic selection part of thermal insulation mode for automatically selecting the corresponding thermal insulation mode from many thermal insulation modes based on the cook information input by cook information input part before cooking; holding temperature control section for controlling temperature, based on thermal insulation mode selected by the automatic selection part of thermal insulation mode and controlling the heat control section by temperature detected by cooker temperature test sensor.

Owner:PANASONIC CORP

Fiber-reinforced high-temperature-resistant thermal insulation and heat preserving ceramic coating and preparation method thereof

InactiveCN102464933ADelivery barrierHigh surface strength of the coatingEpoxy resin coatingsCeramic coatingThermal insulation

The invention relates to a high-temperature-resistant thermal insulation and heat preserving ceramic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by weight: 30-50 percent of film forming substance, 30-40 percent of high-temperature-resistant filler, 10-15 percent of hollow micro beads, 2-5 percent of thermal insulation fiber and 2-8 percent of aid and solvent. The coating has the toughness of an organic coating and the rigidity and hardness of an inorganic coating, has high adhesion, can be used at the high temperature of 400-1,200 DEG C for a long time, and is resistant to chemical reagents, acids, alkalis and oil. A coating film has high surface intensity, and can bear strong shear force without being damaged when a high-temperature pipeline is required to be connected mechanically. The coating has excellent heat preserving performance, and the surface temperature of a pipeline of 350 DEG C can be lowered to be below 100 DEG C by coating the coating outside the pipeline in the thickness of 4-6 millimeters. The coating can be widely applied to heat-resistant protection of the inner and outer surfaces of equipment such as high-temperature steam pipelines, metallurgy high-temperature furnaces, high-temperature valves, high-temperature containers and the like.

Owner:SHENYANG LIGONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com