Patents

Literature

8690 results about "Wellhead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

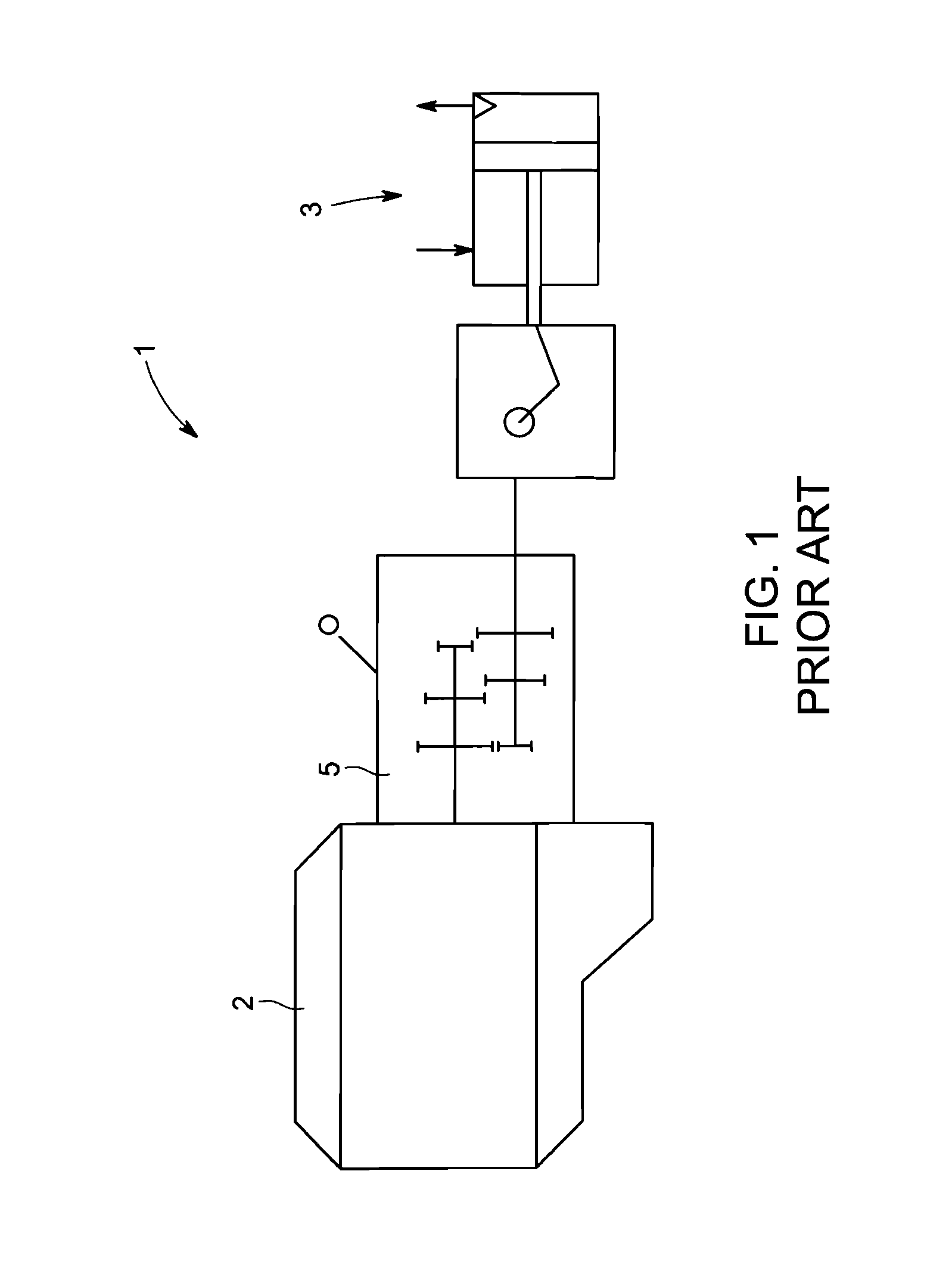

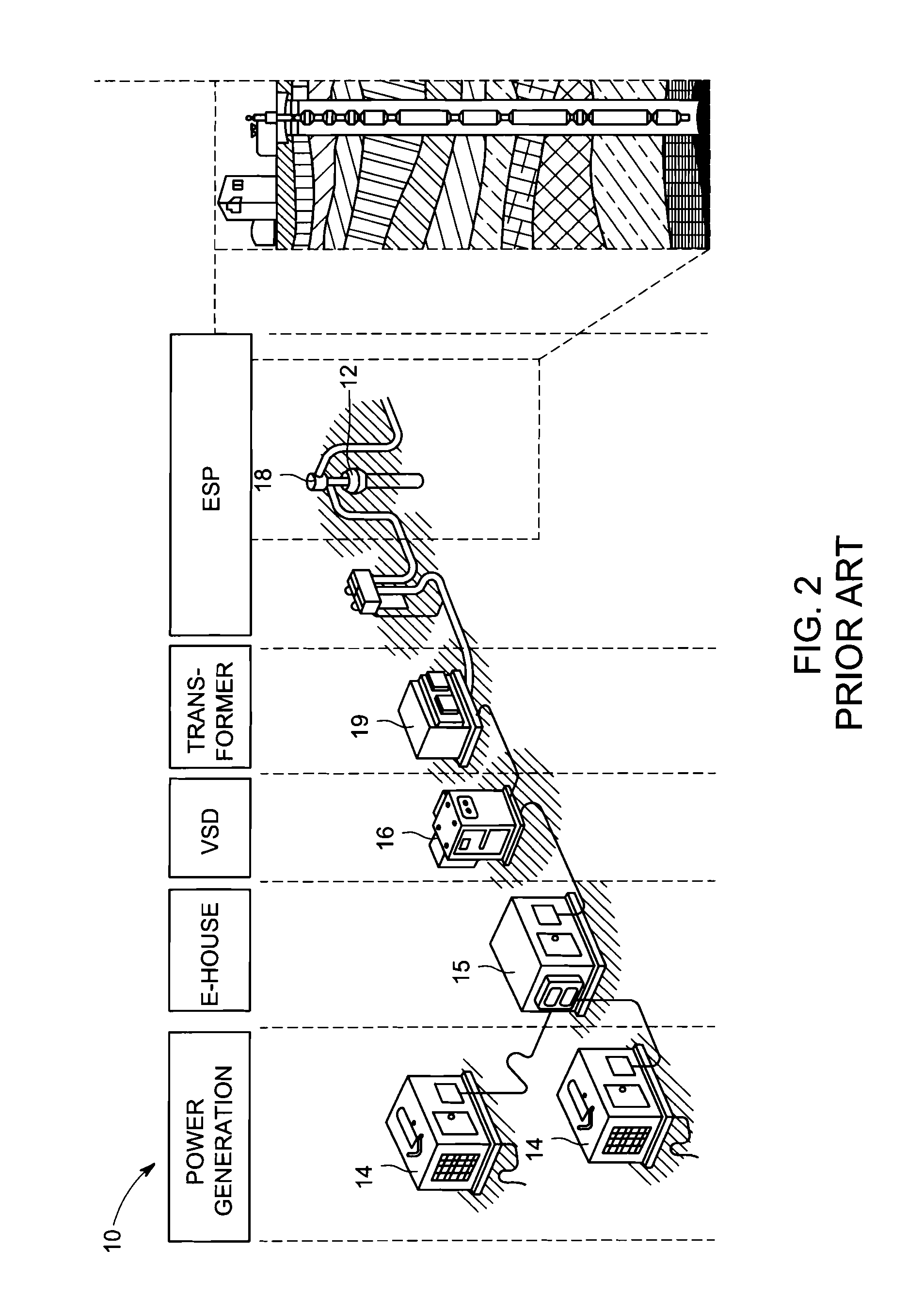

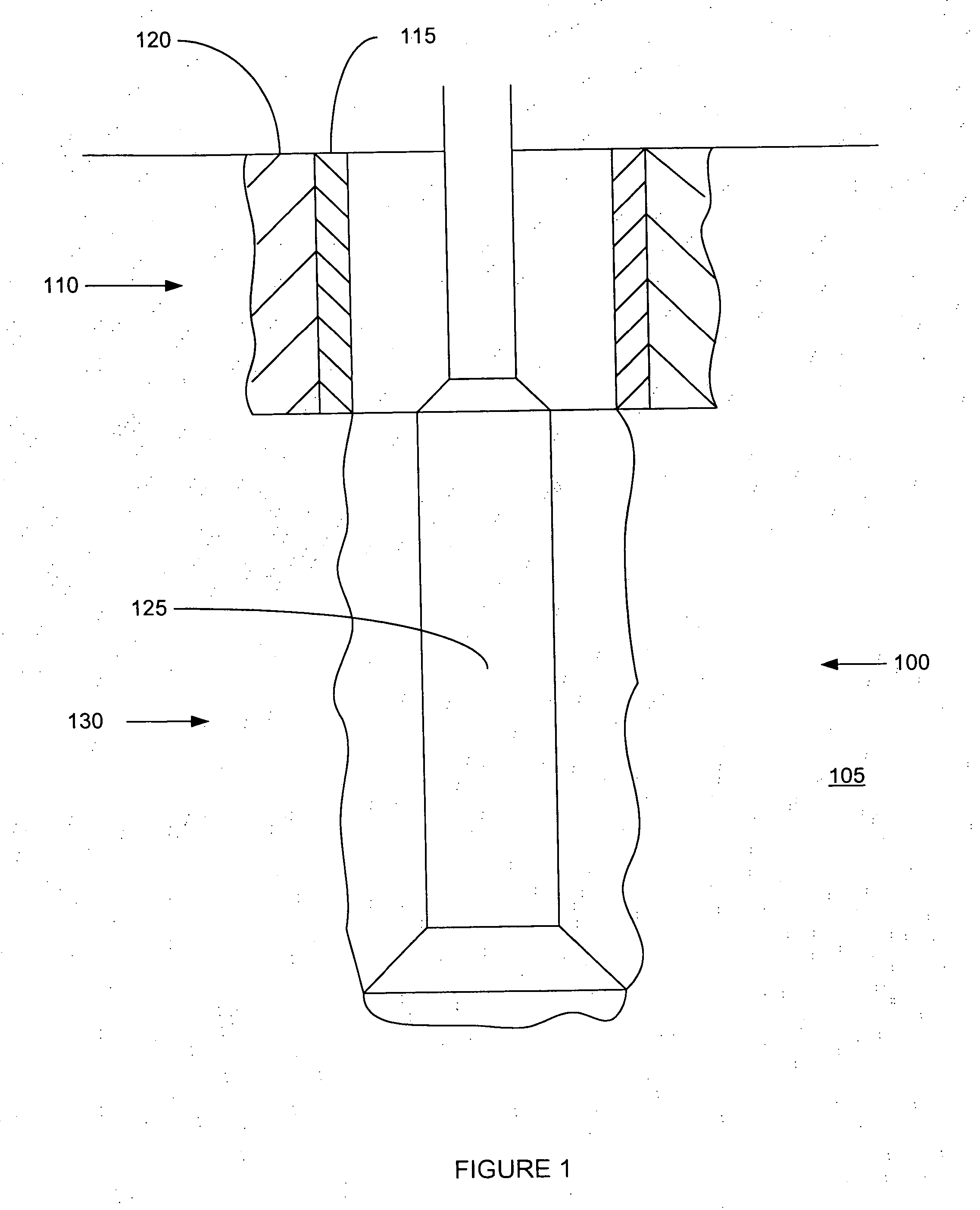

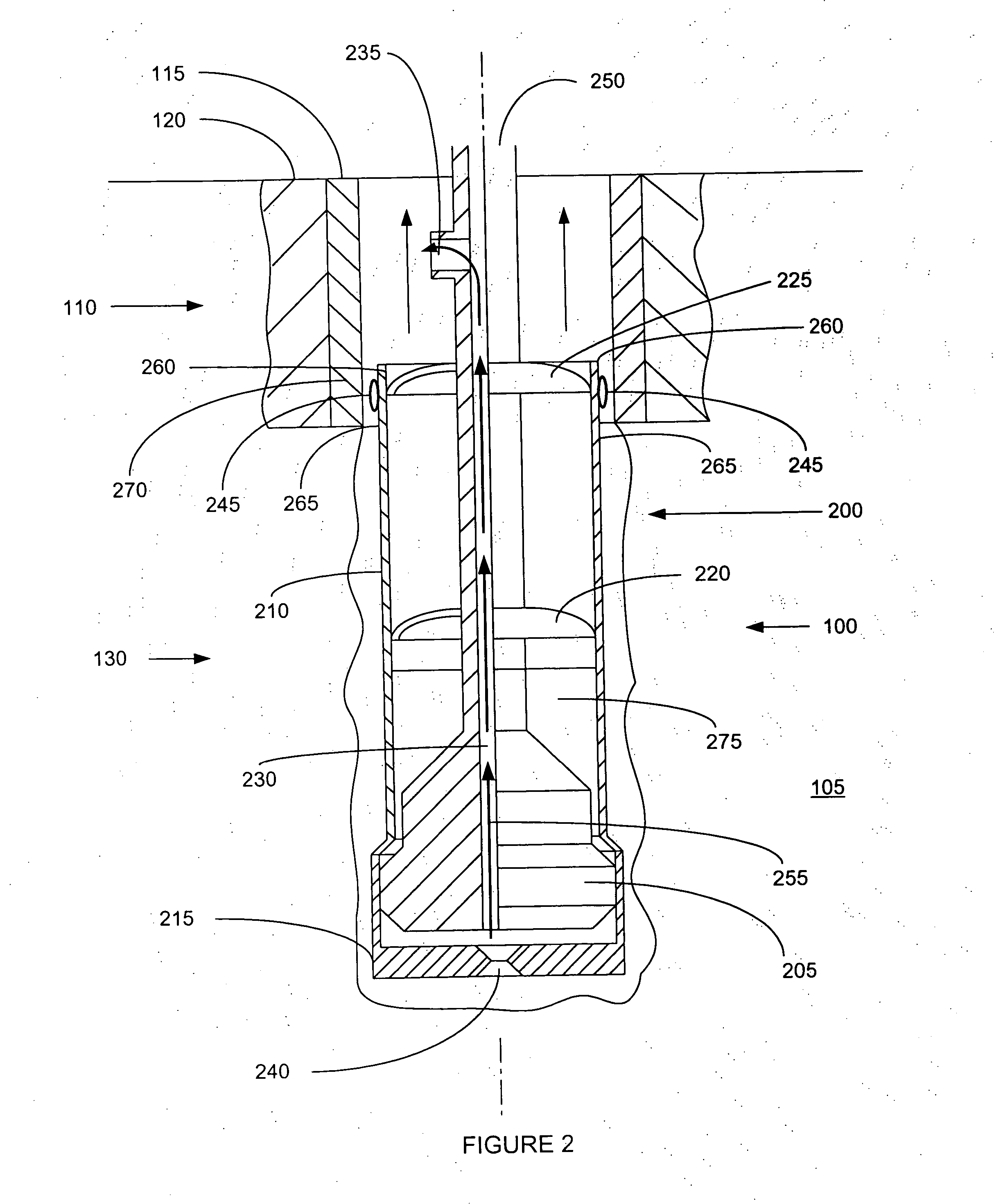

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment.

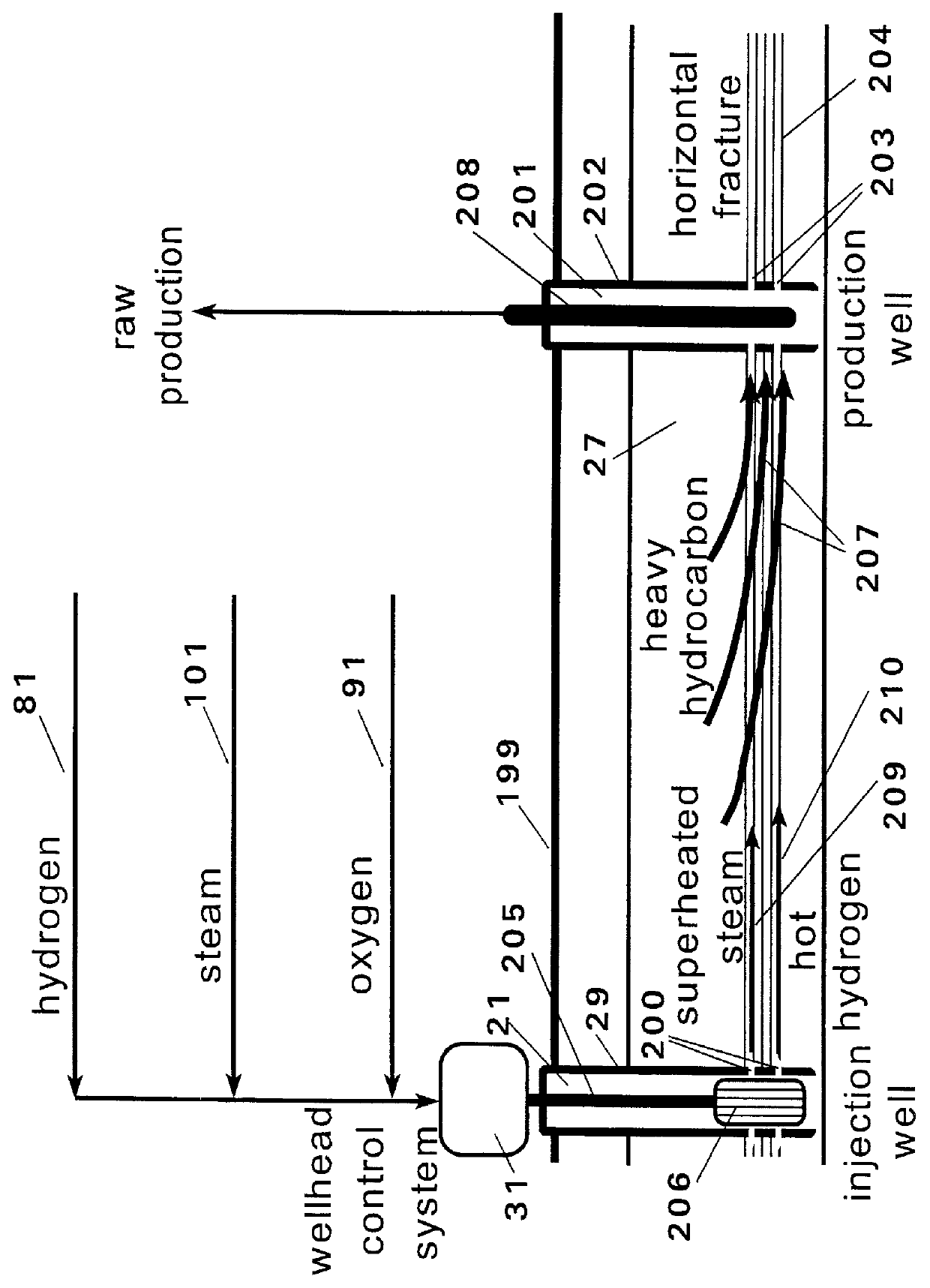

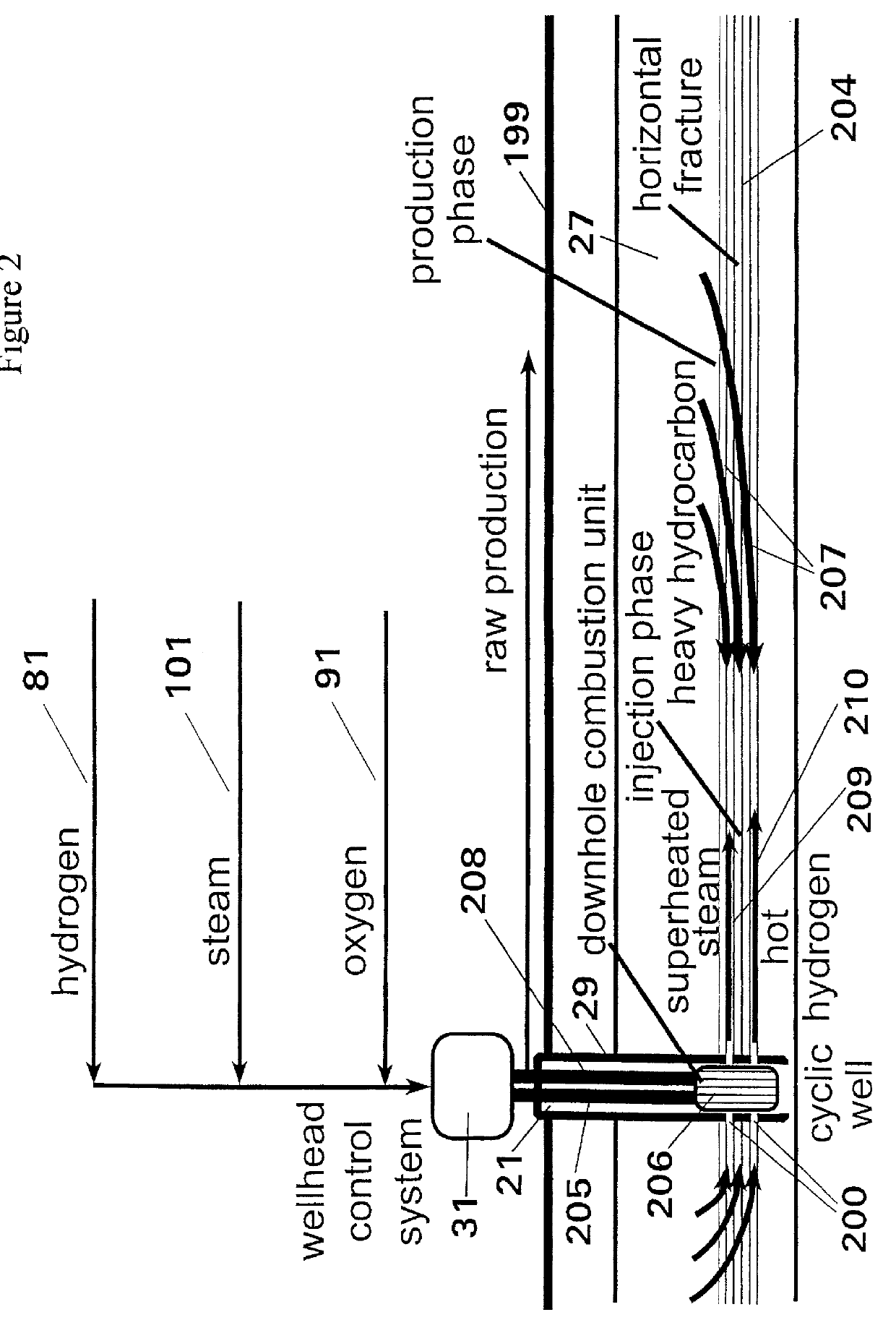

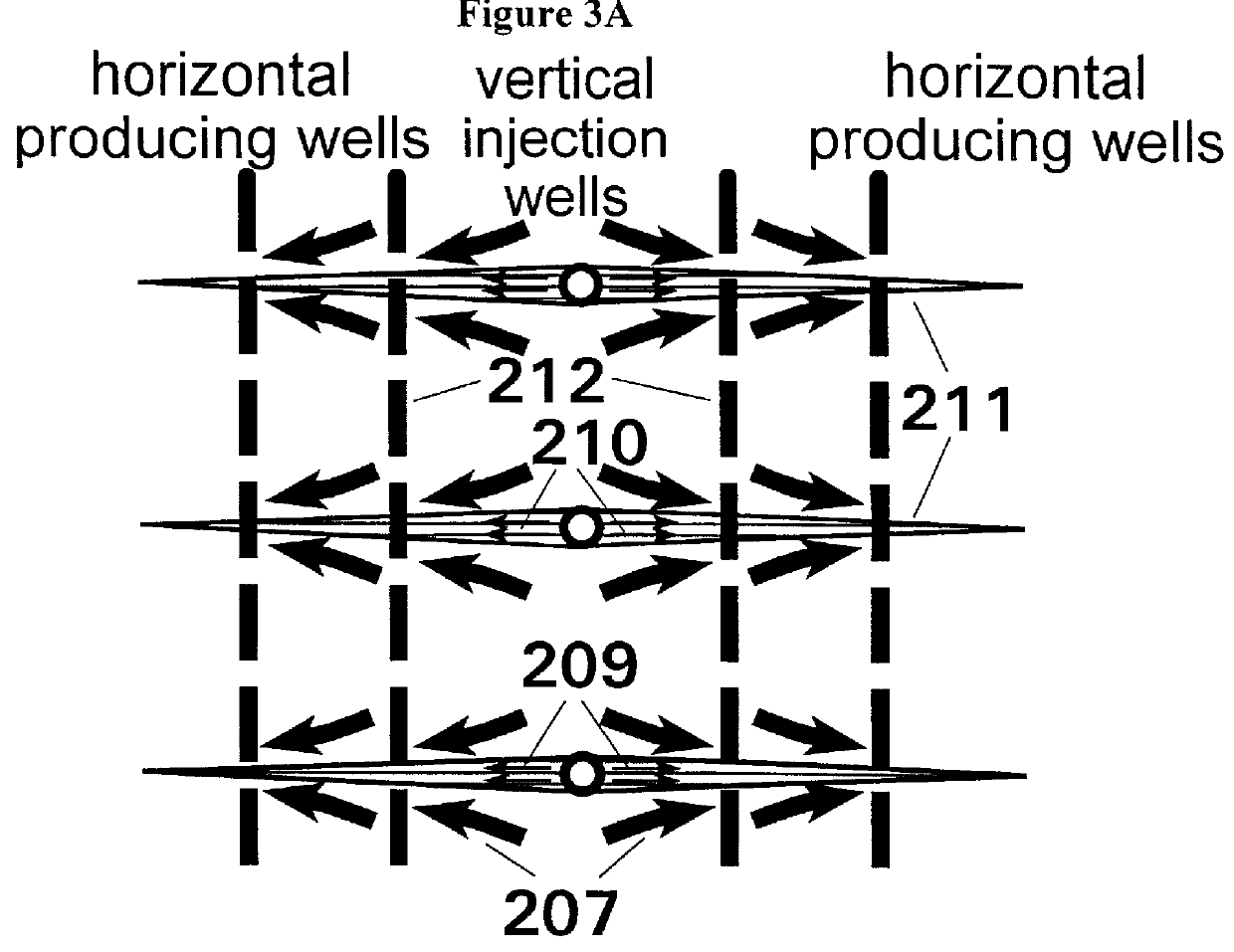

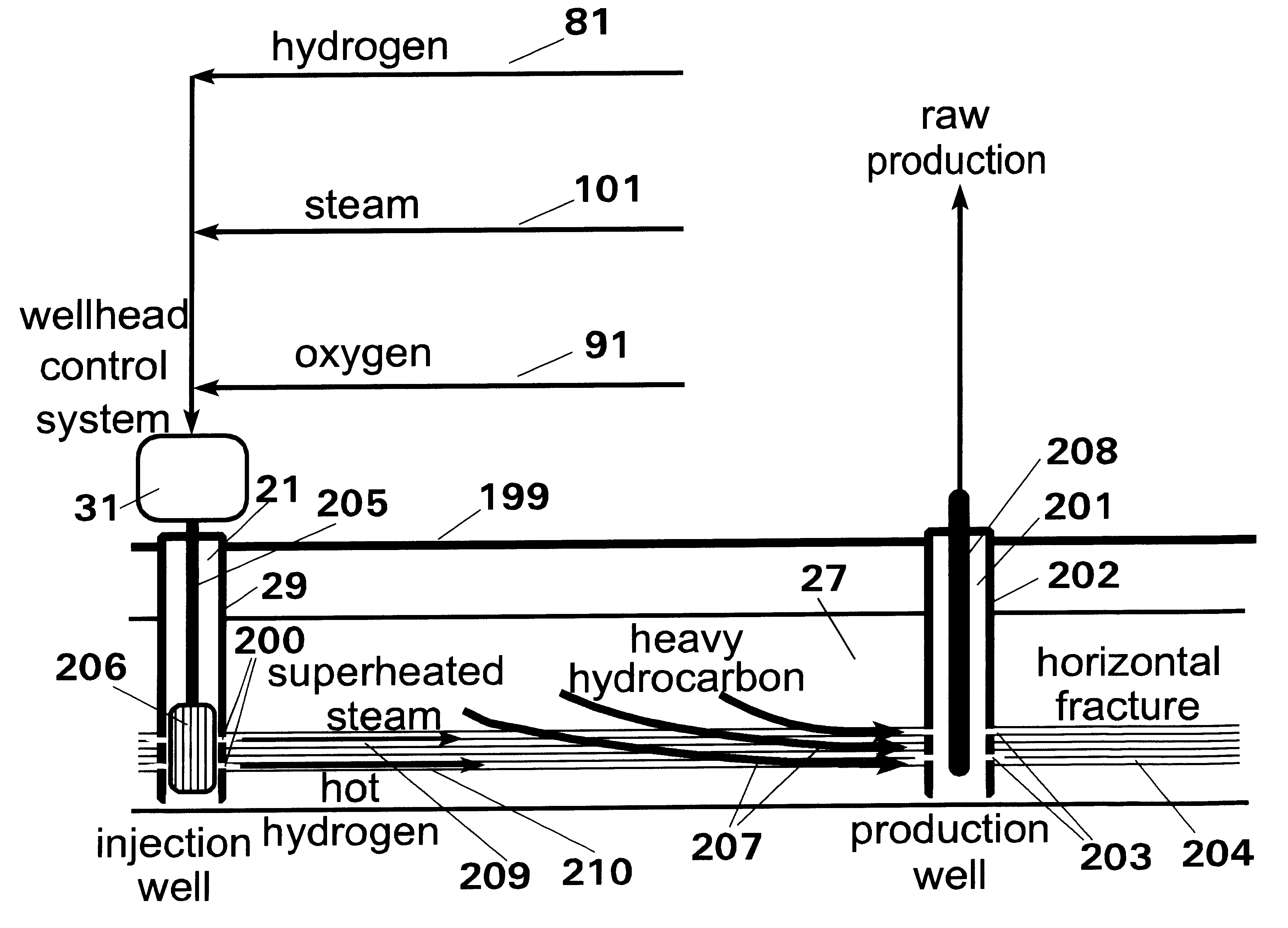

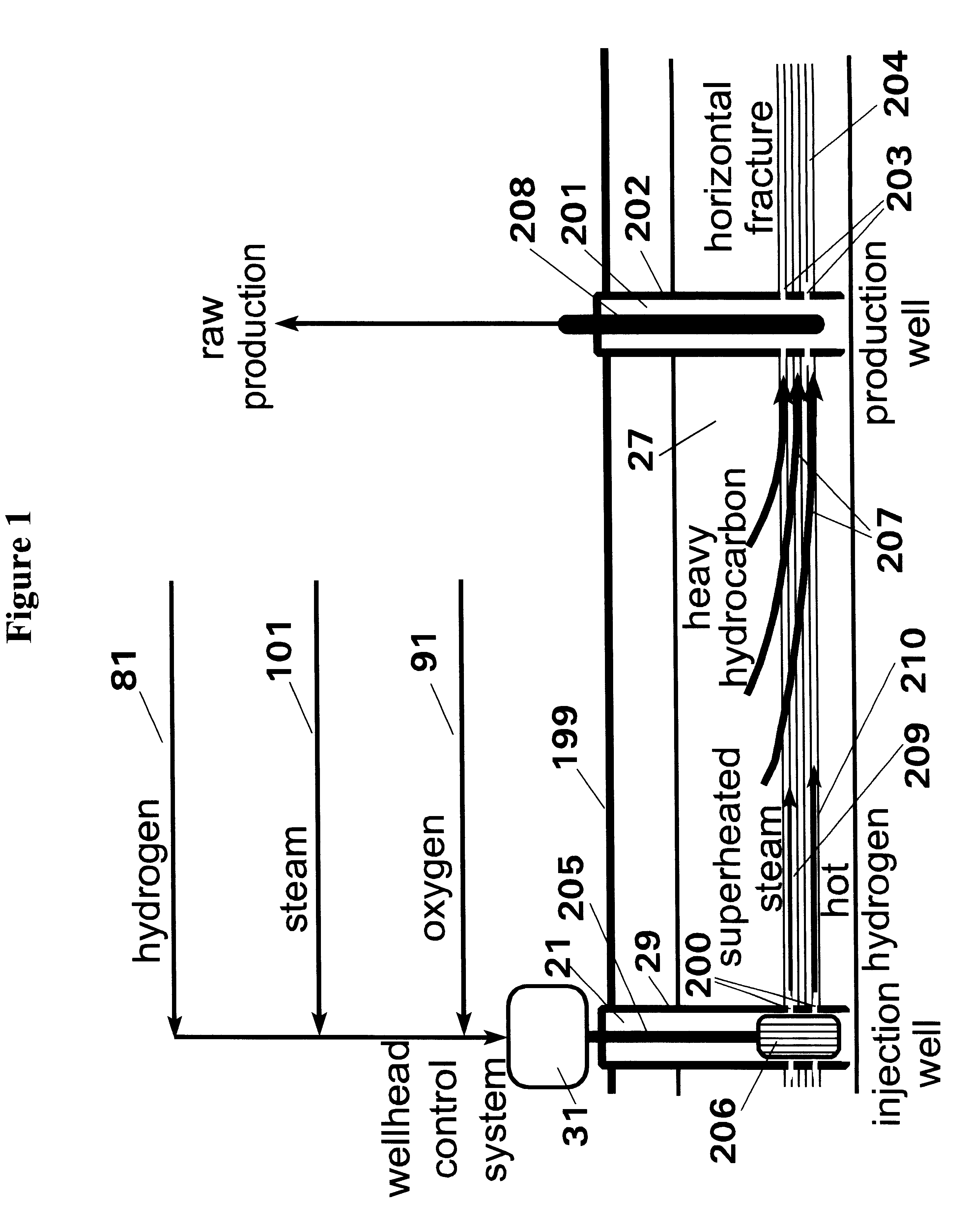

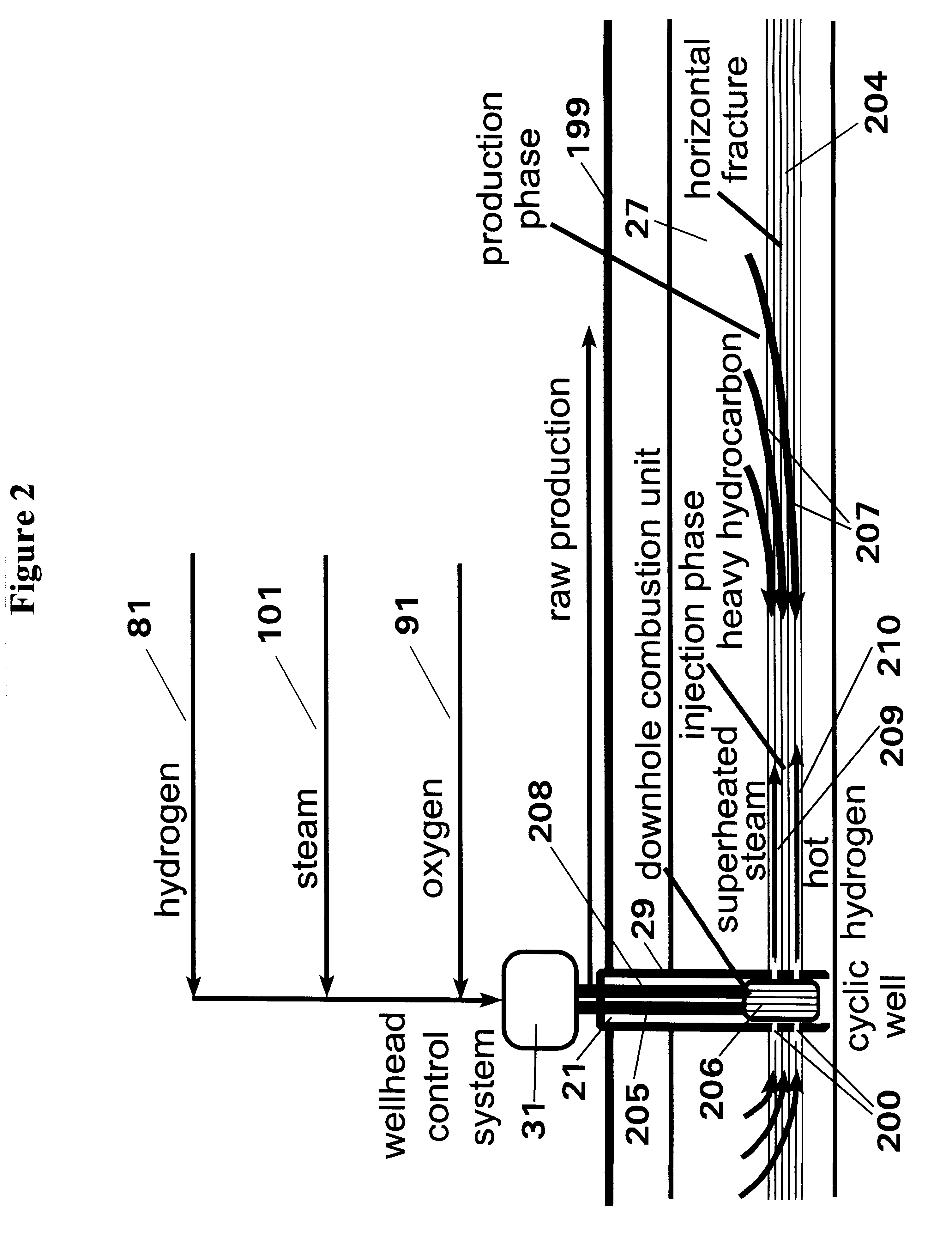

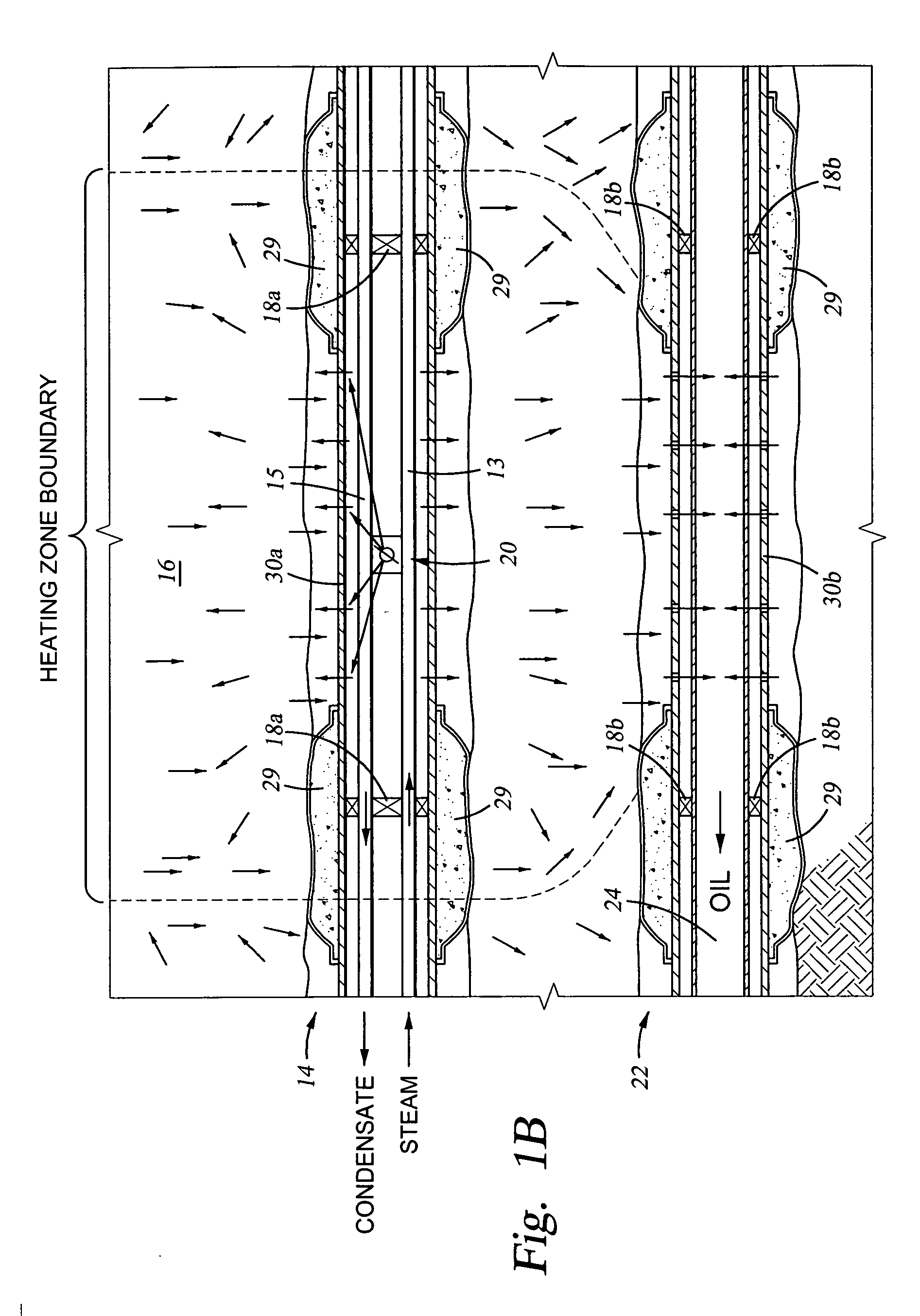

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

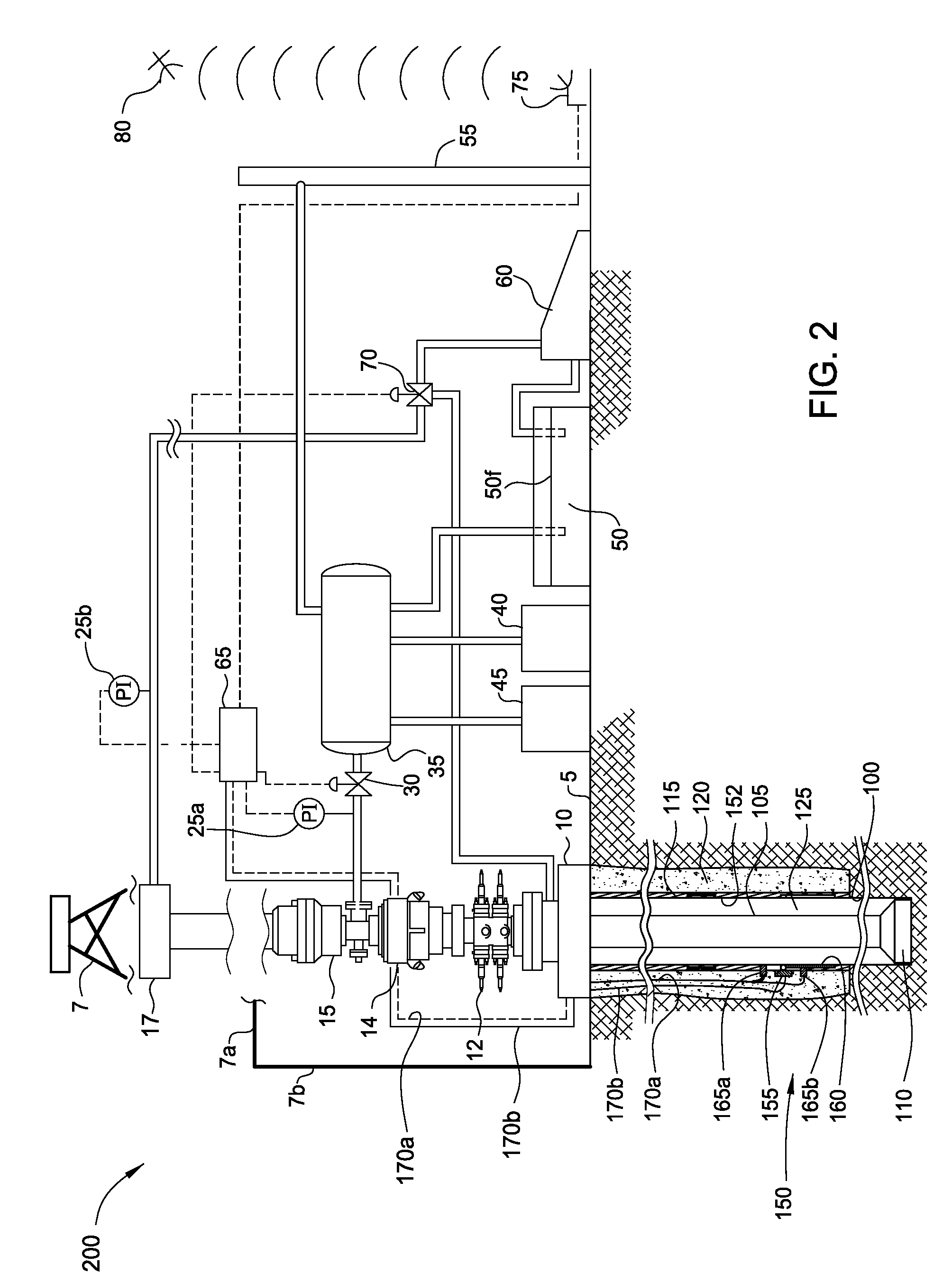

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

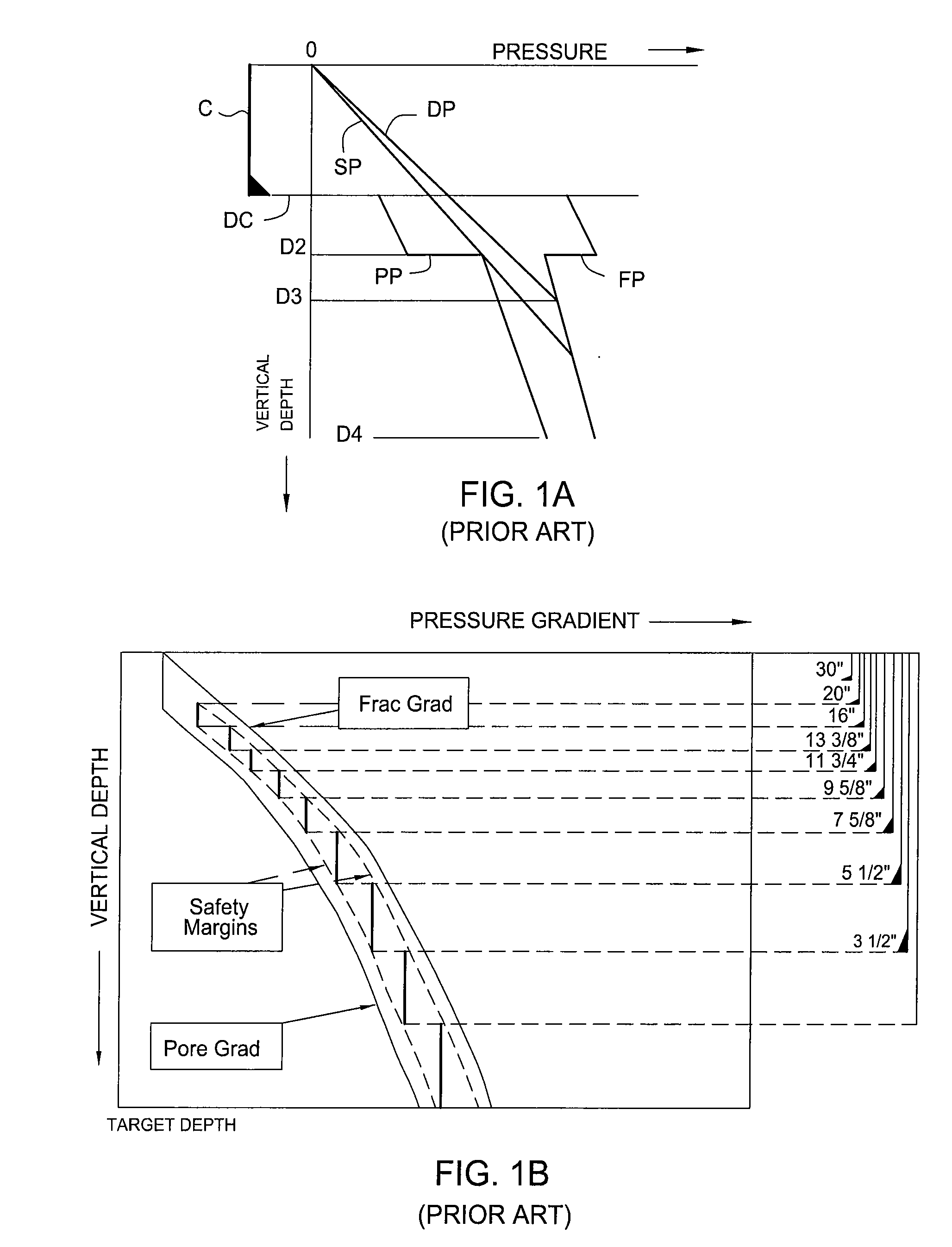

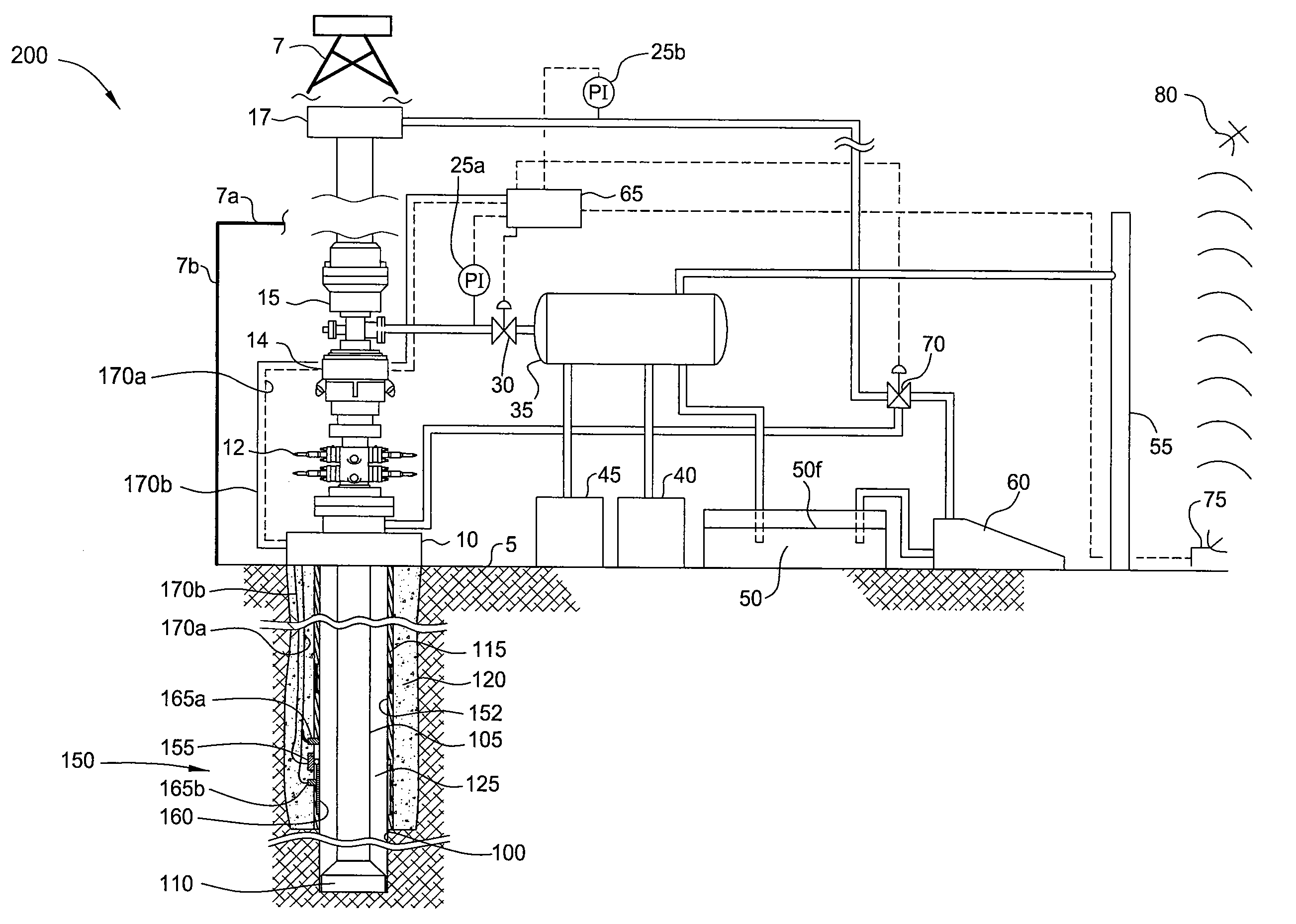

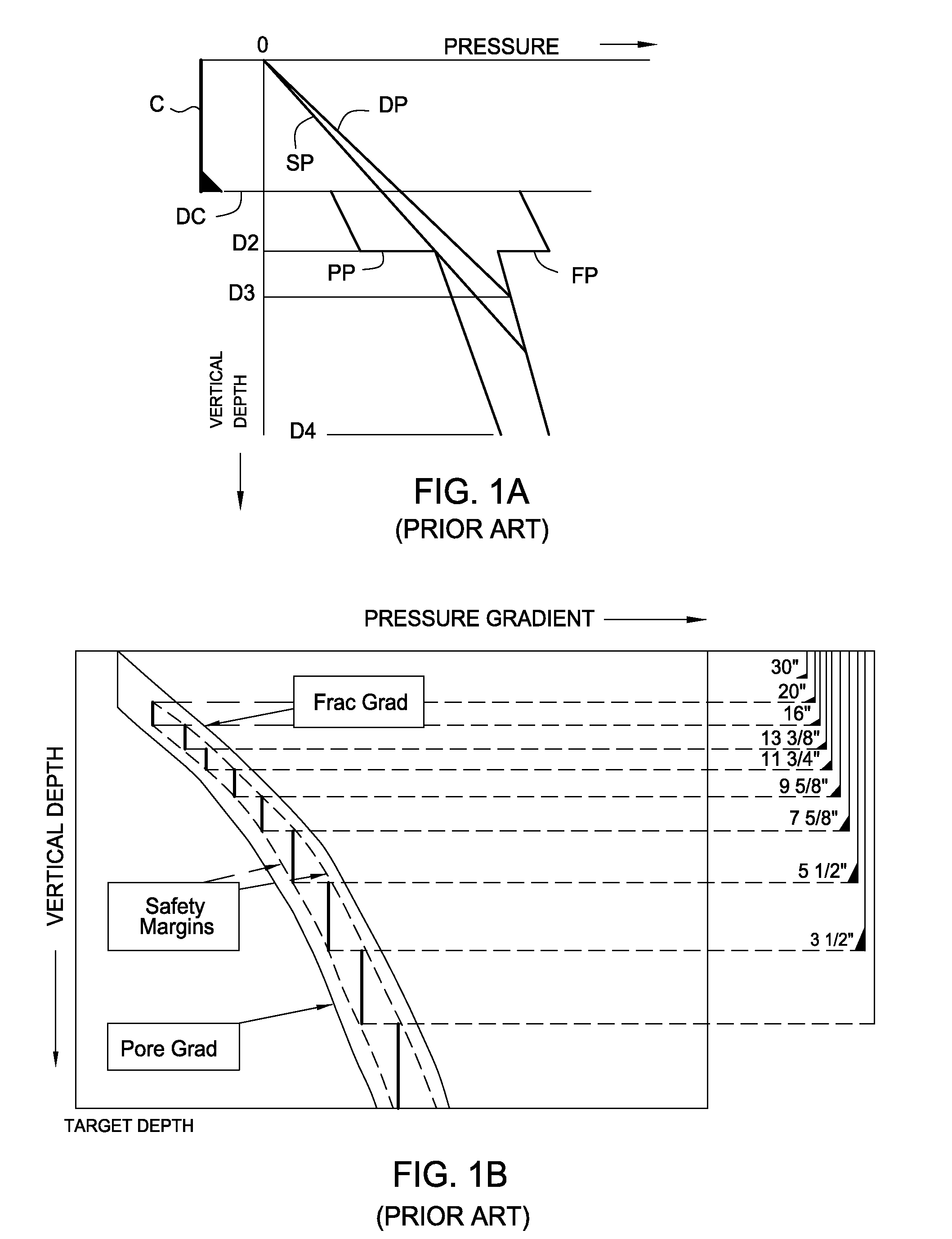

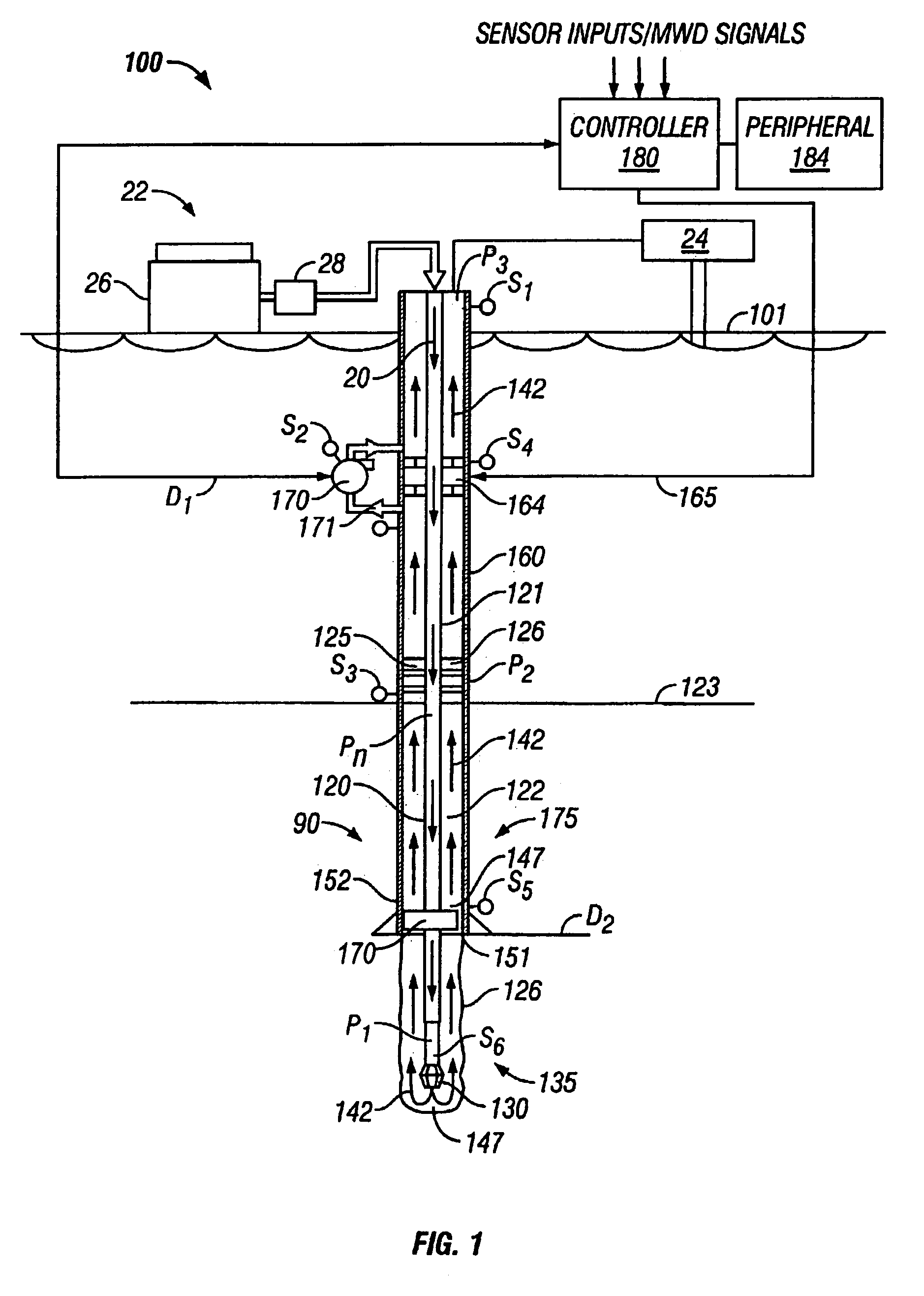

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

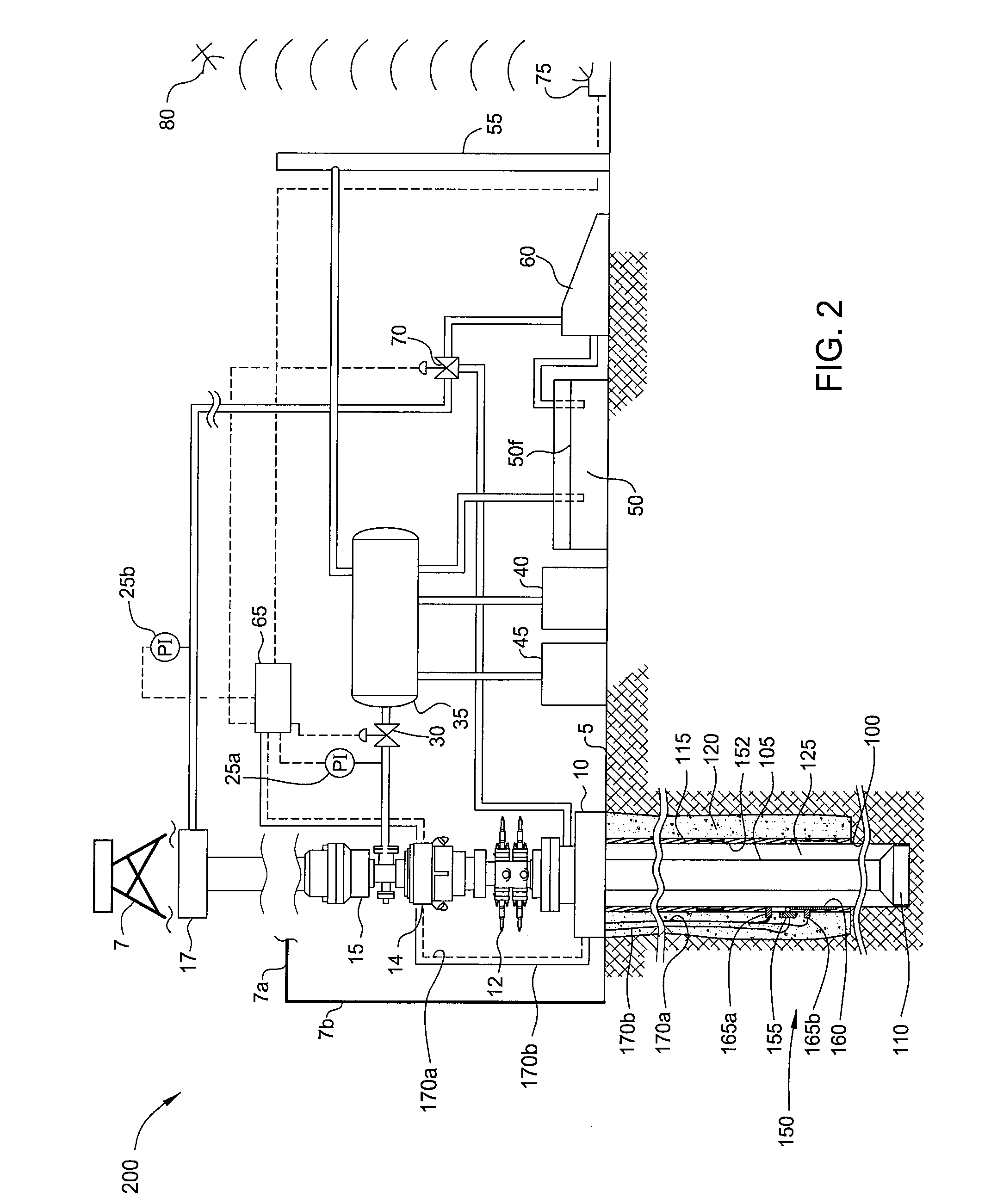

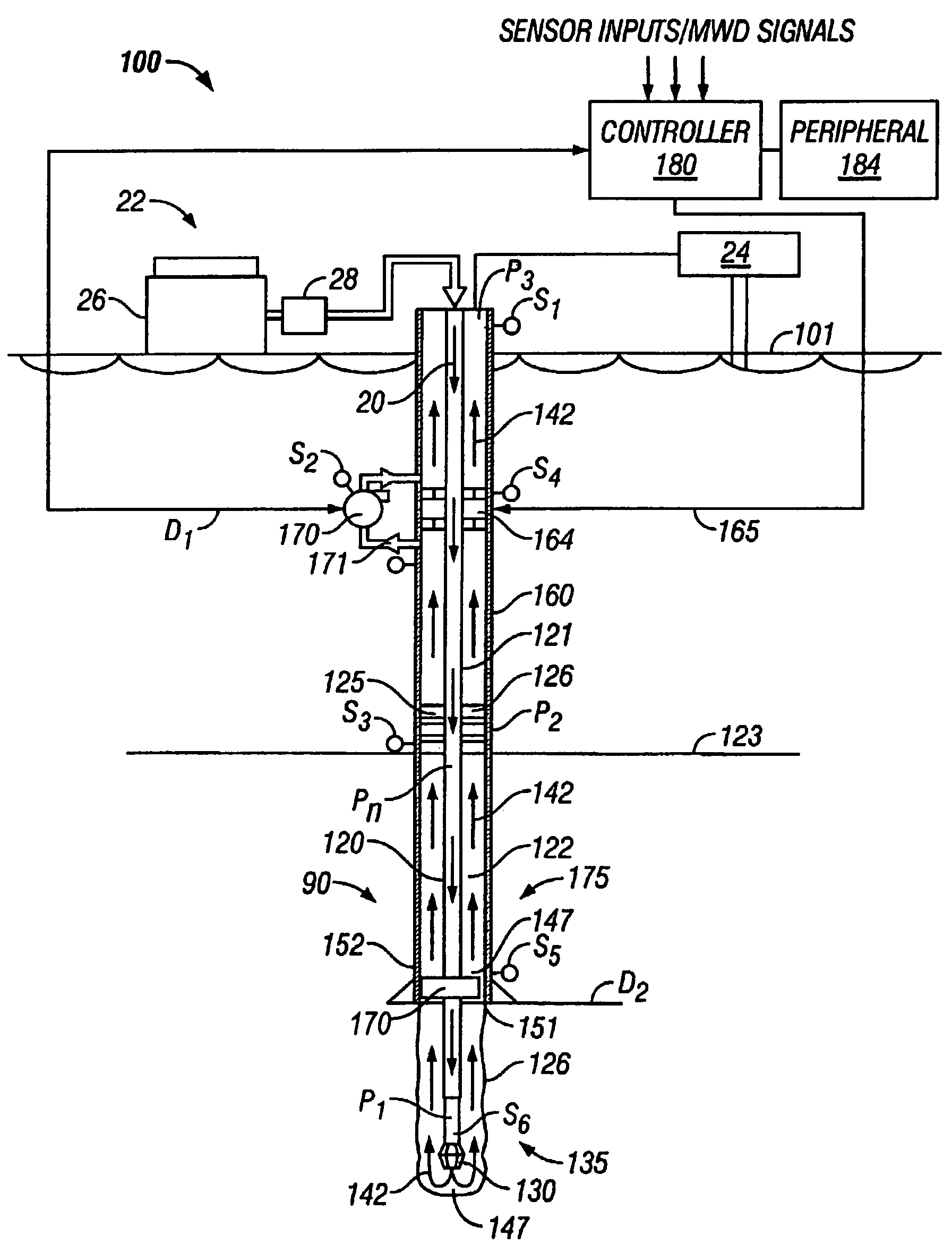

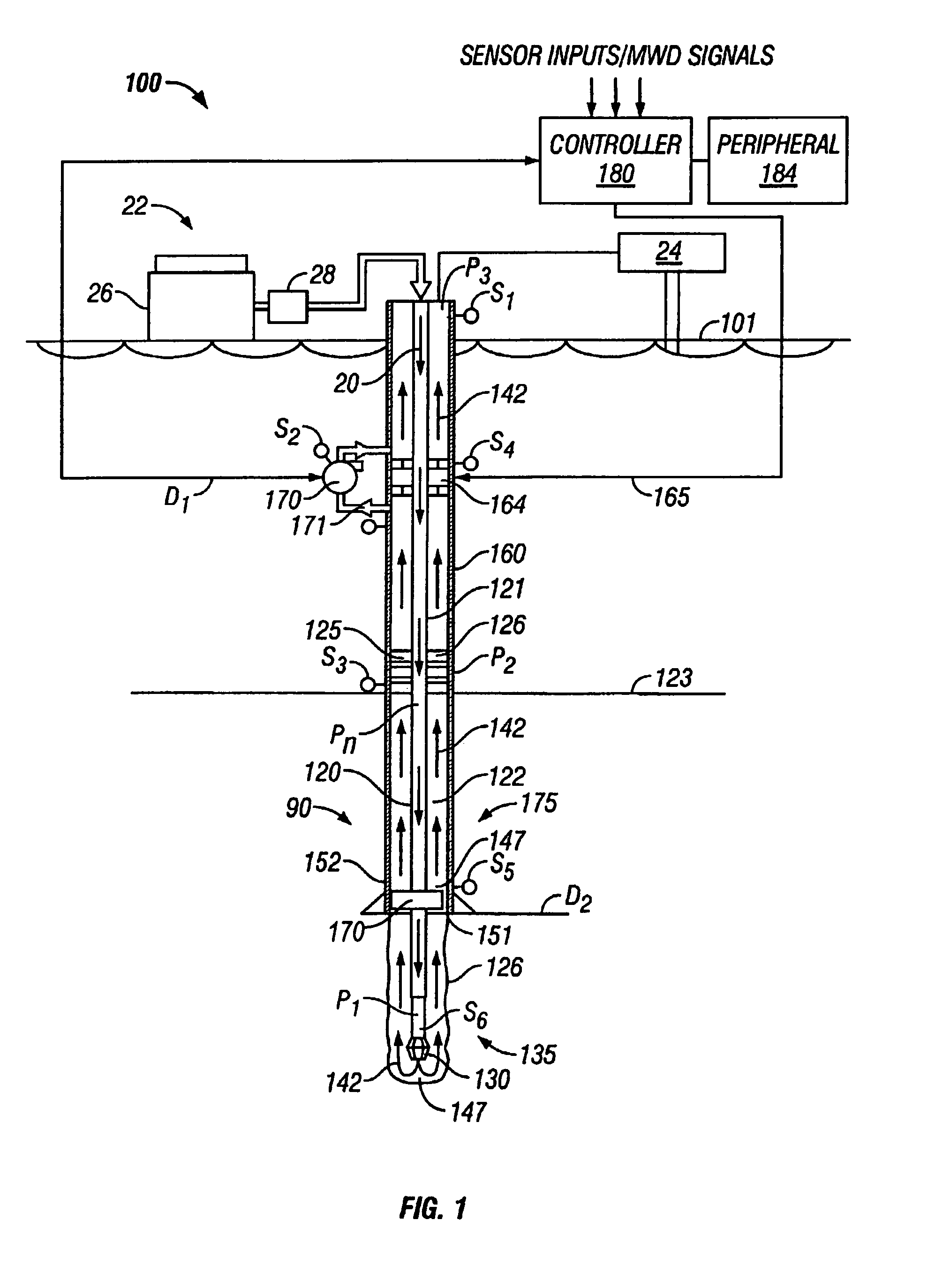

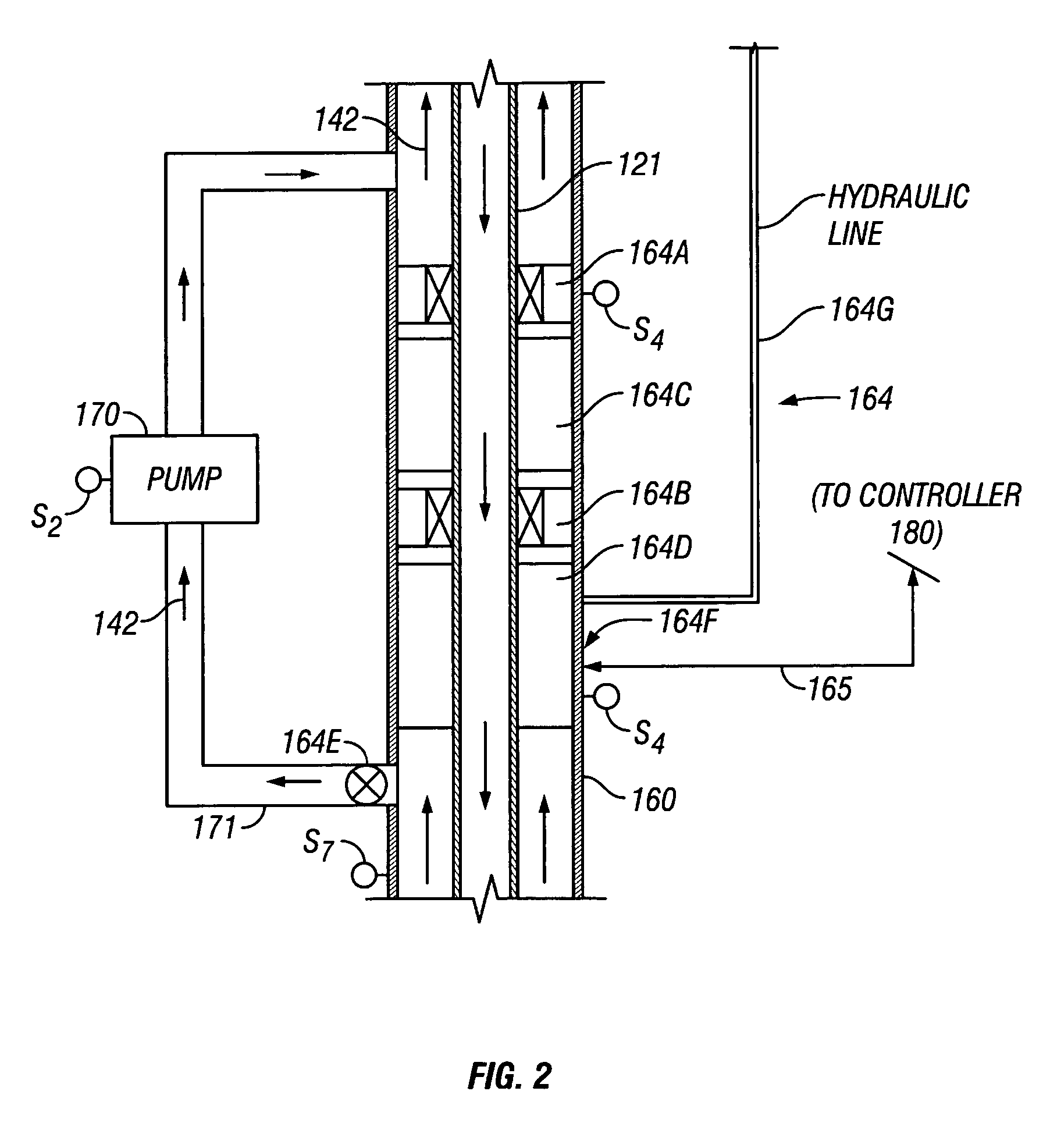

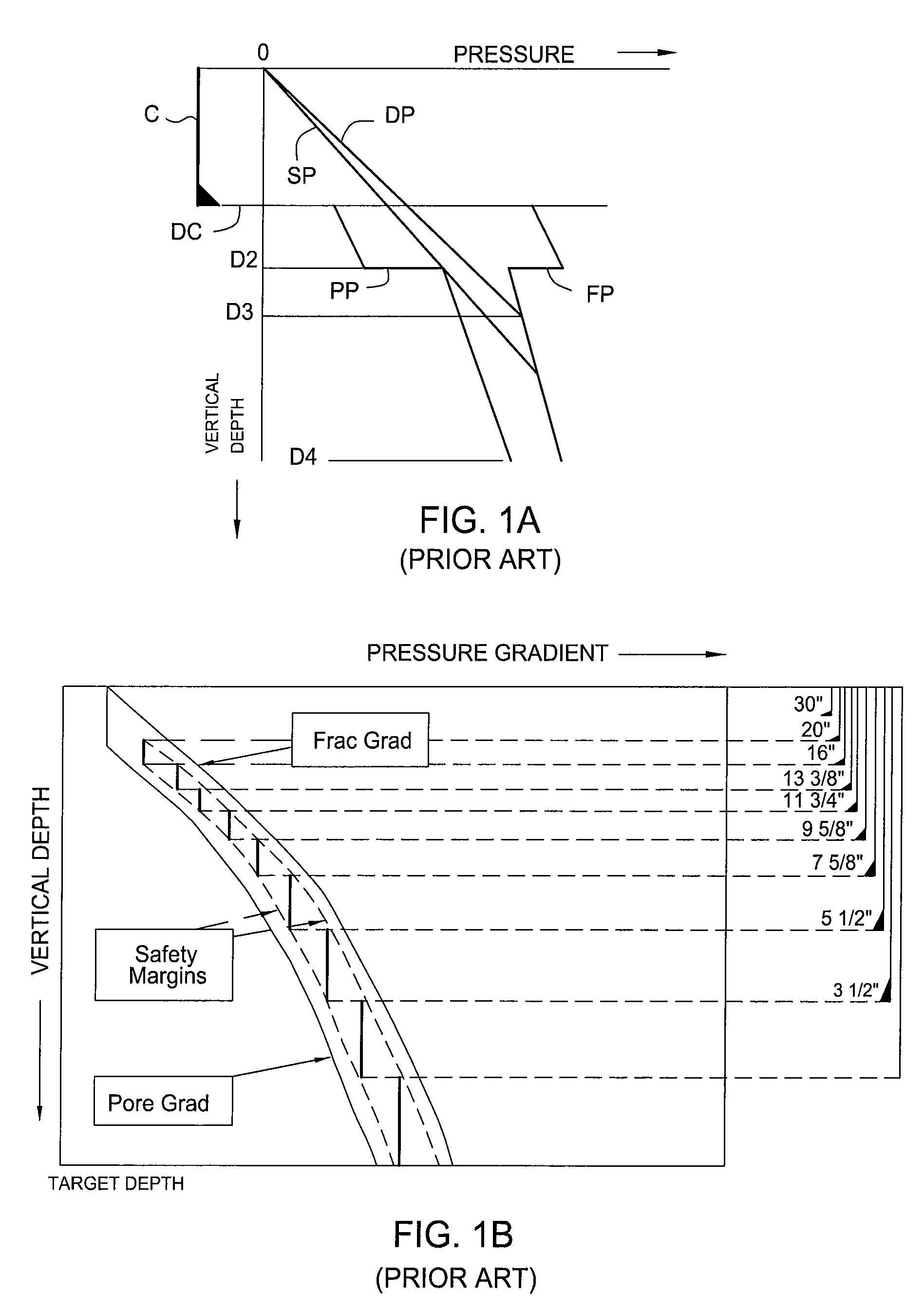

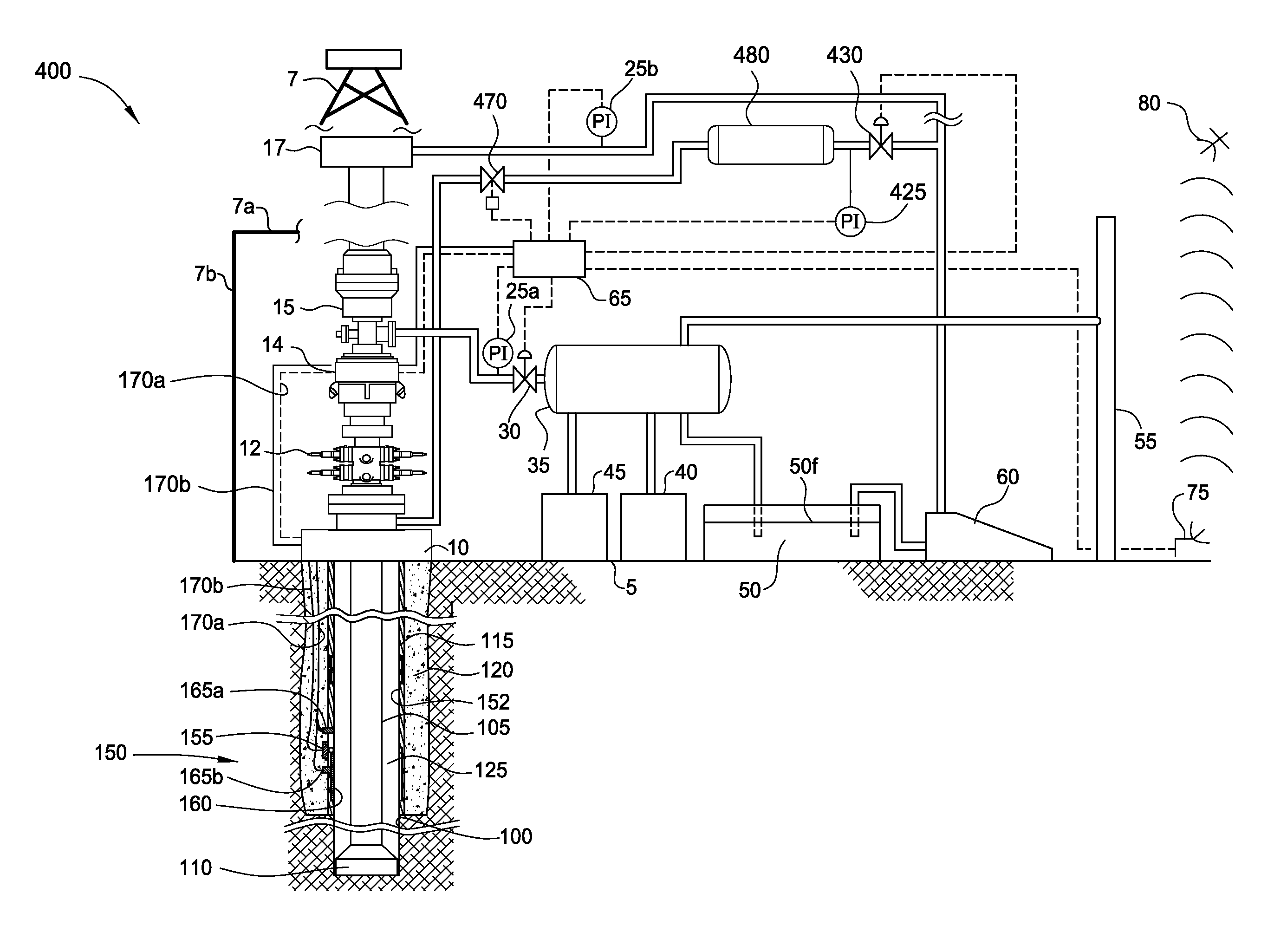

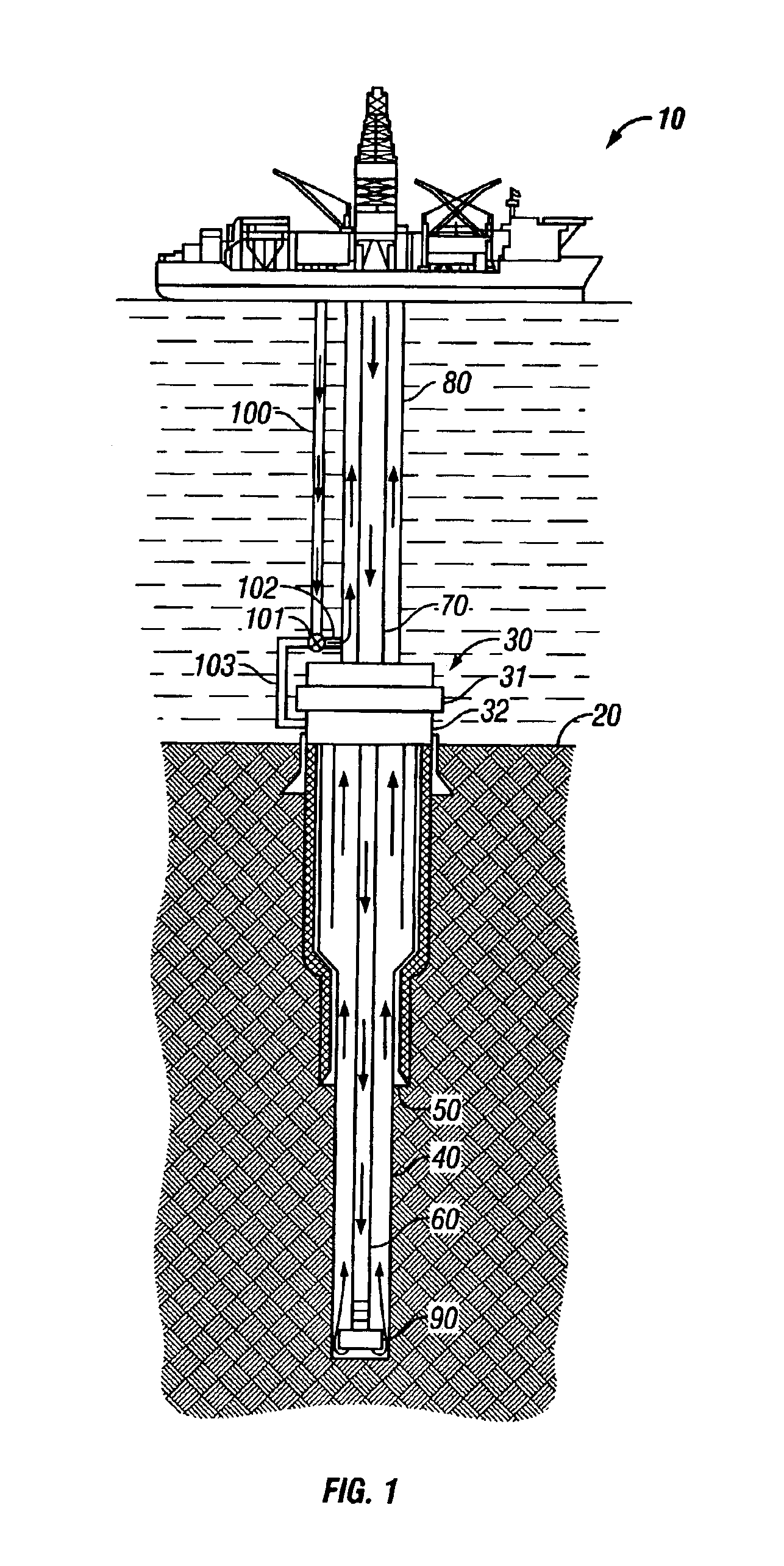

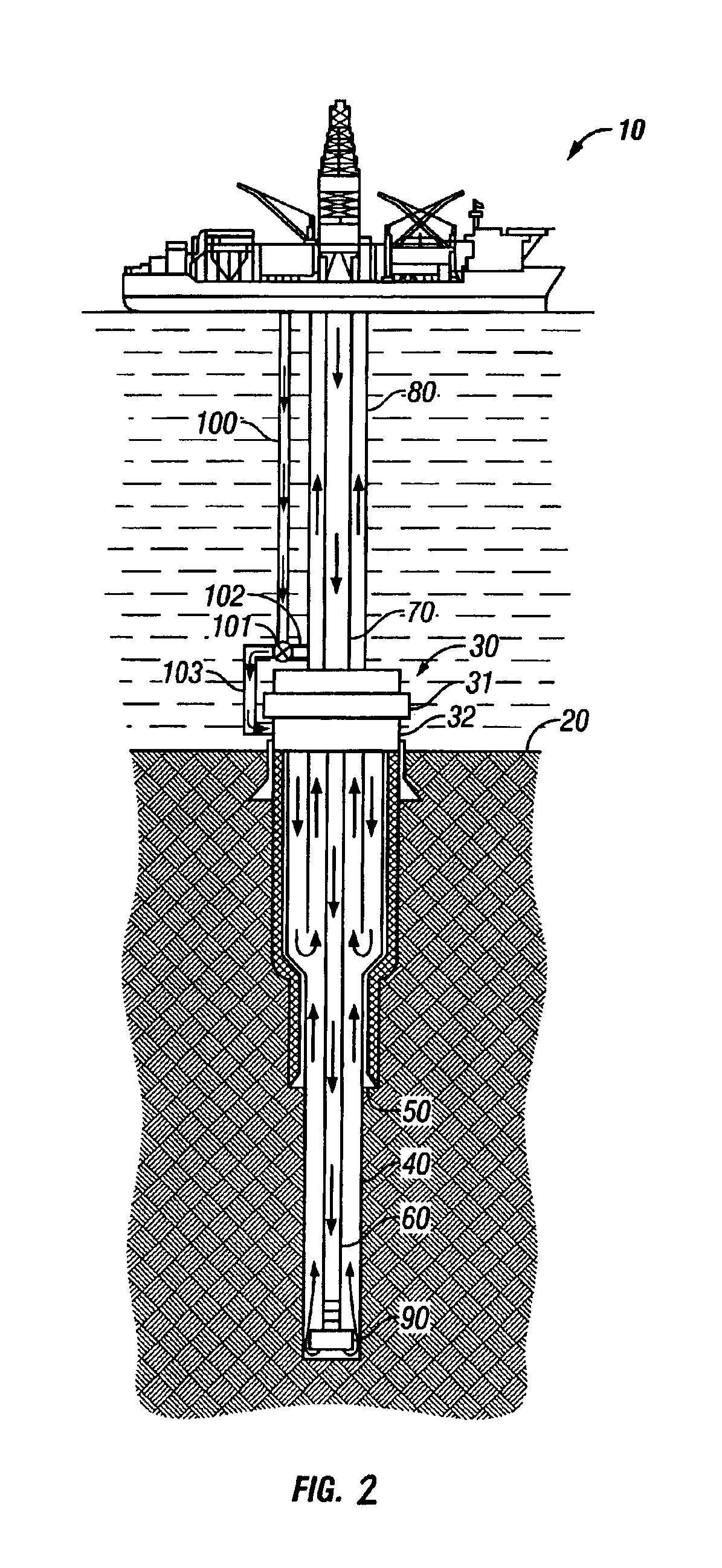

Drilling system and method for controlling equivalent circulating density during drilling of wellbores

A drilling system for drilling subsea wellbores includes a tubing-conveyed drill bit that passes through a subsea wellhead. Surface supplied drilling fluid flows through the tubing, discharges at the drill bit, returns to the wellhead through a wellbore annulus, and flows to the surface via a riser extending from the wellhead. A flow restriction device positioned in the riser restricts the flow of the returning fluid while an active fluid device controllably discharges fluid from a location below to just above the flow restriction device in the riser, thereby controlling bottomhole pressure and equivalent circulating density (“ECD”). Alternatively, the fluid is discharged into a separate return line thereby providing dual gradient drilling while controlling bottomhole pressure and ECD. A controller controls the energy and thus the speed of the pump in response to downhole measurement(s) to maintain the ECD at a predetermined value or within a predetermined range.

Owner:BAKER HUGHES INC

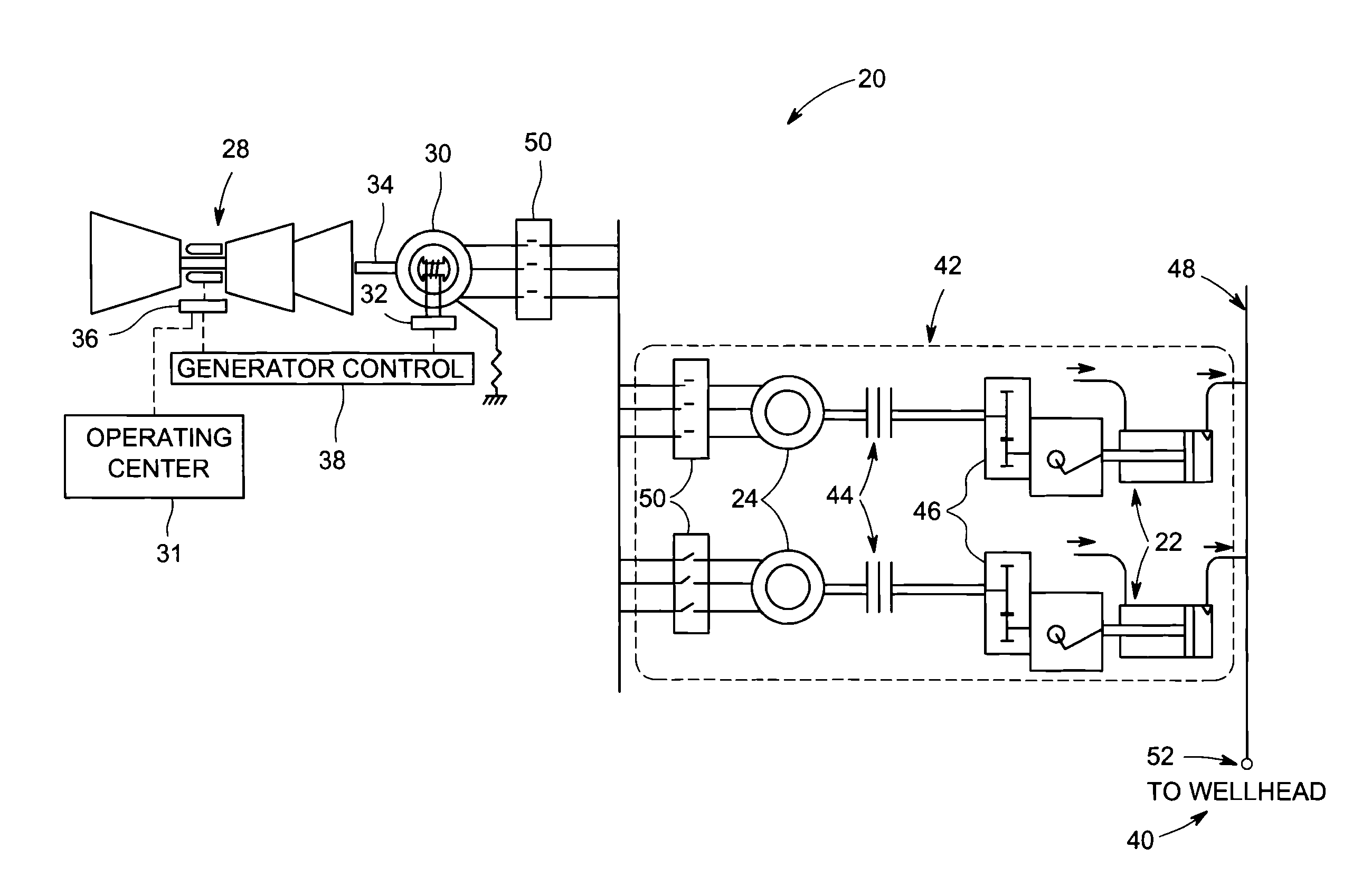

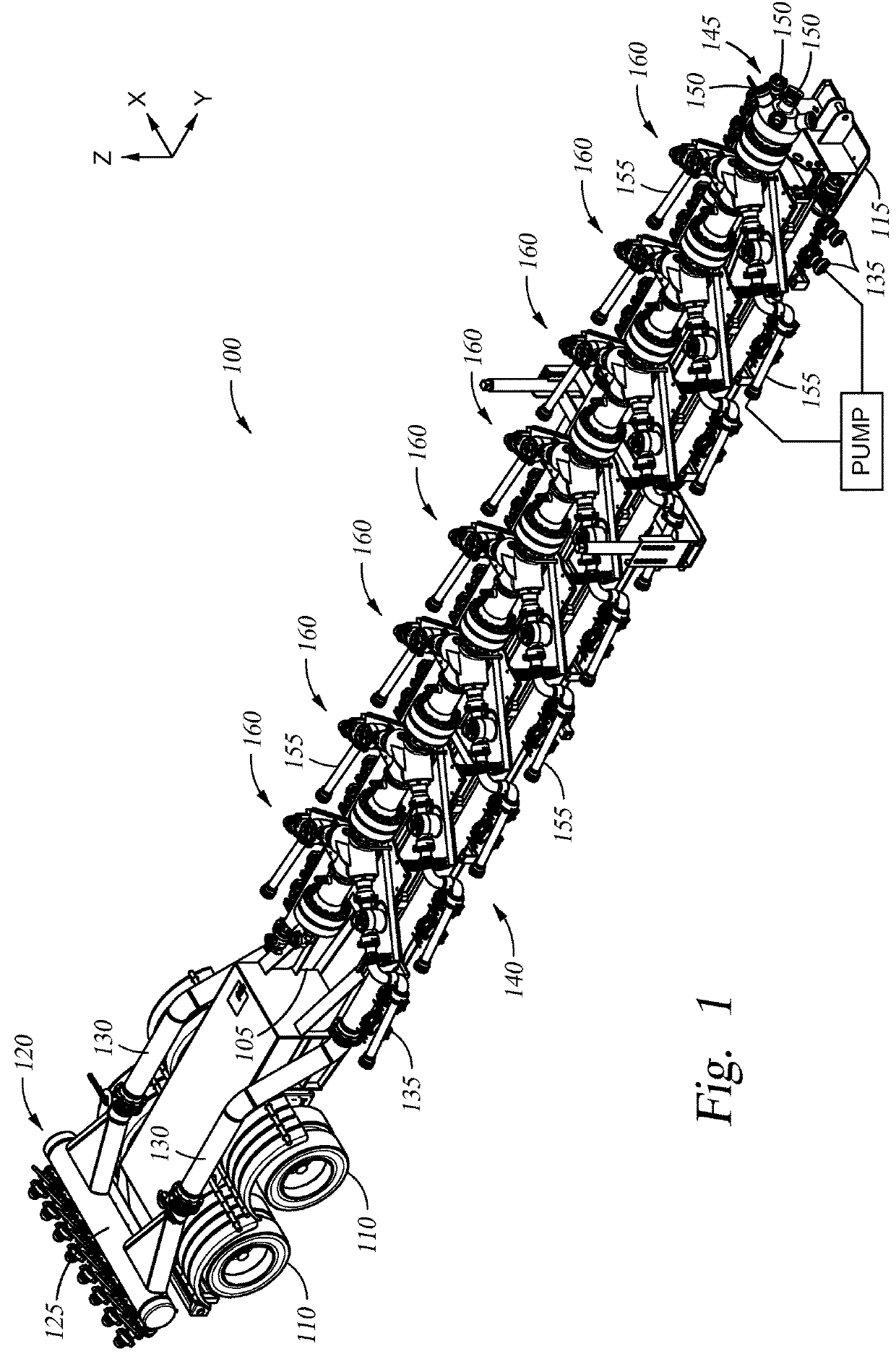

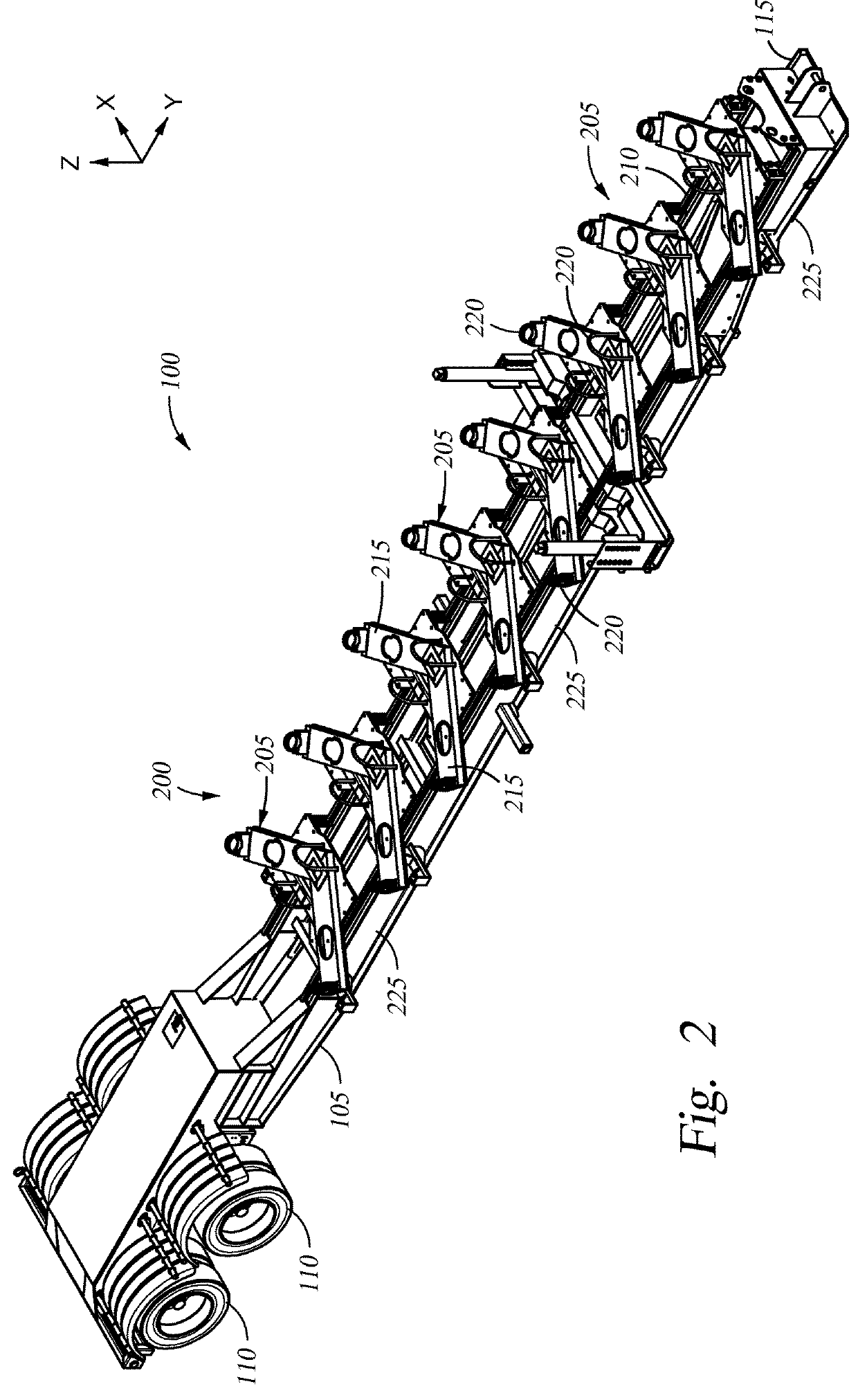

System and method for driving multiple pumps electrically with a single prime mover

A converterless motor-driven pump system includes an off-grid prime mover. The prime mover includes a rotational driveshaft that operates in response to a throttle or fuel input controller to control a rotation speed of the prime mover driveshaft. Operation of the throttle or fuel input controller is based on desired output characteristics of a pumping load. One or more electric power generators are driven by the off-grid prime mover to generate AC or DC power on an electrical bus shared by a plurality of variable speed electric motors. A plurality of pumps is connected to a common manifold shared by the plurality of pumps. The plurality of pumps is driven by the plurality of variable speed electric motors to generate a desired wellhead pressure or pumping load flow rate via the shared common manifold.

Owner:GENERAL ELECTRIC CO

Method for remotely launching subsea pigs in response to wellhead pressure change

A method for sensing and launching pipeline pigs into a pipeline. The method includes pressurizing a pressure accumulator in a pig launching system that includes a pig chamber, a plurality of pigs, a launch tube, and the pressure accumulator. The method further includes sensing a pressure within the pipeline and applying pressure from the pressure accumulator to force a pig through the launch tube and into the pipeline.

Owner:SAIPEM AMERICA

Manifold trailer having a single high pressure output manifold

A manifold trailer is provided and includes a chassis, a low pressure piping system disposed along a length of the chassis, and a single high pressure output manifold disposed along the length of the chassis, the high pressure output manifold terminating at a splitter that distributes fluids from the high pressure manifold to a wellhead.

Owner:FORUM US

Wellhead

A wellhead is formed by extruding a plurality of tubular liners off of a mandrel into contact with an outer casing. The first tubular liner and mandrel are positioned within the wellbore with the tubular liner in an overlapping relationship with the outer casing. At least a portion of the tubular liner is extruded off of the mandrel into contact with the interior surface of the outer casing. The first tubular liner is extruded off of the mandrel by pressurizing an interior portion of the first tubular liner. Subsequent tubular liners are positioned in concentric overlapping relation and similarly extruded off of a mandrel into at least partial contact with the interior surface of the outer casing.

Owner:ENVENTURE GLOBAL TECH LLC

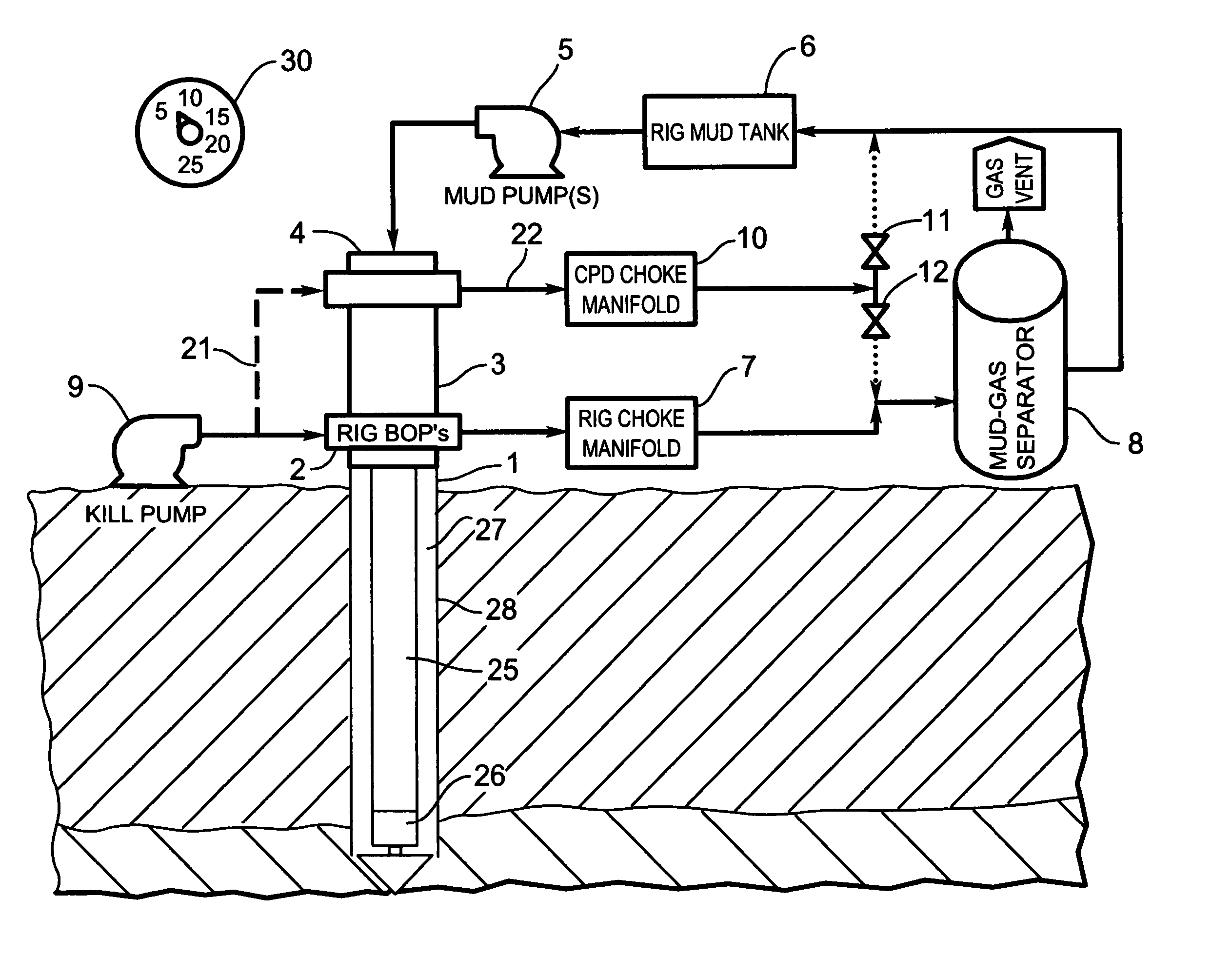

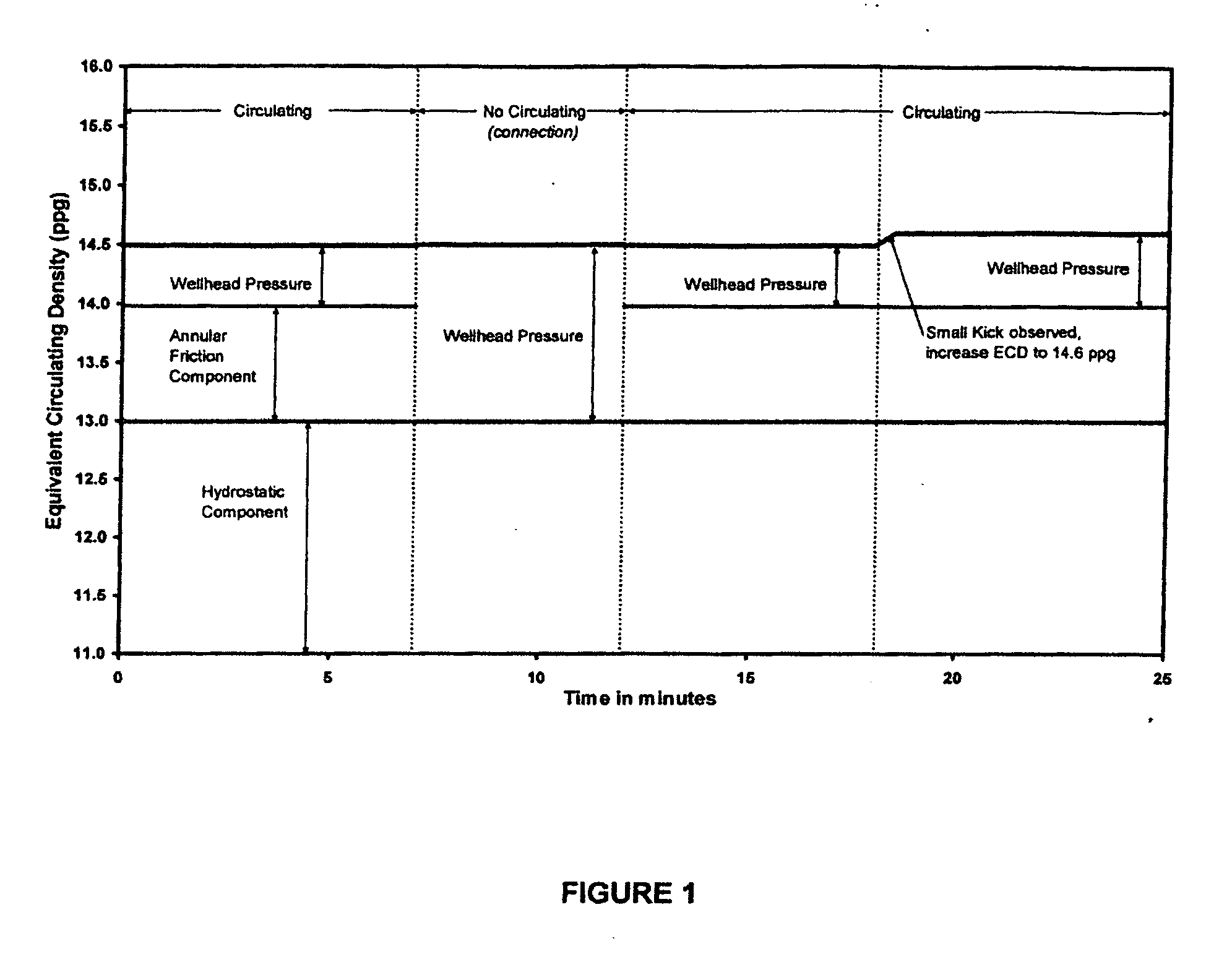

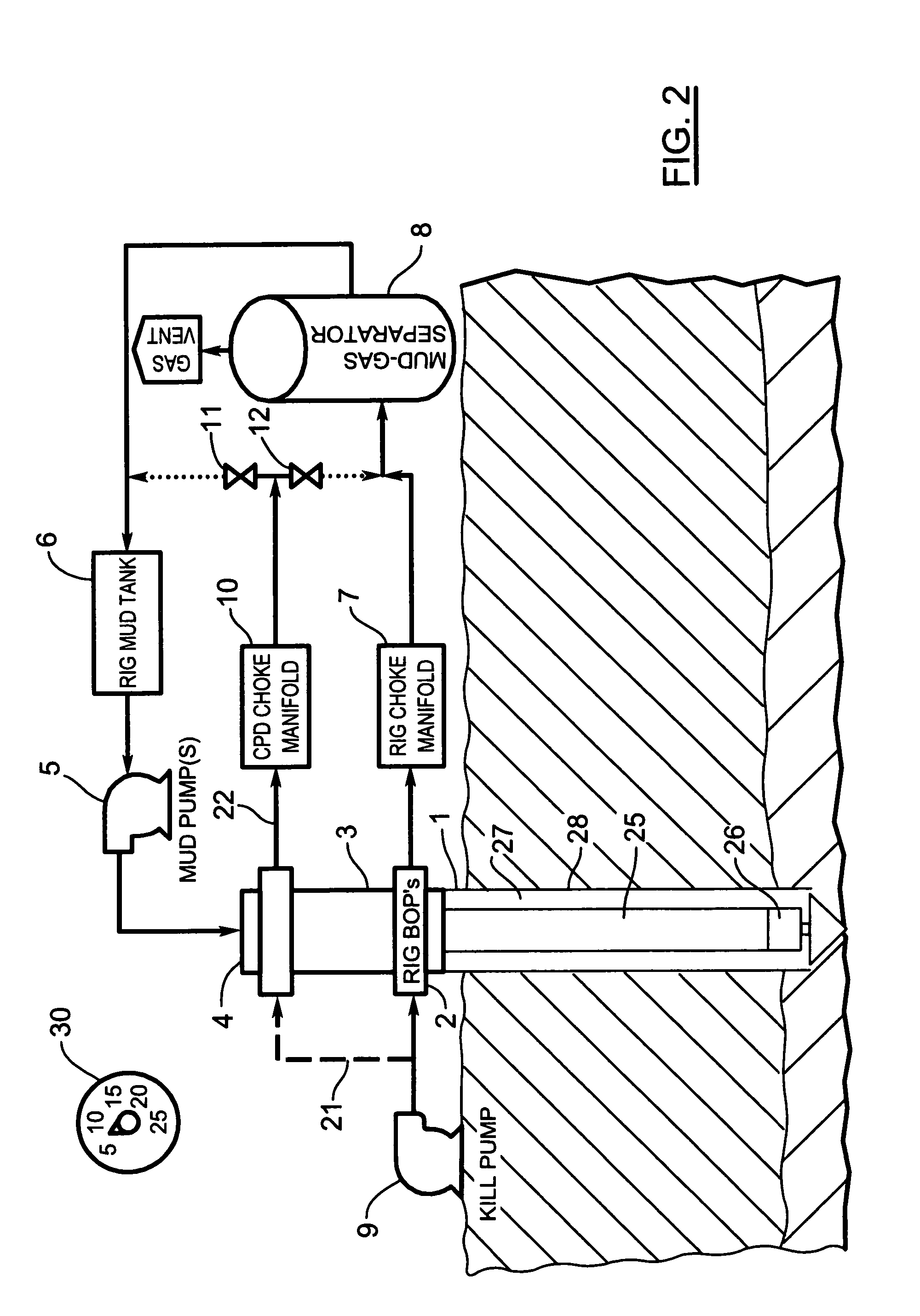

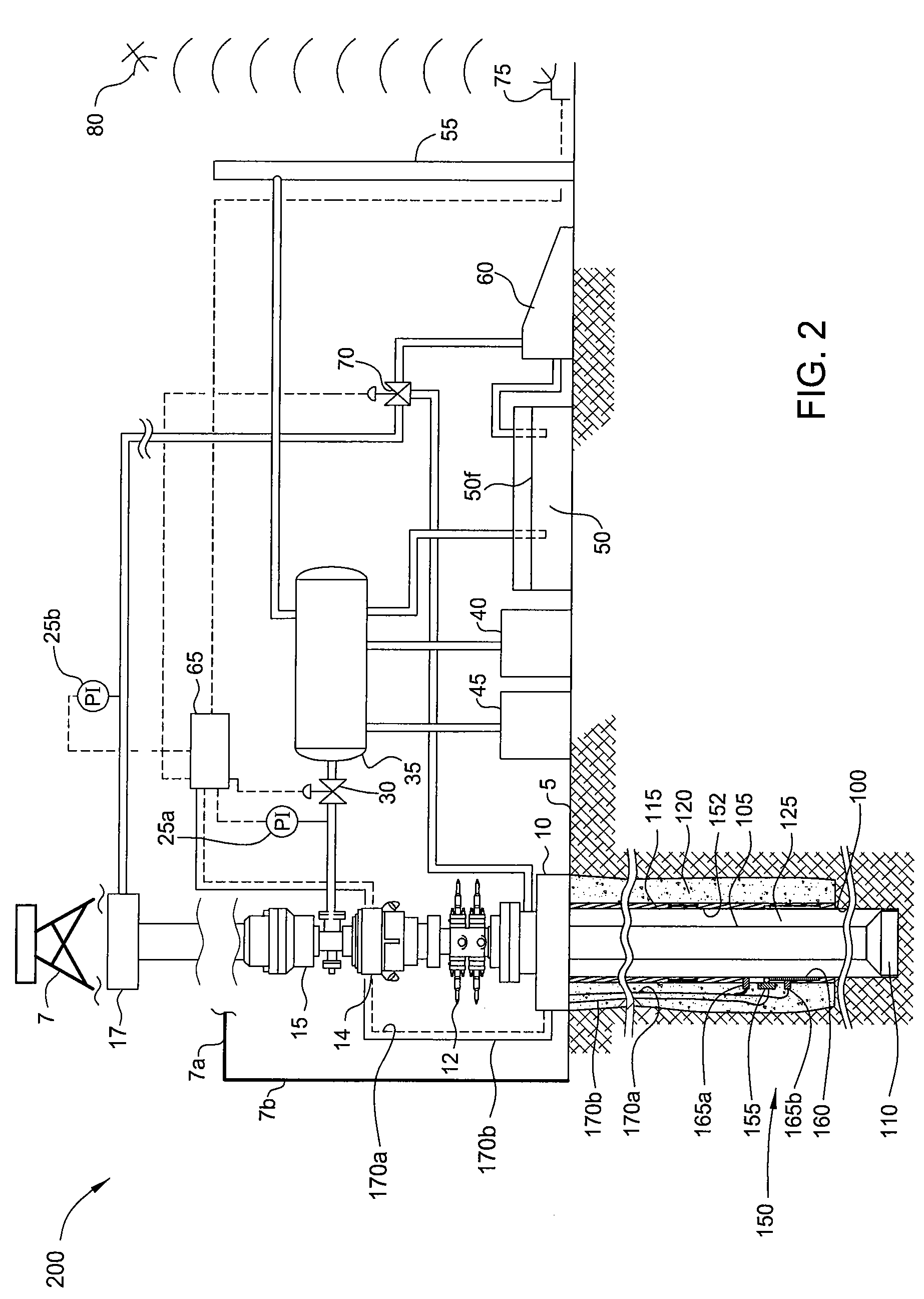

Method of dynamically controlling open hole pressure in a wellbore using wellhead pressure control

ActiveUS20060207795A1Simplified and efficient and relatively inexpensiveIncrease pumping rateFlushingDrilling compositionPressure controlled ventilationThrottle

A method of dynamically controlling open hole pressure within a wellbore having a drill string positioned therein. The method comprising the steps of pumping a fluid down the drill string, into an annulus formed by the drill string and the interior of the wellbore, and then subsequently up the annulus to the surface of the ground; selectively applying wellhead pressure to the annulus through selectively pumping an additional quantity of the fluid or a quantity of a secondary fluid across the annulus; and, controlling the application of wellhead pressure applied to the annulus by controlling one, or both, of (a) the operation of a wellhead pressure control choke, and (b) the flow rate of the additional quantity of fluid or the secondary fluid pumped across the annulus, to thereby maintain open hole pressure within a desired range.

Owner:WEATHERFORD CANADA

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

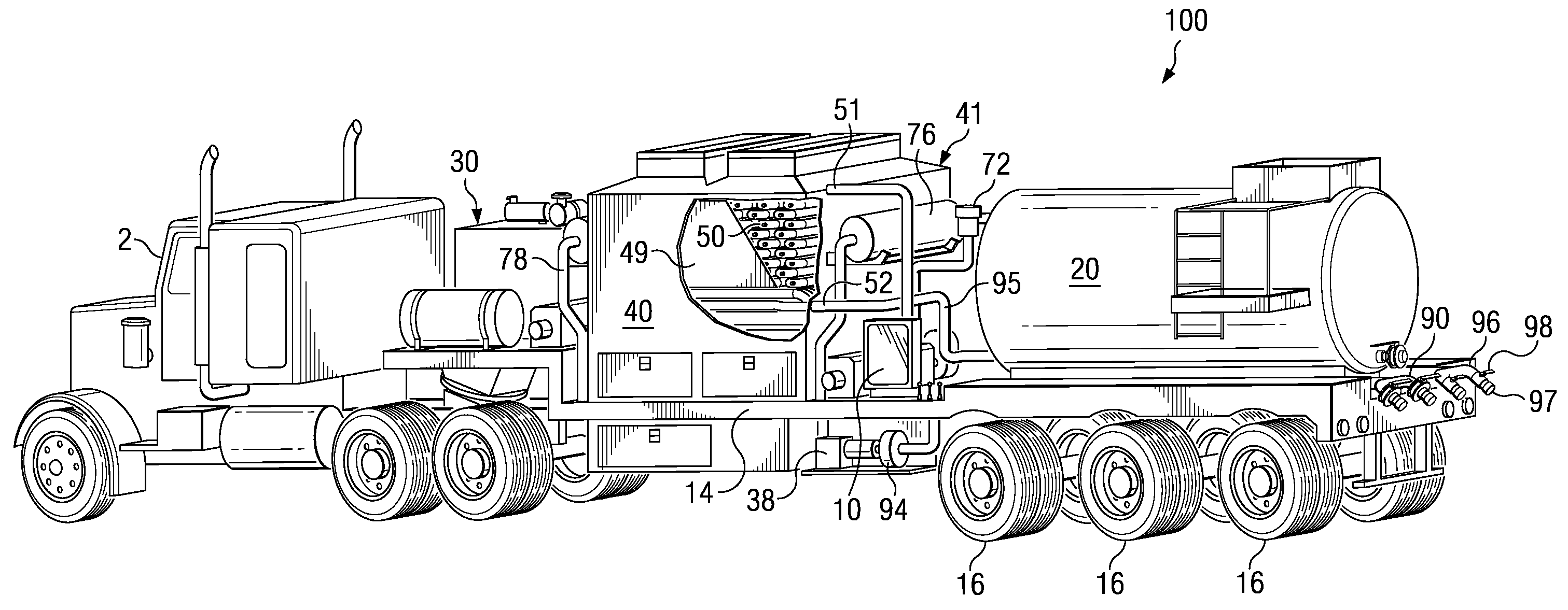

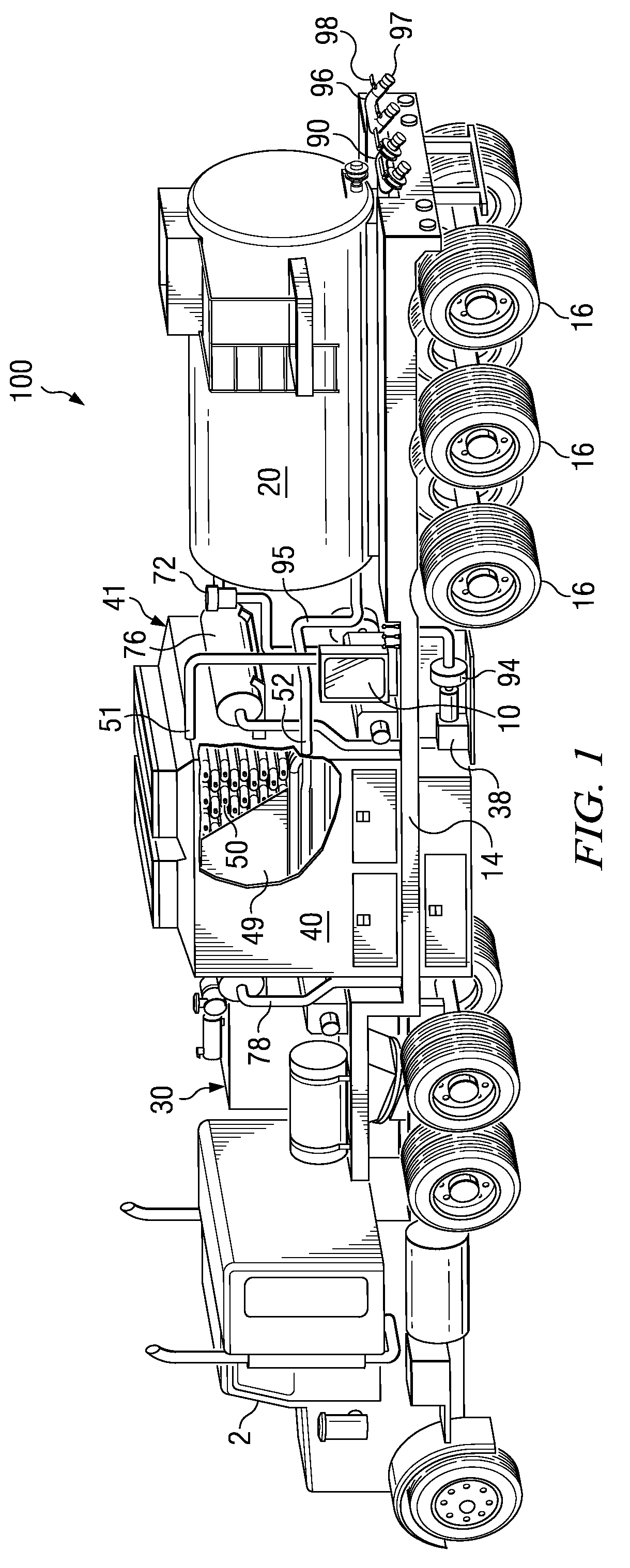

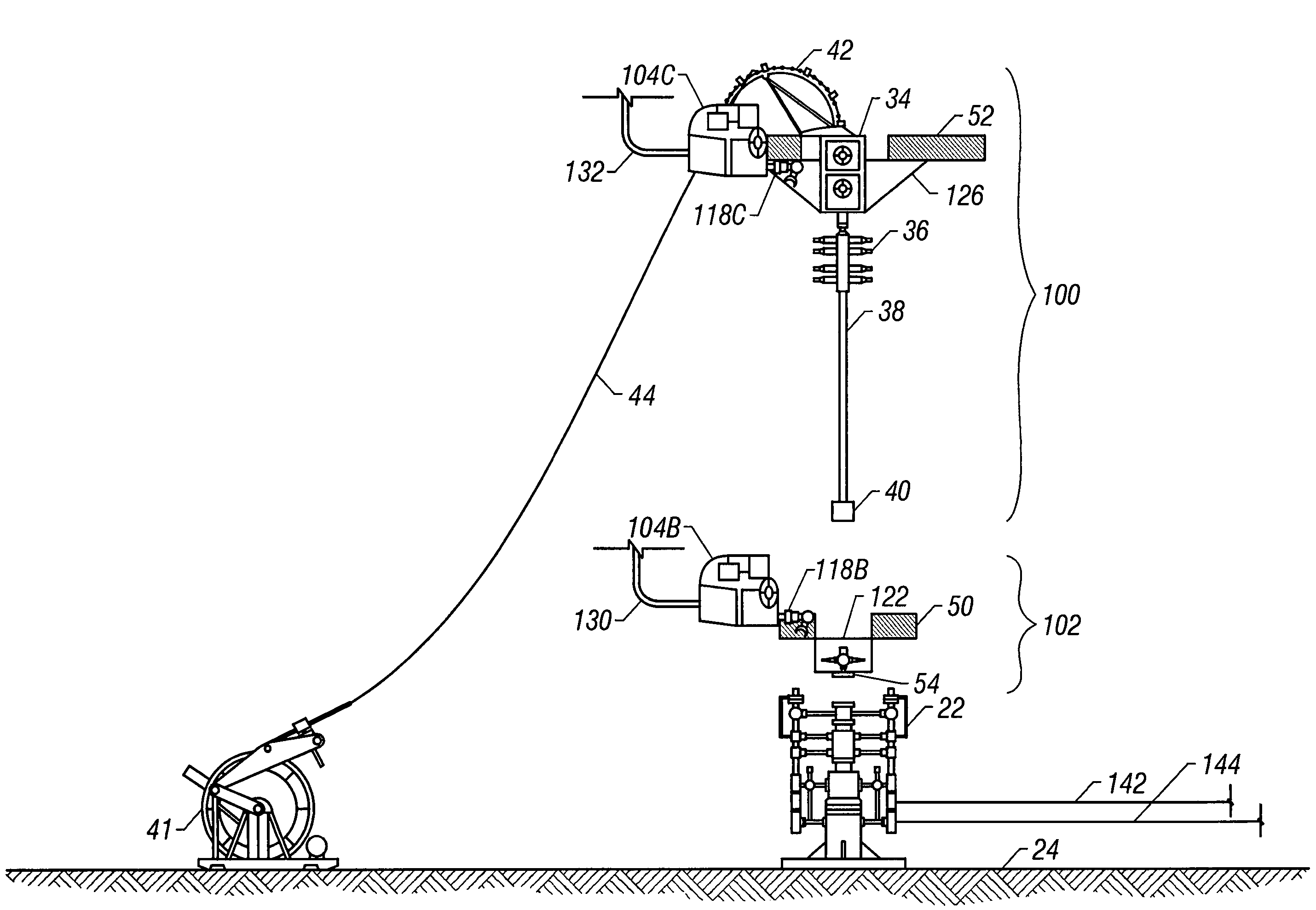

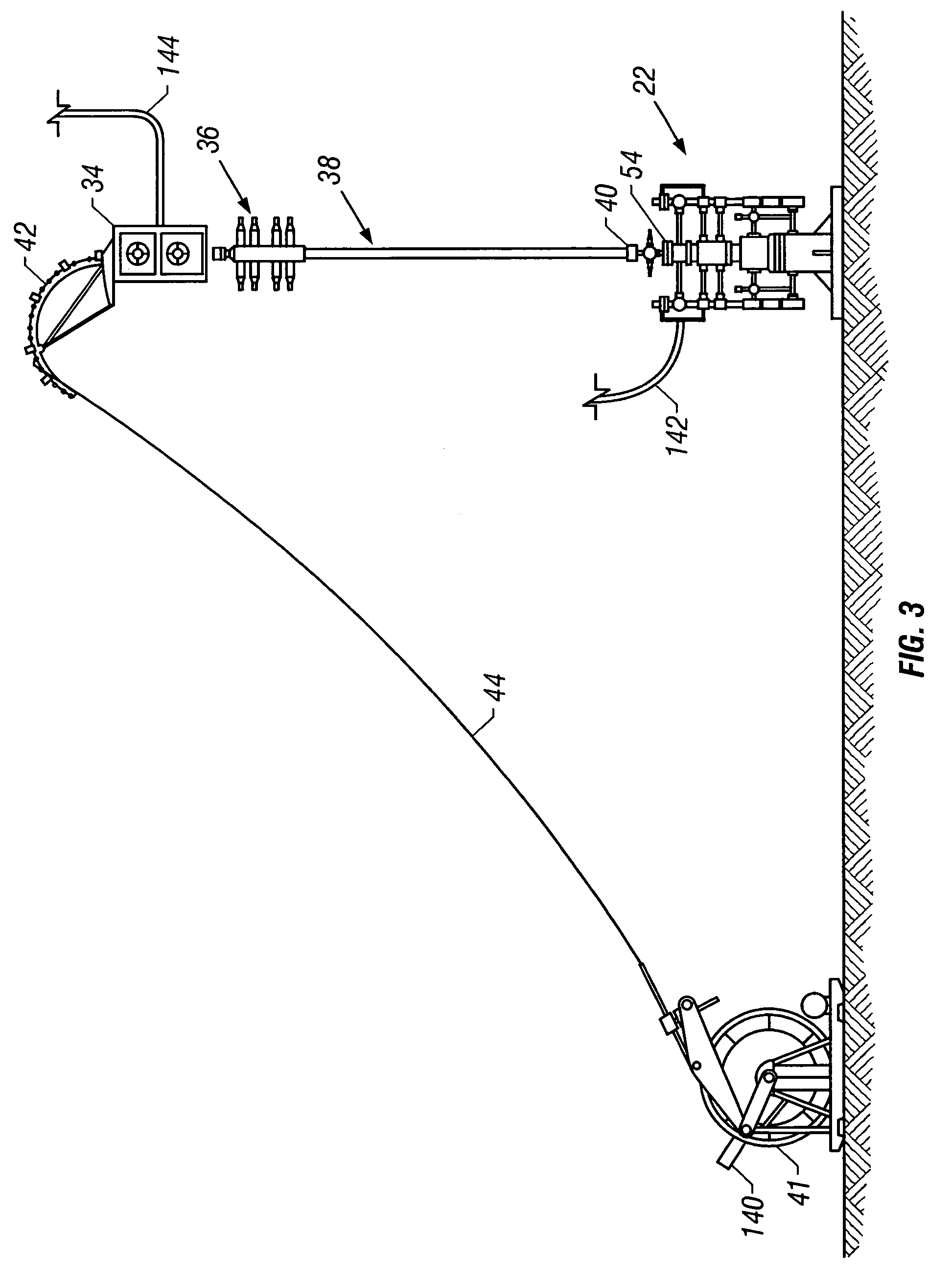

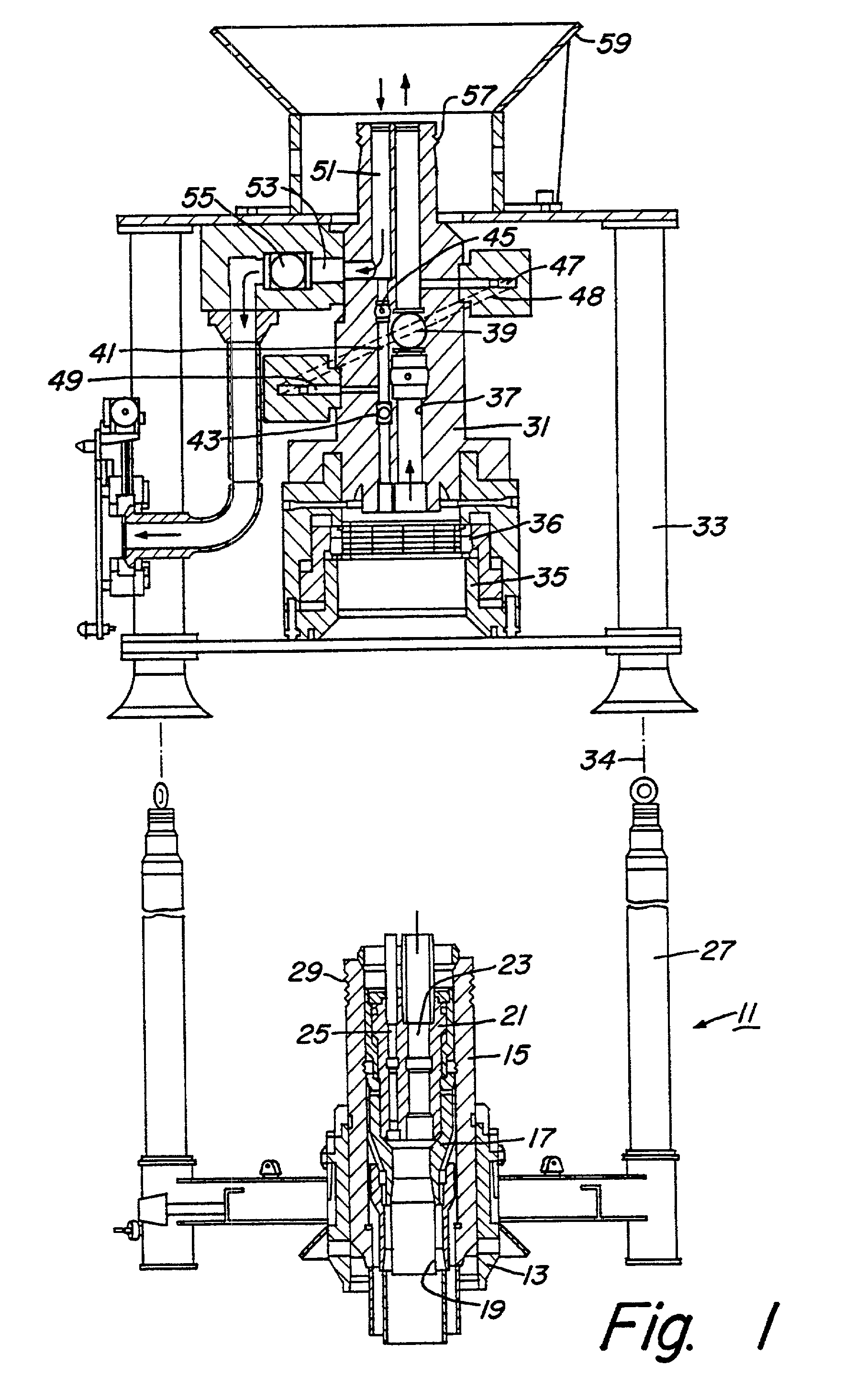

Oil-fired frac water heater

ActiveUS20100000508A1Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankEngineering

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an oil-fired heat exchange system. The present invention is a self-contained unit which is easily transported to remote locations. The present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in ail weather environments. In a preferred embodiment, the oil-fired heat exchanger system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

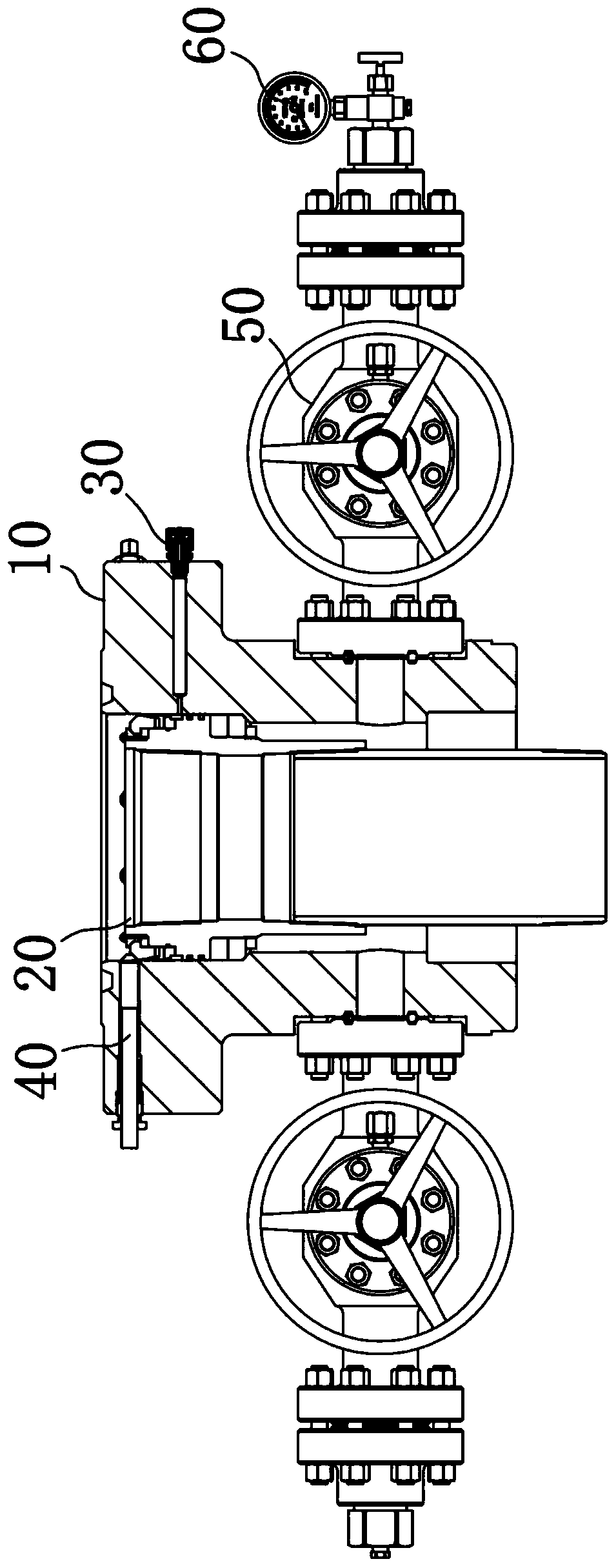

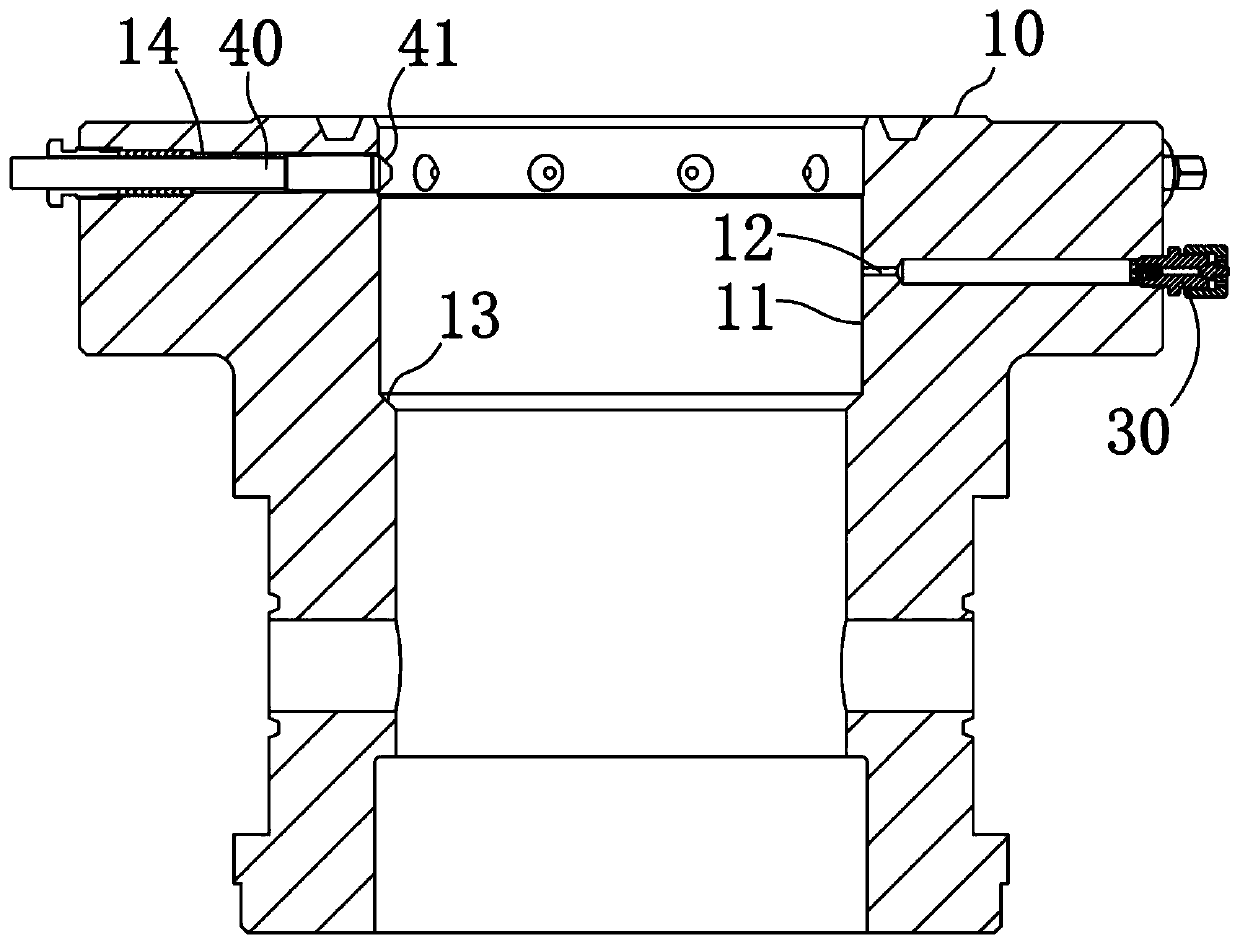

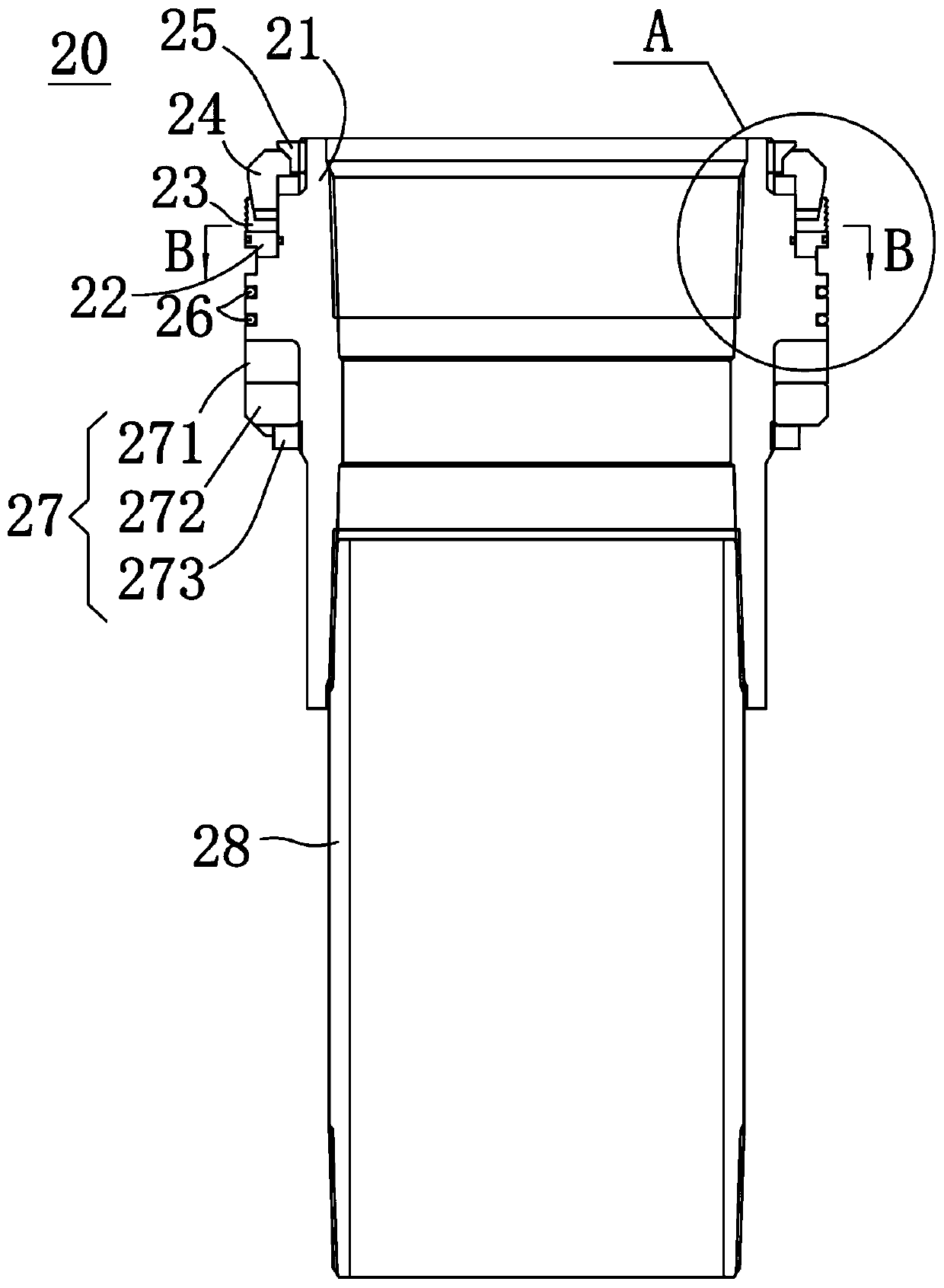

Composite drive mandrel anchoring casing head

The invention discloses a composite drive mandrel anchoring casing head and relates to the technical field of wellhead devices, the composite drive mandrel anchoring casing head comprises a casing head shell and an anchoring mandrel unit, a pressurizing hole is further formed in the side wall of the casing head shell, the first end of the pressurizing hole is connected with an anchoring hole part,and the second end of the pressurizing hole extends to the outer side of the casing head shell. The anchoring mandrel unit comprises an anchoring mandrel body, a slip exciting piece, an anchoring slip and an annular piston body, wherein the slip exciting piece, the anchoring slip and the annular piston body are sequentially arranged on the outer side of the anchoring mandrel body from top to bottom in a sleeving mode. The casing head can meet the hanging requirement of a mandrel hanger, after the anchoring mandrel body and the casing head shell are anchored, pipe column shifting can be avoided, and the stability and the reliability of the casing head are improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

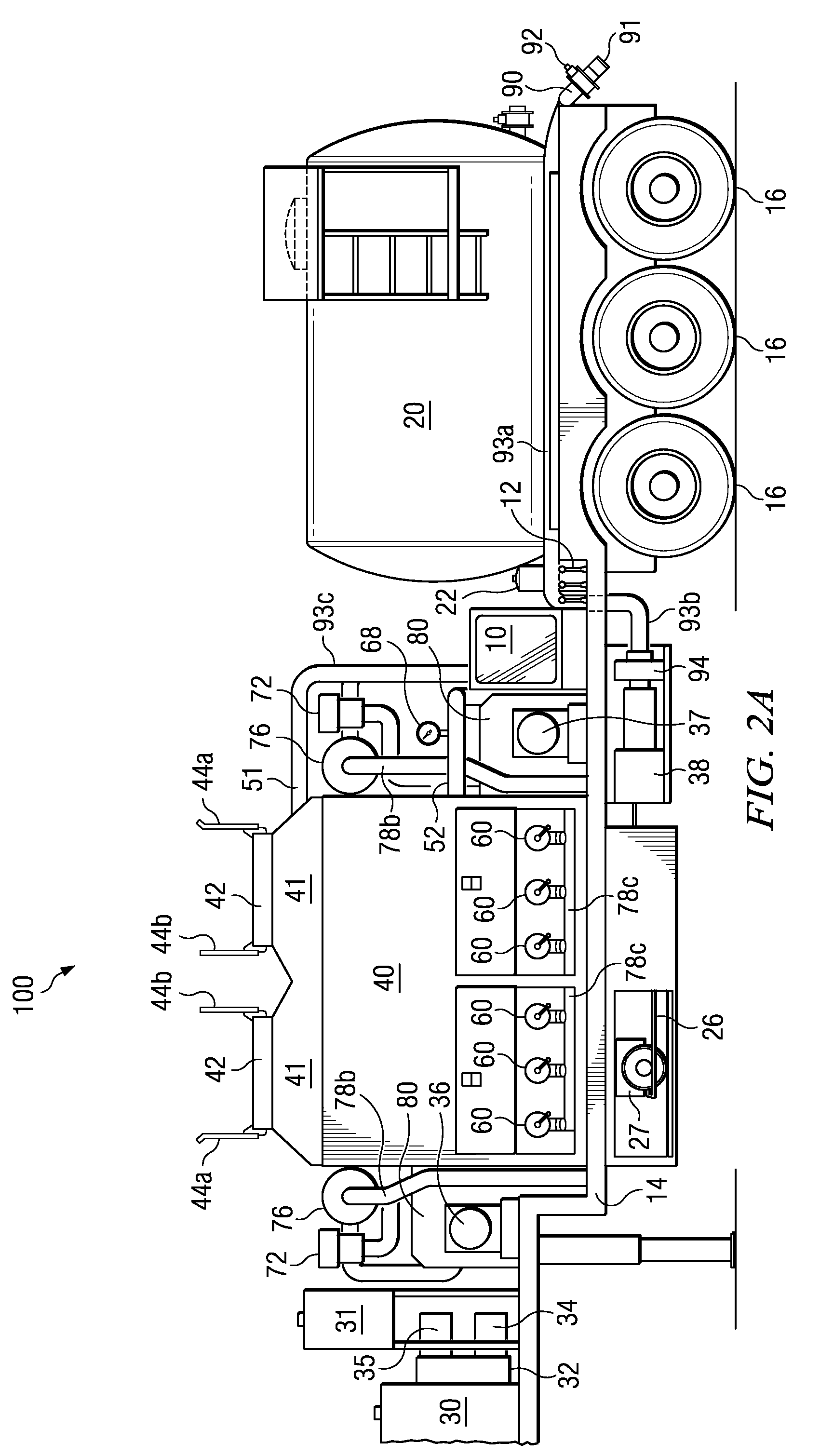

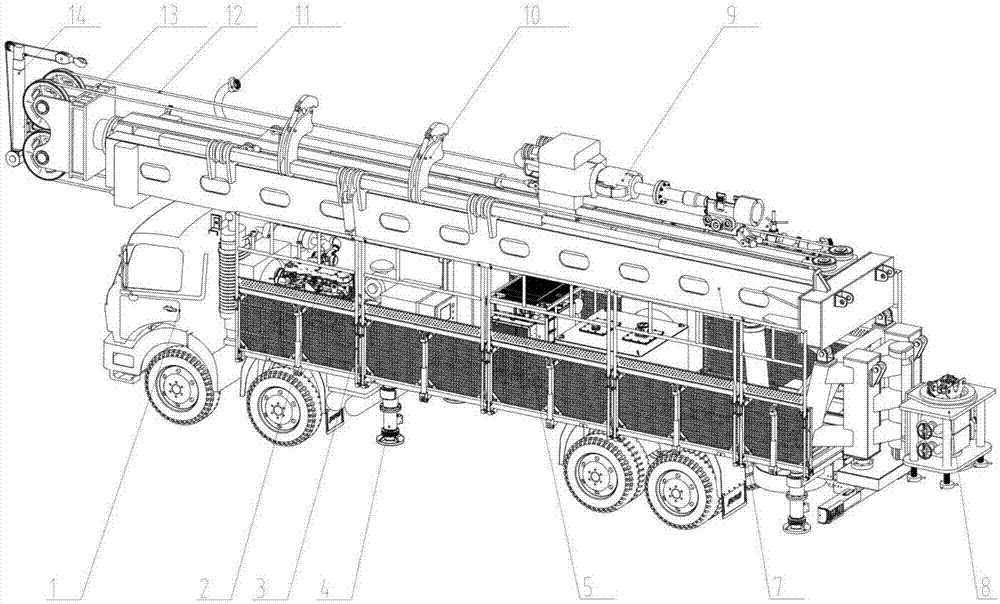

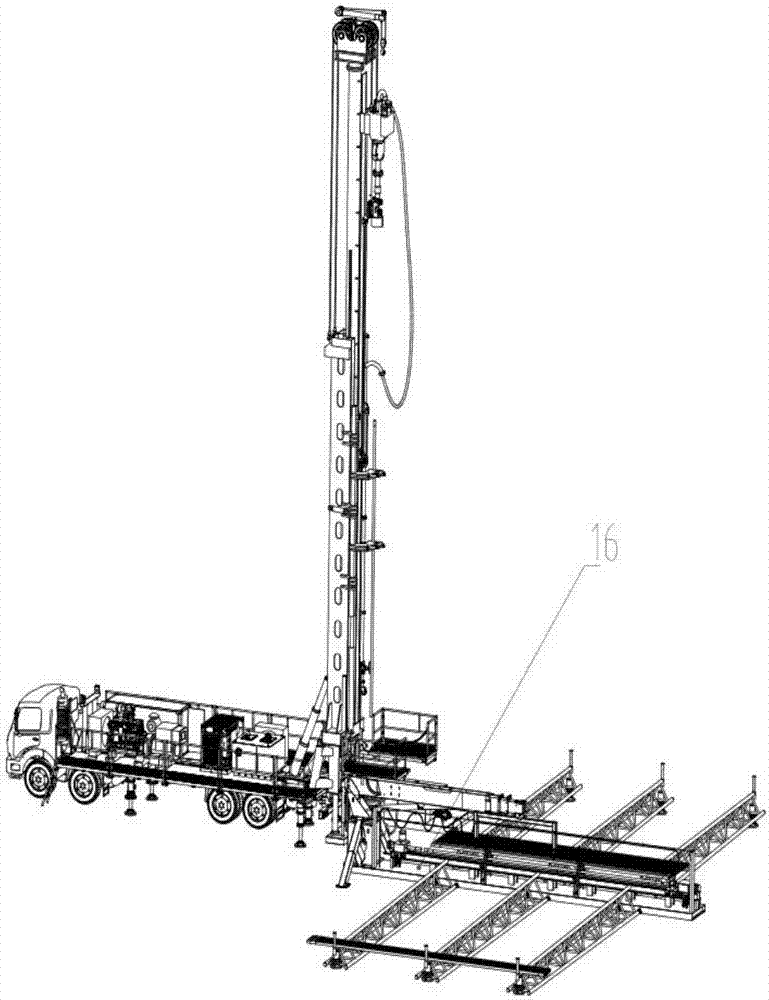

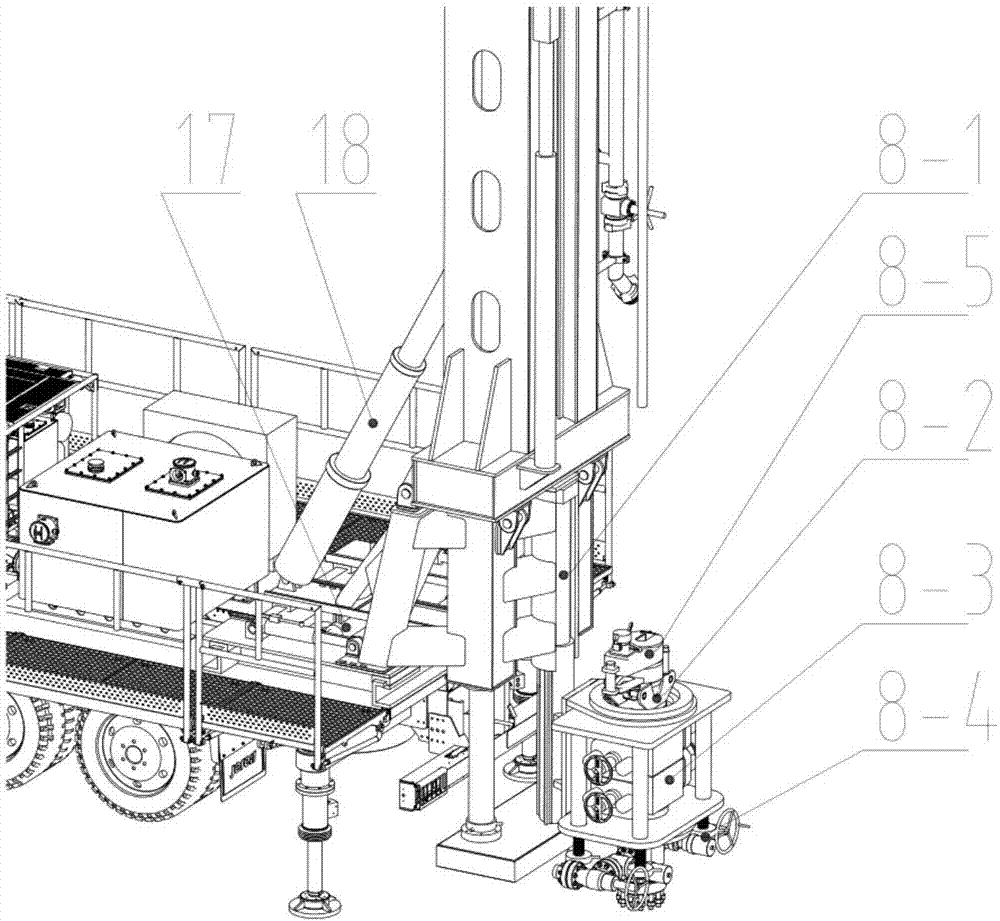

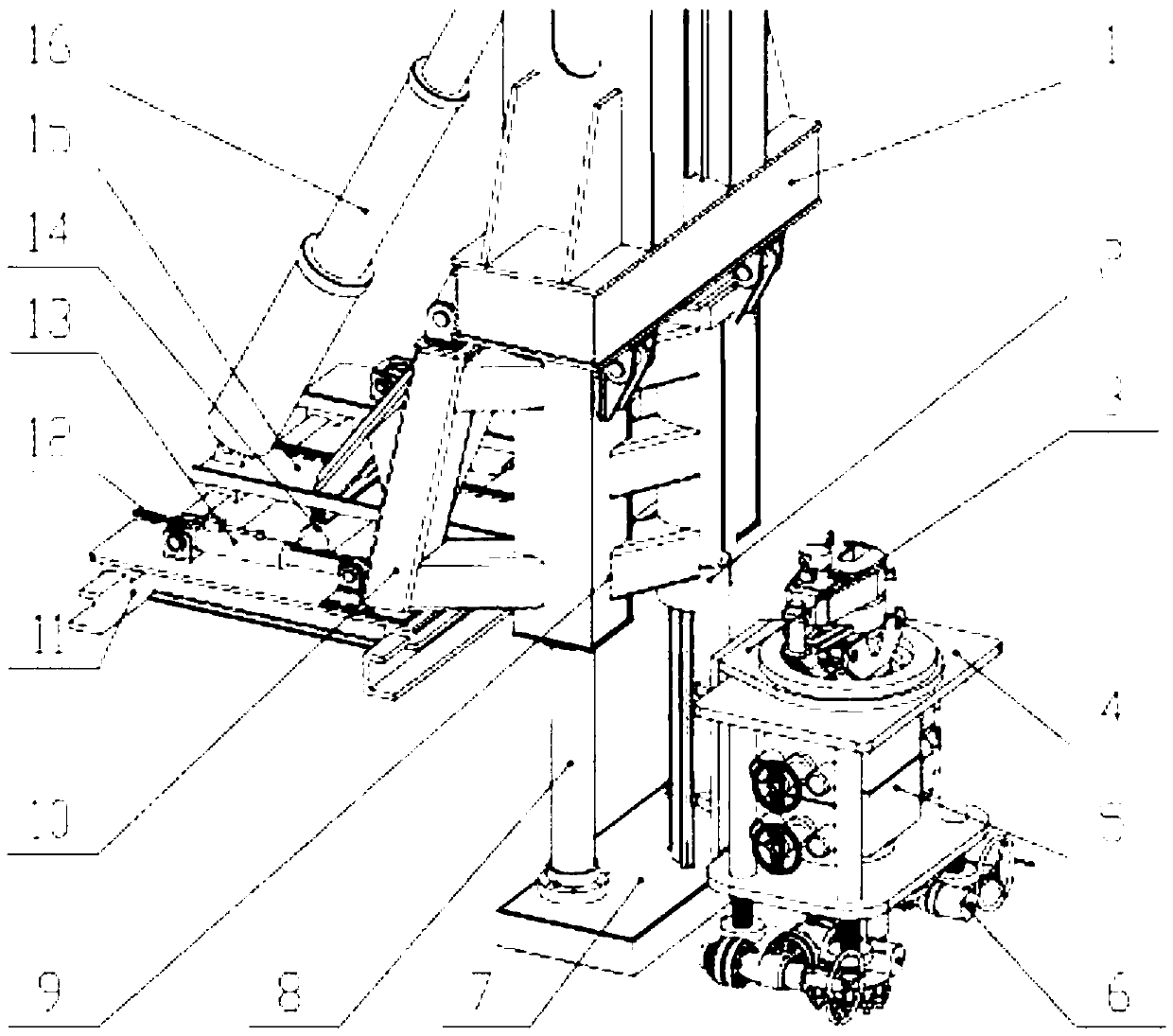

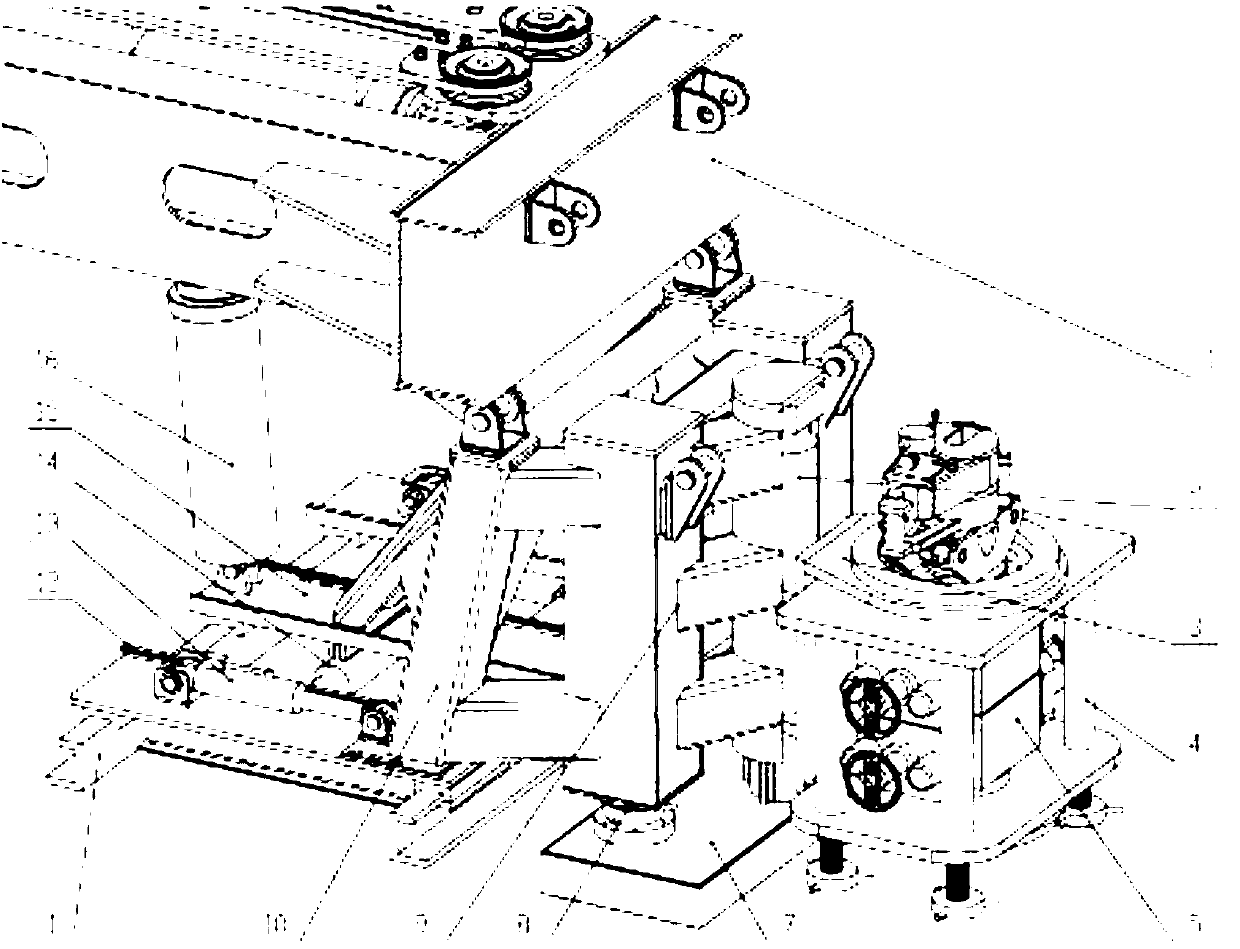

Fully hydraulic intelligent workover rig

InactiveCN107476769ARealize grabbingRealize pipe deliveryDrilling rodsDrilling casingsBlowout preventerTruck

The invention belongs to the field of oil equipment, and particularly relates to a fully hydraulic intelligent workover rig. The fully hydraulic intelligent workover rig is characterized in that an engine 2 and a hydraulic pressure station 5 are installed on a chassis truck 1, in the conveying state, a walkway is folded automatically and stored, a wellhead assembly is fixed to the tail of the chassis truck, after the hydraulic workover rig is moved to a well site, a wellhead is subjected to initial positioning through a reverse image in a cab and positioning and ranging, and then accurate positioning is conducted by moving a rapid positioning device through a derrick; by conducting height adjusting and supporting on a vehicle carrying chassis through hydraulic adjusting landing legs and conducting mechanical locking, rapid positioning and locking of the wellhead are achieved; the automatic folding walkway is designed, and convenient and labor-saving installation is achieved; increasing and decreasing of pressure of a string in a well and setting and control of bit pressure and drilling speed parameters can be achieved automatically, full automatic operations such as tubing string gripping and conveying, automatic fastening and unfastening, automatic discharging and automatic detection are achieved; integrated transport of a blowout preventer is achieved, and separate disassembly and transport are not needed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

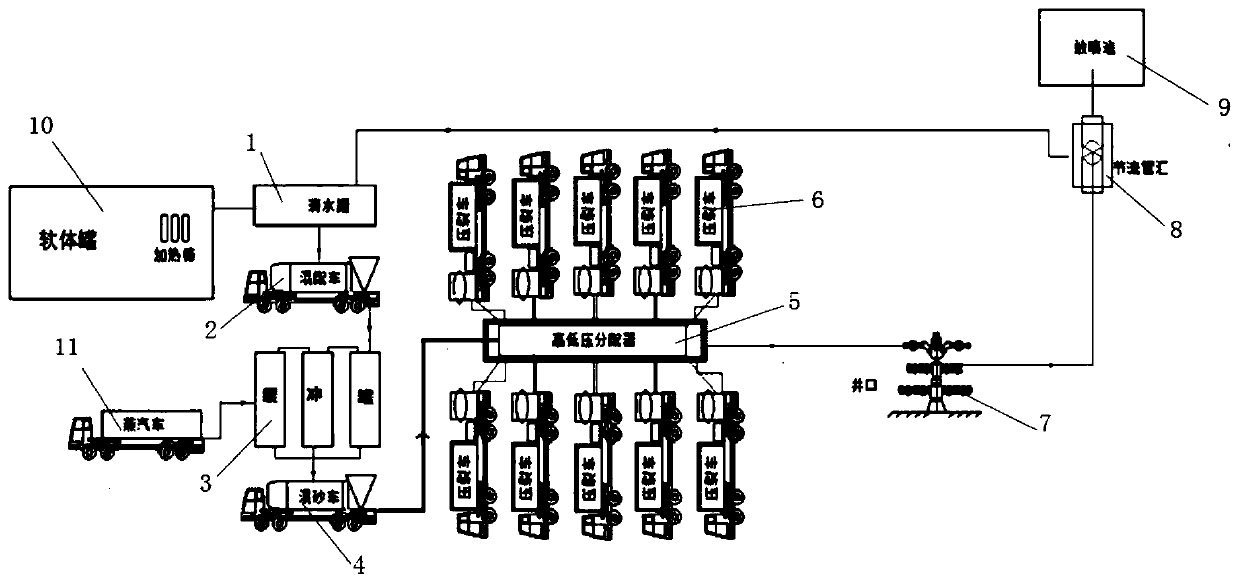

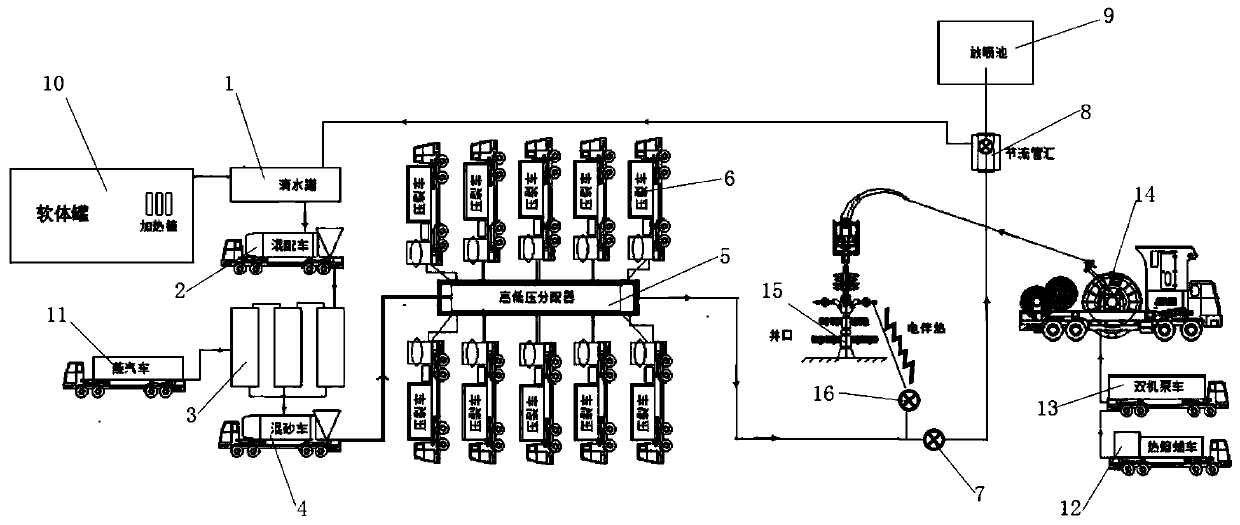

Oil field fracturing system with antifreezing performance

The invention discloses an oil field fracturing system with antifreezing performance. The oil field fracturing system comprises a clear water tank, a mixing vehicle, a buffer tank, a sand mixing vehicle, a fracturing device, a well mouth and a throttling manifold, wherein the outlet of the clear water tank is connected with the inlet of the mixing vehicle, the outlet of the mixing vehicle is connected with the inlet of the buffer tank, and the outlet of the buffer tank is connected with the inlet of the sand mixing vehicle, the outlet of the sand mixing vehicle is connected with an inlet of the fracturing device, a plurality of flanges are arranged at the well mouth, and one flange of the well mouth is connected with the throttling manifold, the other flanges of the well mouth are connected with the outlet of the fracturing device, and the outlet of the throttling manifold flows back to the clear water tank to form a closed circulation system. The oil field fracturing system has the beneficial effects that the liquid can be rapidly heated by adopting a steam automobile, so that the guanidine gum is fully swelled; and when there is no construction at night, the normal operation of the equipment is guaranteed by adopting the full-pipeline circulation and heat preservation, the pipeline is prevented from being disassembled, and equipment freeze-plugging is prevented.

Owner:JEREH ENERGY SERVICES

Fracturing system with antifreezing performance

The invention discloses a fracturing system with the antifreezing performance. The fracturing system comprises a first branch and a second branch, wherein the first branch comprises a clear water tank, a mixing truck, a buffer tank, a sand blender, a fracturing device, a first cock and a throttle manifold connected in sequence; the outlet of the throttle manifold enters the clear water tank through backflow, to form a closed circulating system; the second branch comprises a hot melting wax truck, a dual-machine pump truck, a coiled tubing and a wellhead; the hot melting wax truck, the dual-machine pump truck and the coiled tubing are sequentially connected; the coiled tubing penetrates through the wellhead to enter the shaft bottom; the wellhead in the second branch is connected with the inlet end of the first cock in the first branch through a high-pressure pipeline; and the high pressure pipeline is provided with a second cock close to the inlet end of the first cock. The fracturingsystem has the following beneficial effects: during the construction process, a steamer is adopted to fully swell guanidine gum; and when construction is not carried out, all pipelines are adopted torealize antifreezing and thermal insulation in a circulating manner to avoid pipeline dismantling.

Owner:JEREH ENERGY SERVICES

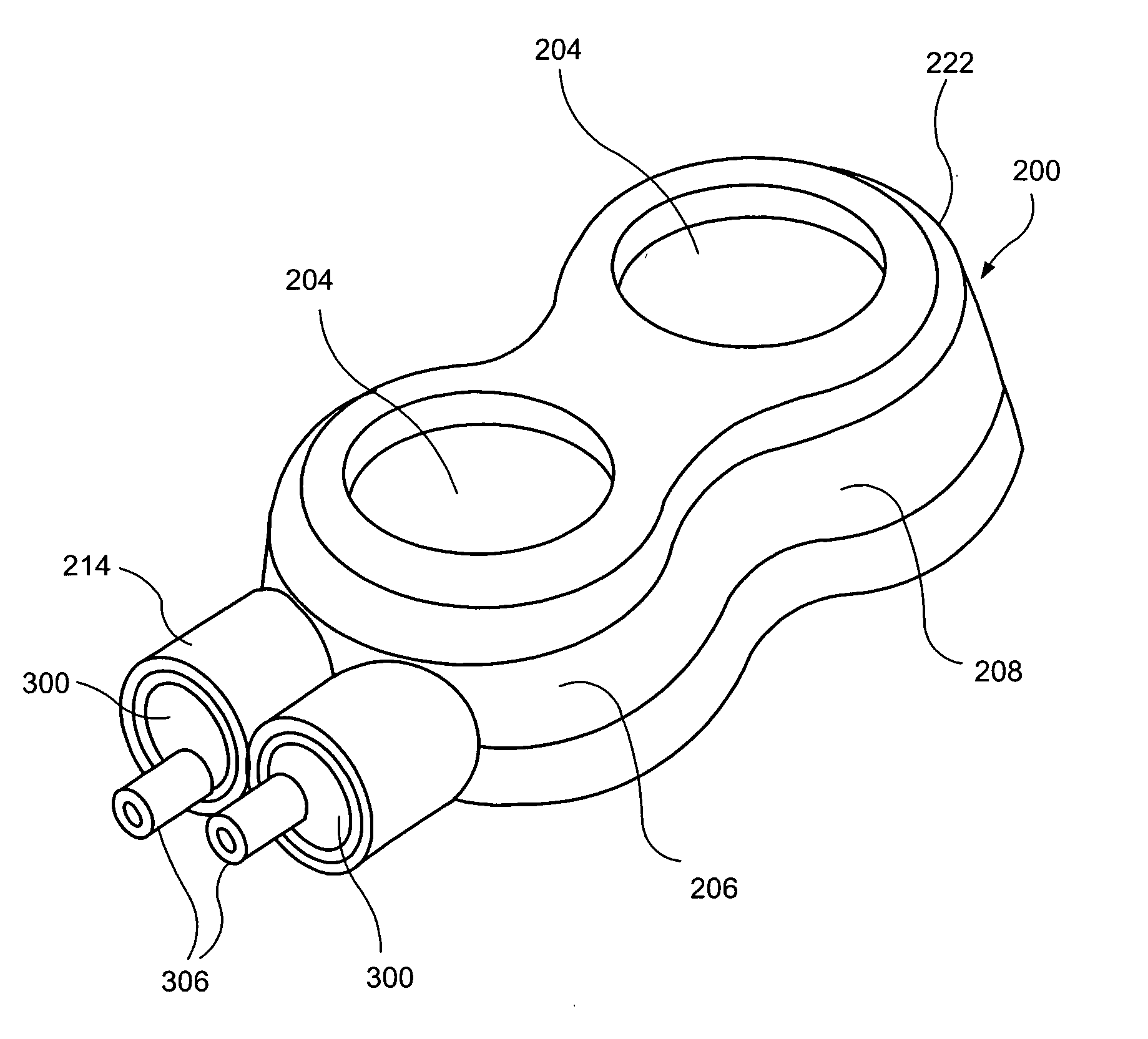

Dual well port device

ActiveUS20050171502A1Pharmaceutical delivery mechanismMedical devicesSubcutaneous implantationThree vessels

A port for implantation within a body, comprises a housing having a proximal surface, a distal surface and a side surface wherein, when the port is implanted within a body in a desired orientation, the proximal surface faces outward toward the skin, the distal surface faces inward away from the skin and the side surface extends between the proximal and distal surfaces and a first well formed within the housing, the first well including a first opening in the proximal surface. A second well is formed in the housing adjacent to the first well and has a second opening formed in the proximal surface. First and second outlet openings formed on the side surface of the port are in fluid communication with the first and second wells, respectively, and are separated from one another by a distance substantially equal to a distance separating lumens of a dual lumen catheter to which the port is to be connected. In addition, a method of infusing fluids to a patient, comprises attaching a dual lumen catheter to a blood vessel of the patient and implanting subcutaneously a port including first and second openings separated by a distance substantially equal to a distance between the dual lumens of the catheter, wherein the first opening is in fluid communication with a first well of the port and the second opening is in fluid communication with a second well of the port. The dual lumen catheter is then connected to the first and second openings of the port and a first fluid is provided to the first well while a second fluid is provided to the second well.

Owner:ANGIODYNAMICS INC

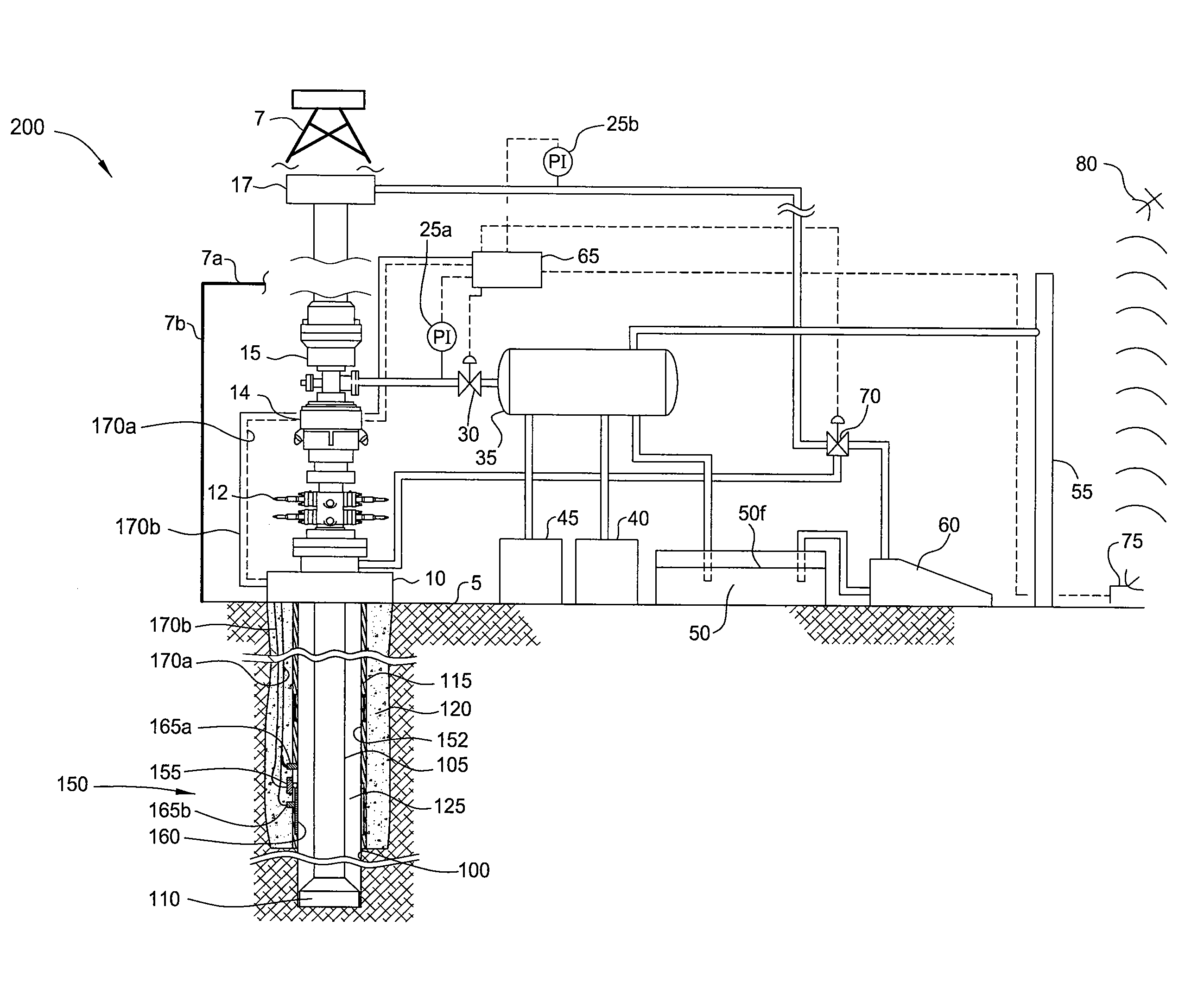

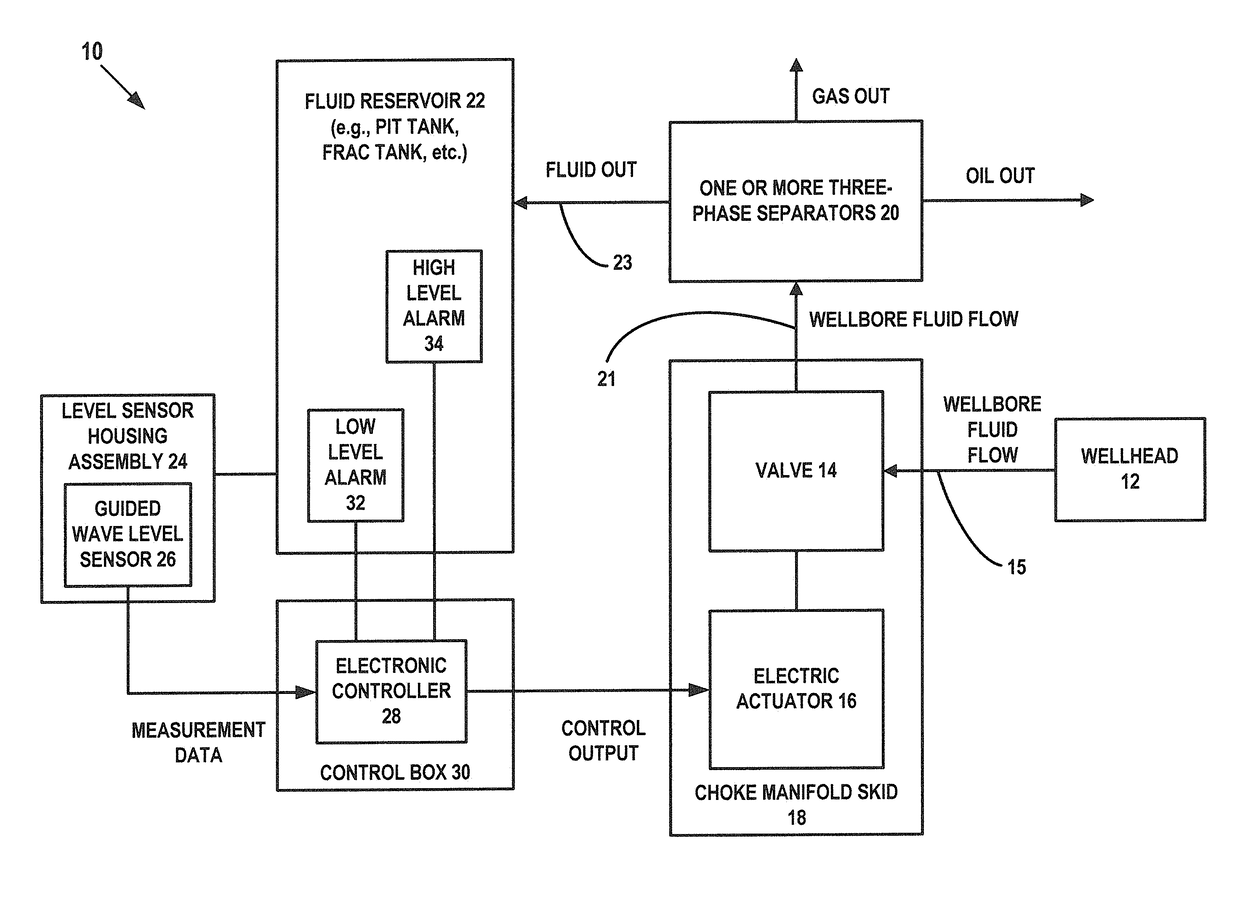

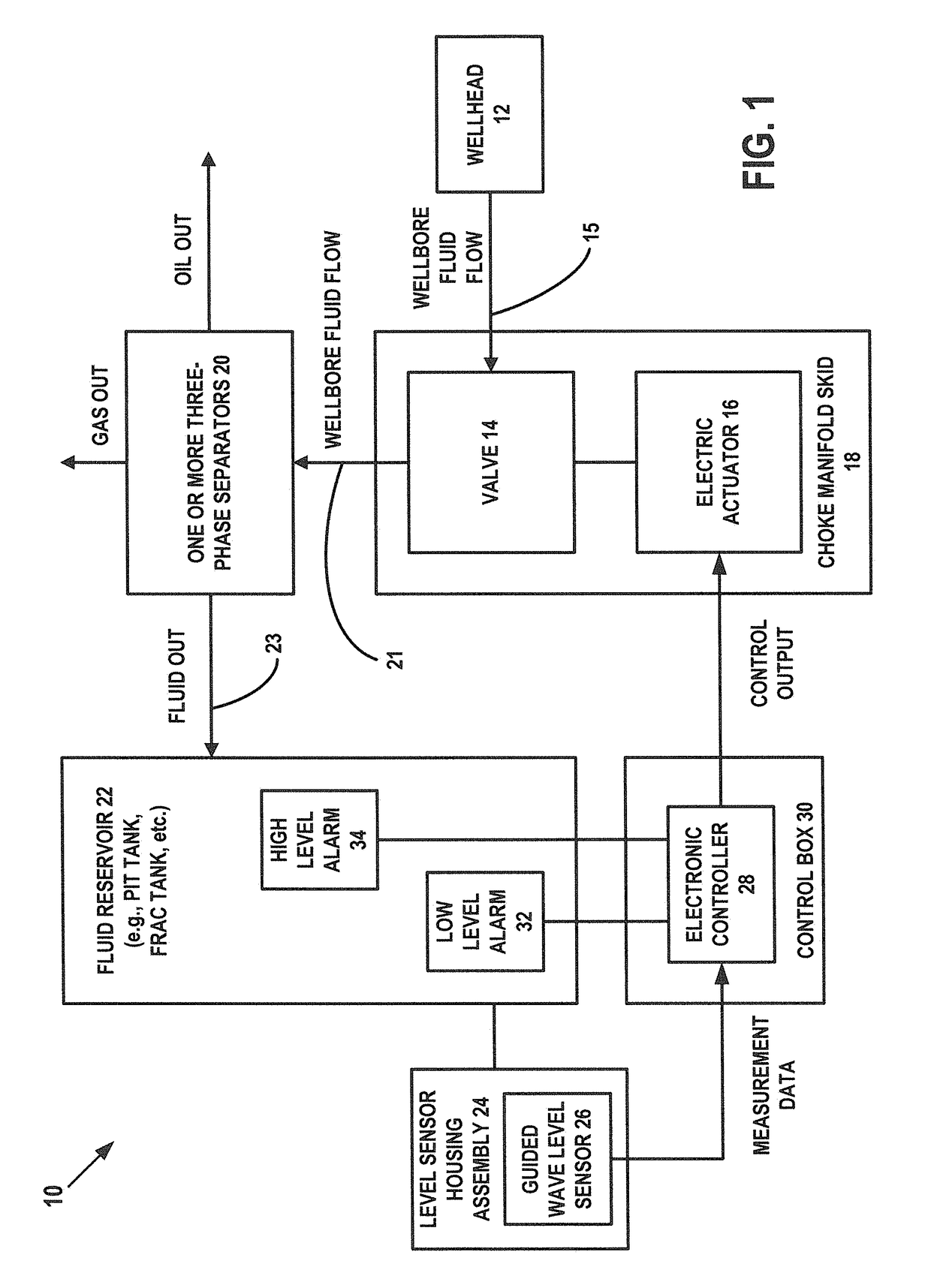

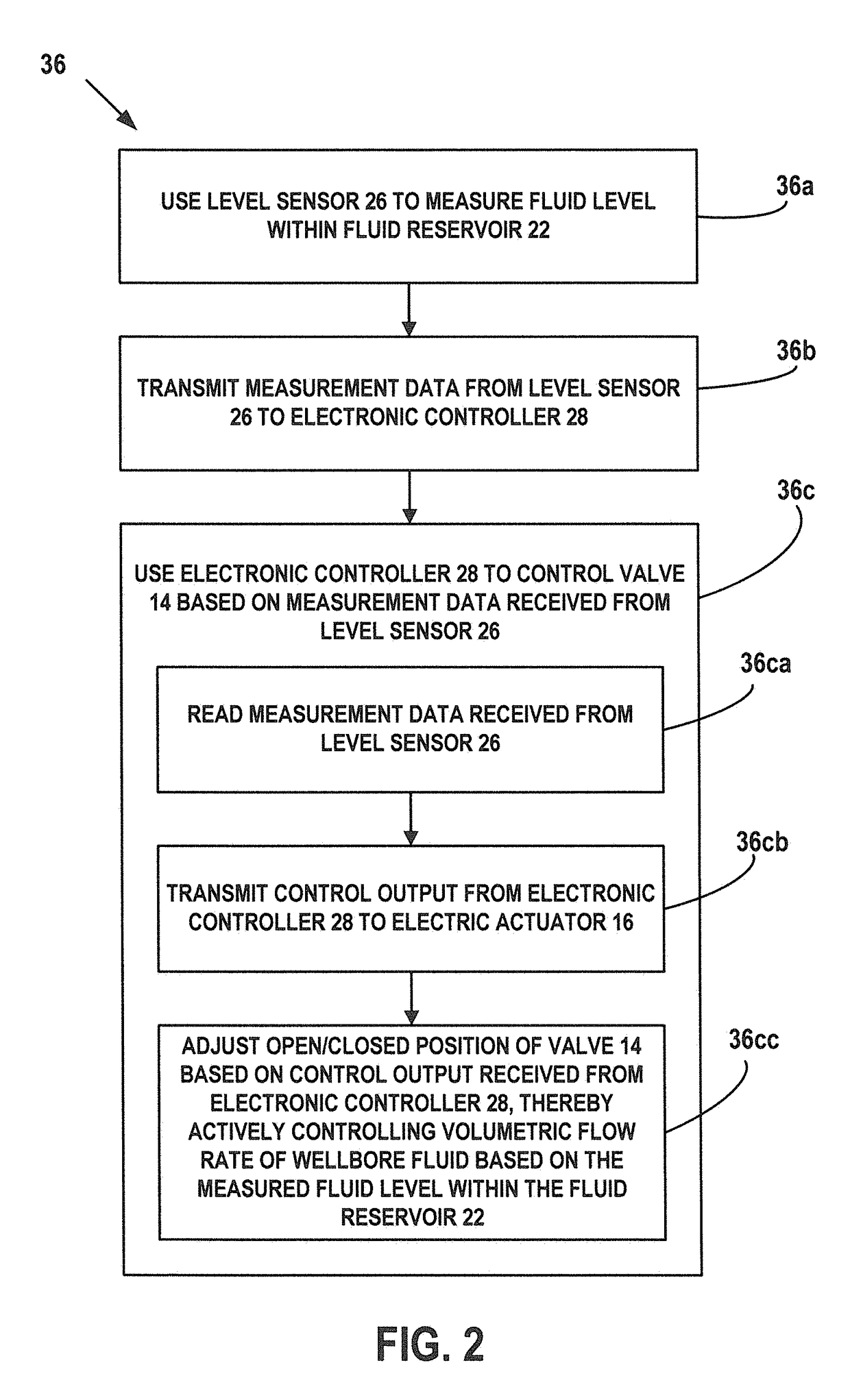

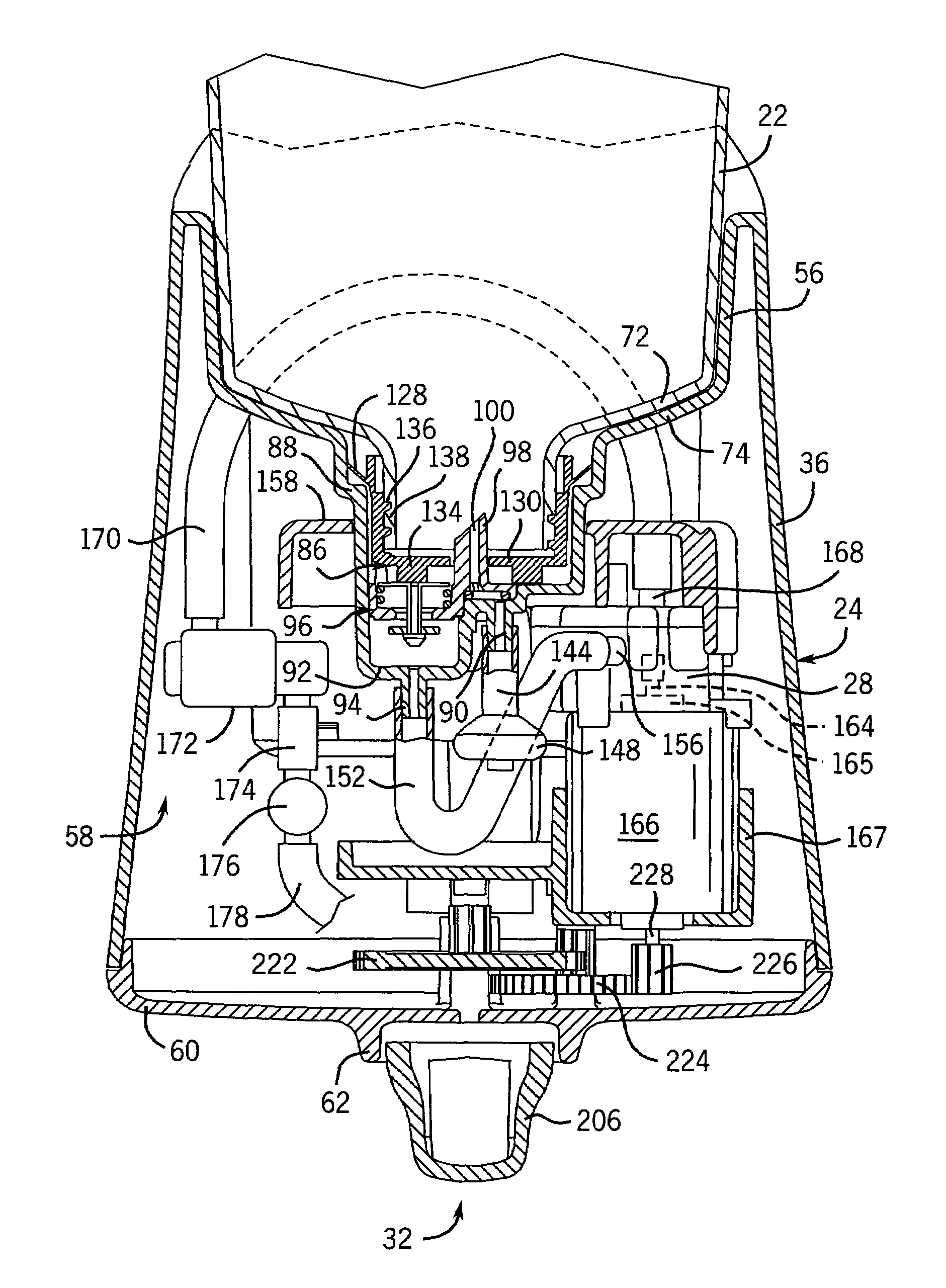

Frac flow-back control and/or monitoring system and methods

ActiveUS20170191350A1Maintain integrityIncrease oil and gas productionSurveyConstructionsElectronic controllerMonitoring system

According to one aspect, a system is adapted to actively control one or more operating parameters associated with: a wellbore extending in a subterranean formation, and / or wellbore fluid flowing out of the wellbore via a wellhead. The system includes one or more sensors; an electronic controller adapted to receive from the one or more sensors measurement data; and a valve through which the wellbore fluid is adapted to flow. The valve is adapted to be in communication with the electronic controller. The active control of the at least one of the one or more operating parameters is adapted to facilitate: maintenance of the integrity of the wellbore, and / or enhancement of oil and / or gas production out of the wellbore. In one embodiment, the wellbore fluid flow is frac flow-back. In another aspect, a system is adapted to monitor vent gas separated from wellbore fluid flowing out a wellhead.

Owner:SPM OIL & GAS PC LLC

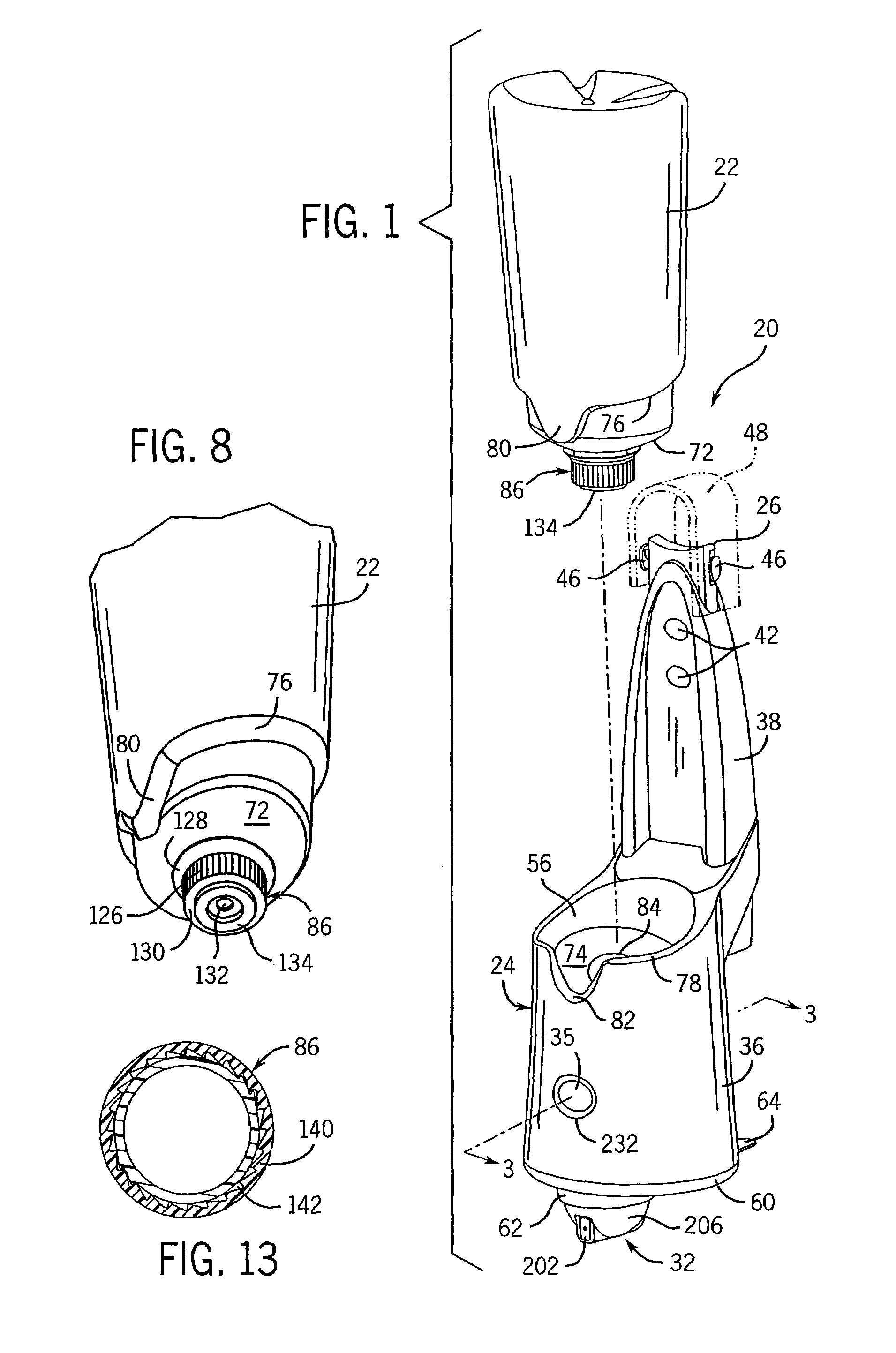

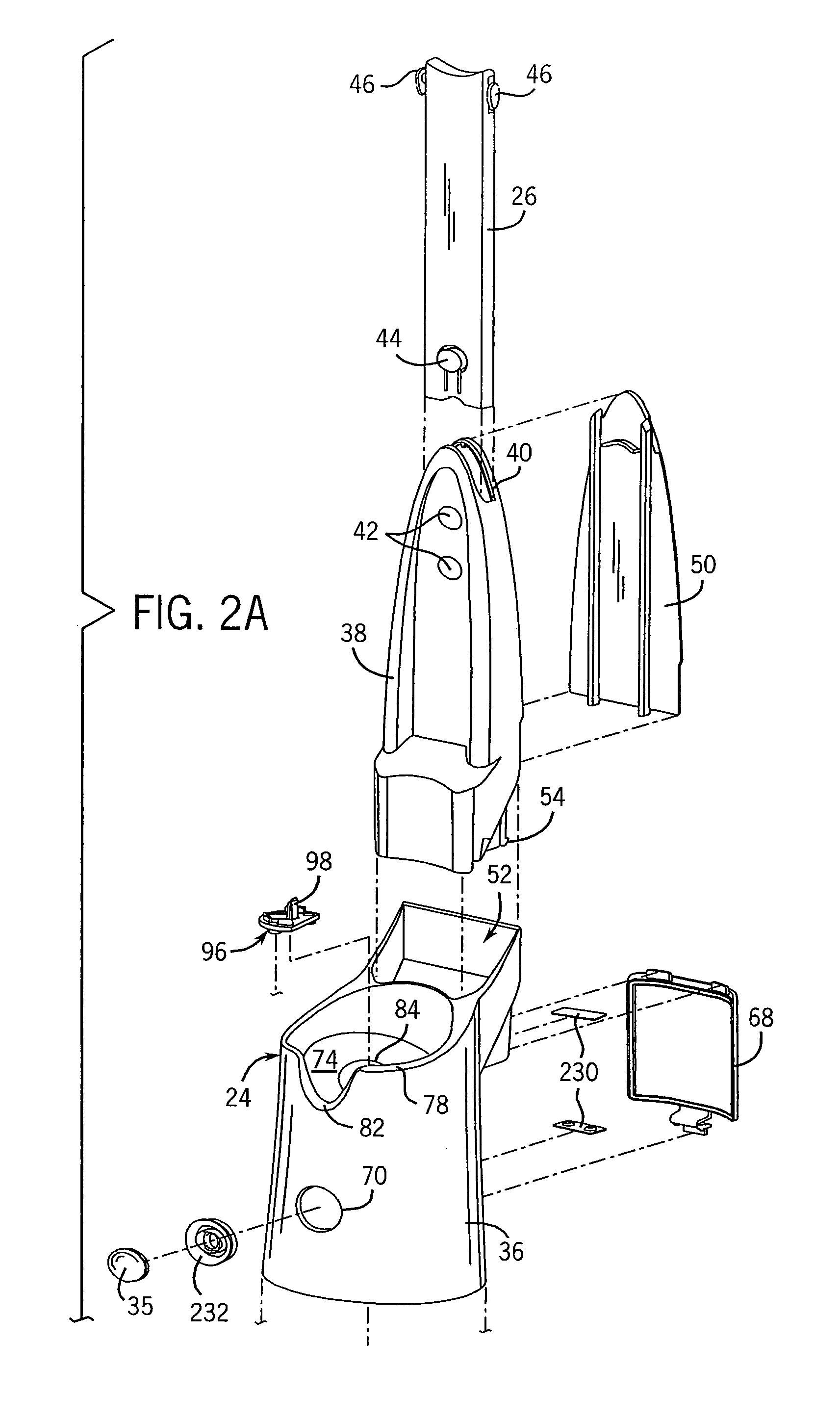

Automated cleansing sprayer having separate cleanser and air vent paths from bottle

An automated sprayer for spraying the walls of a shower enclosure with a liquid cleanser dispenses the cleanser using a pump and rotatable spray head. A motor drives the pump and rotates the spray head. The sprayer has a showerhead mountable housing with a hanger. The housing supports a bottle of cleanser in an inverted fashion. Cleanser is delivered from the bottle through a cleanser conduit in the piercing post into a well of the housing. The bottle is vented from the well through an air vent path in the piercing post or from a well vent outlet through the air vent path in the piercing post. An outlet valve in the well permits outflow of cleanser from the well. Various bottle caps and bottle closures are also provided to improve venting and / or limit cleanser leakage from the bottle when the bottle is installed in the housing.

Owner:SC JOHNSON & SON INC

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

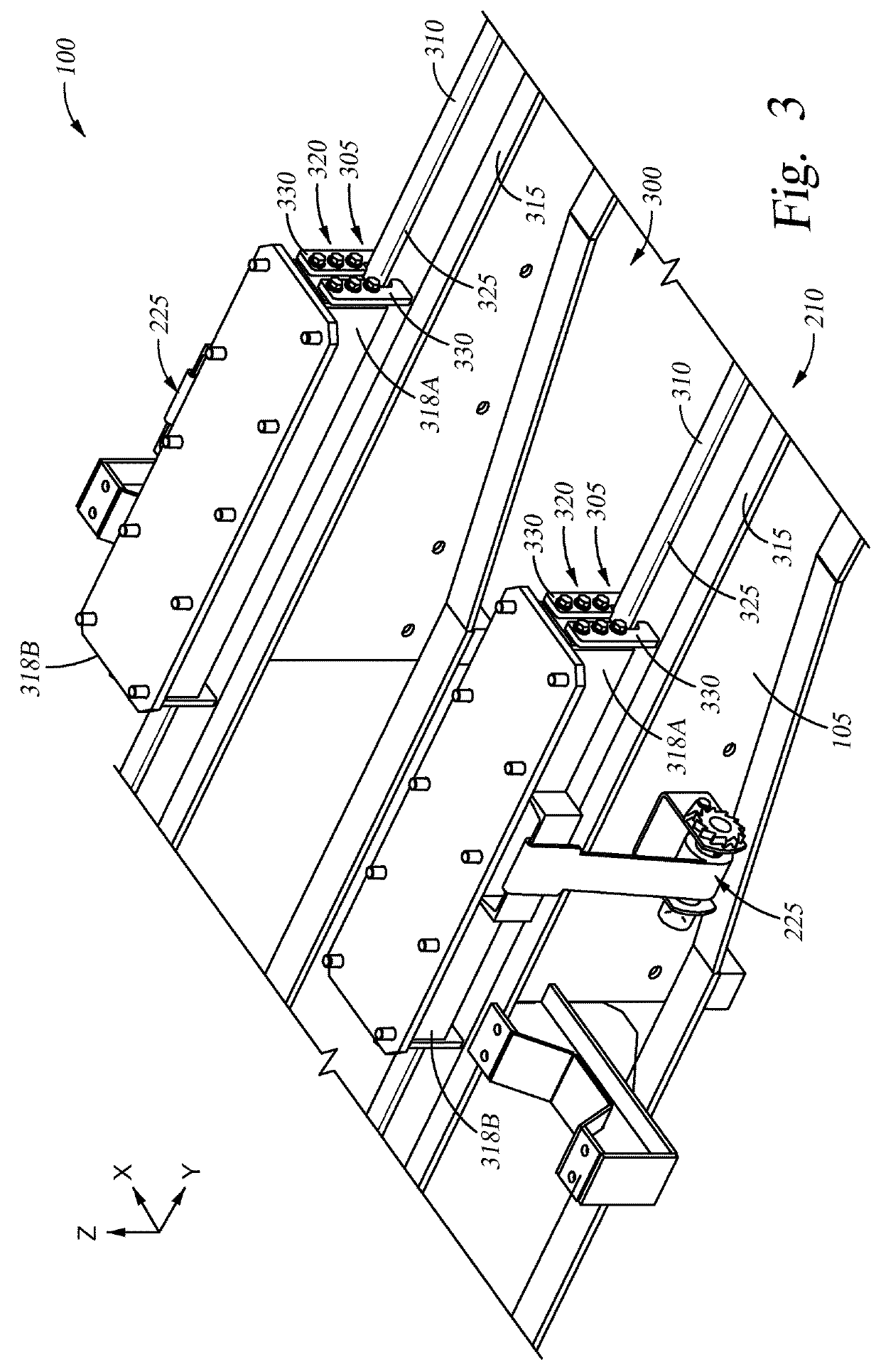

Fast positioning device for derrick moving

InactiveCN107654196AReasonable structural designEasy to useDrilling rodsDerricks/mastsBlowout preventerPetroleum

The invention belongs to the field of petroleum equipment, and particularly relates to a fast positioning device for derrick moving. The fast positioning device for derrick moving is characterized inthat a derrick supporting seat can move in the transverse direction and the longitudinal direction of a chassis vehicle, and the derrick supporting seat integrates a blowout preventer group; and the blowout preventer group can lift, move and rotate around the center of the blowout preventer group, and a lifting cylinder of a derrick is supported on the derrick supporting seat, moves along with thesupporting seat and keeps unchanged relative to the position of the derrick. According to the fast positioning device for derrick moving, well opening aligning is conducted by adjusting the front, back, left and right positions of the derrick on a vehicle, fast and accurate positioning is achieved, in conclusion, a derrick supporting seat structure has the advantages of being reasonable in design, convenient and reliable to use, precise in positioning, automated in control and the like, the derrick can be fast aligned with a well opening, meanwhile, the well opening blowout preventer group isfixed to a fast positioning device, a telescopic liquid cylinder is collected during transported, the blowout preventer group is transported along with the vehicle, the efficiency of workover preparation work is improved, and the labor intensity of operators is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

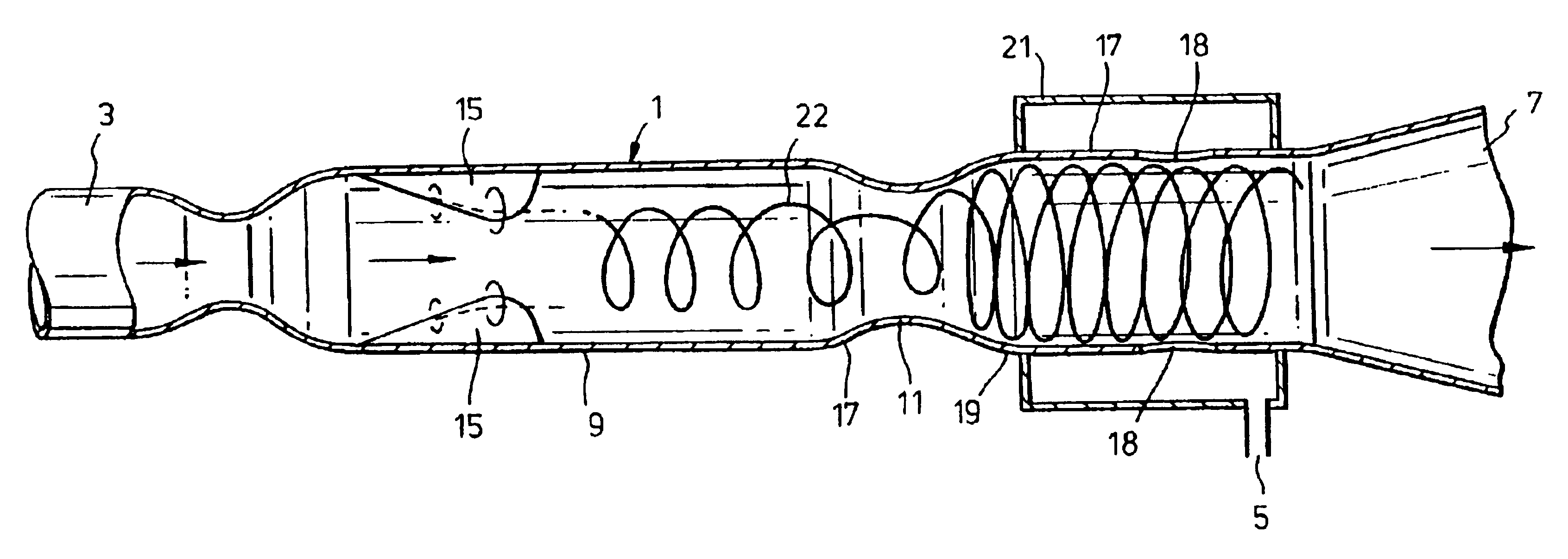

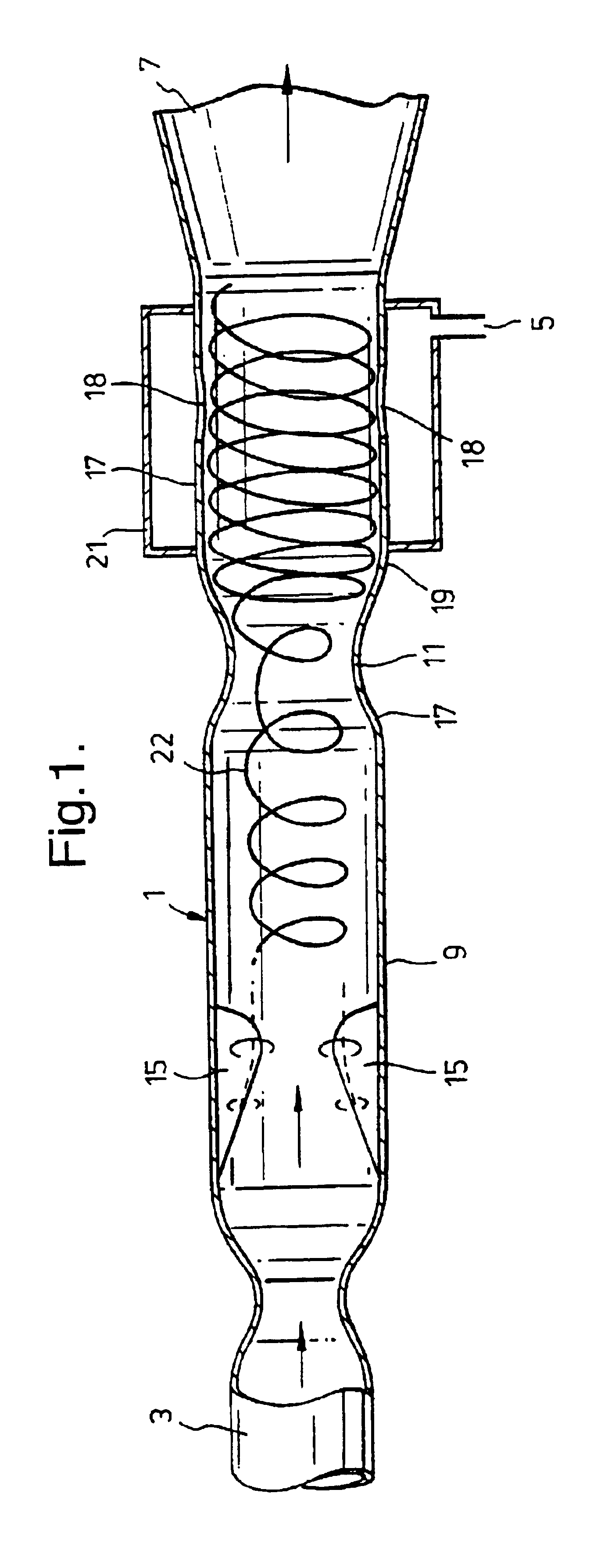

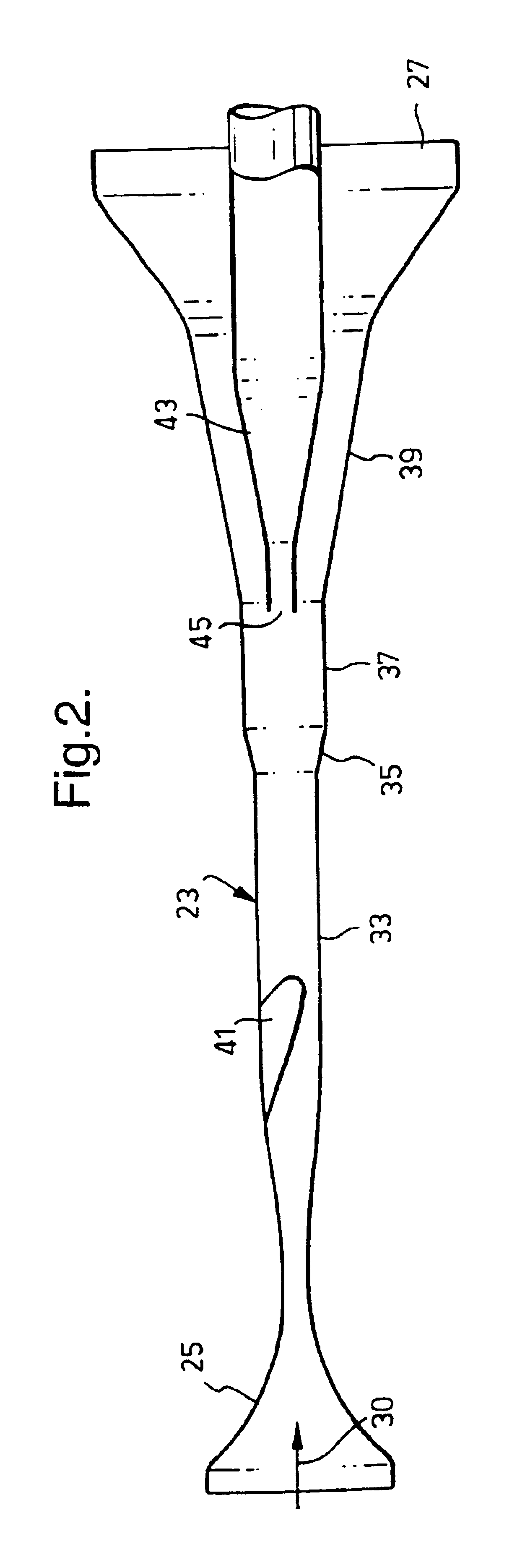

Method for removing condensables from a natural gas stream, at a wellhead, downstream of the wellhead choke

InactiveUS6962199B1Easy to separateDissipates a substantial amount of kinetic energy of the streamSolidificationLiquefactionProduct gasEngineering

The present invention relates to a method for removing condensables from a natural gas stream, at a wellhead, downstream of the wellhead choke thereof. In accordance with the invention there is provided a method for removing condensables from a natural gas stream at a wellhead, the method comprising the steps of: (A) inducing the natural gas stream to flow at supersonic velocity through a conduit of a supersonic inertia separator and thereby causing the fluid to cool to a temperature that is below a temperature / pressure at which the condensables will begin to condense, forming separate droplets and / or particles; (B) separating the droplets and / or particles from the gas; and (C) collecting the gas from which the condensables have been removed, wherein the supersonic inertia separator is part of the wellhead assembly downstream of the wellhead choke. There is also provided a device for removing said condensables from said natural gas that is part of the wellhead assembly downstream of the choke, a wellhead assembly comprising said device.

Owner:TWISTER BV +1

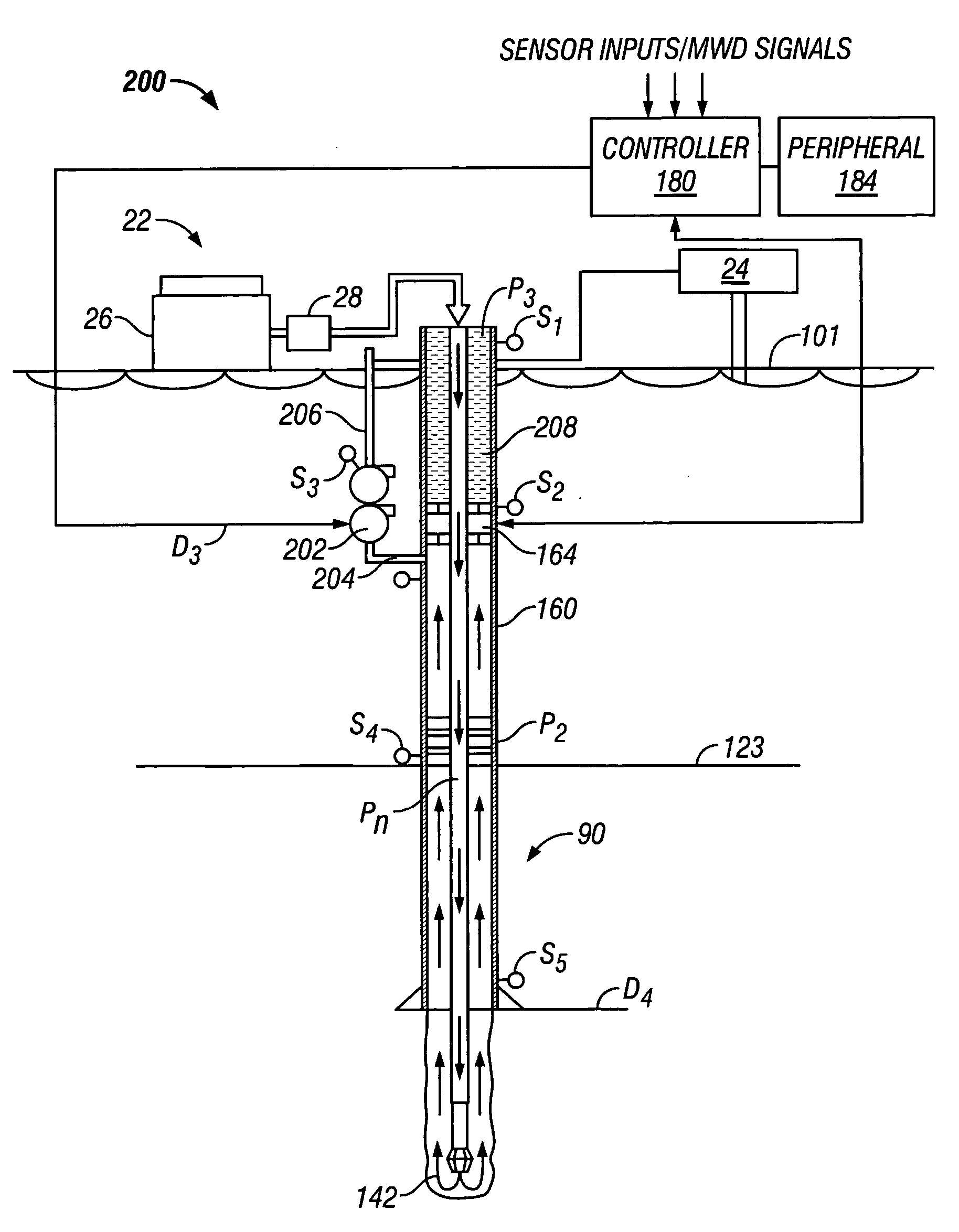

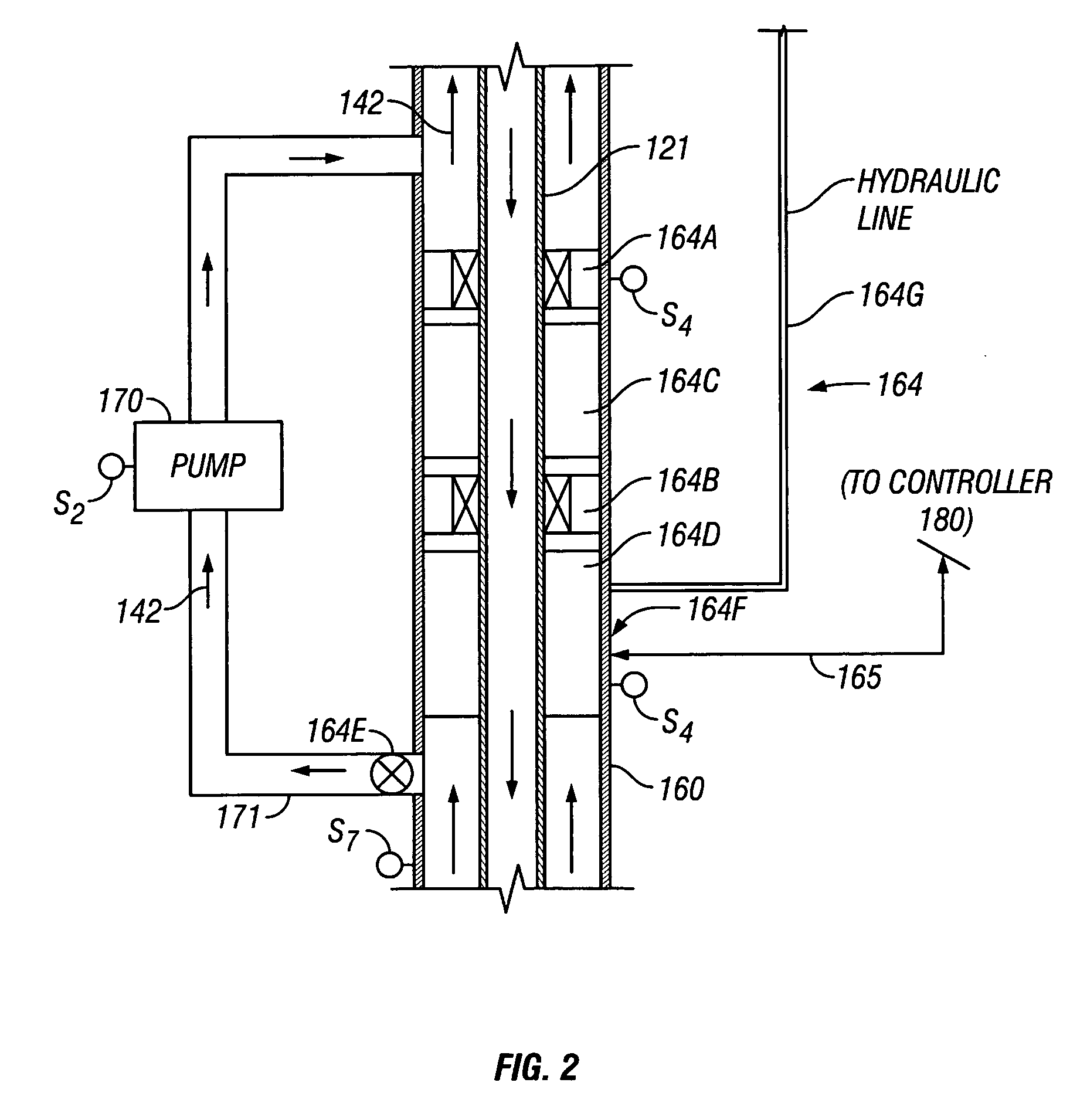

Drilling system and method for controlling equivalent circulating density during drilling of wellbores

A drilling system for drilling subsea wellbores includes a tubing-conveyed drill bit that passes through a subsea wellhead. Surface supplied drilling fluid flows through the tubing, discharges at the drill bit, returns to the wellhead through a wellbore annulus, and flows to the surface via a riser extending from the wellhead. A flow restriction device positioned in the riser restricts the flow of the returning fluid while an active fluid device controllably discharges fluid from a location below to just above the flow restriction device in the riser, thereby controlling bottomhole pressure and equivalent circulating density (“ECD”). Alternatively, the fluid is discharged into a separate return line thereby providing dual gradient drilling while controlling bottomhole pressure and ECD. A controller controls the energy and thus the speed of the pump in response to downhole measurement(s) to maintain the ECD at a predetermined value or within a predetermined range.

Owner:BAKER HUGHES INC

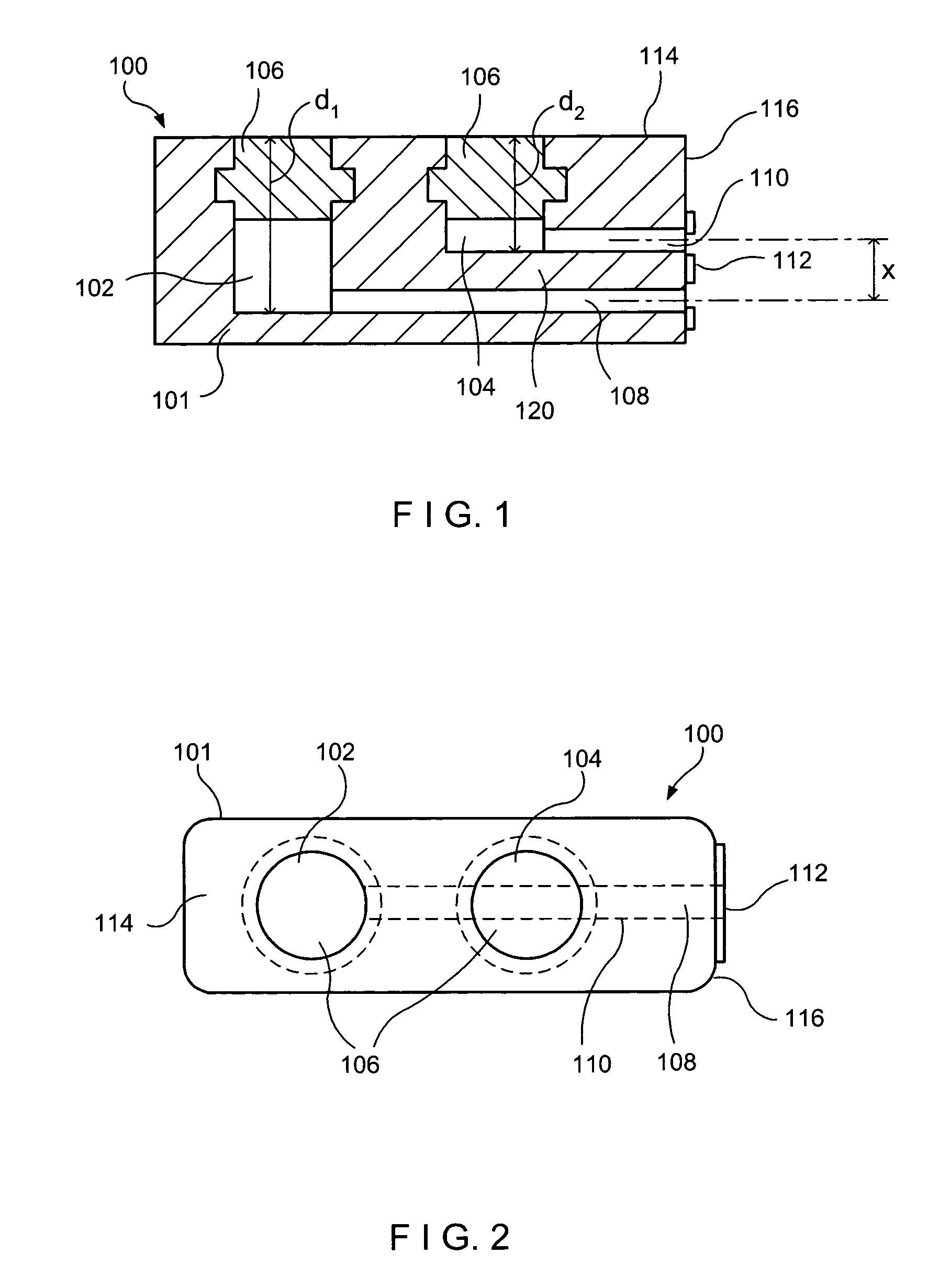

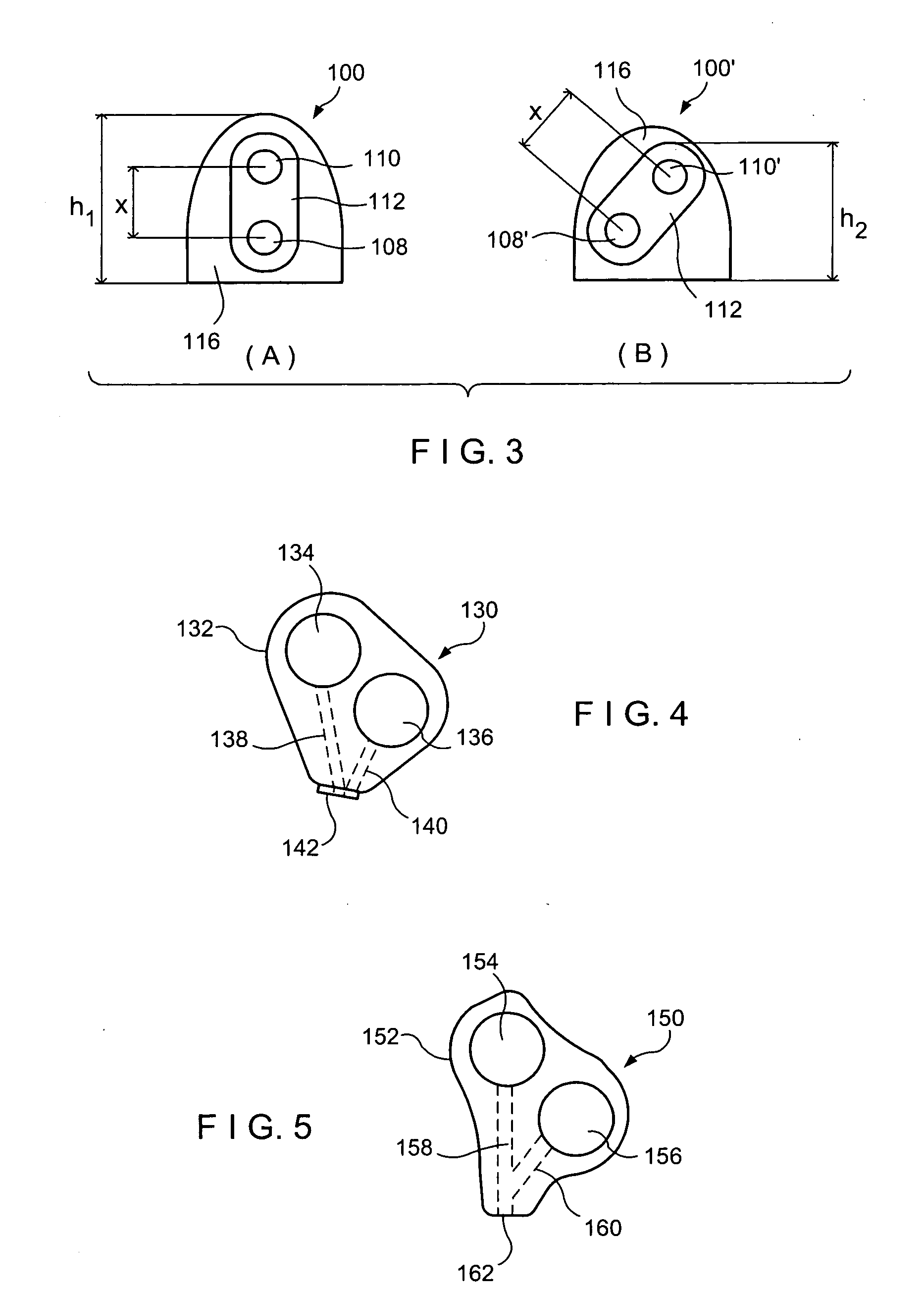

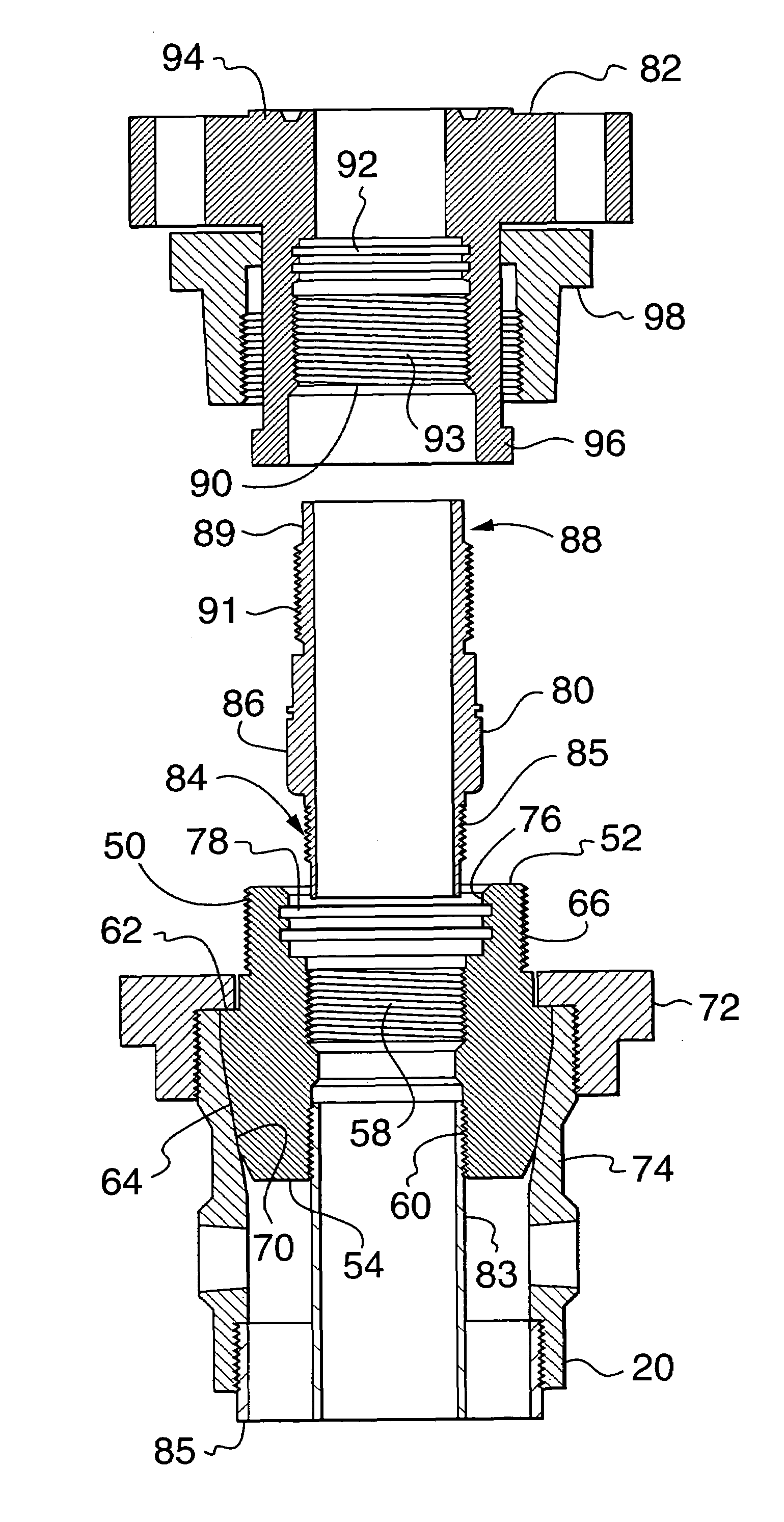

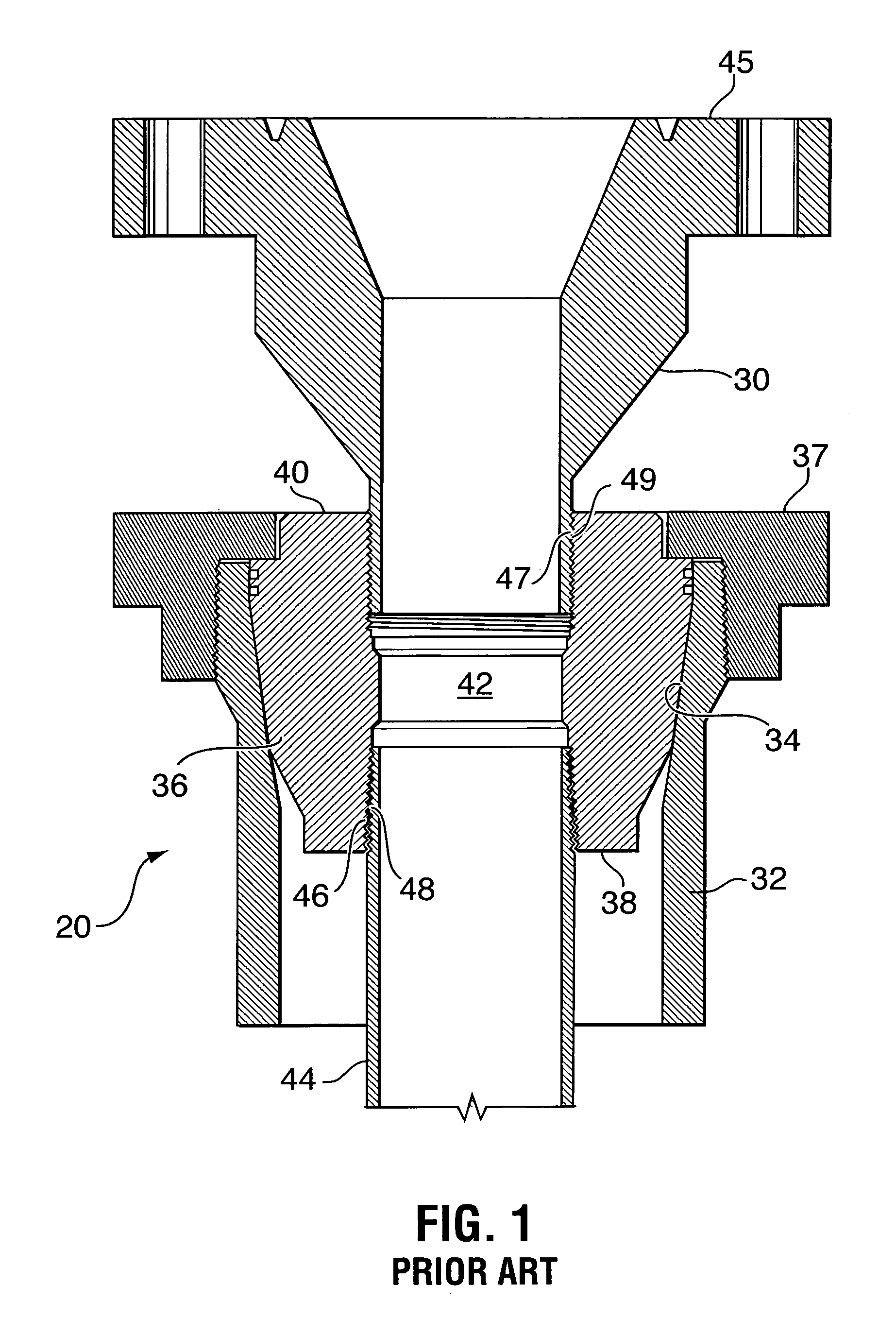

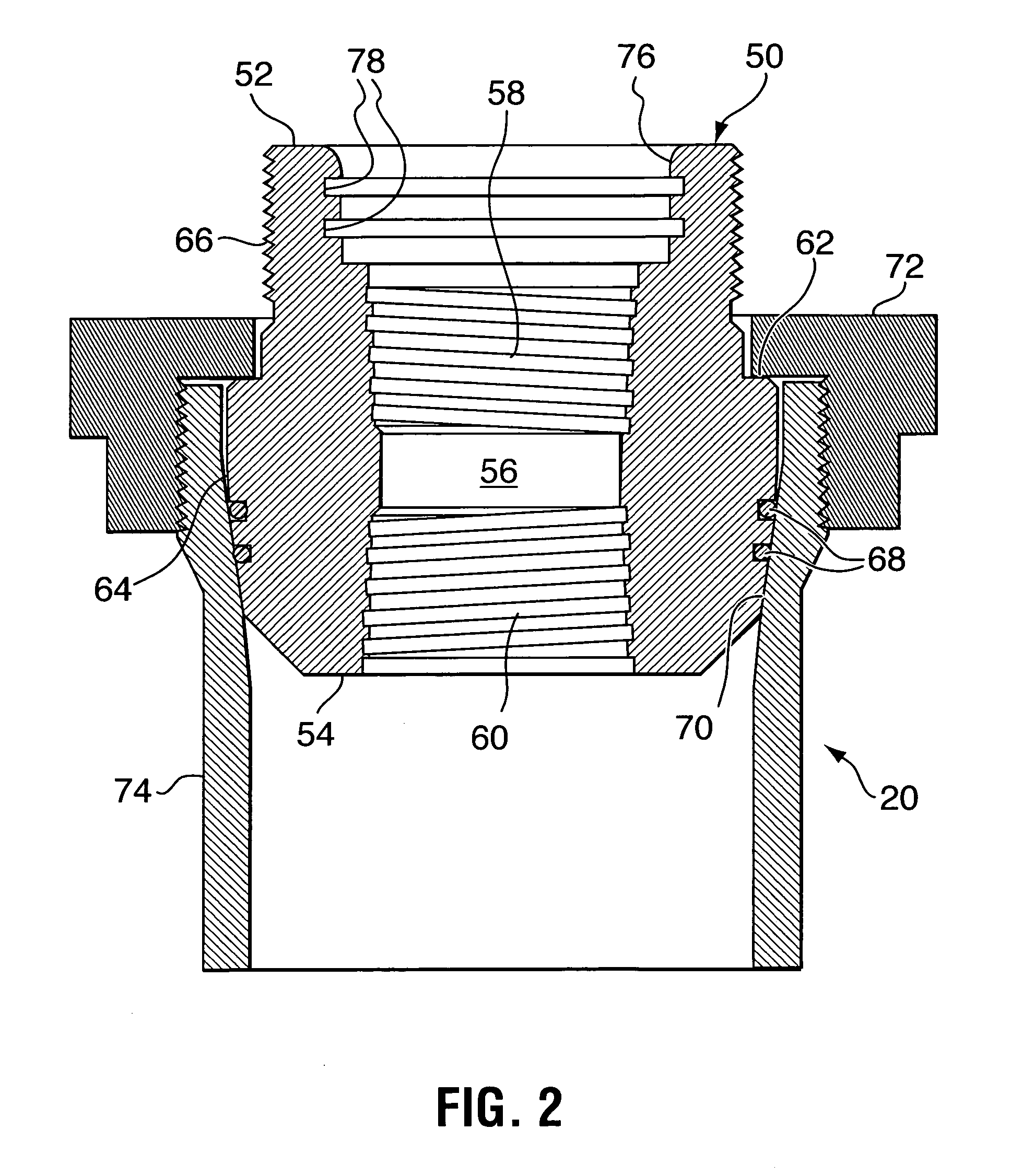

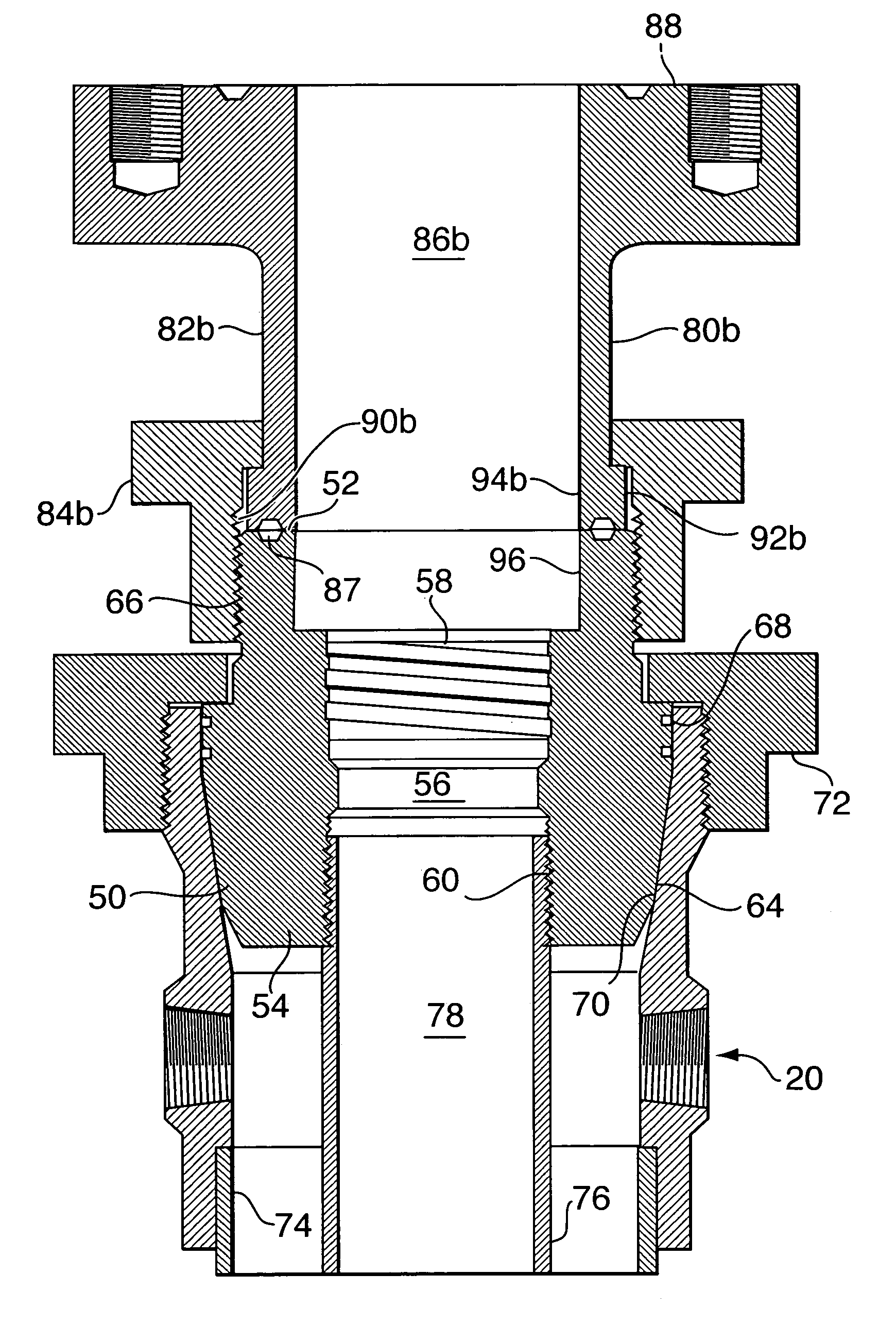

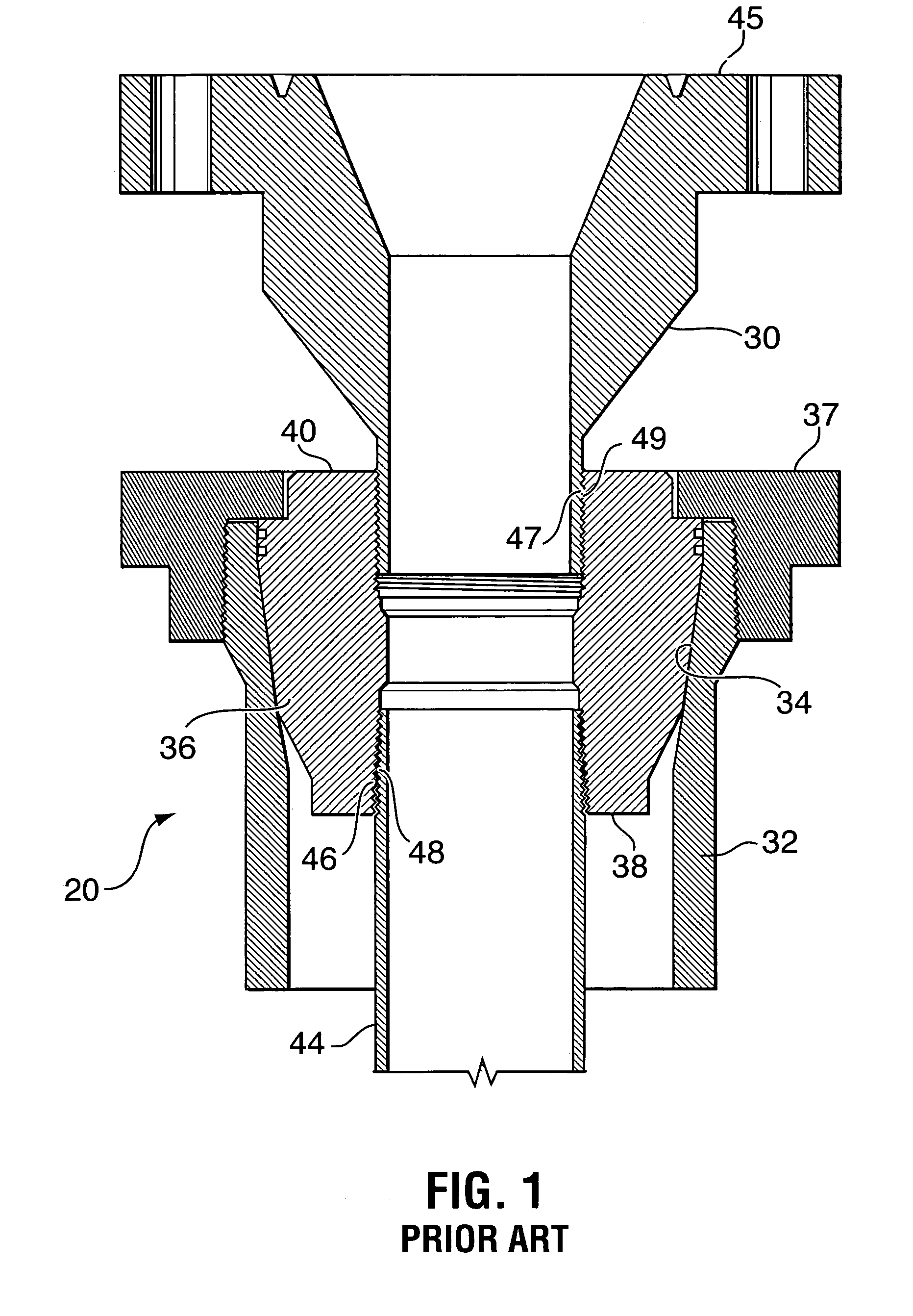

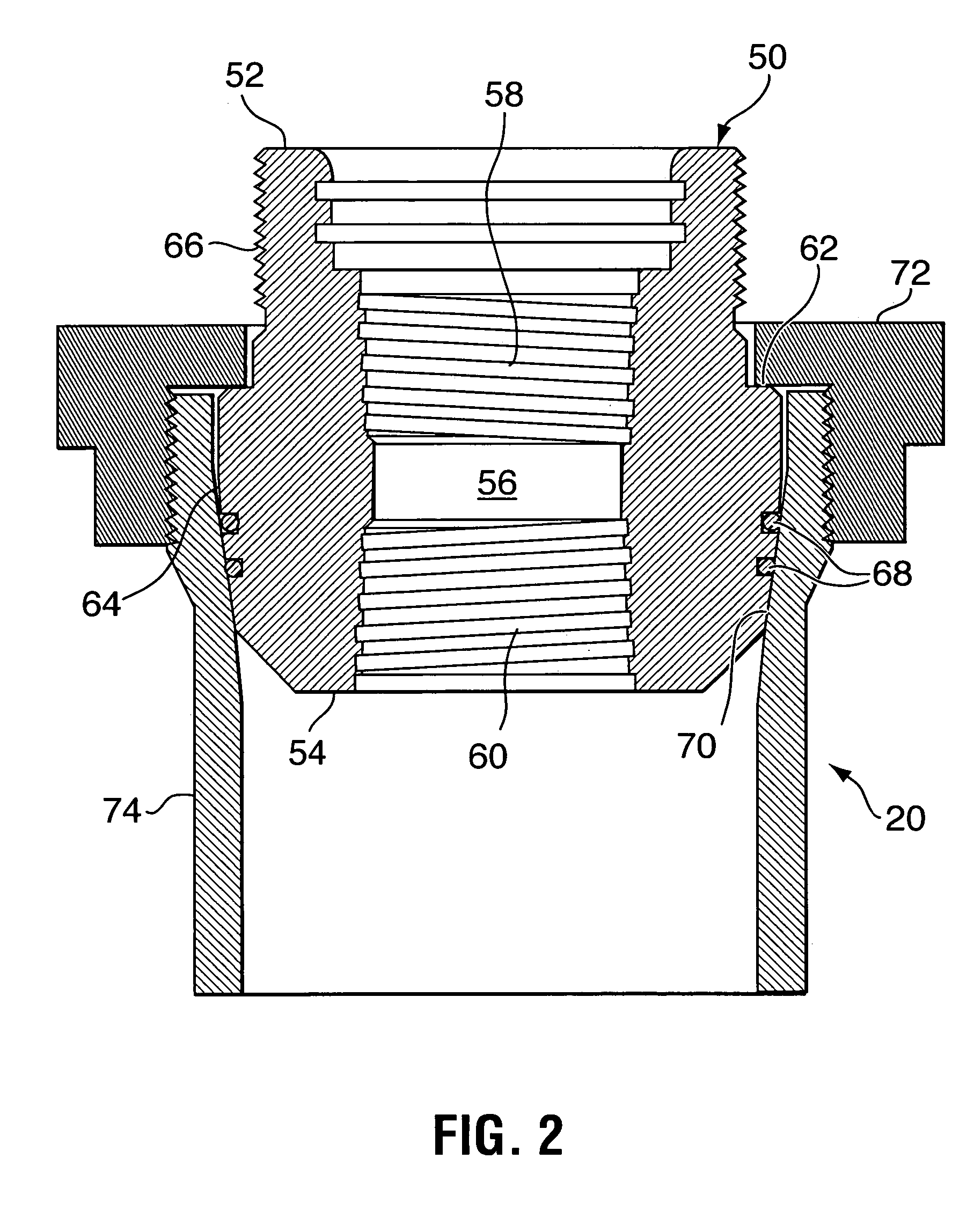

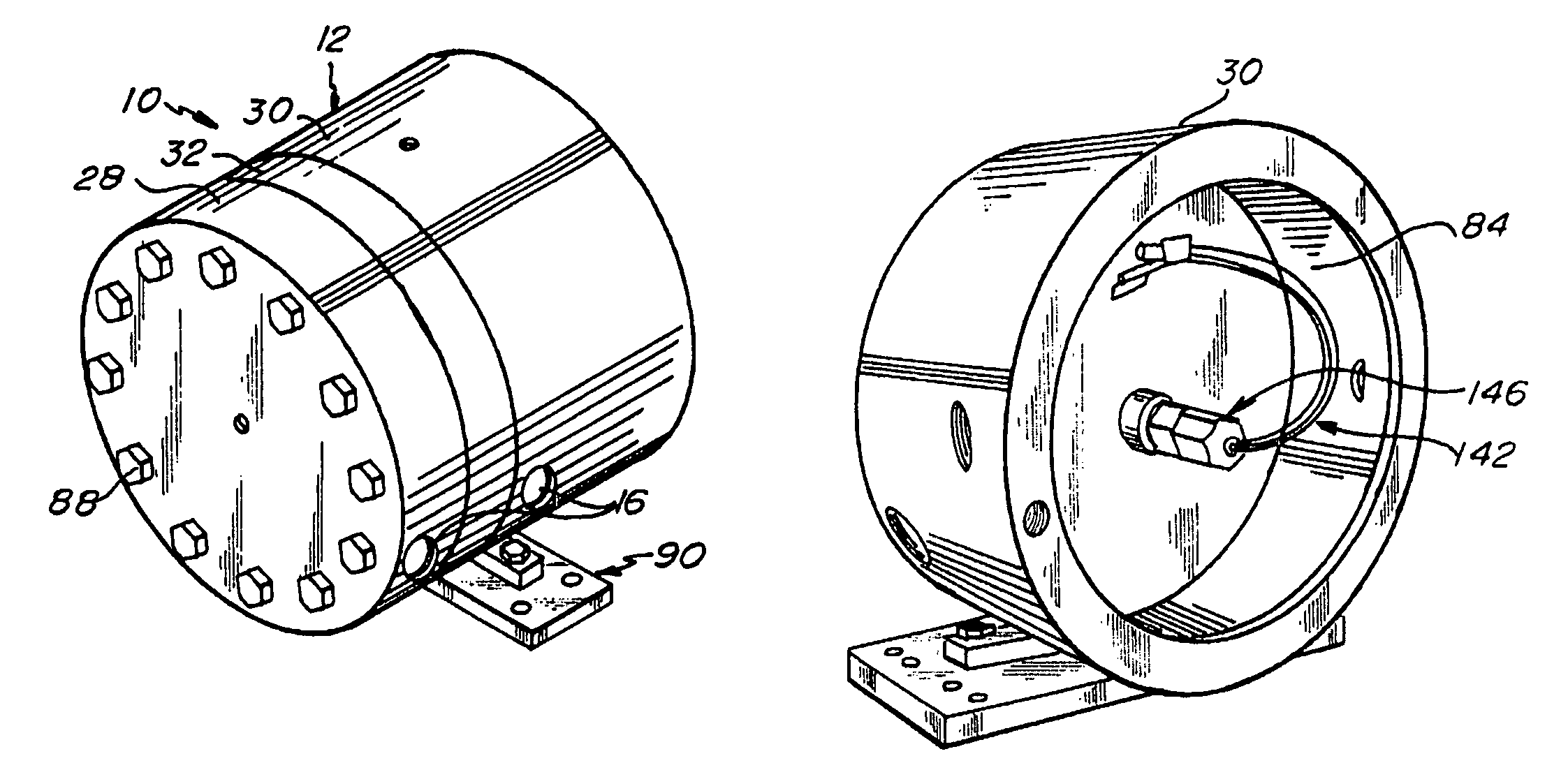

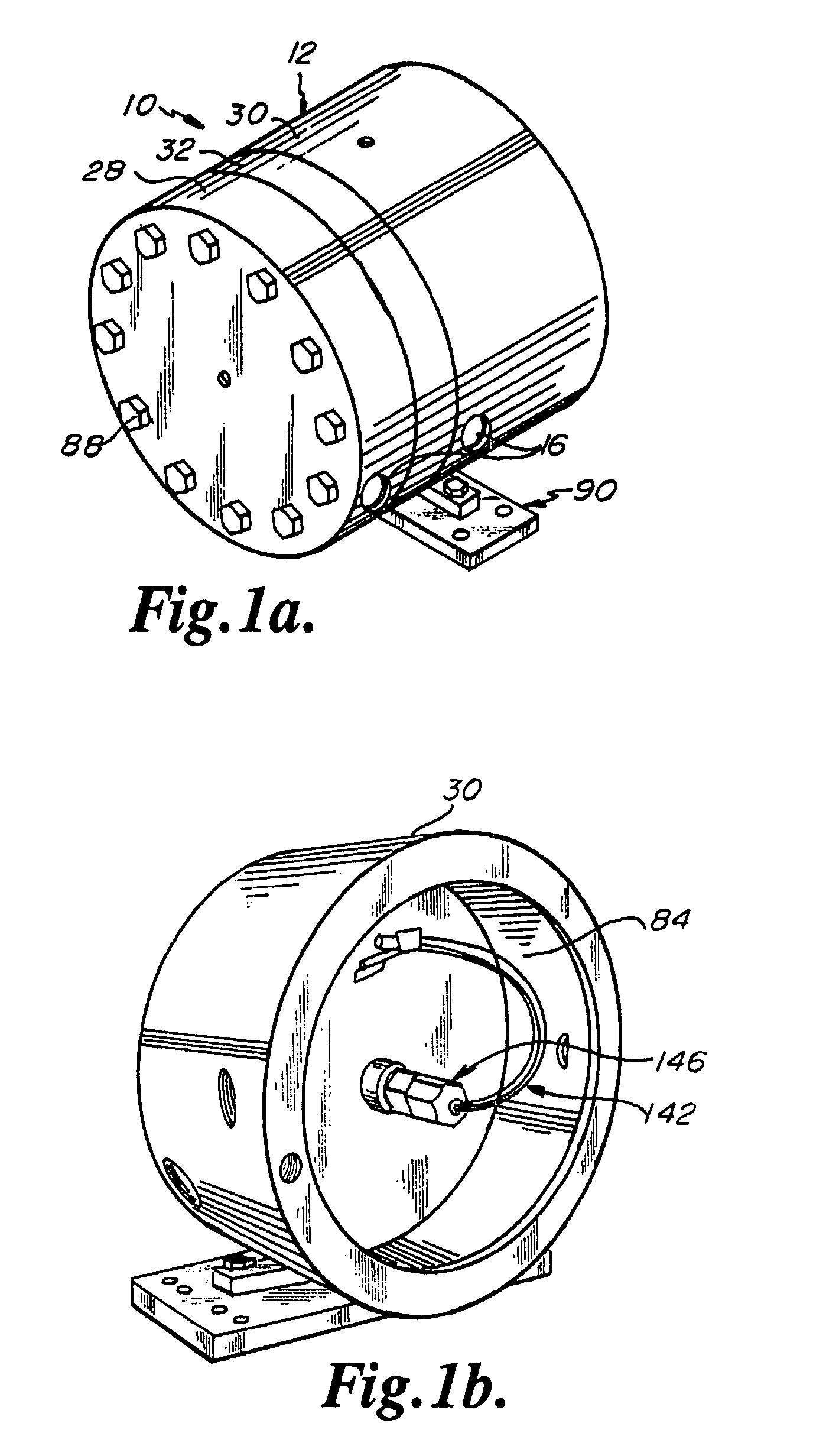

Adapters for double-locking casing mandrel and method of using same

InactiveUS7040410B2Easy procedureImprove work safetyDrilling rodsFluid removalWell stimulationEngineering

Adapters for connecting to a double-locking casing mandrel of an independent screwed wellhead include a lockdown flange with an adapter pin, and a retainer flange that may be used with or without the adapter pin. The retainer flange has a top surface with circumferentially-spaced threaded bores that permit well stimulation equipment to be mounted thereto. The retainer flange threadedly connects to a pin thread at a top of the casing mandrel, and therefore provides a low profile mounting flange for well stimulation equipment.

Owner:OIL STATES ENERGY SERVICES +1

Subsea intervention

Owner:SCHLUMBERGER TECH CORP

Casing mandrel with well stimulation tool and tubing head spool for use with the casing mandrel

InactiveUS7066269B2Rapidly and efficiently and re-completedImprove securityDrilling rodsFluid removalCompletion timeWell stimulation

A casing mandrel for an independent screwed wellhead includes a pin thread adapted for engagement with a box thread of a well stimulation tool lockdown nut for securing the well stimulation tool against the casing mandrel top end. A well stimulation tool and a tubing head spool for use with the casing mandrel are also provided. Safety of well stimulation procedures is thereby improved and well completion time is significantly reduced.

Owner:WELLS FARGO BANK NAT ASSOC +1

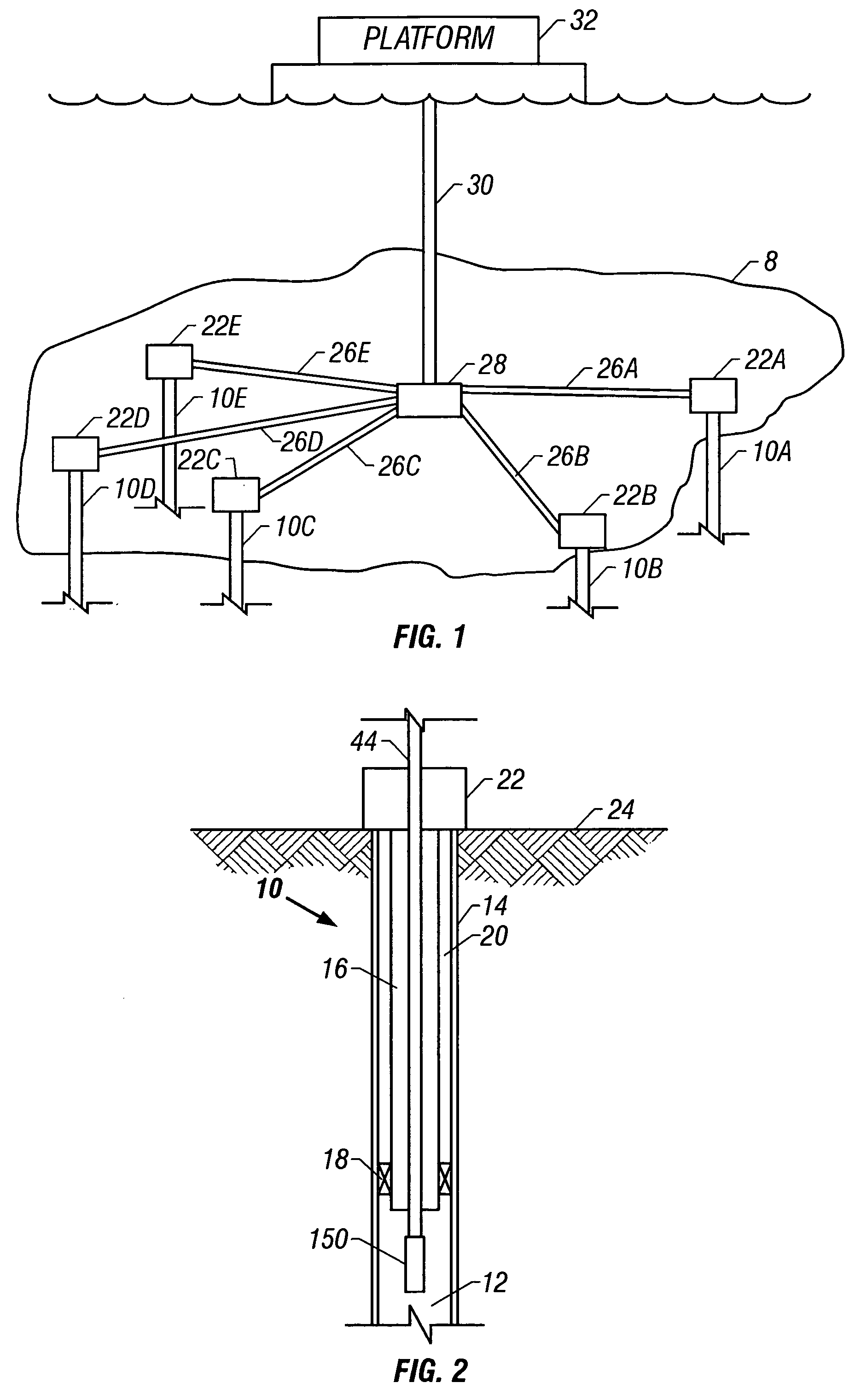

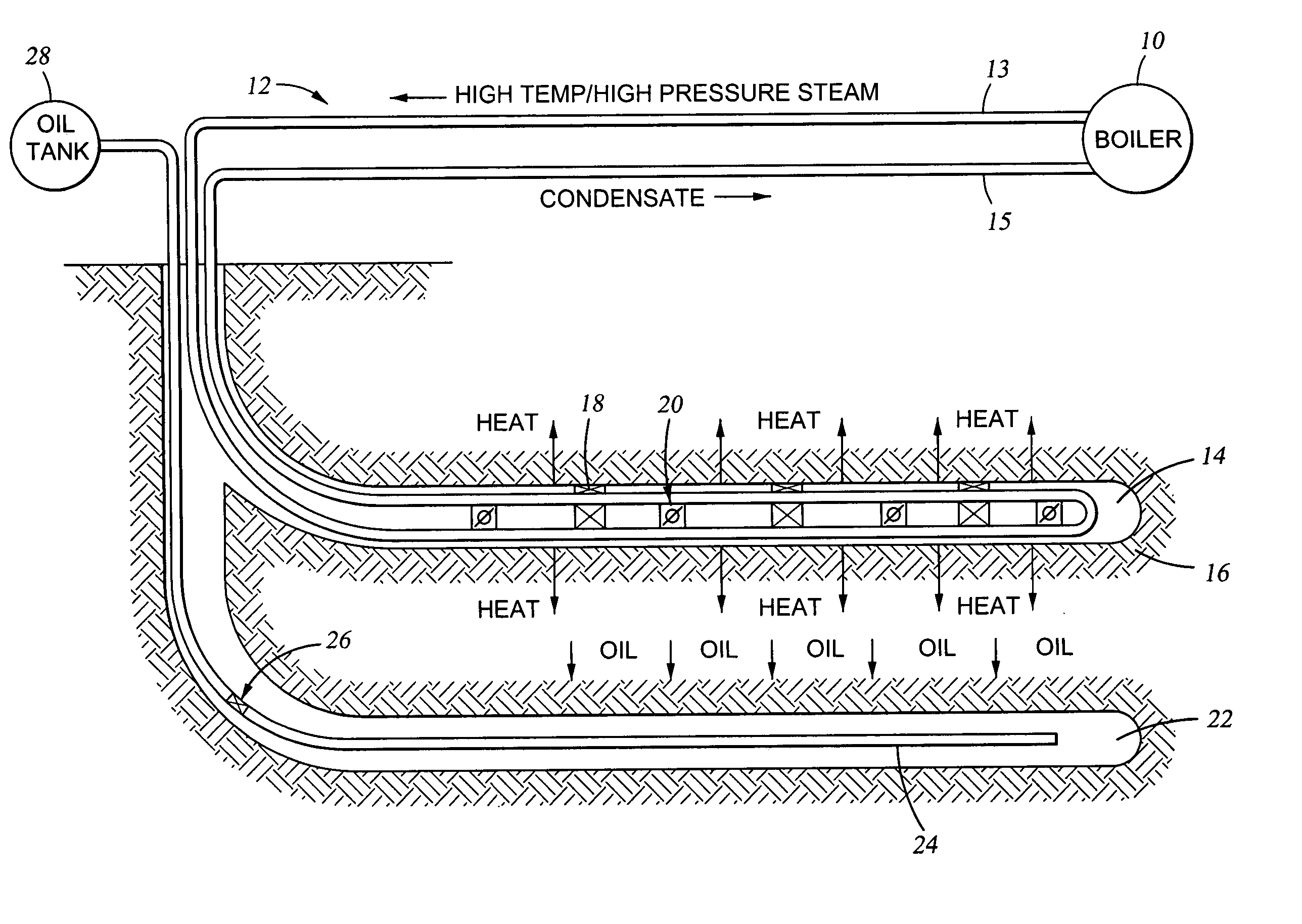

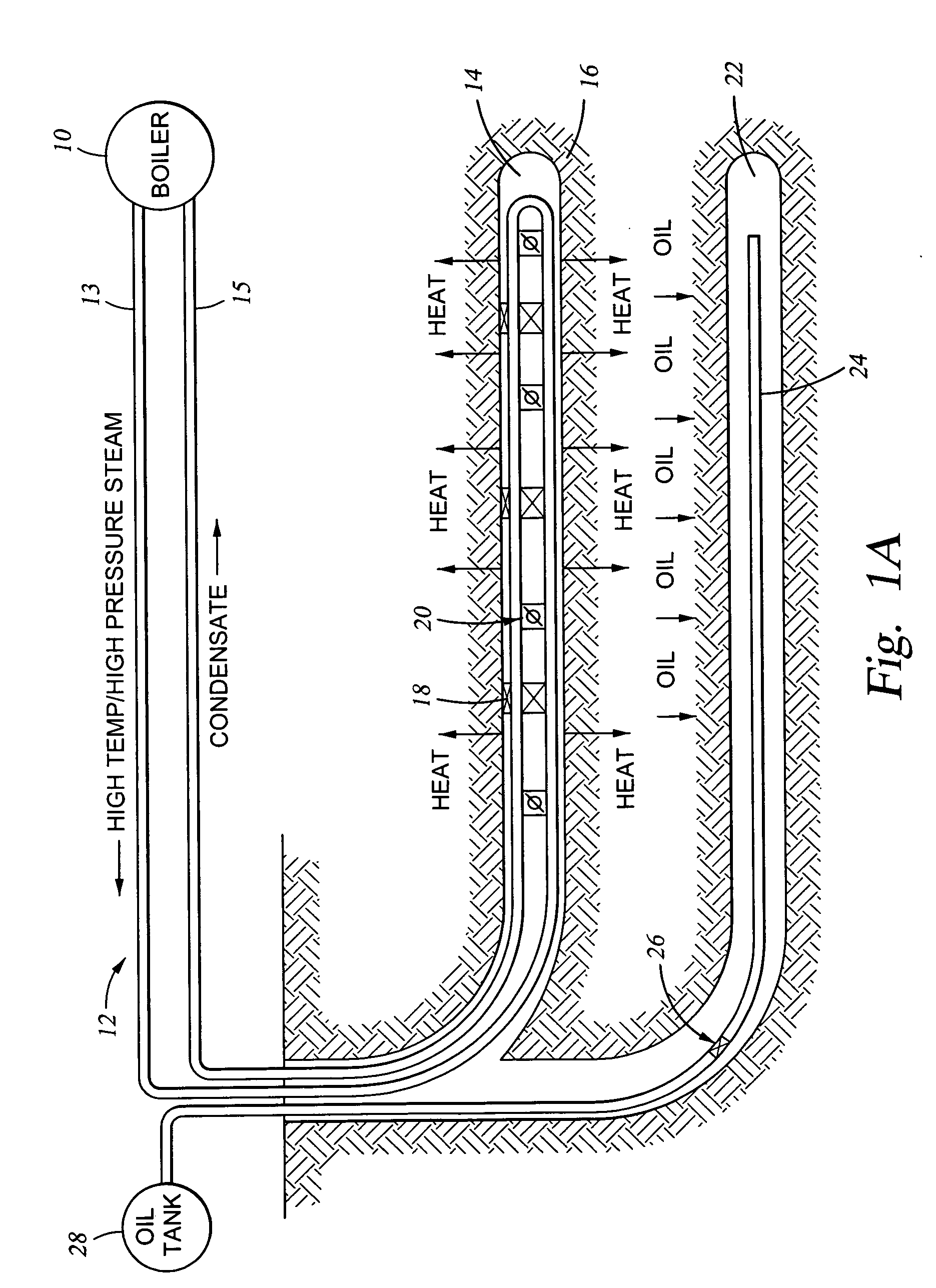

Loop systems and methods of using the same for conveying and distributing thermal energy into a wellbore

ActiveUS20050072567A1Reduces viscosity of oilPromote recoveryInsulationFluid removalThermal energyViscosity

Systems and methods are provided for treating a wellbore using a loop system to heat oil in a subterranean formation contacted by the wellbore. The loop system comprises a loop that conveys a fluid (e.g., steam) down the wellbore via a injection conduit and returns fluid (e.g., condensate) from the wellbore via a return conduit. A portion of the fluid in the loop system may be injected into the subterranean formation using one or more valves disposed in the loop system. Alternatively, only heat and not fluid may be transferred from the loop system into the subterranean formation. The fluid returned from the wellbore may be re-heated and re-conveyed by the loop system into the wellbore. Heating the oil residing in the subterranean formation reduces the viscosity of the oil so that it may be recovered more easily.

Owner:HALLIBURTON ENERGY SERVICES INC

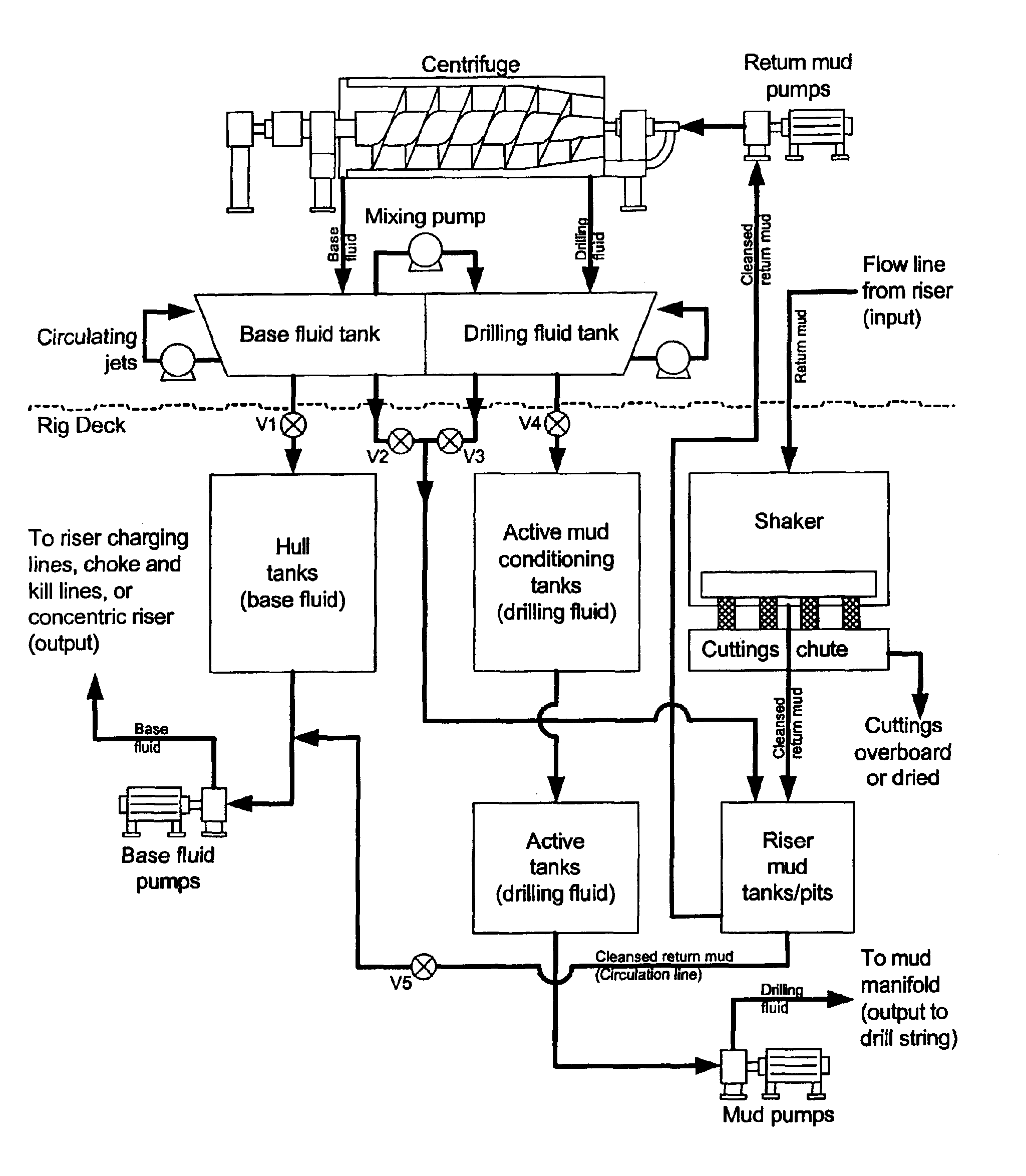

System and method for treating drilling mud in oil and gas well drilling applications

A system and method for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in deep water and ultra deep water applications. A base fluid of lesser density than the drilling mud required at the wellhead is used to produce a diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, a diluted riser mud density at or near the density of seawater may be achieved. The present invention also includes a wellhead injection device for injecting the base fluid into the rising drilling mud. The riser charging lines are used to carry the low density base fluid to the injection device for injection into the return mud. At the surface, the diluted return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the heavier drilling mud from the lighter base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

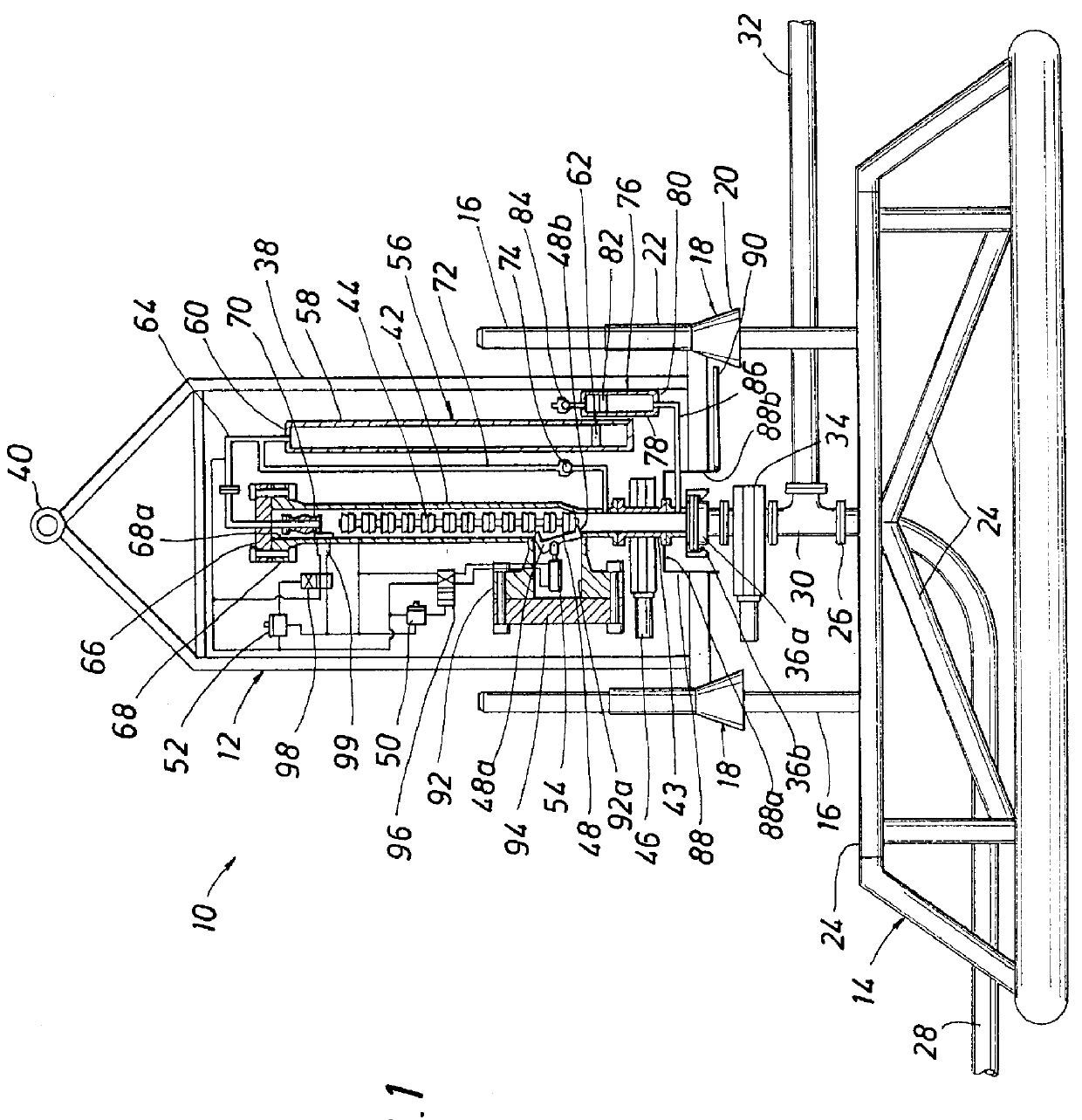

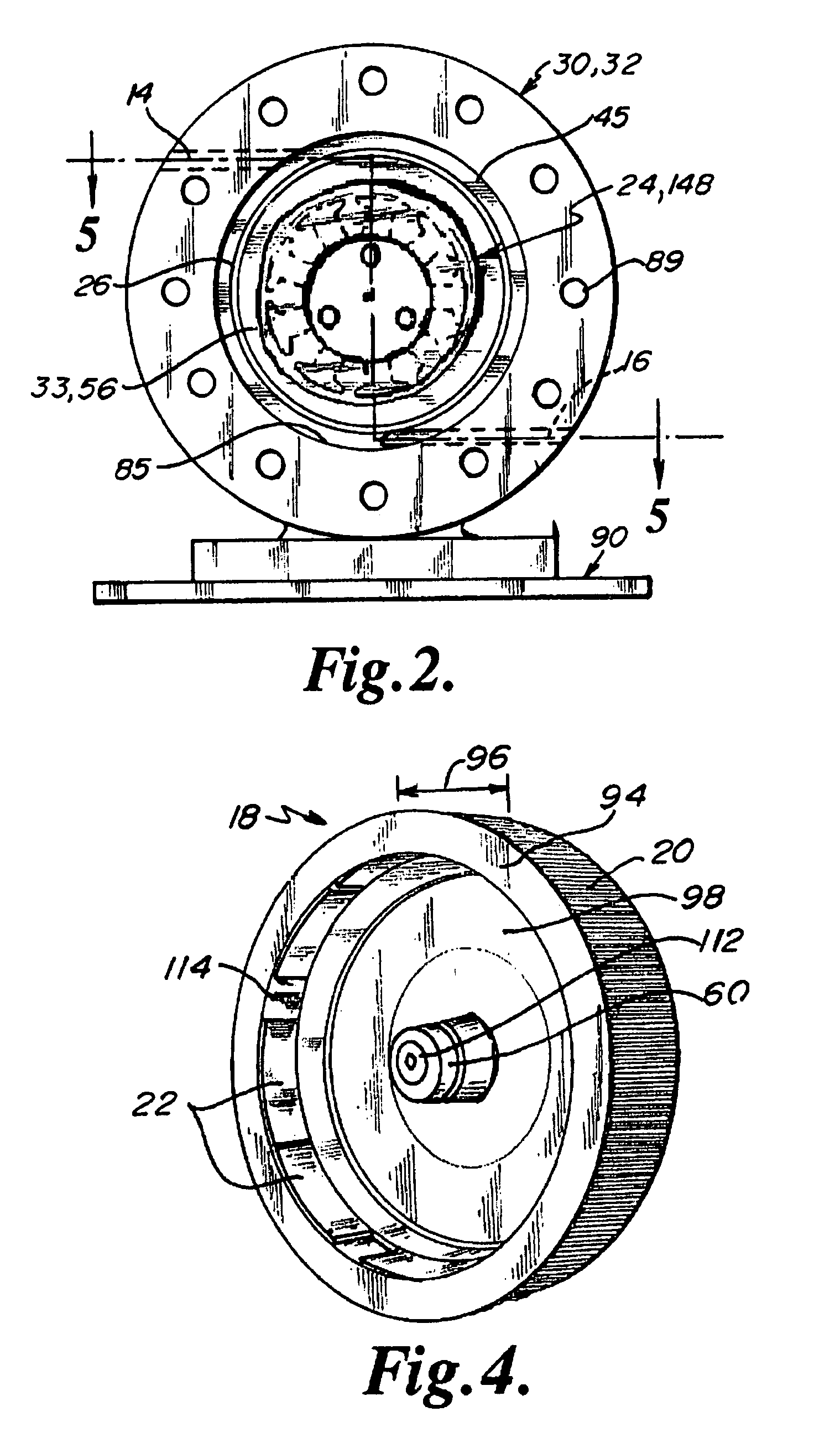

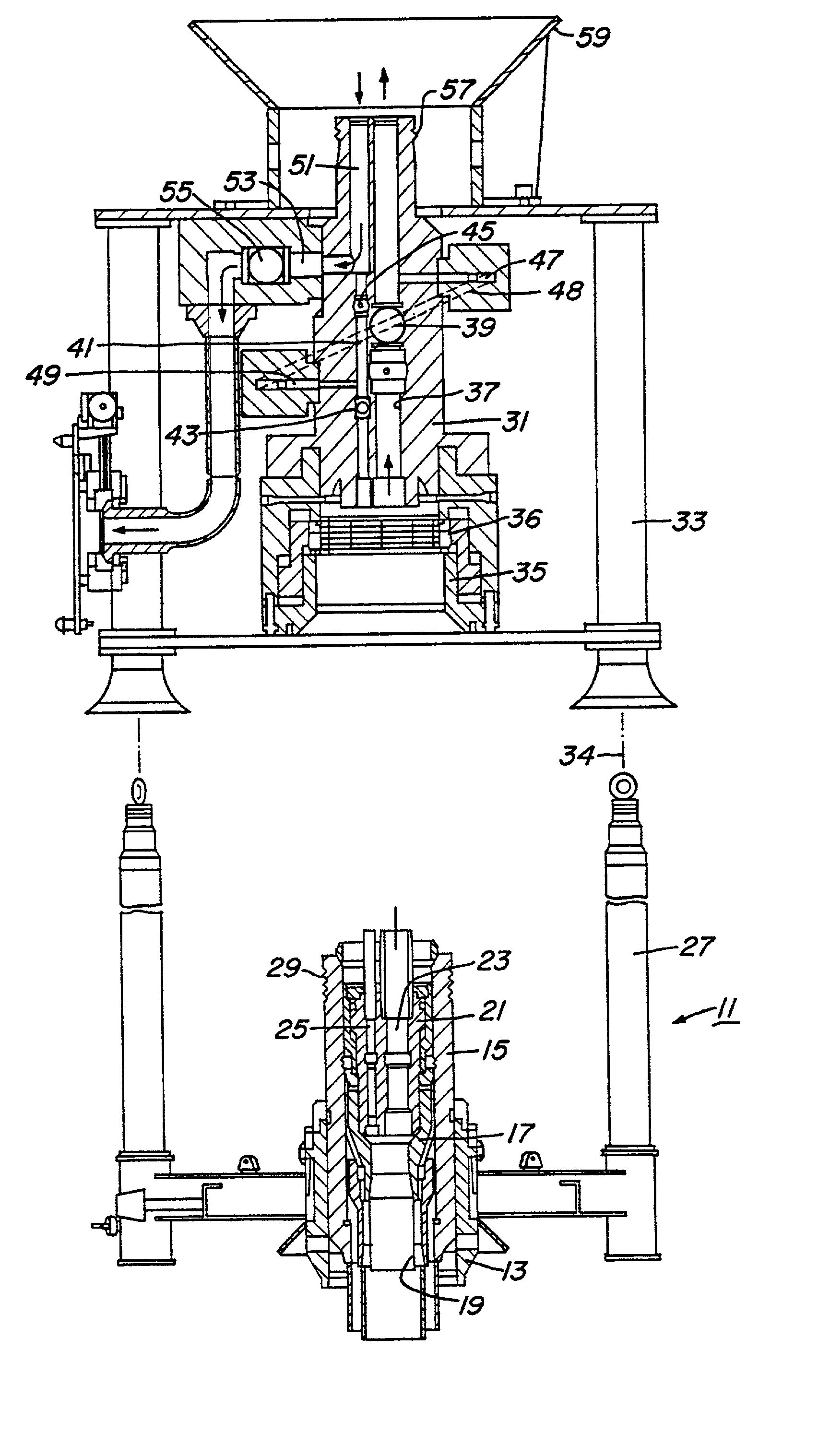

Natural gas turbine generator

ActiveUS7683499B2Minimize explosion hazardEliminating carbon bridging between connectionsMotor/generator/converter stoppersWindingsElectricityMomentum

A turbine generator utilizing a passive high pressure fluid source such as a natural gas well head. The generator includes a core and lead wires encapsulated in a dielectric medium to isolate current-bearing components from the motivating fluid, thereby preventing carbon bridging and reducing the explosion hazard when the motivating fluid is a hydrocarbon. The turbine generator includes a rotor that utilizes the full length as an impingement surface for imparting momentum to the rotor, thereby maintaining a compact design that reduces the overall footprint of the turbine generator. Fluid exits the generator via horizontal passages that penetrate the lower extremities of the turbine generator, preventing the buildup of condensation in the unit.

Owner:REVOLUTION TURBINE TECH LLC

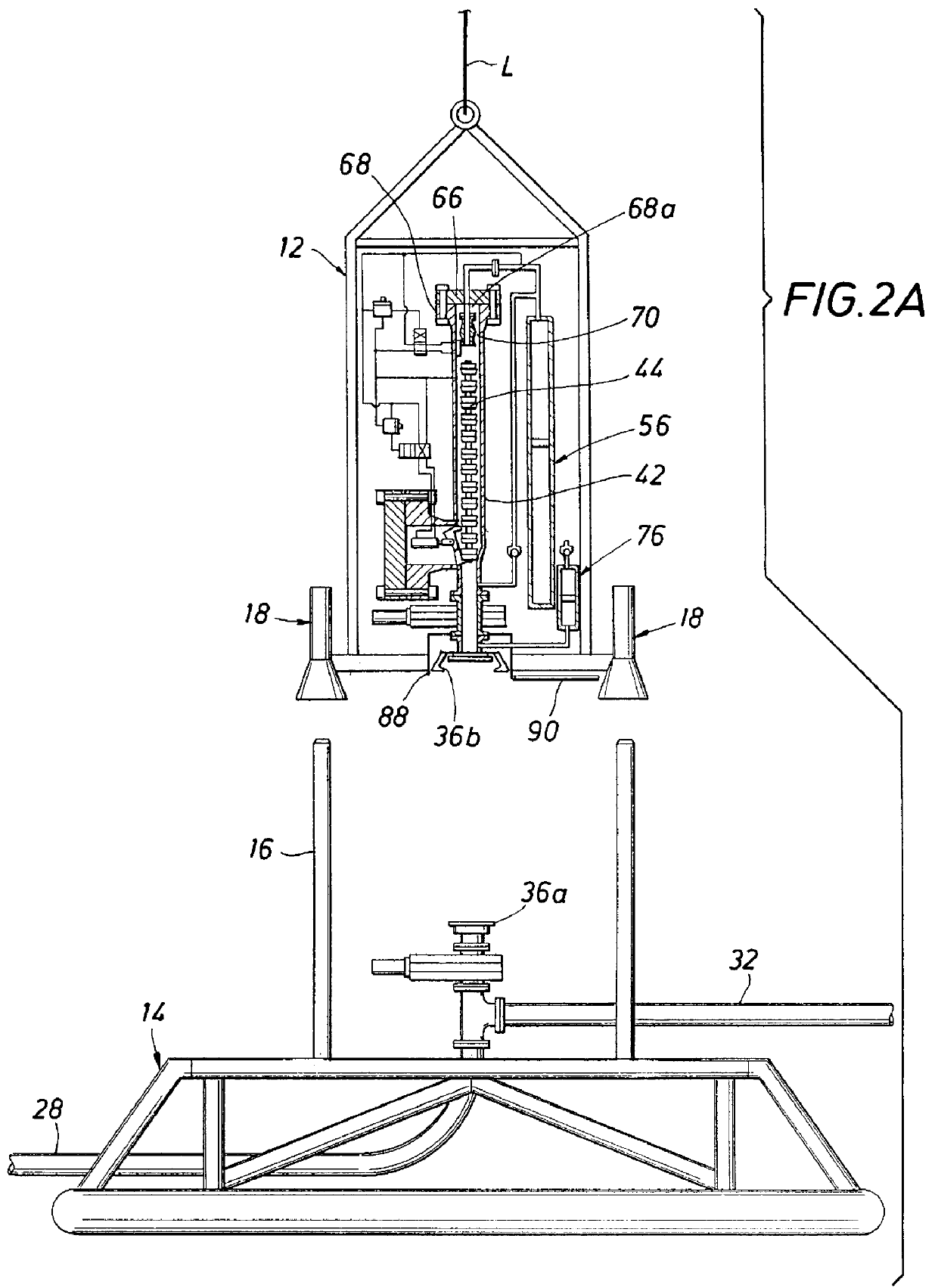

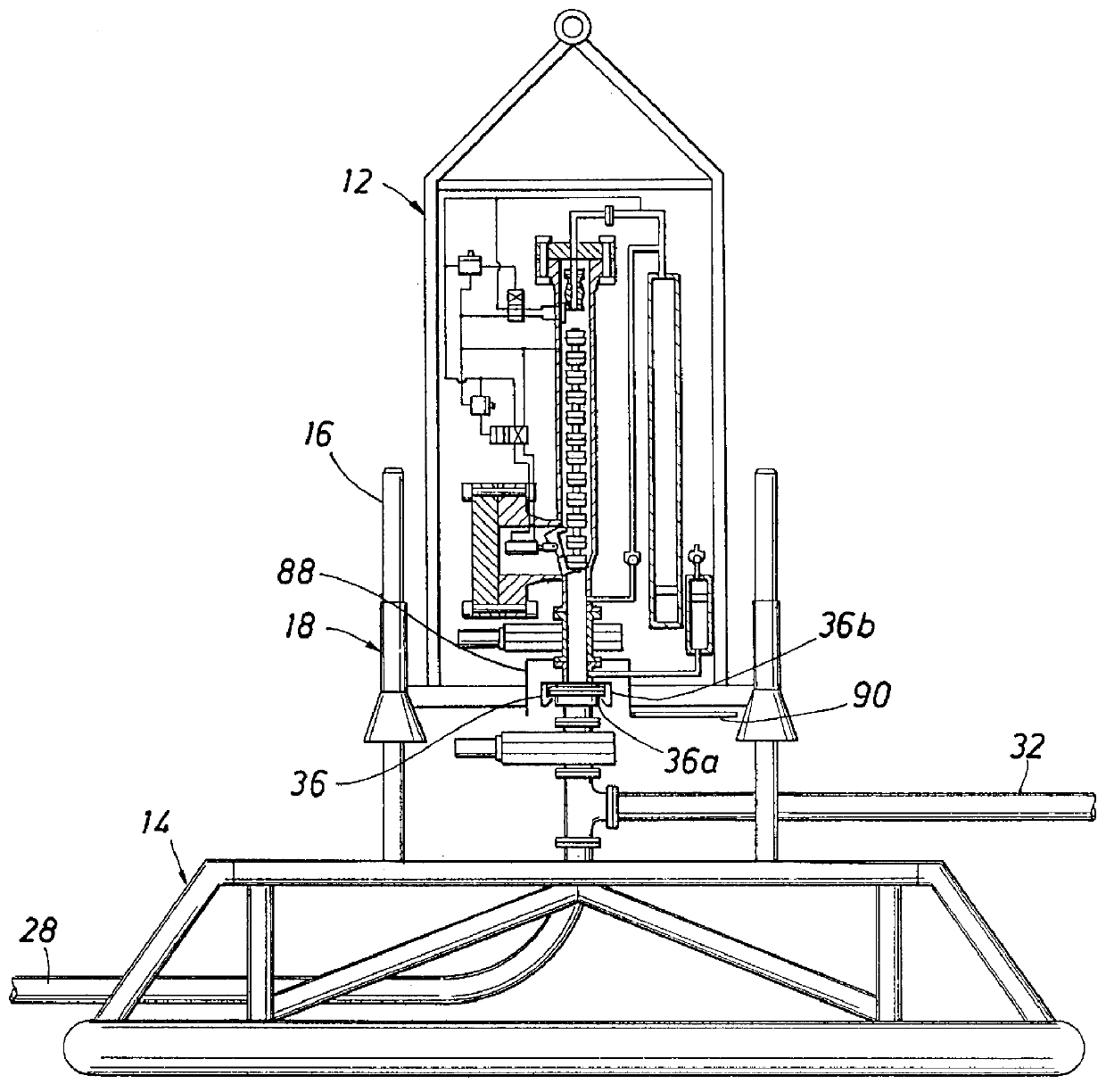

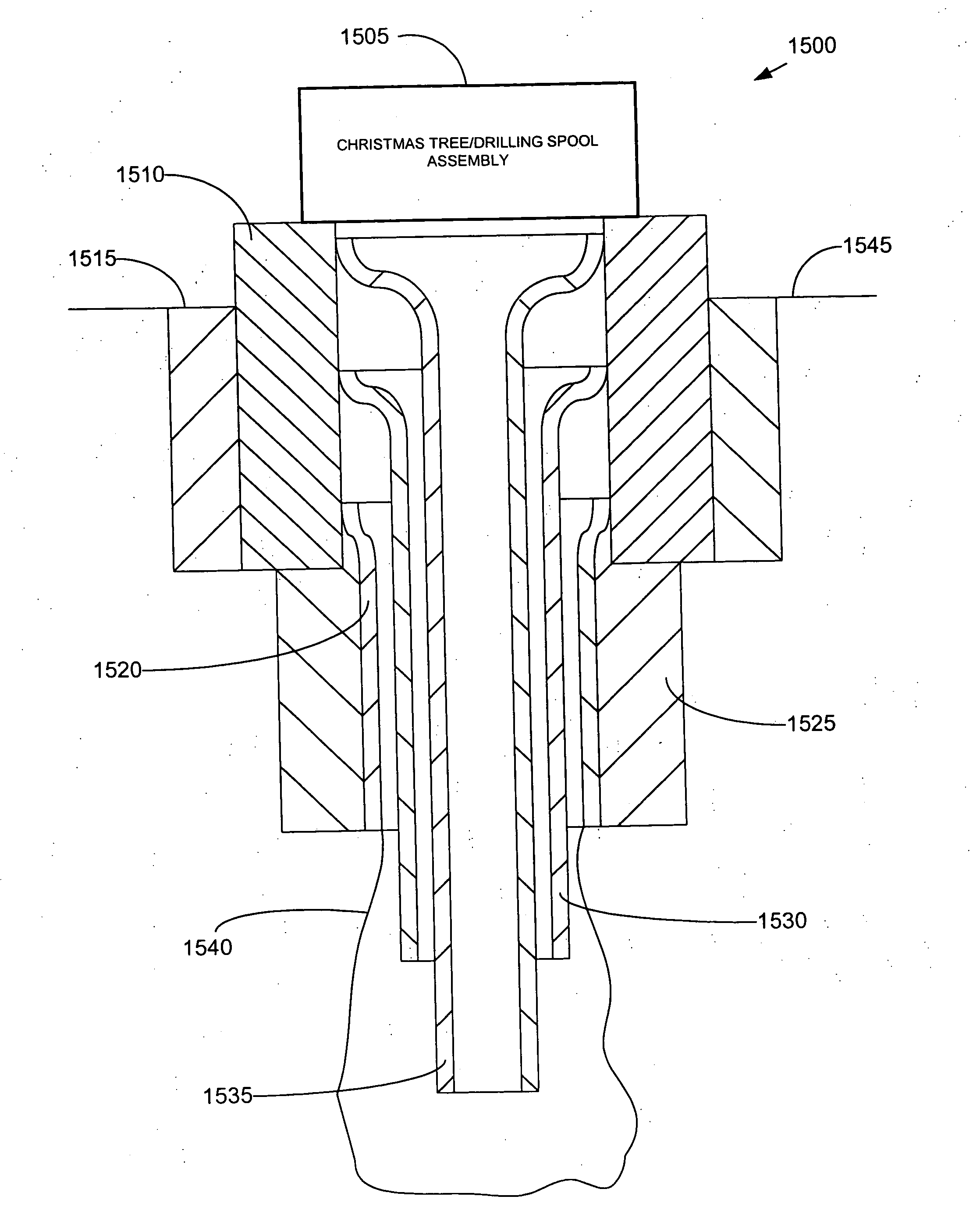

Light-intervention subsea tree system

A subsea well apparatus has features for controlling and monitoring production fluid flow from a well. A Christmas tree lands on a subsea wellhead, the tree having a tubular, open upper end. A first flow passage extends from a lower end of the tree to the upper end for communicating fluid with the well. A second flow passage extends downward from the upper end of the tree and has an outlet on a sidewall of the tree for communicating with a flowline. A production module lands on and is retrievable from the upper end of the tree, the module having a flow loop with one end in communication with the first flow passage and another end in communication with the second flow passage. At least one flow interface device is located in the loop of the production module. The flow interface device may be used to monitor or control the flow and may be a temperature or pressure sensor, a flow or multi-phase flow meter, or a choke.

Owner:ABB VETCOGRAY

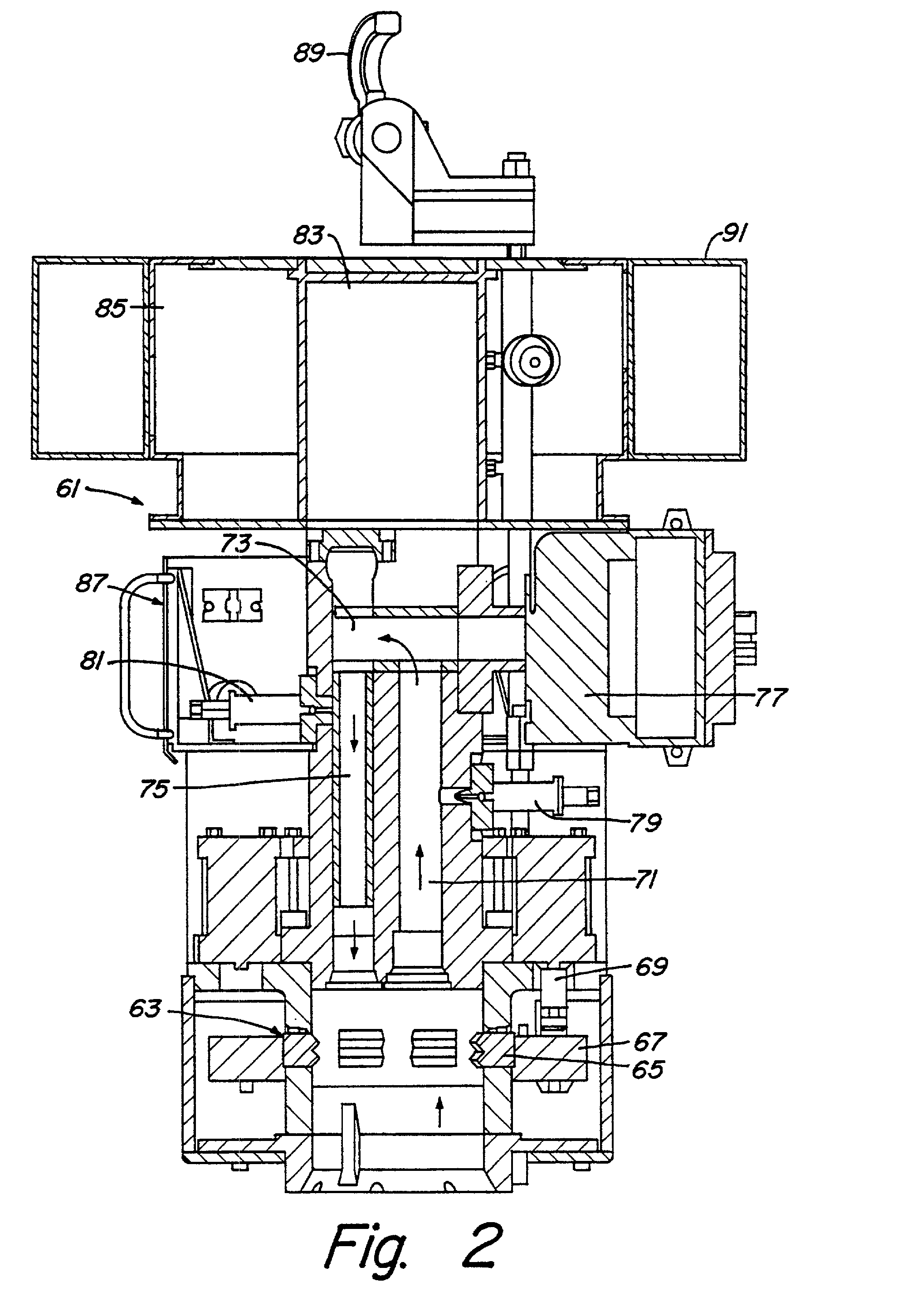

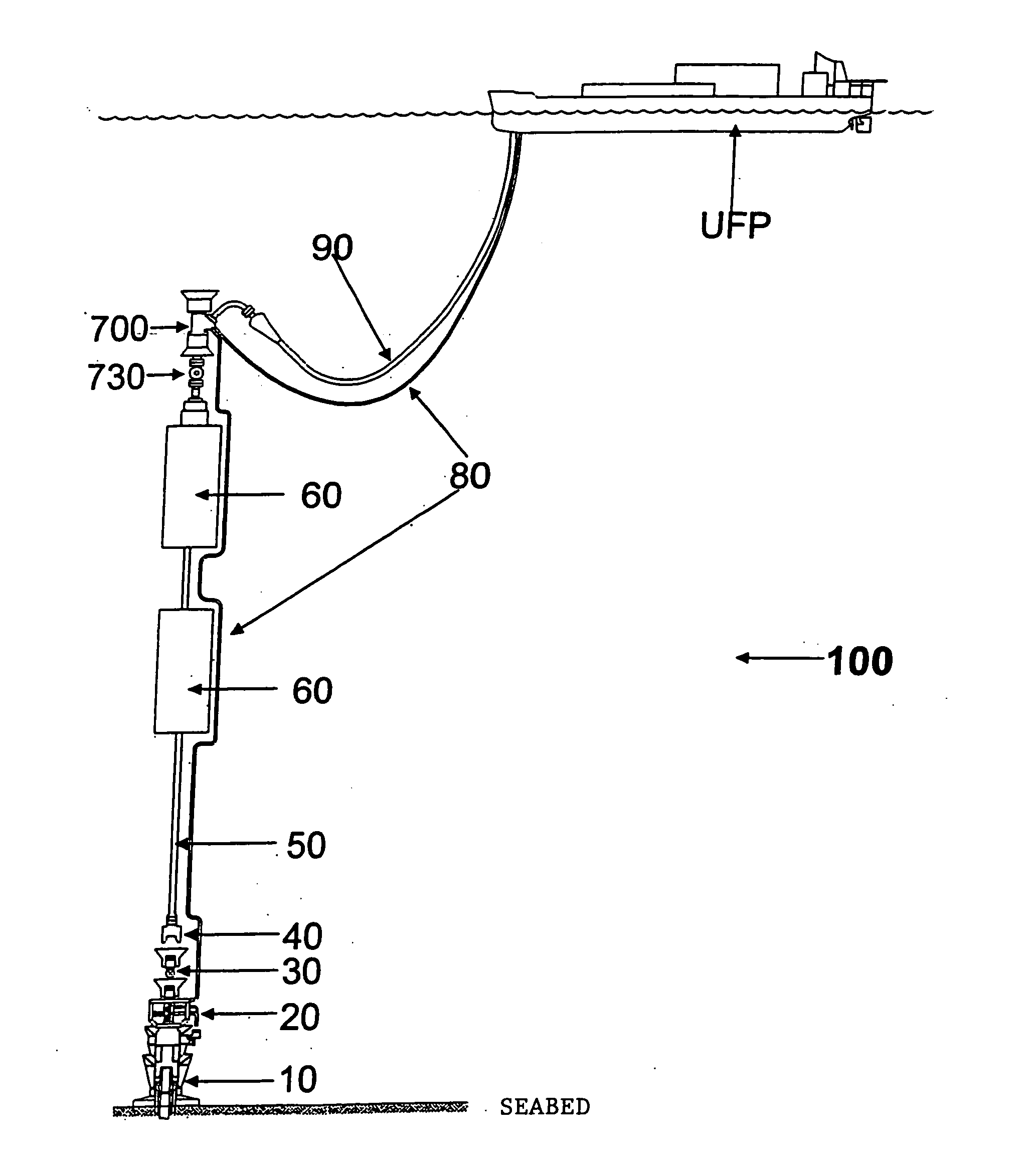

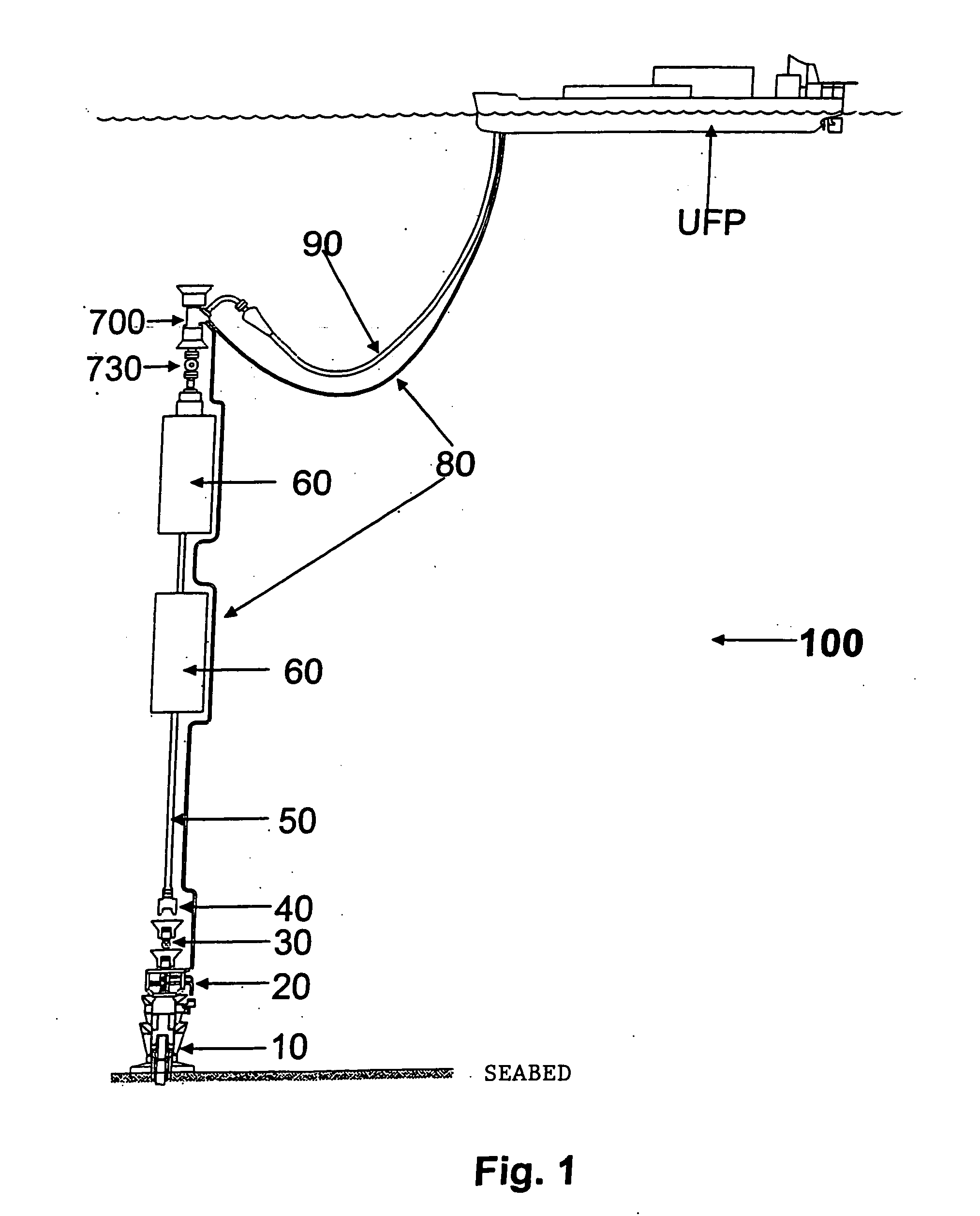

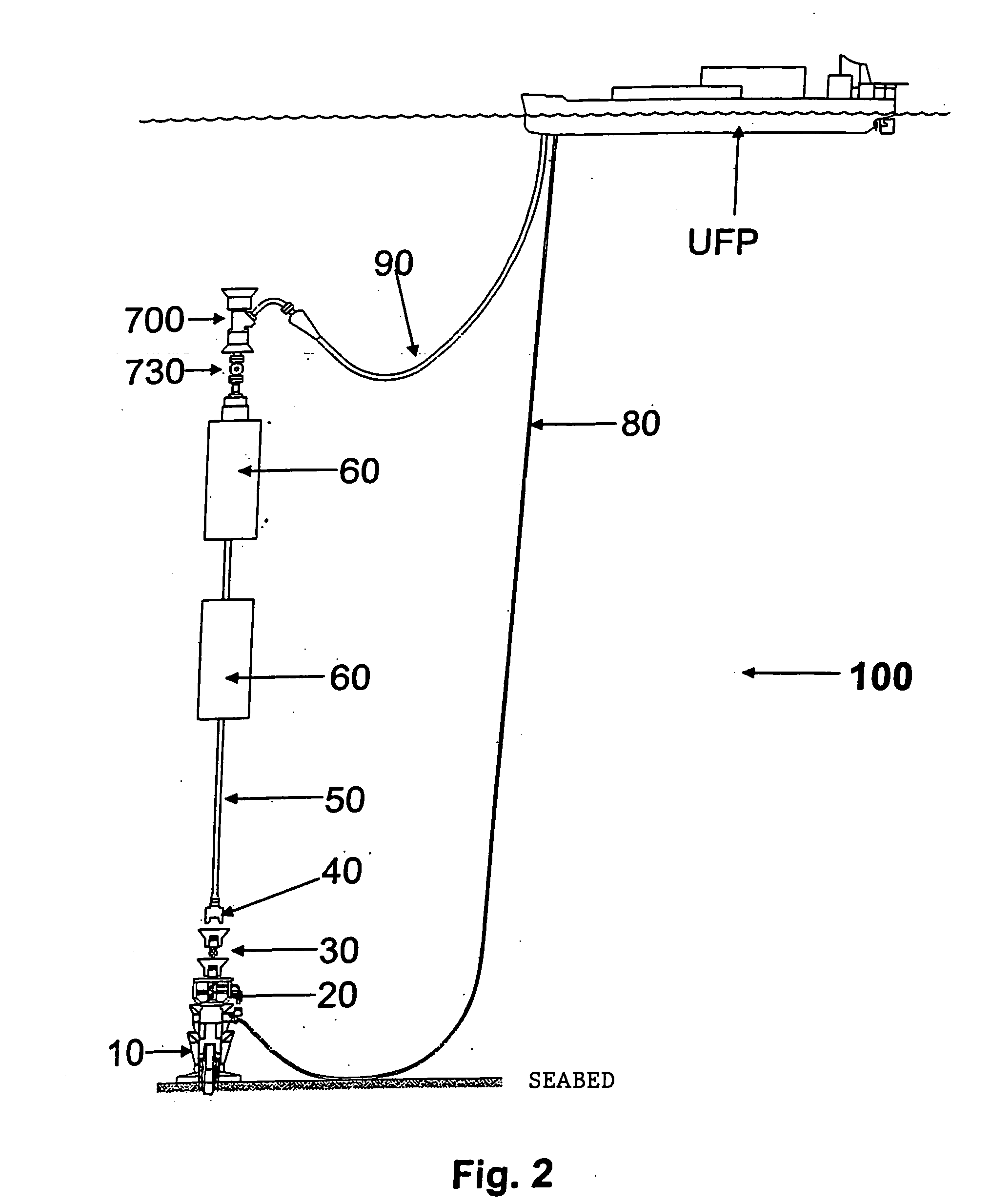

Self-supported riser system and method of installing same

InactiveUS20070044972A1Save rig timeReducing maneuvering stepCargo handling apparatusDrilling rodsBuoyPetroleum oil

A self-supported riser system (100) for an Anticipated Production System (ASP) Test or a Long Duration Production (LDP) Test in a subsea petroleum production system, utilizing an ANM coupled to a wellhead and Floating Production Unit (FPU) is disclosed. The system includes a wellhead at the seabed, connected to an ANM (20) provided with a preventor (BOP of workover) (30). The preventor (30) is connected to a production riser (50) through a connection tool (40). The riser (50), mounted internally within a buoy assembly (60), is maintained under traction with the aid of a buoy assembly. The upper end of the riser (50) is provided with a Subsea Intervention Terminal (700), the Terminal being interlinked to the FPU by a flexible jumper (90) to carry the oil produced to the FPU. Two methods for installing the self-supported riser system (100) are also disclosed.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com