Patents

Literature

1556results about "Tank vehicles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

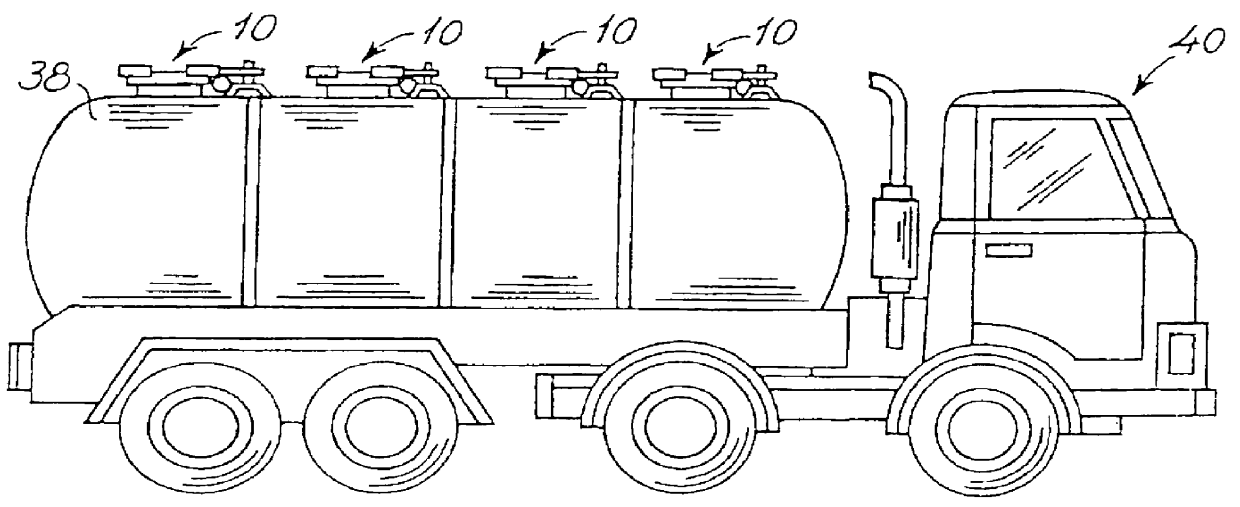

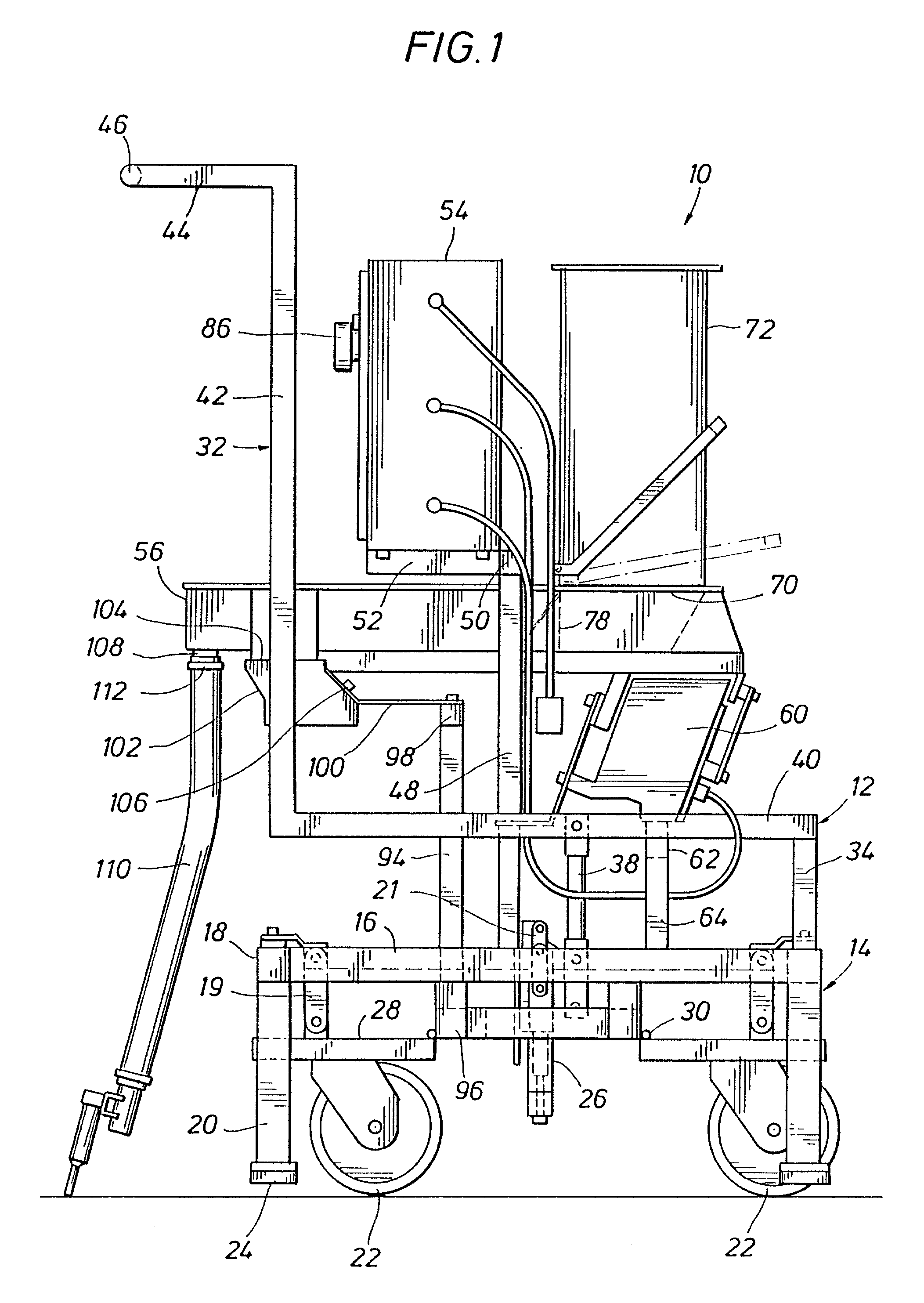

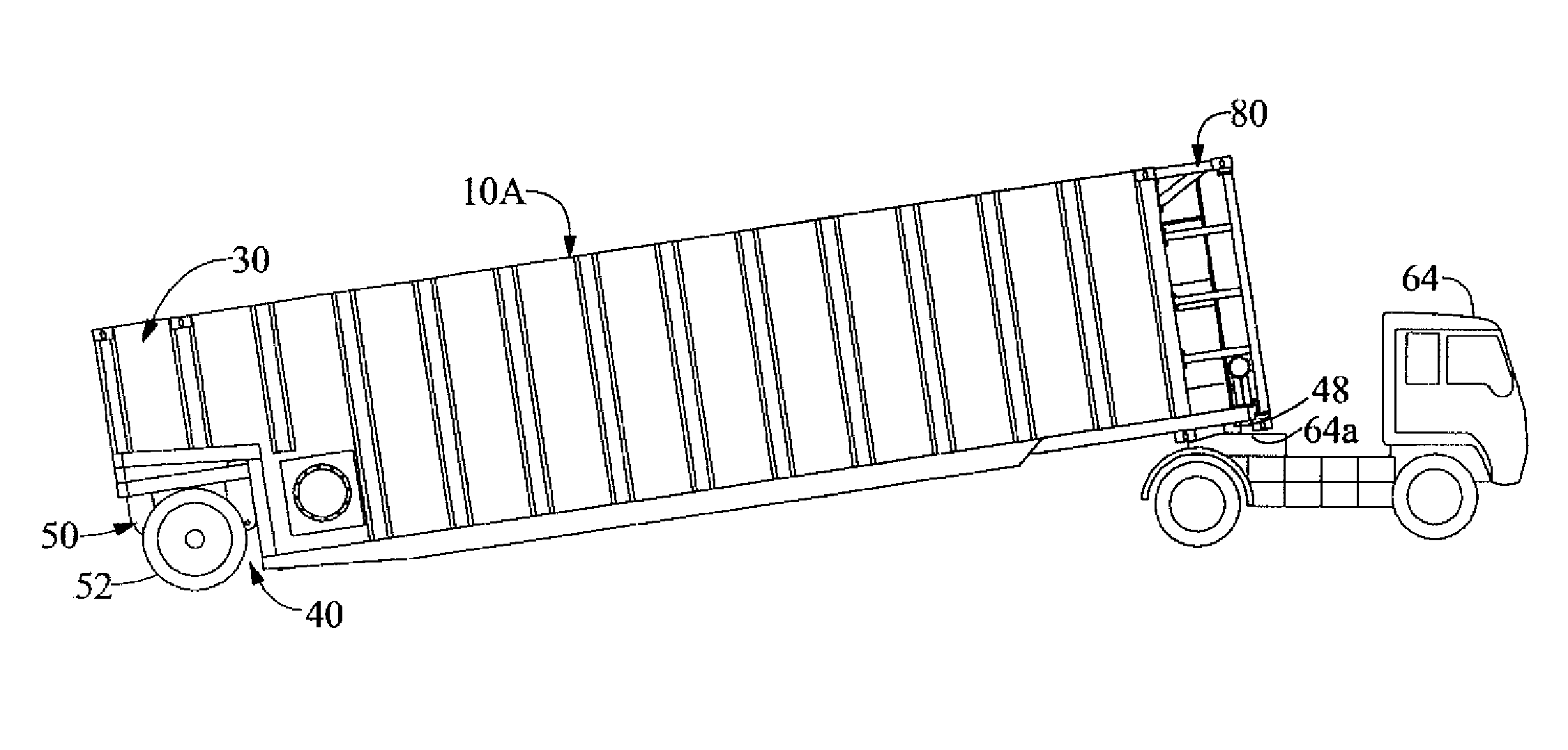

Method and apparatus for supplying bulk product to an end user

InactiveUS7214028B2Eliminate needEfficient transportTank vehiclesMixing operation control apparatusMarine engineeringEngineering

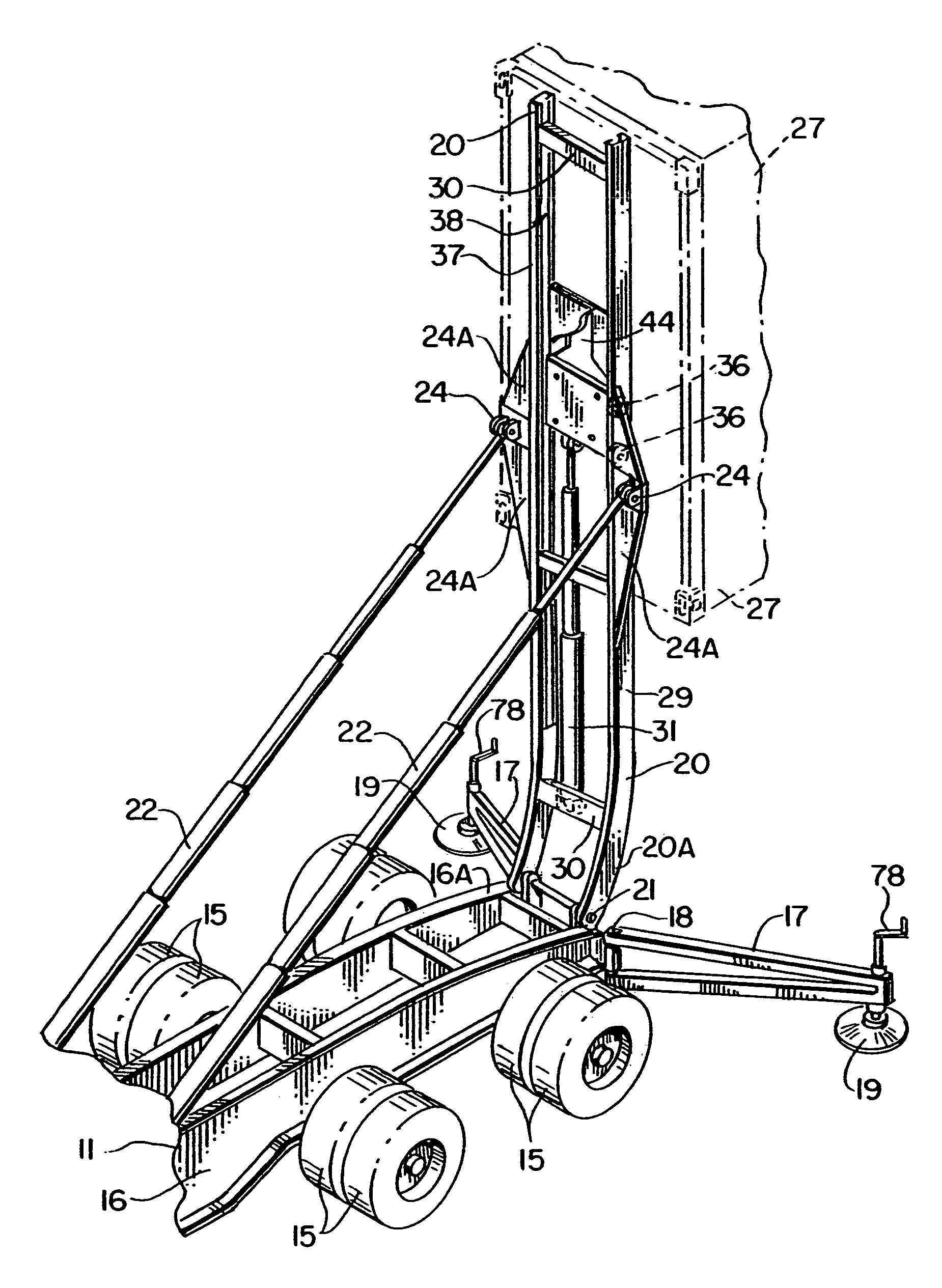

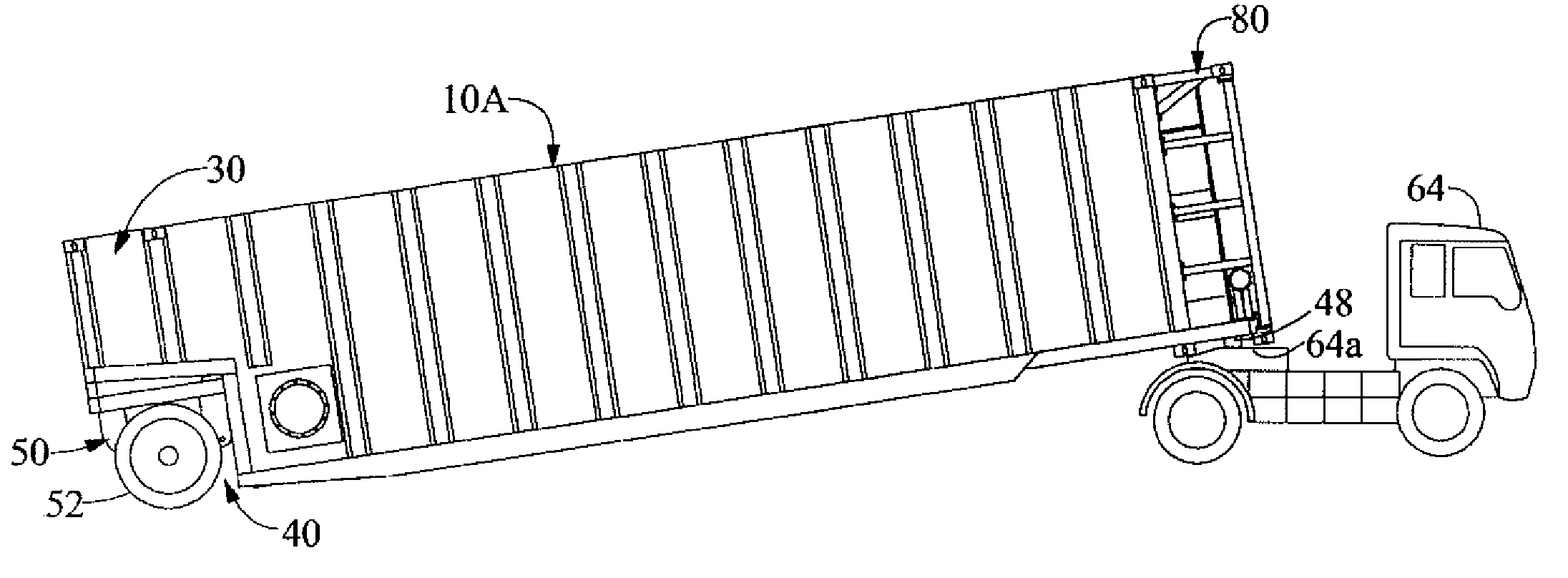

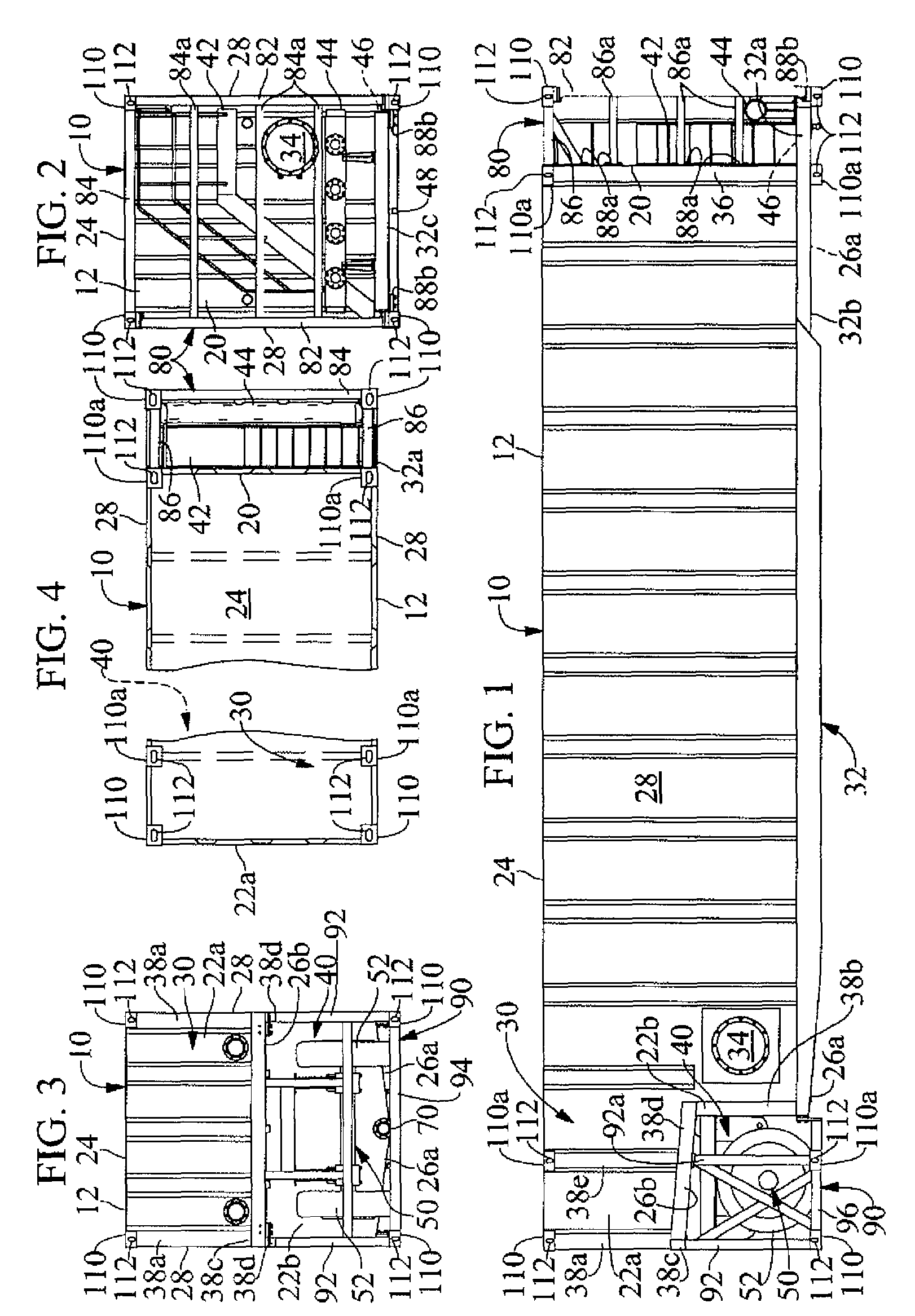

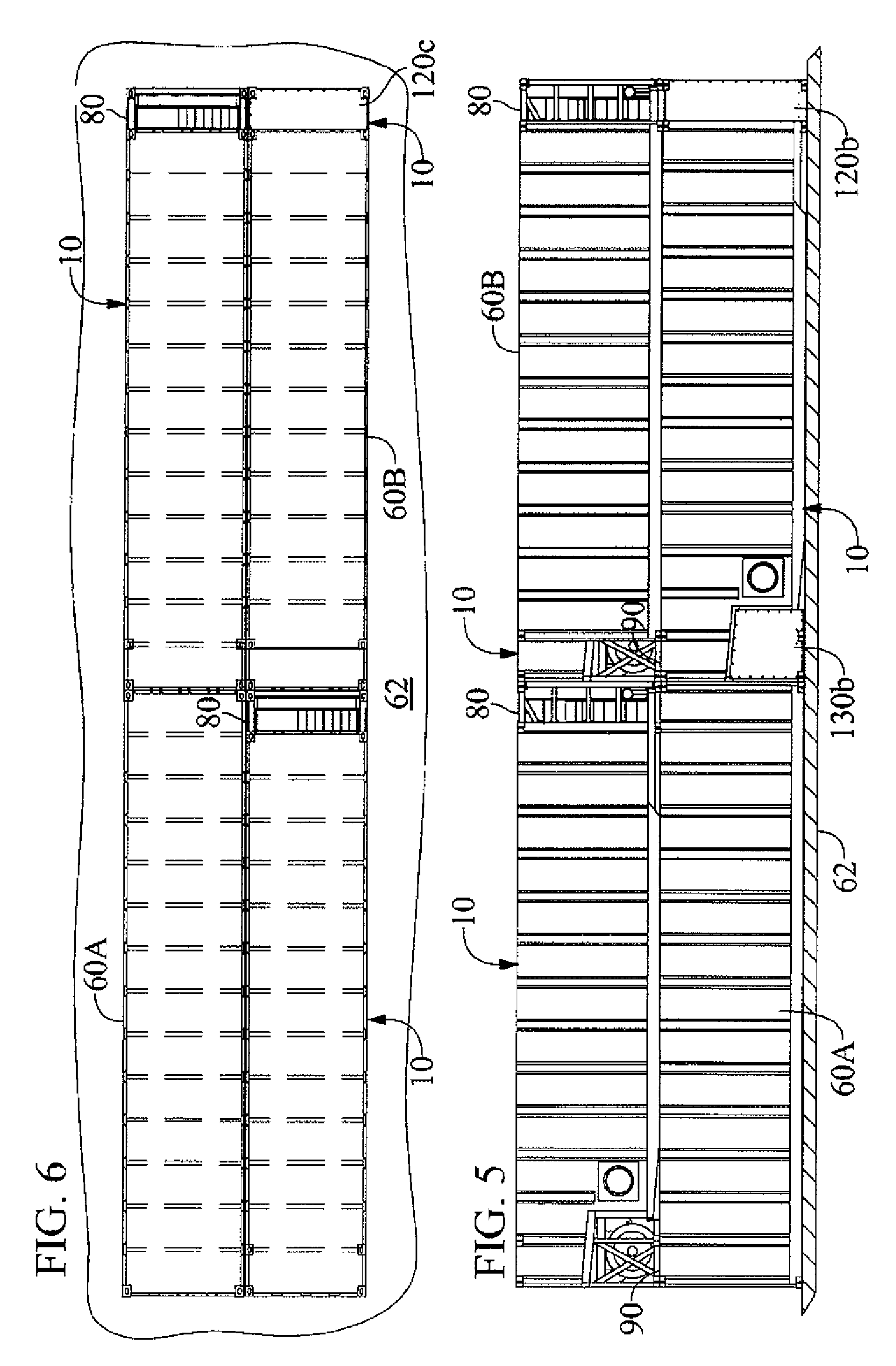

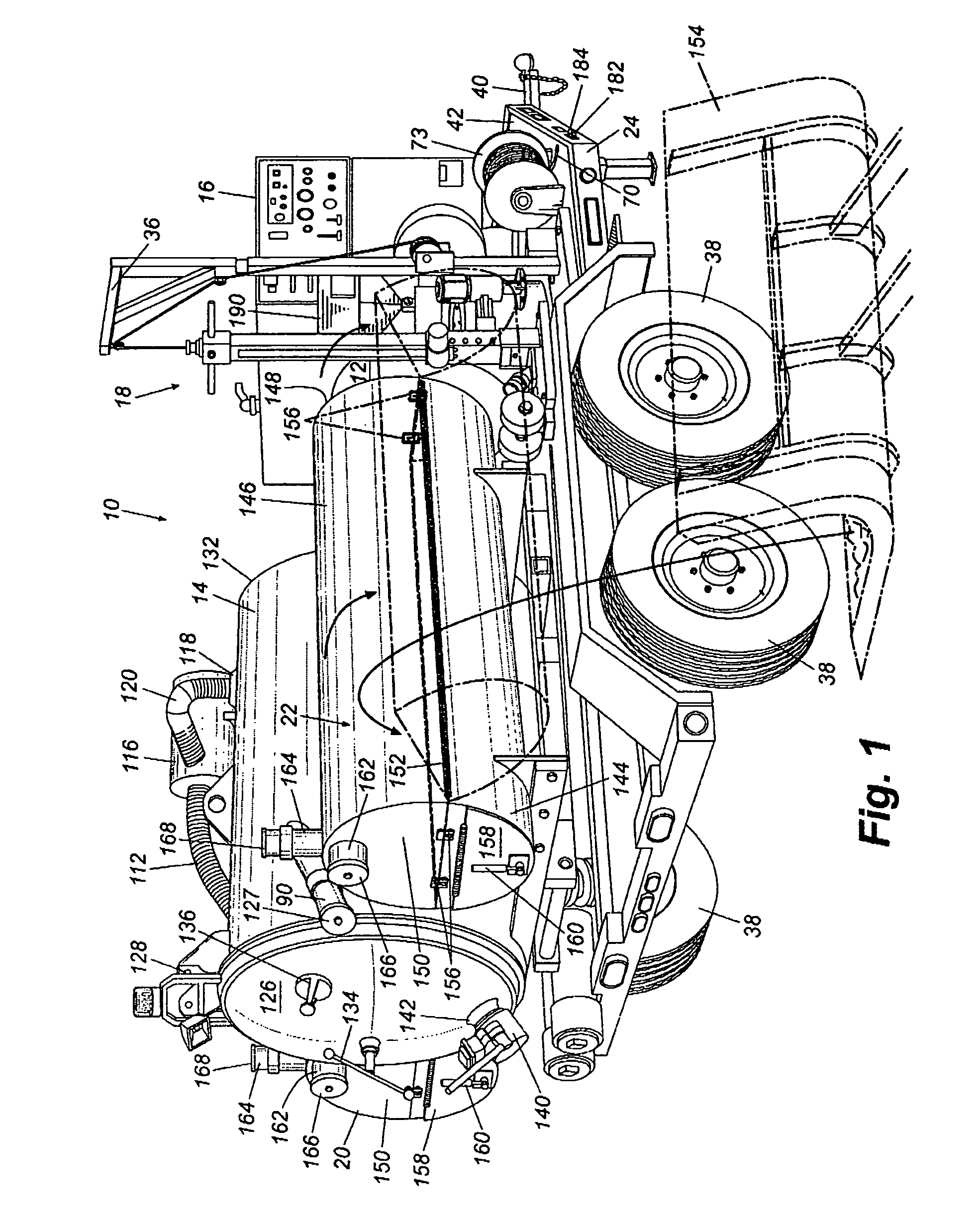

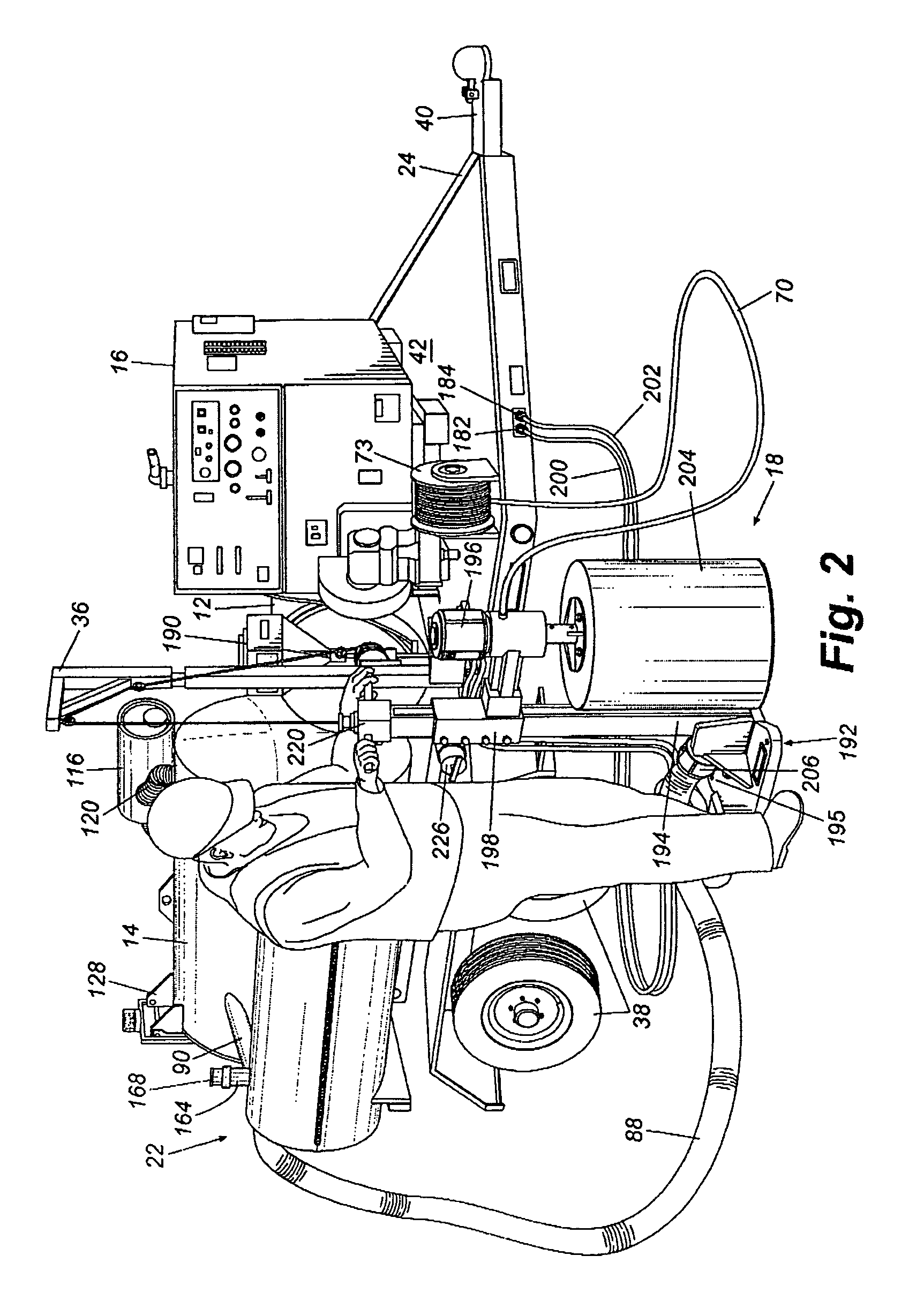

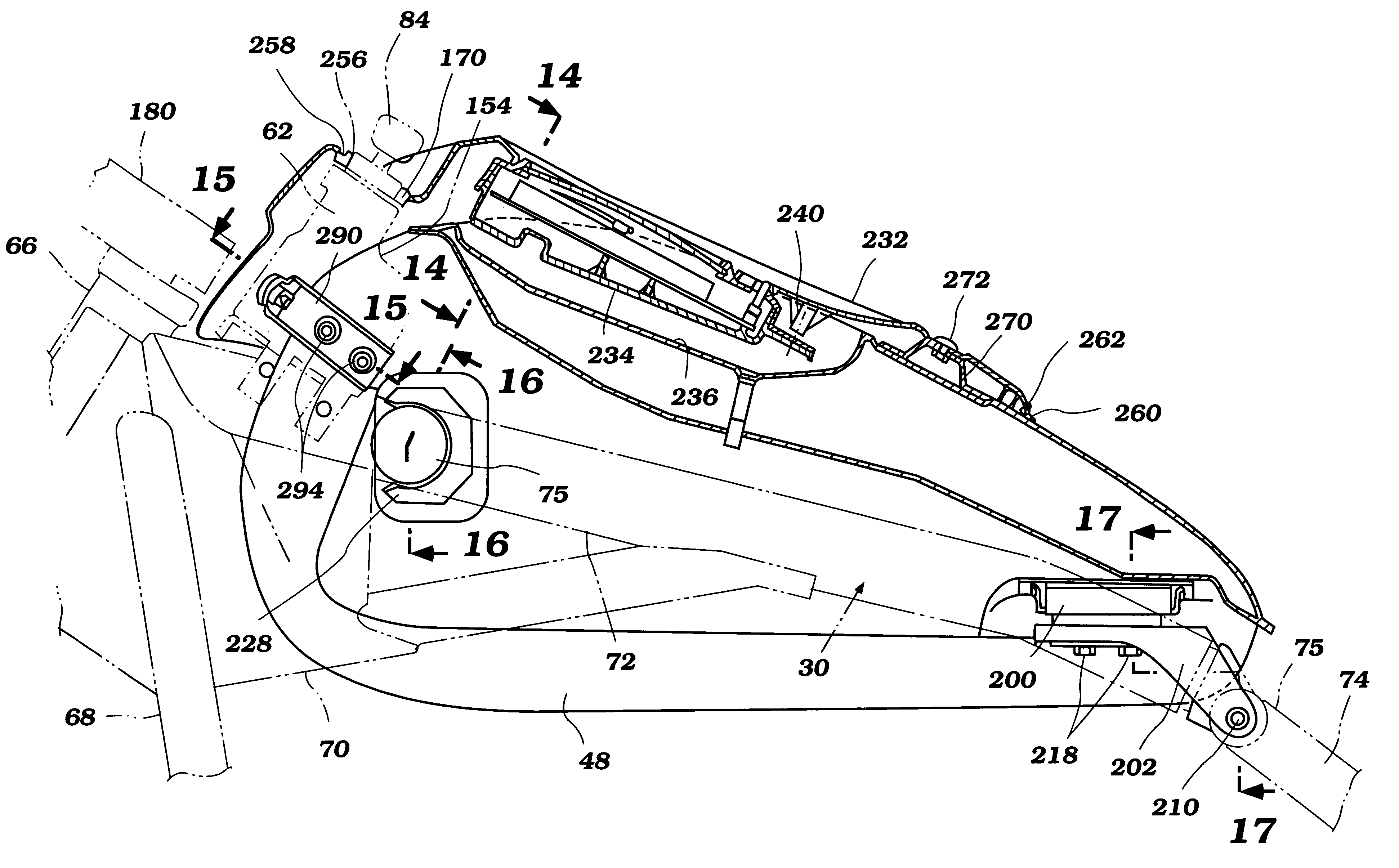

A method and apparatus for supplying bulk material to an end user includes the step of providing a bulk material source that is at a location distant from the end user and a specially configured vessel and trailer apparatus for transporting the bulk material to the end user. The vessel is filled with bulk material at the bulk material source and then transported with a specially configured trailer. Alternatively, at source or destination, the vessel can remain as a temporary storage device, free-standing from the trailer. During transport between the bulk material source and the end user, the vessel is filled or partially filled with a selected bulk material. During transport, the vessel is in a generally horizontal position, supported by the trailer and a specially configured elevator. The vessel is unloaded from the trailer by moving the vessel longitudinally along the trailer and by transferring the vessel from a generally horizontal position upon the trailer to an elevated upright position.

Owner:TILT TANK L L C

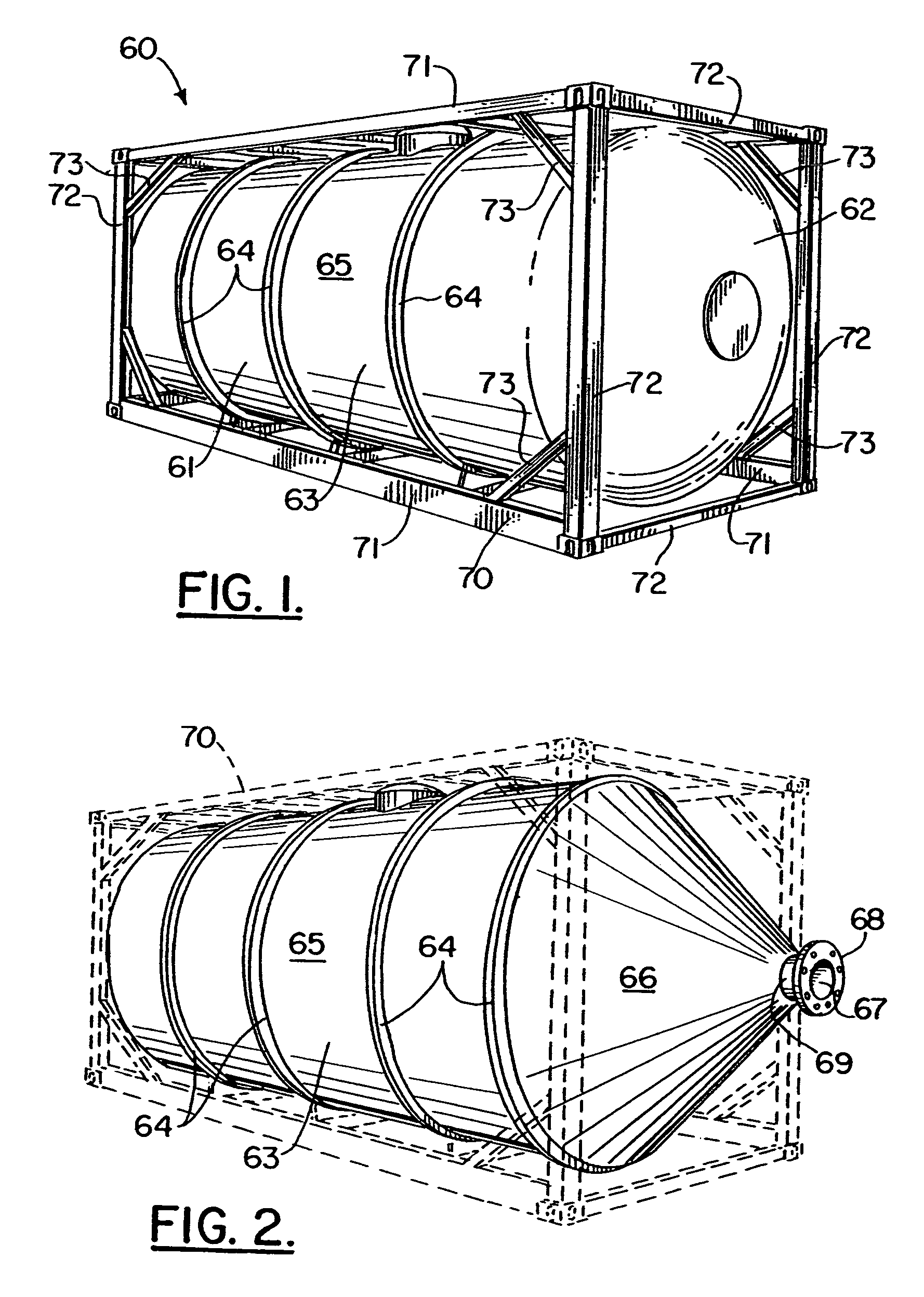

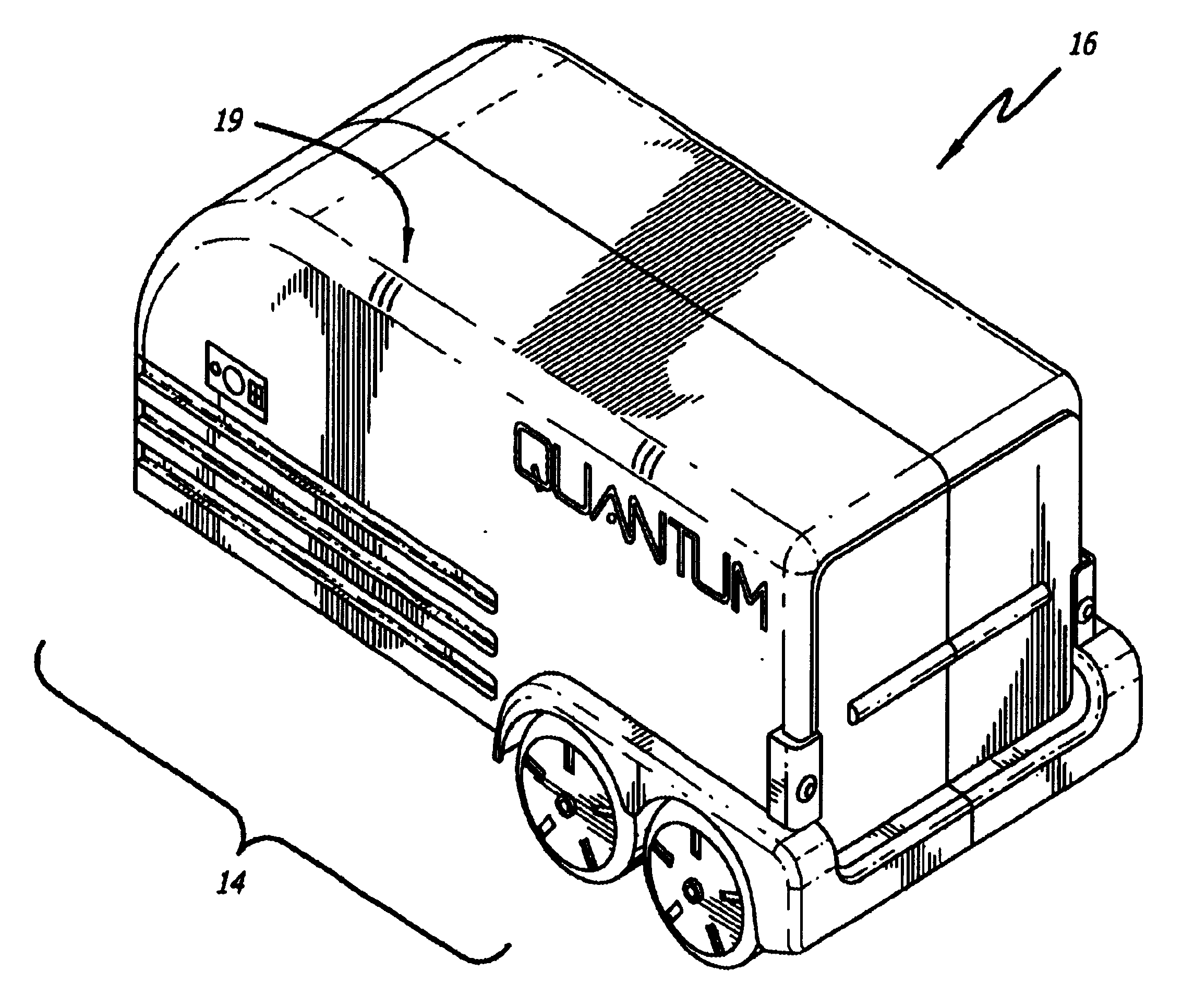

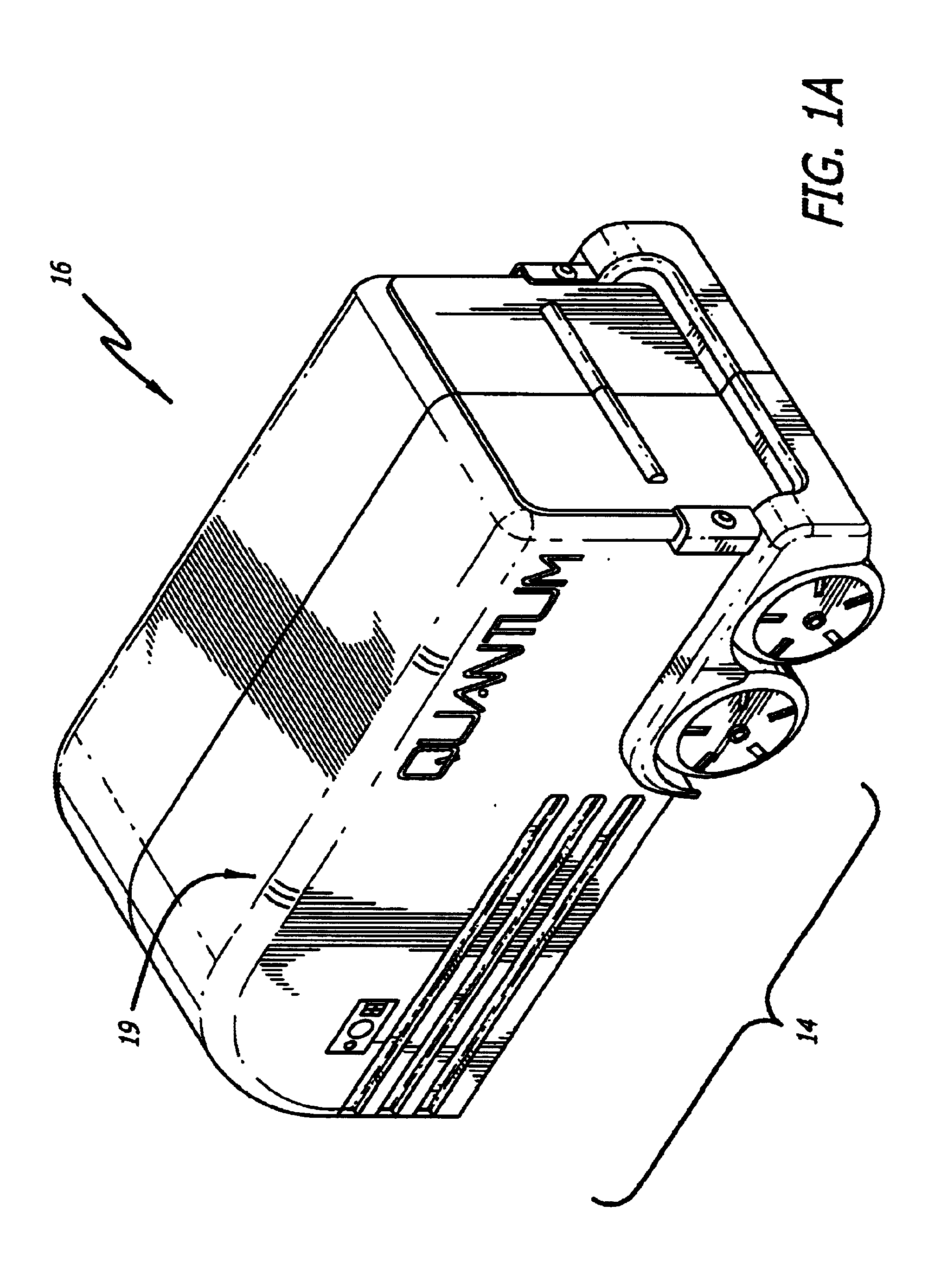

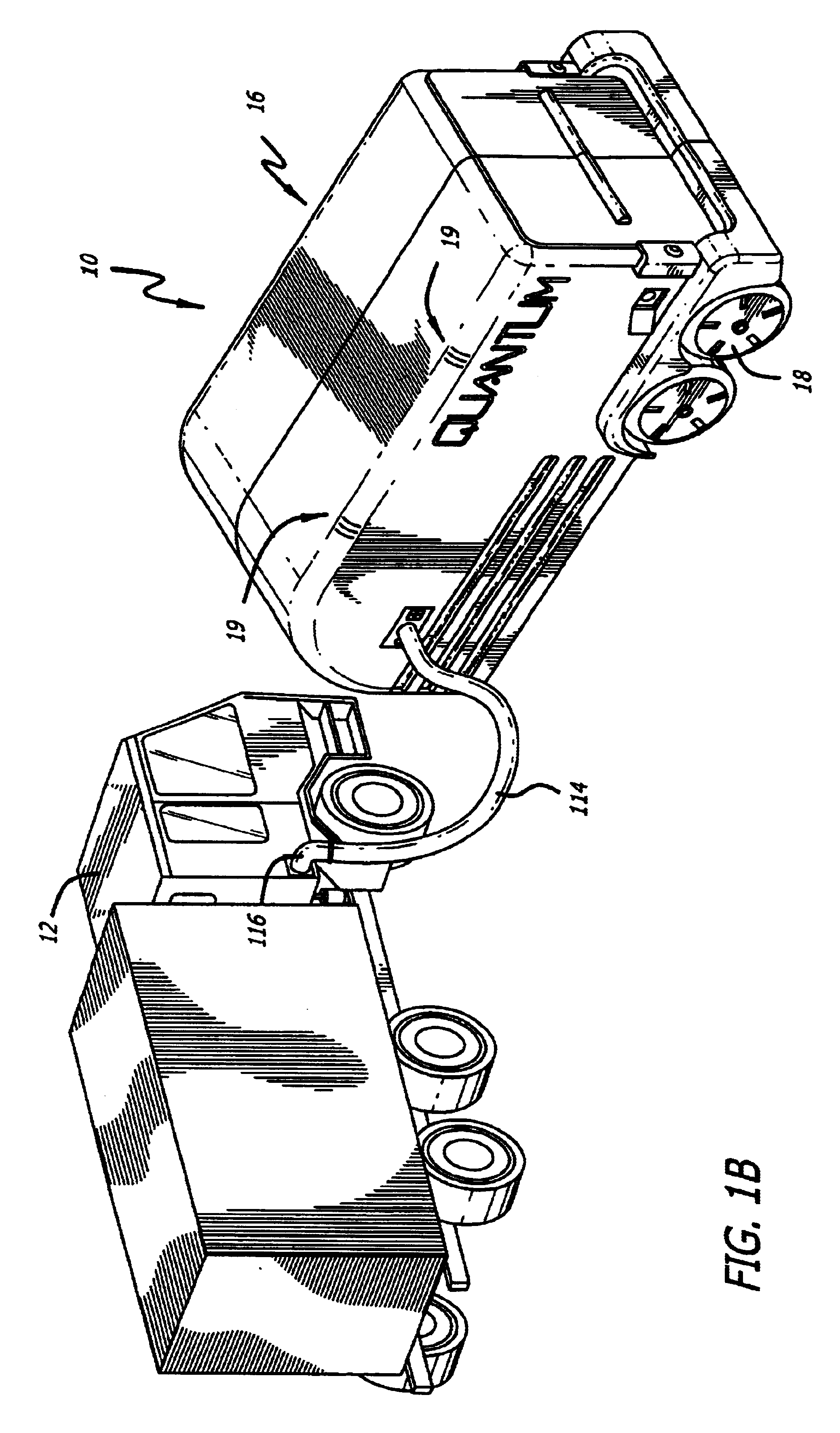

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

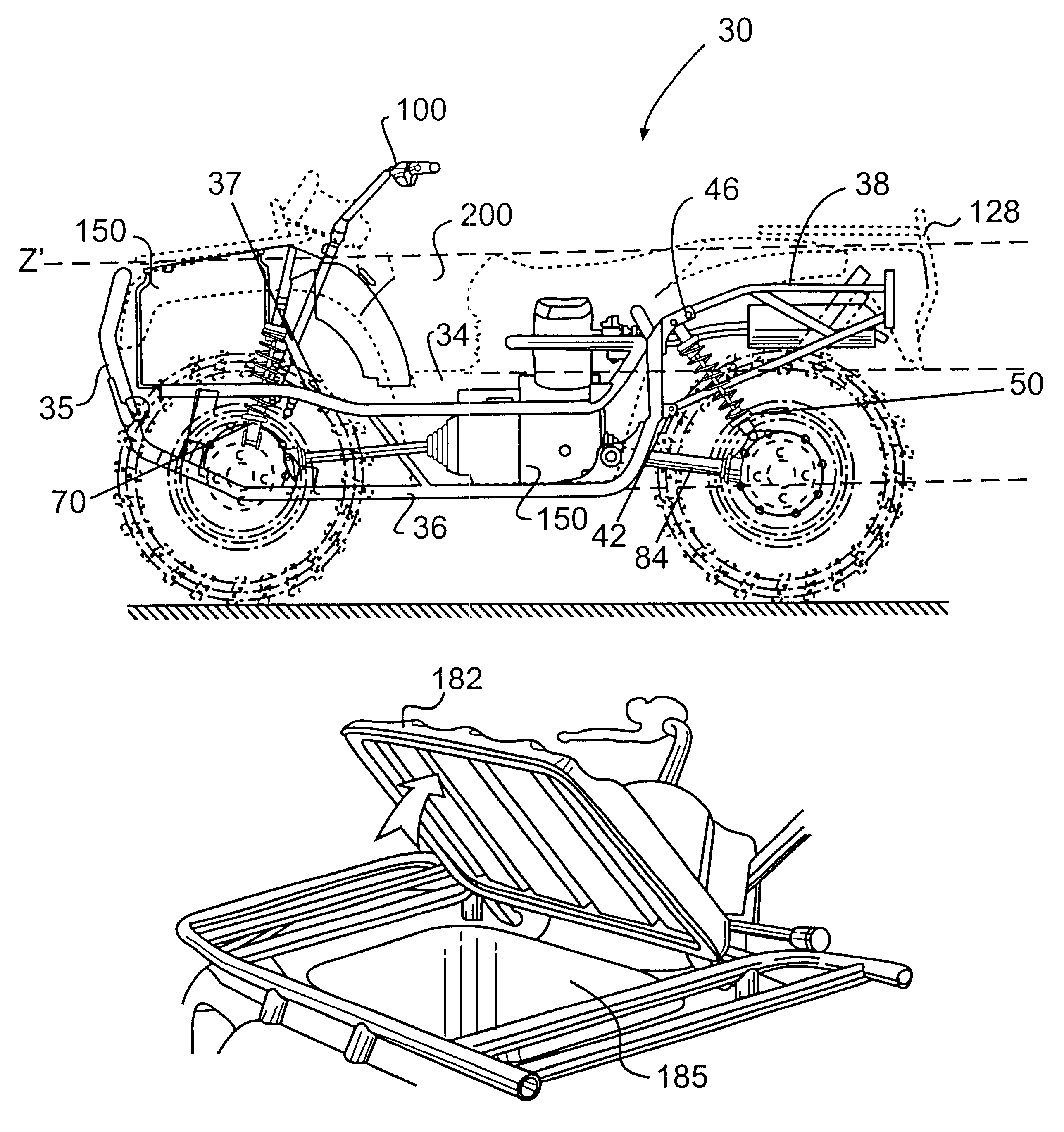

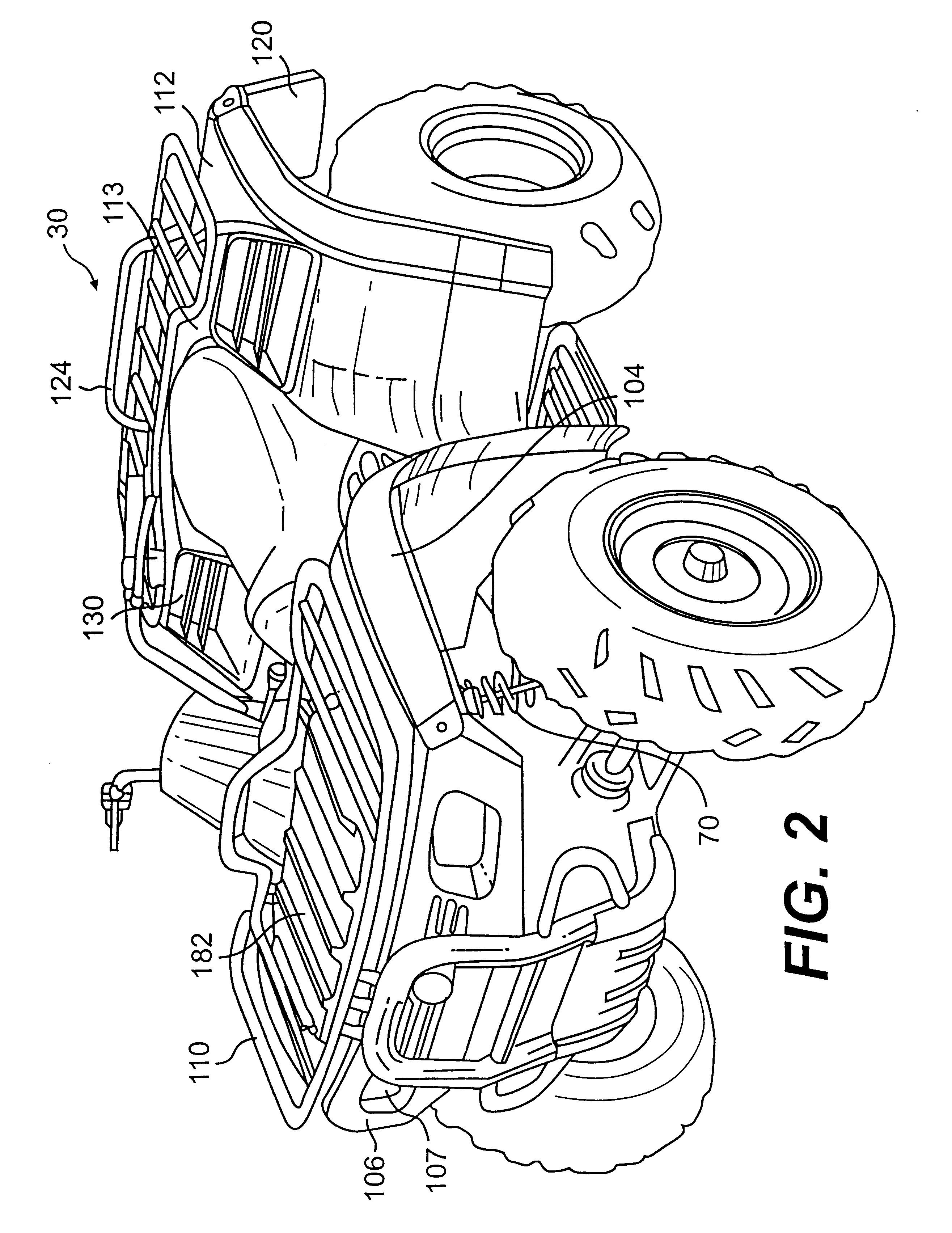

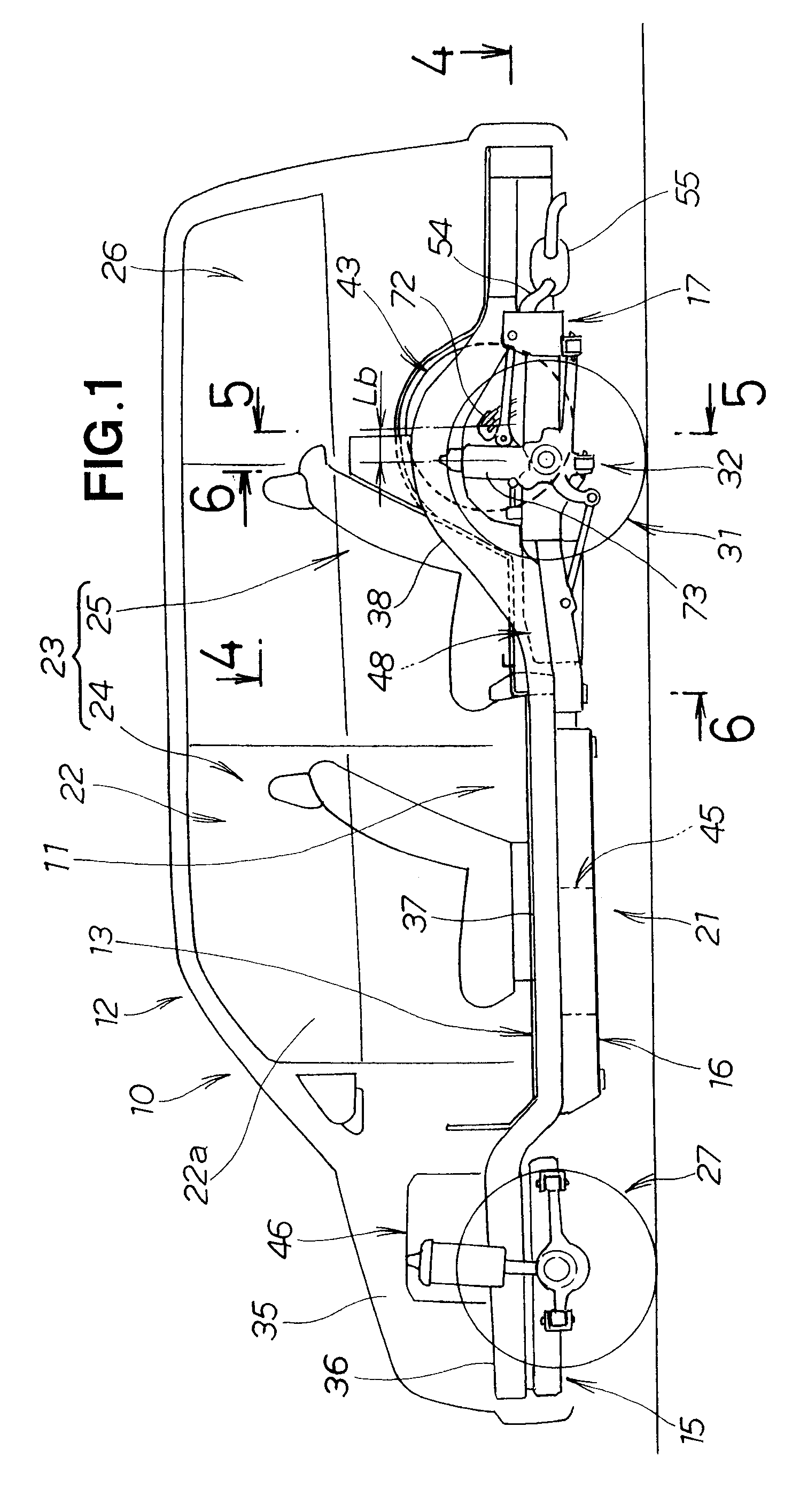

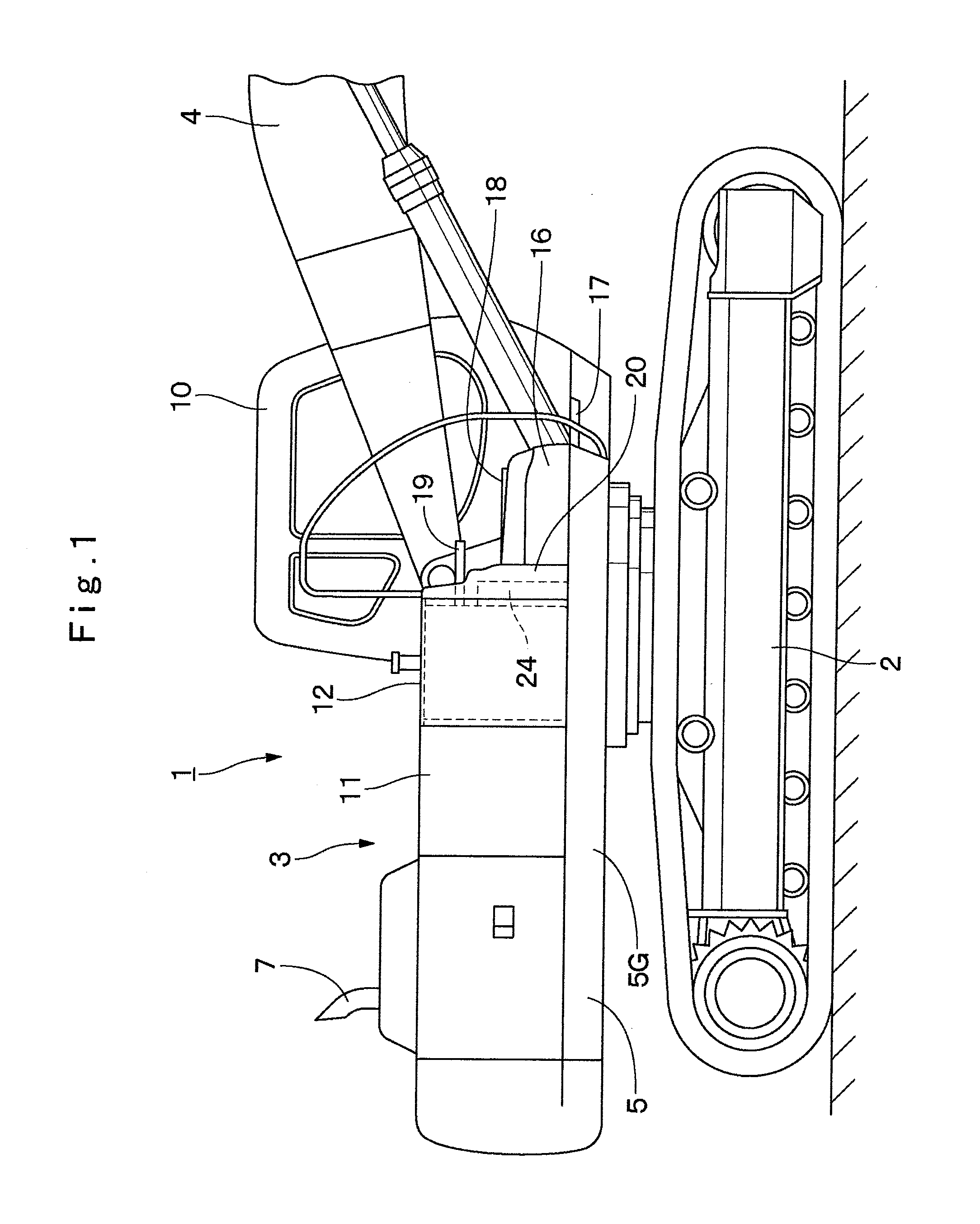

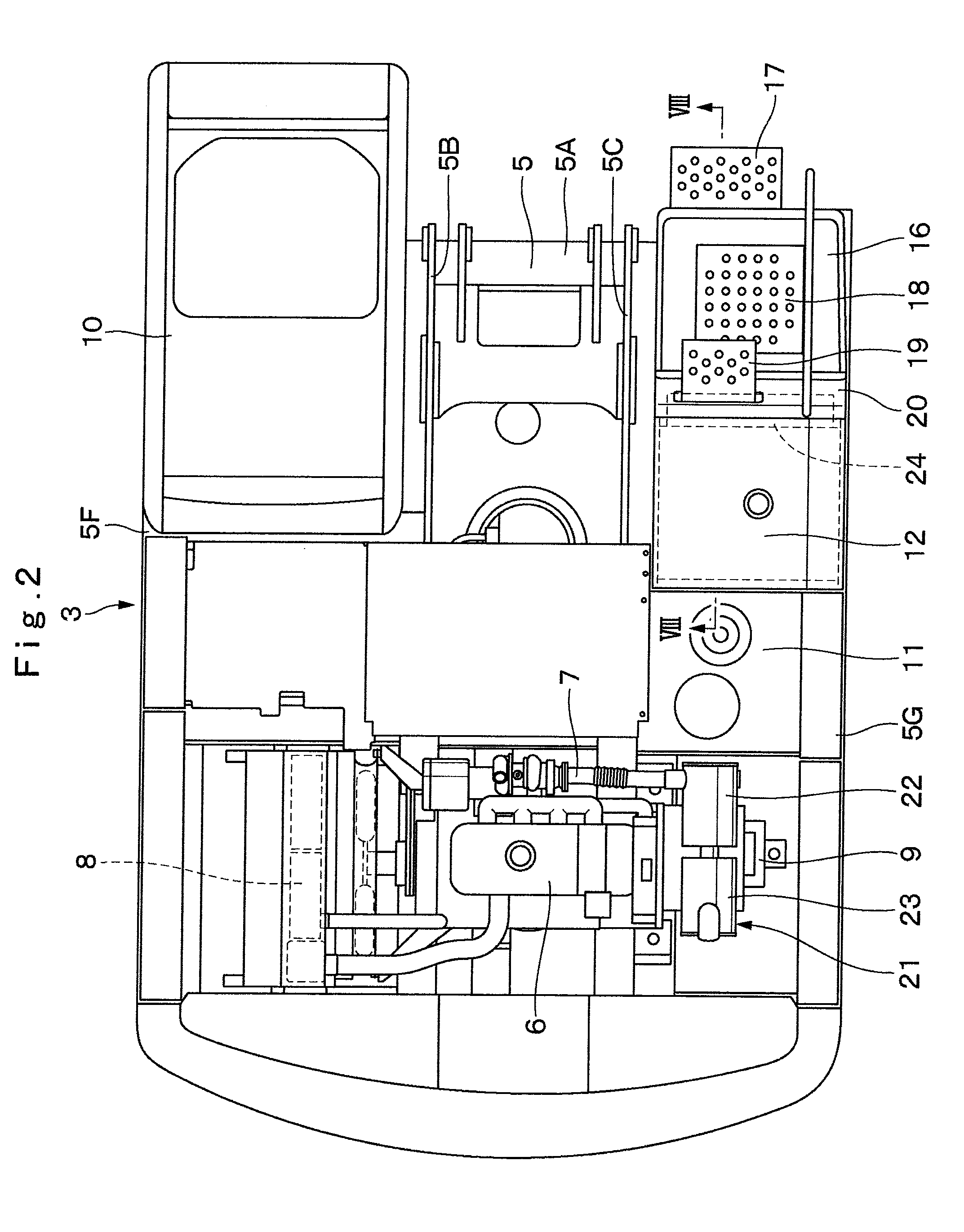

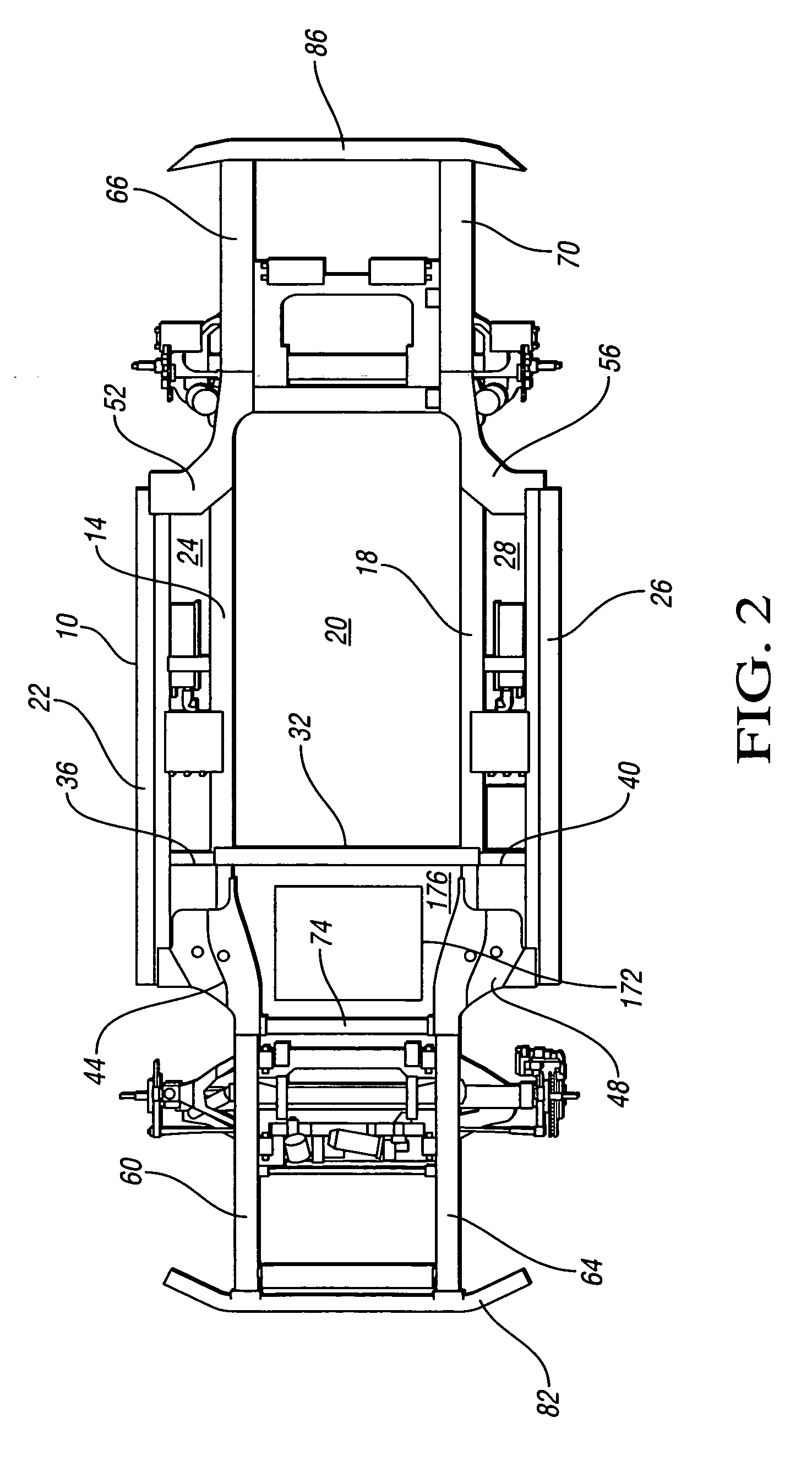

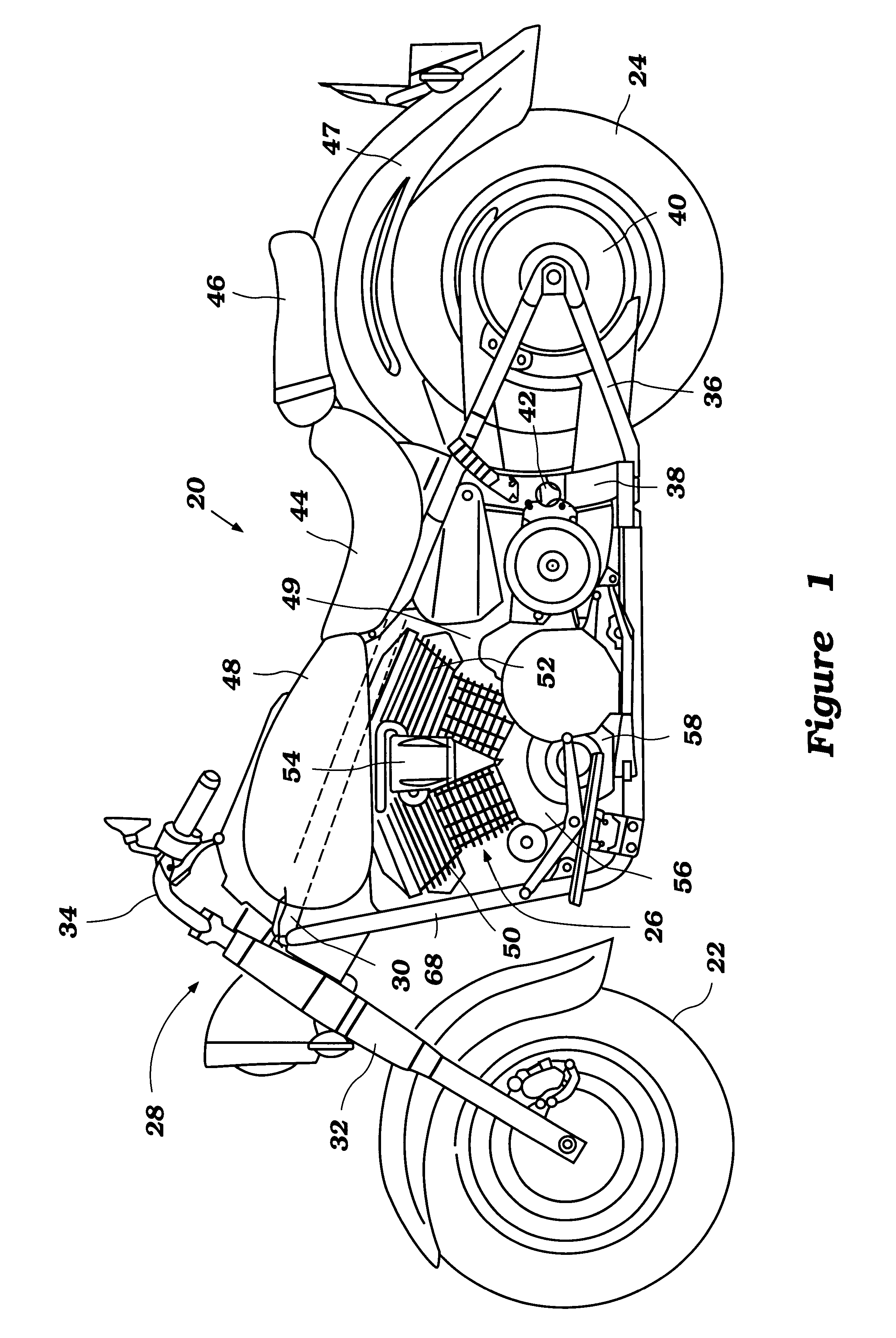

All terrain vehicle

InactiveUS6523634B1Convenient framingAdd featureTank vehiclesMachines/enginesDriver/operatorFuel tank

A straddle-type vehicle, or all terrain vehicle, has an engine located towards the rear of the vehicle such that a main portion of the engine, or power unit, is disposed beneath the seat. The fuel tank extends generally vertically beneath the steering member. The radiator is located at a rear portion of the vehicle rearwardly of the engine where it is protected from collisions and objects striking the front grille. A front storage compartment is also provided in the front portion of the vehicle. The vehicle also has a pivotally connected and removable seat for easy access to the engine. There is also a gap between the seat and the front wheel well through which the driver can pass his feet or where an optional container or auxiliary fuel tank can be secured.

Owner:BOMBARDIER RECREATIONAL PROD INC

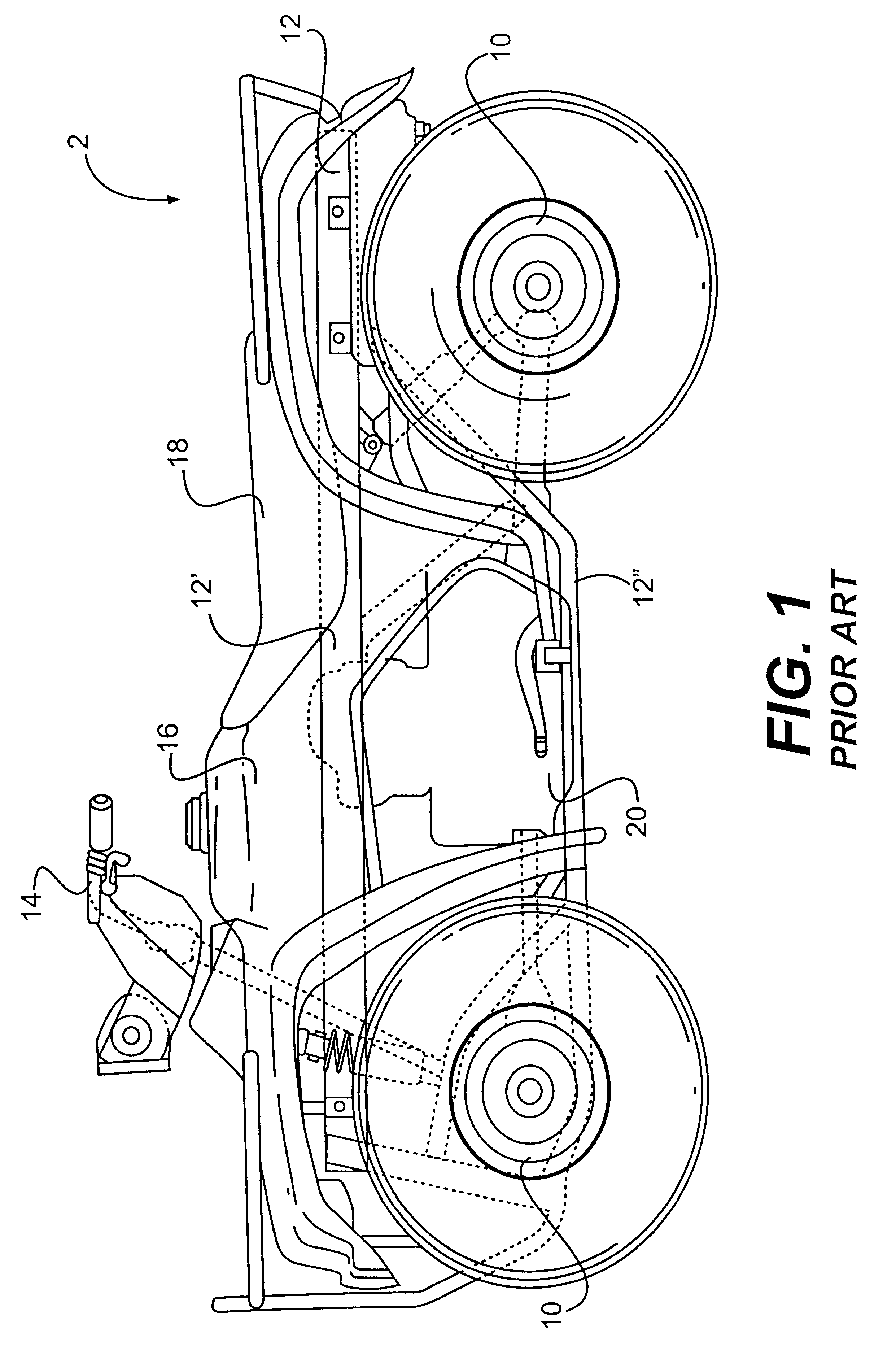

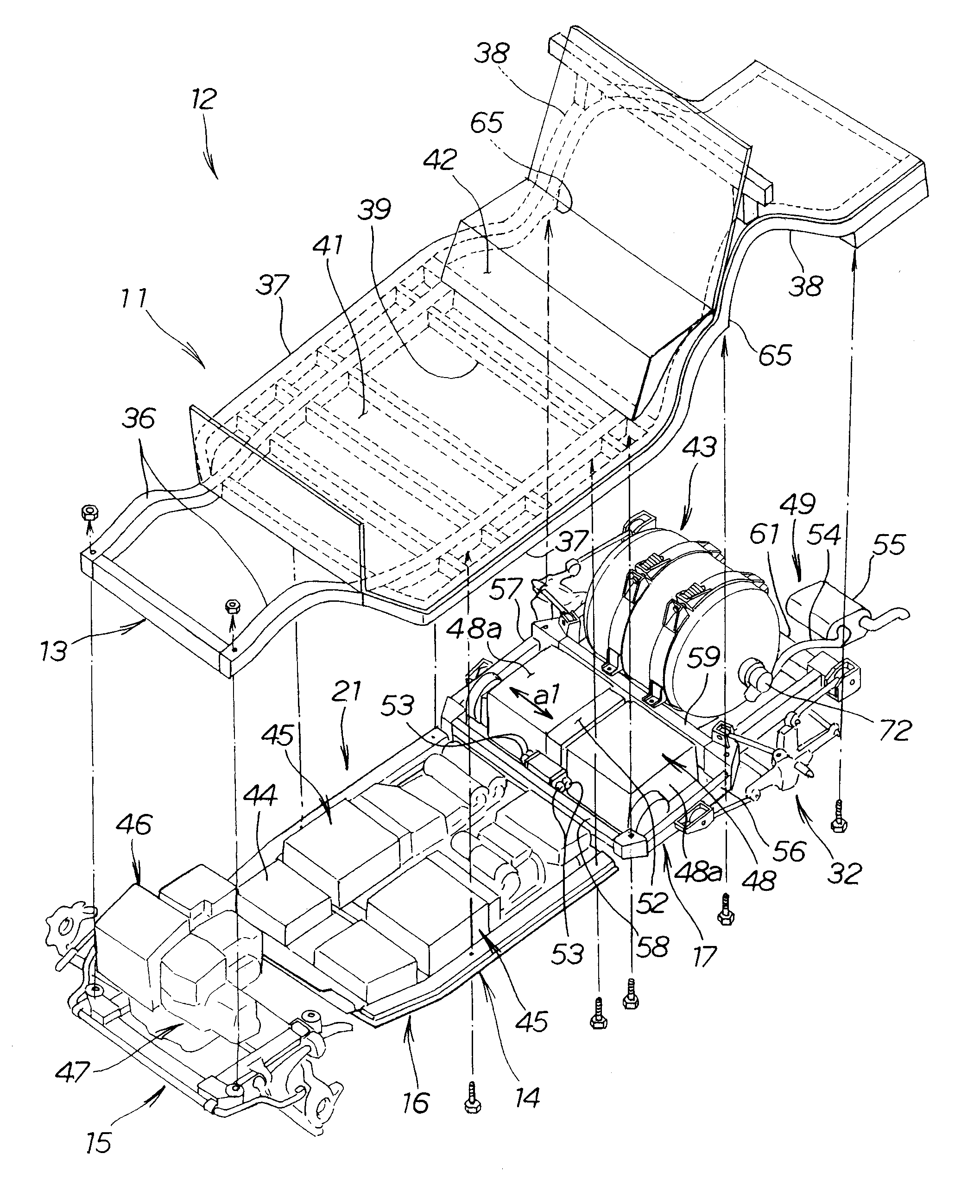

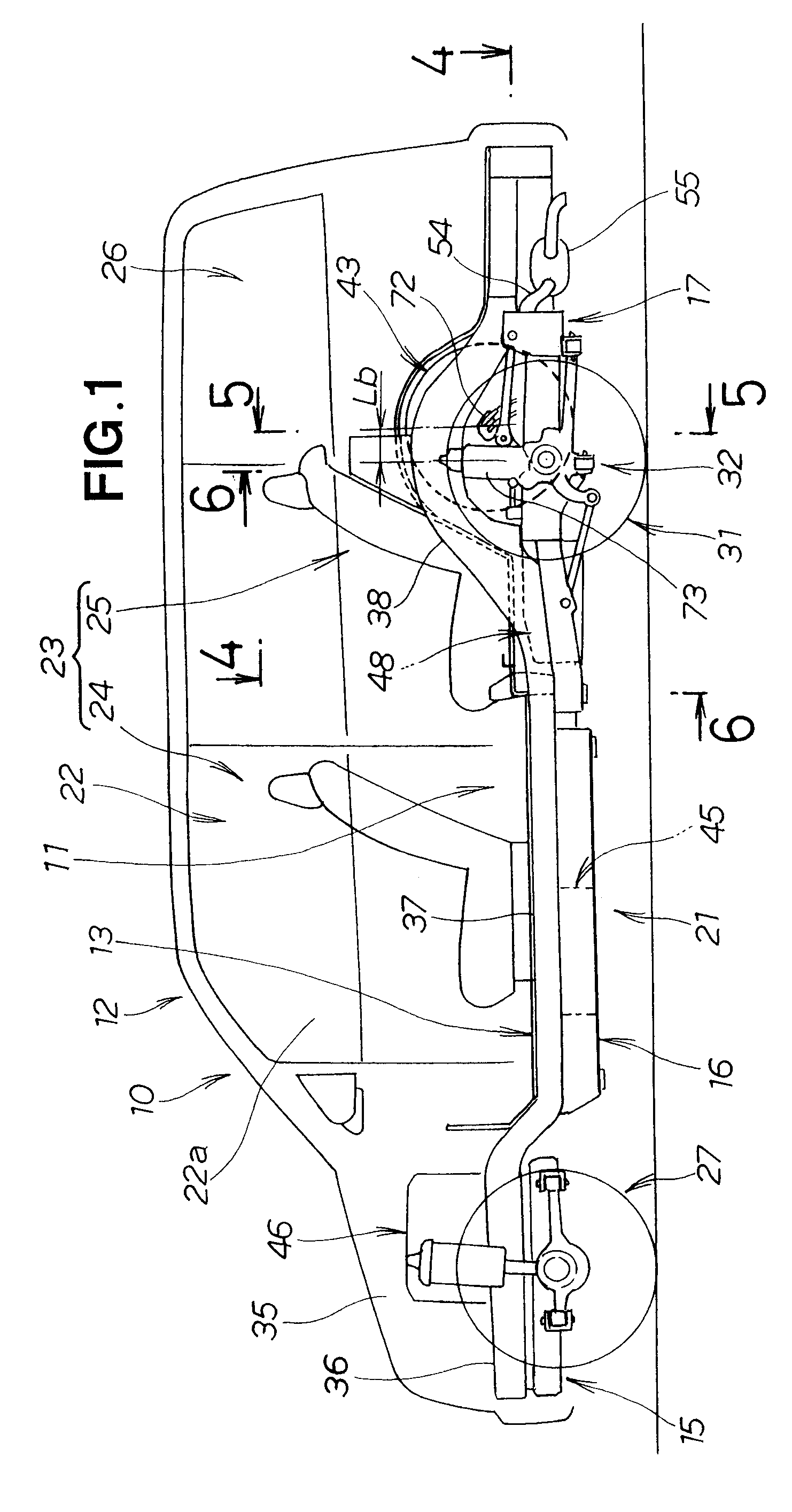

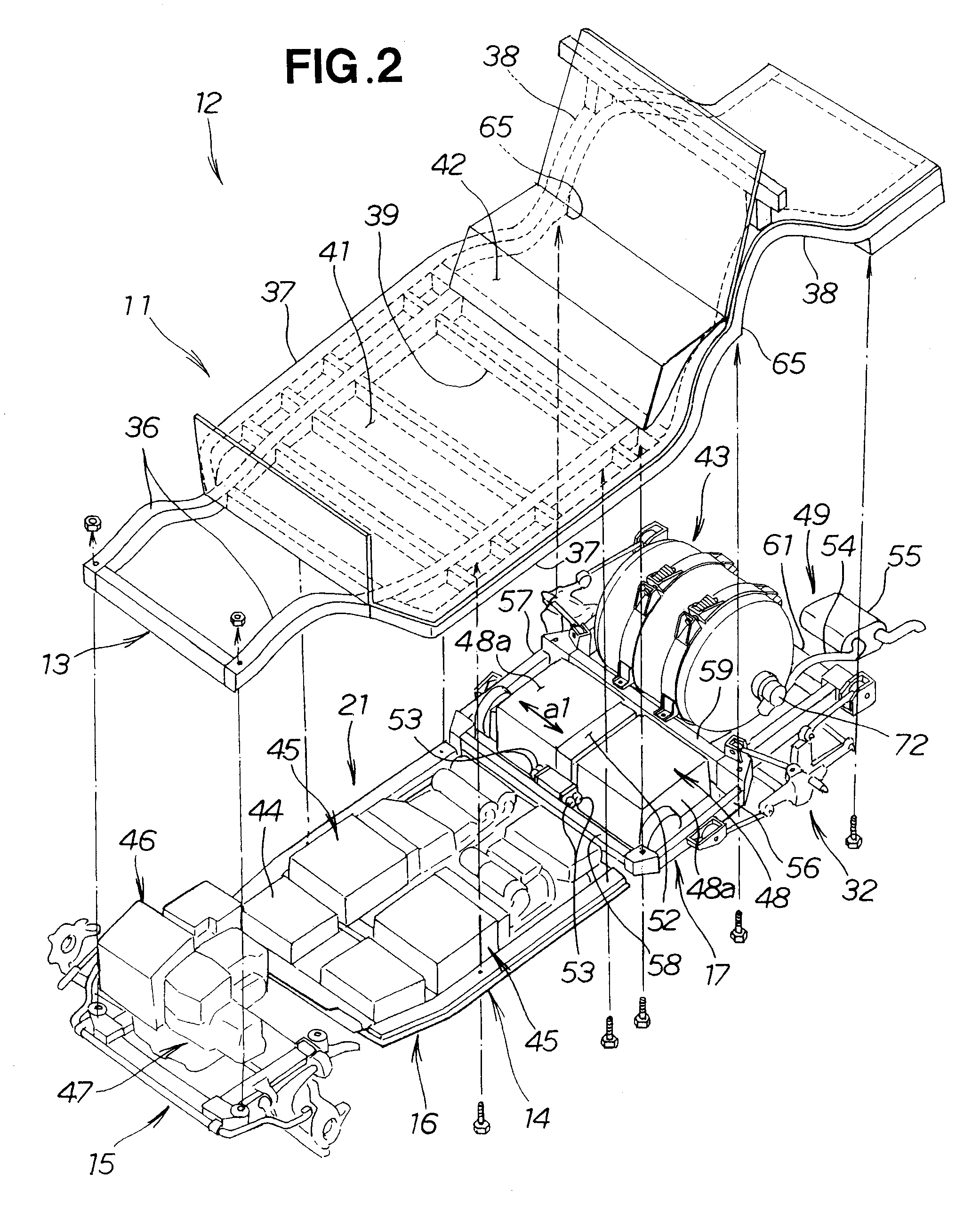

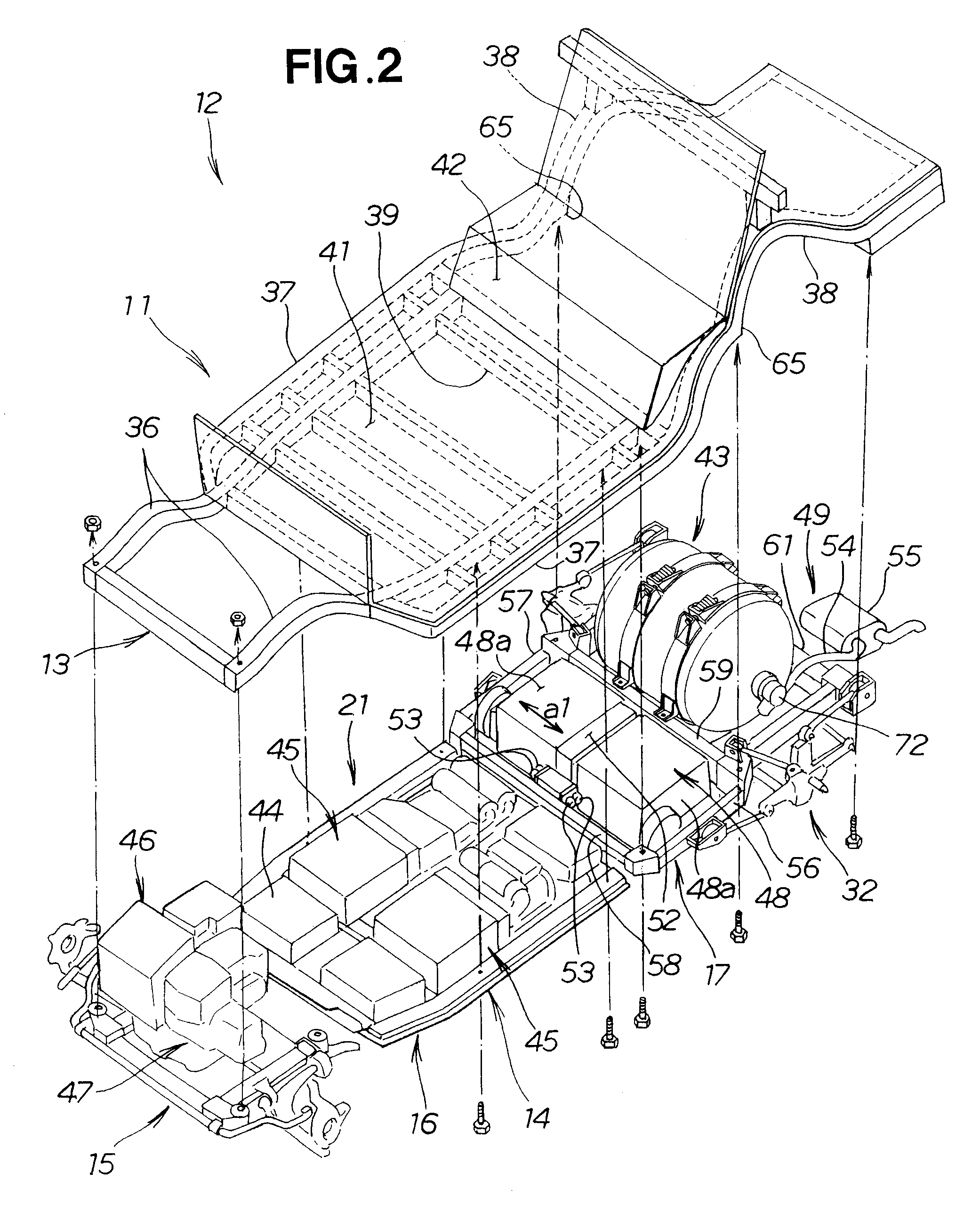

Vehicle body structure

InactiveUS20060289224A1Easy to useLower center of gravityTank vehiclesUnderstructuresVehicle frameFuel tank

A vehicle body structure includes a body frame with a subframe mounted to a lower part of the body frame. The subframe is formed into a rectangular shape and has front, intermediate and rear cross members. A storage battery is designed to be mounted astride the front cross member and the intermediate cross member. A fuel tank is designed to be mounted astride the intermediate cross member and the rear cross member.

Owner:HONDA MOTOR CO LTD

Manifold trailer having a single high pressure output manifold

A manifold trailer is provided and includes a chassis, a low pressure piping system disposed along a length of the chassis, and a single high pressure output manifold disposed along the length of the chassis, the high pressure output manifold terminating at a splitter that distributes fluids from the high pressure manifold to a wellhead.

Owner:FORUM US

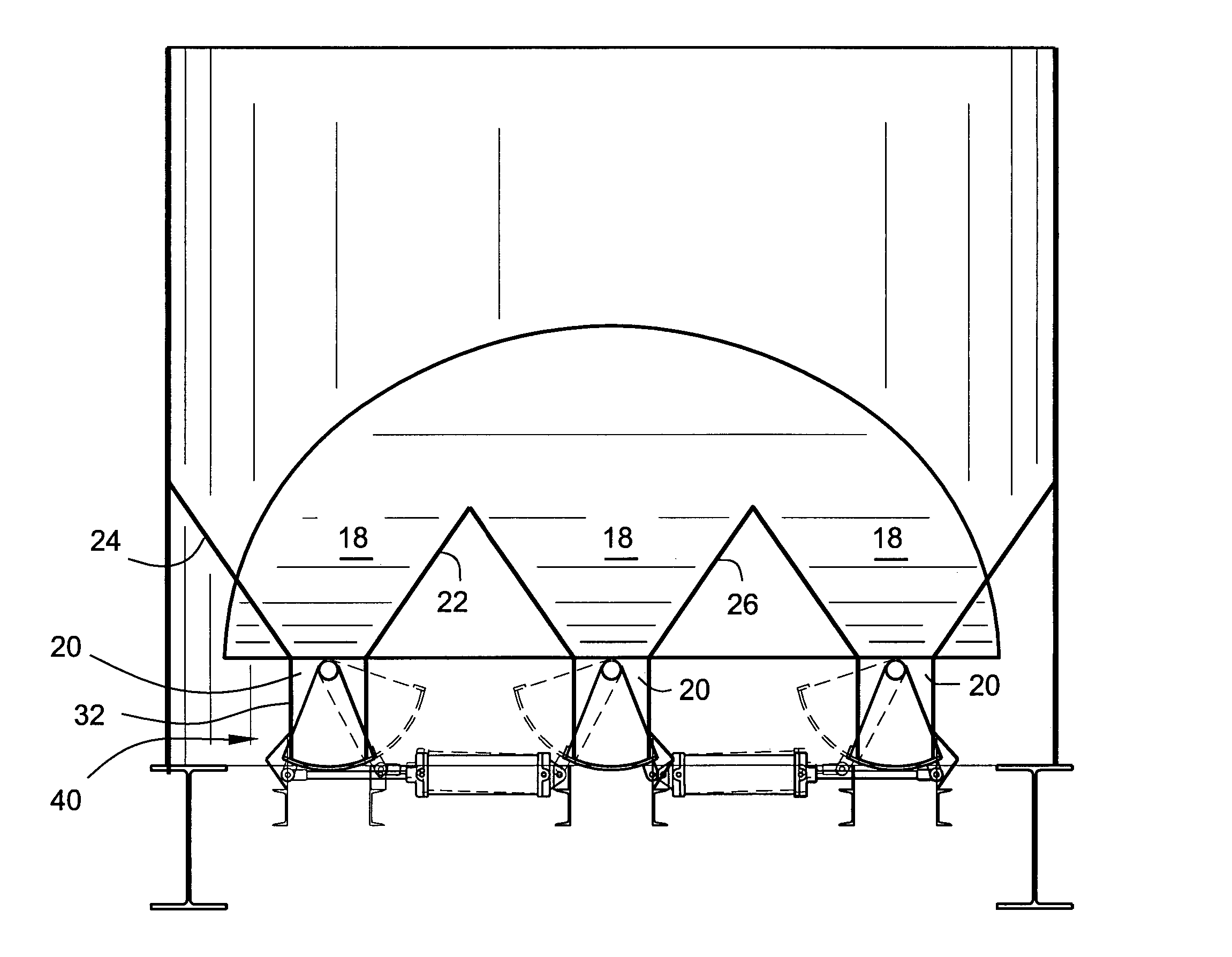

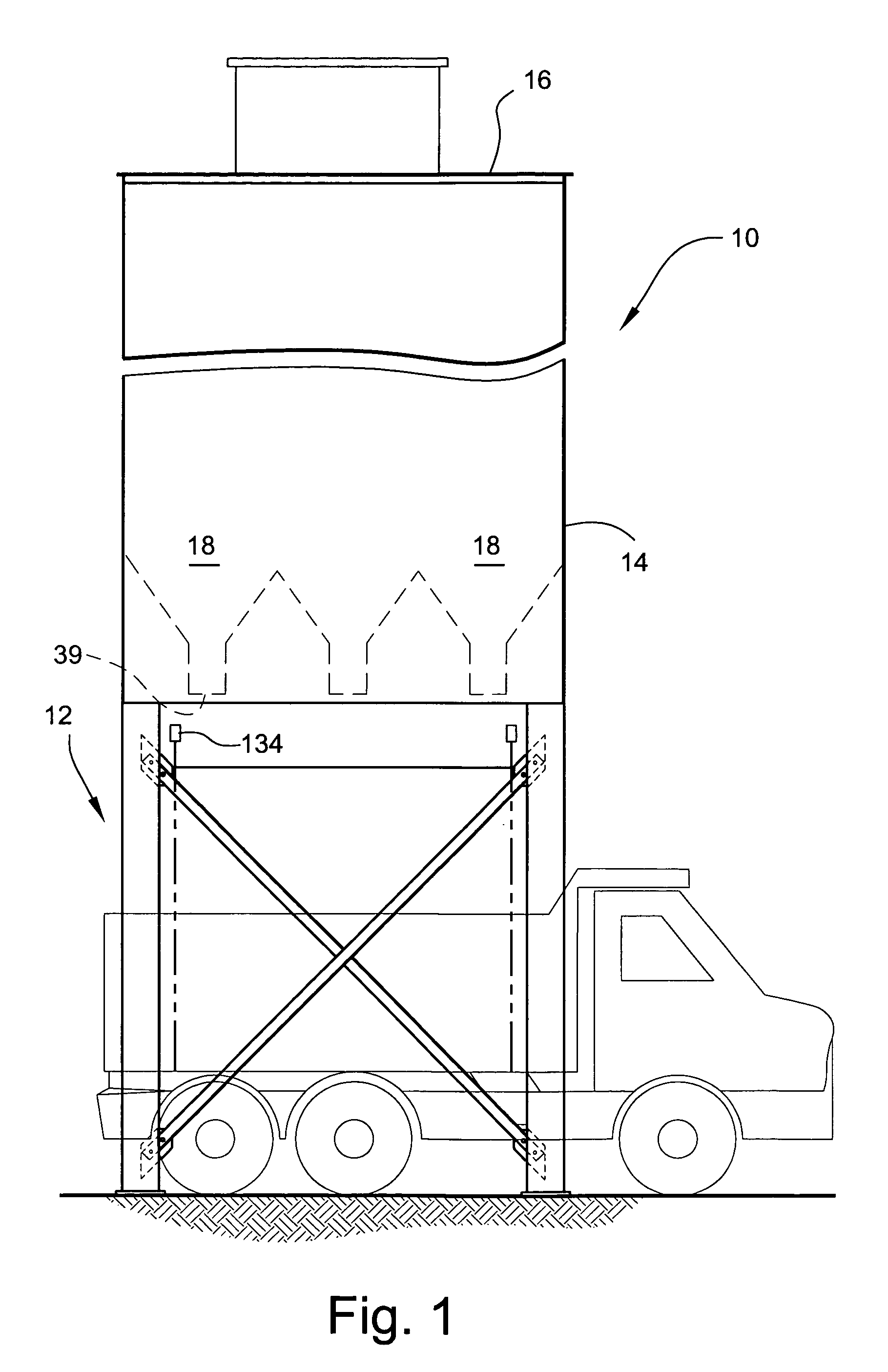

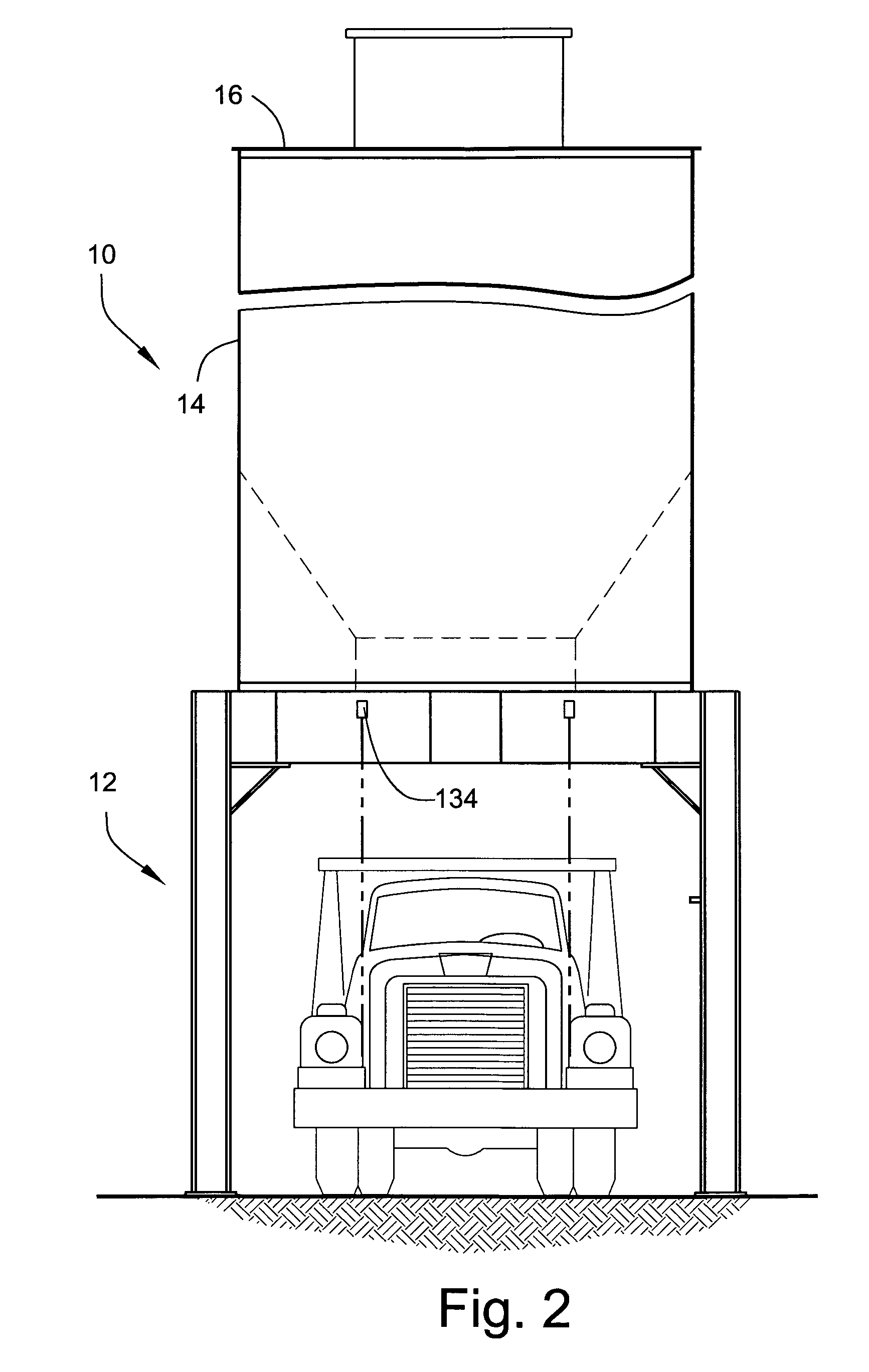

Apparatus and methods for discharging particulate material from storage silos

The silo includes at least three hoppers terminating in rectilinear discharge openings extending lengthwise transversely of a loading area below the discharge openings. Clam gates are movable between open and closed positions to discharge material. The discharge area at the bottom of the silo is increased, facilitating faster loading of trucks with the particulate material.

Owner:GENCOR IND INC

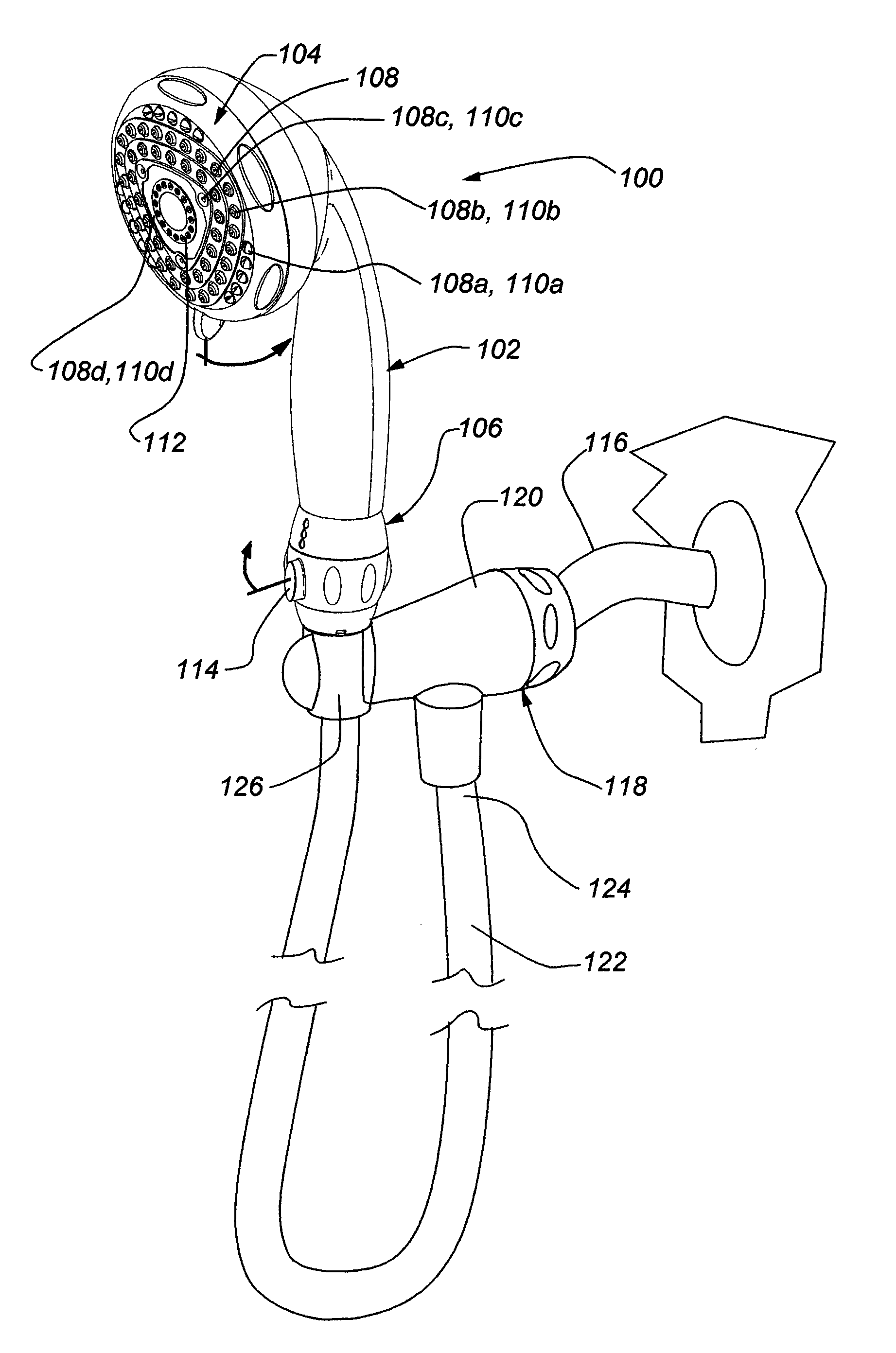

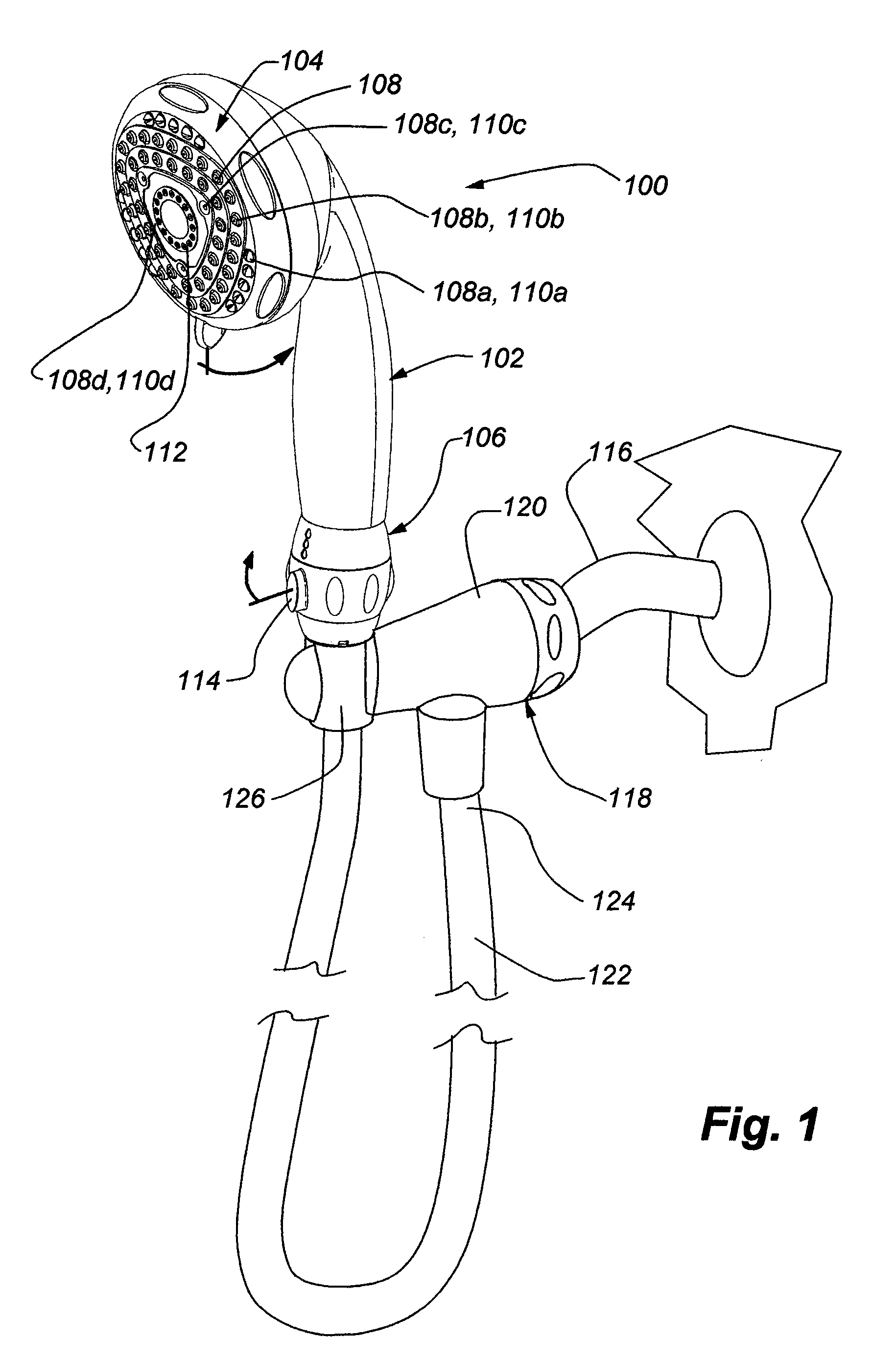

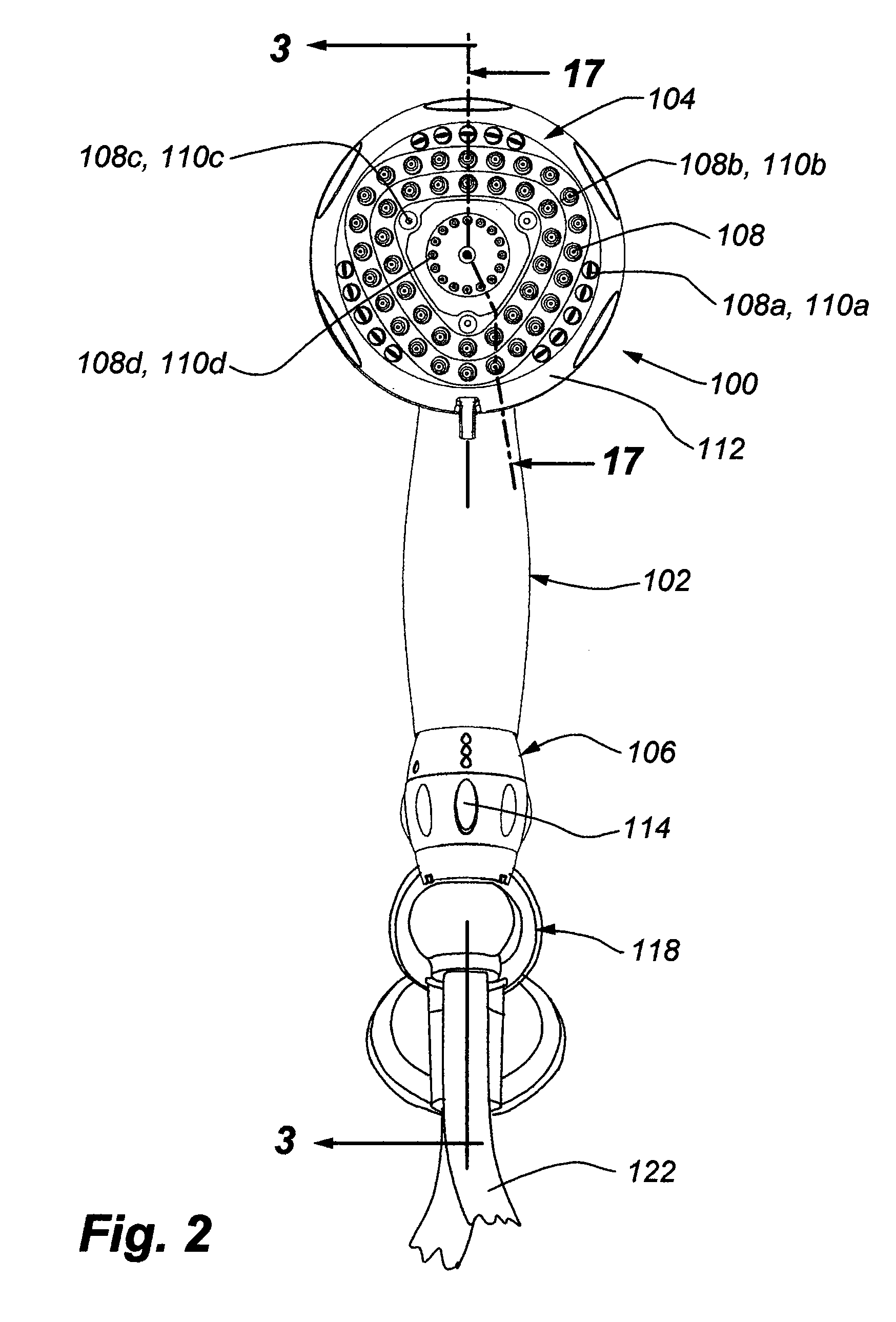

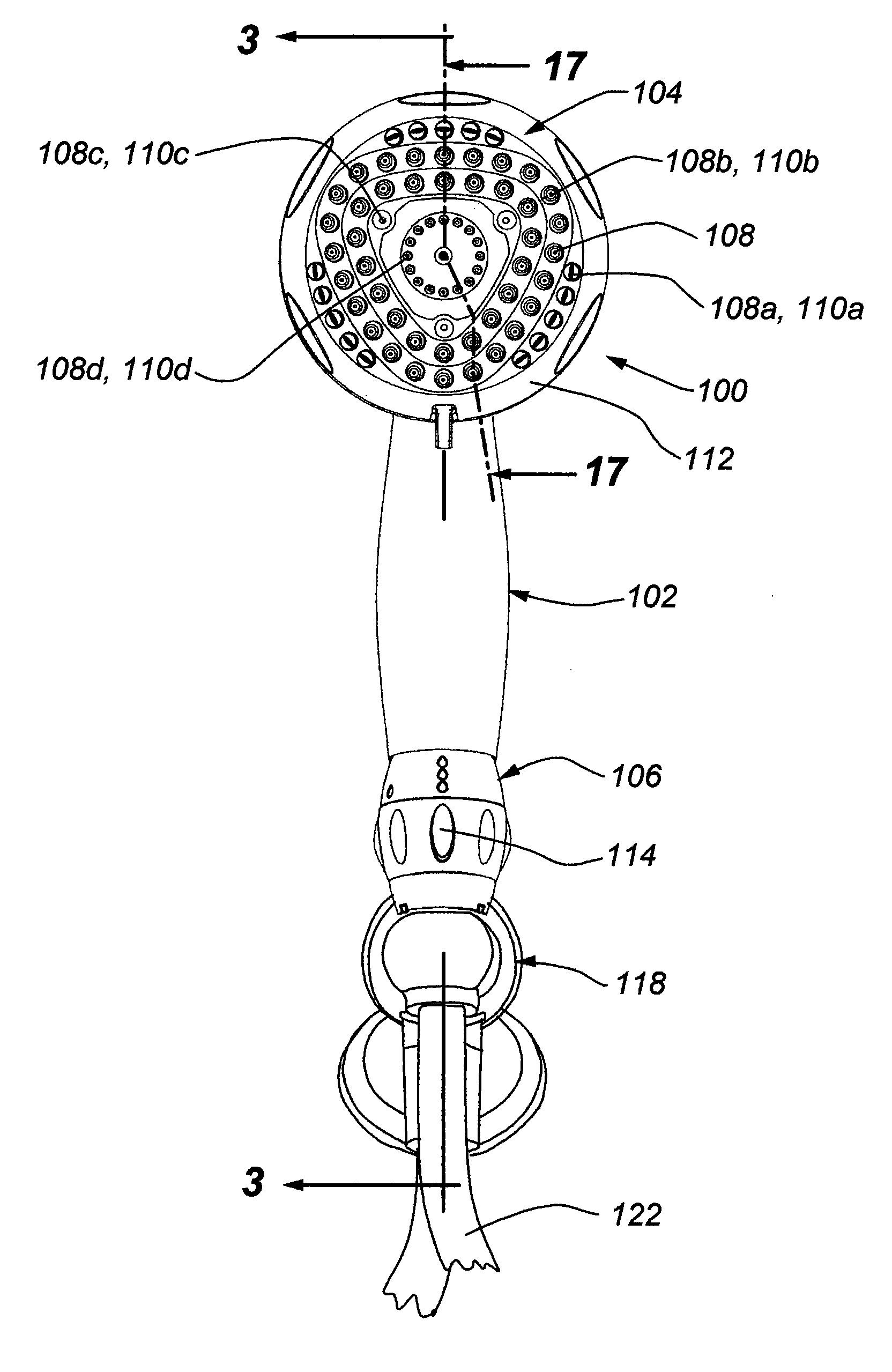

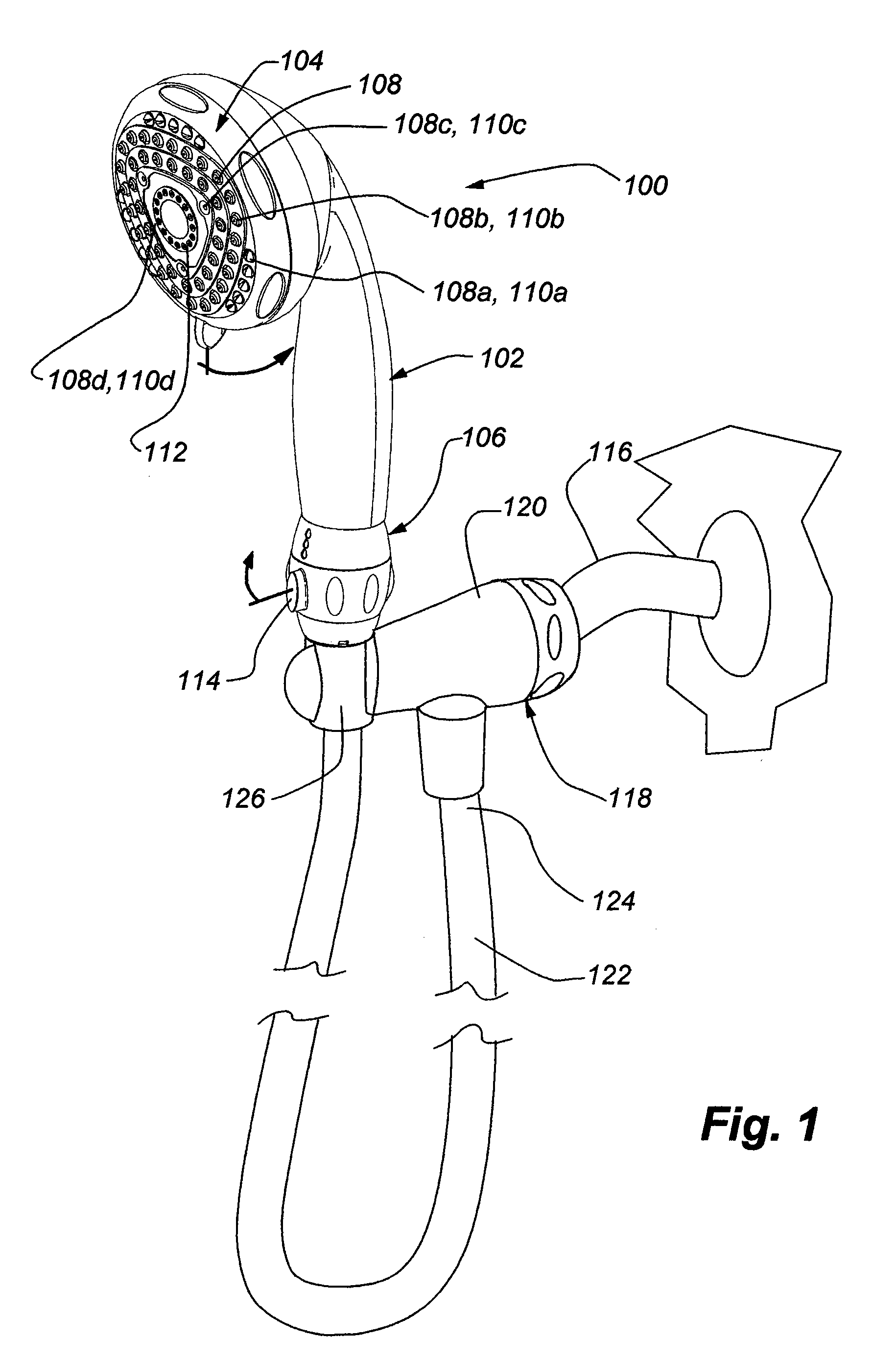

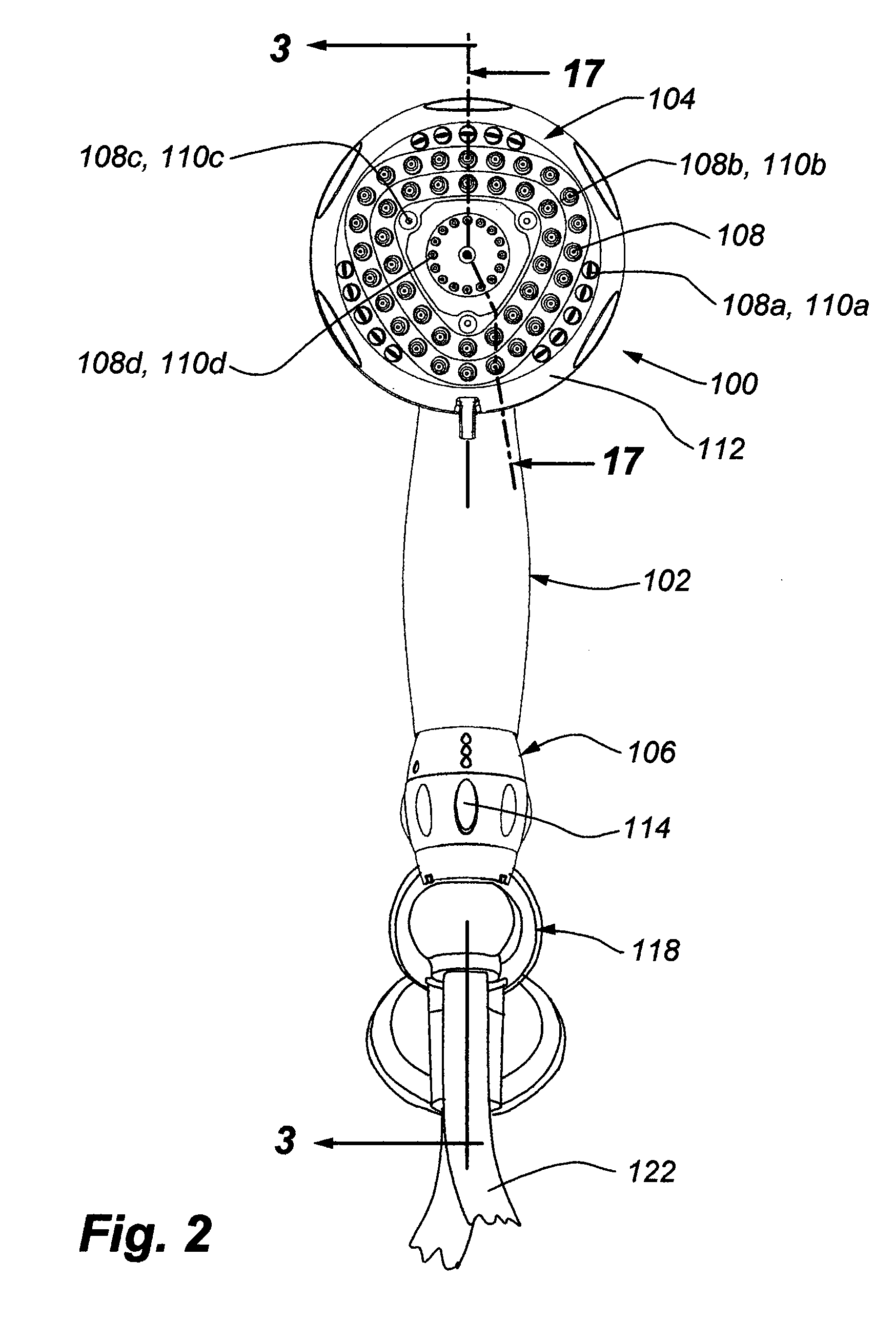

Low flow showerhead and method of making same

A showerhead for a low flow rate may employ one or more of a showerhead housing, a showerhead engine, a flow restrictor and a flow regulation device. The showerhead engine may be moveably connected to the showerhead housing. The showerhead engine may include a back member, an intermediate member, and a front member defining various fluid chambers and apertures that allow for one or more spray modes. The showerhead may include a flow control device to selectively reduce flow to the showerhead engine. The flow control device may also be selectively pause fluid flow for more than one spray mode. The showerhead may include a flow restrictor. The flow restrictor may limit a maximum fluid flow rate of a fluid delivered from the showerhead engine to approximately 1.5 gallons per minute.

Owner:WATER PIK INC

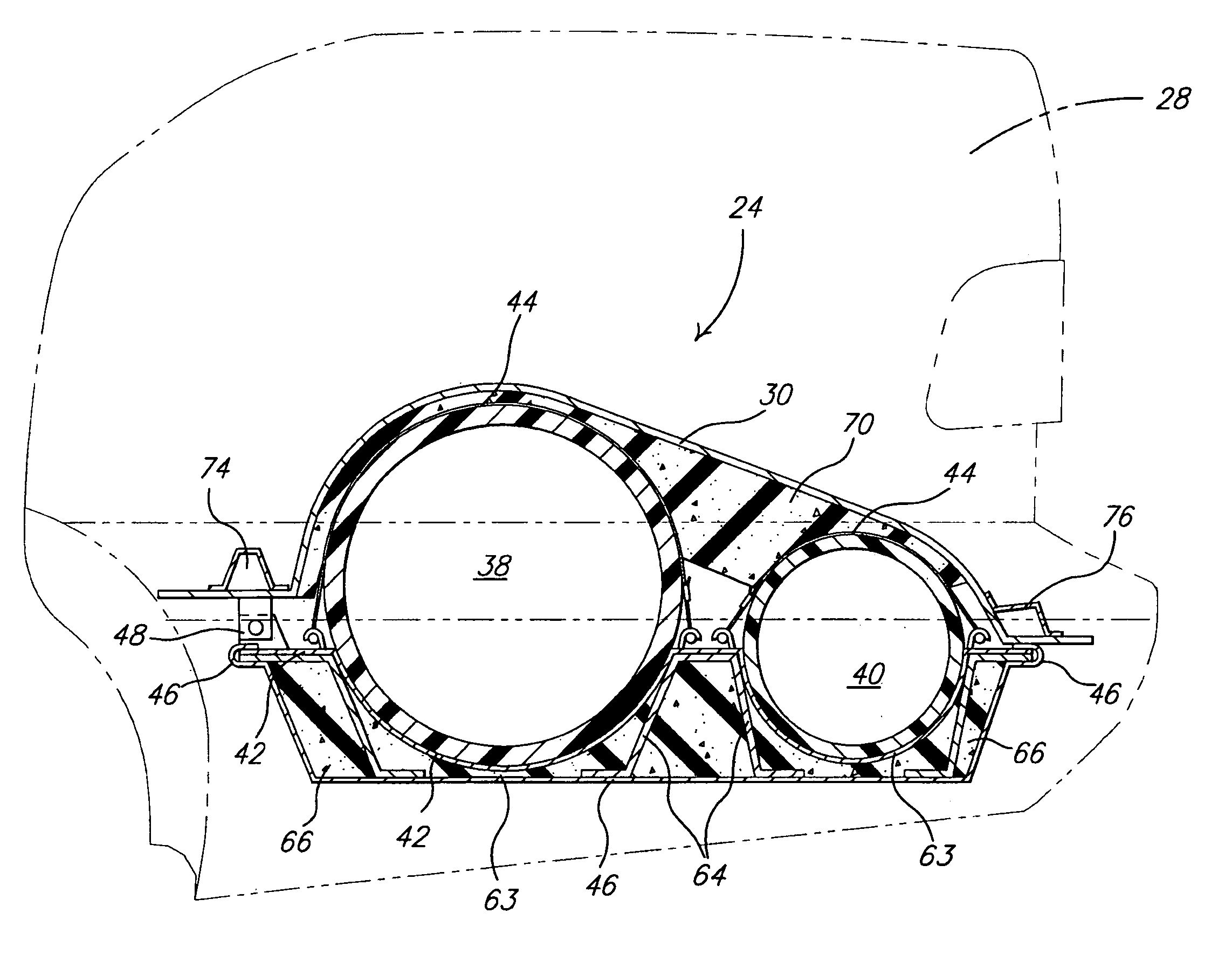

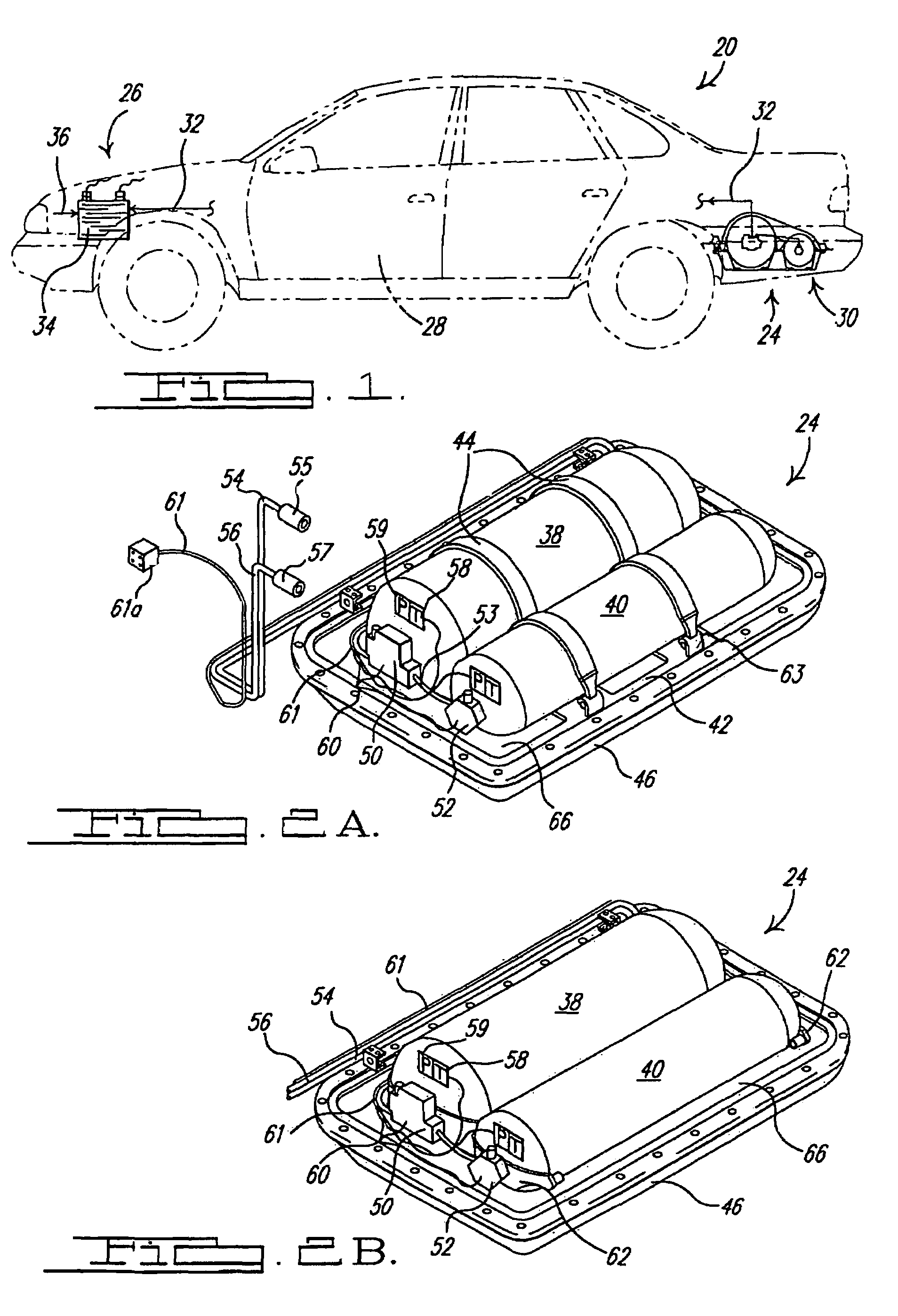

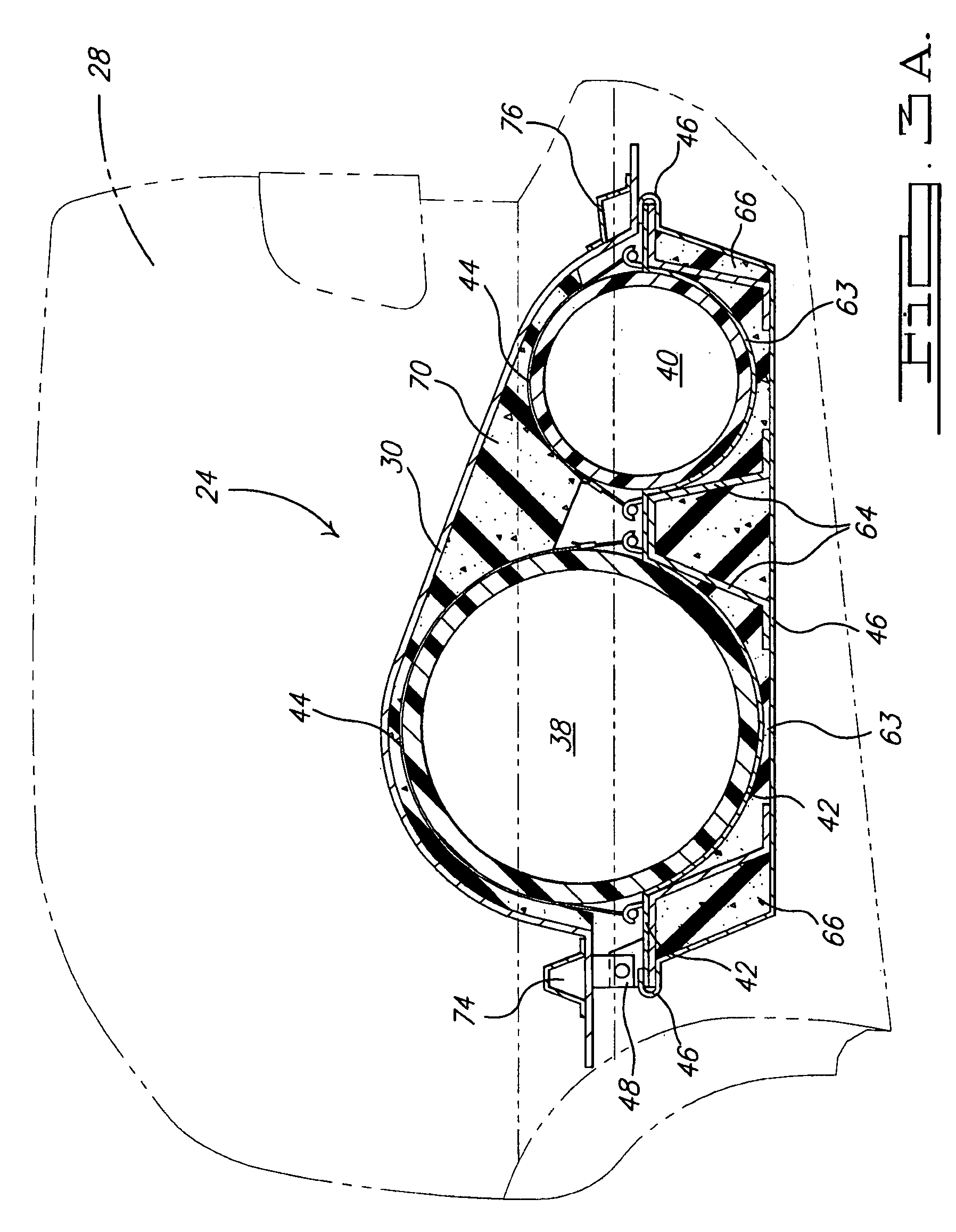

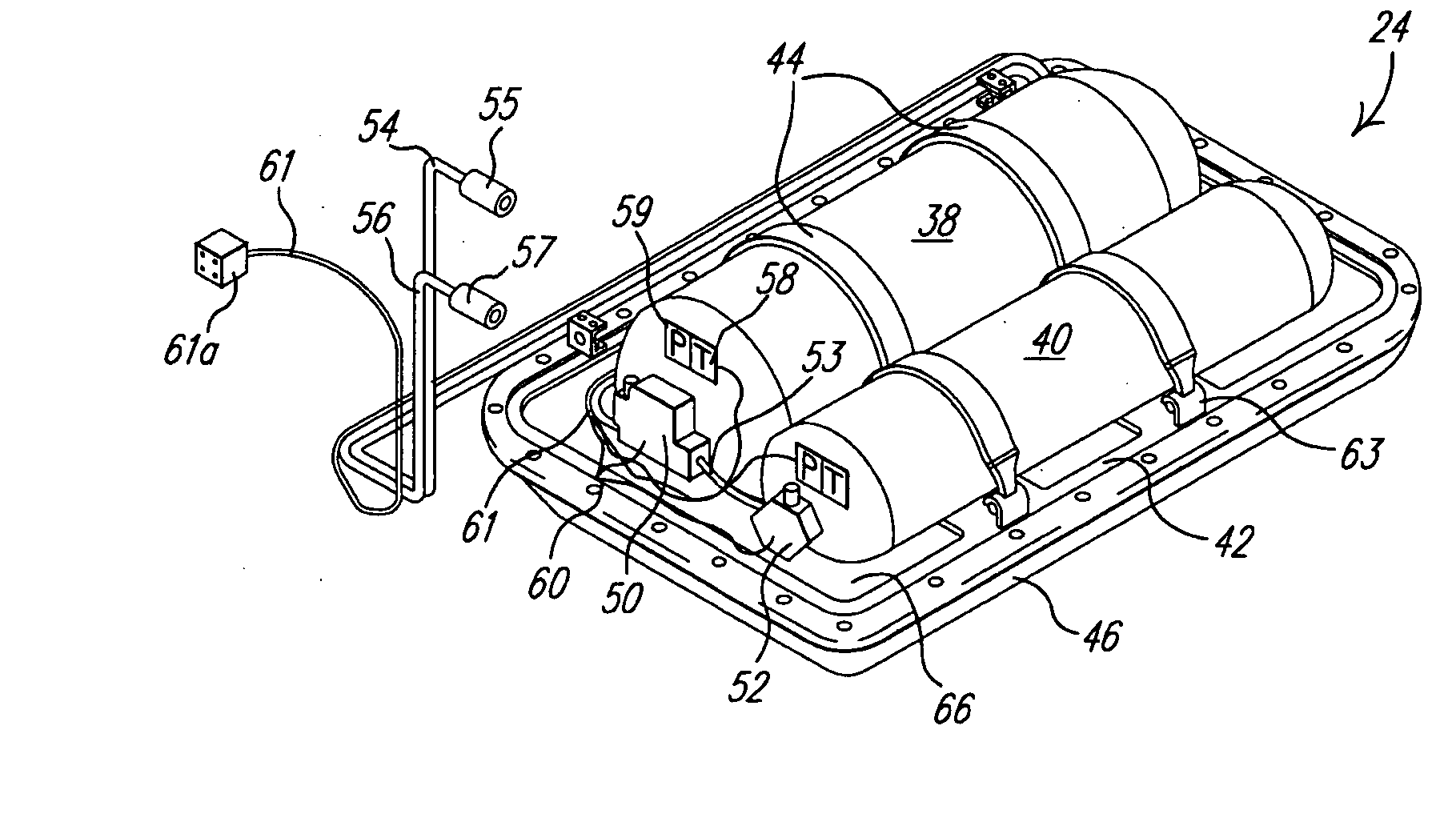

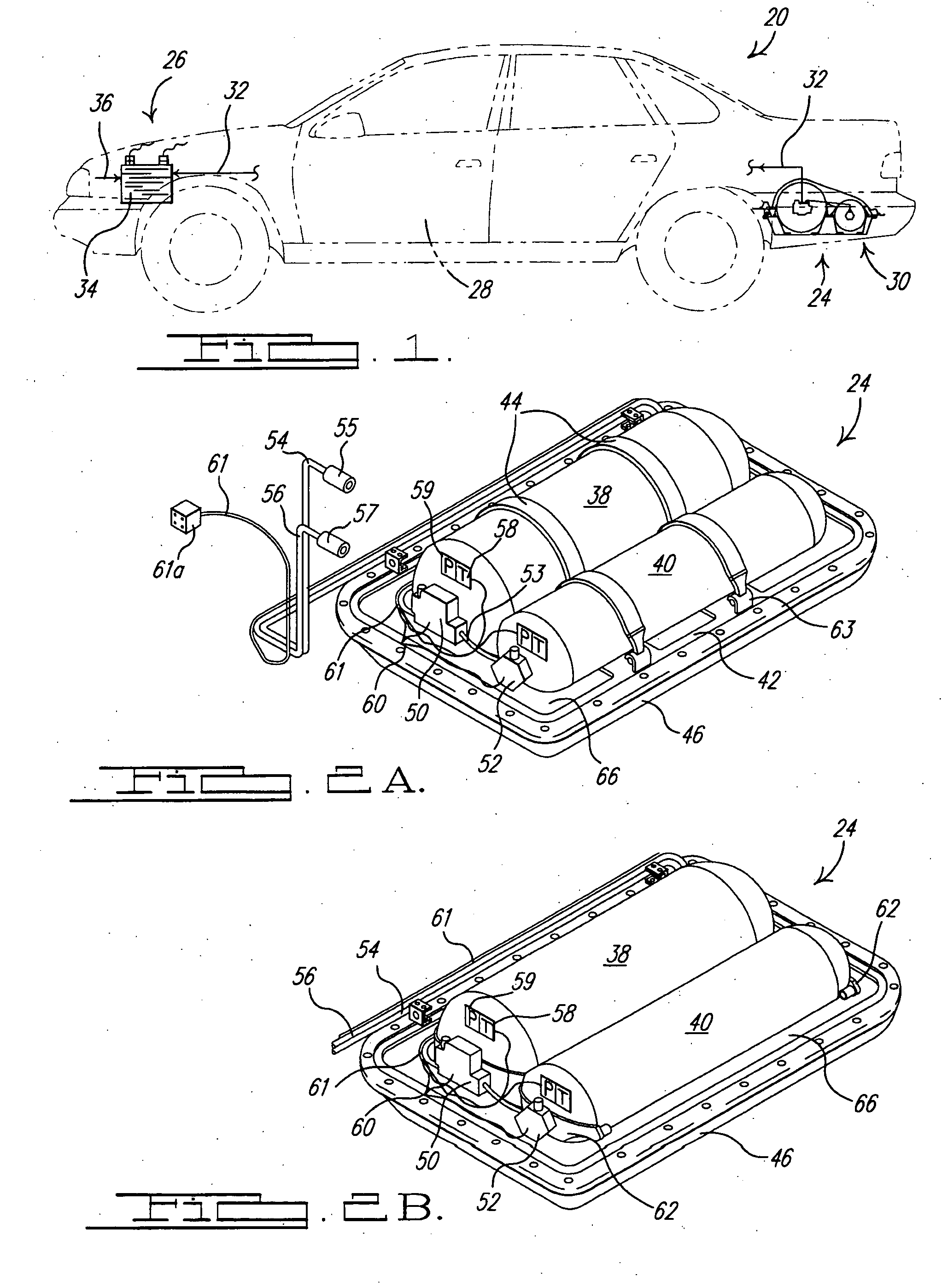

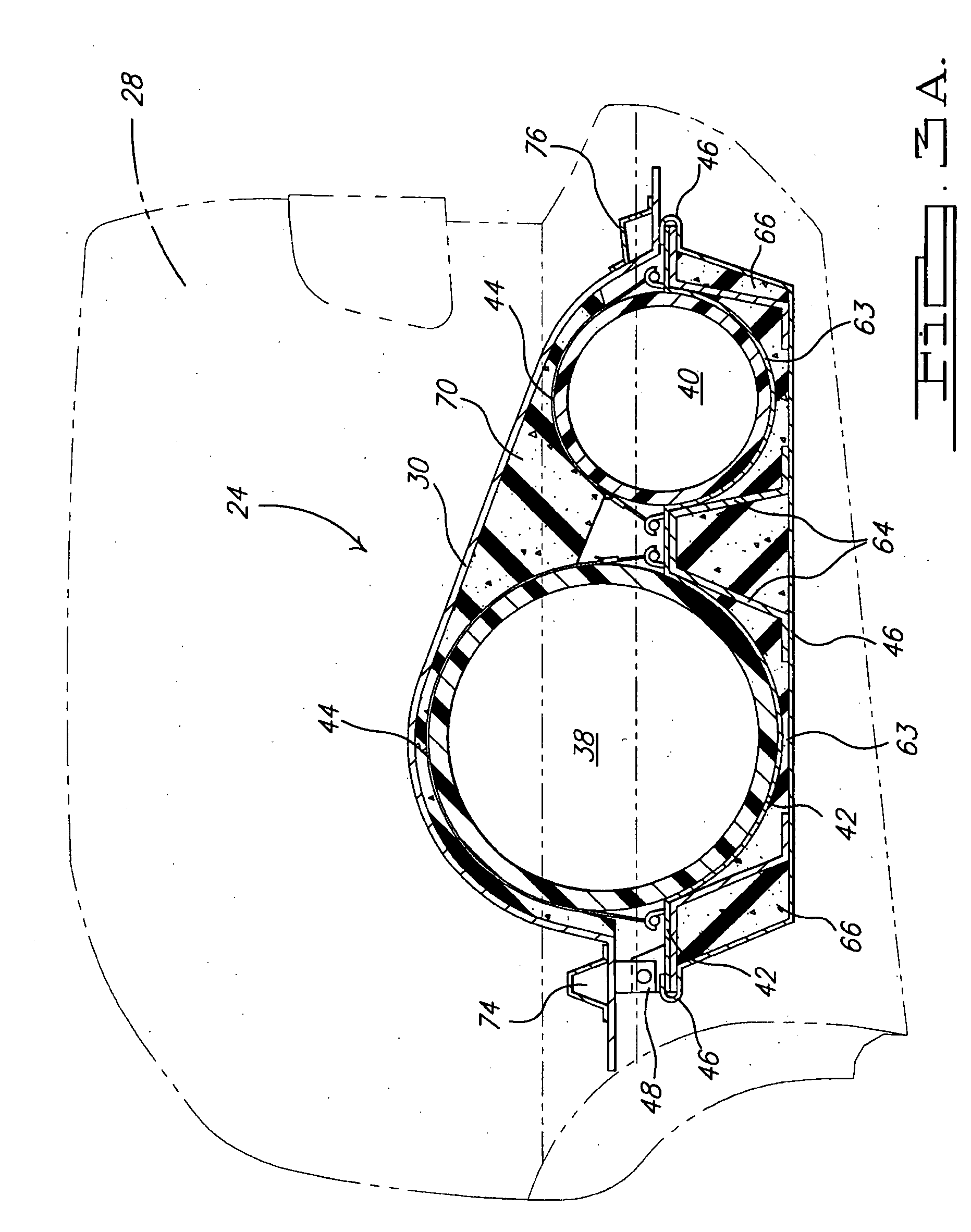

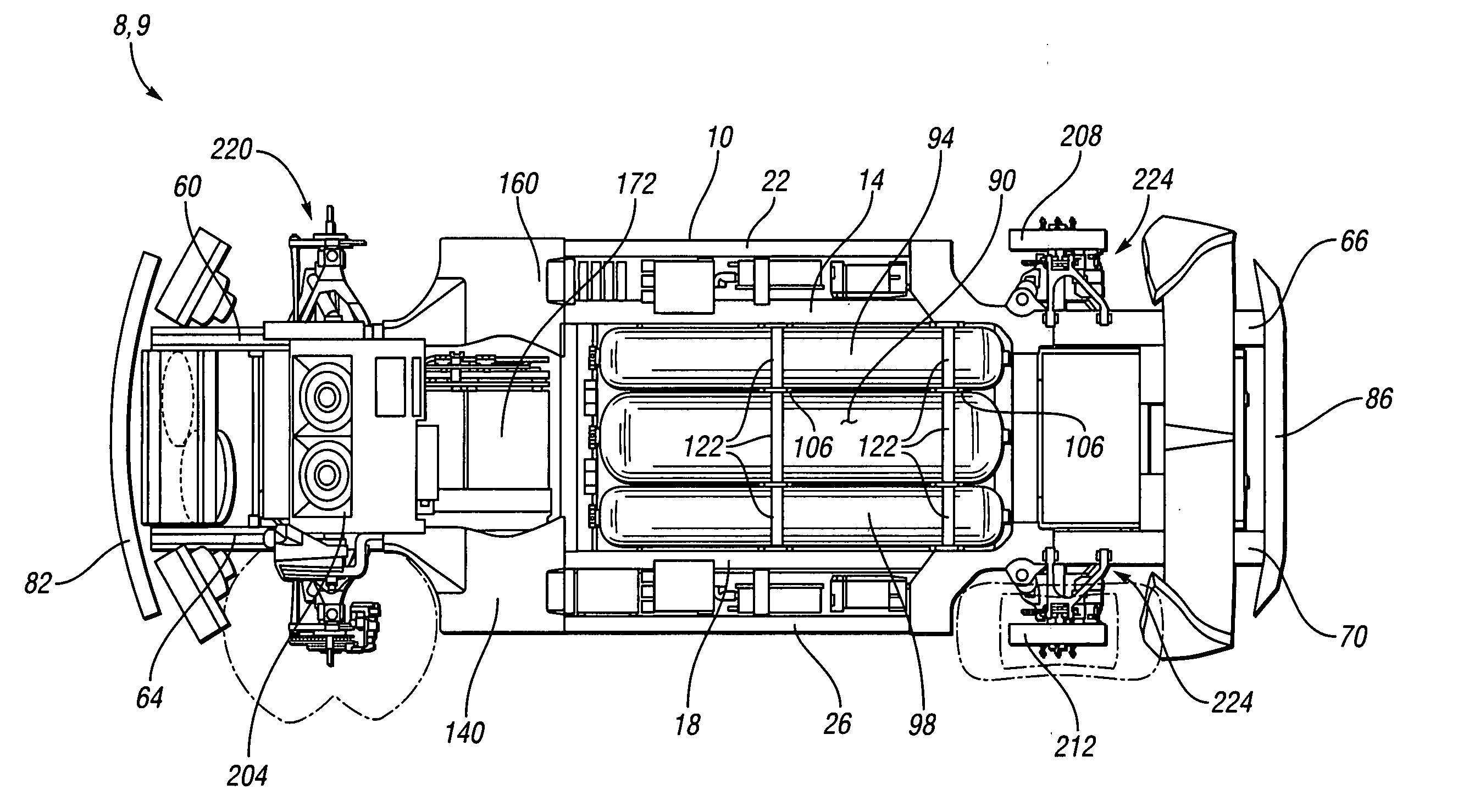

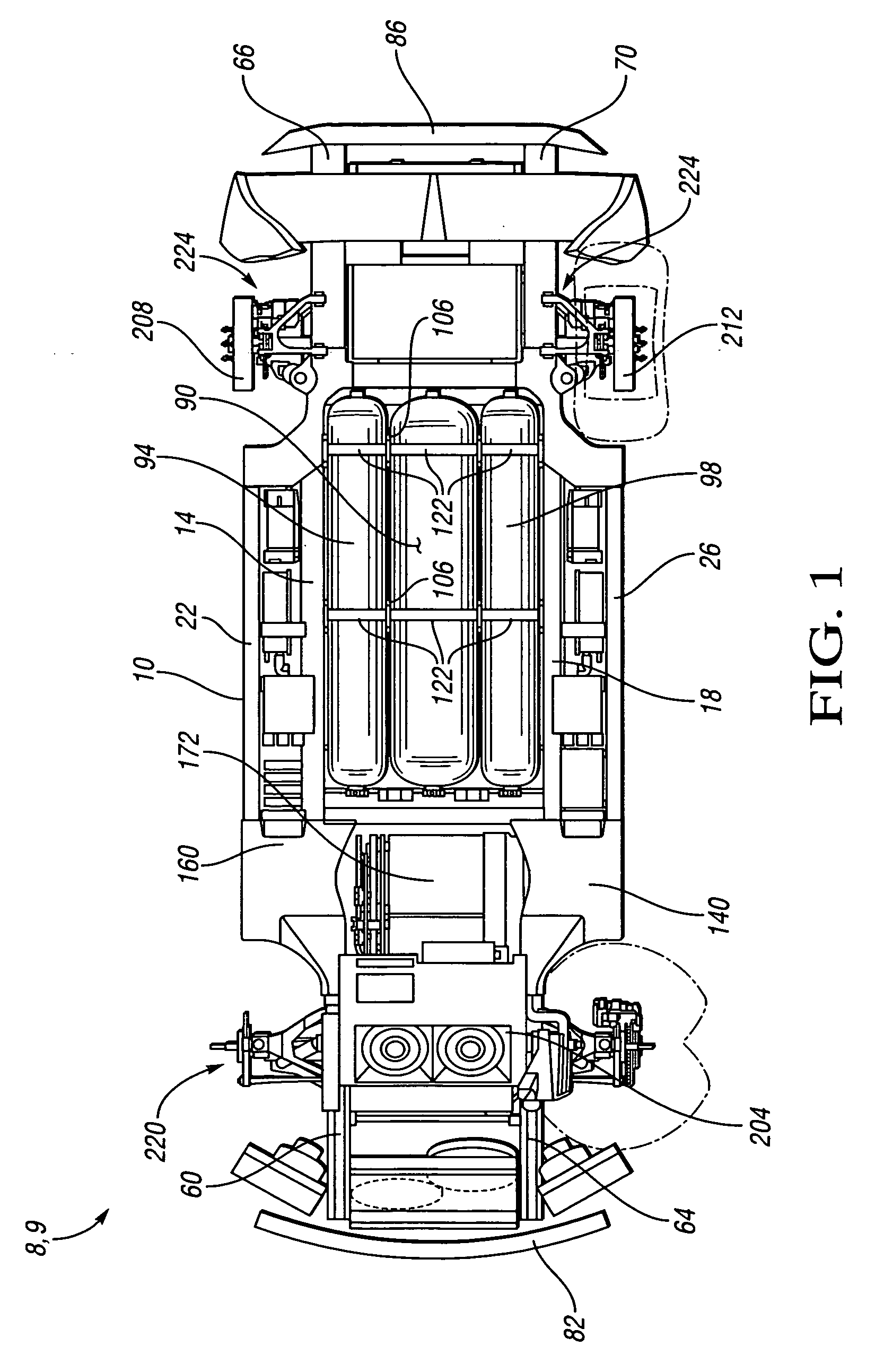

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

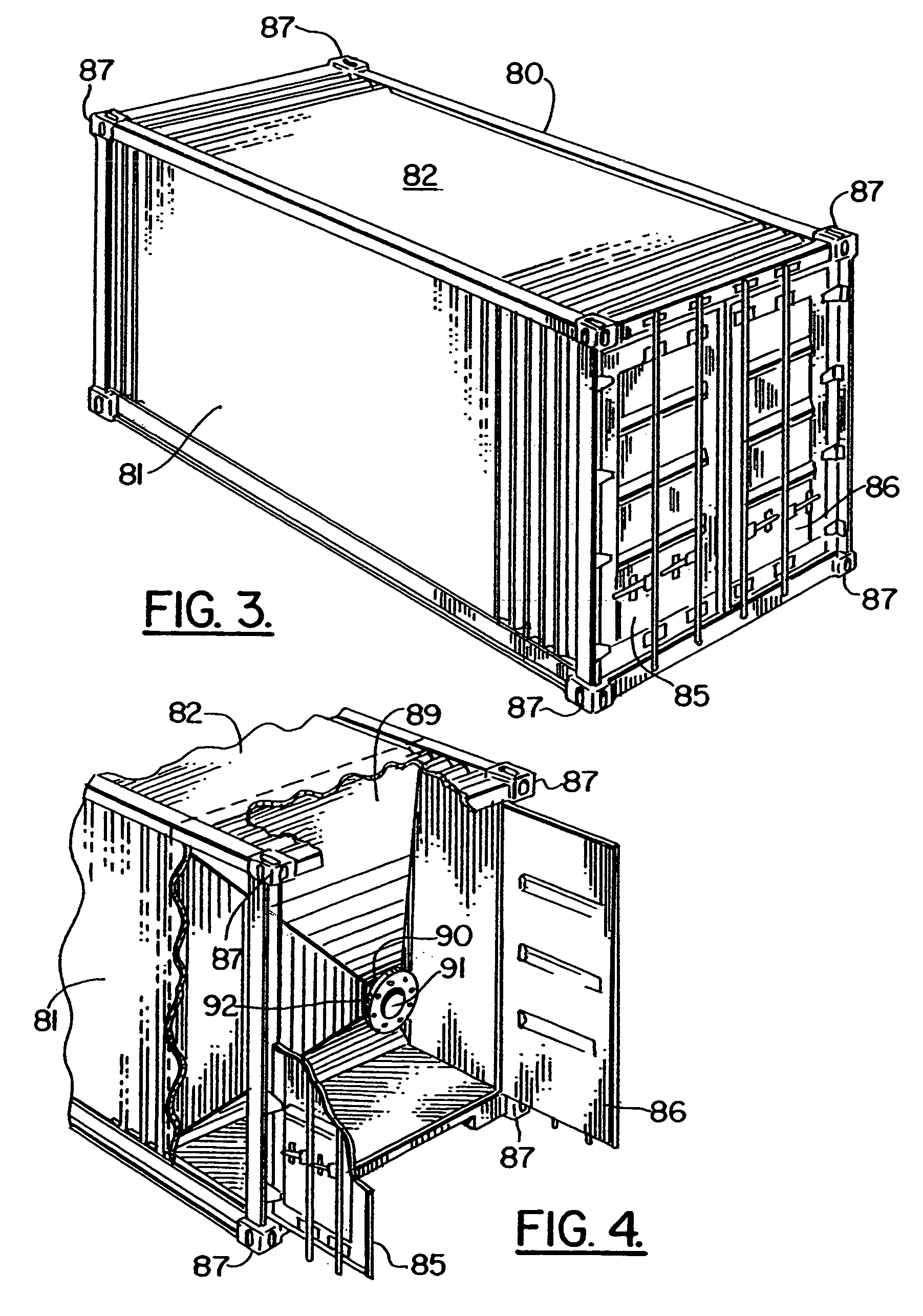

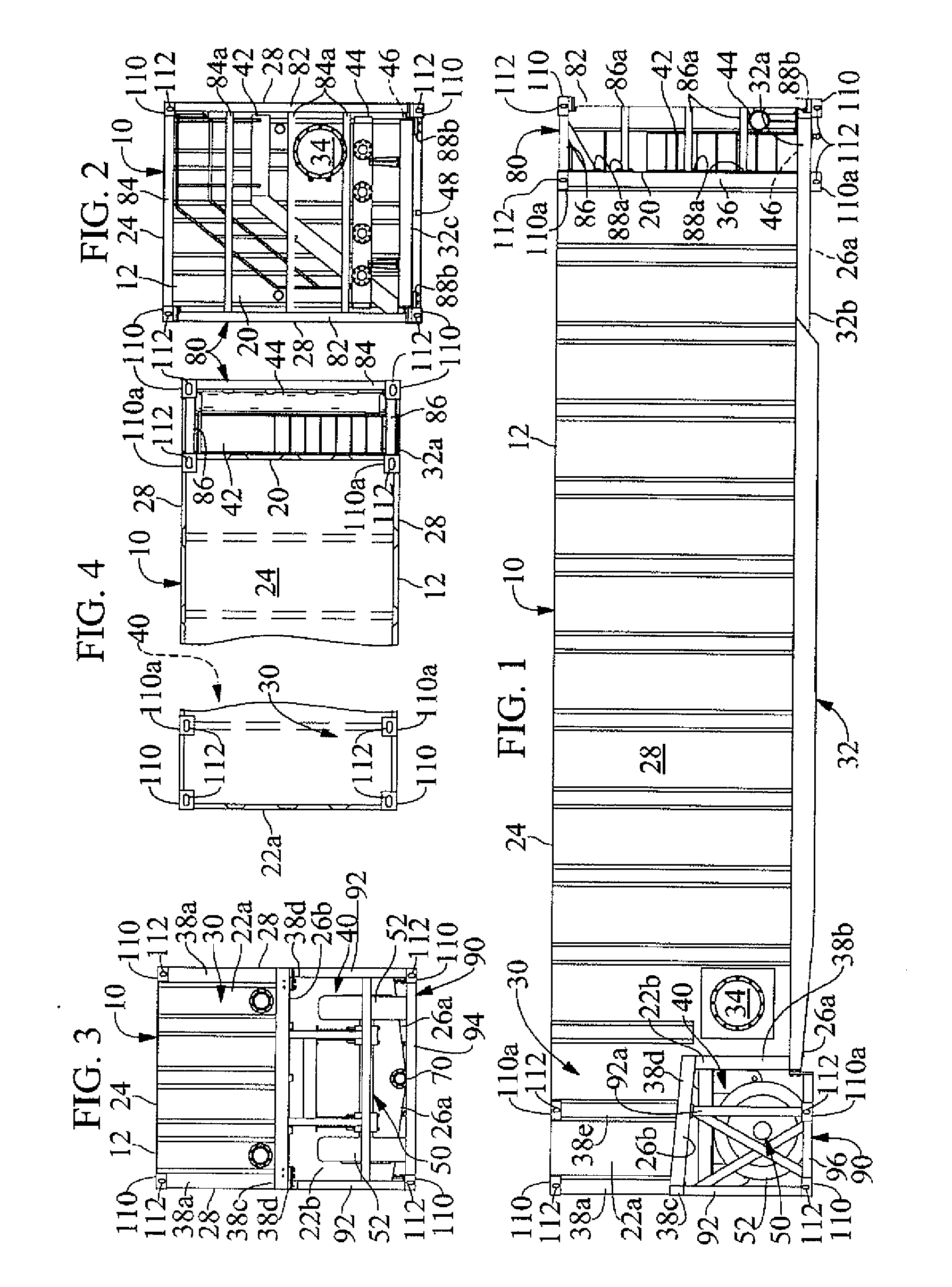

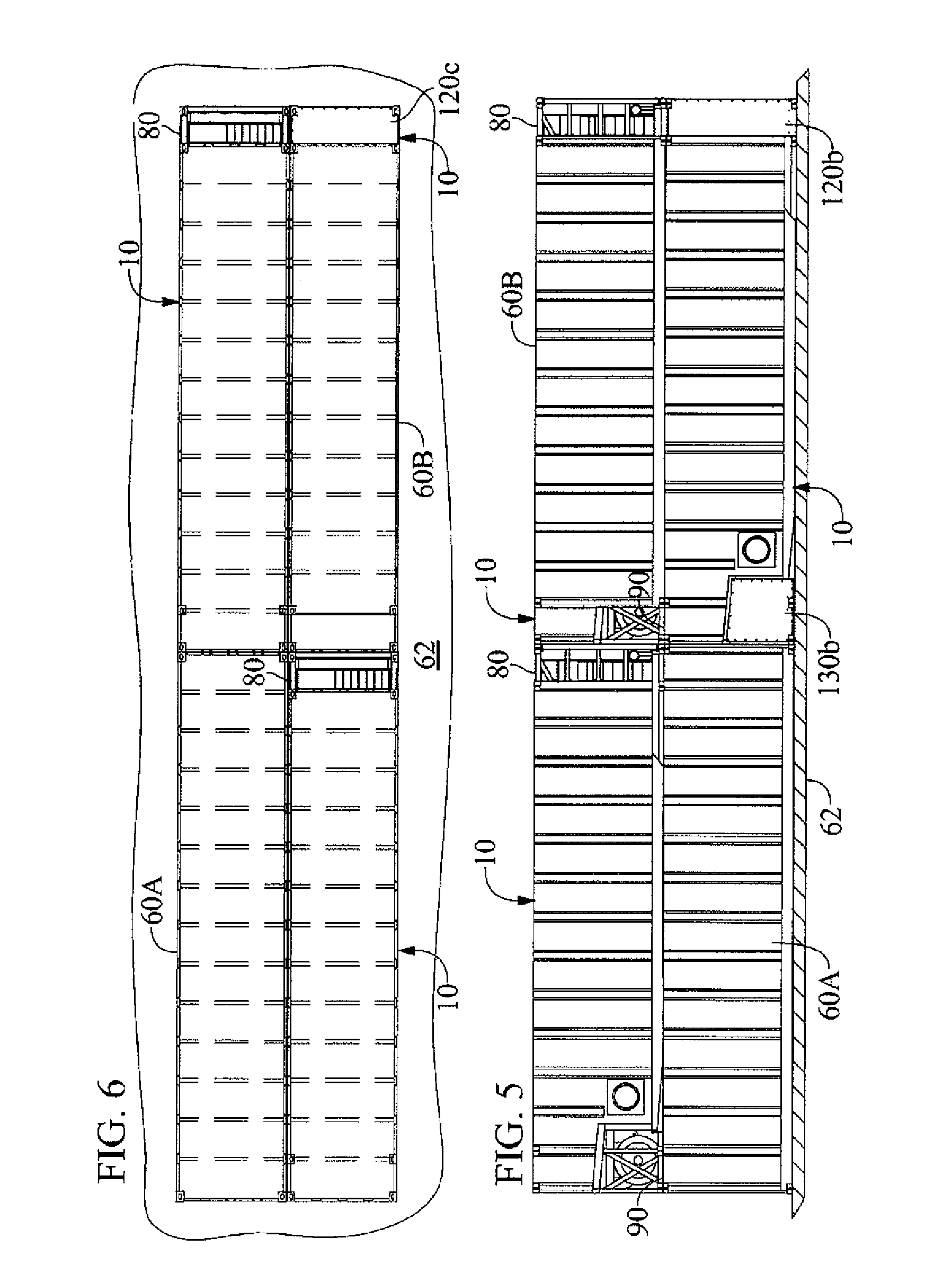

Frac tank storage system

InactiveUS7997623B2Improve protectionReduce freight expenseTank vehiclesLarge containersCargo containerAutomotive engineering

Owner:CHRIS WILLIAMS

Vehicle body structure

InactiveUS7614473B2Easy to useLower center of gravityTank vehiclesUnderstructuresVehicle frameFuel tank

A vehicle body structure includes a body frame with a subframe mounted to a lower part of the body frame. The subframe is formed into a rectangular shape and has front, intermediate and rear cross members. A storage battery is designed to be mounted astride the front cross member and the intermediate cross member. A fuel tank is designed to be mounted astride the intermediate cross member and the rear cross member.

Owner:HONDA MOTOR CO LTD

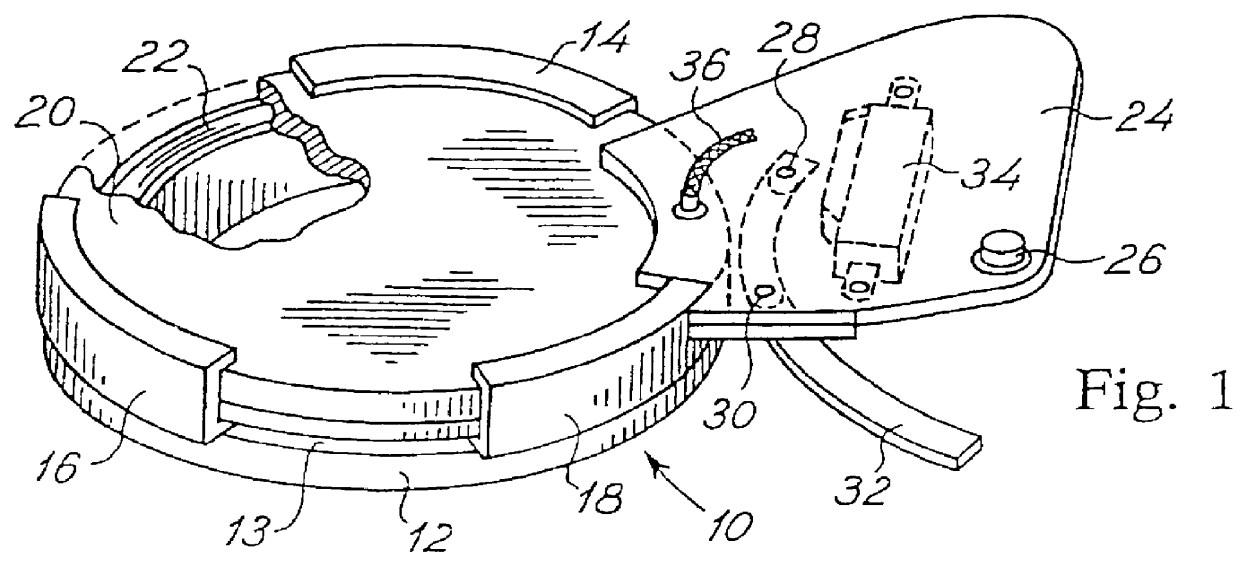

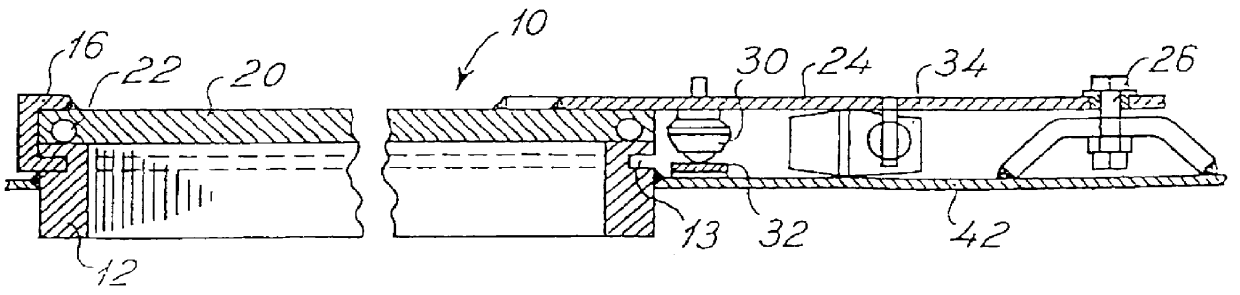

Pivotable and sealable cap assembly for opening in a large container

InactiveUS6053348AAvoid large gapsFunction increaseTank vehiclesClosure using stoppersEngineeringMechanical engineering

A cap unit (10) for a container (38) has a cap (20) and an annular skirt (12). The skirt (12) is mounted in the container (38) defining an aperture, the cap (20) being movable between a first position and a second position. In the first position the cap (20) covers the aperture and seals it, and in the second position the cap uncovers the aperture, the cap (20) being journalled pivotably around an axis (26) perpendicular to the plan defined by the aperture and placed outside the aperture so that the cap may swing between the first position and the second position. Furthermore, the cap (20) and the skirt (12) have respective claw-formed catching means (14, 16, 18) which are adapted to fix the cap (20) in relation to the skirt (12) and allow the cap (20) to swing from a first to a second position. The cap unit (10) has driving means (34) for production of swinging of the cap (20) and the cap unit (10) has an inflatable sealing ring (22) mounted in the cap (20) for sealing against the upper surface of the skirt (12) when the cap (20) is in its first position, or alternatively mounted in the skirt (12) for sealing against the opposite surface of the cap (20).

Owner:MORCH LEO

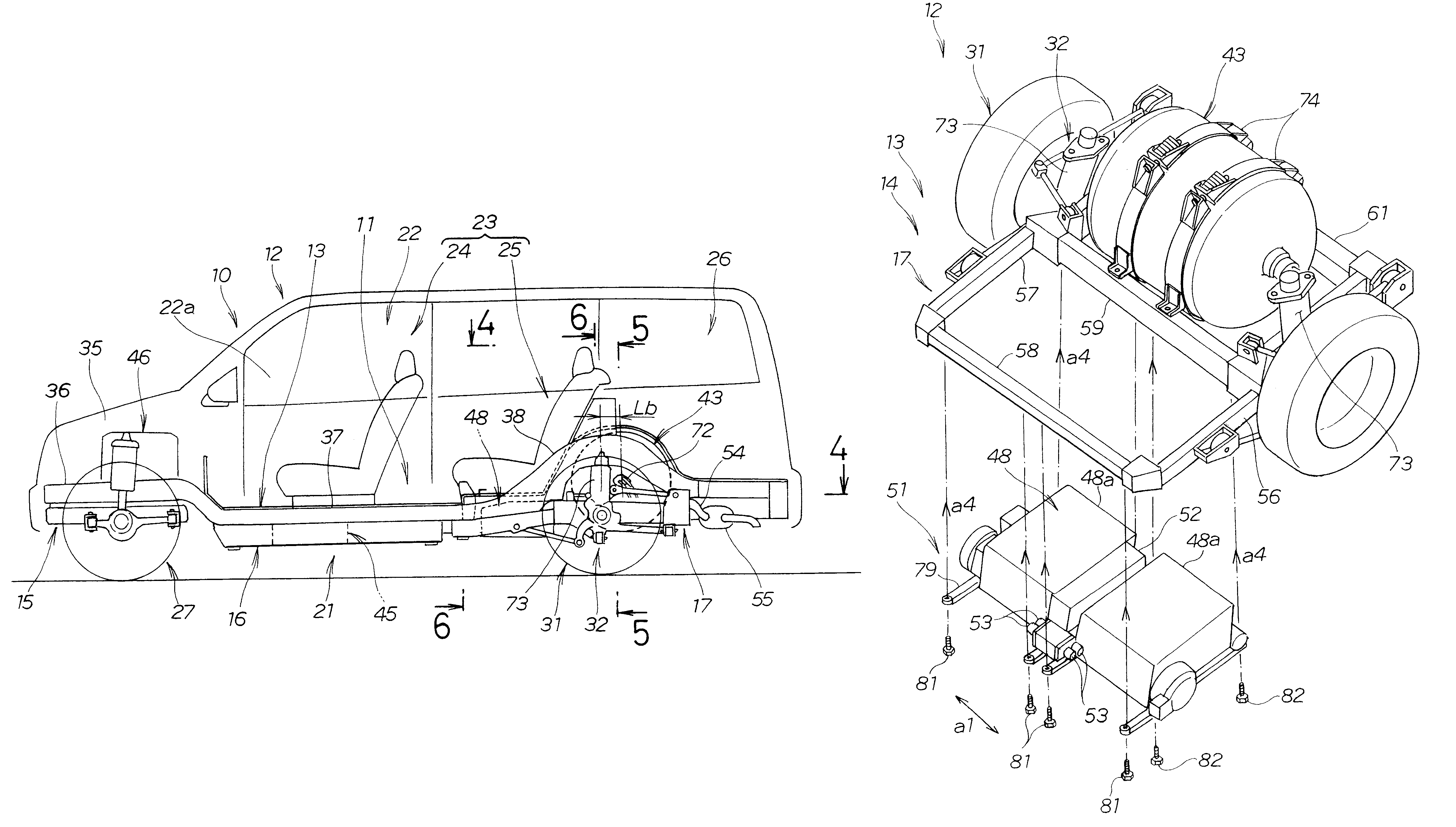

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

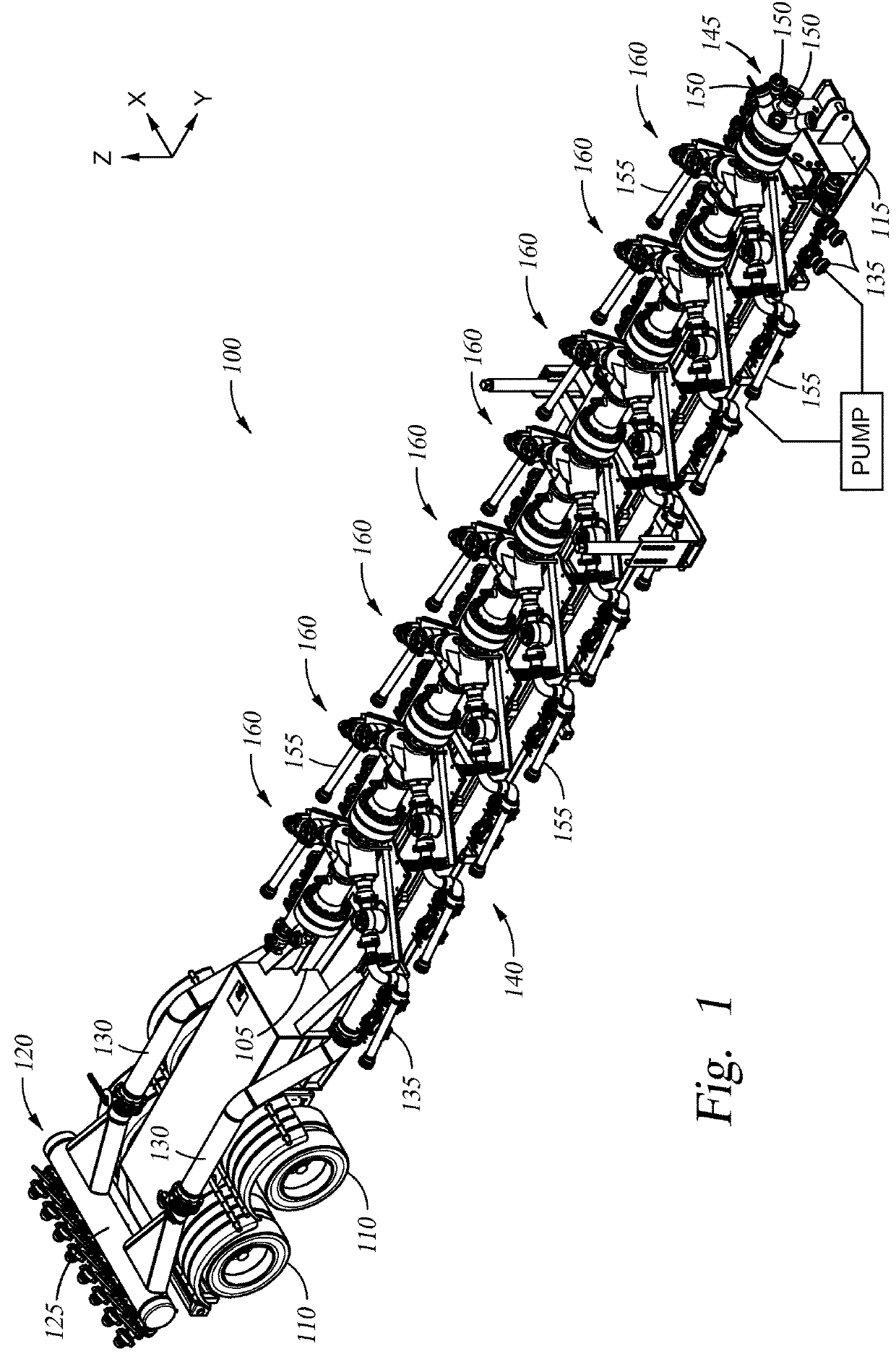

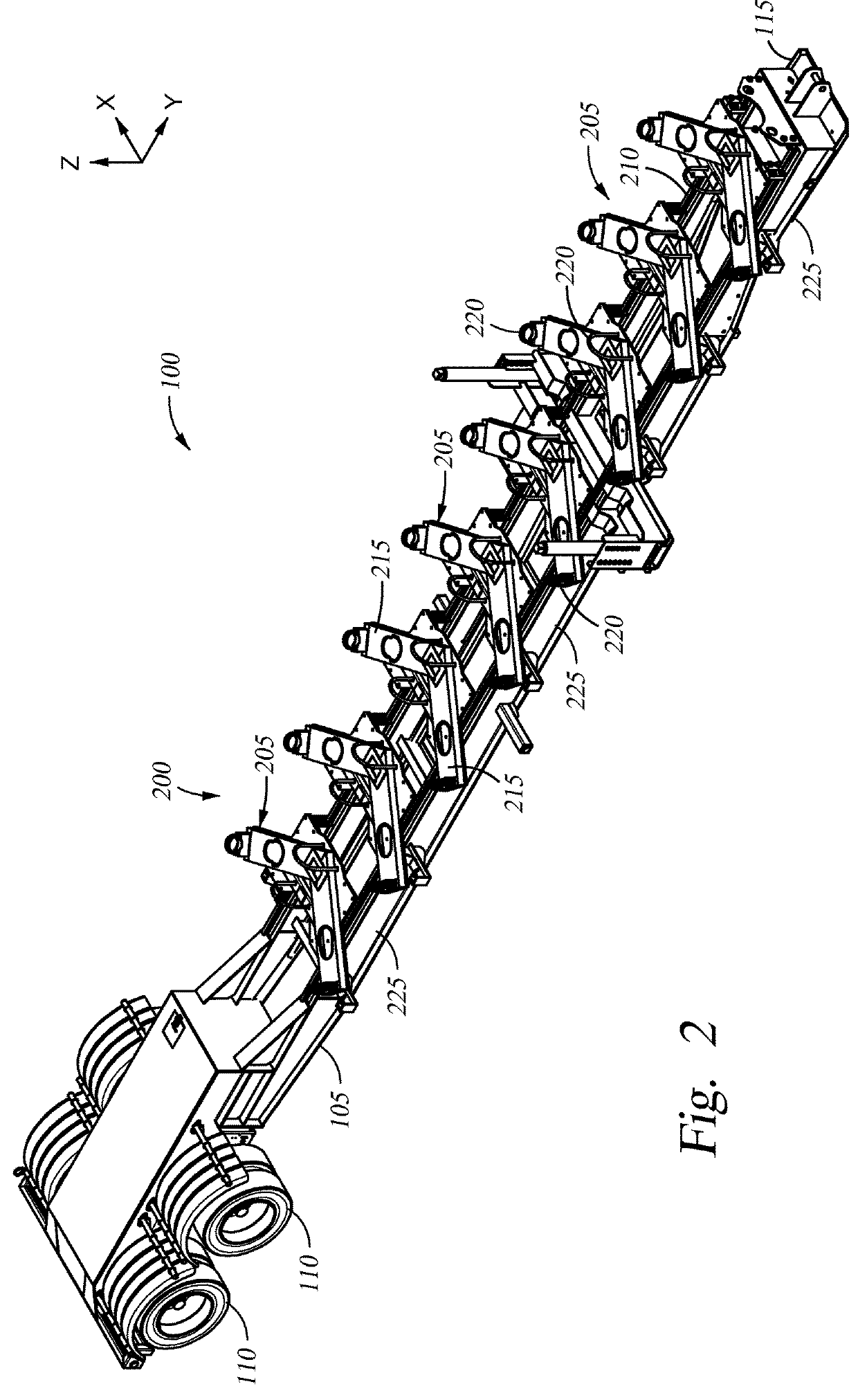

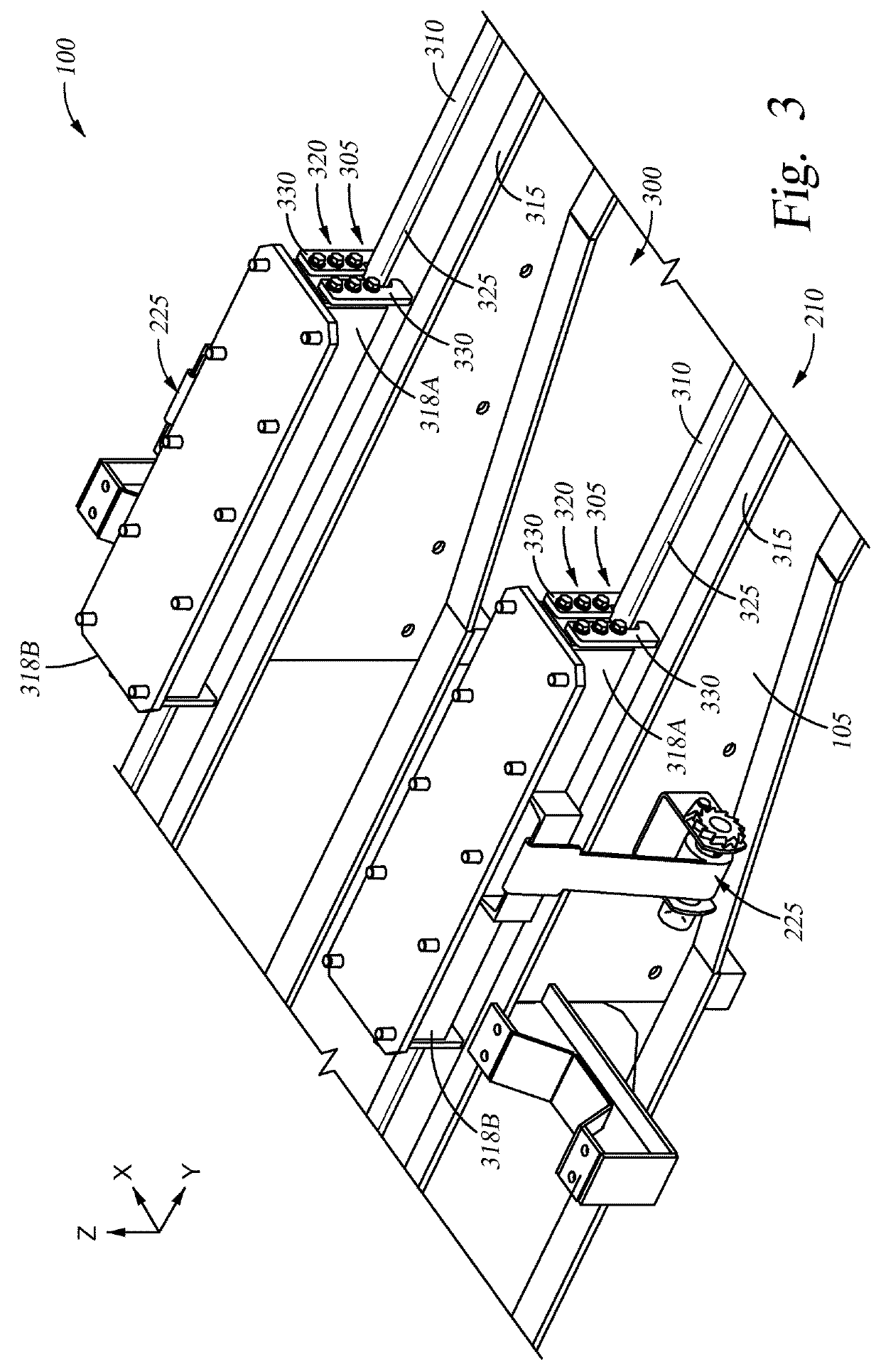

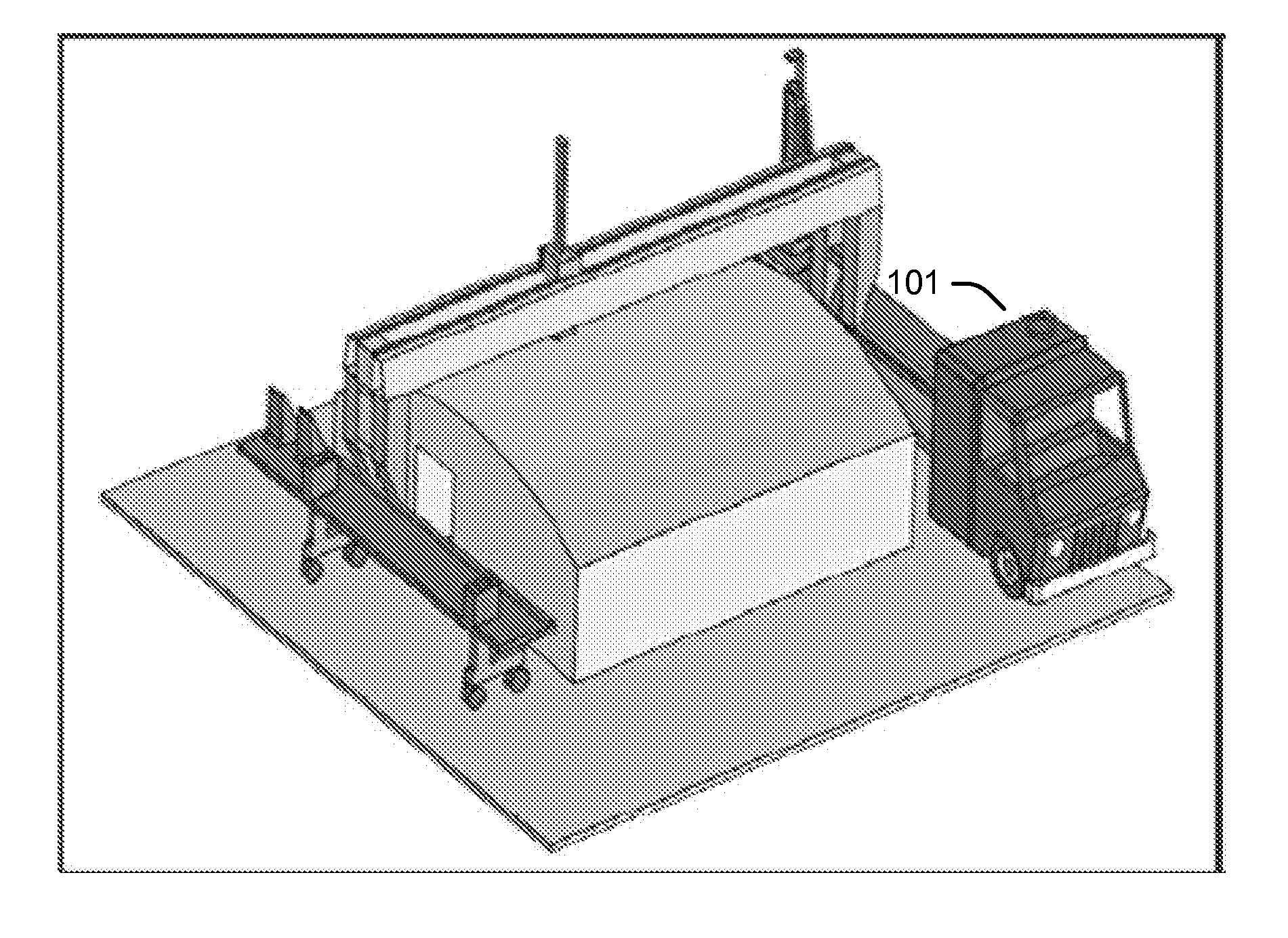

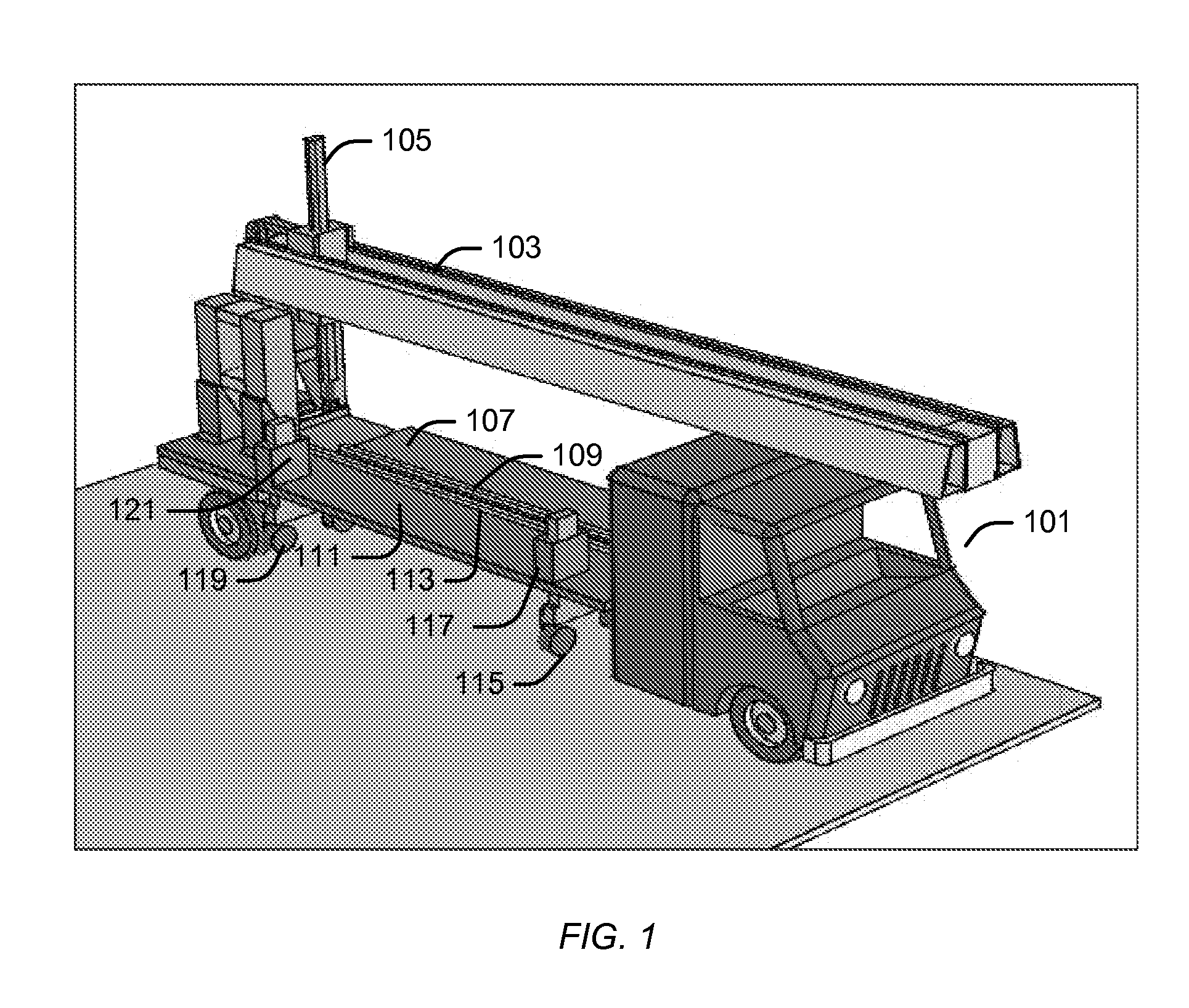

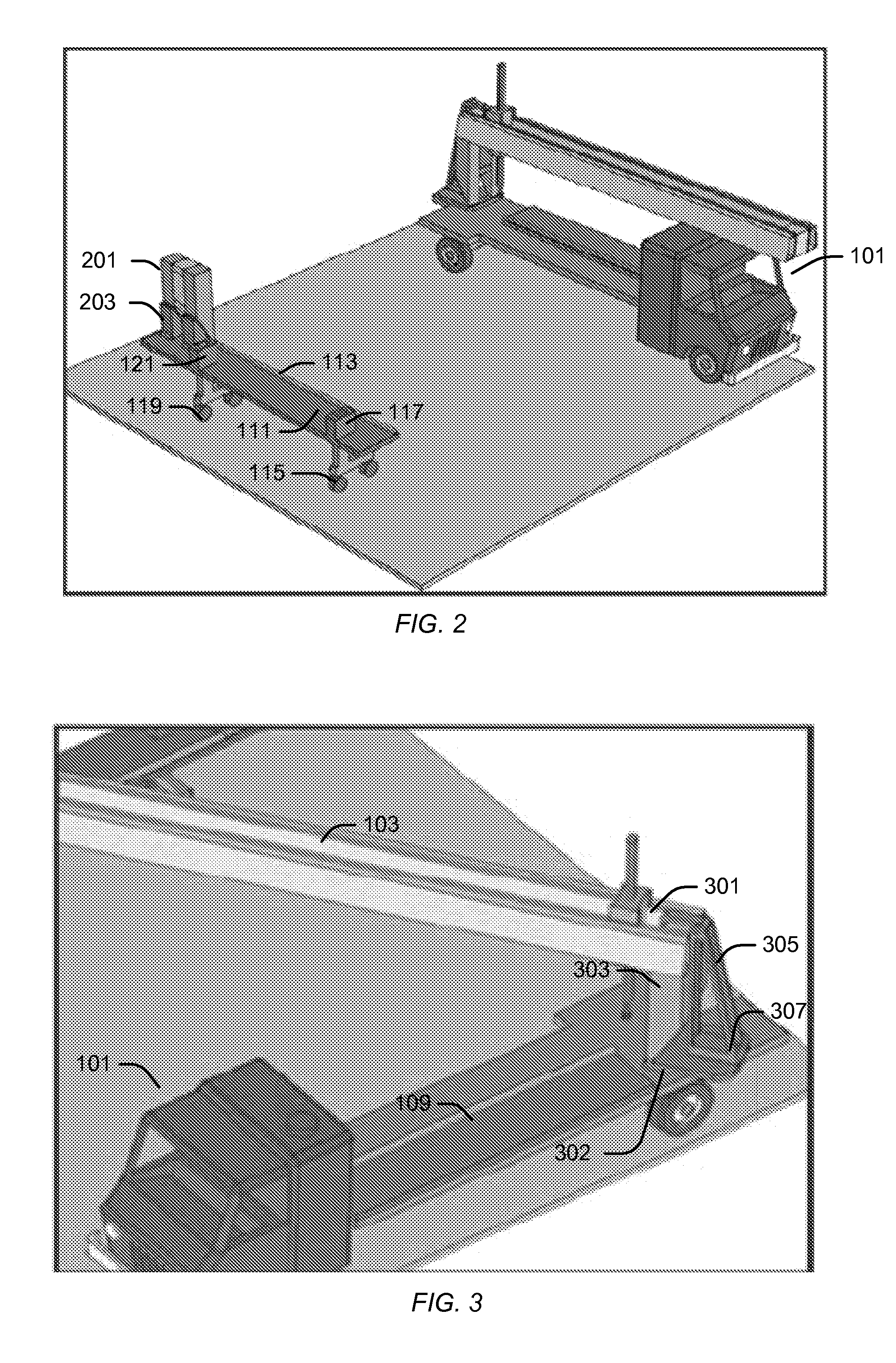

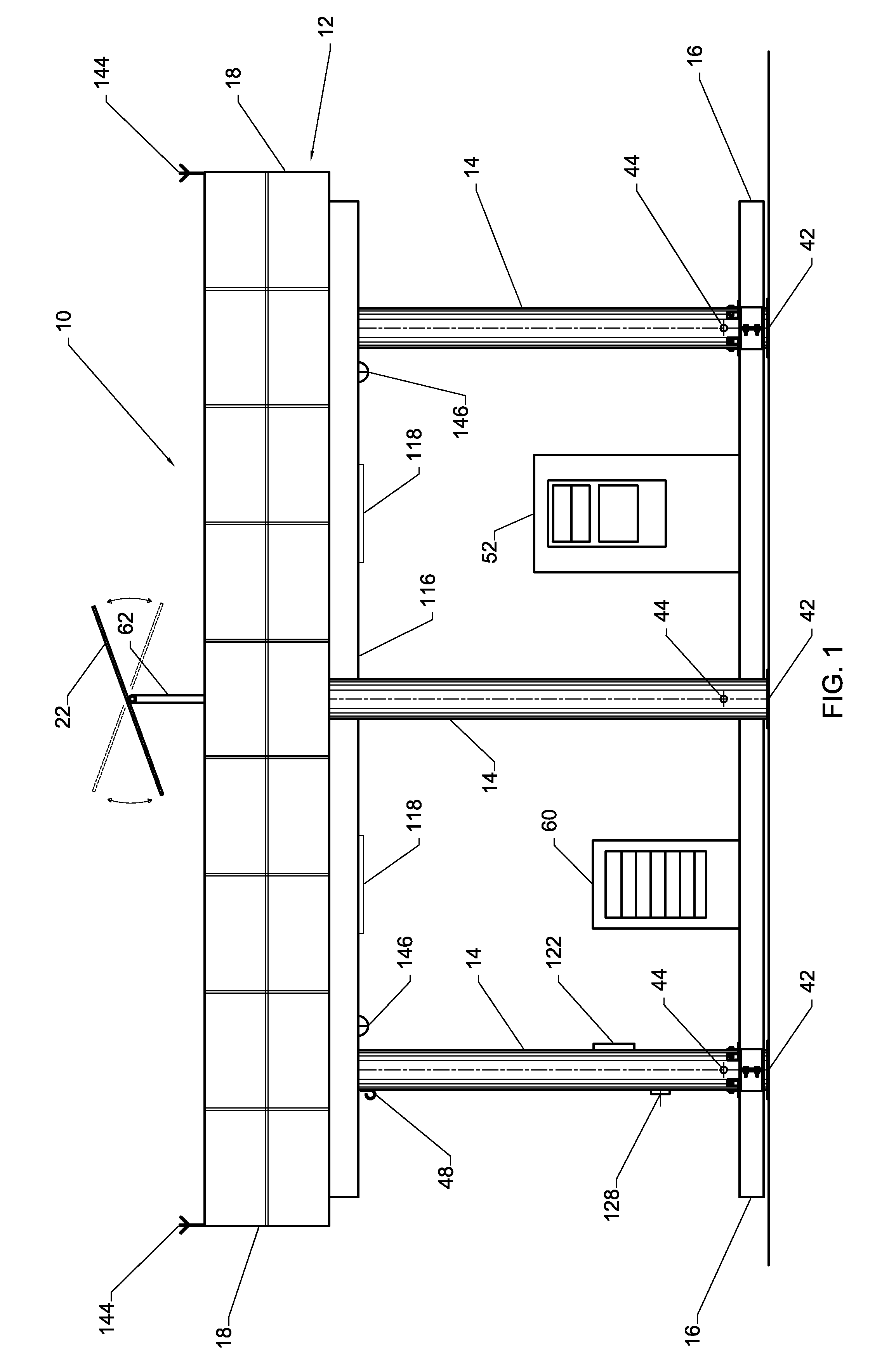

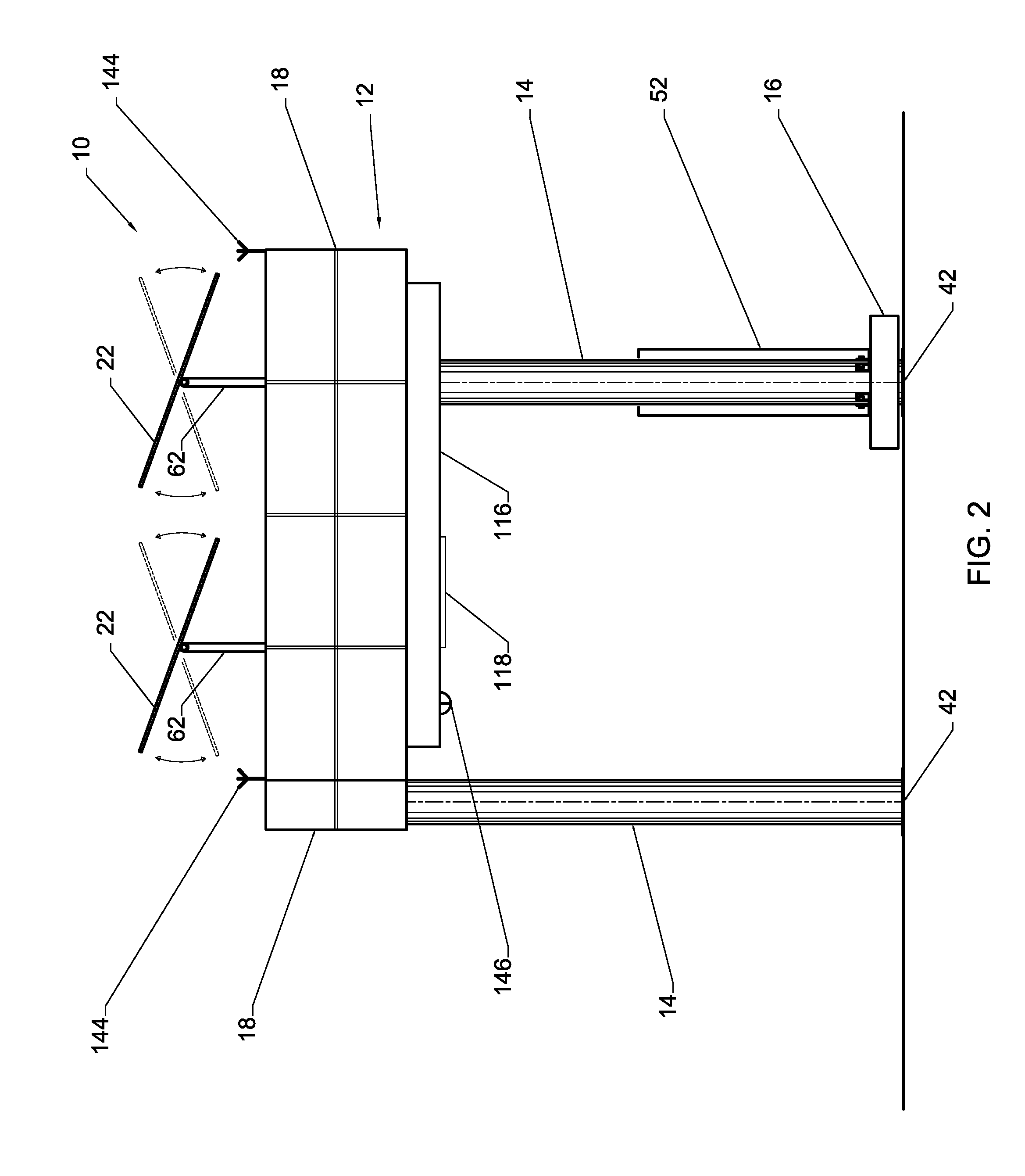

Deployable Contour Crafting

A deployable crafting machine may include a vehicle and a gantry system. The gantry system may be configured to be collapsed on the vehicle during which the gantry system is inoperable and to be expanded during which the gantry system is operable and supported at least in part by the vehicle. A deployable crafting process may include moving a vehicle to a first location while a gantry system is stored on the vehicle in a collapsed and inoperable state and expanding the gantry system into an operable state after the vehicle arrives at the first location during which the gantry system is supported at least in part by the vehicle.

Owner:UNIV OF SOUTHERN CALIFORNIA

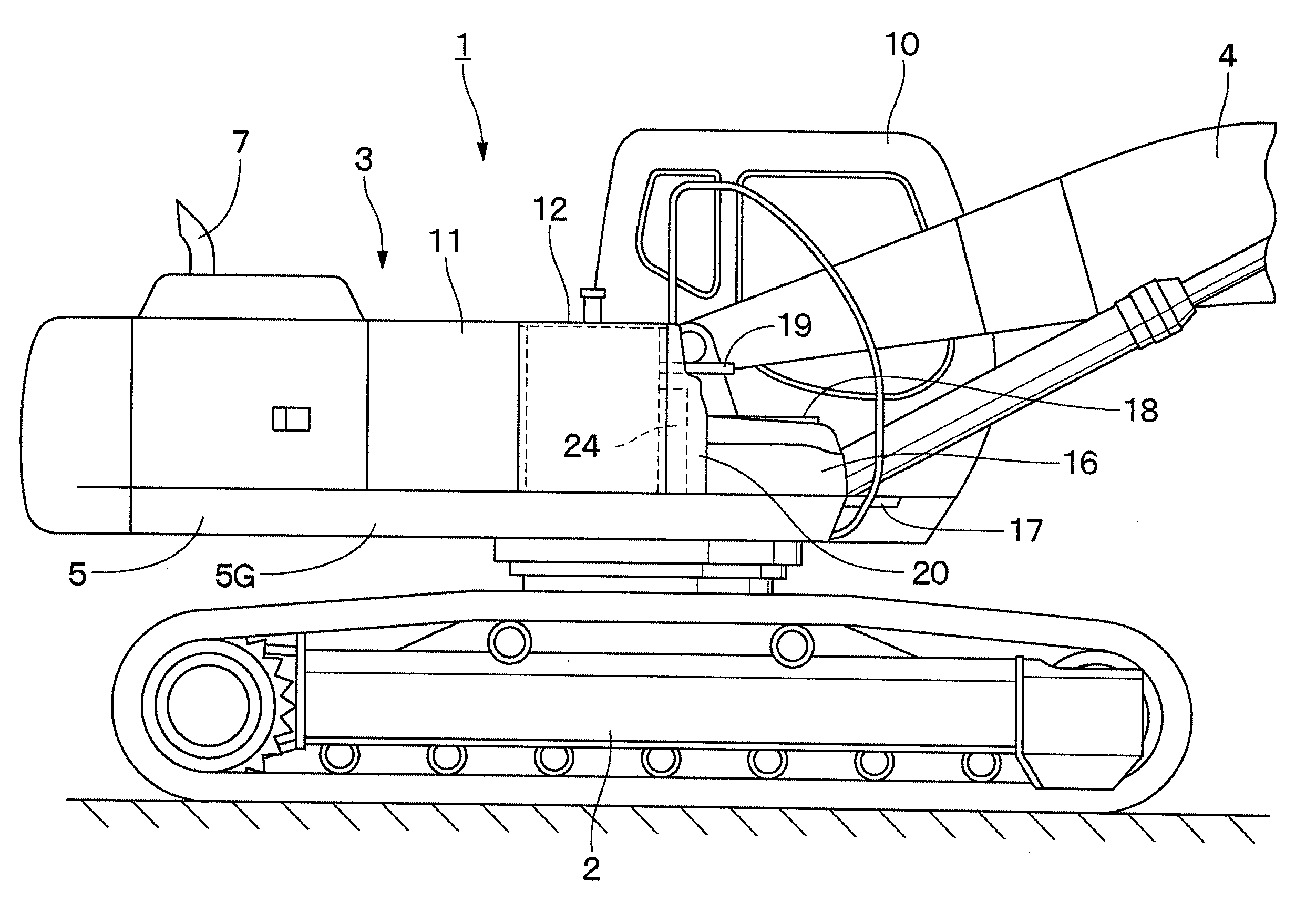

Construction machine

ActiveUS20120067660A1Good lookingIncreased durabilityTank vehiclesExhaust apparatusFuel tankEngineering

A fuel tank (12) is constructed such that a front flange portion (14A1) of a top surface plate (14A) of a second plate (14) extends outside in relation to a front surface plate (13B) of a first plate (13). As a result, a front surplus space (15A) projected in the upper and lower directions in a range of the front flange portion (14A1) of the top surface plate is formed in the front surface side of the front surface plate. A urea water tank (24) is arranged along the fuel tank (12) in such a manner that a rear side portion thereof enters into the front surplus space portion. Therefore, the rear side portion of the urea water tank can enter into the front surplus space using the front surplus space formed in the fuel tank (12), thereby increasing the tank capacity without downsizing the article accommodating box (16).

Owner:NIHON KENKI CO LTD

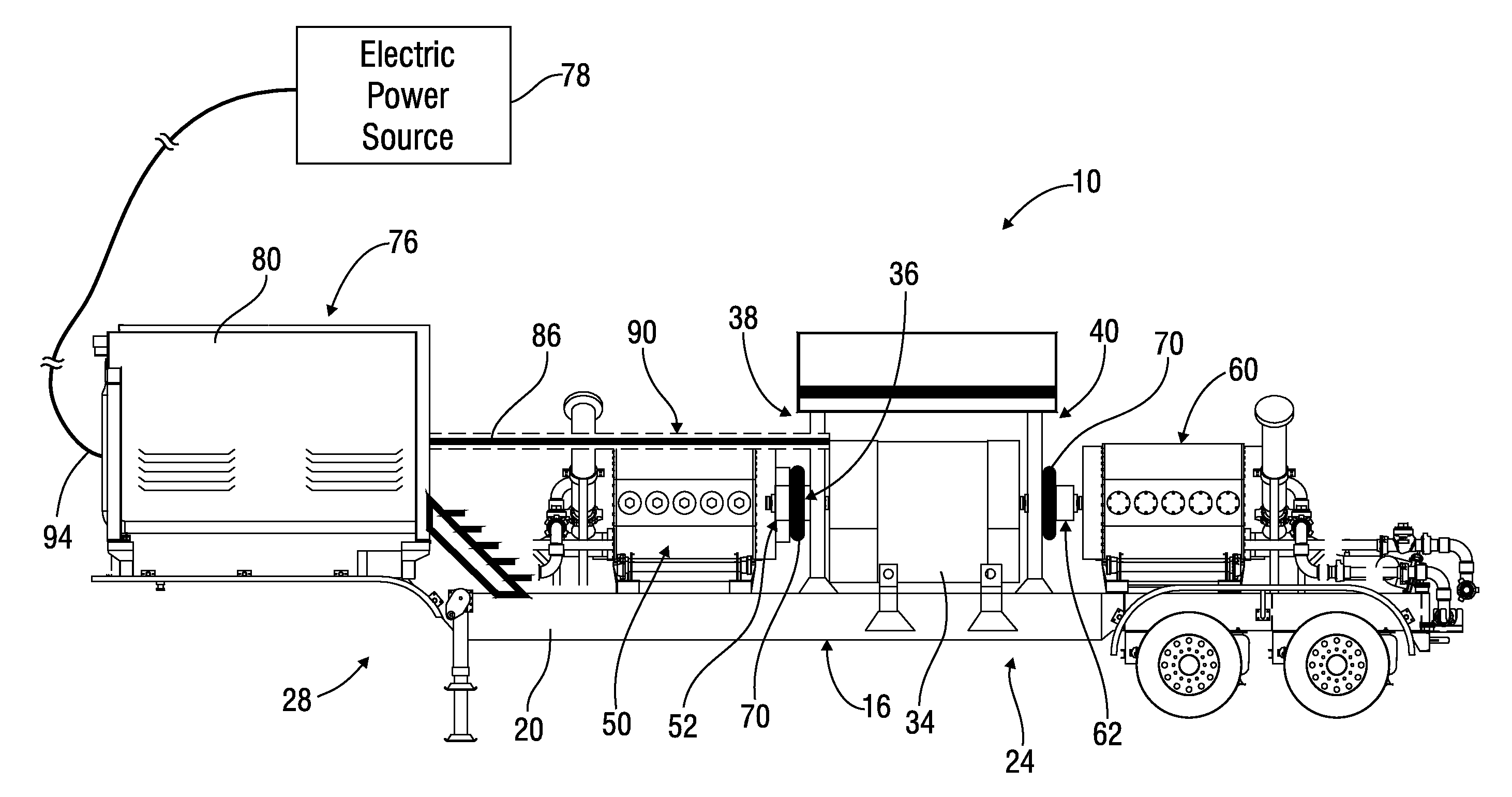

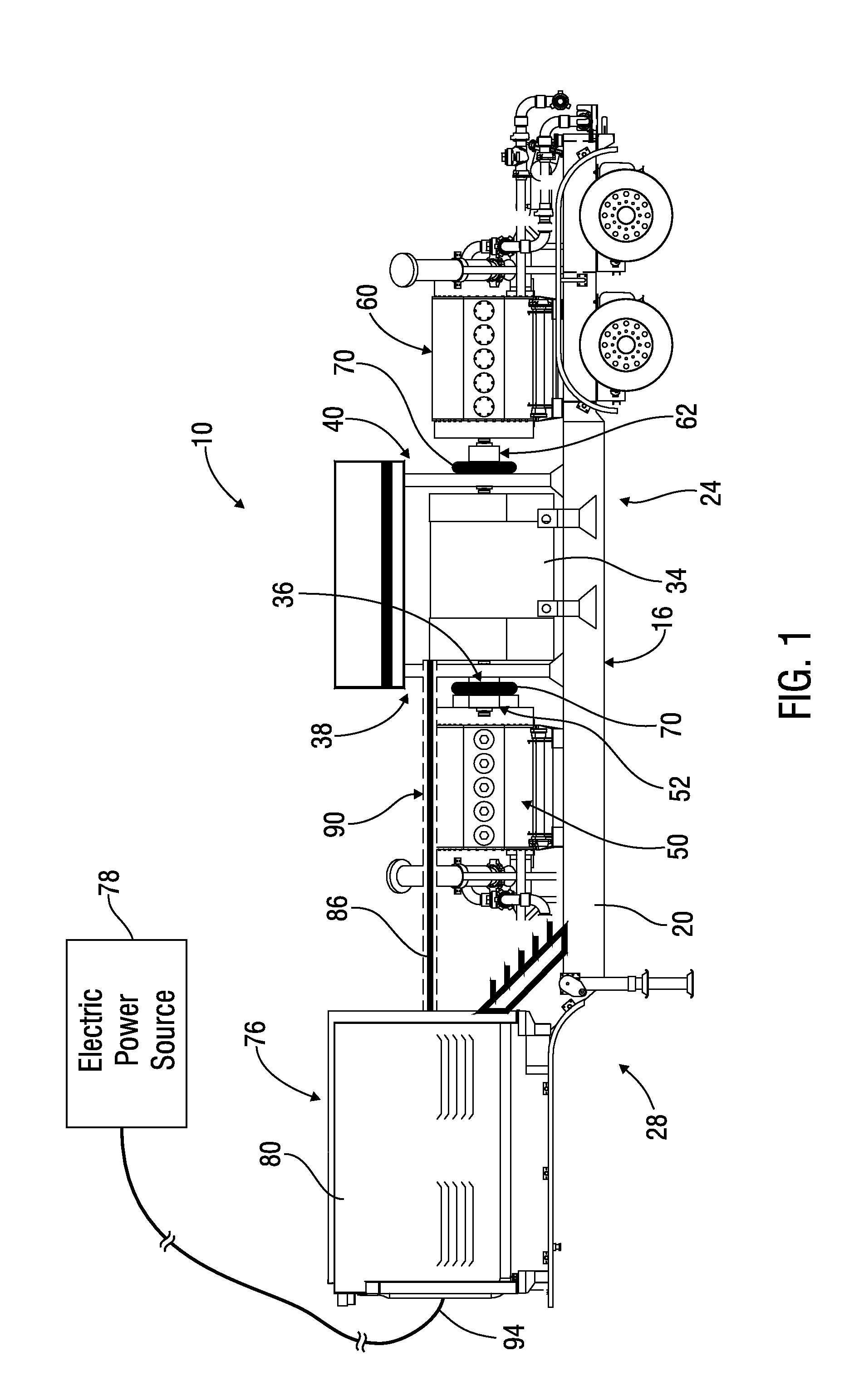

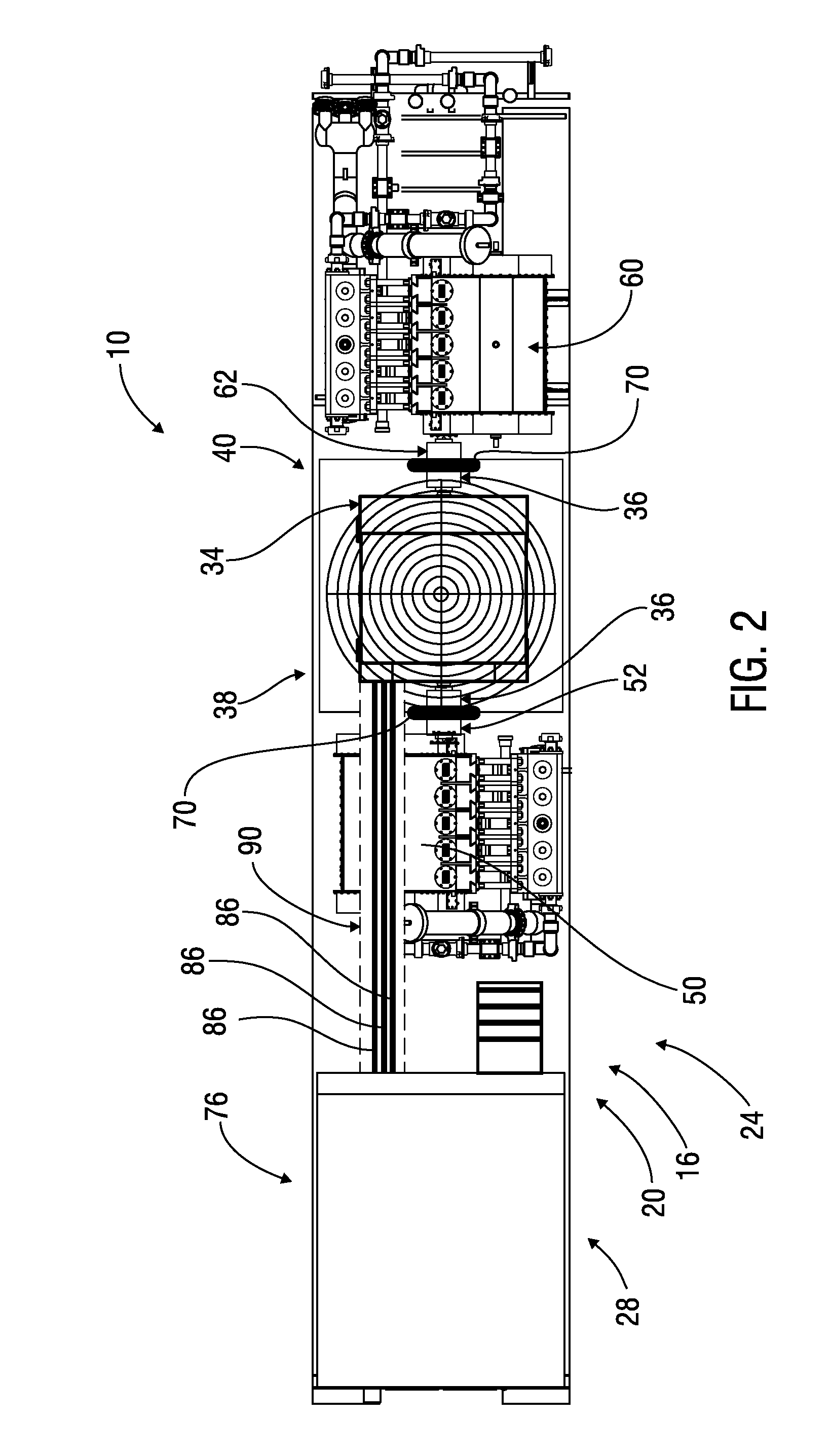

Apparatus and methods for delivering a high volume of fluid into an underground well bore from a mobile pumping unit

Apparatus for pumping fluid into an underground well bore at a well site and being transportable between multiple well sites includes a chassis configured to be transportable between well sites, first and second fluid pumps disposed upon the chassis and configured to pump pressurized fluid into the well bore at the same time and an electric motor disposed upon the chassis and configured to concurrently drive both pumps.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

Low flow showerhead and method of making same

A showerhead for a low flow rate may employ one or more of a showerhead housing, a showerhead engine, a flow restrictor and a flow regulation device. The showerhead engine may be moveably connected to the showerhead housing. The showerhead engine may include a back member, an intermediate member, and a front member defining various fluid chambers and apertures that allow for one or more spray modes. The showerhead may include a flow control device to selectively reduce flow to the showerhead engine. The flow control device may also be selectively pause fluid flow for more than one spray mode. The showerhead may include a flow restrictor. The flow restrictor may limit a maximum fluid flow rate of a fluid delivered from the showerhead engine to approximately 1.5 gallons per minute.

Owner:WATER PIK INC

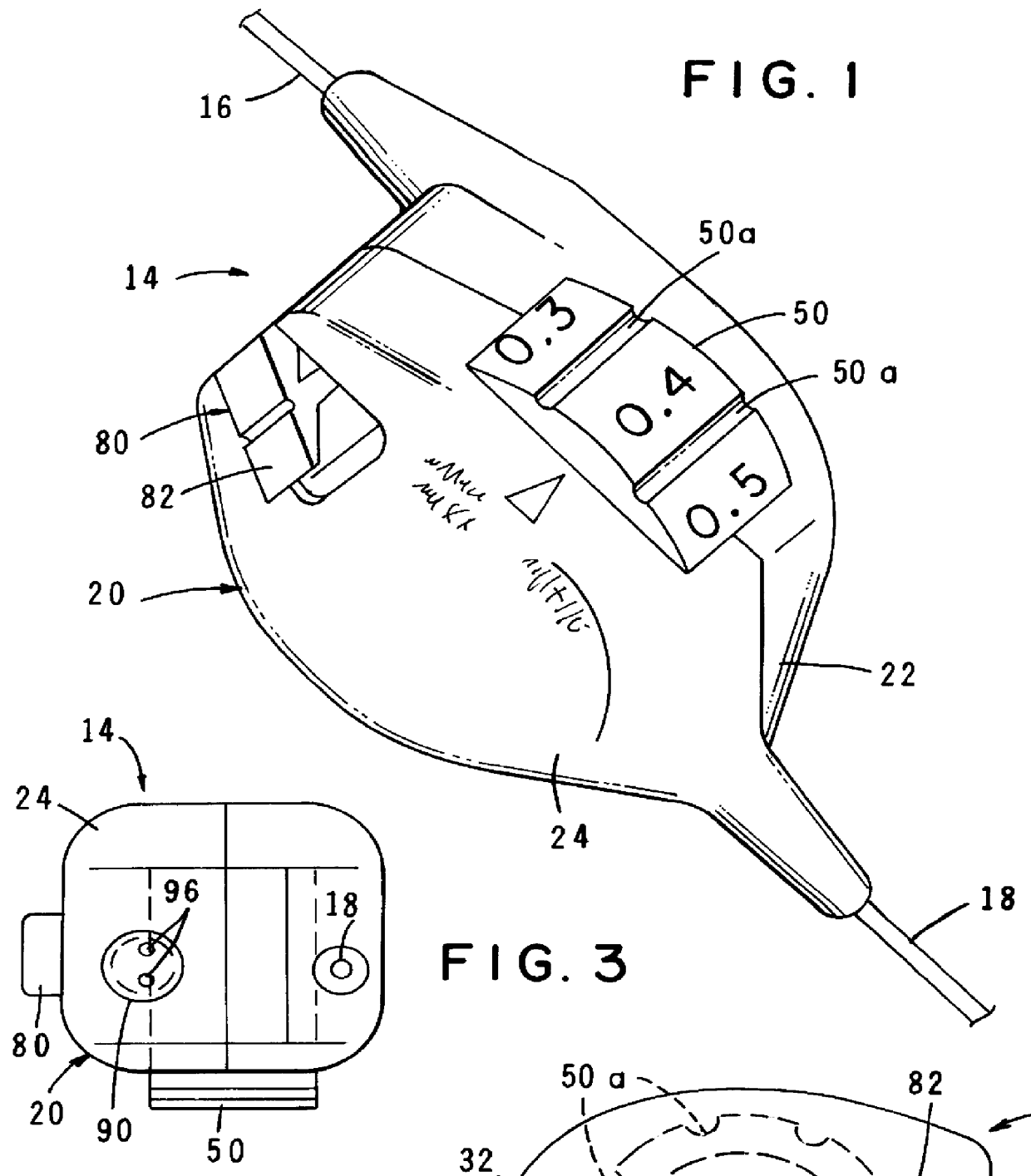

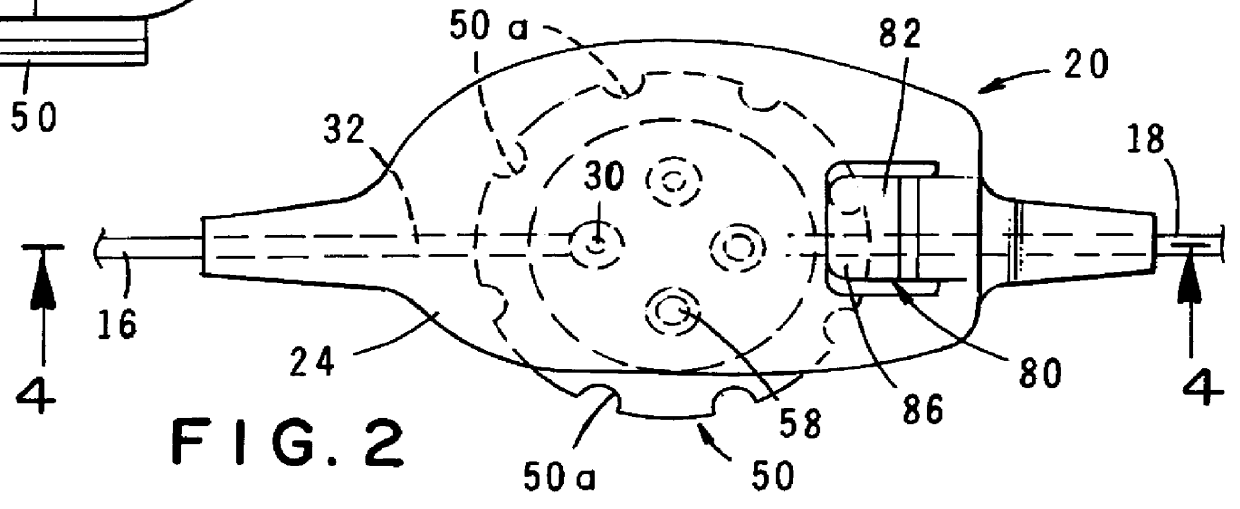

In-line flow rate control device

A readily adjustable flow rate control device having a movable flow control member which includes a plurality of spaced-apart flow restrictors which are adapted to be selectively positioned intermediate a fluid flow path extending between a fluid supply line and a fluid delivery line. The flow restrictors can take the form of porous rate control frits which can be selectively moved into index with the fluid flow path or microbores formed in a rotatable member which can be rotated to selectively move the microbores into index with the fluid flow path.

Owner:PESCADERO BEACH HLDG

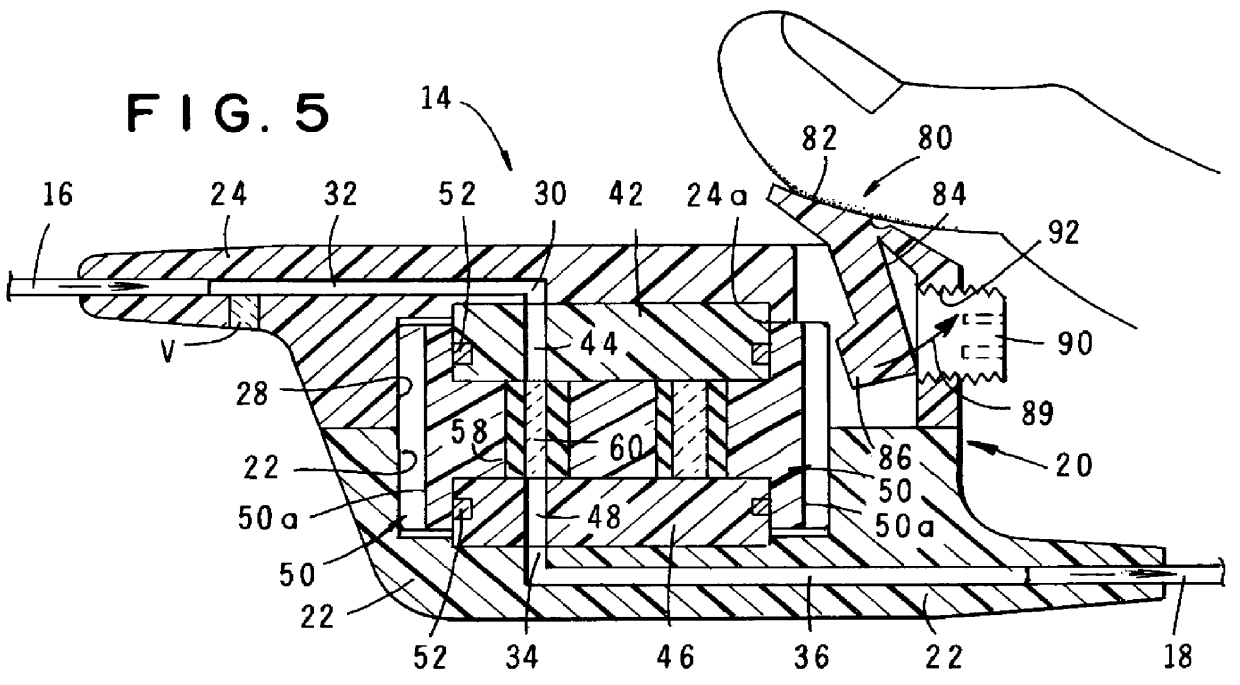

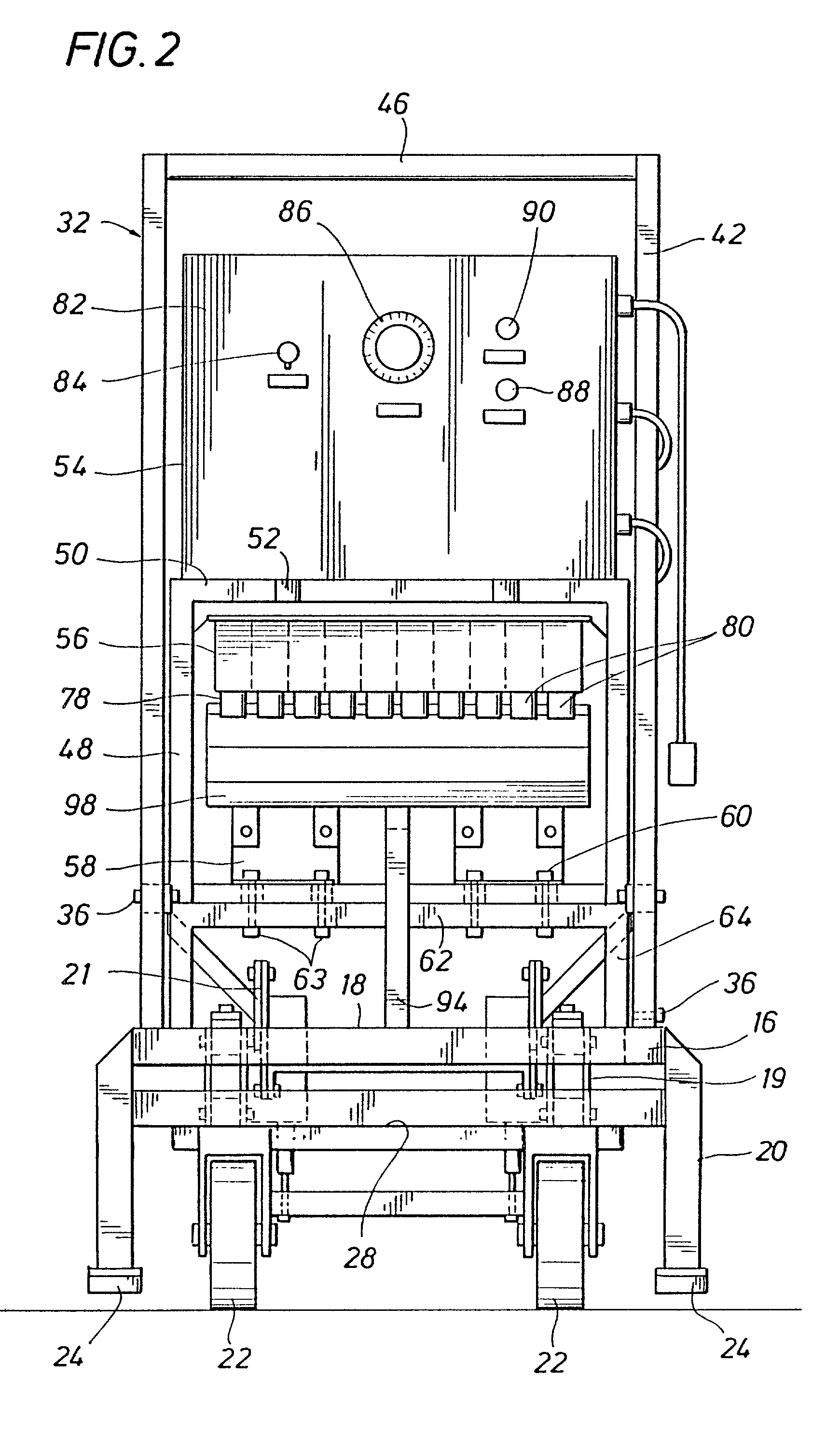

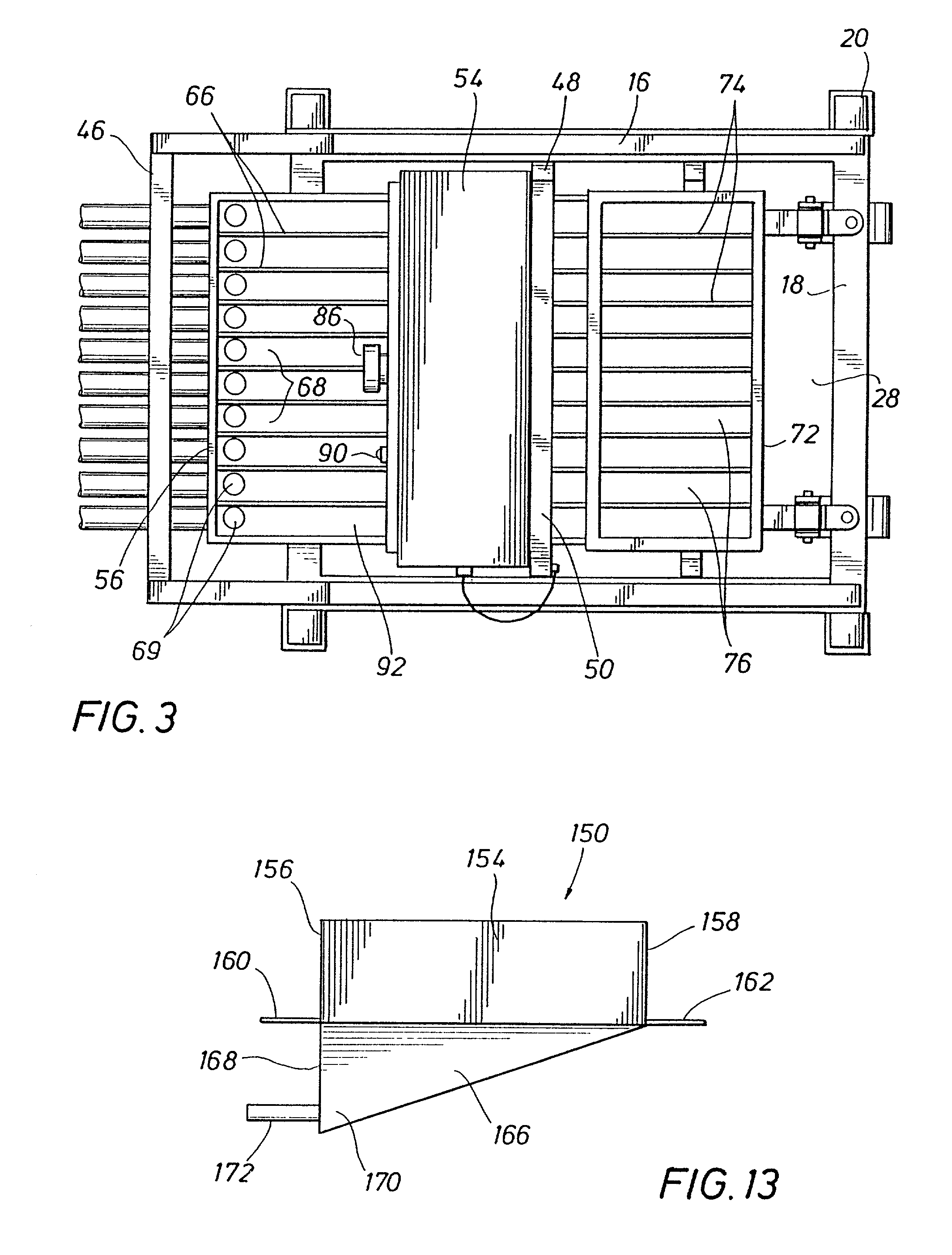

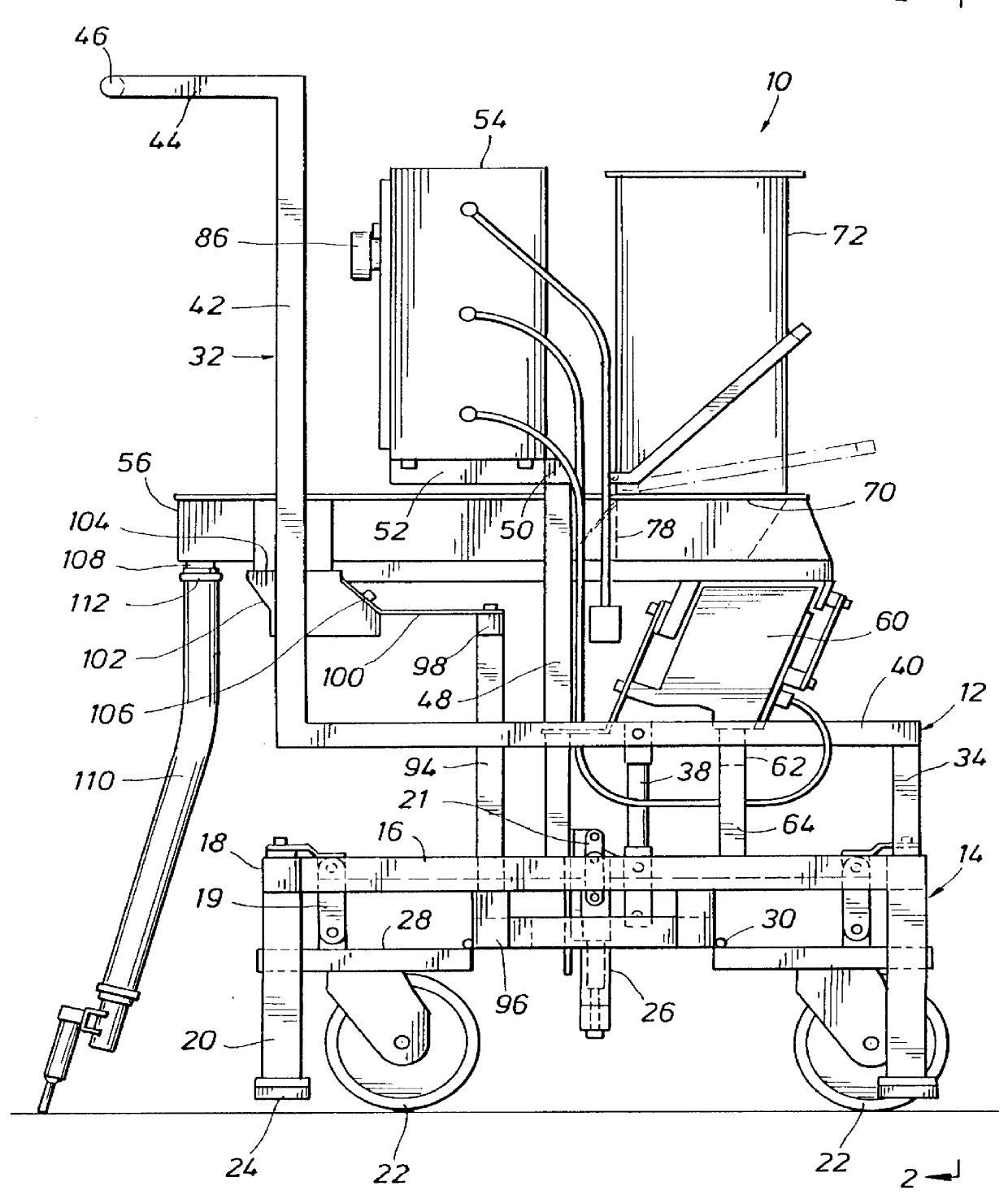

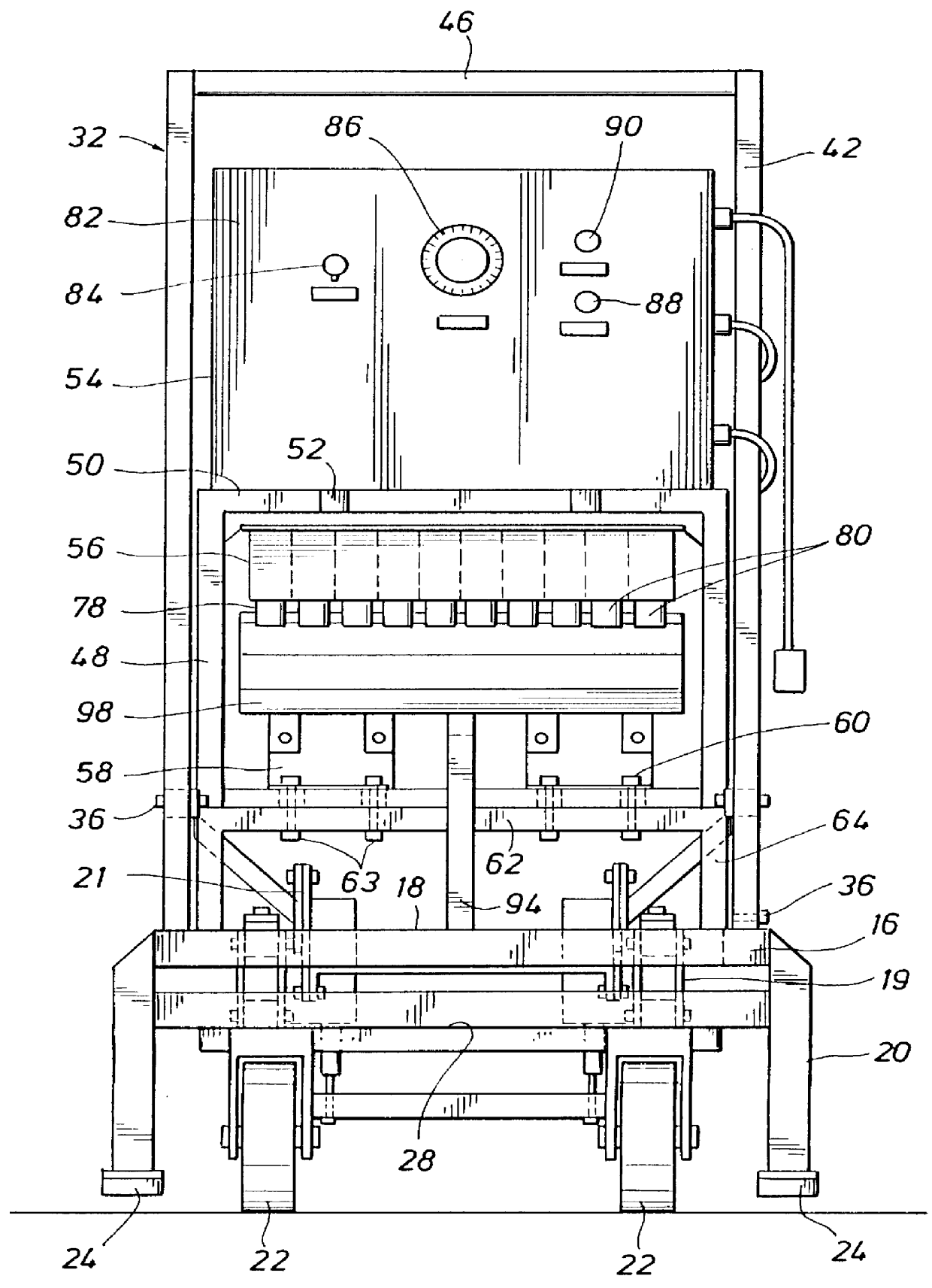

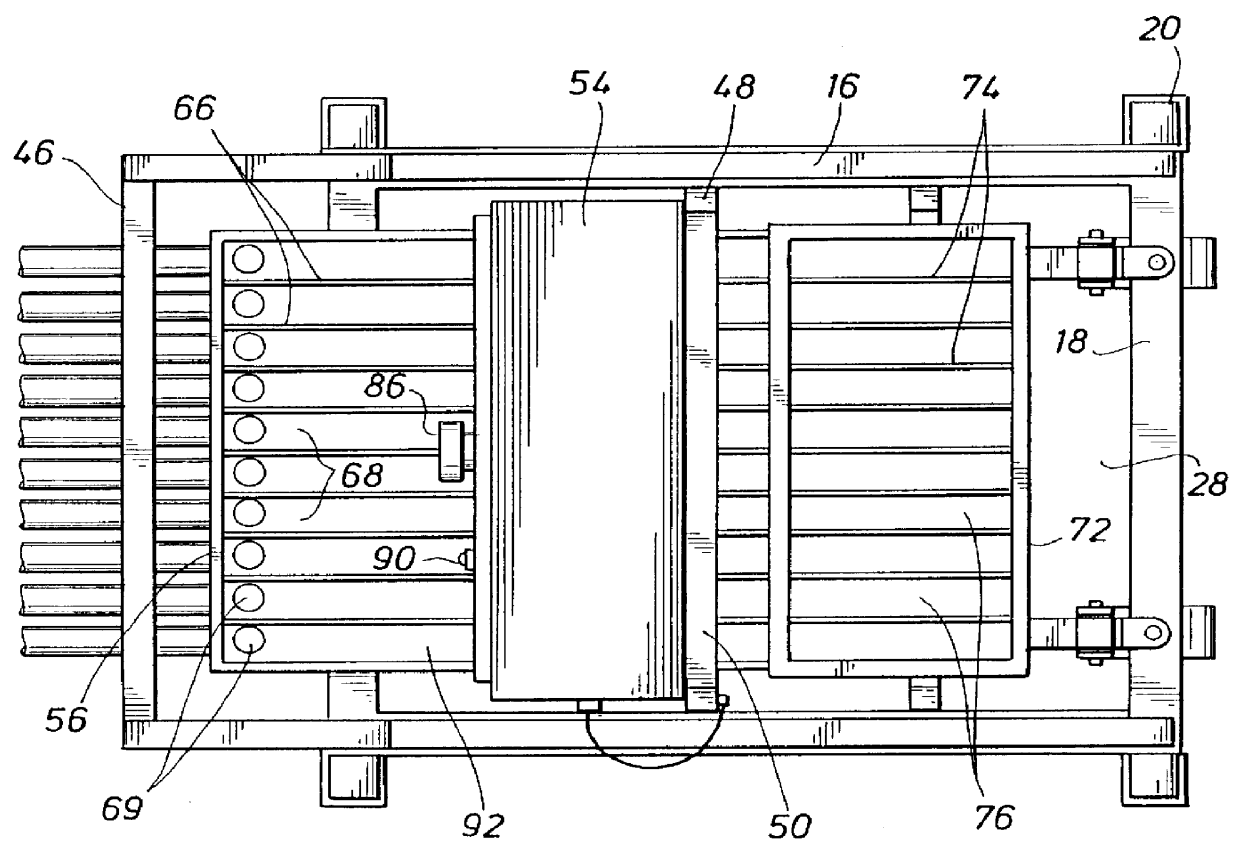

Catalytic reactor charging system and method for operation thereof

InactiveUS20010041117A1Permit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementPtru catalystControl system

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. From the bulk supply, multi-compartment catalyst charging hoppers are individually filled in rapid and accurately measured fashion by mechanized filling equipment having a predetermined sequence of operation that ensures accuracy of volumetric catalyst measurement. The charging hoppers are used for delivery of measured volumes of catalyst of a reactor tube loading mechanism which may take the form of a mobile cart framework being selectively positionable relative to the upper tube sheet and reaction tubes of a catalytic reactor to be charged with catalyst pellets. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. A system is also provided for raising and lowering the charging manifold for efficiency of reactor tube charging operations. An electronic control system is effective for controlling the vibrators to achieve even drop rate from each of the catalyst transfer troughs and to control the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

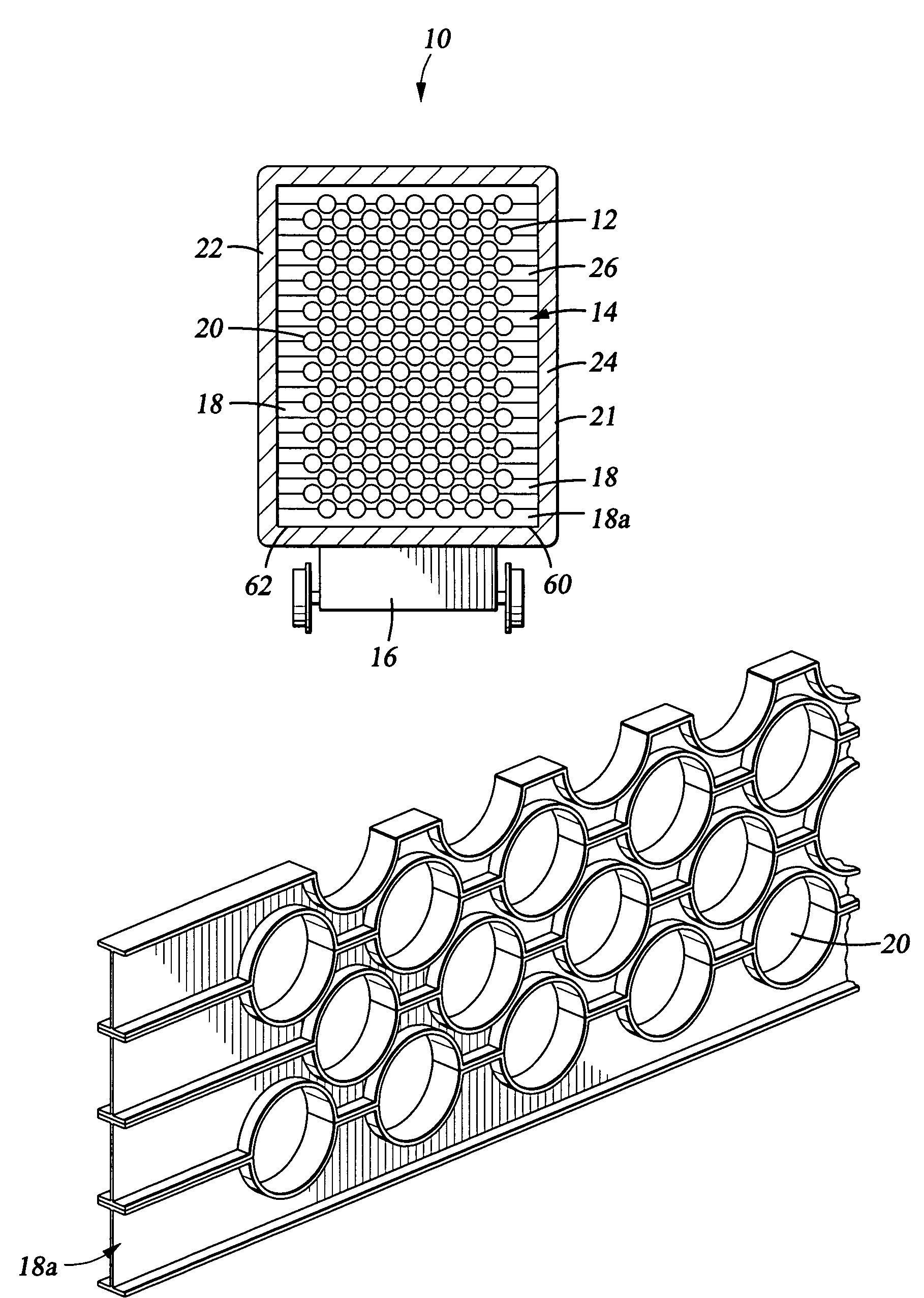

Compressed gas tank carrier assembly

InactiveUS20060061081A1Improve maintainabilityImprove usabilityReactant parameters controlTank vehiclesEngineeringHolding tank

A carrier assembly for a compressed gas storage tank includes a first yoke defining a first concavity, and a second yoke defining a second concavity. The first and second concavities are sufficiently aligned such that a tank is at least partially containable within both the first and second concavities. In an exemplary embodiment, the first yoke also defines a third concavity and the second yoke defines a fourth concavity; the third and fourth concavities are sufficiently aligned such that another tank is at least partially containable therein. Preferably, at least one flexible strap retains the tanks with respect to the yokes.

Owner:GM GLOBAL TECH OPERATIONS LLC

Frac tank storage system

InactiveUS20110109073A1Reduce freight expenseLow costTank vehiclesLarge containersCargo containerAutomotive engineering

Owner:CHRIS WILLIAMS

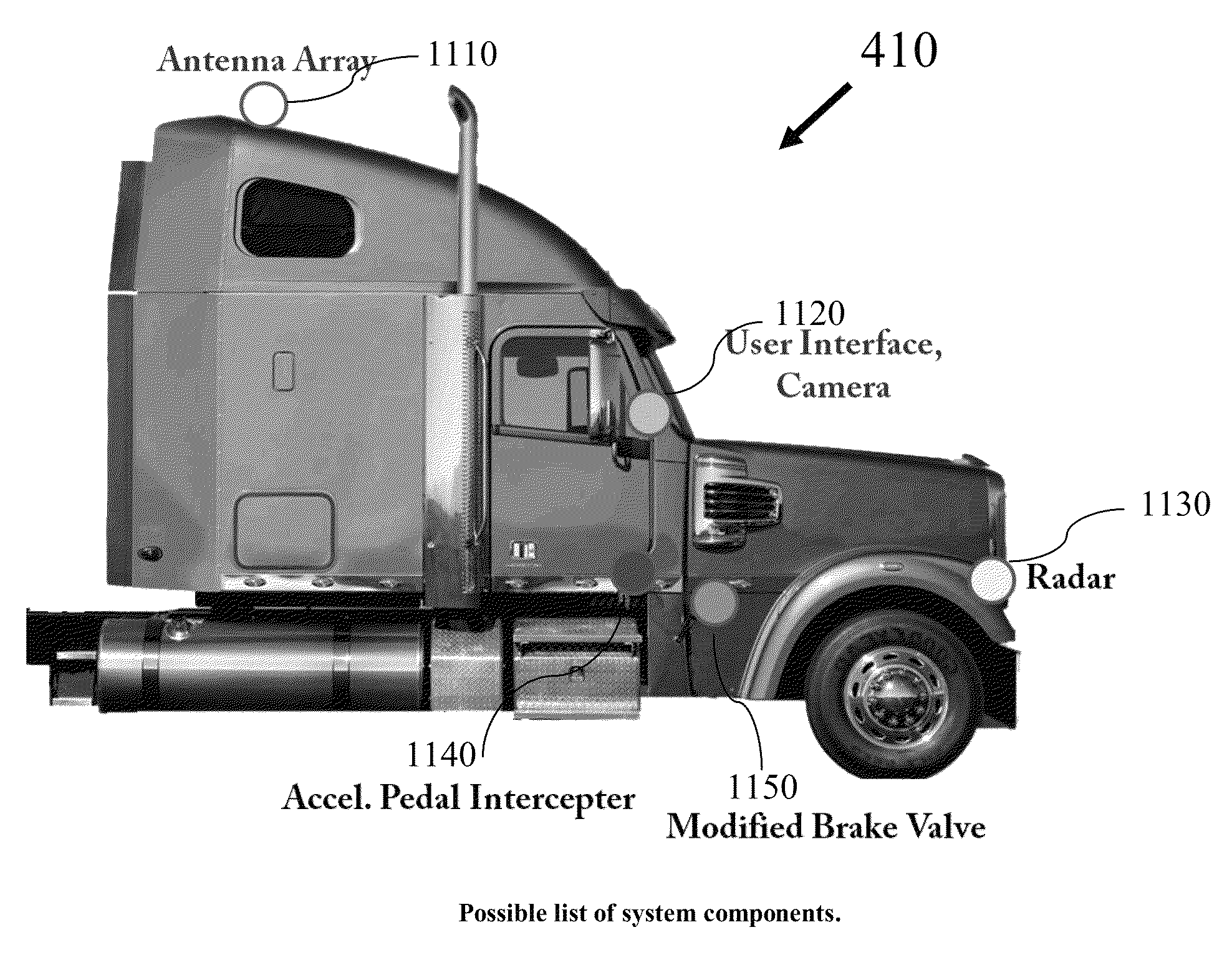

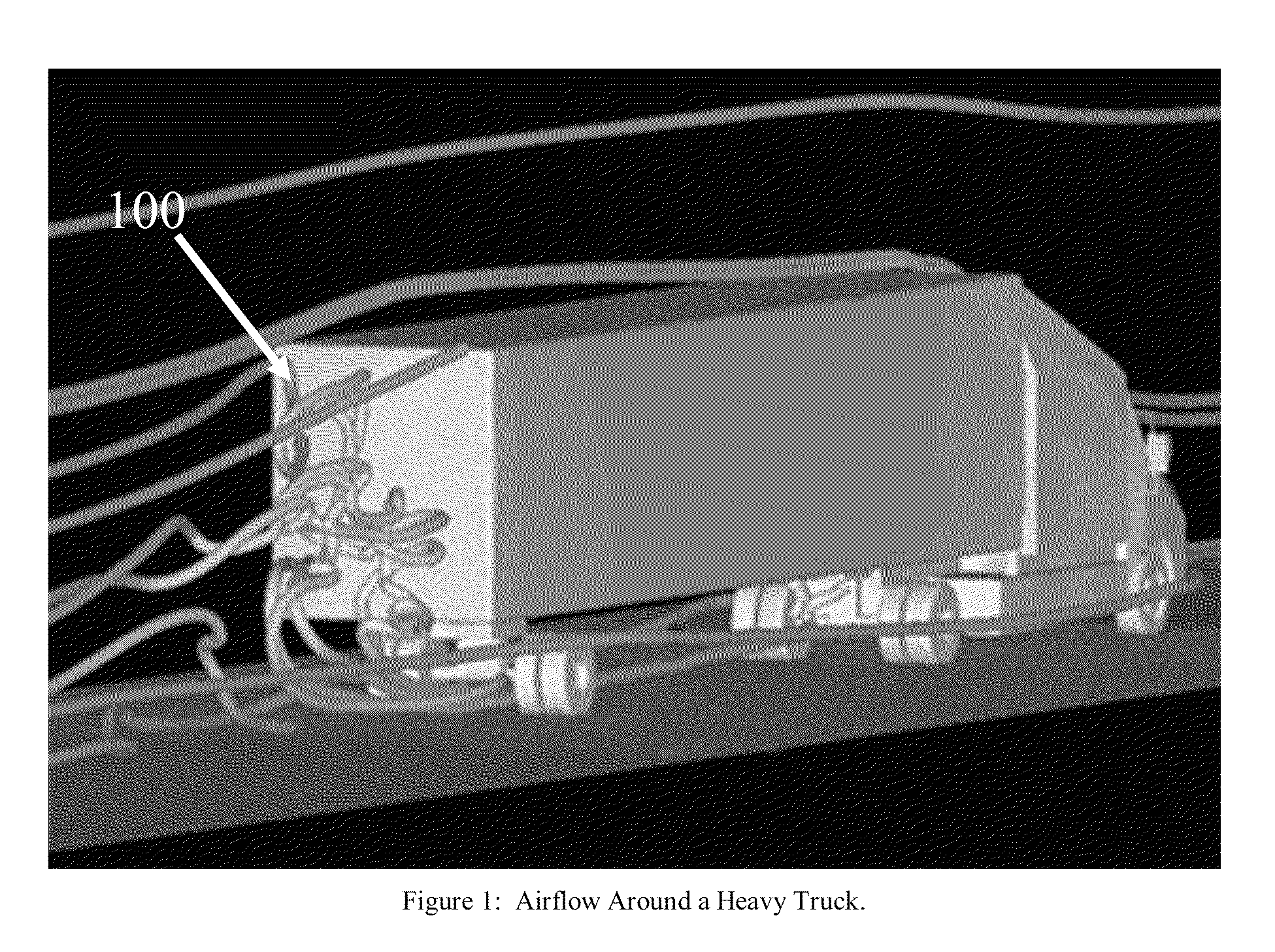

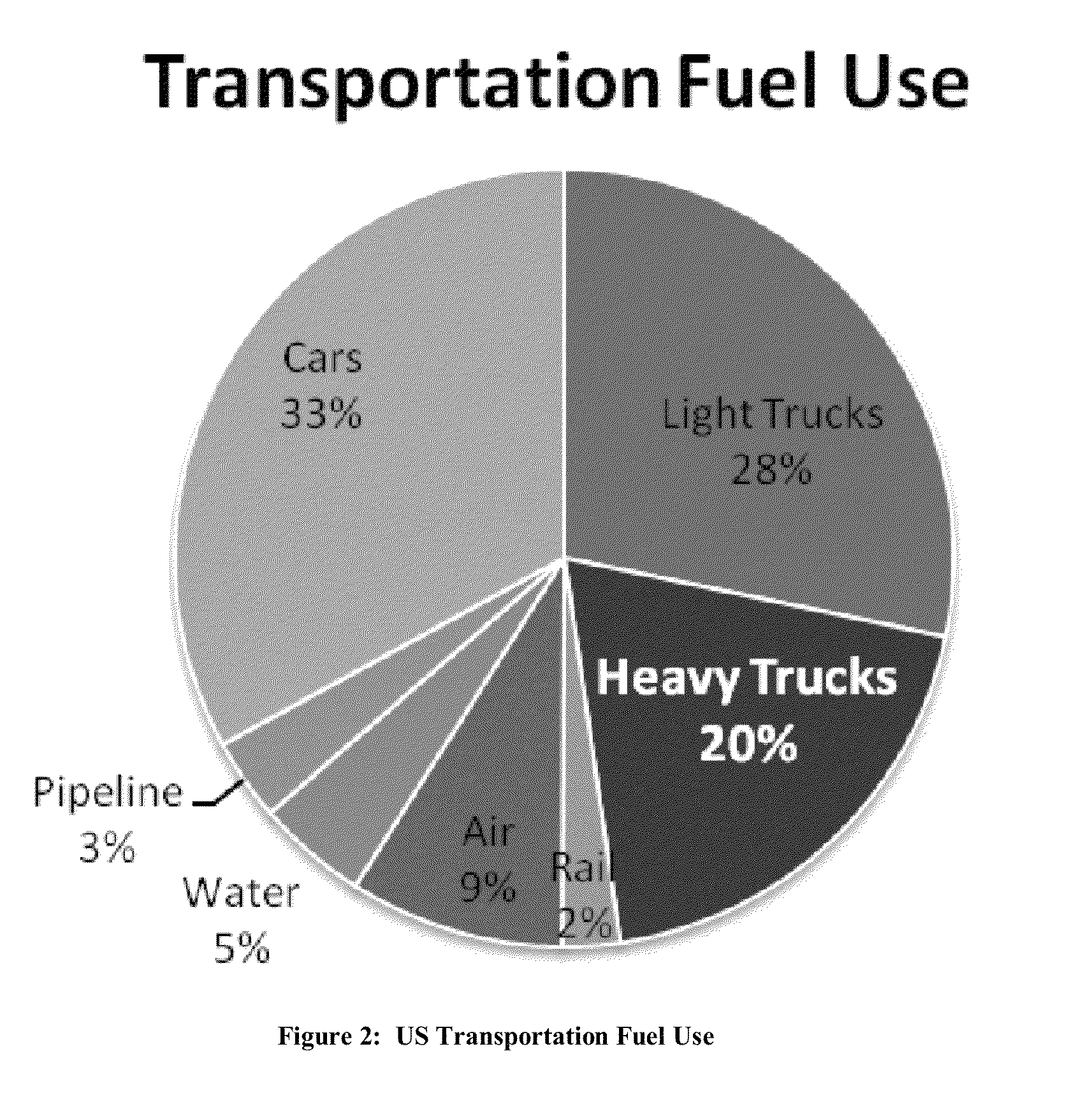

Systems and methods for semi-autonomous vehicular convoys

The present invention relates to systems and methods for vehicles to safely closely follow one another through partial automation. Following closely behind another vehicle has significant fuel savings benefits, but is unsafe when done manually by the driver. On the opposite end of the spectrum, fully autonomous solutions require inordinate amounts of technology, and a level of robustness that is currently not cost effective.

Owner:PELOTON TECH

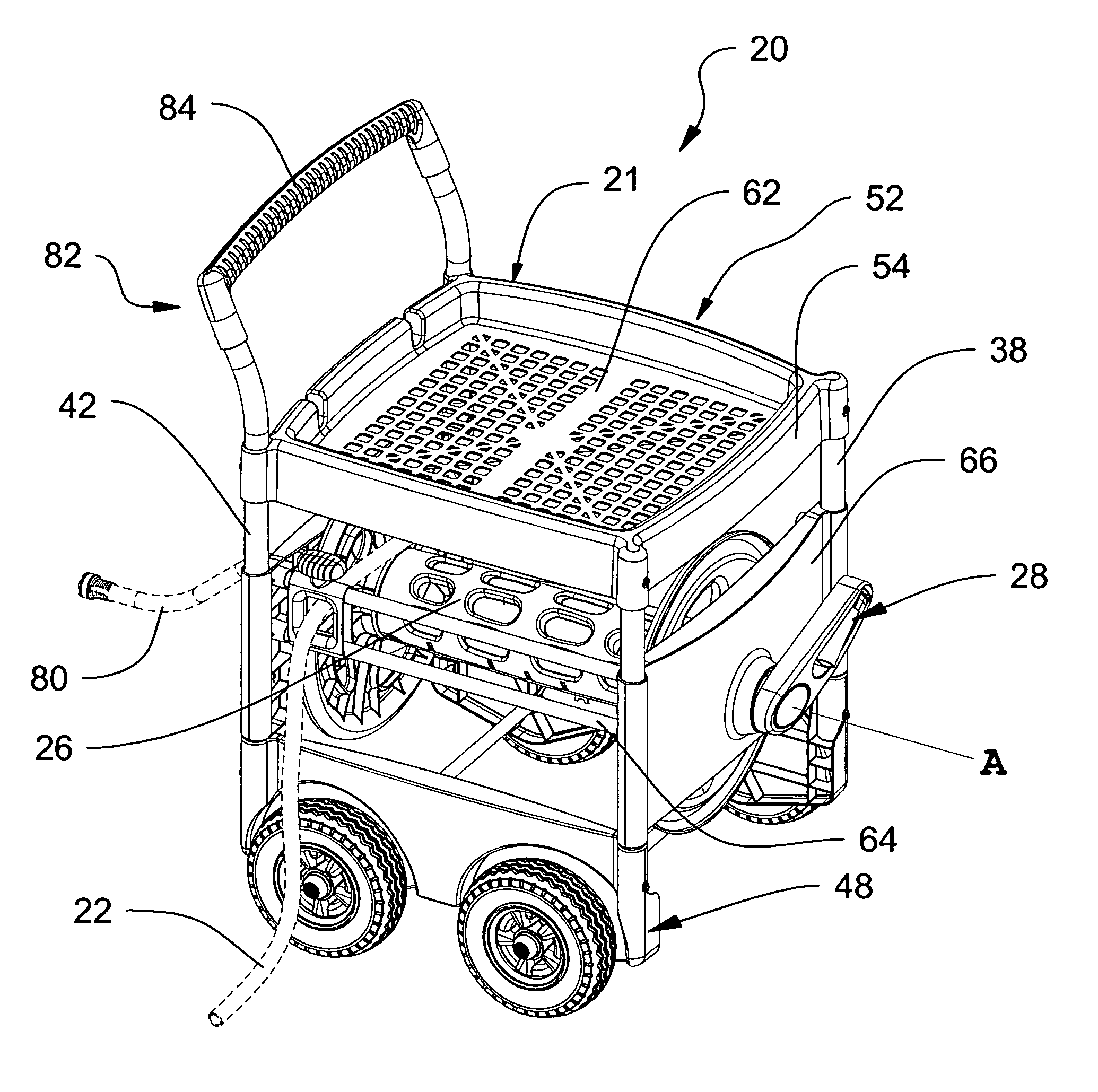

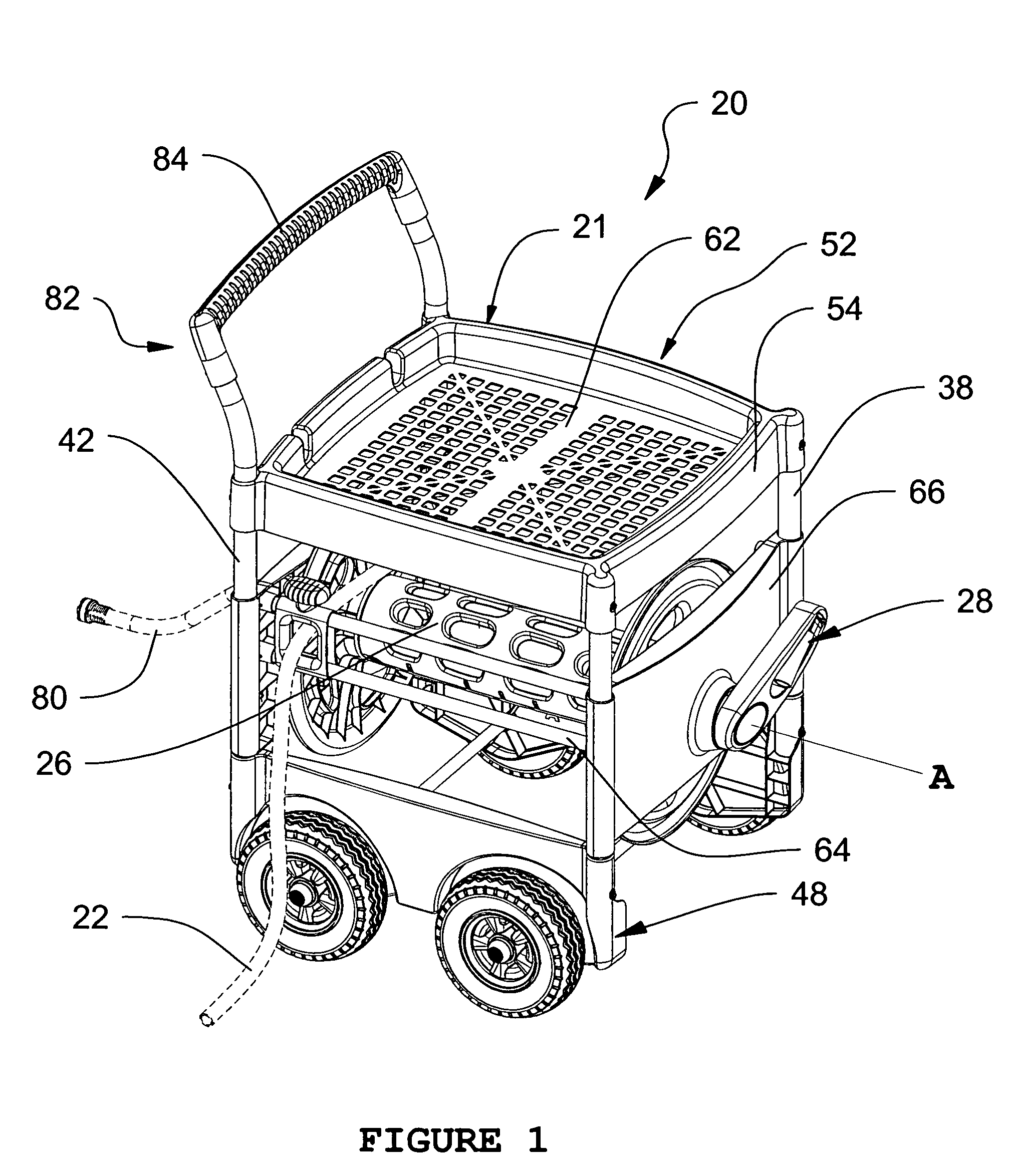

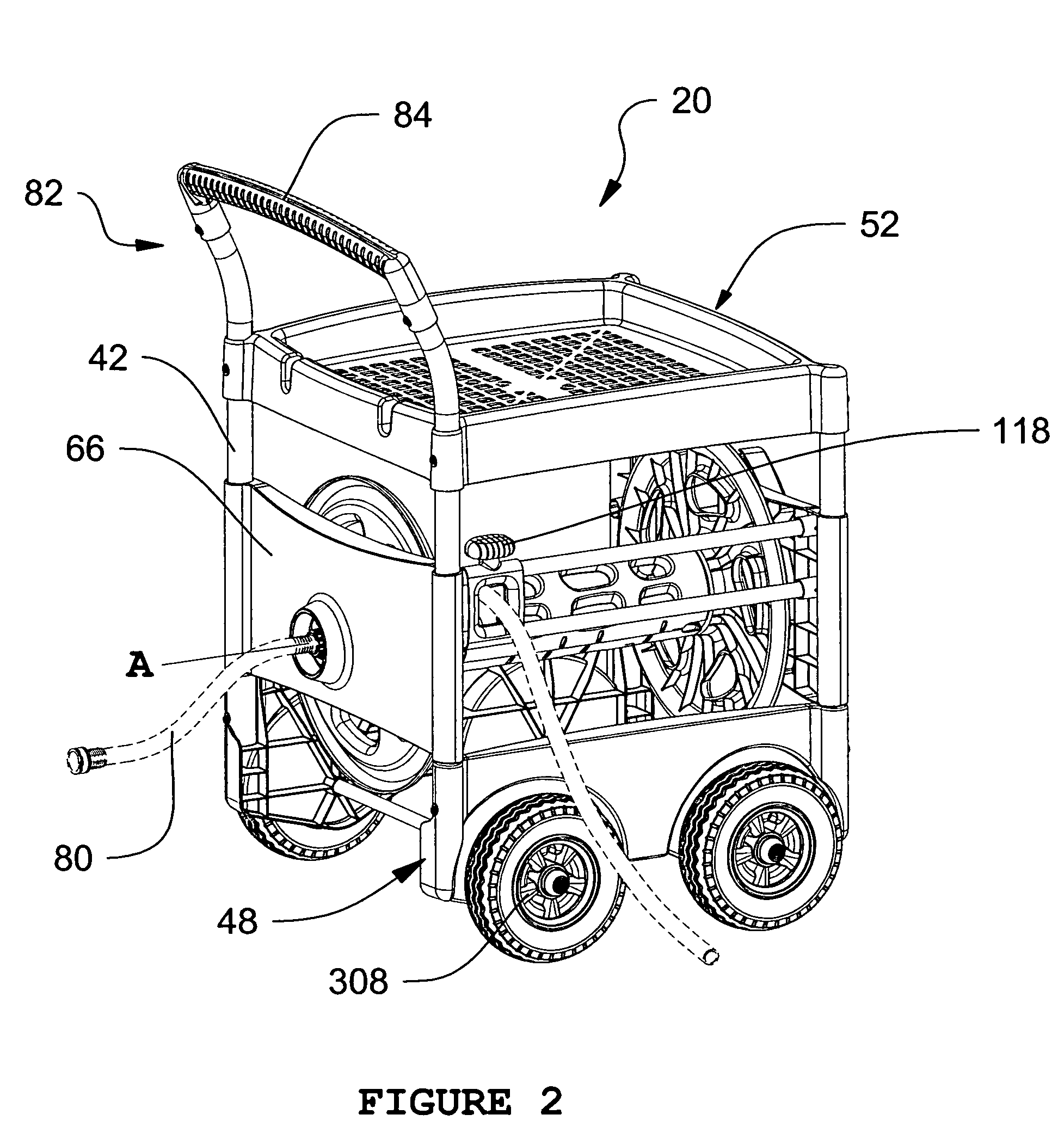

Hose reel cart with tray constructed from plastic and metal structural components

ActiveUS7017603B1Increased durabilityImprove stabilityTank vehiclesWatering devicesEngineeringConductor Coil

The present invention relates to portable hose reel carts for handling and storage of large lengths of flexible hoses, such as garden or air hoses. The cart is constructed of plastic and steel components having a centrally rotatable spool for winding of the flexible hose, a frame for supporting the spool, wheels at each end of the base of the frame, and a handle assembly attached to the frame to facilitate moving the cart. The crank handle assembly which may or may not be foldable for easy storage. The cart includes a large tray for storage and transport of garden supplies.

Owner:SUNCAST

Catalytic reactor charging system and method for operation thereof

InactiveUS6132157APermit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementStructural elementProcess engineering

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold which can be raised and lowered has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. An electronic control system controls the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

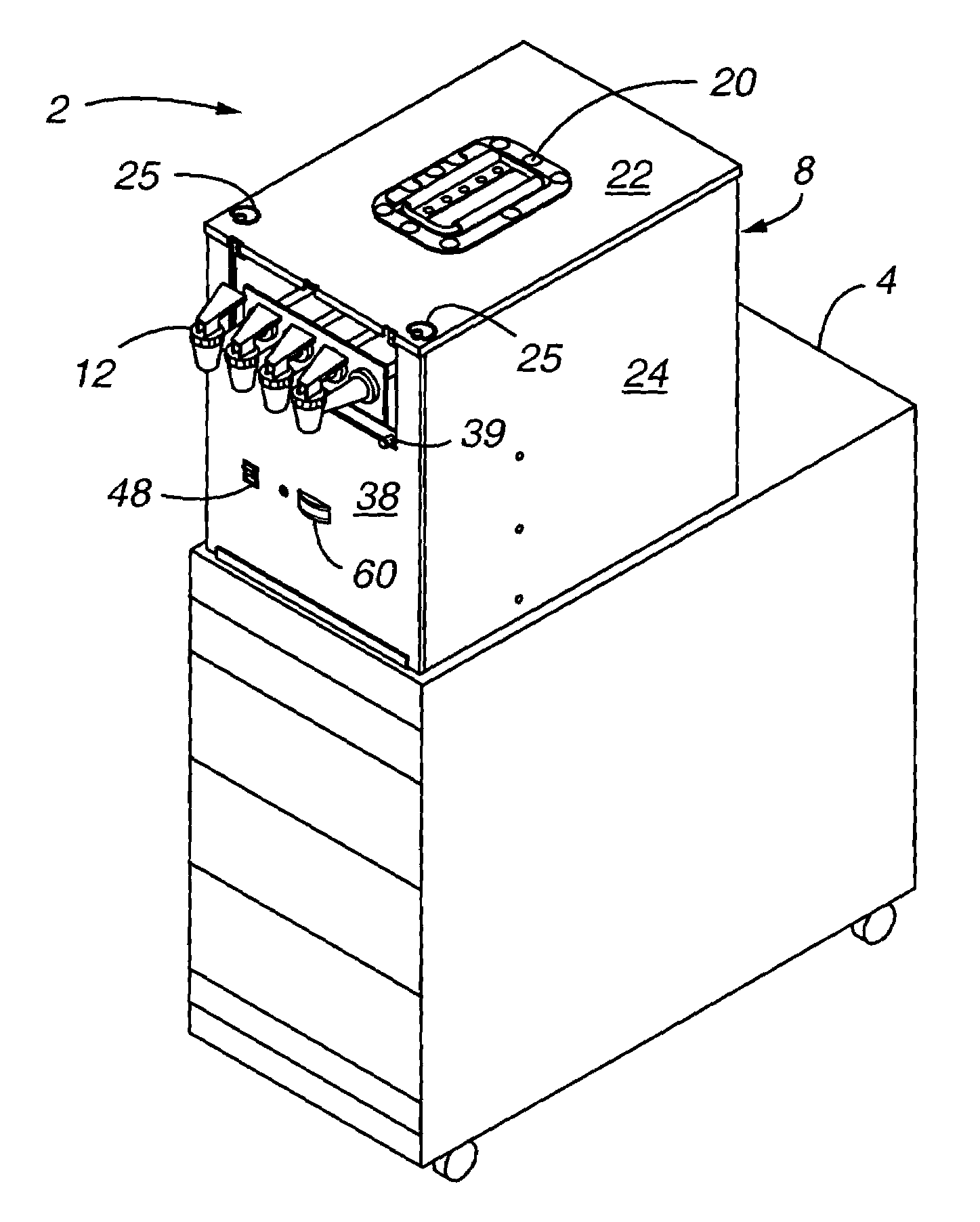

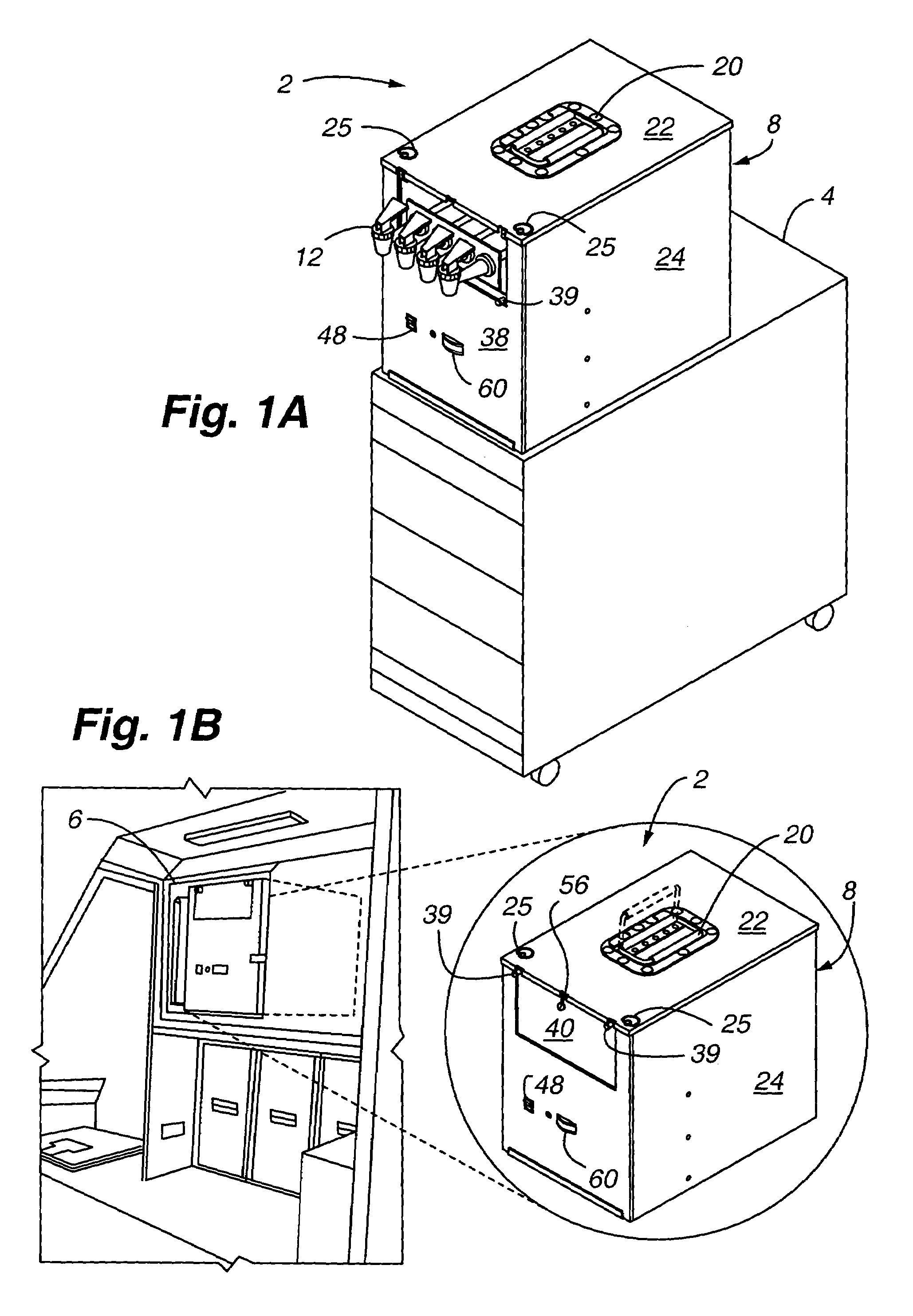

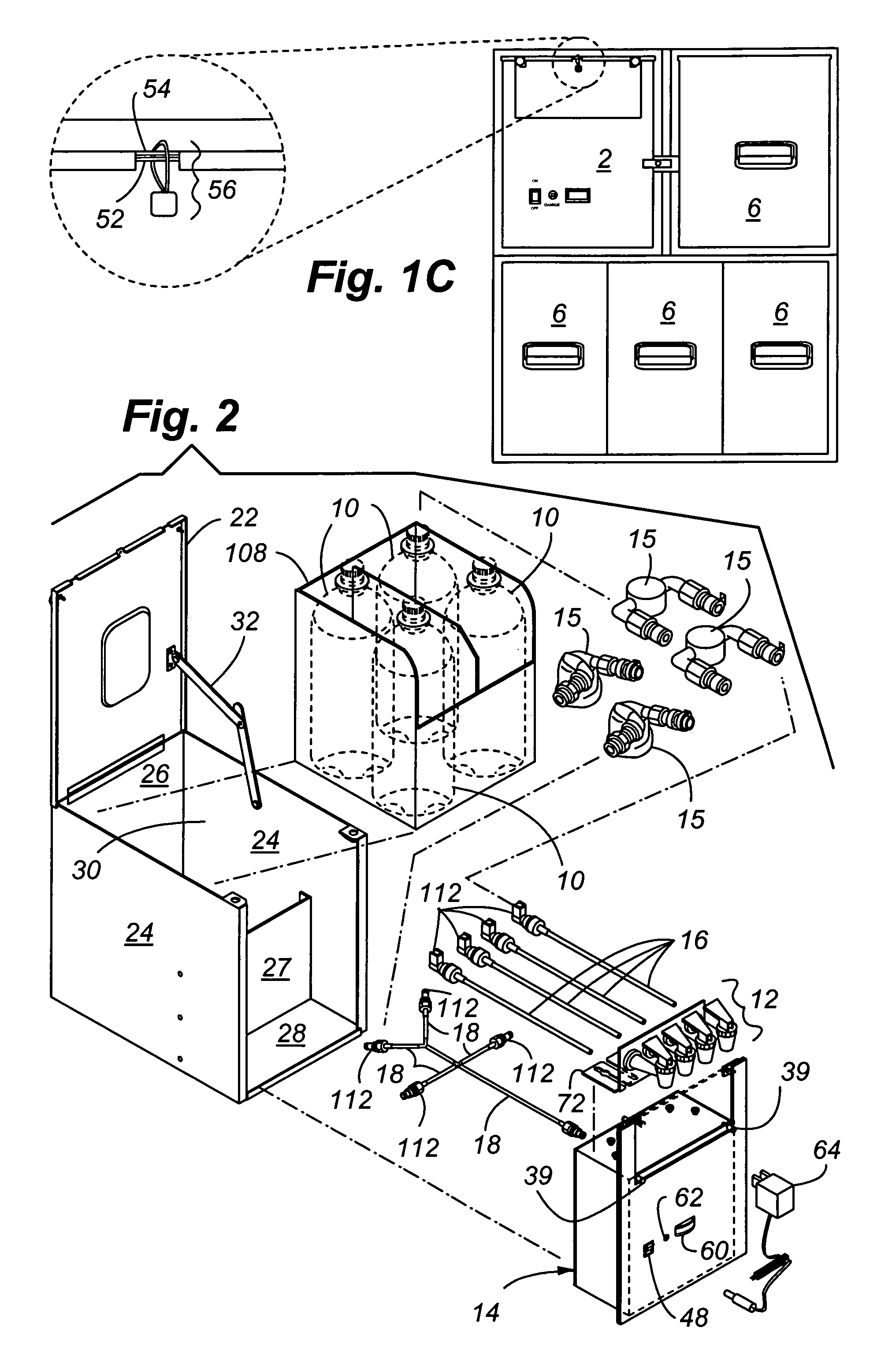

Self-contained beverage dispensing apparatus

InactiveUS7044335B2Minimizes beverage wasteLow costOpening closed containersBottle/container closureEngineering

A self-contained beverage dispensing apparatus, which is adapted for commercial and / or home use as an alternative to traditional canned beverage service, is provided. In one embodiment, the beverage dispensing apparatus is highly portable and of sufficient dimension to be positioned on a conventional airline beverage cart and stored in an aircraft's cargo storage compartment. In one embodiment, the beverage dispensing apparatus can be selectively locked and secured with a mechanism that will indicate whether any pre-flight tampering has occurred. In one embodiment, the beverage dispensing apparatus is further comprised of at least one beverage dispensing mechanism that can be extended from within the housing for use and later retracted for storage. In one embodiment, the beverage dispensing apparatus can be used with beverage containers with mouths of varying sizes.

Owner:SIP SYST

Collection tank

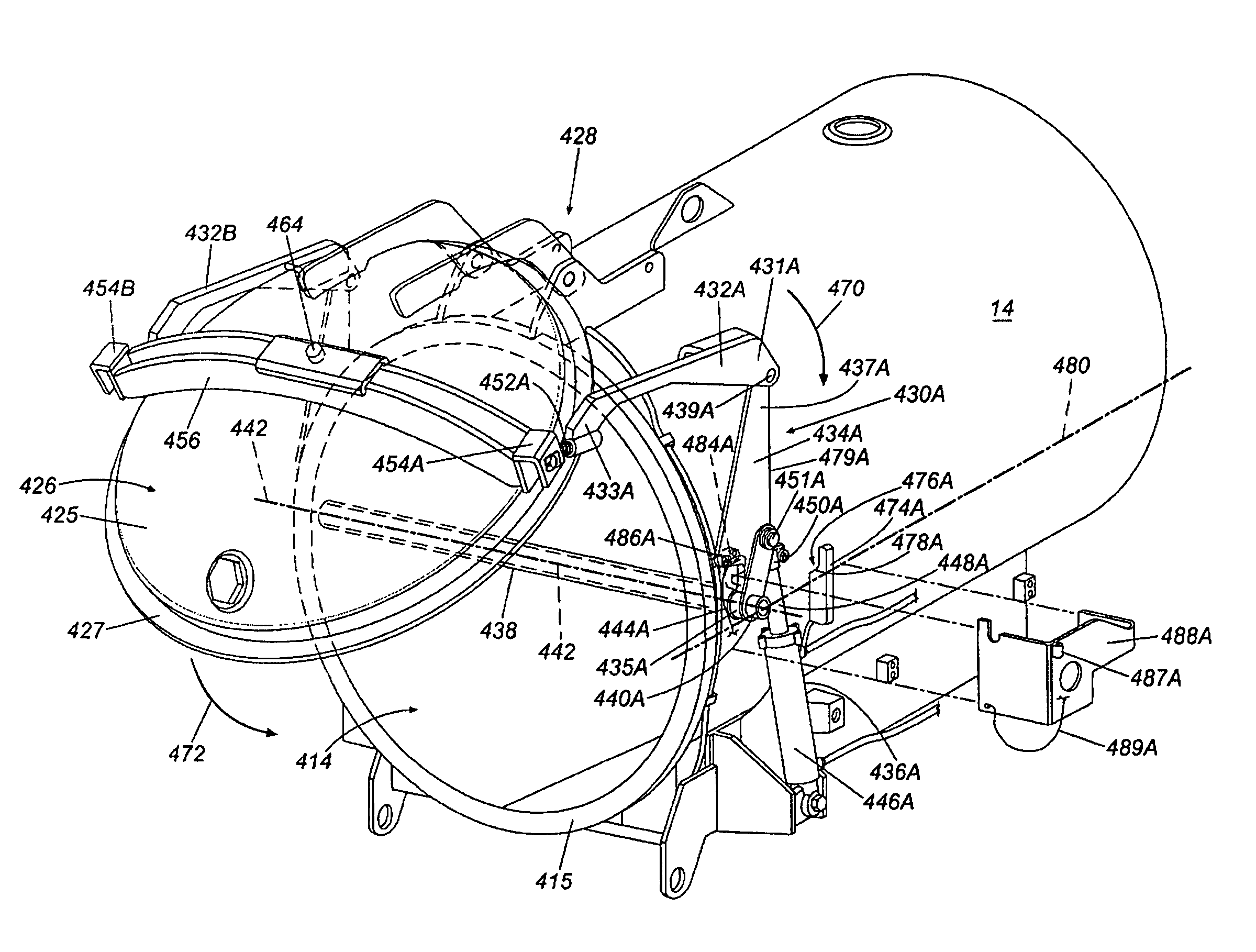

A collection tank for use in a vacuum operated earth reduction system, the collection tank comprising a closed first end, an open second end defining a tank sealing flange and a body extending between the closed first end and the open second end. An internal chamber defined by the body, the closed first end and the open second end has a door coupled to the open second end and is configured to releasably seal the open second end. An automated door closer is coupled to a center of the door, wherein the automated door closer provides a closing force at the center of the door so that the closing force is equally distributed about a periphery of the door to seal the door against the tank sealing flange.

Owner:VERMEER MFG CO

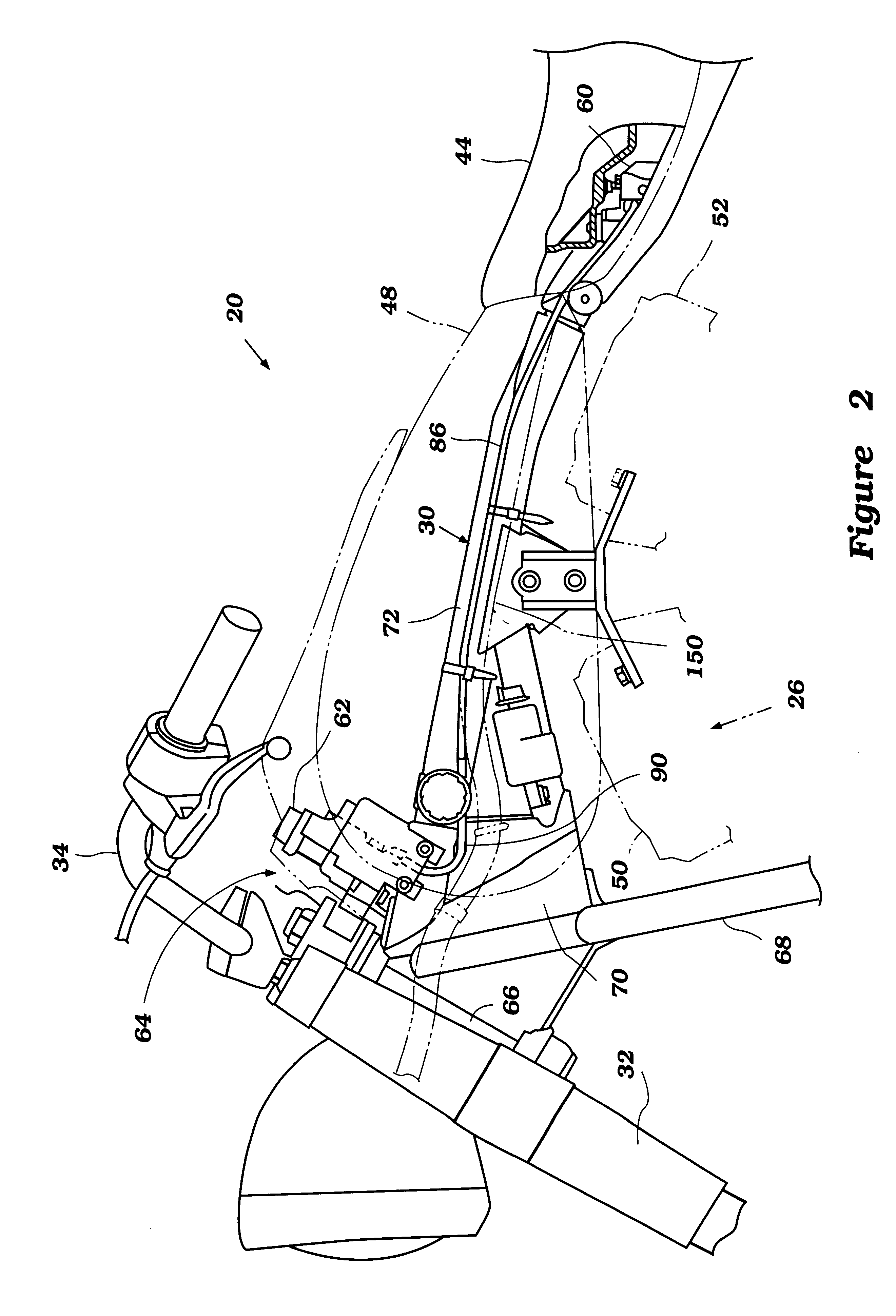

Locking arrangement for motorcycle

A motorcycle includes an integrated locking system. The locking system actuates a seat lock from the main switch as well as a handlebar or steering lock. The steering lock is structured such that an overlap of components results in a locking pin passage that extends into a locking pin chamber. The locking pin passage is substantially shielded by a labyrinth defined by overlapping components. The main switch is positioned forward of at least one gauge and a meter cover surrounds at least the gauge and the main switch as well as covers at least a portion of the fuel tank.

Owner:YAMAHA MOTOR CO LTD

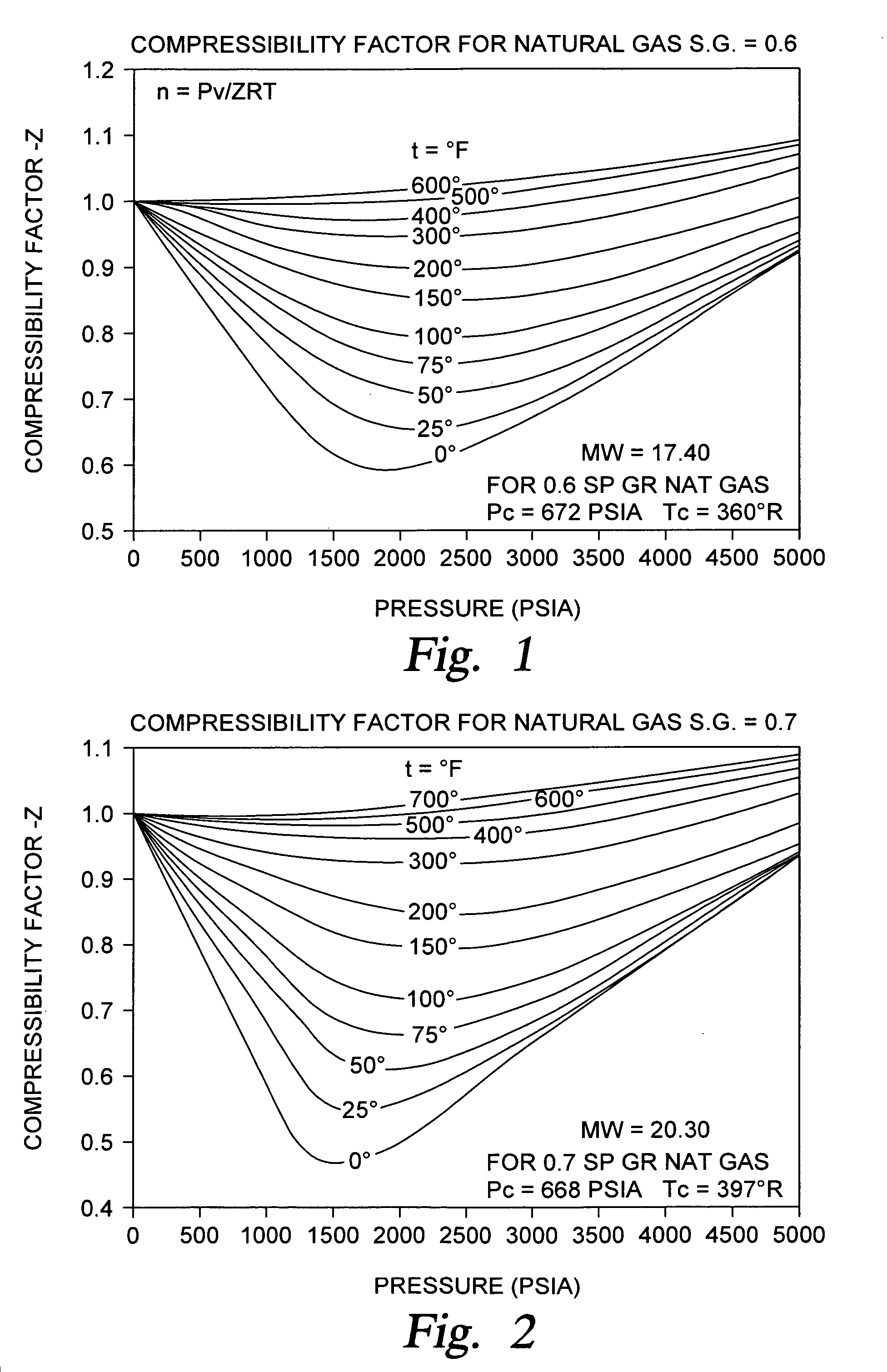

Modular system for storing gas cylinders

InactiveUS6994104B2High procedureIncrease profitabilitySolidificationLiquefactionSystems designGas cylinder

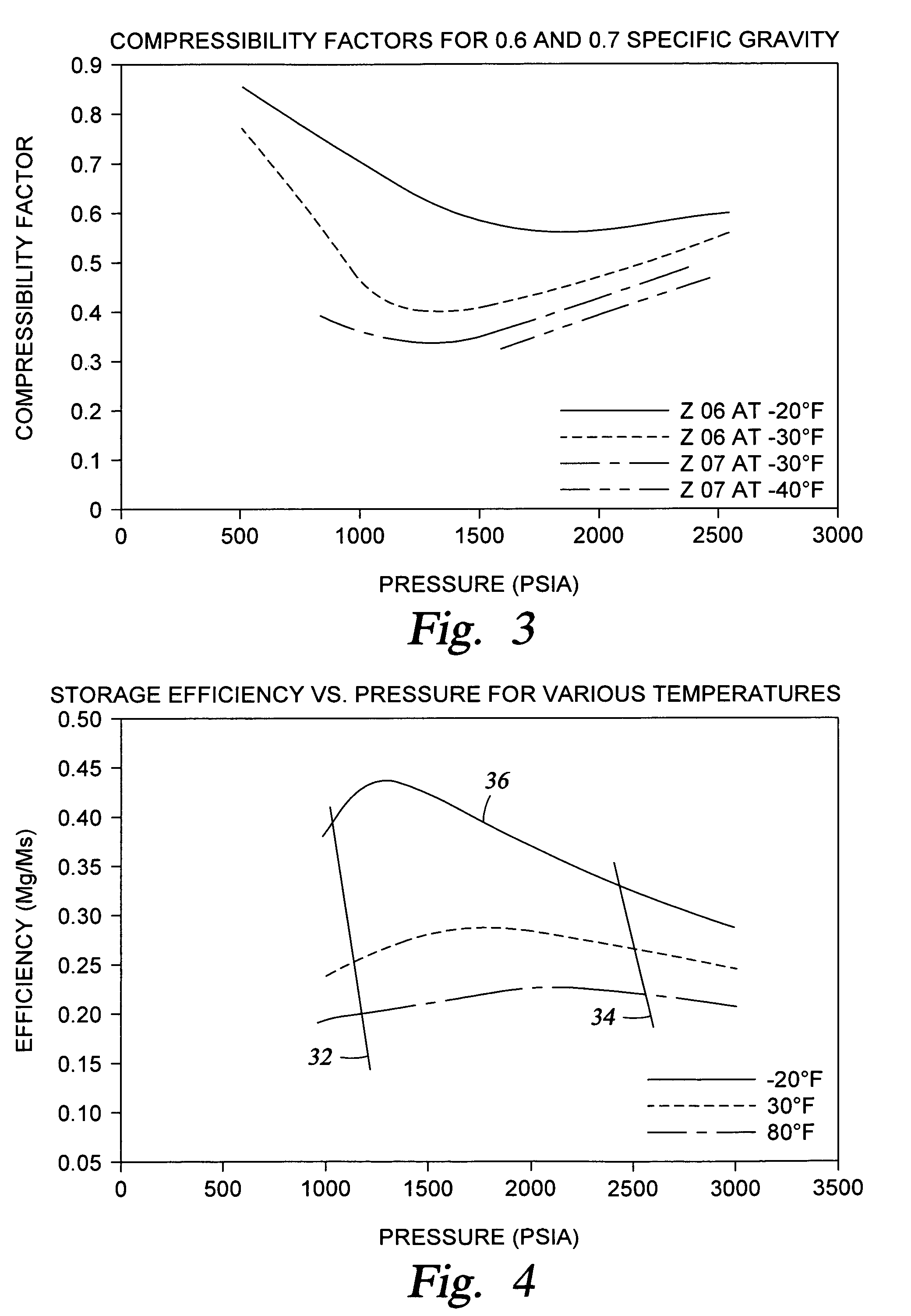

The methods and apparatus for transporting compressed gas includes a gas storage system having a plurality of pipes connected by a manifold whereby the gas storage system is designed to operate in the range of the optimum compressibility factor for a given composition of gas. The pipe for the gas storage system is preferably large diameter pipe made of a high strength material whereby a low temperature is selected which can be withstood by the material of the pipe. Knowing the compressibility factor of the gas, the temperature, and the diameter of the pipe, the wall thickness of the pipe is calculated for the pressure range of the gas at the selected temperature. The gas storage system may either be modular or be part of the structure of a vehicle for transporting the gas. The gas storage system further includes enclosing the pipes in an enclosure having a nitrogen atmosphere. A displacement fluid may be used to offload the gas from the gas storage system. A vehicle with the gas storage system designed for a particular composition gas produced at a given location is used to transport gas from that producing location to a receiving station miles from the producing location.

Owner:ENERSEA TRANSPORT

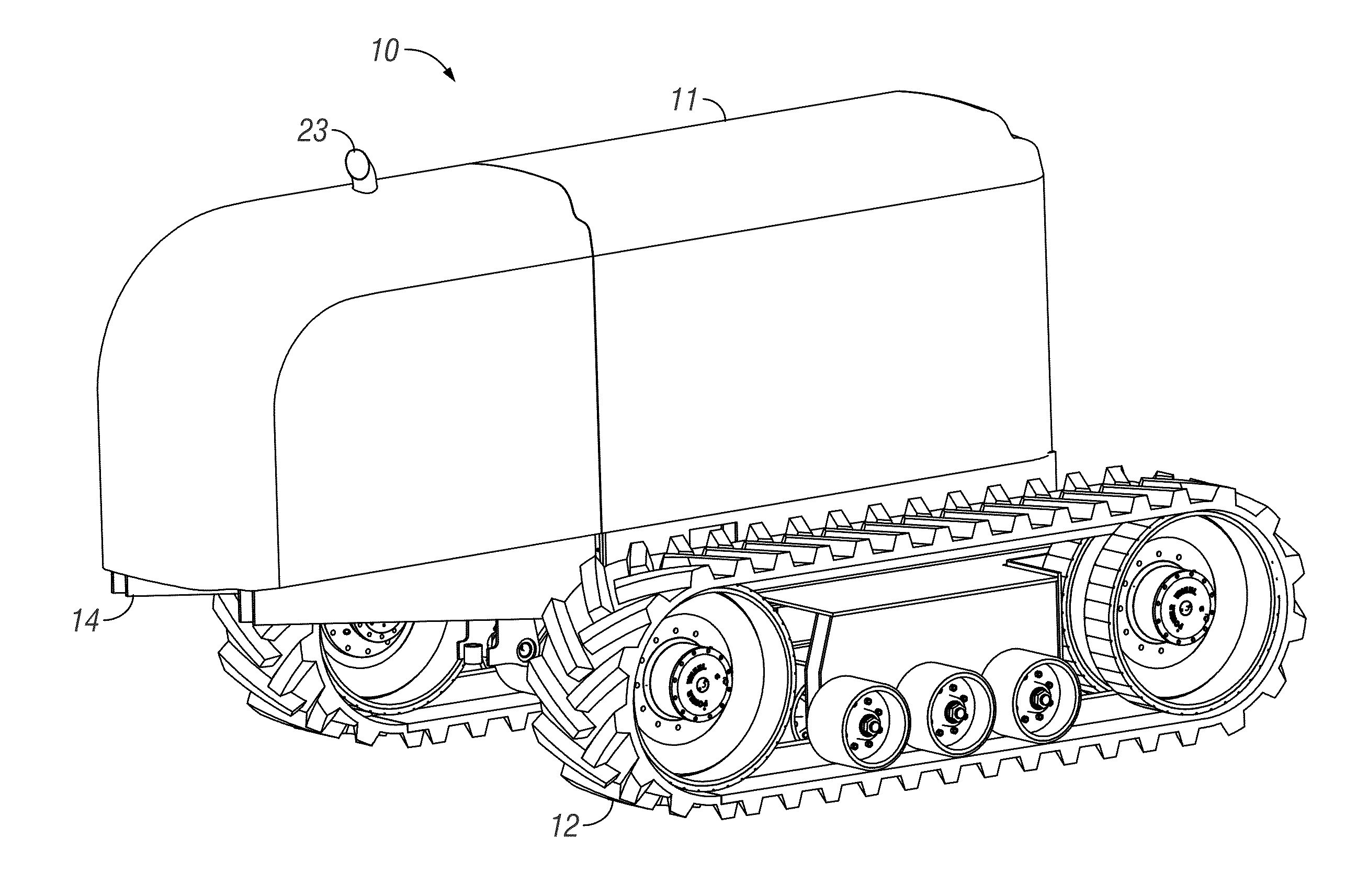

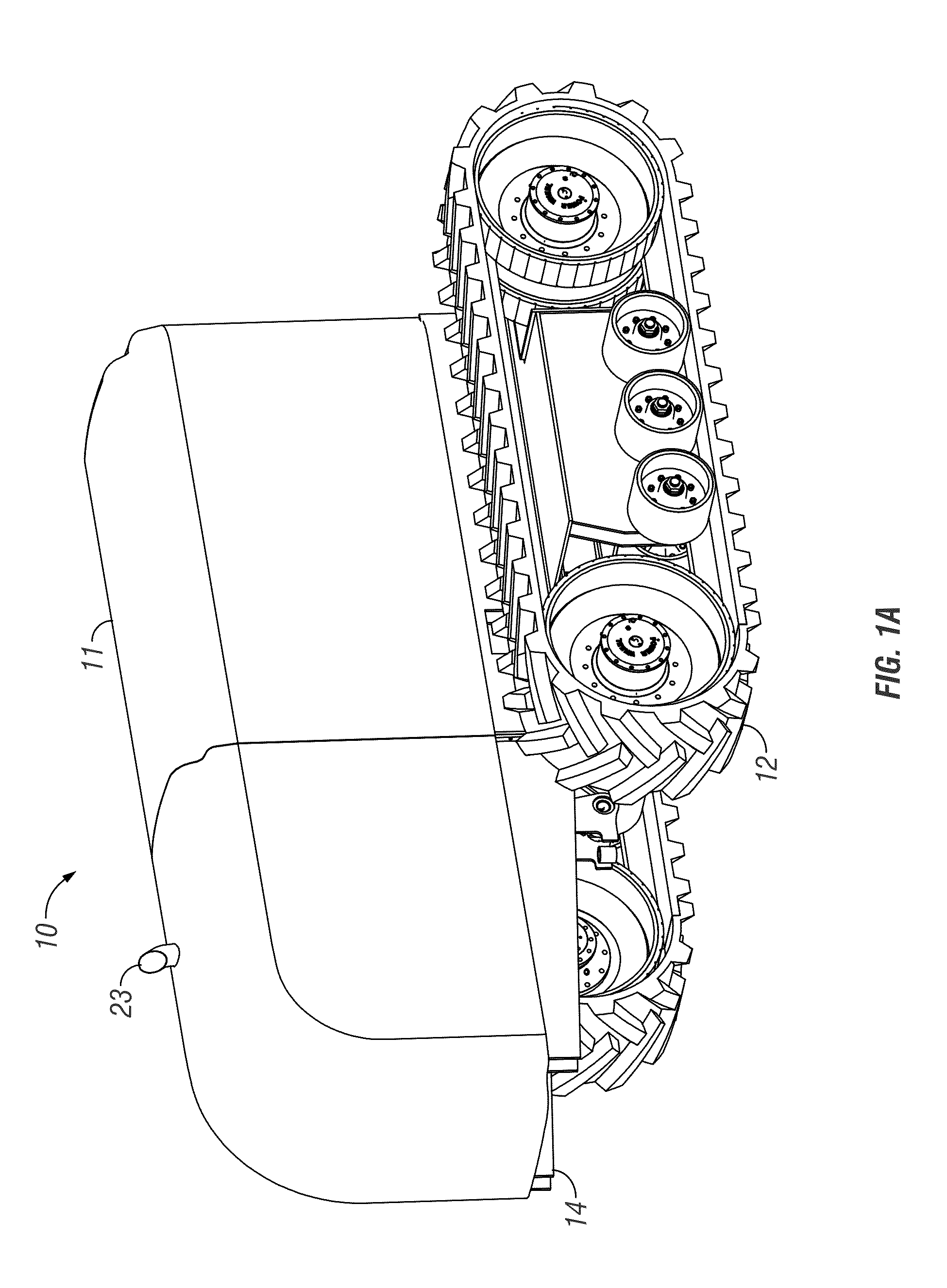

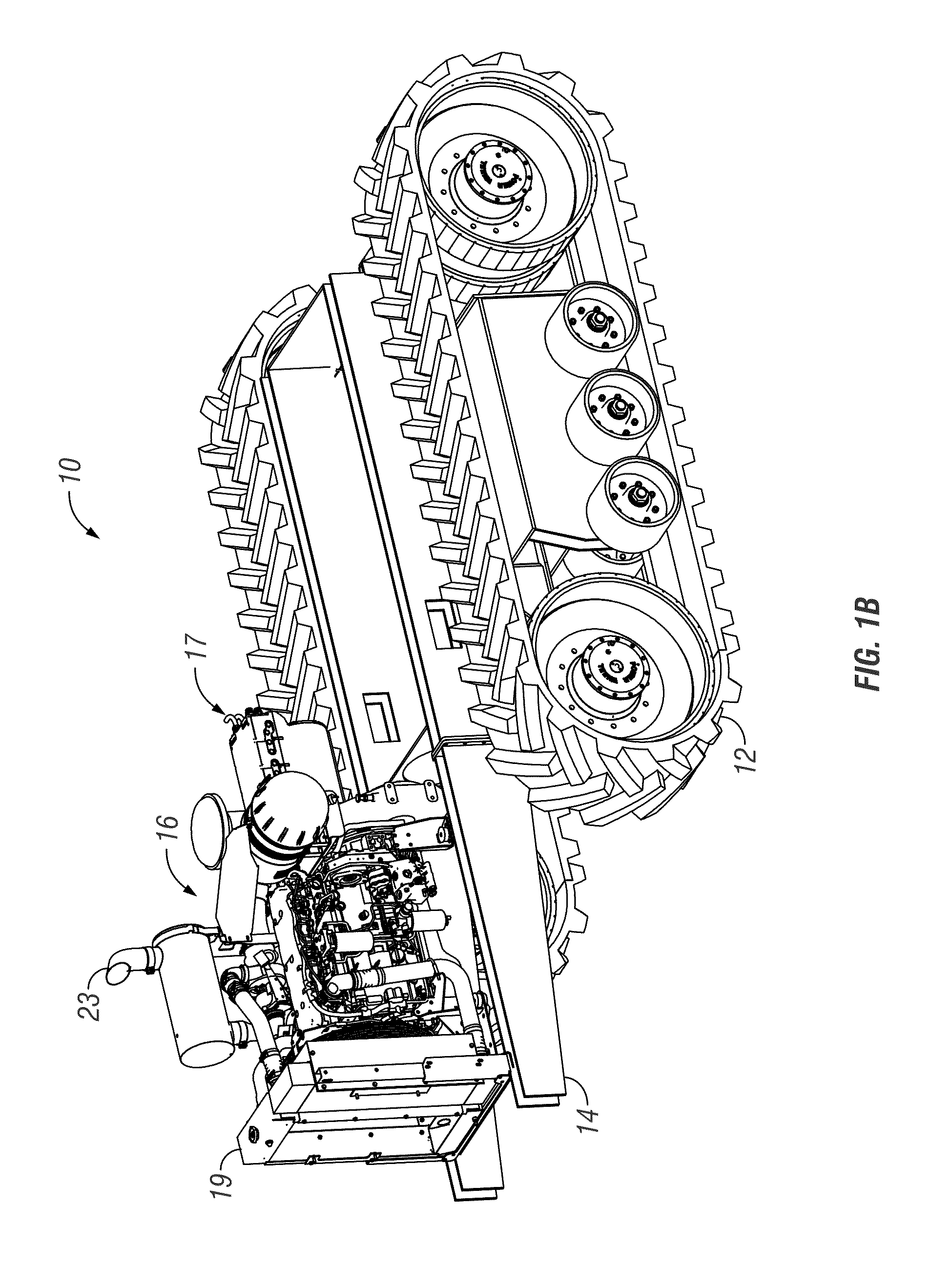

Autonomous systems, methods, and apparatus for ag based operations

ActiveUS20150105965A1Overcome deficienciesAmount of timeAgricultural machinesTank vehiclesOrbitAutopilot

The use of self-powered, autonomous vehicles in agricultural and other domestic applications is provided. The vehicles include a self-propelled drive system, tracks or wheels operatively connected to the drive system, a power supply operatively connected to the drive system, an attachment mechanism for attaching equipment to the vehicle, and an intelligent control operatively connected to the drive system, power supply, and attachment mechanism. The vehicle is configured to connect to the equipment to perform agricultural operations based upon the equipment. Multiple vehicles can be used in a field at the same time. Furthermore, the invention includes the ability to move one or more of the autonomous vehicles from field to field, home to field, or from generally any first location to a second location.

Owner:KINZE MFG INC

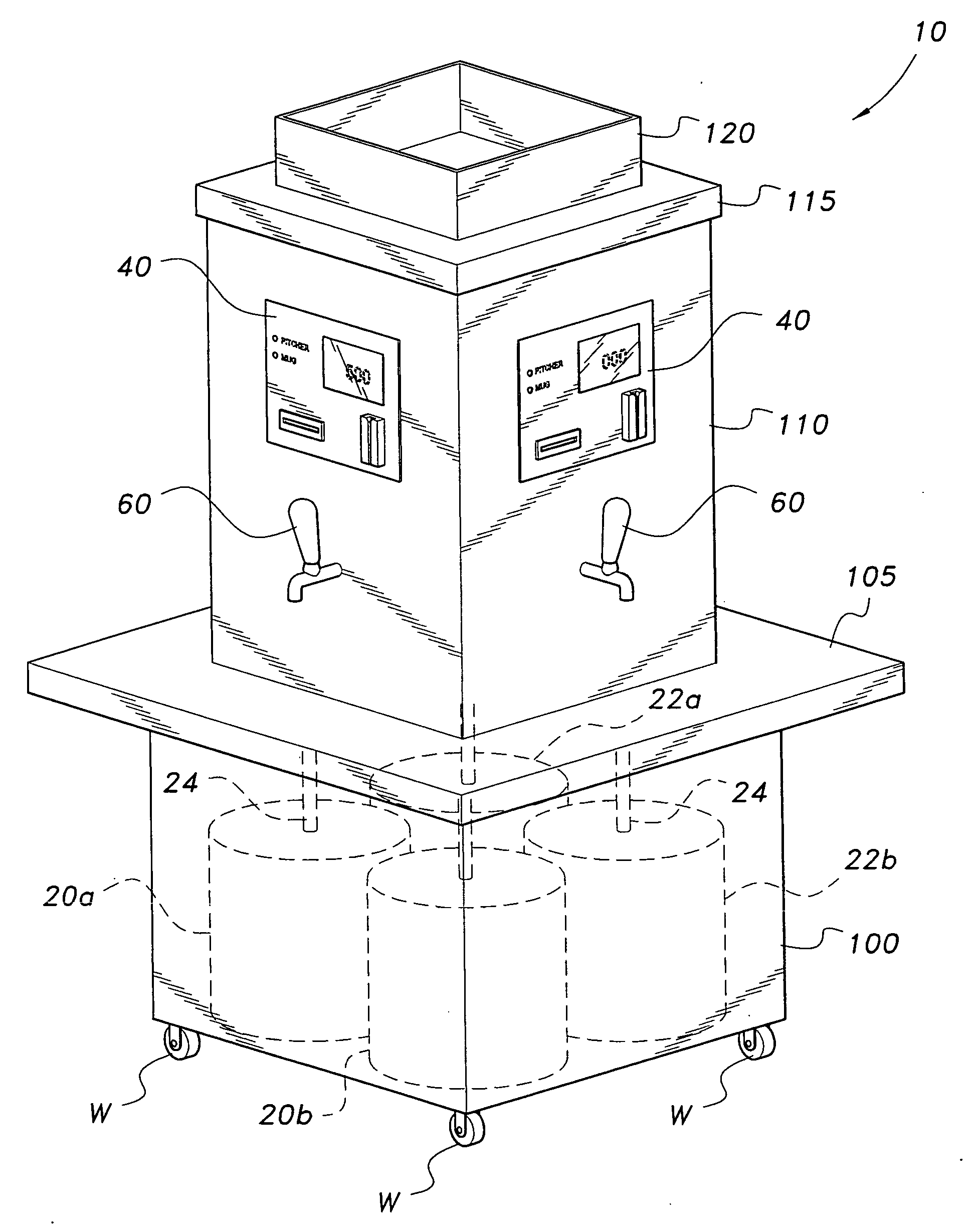

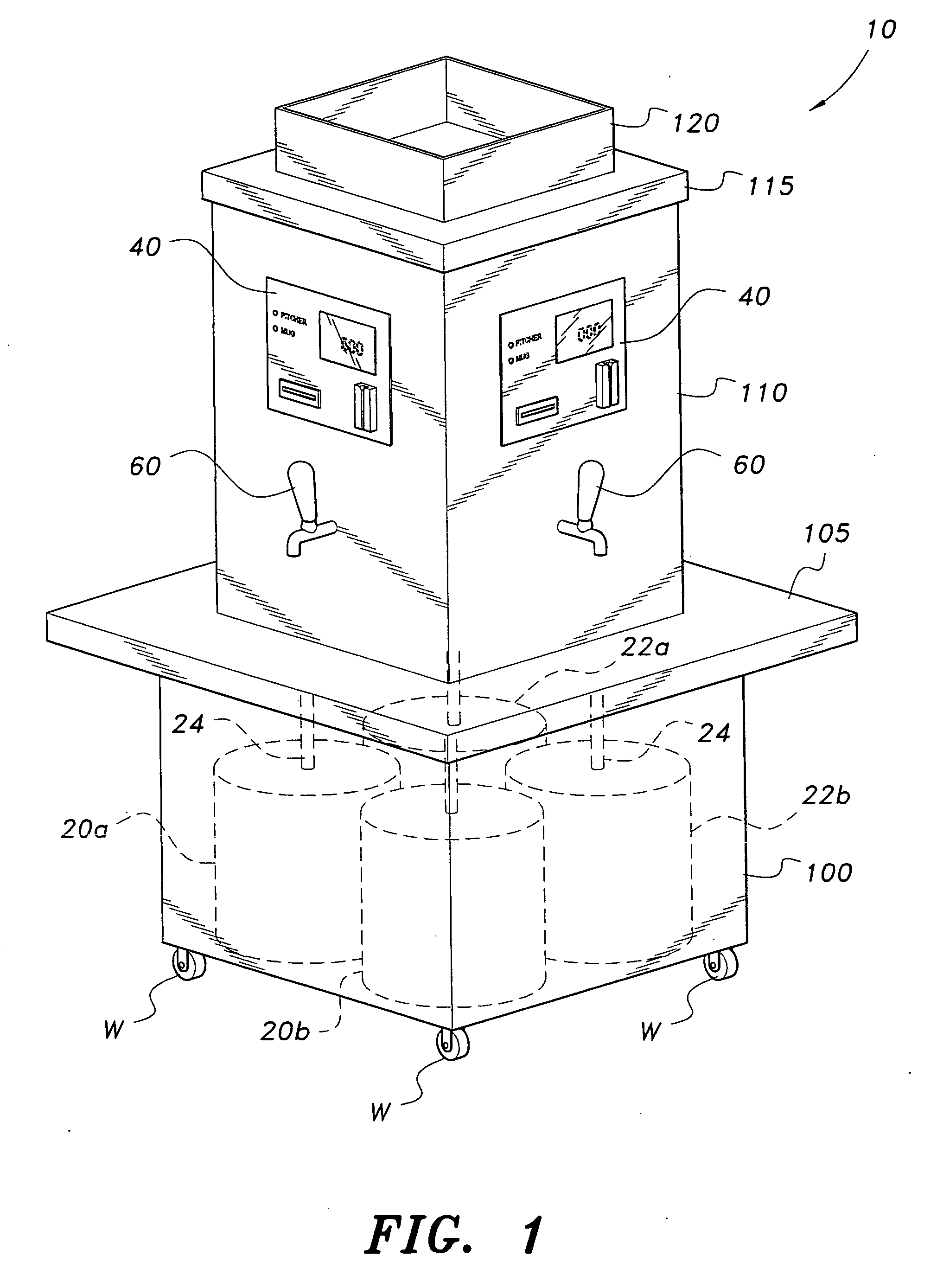

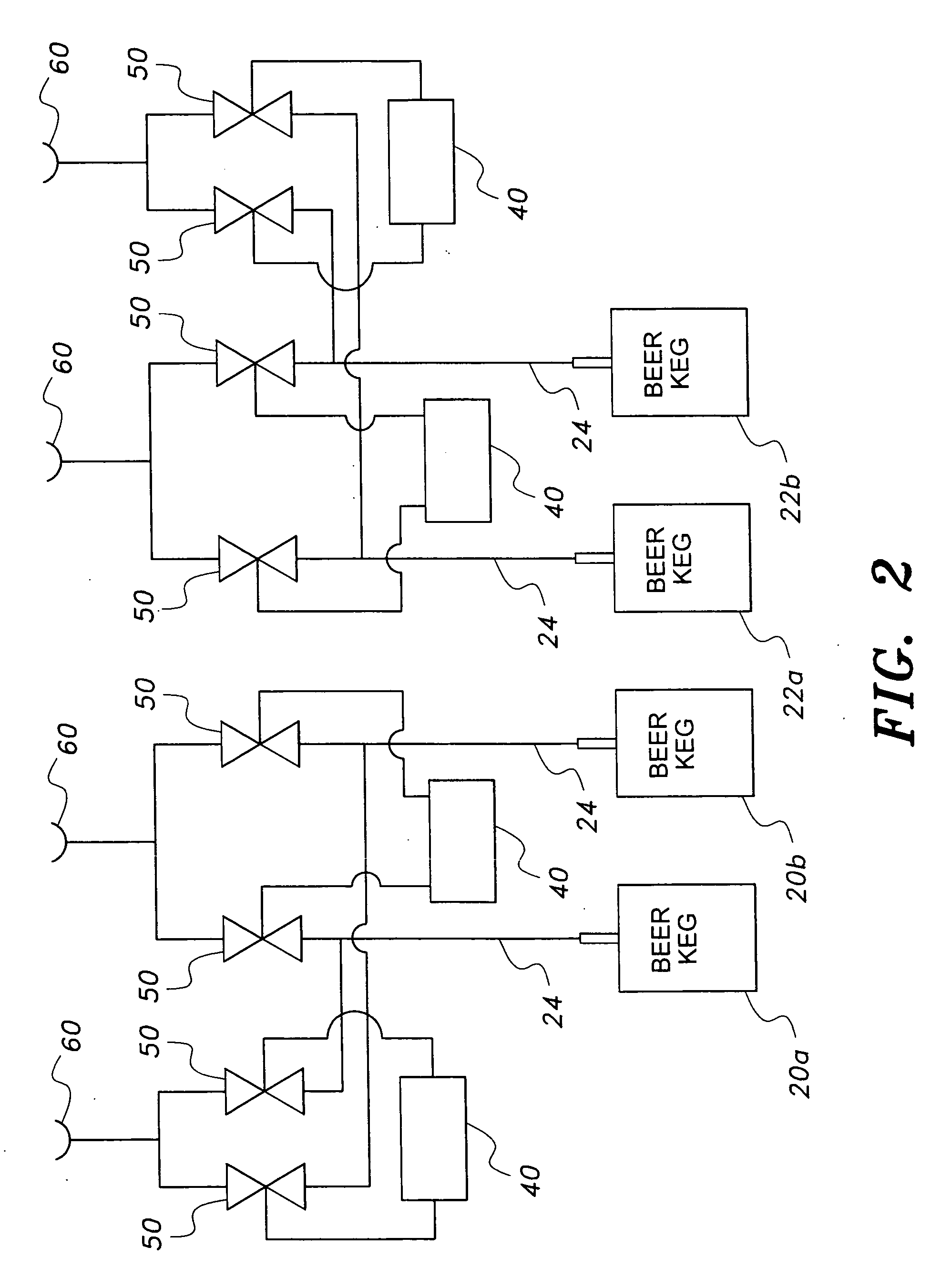

Portable self-serve beer vending station

The portable self-serve beer vending station has a hollow base in which at least two beer kegs are stored. A shelf of the unit is disposed above the base, two or more beer taps being disposed above the shelf to service each keg. A manifold tube extends from the kegs to the beer taps. Money machines, one on each side of the station, accept cash, credit, or debit. The money machine control wires are connected to control valves connected between the manifold outlets and the taps. Each money machine provides a touch screen selection menu or pushbuttons from which patrons can select either a pitcher or mug of beer at a set price. The station may be cylindrical, hexagonal, rectangular, semicircular, or the like. A surround shelf is provided for filling pitchers or mugs. An upper shelf is provided for holding fresh pitchers or mugs.

Owner:DEVERS JEFFREY M +1

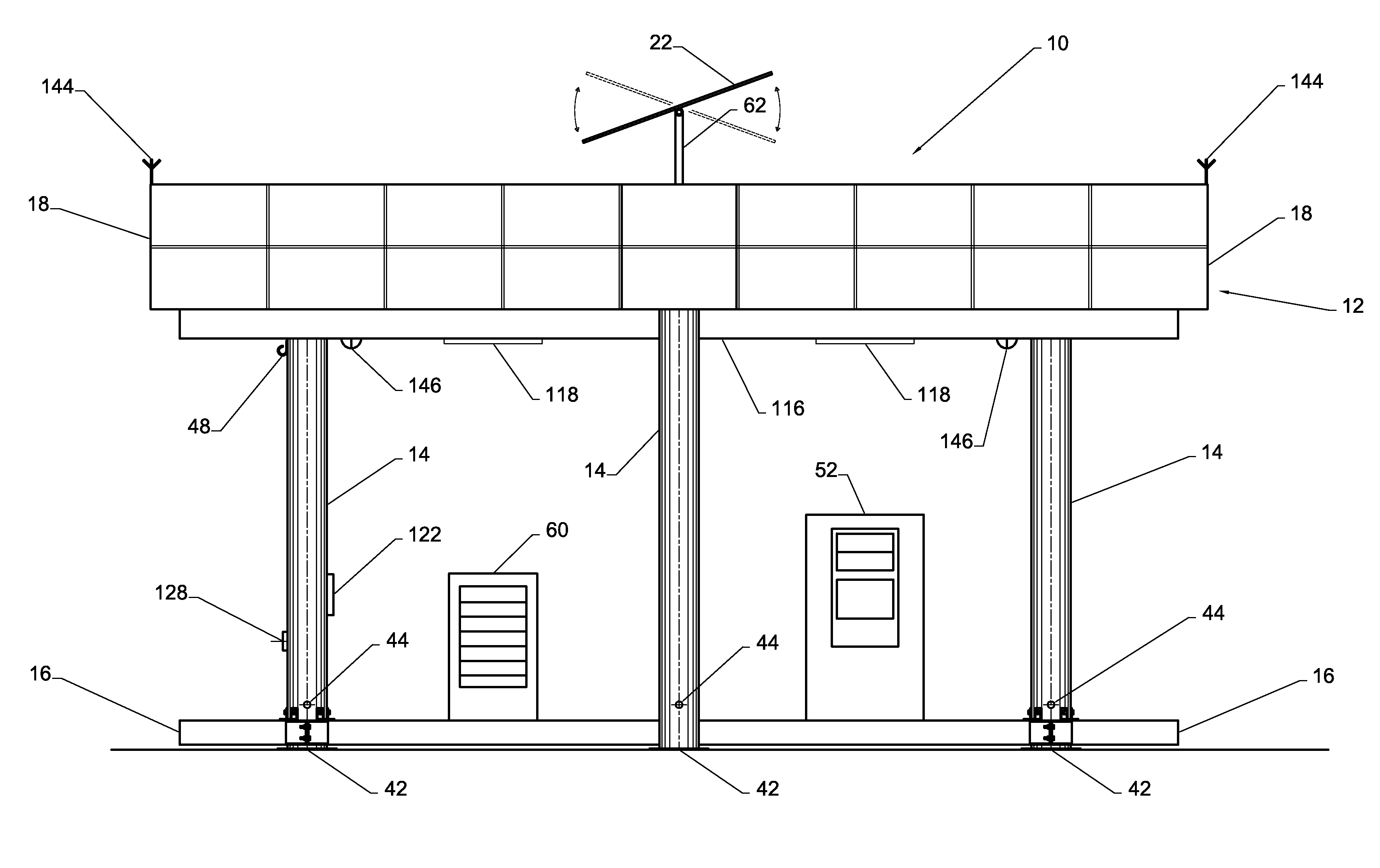

Mobile fuel distribution station

ActiveUS8176931B1Promote exchangeKeep for a long timeCyclesTank vehiclesModularityAutomotive engineering

A modular, environmentally friendly mobile fuel distribution station includes a fuel tank, a support structure having a plurality of legs for supporting an operation platform in an elevated position a predetermined distance above ground, an alternative power generation device, the alternative power generation device being one of a solar power generator and a wind power generator for providing primary power to the mobile fuel distribution station and a central platform operatively connected to at least two of the legs, the at least two of the legs bearing the weight of the central platform, wherein the fuel tank and the alternative power generation device are disposed on the operation platform.

Owner:CAPAT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com