Patents

Literature

393results about "Ingredients storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

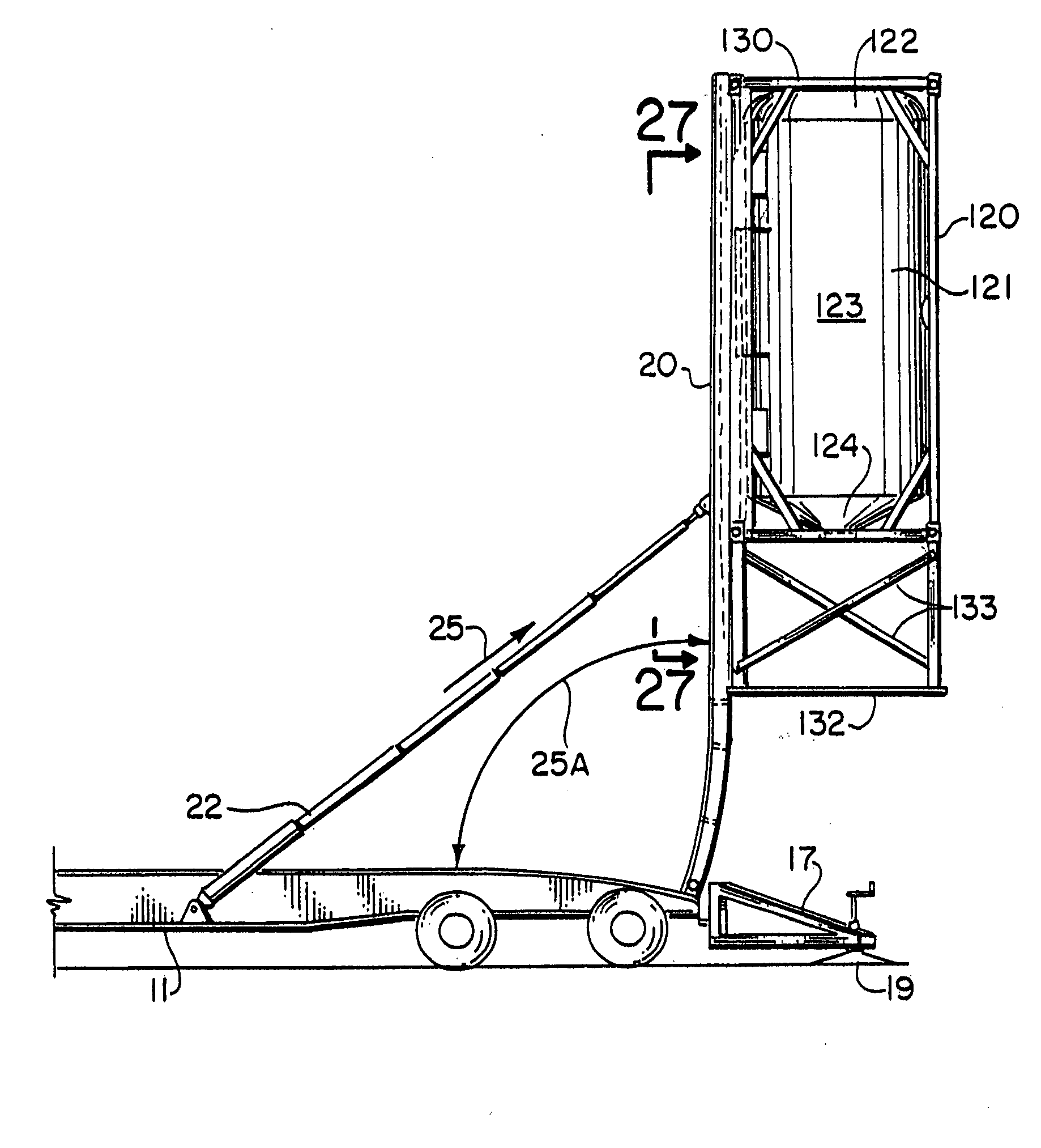

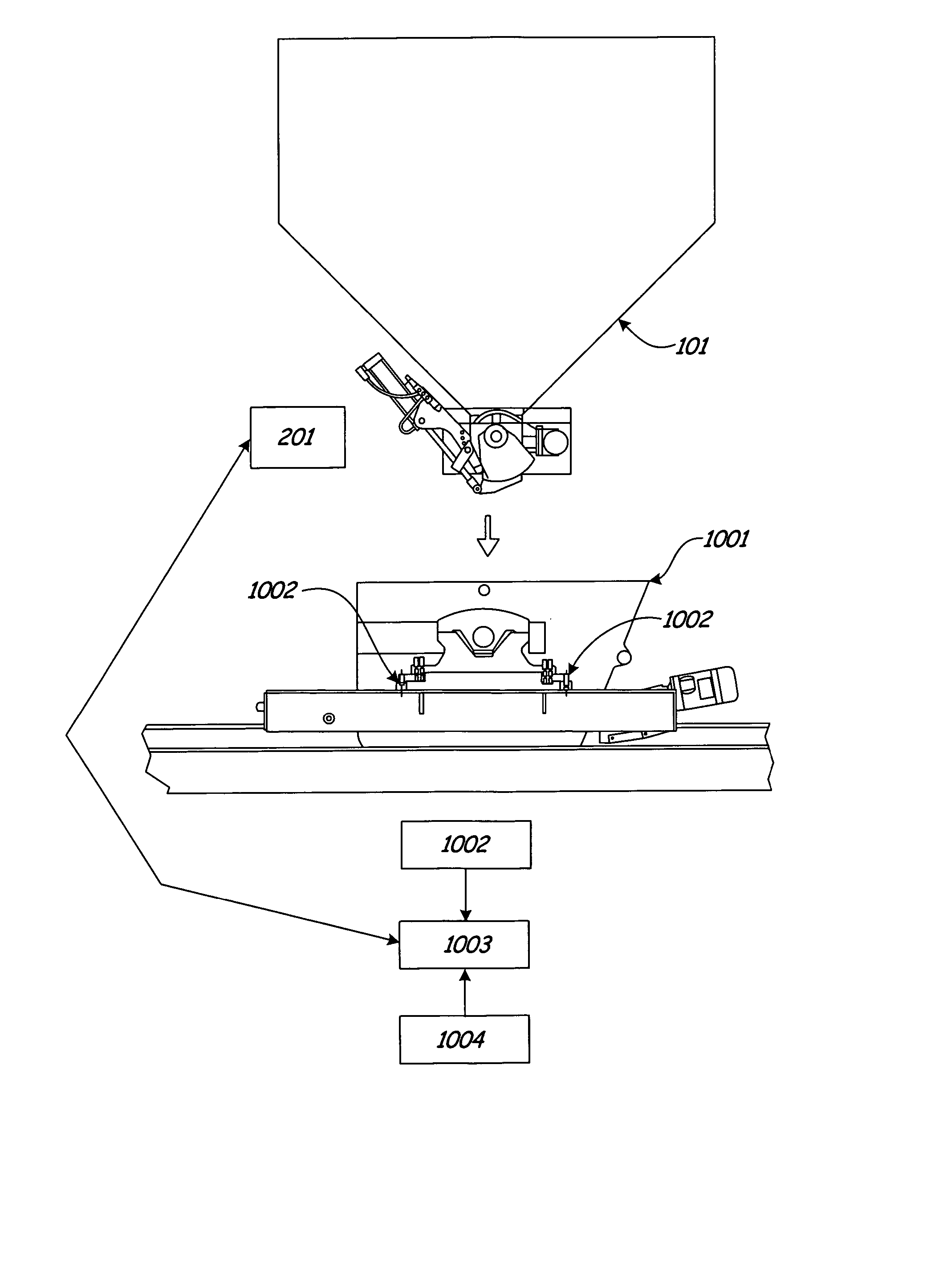

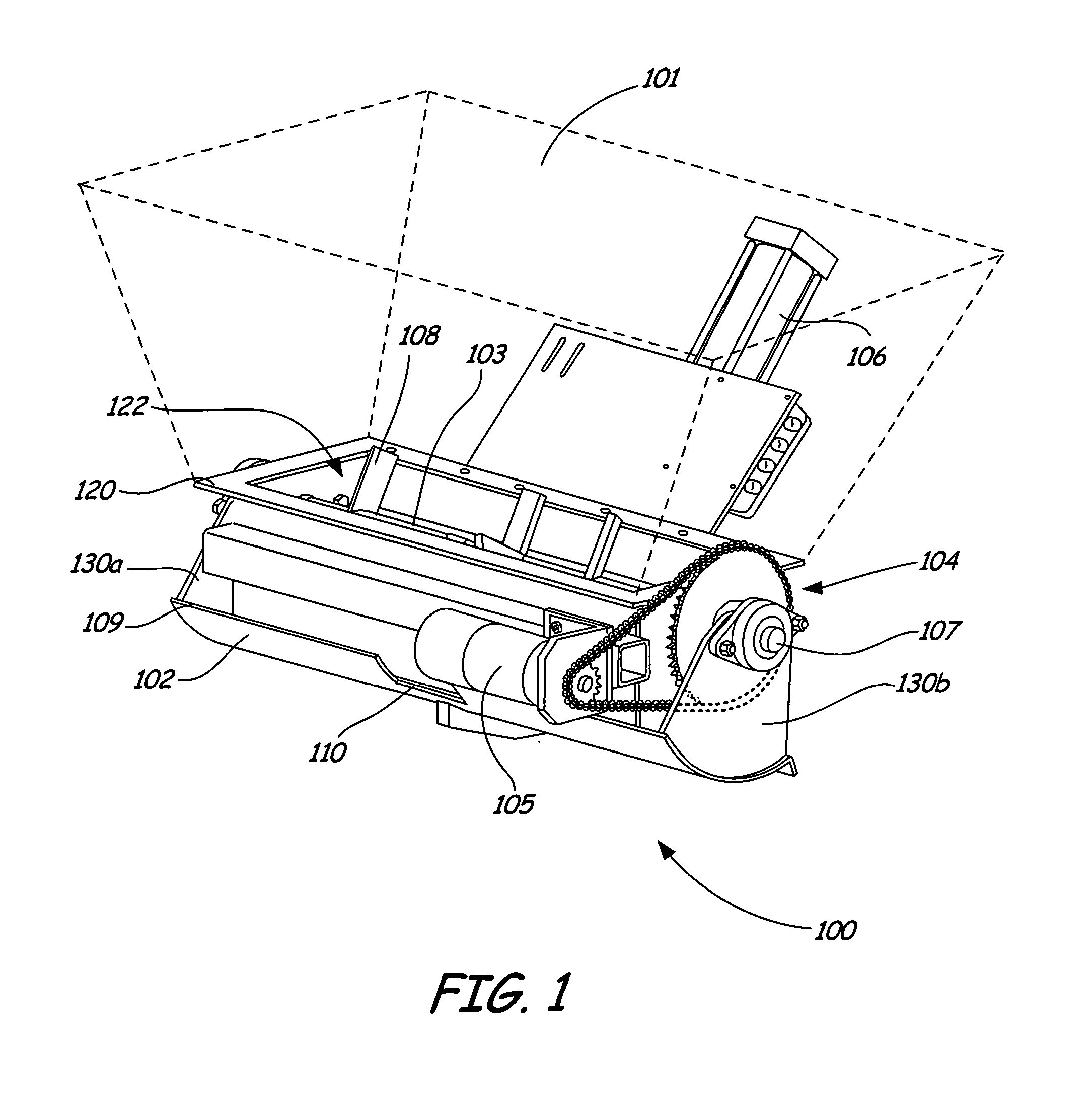

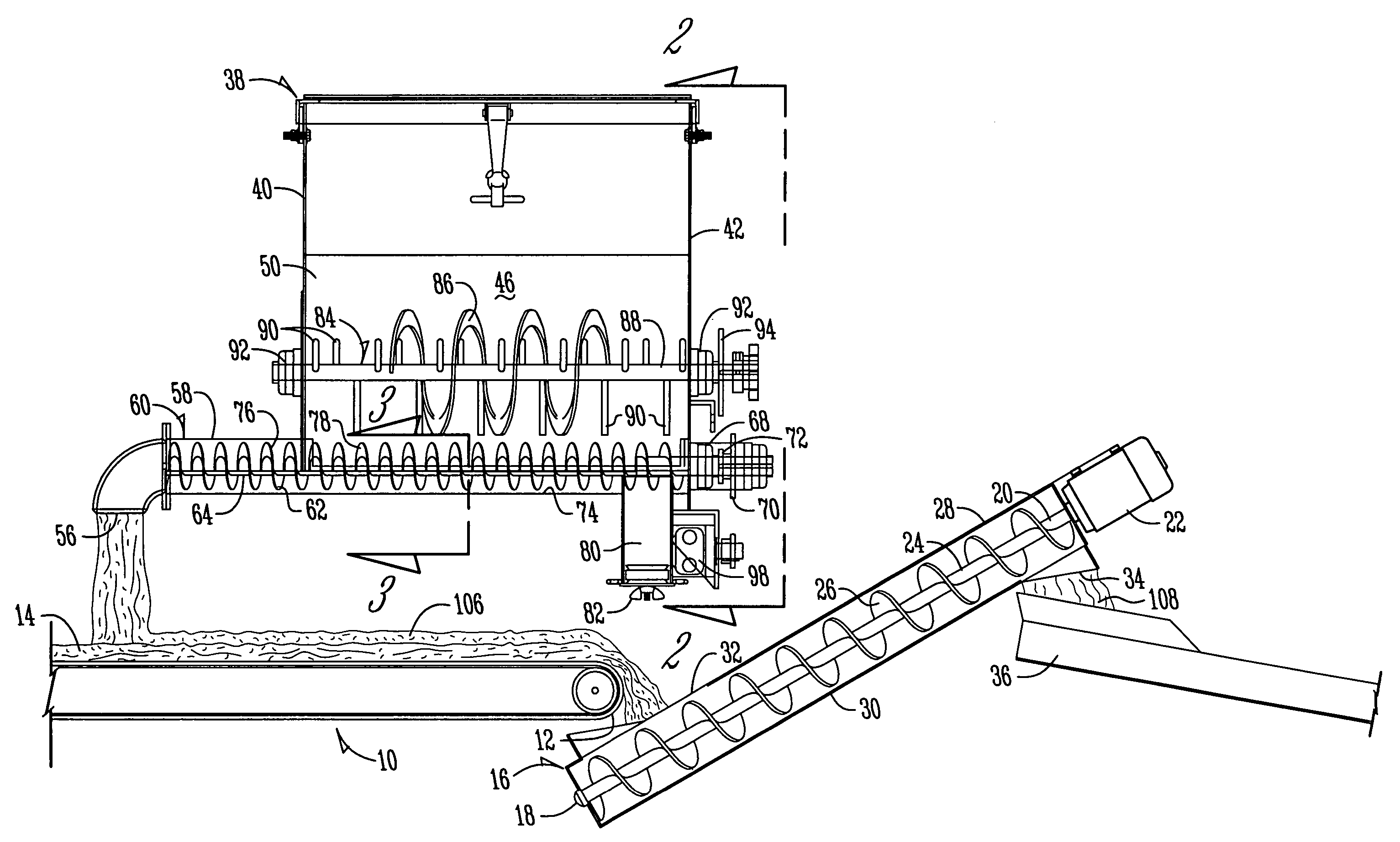

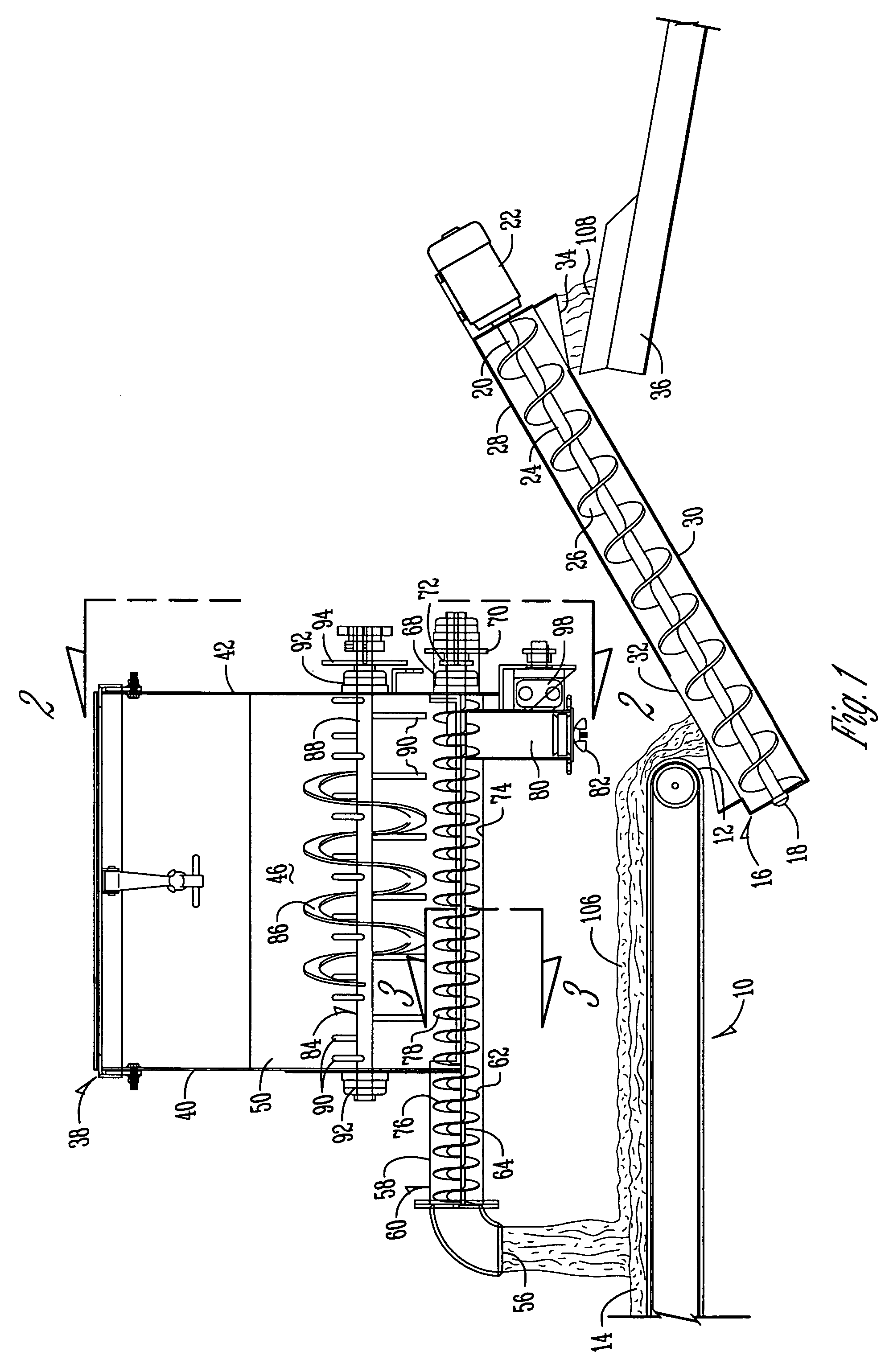

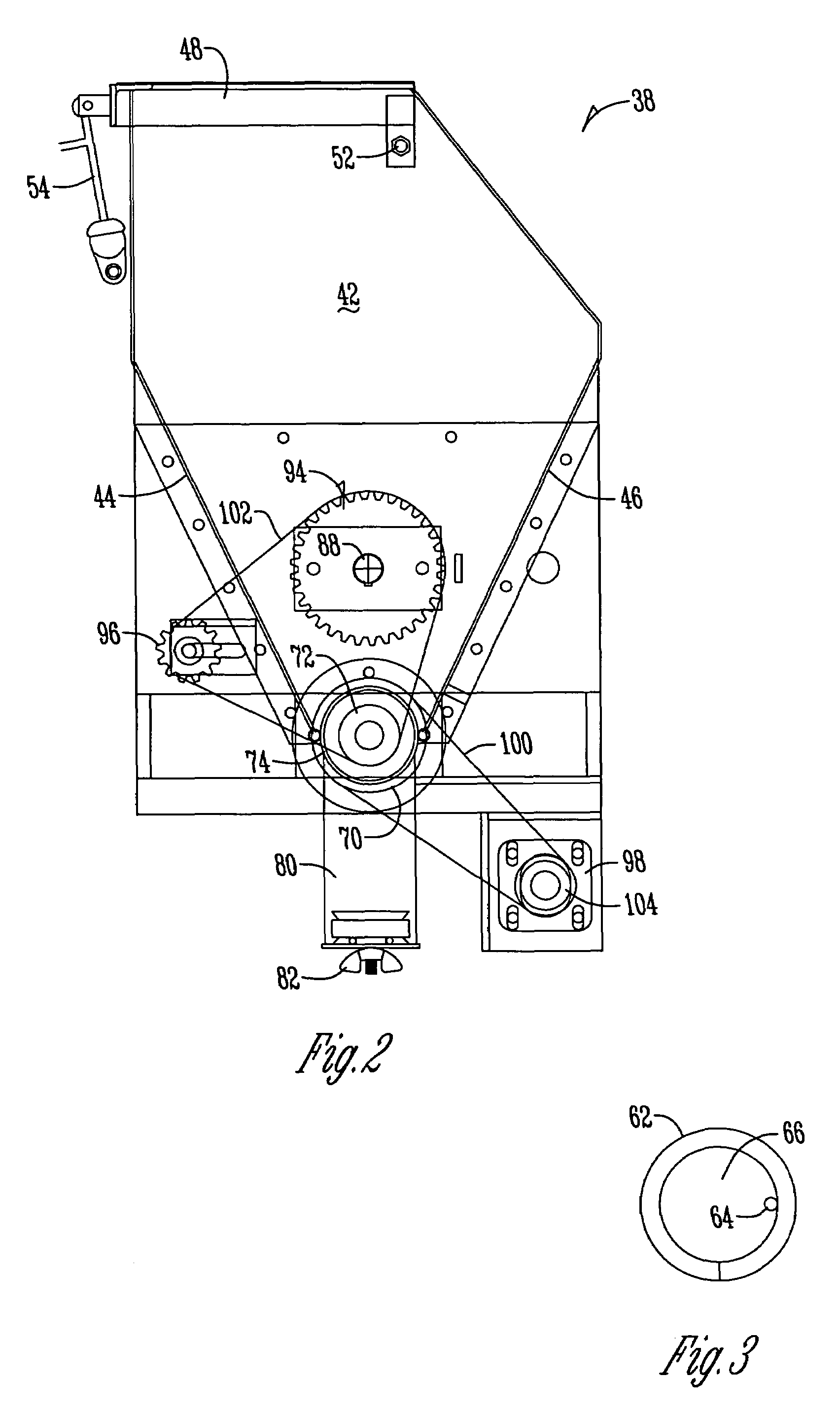

Method and apparatus for supplying bulk product to an end user

InactiveUS7214028B2Eliminate needEfficient transportTank vehiclesMixing operation control apparatusMarine engineeringEngineering

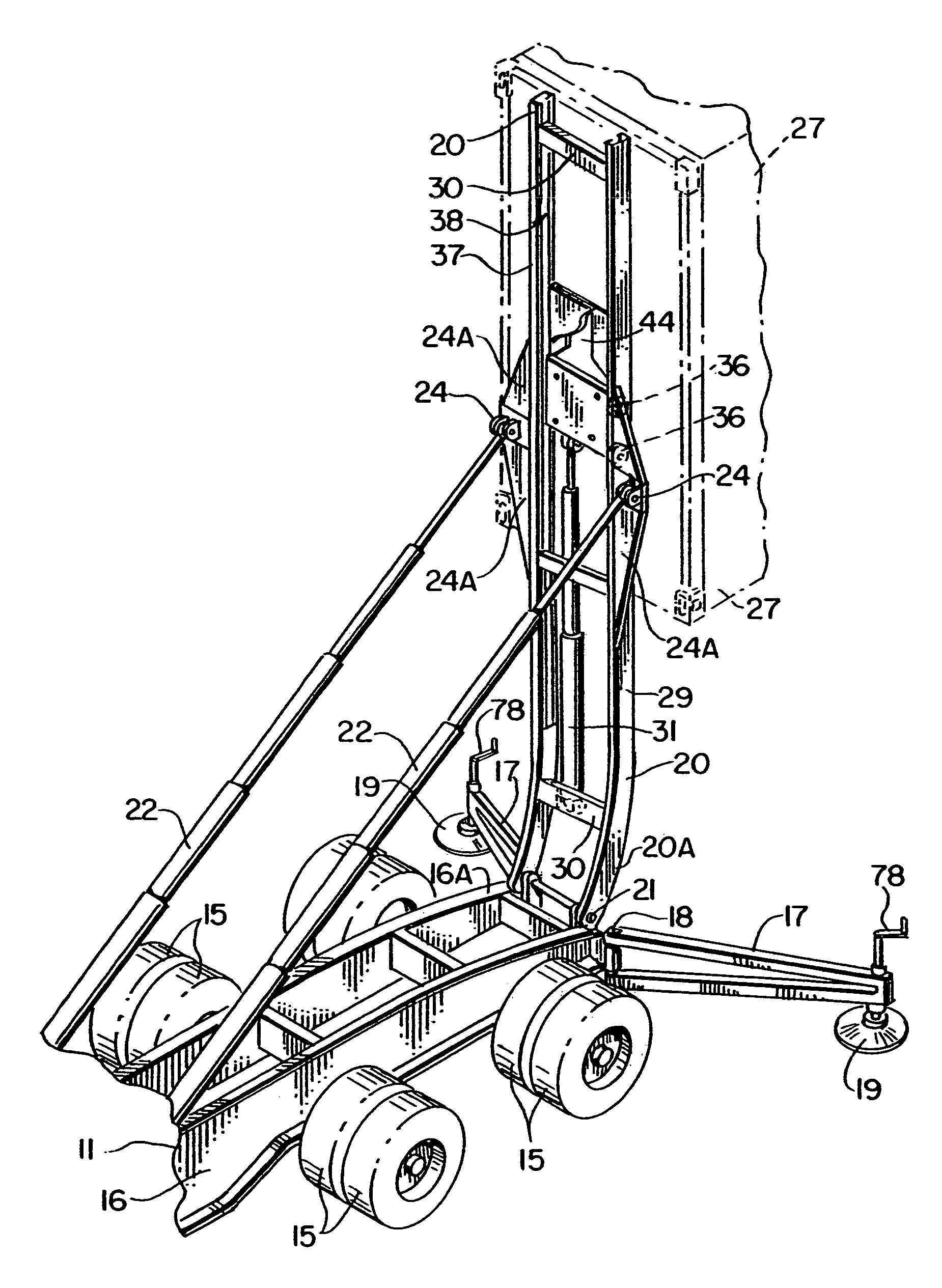

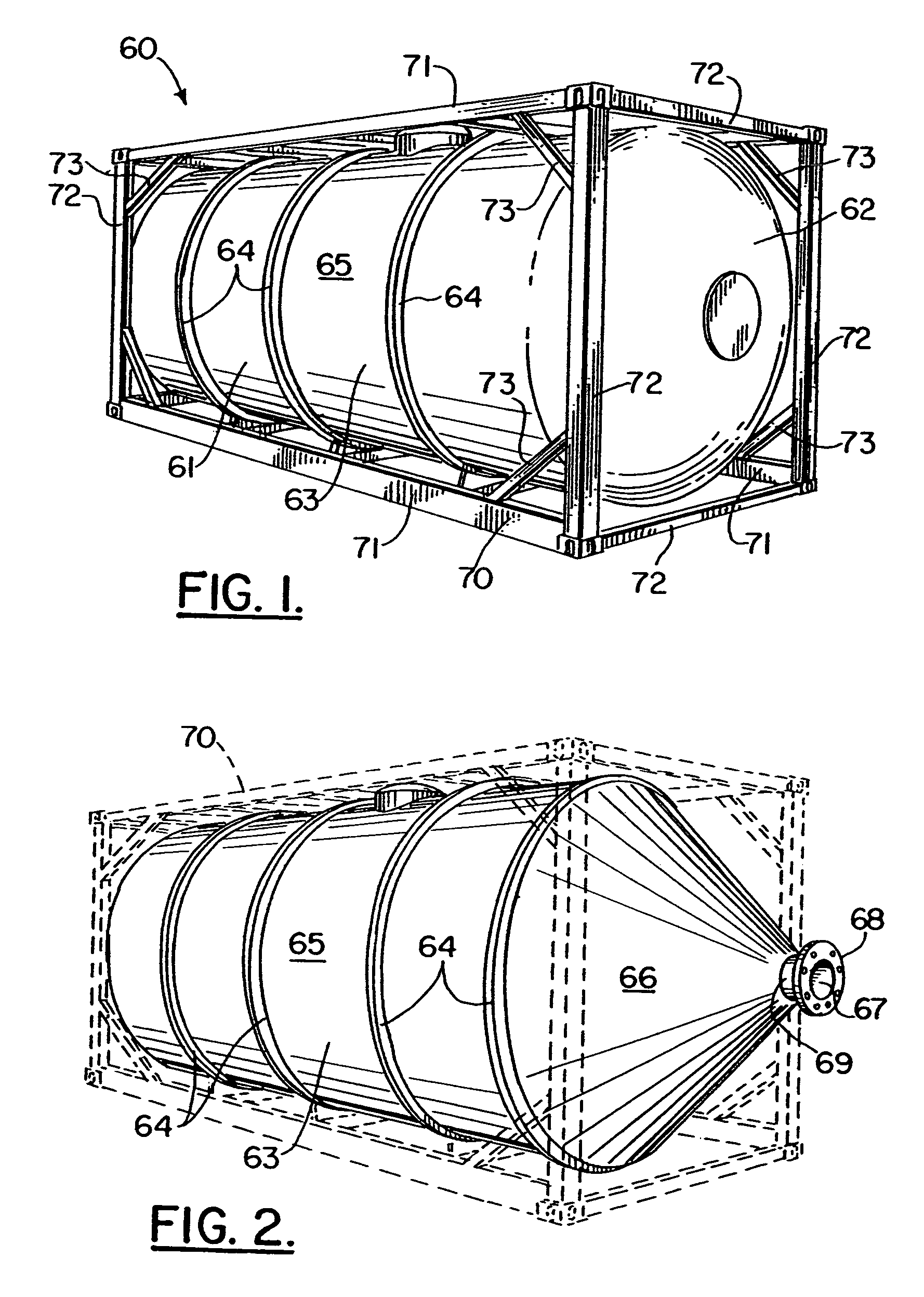

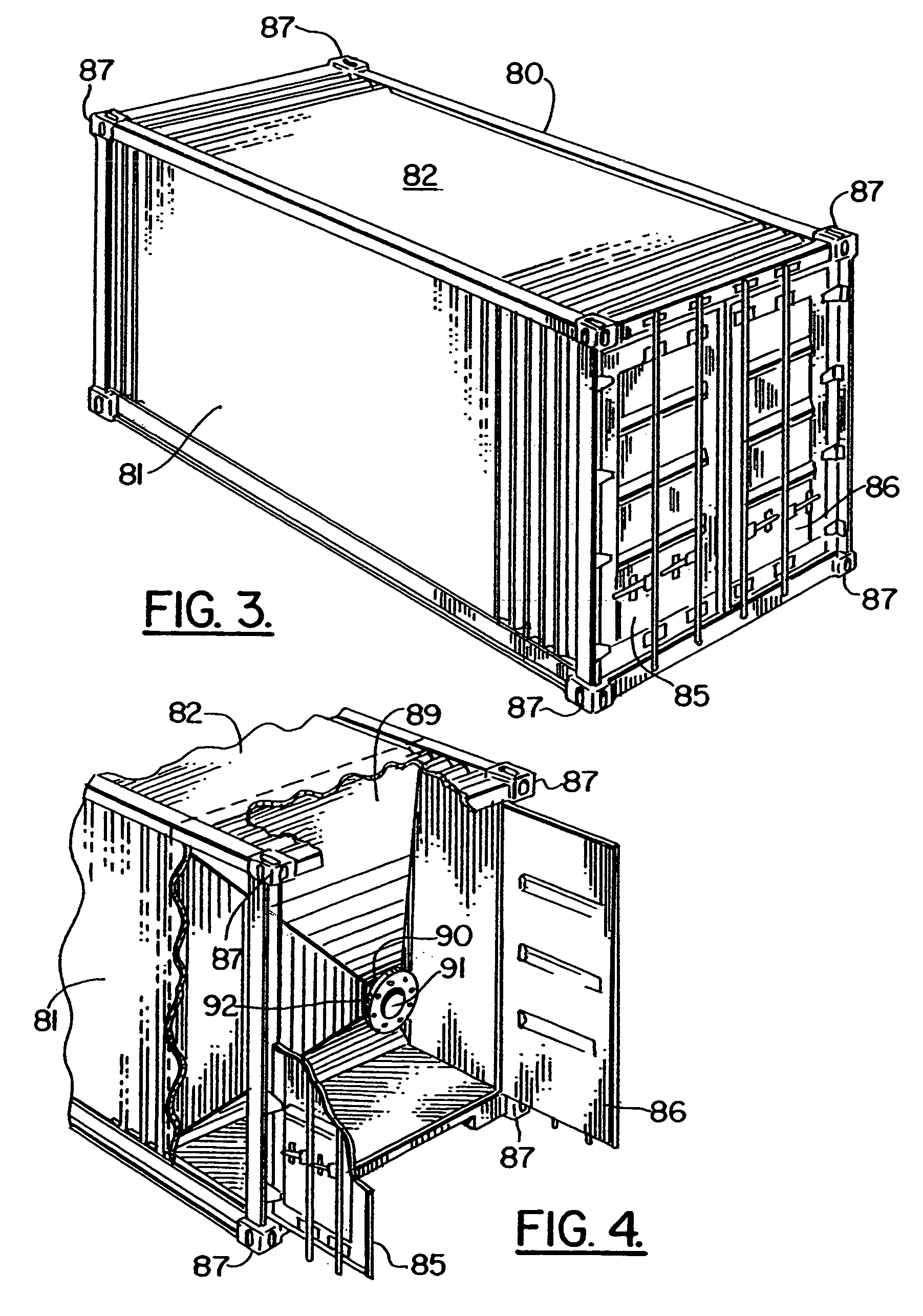

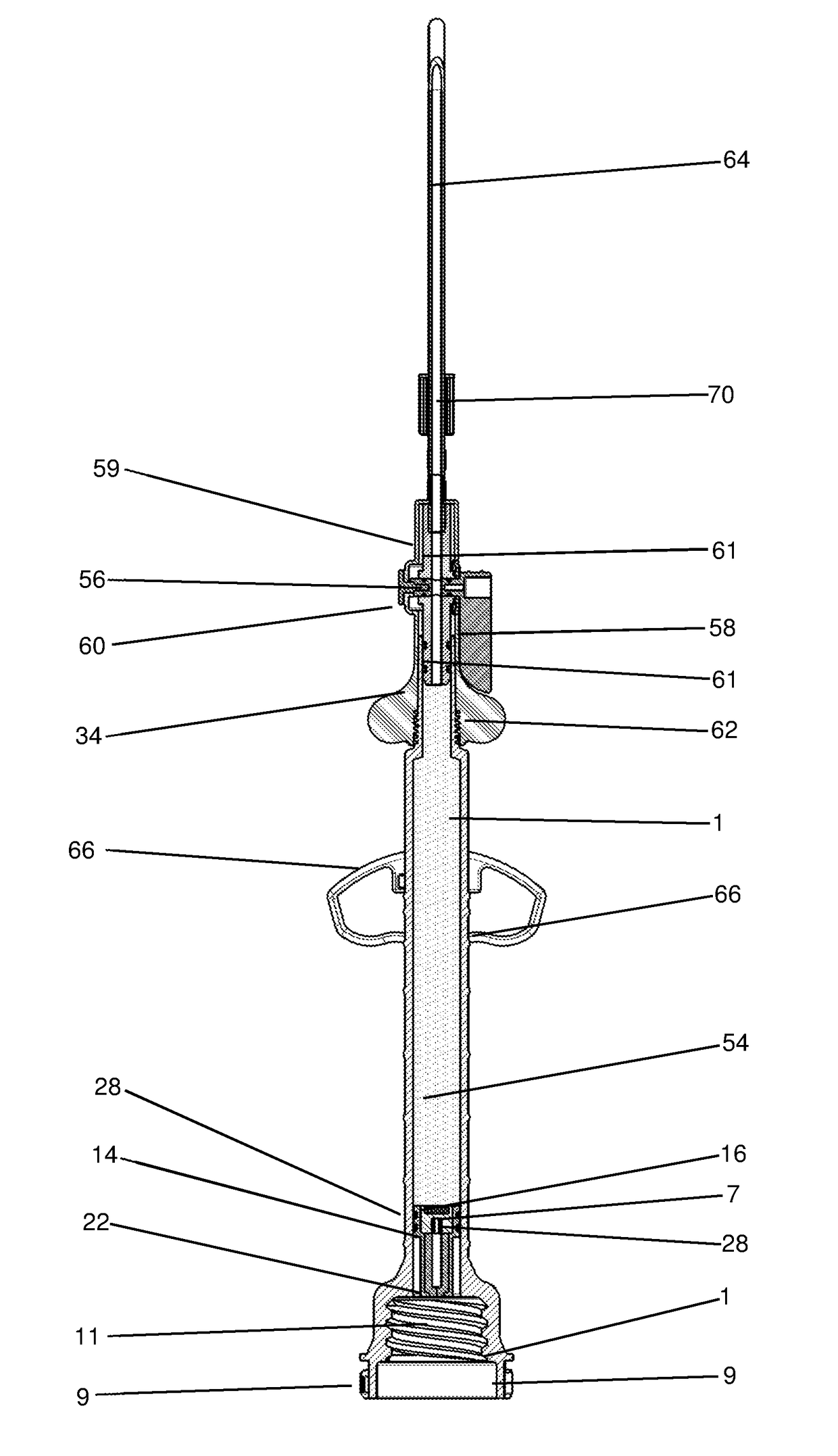

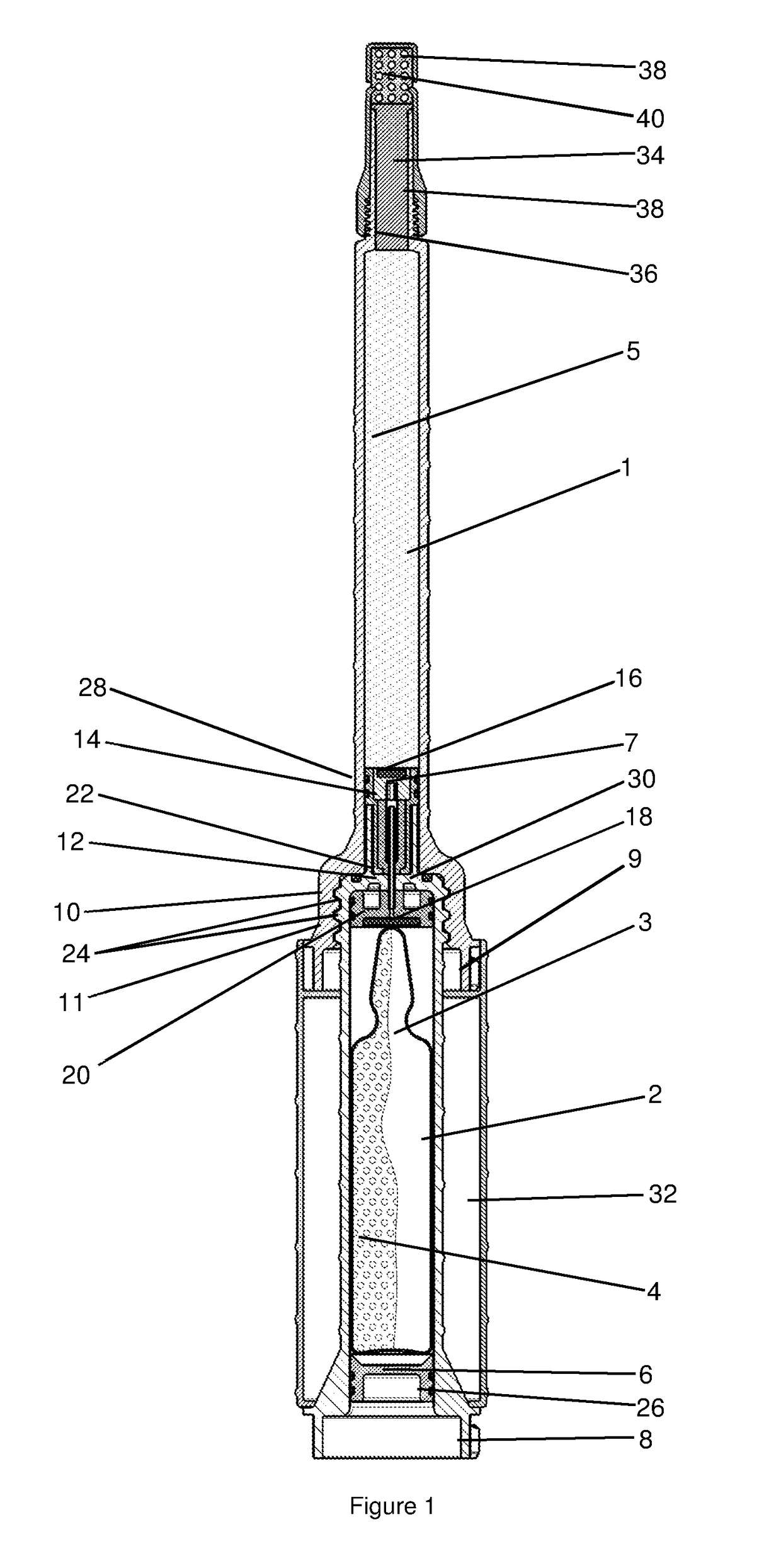

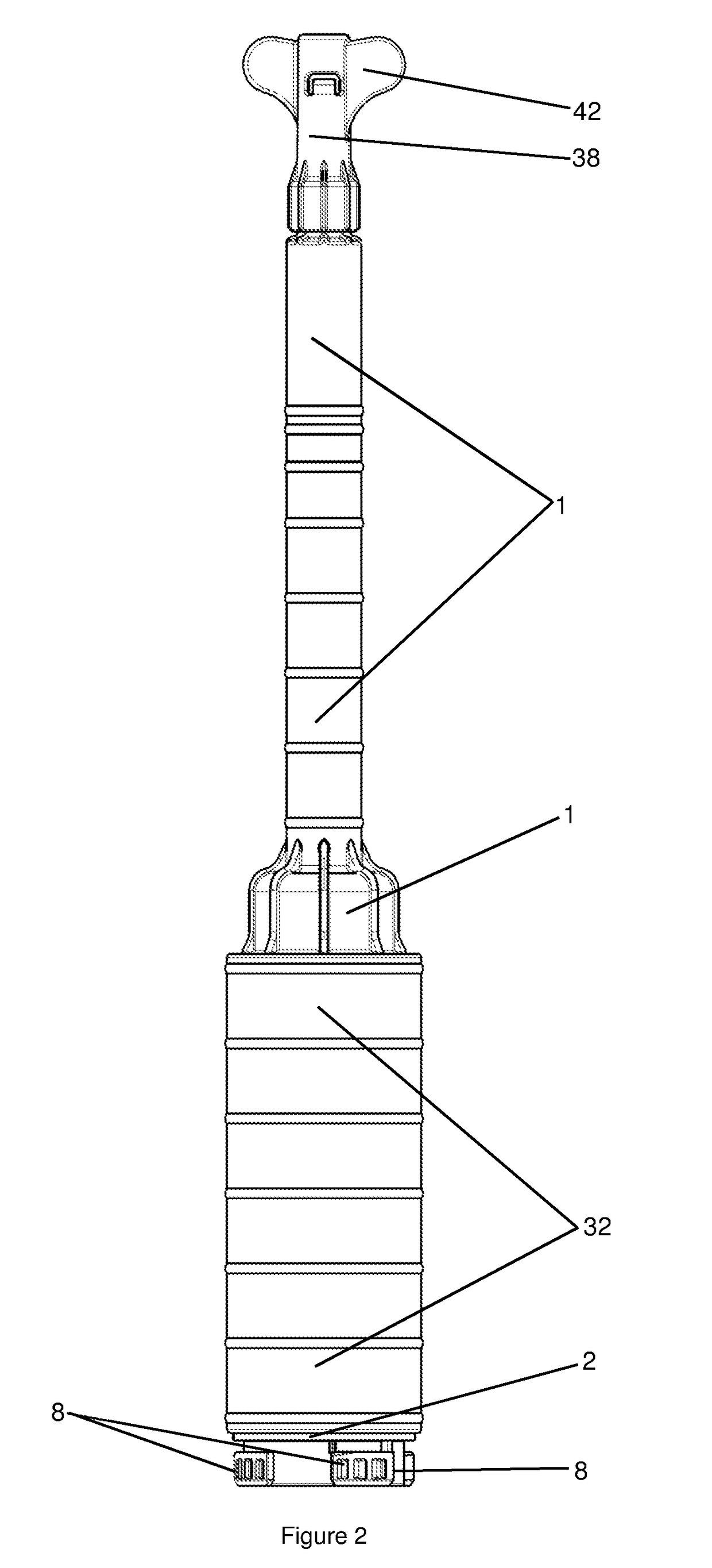

A method and apparatus for supplying bulk material to an end user includes the step of providing a bulk material source that is at a location distant from the end user and a specially configured vessel and trailer apparatus for transporting the bulk material to the end user. The vessel is filled with bulk material at the bulk material source and then transported with a specially configured trailer. Alternatively, at source or destination, the vessel can remain as a temporary storage device, free-standing from the trailer. During transport between the bulk material source and the end user, the vessel is filled or partially filled with a selected bulk material. During transport, the vessel is in a generally horizontal position, supported by the trailer and a specially configured elevator. The vessel is unloaded from the trailer by moving the vessel longitudinally along the trailer and by transferring the vessel from a generally horizontal position upon the trailer to an elevated upright position.

Owner:TILT TANK L L C

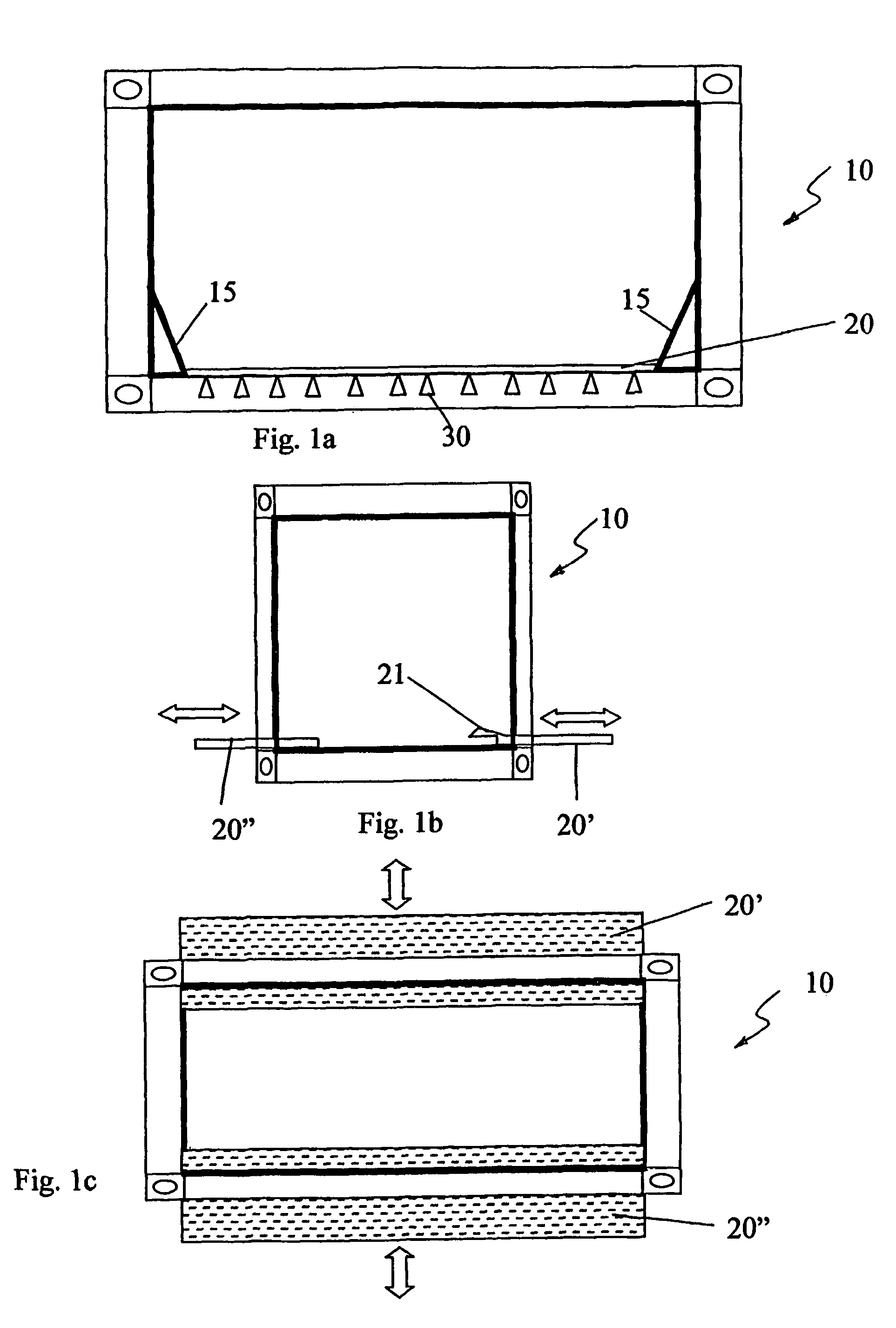

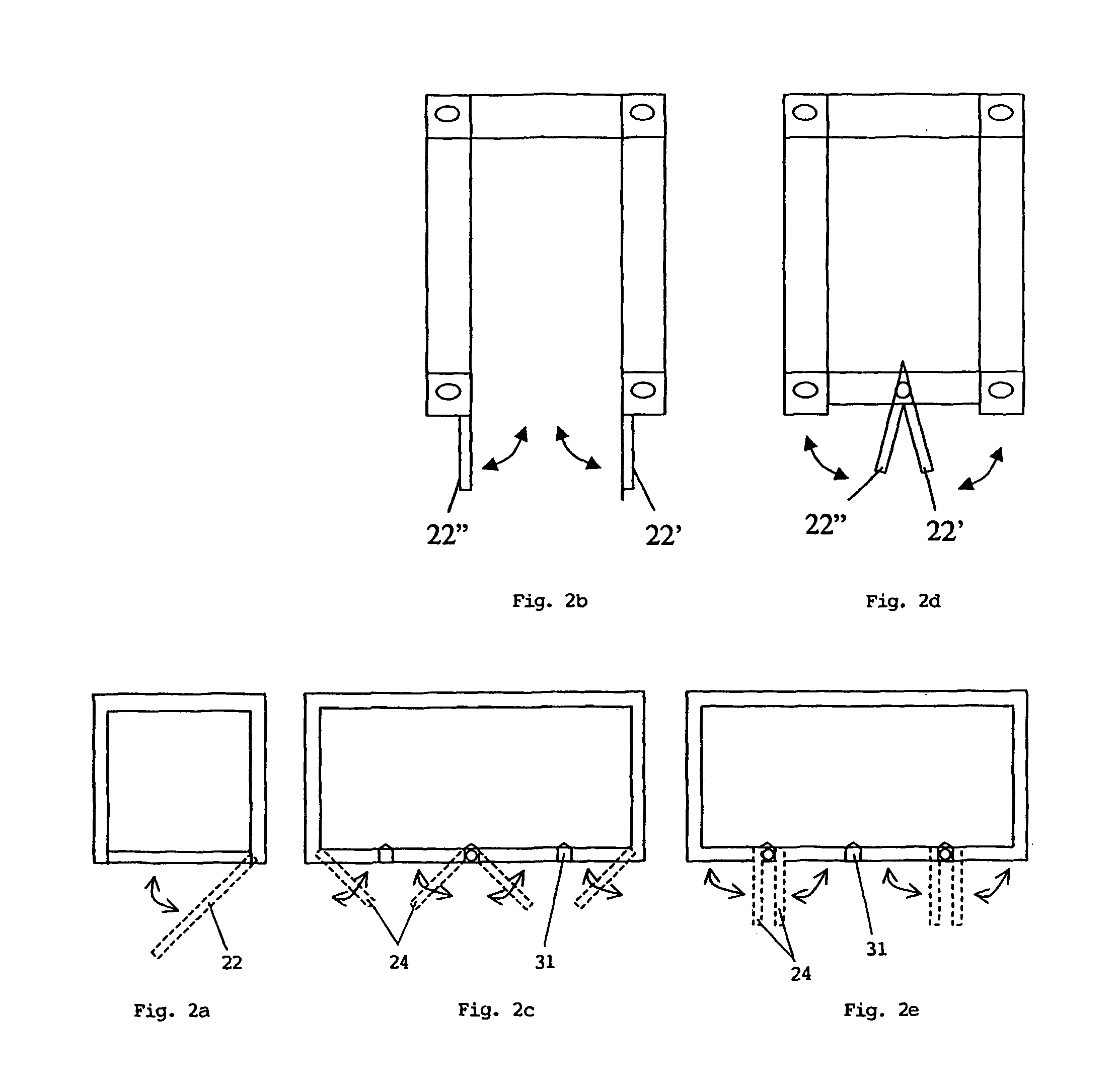

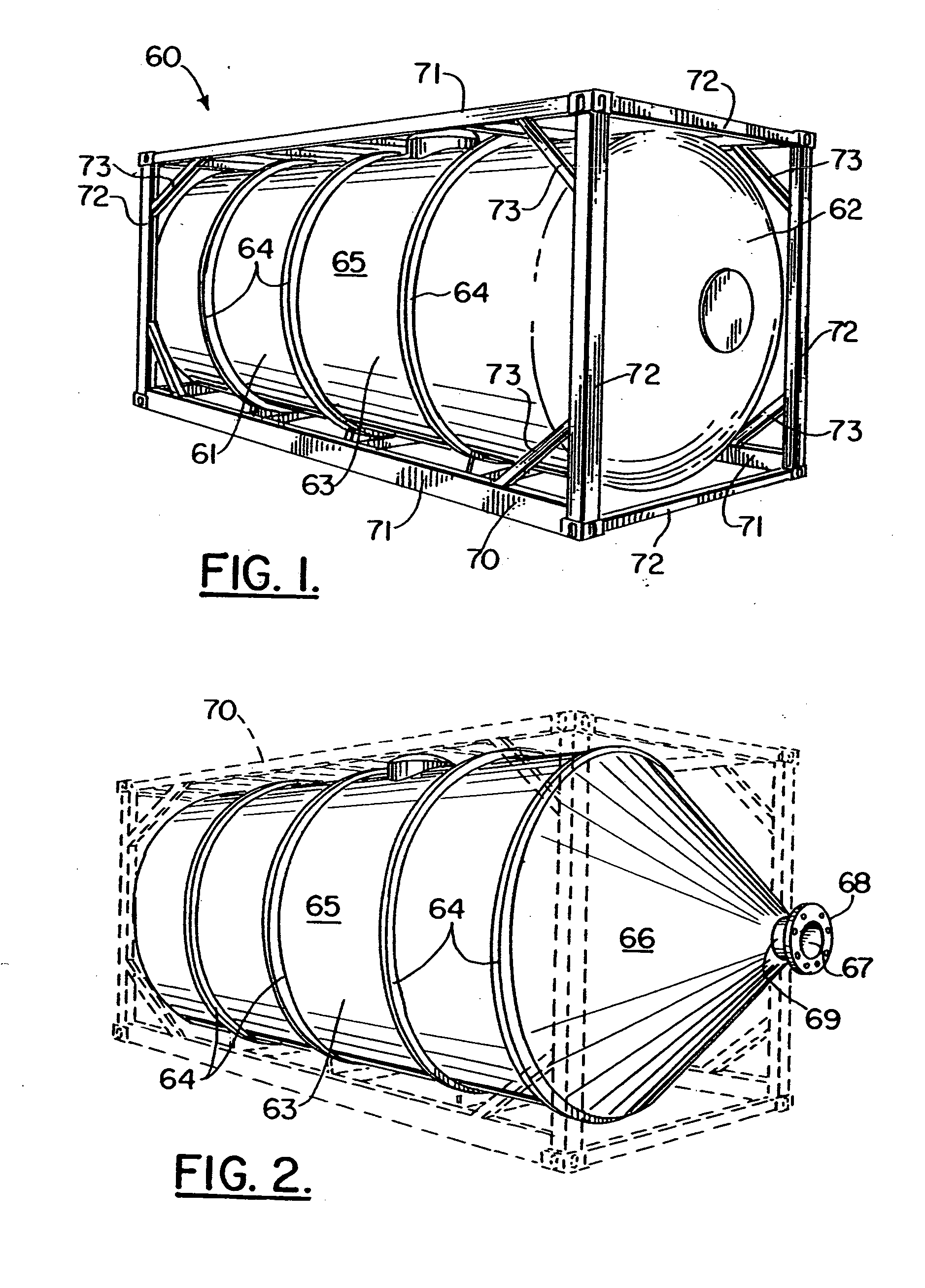

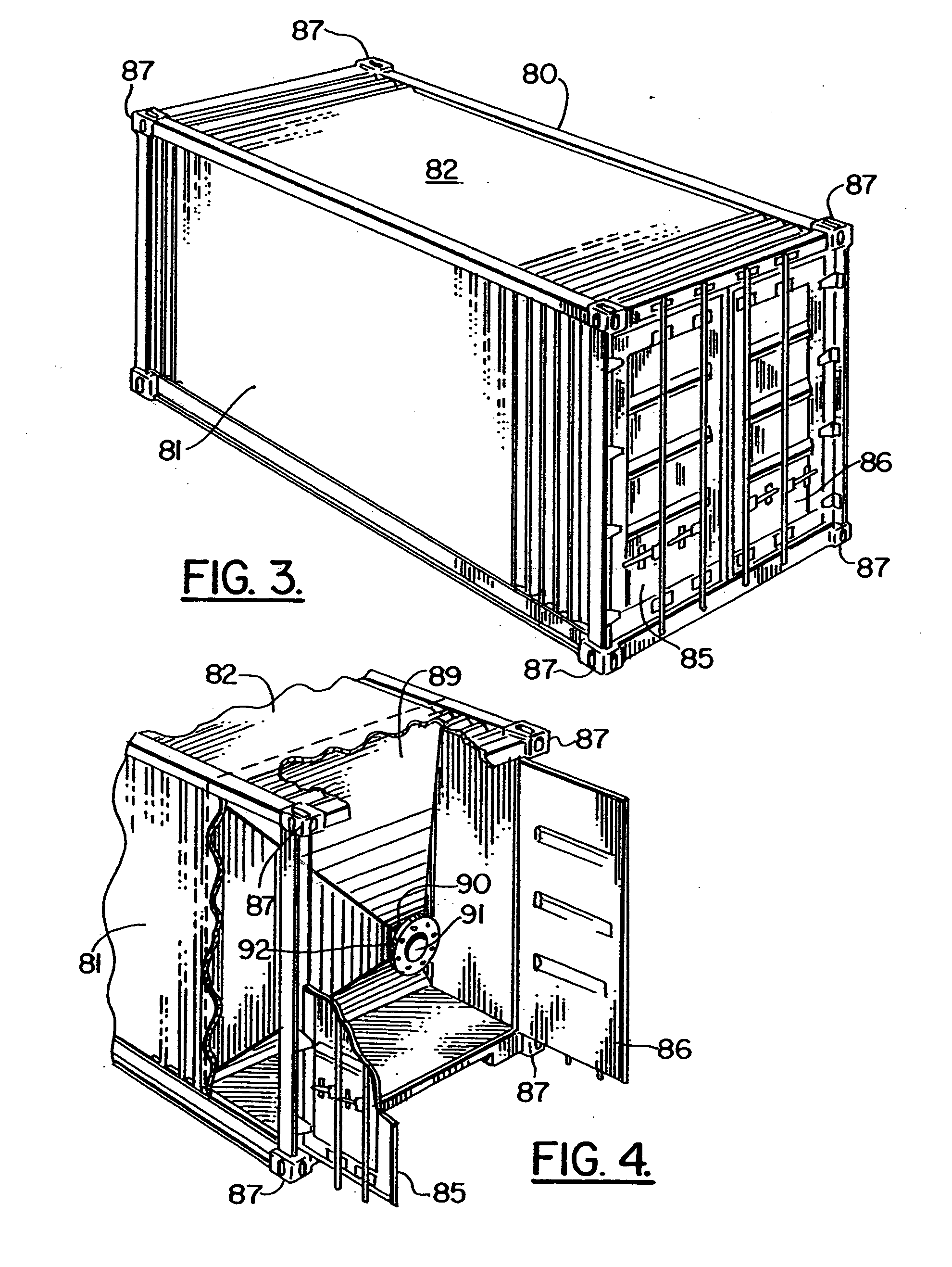

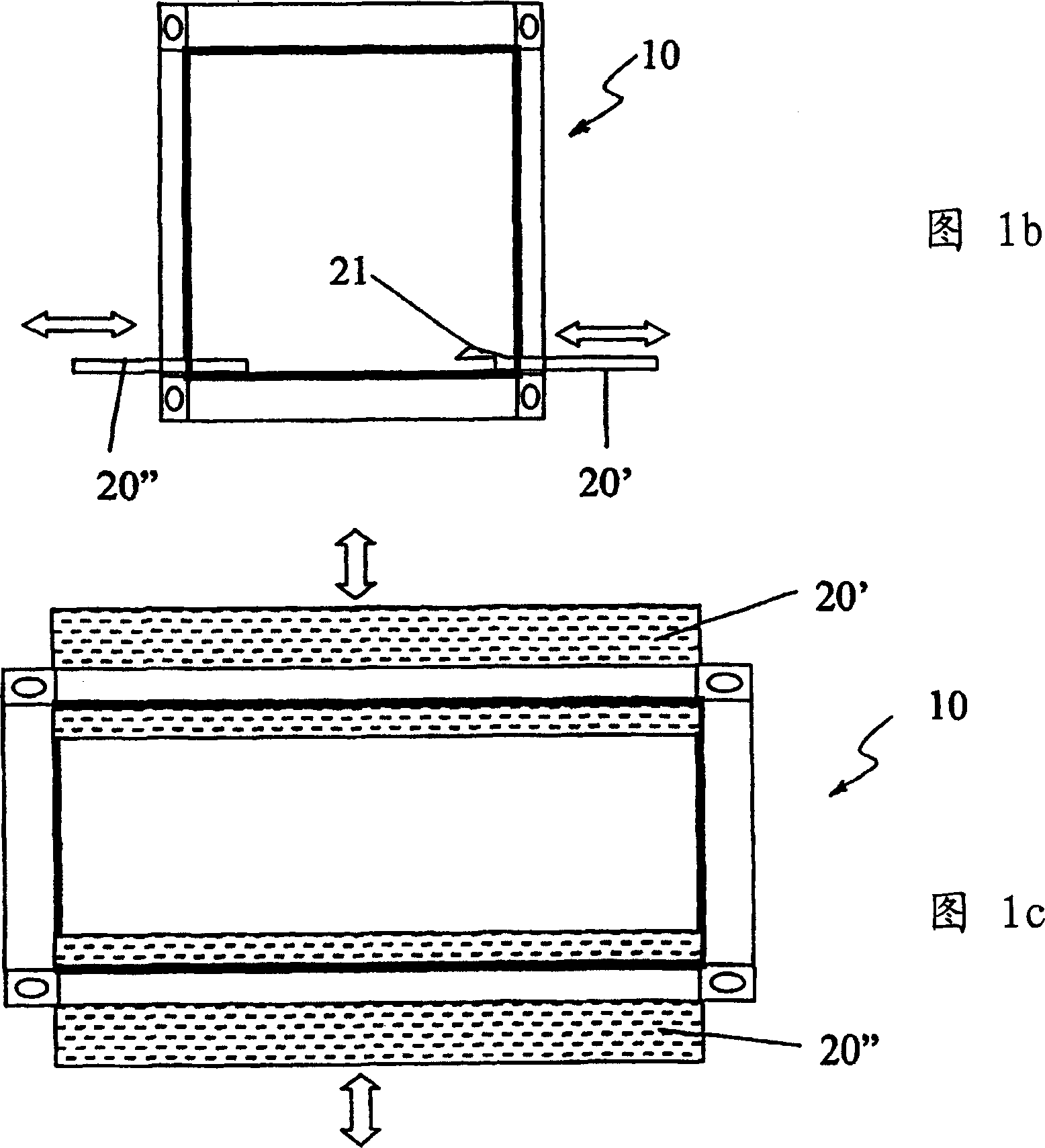

Containerised handling of bulk materials and apparatus therefor

InactiveUS7252309B2Advantageously producedFlow mixersLarge containersParticulate pollutionEngineering

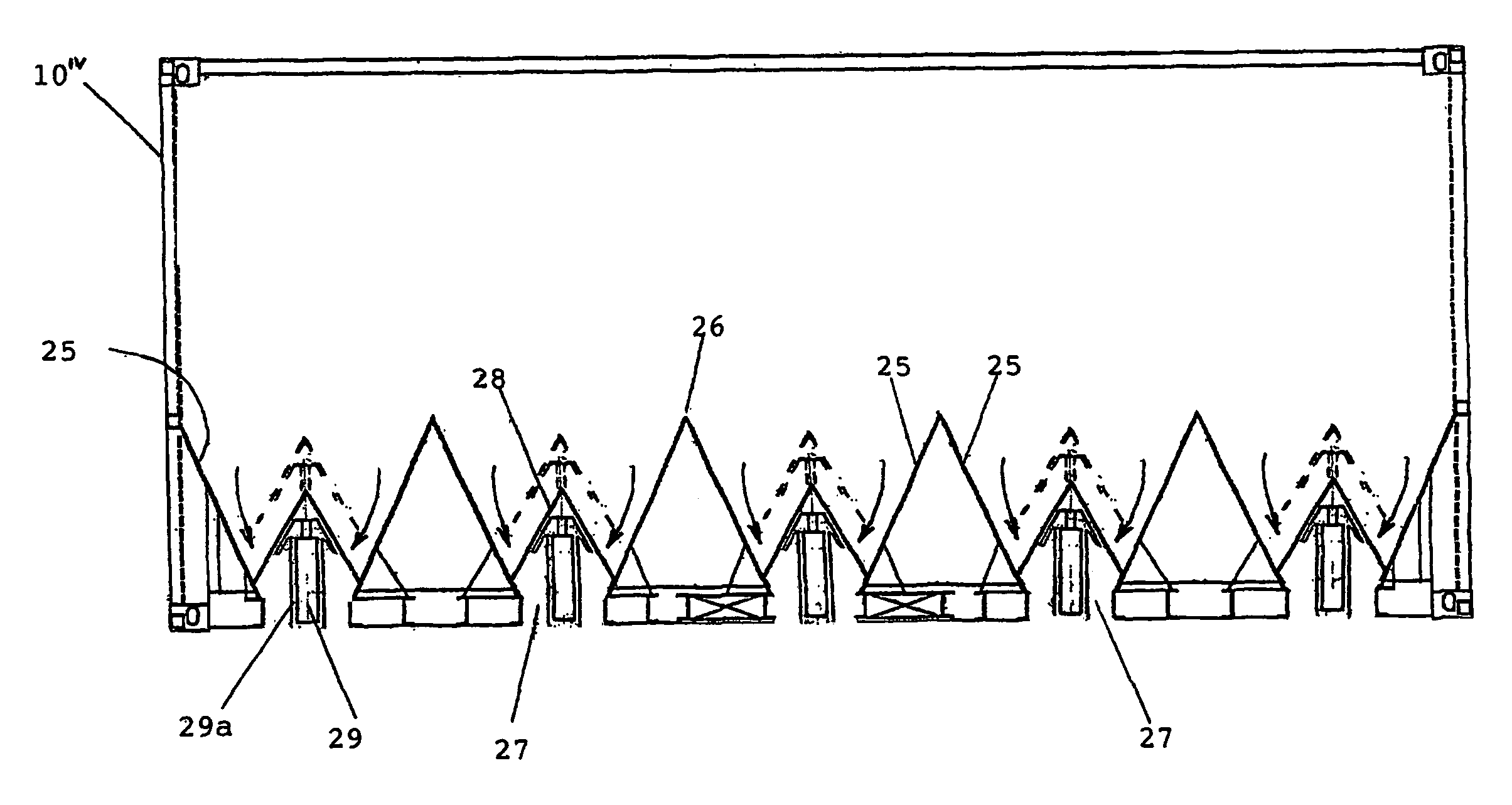

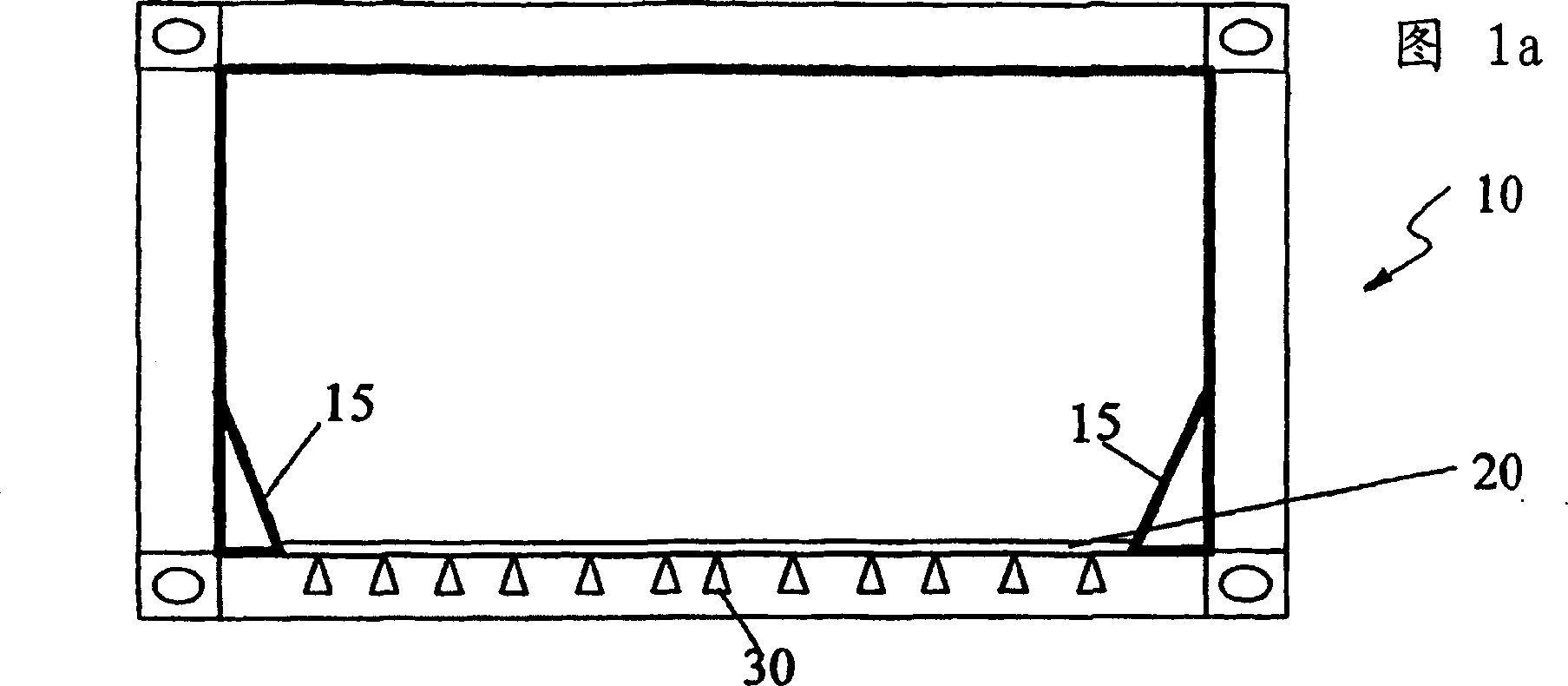

A freight container (10) has a base (20) or a portion thereof that can be opened to discharge its contents. This container (10) has a top which can be opened in similar manner as the base. Another container having at least one compartment, each compartment having a lower section with a reducing cross-sectional area and a pivotably operable closure assembly, with several such closure assemblies being linked together by means of bars. Such a container is used to contain raw building materials for stockpiling of these materials at a container port. It is also used to supply materials to a concrete production plant whee pollution control containers are provided below the supply container and above the scaling and mixing stations to reduce particulate pollution. A pair of slewing apparatuses is also provided to engage both ends of a container and turn the container over about its longitudinal axis, thereby emptying its contents.

Owner:ONG BEE KIM

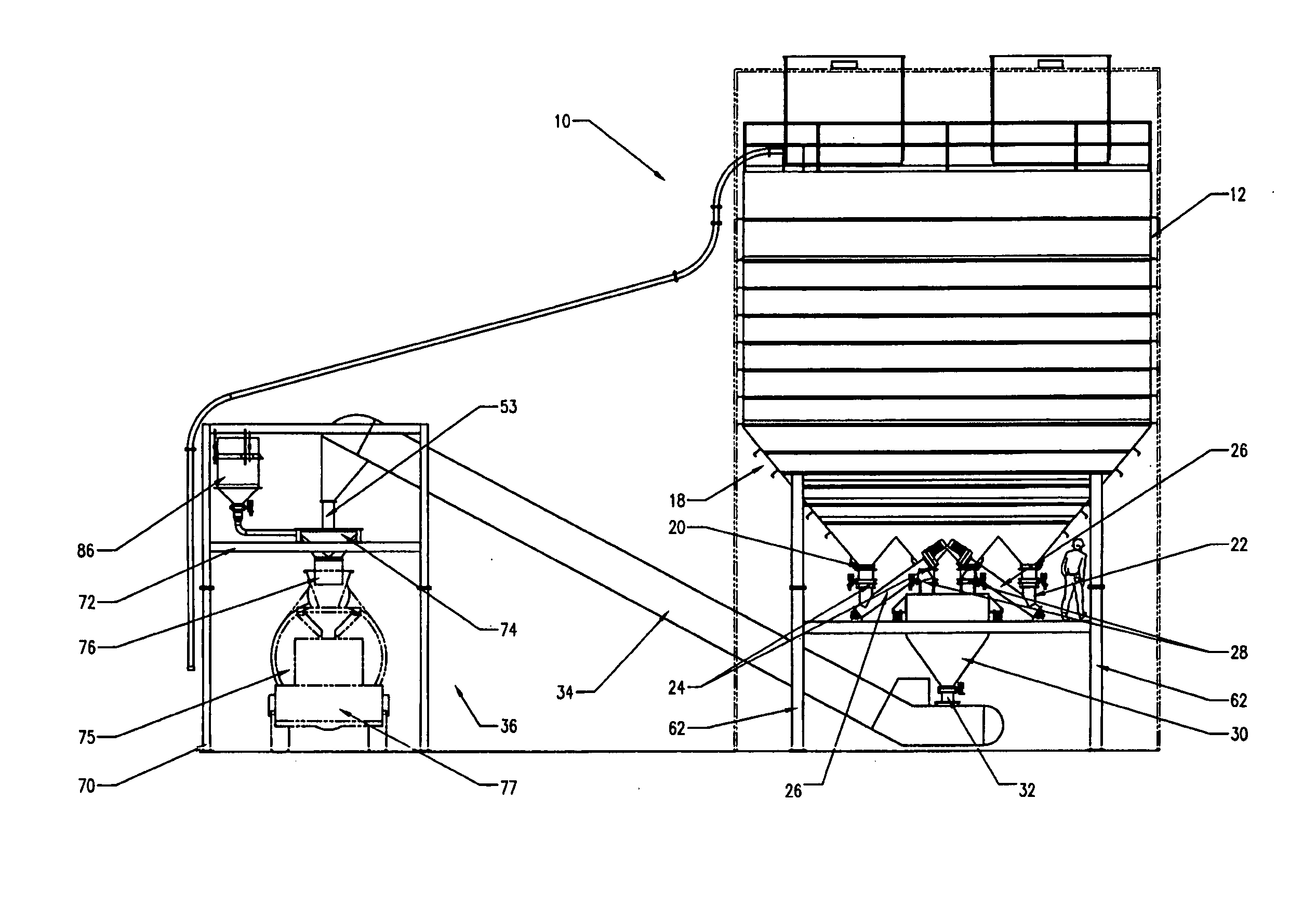

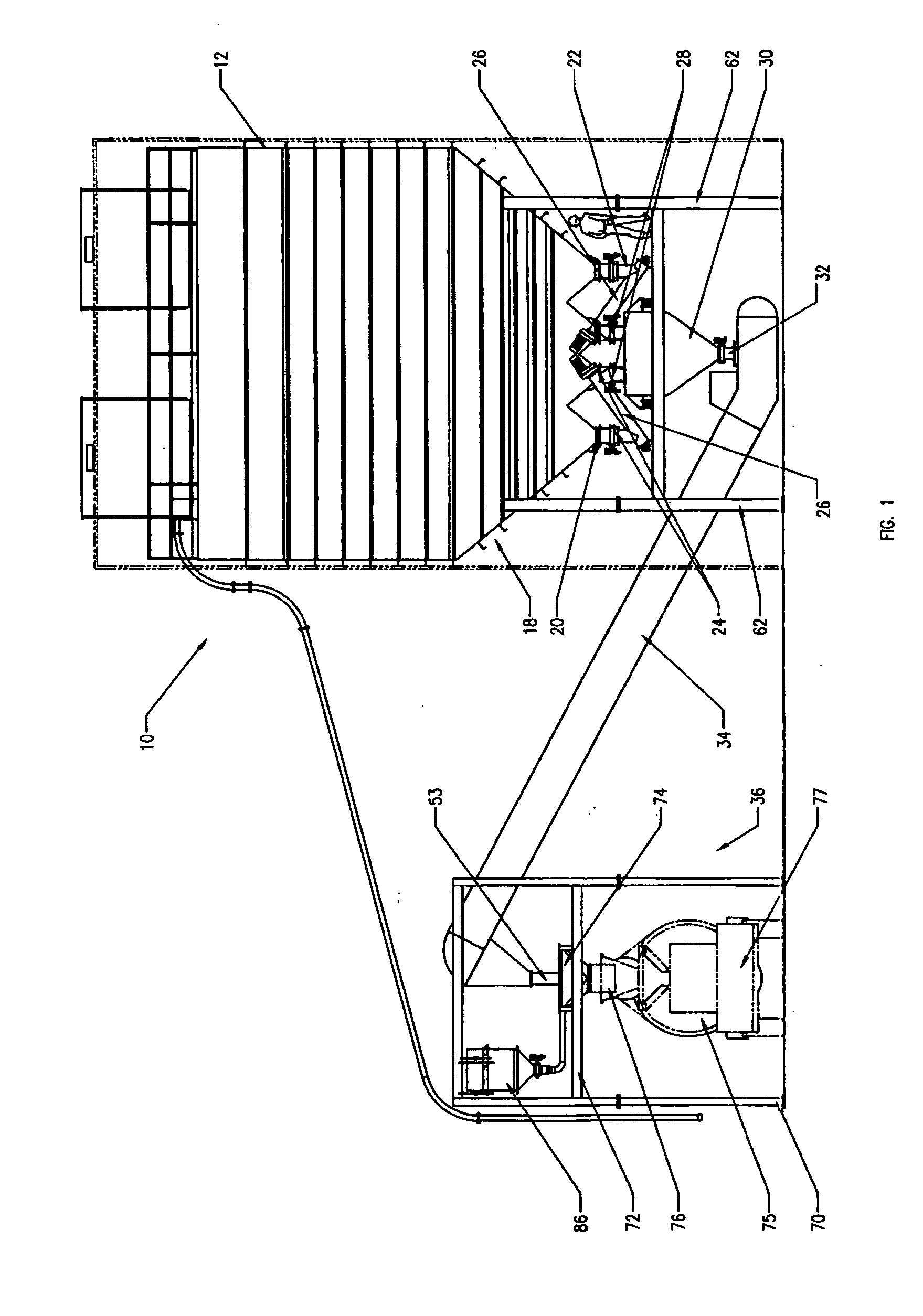

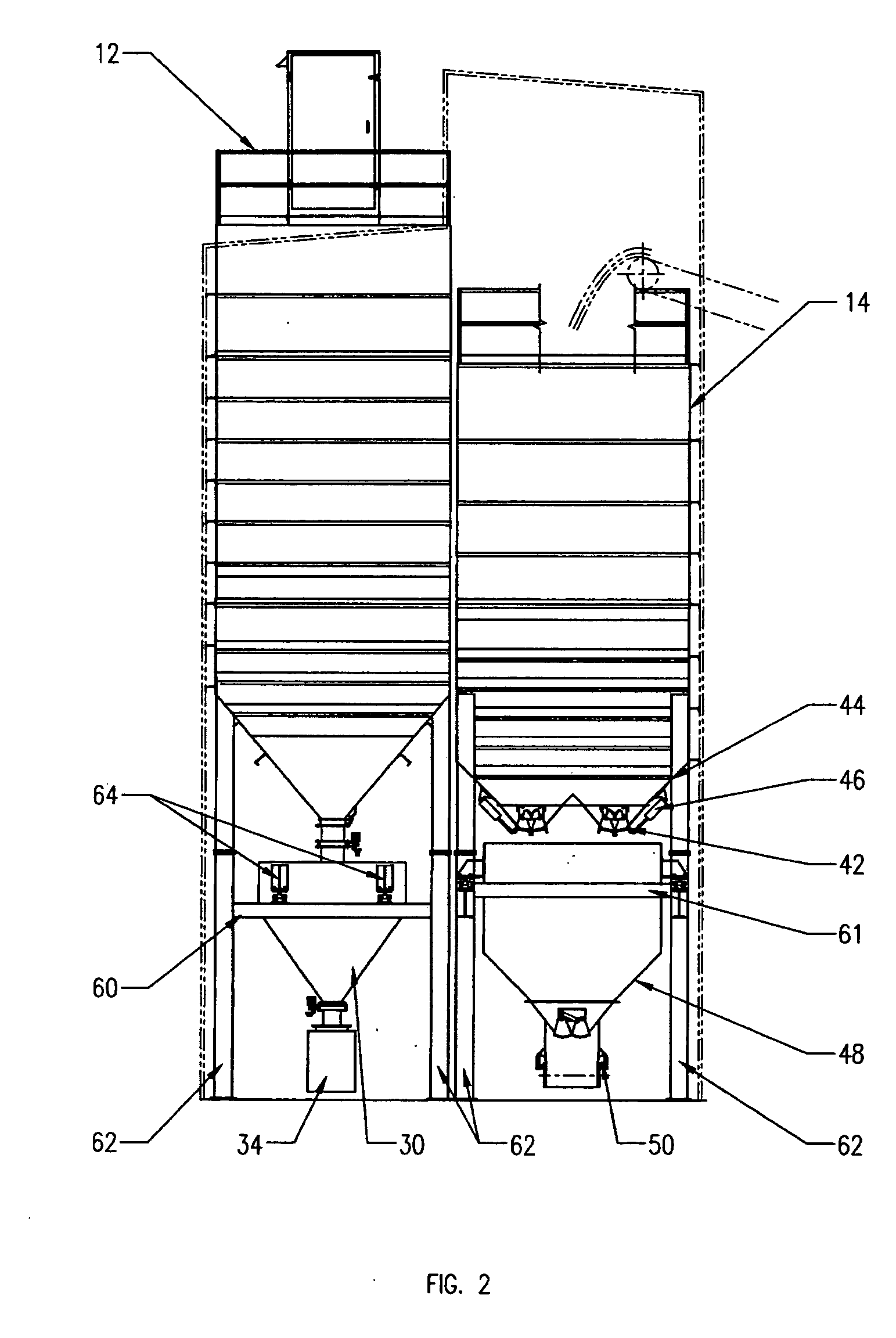

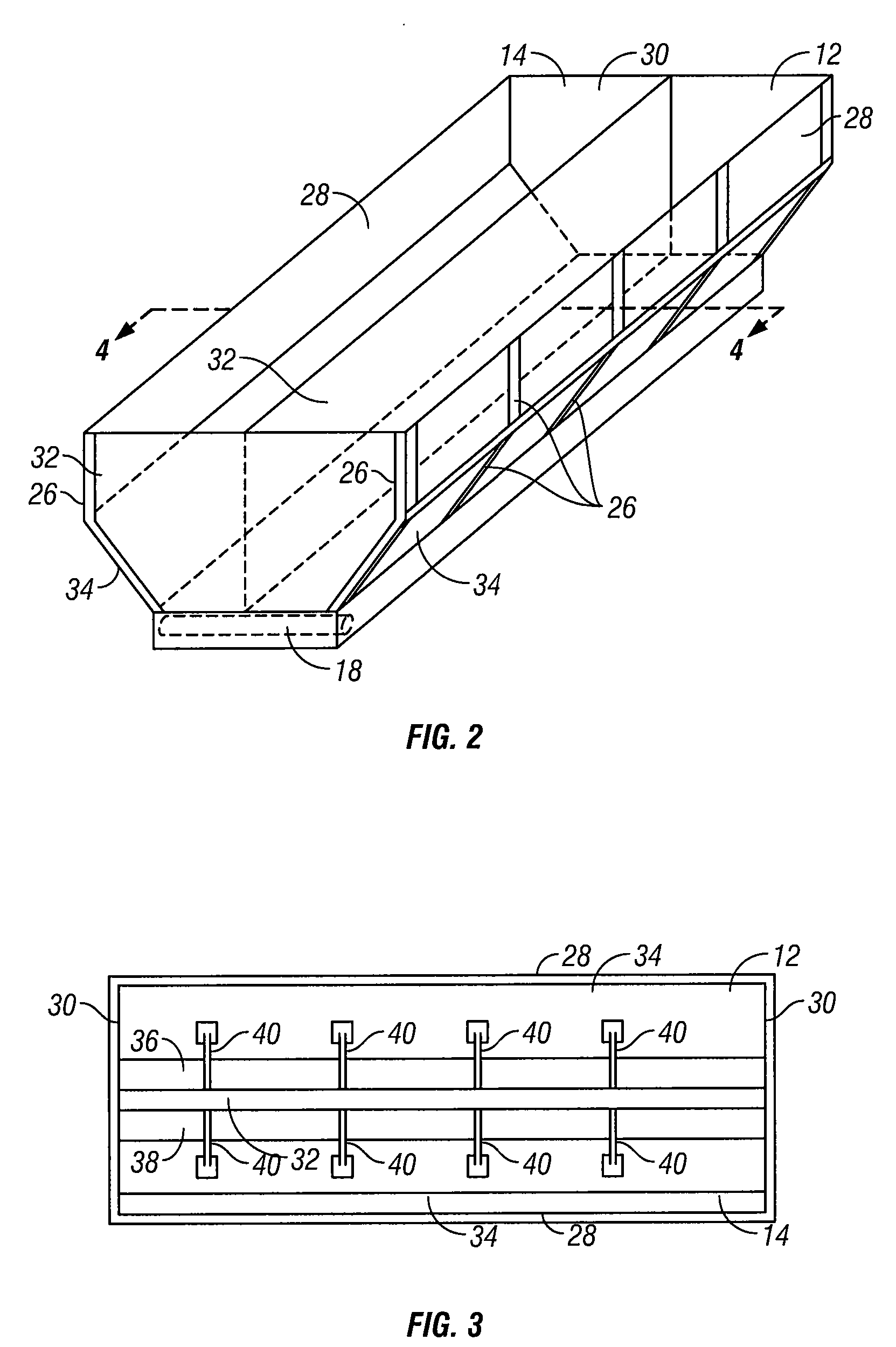

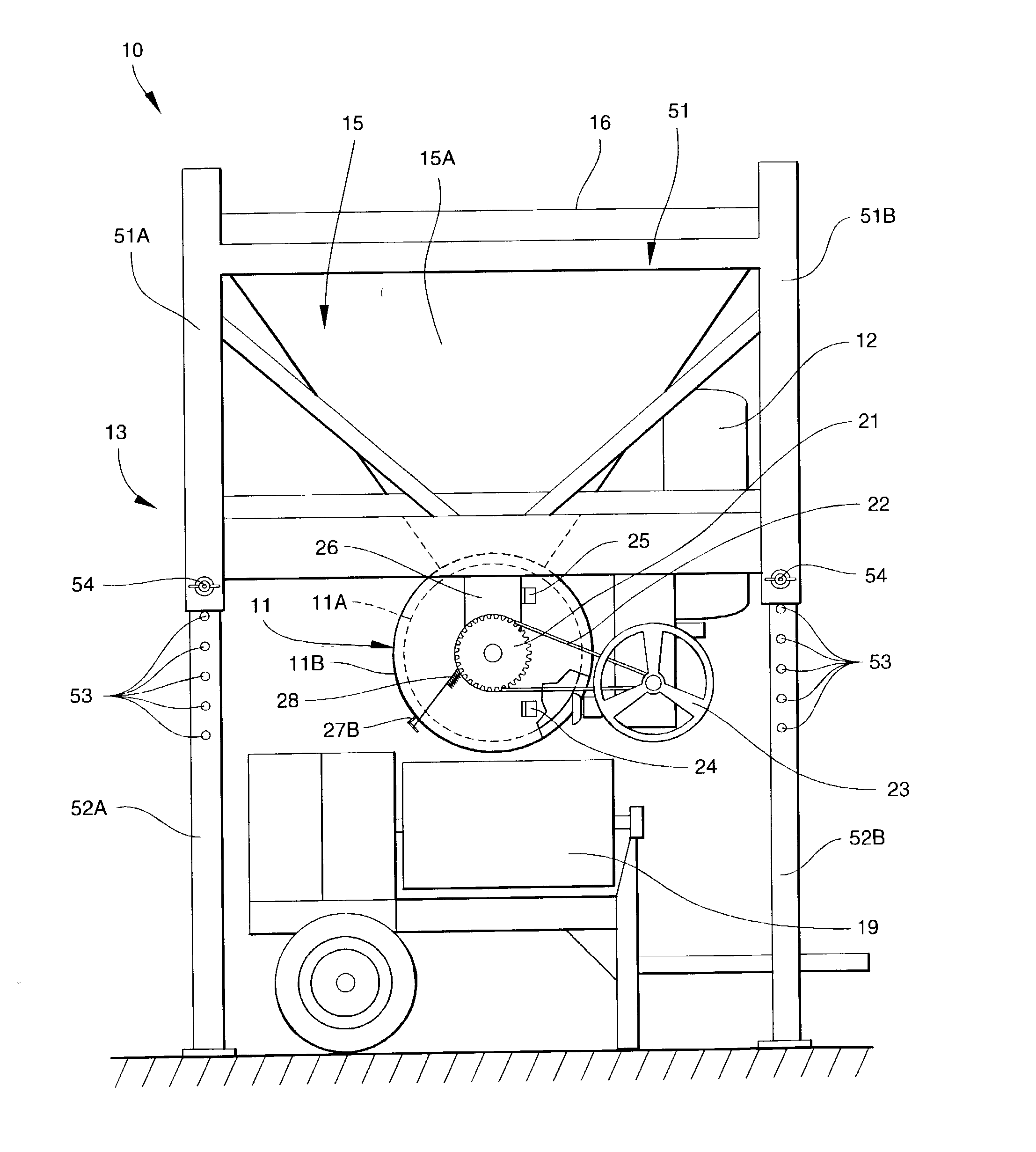

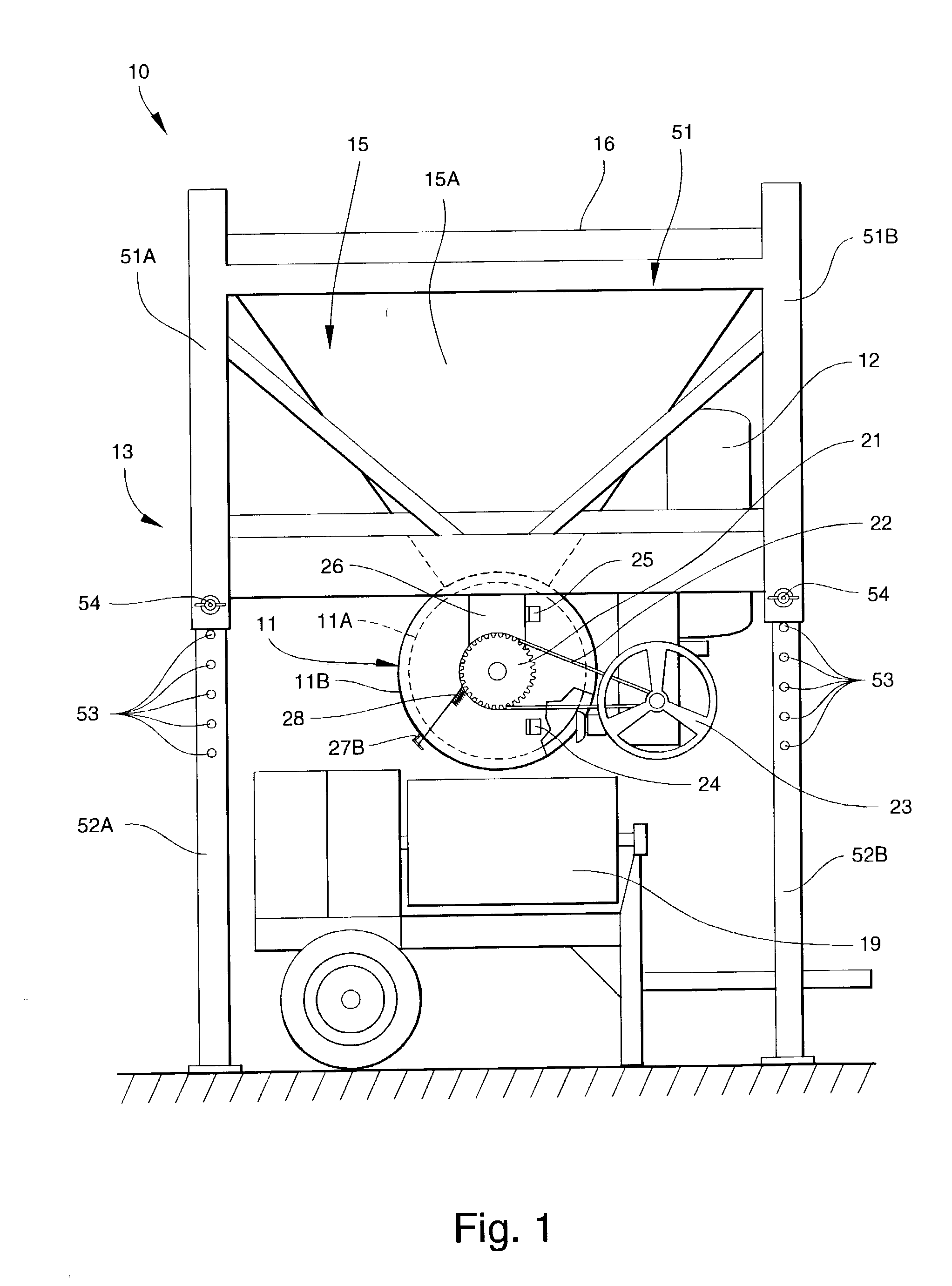

Low profile mixing plant for particulate materials

InactiveUS20050219942A1Mixing methodsMixing operation control apparatusParticulatesProcess engineering

A low profile particulate mixing plant is described. The plant is suitable for discharging the components of a particulate mixture. The plant includes a pair of storage receptacles located side-by-side. Each of the receptacles has a discharge adjacent an underside thereof to transfer a component of the particulate material mix within each receptacle to a respective conveyor at a height adjacent to ground level. The conveyor elevates the components from the discharges to a mixing station spaced from the receptacles. The plant is suitable for use as a concrete mixing plant.

Owner:WALLGREN KRIS

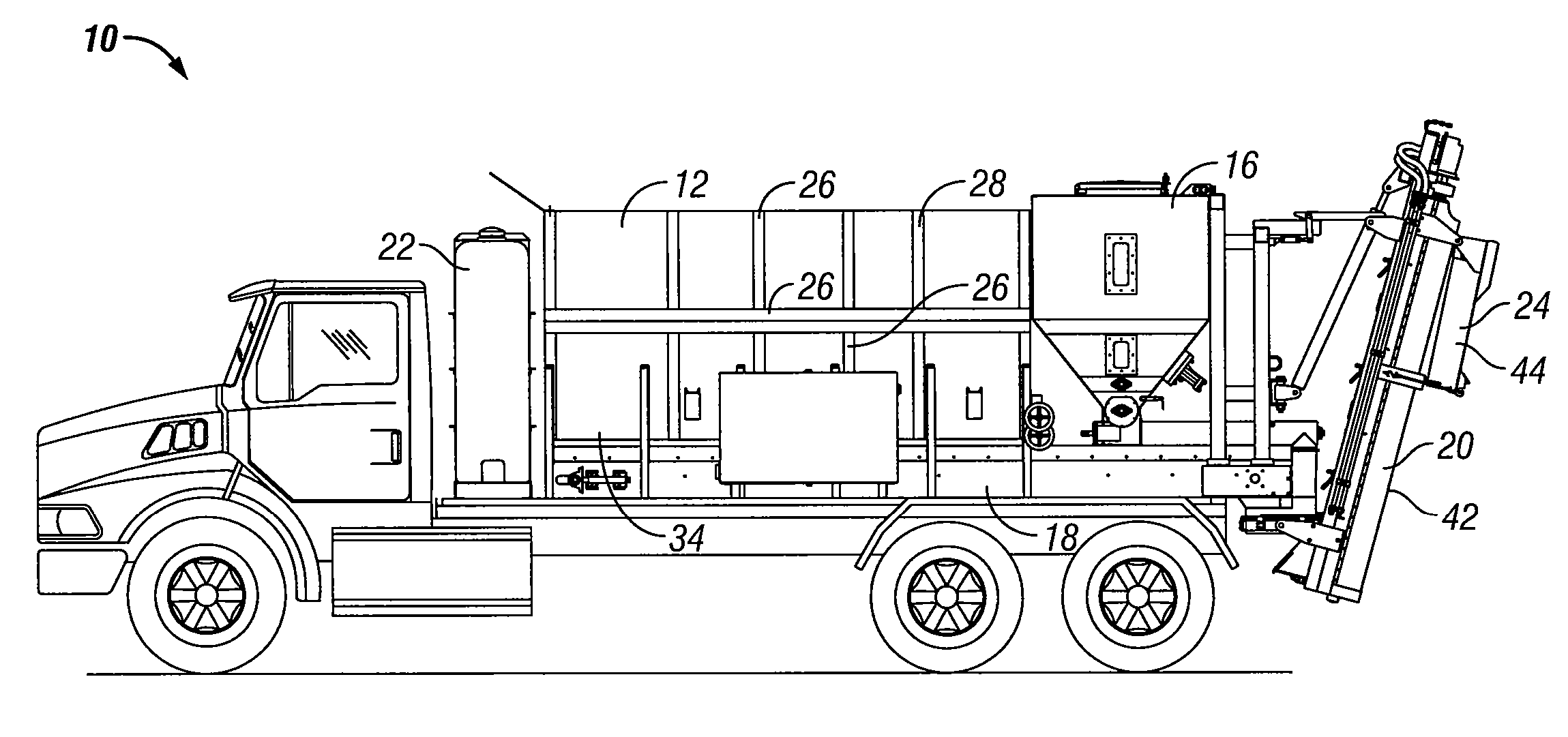

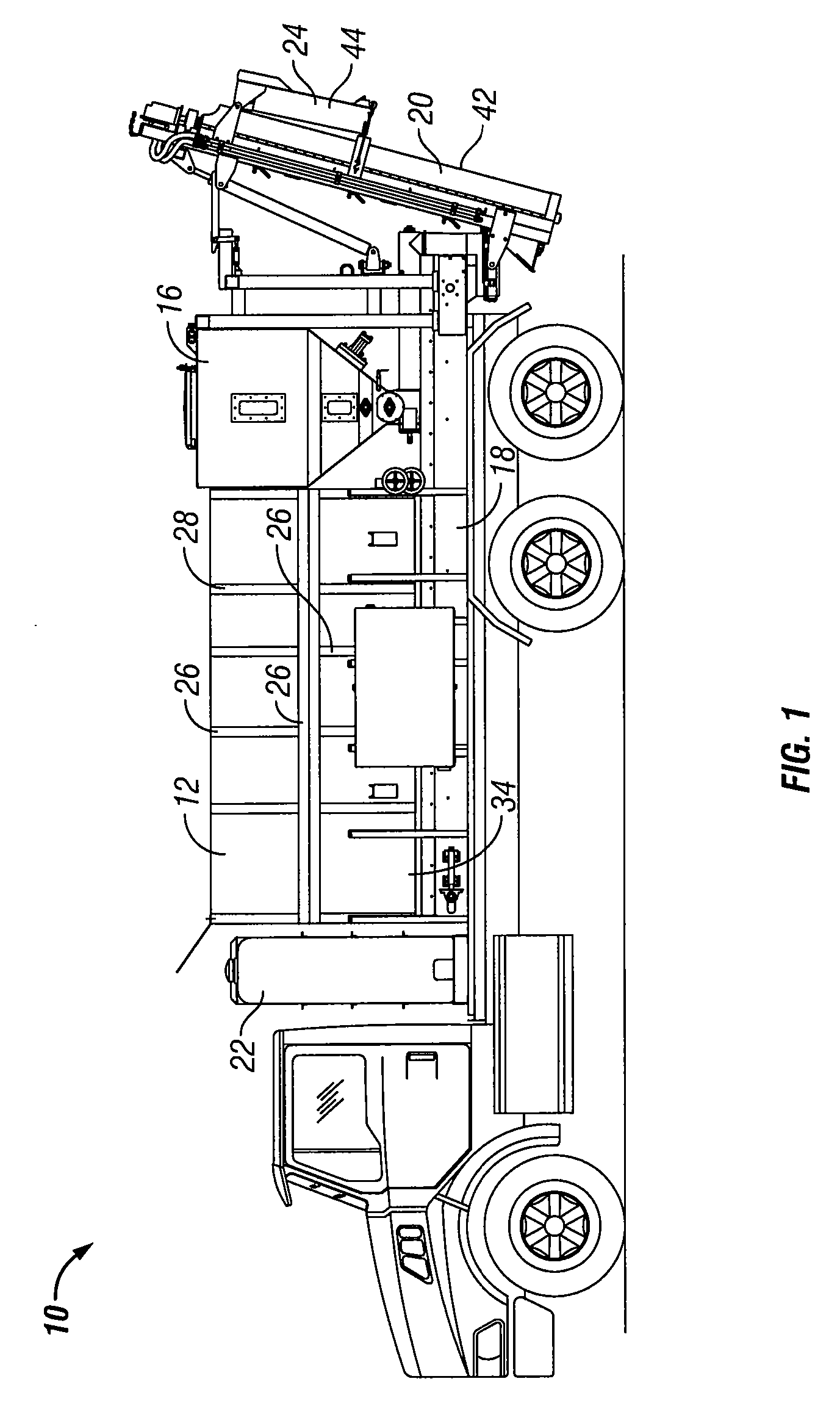

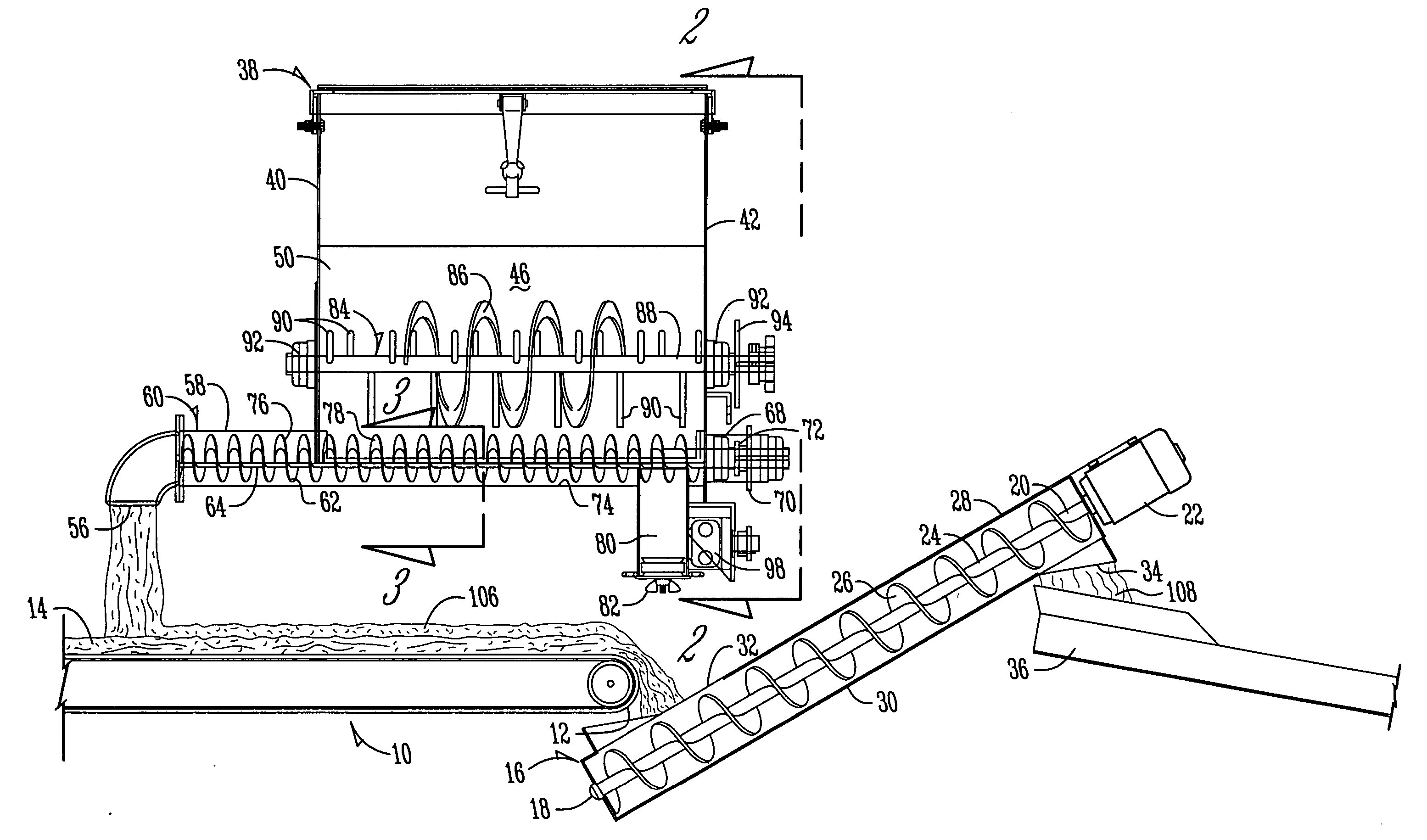

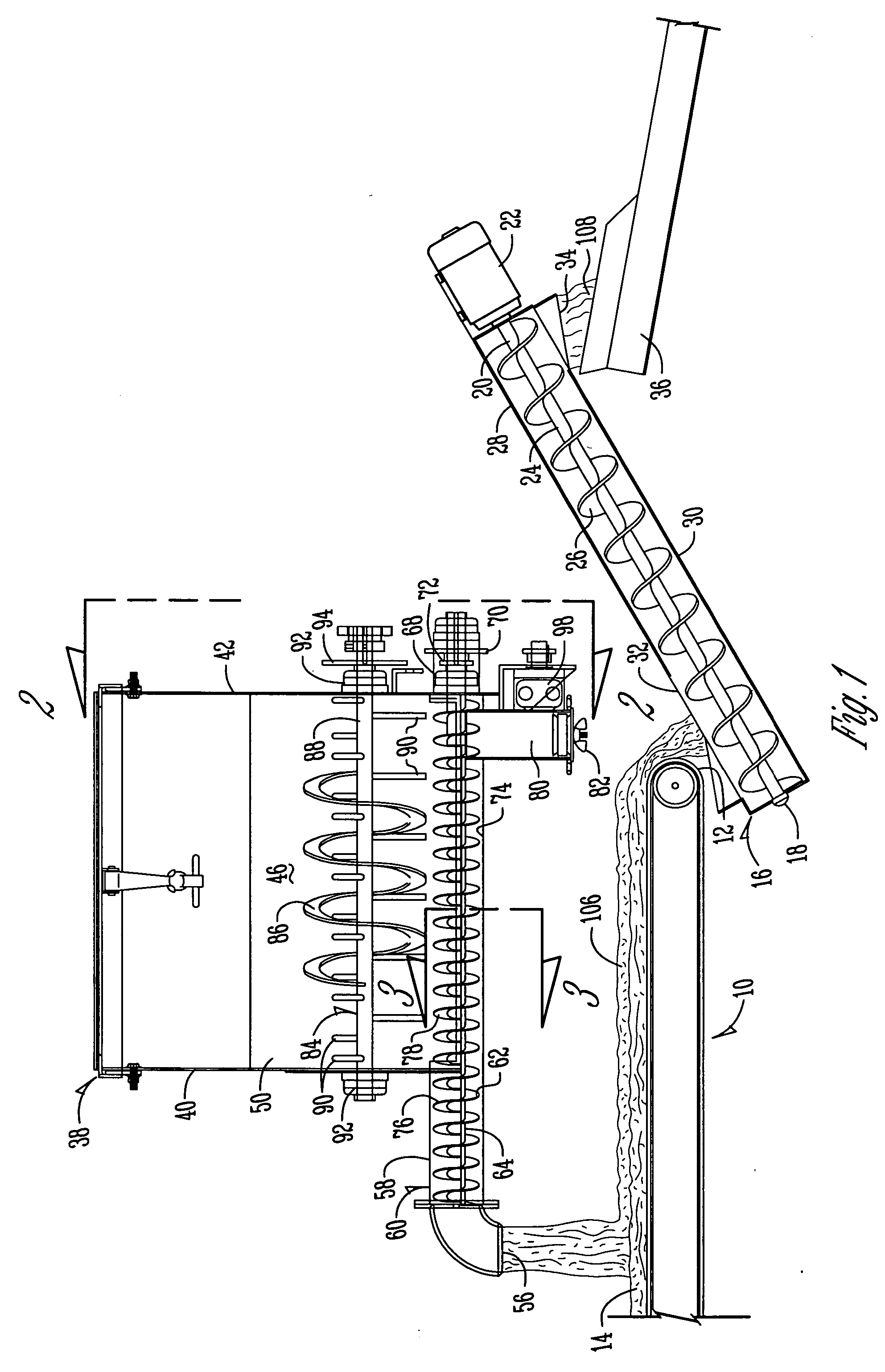

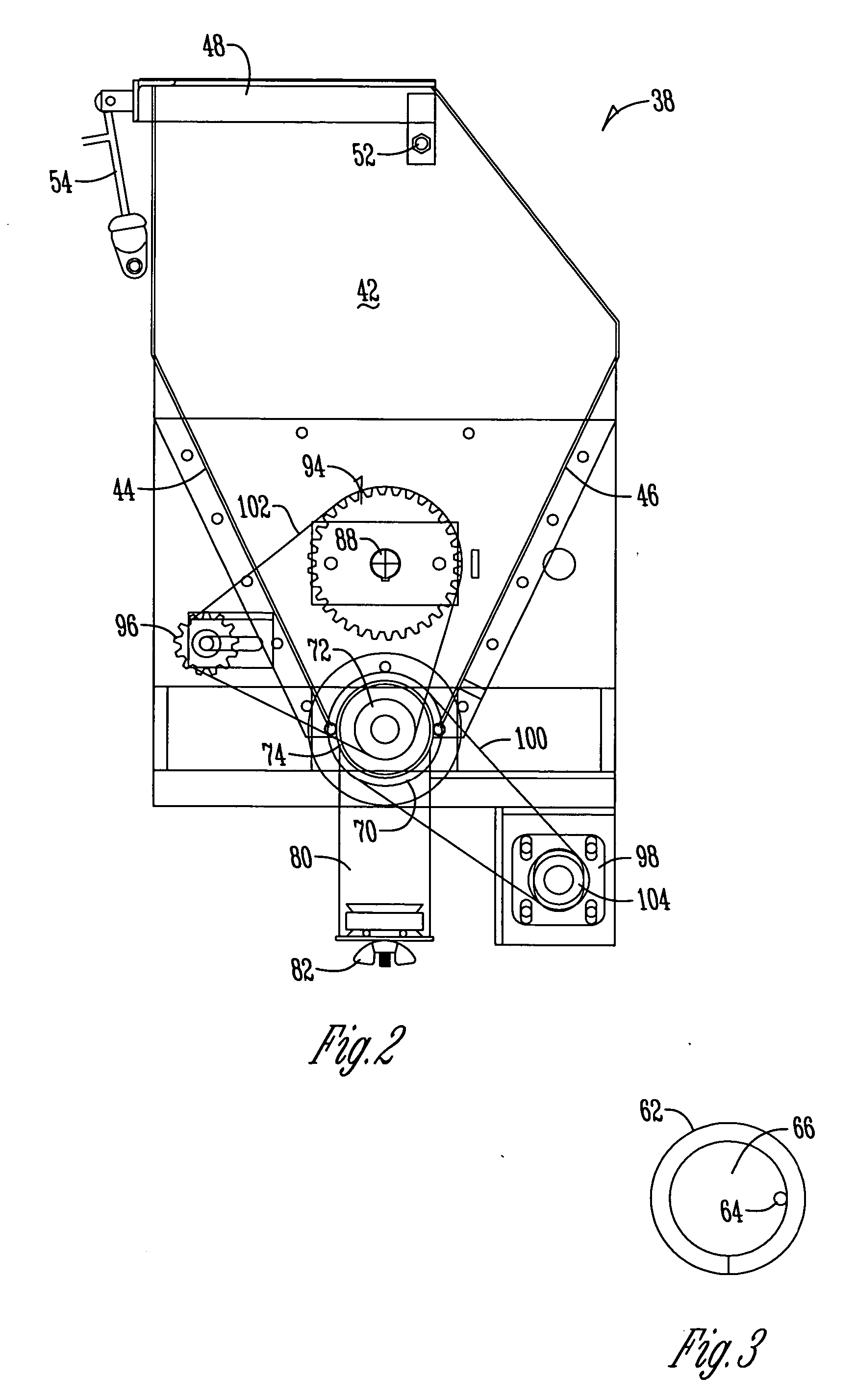

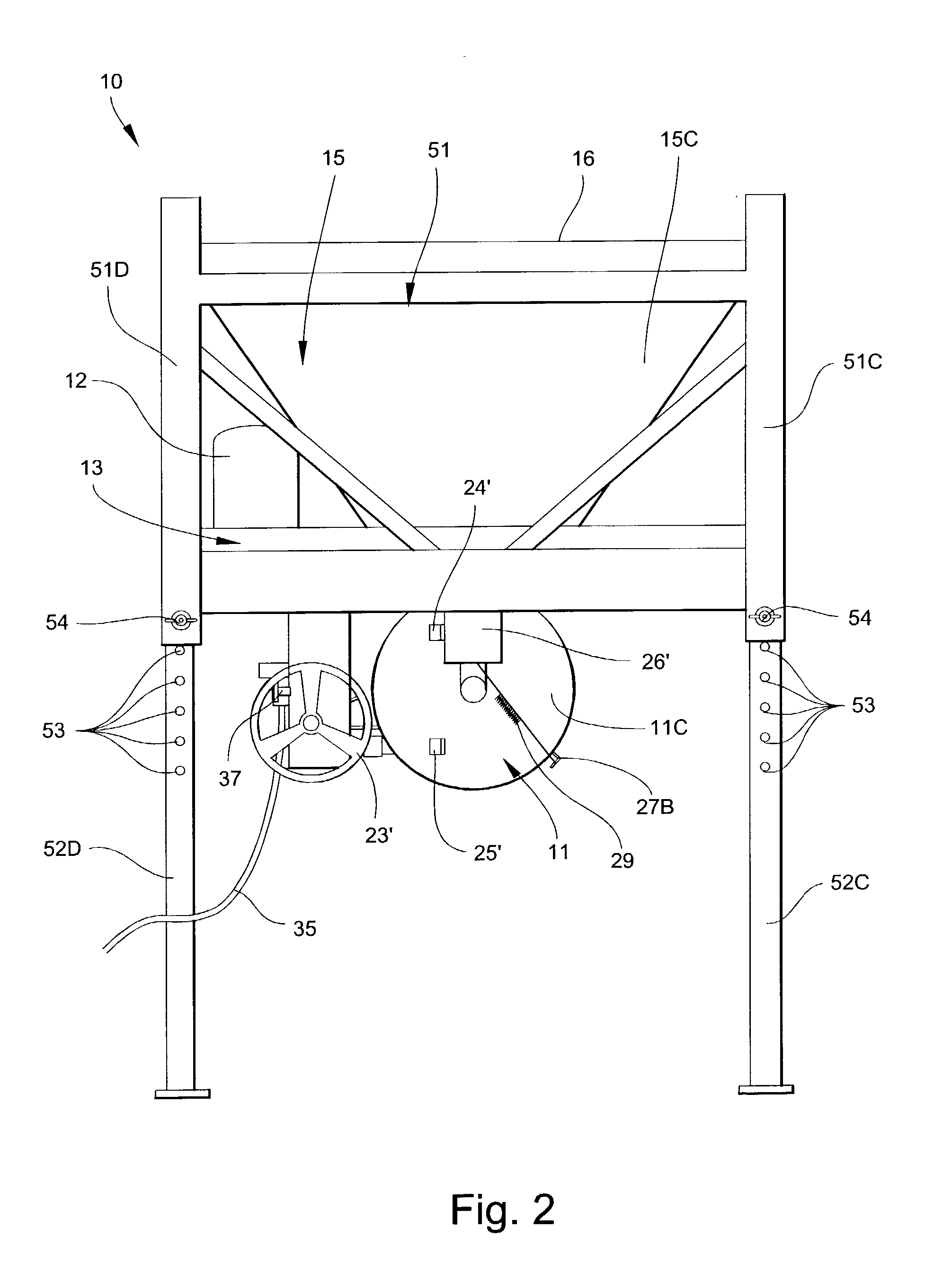

Method and apparatus for supplying bulk product to an end user

InactiveUS20050260062A1Eliminate environmental exposureEliminate product degradationTank vehiclesMixing operation control apparatusMarine engineeringEnd user

A method and apparatus for supplying bulk material to an end user includes the step of providing a bulk material source that is at a location distant from the end user and a specially configured vessel and trailer apparatus for transporting the bulk material to the end user. The vessel is filled with bulk material at the bulk material source and then transported with a specially configured trailer. Alternatively, at source or destination, the vessel can remain as a temporary storage device, free-standing from the trailer. Other similar container configurations are provided as alternate containers for use with the method of the present invention. During transport between the bulk material source and the end user, the vessel is filled or partially filled with a selected bulk material. During transport, the vessel is in a generally horizontal position, supported by the trailer and a specially configured elevator. The vessel is unloaded from the trailer by moving the vessel longitudinally along the trailer and by transferring the vessel from a generally horizontal position upon the trailer to an elevated upright position. The vessel is then lowered from the elevated position to a lowered, final installed position that is behind the trailer. The vessel is preferably loaded with between about 1 and 50,000 pounds of bulk material. The vessel preferably has a volume of between about 500 and 2,000 cubic feet. The same trailer can be used to load an empty vessel. Specially configured outriggers help align the elevator with the vessel during loading of a vessel to the trailer. Different connecting frames can be used as an interface between the elevator and the vessel for differently configured vessels. In an alternate embodiment a trailer—rail—trailer system is disclosed wherein a trailer to transport a vessel to a first terminal, a special rail frame is attached to the vessel enabling a rail car to transport the vessel from a first to a second terminal and a trailer can transport the vessel from the second terminal to a worksite.

Owner:TILT TANK L L C

Two-part storage and mixing device for the production of a bone cement, and pertinent method

Owner:HERAEUS MEDICAL

Containerised handling of bulk materials and appts therefor

A freight container (10) has a base (20) or a portion thereof that can be opened to discharge its contents. This container (10) has a top which can be opened in similar manner as the base. Another container having at least one compartment, each compartment having a lower section with a reducing cross-sectional area and a pivotably operable closure assembly, with several such closure assemblies being linked together by means of bars. Such a container is used to contain raw building materials for stockpiling of these materials at a container port. It is also used to supply materials to a concrete production plant whee pollution control containers are provided below the supply container and above the scaling and mixing stations to reduce particulate pollution. A pair of slewing apparatuses is also provided to engage both ends of a container and turn the container over about its longitudinal axis, thereby emptying its contents.

Owner:王美金

Bin gate for providing variable output flow rates

InactiveUS20070215238A1Precise and Efficient ControlPromote sportsClosuresMovable measuring chambersEngineeringTarget weight

An assembly for controlling delivery of material from a bin opening includes a movable bin gate for closing the bin opening and providing a high flow rate of material when the movable gate is open, wherein a low flow aperture is formed in the bin gate to provide a low flow rate of material when the bin gate is positioned such that only the low flow aperture is open. A two-stage flow enhancer within the bin includes a first stage for impelling material in the direction of the low flow aperture and a second stage for impelling material to exit through the low flow aperture. A controller controls operation of the bin gate to adjust a flow rate of material from the bin opening. The controller may include a sensor for providing an actual weight value of material present in a receiving bin and a memory for storing a target weight value for the amount of material in the receiving bin, wherein the controller adjusts the position of the bin gate and the low flow aperture in response to the actual weight value and the target weight value. The bin gate may also be adjusted in response to one or more tolerance values defining proximity to the target weight value and / or in response to one or more threshold weight values, wherein the threshold weight values are less than the target weight value. A method for controlling delivery of material from a bin opening includes the steps of providing at the bin opening a movable bin gate with a low flow aperture and selectively positioning the bin gate using a single actuator to expose only the low flow aperture to the bin opening for material flow or to expose substantially all of the bin opening for material flow.

Owner:MIXER SYST

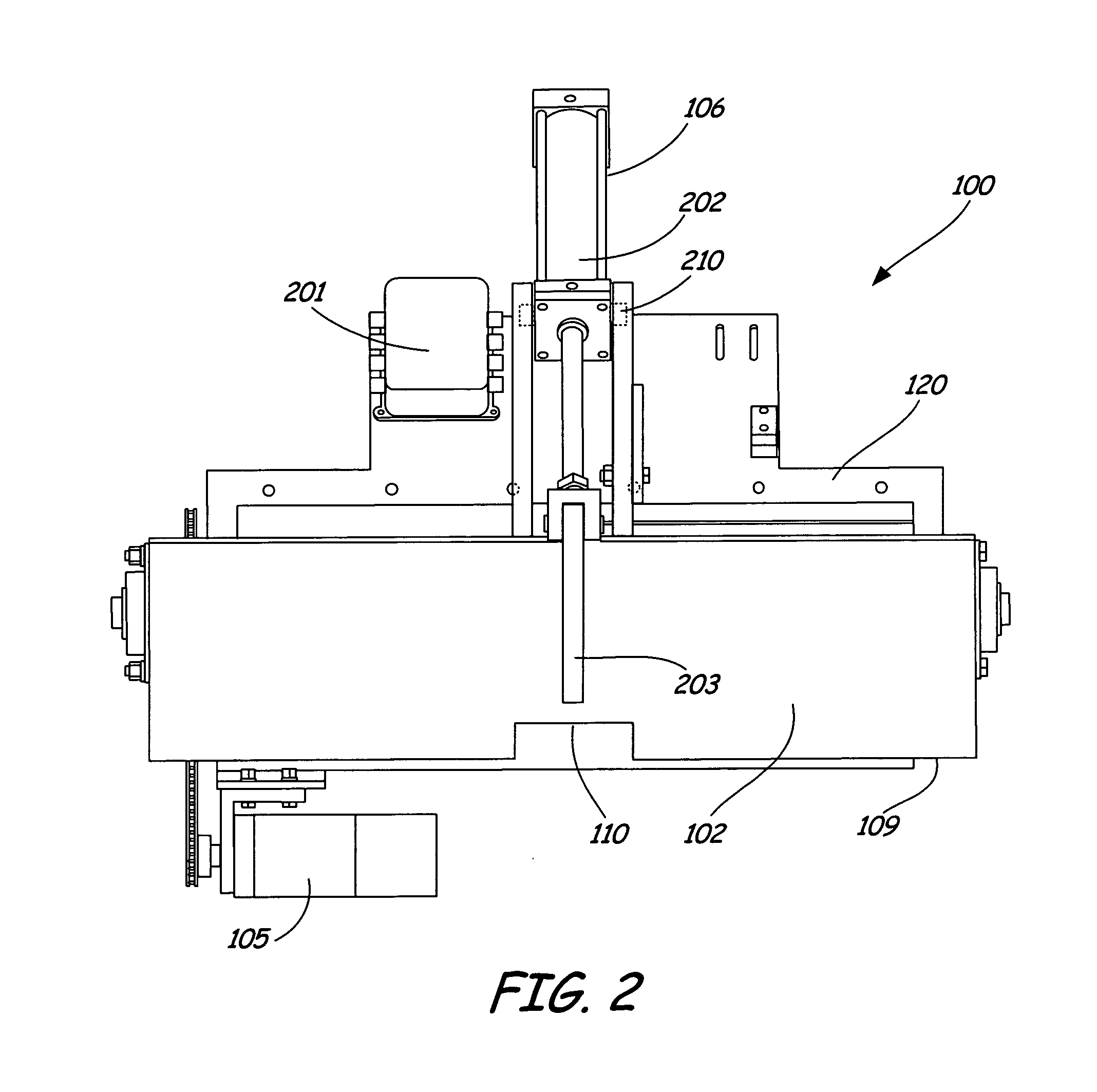

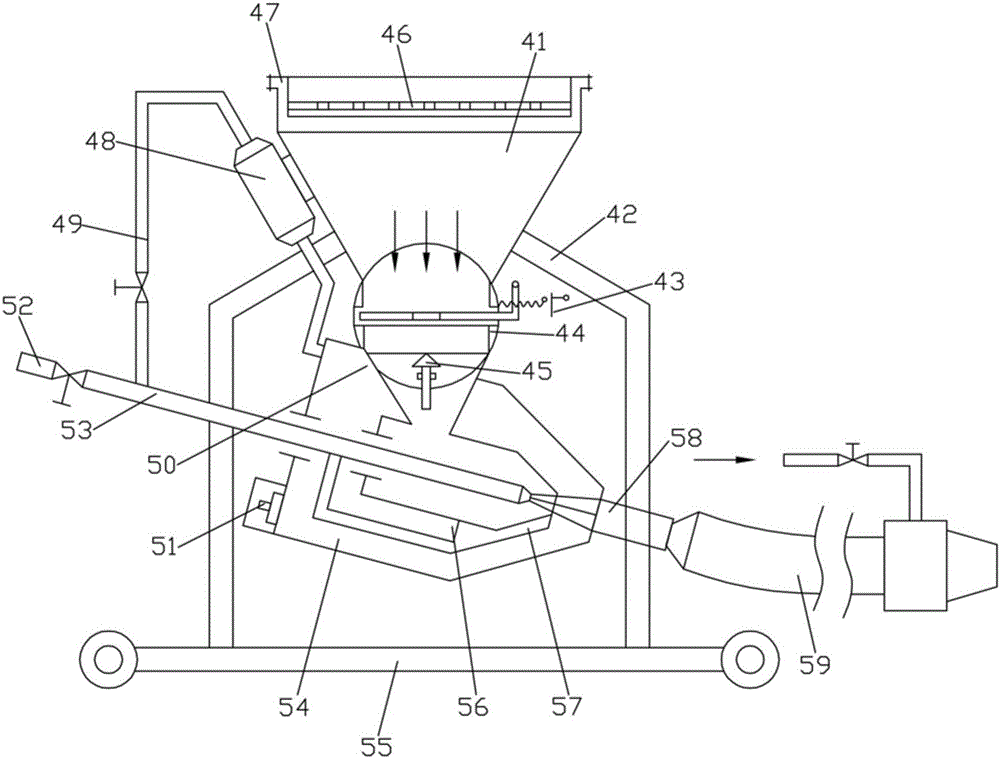

Improved volumetric cement mixer

InactiveUS20070189109A1Reduce coefficient of frictionEliminates bridging problemDischarging apparatusMixing operation control apparatusMaterials scienceExpanded metal

An improved volumetric cement mixer has bins, containers, and troughs formed from UHMW material reinforced with expanded metal. A metal skeletal frame supports the UHMW walls of the sand and gravel bins, while mininizing the weight of the mixer. The UHMW troughs for the boot mixer and discharge chute improve product flow and mixing, and simplifies cleaning of the troughs.

Owner:CEMEN TECH

Apparatus and method for adding pigmentation to concrete mix

ActiveUS20050276152A1Discharging apparatusMixing operation control apparatusEngineeringPigmentations

Owner:CEMEN TECH

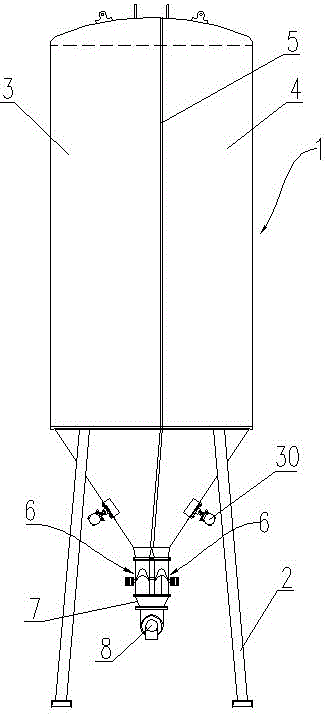

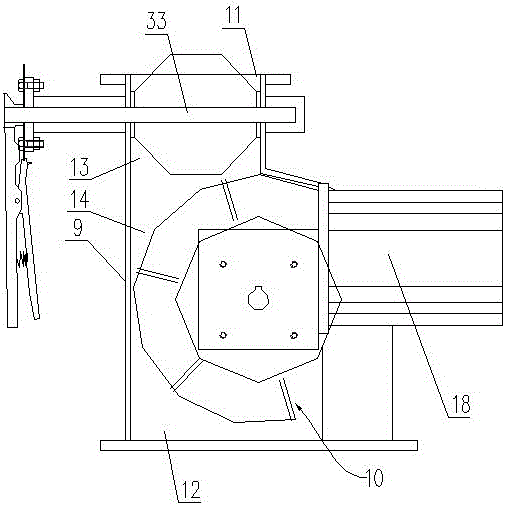

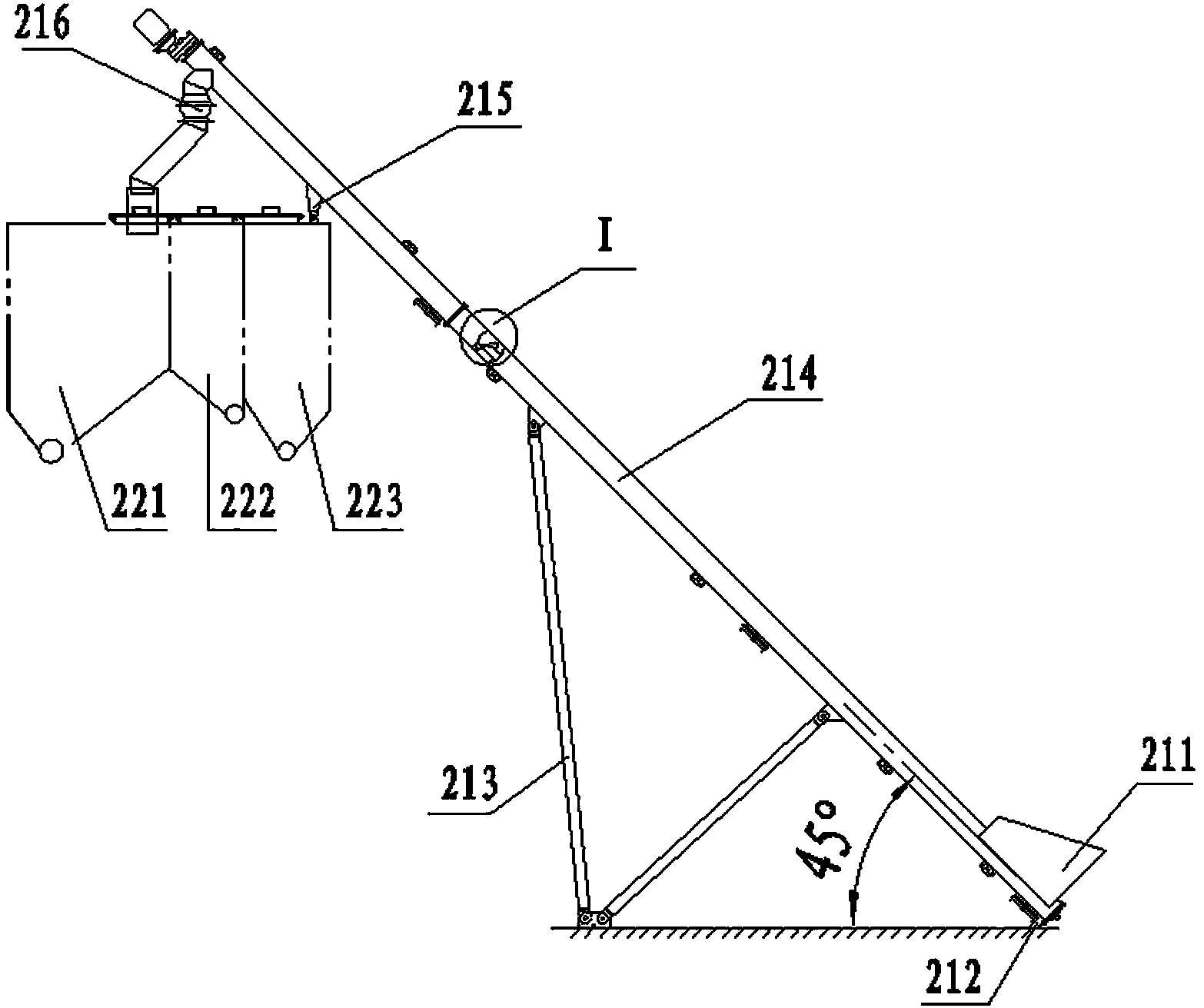

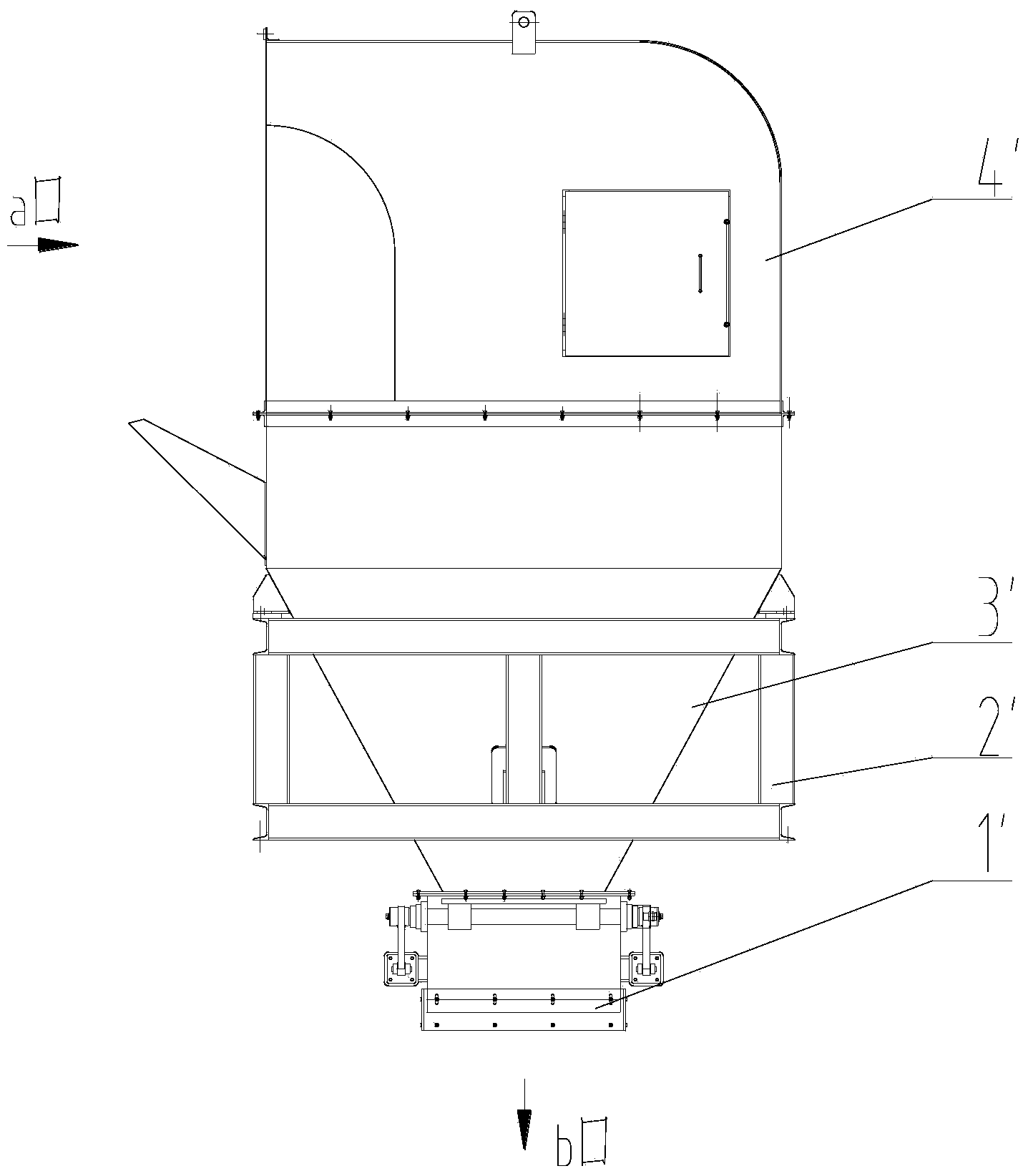

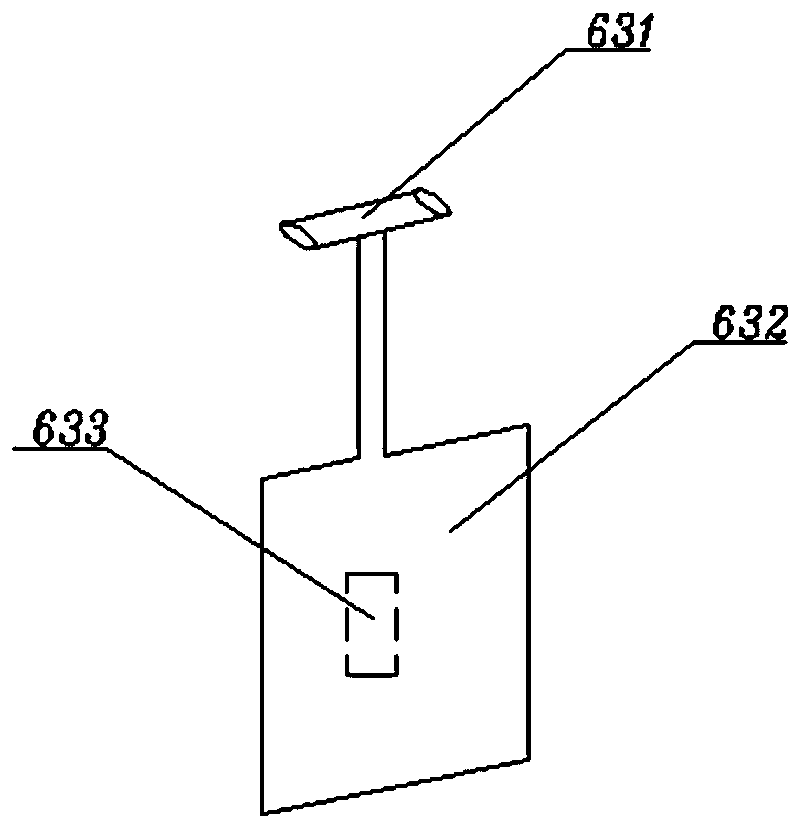

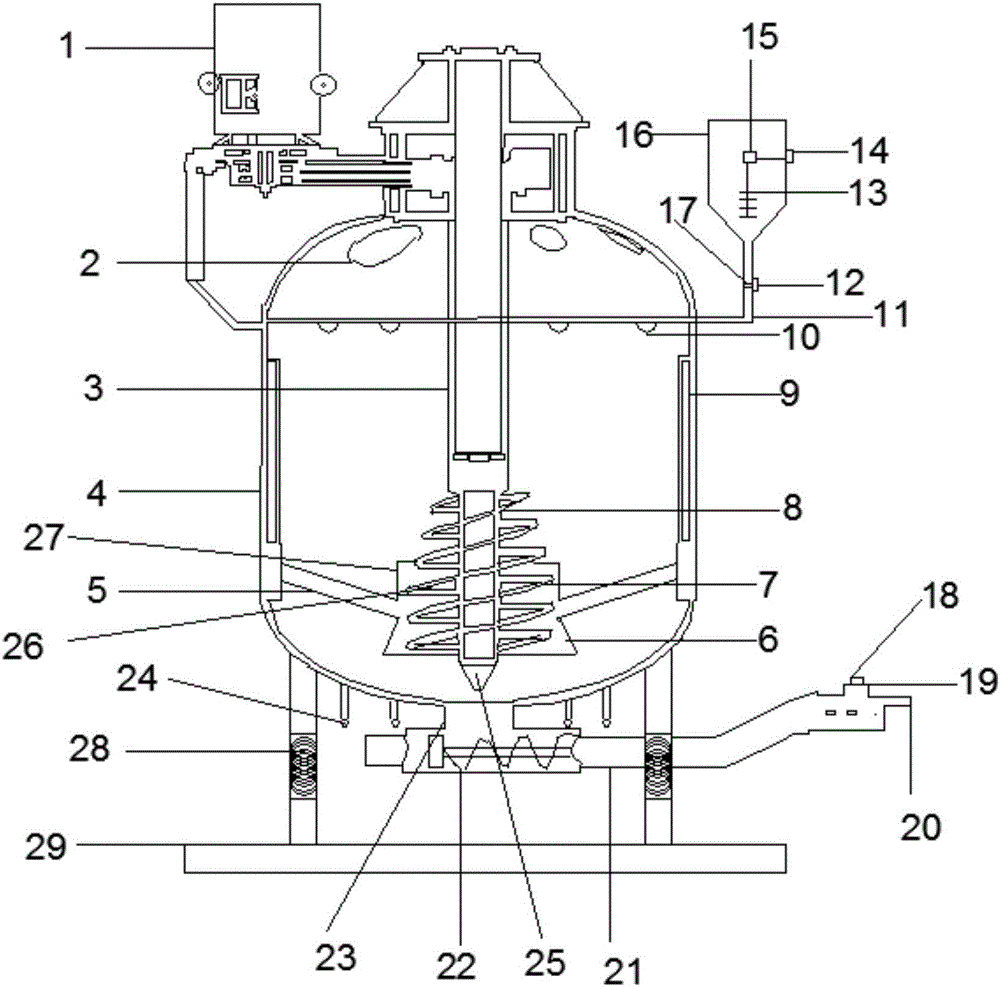

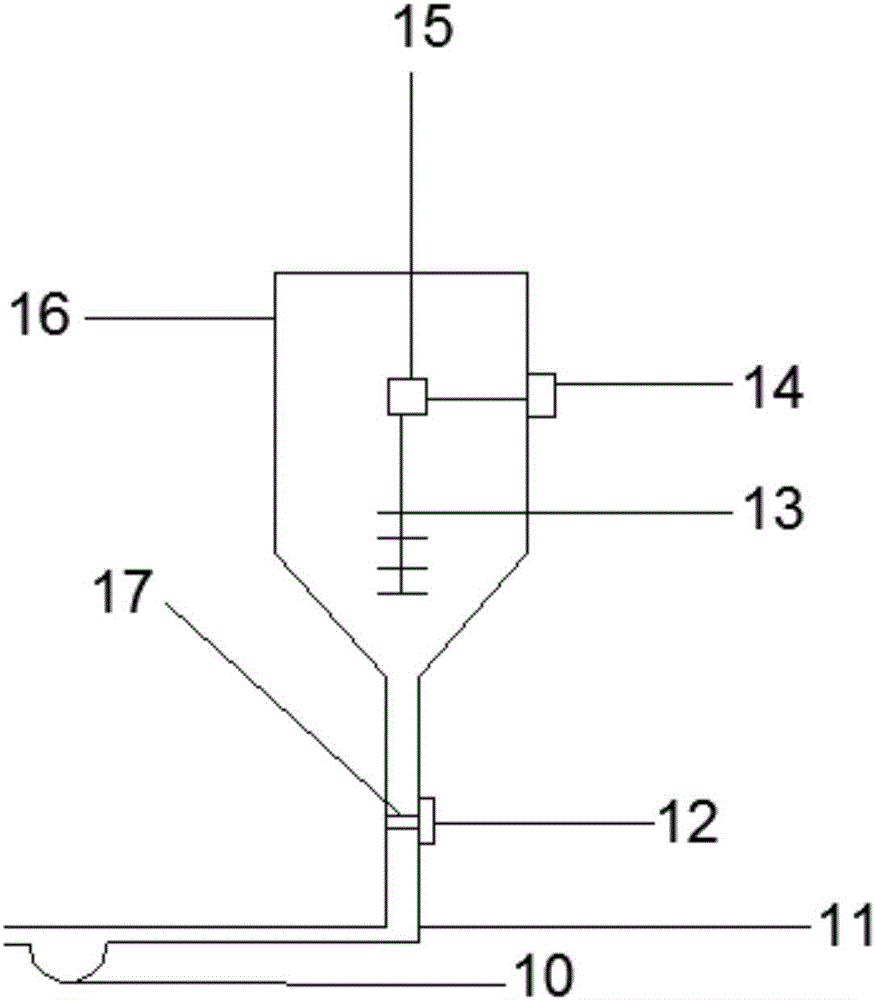

Double-bin proportioning mortar storage tank

ActiveCN105773842AHigh outputEasy to recordMixing operation control apparatusLarge containersBiochemical engineeringUltimate tensile strength

The invention relates to a double-bin proportioning mortar storage tank which comprises a storage tank body (1) and supporting leg (2) assemblies which are fixedly arranged at the lower part of the storage tank body (1) and have the action of supporting, wherein a bin partition plate (5) used for dividing an inner cavity of the storage tank body (1) into an aggregate bin (3) and a cement bin (4) is arranged in the storage tank body (1); the lower end of the storage tank body (1) is divided into an aggregate discharge hole and a cement discharge hole by the bin partition plate (5); quantitative feeding mechanisms (6) are fixedly arranged at the aggregate discharge hole and the cement discharge hole respectively; the lower ends of discharge holes of the quantitative feeding mechanisms (6) simultaneously communicate with the feeding end of a mixing vessel (7); and the discharge end of the mixing vessel (7) communicates with a feeding hole of a continuous stirrer (8) which is fixedly arranged below the storage tank body (1). With double bins, he double-bin proportioning mortar storage tank can simultaneously store aggregates and cement, can conveniently and rapidly realize accurate proportion in the blanking process, can effectively weakens the labor intensity of a worker, can simplify the operation procedure and can also dramatically improve the operation efficiency.

Owner:XUZHOU TIANLONG HYDRAULIC MACHINERY

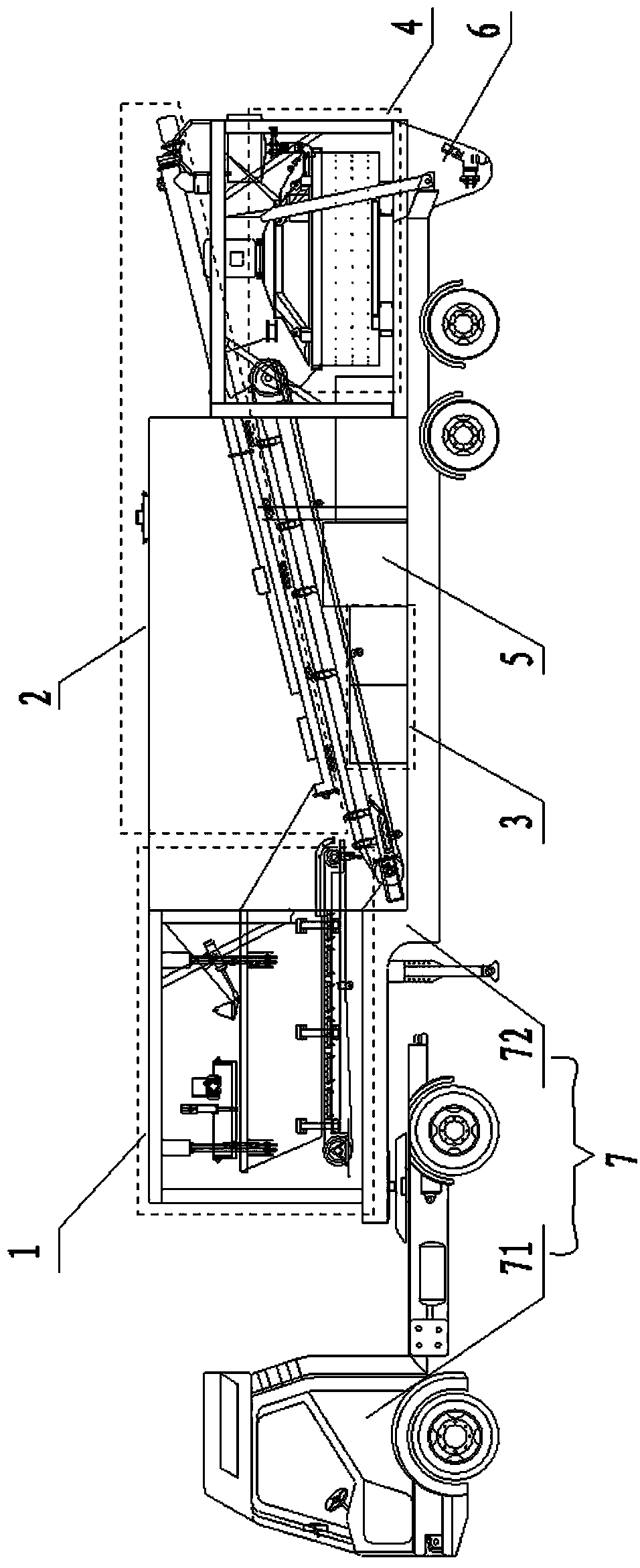

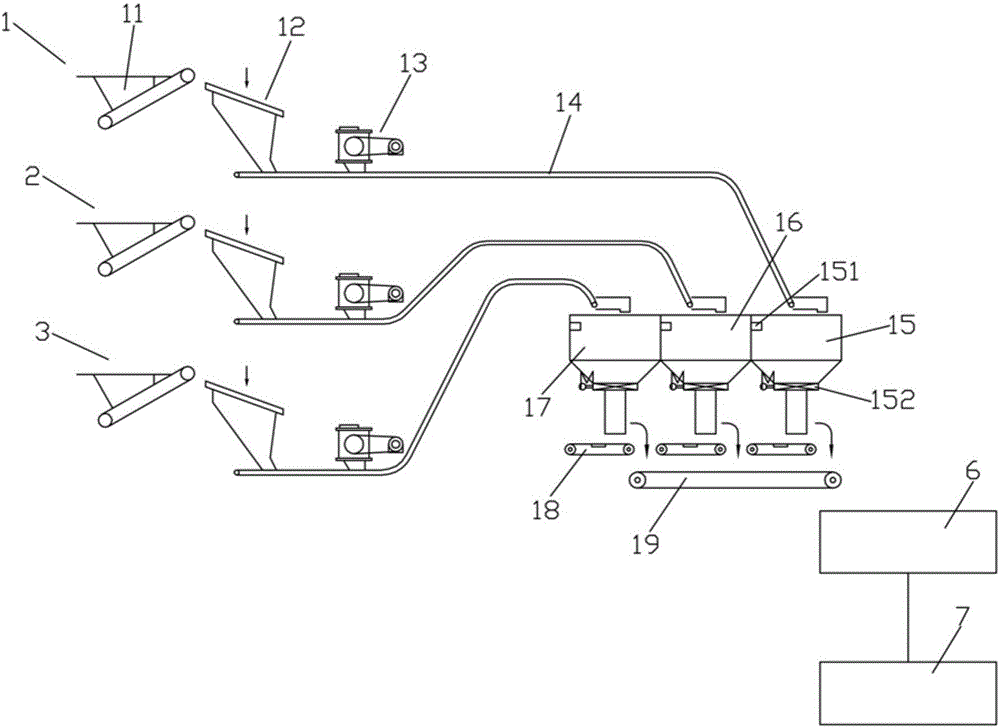

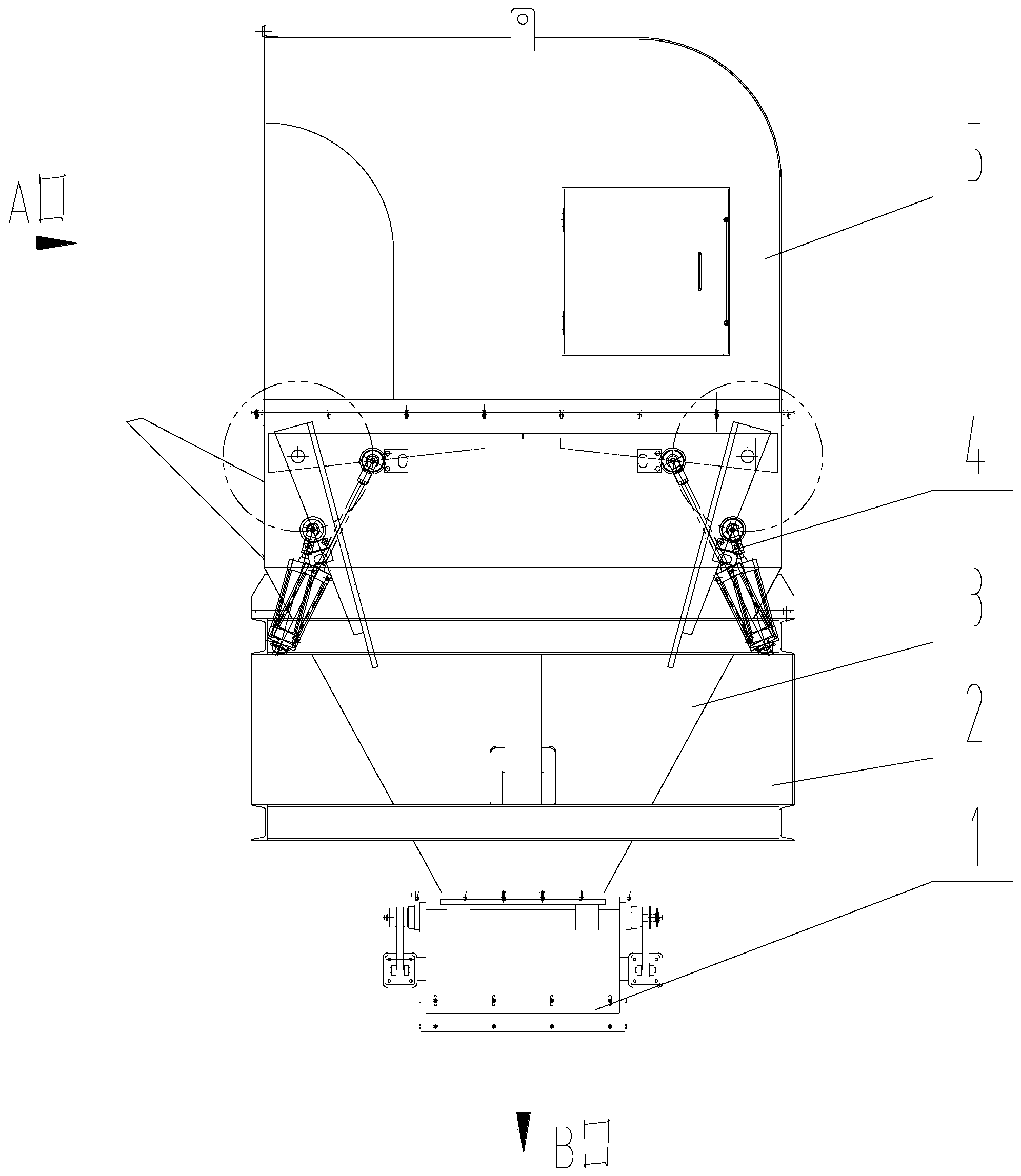

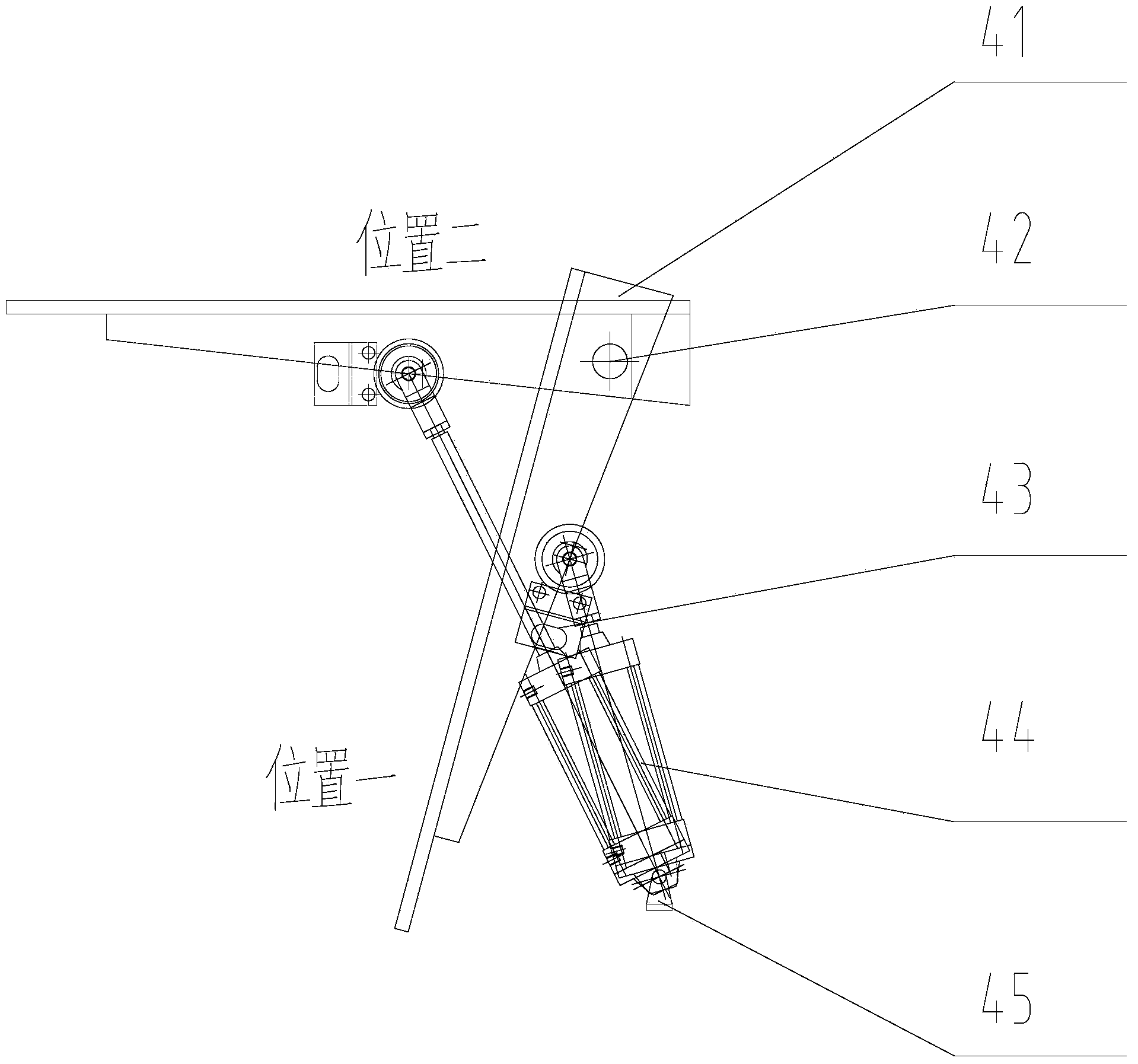

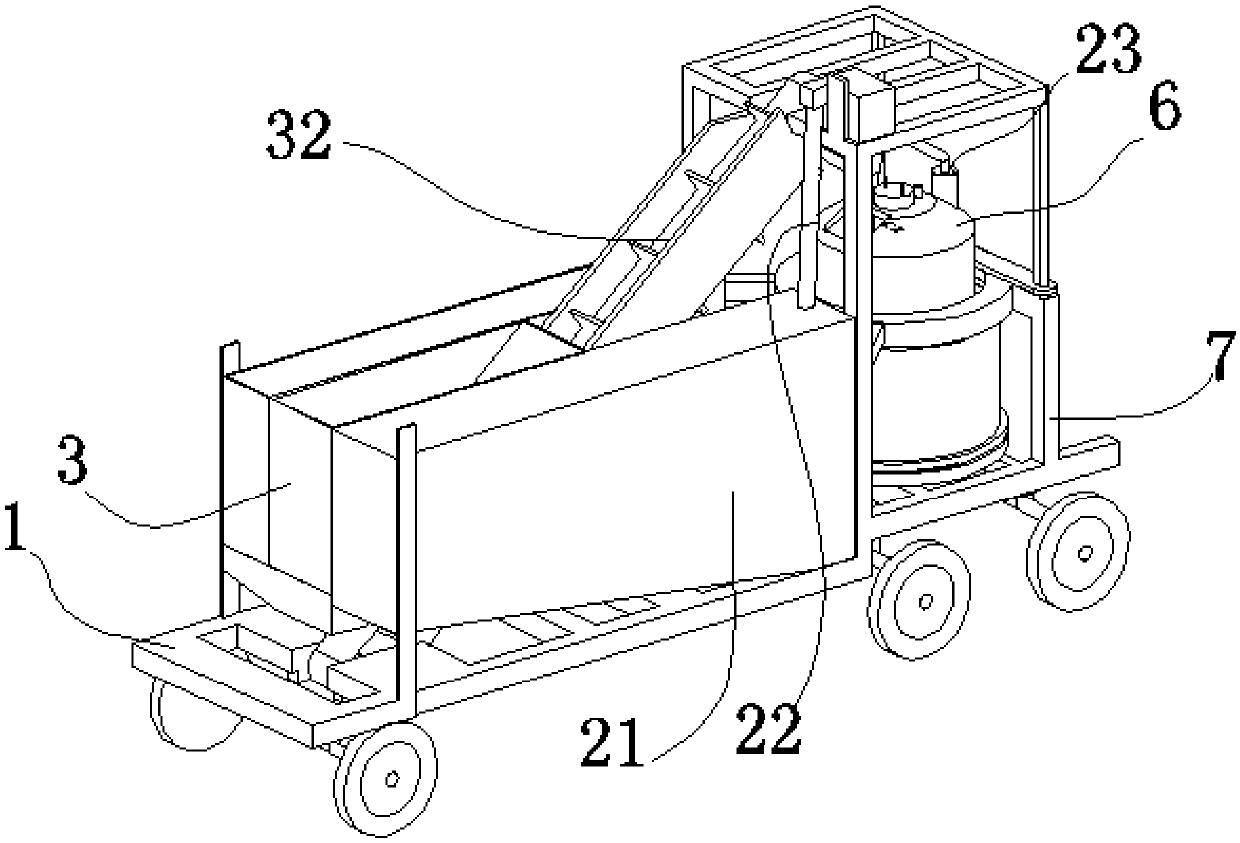

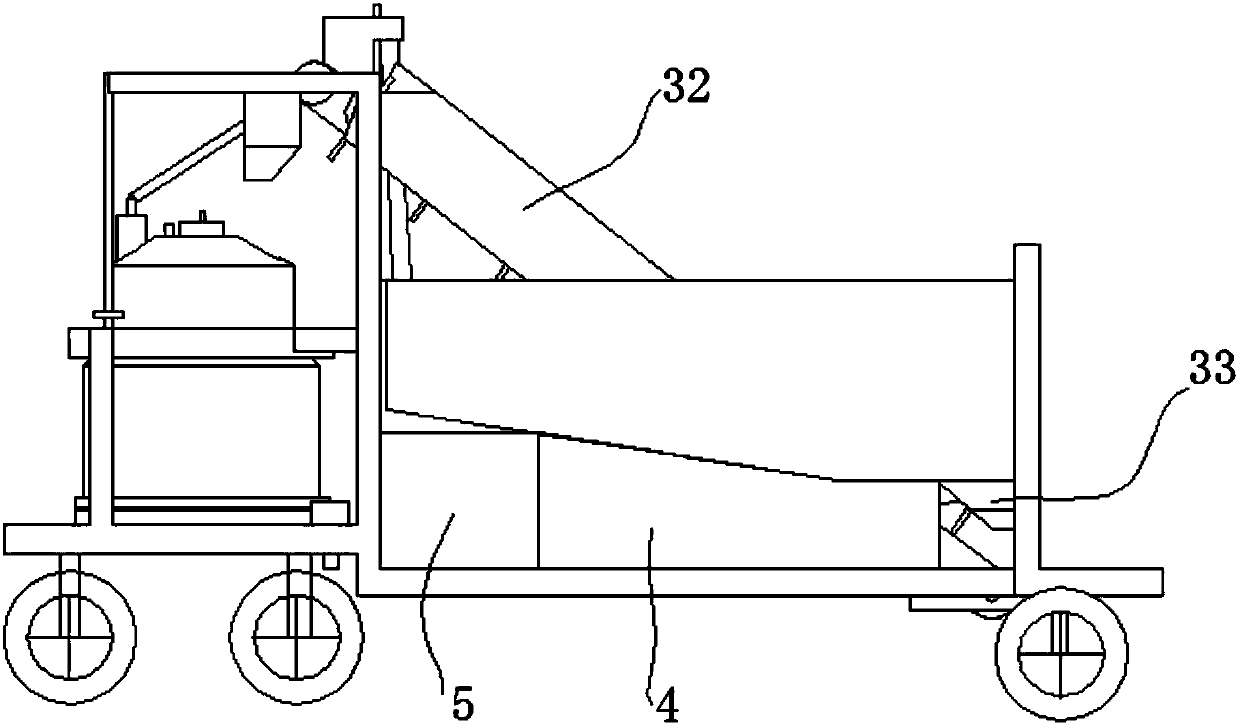

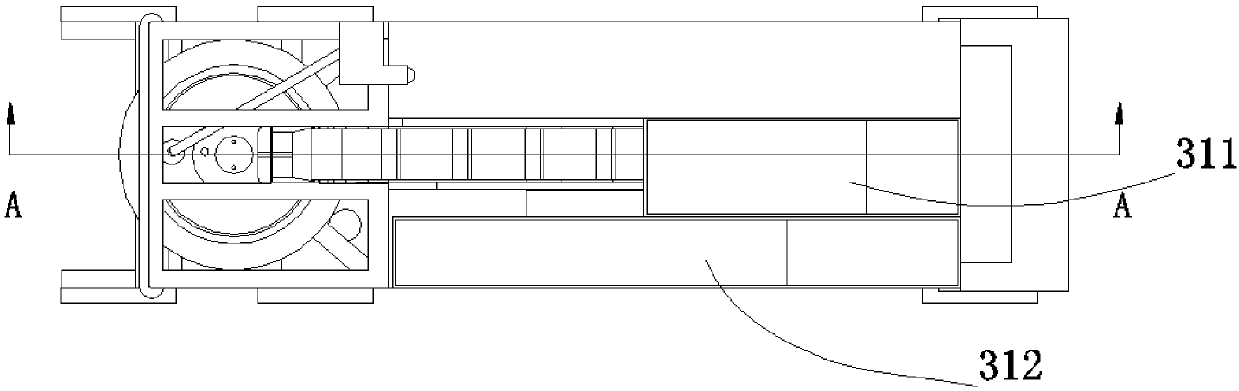

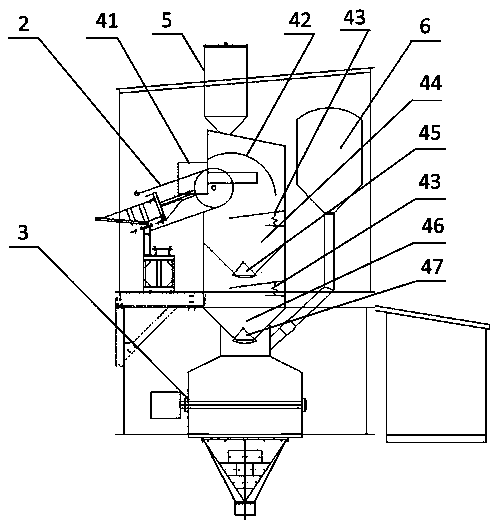

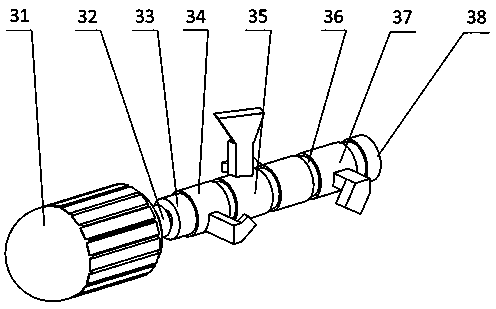

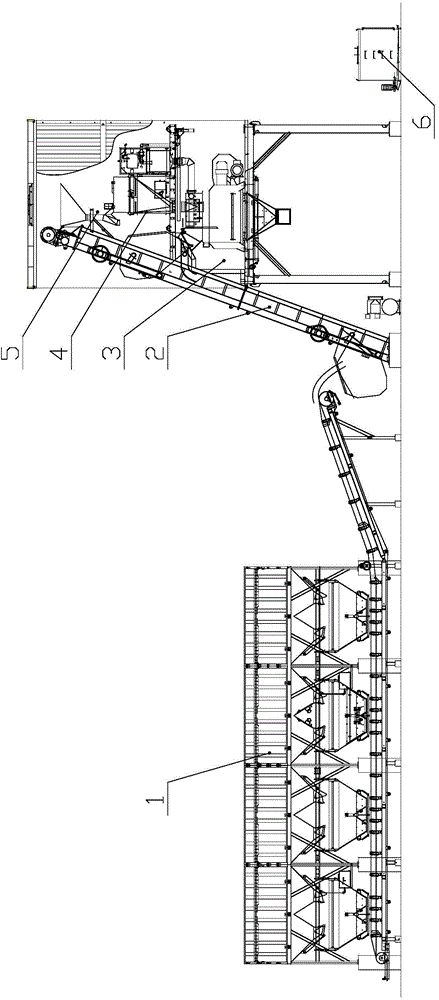

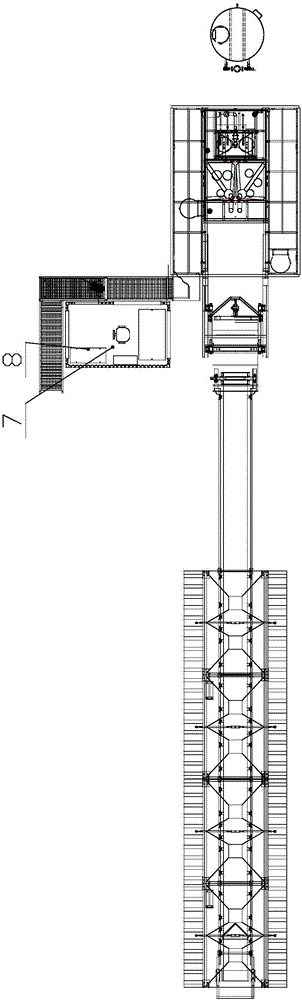

Quickly-moving type concrete mixing station

ActiveCN103660040AShorten the production periodIncrease productivityDischarging apparatusIngredients weighing apparatusMaterial supplyDelivery system

The invention discloses a quickly-moving type concrete mixing station, and relates to the technical field of concrete production equipment. The station comprises an aggregate supplying system, a powdered auxiliary material supplying system, a liquid auxiliary material supplying system, a stirring system, a control panel, a pump delivery system, and a transportation system; wherein the transportation system comprises traction equipment and a trailer plate, the aggregate supplying system, the powdered auxiliary material supplying system, the liquid auxiliary material supply system, the stirring system, the control panel, and the pump delivery system are all arranged on the trailer plate; the aggregate supplying system, the powdered auxiliary material supplying system, and the liquid auxiliary material supplying system all communicate with the stirring system, the stirring system comprises a frame and a stirrer, the stirrer is arranged on the frame; and the pump delivery system is arranged below the material unloading door of the stirrer. The quickly-moving type concrete station has the advantages of compact structure, user-friendliness, and rapid movement, can shorten the construction time and guarantee the concrete quality, satisfies the using requirement of small-batch concrete, improves the construction efficiency, and saves the construction cost.

Owner:SHIJIAZHUANG TIEDAO UNIV +2

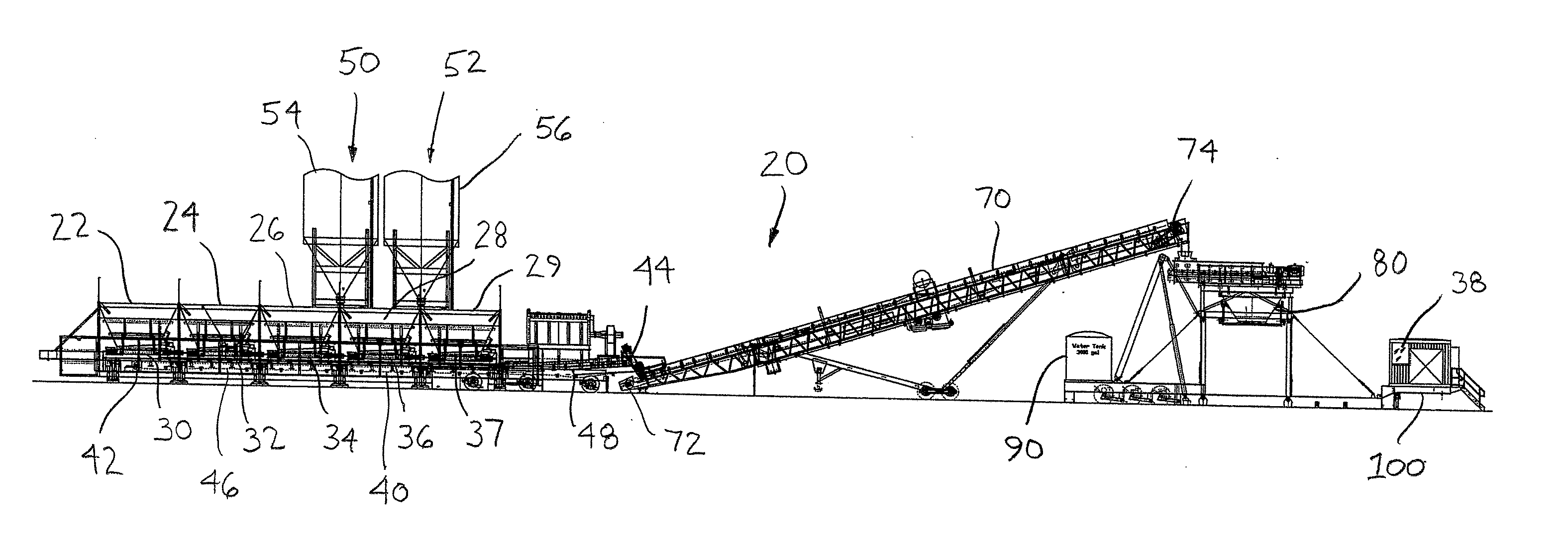

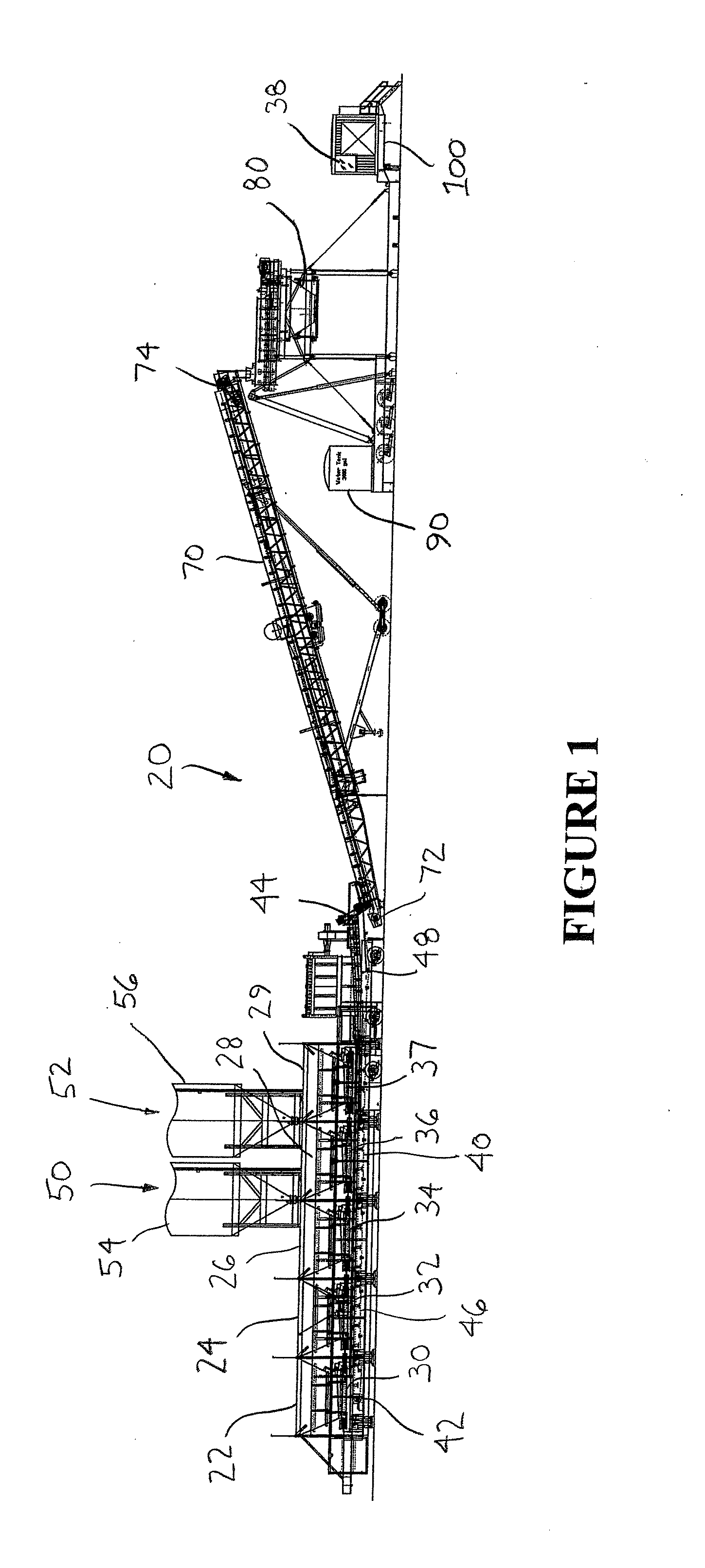

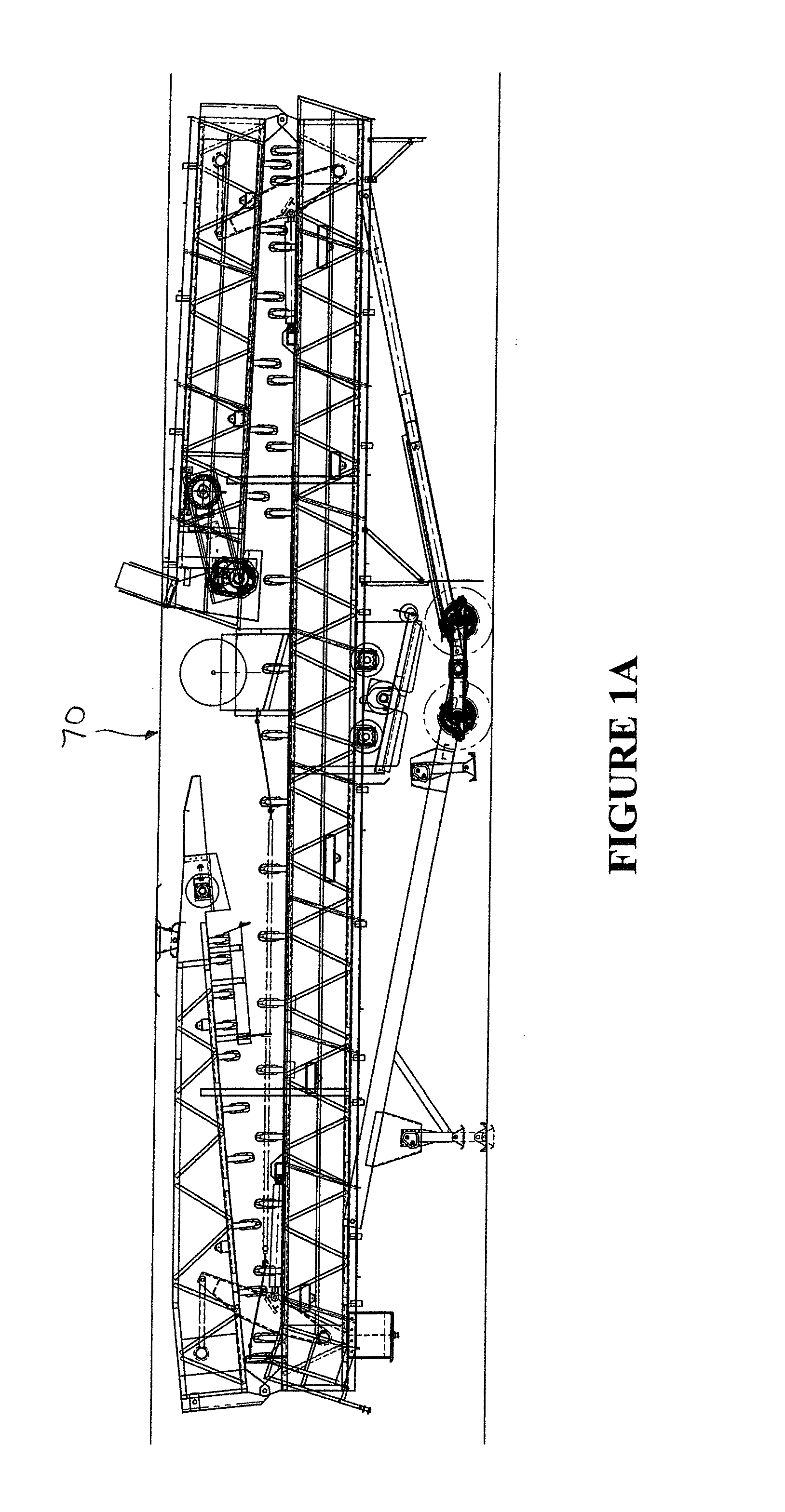

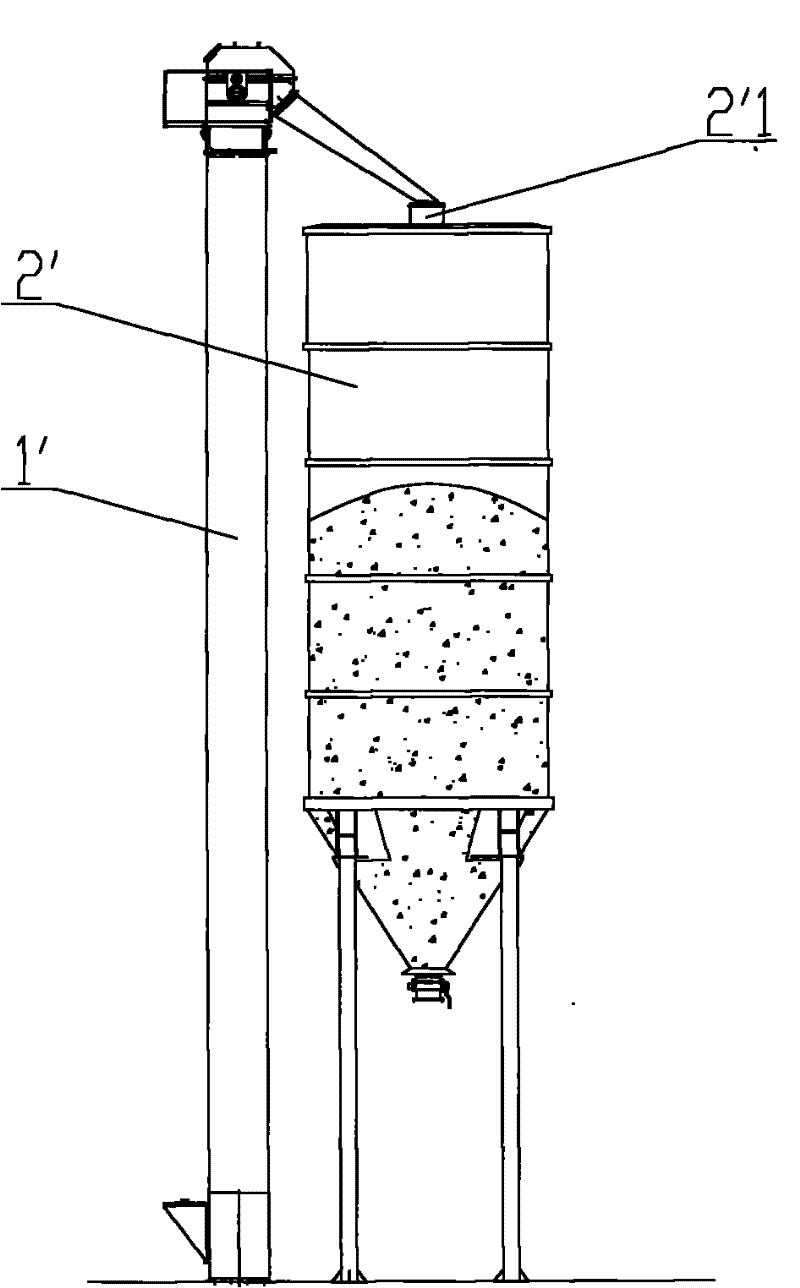

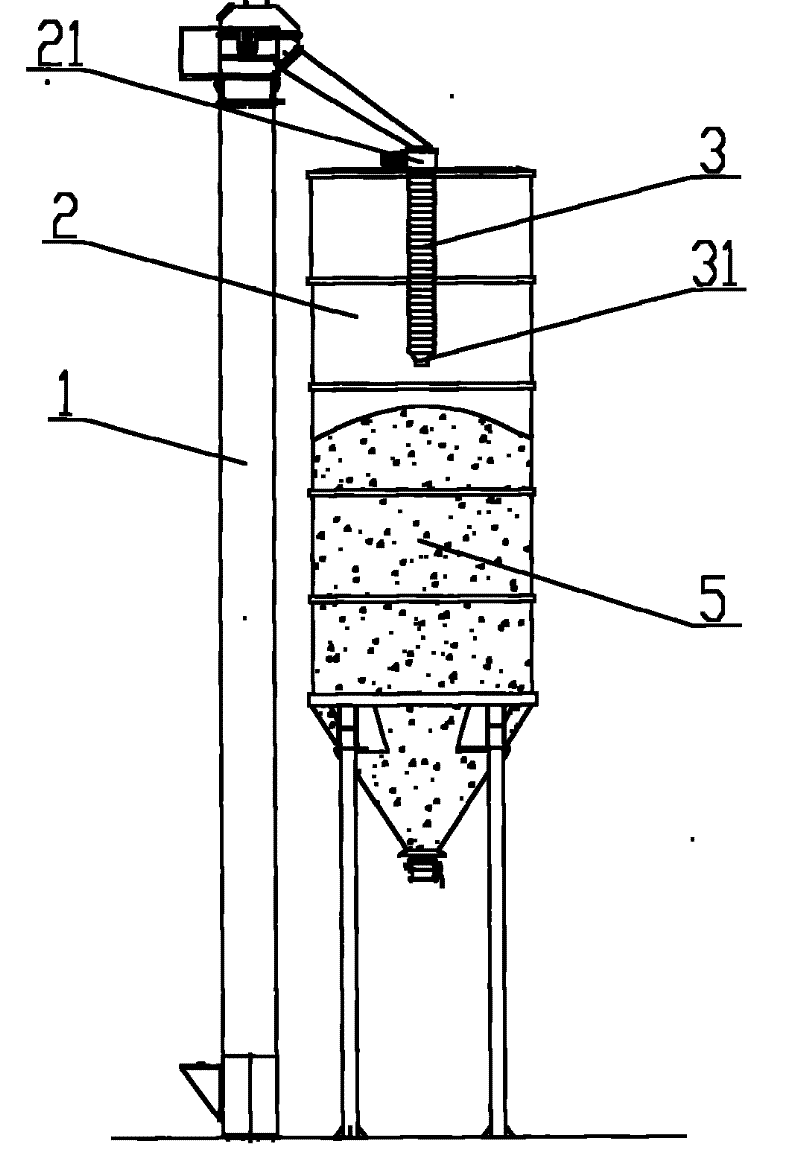

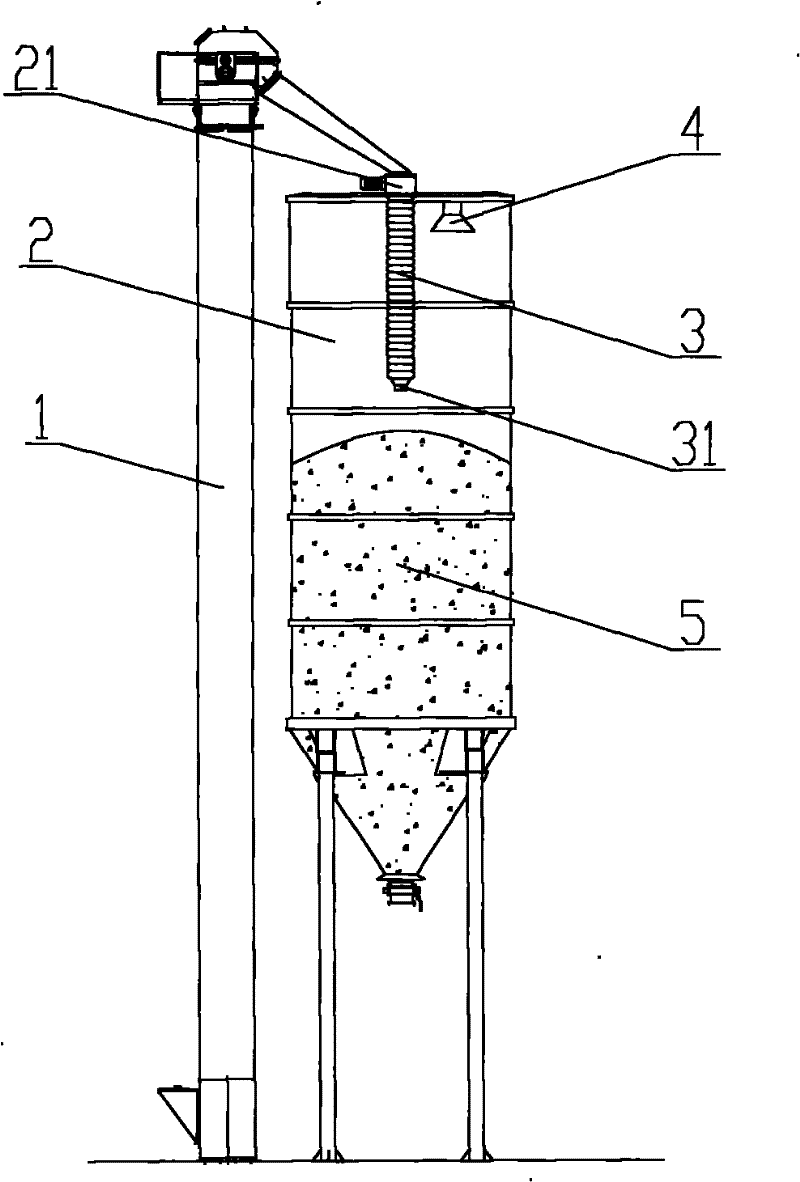

Apparatus and method for a concrete plant

InactiveUS20150103614A1Mixing operation control apparatusTransportation and packagingConcrete plantScrew conveyor

A concrete plant comprising an aggregate feed bin adapted to hold and release aggregate materials, a feed conveyor adapted to receive the aggregate materials from the aggregate feed bin, a collecting belt conveyor adapted to receive the aggregate materials from the feed conveyor, a silo assembly adapted to hold and release components of concrete, a screw conveyor adapted to receive the components of concrete from the silo assembly and convey the components of concrete to the collecting belt conveyor, and a mixer adapted to receive the aggregate materials and components of concrete from the collecting belt conveyor and mix the aggregate materials and components of concrete with water. The amount of aggregate materials received by the collecting belt conveyor from the conveyor and the amount of concrete components received by the collecting belt conveyor from the conveyor are precisely and accurately controlled.

Owner:ASTEC

Concrete integral production system

ActiveCN105922438AStir wellAvoid slump lossDischarging apparatusMixing operation control apparatusMaterial supplyBelt machine

The invention discloses a concrete integral production system. The concrete integral production system comprises a dry material supply device, a concrete stirring device, a spiral extrusion conveying device and a control device; the dry material supply device, the concrete stirring device and the spiral extrusion conveying device are joined in sequence, wherein the dry material supply device includes a cement conveying line, a sand conveying line and a bubble conveying line; and cement, sand and bubble are pneumatically conveyed by the dry material supply device to enter a conveying belt machine, and are conveyed to the concrete stirring device by the conveying belt machine. Raw materials are conveyed by using a remote supply system, and are stirred by adding water in scene, so that dry concrete can be transported remotely or even preserved through sealing, the business scope of a concrete mixing plant is widened, the slump loss of concrete in the transportation process is prevented, and the construction while stirring is realized.

Owner:东莞市交港建材有限公司

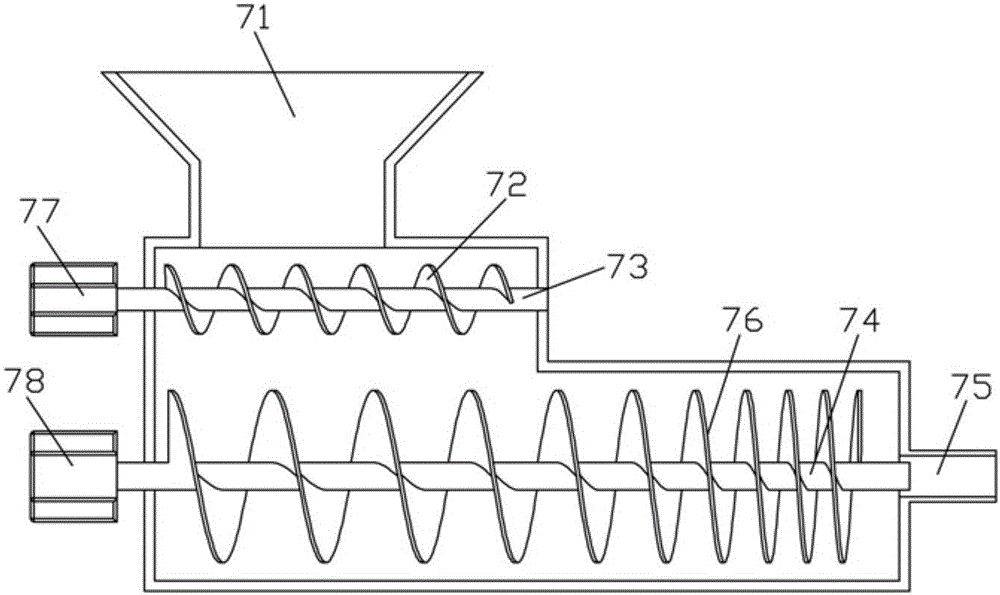

Mixing and blending device for dry-mixed mortar

InactiveCN110315638AEfficient crushingEfficient mixingDischarging apparatusMixing operation control apparatusDry mixingEngineering

The invention provides a mixing and blending device for dry-mixed mortar. The mixing and blending device comprises a mixing tank; the two sides over the mixing tank are each provided with a material storage tank; the material storage tanks are connected with the mixing tank; a first stirring shaft is arranged in the mixing tank; the left half part of the first stirring shaft is provided with a first spiral stirring blade; the right half part of the first stirring shaft is provided with a second spiral stirring blade; the first spiral stirring blade and the second spiral stirring blade are opposite in thread direction; the mixing and blending device further comprises a first motor used for driving the first stirring shaft to rotate; a discharge hole is formed in the middle part of the bottom part of the mixing tank; and the discharge hole is connected with the mixing tank. The mixing and blending device for the dry-mixed mortar provided by the invention is capable of crushing and mixingfeed powder efficiently and rapidly, and is capable of quantitatively adding different raw materials into the storage tanks and mixing the raw materials to guarantee the proportioning accuracy.

Owner:湖北恒诚建设有限公司

Apparatus and method for adding pigmentation to concrete mix

Owner:CEMEN TECH

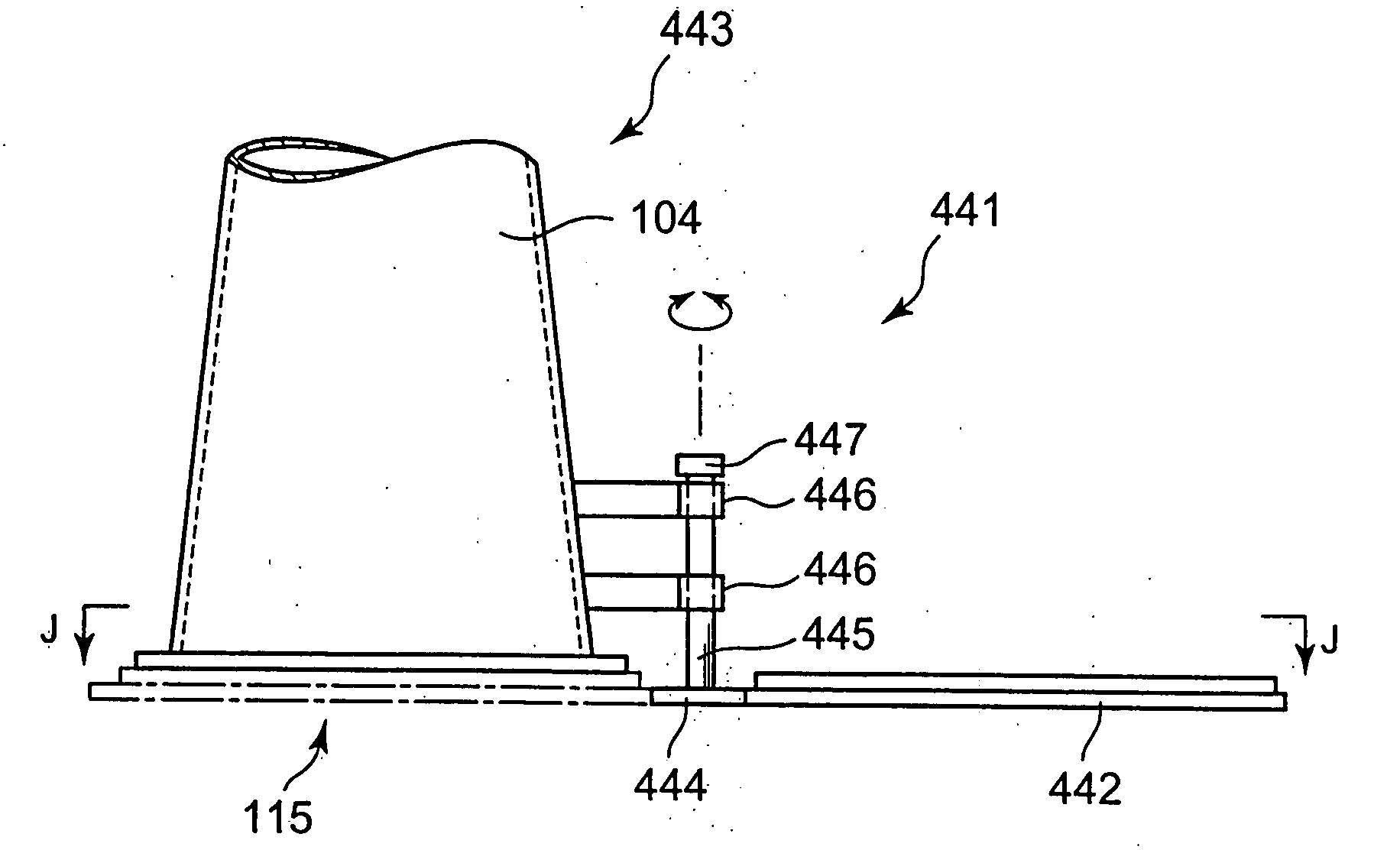

Aggregate holding hopper, concrete stirring station and aggregate distributing control method

ActiveCN104385464AHigh strengthReduce stirring resistanceIngredients storageControl apparatusEngineeringMechanical engineering

The invention discloses an aggregate holding hopper, a concrete stirring station and an aggregate distributing control method. The aggregate holding hopper comprises a hopper body and a hopper valve, the hopper valve is arranged at the lower end of the hopper body, and the hopper is inside provided with a material discharge channel; and the aggregate holding hopper also comprises a material distributing device arranged on the hopper body; and the material distributing device comprises a revolving door mechanism and a driving mechanism, the driving mechanism is used to drive the revolving door mechanism to switch the close state and the open state, the close state of the revolving door mechanism is a state that the material discharge channel is closed, and the open state of the revolving door mechanism is a state that the material discharge channel is opened. The provided aggregate holding hopper is capable of realizing batch-wise pouring of two materials, avoids overlarge stirring resistance in a main machine, and improves the stirring efficiency and the stirring effect.

Owner:三一西北重工有限公司

Automatic addition proportioner in concrete mixer transportation tank truck transportation process

InactiveCN103737726AAdjust and improve quality control metricsSolve the problem of prone to gradation deteriorationMixing operation control apparatusIngredients storageTank truckExtreme temperature

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

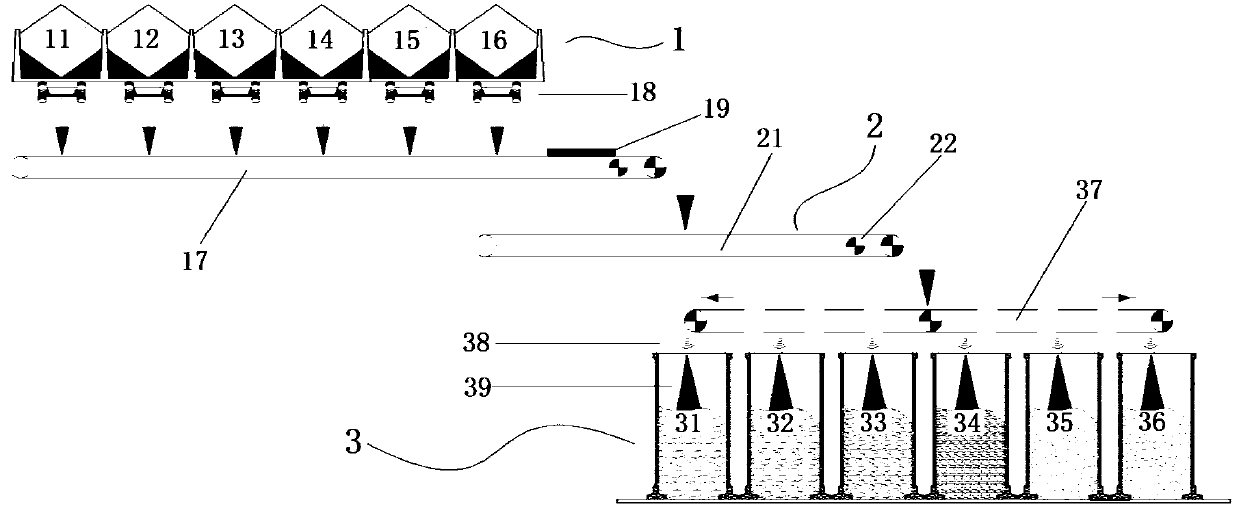

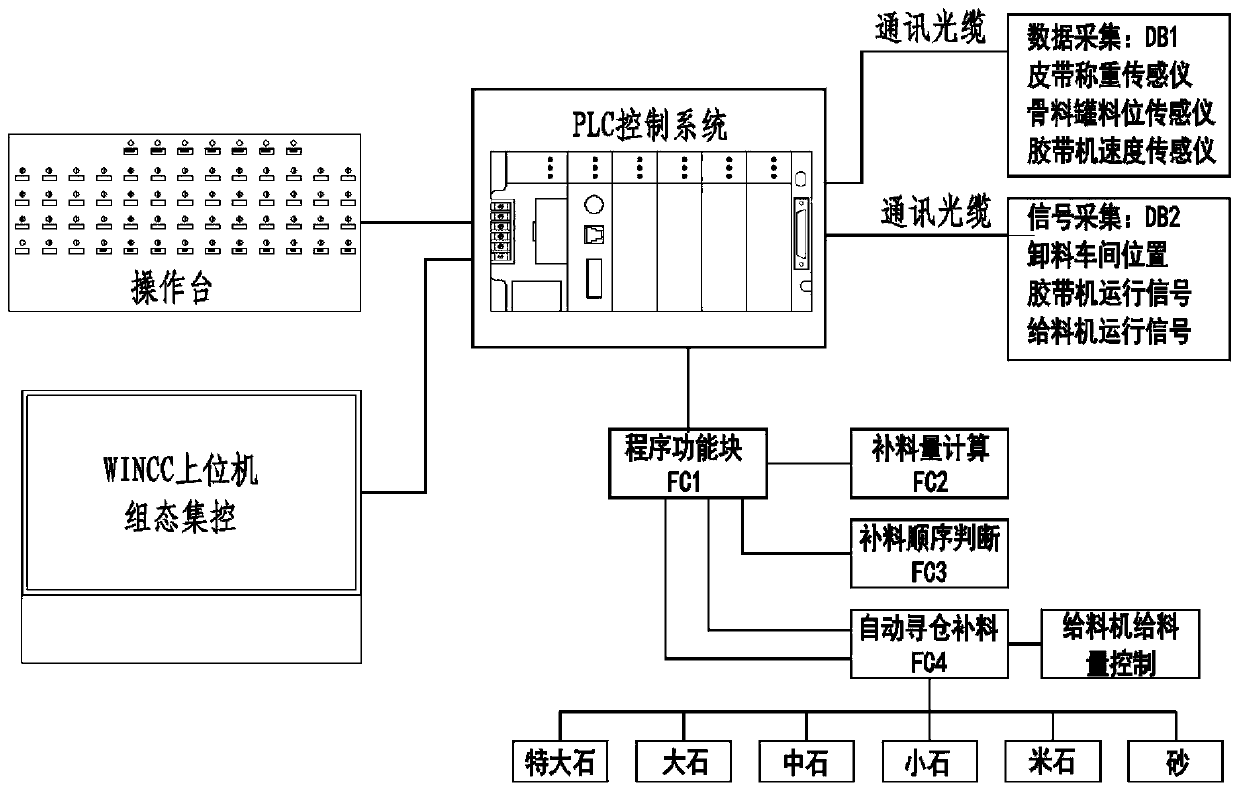

Concrete aggregate automatic bin-searching and feeding system

ActiveCN111331734AOptimal control methodImprove automation control levelMixing operation control apparatusIngredients storageControl systemTransit system

The invention discloses a concrete aggregate automatic bin-searching and feeding system. The concrete aggregate automatic bin-searching and feeding system comprises an aggregate raw material system, aconcrete production system, a belt conveyor transportation system and a control system; the aggregate raw material system comprises storage yards for each raw material with feeders and discharge conveyor belts distributed at the outlet ends; the belt conveyor transportation system comprises a discharge belt conveyor and a long-distance belt conveyor; and the concrete production system comprises aconcrete production device and a storage system, the storage system comprises raw material bins arranged according to the needs of concrete production, and movable material distribution trolleys arecorrespondingly arranged at the tops of the raw material bins. According to the concrete aggregate automatic bin-searching and feeding system, based on the combination of a sensing technology and a PLC control technology, the aggregate transportation amount, the aggregate bin material level, the automatic analyzing and controlling replenishment amount, the replenishment time and the replenishmentsequence are collected, the feeders automatically switch the feeding variety, the material distribution trolleys automatically search bins and replenish materials, the continuous transportation of multi-level aggregate from the aggregate yards to the aggregate storage bins is achieved, and purposes of optimizing the control of a replenishment system and improving the control level are achieved.

Owner:SINOHYDRO BUREAU 7 CO LTD

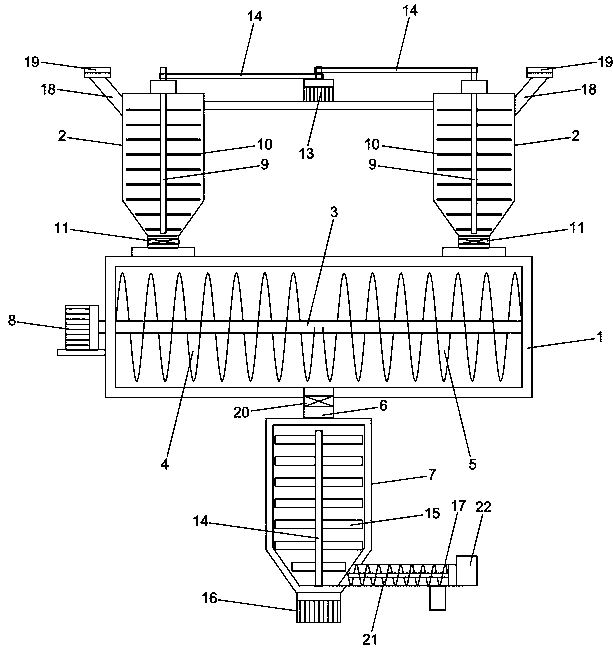

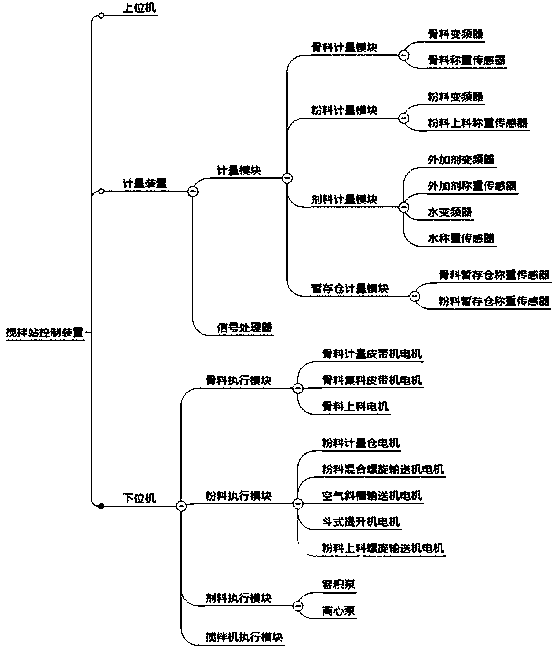

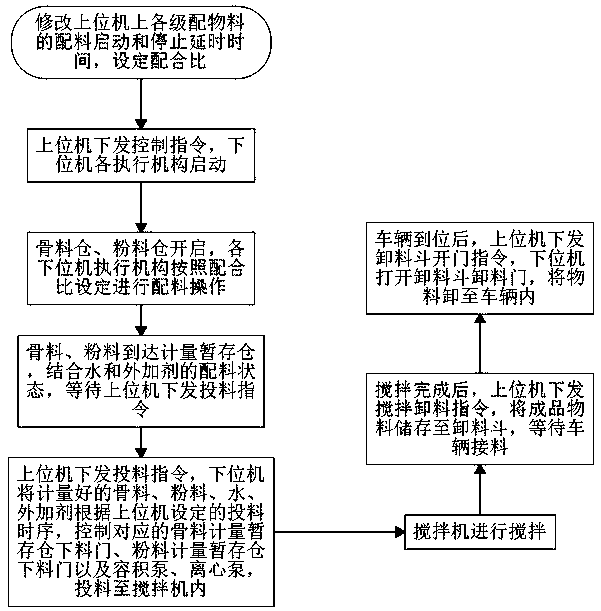

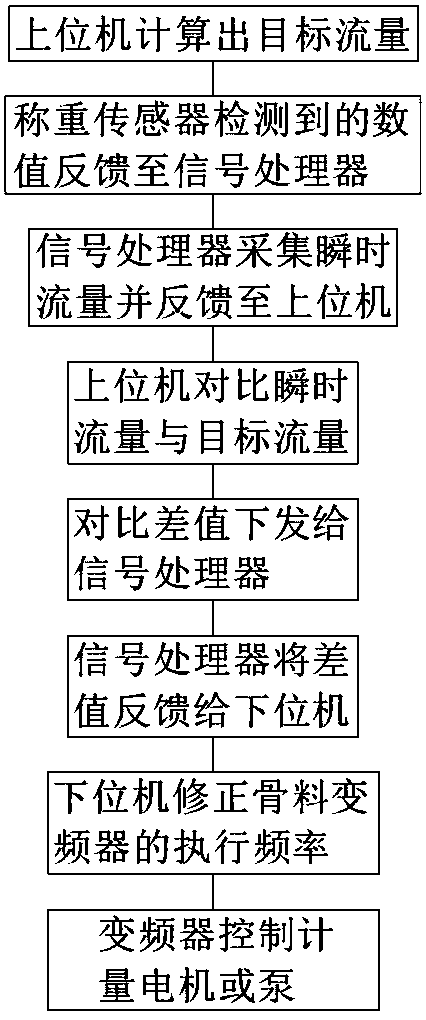

Control method and device of mixing station and mixing station

ActiveCN111331735AShorten mixing timeImprove stirring efficiencyMixing operation control apparatusIngredients proportioning apparatusProcess engineeringIndustrial engineering

The invention discloses a control method and device and a mixing station. By the adoption of the control method, the different proportions of aggregate, powder, water and addition agents are controlled, so that mixing operation of concrete with different grades is achieved. According to the control method, premixing operation of the aggregate, the powder and the agents is achieved, and the mixingefficiency and the mixing quality are improved; the weight and flow dual measurement mode is adopted by the aggregate, the powder and the agents, the aggregate in an aggregate measurement temporary storage bin and the powder in a powder measurement temporary storage bin are subjected to secondary re-check correction, and therefore the batching accuracy is improved; and pre-mixing operation of thewater and the addition agents in a pipeline is achieved by a positive displacement pump and a centrifugal pump, a blending bin and a conveying water pump are not required, and the cost is saved. All in all, the control method and device and the mixing station fulfill the matched material pre-mixing function, saves the cost and improves the batching accuracy, the mixing efficiency and the mixing quality.

Owner:德通智能科技股份有限公司

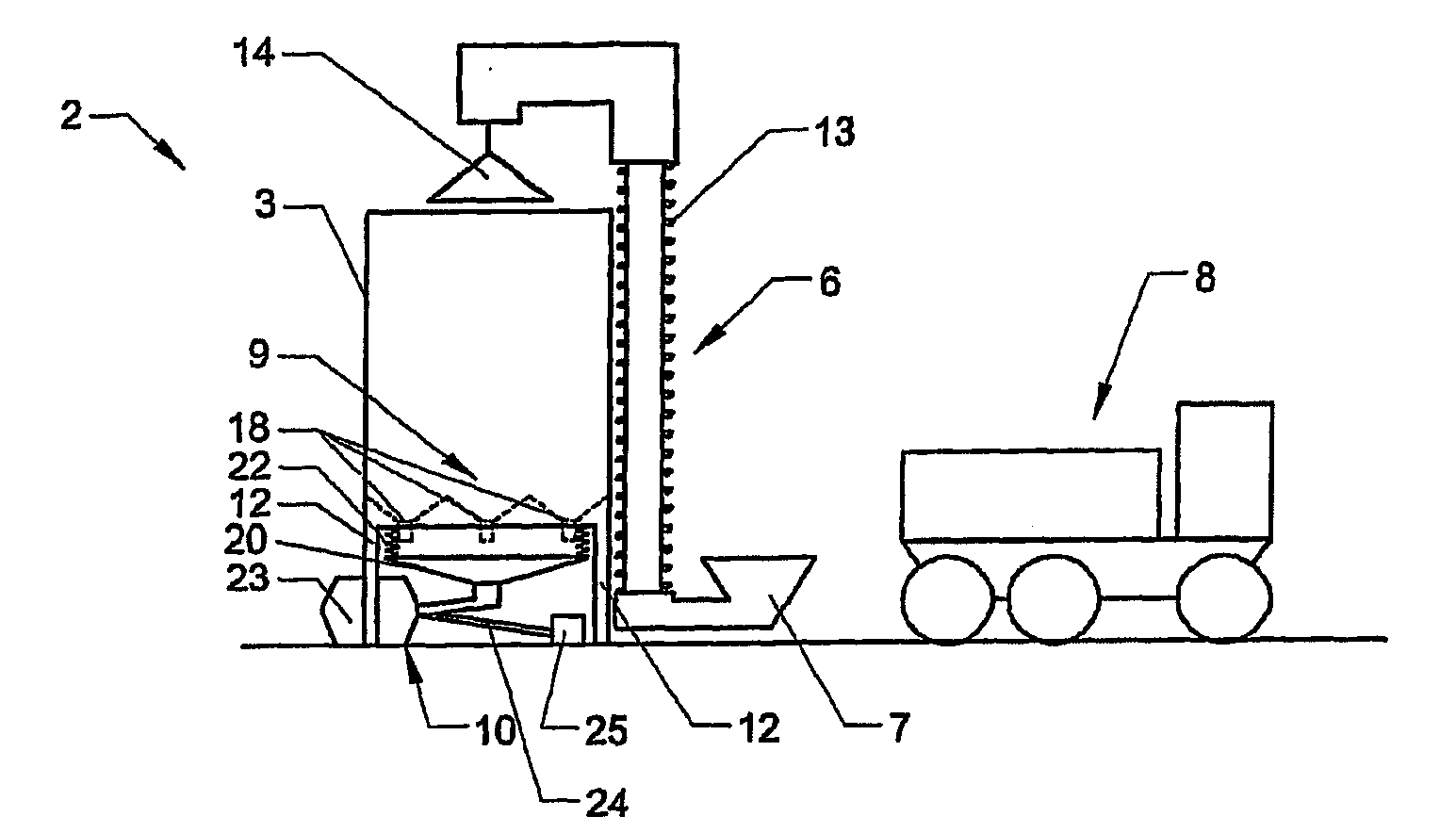

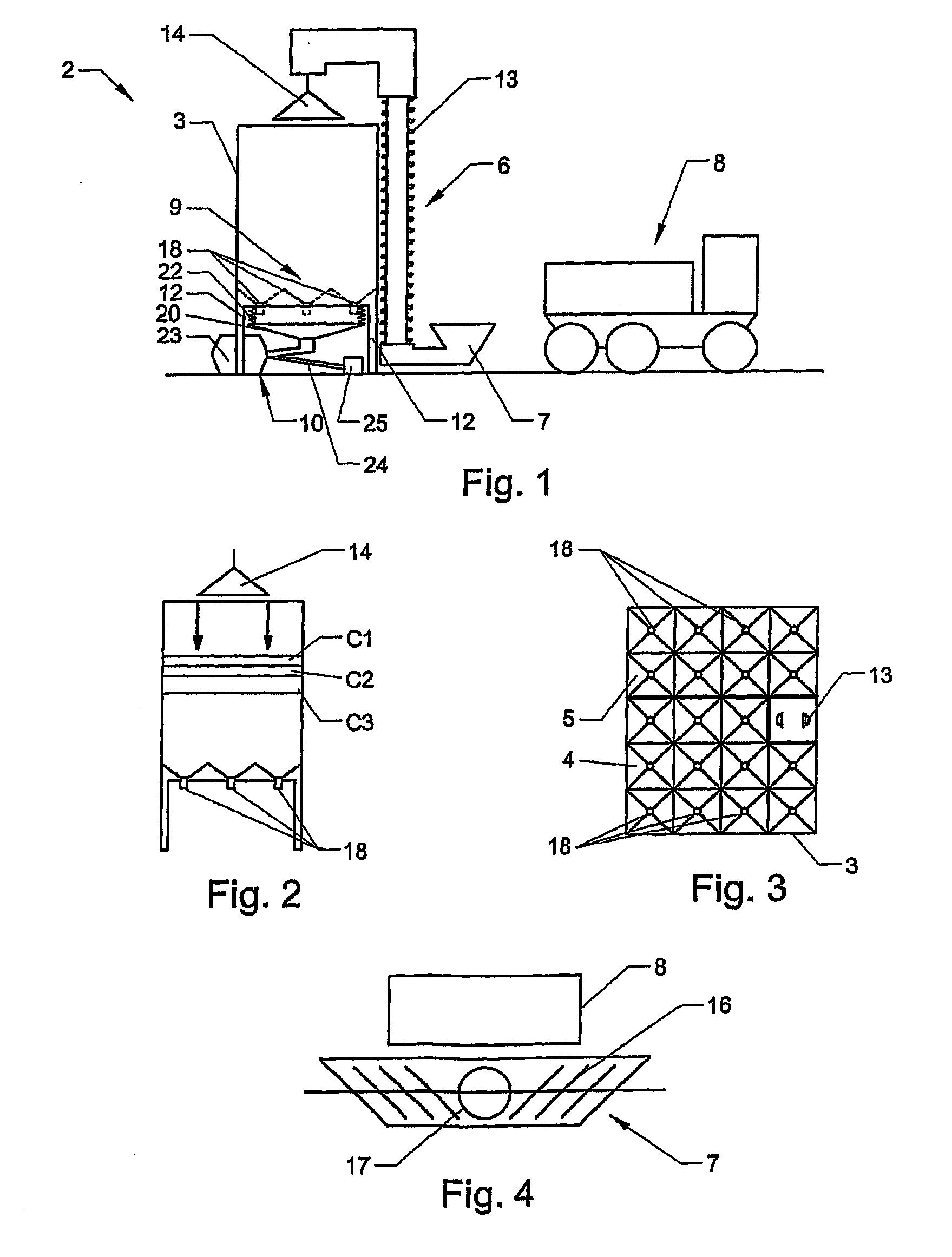

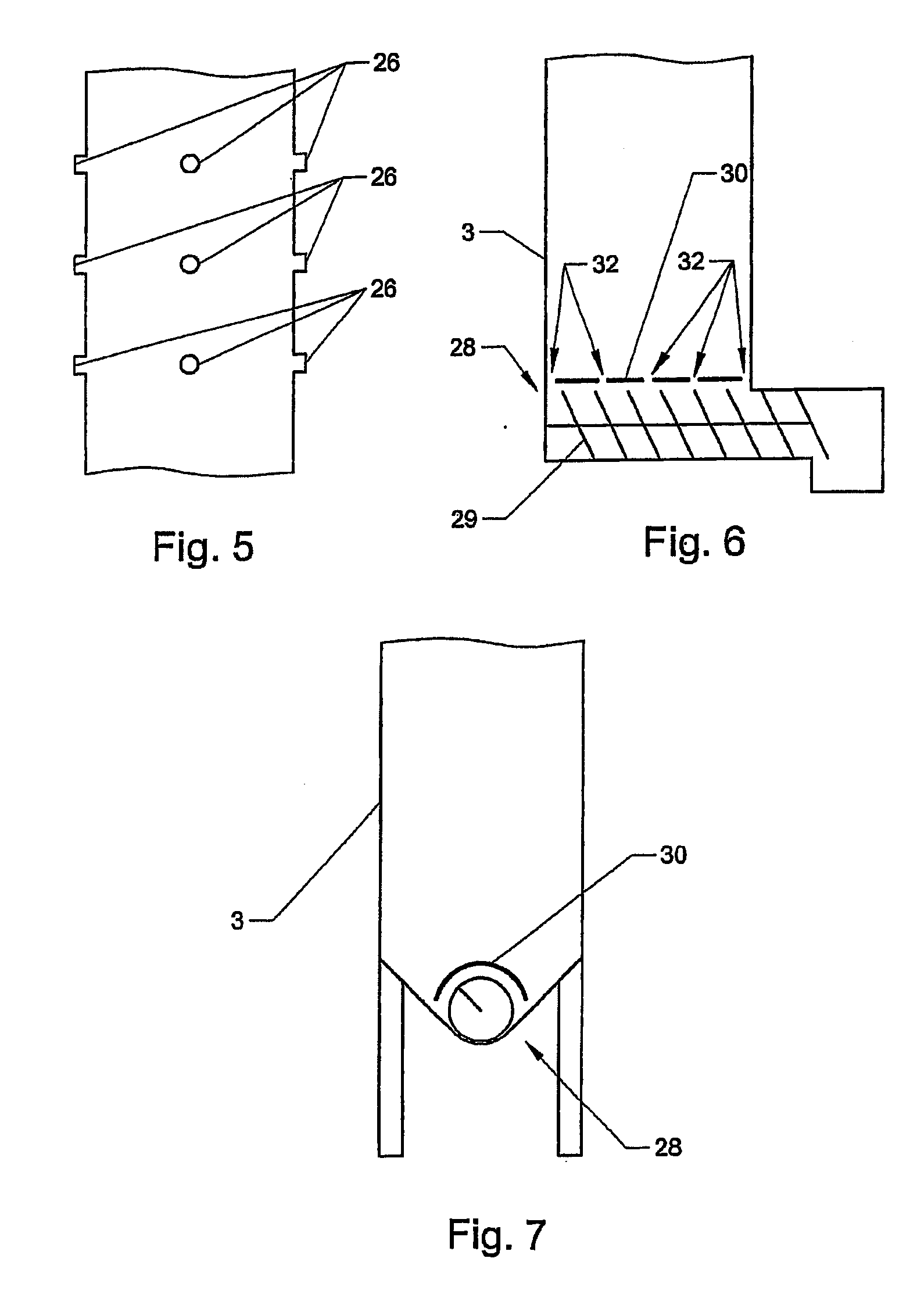

Concrete production plant

InactiveUS20090135665A1Occupy limited spaceMeet the limit requirementsMixing operation control apparatusIngredients storageOil production plantWork site

Owner:CHRISTIAN CONTAMIN

Concrete batching machine

InactiveCN105459269AIncrease varietyHigh strengthMixing operation control apparatusIngredients proportioning apparatusBelt conveyorEngineering

The invention provides a concrete batching machine. The concrete batching machine comprises a machine frame, a storage hopper, a belt conveyor, a weighing hopper, a weighing belt conveyor and an electric cabinet. The storage hopper is fixed to the machine frame. The belt conveyor is arranged at the lower end of the storage hopper. The weighing hopper is arranged below the end, away from the storage hopper, of the belt conveyor. The weighing belt conveyor is arranged at the lower end of the weighing hopper. The concrete batching machine is simple in structure, capable of meeting the requirement for different kinds of batching and high in precision and efficiency.

Owner:TIANJIN DAZHEN CONCRETE

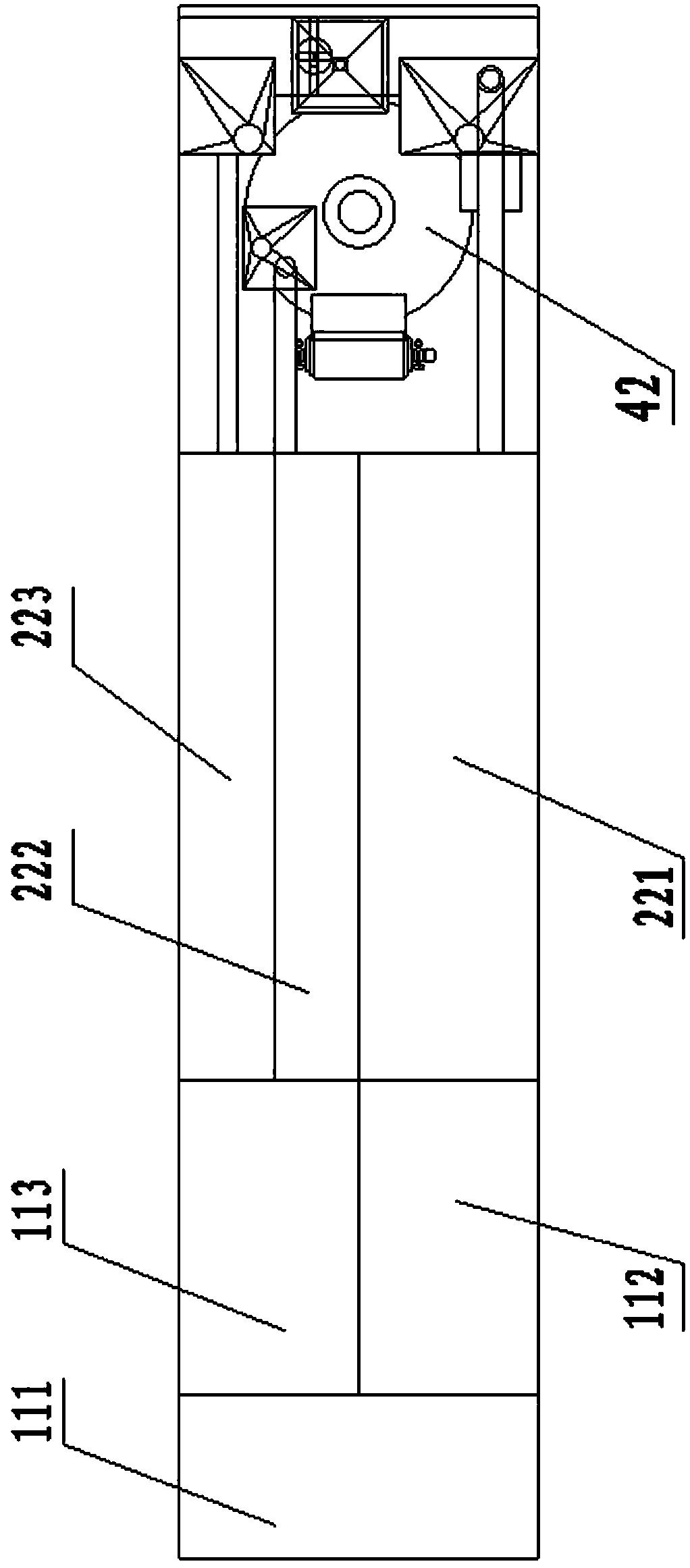

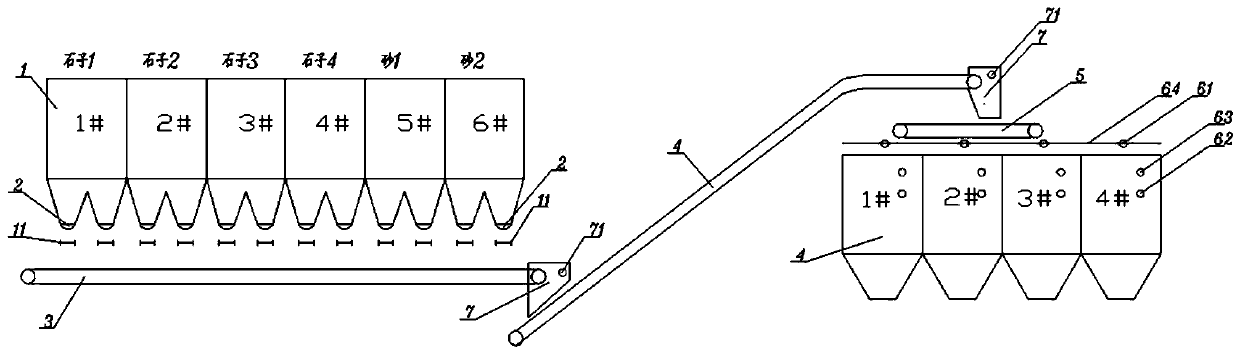

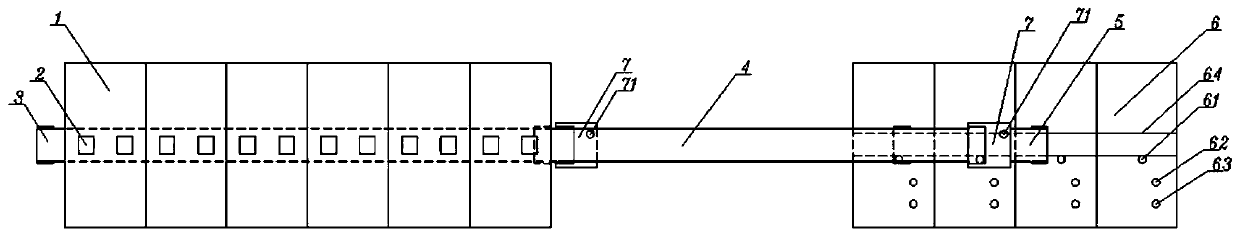

Stirring station aggregate feeding system and control method

PendingCN110394899AImprove reliabilityHigh degree of automationMixing operation control apparatusIngredients storageYardMaterial distribution

The invention discloses a stirring station aggregate feeding system. The stirring station aggregate feeding system comprises a storage yard provided with a plurality of stock bins, a flat belt, an inclined belt, a material distribution belt, and a stirring station provided with a plurality of stock bins, wherein the material distribution belt can rotate forwards and reversely so as to realize blanking at the two ends, a plurality of discharge arc doors are arranged in the storage yard stock bins, each discharge arc door is provided with a material flow detection device, and the flat belt, theinclined belt and the material distribution belt are sequentially connected through transition hoppers; material blockage detection devices are arranged on the transition hoppers, the material distribution belt is arranged on a rail, a position detection device is arranged on the rail, a material level detection device used for detecting the height of the material level in each stock bin and an over-limit inspection devices arranged at the height limit positions are arranged in each stock bin of the stirring station. According to the system, only full inspection signals are arranged, and no material null signals are arranged, so that the loading condition is met as long as material full signals are not detected, and the system can effectively improve the feeding reliability, the working efficiency and the automation level.

Owner:杭州江河机电装备工程有限公司 +1

Storage bin device and dry powder mortar mixing plant containing same

InactiveCN101745985ALower the altitudeReduce height travel for stratified segregationLarge containersIngredients storageEmbedded systemDelamination

Owner:SANY HEAVY IND CO LTD (CN)

Dead angle-free stirring sprinkling machine for pouring

InactiveCN106827240AChange flow fieldProtective envelopeMixing operation control apparatusPretreatment controlSpiral bladeEngineering

The invention discloses a stirring sprinkler with no dead angle for pouring. One end of the stirring shaft in the stirring device passes through the upper end of the stirring tank and is connected with the driving device. The upper screw and the lower screw are set; the water supply device is composed of a water nozzle, a guide pipe, a time controller, a stirring blade, a micro motor, a bevel gear transmission box, a water container and a flow control valve; The discharge port is set at the bottom of the stirring tank and connected with the screw conveyor, and the screw conveyor is connected with the spray gun through the feeding pipe. The invention changes the flow field of the vortex formed by the helical blade, protects the coating of quicklime particles, can supply water intermittently, can improve the uniformity of stirring, greatly increases the service strength and life after solidification, and reduces the eddy current contacting the bottom of the stirring tank and then upwards The energy consumption of changing the flow direction expands the influence range of the vortex and eliminates the dead angle of stirring existing on the liquid surface of the stirring tank.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Volumetric solid and liquid dispenser

InactiveUS20040100857A1Reducing and eliminating riskMinimize risk of injuryControlling ratio of multiple fluid flowsMixing operation control apparatusEngineeringMechanical engineering

A volumetric solid and liquid dispenser includes a drum sized for receiving and containing a predetermined volume of solid material from a solid material supply source. The supply source can be a hopper positioned above the drum. The drum is rotatably mounted to a support frame and can be rotated from a position in which it receives solid material from the supply source to a dispensing position in which it dispenses the solid material into a receptacle below. A liquid metering and dispensing container dispenses a predetermined volume of liquid into the receptacle for mixing with the solid material. The invention is particularly useful for dispensing predetermined volumes of sand and water into a cement mixer for mixing with mortar.

Owner:HARRIS ARCHIE J

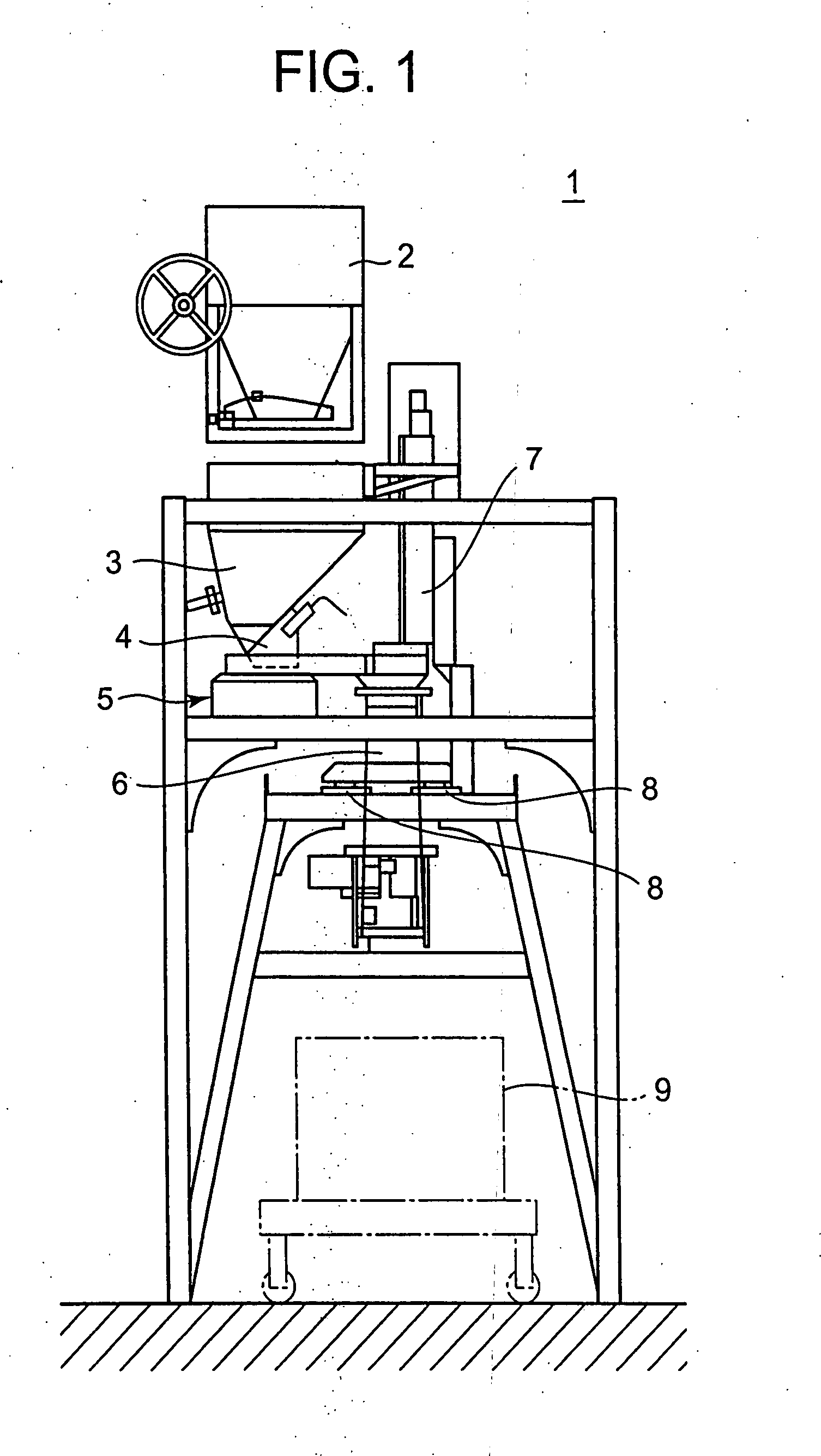

Measuring apparatus and measuring method for concrete-forming materials

InactiveUS20070163333A1Accurate measurementAccurate massWeighing apparatus for materials with special property/formSpecific gravity measurementMeasurement deviceEngineering

A measuring apparatus of submergence aggregate according to the present invention comprising a stock bin for storing fine aggregate, a fine aggregate feed hopper placed under the stock bin, a vibrating feeder placed under a discharge opening of the fine aggregate feed hopper, a screen device placed in the vicinity of an exit of the vibrating feeder, a measurement tank placed under the screen device, an electrode-type displacement sensor as means for measuring a water level placed above the measurement tank, and load cells as mass measuring means for measuring a mass of the measurement tank.

Owner:OBAYASHI CORP

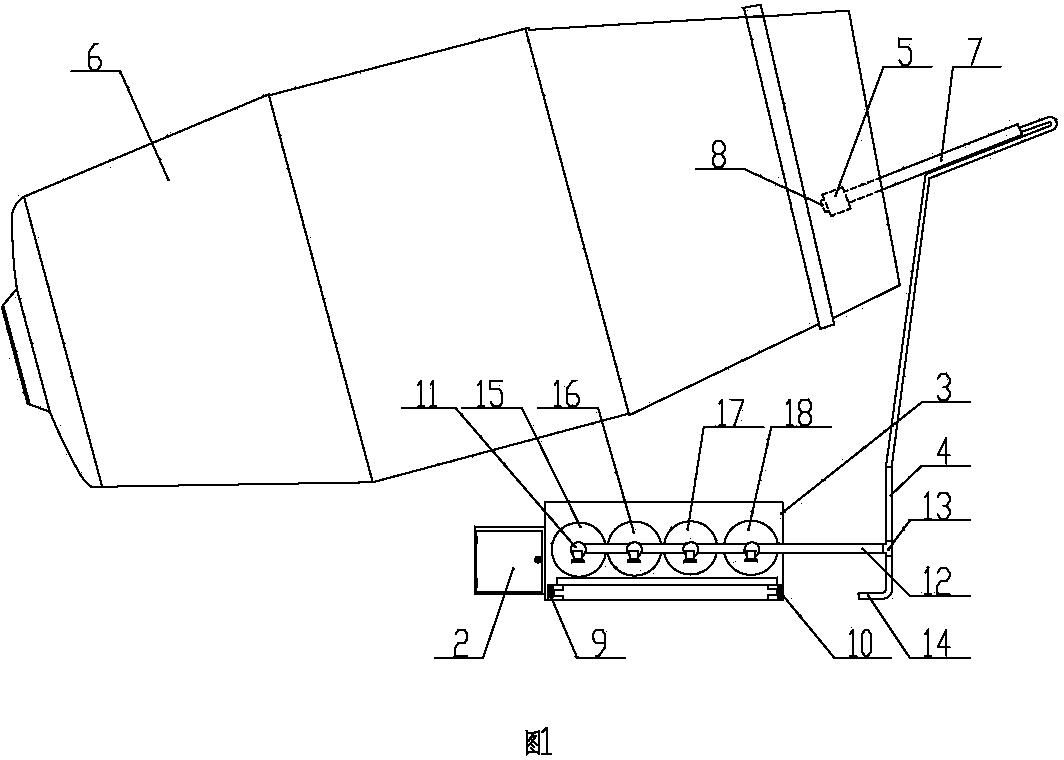

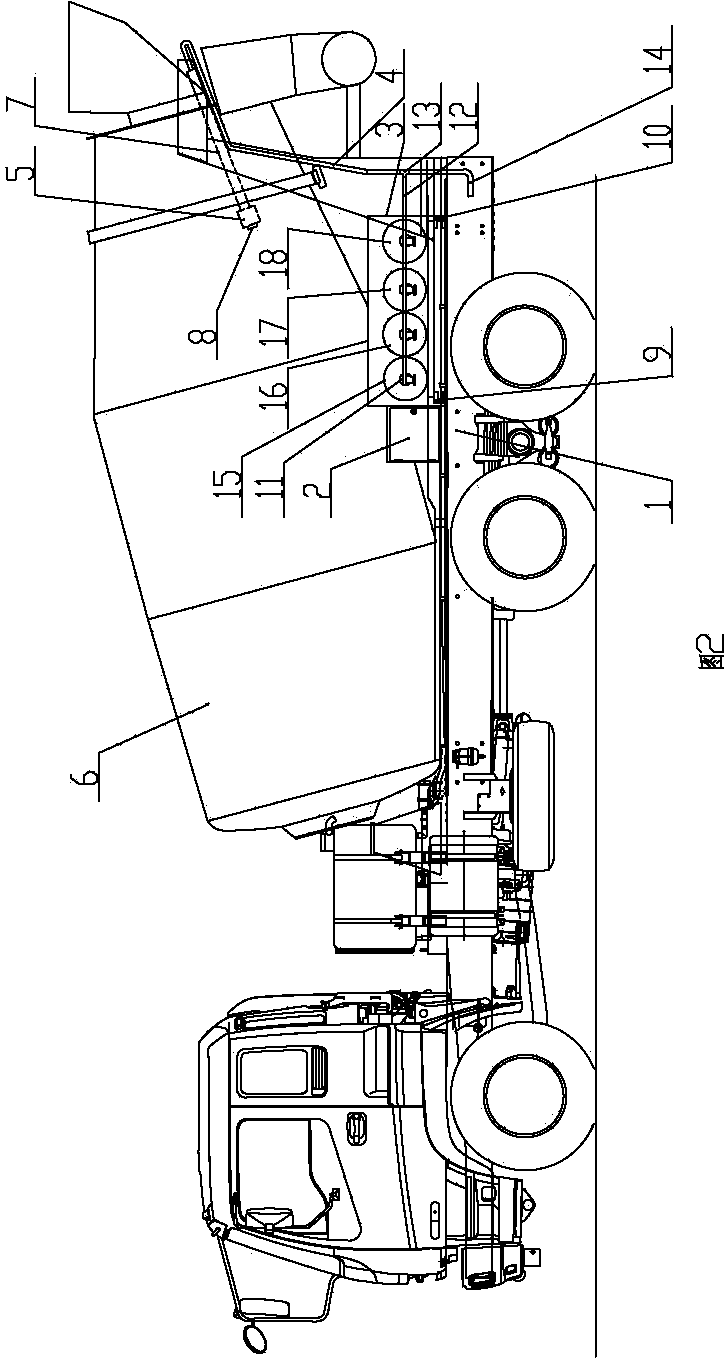

Road concrete transporting and stirring device and using method thereof

ActiveCN107718314ACompact structureEasy to transportMixing operation control apparatusIngredients storageGravity centerElectric control

The invention discloses a road concrete transporting and stirring device and a using method thereof and belongs to the field of concrete production equipment. The problems that an existing stirring device is difficultly transferred to another site and is low in efficiency and extremely inconvenient to operate are solved. The road concrete transporting and stirring device comprises a chassis, a base support, a stirring module, a powder storing and supplying module, an aggregate storing and supplying module, a liquid storing and supplying module, an electric control module, a stirring mechanismfixing module and a cleaning module. The powder storing and supplying module, the aggregate storing and supplying module and the liquid storing and supplying module are all fixed to the base support and connected with the stirring module, and the powder storing and supplying module, the aggregate storing and supplying module, the liquid storing and supplying module, the stirring module and the cleaning module are all connected with the electric control module. The road concrete transporting and stirring device has the advantages that the stirring volume is changeable, the gravity center is adjustable, transporting is convenient, the structure is compact, and the production efficiency is high.

Owner:亳州市爱开发网络科技有限公司

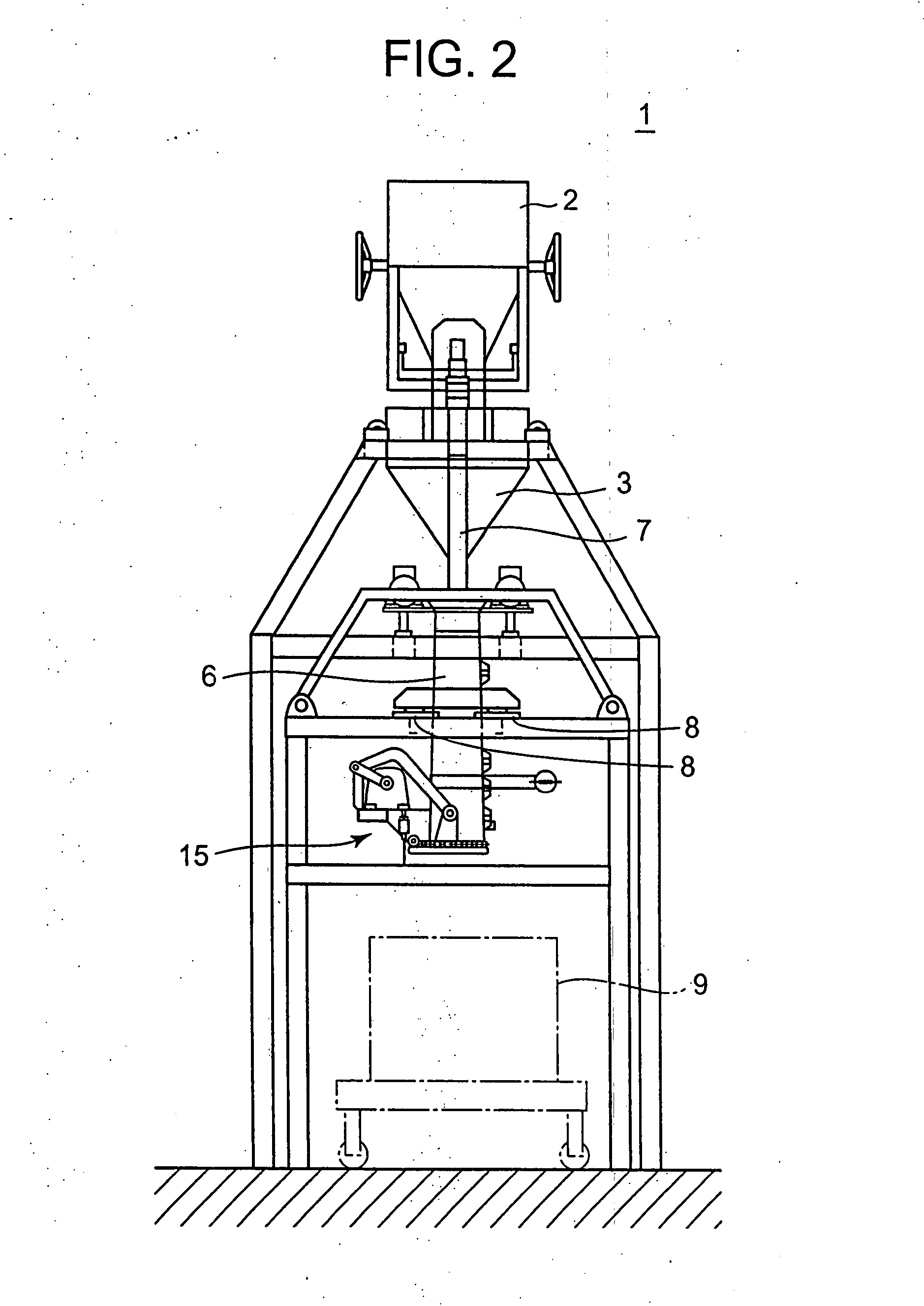

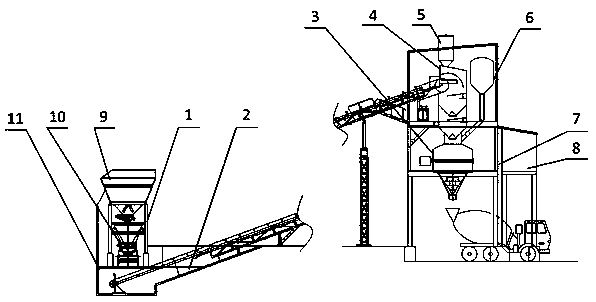

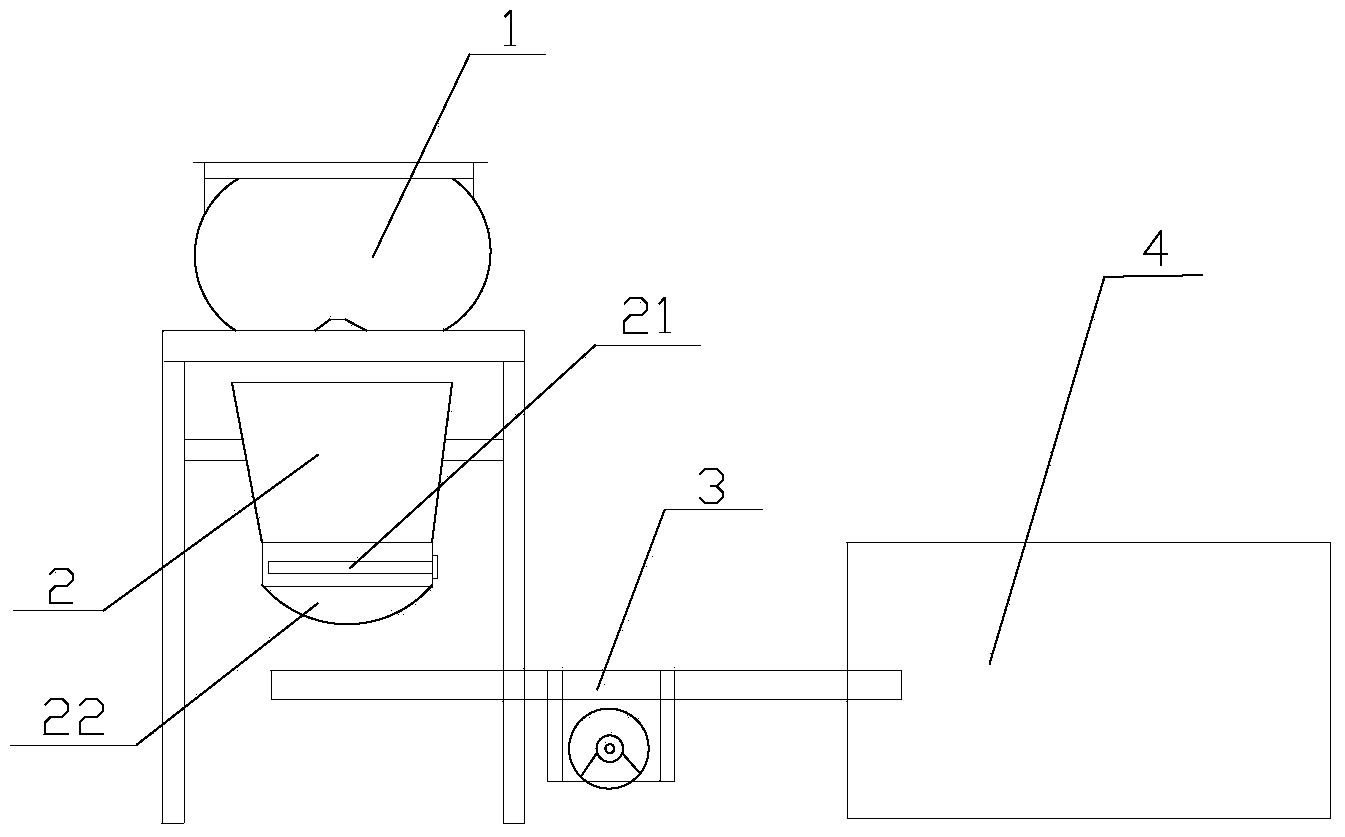

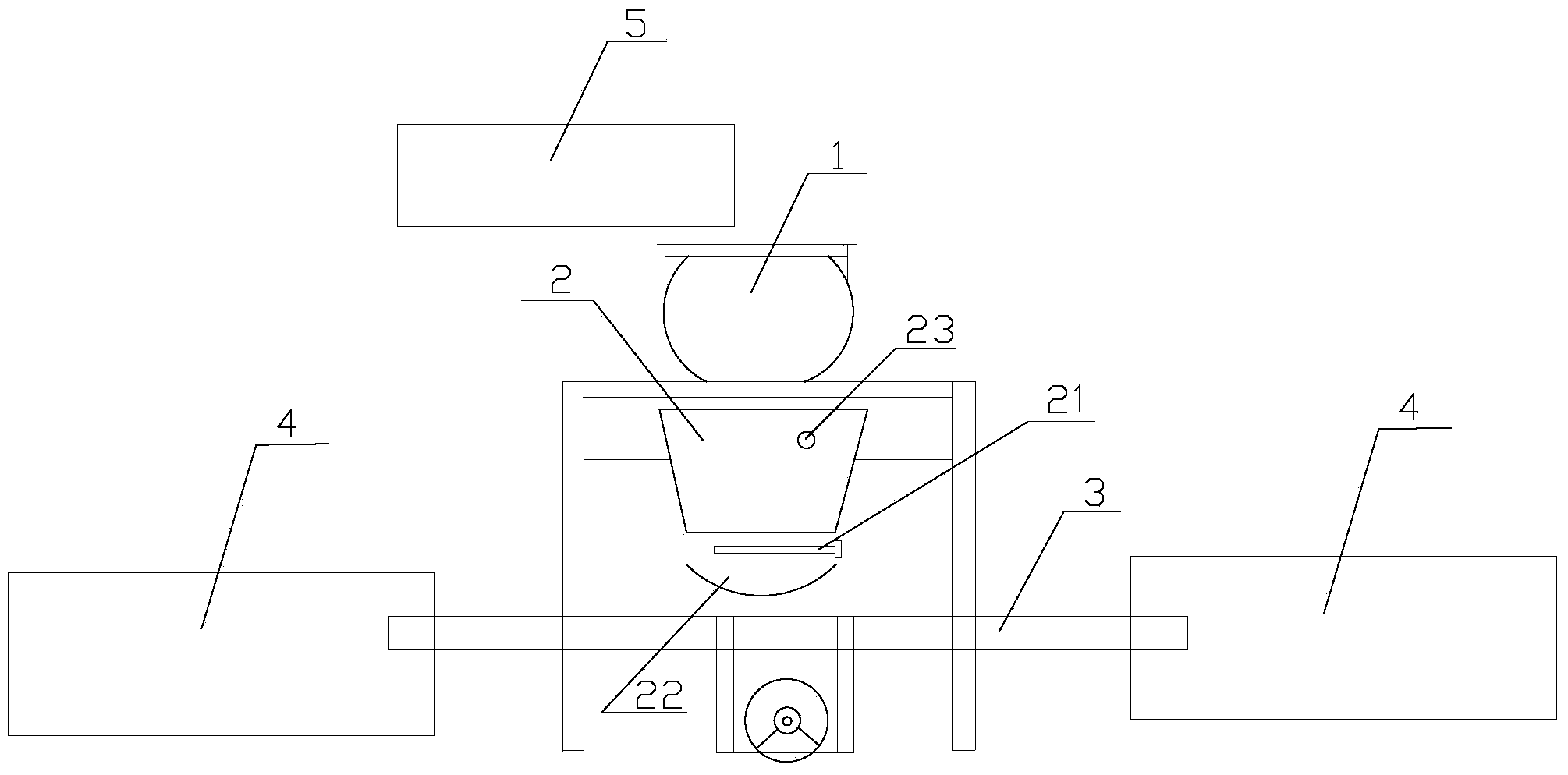

Concrete mixing plant

PendingCN109176890AHigh degree of automationImprove work efficiencyMixing operation control apparatusPretreatment controlElectricityControl system

The invention discloses a concrete mixing plant. The concrete mixing plant comprises a sand stone input station, a conveying belt, a material waiting bin, a mixing device, a steel structure frame anda control system box. The sand stone input station is arranged on the top of the conveying belt. The conveying belt is connected to the side edge of the material waiting bin. The mixing device is arranged below the material waiting bin. The control system box is arranged on the side edge of the mixing device. An arc plate, a second-level material waiting hopper and a first-level material waiting hopper are sequentially arranged in the material waiting bin from top to bottom. A first unloading device and a second unloading device are arranged at the bottom of the first-level material waiting hopper and the bottom of the second-level material waiting hopper correspondingly. A dust removal device is arranged on the outer side of the material waiting bin. A PLC control system is arranged in the control system box. The PLC is electrically connected with the sand stone input station, the conveying belt, the mixing device, the first unloading device and the second unloading device. The concrete mixing plant which is uniform in mixing, capable of reducing raise dust, high in work efficiency and capable of meeting the environment protection requirement is provided.

Owner:GUANGXI DADU CONCRETE GROUP

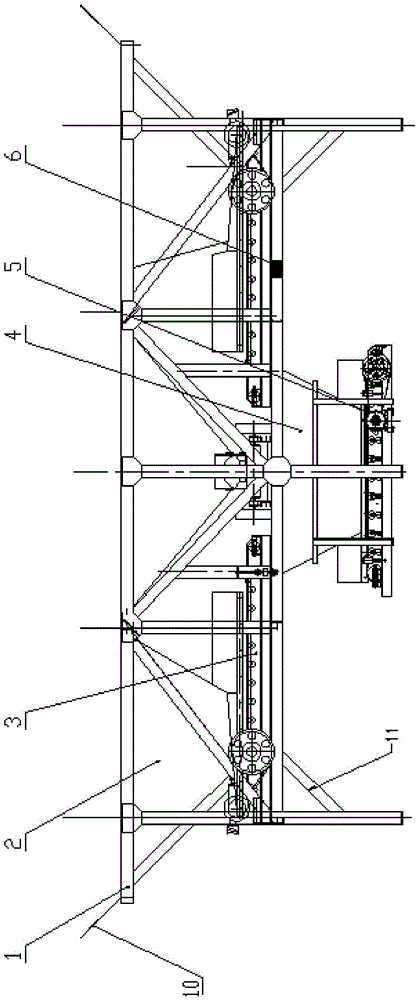

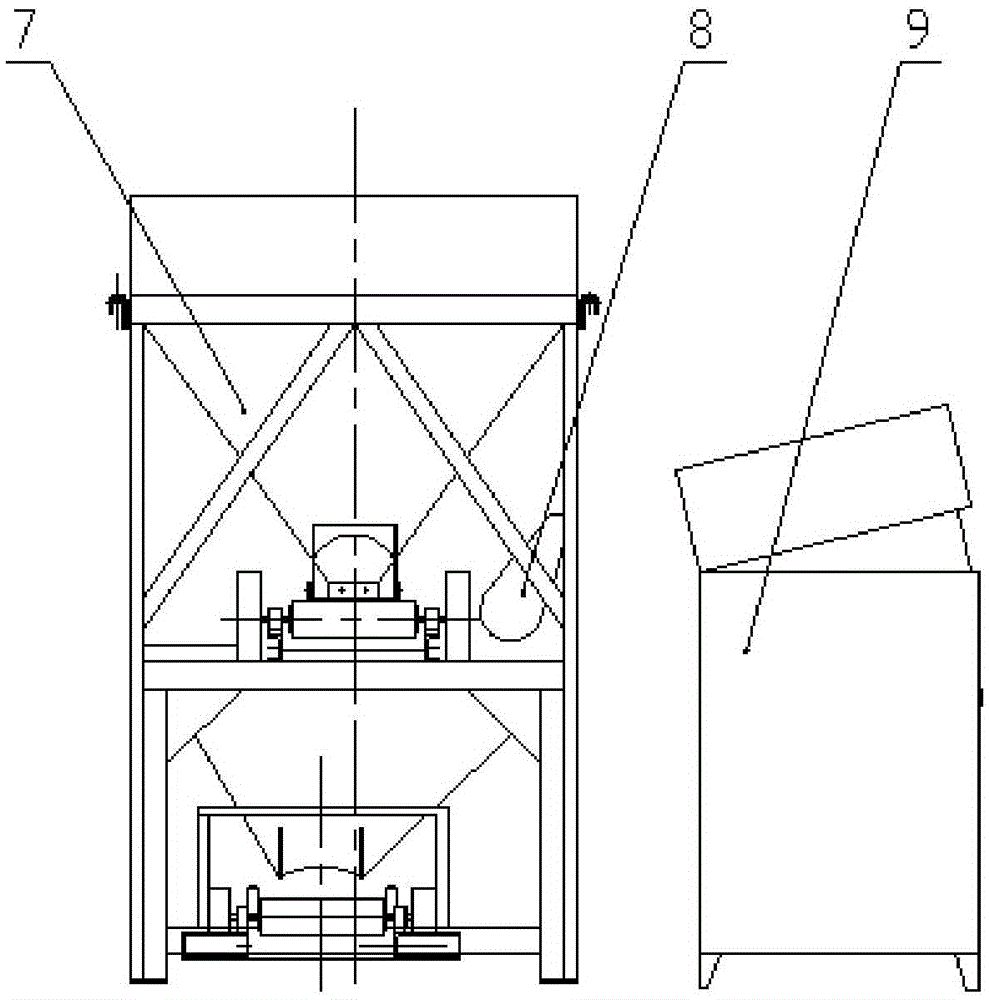

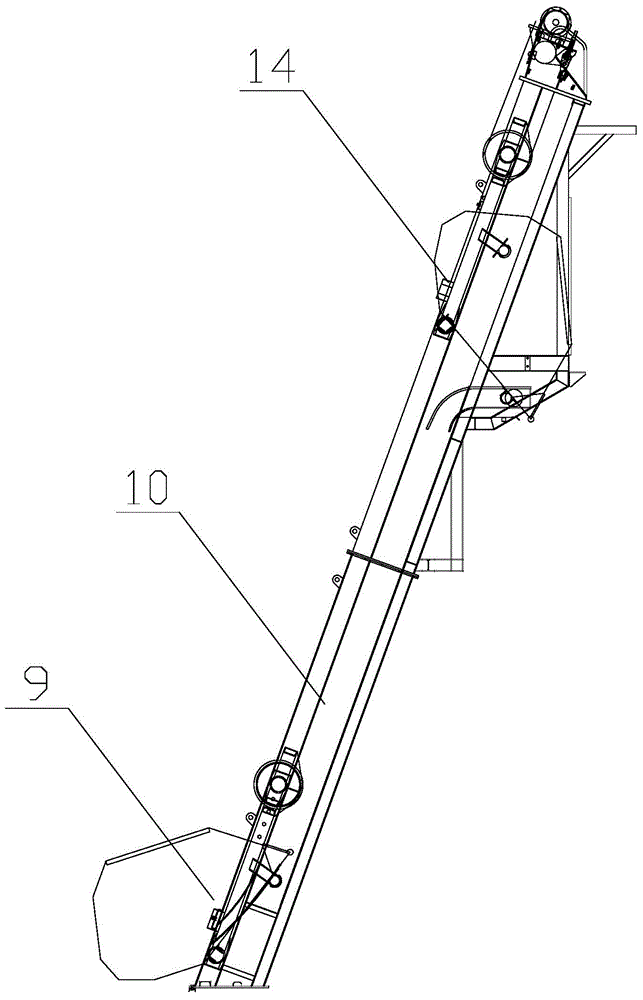

Elevator bucket loading type concrete batching plant

ActiveCN104972565ARunning slowReduce impactMixing operation control apparatusIngredients weighing apparatusControl systemElectrical control

The invention provides an elevator bucket loading type concrete batching plant. The elevator bucket loading type concrete batching plant structurally comprises an aggregate batching system, a hoisting system, a stirring system, a metering system, a water additive system, an electrical control system and a control chamber. The aggregate batching system is connected with the hoisting system through a belt conveyor. The other end of the hoisting system is connected with the stirring system and the metering system. The water additive system is connected with the metering system. The stirring system is connected with the metering system. The stirring system and the metering system are connected with the control chamber through a ladder. By adopting the elevator bucket loading type concrete batching plant, the occupied area is effectively reduced, the service life of a steel cable is prolonged, a bucket is effectively prevented from deflecting even getting stuck when pulled, the installation speed is high, and the installation safety is high.

Owner:SHANTUI JANEOO MACHINERY

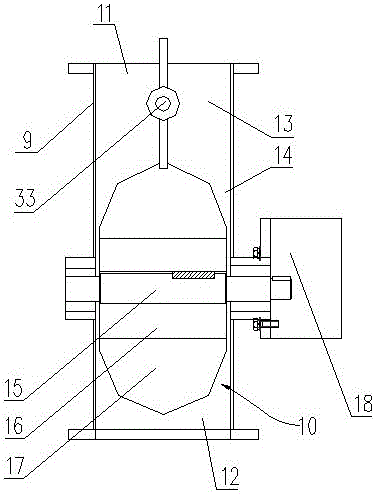

Continuous feeding system for cement pipe making machine

ActiveCN103522404AAvoid cloggingGuaranteed uniformityMixing operation control apparatusFeeding arrangmentsMaterial storageContinuous feeding

The invention provides a continuous feeding system for a cement pipe making machine, and relates to the technical field of cement product production and processing equipment. The continuous feeding system is used for solving the problems that the intermittent type feeding system of an existing cement pipe making machine is low in production efficiency, and faults easily occur. The continuous feeding system for the cement pipe making machine comprises a blender and a conveyor, a material storage bin is arranged between the blender and the conveyor, the blender is connected with the material storage bin, the material storage bin is connected with the conveyor, the conveyor is connected with the pipe making machine, and the size of the material storage bin is larger than or equal to that of the blender. The material storage bin with the matched size is additionally arranged between the blender and the conveyor, the material storage bin temporarily stores blended materials, and therefore blending and conveying operations are simultaneously carried out, production continuity is guaranteed, and production efficiency is improved. A material loosening device is arranged in the material storage bin, uniformity of feed flow of the conveyor is guaranteed, and the blocking fault of the conveyor is avoided.

Owner:SHANDONG ZOTO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com