Patents

Literature

6742 results about "Mixing tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mixing tank is a container that is used to blend several components together. The material that a mixing tank is made of can range from plastic, glass or hard rubber to steel of all types. Stainless steel is often used in the creation of a mixing tank due to the ease of clean-up as well as the smooth surface of the product.

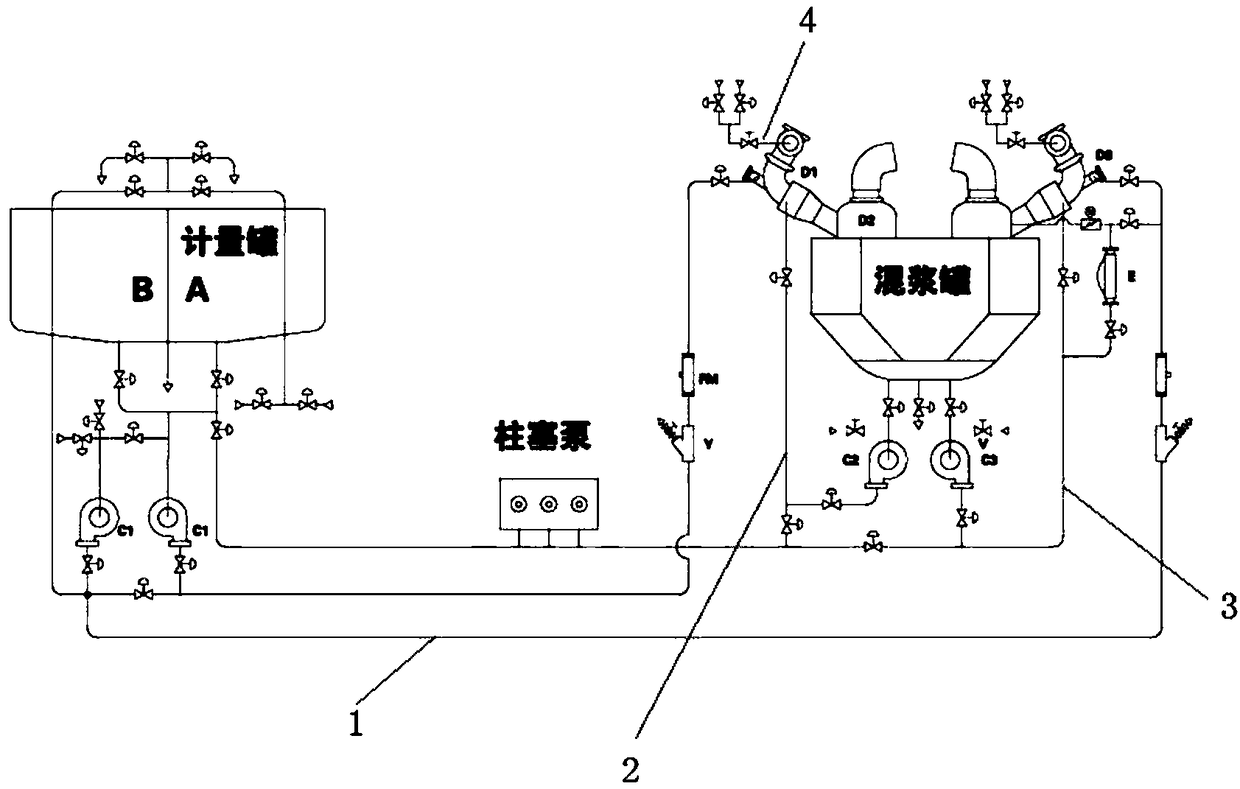

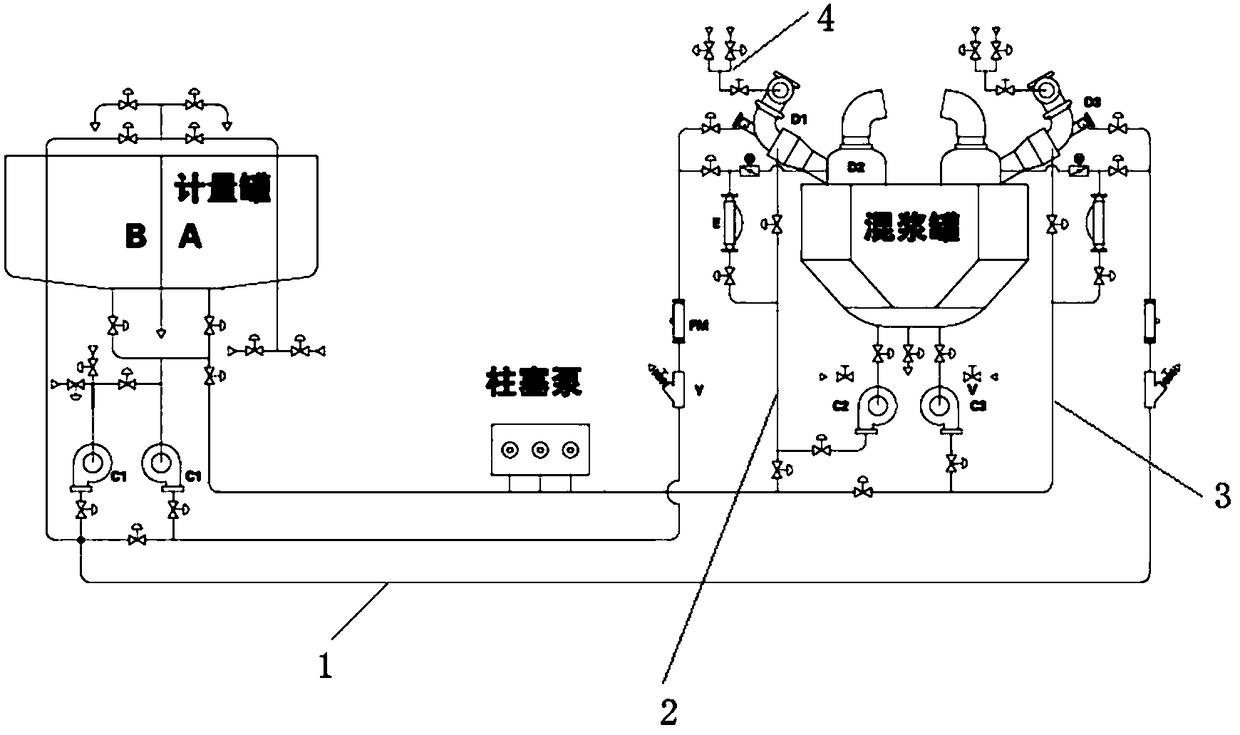

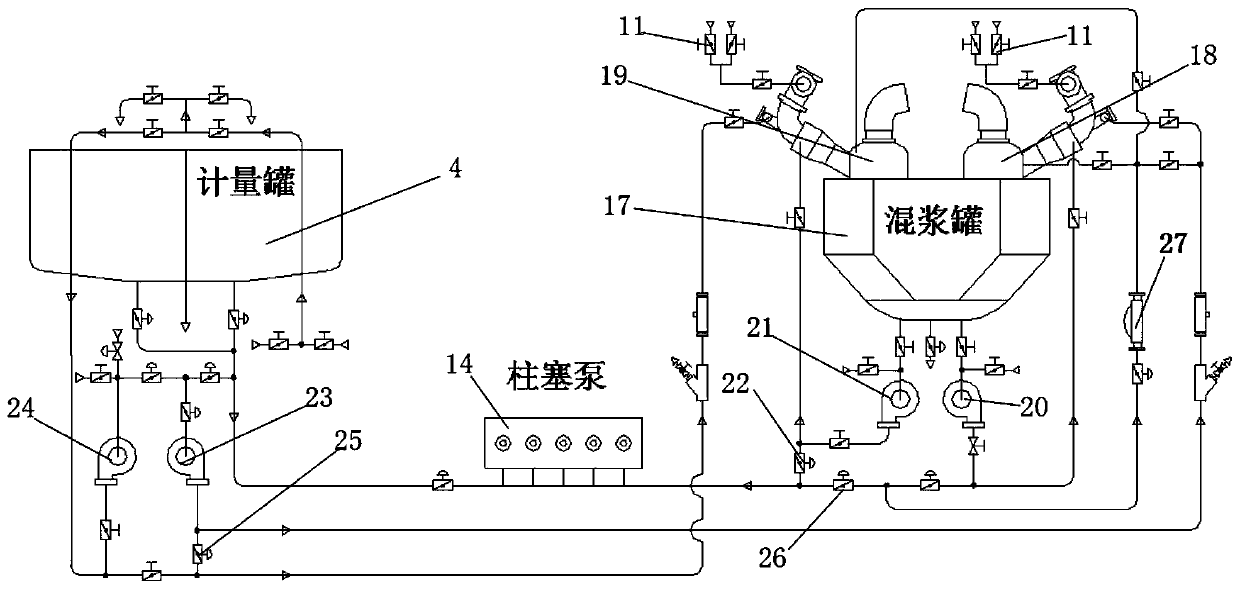

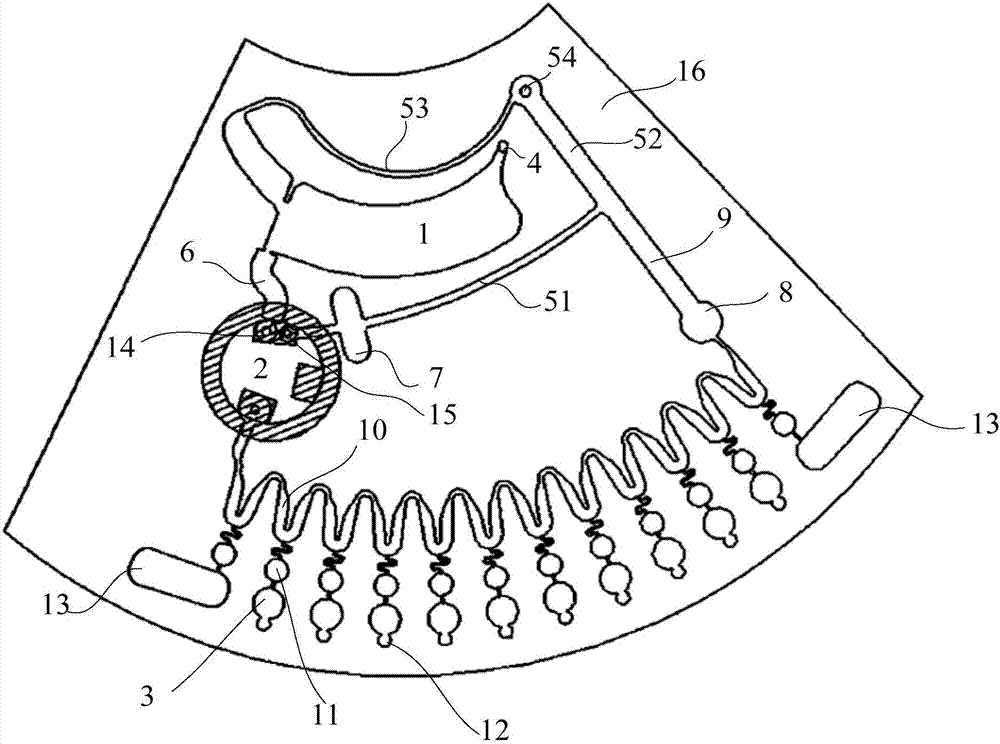

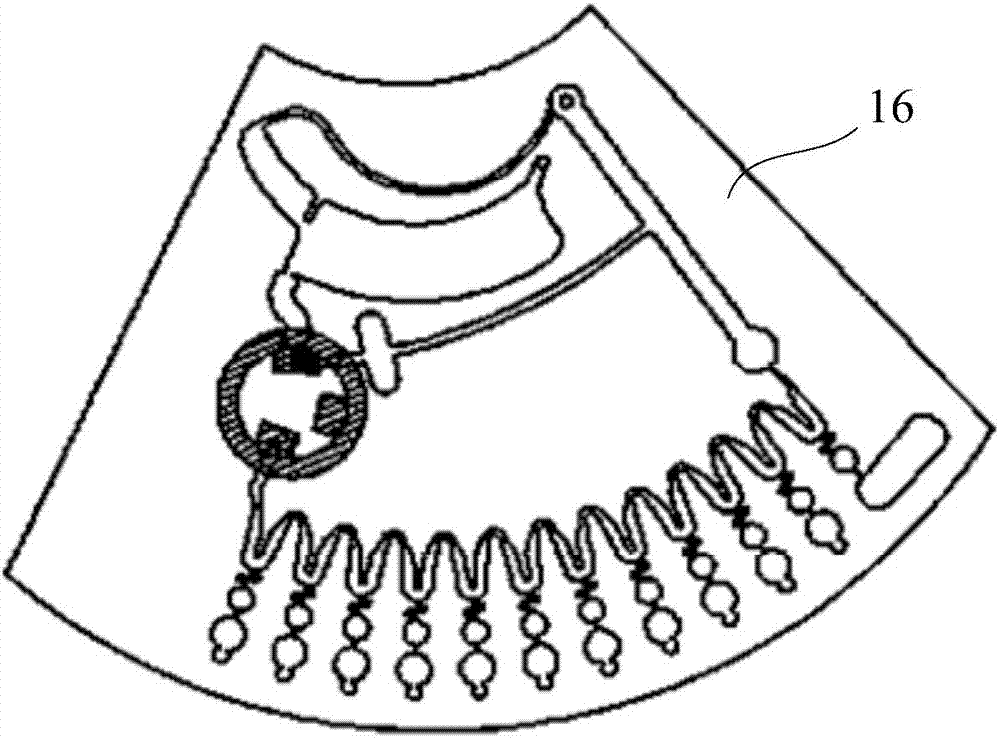

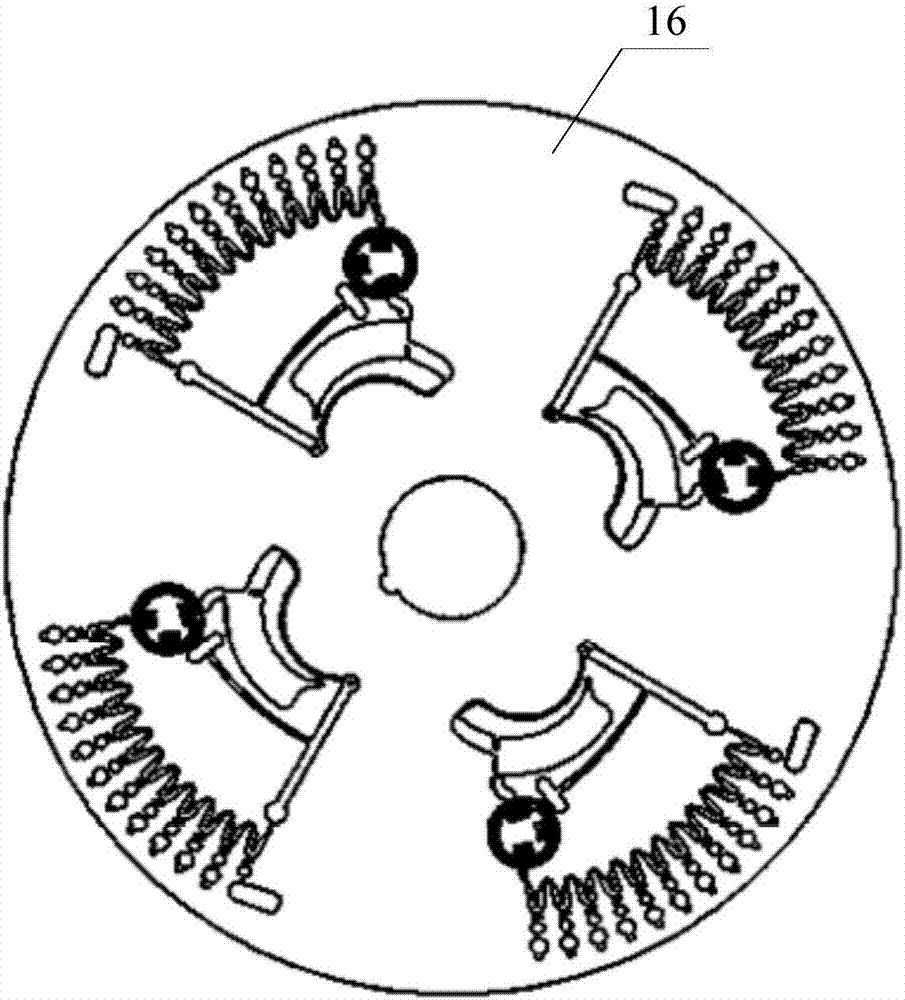

Efficient mixing system for well cementing operation

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

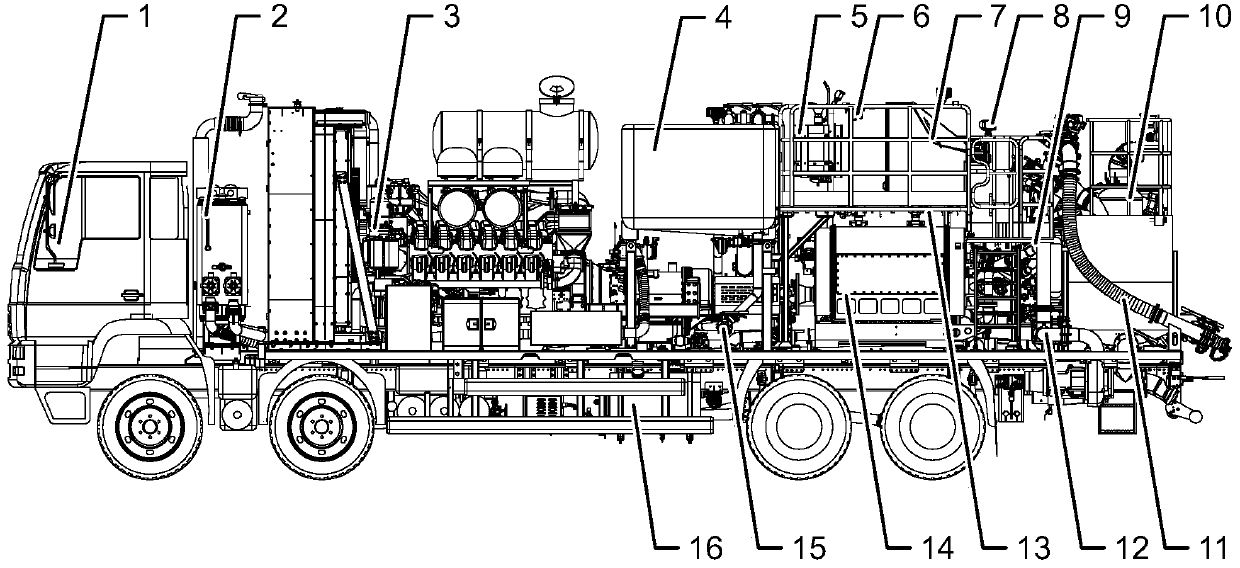

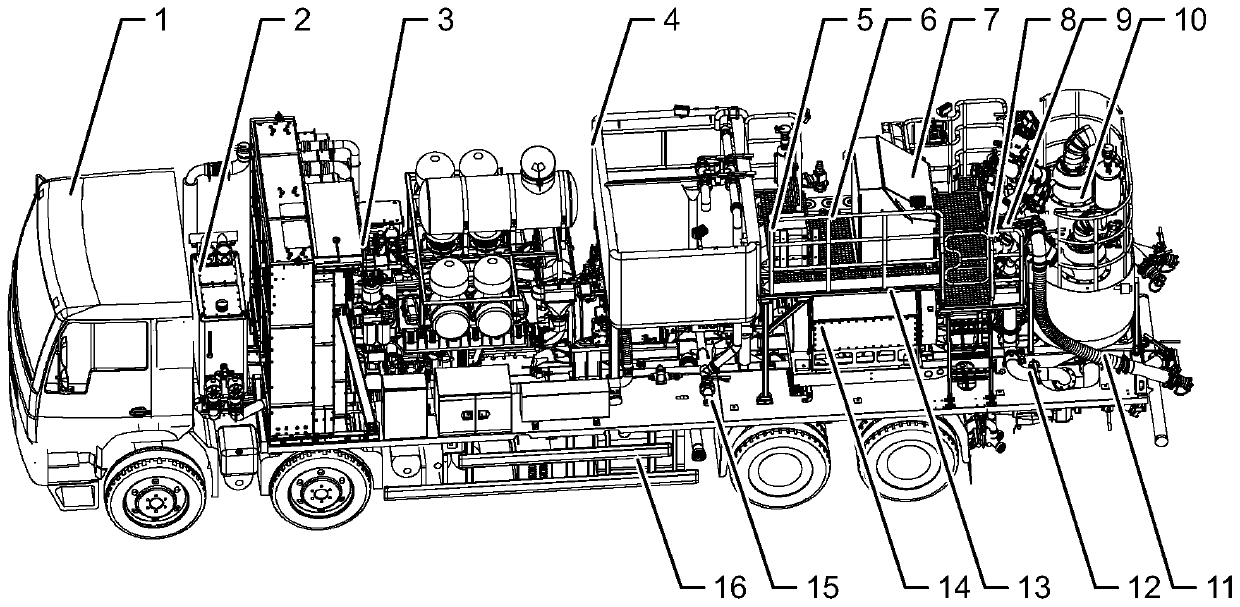

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

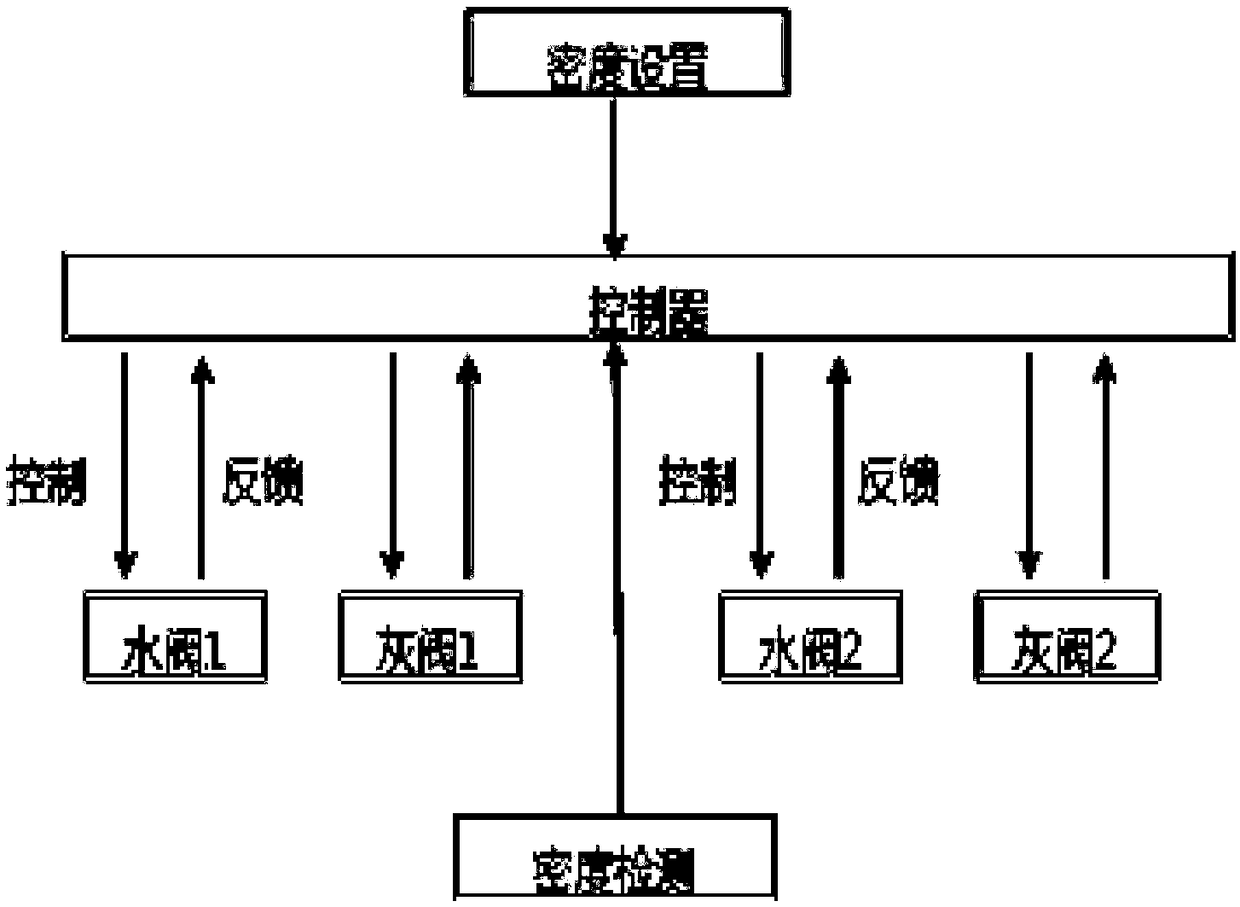

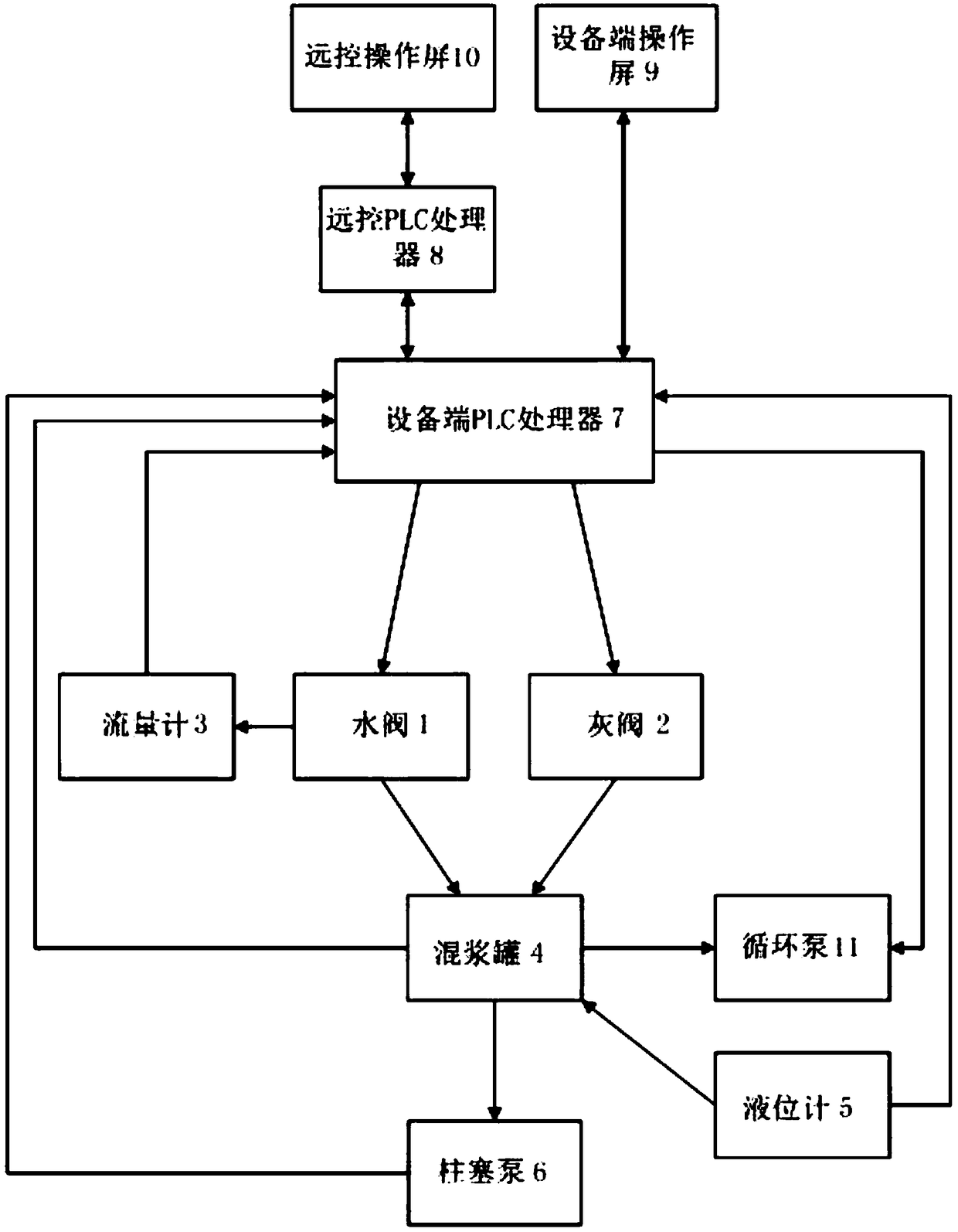

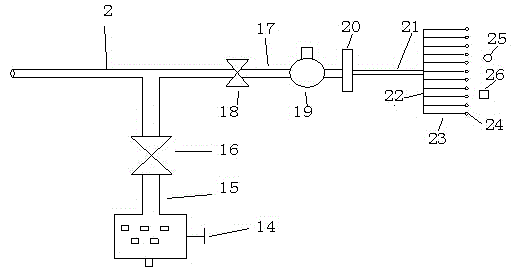

Remote ultra-low-density automatic control system

PendingCN109491318AIncreased level of process automationProgramme control in sequence/logic controllersAutomatic controlSlurry

The invention discloses a remote ultra-low-density automatic control system. The system comprises a control unit, a water valve, a flow meter, a cement valve, a slurry mixing tank, a liquid level meter, a circulation pump and a plunger pump; the cement valve, the water valve, the circulation pump and the plunger pump are connected with the slurry mixing tank separately, the flow meter feeds the water supply amount monitored in real time back to the control unit, the liquid level meter is arranged in the slurry mixing tank, the control unit controls the number of revolutions and preset displacement of the plunger pump to achieve automatic displacement as required, the water demand amount and the cement demand amount are calculated by presetting the water-cement ratio and liquid level valuein the control unit, and therefore the opening degrees of the water valve and the cement valve are controlled; the control unit comprises a remote control unit and an equipment end control unit whichare connected with each other. The remote ultra-low-density automatic control system has the advantage of remote cementing equipment monitoring, remote liquid level automatic control, remote automaticwater supply, remote automatic cement supply, remote automatic premixing, remote automatic density control and remote automatic displacement.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

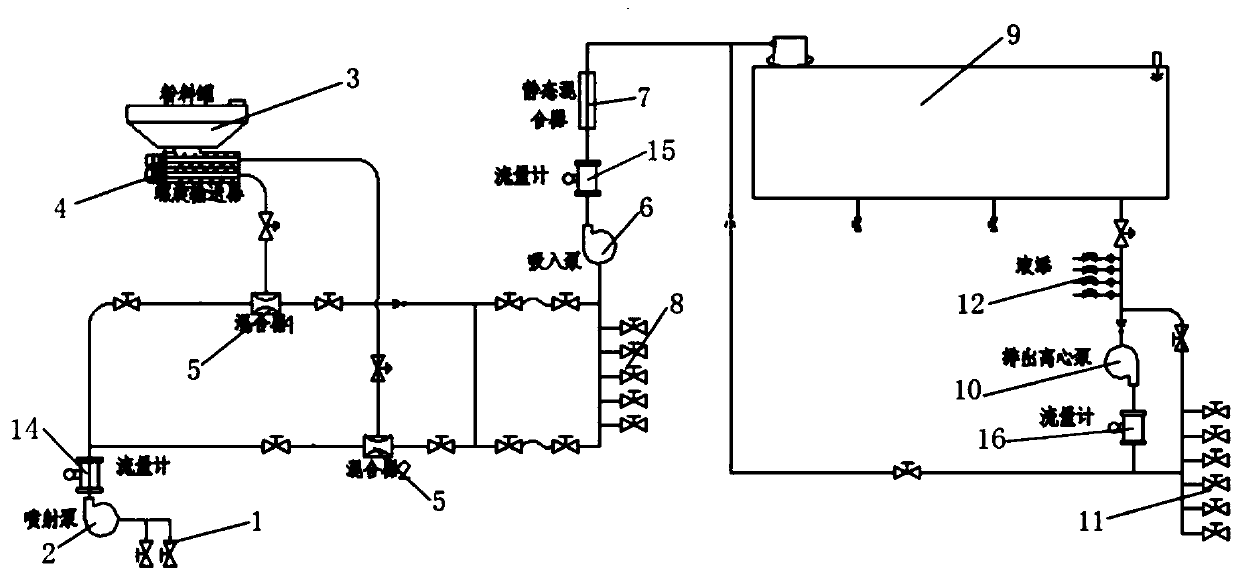

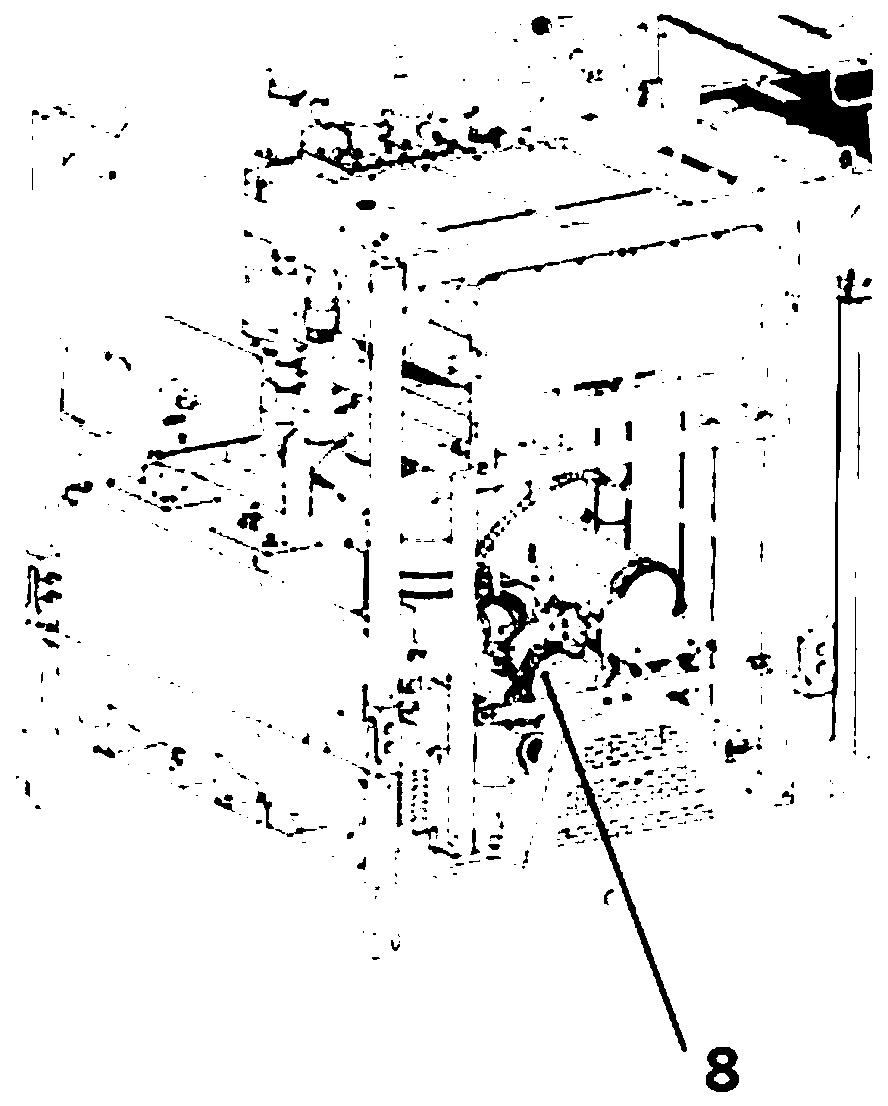

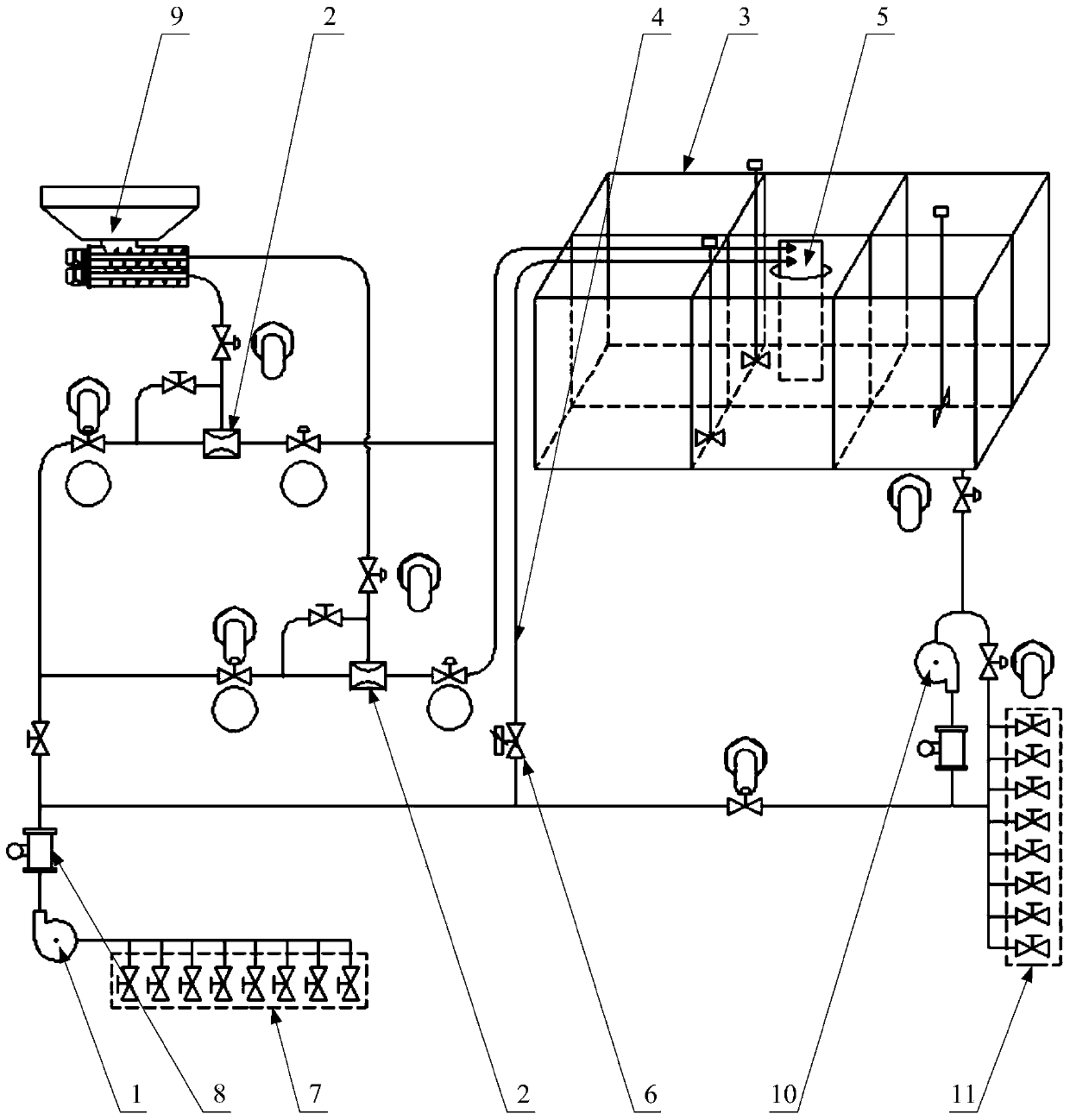

Mixing system

PendingCN110787667AImprove mix qualityImprove mixing efficiencyTransportation and packagingMixing methodsEngineeringStatic mixer

The invention discloses a mixing system. The mixing system comprises a mixing module and an output module, the mixing module comprises a first liquid inlet header, an injection pump, a powder tank anda mixer, the first liquid inlet header is connected with the injection pump, the injection pump is connected with the mixer, and the powder tank provides powder for the mixer; the output module comprises a second liquid inlet header, a suction pump, a second flowmeter, a static mixer, a mixing tank and a liquid discharge manifold, and the second liquid inlet header, the section pump, the second flowmeter, the static mixer, the mixing tank and the liquid discharge manifold are sequentially connected; an outlet of the mixer of the mixing module is connected with an inlet of the suction pump ofthe output module through a valve, and the mixing module and the output module can be used respectively or used in combination as a complete set. The mixing system has the beneficial effects that thesecond liquid inlet header and the static mixer are arranged, mixing with large discharge capacity and high quality can be completed with low energy consumption; and the mixing system is flexible in disassembly and assembly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

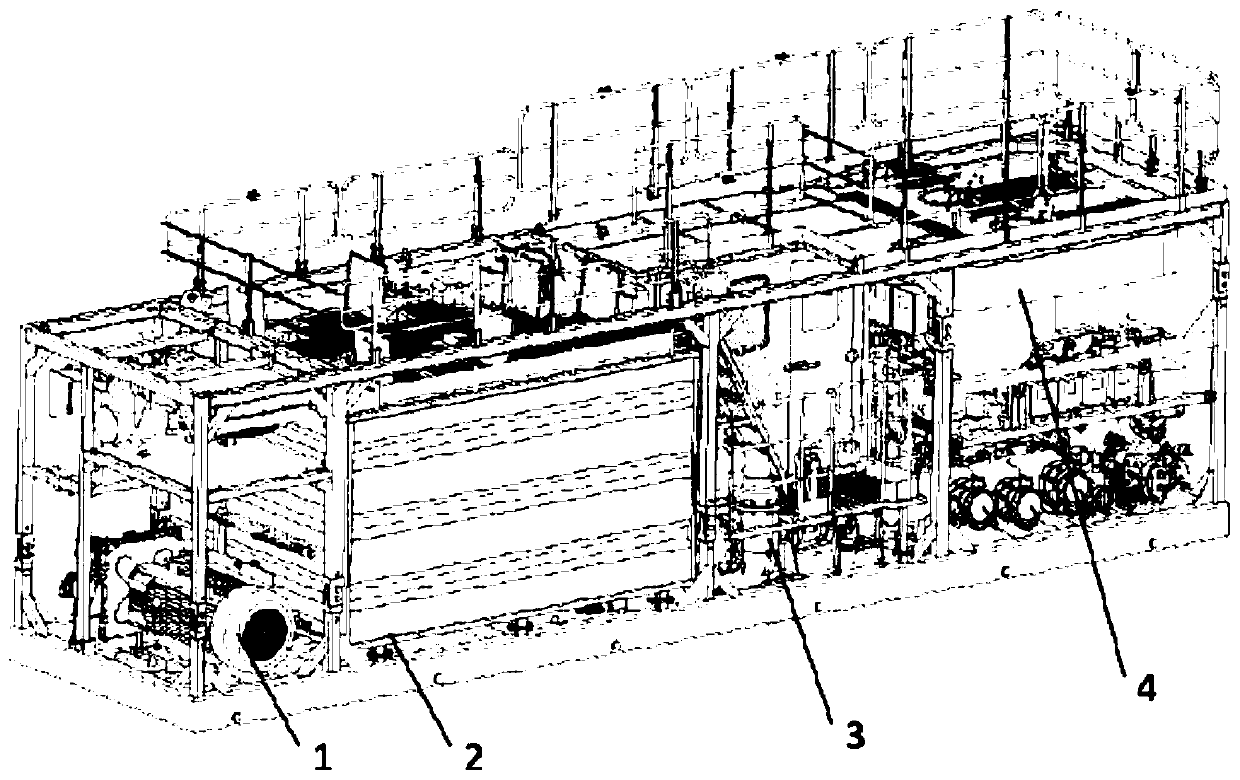

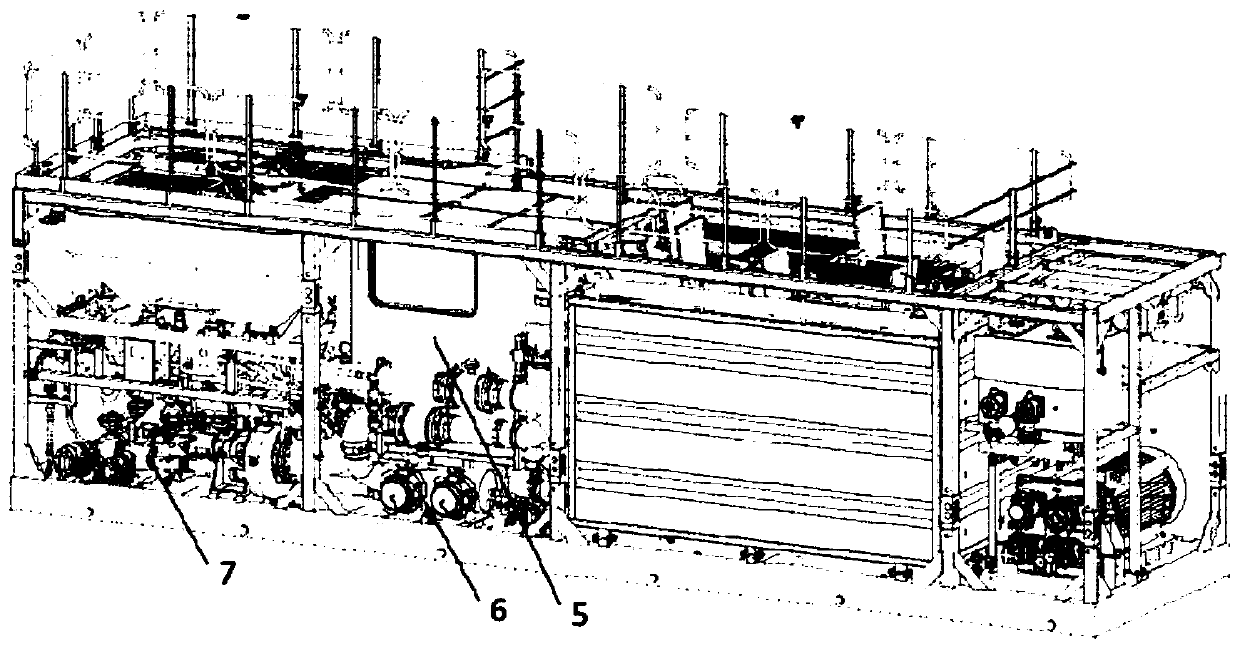

Electric-drive mixing device

PendingCN110252191ALow calorific valueSmall footprintMixing methodsTransportation and packagingElectricityFrequency conversion

The invention discloses an electric-drive mixing device, and relates to the technical field of mixing equipment. The electric-drive mixing device comprises a motor power unit, a mixing tank, a discharge centrifugal pump, a suction centrifugal pump, a powder tank, a control chamber, a drainage manifold, a water-powder mixing manifold, a chemical adding pump and a suction header. The mixing tank is fixedly mounted on one side of the motor power unit, and the control chamber is fixedly mounted on one side of the mixing tank. The electric-drive mixing device has the advantages that a selected motor is a variable-frequency all-in-one machine, that is to say, a frequency converter is integrated with the motor, and there is no independent frequency conversion cabinet, so that the occupied space is remarkably saved, and the device is suitable for vehicle transportation; the variable-frequency all-in-one machine has much lower heat than the motor, a radiator is integrated to a cabinet casing of the motor and the frequency converter, and no plate-fin radiating holes are provided; a large-channel air duct is arranged at a motor and frequency converter casing position of a fan, and accordingly, blockage is avoided.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

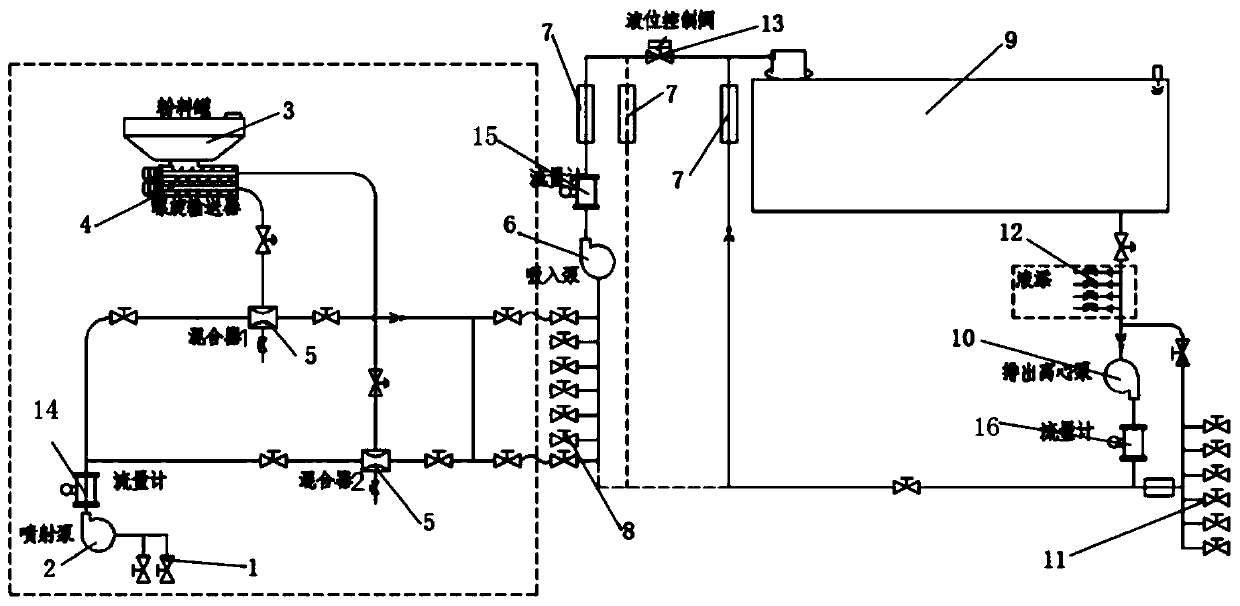

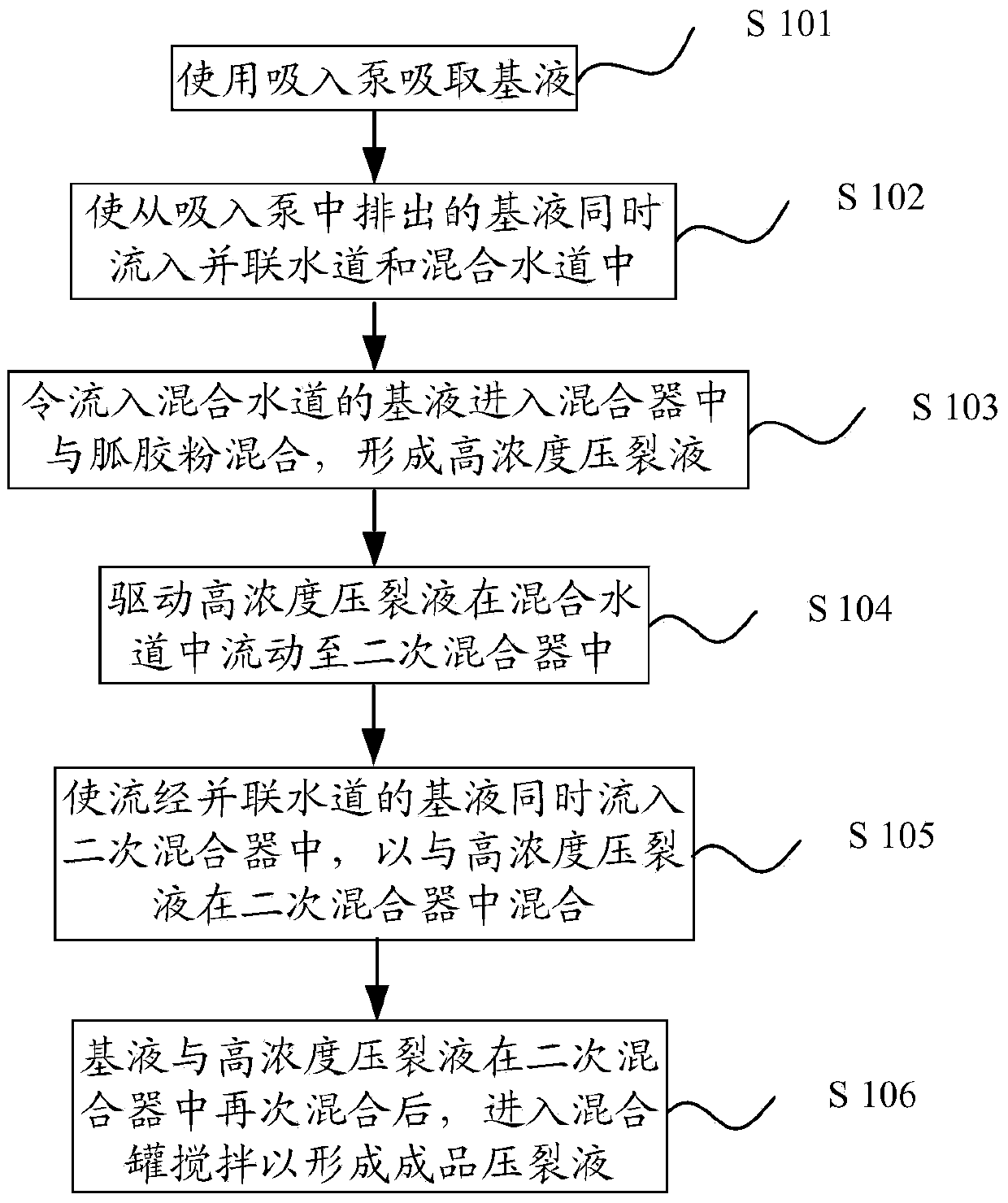

Blending system of fracturing fluid and blending technology of system

InactiveCN103990410AReduce concentrationImprove mixing efficiencyMixing methodsMixersFracturing fluidEngineering

The invention provides a blending system of a fracturing fluid. The blending system comprises a suction pump, a mixer, a mixing tank, a secondary mixer which is arranged between the mixer and the nixing tank and is used for mixing the fracturing fluid again, and a parallel-connection water channel, wherein one end of the parallel-connection water channel is communicated with the suction pump, the parallel-connection water channel and a mixing water channel of the mixer are connected in parallel, and the other end of the parallel-connection water channel is communicated with the secondary mixer. The blending system provided by the invention has the advantages that the parallel water channel is additionally arranged and is connected with the mixing water channel in parallel, a base solution is capable of simultaneously entering two routes, namely the mixing water channel and the parallel-connection water channel, not all of the base solution enters the mixing water channel, a condition that the limitation on blending efficiency is caused by the relatively small flow of the mixing water channel is avoided, the blending time is shortened, the blending energy consumption is reduced, the fracturing fluid is formed through multi-time blending in a double-route manner, the mixing uniformity is improved, and the quality of the fracturing fluid is further optimized. The invention also provides a fracturing fluid blending technology suitable for the blending system of the fracturing fluid.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

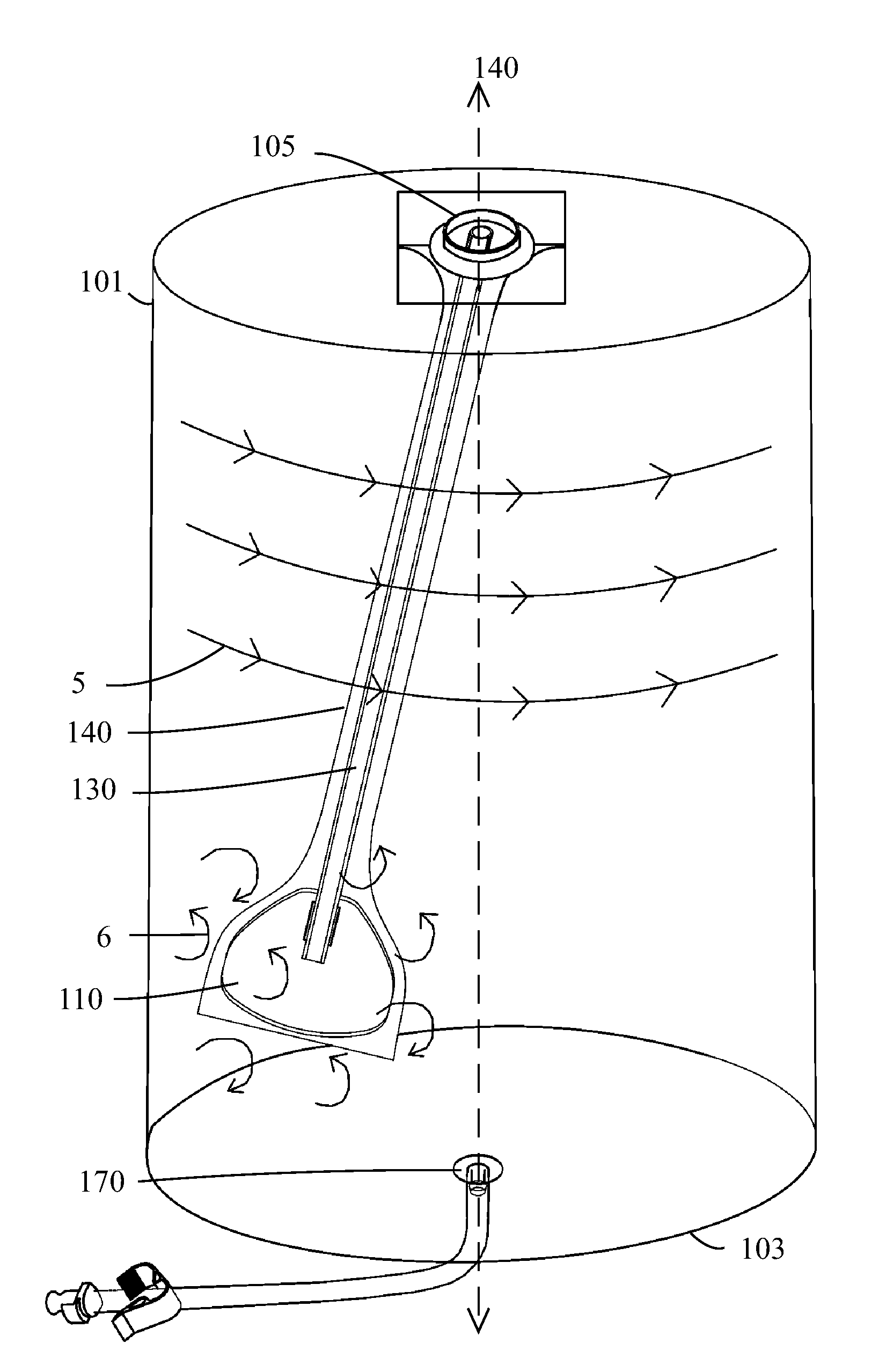

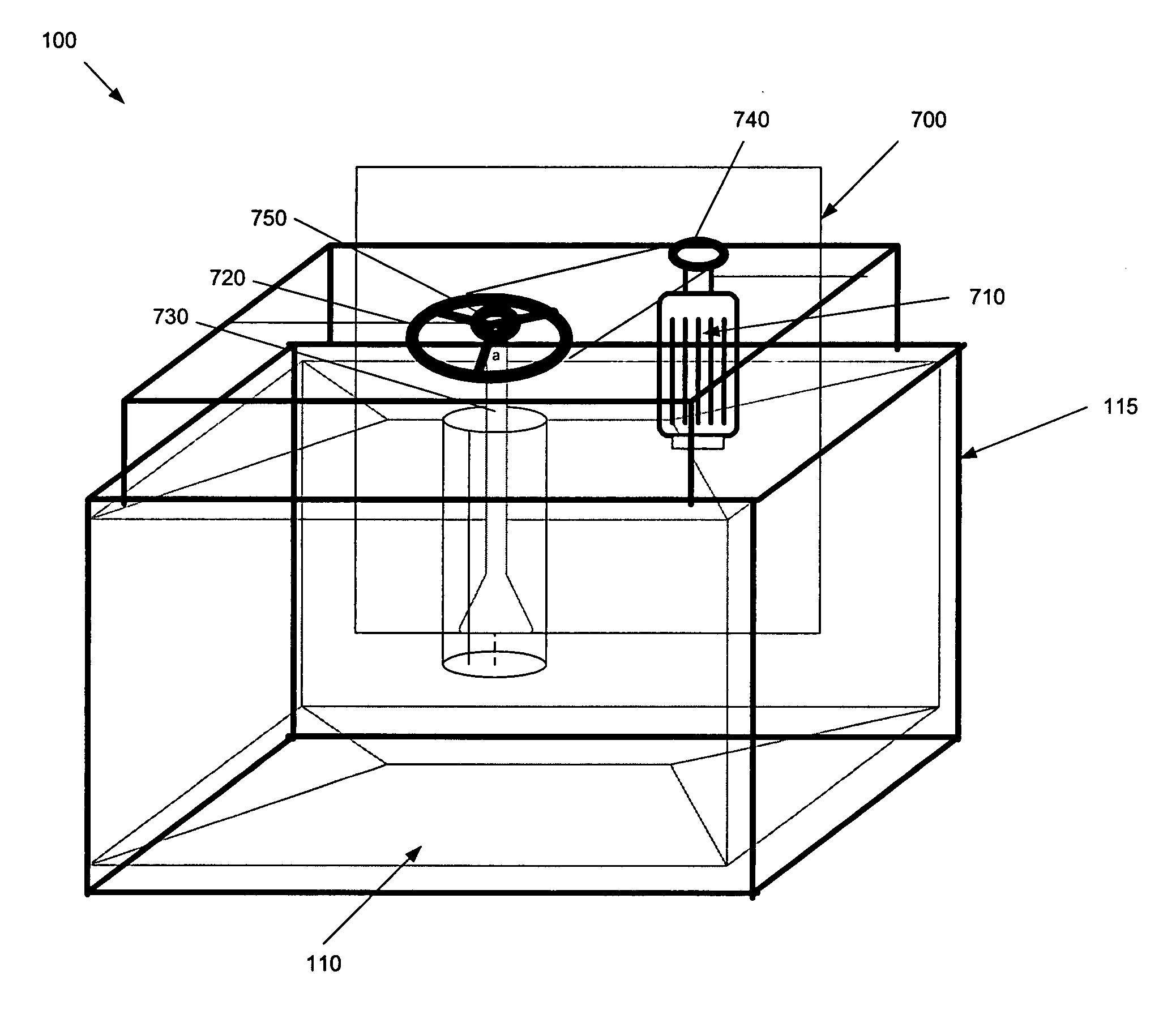

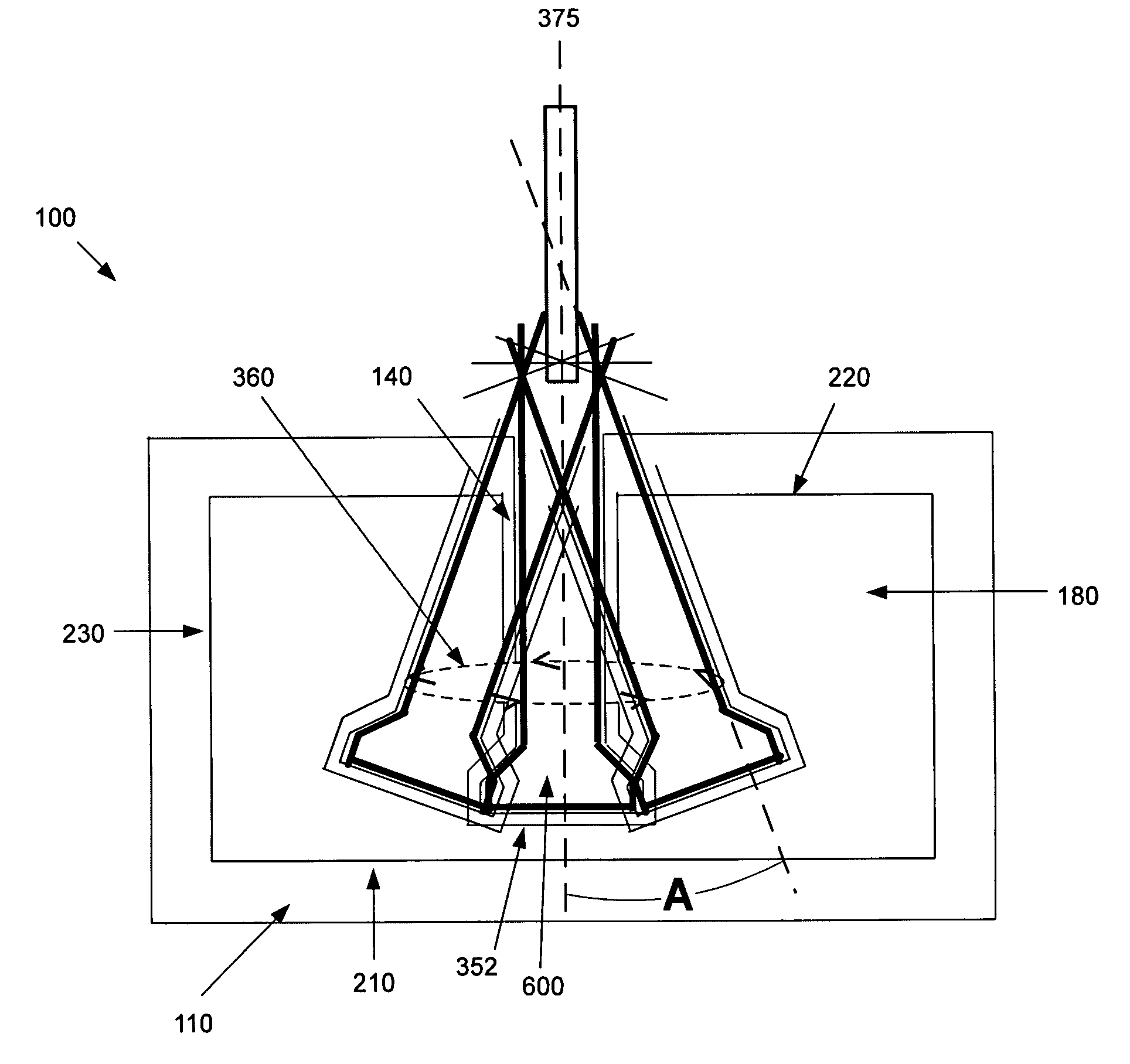

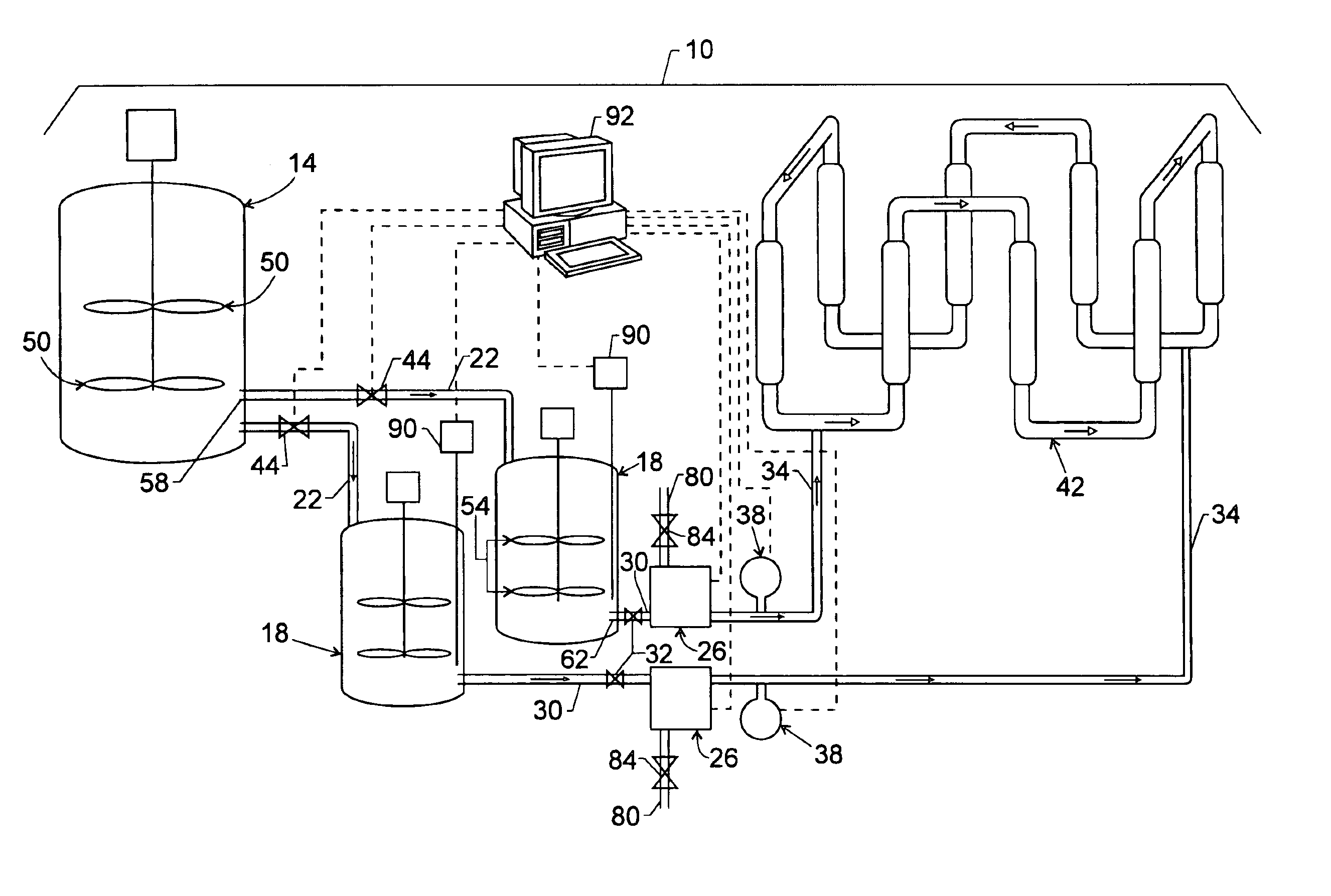

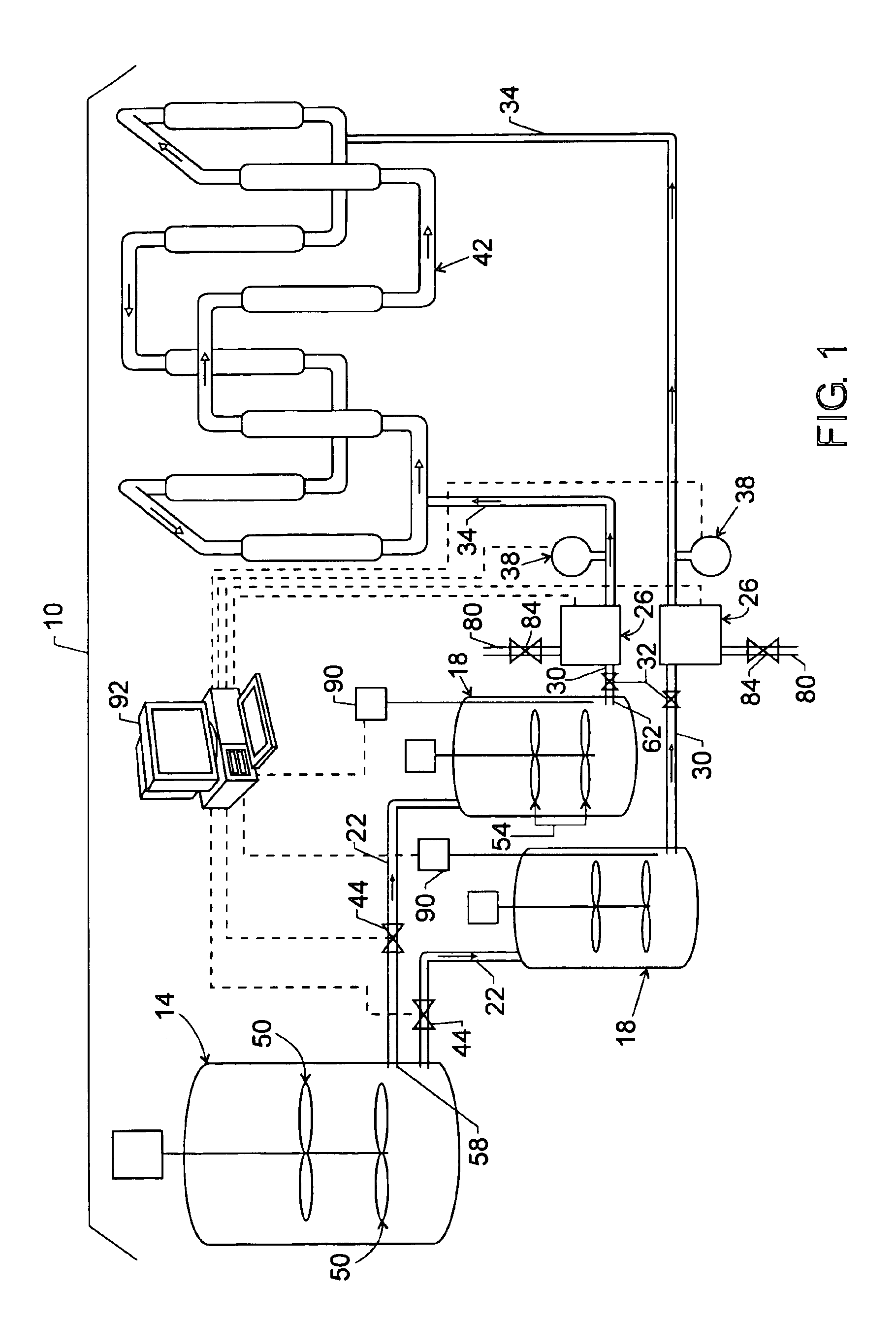

Disposable bioreactor

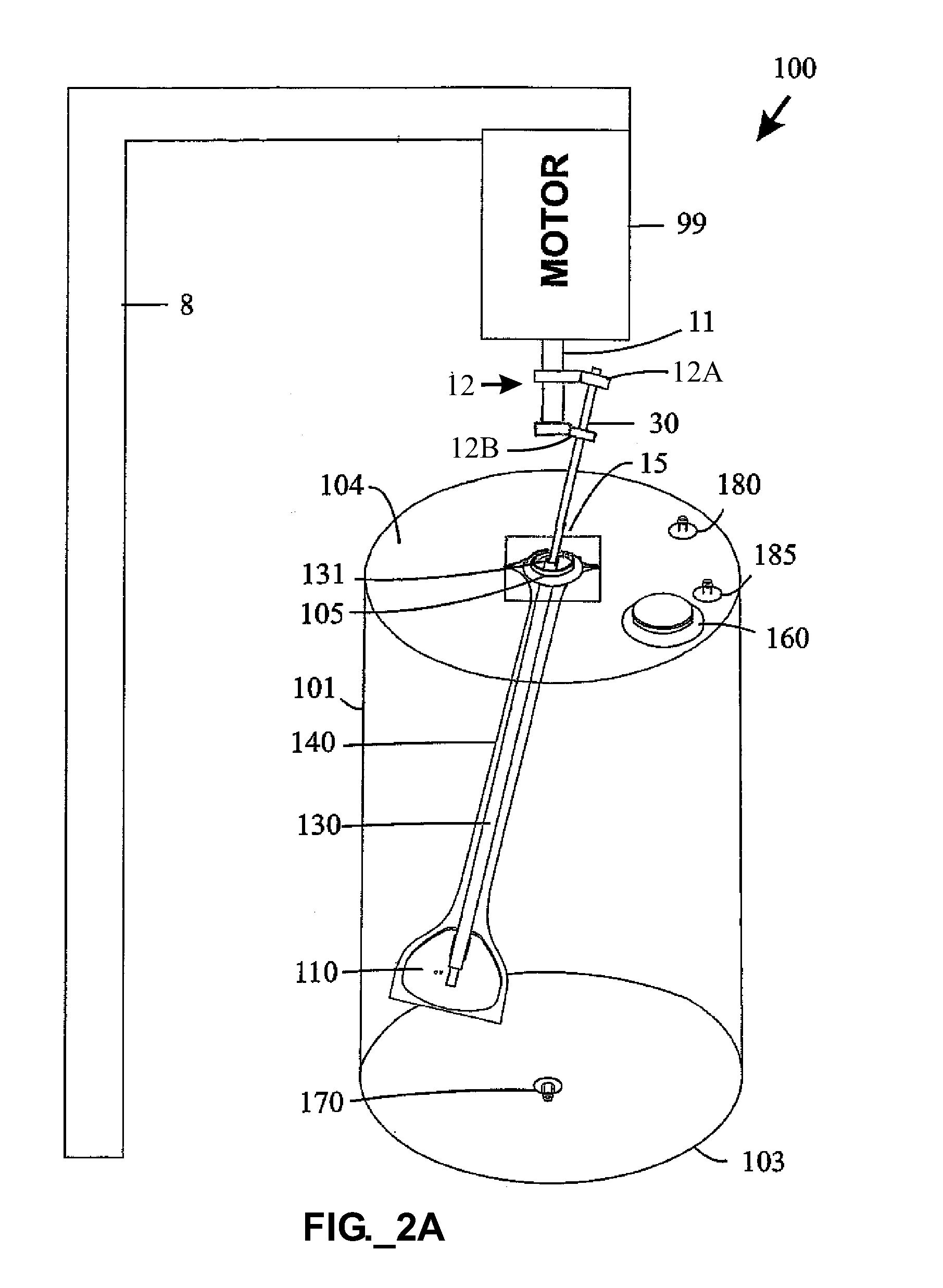

ActiveUS20100015696A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCatheterEngineering

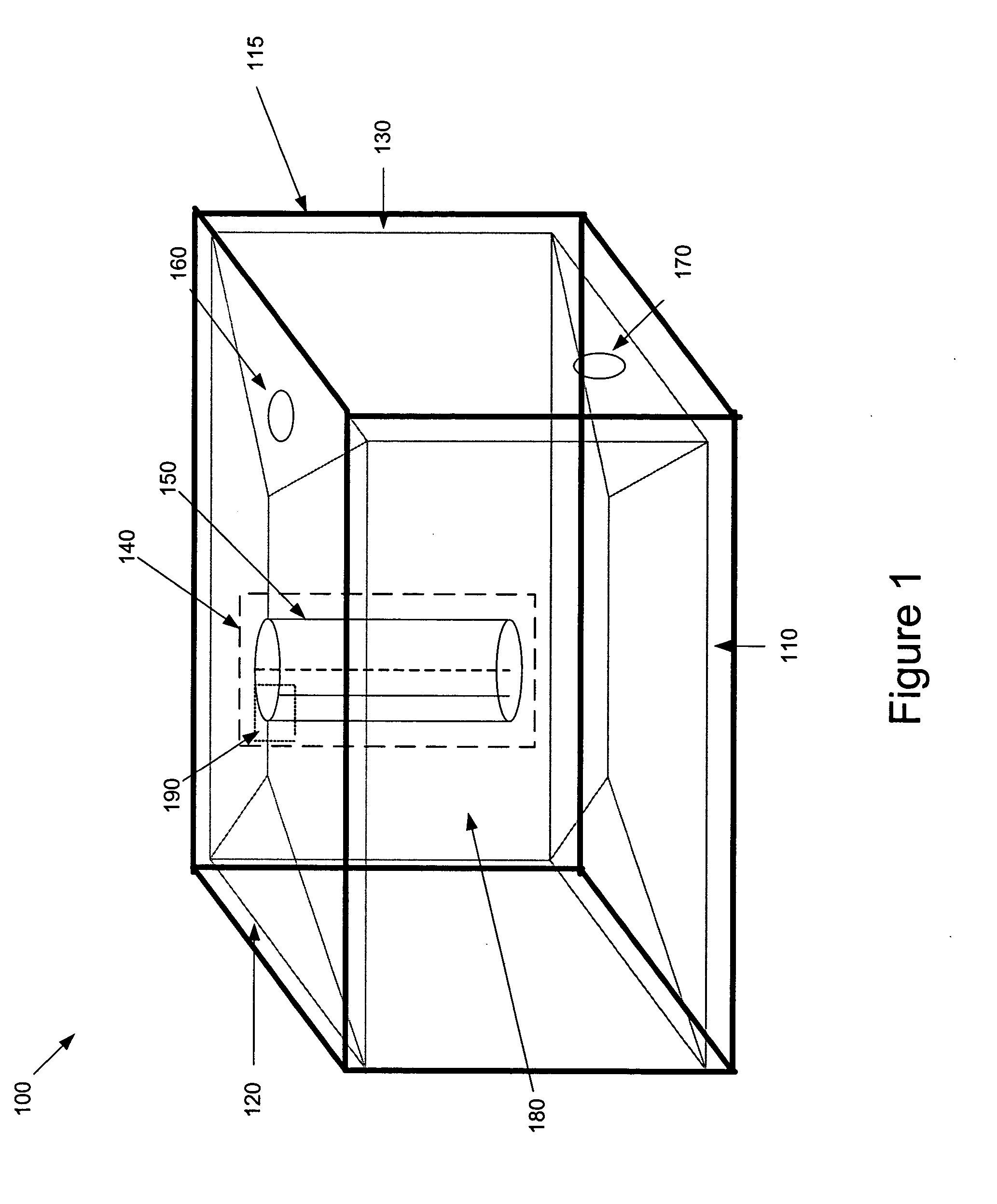

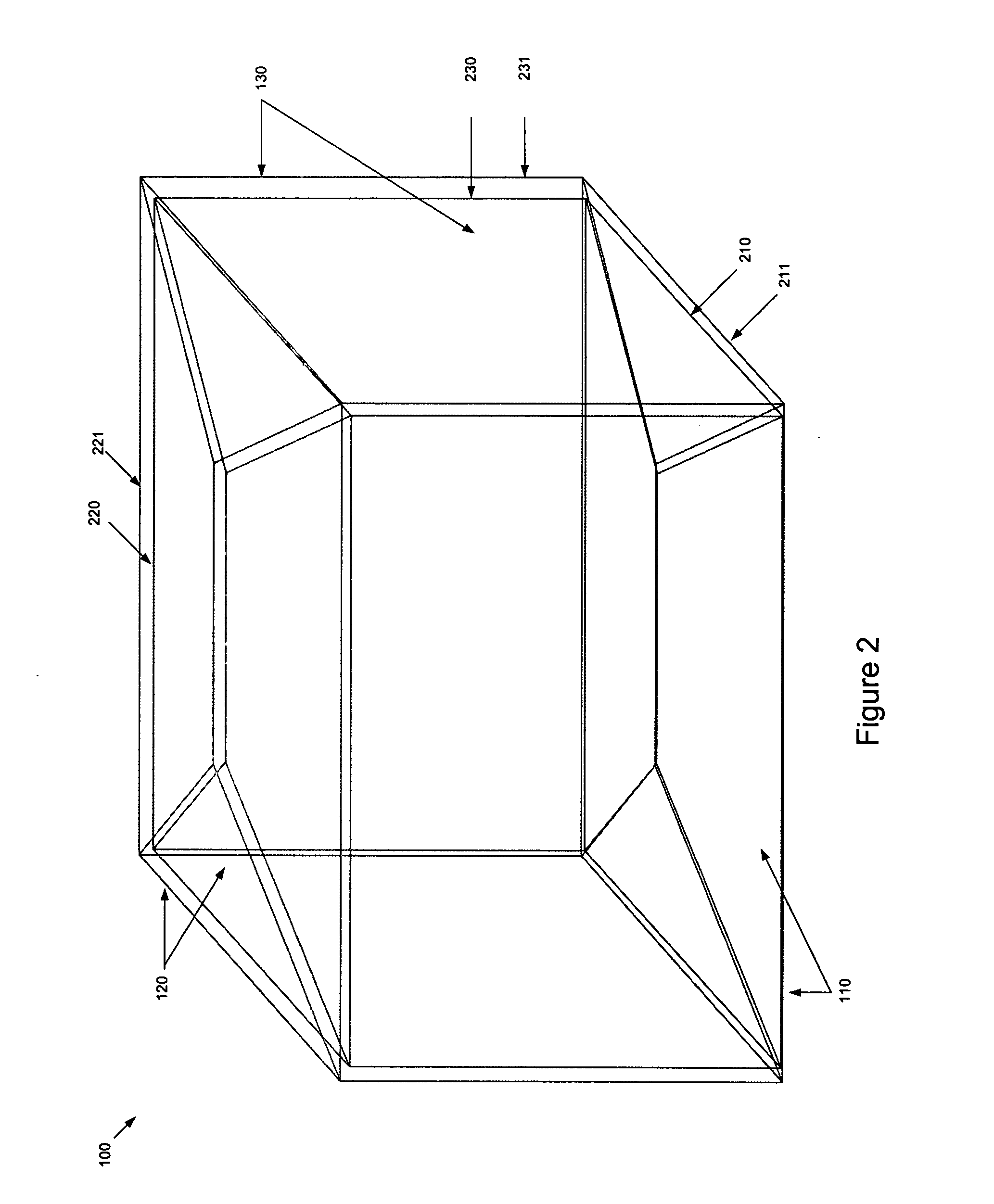

A disposable material processing apparatus, useable as a bioreactor or fermenter, includes a hollow tank (101) and a mixing paddle (110) disposed within the interior of the tank and adapted to mix contents therein. The paddle may be isolated within a flexible sleeve (140). Various functional elements, such as a sparger, sensor, material extraction conduit, material addition conduit, and / or heat exchange element may be provided, and optionally arranged to travel with the paddle within the tank interior. Baffles may protrude into a mixing tank to enhance mixing. A tank and / or sleeve may comprise polymeric film materials.

Owner:PALL LIFE SCI BELGIUM

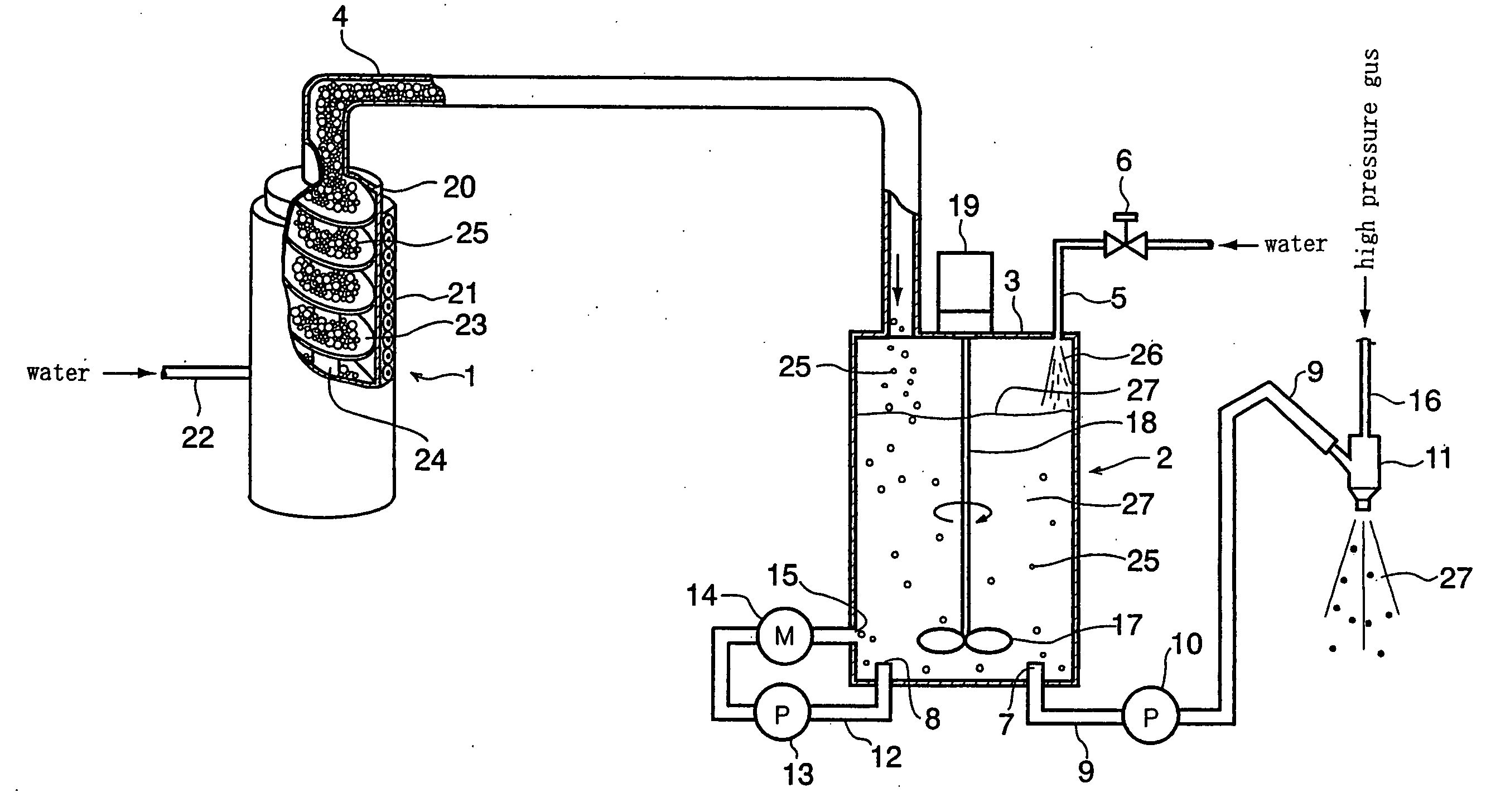

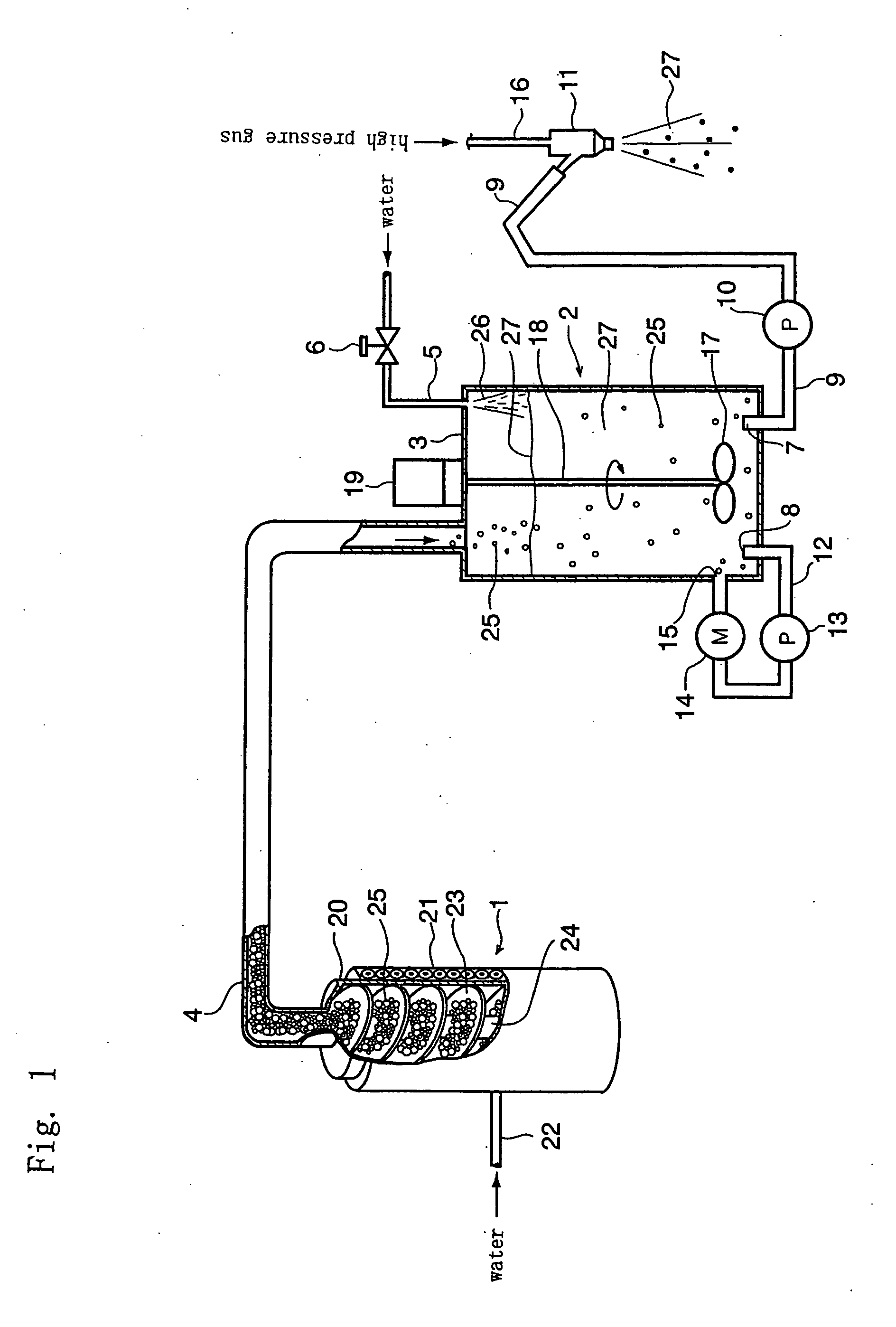

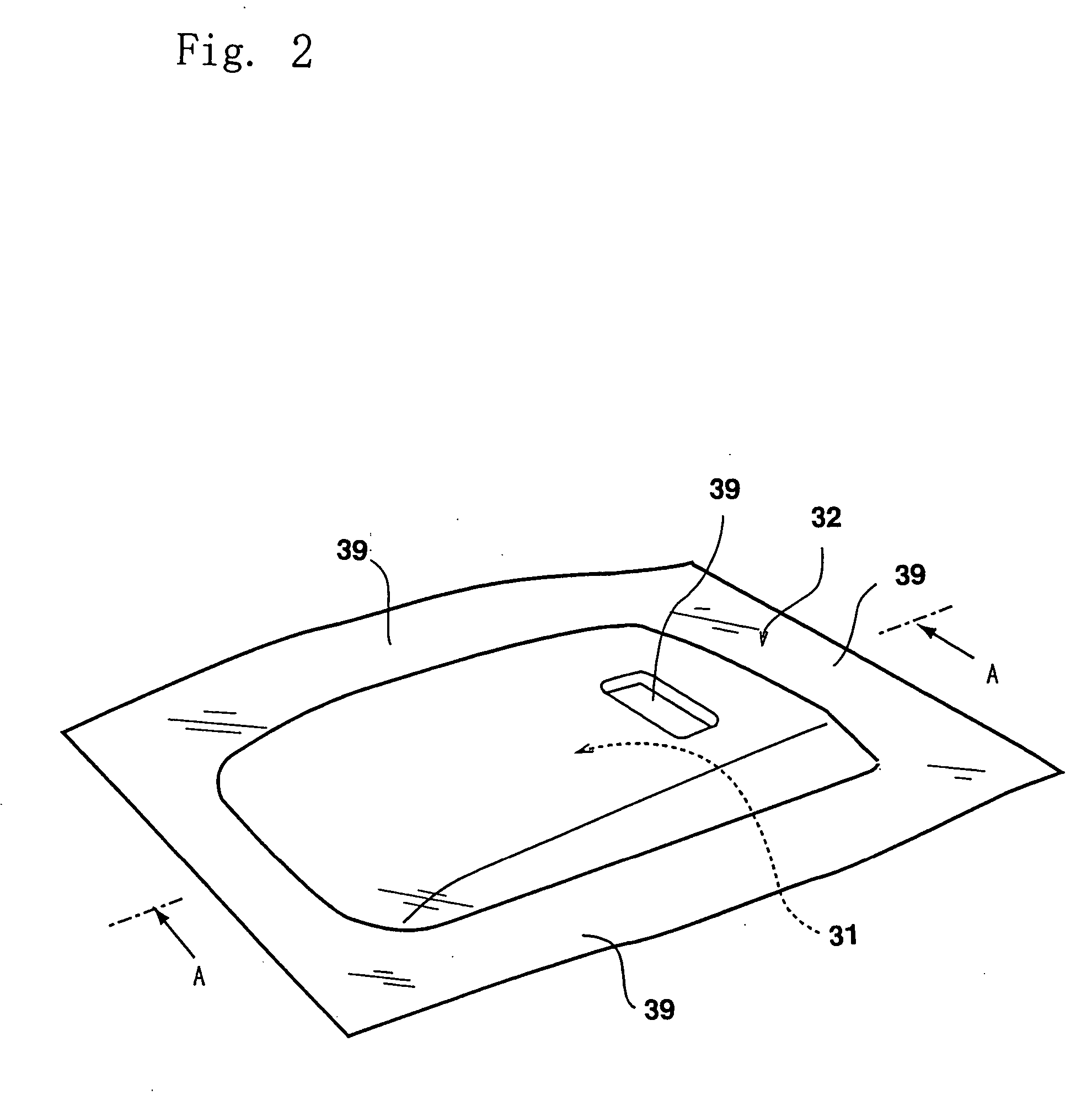

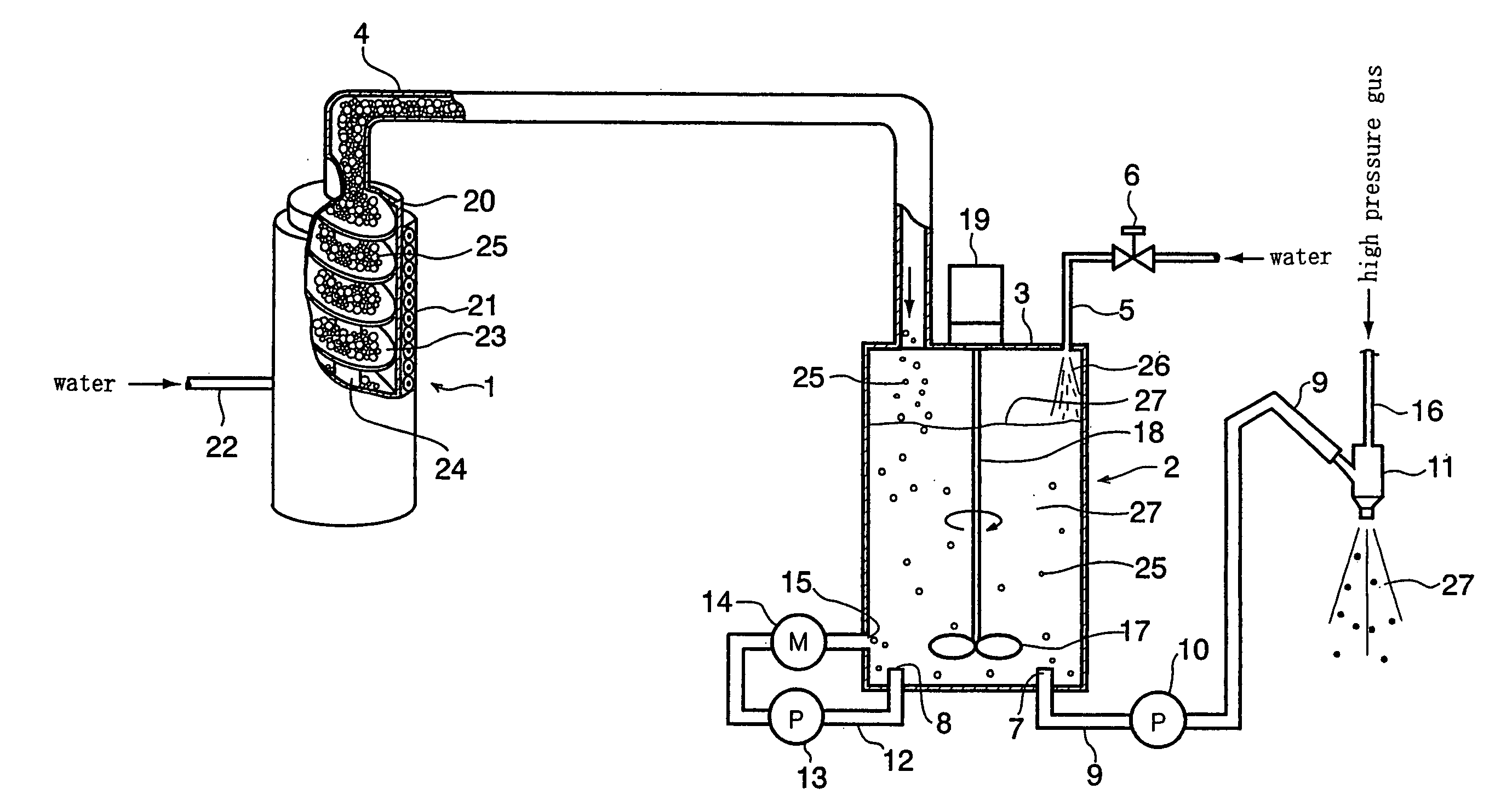

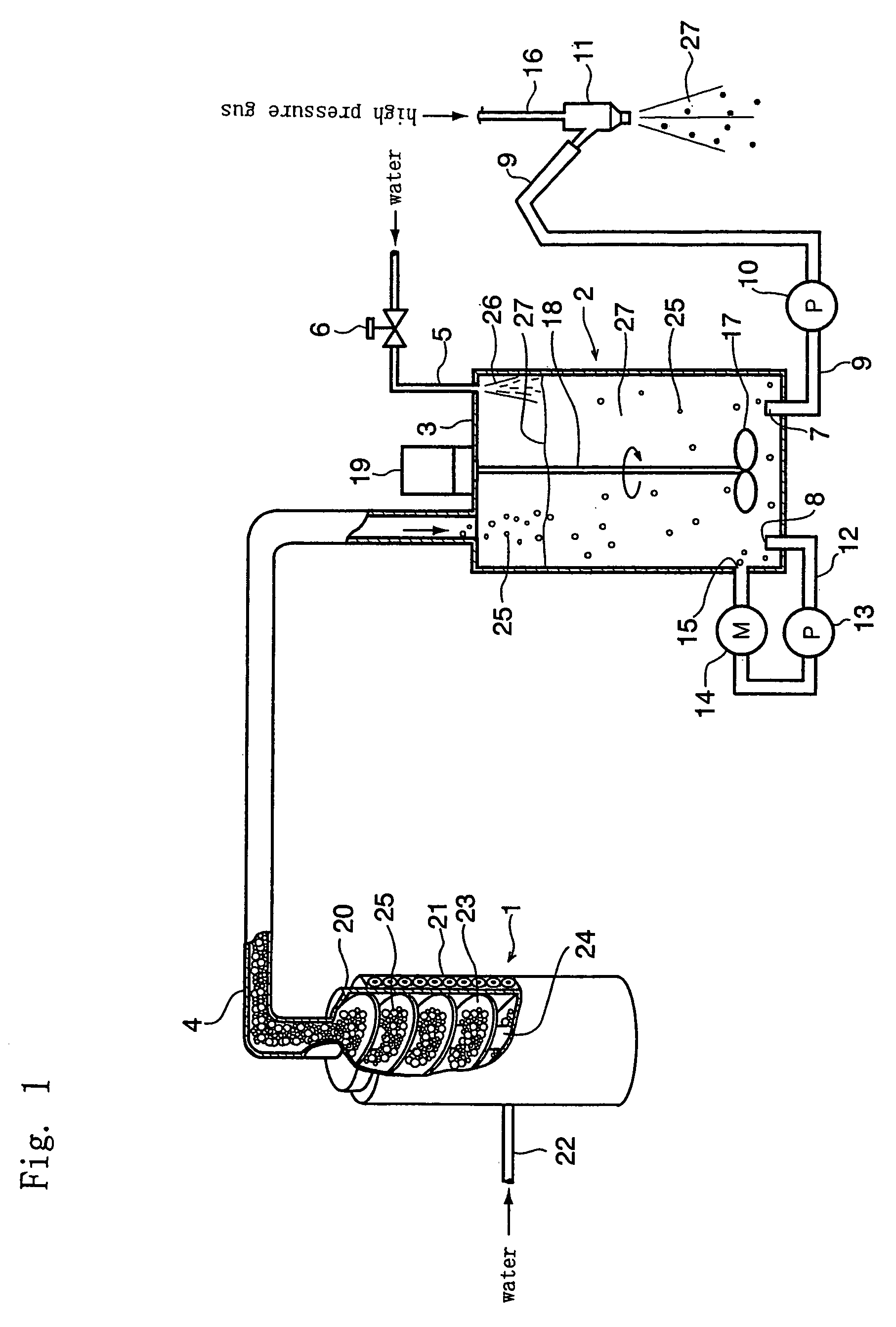

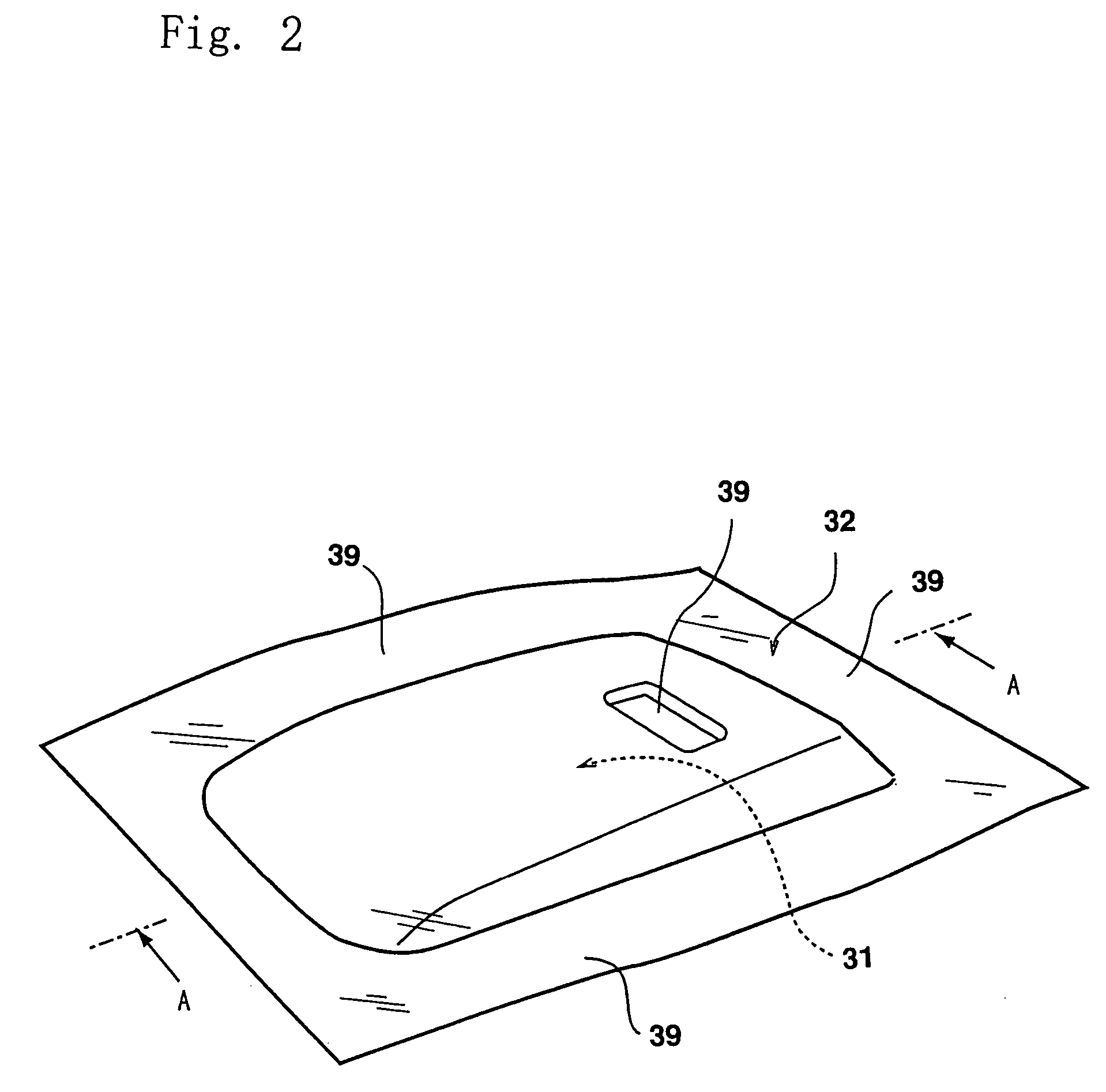

Ice blasting apparatus and trimming method for film insert molding

InactiveUS20050107006A1Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesEngineeringSlurry

An ice blasting apparatus comprises: an ice making device operating a cutting blade to shave off ice freezing on an inner wall of the freezing casing and continuously discharges the shaved ice as flake-shaped ice pellets; an ice mixing tank mixing the ice pellets and water and maintaining the resulting ice slurry at a predetermined concentration with a concentration sensor; and a blast gun blasting the ice slurry. A trimming method is performed on a film insert molding with a film material adhering to a face of a resin molding and extending beyond a periphery edge of the resin molding. A blast gun facing the face with the film adhering to it blasts ice slurry of a required concentration toward the vicinity of the periphery edge of the resin molding to remove the unnecessary portion of the film material extending beyond the periphery edge of the resin molding.

Owner:TOSHIBA MASCH CO LTD

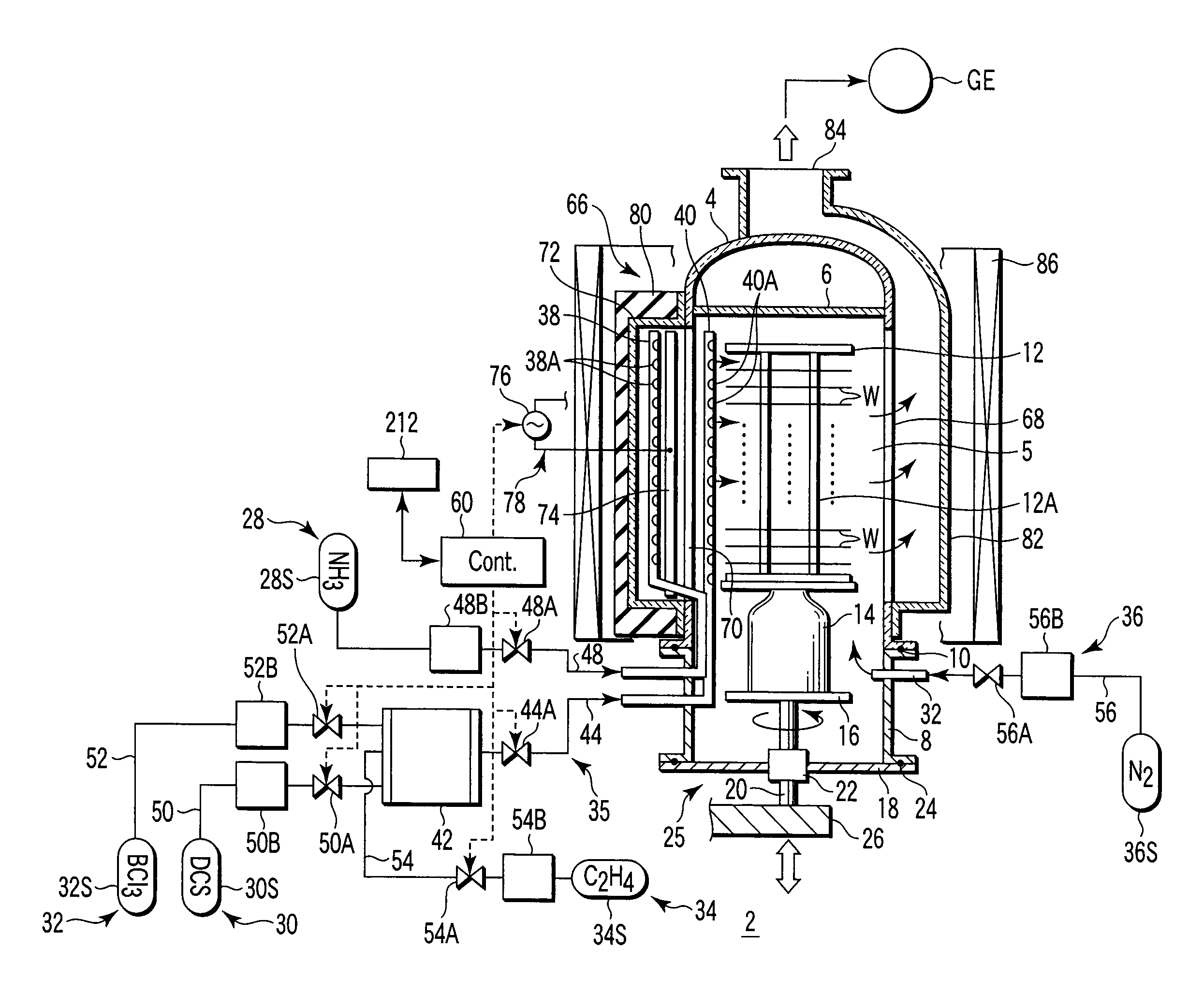

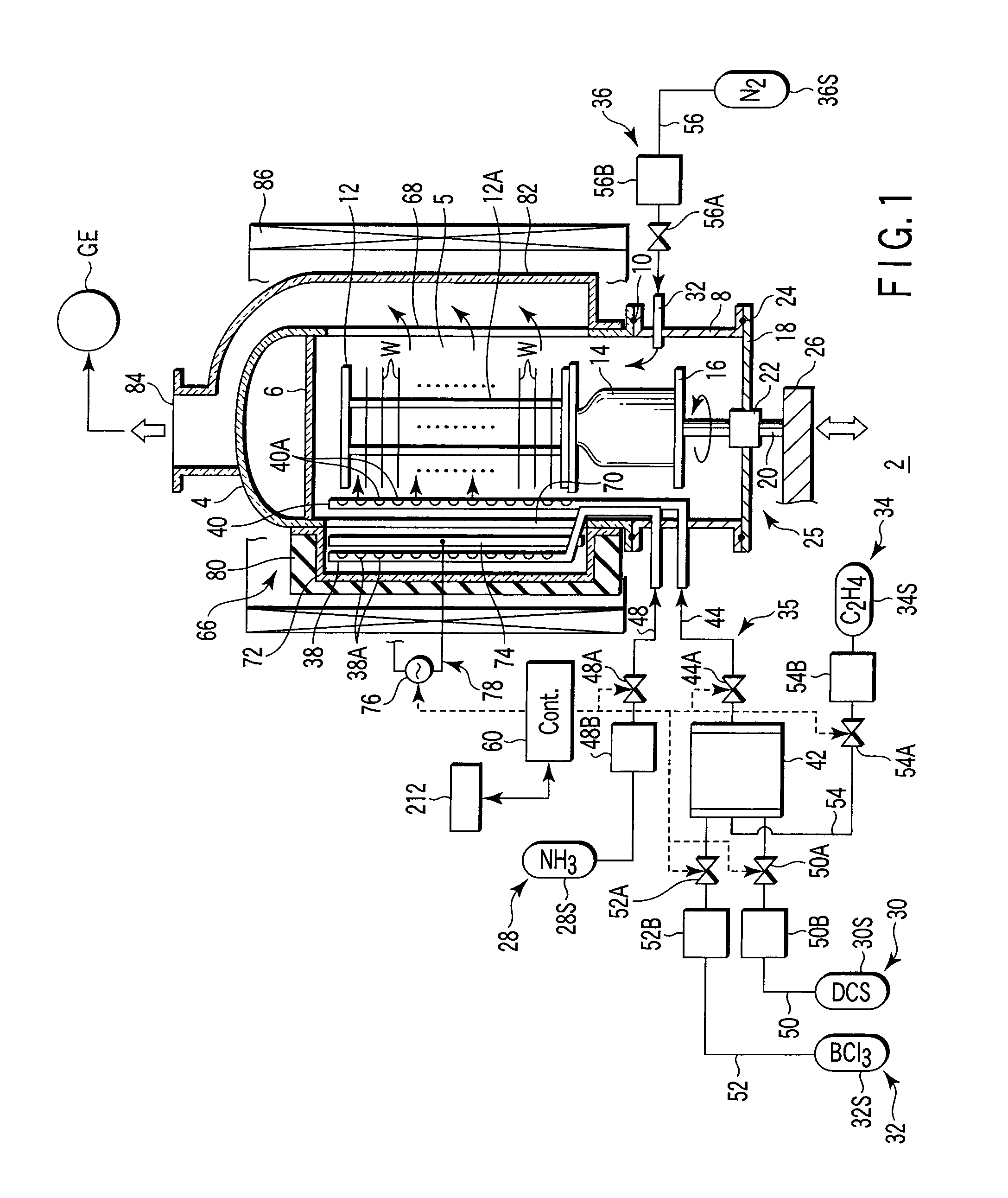

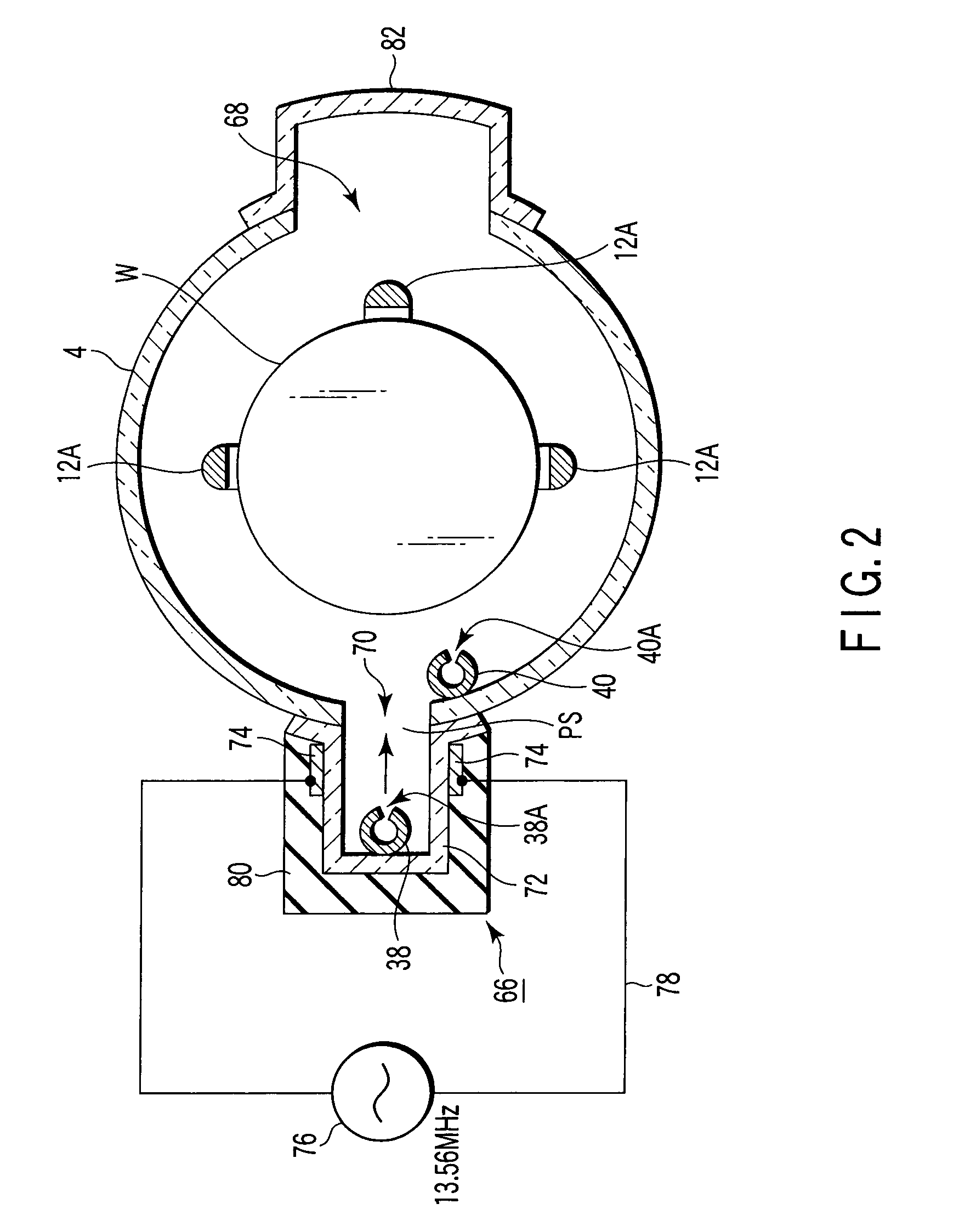

Film formation method and apparatus for semiconductor process

ActiveUS20080274302A1Improving inter-substrate uniformityUniform supplySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringProduct gas

Owner:TOKYO ELECTRON LTD

Ice blasting apparatus and trimming method for film insert molding

InactiveUS7040962B2Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesSlurryFilm material

Owner:TOSHIBA MASCH CO LTD

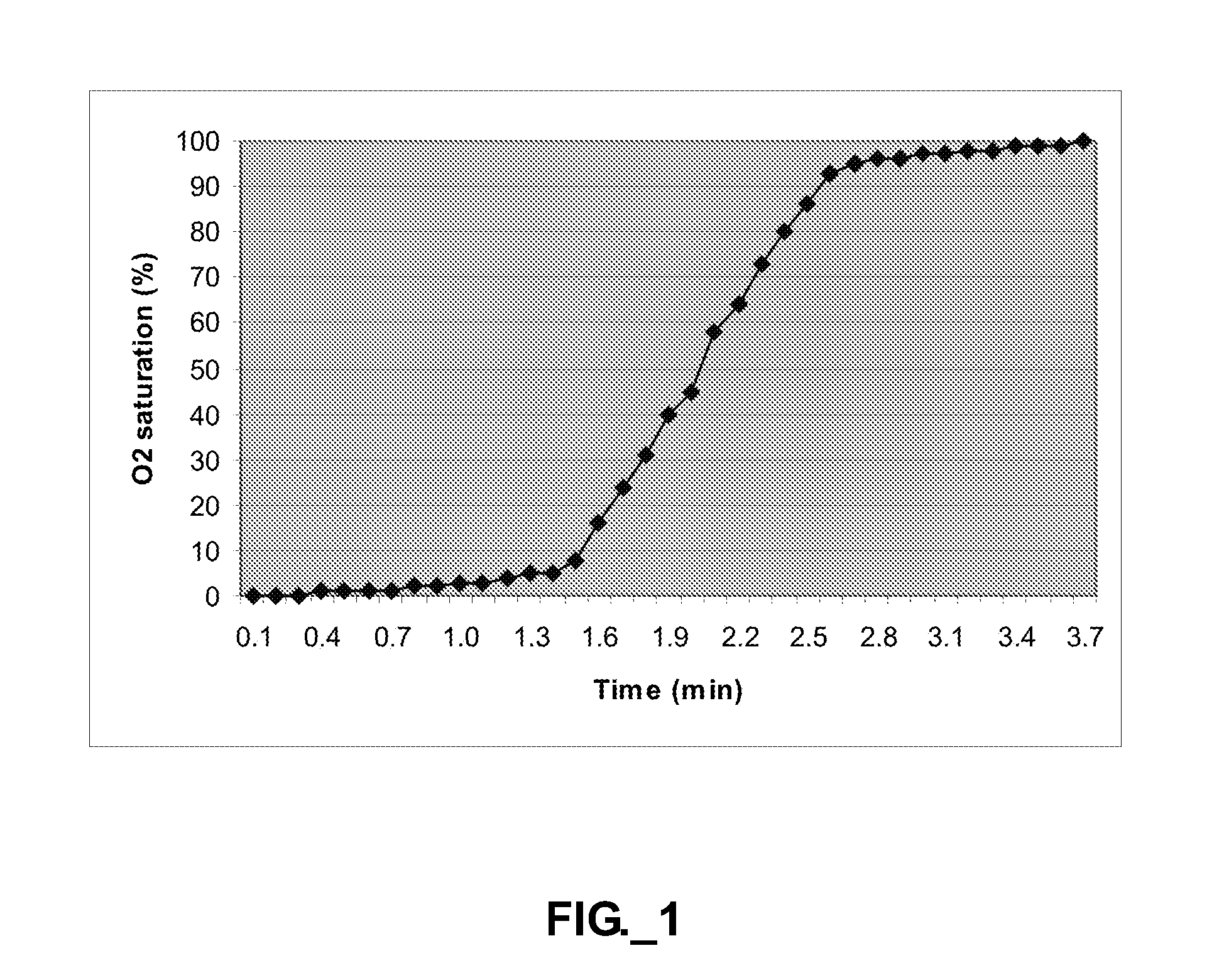

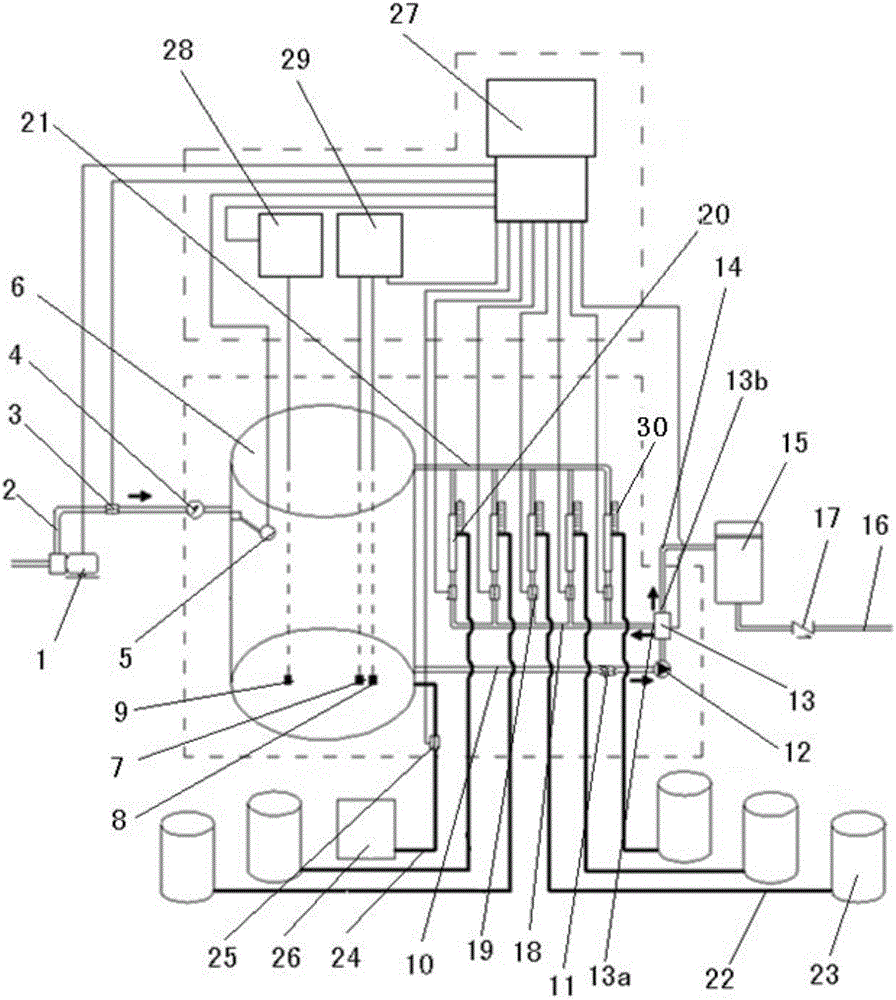

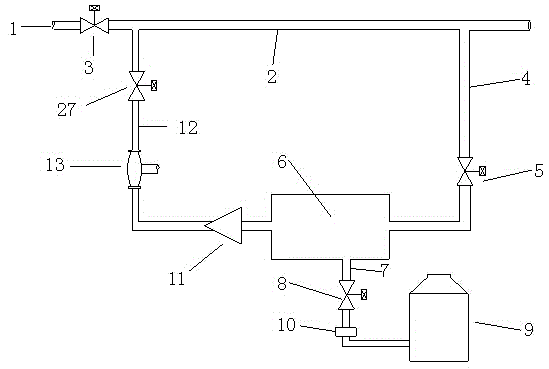

Water, fertilizer and gas integrated trickle irrigation system and method

ActiveCN103141206AReduce volumeIncrease oxygen contentWatering devicesPressurised distribution of liquid fertiliserElectricitySolenoid valve

The invention relates to a water, fertilizer and gas integrated trickle irrigation system and method. The trickle irrigation system comprises a water supply pump, wherein the water supply pump is connected with a mixing tank which is provided with a float ball water level gauge; a pH sensor, an EC (Electric Conductivity) sensor and a DO (Dissolved Oxygen) sensor are arranged in the mixing tank; a water outlet pipe of the mixing tank is connected with a pipeline pump through a two-way solenoid valve; an outlet of the pipeline pump is connected with a three-way solenoid valve; one outlet of the three-way solenoid valve is connected with a mesh filter; another outlet of the three-way solenoid valve is connected with branch pipes of a plurality of Venturi fertilizer injectors; an outlet of each branch pipe is connected with the mixing tank; a liquid inlet of each Venturi fertilizer injector is connected with a tank body; the lowest part of the mixing tank is connected with a submicron bubble generating device through a two-way solenoid valve I; the pH sensor and the EC sensor are connected with an EC / pH controller; the DO sensor is connected with a DO controller; the EC / pH controller and the DO controller are connected with a programmable controller; and each two-way solenoid valves, each three-way solenoid valve, the float ball water level gauge, the water supply pump, the pipeline pump and the submicron bubble generating device are respectively and electrically connected with the programmable controller. The trickle irrigation system and the trickle irrigation method can be widely used in various water, fertilizer and gas integrated trickle irrigation processes.

Owner:CHINA AGRI UNIV

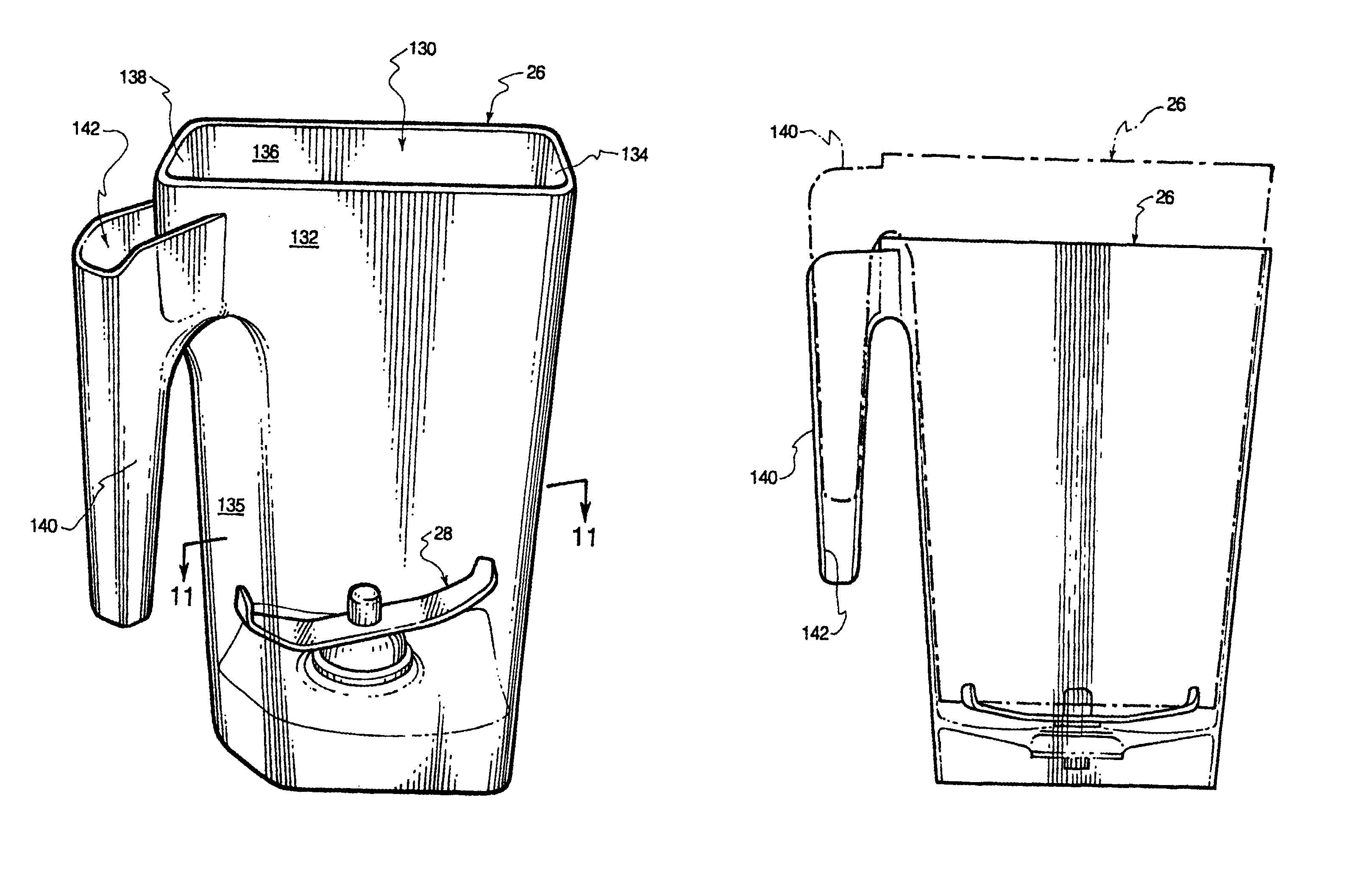

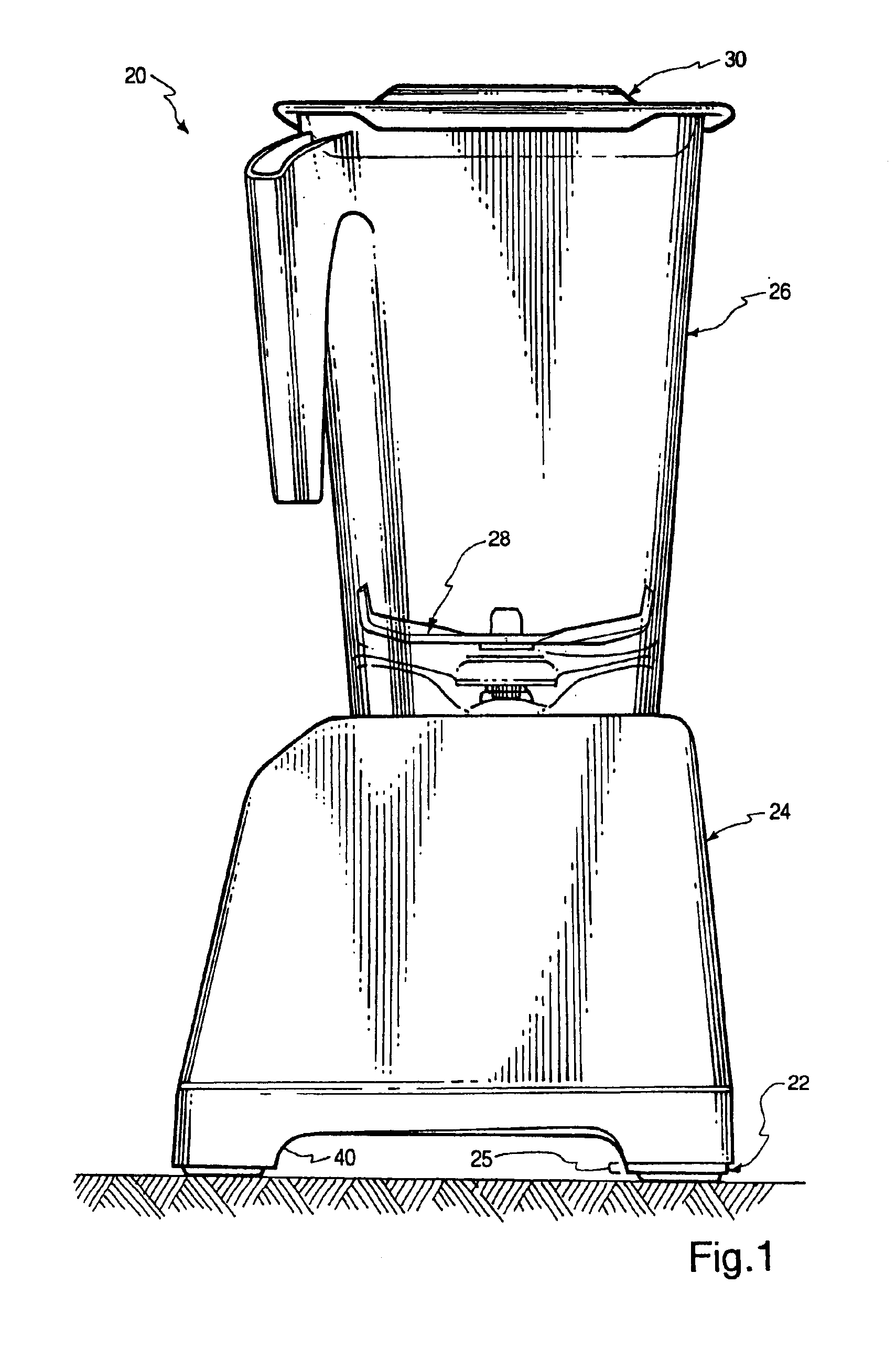

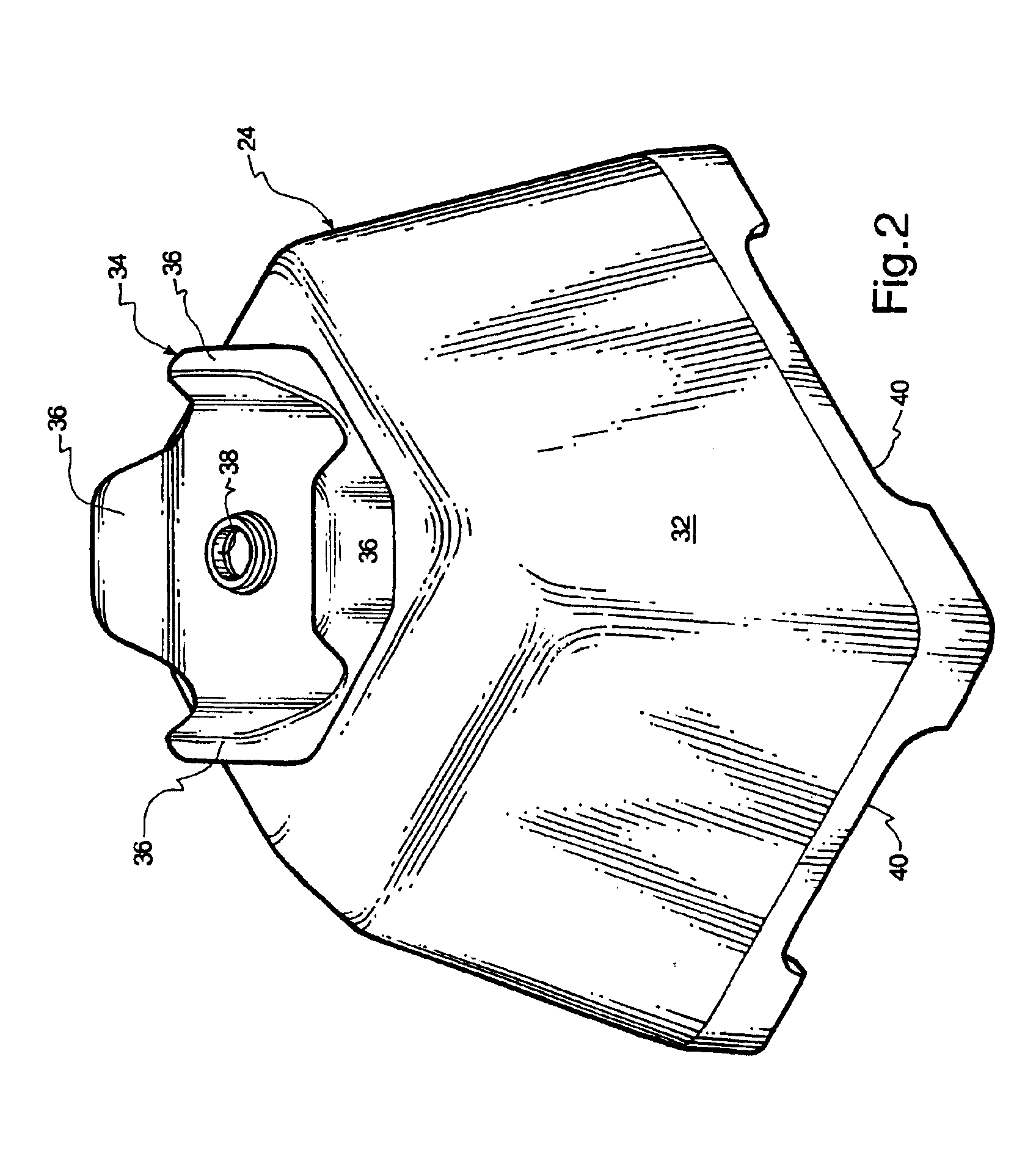

Nestable blending jar apparatus

A blending jar apparatus is disclosed and includes a plurality of walls and a handle secured to one of the plurality of walls. The handle includes an aperture receptive of a handle of another blending jar apparatus. One of the plurality of walls may include a truncated wall, to which the handle is secured.

Owner:BLENDTEC

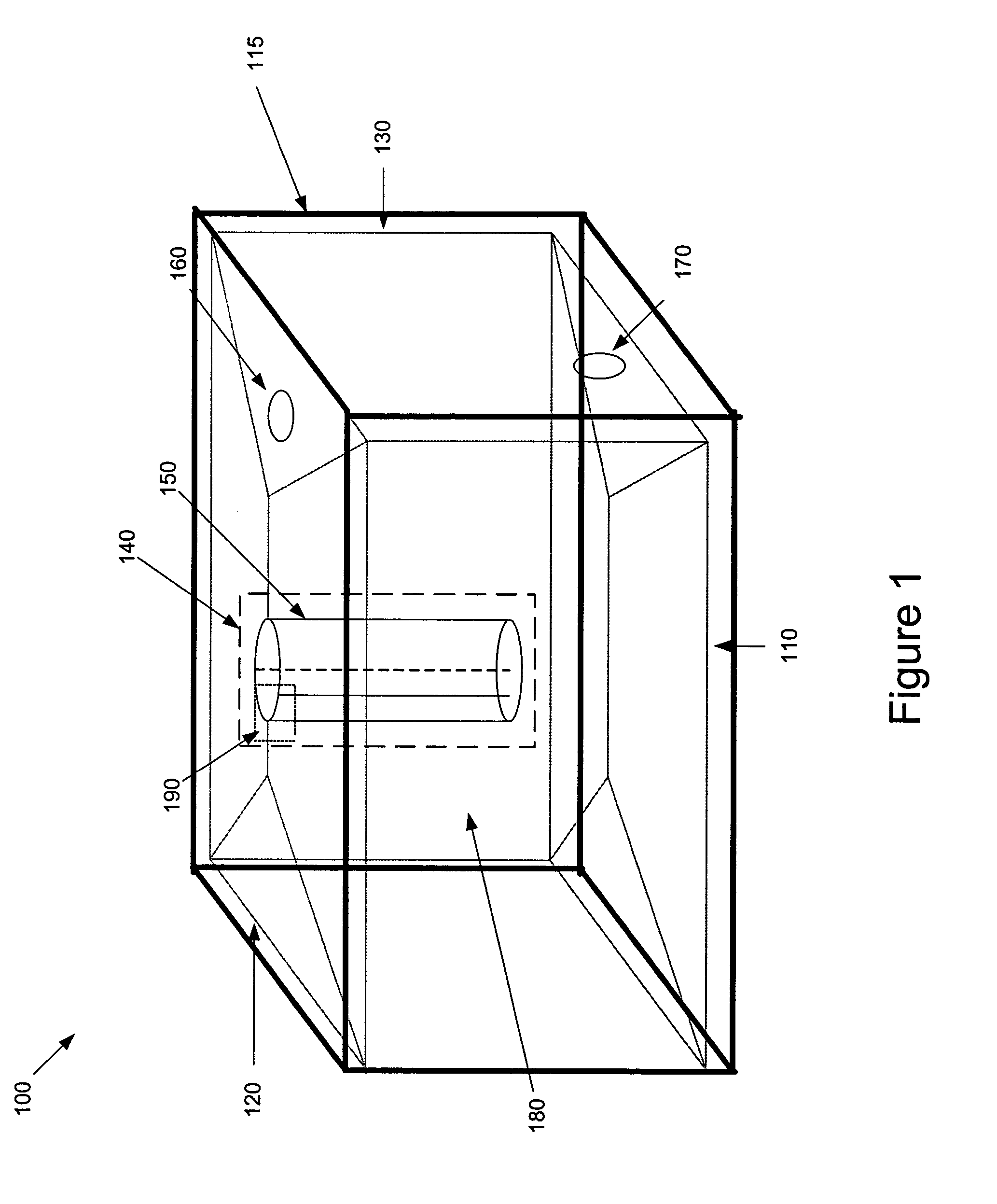

Flexible mixing bag for mixing solids, liquids and gases

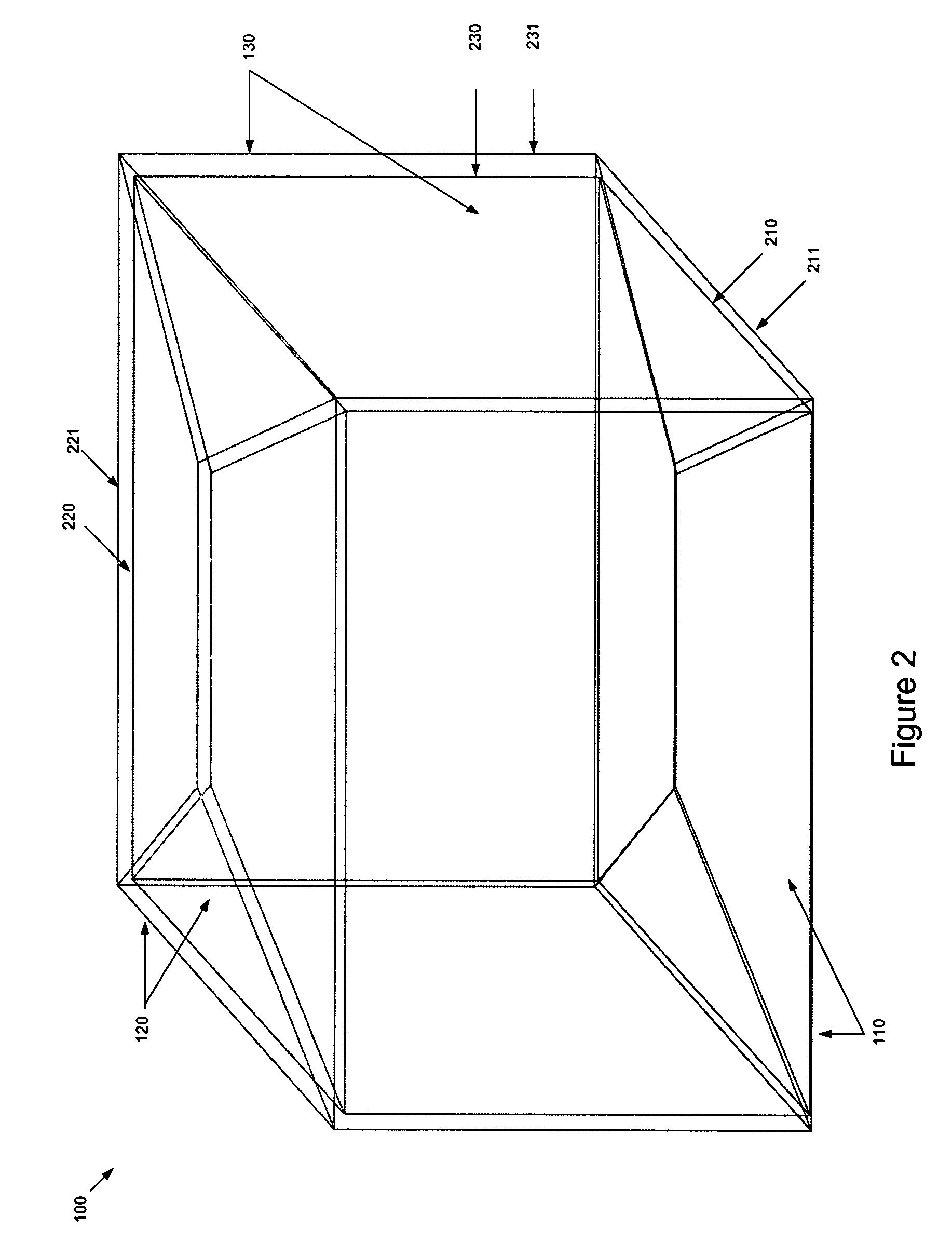

ActiveUS20050078552A1Rotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringMixing tank

In an embodiment, an apparatus includes a disposable and flexible mixing tank having a sealed sleeve therein for arrangement of a mixing device. The volume of the mixing tank is defined by an inner wall of the mixing tank and an inner wall of the sleeve. The mixing tank may be used to mix, store, reconstitute and / or dispense materials therein.

Owner:ADVANCED TECH MATERIALS INC +1

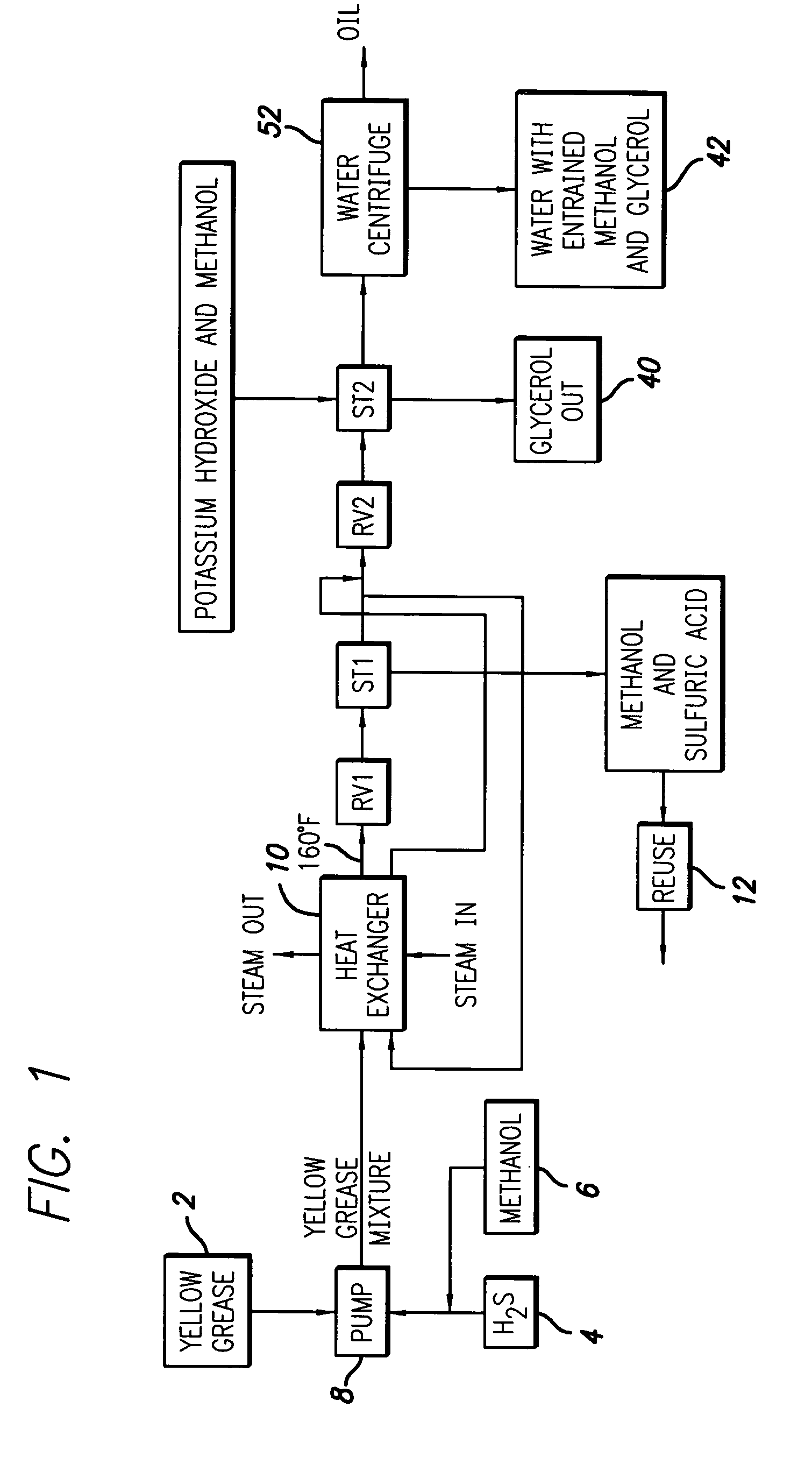

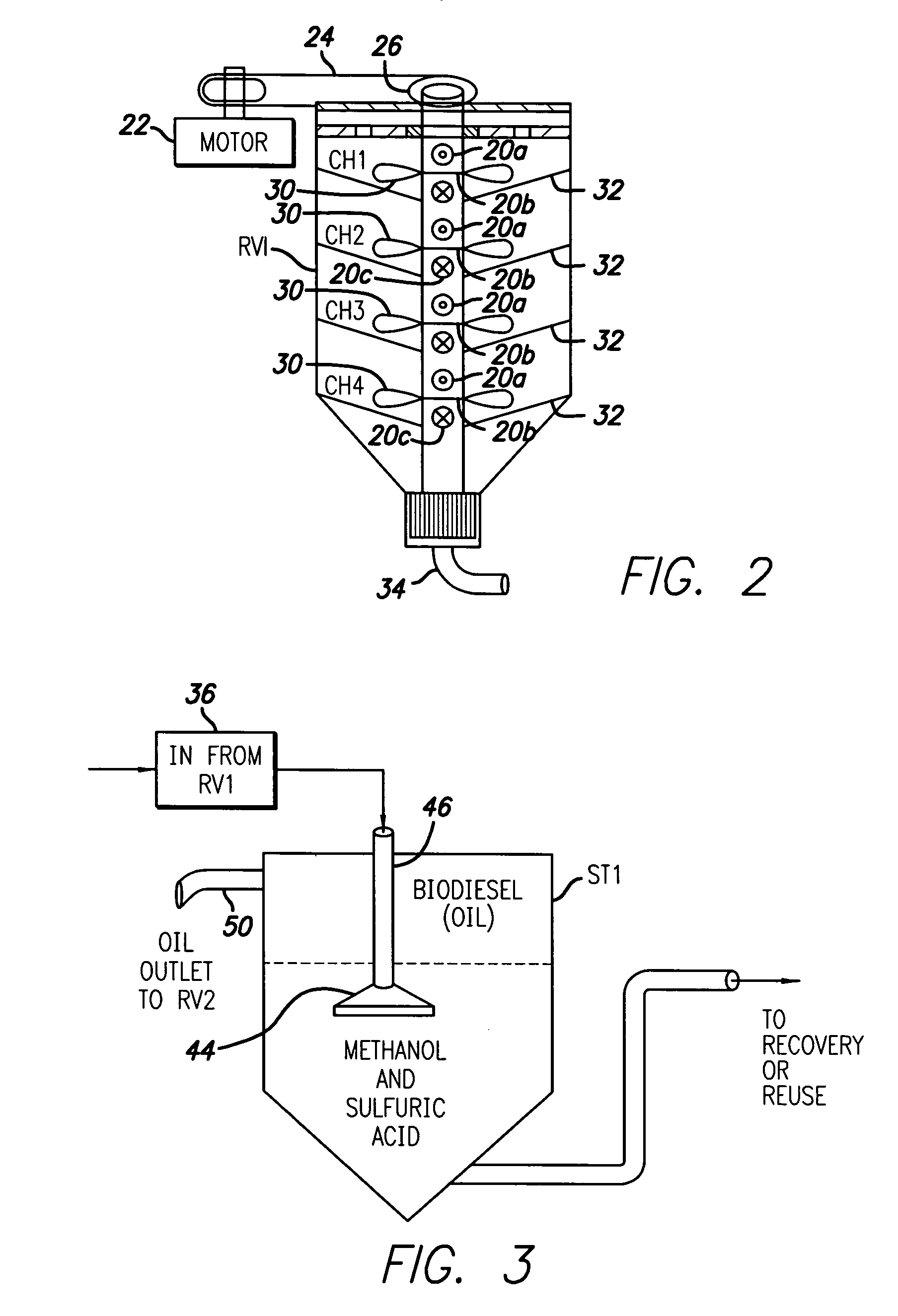

Continuous flow method and apparatus for making biodiesel fuel

InactiveUS20050081435A1Small footprintAvoid small quantitiesTransportation and packagingRotary stirring mixersOil and greaseVegetable oil

In an economical and efficient process and apparatus for producing biofuel from waste oil, such as vegetable oils and animal fats, waste oil is esterified with alcohols to produce alcohol esters and the by-products of the transesterification reaction are recovered. Static pressure may be used as well as continuous flow-through reaction vessels and separation tanks without the need for additional pumps. There may also be specialized reaction tanks that have vertical rotating feed tubes having separators and inlet and outlet openings. The method and device achieves efficient production of biofuel while employing reaction and mixing tanks having a limited size, which in turn permits a smaller plant layout or “footprint”. For example, the largest tank may be in a size of about 36 / 100,000 times the desired plant output in gallons per year. The benefits of the process and apparatus include minimal space for a plant; minimal on-site feedstock needed therefore minimal on-site storage is needed; minimal capital costs to build a plant e.g., reduction by about fifty to sixty five percent (50 to 65%); reduction in construction time from typically over one year to under three months in many plants; minimal energy usage, e.g., reduction by about sixty percent (60%); minimal labor costs due to the automatic continuous flow; minimal pumps needed thereby reducing pump operation and maintenance costs; environmentally friendlier and safer plant design; and due to smaller plant footprint, lower capital cost and minimal construction time enables site selection much nearer to the raw material supplies, thereby minimizing or even eliminating transportation costs for yellow grease or vegetable oil.

Owner:BIO CLEAN FUELS

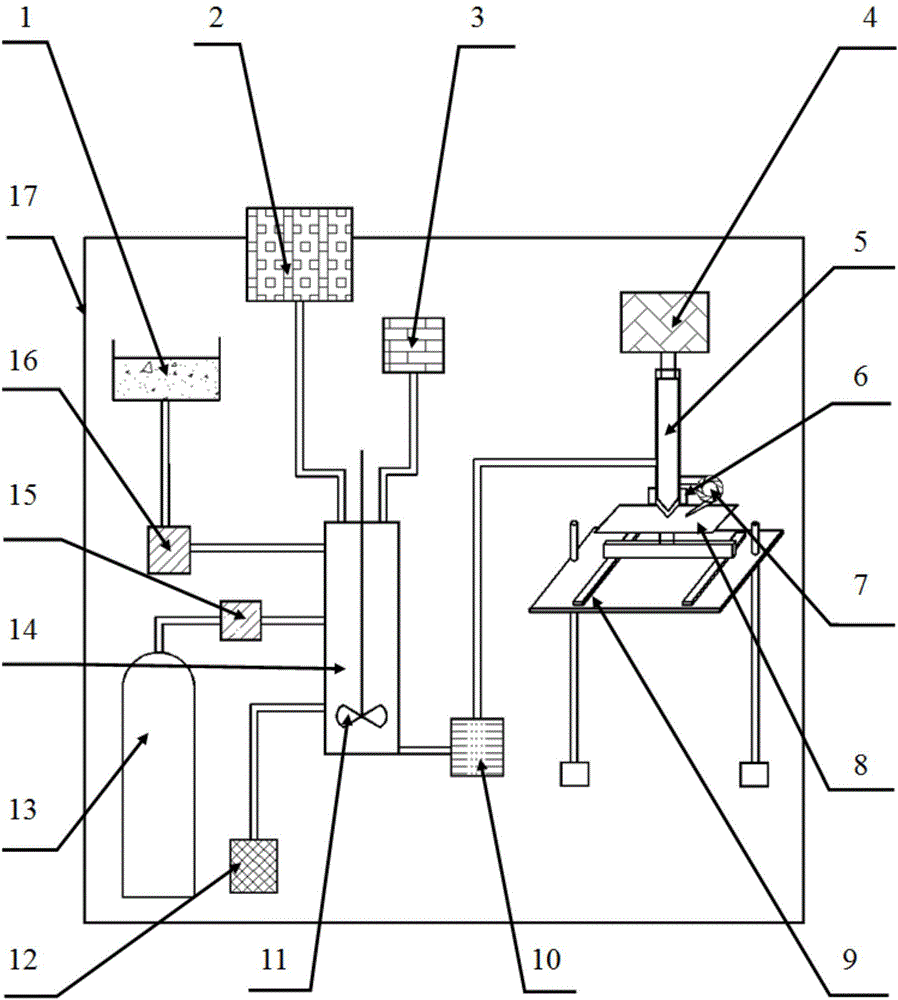

3D printing device and 3D printing method by utilizing supercritical carbon dioxide as solvent

ActiveCN104816478AIncrease profitAvoid emissionsAdditive manufacturing apparatusGas cylinderCarbon dioxide gas cylinder E

The invention discloses a 3D printing device and a 3D printing method by utilizing supercritical carbon dioxide as a solvent. The device mainly comprises a stock unit, an ejection unit, a three-dimensional molding platform unit and a raw material recycling unit, wherein the ejection unit comprises a gas pump, a needle valve, a cooling fan and a resistive heater; the stock unit comprises high polymer material powder, a powder pump, a carbon dioxide gas cylinder, a mixing tank, a liquefied booster pump, a heater, a liquid pump and a gas pump; the three-dimensional molding platform unit comprises an aluminum alloy molding platform and a three-dimensional ball screw sliding table module; and the raw material recycling unit comprises a closed box and a recovered gas pump. According to the method disclosed by the invention, the carbon dioxide gas is turned to be in a supercritical carbon dioxide state, and after the carbon dioxide gas is completely dissolved to produce supercritical carbon dioxide solution containing a high polymer material, the solution is conveyed into the ejection unit by virtue of the liquid pump. The supercritical carbon dioxide serves as a consumable carrier, so that more kinds of high polymer materials are applied to the field of 3D printing, and the overall performances of 3D printing supplies are improved.

Owner:BEIJING UNIV OF CHEM TECH

Flexible mixing bag for mixing solids, liquids and gases

ActiveUS7249880B2Rotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringMechanical engineering

Owner:ADVANCED TECH MATERIALS INC +1

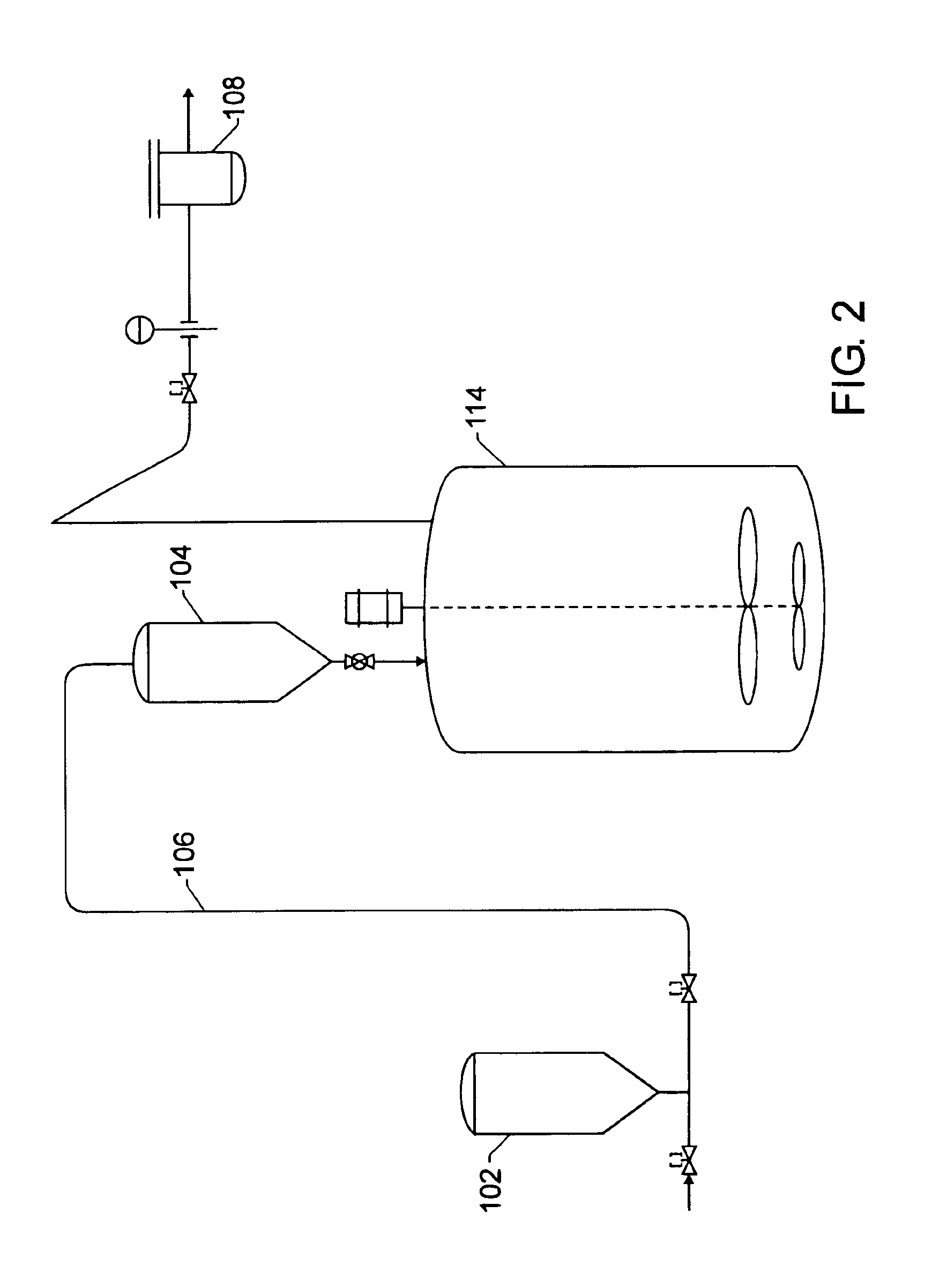

Catalyst slurry feeding assembly for a polymerization reactor

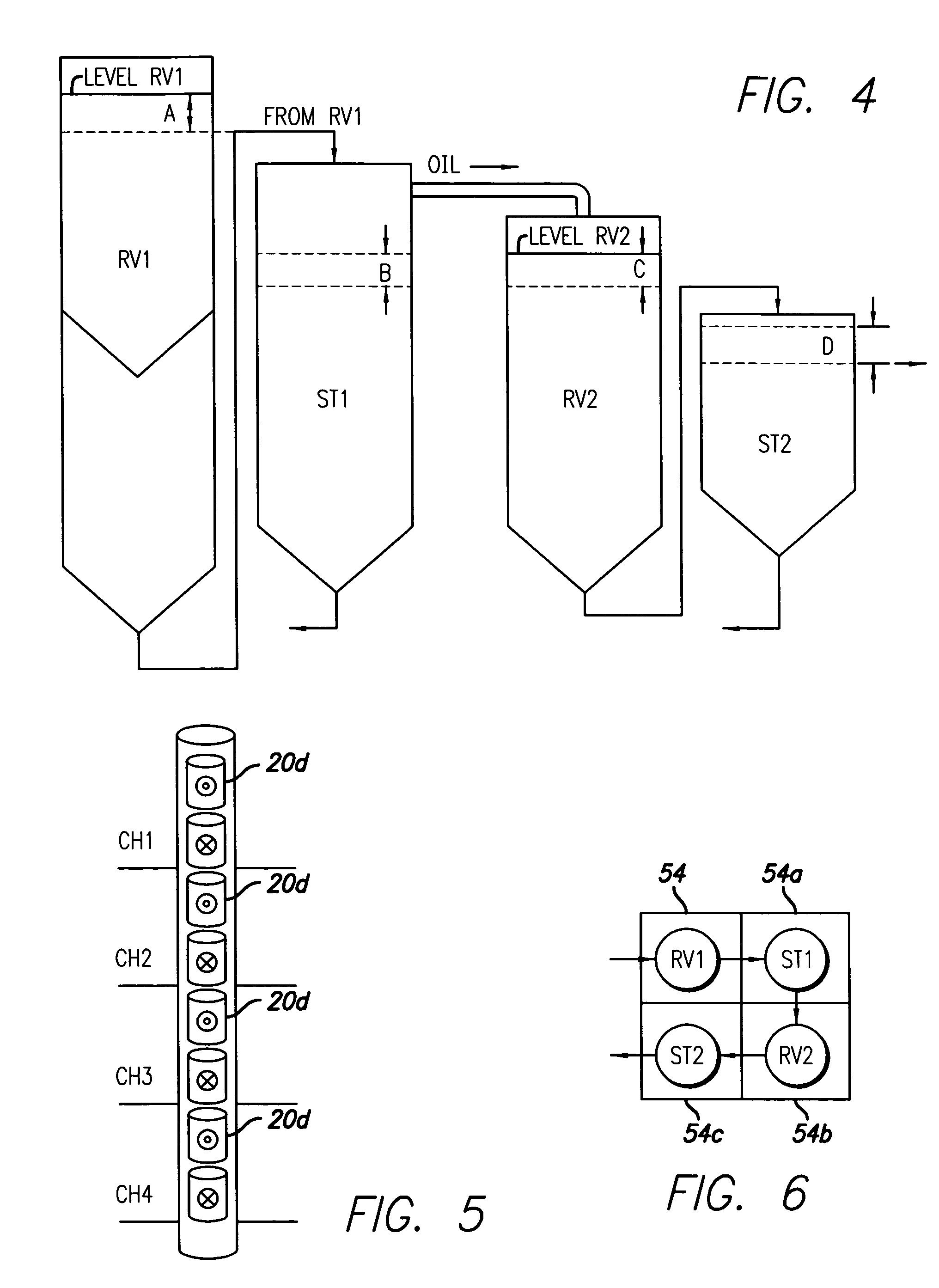

ActiveUS6908971B2Increase heightAvoid necessityChemical/physical/physico-chemical stationary reactorsFlow controlLiquid ratioSlurry

A catalyst slurry for a polymerization reactor can be prepared in a mixing tank and the catalyst slurry fed to one or more storage tanks. The storage tanks can include agitators so that the catalyst slurry is maintained at an essentially homogeneous solids-to-liquid ratio. From the storage tank(s), the catalyst slurry can be pumped to the polymerization reactor along a fluid passage having a flow meter. The flow of the catalyst slurry can be continuous and / or adjusted based on a measured parameter. The catalyst slurry may be continuously and reliability fed to the polymerization reactor.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

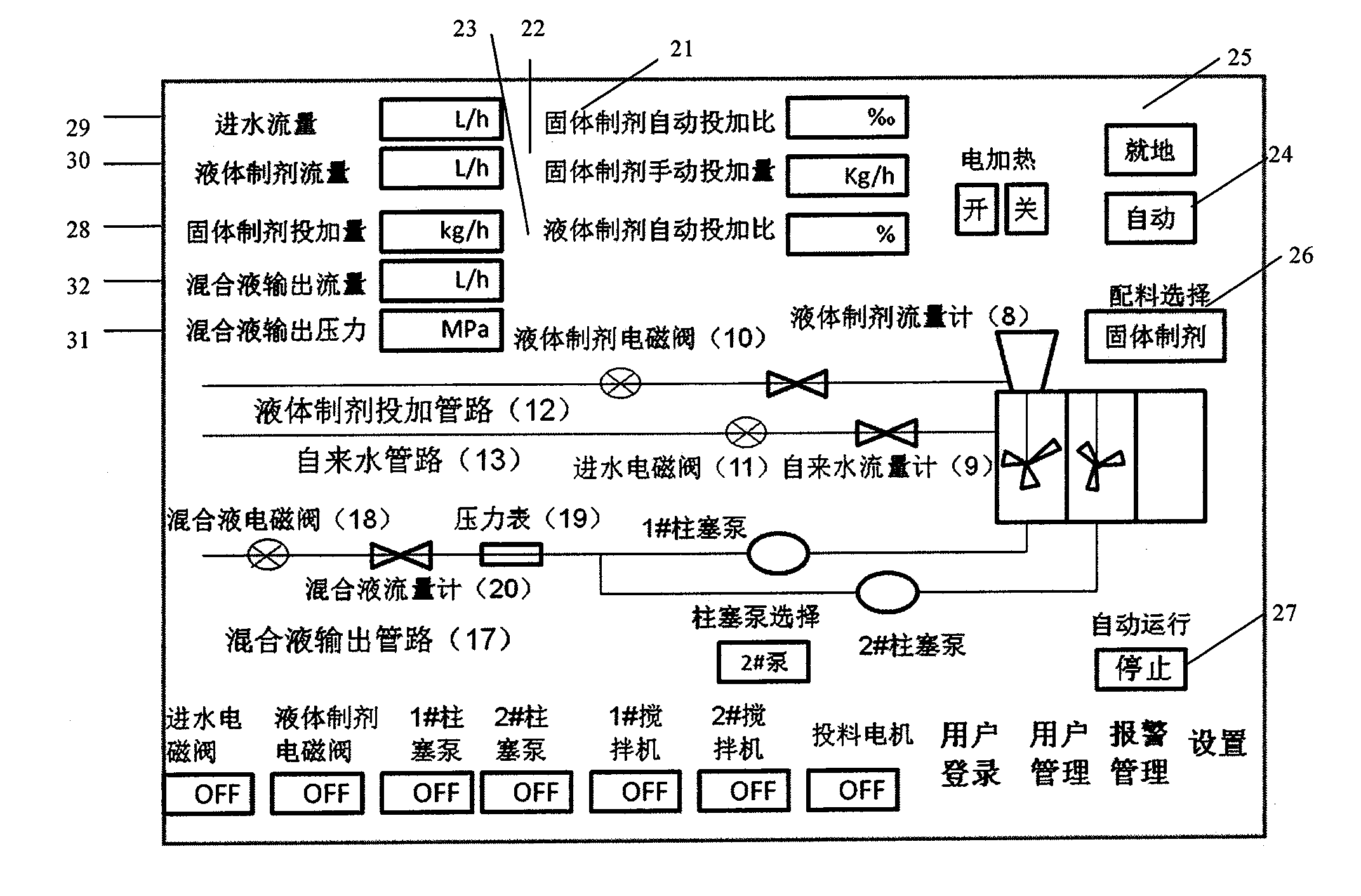

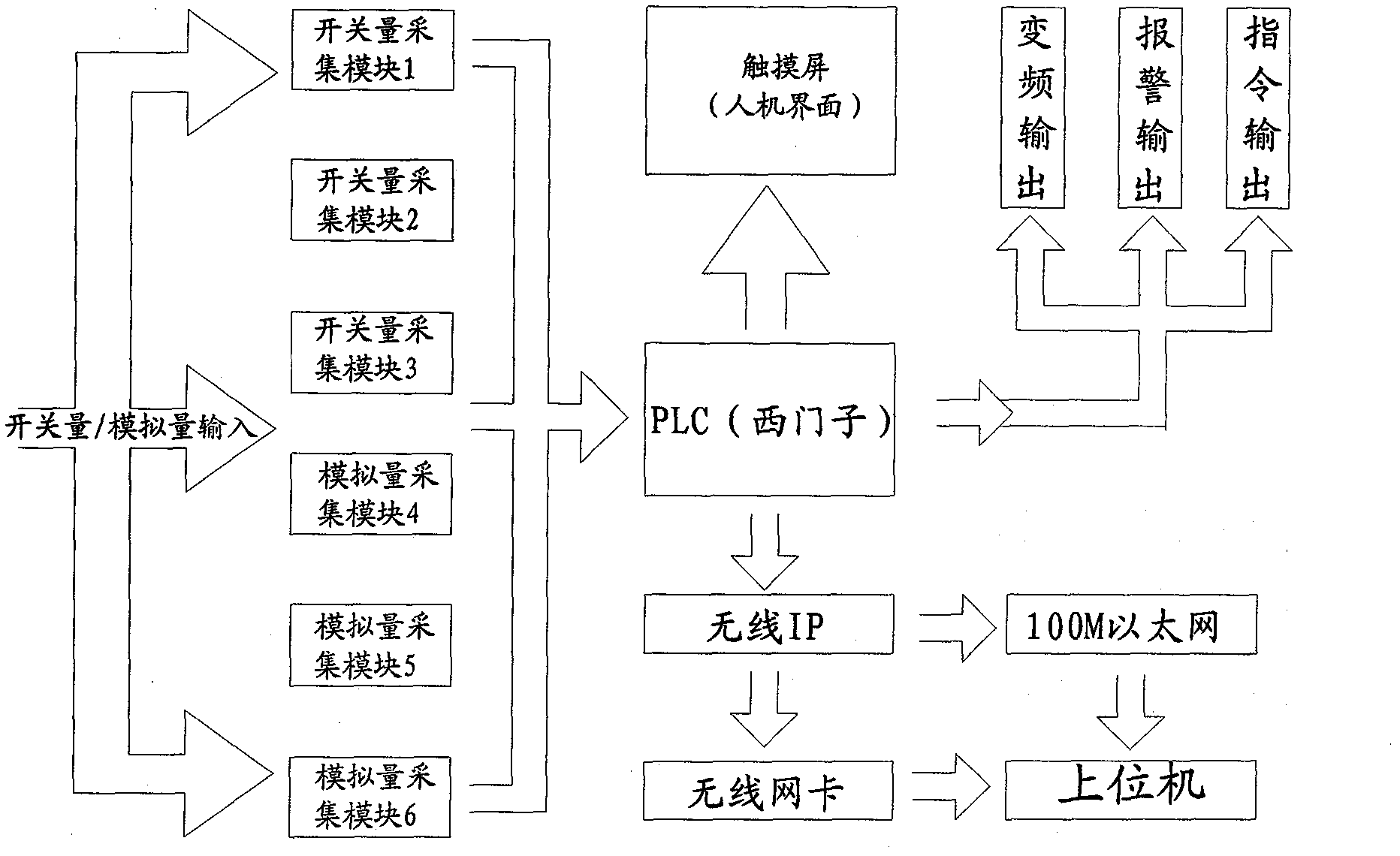

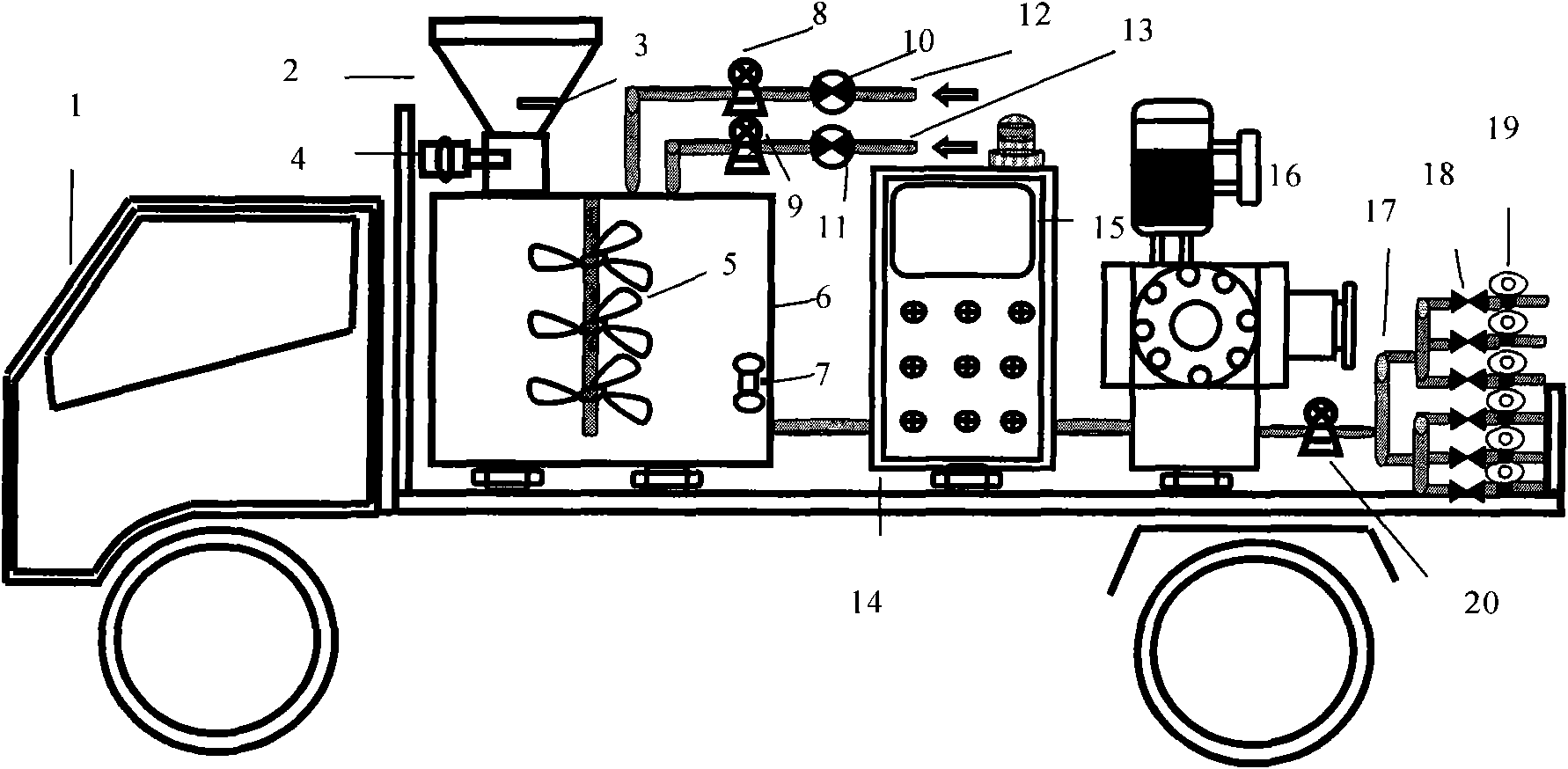

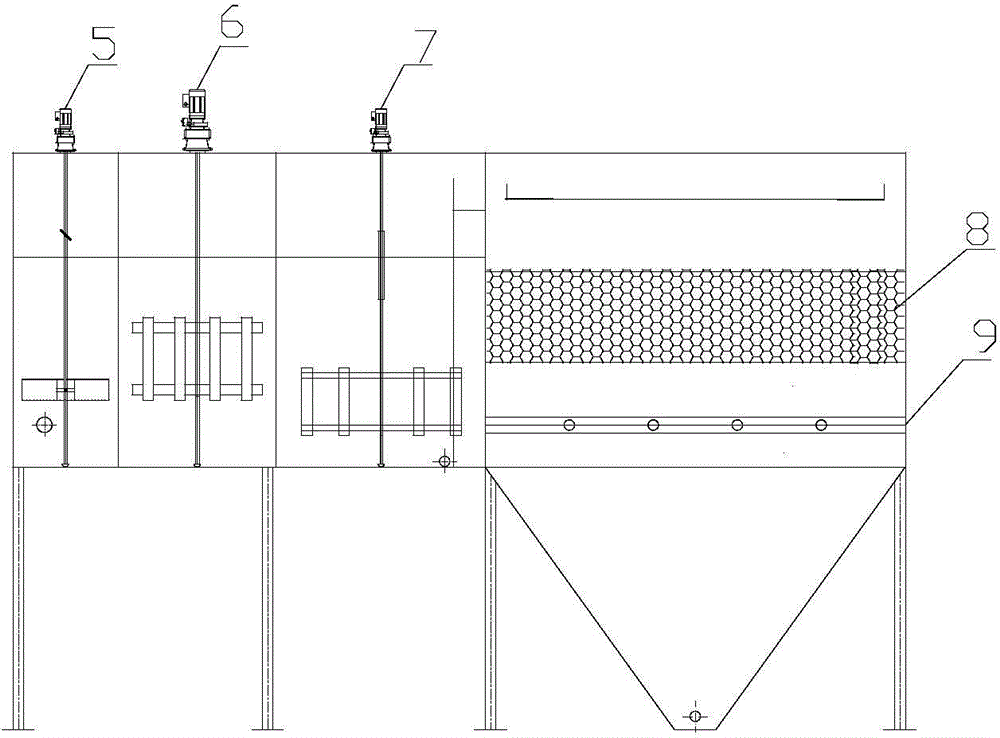

Vehicle-mounted repairing equipment and method for polluted site soil and underground water body

ActiveCN102059247AEfficient injectionShorten the timeContaminated soil reclamationBiological water/sewage treatmentTap waterRestoration device

The invention provides vehicle-mounted repairing equipment for polluted site soil and underground water body, which comprises a dry powder hopper, a level meter, a feeding motor, a stirring machine, a mixing tank, a liquid level meter, a flowmeter, a magnetic valve, a tap water pipe, a liquid preparation feeding pipe, an eclectic cabinet, a touch screen operating system, an alarm, a plunger pump, a mixed liquid output pipe and a pressure meter. A repairing method comprises the steps of: adding a solid preparation into the dry powder hopper, adding the preparation into the mixing tank by using the feeding motor, introducing water or other solvent through a water inlet pipe, stirring by using the stirring machine to ensure that the solid preparation is fully dissolved in water or other solvents to prepare a repairing preparation with required concentration; or directly adding a liquid preparation into the mixing tank, introducing the water or other solvents through the water inlet pipe to ensure that the liquid preparation is diluted into the repairing preparation with the required concentration. Through automatically or manually starting the plunger pump, the repairing preparation is pressurized and injected into a polluted medium through the mixed liquid output pipe and reacts with pollutants in the medium, thus the purpose of efficient repairing is achieved.

Owner:北京九州科睿科技有限公司

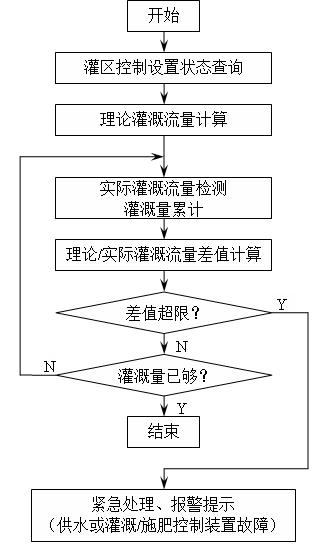

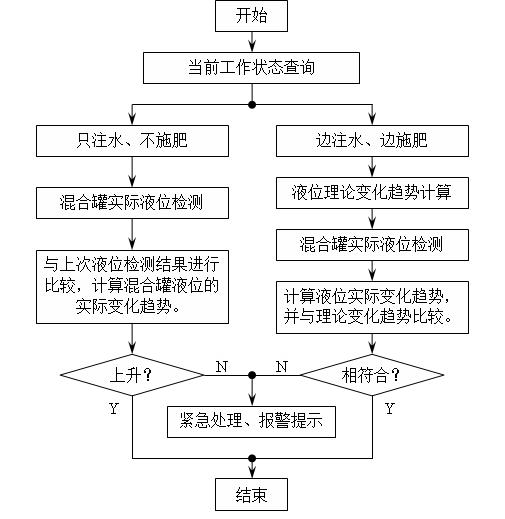

Device and method for monitoring working condition of automatic irrigation fertilizer distributor

InactiveCN102090288ARealize automatic monitoringMeet the ratio requirementsClimate change adaptationWatering devicesSolenoid valveElectrical control

The invention discloses a device and method for monitoring the working condition of an automatic irrigation fertilizer distributor. A fertilizer mixing tank is provided with a device for detecting the liquid level of the fertilizer mixing tank; the output signals of an EC (Electrical Conductivity) value sensor, a pH value sensor, the device of detecting the liquid level of the fertilizer mixing tank and a flow meter are respectively connected with an intelligent controller; a fertilizer-application control solenoid valve, a fertilizer mixing control solenoid valve, an irrigation control solenoid valve, an irrigated area control solenoid valve, a fertilizer adsorption control solenoid valve, a water supply pump and a fertilizer application pump are respectively connected to an electrical control system; and the electrical control system is connected with the intelligent controller. The states of the whole working processes of supplying water, adsorbing a fertilizer, preparing a nutrient solution and irrigating / applying the fertilizer can be monitored, and the practical fertilizer proportion of the nutrient solution conforms to the preset proportion requirement.

Owner:JIANGSU UNIV

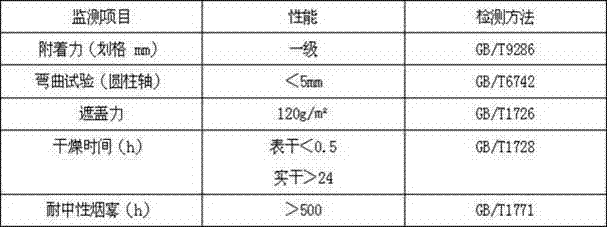

Water-based industrial anticorrosion paint and preparation method

InactiveCN103045053AIncrease resistanceGood construction performanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent based

The invention relates to water-based industrial anticorrosion paint and a preparation method, which belong to a paint coating technology in the field of heavy corrosion protection. The anticorrosion paint comprises the following materials in parts by weight: 35-50 parts of water-based acrylic acid modified epoxide resin with the solid content of 48-50%, 6-15 parts of functional adjuvant, 30-50 parts of anti-rust pigment and 8-25 parts of deionized water. The preparation method of the water-based industrial anticorrosion paint comprises the steps of feeding the deionized water, the functional adjuvant, the water-based acrylic acid modified epoxide resin and the excluder pigment into a mixing tank in sequence, stirring at a speed controlled at 300-500rpm for 25-50min in a feeding process, and obtaining a finished product. Compared with the traditional solvent type paint, various resistance performances are improved significantly, and the water-based industrial anticorrosion paint particularly has the unique advantages of water resistance, no burning, no explosion, no harmful gas volatilization, no irritant smell, and the like. The water-based industrial anticorrosion paint is researched and developed specially for construction in high-temperature environments such as a metering plant and a pump station, and other high-danger and high-temperature painting tasks, has incomparable environmental friendliness, construction comfortability and safety, and is often used for anticorrosion protection and equipment maintenance in the field of the high-danger and high-temperature heavy corrosion protection.

Owner:高文升

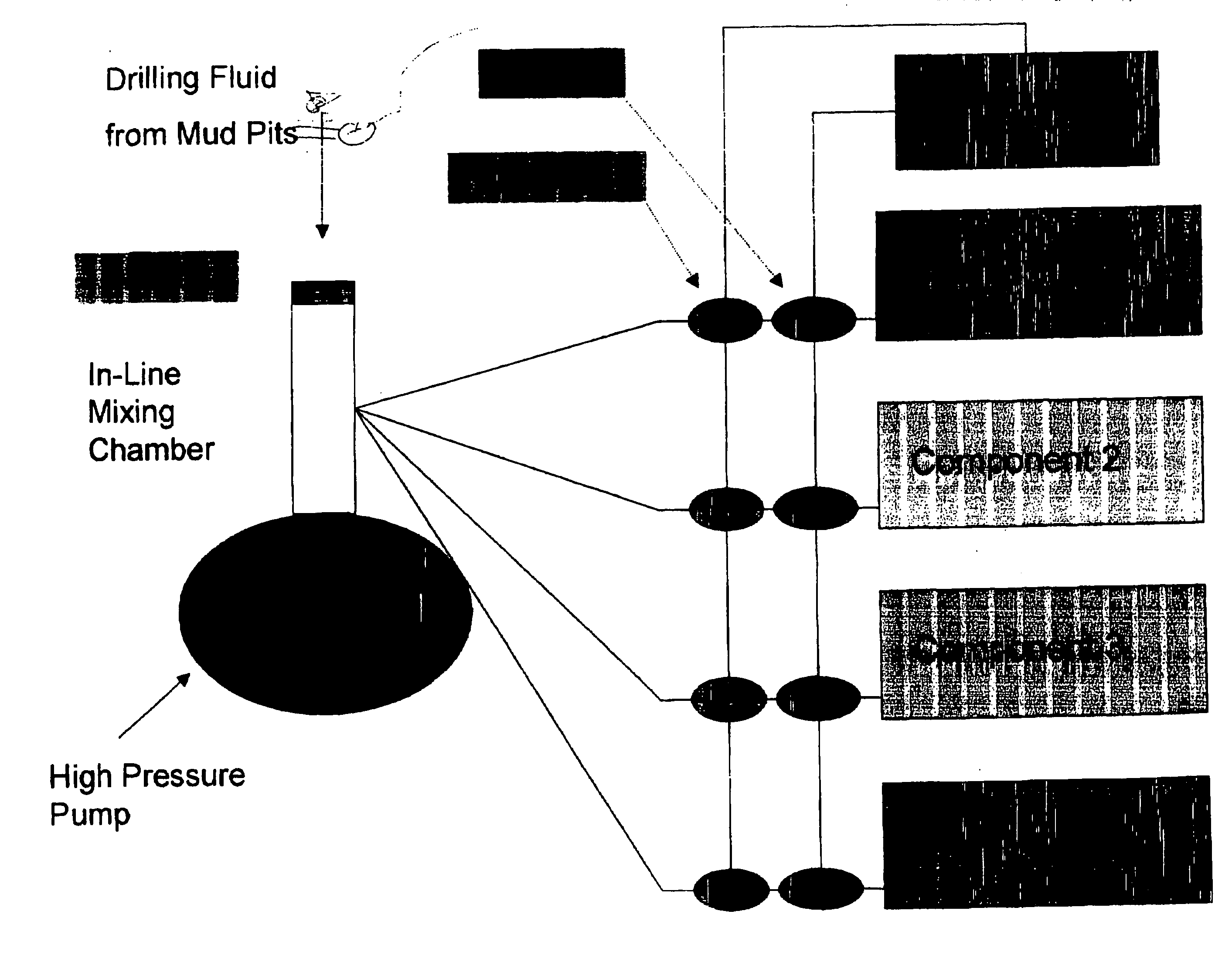

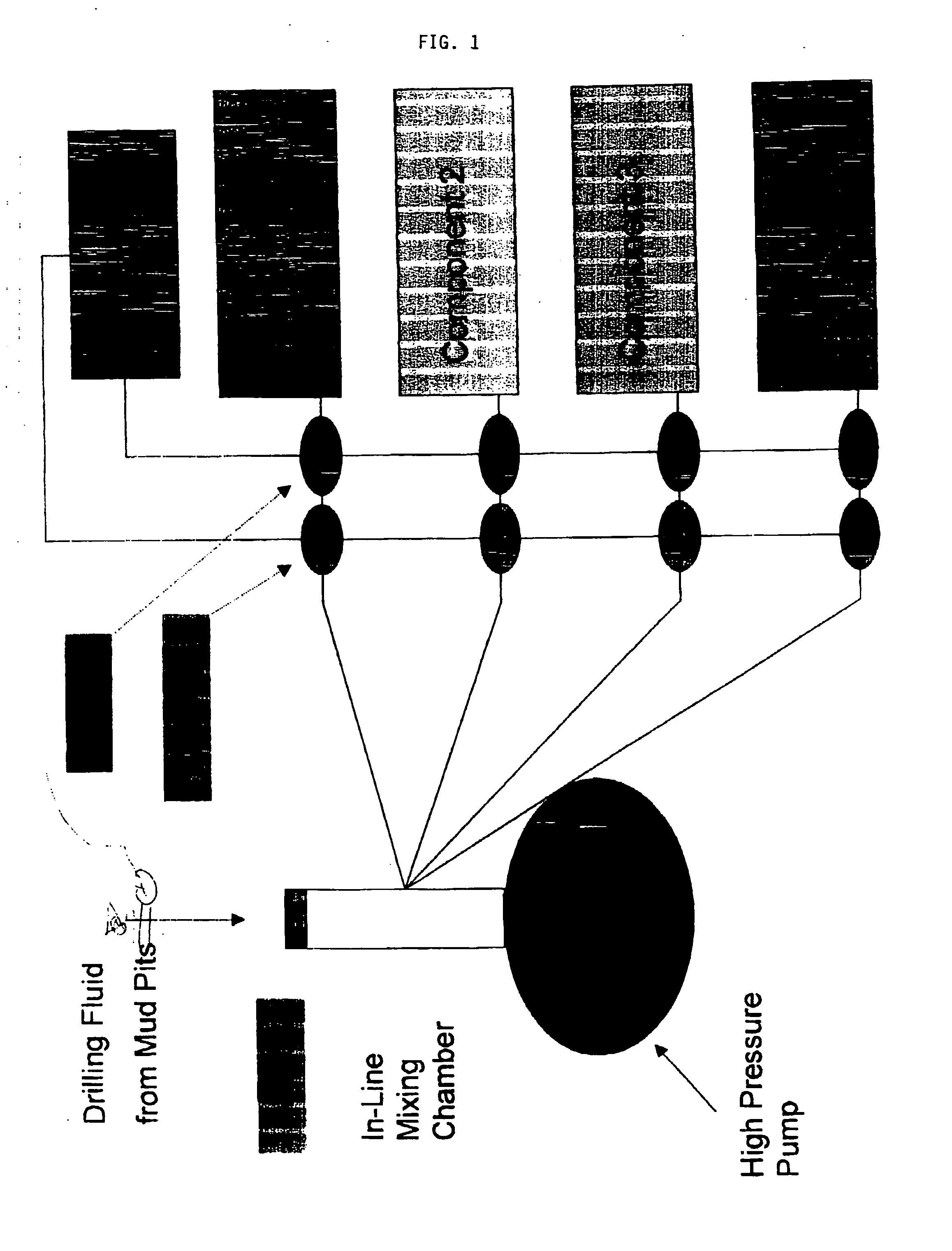

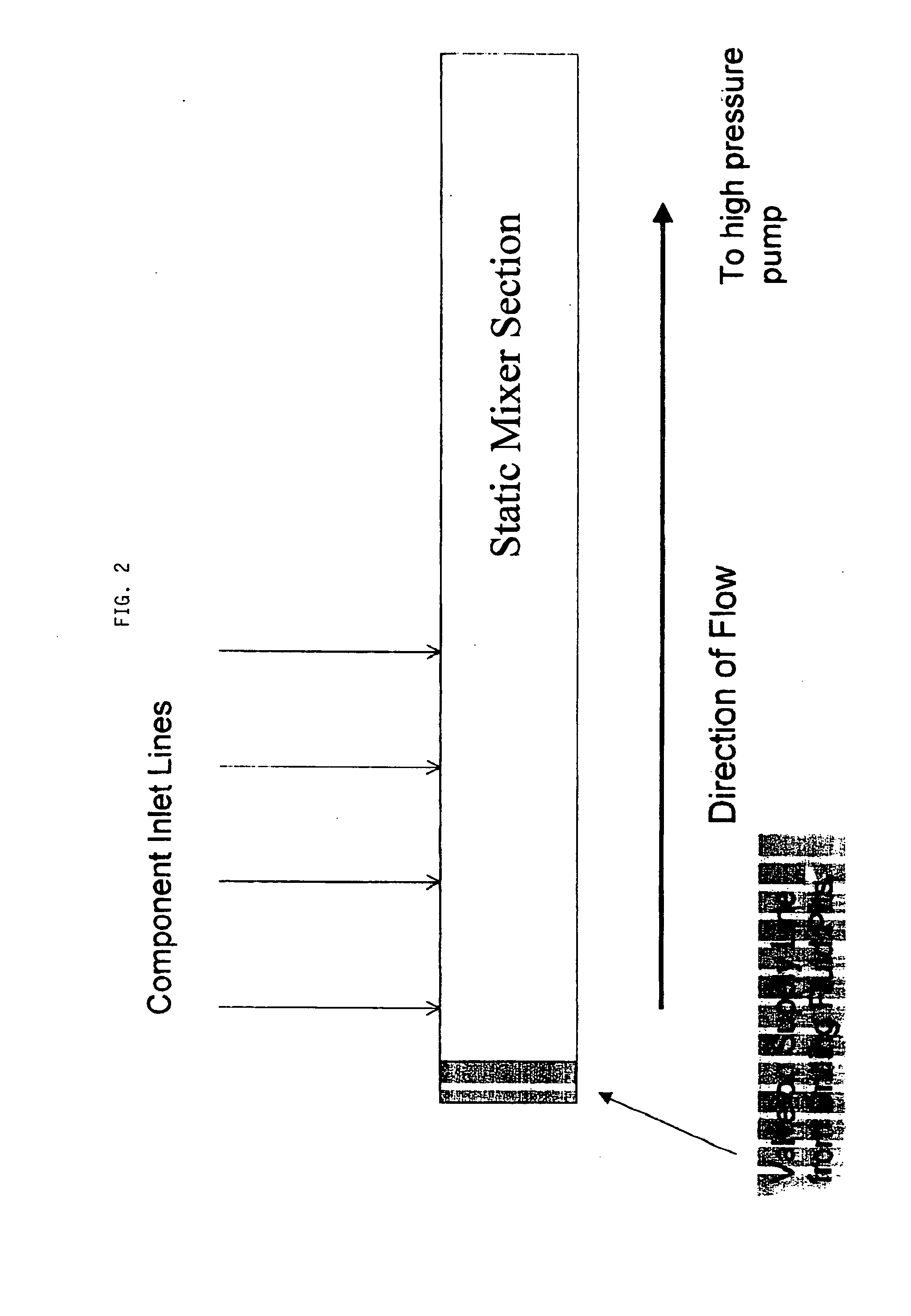

Method and apparatus for performing chemical treatments of exposed geological formations

InactiveUS20050269080A1Increase valueMinimization requirementsDrilling rodsConstructionsChemical treatmentCompound (substance)

Disclosed is a method for strengthening a wellbore with an exposed geological formation, the method including: determining or estimating material properties of the exposed geological formation; determining changes necessary in material properties of the exposed geologic formation to achieve desired improvements in property of the exposed geologic formation; and treating the geological formation to improve material property values by injecting a formulation that hardens in-situ to form a geosynthetic composite. In another aspect, the present invention relates to an apparatus for utilizing the described method with minimal handling of chemicals which is an automated in-line chemical metering and pumping apparatus that requires no large mixing tank.

Owner:SHELL OIL CO

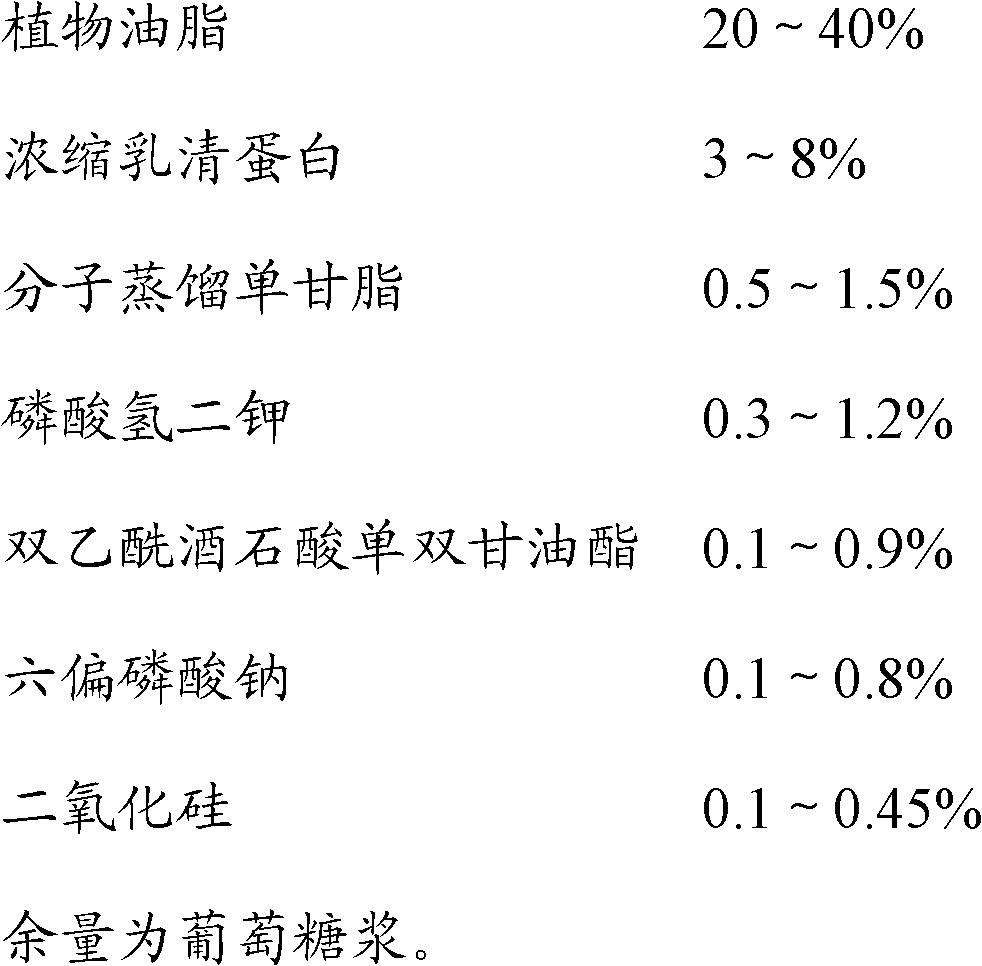

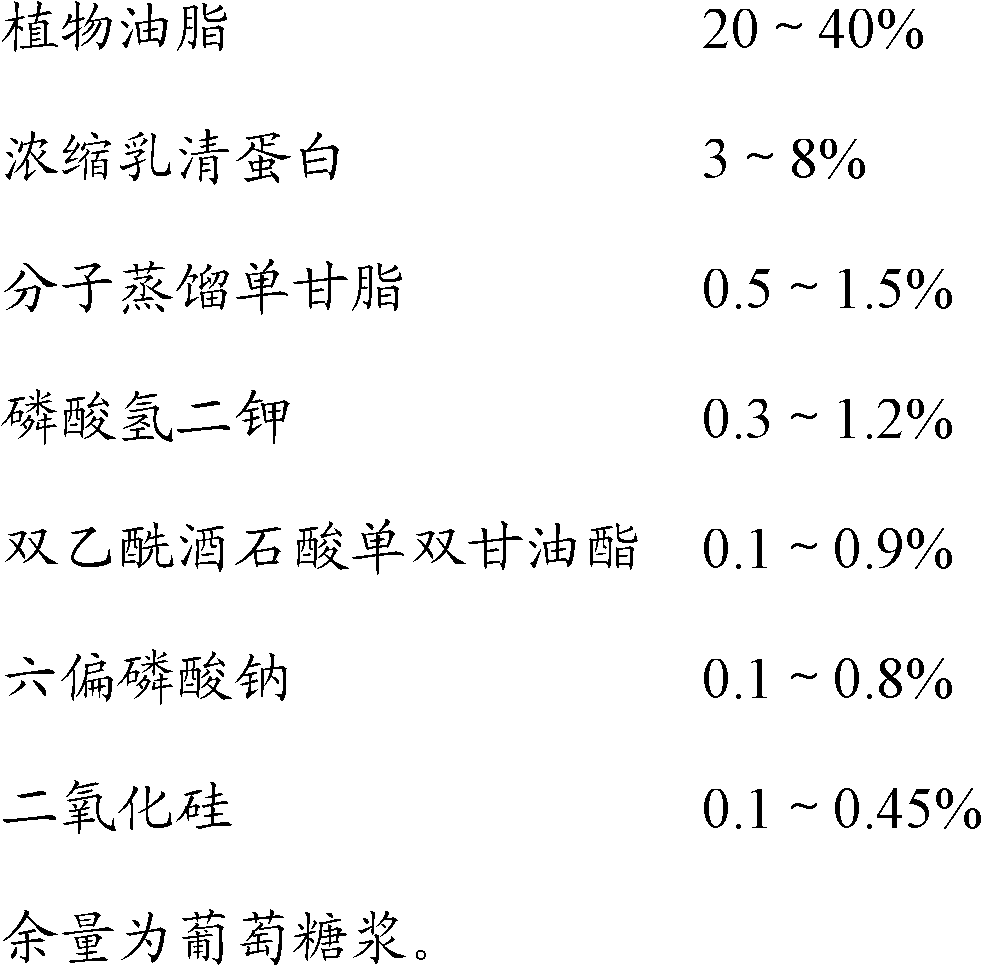

Preparation method of vegetable fat powder

The invention relates to a preparation method of vegetable fat powder. The method comprises the following steps of: (1) an emulsion homogeneous embedding process: uniformly mixing vegetable fat with emulsifying agents in an emulsion tank; uniformly mixing whey protein, moisture maintaining stabilizers and water in a high-speed mixing tank; adding mixed materials in the two tanks into a shearing tank containing glucose syrup; and carrying out homogenization to obtain the vegetable fat powder emulsion solution; and (2) a spray drying process: adding anti-caking agents into vegetable fat powder primary products obtained through emulsion solution spray drying in the step (1) to be uniformly mixed, and obtaining the vegetable fat powder finished products adopting whey protein micro capsules for embedding the vegetable fat powder. The method utilizes the whey protein micro capsule embedding technology for embedding the vegetable fat powder, the external environment is effectively isolated, the oxidation and the rancidity of the vegetable fat powder are avoided, the storage period is prolonged, meanwhile, the milk fragrance and the nutrition of the vegetable fat powder are added, and the prepared milk fragrance beverages is rich in milk flavor without additionally adding essence.

Owner:无锡超科食品有限公司

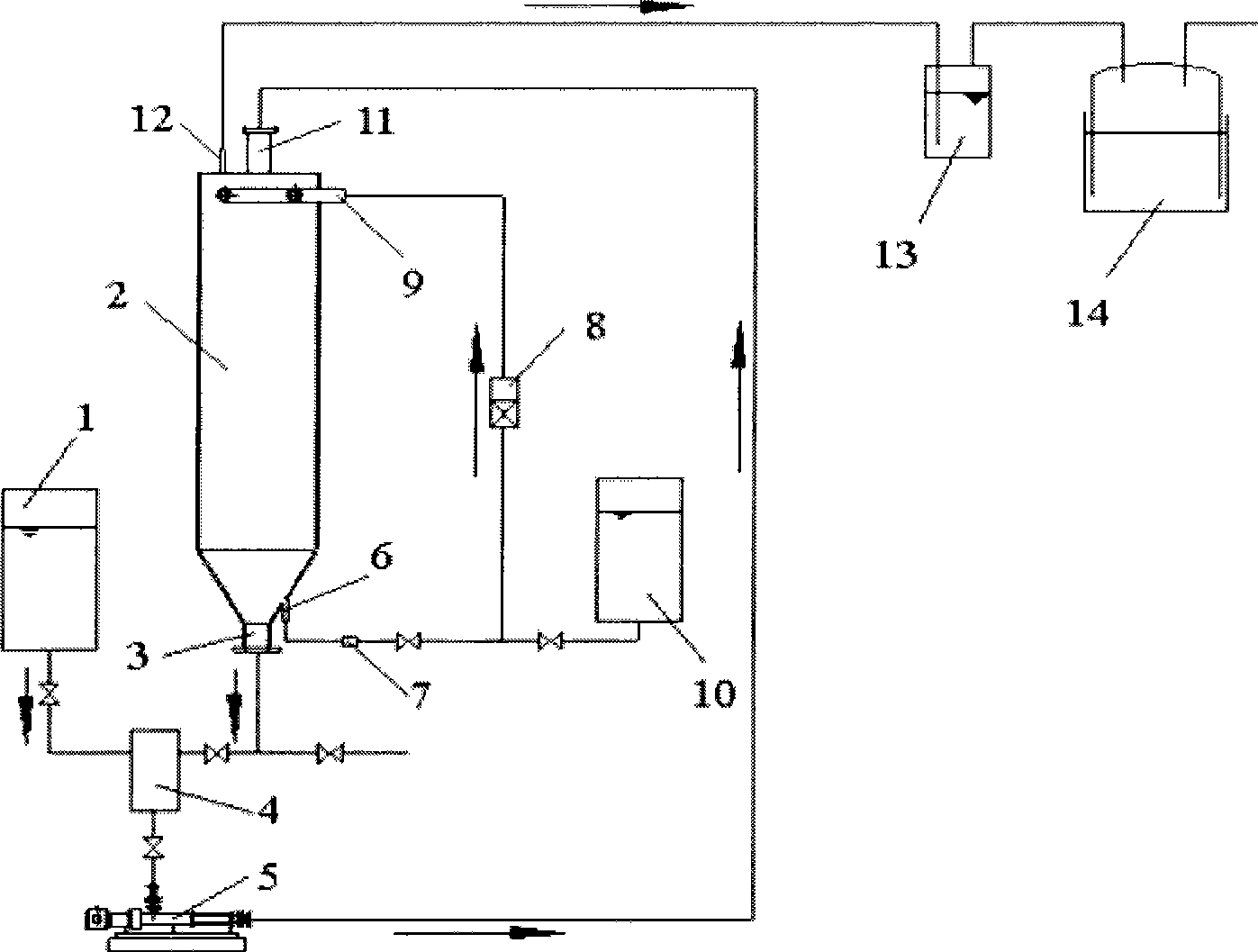

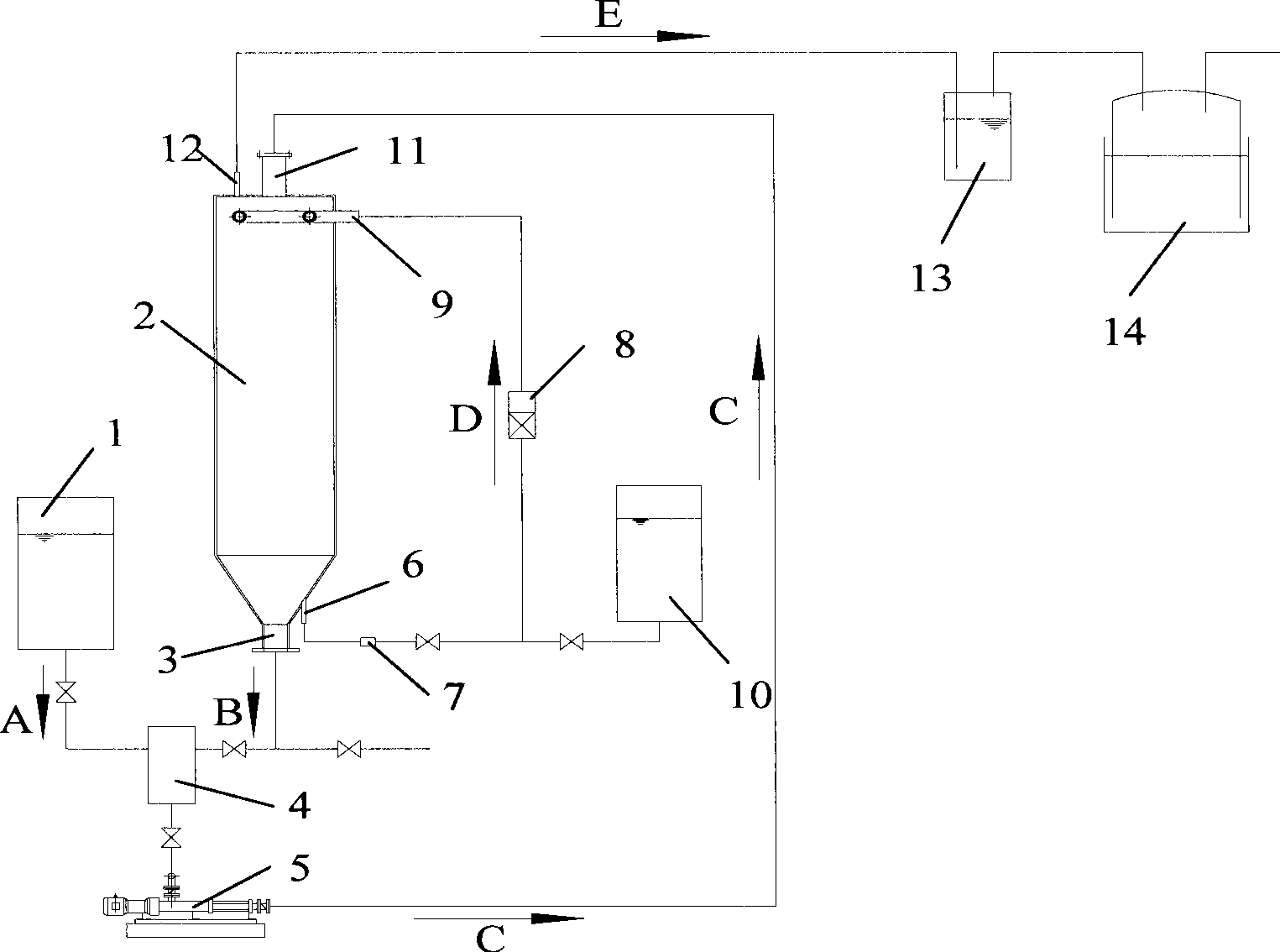

Vertical non-stirred organic waste dry-type anaerobic digestion processing equipment and method

InactiveCN101381674AIncrease volumetric gas production rateOvercome the difficulty of homogeneous mixingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryEngineering

The invention discloses vertical equipment for treating organic waste by dry anaerobic digestion without stirring and a method thereof. The equipment comprises that a feed port and an air outlet are arranged on the vertical digester; a discharge port is arranged on the bottom of the vertical digester; a feeding storage tank is connected with the discharge port of the vertical digester through a pipeline, an inoculation mixing tank and a delivery pump; the discharge port of the vertical digester is connected with the inoculation mixing tank through a control valve; a biogas slurry discharge pipe is arranged on the lower part of the vertical digester, and is connected with a spraying device arranged on the upper part of the vertical digester through a pH value on-line monitor, a reflux pump sequentially; and an alkali solution storage tank is connected with the reflux pump through the pipeline and the control valve. The vertical equipment for treating organic waste by dry anaerobic digestion without stirring and the method thereof overcome the defects of difficult isotrope mixing, easy isotrope acidification and the like of the prior dry anaerobic digestion system, and is applicable to treatment on household organic garbage, kitchen garbage, excrement of fowls and livestocks, agricultural waste, garden garbage, sewage sludge and other organic waste.

Owner:SOUNDGRP CO LTD

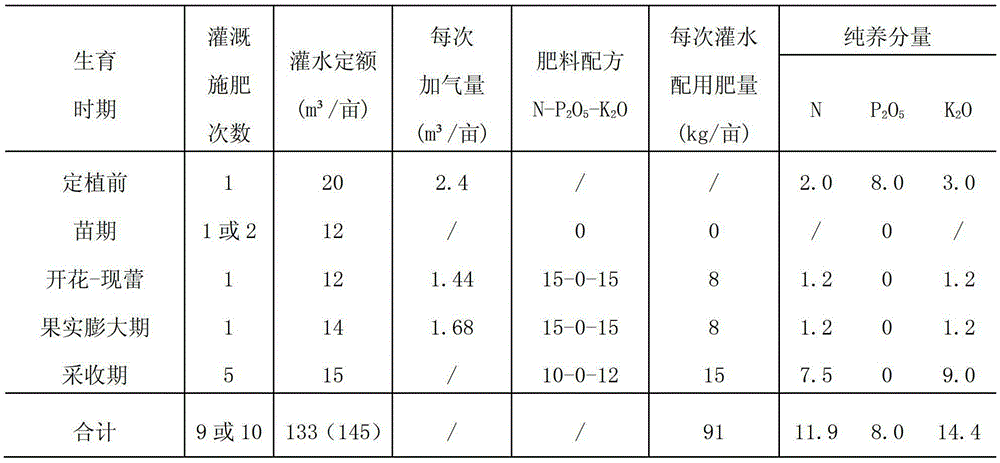

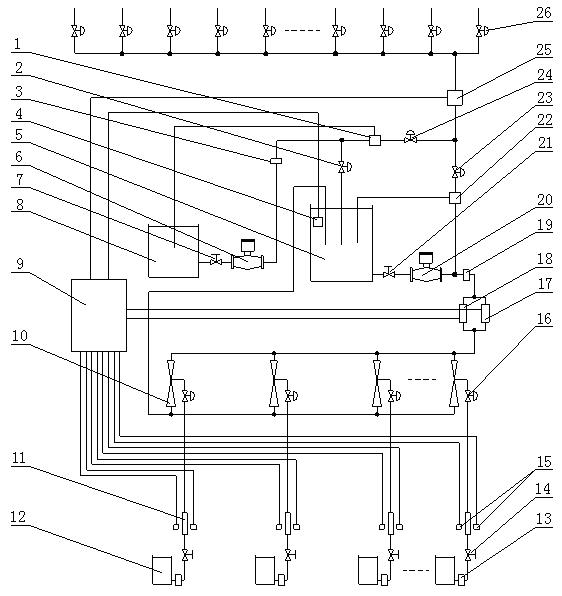

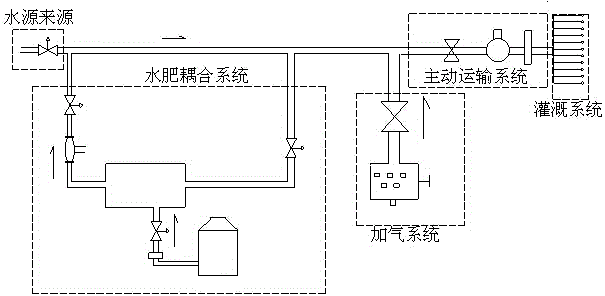

Underground water, fertilizer and gas integrated irrigation system

InactiveCN104871708AFully absorbedImprove hypoxiaClimate change adaptationWatering devicesWater sourceInlet valve

The invention relates to an underground water, fertilizer and gas integrated irrigation system, and belongs to the field of irrigation management. The underground water, fertilizer and gas integrated irrigation system comprises a water source, a water and fertilizer coupling system, an air-entrapping system, an active transport system, an irrigation system and a control system, wherein the water source comprises a running water inlet pipe opening and a check valve; the water and fertilizer coupling system comprises a water inlet valve, a fertilizer mixing tank, a fertilizer mixing valve, a fertilizer storage tank, a flow meter, a filter, a fertilizing pump and a water check valve; the air-entrapping system comprises an air compressor and an electromagnetic valve; the active transport system comprises a transport main pipe; the irrigation system comprises an irrigation main pipe, an irrigation branch pipe, an irrigation hollow billet and a water dropper; and the control system comprises a soil humidity control circuit and an atmospheric pressure test circuit. According to the underground water, fertilizer and gas integrated irrigation system, a certain amount of water and a certain quantity of a fertilizer are provided according to the requirements of crop growth; the root of a plant is ventilated to meet the condition that the root is subjected to aerobic respiration to maintain metabolism and growth and development of the overall plant; the use amount of water and the use quantity of the fertilizer can be effectively reduced; the management is optimized; the labor force is reduced; and the yield is increased.

Owner:KUNMING UNIV OF SCI & TECH

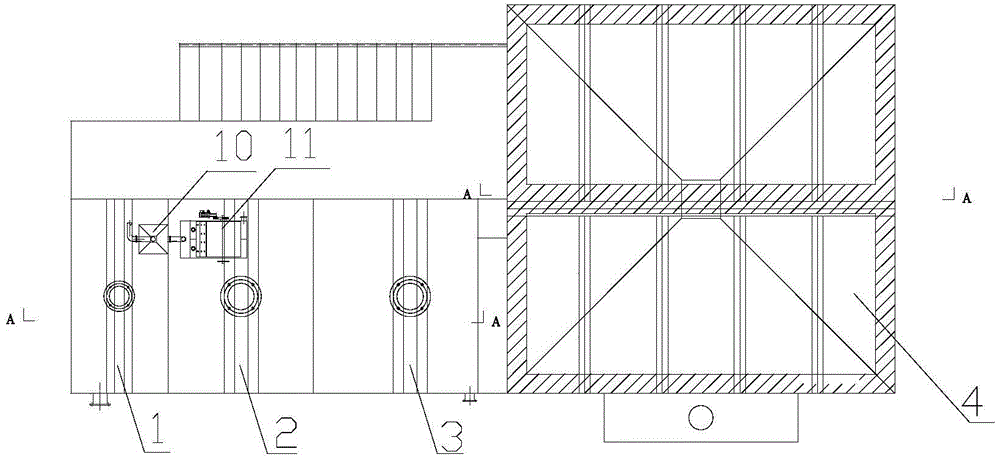

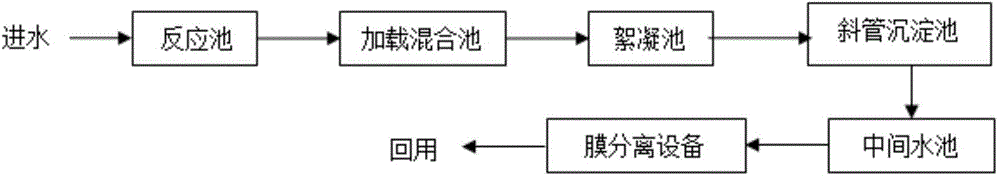

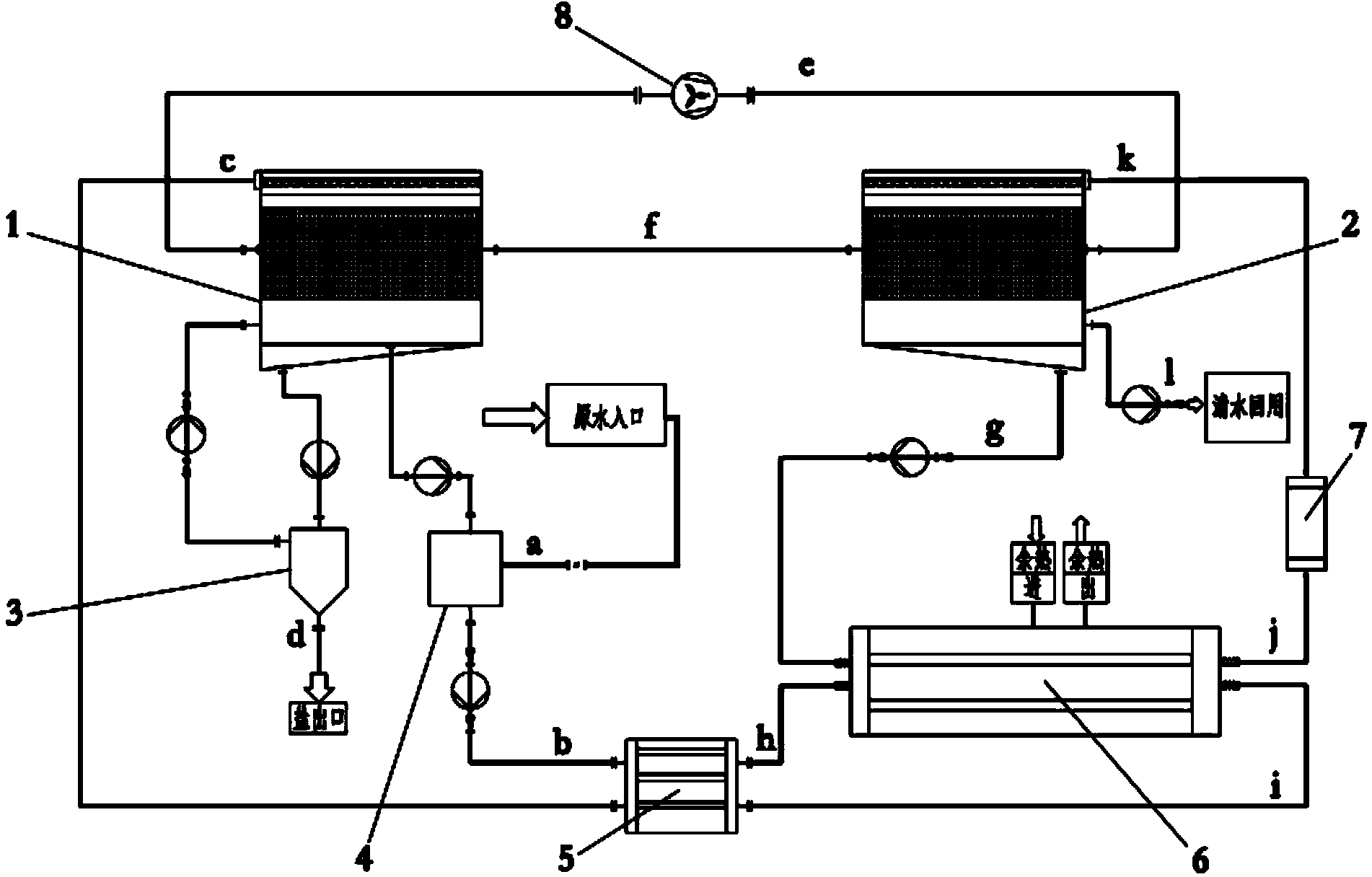

Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045AAvoid or reduce pollutionLow costMultistage water/sewage treatmentParticulatesSolubility

The invention discloses a wastewater reuse method combining magnetic loading coagulation clarification and membrane separation. The method comprises the following steps: (1) a coagulant is added into a reaction tank to form small flocs; (2) the small flocs enter a loading and mixing tank to generate magnetic coagulation cores with magnetic carriers; (3) after the magnetic coagulation cores enter a flocculation tank, a flocculant is added to generate large-particle magnetic floccules; (4) after the magnetic floccules are stirred and dispersed strongly by a high-speed dispersion machine, magnetic carriers which are recycled via a magnetic drum separator return to the step (2), supernatant liquor enters a middle water tank via the collection by a water collecting pipe, after being pressurized by a water pump, the supernatant liquor enters membrane separating equipment for fine filtration, and filtered water is discharged for reusing. The method is used for removing particulate matters, colloid and a part of dissolved organic matters in advance before membrane filtration, so that membrane pollution degrees can be effectively avoided or reduced, and the cleaning period and the service life of membrane components are increased. The method can be used for the resource reutilization of the wastewater in industries of printing and dyeing, electroplating, paper-making and the like, as well as the upgrading and reconstruction and the tail water reuse of sewage treatment plants.

Owner:浙江立丰环保设备有限公司

Integrated micro-fluidic chip

ActiveCN107398307AAvoid pollutionReduce air pressureMaterial analysis by observing effect on chemical indicatorTransportation and packagingProcess engineeringPressure balance

The invention relates to an integrated micro-fluidic chip. At least one integrated reaction unit is arranged on a substrate and at least comprises a sample tank, a mixing tank and a reaction tank which are communicated through a liquid channel, and a sample inlet is formed in one end of the sample tank; and the integrated reaction unit further comprises a gas circuit internal cycle system, one end of the gas circuit internal cycle system is connected with the mixing tank, and the other end of the gas circuit internal cycle system at least comprises a first cycle branch connected with one end, far from the sample inlet, of the sample tank. According to the integrated micro-fluidic chip, the air pressure balance in the sample tank and the mixing tank is guaranteed, so that the smooth flow of a sample in a predetermined channel of the micro-fluidic chip is guaranteed, and a reliable foundation is provided for generating a target product from the sample.

Owner:CAPITALBIO CORP

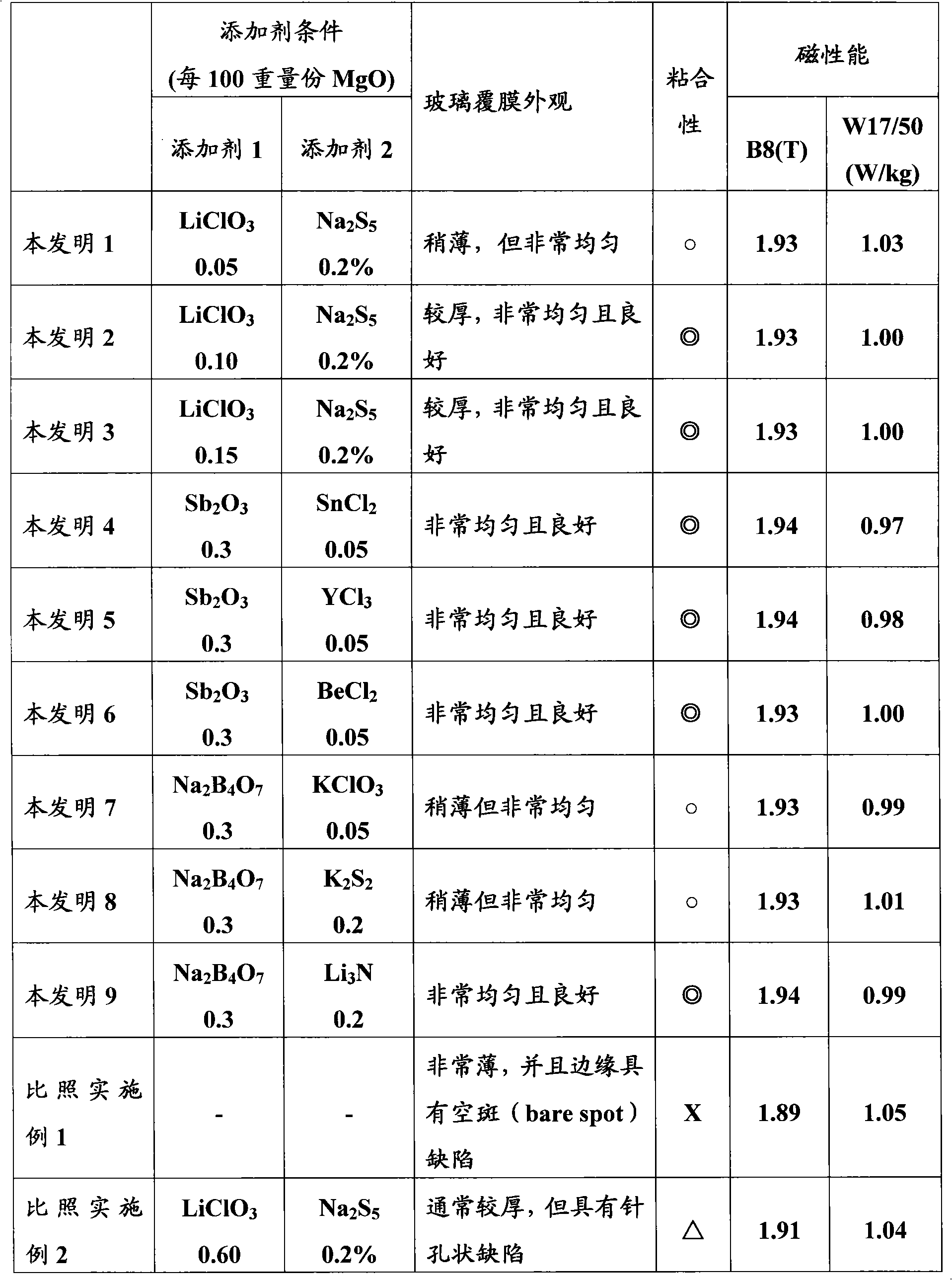

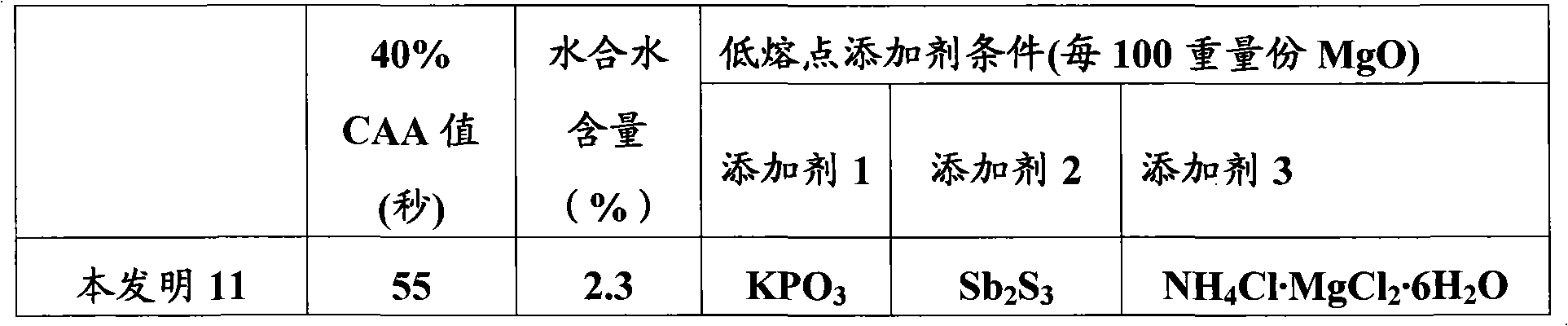

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

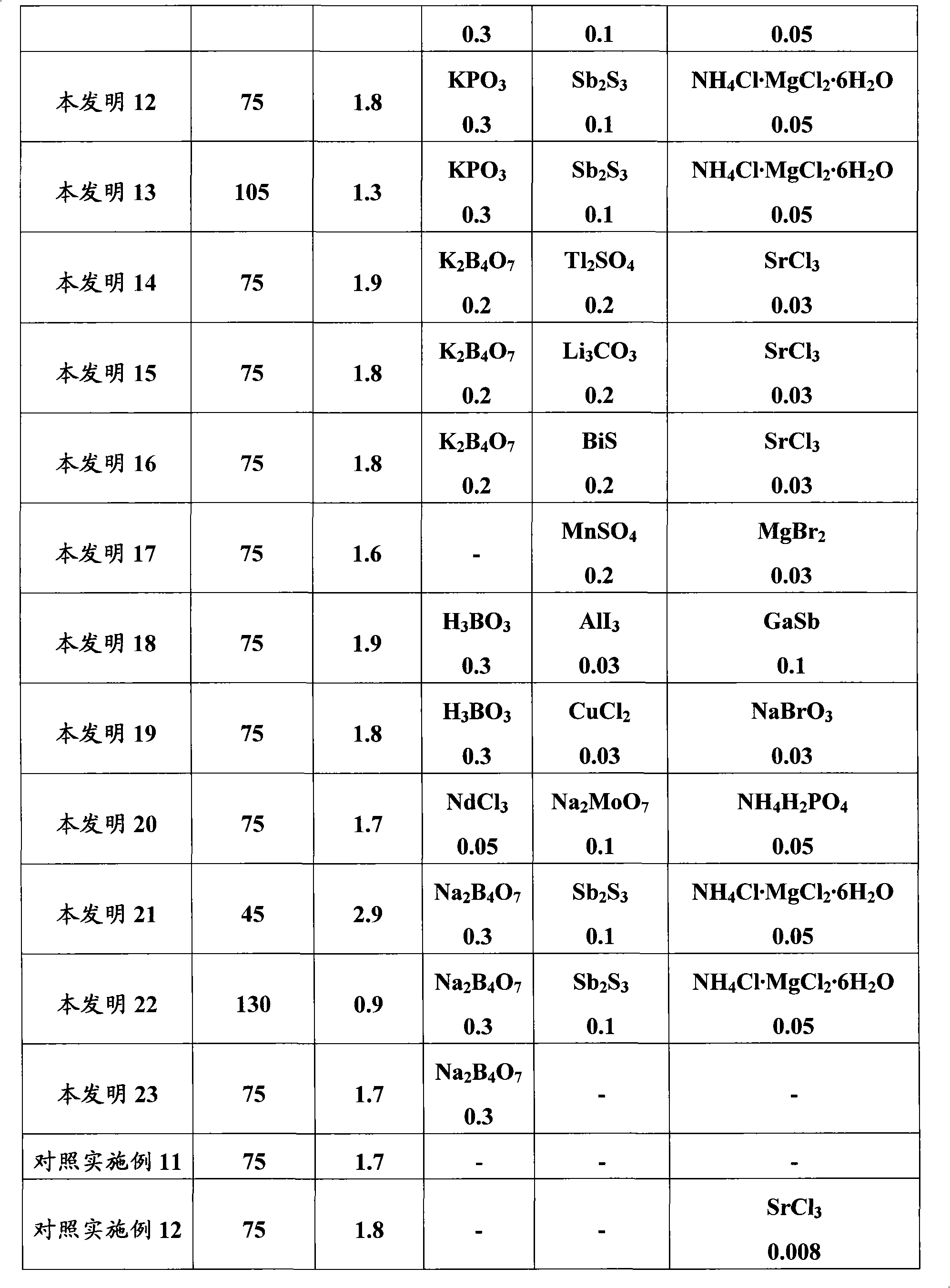

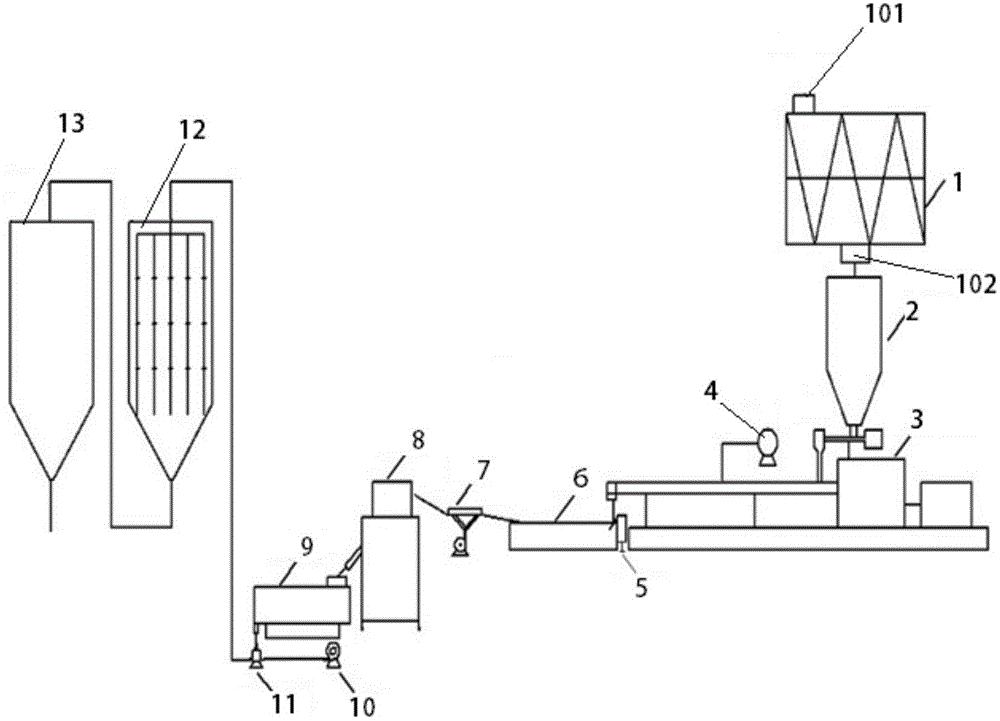

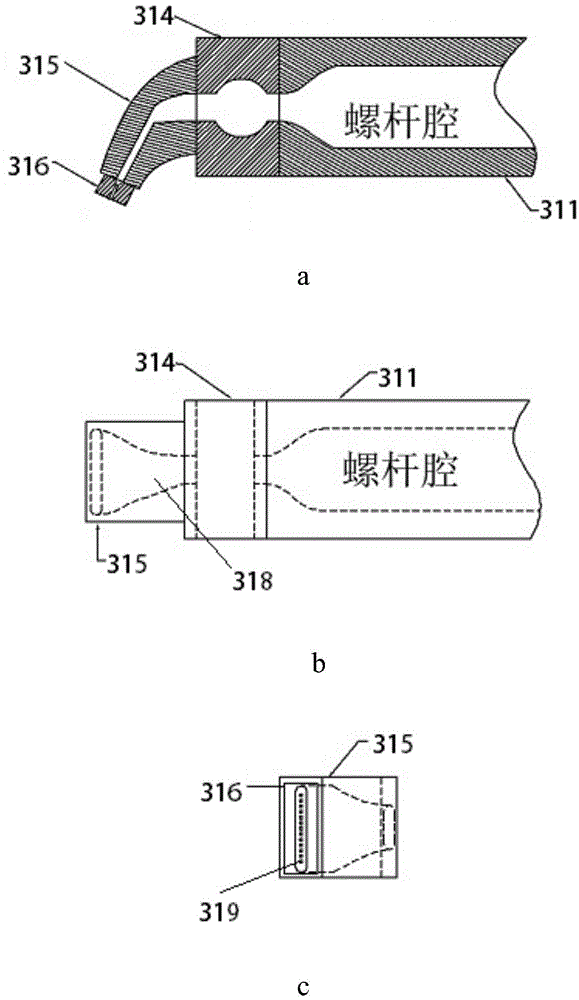

Production method and production equipment of special material for polypropylene melt-blown non-woven fabric

The invention discloses a production method and production equipment of a special material for a polypropylene melt-blown non-woven fabric. The production method comprises the following steps: adding 50-200g of a long-acting stabilizing agent, 25-200g of a short-acting stabilizing agent, 25-160g of a high-temperature-resistant stabilizing agent and 20-100g of a lubricating agent to each 100kg of polypropylene; and mixing by using a mixing machine, and discharging to an extruder, and generating a reaction in a lead-screw reaction section of a double-screw extruder. The production equipment comprises a mixing machine, wherein uniformly mixed raw materials are discharged into an intermediate bunker from a mixed material outlet, an outlet in the bottom of the intermediate bunker is connected with an inlet of the extruder, the extruder is of a dual-screw structure and is used for sending processed materials to a cooling water tank for being cooled by virtue of an inclined water tank, then air-dried by an air dryer, granulated in a granulating machine, screened by a vibrating screen, and sent into a homogenizing and mixing tank by virtue of a rotary discharging device. The production method and the production equipment have the beneficial effects of uniformly mixing the raw materials and solving the difficulty of forming of polypropylene with a high flowing melting index, and are suitable for conventional production.

Owner:HUNAN SHENGJIN NEW MATERIAL

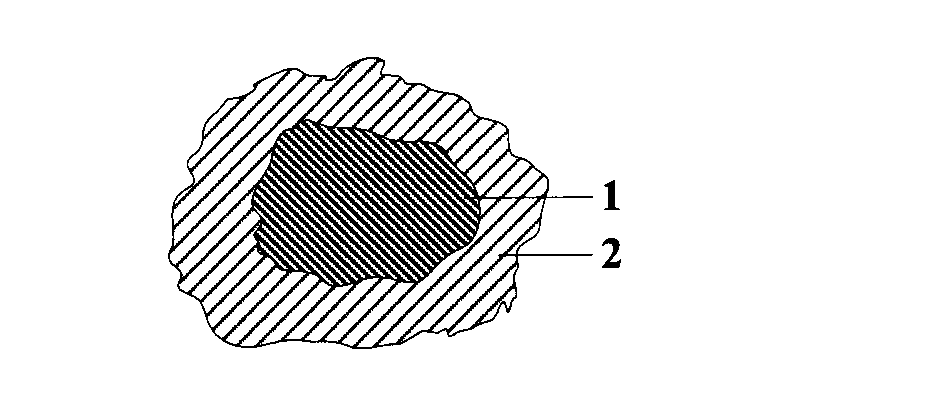

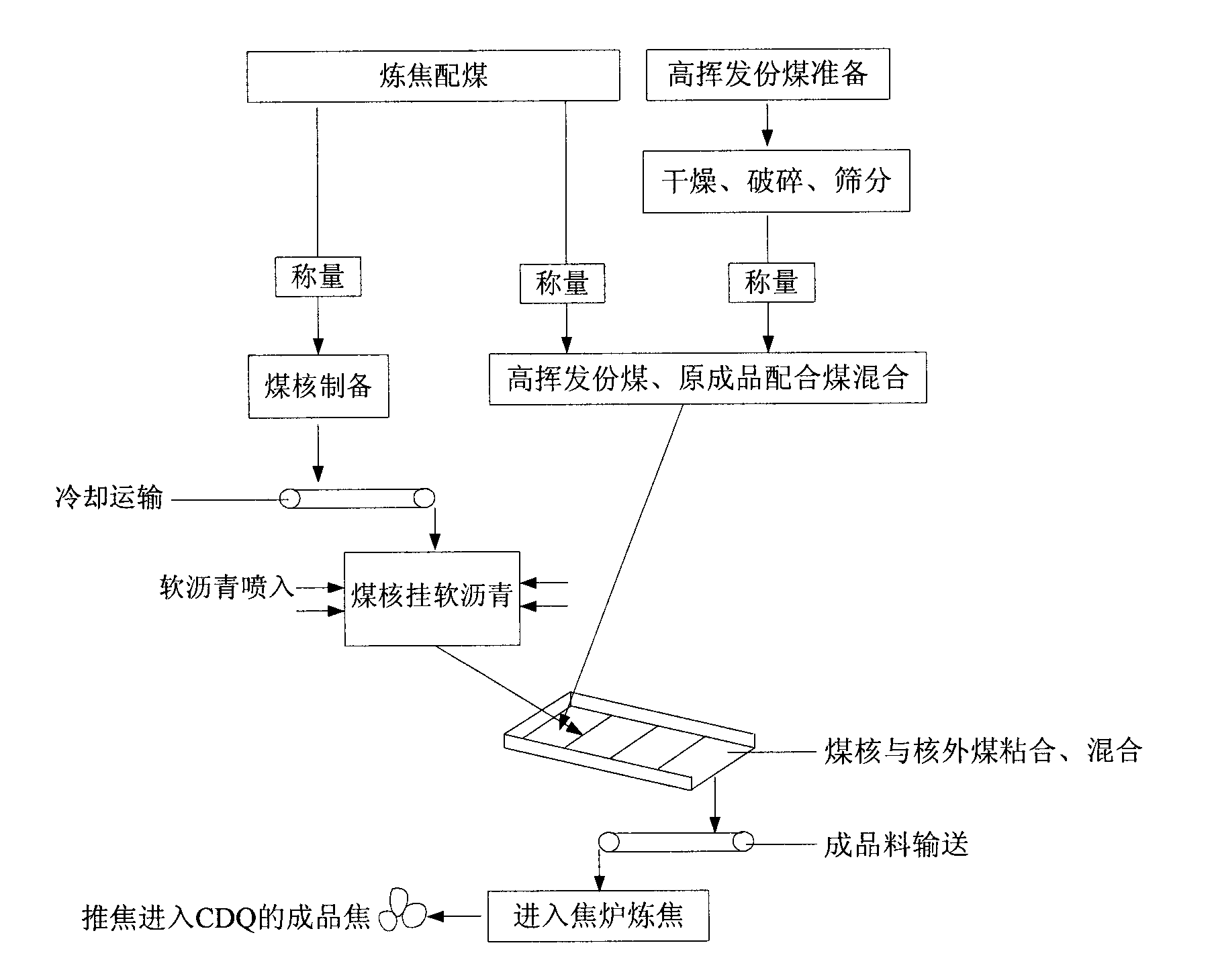

High-reactivity coke and manufacture method thereof

ActiveCN102719264AImprove responseHigh heat intensitySpecial form destructive distillationMethods of productionUltimate tensile strength

The invention provides high-reactivity coke and a manufacture method thereof, and the coke has an internal and external structure, wherein a core is prepared from blended coking coals and an external layer is prepared from high-volatile coals and blended coking coals through mixing. The method comprises: 1, blending coals; 2, preparing coal cores, comprising weighing 45% - 50% of coking coals, preparing the coal cores through crushing, binder addition, and ball-pressing, and sending into a soft asphalt spray room to spray asphalt to get the coal core; 3, processing external coking coals, comprising weighing 20% -25% of high-volatile coals, drying, crushing, screening and then sending particles with a grain size of less than 3 millimeters into a pre-mixer to evenly mix with 30% - 35% of coking coals; 4, preparing raw materials of finished products, comprising sending the external coking coals into a micro-swing mixing tank, and then putting in the coal cores to bond the external coking coals by mixing; 5, coking to get the finished coke. The high-reactivity cokes and manufacture method thereof are not only suitable for the present coke process to produce a high-reactivity and high-strength metallurgical coke with a low cost, but also can improve the operation of blast furnace production, thereby further reducing the ironmaking cost.

Owner:ANGANG STEEL CO LTD

Circulating treatment system and process of high concentration salt-containing wastewater

ActiveCN103466736ALow running costReduce the temperatureWater/sewage treatmentEnergy based wastewater treatmentHigh concentrationWastewater

The invention discloses a circulating treatment system of high concentration salt-containing wastewater. The system comprises an evaporating chamber, a condensation chamber, a solid-liquid separator, a mixing tank, a heat exchanger, a heat pump set, an air cooler and a draught fan, wherein the evaporating chamber, the condensation chamber and the draught fan are connected with each other to form a first circulating loop, a strong saline water outlet of the evaporating chamber is sequentially connected with the mixing tank and the heat exchanger, a water outlet end of the heat exchanger is connected with a tower top of the evaporating chamber to form a second circulating loop, a crystal substance outlet at the bottom of the evaporating chamber is connected with the solid-liquid separator, and a liquid outlet end of the solid-liquid separator is connected with the evaporating chamber to form a third circulating loop. The condensation chamber is sequentially connected with the condensation chamber of the heat pump set, the heat exchanger, the evaporating chamber of the heat pump set and the air cooler. A water outlet end of the air cooler is connected with a tower top of the condensation chamber to form a fourth circulating loop. After circulating treatment of wastewater through the circulating loops, salt in the wastewater can be crystallized and recovered, and water produced can be recycled, so that resourceful and harmless treatment of high concentration salt-containing wastewater is realized.

Owner:KMD BEIJING ENERGY & ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com