Patents

Literature

47results about How to "Avoid or reduce pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045AAvoid or reduce pollutionLow costMultistage water/sewage treatmentParticulatesSolubility

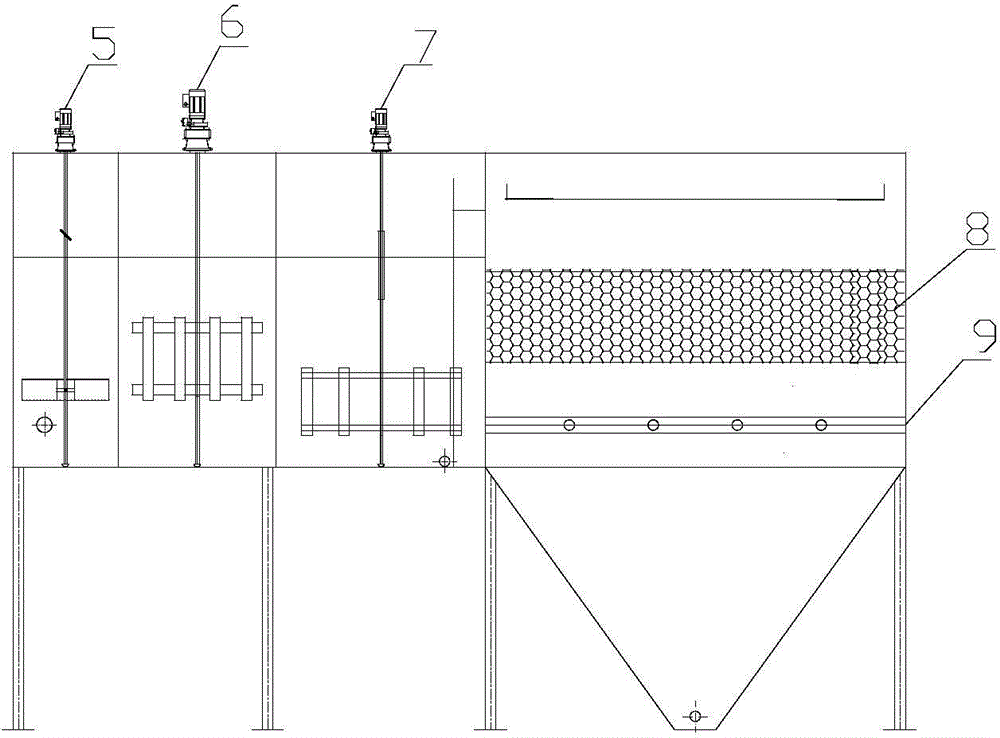

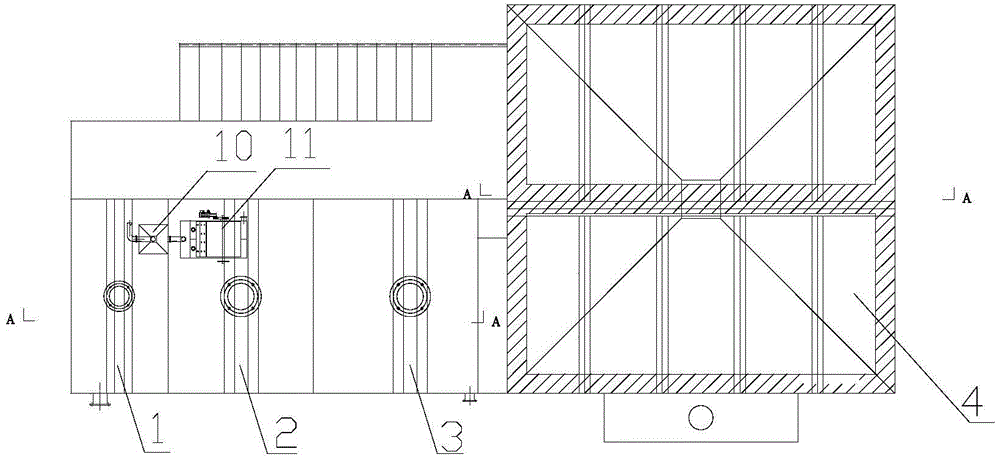

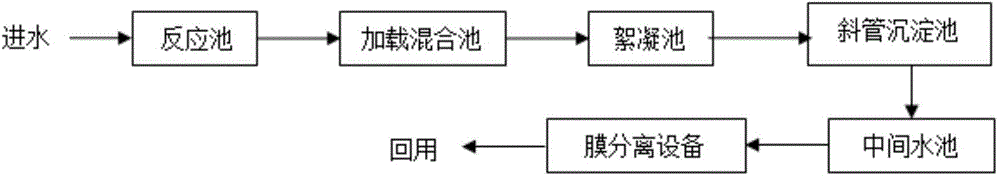

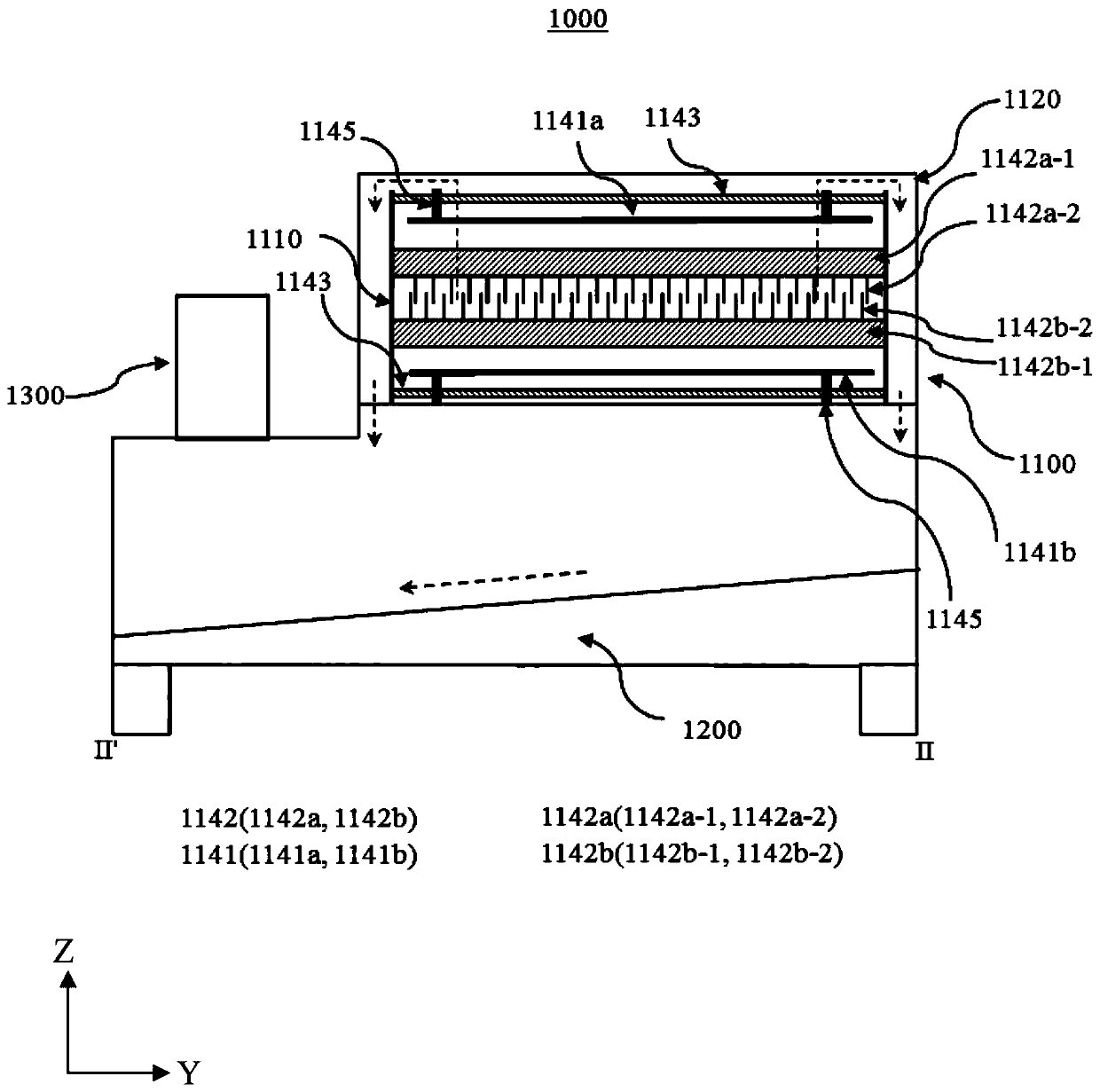

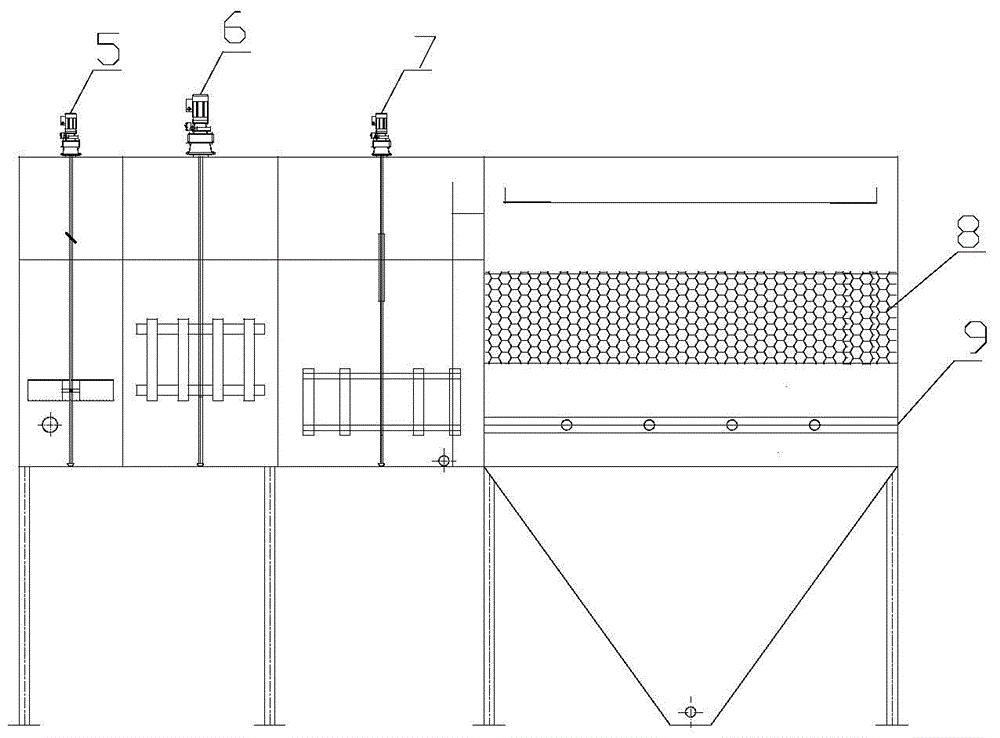

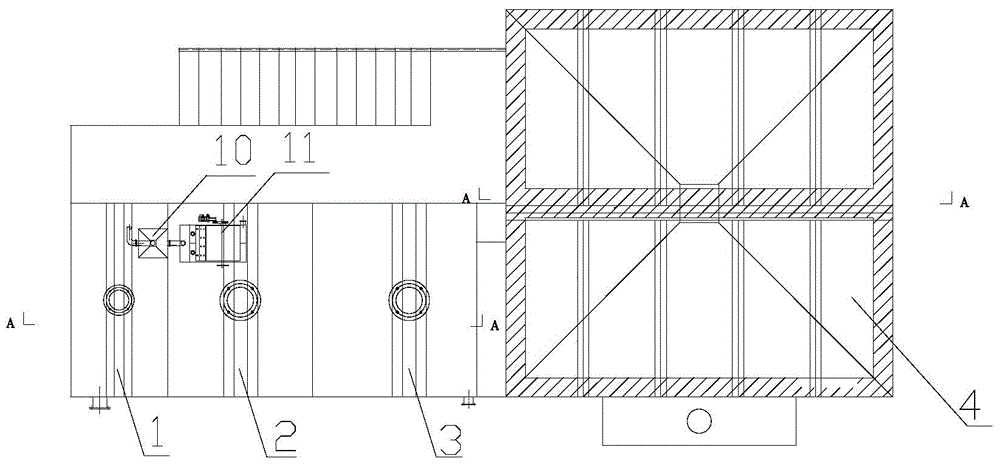

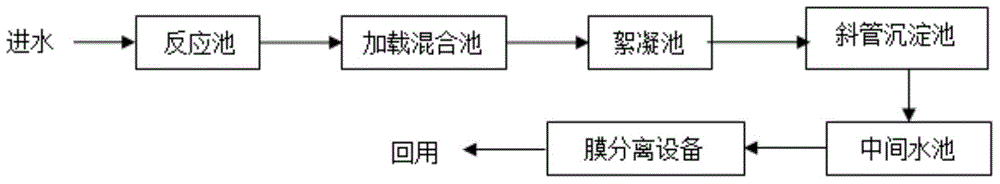

The invention discloses a wastewater reuse method combining magnetic loading coagulation clarification and membrane separation. The method comprises the following steps: (1) a coagulant is added into a reaction tank to form small flocs; (2) the small flocs enter a loading and mixing tank to generate magnetic coagulation cores with magnetic carriers; (3) after the magnetic coagulation cores enter a flocculation tank, a flocculant is added to generate large-particle magnetic floccules; (4) after the magnetic floccules are stirred and dispersed strongly by a high-speed dispersion machine, magnetic carriers which are recycled via a magnetic drum separator return to the step (2), supernatant liquor enters a middle water tank via the collection by a water collecting pipe, after being pressurized by a water pump, the supernatant liquor enters membrane separating equipment for fine filtration, and filtered water is discharged for reusing. The method is used for removing particulate matters, colloid and a part of dissolved organic matters in advance before membrane filtration, so that membrane pollution degrees can be effectively avoided or reduced, and the cleaning period and the service life of membrane components are increased. The method can be used for the resource reutilization of the wastewater in industries of printing and dyeing, electroplating, paper-making and the like, as well as the upgrading and reconstruction and the tail water reuse of sewage treatment plants.

Owner:浙江立丰环保设备有限公司

Novel crushing device for building

InactiveCN106000602AAvoid or reduce pollutionSufficient and effective crushing and processing operationsUsing liquid separation agentGrain treatmentsEngineeringDust pollution

The invention relates to a novel crushing device for a building. The novel crushing device comprises a support frame and a shell, wherein a feeding hole is formed in the top of the left side of the shell; a motor is arranged at the top end of the shell; the output shaft end of the motor is connected with a rotating shaft on which stirring rods are distributed; tapered bulges are distributed at the upper part of the inner side wall of the shell; a left crushing roller, a right crushing roller and a mesh screen are sequentially arranged below the rotating shaft; the right end of the mesh screen is hinged with the inner side wall of the shell; a partition plate is arranged below the mesh screen; the left end of the mesh screen is connected with the partition plate through a spring; the mesh screen is provided with a vibrating motor; partition plate through holes are distributed in the partition plate, and the upper surface of the mesh screen is covered by a filter screen; a first discharging hole is formed in the left side of the shell located above the mesh screen, and a second discharging hole is formed in the right side of the shell located above the partition plate; a water outlet in the bottom of the left side of the shell; a water inlet and a spray head are arranged at the top end of the shell; and a water purifying tank is arranged at the right side of the shell and is connected to the spray head through a water inlet hose. Due to the adoption of the structure, the crushing operation can be more effectively performed, and dust pollution can also be avoided or relieved.

Owner:成都聚立汇信科技有限公司

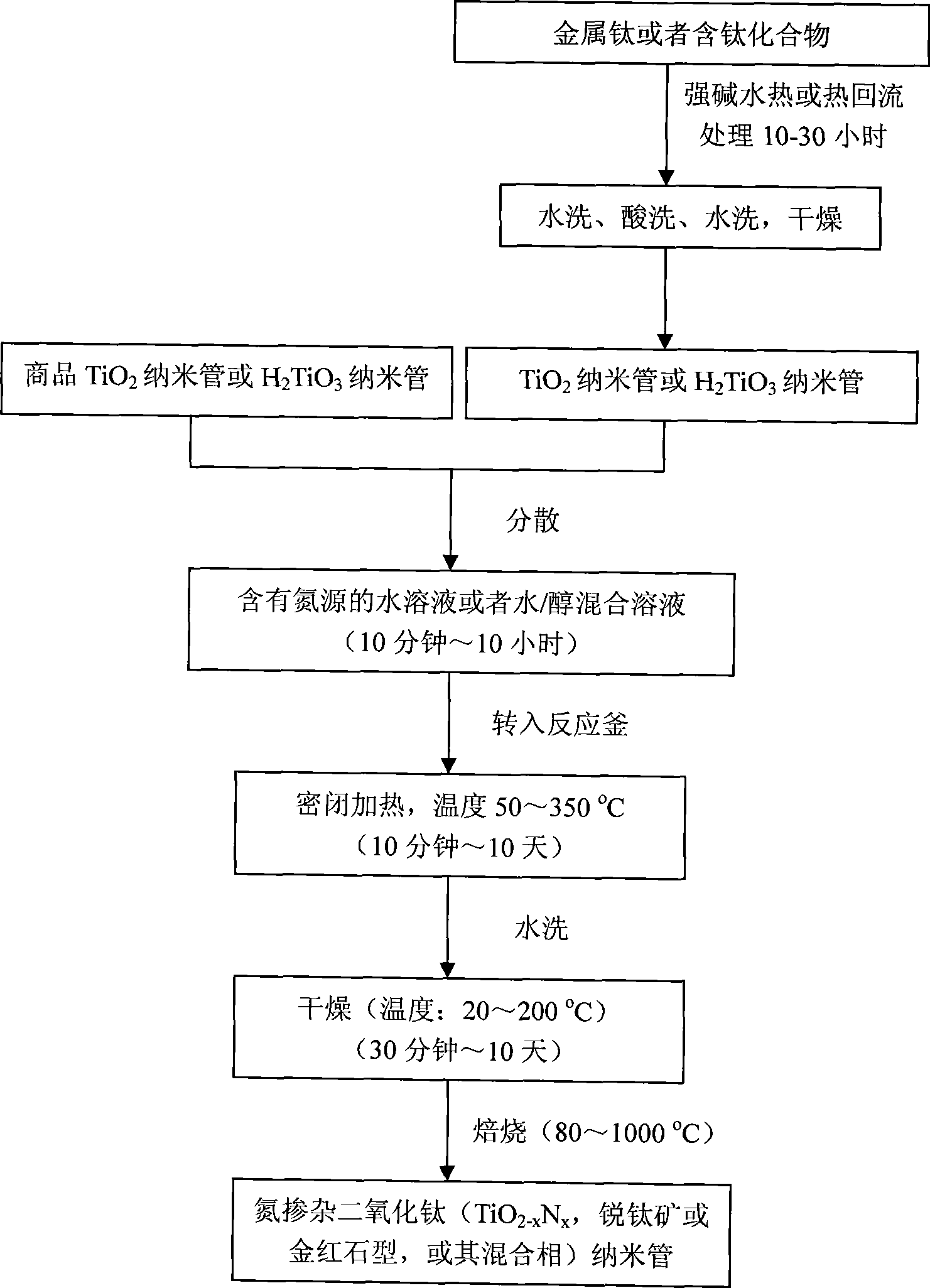

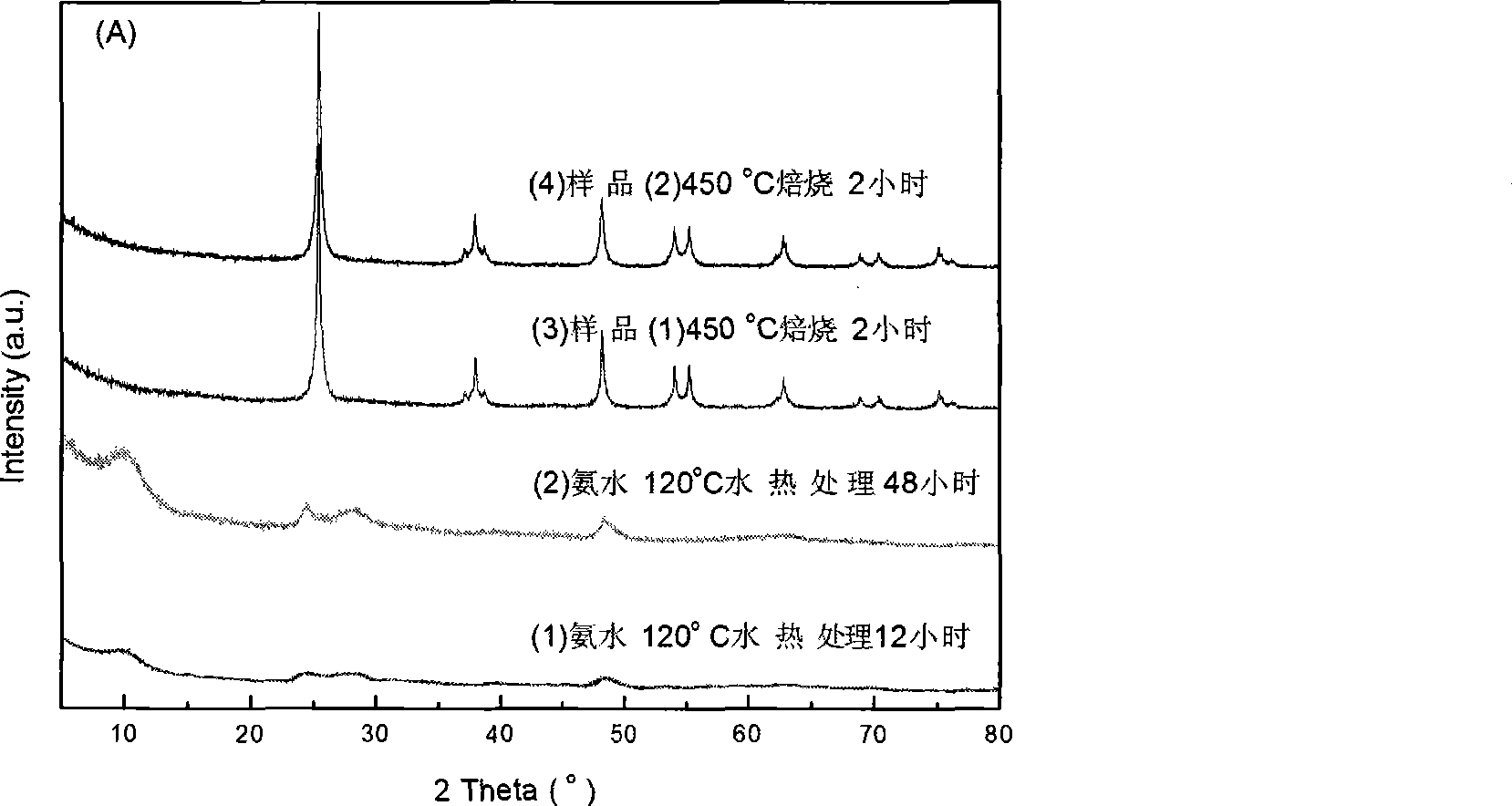

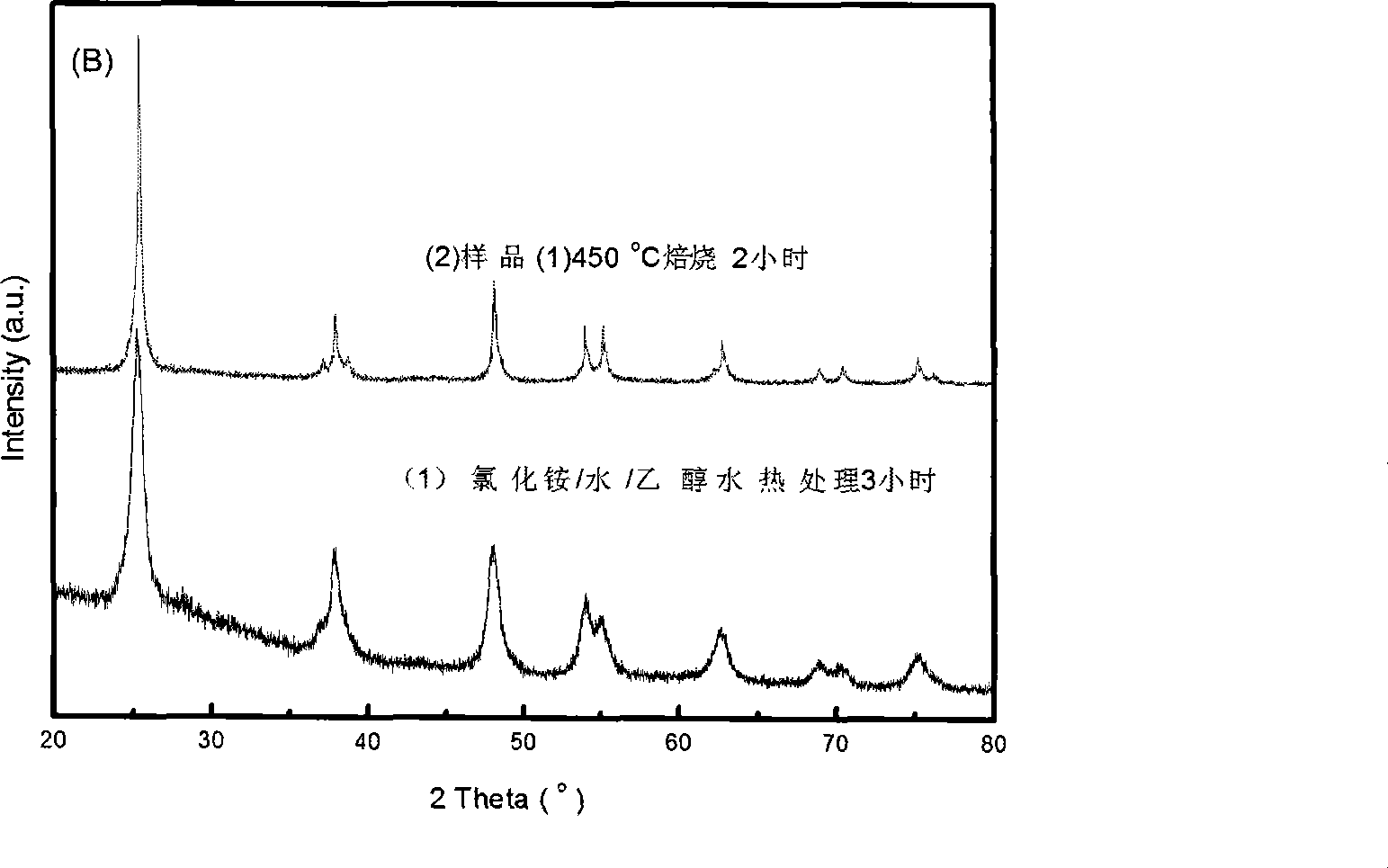

Preparation method and use of visible light responsive nitrogen-doped titanium dioxide nano-tube

ActiveCN101422725AThe tubular structure is intactHigh crystallinityPhysical/chemical process catalystsSolventChemistry

The invention discloses a preparation method of a nitrogen-doped titanium dioxide nanotube with response to visible lights, and comprises the following steps: a. metallic titanium or titaniferous compounds are used for preparing a metatitanic acid nanotube with a hydrothermal or solvothermal method; b. the metatitanic acid or titanium dioxide nanotube that is prepared by step a or a commercial metatitanic acid or titanium dioxide nanotube is dispersed in a water solution with nitrogen sources or a water and alcohol mixed solution, and agitated or ultrasonically processed for 10 minutes to 10 hours; c. serum that is obtained by step b is placed into a reaction kettle with polyfluortetraethylene lining and processed by sealed heating for 10 minutes to 10 days, and the reaction temperature is 50 to 350 DEG C; and d. the product obtained by step c is washed by deionized water, dried and baked, thus obtaining the nitrogen-doped titanium dioxide nanotube. The preparation method of the nitrogen-doped titanium dioxide nanotube of the invention has simplicity, cleanness and environmental protection, is applicable to batch preparation, and has low cost and strong adaptability, wide application of the prepared nitrogen-doped titanium dioxide nanotube.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

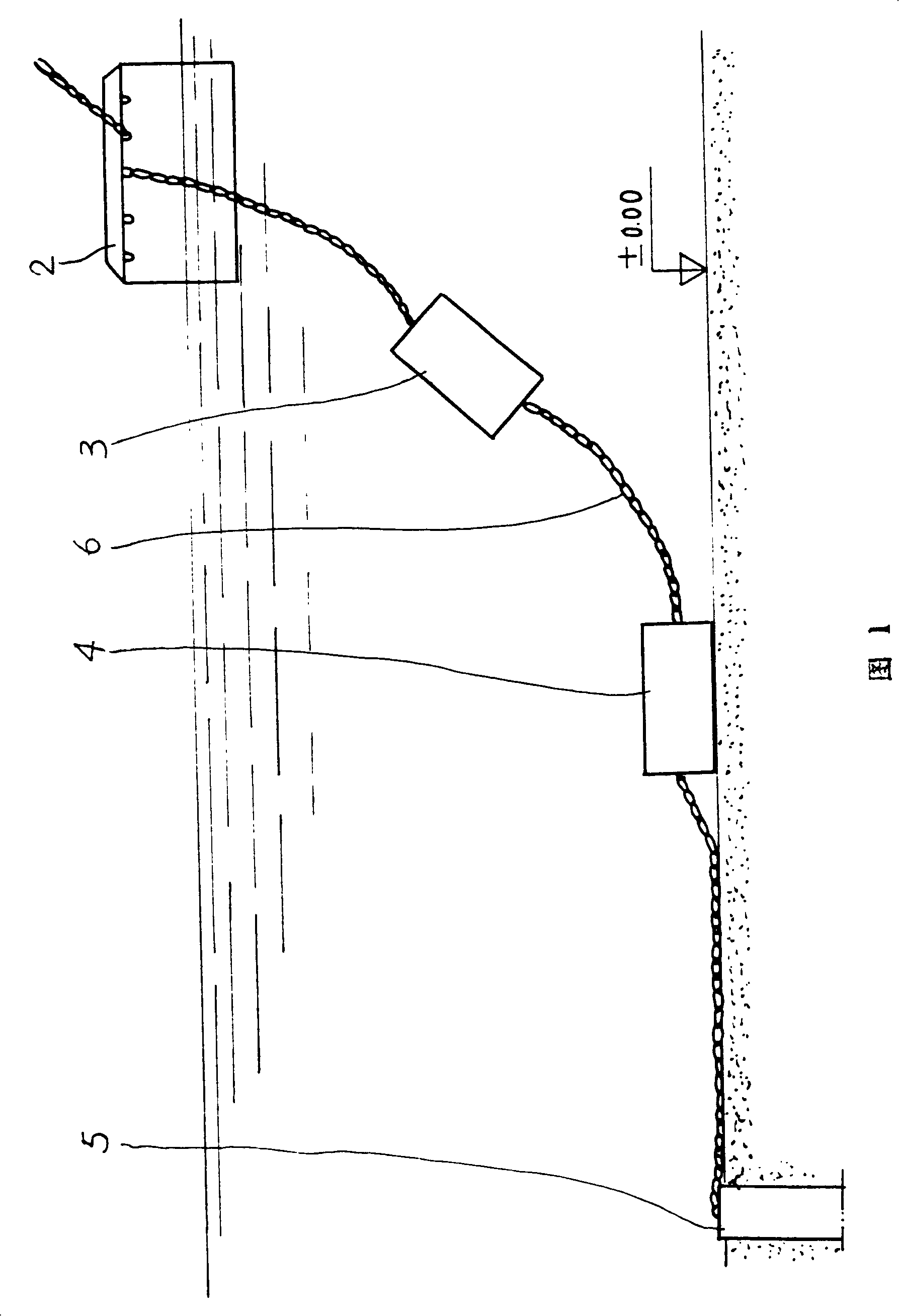

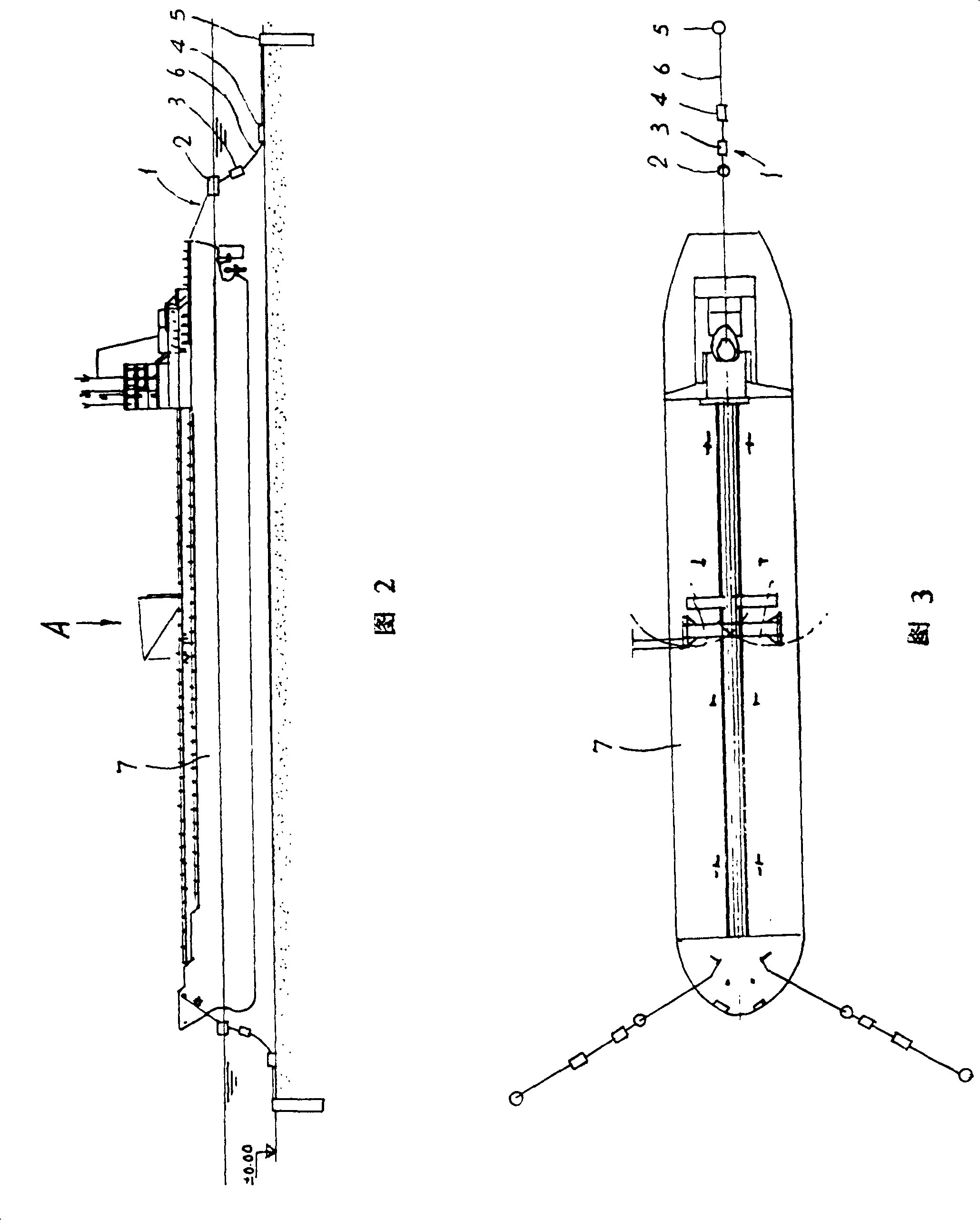

Off land loading and unloading anchoring system and anchoring method for liquid bulk cargo carrier

InactiveCN101157378AIncreased vertical downward forceImprove stabilityAnchorsBulk cargoMooring system

The invention relates to an offshore loading, unloading and mooring system for liquid bulk carriers as well as a mooring method, and the invention is characterized in that the mooring system consists of three sets of mooring device; the mooring device is formed by using connecting components to connect a buoy, a suspension bullback-weight, a chassis bullbacke weight and a anchoring base one by one; when in mooring, each set of mooring device connects the buoy and a carrier together by connecting components, wherein, two sets of mooring device are connected with the head of the liquid bulk carrier; another set of the mooring device is connected with the stern of the liquid bulk carrier; the three sets of mooring device are in Y-shaped arrangement; the mooring system can anchor the liquid bulk carrier in an off-shore sea area to load or unload materials; compared with the prior art, the invention has the advantages of small occupation sea area, low investment, short construction cycle, convenient operation, safety and reliability. Moreover, the invention does not take up shore-line resources, and is easy to be recovered and ruled, as well as especially suitable for the loading and unloading of the liquid bulk carriers.

Owner:陈杰诚

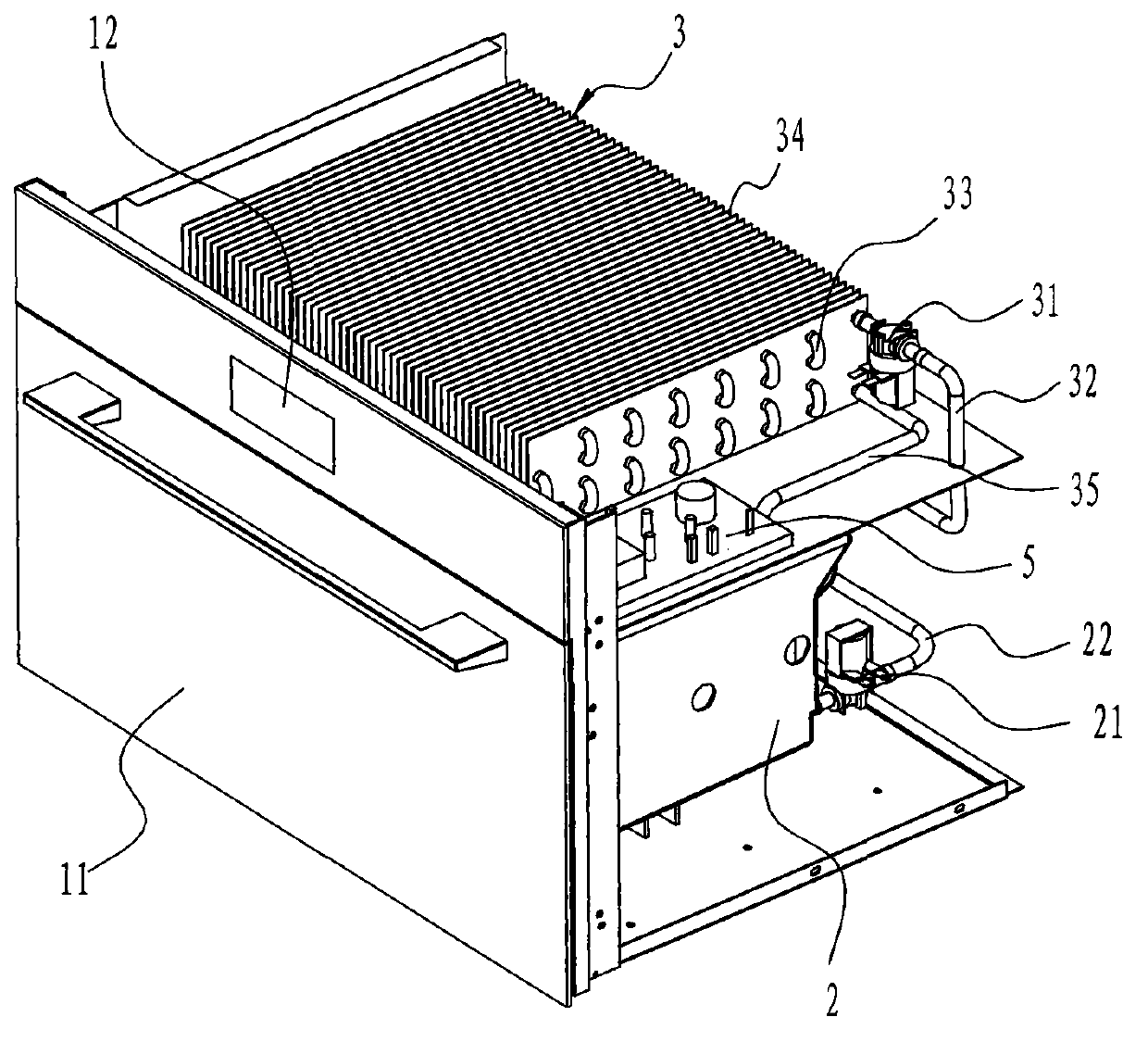

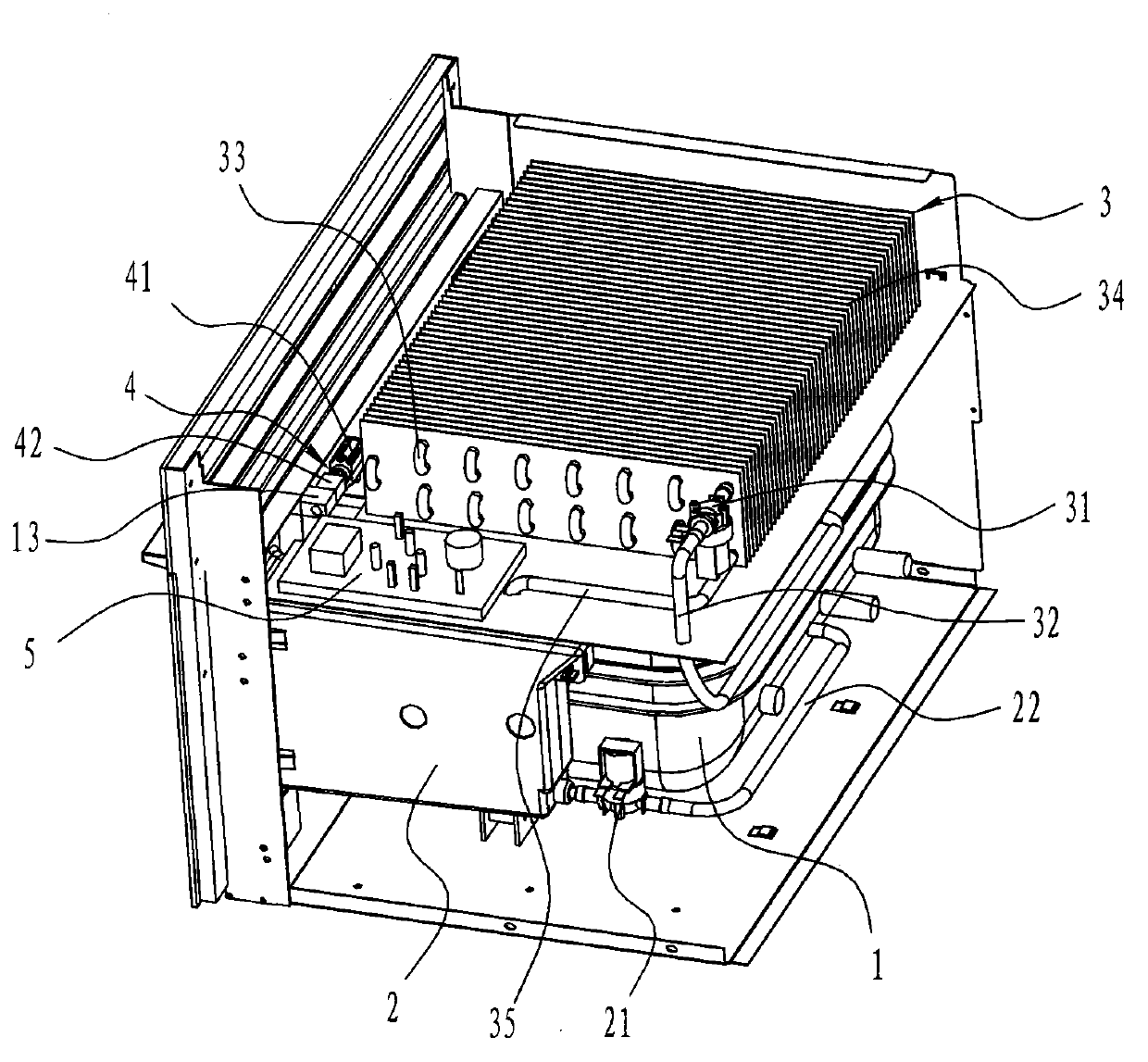

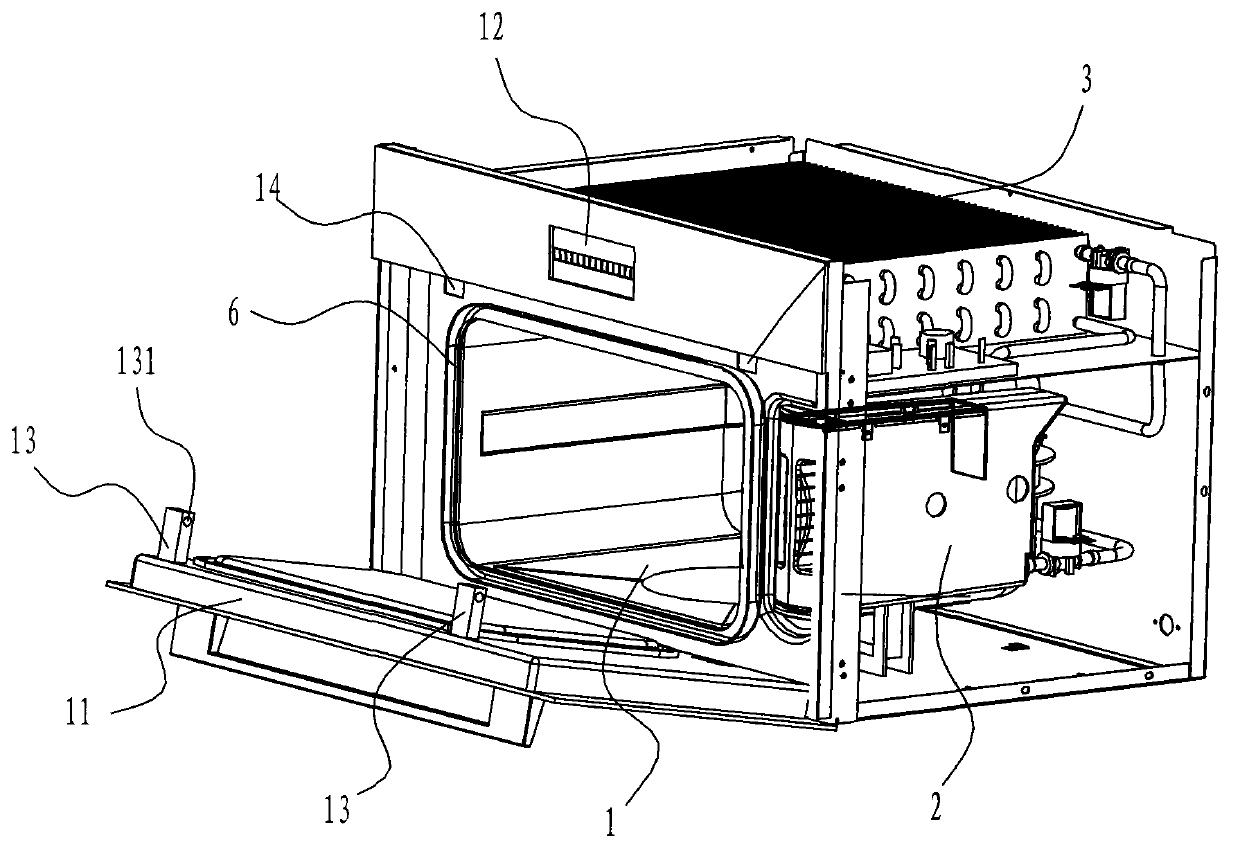

Food heater

ActiveCN103654367AImprove high pressure performanceIncrease steam pressureSteam cooking vesselsSteam pressureWater storage tank

The invention discloses a food heater. The food heater comprises a box body with a heating assembly, and a box door is arranged on the outer surface of the box body. The food heater further comprises an inner container which is sealed by the box door and used for heating food, a steam recovery device and a control circuit, wherein a door lock is arranged between the box door and the inner container, and transnormal steam pressure in the heating box body can be borne by the door lock; the heating assembly comprises a heating part and a water storage tank, water quantitatively output of the water storage tank is heated into steam through the heating part, and food is heated by the steam in the inner container; the steam recovery device is composed of a condenser, a steam pipe and a return pipe, the heating box body and the condenser are connected through the steam pipe, and the condenser and the water storage tank are connected through the return pipe; the control circuit controls the food heater to complete the whole work process; due to a sealing structure between the box door and the inner container, steam pressure in the heating box body is increased, heating efficiency of the heather is improved, a large part of steam is returned to the water storage tank after being condensed through the transnormal pressure in the heating box body, heated water can be utilized in a circulating mode, and environmental pollution caused by steam leakage can be avoided or reduced.

Owner:宁波市安通机械有限公司

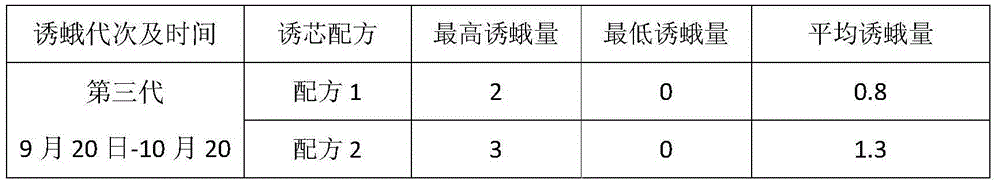

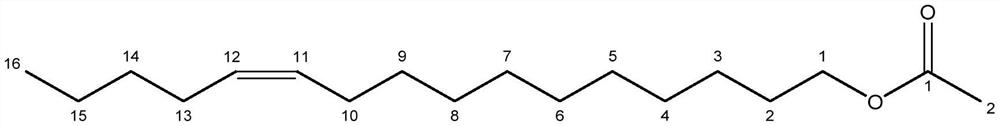

Othaga achatina butler sex attractant composition and application thereof

InactiveCN104996422ASimple structureEasy to synthesizeBiocidePest attractantsAchatinaAdditive ingredient

The invention discloses an othaga achatina butler sex attractant composition and its application. The othaga achatina butler sex attractant composition is composed of the following ingredients: cis11-hexadecenyl acetate, cis11-hexadecanol, cis9-trans12-tetradecene acetate, wherein the ratio of cis11-hexadecenyl acetate to cis11-hexadecanol to cis9-trans12-tetradecene acetate is (5-9): (0-3): (0-3), and cis11-hexadecenyl acetate and cis9-trans12- tetradecene acetate are not both zero at the same time. The othaga achatina butler sex attractant composition is applied in trap and insect forecasting of othaga achatina butler. No matter used for insect forecasting or used for trap and control of othaga achatina butler, the composition provided by the invention is beneficial to protecting natural enemies and enhancing control effect. In addition, application of chemical pesticides can be avoided or minimized so as to reduce pollution, protect the environment and remarkably raise economic, social and ecological comprehensive benefits.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

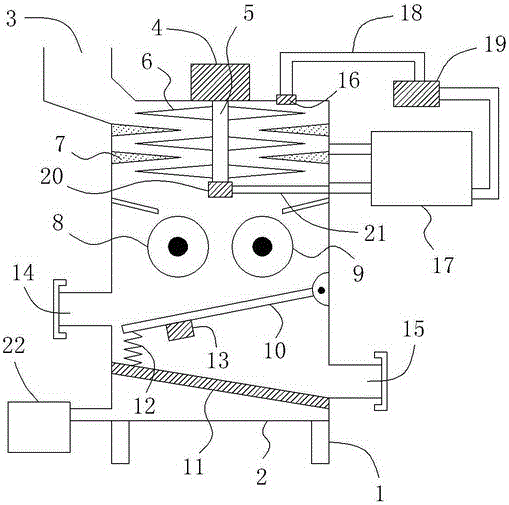

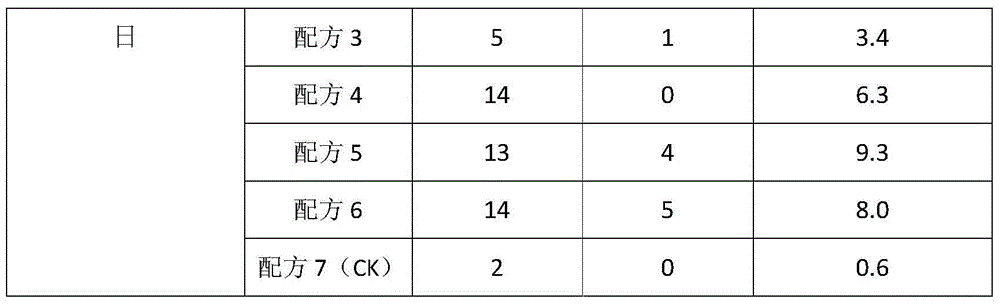

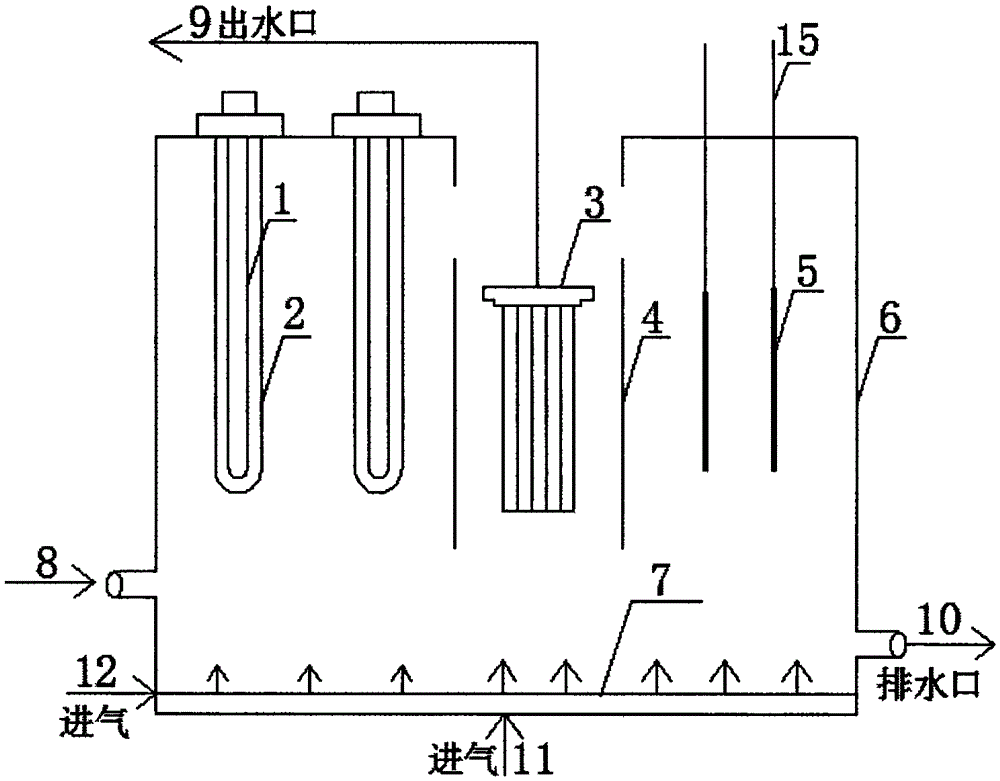

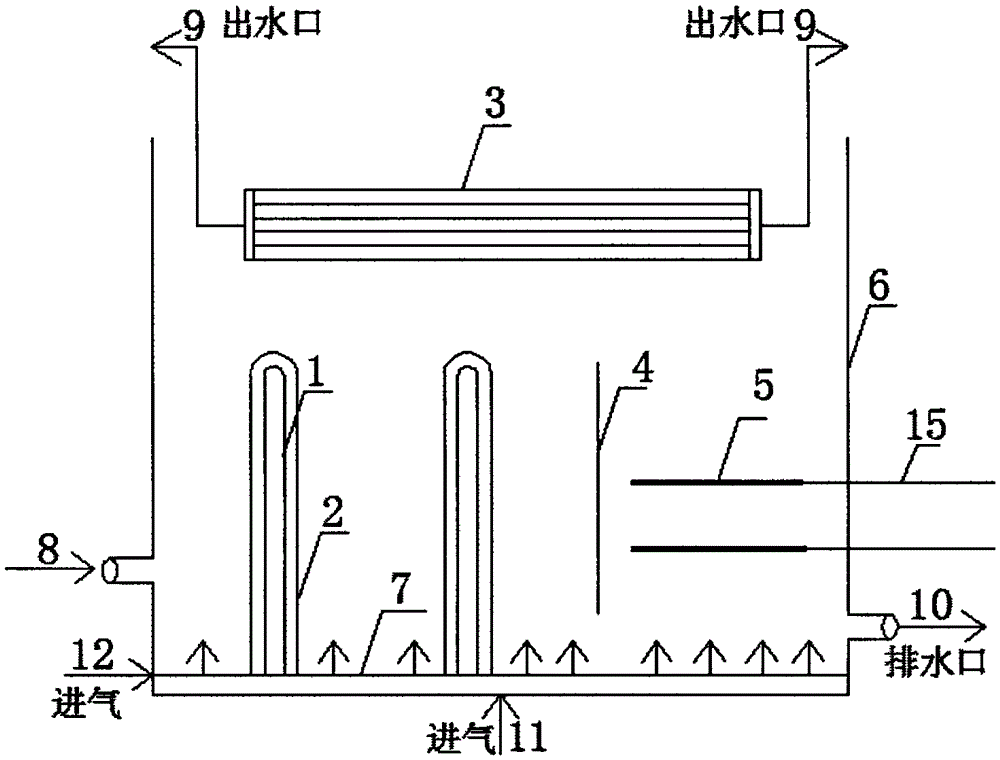

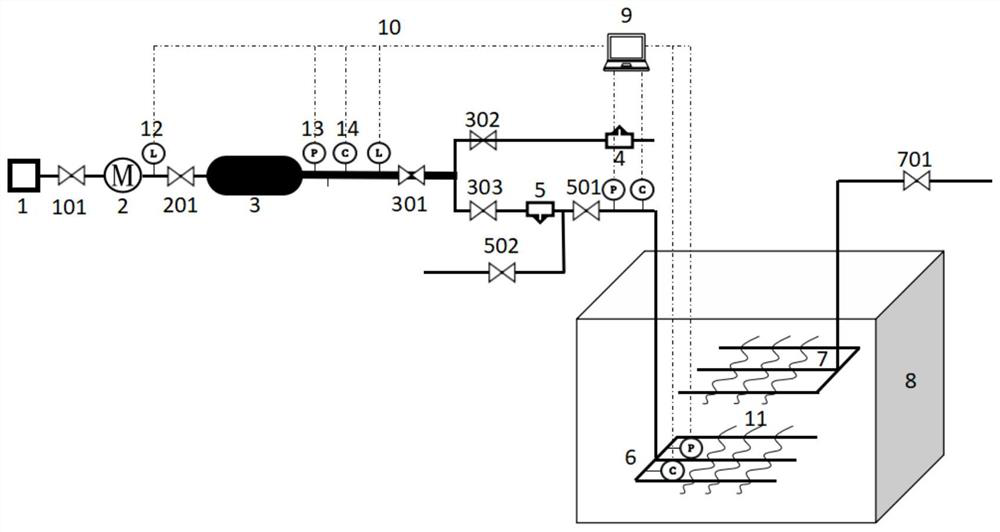

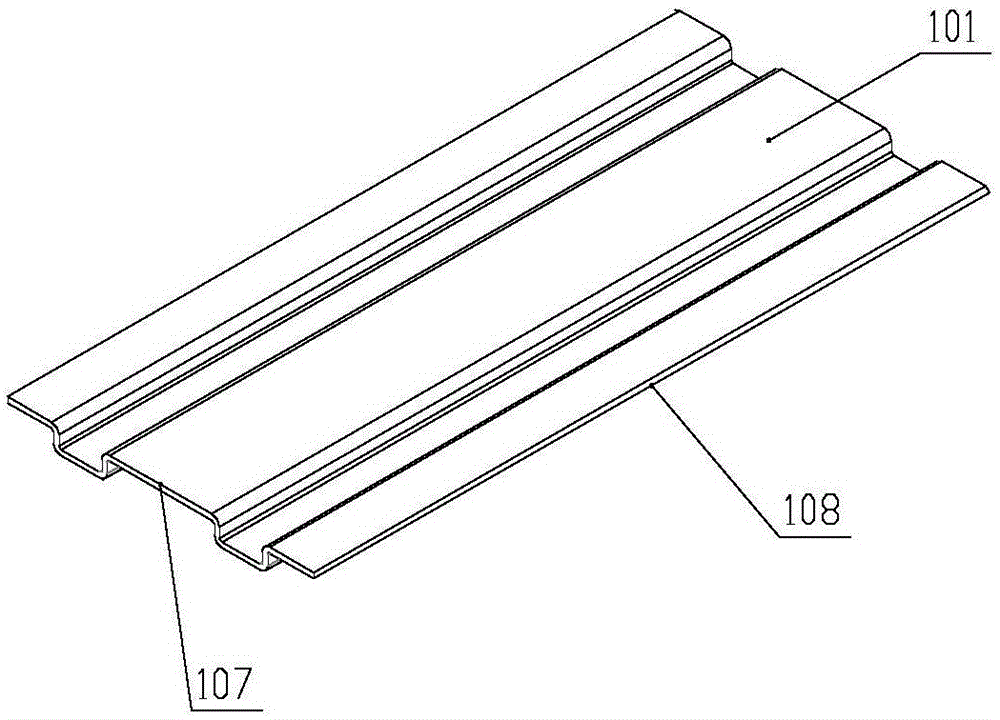

Integrated photoelectrocatalysis-membrane separation fluidized bed reaction device

InactiveCN105481051AEfficient decompositionEasy to separateWater/sewage treatment by irradiationWater treatment compoundsFluidized bedUltraviolet lights

The invention discloses an integrated photoelectrocatalysis-membrane separation fluidized bed reaction device. The reaction device comprises a housing, an ultraviolet source, an electrode plate, a membrane component and an aerating unit. A water inlet and a water outlet are formed in the bottom of the housing. The aerating unit, the ultraviolet source, the electrode plate and the membrane component are arranged in the housing. The membrane component is connected with the housing. The distance between the ultraviolet source and the membrane component as well as the distance between the electrode plate and the membrane component are larger than or equal to the penetrating distance of ultraviolet light and the reaction distance of the electrode plate respectively. According to the integrated photoelectrocatalysis-membrane separation fluidized bed reaction device, multiple functions, including a photocatalysis function, an electrocatalysis function and a membrane separation function, are achieved, the mass transfer performance is good, the catalyst utilization efficiency is high, the catalyst can be recycled, waste water treatment efficiency is high, the structure is simple, and energy consumption is reduced.

Owner:TIANJIN POLYTECHNIC UNIV

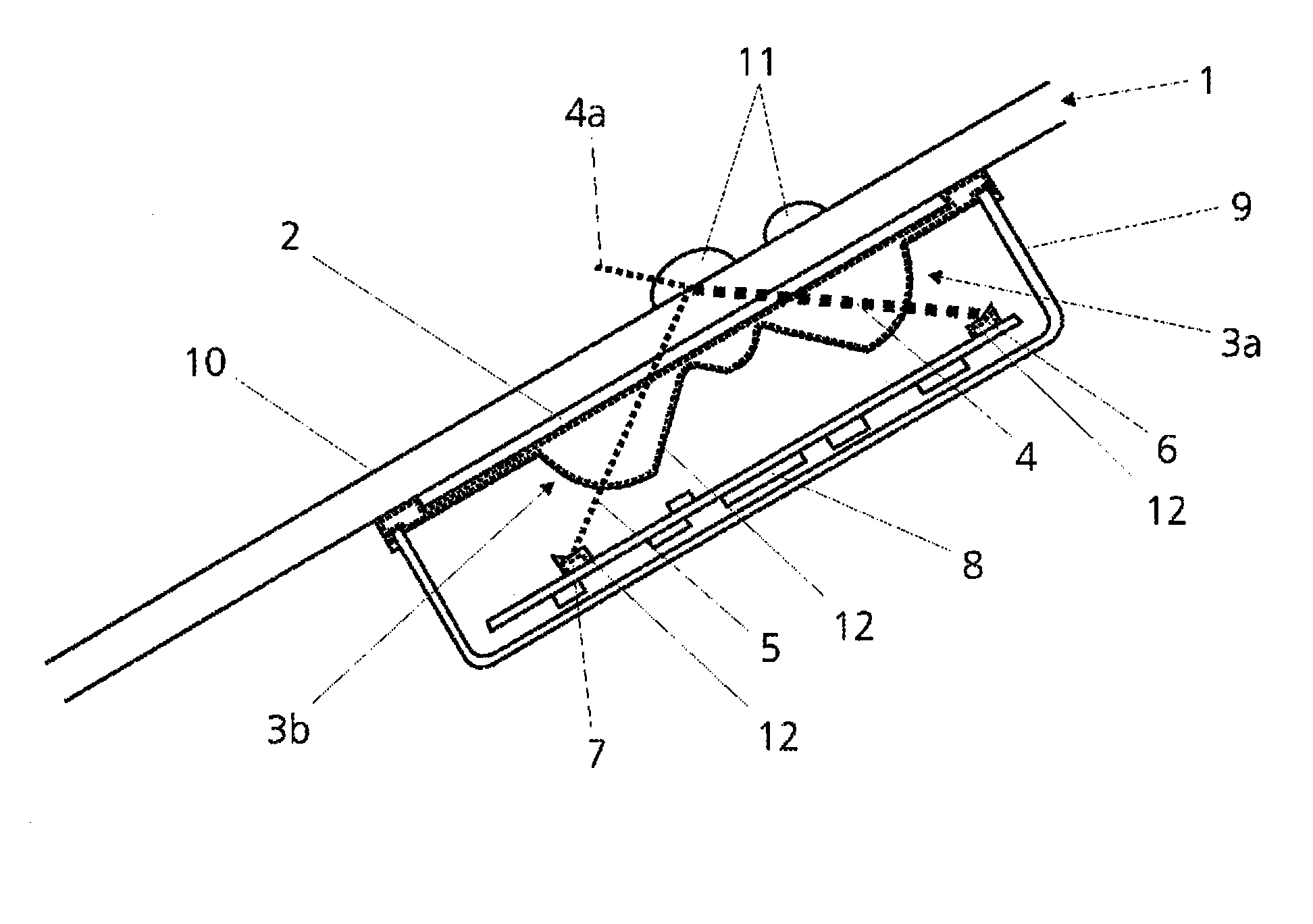

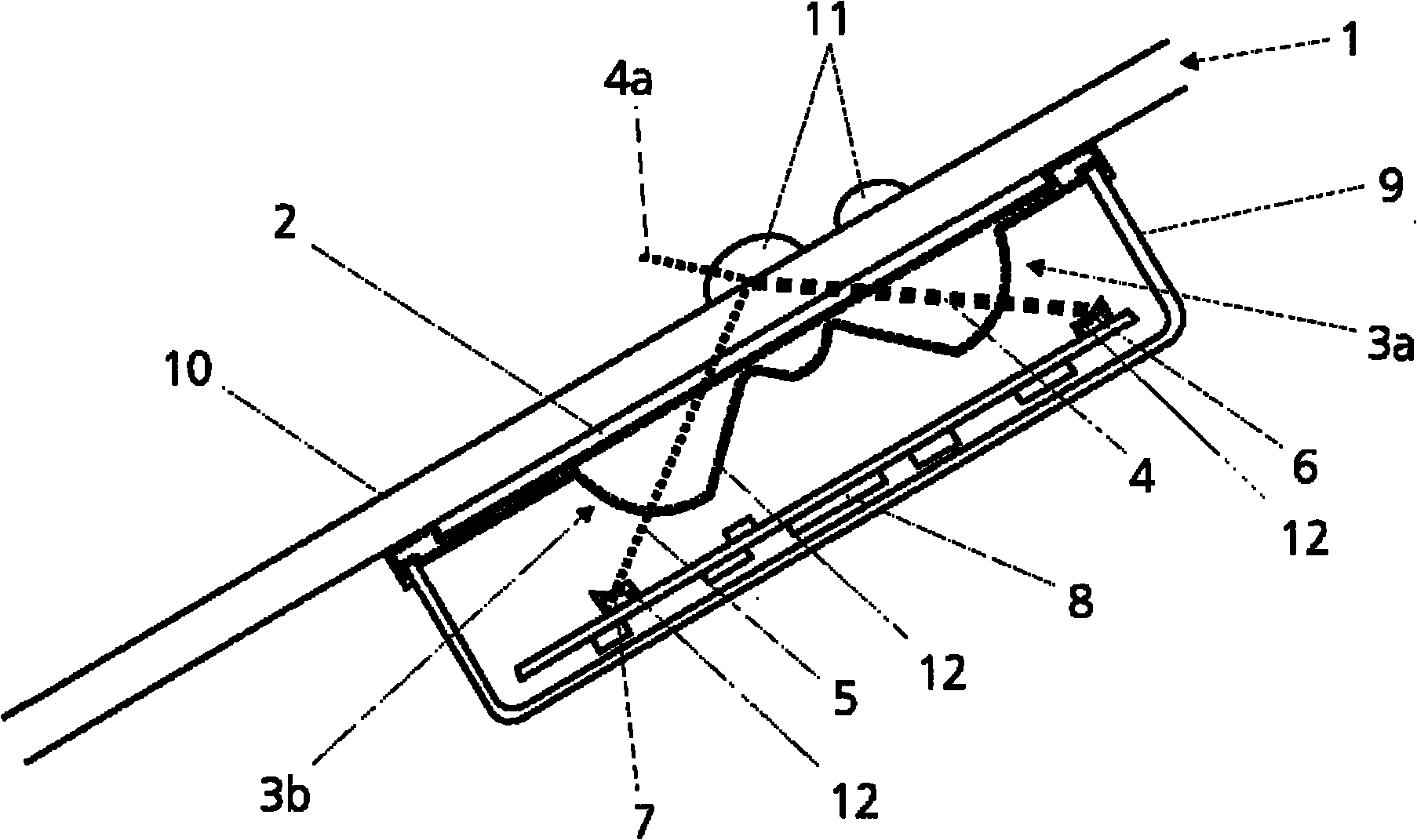

Optical rain sensor device for a motor vehicle

InactiveCN101896378AAvoid or reduce foggingAvoid or reduce pollutionVehicle cleaningMotor vehicle partStructural element

The invention relates to an optical rain sensor device for a motor vehicle, having several structural elements (3a,3b,6,7), specifically at least one electromagnetic radiation source (6), at least one receiving device (7), at least one transmitting optical system (3a) and at least one receiving optical system (3b), wherein electromagnetic radiation (4,5) emitted by at least one radiation source (6) can be received by means of at least one receiving device (7), wherein the electromagnetic radiation (4,5) is forwarded by at least one radiation source (6) by means of at least one transmitting optical system (3a) to a limiting surface (10) of the windshield (1) of the motor vehicle with the motor vehicle exterior, is reflected there and is sent on by means of at least one receiving optical system (3b) to at least one receiving device (7). The surface of at least one of the structural elements (3a,3b,6,7) is provided at least partially with a nanocoating (12) which effects a photocatalytic self-cleaning of the surface.

Owner:ROBERT BOSCH GMBH

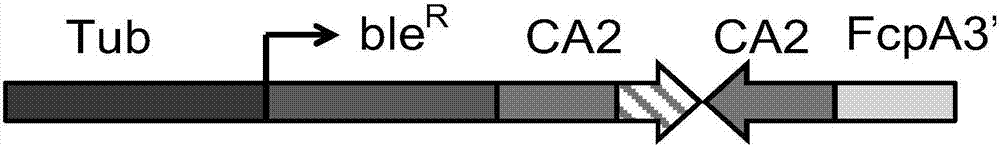

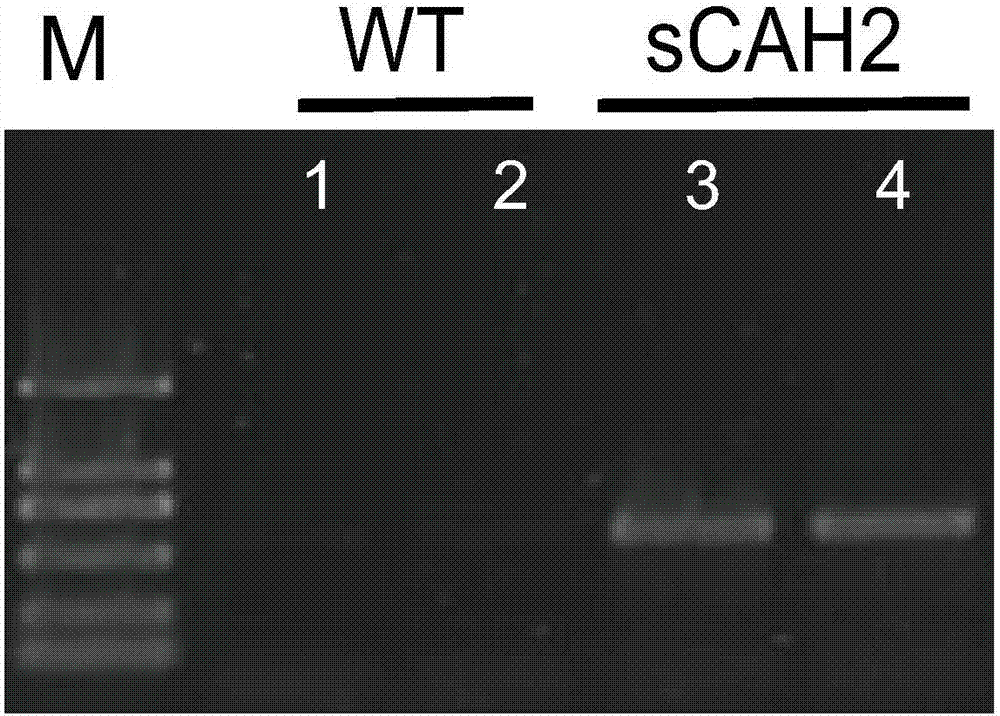

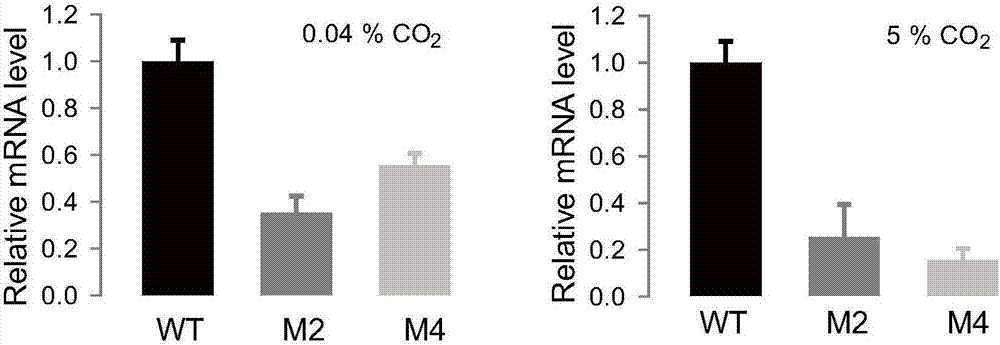

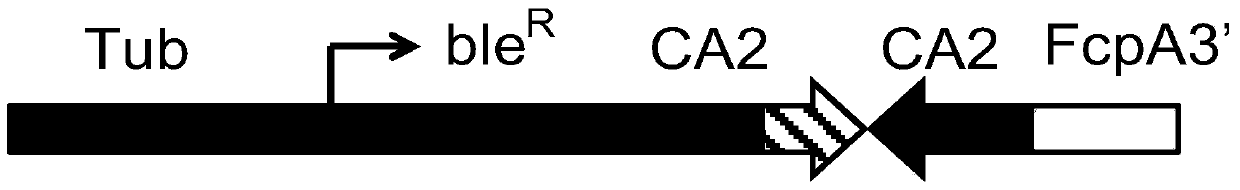

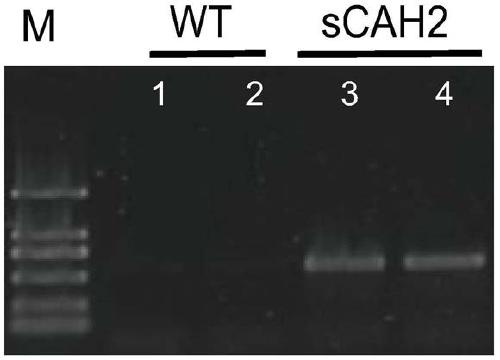

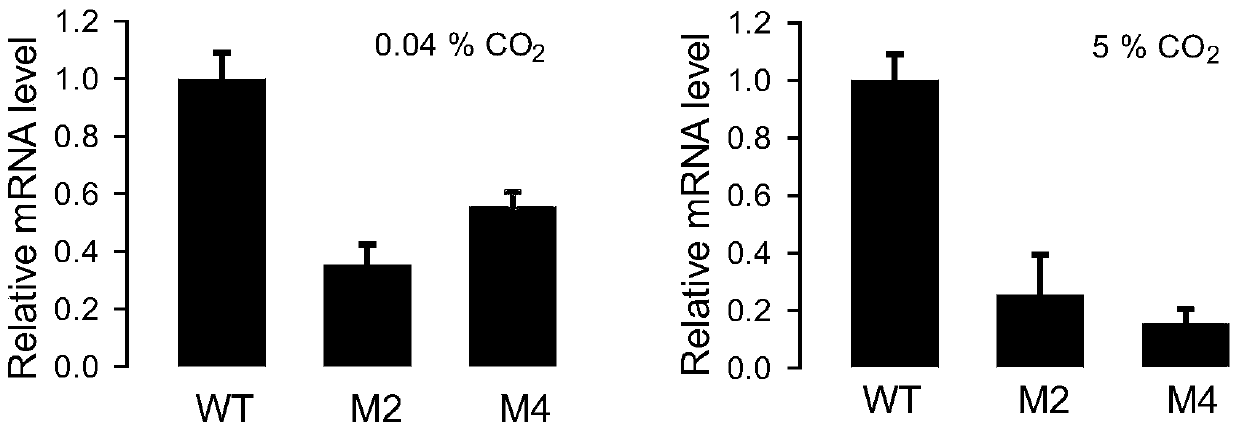

Application of coded chloroplast carbonic anhydrase genes in establishing industrial engineering microalgae capable of resisting high-concentration CO2 and growing quickly

ActiveCN106995817AAvoid or reduce pollutionIncrease growth rateBacteriaVector-based foreign material introductionMicroorganismHigh concentration

The invention belongs to the technical field of microorganism gene engineering, and particularly relates to and discloses application of coded chloroplast carbonic anhydrase genes in establishing industrial engineering microalgae capable of resisting high-concentration CO2 and growing quickly. A method disclosed by the invention provides a basis and a practicable method for the industrial microalgae in fixing industrial CO2 waste gas.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method of microorganism induction bauxite flotation desilicication

A method of microorganism induction bauxite flotation desilicication relates to the technical field of bauxite flotation, by adding microorganism into ore pulp of bauxite, the microorganism carries out surface modification to the mineral in the ore pulp, accordingly, the hydrophilia of the mineral per se is changed, and thus the mineral is more easily subjected to flotation separation. Compared with a conventional flotation technology in the prior art, the method has the advantages of high bauxite recovery rate, good desilicication effect, less energy consumption and reagent consumption, and the like, and furthermore, the method does not cause pollution to the environment; simultaneously, the microorganism treatment time is short, so that the method can be applied to industrialization flotation on a large scale.

Owner:平顶山市华兴浮选工程技术服务有限公司

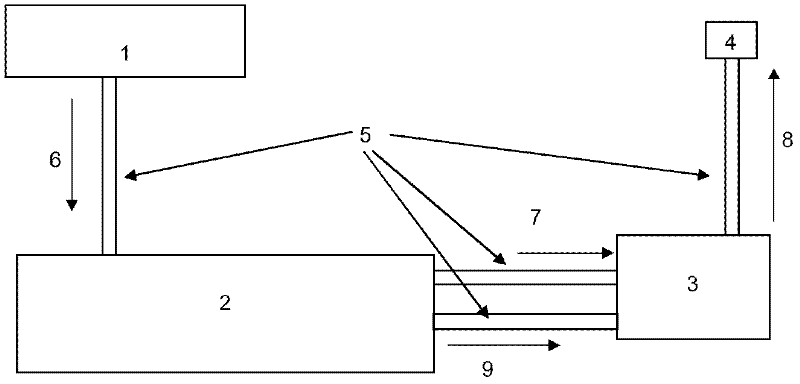

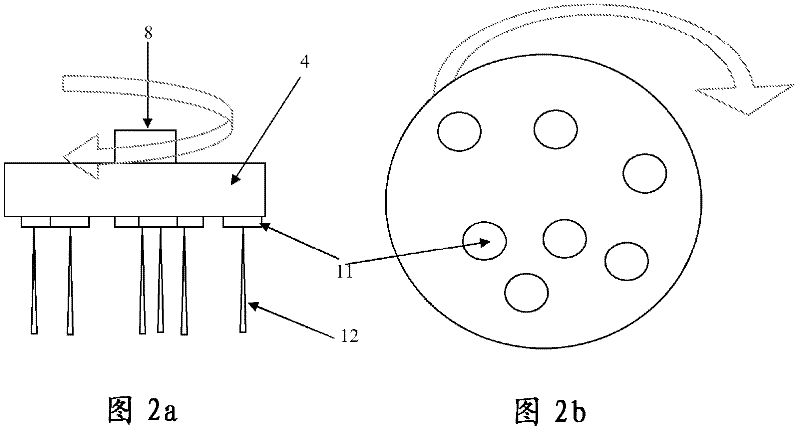

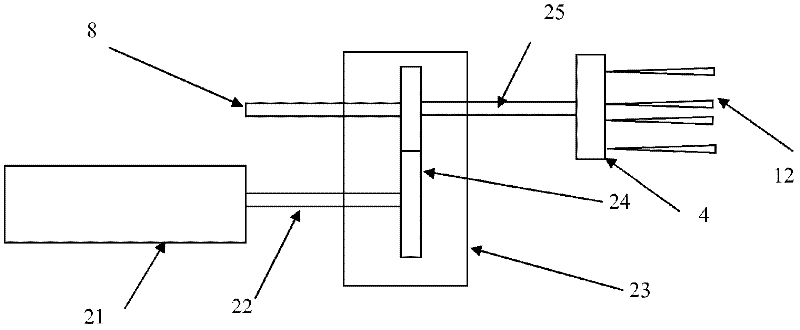

Method and equipment for surface treatment by cryogenic fluid jets

InactiveCN102395446AAvoid or reduce pollutionMovable spraying apparatusAbrasive blasting machinesLiquid jetEngineering

The invention relates to working equipment, particularly for heat treatment, pickling, or the like, implementing high pressure liquid jets at cryogenic temperatures including a rotary or swinging tool (4) comprising one or more nozzles (11) for dispensing high pressure liquid jets at cryogenic temperatures, and a motor (21) for rotating or swinging the tool (4). The motor (21) is connected to the tool (4) via a rotary transmission shaft (22) and a transmission gearbox (23) containing an internal transmission mechanism, typically with sprockets (24) or belts. The equipment further comprises means (28) for feeding dry gas, such as nitrogen or dry air, in communication with the inside of the transmission gearbox (23) designed for and capable of feeding the inside of said transmission gearbox (23) with dry gas. Said injection of gas into the transmission gearbox (23) prevents the contamination of the inside of the transmission gearbox with atmospheric impurities.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

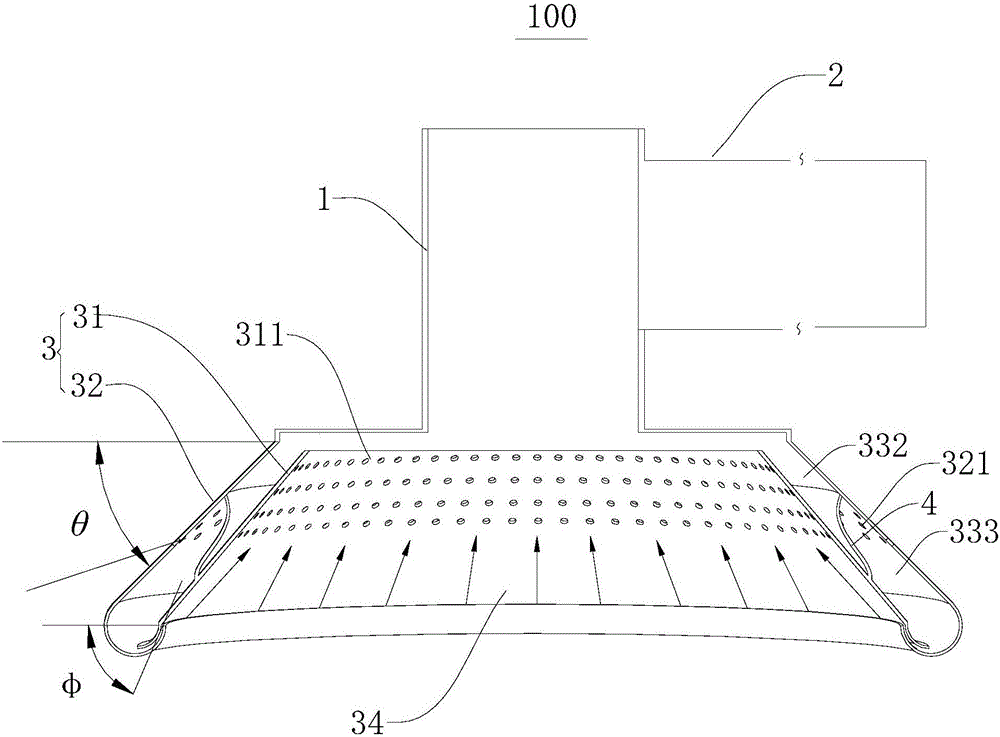

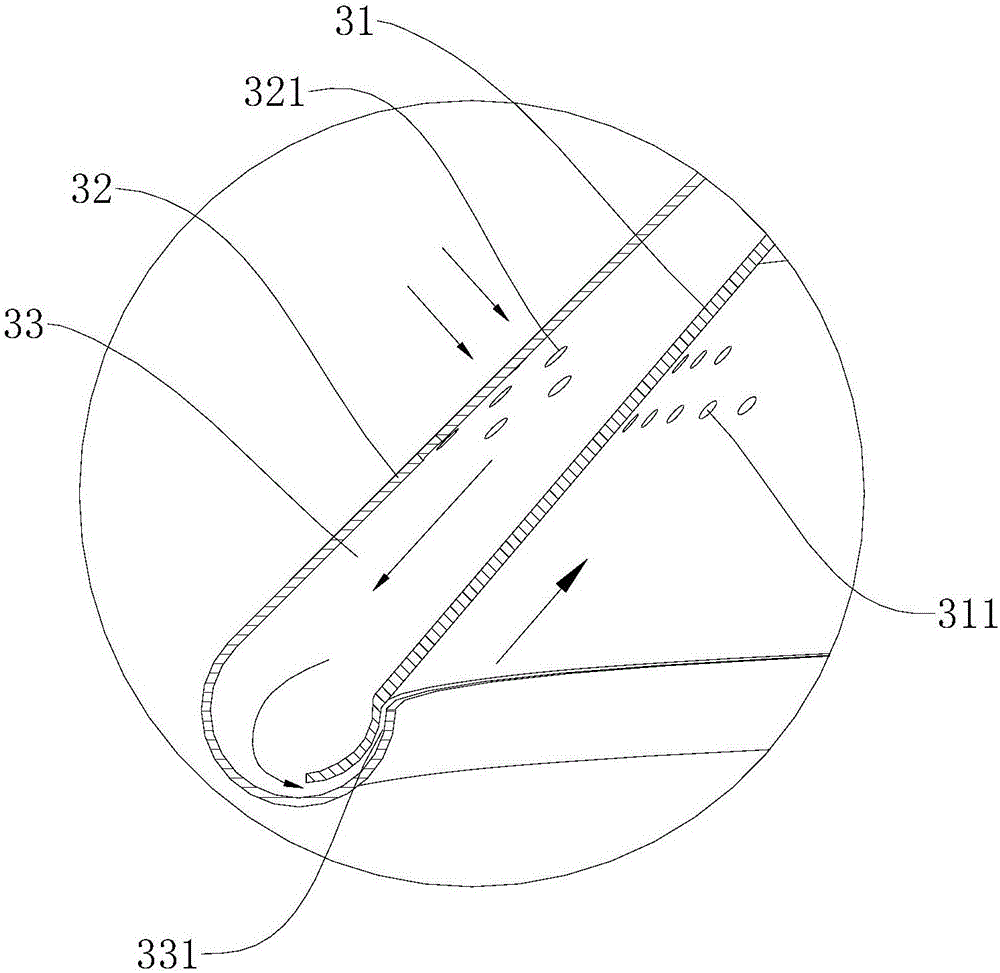

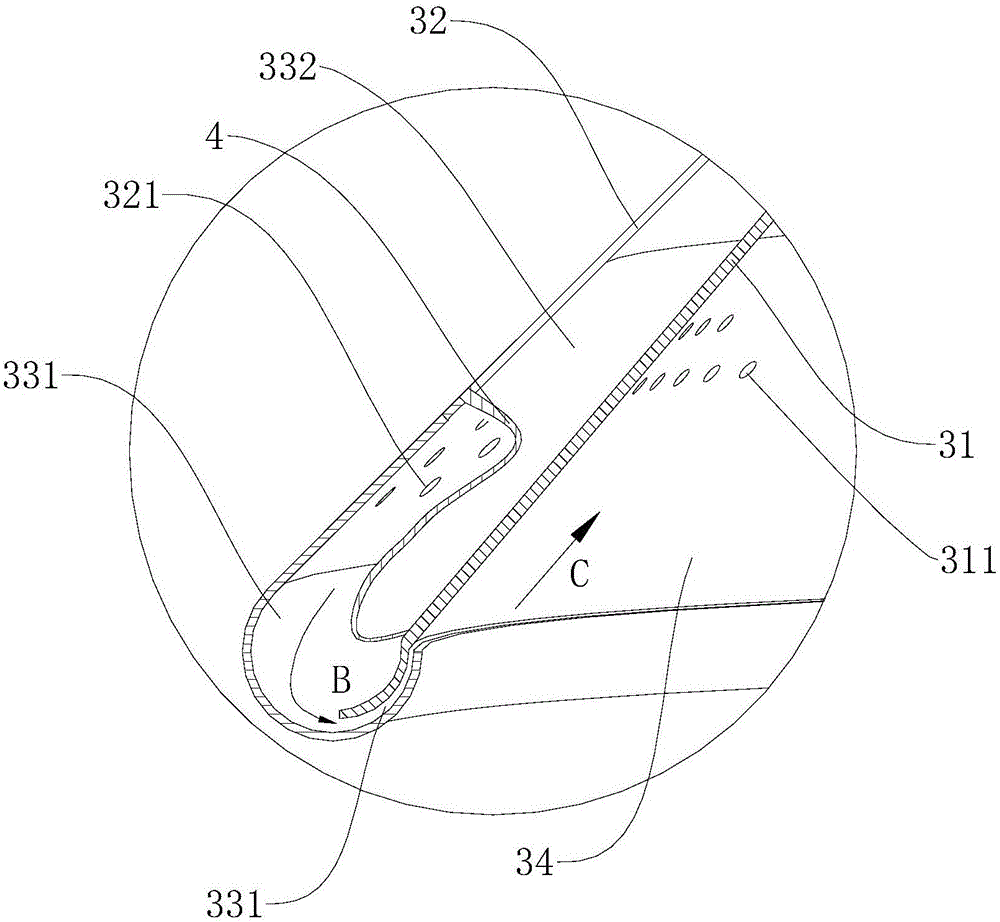

Range hood

ActiveCN106402977AImprove the effect of lampblackSpeed up the flowDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

The invention discloses a range hood which comprises a machine body, a fan system, an oil collecting smoke hood and an auxiliary fan, wherein the fan system is connected with the machine body and is suitable for generating gas flow; the fan system is arranged on the side part of the machine body; the oil collecting smoke hood is connected with the machine body; the oil collecting smoke hood defines a flue which communicates with the fan system; the oil collecting smoke hood comprises an inner cover and an outer cover which are arranged in a spaced mode; an auxiliary air flue is defined between the inner cover and the outer cover; an air inlet which communicates with the auxiliary air flue is formed in the outer cover; an air outlet which communicates with the air flue is formed in the bottom of the inner cover and the bottom of the outer cover in a spaced mode; and the auxiliary fan is arranged in the auxiliary air flue to generate air flow. According to the embodiment of the invention, the range hood disclosed by the invention can achieve the purpose of strongly sucking oil fume, so that the oil fume sucking effect of the range hood is improved, and pollution, on the fan system, of oil stain can be avoided or reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

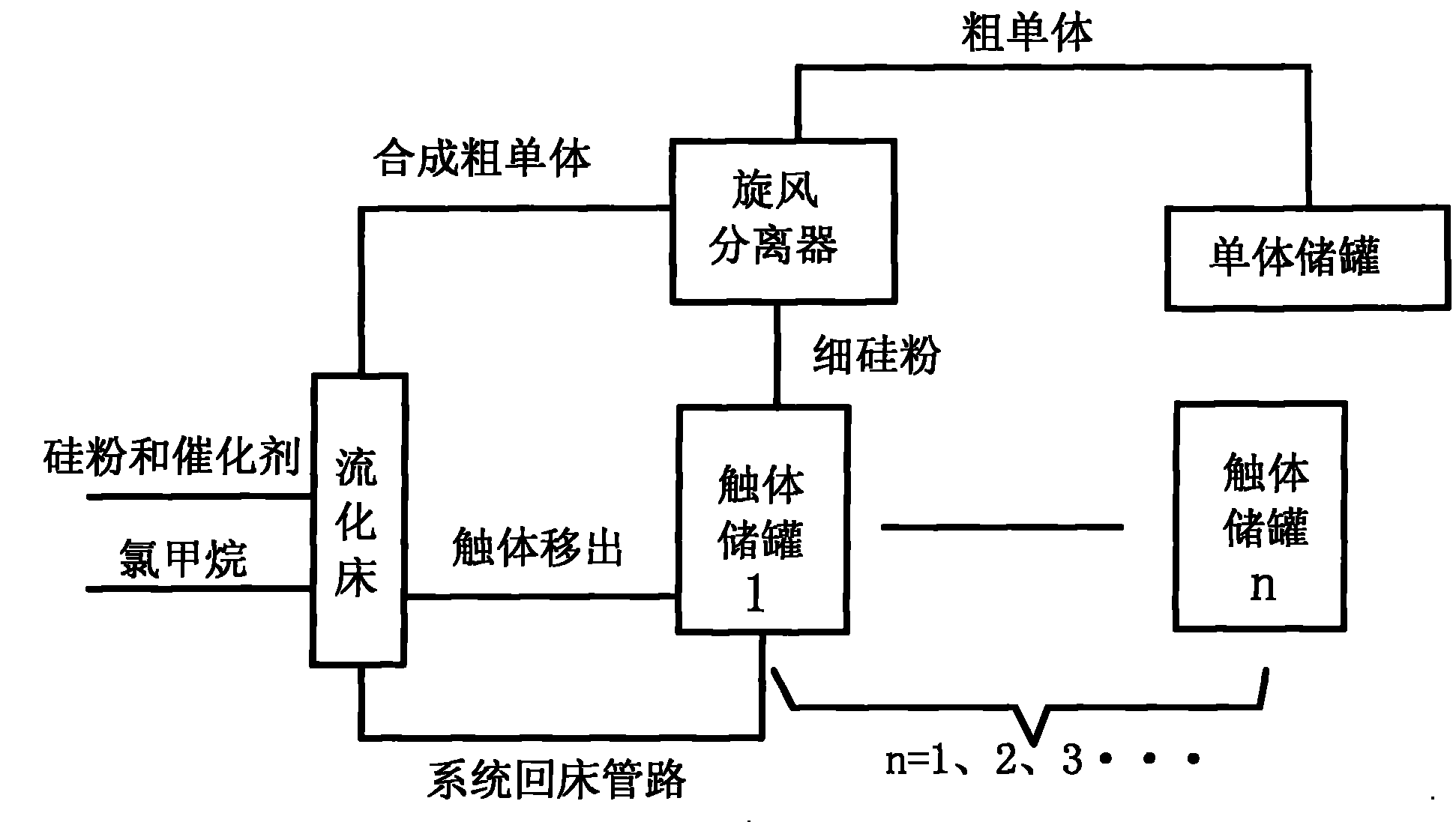

Contact masses processing method during methylchlorosilane synthesis

ActiveCN101456877BHigh activitySelective stabilityGroup 4/14 element organic compoundsChemical/physical processesRecovery methodFluidized bed

The invention relates to the field of organic chemistry, in particular to a method for processing and recovering contacts in the synthetic process of methyl chlorosilane, which is characterized by comprising the following steps: adding an intermediate storage tank of the contacts in the process of synthesizing the methyl chlorosilane; when the selectivity of a target product is reduced to between70 and 90 percent, transferring the contacts in the reaction system to the intermediate storage tank; re-adding new contacts to react in a fluidized bed, and mixing the transferred contacts with fresh silicon powder; and returning the mixture to the fluidized bed to use the mixture as new contacts to be added to the reaction. In the invention, the production method is used to not only ensure the stability of the selectivity for dimethyl dichlorosilane in the synthetic process of the methyl chlorosilane, and prolong the synthetic cycle of organochlorosilane simultaneously. The effective production time of the production device can be up to over 50 days.

Owner:ZHENJIANG JIANGNAN CHEM

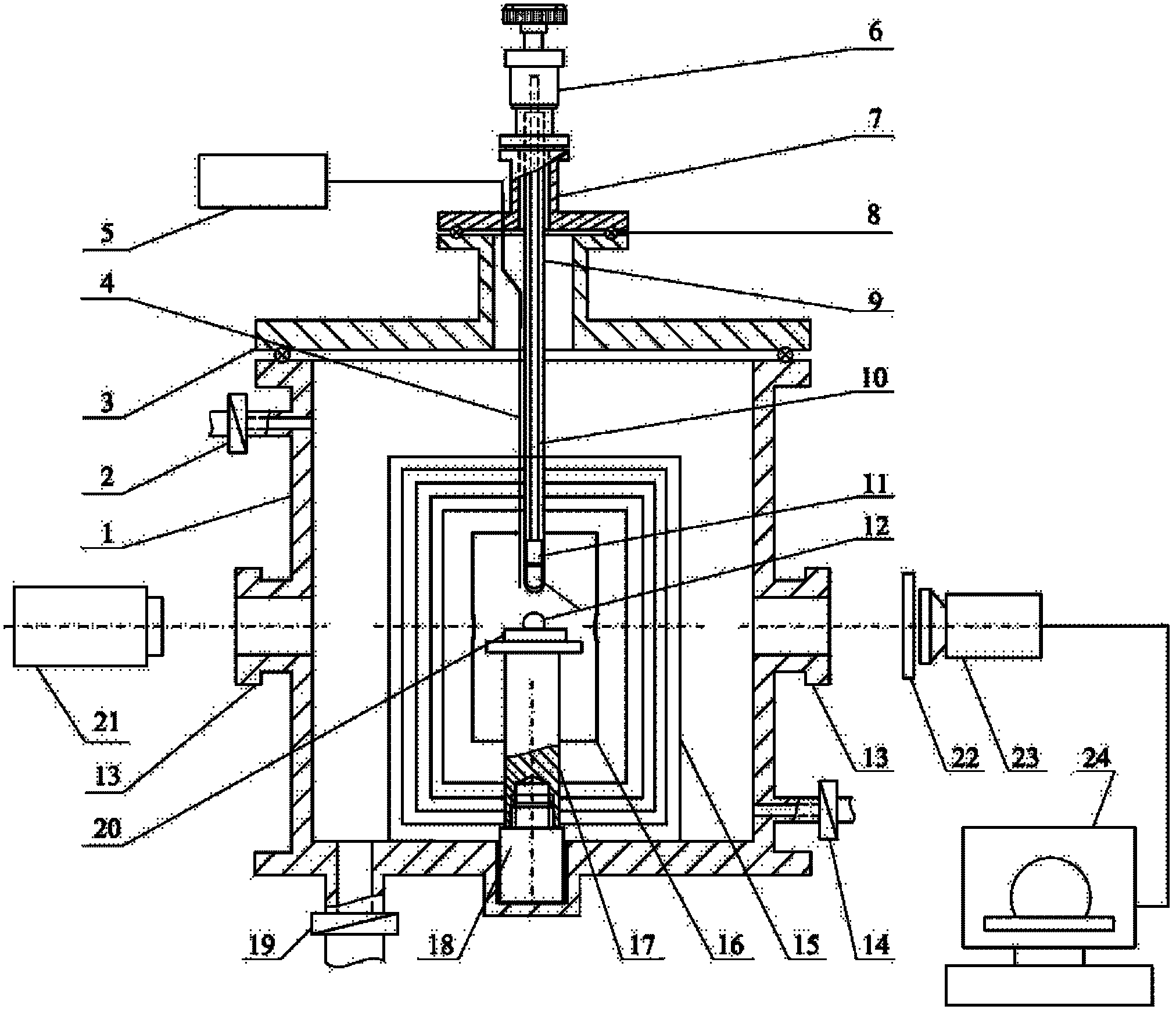

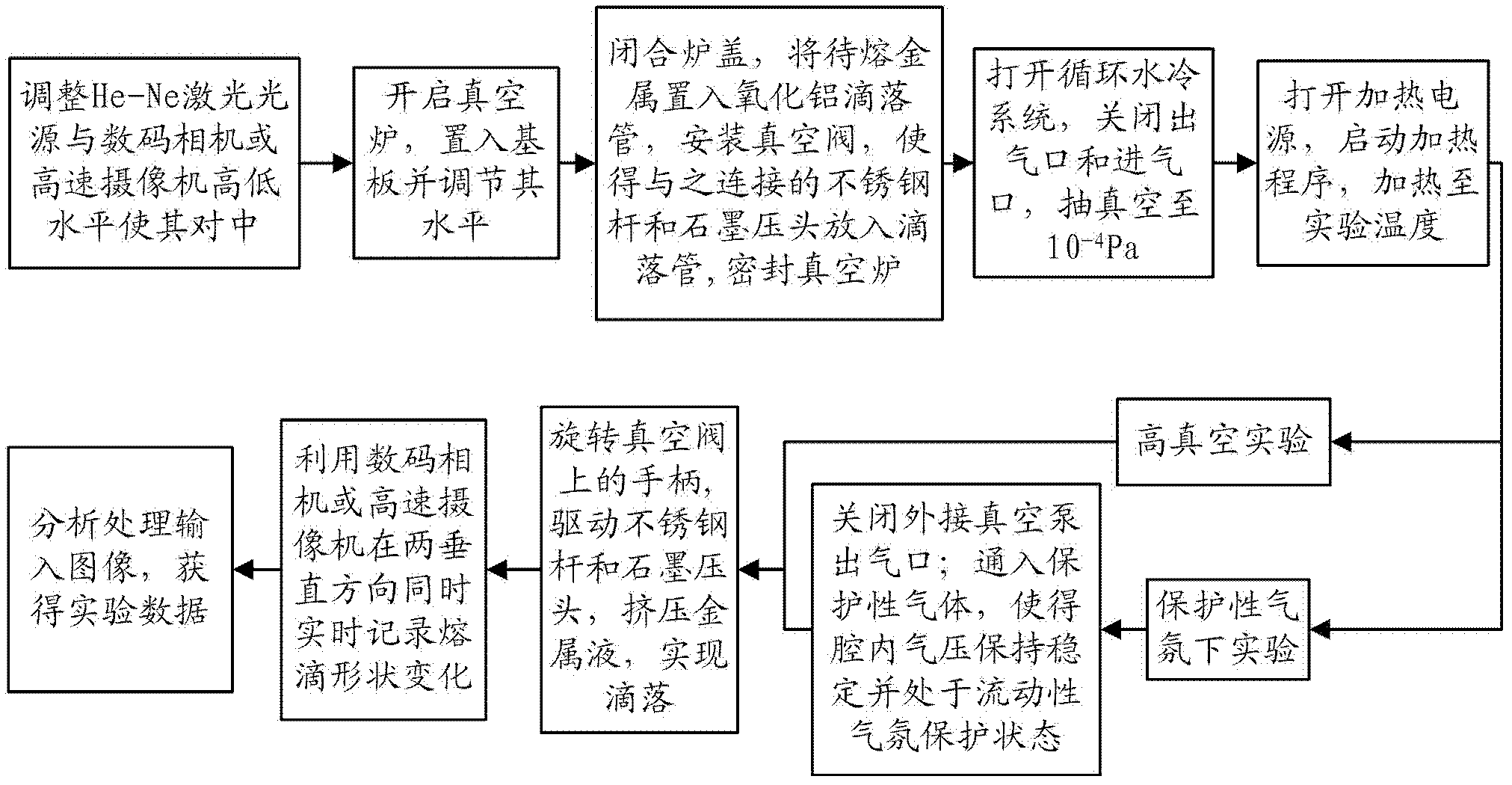

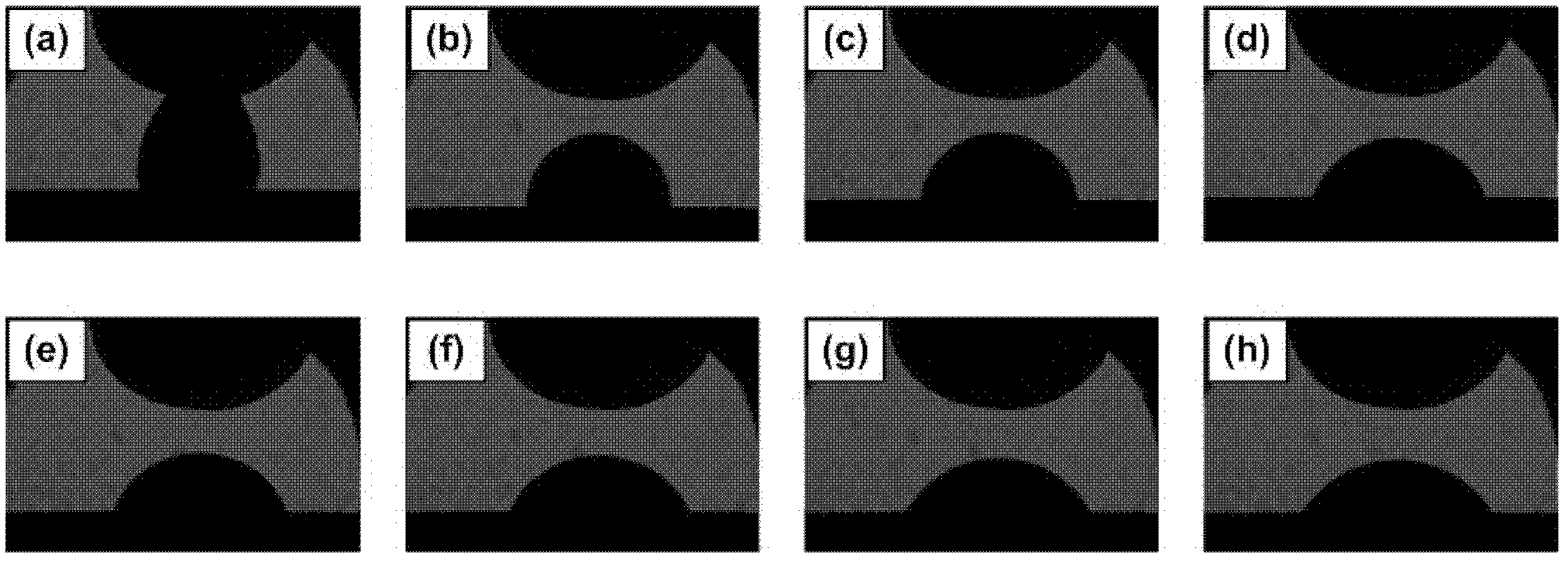

Apparatus and method for determining high temperature wettability

InactiveCN102353620BRealize separate heatingPrevent oxidationSurface/boundary effectFurnace typesRubber ringEngineering

The invention discloses an apparatus and a method for determining high temperature wettability. The apparatus comprises a heater body, a heating portion, an extruding dripping portion, a sample supporting portion and an image acquisition and processing portion. The heater body is comprised of a stainless steel cavity, a furnace lid and a No. 3 fluorine rubber ring bolt connecting together. A shielding layer in the heating portion is arranged in the center of a furnace bottom in the heater body, and a heating member is placed at the center of the shielding layer. The extruding dripping portion is perpendicularly arranged on an upper end of the heater body, and a lower end of a thermocouple in the heating portion, a lower end of the extruding dripping portion and an upper end of a sample bench are placed in the heater body. A substrate is placed at top of the sample bench. Two sets of CCD digital cameras or CMOS high speed cameras in the image acquisition and processing portion and a light source are respectively placed at the front and rear and the left and right of the heater body, and are in a same horizontal line with a symmetric axis of a quartz glass observation window, a wall through hole on the shielding layer and a heating member through hole on the heating member. The invention also provides a method for determining high temperature wettability.

Owner:JILIN UNIV

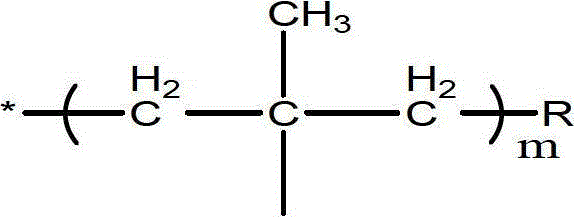

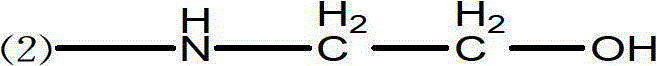

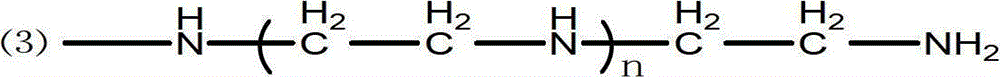

Release agent, non-silicon release film containing release agent and manufacturing method of non-silicon release film

The invention belongs to the technical field of release films, and relates to a release agent, a non-silicon release film containing the release agent and a manufacturing method of the non-silicon release film. The main component of the release agent is a compound containing a polyethylene ester group, the molecular formula of the release agent is shown in the specification, X is a positive integer greater than 0, R is any one or more structural formulae selected from -CnHm,-OCOCnHm and -OCONHCnHm, m is 3-50, n is 1-30, and m and n are integers. The release agent provided by the invention is uniform in coating thickness, can be easily dissolved in aromatic hydrocarbon, alkane solvents or mixed solvents such as toluene, xylene and heptane at 50 DEG C, can realize recycling of a base film, and avoids or reduces environmental pollution caused by industrial plastic waste.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

Electric conduction brush used for solder stripping device and solder stripping device comprising electric conduction brush

PendingCN110725001AEasy to useEx situ realization of withdrawalElectrolysis componentsElectrical connectionEngineering

The invention discloses an electric conduction brush used for a solder stripping device and the solder stripping device comprising the electric conduction brush. The solder stripping device can comprises a cathode plate and the electric conduction brush making contact with a PCB so as to apply voltage to the PCB in the solder stripping process. The electric conduction brush can comprise a brush handle electrically connected to an external power source, brush wires fixed and electrically connected to the brush handle, supporting parts which are overlapped with the brush wires and fixed to the brush handle together with the brush wires so as to support the brush wires, and a fixing part. The fixing part comprises a cover plate, and the cover plate covers part of the brush wires and part of the supporting parts and is combined to the brush handle so as to fix the brush wires and the supporting parts to the position between the brush handle and the fixing part. By the adoption of the solder stripping device comprising the electric conduction brush, the solder stripping rate can be increased, and the solder stripping effect is improved.

Owner:苏州金易得环保科技有限公司

Cocoon fibre cigarette filter tip and producing method

InactiveCN100588336CAvoid or reduce pollutionNo effect on tasteTobacco smoke filtersHigh humidityHazardous substance

The present invention discloses one kind of cigarette filter tip with natural protein fiber silk as the main filter material, which is coated and high temperature and high humidity steam treated to get certain hardness, elasticity and moisture absorbing capacity. Test shows that the cigarette filter tip can block and filter out harmful cigarette smoke matter. The cigarette filter tip made of natural long protein fiber has no toxicity, no inhalation hazard, no environmental pollution, simple preparation process, low cost and wide market foreground.

Owner:SUZHOU UNIV

A wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045BReduce pollutionAvoid or reduce pollutionMultistage water/sewage treatmentParticulatesSolubility

Owner:浙江立丰环保设备有限公司

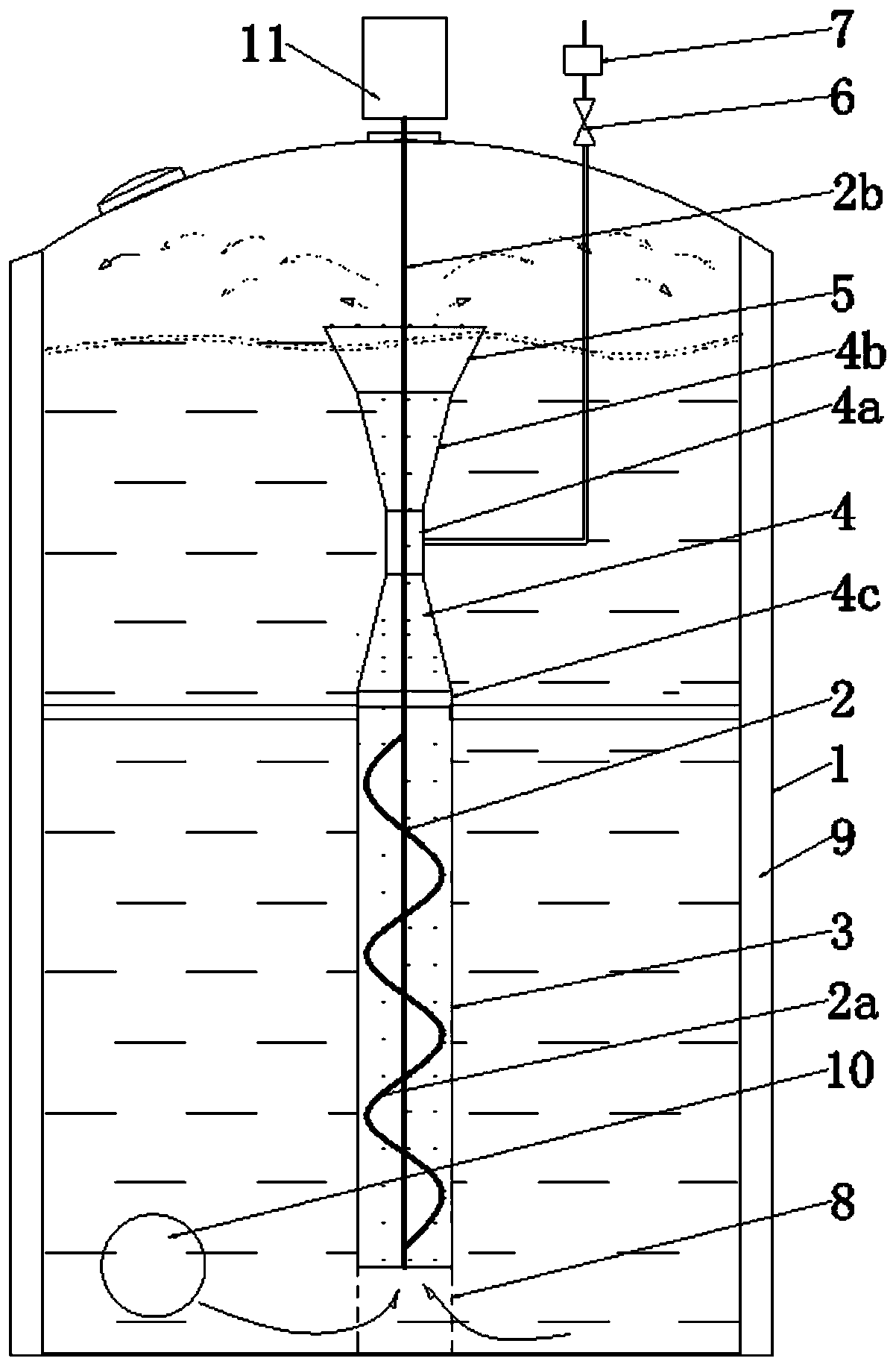

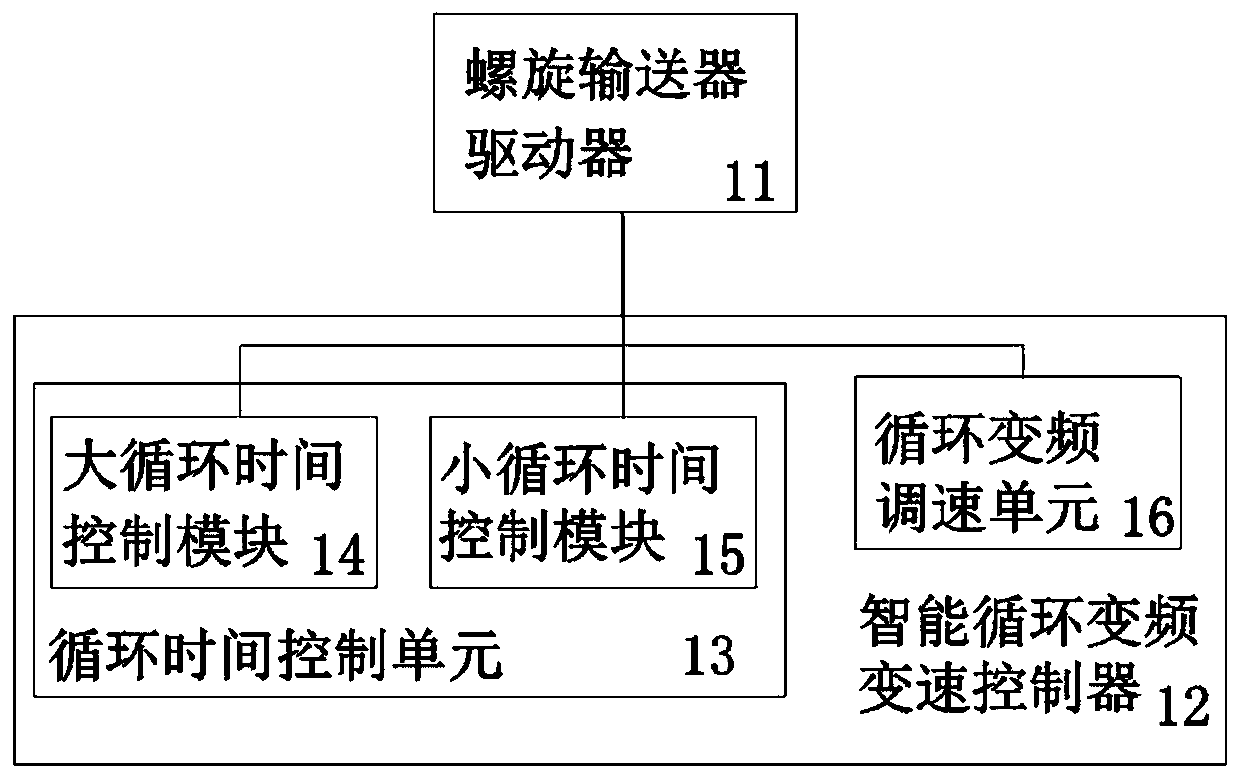

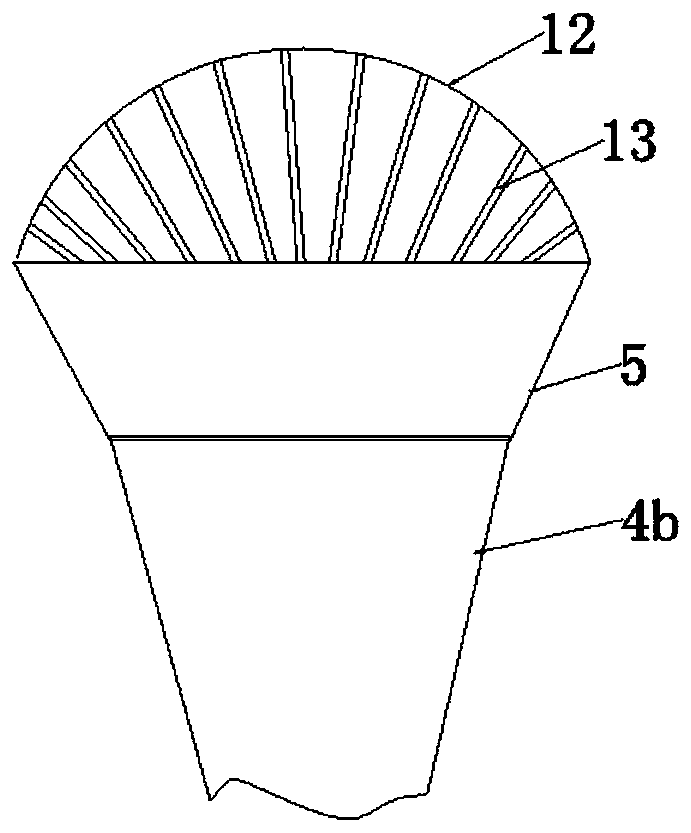

Red wine fermentation circulating device

The invention discloses a red wine fermentation circulating device. The device comprises a conveying device arranged in a corresponding fermentation tank, a corresponding controller connected to the conveying device, and a jet flow mixing spreader, the conveying device is vertically arranged, the lower input end of the conveying device corresponds to the lower part of the fermentation tank, and the upper output end of the conveying device is connected with the lower input end of the jet flow mixing spreader. The red wine fermentation circulating device can automatically circulate and automatically supplement oxygen, and is very simple and reasonable in structure and reliable in operation.

Owner:张国栋

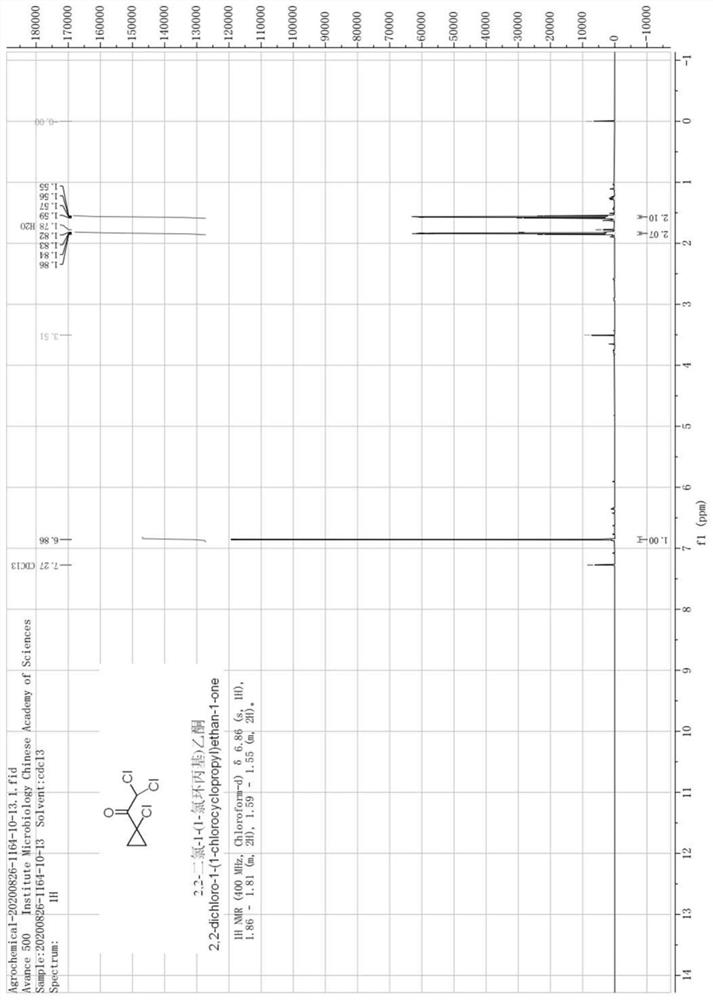

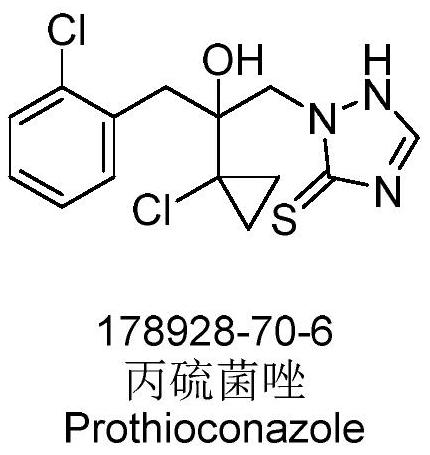

Synthesis method of high-content 2, 2-dichloro-1-(1-chlorocyclopropyl) ethanone for quantitative and qualitative analysis

ActiveCN113511964ATo avoid or reduceImprove qualityOrganic compound preparationCarbonyl compound preparationChemical compoundQualitative analysis

The invention belongs to the technical field of pesticide synthesis, and particularly relates to a synthesis method of high-content 2, 2-dichloro-1-(1-chlorocyclopropyl) ethanone for quantitative and qualitative analysis. According to the method, cyclopropylethanone or chlorinated cyclopropylethanone used as a raw material is chlorinated to obtain the target compound, which can be used for analyzing the impurities of a prothioconazole bulk drug, tracking the sources of the impurities, researching the generation mechanism of the impurities, speculating the properties of the impurities according to the structures so as to control generation of the impurities or find a method for removing the impurities, and finally further improving the quality of the prothioconazole bulk drug and reducing the influence of potential impurities caused by the use of the pesticide prothioconazole on environmental pollution and human body health.

Owner:JINGBO AGROCHEM TECH CO LTD

Shale oil development injection-production system and method

ActiveCN112065343AOvercome capillary resistanceExpand the affected volumeSurveyFluid removalInjection wellPetrology

The invention discloses a shale oil development injection-production system and method. According to the shale oil development injection-production system and method, injection wells containing fracturing fracture nets are arranged in a shale oil reservoir, supercritical water is injected into the shale oil reservoir through a supercritical water injection system, and the supercritical water has high diffusivity and can overcome large capillary resistance; the supercritical water enters pore throat channels where a conventional water drive cannot enter, thus the swept volume is enlarged, the supercritical water is used for dissolving mineral components in the reservoir and conducting mild transformation on the reservoir, so that the pore throat channels are expanded, favorable conditions are created for flowing of shale oil, and the high reaction activity of the supercritical water is utilized, so that the shale oil can be converted from an immature state or a low mature state to a mature state in a short time, and long-chain molecules can also be converted into short-chain molecules, so that the quality and the flowability of the shale oil are improved; and pollution caused by shale oil in the ground refining process can be avoided or reduced, the natural environment is protected, and carbon emission is reduced.

Owner:XI AN JIAOTONG UNIV

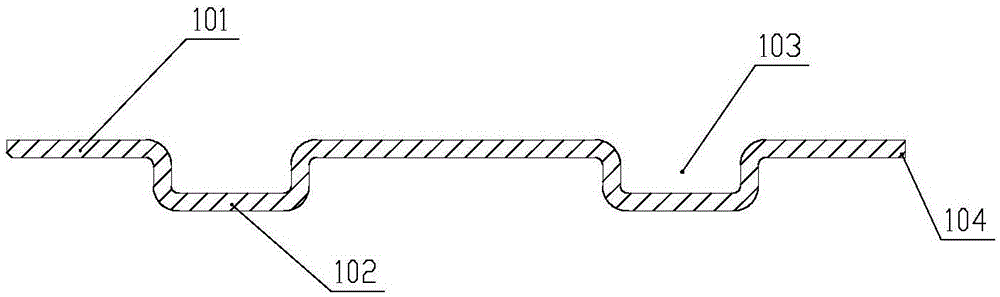

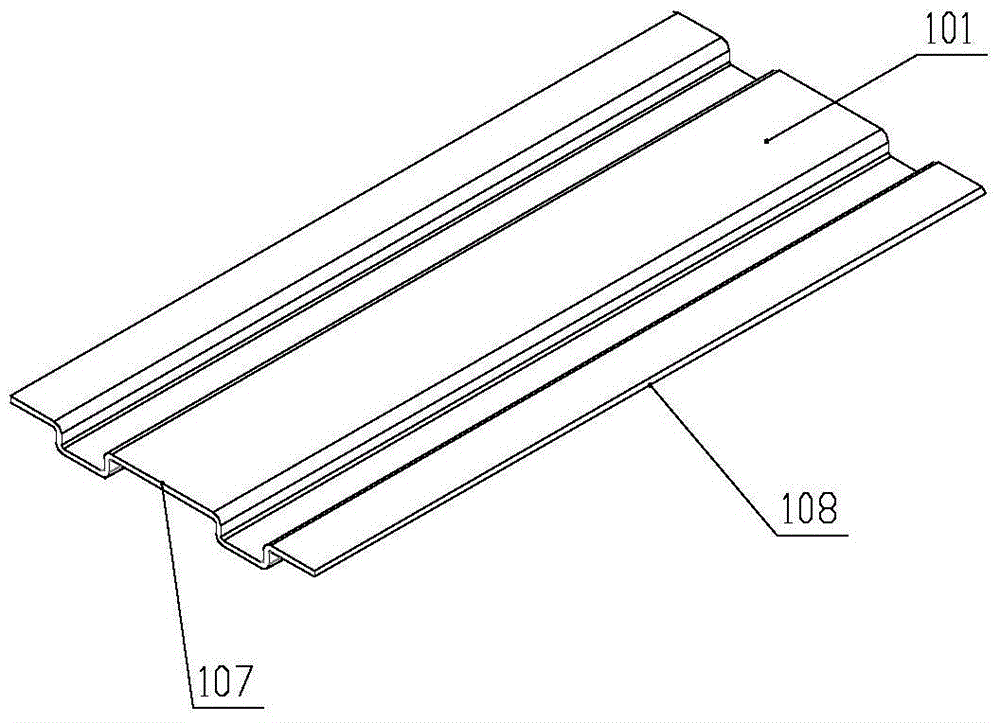

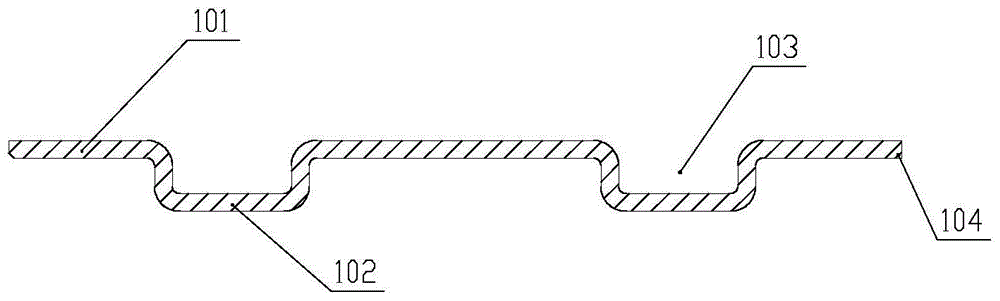

Bimetal spiral steel pipe and manufacturing method thereof

The invention discloses a bimetal spiral steel pipe and a manufacturing method thereof. The steel pipe comprises a pipe body, wherein the pipe body surface extends outwards to form a convex rib which is spirally arranged around the outer wall of the pipe body; the convex rib forms a groove with the pipe body surface and is provided with an auxiliary inner steel band capable of covering the groove notch; and a hollow cavity is formed between the groove and auxiliary inner steel band, and is filled with concrete. The convex rib on the outer wall of the pipe body and the pipe body are integrally formed without any welding seam, and thus, can resist the dynamic load fatigue when bearing the dynamic load. The pipe body inner wall is provided with the auxiliary inner steel band made of a specific metal material, thereby enhancing the corrosion resistance and wear resistance of the steel pipe, avoiding the fluid pollution, reducing the thickness of the steel pipe main body and lowering the material cost. The pipe can be used in the occasions for delivering water or other special media, such as supply or discharge of water, high-corrosivity media, media with higher requirements for purity, high-temperature media and the like, and greatly lowers the manufacturing cost.

Owner:南京大得钢管有限公司

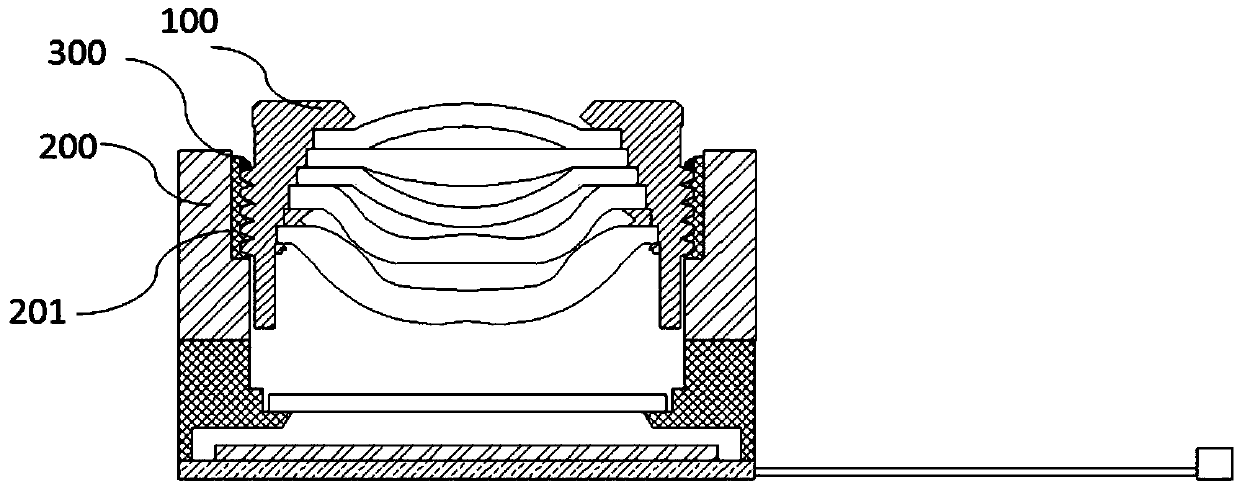

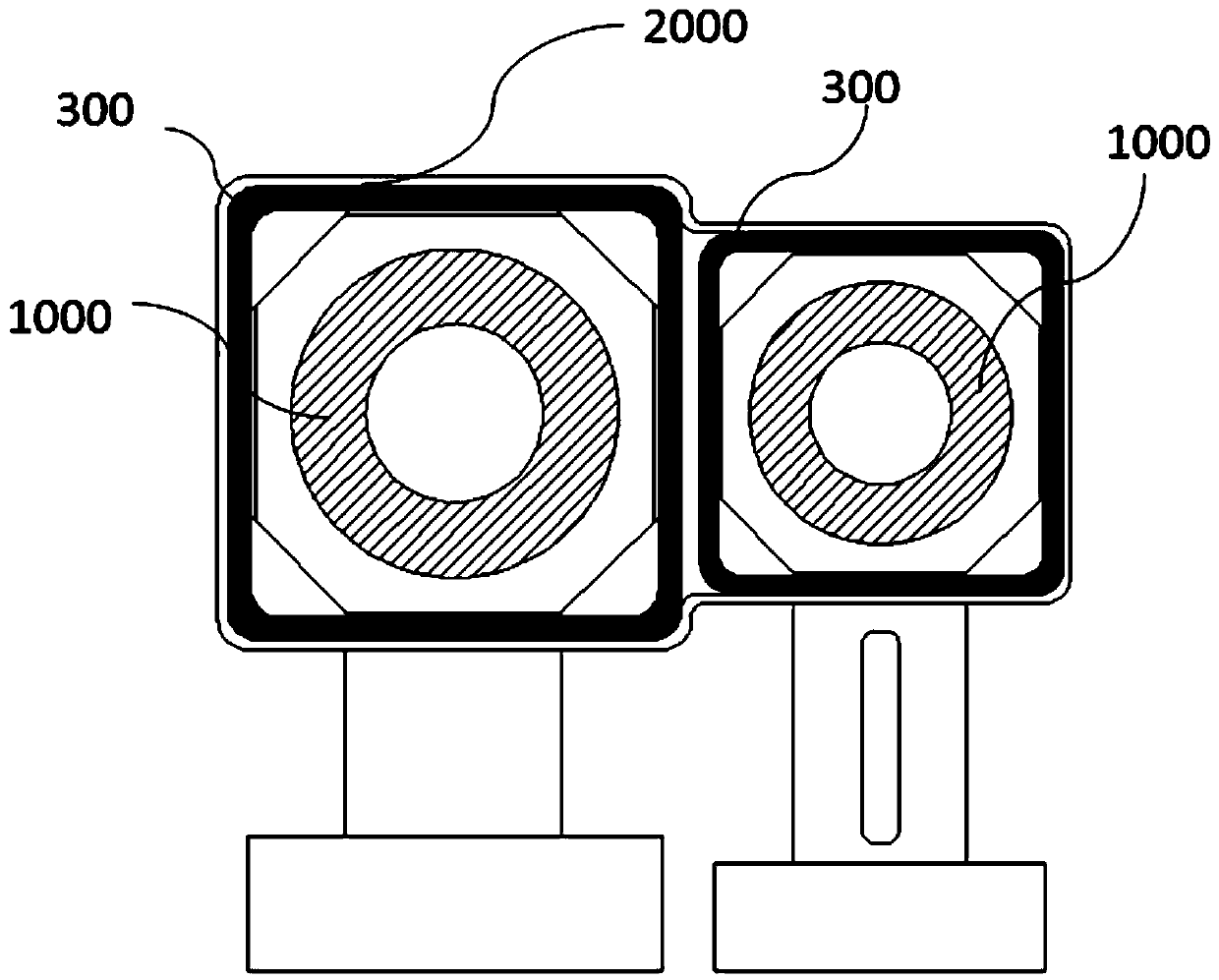

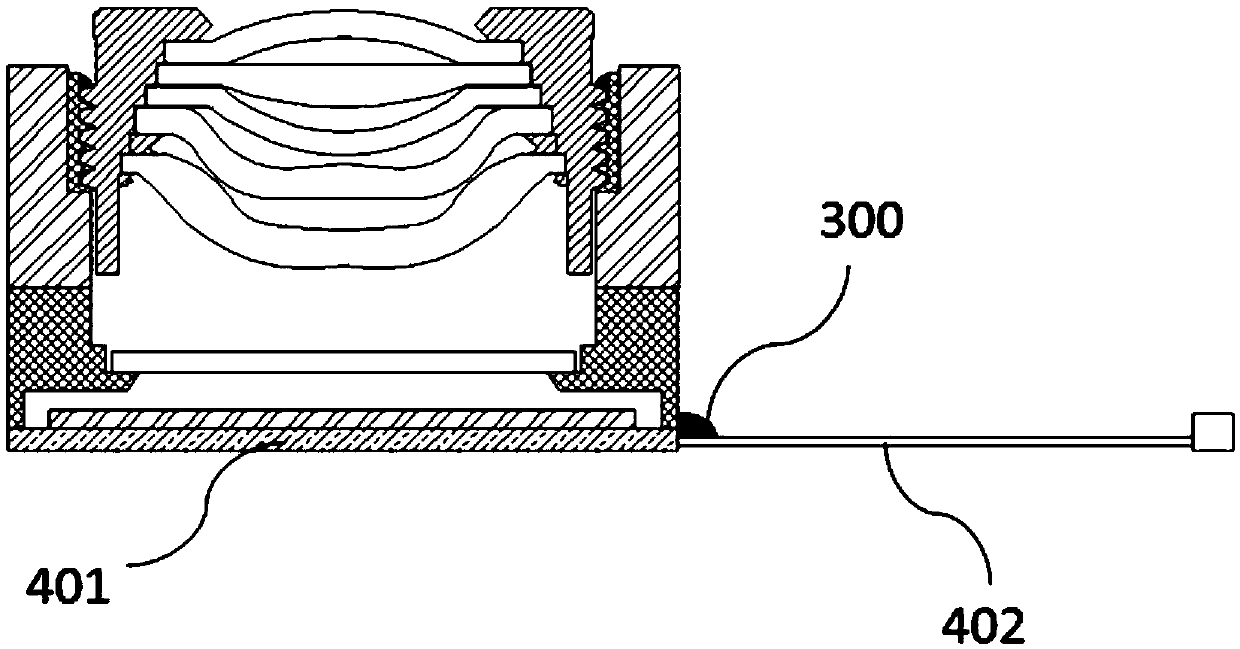

Optical lens, camera module and assembling method thereof

InactiveCN110933258AHigh repair rateReduce manufacturing costTelevision system detailsColor television detailsEngineeringOptics

The invention provides a camera module, which comprises a plurality of camera module components, wherein at least two camera module components are connected through a hot melt adhesive. The inventionfurther provides a corresponding assembling method of the camera module. The method comprises: bonding camera module components by using a hot melt adhesive to obtain a camera module; bonding the camera module components through the hot melt adhesive, which comprises the step that at least two camera module components which are separated from each other are bonded through the hot melt adhesive, orthe connection between the at least two camera module components is reinforced through a hot melt adhesive. According to the invention, the repair rate of the camera module can be improved by adopting the hot melt adhesive, the variation of the optical performance of the camera module caused by a baking process can be avoided or reduced, the external impact can be resisted through the bonding force and the toughness of the hot melt adhesive, and when the camera module is repaired or disassembled, pollution of adhesive material powder or particles to an optical element can be avoided or reduced.

Owner:NINGBO SUNNY OPOTECH CO LTD

A gene encoding chloroplast carbonic anhydrase was used in the construction of high-concentration co 2 and applications in fast-growing industrial engineered microalgae

ActiveCN106995817BAvoid or reduce pollutionIncrease growth rateBacteriaVector-based foreign material introductionBiotechnologyMicroorganism

The invention belongs to the technical field of microorganism gene engineering, and particularly relates to and discloses application of coded chloroplast carbonic anhydrase genes in establishing industrial engineering microalgae capable of resisting high-concentration CO2 and growing quickly. A method disclosed by the invention provides a basis and a practicable method for the industrial microalgae in fixing industrial CO2 waste gas.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

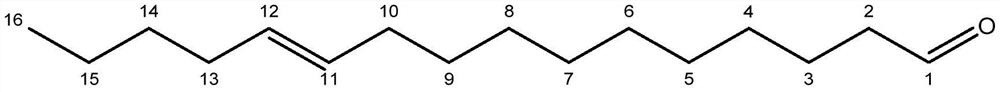

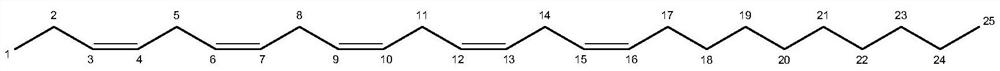

Sex pheromone composition of Pinus sylvestris sylvestris and its lure and application

ActiveCN112889821BEffective booby trapImprove trapping effectBiocidePest attractantsBiotechnologySexual Pheromones

The invention provides a sex pheromone composition of sylvestris sylvestris sylvestris sylvestris and its lure and application. The sex pheromone composition of the present invention comprises trans-11-hexadecenal, cis-11-hexadecene acetate and cis 3, cis 6, cis 9, cis 12, cis 15 ‑Pentacosapentaene, and based on the above-mentioned sex pheromone composition, the sex pheromone lure core of Pinus sylvestris sylvestris was developed, which can effectively trap and kill the male moth of Pinus sylvestris sylvestris. The trapping effect of the male moth is significantly higher than that of the female moth (up to 3 times), which can be applied to the forecasting of the moth and the green control of the moth, avoiding or reducing the use of chemical pesticides, thereby reducing pollution and protecting the environment , has significant economic, social and ecological comprehensive benefits.

Owner:SHANXI AGRI UNIV +2

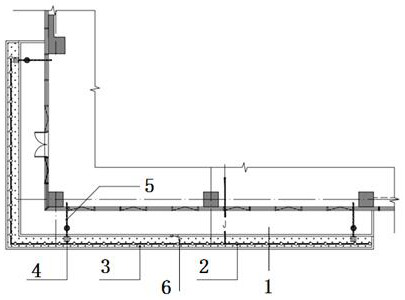

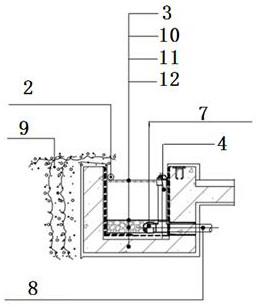

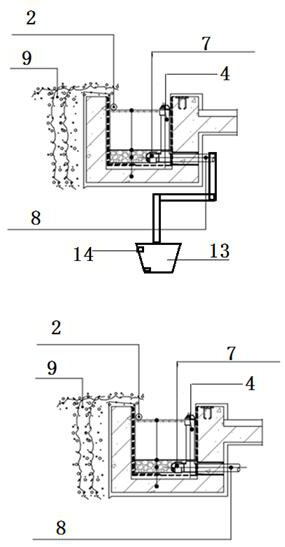

Vertical aerial green planting device for high-rise industrial factory building and control method

InactiveCN113179800ARelieve work stressImprove work efficiencySelf-acting watering devicesCultivating equipmentsIndustrial premisesAgricultural engineering

The invention relates to a vertical aerial greening planting device for a high-rise industrial factory building and a control method. The vertical aerial greening planting device is characterized in that a flower pond is arranged outside each floor of the high-rise industrial factory building, plants are planted in the flower ponds, and the flower ponds are fixed outside balconies and extend along the balconies. Through the arrangement of vertical aerial greening, a space close to the nature is provided for staff, the working pressure is relieved, and the working efficiency is improved; and due to the arrangement of the green plants on the outer facade of the building, beautiful scenery is brought to the appearance of the project.

Owner:广东信鸿产业集团有限公司

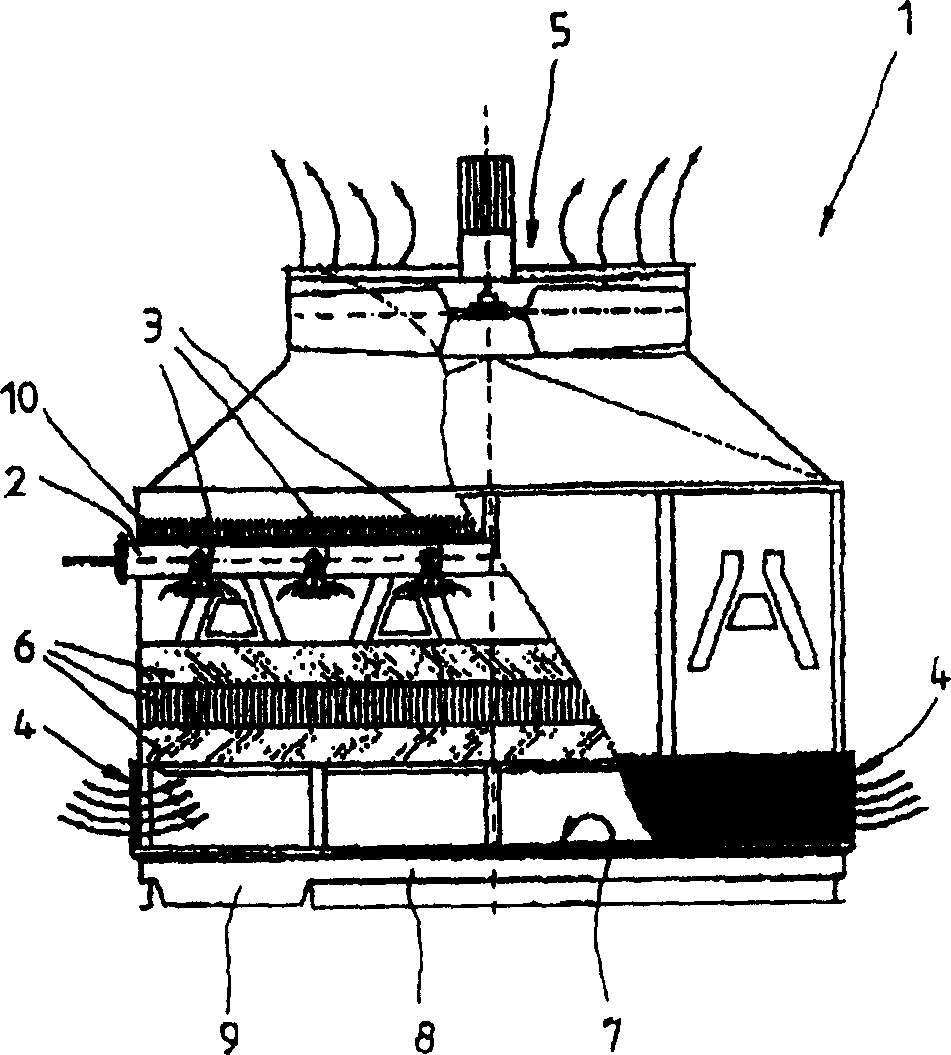

Internal inserts in cooling towers

InactiveCN1540273ALow costSlow trickleSafety devices for heat exchange apparatusCoatingsMicroorganismCooling tower

Owner:SPX COOLING TECH

The preparation method of polyisobutylene amine

ActiveCN103665213BThe preparation process is simple and environmentally friendlyImprove energy savingChemical industryEpoxyAcetic acid

The invention relates to a method for preparing polyisobutylene amine. The method comprises the following steps: dissolving polyisobutylene with more than or equal to 85% of alpha olefinic bonds in a functional solvent, reacting the solution with hydrogen peroxide at 70-95 DEG C in the presence of acetic acid so as to obtain an intermediate product with epoxy polyisobutylene content of more than or equal to 60% after the reaction, and recycling the acetic acid in the mixed solution by virtue of rectification or membrane separation; adding acid, water or alcohol into the epoxy polyisobutylene, and reacting with ammonia or amine substance at 120-200 DEG C so as to obtain the polyisobutylene amine; recycling volatile matters steamed out from a rotary liquid, wherein the mass ratio of the polyisobutylene, the acetic acid and the hydrogen peroxide is 1:(0.02-0.3):(0.1-0.6); the molar ratio of the epoxy polyisobutylene, the catalytic solvent and the amine substance added in the aminolysis process is 1:(1-10):(2-20); the method is environment-friendly in preparation process, obvious in energy-saving effect and capable of avoiding or reducing resource waste or possible environmental pollution and realizing a recycling economic development mode.

Owner:PETROCHINA CO LTD

Recycling method of alkaline pulping by-product

PendingCN114481664AGreat advantageIncrease productionPulp by-products recoveryBlack liquorWoody plant

The invention relates to a recycling method of an alkaline pulping byproduct. Lignin and alkali in black liquor are separated through step-by-step multiple acidification concentration. The method comprises the following steps: neutralizing the black liquor by using flue gas to reduce the pH value of the black liquor, separating out lignin in the black liquor, greatly improving the concentration of the lignin, enabling the lignin in the black liquor to form large particle precipitates with compact structures by using sulfuric acid and / or a flocculating agent, filtering out the lignin, and further dehydrating the lignin to obtain a lignin product. And causticizing the residual clear liquid after the lignin is stripped by lime, respectively cooking the plant raw material and washing the paper pulp, and using the obtained insoluble calcium salt as a building material. The method can be used for alkaline pulping of woody plants and non-woody plants. And technical support is provided for realizing net zero emission of carbon dioxide.

Owner:汪雨欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com