Contact masses processing method during methylchlorosilane synthesis

A technology of methylchlorosilane and dimethyldichlorosilane is applied in the field of treatment and recovery of contact bodies in the synthesis process of methylchlorosilane, and can solve the problem of affecting the effective production time of a methylchlorosilane device, affecting the economic benefits of enterprises, and reducing silicon dioxide. And copper waste and other problems, to increase the effective production time, improve the economic benefits of enterprises, selectivity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

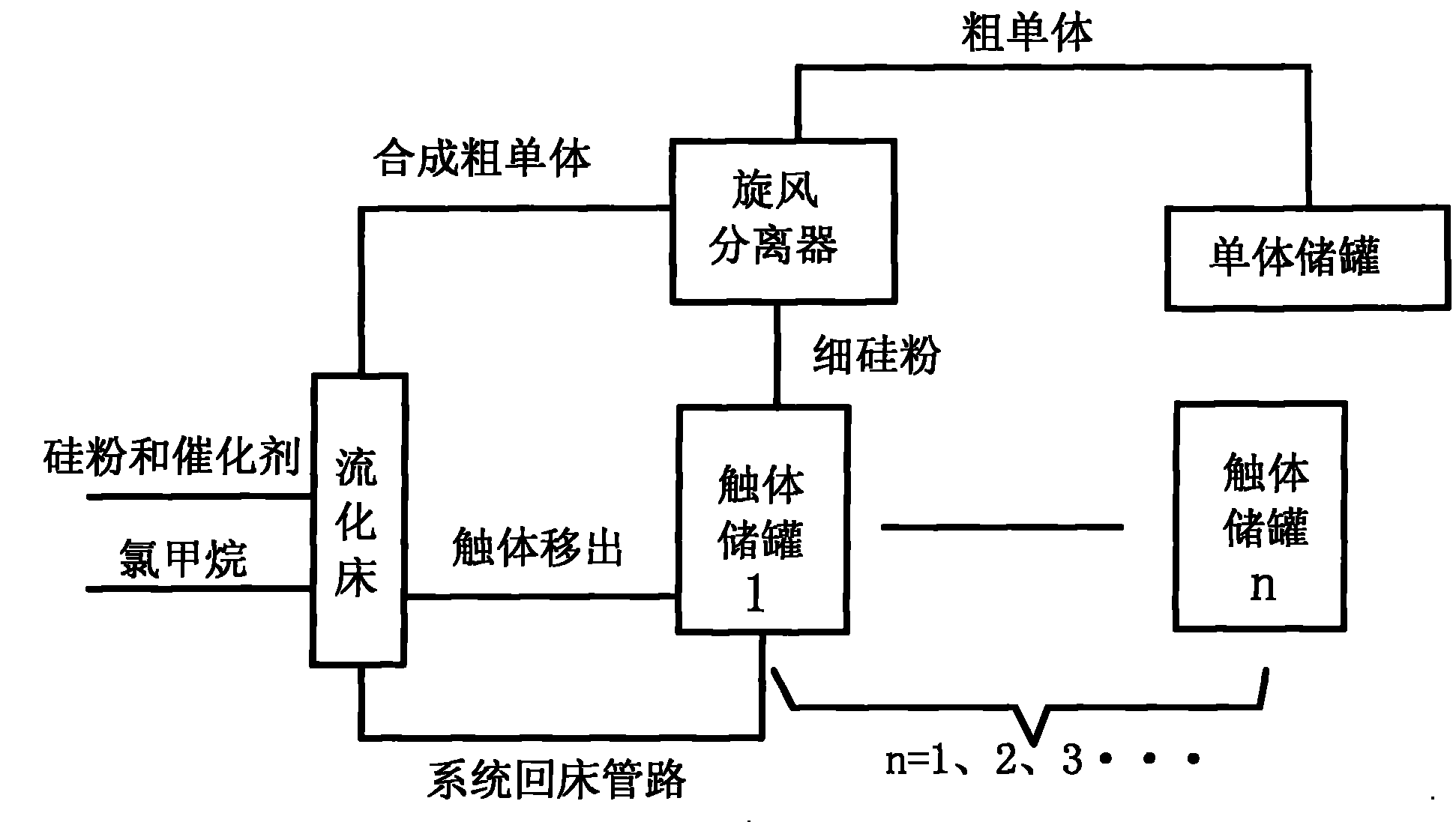

Image

Examples

Embodiment 1

[0018] 42 tons (t) of silicon powder and copper powder (silicon powder: copper powder = 20:1, which is the weight ratio) active contacts, pre-added to the fluidized bed, reacted after being fluidized by methyl chloride, the reaction temperature is 280 ° C, the reaction The pressure is 0.3Mpa, and the gas velocity is 0.20m / s. The gas phase reaction product is discharged from the synthesis gas outlet. As the bed height decreases, the active contacts and co-catalysts are continuously supplemented during the reaction. The co-catalyst is a mixture of zinc powder, antimony and aluminum powder. The powder ratio is 3:2:2, 800kg in total. When the selectivity of M2 in the synthesis gas is reduced to 80% (that is, the reaction lasts for 25 days), suspend the addition of the contact body, pressurize the contact body in the fluidized bed with nitrogen gas, and press out the contact body in the storage tank, the contact body is about 53.4t , The silicon powder collected by the cyclone sep...

Embodiment 2

[0021] 46 tons (t) of silicon powder and copper powder (silicon powder: copper powder = 22:1) are active contacts, which are added to the fluidized bed in advance and reacted after being fluidized by methyl chloride. The reaction temperature is 300°C and the reaction pressure is 0.3Mpa. , the gas velocity is 0.18m / s. The gas phase reaction product is discharged from the synthesis gas outlet. As the bed height decreases, the ratio of fresh silicon powder, copper catalyst and cocatalyst zinc powder, antimony and aluminum powder to the mixture is continuously replenished during the reaction. The ratio is 2:1: 1 total 750kg, when the selectivity of M2 in the synthesis gas was reduced to 79% (i.e., reacted for 25 days), suspend adding the contact body, pressurize the contact body in the fluidized bed with nitrogen to press out in the storage tank, contact The volume is about 52.7t, and the silicon powder collected by the cyclone separator during the reaction is 40.8t, which is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com