Patents

Literature

562 results about "Dimethyldichlorosilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

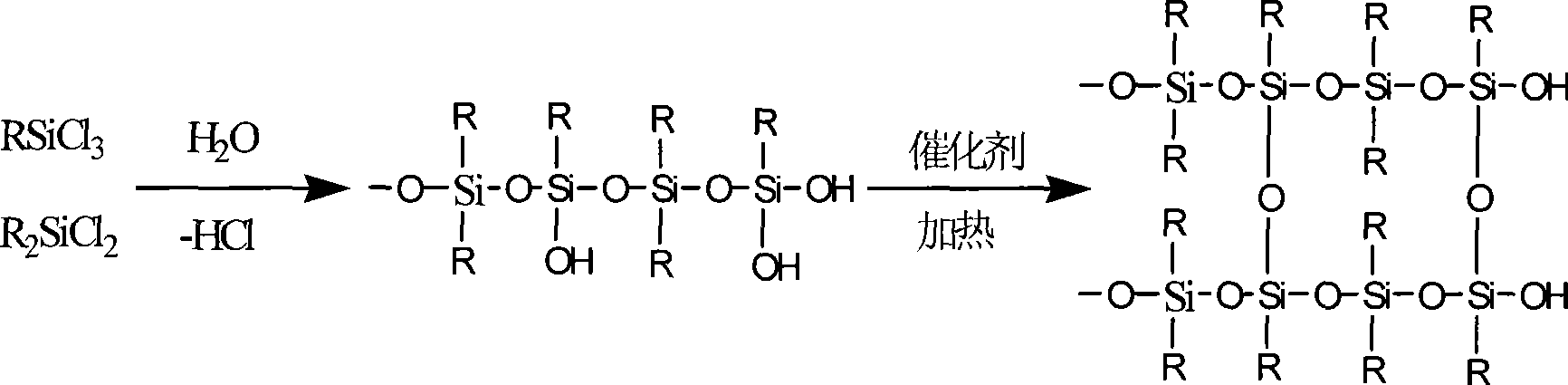

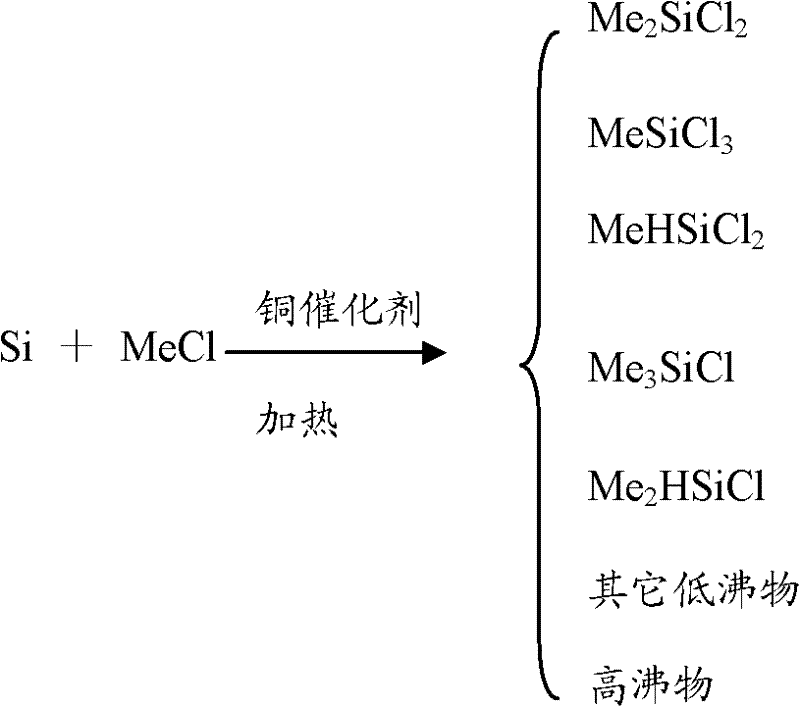

Dimethyldichlorosilane is a tetrahedral, organosilicon compound with the formula Si(CH₃)₂Cl₂. At room temperature it is a colorless liquid that readily reacts with water to form both linear and cyclic Si-O chains. Dimethyldichlorosilane is made on an industrial scale as the principal precursor to dimethylsilicone and polysilane compounds.

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

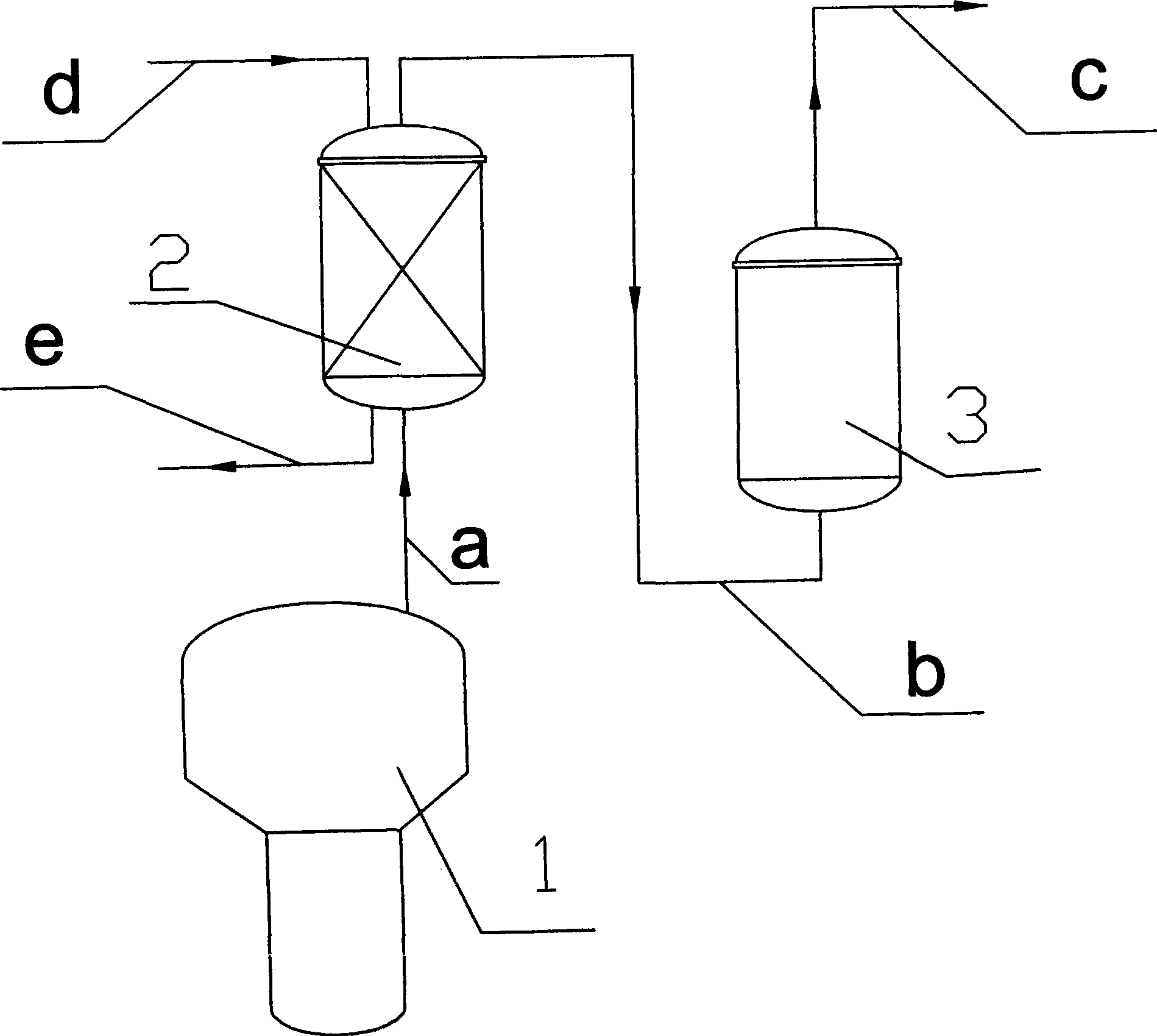

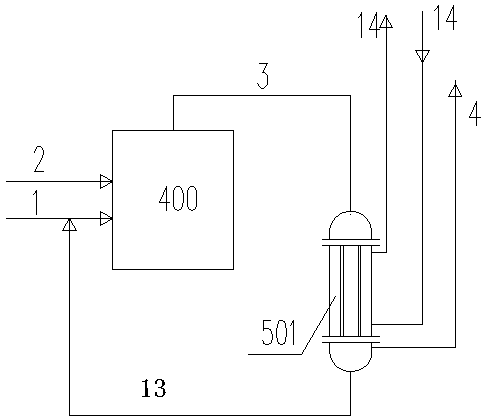

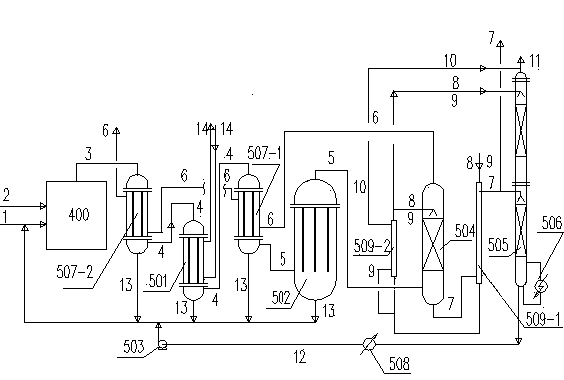

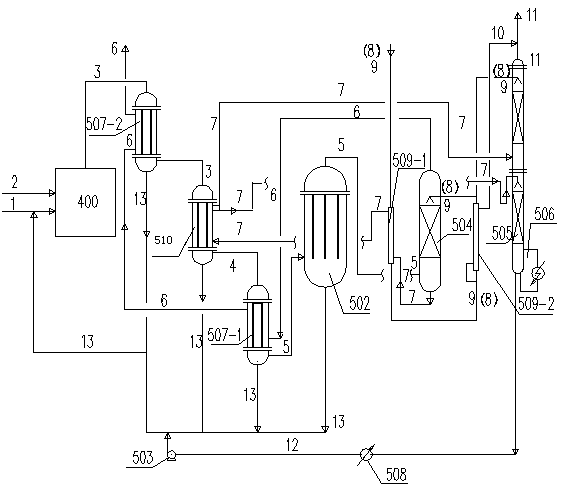

Technique for reducing impurity content in gas phase hydrogenchloride from hydrolysis of dimethyldichlorosilane

InactiveCN101423193ALow impurity contentHigh yieldChlorine/hydrogen-chloride purificationGas phaseHydrolysate

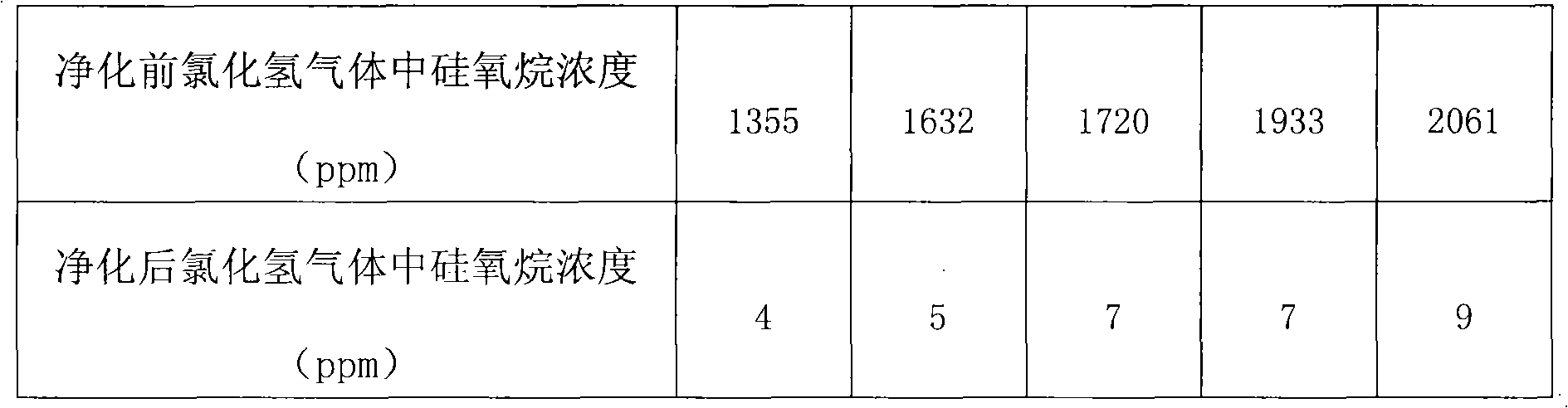

The invention discloses a process method used for reducing the content of impurities in gas-phase hydrogen chloride after hydrolysis of dichlorodimethyl silane, comprising the steps as follows: a two-step device is used for separating the impurities; a vapour liquid separator leads the mixed hydrogen chloride gas generated after the hydrolysis of dichlorodimethyl silane to enter a washing tower of a guide structure so as to remove most of impurities; subsequently, the hydrogen chloride gas with most of impurities removed is arranged into the bottom of a demister; the adsorption medium at the internal layer of the demister is porous fiber which is used to adsorb the siloxane impurity in the hydrogen chloride gas; and the hydrogen chloride gas with the siloxane impurity removed is sent to a methyl chloride device to carry out the subsequent process. The method reduces the content of the impurities in the hydrogen chloride gas, improves the yield of hydrolysate of the dichlorodimethyl silane, keeps the pressure of the hydrogen chloride gas at a high level after purification, does not generate a great deal of waste acid, avoids the disposal of waste acid, and has low energy consumption and low equipment expense.

Owner:浙江恒业成有机硅有限公司

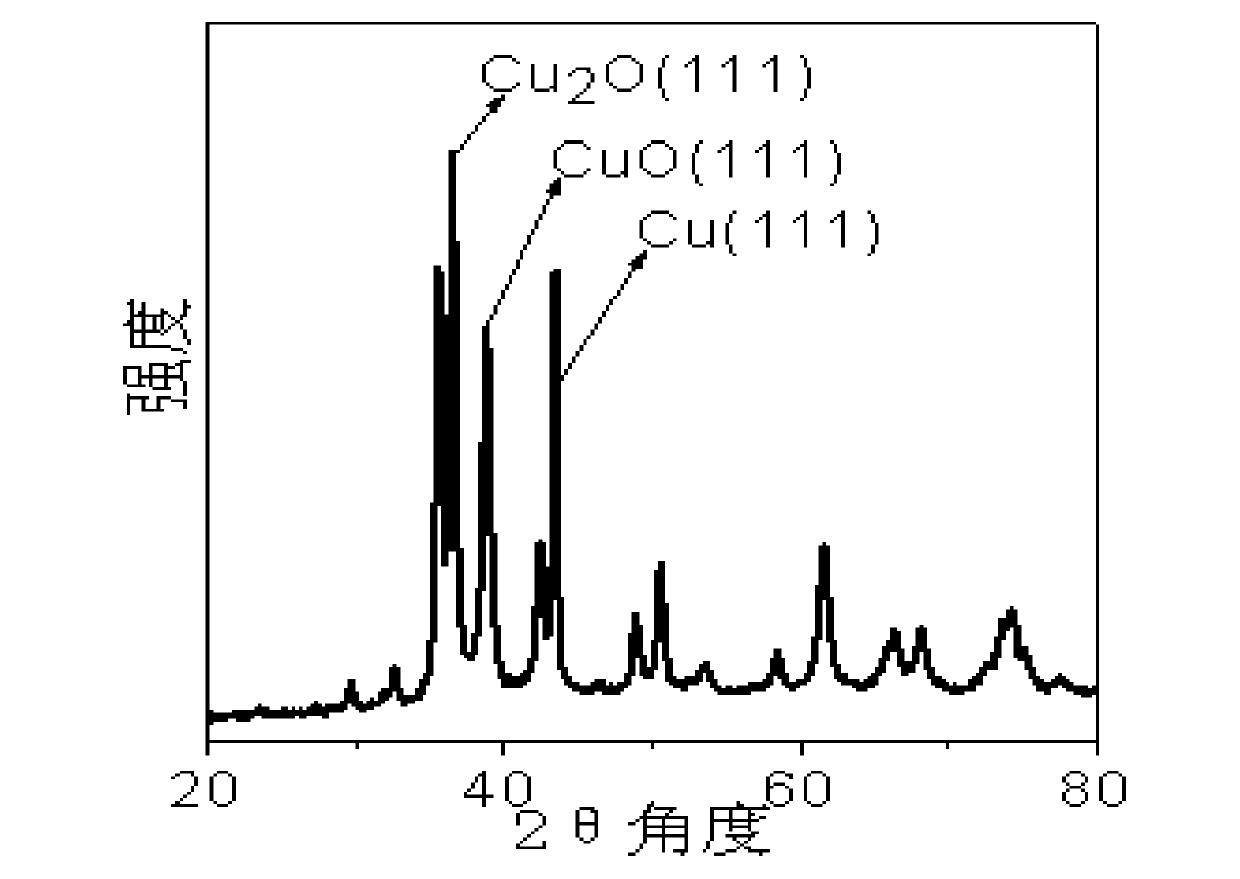

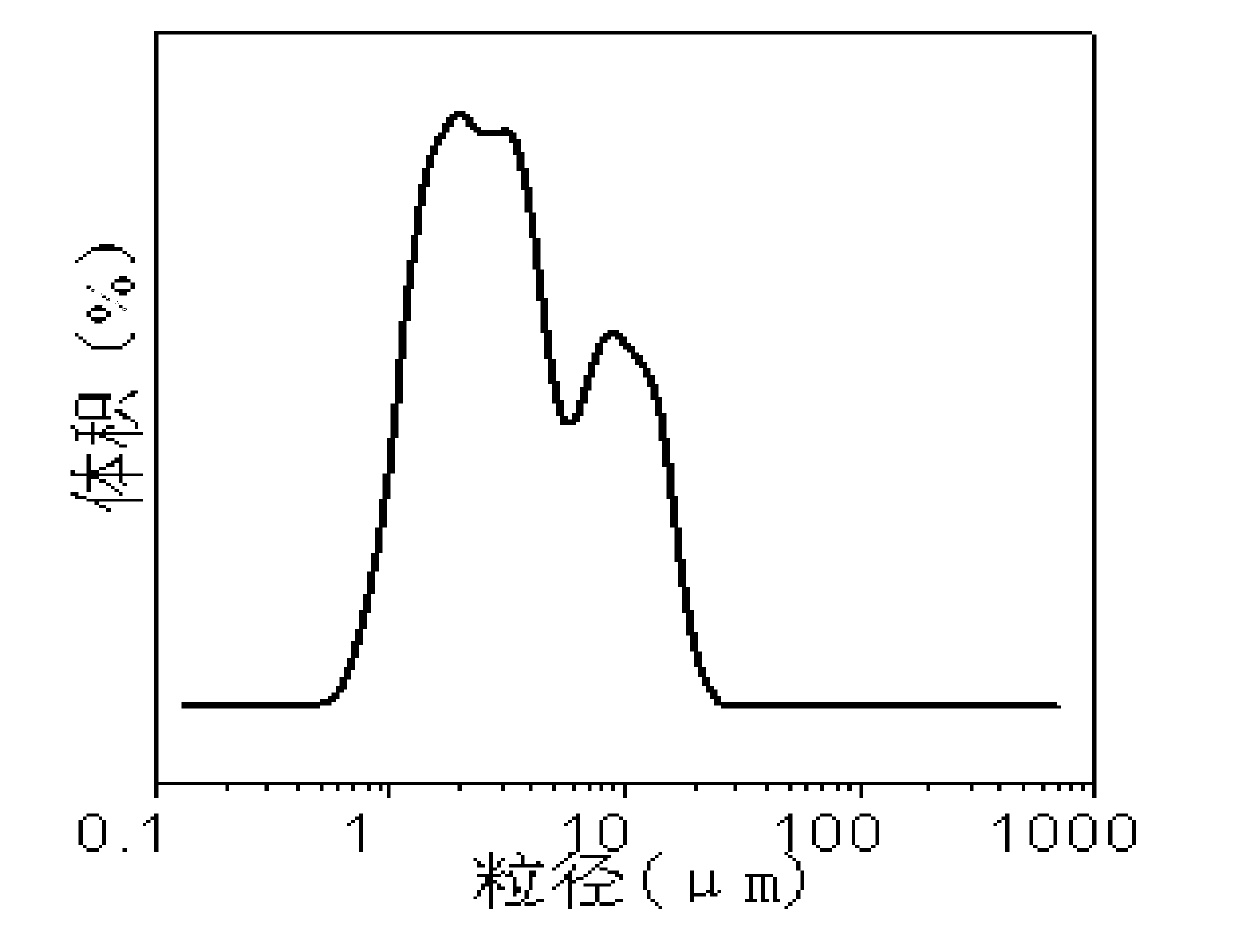

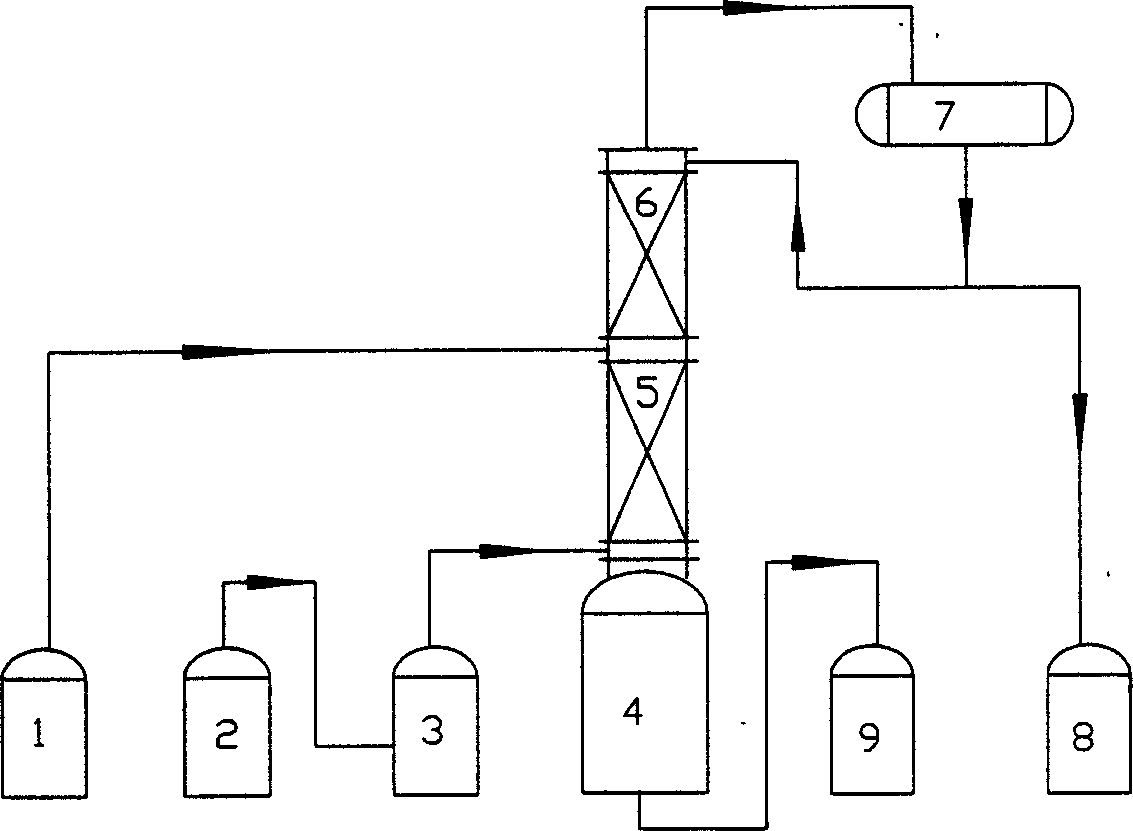

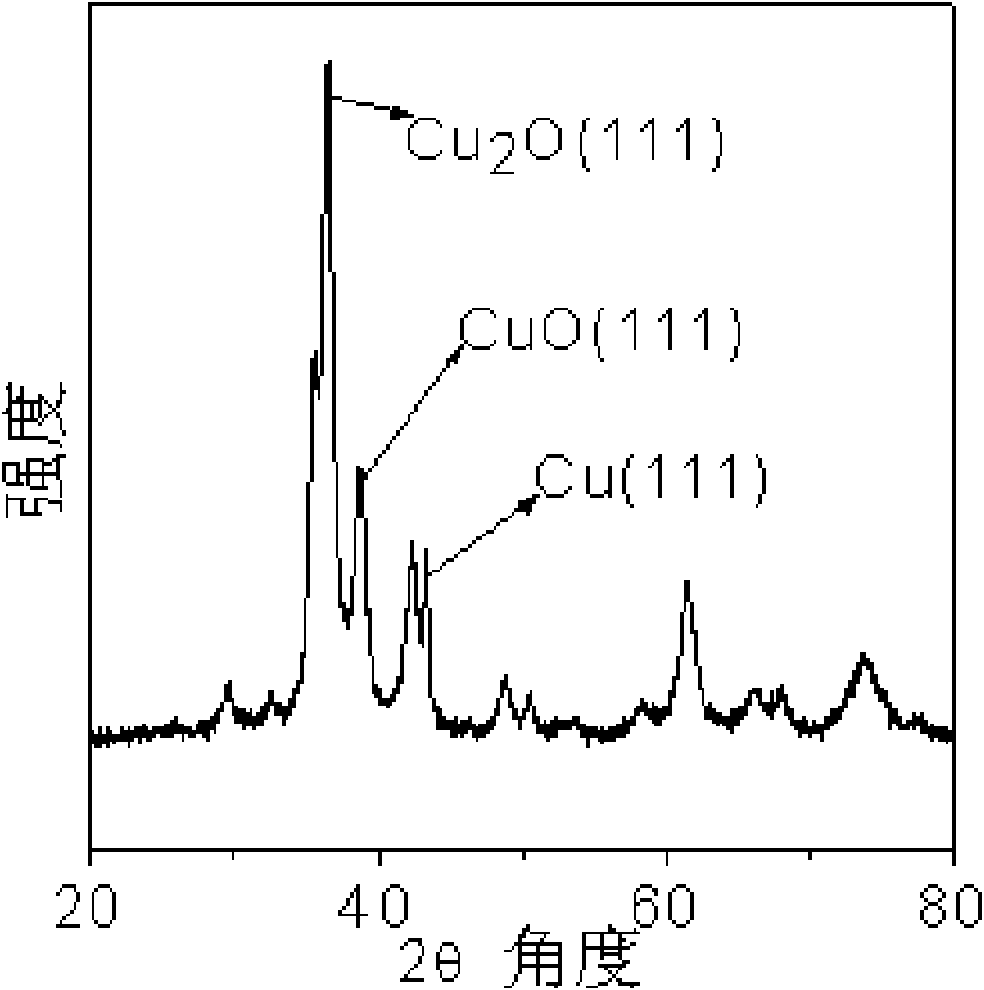

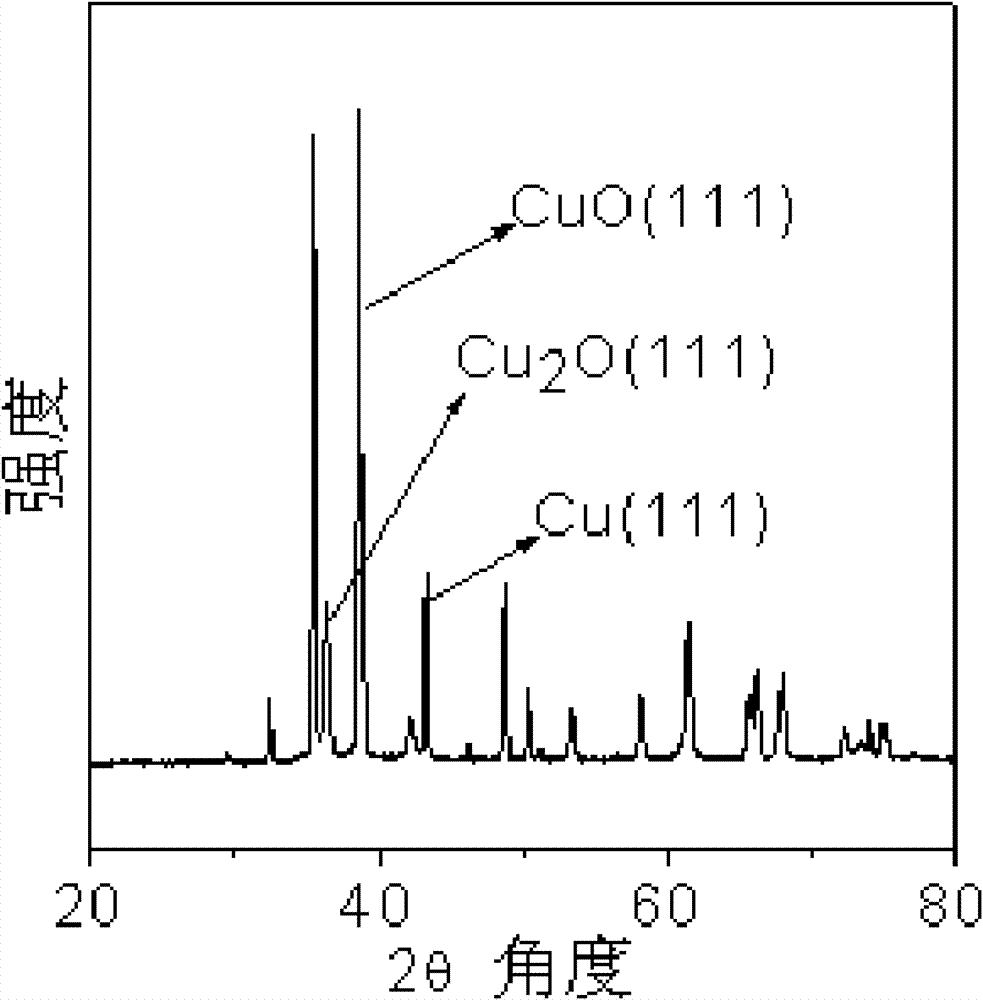

Method preparing catalyzer through liquid phase ball-milling partial reduction method and ternary copper catalyzer

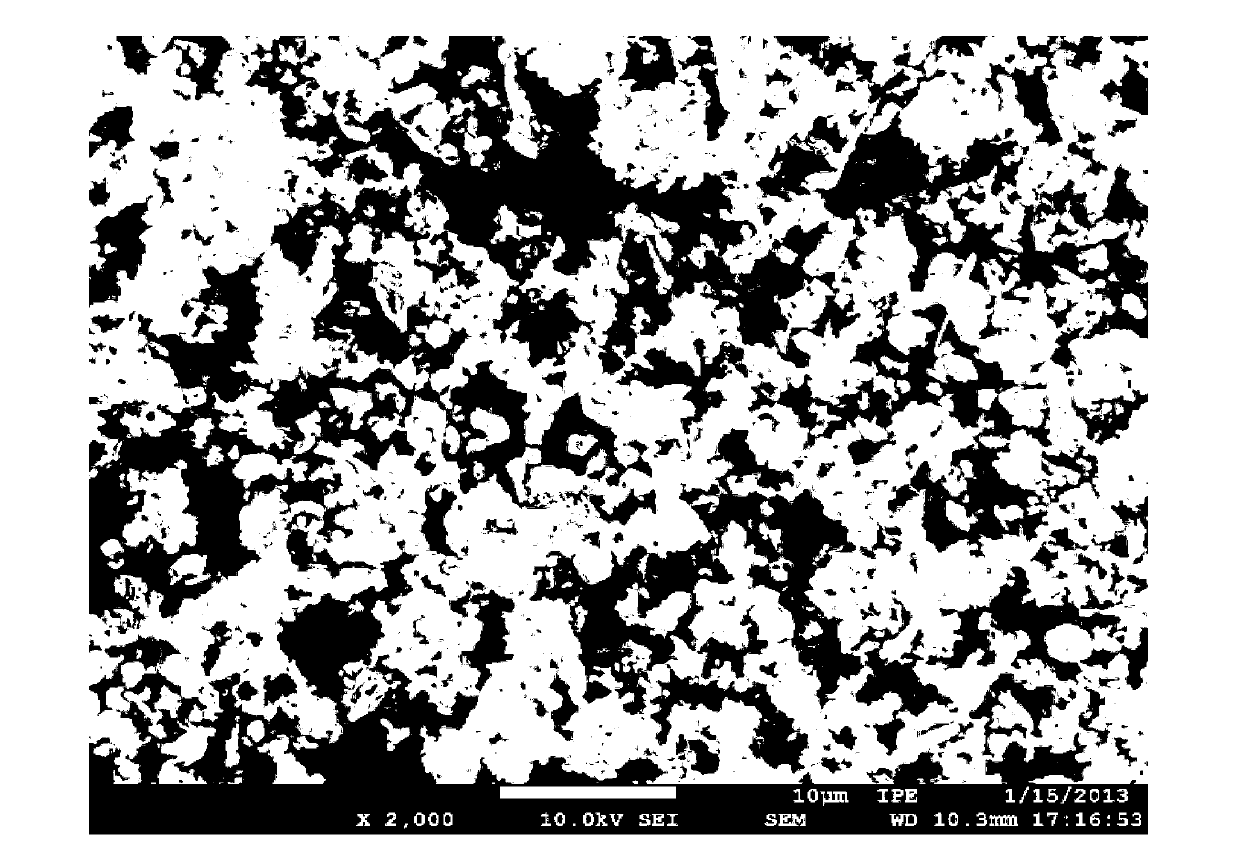

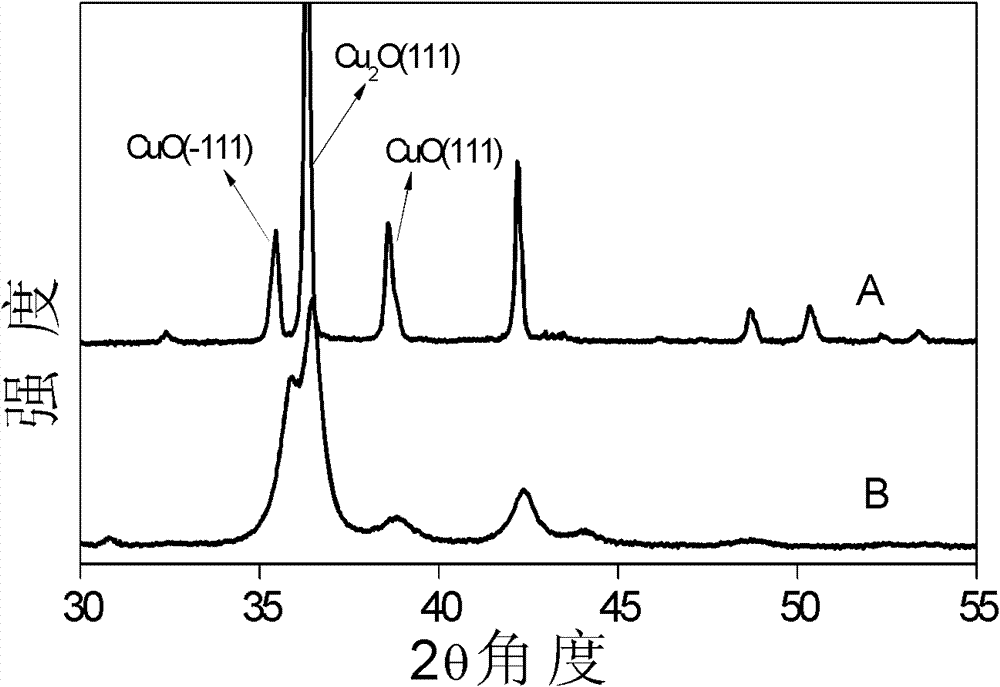

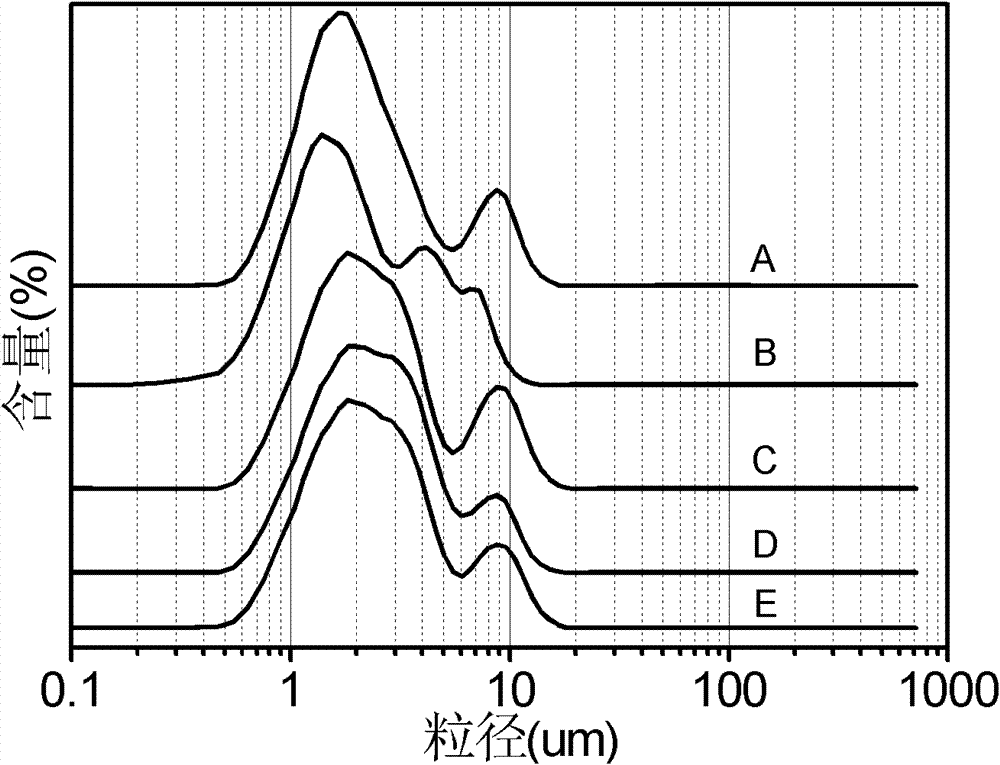

ActiveCN103127936AEnhanced ability to participate in reduction reactionsEnhanced interactionGroup 4/14 element organic compoundsCatalyst activation/preparationFiltrationCopper oxide

The invention relates to a method preparing a copper catalyzer used for dimethyldichlorosilance synthetic reaction through a liquid phase ball-milling partial reduction method. The method includes the steps of taking copper oxide as raw material, adding solvent media containing reducing substances, enabling copper oxide particles to become small and achieve partial reduction through mechanical ball-milling, obtaining the copper-based catalyzer containing the ternary components of copper, cuprous oxide, copper oxide after suction filtration, drying and smashing, and obtaining the ternary copper catalyzer with adjustable components and controllable particles through adjusting the parameters of reducing agent types, concentration and ball-milling conditions. In catalytic reaction of organosilicone monomer synthesis, the catalyzer is high in catalytic activity and selectivity and helpful for improving the processing ability of an existing organosilicone monomer device, reduces production cost, and improves the yield of target products. The method preparing the catalyzer through the liquid phase ball-milling partial reduction method is simple in process, mild in condition and convenient to operate, and brings convenience to achieve large scale production.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

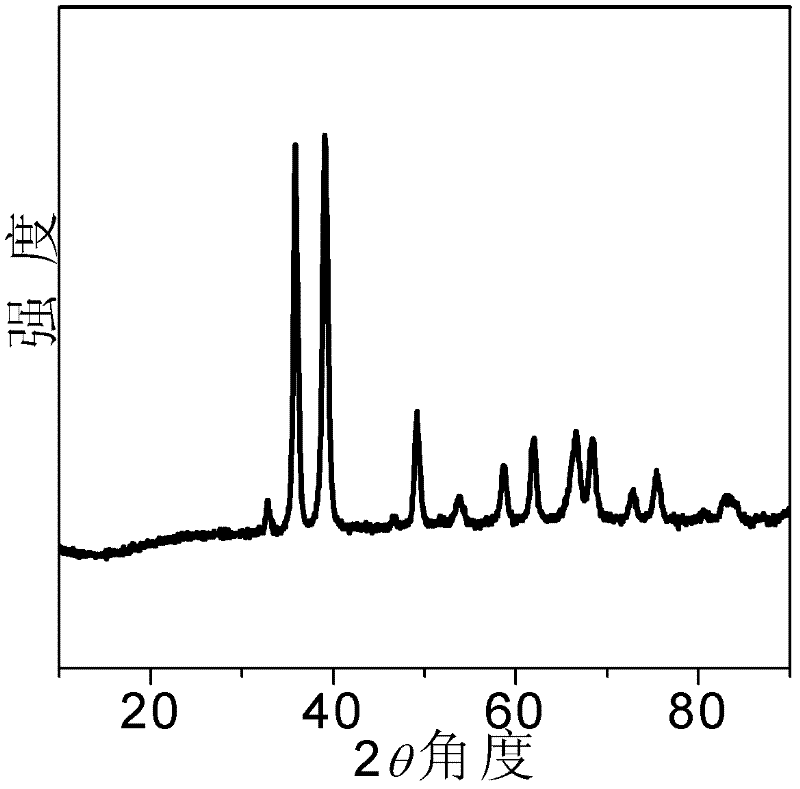

Cu-Cu2O-CuO ternary copper-based solid solution catalyst and its preparation method

InactiveCN102773099AHigh selectivityHigh yieldGroup 4/14 element organic compoundsCatalyst activation/preparationCopper oxideSolid solution

The invention relates to the organosilicon monomer synthesis field, and particularly relates to a Cu-Cu2O-CuO ternary copper-based solid solution catalyst and its preparation method. The method comprises the following steps of: 1) taking a mixture composed of 0.5-40wt% of metal copper powder and 20-80wt% of copper oxide as a raw material, conducting heat treatment at a temperature of 600-1000DEG C for 0.5-12h under inert gas protection, and then carrying out ageing at a temperature of 300-600DEG C for 1-15h so as to obtain a ternary copper-based solid solution; and 2) subjecting the ternary copper-based solid solution from step 1) to shattering and milling to obtain the Cu-Cu2O-CuO ternary copper-based solid solution catalyst. The copper-based solid solution catalyst prepared in the invention shows high dimethyldichlorosilane selectivity and silicon power raw material conversion rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method of preparing dimethyl dichloro silicane using organic silicon high boiling point substance

InactiveCN1590389ALoose requirementsImprove securityGroup 4/14 element organic compoundsBoiling pointDichlorosilane

A process for preparing dimethyl dichlorosilane from the high-boiling-point residue generated in synthesizing methyl chlorosilane includes filling catalyst in gas preheater, passing chloromethane (or hydrogen chloride) gas through it, carrying catalyst into reactor while introducing said residue to it, and separating dimethyl dichlorosilane from the cooled substance at tower top.

Owner:PETROCHINA CO LTD

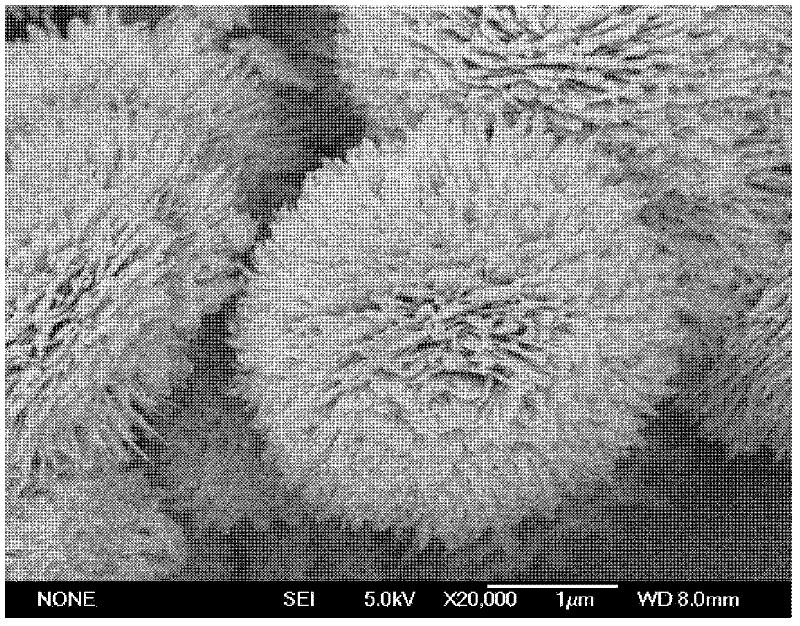

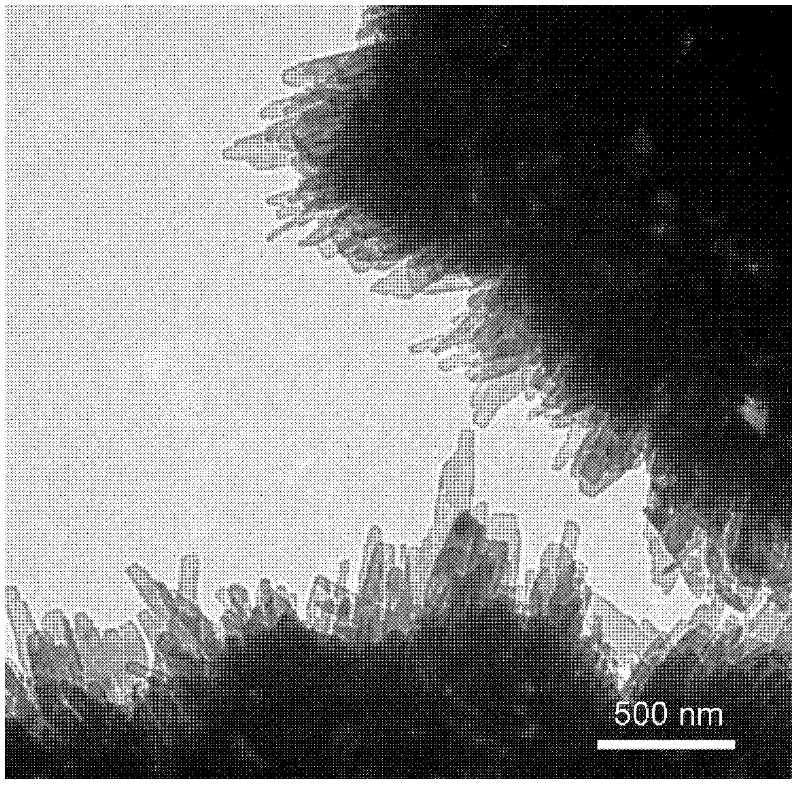

Flower-like copper oxide catalyst and preparation method and application thereof

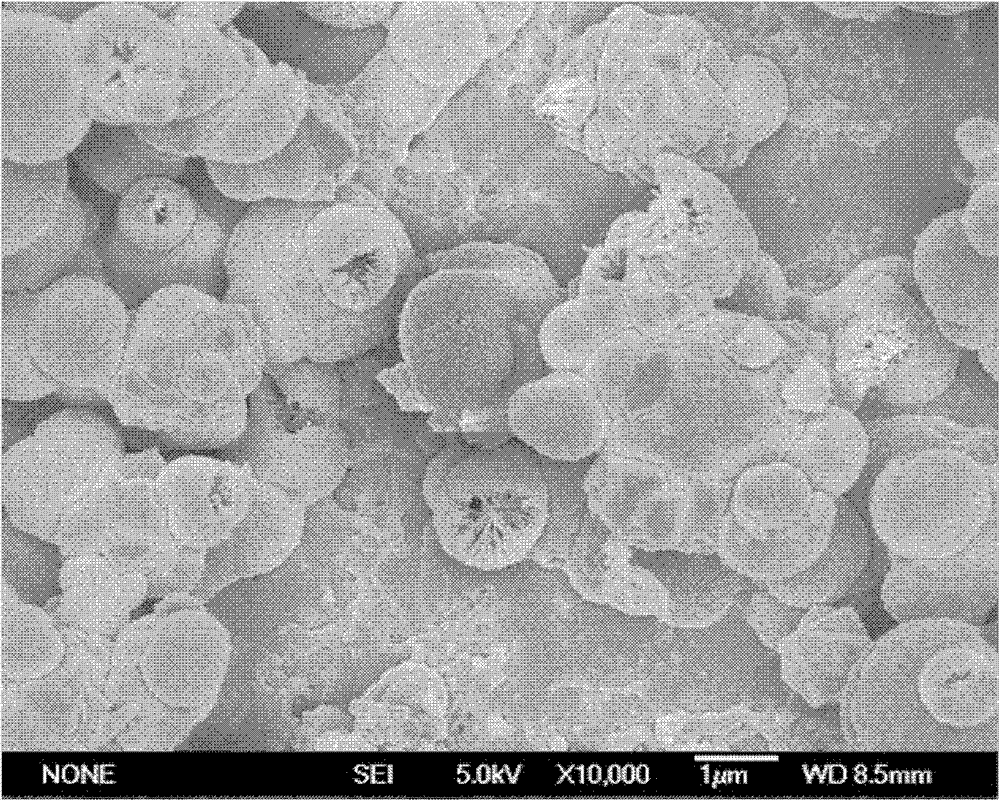

InactiveCN102502770ASimple manufacturing processLow priceNanotechnologyCopper oxides/halidesReaction temperatureCopper oxide

The invention relates to a flower-shaped copper oxide catalyst and a preparation method and application thereof to the direct synthesis of an organic silicon monomer. The preparation method of the flower-shaped copper oxide catalyst comprises the following steps: (1) adding copper salt to ethanol or mixed solvent of ethanol and water to form solution; and (2) stirring and adding ammonia, strong alkali and nitrate to the solution in sequence to obtain a homogeneous solution, transferring the homogeneous solution to a reactor to carry out the thermal reaction of a solvent, and controlling the amount of the product of reaction, the reaction temperature and the reaction time to obtain the lower-shaped copper oxide catalyst. The preparation process of the flower-shaped copper oxide catalyst has simple experiment procedures and low cost, is convenient to operate, is environment-friendly and can be produced on a large scale. The prepared flower-shaped copper oxide powder can be used as the catalyst to the field of the direct synthesis of the organic silicon monomer, and particularly, the flower-shaped copper oxide powder is highly selective for the dimethyldichlorosilane monomer.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

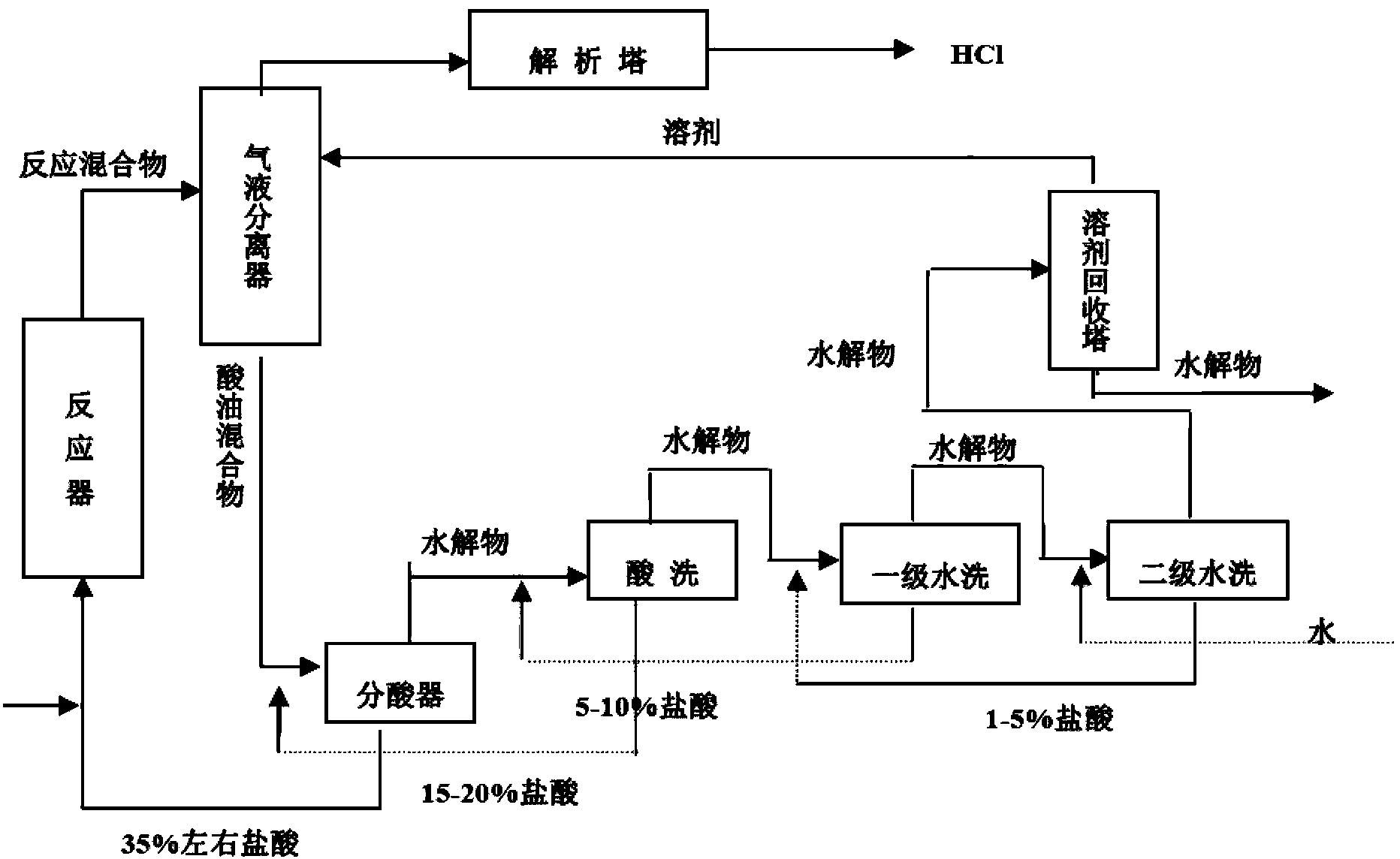

Method for preparing dimethyl silicone polymer by hydrolyzing dimethyl dichlorosilane with concentrated acid

The invention discloses a method for hydrolyzing dimethyl dichlorosilane with concentrated acid. The method comprises the following steps: mixing the dimethyl dichlorosilane with hydrochloric acid to carry out hydrolytic reaction; mixing the obtained reaction liquid with a solvent; finally, performing separating operation on the obtained mixed solution to obtain hydrolysis product and hydrogen chloride gas. Through the adoption of the method, the content of cyclic polysiloxane in hydrolysate obtained from the dimethyl dichlorosilane through the concentrated acid hydrolyzing method is effectively increased; the design is reasonable, hydrolysate with low chlorine ion content can be obtained in no need of multi-stage phase separation procedures, and the hydrochloric acid and solvent obtained after separation can be recycled, so that the resource use ratio is improved, and the production cost is saved.

Owner:HOSHINE SILICON IND CO LTD

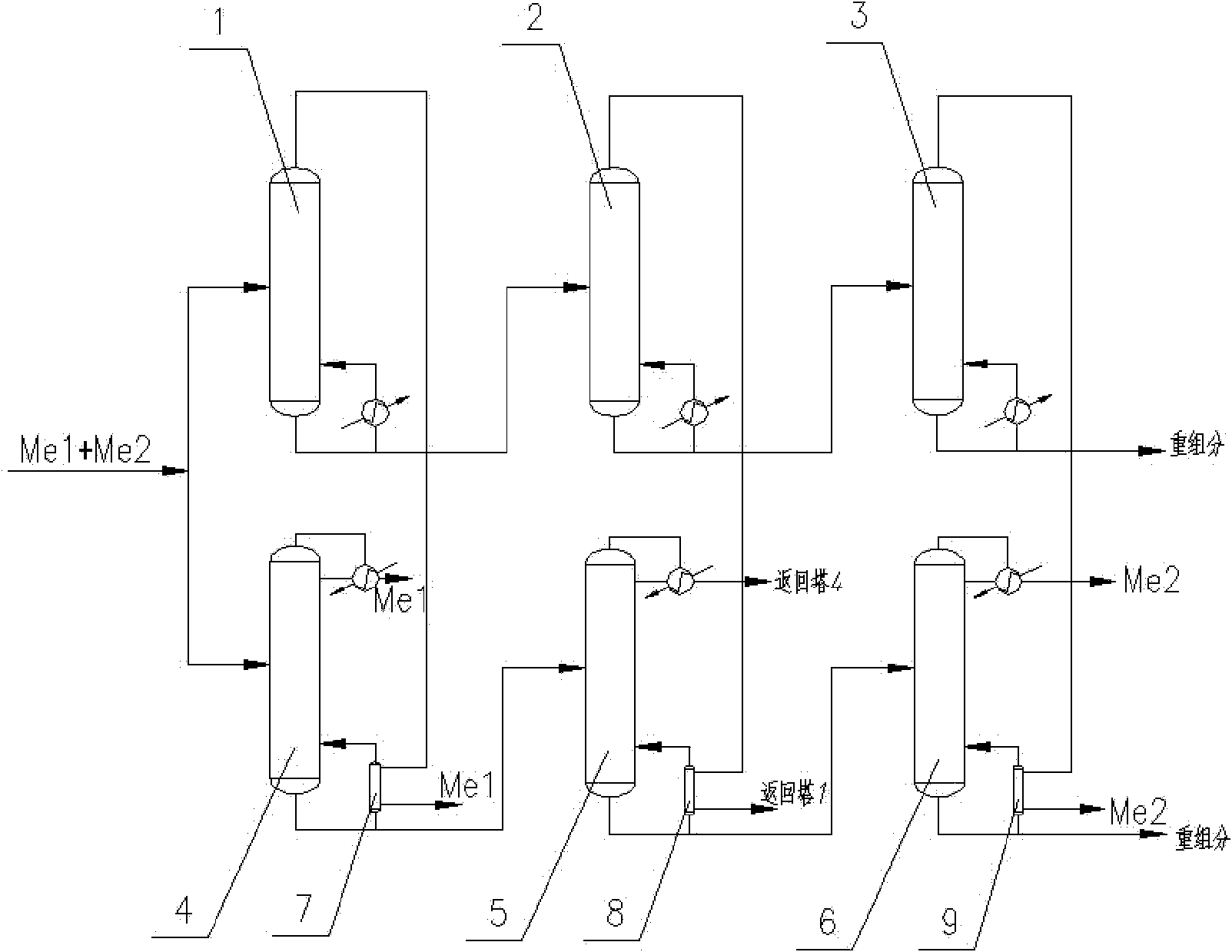

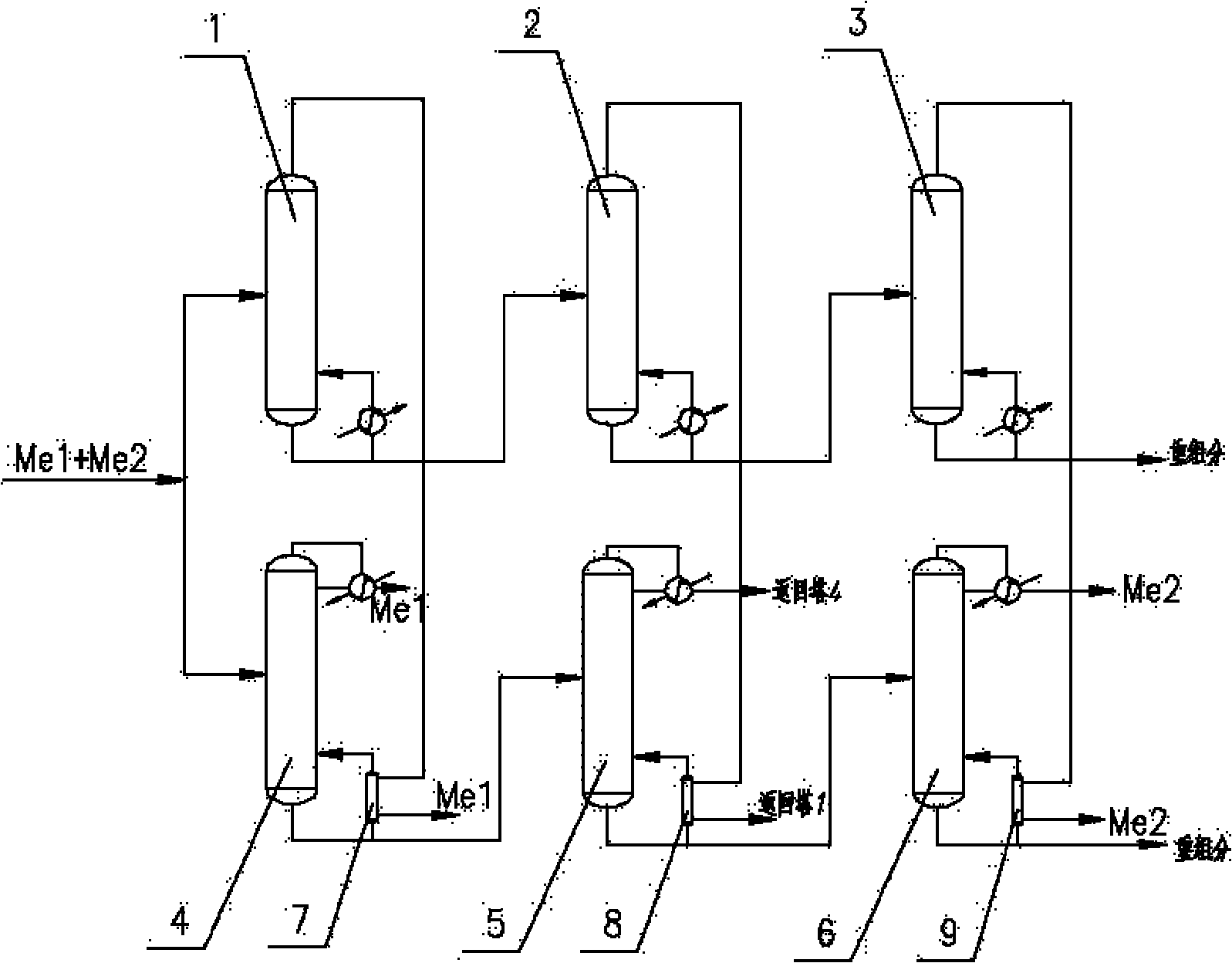

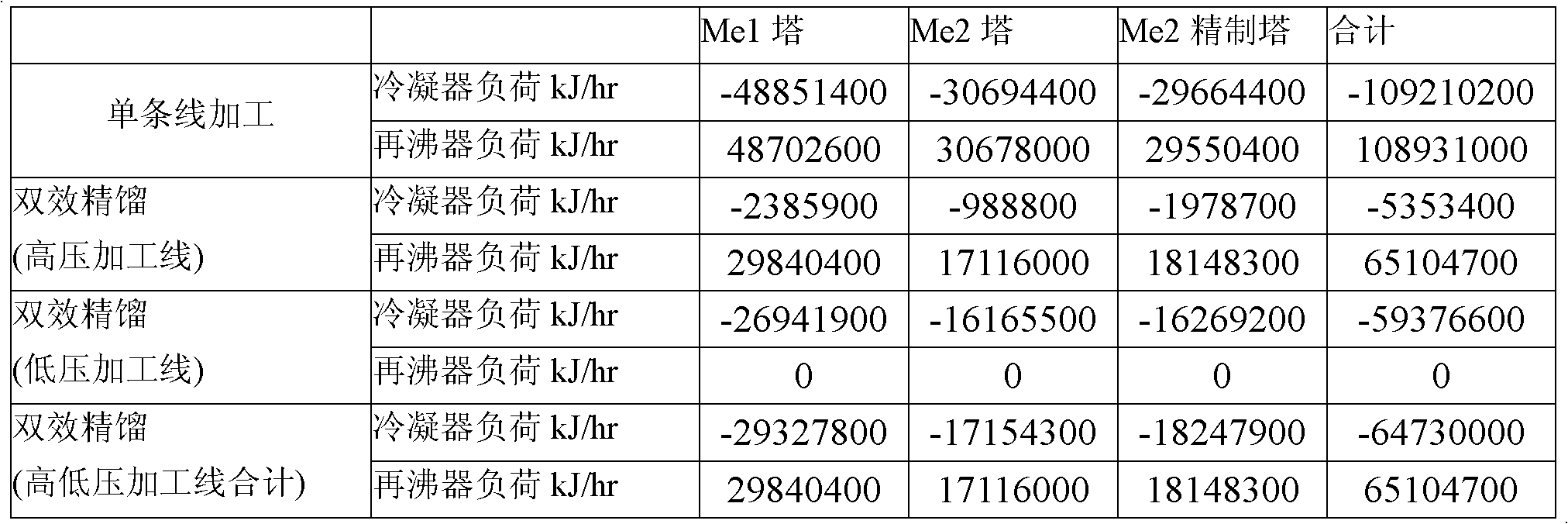

Methyl chlorosilane parallel double-effect distillation method

ActiveCN101857606AReduce tower diameterRealize secondary useSilicon organic compoundsChemical industryGas phaseReboiler

The invention discloses a methyl chlorosilane parallel double-effect distillation method. The method comprises the following steps: the synthetic product of methyl chlorosilane passes through a heavy component removing tower for removing heavy components and a light component removing tower for removing light components, the mixture of dimethyldichlorosilane and methyltrichlorosilane can be obtained, the mixture is divided to two parts to be sent to two parallel distillation systems of high-pressure refining and low-pressure refining, wherein one part enters in a high-pressure refining distillation system composed of a methyltrichlorosilane high-pressure tower and a dimethyldichlorosilane high-pressure tower, the other part enters in a low-pressure refining distillation system composed of a methyltrichlorosilane low-pressure tower and a dimethyldichlorosilane low-pressure tower, and the overhead gas phases of the methyltrichlorosilane high-pressure tower and the dimethyldichlorosilane high-pressure tower are separately used as the heat sources of the tower bottom reboilers of the methyltrichlorosilane low-pressure tower and the dimethyldichlorosilane low-pressure tower. By adopting two parallel processing lines, energy consumption can be reduced by more than 20%- 40% and the amount of circulating water can be saved.

Owner:TIANJIN UNIV

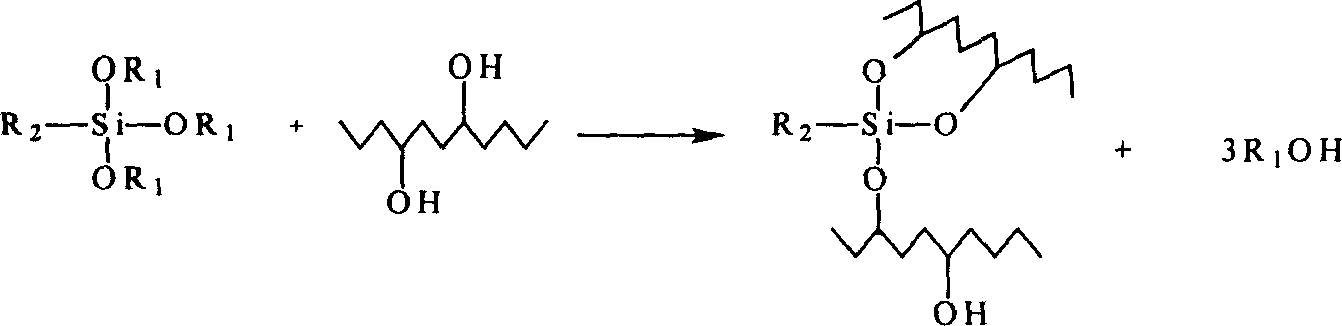

Surface treatment of nanoparticles to control interfacial properties and method of manufacture

InactiveUS20050222325A1Material nanotechnologySynthetic resin layered productsPersonal care3-mercaptopropyltrimethoxysilane

A surface treated particle comprising a plurality of inorganic, metallic, semi-metallic, and / or metallic oxide particles and a star-graft copolymer with looped and / or linear polymeric structure on a star-graft copolymer, obtainable by a heterogeneous polymerization reaction in the particle surface proximity, encapsulating at least a portion of said particles and a method for making the same. The surface treatment comprises: Si (w, x, y, z), where: w, x, y, and z are mole percent tetrafunctional, trifunctional, difunctional, and monofunctional monomeric units, respectively; w, x, y, and z are about 0-50, 0-50, 5-99, and 0-5, respectively; w is tetraethylorthosilicate; x is selected from the group consisting of γ-glycidoxypropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, methyltrimethoxysilane, n-propyltrimethoxysilane, isobutyltrimethoxysilane, n-hexyltrimethoxysilane, n-octyltrimethoxysilane, n-octadecyltrimethoxysilane, phenyltrimethoxysilane, 3-(trimethoxysilyl)propylsuccinic anhydride, heptadecafluorotrimethoxysilane, 3-isocyanatopropyltrimethoxysilane, 2-(diphenylphosphino)ethyltrimethoxysilane, 3-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane, n-(trimethoxysilylpropyl)EDTA, pentafluorophenylpropyltrimethoxysilane, trifluoropropyltrimethoxysilane, and the triethoxy-containing counterparts of these monomers; y is selected from the group consisting of dicyclohexyldimethoxysilane, diethyldiethoxysilane, dimethyldichlorosilane, dimethyldiethoxysilane, dimethyldimethoxysilane, diphenyldiethoxysilane, diphenyldimethoxysilane, di-n-hexyldichlorosilane, n-hexylmethyldichlorosilane, methyldodecyldiethoxysilane, n-octylmethyldimethoxysilane, and the diethoxy-containing counterparts of these monomers; and z is selected form the group consisting of n-octadecyldimethylmethoxysilane, triethylsilanol, trimethylethoxysilane, trimethylmethoxysilane, and the ethoxy-containing counterparts of these monomers. Product(s) per se, defined as surface treated ZnO and / or TiO2, and the use of the product(s) per se in personal care formulations are excluded.

Owner:NANOPHASE TECH CORP

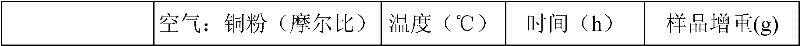

Reparation method of ternary copper CuO-Cu2O-Cu catalyst for synthesizing methyl chlorosilane

InactiveCN102671660AEasy to operateEasy to controlGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsSilanesNitrogen

The invention relates to the field of the preparation of catalysts, and in particular relates to a preparation method of a ternary copper CuO-Cu2O-Cu catalyst for synthesizing methyl chlorosilane. The preparation method comprises the following steps of: putting copper powder into a heating furnace, replacing air in the heating furnace by use of nitrogen, carrying out primary oxidation in the medium temperature stage of 250-400DEG C, carrying out ball milling, rupturing a surface oxidation film stopping copper particles to be further oxidized, carrying out secondary oxidation in the medium temperature stage of 250-400DEG C, carrying out ball milling, and adjusting the component content and particle size of the catalyst through the twice oxidation and the ball milling, so as to obtain the product CuO-Cu2O-Cu catalyst, wherein the molar ratio of the air passing quantity to copper powder in the process of oxidization is 10:(1-10), the ventilation reaction time is 0.5-5 hours, the mass ratio of the ball-milled bead to the material in the process of ball milling is 20:(1-10), and the ball milling time is 0.5-8 hours. The component content and particle size of the catalyst of the preparation method can be optimally adjusted, so that the catalyst is higher in dimethyl dichloro-silane yield and silicon power raw material conversion ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Energy-saving water-saving organic silicon monomer rectifying method

ActiveCN101798322AImprove operational safetyIncrease operating pressureSilicon organic compoundsChemical industryWater vaporReboiler

The invention discloses an energy-saving water-saving organic silicon monomer rectifying method which adopts a cis cleavage multi-tower flow. In the rectifying method, the tower top material steam of a high-boiling component removing tower firstly enters a main distribution manifold, then heat is respectively supplied for tower bottom reboilers of a low-boiling component removing tower, a light component removing tower, a hydrogenous tower, an azeotropic tower, a trimethylchlorosilane separating tower, a methyl trichloro silicane separating tower and a dimethyldichlorosilane separating tower through the main distribution manifold, the tower top material steam of the high-boiling component removing tower after heat supply is condensed into liquid, is then cooled to the reflux temperature through an air cooler and enters a tower top reflux tank of the high-boiling component removing tower, a second reboiler is connected with the tower bottom of the dimethyldichlorosilane separating tower, and vapor is adopted for the heat exchange of the reboiler. By adopting the method, because the operating pressure and the operating temperature of the high-boiling component removing tower and the methyl trichloro silicane separating tower with larger cooling quantity requirements are increased, at least two towers in the flow have the condition of adopting air cooling, thereby reducing the circulating water quantity and decreasing the evaporation loss; and the energy-saving water-saving organic silicon monomer rectifying method has strong operation controllability, flexible mode, multiple control means, smaller pressure increasing amplitude and high operation security.

Owner:TIANJIN UNIV

Method for generating dimethyldichlorosilance by utilizing disproportionation reaction

ActiveCN101824046AImprove resource utilizationReasonable designGroup 4/14 element organic compoundsResource utilizationReaction temperature

The invention relates to a method for generating dimethyldichlorosilance by utilizing disproportionation reaction, which belongs to the technical field of the comprehensive utilization of three wastes in the production process of methyl chlorosilane. The invention is characterized by comprising the following steps: generating the dimethyldichlorosilance by using methyl trichlorosilane and trimethylchlorosilane as organic silicon monomers, or a high boiling object and a low boiling object as the organic silicon monomers, or the mixture of the methyl trichlorosilane, the trimethylchlorosilane, the high boiling object and the low boiling object as the organic silicon monomers as raw materials under the single or combined catalytic action of aluminum powder and anhydrous aluminum trichloride as catalysts. In the invention, reaction is generated in a high-pressure agitating kettle at the temperature of 180 to 350 DEG C, and in the reaction, the reaction pressure is controlled by the reaction temperature, i.e. the higher the reaction temperature is, the higher the reaction pressure is, and the maximum conversion rate of a target product can reach more than 70 percent. The invention improves the resource utilization level of methyl organic silicon monomer production, the dimethyldichlorosilance is produced in lower cost, and the invention has simple and easy operation and is suitable for large-scale popularization and utilization.

Owner:HANGZHOU JINFADA CHEM IND

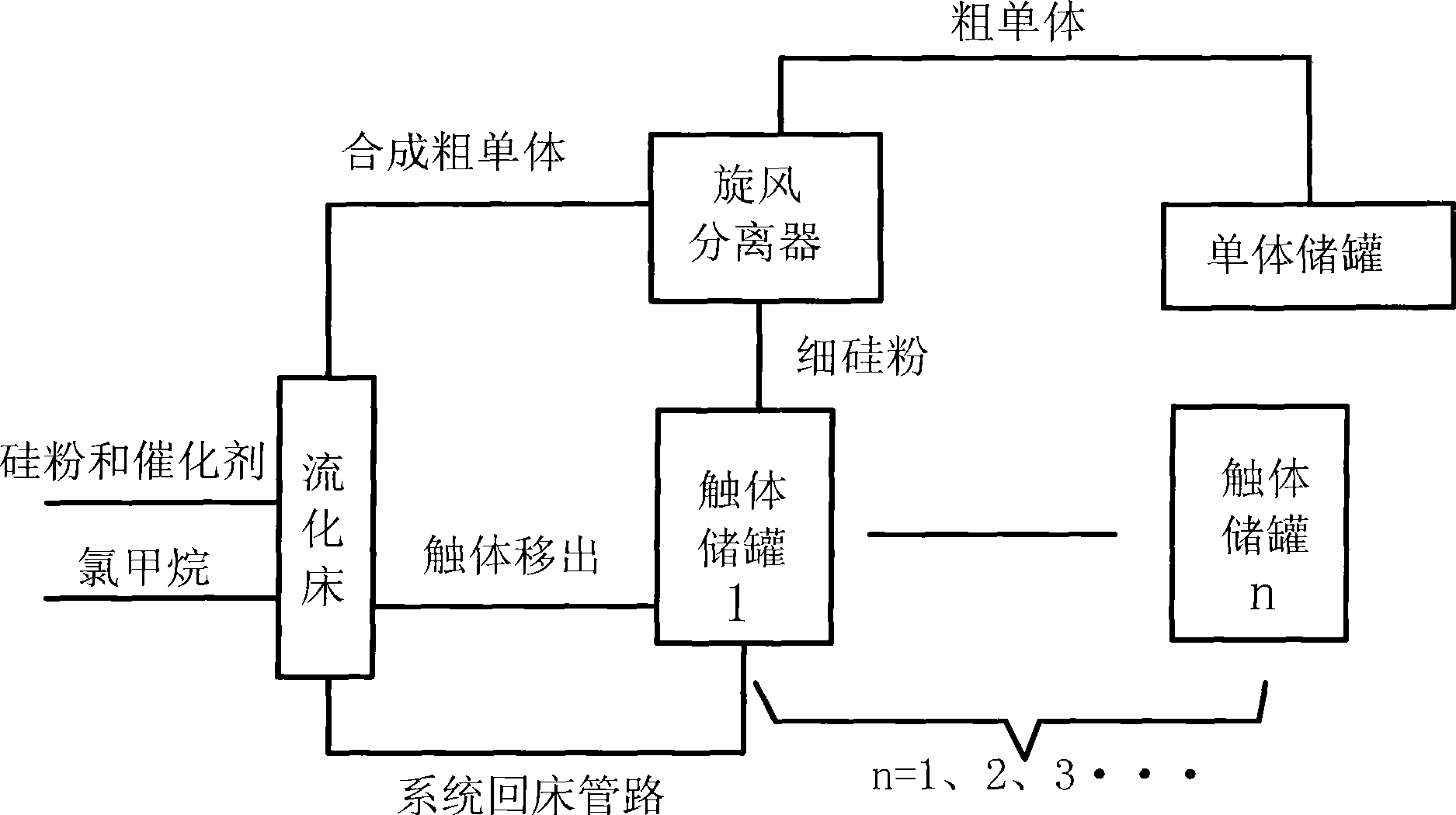

Contact masses processing method during methylchlorosilane synthesis

ActiveCN101456877AIncrease annual outputHigh selectivityGroup 4/14 element organic compoundsChemical/physical processesRecovery methodFluidized bed

The invention relates to the field of organic chemistry, in particular to a method for processing and recovering contacts in the synthetic process of methyl chlorosilane, which is characterized by comprising the following steps: adding an intermediate storage tank of the contacts in the process of synthesizing the methyl chlorosilane; when the selectivity of a target product is reduced to between 70 and 90 percent, transferring the contacts in the reaction system to the intermediate storage tank; re-adding new contacts to react in a fluidized bed, and mixing the transferred contacts with fresh silicon powder; and returning the mixture to the fluidized bed to use the mixture as new contacts to be added to the reaction. In the invention, the production method is used to not only ensure the stability of the selectivity for dimethyl dichlorosilane in the synthetic process of the methyl chlorosilane, and prolong the synthetic cycle of organochlorosilane simultaneously. The effective production time of the production device can be up to over 50 days.

Owner:ZHENJIANG JIANGNAN CHEM

Preparation method for thermoset high temperature resistant methyl phenyl silicone resin

The invention discloses a preparation method for thermoset high temperature resistant methyl phenyl silicone resin, which relates to the technical field of resin preparation and comprises the steps of utilizing toluene or dimethylbenzene or mixed solution of the toluene and dimethylbenzene to serve as a solvent, utilizing methyl trichlorosilane, dichlorodimethylsilane and methylphenyldichloros as monomer raw materials, dropping mixed solution of acetone and water into the raw materials under the condition of ice-water bath, ensuring that the dropping is finished within 3-5 hours, obtaining a prepolymer of the methyl phenyl silicone resin, performing condensation and curing on the obtained prepolymer above 150 DEG C after pressure of the prepolymer is reduced and the prepolyme is concentrated, the adopted condensation catalyst is caprylate or naphthenate, particularly is stannous octoate, zinc isoocatanoate, cobalt naphthenate and dibutyltin dilaurate. The resin is semi-transparent hard or elastic solid, can not be dissolved or fused, and can be resistant to high temperature above 200 DEG C, and can be used as silicon rubber or a plastic filler.

Owner:JIANGSU UNIV

Method for cracking treatment of organic silicon waste residue slurry

The invention relates to method for the cracking treatment of waste residues slurry produced in a synthesis process of an organic silicone monomer. The comehtod comprises: adding a high-boiling material of the same mass into a organic silicon waste residue slurry liquid and solid mixture containing 20 percent of solid to prepare a cracking feed solution, wherein a catalyst is tri-n-butylamine andthe cracking reaction temperature is 80 to 160 DEG C; and introducing HCl gas, wherein the ratio of the feed speeds of the hydrogen chloride and the raw material mixed liquid is 1:1.05-1:1.12. The method has the advantages that: the residue slurry containing 20 percent of solid is used in combination with the high-boiling material, so a monosilane product can be separated directly in a cracking process; the conversion rate is over 70 percent; the selectivity of dimethyldichlorosilane is over 35 percent; the selectivity of methylsilane is over 40 percent; and the slurry residue obtained after cracking having certain liquidity and can be further treated.

Owner:PETROCHINA CO LTD

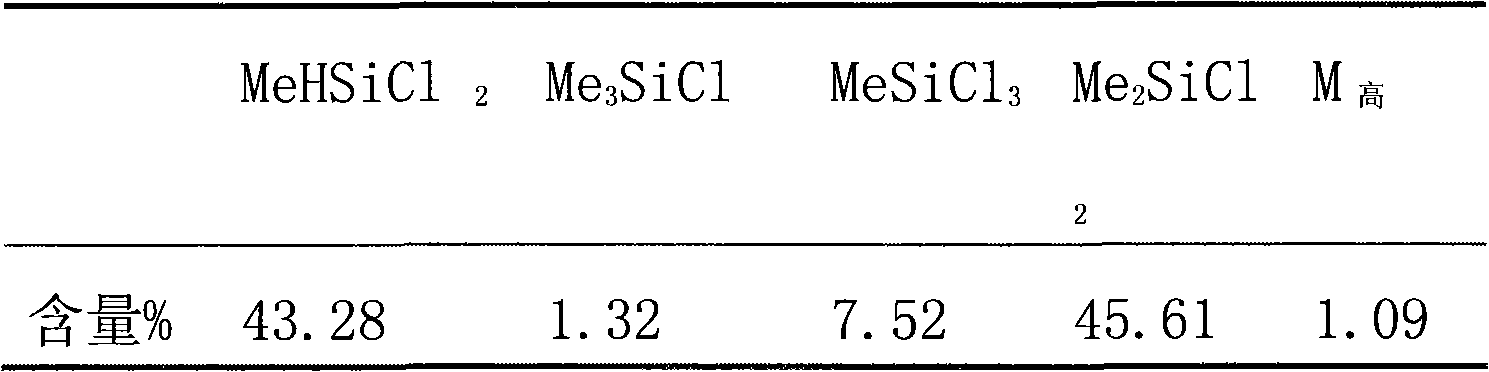

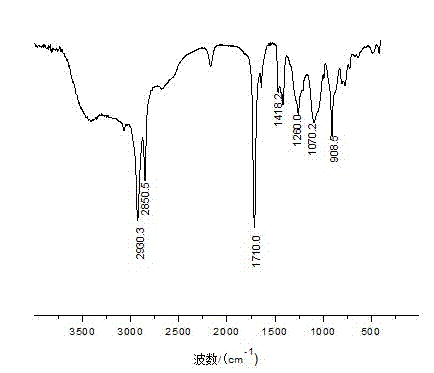

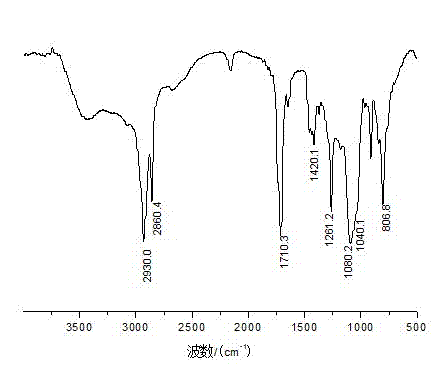

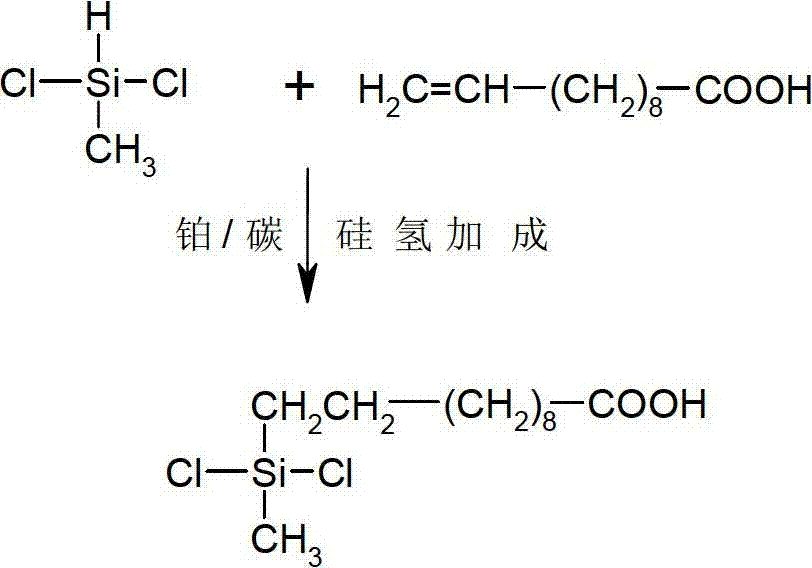

Preparation method of carboxyl silicone oil

InactiveCN102731787AThe synthesis process is simpleRaw materials are easy to getFibre treatmentSilanesHydrosilylation

The invention discloses a preparation method of carboxyl silicone oil. Undecylenic acid and methyl hydrogen dichlorosilane are taken as raw materials to be subjected to direct hydrosilylation in the presence of a platinum / carbon catalyst to obtain 11-carboxyl undecyl methyl dichlorosilane; and the carboxyl silane monomer 11-carboxyl undecyl methyl dichlorosilane and dimethyldichlorosilane are subjected to co-hydrolysis and equilibrium polycondensation to obtain 11-carboxyl undecyl methyl silicone oil. The preparation method has the following advantages: the preparation process of carboxyl silicone oil is simplified by adopting the method for preparing the carboxyl silane monomer by one step through the direct addition reaction; the raw materials adopted for synthesis are industrial raw materials and are suitable for industrial large-scale production; and after being prepared into emulsion and compounded with amino silicone oil emulsion, the prepared carboxyl silicone oil can provide very good softness and full hand feel when being applied to textile finishing.

Owner:SUZHOU UNIV

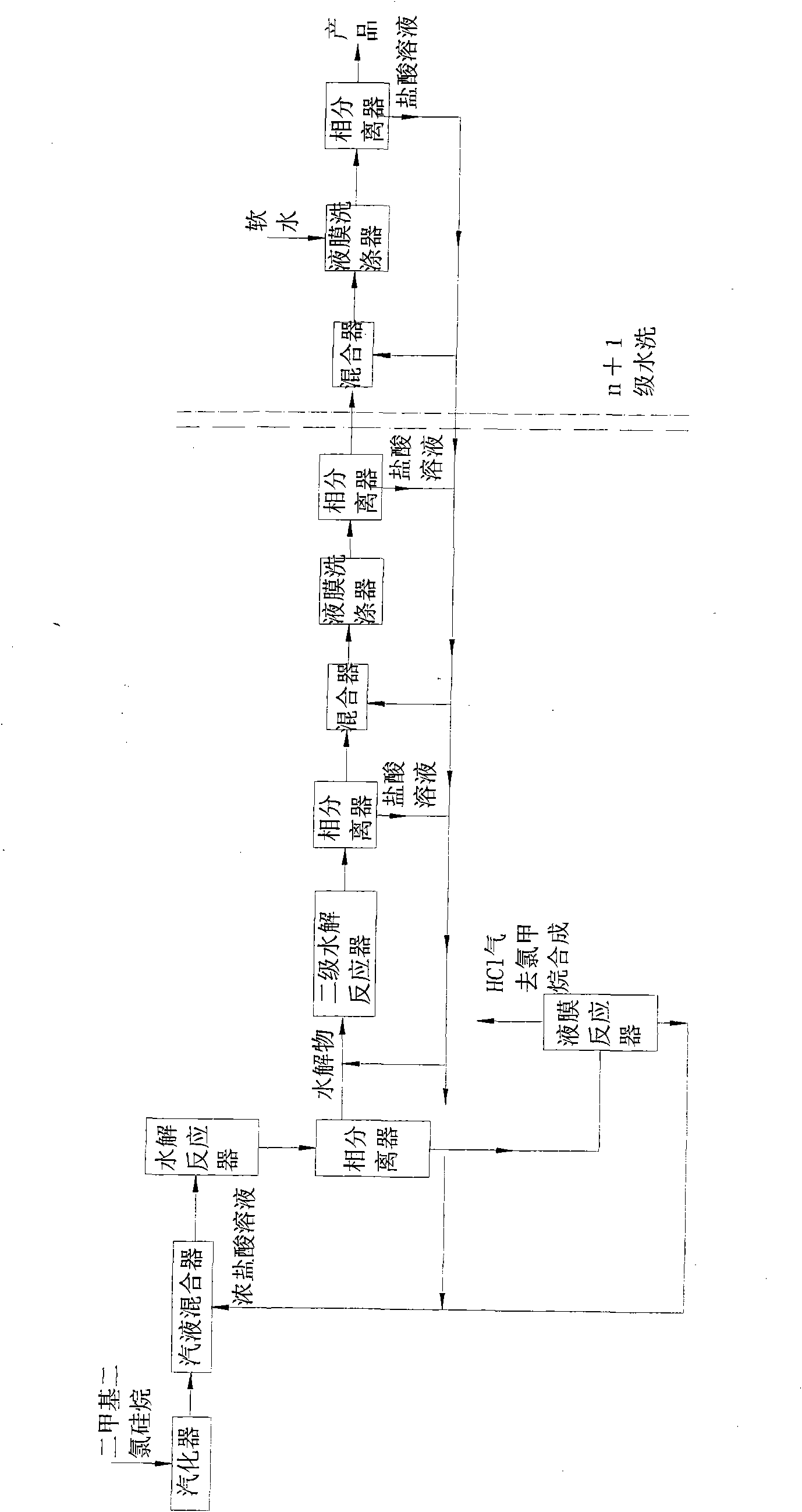

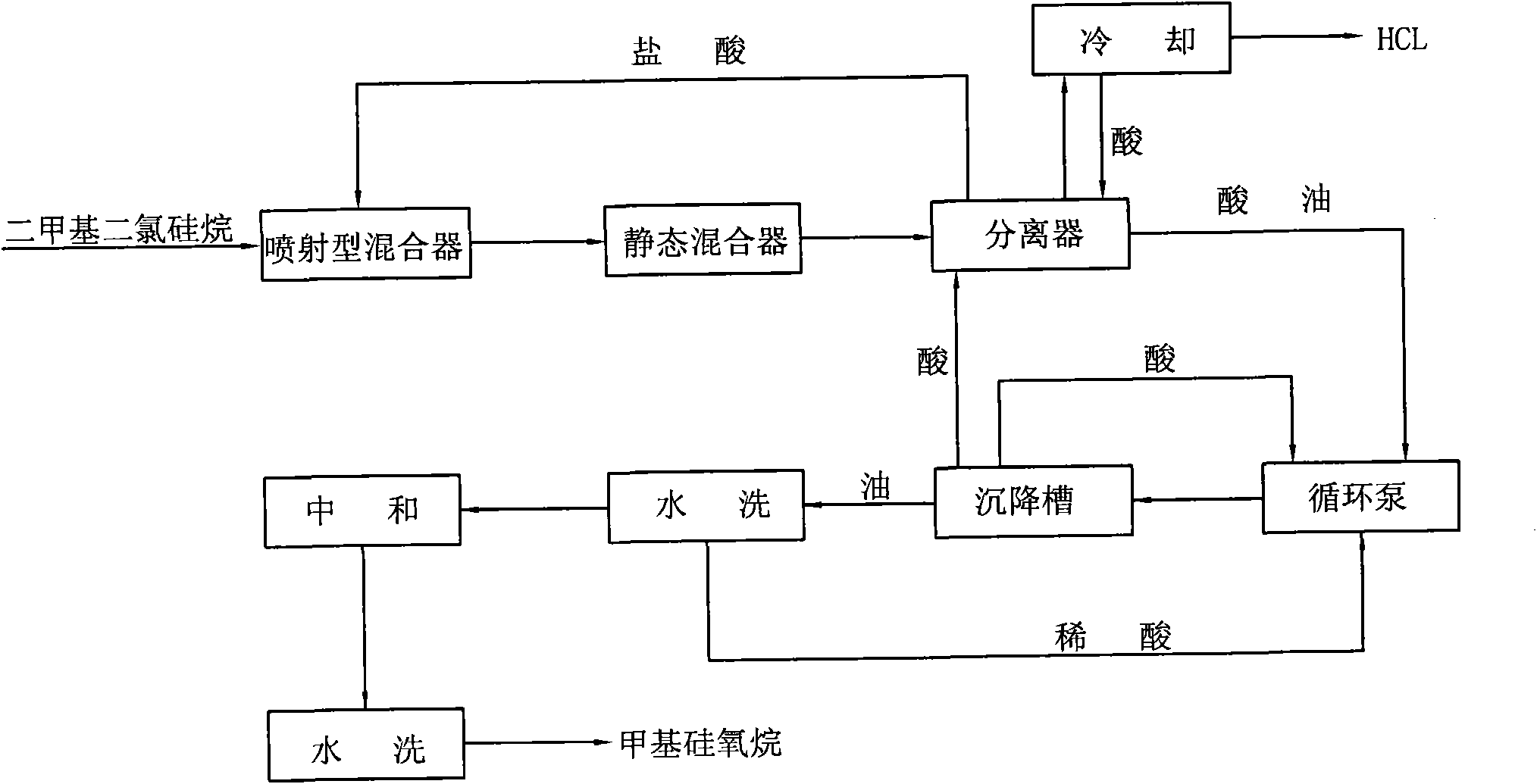

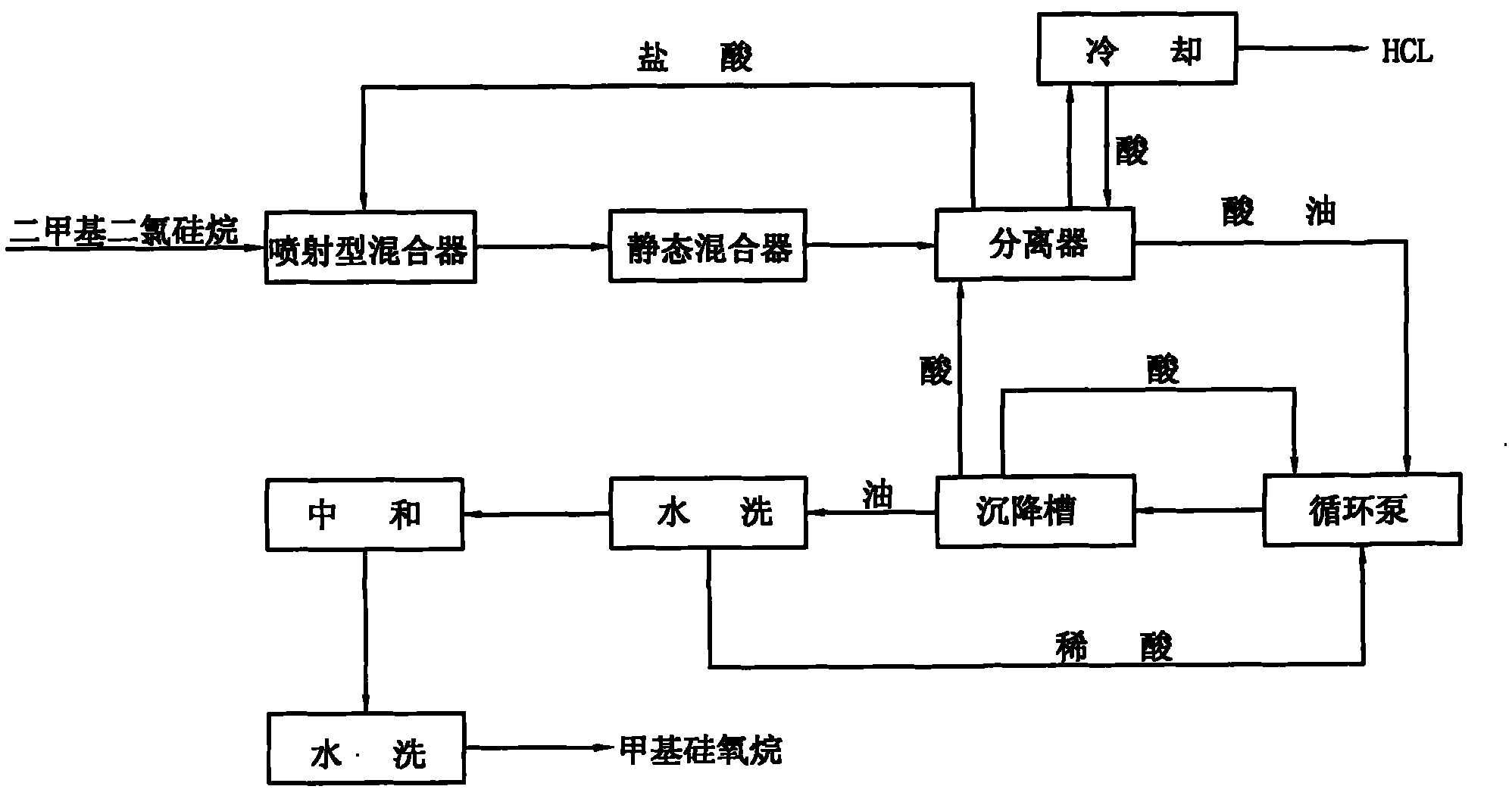

Method for hydrolyzing dimethyldichlorosilane in saturated acid

The invention relates to a hydrolysis technology of methyl chlorosilane, in particular to a technology for hydrolyzing dimethyldichlorosilane in saturated acid and preparing high cyclosiloxane and hydrolysate with low chloride ions. The technology is characterized by comprising the following steps: mixing vaporized dimethyldichlorosilane with concentrated hydrochloric acid to perform hydrolysis reaction, sending the reaction solution to a phase separator for separation, using the separated crude hydrolysate and concentrated hydrochloric acid to perform hydrolysis reaction again, sending the reaction solution to the phase separator to separate hydrolysate and acid solution, washing the hydrolysate with water, sending the hydrolysate to the phase separator to separate polydimethylsiloxane and acid solution, sending the concentrated hydrochloric acid separated through the first hydrolysis separation to a liquid membrane reactor to separate hydrogen chloride gas, and sending concentrated hydrochloric acid back to the hydrolysis reactor for circular reaction, wherein the acid solutions separated through the other steps are also used for circular reaction. By adopting the method of the invention, the operation process is simplified, the energy consumption is reduced and the production cost is lowered.

Owner:ZHENJIANG JIANGNAN CHEM

Method for preparing inertia high-boiling silicone oil from organic silicone high-boiling residues

The invention discloses a method for preparing inertia high-boiling silicone oil from organic silicone high-boiling residues. With organic silicone high-boiling residues as the reaction raw material, the method includes the four steps of hydrolysis, hydrosilylation, neutralization, and devolatiligation and decoloration. The organic silicone high-boiling residues as the raw material are rectified high-boiling residues or decomposed high-boiling residues. The rectified high-boiling residues are high-boiling residues obtained by separating dimethyldichlorosilance out of the organic silicone high-boiling residues in advance through rectification. The decomposed high-boiling residues are high-boiling residues obtained by decomposing the organic silicone high-boiling residues in advance through a decomposing device and separating out monosilane. The decomposed high-boiling residues or rectified high-boiling residues which are difficult to process and use are used as the raw material, and the inertia high-boiling silicone oil which is controllable in viscosity, low in activity and high in stability is prepared through hydrolysis, addition and other reaction. The method is controllable in reaction process, simple in post-processing method, conventional in reaction device, high in production efficiency, stable in product quality and suitable for large-scale industrial production.

Owner:浙江中天东方氟硅材料股份有限公司

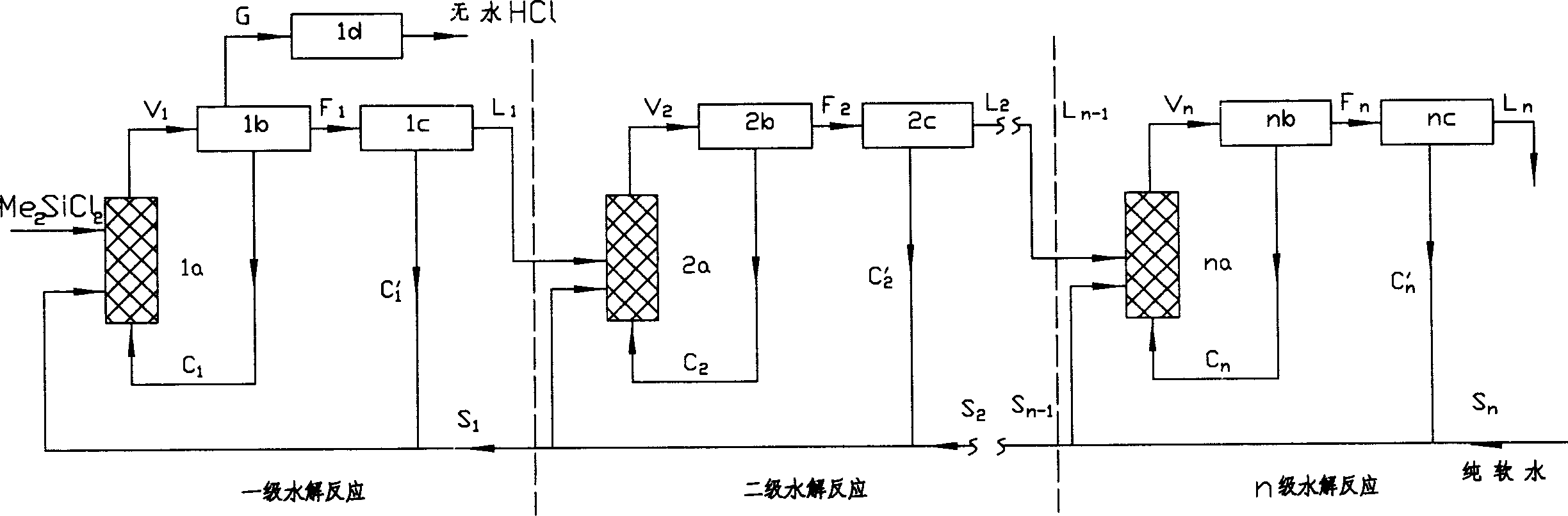

Continuous hydrolysis process of organic dichlorosilane

A continuous hydrolysis process for organic dichlorosilane in order to prepare low-viscosity linear or cyclic organic siloxane includes at least three stages of cyclic hydrolysis reaction system. Each cyclic hydrolysis reaction system includes internal and external cyclic units.

Owner:蓝星安迪苏股份有限公司

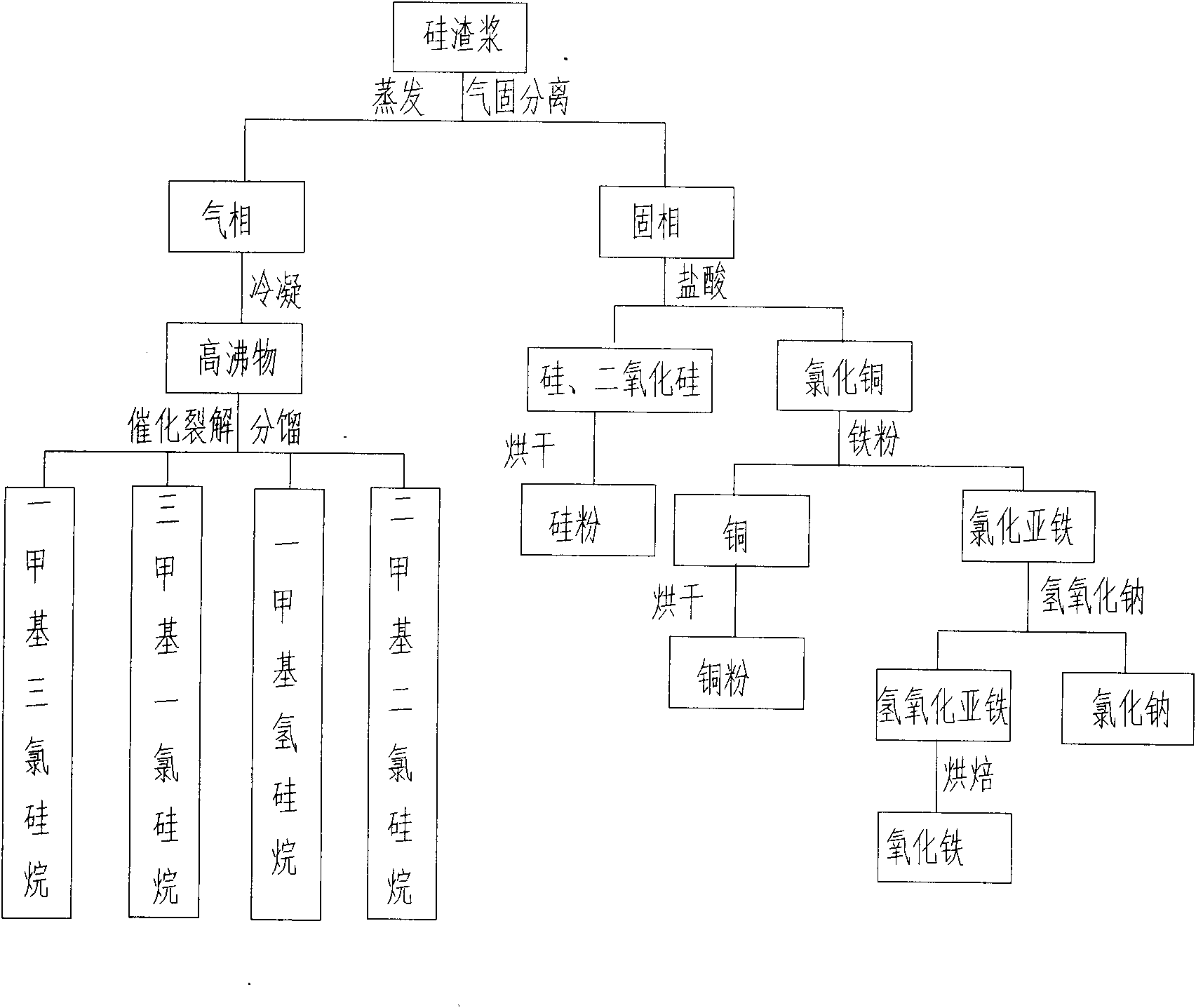

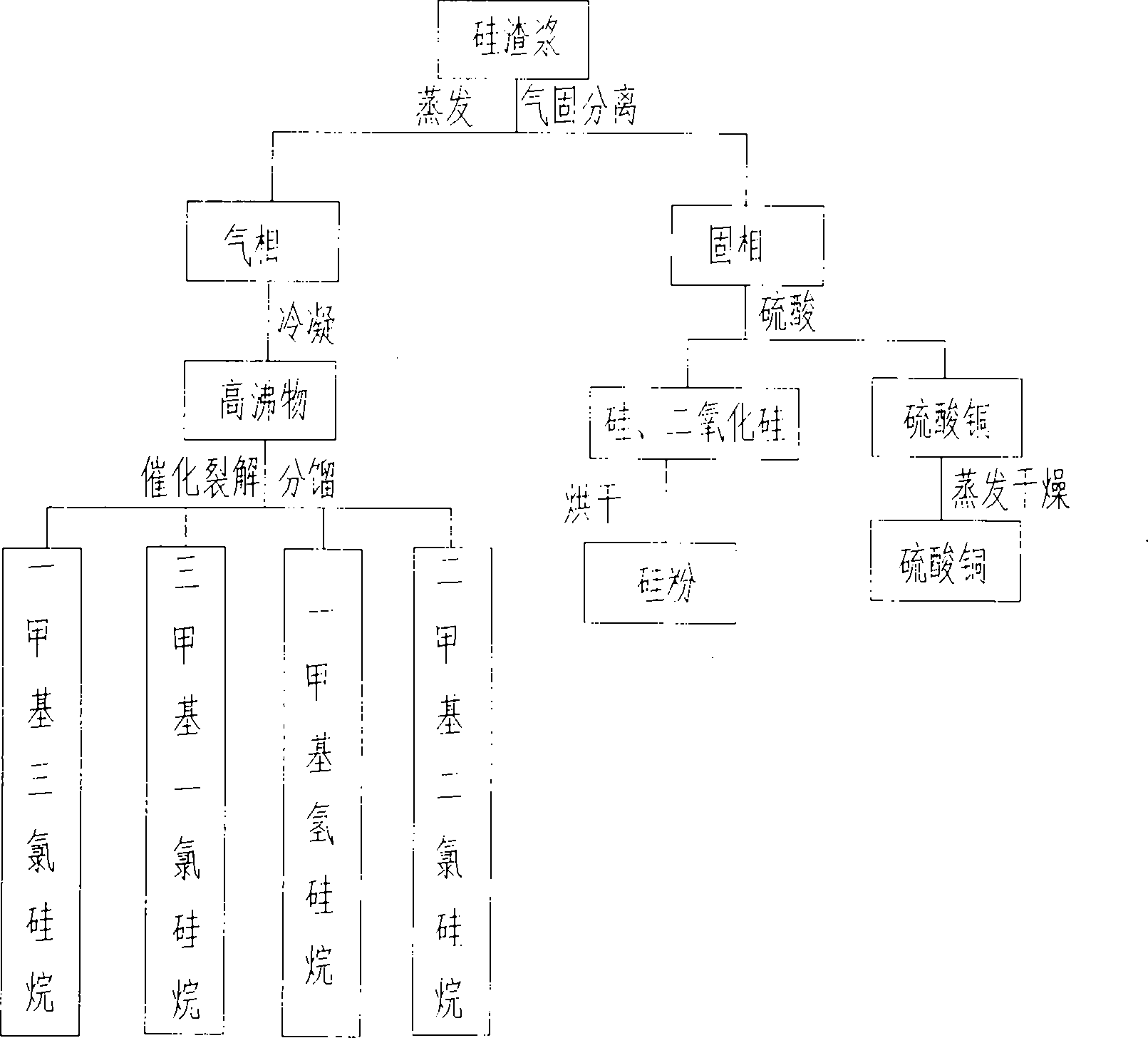

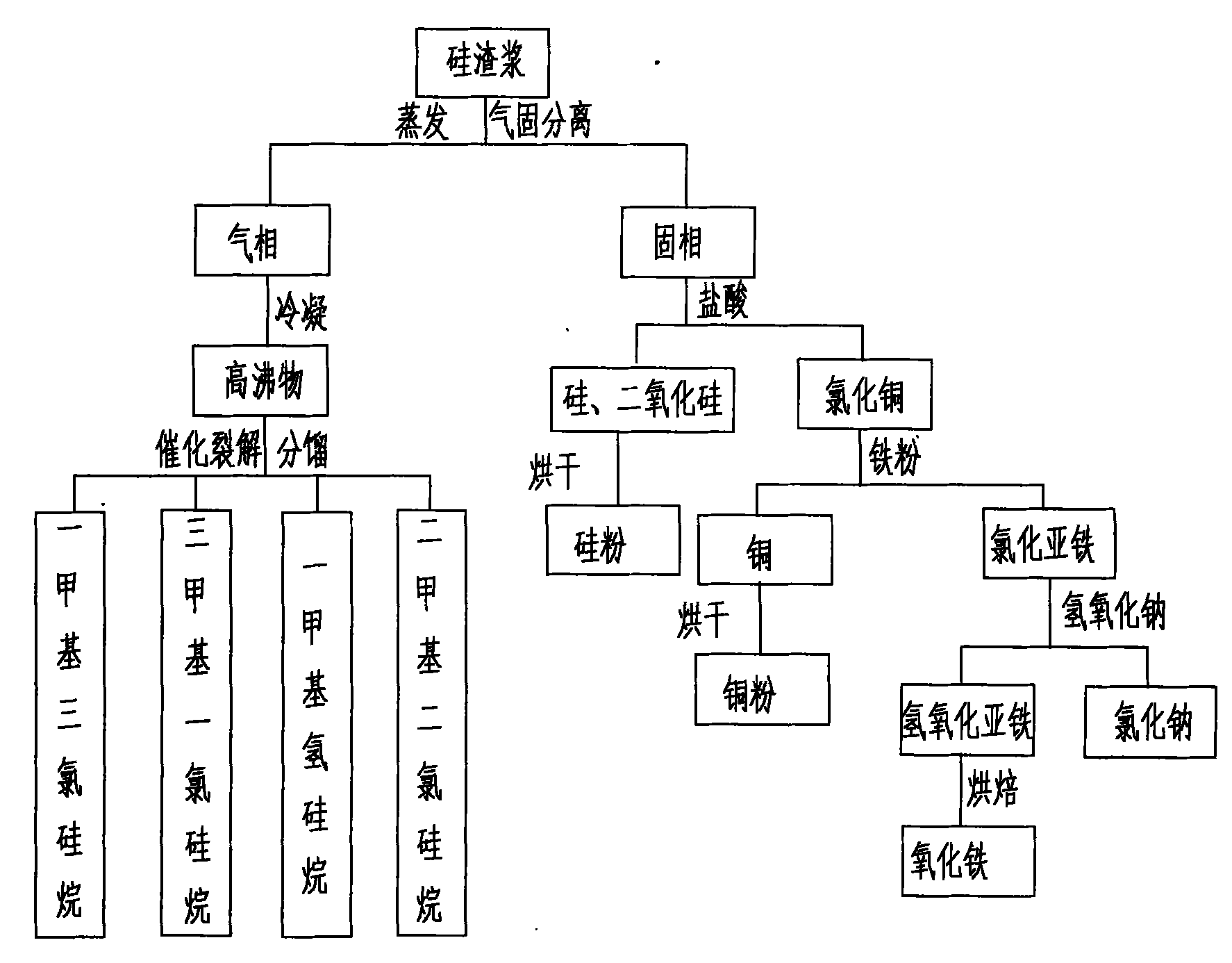

Processing and recycling process for silicon slurry

PendingCN102174674AGuaranteed to drive normallyEliminate pollutionSilicon organic compoundsFerrous oxidesGas phaseSilanes

The invention provides a processing and recycling process for silicon slurry, which comprises the steps as follows: silicon slurry is evaporated for gas and solid separation; high boiling point substances are obtained after the gas phase is condensed; the high boiling point substances react with hydrogen chloride to be cracked into mixed monomers such as methyl trichloro silicane, trimethyl chloro silicane, methyl silane, dimethyl dichloro silicane and the like; and after the fractionation, each pure monomer product can be obtained. The solid phase separated through evaporation mainly contains cuprous oxide, silicon, silicon dioxide and the like; hydrochloric acid (or sulfuric acid) is added into the solid phase to extract copper chloride (or copper sulfate, which can be sold directly) by a chemical method; and silicon and silicon dioxide are separated out. Iron powder is added into a copper chloride solution for extracting copper and ferrous chloride, and sodium hydroxide is added into the ferrous chloride solution for extracting ferrous oxide. The processing and recycling process is environment-friendly and can eliminate pollution, and meanwhile can recover various by-products from silicon slurry, thereby having well economic benefits.

Owner:上海竟茨环保科技有限公司

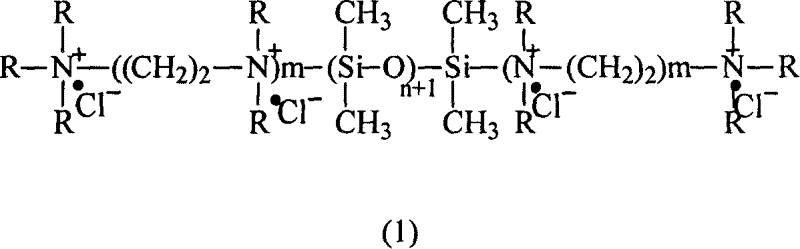

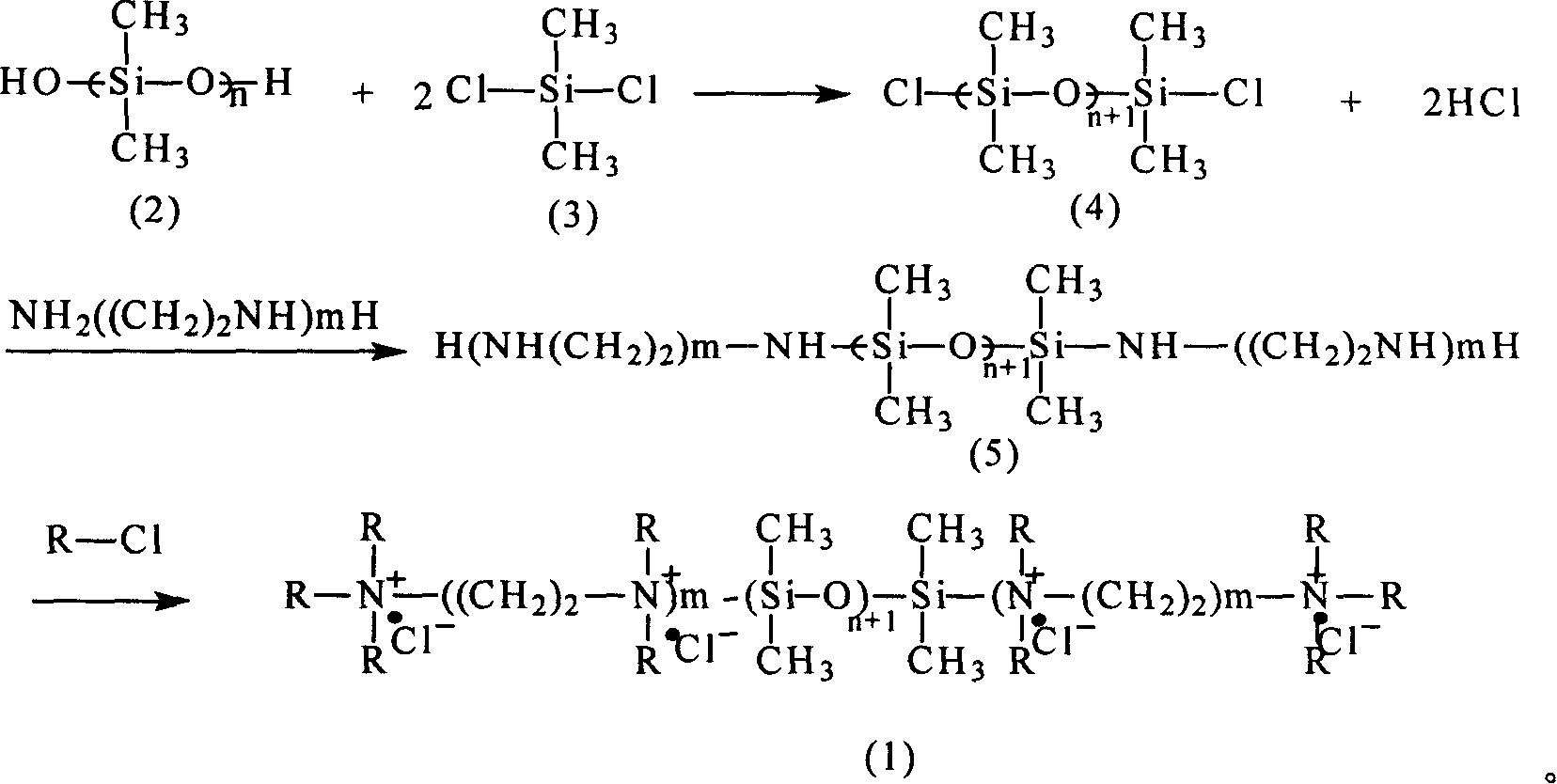

Cation, reactnig silicone coloring fixing agent and preparing method thereof

InactiveCN1583763AGood color fixing effectDoes not affect colorGroup 4/14 element organic compoundsDyeing processSilicone oilReaction type

A cationic organic silicon compound of reaction type color-fixing agent, is obtained by: react hydroxy silicone oil, dimethyl dichlorosilicane, amine, siloxane, together with quaternary ammonium agent. The durable color-fixing agent is of environmental protection. It improves color-fixing effect of active dyes in difficulty for color fixing and low fastness for washing. Besides those advantages, it is helpful for softening and has bactericidal effect. It can be used in direct dye and acidic dye to increase the wet fastness in fabrics, improve wear and sunshine tolerance, less influence in colors and tones of fabrics and have brighten and strengthen fuscous.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for removing and recycling dimethyldichlorosilane from hydrochloric acid gas

The invention discloses a process for removing and recycling dimethyldichlorosilane from hydrochloric acid gas. A frozen brine graphite cooler is used. The process is characterized by comprising the following steps: volatilizing liquid CH3Cl to obtain low temperature less than -50 DEG C; absorbing dimethyldichlorosilane by using CH3Cl at low temperature; and separating absorption liquid into gas having more than 99.9% (wt) of CH3Cl in purity and a residue having more than 99.9% (wt) of dimethyldichlorosilane through rectification. According to the process, an original frozen brine graphite cooler can be adopted; cooling capacity can be obtained by using evaporation of the residue in an absorption tower so as to cool the raw material HCl to the temperature less than -20 DEG C; the whole process is performed in closed cycle, thus dimethyldichlorosilane in a gas phase of the raw material HCl can be thoroughly removed, the separated dimethyldichlorosilane can be treated up to the standard and returned to a dimethyldichlorosilane hydrolysis step; and the process has the advantages of simplicity in method, economy and practicability, low operation cost, little pollution and environment friendliness.

Owner:余家骧

Ternary copper catalyst CuO-Cu2O-Cu for synthesis of dimethyldichlorosilane and its preparation method

InactiveCN102773100AWell formedLow priceGroup 4/14 element organic compoundsCatalyst activation/preparationCopper(II) oxideControllability

The invention relates to the field of catalysts used for synthesis of dimethyldichlorosilane, in particular to a ternary copper catalyst CuO-Cu2O-Cu for synthesis of dimethyldichlorosilane and its preparation method. The method comprises the following steps of: 1) taking copper oxide powder as a raw material, adding a reducing gas, controlling its flow to make the flow of the reducing gas introduced into per gram of CuO particles at 0.1ml / min-100ml / min, maintaining the temperature at 100DEG C-600DEG C, carrying out a reduction reaction for 0.5h-6h, thus obtaining partially reduced copper oxide; and 2) subjecting the partially reduced copper oxide obtained in step 1) to breaking and ball-milling, thus obtaining the ternary copper catalyst for synthesis of dimethyldichlorosilane. With copper oxide as the raw material, the method prepares the ternary copper catalyst CuO-Cu2O-Cu through a one-step reaction, and has the advantages of simple technological process, convenient operation, strong process controllability, and easy mass production. The prepared catalyst shows high dimethyldichlorosilane selectivity and silicon powder material conversion rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for preparing polysiloxane by hydrolyzing dimethyl dichlorosilane

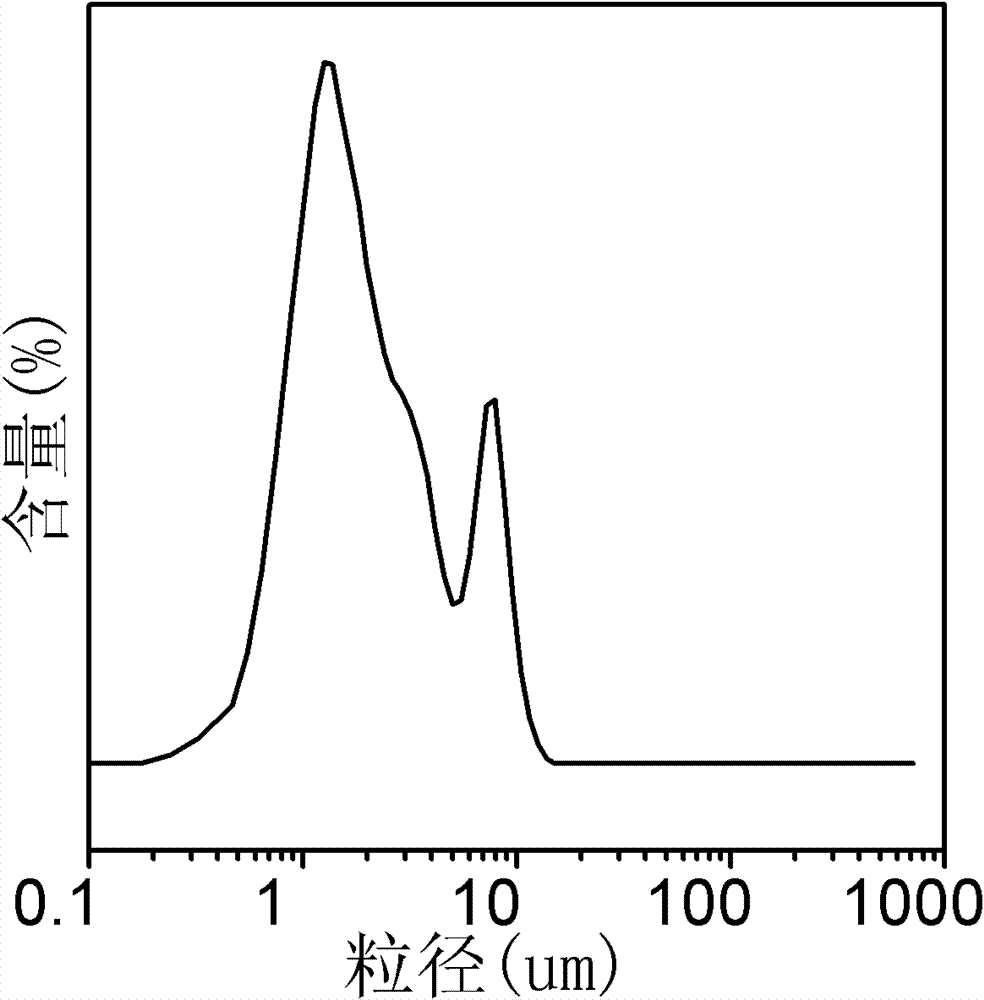

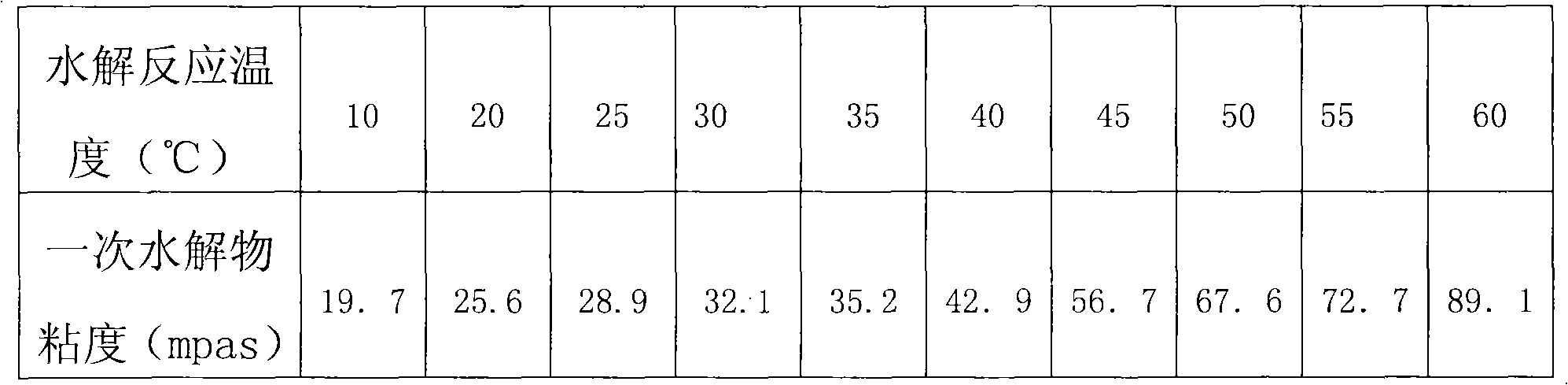

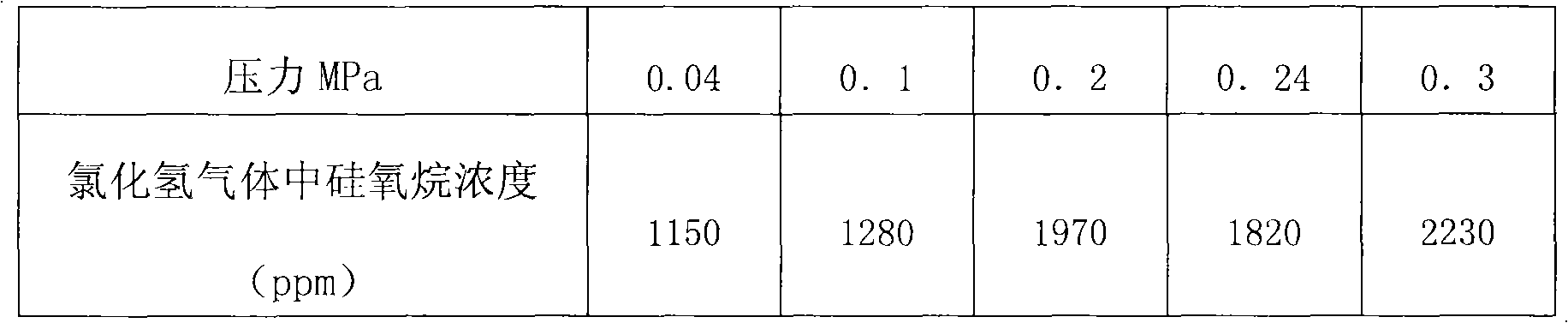

The invention relates to a method for preparing polysiloxane by hydrolyzing dimethyl dichlorosilane, which comprises two continuous hydrolysis steps (1) and (2) and a neutralization step (3): step (1), dimethyl dichlorosilane, concentrated hydrochloric acid of the concentration greater than 35 percent and dilute generated by secondary hydrolysis are hydrolyzed at 10-60DEG C and under the pressure of 0-0.3MPa according to the weight ratio of 1: 1.5: 0.5-1: 1.5: 3; step (2), hydrolysis is carried out in excess water, and the reaction temperature is normal temperature; and step (3), the neutralization reaction is carried out, resin is adopted to adsorb a filter unit, the stuffing is cation-base exchange resin with large surface area, and the height of the stuffing is 2-4 meters; the content of the hydrolysate Cl- is less than 10ppm, the product siloxane prepared in the method has the viscosity less than 50mPa.S, and the content of impurity in hydrogen chloride gas is less than 10ppm.

Owner:PETROCHINA CO LTD

Cracking process of organosilicon high-boiling components

The invention relates to a cracking process of organosilicon high-boiling components.. The cracking process is characterized in that organosilicon high-boiling components are used as raw materials and are subjected to impurity removal, N,N-dimethylaniline, N,N-diethylformamide or tri-n-butylamine are selected as a catalyst, the catalytic cracking is performed inside a reaction vessel to which hydrogen chloride gas is introduced, and finally, dimethyldichlorosilane, monomethyltrichlorosilane, monomethyldichlorosilane and trimethylchlorosilane are respectively recovered through a layered cooling tower at different temperatures. The cracking process has the advantages that the matching is reasonable, the operation is simple, the recovery ratio is high, and more than 60% of dimethyldichlorosilane product with high added value can be obtained.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Improved producing process of methyl chlorosilane

InactiveCN1560056AGood effectFully lysedGroup 4/14 element organic compoundsDimethylaniline N-oxideDichlorosilane

The invention relates to an improvement of the producing method of methylchlorosilane, adding methylchlorodisilane, and a catalyst N, N-dimethylaniline1 accounting for 1-2% of the weight of methylchlorodisilane into a cracking kettle, making the materials a certain quantity, where the kettle is installed with a fractionating tower. It controls temperature at 90-110 deg.C, charging hydrogen chloride into the materials, making the molar ratio of methylchlorodisilane to hydrogen chloride 1 to 0.9-5.5, and its characteristic: the ratio of the height of the crackling kettle to the diameter = 1.0-2.0; the flux of the hydrogen chloride is 16 cu m / h; reacting for 5 hours, and then supplementing methylchlorodisilane into the kettle, and later supplementing once at 2h intervals, supplementing the hydrogen chloride once 200 kg, and completing in 0.5 h; supplementing the catalyst 2 kg at 4h intervals and completing in 10 minutes. It continuously reacts for 28-36 h, and collects condensate. It does not preprocess raw materials, and the sum of methylhydrodichlorosilane and dimethyldichlorosilane higher than that of existing techniques.

Owner:吉林市凇泰化工有限责任公司

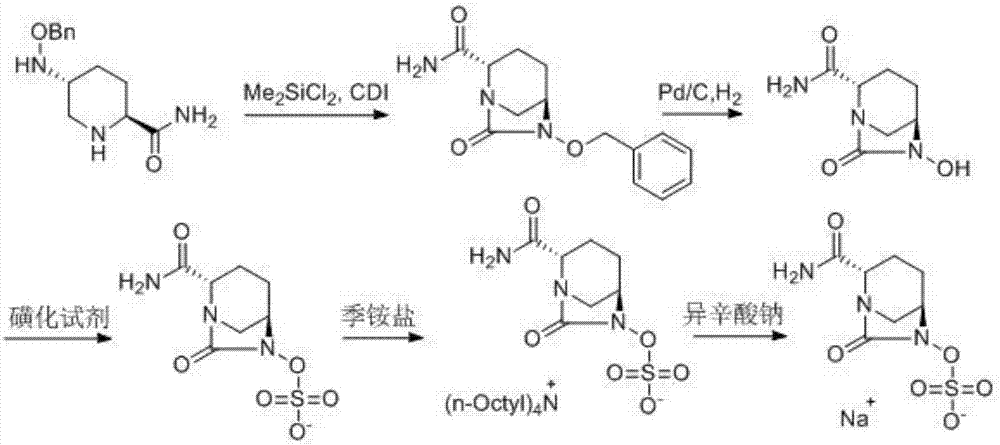

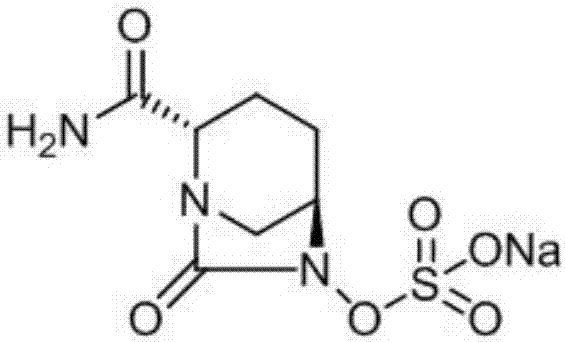

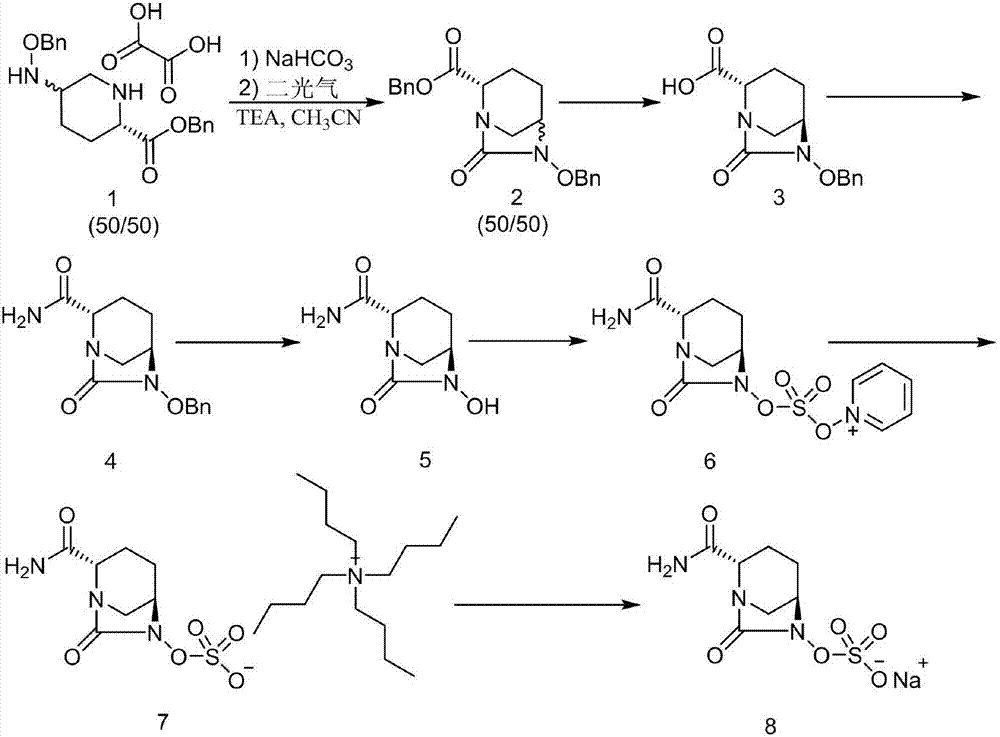

Synthetic method for avibactam sodium salt

ActiveCN107417686ALow priceReduce manufacturing costOrganic chemistryIon exchangeCarbonyldiimidazole

The invention discloses a synthetic method for avibactam sodium salt. The method comprises the following steps: taking (2S, 5R)-5-[(benzyl oxyl) amino] piperidine-2-formamide as a starting material; constructing a urea ring by carbonyl diimidazole under the effect of dimethyldichlorosilance to obtain (2S, 5R)-6-(benzyl oxyl)-7-oxo-1,6-diazabicyclo [3.2.1] octane-2-formamide; then carrying out hydrogenation to remove benzyl; carrying out sulfonation reaction on the compound and a sulfonated reagent; synthesizing into a quaternary ammonium salt intermediate by using quaternary ammonium salt; and finally carrying out ion exchange to obtain the avibactam sodium salt. The improved process is low in cost, simple and convenient to operate, good in product quality and suitable for industrial production. In a process of synthesizing the intermediate (2S, 5R)-6-(benzyl oxyl)-7-oxo-1,6-diazabicyclo [3.2.1] octane-2-formamide, dimethyldichlorosilance which is low in price is used, and therefore, the production cost is greatly reduced.

Owner:JIANGXI FUSHINE PHARMA CO LTD

Dimethyl dichlorosilane hydrolysis method for directly producing gaseous hydrogen chloride

ActiveCN101817505ARealize self-flowing transportationAvoid easy cloggingGroup 4/14 element organic compoundsChlorine/hydrogen-chlorideDichlorosilaneChloride

The invention discloses a dimethyl dichlorosilane hydrolysis method for directly producing gaseous hydrogen chloride, and belongs to the technical field of hydrolysis during the production of methyl chlorosilane. The method comprises the following steps of: pre-mixing the dimethyl dichlorosilane and concentrated hydrochloric acid through a jet mixer and then feeding the mixture into a static mixer for hydrolysis of concentrated hydrochloric acid with pressure so as to obtain a reaction mixture; introducing the reaction mixture into a combined separator with a plate type tower; separating the acid oil, acid and gas from the reaction mixture; and processing the acid oil, the acid and the gas respectively. The method ensures complete reaction and complete separation so as to obtain relatively pure hydrogen chloride gas and ensure difficult blockage of a methyl chloride synthesizer and pipelines thereof through forcible hydrolysis of the static mixer and separation of the combined separator with the plate tower in coordination with water removal by condensation; and the hydrogen chloride per se has pressure so as to realize the gravity feed of the hydrogen chloride. The method can obviously improve the product yield; and the unit consumption of the dimethyl dichlorosilane per ton of methyl siloxane is below 1.7 tons.

Owner:HANGZHOU JINFADA CHEM IND

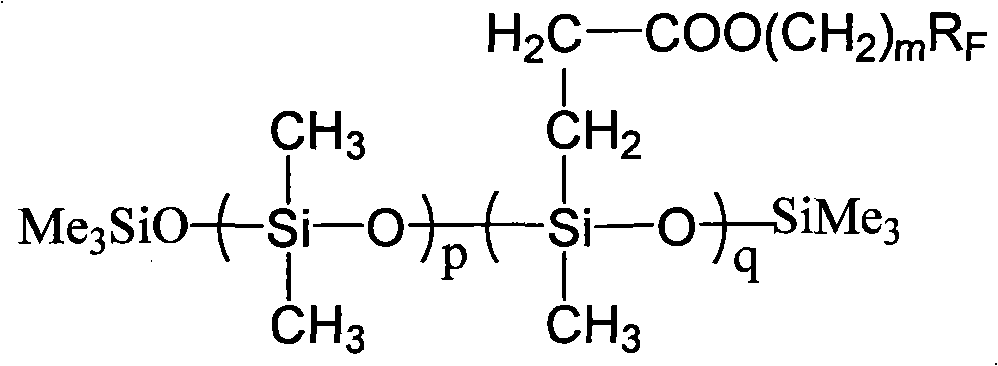

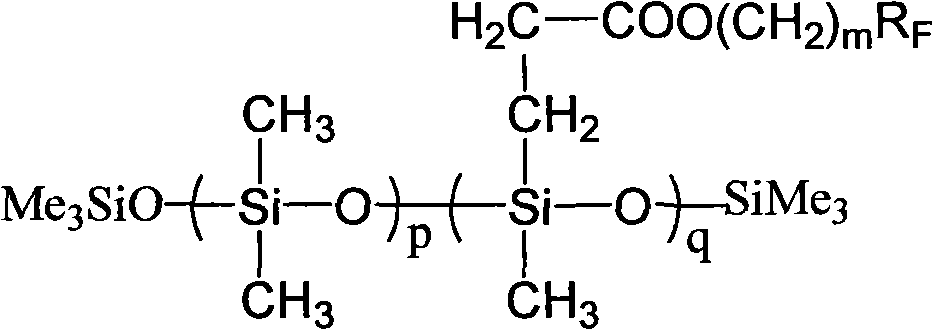

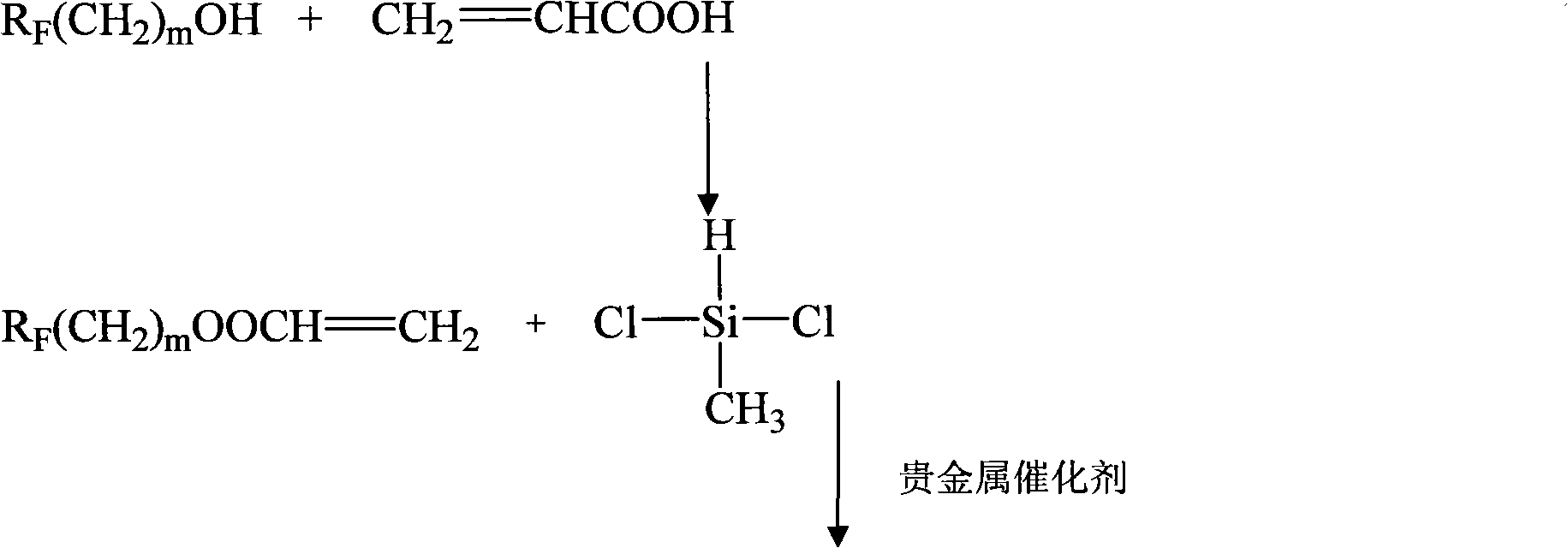

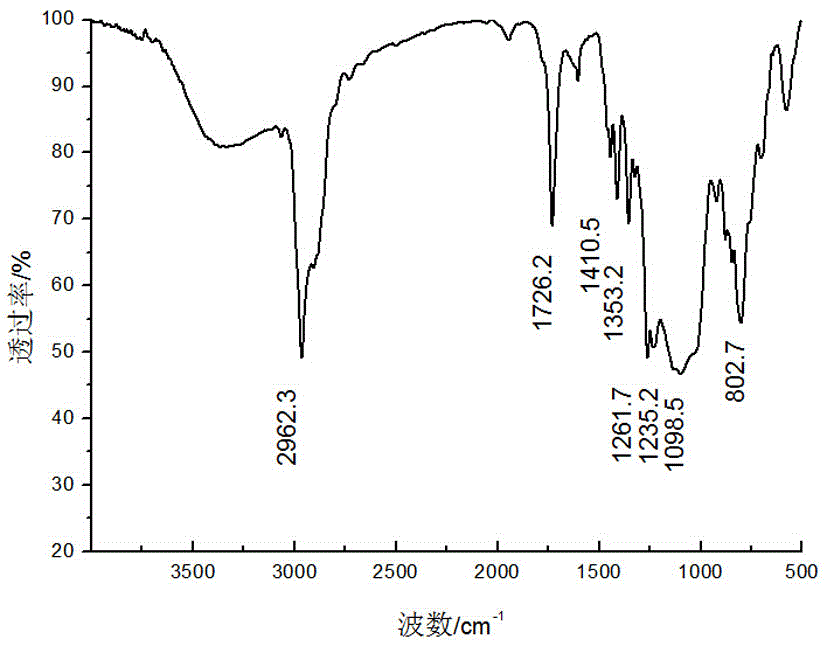

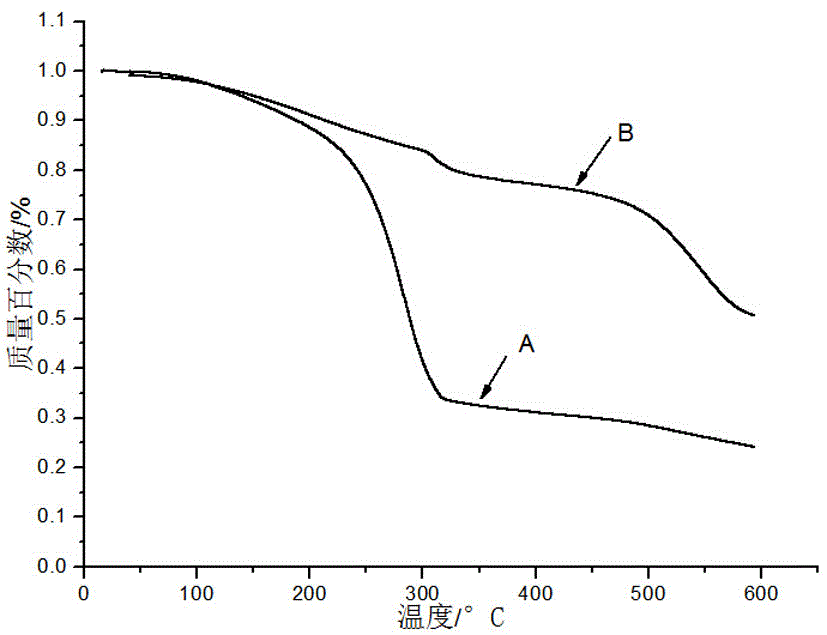

Preparation method of fluorosilicon oil with high-efficiency defoaming performance

ActiveCN101780385AHigh surface energyGood defoamingTransportation and packagingMixingDisiloxaneSilanes

The invention discloses fluorosilicon oil with a high-efficiency defoaming performance and a preparation method thereof. Acroleic acid and fluorine-containing fatty alcohol generate esterification reaction under the effect of a catalyst to synthesize fluorine-containing fatty alcohol acrylate; the fluorine-containing fatty alcohol acrylate and dichloromethyl silane generate silicon hydrogen addition reaction to obtain fluorine-containing dichlorosilane; the fluorine-containing dichlorosilane and dimethyl dichlorosilane generate dechlorination cyclization reaction under the effect of a metal oxide; and finally, under the effect of a blocking agent hexamethyl disiloxane, the fluorosilicon oil is obtained by ring-opening polymerization reaction. The fluorosilicon oil has low surface tension and good defoaming and foam inhibiting effects as an oil defoamer.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Modified fluorine-containing silicone oil and preparation method thereof

The invention discloses modified fluorine-containing silicone oil and a preparation method thereof. The preparation method of the modified fluorine-containing silicone oil comprises the following steps: firstly reacting hydrogen-containing dichloromethylsilane which serves as a starting material, chloroplatinic acid which serves as a catalyst and octavinyl polyhedral oligomeric silsesquioxane (POSS) to synthesize a vinyl polyhedral oligomeric silsesquioxane dichloromethylsilane monomer; then carrying out hydrolysis co-balance by the monomer, dimethyldichlorosilance and trimethylchlorosilane to prepare vinyl polyhedral oligomeric silsesquioxane side group silicone oil; and finally carrying out single electron transfer reaction (SET) by vinyl and perfluoroalky iodide in a vinyl polyhedral oligomeric silsesquioxane structure of the side group to prepare the modified fluorine-containing silicone oil. According to the modified fluorine-containing silicone oil, octavinyl polyhedral oligomeric silsesquioxane is added in a side chain of the silicone oil, so that the heat resistance of the silicon oil is improved; by virtue of the fluoroalkylation reaction, the surface tension of the fluorine-containing silicone oil is reduced. The modified fluorine-containing silicone oil is excellent in water and oil repellency and resistance to high temperature; the high-temperature-resistant fluorine-containing silicone oil is mild in reaction conditions, simple and convenient tin preparation process and easily available in raw materials, and is suitable for industrial production.

Owner:苏州盛泽科技创业园发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com