Method for hydrolyzing dimethyldichlorosilane in saturated acid

A technology of dimethyldichlorosilane and polydimethylsiloxane, which is applied in the field of hydrolysis technology of methylchlorosilane, can solve the problem that no linear siloxane treatment process is involved, gaseous hydrogen chloride and hydrolyzate rings cannot be directly obtained. It can save energy, reduce production costs, and simplify the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

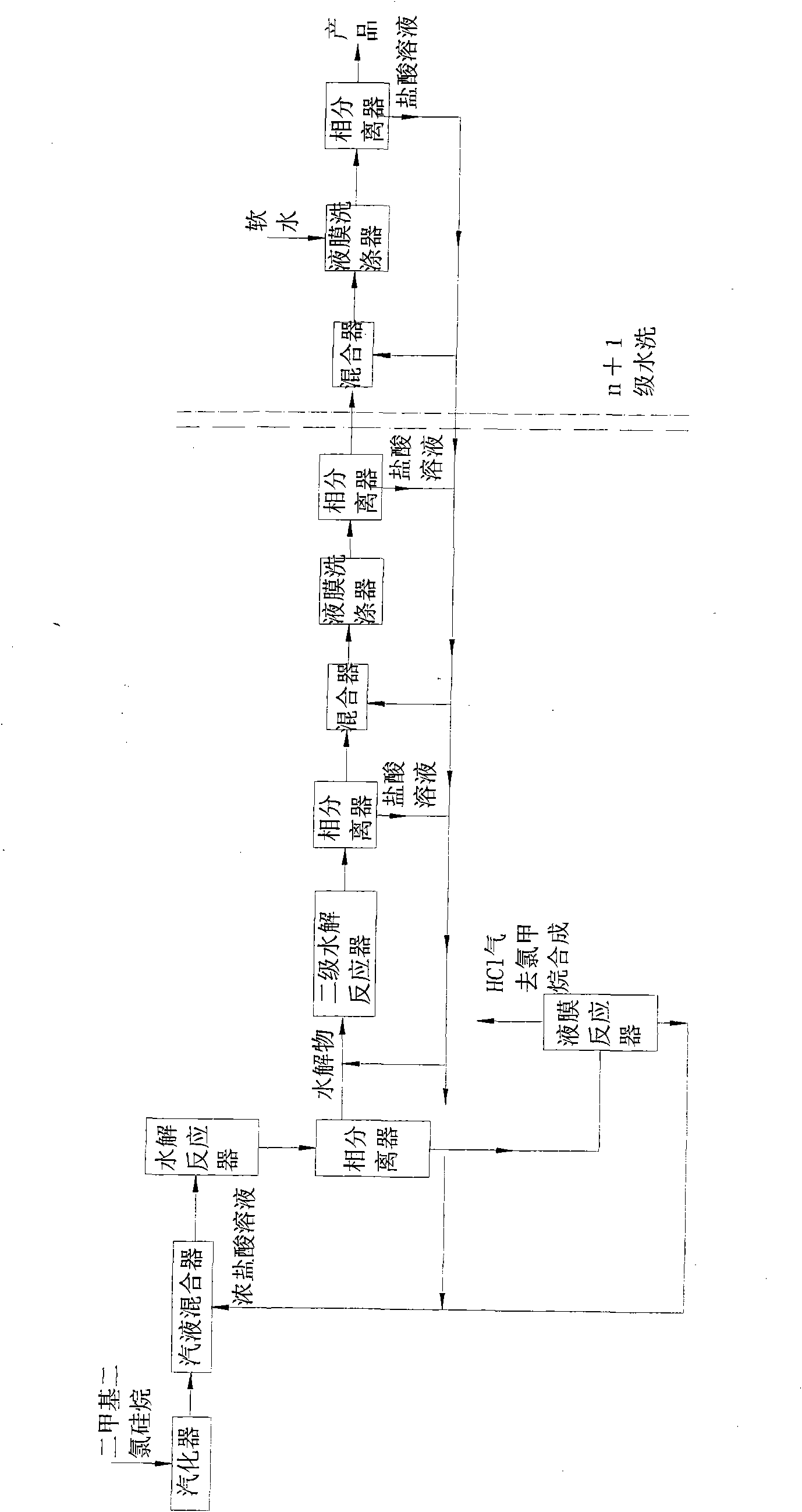

Image

Examples

Embodiment 1

[0023] first stage hydrolysis

[0024] 1500kg / hr dimethyldichlorosilane enters the gas-liquid mixer together with 18000kg / hr, 48% circulating concentrated hydrochloric acid after gasification, the temperature of the hydrolysis reaction system is kept at 25±5°C, and the pressure is 0.21Mpa(G). The residence time of the product in the reaction system is 40s. The reacted mixture is separated in the phase separator, and the separated concentrated acid enters the liquid membrane reactor to separate the HCL gas. The obtained crude hydrolyzate 910kg / hr enters the secondary hydrolysis.

[0025] Second stage hydrolysis

[0026] 910kg / hr crude hydrolyzate and 8000kg / hr circulating hydrochloric acid with a concentration of 32% enter the secondary hydrolysis reactor. The temperature of the reaction system is 30°C and the pressure is normal pressure. The residence time of the hydrolyzate in the reaction system is 55s. The reacted mixture enters the phase separator to obtain 882kg / hr hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com