Patents

Literature

253results about How to "Reduce Chloride Content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

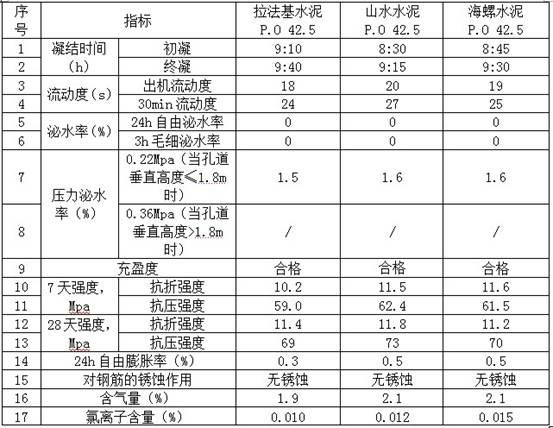

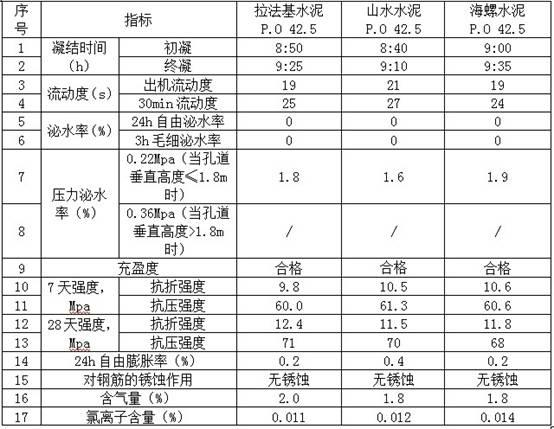

Concrete pipeline mud-jacking agent and preparation method

The invention belongs to the field of building materials, and particularly relates to a concrete pipeline mud-jacking agent and a preparation method thereof. The invention adopts the technical scheme that the concrete pipeline mud-jacking agent comprises the following components in percentage by weight: 0.5 to 2 percent of efficient water reducing agent, 0.1 to 0.5 percent of stabilizer, 1 to 5 percent of early expansion agent, 35 to 55 percent of medium and later expansion agent, 0.1 to 1 percent of retarder, 0.2 to 1 percent of rust inhibitor, 0.05 to 0.1 percent of air entraining agent and 50 to 60 percent of mineral admixture. The concrete pipeline mud-jacking agent has the advantages of wide raw material source, good mobility, high strength, no bleeding or layering, good durability, ageing resistance, low chlorine ion content, no corrosion to steel bars, firmness, high filling property, one-time mud-jacking construction, capability of making slurry in a pipeline compact and pore-free, no shrinkage, no rust corrosion of prestressed steel bars, and firm adhesion with concrete.

Owner:济南鲁新新型建材股份有限公司

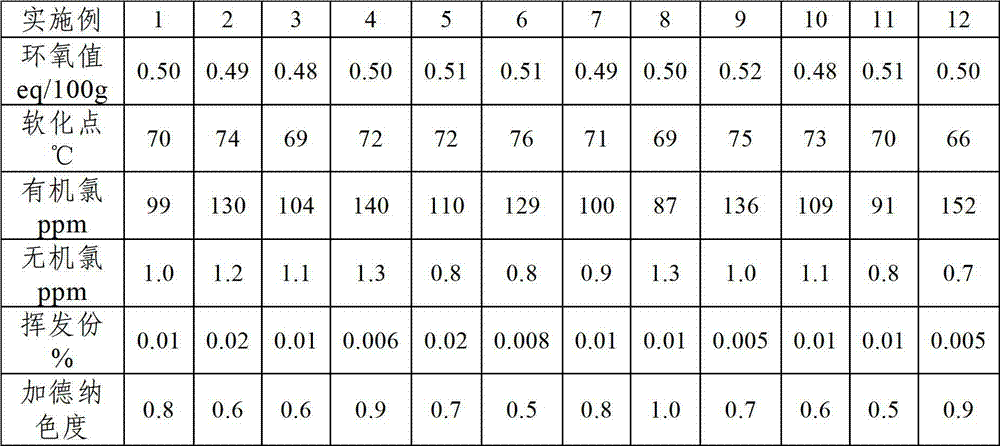

Method for synthesizing light color low-chlorinity o-cresol-formaldehyde epoxy resin

The invention discloses a method for synthesizing a light color low-chlorinity o-cresol-formaldehyde epoxy resin. The method comprises the following steps of: 1, dissolving o-cresol-formaldehyde resin in an organic solvent to obtain an o-cresol-formaldehyde resin solution, adding epoxy chloropropane and a reductant into the o-cresol-formaldehyde resin solution for reductive decoloration reaction of the o-cresol-formaldehyde resin; 2, adding a phase transfer catalyst and a cocatalyst into the reaction system and refluxing under reduced pressure and performing etherification reaction; 3, adding an alkali catalyst into a product of etherification reaction and performing ring-closure reaction; and 4, filtering, washing, reducing pressure and removing the solvent and the unreacted epoxy chloropropane from washed entrapment materials to obtain the light color low-chlorinity o-cresol-formaldehyde epoxy resin of which the Gardner chromaticity is not more than 1 and the chlorinity is not more than 200 ppm. The o-cresol-formaldehyde epoxy resin prepared by the method can meet the requirements for softening point and epoxy value, and is characterized in that the chlorine ion content in the o-cresol-formaldehyde epoxy resin is very low and is less than 200 ppm, and the Gardner chromaticity of the o-cresol-formaldehyde epoxy resin is not more than 1.

Owner:THE NORTHWEST RES INST OF CHEM IND

Method for preparing polycarboxylic acid retarding water reducer

The invention belongs to the technical field of methods for preparing polycarboxylic acid water reducers. A method for preparing a polycarboxylic acid water reducer comprises the following: a step 1 of esterification, in which a poly(ethylene glycol methyl ether)acrylate macromonomer is synthesized by using methoxy polyethylene glycol and acrylic acid in a molar ratio of 1:1.1 to 1:1.5 at 100 to 120 DEG C, water is separated out in a reaction process, and the molecular weight of the macromonomer is 1,250 to 3,000; and a step 2 of polymerization, in which aqueous solution of the macromonomer is prepared, an unsaturated monomer and a catalyst A are added in turn at 40 to 50 DEG C, the temperature is kept constant at 28 to 40 DEG C, aqueous solution of anhydrous sodium hydrogensulfite or vitamin c is dripped, the concentration of a solid content is kept between 35 to 45 percent by adjusting water content, stirring is stopped, and the solution is allowed to stand for 1 to 1.5 hours, the pH value is kept between 6 and 8 by alkaline reagent after the reaction is finished, and the catalyst A is peroxyacetic acid or potassium peroxydisulfate. The invention has the advantages of low cost, simple process and high product performance.

Owner:河北智胜工程技术有限公司

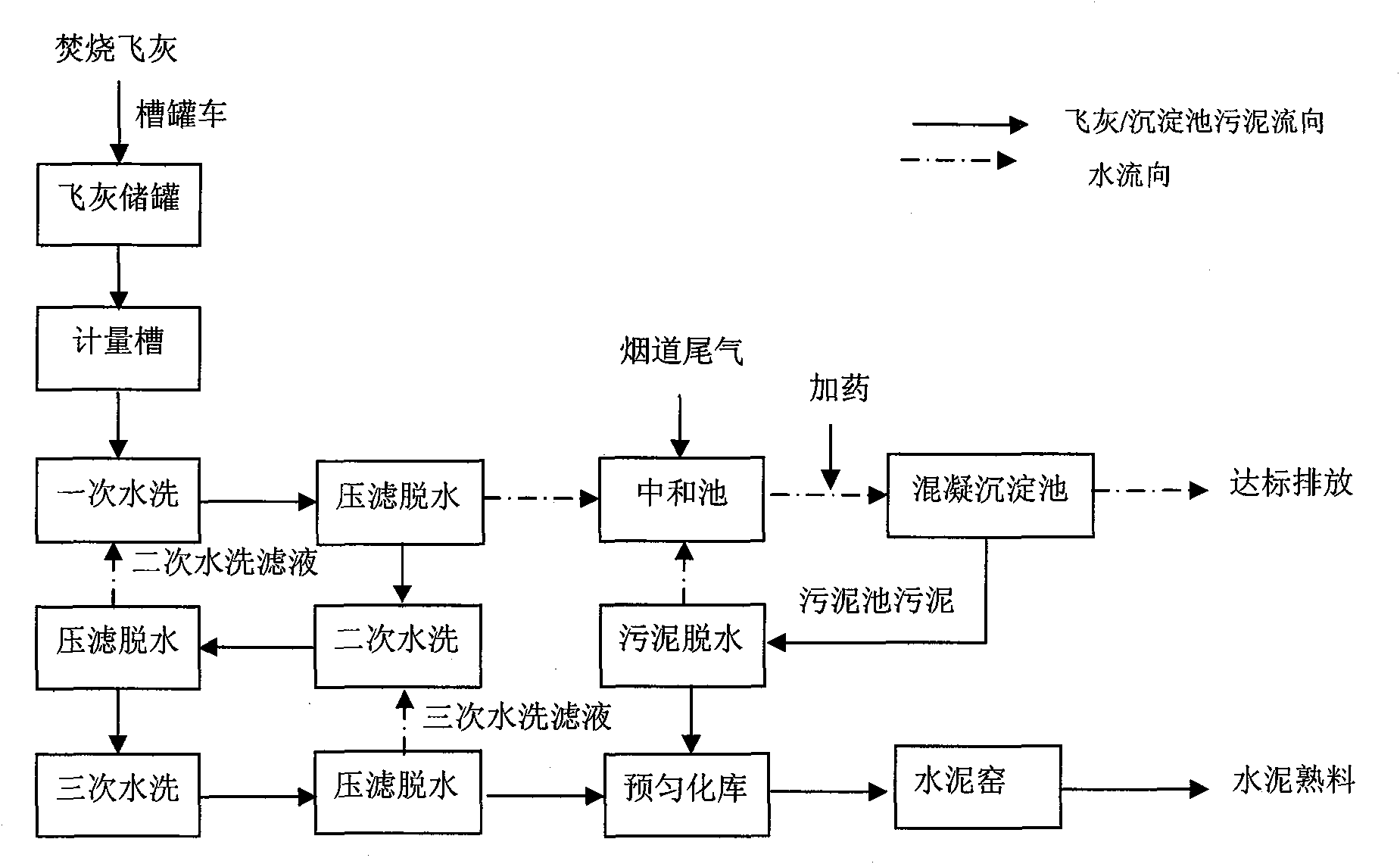

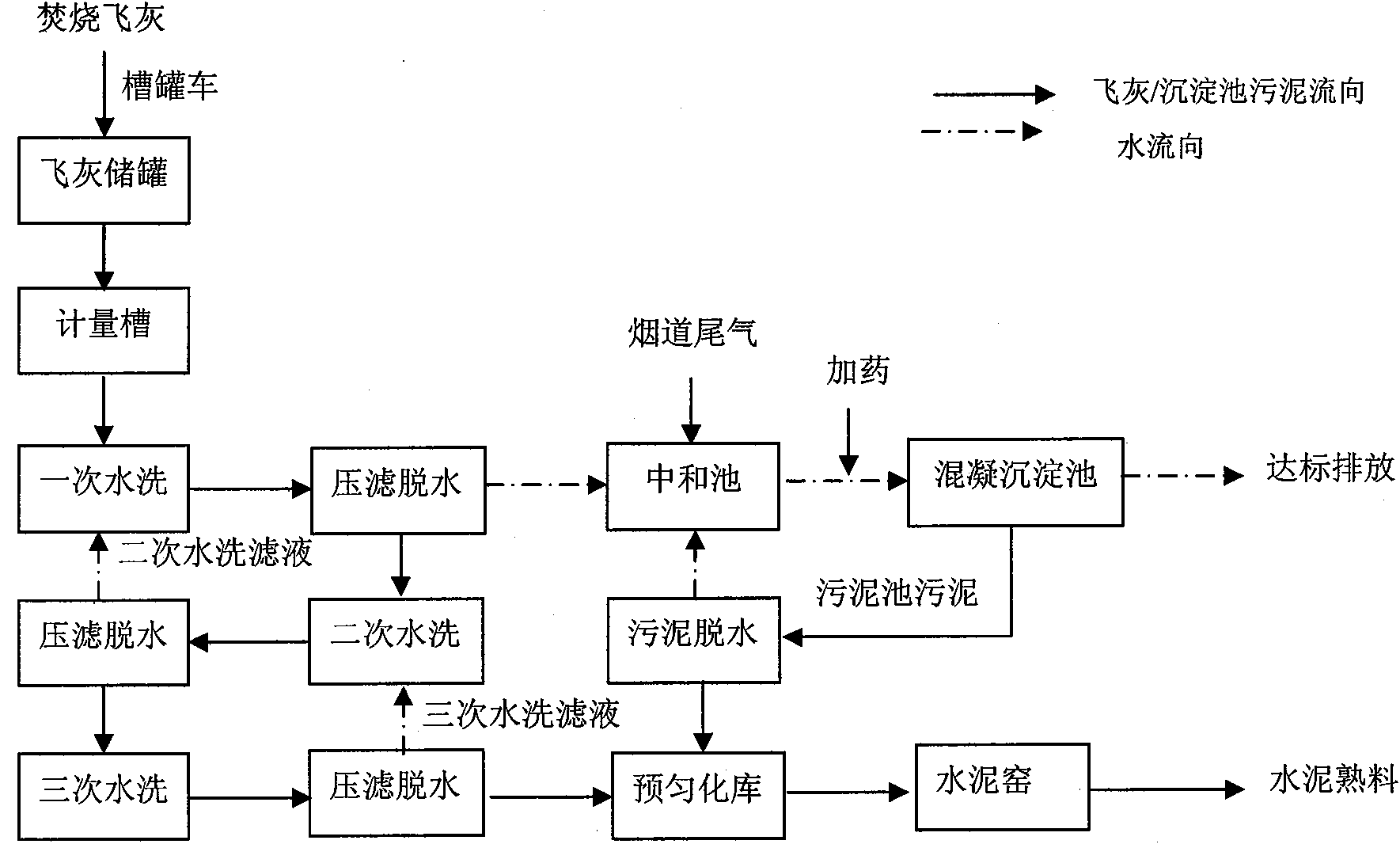

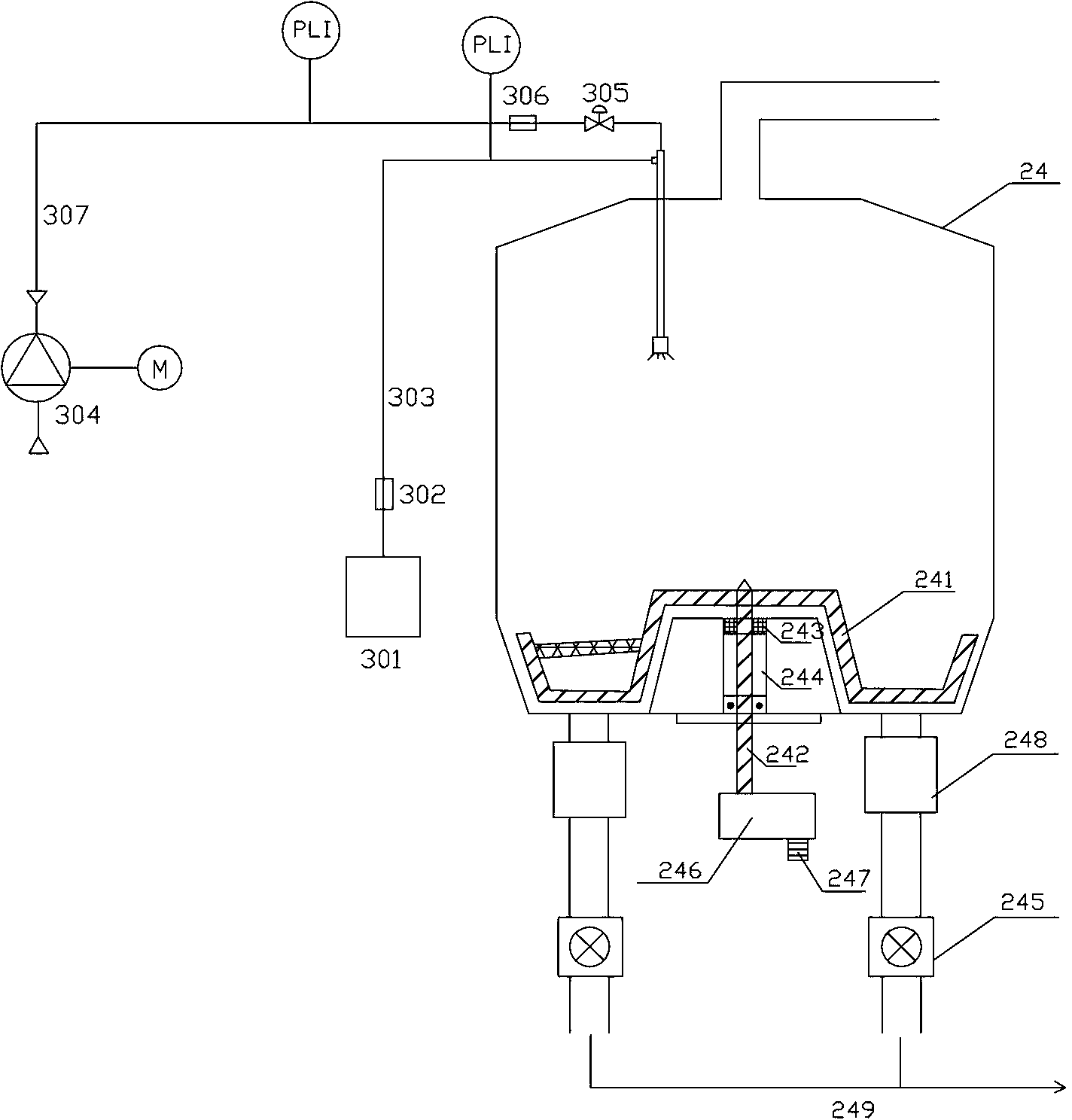

Incineration fly ash cement kiln synergic processing process

ActiveCN101913785AAvoid high energy consumptionReduce Chloride ContentCement productionIonHeavy metals

The invention provides an incineration fly ash cement kiln synergic processing process comprising the following steps of: a, carrying out washing treatment on incineration fly ash twice to three times; b, dewatering the incineration fly ash subjected to the washing treatment in a dewatering device to obtain a fly ash filter cake, wherein the water ratio of the fly ash filter cake is 25-30 percent, and the concentration of chloride ions is 0.3-0.6 percent; c, processing washing waste water generated in the step a through a carbonization-coagulating sedimentation process to obtain waste water processing precipitates; d, mixing the waste water processing precipitates and the fly ash filter cake with cement raw materials in proportion, wherein obtained materials are used as production raw materials of cement clinker; and e, calcining the production raw materials of the cement clinker under the condition of high temperature of 1100-1450 DEG C. The incineration fly ash cement kiln synergic processing process has little energy consumption and can be used for efficiently treating heavy metal, overcomes the defect that a non-ferrous metal extraction technology can not eliminate organic pollutants contained in the fly ash and realizes the thorough harmlessness of the fly ash.

Owner:杭州易辉环保科技有限公司

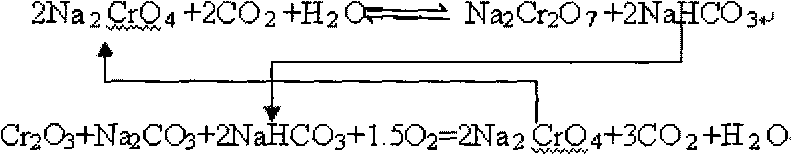

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

Method for lowering content of chloridion in tobacco stems and extracting nicotine simultaneously and application of method in preparation of reconstituted tobacco

InactiveCN103054159AReduce contentImprove use valueTobacco preparationTobacco treatmentBiotechnologyOrganic acid

Disclosed are a method for lowering the content of chloridion in tobacco stems and extracting nicotine simultaneously and the application of the method in preparation of reconstituted tobacco. The method includes: adding the tobacco stems into an extracting tank, adding 2-5 times of ethanol of 40%-80% according to a weight ratio, stirring and extracting for 10-20 minutes under the condition of 30-60 DEG C prior to filtering, and separating to obtain primary extracting solution and a primary solid portion; concentrating the primary extracting solution to obtain primary extractum, adjusting the pH value of the primary extractum to be 8-10, extracting with solvent dichloromethane to obtain coarse nicotine, and adding organic acid to adjust the pH value to be 3-5 to obtain organic acid nicotine; extracting the primary solid portion with water of 50-70 DEG C for 15-30 minutes prior to filtering, and separating to obtain secondary extracting solution and a secondary solid portion with the content of chloridion lowered, namely low chloridion tobacco stems; concentrating the secondary extracting solution to obtain secondary extractum; and subjecting the secondary solid portion to the paper-making process reconstituted tobacco production process to obtain a base. By the method, the content of chloridion in the expansion cut stems can be effectively lowered while nicotine generated during the process of lowering of the content of chloridion can be effectively extracted and recovered, and the obtained low-chloridion tobacco stems and nicotine can be used in reconstituted tobacco production to obtain reconstituted tobacco low in chloridion content.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

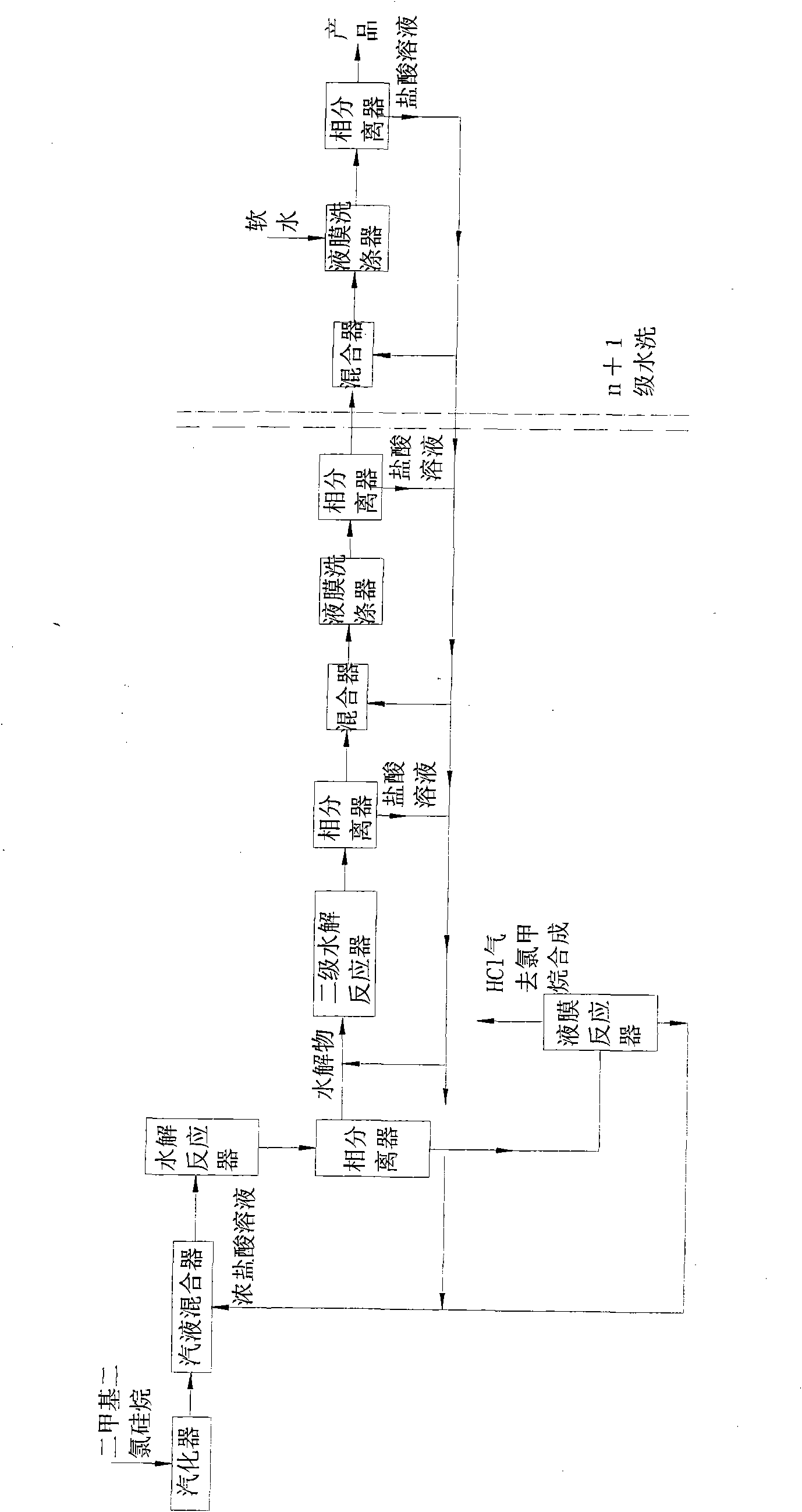

Method for hydrolyzing dimethyldichlorosilane in saturated acid

The invention relates to a hydrolysis technology of methyl chlorosilane, in particular to a technology for hydrolyzing dimethyldichlorosilane in saturated acid and preparing high cyclosiloxane and hydrolysate with low chloride ions. The technology is characterized by comprising the following steps: mixing vaporized dimethyldichlorosilane with concentrated hydrochloric acid to perform hydrolysis reaction, sending the reaction solution to a phase separator for separation, using the separated crude hydrolysate and concentrated hydrochloric acid to perform hydrolysis reaction again, sending the reaction solution to the phase separator to separate hydrolysate and acid solution, washing the hydrolysate with water, sending the hydrolysate to the phase separator to separate polydimethylsiloxane and acid solution, sending the concentrated hydrochloric acid separated through the first hydrolysis separation to a liquid membrane reactor to separate hydrogen chloride gas, and sending concentrated hydrochloric acid back to the hydrolysis reactor for circular reaction, wherein the acid solutions separated through the other steps are also used for circular reaction. By adopting the method of the invention, the operation process is simplified, the energy consumption is reduced and the production cost is lowered.

Owner:ZHENJIANG JIANGNAN CHEM

Method for preparing chlorine-removal alkali residue mixture by utilizing alkali residues through ammonia-soda process and application of chlorine-removal alkali residue mixture

ActiveCN104190690AImprove dechlorination effectReduce Chloride ContentSolid waste managementSolid waste disposalChlorideEthyl Chloride

The invention discloses a method for preparing a chlorine-removal alkali residue mixture by utilizing alkali residues through an ammonia-soda process. The method comprises the following steps: step 1, crushing returned sand and returned stones, and grinding to obtain returned sand and returned stone powder; step 2, soaking the returned sand and returned stone powder in water for 0.5-14 days, digesting overburnt calcium oxide, mixing the digested returned sand and returned stone powder, alkali residues and water, wherein a ratio of dry mass of the digested returned sand and returned stone powder to the alkali residues is 2:8 to 5:5 based on the mass percentage of the materials, and the total mass of the water is 1.5 to 8 times that of total dry mass of the digested returned sand and returned stone powder and alkali residues; or mixing the returned sand and returned stone powder, the alkali residues and water, soaking the mixture for 0.5-14 days, and digesting the overburnt calcium oxide; and step 3, performing filter pressing treatment, thereby obtaining the chlorine-removal alkali residue mixture of which the chloride ion content is lower than 0.30 percent of the total mass of solids in the mixture. The invention also discloses application of the chlorine-removal alkali residue mixture. The method and application disclosed by the invention are good in chlorine removal effect, simple in process, energy-saving and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

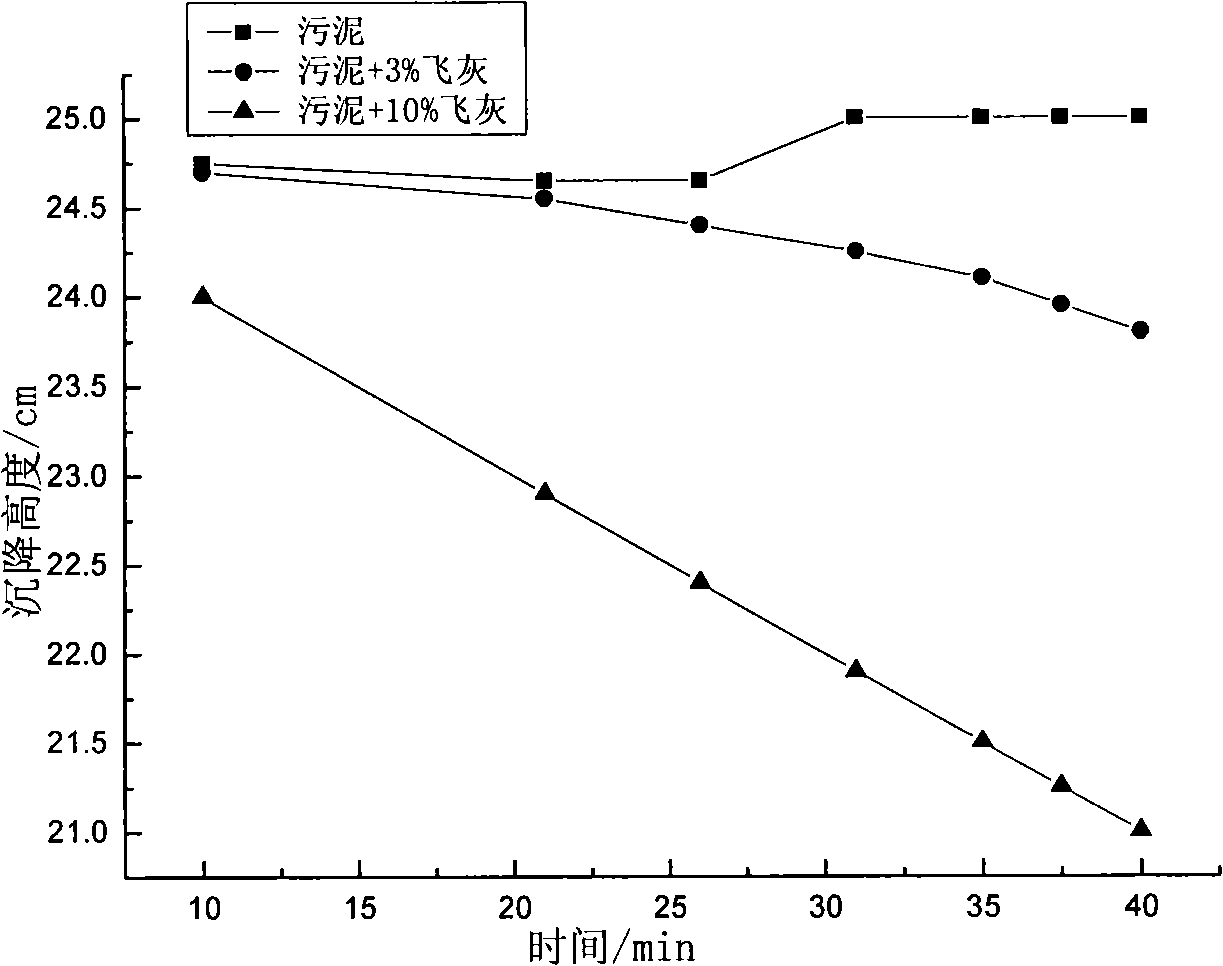

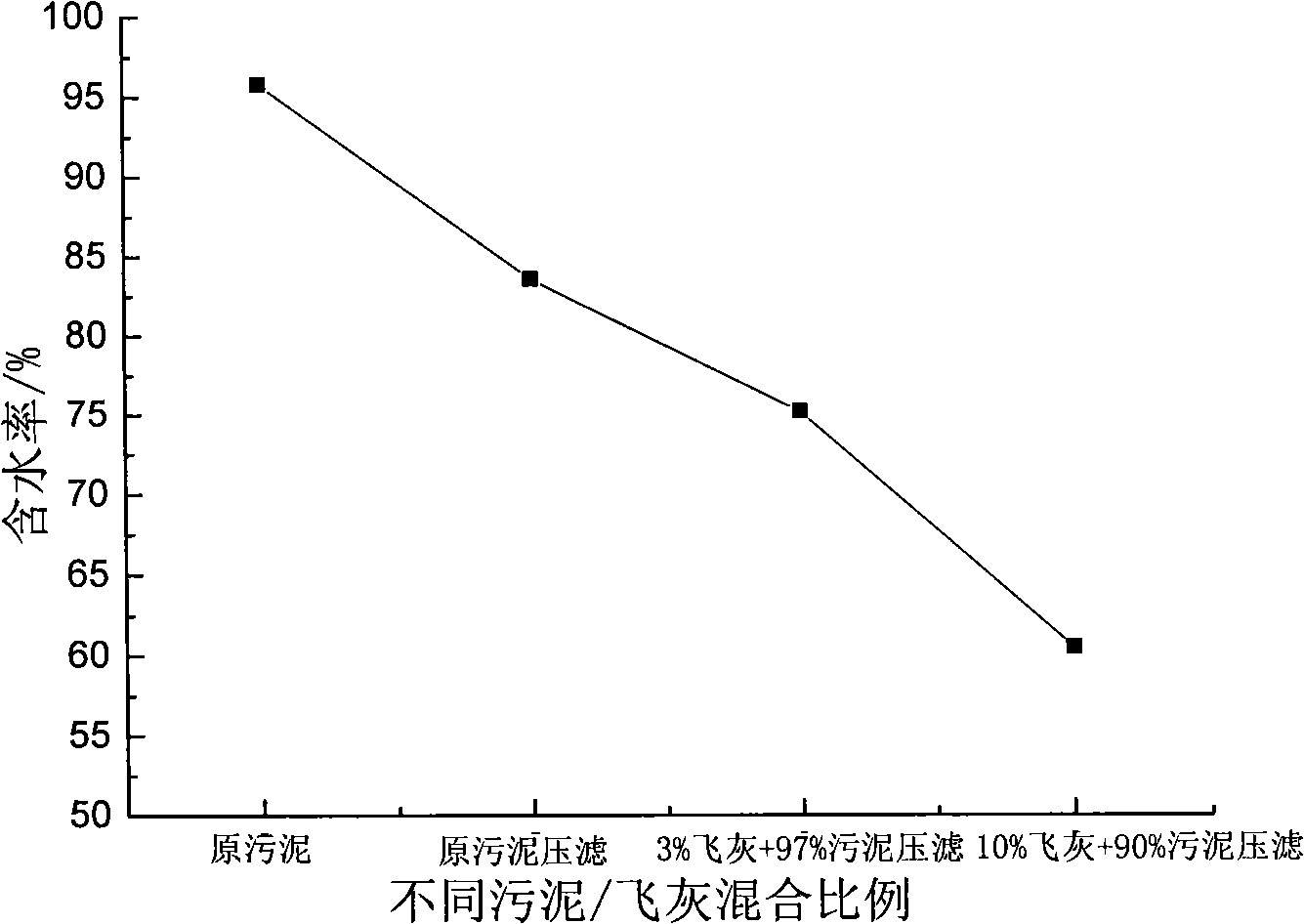

Method for cooperative reclaiming flyash and sludge in refuse incineration

InactiveCN101279825AReduce moisture contentHigh calorific valueSludge treatmentSolid waste managementIon contentResource utilization

The invention relates to a method for fly ash and sludge disposal resource utilization from refuse incineration, which belongs to the environmental engineering technique field. The method adopts the following processes: fly ashes and sludge are mixed in proportion of 1: 10-1: 50 under the normal temperature, wherein the mass unit of fly ashes is gram and the volume unit of sludge is milliliter, proper heavy metal stabilizer is added to the mixture for fully mixing and agitation for fifteen to thirty minutes, and the control range of the pH value is between 9 and 12. The fly ash and sludge mixture can be obtained by washing, pressure filtration and drying. The water content of the sludge is reduced, the heat value is increased and the chloride ion content in the fly ashes is reduced through the synergistic disposal. The treated fly ash and sludge mixture can meet the material requirements of the cement production, thereby realizing the fly ash / sludge synergistic resource utilization.

Owner:SHANGHAI UNIV

Method for recycling glyphosate mother solution

ActiveCN104944398AReduce Chloride ContentReduce contentPhosphatesGroup 5/15 element organic compoundsIonChemistry

The invention discloses a method for recycling glyphosate mother solution, and belongs to the technical field of chemical engineering. The method comprises the following steps: producing glyphosate and glyphosate mother solution by a glycine method or an iminodiacetic acid method; concentrating the glyphosate mother solution; carrying out an oxidization treatment on the glyphosate mother solution concentrate; cooling and crystallizing the glyphosate mother solution oxidation solution, taking out the crystallized glyphosate mother solution oxidation solution and concentrating; concentrating the permeate to obtain a sodium chloride product, and reusing the distillate; adjusting the pH value of the concentrate to 3-4, and then carrying out a photocatalytic oxidation reaction; adjusting the pH value to obtain a disodium hydrogen phosphate product or a trisodium phosphate product. According to the method disclosed by the invention, the concentration treatment is carried out before the glyphosate mother solution is oxidized, thus reducing the content of chloride ions in the glyphosate mother solution, increasing the concentration of the reactant, and increasing the efficiency of the subsequent oxidization reaction; hydrogen peroxide photocatalytic oxidation is carried out on the concentrate, the reaction is thorough, the oxidability is better, the substances difficult to oxidize by oxygen-enriched wet oxidization can be oxidized, and the reaction conditions are moderate.

Owner:JIANGXI JINLONG CHEM +1

A kind of preparation method of chlorinated polyethylene

The invention relates to the field of chlorinated polyethylene preparation, in particular relates to a preparation method of chlorinated polyethylene based on hydrochloric acid suspension chlorination. The method comprises the following steps: adding polyethylene used as a raw material in a chlorination reactor containing 18-25% hydrochloric acid, a surfactant, an initiator and a dispersing agent, and heating to above 70 DEG C under the condition of stirring; introducing chlorine gas at a certain temperature and pressure, and opening a connection valve of the reaction kettle and a graphite cooler when the temperature in a kettle reaches 120 DEG C and the pressure in the kettle exceeds 0.4MPa so that steam enters the cooler to be condensed into liquid; respectively separating gaseous hydrogen chloride and liquid hydrochloric acid by a gas-liquid separator and discharging gaseous hydrogen chloride and liquid hydrochloric acid respectively; after introduction of chlorine is finished, closing the connection valve of the reaction kettle and the graphite cooler; introducing cooling water into the clamp sleeve of the reactor so that the temperature of the material is reduced to less than80 DEG C; and washing solid material obtained by solid-liquid separation with water, and drying so as to prepare chlorinated polyethylene. Chlorinated polyethylene prepared by the method can be used as an impact resisting modifier of plastic and a special synthesis rubber.

Owner:杭州新元化工技术开发有限公司

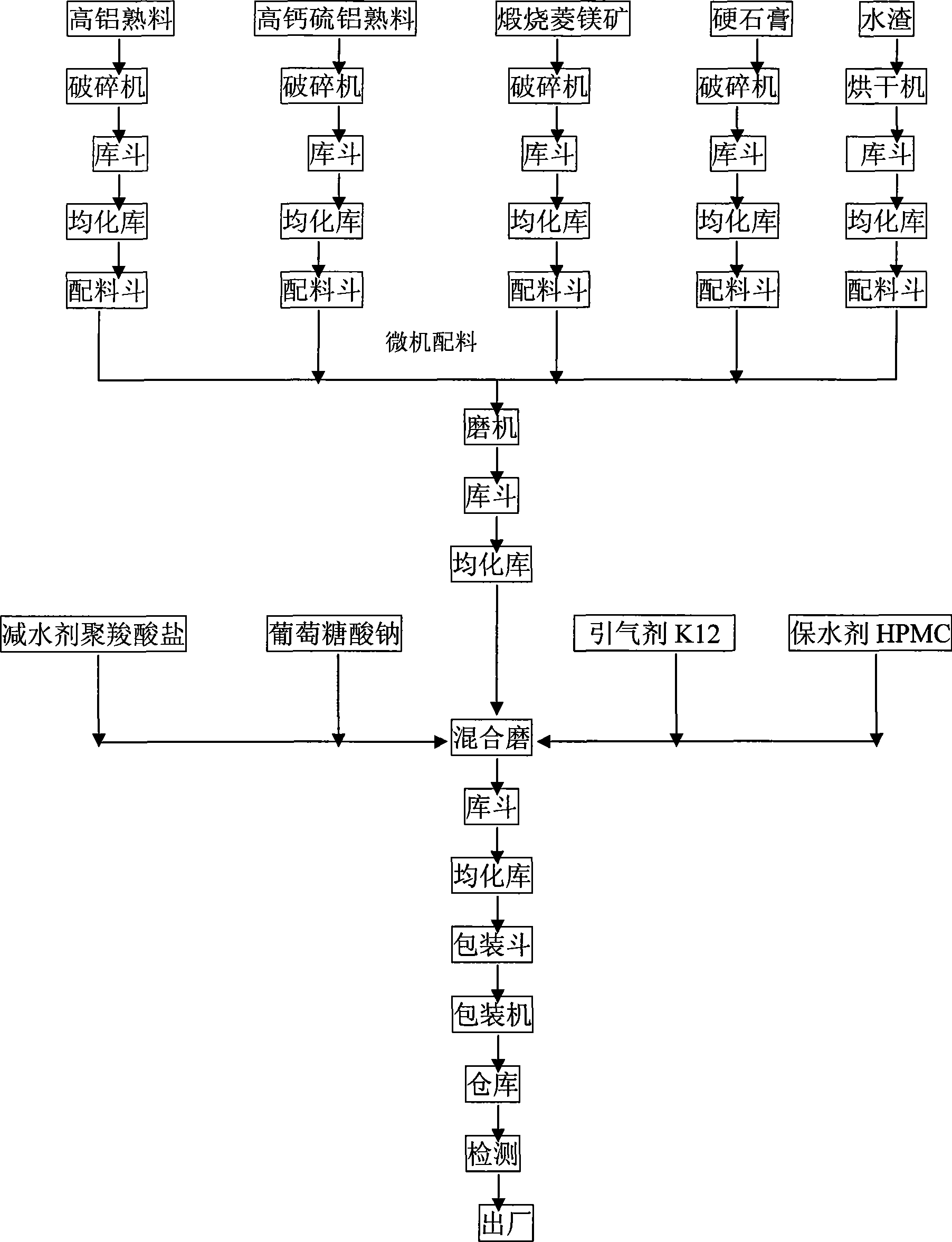

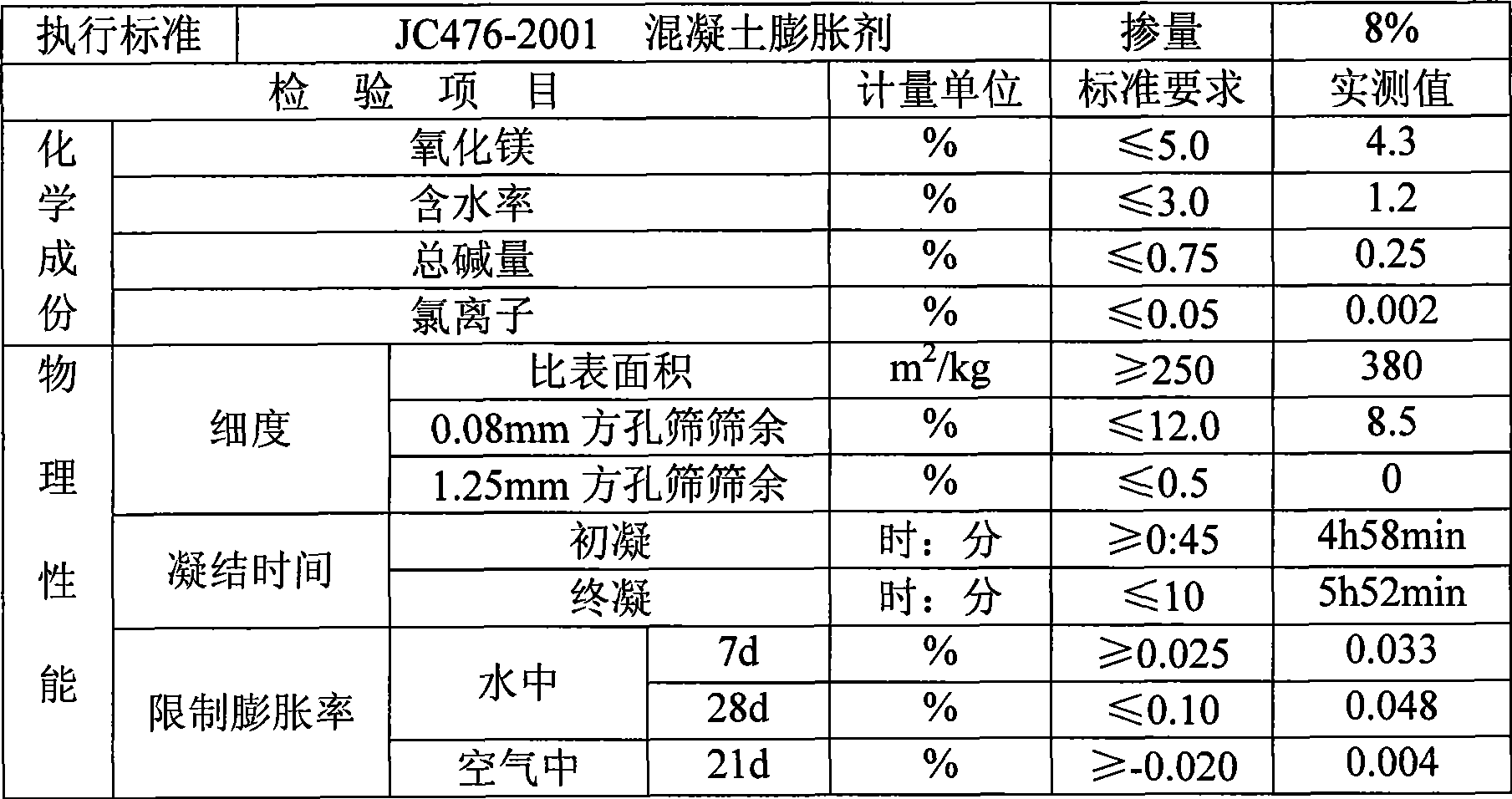

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

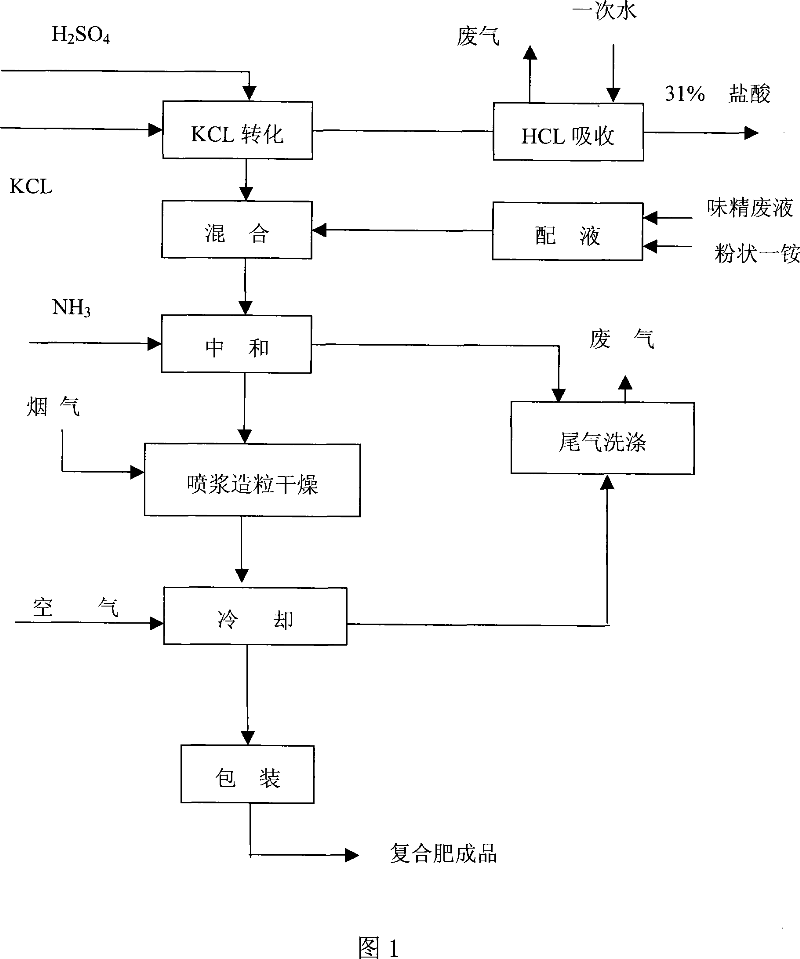

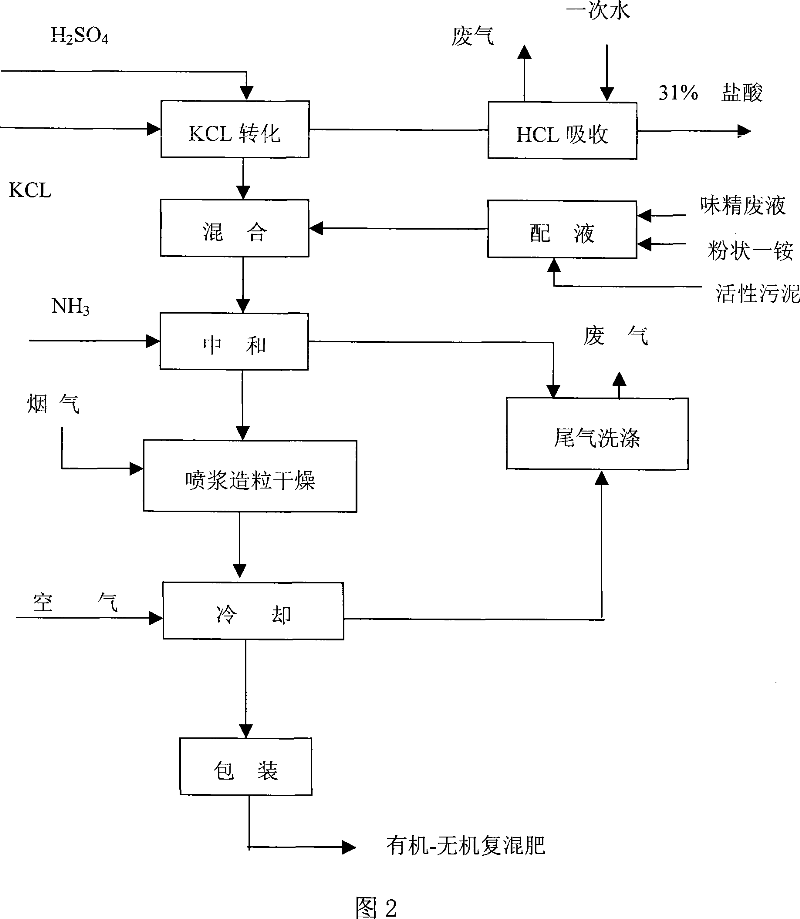

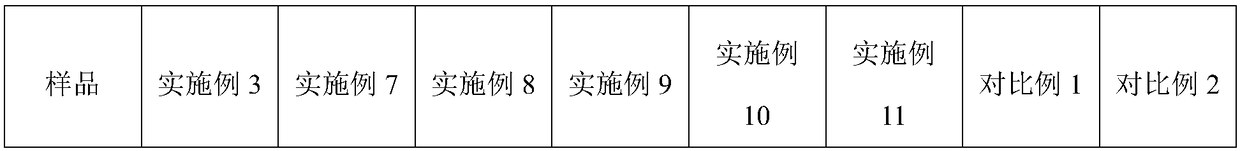

Method for producing agricultural fertilizer by using waste liquid of monosodium glutamate

InactiveCN101037353AReduce consumptionIncrease profitSuperphosphatesClimate change adaptationMonosodium glutamateHigh concentration

The invention discloses a method for producing farm fertilizer by monosodium glutamate tail washings with a primary raw materials: monosodium glutamate tail washings containing a solid content of 8-50%, active sludge with an organic matter content more than 50%, sulphuric acid with a concentration of 90-98%, potassium chloride with a pureness of 95-98%, powdered monoammonium phosphate with a total nutrition of 55-60%, liquid ammonia. The potasium bisulfate is got by a reaction of potassium chloride and concentrated sulfuric acid. A mixing ammonium liquid is obtained by introducing the powdered monoammonium phosphate and active sludge into the monosodium glutamate tail washings. The mixing ammonium liquid mixes with the potasium bisulfate to form mixed acid. Slurry is produced by feeding the gas ammonia into the mixed acid for a neutralization reaction. The slurry produces the compound fertilizer of potassium sulfate style and organic-mineral compound fertilizers by spouting of stock, prilling and drying. The method can make the material fully mix and get an even slurry liquid with an excellent flowability which fits for the spouting of stock and prilling. Therefore, it may produce standard compound fertilizer containing organic matters and organic-mineral compound fertilizers in potassium sulfate style with a low, medium, high concentration.

Owner:梅花生物科技集团股份有限公司

Rubber-plastic blending foam material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a rubber-plastic blending foam material and a preparation method thereof. The rubber-plastic blending foam material is prepared from components in parts by weight as follows: 25-35 parts of a rubber-plastic blending material, 5-8 parts of a foaming agent, 0.05-0.3 parts of a vulcanizing agent, 1.5-1.8 parts of an accelerant, 25-35 parts of filler, 5-8 parts of carbon black, 0.5-1 part of paraffin, 15-20 parts of chlorinated paraffin, 0.1-0.2 parts of stearic acid, 1-2 parts of epoxy soybean oil,0.3-0.5 parts of zinc oxide, 0.5-1 part of polyethylene glycol and 0.1-0.5 parts of an anti-aging agent. By means of proportion optimization selection of the components, content of chlorine ions in the obtained rubber-plastic blending foam material is lower than 400 ppm, and after a copper pipe is wrapped with the material and used for 240 h at the temperature of 60 DEG C and humidity of 95% plusor minus 3%, the color of the copper pipe can be close to that of a copper tube which is not wrapped with the rubber-plastic blending foam material.

Owner:HEBEI SHENZHOU THERMAL INSULATION BUILDING MATERIAL GRP CO LTD

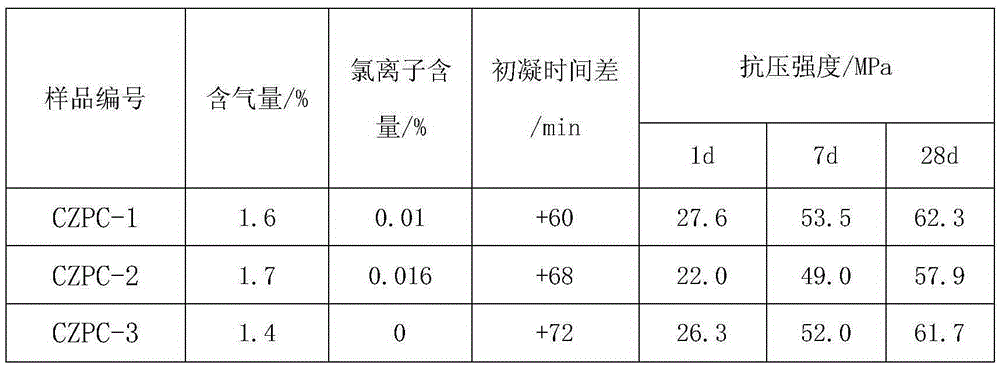

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

The invention discloses a polycarboxylate superplasticizer with super high early strength and a preparation method of the polycarboxylate superplasticizer. The polycarboxylate superplasticizer is prepared as follows: amine polyoxyethylene ether, acrylic acid, maleic hydroxy acid ester and allyl amine are taken as monomers and added with an inorganic peroxide initiator for free radical copolymerization, main chains of molecules of the superplasticizer contain carboxylic acid groups, sulfonic acid groups and amino groups simultaneously, side chains adopt long-chain polyamine ether, and the ratio of polyoxyethylene ether to acrylic acid to water to maleic hydroxy acid ester to allyl amine to the inorganic peroxide initiator in parts by mass is 100:(20-30):(100-150):(2-10):(2-10):(0.1-0.5). The invention further provides the preparation method of the polycarboxylate superplasticizer. The polycarboxylate superplasticizer with super high early strength has the advantages of short setting time, high early strength, good adaptability, extremely low chlorine ion content and capability of improvement of the concrete durability; meanwhile, the production process is simple, low in cost, environment-friendly and pollution-free, and mass production can be realized.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

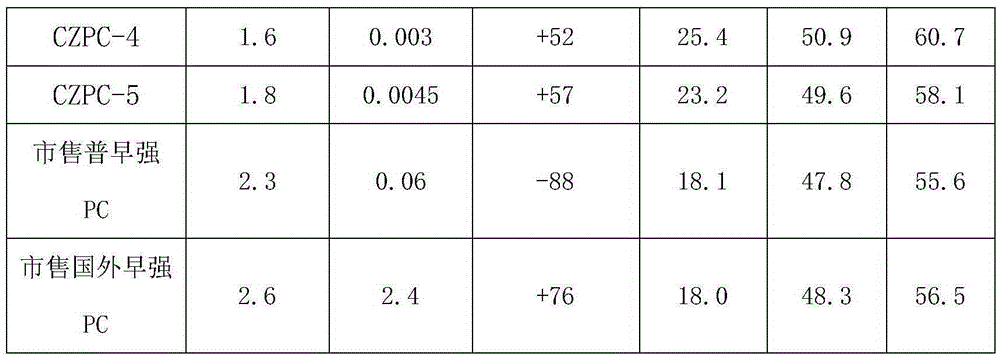

Snowmelt agent

InactiveCN101671539AImprove snow removal effectGood snow removal effectOther chemical processesRoad surfaceSnowmelt

The invention relates to a snowmelt agent, which is a composite snowmelt agent and comprises the following components and contents (weight) in percentage by weight: 80 to 95 percent of acetate and 5 to 20 percent of chloride. Compared with the prior art, the snowmelt agent has good snow removing effect and low chloride content, can reduce the corrosivity of the snowmelt agent obviously, effectively protects pavement and bridges, prolongs the service life of public facilities and reduces the cost while achieving excellent snow removing effect.

Owner:SHANGHAI CITY CHANGNING DISTRICT JUNIOR SCI &TECH GUIDANCE STATION +2

Method for improving combustibility of cigar tobacco leaves

ActiveCN103120362AReduce Chloride ContentImprove combustion performanceTobacco preparationTobacco treatmentNatural factorAqueous solution

The invention discloses a method for improving combustibility of cigar tobacco leaves. The method for improving combustibility of the cigar tobacco leaves includes the following steps: (1) to-be processed tobacco leaves with poor combustibility are immersed in saccharifying enzyme water solution for 5 to 10 minutes, and the water solution comprises saccharifying enzyme, by weight, 3 %o-5%o; (2) the immersed tobacco leaves are dehydrated, and the moisture content is adjusted to be within 28% to 32%, and the dehydrated tobacco leaves are fermented for 15 days to 40 days under the condition that the temperature is within 40 DEG C to 50 DEG C and the humidity is within 80% to 90%; (3) the moisture content of the fermented tobacco leaves is adjusted to be within 10% to 15%. The method for improving combustibility of the cigar tobacco leaves is capable of effectively reducing the chlorine ion content in the tobacco leaves and improving the combustibility of the tobacco leaves on the premise that specific fragrance and sensory quality of the tobacco leaves are conserved. The method for improving combustibility of the cigar tobacco leaves is free from influences of natural factors and the like, stable in result and reliable in quality.

Owner:HUBEI CHINA TOBACCO IND

Environmentally-friendly and high-grade sofa leather production process

ActiveCN109628653ARaise the pHReduce formaldehyde contentTanning treatmentPre-tanning chemical treatmentOrganic solventAcrylic resin

The invention relates to the technical field of leather manufacturing processes, and provides an environmentally-friendly and high-grade sofa leather production process. According to the environmentally-friendly and high-grade sofa leather production process, an organic pretanning agent F-90 is adopted to pretreat softened leather, main tanning is carried out on pre-tanned white wet leather by adopting an aldehyde tanning agent, a vegetable tanning agent, an aromatic synthetic tanning agent, an amino resin tanning agent and an acrylic resin tanning agent are adopted for retanning, cross-linking can be formed among the vegetable tanning agent, collagen and the aldehyde tanning agent, and a vegetable-aldehyde synergistic tanning effect is achieved, so that the water-washing resistance, organic solvent resistance and shrinkage temperature of obtained crust leather are improved; moreover, the environmentally-friendly and high-grade sofa leather production process is a technical skill integrating tanning, neutralization, retanning and dyeing, uniform patterns are easy to produce on the grain surface of obtained sofa leather, and the process is suitable for the mill operation; and the shrinkage temperature is higher than 85 DEG C, and physical and mechanical properties and sensory properties meet the standard of chrome-free tanning leather.

Owner:XINGYE LEATHER TECH CO LTD

Low-chloride snow-melting agent and preparation method and application thereof

InactiveCN105754549AStrong ability to melt snow and iceReduce Chloride ContentOther chemical processesUreaEnvironmental resistance

The invention belongs to the technical field of environmentally friendly chemicals, particularly relates to a low-chloride snow-melting agent and further discloses a preparation method of the low-chloride snow-melting agent.According to the low-chloride snow-melting agent, sodium borate, sodium formate, calcium chloride, ammoniom acetate, ethylenediamine tetraacetic acid disodium, urea, potassium citrate, sodium gluconate and sodium bentonite serve as preparation raw materials, the content of chlorine salt is low, adopted raw materials are all ingredients which are safe, free of toxin and environmentally friendly and completely meet the requirement for environmentally friendliness.The prepared low-chloride snow-melting agent has the advantages of being low in freezing point (the freezing point of 200 g / L is lower than minus 11 DEG C), high in dissolution velocity (the speed is higher than 10 g / min), high in ice melting capacity (90% higher than snow melting capacity of sodium chloride) and small in corrosion of carbon steel materials (corrosion is smaller than 0.03 mm / a), can be widely applied to snow melting and freezing prevention of various roads, is low in chlorine ion content of a product and is consistent with the current development requirement of environmental protection.

Owner:黄山九星环保科技股份有限公司

Waterproof concrete compacting agent and preparation method thereof

The invention discloses a waterproof concrete compacting agent and a preparation method thereof. The compacting agent consists of the following raw material components in percentage by weight: 10 to 13 percent of potassium hydroxide, 0.5 to 1 percent of volcanic ash, 0.5 to 1 percent of potassium oleate, 10 to 12 percent of sulfur, 0.5 to 1 percent of glycerol, 3 to 5 percent of triethanolamine, 0.5 to 1 percent of citric acid, 0.5 to 1.5 percent of ferric oxide, 0.5 to 1 percent of sodium fluosilicate, and the balance of water. Chemical crystal or colloid generated by chemical reaction of components in the compacting agent and silicon, calcium, sodium, magnesium and the like in cement can effectively prevent permeation of water molecules and effectively control cracking. The compacting agent contains extremely low harmful substances, particularly has extremely low chlorine ion content and ammonia content, reduces damage to steel bars and concrete, and is beneficial to environmental protection.

Owner:北京龙阳伟业科技股份有限公司

Auxiliary agent for reducing low temperature reduction index of sintering ore

InactiveCN101144119AReduce Chloride ContentReduce low temperature reducing pulverization indexGranularityChloride

The present invention relates to the manufacture and an application method for auxiliary agent which can reduces the low temperature reducibility index of sintered ore. With the weight percentage ratio, the auxiliary agent has the chemical formula that boric acid is 3-5 percent, calcium chloride is 30-40 percent, calcium nitrate is 30-40 percent, magnesium sulfate is 25-30 percent, and fatty alcohol polyoxyethylene ether is 1-10 percent; the chemical agent with suitable content and granularity is evenly mixed, and is packed and sealed into bags with 25 kg per bag. The prepared auxiliary agent is completely dissolved with water of 3 percent content, and the prepared solution is sprayed to the sintered ore with 3.4 kg / ton content. The present invention provides the preparation and the application method of the chemical agent suitable for reducing the low temperature reduction and the pulverization of the sintered ore with simple formula, remarkable effect, low cost, and simple application method, and by adopting the auxiliary agent, the low temperature reduction and pulverization indexes of the sintered ore can be effectively reduced by about RDI + 3.15 mm 10 percent.

Owner:LAIWU IRON & STEEL GRP

Process and equipment for preparing nickel oxide product and recovering hydrochloric acid through nickel chloride solution

InactiveCN103058288ANo emissionsReduce consumptionNickel oxides/hydroxidesPreparation from chloridesCooking & bakingReaction temperature

The invention relates to the technical field of preparing nickel oxide and recovering hydrochloric acid, and in particular relates to a process and equipment for preparing nickel oxide and recovering hydrochloric acid. The equipment comprises a nickel oxide solution tank for recovering waste acid, a waste acid filter, a pre-concentrator, a baking furnace, a furnace top spraying device, burners in tangent distribution, a rotary horizontal mixer, a breaker, a rotary valve, a nickel oxide powder pneumatic conveying and collecting system, a first-stage absorption tower, a second-stage absorption tower, a smoke exhaust fan, a washing tower, a feeding pump sealing as well as cooling water circulating and supplying device, a pyrolysis acid storage tank, a conveying pipeline, a gas and liquid separator, a chimney, a dust extractor, a pneumatic feeding device, a feeding pipeline online cleaning device, a combustion supporting and heating device, a back-flushing flow aiding device, a chlorine removal device and an air purifier. The process and the equipment for preparing nickel oxide and recovering hydrochloric acid have the following advantages that reaction temperature regulating range of the baking furnace is widened, waste gas reaches the discharge standard, equipment utilization rate of the baking furnace is improved, and environmental pollution is avoided.

Owner:赫东波

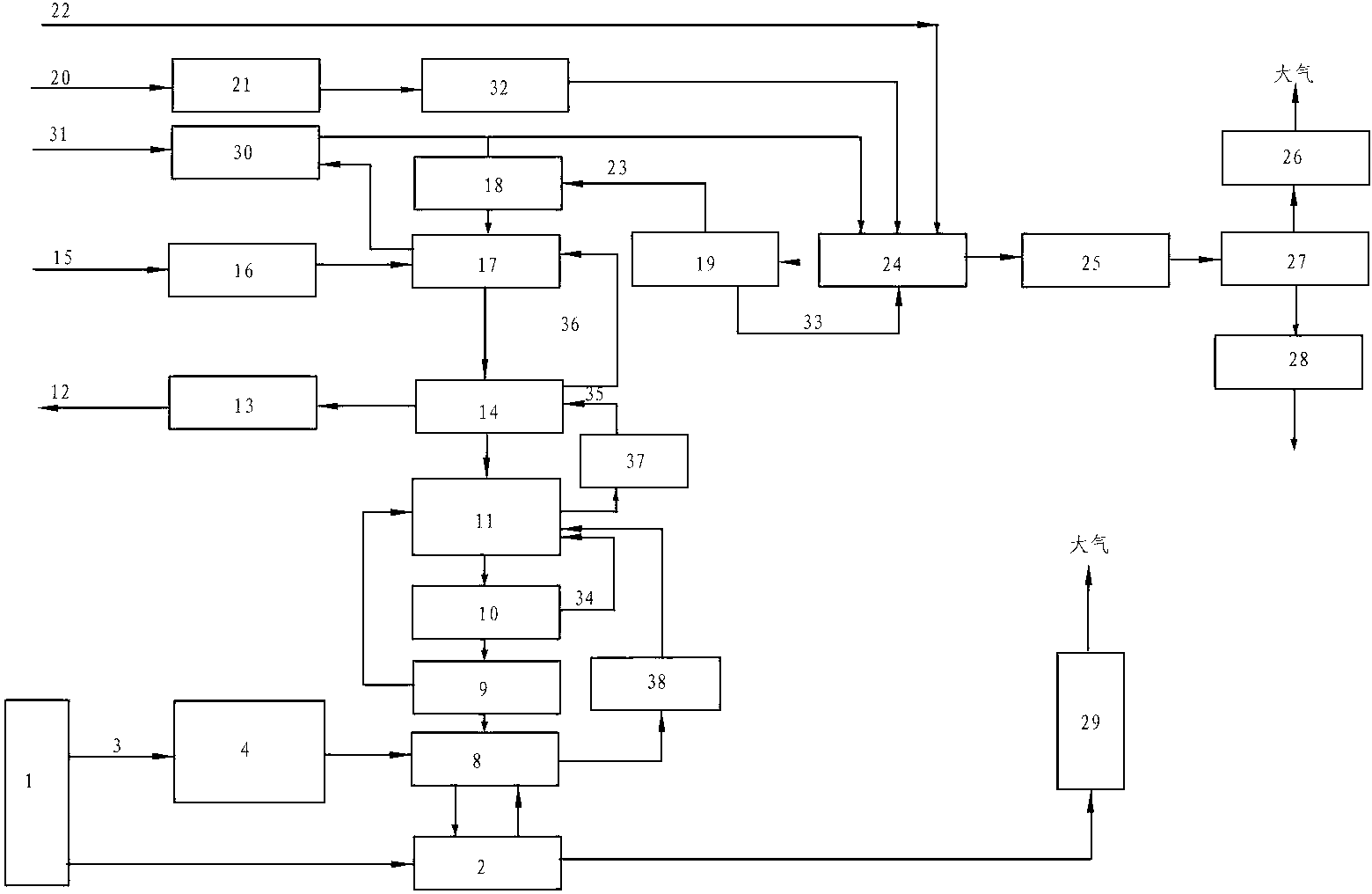

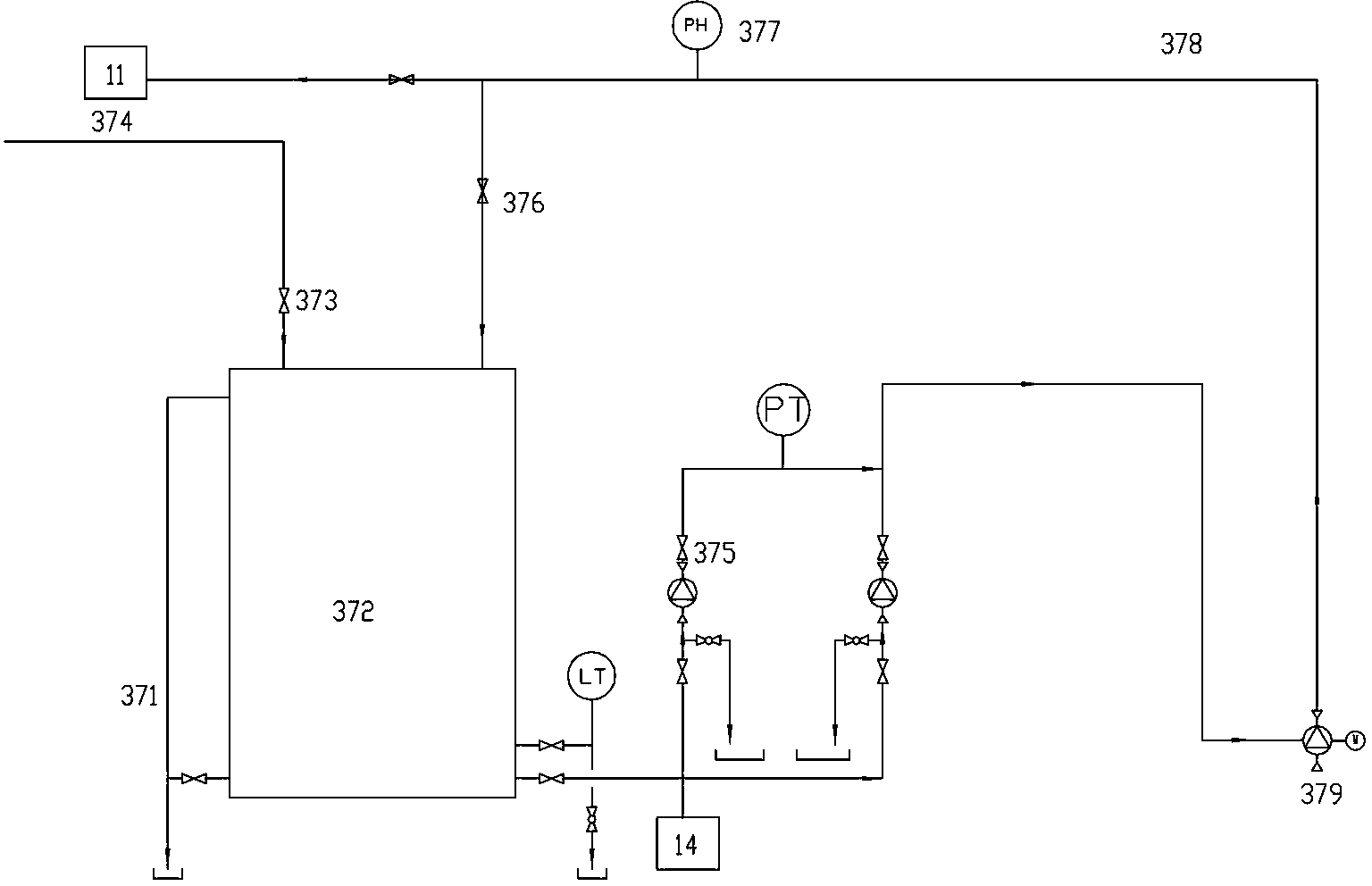

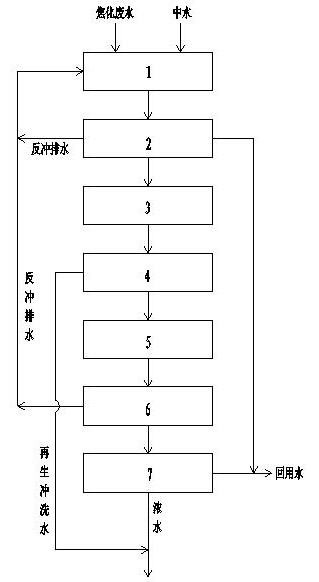

Recycle method of recycled water

InactiveCN102167478AReduce alkalinityAchieve reuseSolid fuelsWater/sewage treatment bu osmosis/dialysisActivated carbon filtrationReverse osmosis

The invention discloses a recycle method of recycled water, which comprises the steps of: mixing cooked wastewater with the recycled water by the biochemically-treated and deeply-treated discharged water; and treating the mixed water through a lime+flocculation precipitating working procedure, a multi-medium filtering working procedure, a filtering working procedure by active carbon, a softening working procedure by a softener, an ultra-filtering working procedure and a reverse osmosis working procedure to obtain recycling water, wherein the recycling water is used as compensating water of circulating water, greening water, boiler water or fire fighting water. The recycle method of the recycled water can be used for wholly recycling the cooker wastewater; and the recycle method of the recycled water is used for mixing the cooked wastewater with the recycled water such as the circulating water wastewater, deoxidization station reverse osmosis concentrated water, the boiler wastewater and the like through the biochemically-treated and the deeply-treated discharged water and then treating the mixing water together, so that the quality of the recycled water is improved, the treatment difficulty is reduced, and the recycled water is high in yield and low in cost.

Owner:KAILUAN GRP +1

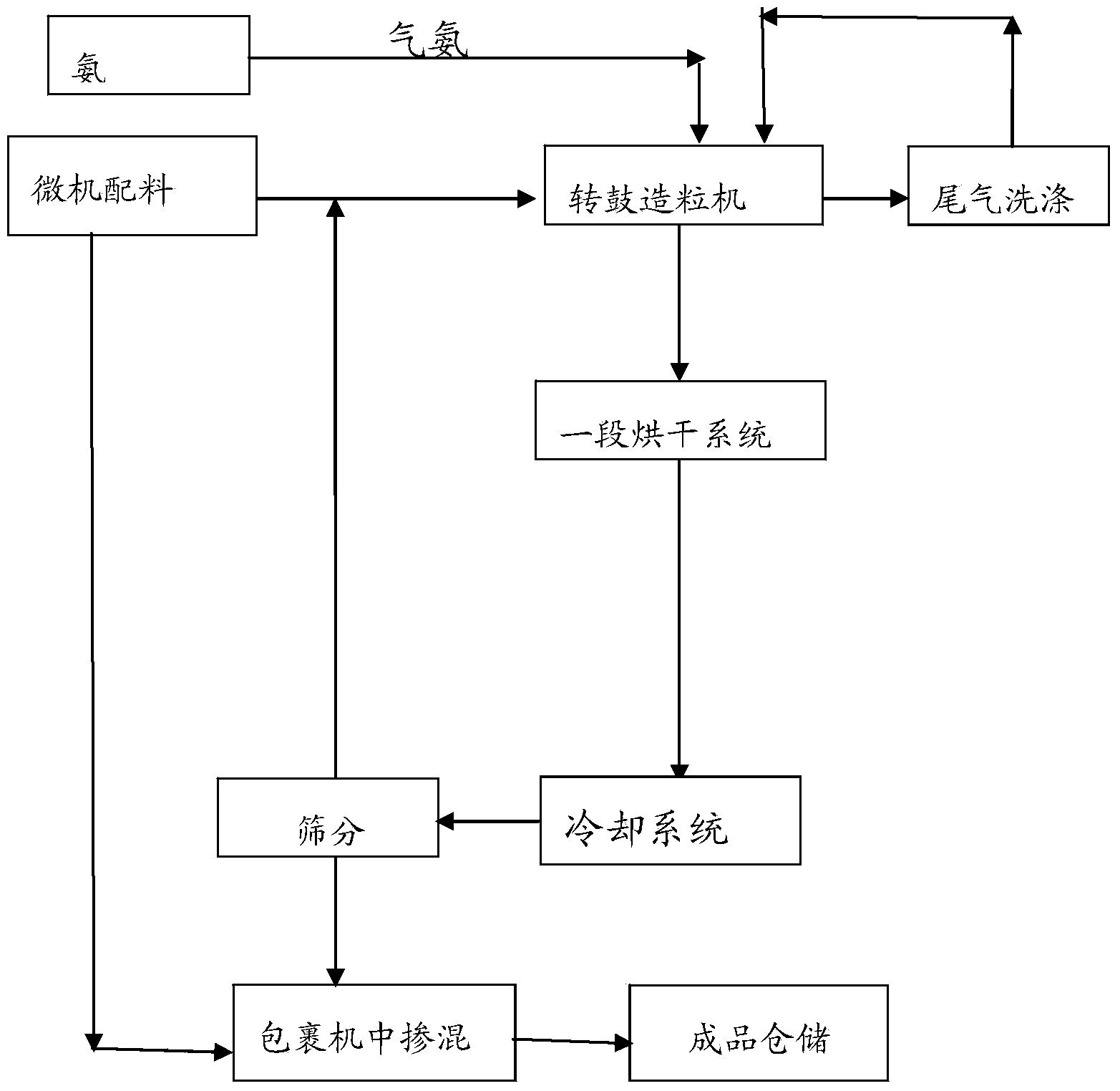

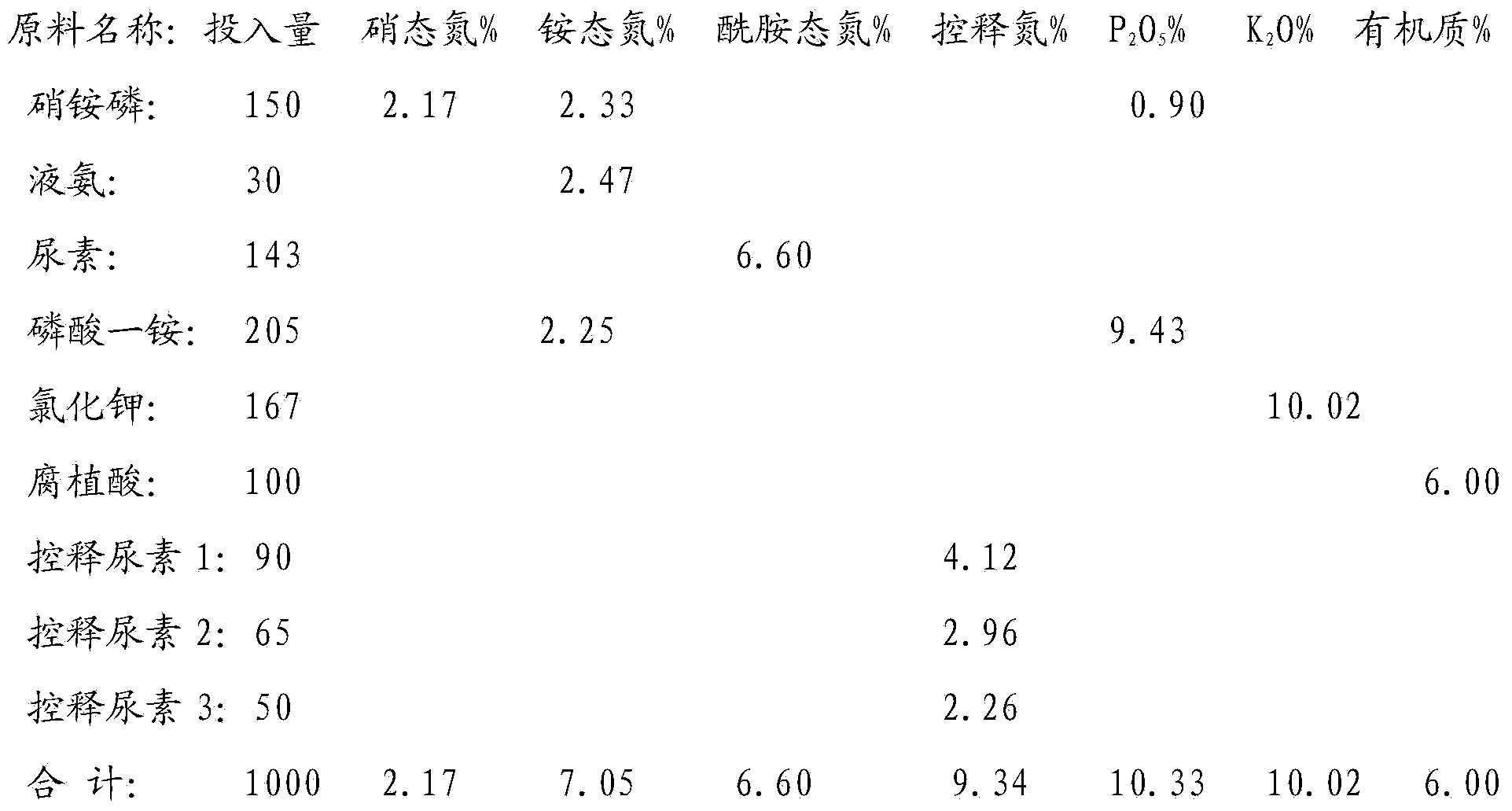

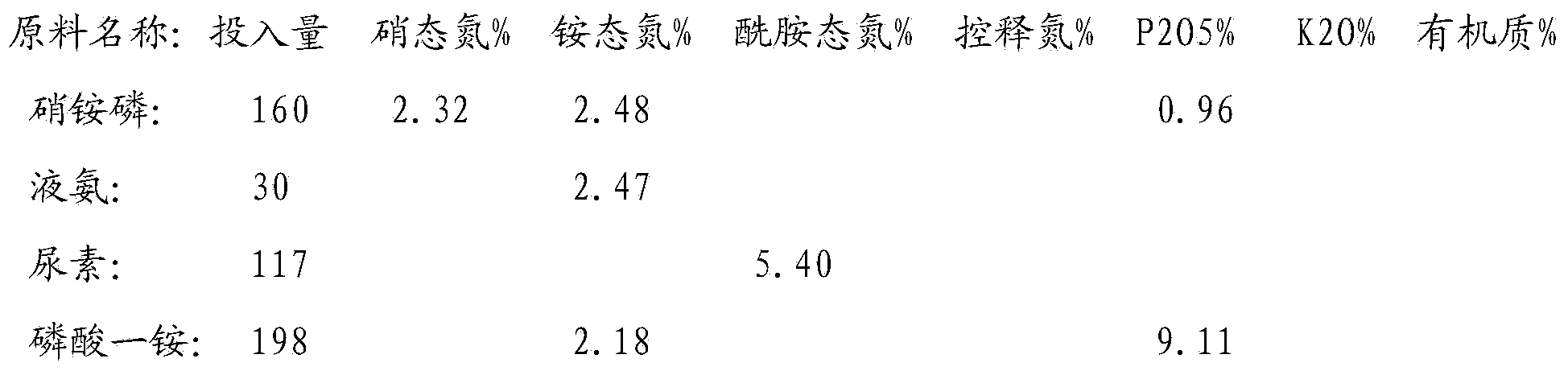

Whole-process nutrient supply type composite fertilizer and preparation method thereof

The invention discloses a whole-process nutrient supply type composite fertilizer and a preparation method thereof. A raw material containing nitrate nitrogen, ammonium nitrogen, amide nitrogen, controlled release nitrogen and organic matters is added in the material. The components of the whole-process nutrient feeding type composite fertilizer are effectively proportioned in percentage by mass on the basis of nitrogen content: 2-4% of nitrate nitrogen, 5-8% of ammonium nitrogen, 5-8% of amide nitrogen and 6-10% of controlled release nitrogen, the contents of phosphorus and potassium are determined according to different product proportions, and the content of the organic matters is not less than 6%. In the production process, the viscosity of urea nitrate generated in a reaction of ammonium nitrate phosphate and urea and granulation tail gas washing water are used as liquid phase amount necessary for granulation to finish the material granulation process, in order to prevent excessive urea nitrate from being generated in the granulation process, ammonia gas is directly introduced into the material layer of a rotor drum granulator to finish the ammoniation treatment of ammonium nitrate phosphate and control the quantity of the urea nitrate generated in the reaction. The fertilizer not only can improve the utilization rate of fertilizer nutrients and ensure the whole-process nutrient supply of crops so as to increase the yield of the crops and improve the quality, but also can avoid harm caused by escherichia coli and such toxic substances as heavy metal, improve the soil, reduce the soil salinity and fertilize the land.

Owner:天津芦阳肥业股份有限公司

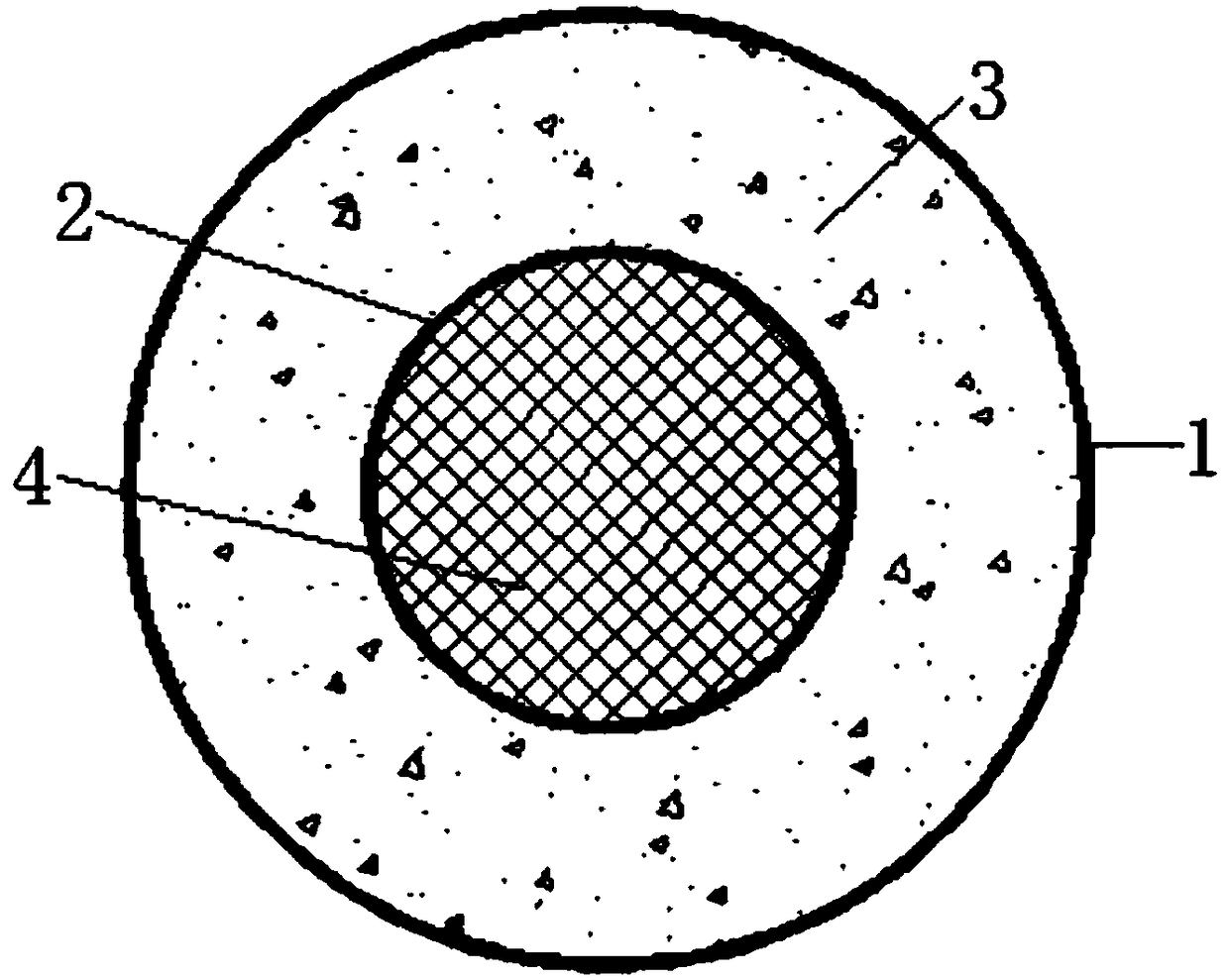

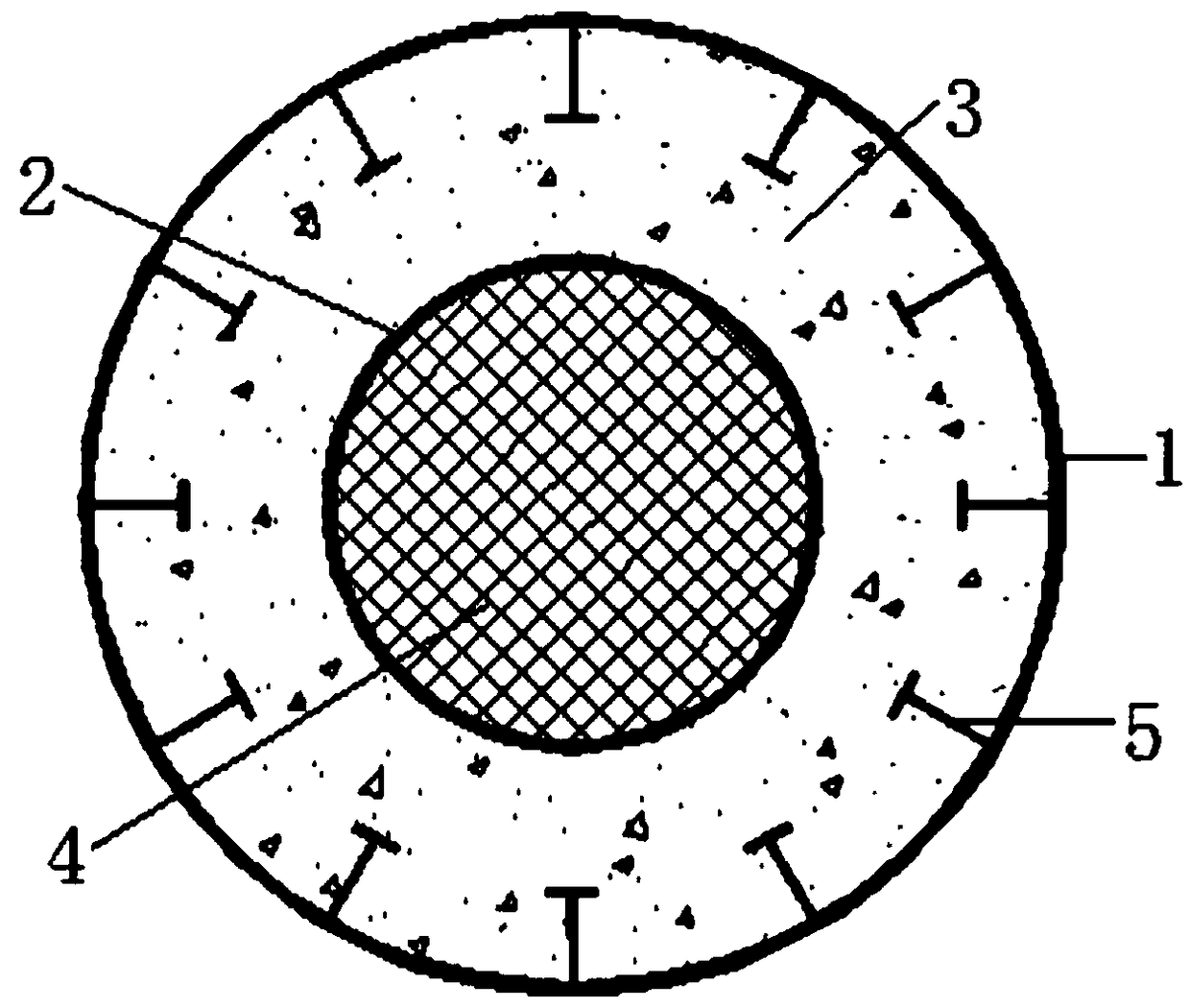

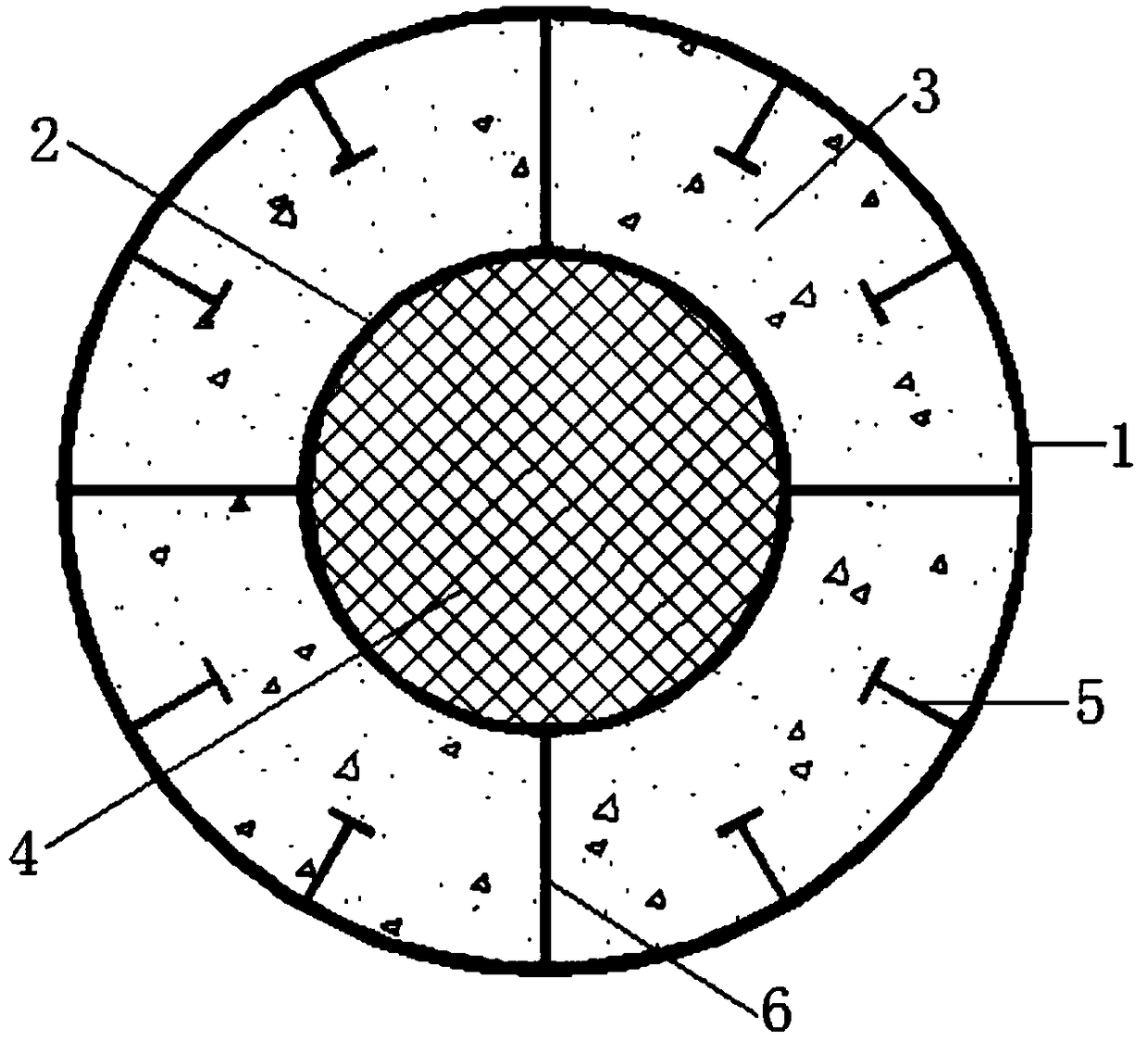

Composite steel pipe UHPC damping column pier

InactiveCN108360748ASolve the problem of corrosionImprove ductilityStrutsSolid waste managementShock resistanceSteel tube

The invention relates to the technical field of civil engineering, and especially relates to a composite steel pipe UHPC damping column pier. The composite steel pipe UHPC damping column pier is composed of an external steel pipe, an internal steel pipe, an UHPC layer and a rubber concrete layer; the internal steel pipe is sleeved in the external steel pipe, a part between the inner wall of the external steel pipe and the outer wall of the internal steel pipe is filled with the UHPC layer, and an internal part of the internal steel pipe is filled with the rubber concrete layer. The composite steel pipe UHPC damping column pier uses the advantages of steel pipe, UHPC and the rubber concrete, can better solve the anticorrosion problem of the steel pipe concrete, increases the endurance of amember, reduces the life-cycle cost of the member, and prolongs the life period of the member; the damping column pier has the advantages of energy saving and environmental protection, accords with continuous development requirement of green building idea and building industry; the member has the advantages of large carrying capacity reserve, good ductility, seismic performance and fatigue resistance, excellent shock resistance, and good damping performance, and has excellent seismic performance and good damping capability.

Owner:HUBEI ENG UNIV

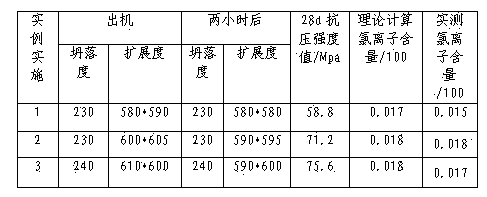

Low-chloride ion high-performance concrete

InactiveCN103708781AExcellent workability and pumpabilityImprove workabilitySolid waste managementSilica fumeIon

The invention belongs to the technical field of the concrete and in particular relates to a low-chloride ion high-performance concrete. The low-chloride ion high-performance concrete is prepared from the following raw materials in parts by weight: 280-360 parts of cement containing 0.005% of chloride ions, 30-50 parts of silica fume containing 0.018% of chloride ions, 70-115 parts of coal ash containing 0.005% of chloride ions, 70-120 parts of mineral powder containing 0.007% of chloride ions, 155-165 parts of water, 660-775 parts of sand containing 0.007% of chloride ions, 976-1098 parts of broken stone containing 0.001% of chloride ions, and 7.50-9.65 parts of water reducing agent containing 0.03% of chloride ions. The total content of chloride ions in the concrete provided by the invention is controlled within the range from 0.015% to 0.018%; and the concrete has the advantages of high workability, high strength and high durability; besides, the strength of the concrete is in the range from C50 to C65.

Owner:亚泰集团沈阳建材有限公司 +1

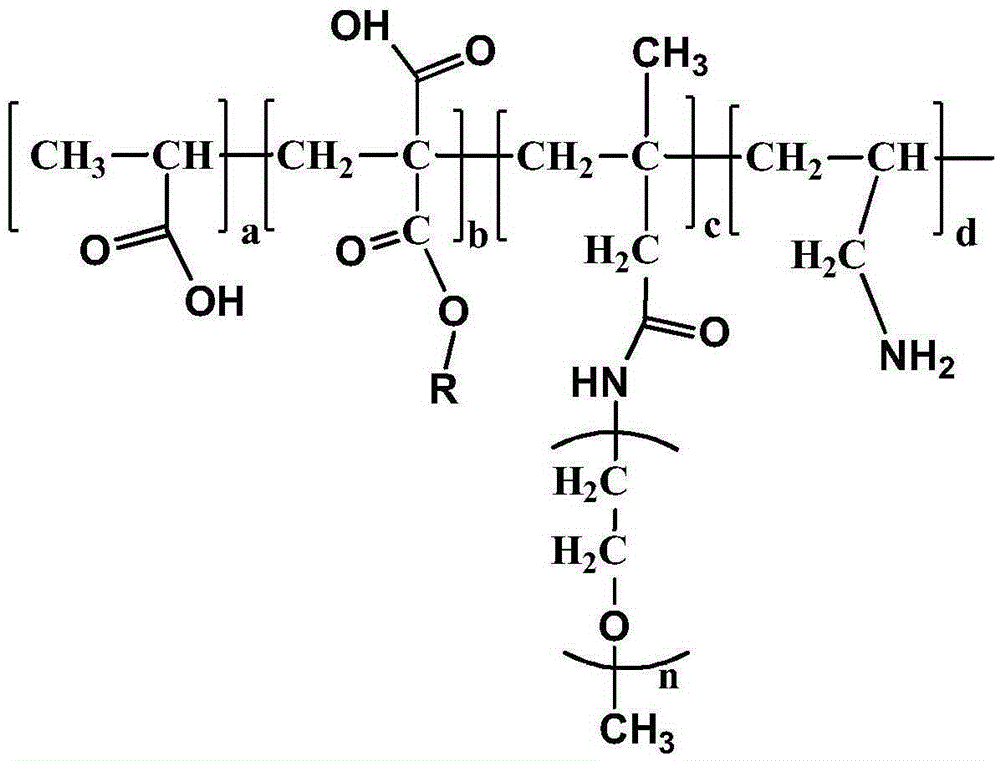

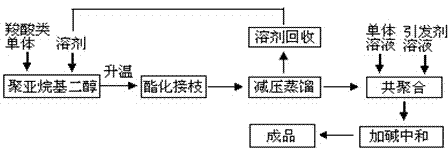

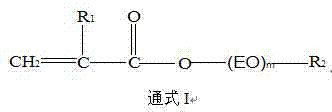

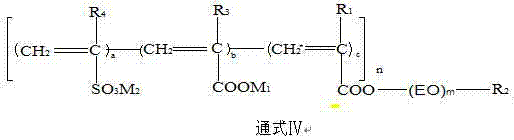

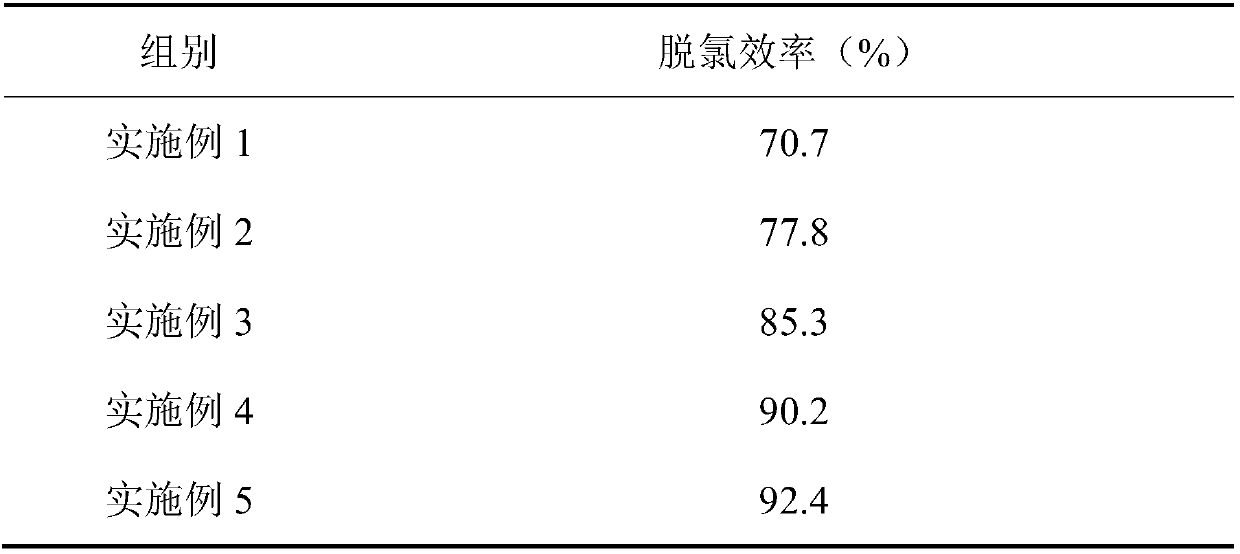

Preparation method of grafted copolymer and air-entraining and slump-retaining polycarboxylate concrete water reducer

The invention belongs to the technical field of concrete admixtures in chemical building materials, and particularly relates to a preparation method of a grafted copolymer and an air-entraining and slump-retaining polycarboxylate concrete water reducer. The air-entraining and slump-retaining polycarboxylate air-entrained concrete efficient water reducer is synthesized by the following steps: introducing a double bond in the process of preparing a macromonomer with reaction activity through utilization of polyoxyalkylene ether monomers; copolymerizing a product obtained from the former step and carboxylic acid monomers and allylsulfonate monomers in a solution so as to introduce a long side chain. The preparation technology is very simple; the reaction condition is easy to control; industrial three wastes are not generated in the production process; the solvent can be recycled after being recovered; and the solvent recovery rate reaches 98%-100%, so that the economic benefits are ensured; and the environmental pollution is avoided.

Owner:山东天汇科技有限公司

Method for removing alkaline dross chloride ions through surfactant

The invention discloses a method for removing alkaline dross chloride ions through surfactant. The method comprises the following steps of after alkaline dross, the surfactant and water are mixed according to the mass ratio of 50: (1-10): (150-300), stirring the materials completely till uniform slurry is obtained; then, conducting filter pressing through a filter press, so that filter cakes are obtained; and conducting drying, so that dechlorinated alkaline dross is obtained, and removal of the chloride ions in the alkaline dross is completed. The method for removing the alkaline dross chloride ions is simple in process and good in effect; energy is saved, and environment protection is achieved; the surfactant is mixed to the alkaline dross, so that an agglomeration structure in the alkaline dross is destroyed, and thus the accumulation volume of the alkaline dross is reduced; after filter pressing is completed, the content of the chloride ions in the alkaline dross is further lowered; the obtained dechlorinated alkaline dross can be massively applied to building materials, and thus the problem of alkaline dross disposal is effectively solved; and the problem that the alkaline dross cannot be regenerated and reused on a large-scale can be solved conveniently.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of dinitrosodiammine platinum

InactiveCN102285693ASolve the problem of excessive potassium ion content in P saltReduce Chloride ContentAmmonium nitratesRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydrazine compoundElemental analysis

The invention discloses a preparation method of noble metal compound dinitrosodiammine platinum [Pt(NH3)2(NO2)2] used in the process of cyanide-free electroplating and platinum plating. Chloroplatinic acid and hydrazine hydrochloride are used as a reducing agent to reduce chloroplatinic acid to chloroplatinous acid, prepare dichlorotetraammonium platinum by a one-pot method, and then react with excess sodium nitrite to obtain dinitrosodiammine platinum. The invention accurately reduces chloroplatinic acid to chloroplatinous acid, and then prepares dichlorotetraammonium platinum by one-pot cooking method, and further reacts with sodium nitrite to prepare P salt, which effectively solves the excessive potassium ion content of P salt in the traditional preparation method The problem. The elemental analysis of the P salt prepared by the invention is basically consistent with the theoretical value, does not contain potassium ions, and the contents of sodium ions and chloride ions are both lower than 50PPM.

Owner:陕西瑞科新材料股份有限公司

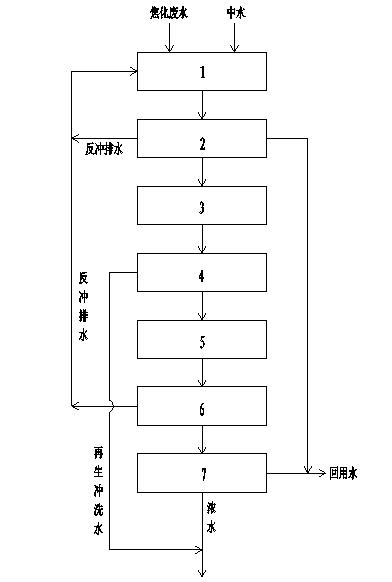

Method of continuously removing chloride ions from circulating water for water-quenched slag at low cost

InactiveCN110002566AGuaranteed efficiencyGuaranteed continuityWater contaminantsWaste water treatment from metallurgical processIon contentSludge

The invention relates to the field of sewage treatment, in particular to a method of continuously removing chloride ions from circulating water for water-quenched slag at low cost. The method comprises the steps of: step 1: recovering aluminum from waterworks sludge for treatment to prepare aluminum hydroxide as an aluminum source, and taking calcium oxide or calcium hydroxide as a calcium source,step 2: calculating a total amount of chloride ions in the water and dosage of calcium and aluminum agents according to a measured chloride ion concentration of the circulating water for the water-quenched slag, step 3: adding the agents into the circulating water for the water-quenched slag, performing stirring for reaction, standing and filtration, and detecting a chloride ion content in the circulating water after the filtration, step 4: feeding carbon dioxide to regulate a pH (potential of hydrogen) of the circulating water to be less than 8.5. The treated circulating water can be used for secondary dechloridation or dechloridation for many times; conditions are completely referred to the above steps; after the continuous dechloridation, water quality reaches the standard; and the circulating water can be used for circular water quenching. The method makes full use of renewable resources and is energy-saving, environmentally friendly and high in treatment efficiency, and the agents are cheap and easy to obtain.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com