Patents

Literature

1233 results about "Deoxidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deoxidization is a method used in metallurgy to remove the oxygen content during steel manufacturing. In contrast, antioxidants are used for stabilization, such as in the storage of food. Deoxidation is important in the steelmaking process as oxygen is often detrimental to the quality of steel produced. Deoxidization is mainly achieved by adding a separate chemical species to neutralize the effects of oxygen or by directly removing the oxygen.

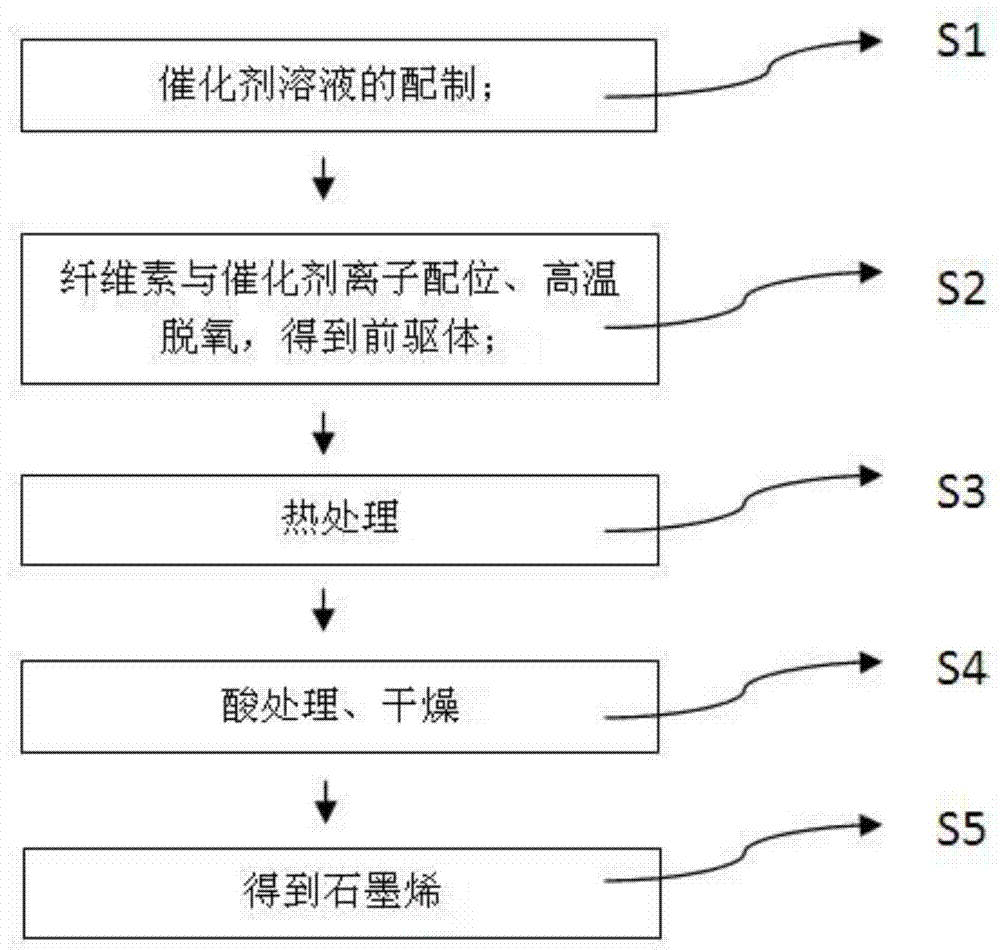

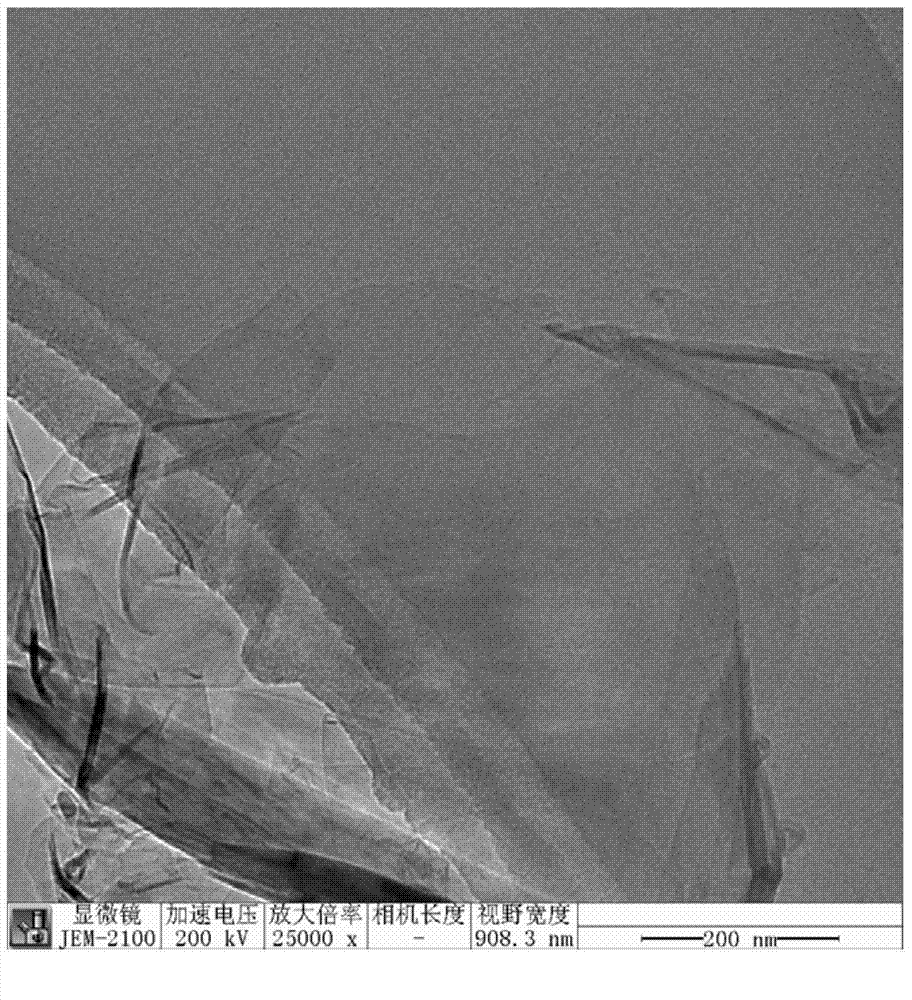

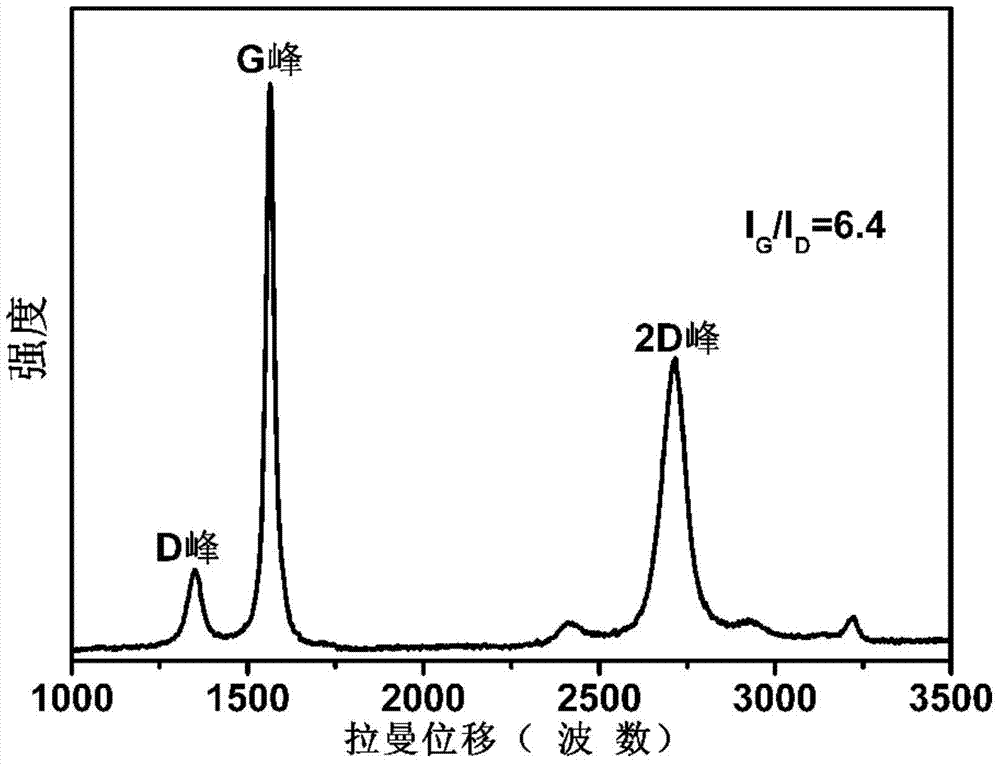

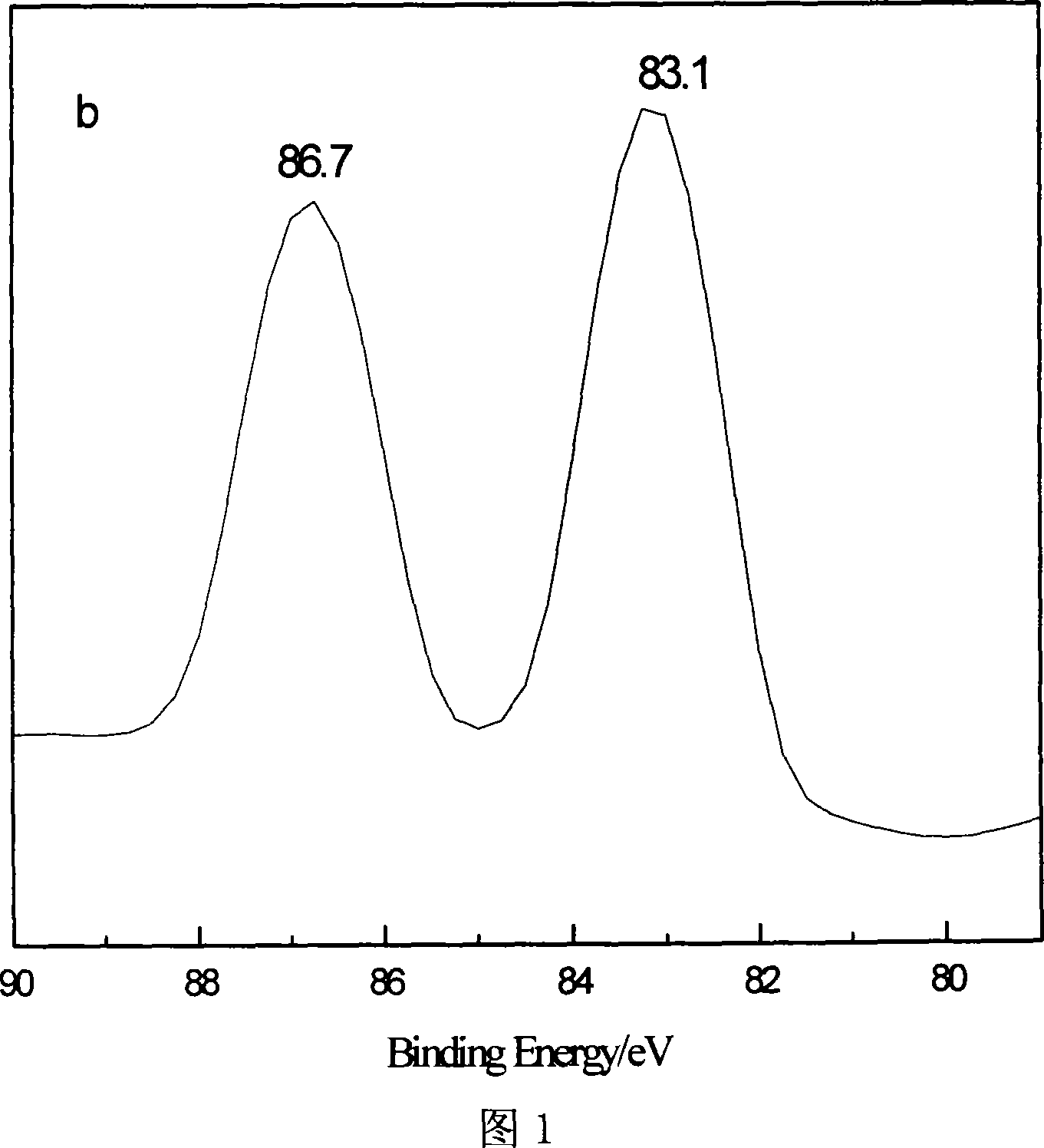

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

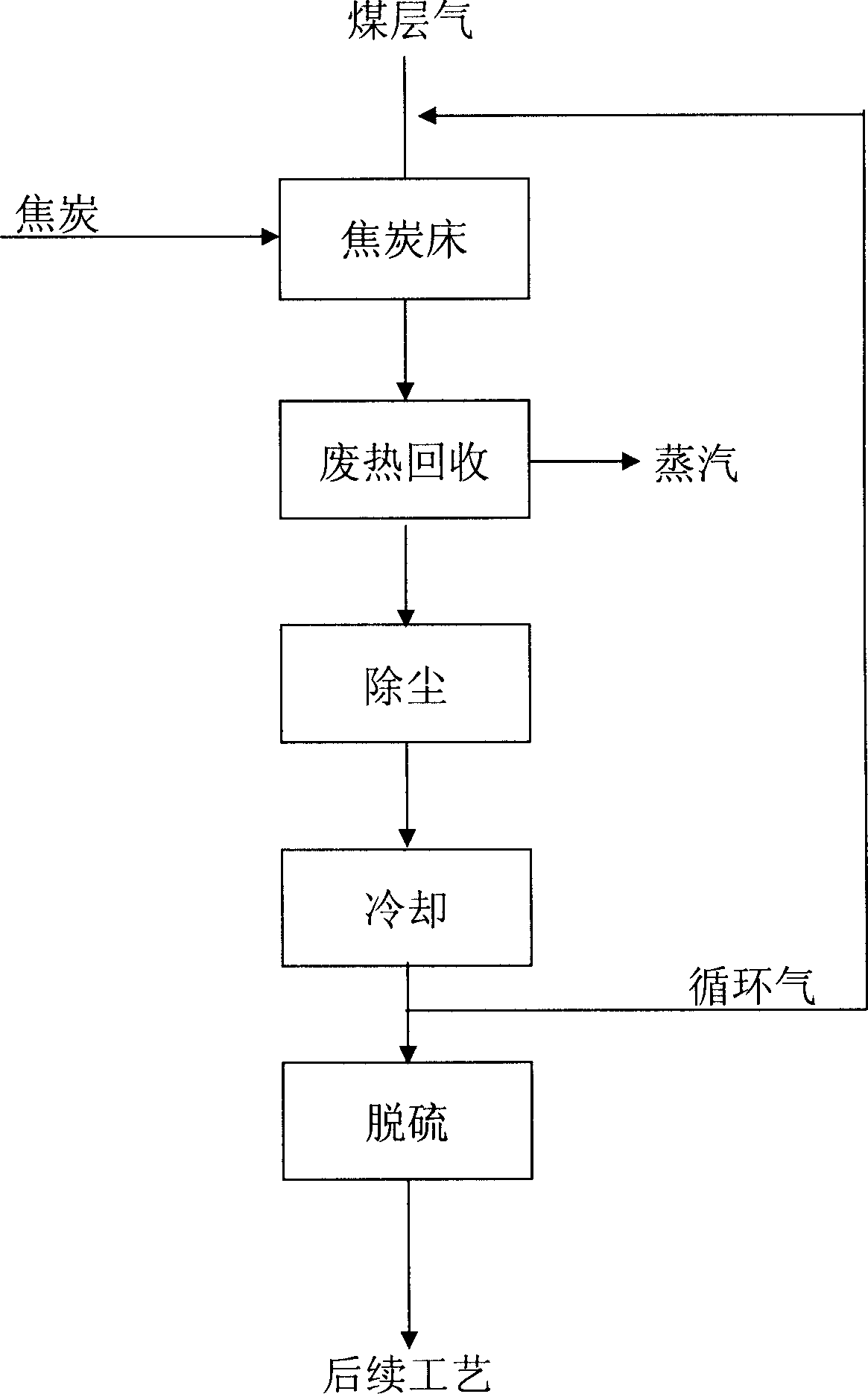

Coal bed gas coke deoxidization technique

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

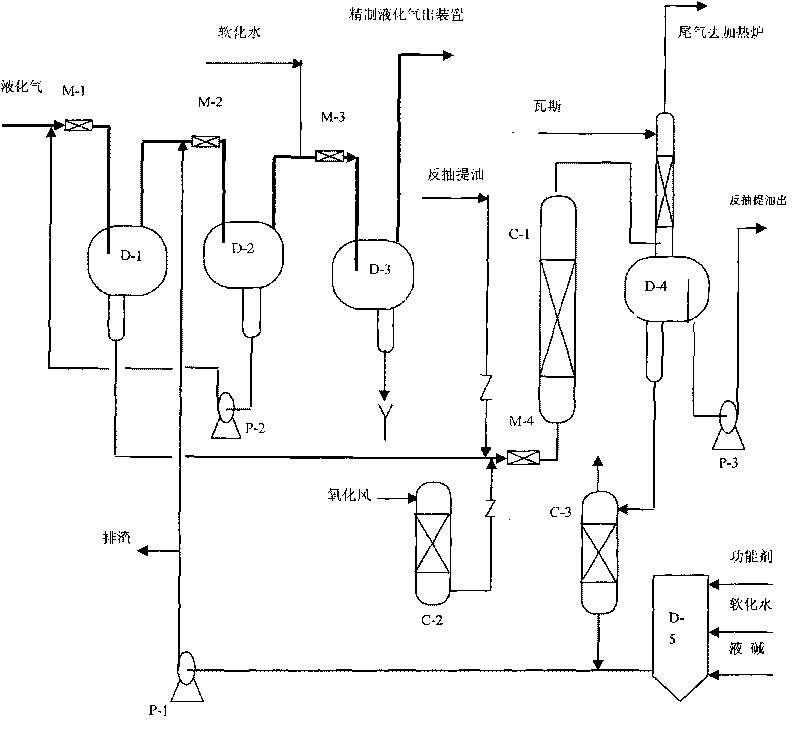

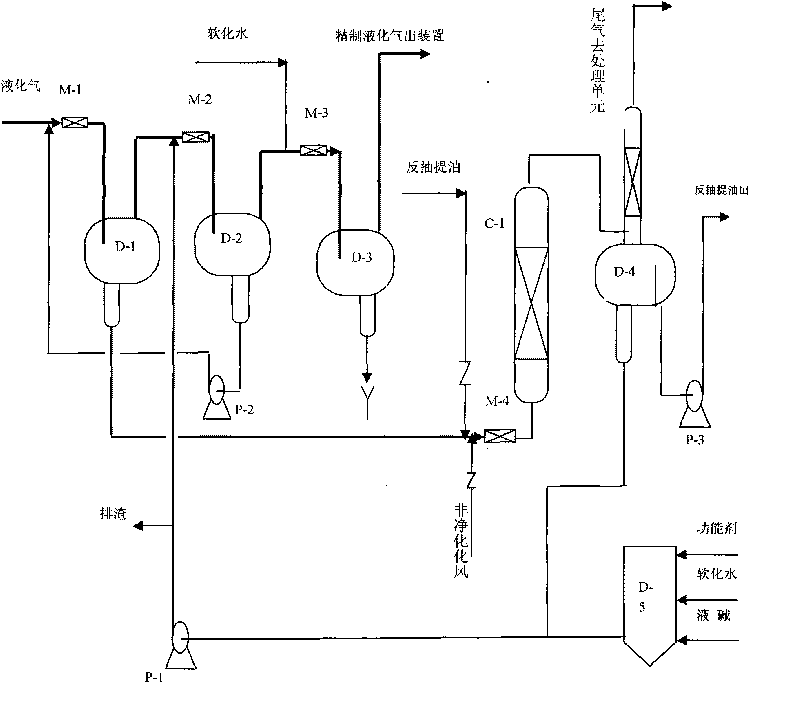

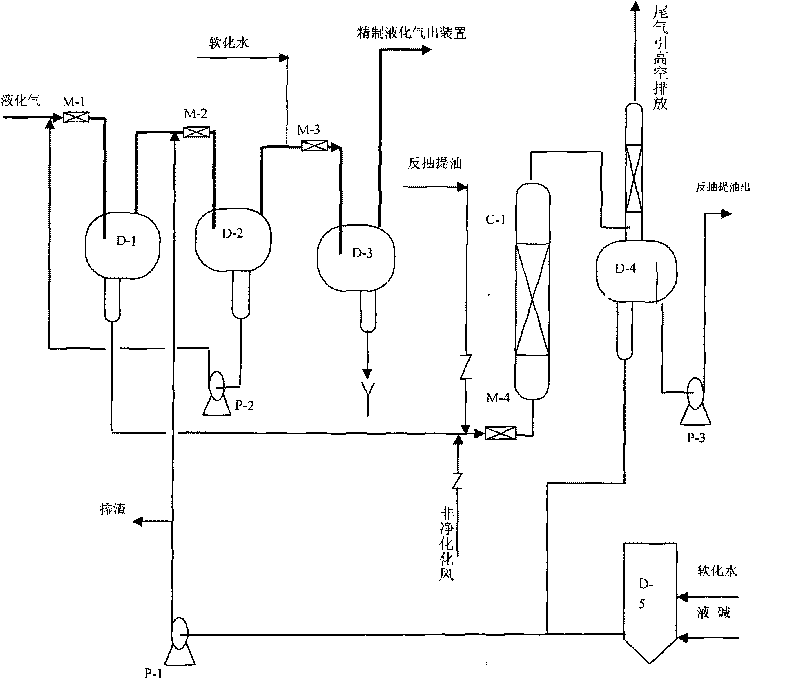

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

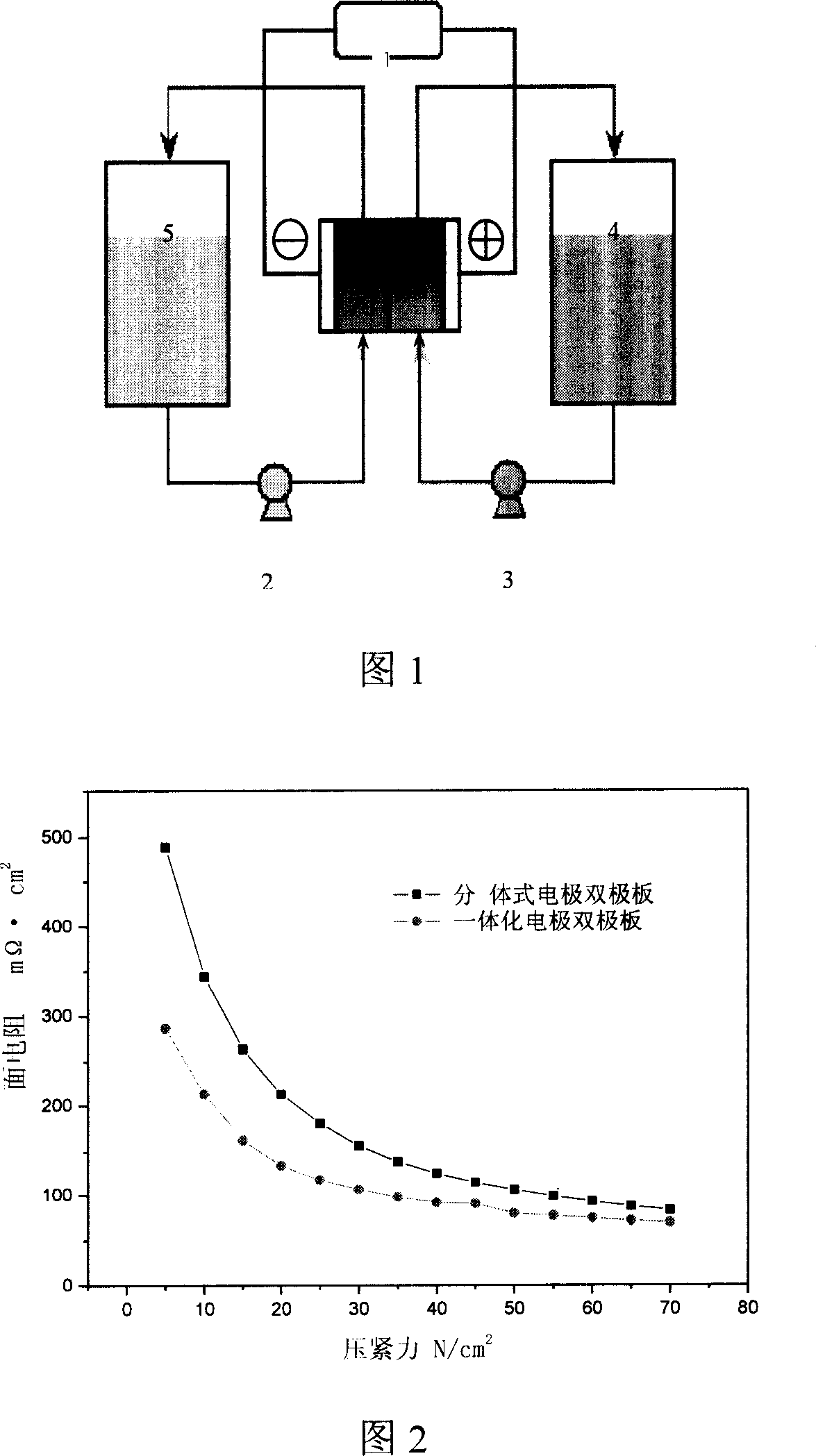

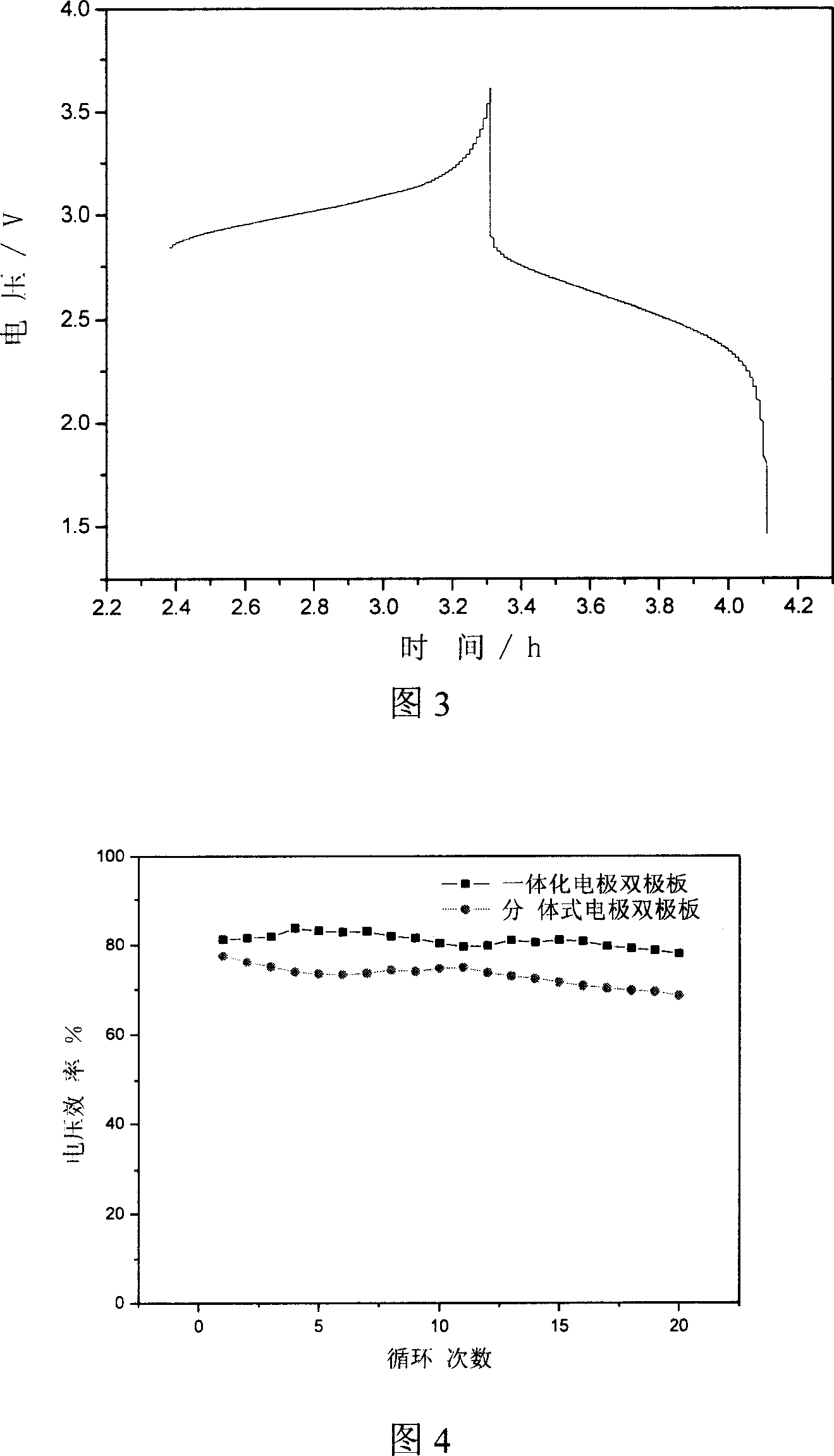

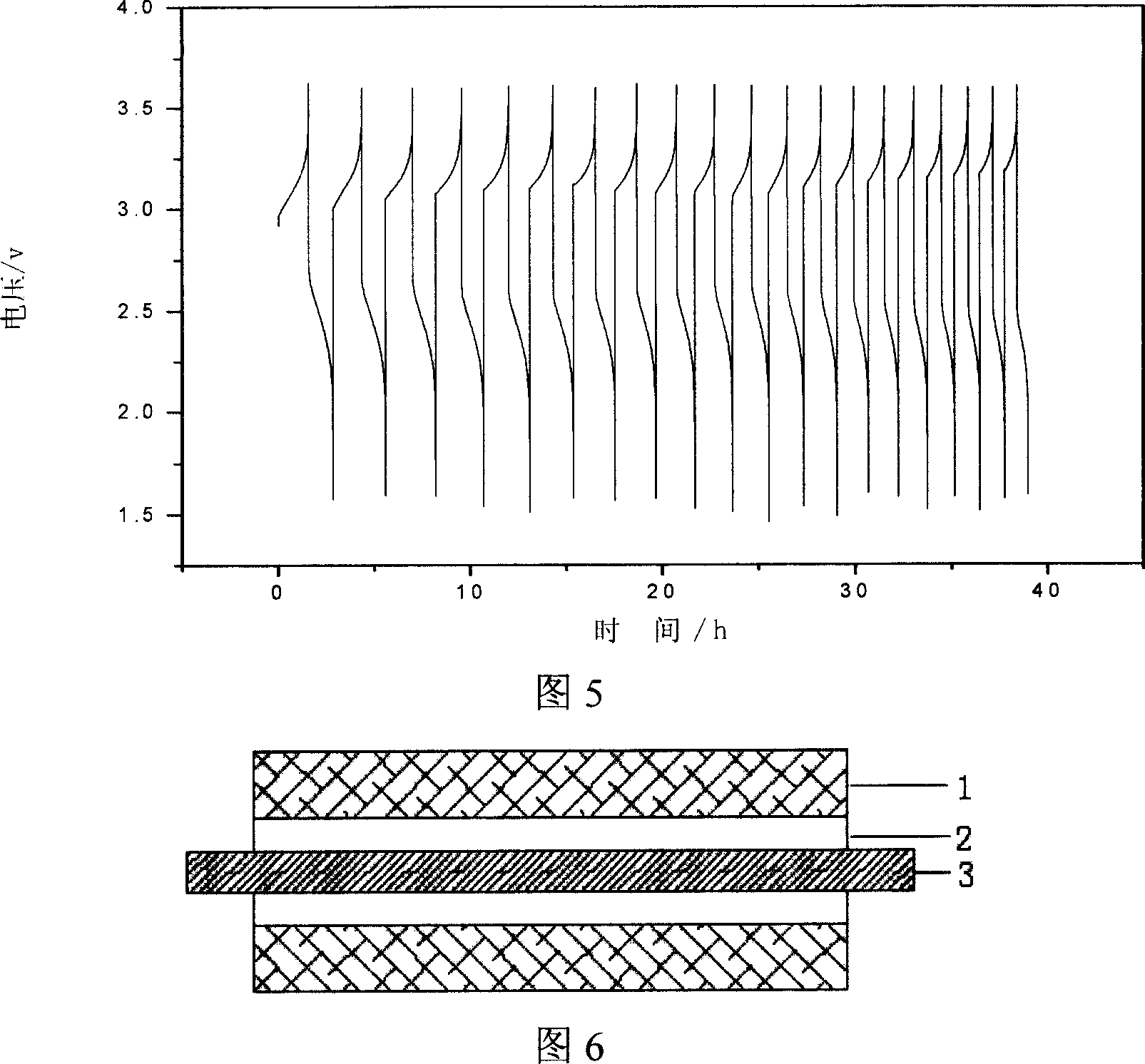

Integrated pole dual-pole board for oxidation deoxidization liquid energy-storing battery and its preparation

InactiveCN101009376AReduce contact resistanceImprove efficiencyElectrode manufacturing processesElectrode carriers/collectorsElectrical resistance and conductanceStored energy

The invention relates to the oxidation-reduction liquid stored-energy cell, especially integral electrode dipole plate and preparation, the integral electrode dipole plate includes: multiple-arch electrode and dipole plate, viscous conducting layer which is between the dipole plate and multiple-arch electrode, that is the multiple-arch electrode and dipole plate are felt to the dipole plate via the viscous conducting material. The advantages of the invention are: the integral electrode dipole plate can decrease the contact resistance between the multiple-arch electrode and dipole plate evidently, increase the voltage efficiency and energy efficiency of the oxidation-reduction liquid stored-energy cell, at the same time the distribution of the electrolyte in electrode is more even; the conductivity of the integral electrode dipole plate is perfect, the electrochemistry property is high, the chemical property is stable, it possesses high practicality value and wide application foreground.

Owner:DALIAN RONGKE POWER

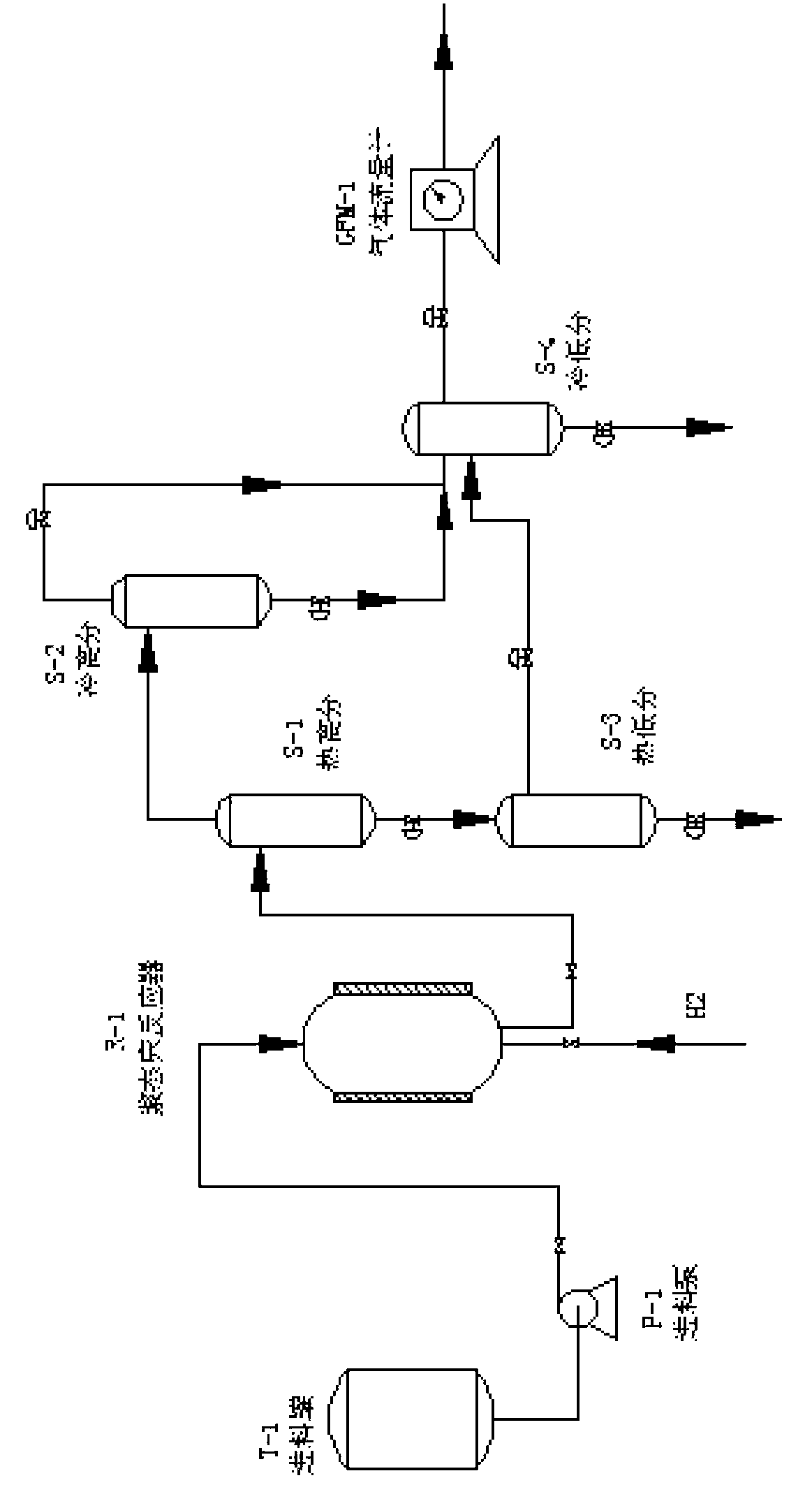

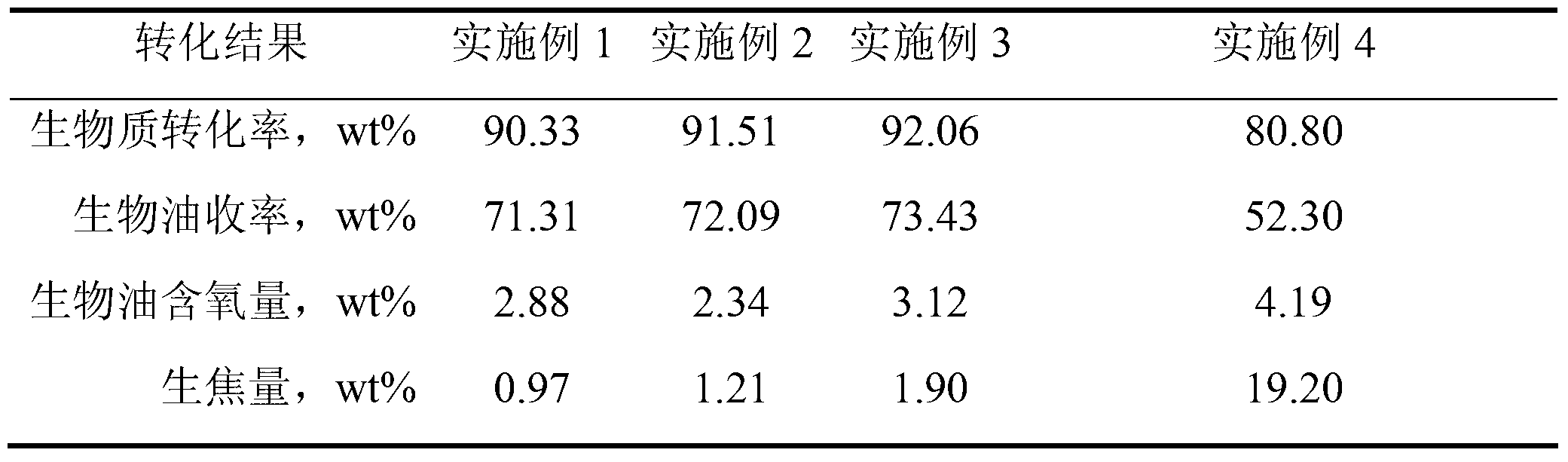

Heavy oil and biomass hydrogenation coliquefaction treatment process

ActiveCN103242871AGood deoxidation effectUniform reaction temperatureBiofuelsHydrocarbon oil crackingDistillationHydrogen pressure

The invention relates to a heavy oil and biomass hydrogenation coliquefaction treatment process in which one or two of heavy oil and biomasses are used as raw materials in vacuum gas oil with the distillation range of 360-540 DEG C and FCC (Fluid Catalytic Cracking) oil slurry. In the process, an oil-soluble transition metal organic compound with hydrogenation activity is used as a catalyst, dimethyl sulfide is used as a vulcanizing agent, a full-back-mixing type empty barrel reactor is used as a slurry column hydrogenation reactor, the reaction temperature is uniform, and the structure is simple. By using the process, the conversion rate of the biomasses can be up to over 90wt% at lower hydrogen pressure of 4-8MPa and the temperature of 370-430 DEGC, and the yield of oil phases is up to over 70wt%. A dispersive hydrogenation catalyst adopted in the process can be used for greatly reducing the quantity of green cokes and taking a better deoxidization effect on the biomasses.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

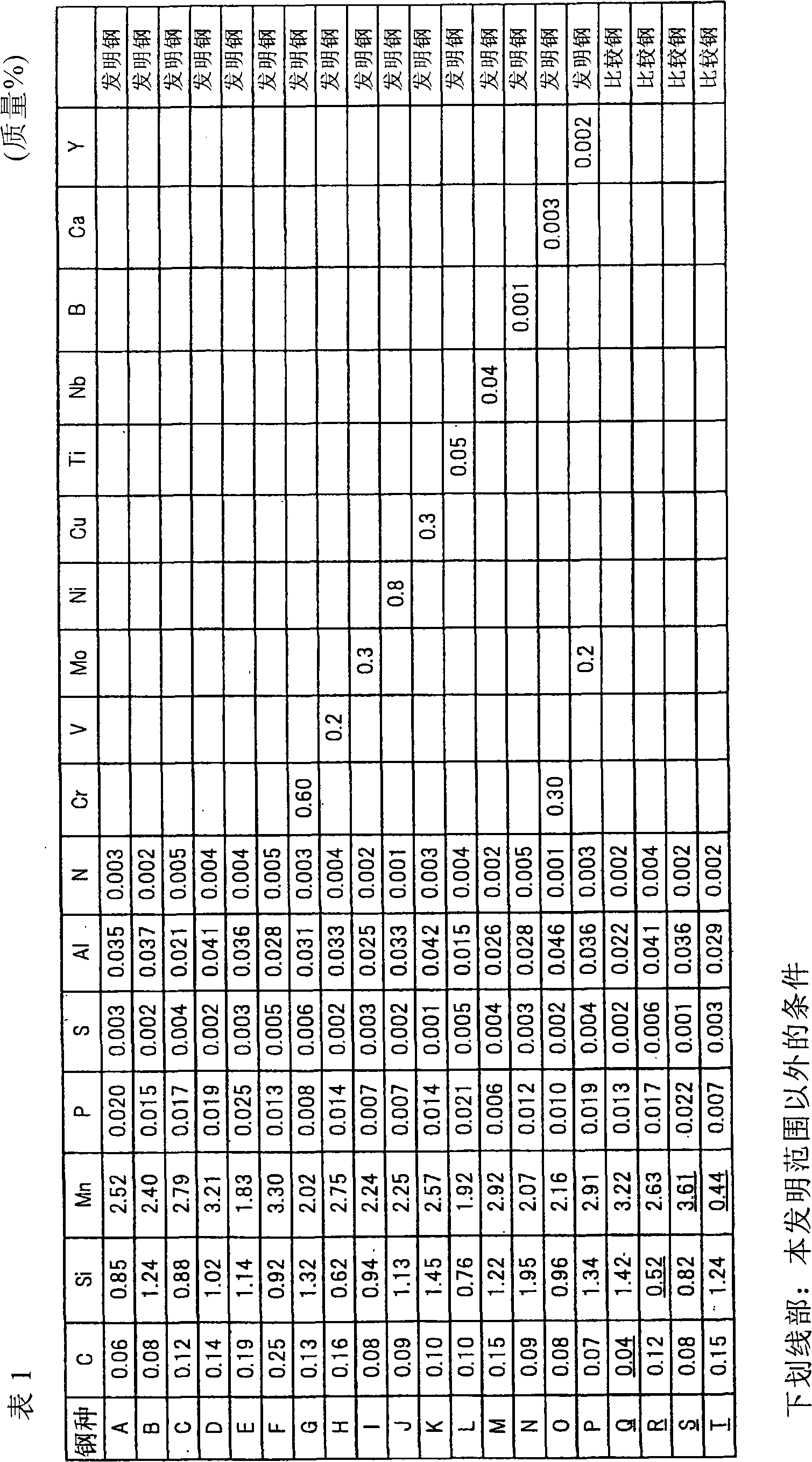

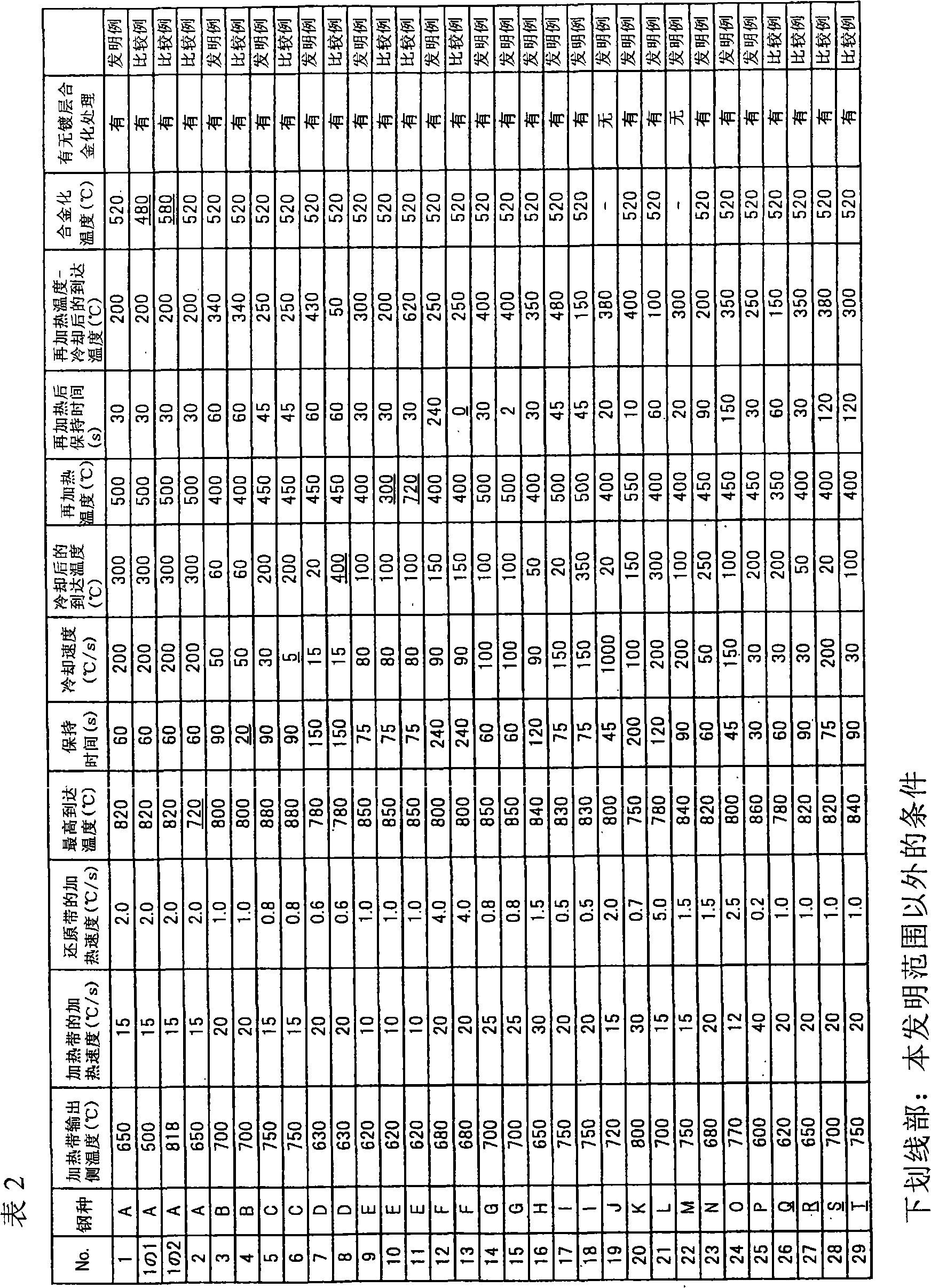

High-strength hot dip zinc plated steel sheet having excellent moldability, and method for production thereof

ActiveCN101641456AGood formabilityHot-dipping/immersion processesNanotechnologySheet steelChemical composition

Disclosed is a high-strength hot dip zinc plated steel sheet having excellent moldability, which has a ¢TS OE(total elongation)! value of 15000 MPa % or more and a ¢TS OE(hole expanding rate)! value of 45000 MPa % or more as measured on a steel having a tensile strength of 780 MPa or more under such conditions where the amount of Al added is at the same level as employed in the conventional deoxidization. Also disclosed is a method for producing the steel sheet. Specifically disclosed is a high-strength hot dip zinc plated steel sheet having excellent moldability, which has the following chemical composition (by mass): C: 0.05 to 0.3%, Si: more than 0.60% and not more than 2.0%, Mn: 0.50 to 3.50%, P: 0.003 to 0.100%, S: 0.010% or less, Al: 0.010 to 0.06%, and N: 0.007% or less, with the remainder being Fe and unavoidable impurities, wherein the steel sheet structure has a standard deviation of the nano-hardness of 1.50 GPa or less.

Owner:JFE STEEL CORP

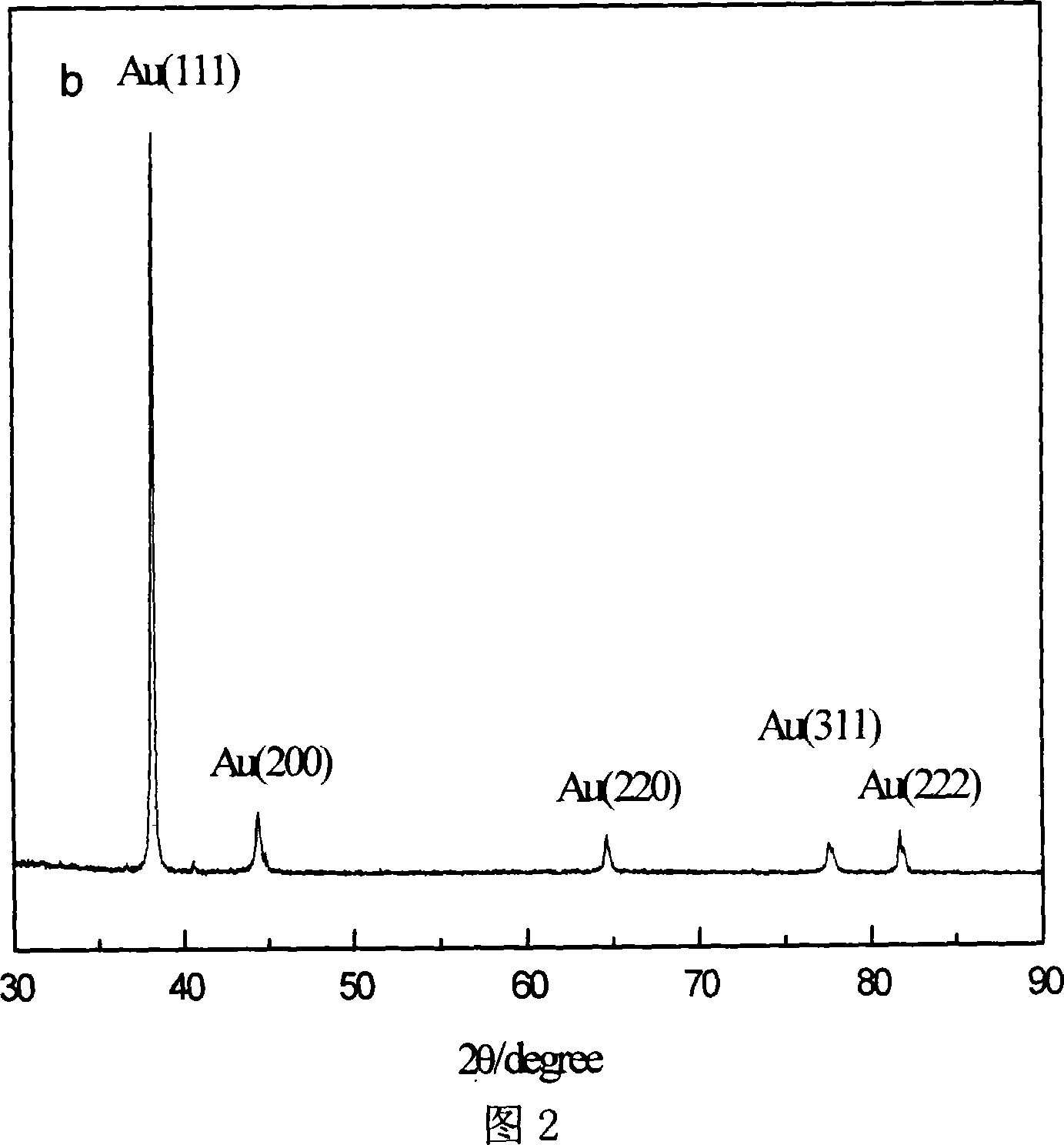

Cotton fabric inorganic nanometer antibiotic finishing agent and preparation method thereof

InactiveCN101368331ANo storage stabilityGood storage stabilityNon-macromolecular adhesive additivesCoatingsDeoxidizationBroad spectrum

The invention discloses ramie cotton fabric inorganic nanometer antibacterial finishing agent and a preparation method thereof. Silver nitrate and micro-molecular organic or inorganic reducing agent, such as ascorbic acid, tannic acid, tartaric acid and the like, are added into polyethyleneglycol and the mixture engages in deoxidization under 5-100 DEG C, producing nanometer silver with good dispersivity and stability. The polyethyleneglycol accounts for 50-90%of the weight and the ratio of silver salt to micro-molecular reducing agent is 1:1-4:1. The prepared nanomemter silver is dispersed in aqueous medium so as to get nanometer silver finishing agent and the weight percentage of nanometer silver is 0.25%-0.5%. The ramie cotton fabric can be made into composite material with excellent antibacterial effect after being soaked in the finishing agent. The fabric made from the antibacterial finishing agent has the characteristics of quick, efficient, broad-spectrum and lasting antibacterial effect. The preparation method and the finishing process are simple in technique and low in cost and have no pollution and are easy to industrialize.

Owner:ZHEJIANG CONSTR INVESTMENT GRP CO LTD

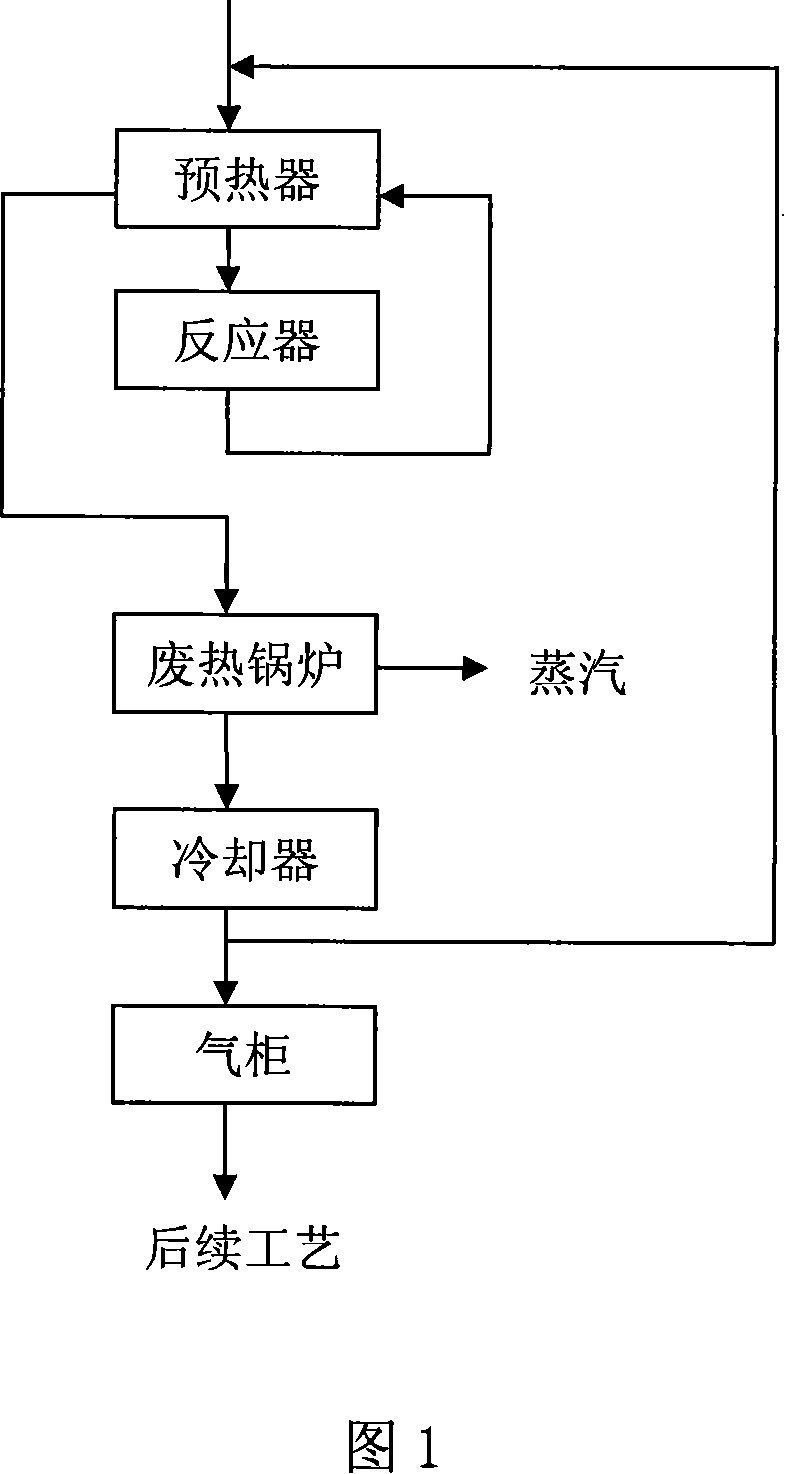

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

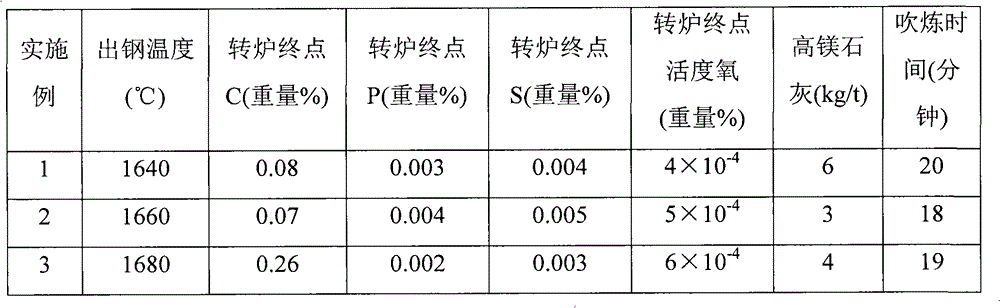

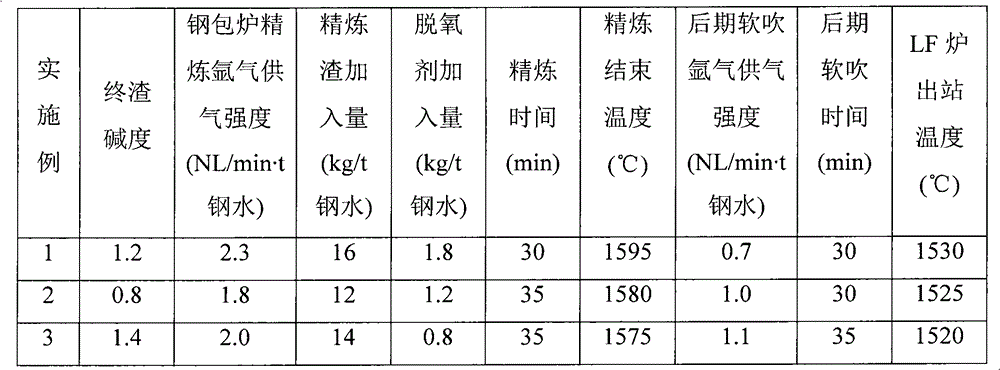

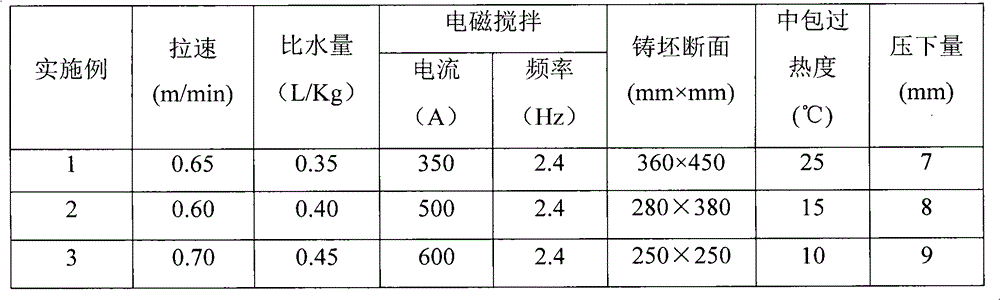

Method for smelting ultra-low-carbon steel

InactiveCN101215618ARealize continuous pouringRealize multi-furnace continuous pouringManufacturing convertersSlagSulfur

The invention relates to a process for smelting ultra-low-carbon steel, which comprises melted iron pretreatment desulfuration, converter smelt, LF furnace refining, RH vacuum process and continuous casting procedure in turn. Converter smelt tapping adopts non deoxidization tapping, steel which is tapped off is refined by LF ladle furnace before carried out melt iron vacuum decarburization processing, wherein refining is mainly used to proceed modifying property processing and further desulfuration and heating for top slag of melted iron, and the melted iron is reinforced with positive oxygen blowing decarburization after shifted into a RH vacuum container. The process can control carbon, nitrogen and sulfur in steel to preset objects which are required, and has excellent castability when a casting machine casted, thereby realizing casting by several furnaces.

Owner:BENGANG STEEL PLATES

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

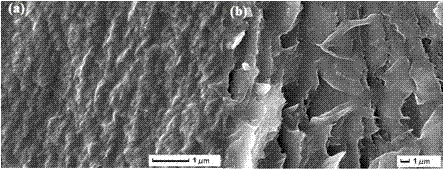

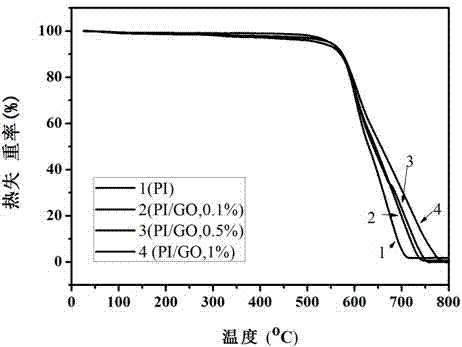

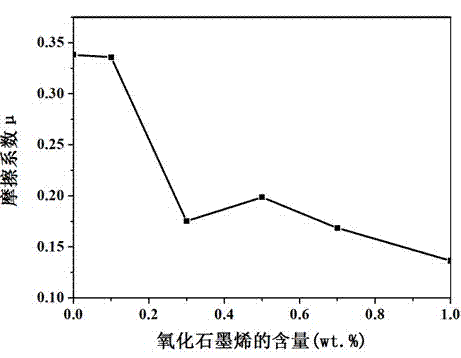

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

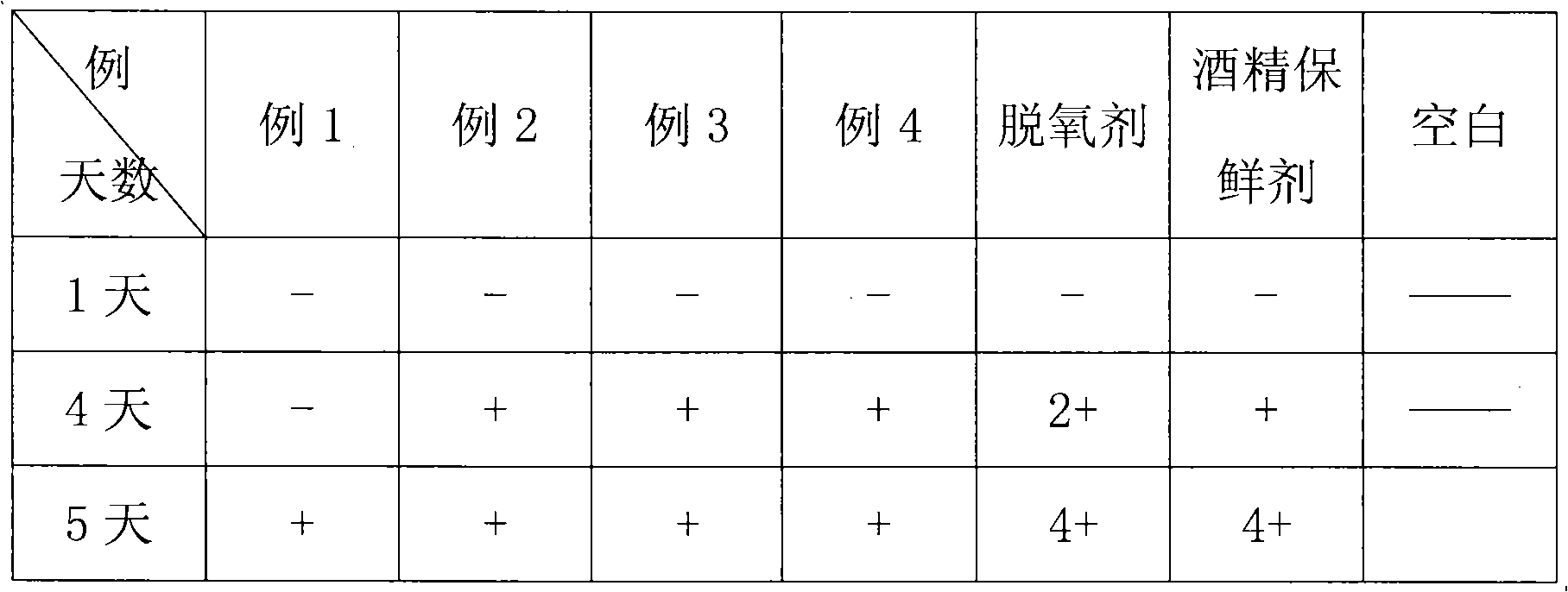

Bacterium-restraining deoxidization dual-purpose food antistaling agent and preparation thereof

The invention relates to an antibacterial deoxidizing double-effect food preservative, which is formed by combining a deoxidizer component with a bacteriostat component, wherein the deoxidizer component accounts for 60-90 percent, and the bacteriostat component accounts for 10-40 percent. The bacteriostat component comprises an adsorption carrier and an antibacterial solution. The adsorption carrier comprises salep, silicon dioxide, vermiculite, diatomaceous earth, zeolite, bentonite, fiber, etc. The antibacterial solution comprises one of or the composite mixture of edible alcohol and propylene glycol. Antibacterial synergist comprises allyl isothiocyanate, allicin, cinnamic aldehyde, cinnamic acid, carvacrol, eugenol, thymol, citral, etc. The antistaling agent integrates double protection functions of absorbing oxygen, sterilizing and inhibiting bacteria, which is remarkable in preservation effect and wide in application range.

Owner:GUANGDONG GUANGYI TECH IND

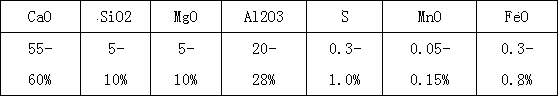

Smelting process of high-carbon bearing steel

The invention discloses a smelting process of high-carbon bearing steel. High-alkalinity refining slag with the alkalinity value of 6-9 is obtained through adding conditioned slag and a deoxidizing agent, so that relatively good desulfuration and deoxidization effects are achieved, the content of S can be reduced to about 0.002%, and the content of O can be reduced to be less than 7ppm. Meanwhile, in order to avoid brittle impurity generation caused by overhigh alkalinity of refining slag, the content Al of the molten steel is strictly controlled in a smelting process, enough aluminum blocks for deoxidizing are added at one step in a tapping process, and no aluminum is replenished in the subsequent process, so that a deoxidized product is prevented from being floated; the content of Al in the refining slag is controlled at about 0.010%, so that secondary oxidation caused in a pouring process is reduced. On the other hand, the value of CaO / Al2O3 in the refining slag is controlled at about 1.7, so that the melting point of slag is relatively low, the flowability of the slag is relatively good, the steel slag is easy to separate, and the slag rolling and reduction reaction of molten steel in a vacuumizing process are reduced. Therefore, D-type inclusions in the bearing steel are effectively prevented from being increased, and the rating standards of inclusions in the bearing steel are reached.

Owner:ZENITH STEEL GROUP CORP +1

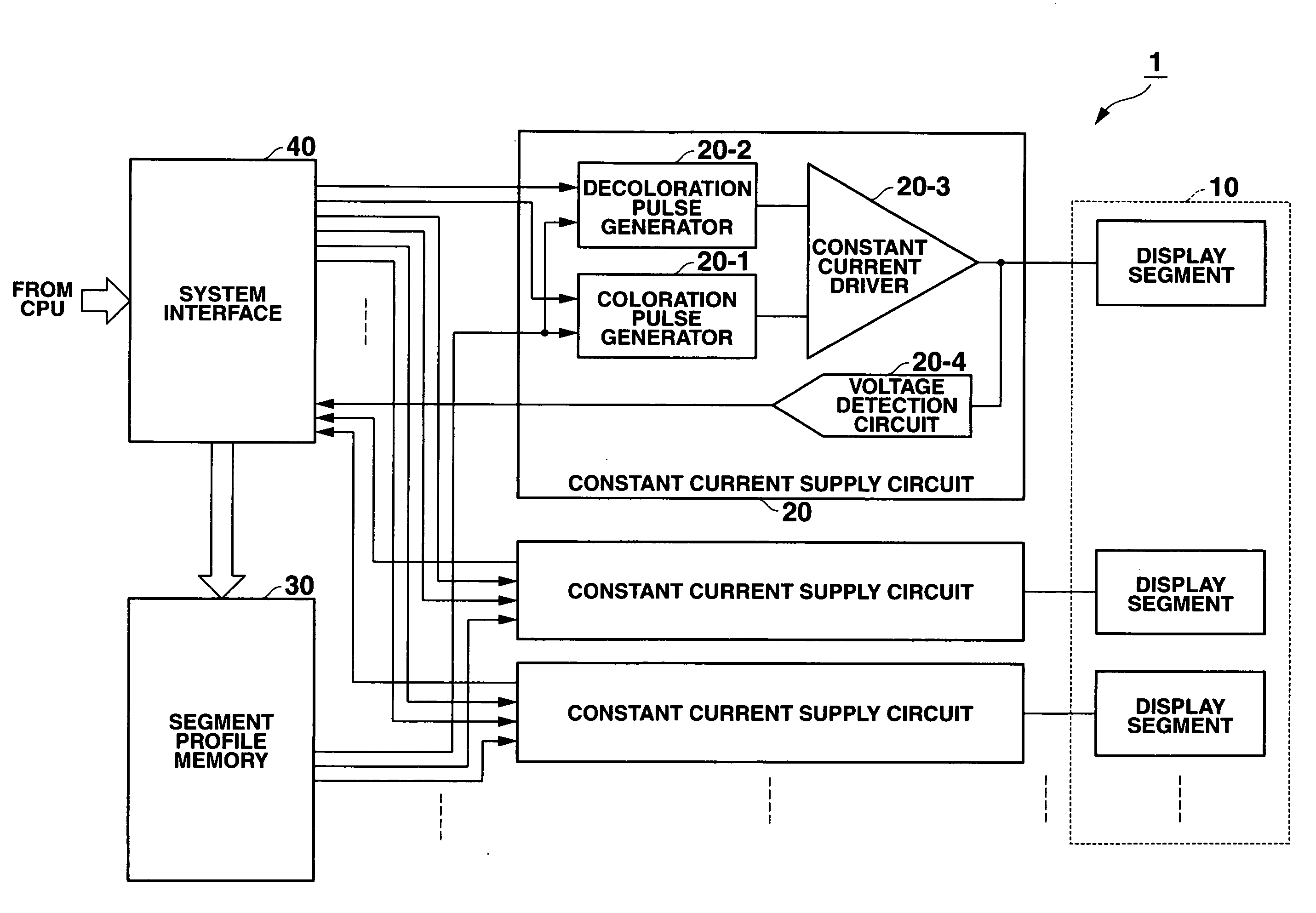

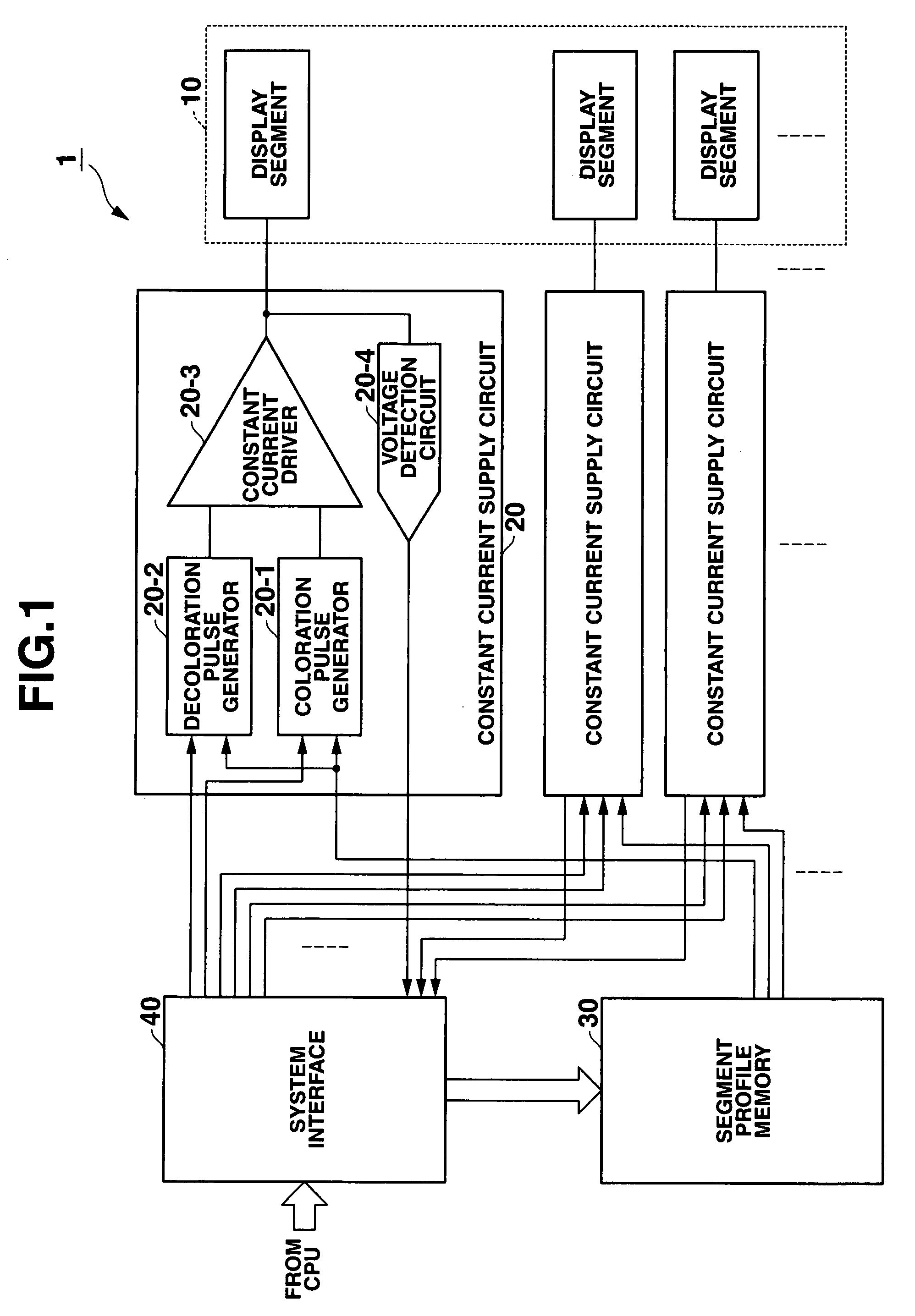

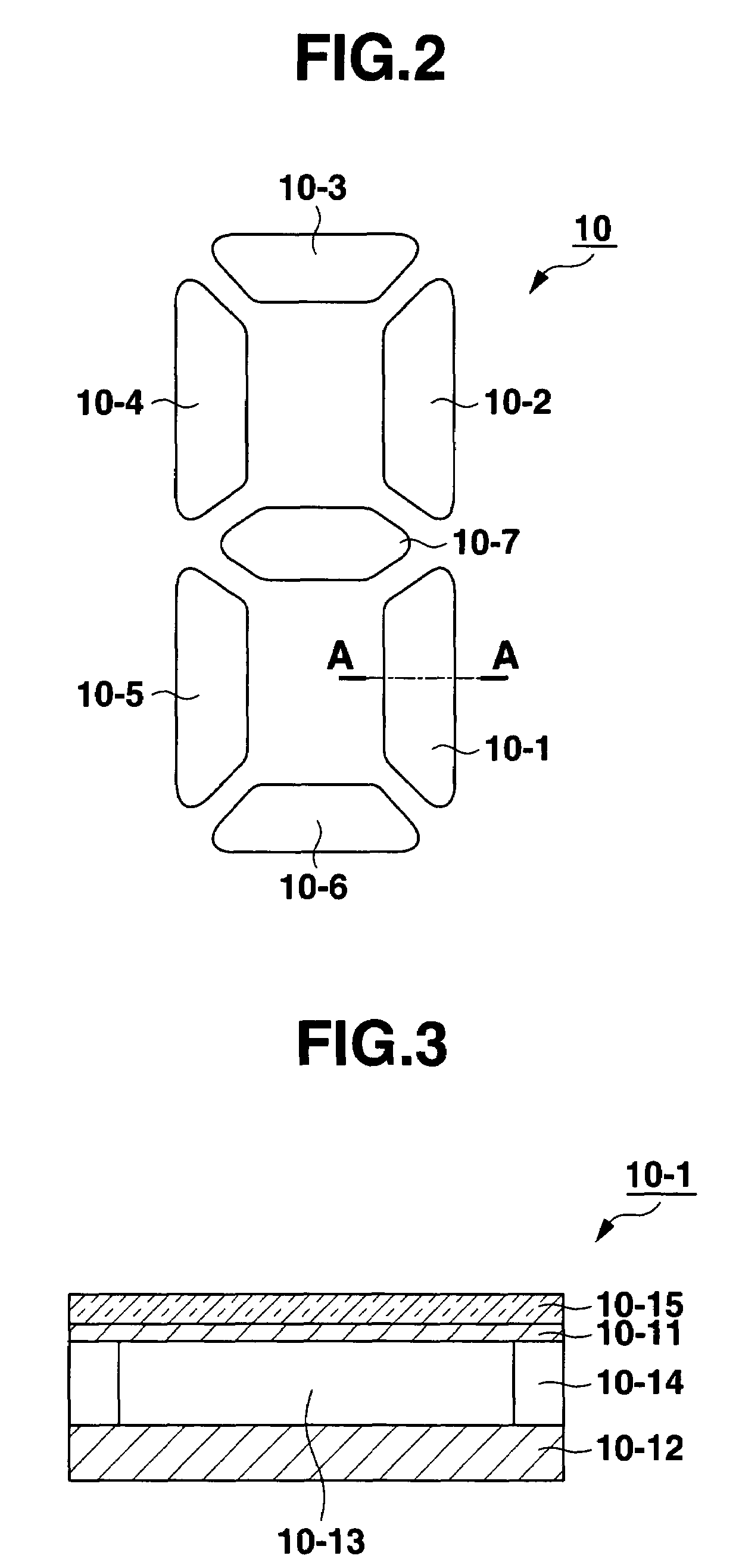

Display drive device and display device

InactiveUS7724415B2Excessively generatedImprove display qualityStatic indicating devicesNon-linear opticsElectrical polarityDisplay device

A display drive device comprises a display element being colored by injecting an electric charge into an electrolyte via an display electrode due to an oxidation-deoxidization reaction and being decolored by injecting an electric charge having an inverse polarity of the electric charge into the electrolyte, at least one constant current supply circuit which supplies a constant current as a decoloration current pulse having a predetermined pulse width to the display electrode upon the decoloration, a voltage detection circuit which detects a voltage value generated in the display electrode, and a control circuit which controls an operation of the constant current supply circuit intermittently and repeatedly supplying the decoloration current pulse from the constant current supply circuit to the display electrode upon the decoloration, and ending the decoloration on the basis of a voltage value to be detected by the voltage detection circuit.

Owner:CASIO COMPUTER CO LTD

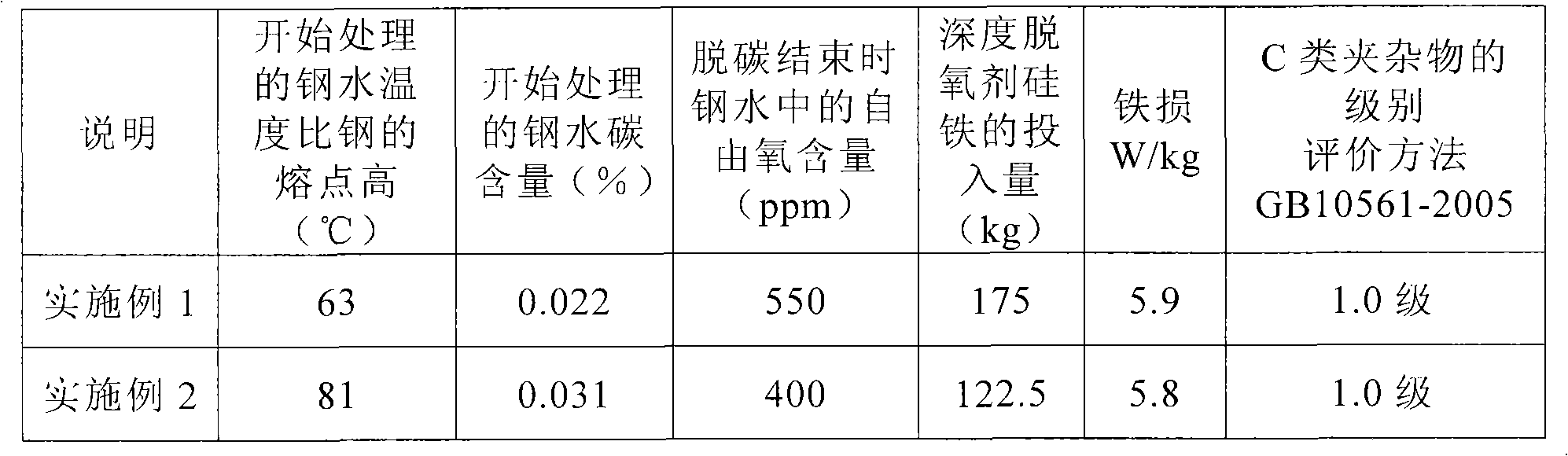

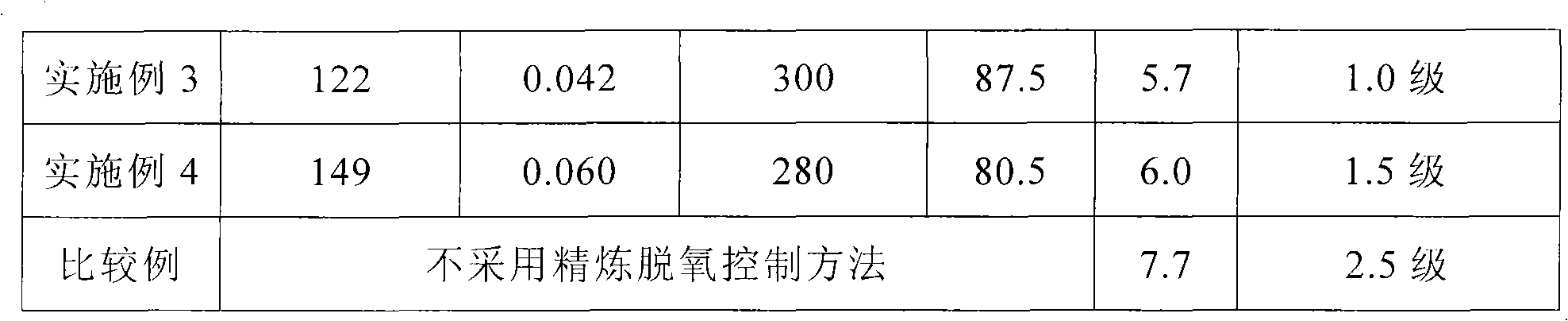

High-grade non-oriented silicon steel with excellent magnetism and smelting method for high-grade non-oriented silicon steel

The invention discloses a method for smelting high-grade non-oriented silicon steel with excellent magnetism. The method comprises the following steps of: 1) smelting, namely smelting the following chemical components: less than or equal to 0.005 weight percent of C, 2.6 to 3.4 weight percent of Si, 0.2 to 0.5 weight percent of Mn, less than or equal to 0.2 weight percent of P, less than or equal to 0.005 weight percent of S, 0.3 to 1.6 weight percent of Al, less than or equal to 0.005 weight percent of N, less than or equal to 0.005 weight percent of O, less than or equal to 0.0015 weight percent of Ti, and the balance of Fe and inevitable inclusions, and modifying ladle top slag in the tapping process of a converter so as to ensure that the ladle top slag comprises 30 to 37 weight percent of CaO, 7 to 20 weight percent of SiO2, 35 to 45 weight percent of Al2O3, 5 to 9 weight percent of MgO, and 0.6 to 2.6 weight percent of T.Fe+MnO when the Ruhrstahl-Heraeus (RH) refining treatment begins; 2) performing RH refining, namely deoxidizing by using ferrosilicon when the decarburization of the RH refining is finished, wherein the adding speed of the ferrosilicon is less than or equal to 12.5kg / ton / min; and 3) adding 0.5 to 2.0 kg of calcium alloy into each ton of molten steel for the denaturation control of inclusions after the deoxidization and alloying are performed through the RH refining.

Owner:BAOSHAN IRON & STEEL CO LTD

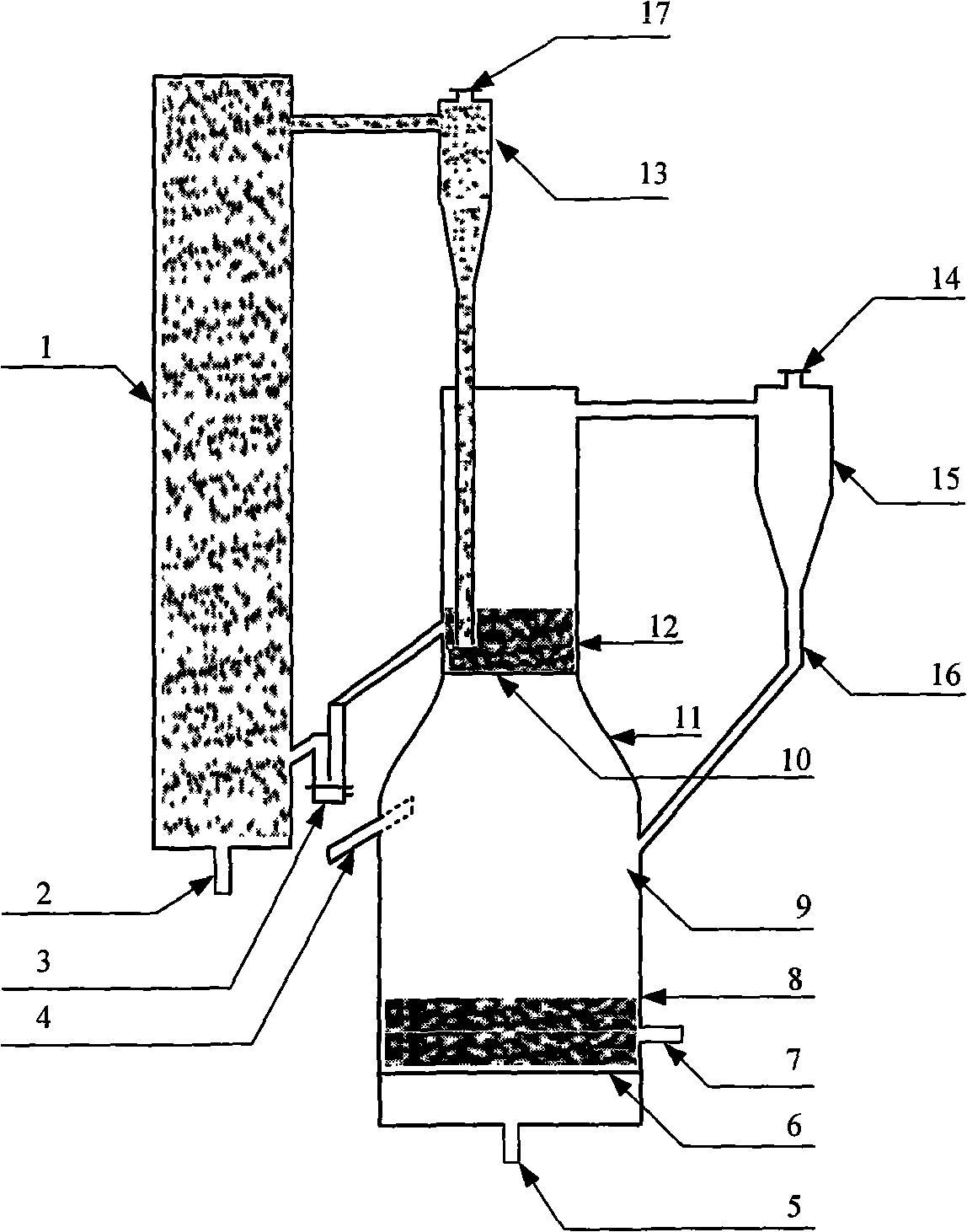

Double distribution plate coal-base serial fluidized-bed chemical chain combustion apparatus

InactiveCN101261010ALow costIncrease profitFluidized bed combustionIndirect carbon-dioxide mitigationDeoxidizationBubbling fluidized bed

The invention belongs to the gas-solid fluidized bed reactor field and relates to a dual-distributing plate coal-based serial fluidized bed chemical-chain combustion apparatus suitable for the chemical-chain combustion of burning coal and other solid fuels; the bottom of a bubbling fluidized bed is provided with a gas inlet and a feed port; the inside of the bubbling fluidized bed is divided into three regions by two distributing plates; the bottom of a low gas velocity region and the bottom of a high gas velocity region are respectively provided with a distributing plate; the middle between two regions is provided with a transition region with a reduce section to realize different gas flow velocities in the low gas velocity gasification region and the high gas velocity deoxidization region; the upper part of a bubbling fluidized bed is in tubular communication with the upper part of a cyclone separating device; the top of the cyclone separating device is provided with an exhaust port which is communicated with a gas inlet of the bubbling fluidized bed; the lower part of the cyclone separating device is pumped to the low gas velocity gasification region by a feed leg; the bottom of the high gas velocity deoxidization region is communicated with a circulating fluidized bed by a feed returning device; the bottom of the circulating fluidized bed is provided with an air inlet; the upper part of the circulating fluidized bed is communicated with the cyclone separating device. The dual-distributing plate coal-based serial fluidized bed chemical-chain combustion apparatus has the advantages of low cost, flexible operation, high thermal efficiency, wide application range, etc.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing graphite series nano fluid

InactiveCN101186808AImprove thermal conductivityNo wearHeat-exchange elementsCarbon nanotubeMaterials science

The invention discloses a process for preparing nanophrase fluid of graphite, which comprises graphitic oxidation, surface modification and deoxidization of graphitic oxidation with surface modification. The surface modification means that surfaces of achieved 100 parts by mass of graphitic oxidation are modified to prepare graphitic oxidation with surface modification by 1-20 parts by mass of surface modifying agent. Deoxidization of graphitic oxidation with surface modification means that nanophrase graphite with surface modification is achieved by deoxidizing 100 parts by mass of products with 1-100 parts by mass of deoxidization agent. Finally the nanophrase graphite is prepared into nanophrase fluid of graphite, which is dispersed in dispersive medium by ultraphonic wave. The process of the invention can produce nanophrase fluid with high thermal conductivity, and replace nanophrase fluid of diamond, carbon nanotubes, carbon 60 and the like. Further the process of the invention has the advantages of simple technique, low cost, rich raw materials supply, and stable products, which cause no abrasion to heat exchangers.

Owner:SOUTH CHINA UNIV OF TECH

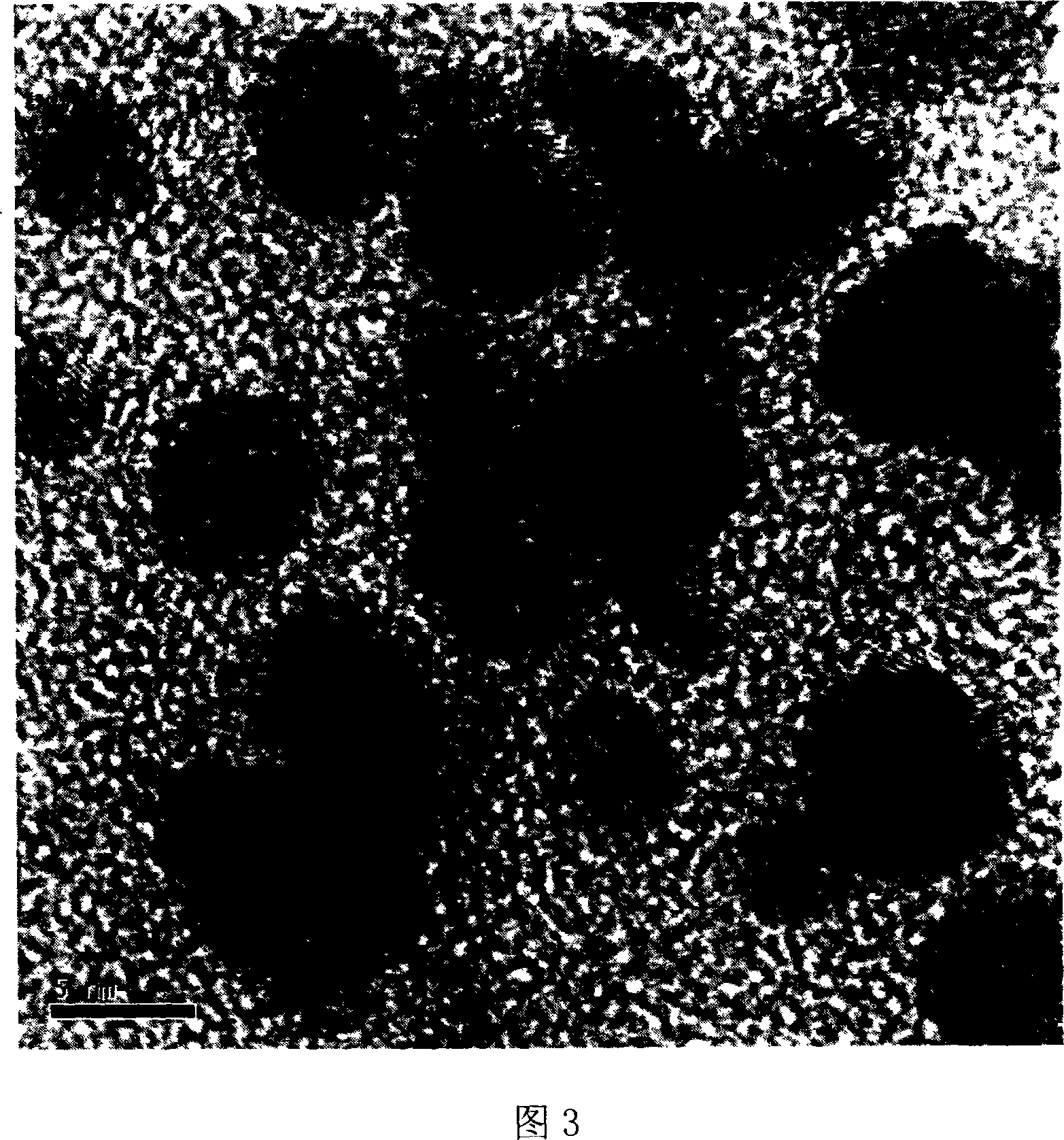

Method for preparing antibacterial composite material with nano silver particles evenly dispersed in polymeric matrix

The invention discloses a method for preparing an antibacterial composite material with nano-silver particles evenly dispersed in a polymeric matrix, which belongs to technique for preparing antibacterial nano composite materials and comprises the following steps: preparing styrene / methyl methacrylate hybrid monomers, a sodium dodecyl sulfate hybrid monomer solution, a silver nitrate aqueous solution and a trisodium citrate aqueous solution; mixing the silver nitrate aqueous solution and the trisodium citrate aqueous solution with the sodium dodecyl sulfate hybrid monomer solution according to a volume ratio to obtain a micro-emulsion containing silver nitrate and a micro-emulsion containing trisodium citrate; stirring and mixing the two micro-emulsions to obtain a stable micro-emulsion having hybrid monomers of continuous phases and containing the nano-silver particles; and then dispersing the emulsions in distilled water to prepare a common emulsion, introducing nitrogen for deoxidization, adding an initiator to perform emulsion polymerization reaction, using sodium chloride to perform emulsion-breaking and separation on the product, fully washing the product with deionized water, and soaking the product in ethanol, and drying the product to constant weight so as to obtain the antimicrobial nano-silver / poly(styrene-methyl methacrylate) composite material. The method has simple preparation processes and can make the nano-silver particles evenly dispersed in the polymer matrix, and the prepared composite material has broad-spectrum bactericidal property, and has high fatality rate to Escherichia coli, bacillus subtilis, staphylococcus aureus and pseudomonas aeruginosa in 24 hours.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

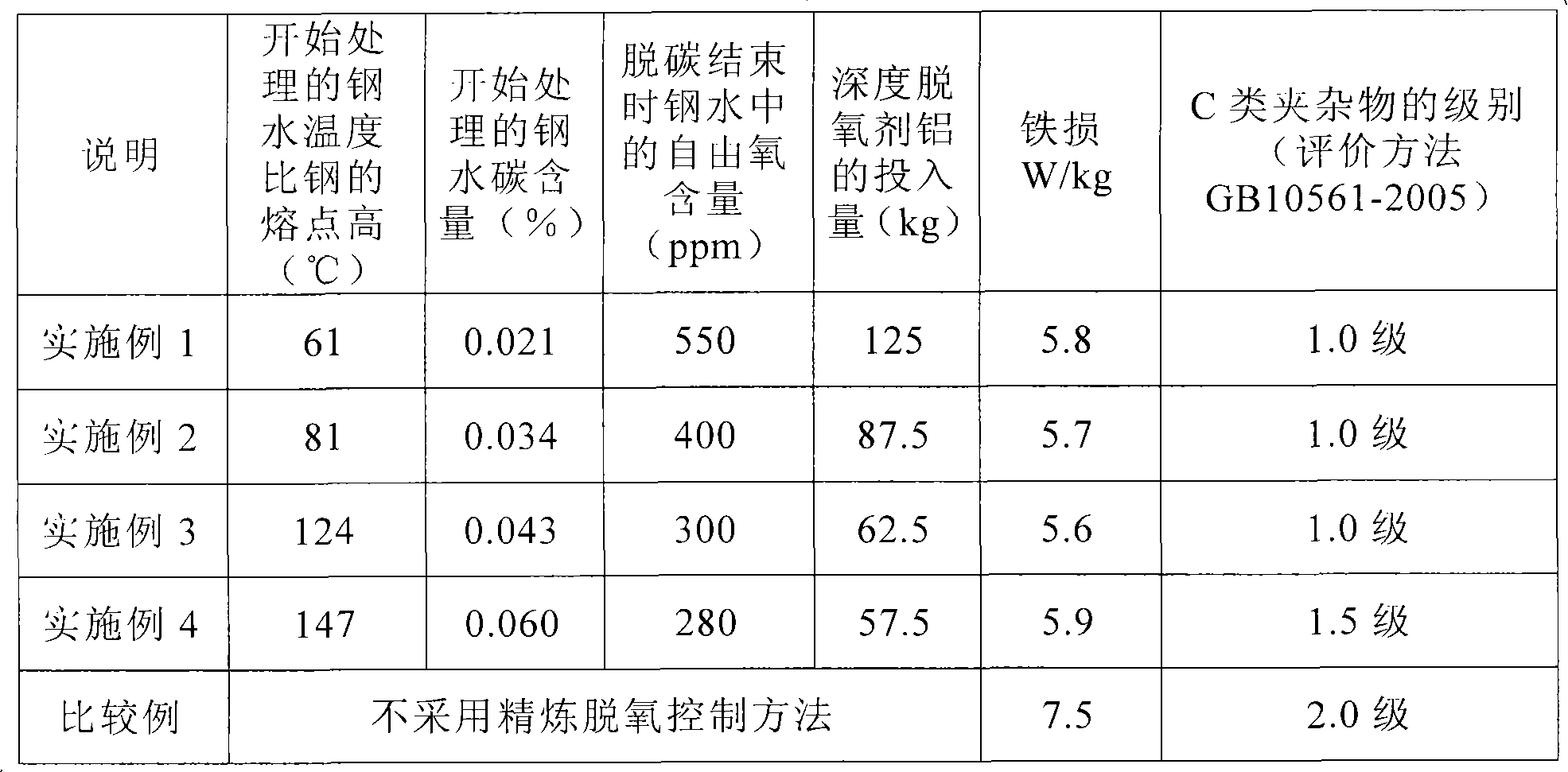

Non-oriented silicon steel RH refinement and deoxidation control method

InactiveCN101768653APrecise deoxygenation controlWide process applicabilityMolten steelOxygen content

The invention discloses a non-oriented silicon steel RH refinement and deoxidation control method. The method includes the following steps that firstly, the non-oriented silicon steel includes the following mass percent of smelted components: less than or equal to 0.005 percent of C, 0.25-2.5 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.08 percent of P, less than or equal to 0.005 percent of Al, less than or equal to 0.008 percent of S, less than or equal to 0.003 percent of N, and the rest percent of Fe and unavoidable impurities; secondly, the smelted molten steel is processed by the RH refinement method and when the RH refinement begins, the molten steel temperature is higher than the melting point of steel by 60-150 DEG C and the carbon content of the molten steel is controlled within 0.02-0.06 percent which refers to mass percent; when decarbonization in RH refinement is ended, the free oxygen content in the molten steel is 250-550ppm; deep deoxidization is made after decarbonnization, and the input amount of the deoxidizing agent Y = K * (The oxygen concentration at the end of decarbonization (ppm)-50), wherein, the deoxidization agent is aluminum, silicoferrite or threadlike carbon. The invention has the advantages of reducing the impurity quantity in the steel, changing the morphology, realizing the deoxidized refinement control in the RH refinement process and improving the product performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing nanometer metal by plasma deoxidization in low termprature

The present invention relates to material technology, and is low temperature plasma reduction process for preparing nanometer metal. The production process includes: filling metal salt into vacuum chamber of plasma discharger, vacuumizing the vacuum chamber, introducing plasma discharge gas to pressure of 30-200 Pa, and applying DC or AC voltage of 200-5,000 V with a high voltage power source to discharge the gas and to form plasma reducing the metal salt for 5-120min, so as to prepare nanometer metal particle. The production process has simple equipment, easy operation, low power consumption, great metal treating amount and environment friendship; and the prepared nanometer metal particle has high purity, small size, narrow size distribution, high dispersivity, excellent performance and unique compounding performance with other material, and may find wide application foreground in molecular device, chemical / biological sensor and other fields.

Owner:TIANJIN UNIV

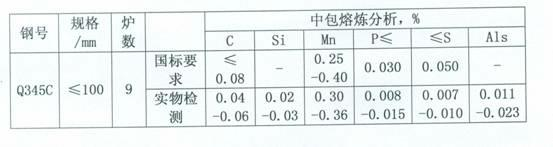

Low-carbon low-silicon high-quality carbon structural steel and production method thereof

The invention discloses a low-carbon low-silicon high-quality carbon structural steel and a production method thereof. The structural steel comprises the following chemical components in percentage by weight: less than or equal to 0.06% of C, less than or equal to 0.03% of Si, 0.35-0.50% of Mn, less than or equal to 0.018% of P, less than or equal to 0.012% of S, 0.005-0.025% of Als, and the balance of Fe and residual elements. The production method disclosed by the invention comprises the following steps: KR (knotted reactor) hot metal pretreatment of high-quality hot metal, processing with a top-bottom combined blowing converter, pre-deoxidization of molten steel, alloying of molten steel, final deoxidization process of molten steel, argon blowing process, continuous casting and casting blank stack cooling. In order to ensure the high quality of molten steel smelted with converter, the good quality of raw and auxiliary materials used in the converter smelting process must be guaranteed, wherein the raw and auxiliary materials include hot metal, waste steel, lime, light-burnt magnesium ball, ore, alloy, deoxidizer, aluminum wire, refining slag, calcium carbide, fluorite and covering agent. The invention has the advantages of simple process, strong adaptability and relatively low cost.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

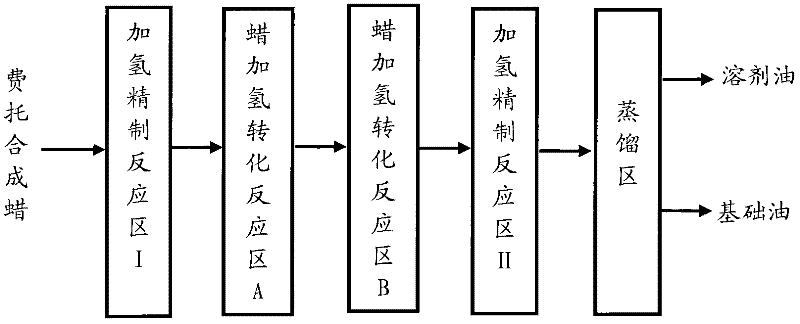

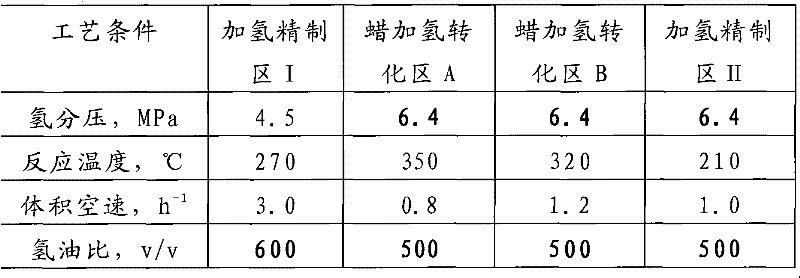

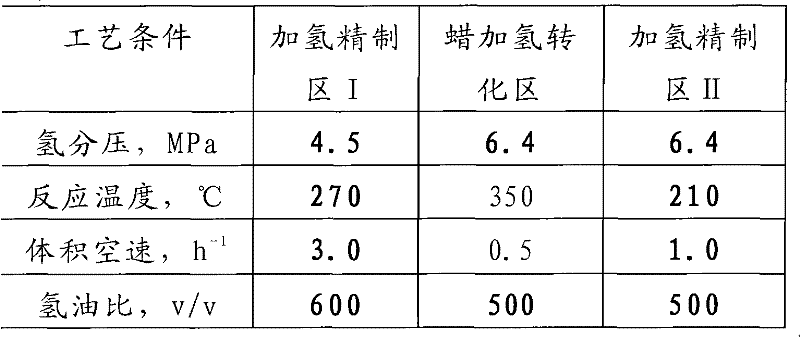

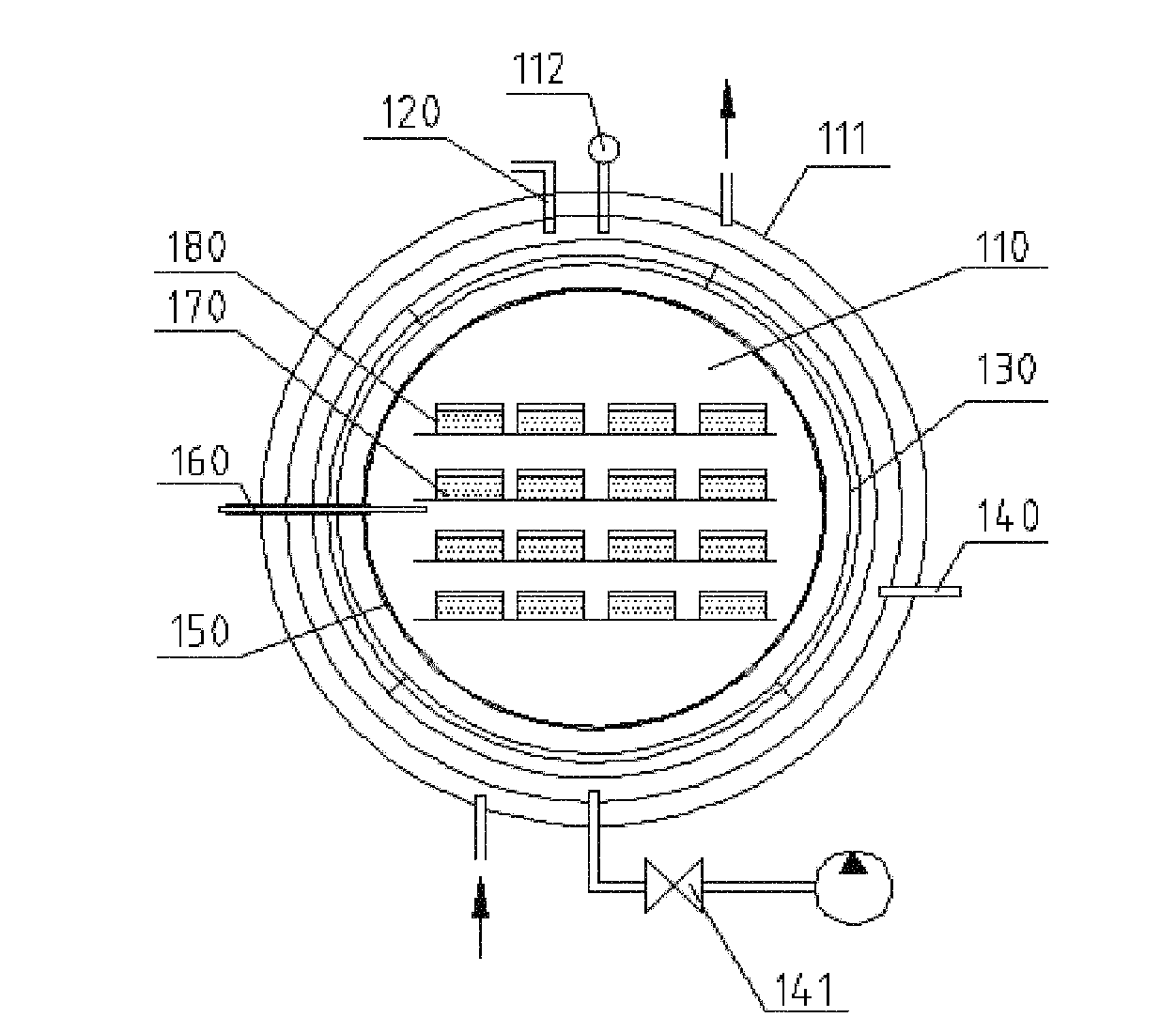

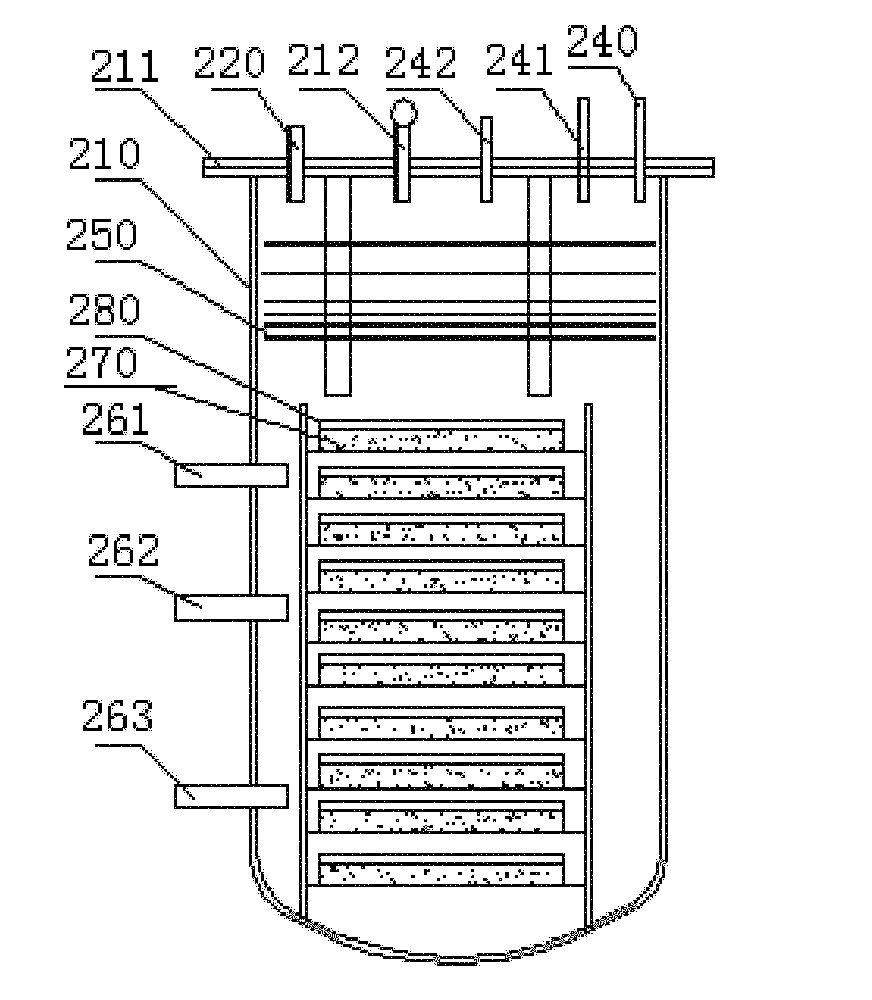

Method for producing base oil of lubricating oil by using Fischer-Tropsch synthesis wax

ActiveCN102533329AHigh yieldTreatment with hydrotreatment processesLubricant compositionWaxIsomerization

The invention relates to a method for producing base oil of lubricating oil by using Fischer-Tropsch synthesis wax. The method comprises the following steps of: (a) enabling the Fischer-Tropsch synthesis wax to be in contact with a hydrofining catalyst in a hydrofining reaction region I to obtain the Fischer-Tropsch synthesis wax subjected to hydrogenating alkene saturation and deoxidization; (b) enabling the Fischer-Tropsch synthesis wax obtained in the step (a) to be in contact with a hydrogenating isomerization catalyst in a wax hydrogenating conversion reaction region A to obtain wax converting generation oil with depression of pour point; (c) enabling the wax converting generation oil obtained in the step (b) to be in contact with the hydrogenating isomerization catalyst in a wax hydrogenating conversion reaction region B to obtain a wax converting generation oil with further depression of pour point; (d) enabling the wax converting generation oil with further depression of pour point, obtained in the step (c), to be in contact with the hydrofining catalyst in a hydrofining reaction region II to obtain wax converting generation oil subjected to hydrofining; and (e) separating the generation oil obtained in the step (d) in a distillation region to obtain the base oil of the lubricating oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

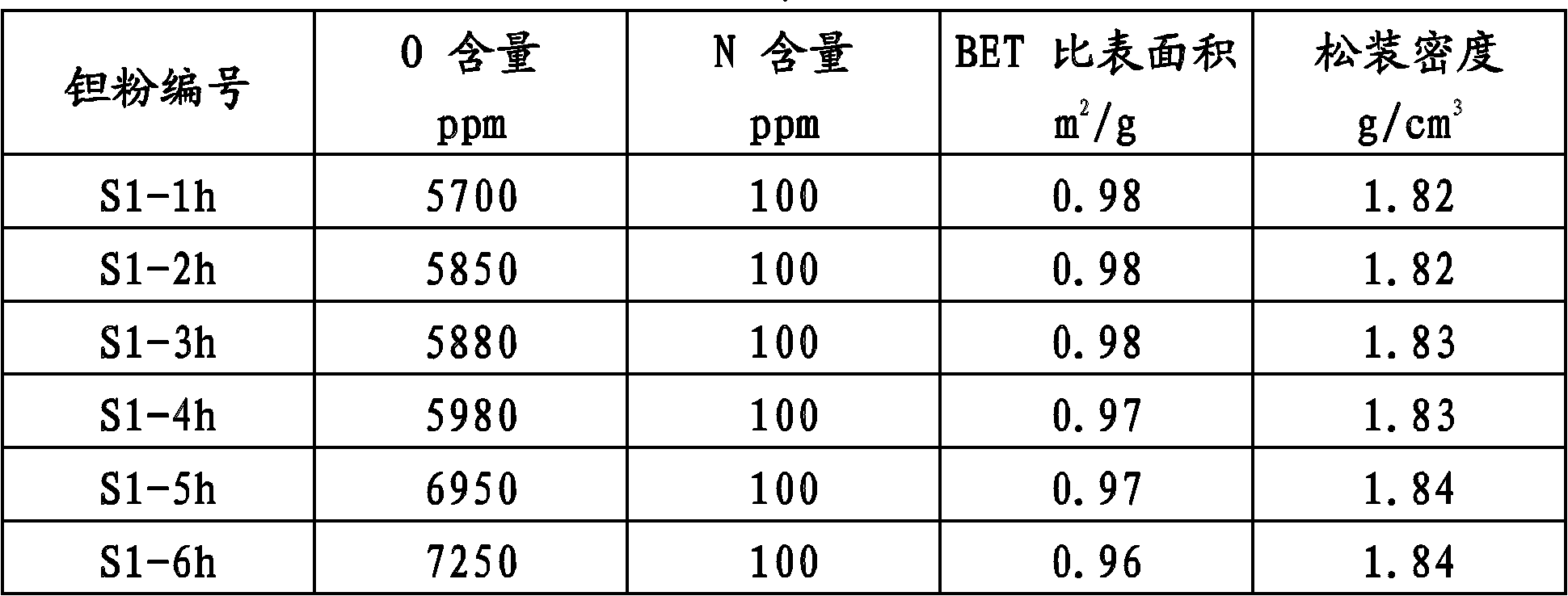

Thermal treatment method of tantalum powder

ActiveCN102120258AReduce oxygen contentThere will be no problem of intense oxidationPorosityElectrolysis

The invention relates to a thermal treatment method of tantalum powder. The method comprises the following stages: (1) a vacuum thermal treatment stage: placing the raw tantalum powder with the porosity of 80-98% into a crucible in such a manner that the thickness of the tantalum powder in the crucible is less than 60 mm; heating the crucible in a heating furnace in vacuum at 900-1,400 DEG C; andthen cooling the crucible to the room temperature and passivating the tantalum powder to obtain the condensed tantalum powder; and (2) a deoxidization thermal treatment stage: uniformly mixing the condensed tantalum powder obtained in the stage (1) with a reducing agent to obtain the mixed powder; placing the mixed powder in the crucible in such a manner that the thickness of the mixed powder in the crucible is less than 60 mm; heating the crucible in a heating furnace in vacuum or inert atmosphere at 700-1,100 DEG C; then cooling the crucible to the room temperature and passivating the obtained tantalum powder; performing pickling to remove the residual reducing agent; and drying and screening to obtain the tantalum powder suitable for an electrolytic capacitor. The tantalum powder prepared by the method provided by the invention has low oxygen content and good electrical performance.

Owner:NINGXIA ORIENT TANTALUM IND

Method for smelting tire cord steel and method for continuously casting tire cord steel

ActiveCN103060513ARealize clean productionInclusion deformable strongManufacturing convertersIngotOxygen content

The invention discloses a method for smelting tire cord steel and a method for continuously casting tire cord steel; the methods comprise the following steps of: (1), carrying out primary smelting on molten iron or semi-steel by converter top-bottom blowing, and tapping into a steel ladle without deoxidization; (2), carrying out recarburization and pre-alloying on the molten steel in the tapping process, so on the basis of the total weight of the molten steel, the activity oxygen content in the molten steel is 0.004-0.008wt%, the C content is 0.64-0.68wt% and the Al content is less than 0.4wt%; (3), blowing argon to the molten steel in the steel ladle after tapping, and carrying out vacuum refining and alloy fine adjustment; and (4), carrying out ladle furnace refining on the molten steel which is subjected to the vacuum refining by using the manner of bottom blowing argon, adding refining slags batch by batch and adding deoxidizing agents batch by batch, so the total content of FeO and MnO in the steel ladle top slag is less than or equal to 10wt%. In the methods, the tire cord steel is produced by using the technological process consisting of converter primary smelting, vacuum refining and steel ladle furnace refining and cogged ingot continuous casting pouring, and thus the clean production of tire cord steels is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing high-titanium iron by step-by-step metal thermal reduction

The invention discloses a method for preparing high-titanium iron by step-by-step metal thermal reduction, which comprises an aluminum thermal reduction smelting step and a reinforced reduction refining step, wherein the raw materials include rutile or high-titanium slag, aluminum powder, iron ore concentrate, slag forming agent and KClO3 in a mass ratio of 1.0: 0.37-0.50: 0.05-0.10: 0.15-0.25: 0.20-0.25, and the smelting temperature is 1,900 to 2,200 DEG C; the reinforced reduction refining time in the second step is 10 to 30 minutes, and after the refining is finished, a high-titanium iron alloy is obtained by cooling, ingot formation and impurity removal; and the composite reducing agent is calcium-magnesium alloy. The method has the advantages of wide raw material source and low production cost; the step-by-step reduction operations are adopted in the method, the reduction smelting of the first step is performed under the condition that the aluminum is insufficient, and the calcium-magnesium alloy composite reducing agent is adopted in the deoxidization refining of the second step, so the Al residue in the high-titanium iron alloy is remarkably reduced, and oxygen is effectively removed; and the transfer of high-temperature melt is realized by casting, and the metal slag separation process is reinforced.

Owner:NORTHEASTERN UNIV

Refining agent for copper and copper alloy smelting

A refining agent for copper and copper alloy smelting is characterized in that the components of the refining agent are 5 to 15 percent by weight of calcium fluoride, 1 to 5 percent by weight of silicon dioxide, 1 to 5 percent by weight of titanium dioxide, 2 to 10 percent by weight of sodium fluosilicate, 40 to 60 percent by weight of sodium carbonate and the balance sodium tetraborate; the refining agent materials are weighed according to a formula, uniformly mixed, placed into a drying box and dried under 120 DEG C for an hour, and a metallographic inlaying machine is used for manually pressing the refining agent into the shape of a sheet. The refining agent has the advantages that the refining agent is integrated with the functions of deoxidization, degasification, impurity removal and the like, and has strong adsorbing, dissolving and combination slagging capabilities; the surface tension between the refining agent and metal melt is high, the refining agent can promote molten slag to float up, so that the molten slag can be better separated from molten metal, and thereby the effects of refining, impurity removal and melt purification are achieved; the refining agent has high chemical stability and thermal stability, does not have the corrosion effect on metal and the furnace lining, and cannot chemically react with the molten metal, the refining agent and the molten metal cannot be melted into each other as well, and thereby the original composition and properties of alloy are guaranteed; and the refining agent does not have public hazard, is safe and environment-friendly, is convenient to use, and is cheap.

Owner:NANCHANG UNIV

Aluminum-containing cold forging steel smelting process

ActiveCN103469050AEfficient control back to SiGuaranteed liquidityManufacturing convertersAluminateSmelting process

The invention discloses an aluminum-containing cold forging steel smelting process, comprising the steps of blast furnace molten iron making, processing by a converter, refining and continuous casting, wherein requirements of molten iron are as follows: P is not more than 0.10%, Si is not more than 0.50% and not less than 0.30%, S is not more than 0.030%; requirements in converter refining are as follows: CaO is not less than 85%, activity degree is not less than 280 and SiO2 in fluorite is not more than 6%; low-Si pre-melted slag or refining agent replaces partial CaO and fluorite in a converter steel discharging process for rapid slag making, a refining furnace deoxidizing agent is applicable to slag deoxidization after stirring calcium carbide and aluminum particles, and Si-containing material is prohibited; during continuous casting, pure Ca lines are applicable between a medium packet impact zone and various flows, so that calcium aluminate which is low in melting point and is from reaction of Al2O3 generated from medium packet through secondary oxidation and Ca floats and is removed. The process can reduce the content of Si in steel, improve Al content and guarantee continuous pouring of molten steel.

Owner:ZENITH STEEL GROUP CORP

Treatment method of scrap copper

The invention discloses a treatment method of scrap copper. The treatment method is characterized by comprising the following steps: (1) carrying out detection and analysis on the scrap copper to be melted, and determining the application and smelting production process of the scrap copper according to the alloy components of the scrap copper; (2) according to the analytic result, removing impurity metal elements in the scrap copper on the basis of processes such as loading, melting, oxidizing, degassing, slagging, deslagging, reducing and refining for red impure copper and high-copper alloy;and (3) carrying out degassing, deslagging and deoxidization reduction on liquid copper obtained in the step (2) again. In the invention, a high-quality copper material is produced by directly utilizing the scrap copper, thus the treatment method has the advantages of low investment, low energy consumption, simple production process, low production cost and little environment pollution, valuable metals in the scrap copper can be reasonably utilized, and the competitiveness of a product in market competition can be greatly improved.

Owner:JINCHUAN GROUP LIMITED

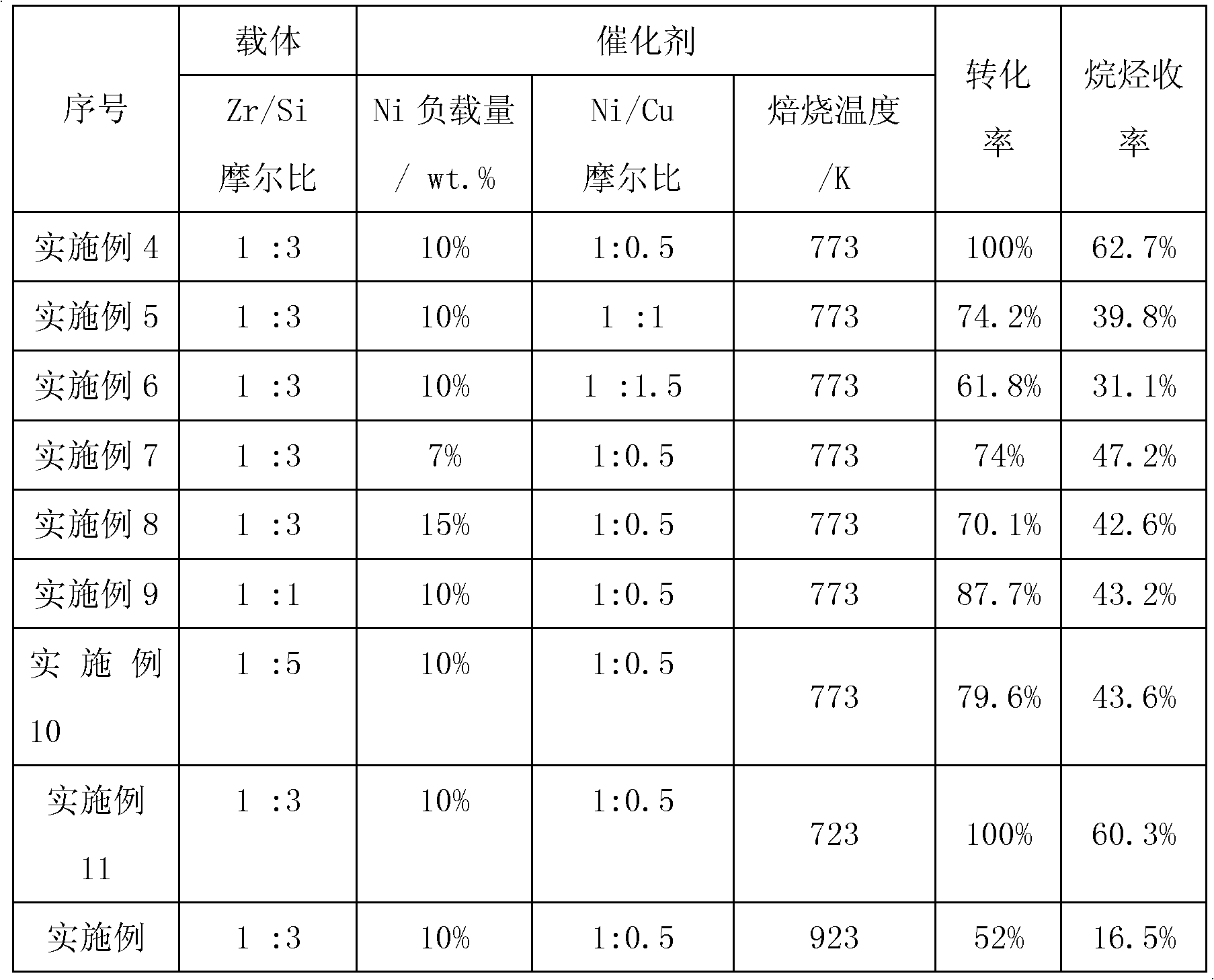

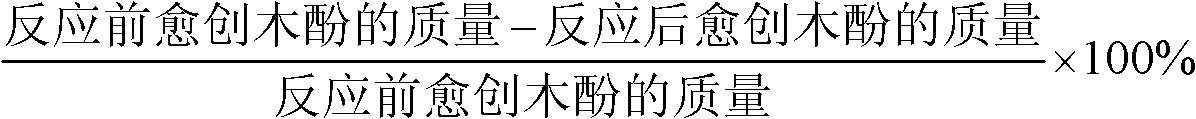

Catalyst for catalyzing hydrogenation deoxidation reaction of guaiacol and preparation method thereof

ActiveCN102430409AEasy to prepareHigh reactivityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaneGuaiacol

The invention provides a cheap catalyst for catalyzing the hydrogenation deoxidization reaction of guaiacol and a preparation method thereof. The catalyst comprises the following components: a carrier ZrO2-SiO2 binary composite oxide, and two active metals of Ni and Cu, wherein the two active metals of Ni and Cu are loaded on the binary composite oxide through an immersion process. The ZrO2-SiO2 binary composite oxide which is prepared through a chemical precipitation process is used as the carrier of the catalyst, wherein the Zr / Si molar ratio is 1:1-5; and the two active metals of Ni and Cu are loaded on the carrier through the immersion process, wherein the Ni load capacity is 7-15wt%, and the Ni / Cu molar ratio is 1:0.5-1.5. The catalyst prepared in the invention has the advantages of cheap raw material, simple preparation method, high reaction activity, good carbon deposition resistance, and long service life. According to the catalytic activity evaluation of the catalyst, the conversion rate of guaiacol is near to 100%, and the top alkane yield can reach 62.7%.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

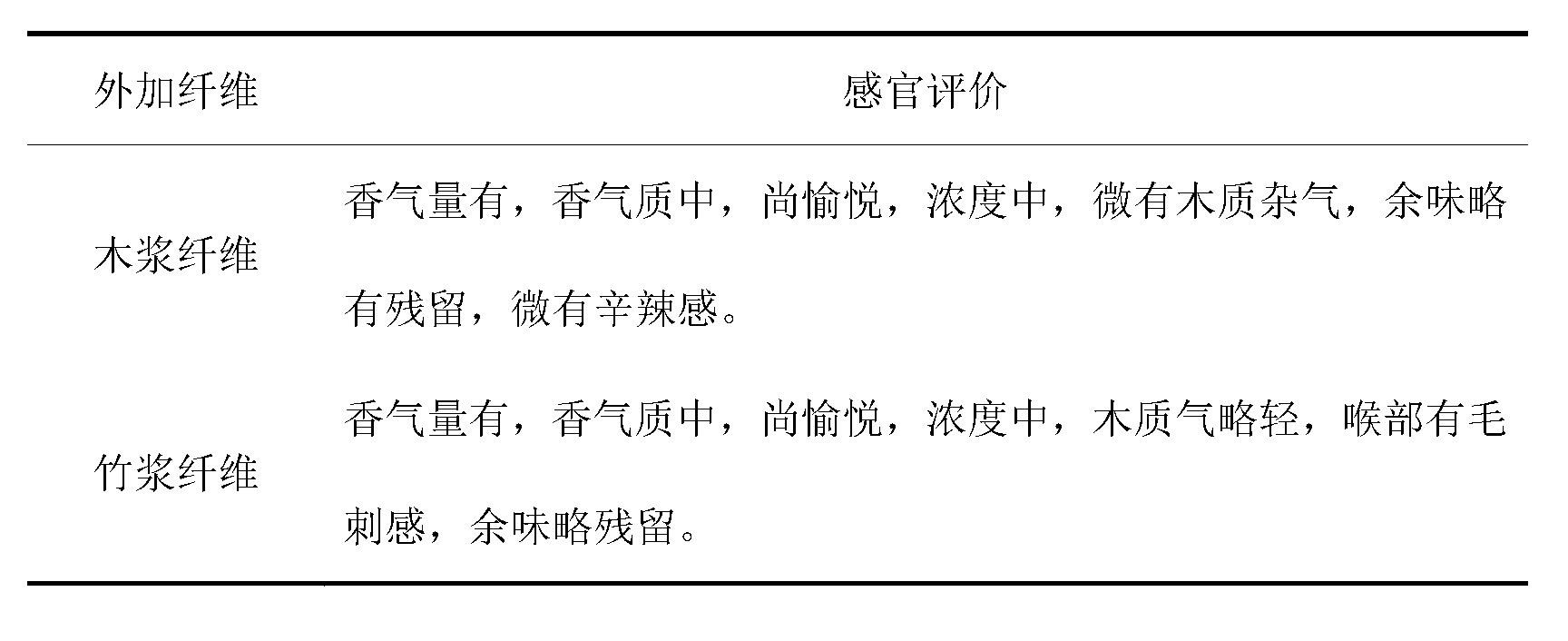

Method for reproducing tobacco leaves by paper-making method through bamboo pulp fibers instead of wood pulp fibers

The invention relates to a method for reproducing tobacco leaves by a paper-making method through bamboo pulp fibers instead of wood pulp fibers and belongs to the field of tobacco leaf reproduction. The method comprises a step a of preparing the bamboo pulp fibers, a step b of preparing a coating solution, a step c of manufacturing paper with pulp on a film base and a step d of preparing the reproduced tobacco leaves by the paper-making method, and particularly comprises the following steps of: boiling aired large dendrocalamus giganteus to prepare bamboo slurry, and carrying out deoxidization treatment to obtain deoxidized bamboo pulp; uniformly mixing 40% of a tobacco stem extract, 55% of fragment / tobacco powder mixed extract and 5% of flavors and fragrances in mass percentage to obtain the coating solution; mixing 45% by mass of tobacco stem residual dreg initially-milled pulp with the beating degree of 8-degree SR and 45% by mass of fragment and tobacco powder mixed residual dregs to obtain the film base; adding 10% by mass of deoxidized bamboo pulp fibers, and mixing uniformly and grinding; preparing the film base after the beating degree is 35-48-degree SR; carrying out conventional coating on the film base prepared by the step c by utilizing the coating solution prepared by the step b, and drying; controlling the water content of a finished product to 10-12%; and slicing for future use. The method disclosed by the invention has the advantages of simple and feasible method and stable quality of the reproduced tobacco leaves.

Owner:YUNNAN RES INST OF TOBACCO SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com