Patents

Literature

524 results about "Market competition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Competition for a market refers to the struggle to create a new market, or to erect a new standard, and it is usually associated with the process of innovation that brings new displacing technologies to market. Competition in a market is the conventional view of competition, and concentrates on the actions of incumbents...

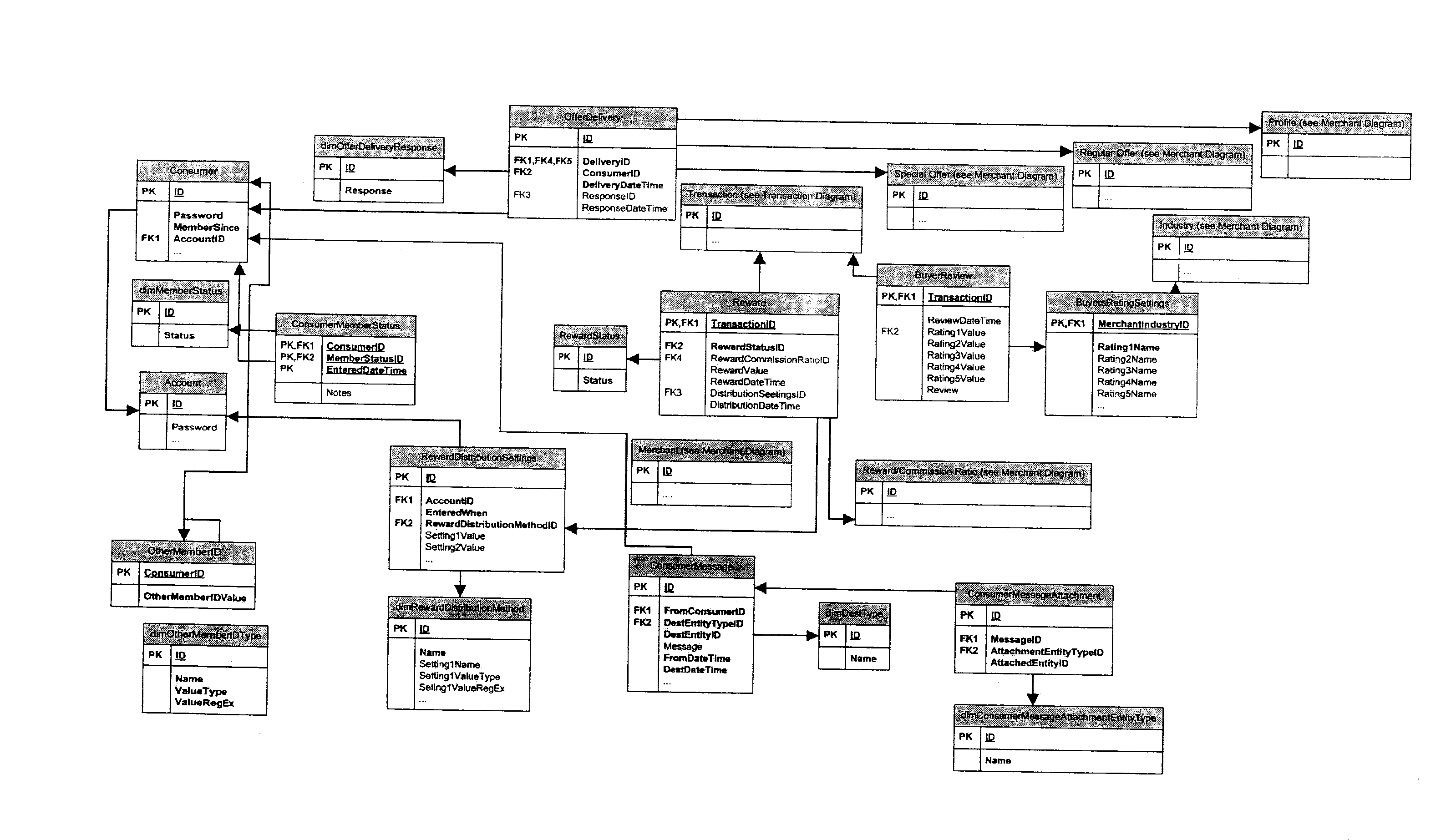

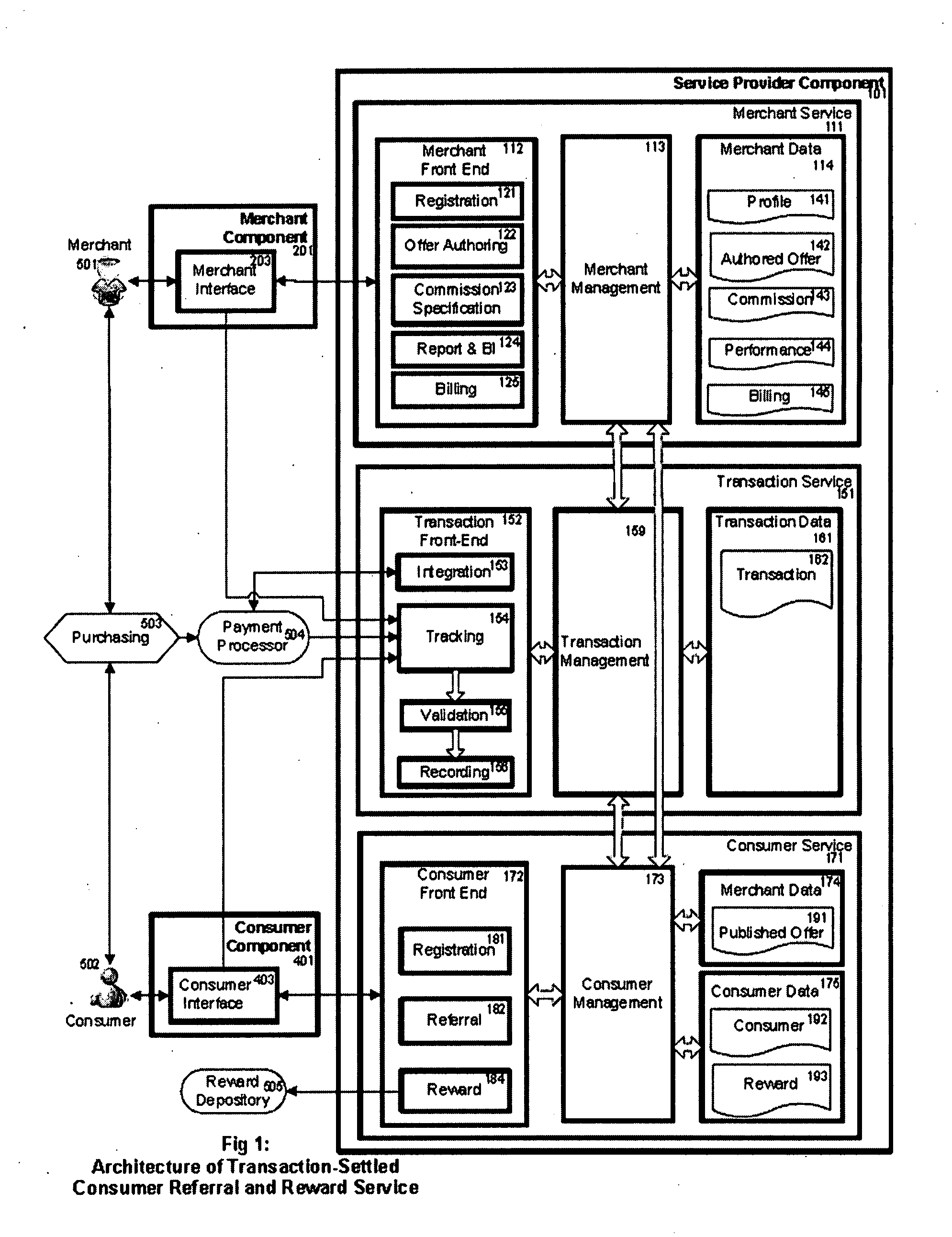

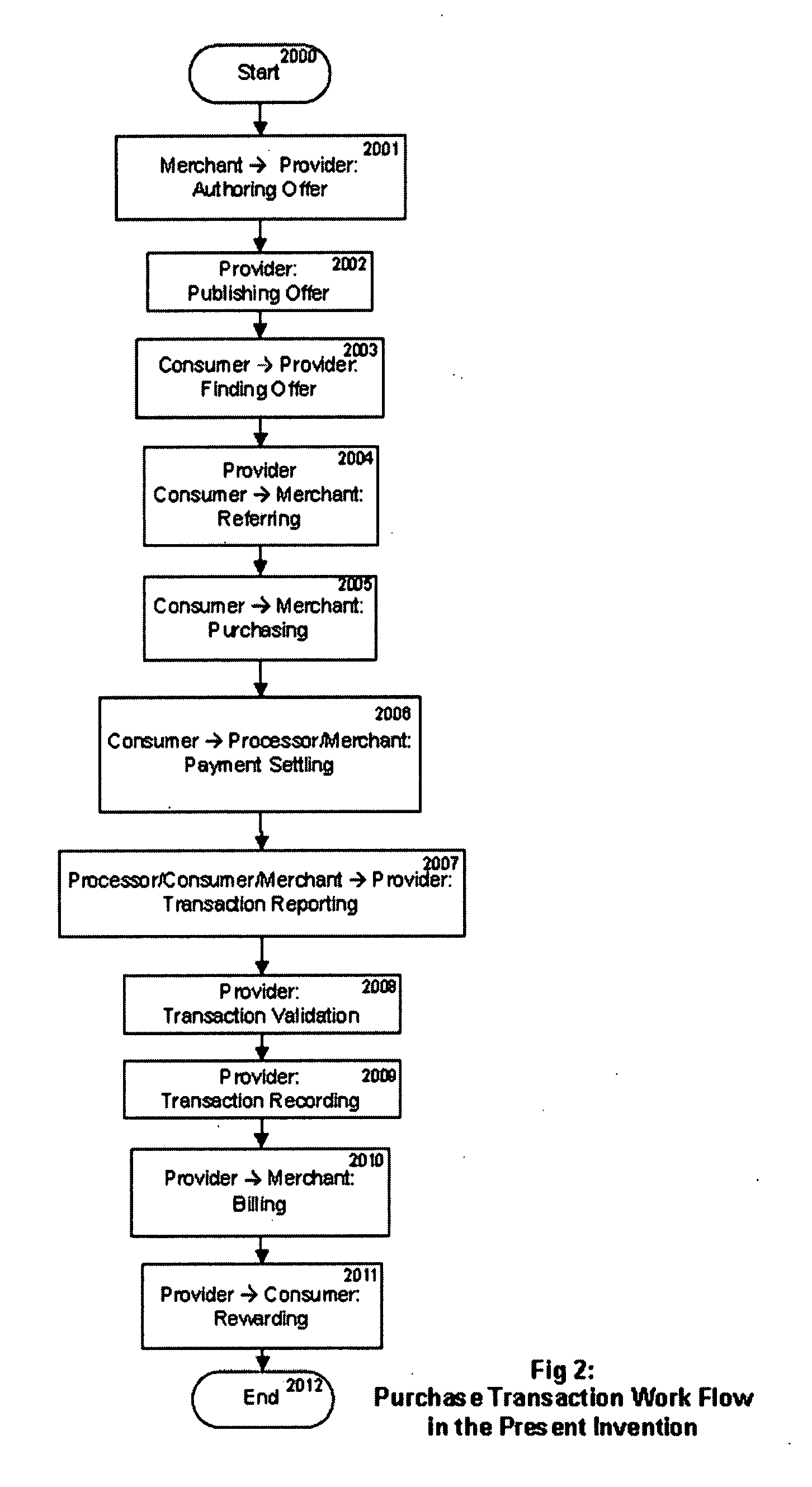

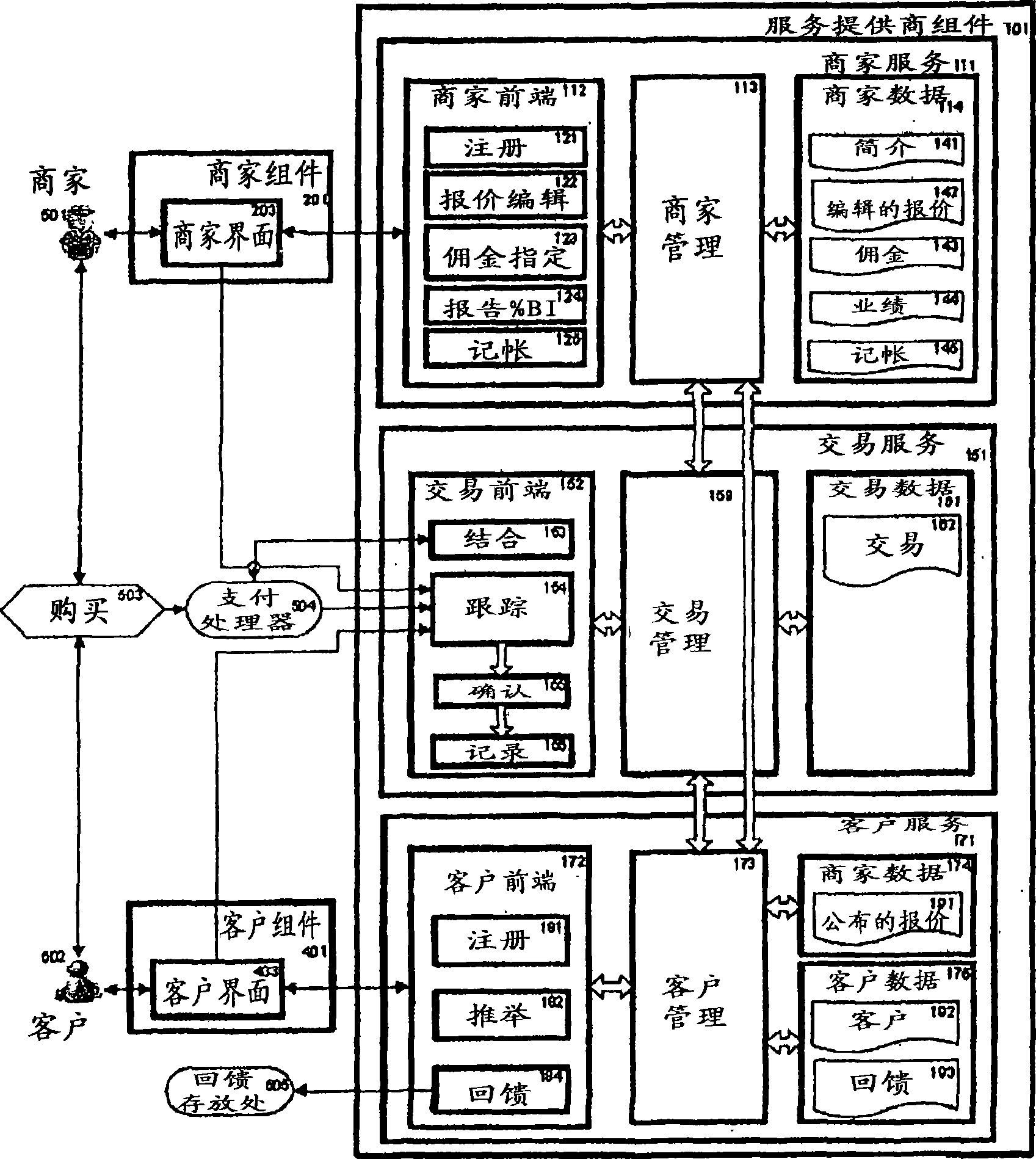

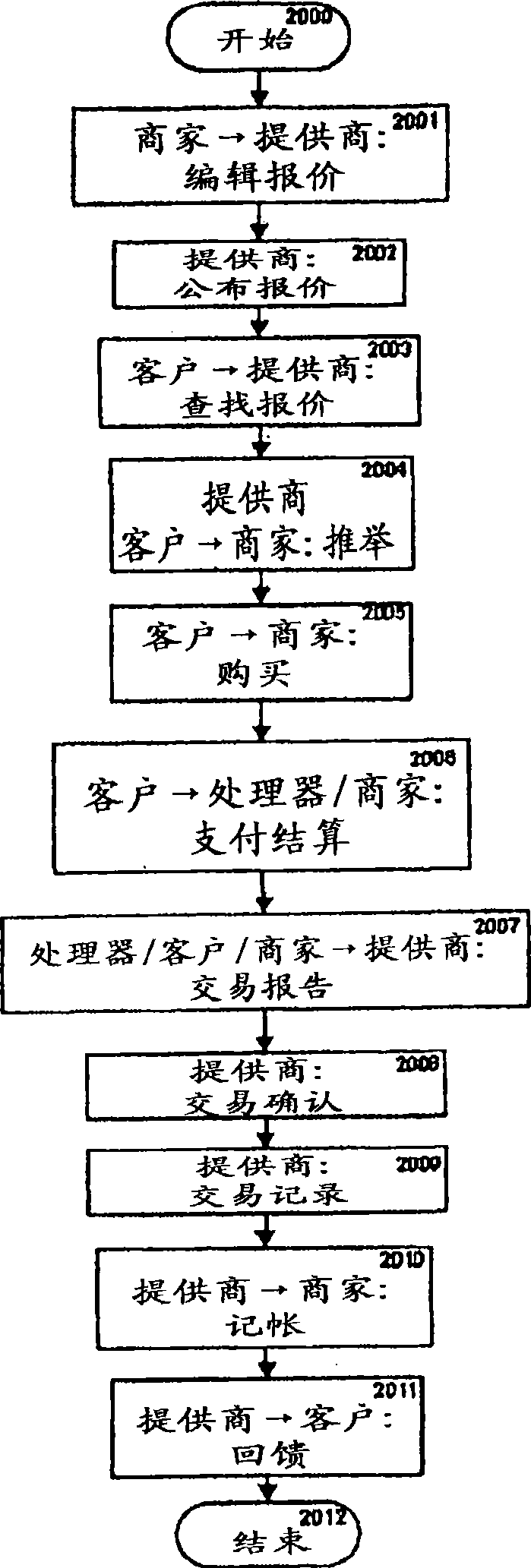

Purchase-transaction-settled online consumer referral and reward service using real-time specific merchant sales information

InactiveUS20070288312A1Easy to manufactureEffective trackingAdvertisementsBuying/selling/leasing transactionsPaymentReward system

A purchase-transaction-settled online consumer referral and reward system and method using real-time specific merchant sales information is provided. The system offers merchants a one-stop place for freely publishing of their real-time and specific sales offers and offers a risk-free service to merchants to use, who will be charged only after a referred purchase occurs and a revenue income is made. The system also allows merchants to determine how much they pay to the service provider for each referred purchase transaction, based on their profit margin and market competitiveness and the system serves all merchants, online or offline, big or small, and regardless of buy, sell, and payment settlement technologies in use. The system also offers consumers a one-stop place for finding matching sales offers specifically meeting their needs, refers consumers to merchants to buy at existing merchant establishments and rewards consumers with each purchase transaction led from the service provider.

Owner:PAYPAL INC

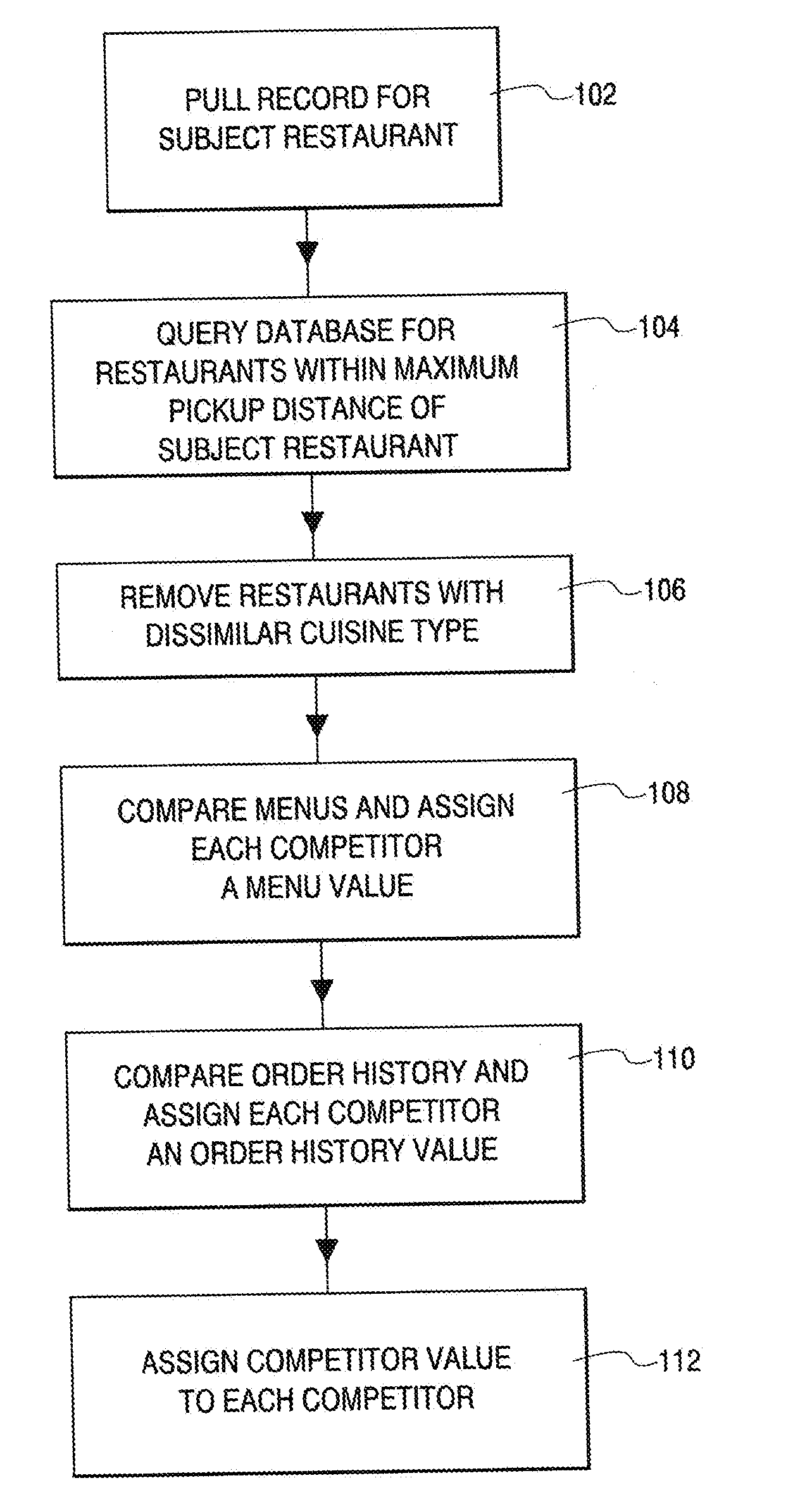

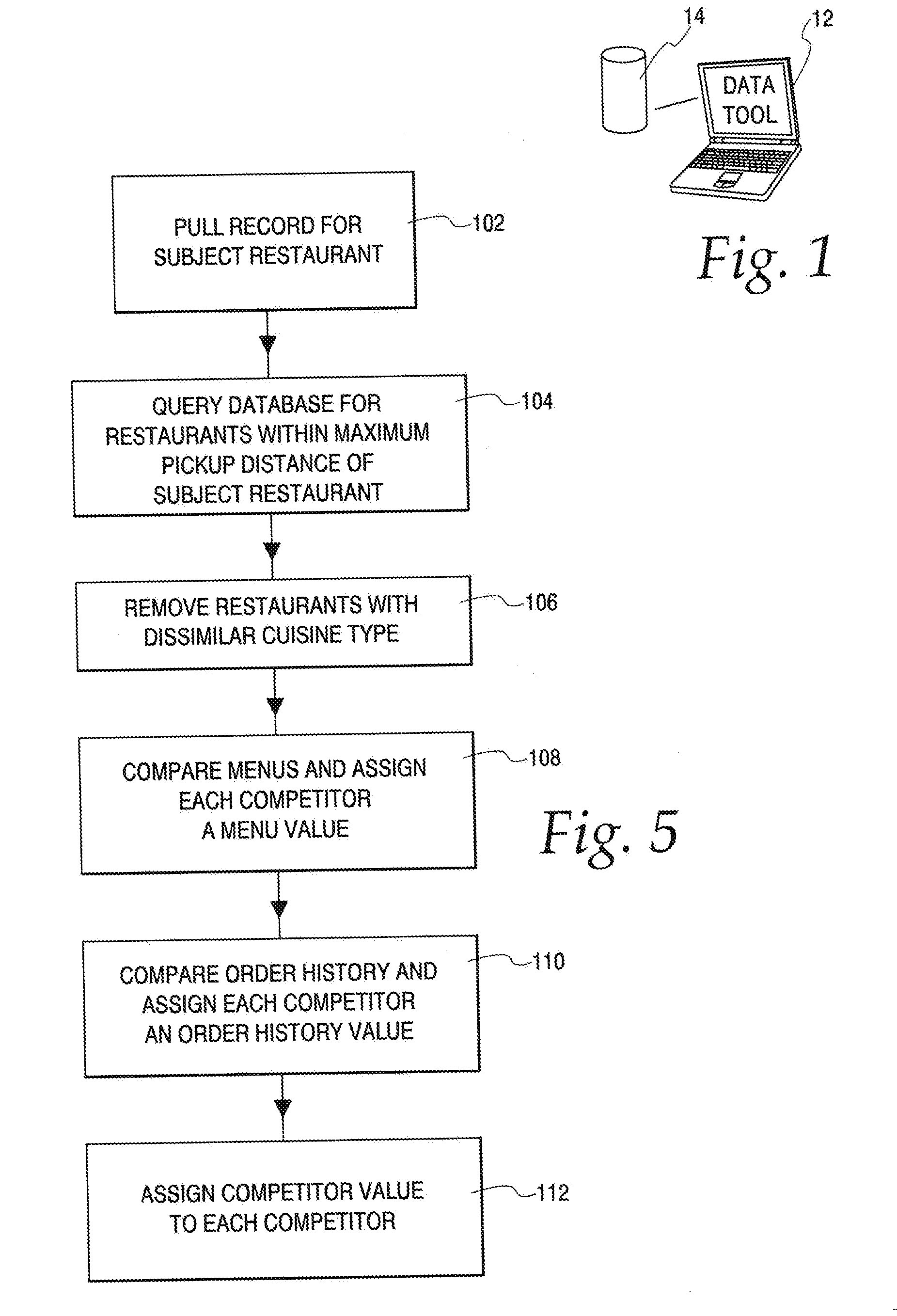

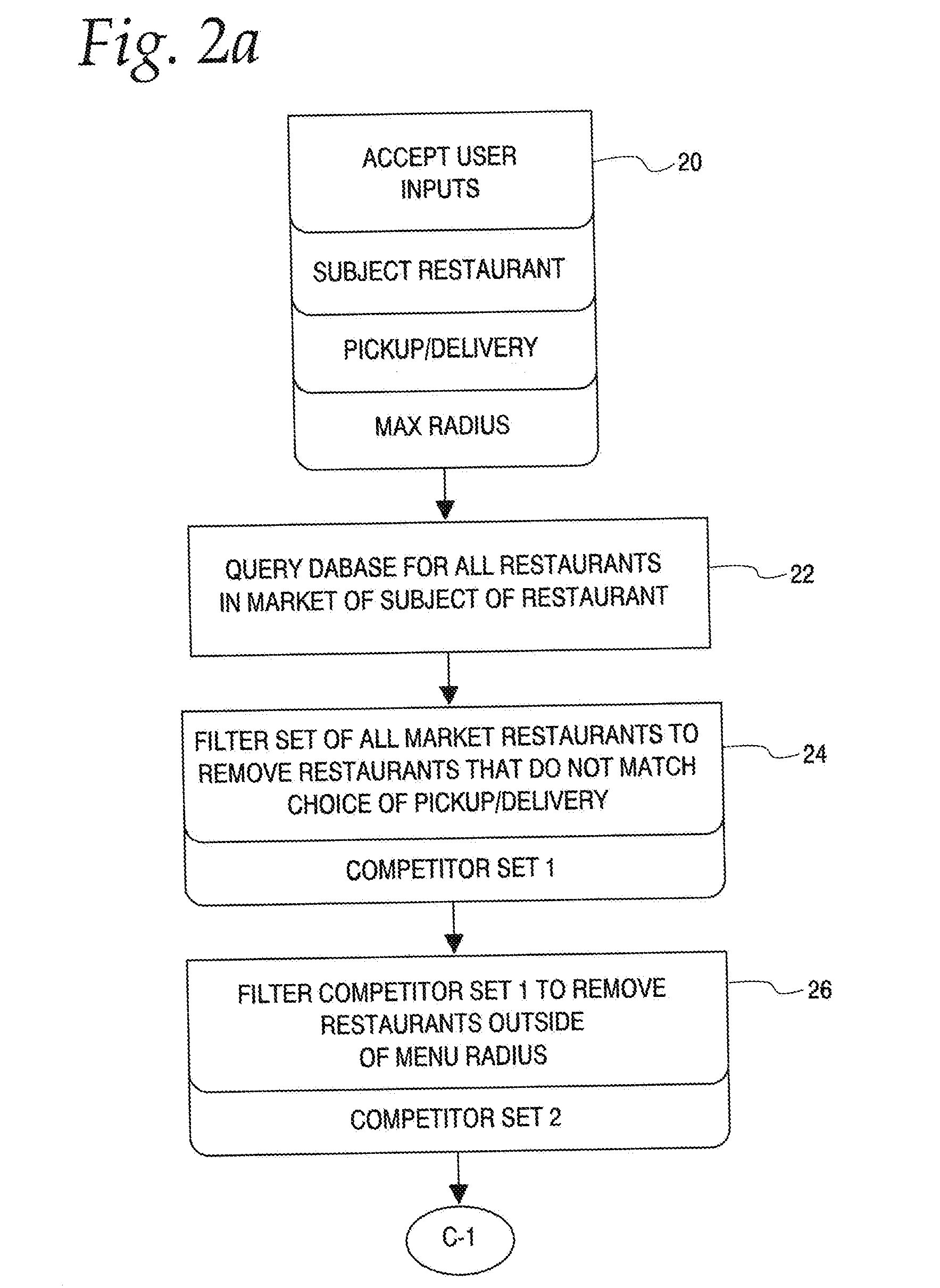

Utility for Creating Heatmaps for the Study of Competitive Advantage in the Restaurant Marketplace

Owner:GRUBHUB HLDG

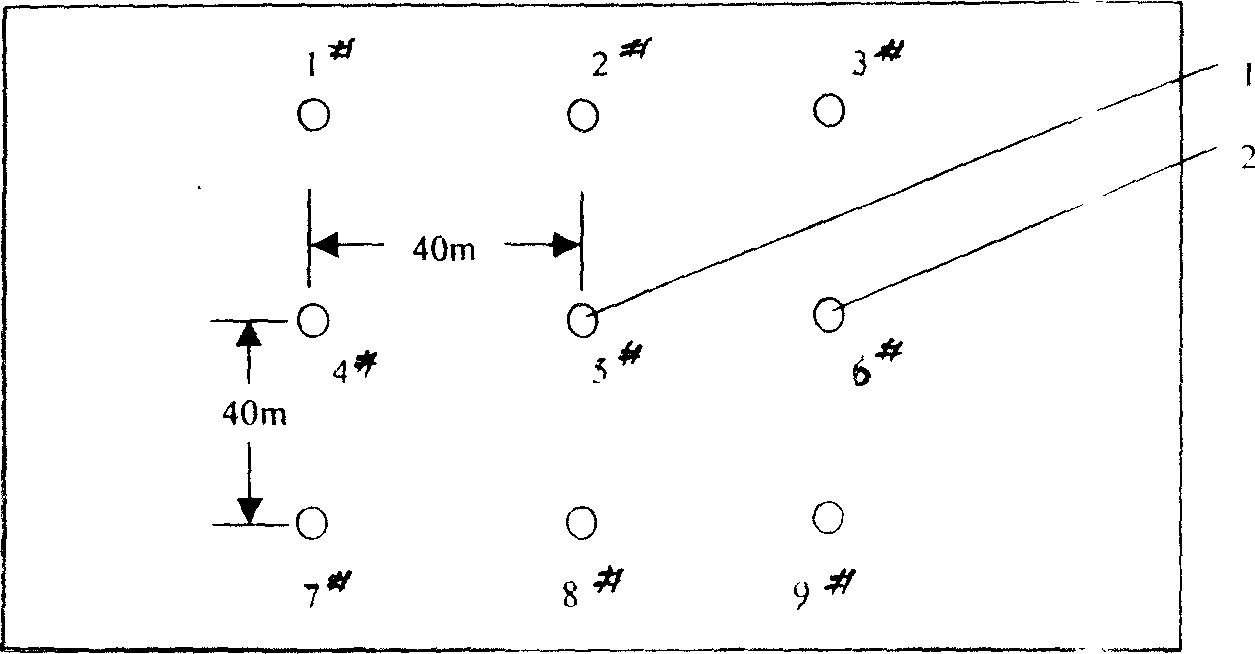

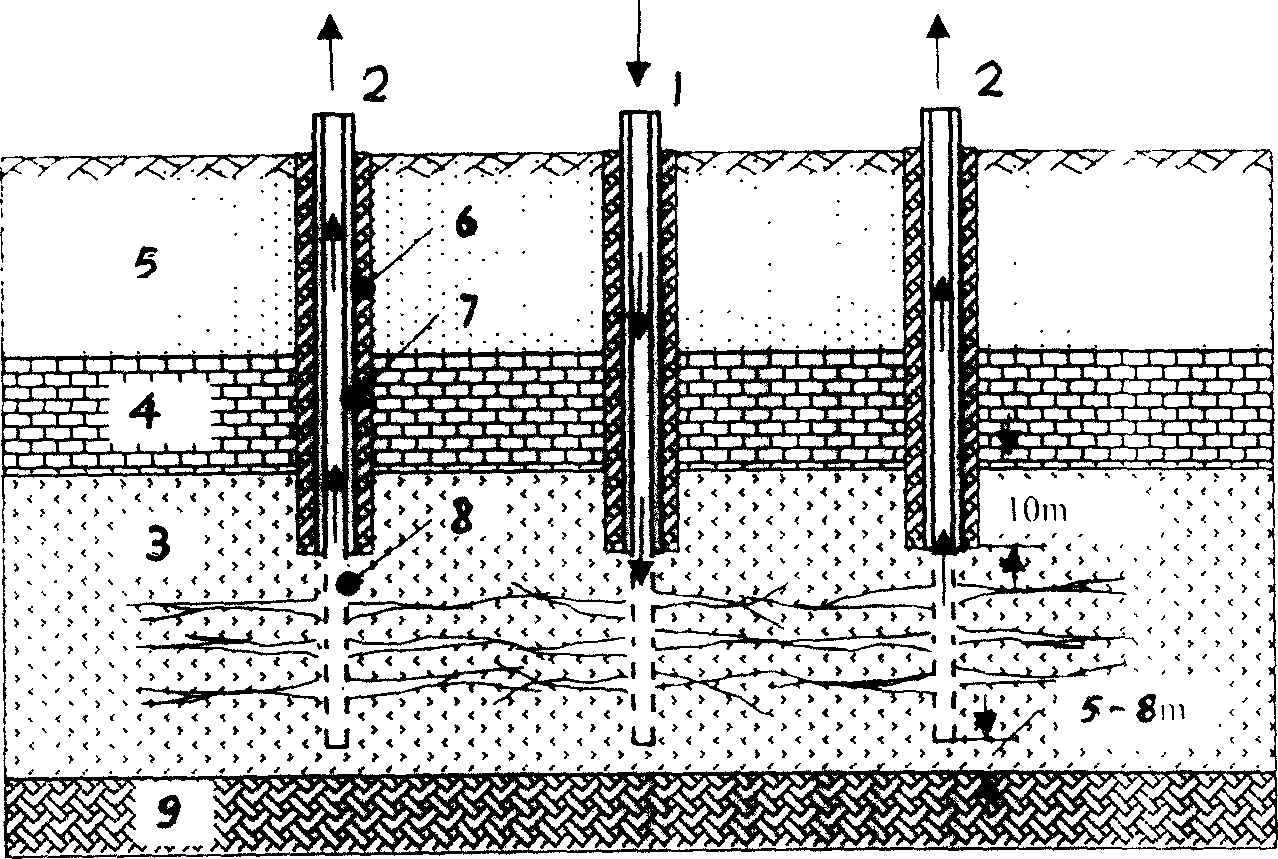

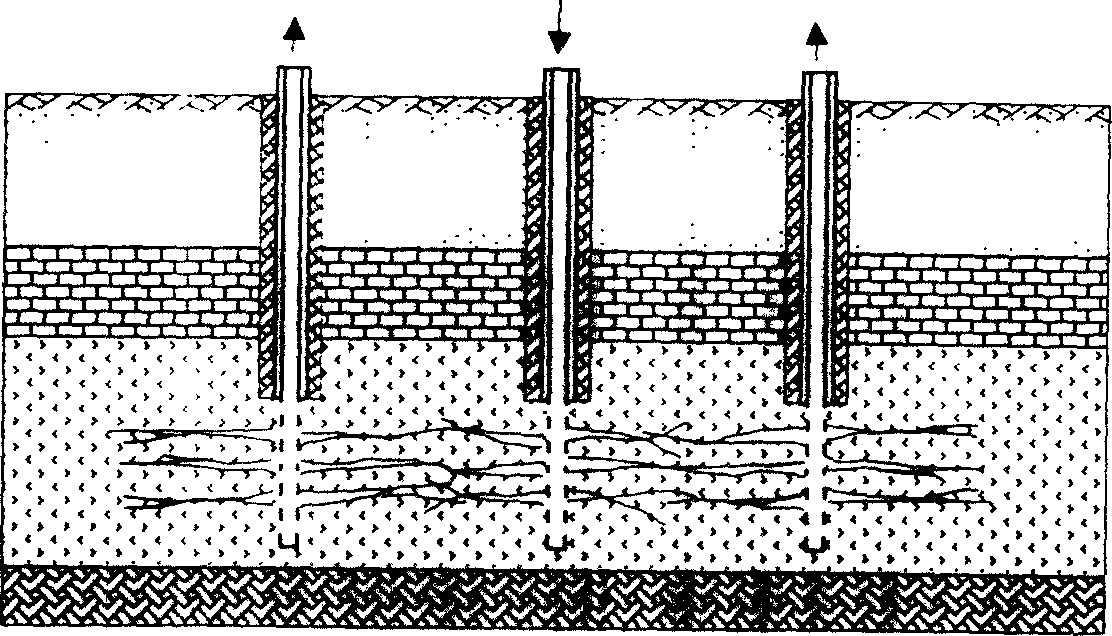

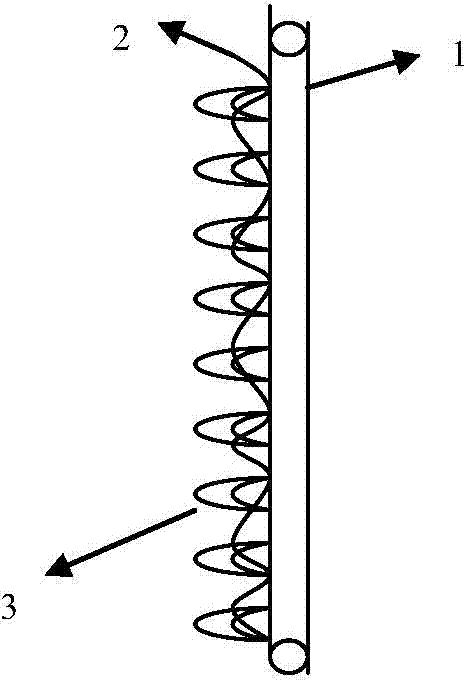

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

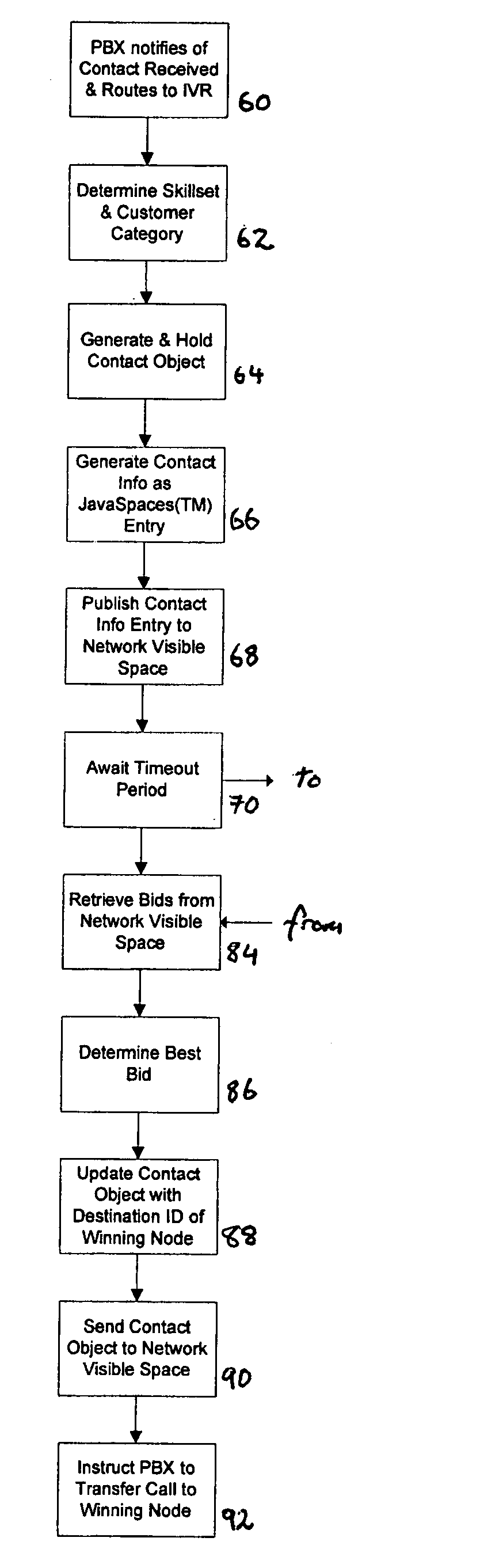

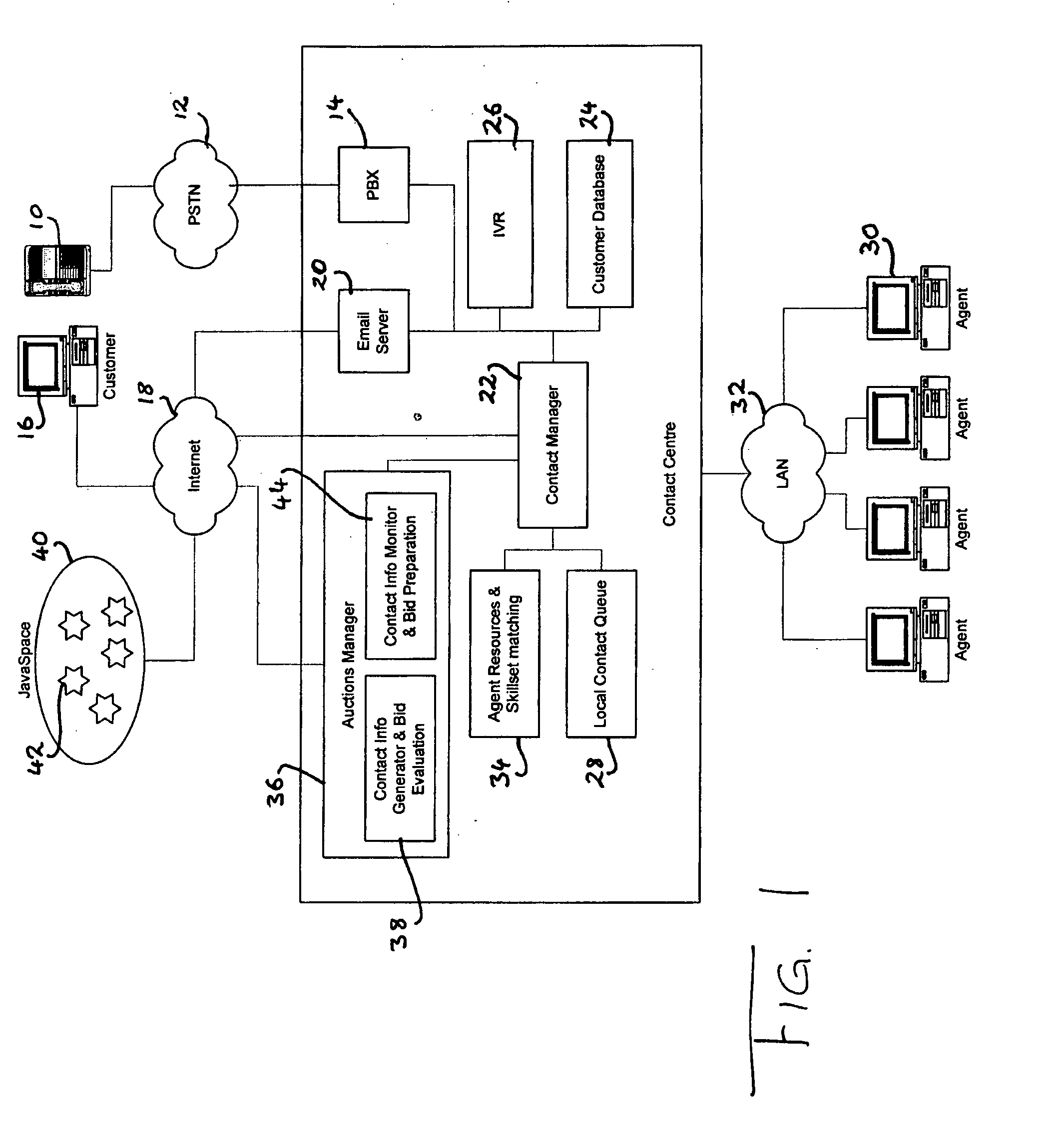

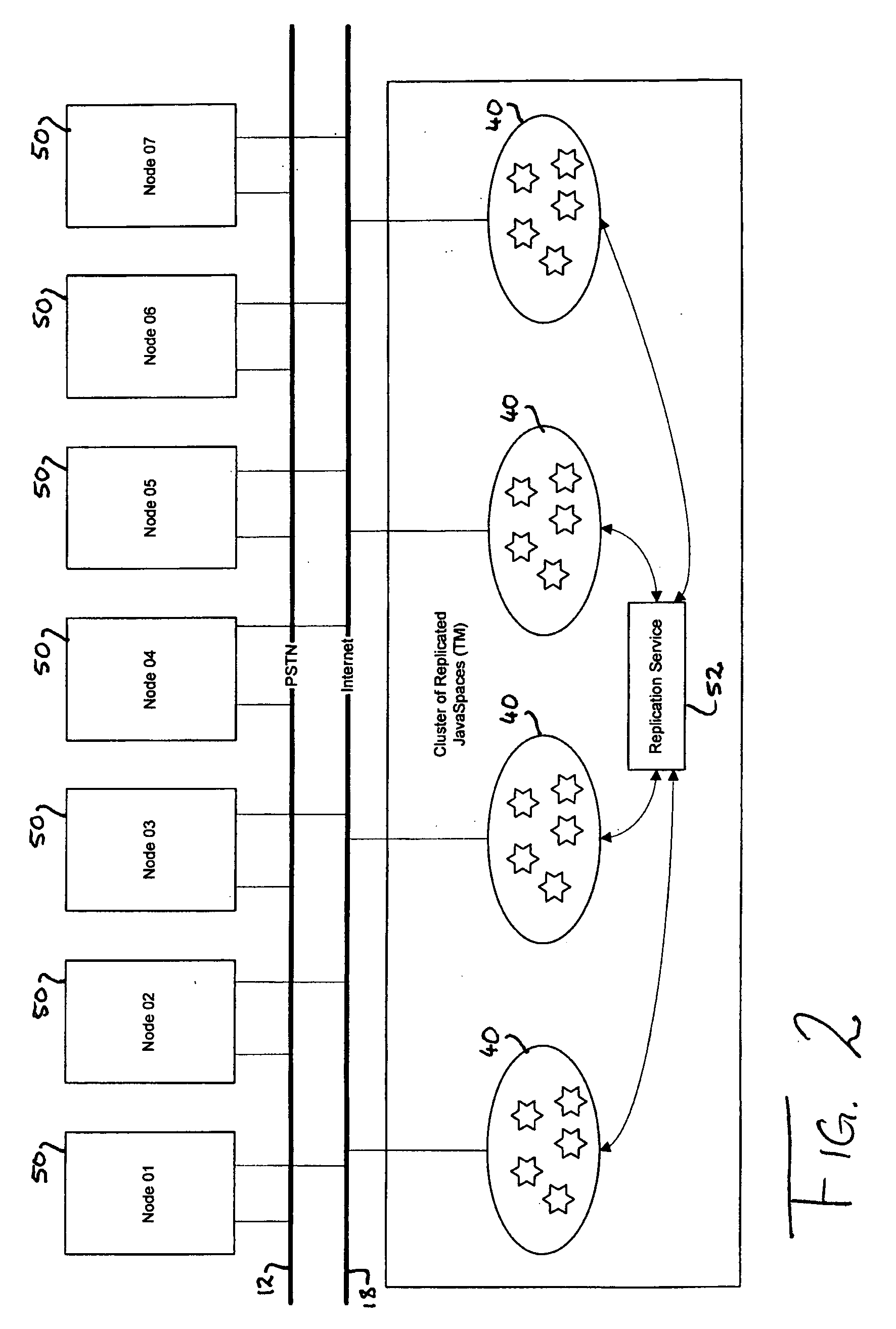

Method and system for distributing contacts within a network

InactiveUS20050125487A1Good serviceLimited accessDigital data processing detailsMultiple digital computer combinationsQuality of serviceMarket competition

Contacts received by a contact centre are auctioned to other contact centres to determine an optimum service or cost for each contact. By publishing requests for bids to a network visible space, multiple contact centres or agents can monitor for new requests, and if they can service the request, submit bids to take over the contact at the best price or service level. This enables contacts to be optimally distributed over a network without maintaining centrally records of currently available resources and current statistics for each contact centre. This also adds market competition to the distribution of contacts, providing the potential to increase the overall quality of service and to reduce costs.

Owner:AVAYA INC

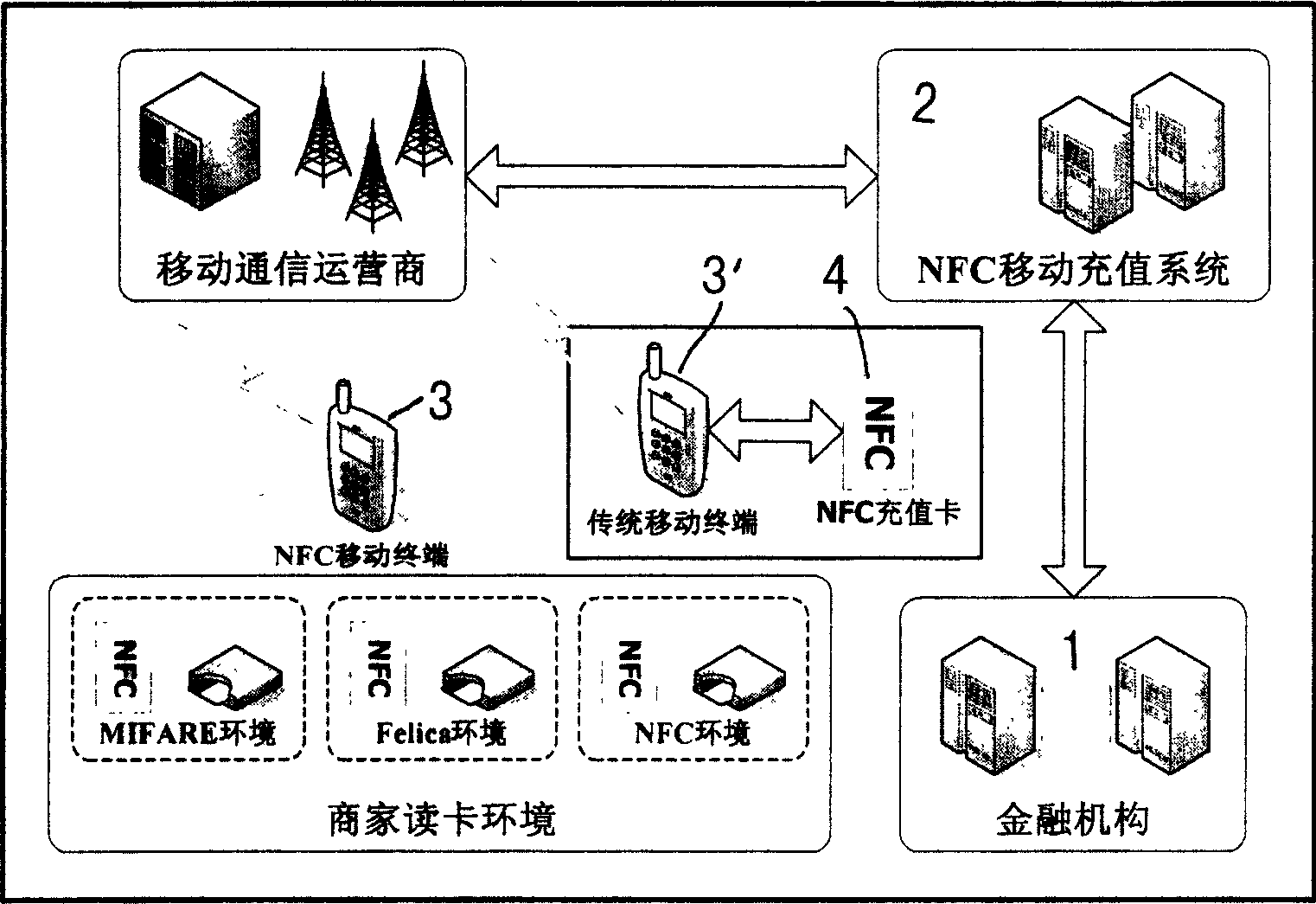

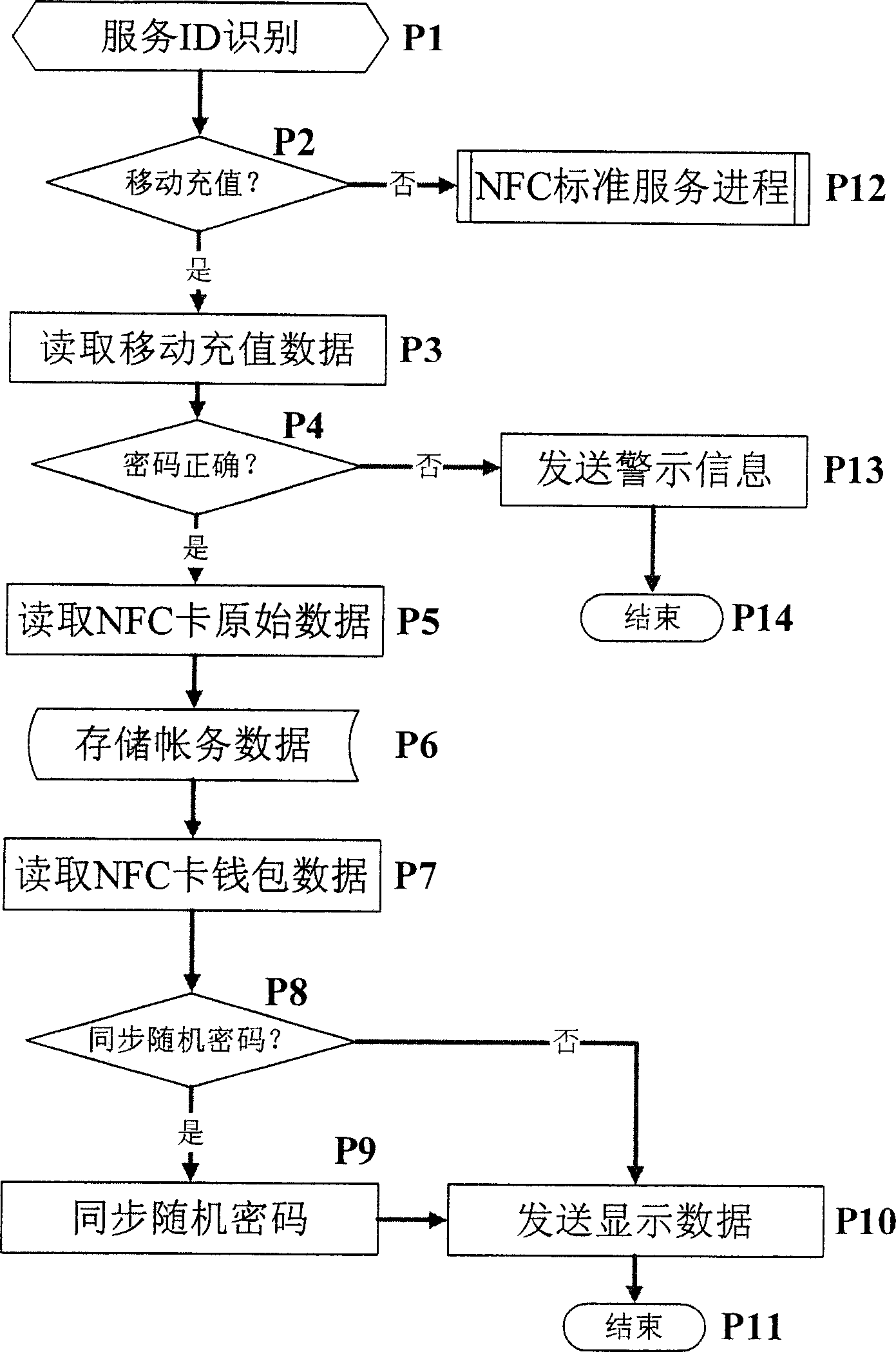

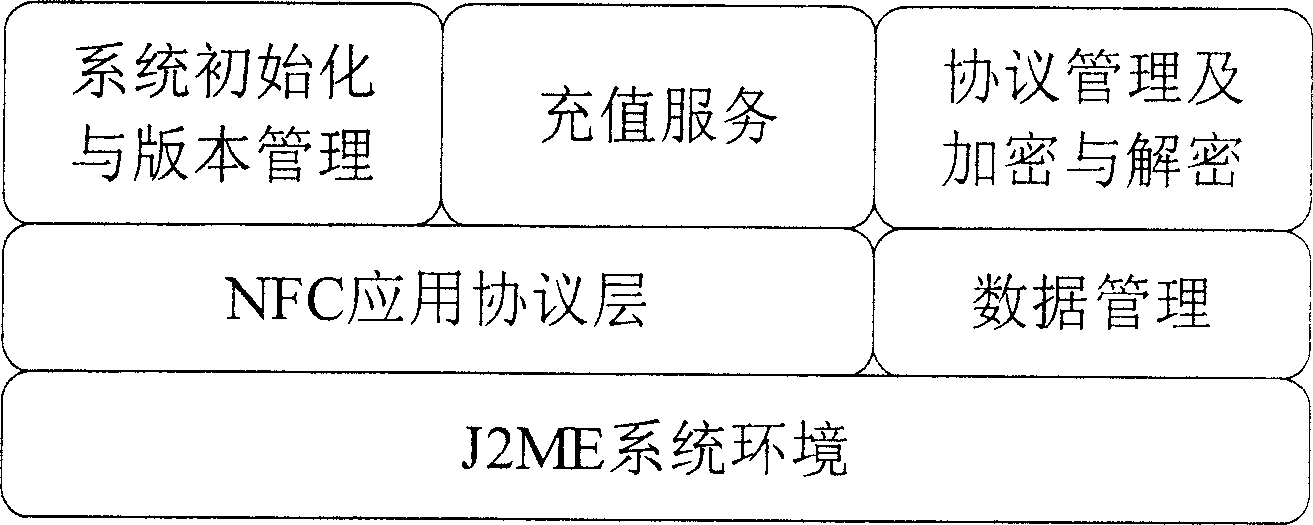

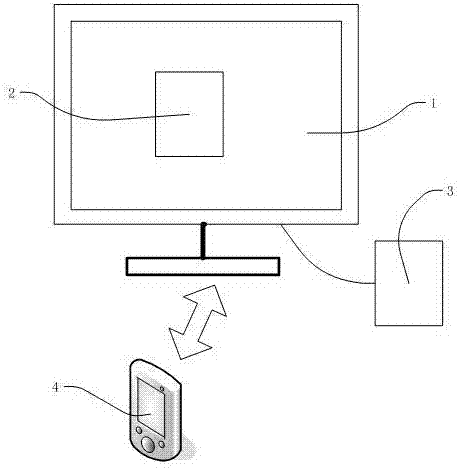

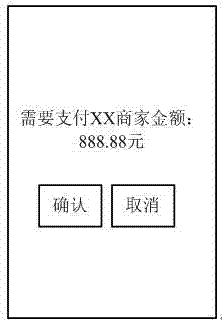

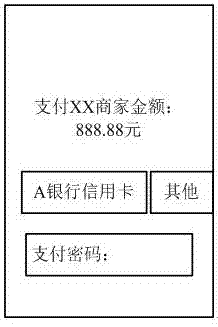

Mobile payment method based on mobile communication network

InactiveCN1835007AMeet the needs of economic developmentEnsure safetyPayment architectureCommerceCryptographic protocolMobile charge

The invention is a mobile payment method based on mobile communication network, characterized in: adopting communication protocol and technical criterion of financial trade standard to perform bidirectional data transmission and electronic transaction between NFC mobile charging system and financial institution, and by wireless channel of mobile communication operator, adopting special communication protocol, safe protocol and encryption protocol to implement bidirectional data transmission and electronic transaction between traditional mobile terminal and NFC mobile charging system. As compared with the existing technique, it has the following outstanding advantages of: 1) it can effectively improve market competition capacity of mobile communication operator and financial institution; 2) it provides a convenient and safe payment mode for a user of handset with NFC mobile charging system, and can assure capital safety in the NFC mobile charging system; 3) the user of NFC mobile terminal need not pay fees to any financial institution.

Owner:浙江通普通信技术有限公司 +2

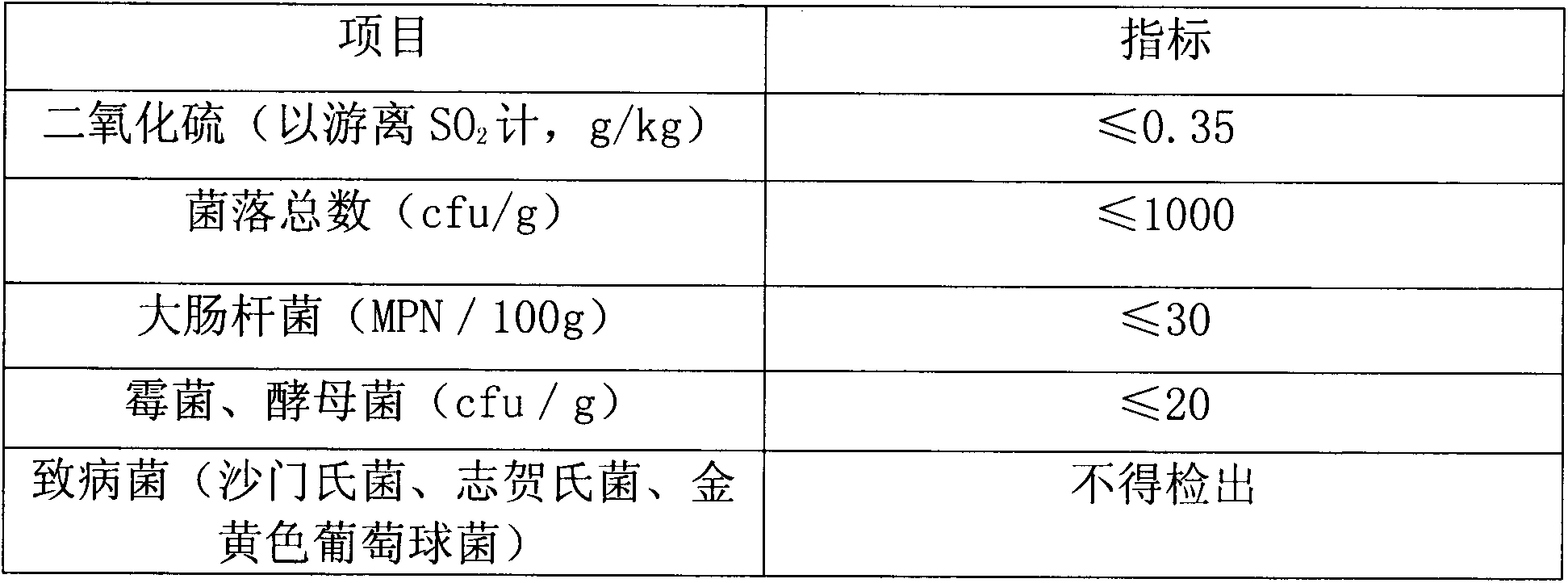

Preserved passion fruits and processing method thereof

The invention discloses preserved passion fruits and a processing method thereof. The method comprises the concrete steps of firstly, cleaning and cutting fresh passion fruits as raw materials, and separating peels from pulp by removing the pulp; secondly, boiling the peels, removing cuticula, enzymatically hydrolyzing, protecting the color and sugaring; thirdly, mixing the pulp with white granulated sugar and citric acid or citric acid to prepare mixed pulp, and burying the mixed pulp into the peels; finally performing processes of drying, cooling and the like to prepare finished products of preserved passion fruits. According to the method, the selectivity on fruit raw materials is good; the processed preserved passion fruits keep the original aroma and taste of passion fruits, are bright as ever and soft in mouth feel, and have remarkable market competition advantages; a new way is opened up for deep processing of the passion fruits, a very good method is provided for improving the value of the passion fruits, and relatively large profit space is created for enterprises.

Owner:广西田阳嘉佳食品有限公司

Method for preparing activated charcoal by using discarded jatropha curcas husk

The invention discloses a method for preparing active carbon with waste barbadosut shells, and is characterized in that: the waste barbadosut shells are firstly sieved and crumbled, then carbonization and activation are carried out by a physical method or a chemical method so as to obtain the active carbon. The invention not only has abundant raw material sources, so nonrenewable resources such as coal, tar and valuable wood materials that are used commonly at present can be saved, but also has low product cost, high added value, good performance and obvious market competition advantages, besides, the environment pollution problems caused by stack or burning of the waste barbadosut shells are solved, therefore, a new way of taking use of the resources fully is found, meanwhile, an important link is filled for the production mode of circular economy characterized in low investment, high efficiency and zero pollution of the waste barbadosut shells.

Owner:SICHUAN UNIV

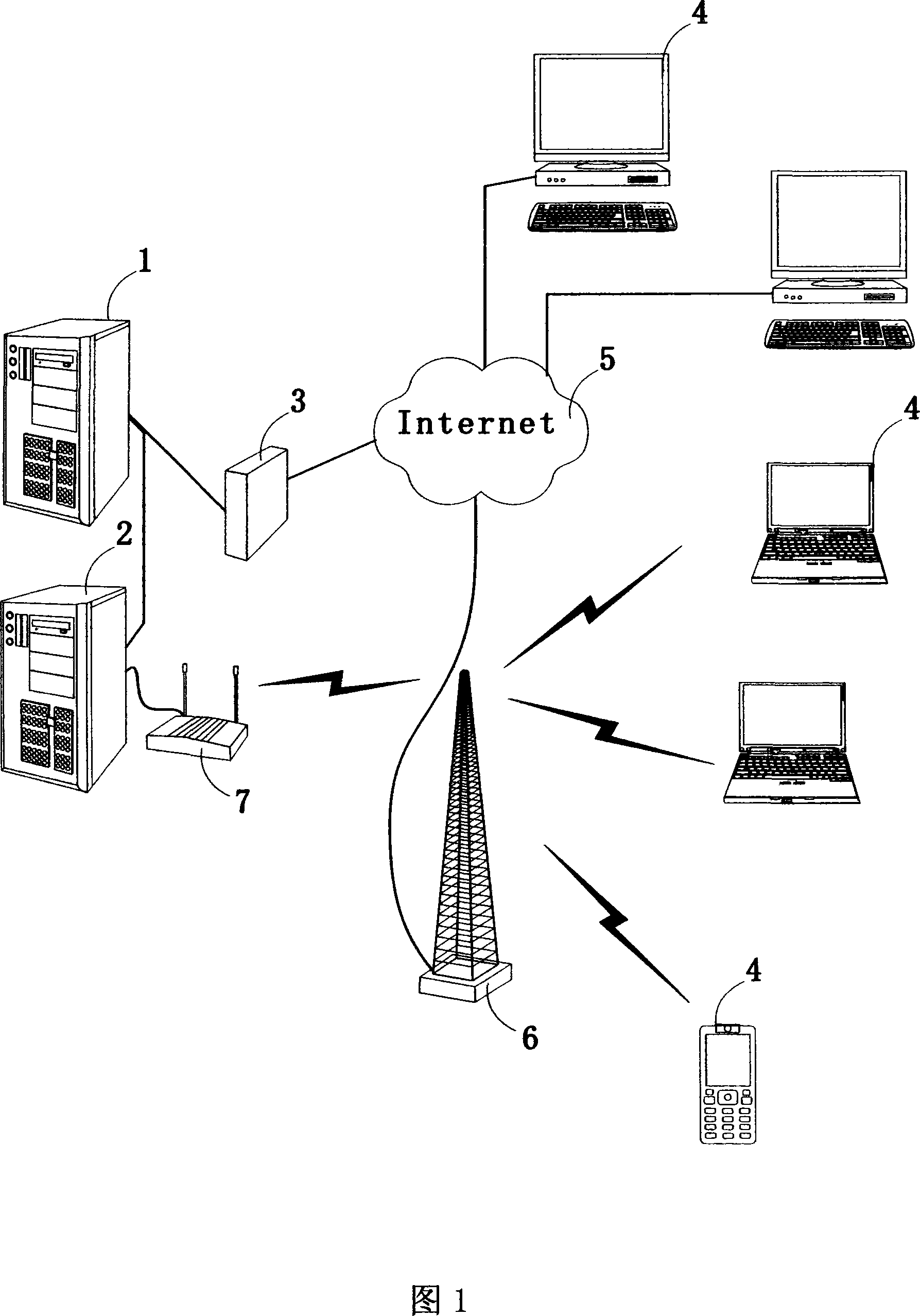

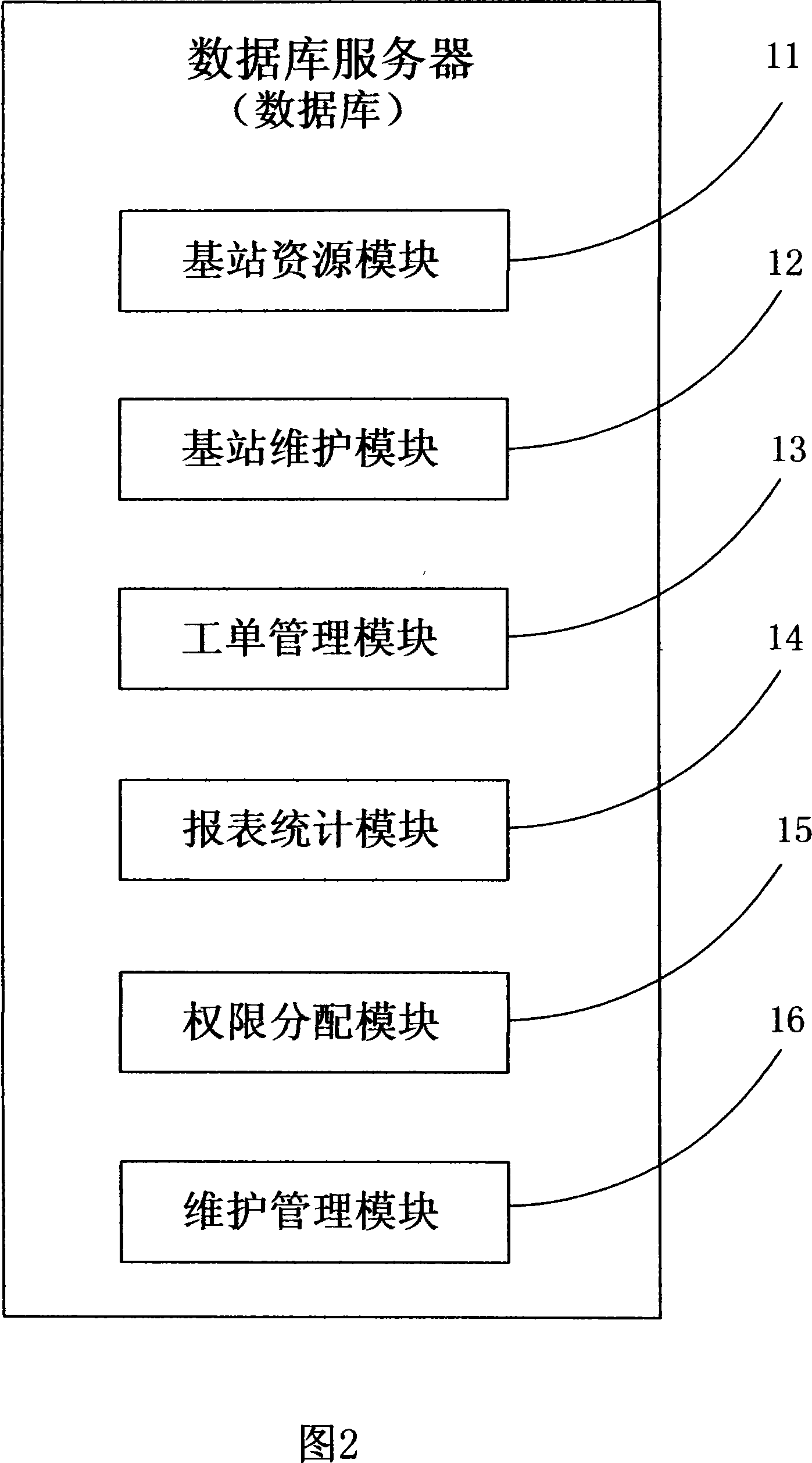

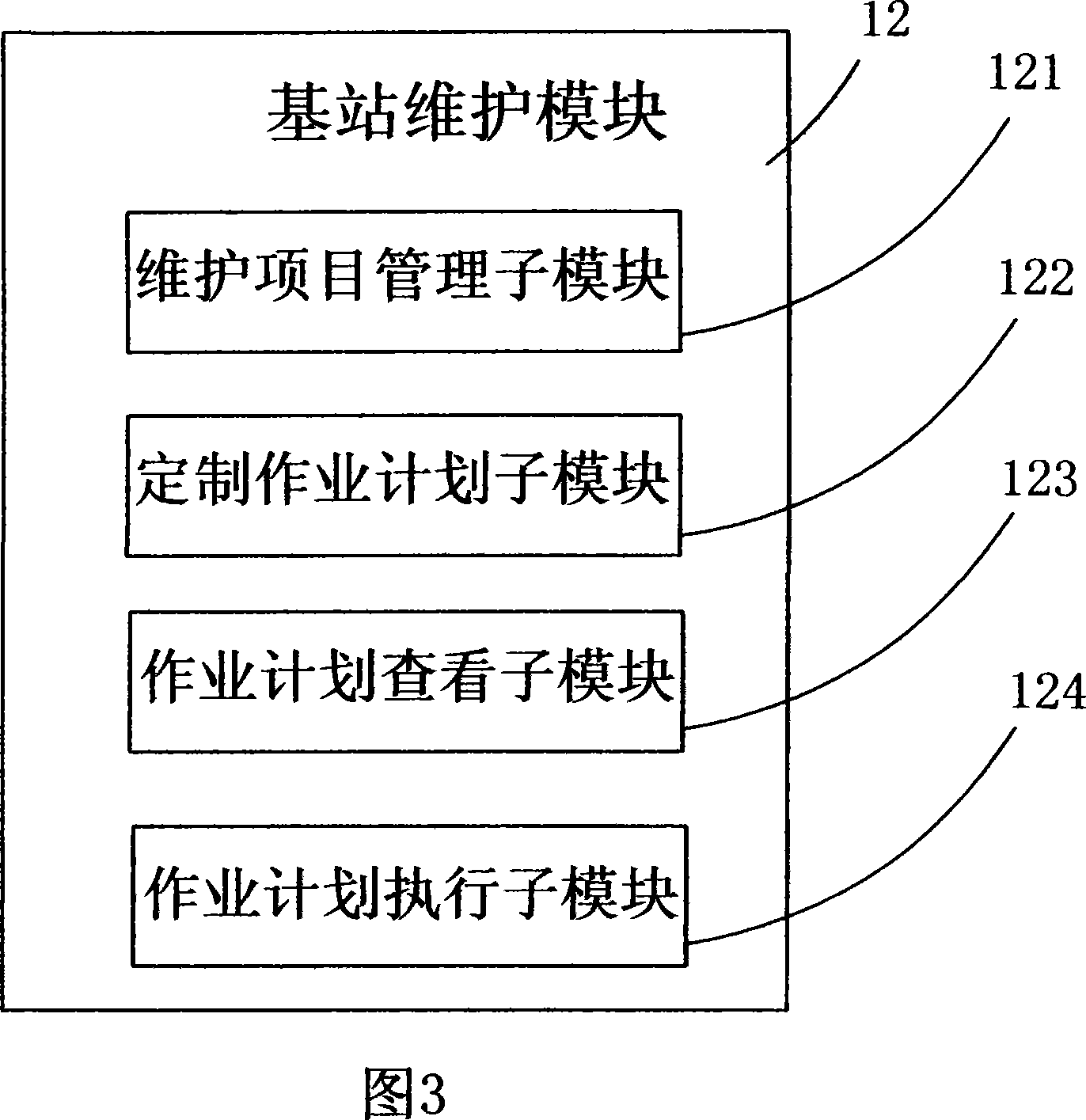

Base station maintenance management system and method

InactiveCN101056449AImprove efficiencyOvercoming the disadvantages of traditional processesRadio/inductive link selection arrangementsWireless communicationWeb serviceDatabase server

A base station maintaining management system and method in which the maintaining and management are electrified. The system includes a database server, a WEB server, a plurality of user terminals, wherein the database server is connected with the WEB server, a user logs on the WEB server via Internet or a wireless network by using a user terminal, then enters the database server based on granted right and operates related information; the invention combines a wireless communication technic, a database technic and an Internet browse technic, drastically changes a manual maintaining mode of conventional base station management so as to impel the base station maintaining management to be scientized, maintaining execution to be controllable, maintaining operation to be quantized, and improves a technic predominance of a mobile communication operator in market competition, has significances for network establishment, new service development and popularization, market business of the mobile communication operator.

Owner:XIANGYANG BRANCH CHINA MOBILE GRP HUBEI CO LTD

Treatment method of scrap copper

The invention discloses a treatment method of scrap copper. The treatment method is characterized by comprising the following steps: (1) carrying out detection and analysis on the scrap copper to be melted, and determining the application and smelting production process of the scrap copper according to the alloy components of the scrap copper; (2) according to the analytic result, removing impurity metal elements in the scrap copper on the basis of processes such as loading, melting, oxidizing, degassing, slagging, deslagging, reducing and refining for red impure copper and high-copper alloy;and (3) carrying out degassing, deslagging and deoxidization reduction on liquid copper obtained in the step (2) again. In the invention, a high-quality copper material is produced by directly utilizing the scrap copper, thus the treatment method has the advantages of low investment, low energy consumption, simple production process, low production cost and little environment pollution, valuable metals in the scrap copper can be reasonably utilized, and the competitiveness of a product in market competition can be greatly improved.

Owner:JINCHUAN GROUP LIMITED

Method for preparing activated charcoal by using discarded edible mushroom slag

The invention discloses a method for preparing active carbon with waste edible fungi residues, and is characterized in that: the waste edible fungi residues are firstly sieved and go through acid washing, then are dried, crumbled or dried, crumbled and molded, and finally the active carbon is obtained upon carbonization and activation. The invention not only has abundant raw material sources, so nonrenewable resources such as coal, tar and valuable wood materials that are used commonly at present can be saved, but also has low product cost, high added value, obvious market competition advantages, prominent economic and social benefits, besides, a new way is found for solving the environment pollution caused by the waste fungi residues, thereby realizing series production of producing fungi and preparing active carbon with the fungi residues.

Owner:SICHUAN UNIV

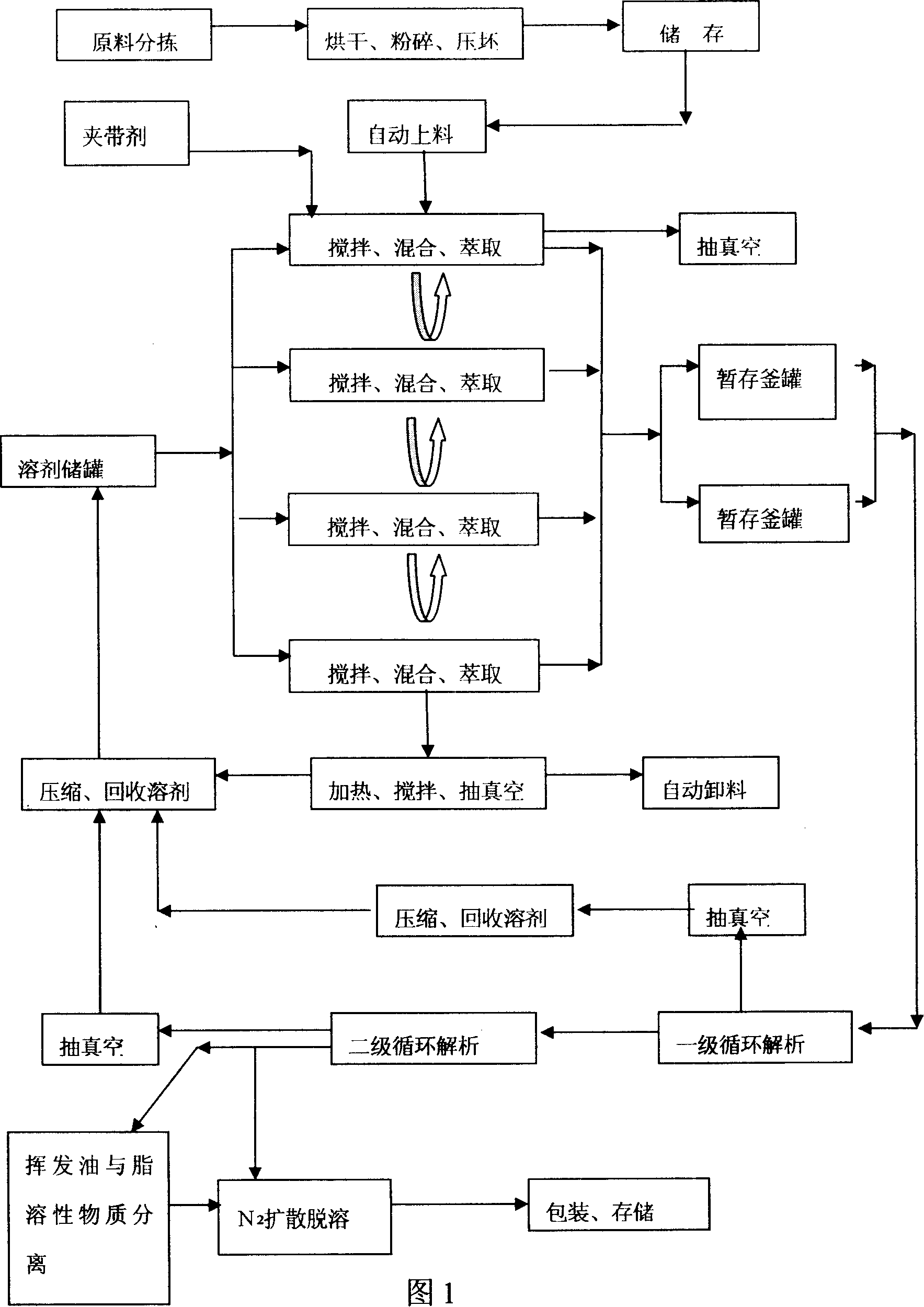

Sub-critical fluid extraction solvent and abstraction method

InactiveCN101161324AHigh extraction rateIncrease profitSolid solvent extractionSulfur hexafluorideAdditive ingredient

The present invention relates to a dissolvent with effective ingredient extracted from the plant-and-animal raw material and the extraction method thereof. One subcritical fluid extraction solvent includes an extraction solvent of a compound or composition extracted from the raw material containing compound or composition as component element, and the solvent is mainly characterized in that the liquid sulfur hexafluoride works as the extraction solvent. The invention also includes a method for extracting the subcritical fluid extraction solvent. The advantage of the invention is that the extraction and separation of the target component in the natural product are optionally executed to further increase the extraction rate of the intermediate product and the usage factor of the raw material while the unique dissolving character of the sulfur hexafluoride and the mixed solvent thereof to the liposoluble active ingredient is used. The physical features of strong dissolving capacity and low boiling point of the sulfur hexafluoride and the mixed solvent thereof are used to reduce the consumption quantity of the energy source, dissolvent of the system and the cost, and increase the market competition ability of the intermediate product.

Owner:韩延欣 +2

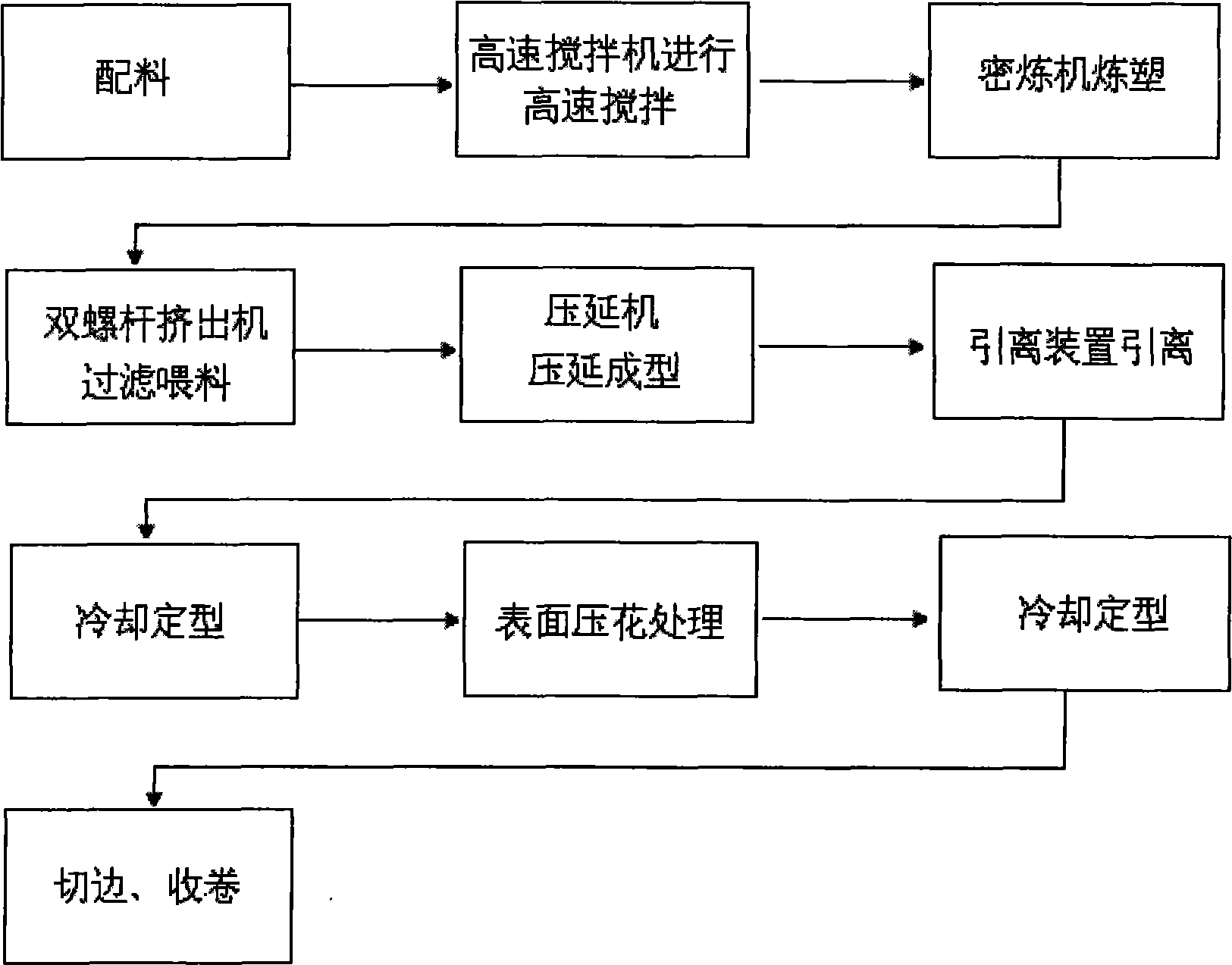

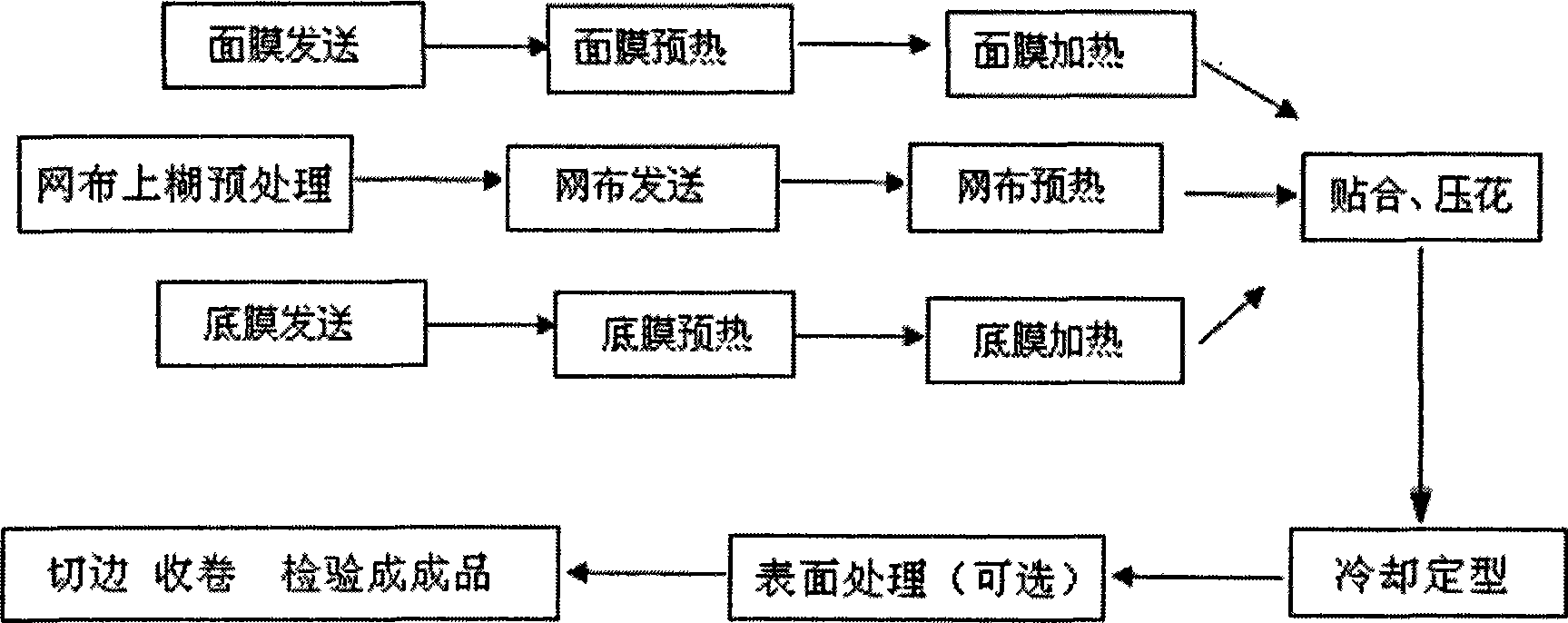

High-elastic wear-resistant calendered film production process

The invention provides a high-elastic wear-resistant calendered film production process which comprises the steps of: material preparation, high-speed stirring, plastification by an internal mixer, filtering feeding by a double-screw extruder, molding by a calendar, distraction device, cooling sizing, surface embossing processing, cooling sizing, trimming and rolling. The technical flow is scientific and reasonable; material reaction is sufficient; yield and product quality are significantly improved, and market competition capability of the product is improved, therefore, the production process has obvious economic benefit and is suitable for large-scale promotion and application.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Glazing method and special equipment therefor

The invention discloses a glazing method and the specialized equipment, which transfers the solid ceramic product into the glazing die cavity of the glazing box of the automatic glazing equipment through a transmission device, drives the rotation of the ceramic product inside the glazing die cavity through a driving device, enabling the glazing of the whole peripheral surface by the glaze extractor of the glazing equipment, and transfers the glazed ceramic product outside the glazing equipment through the transmission equipment. The glazing specialized equipment comprises an automatic glazing equipment and the transmission device; wherein, the transmission device comprises a transmission apparatus and a plurality of movable workpiece supporting disks which are arranged on the transmission apparatus and connected with the driving device driving the rotation of the disks. Compared with the prior art, the glazing method and the specialized equipment has the advantages of high degree of automation, simple operation, high glazing quality, greatly improved production efficiency, available smooth glaze layer or alabaster glaze layer coated, various satisfied clients, and improved market competition of the products.

Owner:李劲松

Purchase-transaction-settled online consumer referral and reward service using real-time specific merchant sales information

InactiveCN101443804AConvenient purchase agreementFinanceBuying/selling/leasing transactionsEarnoutService provision

A purchase-transaction-settled online consumer referral and reward system and method using real-time specific merchant sales information is provided. The system offers merchants a one-stop place for freely publishing of their real-time and specific sales offers and offers a risk-free service to merchants to use, who will be charged only after a referred purchase occurs and a revenue income is made. The system also allows merchants to determine how much they pay to the service provider for each referred purchase transaction, based on their profit margin and market competitiveness and the system serves all merchants, online or offline, big or small, and regardless of buy, sell, and payment settlement technologies in use. The system also offers consumers a one-stop place for finding matching sales offers specifically meeting their needs, refers consumers to merchants to buy at existing merchant establishments and rewards consumers with each purchase transaction led from the service provider.

Owner:CALIBER DATA INC

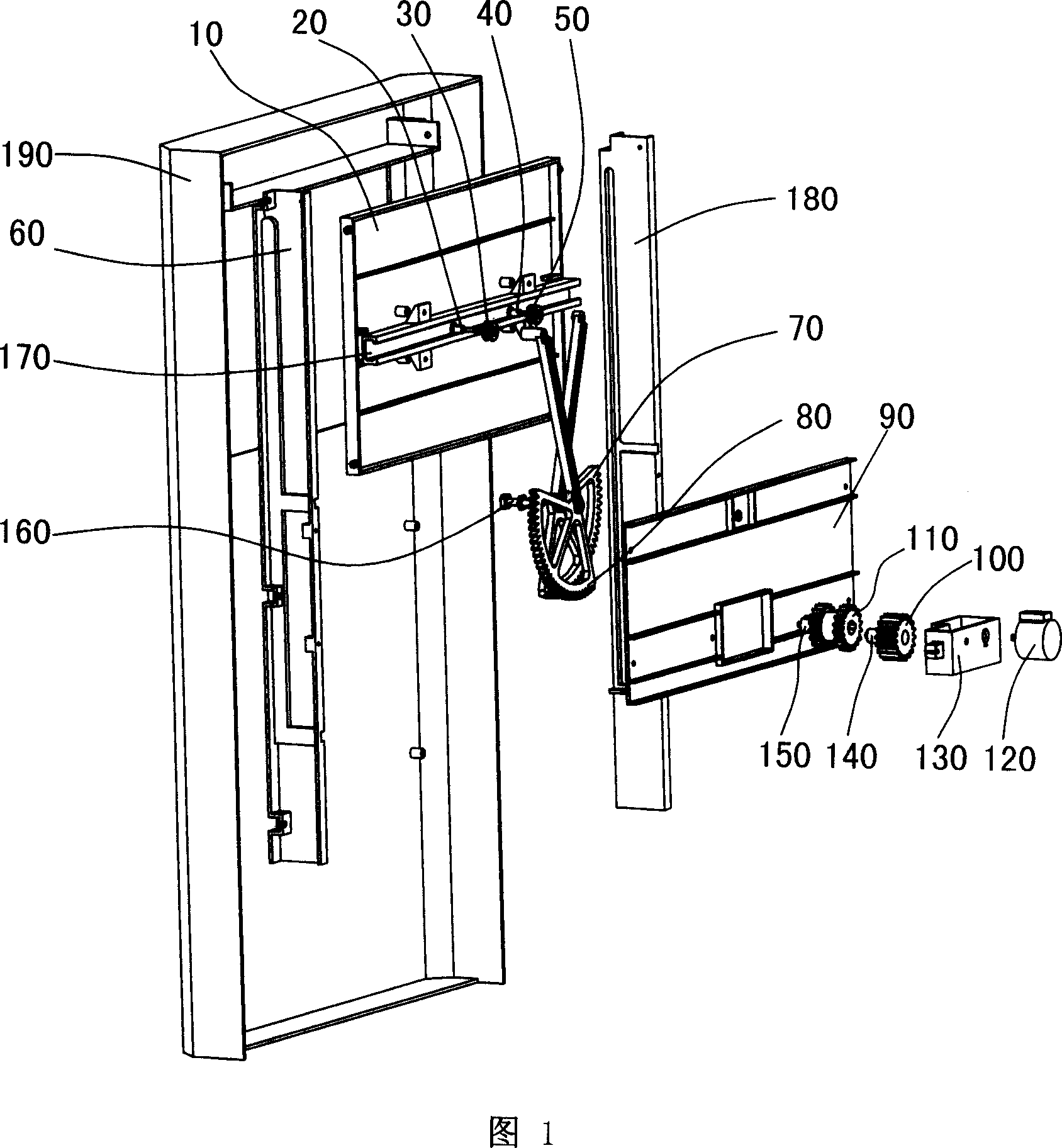

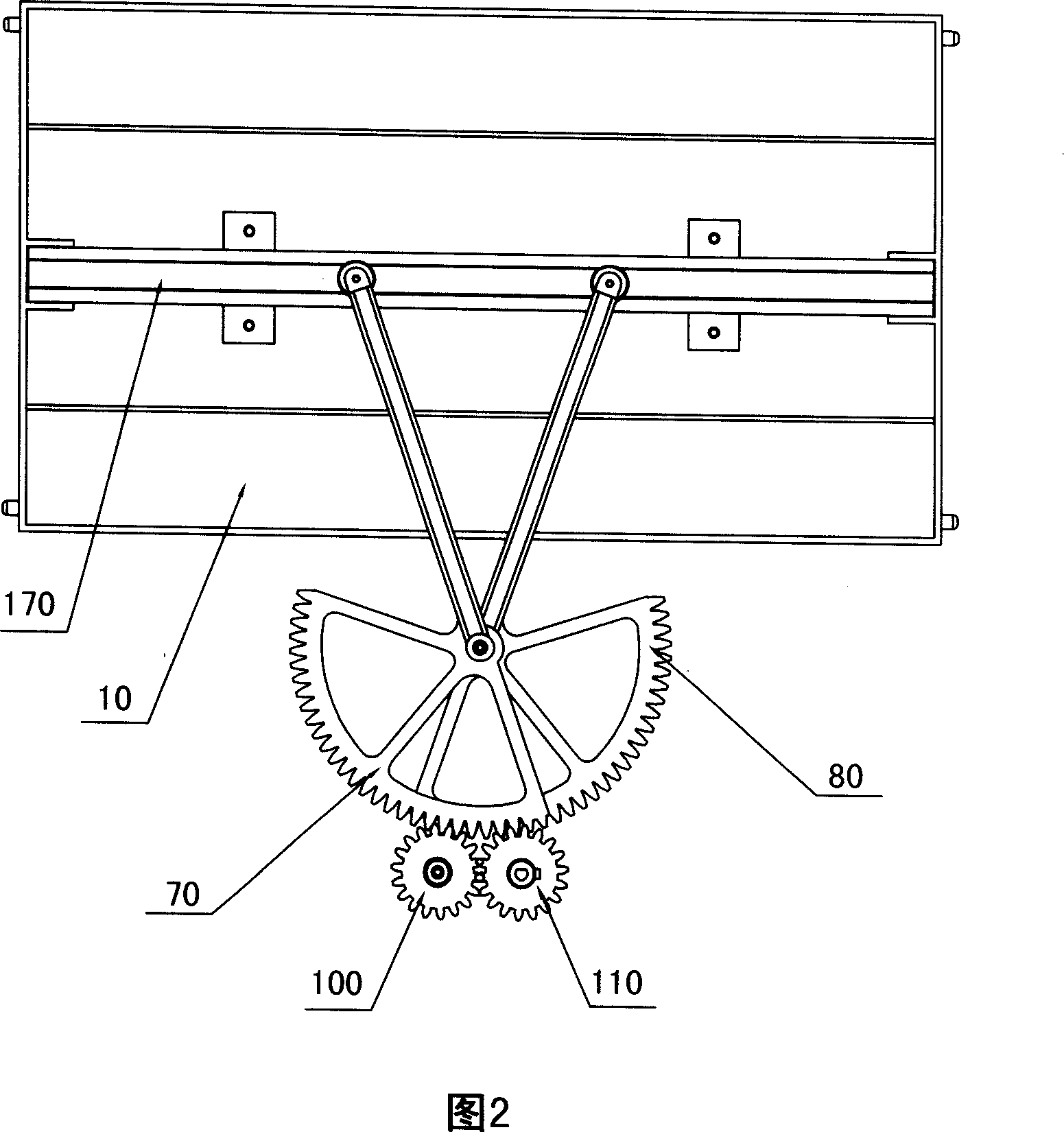

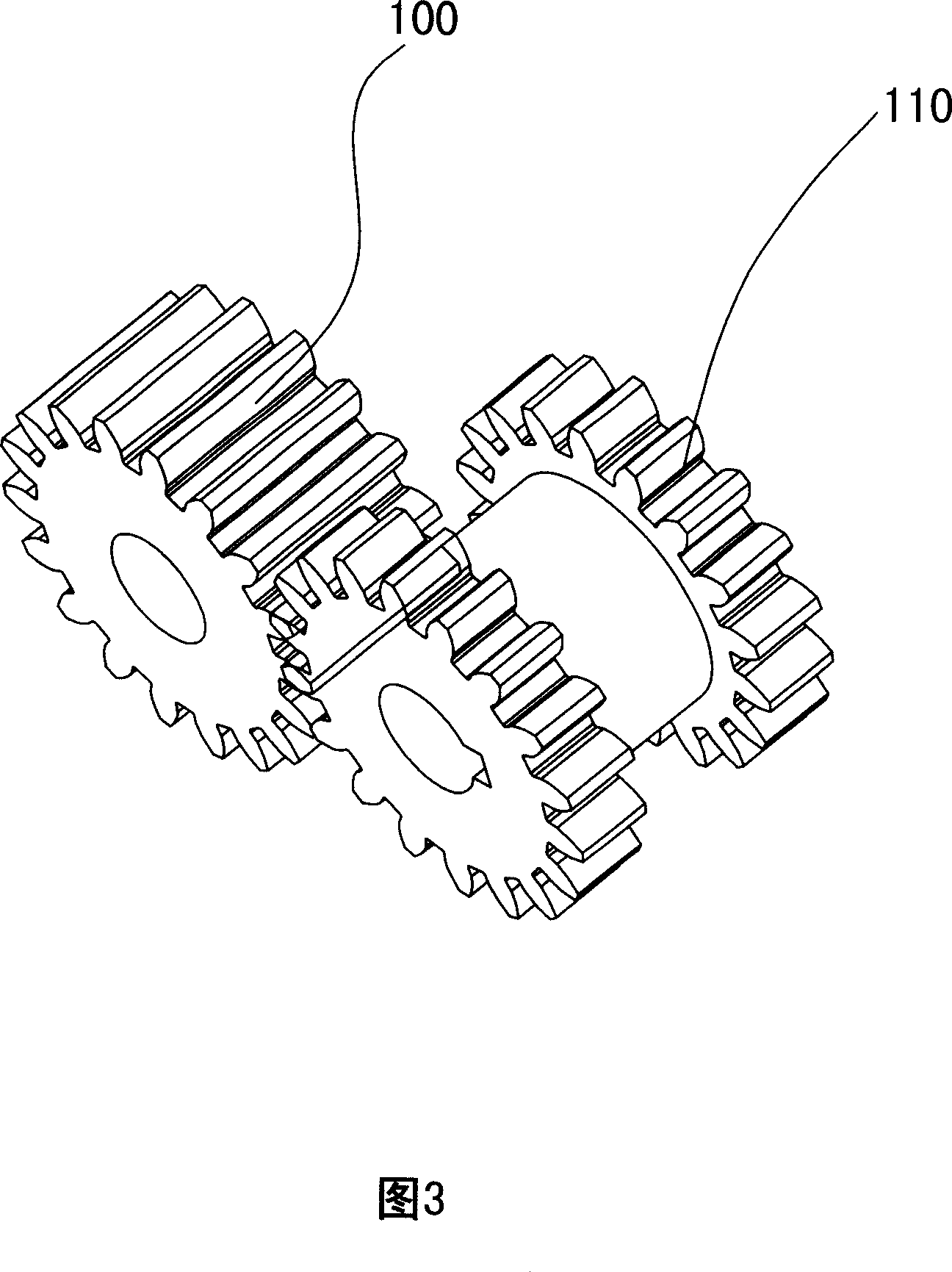

Cabinet air-conditioner with air exhaust opening slide door and start and stop method for slide door

ActiveCN101063538AGuaranteed aestheticsImprove cleanlinessLighting and heating apparatusAir conditioning systemsEngineeringMarket competition

The invention provides a cabinet-type air conditioner with air-exhaust sliding gate of easy structure, low cost, stable sliding and long performance life for better market competition, comprising a upper panel, a lower panel, a sliding gate arranged in front of the air-exhaust which can be shut off by the sliding gate moving up and down, a gate driving device arranged on the inner side of the sliding gate and at the rear of upper panel, and left and right frames which are arranged at the back of upper panel and provided with frame tracks guiding the sliding gate to slide, wherein the gate driving device comprises a driving element, a gear element and a track which is a horizontal strip structure with a horizontal chute in the middle and arranged at the rear of the sliding gate, the gear element is connected with a pendulum bar with a rolling element at the end which is arranged in the horizontal chute in the middle of the track to roll.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method for folic acid

InactiveCN102558180AReduce manufacturing costReduce labor intensityOrganic chemistrySodium acetateSodium acetrizoate

The present invention relates to a preparation method for folic acid. The method comprises the following process steps: (1) weighing various raw materials according to a weight part ratio; (2) adopting a liquid alkali to adjust the pH value of the raw materials at the temperature of 25-55 DEG C to maintain the pH value of 2.0-5.0, and carrying out a cyclization reaction for 4-9 hours to obtain the folic acid crude product. With the method of the present invention, the folic acid production cost is reduced; the price of the liquid alkali (the sodium hydroxide aqueous solution) is significantly less than the price of sodium acetate, and the use amount is reduced, such that the production cost is substantially reduced, and the market competition ability of the folic acid is enhanced; the sodium acetate is the solid, and can be used before dissolving in the water and adjusting the pH value, and the liquid alkali is the liquid, such that the dissolution operation is eliminated, and the labor intensity of the worker is reduced.

Owner:JIHENG PHARMA HENGSHUI CITY

Method for improving extraction ratio of trehalose

InactiveCN101230407ATotal production cost reductionAchieving a green circular economySaccharides productionChromatographic separationSimulated moving bed

The invention discloses a method of increasing the extraction yield of trehalose, which belongs to sugar industry technical field. Adopting the techniques of hydrogenation and chromatographic resolution, the microorganism or enzyme are used for transforming the starch and the trehalose obtained undergoes the hydrogenation reaction with the mixing solution of the maltose, glucose and maltotriose; therefore the impurity in the mixing solution produces the maltitol, sorbierite and maltotriitol; the trehalose has no reducibility, and is stable in the hydrogenation reaction; and the trehalose is separated from the maltitol, sorbierite and maltotriitol in the mixing solution by the chromatographic resolution technique simulating the moving bed; and the purity and extraction yield of the trehalose are largely increased; the trehalose is crystallized by cooling, and the trehalose product is finally obtained. Compared with the technique of producing the trehalose by adopting the original microorganism or enzyme method, the technique of the invention increases the extraction yield over 80 percent, the sub product maltitol has a comparatively high utilization value; and therefore the production cost for producing the trehalose and the market price are reduced, which makes sense for increasing the market competition of trehalose.

Owner:FUTASTE PHARM CO LTD

Galvanized self-lubricating metal material

InactiveCN101608311AImprove the lubrication effectAccelerated corrosionMetallic material coating processesBase-materialsChromium CompoundsSurface roughness

The invention relates to a galvanized self-lubricating metal material which comprises a galvanized metal substrate and a self-lubricating coating positioned on the galvanized metal substrate, wherein the self-lubricating coating is a product after a self-lubricating agent composition is solidified; the self-lubricating agent composition contains a trivalent chromium compound, silica gel and organic carboxylic acid and has the pH value of 4-7. Because the galvanized self-lubricating metal material is formed by solidifying the self-lubricating agent composition which contains the trivalent chromium compound, the silica gel, water and the organic carboxylic acid, the galvanized self-lubricating metal material not only has high lubricating property and corrosion resistance, but also can greatly reduce the requirement on the substrate of the galvanized self-lubricating metal material, and a hot dip galvanized plate with large surface roughness volatility and low price can be used as the substrate, thus the galvanized self-lubricating metal material has stronger market competition and higher economic benefit and represents the development direction of self-lubricating plates.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Composite material high-power RF coaxial connector

InactiveCN101247014ALow costGuaranteed Electrical CharacteristicsCoupling contact membersCouplings bases/casesElectrical conductorEngineering

The present invention discloses a compound material high power RF coaxial linker which comprises of inner conductor, crust, insulation, outer conductor, cable clip, rear thread sleeve and seal ring. Insulation is set between inner conductor and outer conductor, seal ring is set between crust and rear thread sleeve, crust coats on surface of outer conductor, cable clip and rear thread sleeve, the inner conductor and outer conductor on circuit are made from copper alloy, the crust and rear thread sleeve is made from aluminum alloy or stainless steel or project plastic. The present invention changes the original conductor made from copper alloy totally to conductor made from compound material, reduces cost under the premise of ensuring product capability, improves the market competition of products and meets the requirement of market.

Owner:JIANGSU JST TECH

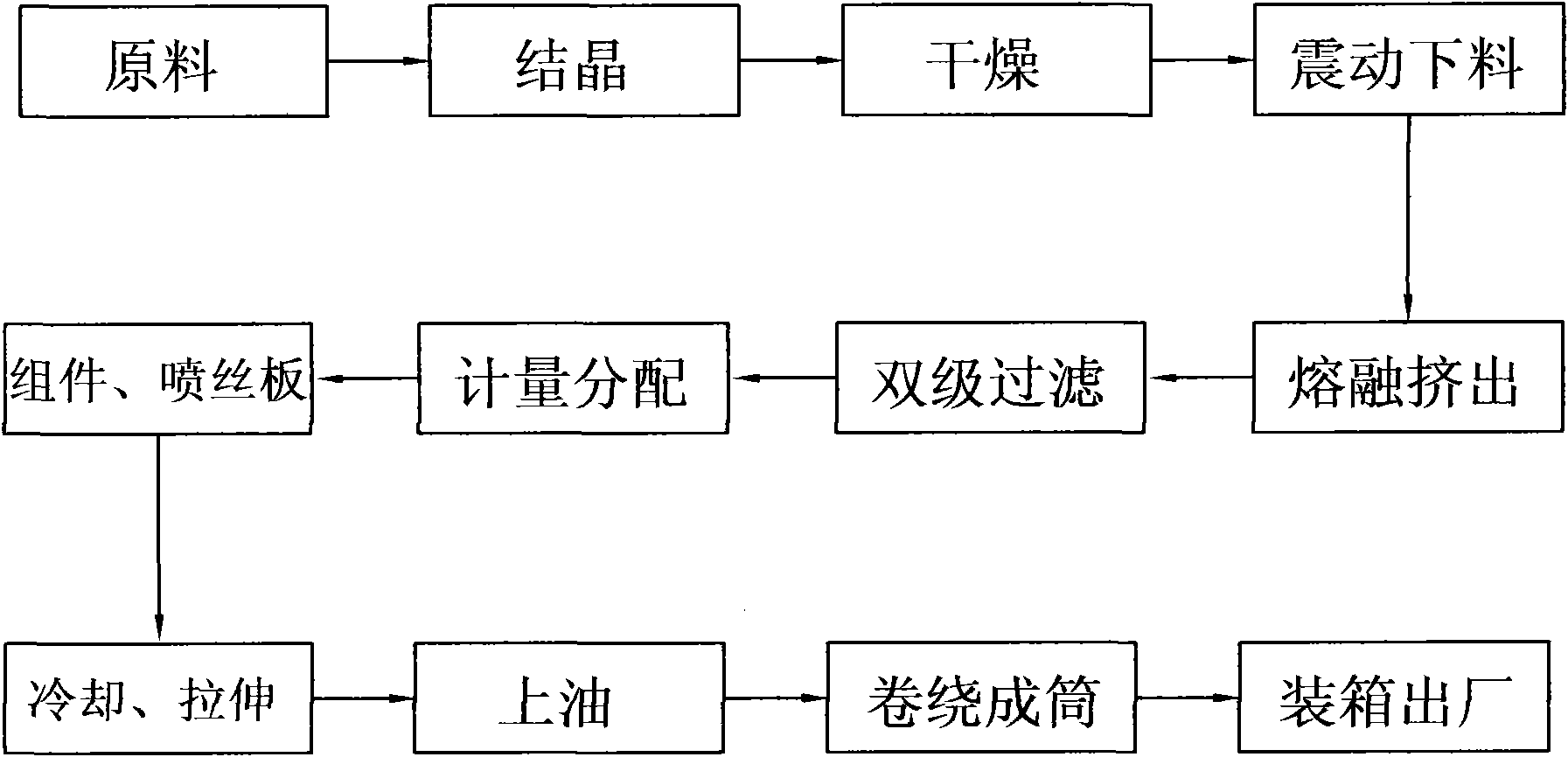

Process for producing polyester spunbonded pre-oriented yarn from waste polyester bottle chips

InactiveCN101550608AIncrease the areaUniform descent runFilament forming substance formingSpinning head liquid feederPolyesterYarn

The invention relates to a process for producing polyester spunbonded pre-oriented yarn from waste polyester bottle chips, belongs to the polyester filament manufacturing technology field. The invention adopts waste PET bottle as material, comprises the following steps: crystallizing the processed bottle chips, drying to the water content no more than 30ppm; mounting miniature shock pneumatic hammer on the pipeline outer wall to realize slight shock form for conveying the dried bottle chips to a screw extruder; controlling the temperatures of the areas of the screw extruder at 288-308 degrees centigrade; removing the impurities in he melt by a double stage filter and a booster pump; metering and distributing the melt by a metering pump, extruding to spinning jet board assembly; cooling, stretching, oiling, winding into cylinder and cartonning. The invention reduces resource waste and environmental pollution, achieves characteristics of continuous production and high production efficiency; can obtain product with high strength, uniform color, stable quality and low cost; improve the class of the waste polyester bottle chips produced textile product; and improves market competition ability of the product.

Owner:绍兴柯桥南红纱业有限公司

Payment method, corresponding portable terminal, third-party payment platform

ActiveCN107146077AIncrease competitionReduce dependencePayment protocolsPayments involving neutral partyPayment orderMarket competition

A payment method comprises the steps of A setting the usage region a of a payment mode A via a third-party payment platform; B when the third-party payment platform is utilized to pay, using the third-party payment platform to obtain the position information of a user payment device, and if the position information is within the range of the usage region a, using the payment mode A to pay. After adopting the technical scheme of the present invention, users can set the information of various payment methods via the third-party payment platform, such as the usage regions, the merchant information, the payment times, the payment quota, etc., by reasonably using the various payment methods, the users are convenient, the payment market competition focusing on the users is promoted, the popularization and the mutual competition of different payment methods are also convenient, and the dependence of the banks on the third-party payment providers is reduced technically.

Owner:广州市智专信息科技有限公司

Three-dimensional loop flannelette shell fabric and preparation method thereof

ActiveCN103696111AIncreasing the thicknessIncrease warmthSucessive textile treatmentsWeft knittingYarnPolyester

The invention relates to a three-dimensional loop flannelette shell fabric and a preparation method thereof. The shell fabric is in a plating lining loop structure, the shell yarn is pure cotton combed yarn, the middle connecting yarn is filament polyester fiber, and the velvet lining yarn is polyester and cellulosic fiber blended yarn or pure cotton yarn. The preparation method comprises the steps of untwisting, knitting, fabric slitting, curling and finishing, rubber carpet shrunk finishing, and dyeing finishing. The three-dimensional loop flannelette shell fabric recovers the characteristics that ordinary non-napping loop flannelette is not ordered enough in loop and not fluffy enough for hand feeling, the thickness and heat retention property of the shell fabric are increased, and the additional value of the product is improved, so that the three-dimensional loop flannelette shell fabric is more advantageous in market competition, and is low in cost, simple in technology and good in market prospect.

Owner:NINGBO DAQIAN TEXTILE

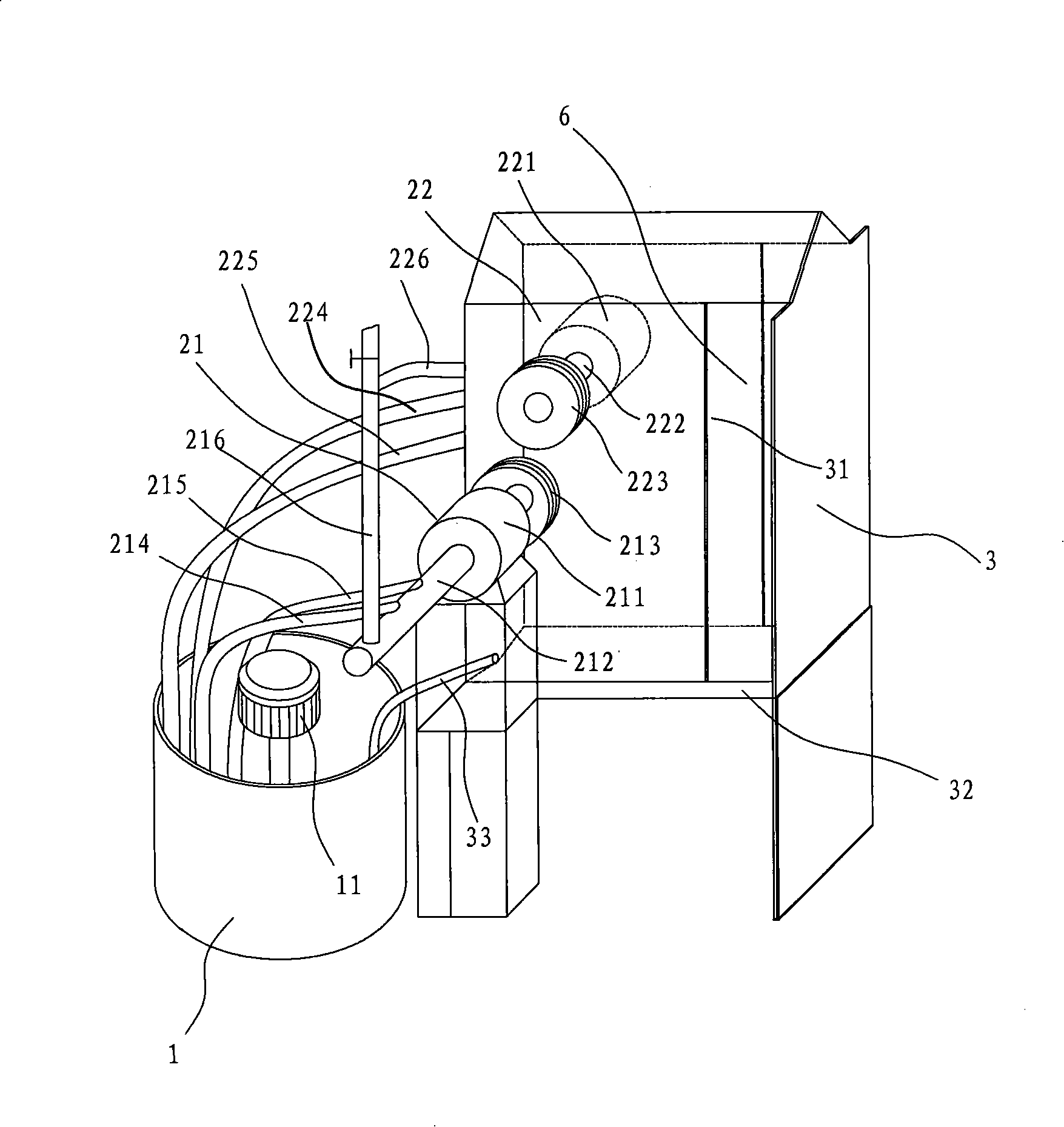

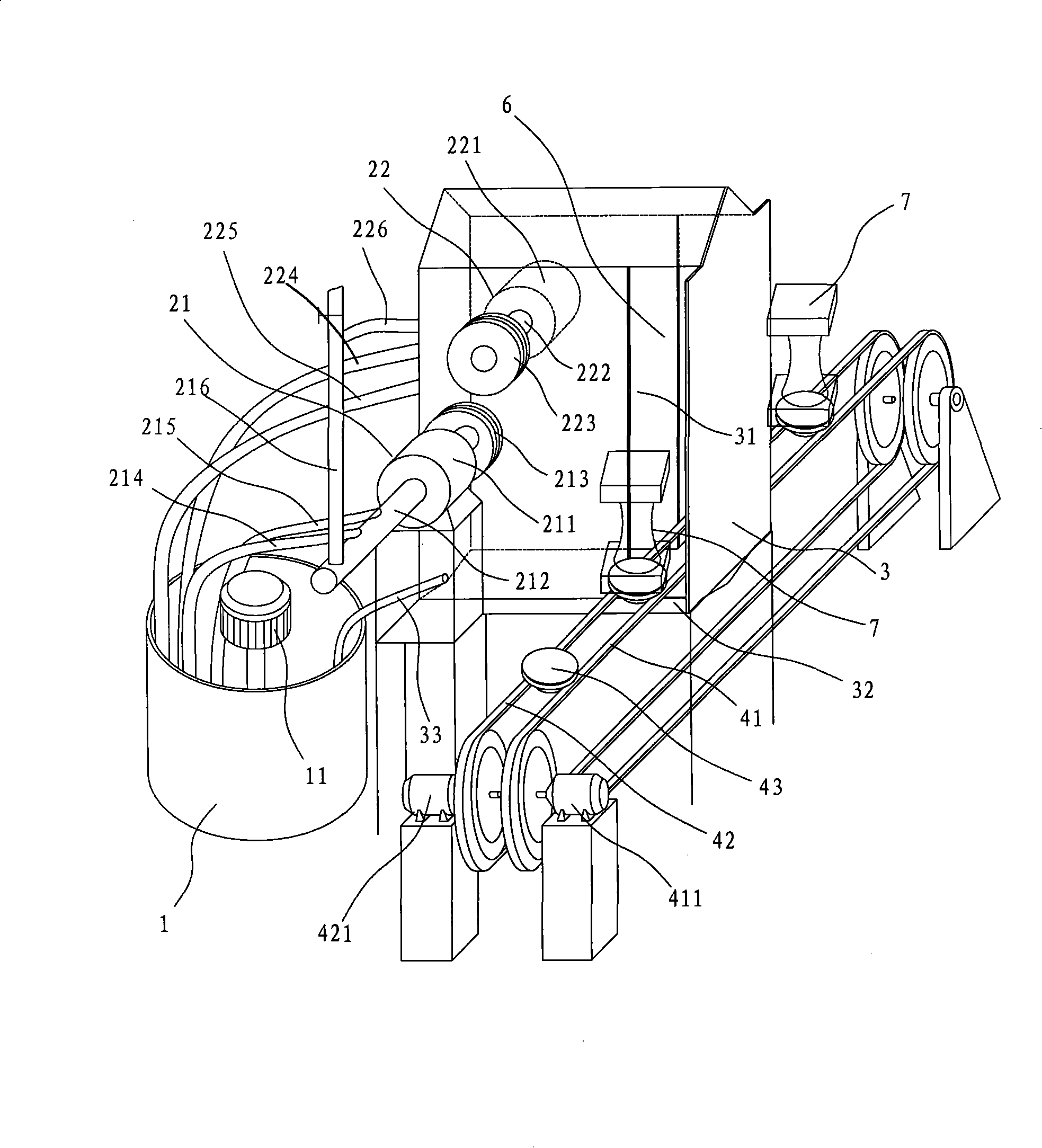

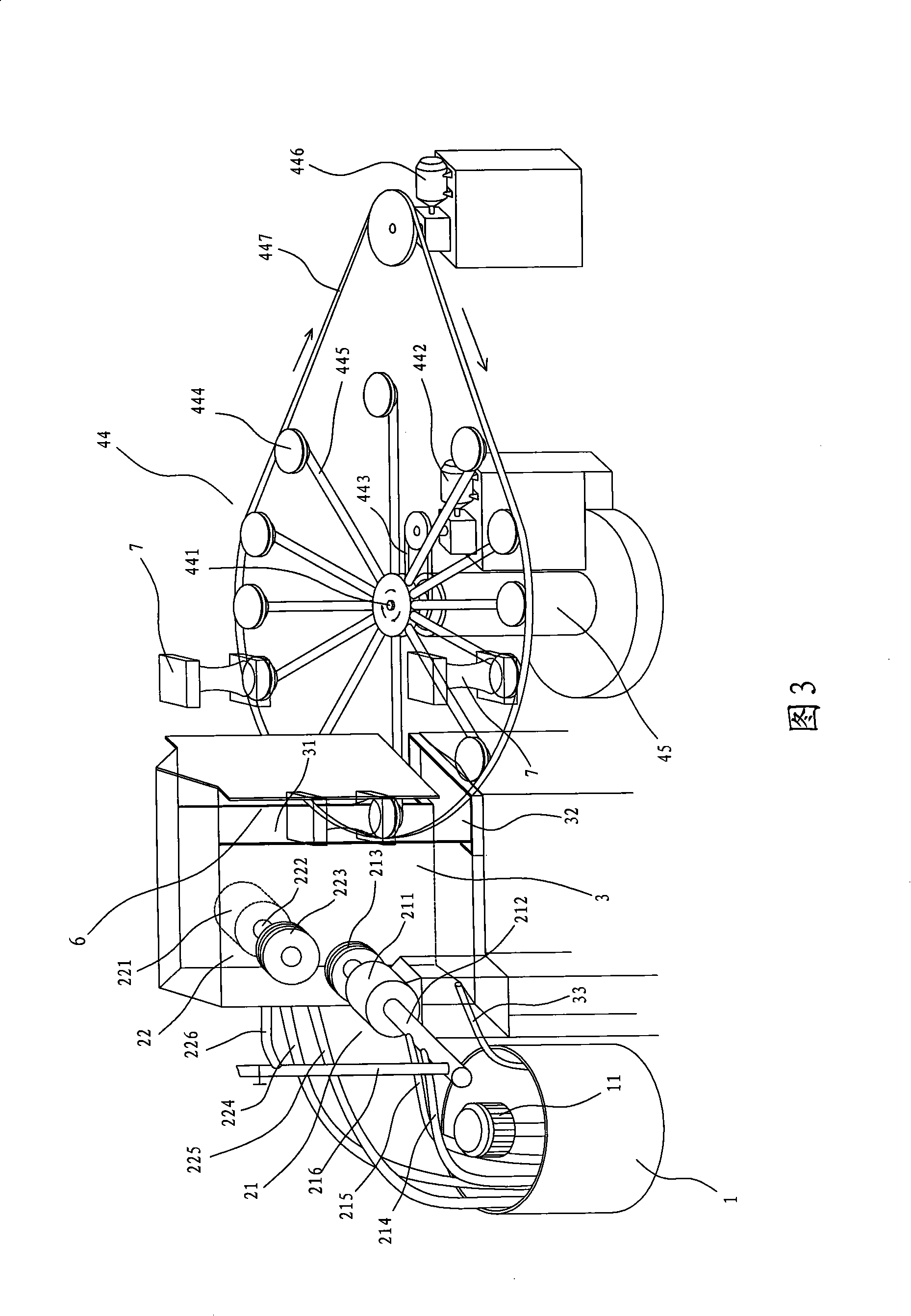

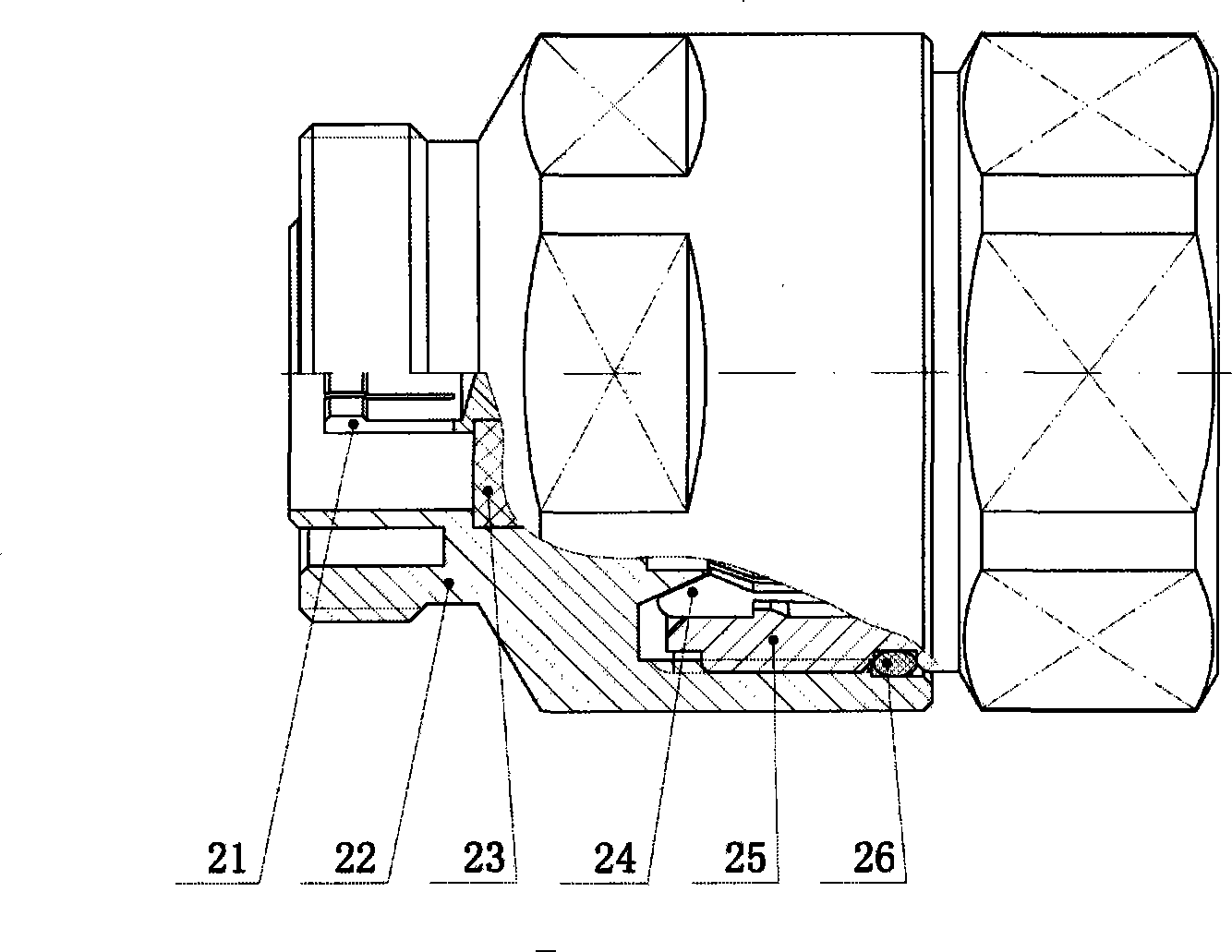

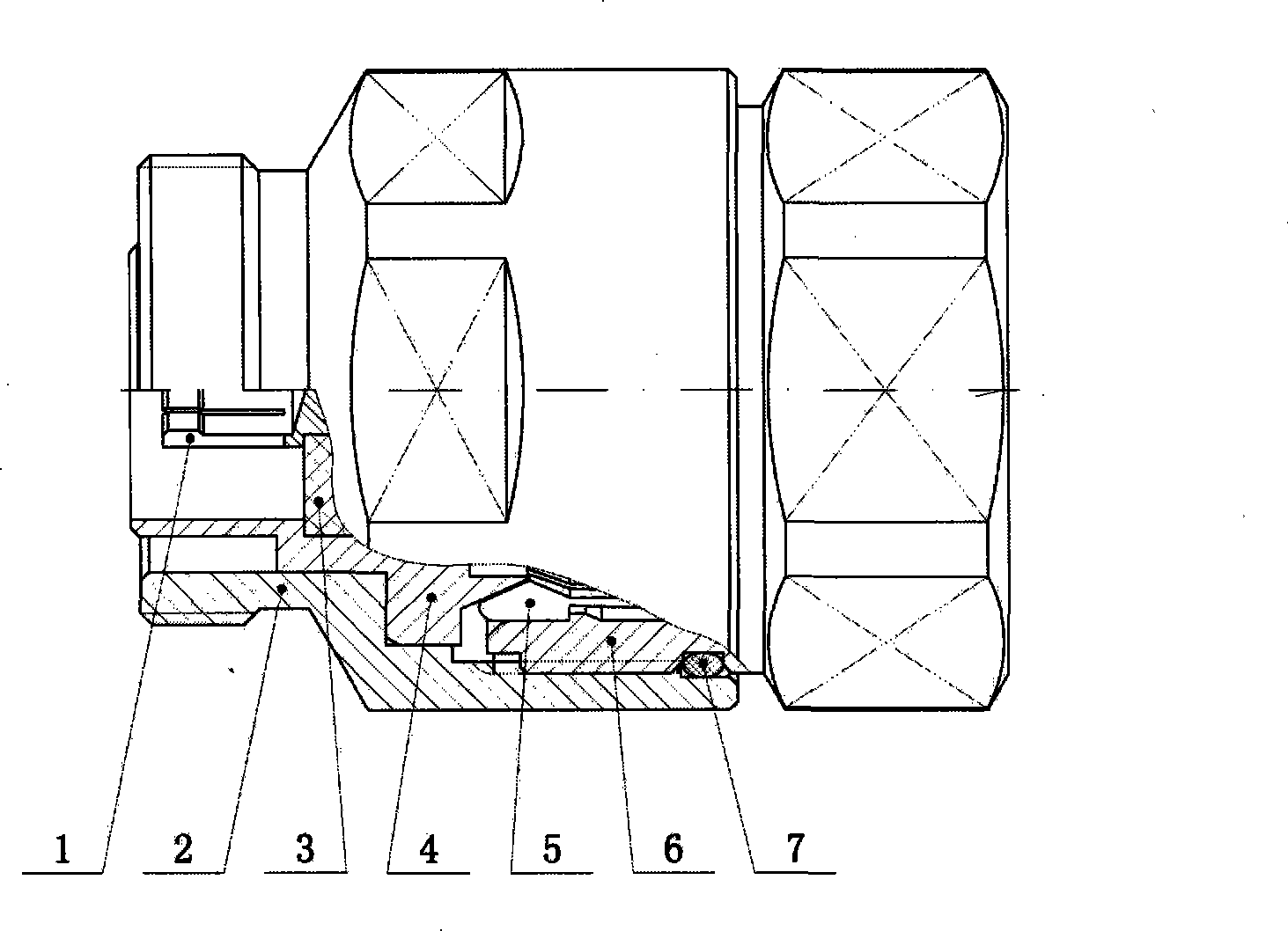

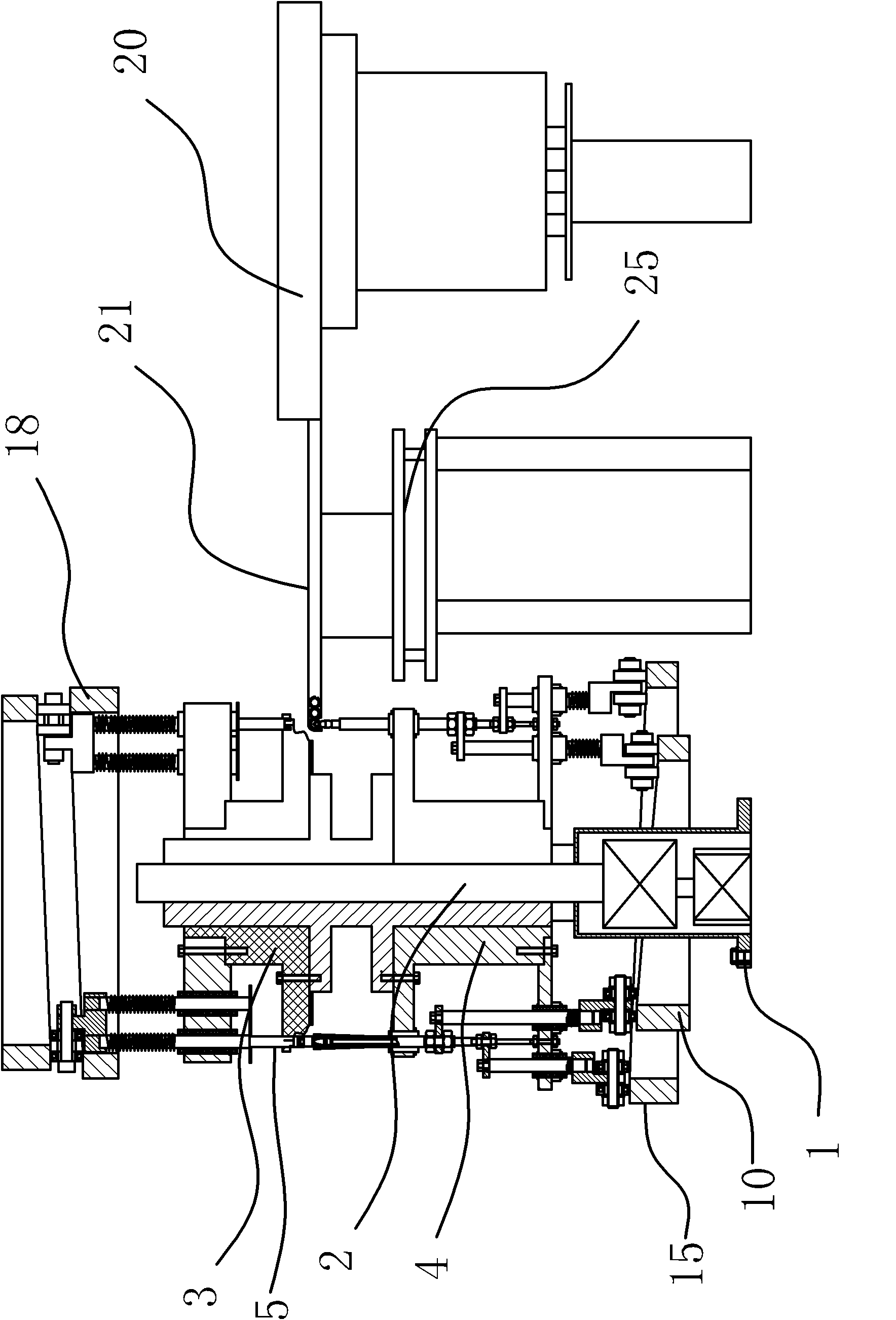

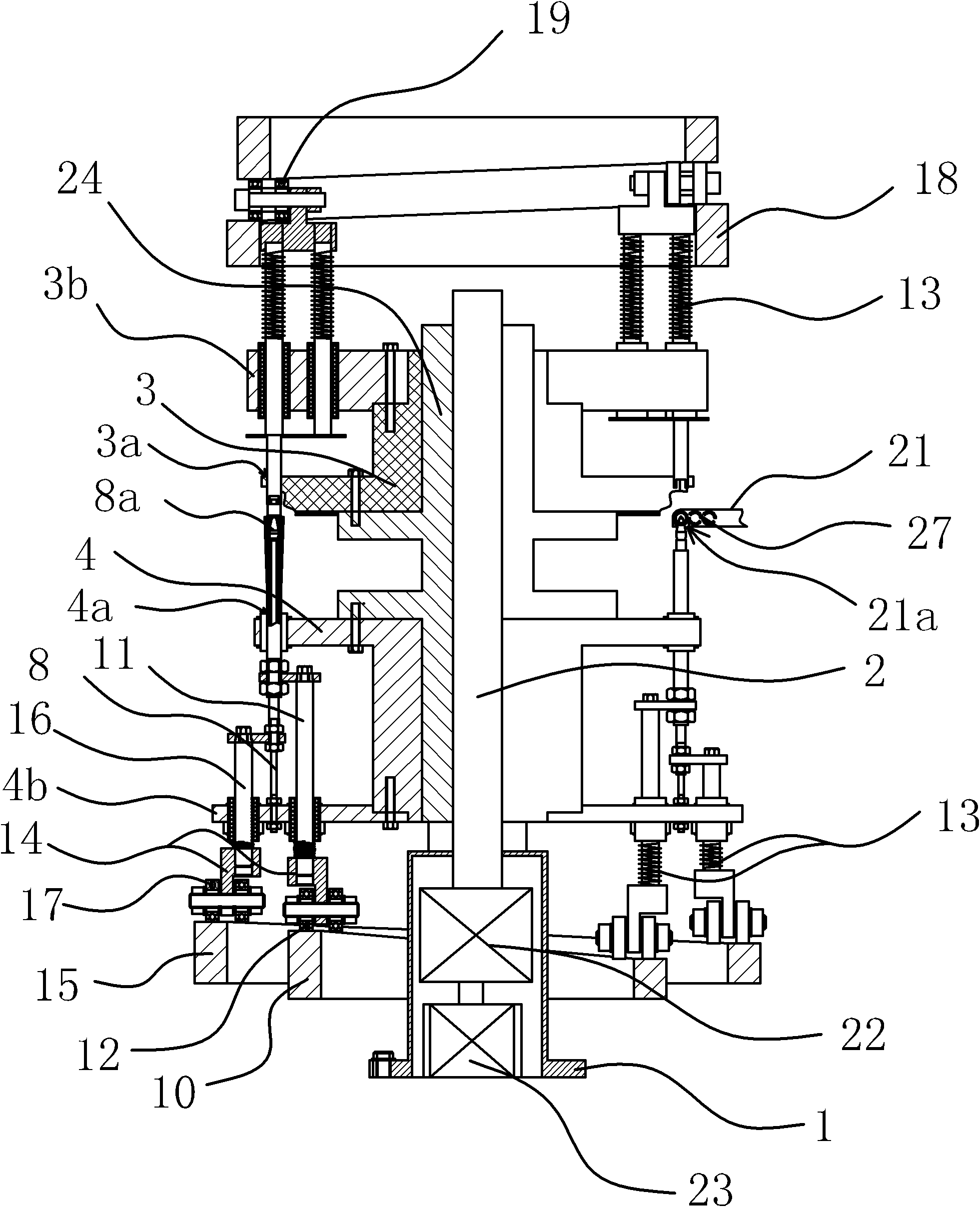

Assembly device for needle stand seal ring of safe self-destruction type injector assembly machine

The invention provides an assembly device for a needle stand seal ring of a safe self-destruction type injector assembly machine, belongs to the technical field of medical apparatus and instruments, and solves the technical problems of complicated integral structure, weak market competition and the like in the prior art. The assembly machine comprises a frame, wherein the frame is provided with upper and lower rotary tables which are connected with a dynamic mechanism and can rotate synchronously. The assembly device comprises a grab bar which is arranged on the upper rotary table and used for positioning a needle stand, and the lower rotary table is provided with a circling mechanism which can receives a seal ring on a feeding mechanism and can open the seal ring along with the rotation of the lower rotary table; and when the seal ring is opened to a state that the inner diameter of the seal ring is greater than the outer diameter of the needle stand, the circling mechanism can sleeve the seal ring on the needle stand under the action of the lower rotary table. The assembly device ensures that the whole structure of the assembly machine can be simpler, saves production cost, and improves market competition.

Owner:玉环市正日科技有限公司

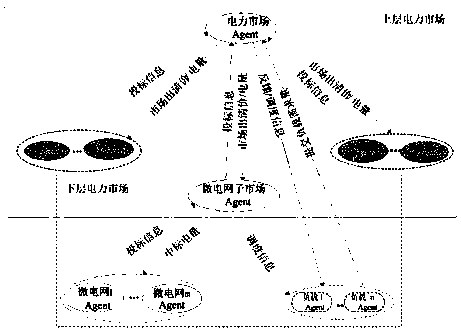

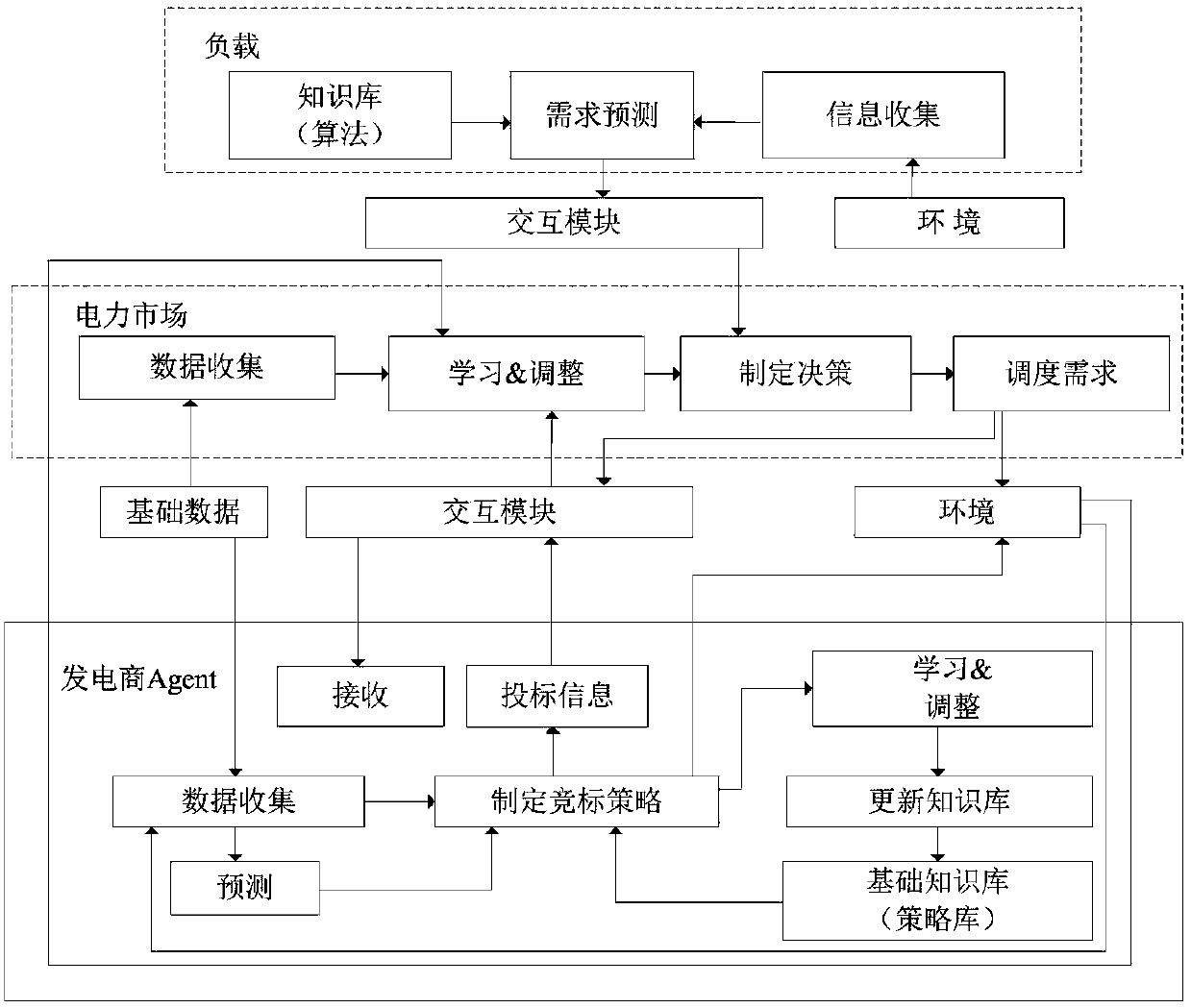

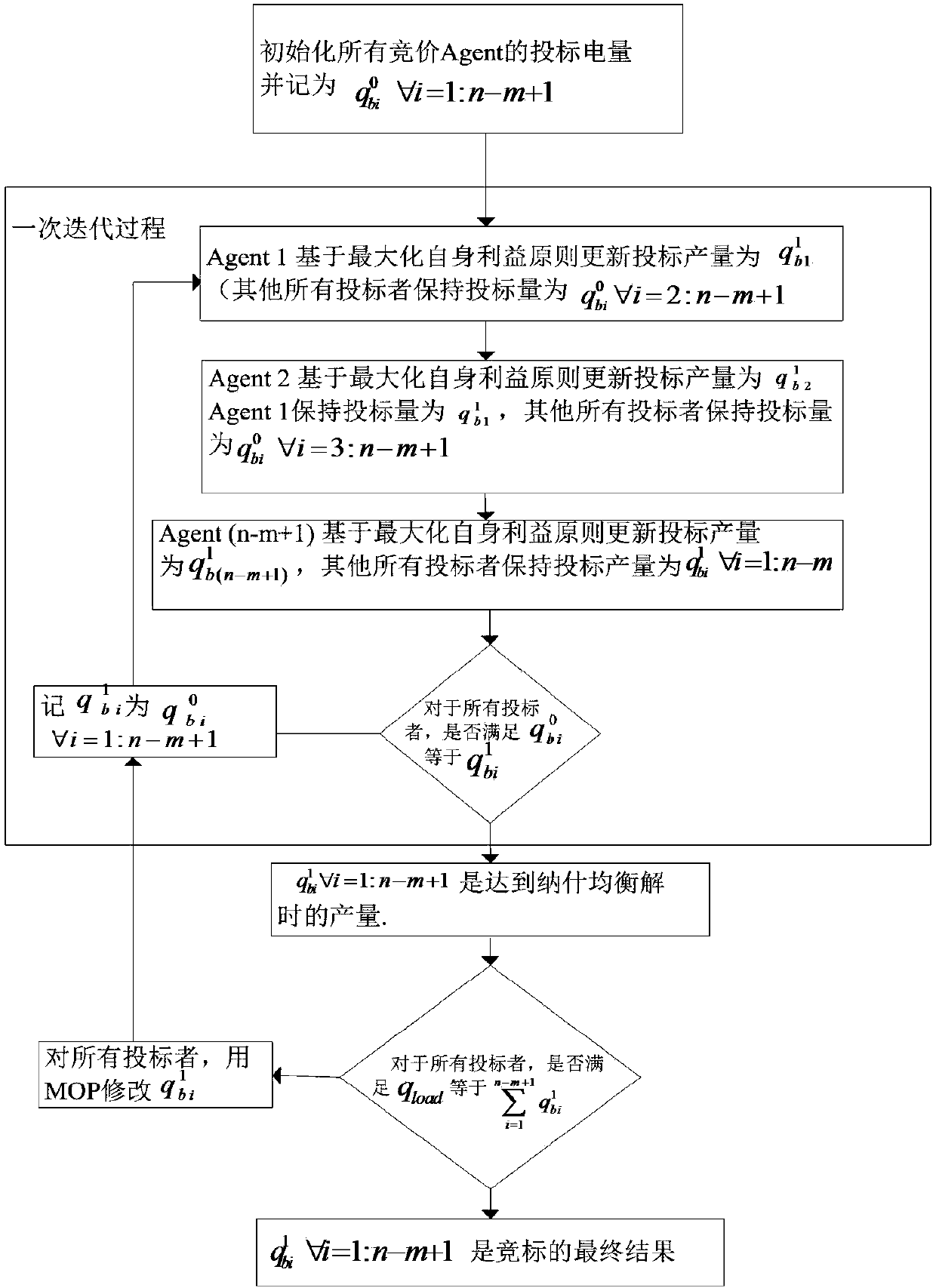

Microgrid electric power market dual-layer bidding method based on multi-agent system and game method

InactiveCN107067281ARaise the ratioGuarantee market operationMarket predictionsMicrogridElectricity market

A microgrid electric power market dual-layer bidding method based on a multi-agent system and the game method comprises: constructing a dual-layer bidding system based on multi-agent system, dividing an actual electricity market into two electricity submarkets, and in the upper layer of the electricity market, allowing a microgrid to participate in market bidding with traditional generation companies in an alliance mode; in the lower layer of the electricity market, taking the market shares obtained by the microgrid alliance in the competition of the upper layer of the electricity market as a market requirement amount, performing market competition between the microgrids again, and finally taking the obtained market shares as the final electric quantity obtained by the microgrids in the whole electricity market competition; constructing an electricity market dual-layer bidding model based on the game method; performing solution of the upper layer of the electricity market; performing solution of the lower layer of the electricity market; and verifying the utility validity of the dual-layer bidding system based on the multi-agent system through a simulation experiment. The microgrid electric power market dual-layer bidding method based on the multi-agent system and the game method improve the proportion of renewable and clean energy resource provided by the microgrid in the energy market.

Owner:YANSHAN UNIV

Convenient bean jelly and method for producing the same

The invention relates to a convenient bean starch and a making method thereof, the raw materials are: potato starch or any combination of the potato starch with sweet potato starch, gram flour, yellow rice flour, small rice flour, rice flour, core flour, glutinous rice flour and buckwheat flour and water; the auxiliary materials are: edible gelatine, alum and edible salt. A seasoning package is composed of salt water, vinegar, chili oil, dry bean curd and lotus seeds which are fried broad bean seeds; the convenient bean starch is obtained by processing bean starch; the technology of the invention successfully discloses the convenient bean starch and the series of products in three years of scientific research against the outstanding problems on the production of the prior bean starch, the series of the products have the absolute advantages of excellent quality, easy preservation and no deterioration, and the mechanical and industrial production mode which can replace the traditional production mode with low quality of the bean starch, low production efficiency, poor market competition and difficult preservation packaging is realized, thereby having positive social benefits.

Owner:山西大瑞食品加工有限公司

Active material of super lead storage battery plate

InactiveCN102024946AImprove conductivityImprove low temperature resistanceLead-acid accumulator electrodesFiberHigh rate

The invention discloses an active material of a lead storage battery plate. An anode active material comprises the following components by weight: 100kg of lead powder, 0.01 to 2kg of conductive fiber, 0.1 to 5kg of metallic oxide, 0.1 to 2kg of conductive carbon material, 0.01 to 1kg of sodium carboxymethyl cellulose and 1 to 15kg of diluted sulfuric acid; and a cathode active material comprises the following components by weight: 100kg of lead powder, 0.01 to 2kg of conductive fiber, 0.1 to 5kg of conductive carbon material, 0.1 to 0.6kg of barium sulfate, 0.2 to 1kg of humic acid, 0.01 to 0.1kg of lignin and 1 to 15kg of diluted sulfuric acid. The components and ratio of the active material are improved and optimized, and the active material comprises various carbon materials, so a super lead storage battery consisting of the plate made of the active material has high low-temperature performance, high rate charge and discharge performance and long charge and discharge cycle life, and particularly has strong market competition advantages when applied to electrically-driven vehicles.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

Hardened fat and method of preparing the same

InactiveCN101108999AOvercoming the inherent drawbacks of hydrogenationImprove performanceFatty acid hydrogenationRapeseedMarket competition

The invention relates to a hydrogenated oil and fat, which is an animal and plant wax. The invention adopts two or more raw materials of palm oil, soybean oil, cottonseed oil, peanut oil, rapeseed oil, sesame oil, olive oil, corn oil, rice bran oil, coconut oil, cacao oil, sunflower seed oil, etc. plant oil and fat and beef tallow, sheep fat, pig fat, fish oil, etc. animal oil and fat. The raw materials are added with a copper-nickel binary catalyst and thoroughly mixed and then the hydrogenated oil and fat is prepared by a hydrogenation reaction when the mixture ratio reaches 100 per cent. The technique procedure of the preparation method is that: raw material mixture to adding catalyst to hydrogenation system vacuum pumping to hydrogenation system temperature rising to hydrogenation system hydrogen filling. The hydrogenated oil and fat of the invention has the good integrity performance of the high melting point, high hardness and high tenacity and strong adhesion; the invention has wide application, not only acts as a paraffin additive, but also as an animal and plant wax; the invention features the simpler operation, low manufacture cost and stronger market competition.

Owner:EAST CHINA UNIV OF SCI & TECH

Production process for composite material of swimming pool

ActiveCN101509199AAvoid the pitfalls of hydrolytic degradationScientific and reasonable production processSynthetic resin layered productsLaminationFiberPolyester

The invention provides a process for producing a swimming pool composite material, comprising: using a coating impregnator to carry out PVC paste adhesive pretreatment for polyester fiber fabrics, carrying out double-face lamination with a PVC film in a laminating machine under high temperature state, and cooling to form a composite material for overwater leisure and recreation equipment. The producing process is scientific and reasonable; and the product has the advantages of good physical properties such as peeling strength, tearing strength, hand feeling resilience and the like, lower cost, vivid appearance varieties, good antibacterial anti-algae performance and air tightness, long service life, hydrostatic pressure resistance, higher market competition and remarkable economic benefit.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Process for preparing pesticide microcapsules by interfacial polymerization method

InactiveCN101731210AIncrease coveragePlay a sustained release effectBiocideAnimal repellantsWater basedOil phase

The invention discloses a process for preparing pesticide microcapsules by an interfacial polymerization method. On the basis of the conventional process, urea replaces polyamine and polyalcohol in water soluble monomers. The pesticide microcapsules prepared by the process have high cladding ratio of over 98 percent and the particle size of between 3 and 5mu m, has the characteristic of a water-based preparation, and has better sustained-release effect; the urea replaces polyamine and polyalcohol and is directly dissolved in water to form aqueous solution; and then isocyanate and pesticide active ingredients form an oil phase which is dispersed in the aqueous solution for interfacial polymerization. Compared with the traditional interfacial polymerization method, the urea material is easily obtained, the price is low, and the production cost can be obviously reduced; and the urea is directly dissolved in water to form the aqueous solution, the dropwise addition link is reduced, the requirement on equipment is lower, the operation is more simple, the process is suitable for industrial production, and the pesticide microcapsules have strong market competition strength.

Owner:HEBEI AGRICULTURAL UNIV.

Resin reinforced high-speed grinding wheel

The invention relates to a resin-reinforcing high-speed grinding wheel. The invention is characterized in that each group comprises A24<#,, A30<#>, A36<#>, resin liquids, resin powders, sulfur concentrate powders, cryolites, light calcium carbonates and carbon blacks. After a qualified inspection to each group, the components are weighted according to the prescription and are mixed through a 80-mesh sieve, and the mixture is griddled through a 8-mesh sieve to become a finished material. Then the finished material is loosened through the sieve and then is put into a mould. After the material is spread and scraped, a web piece and a bore-ring are put into the mould, and then the mould is put into a pressing machine for pressing, with a pressure of no less than 150MPa and a temperature ranging from 40 to 60 degree centigrade. After the pressure is preserved for 30 seconds the mould is disassembled and the material is put into a furnace for hardening. After hardening, the qualified product is the eligible product. The invention, on a basis of not reducing the product safety and various technical indexes, makes use of the home common raw materials and selects an excellent prescription so as to reduce the product cost and enhance the market competition as much as possible. The invention is characterized in that the strength is high; crash can be avoided and the grinding effect is good.

Owner:沈阳市盛世磨料磨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com