Sub-critical fluid extraction solvent and abstraction method

A subcritical fluid and extraction solvent technology, applied in the direction of solid solvent extraction, etc., can solve the problems of enlarging the effective volume of equipment and restricting industrial application, etc., and achieve the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

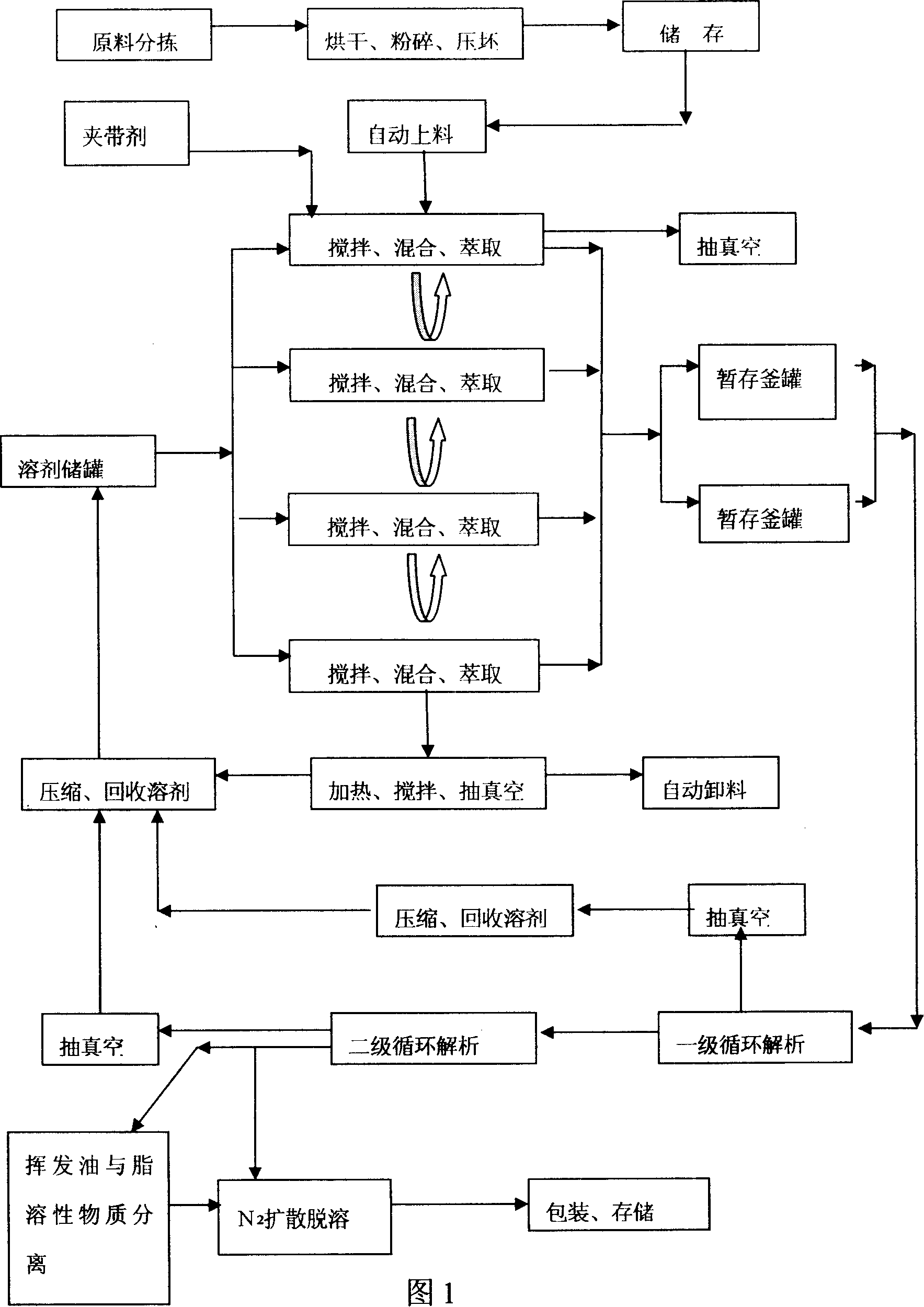

Method used

Image

Examples

Embodiment 1

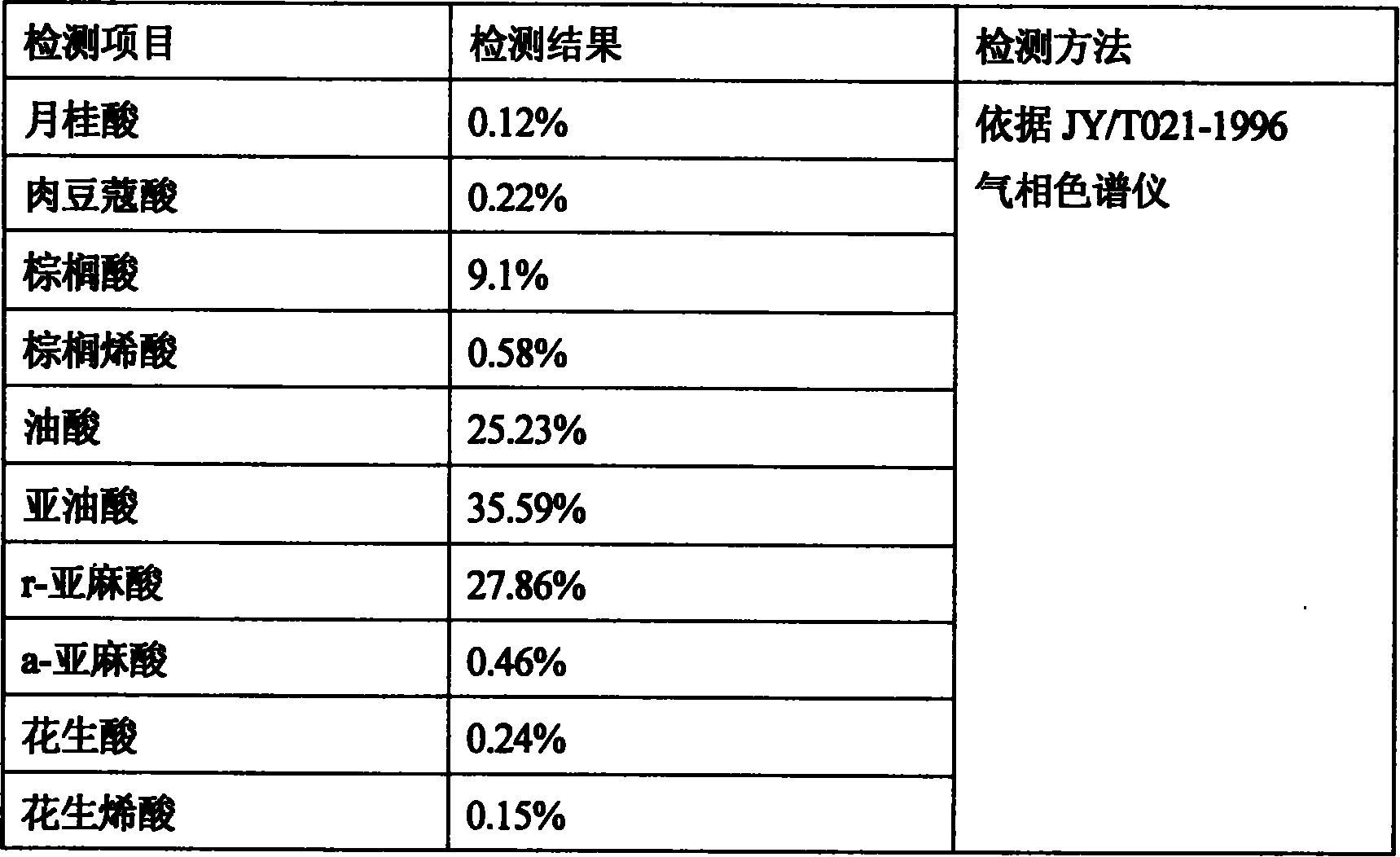

[0052] Example 1: Subcritical fluid extraction of seabuckthorn seed oil: the seabuckthorn seeds are crushed to a particle size of 2mm-80 mesh; the automatic feeder sends the raw materials into the extraction kettle, and stops when the volume of the raw materials reaches 1 / 3 of the volume of the extraction kettle Load the material, close the inlet and outlet control valves; reduce the vacuum of the extraction kettle to 1×10 4 Below pa, eliminate non-condensable gas in the system; control the temperature of the solvent storage tank 4 pa-5×10 -2 Under pa vacuum, the mixed solution is desorbed and evaporated in the analysis kettle to complete the preliminary separation of the solvent and seabuckthorn seed oil; the mixed solution coarsely separated by the primary analysis is injected into the secondary analysis kettle by a transfer pump, and heated by a jacketed heat exchanger. At 5×10 -2 Under the pa high vacuum state, the solvent is further analyzed and evaporated to complete the com...

Embodiment 2

[0056] Example 2: Subcritical fluid extraction of tanshinone IIA: pulverize the raw materials of Danshen to control the particle size between 2mm-80 mesh; the automatic feeder sends the raw materials into the extraction kettle, and when the volume of the raw materials reaches 1 / 3 of the volume of the extraction kettle, stop feeding , Close the inlet and outlet control valves; reduce the vacuum of the extraction kettle to 1×10 4 Below pa, remove the non-condensable gas in the system; mix sulfur hexafluoride and heptafluoropropane in equal volumes, and control the temperature of the mixed solution to be less than 35°C and pressure less than 0.8MPa to keep it in a liquid state; according to the volume of the solvent and the raw material 2.5:1 Inject the liquid mixed solution into the extraction kettle and stir and mix with the raw materials of Salvia miltiorrhiza; inject the purity 95% ethanol entrainer according to the volume ratio of the solvent and the entrainer 10:1 to change the...

Embodiment 3

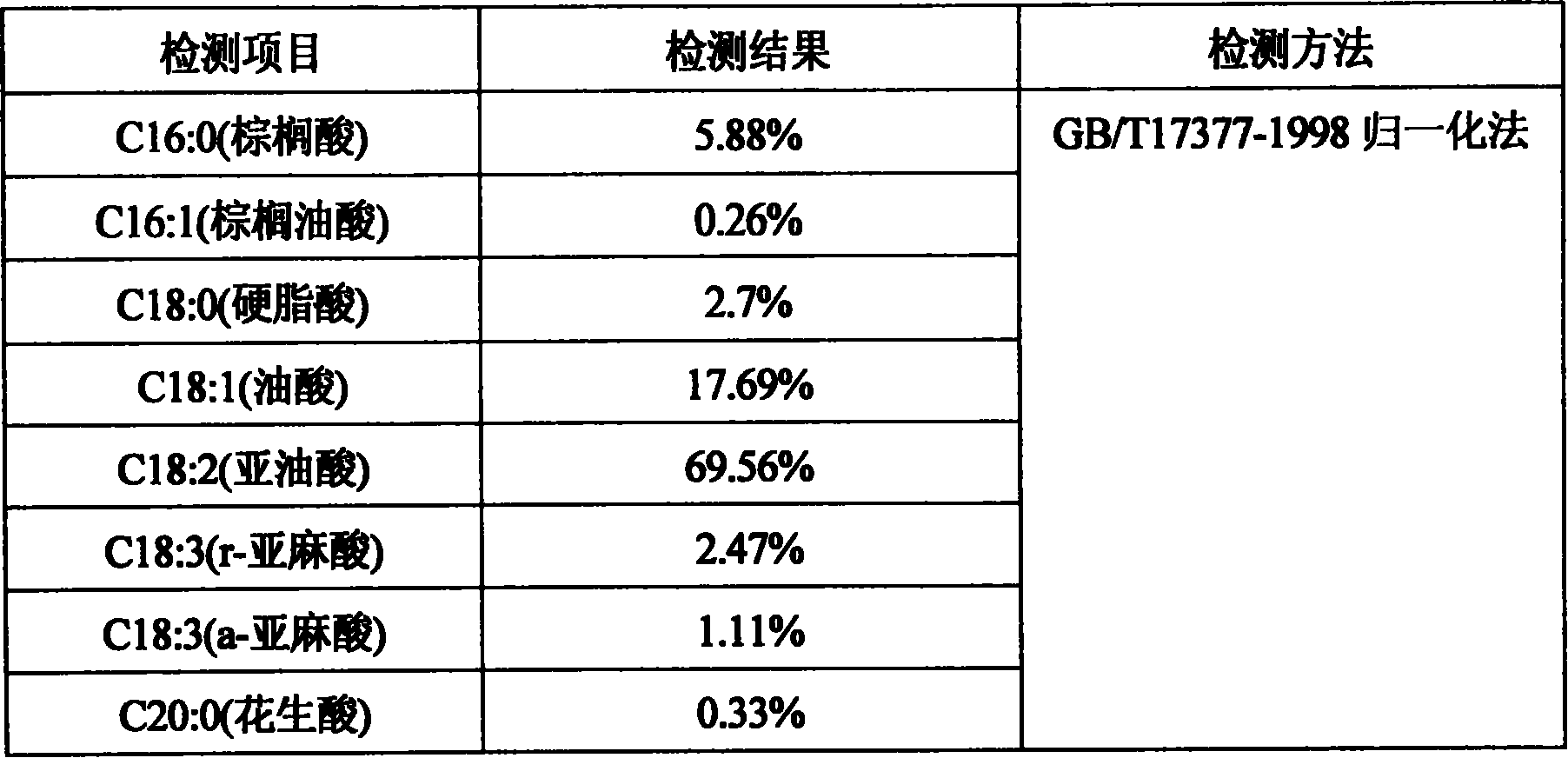

[0059] Example 3: Subcritical fluid extraction of wolfberry seed oil: mix sulfur hexafluoride and tetrafluoroethane in a volume ratio of 6:4, and control the temperature of the solvent storage tank to be less than 35°C and pressure less than 0.8 MPa to maintain mixing The solvent is in a liquid state; the wolfberry seed material is crushed to 2mm-80 mesh and then added to the extraction kettle. When the volume of the raw material reaches 1 / 3 of the volume of the extraction kettle, stop feeding and close the inlet and outlet control valves; reduce the vacuum of the extraction kettle to 1× 10 4 Below pa, remove the non-condensable gas in the system; then pour the mixed solvent of sulfur hexafluoride and tetrafluoroethane into the extraction kettle at a volume ratio of 2.5:1 between the solvent and the raw material, and stir and mix with the raw material of wolfberry seeds; To 45℃, hold time for 50 minutes, complete one immersion extraction; repeat extraction three to five times, com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com