Patents

Literature

217 results about "Separation factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation factor. The separation factor is the quotient of the ratio of the isotope frequency of a certain isotope to the sum of isotope frequencies of other isotopes after a separation process and this ratio prior to the separation process.

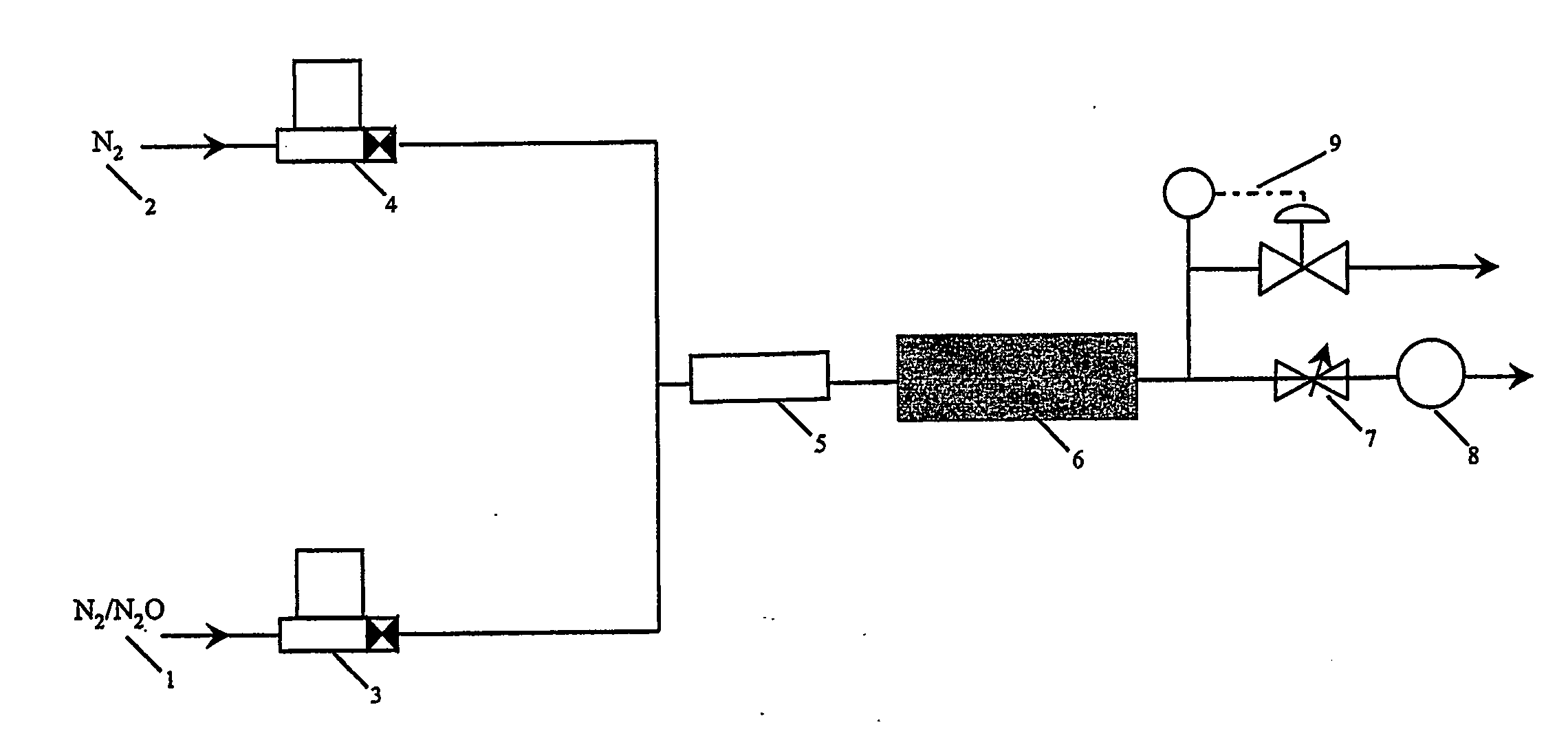

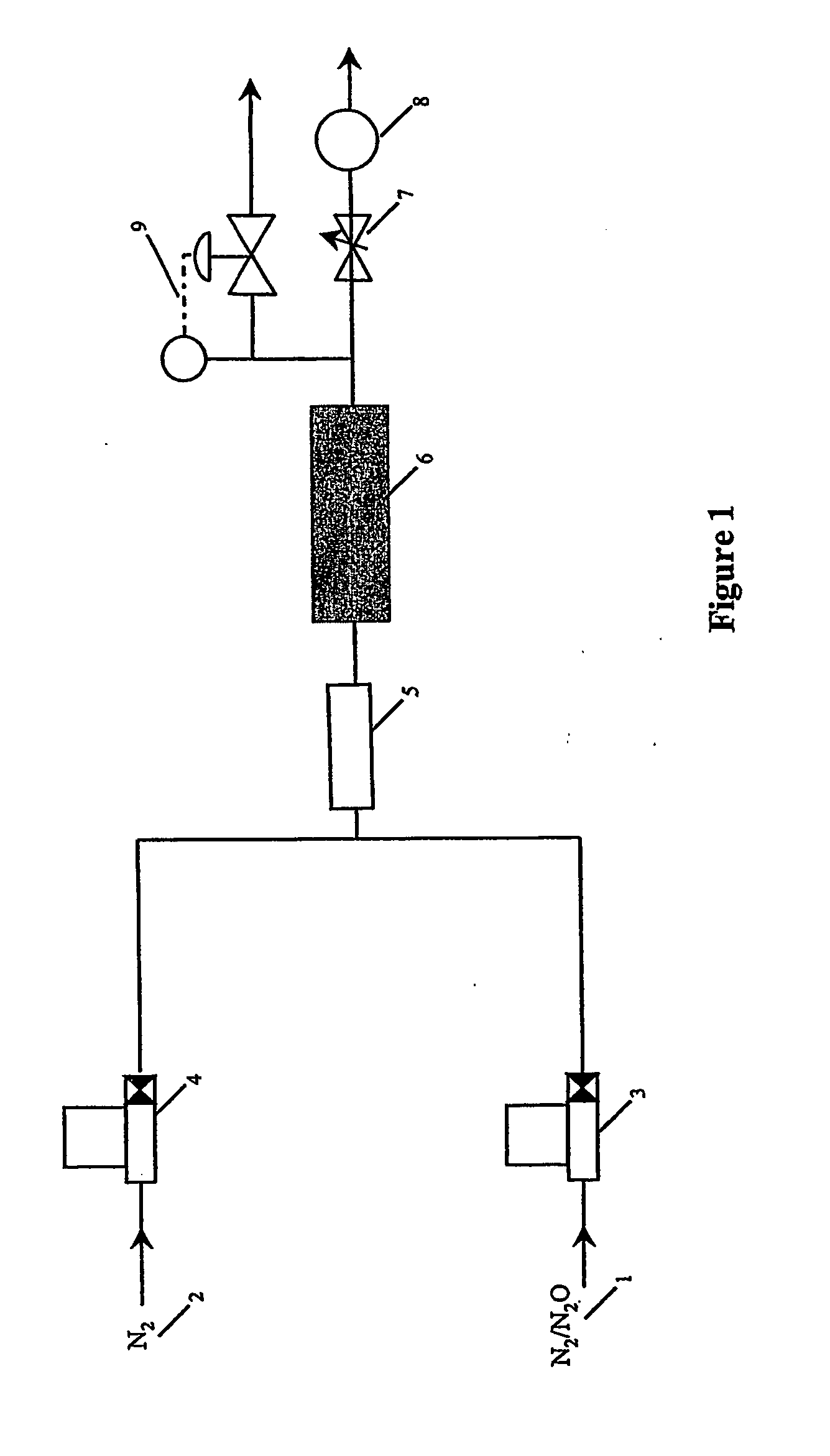

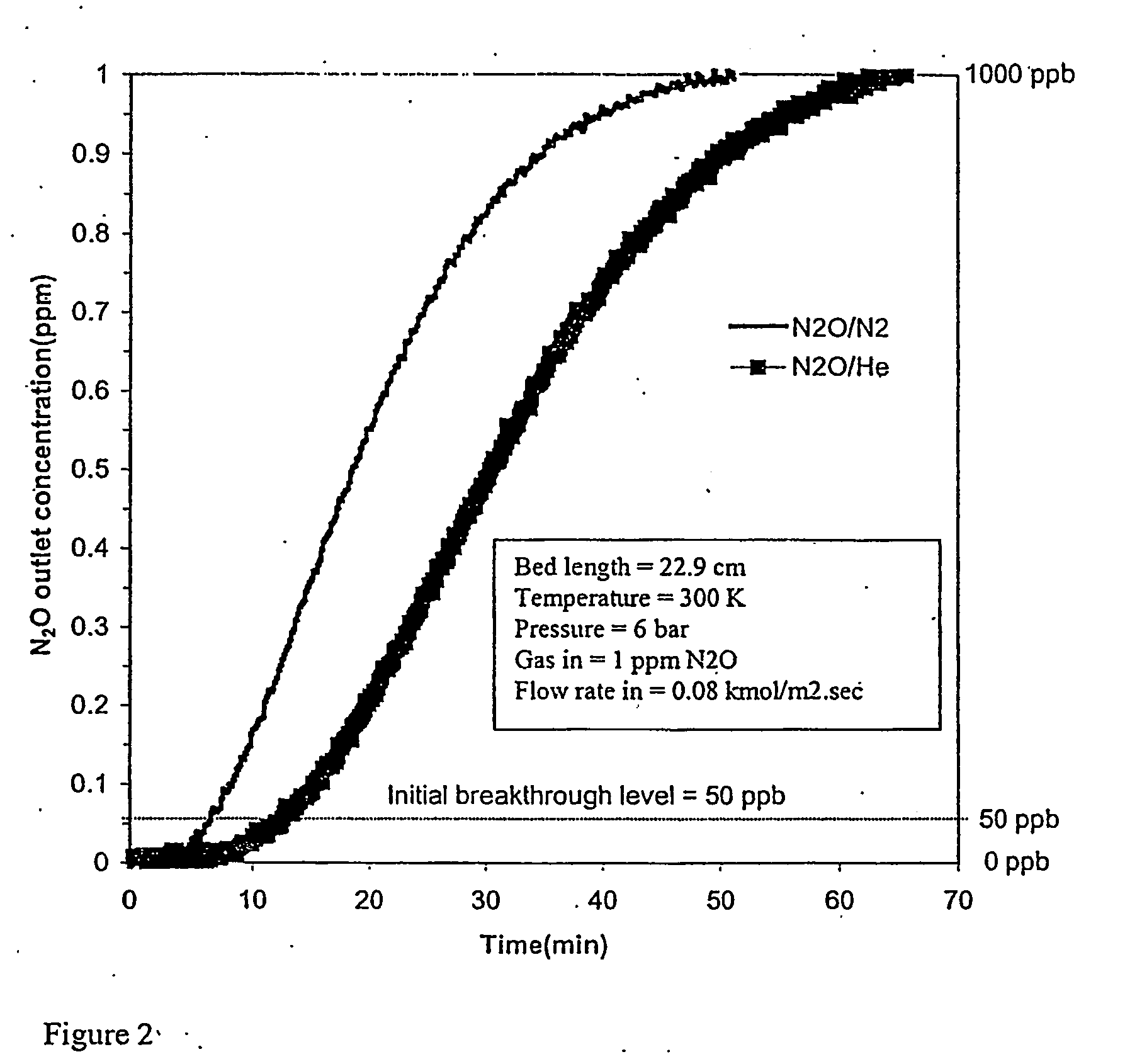

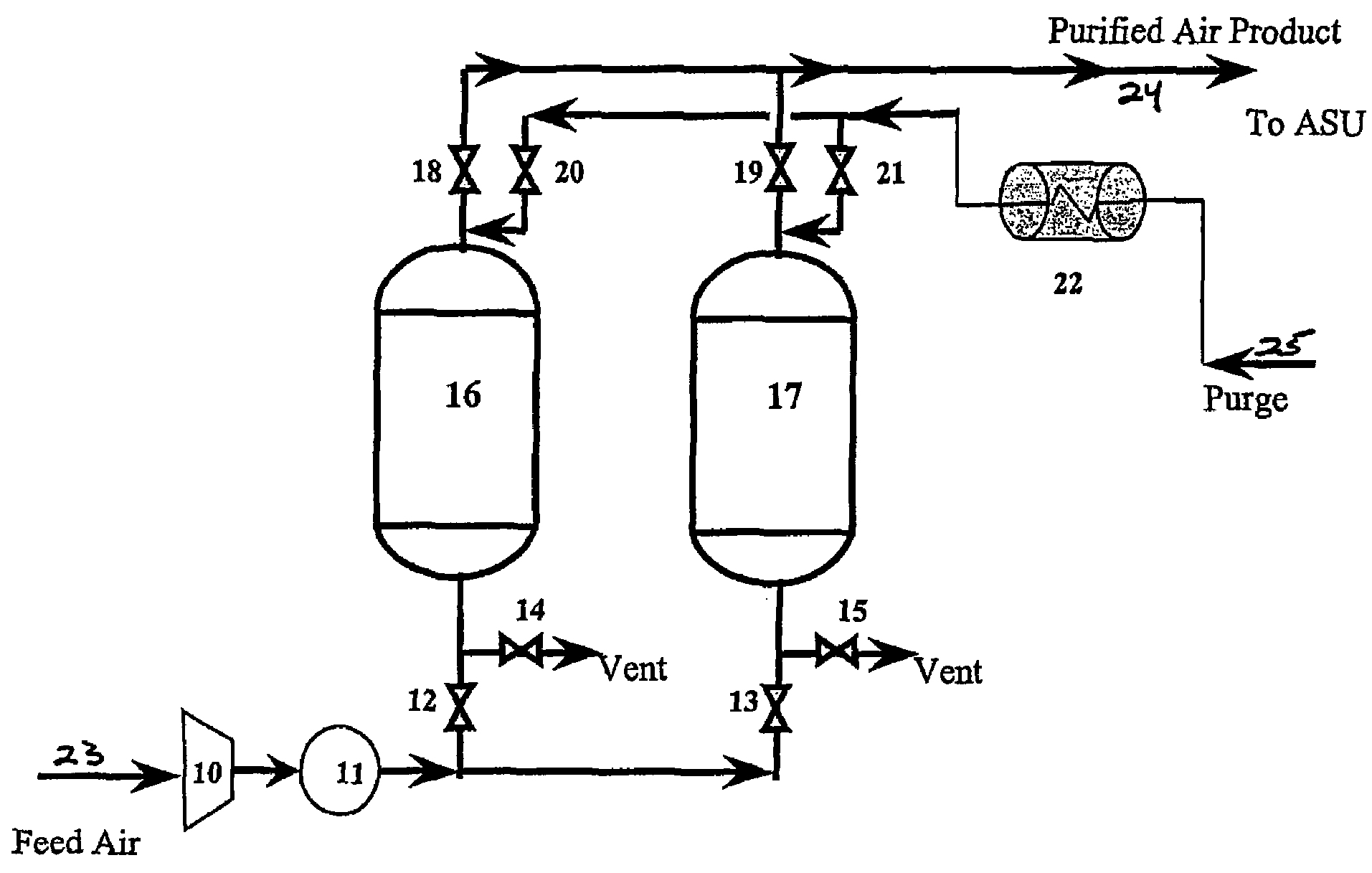

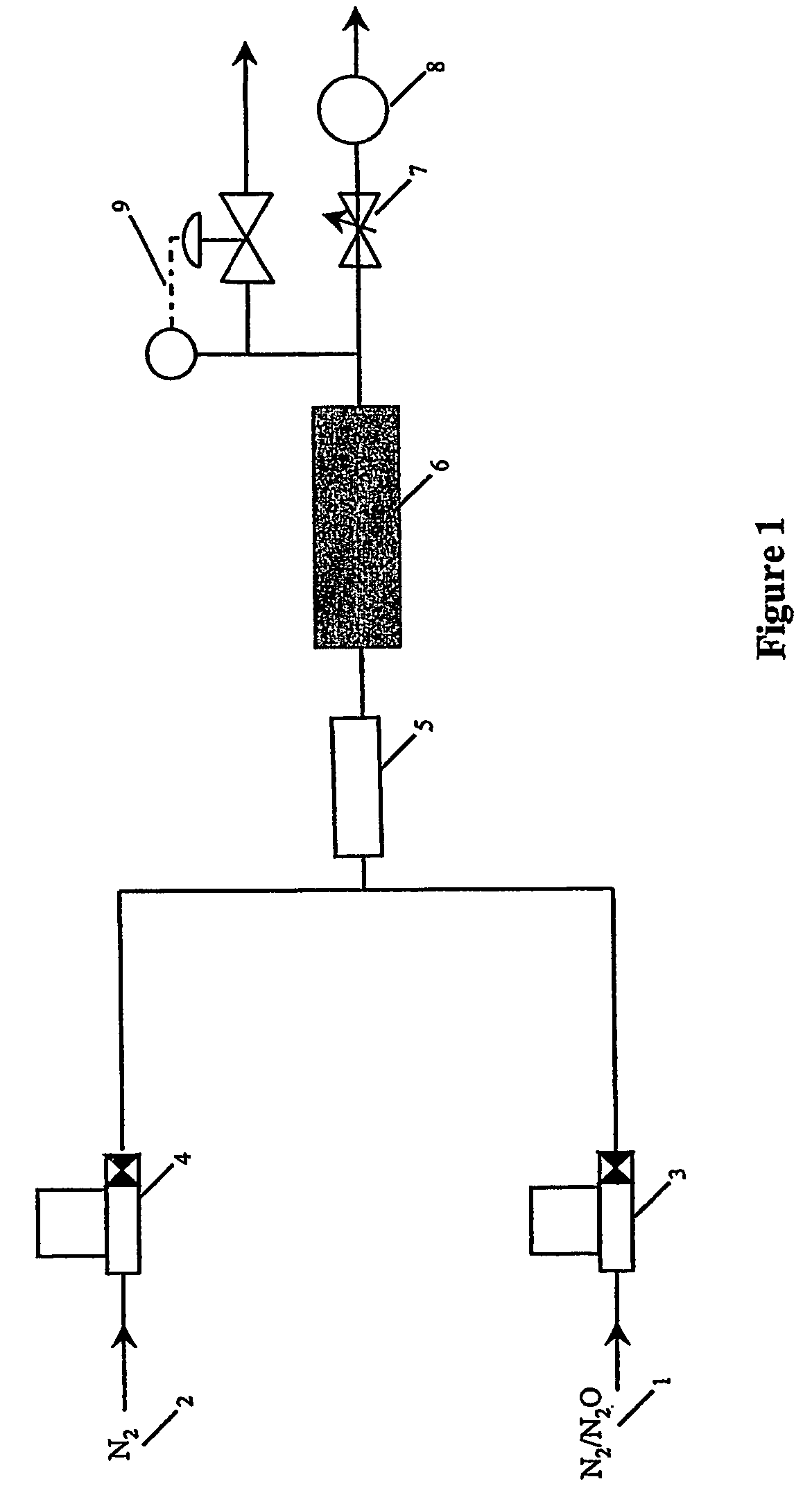

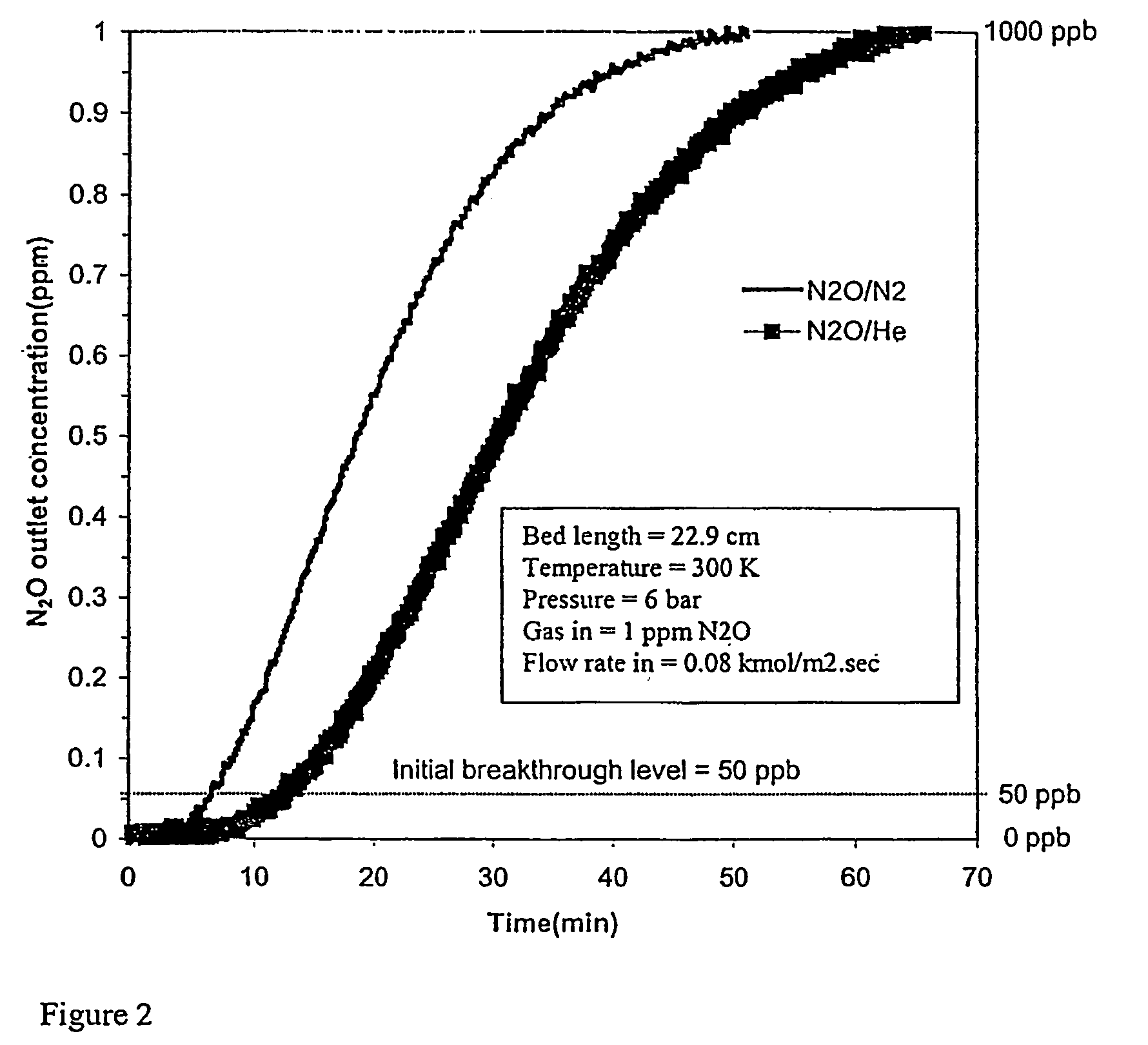

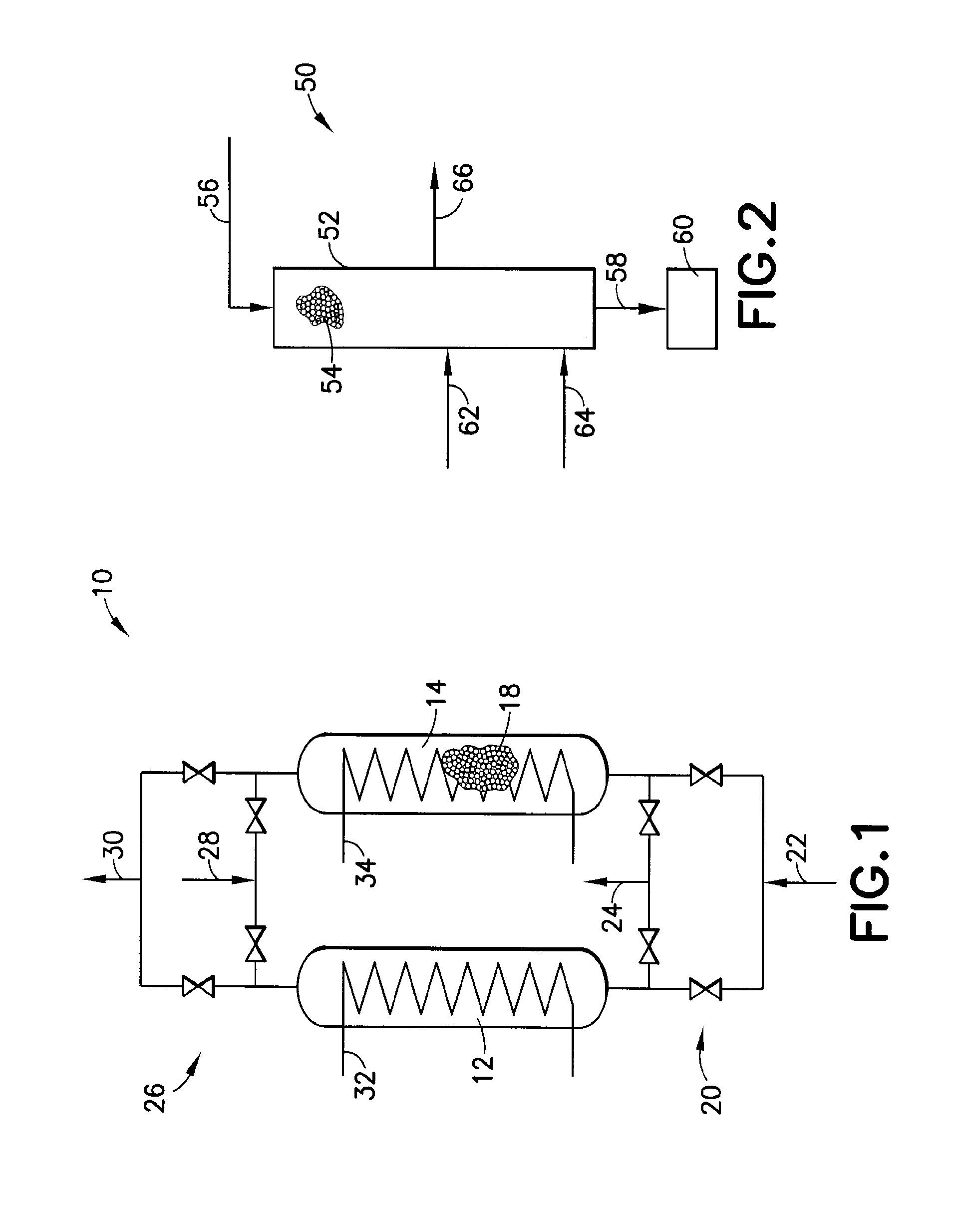

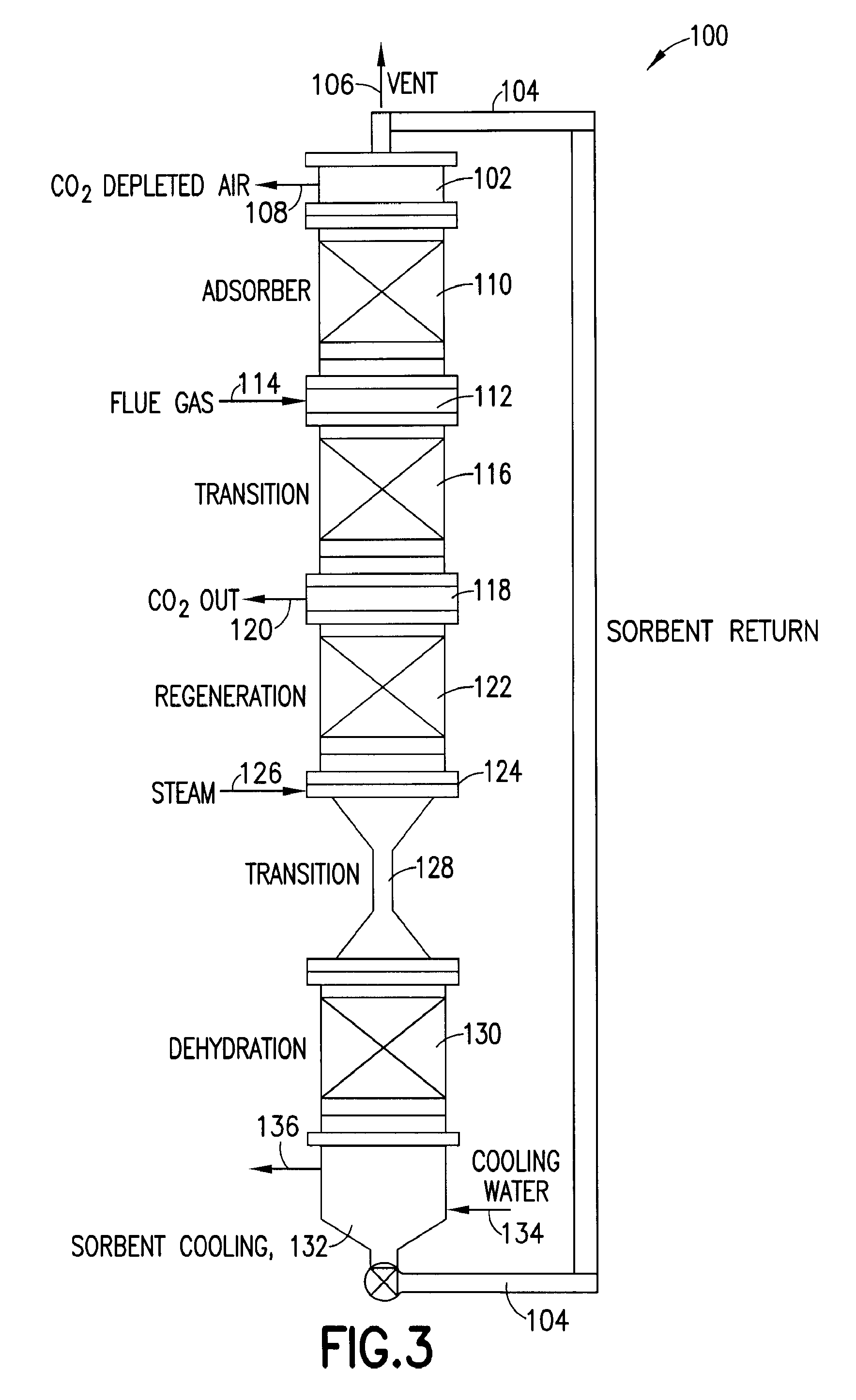

Method and apparatus for gas purification

InactiveUS20060162556A1Superior N2O removal efficiencyNitrous oxide captureGas treatmentSeparation factorSorbent

This invention comprises an adsorption process for the removal of at least N2O from a feed gas stream that also contains nitrogen and possibly CO2 and water. In the process the feed stream is passed over adsorbents to remove impurities such as CO2 and water, then over an additional adsorbent having a high N2O / N2 separation factor. In a preferred mode the invention is an air prepurification process for the removal of impurities from air prior to cryogenic separation of air. An apparatus for operating the process is also disclosed.

Owner:PRAXAIR TECH INC

Method and apparatus for gas purification

Owner:PRAXAIR TECH INC

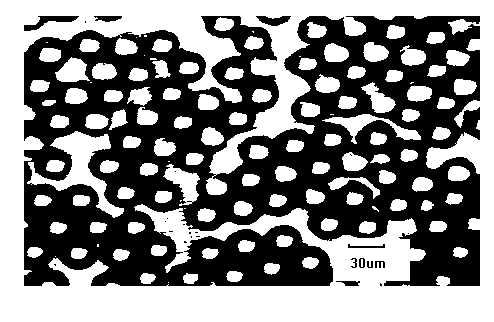

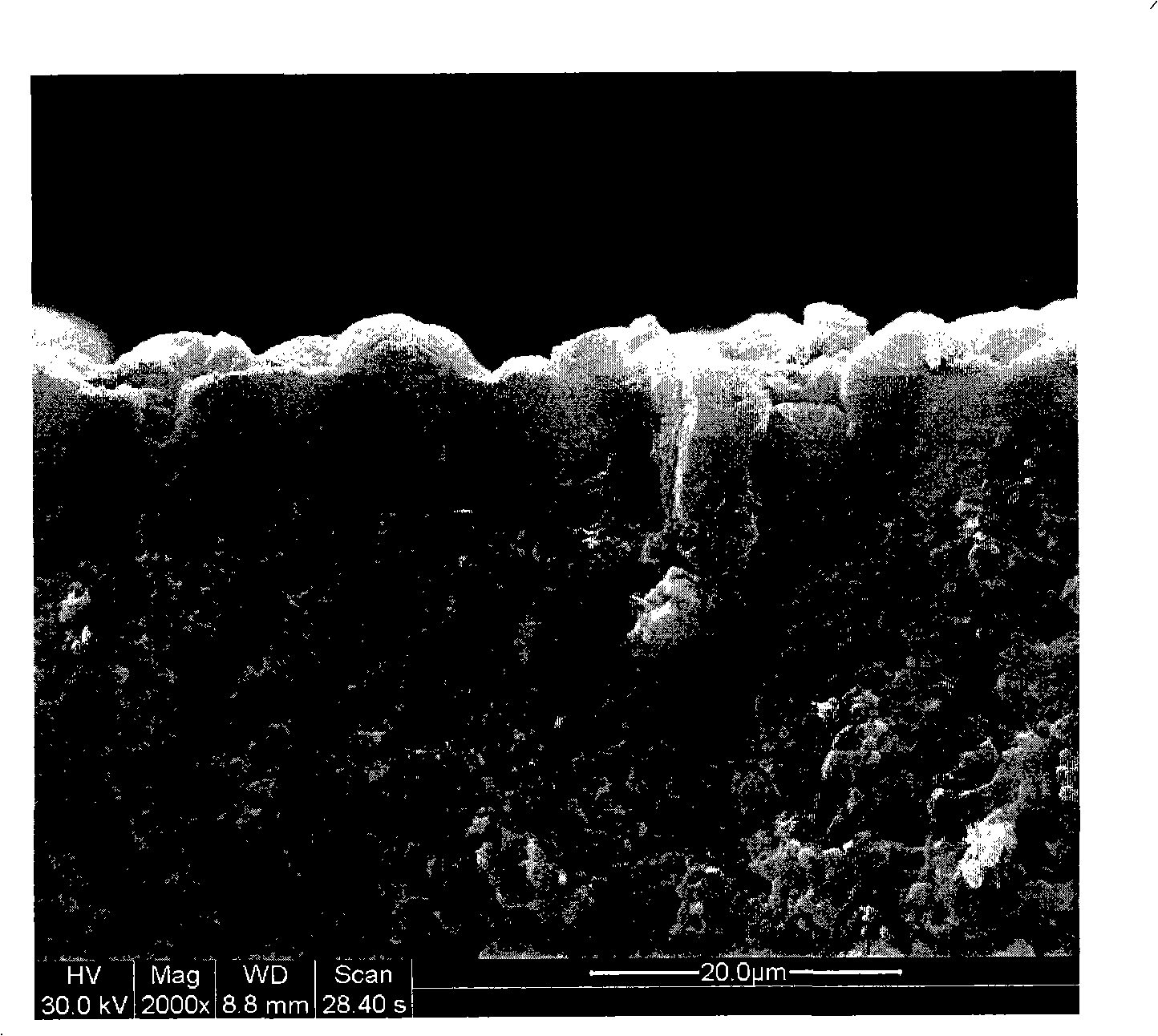

Priority dealcoholization PDMS/PVDF multi-layer compound film and preparation method thereof

InactiveCN101143305ASimple production processReduce manufacturing costSemi-permeable membranesCross-linkSeparation factor

The invention relates to an ethanol-permselective PDMS / PVDF multilayered composite membrane and the preparation method, which belongs to a pervaporation membrane separation field. The multilayered composite membrane is made based on the following processes: firstly, the PVDF porous basal membrane is prepared by a two-faced wiped film of kynoar polyvinylindene fluoride (PVDF) solution on the polyester non-woven fabric support layer using submersion and sedimentation transformation method; secondly, the membrane liquid, which contains dimethyl silicone polymer (PDMS), cross linking agent and catalyst, is prepared, and the PVDF porous basal membrane is immersed in the membrane liquid for 10s-1min. Each of two sides of the PVDF basal membrane are coated with a layer of silicone base by using immersion and painting method, and then the PVDF basal membrane is dried and cross linked, and so the multilayered composite membrane is made. The existing pure PDMS membrane has bad separability to ethanol aqueous solution, and the highest separation factor is 10.8 ([EtOH] equals to 8wt percent, 30 DGE C). The multilayered symmetrical composite membrane made of the invention has an excellent ethanol-permselective property to low concentration ethanol aqueous solution (5wt percent-30wt percent), and for the ethanol aqueous solution which has a concentration of 5wt percent, the separation factor ¿” value equals to 15, and the permeation flux J equals to 450g / m2h, under the temperature of 60 DGE C.

Owner:TSINGHUA UNIV

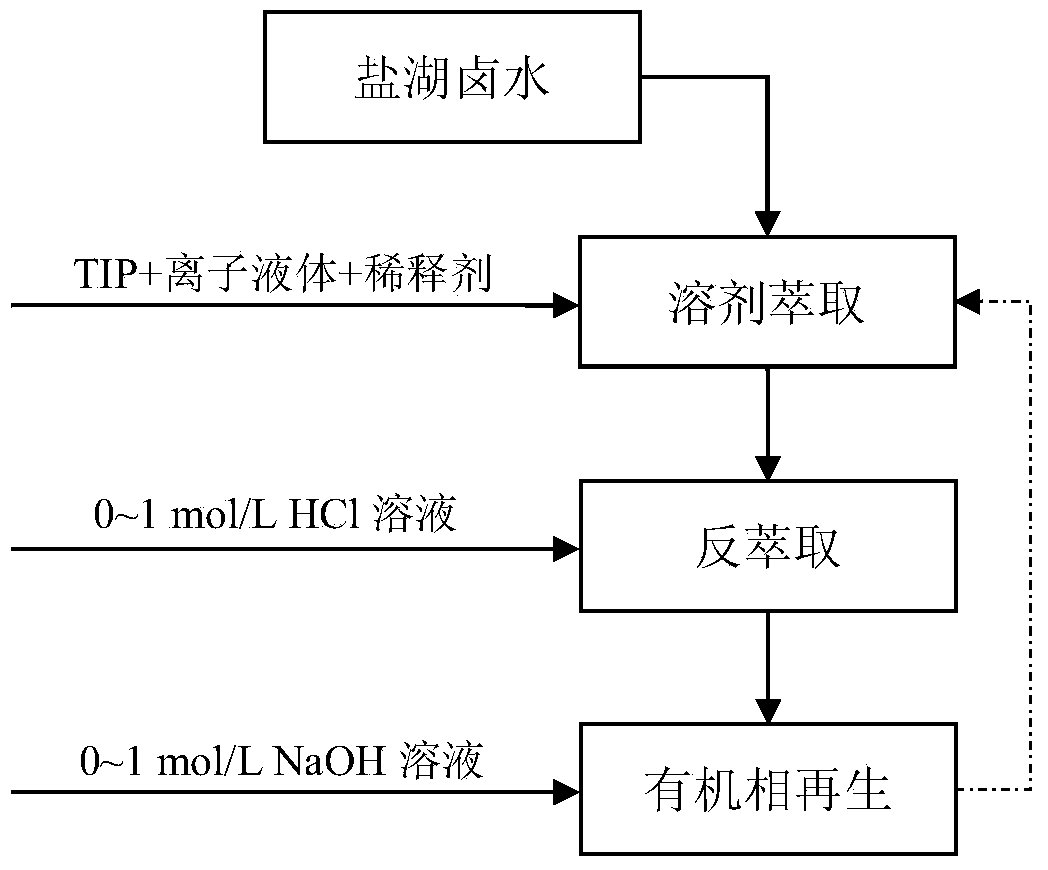

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

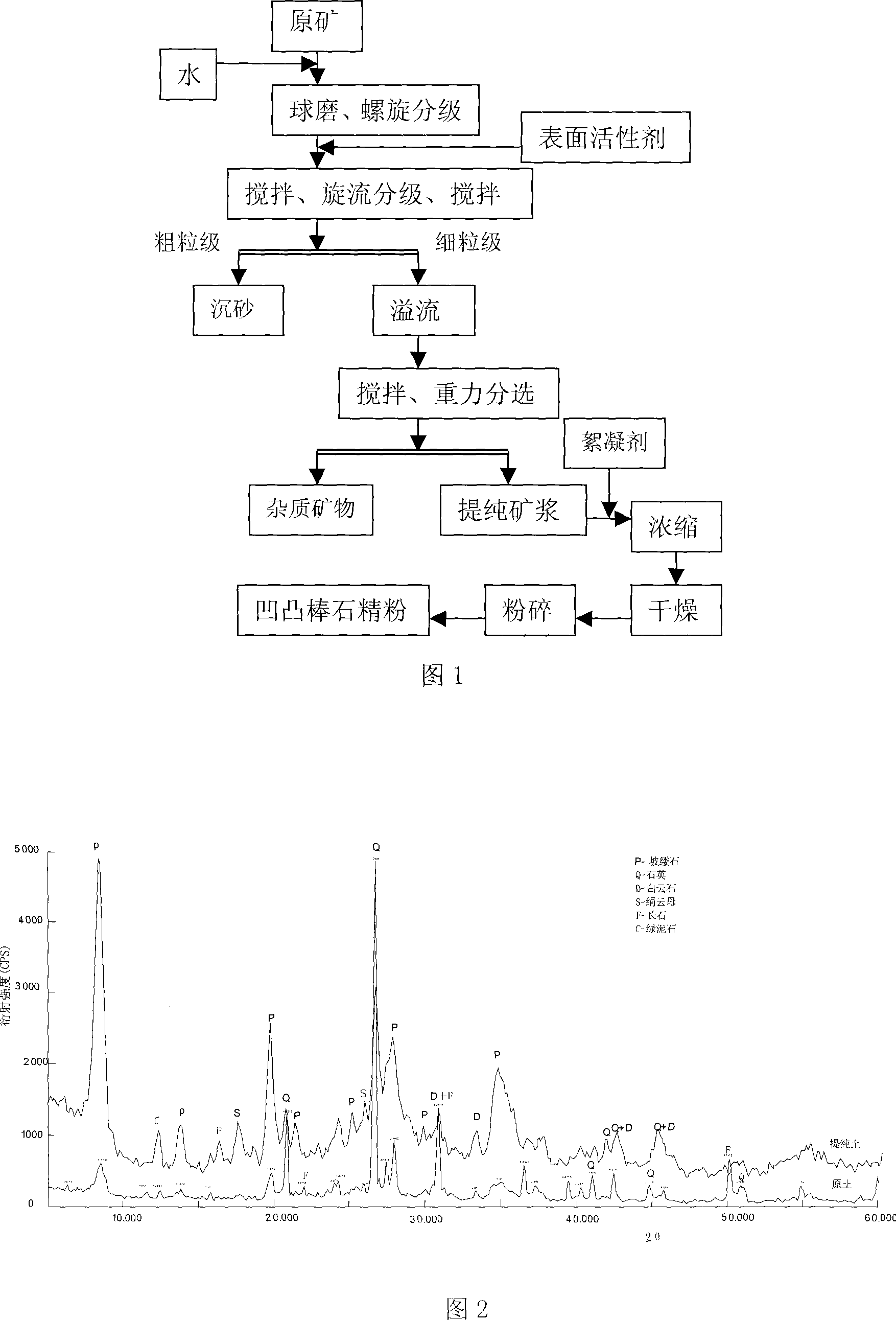

Method for purifying and processing attapulgite clay mineral

InactiveCN101214968AMeet the needs of industrial mineral processing and purificationEase of industrial productionEnergy inputSilicon compoundsSeparation factorClay minerals

The invention relates to a purifying and processing method of attapulgite clay minerals, which belongs to the technical field of the wet separating technique of minerals. The specific steps comprise utilizing spiral classifier for primary purification, utilizing cyclone classifier for secondary purification, employing gravity separation equipment for three-stage purification, concentration, drying and disintegration, thereby preparing ultrafine powders of the purified attapulgite clay minerals with the average particle size of 0.93-2.0 micron, and particle size of the largest particle is 3.5-5.0 micron. The method employs spiral classifier to remove the partly impure minerals with bigger particles in raw ores in advance, reinforcing the dispersion effect and the difference of suspension property of the attapulgites and impure minerals by means of surfactants, increasing separation factor, utilizing gravity separation equipment to separate the impure minerals and the attapulgite clay minerals efficiently, thereby overcoming the shortcomings that the prior art is difficult to achieve industrial production and obtain qualified purification products.

Owner:HEBEI UNIV OF TECH

Carbon pyrolyzate adsorbent having utility for co2 capture and methods of making and using the same

A particulate form carbon pyrolyzate adsorbent, having the following characteristics: (a) CO2 capacity greater than 105 cc / gram at one bar pressure and temperature of 273° Kelvin; (b) CO2 Working Capacity greater than 7.0 weight percent; (c) CO2 heats of adsorption and desorption each of which is in a range of from 10 to 50 kJ / mole; and (d) a CO2 / N2 Henry's Law Separation Factor greater than 5. The carbon pyrolyzate material can be formed from a polyvinylidene chloride-based polymer or copolymer, or other suitable resin material, to provide an adsorbent that is useful for carbon dioxide capture applications, e.g., in treatment of flue gases from coal-fired power generation plants.

Owner:ENTEGRIS INC

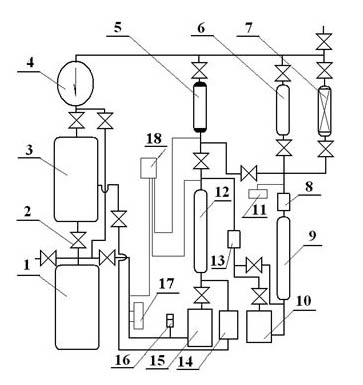

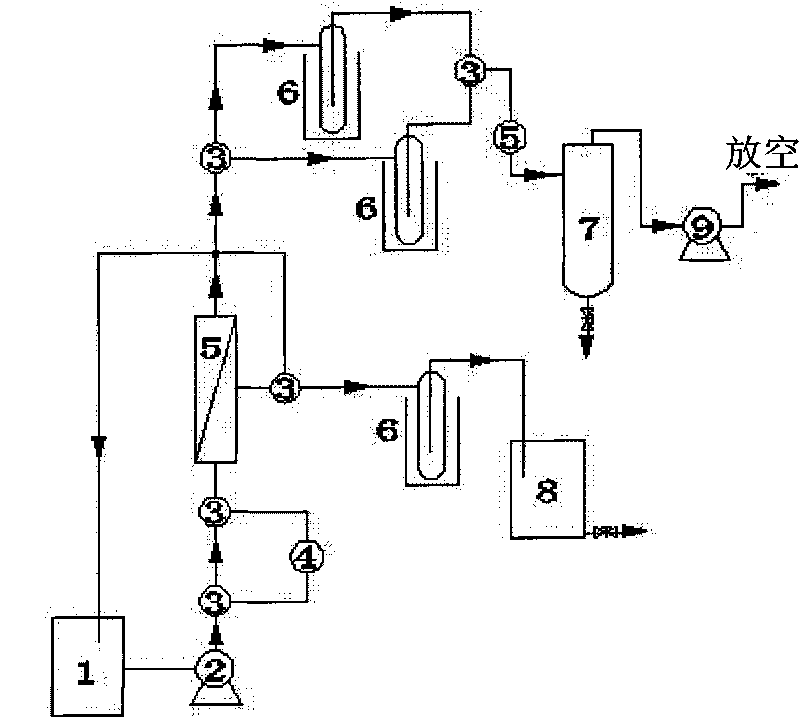

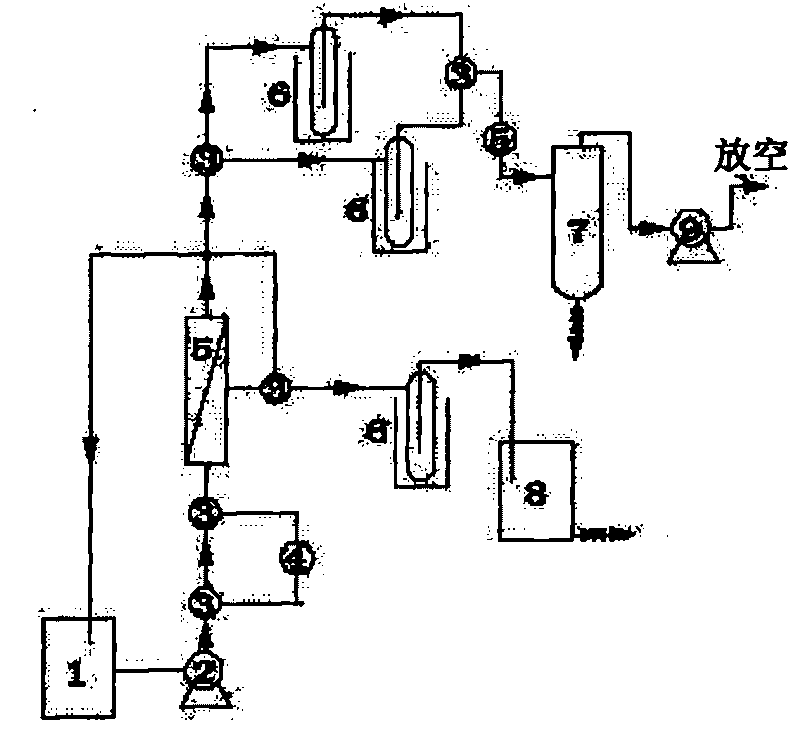

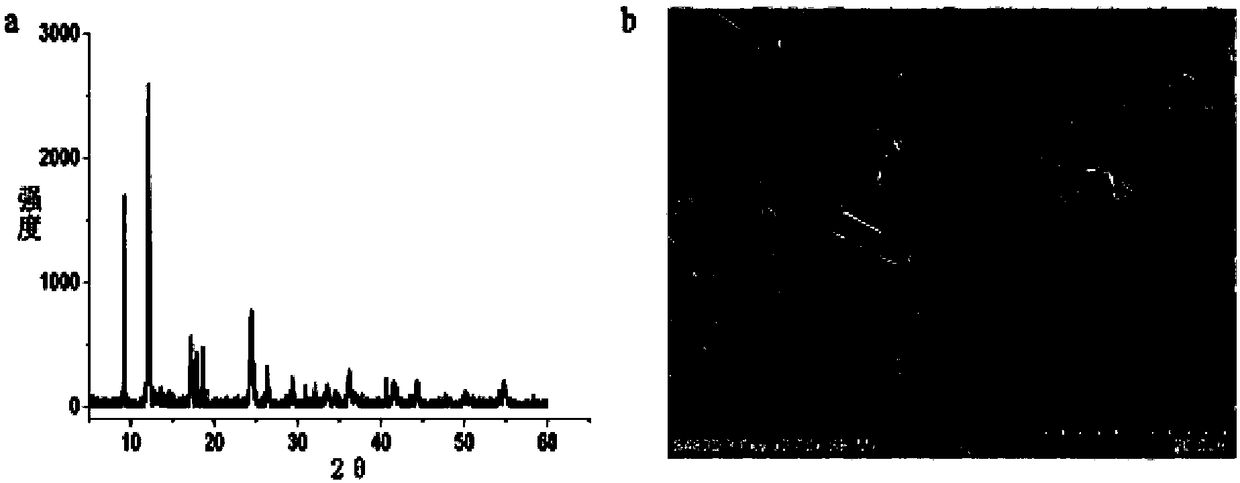

Low-temperature displacement chromatography hydrogen isotope separation device and method

ActiveCN101850215AAchieving Self-Displacement ChromatographyOvercome the disadvantage of low separation coefficientCation exchanger materialsOrganic anion exchangersSeparation factorGas release

The invention provides a low-temperature displacement chromatography hydrogen isotope separation device and a method. The invention makes the mixed gas of hydrogen isotope gas and helium after being cooled sequentially pass through a cooled main separation column and a cooled product gas collecting column which are filled with granulate palladium-loaded aluminum trioxide (Al2O3 / Pd) to obtain the product gas rich in heavy isotope components of deuterium and tritium; a hot helium flow passes through and heats the main separation column so as to make the released gas sequentially pass through the cooled secondary separation column and the product gas collecting column which are filled with granulate palladium-loaded aluminum trioxide (Al2O3 / Pd) to obtain the product gas rich in heavy isotopecomponents of deuterium and tritium; after the product gas is collected, middle rich gas flowing out from the secondary separation column is directly fed back into a raw material gas tank; and after the middle rich gas feedback process is accomplished, the main separation column and the secondary separation column are heated, and the gas released by heating is collected via a tail gas collecting column. The separation device has simple structure, reasonable separation process, and low cost for the construction and operation of the device. The invention has higher separation factor for hydrogen isotope separation.

Owner:SICHUAN INST OF MATERIALS & TECH

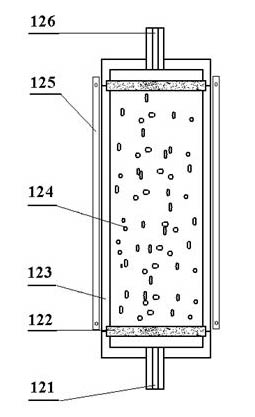

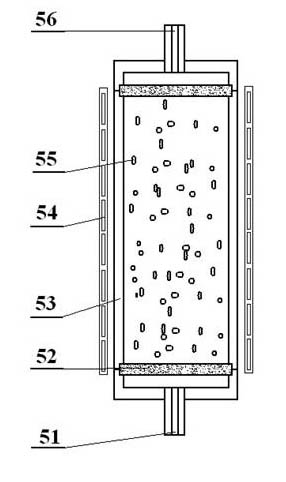

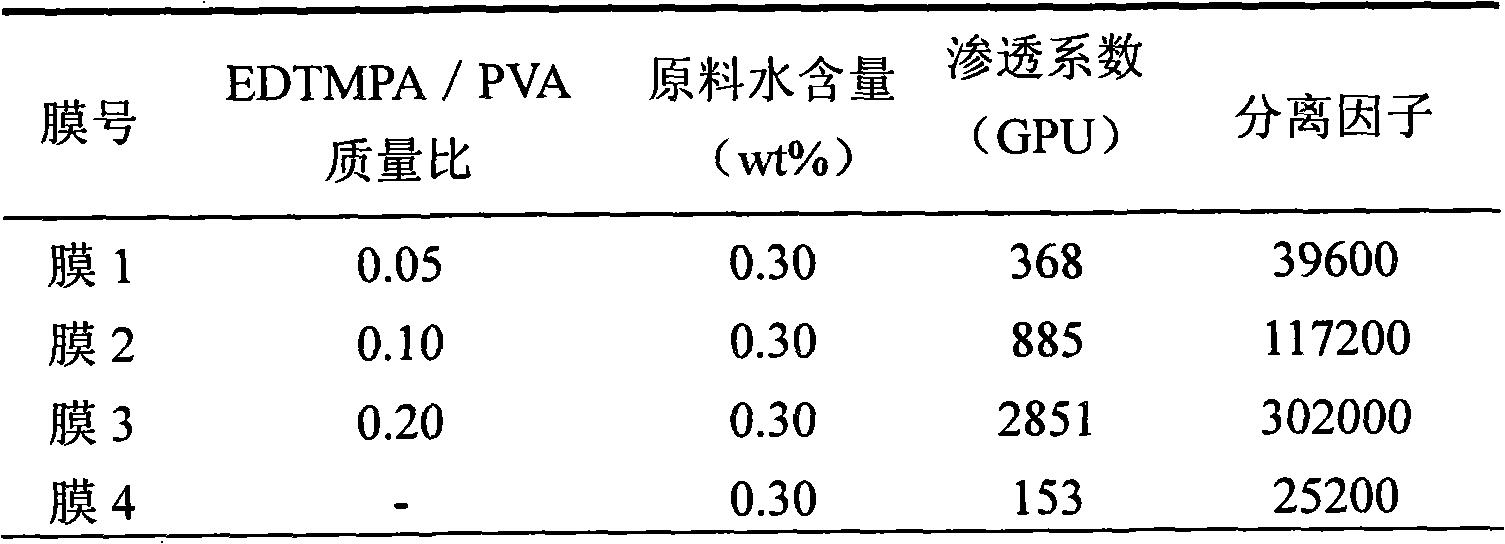

Hollow fiber compound film, preparation and application

InactiveCN101259381AEasy to makeImprove controllabilitySemi-permeable membranesSeparation factorFiber

The invention relates to a preparation method and application of a hollow fibre compound membrane; PVA, EDTMPA and PS are taken as raw materials; the mass ratio of the EDTMPA to the PVA is 1 to 50 : 50 to 99; a PS hollow fibre is used as a supporting layer; the preparation method includes that: the PVA is dissolved into water to be prepared into a solution with a mass concentration of 4 to 7 percent; the EDTMPA is added into the PVA water solution, the mixture is subject to stirring and filtering for impurity removal so as to obtain a casting solution which stands for defoaming, then the PS hollow fibre supporting layer is dipped into the foam-free casting solution and is dried. The invention has simple preparation, strong controllability, high separating property, abundant raw materials and low price; when the invention is used for removing the water in propylene, the permeability coefficient can reach 2851GPU and the separation factor is 302000.

Owner:TIANJIN UNIV

Composite fiber membrane with chiral molecular imprint and its prepn and application

InactiveCN1772356ADiverse identificationHigh selectivitySemi-permeable membranesFiberSeparation factor

The present invention discloses composite fiber membrane with chiral molecular imprint and its preparation process and application. The composite fiber membrane with chiral molecular imprint has excellent identifying selectivity. For example, the composite fiber membrane with L-DBTA as template molecule has high identifying selectivity on L-DBTA only, low identifying selectivity on other compounds and separation factor on racemic L, D-DBTA solution up to 2.7. Altering the temperature molecules can obtain different composite fiber membrane for separating several kinds of racemic compounds.

Owner:EAST CHINA UNIV OF SCI & TECH

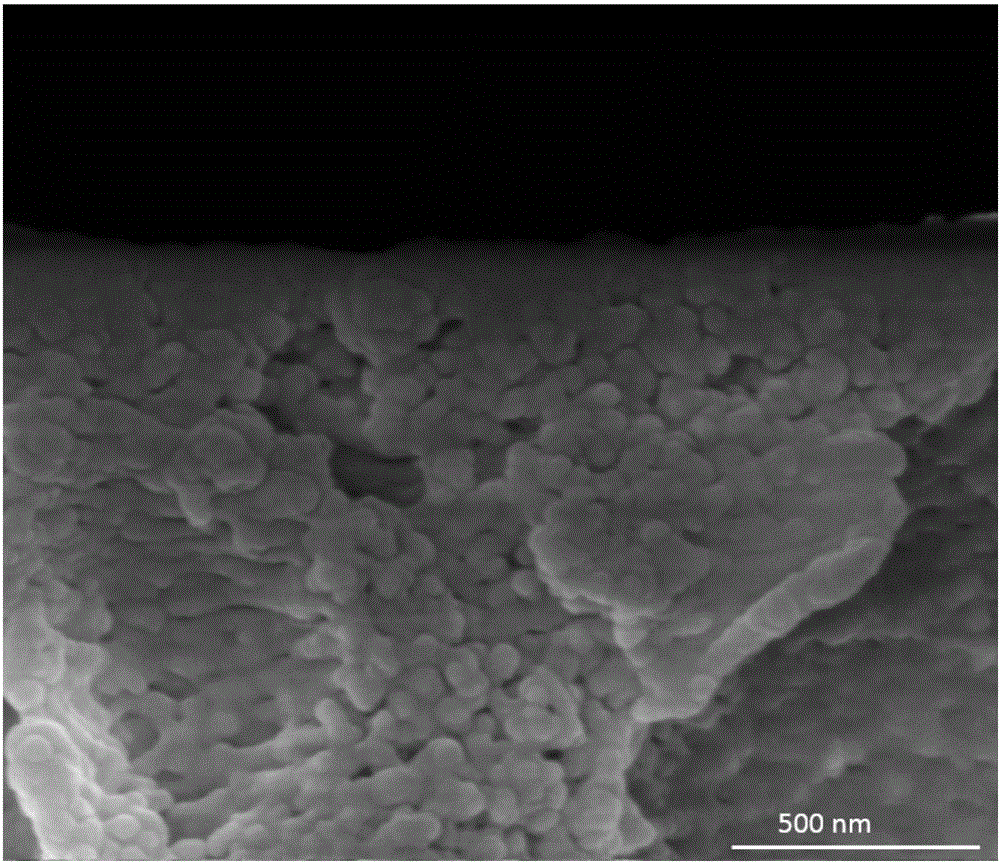

A preparation method of hydrophobic nano-mesoporous molecular sieve filled PDMS composite membrane

ActiveCN102294182AGuaranteed uptimeHigh separation selectivitySemi-permeable membranesSeparation factorMolecular sieve

The invention discloses a preparation method of a hydrophobic nano mesoporous molecular sieve filling PDMC composite film, comprising the following steps: using a casting solution containing polydimethylsiloxane (PDMS), hydrophobic mesoporous molecular sieve, cross-linking agent, catalyst, and solvent to wipe film on the upper layer of a porous ultrafiltration membrane supported by polyester non-woven, and heating until crosslinking completely to obtain the composite film. The obtained mesoporous molecular sieve modified by surface silane coupling agent is combined with the PDMS substrate tightly, and is dispersed uniformly in the PDMS substrate. The preparation method has the advantages of simple process and cheap selected materials. The composite film has strong swelling resistance in dimethyl carbonate(DMC) / methanol azeotrope, and excellent DMC permselective property. When the filling weight ratio of the mesoporous molecular sieve is 30 %, the separation factor alfa is 4.07, the penetration flux J is 1.13 kg / m<2>h([DMC]=30 wt%, 40 DEG C).

Owner:TSINGHUA UNIV

High-flux molecular-sieve alcohol permselective membrane and preparation method thereof

ActiveCN101920170AGood effectReduce mass transfer resistanceSemi-permeable membranesPorositySeparation factor

The invention relates to a high-flux molecular-sieve alcohol permselective membrane and a preparation method thereof. The high-flux molecular-sieve alcohol permselective membrane is composed of a support body and a membrane layer, wherein the support body is yttrium-stabilized zirconia porous material, the membrane layer is a Silicalite-1 molecular sieve membrane, the average pore size of the support body is 0.1-5 mu m, and the porosity is 10-75%. The invention also discloses a preparation method of the hollow fiber alcohol permselective membrane. The alcohol permselective membrane has outstanding separating property. When the alcohol permselective membrane is used in an ethanol / water system, the permeation flux is enhanced by 3-20 times. The alcohol permselective membrane has higher separation factor and favorable repetitiveness, and especially has favorable effect since the alcohol permselective membrane is composed of the hollow fiber support body. The alcohol permselective membrane is used in the fields of permeating vaporization, gas separation and the like, and has important meaning in the industrial application of alcohol fermentation liquor concentration.

Owner:NANJING UNIV OF TECH

Preparation of osmotic vaporizing alcohol permselective zeolite filling silicon rubber compound film

ActiveCN101264429ASimple production processReduce manufacturing costSemi-permeable membranesSeparation factorCross-link

The invention relates to a pervaporation alcohol permselective zeolite filled silicone rubber composite membrane, belonging to pervaporation membrane separation technological field, which is characterized in that a polyester non-woven fabric support layer is film-wiped by polyvinylidene fluoride (PVDF) solution; a PVDF porous basement membrane is obtained by using an immerse precipitation transformation method; after the MFI type zeolite is processed by hydrofluoric acid, a membrane solution containing the MFI type zeolite, dimethyl silicone polymer(PDMS), a cross-linking agent and a catalyst is prepared; the PVDF porous basement membrane is film-wiped and air-dried in ambient temperature to cross-link completely. The separation performance of prior non-zeolite filled PDMS membrane to ethanol water solution is bad, and the separation factor and permeation flux are low. The pervaporation alcohol permselective zeolite filled silicone rubber composite membrane processed in acid has the advantages of good performance; the ethanol water solution concentration is 5 wt%, the separation factor Alpha in 50 DEG C is 16.3, and the permeation flux is J=132.7g / m2h.

Owner:北京清源洁华膜技术有限公司

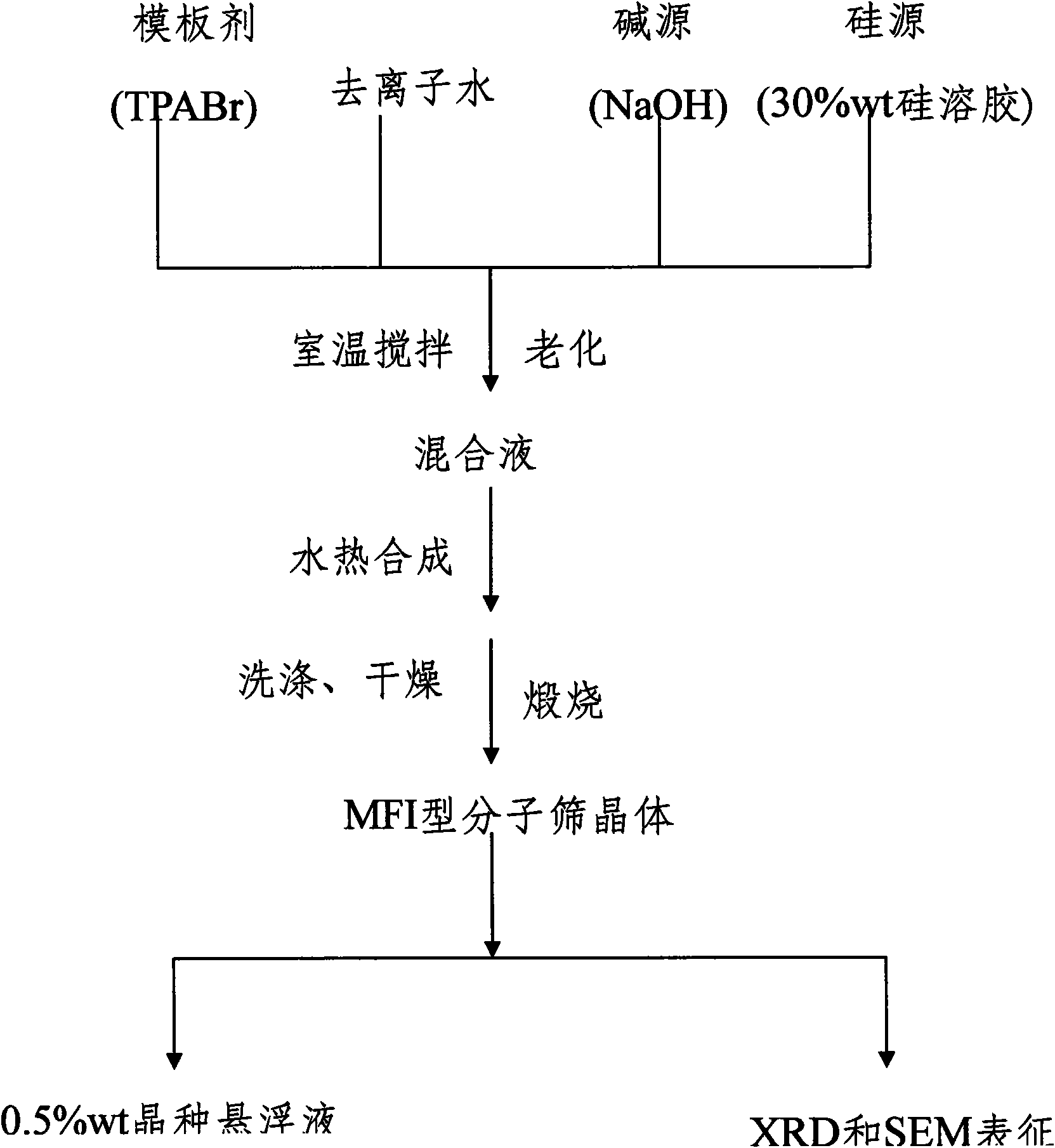

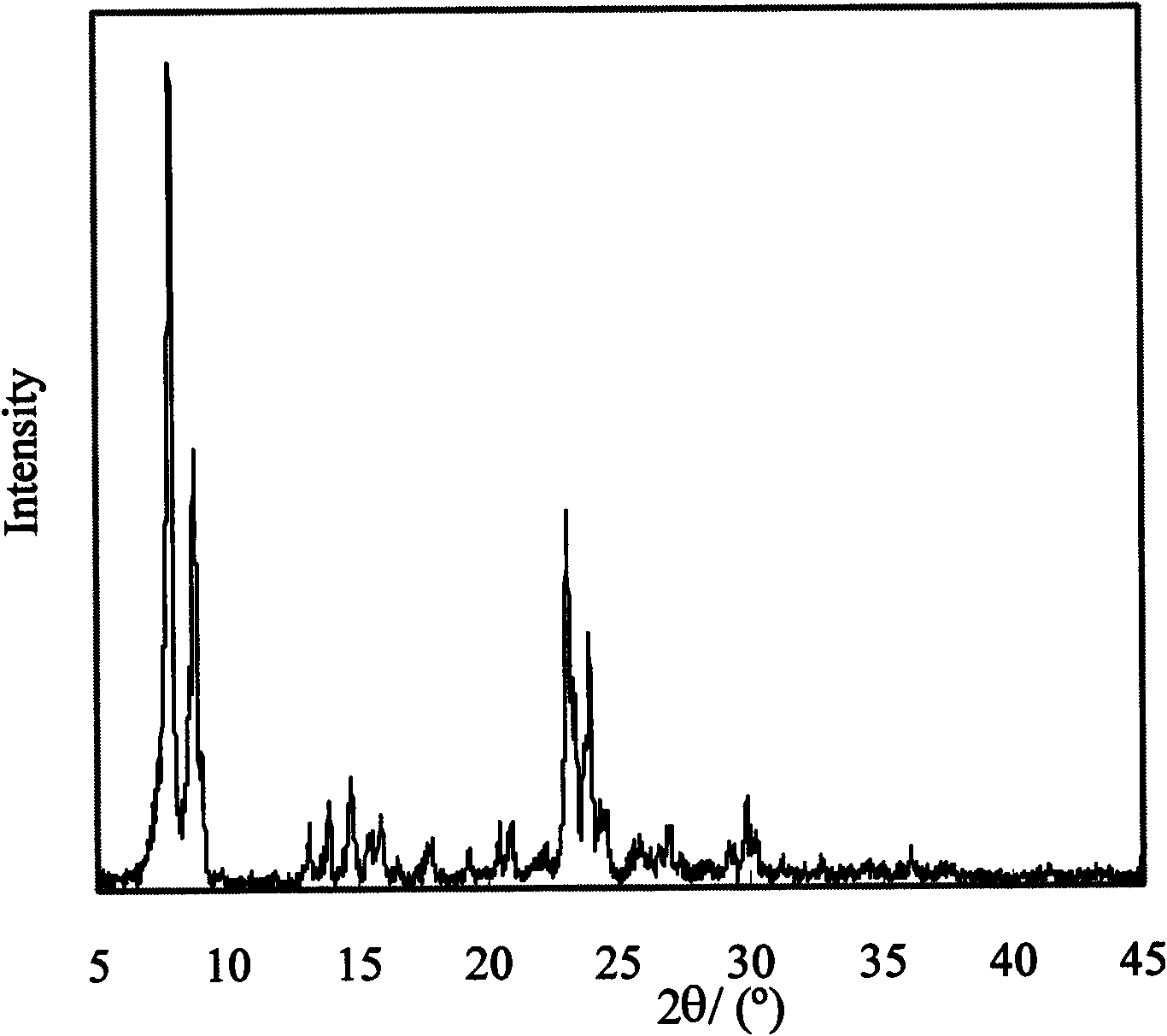

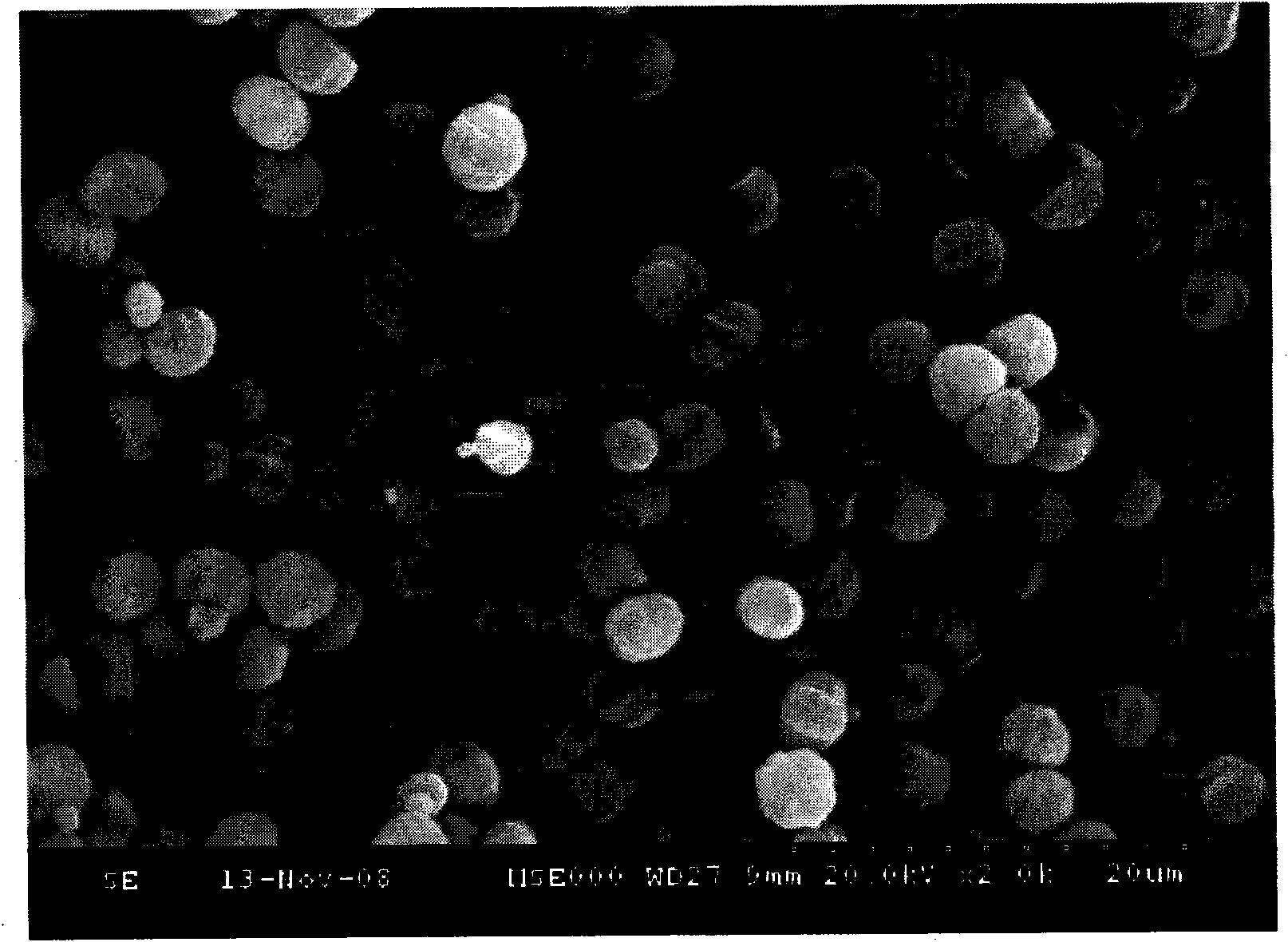

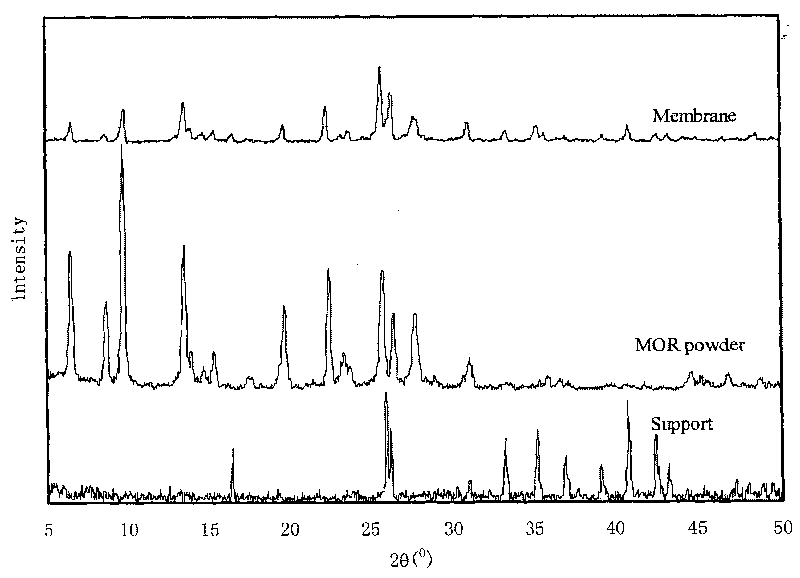

Method for preparing high-performance Silicalite-1 molecular sieve membrane by using TPABr as template agent

ActiveCN101648712AImprove permeabilityHigh selectivityMolecular-sieve and base-exchange compoundsSeparation factorMolecular sieve

The invention discloses a method for preparing a high-performance Silicalite-1 molecular sieve membrane, which comprises the following steps: using cheap TPABr and silica sol as raw materials for preparing a high-activity Silicalite-1 molecular sieve crystal; using the crystal as a seed crystal to be loaded on the outer surface of a supporting body, and carrying out the high-temperature hydrothermal crystallization in the diluted synthetic liquid using TPABr as the template agent to obtain the high-performance Silicalite-1 molecular sieve membrane. The invention is characterized by adopting asecondary growth hydrothermal method and carrying out the high-temperature (180-210 DEG C) hydrothermal one-step synthesis of the diluted synthetic liquid using TPABr as the template agent (300-750 ofH2O / SiO2, 0.1-0.5 of TPABr / SiO2, and 0.1-0.5 of NaOH / SiO2) on the surface of a porous tubular mullite carrier to form the high-performance Silicalite-1 molecular sieve membrane. The method not only effectively uses the cheap TPABr to replace TPAOH to prepare the molecular sieve membrane, but also greatly reduces the demand quantity of the silicon source and the template agent in the membrane synthetic liquid, thereby greatly reducing the membrane preparing cost. By applying the prepared Silicalite-1 molecular sieve membrane to a pervaporation test in a 60 DEG C ethanol / water (5 / 95 wt %) mixedsystem, the permeation flux and the separation factor can reach 1.71kg / m<2>.h and 66 respectively. The invention obviously improves the permeation flux and the selectivity of the Silicalite-1 molecular sieve membrane, reduces the production cost and is suitable for industrial production.

Owner:JIANGXI NORMAL UNIV

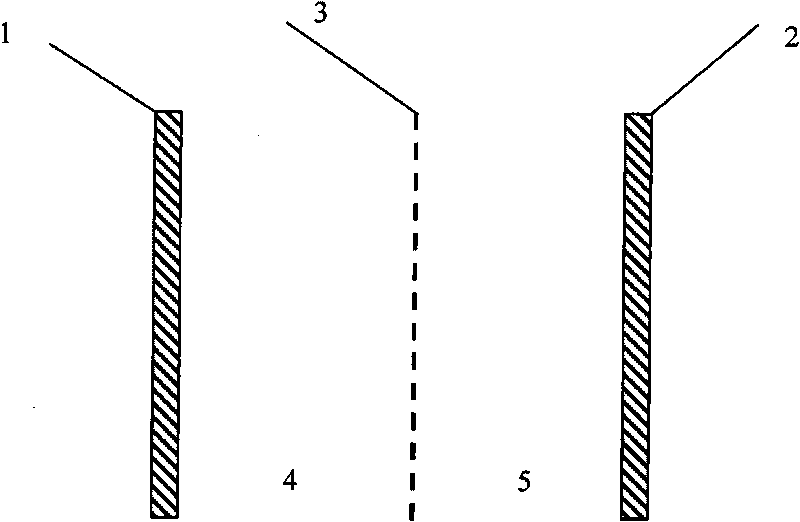

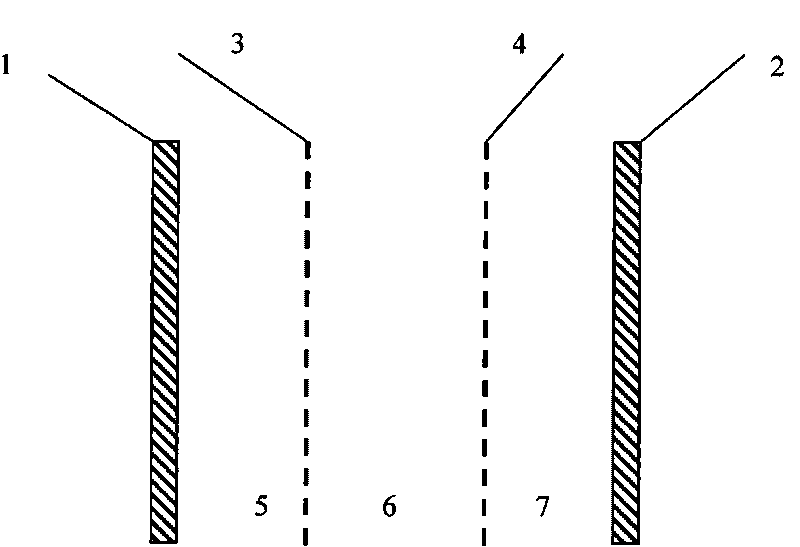

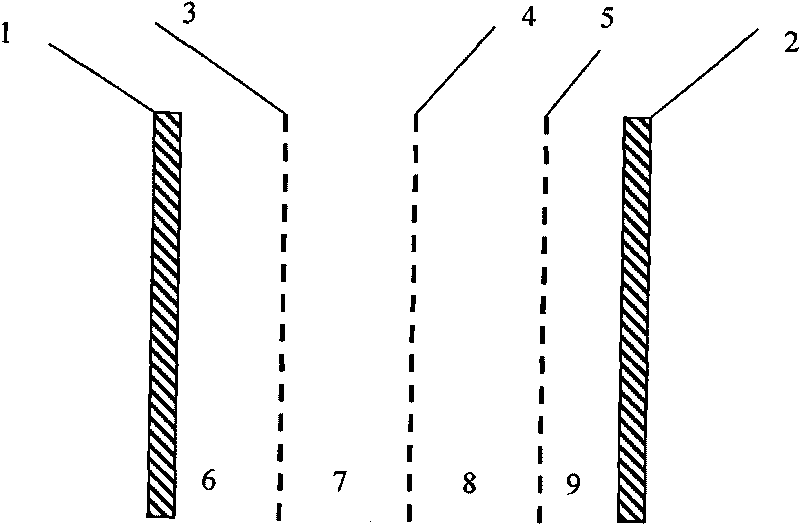

Method and device for separating electric field-separation membrane coupling

InactiveCN101716465AReduced activityReduce riskSemi-permeable membranesDispersed particle separationSeparation factorScreening effect

The invention discloses a method and a device for separating electric field-separation membrane coupling, which are characterized in that: separation membranes with different natures are parallelly arranged, and the outmost sides are provided with electrodes so as to form a plurality of layers of runners formed between the separation membranes and between the separation membranes and the electrodes; and fluid to be separated flows through the runners in a staggered way, and a DC electric field is applied in the direction vertical to the runners, so that electriferous molecules or microparticles generate deviation or dialytic electrophoretic behavior under the condition of the electric field, and an aperture screening effect of the separation membranes is combined so as to realize the process of quick and high-efficiency separation. The process can be performed only under the driving of the electric field, and also can be performed under the driving of the electric field and pressure. Compared with the conventional membrane process and electrophoresis process, the method and the device can greatly improve concentration and separation efficiency, improve separation factors, realize the separation which cannot be realized by the conventional membrane process, obviously reduce membrane fouling and improve the service life of the membranes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Three-layer composite membrane of sodium alginate, polydopamine-polyethyleneimine and polyacrylonitrile, and preparation and application of three-layer composite membrane

InactiveCN104785121AEnhance the interface forceIncrease forceDistillationSeparation factorUltrafiltration

The invention discloses a three-layer composite membrane of sodium alginate, polydopamine-polyethyleneimine and polyacrylonitrile. A polyacrylonitrile ultrafiltration membrane is used as a supporting layer, the polydopamine-polyethyleneimine is used as a middle layer, and the sodium alginate is used as a separation layer. The three-layer composite membrane is prepared from the following steps: prewetting the polyacrylonitrile ultrafiltration membrane by ethyl alcohol, fixing the prewetted polyacrylonitrile ultrafiltration membrane to a container, and then preparing a tris(hydroxymethyl)methyl aminomethane solution containing dopamine and polyethyleneimine; pouring the solution into the container, enabling the dopamine and the polyethyleneimine to react on the surface of a basement membrane so as to obtain a double-layer membrane of polydopamine-polyethyleneimine and polyacrylonitrile; coating a sodium alginate solution on the double-layer membrane of polydopamine-polyethyleneimine and polyacrylonitrile so as to obtain the three-layer composite membrane. The preparation process is simple, raw materials are easy to access, and conditions are moderate, the prepared three-layer composite membrane of sodium alginate, polydopamine-polyethyleneimine and polyacrylonitrile is used for separating ethyl alcohol from water, and has higher permeation flux and more separation factors.

Owner:TIANJIN UNIV

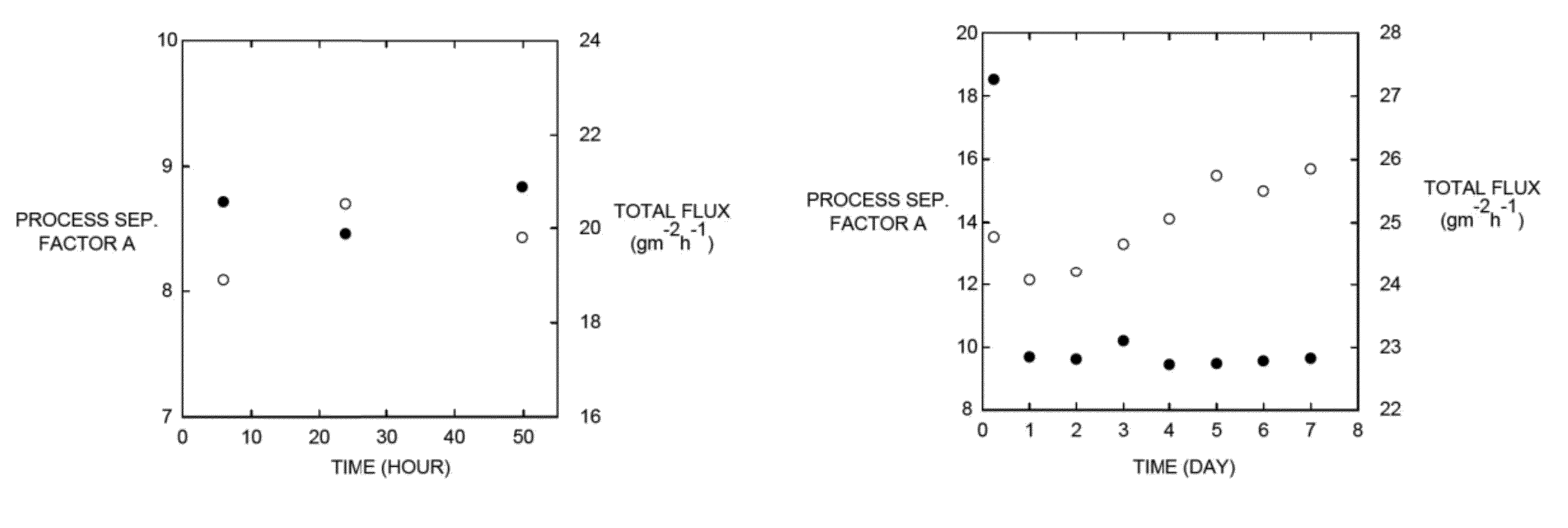

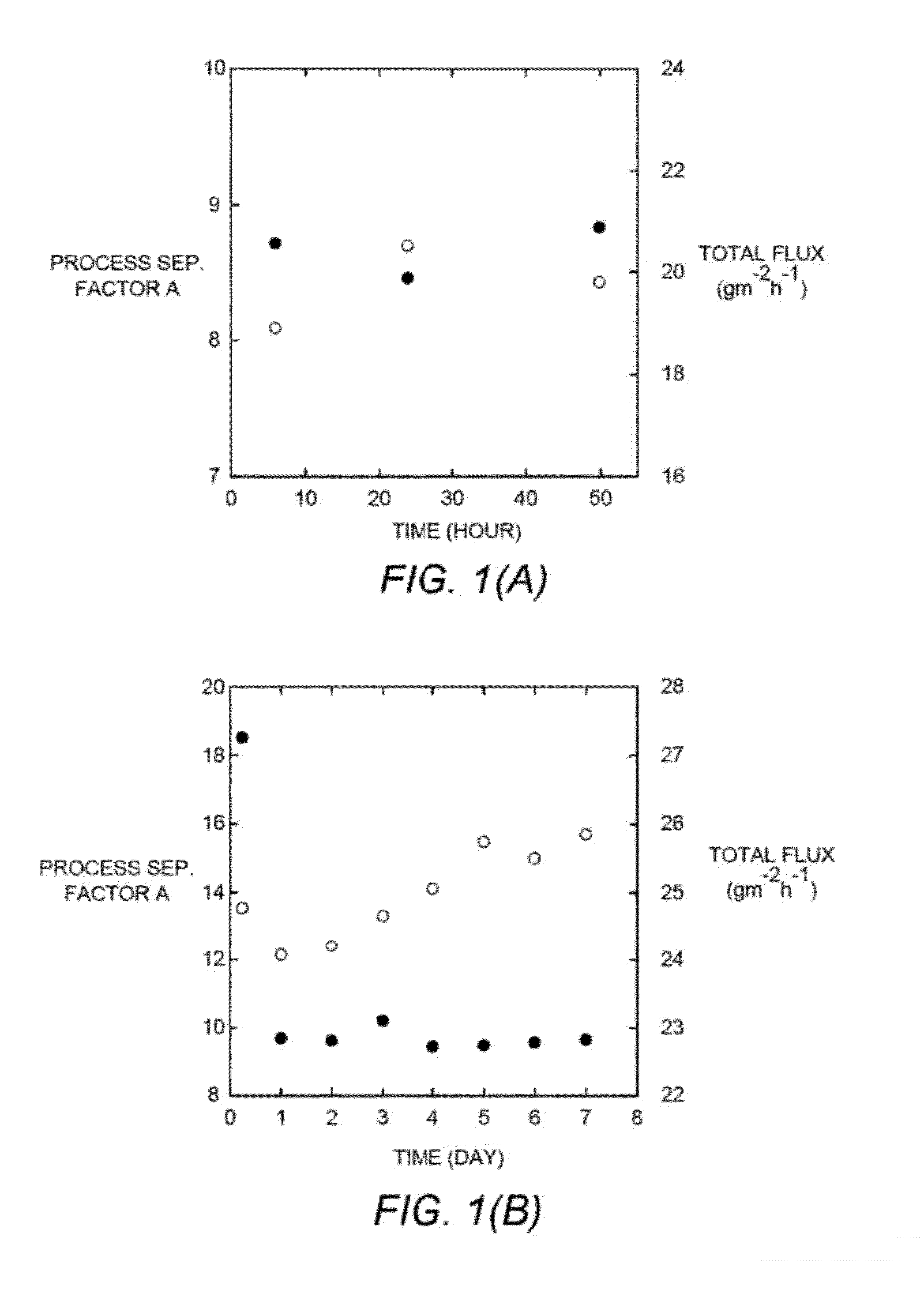

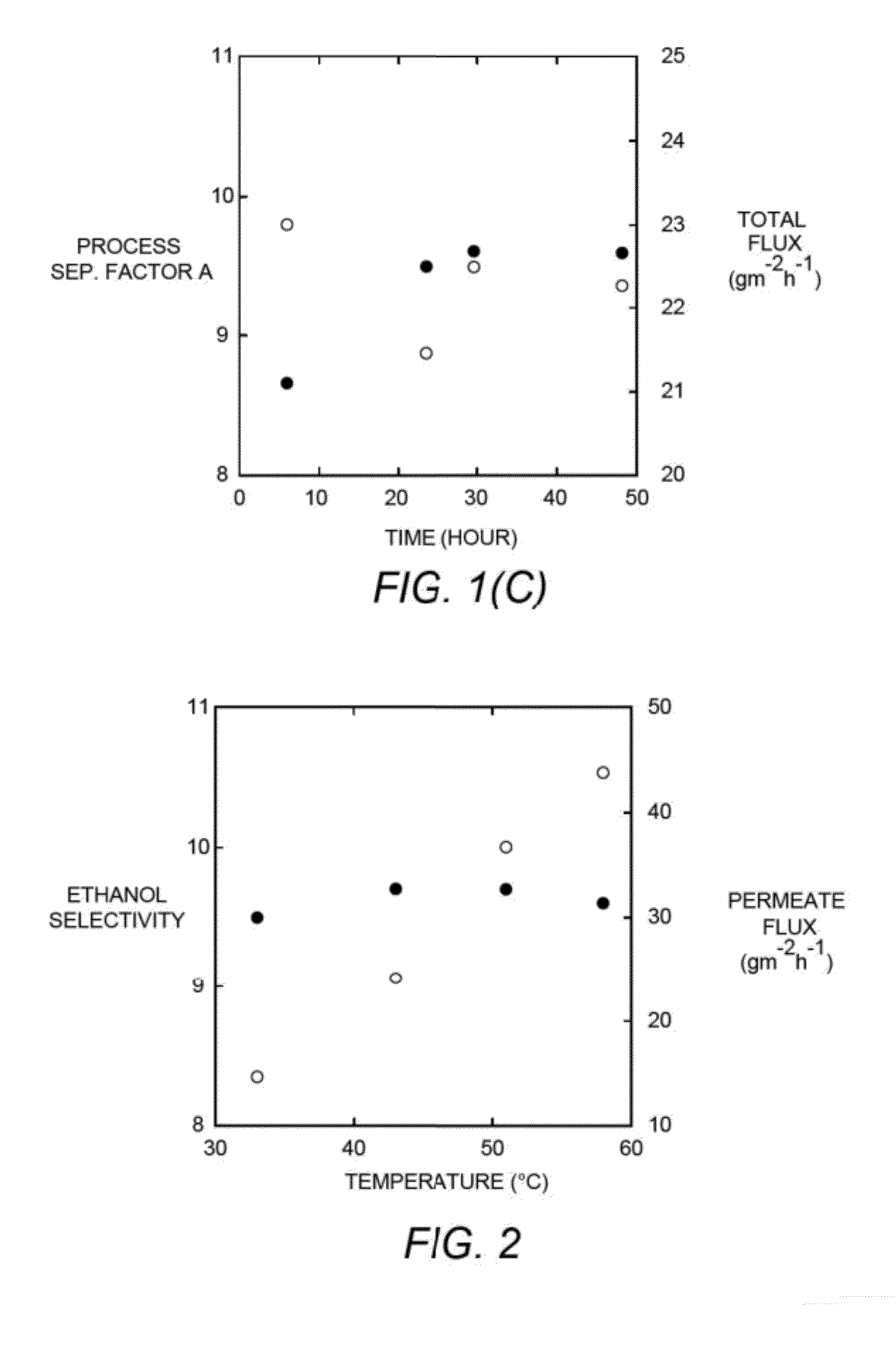

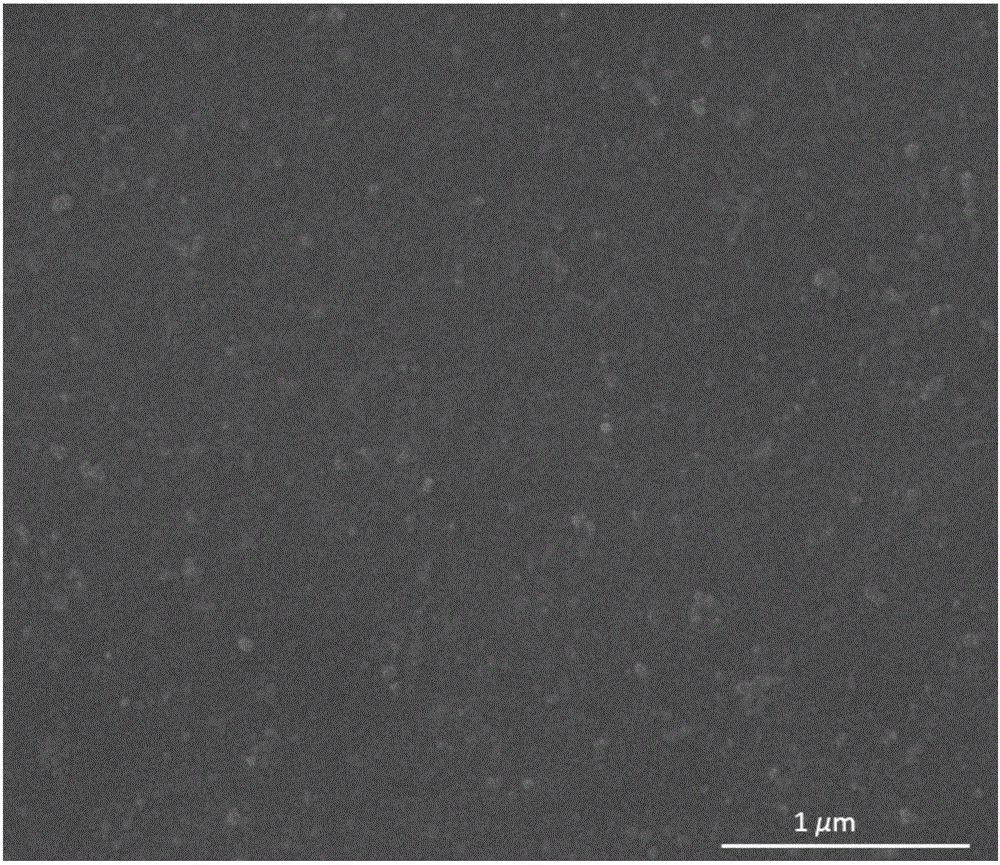

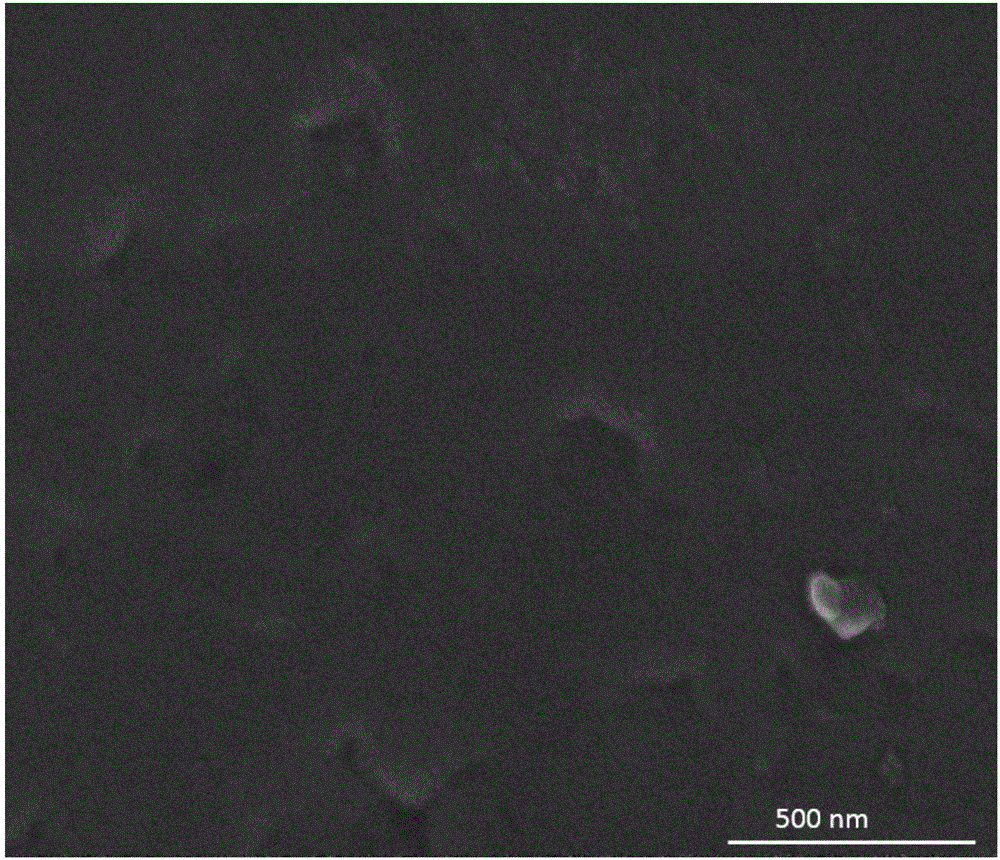

Nanostructured polymer membranes for selective alcohol transport

The present invention relates to copolymer compositions for alcohol-selective membranes and methods of selectively separating an alcohol such as ethanol from an aqueous solution using such membranes. The copolymer compositions may be block copolymers of polystyrene-polybutadiene-polystyrene (hereafter “SBS”) having cylindrical morphologies; graft diblock copolymers synthesized by ring-opening metathesis polymerization of two cycloalkene monomers, wherein at least one of the cycloalkene monomers is substituted with one or more polydialkylsiloxane groups; or triblock copolymers comprising a middle block comprising a polymerized cycloalkene monomer and two end groups. The synthesized graft and triblock copolymer compositions may have a spherical, lamellar, cylindrical, double diamond, or gyroid morphologies. The copolymer compositions may contain a structural block that imparts essential mechanical properties to the membrane (e.g., polystyrene) and may also contain an alcohol transporting block (e.g., polydimethylsiloxane or polybutadiene). The copolymer compositions may have a domain spacing and a flux, where the flux increases as the domain spacing increases. The copolymer compositions may also have an alcohol separation factor that increases as the domain spacing increases. The separation method may be carried out using pervaporation or vapor permeation techniques.

Owner:RGT UNIV OF CALIFORNIA

Method of preparing perm-selective porous membrane and method of separating gases using porous membrane prepared thereby

ActiveUS20180272288A1Improve stabilityImprove thermal stabilitySemi-permeable membranesMembranesSeparation factorDiffusion methods

The present invention relates to a method of preparing a perm-selective porous membrane and a method of separating gases using the prepared porous membrane. According to the present invention, a membrane is synthesized using a hierarchically structured alumina porous support by a counter diffusion method. During this synthesis, the diffusion rate of metal ions loaded on the porous support is controlled by controlling the pore size of the porous support, and the position at which the membrane is synthesized is controlled by synthesizing the membrane inside the support. This can increase the physical stability of the membrane and make the membrane thicker so as to ensure higher H2 / CO2 separation factors.

Owner:KOREA UNIV RES & BUSINESS FOUND

Preparation of intercrossed network water dealcoholizing pervaporation membrane

ActiveCN101279212AStable structureImprove performanceSemi-permeable membranesSeparation factorCross-link

The invention discloses a preparation method for an interpenetrating network dealcoholization pervaporation membrane, which includes the following steps: 1) preparing membrane producing materials: mixing well an inorganic additive, an evocating agent, a solution and a component I and a component II constituting the interpenetrating network to form the membrane producing materials; 2) the interpenetrating network is formed through cross bonding: adding catalyst in the membrane producing materials and mixing at a temperature ranging from 20 DEG C to 30 DEG C for 10 to 20 hours, and then adding a cross linker to mix and perform cross linking reaction at a temperature ranging from 50 DEG C to 70 DEG C for 2 to 6 hours, thus acquiring a casting solution; 3) membrane casting and post treatment: carrying out membrane casting and post treatment of the casting solution, thus acquiring the interpenetrating network dealcoholization pervaporation membrane. The interpenetrating network dealcoholization pervaporation membrane with hydrophobic nature prepared by the method of the invention is characterized by strong swelling resistance ability, high separation factor and so on.

Owner:CHINA PETROLEUM & CHEM CORP

Polyethylenimine-tannic acid/hydrolyzed polyacrylonitrile ultrathin composite membrane, and preparation and application thereof

ActiveCN106807251AEasy to prepareImprove performanceSemi-permeable membranesSeparation factorFiltration membrane

The invention discloses a polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane. The thickness of the polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane is smaller than 300 nm. The polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane comprises polyethylenimine layers and tannic acid layers. Reactive layer-by-layer self-assembly is carried out by the aid of polyethylenimine and tannic acid to form the polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane. Alternate assembly frequencies of polyethylenimine solution and tannic acid solution are 1.5-5.5. A procedure for preparing the polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane includes preparing polyacrylonitrile ultra-filtration membranes and hydrolyzing the polyacrylonitrile ultra-filtration membranes; preparing the polyethylenimine solution and the tannic acid solution and regulating the pH (potential of hydrogen) of the polyethylenimine solution and the pH of the tannic acid solution by the aid of HCl and NaOH; carrying out alternate assembly by the aid of the polyethylenimine solution and the tannic acid solution in a shaking table. The polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane, the preparation and the application have the advantages that a method for preparing the polyethylenimine-tannic acid / hydrolyzed polyacrylonitrile ultrathin composite membrane is simple and convenient, excellent intramembrane covalence effects can be realized, and prepared membrane materials can be used for pervaporation ethanol dehydration, are excellent in permeation flux and have excellent separation factors.

Owner:TIANJIN UNIV

Method for dehydrating furfural by pervaporation of NaA zeolite molecular sieve membrane

InactiveCN101721920ARaise the gradeReduce energy consumptionOrganic chemistryDistillationMolecular sieveSeparation factor

The invention discloses a method for dehydrating furfural by the pervaporation of a NaA zeolite molecular sieve membrane, which belongs to the technical field of chemical engineering and relates to the preparation of a high-performance NaA molecular sieve membrane on the outside surface of a porous carrier and the use of the NaA molecular sieve membrane in furfural dehydration. The method is characterized in that: the NaA molecular sieve membrane is prepared from Na2O, SiO2, Al2O3 and H2O in a molar ratio of 1.2-2.0:2:1:100-200; the carrier coated with seed crystals is placed in a high-pressure reaction kettle, synthesizing liquid is filled into the reaction kettle, the reaction kettle is sealed and then placed in an environment where the temperature is 50 to 100 DEG C to perform synthesis for 2 to 24 hours, the NaA molecular sieve membrane prepared is soaked in deionized water till the NaA molecular sieve membrane is neutral, and the NaA molecular sieve membrane is placed in an oven at 50 to 100 DEG C to be dried; and with the adopted process for dehydrating the furfural by the pervaporation of the NaA zeolite molecular sieve membrane, the water / furfural separation factor of the NaA zeolite molecular sieve membrane is more than10,000, the furfural content reaches over 99.5 weight percent, and the separation effect reaches an international advanced level. The invention has the advantage of providing a separation technique for dehydrating furfural, which is effective, environmentally-friendly and economic and has a high industrial application value and a practical significance.

Owner:DALIAN UNIV OF TECH

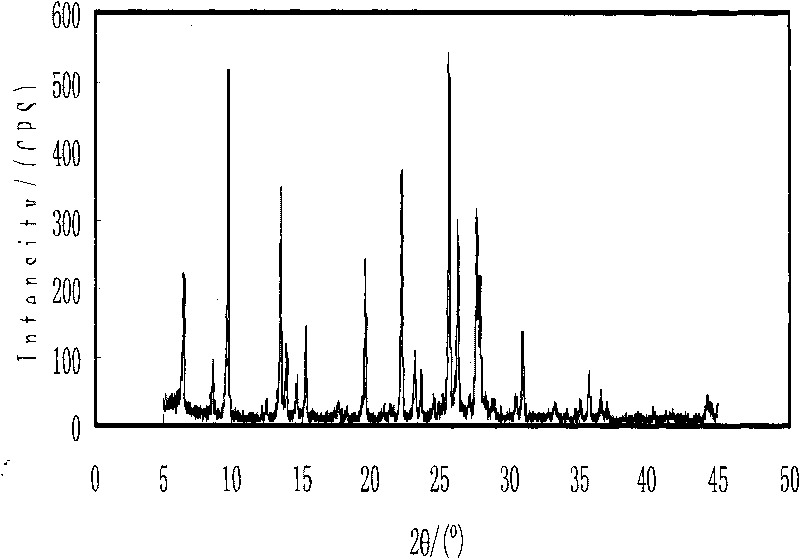

Method for preparing fluorine-containing mordenite zeolite membrane

The invention provides a method for preparing high-performance fluorine-containing mordenite zeolite membrane. The method is characterized in that crystallization is performed for 5 to 30 hours at a synthesis temperature between 130 and 190 DEG C by a secondary growth method so as to form a layer of dense defect-free fluorine-containing mordenite zeolite membrane on the outer surface of a porous tubular supporting body; the molar ratios of synthesis materials are as follow: the molar ratio of SiO2 to Al2O3 is 10 to 60; the molar ratio of H2O to SiO2 is 15 to 60; the molar ratio of Na2O to SiO2 is 0.15 to 0.5; and the molar ratio of F- to SiO2 is 0.01 to 2. NaF, KF, AlF3, (NH4) SiF6 and NH4F and the like can be used as a fluoride source. The preparation method avoids adding expensive organic template agents, and the fluoride source added greatly improves the permeability and acid resistance of the membrane. For example, when the method is applied to permeation experiment on water / ethanol (10 / 90 percent by weight) system at 75 DEG C, the average water permeation flux J is 1.2 to 2.5 kg / m2 h; the separation factor (alpha) is more than 1,000; and the synthesized membrane still maintains good stability in acid solution with a pH of less than 1. The method has the advantages of simple novel process, good repeatability and suitability for industrial production.

Owner:JIANGXI NORMAL UNIV

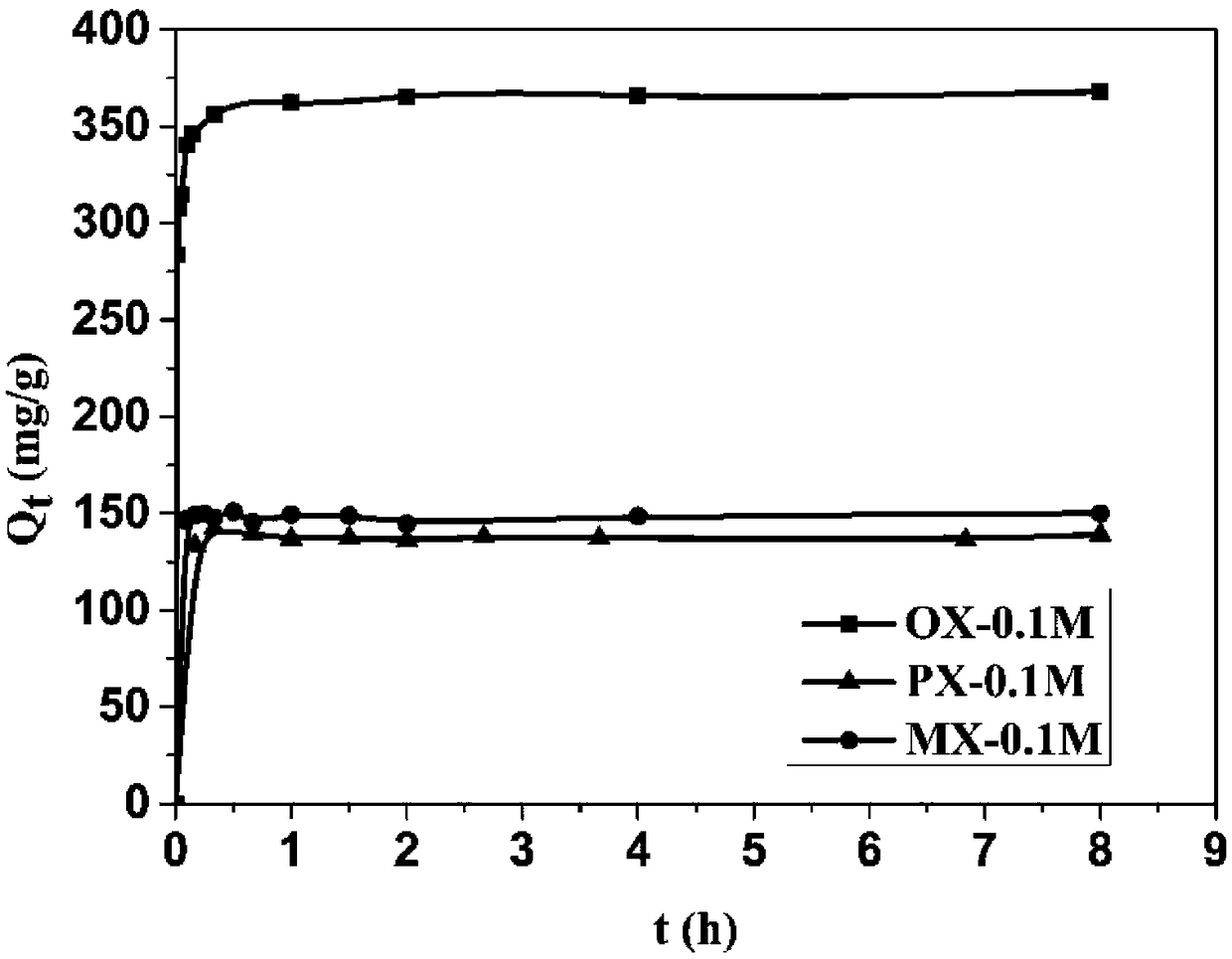

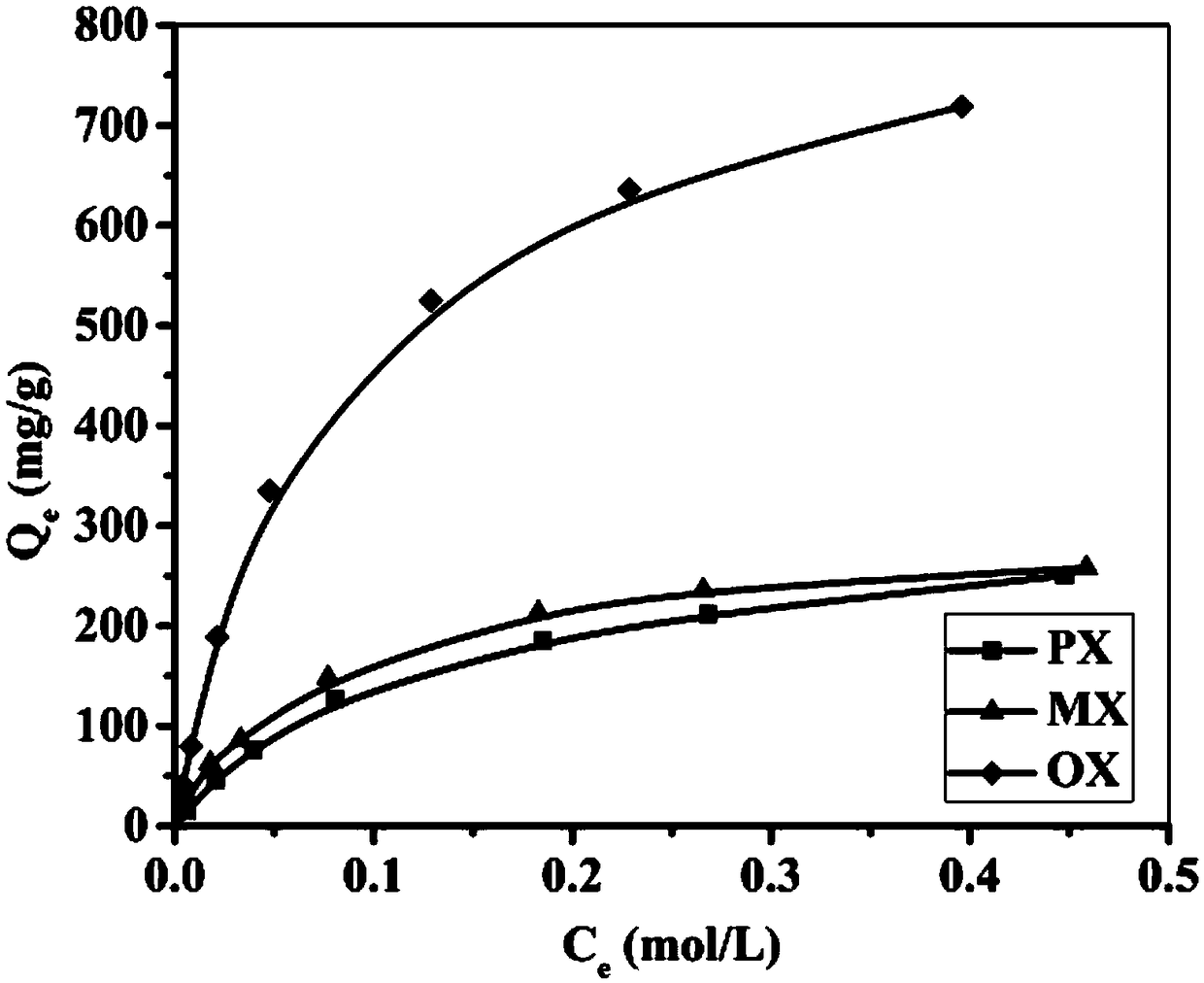

Method for separating xylene mixture by using metal organic framework material MIL-53 (Cr) and compound as adsorption stationary phase

InactiveCN109173341ALarge specific surface areaEasy to separateIon-exchange process apparatusOther chemical processesSeparation factorStationary phase

The invention discloses a method for separating a xylene mixture by using a metal organic framework material MIL-53 (Cr) and a compound as an adsorption stationary phase. The method comprises the following steps: separating a liquid xylene mixture by using a metal organic framework material MIL-53 (Cr) and a compound as a SMB adsorbent; and then calculating the concentration of the xylene mixturein a solution after gas chromatography detection and the initial solution concentration to obtain the adsorption amount and selectivity. The metal organic framework material MIL-53 (Cr) for separatingan xylene isomer has a high specific surface area (greater than or equal to 1550 m<2> / g) and good morphology features, has excellent separation ability of the xylene mixture, wherein the separation factor reaches 22 and the adsorption capacity reaches 8.2 mol / kg, and has an extremely fast adsorption rate, which can reach a saturated adsorption capacity of 95% or more in half an hour.

Owner:TIANJIN UNIV

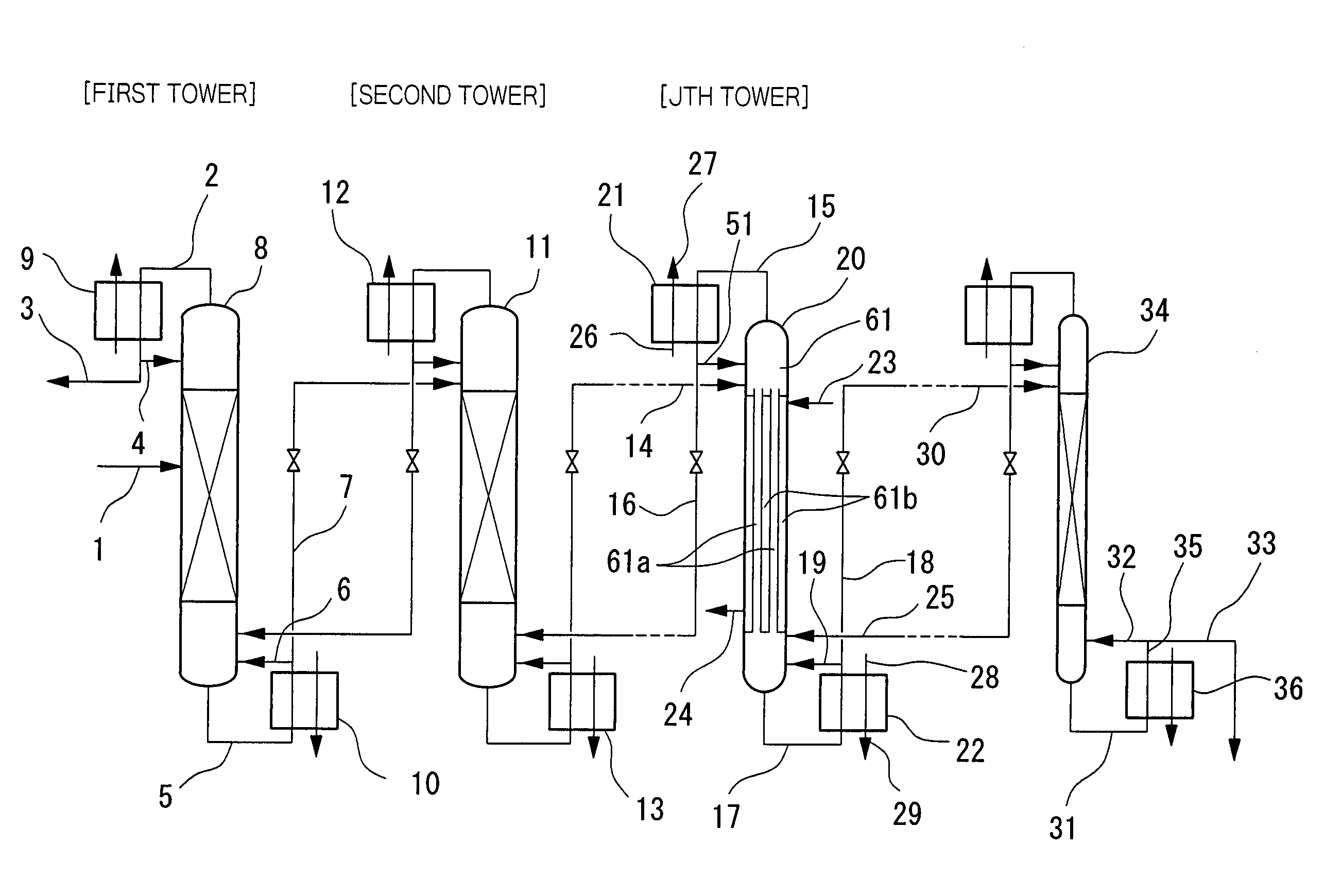

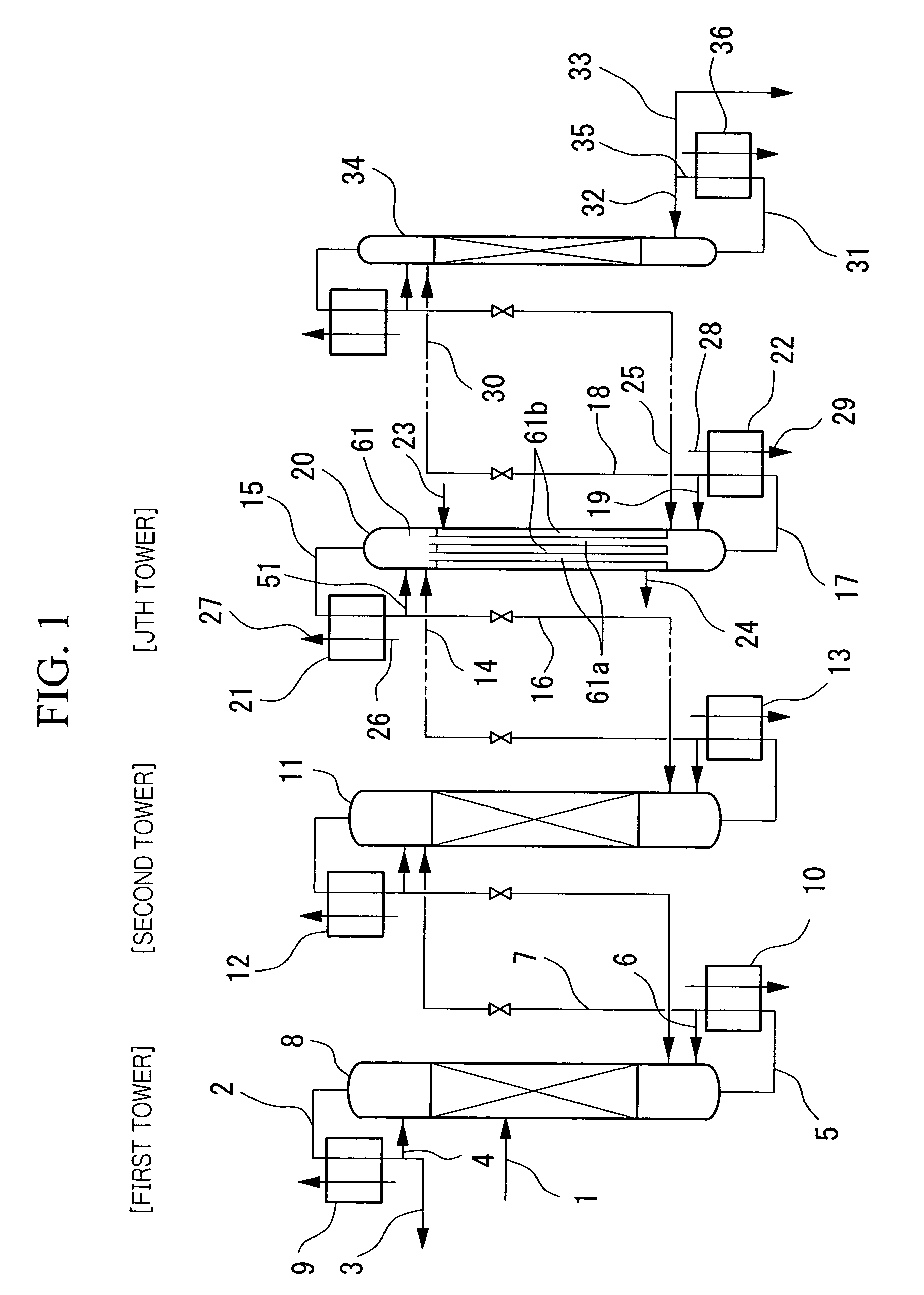

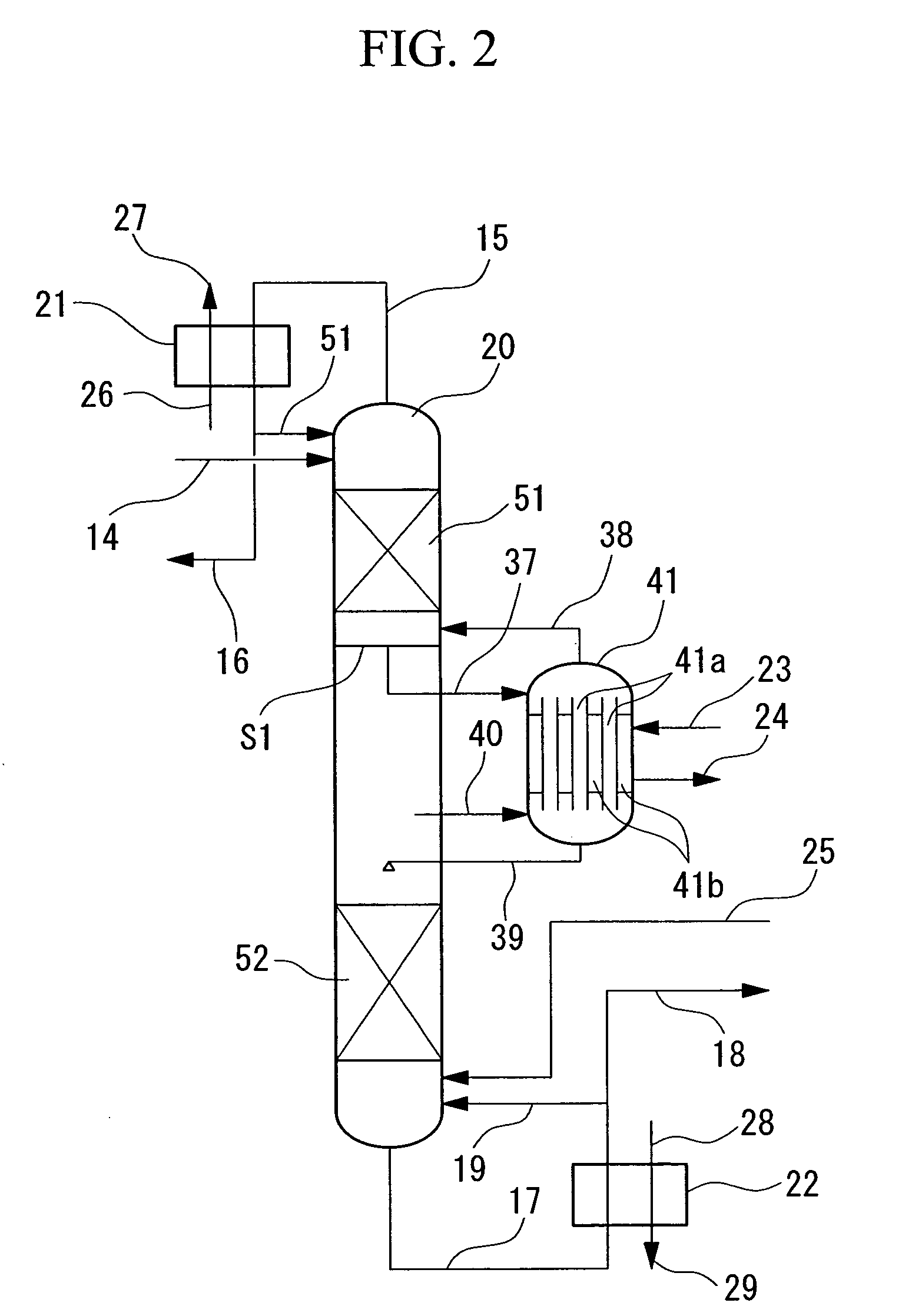

Method and device for separation and concentration by evaporation of mixture with separation factor of approx. 1

InactiveUS7297237B2Minimize liquid holdupIncreasing liquid holdupSolidificationOxygen/ozone/oxide/hydroxideProduction rateSeparation factor

By using a dephlegmator which conducts distillation concurrently with heat exchange within at least one distillation column, or a portion of one distillation column, of a distillation cascade, the quantity of liquid holdup within the distillation apparatus is reduced and the start-up time is shortened. Consequently, the operational costs associated with startup are reduced, and productivity is improved markedly.

Owner:ASANO

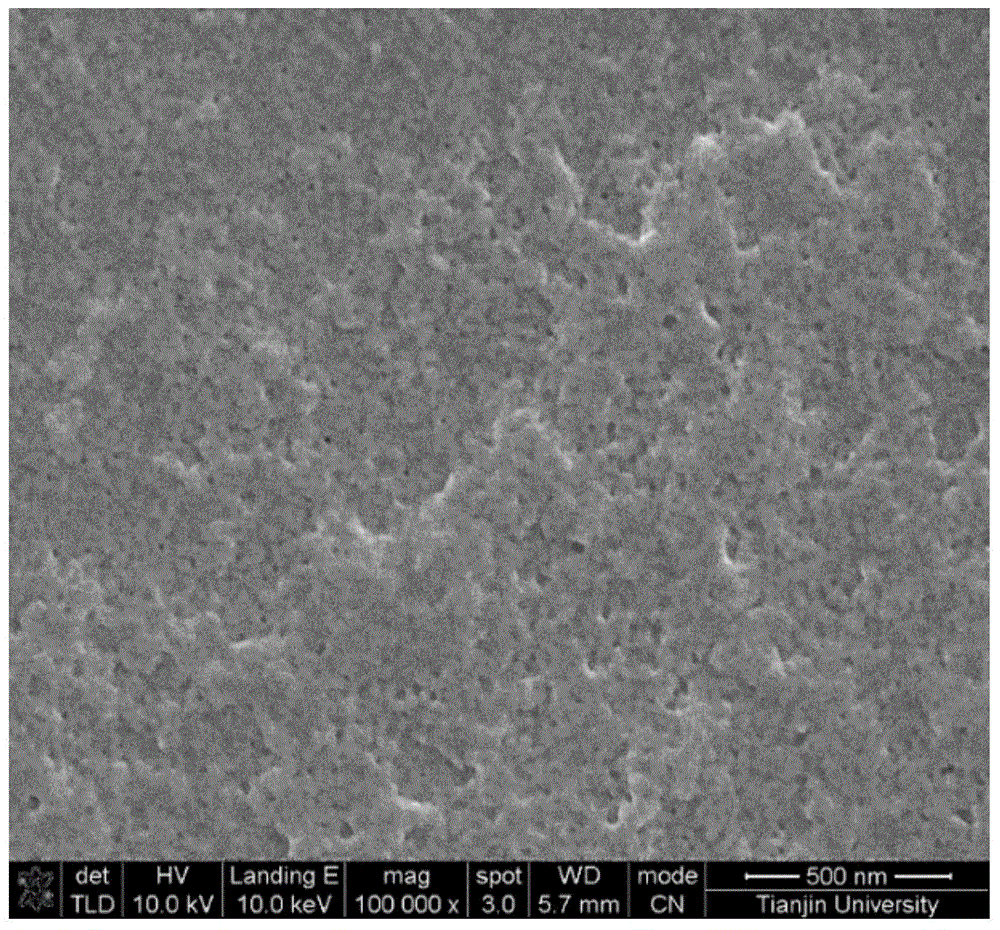

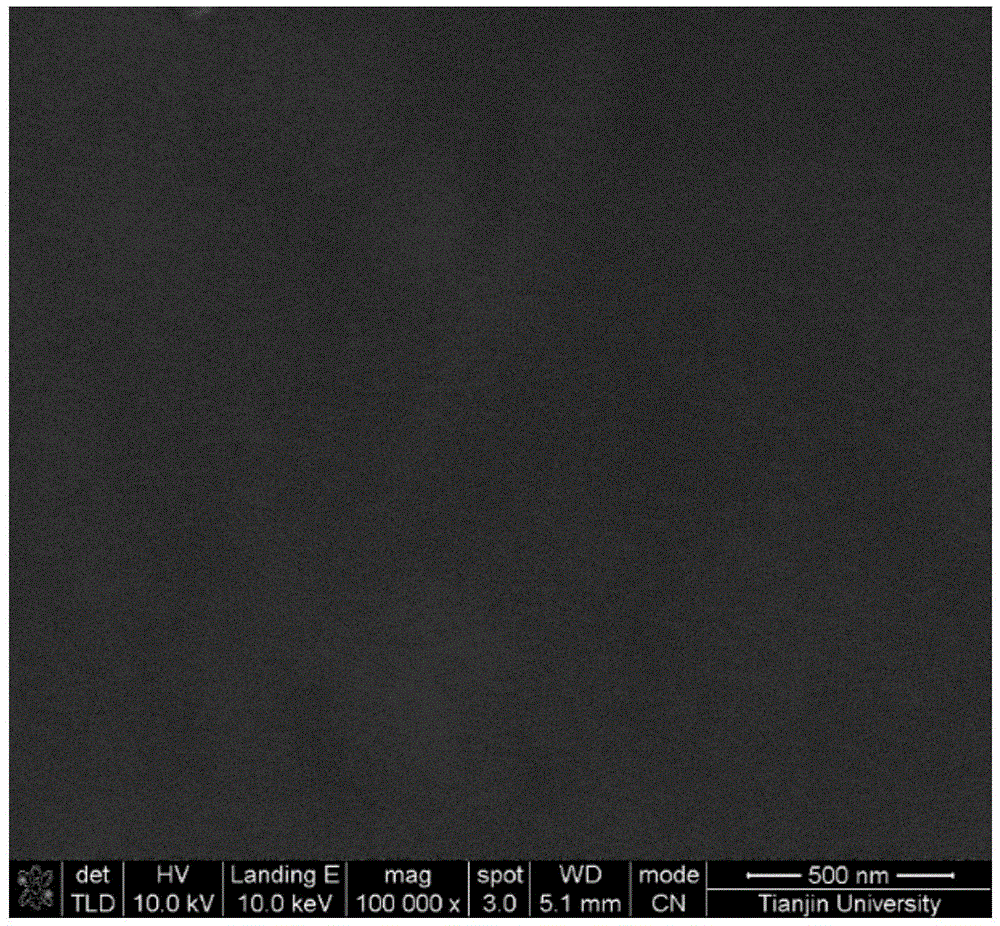

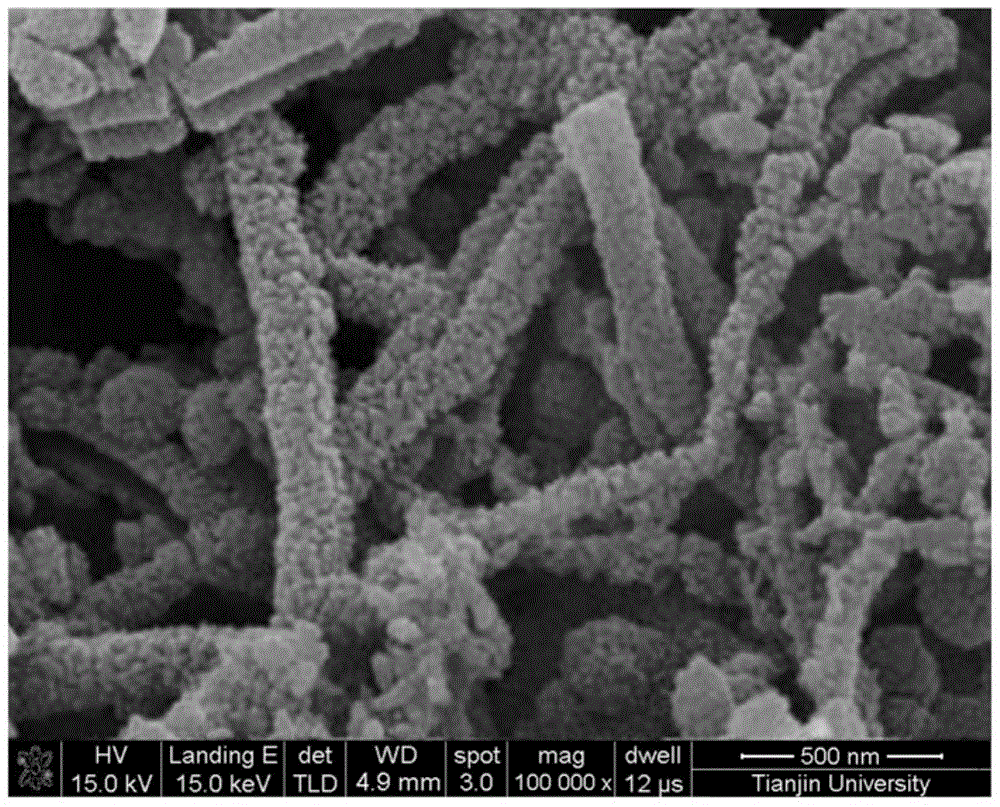

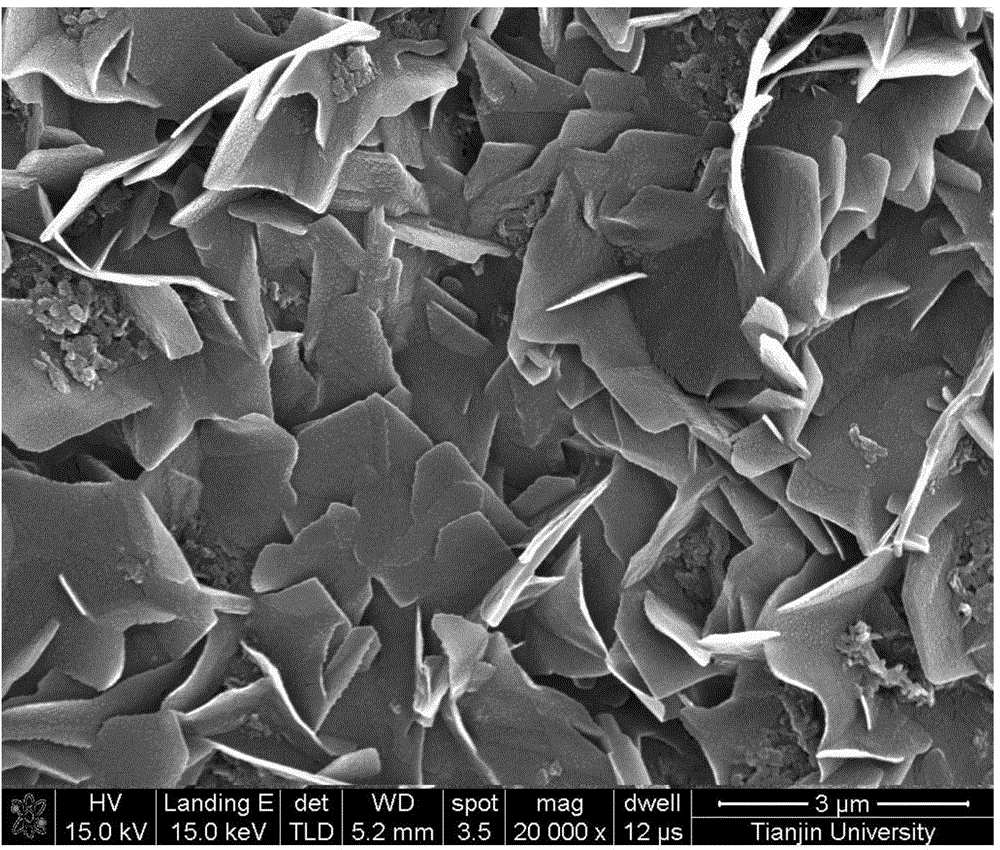

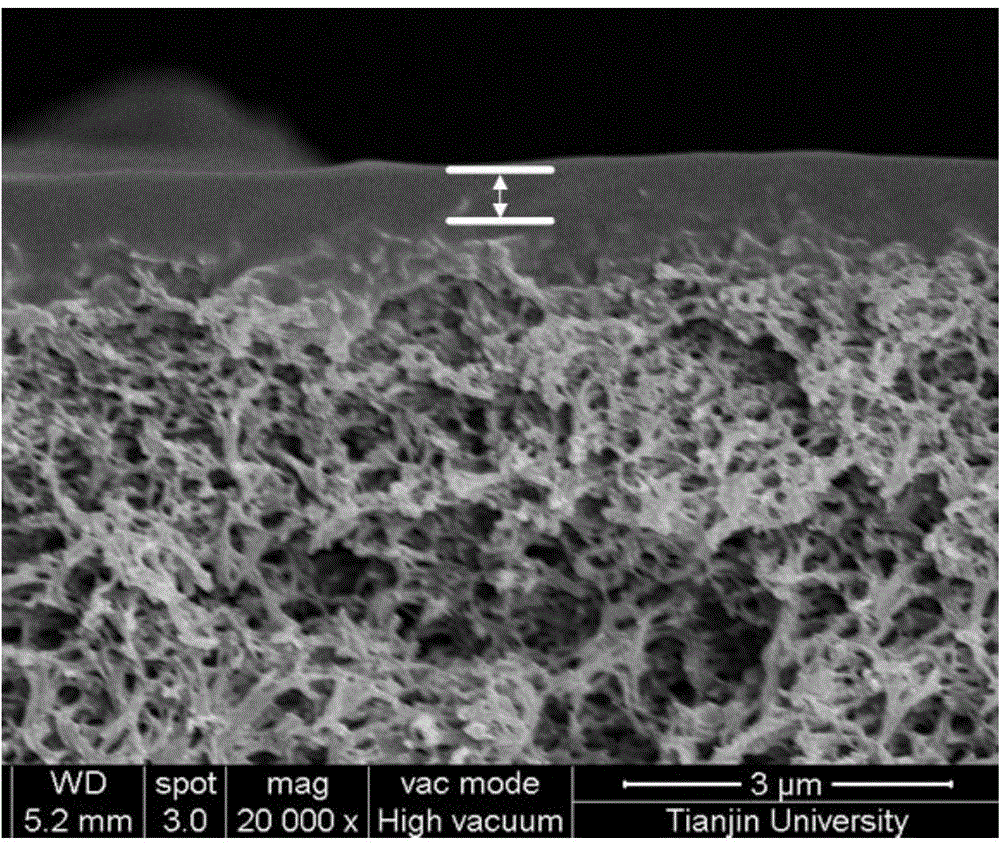

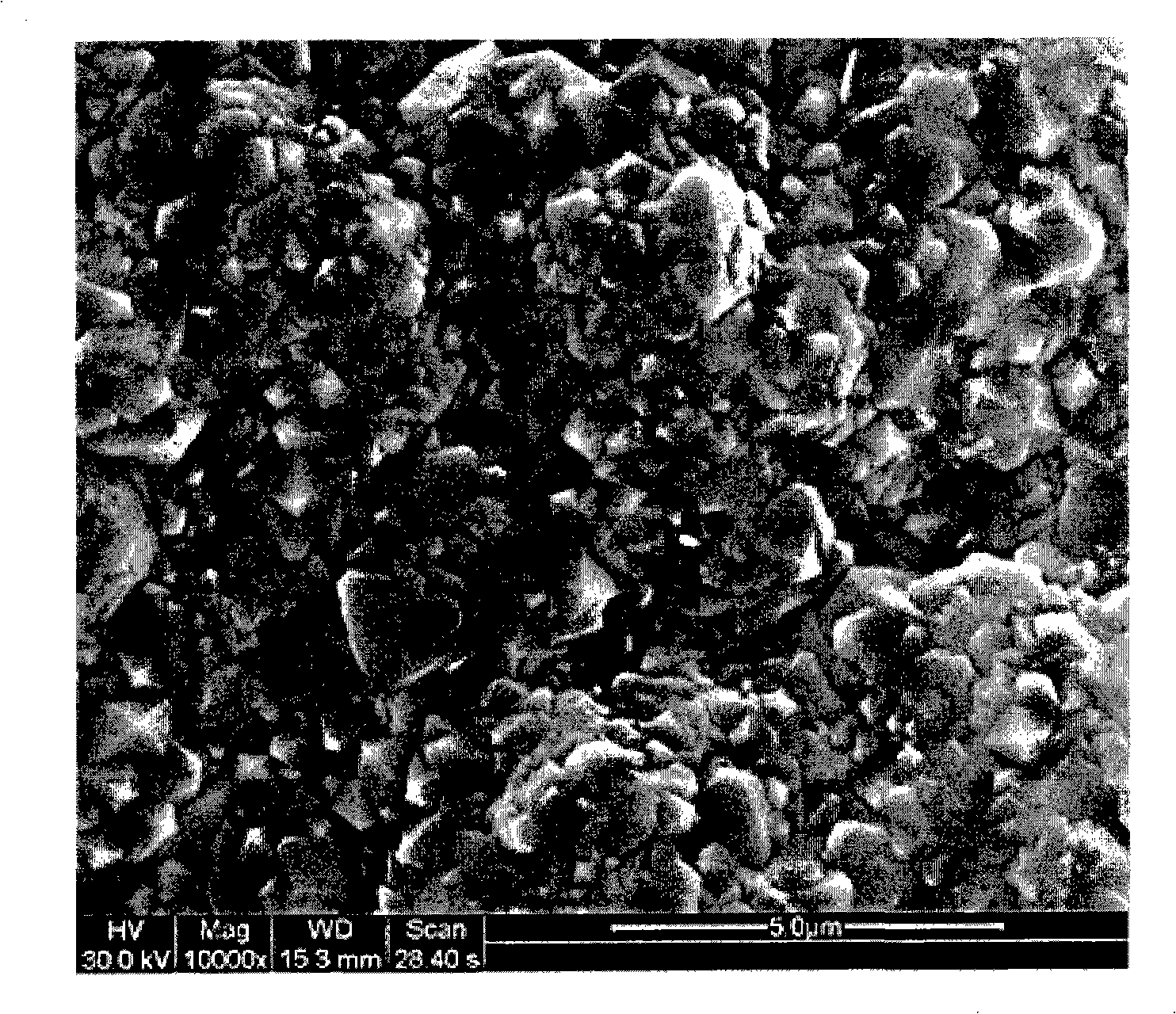

Preparation method of self-assembled folded rGO composite membrane

ActiveCN108295666ASolve the flux is smallResolve separabilityMembranesDistillationSeparation factorWater treatment

The invention discloses a preparation method of a self-assembled folded rGO composite membrane used for dehydration of organic matter and belongs to the field of membrane separation. The method comprises steps as follows: GO (graphene oxide) is sucked to a pretreated porous base membrane with rich amino, then, the base membrane is put in a preheated organic solvent to be modified and put in a glutaraldehyde water solution to be crosslinked, then, a polyelectrolyte is sucked to the surface of the modified GO composite membrane, and finally, the modified GO composite membrane is put in a water solution of a crosslinking agent to be crosslinked. The preparation process is simple, the film forming time is short, the composite membrane is applied to the field of pervaporation, the problems thatthe GO composite membrane has small flux and low separation factor in the pervaporation process are solved, and the composite membrane has uniform and compact surface and can be widely applied to thefield of water treatment.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting and separating bacitracin

InactiveCN102153633AHigh yieldStructure is not destroyedDepsipeptidesPeptide preparation methodsSeparation factorUltrafiltration

The invention relates to a method for extracting and separating bacitracin. The method is characterized by comprising the following steps of: (1) extracting and separating bacitracin concentrated liquor by ultrafiltration, namely acidizing bacitracin fermentation liquor, filtering or centrifuging by a vibrating screen to remove thalli, removing the thalli and macromolecular impurities by the ultrafiltration, removing an inorganic salt by resin adsorption and performing evaporation concentration under vacuum to obtain the bacitracin concentrated liquor; and (2) preparing a bacitracin crystalline solid by using the bacitracin concentrated liquor, namely performing production steps of extracting, decolorizing, nanofiltration, crystallizing and separating, drying, crushing, sieving, checking, the packaging of a finished product and the like on the bacitracin concentrated liquor to obtain the qualified bacitracin product. The method has the characteristics of high efficiency, simple equipment, high economy, large separation factor, high selectivity, low energy consumption, no secondary pollution, and the like, and is particularly suitable for the large-scale industrial production of the bacitracin; and operation can be performed continuously at the room temperature.

Owner:JIANGSU JIUYANG BIOLOGICAL PHARMA

Preparation of polyvinylamine/polyaniline mixed matrix membranes used for separation of gas containing carbon dioxide

InactiveCN104801207AIncreased permeability selectivityImprove stabilitySemi-permeable membranesDispersed particle separationSeparation factorPermeation

The invention provides a preparation of polyvinylamine / polyaniline mixed matrix membranes used for separation of gas containing carbon dioxide. According to the preparation method, polyaniline nanosheets or nanotubes are prepared; polysulfone or polyether sulfone ultrafilter membranes are taken as base membranes; the base membranes are coated with a coating liquid prepared via mixing of the polyaniline nano material with polyvinylamine and water; and the separation membranes are obtained via drying at a certain temperature under certain relative humidity. Advantages are that: the mixed matrix gas separation membranes prepared from polyaniline nanosheets or nanotubes and polyvinylamine possesses high CO2 penetration selectivity and excellent stability, and is suitable for separation of gas containing CO2. When the mixed matrix gas separation membranes are used for separation of a CO2 / N2 mixed gas (CO2 volume fraction ranges from 10 to 20%), CO2 permeation rate ranges from (300 to 3100)*10<-6>cm<3>(STP)*cm<-2>*s<-1>*cmHg<-1>, and CO2 / N2 separation factor ranges from 80 to 300.

Owner:TIANJIN UNIV

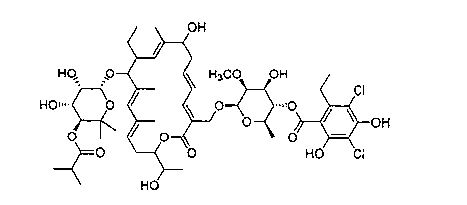

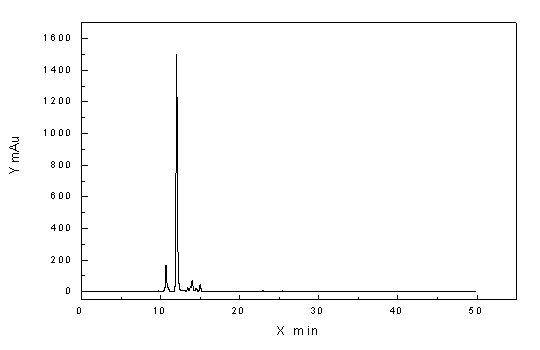

Method for purifying tiacumicin B by high performance liquid chromatography

ActiveCN102993251AGood removal effectEasy to separateSugar derivativesSugar derivatives preparationSeparation factorState of art

The invention provides a method for purifying tiacumicin B by high performance liquid chromatography, wherein in the method, Uni30BPC monodisperse polymer microspheres are used as fillers for performing column chromatography in a purification and chromatography column. The invention provides a method which is better in separation effect for tiacumicin B, wherein a novel medium which is high in separation factor and column efficiency is adopted, thus overcoming the shortages of low separation factor and bad column efficiency existing in the prior art, having a good removal effect for various impurities in tiacumicin B, and being high in preparation purity and recovery rate.

Owner:SUZHOU NANOMICRO TECH CO LTD

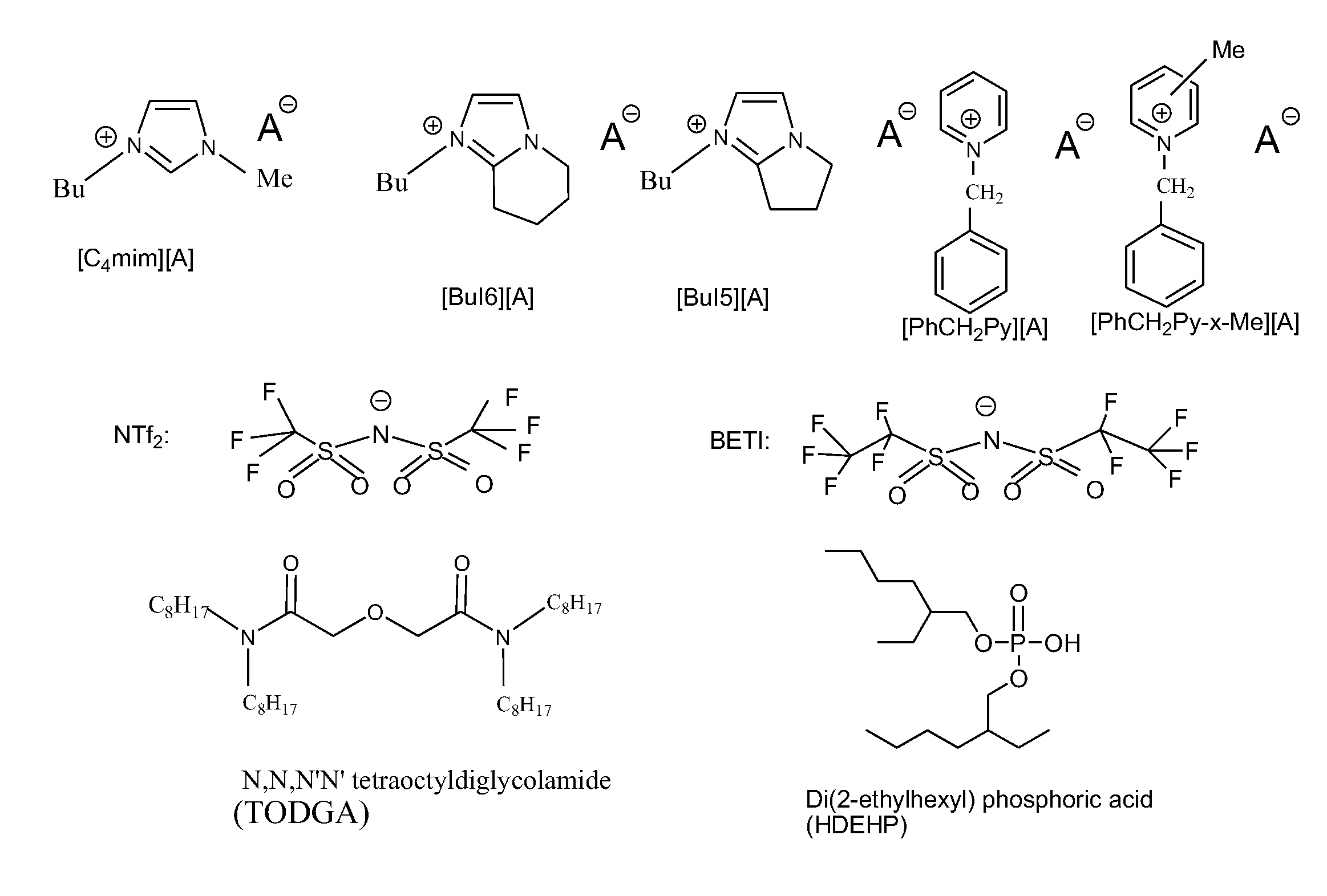

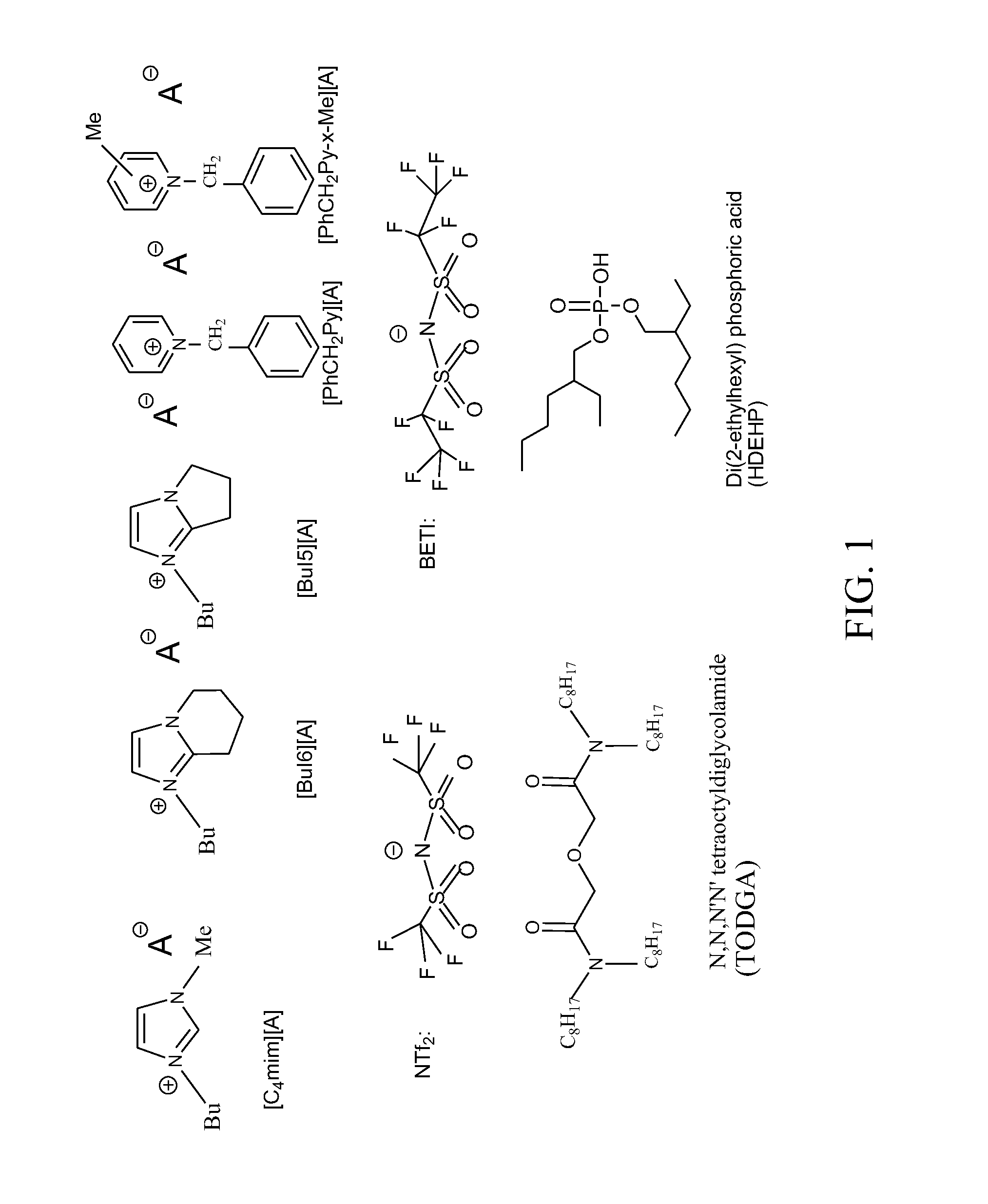

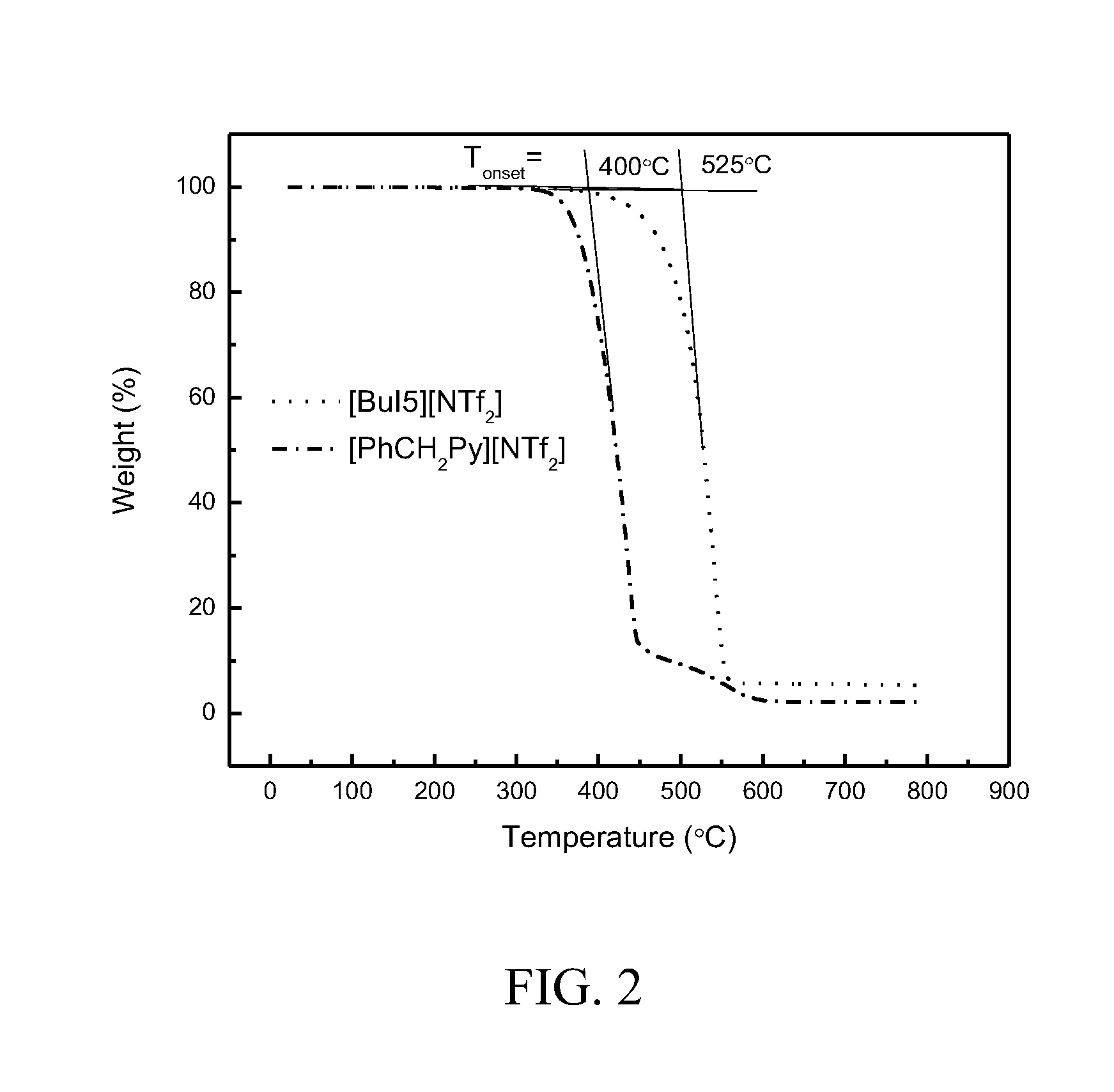

Methods for separating medical isotopes using ionic liquids

InactiveUS20140072485A1Broad temperature range of stabilityImprove conductivityTransuranic element compoundsSolvent extractionSeparation factorIsotope

A method for extracting a radioisotope from an aqueous solution, the method comprising: a) intimately mixing a non-chelating ionic liquid with the aqueous solution to transfer at least a portion of said radioisotope to said non-chelating ionic liquid; and b) separating the non-chelating ionic liquid from the aqueous solution. In preferred embodiments, the method achieves an extraction efficiency of at least 80%, or a separation factor of at least 1×104 when more than one radioisotope is included in the aqueous solution. In particular embodiments, the method is applied to the separation of medical isotopes pairs, such as Th from Ac (Th-229 / Ac-225, Ac-227 / Th-227), or Ra from Ac (Ac-225 and Ra-225, Ac-227 and Ra-223), or Ra from Th (Th-227 and Ra-223, Th-229 and Ra-225).

Owner:UT BATTELLE LLC

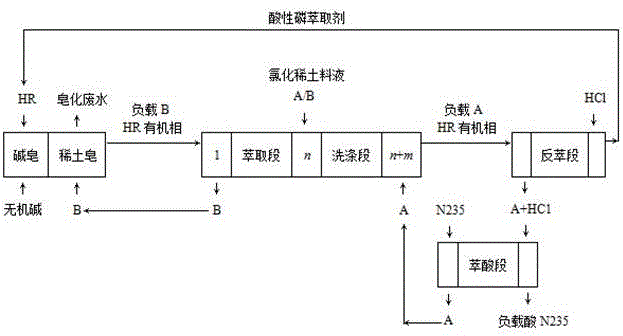

Technological method of full load fractional extracting and separating rare earths

InactiveCN104532022AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSeparation factorWater discharge

The invention relates to a technological method of full load fractional extracting and separating rare earths. According to the technological method disclosed by the invention, P507 or P204 serves as a rare earth extractant; in a fractional extraction separation technology, N235 serves as an acid extraction agent, and a mixed alcohol serves as an acid extraction segment of an N235 organic phase regulator; an easily-extracted rare earth component solution with a pH value to be 1-4 serves as a washing solution; by virtue of the acid extraction action of the N235 in the acid extraction segment, the side effects of hydrogen ion washing are eliminated, so that the separation factor of the rare earths is ensured not to be lowered, and the extraction quantity of the extractant in a fractional extraction system is also ensured. Compared with the traditional fractional extraction separation technology, the acid and alkali consumption in the process of the rare earth separation technology can be greatly lowered, wherein the consumption of a basic reagent is lowered by 34-62 percent, and the consumption of hydrochloride is lowered by 16-29 percent; the waste water discharge in the process of the rare earth extraction separation technology is greatly reduced, the greening degree of rare earth separation is greatly increased; the grade amount of extraction tank is reduced by 22-46 percent, the total investment of the rare earth extraction separation technology is lowered; the separation cost is greatly lowered.

Owner:NANCHANG HANGKONG UNIVERSITY

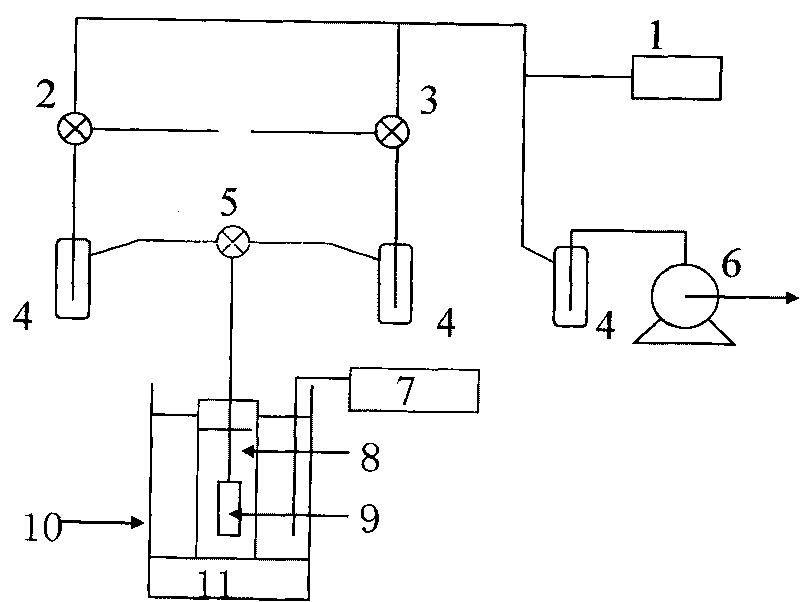

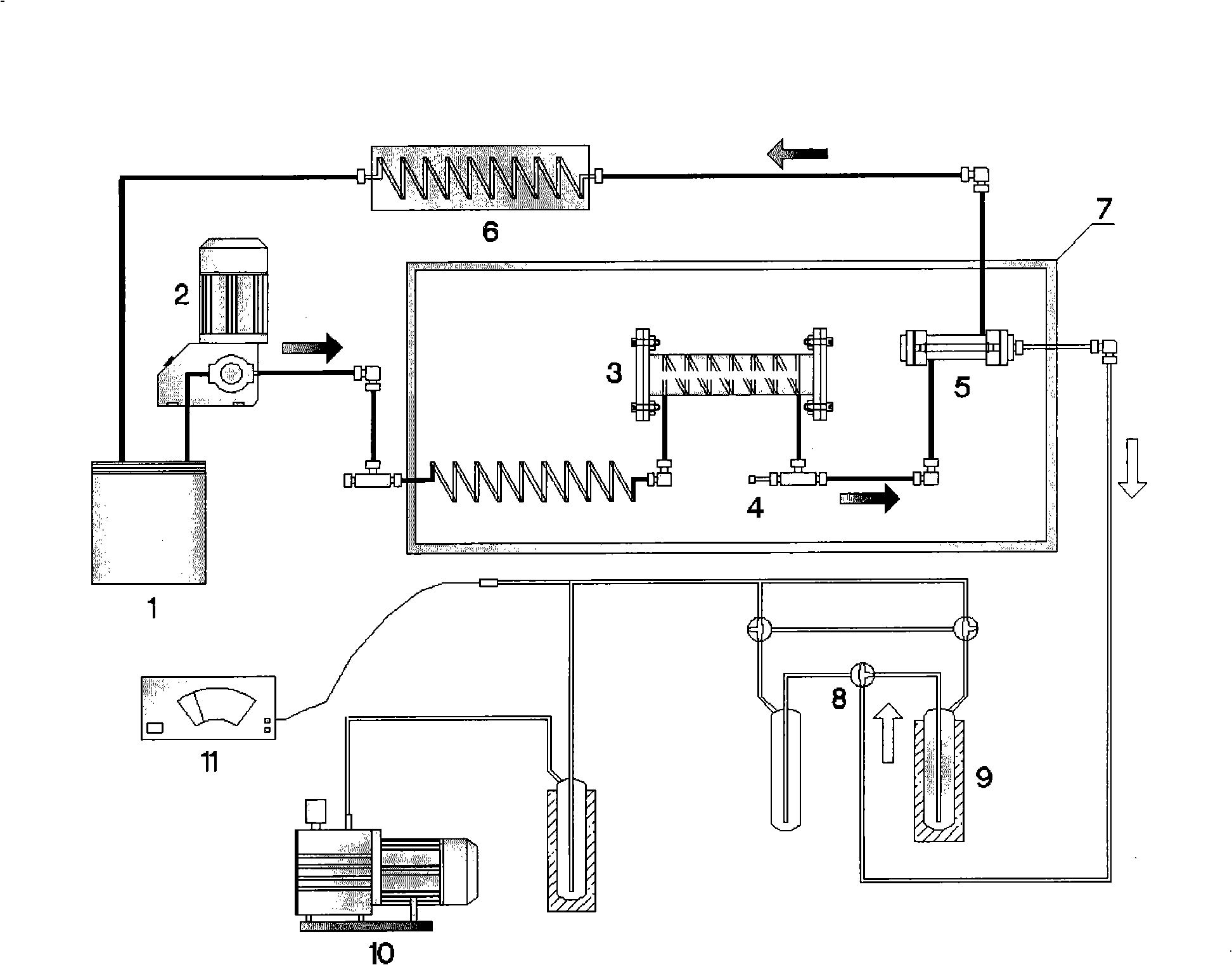

Method for preparing high-performance Y type molecular sieve film and application of the same in organic mixture separation

InactiveCN101318665AHigh purityShort synthesis timeFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteSeparation factorMolecular sieve

The invention provides a method for preparing a high-performance Y-type molecular sieve membrane and an application to the separation of organic mixture. The method is characterized in that a new high-temperature closed hydro-thermal synthesis reaction method is adopted, a layer of dense NaY-type molecular sieve membrane forms on the surfaces of three porous tubular support body. The synthetic time of preparation process is short, and the process of the membrane forming is simple. The membrane prepared by the method has fewer defects, the synthesized NaY-type molecular sieve membrane is used in the separation of organic mixtures by adopting a self-control permeating and vaporizing device, the process of the separation is simple and is easy to be operated and controlled, the separating property is good, the Y-type molecular sieve membrane has high permeation flux and high separation factor while the Y-type molecular sieve membrane is applied to methanol / methyl tert-butyl ether, ethanol / ethyl tertiary butyl ether and benzene / cyclohexane, the NaY-type molecular sieve membrane particularly synthesized by stainless steel support body has extremely high permeation flux.

Owner:JIANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com