Patents

Literature

1744 results about "Adsorption method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adsorption is the simplest way to immobilize enzymes. Usually, adsorption method is to adsorb several components on the surface using porous solid materials and then desorb the prediction components to achieve the purpose of separation and enrichment using suitable solvent, heating, or blowing gas [48].

Adsorption methods

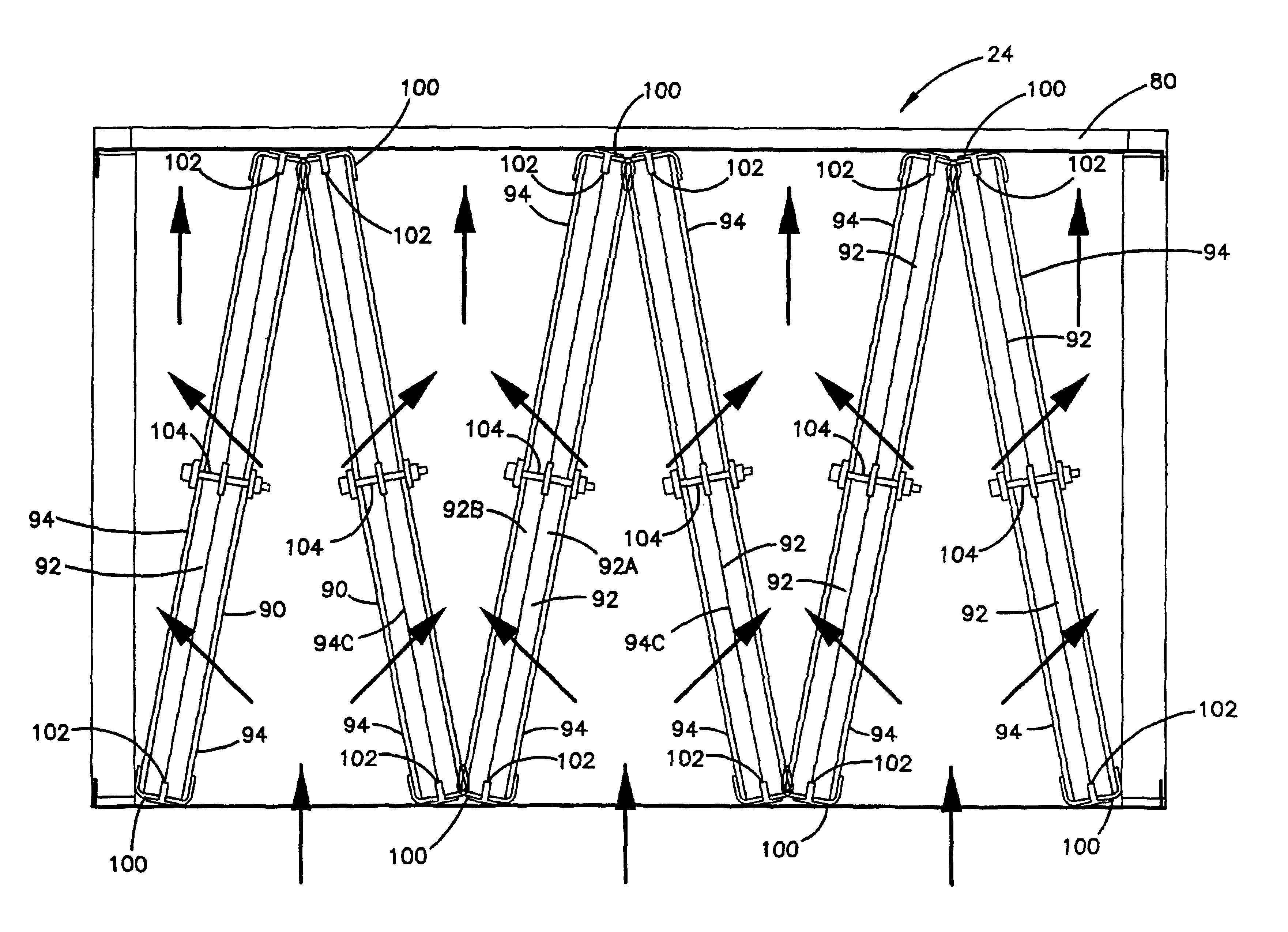

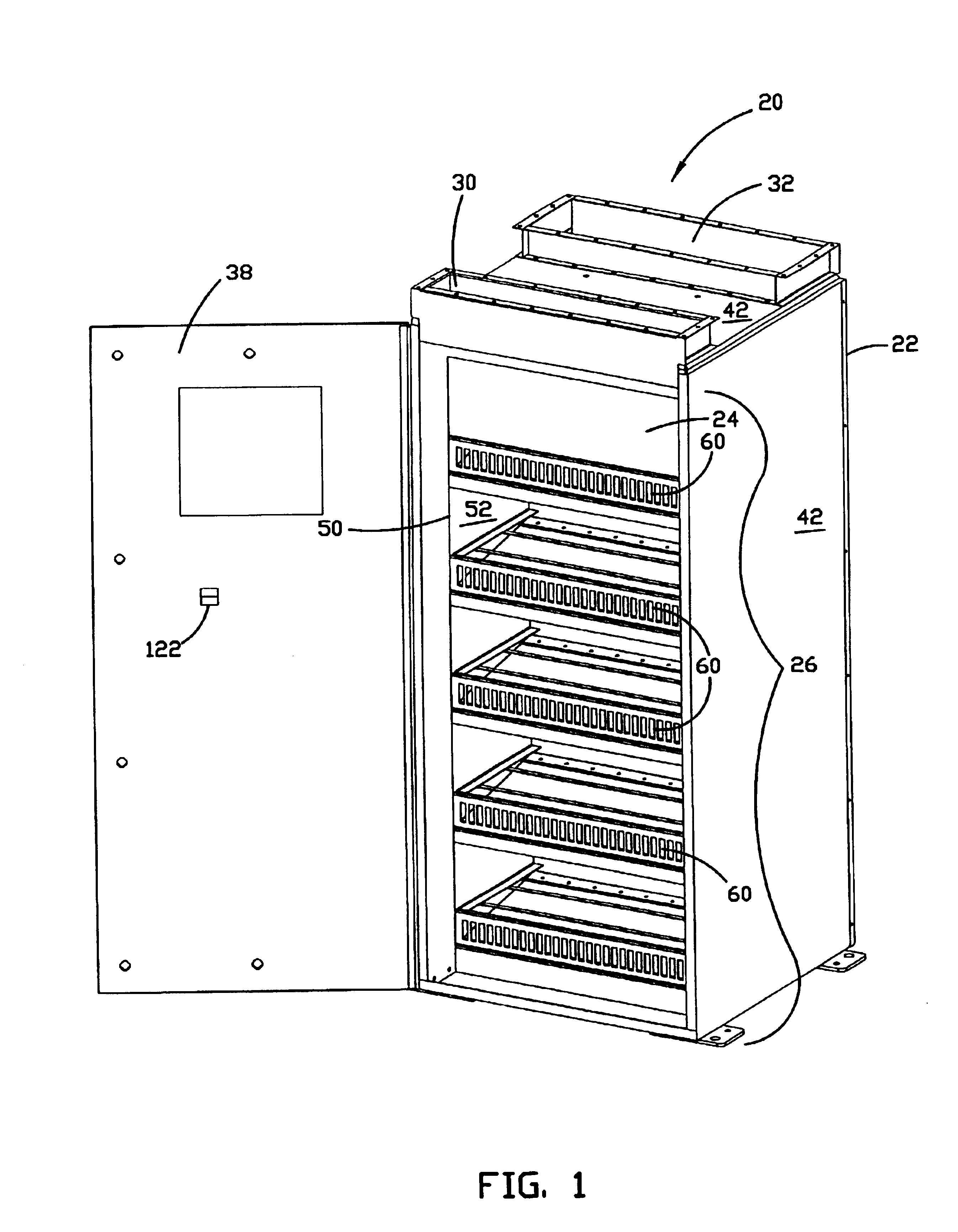

An adsorption bed arrangement includes a plurality of adsorption elements, a housing, and a gasket member. Each of the adsorption elements has a first adsorptive media and a second adsorptive media, which remove different contaminants from an incoming air stream. For example, the first adsorptive media removes acidic contaminants and the second adsorptive media removes basic contaminants. The housing defines an interior, a plurality of inlet openings, and a plurality of outlet openings. The adsorption elements are positioned within the housing interior and the housing is selectively openable to provide access to the adsorption elements. A method for changing the media includes removing an access panel from the adsorption bed housing to expose a cover member covering an end of an adsorption element; removing the cover member to expose media within the element; and pouring the media from the element.

Owner:DONALDSON CO INC

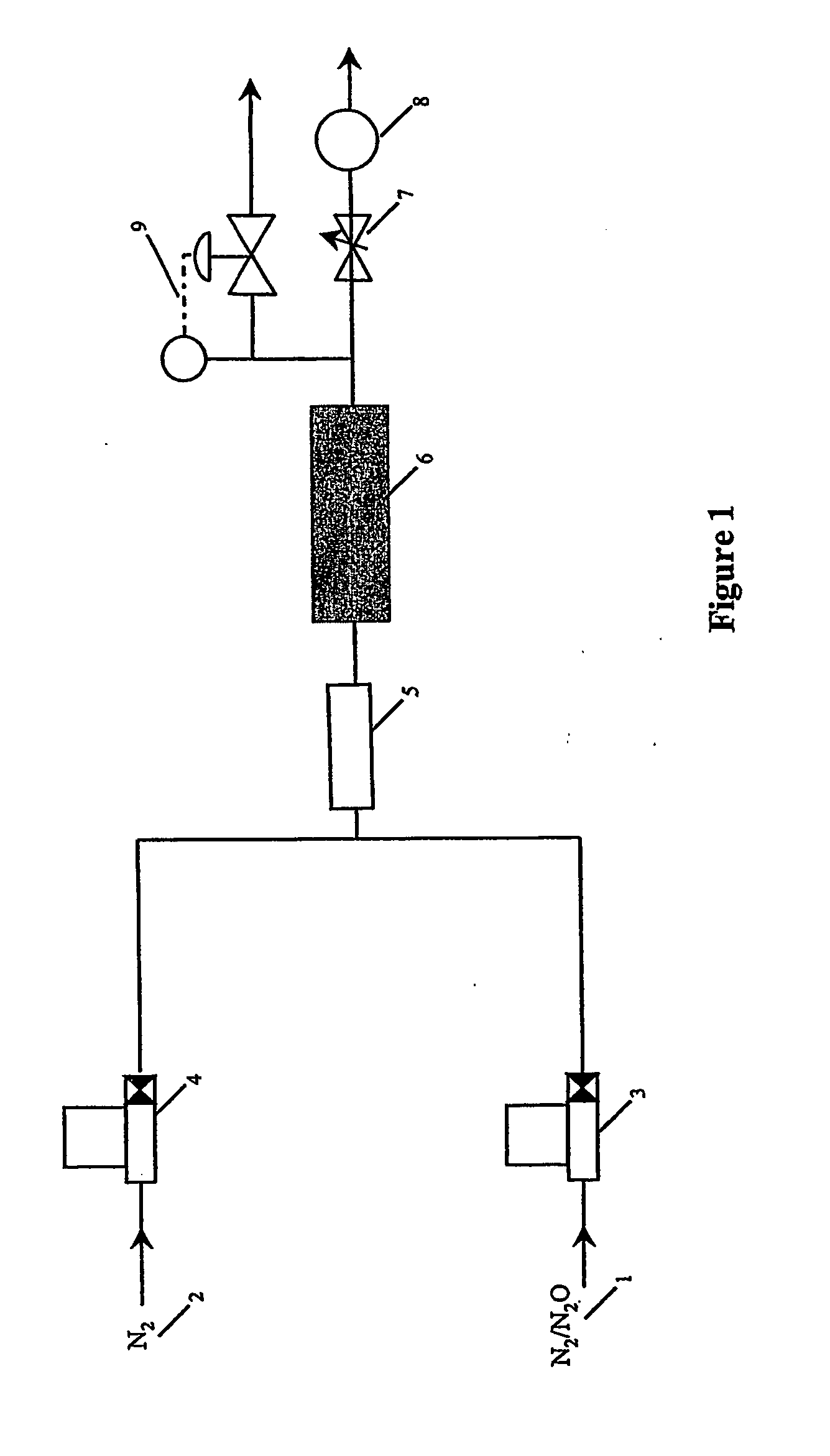

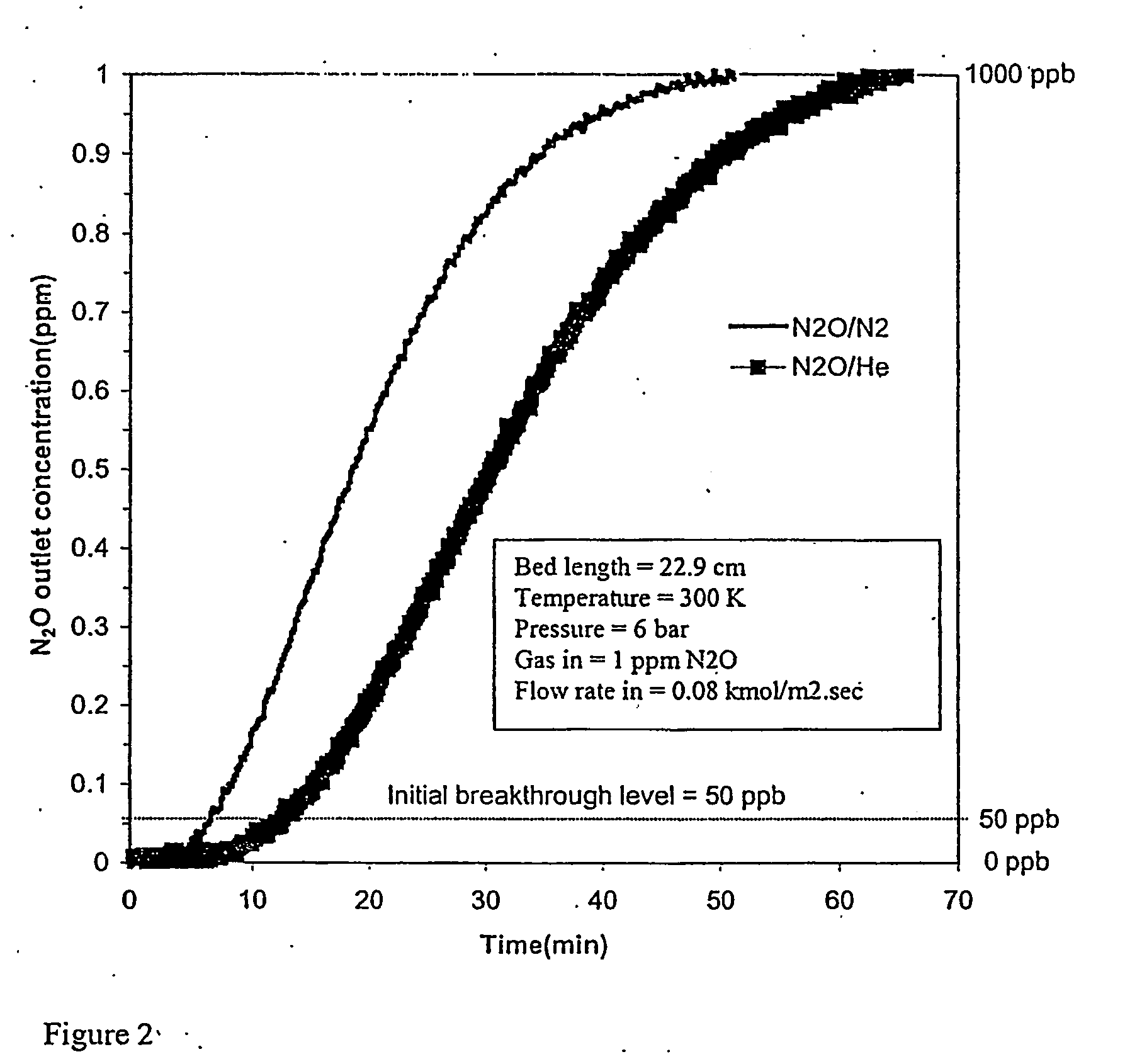

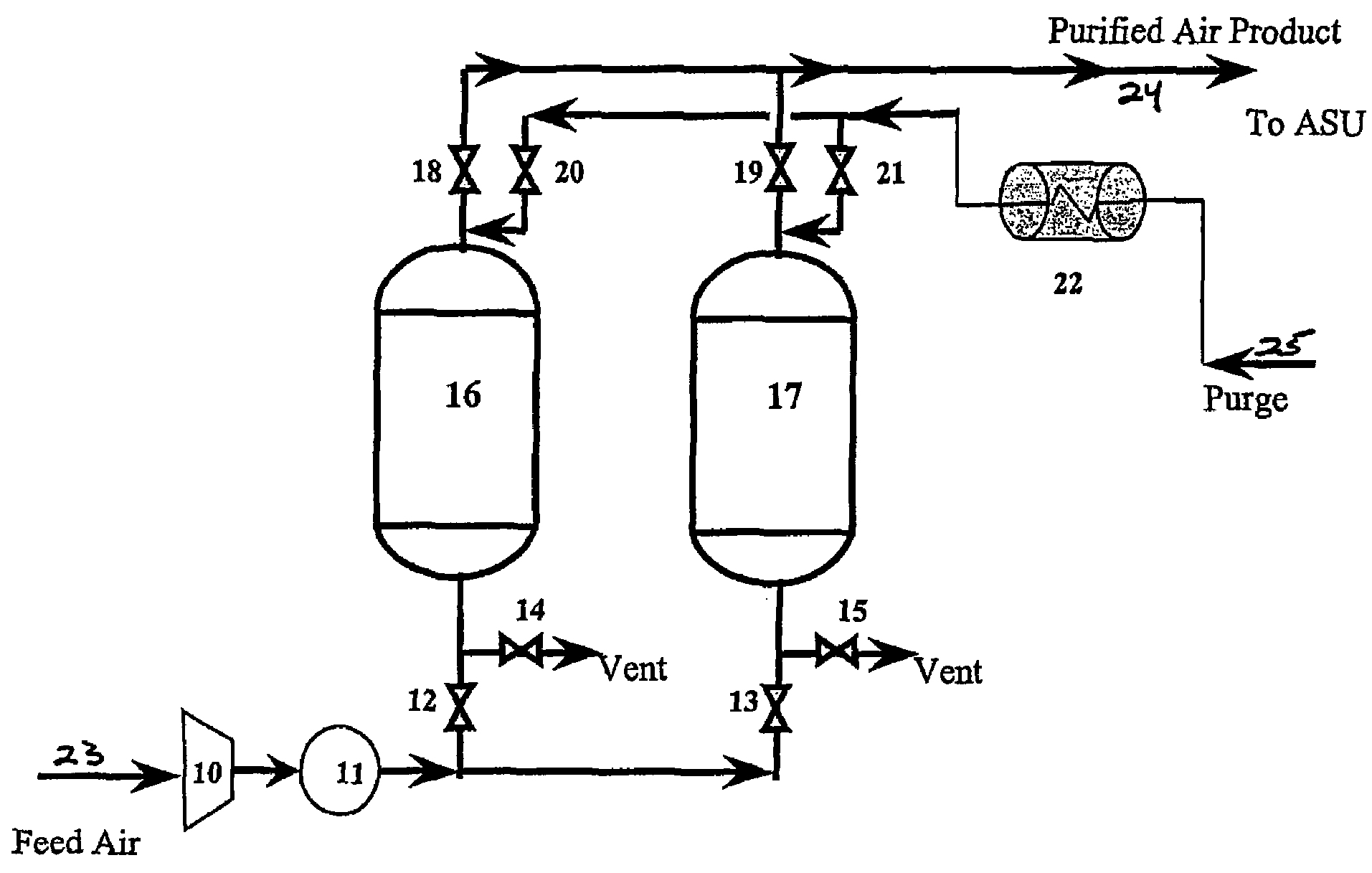

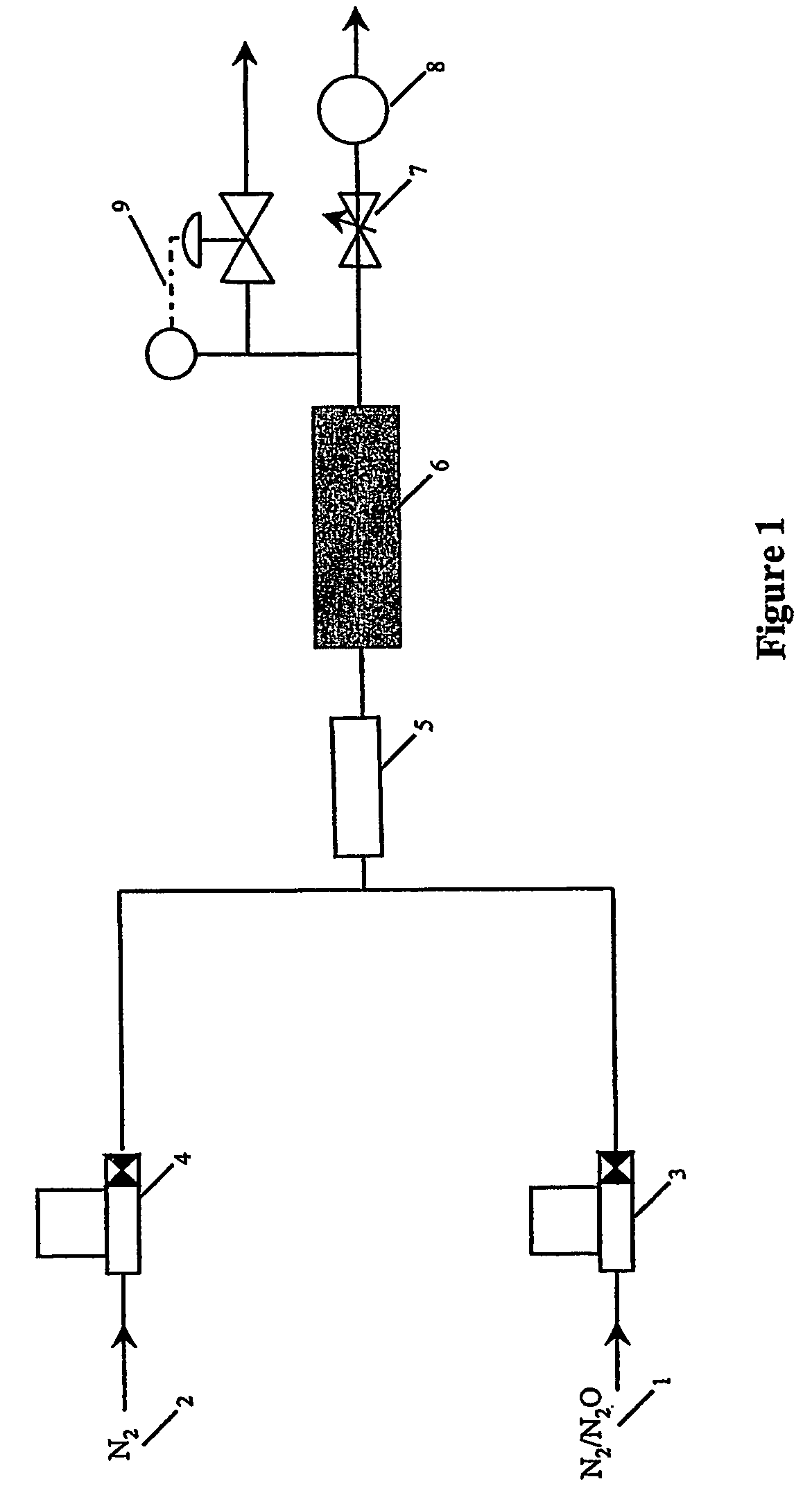

Method and apparatus for gas purification

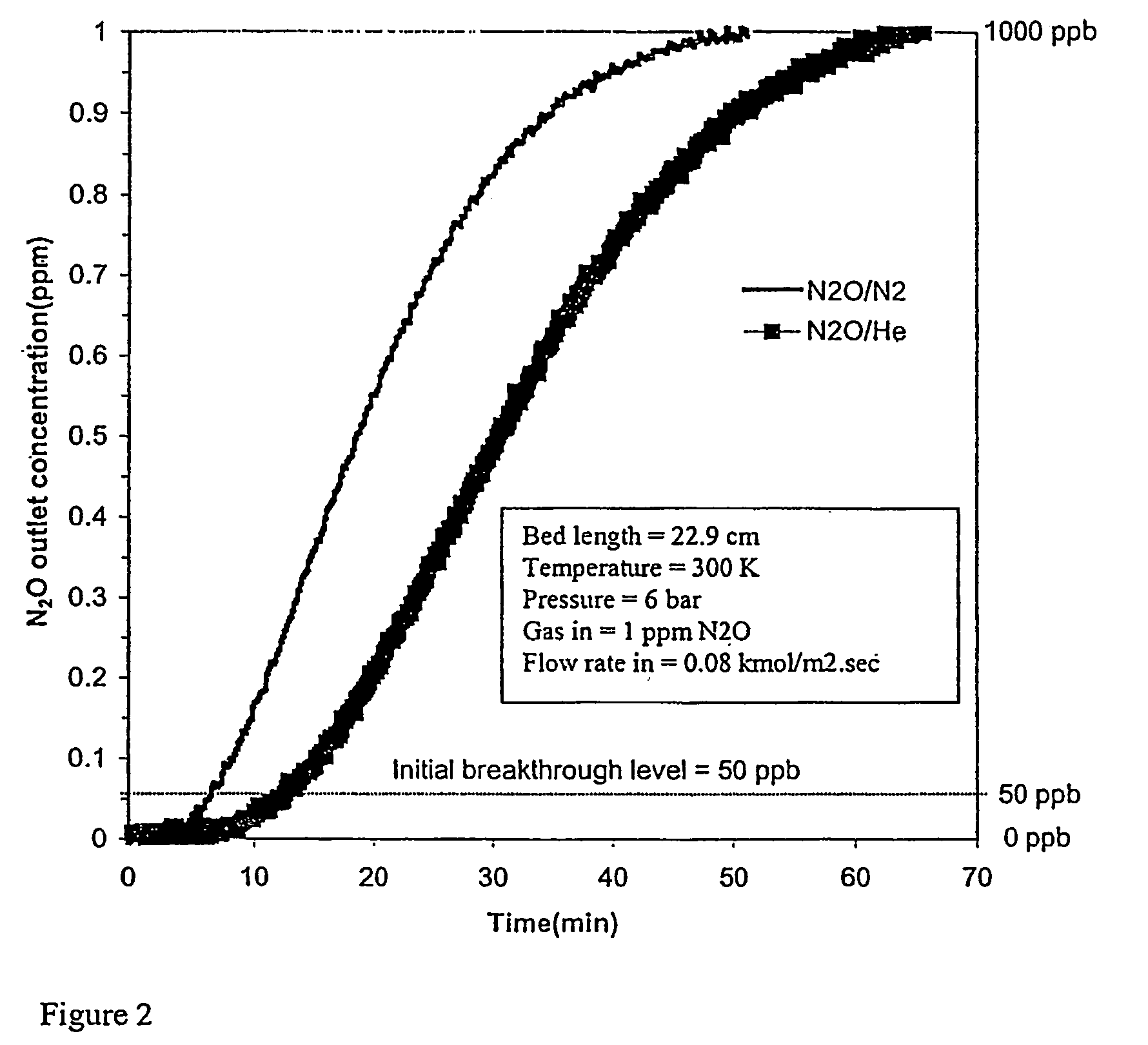

InactiveUS20060162556A1Superior N2O removal efficiencyNitrous oxide captureGas treatmentSeparation factorSorbent

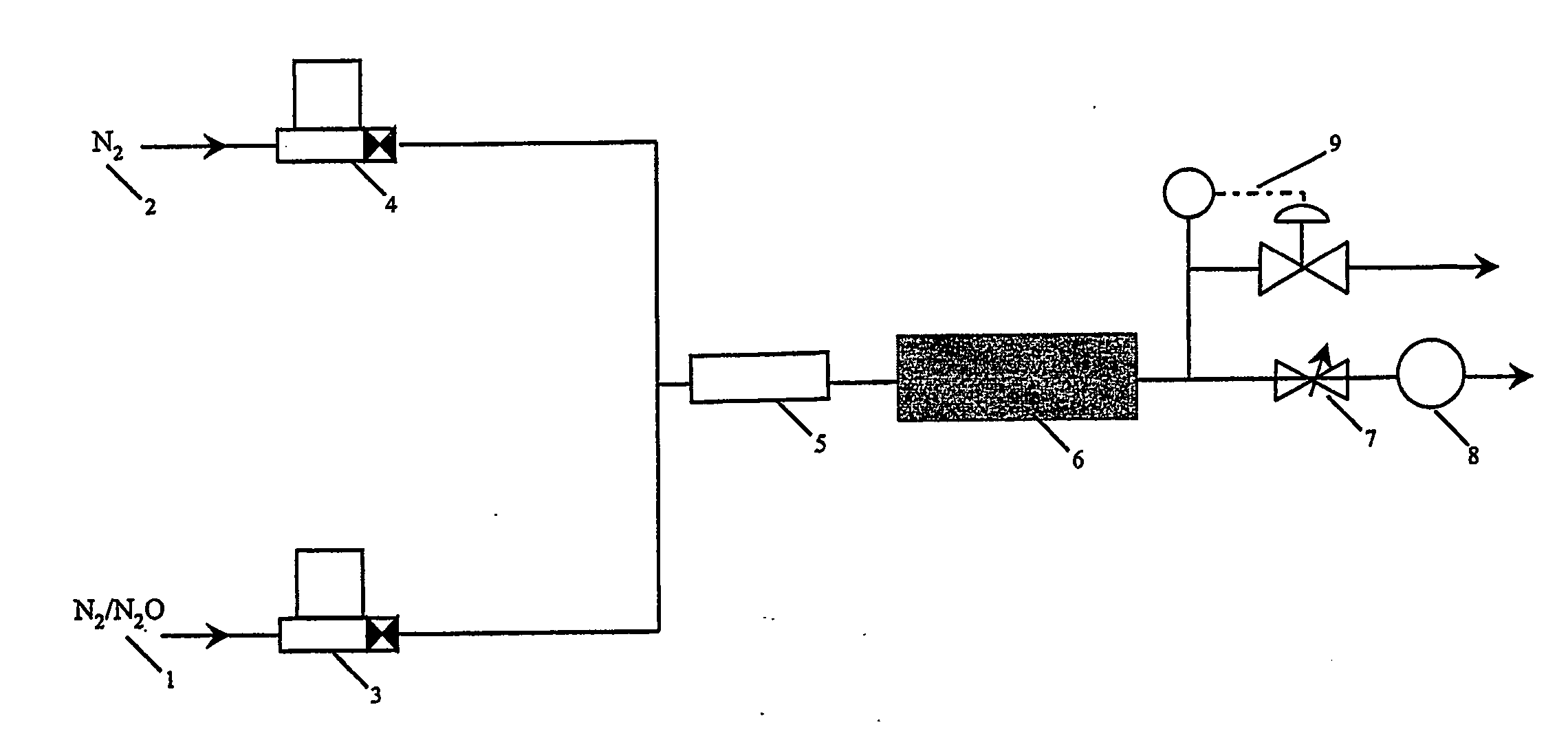

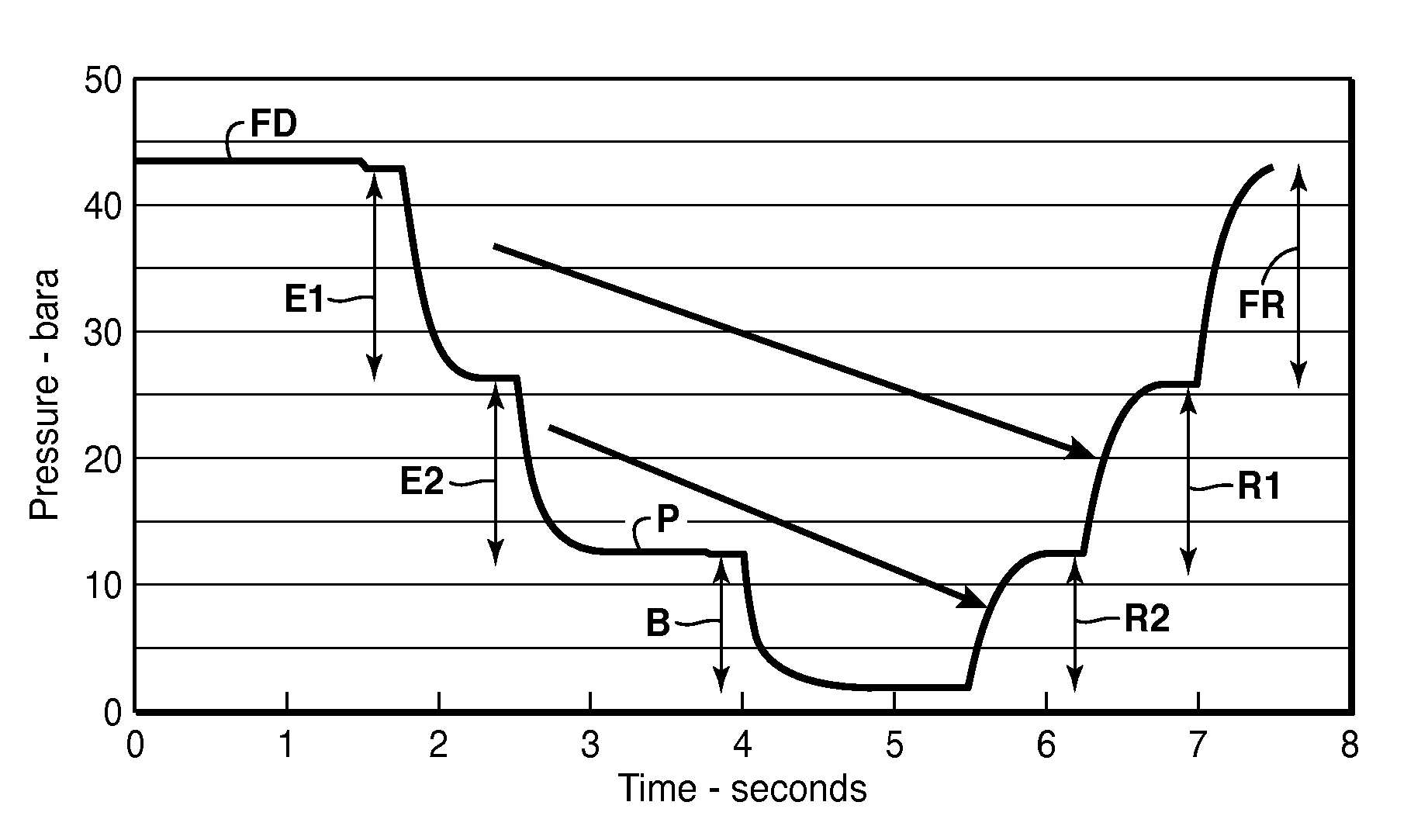

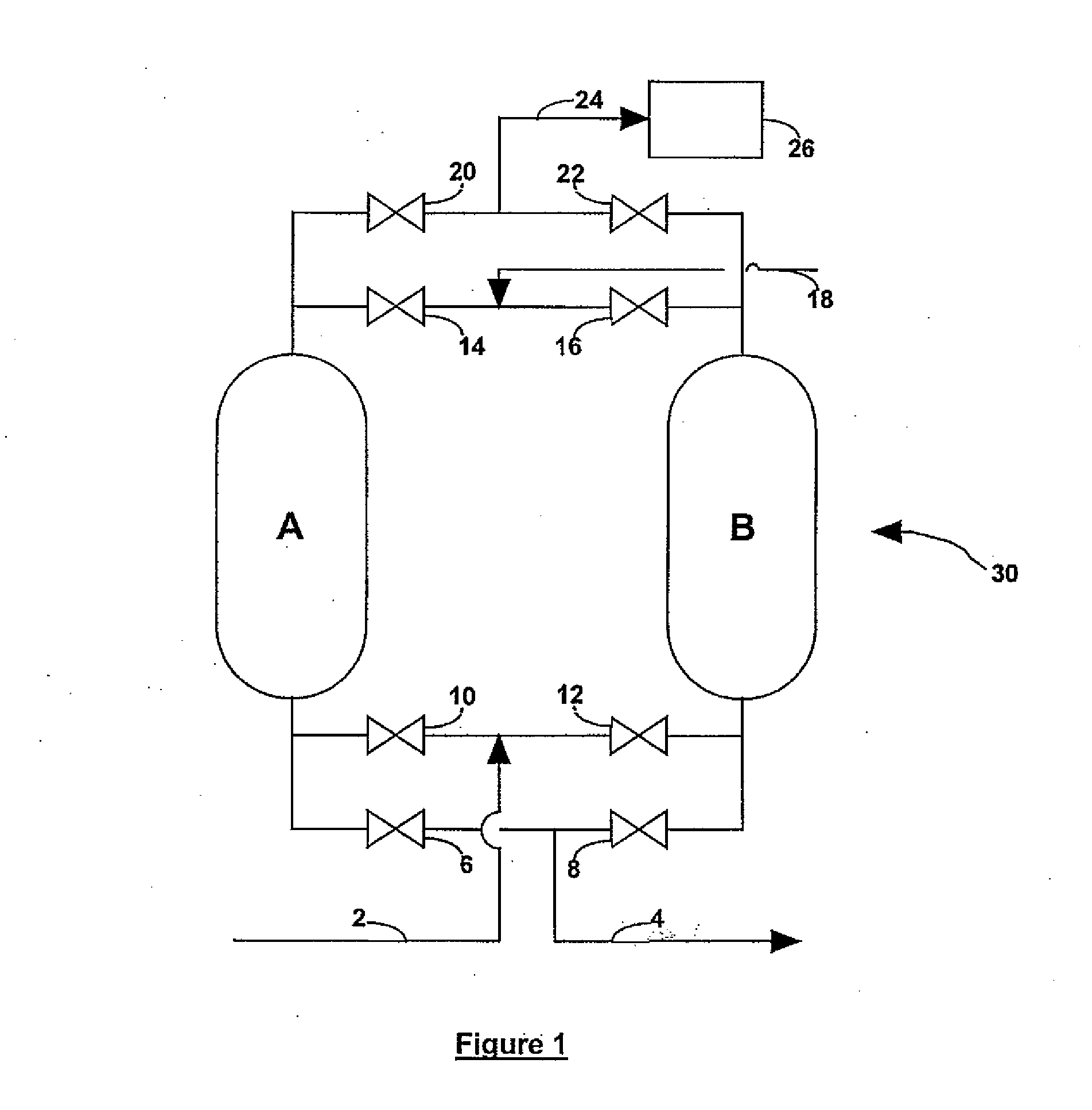

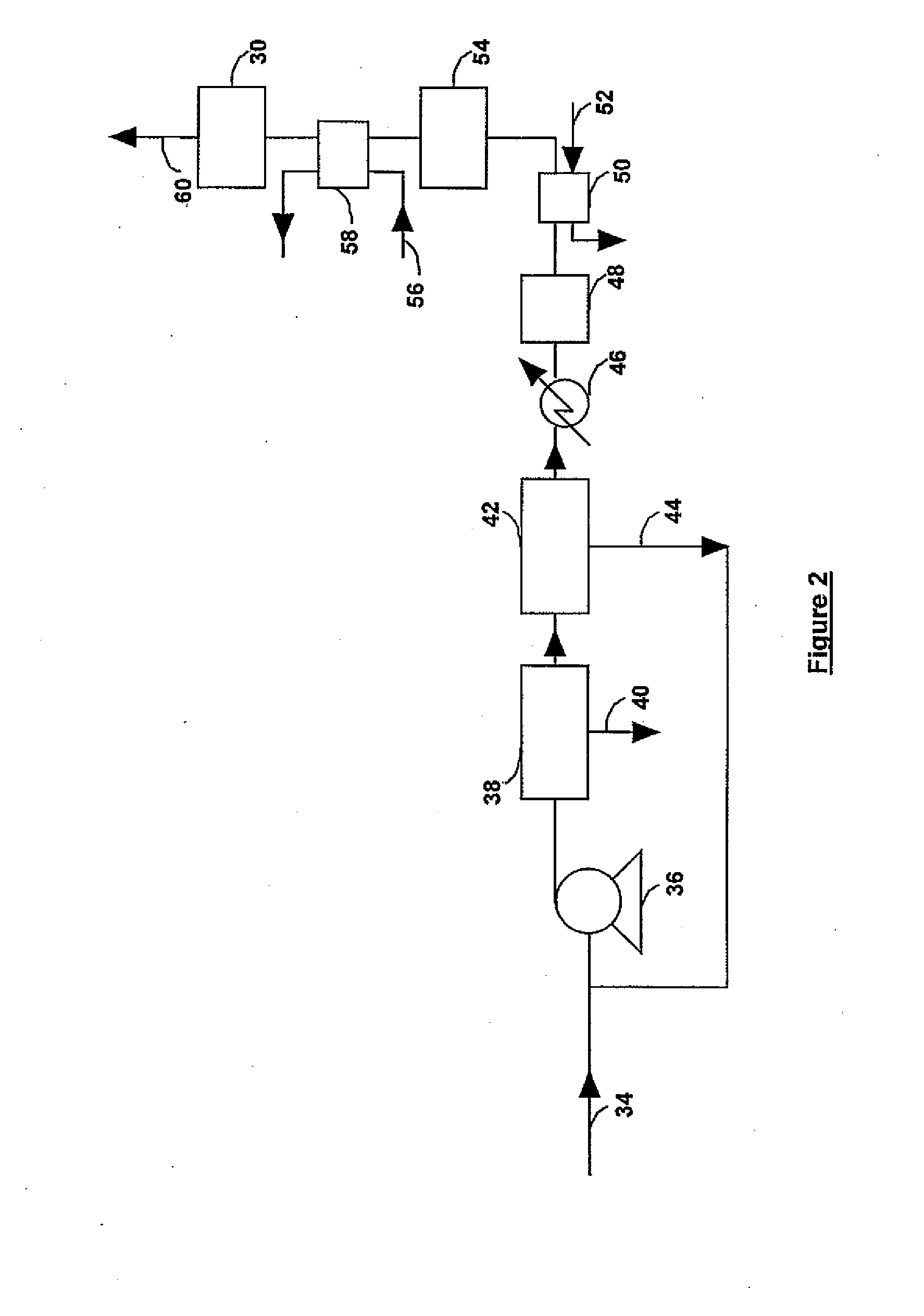

This invention comprises an adsorption process for the removal of at least N2O from a feed gas stream that also contains nitrogen and possibly CO2 and water. In the process the feed stream is passed over adsorbents to remove impurities such as CO2 and water, then over an additional adsorbent having a high N2O / N2 separation factor. In a preferred mode the invention is an air prepurification process for the removal of impurities from air prior to cryogenic separation of air. An apparatus for operating the process is also disclosed.

Owner:PRAXAIR TECH INC

Method and apparatus for gas purification

Owner:PRAXAIR TECH INC

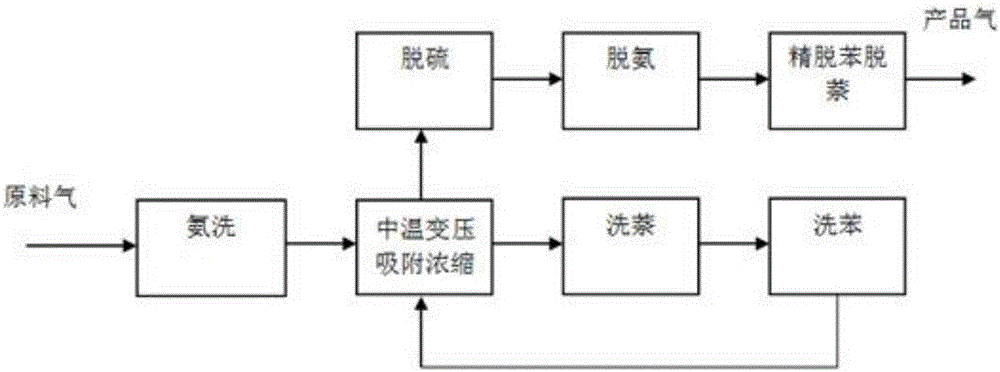

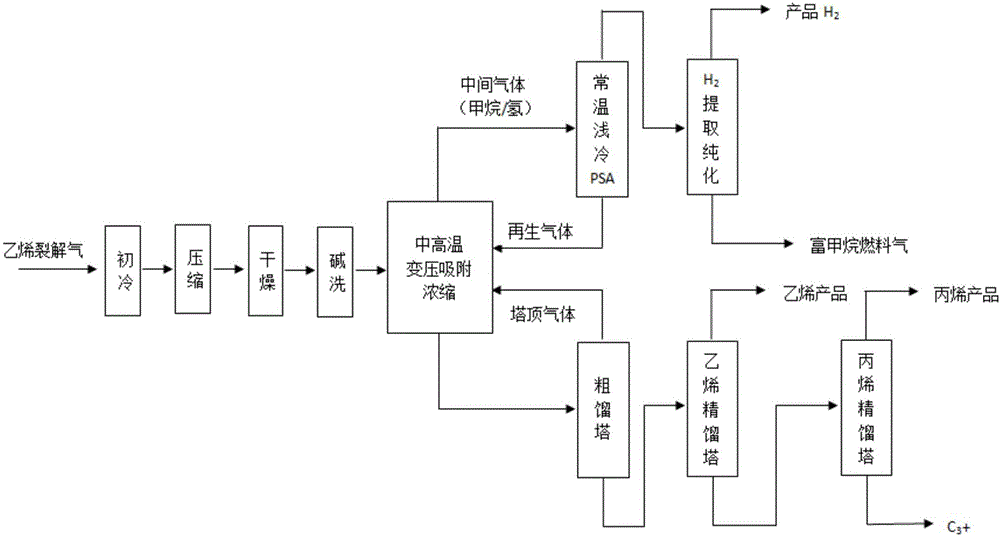

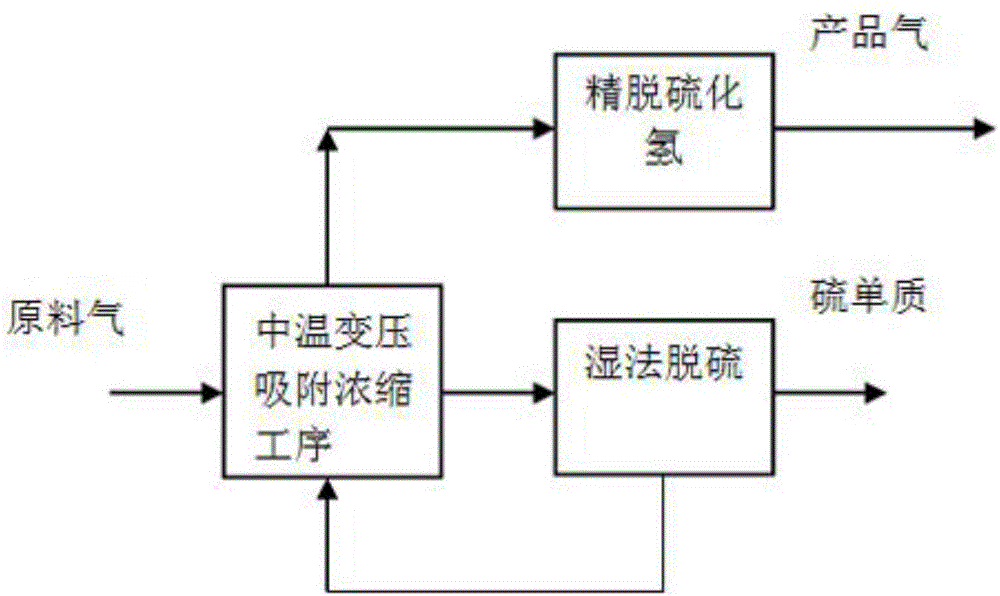

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

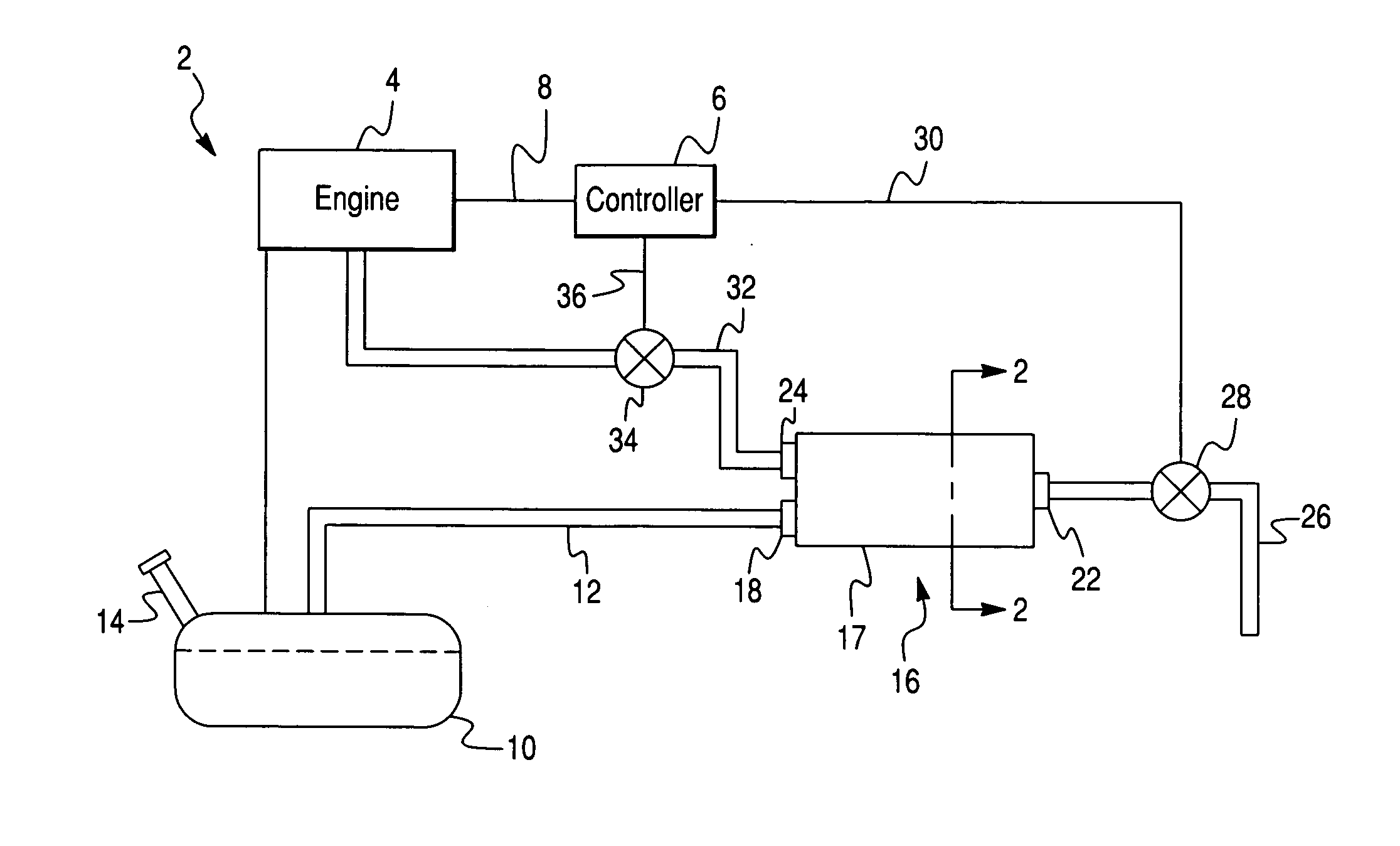

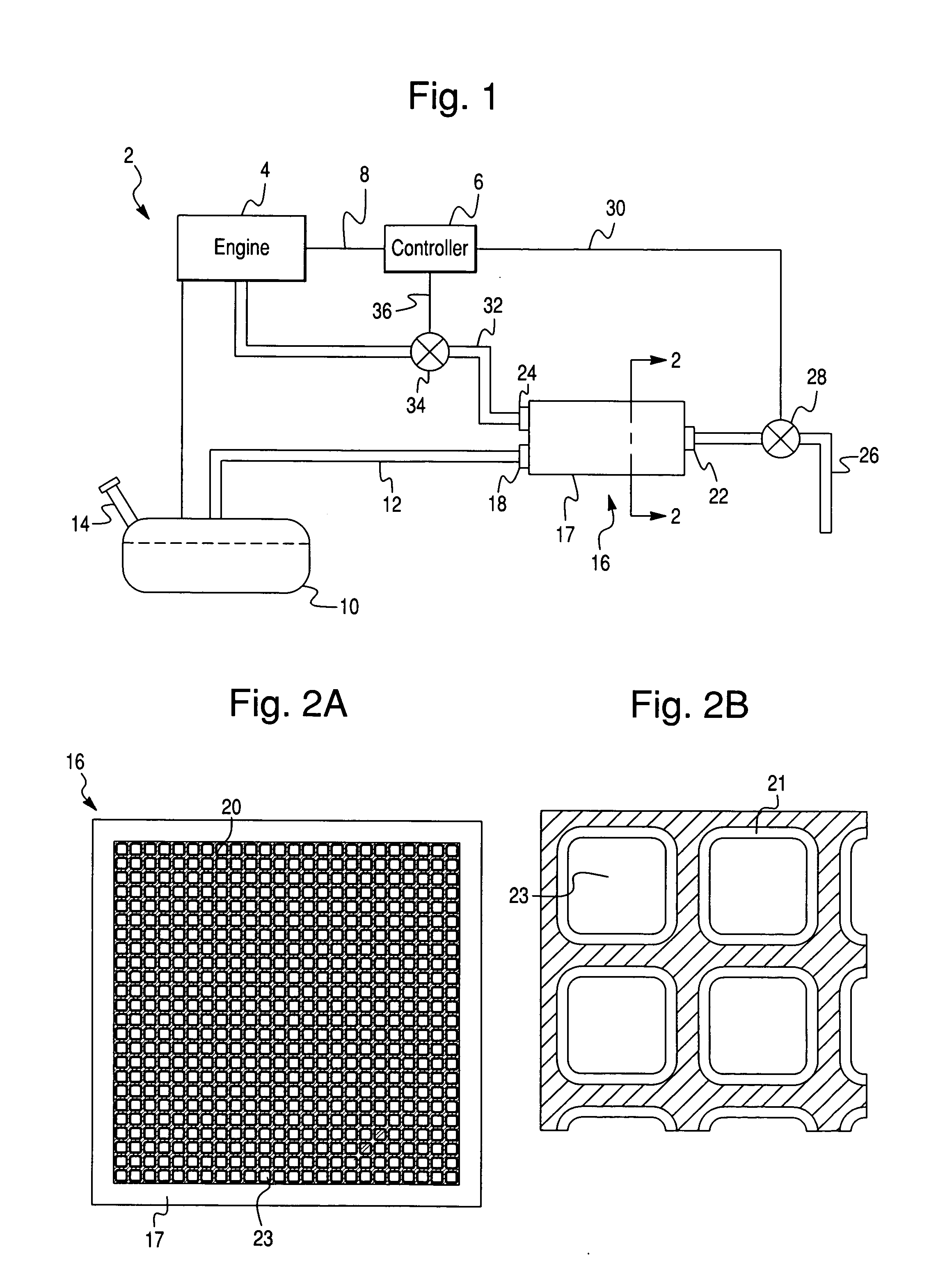

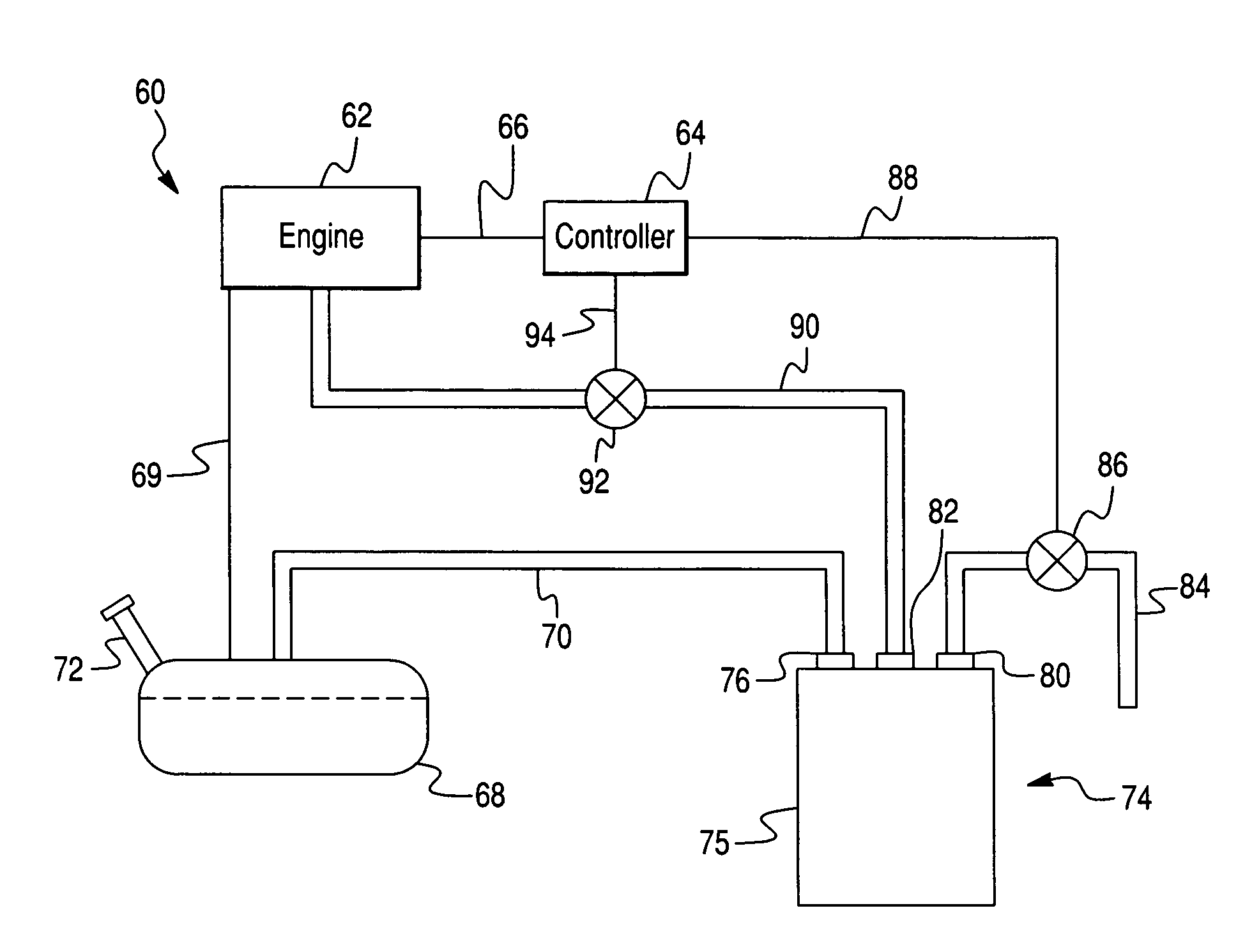

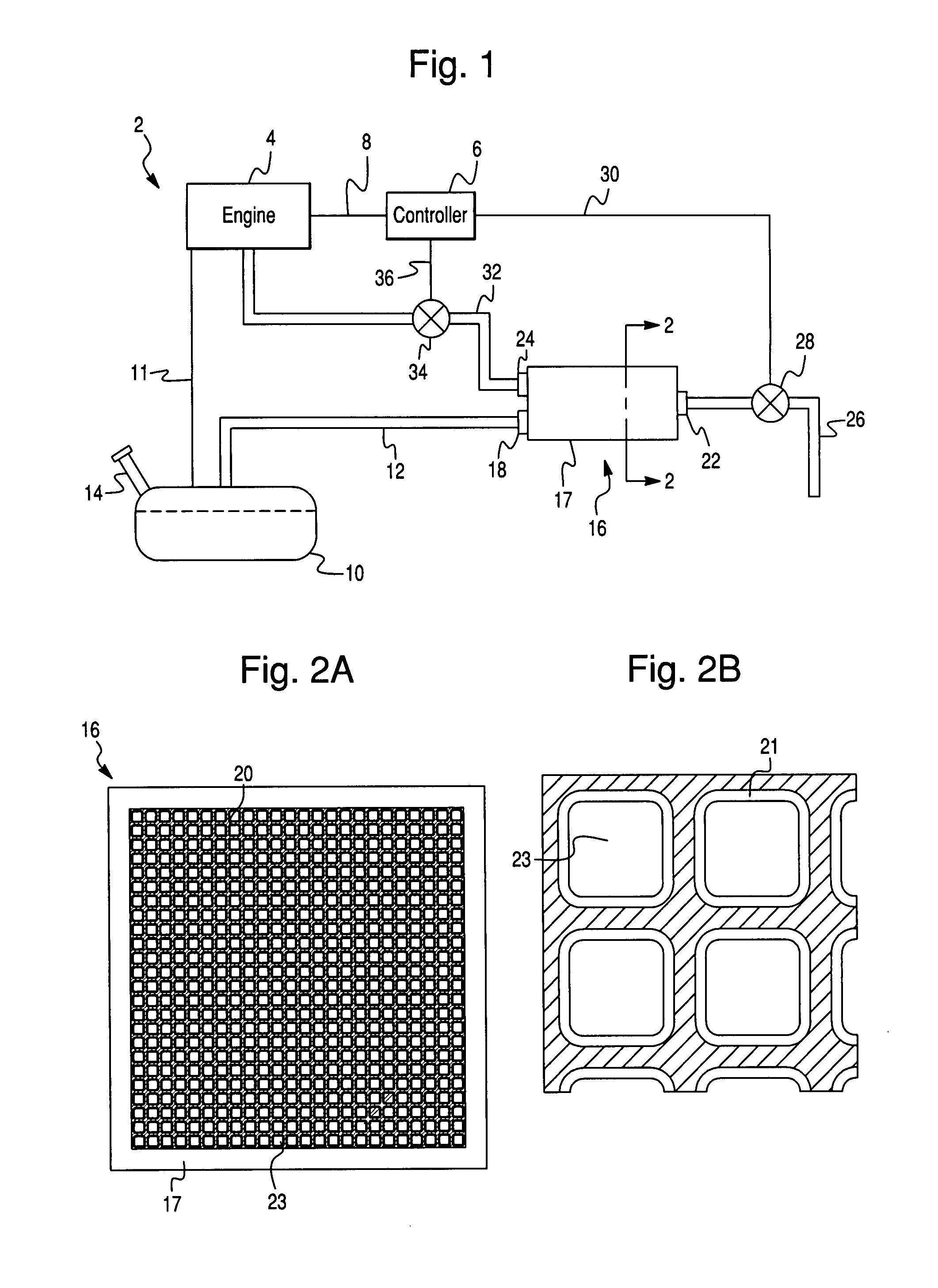

Hydrocarbon adsorpotion method and device for controlling evaporative emissions from the fuel storage system of motor vehicles

ActiveUS20070113831A1Reducing vapor releasedReduce the amount of fuelGas treatmentNon-fuel substance addition to fuelHydrocotyle bowlesioidesSlurry

The present invention is directed to an evaporative emissions control apparatus for minimizing fuel vapor emissions from a fuel storage system in a vehicle with an internal combustion engine. More specifically, the present invention is directed to an evaporative emissions control apparatus comprising a canister filled with a hydrocarbon adsorbent. The present invention is also directed an evaporative emissions control apparatus comprising a support substrate, which is coated with a hydrocarbon adsorbent slurry.

Owner:BASF CATALYSTS LLC

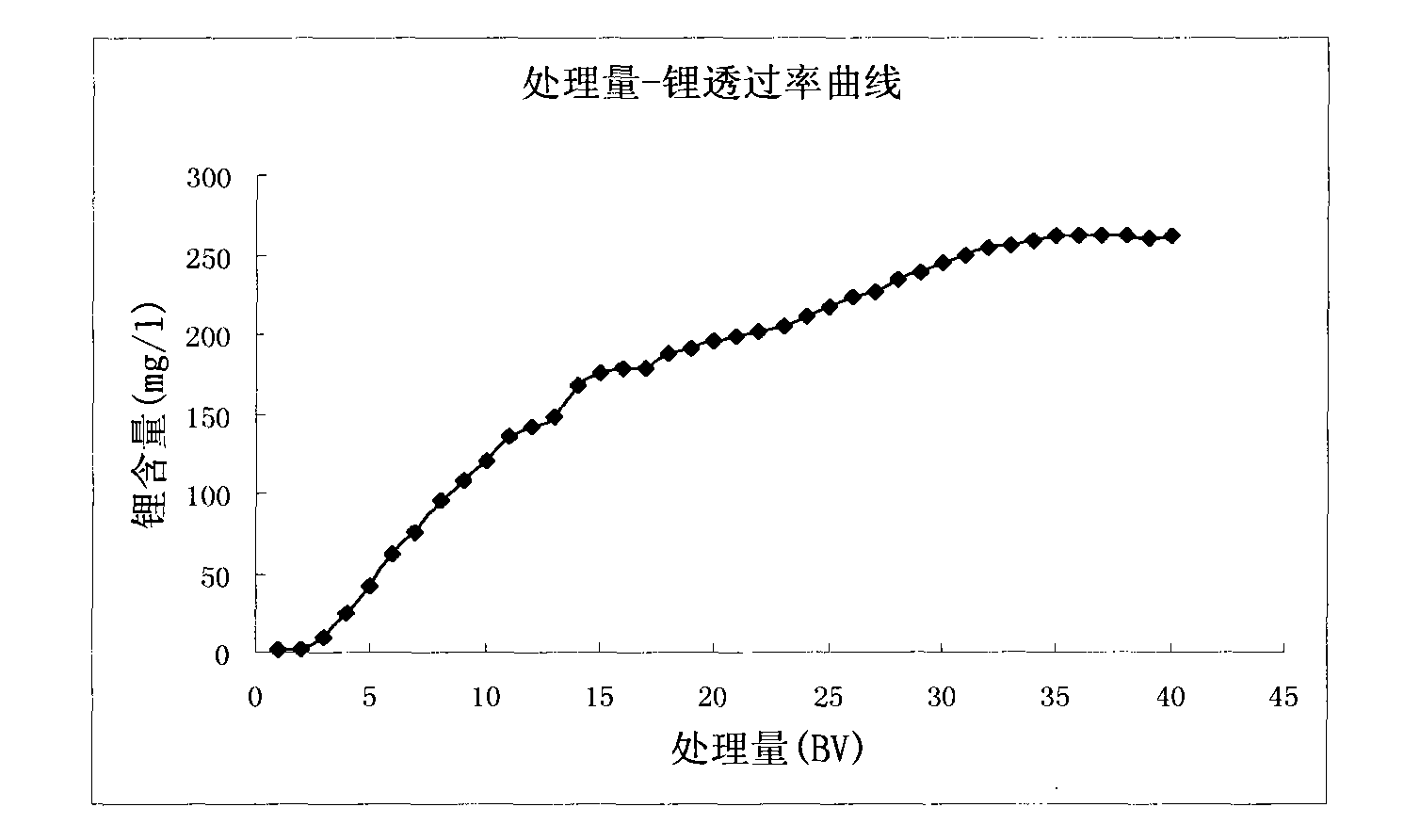

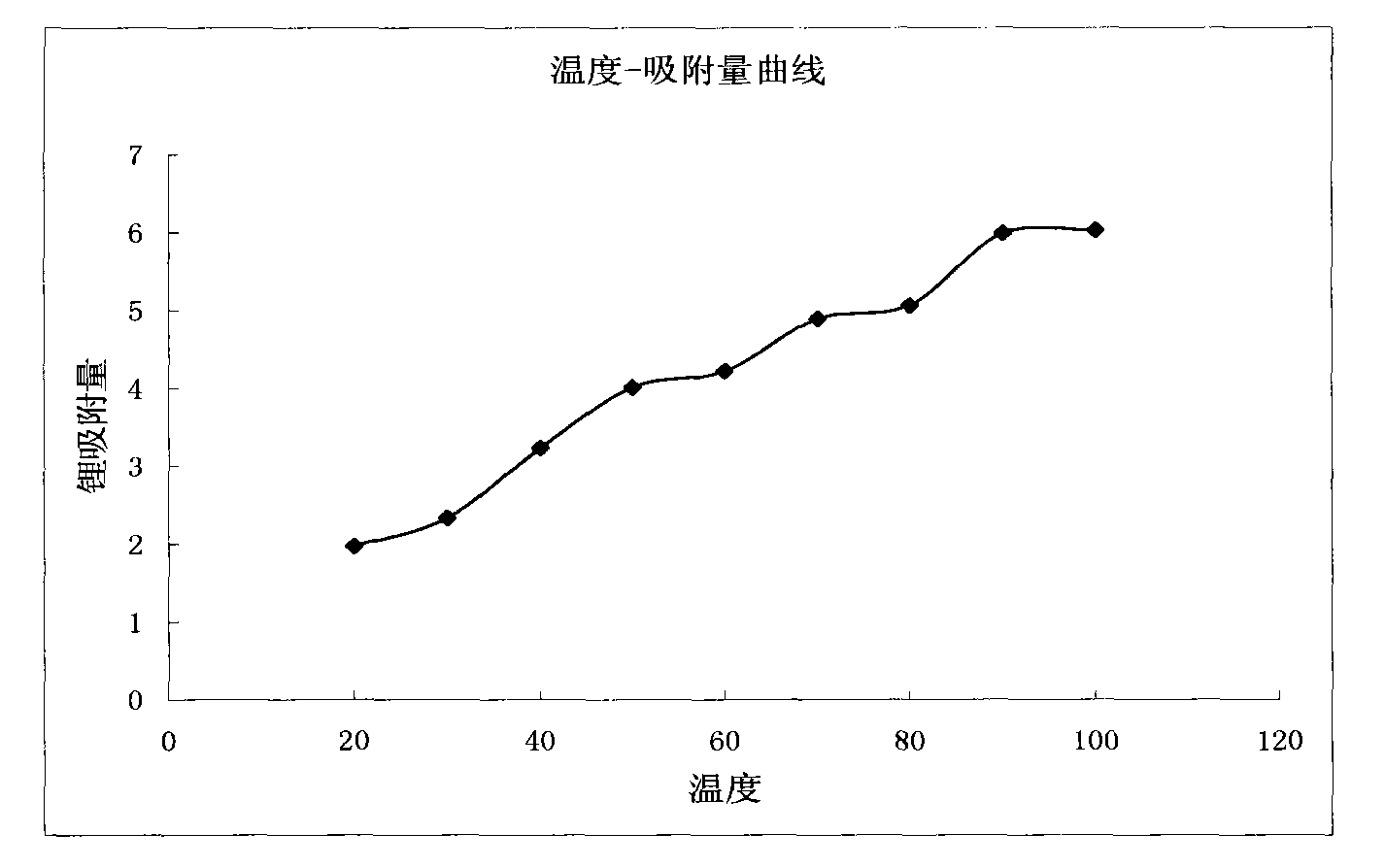

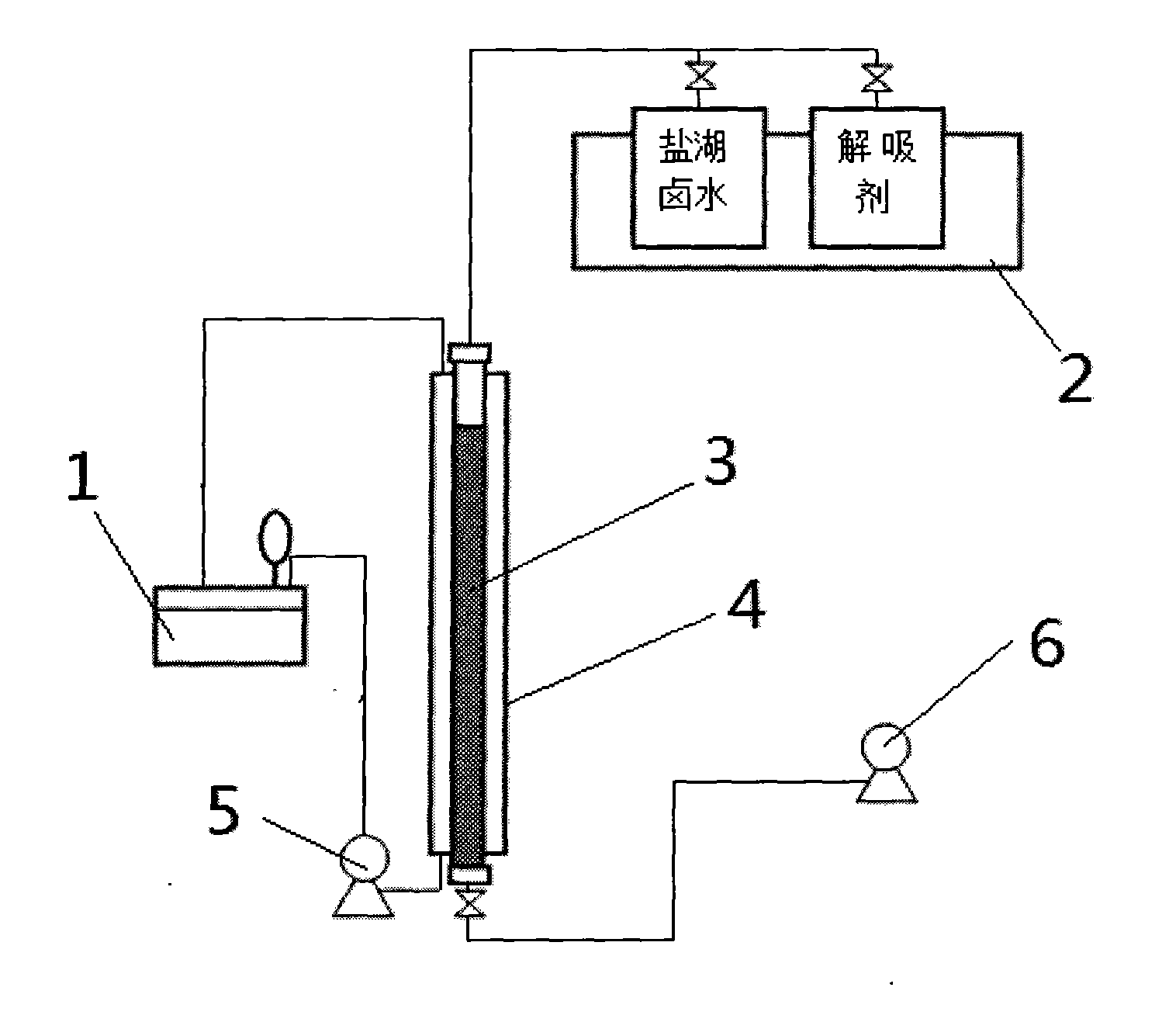

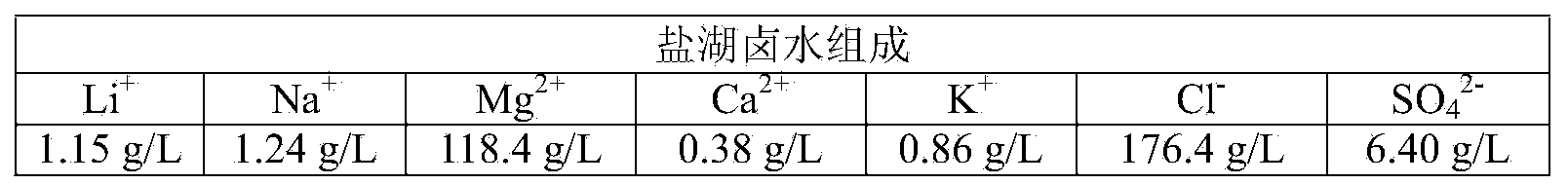

Method for extracting lithium from salt lake brine by adsorption method

ActiveCN101928828ALow investment costHigh adsorption capacityProcess efficiency improvementSODIUM CATIONSalt lake

The invention discloses a method for extracting lithium from salt lake brine by an adsorption method. The method comprises the following steps of: (1) making the salt lake brine pass through aluminum salt-containing adsorption resin at a speed of between 5 and 10 BV / H at the temperature of between 20 and 100 DEG C to ensure that the lithium ions in the salt lake brine are adsorbed on the adsorption resin; (2) making lithium ion eluant pass through the aluminum salt-containing adsorption resin at a speed of between 5 and 10 BV / H at the temperature of between 20 and 100 DEG C to ensure that thelithium ions adsorbed on the aluminum salt-containing adsorption resin are eluted and desorbed into the eluant solution so as to obtain desorption liquid; and (3) making the desorption liquid pass through common sodium cation exchange resin at a speed of between 5 and 10 BV / H to remove magnesium from the desorption liquid, and then concentrating to obtain a lithium salt. The method has the advantages of low consumption of chemical materials, simple process, easy operation and no pollution.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

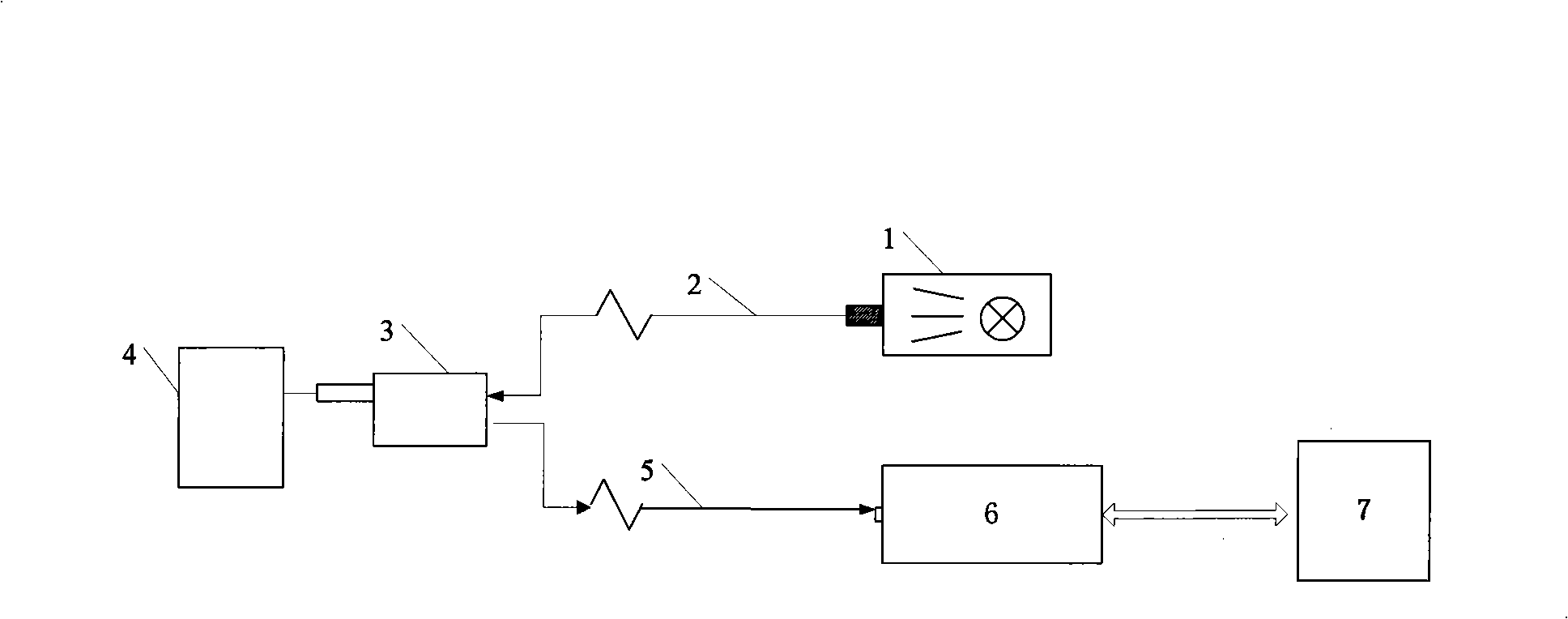

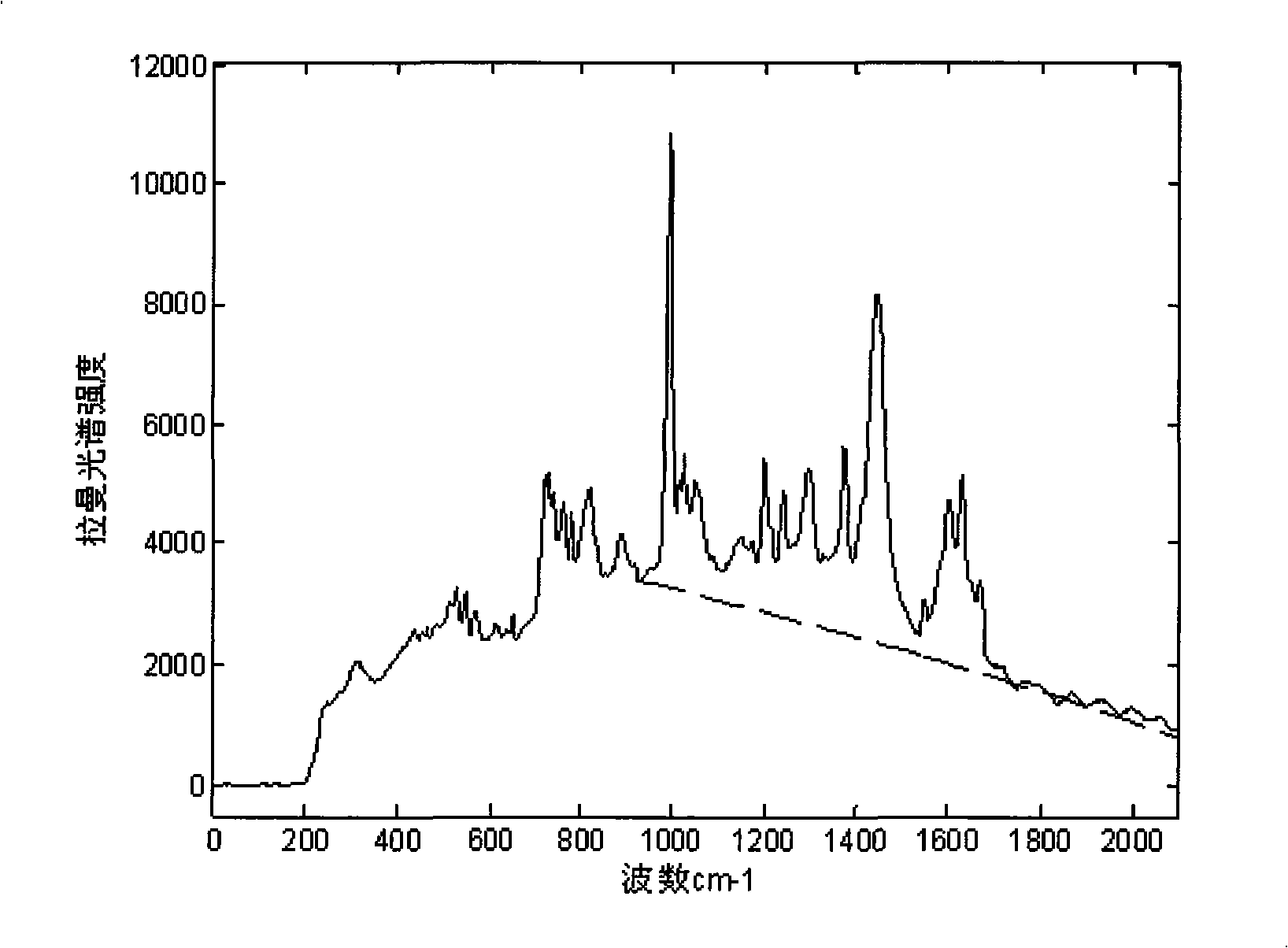

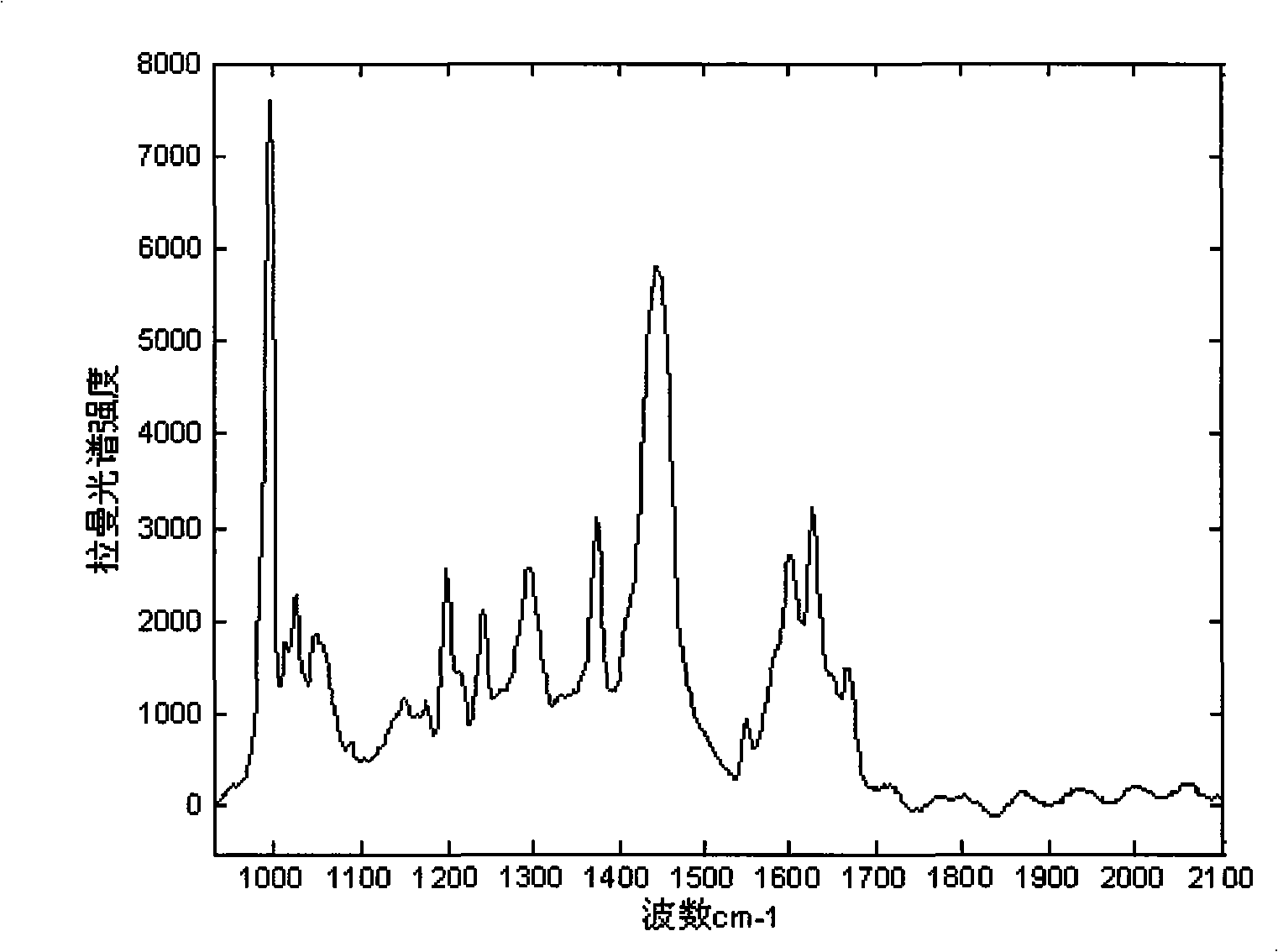

Method for measuring gasoline olefin content based on Raman spectrum

InactiveCN101403696AImprove detection accuracyReduced measurement timeRaman scatteringOil processingFiltration

The invention discloses a method used for measuring the content of gasoline olefin on the basis of Raman spectra, sequentially comprising the steps as follows: the content of olefin in a training sample is measured by a fluorescent indicator adsorption method or a multidimensional gas chromatography; the Raman spectra of the training sample is measured; the measured Raman spectra is preprocessed by smooth filtration, benchmark line correction and standard normalization; a gasoline olefin content correction model is established by applying a least squares support vector machine on the Raman spectra of the preprocessed training sample and the measured olefin content; the Raman spectra of the oil sample to be measured is measured and the Raman spectra is preprocessed by smooth filtration, benchmark line correction and standard normalization; and the olefin content of the oil sample to be measured is calculated according to the correction model. The method combines the Raman spectra with the least squares support vector machine to analyze the content of the olefin in the gasoline, obviously improves the detection precision, greatly shortens the measurement time simultaneously, has no consumption of the sample during the measurement process, and has important significance on the quality control during the oil processing.

Owner:ZHEJIANG UNIV

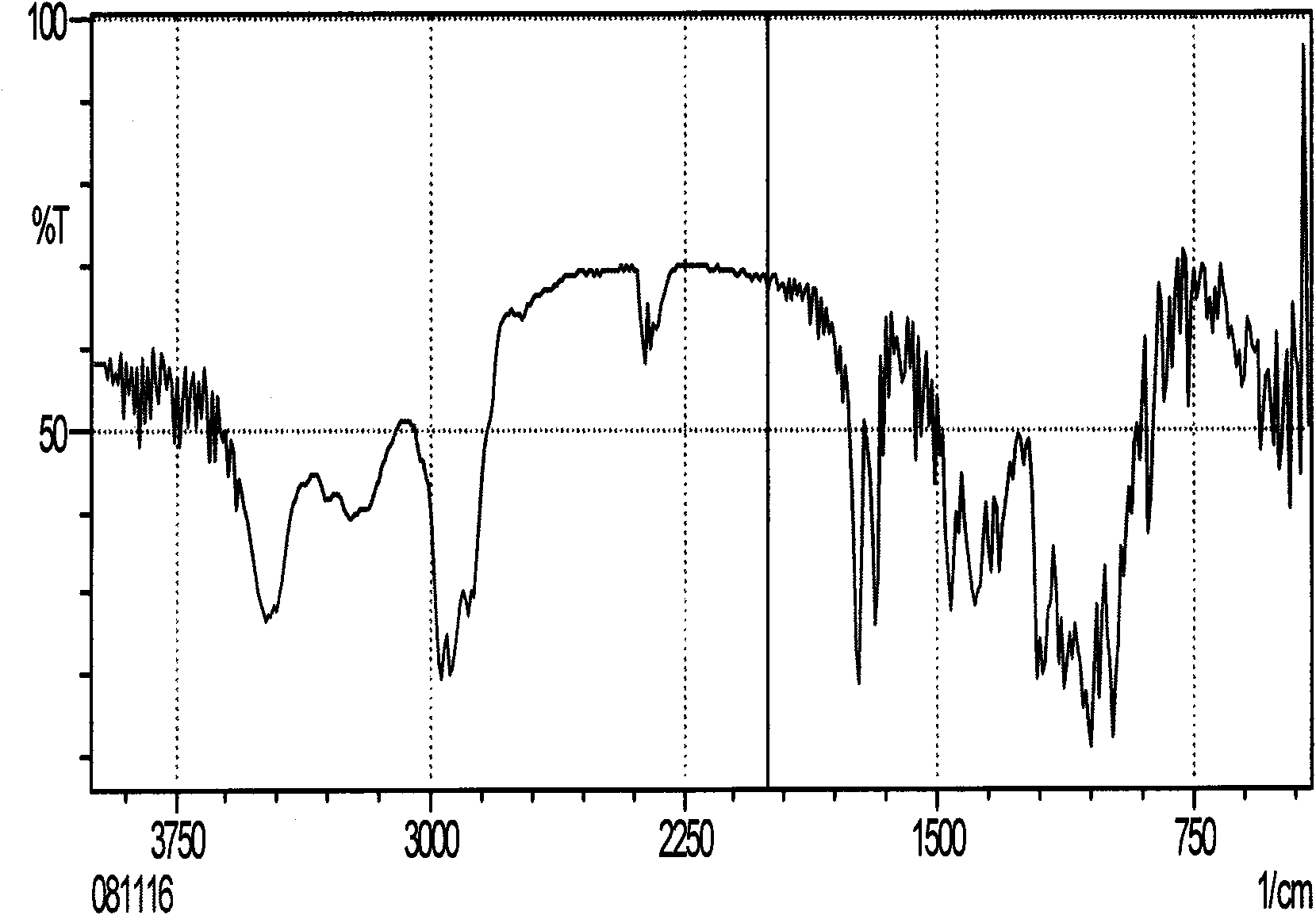

Adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound

InactiveCN101589709AHas biodegradable propertiesQuality improvementBiocideAnimal repellantsBurst effectPhosphate

The invention discloses an adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound, which comprises the following steps: soaking a nano hydroxyapatite carrier in phosphate buffer solution, then adding a starting material into the buffer solution and continuously stirring the mixture to form compound solution, finally centrifuging the compound solution to obtain sediment, and drying the sediment to obtain the compound. By using a porous structure of the nano hydroxyapatite self to embed medicaments into an internal grid of the carrier, the burst effect of the medicaments is avoided, the medicinal effect is long, the medicament residue is greatly reduced, and the medicaments are safer. A product obtained by using the nano hydroxyapatite as a pesticide and fertilizer carrier has the advantages of reliable quality, strong stability, safe use and low cost, greatly improves the medicament loading amount and adsorption amount, is easy for continuous production, and has good application prospect.

Owner:JILIN UNIV

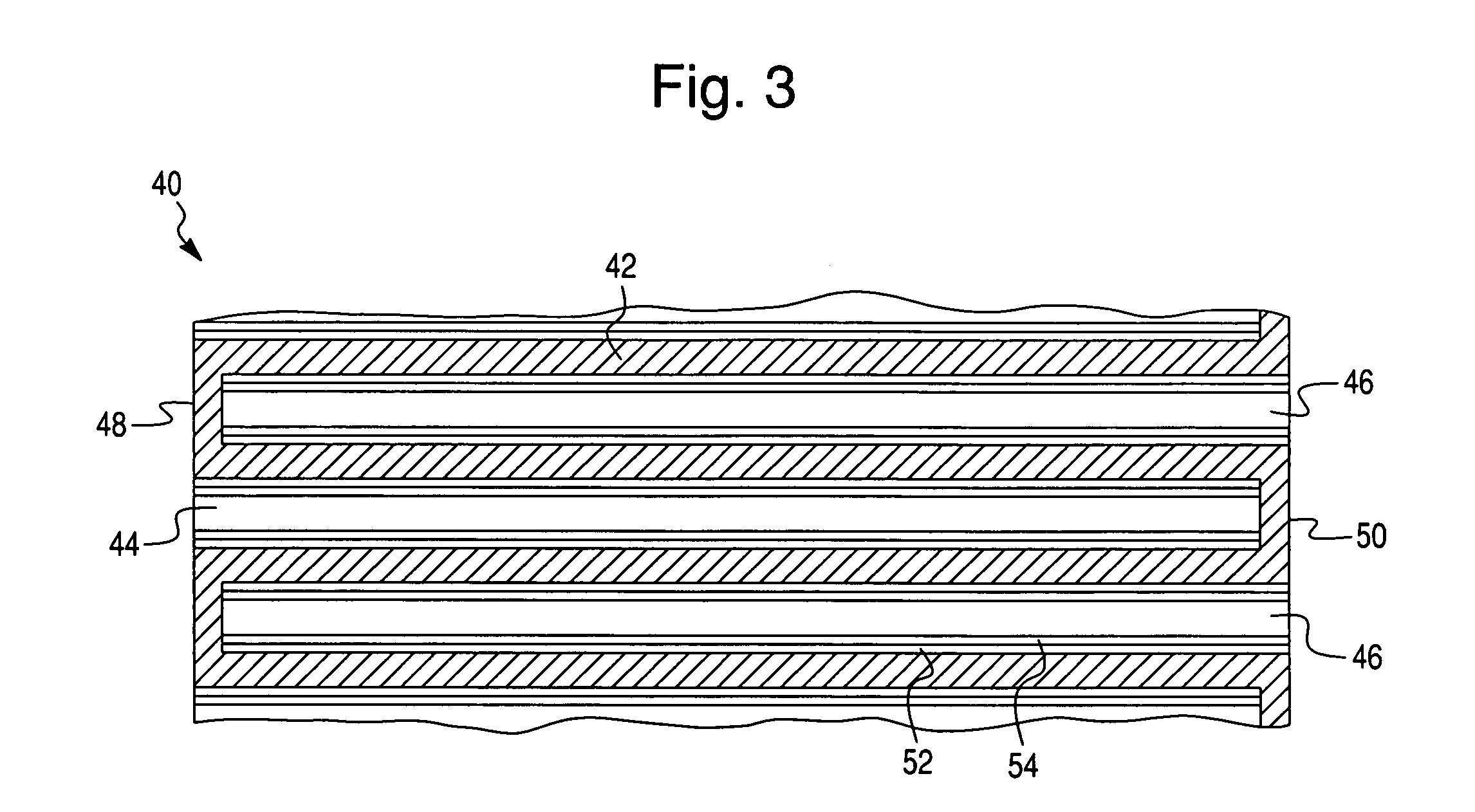

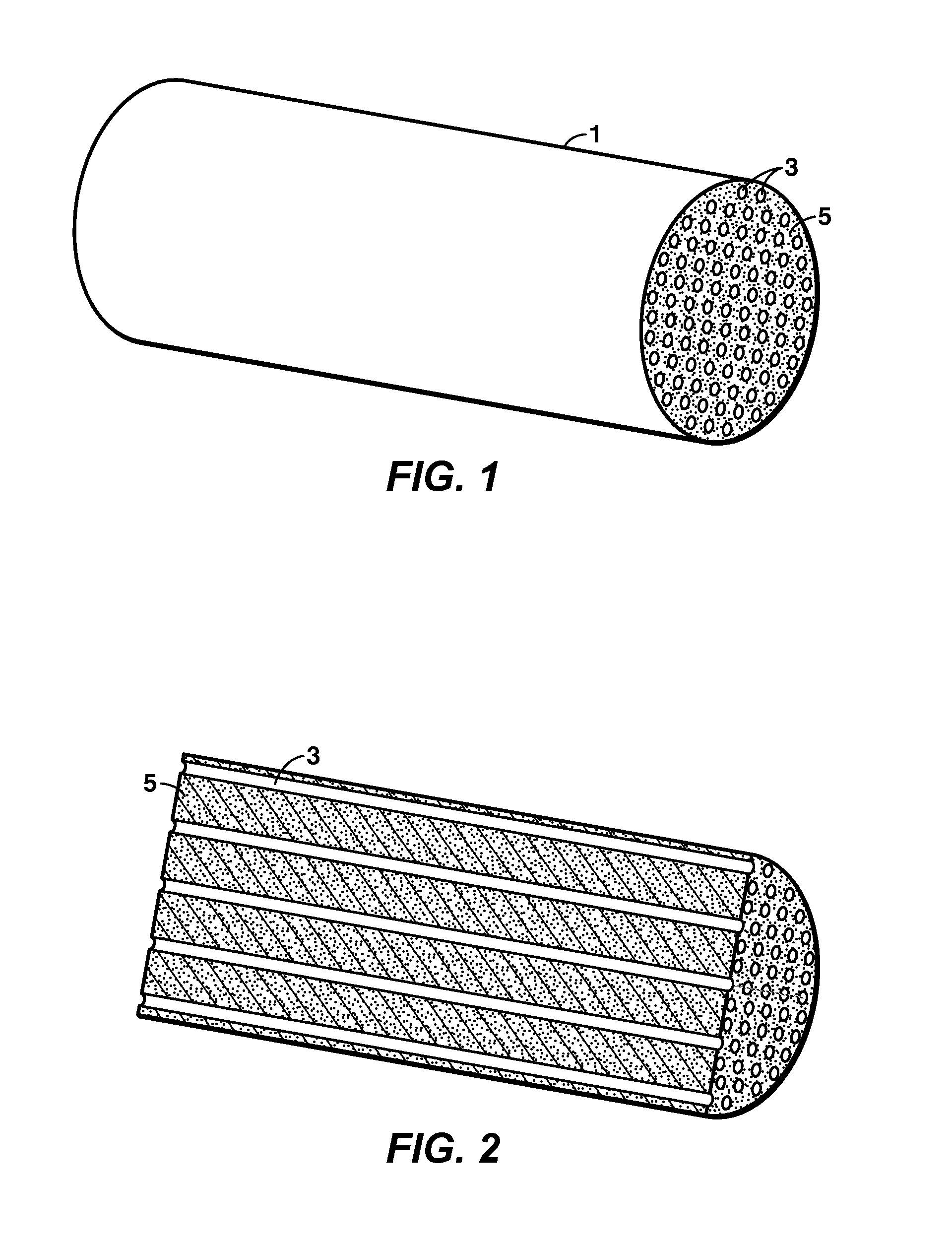

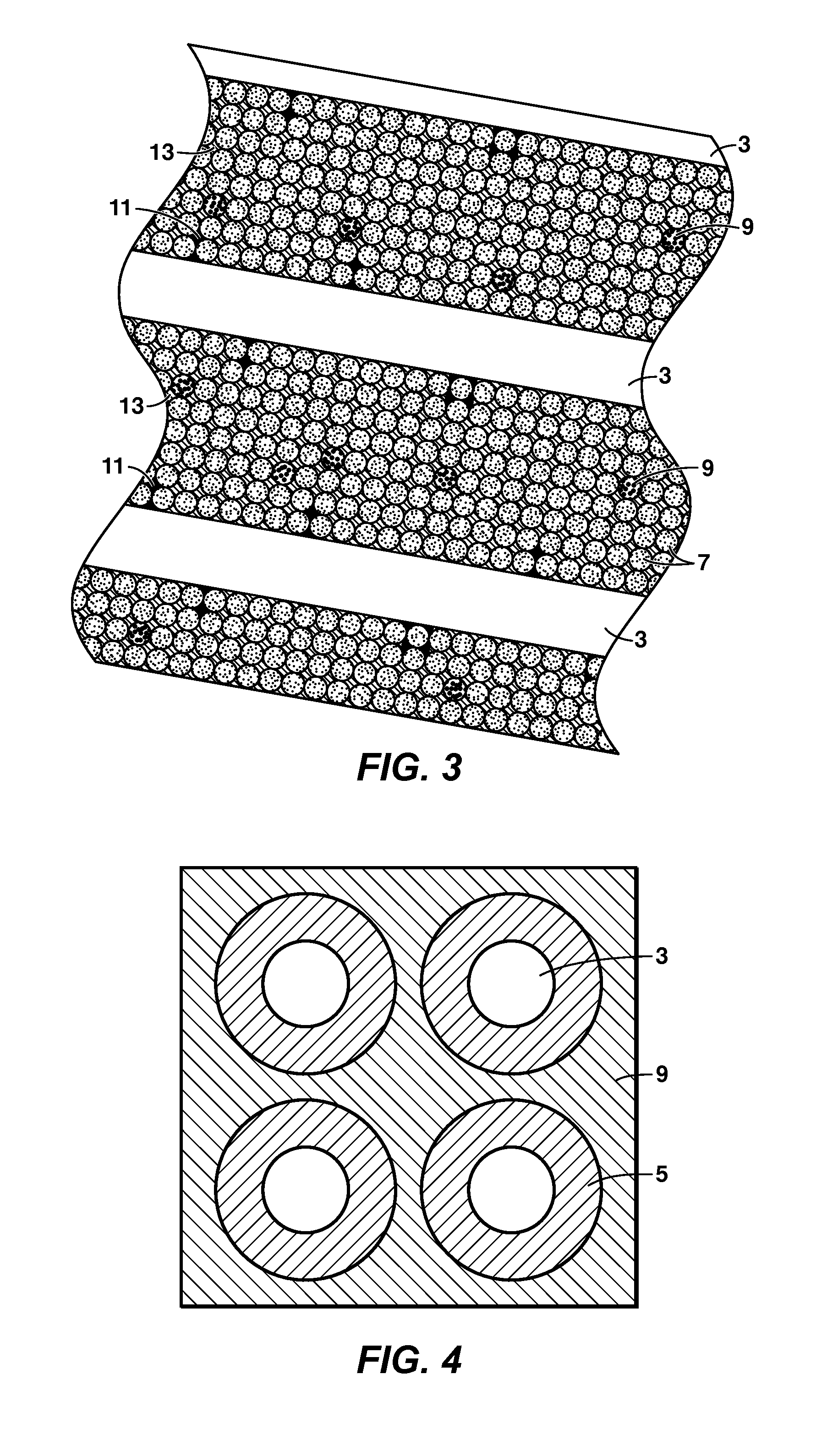

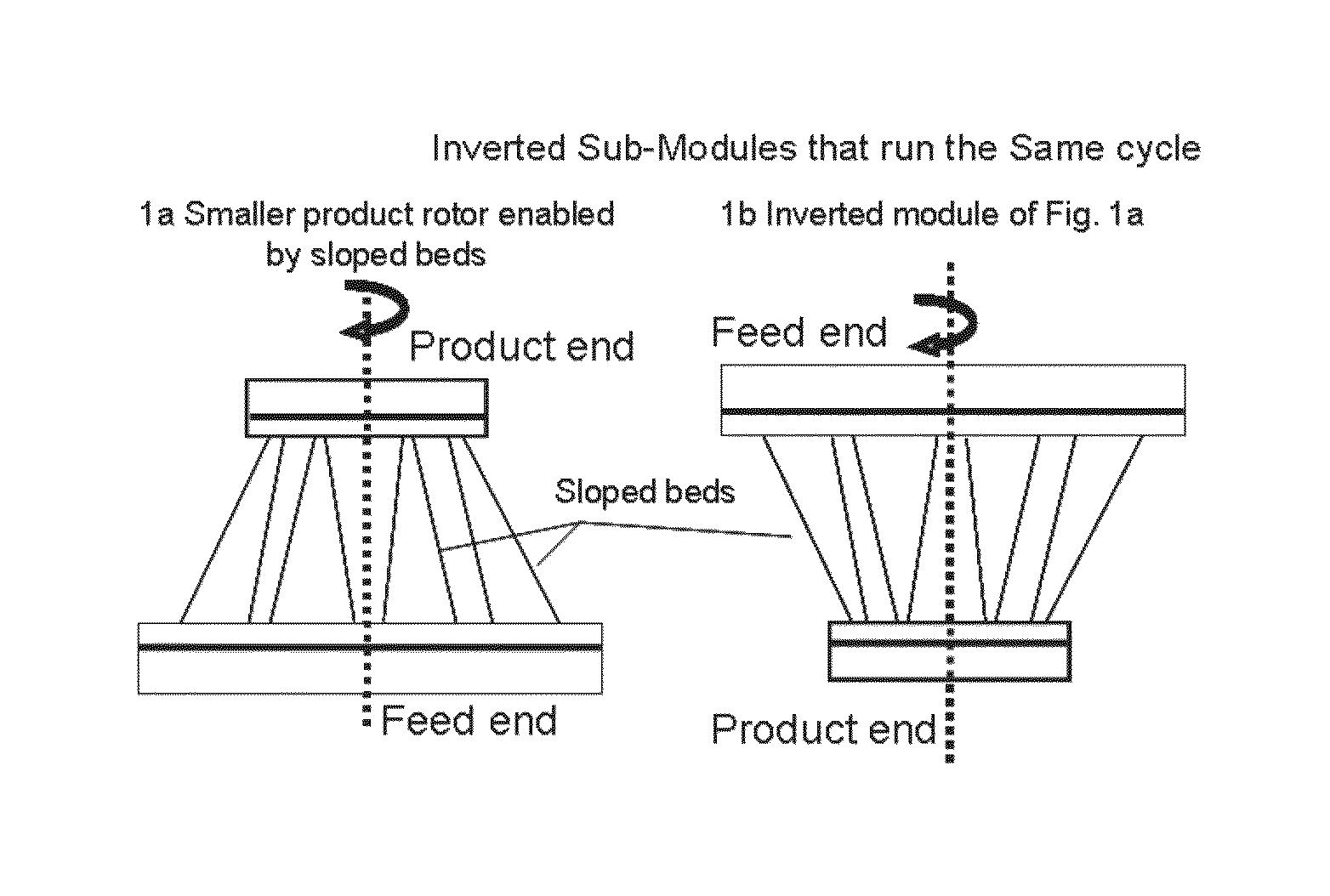

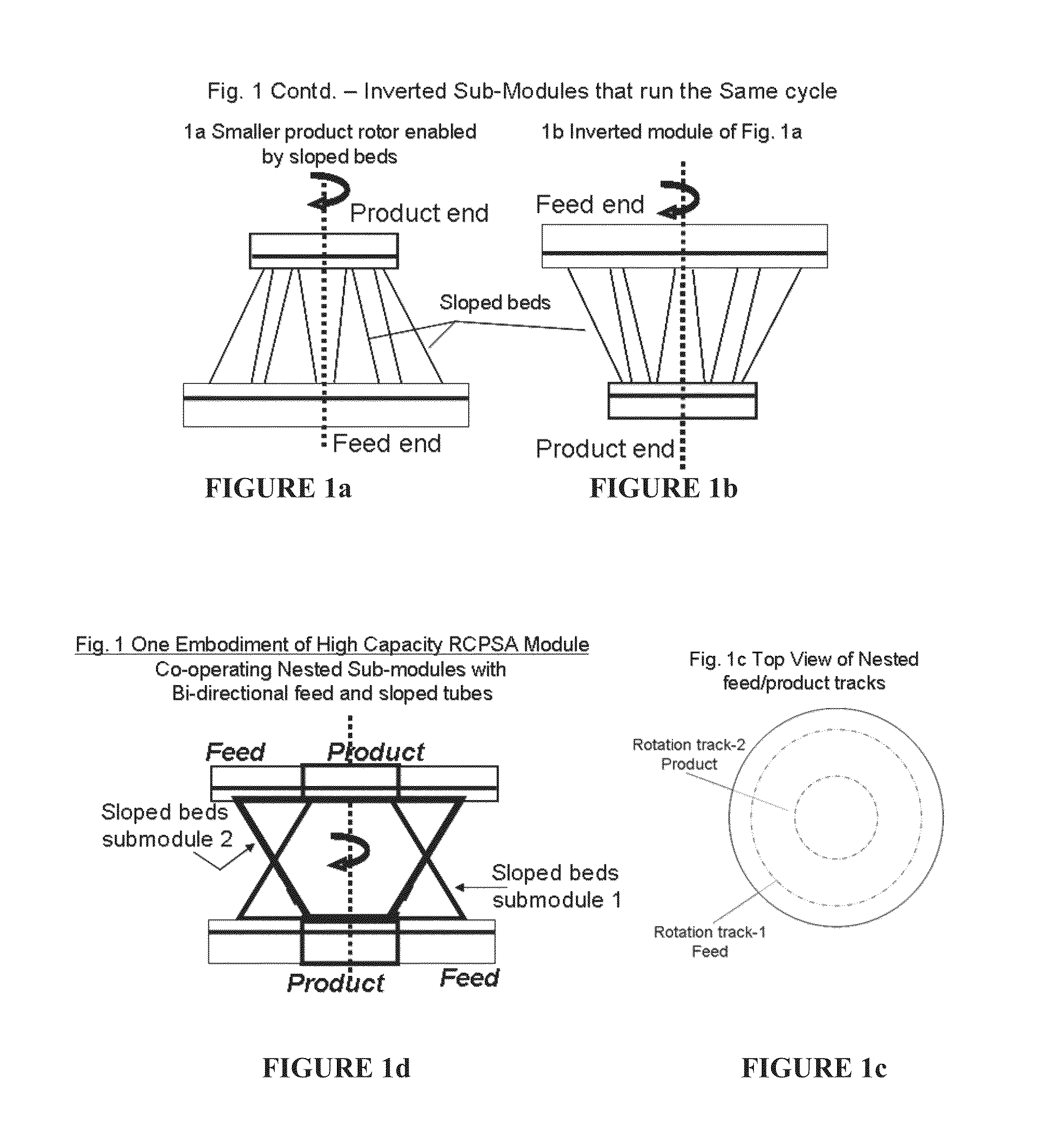

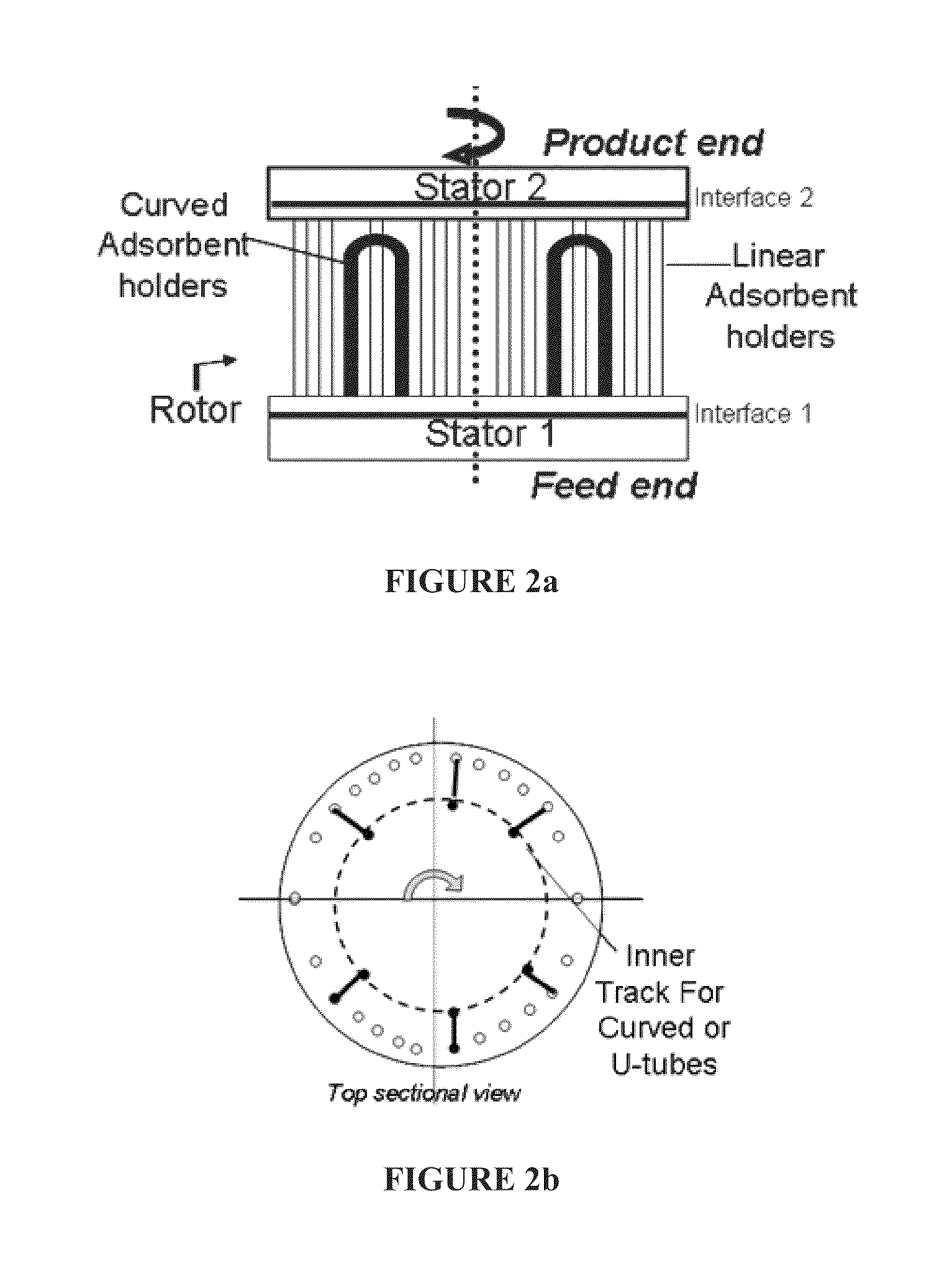

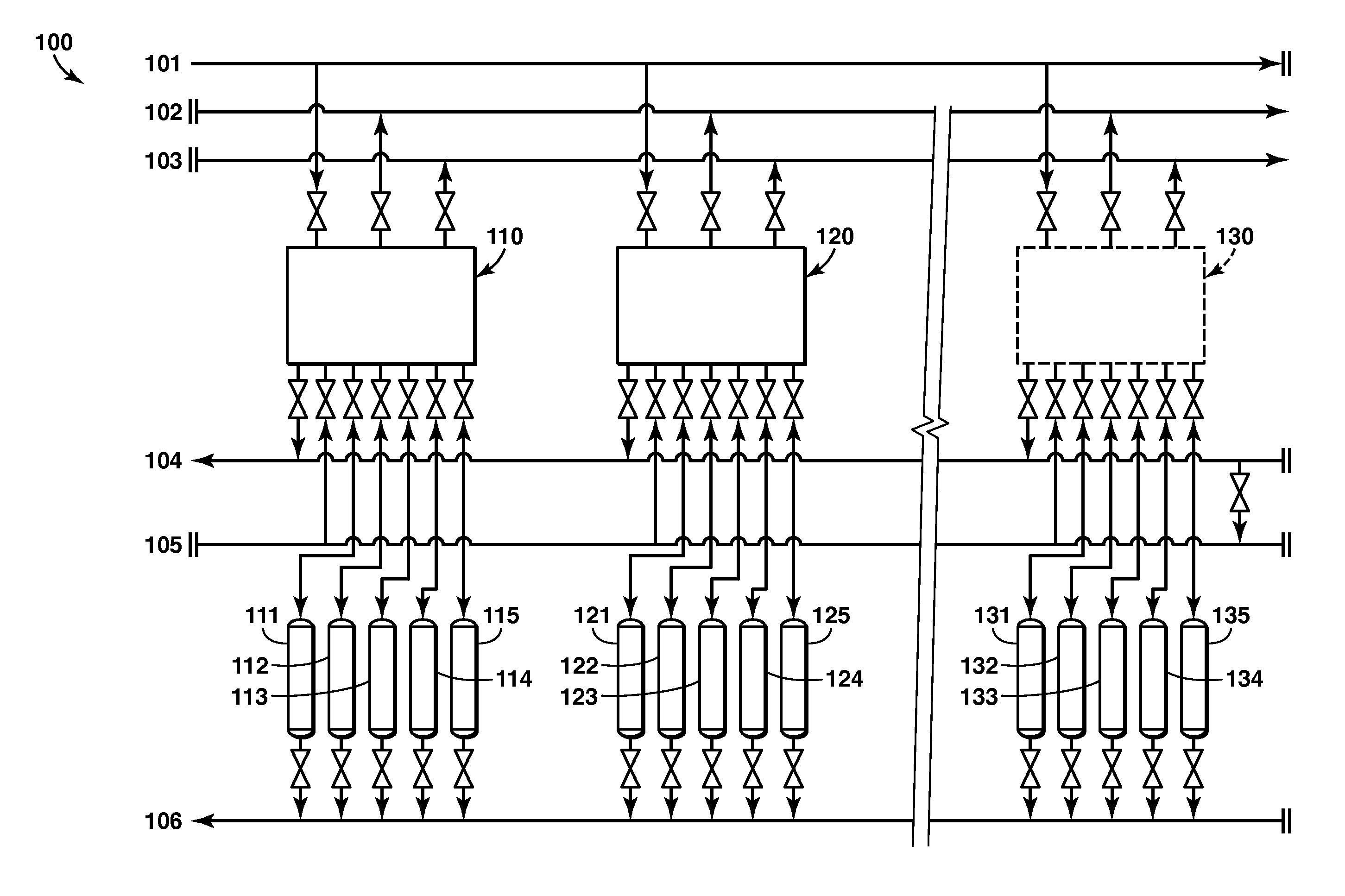

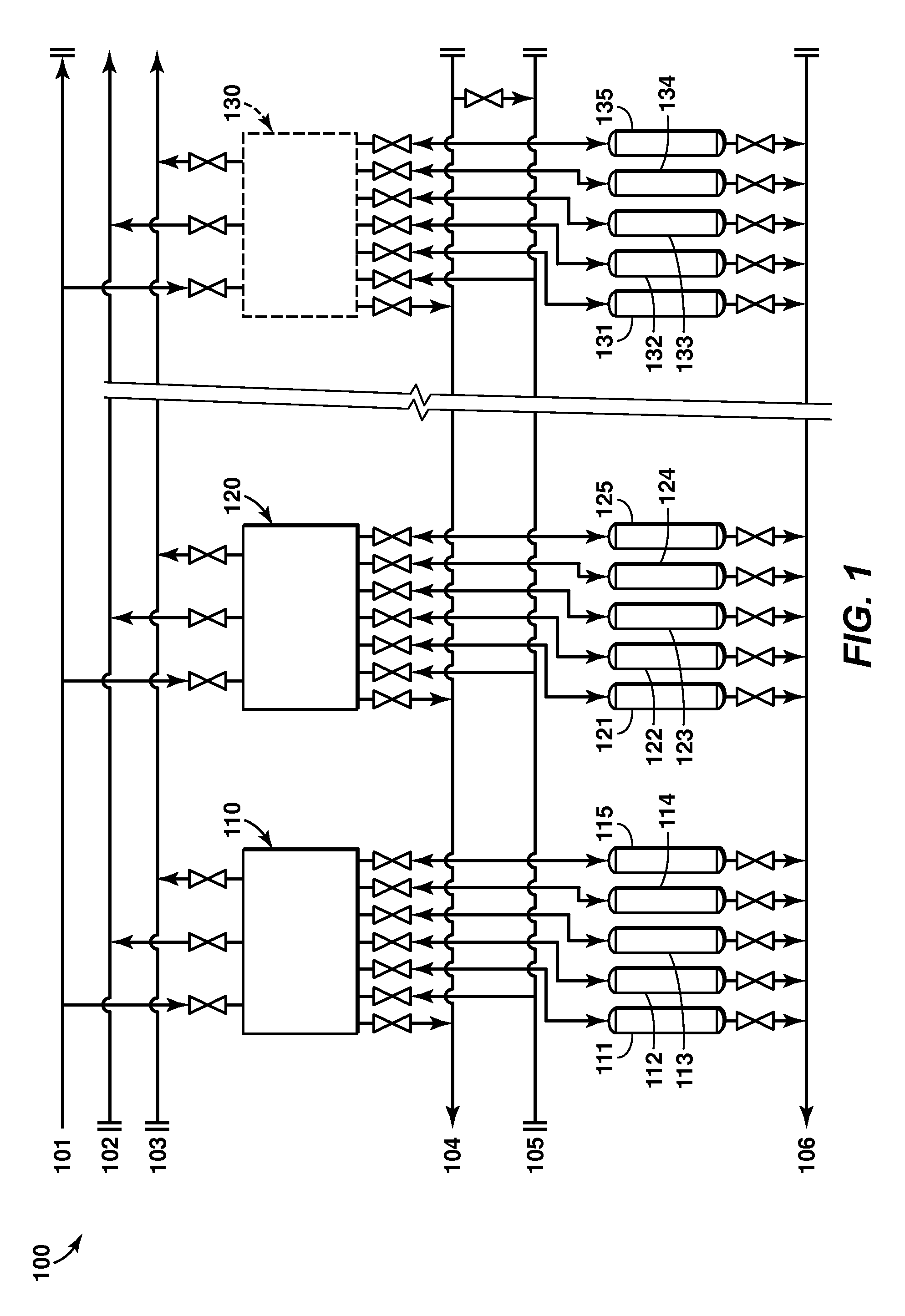

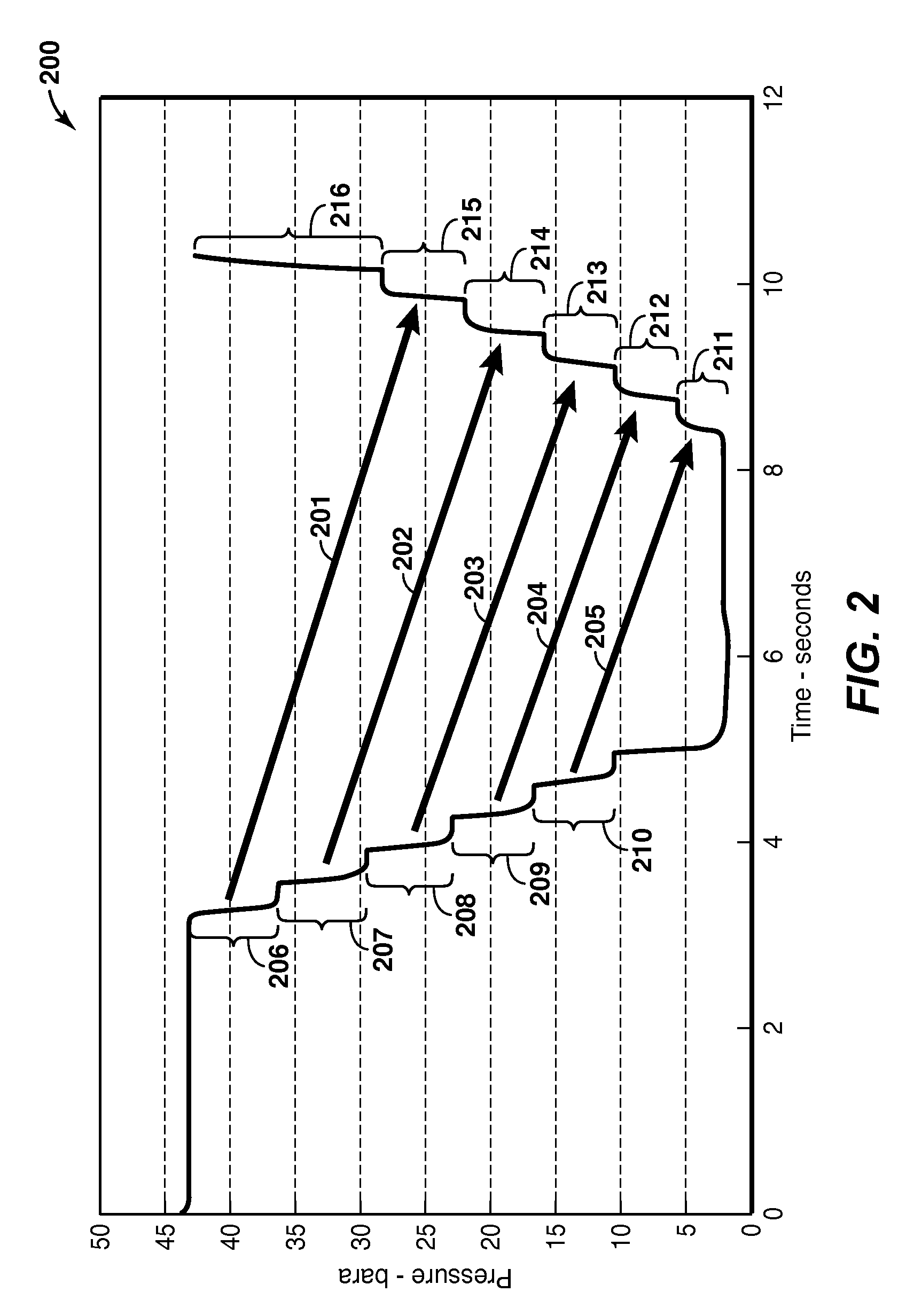

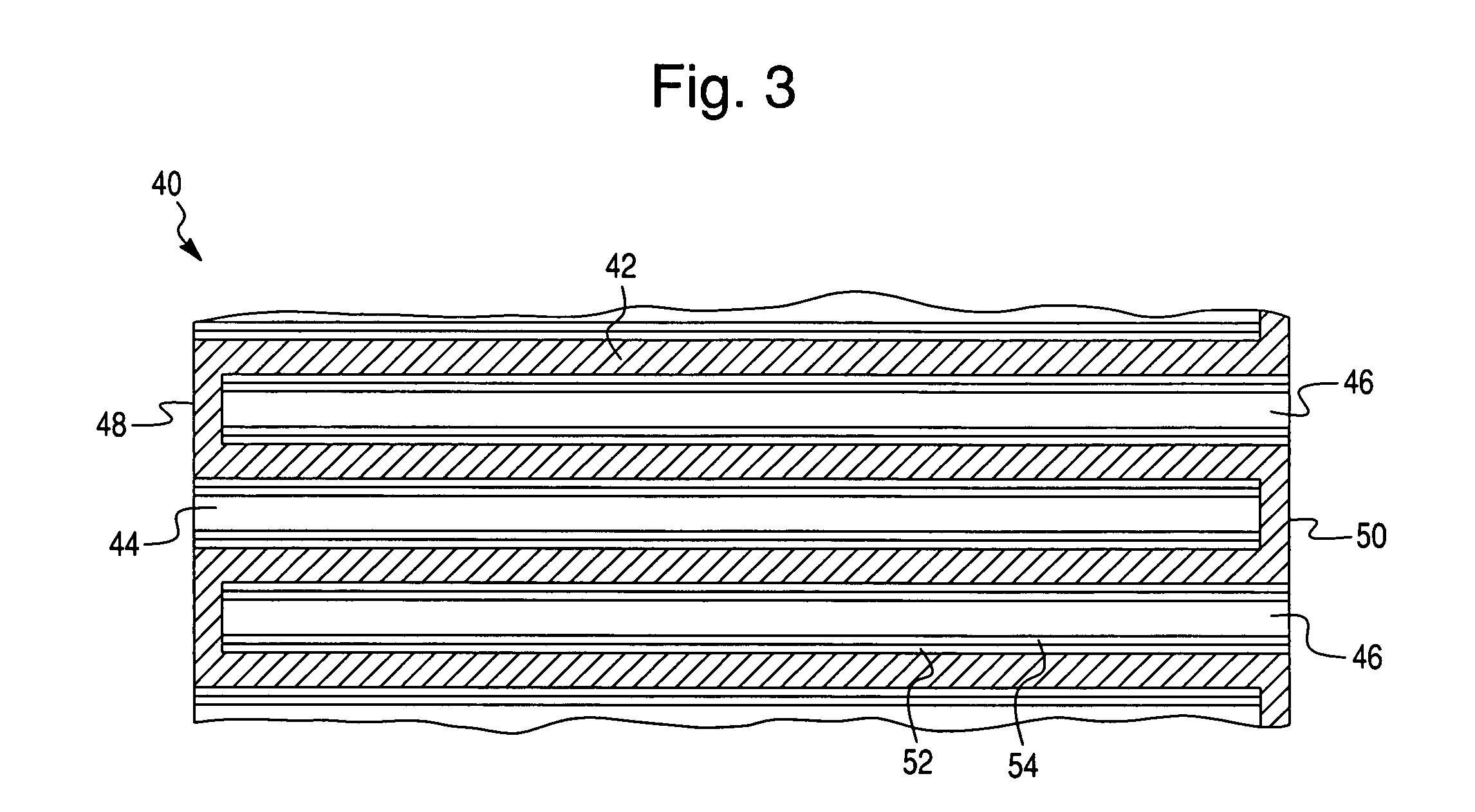

Methods of removing contaminants from hydrocarbon stream by swing adsorption and related apparatus and systems

A pressure swing adsorption process for removal of CO2 from natural gas streams through a combination of a selective adsorbent material containing an effective amount of a non-adsorbent filler, adsorbent contactor design, and adsorption cycle design. The removal of contaminants from gas streams, preferably natural gas streams, using rapid-cycle swing adsorption processes, such as rapid-cycle pressure swing adsorption (RC-PSA). Separations at high pressure with high product recovery and / or high product purity are provided through a combination of judicious choices of adsorbent material, gas-solid contactor, system configuration, and cycle designs. For example, cycle designs that include steps of purge and staged blow-down as well as the inclusion of a mesopore filler in the adsorbent material significantly improves product (e.g., methane) recovery. An RC-PSA product with less than 10 ppm H2S can be produced from a natural gas feed stream that contains less than 1 mole percent H2S.

Owner:EXXONMOBIL UPSTREAM RES CO

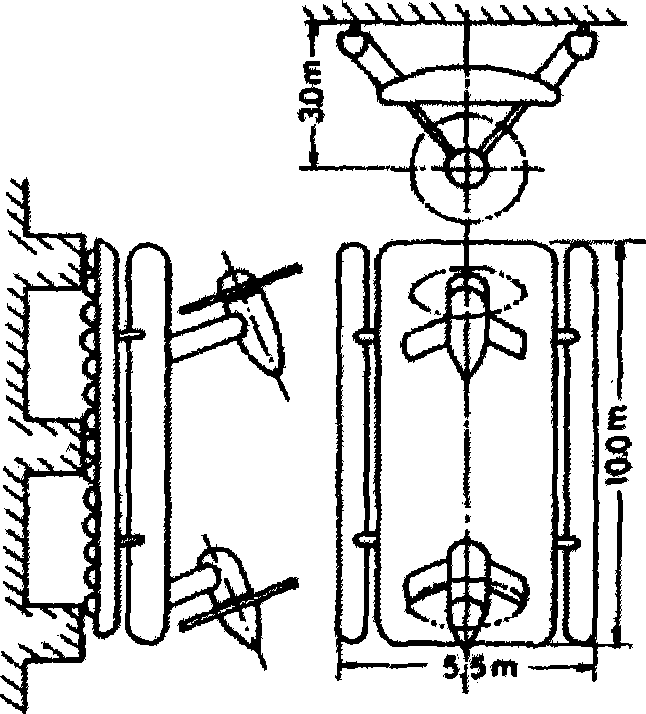

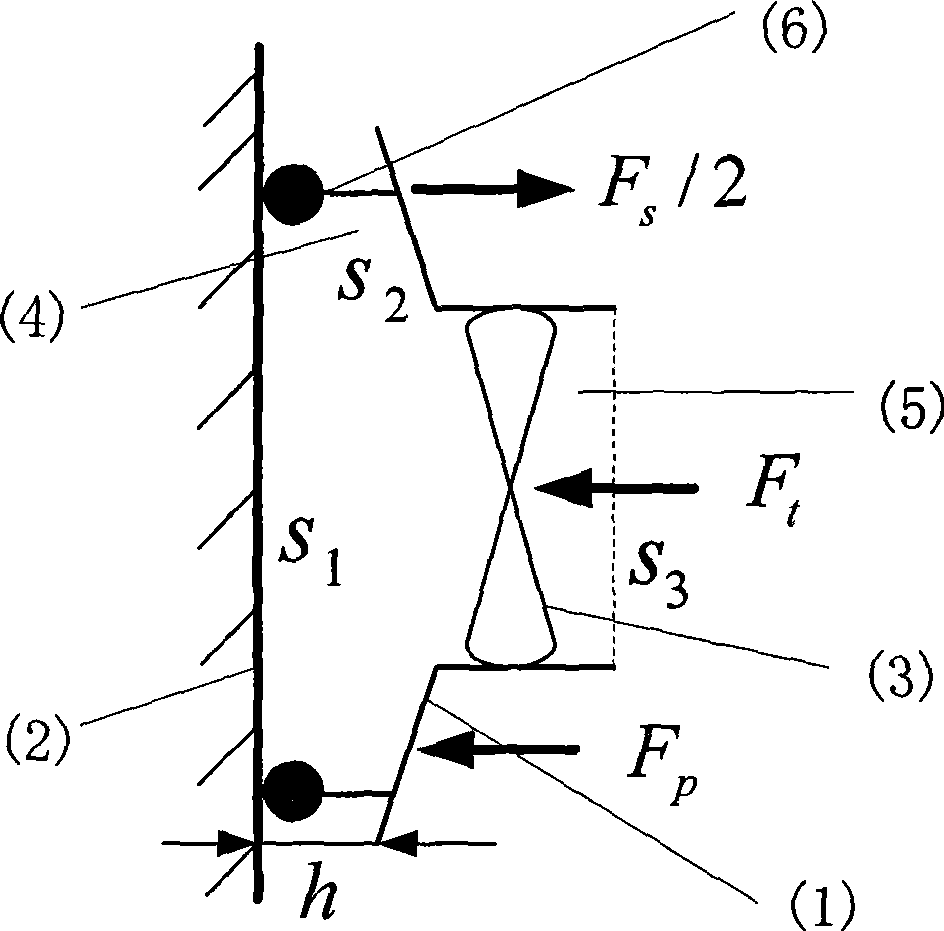

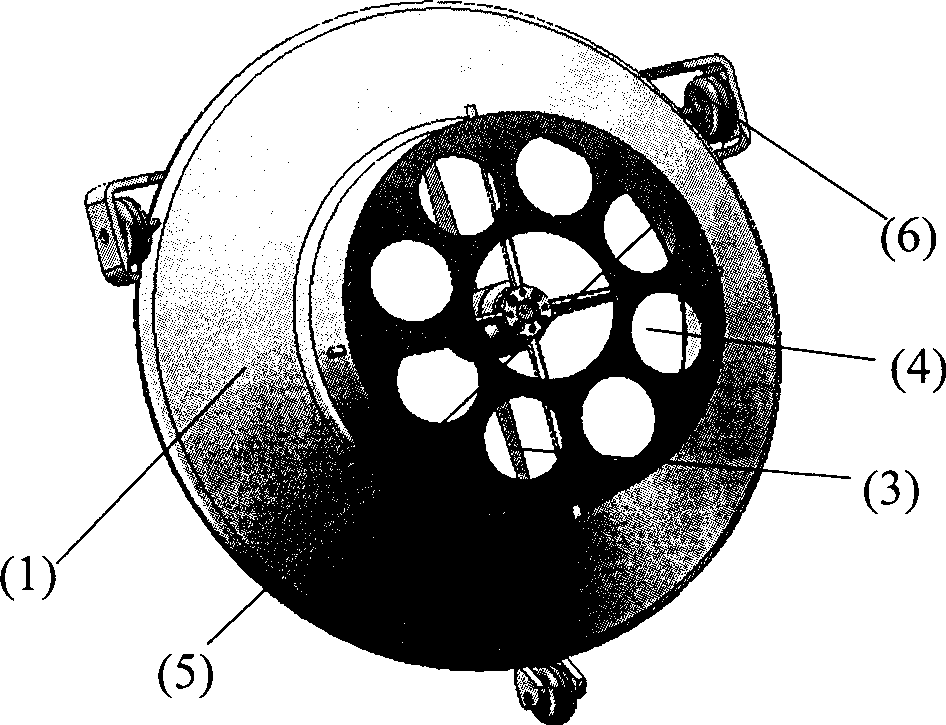

Backward thrust and negative pressure combined adsorption method for wall climbing robot and implementation thereof

The invention relates to a reverse thrust and negative pressure combined adsorption method applied to a wall-climbing robot and realization thereof. When a suction disk(1) of the wall-climbing robot is contacted with the wall surface, air flow enters a cavity(4) of the suction disk(1) from the gap between the suction disk(1) and the wall surface through a propeller(3) rotating at a high speed in a guiding channel, and is discharged from the guiding channel (5) in which the propeller(3) on the top of the suction disk(1) is arranged, and the superimposed effect of the adsorption force generated due to the negative pressure state in the suction disk(1) and the reverse thrust generated due to the high-speed rotation of the propeller(3) in the guiding channel is formed, so that the adsorption force between the suction disk(1) of the wall-climbing robot and the wall surface is kept in the range of enough threshold value. The robot is ensured to be dynamically adsorbed on the wall surface, and flexibly moved. By the application of the theory and the realization method, the wall-climbing robot can realize small size, light weight, low noise, energy conservation, unnecessary complex suction disk sealing device and strong obstacle crossing capability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Increasing scales, capacities, and/or efficiencies in swing adsorption processes with hydrocarbon gas feeds

Owner:EXXON RES & ENG CO

Air purification medium unit, air purification device and air purification method

ActiveCN103742988AImprove efficiencySolution to short lifeLighting and heating apparatusSpace heating and ventilation detailsHigh concentrationFiber

The invention relates to an air purification medium unit, an air purification device and an air purification method. The air purification medium unit comprises an upstream filtering unit, a middlestream adsorption-desorption unit, and a downstream photocatalysis unit. Meanwhile, with the air purification medium unit, the air purification device is designed and a set of the air purification method is formed. By aiming at characteristics of light catalysis and an adsorption method, the adsorption method is combined with photocatalysis, so that activated carbon and activated carbon fiber adsorption and desorption-TiO2 (titanium dioxide) photocatalysis technology becomes an air purification technology with high efficiency and long service life. On the one hand, the activated carbon or the activated carbon fiber is desorbed to be regenerated in situ, thereby reducing the original replacement cycle of a filter element; and on the other hand, the activated carbon or the active carbon fiber is desorbed to provide a high-concentration reaction environment for the photocatalysis of TiO2, so as to accelerate the reaction rate.

Owner:北京铠钺防护科技有限公司

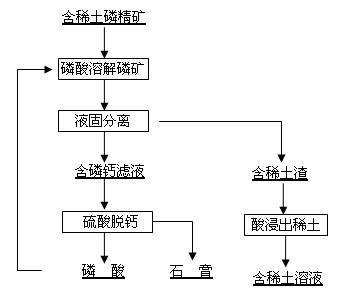

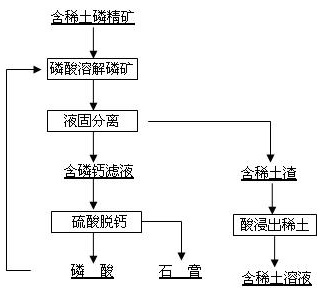

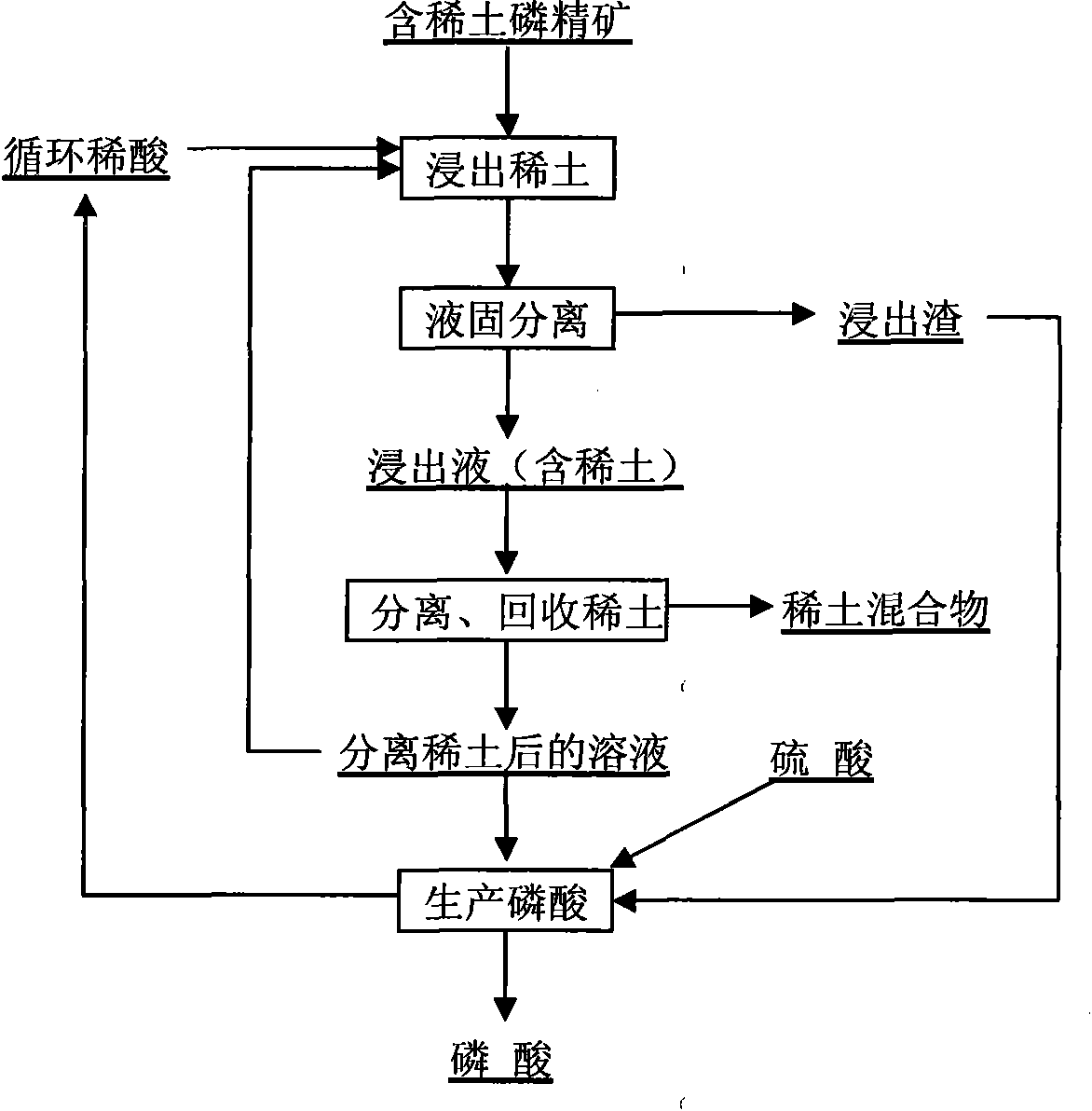

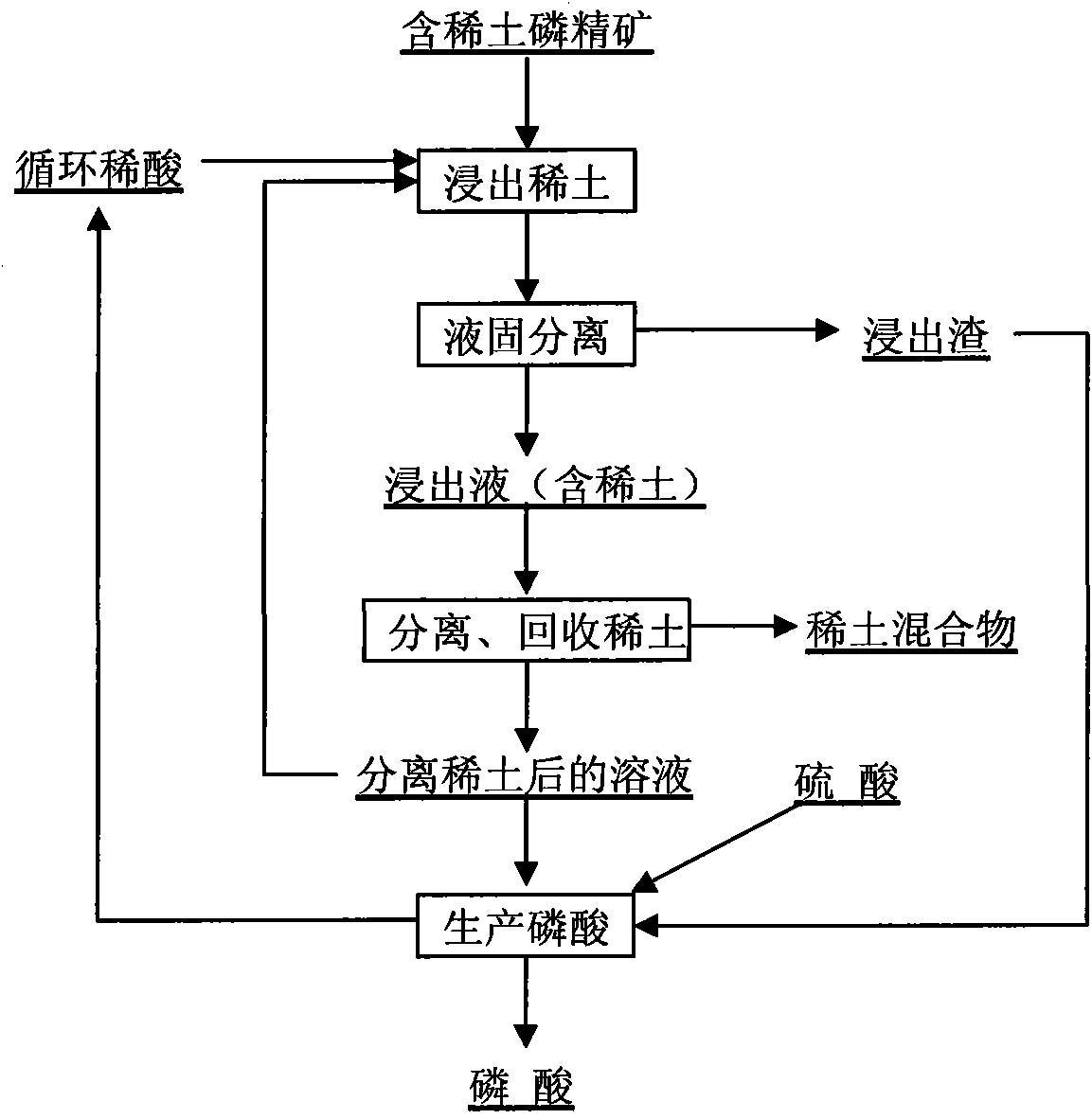

Method for separating tombarthite from phosphorus ore

The invention discloses a method for separating tombarthite from phosphorus ore and relates to the method for separating the tombarthite from the phosphorus ore containing the tombarthite. The method is characterized in that the process steps are as follows: (1) mixing phosphate concentrate containing the tombarthite with a phosphoric acid solution for performing reaction; (2) filtering for getting a reaction solution and slag containing the tombarthite; (3) adding acid into the slag containing the tombarthite for leaching for getting leachate containing the tombarthite, and further recycling the tombarthite through one or more of an extraction method, an ion exchange adsorption method, a precipitation method and a crystallization method; and (4) performing decalcification on the reaction solution obtained by filtration and then returning to the step (1). By adopting the method, the precipitation rate of the tombarthite in the phosphorus ore is greater than 85%, the slag rate is small, the grade of the tombarthite in the slag is high, the leaching rate of the tombarthite in the slag is high, no additives are added during the process and the product quality of the phosphoric acid is not affected; and furthermore, the phosphoric acid used during the process can be self-produced and can also be circulating dilute phosphoric acid, dilute phosphoric acid and the like generated during the production process of the phosphoric acid, thereby being tightly linked with the production process of the phosphoric acid through the sulfuric acid method.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Methods of removing contaminants from a hydrocarbon stream by swing adsorption and related apparatus and systems

Owner:EXXONMOBIL UPSTREAM RES CO

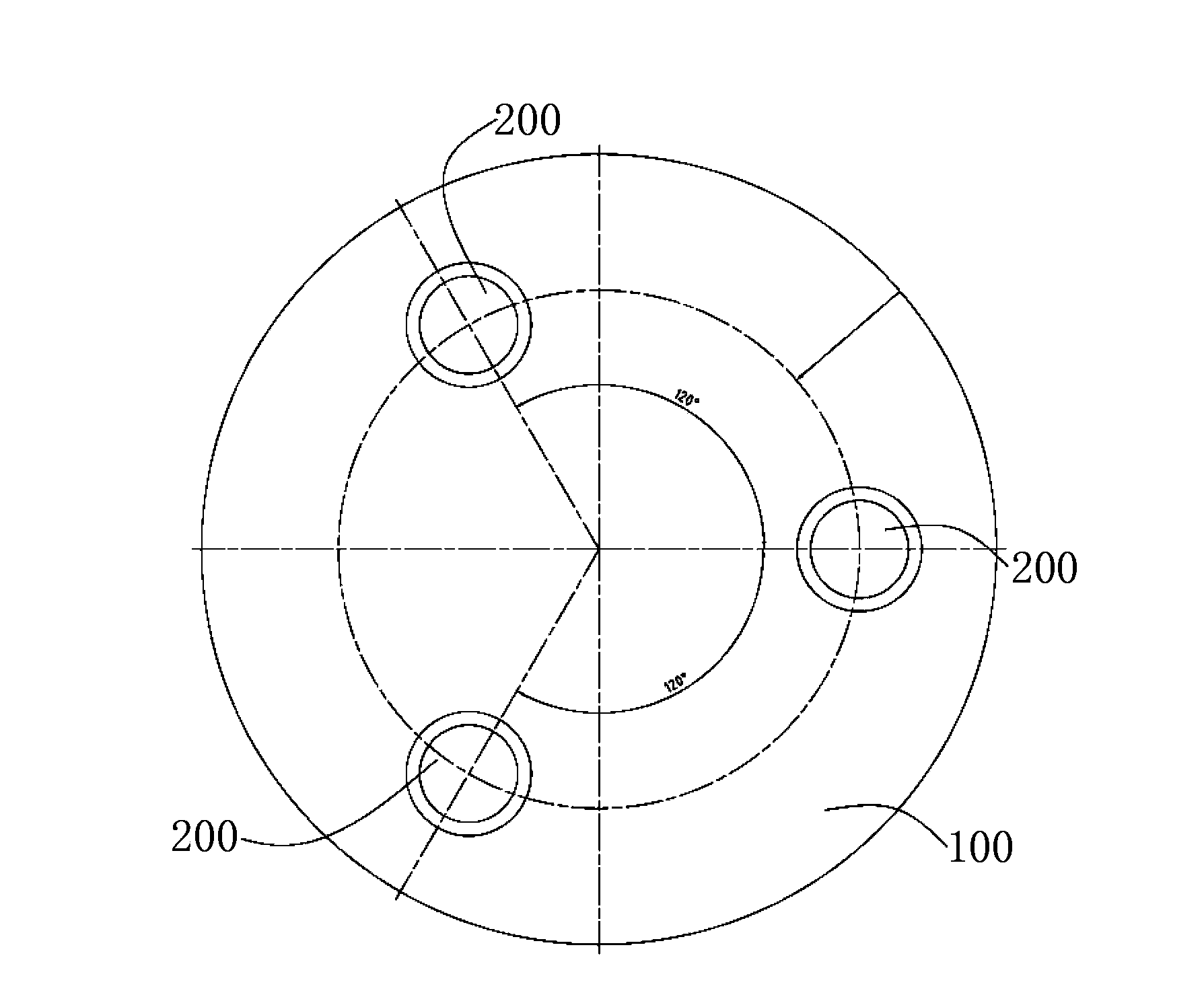

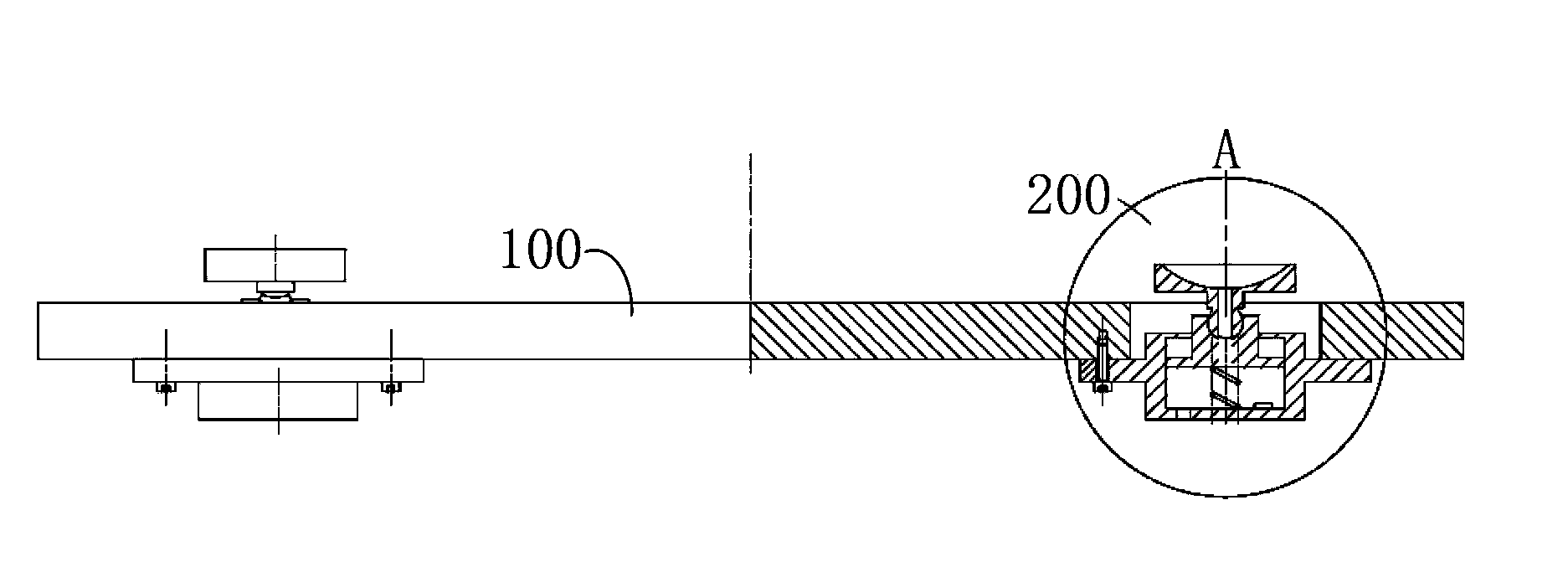

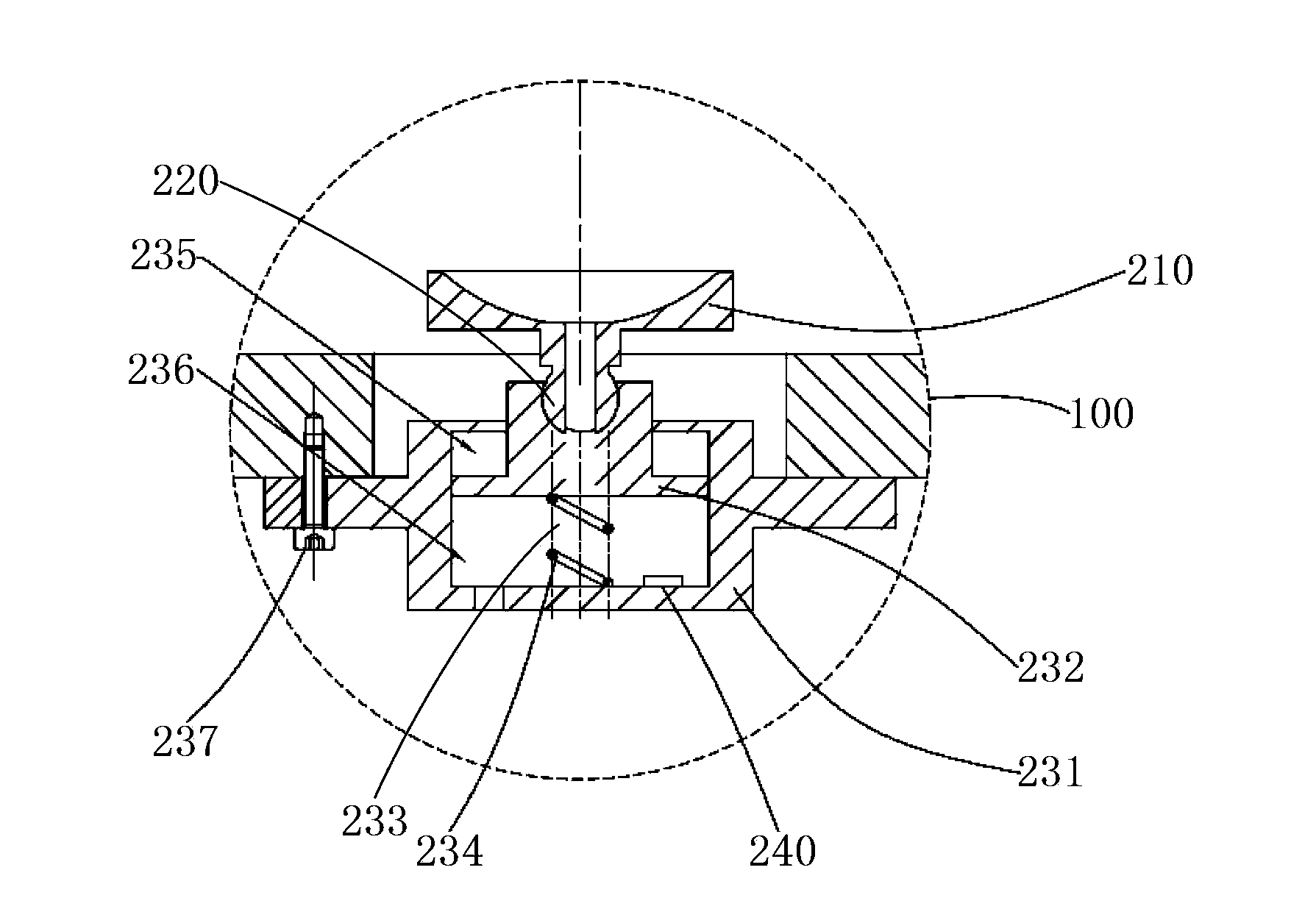

Sucking device for warped silicon wafer and sucking method thereof

ActiveCN103904011ASleeve/socket jointsSemiconductor/solid-state device manufacturingSilicon chipPosition sensor

A warped silicon-chip adsorption device and an adsorption method thereof. The device has a chuck (100) for vacuum adsorption of silicon-chip and at least three suction head assemblies (200). The chuck (100) has at least three openings (101), and each opening corresponds to a suction head assembly (200), wherein each suction head assembly (200) includes a cylinder (230) fixedly connected to the chuck (100), and nozzles (210) movably connected to the cylinder (230). The nozzles (210) can be all in the opening (101) or at least a portion of the nozzles (210) can be located above the surface of the chuck (100) driven by the cylinder (230). Through increasing at least three suction head assemblies (200) in the chuck (100), the warped silicon-chip (300) can be adsorbed and stretched by the suction head assembly (200) until the lower surface of the warped silicon-chip (300) is attached to the upper surface of the chuck (100), thus the adsorption of the warped silicon-chip (300) is completed.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

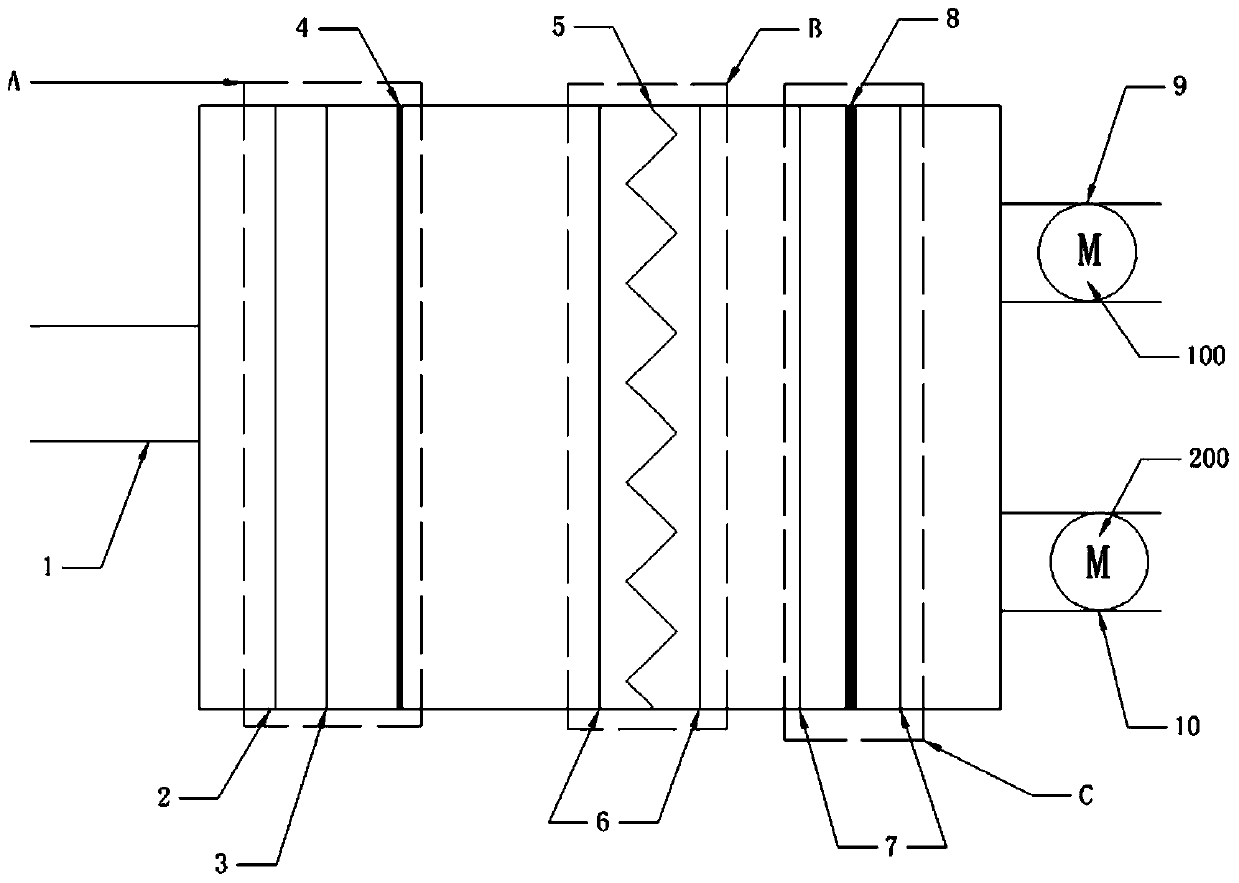

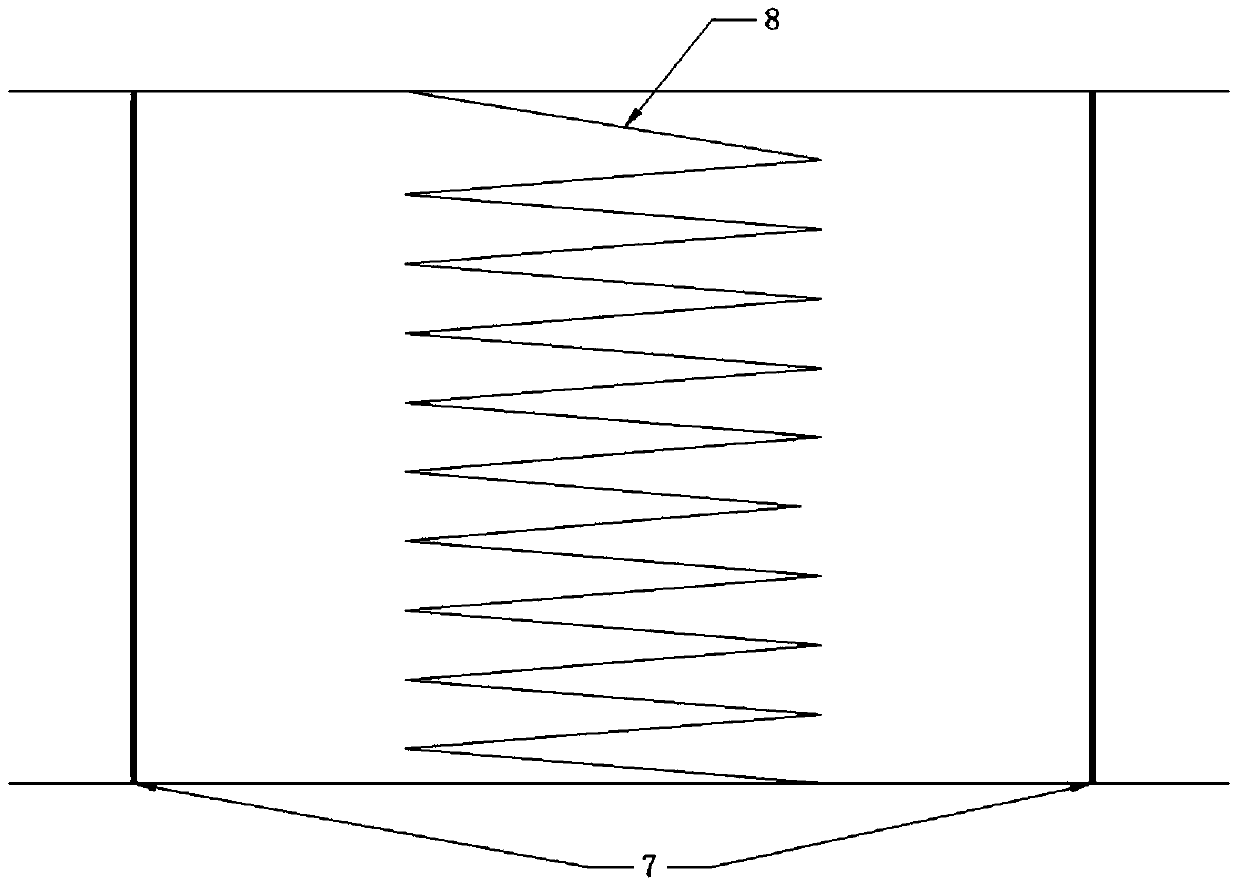

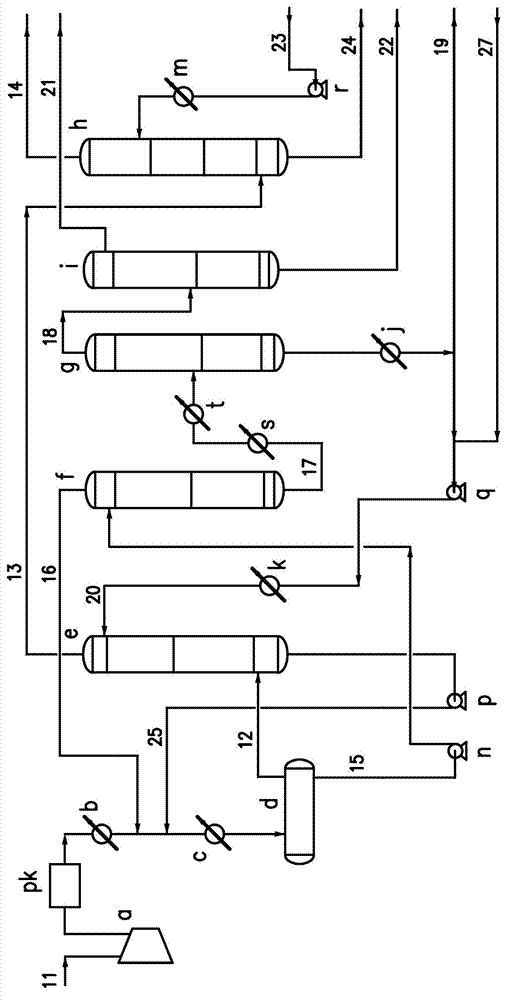

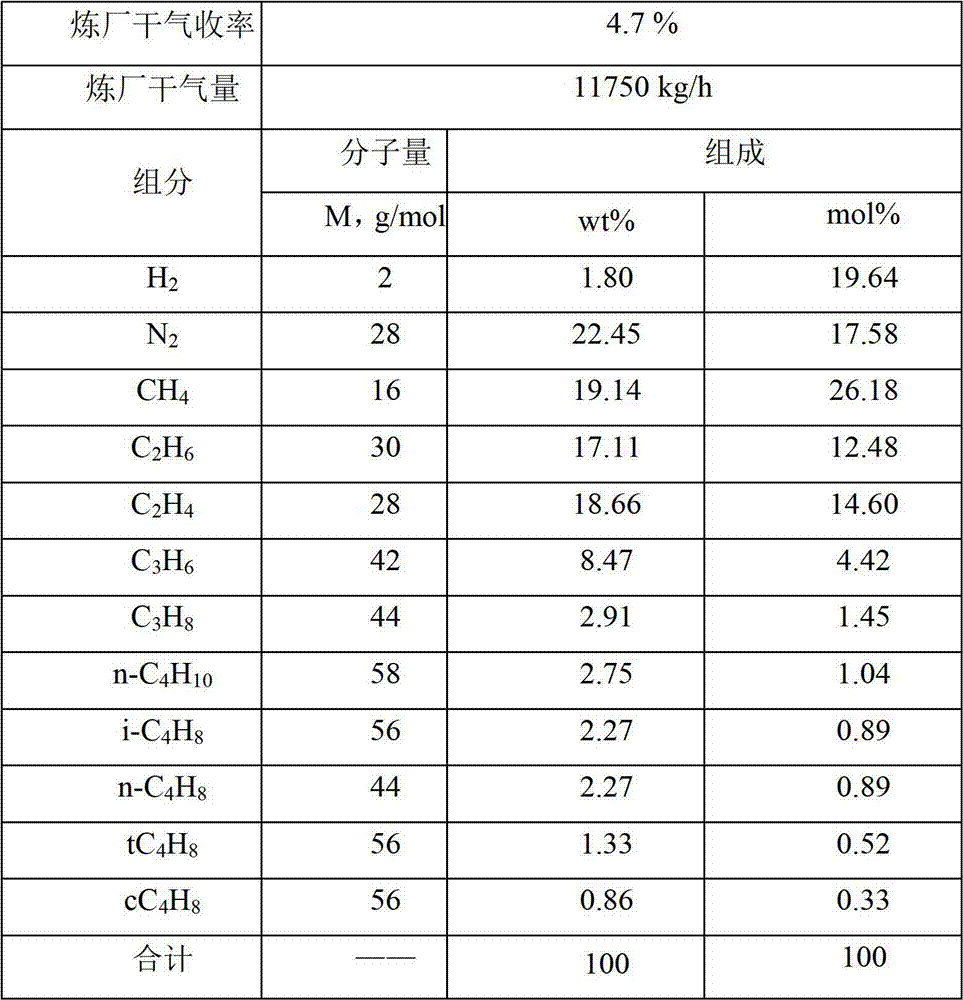

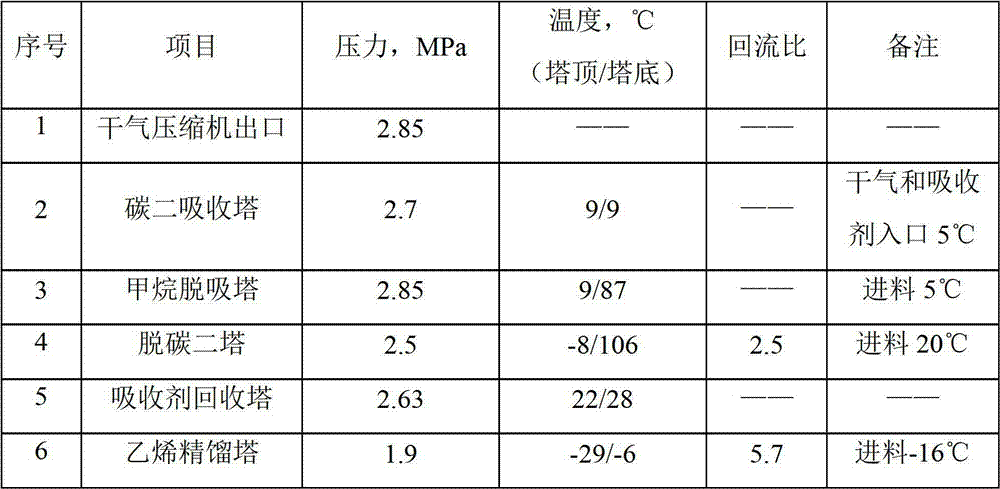

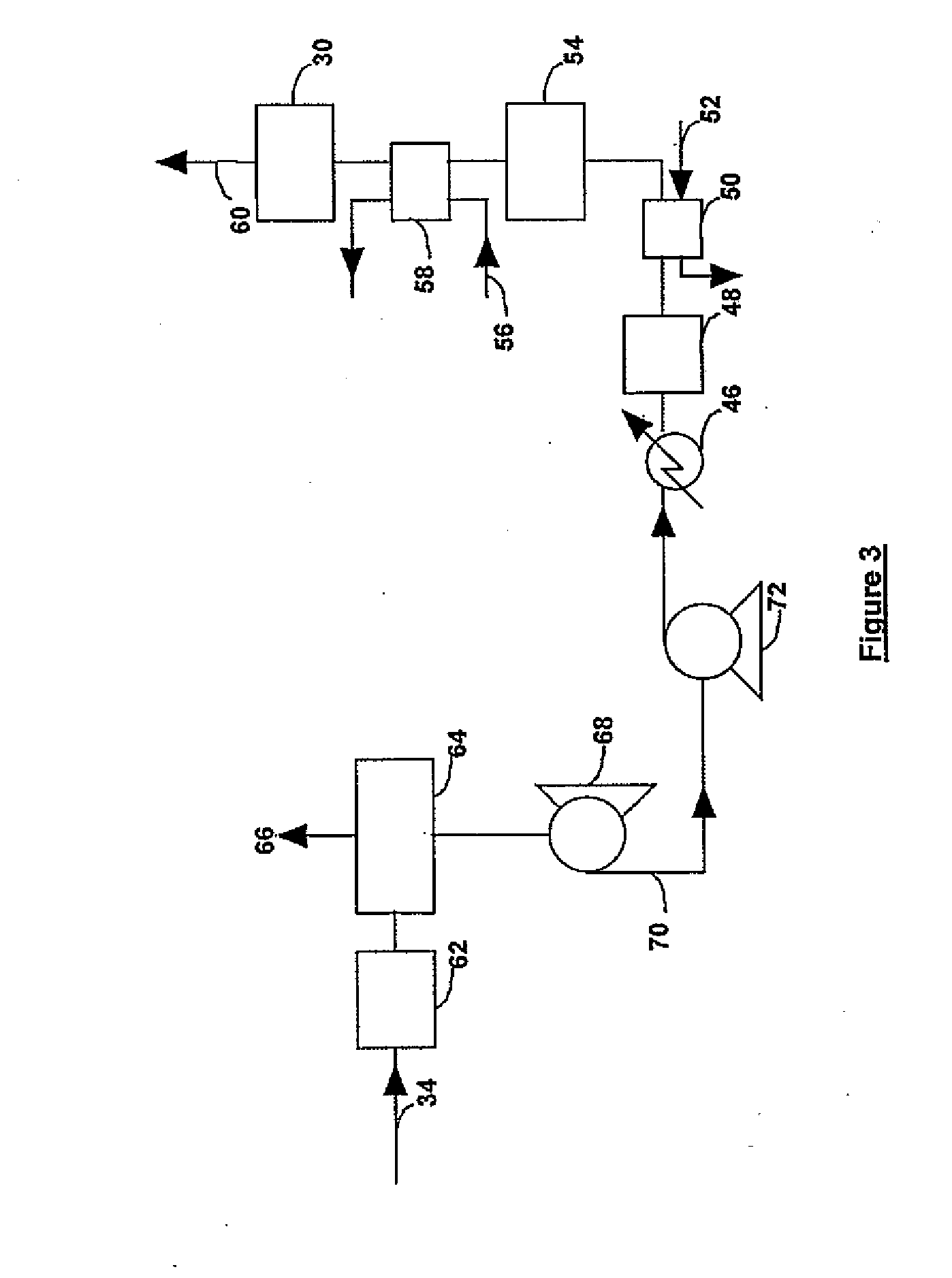

Recovering system and method of C2 in refinery dry gas by compound adsorption method

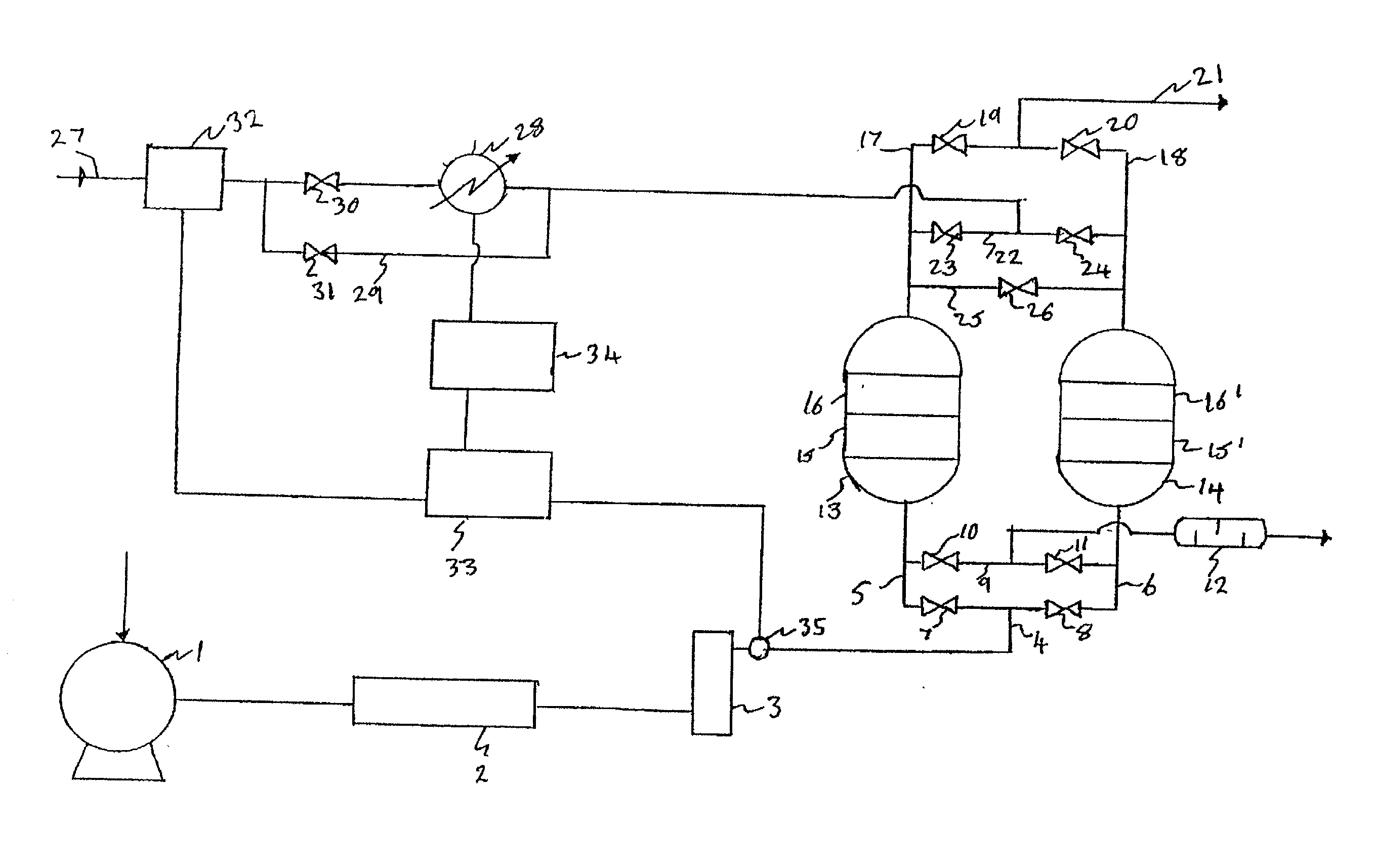

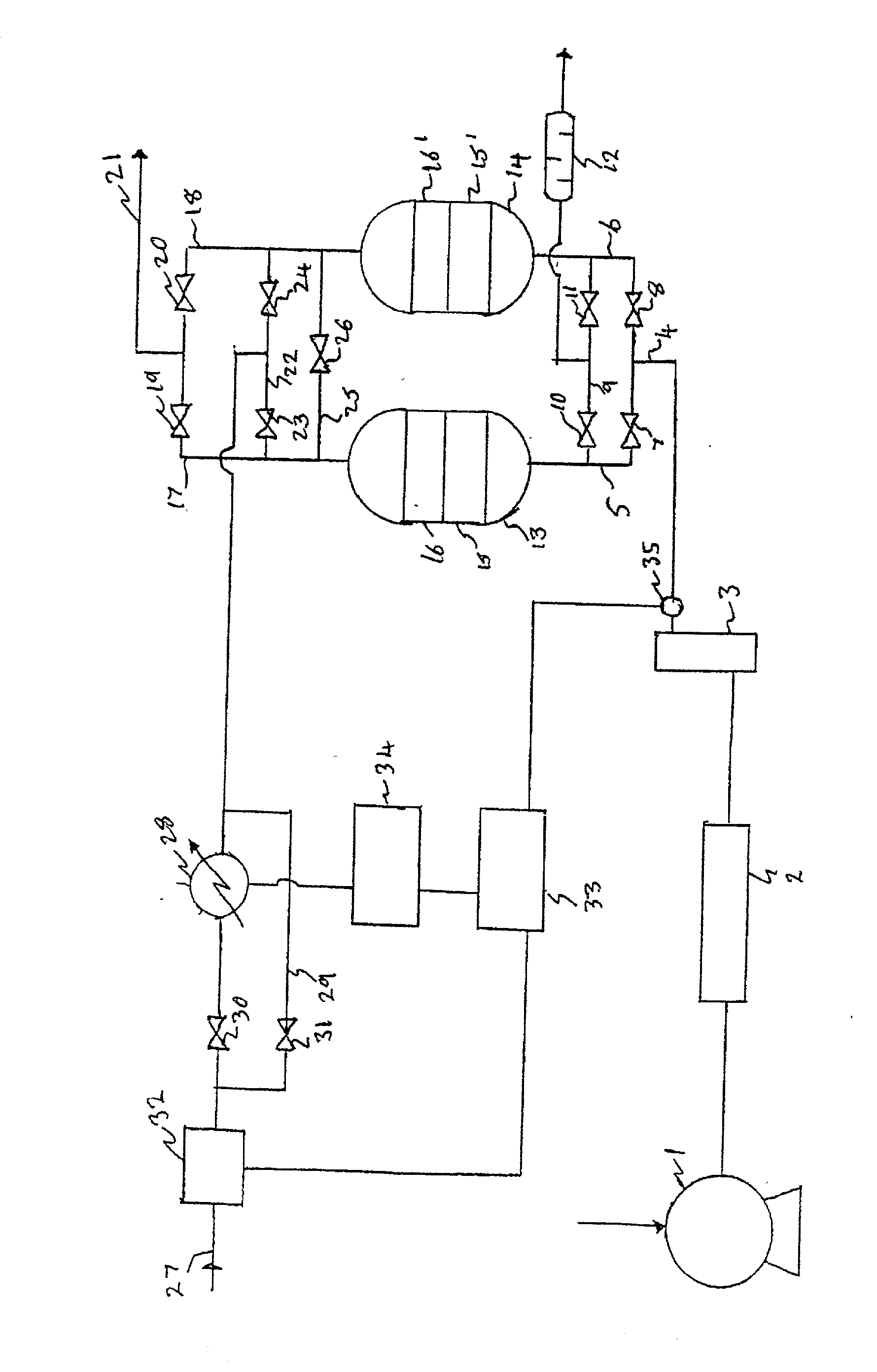

ActiveCN103588604AModerate operating conditionsGuaranteed RecoveryEthylene productionAbsorption purification/separationFluid phaseProcess engineering

The invention provides a recovering system and a method of C2 in refinery dry gas by a compound adsorption method. The recovering system comprises a compressor, a pretreatment unit, a refinery dry gas cooling unit, a compound adsorption unit and a rectification unit. The adsorption unit comprises a gas-liquid separating tank, a C2 adsorption tower, and a methane desorption tower. The rectification unit comprises a C2 removing tower and an ethylene rectification tower. The refinery dry gas, after being compressed, pretreated and cooled, is subjected to gas-liquid separation to obtain a gas phase and a liquid phase. The gas phase is fed into the C2 adsorption tower and subjected to C2 adsorption by using a C4 mixture or a C5 mixture as an absorbent. The liquid phase is fed into the methane desorption tower, and subjected to methane desorption through stripping. The mixed adsorption oil at the bottom of the C2 adsorption tower and desorption gas at the top of the methane desorption tower are returned to the gas-liquid separation tank after being mixed and cold with the refinery dry gas. Tower bottom of the methane desorption tower is cooled and fed into the C2 removing tower and the ethane rectification tower to be rectified to obtain an ethylene product and an ethane product. The method provided by the invention adopts moderate operating conditions. The ethylene and the ethane both have the high recovering rate and the high purity.

Owner:CHINA PETROCHEMICAL CORP +1

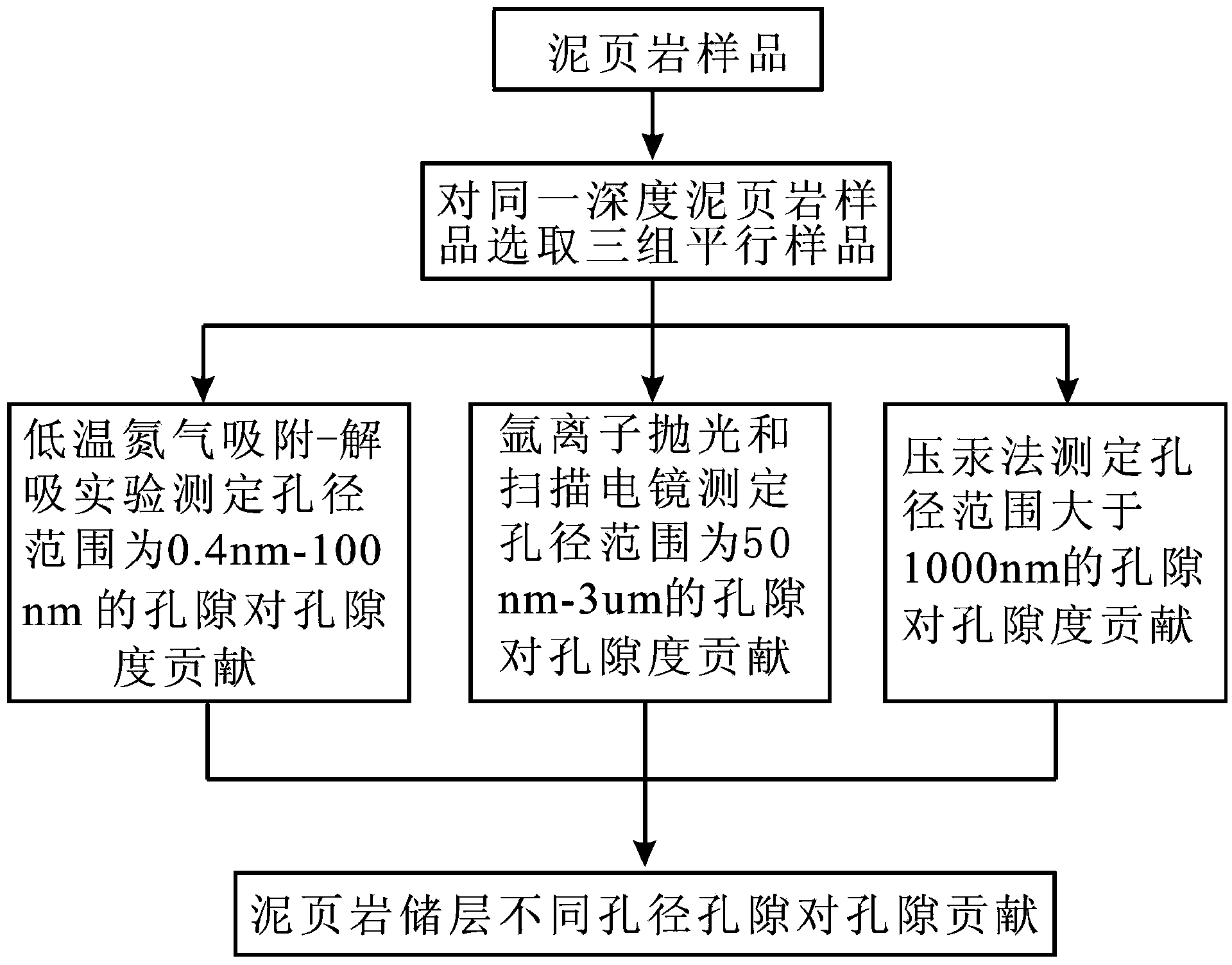

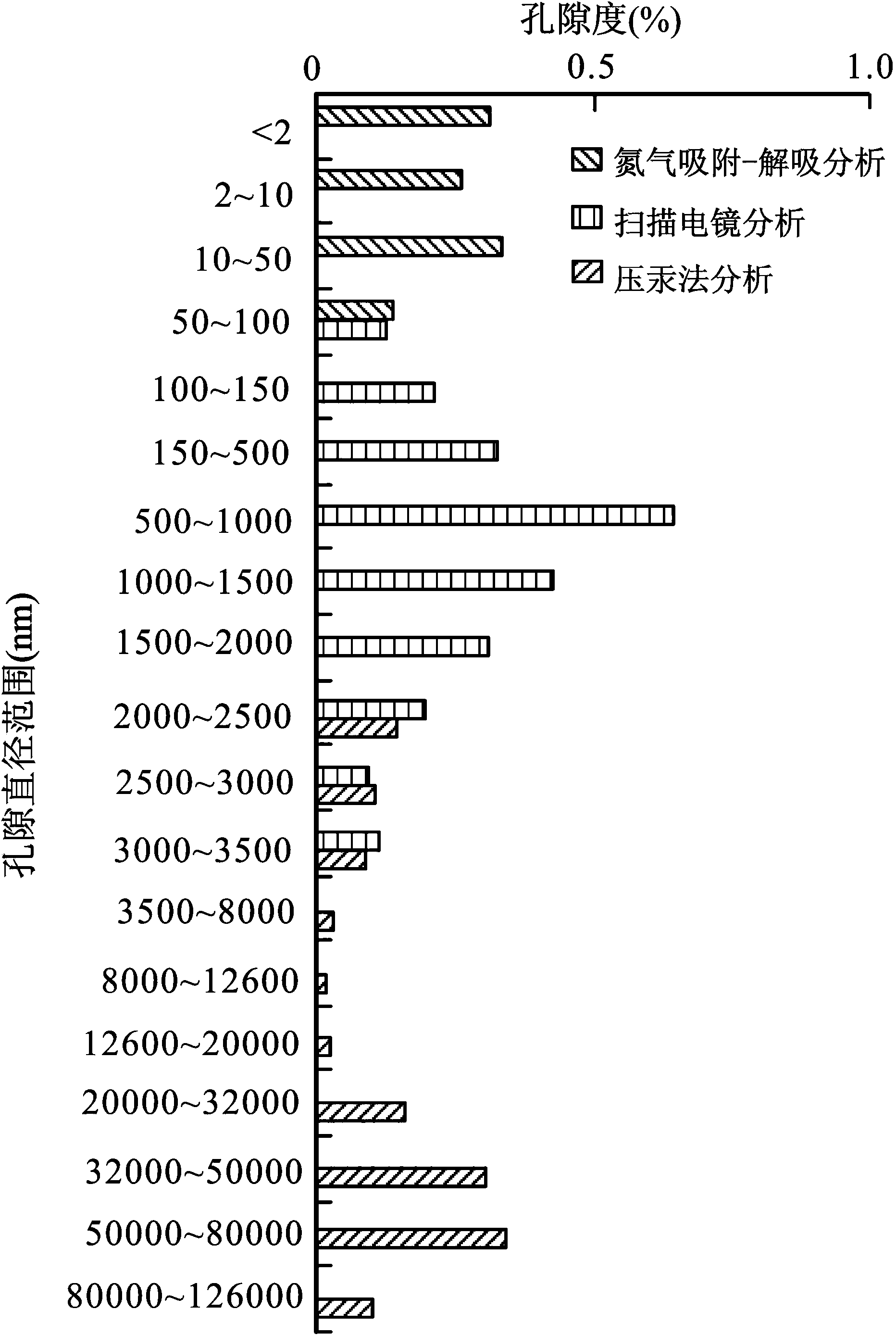

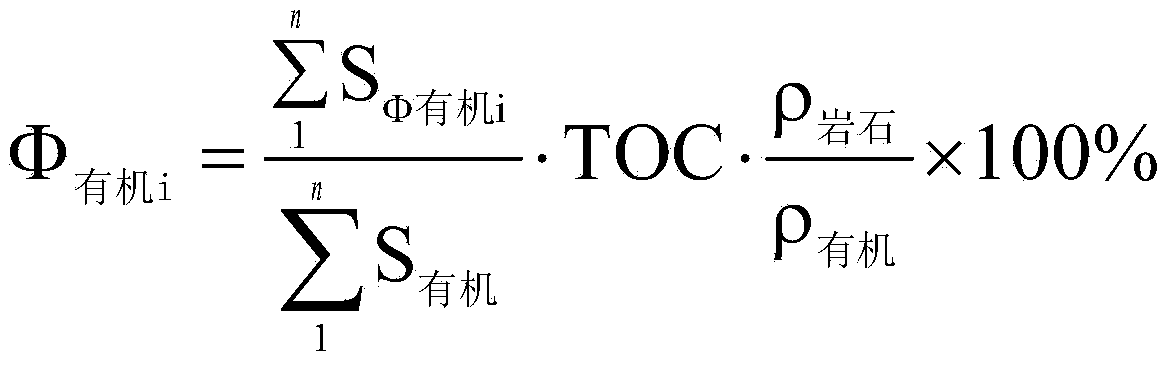

Method for determining contribution of pores with different apertures in shale reservoir stratum to porosity

InactiveCN103512838AAchieving precise measurementsEasy to operatePermeability/surface area analysisPorosityAnalysis data

The invention discloses a method for determining contribution of pores with different apertures in a shale reservoir stratum to porosity, and belongs to the technical field of petroleum, geology and mining exploration and development. The method comprises the following steps: selecting three groups of parallel samples from shale reservoir stratum samples at the same depth; carrying out a low-temperature nitrogen adsorption-desorption experiment on the first group of samples to determine contribution of the pores with aperture ranging from 0.4-100 nm to the porosity; carrying out argon ion polishing and electron scanning microscope examination on the second group of samples to determine the contribution of the pores with aperture ranging from 50 nm to 3 microns to the porosity; carrying out mercury intrusion analysis on the third group of samples to determine the contribution of the pores with aperture greater than 1000 nm to the porosity; synthesizing the analytic data of the three groups of parallel samples, and obtaining the determination results of contribution of the pores with different apertures in the shale reservoir stratum to the porosity. The method can determine the contribution of the pores with different apertures in the shale reservoir stratum to the porosity, and overcomes the defect of the conventional gas adsorption method and the mercury intrusion method for determining the contribution of the pores with different apertures in the shale reservoir stratum to the porosity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

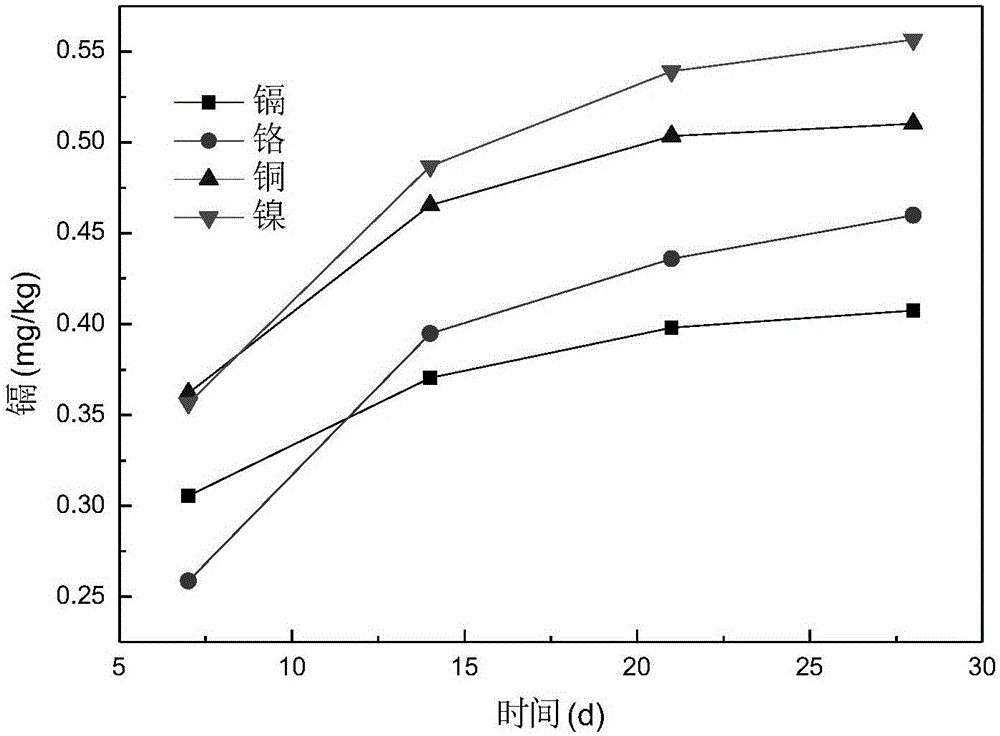

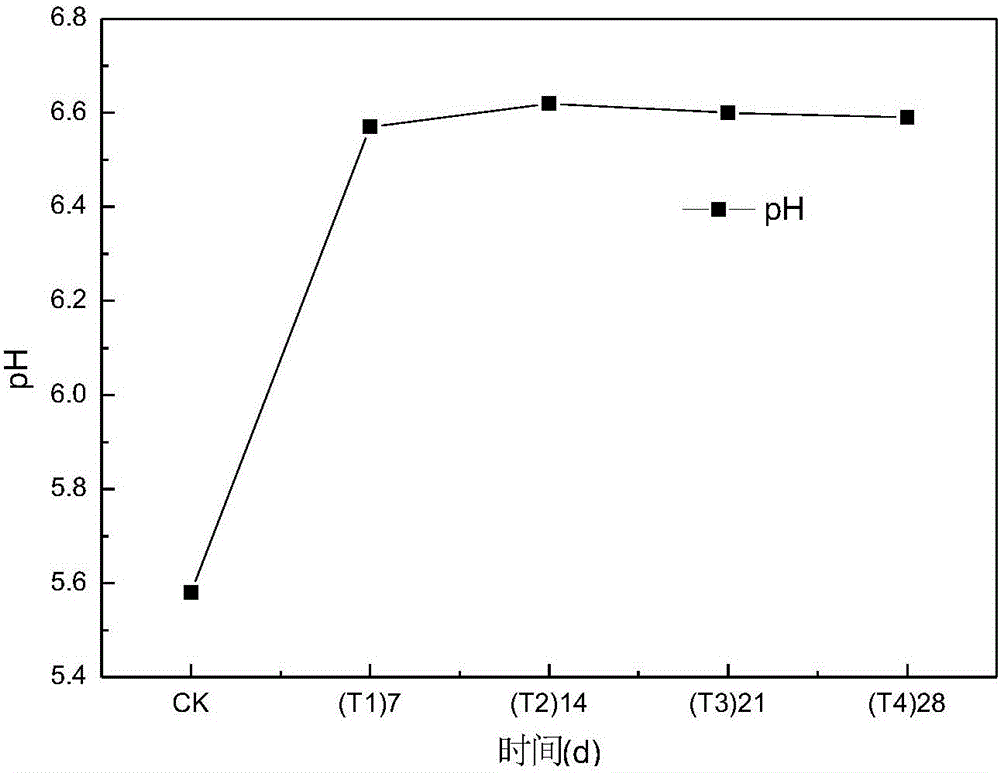

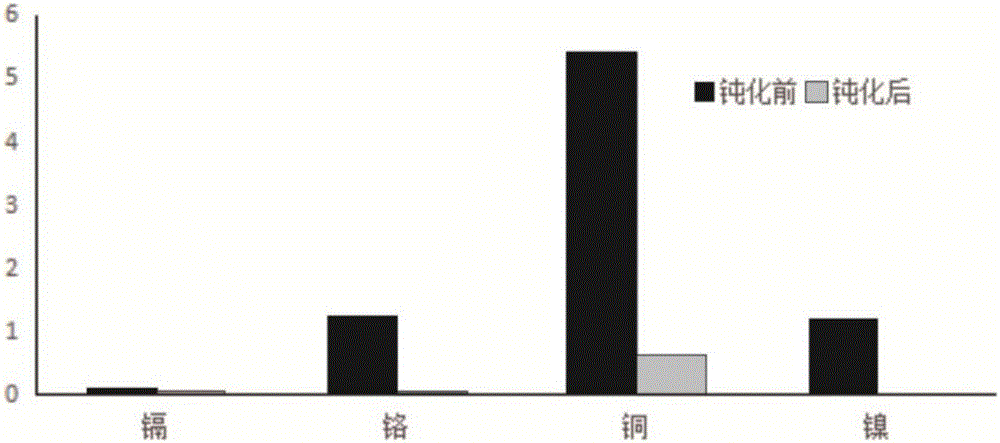

Passivator for remediation of farmland soil subjected to combined pollution of heavy metals, and preparation method and use method of passivator

InactiveCN106800933AImprove adsorption capacityImprove water retentionAgriculture tools and machinesMagnesium fertilisersIon exchangeBinding state

The invention relates to a passivator for remediation of farmland soil subjected to combined pollution of heavy metals such as cadmium, chromium, copper and nickel, and a preparation method and a use method of the passivator. The passivator is prepared from a passivator A and a passivator B, wherein the passivator A is prepared from montmorillonite, kieselguhr, sepiolite, illite and ferrous sulfate; the passivator B is prepared from periclase, calcite, calcium magnesium phosphate fertilizer, plant ash and calcium hydroxide; the passivator is suitable for the farmland soil subjected to the combined pollution of the cadmium, the chromium, the copper and the nickel, and is prepared from the multiple different porous absorption materials with specific contents and a passivation material; the components of the passivator have complementary advantages, and the principles such as absorption and stabilization are combined; the combination forms of the heavy metals are effectively enhanced by ion exchange, complexing, chelating and adsorption methods, and the combination forms are converted into more stable strong organic binding states and residue states, so that the effective state contents of the heavy metals in the farmland soil are effectively reduced, and the passivation effect is long-acting and stable; therefore, the passivator has a great repair effect for the farmland soil subjected to combined pollution of the cadmium, the chromium, the copper and the nickel.

Owner:SICHUAN YIKE ENVIRONMENTAL PROTECTION SCI ANDTECH

Process for treating a feed gas

Owner:AIR PROD & CHEM INC

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:JAIN RAVI +1

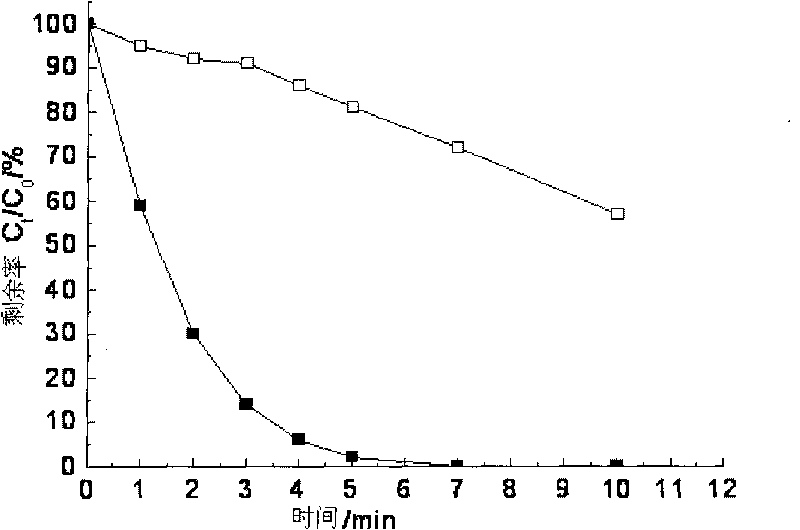

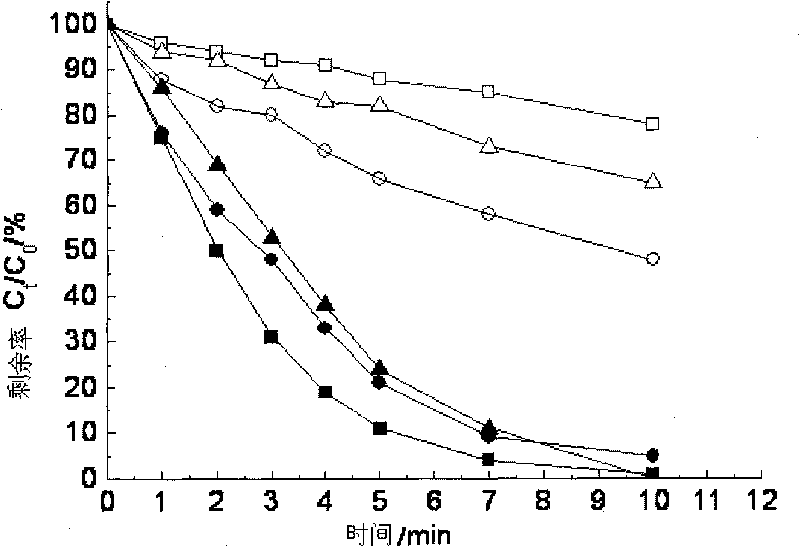

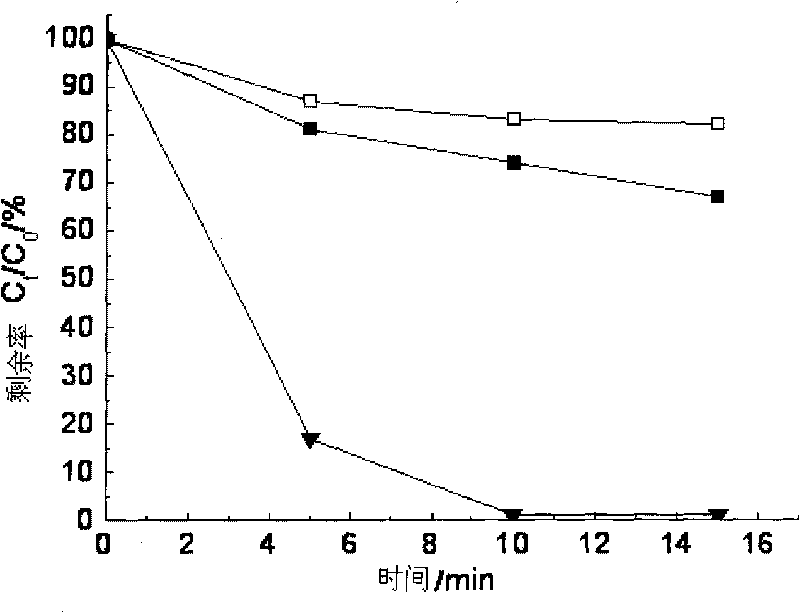

Light promoting dehalogenation compound medicament/light combined method for removing halogenated organic matters in water

InactiveCN101708883AQuick removalImprove utilization efficiencyWater/sewage treatment by irradiationWater contaminantsOptical radiationHigh energy

Owner:HARBIN INST OF TECH

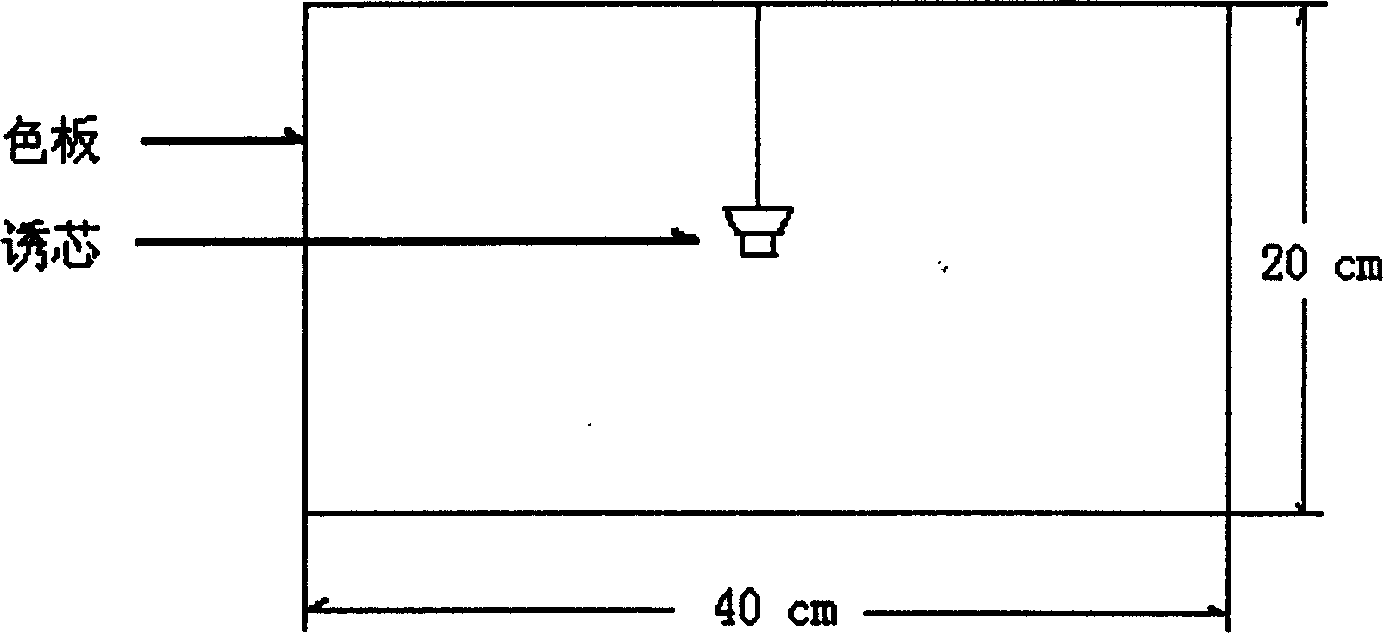

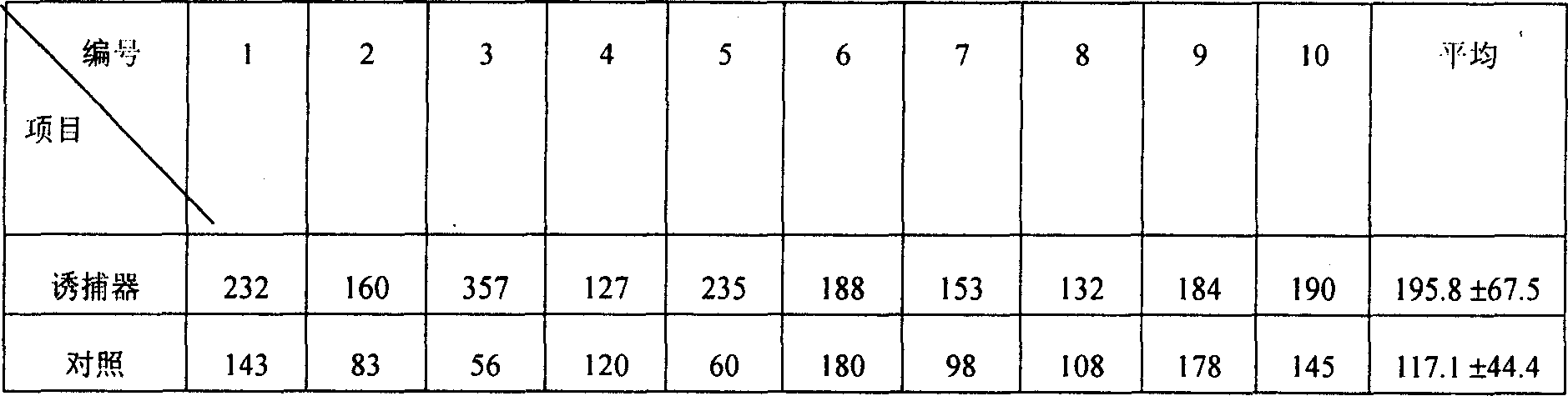

Method for trapping Empoasca vitis Gothe imago/nymph and Aleurocanthus spiniferus imago

InactiveCN1568685AAdapt to productionNo pollution in the processInsect catchers and killersAdditive ingredientBud

The invention discloses a trap method for Empoasca vitis Gothe imago,nympha and spiny white fly imago, comprising the steps: 1)separating and authenticating 9 volatile matter from sturdy tea twig using adsorption method 2) determining three volatile ingredient with allure activity using biological determination method 3)respectively preparing three active ingredient, concentration 0.01-20mu g / ml, mixing according to 1:0.2-1.5:0.1-1, preparing attractant, 4)determining three colors with alluring effect to Empoasca vitis Gothe and spiny white fly from ten colors in the tea garden allure experiment, three colors being parrot green, bud green and jasmine yellow 5) combining attractant with bud green and jasmine yellow, making trapper for Empoasca vitis Gothe and spiny white fly The advantage of the invention : 1)no pollution, adapting to organic tea and nuisance free tea production, 2) low cost.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Method for extracting lithium from salt lake brine by using adsorption method

The invention discloses a method for extracting lithium from salt lake brine by using an adsorption method. The method comprises the following steps of adding an absorbent in the brine; absorbing the lithium ions in the brine to the absorbent; then treating by using a ceramic membrane; retaining the absorbent in a concentrated solution; subjecting the concentrated solution to plate-frame pressure filtration to obtain an absorbent filter cake; removing most of impurities and water from the brine; washing the filter cake with water and desorbing with an eluent to obtain a desorption solution; removing magnesium from the desorption solution by passing the desorption solution through a weak acid type cation exchange resin; concentrating with a reverse osmosis membrane to obtain a refined lithium solution for preparing lithium carbonate. The method is simple in process and can be operated easily. The absorbent has high utilization efficiency; a lithium-extracting process is short; and the content of the prepared lithium solution is high.

Owner:JIANGSU JIUWU HITECH

Hydrocarbon adsorption method and device for controlling evaporative emissions from the fuel storage system of motor vehicles

ActiveUS7753034B2Reduce releaseReduce the amount of fuelGas treatmentNon-fuel substance addition to fuelSlurryEngineering

The present invention is directed to an evaporative emissions control apparatus for minimizing fuel vapor emissions from a fuel storage system in a vehicle with an internal combustion engine. More specifically, the present invention is directed to an evaporative emissions control apparatus comprising a canister filled with a hydrocarbon adsorbent. The present invention is also directed an evaporative emissions control apparatus comprising a support substrate, which is coated with a hydrocarbon adsorbent slurry.

Owner:BASF CATALYSTS LLC

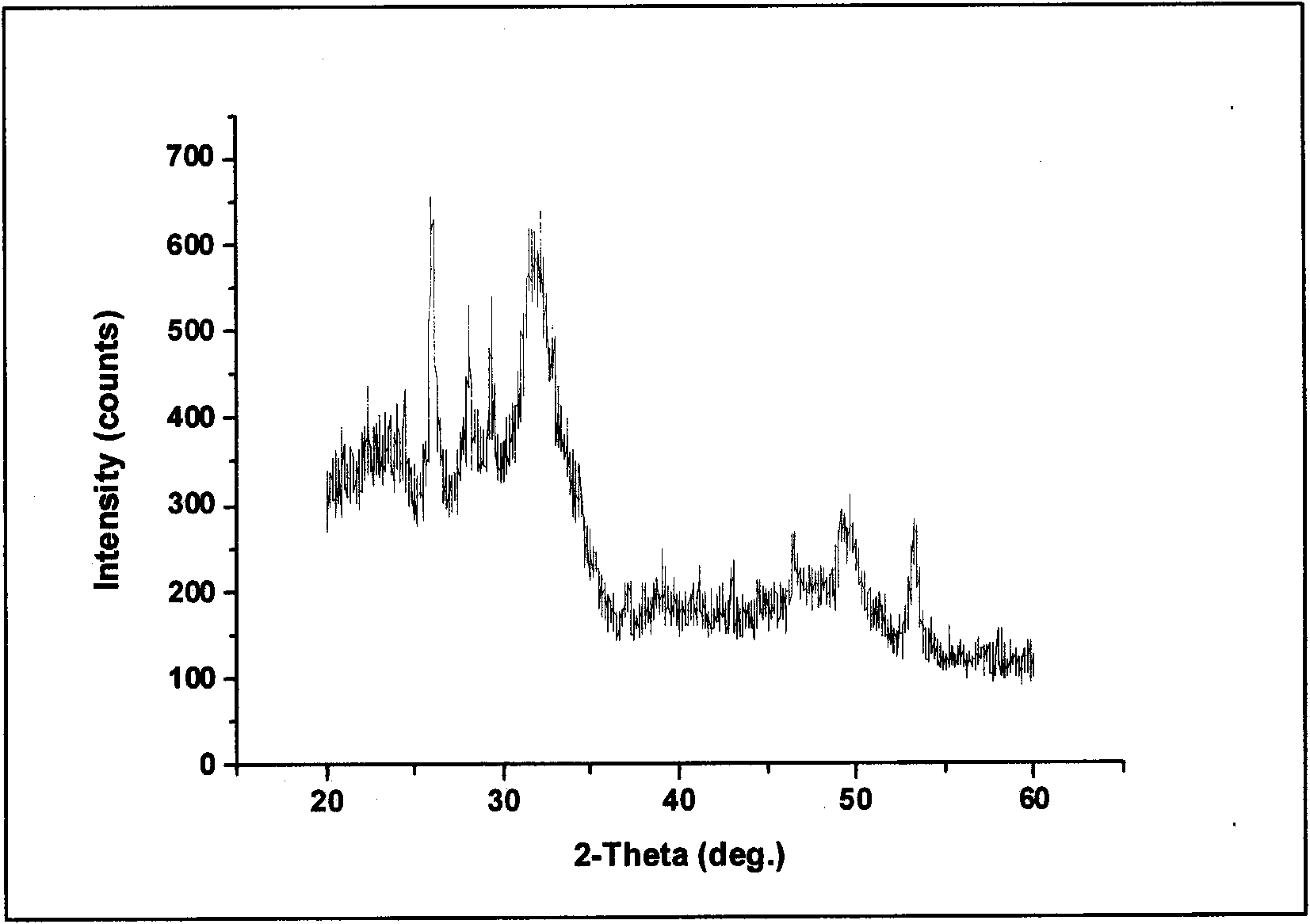

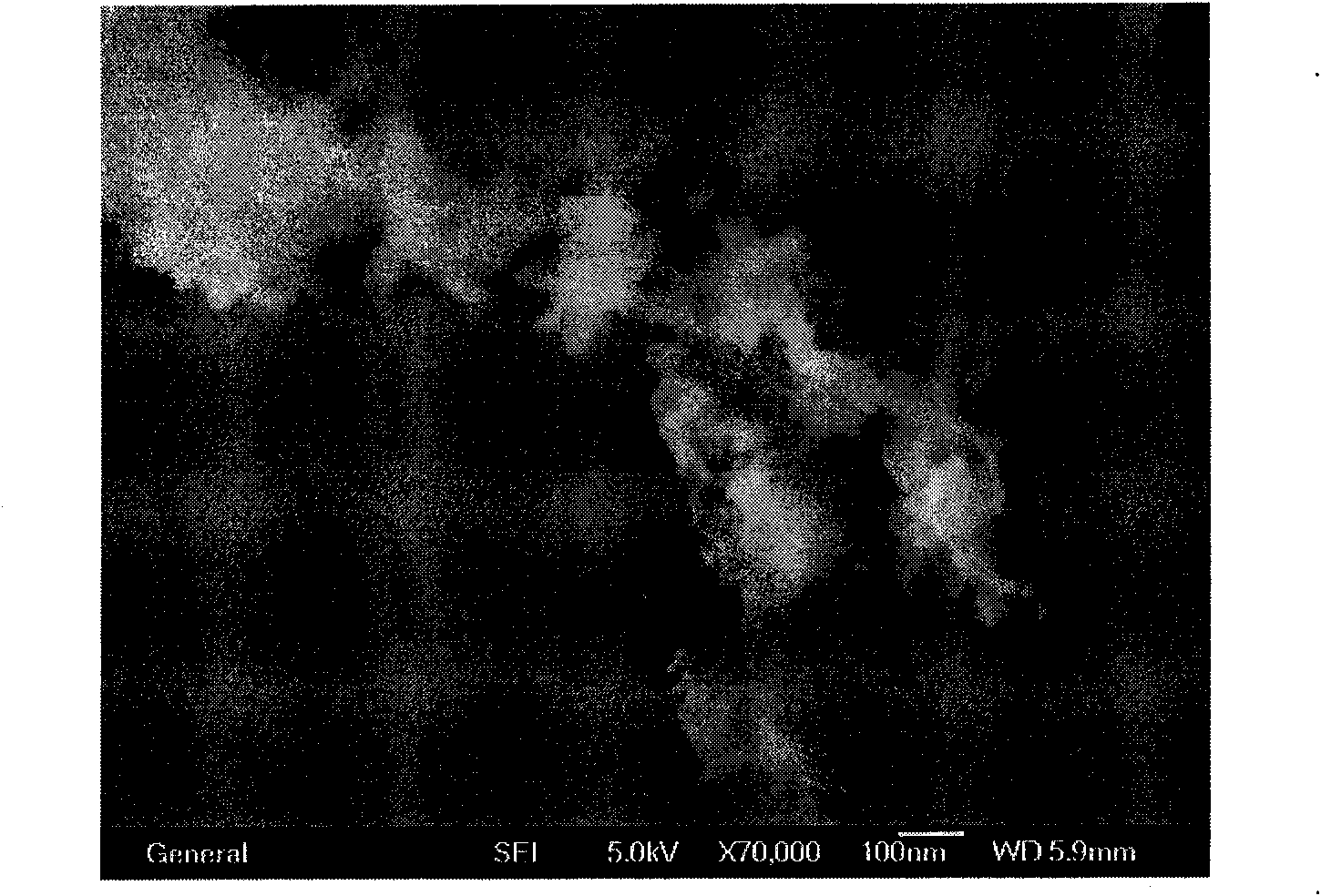

Manganese dioxide/carbon combined electrode and electric adsorption method for electrically adsorbing heavy metal ions from water

ActiveCN103936116ALarge specific surface areaEfficient removalDispersed particle separationWater/sewage treatmentCapacitanceElectricity

The invention relates to a manganese dioxide / carbon combined electrode and an electric adsorption method for electrically adsorbing heavy metal ions from water. The manganese dioxide / carbon combined electrode is manufactured by taking a carbon material as a substrate and supporting manganese dioxide on the substrate. A voltage is applied to the manganese dioxide / carbon combined electrode so that electropositive heavy metal ions in water migrate to a cathode under the action of electric field force, and therefore, heavy metal ions in water are removed by electric adsorption. The manganese dioxide / carbon combined electrode is simple in preparation method, large in capacitance, high in electrochemical stability and large in specific surface area of electrode, and thus very suitable for being used as an electric adsorption electrode material; under the action of the applied electric field, the adsorption effect of the supported manganese dioxide on heavy metal ions is enhanced, quick and efficient removal of heavy metal ions in water can be realized and quick and convenient regeneration of the electrode material also can be realized; the shortcoming in the prior art low-concentration heavy metal ions in water are hardly removed is overcome, and therefore, the manganese dioxide / carbon combined electrode and the electric adsorption method can be used for removing the heavy metal ions having the concentration of several to dozens of ppm out of water.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

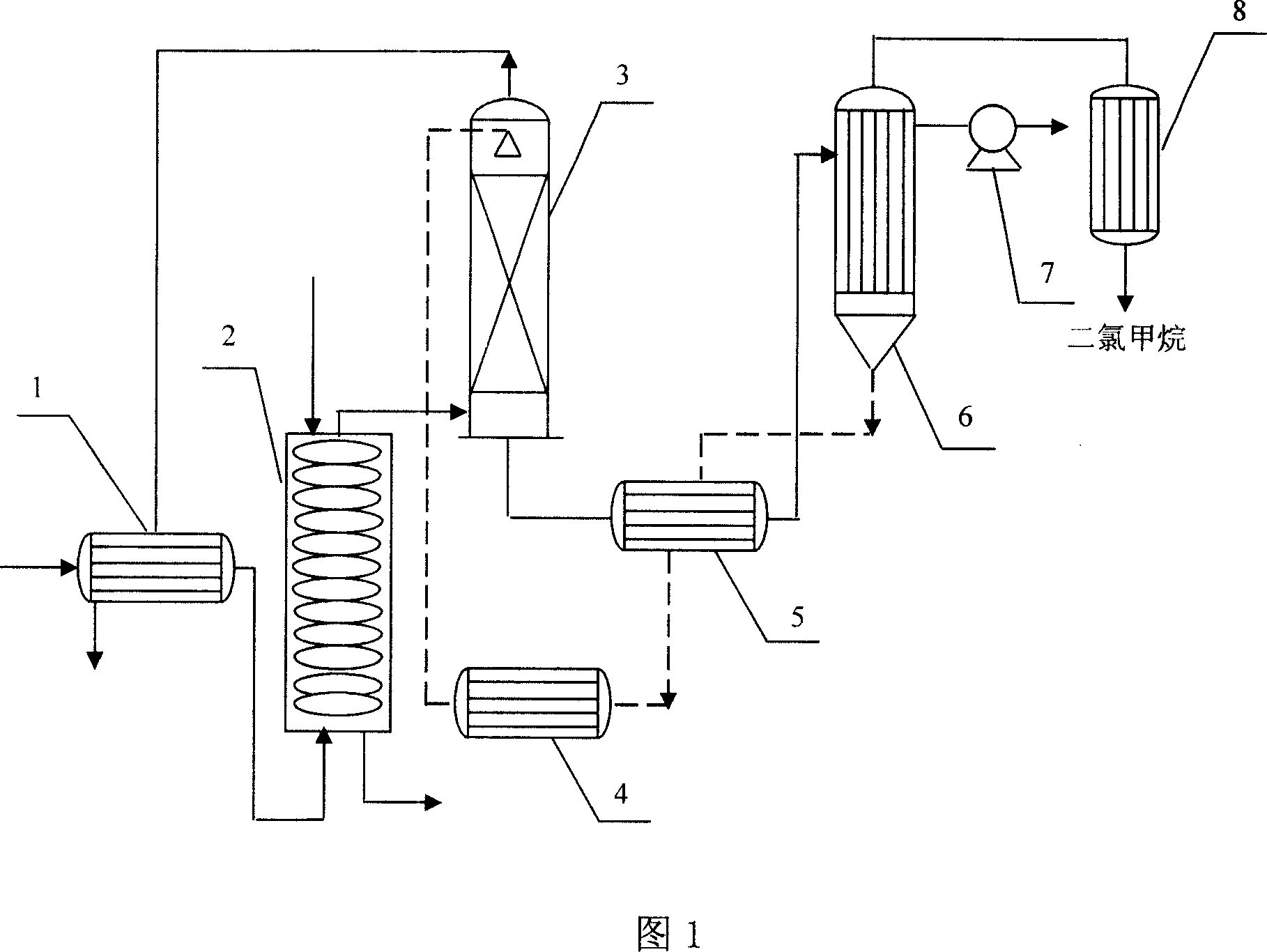

Method for reclaiming methylene chloride from waste gas

InactiveCN1962028ASmall poison spotThe content adapts to a wide rangeDispersed particle separationVapor condensationRecovery methodChloride

The invention relates to a method for recycling carrene of waste gas, wherein the invention uses condense-adsorption method to recycle the carrene of organic waste gas; uses water as cooling medium to condense the waste gas; then uses dimethyl formamide in the stuff adsorption tower as absorber to absorb the carrene; the absorber is analyzed in passive pressure in degrade vaporizer, to regenerate the absorber and form loop-close circulation. The invention has low cost and high efficiency.

Owner:TSINGHUA UNIV

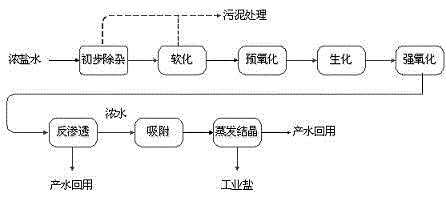

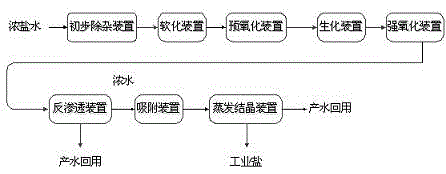

Method and device for realizing zero emission of strong brine

ActiveCN105541017ATake advantage ofEase of useGeneral water supply conservationWater treatment compoundsLoad resistanceEvaporation

The invention provides a method and a device for realizing zero emission of strong brine, overcoming the defects that the existing strong brine treatment technology is high in crystallized impurity salt treatment cost and severe in harm. The impurity removal, softening, pre-oxidation, biochemical and strong oxidation techniques are used for purifying the strong brine, the strong brine after being treated is pre-concentrated by adopting a reverse osmosis way, the reverse osmosis concentrated water is further purified by adopting an adsorption method, and finally the evaporation and quality-divided crystallization technology is used for separating the water to obtain industrial salt. By adopting the method and device, the zero emission of the strong brine is realized, the emission of dangerous waste is reduced, and the recycling is realized. Meanwhile, the general process is mature, the design is reasonable, the impact load resistance is relatively high, the chemical source is convenient, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

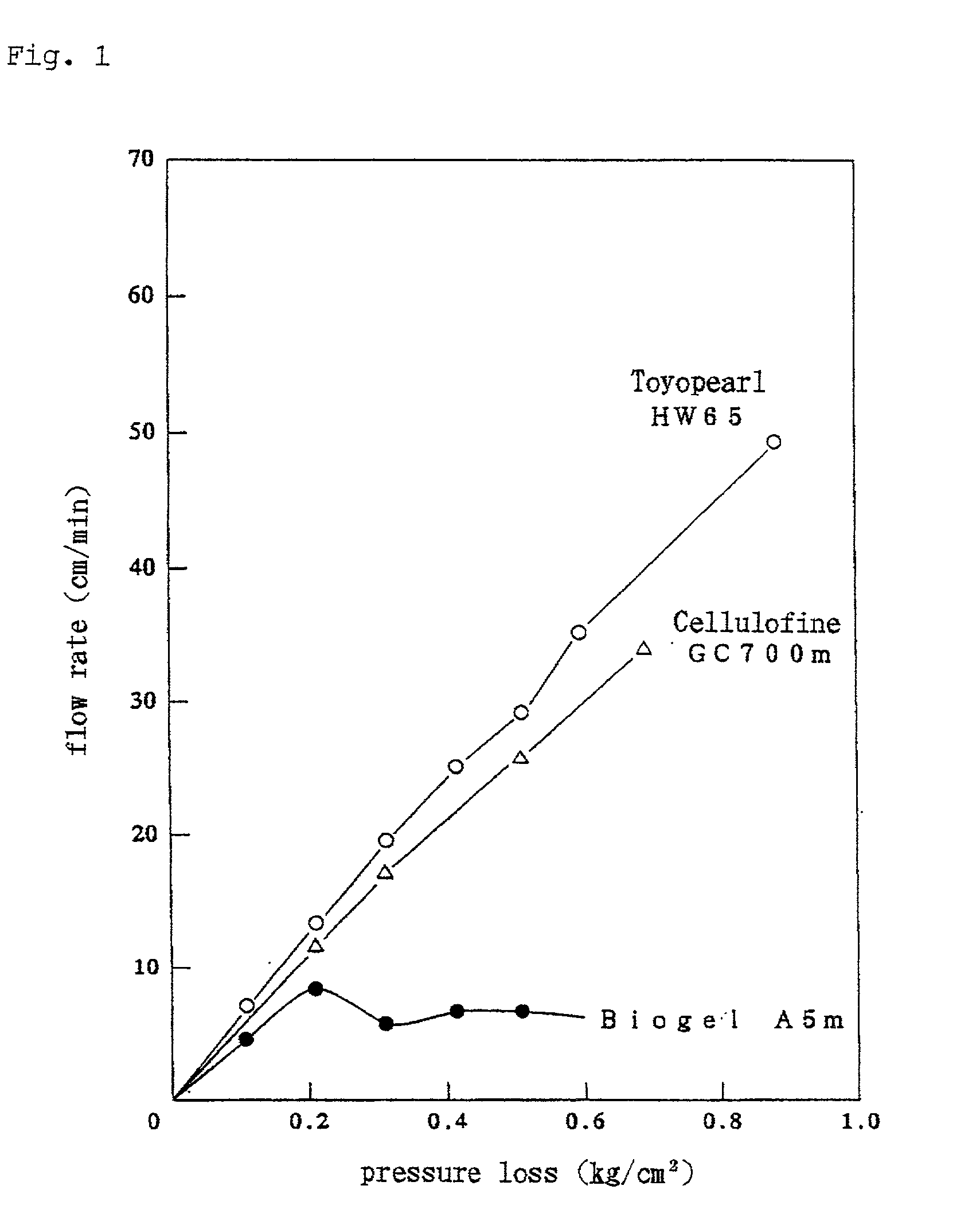

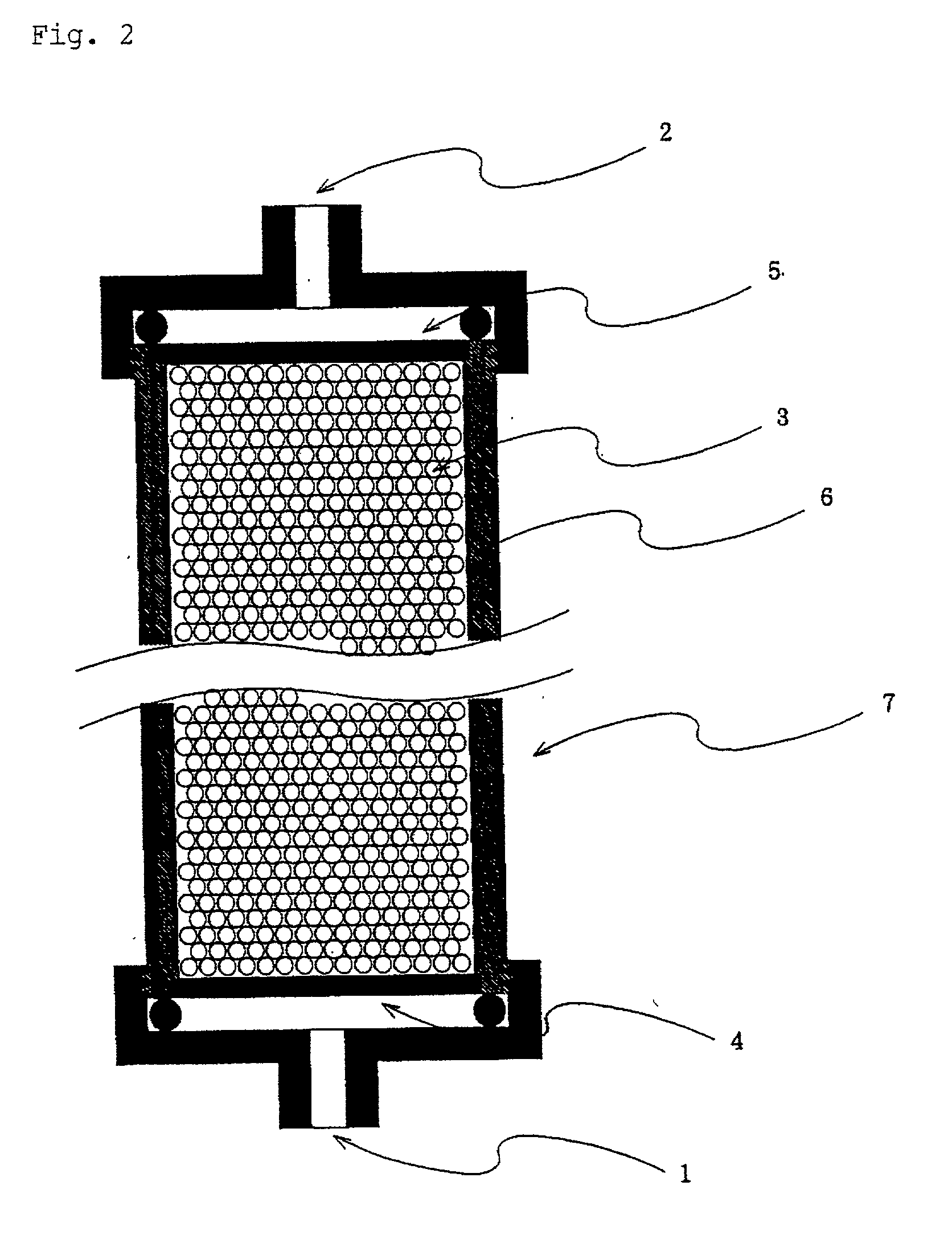

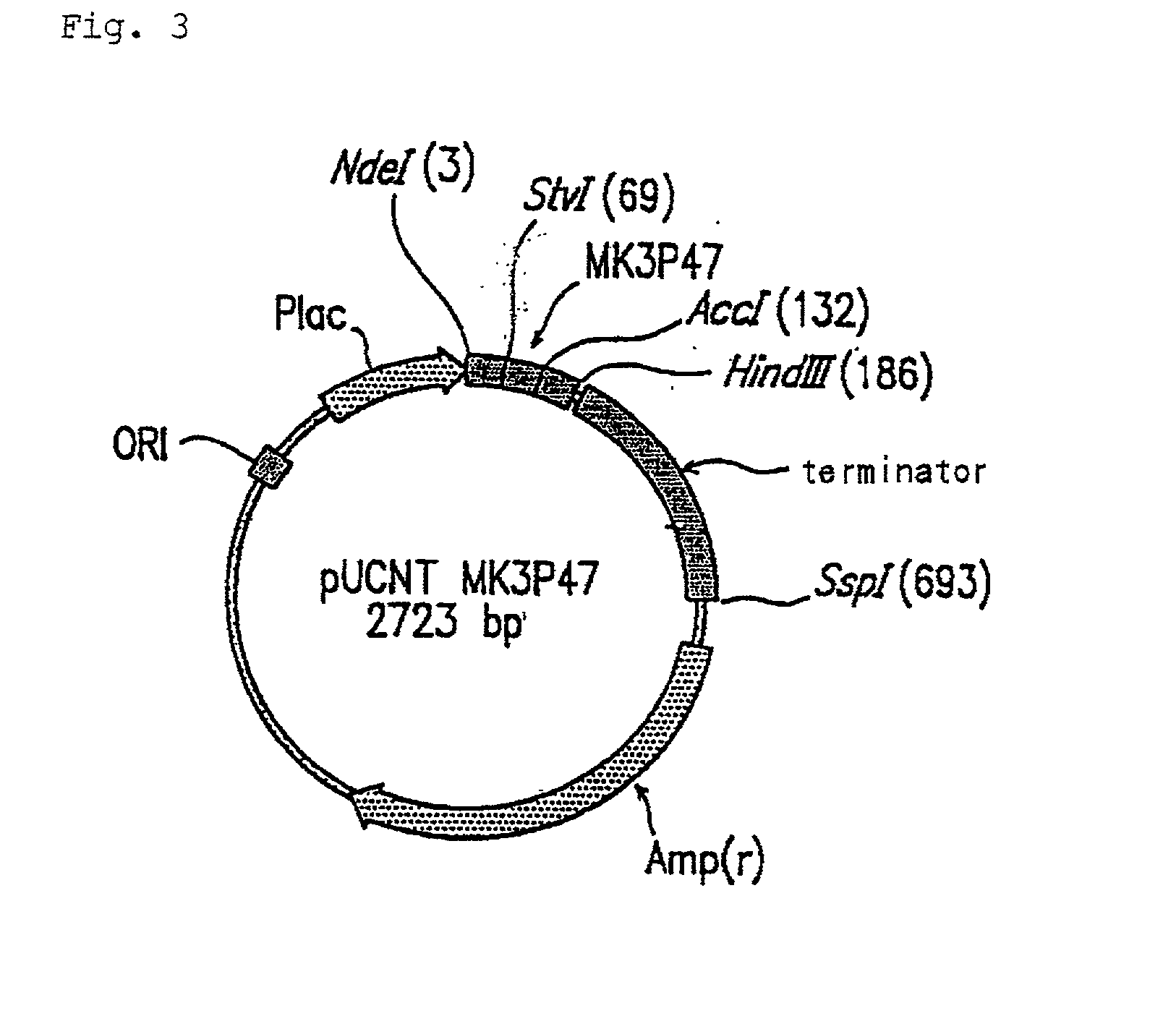

Adsorbent for eliminating hepatitis c virus, adsorber, and adsorption method

InactiveUS20030044769A1High adsorbing affinityImprove performanceOrganic active ingredientsBiocideInterferon therapySorbent

An adsorbent for removing hepatitis C virus which has the ability to adsorb HCV particles, particularly immune-complex HCV particles, from a patient's body blood safely and with high efficiency and high selectivity for enhancing the efficacy of interferon therapy, an HCV adsorption apparatus including said adsorbent, and a adsorbing method for removing HCV are provided. An adsorbent for removing hepatitis C virus which comprises a compound capable of adsorbing hepatitis C virus as immobilized on a water-insoluble carrier, an adsorption apparatus including said adsorbent, and an adsorbing method for removing HCV.

Owner:KANEKA CORP

Method for removing tetracycline in water by adsorption method

InactiveCN101333011AImprove adsorption capacityEasy to operateWater/sewage treatment by sorptionActivated carbonTreatment effect

The invention discloses a method for eliminating tetracycline in the water by a adsorption method; Mesoporous carbon is taken as adsorbent to adsorb and eliminate the tetracycline in the water; the method particularly includes the following steps: 1) synthesizing a template SBA-15 of the mesoporous carbon; 2) taking the SBA-15 as the template to synthesize mesoporous carbon CMK-3; 3) taking the mesoporous carbon CMK-3 as an adsorbent to adsorb tetracycline in water. By adopting the adsorption method to eliminate the tetracycline in the water, the method of the invention can achieve the adsorption performance which is significantly superior to that of the traditional adsorbing material (like activated carbon). Furthermore, the method of the invention has simple operation and significant treatment effect, and the material is easy to be obtained. The method of the invention has high economic and environmental benefits on the elimination of the tetracycline in the water of a micro-polluted water source.

Owner:NANJING UNIV

Method for recovering rare earth from rare-earth-contained phosphorite

The invention discloses a method for recovering rare earth from rare-earth-contained phosphorite, which relates to the method for recovering the rare earth from phosphorite and is characterized by comprising the following steps: mixing a rare-earth-contained phosphate concentrate with a phosphoric acid solution for stirring reaction; immersing the rare earth into the solution; carrying out solid-liquid separation to obtain a rare-earth-contained phosphoric acid solution; then, separating and recovering the rare earth from the rare-earth-contained phosphoric acid solution through uniting one or several of an extraction method, an ion exchange adsorption method, a precipitation method and a crystallization method; and enabling the phosphoric acid solution after slag is leached and the rare earth is separated and recovered to enter a wet-process phosphoric acid production system to produce a phosphoric acid. In the method for recovering the rare earth from the rare-earth-contained phosphorite, by taking the phosphoric acid solution as a leaching agent, the rare earth is extracted from the rare-earth-contained phosphorite without adding a surface active agent, thereby, the quality of a phosphoric acid product is not influenced, and the rare-earth leaching rate is about as high as 90 percent, and moreover, the leaching agent for leaching the rare earth is the phosphoric acid generated in the phosphoric acid production course, and can also be circular dilute phosphoric acid, diluted phosphoric acid and the like generated in the phosphoric acid production course. The method for recovering the rare earth from the rare-earth-contained phosphorite is tightly linked with a sulfuric acid-method phosphoric acid production process.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com