Patents

Literature

8001 results about "Separation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

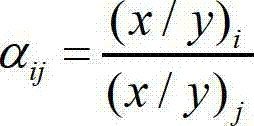

A separation process is a method that converts a mixture or solution of chemical substances into two or more distinct product mixtures. At least one of results of the separation is enriched in one or more of the source mixture's constituents. In some cases, a separation may fully divide the mixture into pure constituents. Separations exploit differences in chemical properties or physical properties (such as size, shape, mass, density, or chemical affinity) between the constituents of a mixture.

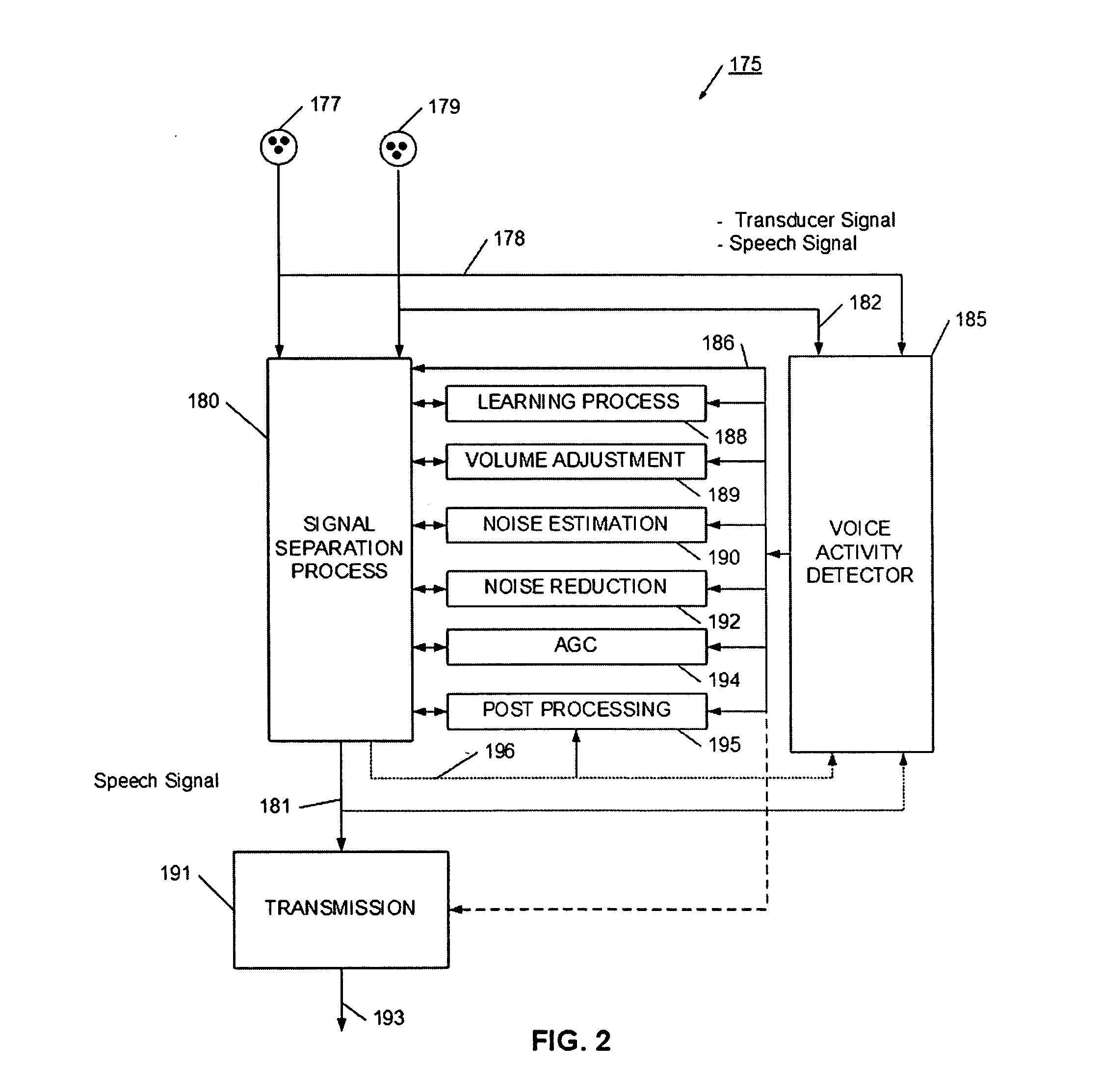

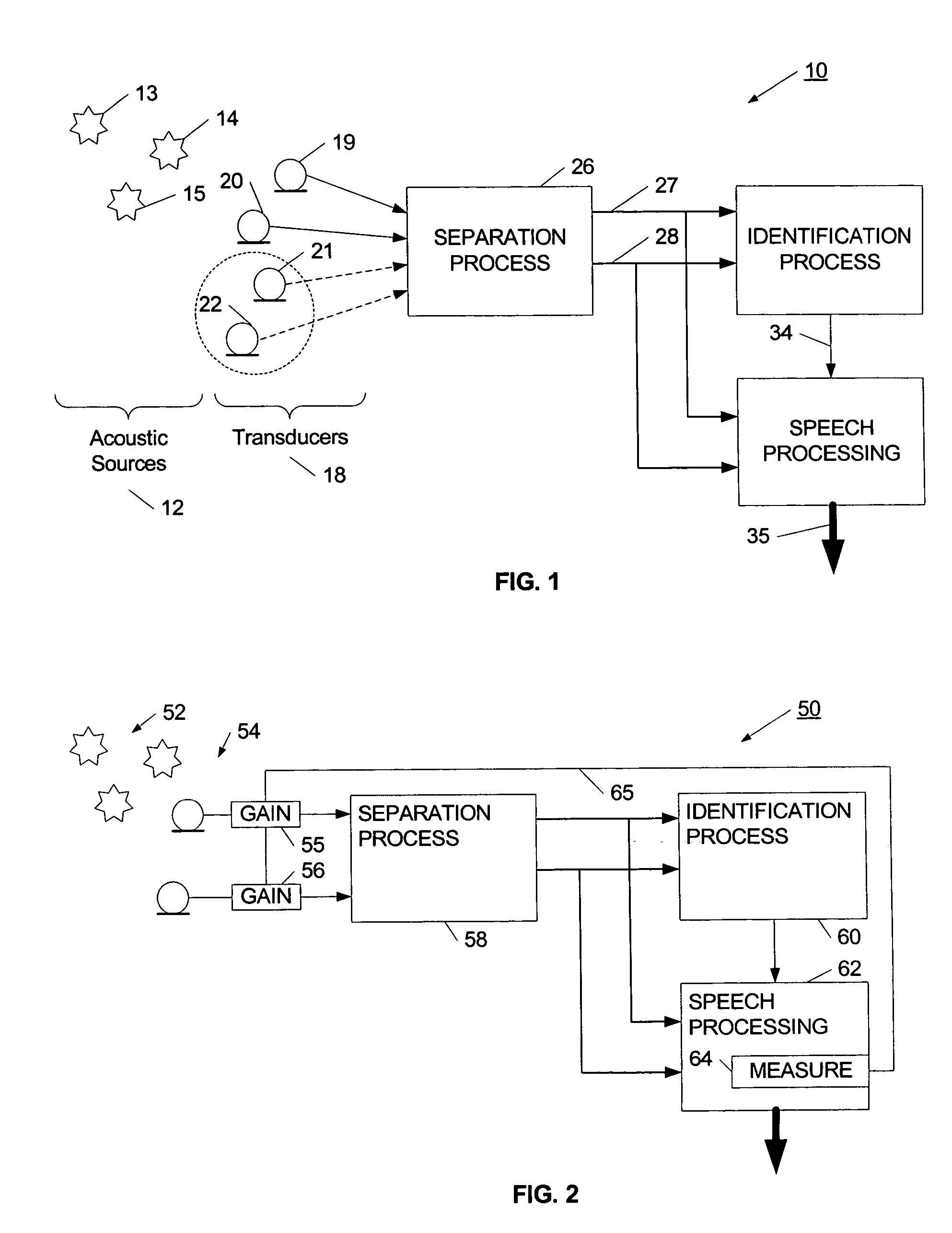

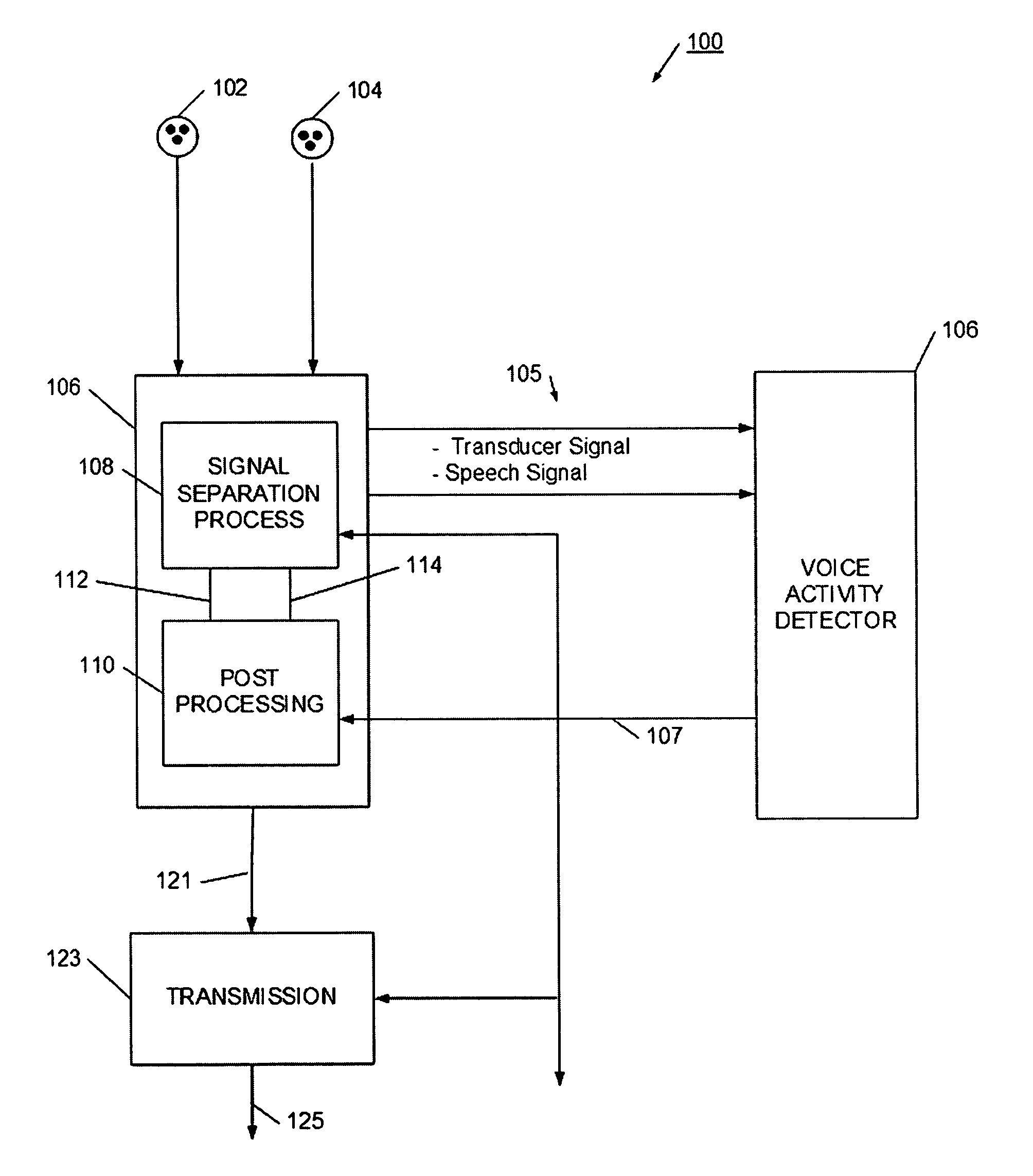

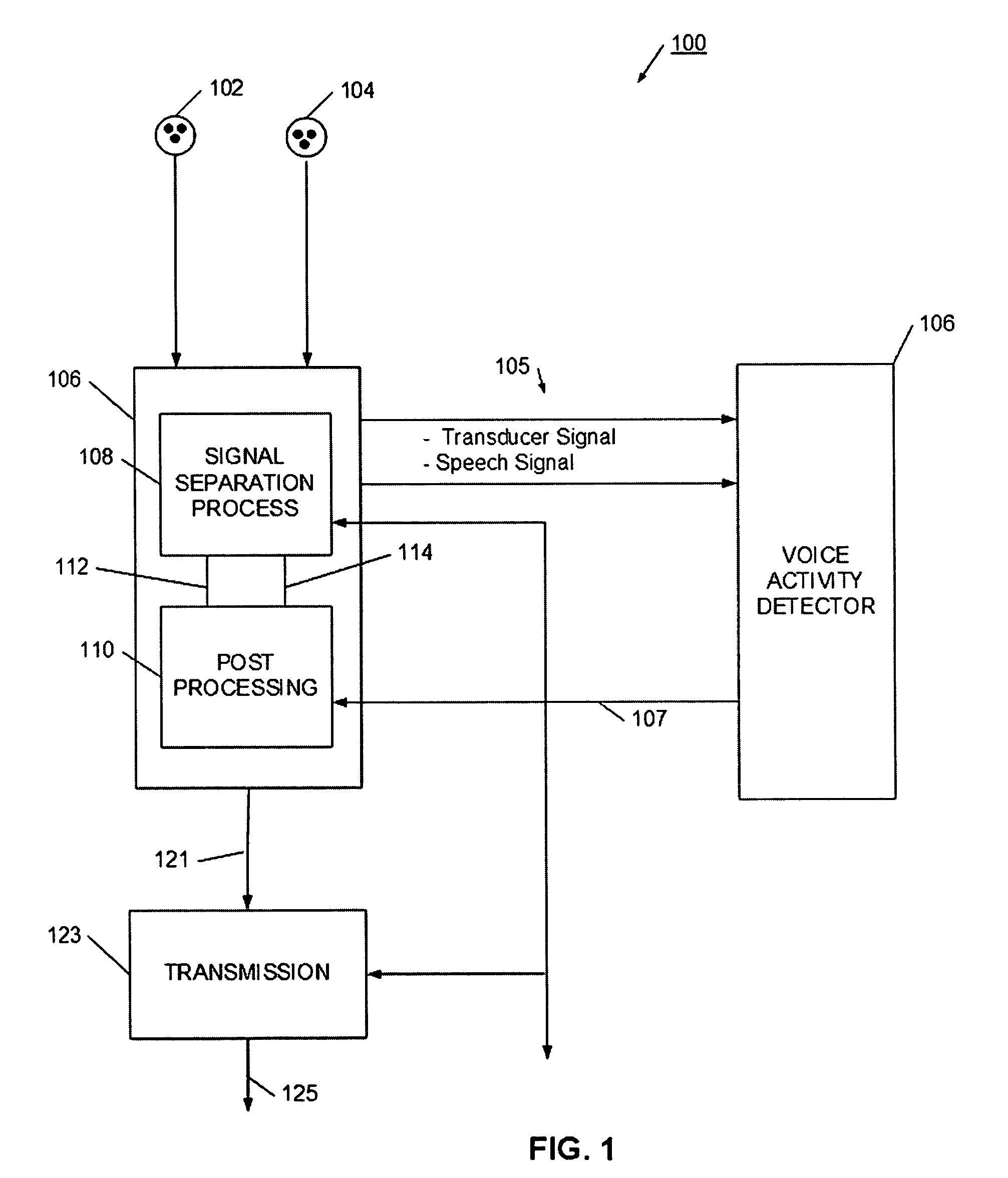

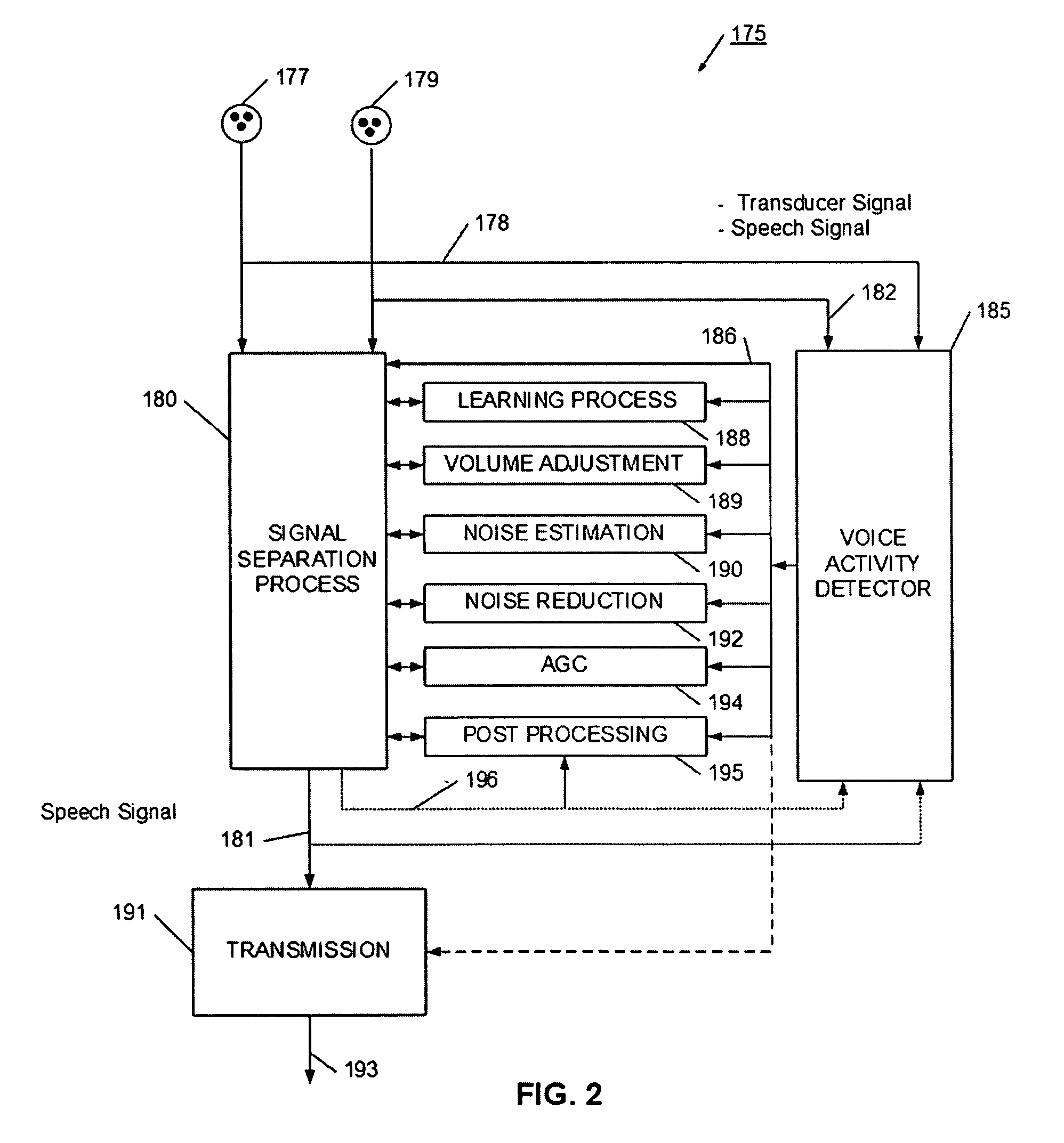

Robust separation of speech signals in a noisy environment

ActiveUS20070021958A1Improve voice qualityRobust and accurate detectionMicrophonesSpeech recognitionControl signalVoice activity

A method for improving the quality of a speech signal extracted from a noisy acoustic environment is provided. In one approach, a signal separation process is associated with a voice activity detector. The voice activity detector is a two-channel detector, which enables a particularly robust and accurate detection of voice activity. When speech is detected, the voice activity detector generates a control signal. The control signal is used to activate, adjust, or control signal separation processes or post-processing operations to improve the quality of the resulting speech signal. In another approach, a signal separation process is provided as a learning stage and an output stage. The learning stage aggressively adjusts to current acoustic conditions, and passes coefficients to the output stage. The output stage adapts more slowly, and generates a speech-content signal and a noise dominant signal. When the learning stage becomes unstable, only the learning stage is reset, allowing the output stage to continue outputting a high quality speech signal.

Owner:QUALCOMM INC

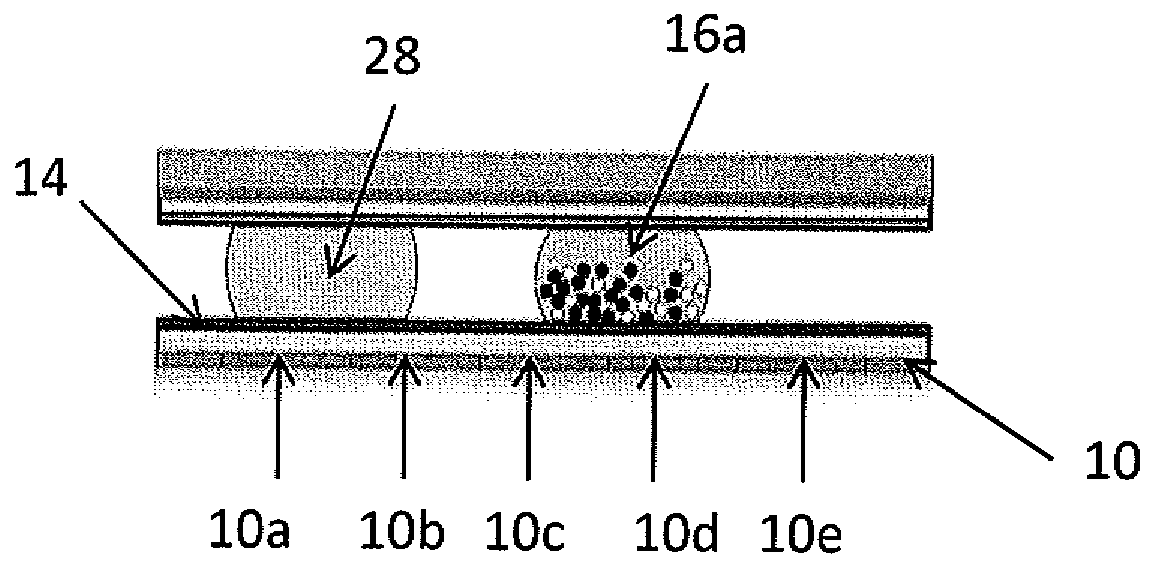

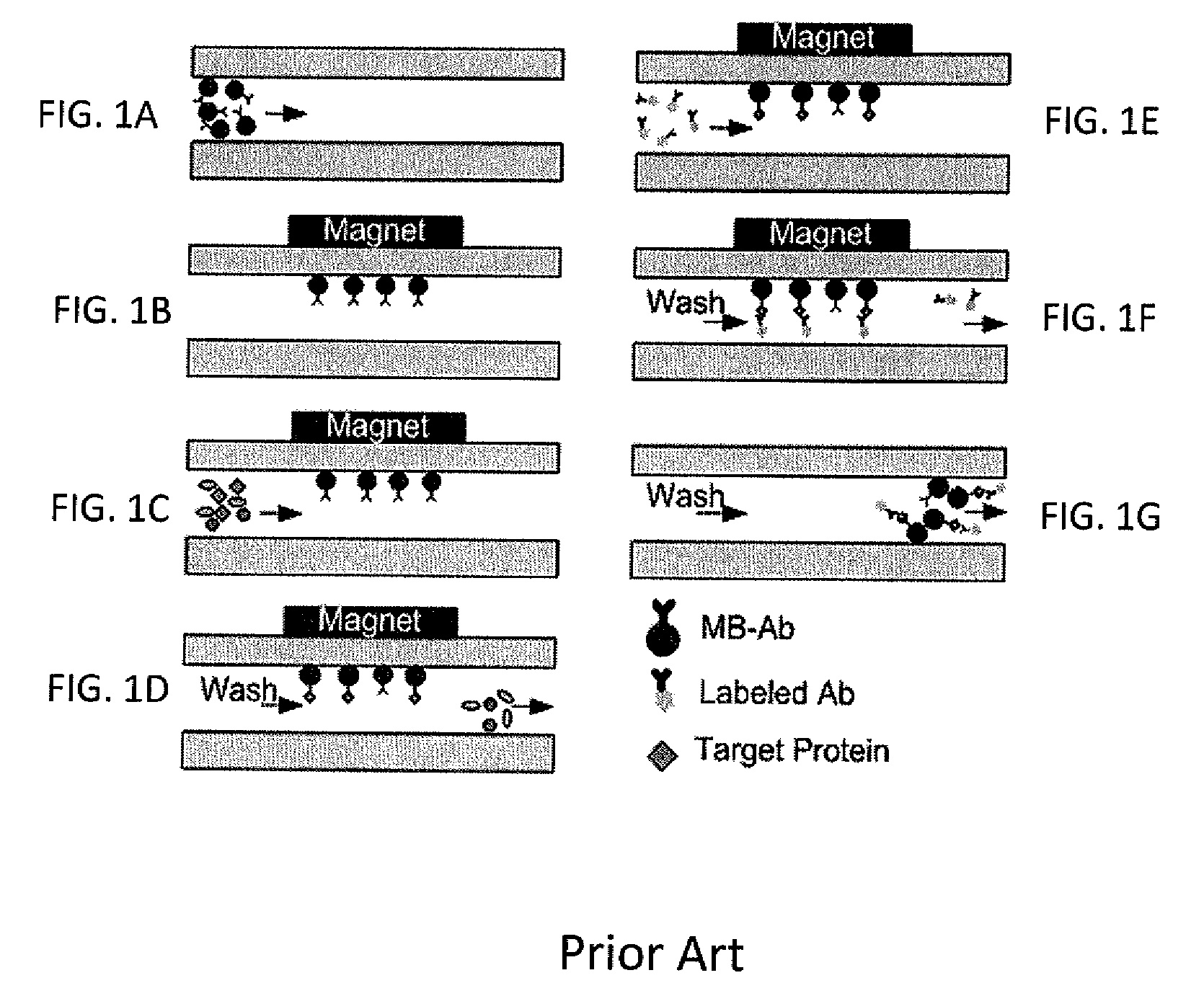

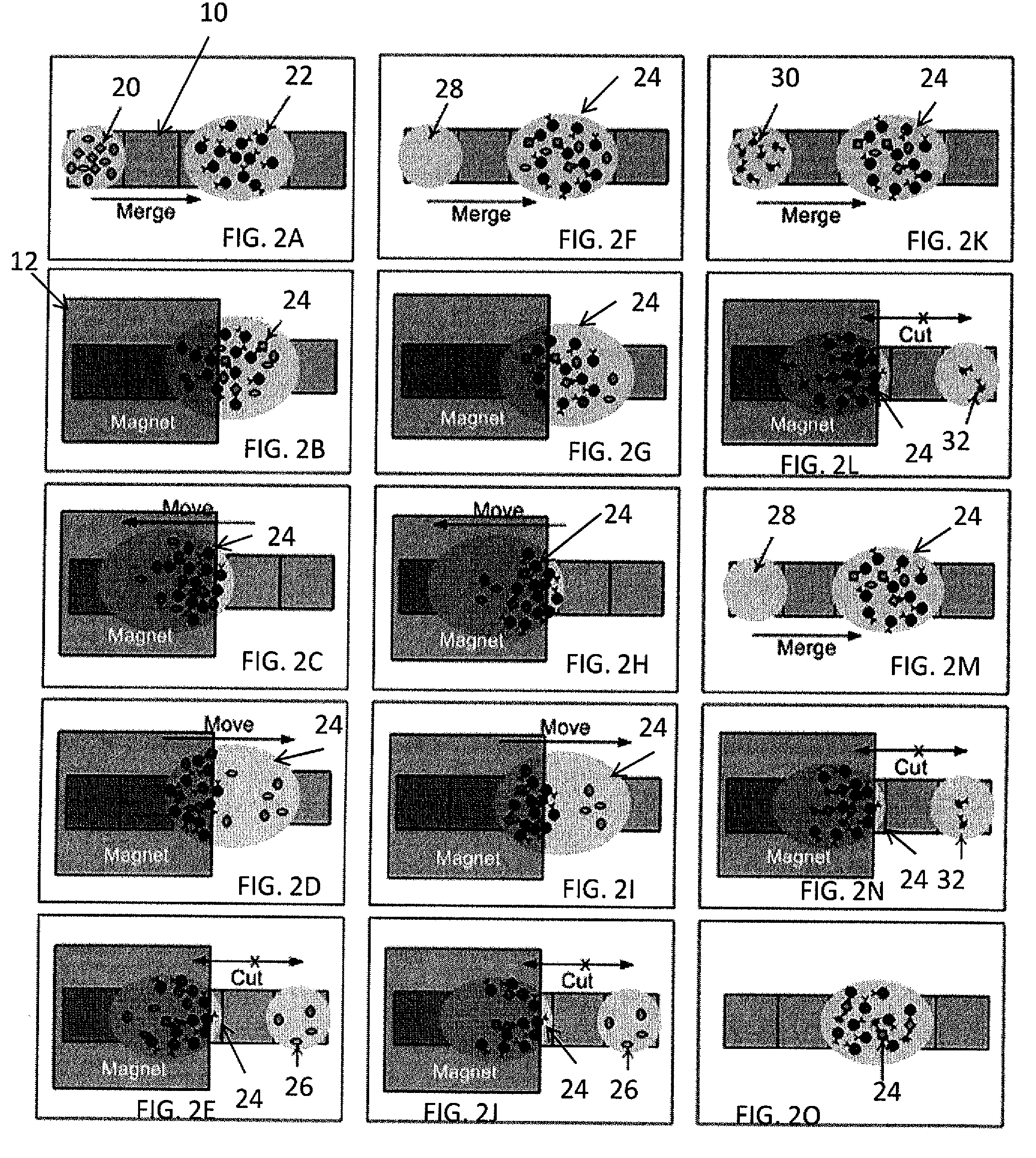

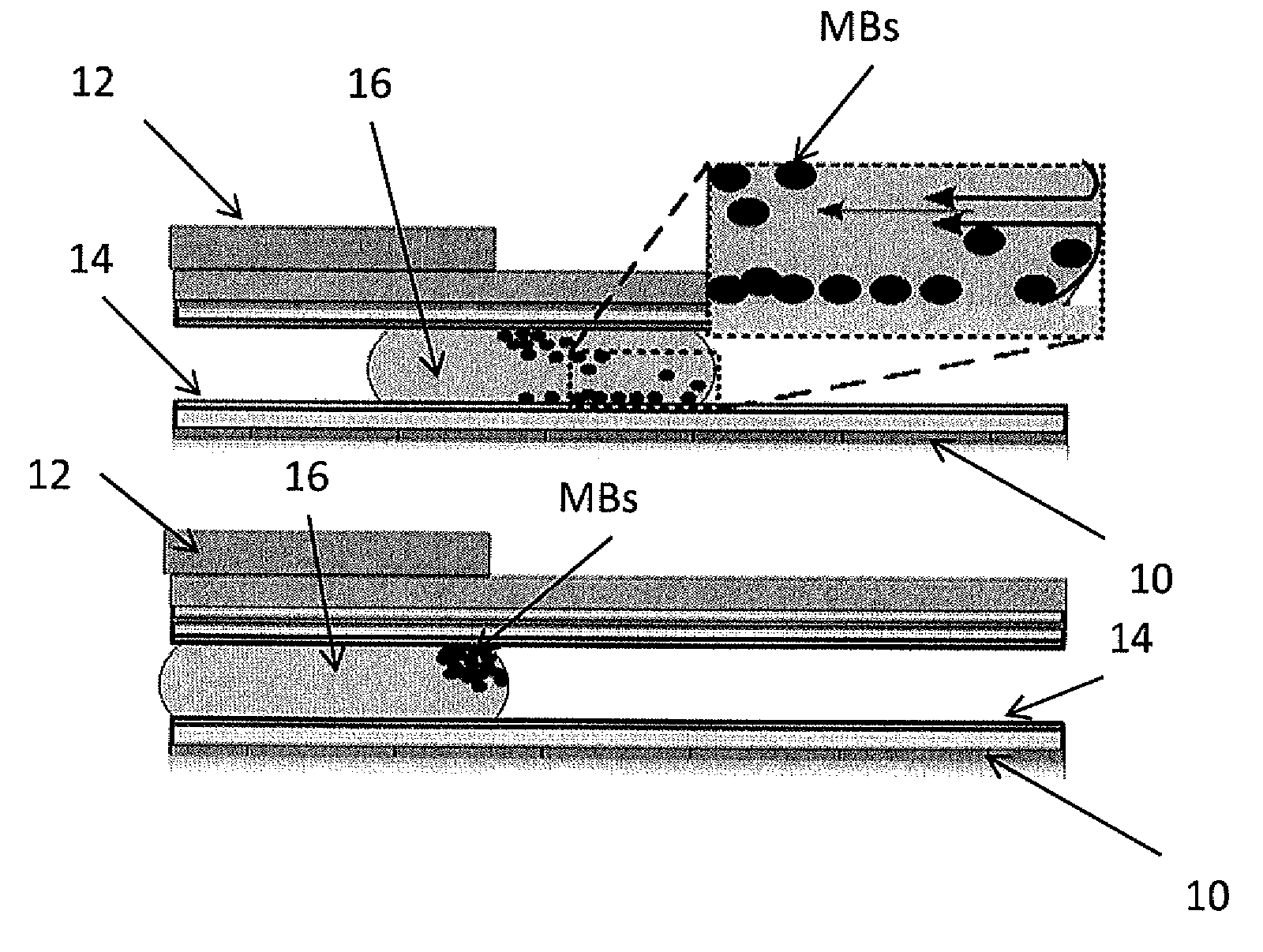

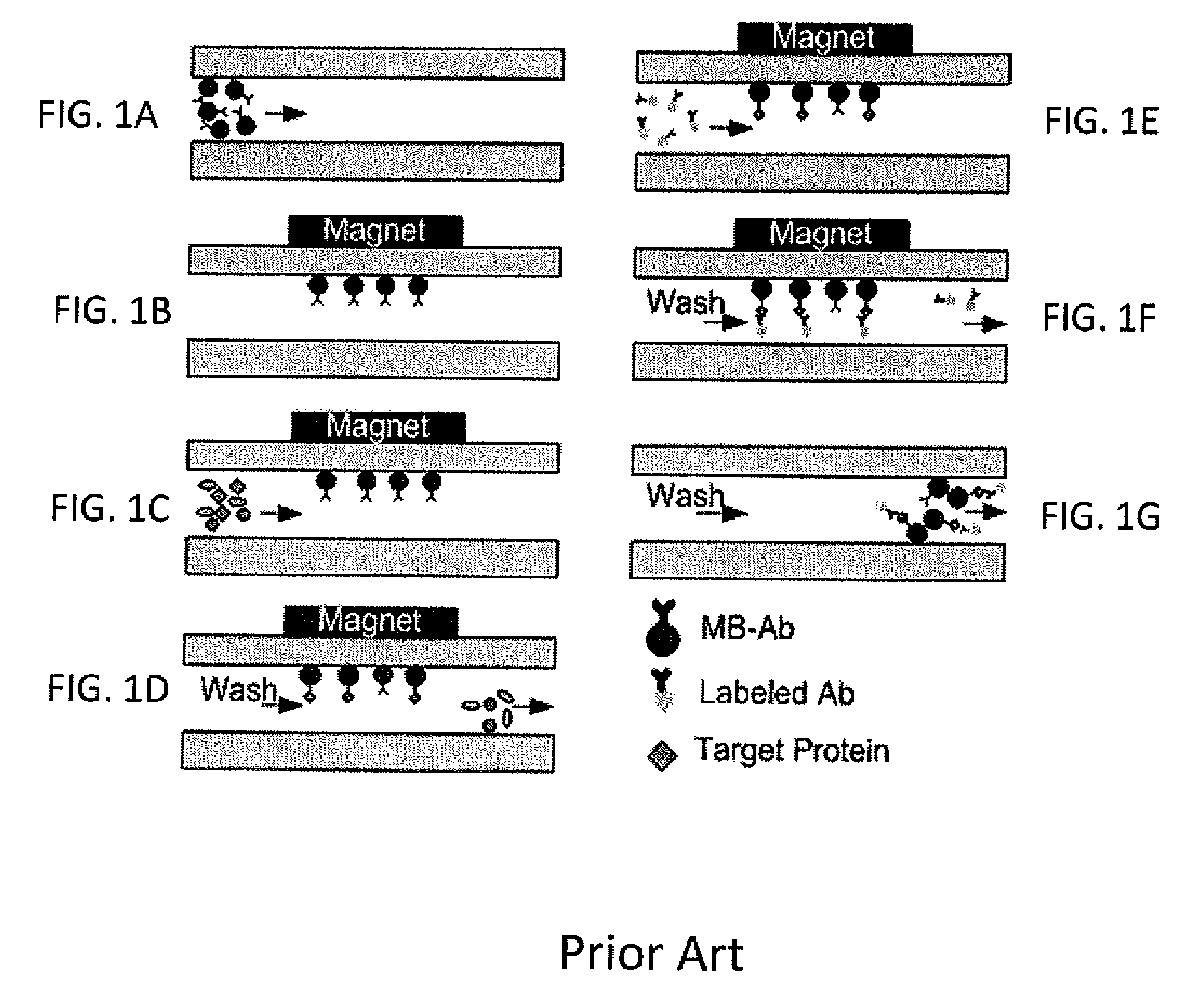

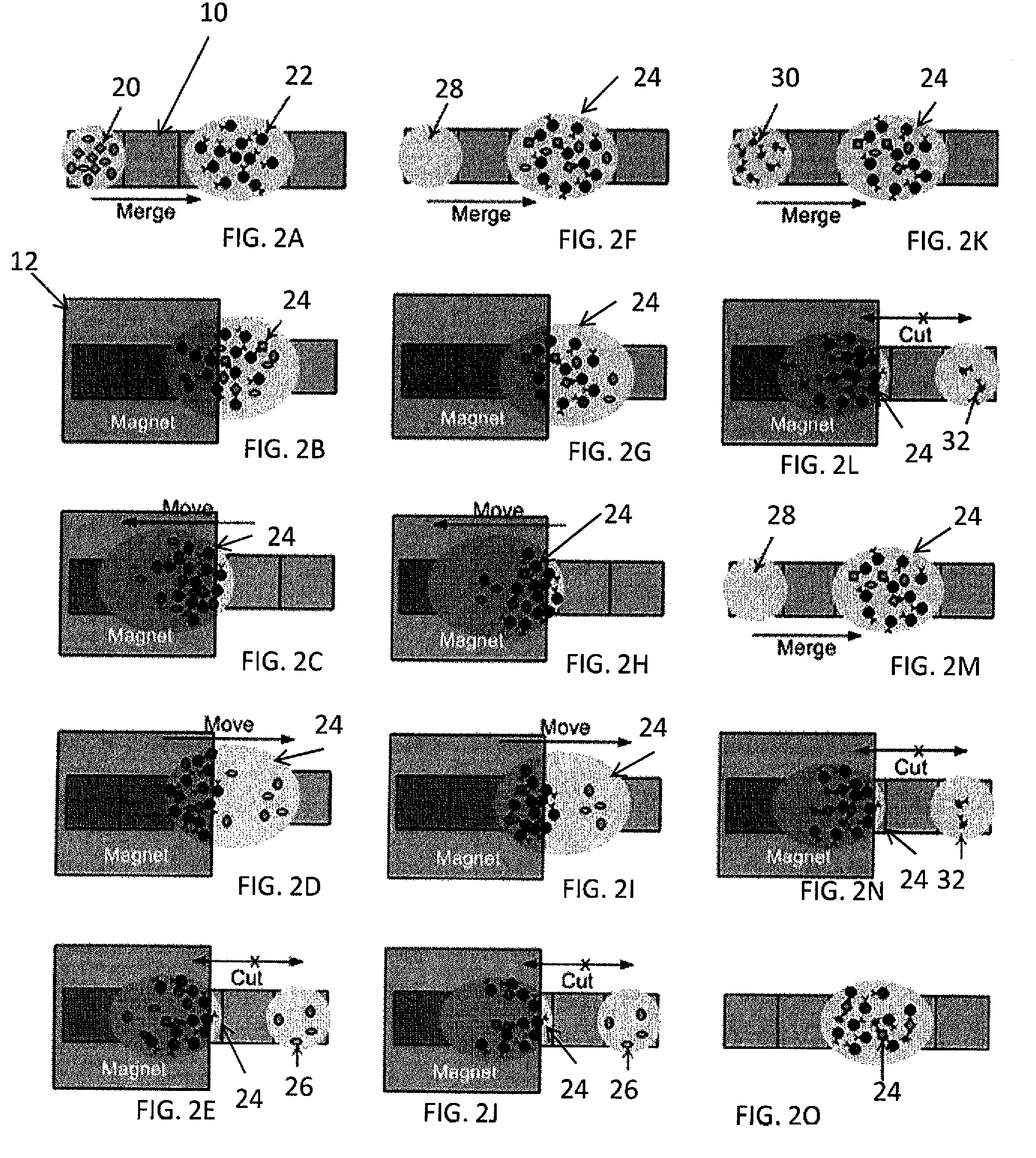

Method for using magnetic particles in droplet microfluidics

ActiveUS20090283407A1Increasing concentration of targetReduce concentrationElectrostatic separatorsLiquid separation by electricityEngineeringDroplet microfluidics

Methods of utilizing magnetic particles or beads (MBs) in droplet-based (or digital) microfluidics are disclosed. The methods may be used in enrichment or separation processes. A first method employs the droplet meniscus to assist in the magnetic collection and positioning of MBs during droplet microfluidic operations. The sweeping movement of the meniscus lifts the MBs off the solid surface and frees them from various surface forces acting on the MBs. A second method uses chemical additives to reduce the adhesion of MBs to surfaces. Both methods allow the MBs on a solid surface to be effectively moved by magnetic force. Droplets may be driven by various methods or techniques including, for example, electrowetting, electrostatic, electromechanical, electrophoretic, dielectrophoretic, electroosmotic, thermocapillary, surface acoustic, and pressure.

Owner:RGT UNIV OF CALIFORNIA

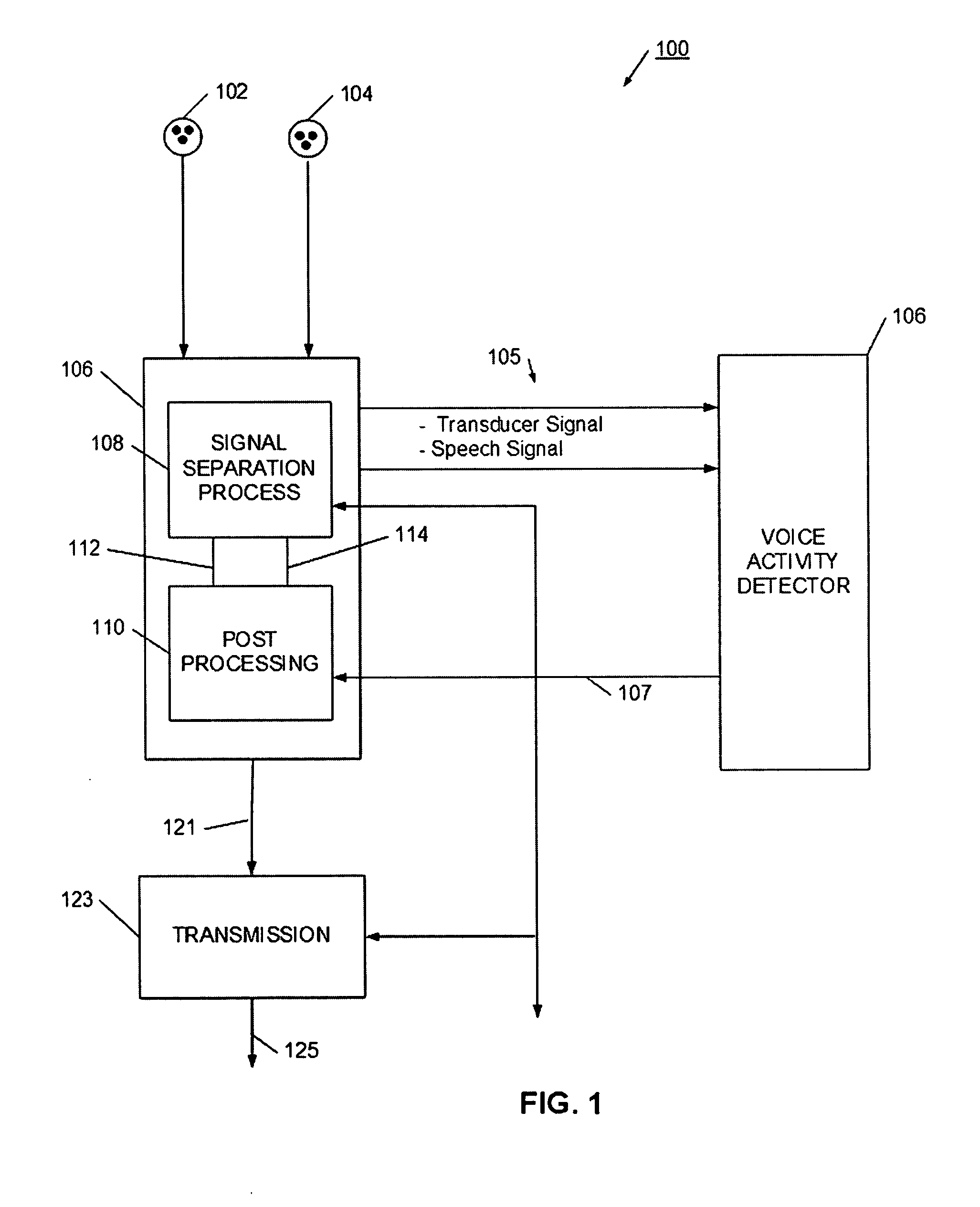

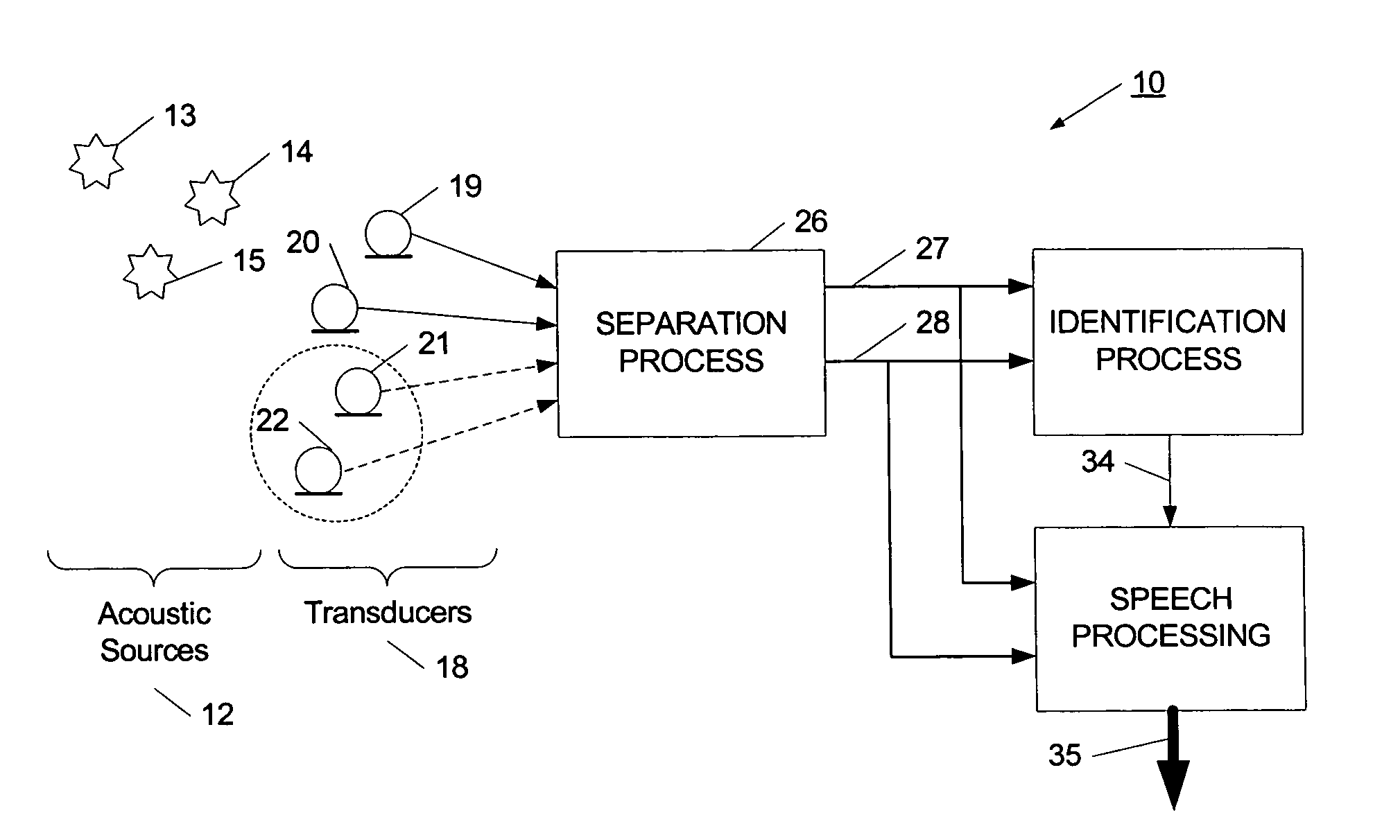

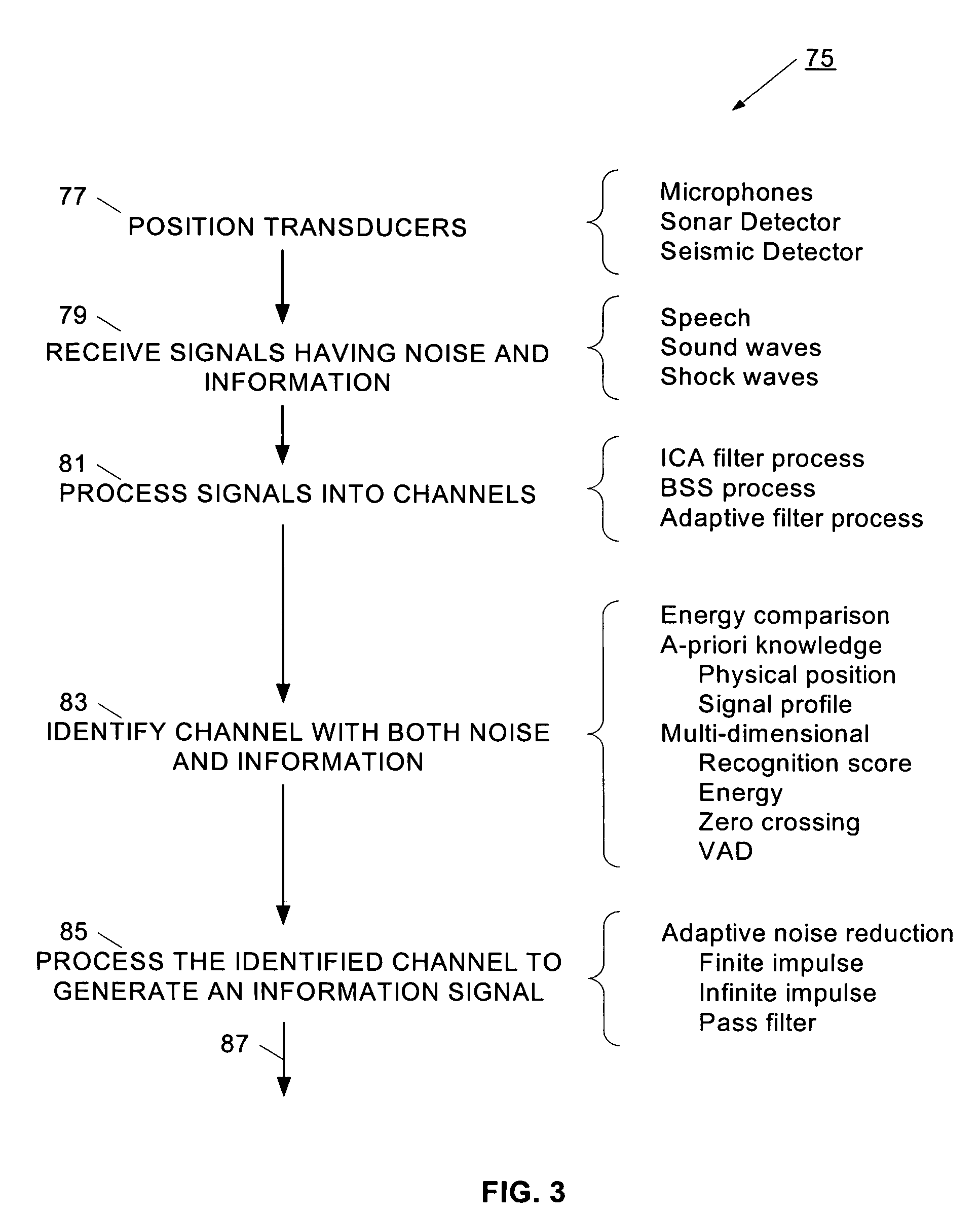

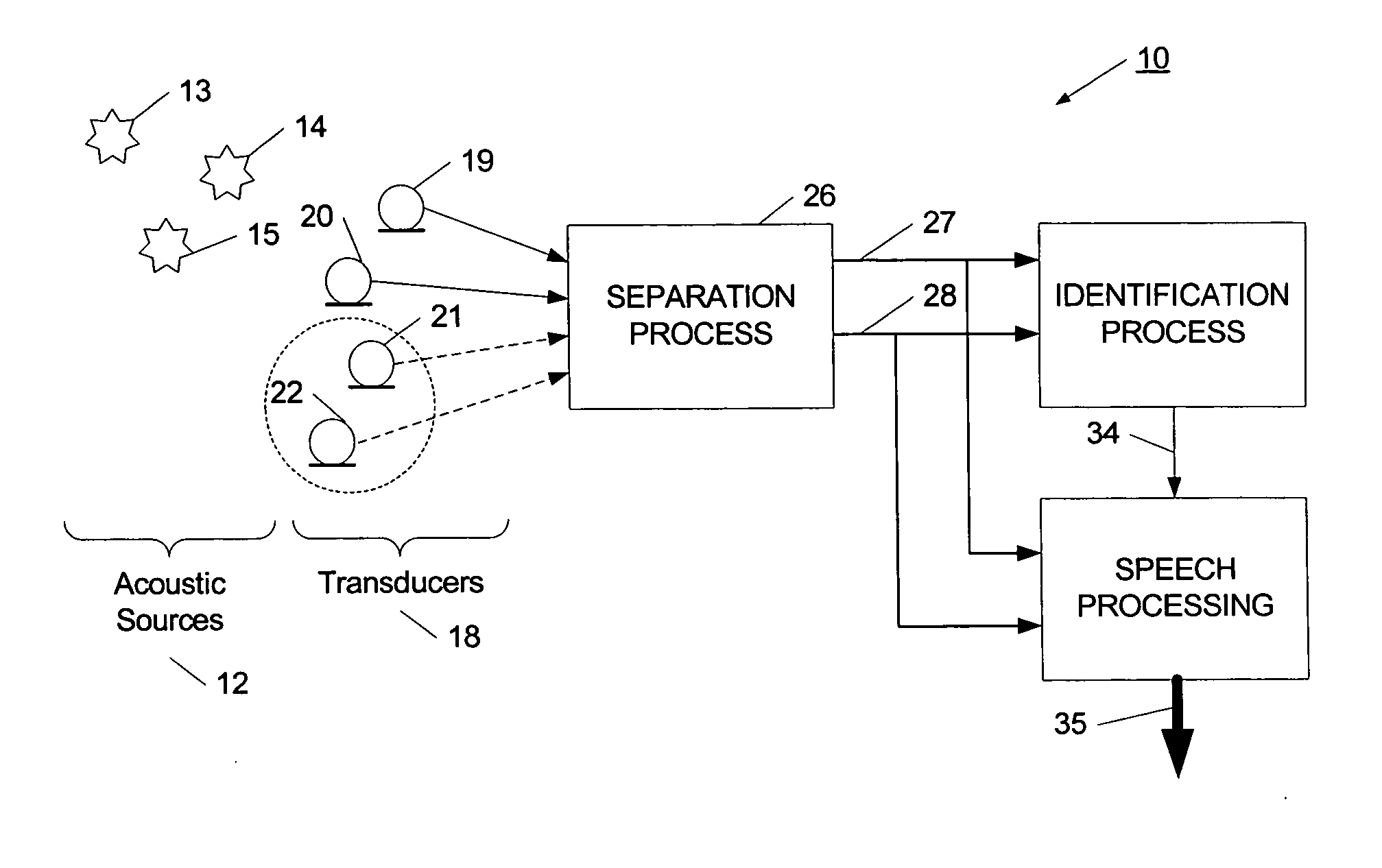

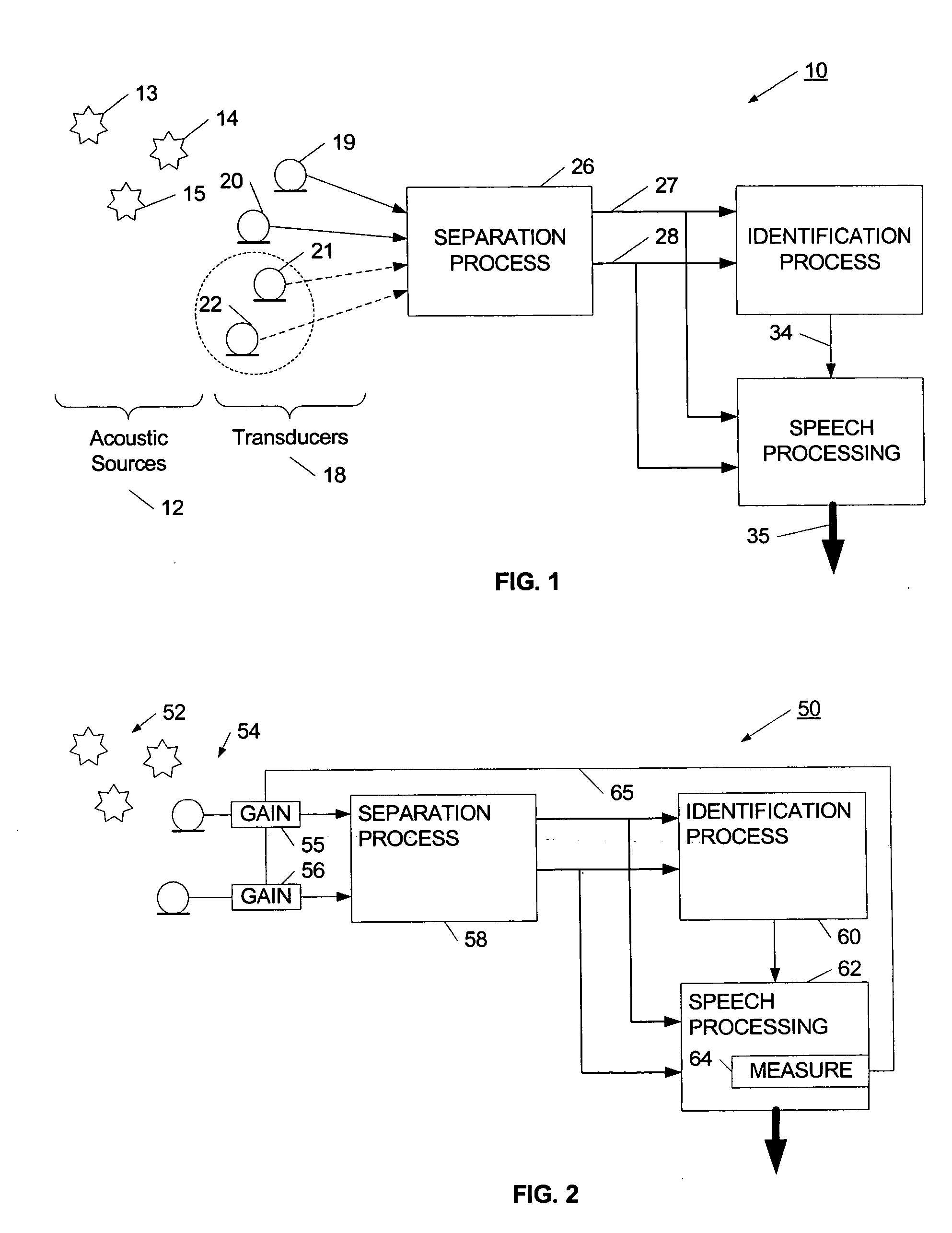

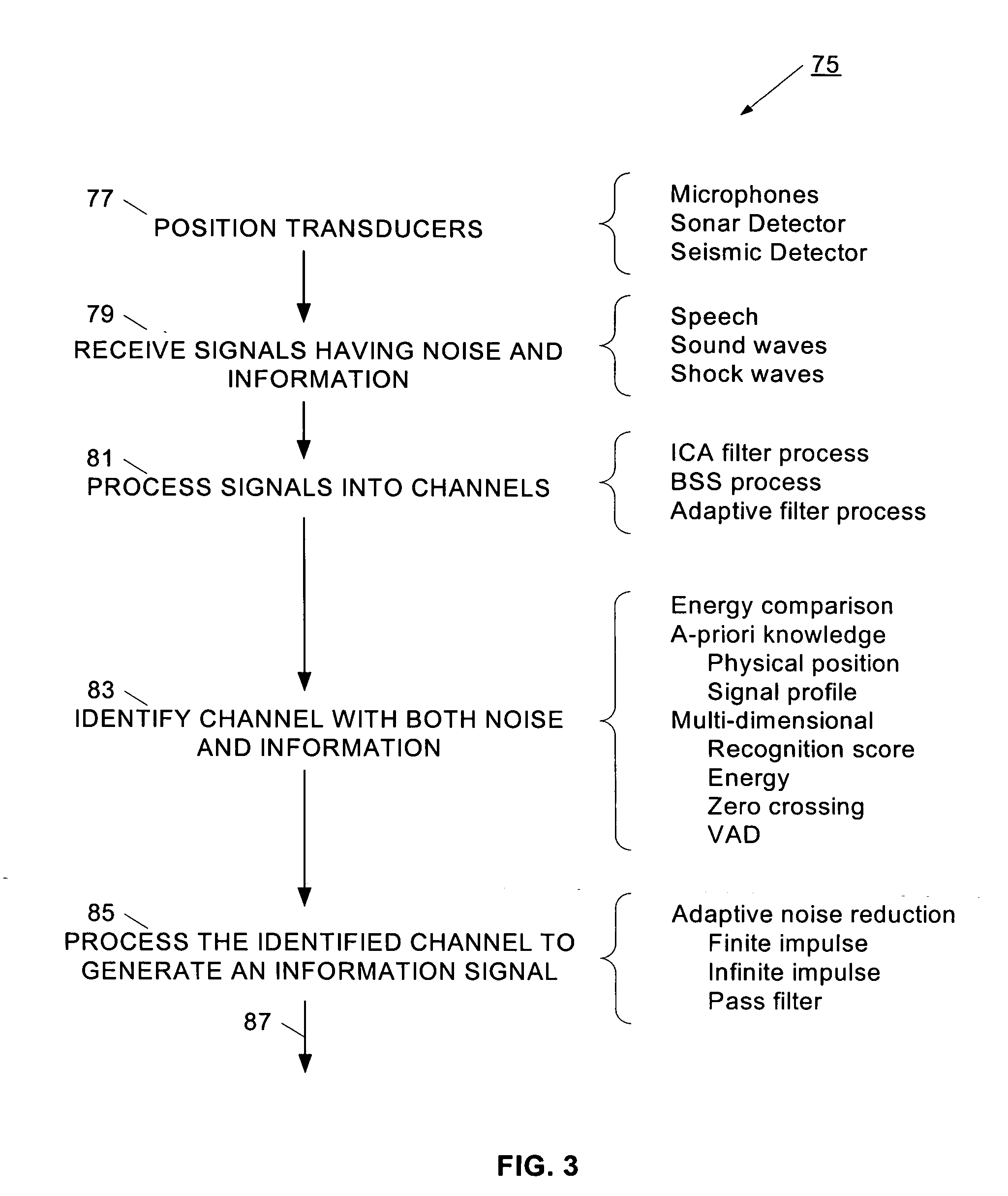

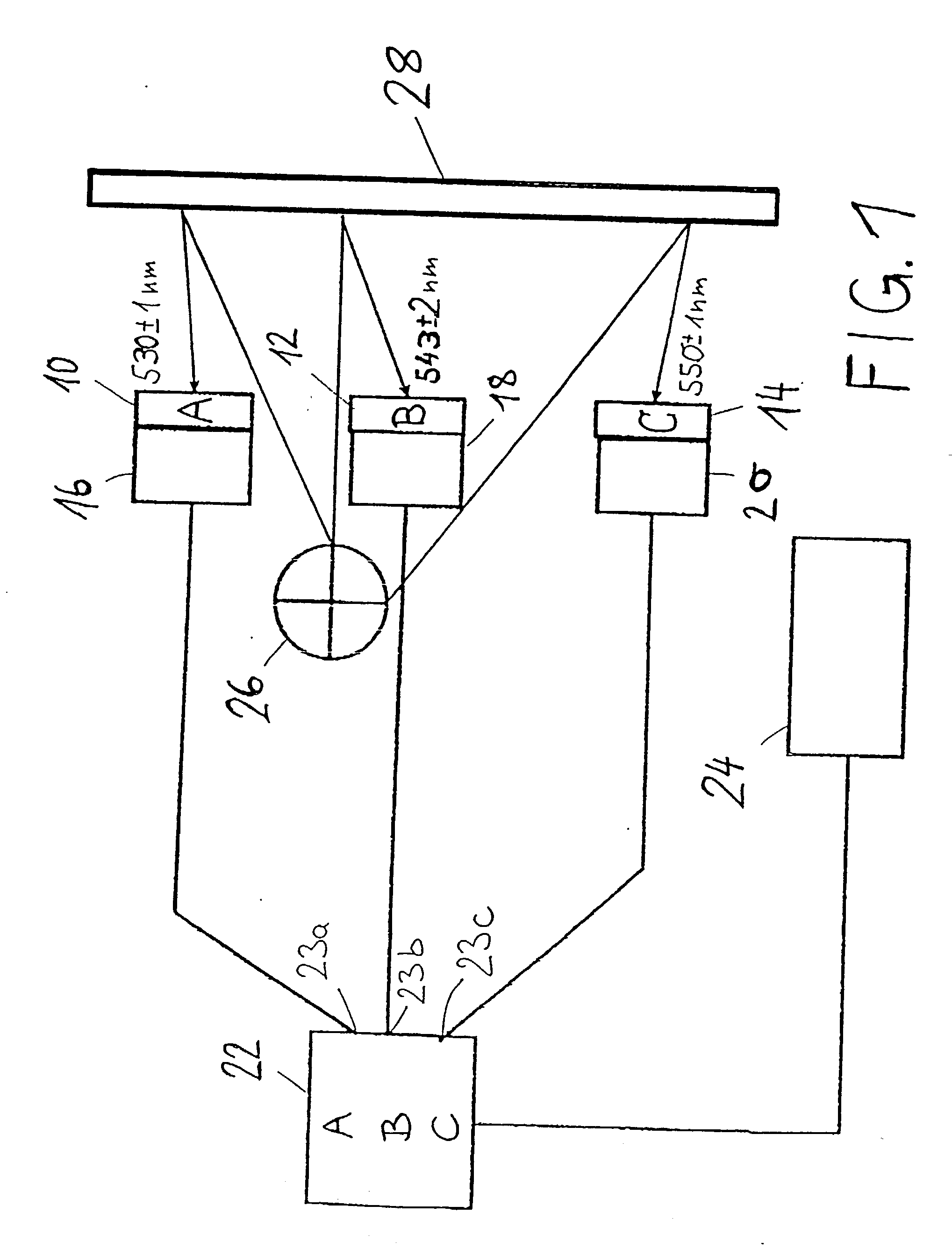

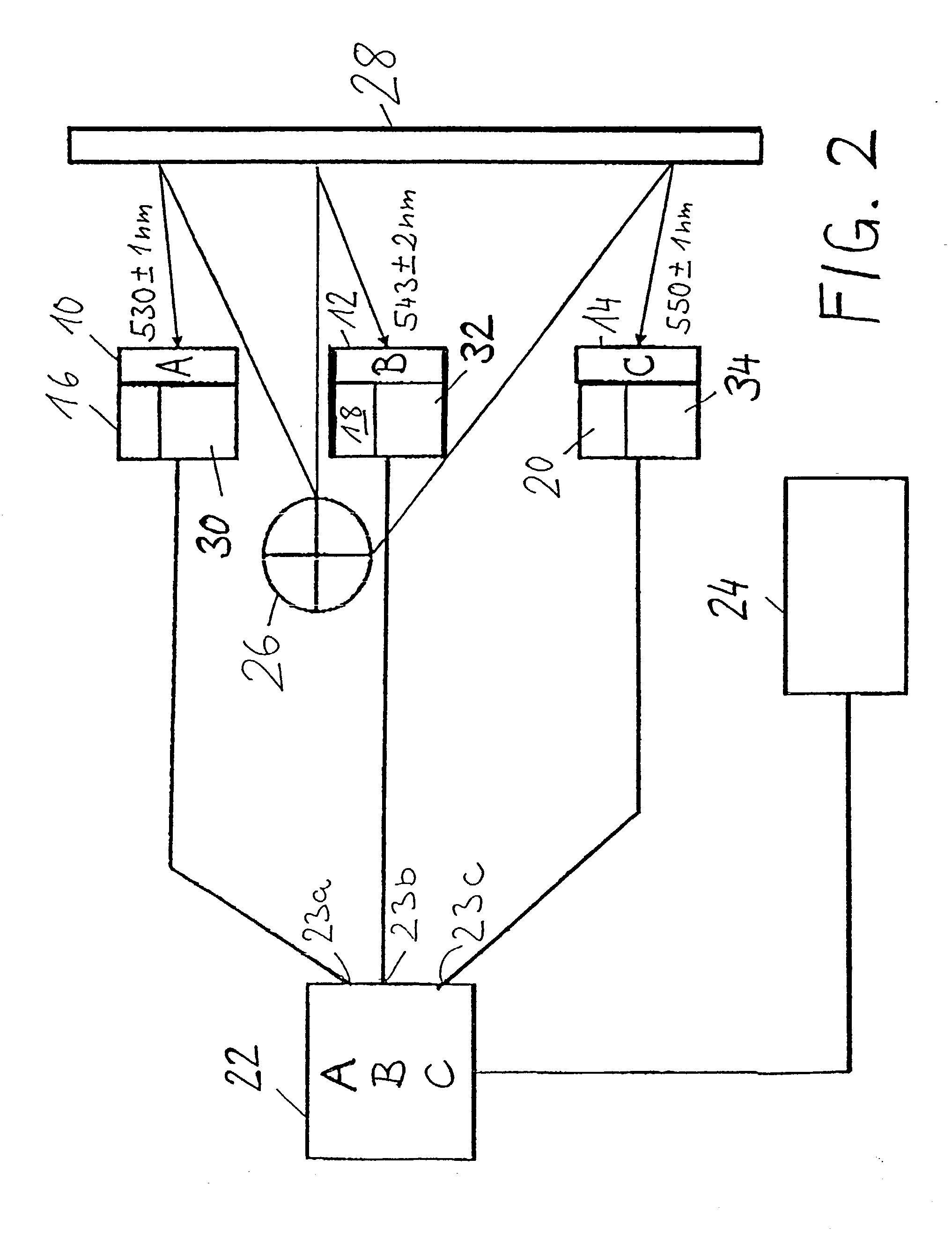

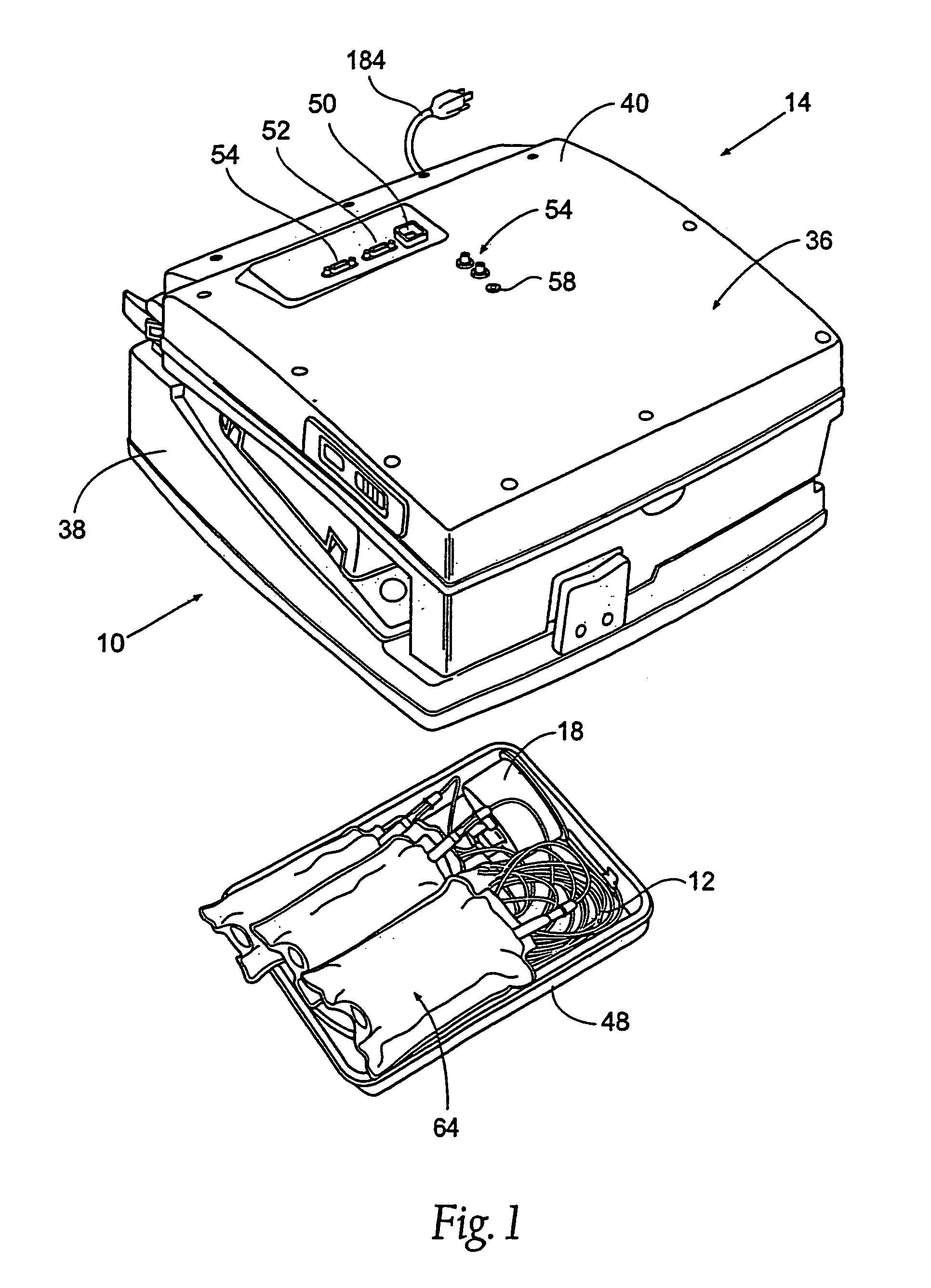

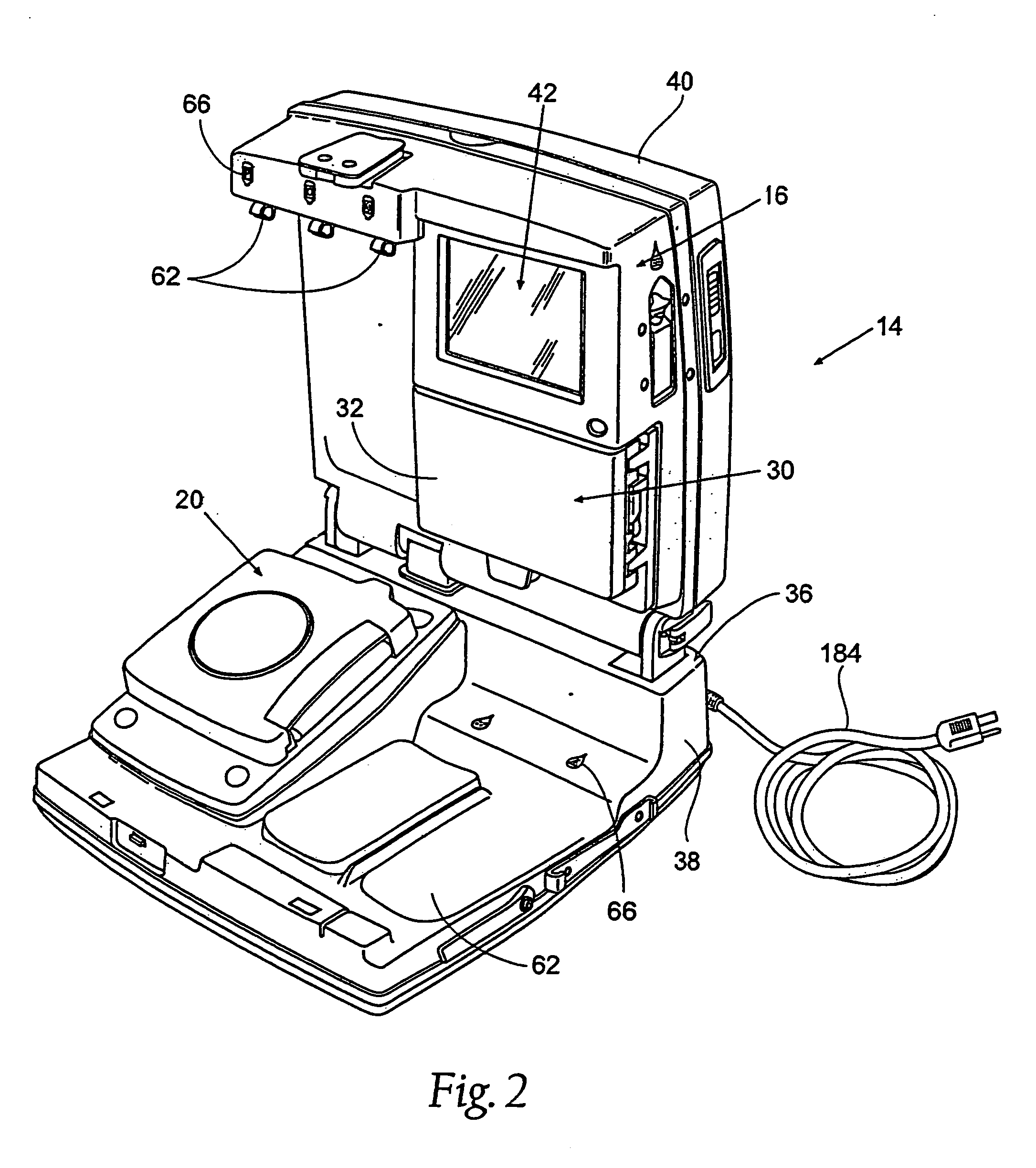

Separation of target acoustic signals in a multi-transducer arrangement

ActiveUS7099821B2Efficiently reduce or eliminate the noise componentEfficient removalTwo-way loud-speaking telephone systemsSignal processingTransducerEngineering

The present invention provides a process for separating a good quality information signal from a noisy acoustic environment. The separation process uses a set of at least two spaced-apart transducers to capture noise and information components. The transducer signals, which have both a noise and information component, are received into a separation process. The separation process generates one channel that is substantially only noise, and another channel that is a combination of noise and information. An identification process is used to identify which channel has the information component. The noise signal is then used to set process characteristics that are applied to the combination signal to efficiently reduce or eliminate the noise component. In this way, the noise is effectively removed from the combination signal to generate a good qualify information signal. The information signal may be, for example, a speech signal, a seismic signal, a sonar signal, or other acoustic signal.

Owner:RGT UNIV OF CALIFORNIA +1

Separation of target acoustic signals in a multi-transducer arrangement

ActiveUS20050060142A1Efficient removalQuality improvementSignal processingEarpiece/earphone attachmentsSeparation processEngineering

The present invention provides a process for separating a good quality information signal from a noisy acoustic environment. The separation process uses a set of a least two spaced-apart transducers to capture noise and information components. The transducer signals, which have both a noise and information component, are received into a separation process. The separation process generates one channel that is substantially only noise, and another channel that is a combination of noise and information. An identification process is used to identify which channel has the information component. The noise signal is then used to set process characteristics that are applied to the combination signal to efficiently reduce or eliminate the noise component. In this way, the noise is effectively removed from the combination signal to generate a good qualify information signal. The information signal may be, for example, a speech signal, a seismic signal, a sonar signal, or other acoustic signal.

Owner:RGT UNIV OF CALIFORNIA +1

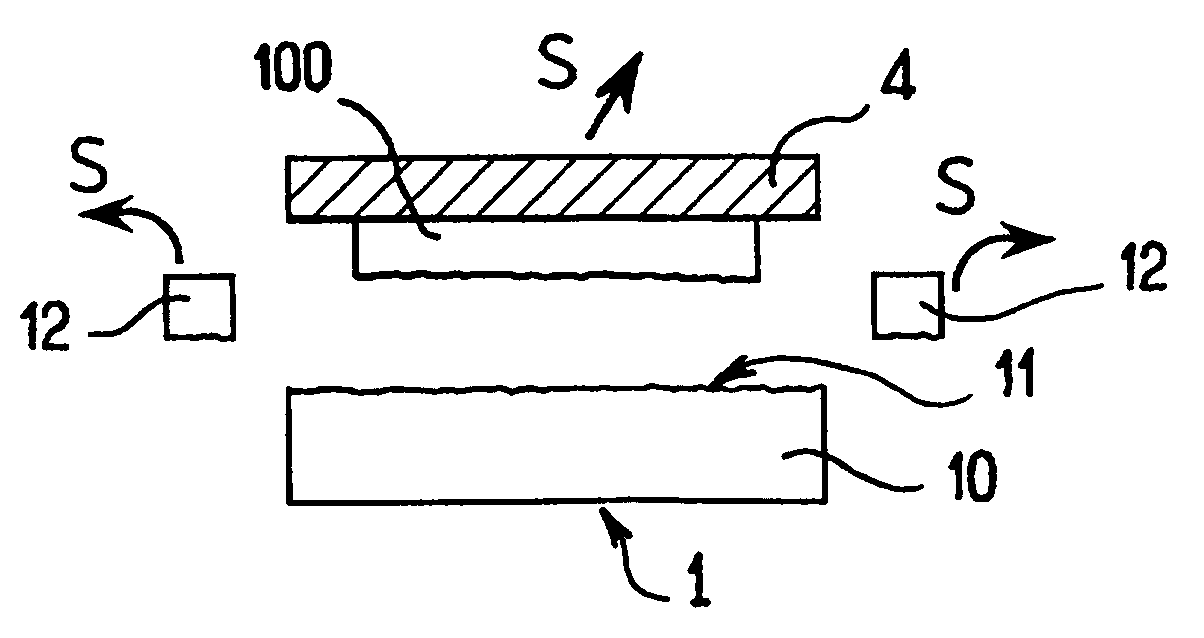

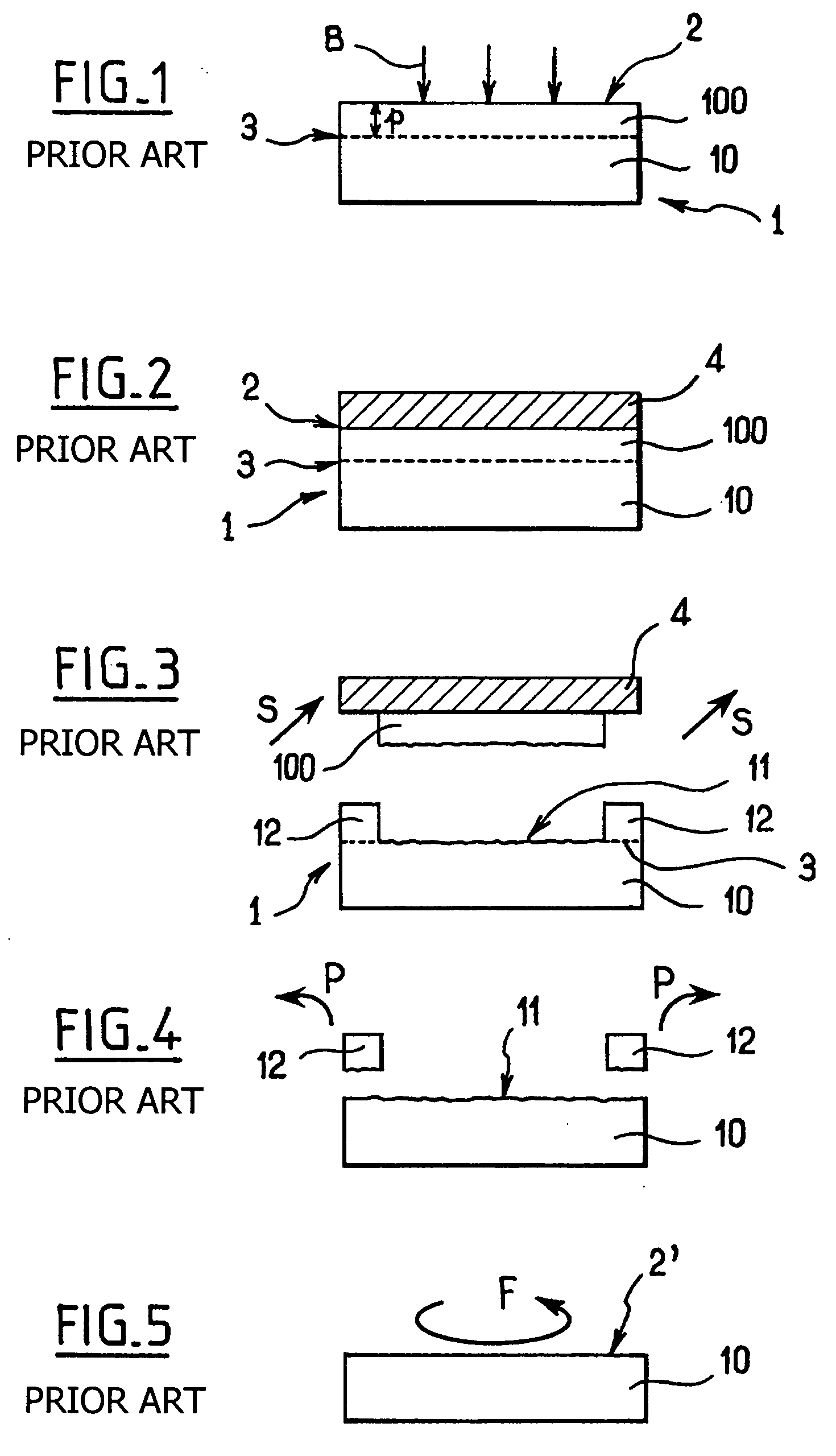

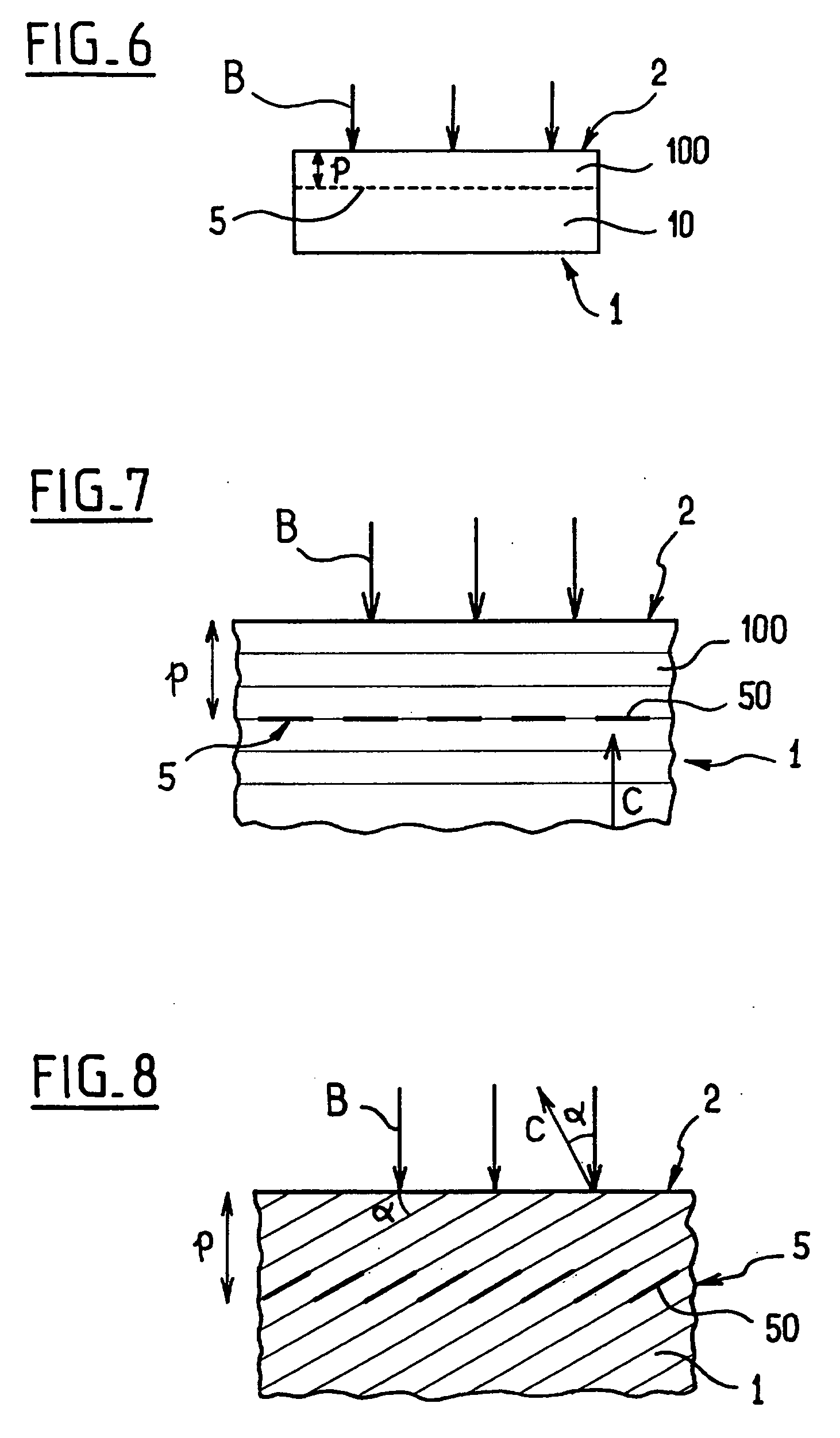

Methods for transferring a useful layer of silicon carbide to a receiving substrate

InactiveUS20050266659A1Easy to recycleSolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessOptoelectronics

Owner:SOITEC SA

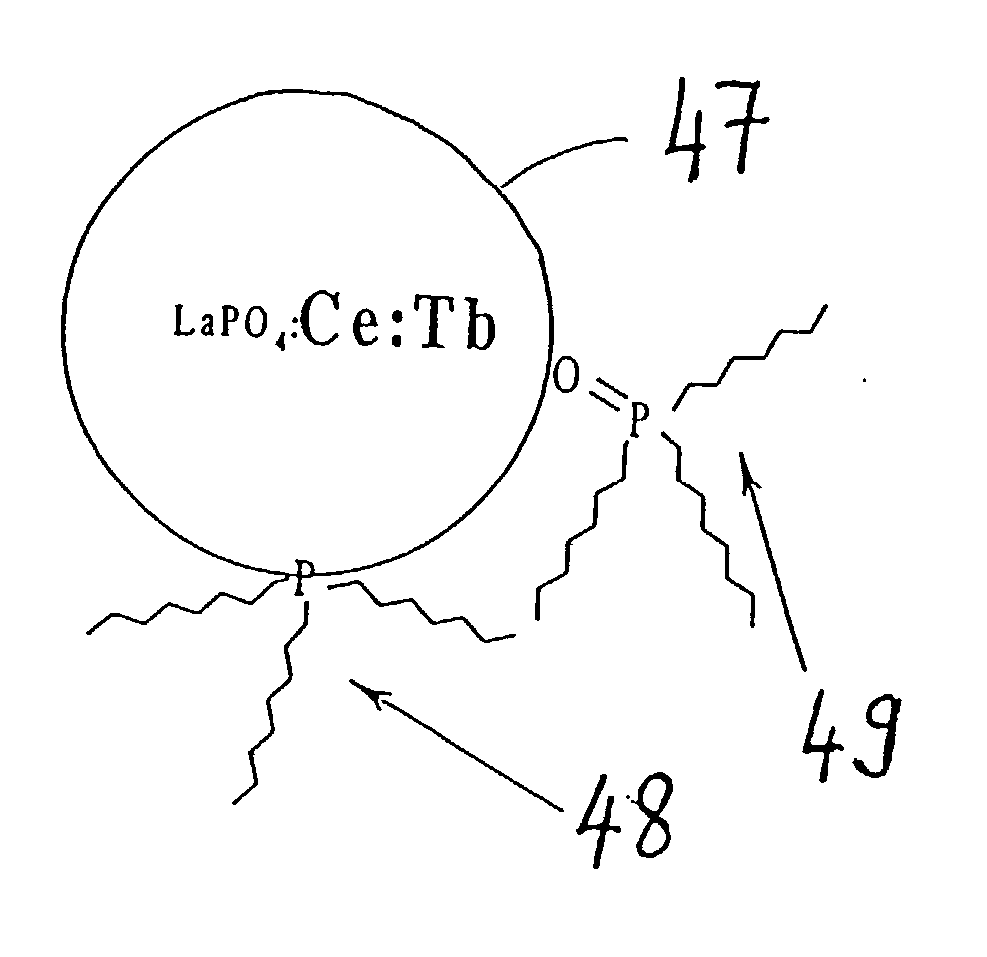

Synthesis of nanoparticles

InactiveUS20030032192A1High sensitivityIncreasing efficiency of collectorOptical radiation measurementMaterial nanotechnologyDopantOrganic solvent

The present invention relates to methods for the preparation of inorganic nanoparticles capable of fluorescence, wherein the nanoparticles consist of a host material that comprises at least one dopant. The synthesis of the invention in organic solvents allows to gain a considerably higher yield compared to the prior art synthesis in water. All kinds of objects can advantageously be marked and reliably authenticated by using an automated method on the basis of a characteristic emission. Further, the size distribution of the prepared nanoparticles is narrower which renders a subsequent size-selected separation process superfluous.

Owner:CENT FUR ANGEWANDTE NANOTECH

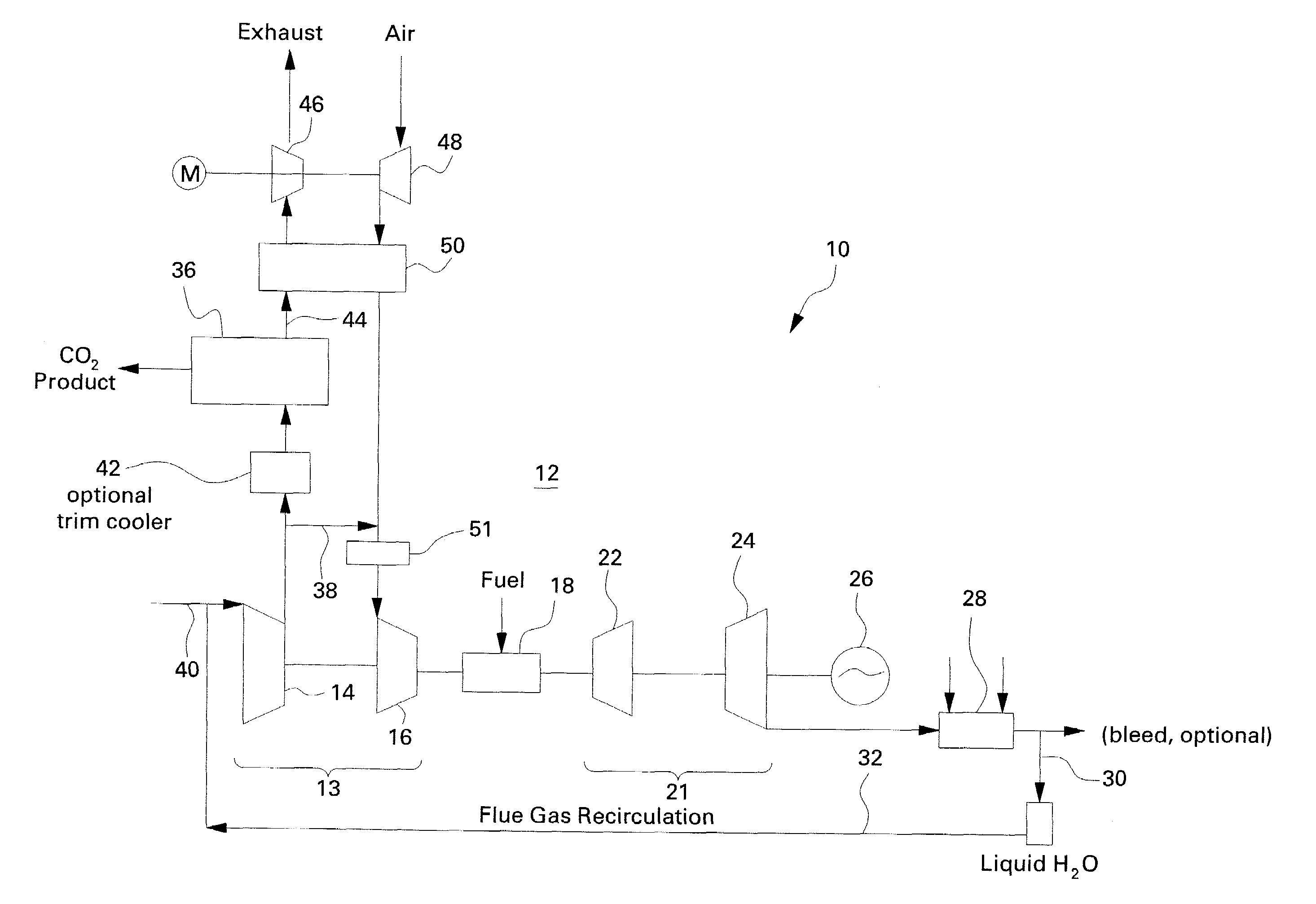

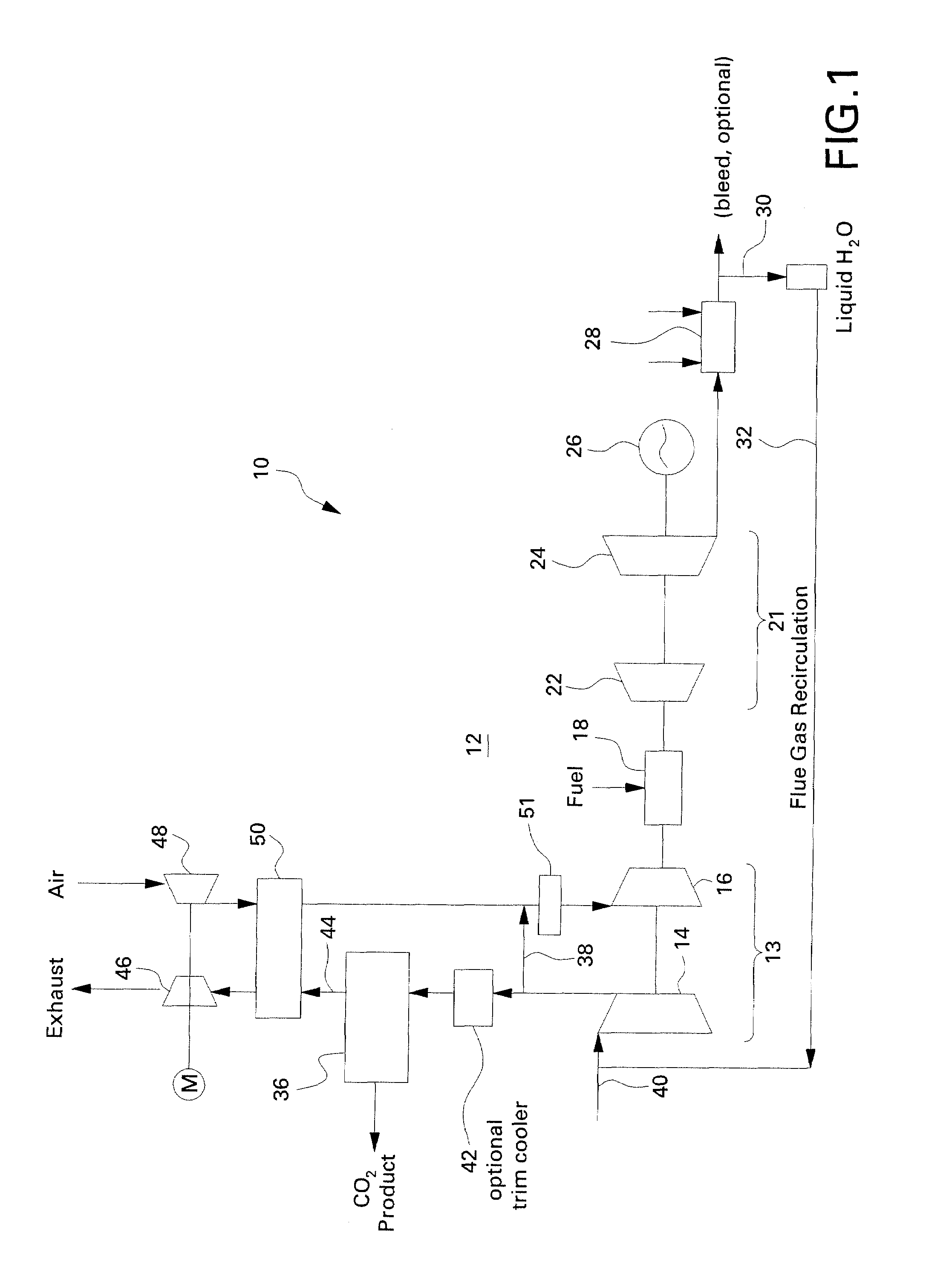

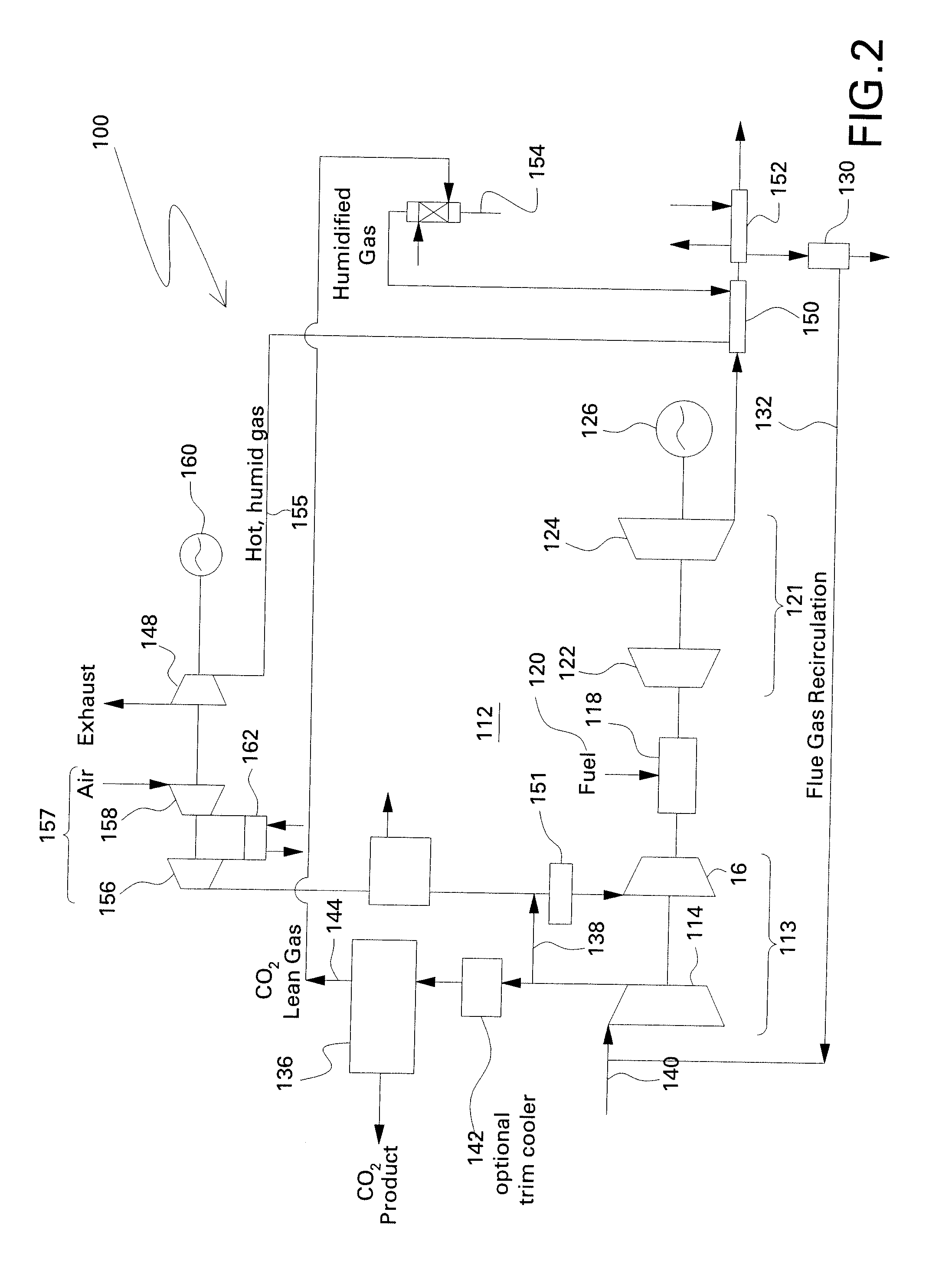

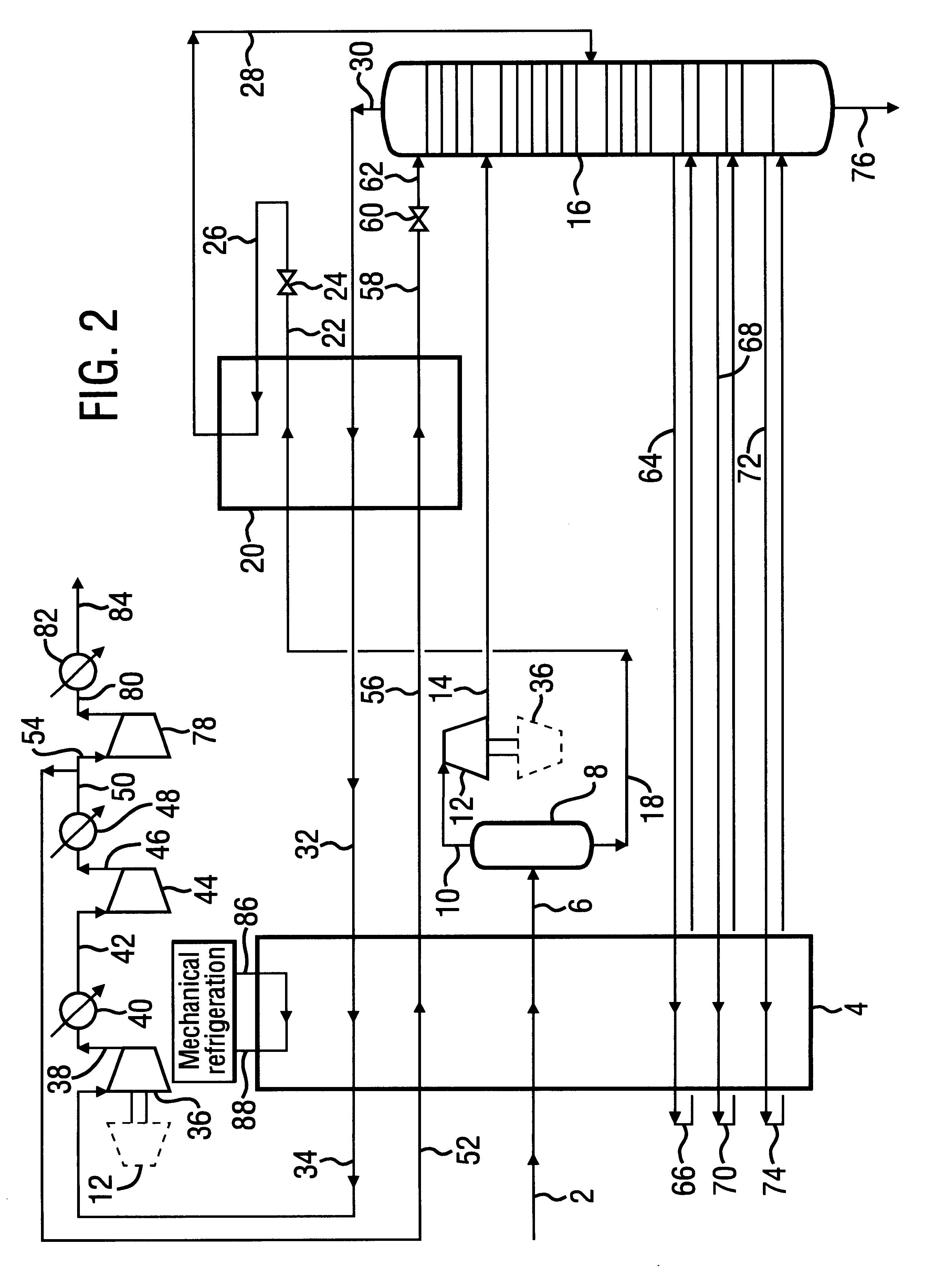

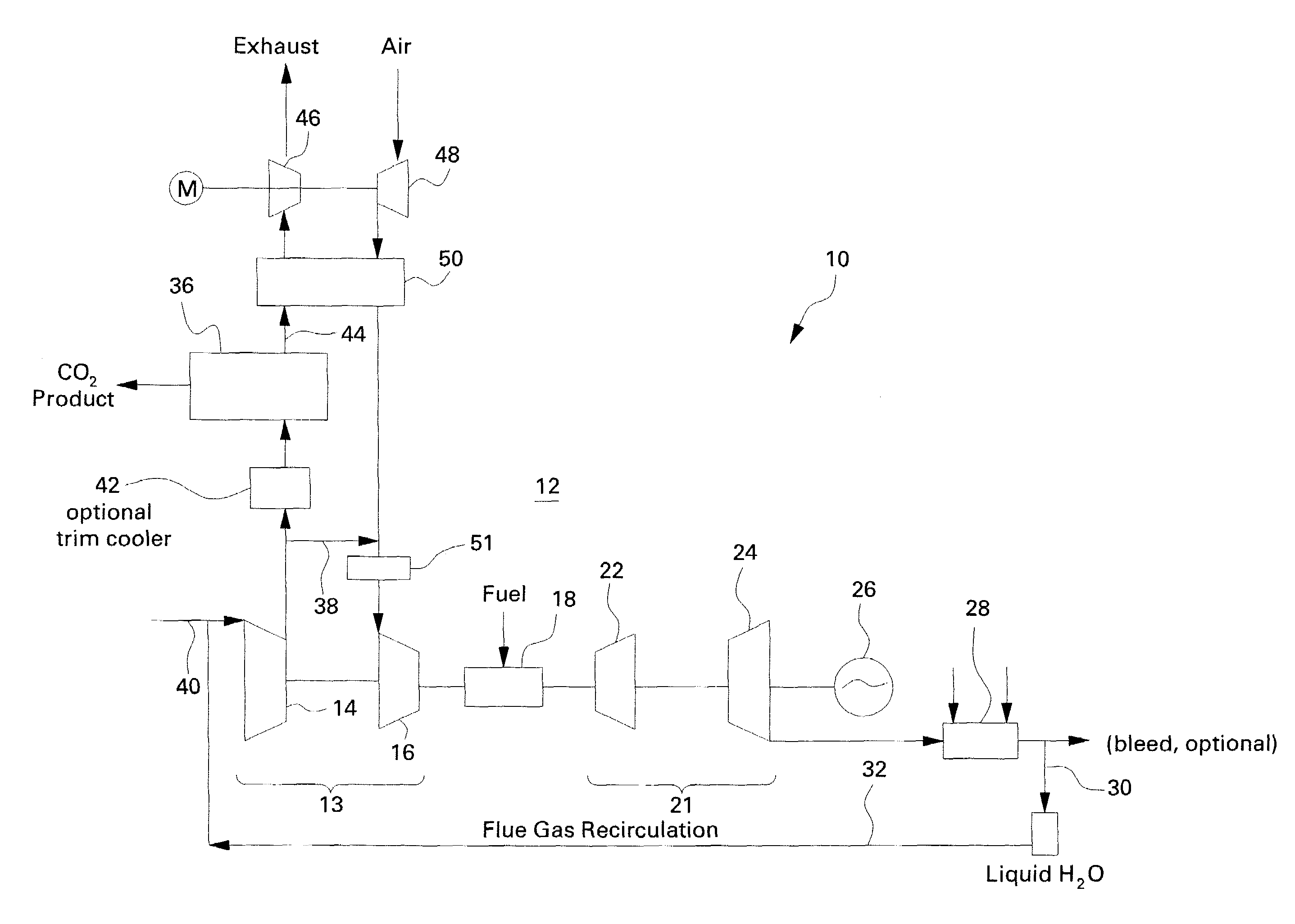

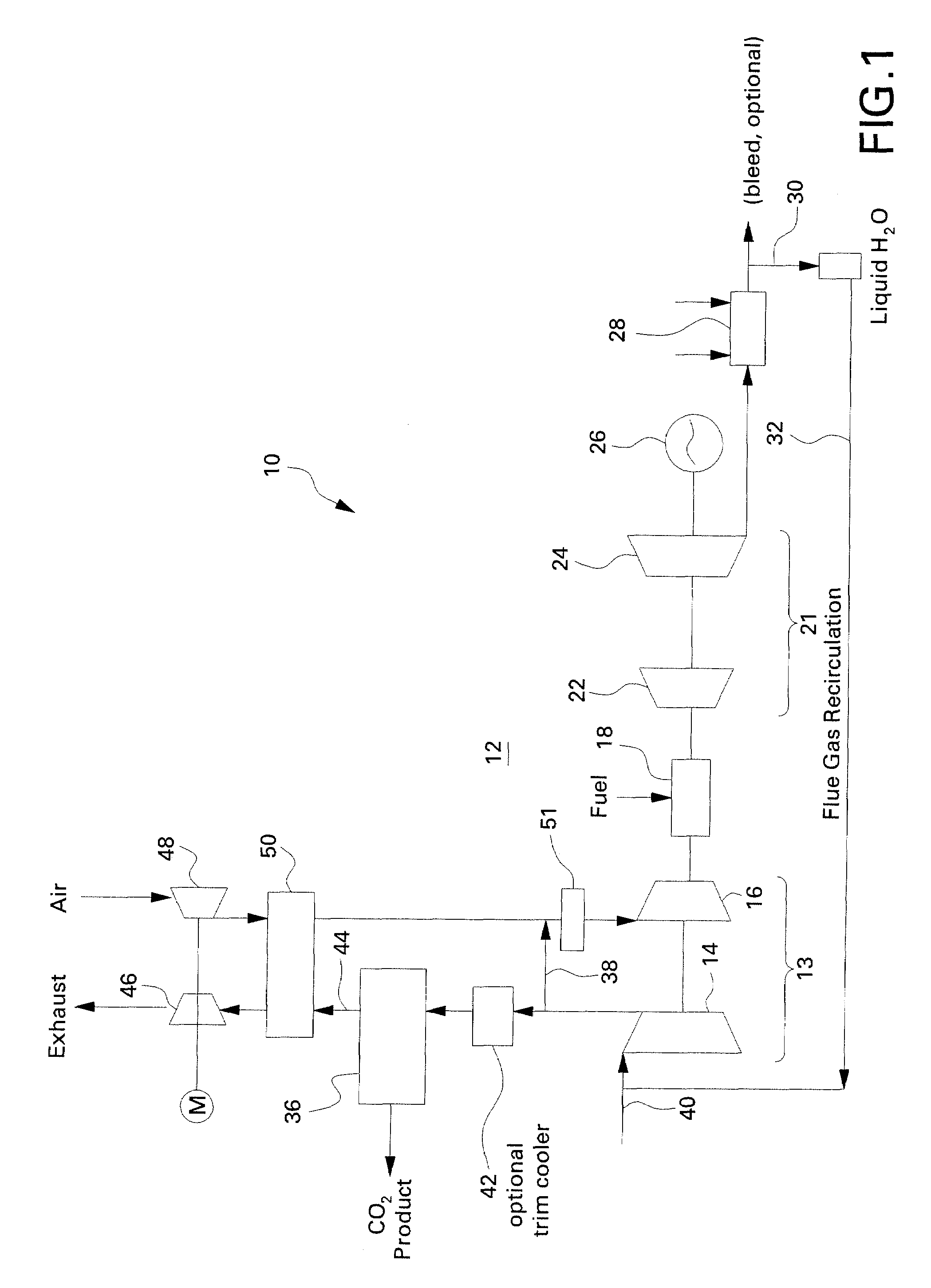

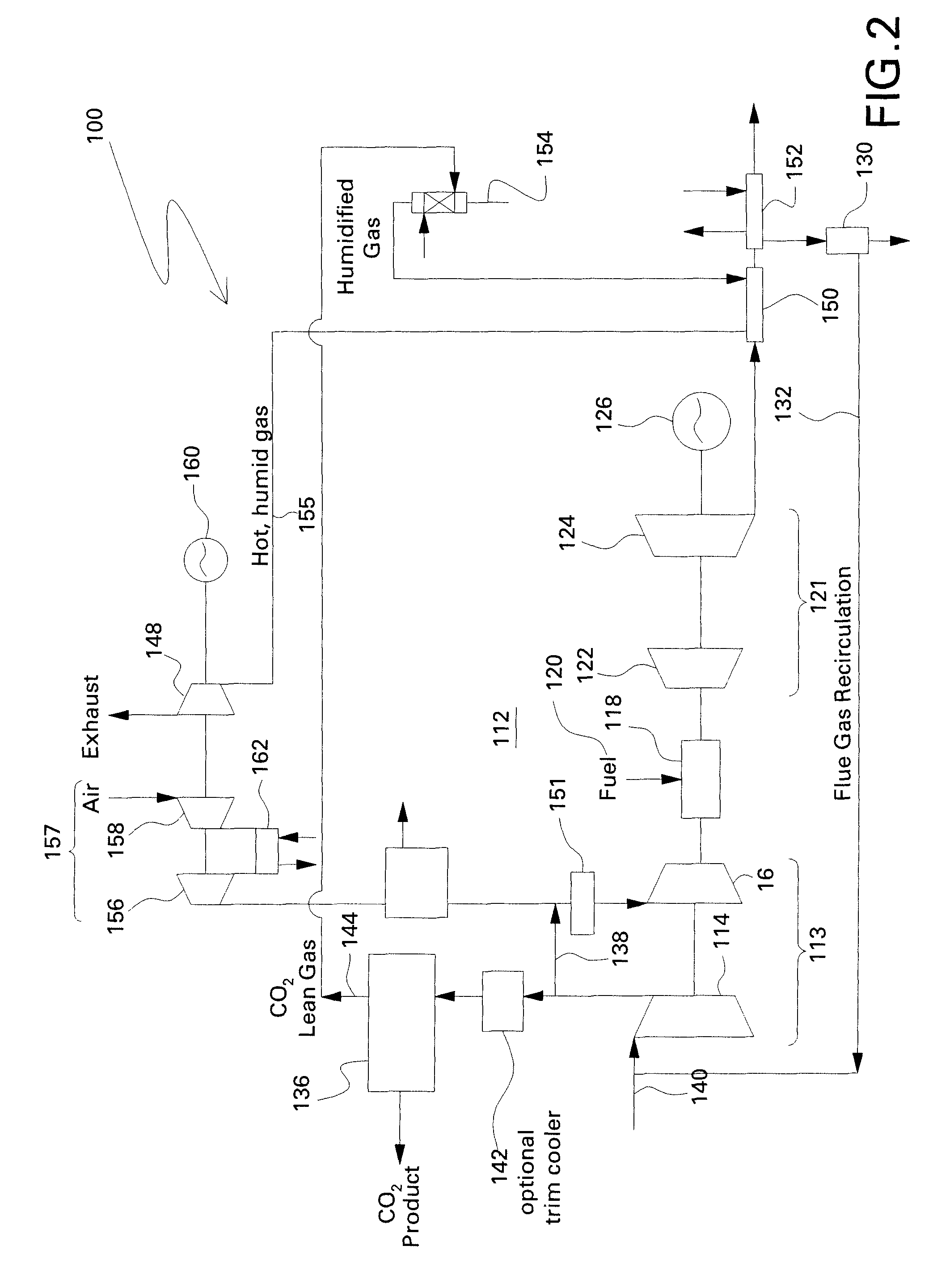

Power plants that utilize gas turbines for power generation and processes for lowering co2 emissions

ActiveUS20080104958A1Reduce carbon dioxide emissionsEmission reductionGas treatmentInternal combustion piston enginesPower stationWorking fluid

Power plants and process for lowering CO2 emissions generally includes extracting a portion of the recirculated CO2-rich flue gas mid-way through the compression pathway of a gas turbine and removing the CO2 in a separation unit. The remaining portion of the CO2 rich flue gas (i.e., the portion of the recirculated flue gas that was not fed to the separation unit) is mixed with fresh air coming from an additional compressor-expander and then fed back to the compression pathway. As a result, flue gas recirculation increases the CO2 concentration within the working fluid, leading to an additional increase in CO2 partial pressure. As the concentration and partial pressure of CO2 is increased, a lower energy penalty is observed to remove the CO2. Moreover, a reduced volume is fed to the CO2 separation unit during operation. Consequently, the size of the separation equipment can be reduced as well as the energy required for the separation process.

Owner:GENERAL ELECTRIC CO +1

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

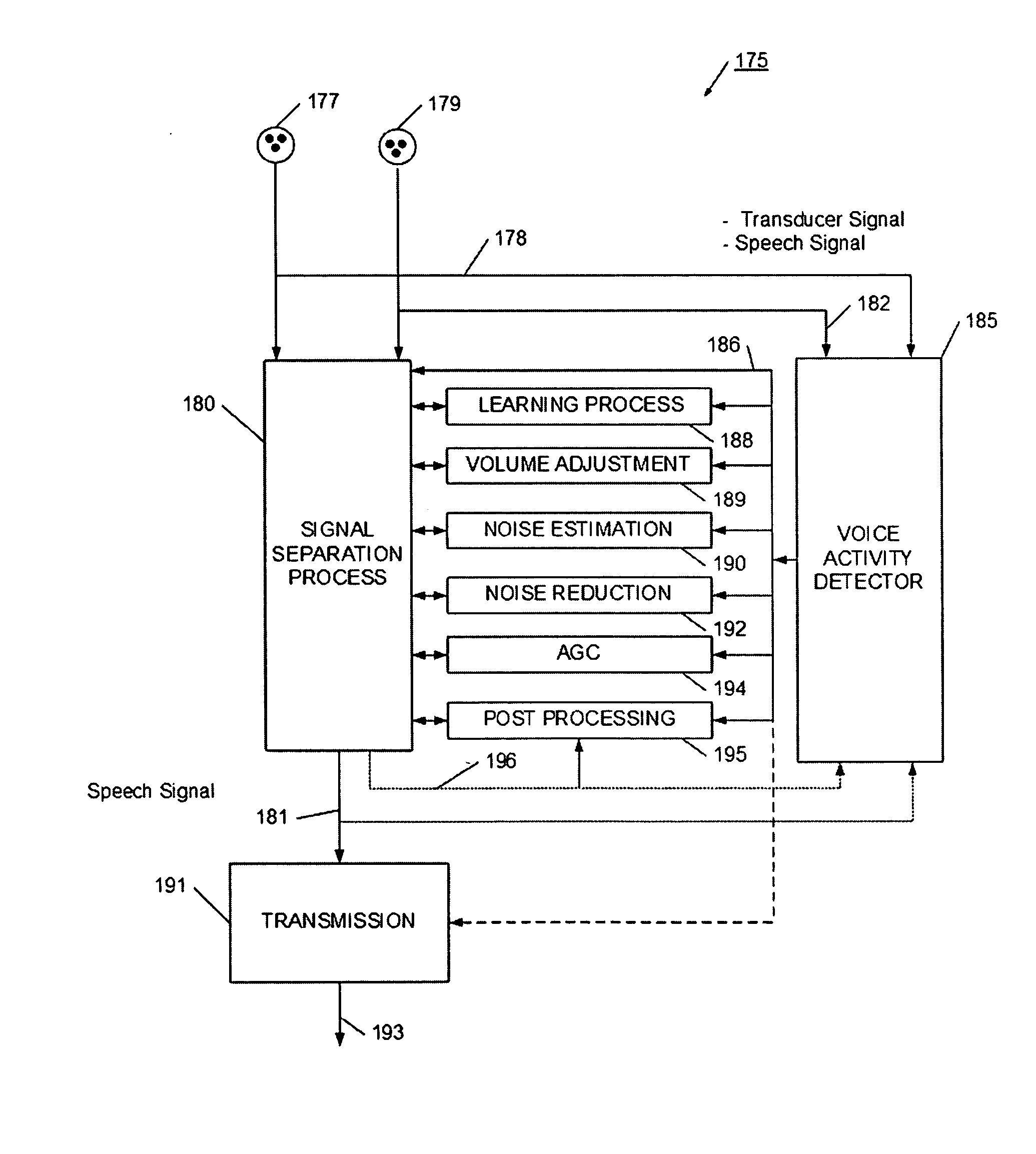

Robust separation of speech signals in a noisy environment

ActiveUS7464029B2Improve voice qualityRobust and accurate detectionMicrophonesSpeech recognitionControl signalVoice activity

A method for improving the quality of a speech signal extracted from a noisy acoustic environment is provided. In one approach, a signal separation process is associated with a voice activity detector. The voice activity detector is a two-channel detector, which enables a particularly robust and accurate detection of voice activity. When speech is detected, the voice activity detector generates a control signal. The control signal is used to activate, adjust, or control signal separation processes or post-processing operations to improve the quality of the resulting speech signal. In another approach, a signal separation process is provided as a learning stage and an output stage. The learning stage aggressively adjusts to current acoustic conditions, and passes coefficients to the output stage. The output stage adapts more slowly, and generates a speech-content signal and a noise dominant signal. When the learning stage becomes unstable, only the learning stage is reset, allowing the output stage to continue outputting a high quality speech signal.

Owner:QUALCOMM INC

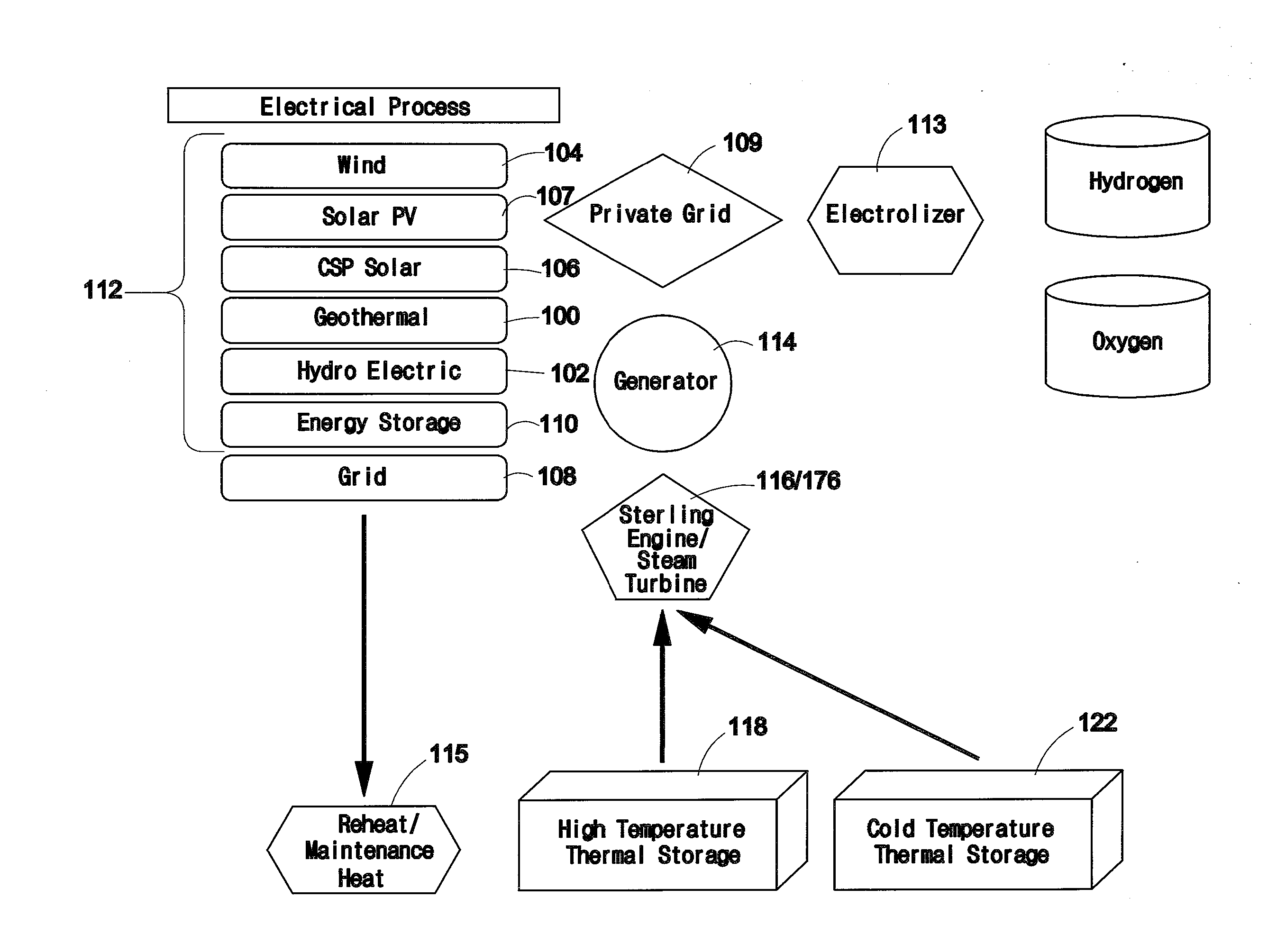

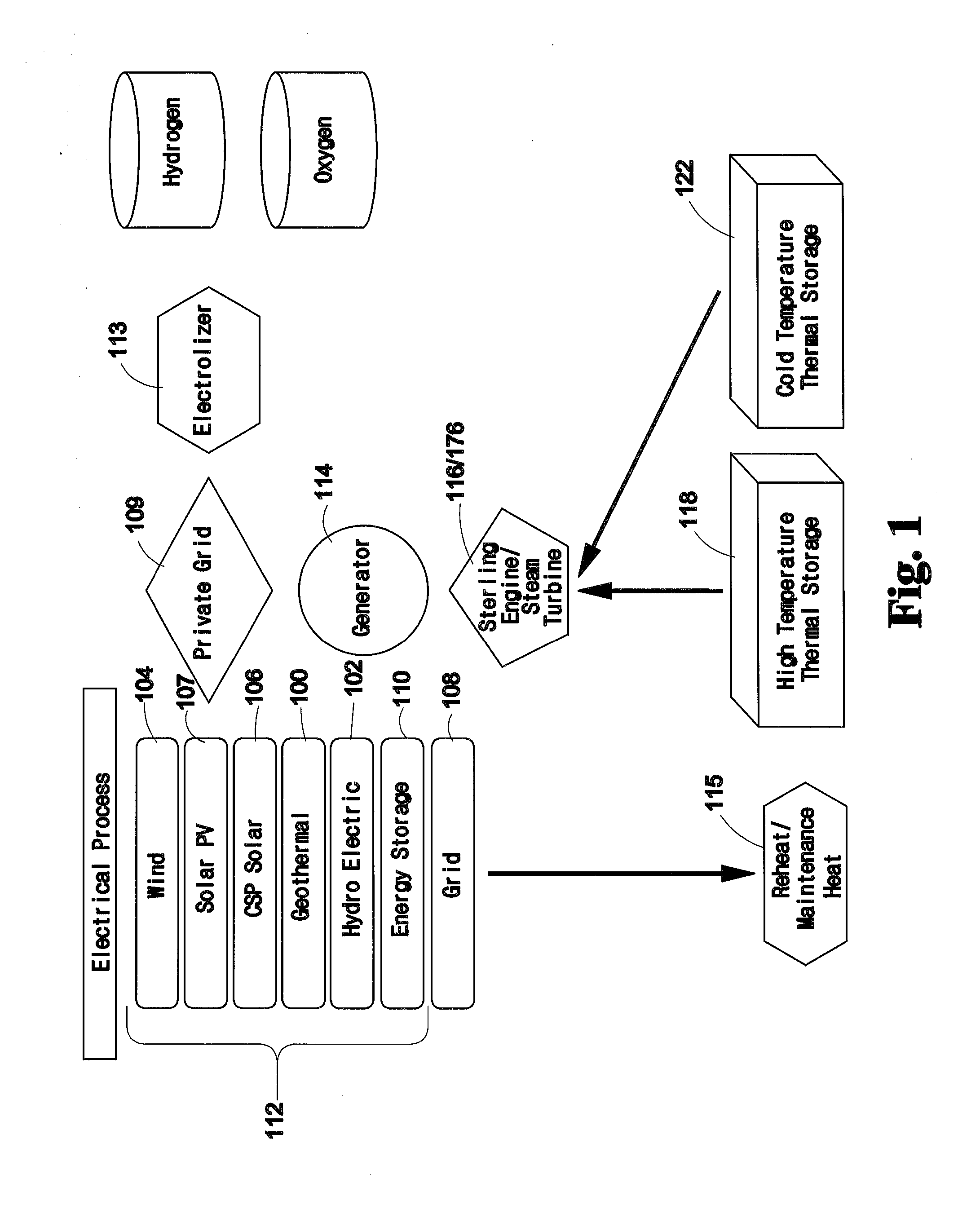

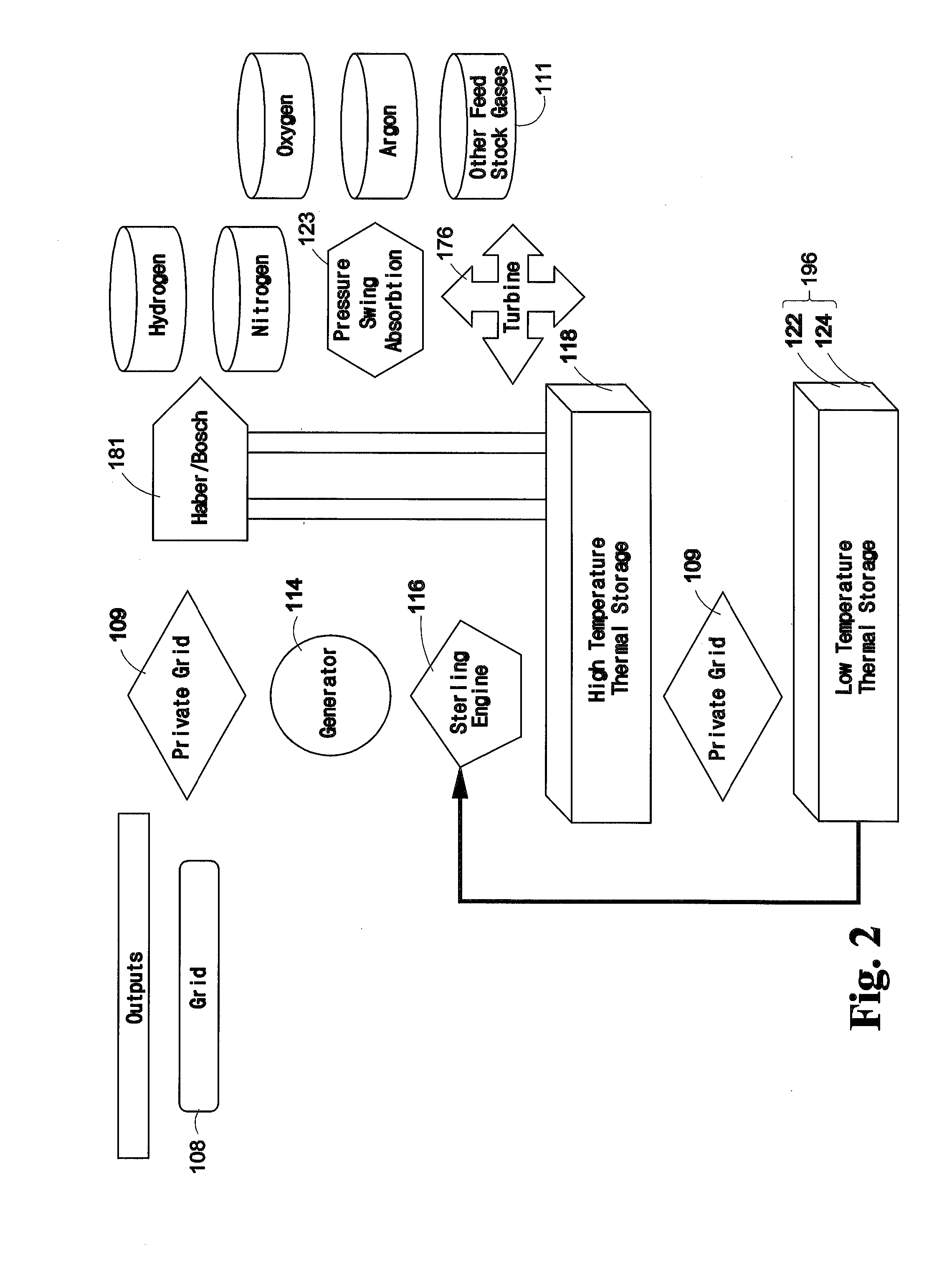

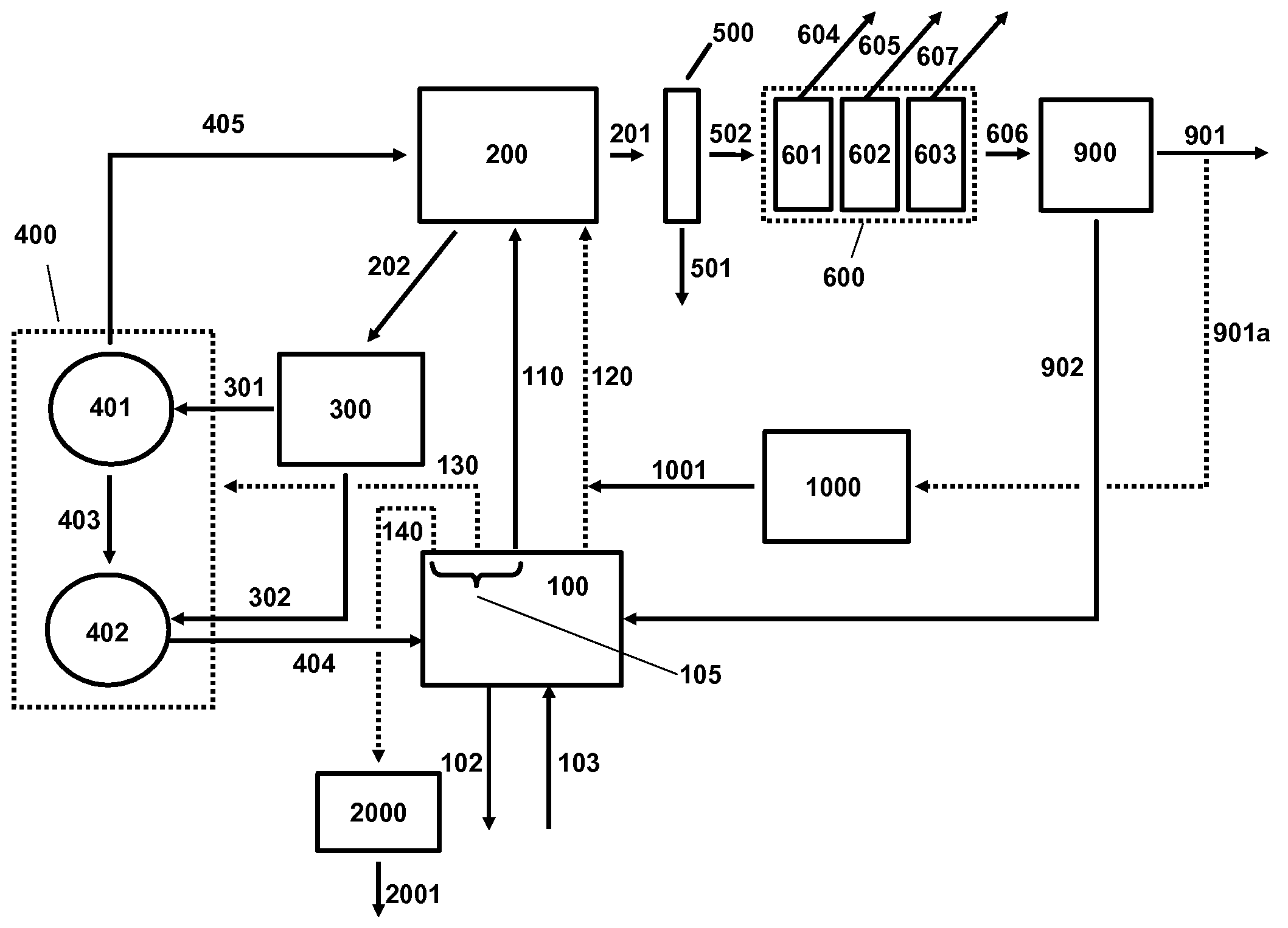

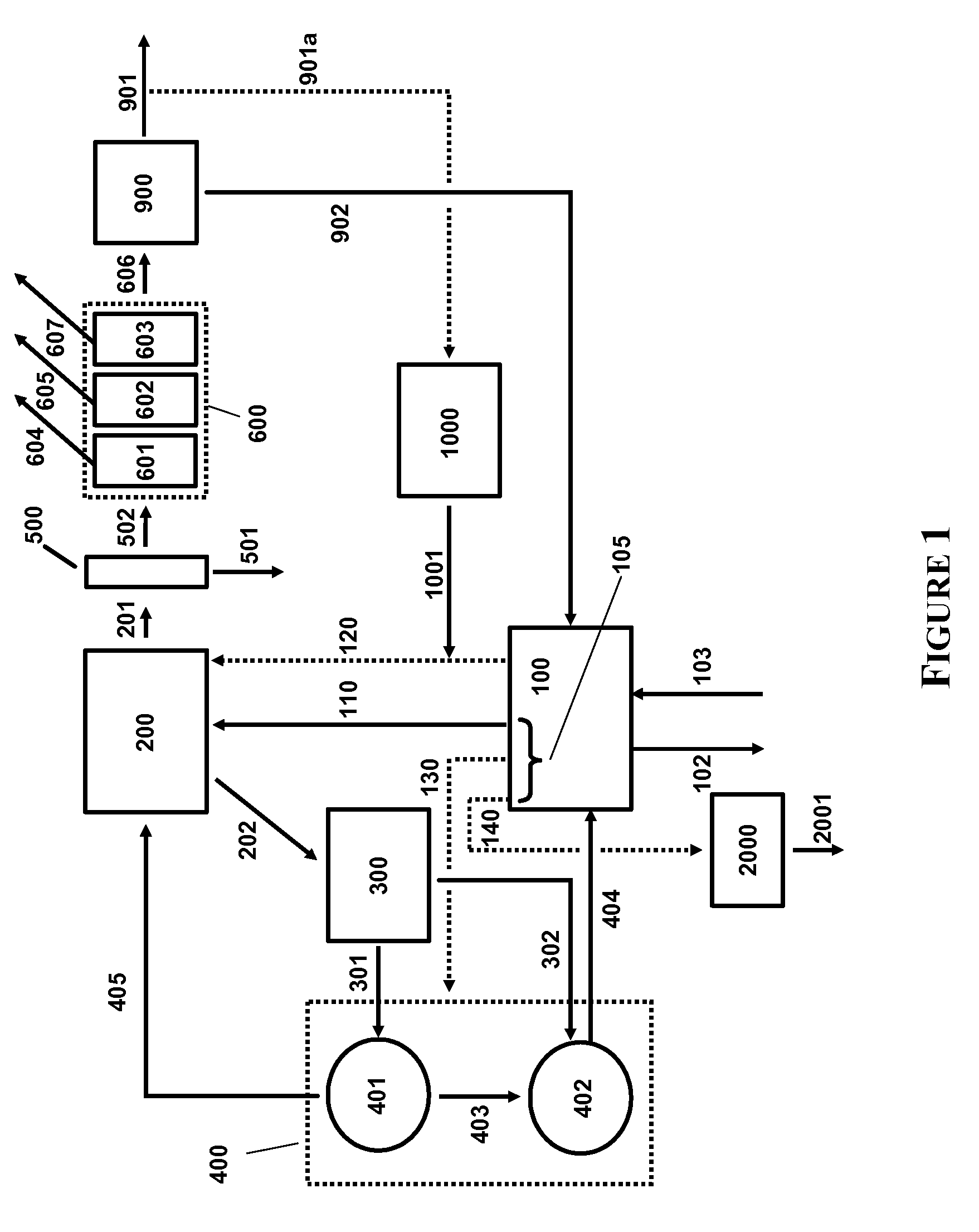

Quintuple-Effect Generation Multi-Cycle Hybrid Renewable Energy System with Integrated Energy Provisioning, Storage Facilities and Amalgamated Control System Cross-Reference to Related Applications

InactiveUS20150143806A1Lowering expensiveIncrease energy generatedSolar heating energyInternal combustion piston enginesEnergy recoveryOpen architecture

Provided is a consumer to industrial scale renewable energy based quintuple-generation systems and energy storage facility. The present invention has both mobile and stationary embodiments. The present invention includes energy recovery, energy production, energy processing, pyrolysis, byproduct process utilization systems, separation process systems and handling and storage systems, as well as an open architecture for integration and development of additional processes, systems and applications. The system of the present invention primarily uses adaptive metrics, biometrics and thermal imaging sensory analysis (including additional input sensors for analysis) for monitoring and control with the utilization of an integrated artificial intelligence and automation control system, thus providing a balanced, environmentally-friendly ecosystem.

Owner:FRIESTH KEVIN LEE

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

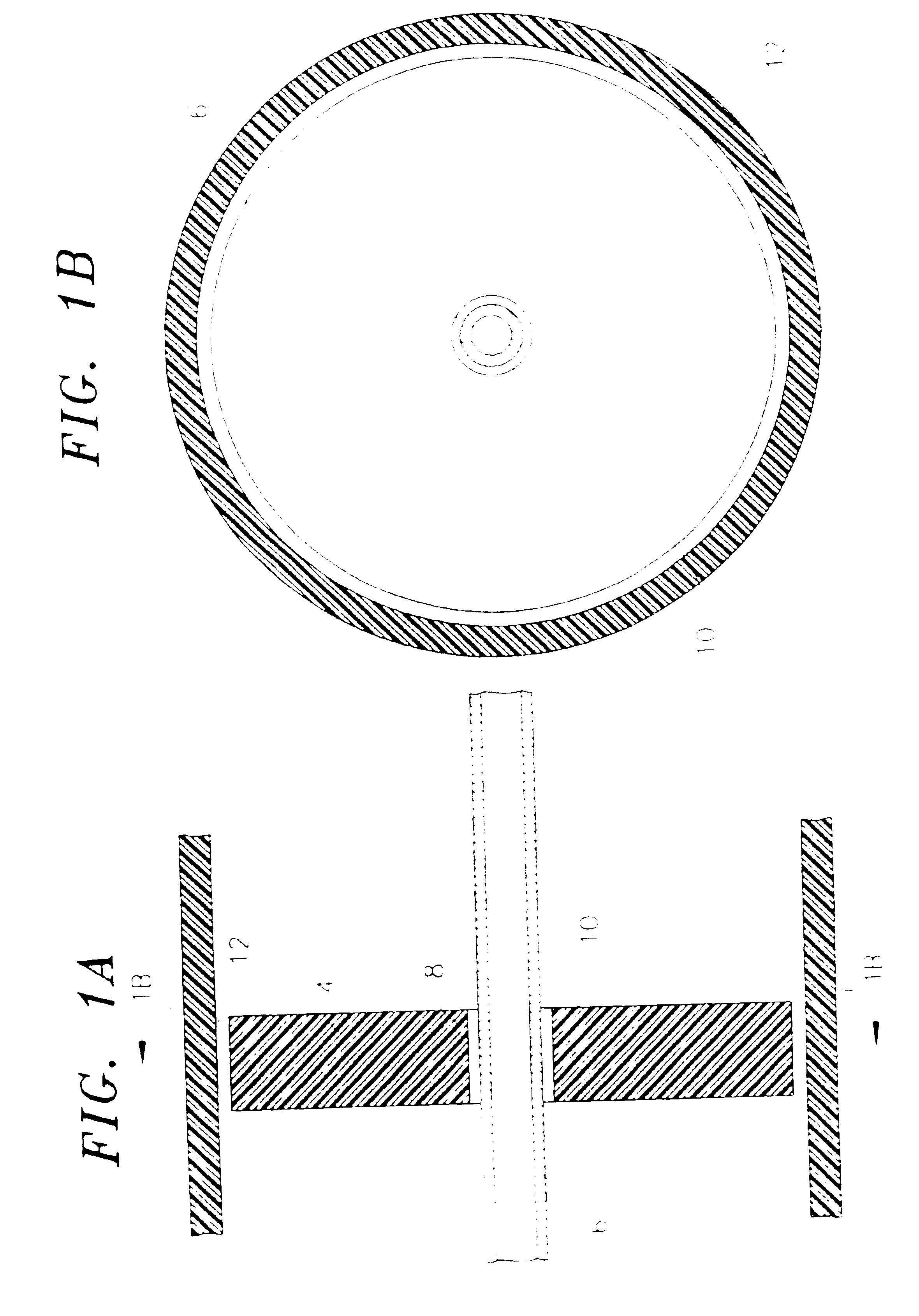

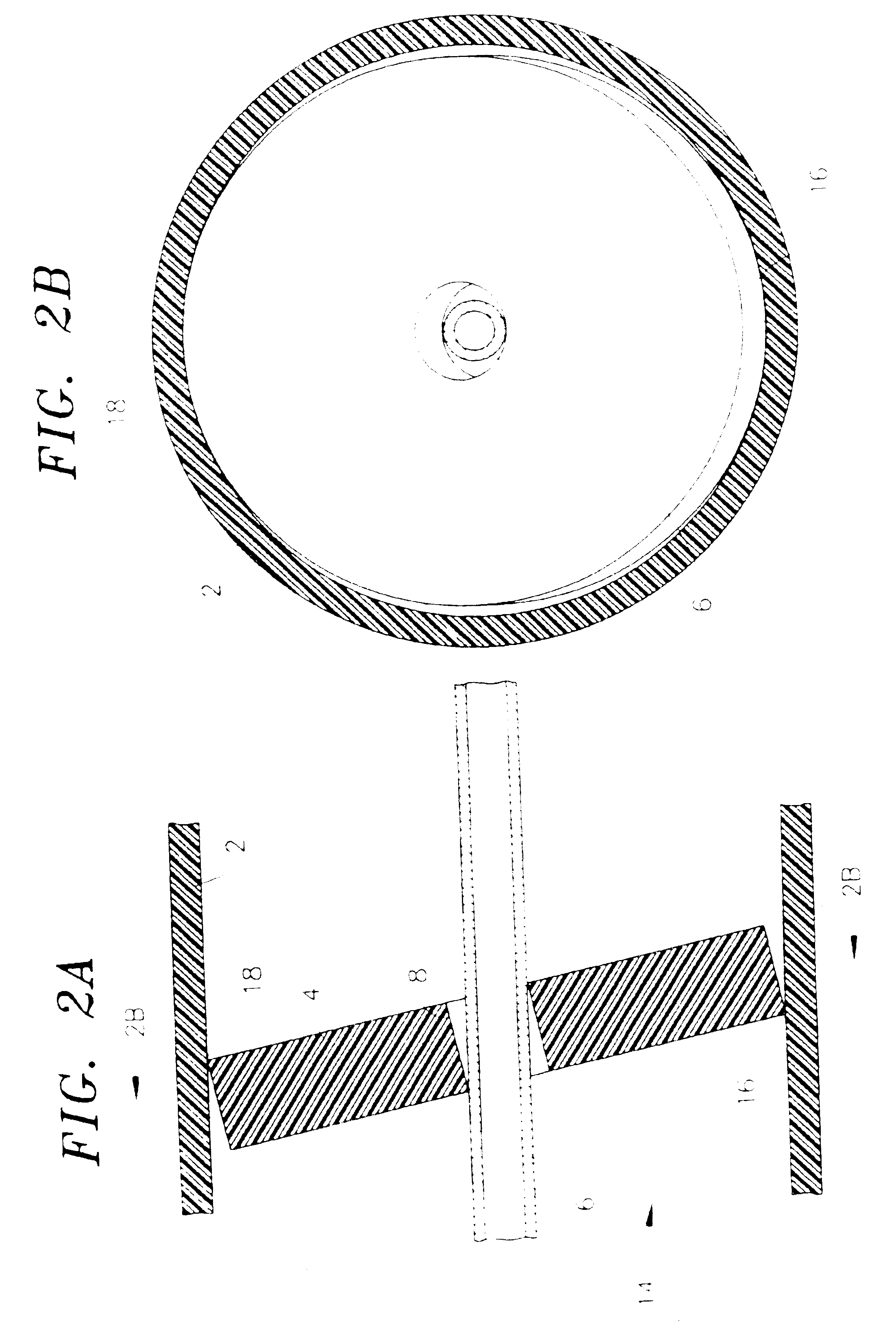

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

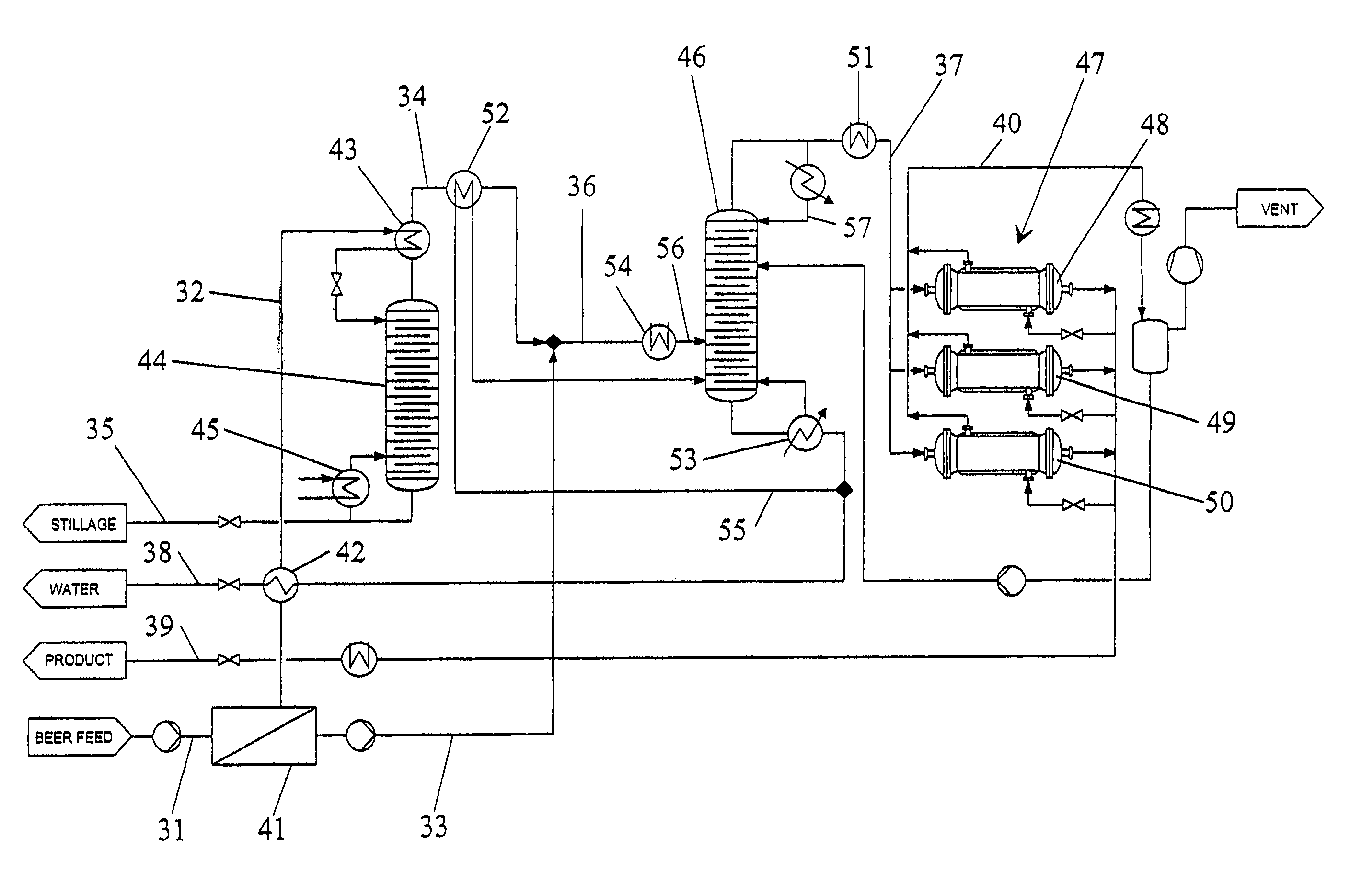

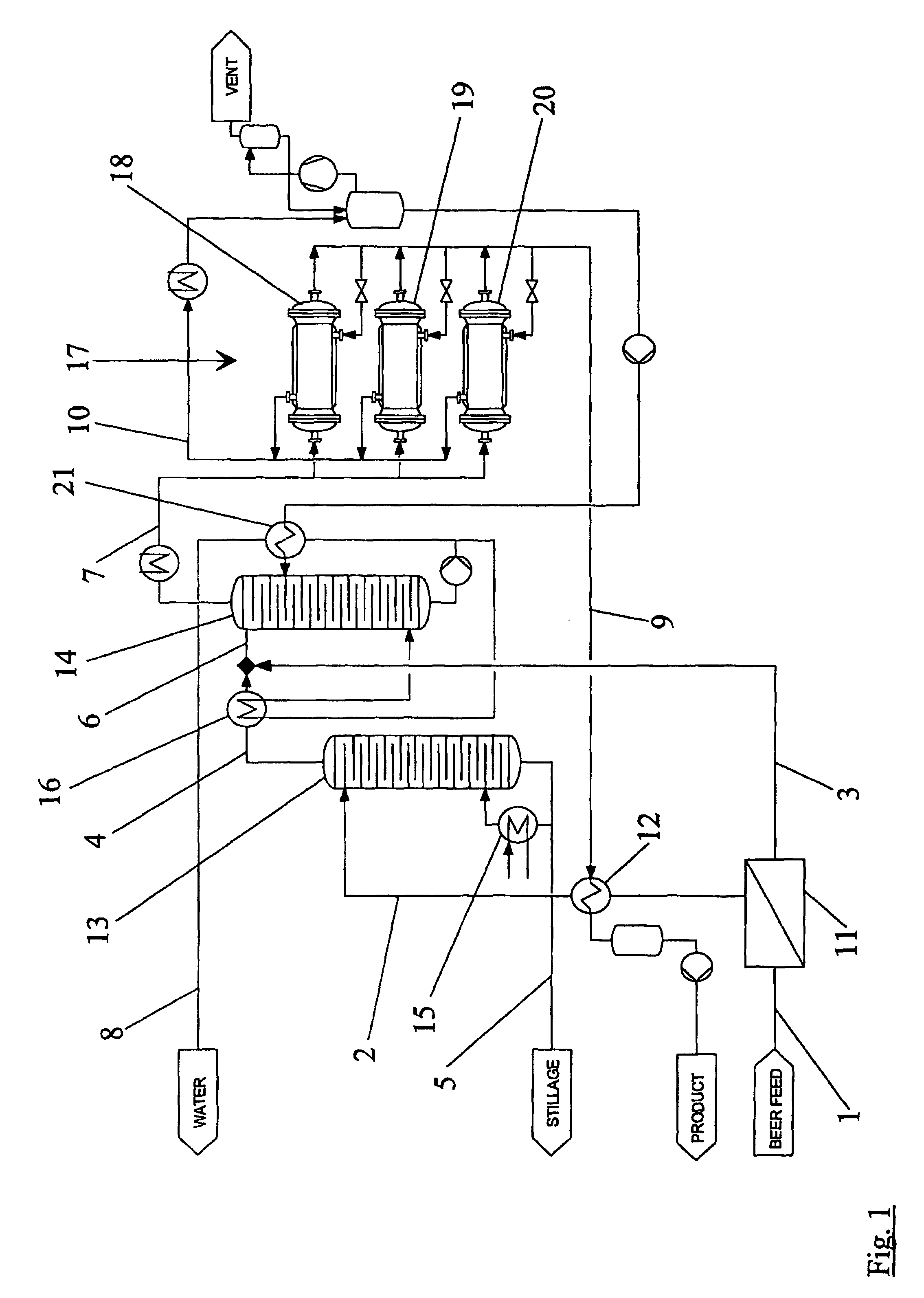

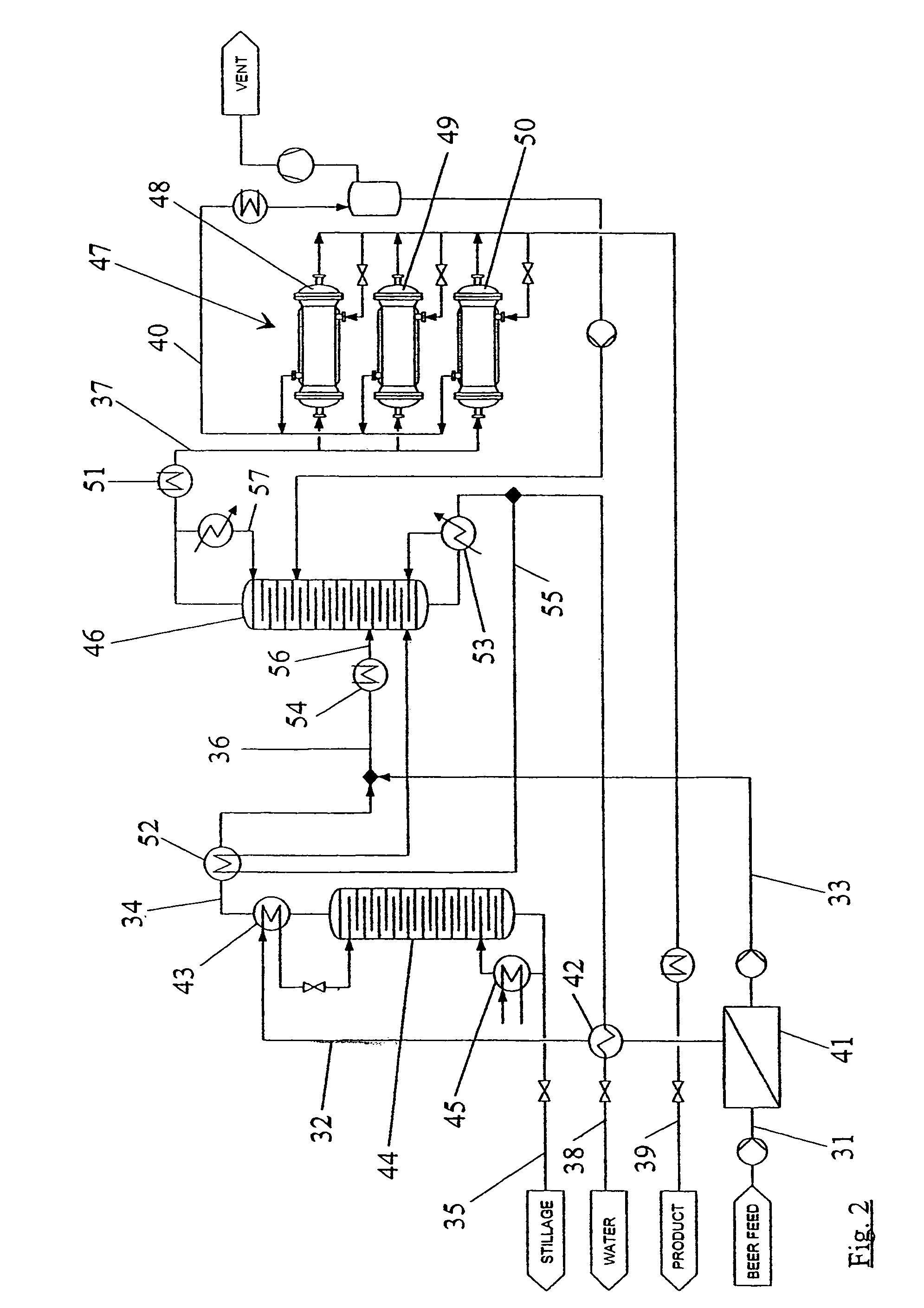

Distillation method

A method for distilling ethanol from a mash includes feeding a fluid to a first distillation column. The fluid and a distillate of the first distillation column are delivered to a second distillation column. The fed fluid and / or distillate of the second distillation column is / are purified in a first and / or last step of the method by a membrane separation process.

Owner:WHITE FOX TECH LTD

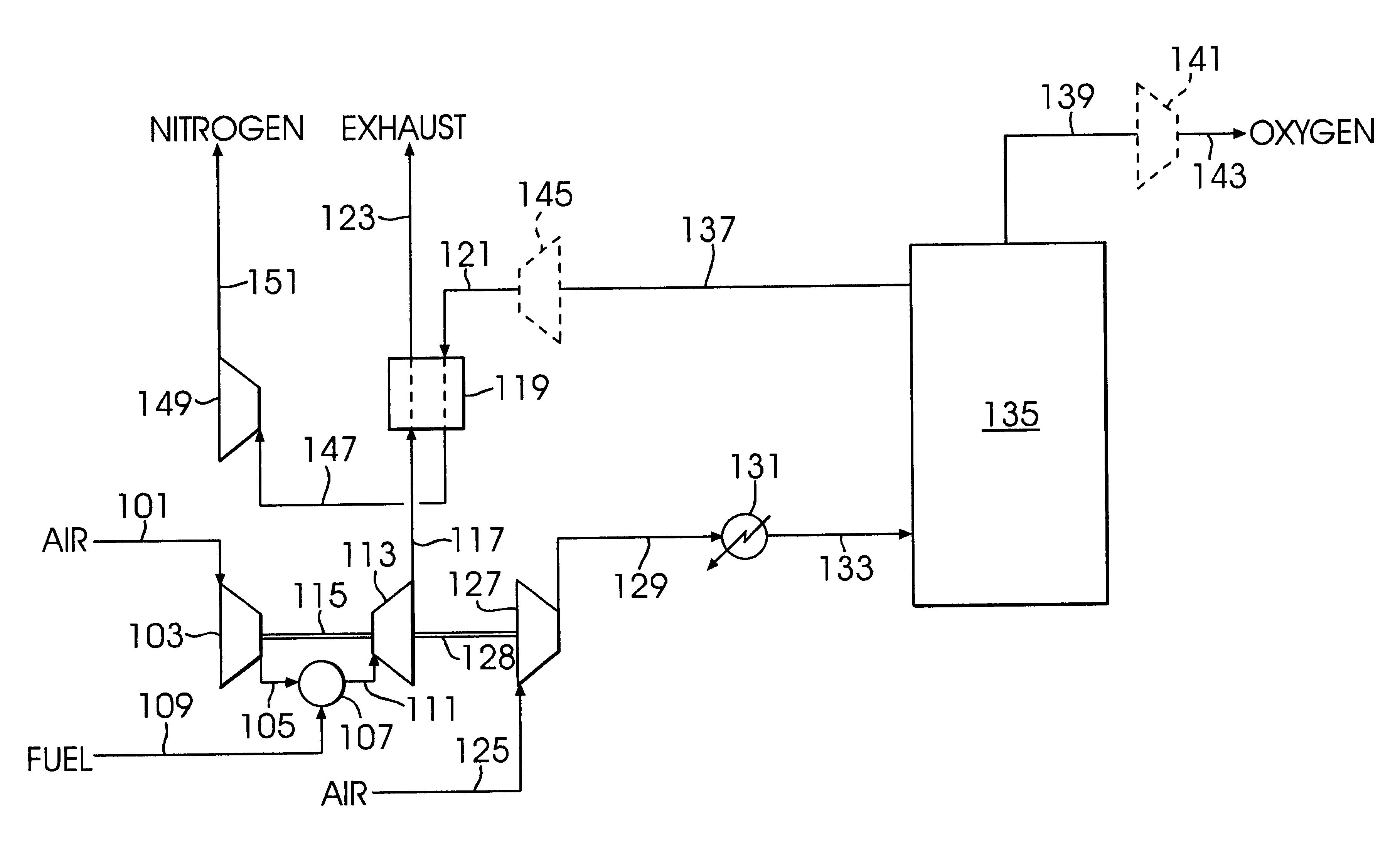

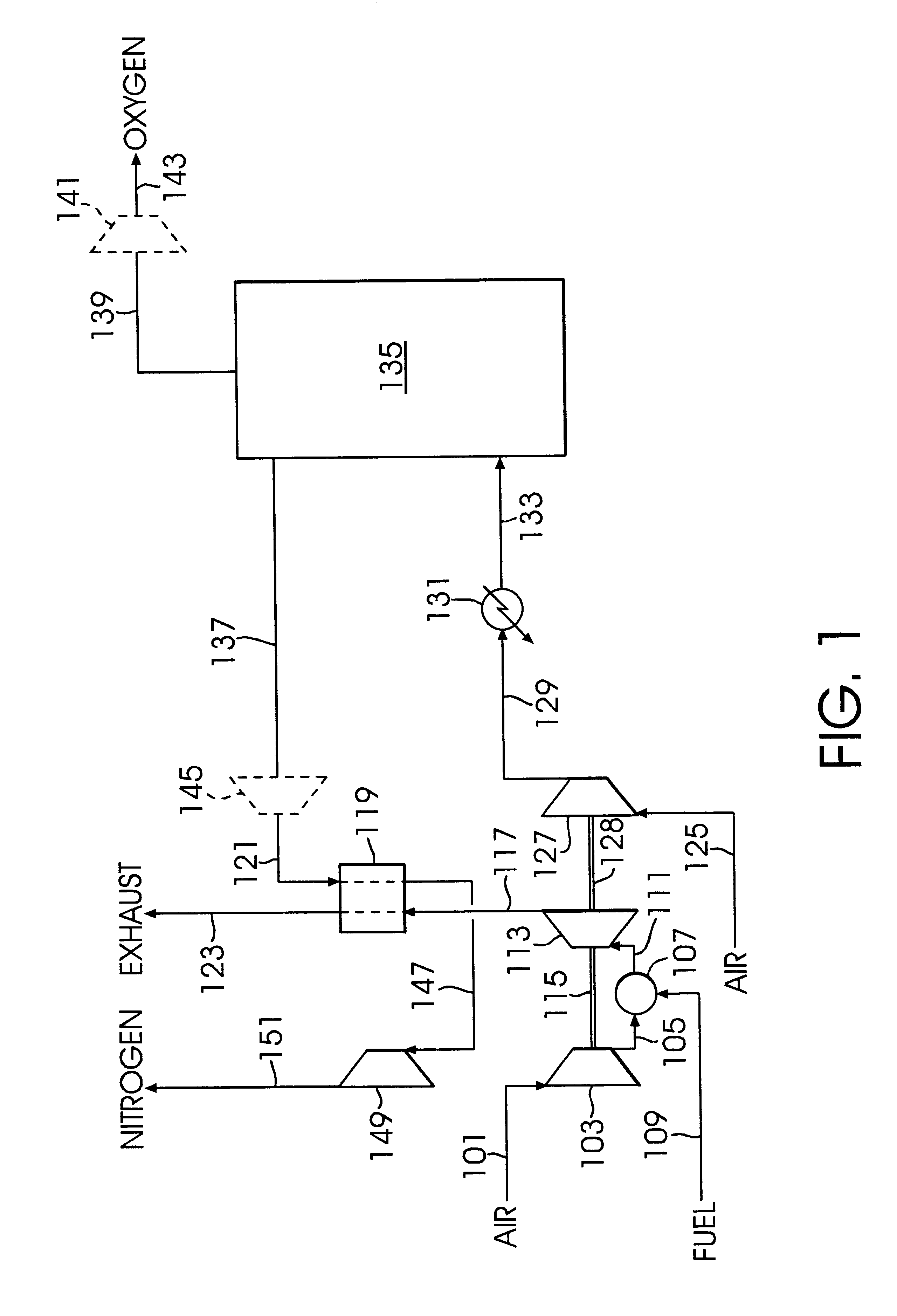

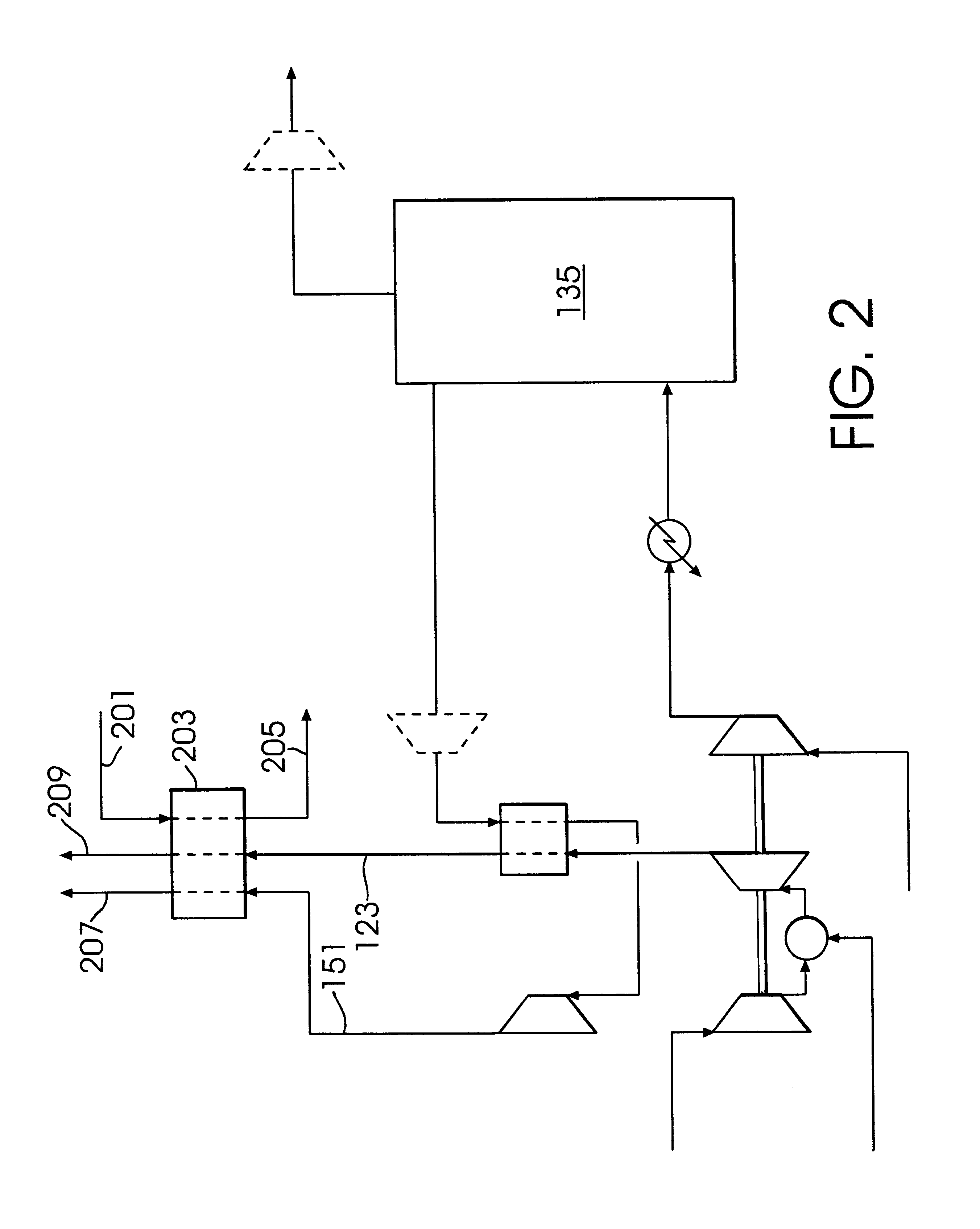

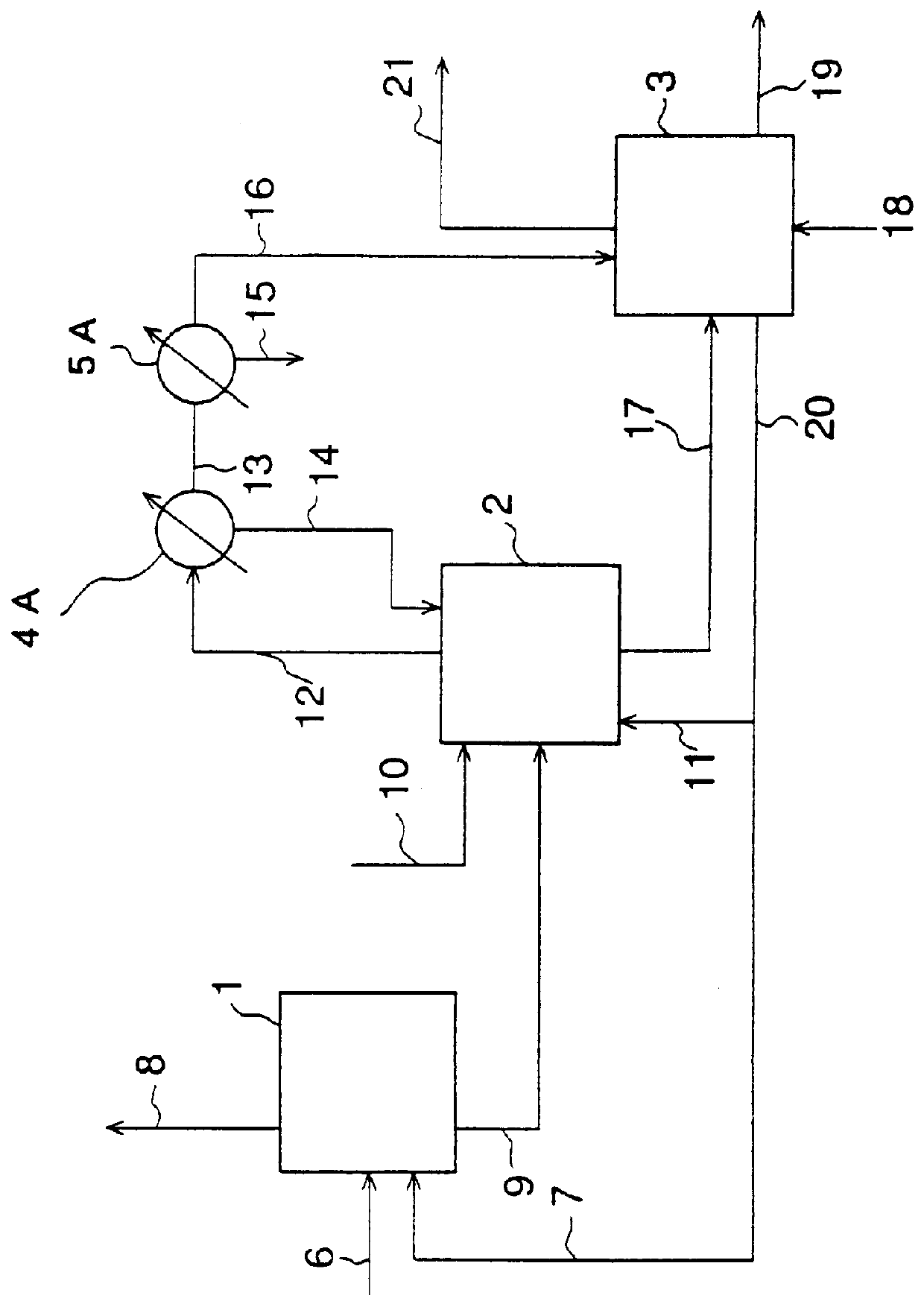

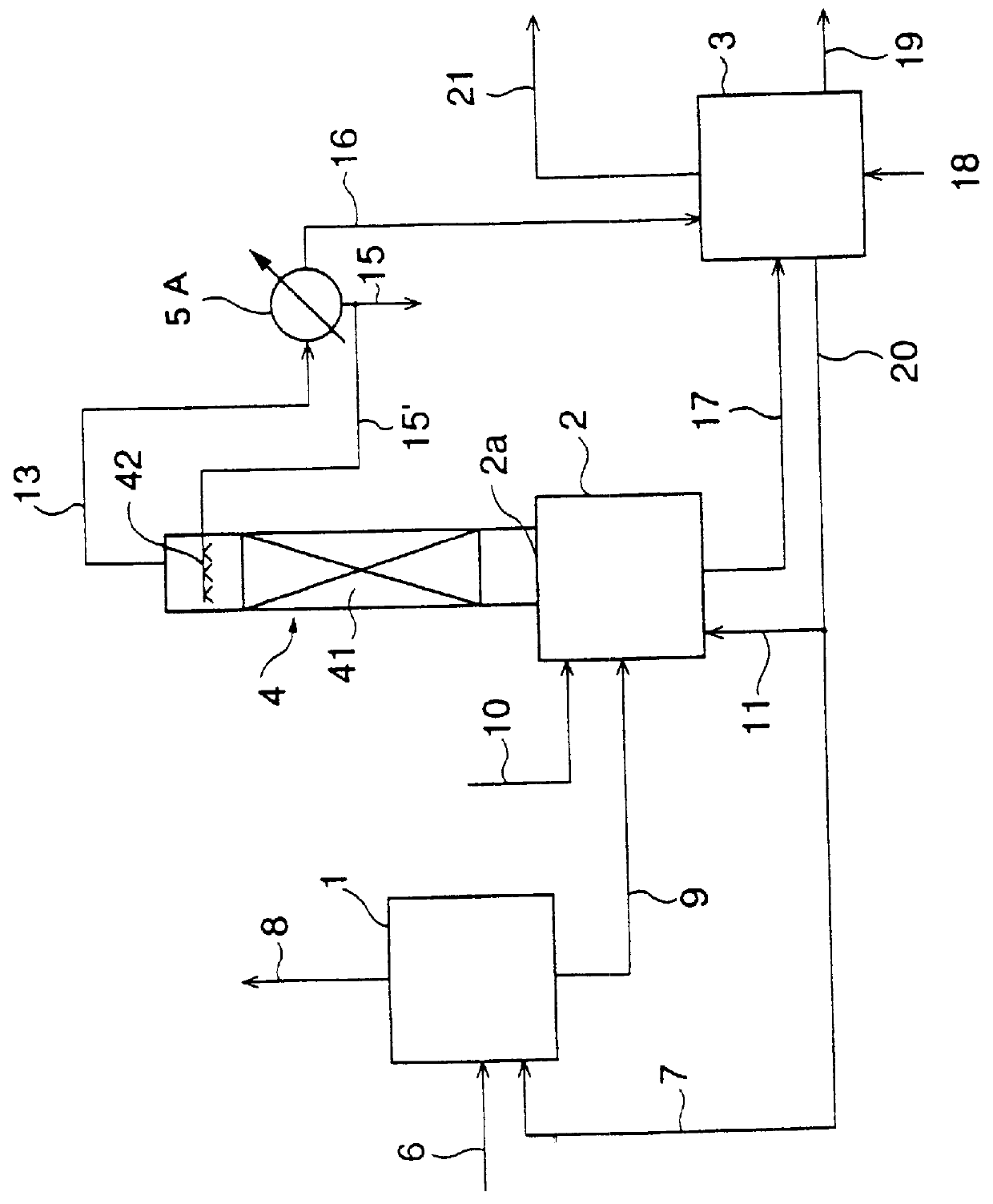

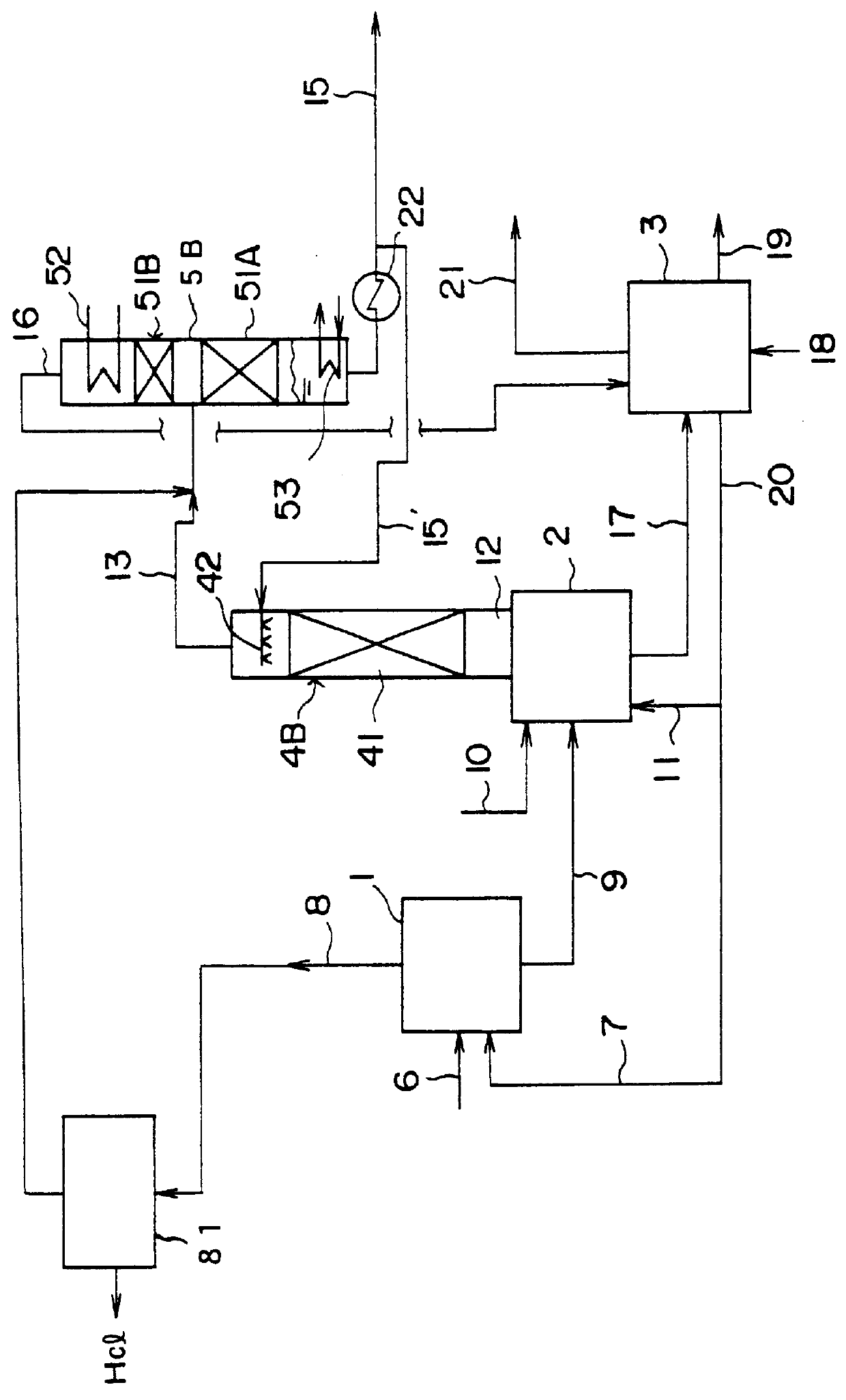

Air separation process integrated with gas turbine combustion engine driver

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

Reduced Carbon Footprint Steam Generation Processes

Processes for the generation of steam are provided for use in an integrated catalytic gasification process for converting carbonaceous materials to combustible gases, such as methane. Generally, the exhaust gas from a steam generating reactor is provided along with steam, a carbonaceous feedstock, and a gasification catalyst, to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, the carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide. As substantially all the carbon dioxide produced from the steam generation process and the gasification process are subsequently directed though gas purification and separation processes, substantially all the carbon dioxide may be recovered, yielding a process having a near zero carbon footprint.

Owner:SURE CHAMPION INVESTMENT LTD

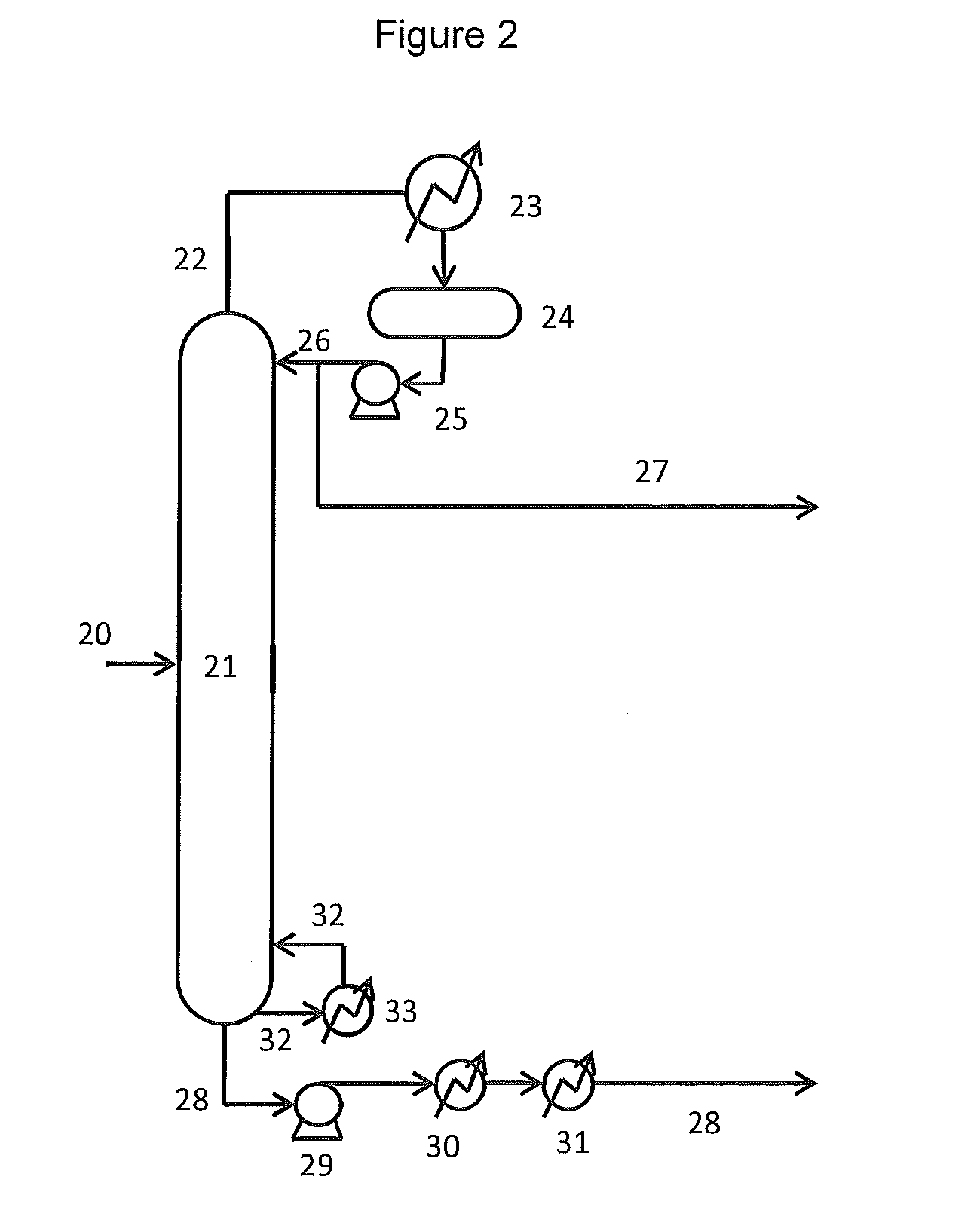

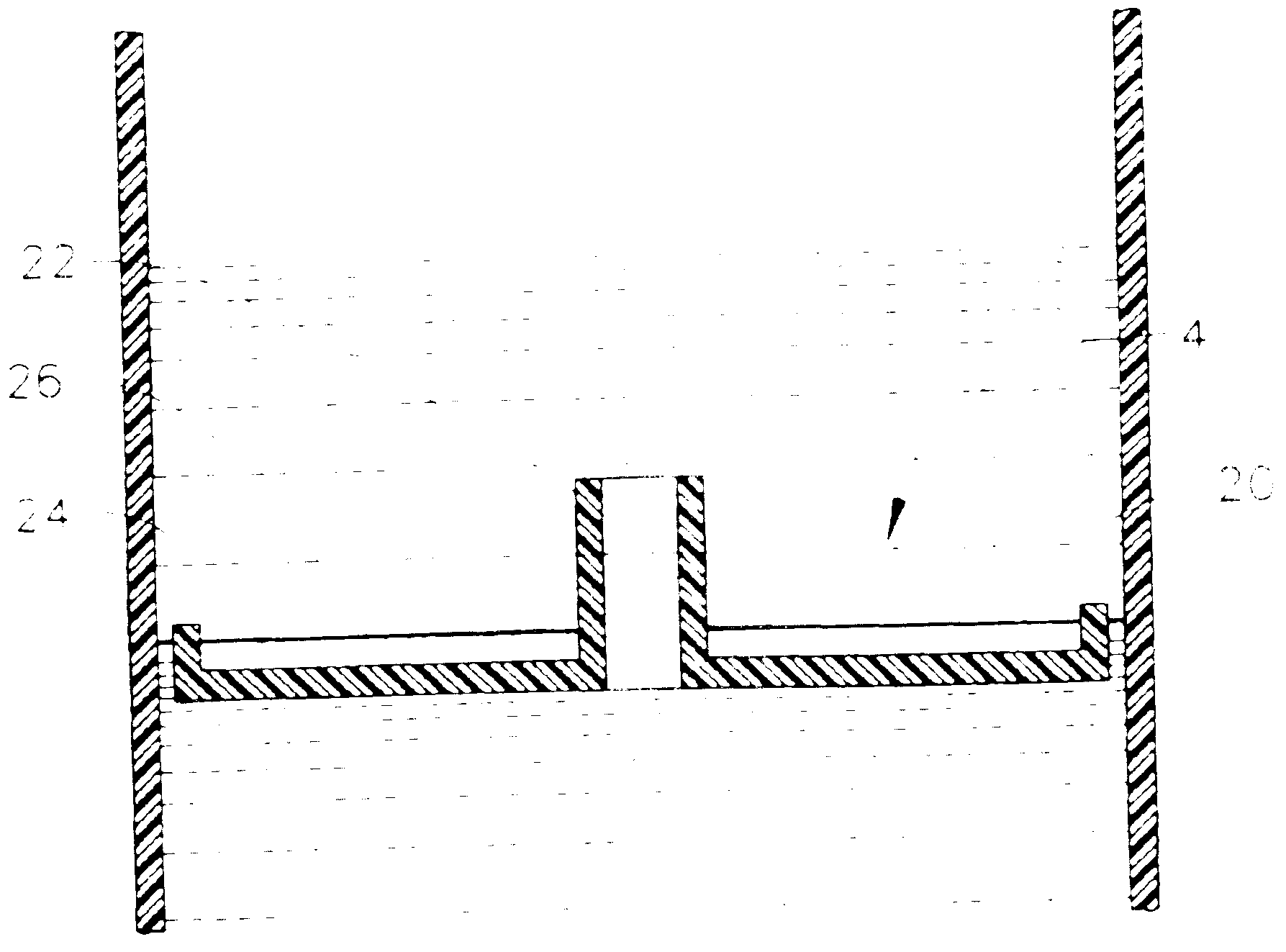

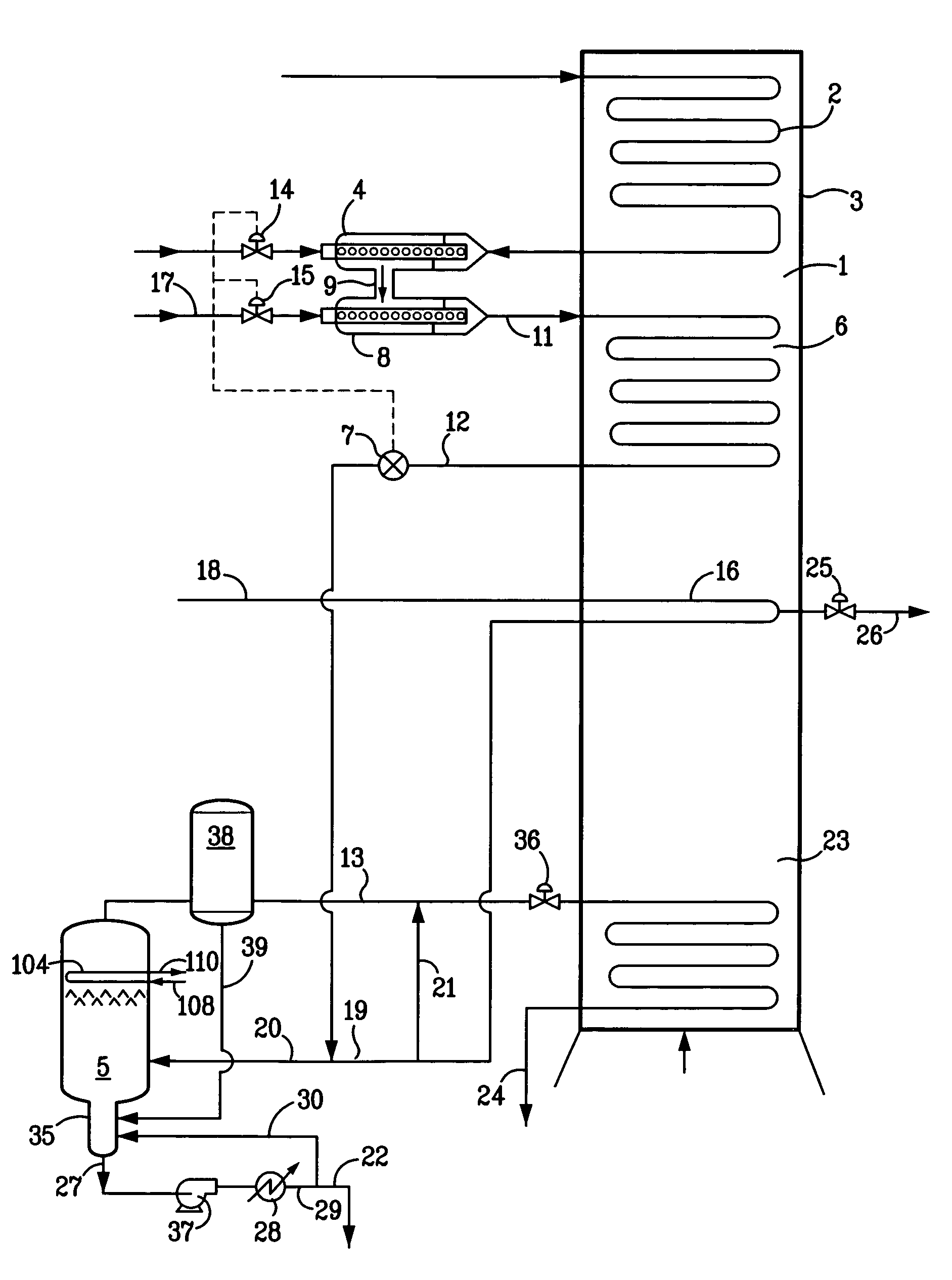

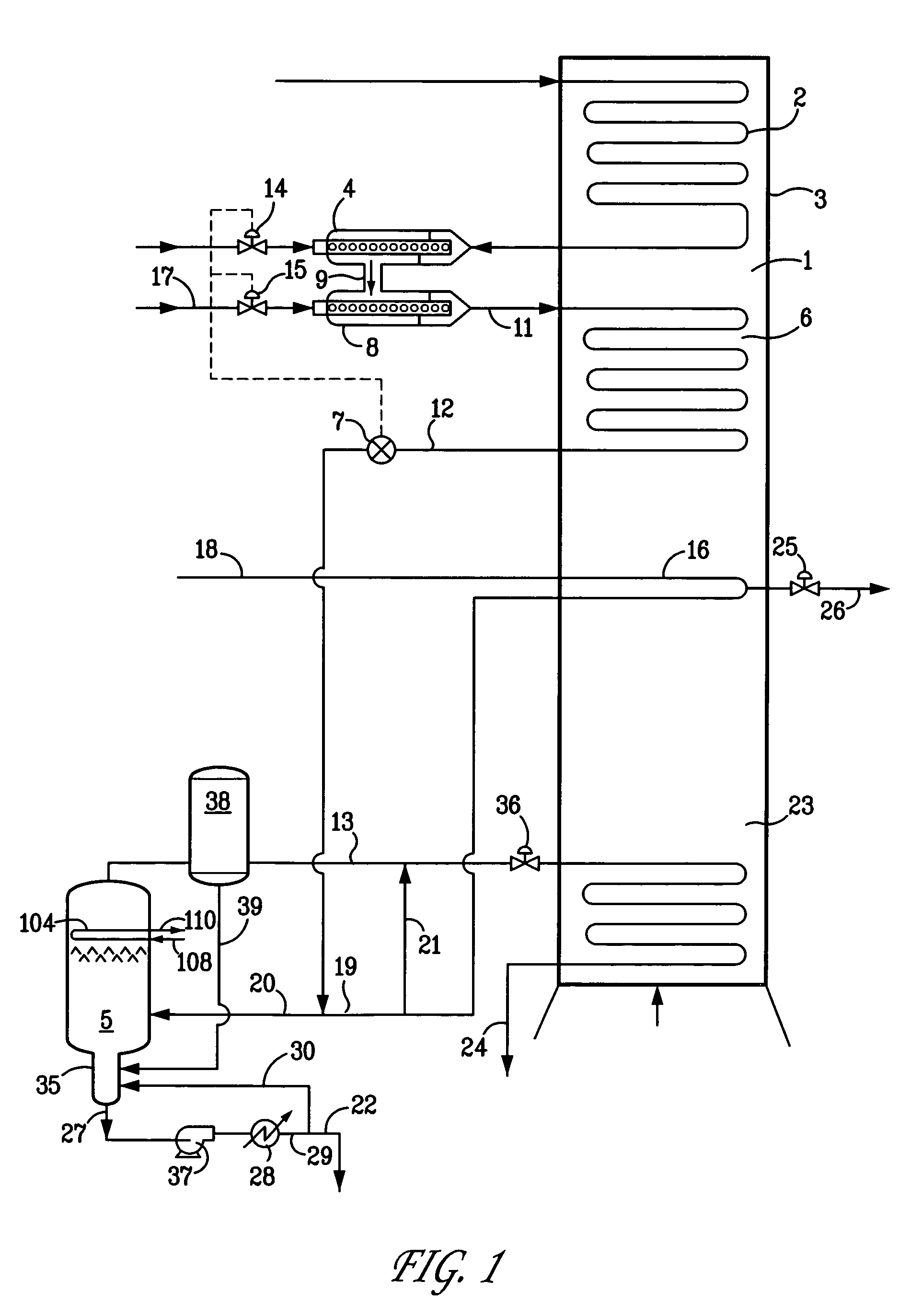

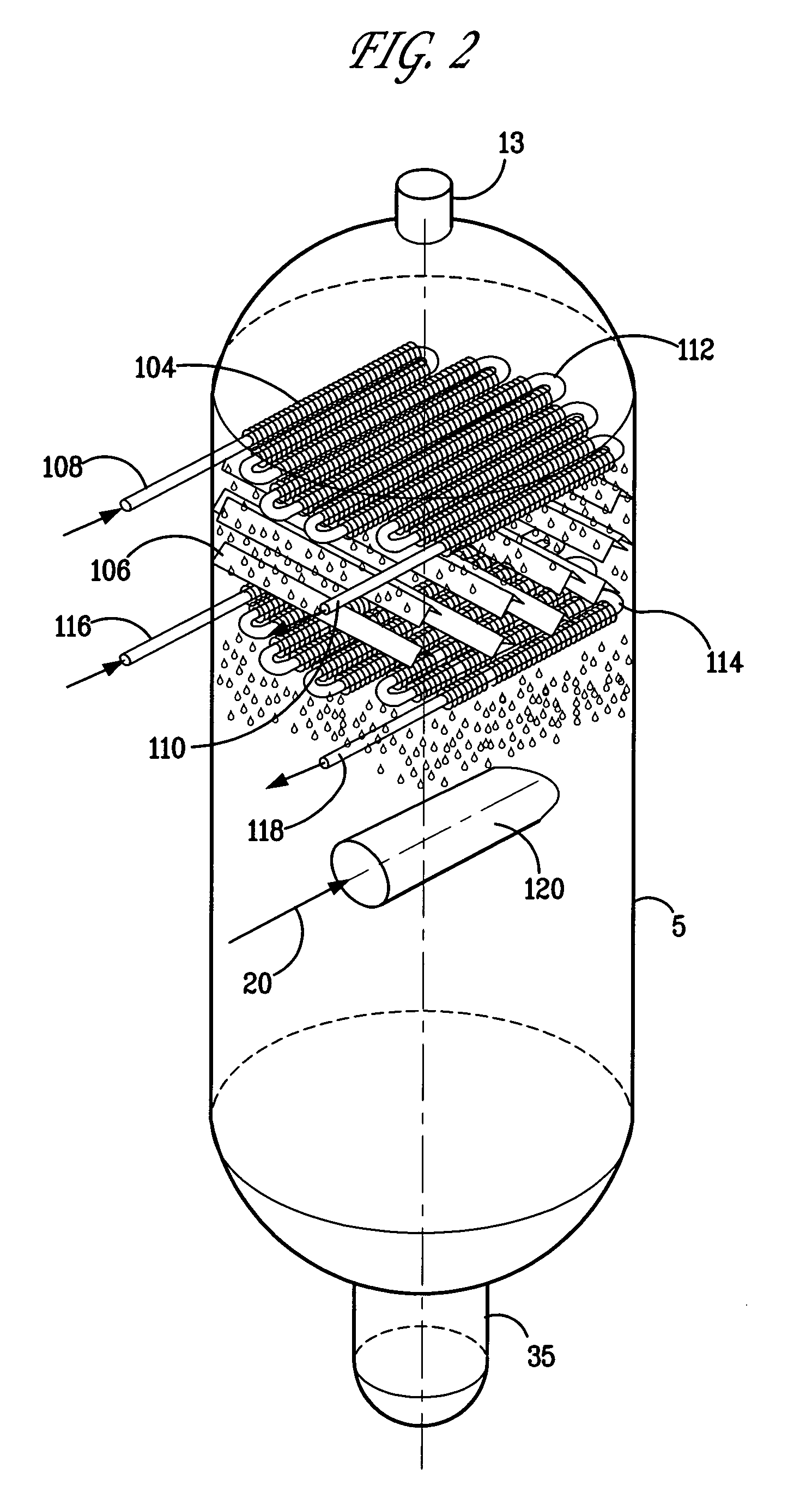

Cracking hydrocarbon feedstock containing resid utilizing partial condensation of vapor phase from vapor/liquid separation to mitigate fouling in a flash/separation vessel

A process is provided for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, optionally further heating the mixture, flashing the mixture within a flash / separation vessel to form a vapor phase and a liquid phase, partially condensing the vapor phase by contacting with a condenser within the vessel, to condense at least some coke precursors within the vapor while providing condensates which add to the liquid phase, removing the vapor phase of reduced coke precursors content as overhead and the liquid phase as bottoms, heating the vapor phase, cracking the vapor phase in a radiant section of a pyrolysis furnace to produce an effluent comprising olefins, and quenching the effluent and recovering cracked product therefrom. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

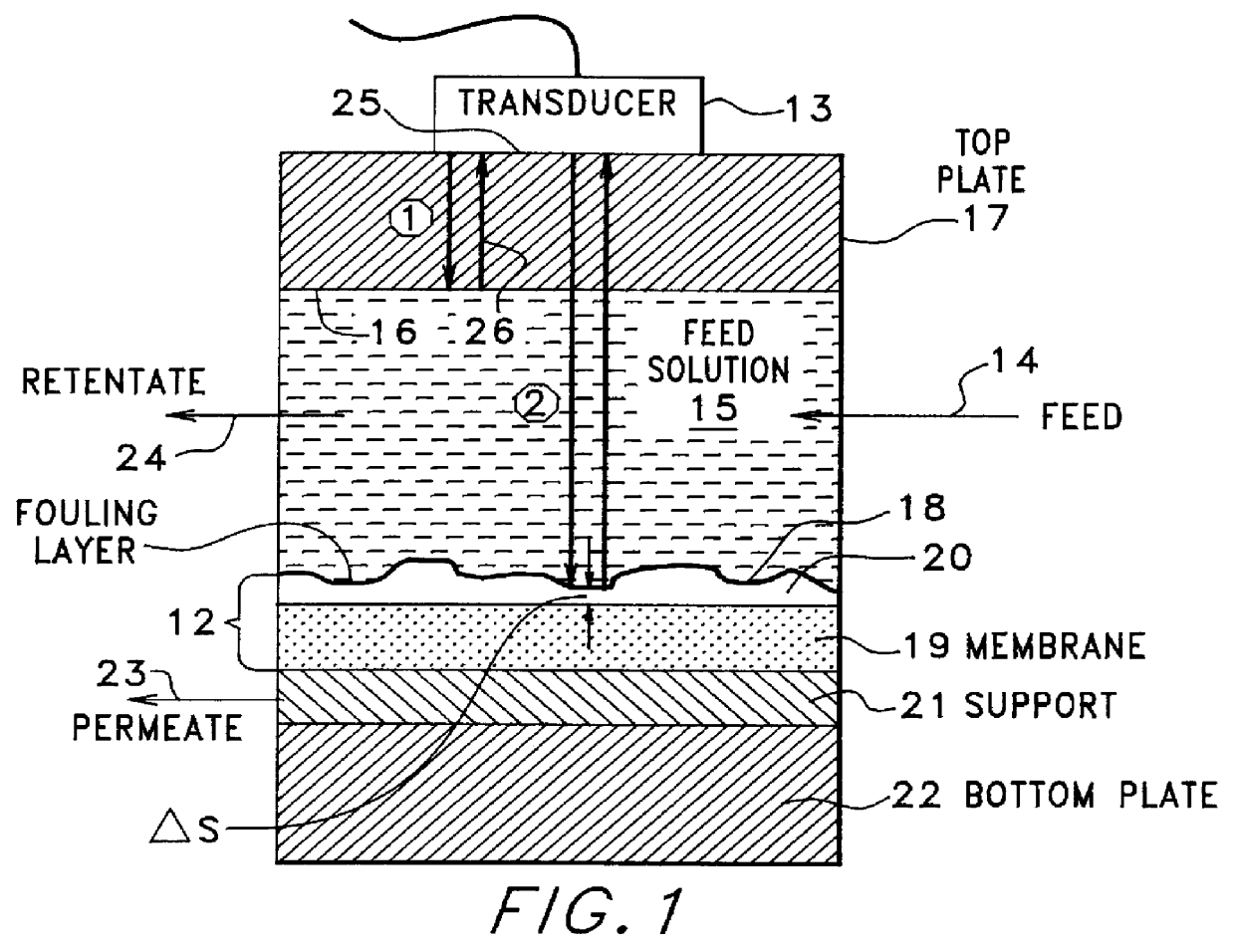

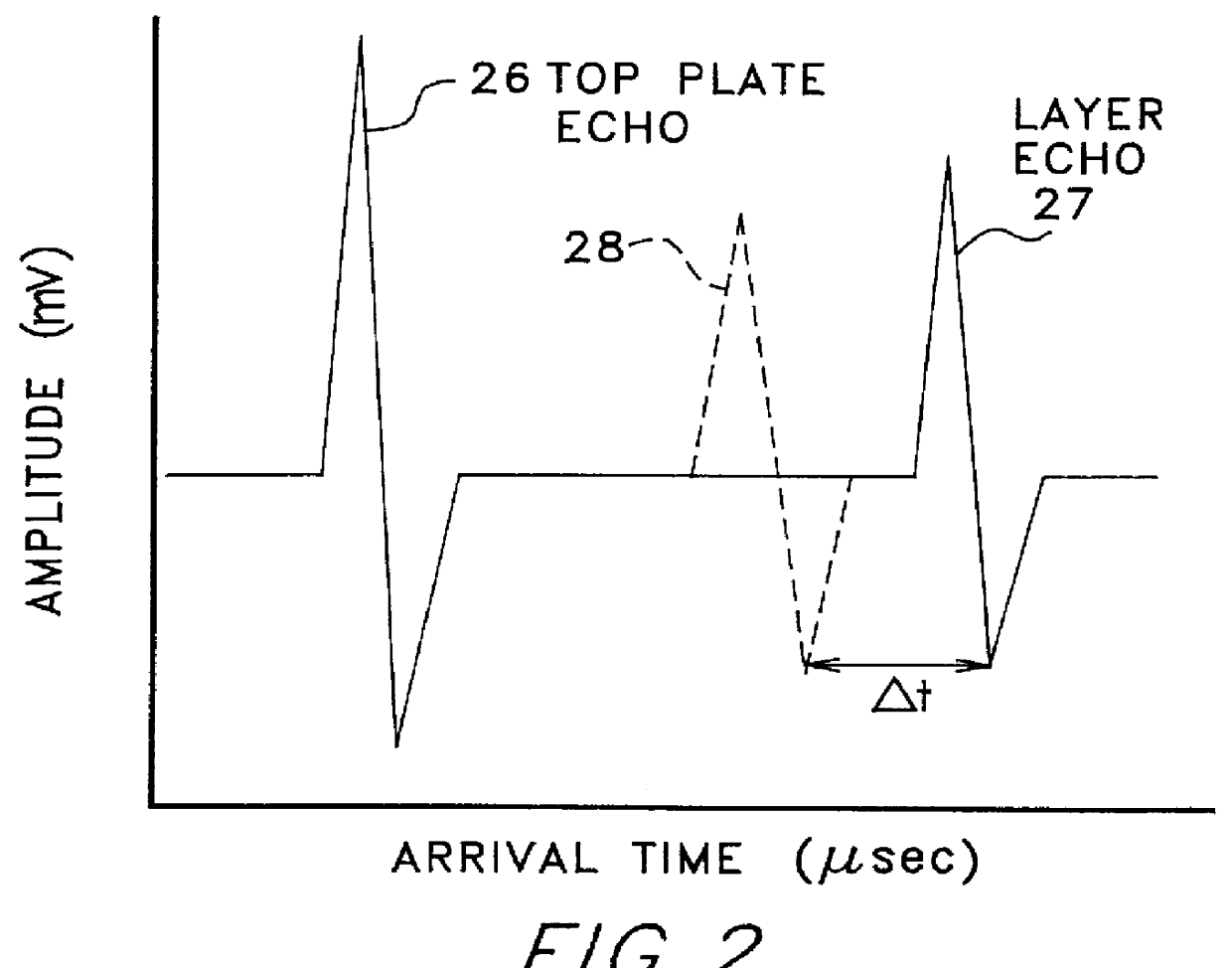

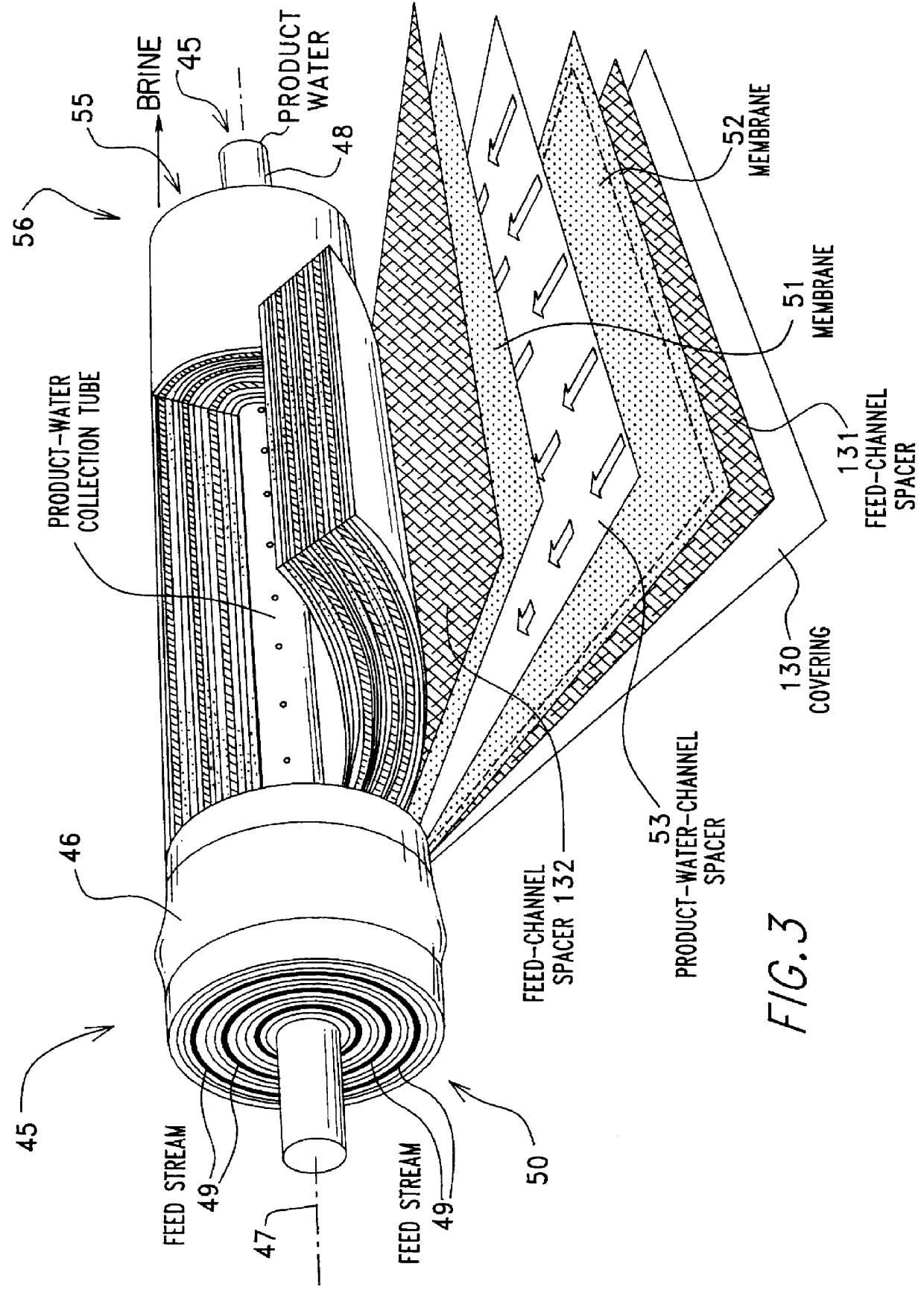

Method and apparatus for determining the state of fouling/cleaning of membrane modules

InactiveUS6161435AVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainSpiral wound

The fouling state of a polymeric membrane within the high pressure housing of a spiral wound or a hollow fiber membrane module is determined. An ultra sonic transducer positioned with its emitting face in physical engagement with the outer surface of the housing is pulse energized by a pulser / receiver device. A membrane echo signal is detected by a receiver of the pulser / receiver device. A reference echo signal indicative of a fouled or an unfouled state of the membrane is compared to the echo signal to determine the membrane fouling state. The echo to reference comparing step can be based upon comparing amplitude domain signals, comparing time-domain signals, comparing combinations of amplitude domain and time-domain signals, and comparing transformations of amplitude domain and time-domain signals. A clean or a fouled reference echo can be provided from a clean or a fouled membrane and then stored for use during a liquid separation process, or a clean reference echo signal can be obtained on-line from a second transducer whose echo signal is derived from an area of the membrane known to remain relatively unfouled during the liquid separation process, or a clean or fouled reference echo signal can be provided for later use during a cleaning process or during a liquid separation process. Multiple transducers and a switching network can sample the fouling state at different positions within the membrane module.

Owner:UNIV TECH

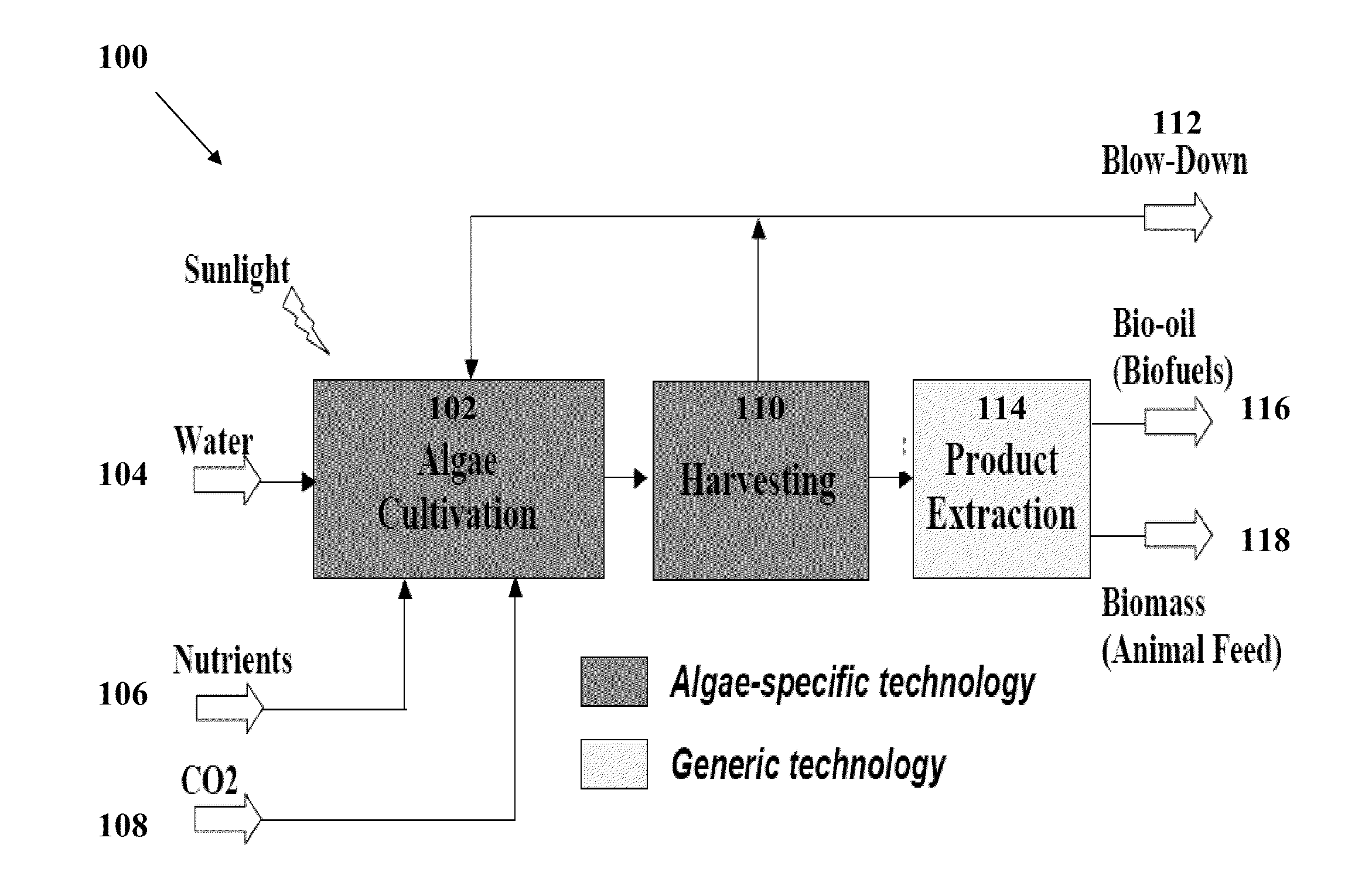

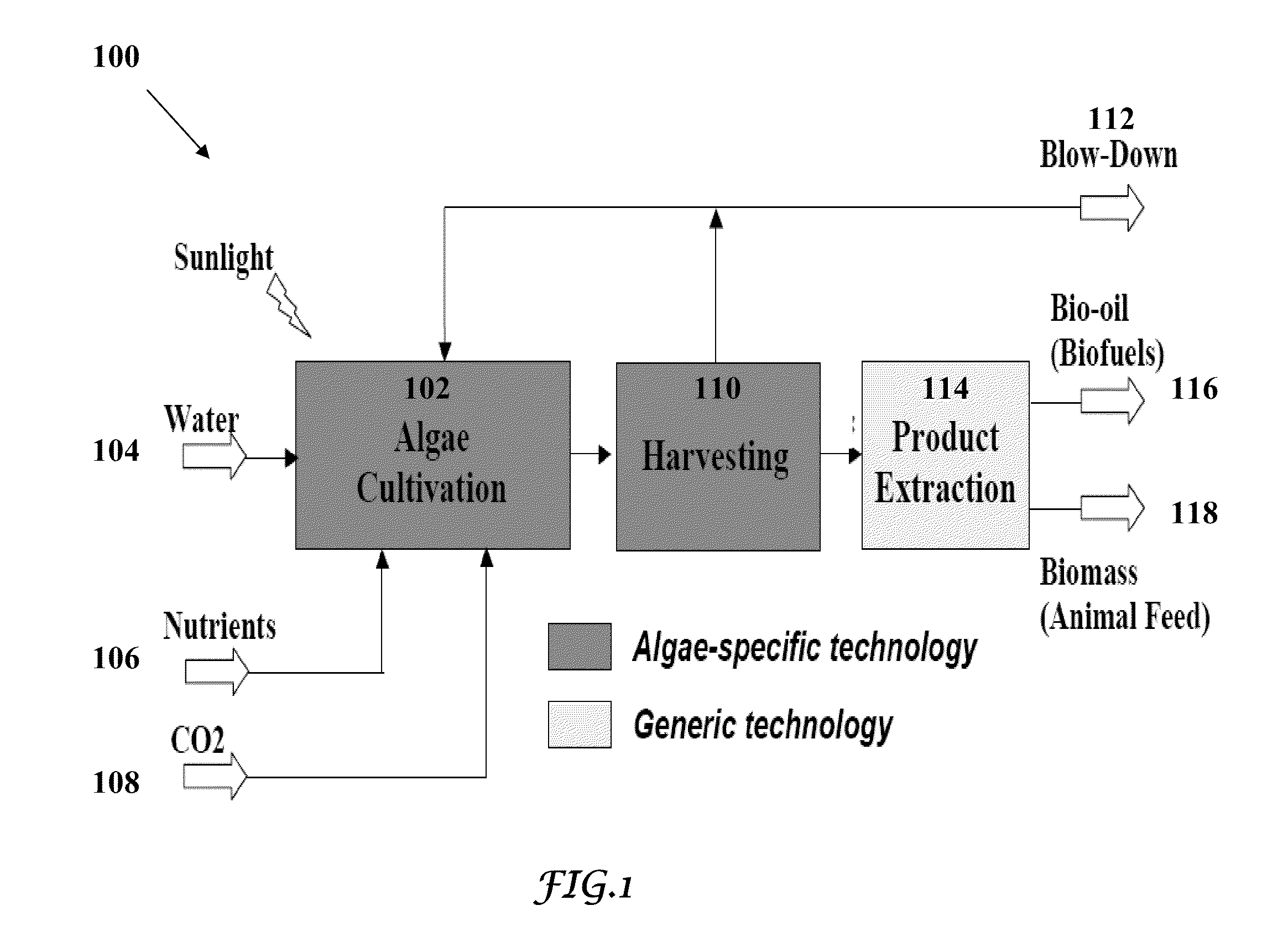

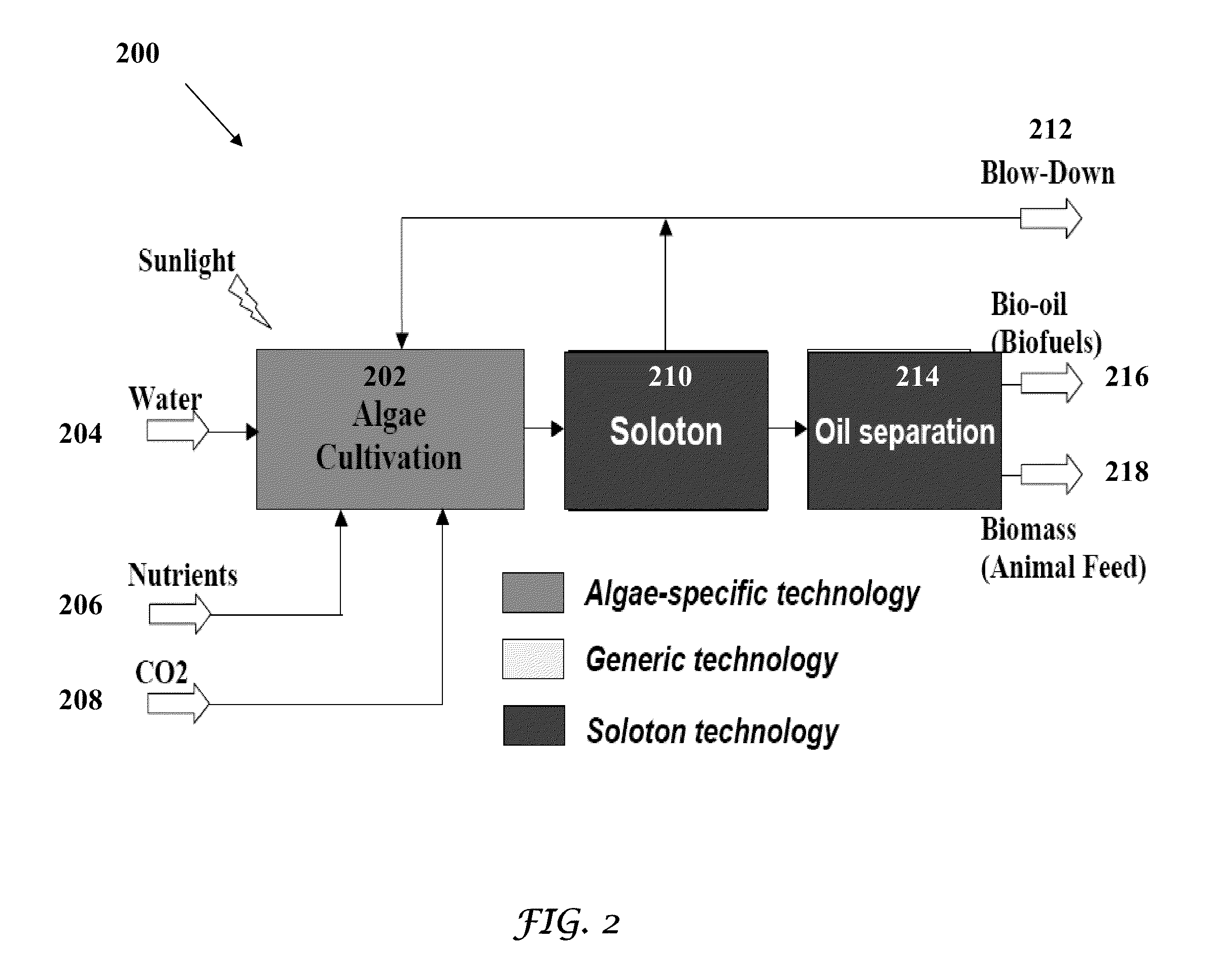

Novel Process for Separating Lipids From a Biomass

InactiveUS20100261918A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelAlgae

A novel low cost separation process for separating lipid oil from an algal biomass for biofuel production is described herein. The process of the present invention comprises of two steps: (i) breaking the algae cells and (ii) separation of the lipid oils from the broken cells. The separated lipids are extracted by conventional techniques followed by conversion to a biofuel.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

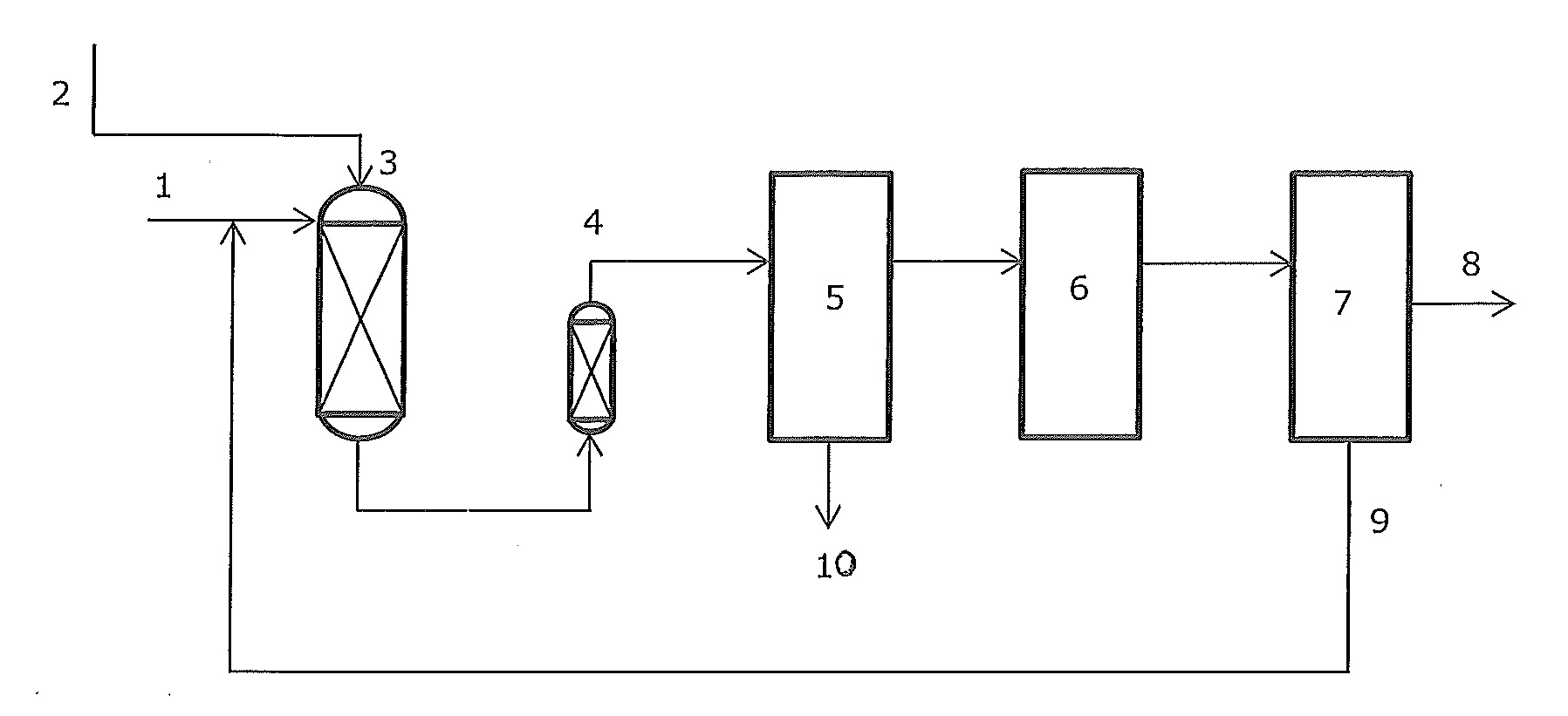

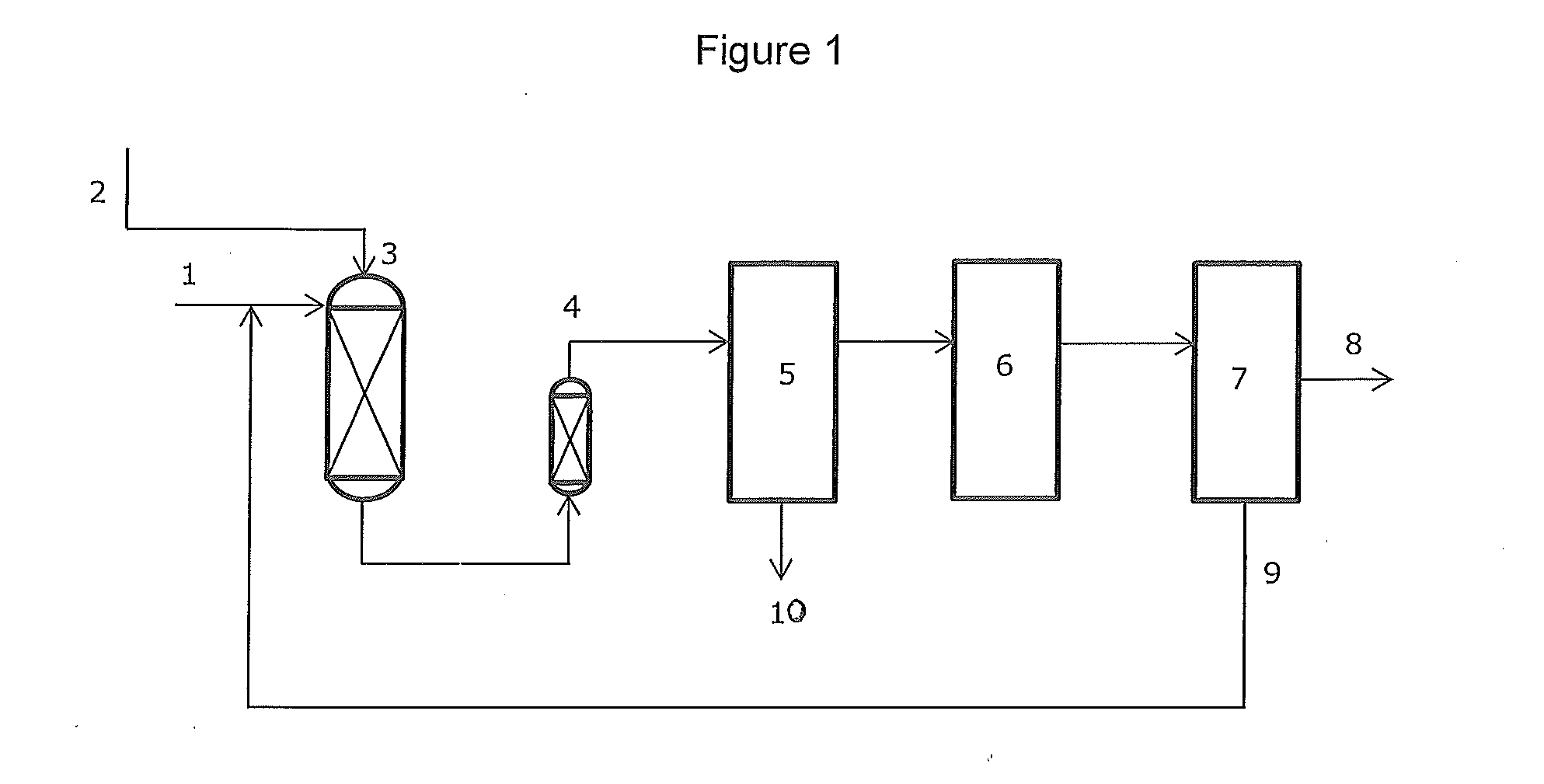

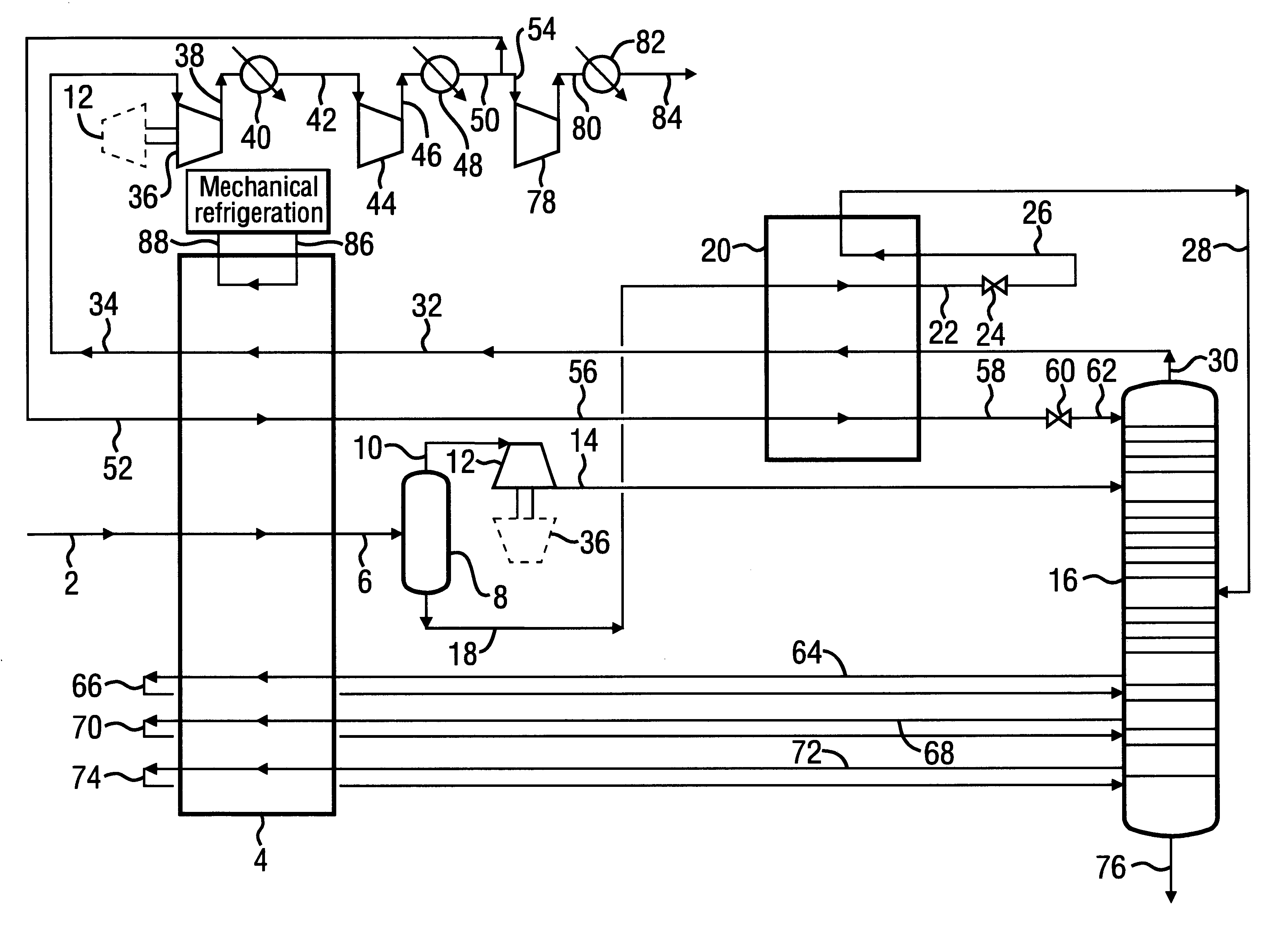

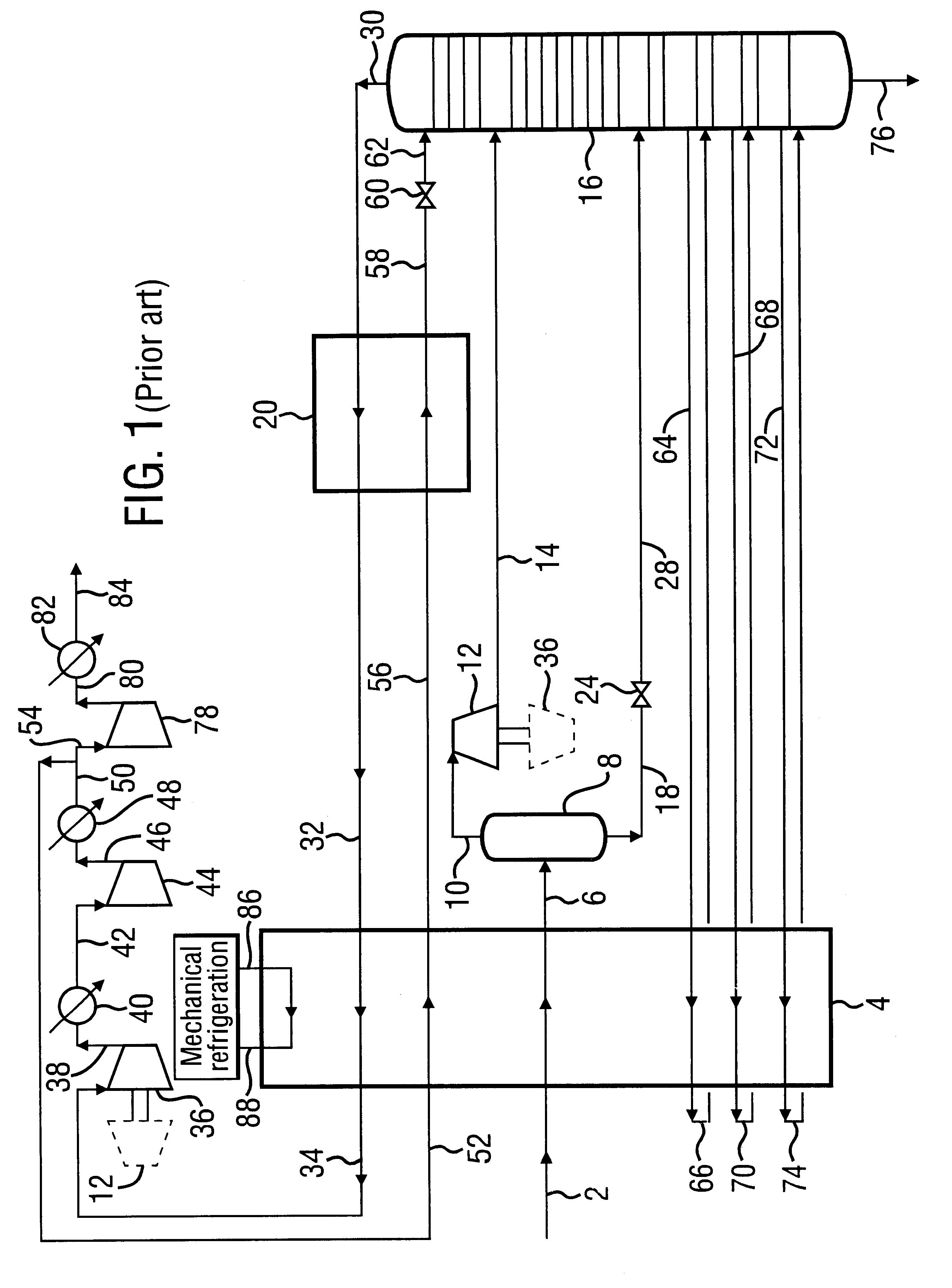

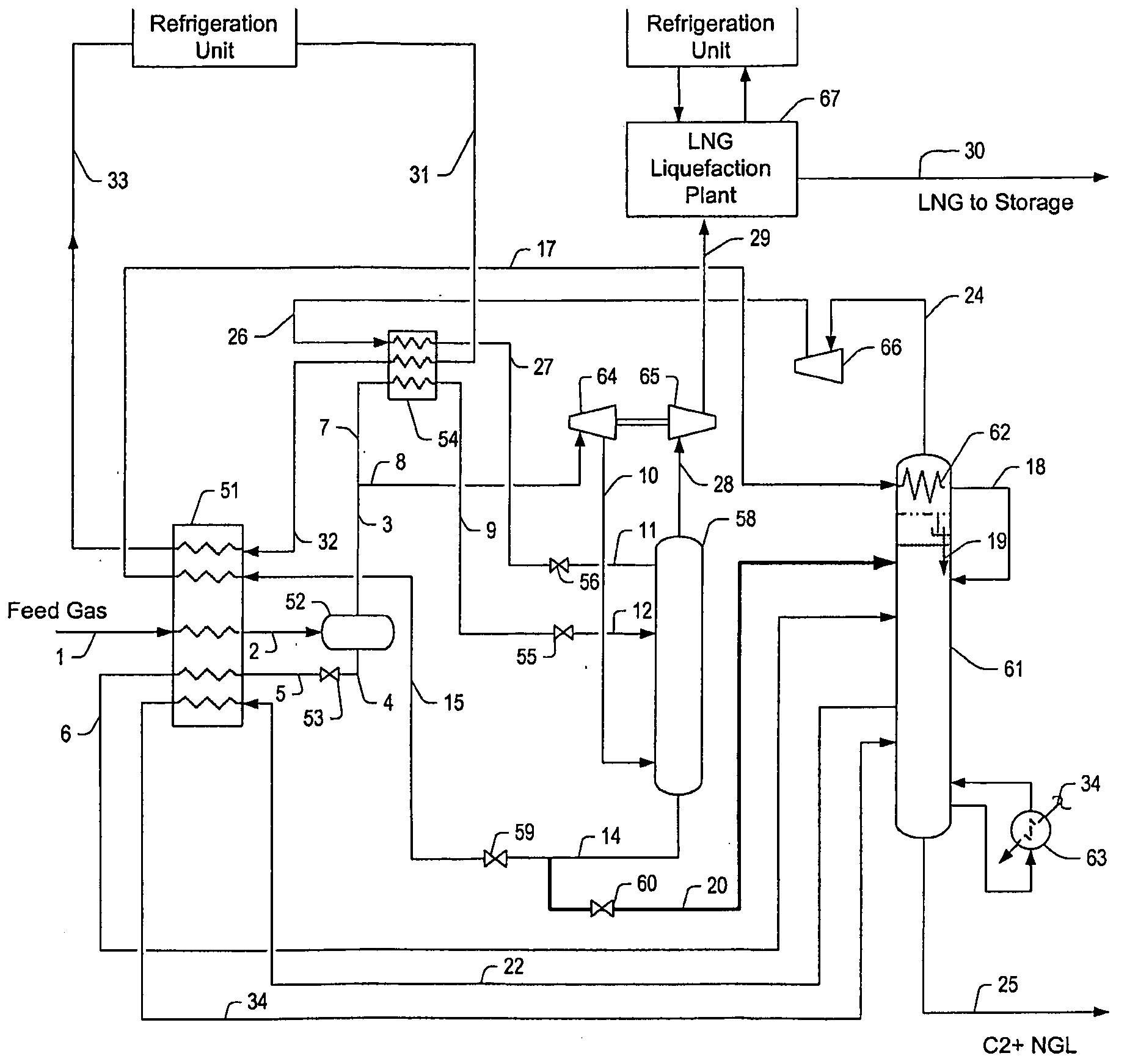

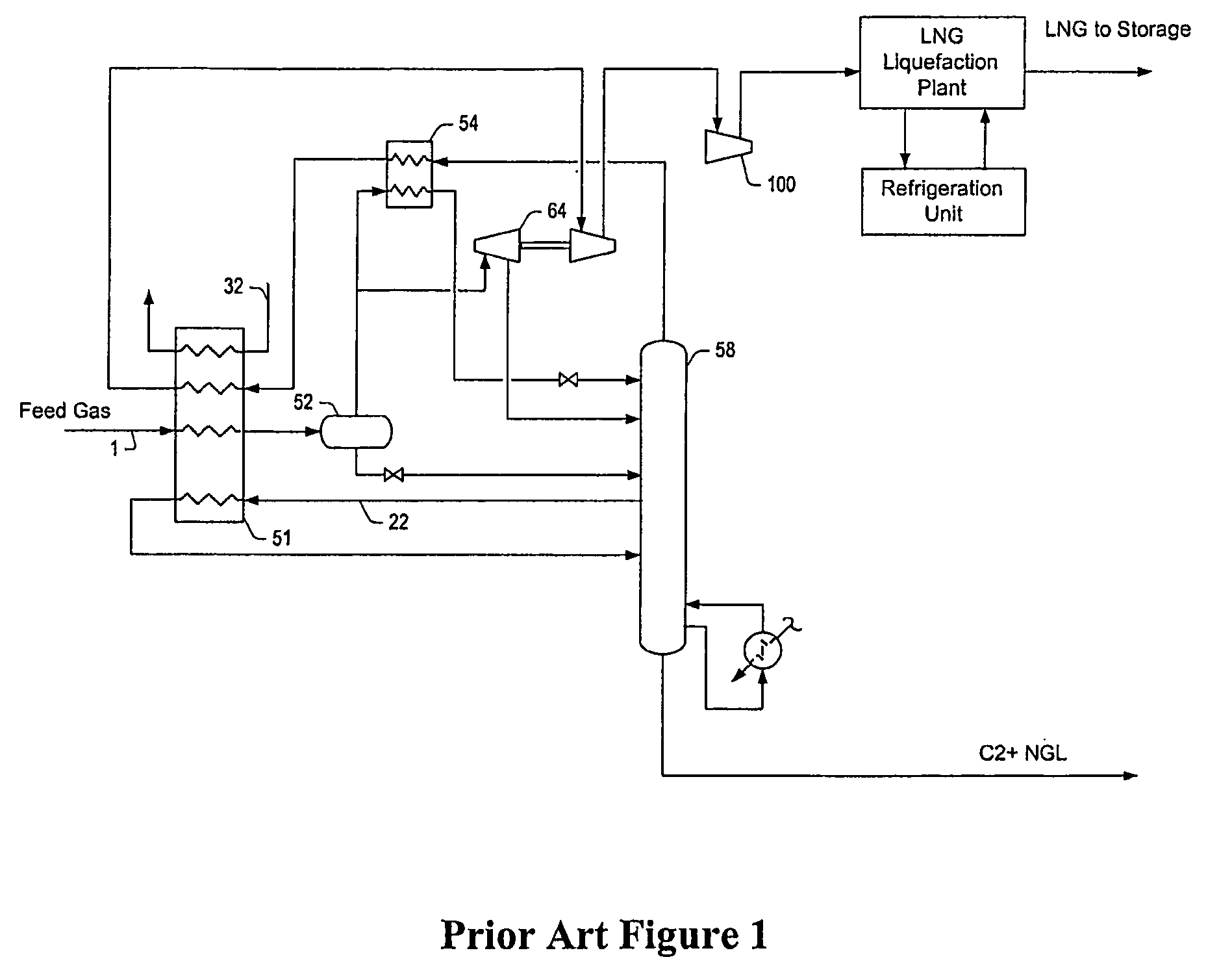

Hydrocarbon separation process and apparatus

InactiveUS6363744B2Reduce the temperaturePromote recoverySolidificationLiquefactionPhysical chemistryRefrigeration

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column.Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column.The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

Power plants that utilize gas turbines for power generation and processes for lowering CO2 emissions

Owner:GENERAL ELECTRIC CO +1

Porous metal organic framework material based on transition metal cobalt and preparation method thereof

InactiveCN102962036AGood application effectIncrease surface areaOther chemical processesGaseous fuelsMetal-organic frameworkCobalt

The invention relates to a porous metal organic framework material based on transition metal cobalt and a preparation method thereof. The metal organic framework material is a compound with supramolecular porous network structure and formed by self-assembly of metal ions and organic ligands through coordination complexation. The porous cobalt-based metal organic framework material contains one or more metal ions, and one or more organic ligands; and at least one of the metal ions is Co (II). The porous cobalt-based organic framework material has excellent selective adsorption on CH4 in a separation process of CH4 and N2; and the advantage of adsorption selectivity on CH4 is particularly evident under low pressure. The material is particularly suitable for development and recovery of oil field gas, coal bed methane and biogas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

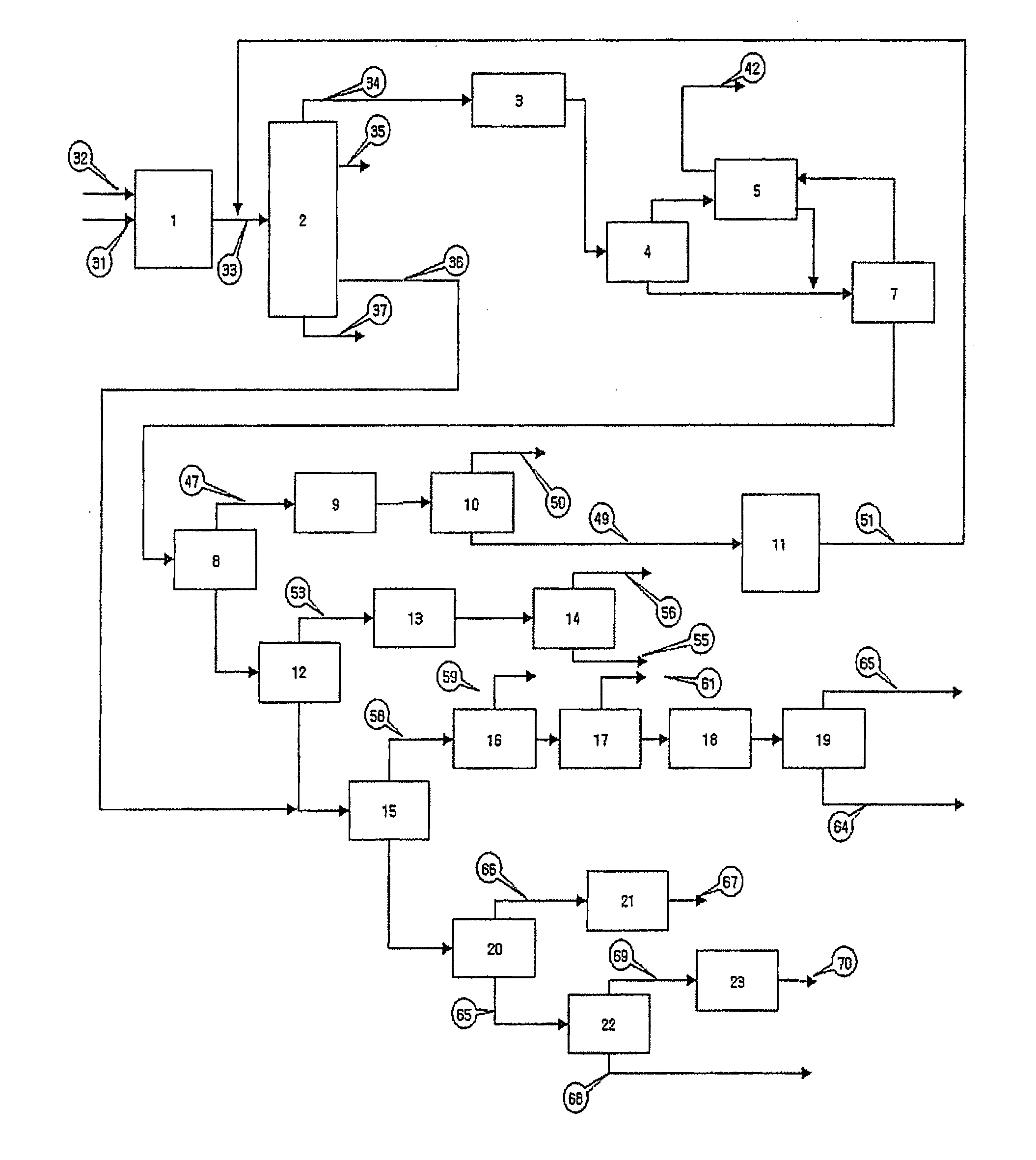

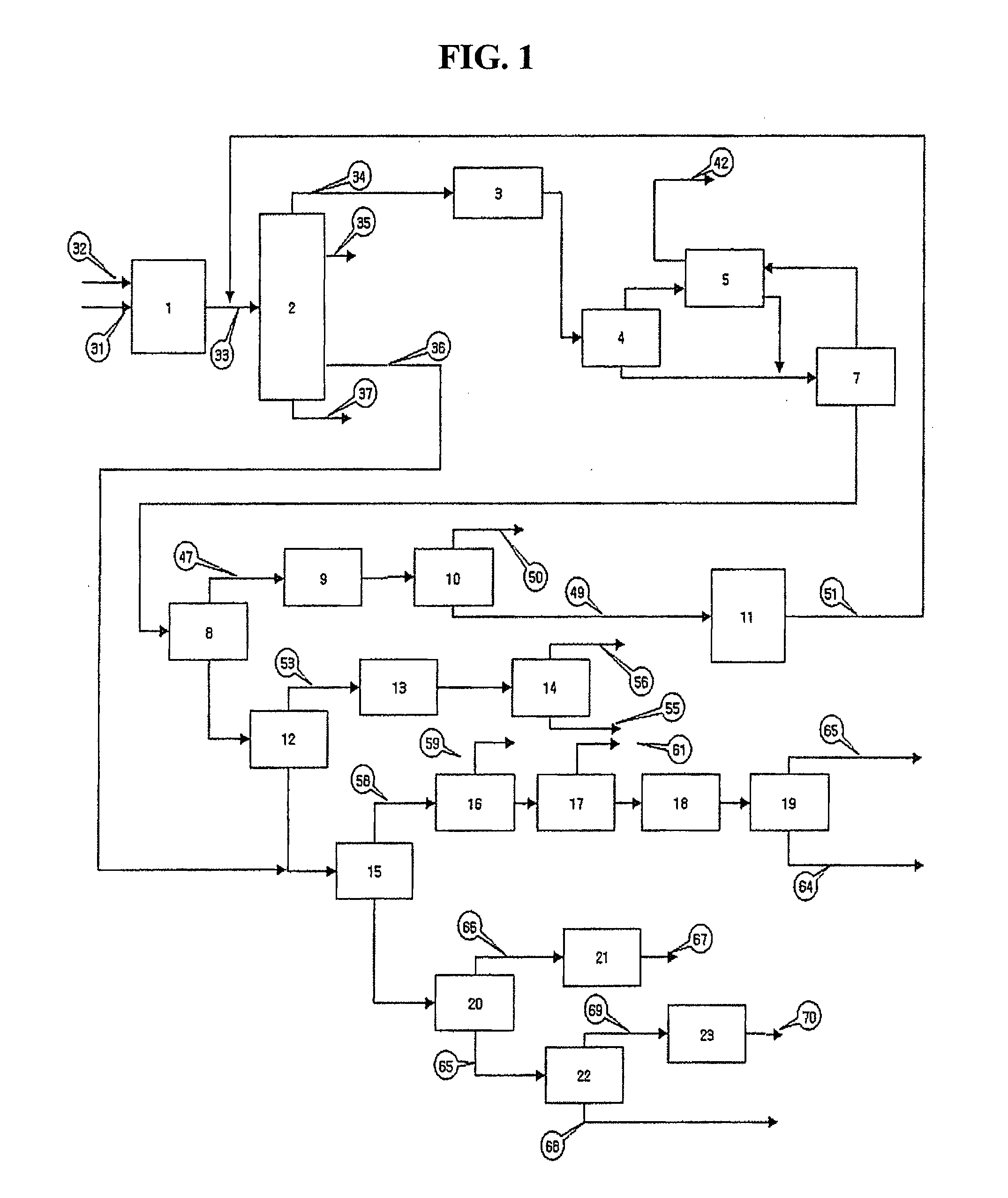

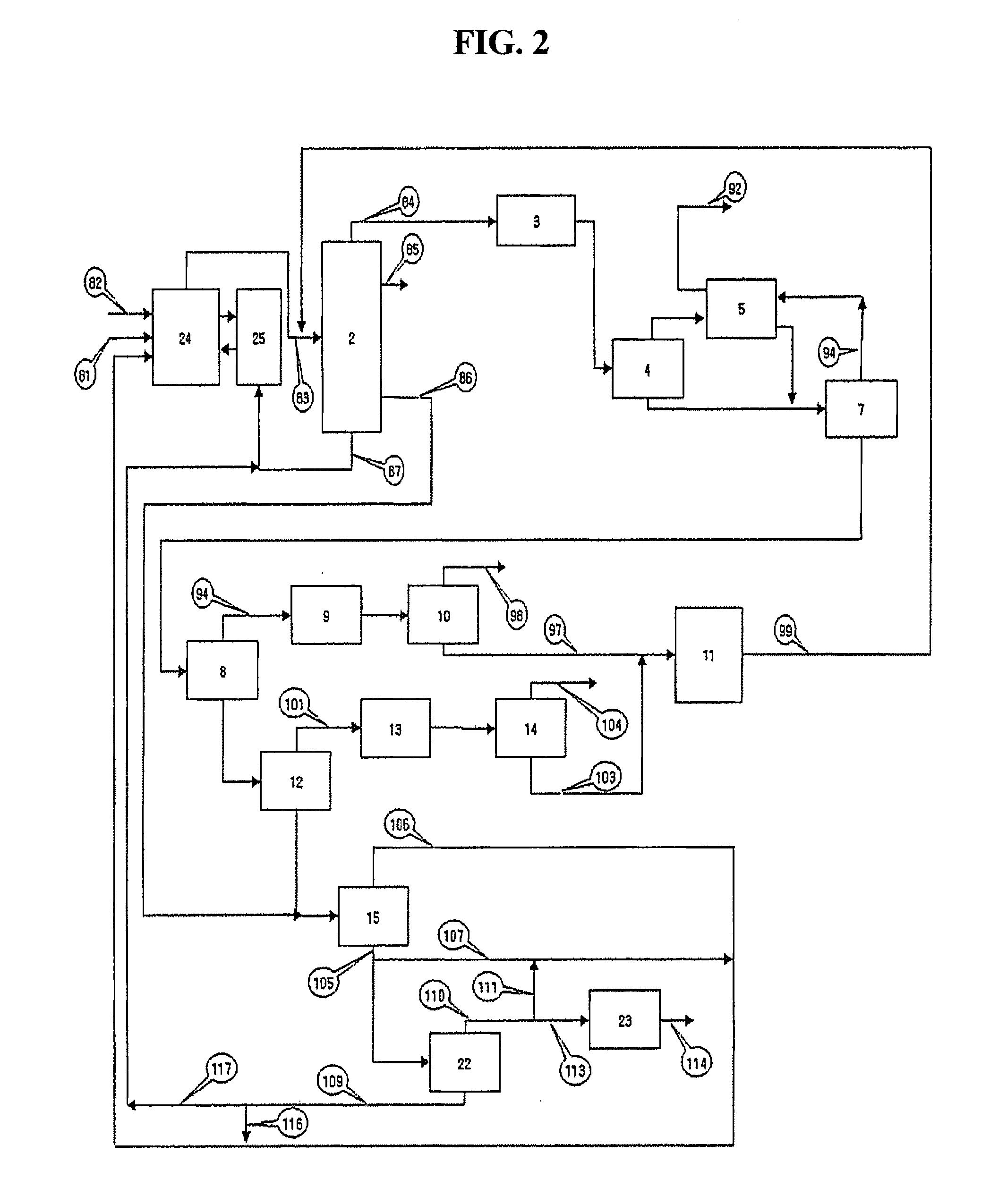

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

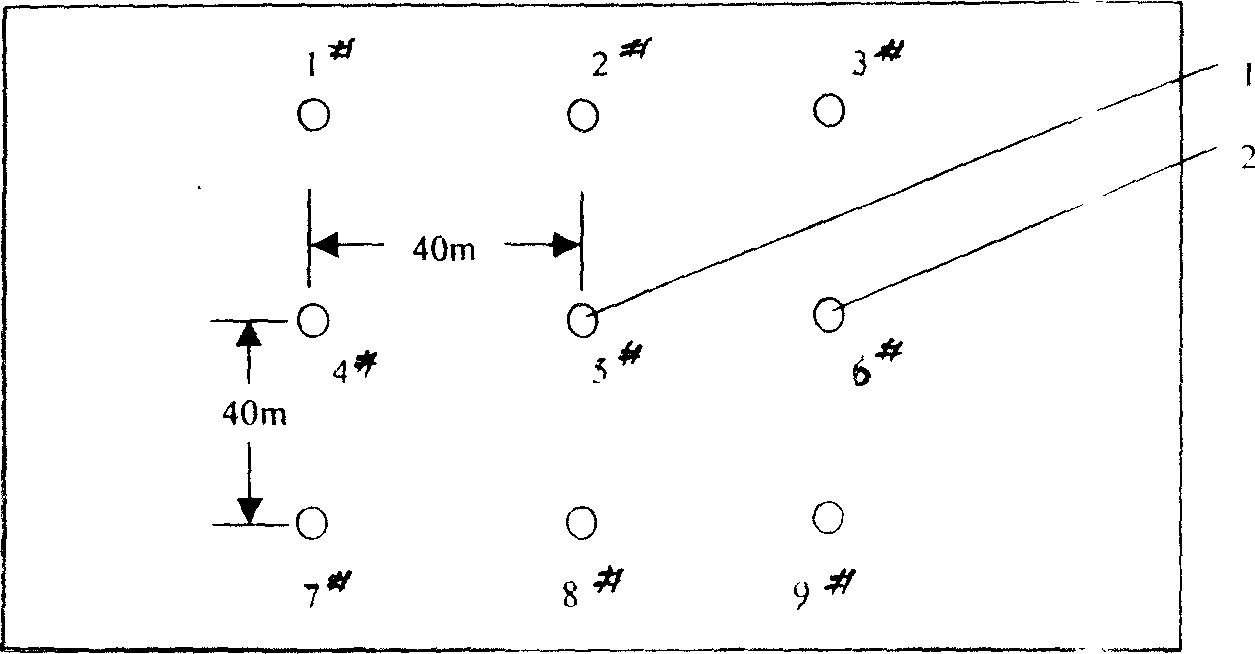

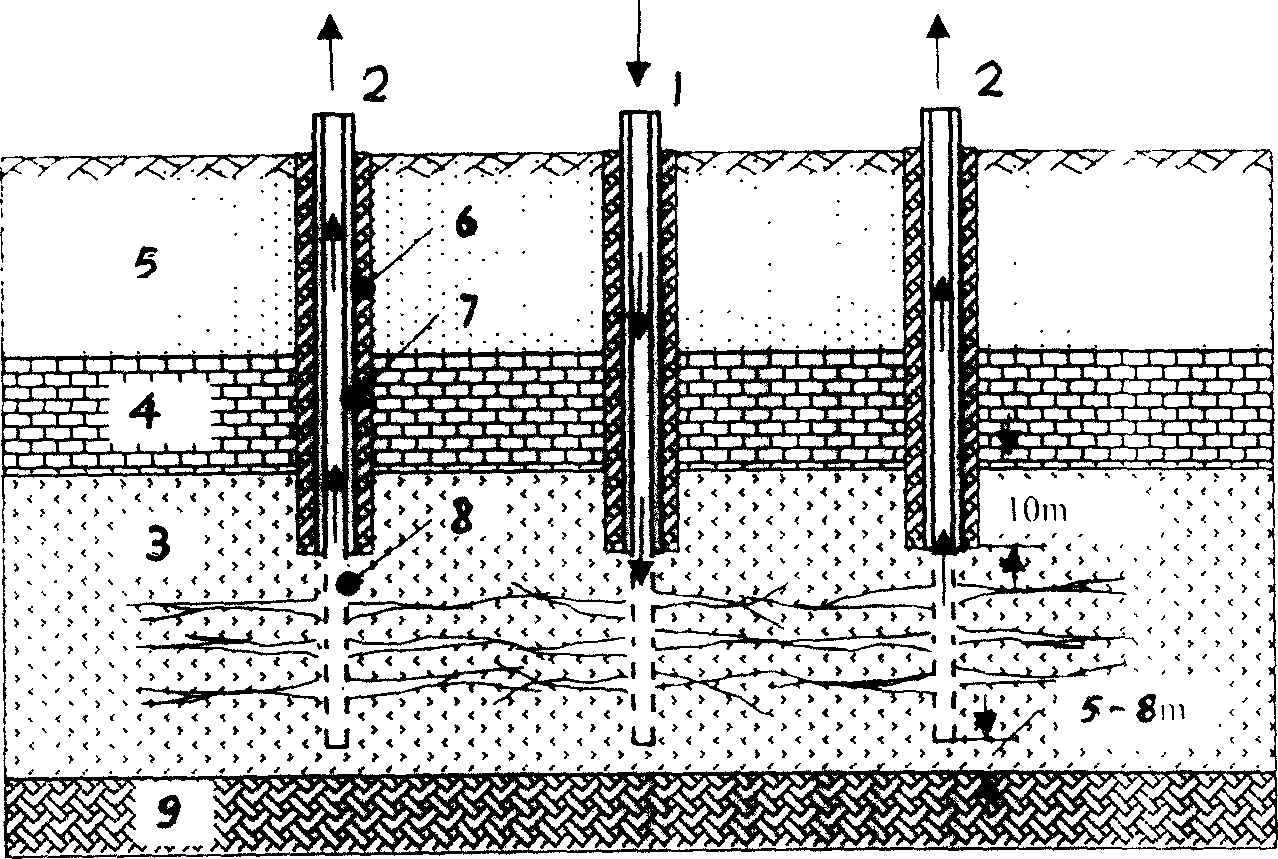

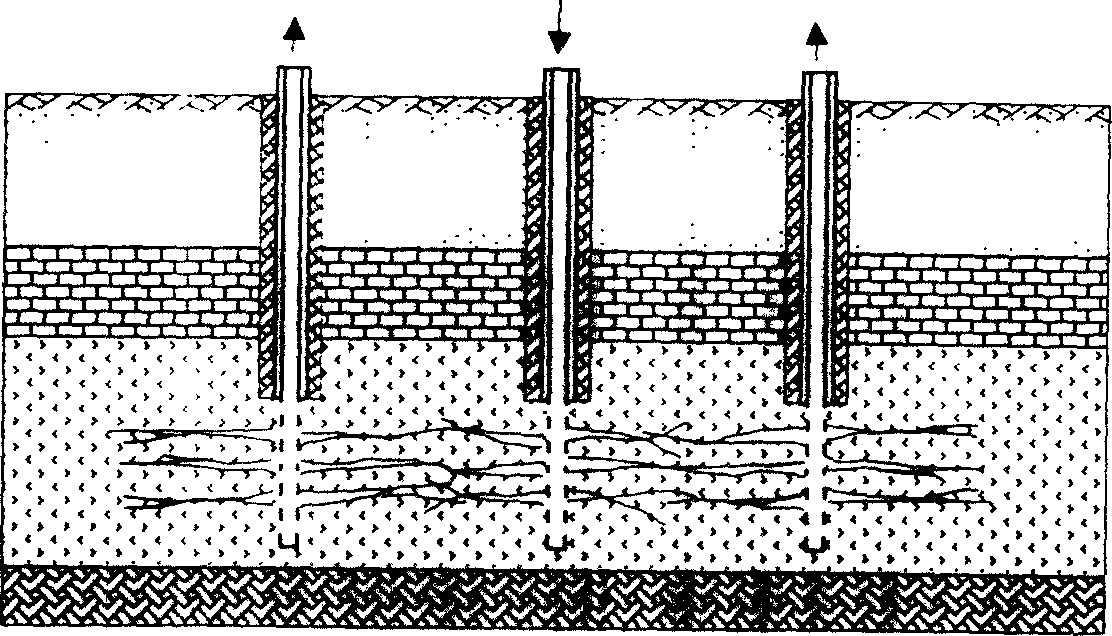

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

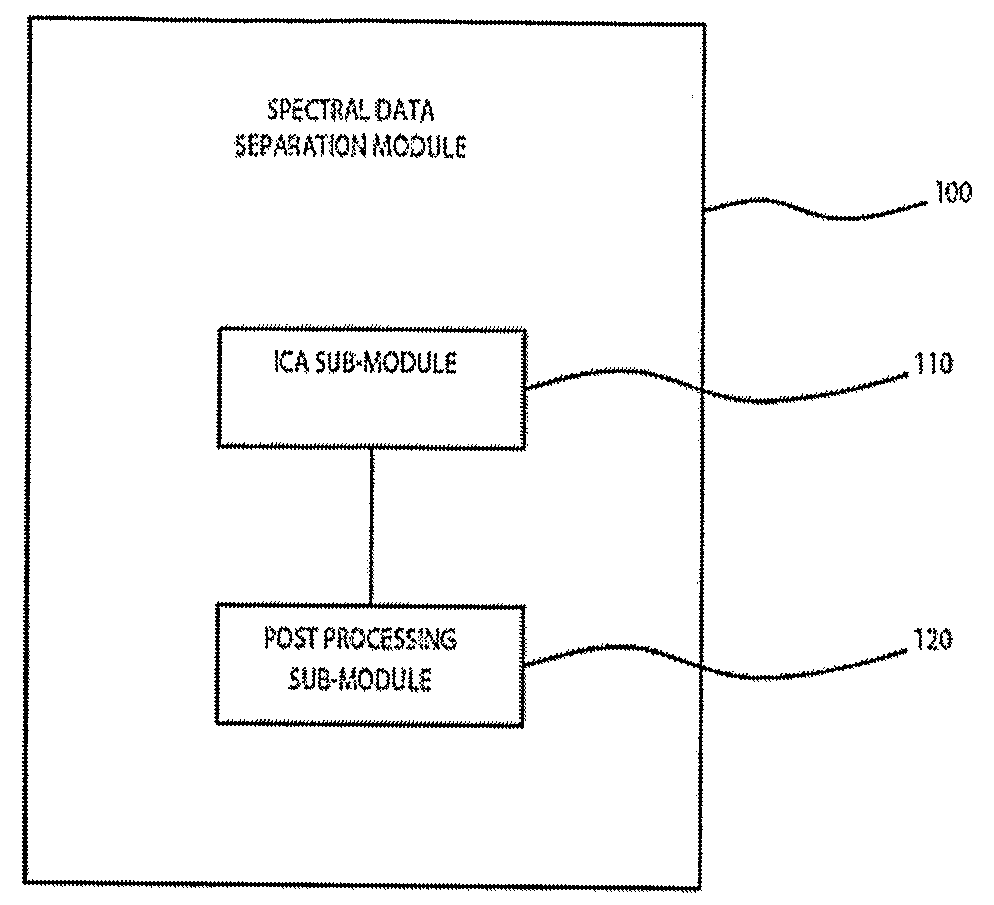

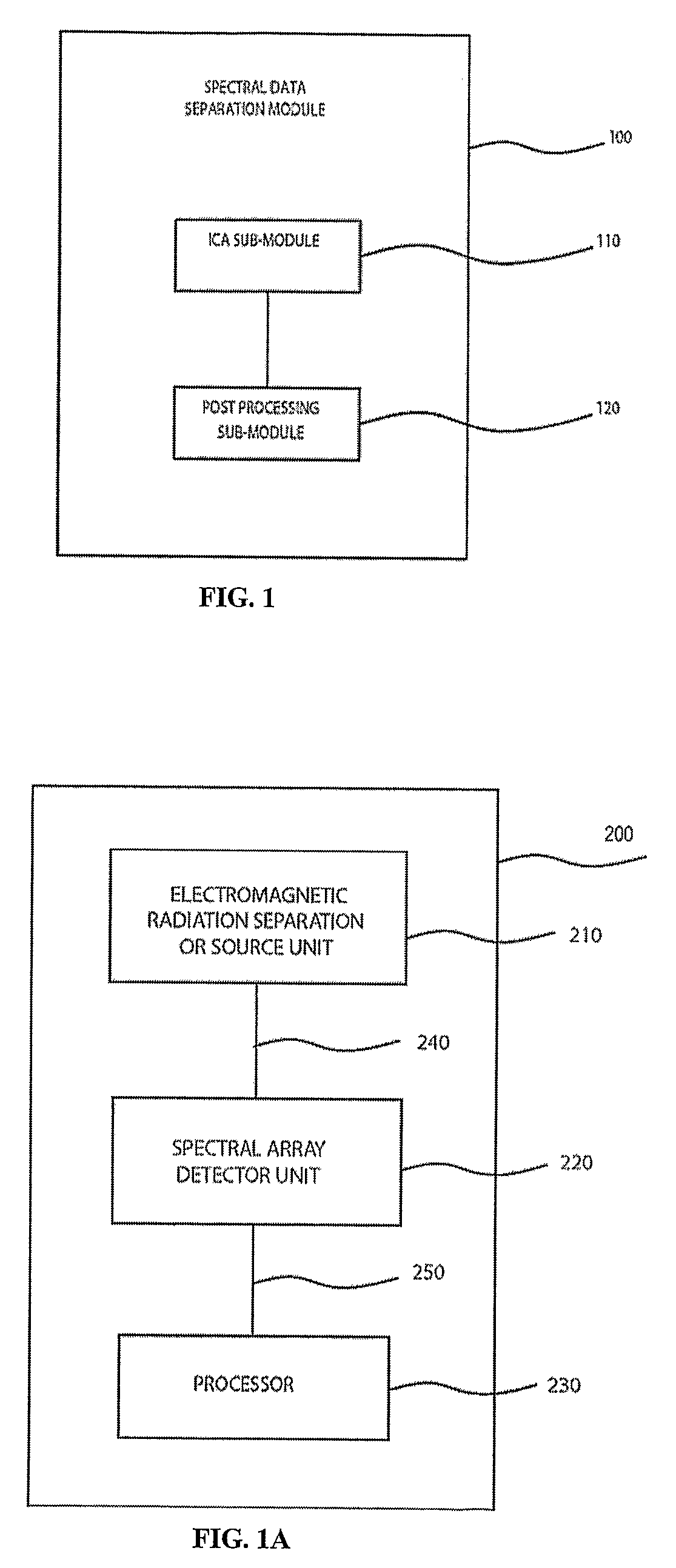

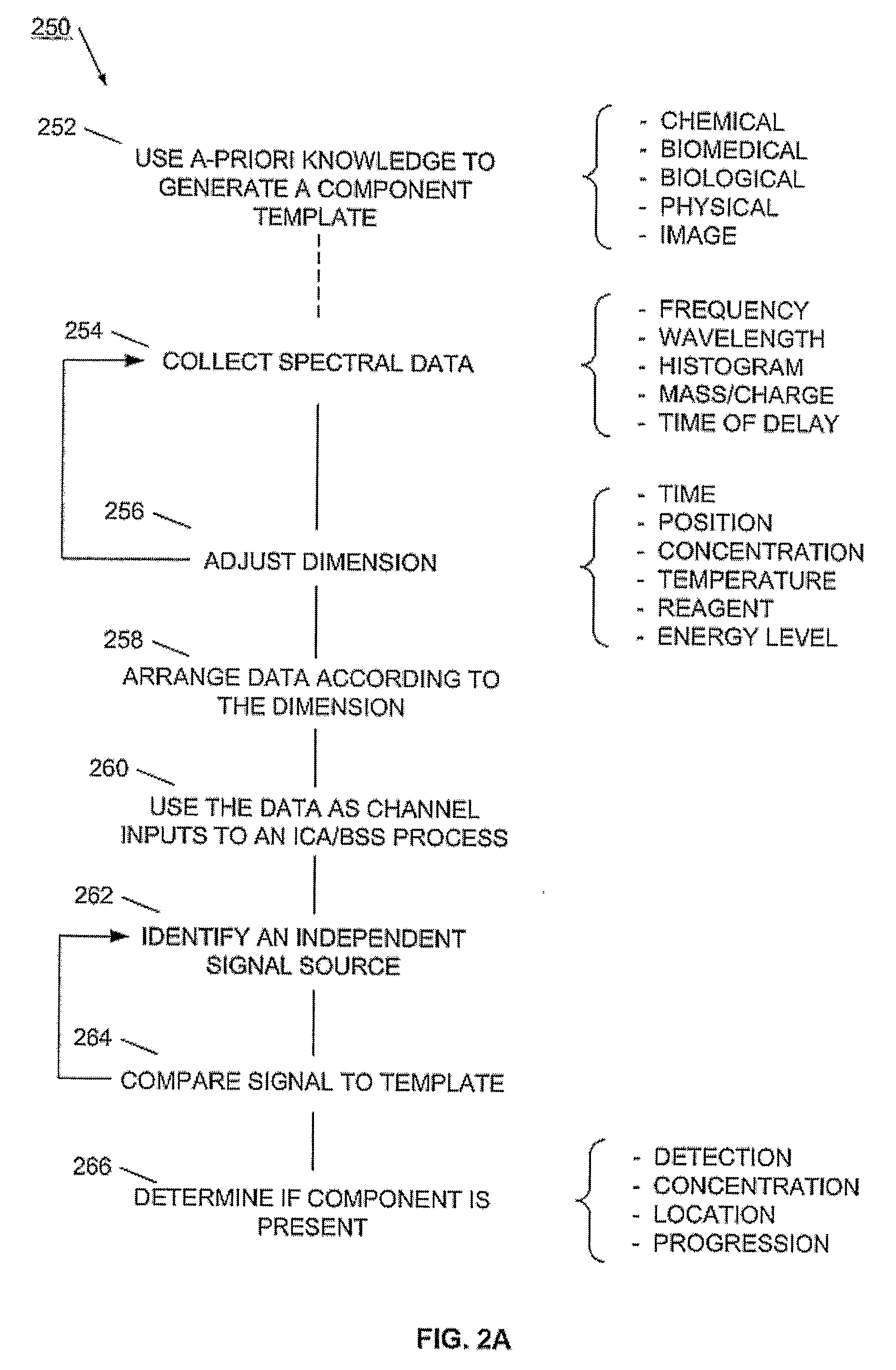

System and Method for Spectral Analysis

InactiveUS20090001262A1High detection sensitivityIncreased chemical shift dispersionIsotope separationCharacter and pattern recognitionFtir spectraIndependent component analysis

The system and method for spectral analysis uses a set of spectral data. The spectral data is arranged according to a second dimension, such as time, temperature, position, or other condition. The arranged spectral data is used in a signal separation process, such as an independent component analysis (ICA), which generates independent signals. The independent signals are then used for identifying or quantifying a target component.

Owner:SIGMED

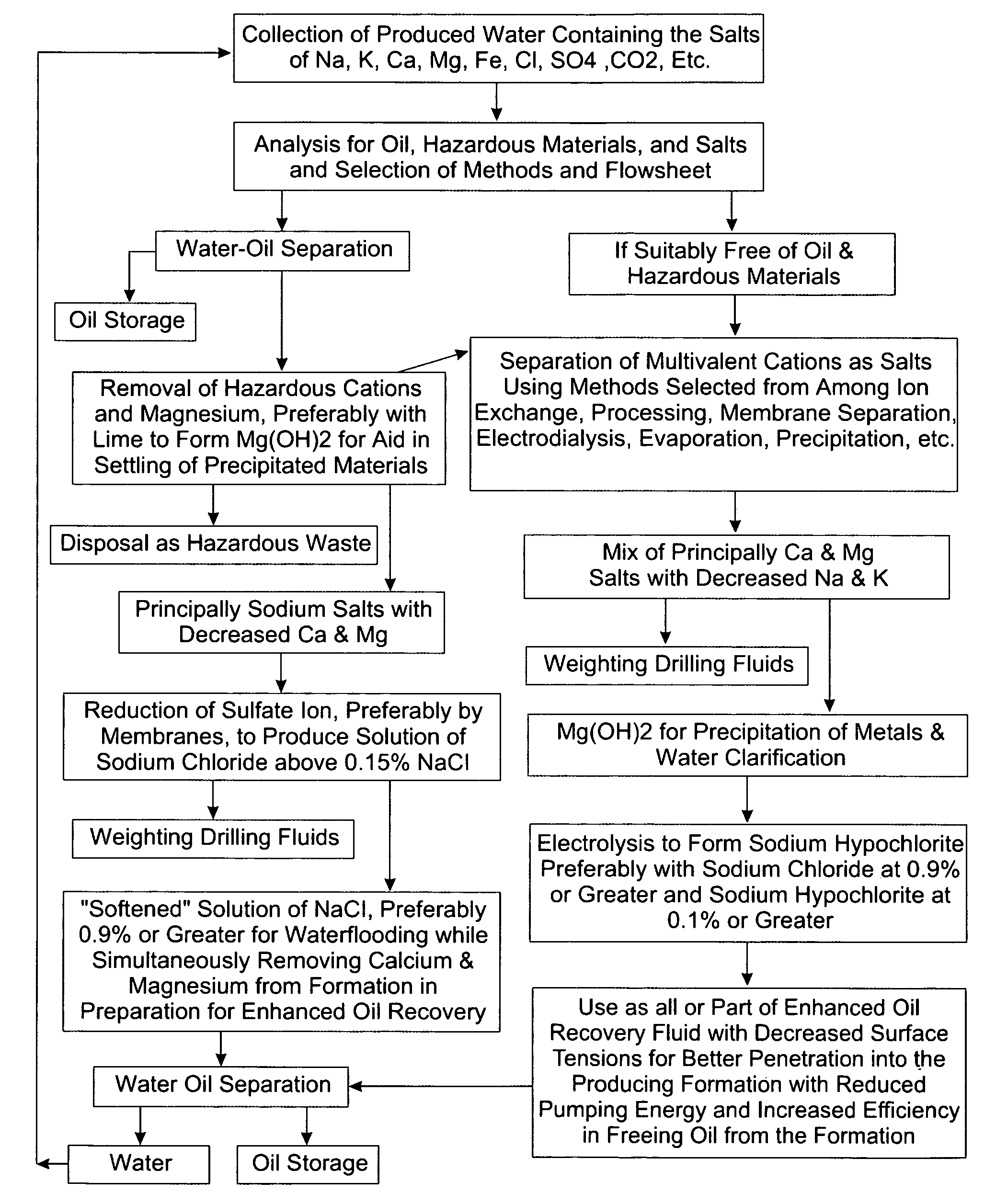

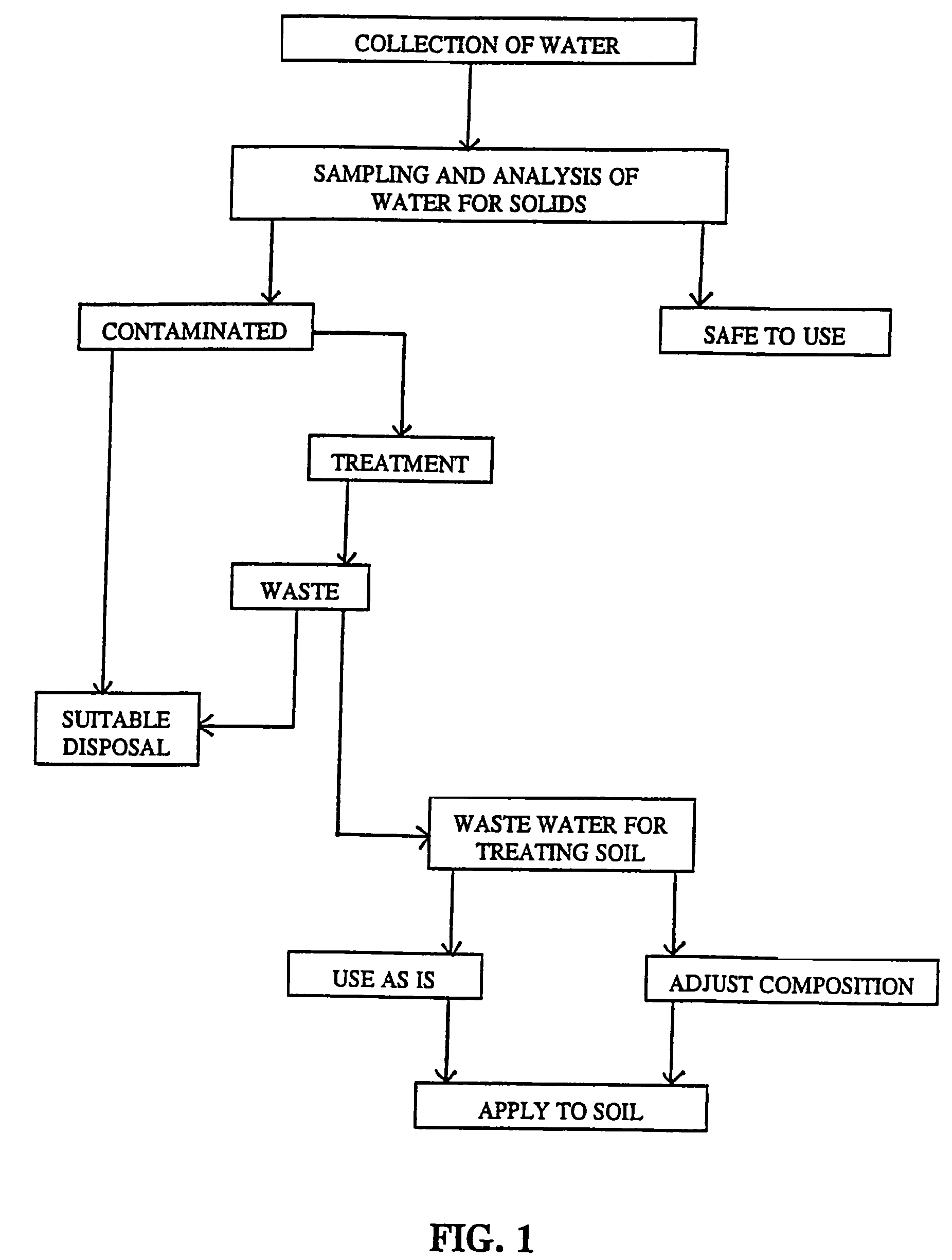

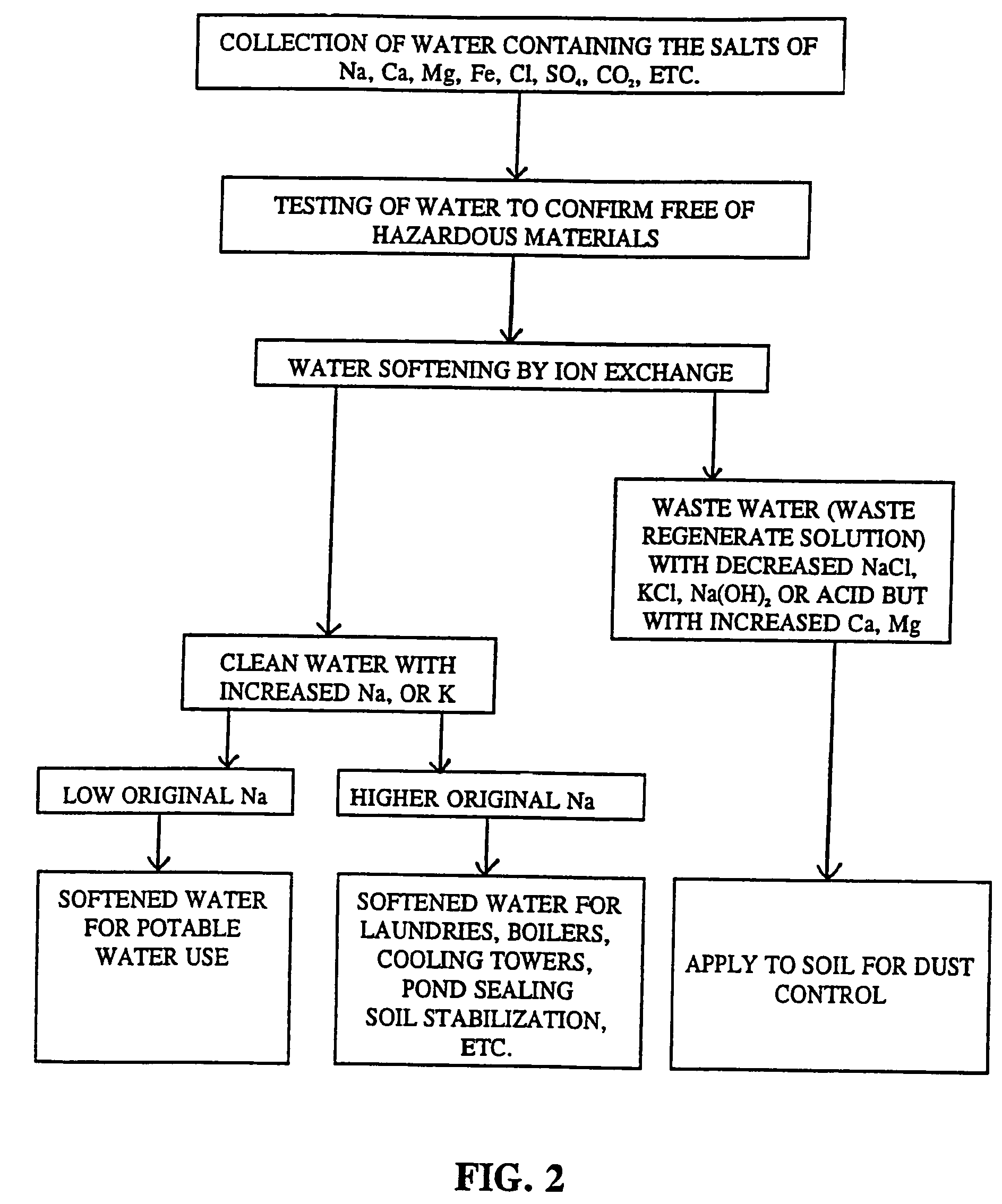

Methods of improving oil or gas production with recycled, increased sodium water

InactiveUS7717173B2Reduction tendencySpecific water treatment objectivesScale removal and water softeningLiquid productEnvironmental engineering

A method of improving oil or gas well production has the steps of (a) collecting contaminated water having 0.15% or more by weight of the salts of Na, Ca, Mg, K, Cl, SO4 or CO3 or combinations thereof (b) separation processing the contaminated water to produce i.) a first separated liquid product having increased sodium chloride and decreased magnesium chloride and calcium chloride or combinations thereof than the collected water, and ii) a second solid or liquid product having decreased sodium chloride and increased magnesium chloride and calcium chloride or combinations thereof than the collected water, and (c) injecting the first liquid product into an oil or gas well formation to improve production.

Owner:ECYCLING

Method for using magnetic particles in droplet microfluidics

Methods of utilizing magnetic particles or beads (MBs) in droplet-based (or digital) microfluidics are disclosed. The methods may be used in enrichment or separation processes. A first method employs the droplet meniscus to assist in the magnetic collection and positioning of MBs during droplet microfluidic operations. The sweeping movement of the meniscus lifts the MBs off the solid surface and frees them from various surface forces acting on the MBs. A second method uses chemical additives to reduce the adhesion of MBs to surfaces. Both methods allow the MBs on a solid surface to be effectively moved by magnetic force. Droplets may be driven by various methods or techniques including, for example, electrowetting, electrostatic, electromechanical, electrophoretic, dielectrophoretic, electroosmotic, thermocapillary, surface acoustic, and pressure.

Owner:RGT UNIV OF CALIFORNIA

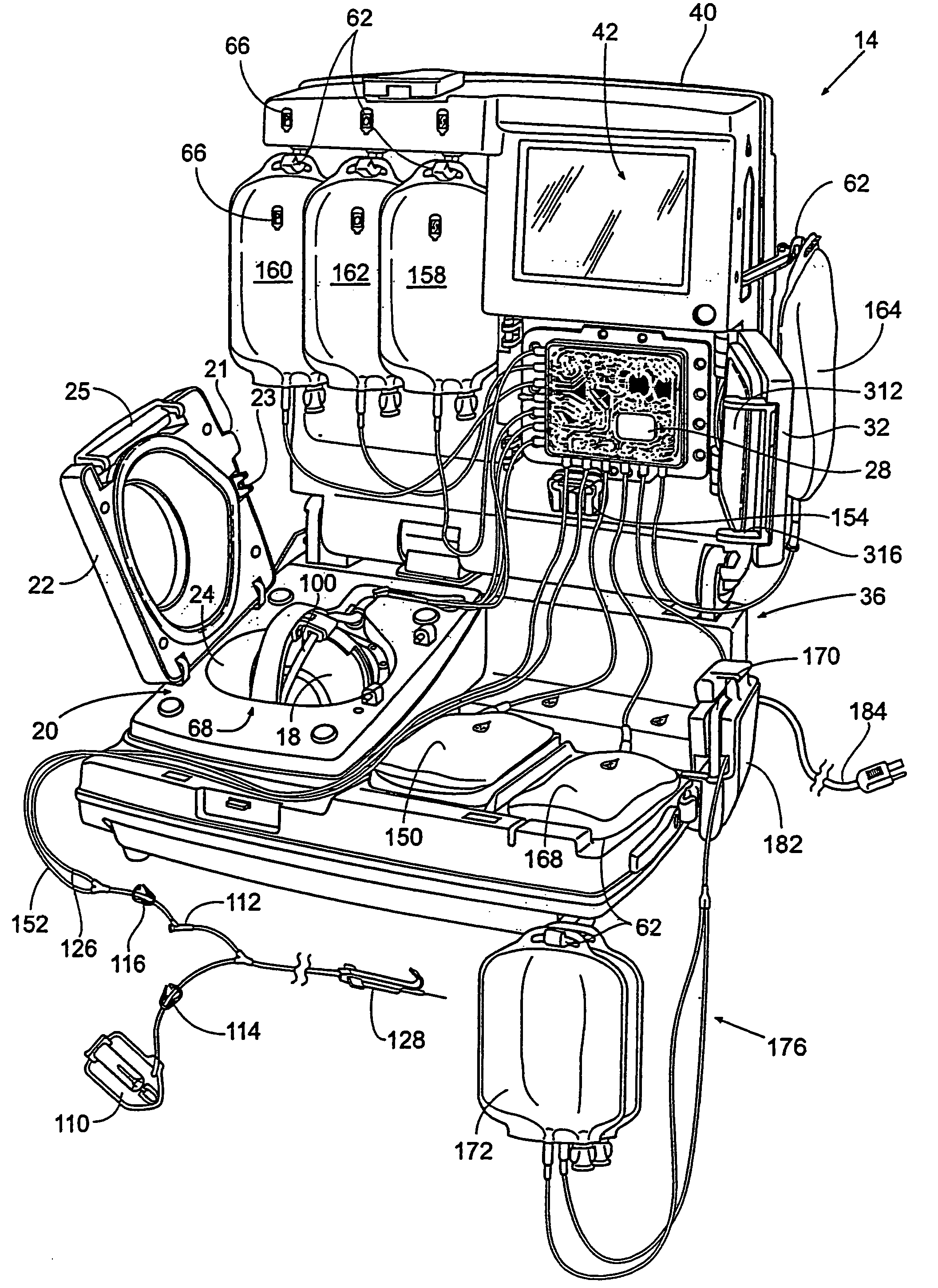

Red blood cell processing systems and methods which control red blood cell hematocrit

InactiveUS7011761B2Optimize procedure timeAvoid adjustmentLiquid separation auxillary apparatusWater/sewage treatment by centrifugal separationMedicineHandling system

Processing systems and methods comprise a separation device that, in use, performs a separation process including separation of red blood cells from blood or a suspension containing red blood cells. The systems and methods include an outlet line coupled to the separation device to remove red blood cells from the separation device, at least in part, while the separation process occurs. A sensor associated with the outlet line senses hematocrit of red blood cells removed from the separation device and generates a sensed hematocrit output. A controller is coupled to the separation device to control removal of red blood cells from the separation device based, at least in part, upon the sensed hematocrit output.

Owner:FENWAL

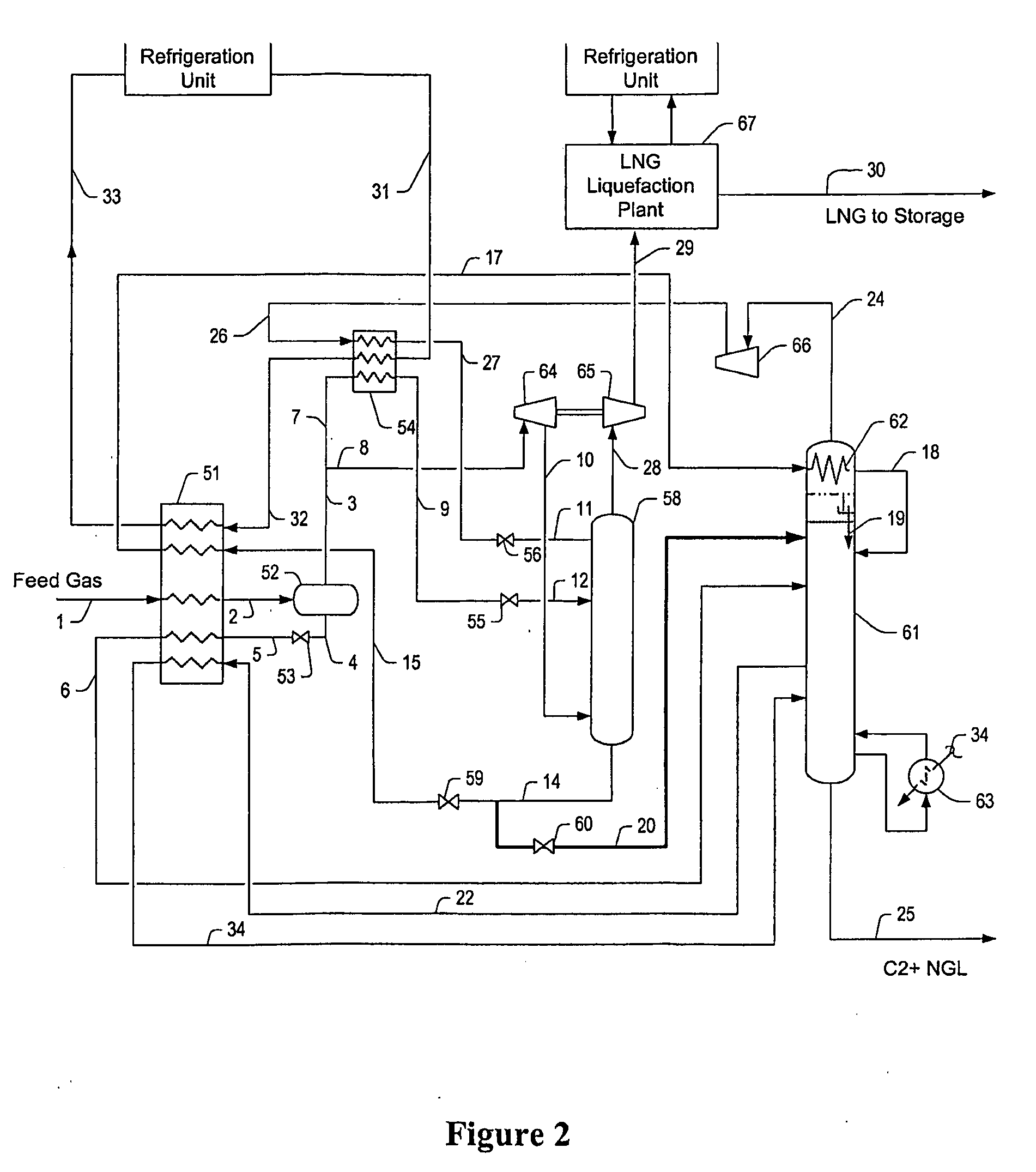

Intergrated Ngl Recovery and Lng Liquefaction

Contemplated plants include a refluxed absorber and a distillation column, wherein the absorber is operated at a higher pressure than the distillation column to thereby produce a cryogenic pressurized lean gas. The lean gas is further compressed to a pressure suitable for liquefaction using energy from feed gas vapor expansion. Desired separation of C2 products is ensured by temperature control of the absorber and distillation column using flow ratios of various streams within the plant, and by dividing the separation process into two portions at different pressures.

Owner:FLUOR TECH CORP

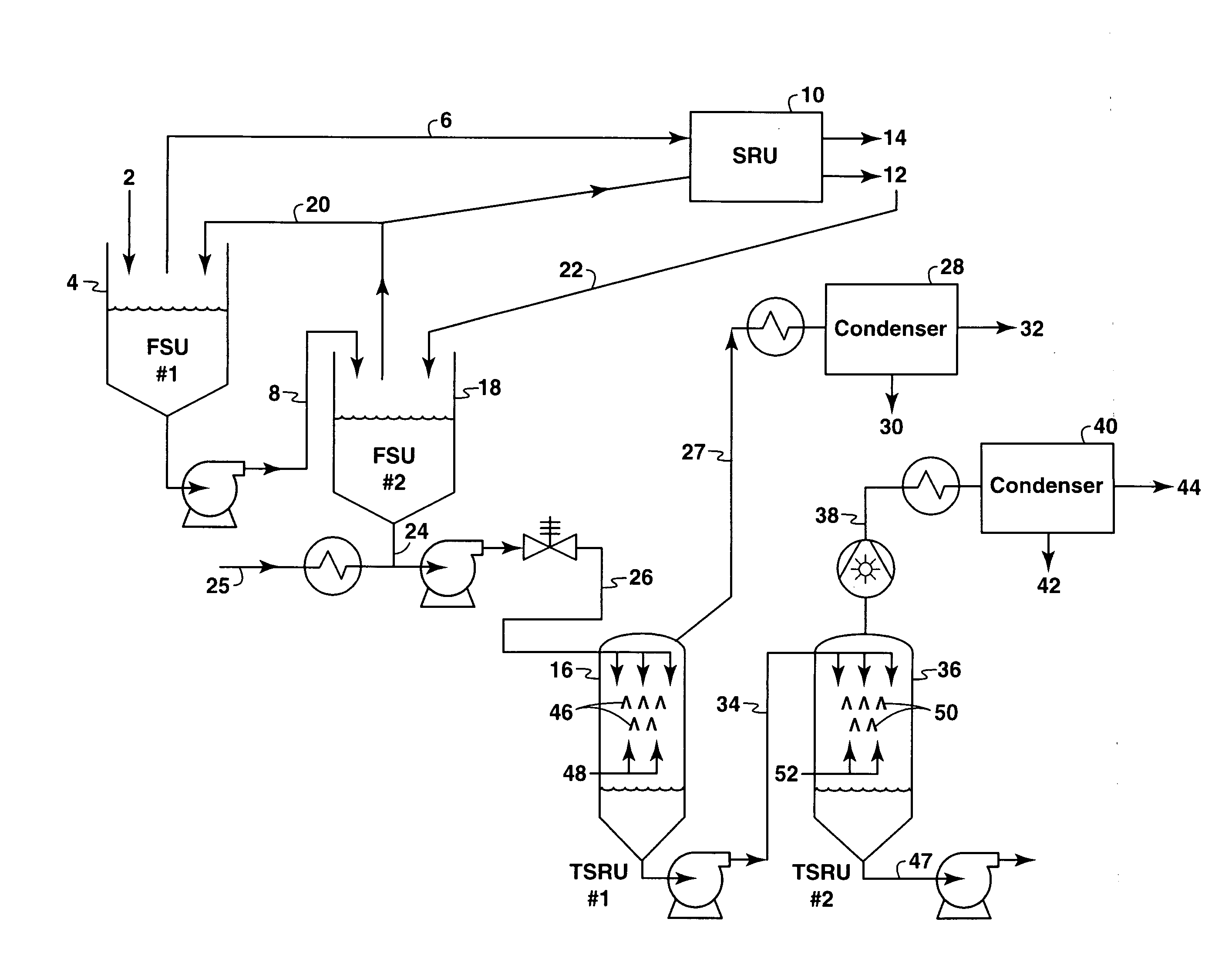

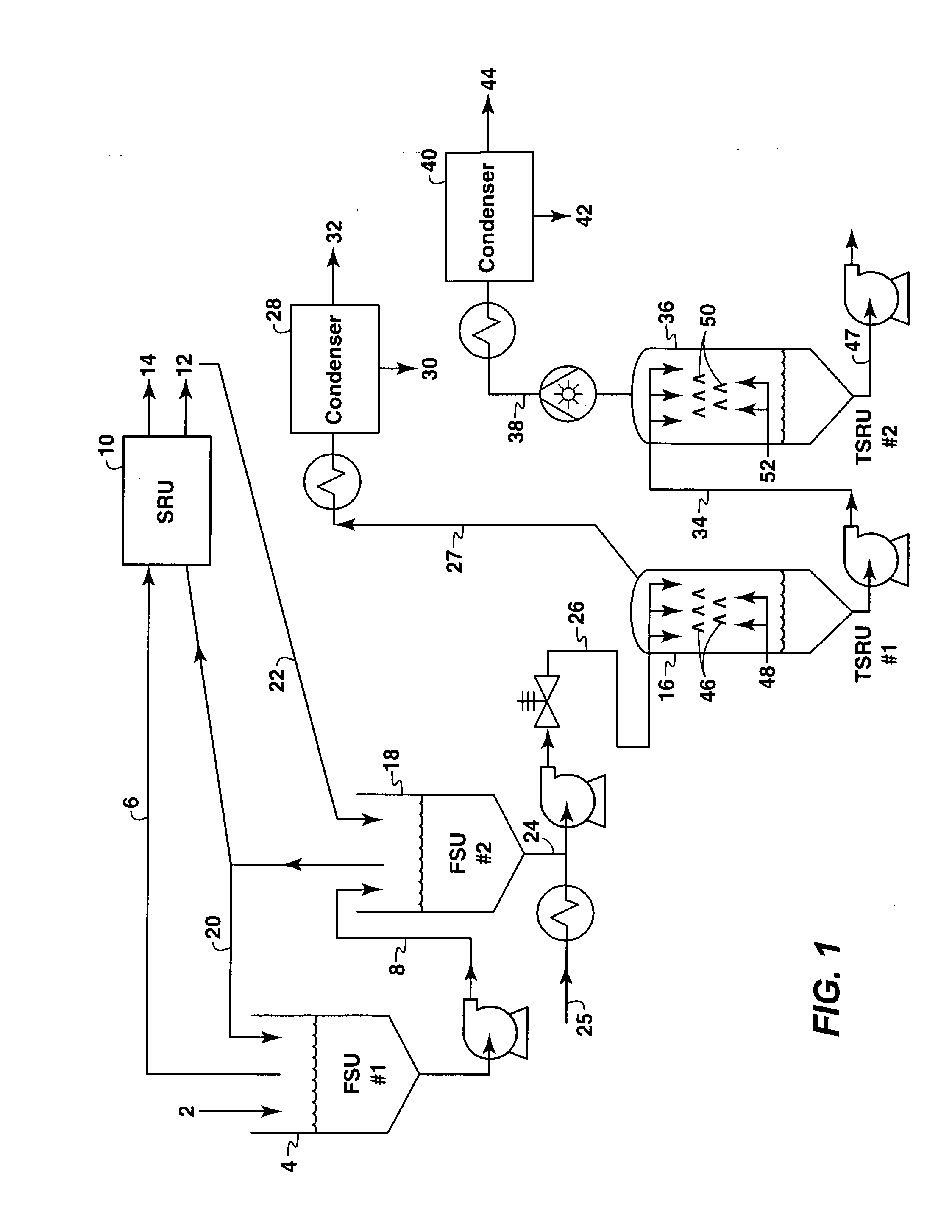

Process For Recovering Solvent From Ashphaltene Containing Tailings Resulting From A Separation Process

InactiveUS20100126906A1Liquid hydrocarbon mixture productionPetroleum wax recoveryVaporizationSolvent

A process for recovering paraffinic solvent from tailings produced in the treatment of bitumen froth comprising introducing the tailings into a tailings solvent recovery unit (TSRU), the TSRU having internals, and distributing the tailings over the internals. An inert gas or steam is then introduced below the internals and above the liquid pool for enhancing the vaporization of the contained solvent. Solvent is vaporized from asphaltene agglomerates. In one embodiment, the process is affected in the absence of mechanical means used to substantially break up asphaltene agglomerates or to prevent the agglomeration of asphaltene. In another aspect, the process comprises introducing the tailings into a first TSRU as described above and then into a second TSRU operated at a lower pressure. In another aspect, internals are optionally present and steam or inert gas is injected in the liquid pool.

Owner:EXXONMOBIL UPSTREAM RES CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com