Patents

Literature

3028results about How to "Continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

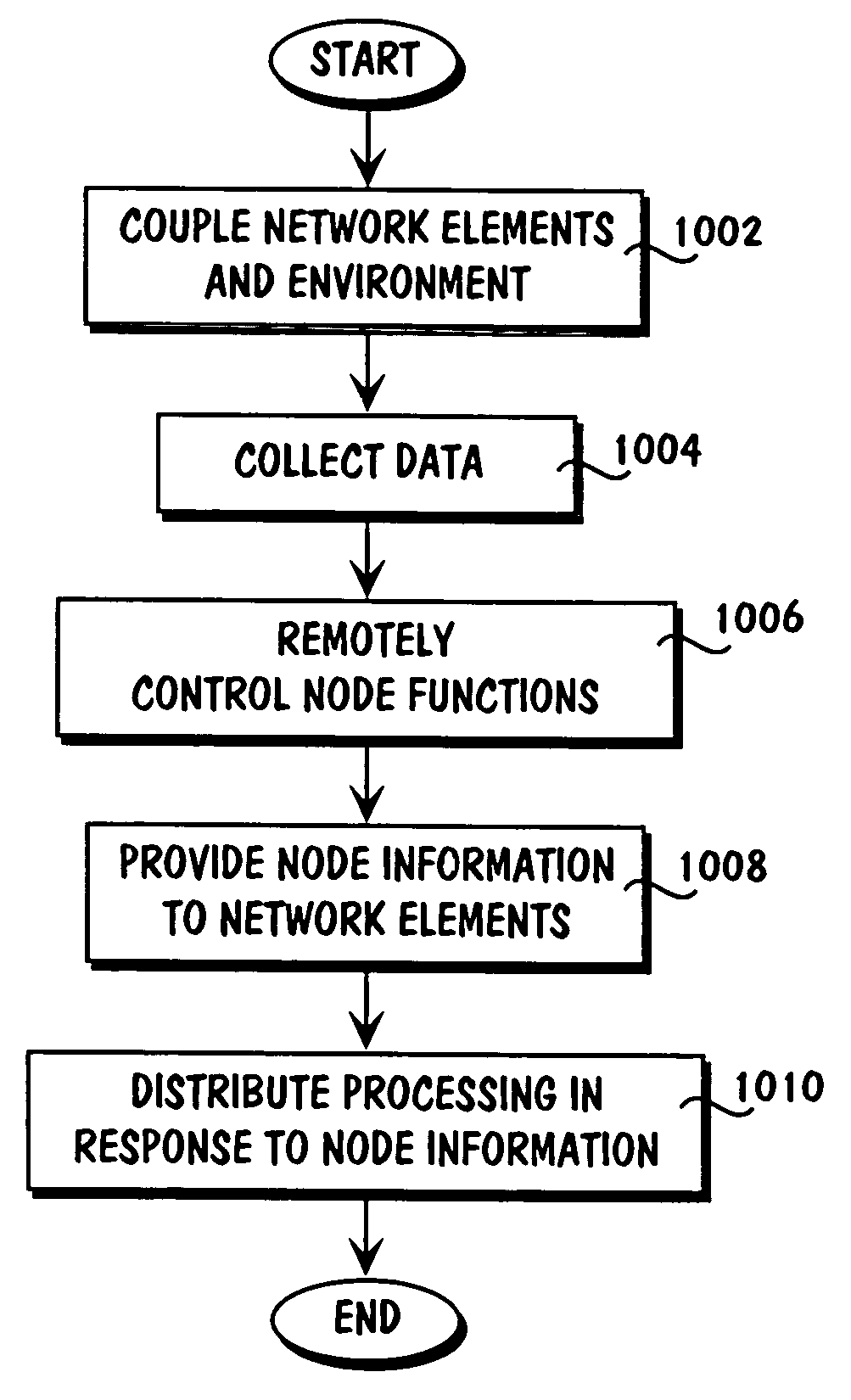

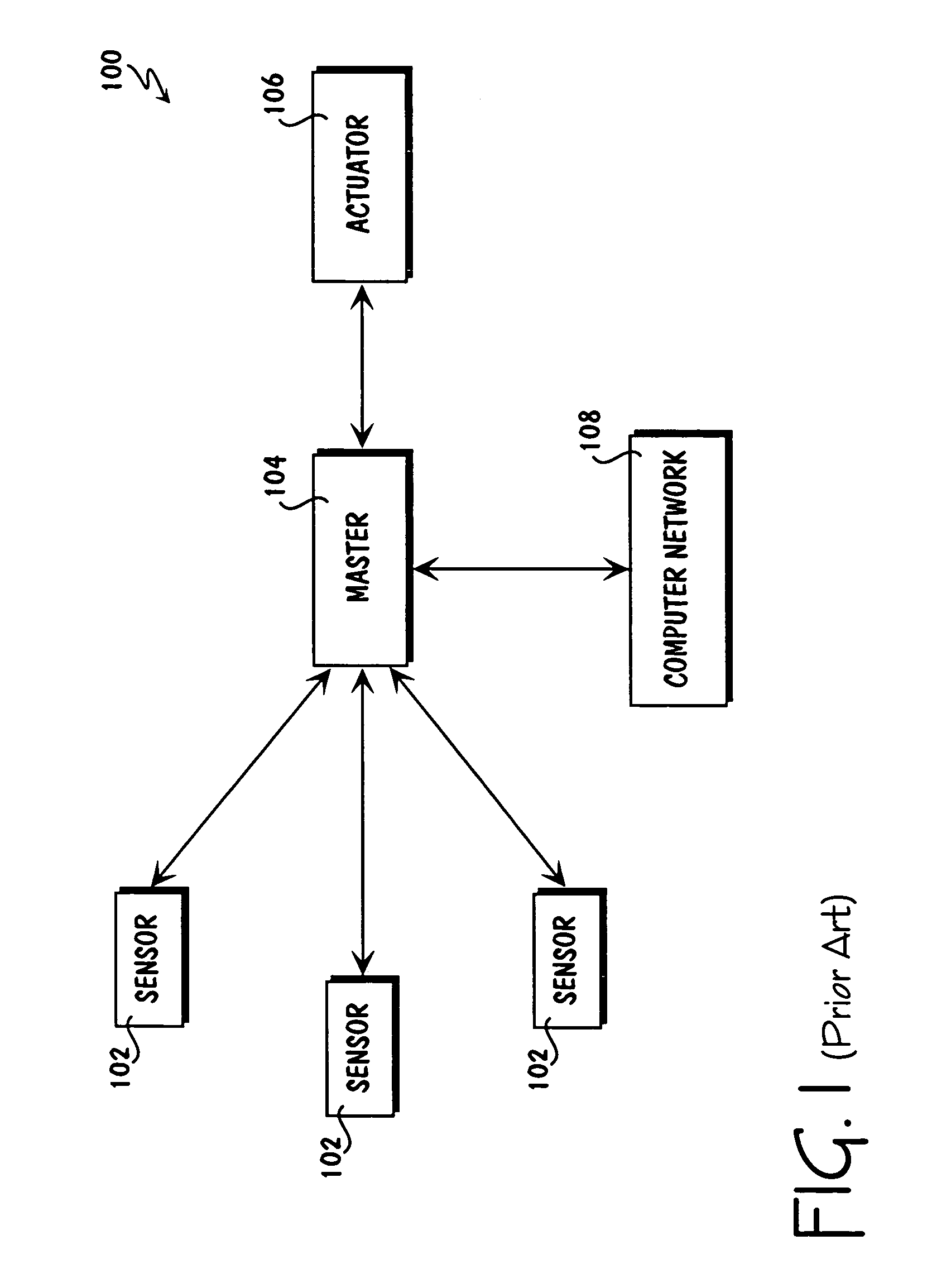

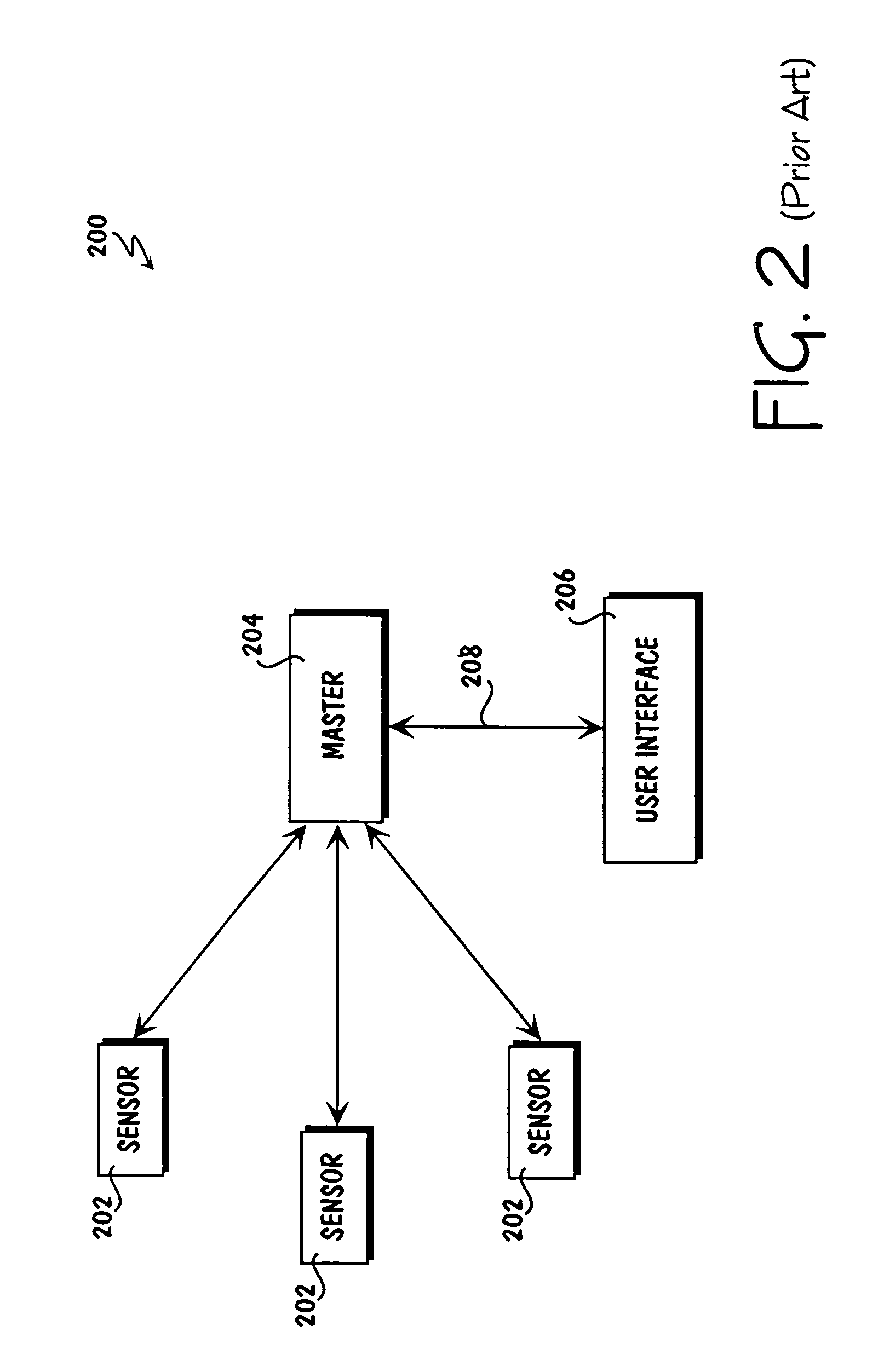

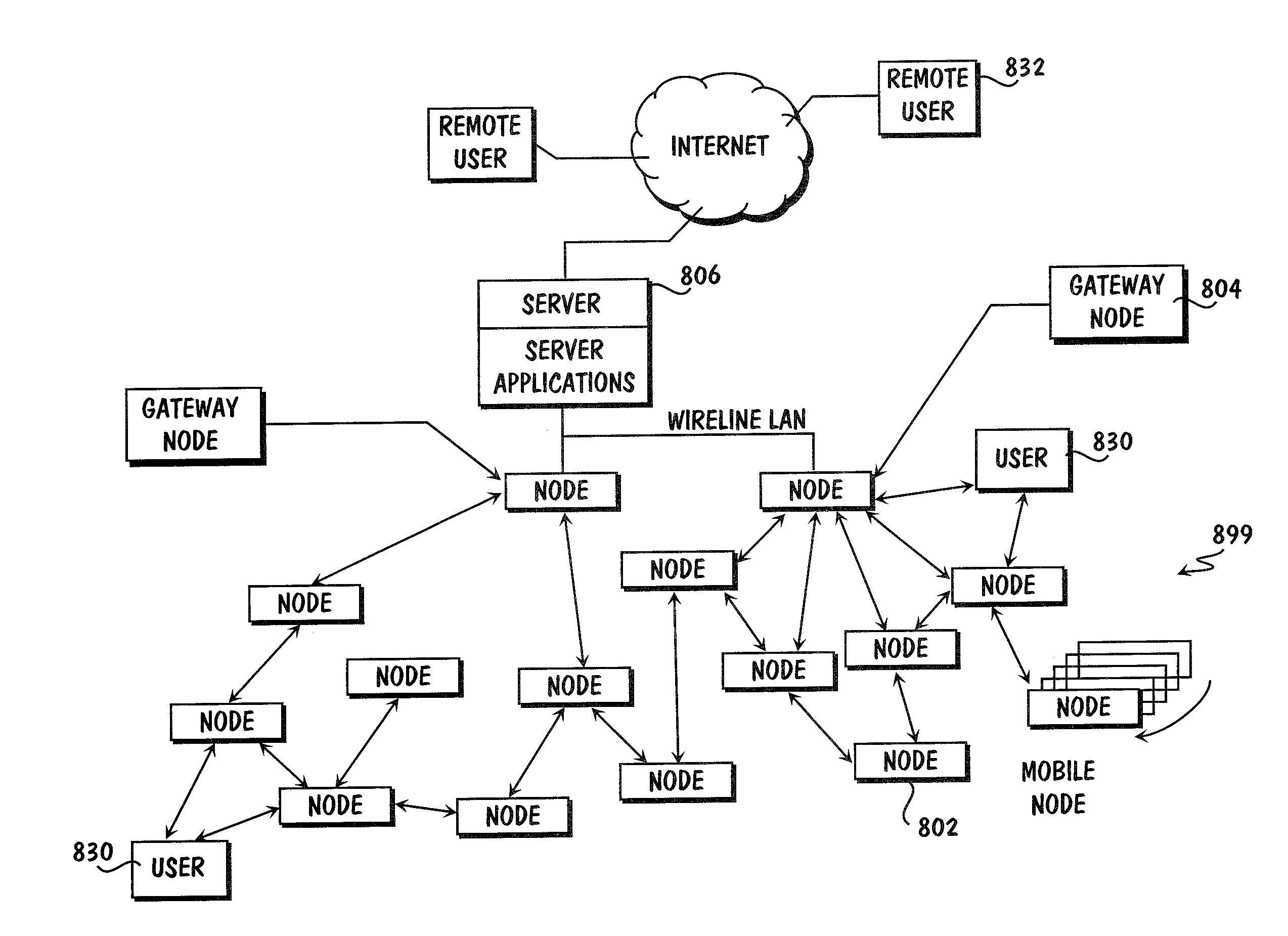

Method for collecting and processing data using internetworked wireless integrated network sensors (WINS)

InactiveUS7020701B1High reliability accessEasy to operateEnergy efficient ICTPower managementReconfigurabilityMonitoring and control

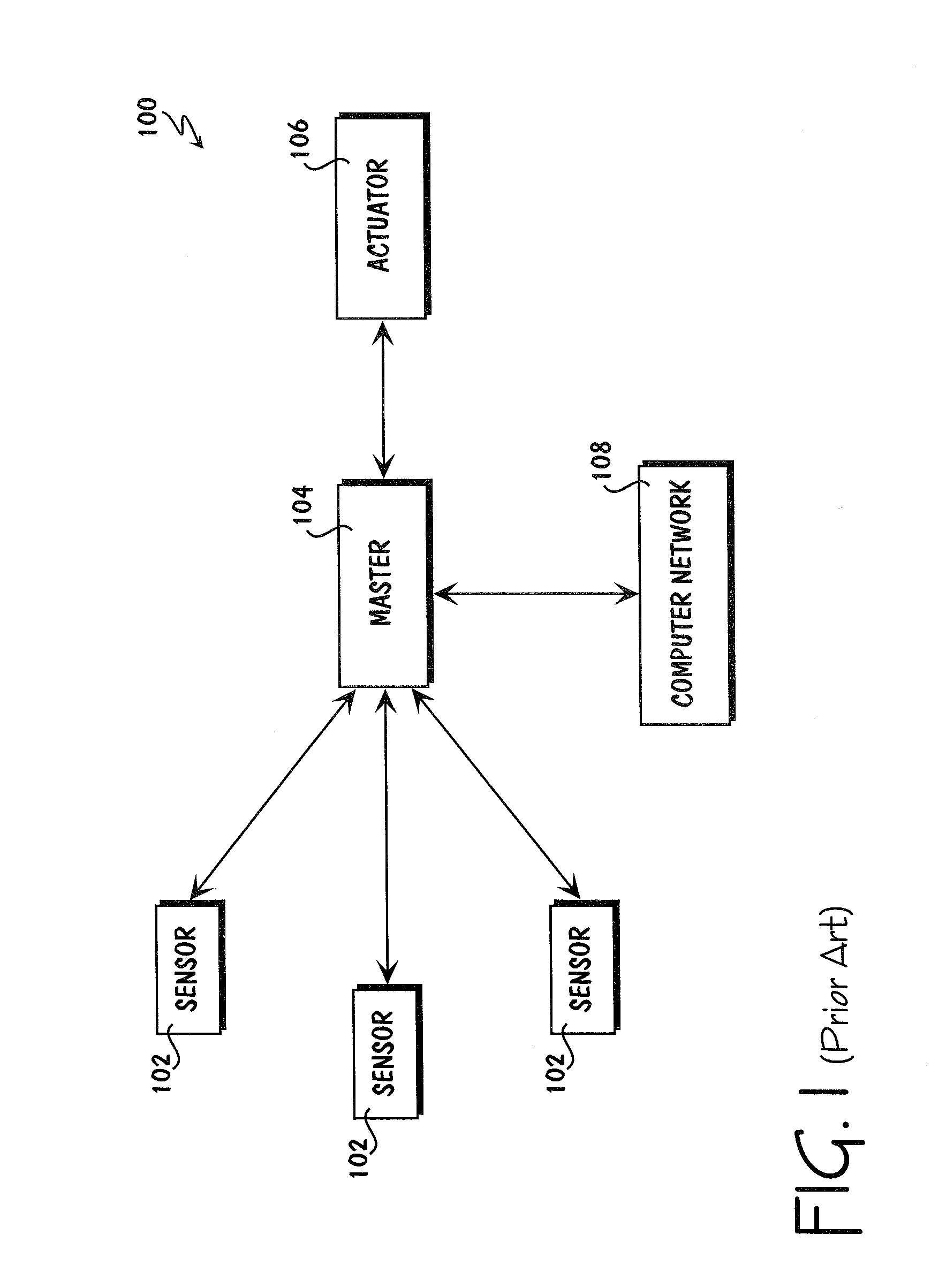

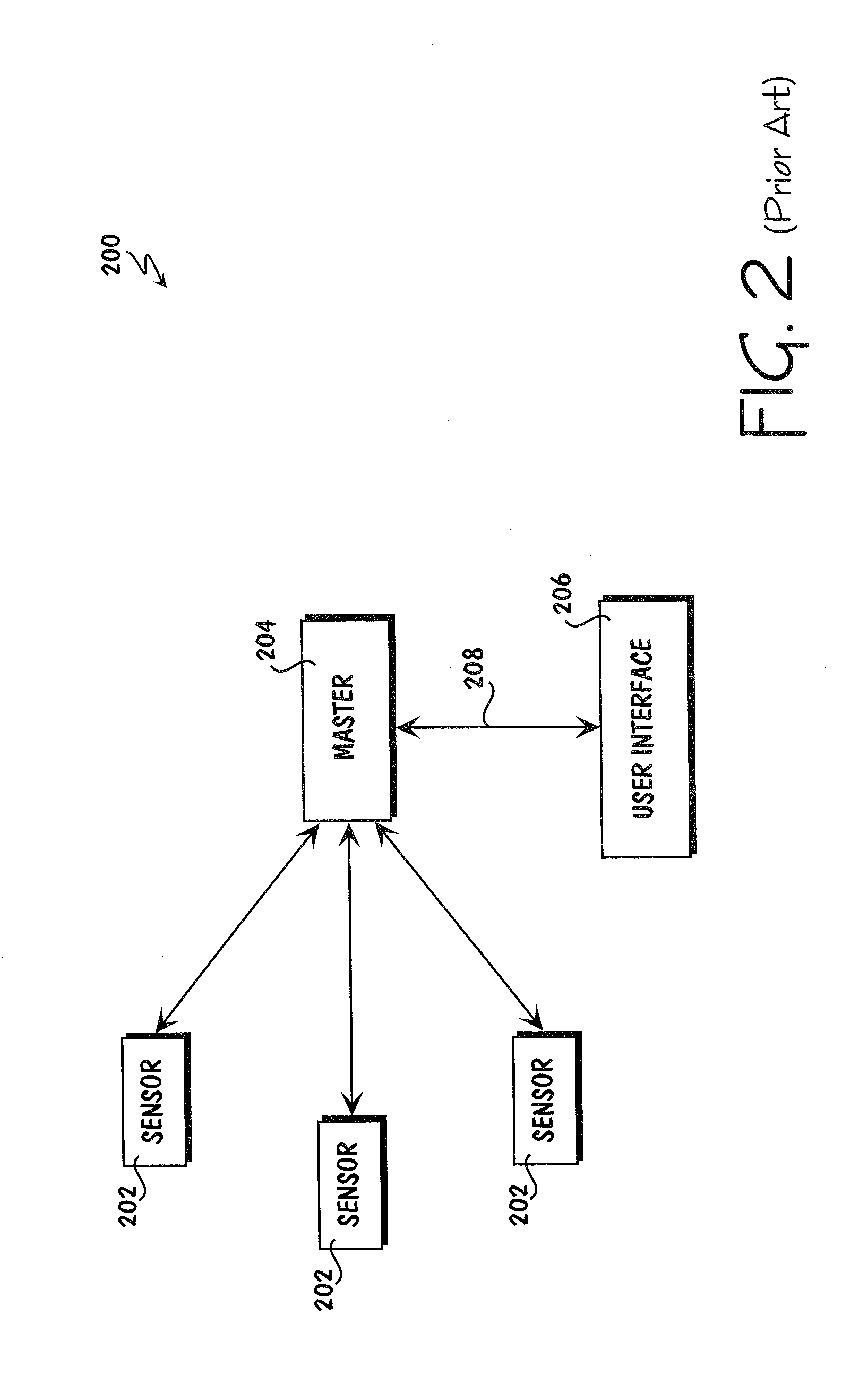

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

Apparatus for internetworked wireless integrated network sensors (WINS)

InactiveUS20100148940A1High reliability accessEasy to operateAntenna supports/mountingsDigital computer detailsReconfigurabilityMonitoring and control

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

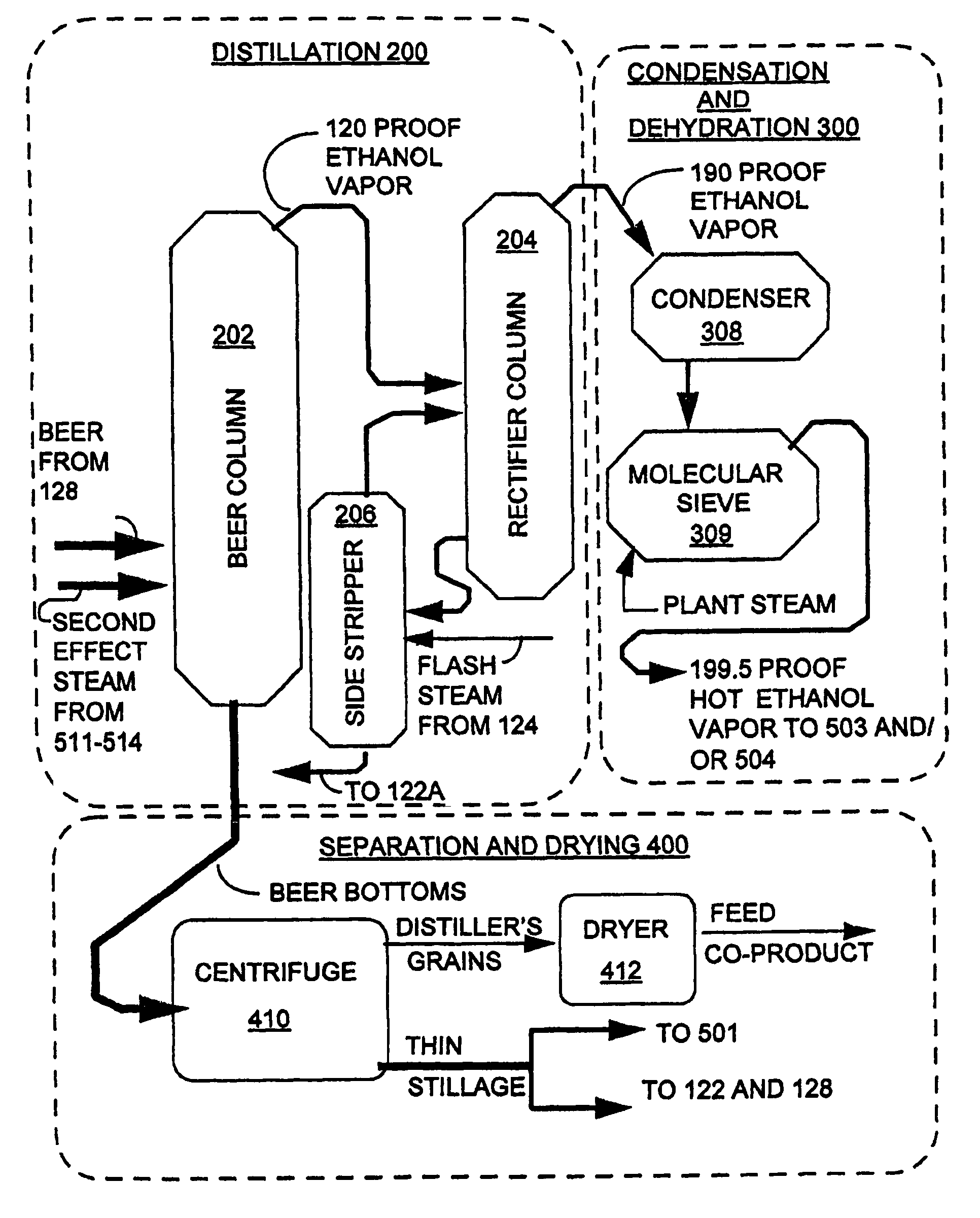

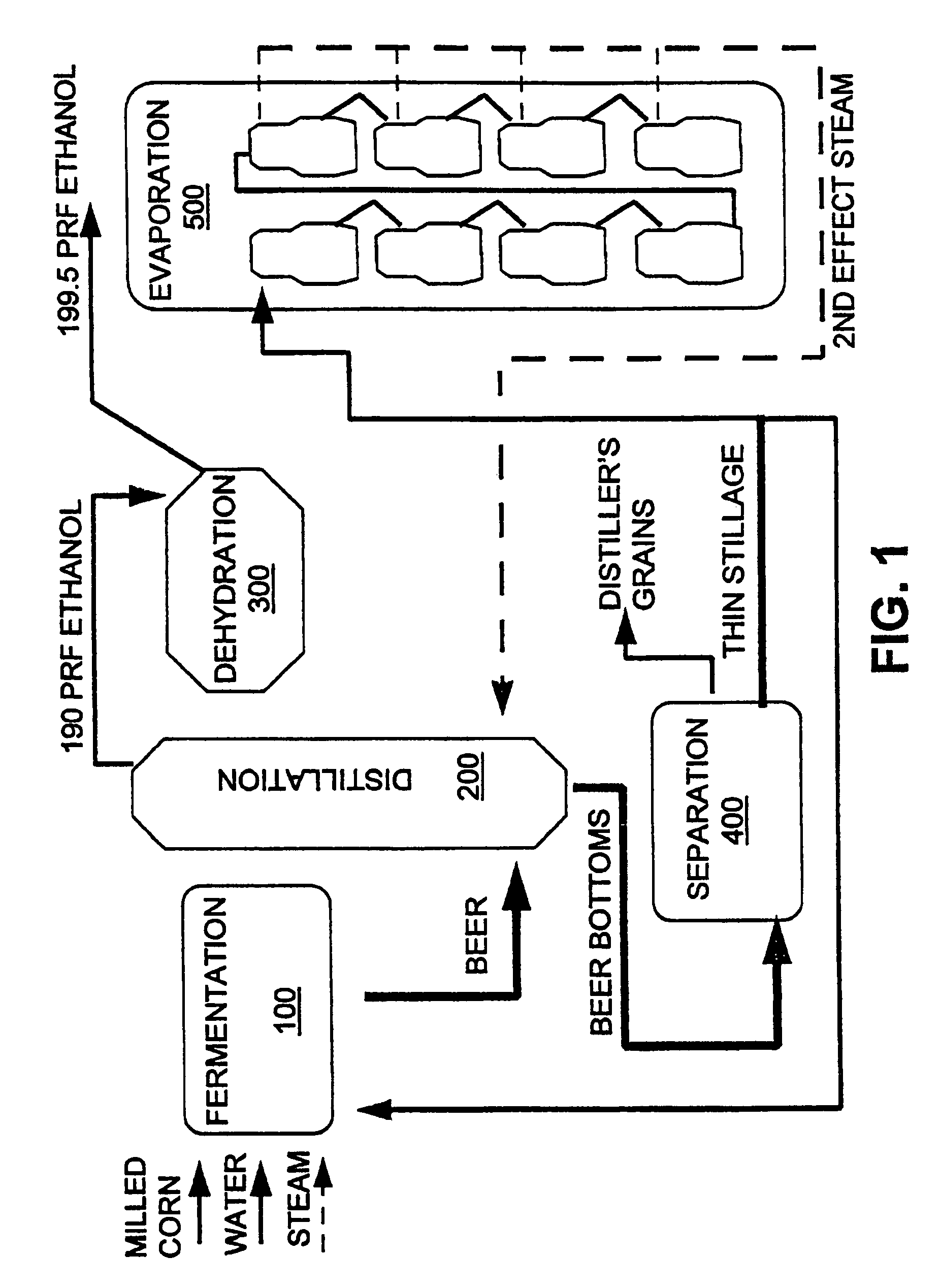

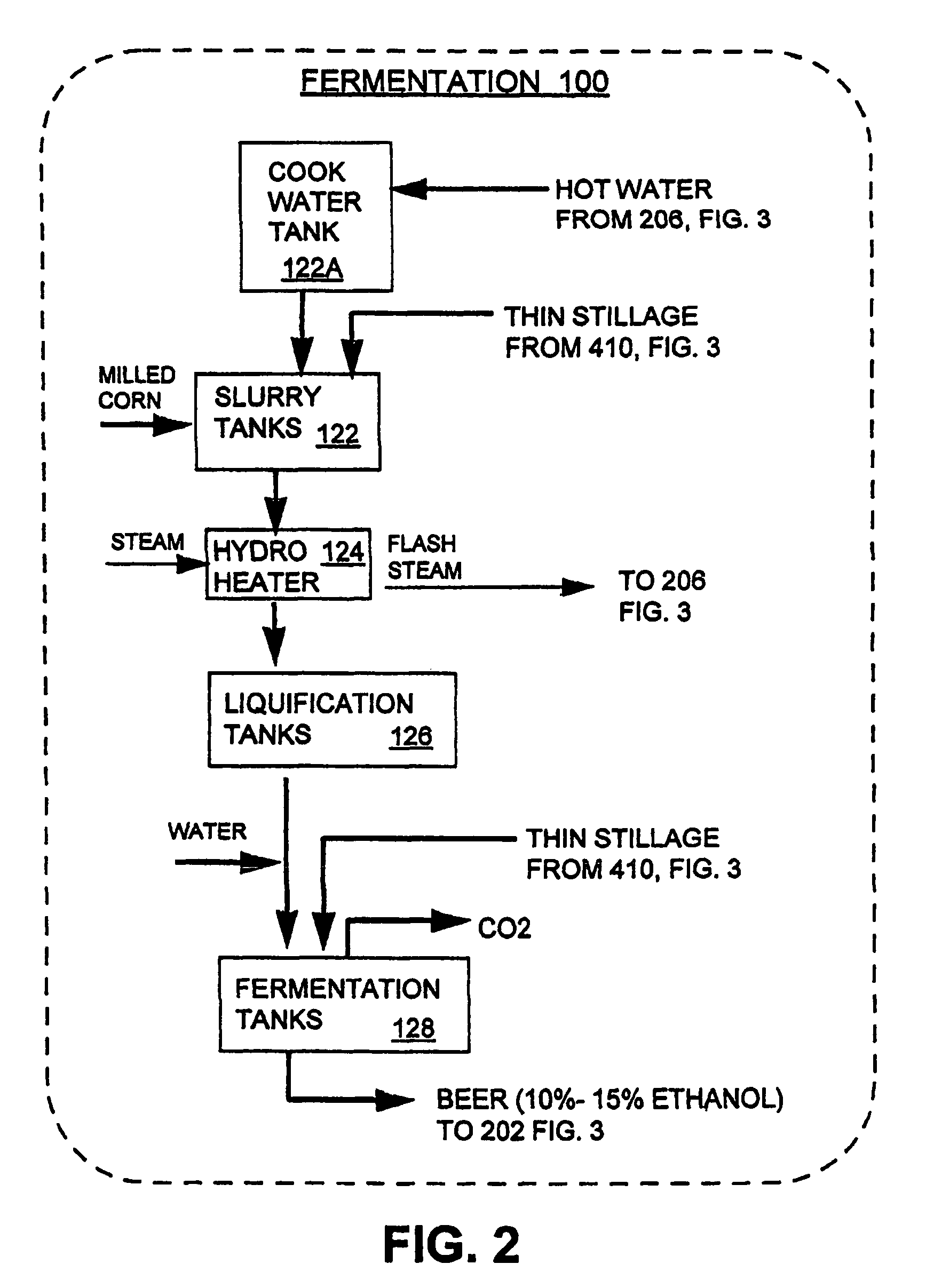

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

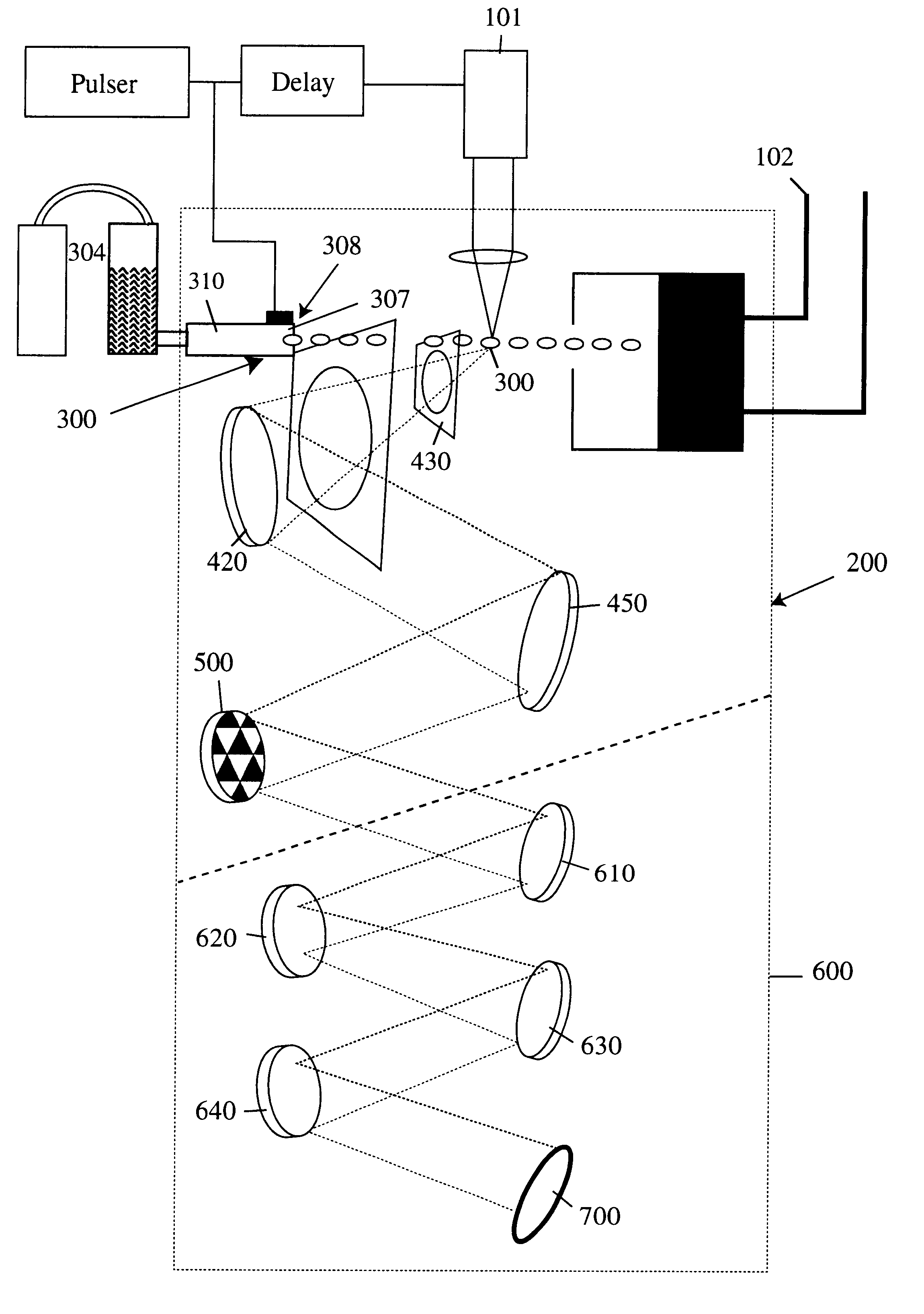

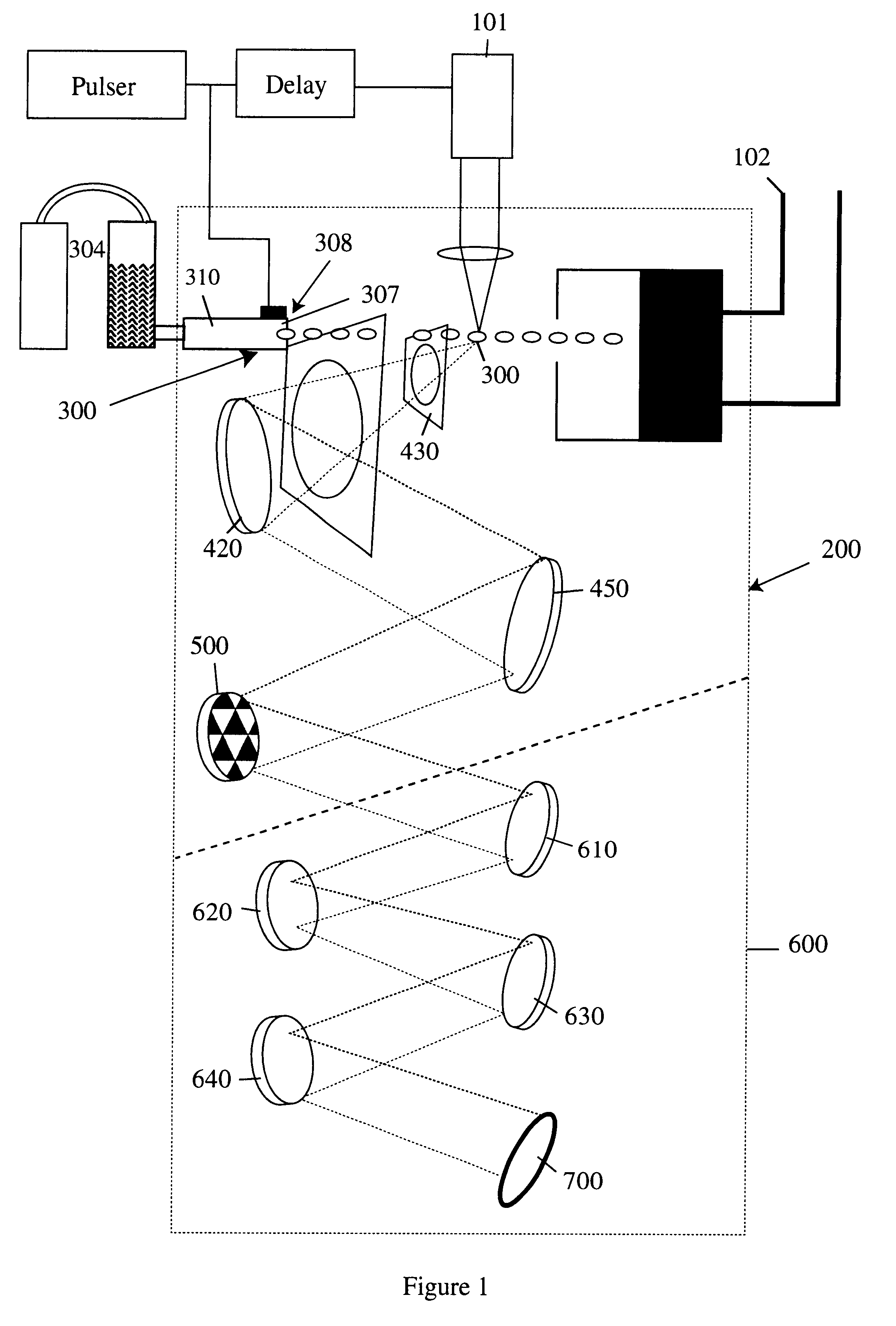

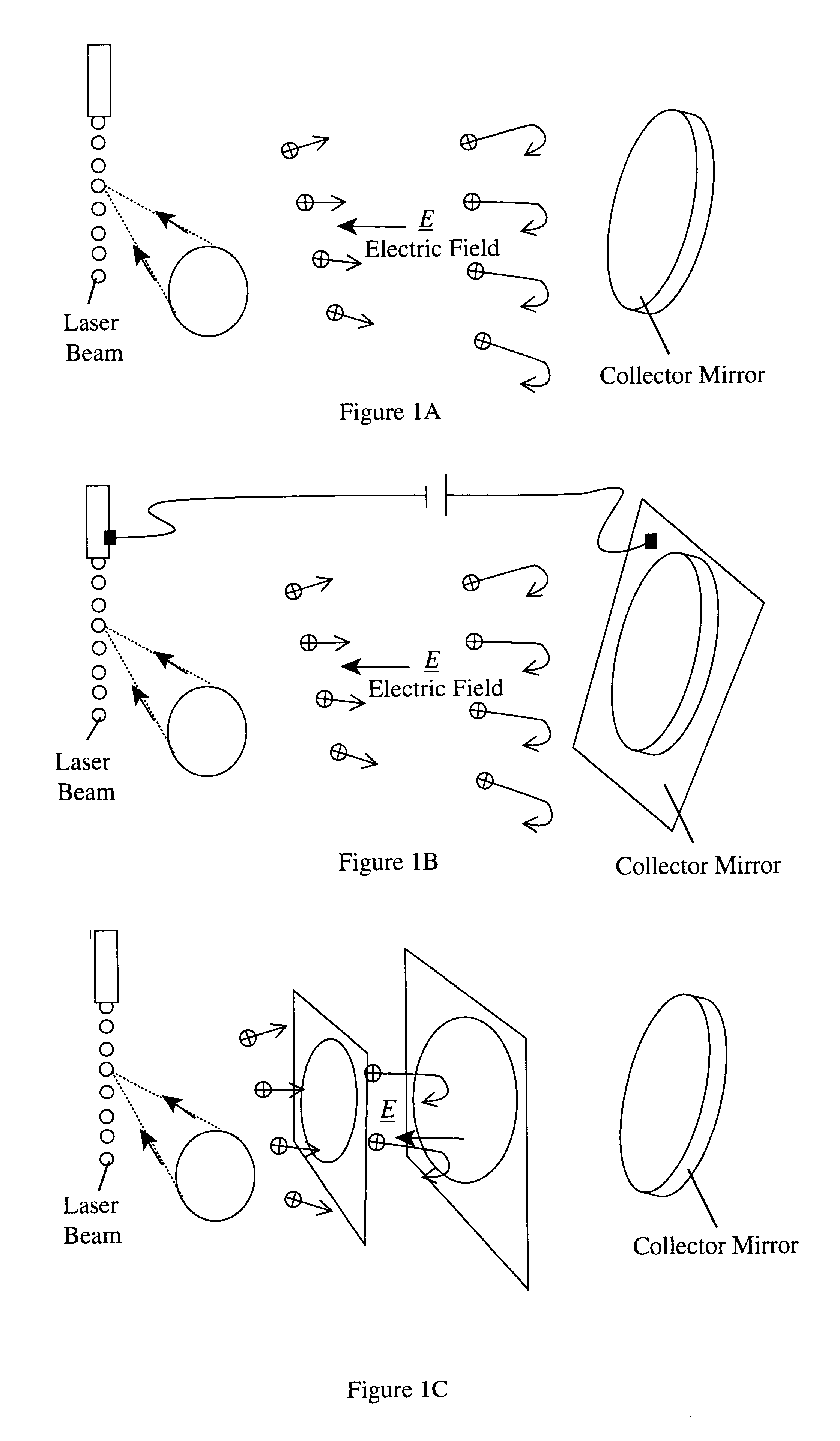

Laser plasma source for extreme ultraviolet lithography using a water droplet target

InactiveUS6377651B1Avoid componentsEasy to operateNanoinformaticsPhotomechanical exposure apparatusAuxiliary electrodeExtreme ultraviolet

A laser produced extreme ultraviolet (EUV) source based on a water droplet target has been implemented an auxiliary electrode system between the source and the first collector mirror. The auxiliary electrode system creates a repeller electric field, possibly a dc voltage imposed on the mirror that slows down and reverses the trajectories of ions from the source before they impact the collection mirror. The source modified according to the invention was evaluated with respect to the demands of EUV lithography and found to have much extended operational lifetimes. The spectral distribution of the generated radiation as well as the conversion efficiency into line radiation at 13 nm was determined. Long time measurements of the reflectivity of silicon / molybdenum multilayer mirrors for up to from 107 to 109 shots show the useful influence of the treatment of ions emitted from the source. Several methods of debris reduction were tested and discussed. Surface analysis of the treated multilayer mirrors of is presented. Long time measurements of the reflectivity of silicon / molybdenum multilayer mirrors for up to 109 shots show the advantage provided by this invention.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

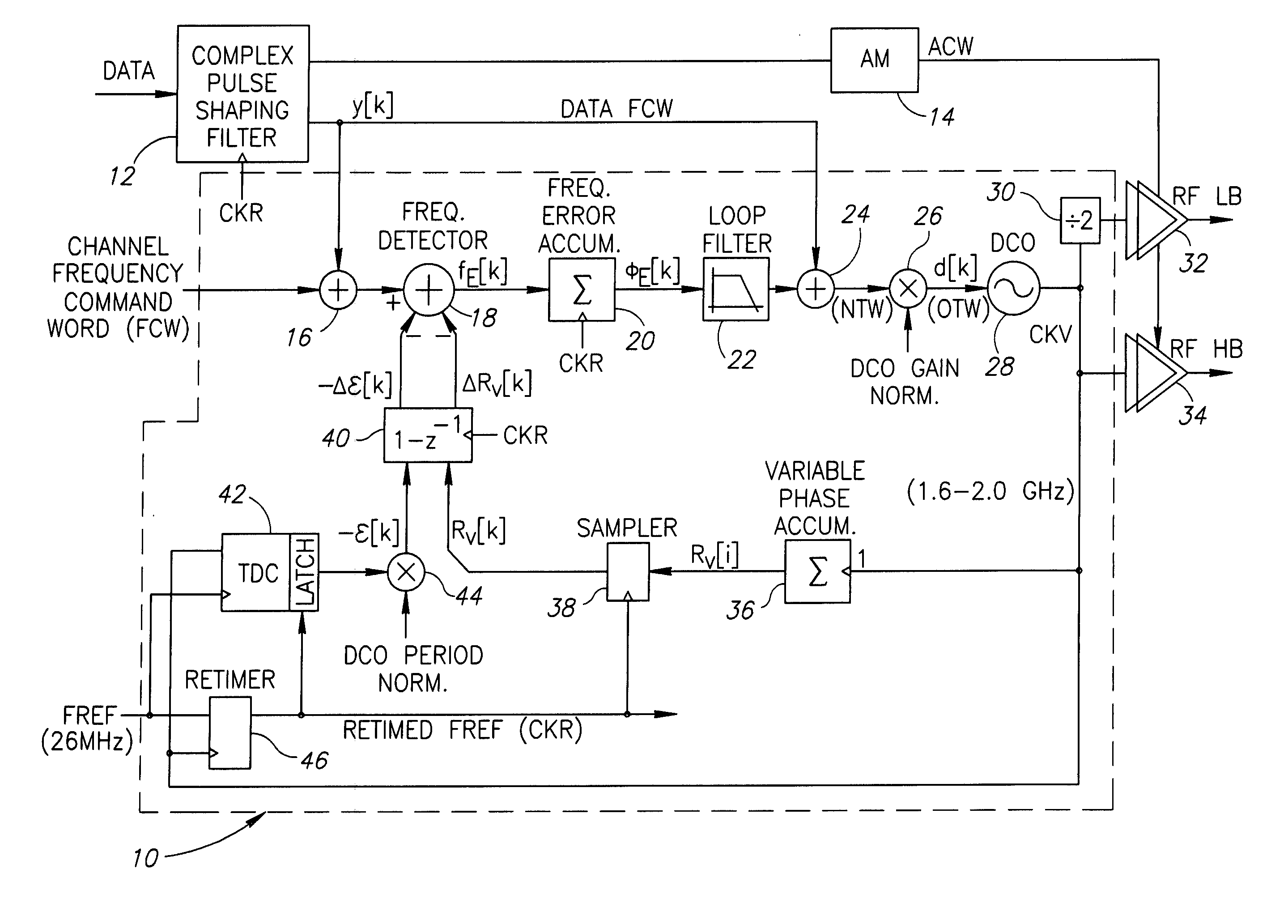

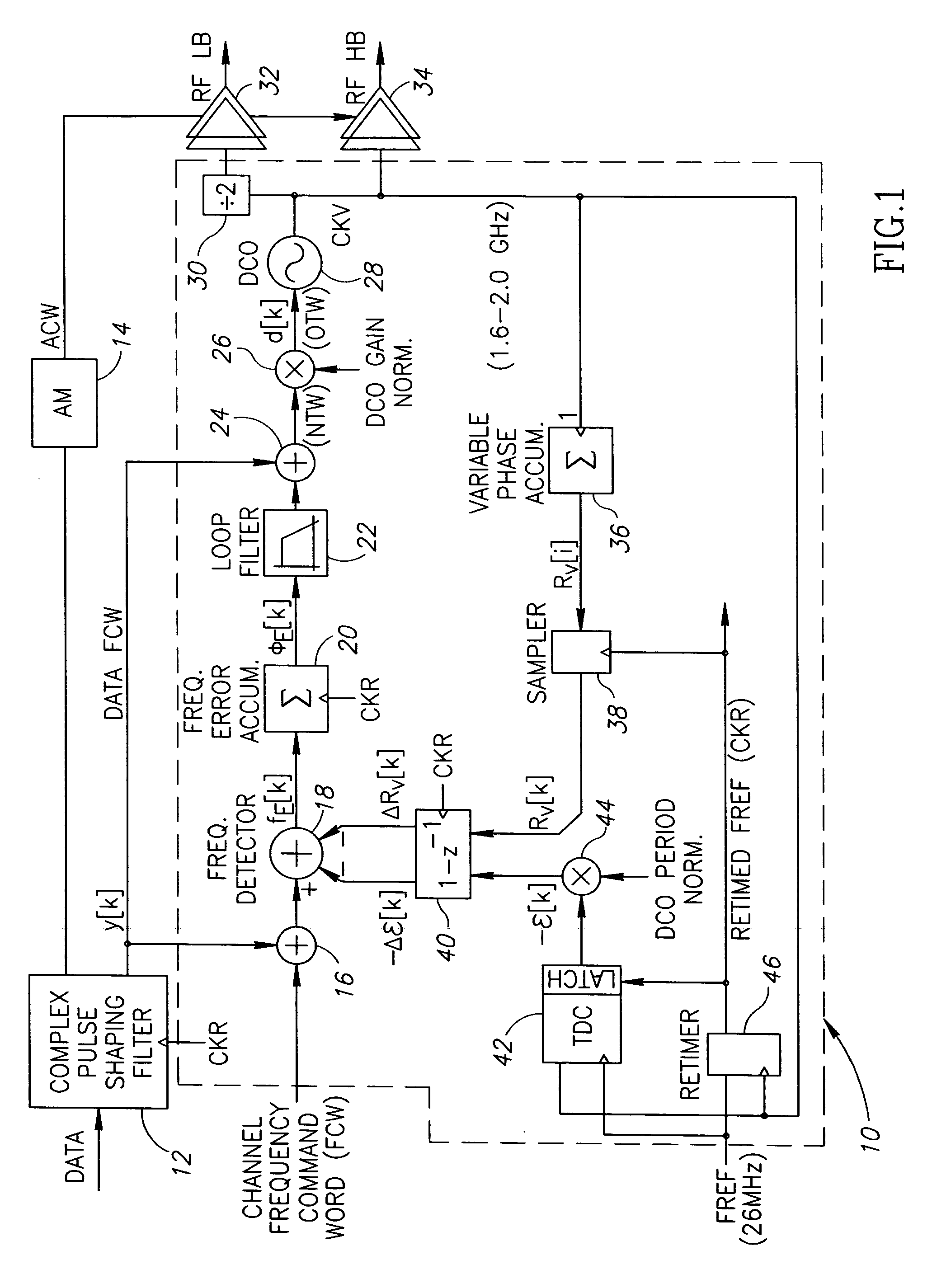

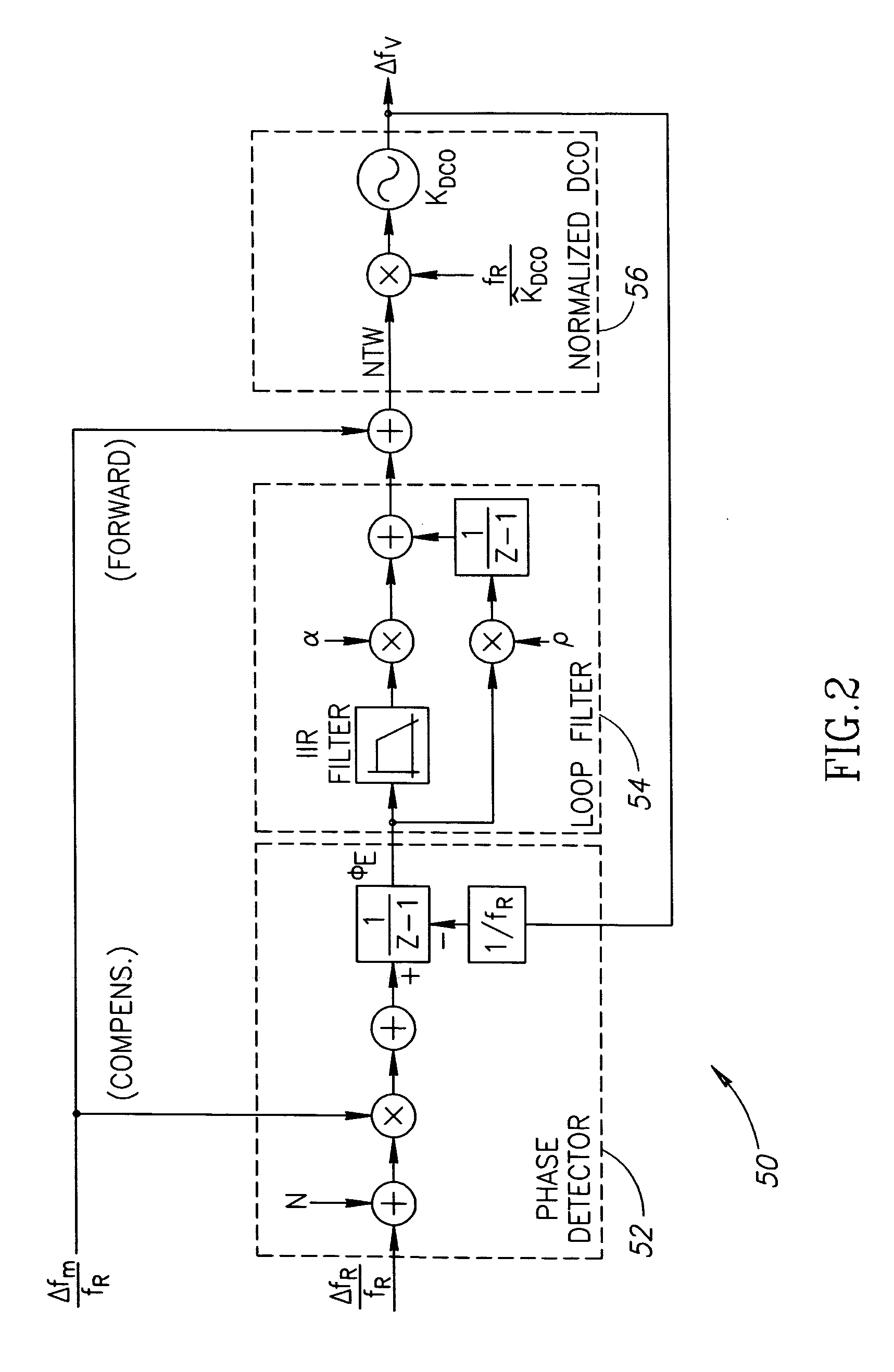

Gain calibration of a digital controlled oscillator

ActiveUS20060033582A1Good estimateImprove performancePulse automatic controlAngle modulation detailsSteep descentDigital control oscillator

A novel apparatus for and a method of estimating, calibrating and tracking in real-time the gain of a radio frequency (RF) digitally controlled oscillator (DCO) in an all-digital phase locked loop (ADPLL). Precise setting of the inverse DCO gain in the ADPLL modulating path allows direct wideband frequency modulation that is independent of the ADPLL loop bandwidth. The gain calibration technique is based on a steepest descent iterative algorithm wherein the phase ADPLL error is sampled and correlated with the modulating data to generate a gradient. The gradient is then scaled and added to the current value of the DCO gain multiplier.

Owner:TEXAS INSTR INC

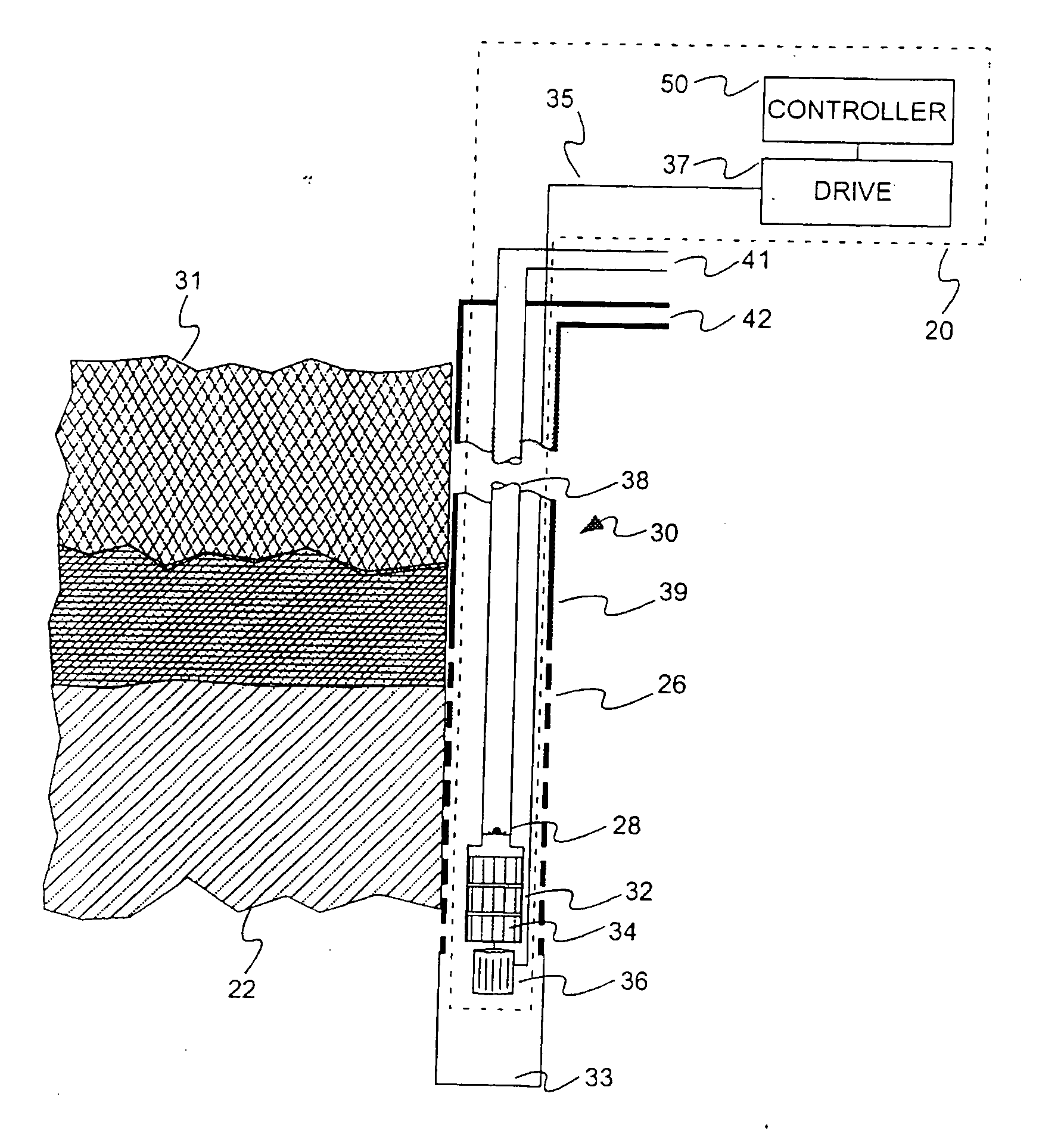

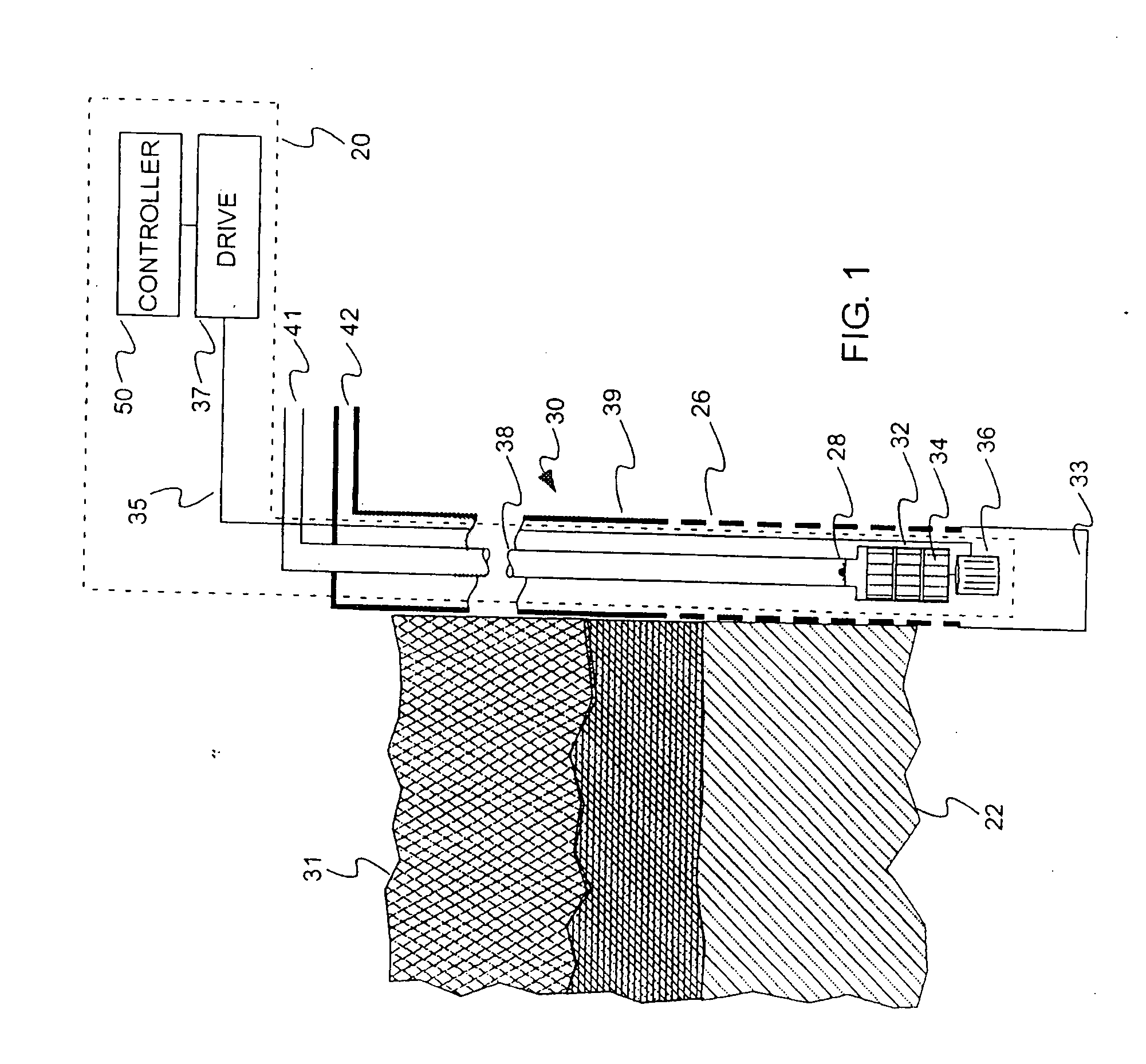

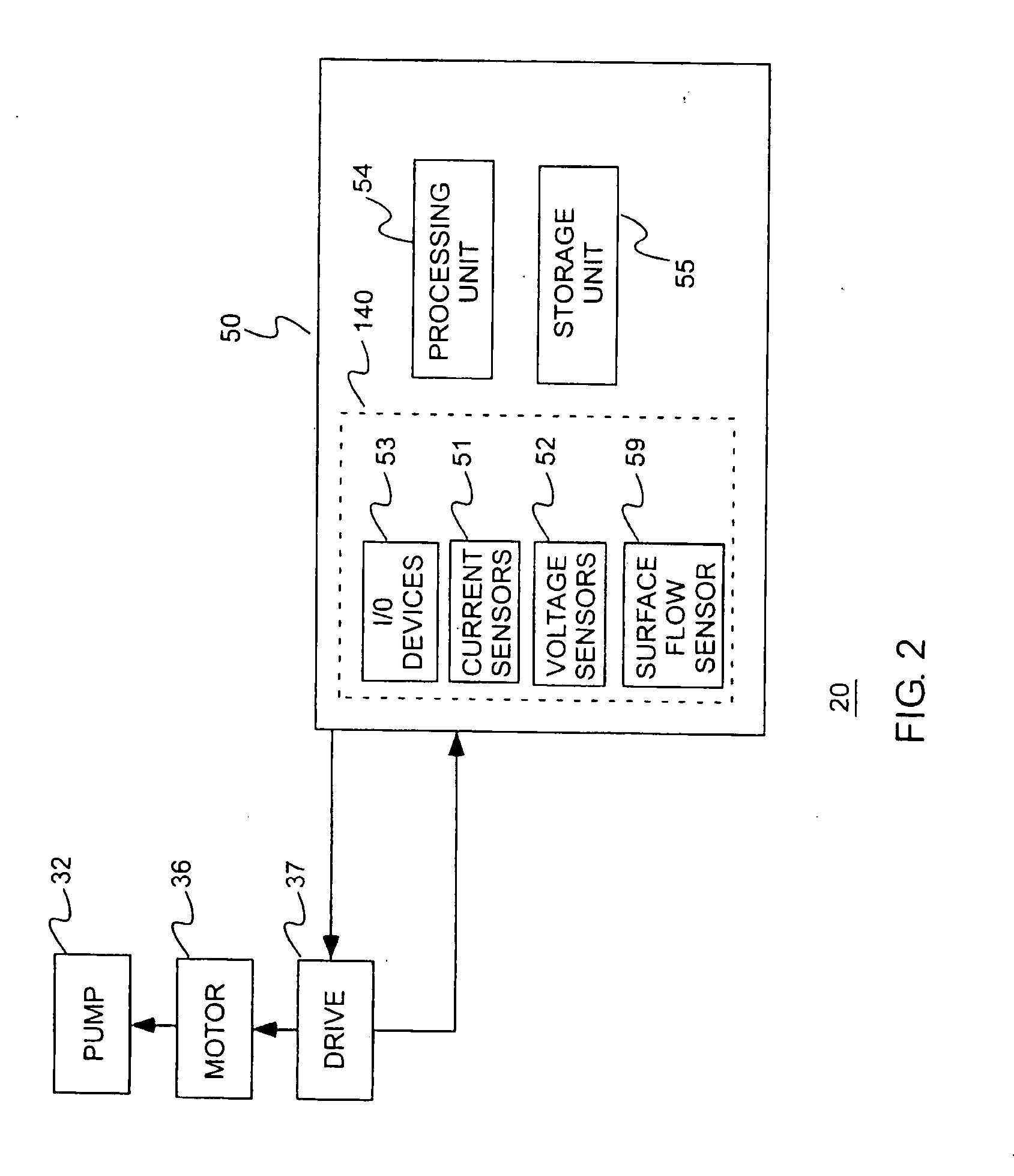

Determination And Control Of Wellbore Fluid Level, Output Flow, And Desired Pump Operating Speed, Using A Control System For A Centrifugal Pump Disposed Within The Wellbore

ActiveUS20080067116A1Enhance market appealBroad possible marketLevel controlWind motor controlEngineeringSystem parameters

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

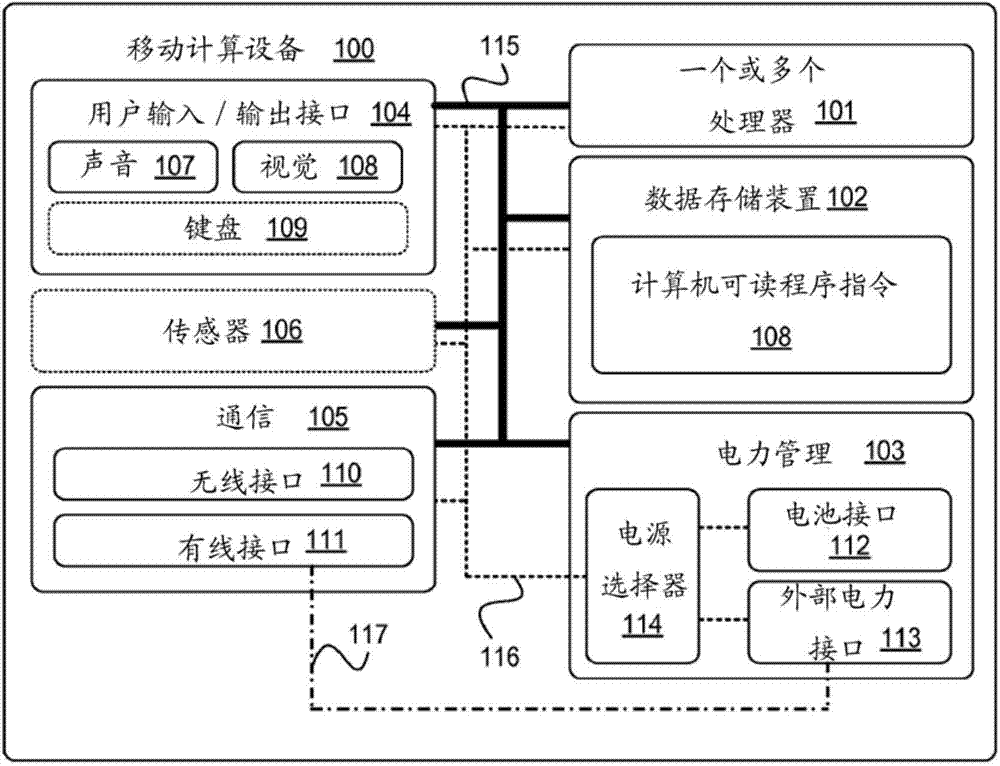

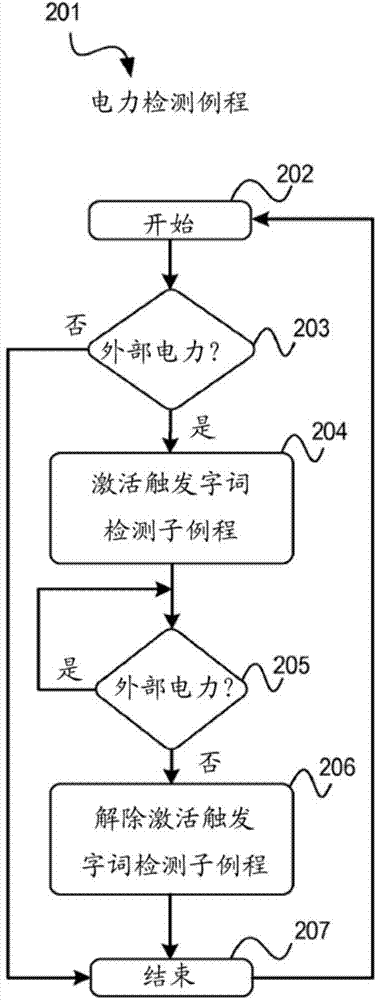

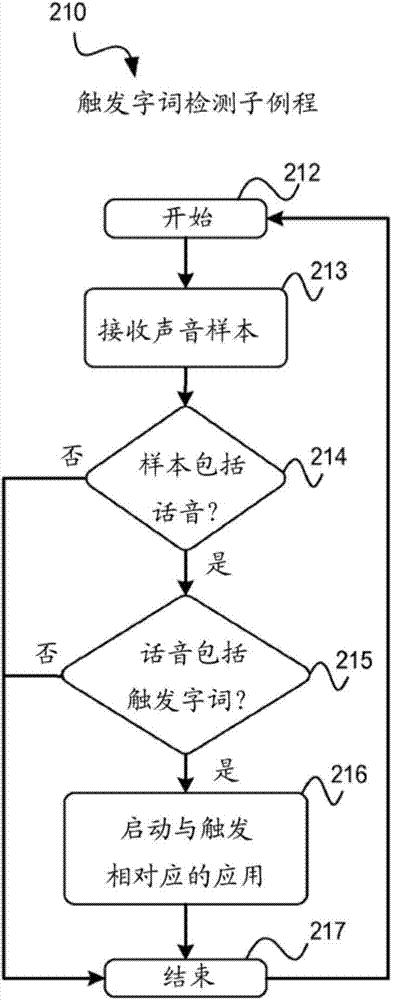

Systems and methods for continual speech recognition and detection in mobile computing devices

ActiveCN103930945AInfluence IgnoreContinuous operationSound input/outputSpeech recognitionElectric powerSubroutine

The present application describes systems, articles of manufacture, and methods for continuous speech recognition for mobile computing devices. One embodiment includes determining whether a mobile computing device is receiving operating power from an external power source or a battery power source, and activating a trigger word detection subroutine in response to determining that the mobile computing device is receiving power from the external power source. In some embodiments, the trigger word detection subroutine operates continually while the mobile computing device is receiving power from the external power source. The trigger word detection subroutine includes determining whether a plurality of spoken words received via a microphone includes one or more trigger words, and in response to determining that the plurality of spoken words includes at least one trigger word, launching an application corresponding to the at least one trigger word included in the plurality of spoken words.

Owner:GOOGLE LLC

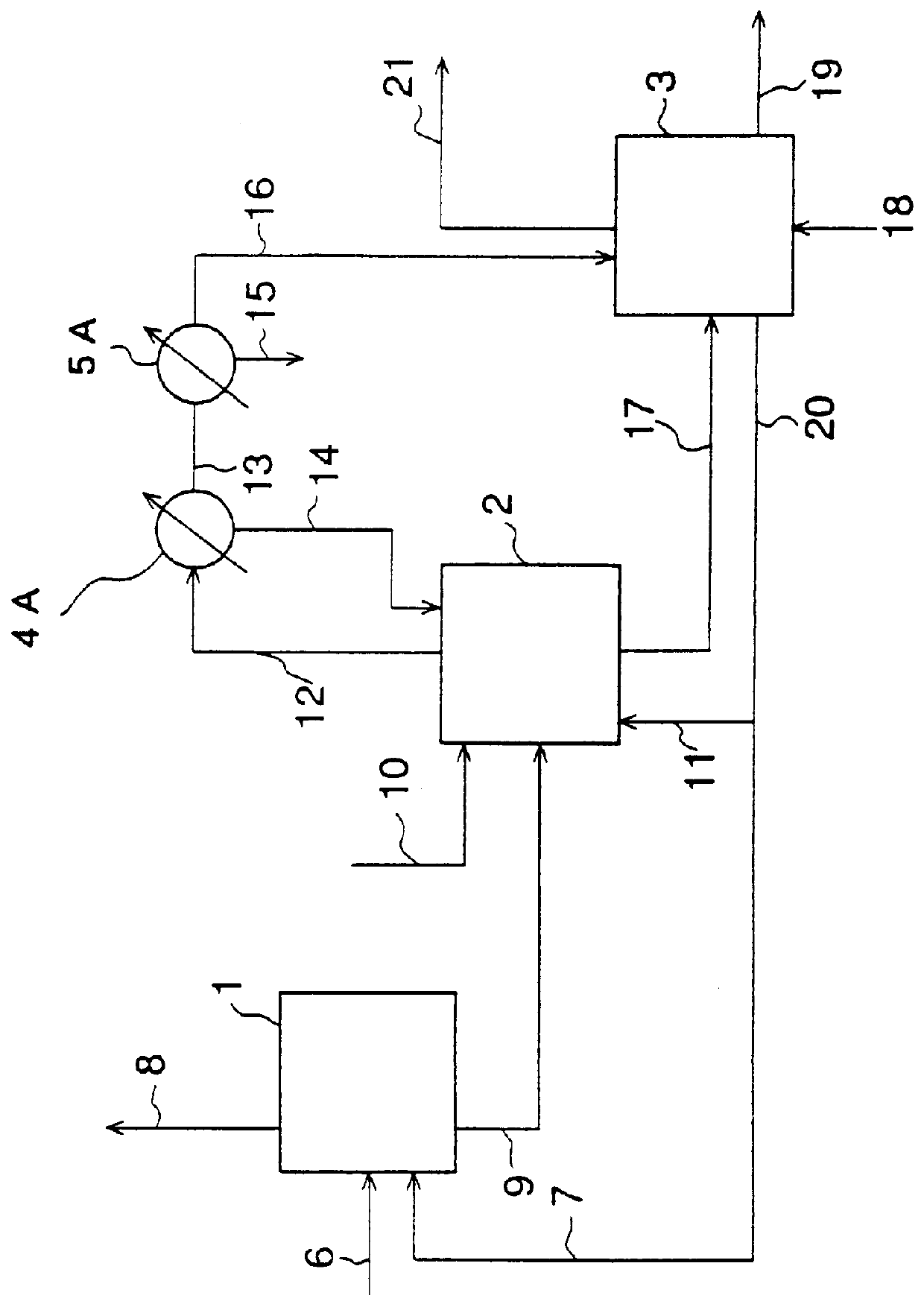

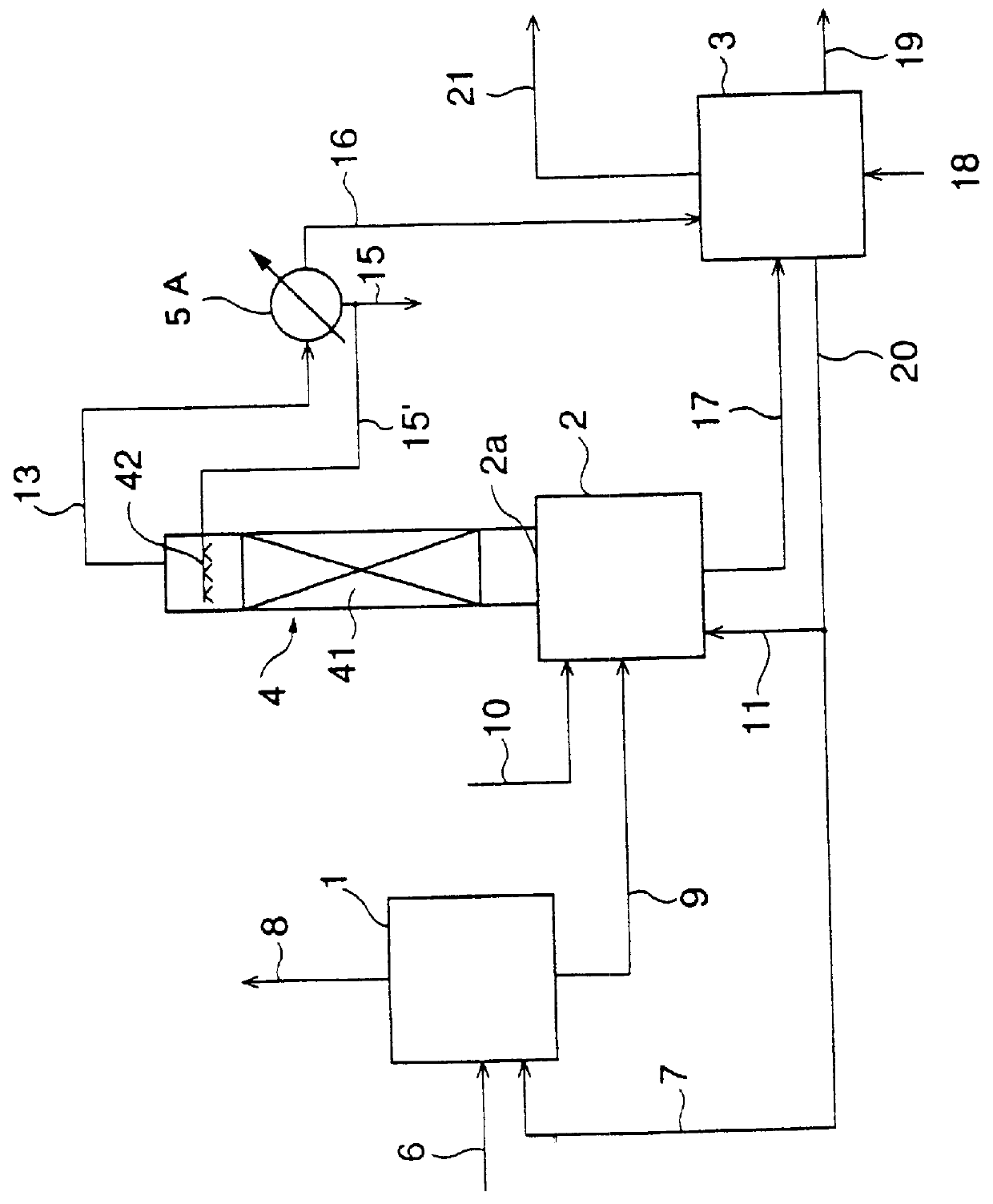

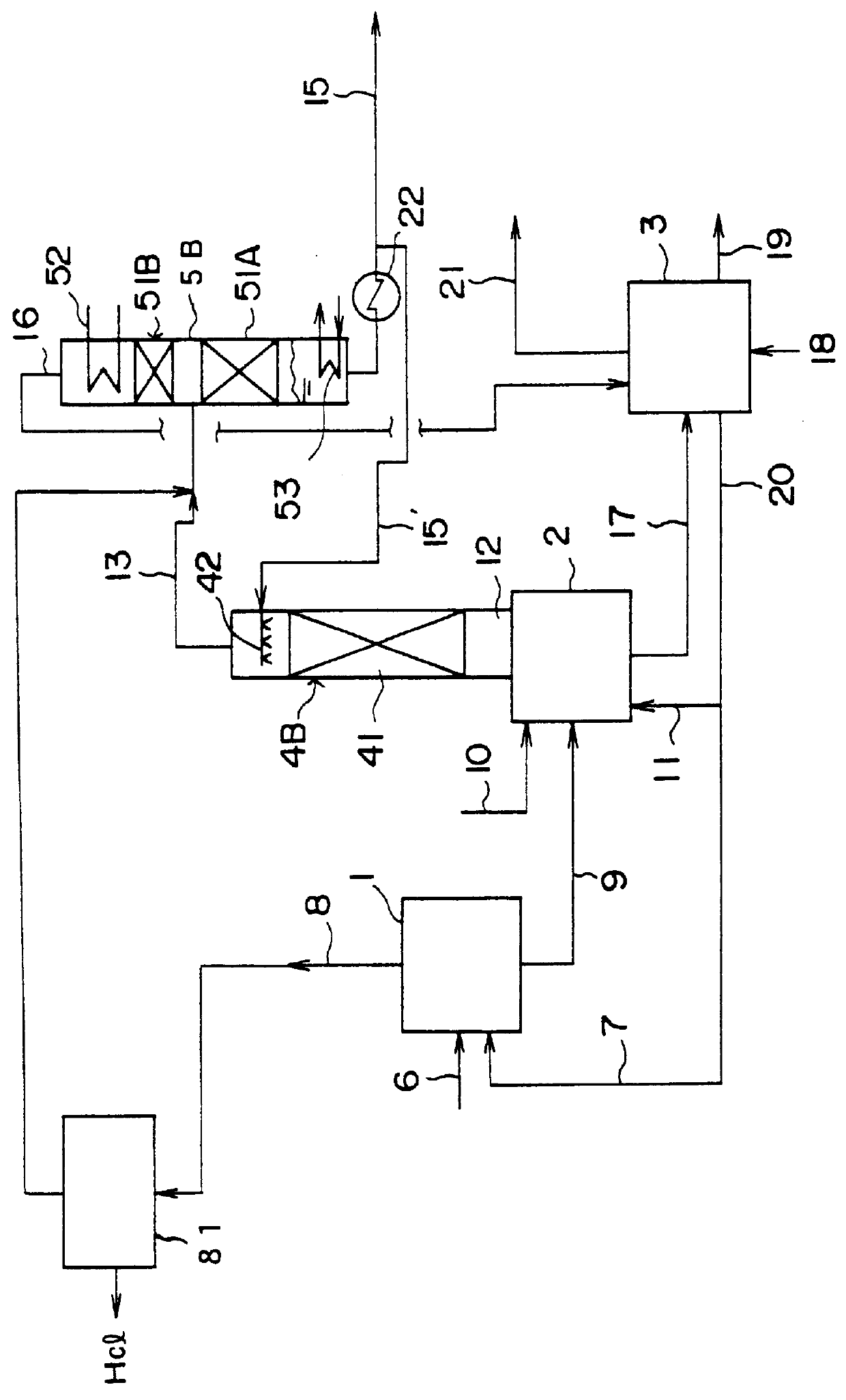

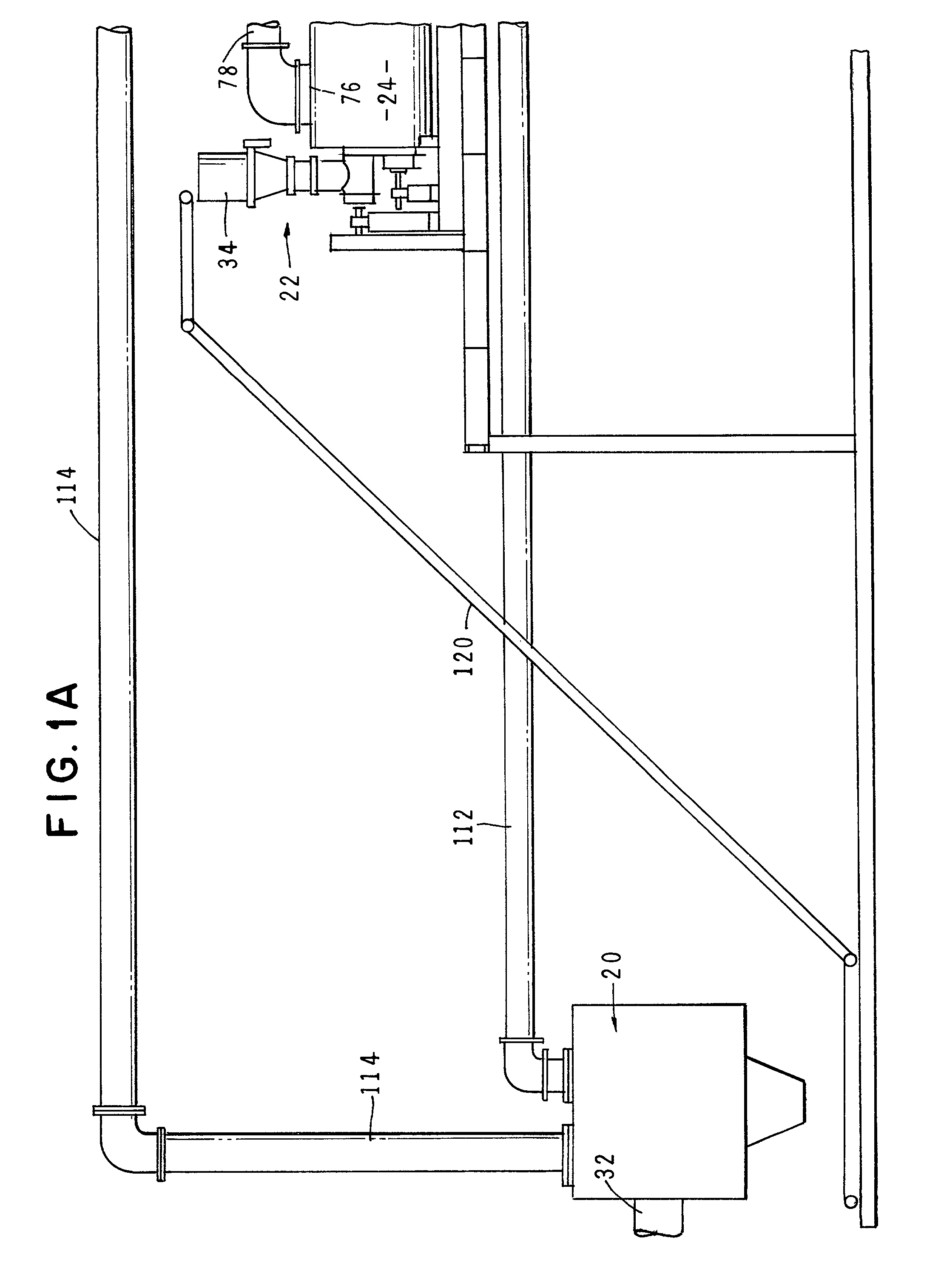

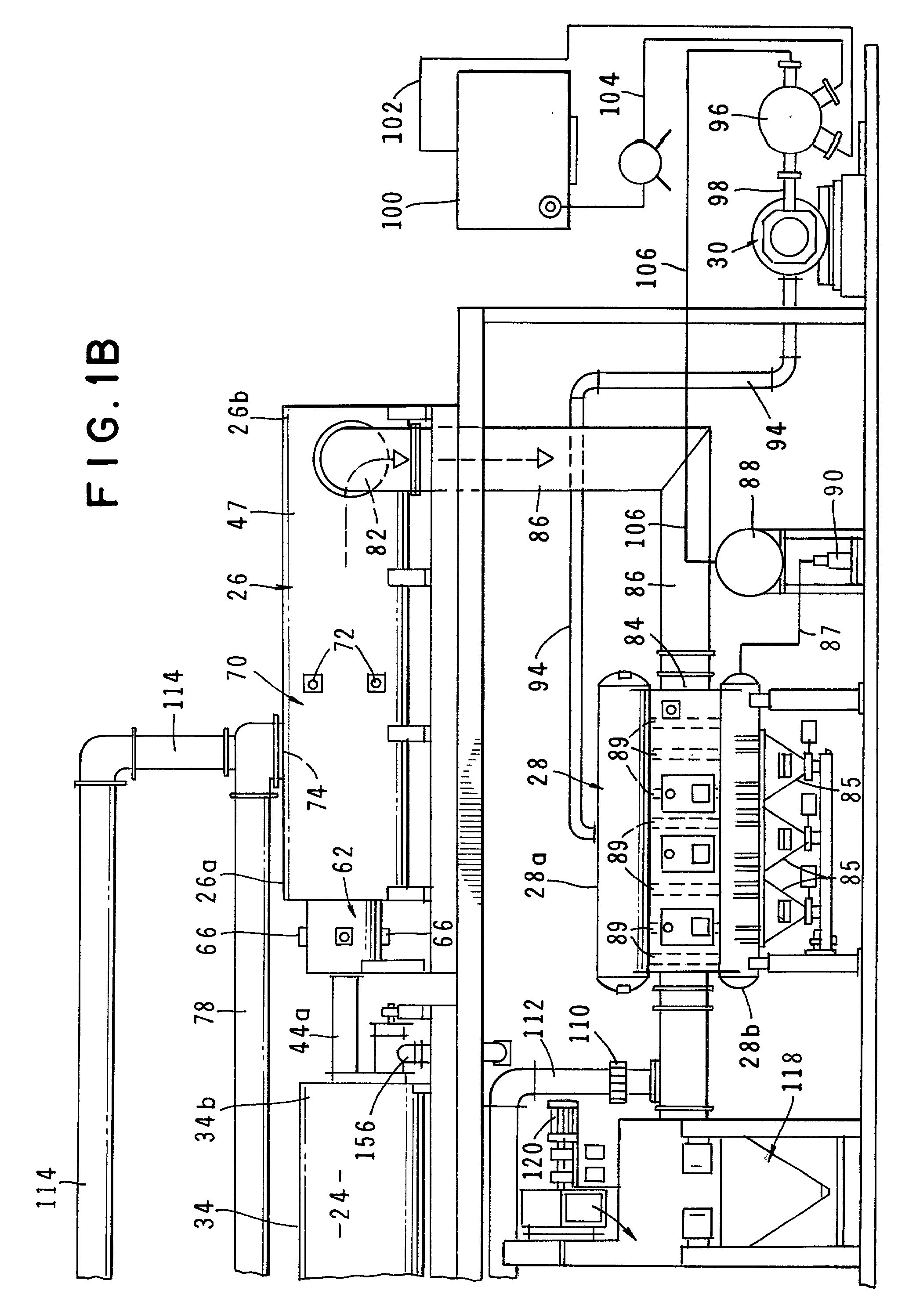

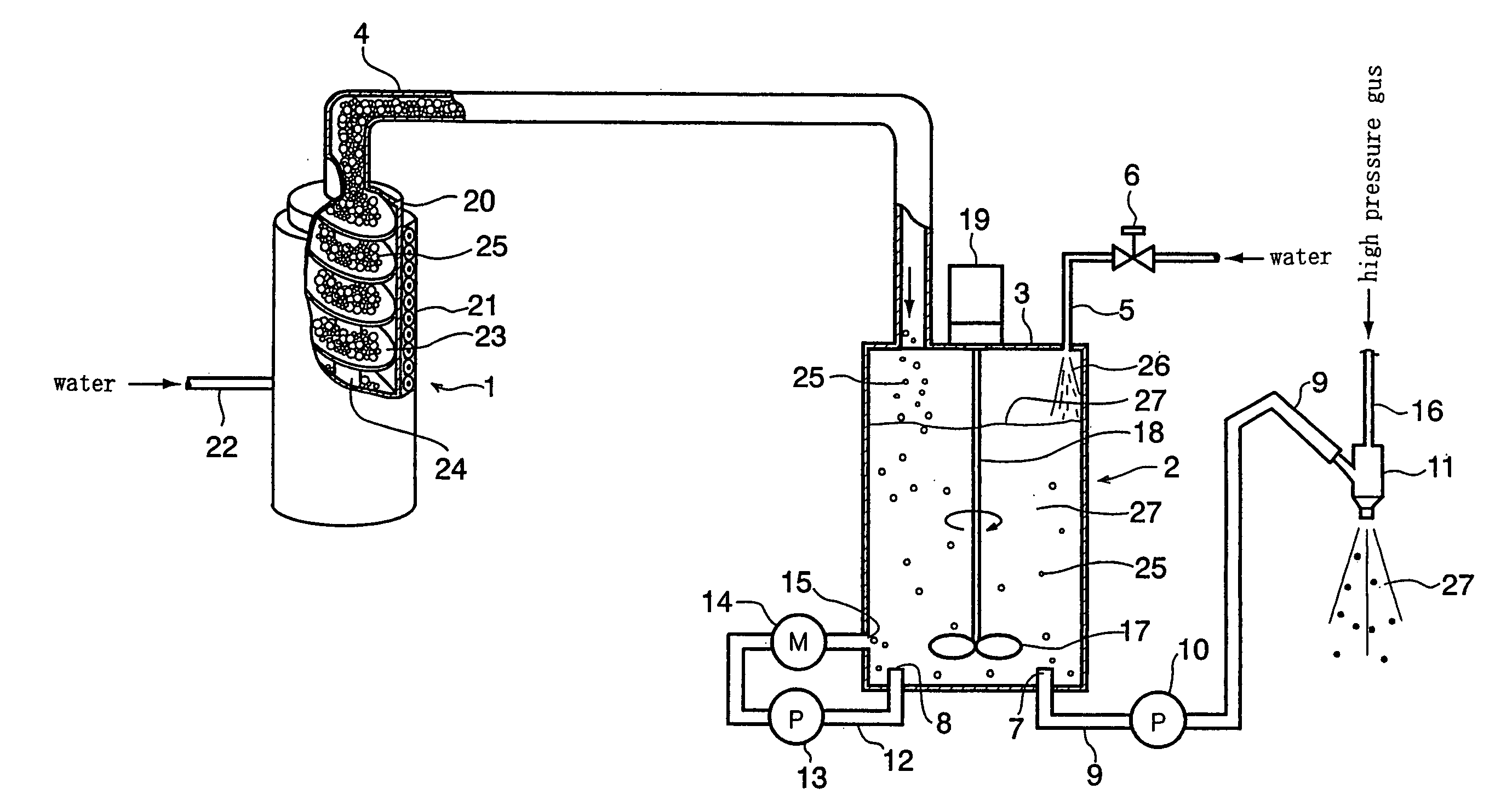

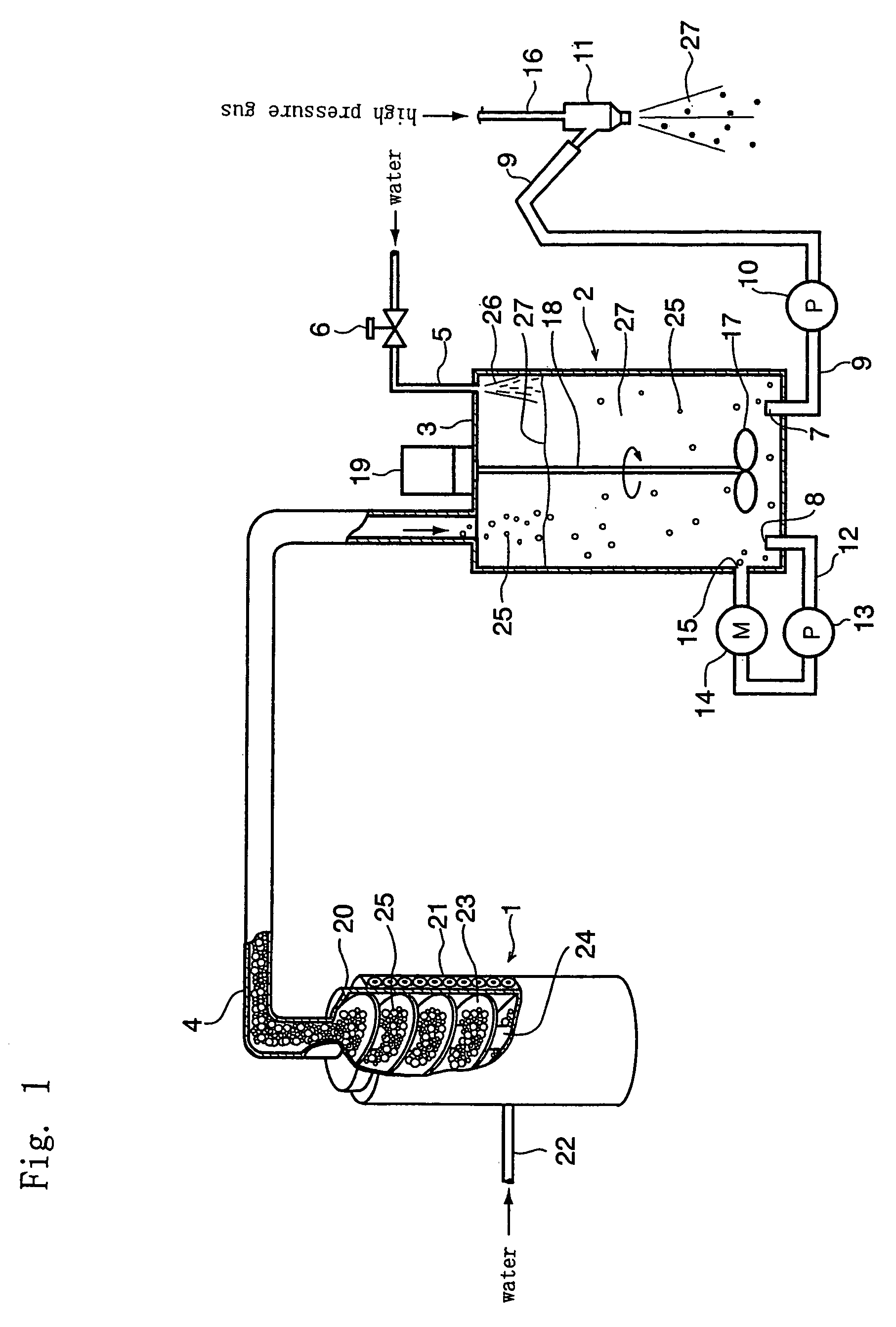

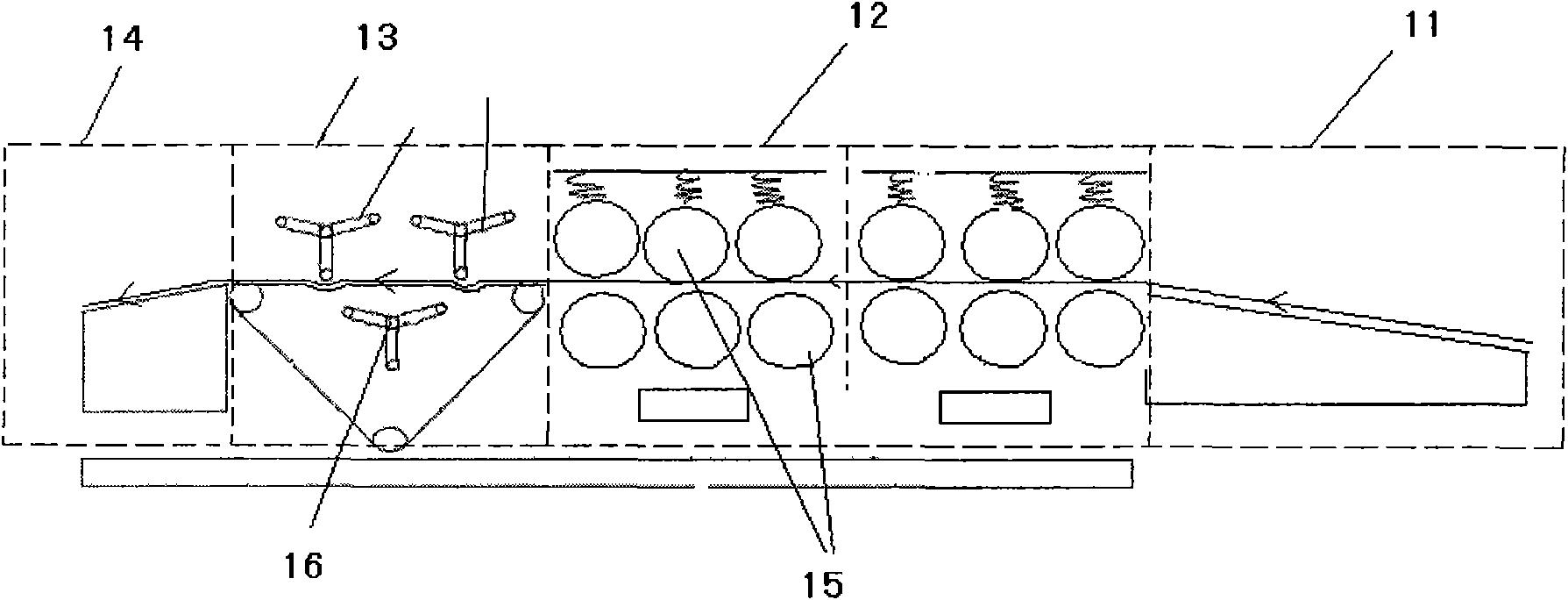

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

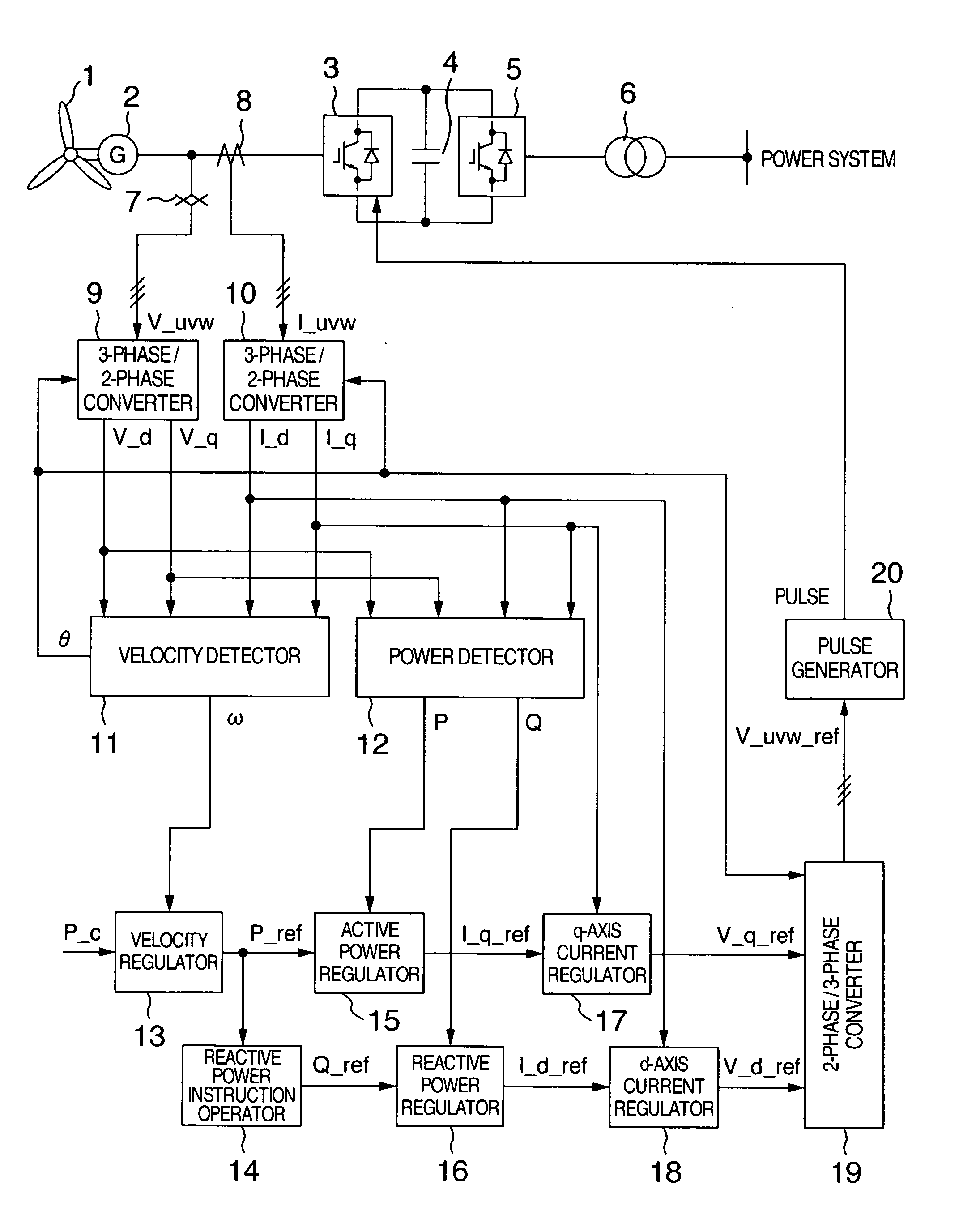

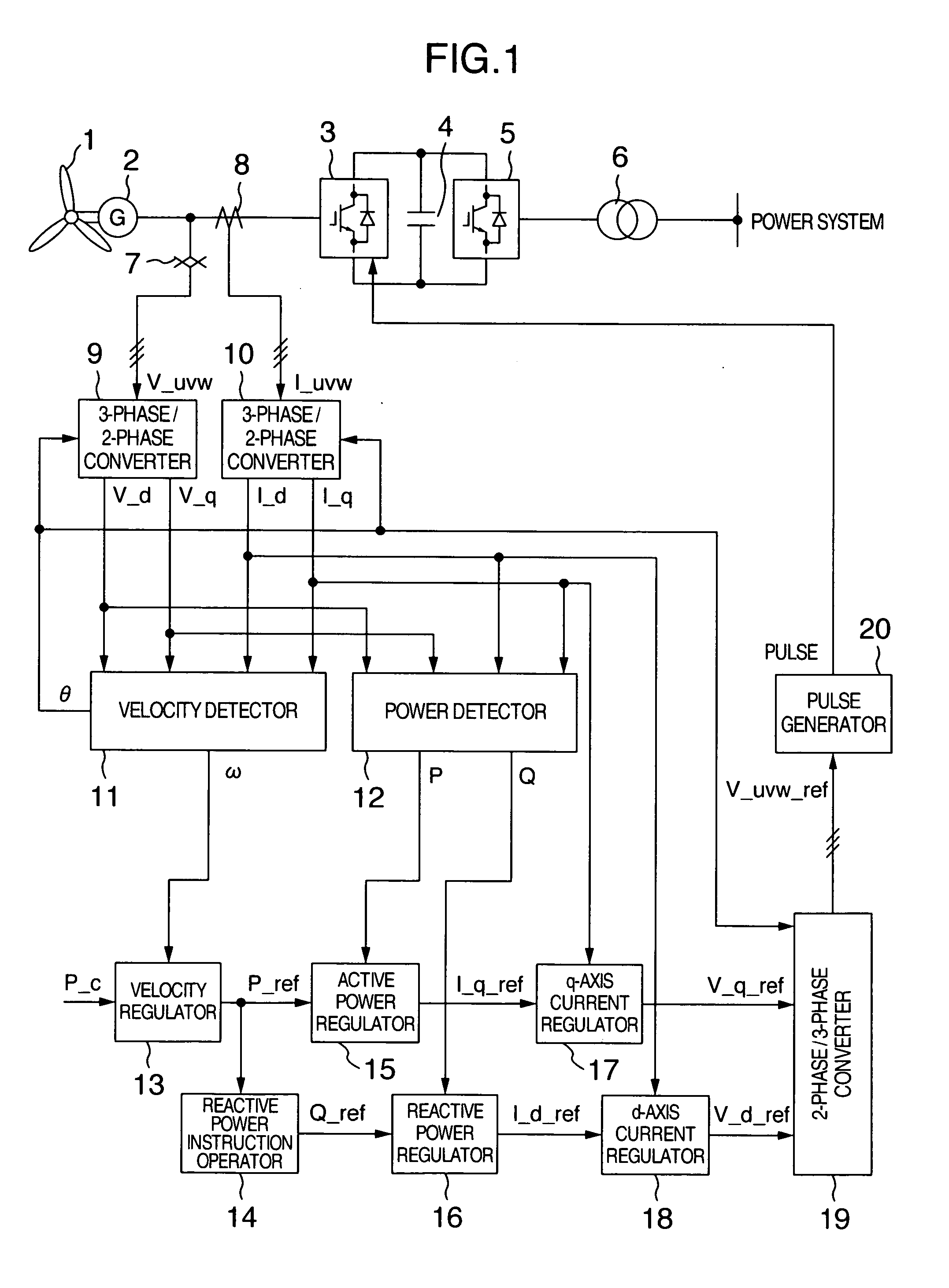

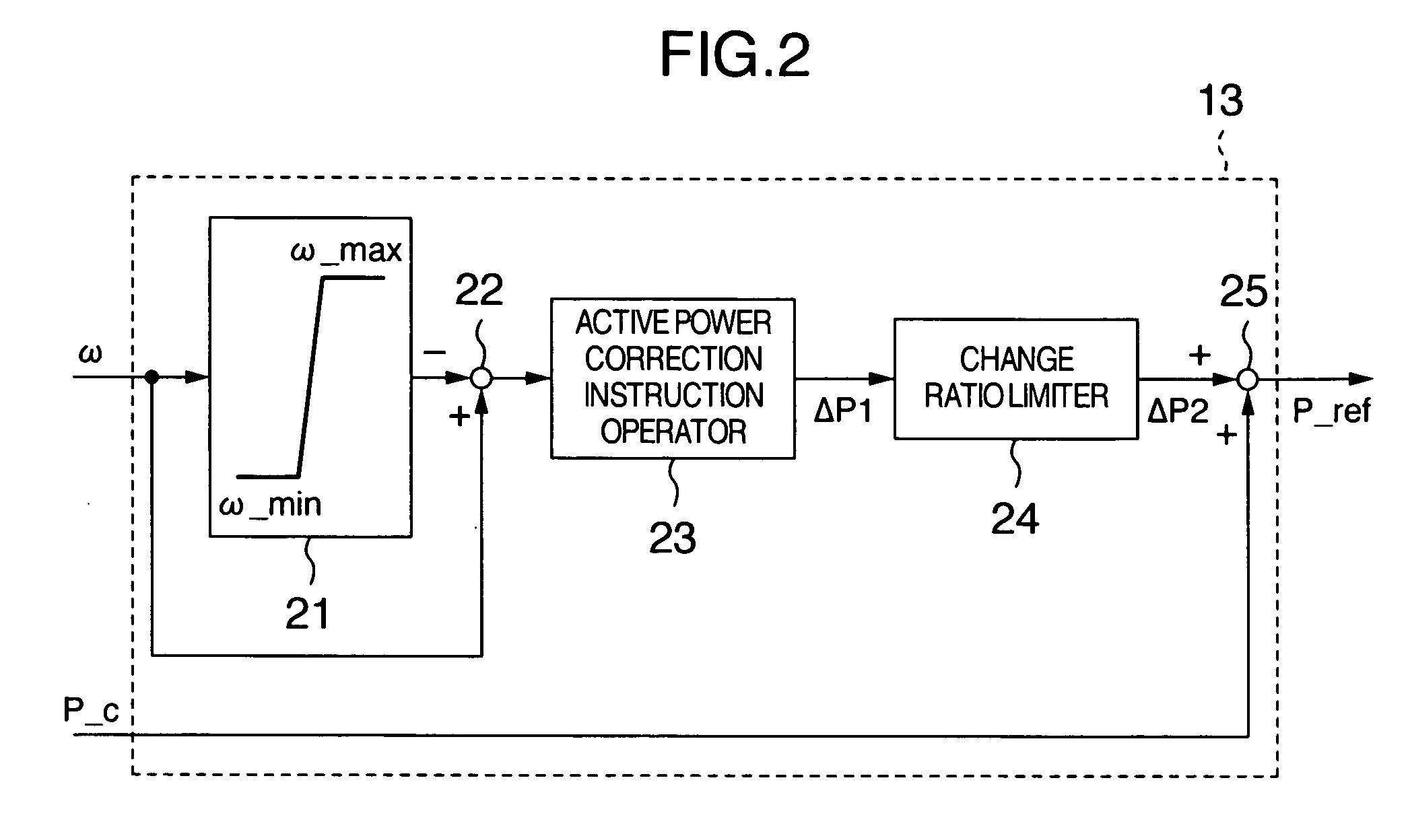

Wind turbine generator system

ActiveUS20060028025A1Suppress rotational velocityAvoid stopWind motor controlStatic indicating devicesTurbineContinuous operation

A wind turbine generator system can regulate the rotational velocity of the wind turbine within an operation range even when the wind velocity suddenly changes and can perform continuous operation of the wind turbine. The wind turbine generator system includes a generator connected to the shaft of the wind turbine and a converter connected to the generator. When the rotational velocity of the wind turbine is within a predetermined range, power outputted from the generator is controlled so as to follow the instruction concerning the generator output given from the wind turbine to the converter. When the rotational velocity of the wind turbine is out of the predetermined range, the power outputted from the generator is controlled without following the instruction concerning generator output given from the wind turbine to the converter.

Owner:HITACHI IND PROD LTD

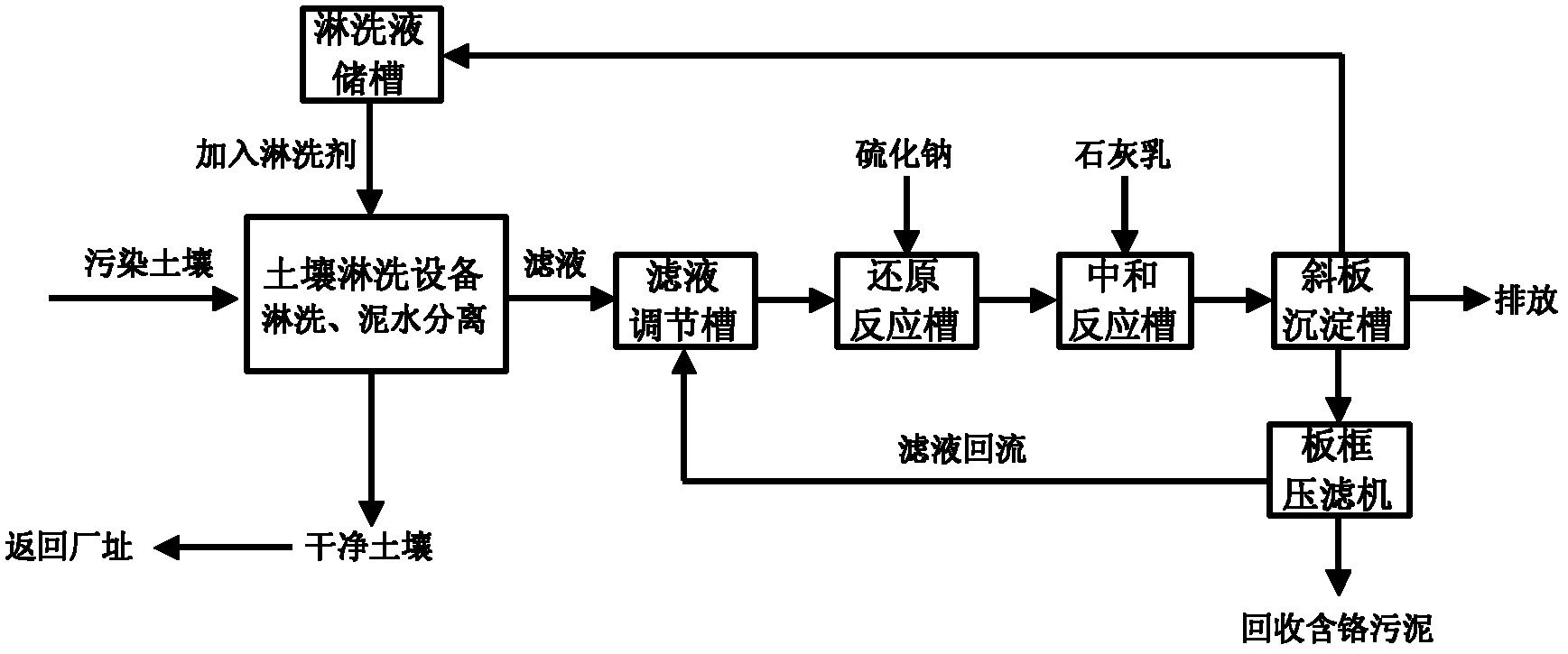

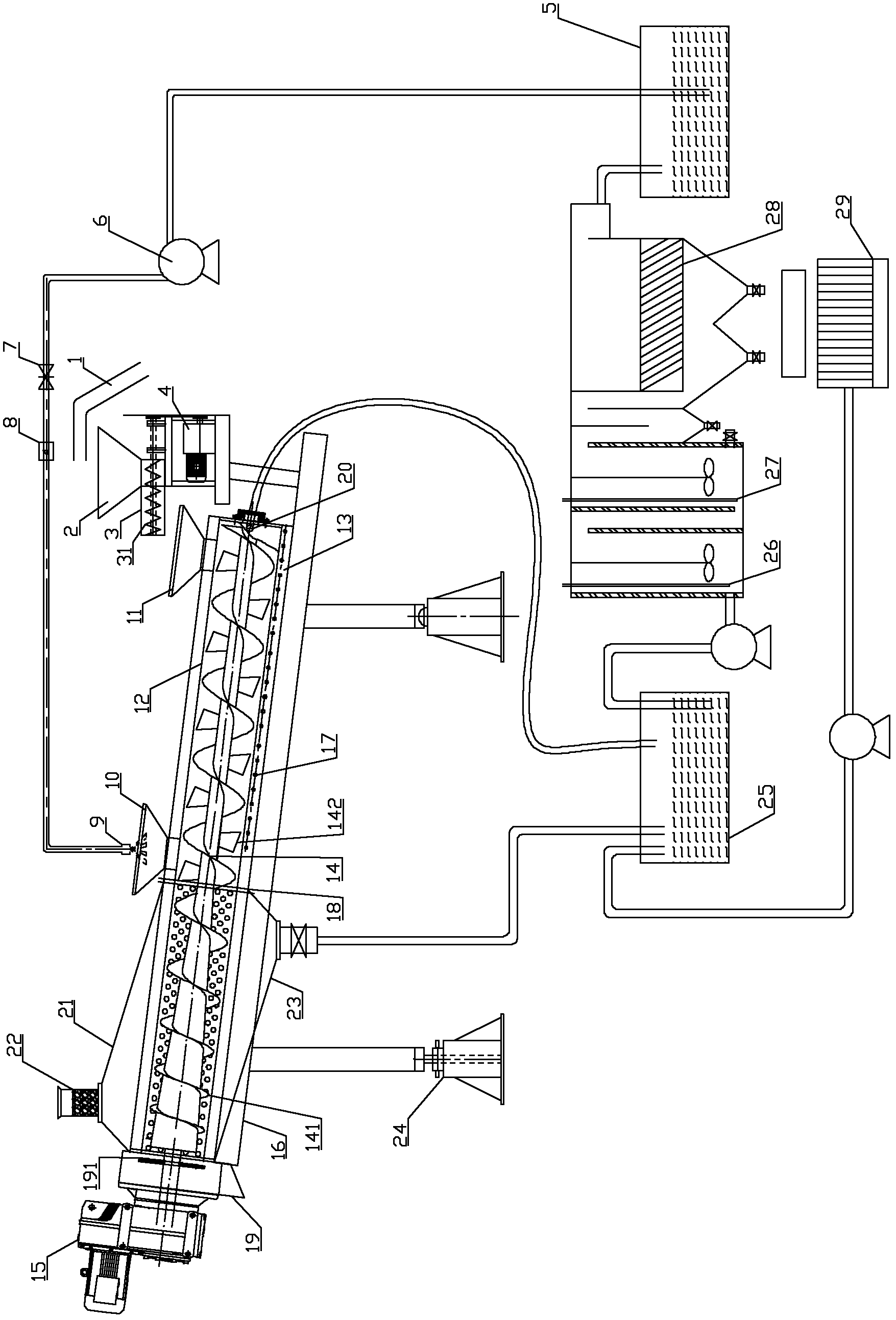

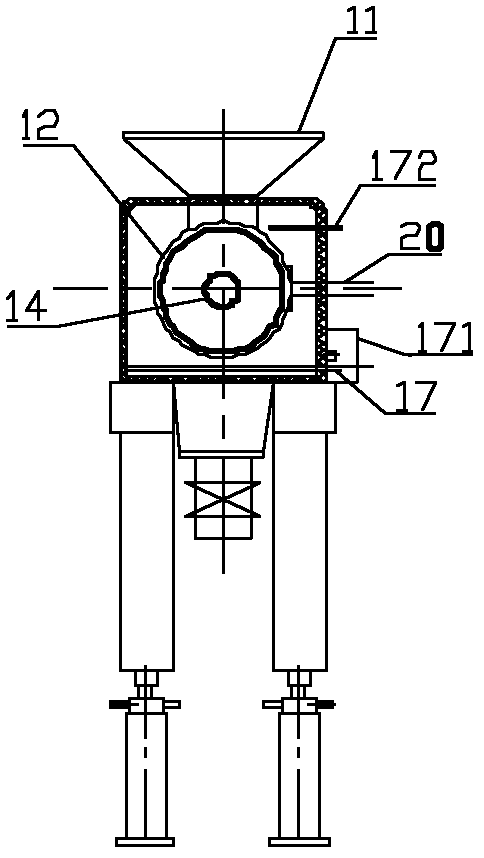

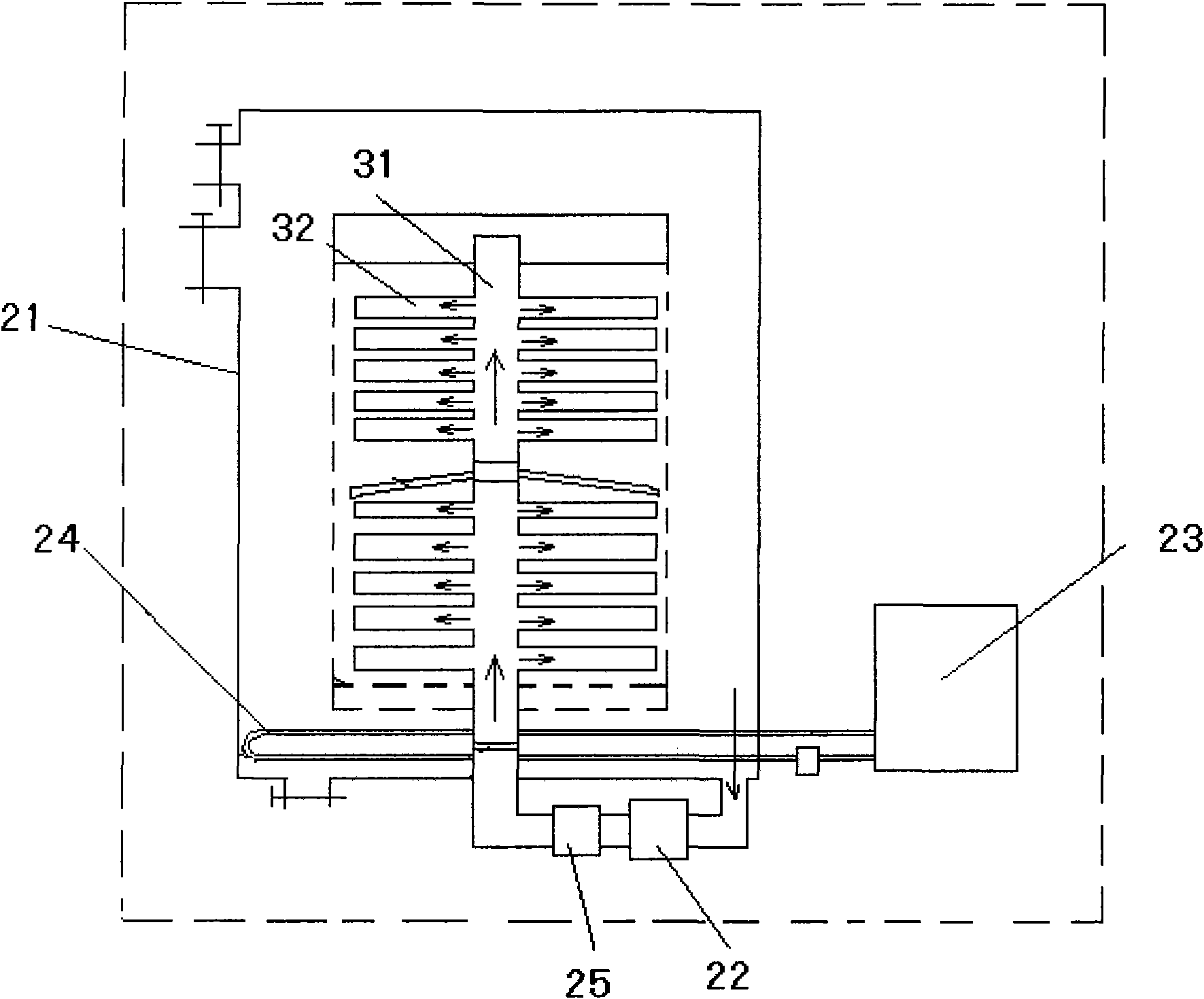

Ectopic leaching restoring device and restoring method for chromic slag polluted soil

ActiveCN102601106AContinuous operationRealize emergency handlingContaminated soil reclamationAutomatic controlSlag

The invention relates to an ectopic leaching restoring device and a restoring method for chromic slag polluted soil. The device is provided with an integrated soil leaching and dewatering system and mainly comprises a feeding system, a soil leaching-dewatering system, a waste gas treating system, an elution collecting treating system and an automatics control system. The chromic slag polluted soil firstly enters a reaction tank leaching section through the feeding system; a chrome-containing component in the soil is transferred into a liquid phase of a leaching agent; the liquid phase is rotated following a spiral stirring thruster; a muddy water mixture is conveyed into a reaction tank dewatering section; the filtrate is discharged through a tank wall with a water-permeable filtering function; the remained soil is conveyed to a mud discharging device following the rotating of the spiral stirring thruster; and lastly, the soil after being leached and dewatered is discharged. The device provided by the invention has the advantages that a power source is utilized to realize the soil leaching and muddy water separating, the energy consumption is low, the structure is simple, the use is convenient, the treating efficiency is high, and the purified degree of the polluted soil after being treated by using the device is above 85%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

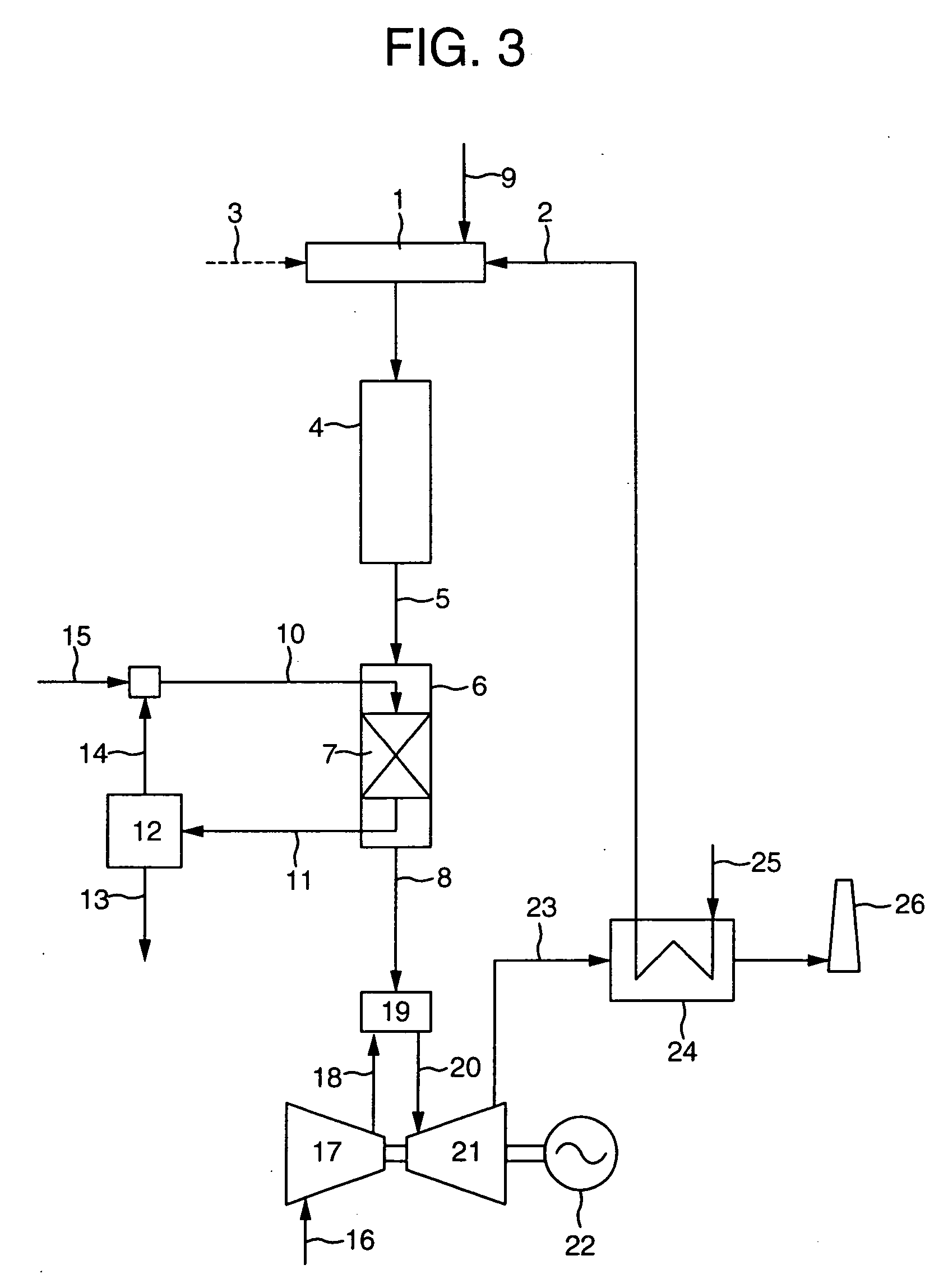

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

InactiveUS20060011511A1Reduce equipment costsReduce runningThermal non-catalytic crackingHydrogenScavengerCombustor

Owner:HOKARI NOBUYUKI +4

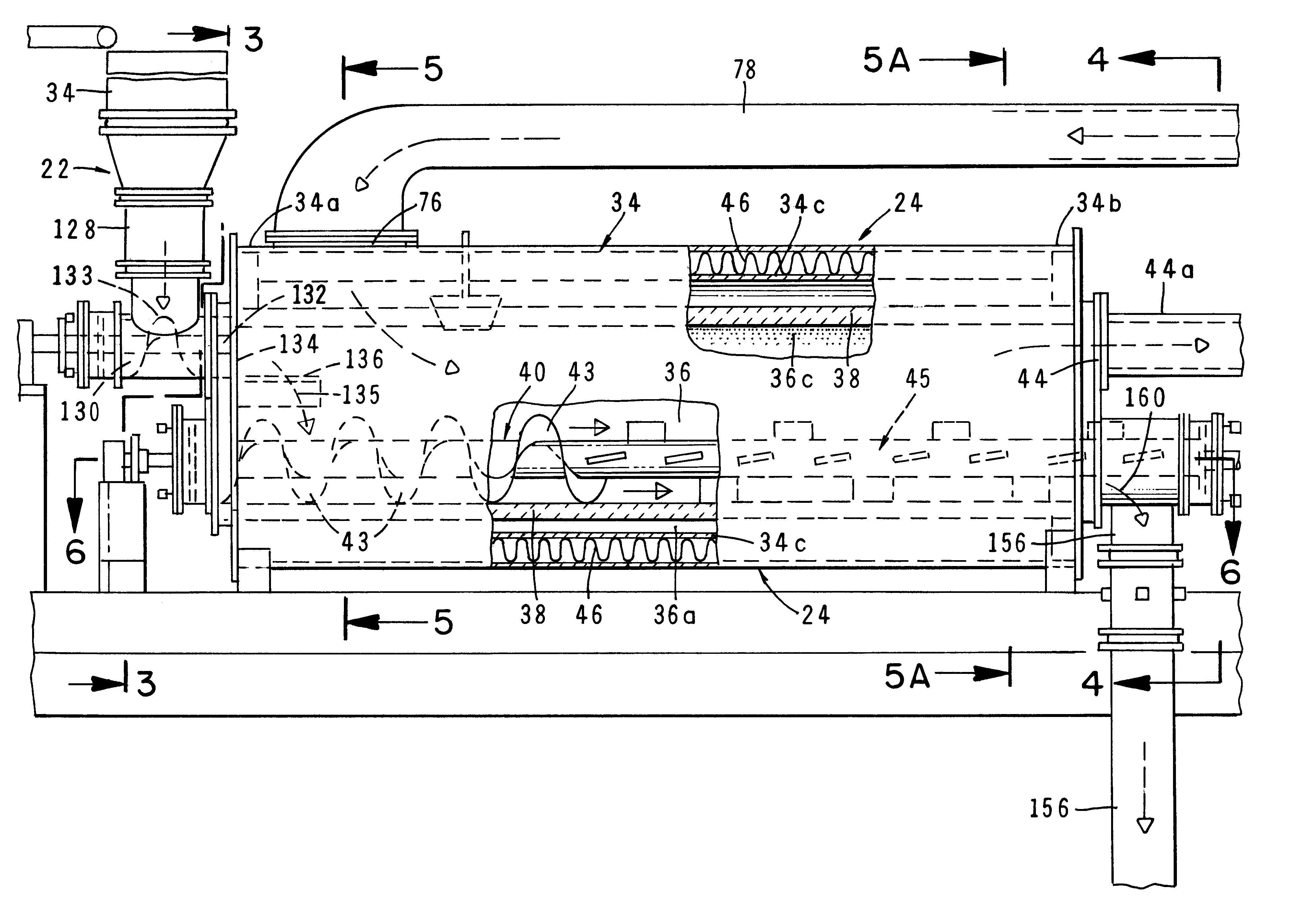

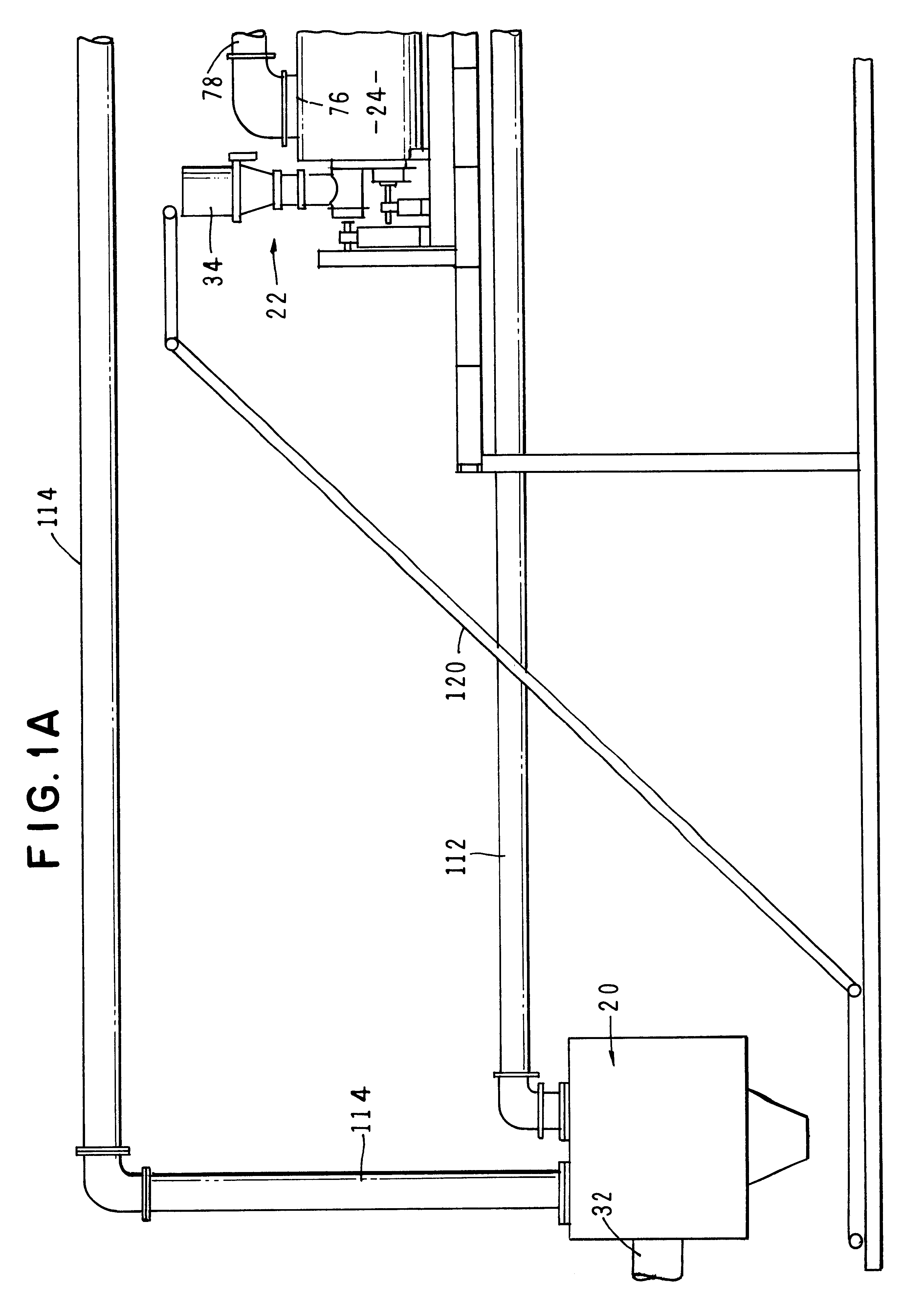

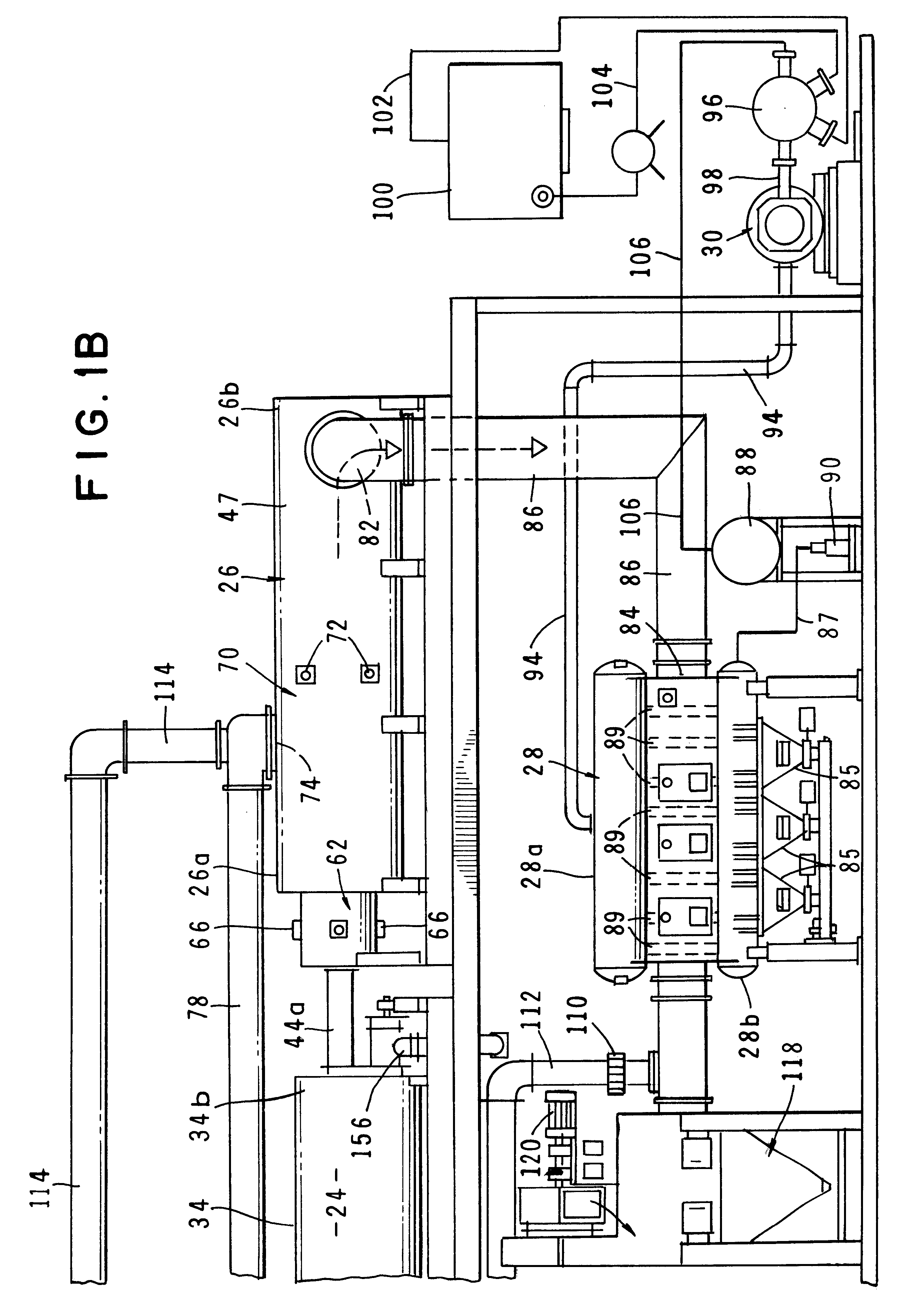

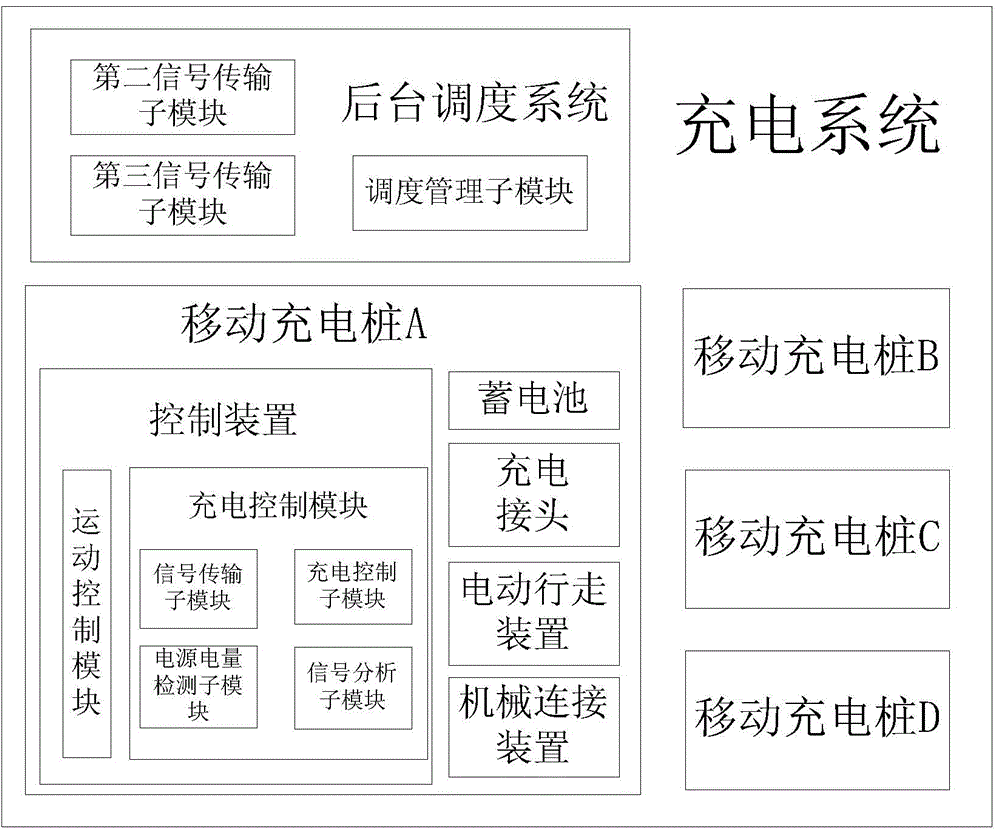

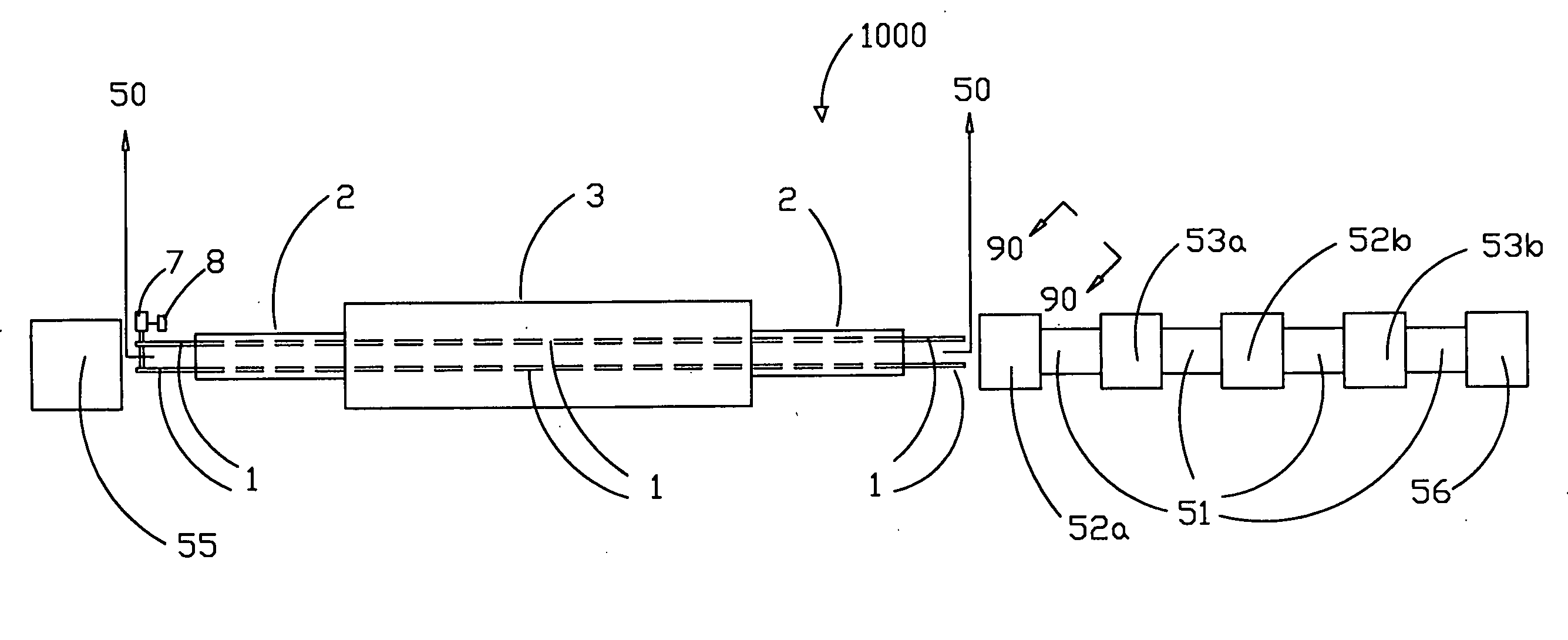

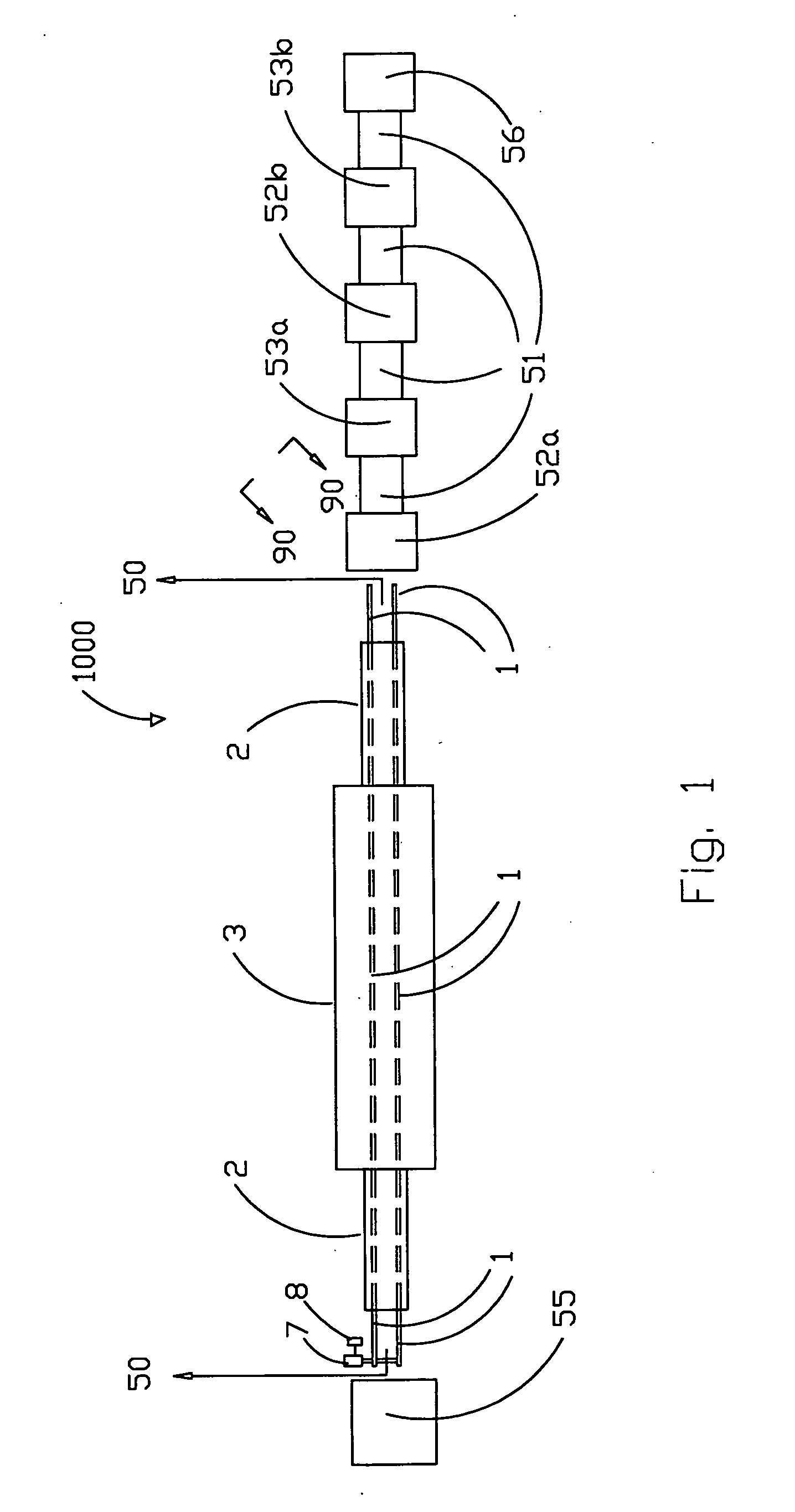

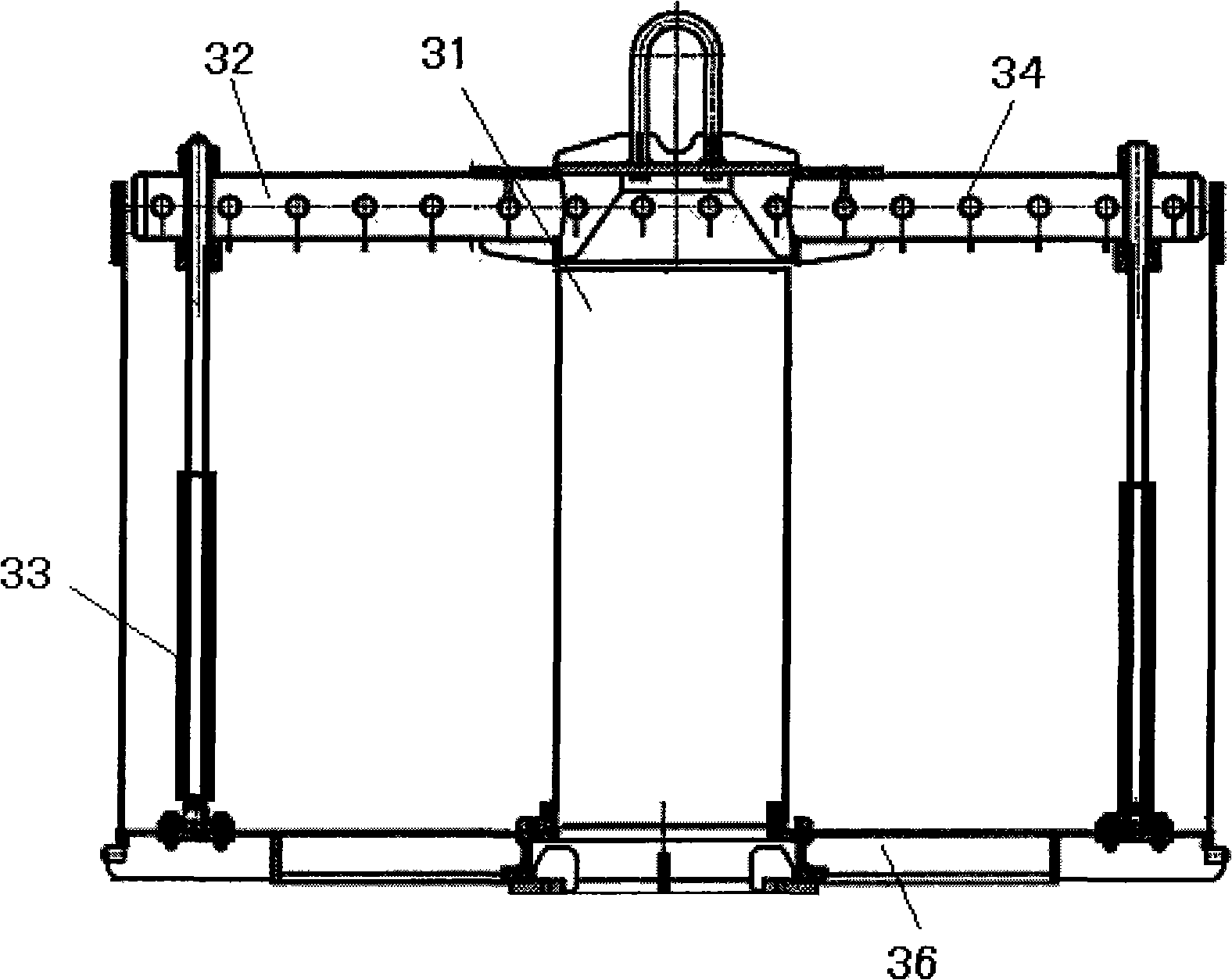

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

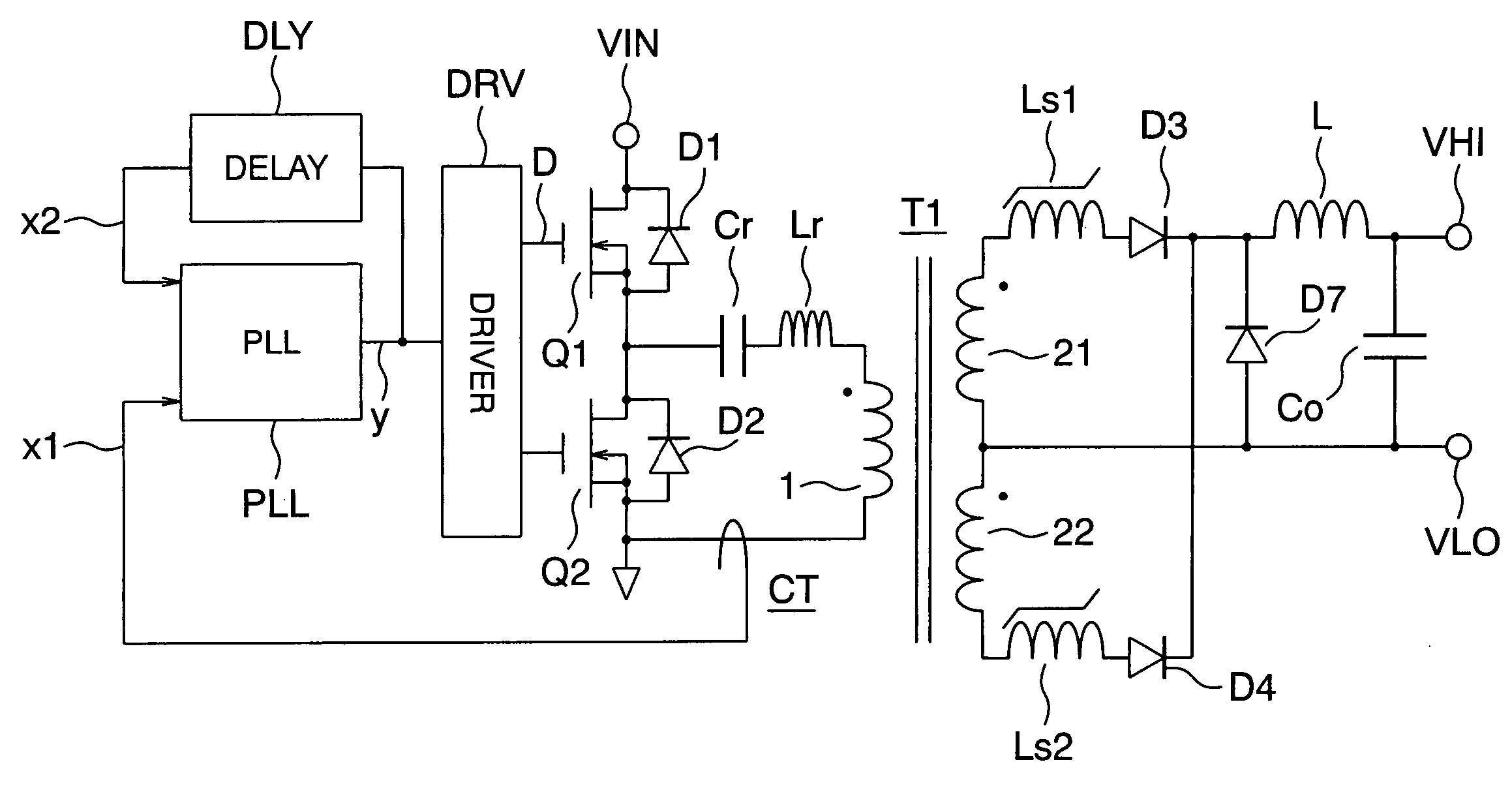

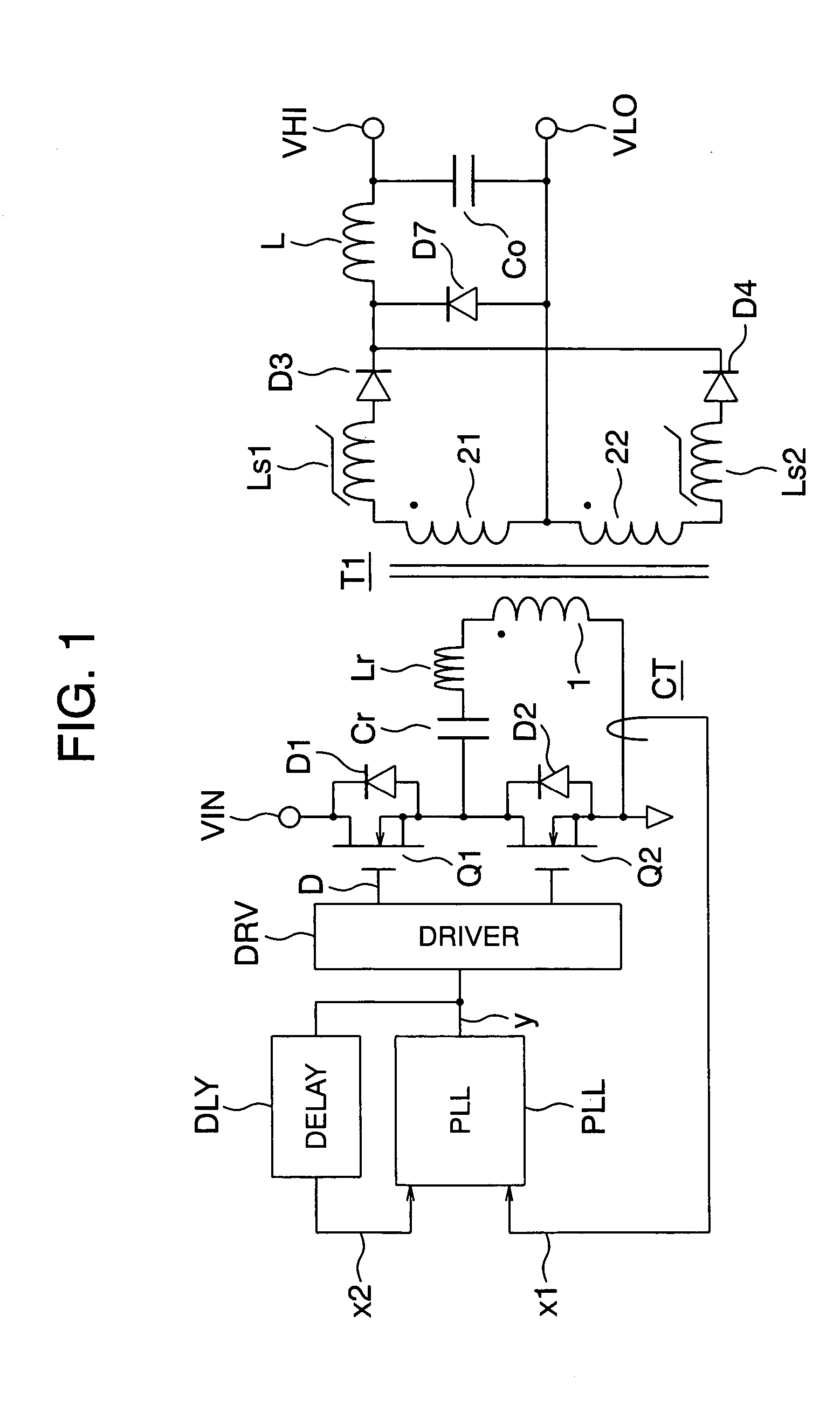

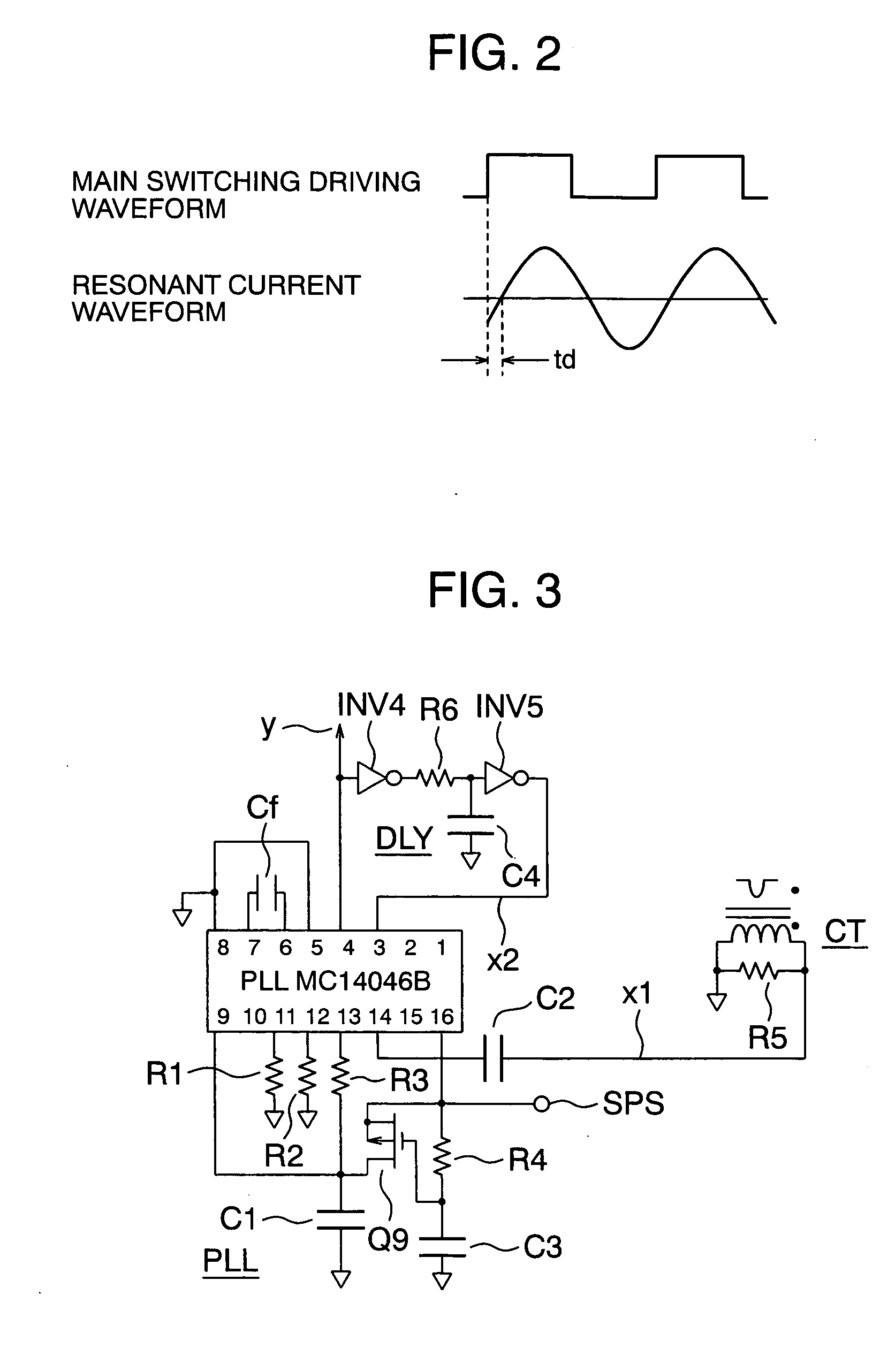

Resonant converter and control method thereof

InactiveUS20050099827A1Simple designReliable soft switching operationAc-dc conversion without reversalEfficient power electronics conversionSoft switchingZero phase

A resonant converter which can realize its easy design, eliminate the need for its adjustment, realize reliable soft switching operation, and increase an efficiency. A driver DRV of a main switching device uses a PLL circuit PLL to apply frequency tracking control in such a manner that a driving frequency fsw is made to track a resonant frequency fr (or 1 / N thereof, N being an odd number) and that the phase of the driving frequency fsw leads the current zero phase of the resonant frequency fr always by a desired time. As a result, such an optimum condition can be kept that the main switching device is triggered immediately before the zero-cross point of a resonant current. Thus the resonant converter which can always satisfy the optimum operational conditions, realize soft switching operation, and increase an efficiency can be realized with an easy design and a manufacturing adjustment-free arrangement.

Owner:HITACHI LTD

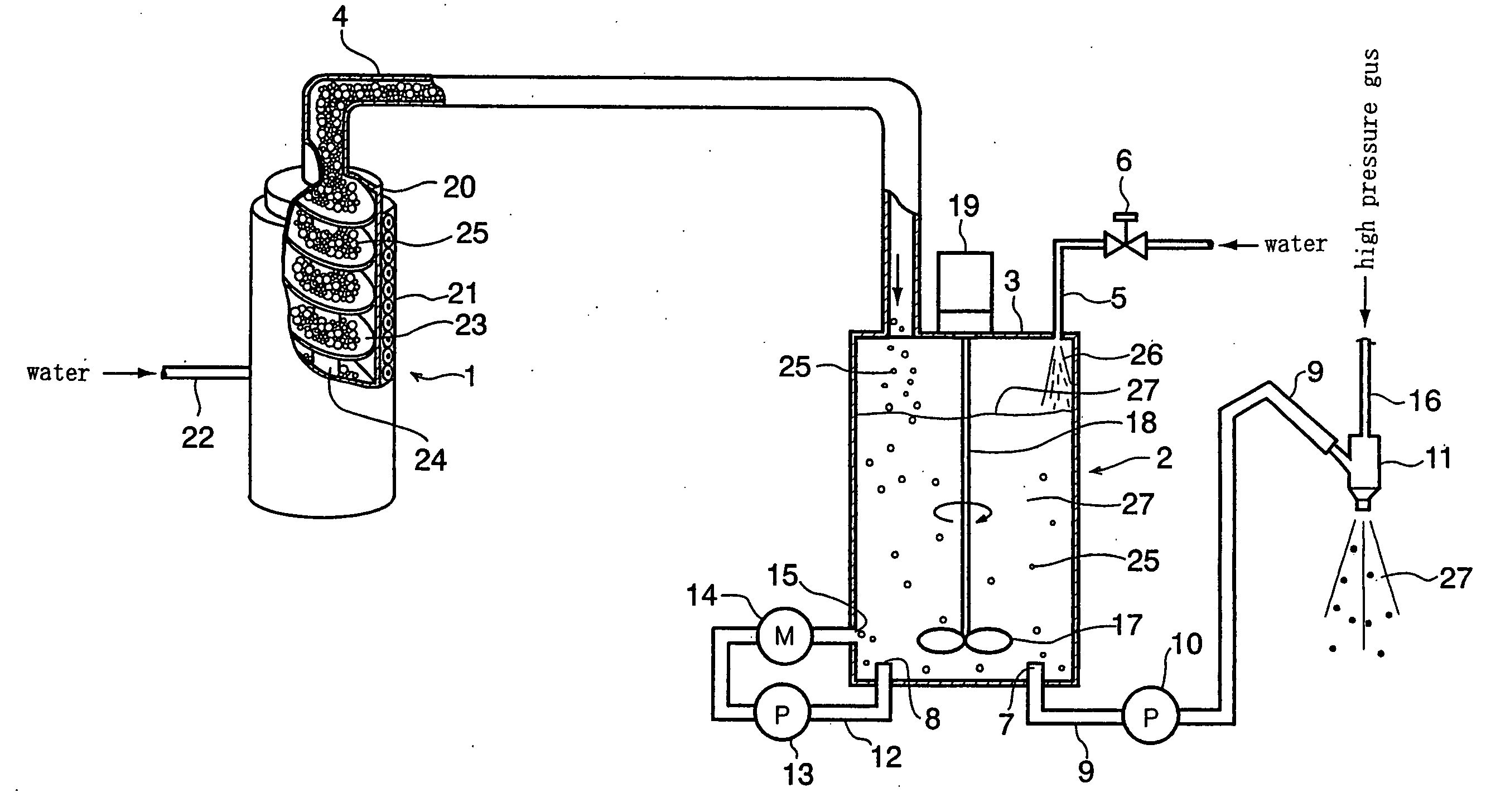

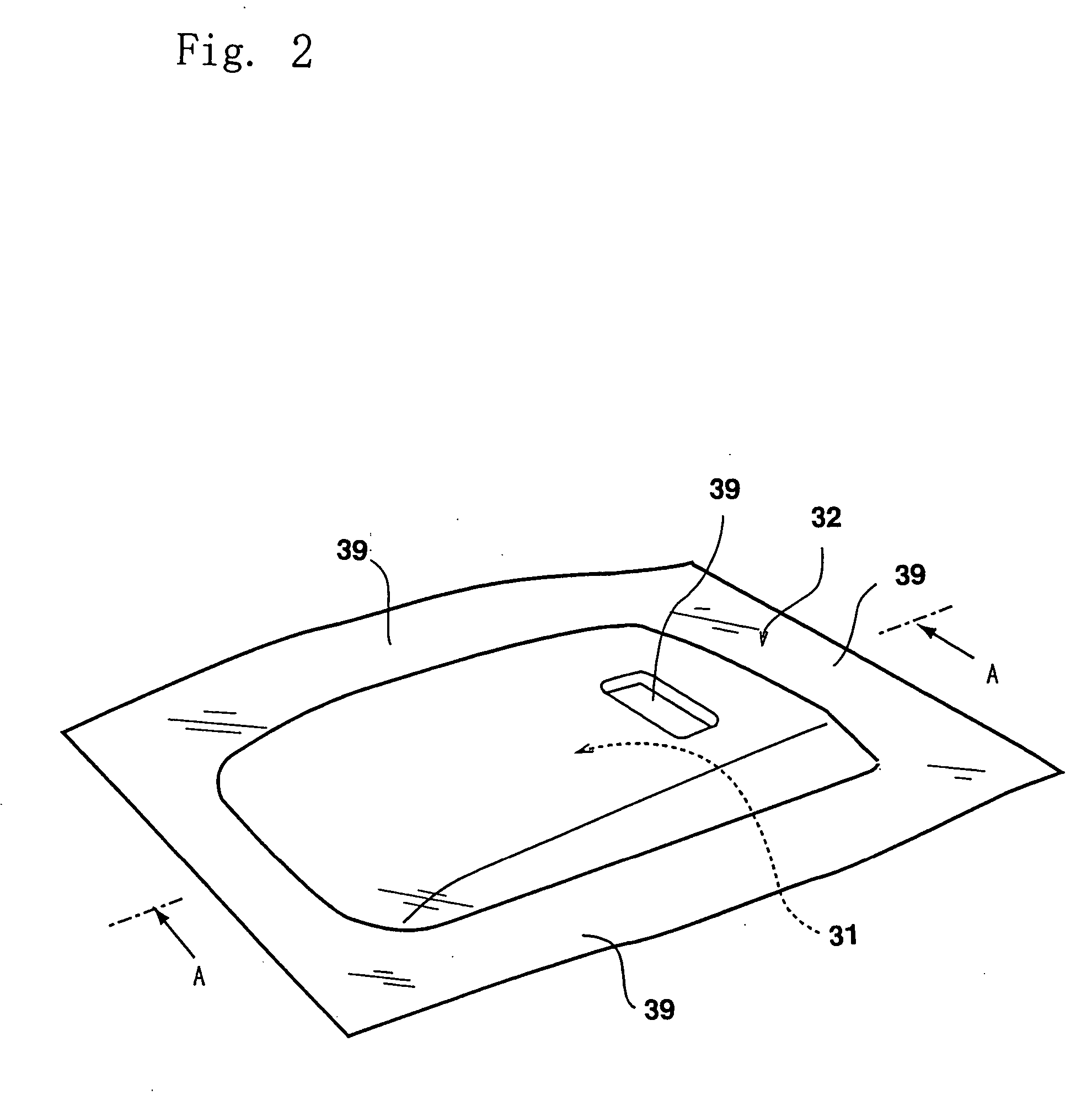

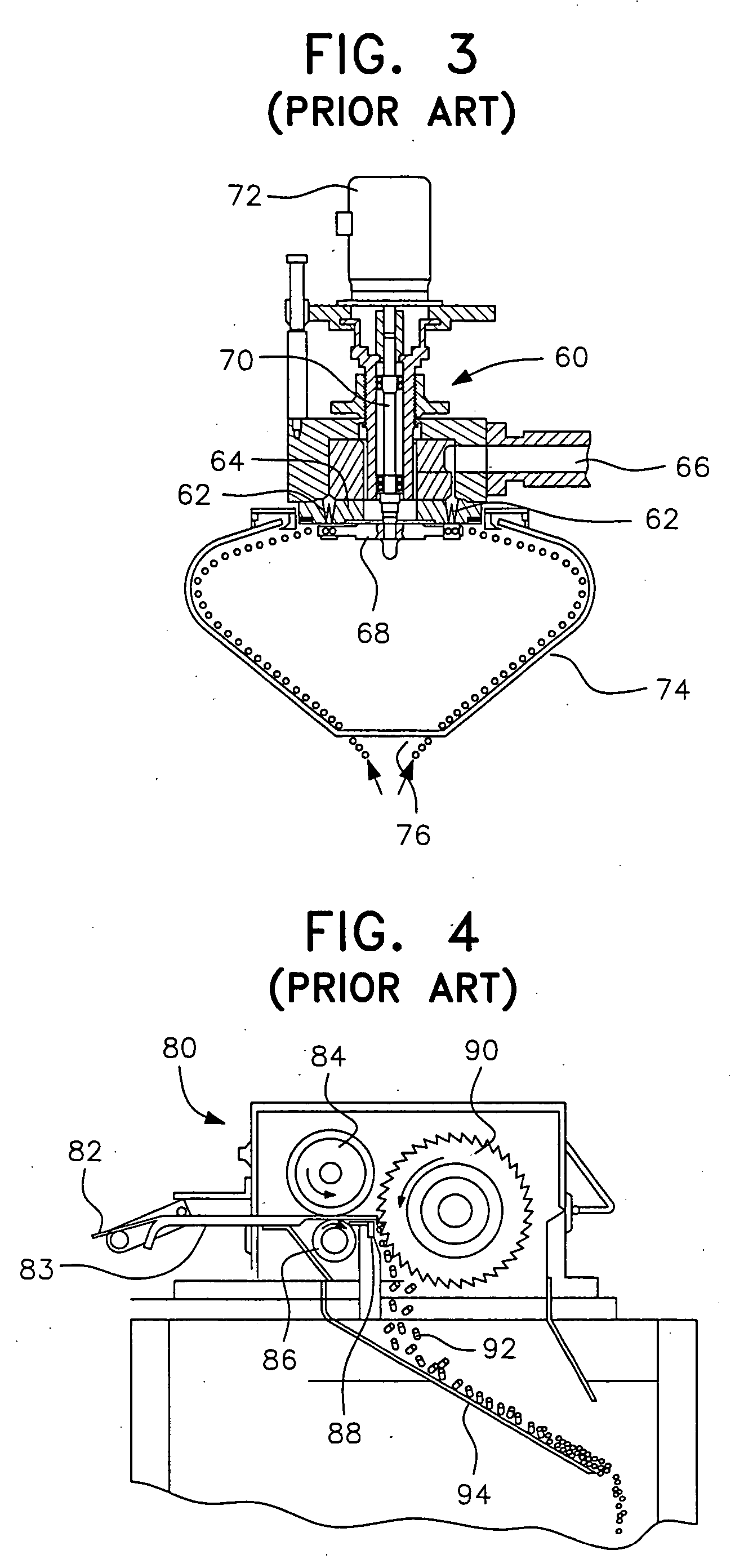

Ice blasting apparatus and trimming method for film insert molding

InactiveUS20050107006A1Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesEngineeringSlurry

An ice blasting apparatus comprises: an ice making device operating a cutting blade to shave off ice freezing on an inner wall of the freezing casing and continuously discharges the shaved ice as flake-shaped ice pellets; an ice mixing tank mixing the ice pellets and water and maintaining the resulting ice slurry at a predetermined concentration with a concentration sensor; and a blast gun blasting the ice slurry. A trimming method is performed on a film insert molding with a film material adhering to a face of a resin molding and extending beyond a periphery edge of the resin molding. A blast gun facing the face with the film adhering to it blasts ice slurry of a required concentration toward the vicinity of the periphery edge of the resin molding to remove the unnecessary portion of the film material extending beyond the periphery edge of the resin molding.

Owner:TOSHIBA MASCH CO LTD

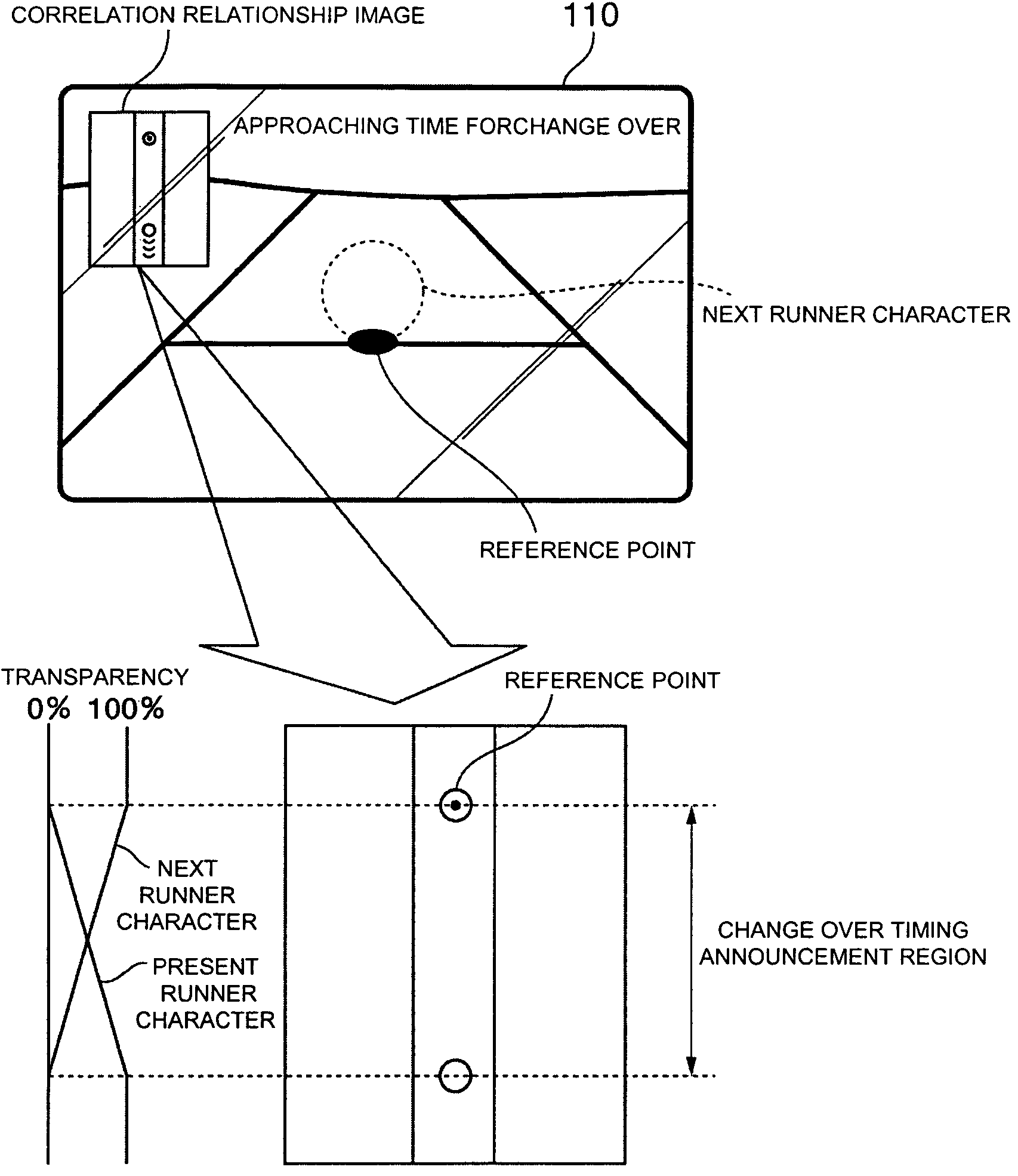

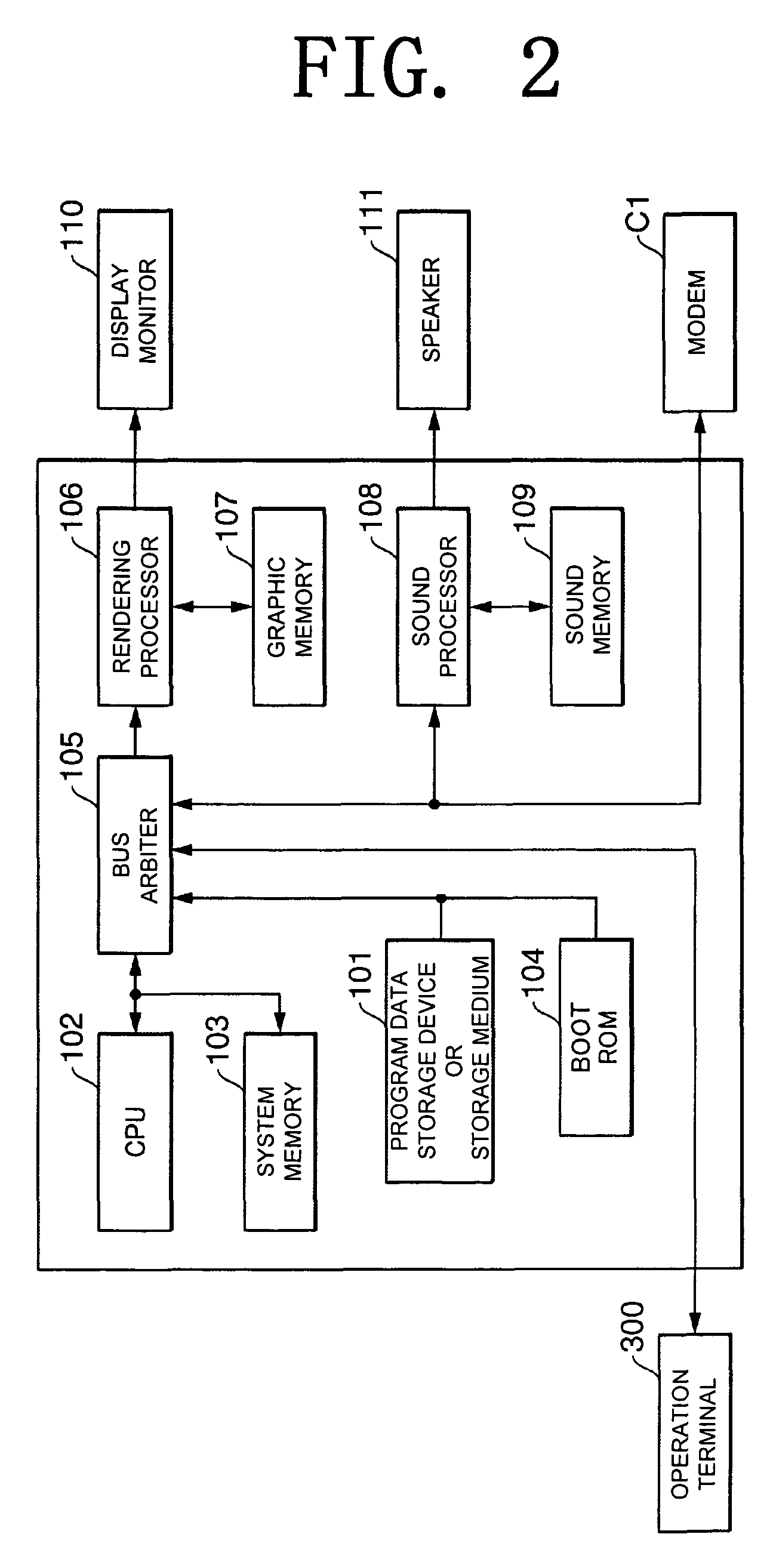

Game system with changing character control

ActiveUS7749056B2Continuous operationPrevent dishonest changingVideo gamesImage data processingMultimedia

To provide a game system in which each of the players in turn controls a common character (operation object) so as to enjoy a continuous electric game; and to provide a game system in which a previous player who has been replaced by another player still has willing to participate in the game.There is provided a game system to which a plurality of players can access via respective operation terminals. According to input data from the operation terminals, a calculation processing device executes a game program, judges that a plurality of players are participating in the game, establishes teams, each consisting of a plurality of players, assigns a common character to each team, decides a reference point when the operation of the character is to be performed by another player belonging to the same team according to the program, judges whether the character has reached the reference point according to the parameter of the character, and, if the judgment is yes, offers the operation right of the character to another player, and controls the game system to continue the operation of the character addording to the signal from the operation terminal of the another player.

Owner:SEGA CORP

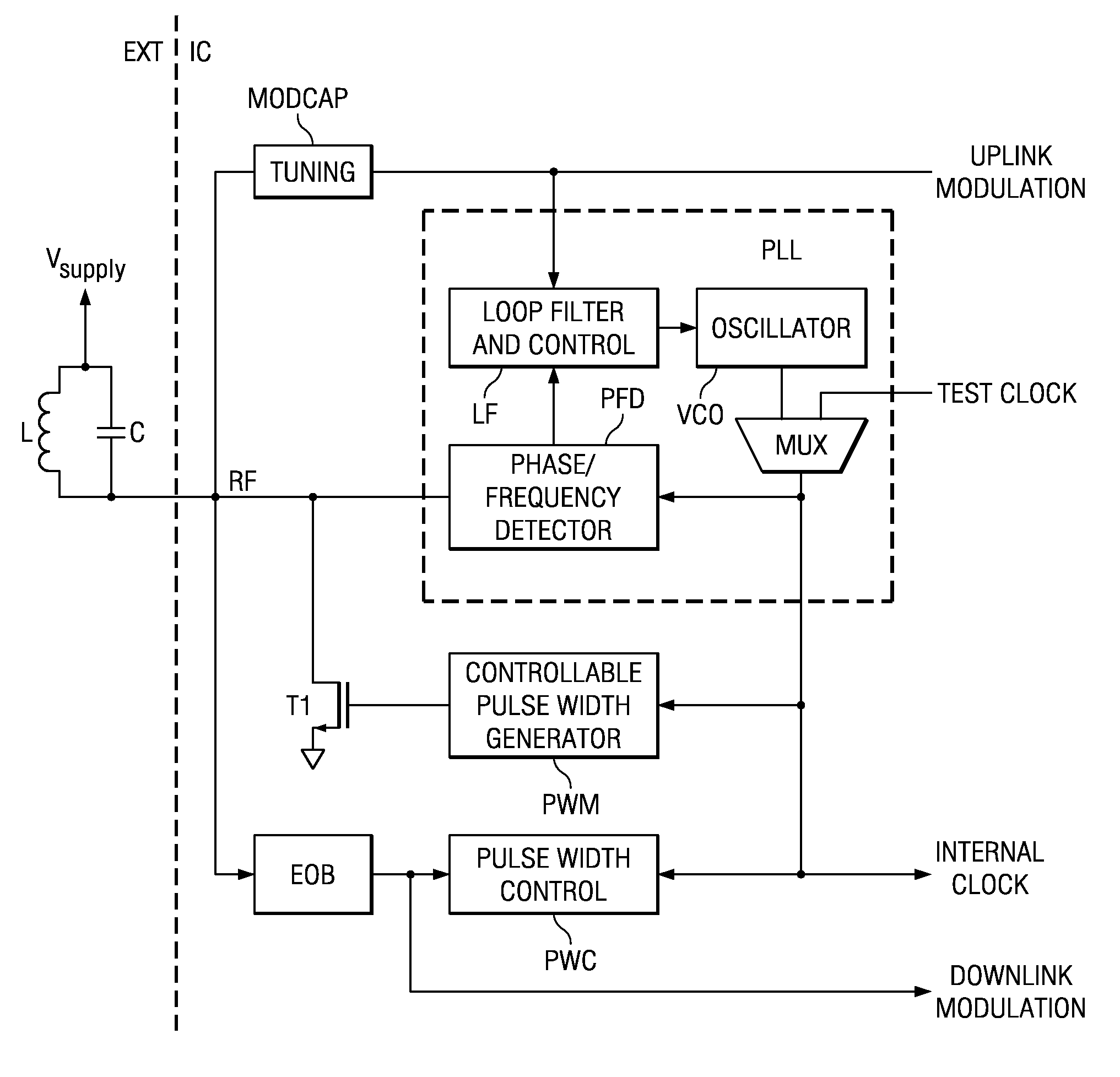

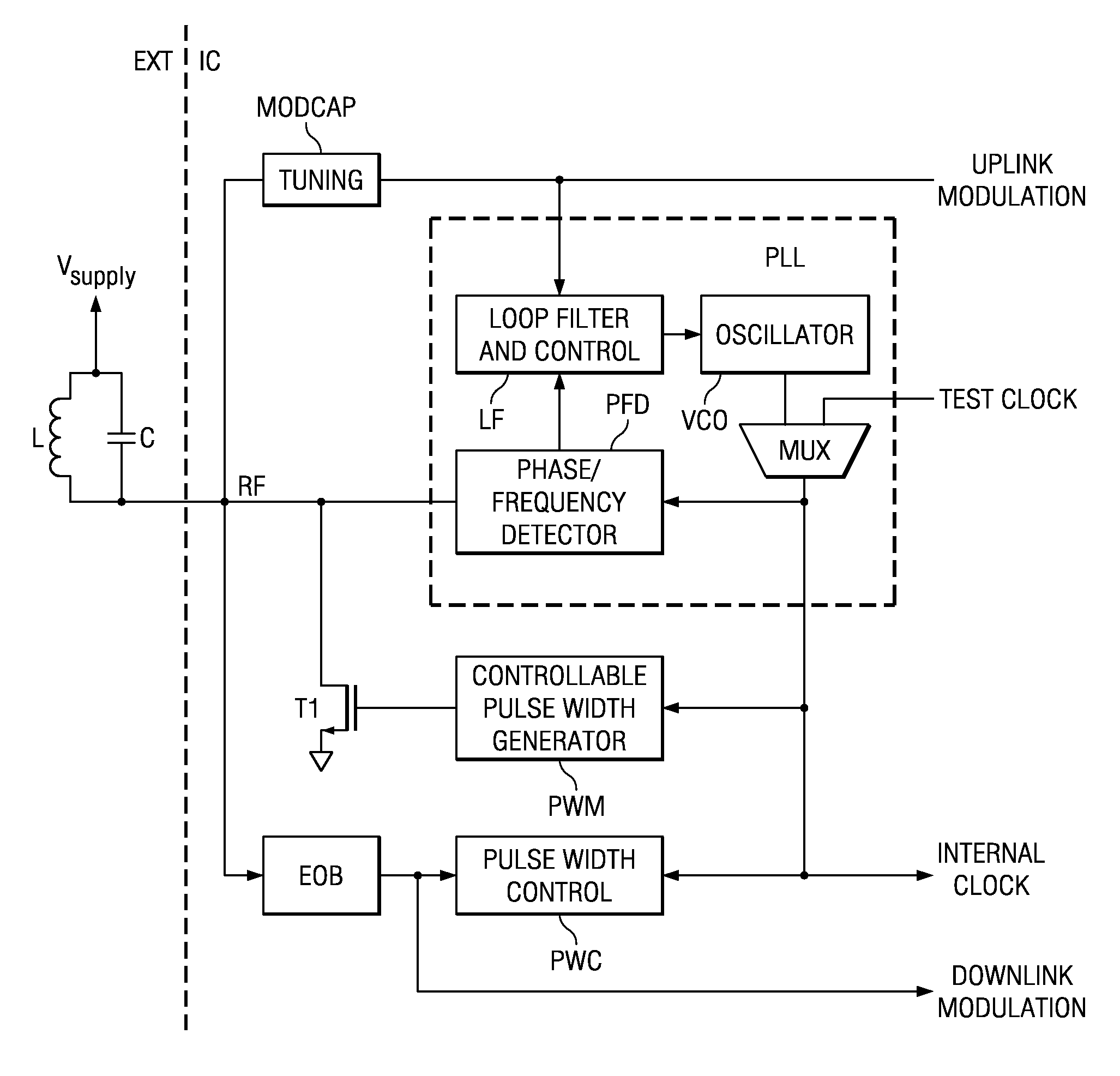

RFID transponder with pll

ActiveUS20090174592A1The testing process is simpleLow costTransmissionRecord carriers used with machinesAudio power amplifierEngineering

An RFID transponder comprises an antenna for receiving data in a downlink mode and transmitting data in an uplink mode, with a modulation stage for modulating uplink data and a demodulation stage for demodulating downlink data. A class C amplifier is provided, which has a resonant circuit, a plucking device coupled to the resonant circuit, and a controllable pulse width generator coupled to the plucking device. The controllable pulse width generator is adapted to periodically switch the plucking device on and off so as to maintain an oscillation of the resonant circuit. The transponder further comprises a phase locked loop configured to be locked to an oscillating signal received through the antenna and to be switched into a free running mode without being locked to the oscillating signal received through the antenna, thereby being adapted to output an independent internal clock signal for the RFID transponder.

Owner:TEXAS INSTR INC

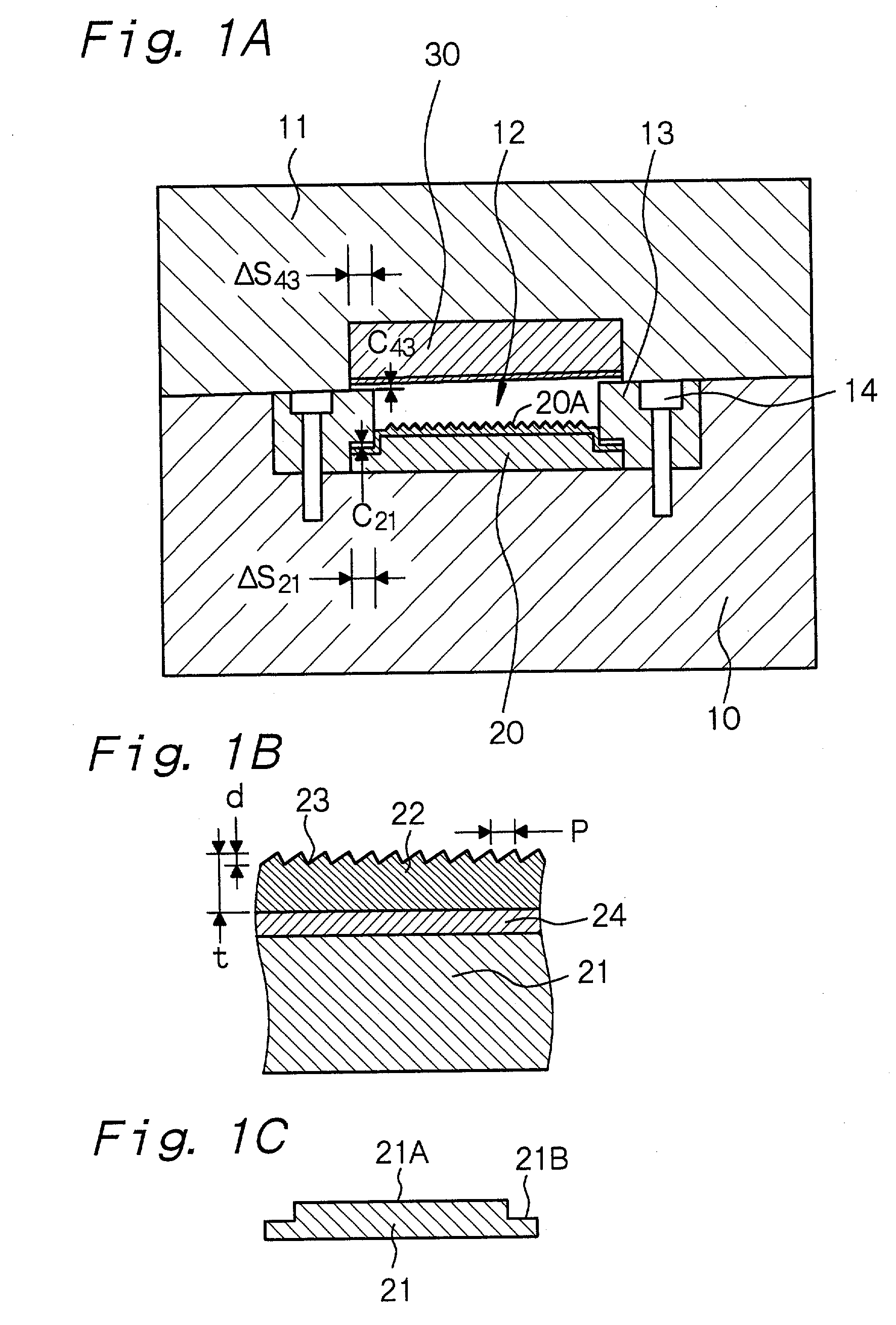

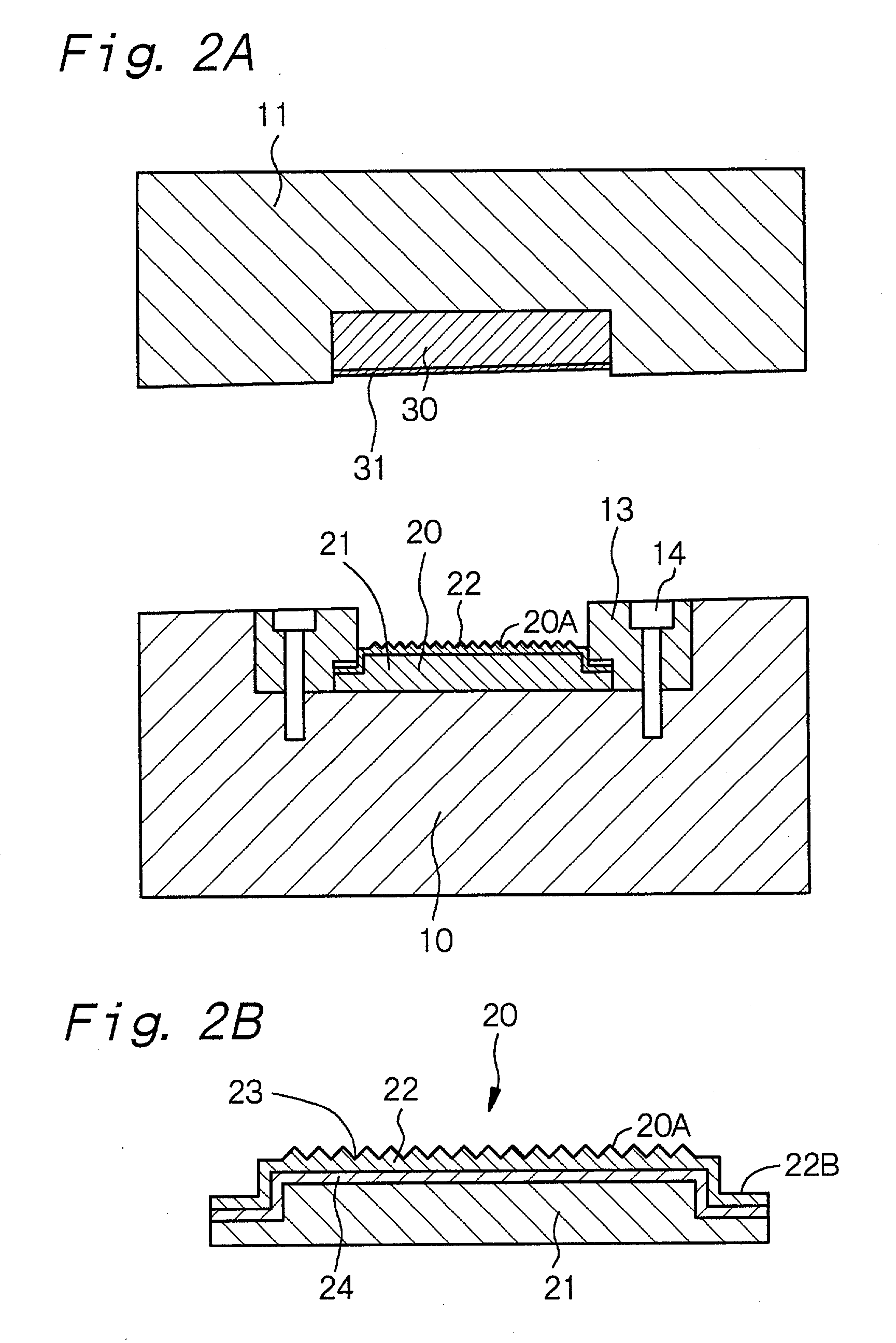

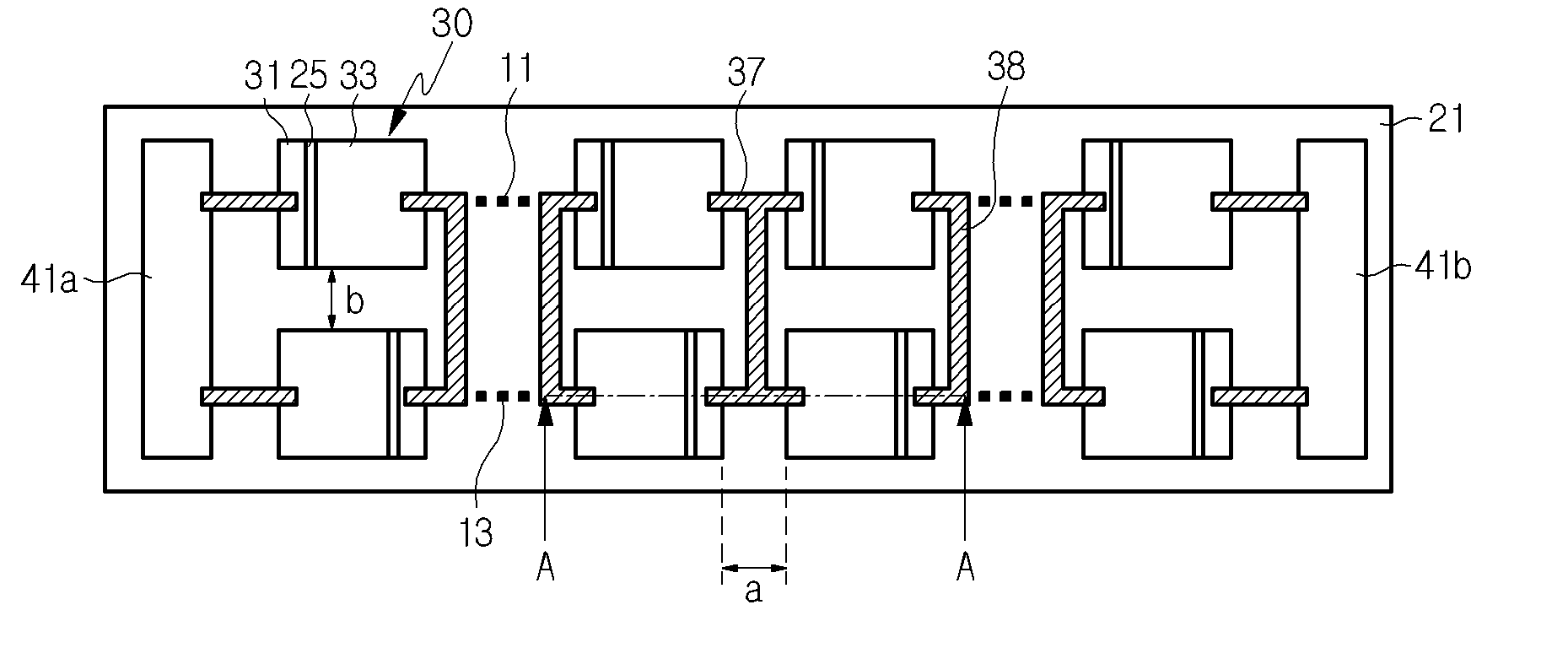

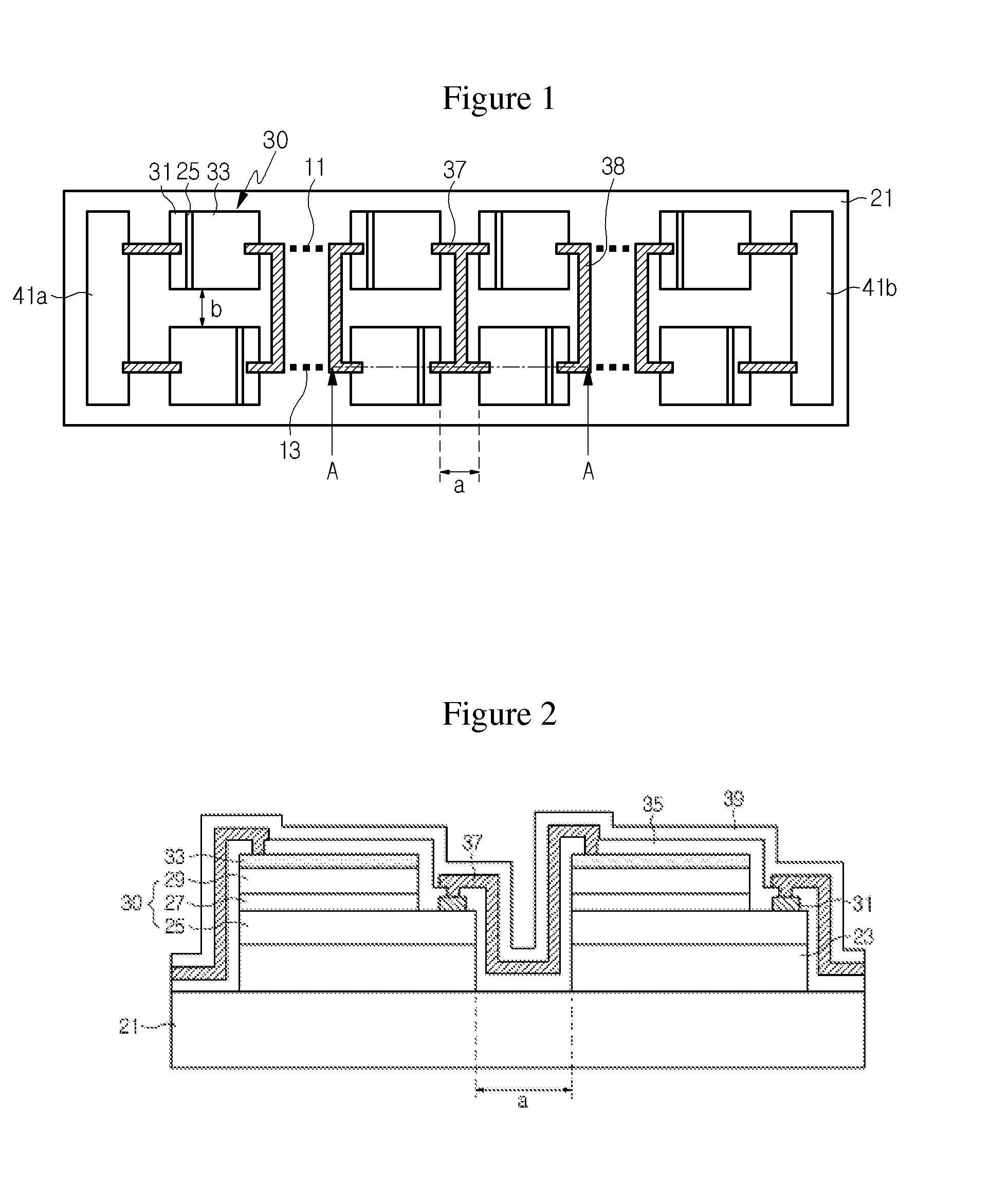

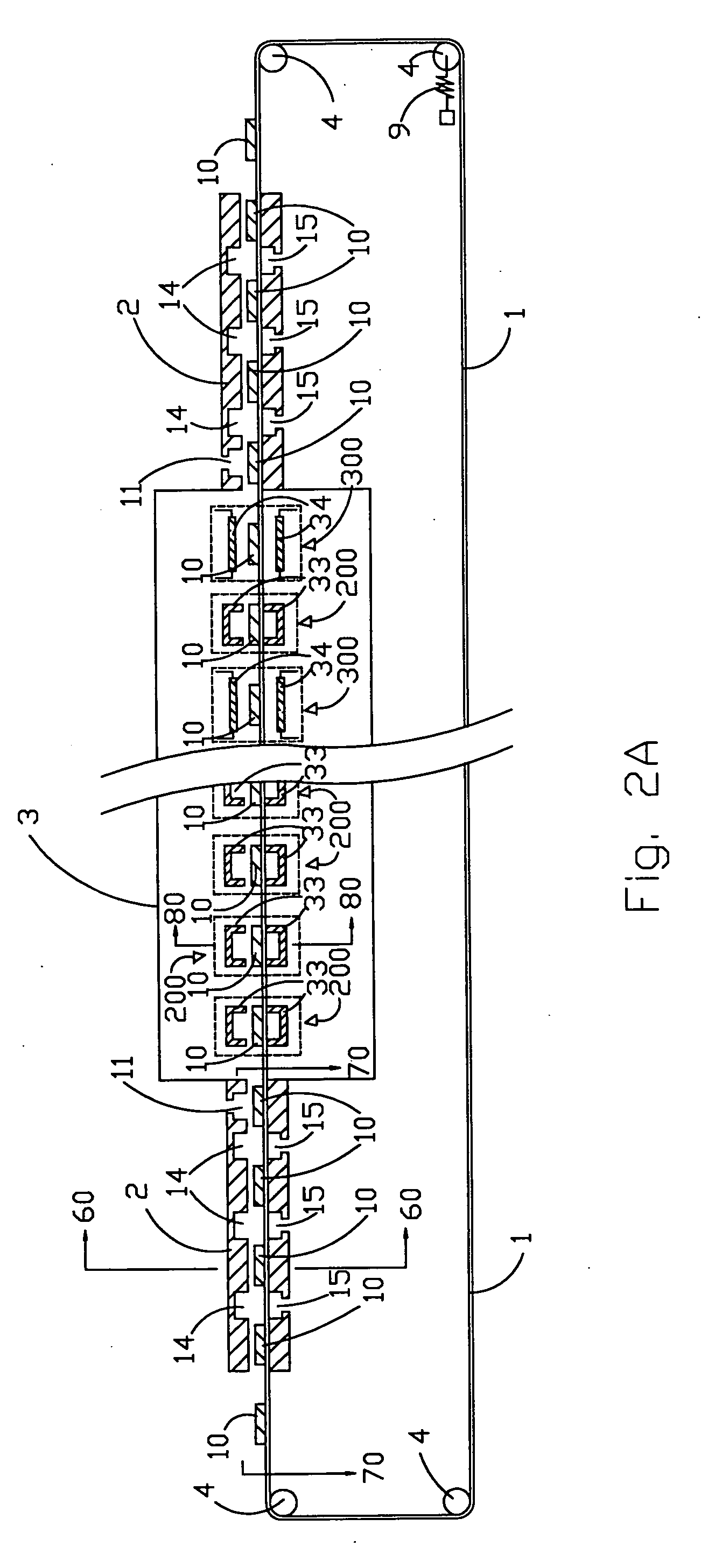

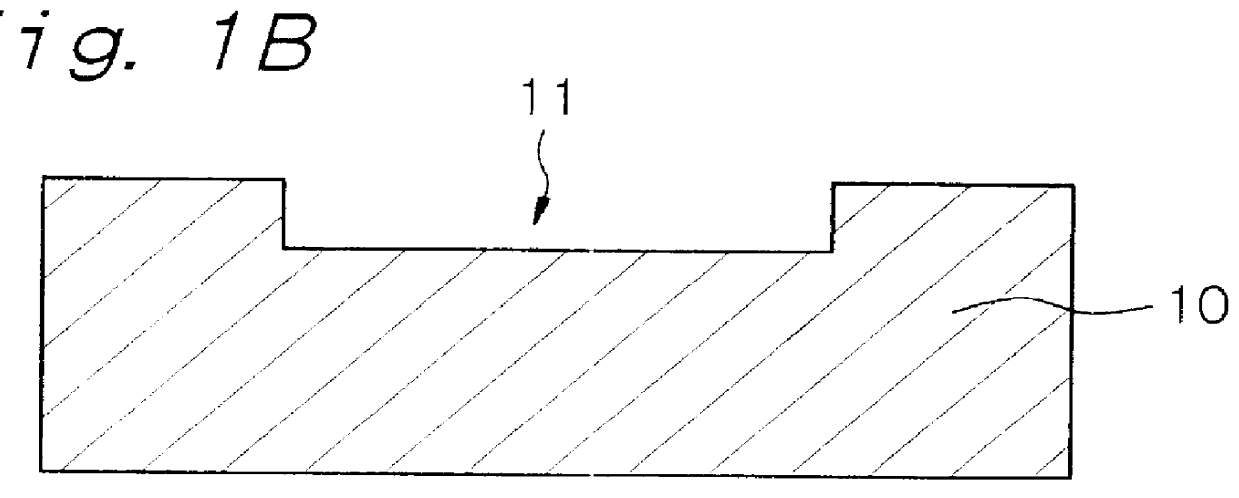

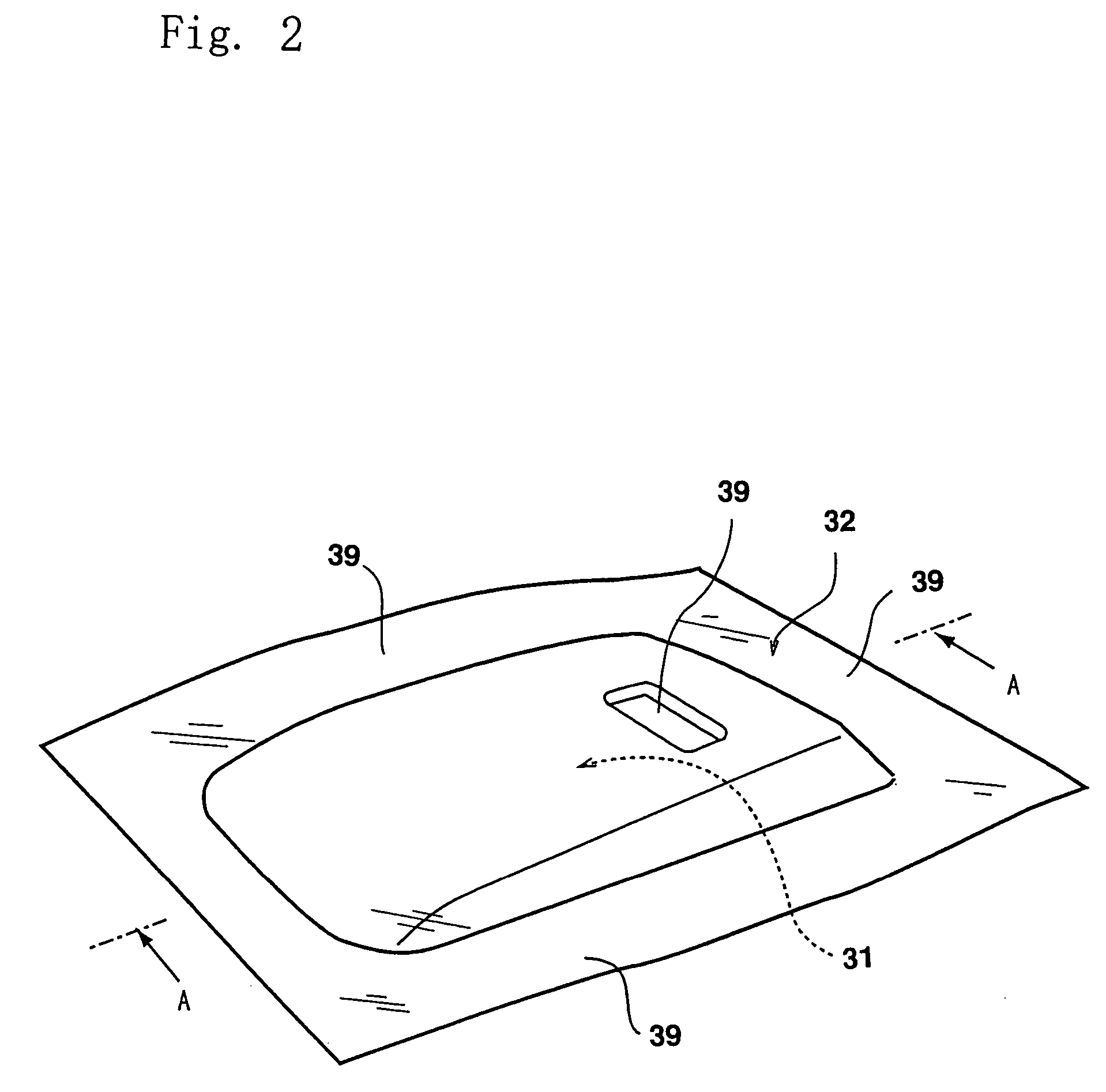

Light guide plate made of transparent resin, molding method thereof, insert block, mold assembly, and area light apparatus

InactiveUS20020181224A1Accurately reliably formedCorrect formatMechanical apparatusMouldsLight guideMechanical engineering

A light guide plate which is made of a transparent resin and has a first main surface and a second main surface opposite to said first main surface, said first main surface having a surface portion provided with convex portions having a height of 5x10-7 m to 6x10-5 m each and a pitch of 5x10-7 m to 4x10-4 m, each convex portion having a tip portion, and the convex portions of at least 80% of the total convex portions having the tip portions having a radius of curvature of 2x10-6 m or less.

Owner:MITSUBISHI ENG PLASTICS CORP

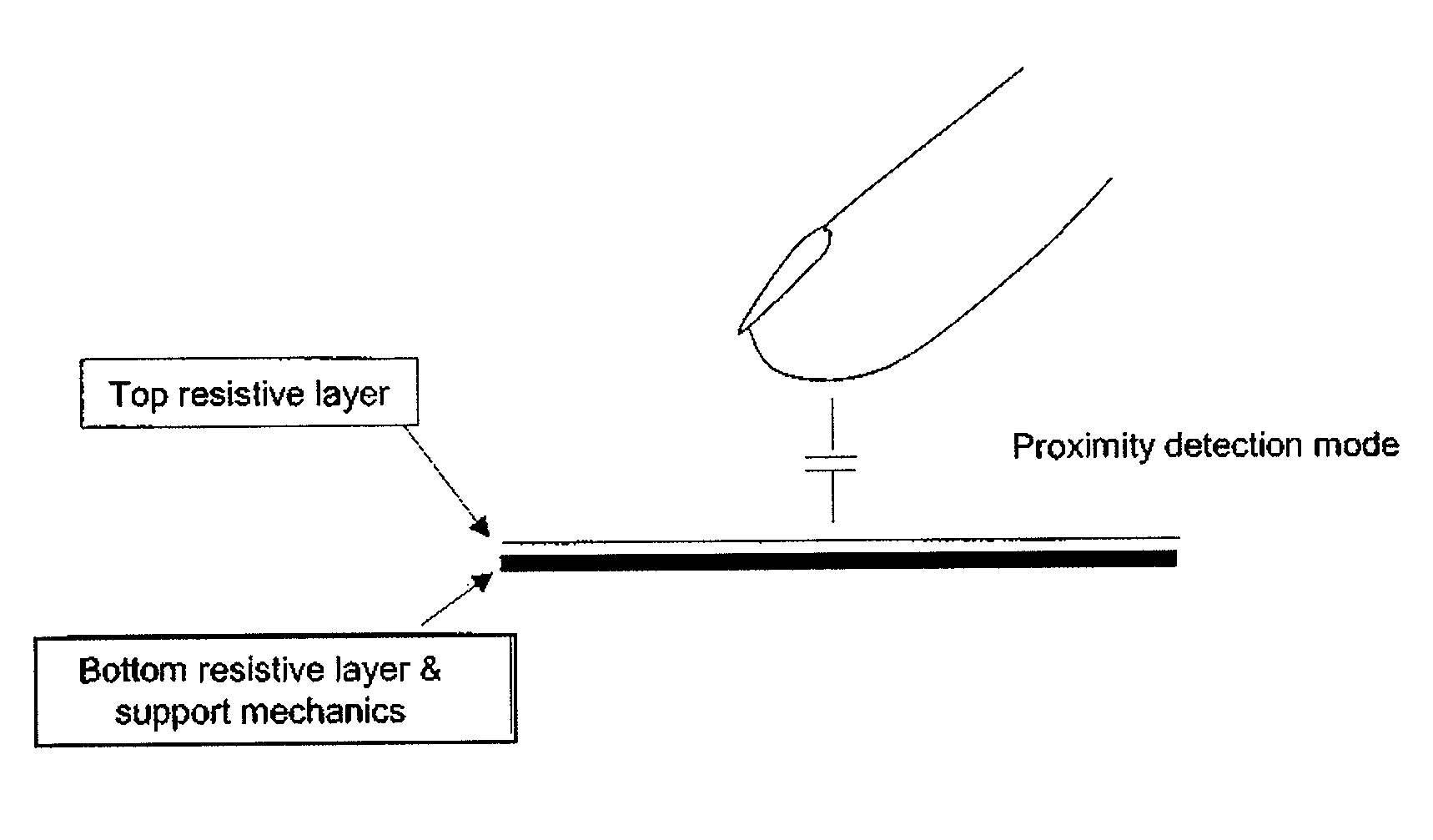

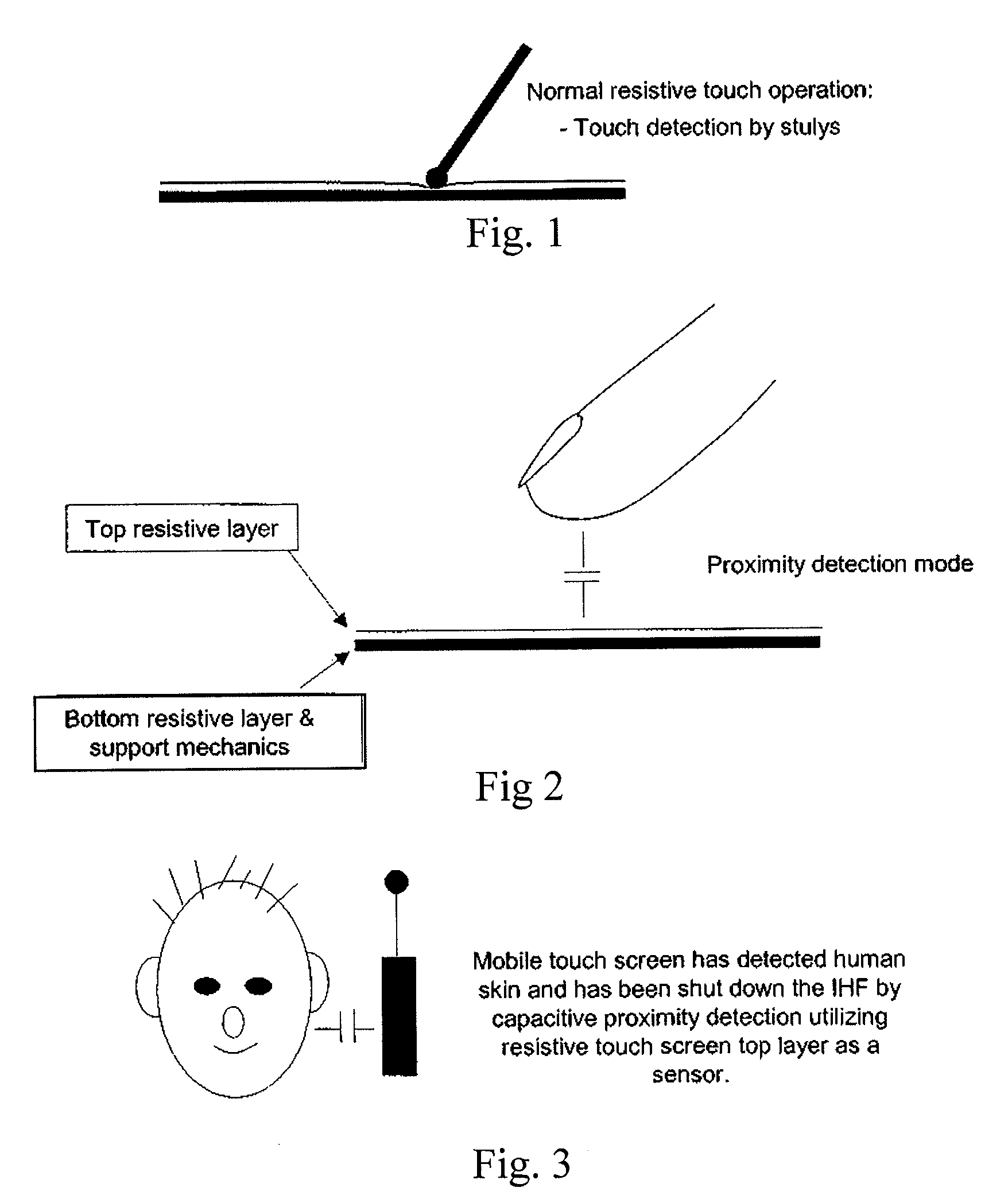

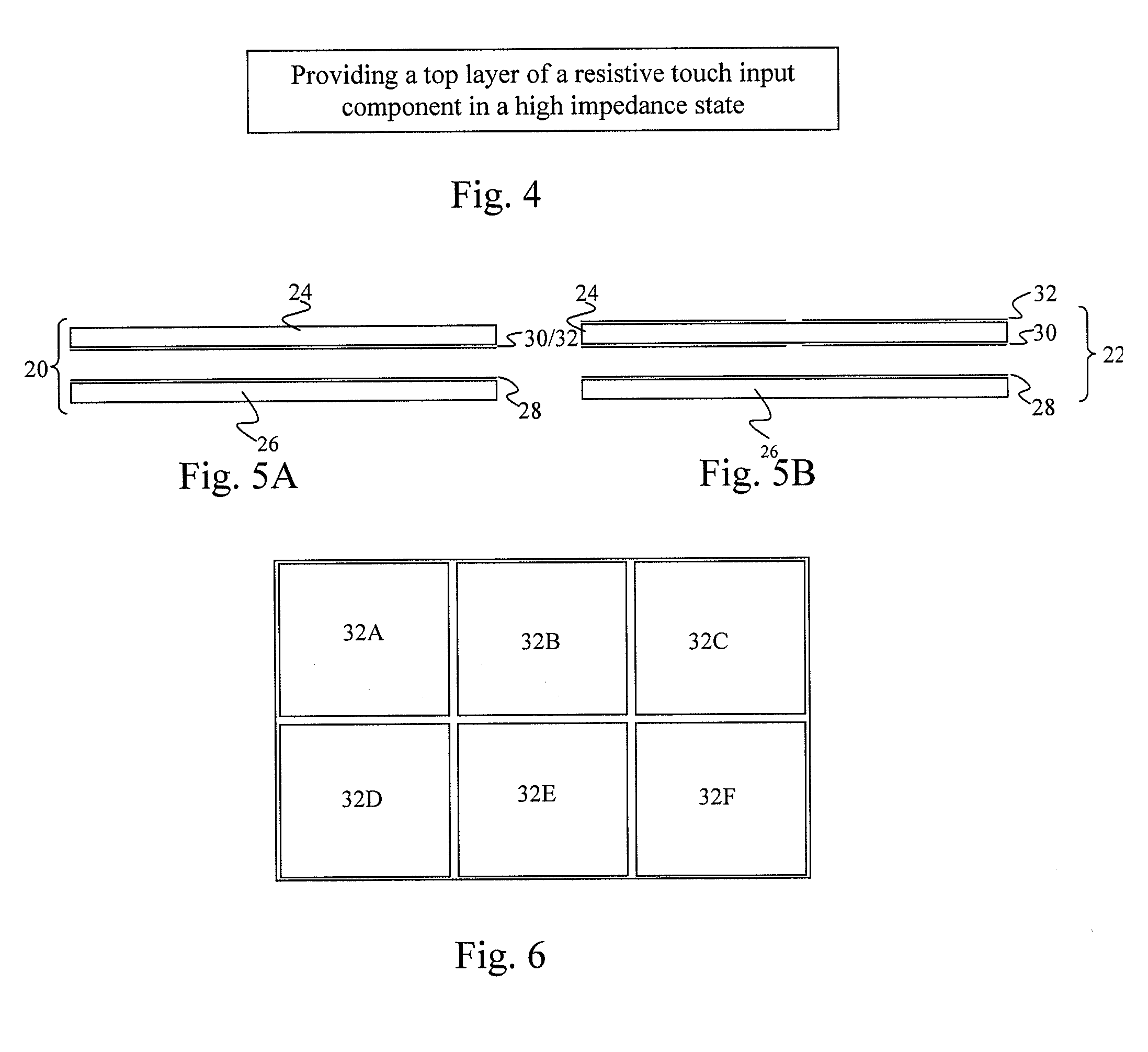

Method and device for operating a resistive touch input component as a proximity sensor

InactiveUS20090194341A1Simple and fast calibrationEasy to detectEnergy efficient ICTTransmission systemsProximity sensorEngineering

A device is provided which includes a resistive touch input component. The resistive touch input component may operate as a proximity sensor and may include upper and lower conductive layers. The upper conductive layer may be in a higher impedence state than the lower conductive layer. A method for controlling a resistive touch input component is also provided in which at least a first terminal of a device is provided for connecting the upper conductive layer in a high impedence state, and in which at least one second terminal is provided for connecting a lower conductive layer in a state capable of operating the touch input component. Corresponding computer program products and devices are also provided.

Owner:NOKIA CORP

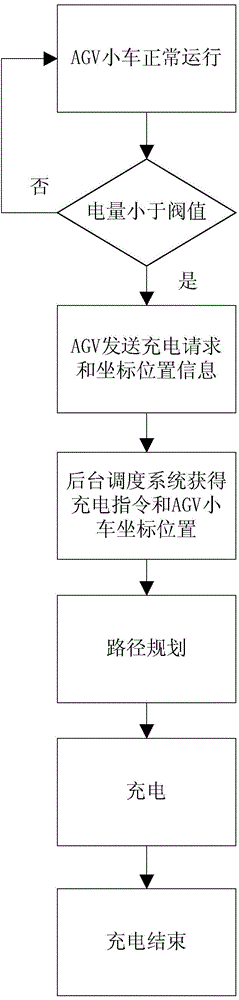

Charging method of automatic guided vehicle (AGV), movable charging pile and charging system

ActiveCN104836293ATimely chargingContinuous operationSecondary cells charging/dischargingElectric powerCharging stationElectrical and Electronics engineering

The invention provides a charging method of an automatic guided vehicle (AGV), a movable charging pile according to the charging method, and an AGV charging system. A moving path is independently planned through the movable charging pile, and the AGV is actively charged when the movable charging pile arrives at the AGV. Not only are AGV moving to a charging station for charging and working time occupation prevented, but also no interference and obstruction among different movable charging piles in a movement path are prevented. Furthermore high equipment utilization rate and in-time charging to the AGV are realized. The movable charging pile of the invention can move simultaneously with charged equipment for ensuring connection of charging interfaces, realizing continuous charging and ensuring continuous and non-stopped operation of the AGV. Furthermore, through scheduling by a background scheduling system, not only can charging timeliness be ensured, but also beforehand time arrangement for the movable charging pile can be realized, thereby ensuring most timely and most reasonable charging opportunity for the AGV in a busy charging task.

Owner:HANGZHOU JIAZHI TECH CO LTD

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

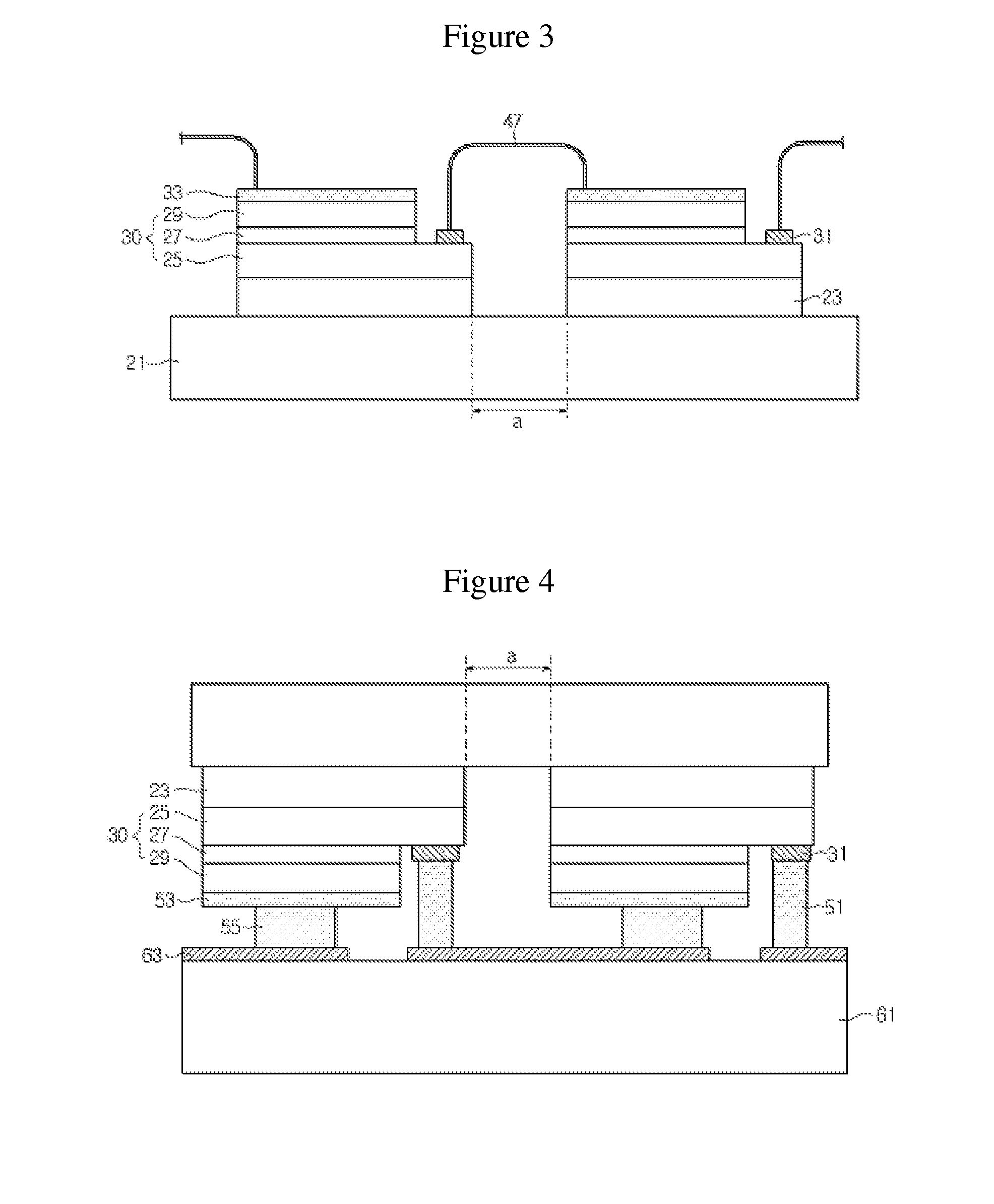

Ac light emitting diode

ActiveUS20100117101A1Improve operating characteristicsAvoid Overvoltage ProblemsSolid-state devicesSemiconductor devicesAC powerLight-emitting diode

Owner:SEOUL VIOSYS CO LTD

Apparatus and processes for the mass production of photovoltaic modules

InactiveUS20050158891A1Time stableImprove throughputPolycrystalline material growthSemiconductor/solid-state device manufacturingAbrasive blastingVacuum pressure

An apparatus and processes for large scale inline manufacturing of CdTe photovoltaic modules in which all steps, including rapid substrate heating, deposition of CdS, deposition of CdTe, CdCl2 treatment, and ohmic contact formation, are performed within a single vacuum boundary at modest vacuum pressures. A p+ ohmic contact region is formed by subliming a metal salt onto the CdTe layer. A back electrode is formed by way of a low cost spray process, and module scribing is performed by means of abrasive blasting or mechanical brushing through a mask. The vacuum process apparatus facilitates selective heating of substrates and films, exposure of substrates and films to vapor with minimal vapor leakage, deposition of thin films onto a substrate, and stripping thin films from a substrate. A substrate transport apparatus permits the movement of substrates into and out of vacuum during the thin film deposition processes, while preventing the collection of coatings on the substrate transport apparatus itself.

Owner:COLORADO STATE UNIVERSITY

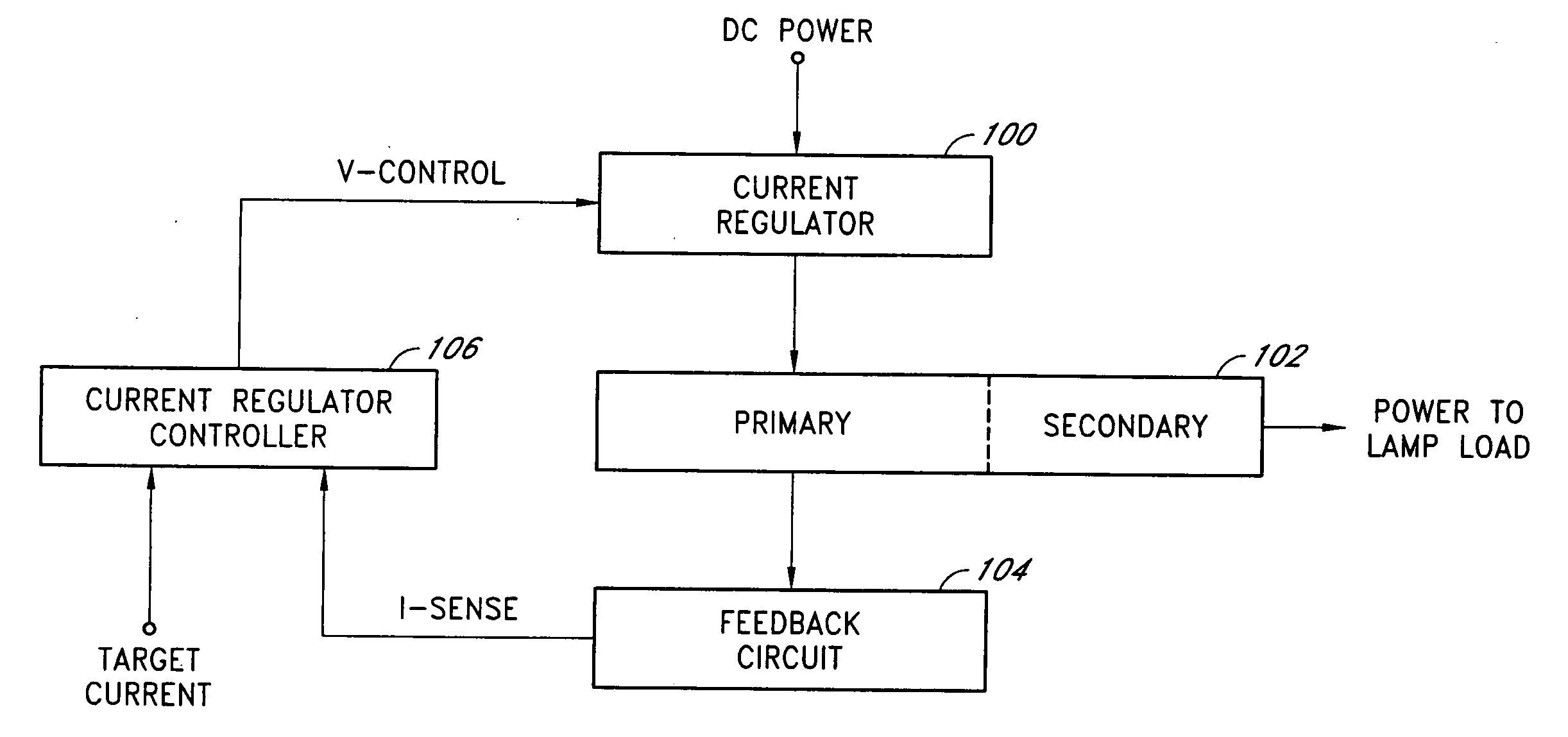

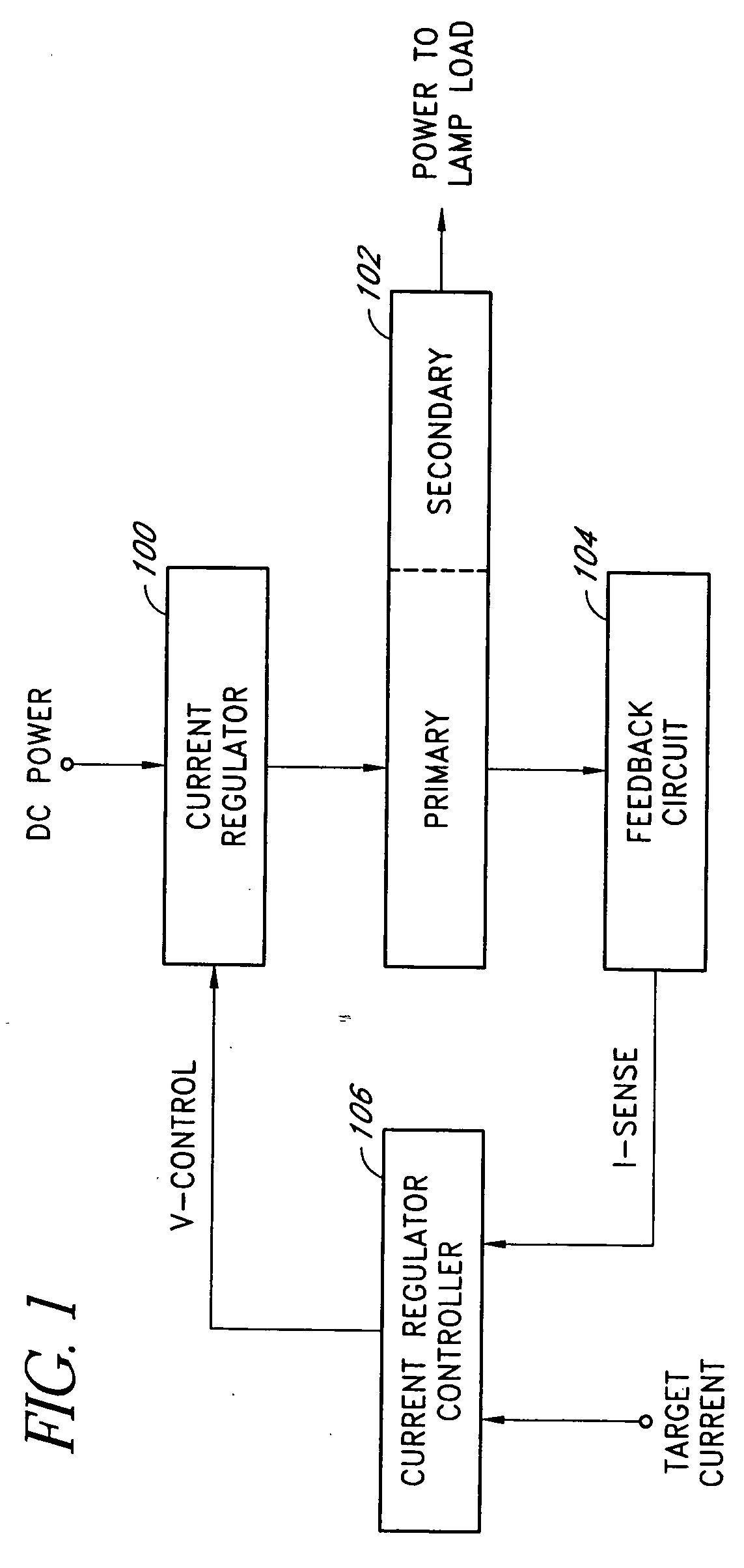

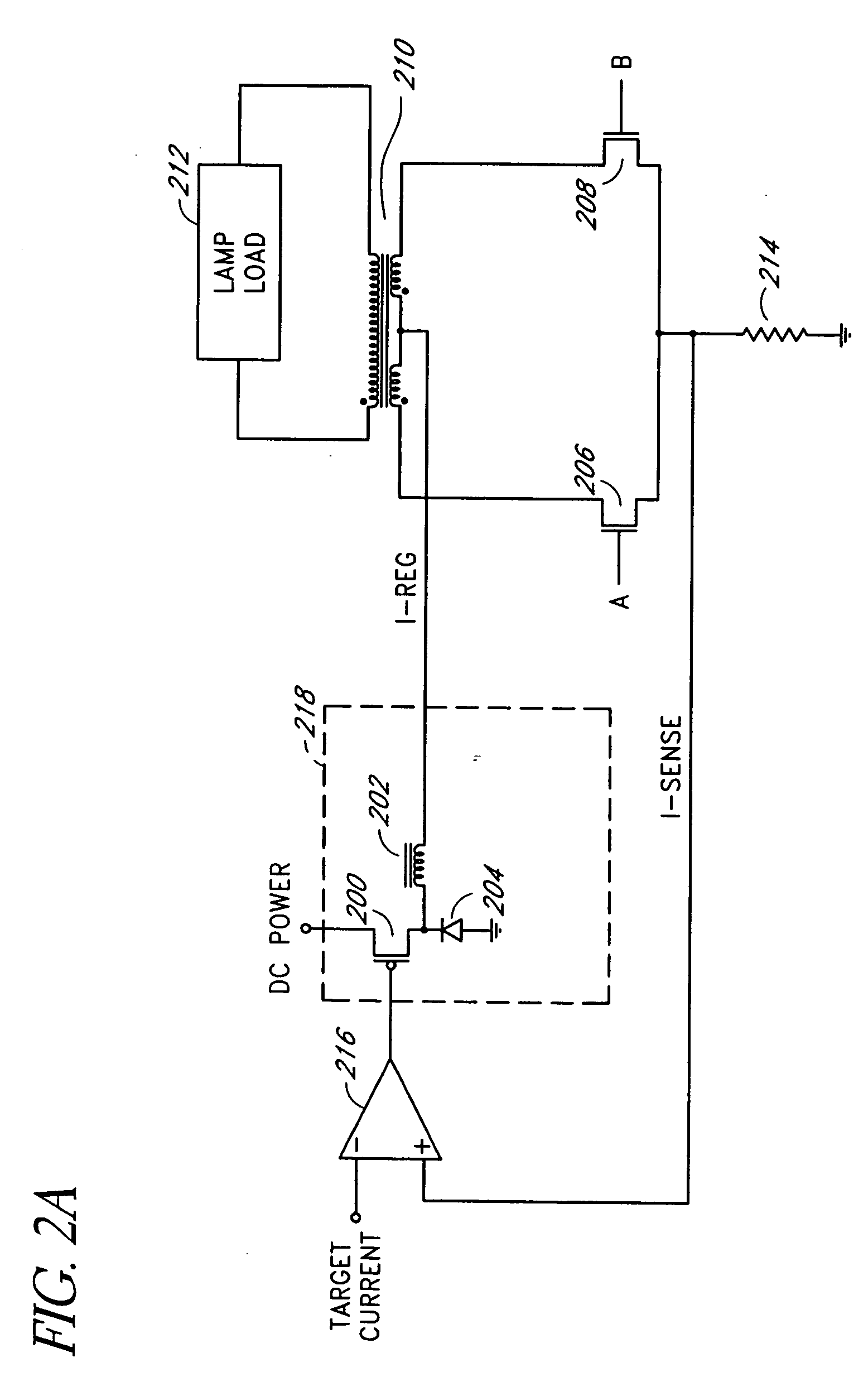

Current-mode direct-drive inverter

InactiveUS20050162098A1Increased operating lifeStable light outputElectroluminescent light sourcesSemiconductor lamp usageOutput transformerTime-sharing

An efficient and flexible current-mode driver delivers power to one or more light sources in a backlight system. In one application, the current-mode driver is configured as an inverter with an input current regulator, a non-resonant polarity-switching network, and a closely-coupled output transformer. The input current regulator can output a regulated current source in a variety of programmable wave shapes. The current-mode driver may further include a rectifier circuit and a second polarity-switching network between the closely-coupled output transformer and a lamp load. In another application, the current-mode driver delivers power to a plurality of light sources in substantially one polarity by providing a regulated current to a network of time-sharing semiconductor switches coupled in series with different light sources coupled across each semiconductor switch.

Owner:POLARIS POWERLED TECH LLC

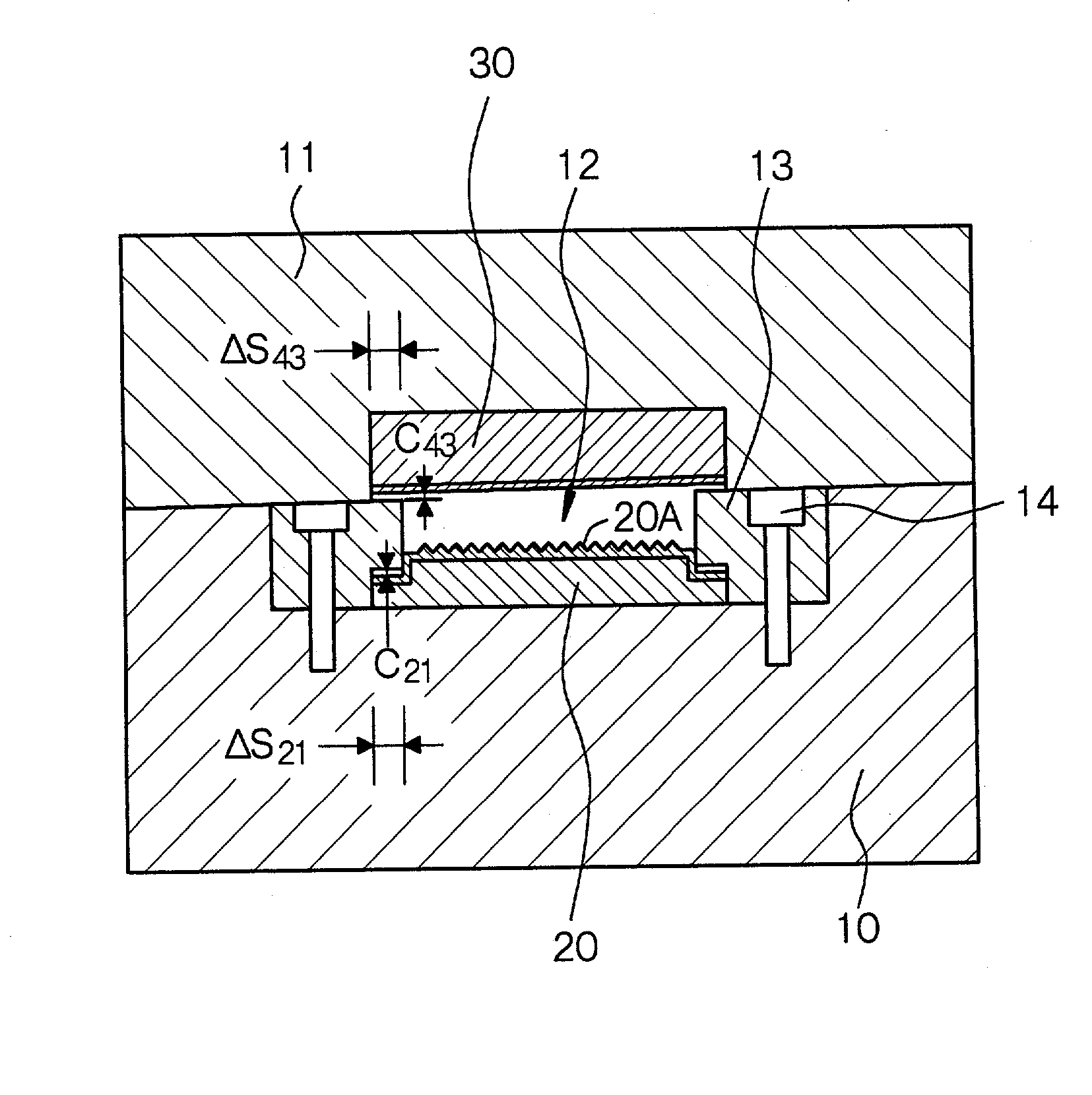

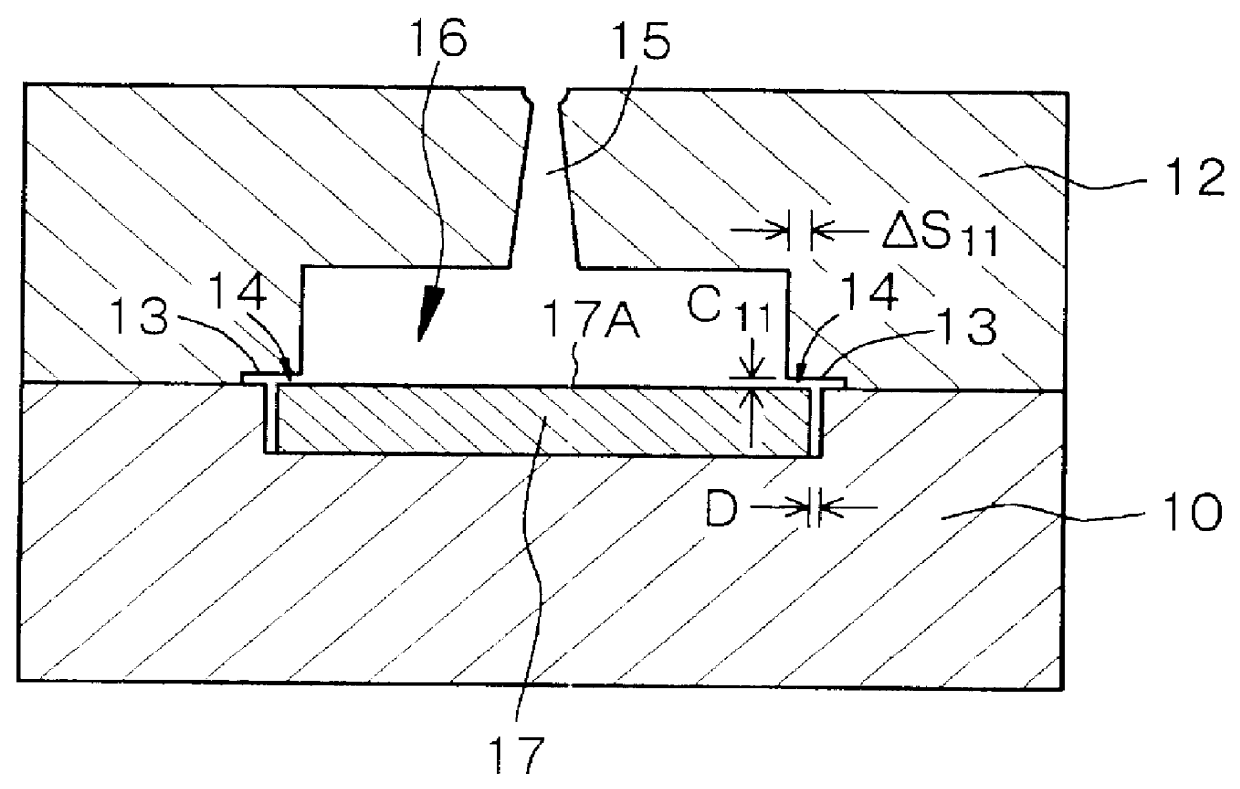

Mold assembly for molding thermoplastic resin and method of manufacturing molded article of thermoplastic resin

InactiveUS6165407AReduce residual stressReduce injection pressureConfectioneryOptical articlesMaterials scienceThermal conductivity

A mold assembly for molding a thermoplastic resin, which comprises; (a) a first mold member and a second mold member for manufacturing a molded article of a thermoplastic resin, (b) an insert block provided in the first mold member, said insert block constituting part of a cavity, having a thickness of 0.1 mm to 10 mm and being formed of a material having a thermal conductivity of 2x10-2 cal / cmxsecx DEG C. or less, and (c) a molten thermoplastic resin introduction portion provided in the second mold member, wherein an insert block covering portion is formed in the second mold member, and when the first mold member and the second mold member are clamped to each other, (A) a clearance between the insert block and the insert block covering portion is equal to, or less than, 0.03 mm, and (B) an amount of overlapping of the insert block and the insert block covering portion is equal to, or greater than, 0.5 mm.

Owner:MITSUBISHI ENG PLASTICS CORP

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN1864828AAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

The invention discloses a method for preparing intensified netted hollow fiber membrane, belonging to technology for preparing hollow fiber membrane. The process comprises: taking polyvinylidene fluoride as membrane material, N,N-dimethyl formamide as disslovant, polyvinyl pyrrolidon as additive, preparing membrane liquid according to a certain proportion among them; textiling hollow fiber membrane under certain temperature, pressure and dragging speed; braiding net with synthetic fiber out of hollow fiber membrane, putting intensified hollow fiber membrane sequentially through membrane producing liquid and coagulating bath; coating and congealing under certain temperature, pressure and dragging speed, and getting final product. The invention is characterized in that there is no clogging, the flow resistance is small, stretching intensity amounts to 10-50 MPa, bursting strength is 0.5-1 MPa, and the process is continous and easy for industrialization.

Owner:TIANJIN UNIV

Ice blasting apparatus and trimming method for film insert molding

InactiveUS7040962B2Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesSlurryFilm material

Owner:TOSHIBA MASCH CO LTD

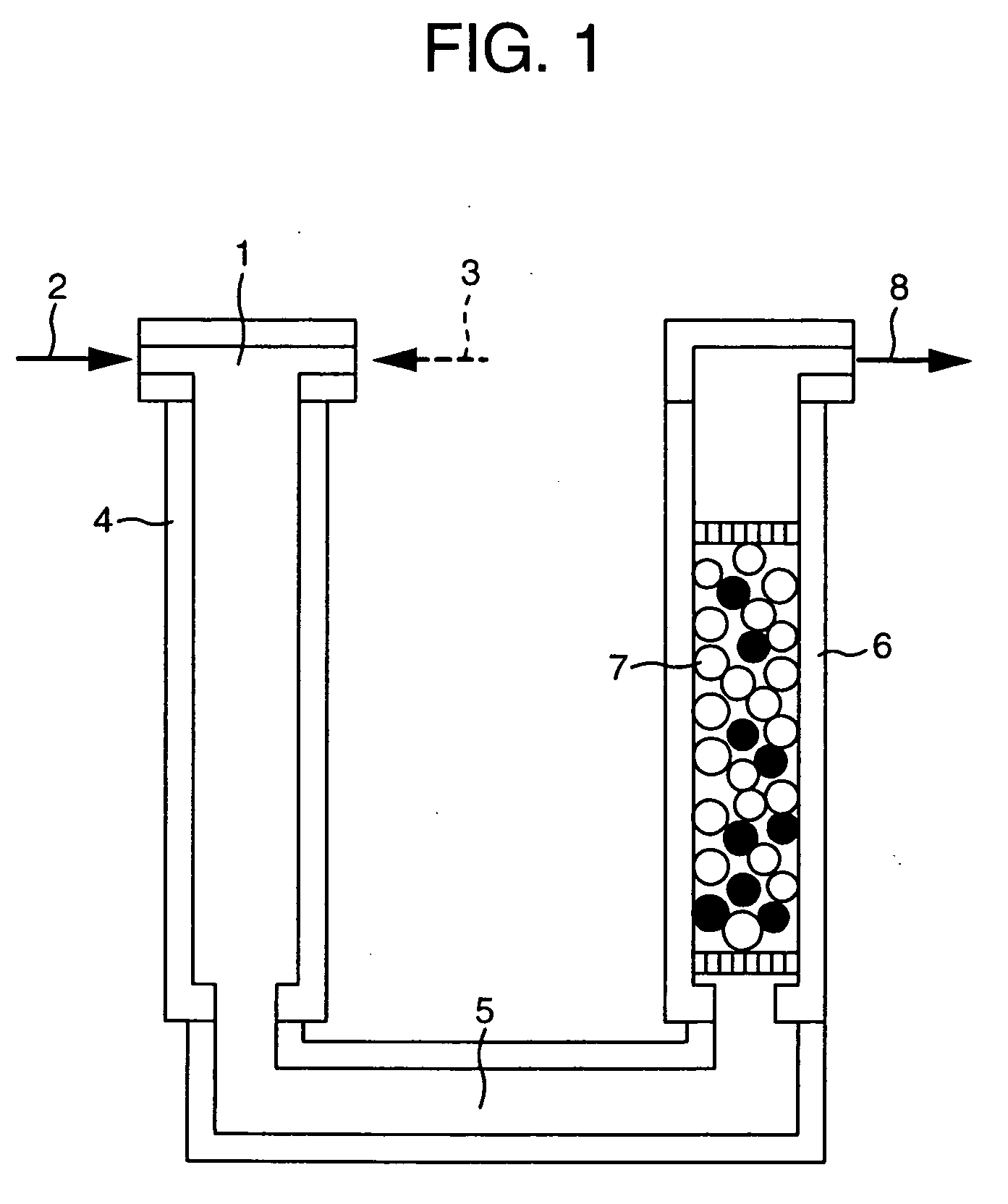

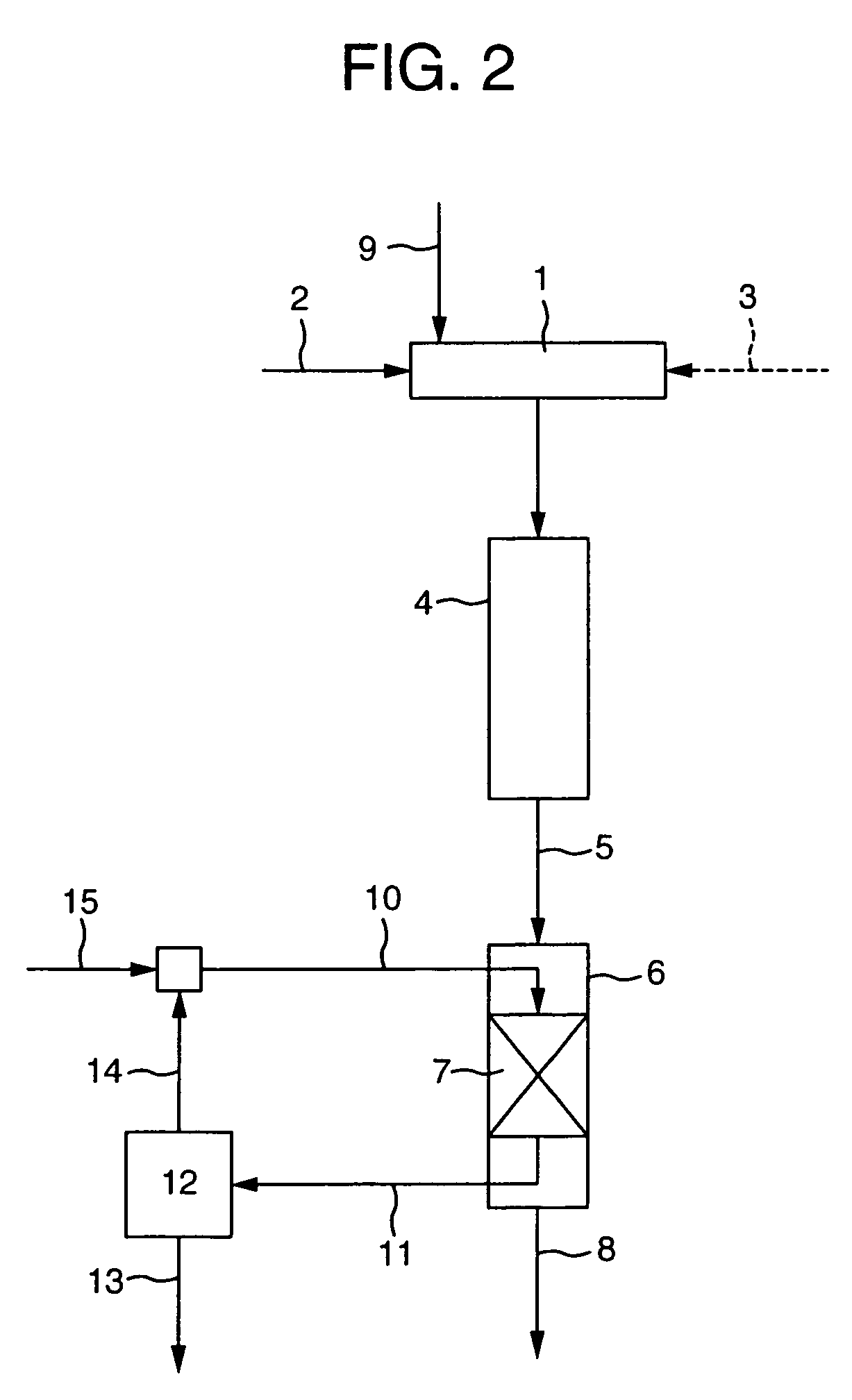

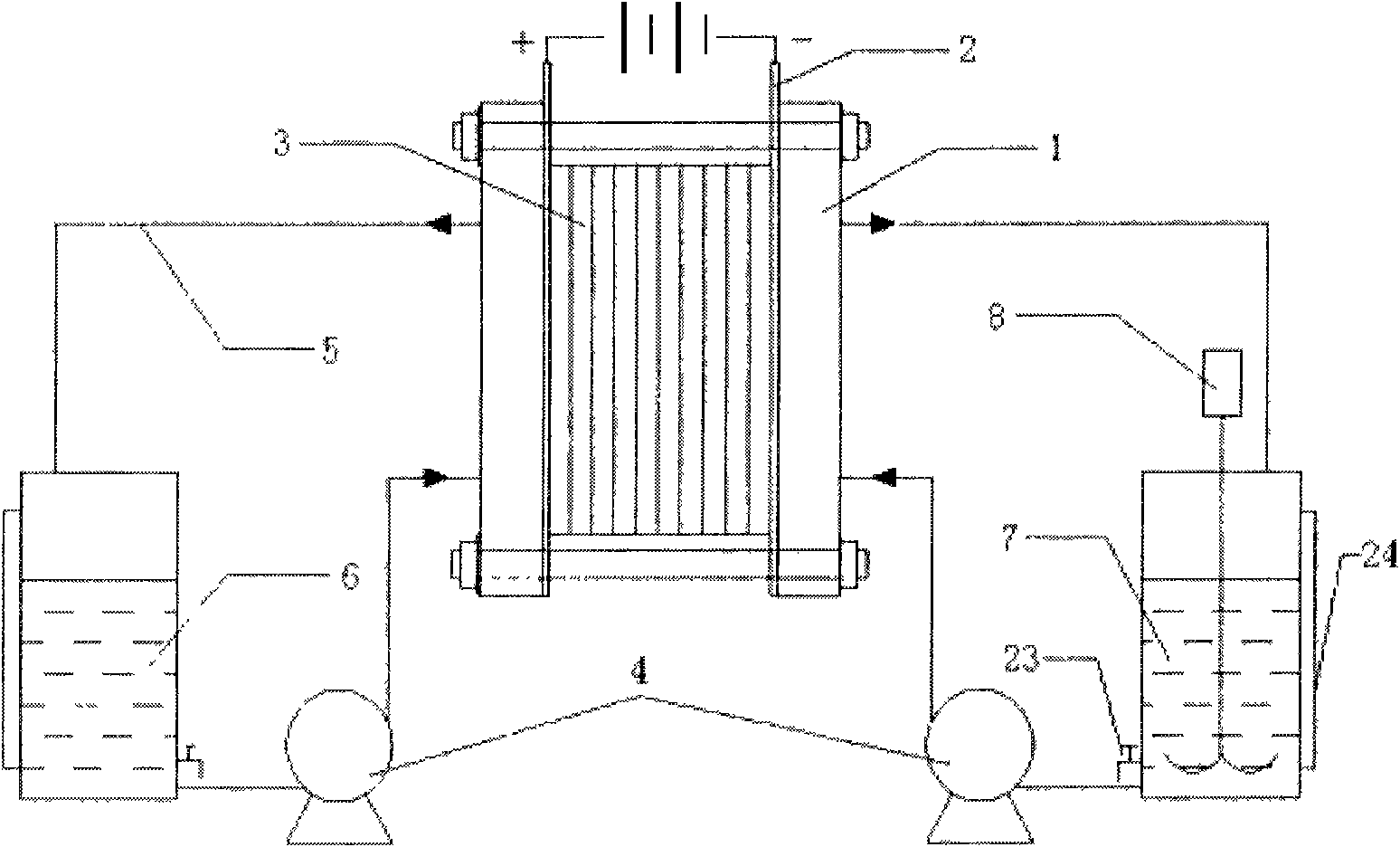

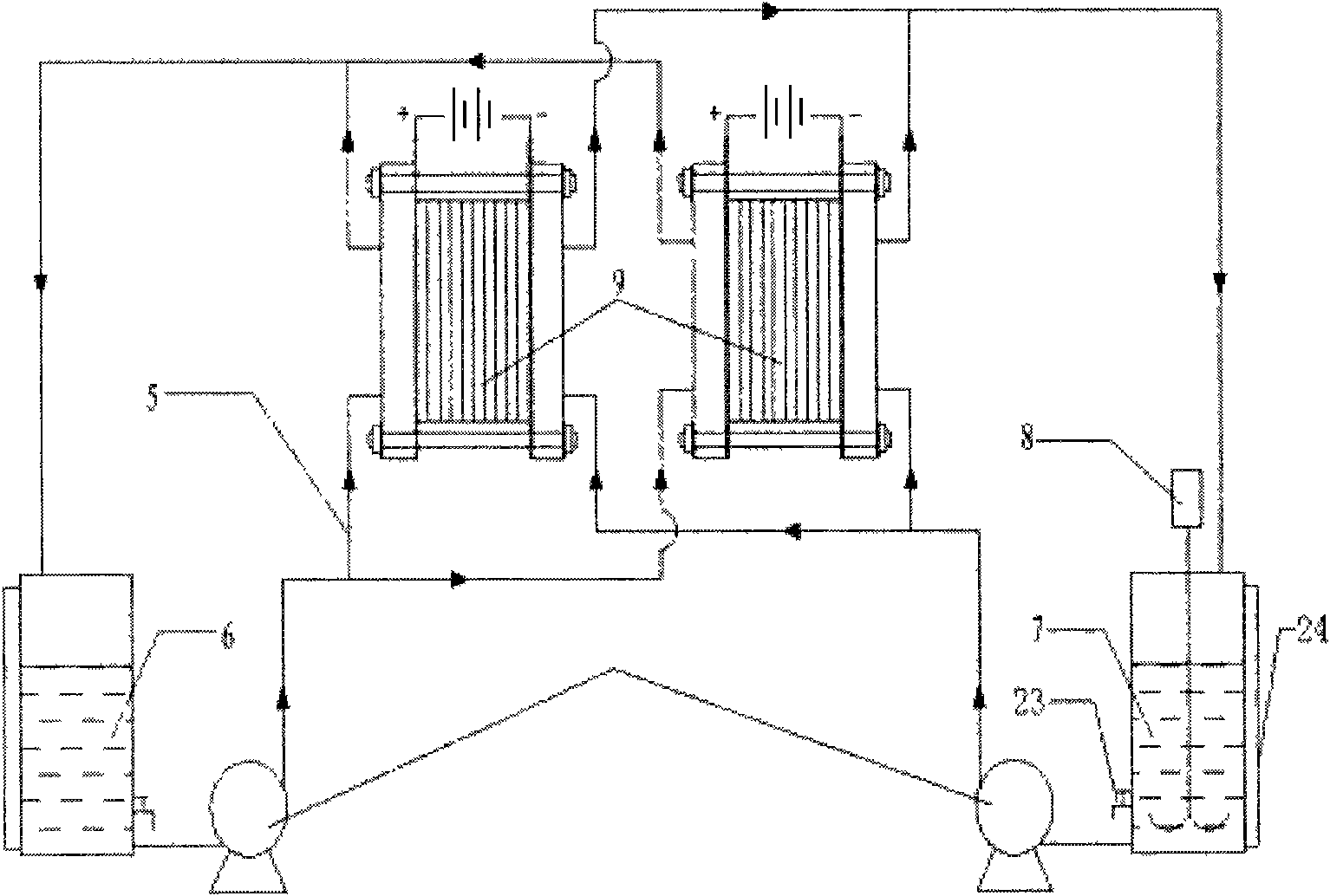

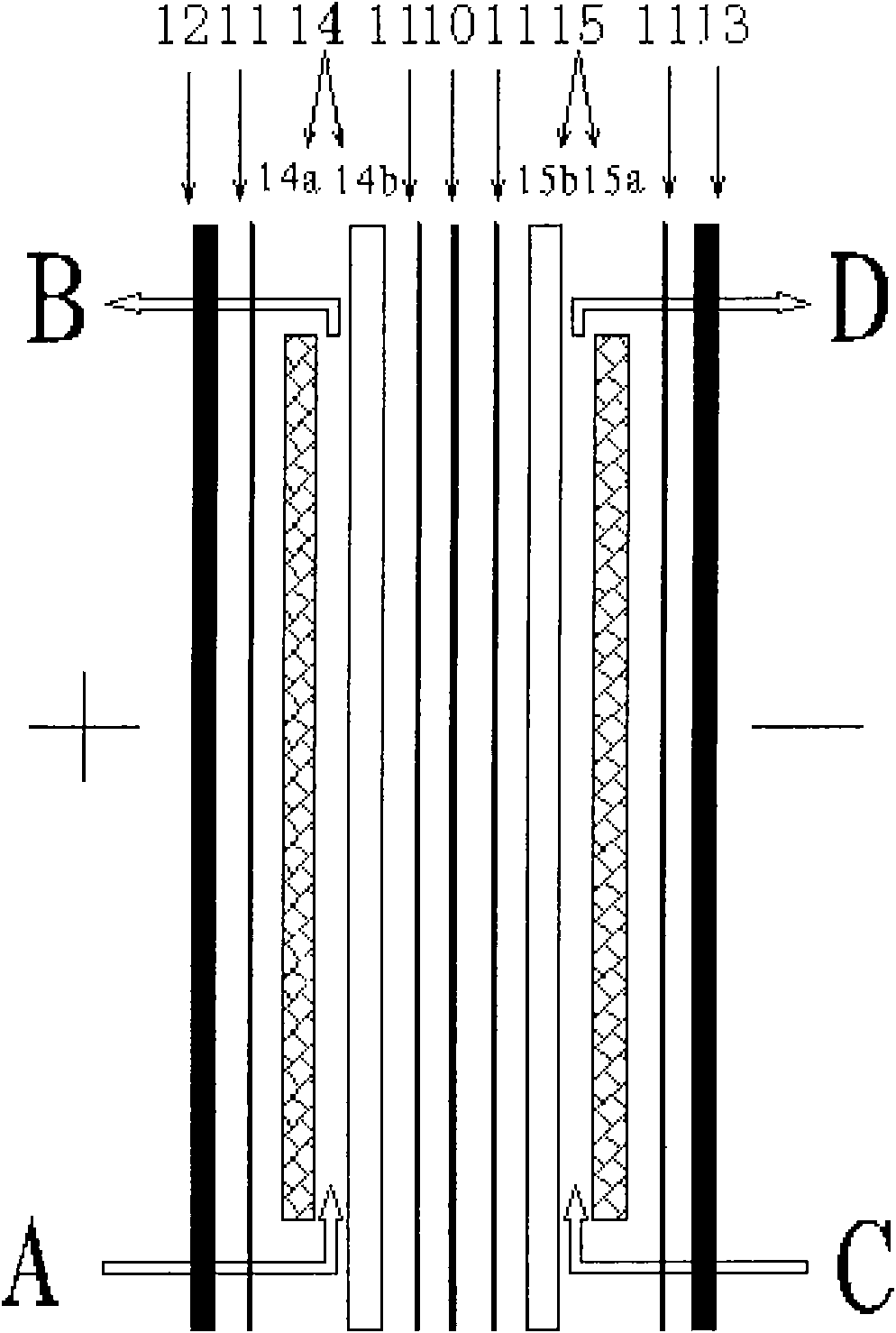

Method for preparing vanadium battery solution or adjusting capacity and special device thereof

InactiveCN101619465ARapid responseContinuous operationElectrolysis componentsRegenerative fuel cellsVanadium CompoundsOxygen

The invention relates to a method for preparing vanadium battery solution or adjusting the capacity, wherein an adopted electrolysis unit comprises an electrolytic cell group, an anode electrolyte storage tank, a cathode electrolyte storage tank, a liquid conveying pipeline and a pump, a mode of forced convection is adopted so that the anode electrolyte and the cathode electrolyte stored in the anode electrolyte storage tank and the cathode electrolyte storage tank respectively flow through the anode and the cathode of the electrolytic cell group respectively, a voltage is applied between the anode and the cathode of the electrolytic cell group to generate direct current capable of generating oxygen and deoxidizing a vanadium compound, and after finishing electrochemical oxidation and reduction reaction, the anode electrolyte and the cathode electrolyte flowing through the anode and the cathode of the electrolytic cell group return to the anode electrolyte storage tank and the cathode electrolyte storage tank. The electrolysis method is applied to preparing electrolyte for a full vanadium liquid stream battery and restoring the capacity of the full vanadium liquid stream battery off line or on line.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

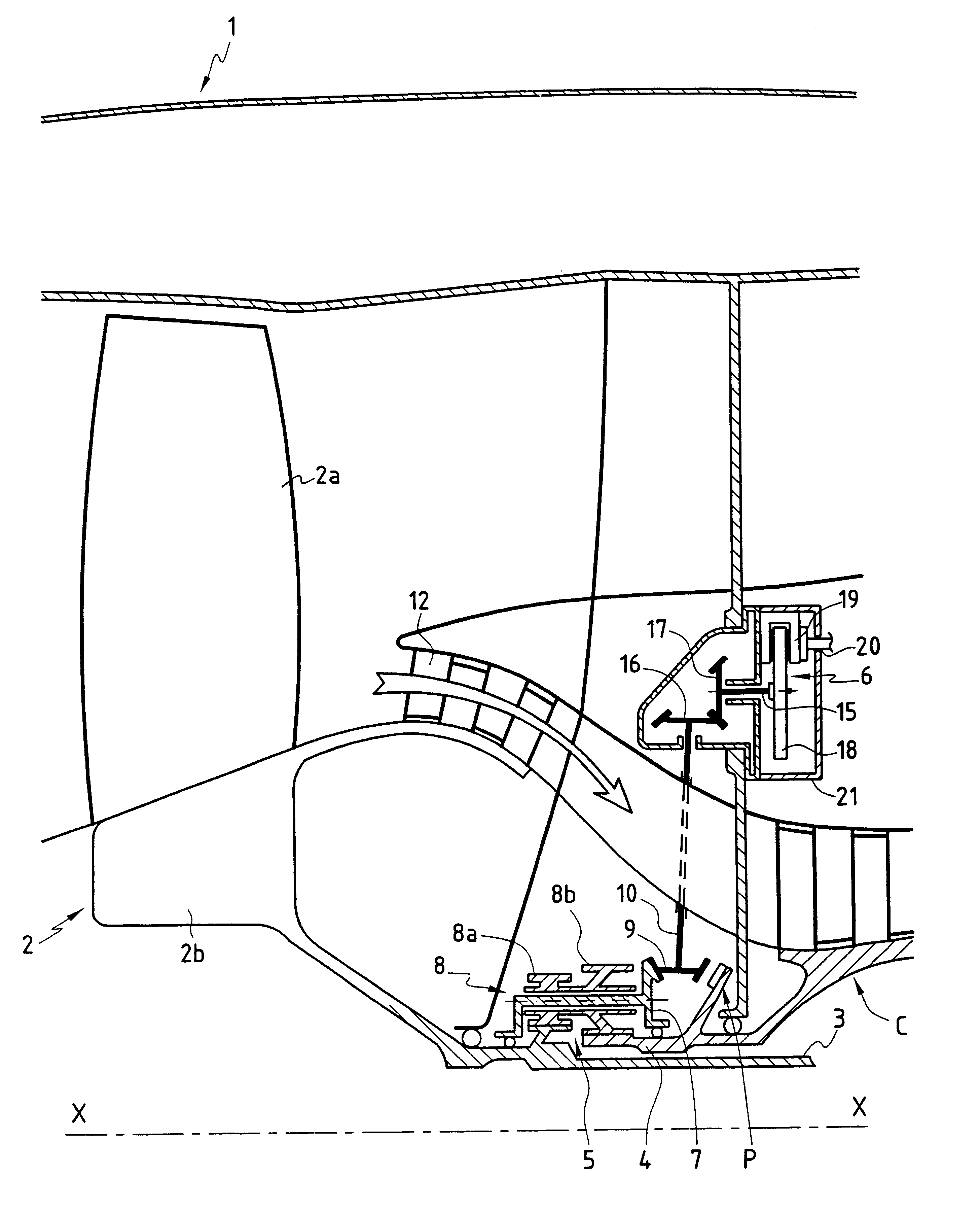

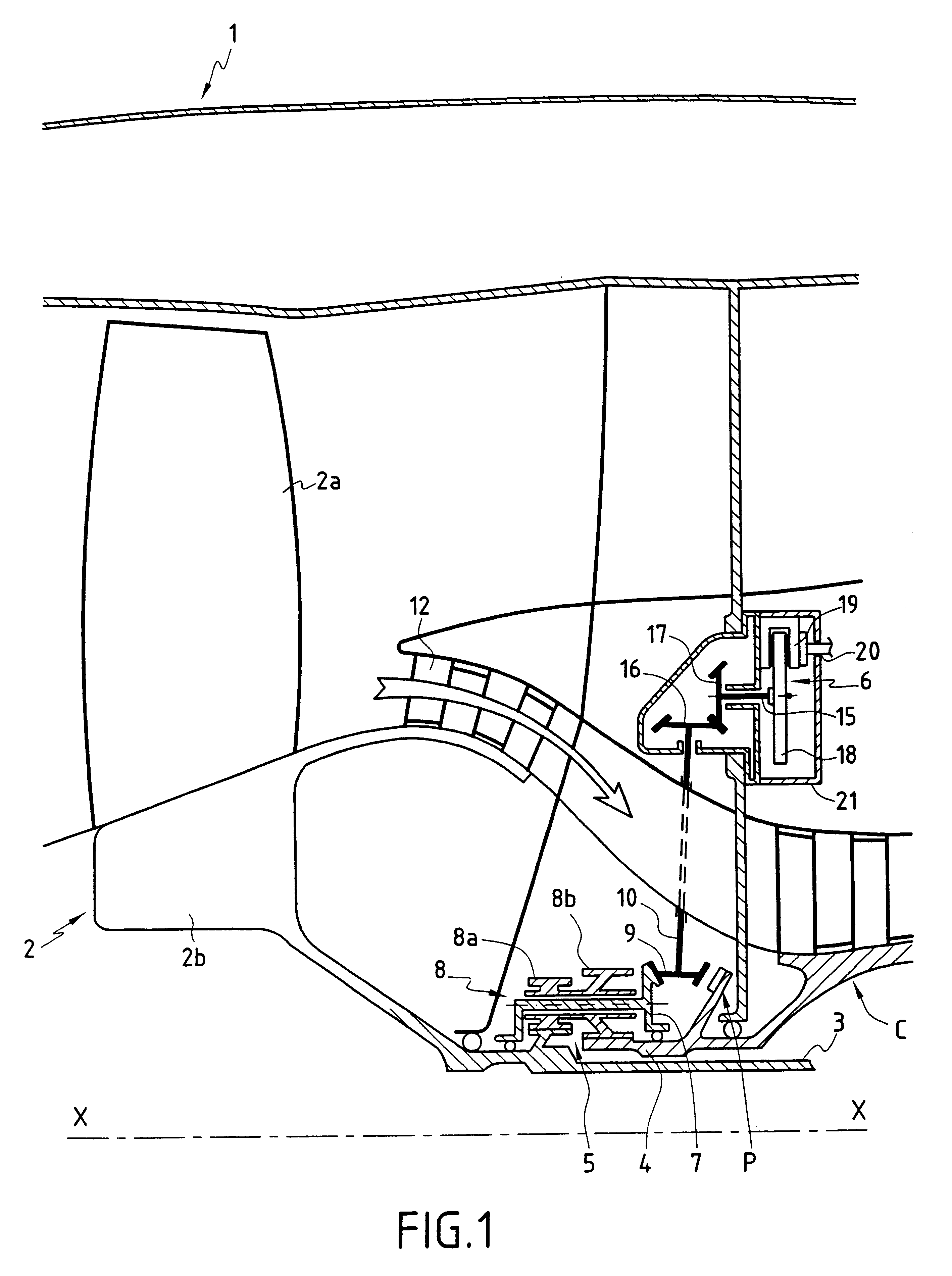

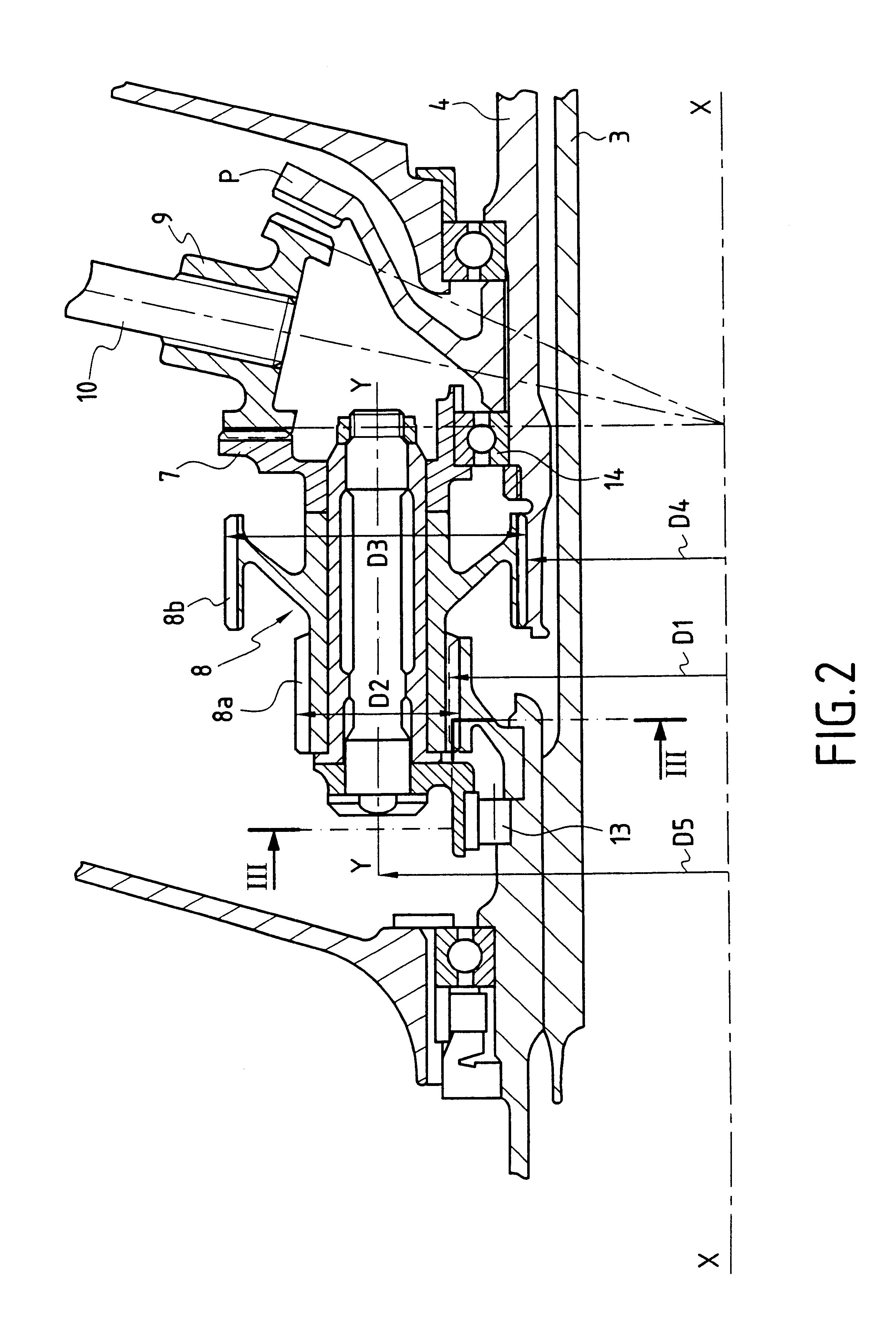

Emergency device for relighting a windmilling turbojet

InactiveUS6672049B2Continuous operationMitigate such drawbackTurbine/propulsion engine ignitionTurbine/propulsion engine startersHigh pressureTurbine

An emergency device for relighting a windmilling turbojet, the jet comprising a fan driven by a low-pressure turbine via a first shaft and a compressor driven by a high-pressure turbine via a second shaft disposed coaxially around the first shaft, a differential interconnecting said first and second shafts while compensating for their different speeds of rotation in normal operation or the turbojet, and a braking system connected to the differential so as to enable it to be slowed down or blocked when the turbojet shuts down, thereby enabling the first shaft to entrain the second shaft so that it reaches a speed that favors relighting of the turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

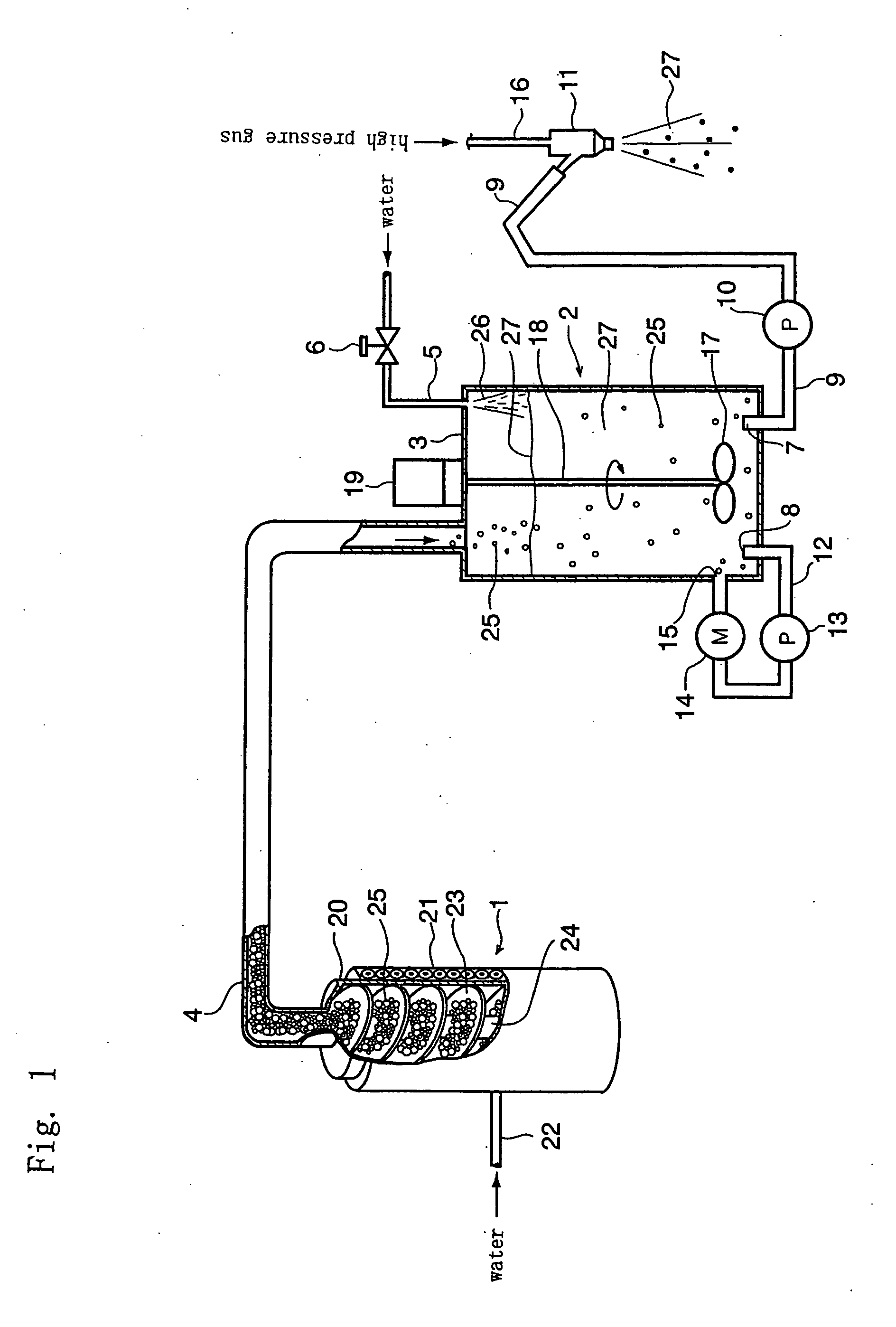

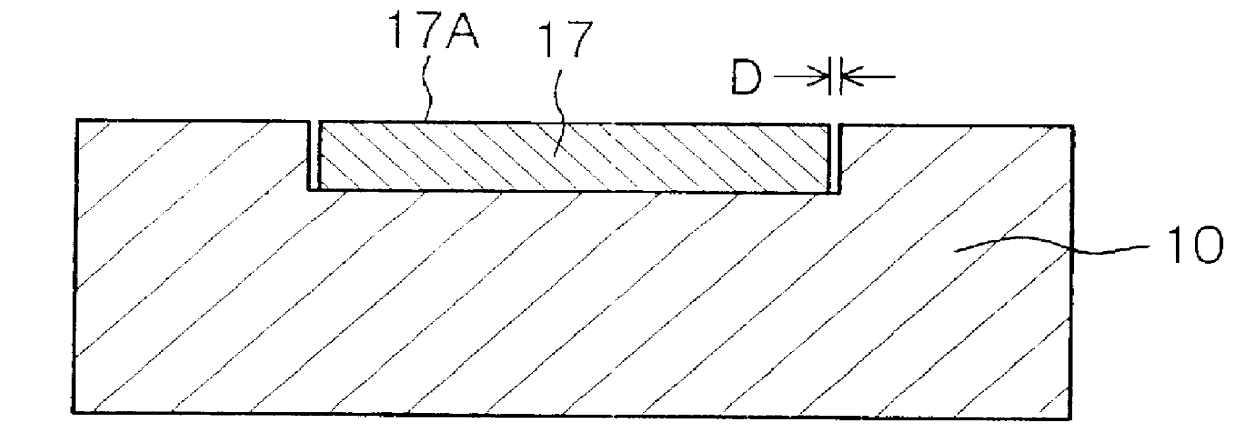

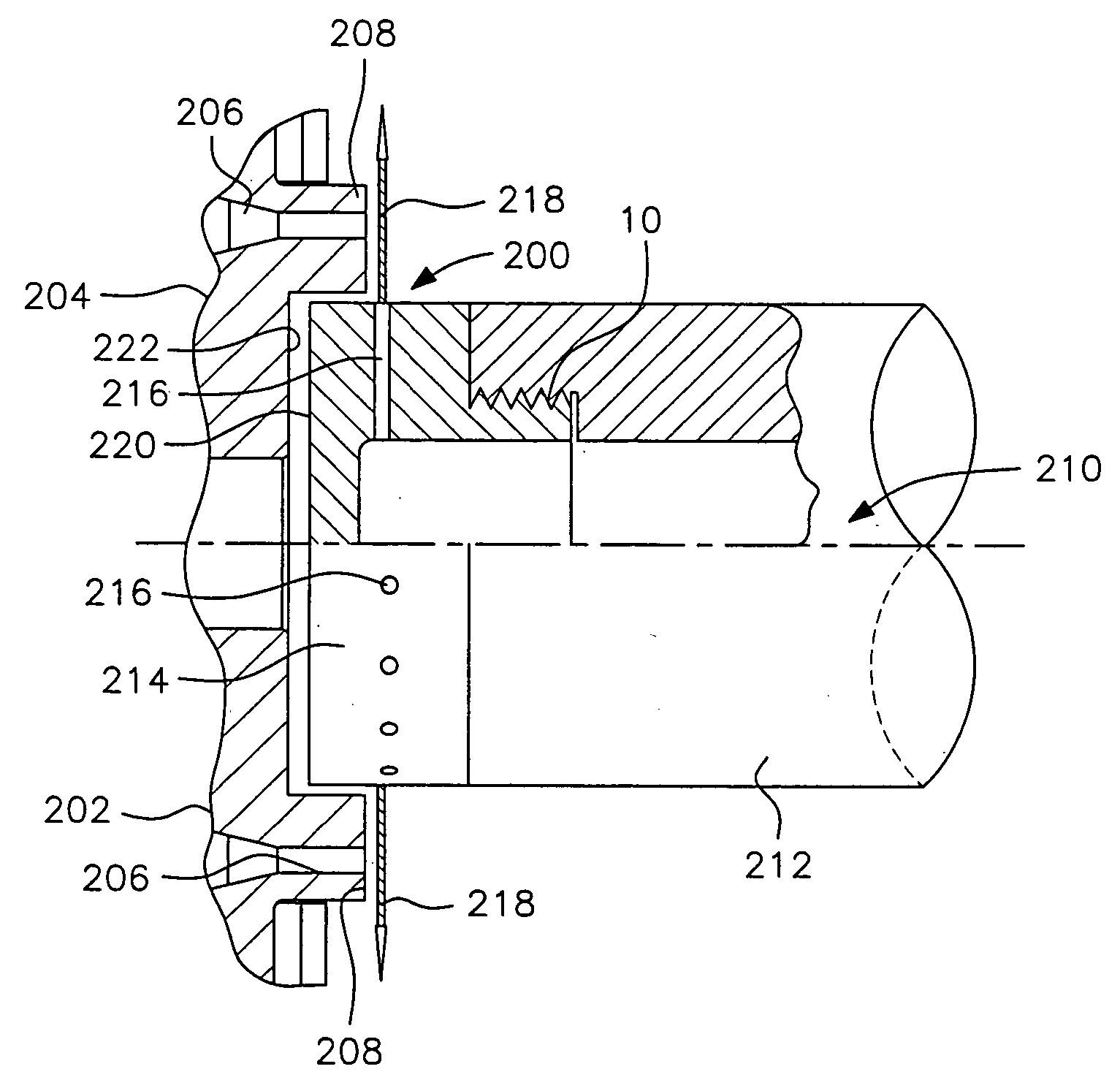

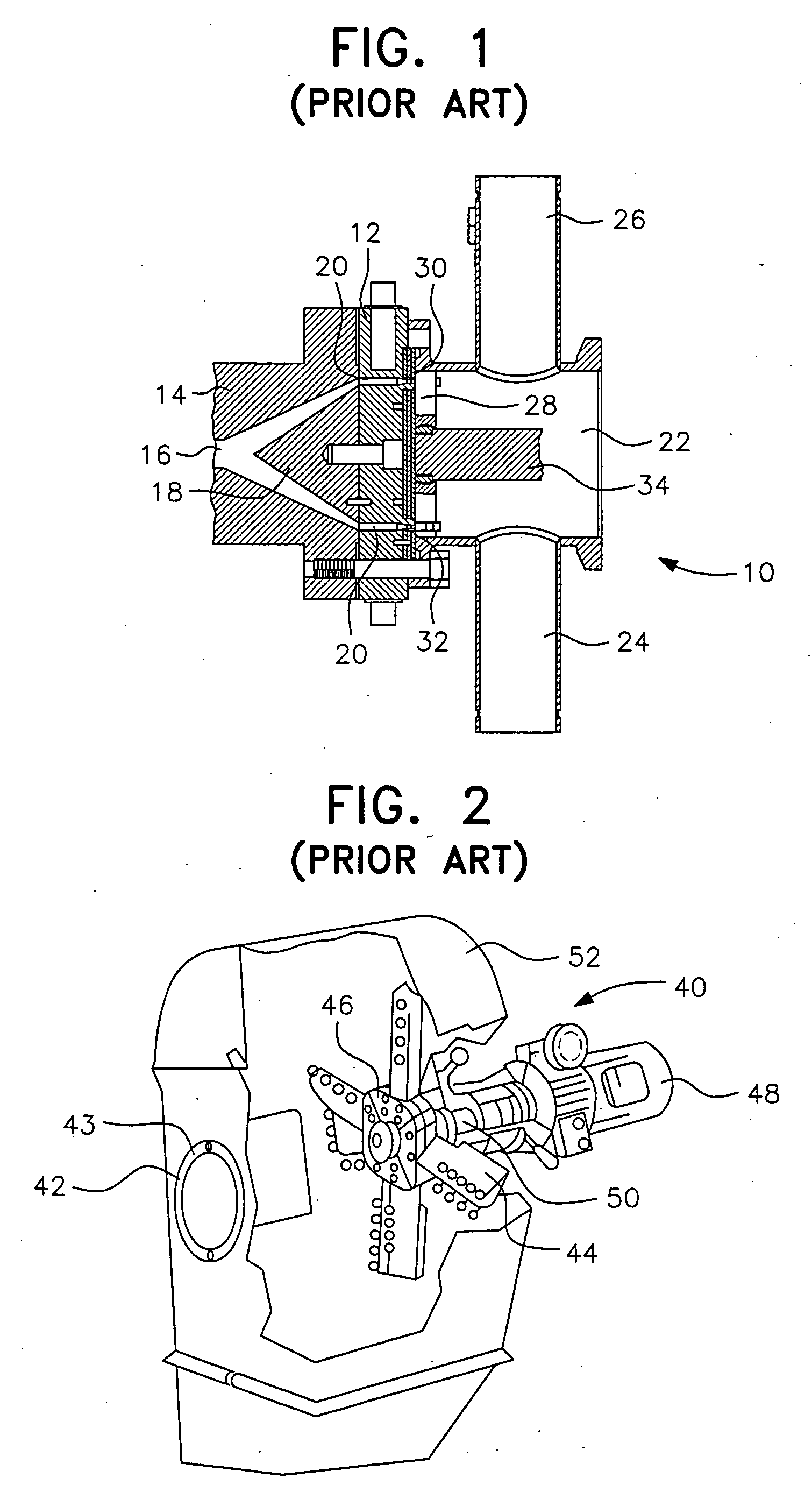

High pressure liquid jet cutting system and method for forming polymer pellets

InactiveUS20050077644A1Without unnecessary down timeContinuous operationMouldsConfectioneryWater basedLiquid jet

A system and method for pelletizing extruded materials, such as thermoplastic polymers in various pelletizing applications, including underwater, hot face, and strand pelletizing applications, utilizes a high pressure liquid delivered to one or more nozzles which direct a high pressure liquid jet cutting stream at the extruded polymer strand to cut the strand into pellets. The system and method are particularly applicable to underwater pelletizers utilizing water or water-based solutions. In a preferred underwater pelletizing embodiment, a plurality of nozzles are mounted on a rotating nozzle hub which is fed high pressure water through sealed hollow pelletizer and hollow motor shafts. The high pressure water jet cutting streams exiting the rotating nozzles are preferably in the form of a flat V-shaped spray with a spread angle of about 15° to about 45° and an approach angle between 0° and 60°, depending upon the pelletizing application.

Owner:GALA INDUSTRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com