Patents

Literature

8121 results about "Pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pitch is a viscoelastic polymer which can be natural or manufactured, derived from petroleum, coal tar, or plants. Various forms of pitch may also be called tar, bitumen, or asphalt. Pitch produced from plants is also known as resin. Some products made from plant resin are also known as rosin.

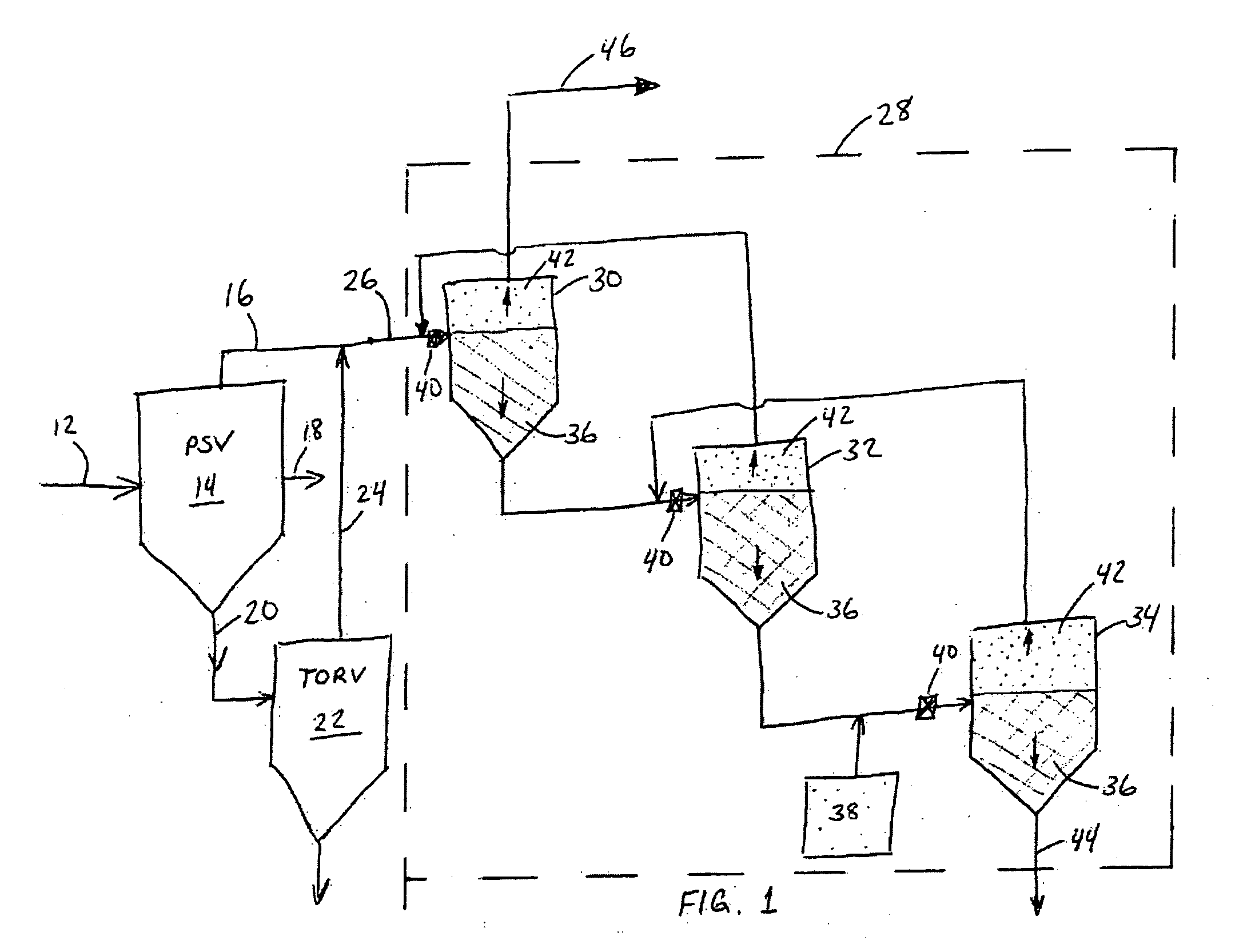

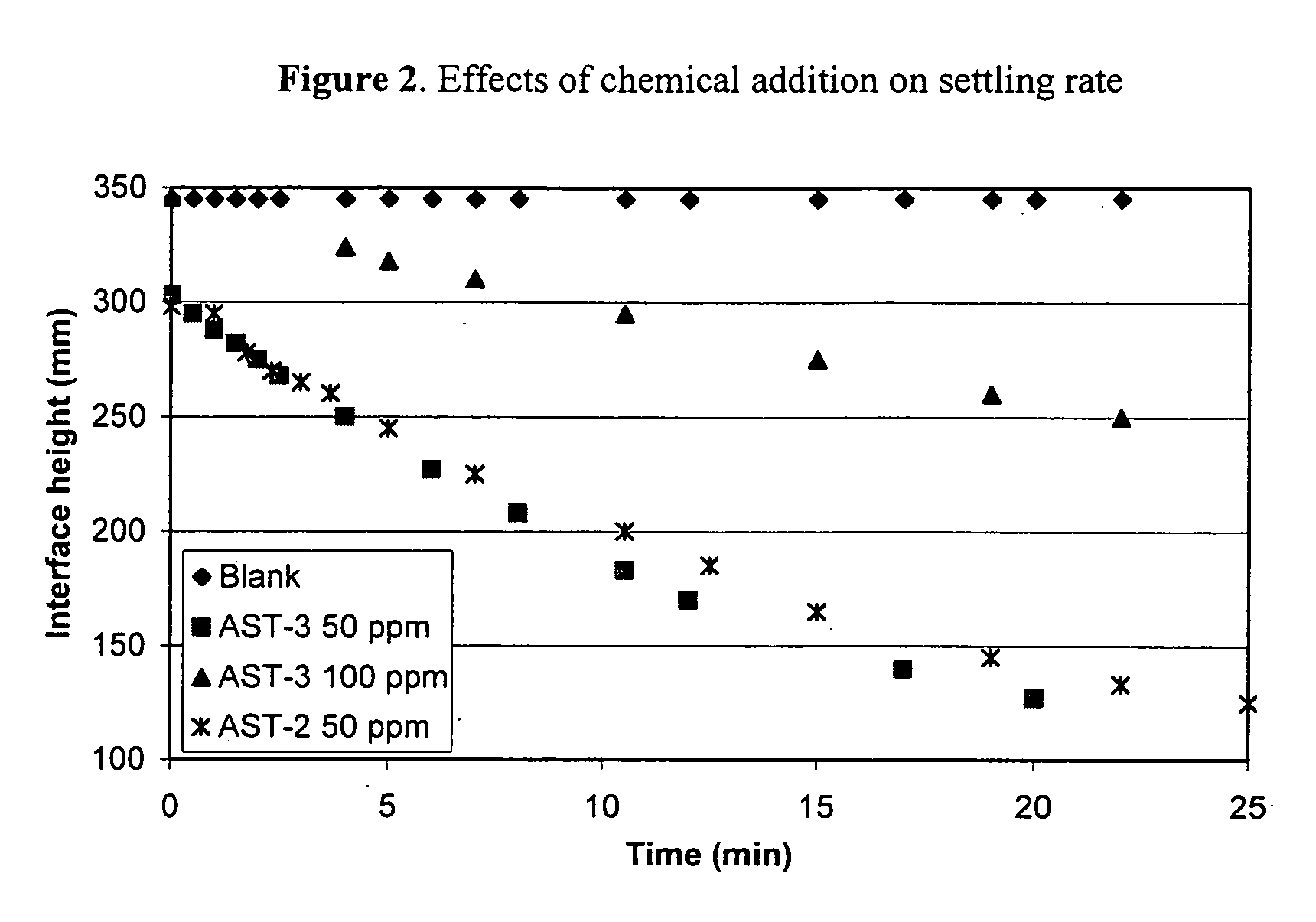

Zone settling aid and method for producing dry diluted bitumen with reduced losses of asphaltenes

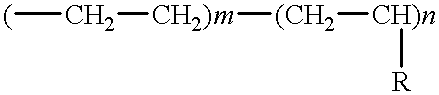

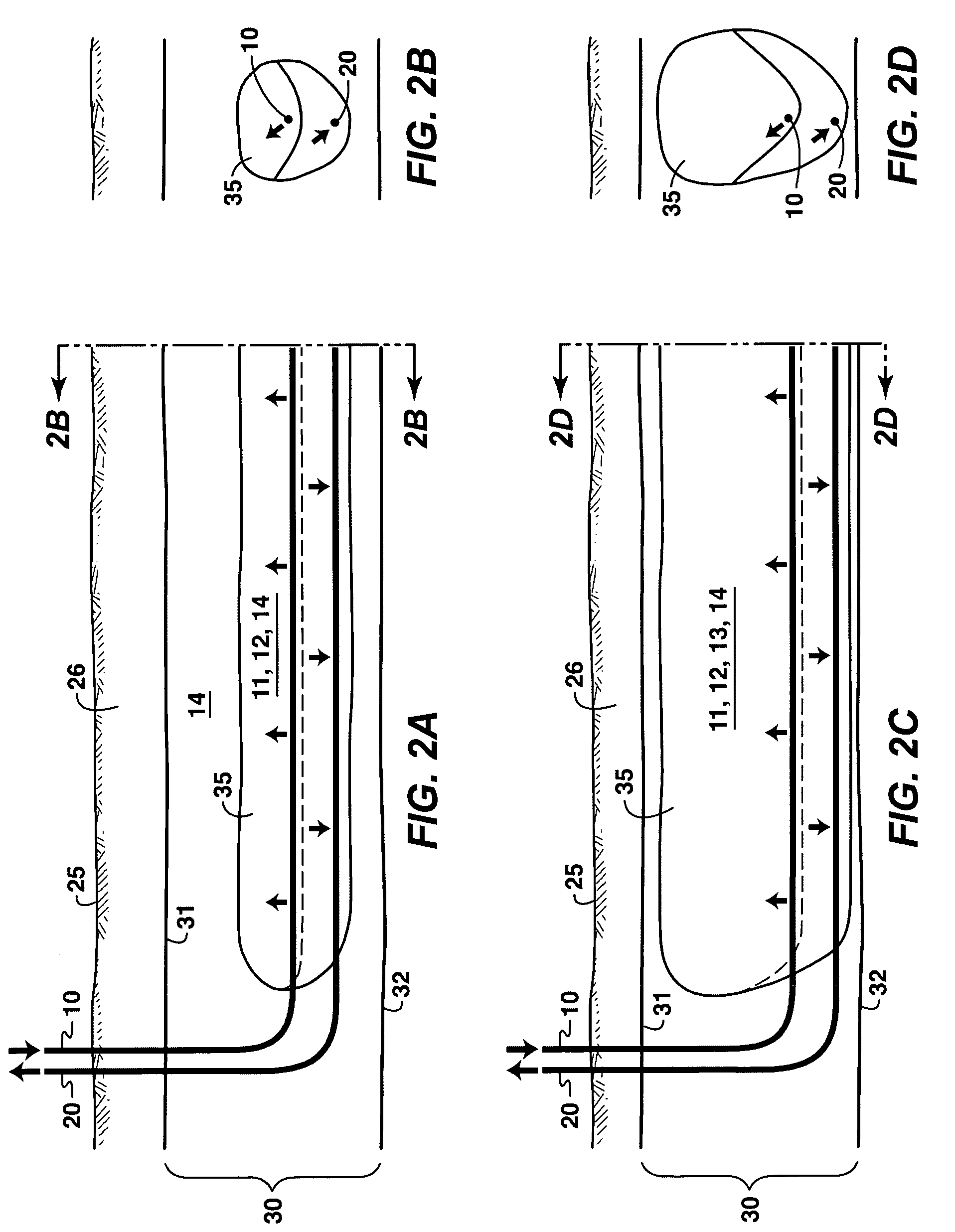

A method includes diluting a bitumen source, such a bitumen froth from a hot water extraction process, with a hydrocarbon diluent such as naphtha, contacting the bitumen with a zone settling aid such as a polyoxyalkylate block polymer, flocculating water and fine solids in the diluted bitumen, separating the flocculated water and fine solids from the solvent-diluted bitumen, and producing dry, clean diluted bitumen. Preferably, the diluted bitumen will have less than 1.0 wt % water, but most preferably less than 0.7 wt % water. The method may further comprise maintaining the diluted bitumen under conditions that avoid the precipitation of asphaltenes from the bitumen, preferably such that the dry, clean diluted bitumen comprises essentially all, such as greater than 96%, of the asphaltene content from the bitumen source. Counter-current flow may be performed in a series of zone settling stages, such as with gravity settling.

Owner:SYNCRUDE CANADA LTD +1

Products useful as roof shingles and a process for making such products

InactiveUS6194519B1ExpensePromote degradationRoof covering using tiles/slatesOther chemical processesElastomerRubber material

The present invention relates to low-cost, efficiently-manufactured, polymer-based products useful as roofing shingles and similar products. The inventive shingles are weatherproof, inexpensive to manufacture and durable, particularly as contrasted with conventional shingles in areas of the country subject to hail damage. The invention also includes a method of making such shingle products. In a preferred embodiment, products of this invention use rubber material as the polymer base in combination with specific types of polyolefins. The rubber material can be most efficiently provided by the use of crumb rubber particles from spent automobile tires and other recycled rubber debris which are readily available and of very low cost. The products will have an average life far greater than that of current commercial roofing shingles, which are made using fiberglass or asphalt.The products of the instant invention are produced by extrusion as a mixture of materials, which product and its materials can be summarized as follows as a roofing shingle product which comprises:a. one or more side-branched polyolefins as an elastomer;b. optionally a blend of additional synthetic polymers, such as ethylene and propylene, as a second elastomer; andc. a rubber fraction, preferably obtained in part from recycled spent automotive or truck tires, and similar sources of waste rubber (sometimes known as "crumb rubber"), ground or recycled into particles having a mesh size of from 10 to 30 (i.e., approximately from about 500 to about 1000 microns).

Owner:MONTY MCWILLIAMS +3

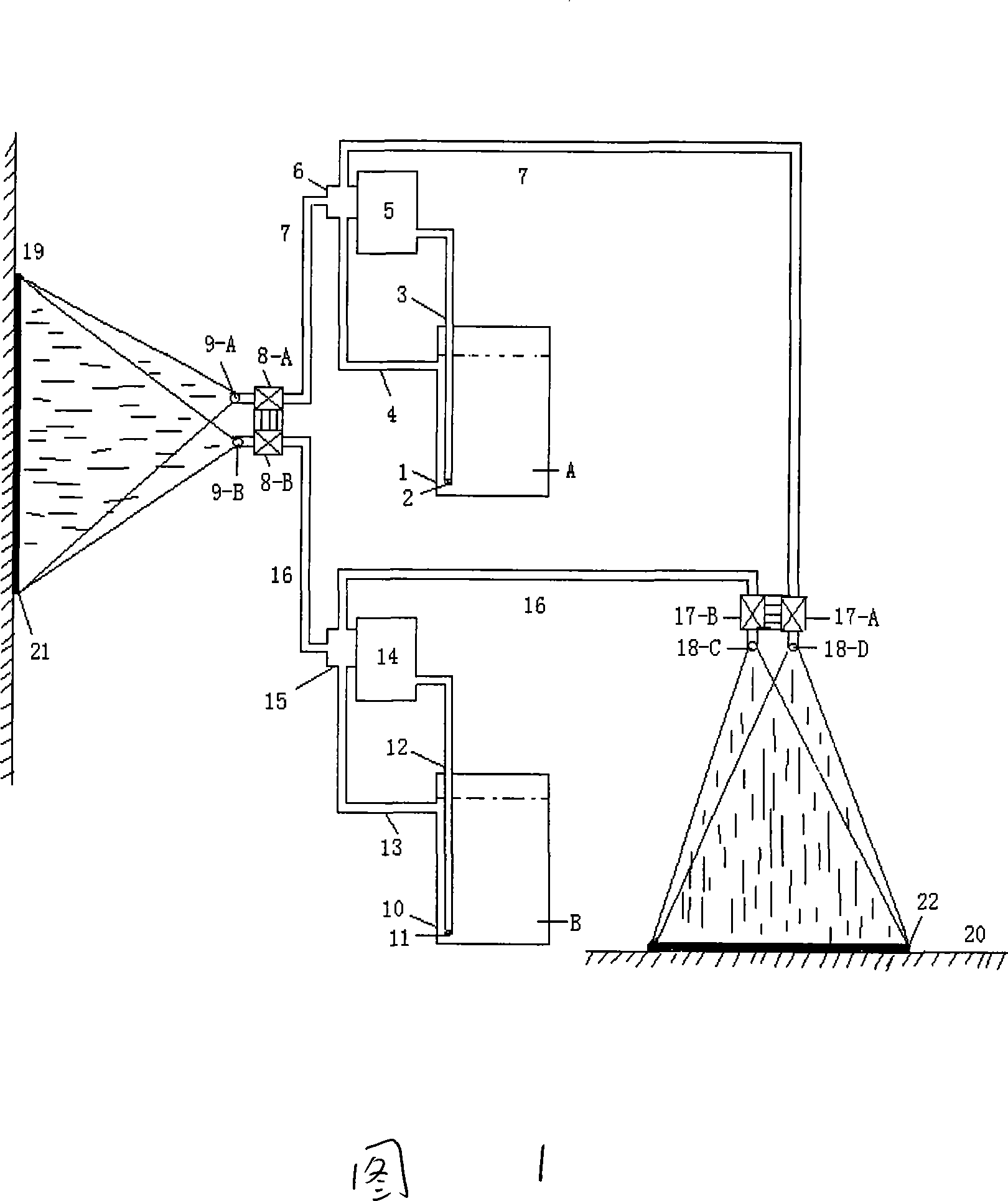

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

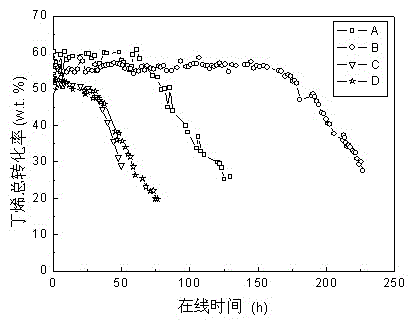

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

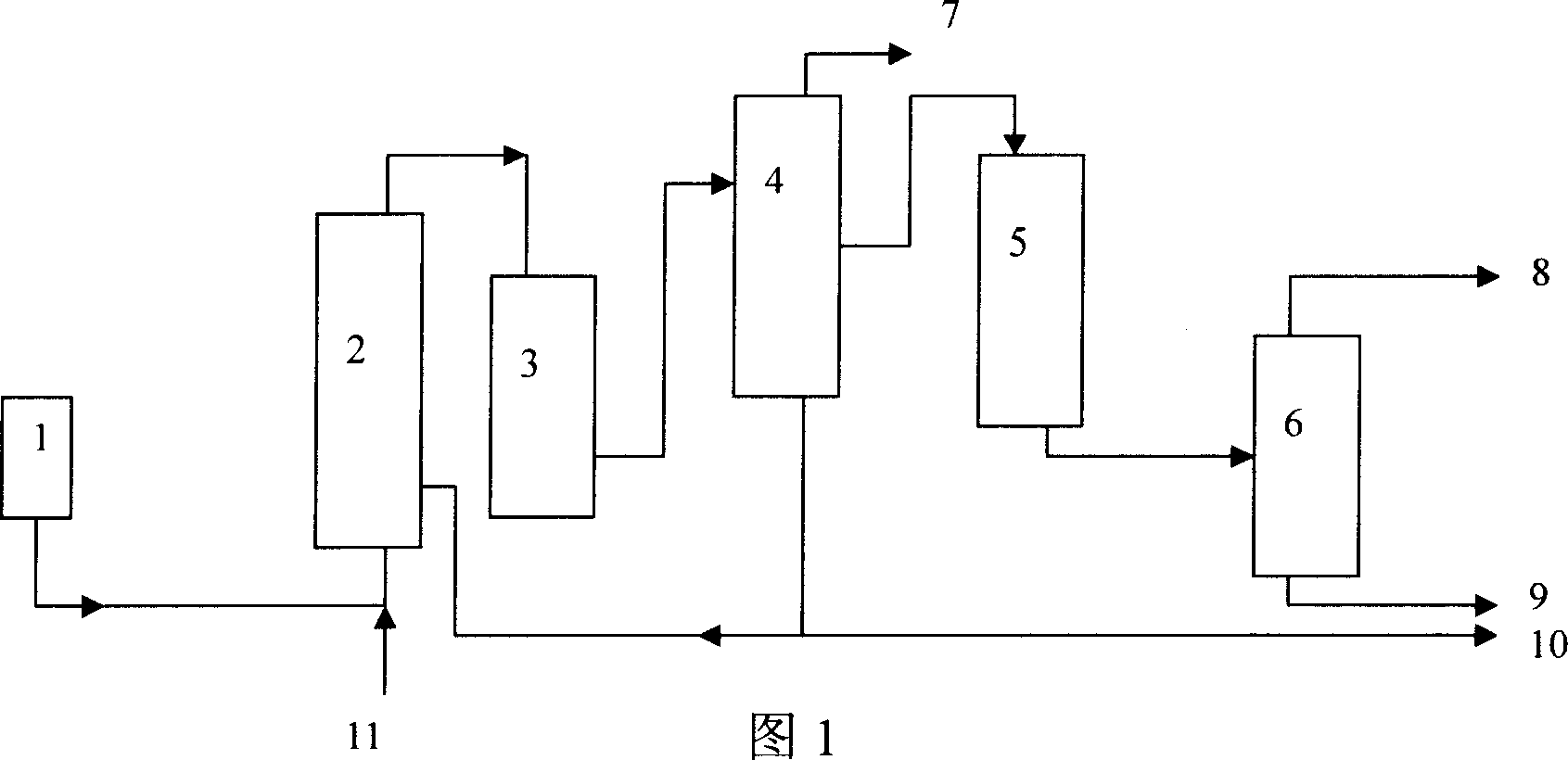

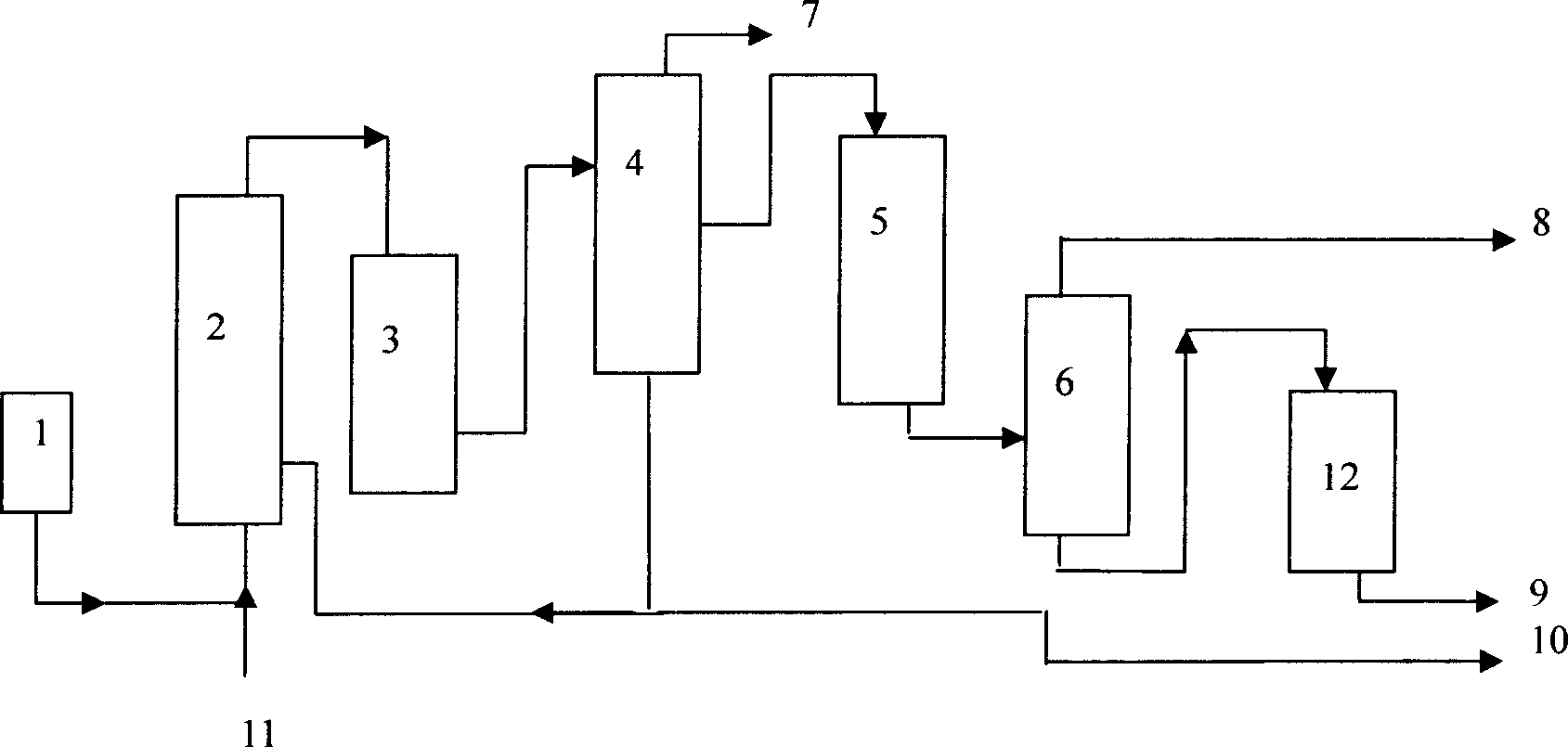

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

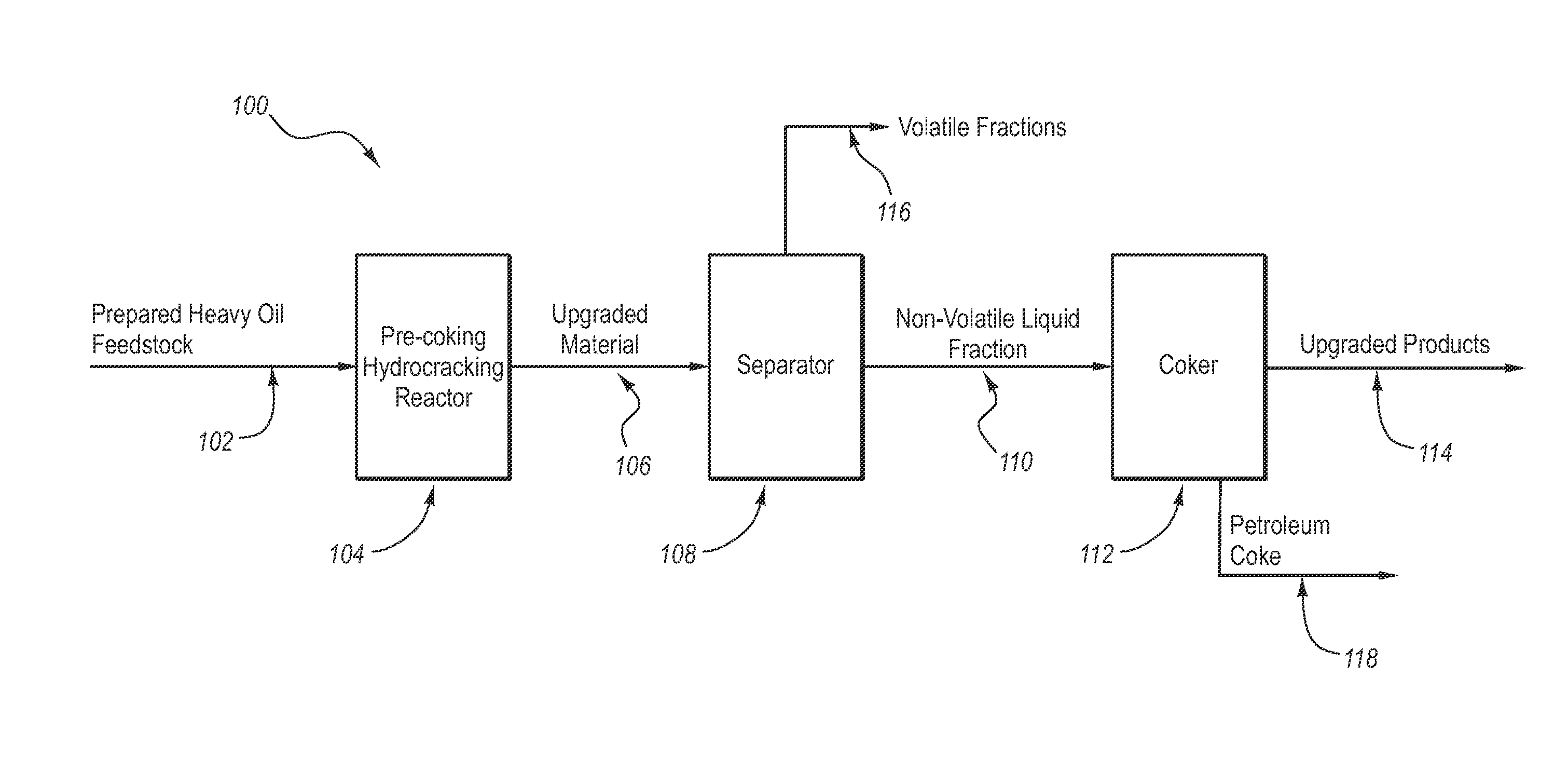

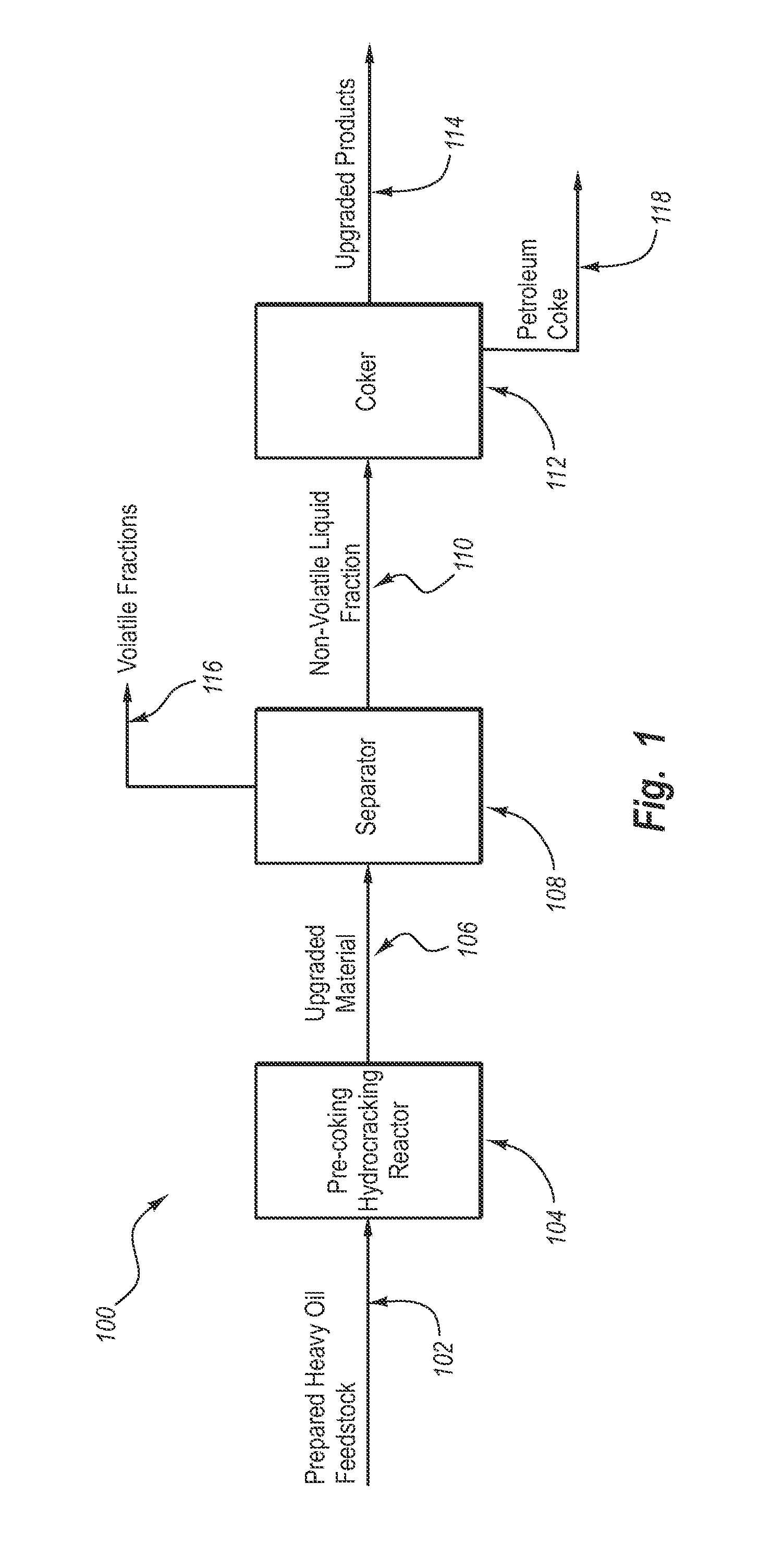

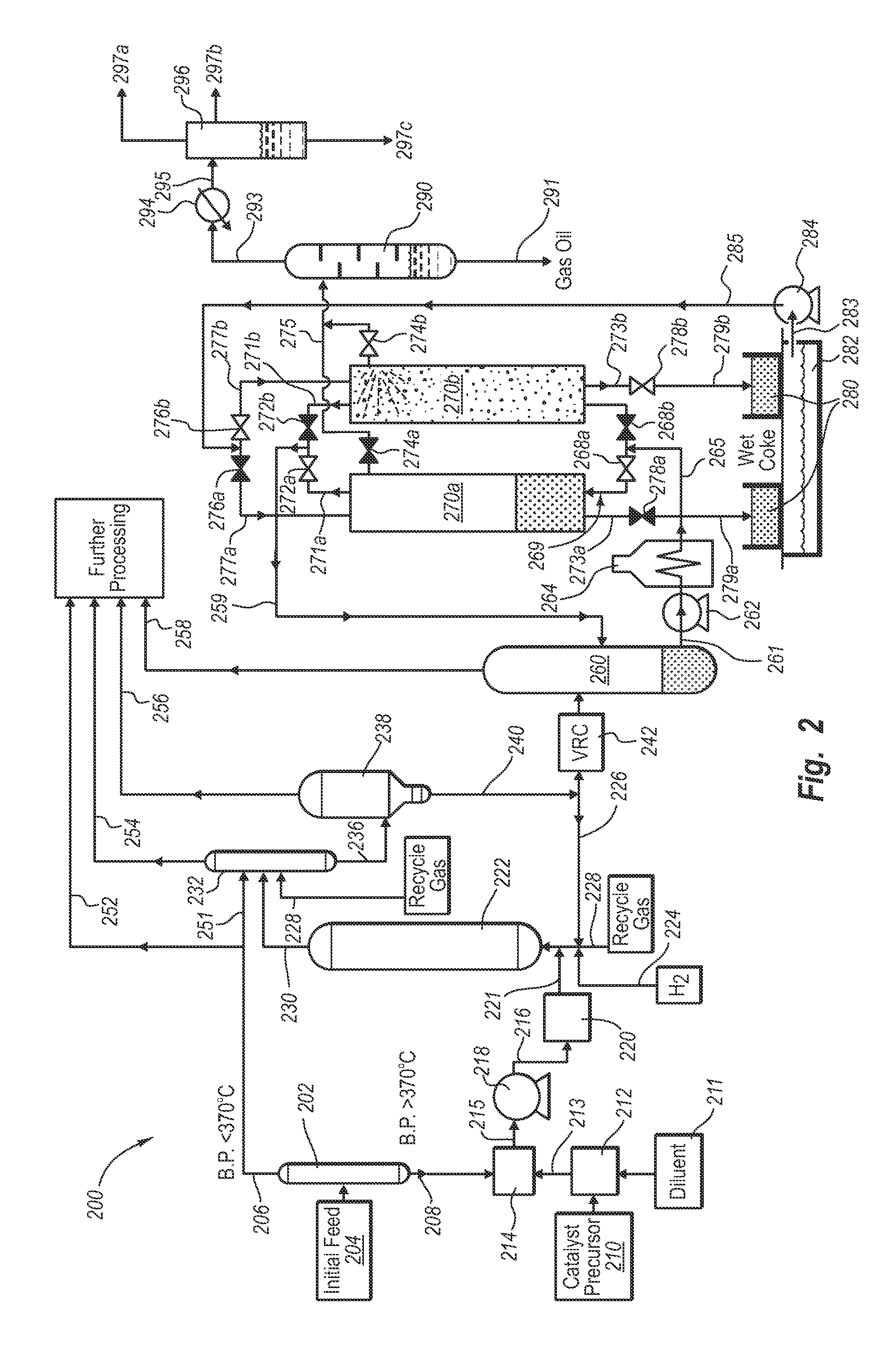

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

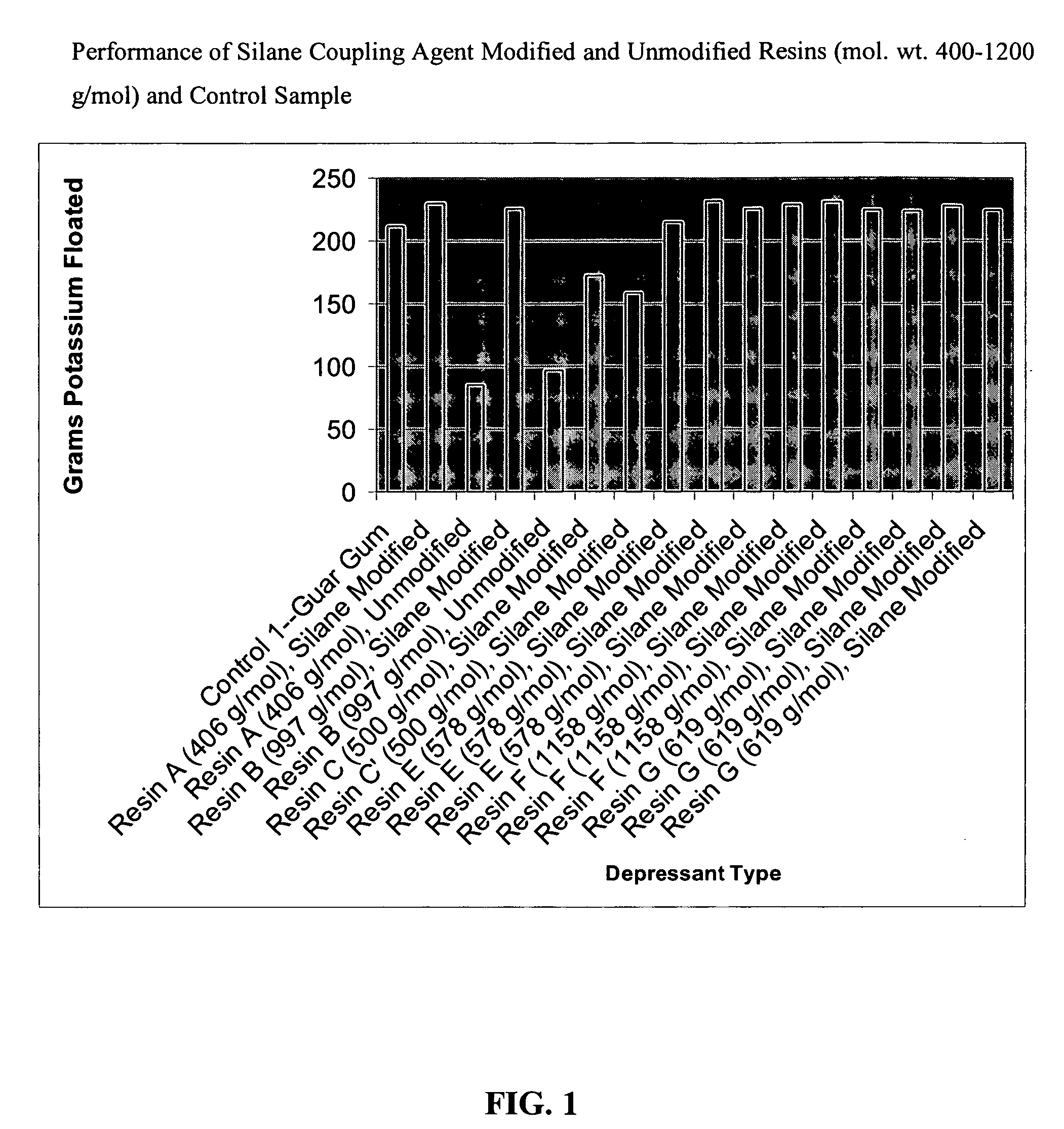

Modified amine-aldehyde resins and uses thereof in separation processes

InactiveUS20060151360A1Highly selective bindingWaste water treatment from quariesPigmenting treatmentIonAldehyde formation

Modified resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These modified resins are especially useful as froth flotation depressants in the beneficiation of many types of materials (e.g., mineral and metal ores), including the beneficiation of impure coal comprising clay impurities, as well as in the separation of valuable bitumen from solid contaminants such as sand. The modified resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water. The modified resins comprise a base resin that is modified with a coupling agent, which is highly selective for binding to solid contaminants and especially siliceous materials such as sand or clay.

Owner:INGEVITY SOUTH CAROLINA

Azetidinium-functional polysaccharides and uses thereof

The present invention relates to polysaccharides that have been modified by providing azetidinium functionality thereto. Such functionality can be provided by crosslinking a polysaccharide with a resin having azetidinium functional groups. In one or more aspects, the polysaccharide can comprise one or more of starch, guar gum, alginate or derivatives thereof. Polysaccharides having azetidinium functionality according to the present invention are suitable for multiple uses. Such uses include, but are not limited to, removal of one or more solid materials from a liquid, beneficiation of an ore, removal of metallic ions from a liquid; providing oil from bitumen; and removal of mercury from synthetic gypsum. Other uses of the functionalized polysaccharides of the present invention include hydroseeding, dust control and corosion control.

Owner:GEORGIA PACIFIC CHEM LLC

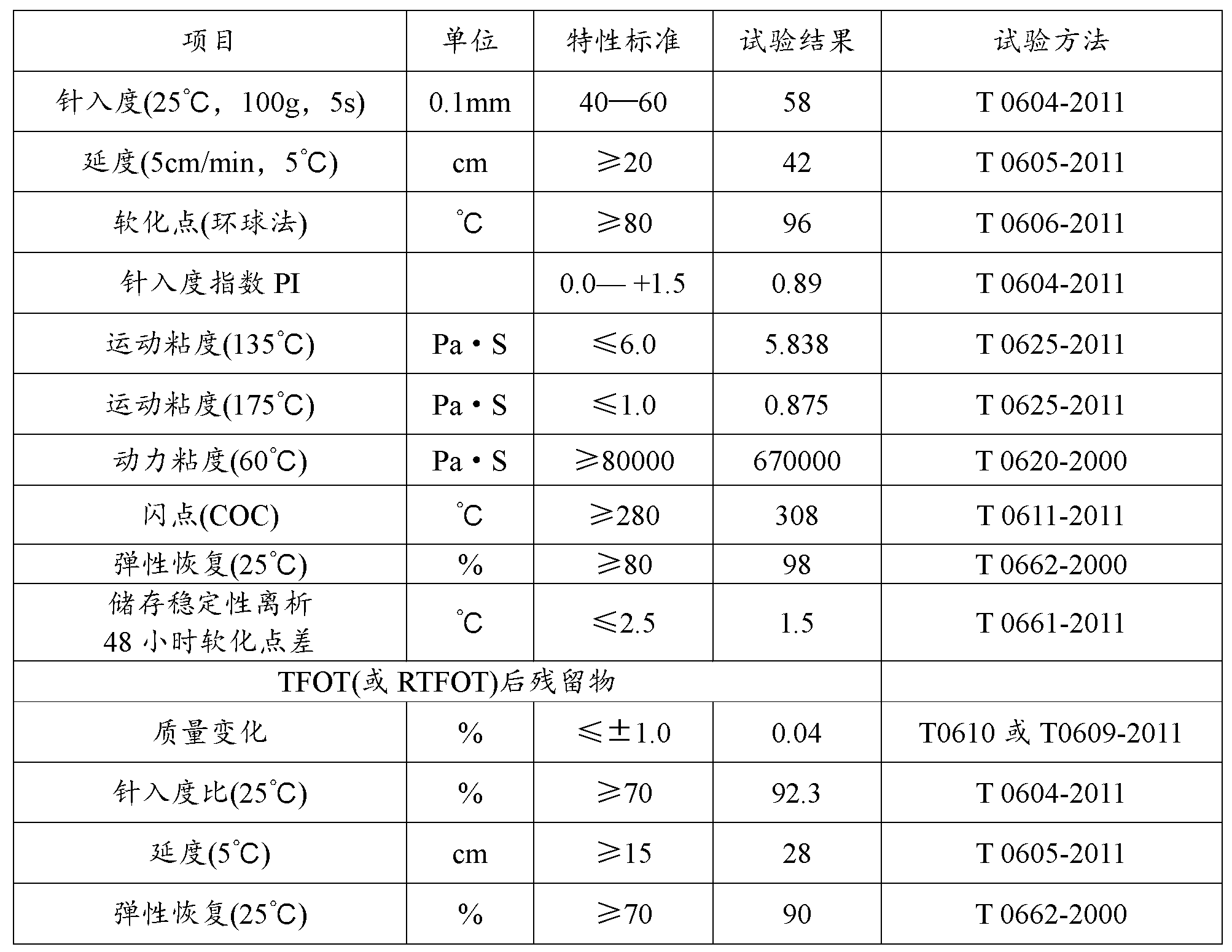

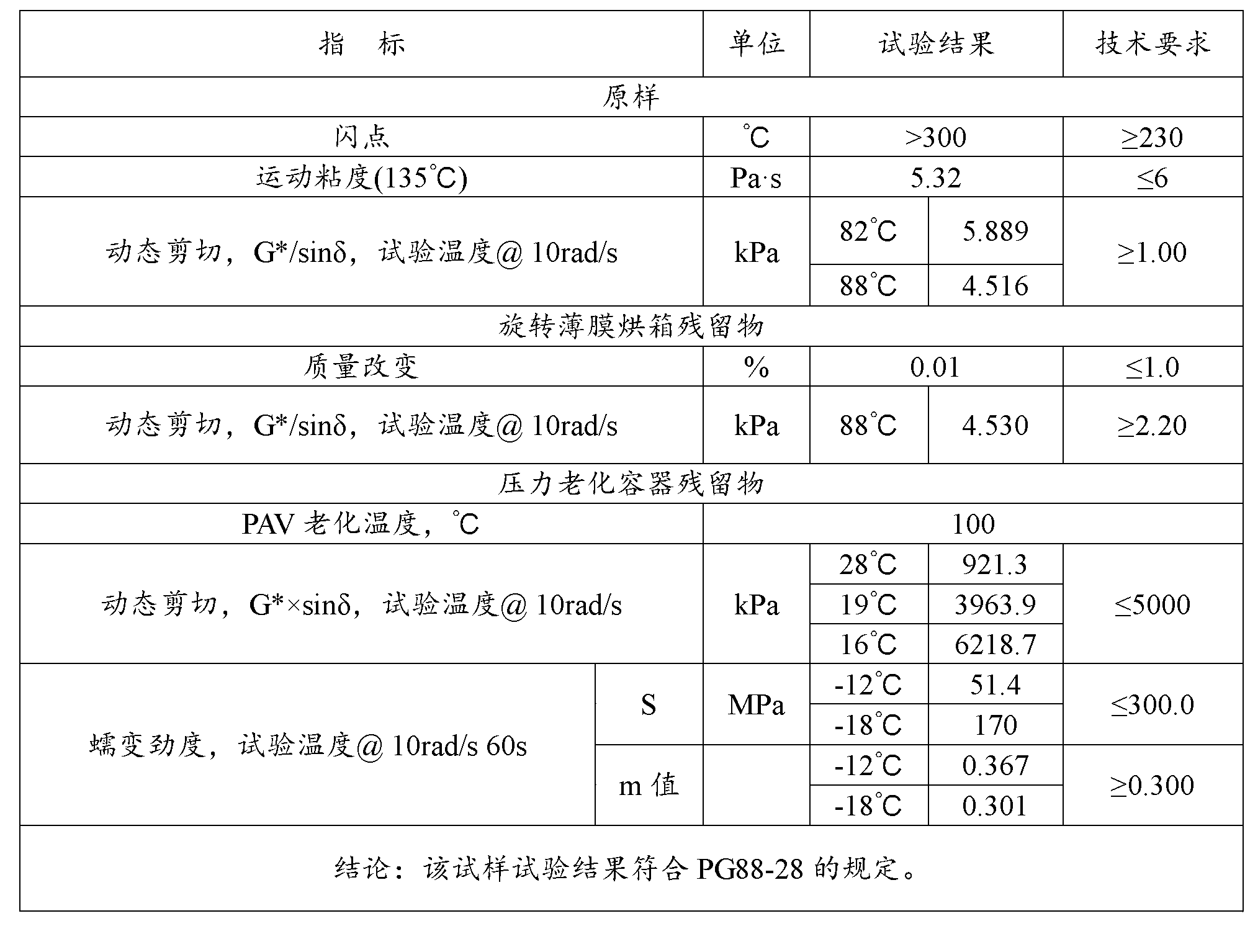

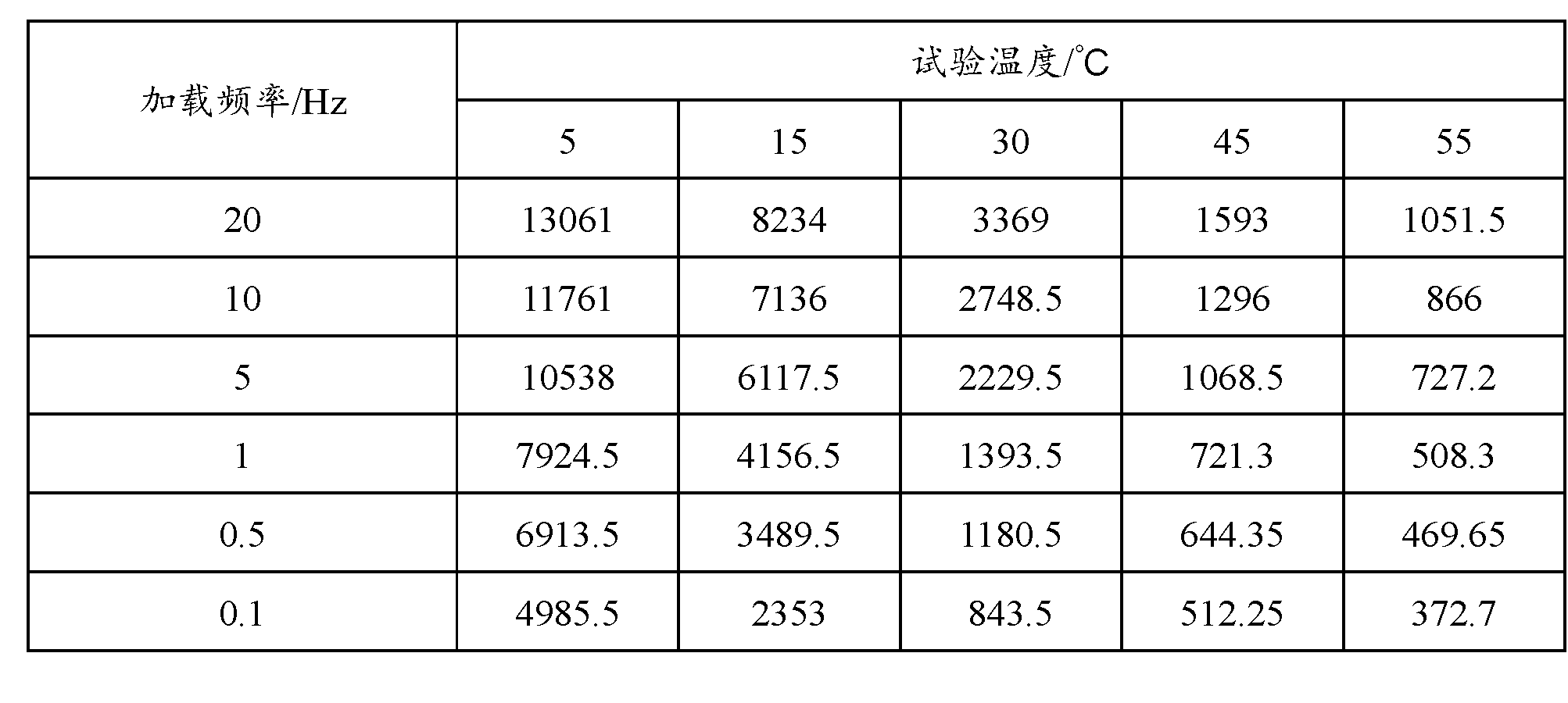

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

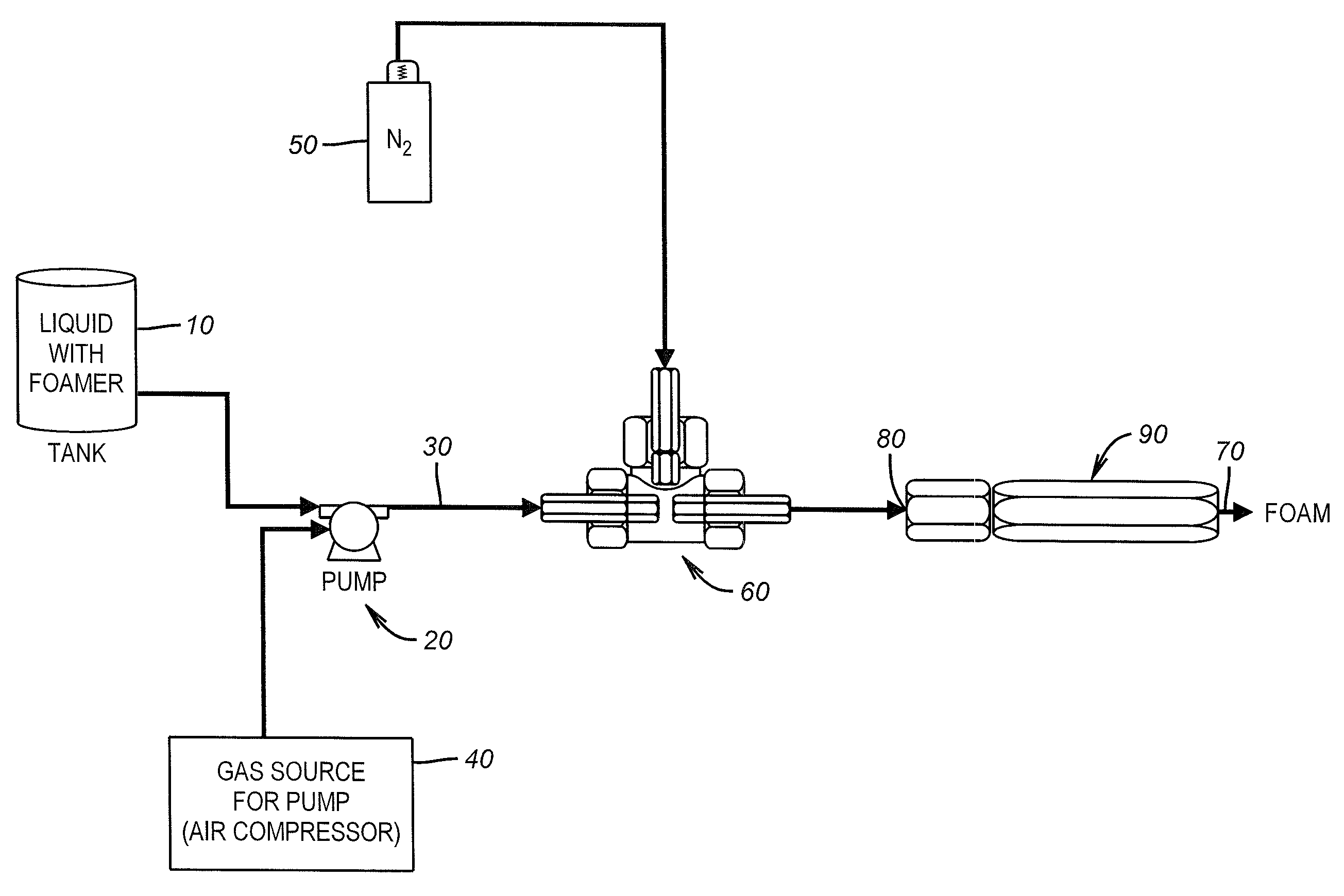

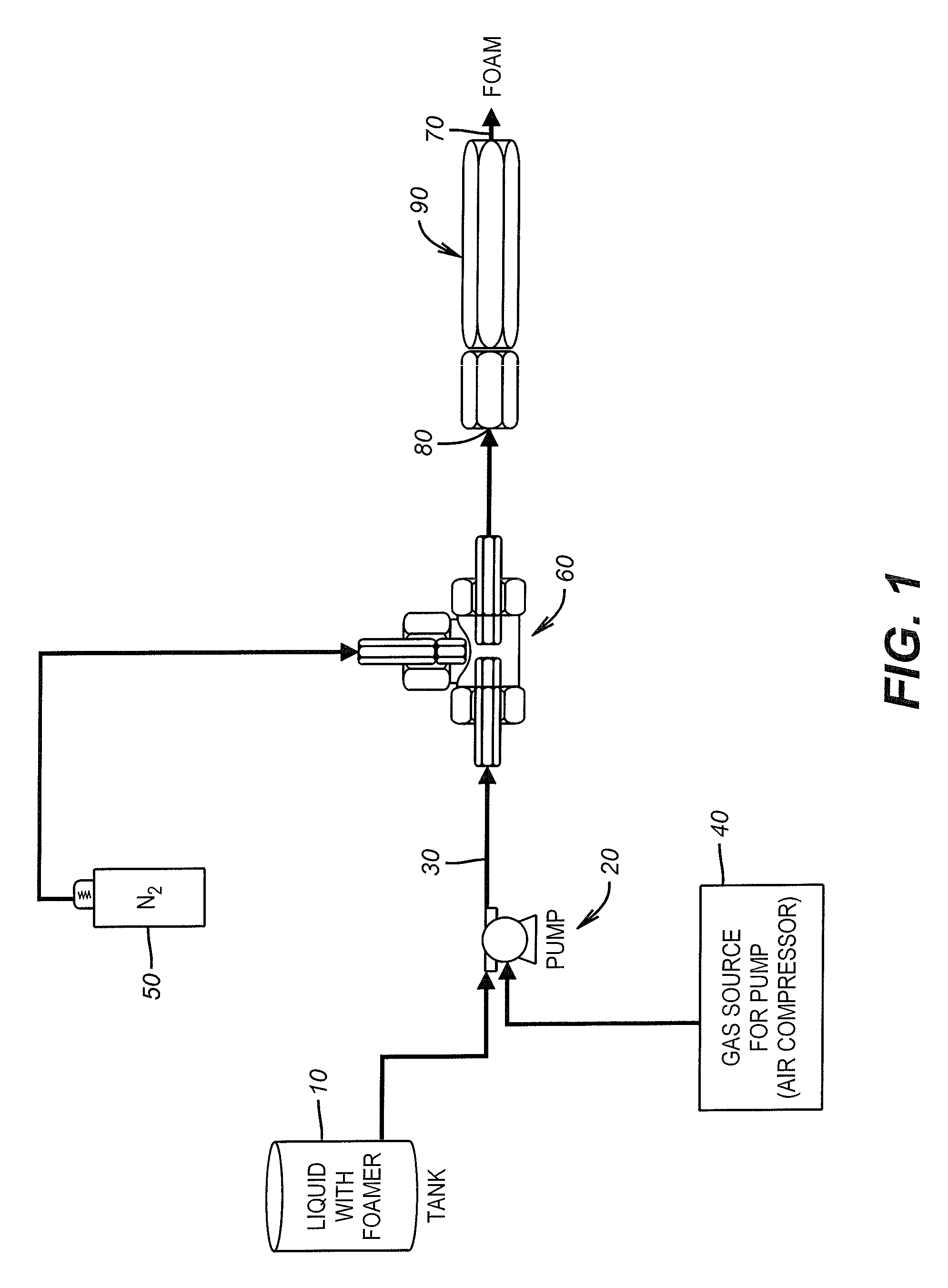

Method of Treating Flow Conduits and Vessels with Foamed Composition

InactiveUS20090114247A1Lower hydrostatic loadingReduce liquid volumeHollow article cleaningCleaning apparatusFoaming agentMedicine

The annular surface between the tubing and casing of an oil or gas well as well as flow conduits and vessels may be contacted with a foamed treatment composition containing a gas, a foaming agent and a treatment agent. The treatment agent may be an inhibitor or removal agent for scales, corrosion, salts, paraffins or asphaltenes. The foam, upon destabilization, renders a thin film of concentrated treatment agent on the external surfaces of the tubing, inside the casing and in the perforations of the oil or gas well or on the flow conduits or vessels.

Owner:BAKER HUGHES INC

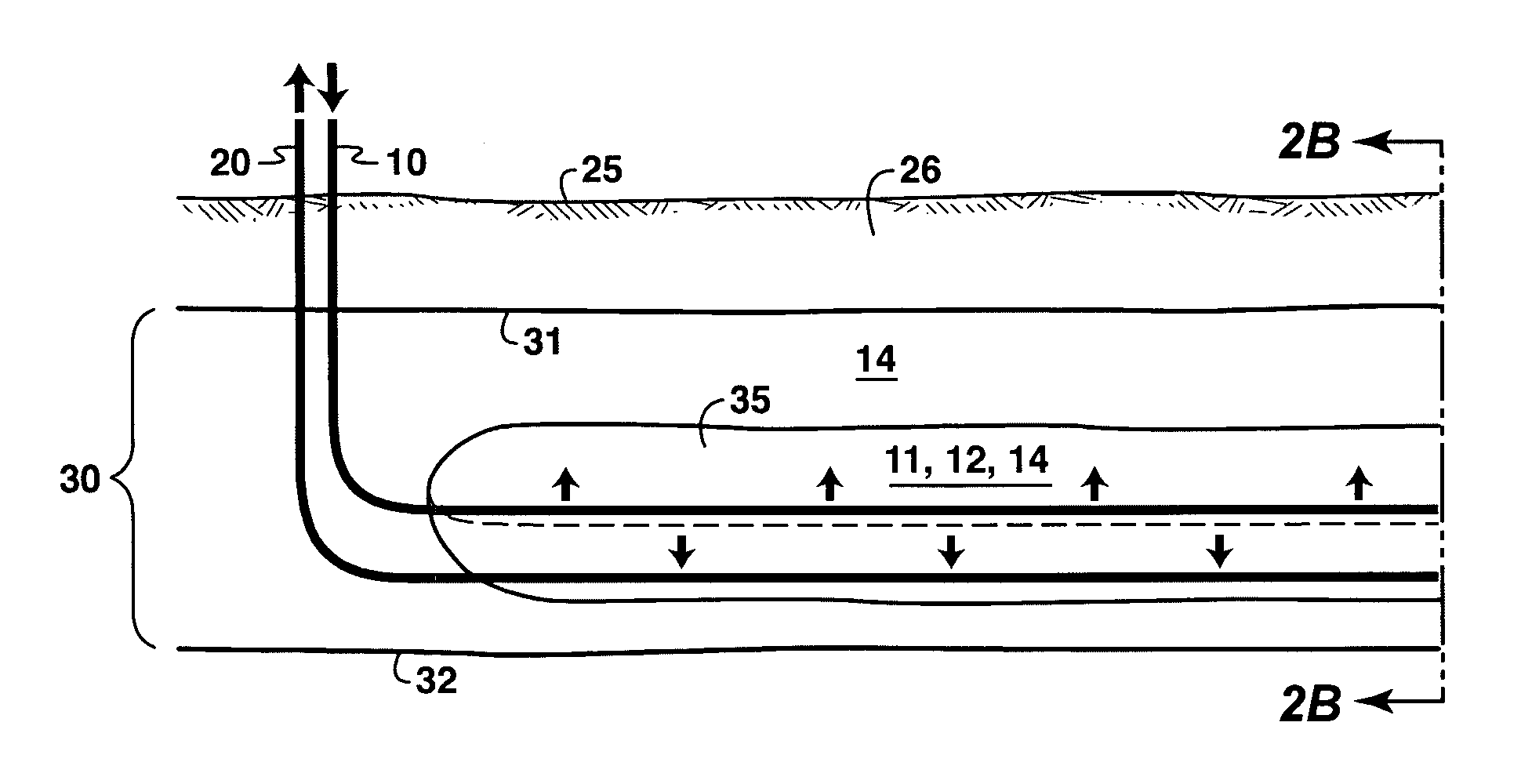

Methods of Improving Heavy Oil Production

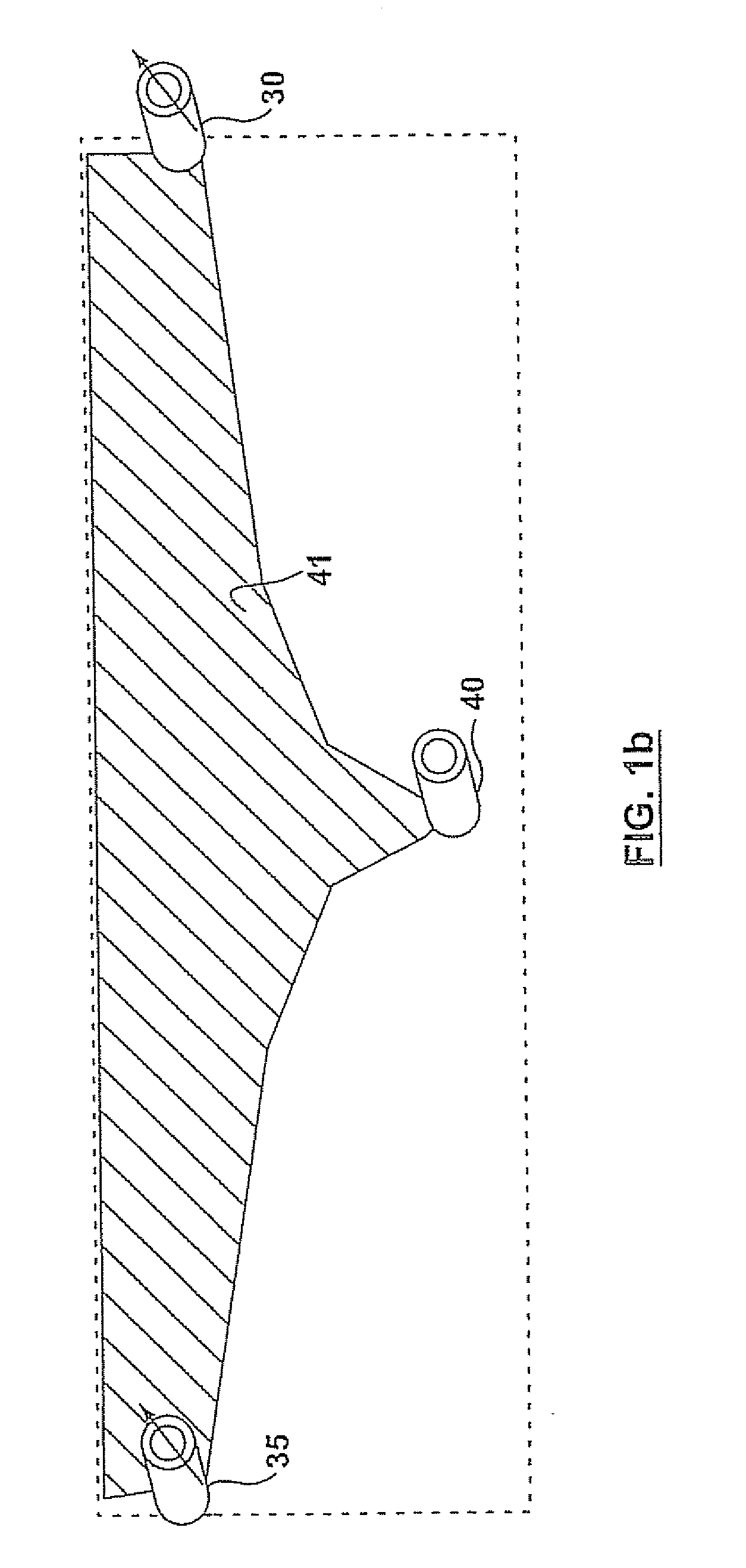

The invention provides an improved method for extracting heavy oil or bitumen contained in a reservoir. The invention involves directing the formation of a solvent fluid chamber through the combination of directed solvent fluid injection and production at combinations of horizontal and / or vertical injection wells so as to increase the recovery of heavy oil or bitumen contained in a reservoir. The wells are preferably provided with flow control devices to achieve uniform production.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

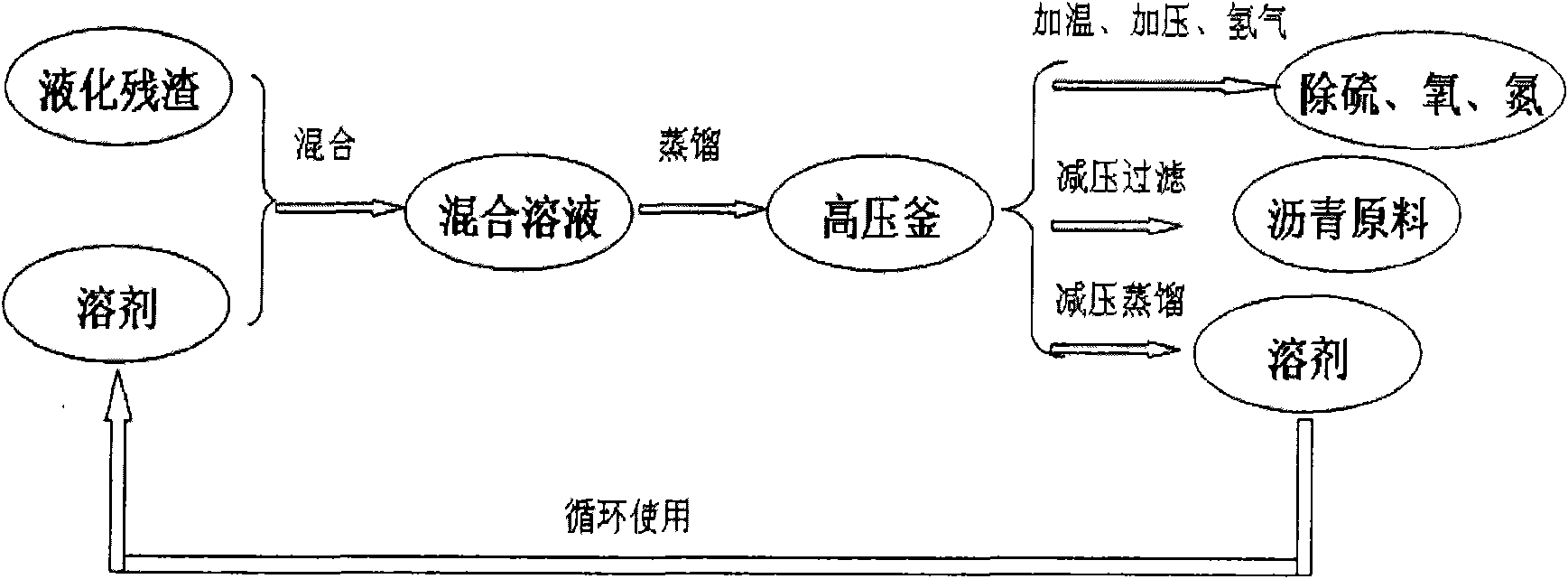

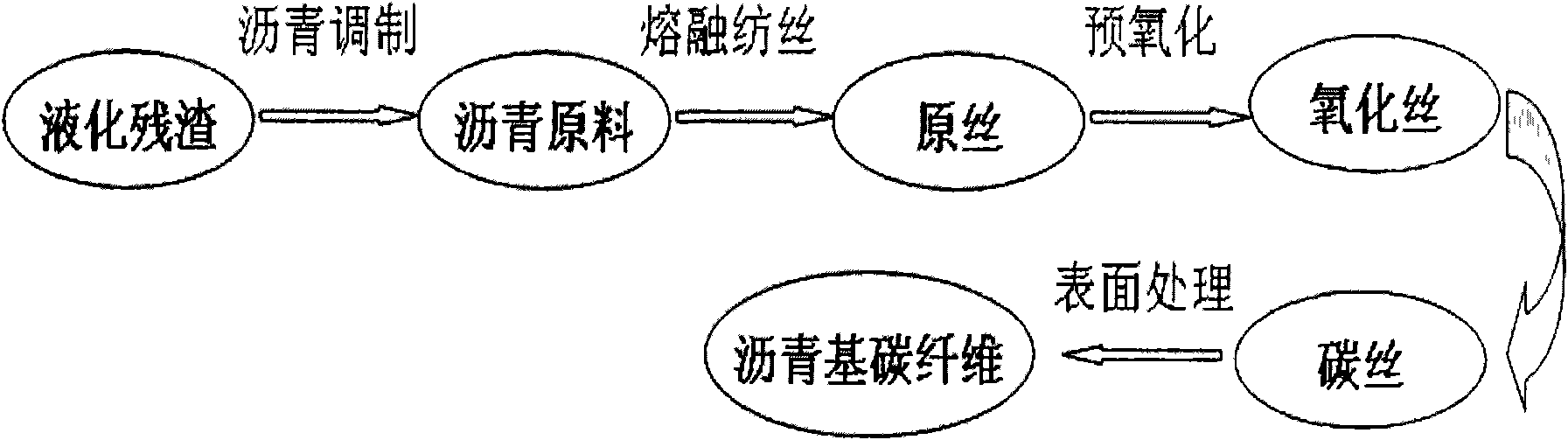

Asphalt-base carbon fiber prepared by coal directly liquefied residues and preparation method thereof

The invention discloses a method for preparing asphalt-base carbon fiber by taking coal directly liquefied residues as a raw material. The method comprises the following steps that: mixed solution of coal directly liquefied residue powder and tetrahydroquinoline solvent is filled into a high pressure autoclave, and is heated to a temperature of between 150 and 400 DEG C after air in the autoclave is replaced by nitrogen; hydrogen is introduced into the autoclave while pressure is increased to 2 to 50MPa; most elements, such as sulfur, oxygen, nitrogen and the like, contained in original residues are removed through distilling under reduced pressure; removing tetrahydroquinoline insoluble substance through filtering under reduced pressure, reclaiming the tetrahydroquinoline solvent through distilling under reduced pressure, and recycling the tetrahydroquinoline solvent; and the obtained tetrahydroquinoline soluble substance can be produced into the asphalt-base carbon fiber through melt spinning, pre-oxidation, low temperature carbonization, high temperature carbonization, superficial treatment, post treatment and other processes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

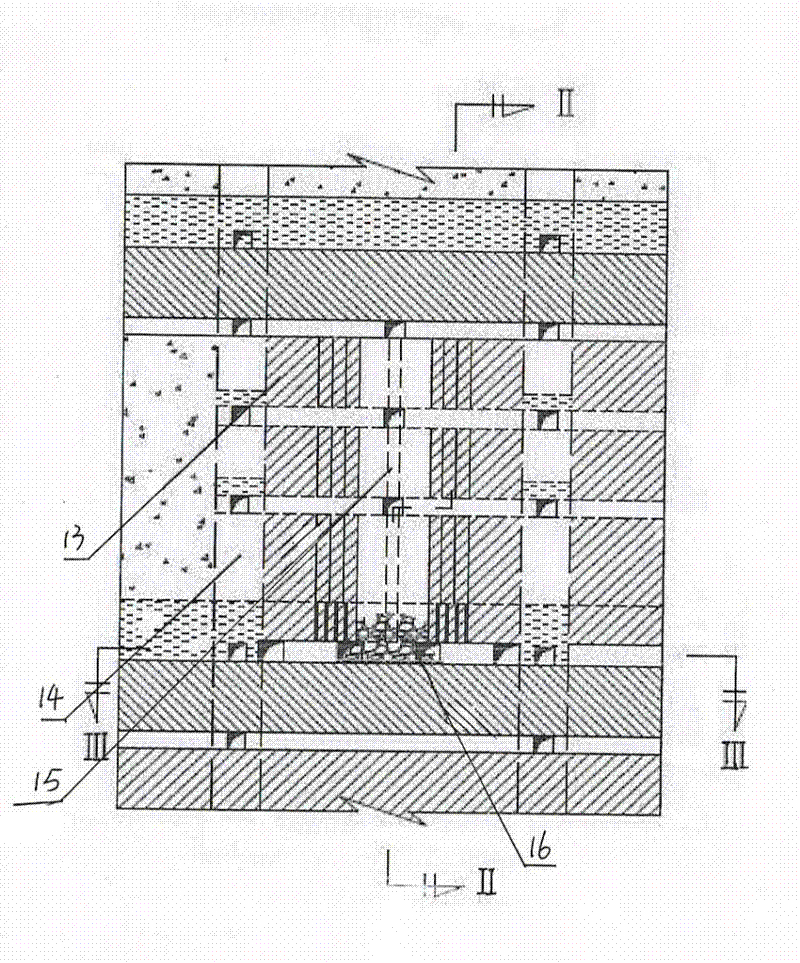

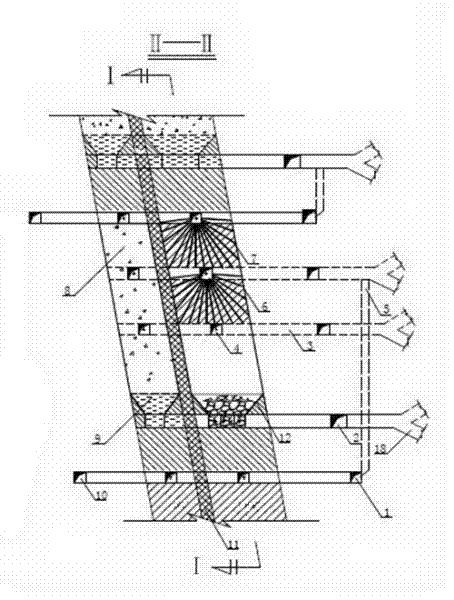

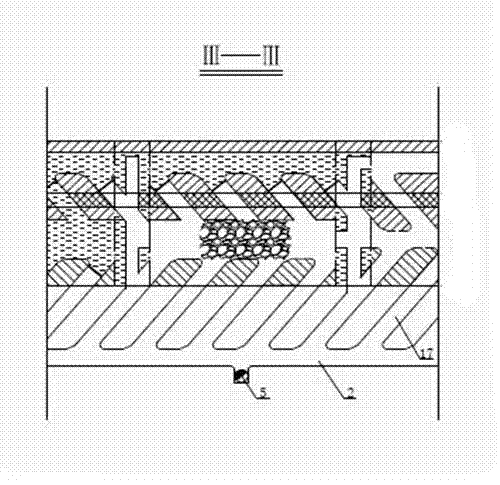

High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

InactiveCN102418526AAvoid damageIncrease productivityUnderground miningSurface miningMining engineeringSlag

The invention discloses a high-sublevel subdivision mining method of a moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along a strike. The high-sublevel subdivision mining method comprises four steps of exploiting, mining preparation, cutting and recovery, wherein a footwall intermediate-section main roadway is respectively arranged on a high sublevel along a top plate and a bottom plate of the orebody, and the intermediate-section main roadways of the top plate and the bottom plate are connected through a communication channel at intervals of 100m, therefore reduced roadway cutting construction, small development rate and simple process are achieved; after overall blasting of a stope is finished, a large amount of concentrated ore drawing is carried out, and the production efficiency is high; tail sand is adhered and filled after space pillars are mined first, then rooms are evacuated, and the rooms are filled with waste rocks or tail sand in a non-adhering way, thus recovery rate is high; and the high-sublevel subdivision mining method has little damage to the environment and capabilities of changing oredressing tail sand and waste rocks generated in open-air production into valuables and reducing geological disaster from happening. Due to the adoption of the high-sublevel subdivision mining method disclosed by the invention, ore recovery rate can be increased, ore dilution rate and emission of mine wastes are reduced, capacity of slag disposal pit is relatively increased, expropriation of land is decreased, and mineral land harmony is promoted.

Owner:WENGFU (GRP) CO LTD

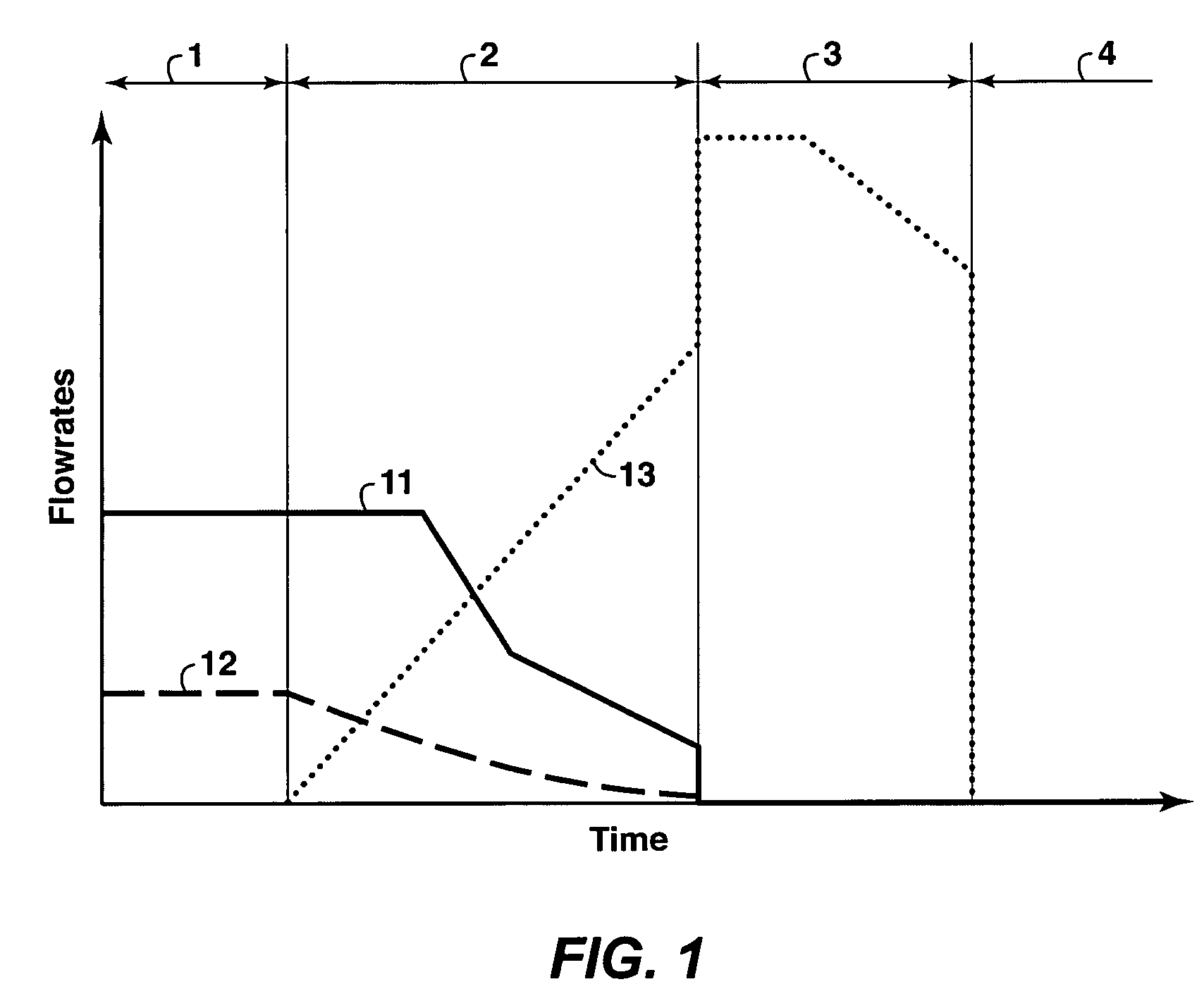

Process for in situ recovery of bitumen and heavy oil

A process is described for in situ recovery of bitumen or heavy oil from a reservoir having a horizontal injection well and a horizontal production well. The process includes a first phase in which steam and a heavy hydrocarbon solvent are injected into the reservoir, a second phase in which the steam and heavy hydrocarbon injections are transitioned to a light hydrocarbon solvent injection, and a third phase in which a light hydrocarbon solvent is injected without further steam or heavy hydrocarbon injection. A displacement gas may be added during any of the phases, and production of hydrocarbons continues throughout all phases. The process employs a high-production start-up phase, followed by lower cost phases which progress a depletion chamber within the reservoir.

Owner:EXXONMOBIL UPSTREAM RES CO

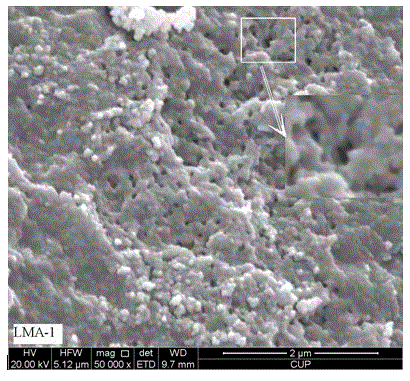

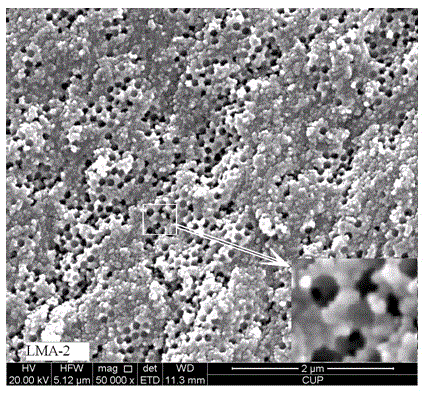

Alumina carrier with composite pore structure and preparation method thereof

ActiveCN102614934AExtend your lifeHigh selectivityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceMicrosphere

The invention discloses a preparation method of an alumina carrier with a composite pore structure, which comprises the steps of mixing and roasting an aluminum-contained compound and a composite template, wherein the composite template comprises a mesoporous template selected from at least one of a polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer, polyethylene glycol, dodecylamine, hexadecyl trimethyl ammonium bromide, lauric acid, stearic acid and fatty alcohol polyoxyethylene ether and a macroporous particulate template selected from polystyrene microspheres with the particle size of greater than 50nm, polymethyl methacrylate microspheres, biomaterial particles, asphalt particles or heavy oil residues; and the weight ratio of the mesoporous template to the macroporous particulate template to the aluminum-contained compound (by alumina) is 0.1-2:0.1-0.7:1. The invention also discloses the alumina carrier simultaneously having mesoporous tunnels and macroporous tunnels prepared through the method, wherein mesopores account for 40-90% of the total pore volume, and macropores account for 10-60% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP

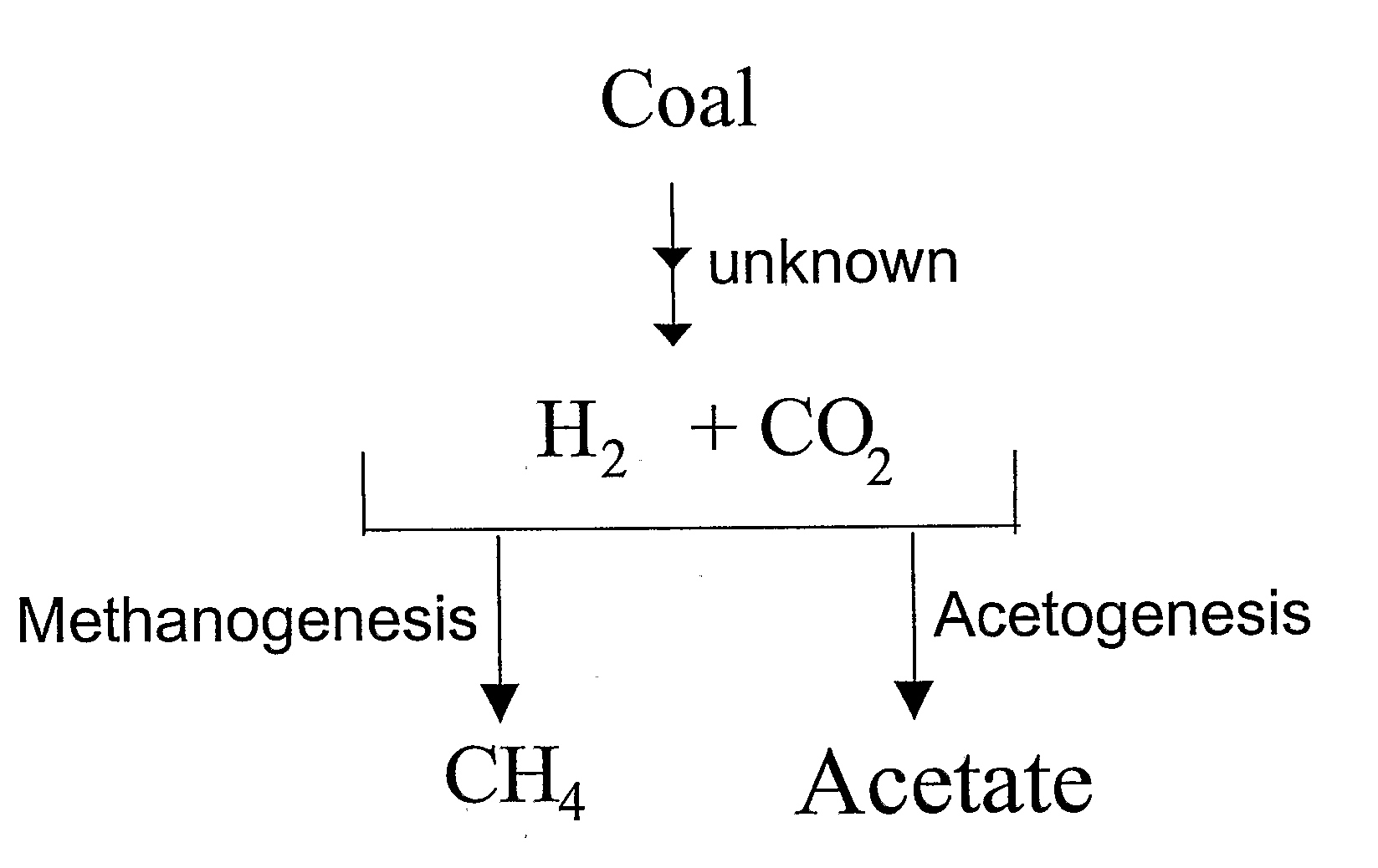

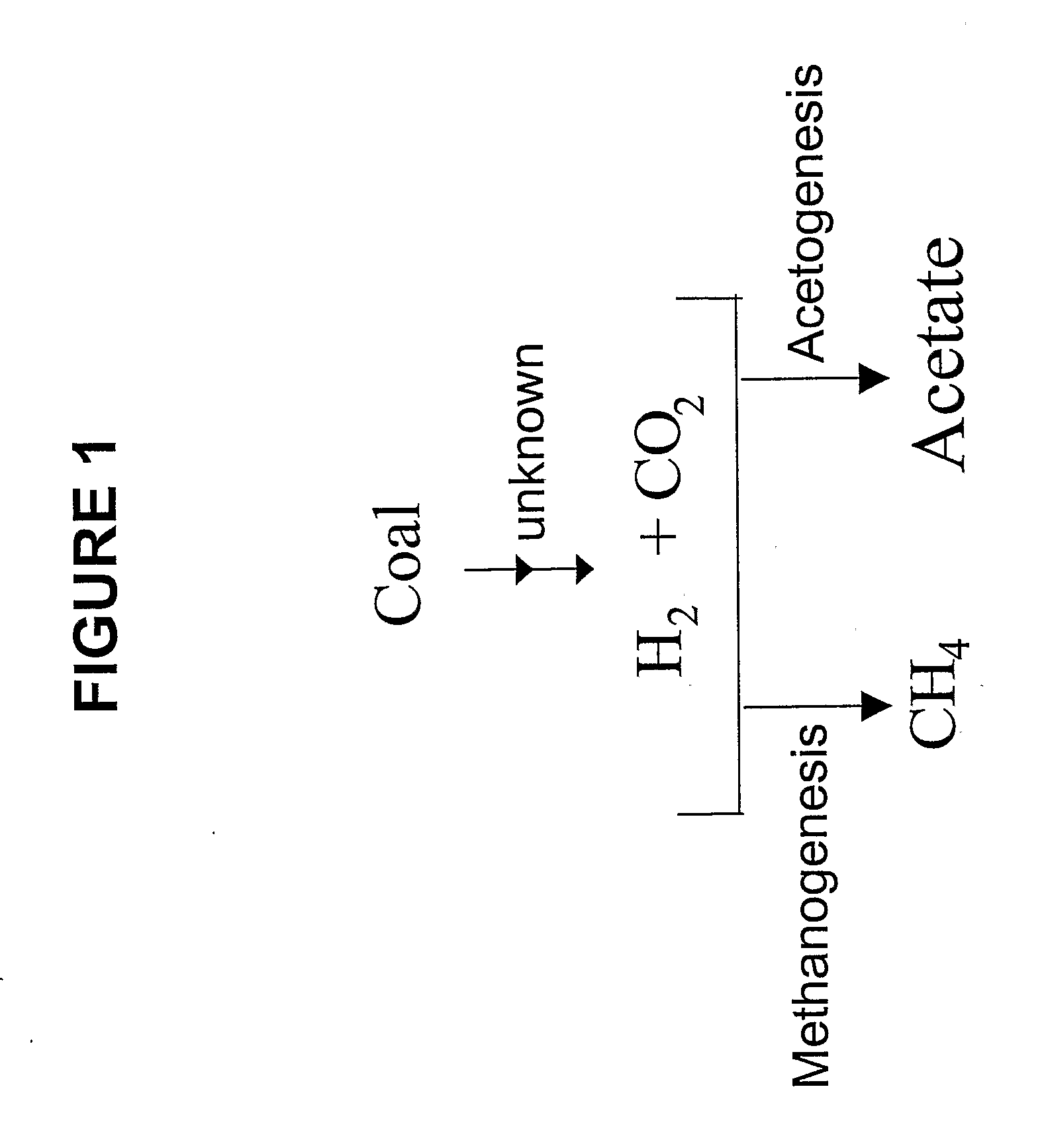

Generation of Hydrogen from Hydrocarbon Bearing Materials

ActiveUS20070248531A1Enhanced methanogenesisIncreased hydrogen productionHydrogenWaste based fuelHydrocotyle bowlesioidesSand granules

Disclosed are strategies for the economical microbial generation of hydrogen, useful as an alternative energy source, from hydrocarbon-rich deposits such as coal, oil and / or gas formations, oil shale, bitumen, tar sands, carbonaceous shale, peat deposits and sediments rich in organic matter through the management of the metabolism of microbial consortia.

Owner:TRANSWORLD TECH

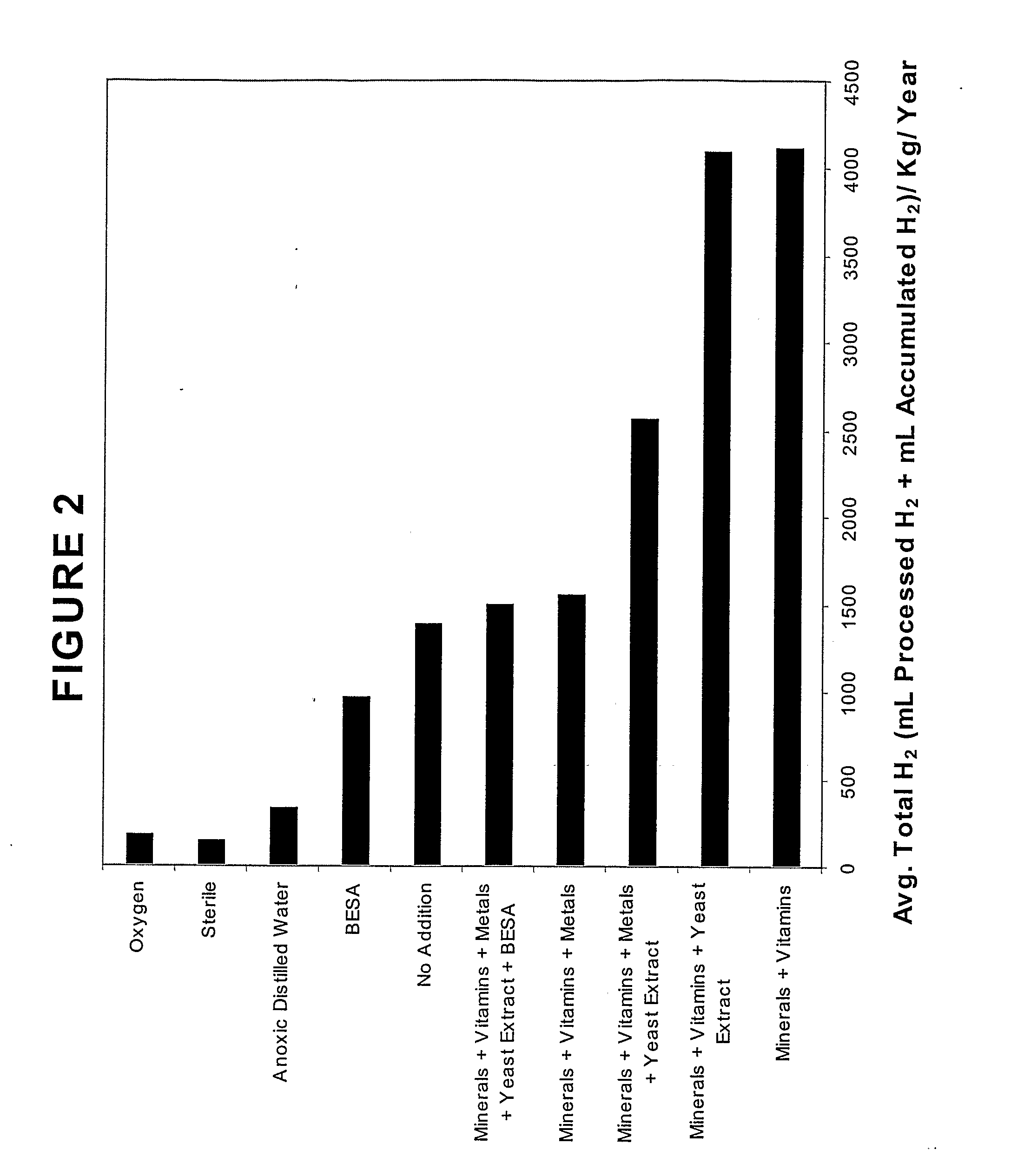

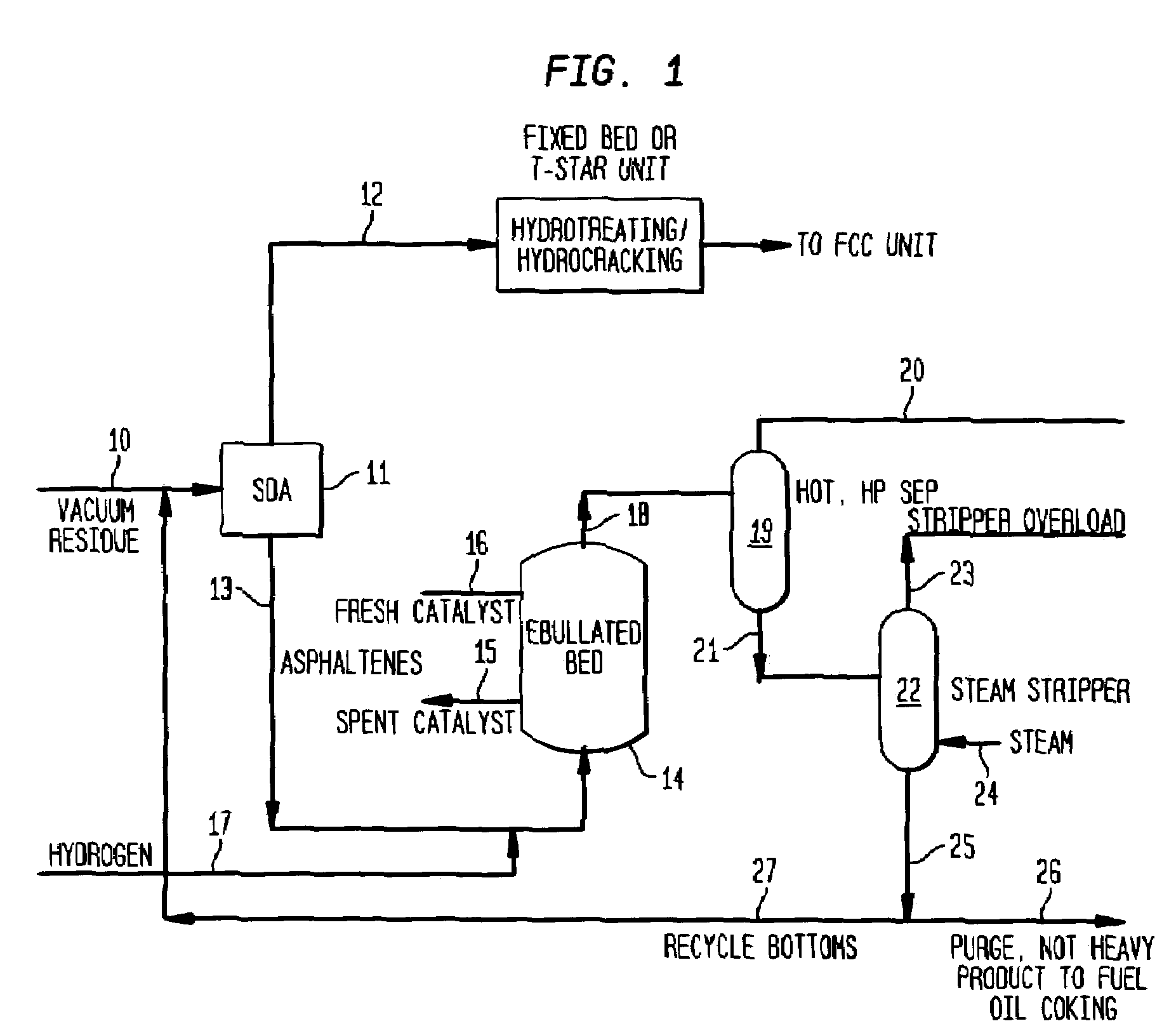

Integrated SDA and ebullated-bed process

ActiveUS7279090B2Wide pore catalystMost efficientTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit.The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

Method for displacing oil base drilling muds and/or residues from oil base drilling mud using water-in-oil emulsion

ActiveUS7188676B2Improve breathabilityEfficacious in displacingCleaning apparatusFluid removalParticulatesParaffin wax

Fluid producing wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted solid particulates, including pipe dope, asphaltenes and paraffins. Such emulsions are of particular applicability in the displacement of oil base drilling muds and / or residues from such muds from producing wells. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

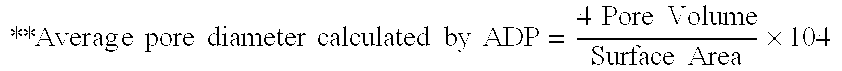

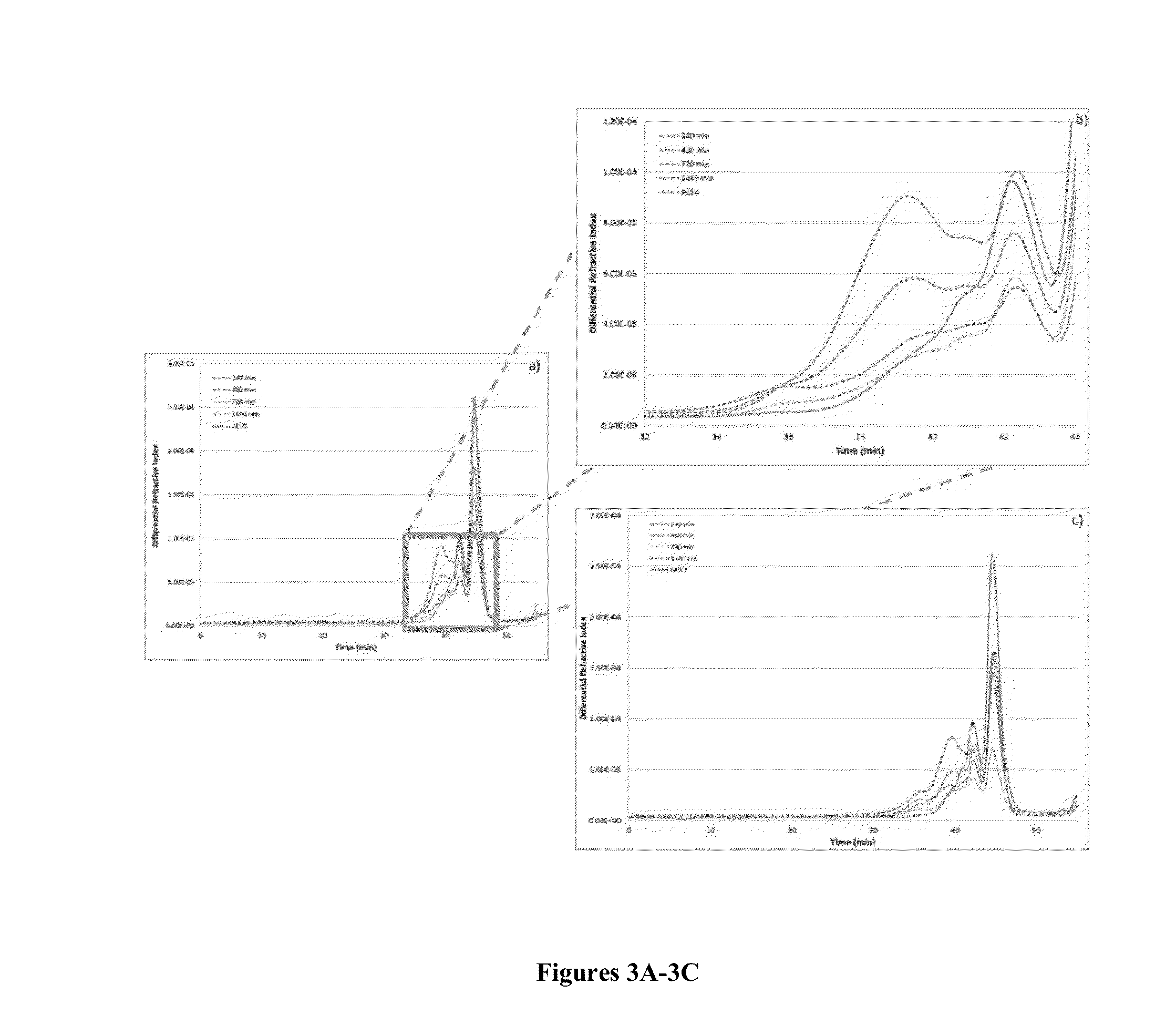

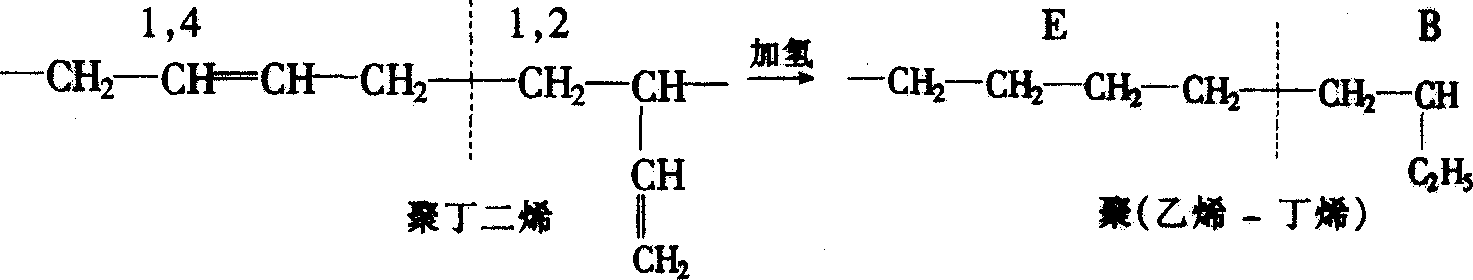

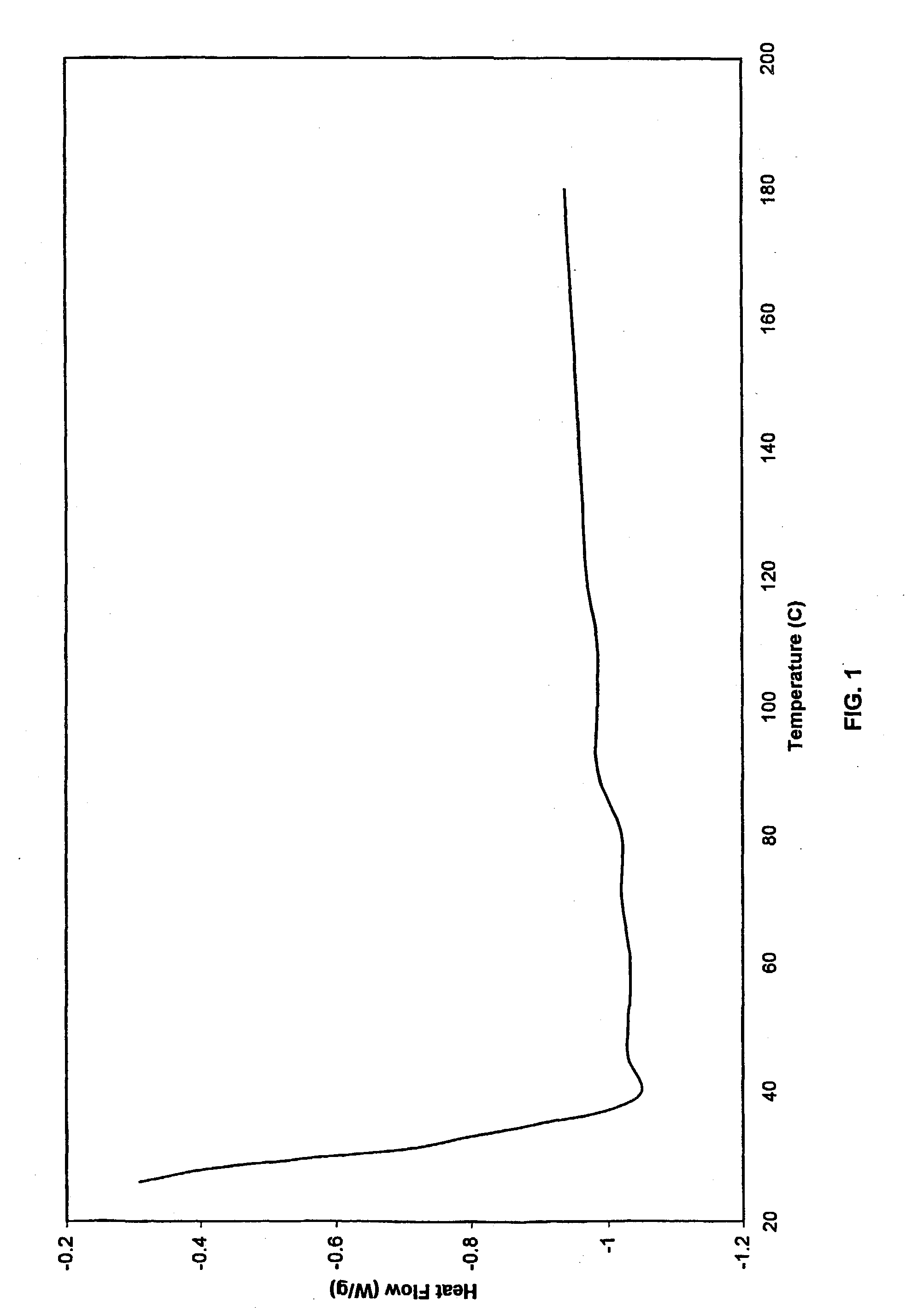

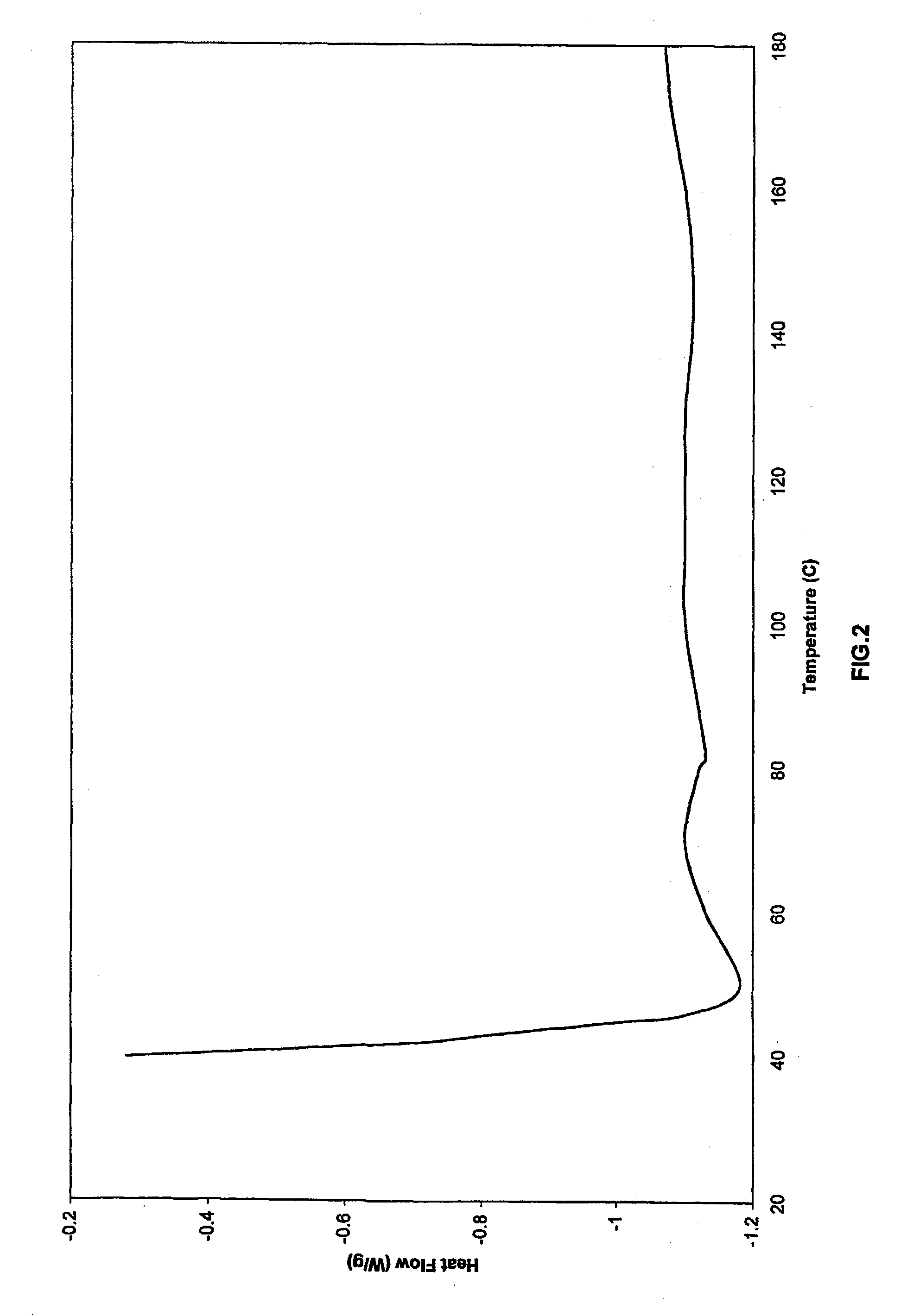

Thermoplastic elastomers via atom transfer radical polymerization of plant oil

The present invention relates to a block copolymer comprising at least one PA block and at least one PB block. The PA block represents a polymer block comprising one or more units of monomer A, and the PB block represents a polymer block comprising one or more units of monomer B. Monomer A is a vinyl, acrylic, diolefin, nitrile, dinitrile, or acrylonitrile monomer. Monomer B is a radically polymerizable plant oil monomer containing one or more triglycerides. The present invention also relates to a method of preparing a thermoplastic block copolymer by radical polymerizing a radically polymerizable monomer with a radically polymerizable plant oil monomer containing one or more triglycerides, in the presence of an initiator and a transition-metal catalyst system to form the thermoplastic block copolymer. The polymerized plant oil-based block copolymers are useful in a variety of applications, such as asphalt modifiers, rubber compositions, adhesives, tires, in the automobile industry, footwear, packaging, etc.

Owner:IOWA STATE UNIV RES FOUND

Bitumen modifier for traffic tracking resistance and modified bitumen and mixer thereof

ActiveCN101063000AGood storage stabilityReduce energy consumptionIn situ pavingsBuilding insulationsPolyolefinThermoplastic elastomer

The invention discloses a pitch modifier for traffic anti-rut, modified asphalt and bituminous mixture, which is characterized by the following: allocating 20-200 wt thermoplastic elastomer ethenyl aromatic hydrocarbon-conjugated diene block copolymer and 5-950 wt polyolefin; setting the thermoplastic elastomer ethenyl aromatic hydrocarbon-conjugated diene block copolymer as SBS, SIS, SEBS and or SEPS; setting the polyolefin as PE, PP, EVA, APP, APAO, POE, HDPE, LDPE and or LLDPE; setting the mass percent of adding basic pitch at 1%-7%; increasing high-temperature behavior and anti-rut ability distinctively; modifying anti-water damage and anti-low temperature property. This craft is simple, which avoids the problem of bad stability of modified asphalt storage.

Owner:深圳前海海川新材料科技有限公司

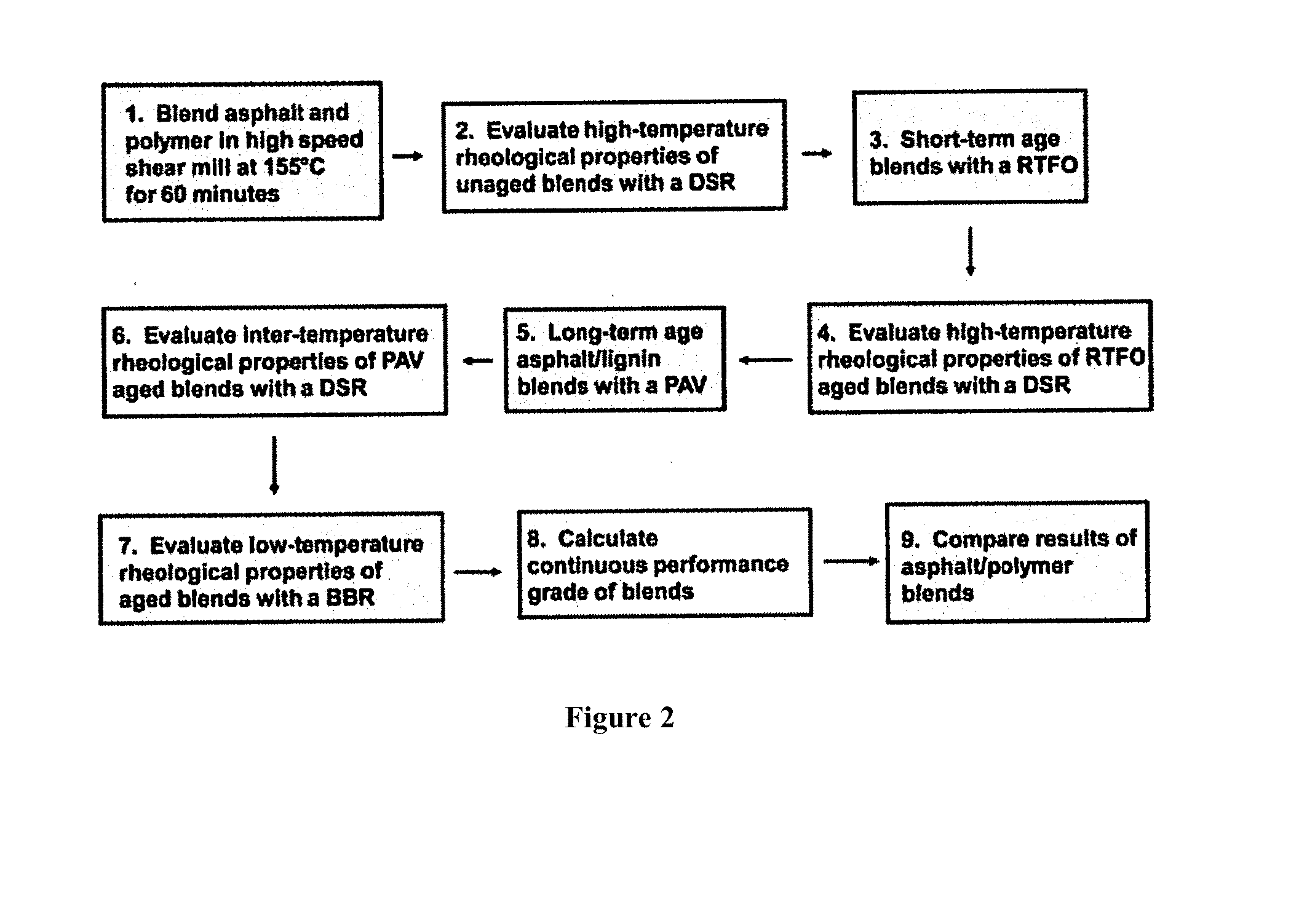

Petroleum asphalts modified by liquefied biomass additives

InactiveUS20030212168A1Increased durabilityReduce fatigue failureOrganic compound preparationCarboxylic acid esters preparationPhysical chemistryFatty acid

Liquefied biomass (16) obtained from direct liquefaction and / or fast-pyrolysis is reacted with mixtures of fatty acids (24) in the presence of an oxidizer (28) and with various reactive monomer and polymer additives (46, 48, 50) to create tailored compatibilizer-like bio-additives (34) that are compatible with petroleum asphalts. By judiciously selecting appropriate additives and additional constituent, such as non-reactive (18) and reactive diluents (30), these bio-additives can be tailored to modify low-temperature properties, high-temperature properties, compatibility with aggregate materials, application characteristics, and other properties of petroleum asphalts for paving, roofing and sealing uses.

Owner:WHITE DONALD H +1

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

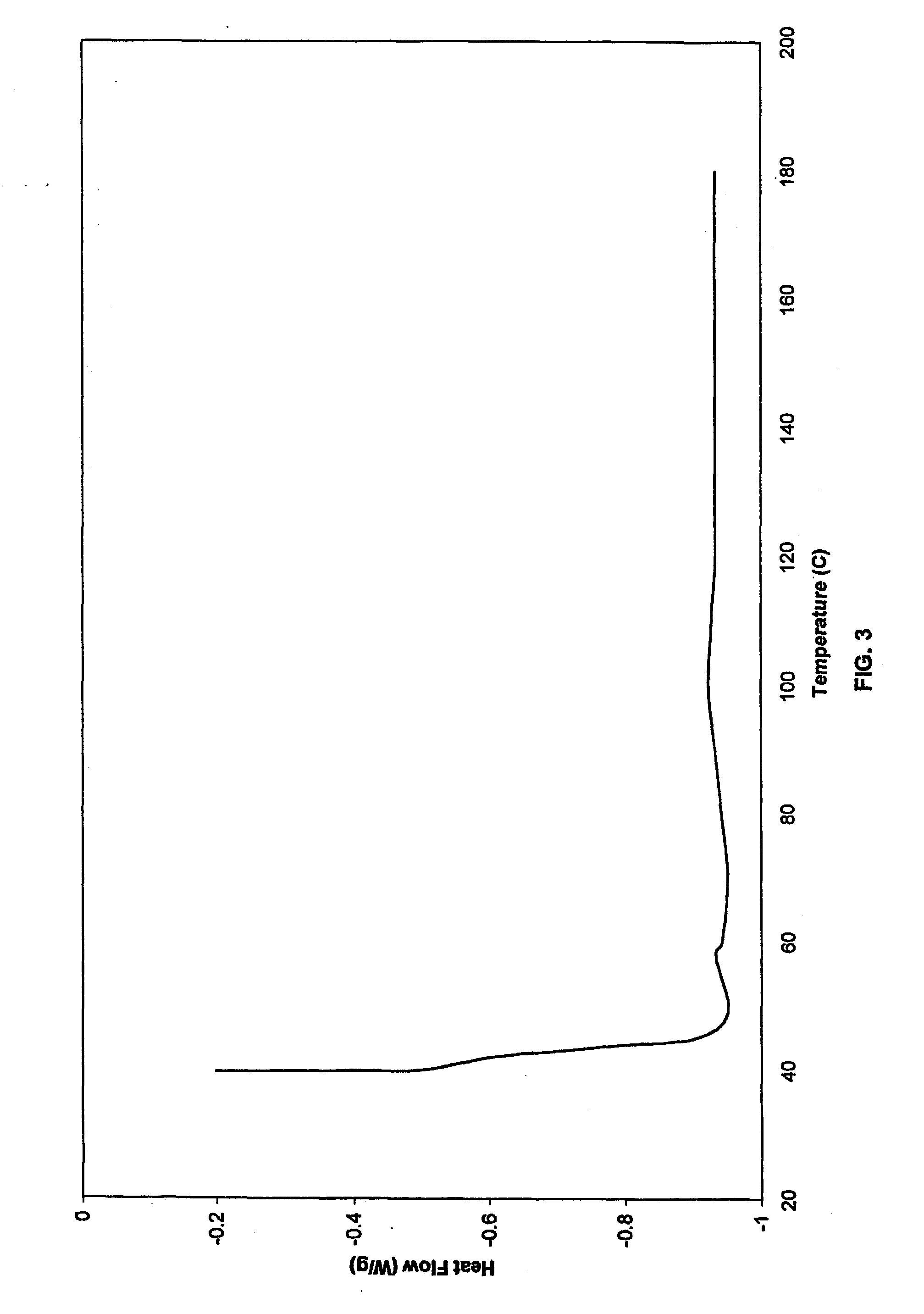

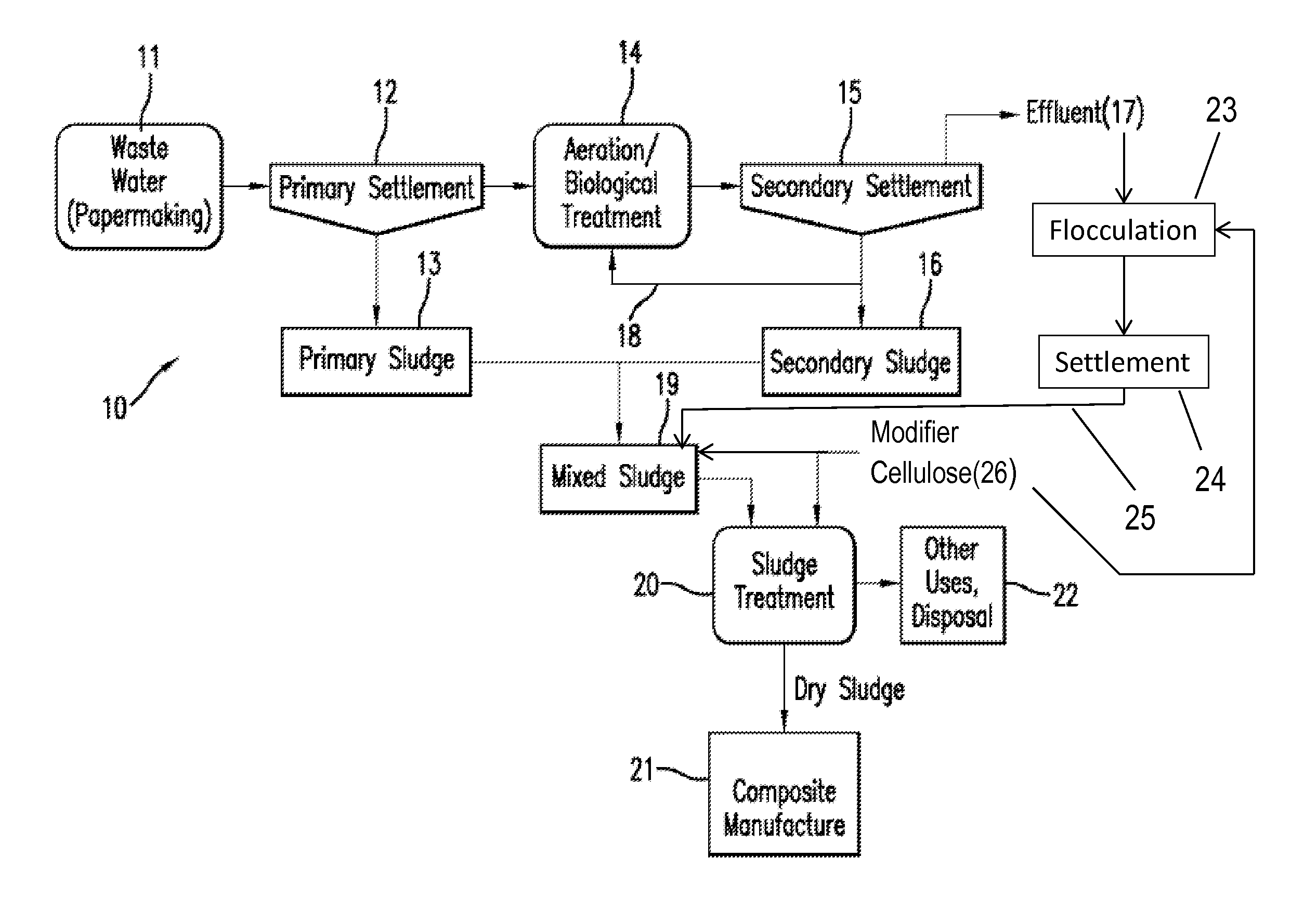

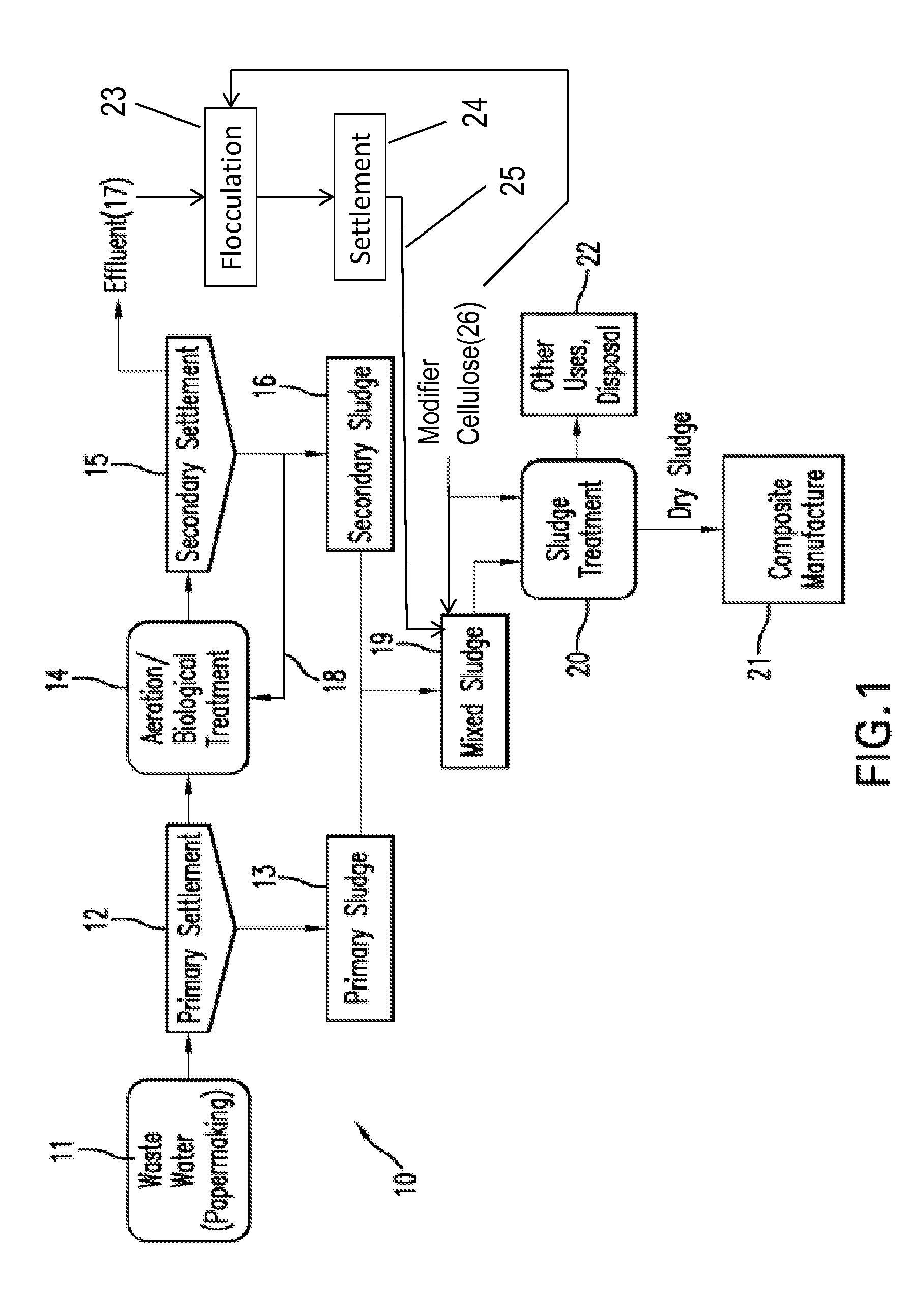

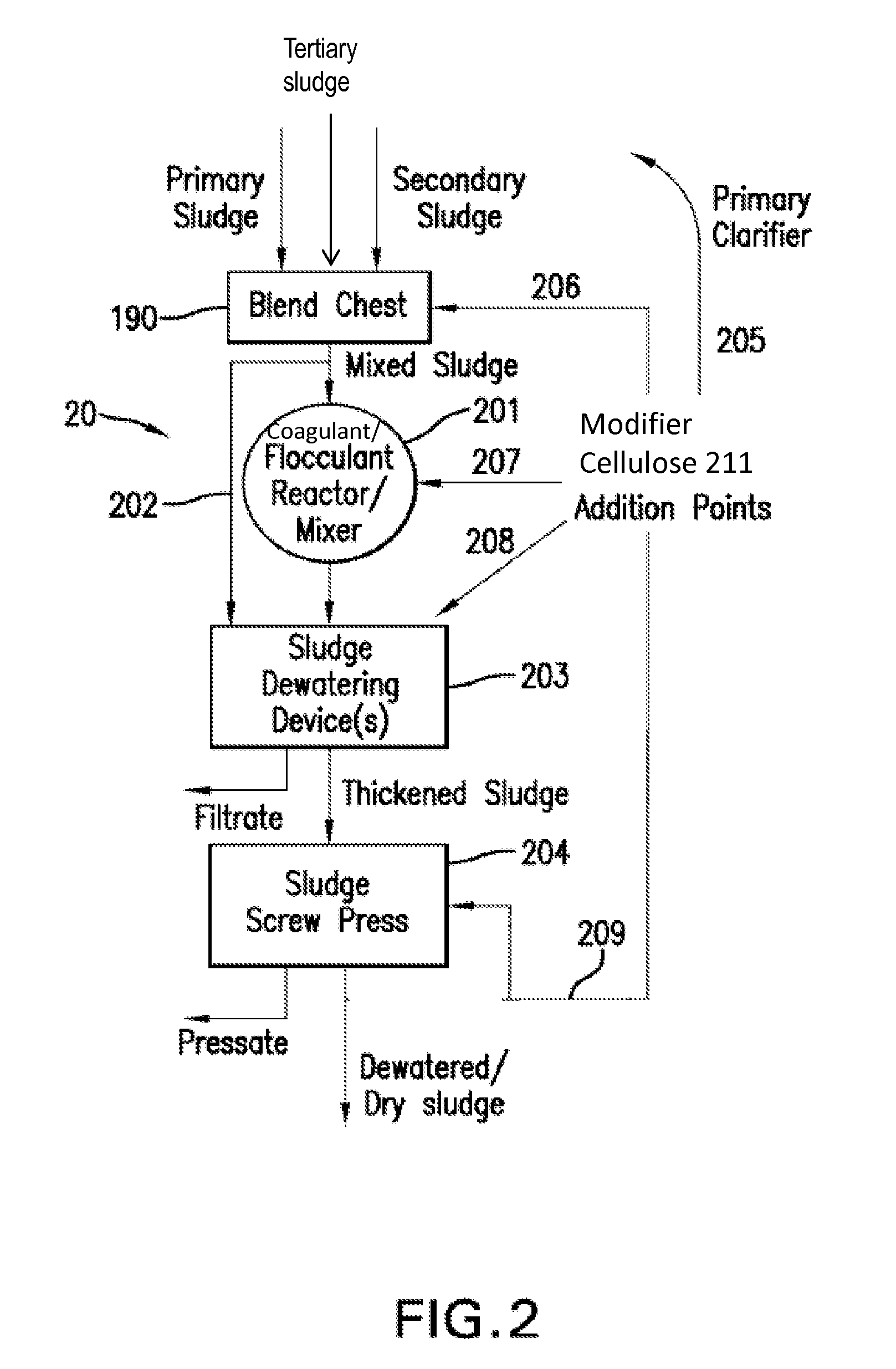

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

Biodegradable oil external emulsion for removal of asphaltene and/or paraffin from producing oil wells

A biodegradable and environmentally friendly oil external emulsion for the removal of asphaltenes, paraffin's, and / or scales which accumulate in the well bores and walls of the pipes used to bring the oil up from the underground deposits, and methods of using and formulating the composition are disclosed. The emulsion comprises oil extracted from orange peels as the external continuous phase and acid as the internal phase. The emulsion has a particular utility in cleaning asphaltenes and paraffin residues from the well formation surface, well cuttings, and down hole and surface oil well drilling and production equipment.

Owner:CUDD PRESSURE CONTROL

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

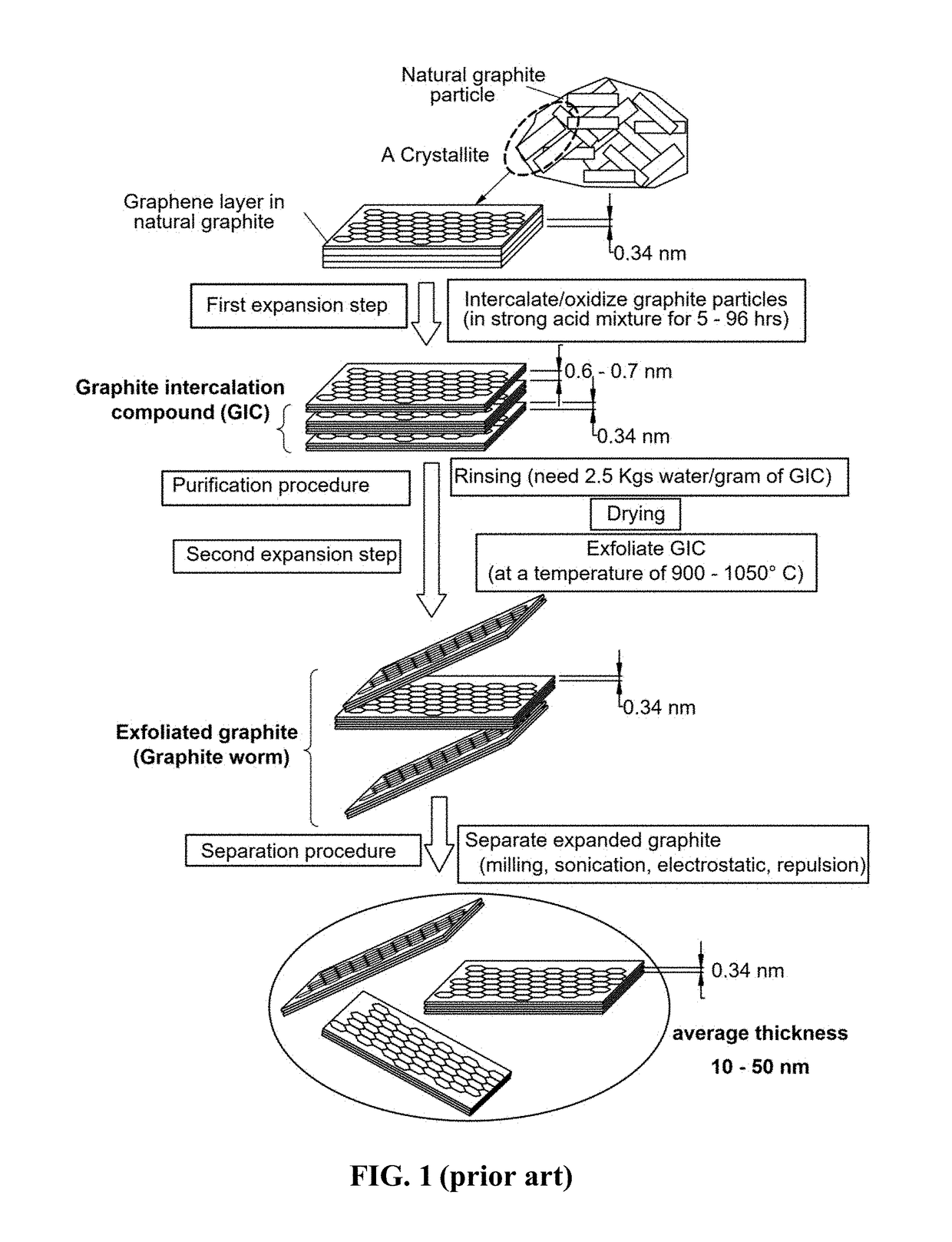

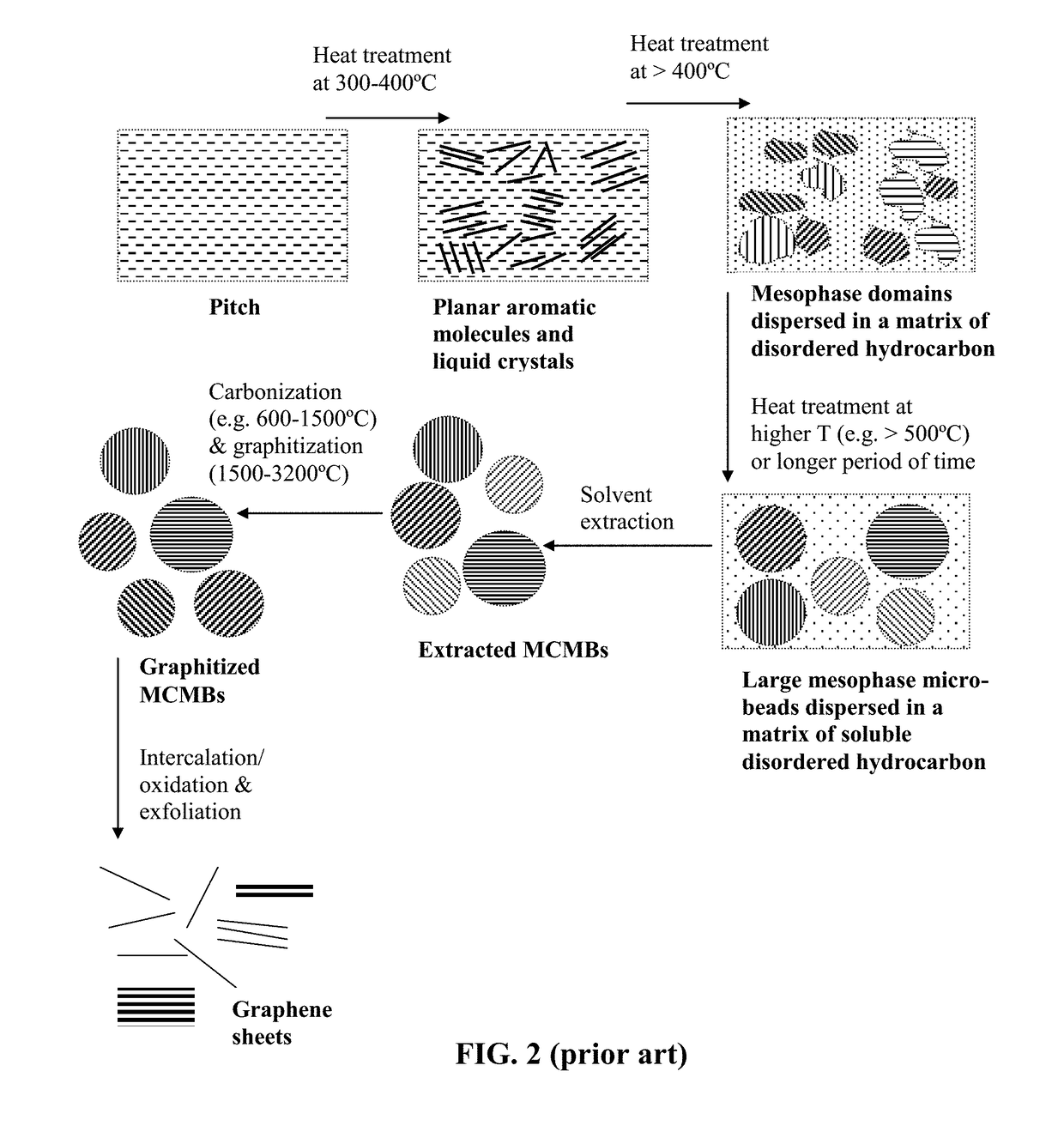

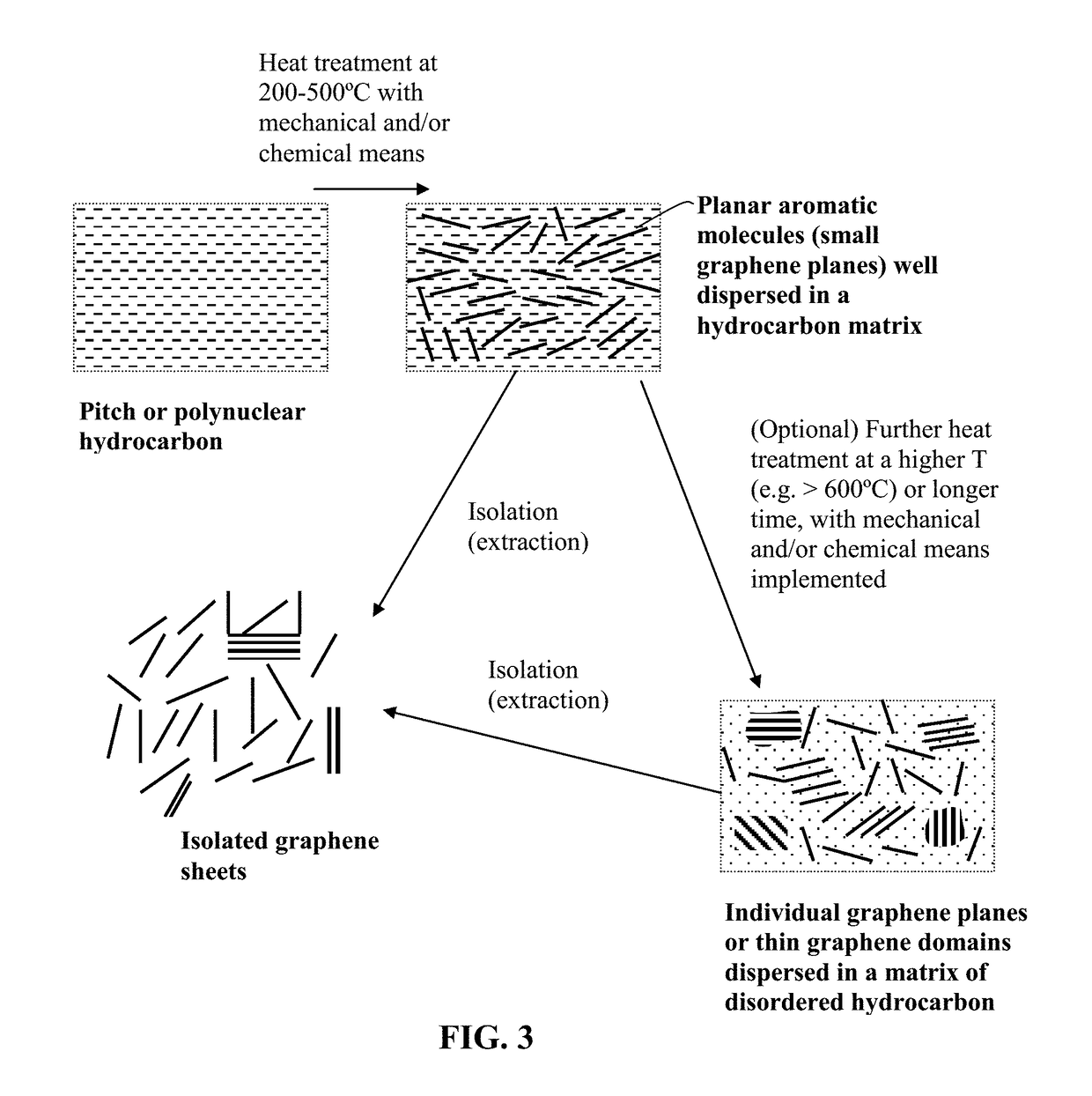

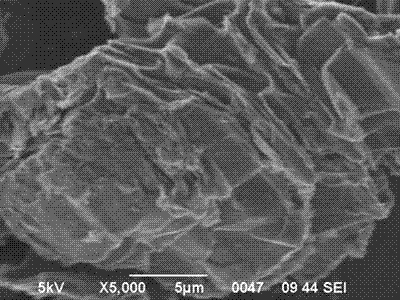

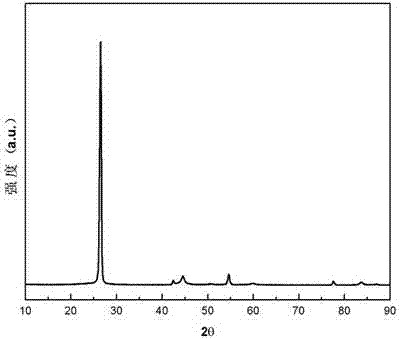

Production of graphene materials directly from carbon/graphite precursor

Provided is a method of producing isolated graphene sheets directly from a carbon / graphite precursor. The method comprises: (a) providing a mass of aromatic molecules wherein the aromatic molecules are selected from petroleum heavy oil or pitch, coal tar pitch, a polynuclear hydrocarbon, or a combination thereof; (b) heat treating this mass and using chemical or mechanical means to form graphene domains dispersed in a disordered matrix of carbon or hydrocarbon molecules, wherein the graphene domains are each composed of from 1 to 30 planes of hexagonal carbon atoms or fused aromatic rings having a length or width from 5 nm to 20 μm and an inter-graphene space between two planes of hexagonal carbon atoms or fused aromatic rings no less than 0.4 nm; and (c) separating and isolating the planes of hexagonal carbon atoms or fused aromatic rings to recover graphene sheets from the disordered matrix.

Owner:GLOBAL GRAPHENE GRP INC

High performance water-based mud system

InactiveUS20050187113A1Premature consumptionEffectively stopFluid removalFlushingWater basedPolystyrene

A drilling fluid or mud additive having several components, including leonardite (humic acid); potassium acetate; partially hydrolyzed polyacrylamide (PHPA); polyanionic cellulose polymer (PAC); sulfonated asphalt; sulfoalkylated tannin; polystyrene maleic anhydride copolymer; micronized cellulose fiber; and calcium carbonate. These components are preferably premixed in a dry formulation as a powder or as pellets, and shipped to the site in bags or bulk tanks. This offers substantial advantages over the prior art in that the drilling mud of the present invention may be formed simply by adding the dry mix to a predetermined amount of water, and is thus much easier to make than the prior art wet mix drilling fluids, which typically require precise ratios of several different powders and liquids to be mixed together. Hydration buffers help keep the powder or pellets dry and flowable.

Owner:HAYES JAMES R

Preparation method of asphalt liquid phase coated modified artificial graphite lithium battery cathode material

ActiveCN103682350AImprove first-time efficiencyHigh specific capacityCell electrodesDischarge efficiencyPhysical chemistry

The invention provides a preparation method and an application of an asphalt liquid phase coated modified artificial graphite lithium battery cathode material. The method comprises the steps of mechanically grinding petroleum coke, mixing with an appropriate amount of (3-8%) asphalt powder after stage treatment, performing reaction for 6-10h in a moderate temperature reaction kettle at 500-650 DEG C, performing reshaping stage treatment again, performing reaction for 36-72h at 2400-3000 DEG C for high-temperature graphitization treatment, finally obtaining an unmodified artificial graphite material through stage treatment, then further dissolving the unmodified artificial graphite material and asphalt in a dispersing agent, stirring to obtain uniform mixing liquid, preparing the uniform mixing liquid into composite powder with a closed cycle spray dryer, heating for 1-5h at 700-1100 DEG C, and finally obtaining the asphalt liquid phase coated modified artificial graphite material. After the asphalt liquid phase coated modified artificial graphite prepared by the method is applied to a lithium battery, the artificial graphite shows excellent electrochemical properties such as high first charge-discharge efficiency, high specific capacity and good cycle performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

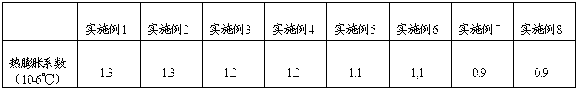

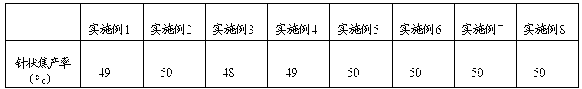

Bitumen compositions and preparation method thereof

InactiveCN101100553AImprove high temperature stabilityHigh high temperature stabilityBuilding insulationsEmulsionPetroleum

An asphalt composite and its production are disclosed. The composite consists of modified asphalt 63-70 wt% and soap liquid 30-37 wt%; the modified asphalt contains petroleum asphalt 84-92 wt%, polymer 3.5-5 wt%, stabilizer 0.05-0.2 wt%, compatible agent 4-10 wt% and filler 0-3 wt%; the soap liquid contains 0.8-1.5 wt% emulsifier, 0.1-0.2 wt% emulsion stabilizer, thickening agent 0.03-0.06 wt% and water 100%. The pH value is adjusted to 1.5-2.5 by concentrated sulfuric acid. The process is carried out by: preparing modified asphalt, preparing soap liquid, and emulsifying. The evaporating residue content is 63-70 wt%, demulsifying rate is less than 40% and evaporating residue softening point is equal to or greater than 60 deg. C.

Owner:中咨公路养护检测技术有限公司

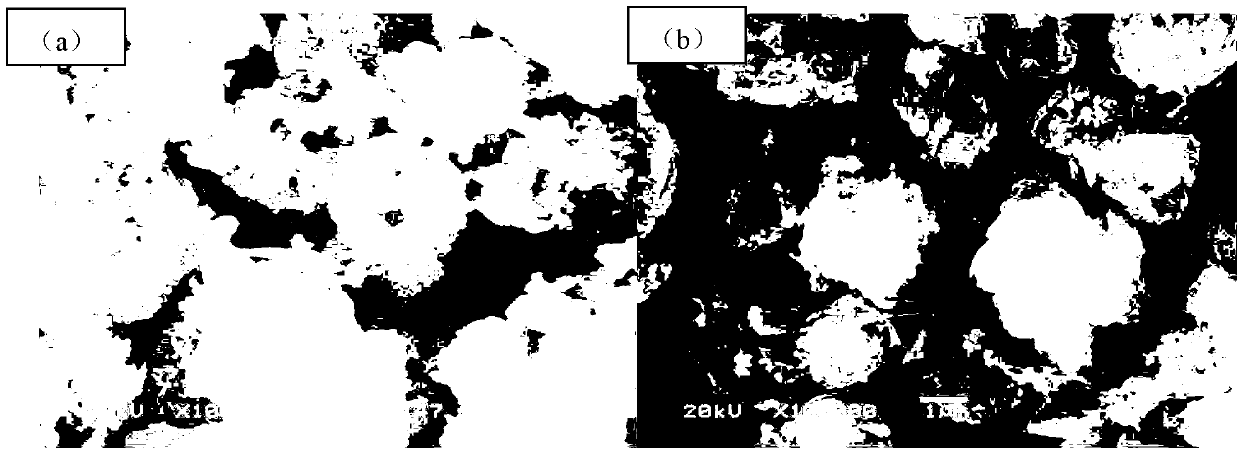

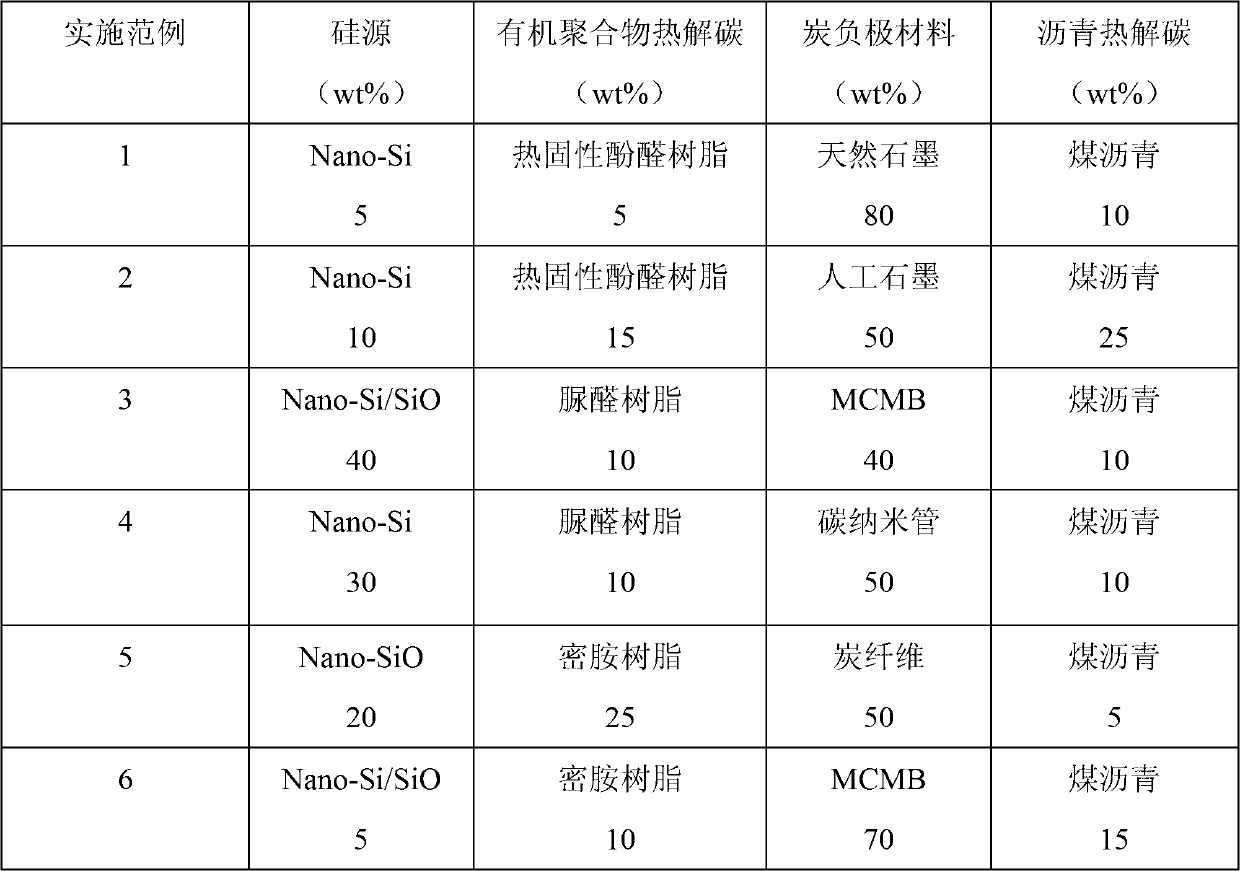

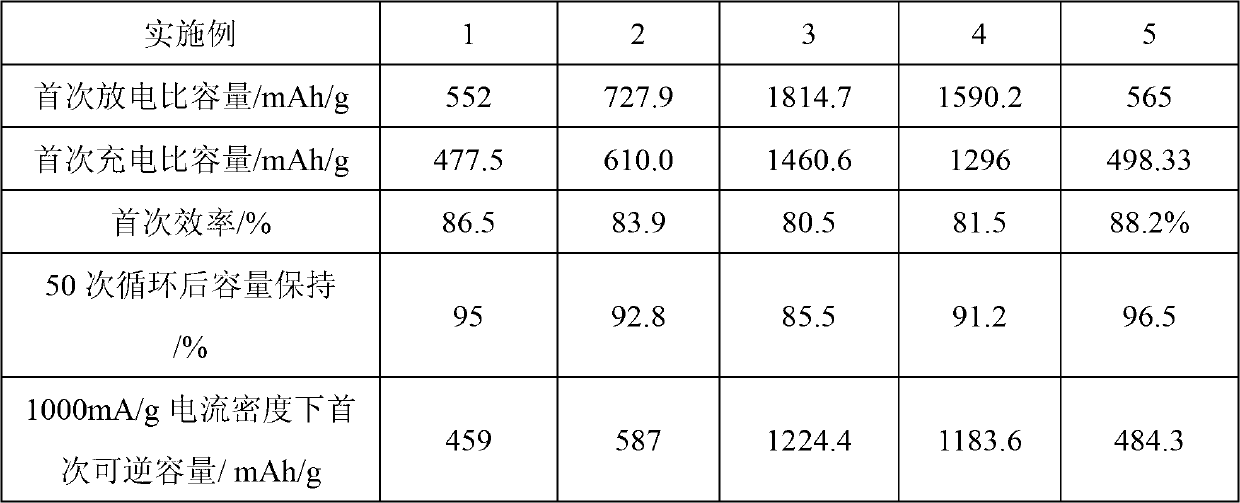

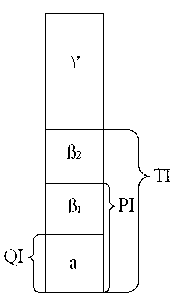

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

Technology for preparing needle coke raw material from coal-tar pitch

ActiveCN103013566ASuitable for adjusting extraction volumeHigh desulfurization efficiencyWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystCoke

The invention provides a technology for preparing a needle coke raw material from coal-tar pitch. The technology comprises the following steps of 1, fully mixing asphalt and a solvent, and removing insoluble substances in the mixture by a physical separation method, wherein the solvent is a mixture of coal light oil and coal aromatic oil or is a mixture of BTX and coal aromatic oil; a mass ratio of the coal light oil or the BTX to the coal aromatic oil is in a range of (20: 80) to (95: 5); and a mass ratio of the solvent to the asphalt is in a range of 0.5 to 10, 2, feeding a clear liquor without the insoluble substances into a separator, and separating the light solvent from the clear liquor to obtain a heavy fraction having low QI, and 3, carrying out hydrotreatment on the heavy fraction in the presence of a hydrogenation catalyst at a temperature of 300 to 450 DEG C under the pressure of 5 to 20MPa. The needle coke raw material obtained by the technology has low sulfur content and a small expansion coefficient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

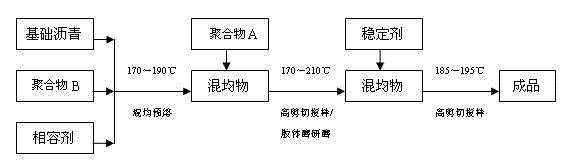

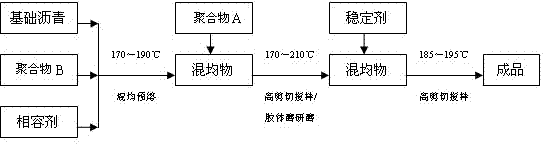

Caulking asphalt for roads and bridges, and preparation method for caulking asphalt

ActiveCN102433007AEvenly dispersedModerate penetrationPaving detailsBridge structural detailsEngineeringAsphalt

The invention discloses caulking asphalt for roads and bridges. The caulking asphalt is prepared from the following raw materials in percentage by mass: 60 to 85 percent of base asphalt, 5 to 15 percent of polymer A, 0 to 15 percent of polymer B, 3 to 10 percent of compatilizer and 0 to 3 percent of stabilizing agent. The caulking asphalt product for the roads and bridges is appropriate in needle penetration, high in softening point, heat resistance and extension, and flexibility at low temperature, and good in elastic recovery performance, is insoluble, and waterproof, does not flow at high temperature, and is resistant to impact at low temperature, does not crack and has high durability, and sandstone and sundries are prevented from being embedded into the caulking asphalt,; and the invention also discloses a preparation method for the caulking asphalt, and the preparation method is novel and simple, and is low in cost.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com