Patents

Literature

337results about How to "Improve first-time efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for supplementing lithium for negative electrode of lithium ion battery

ActiveCN102916165AAvoid LithiumAvoid deformationElectrode manufacturing processesElectrolyte/reactants regenerationMetallic lithiumElectrical battery

The invention belongs to the technical field of lithium ion batteries, in particular to a method for supplementing lithium for a negative electrode of a lithium ion battery. The method comprises the following steps: spraying or dripping an organic lithium solution on a surface of a negative electrode in an inert atmosphere, so that lithium ions in the organic lithium solution are reverted to metal lithium which is embedded into the negative electrode; and drying the negative electrode. Compared with the prior art, in the method, the organic lithium solution is sprayed or dipped on the surface of the negative electrode evenly so as to realize lithium supplementation in a wet process, thereby effectively avoiding metallic lithium powders floating in the air in a dry process to ensure safe production; and the whole process is simple, the cost is lower, the amount of the lithium supplementation can be controlled accurately through the amount and the time by spraying or dripping the organic lithium solution so as to supplement the lithium evenly, thereby preventing lithium precipitation and deformation of the negative electrode and improving the initial efficiency of the battery. Therefore, the the energy density of the battery is improved. Additionally, the invention further discloses another method for supplementing the lithium for the negative electrode of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH +1

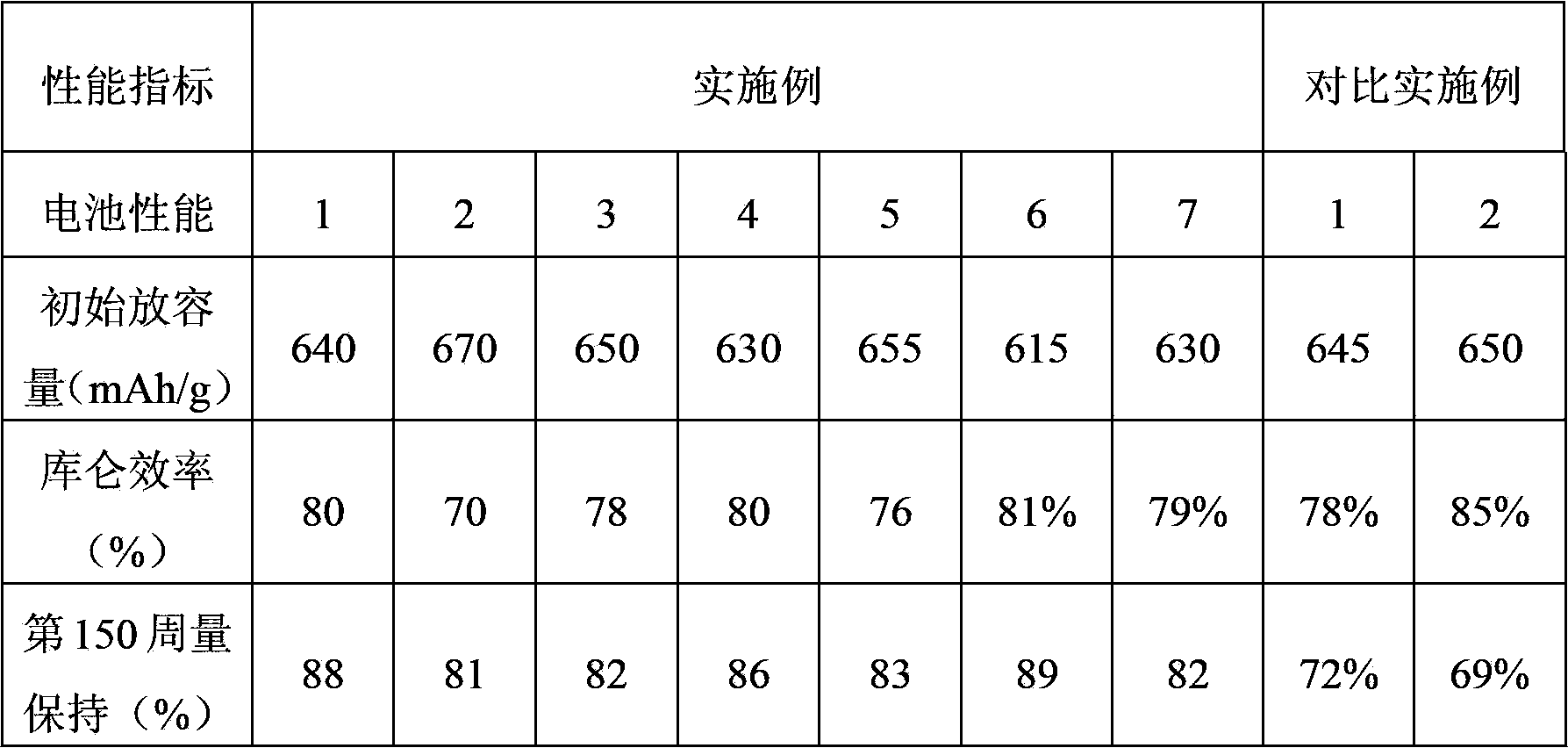

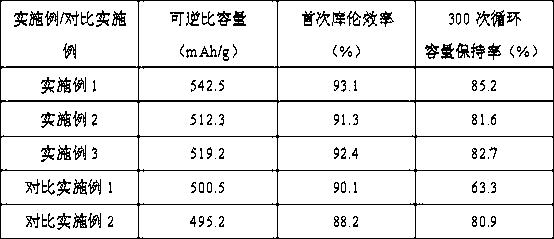

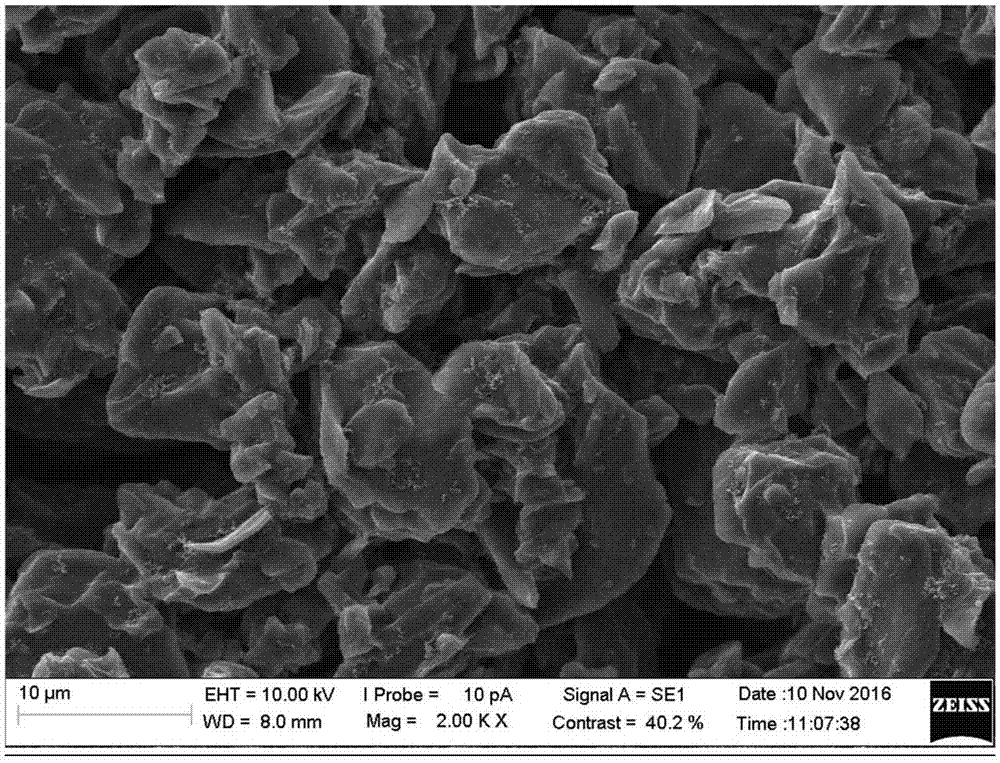

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Lithium ion battery and anode strip thereof and stabilization lithium metal powder

ActiveCN102642024AImprove lithiation efficiencyImprove electronic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical conductorElectrical battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to stabilization lithium metal powder. The stabilization lithium metal powder has a core shell structure; and the core layer is formed by lithium metal and is a composition consisting of an electron good conductor and a lithium ion good conductor. Compared with the prior art, the stabilization lithium metal powder provided by the invention has the advantages that: in the process of performing pre-lithiation of the anode-active material by use of the stabilization lithium metal powder, no limitation is imposed on the pressure of the cold pressing process, the 'dead lithium' disabling lithiation reaction is not produced, and the lithiation efficiency of the lithium metal powder is improved; and moreover, since the shell layer left on the electrode surface has good electron and lithium ion conductivity after the pre-lithiation, the electron and ion conductivity of the anode can be effectively improved so as to improve the electrochemical performance of the battery. In addition, the invention also discloses an anode strip performing pre-lithiation by use of the stabilization lithium metal powder, and a lithium ion battery comprising the anode strip.

Owner:NINGDE AMPEREX TECH +1

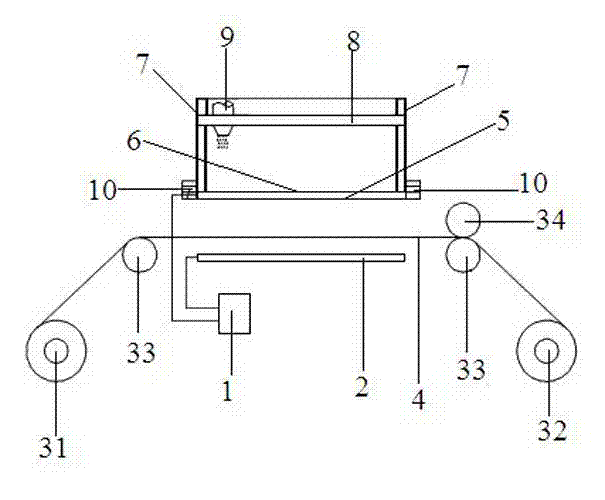

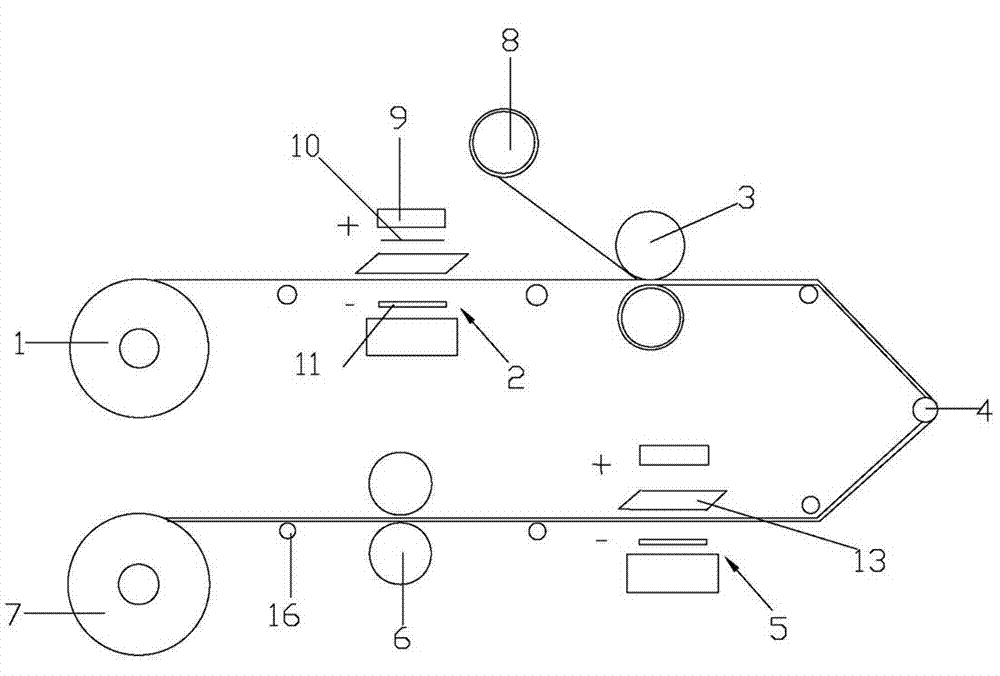

Method for supplementing lithium powder to lithium-ion battery negative plate

ActiveCN102779975AImprove first-time efficiencyIncrease battery capacityElectrode manufacturing processesElectric fieldLithium electrode

The invention belongs to the technical field of lithium-ion battery, and in particular relates to a method for supplementing lithium powder to a lithium-ion battery negative plate. The method comprises the following steps: a first step, putting the cold-pressed negative plate on an unwinding and rewinding mechanism, and putting lithium powder to a feeding mechanism above the negative plate; a second step, adding electric fields and opening the feeding mechanism, so that the lithium powder is adsorbed on the surface of the negative plate under the action of the electric fields; and a third step, rolling the negative plate adsorbed with the lithium powder. Compared with the prior art, the method can control the movement of the lithium powder to overcome the flotation of metal lithium powder in air through electrostatic effect provided by the electric fields, and can simultaneously control the addition of the lithium powder and the dispersion degree of the lithium powder on the negative plate, thereby uniformly, quantitatively and precisely dispersing the lithium powder on the surface of the negative plate. Besides, the whole process provided in the invention is only needed to be carried out in a drying environment without adding the lithium powder in a process of preparing slurry, has a simple manufacture process and low cost, and is suitable for large-scale production.

Owner:NINGDE AMPEREX TECH

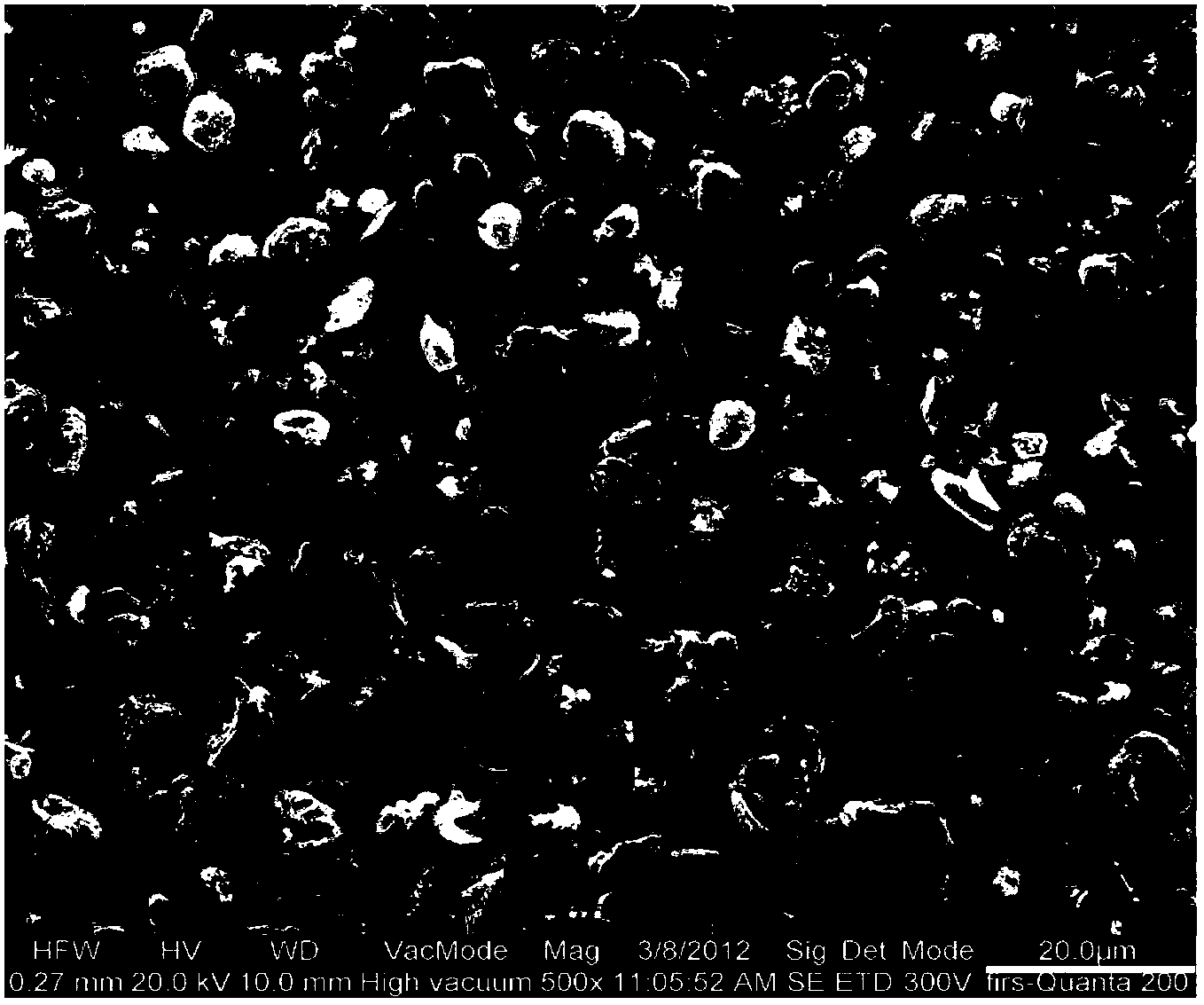

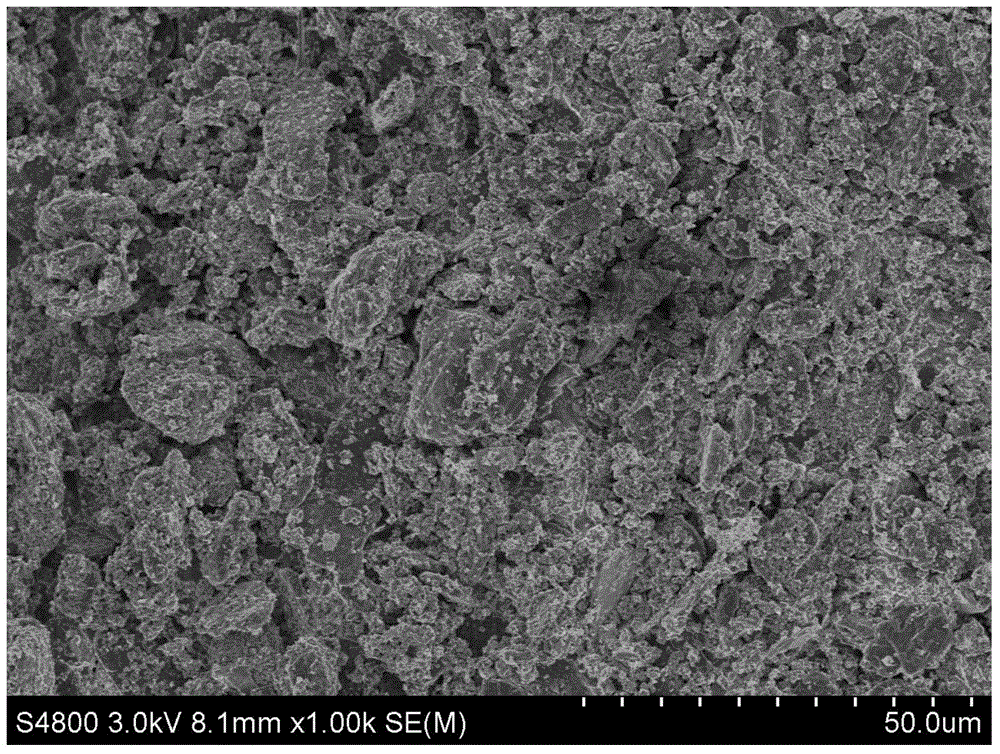

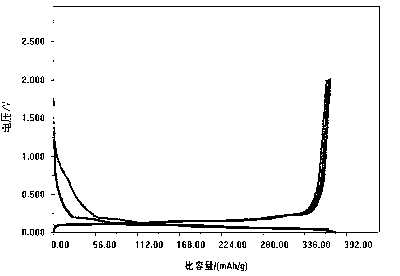

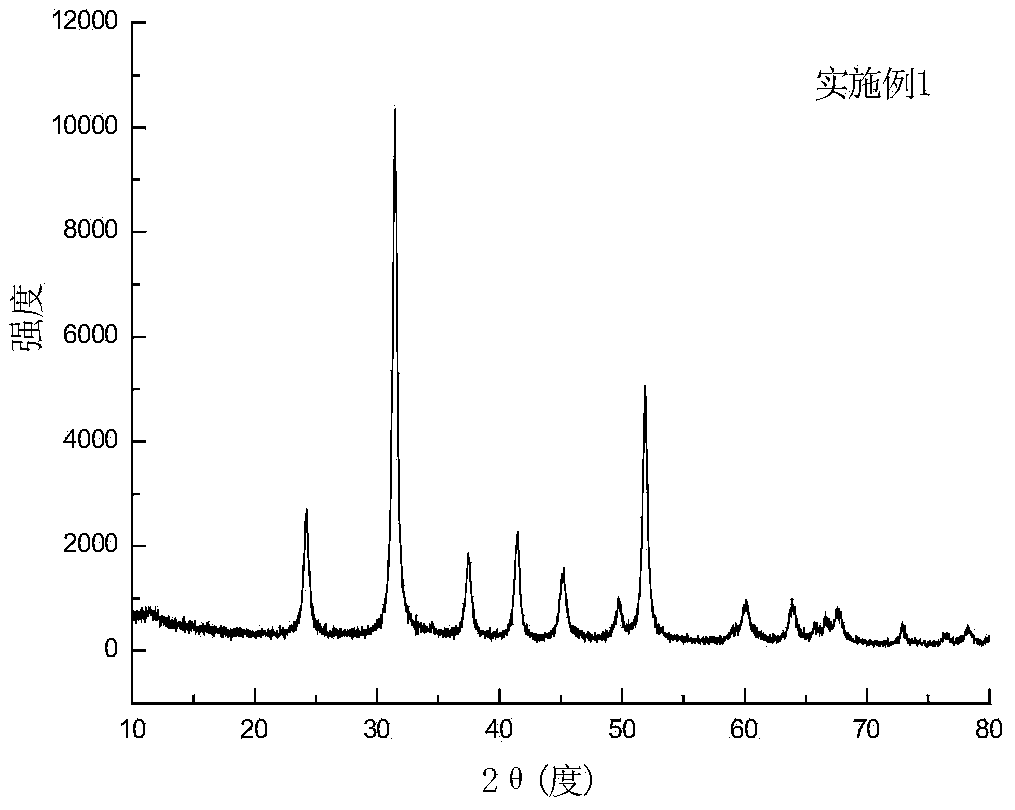

SiOx based composite negative electrode material, preparation method and battery

ActiveCN103647056AGood dispersionQuick blend effectCell electrodesLi-accumulatorsCarbon coatingSilicon oxide

The invention relates to a high-capacity SiOx based composite negative electrode material, a preparation method and a battery, wherein the negative electrode material comprises a silicon oxide material, a carbon material and an amorphous carbon coating layer; the silicon oxide material is silicon oxide or silicon oxide material modified in a carbon coating manner; surfaces of carbon material particles are coated with the silicon oxide material. A preparation method of the high-capacity SiOx based composite negative electrode material comprises the steps of performing physical processing or carbon coating modification on a silicon oxide raw material, thus obtaining a micron-sized silicon oxide material; and then mechanically fusing, coating with a solid phase and sintering at a high temperature to obtain the high-capacity negative electrode material. Through the high-capacity SiOx based composite negative electrode material, the effect of uniform dispersing and coating of the micron-sized silicon oxide particles on the surfaces of the carbon material particles can be achieved by virtue of the combination of mechanical fusion and solid-phase coating processes. The silicon oxide particles are well dispersed on the surface of the carbon material particle; the strength of bonding between the silicon oxide particles and the carbon material particles is high; the recycling performance of the material can be greatly improved; and meanwhile, the high-capacity SiOx based composite negative electrode material is high in first efficiency (breaking through the theoretical efficiency of SiOx), low in expansion rate, long in service life, environmental-friendly, pollution-free and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD

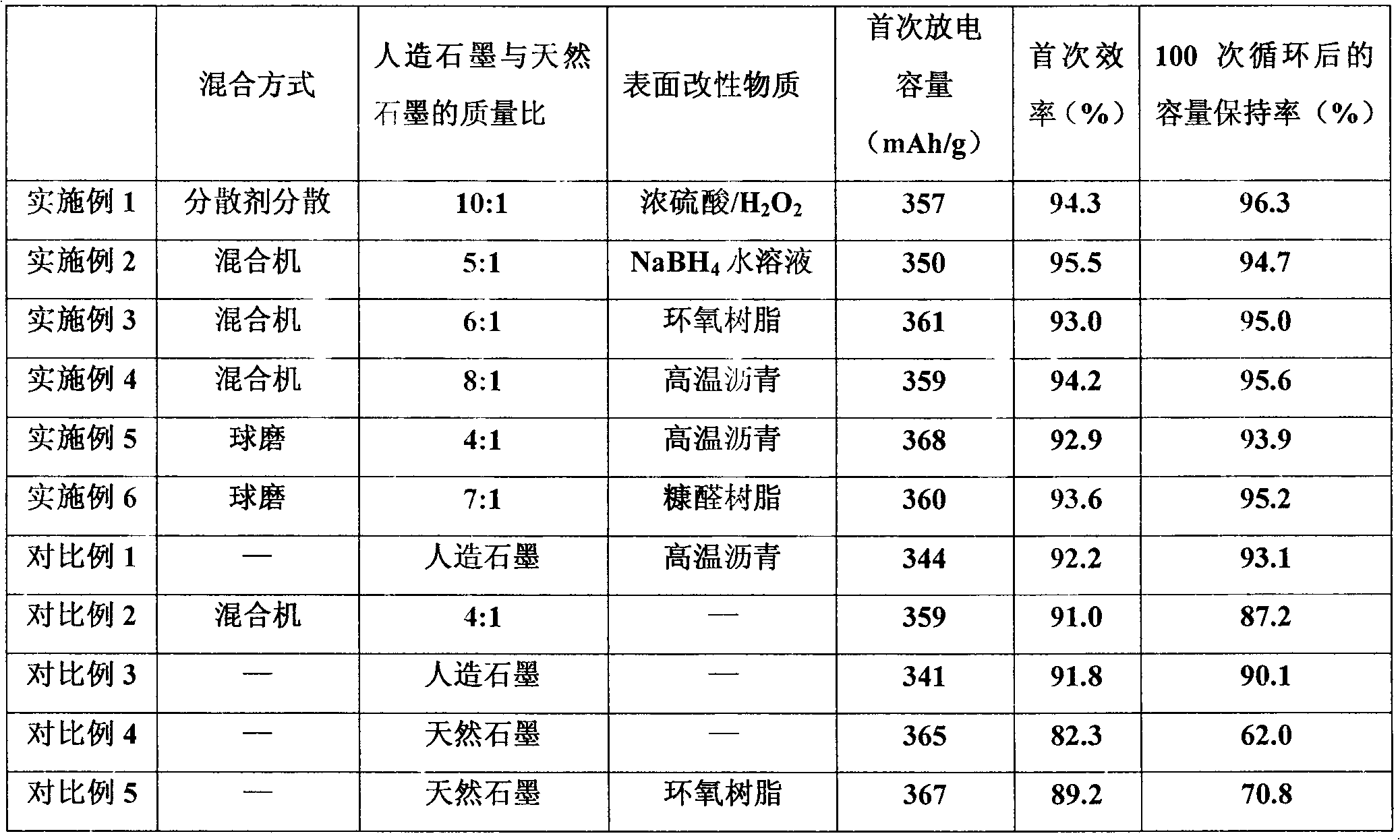

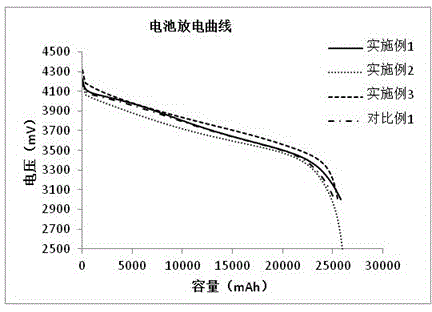

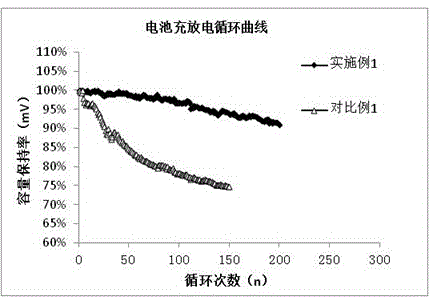

High-capacity graphite material and preparation method as well as application thereof

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

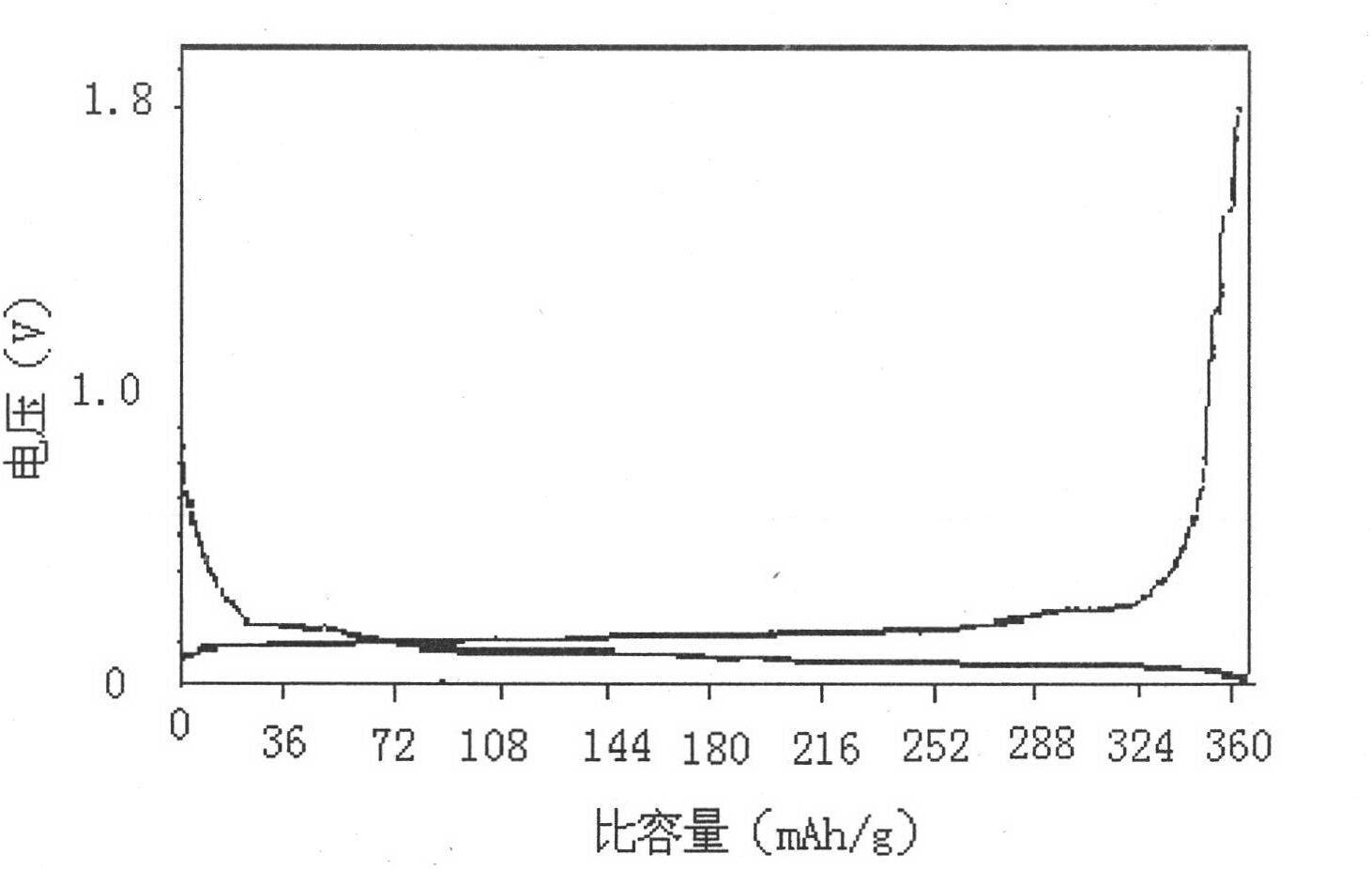

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

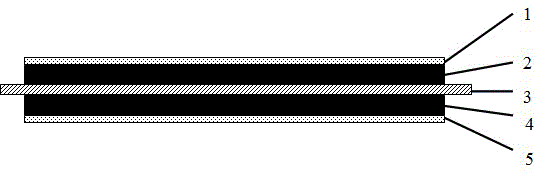

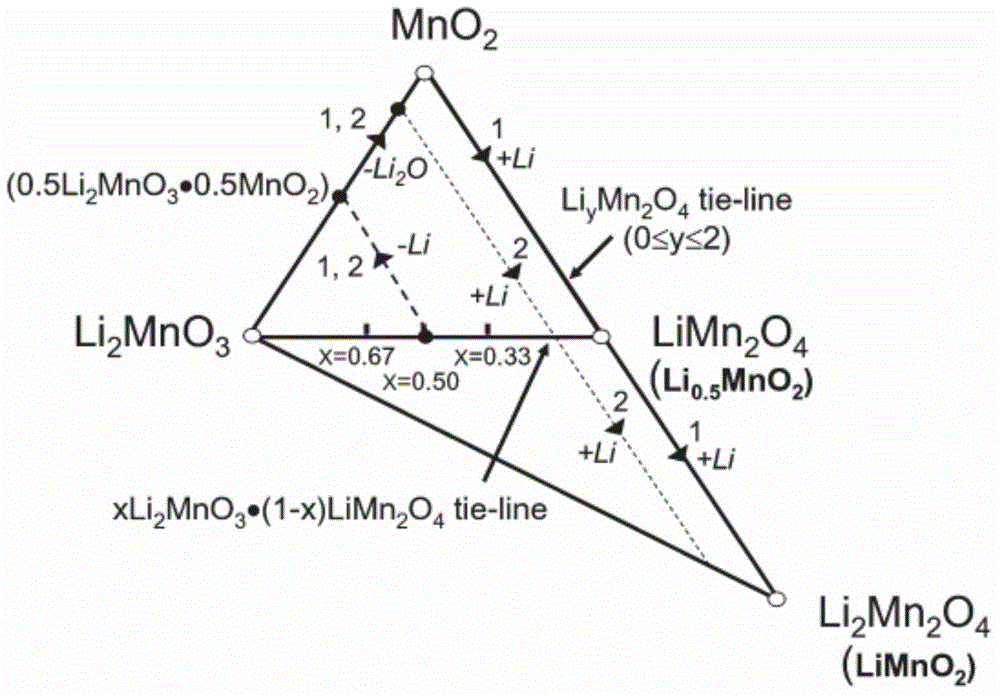

Lithium ion battery adopting lithium-rich manganese-based material as positive electrode and preparation method of lithium ion battery

InactiveCN103560250AIncrease energy densityStable structureMaterial nanotechnologyElectrode carriers/collectorsHigh energyManganese

The invention discloses a lithium ion battery adopting a lithium-rich manganese-based material as a positive electrode and a preparation method of the lithium ion battery. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode comprises a positive electrode, a positive electrode surface coating, a negative electrode, a diaphragm and electrolyte. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode has the advantages of high energy density, good multiplying power property and long cycling service life.

Owner:TIANJIN ENERGIES

Negative pole piece for lithium battery, preparation method of negative pole piece and lithium battery with negative pole piece

InactiveCN103022413AEvenly dispersedEffectively place the peelLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrical batteryNickel–lithium battery

The invention belongs to the technical field of lithium batteries, and in particular relates to a negative pole piece for a lithium battery. The negative pole piece comprises a current collector and a graphitic layer arranged on the current collector, and further comprises a protecting layer and a metal lithium layer, wherein the protecting layer is arranged on the graphitic layer; and the metal lithium layer is arranged on the protecting layer. Compared with the prior art, the negative pole piece is provided with the protecting layer on the surface of the graphitic layer, and the metal lithium layer on the surface of the protecting layer, when the negative pole piece is assembled into the lithium battery, metal lithium powder diffuses in the negative pole piece in an electrochemical manner, so that the first time efficiency of a negative pole is improved, and moreover, the energy density of the lithium battery is increased, and the capacity of the lithium battery is enhanced; and at the same time, the protecting layer is equivalent to a buffer layer which can effectively prevent the graphitic layer from internally peeling off, so that the stability of an SEI (Solid Electrolyte Interphase) membrane on the surface of the negative pole piece is improved, and the circulation performance of the battery is improved. In addition, the invention also discloses a preparation method of the negative pole piece and a lithium battery with the negative pole piece.

Owner:DONGGUAN AMPEREX TECH

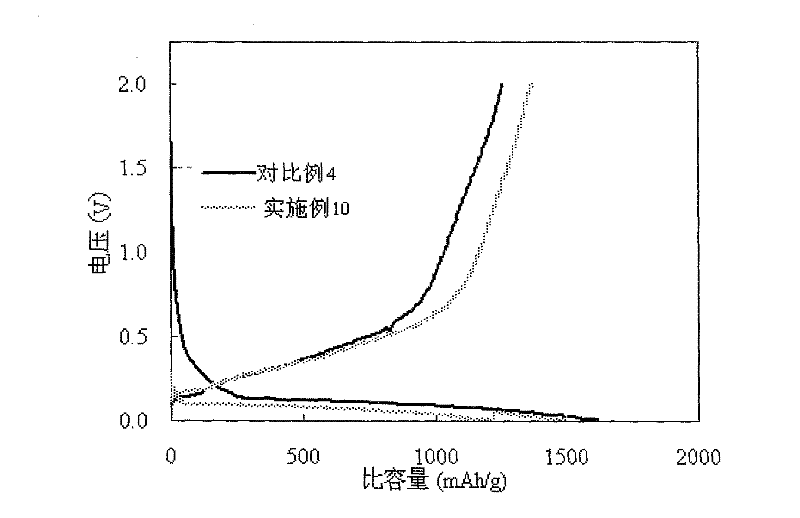

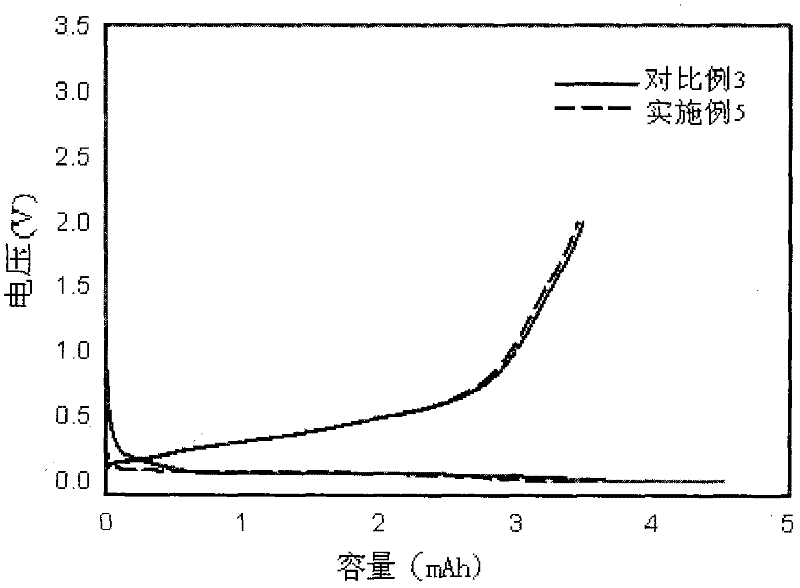

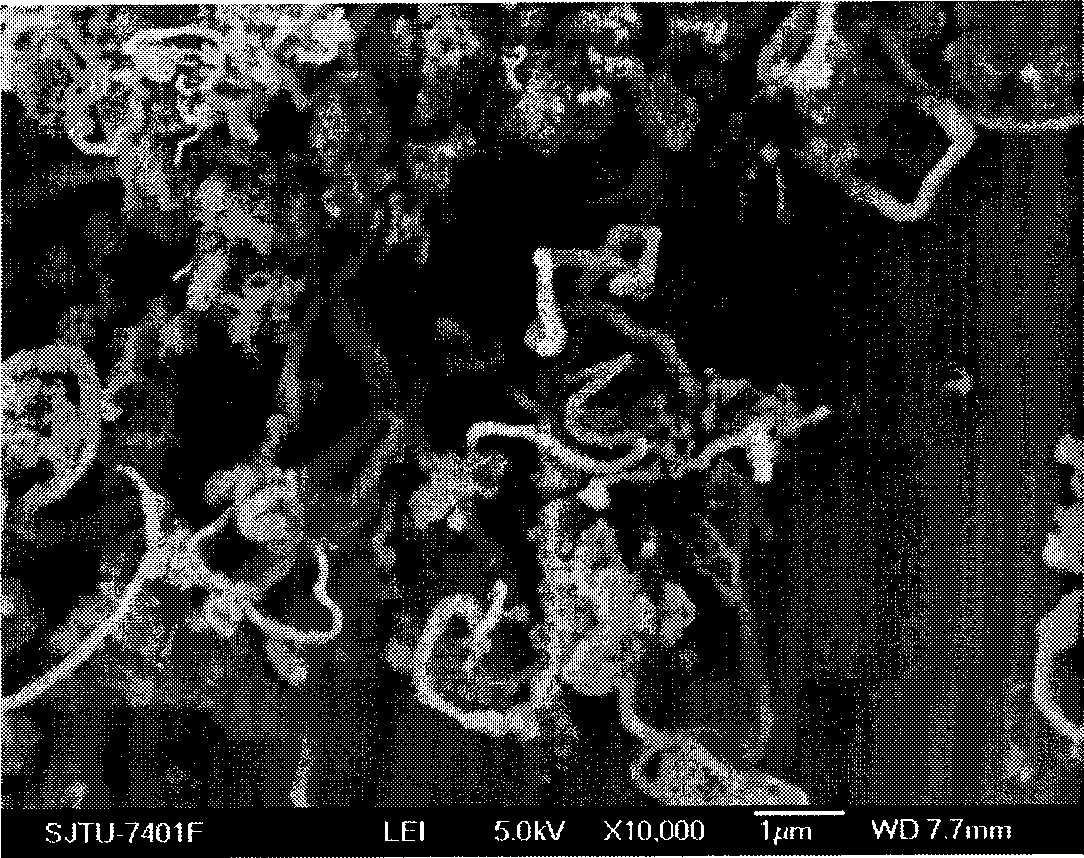

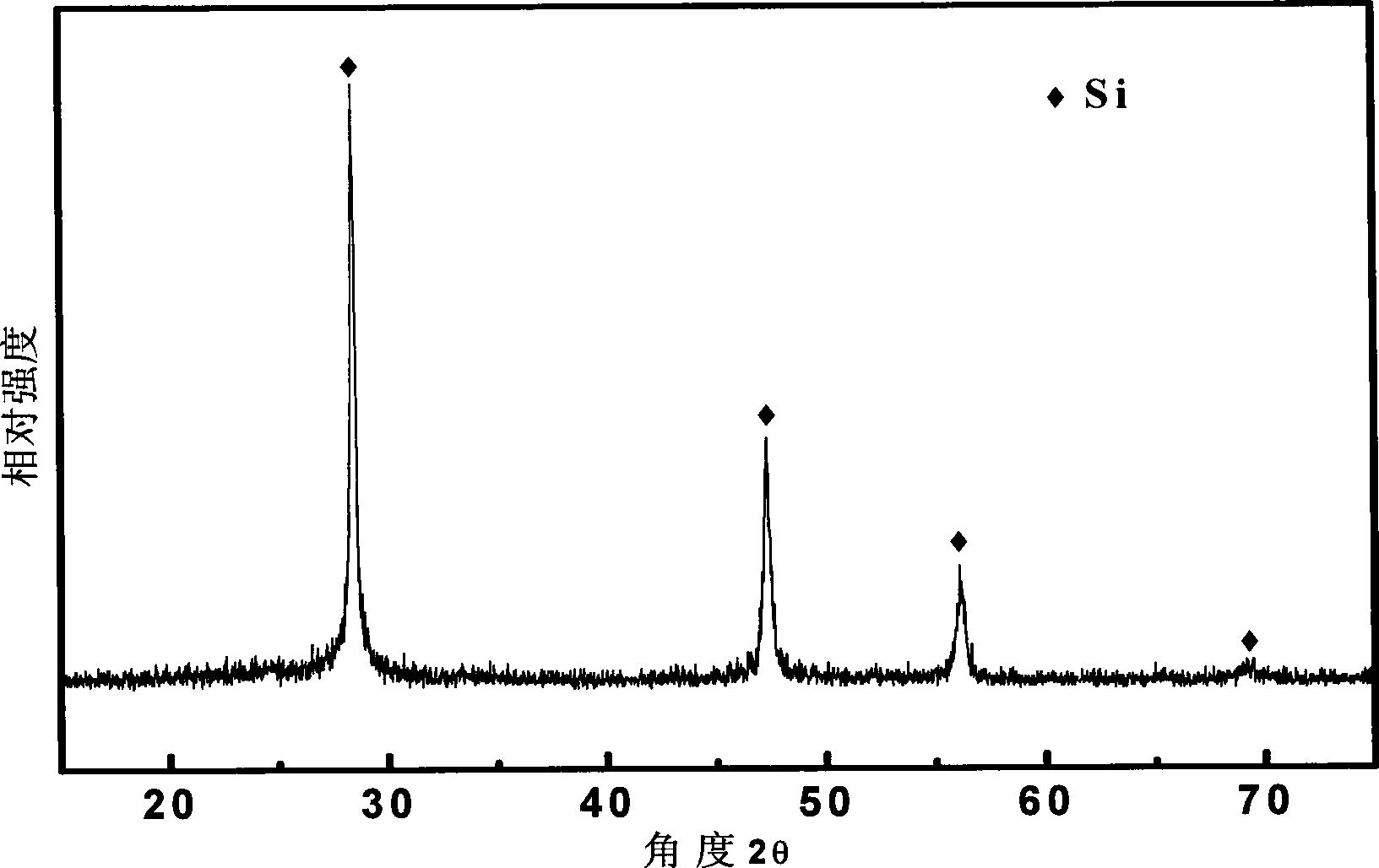

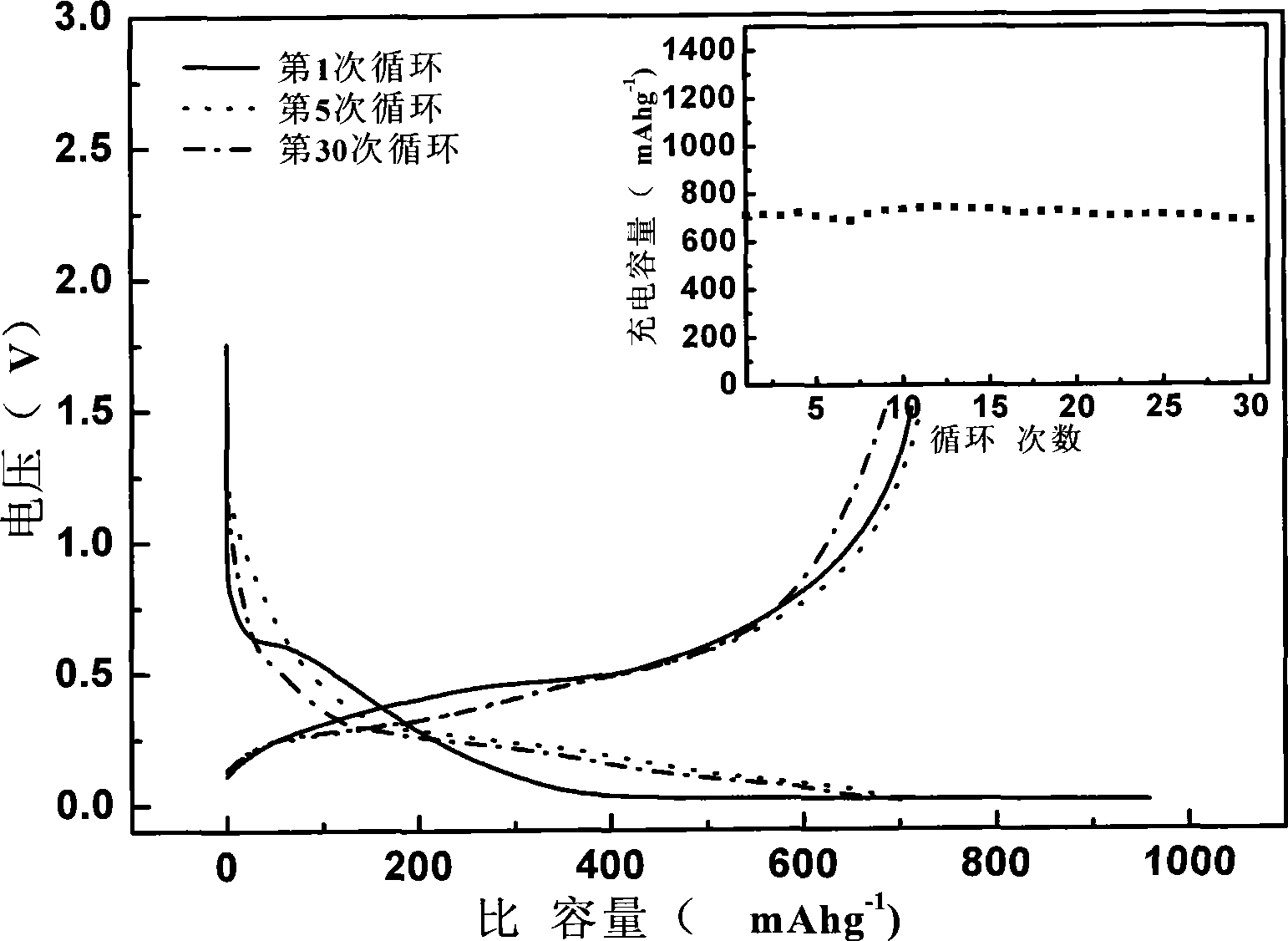

Method for preparing silicon composite cathode material of lithium ion battery

InactiveCN101510602AEvenly dispersedHigh purityElectrode manufacturing processesSiliconSolventCarbon source

The invention discloses a preparation method of a silicon composite anode material for lithium ion batteries and the silicon composite anode material is composed of nc-Si / packing carbon / cracking carbon. Packing carbon powder is adopted as scattered matrix, Li-Si alloy powder is adopted as a reducing agent and a liquid silicon halide or a liquid silane halide is chemically deoxidized by the high-energy ball milling; afterwards, heat treatment and solvent washing are conducted over the deoxidized silicon halide or silane halide under the shielding gas so as to obtain an nc-Si / packing carbon complex, wherein the nc-Si is nanometer porous silicon and nanometer silicon fiber. The nc-Si / packing carbon complex passes through the high-molecular carbon source cladding and heat treatment under the shielding gas to obtain an nc-Si / packing carbon / cracking carbon composite anode material. A charge-discharge test of constant current is conducted at a current density of 0.1 mA / mg to 0.3 mA / mg; the coulombic efficiency of the first circulation of the silicon composite anode material reaches up to 70 percent to 80 percent; and after 30 circulations, the reversible capacity reaches 680 mAh / g and the capacity retention rate reaches more than 95 percent.

Owner:SHANGHAI JIAO TONG UNIV

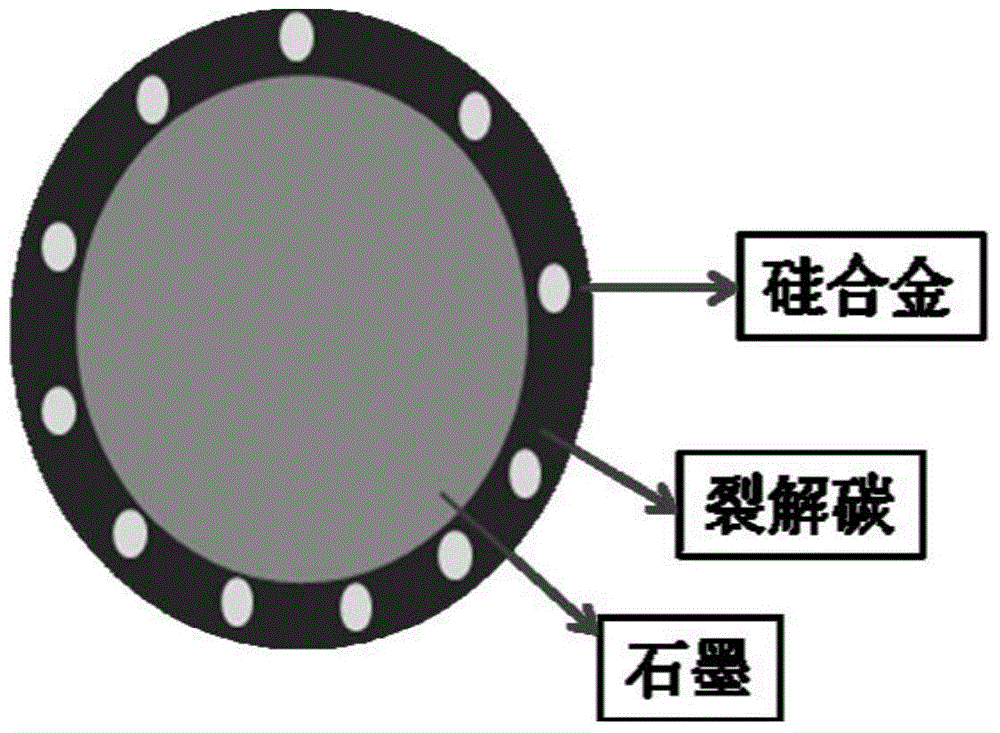

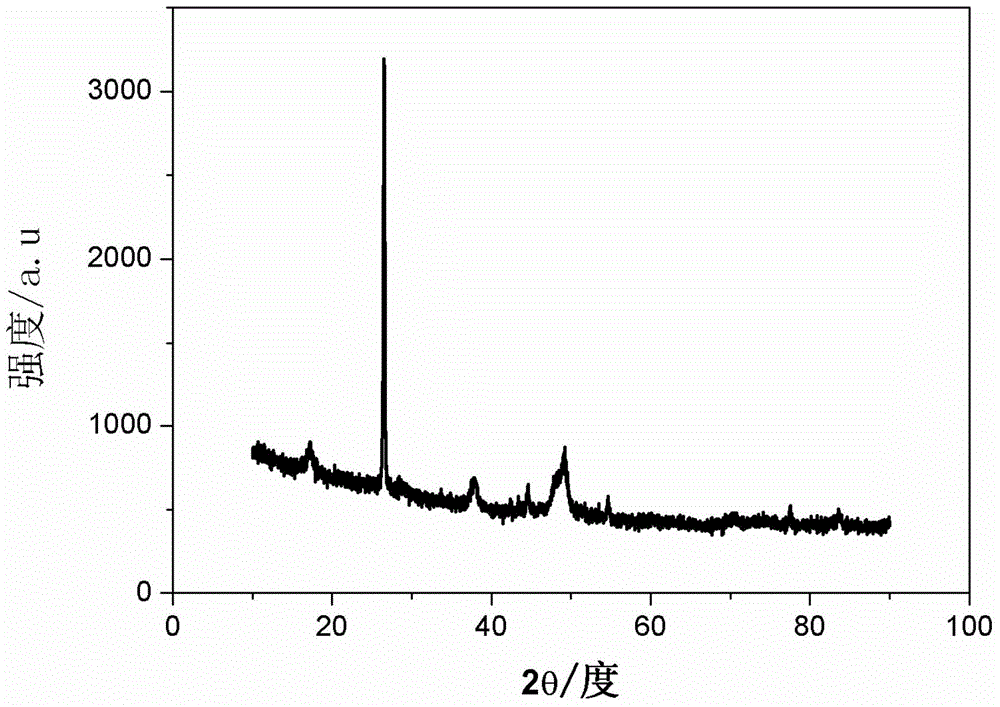

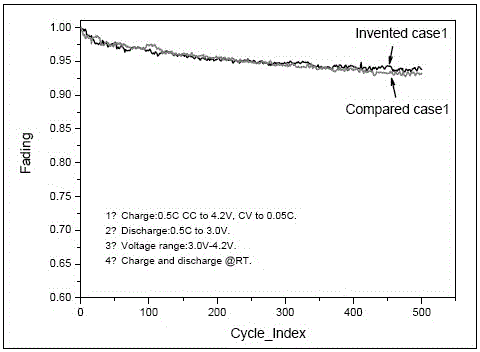

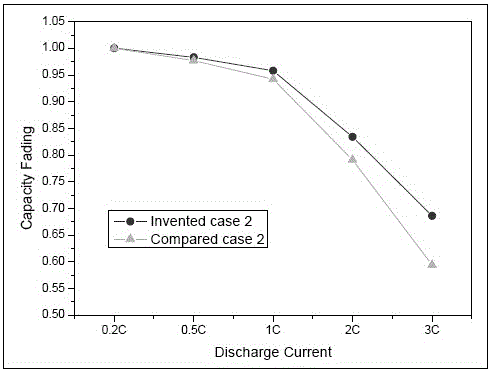

Silicon alloy composite anode material, preparation method and lithium ion battery

ActiveCN104617269AIncrease capacityStable structureCell electrodesSecondary cellsSilicon alloyGraphite

The invention discloses a silicon alloy composite anode material and a preparation method thereof as well as a lithium ion battery employing the anode material. An inner core of the anode material comprises graphite and silicon alloy applied to the surface of the graphite, and a shell is a pyrolytic carbon layer. The silicon alloy anode material with a core-shell structure is prepared in combination with nanocomposite, surface modification and coating modification technologies. The silicon alloy composite anode material is high in compaction density, good in processing performance, high in conductivity, high in first efficiency (more than 90%) and excellent in cyclic stability (400-time cyclic capacity retention rate is more than 92%); the preparation process of the anode material provided by the invention is simple, environment-friendly and pollution-free, and raw materials are low in cost.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

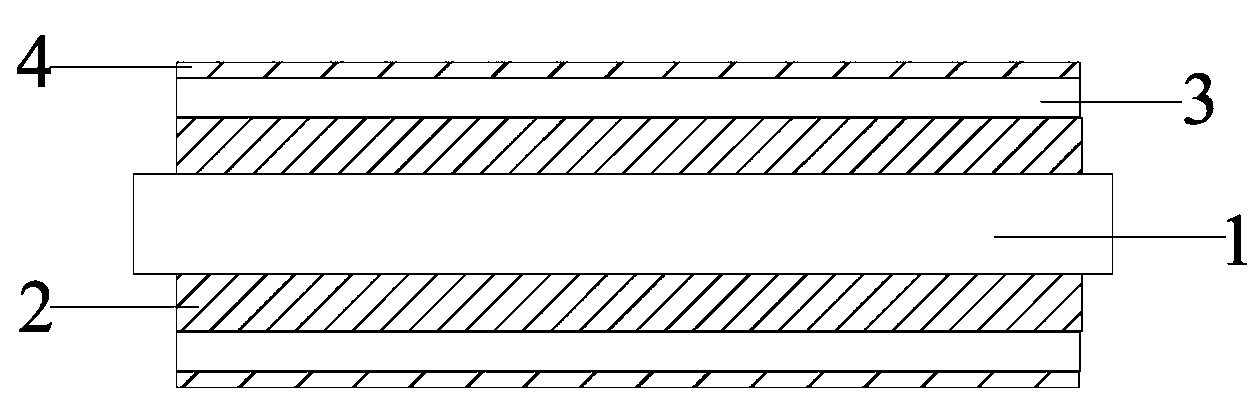

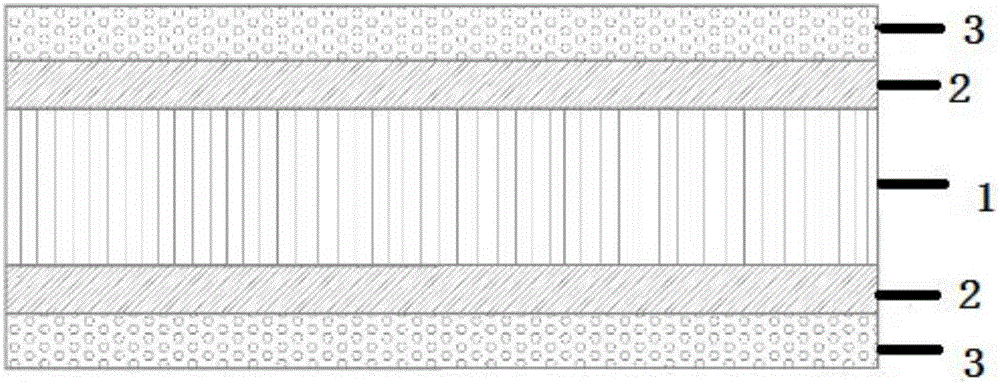

Lithium ion battery composite diaphragm, preparation method thereof and lithium ion battery

ActiveCN106129315AReduce irreversible capacityImprove first-time efficiencySecondary cellsCell component detailsPolyolefinPhysical chemistry

The invention relates to a lithium ion battery composite diaphragm, a preparation method thereof and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery composite diaphragm comprises a diaphragm matrix, wherein the diaphragm matrix is a polyolefin microporous membrane or a polyolefin microporous membrane whose surface is coated with a ceramic layer; a surface of the diaphragm matrix is coated with a lithium supplementing layer; and the lithium supplementing layer contains lithium powder. According to the lithium ion battery composite diaphragm, the surface of the diaphragm is provided with the lithium supplementing layer, lithium required for forming an SEI (Solid Electrolyte Interface) film is filled up, supplementationis provided for lithium ions consumed by formation of the SEI film on a surface of a negative pole piece, the irreversible capacity of the lithium ion battery is reduced, and the initial efficiency, the cycle performance and the energy density of the lithium ion battery are improved.

Owner:LUOYANG LIRONG NEW ENERGY TECH

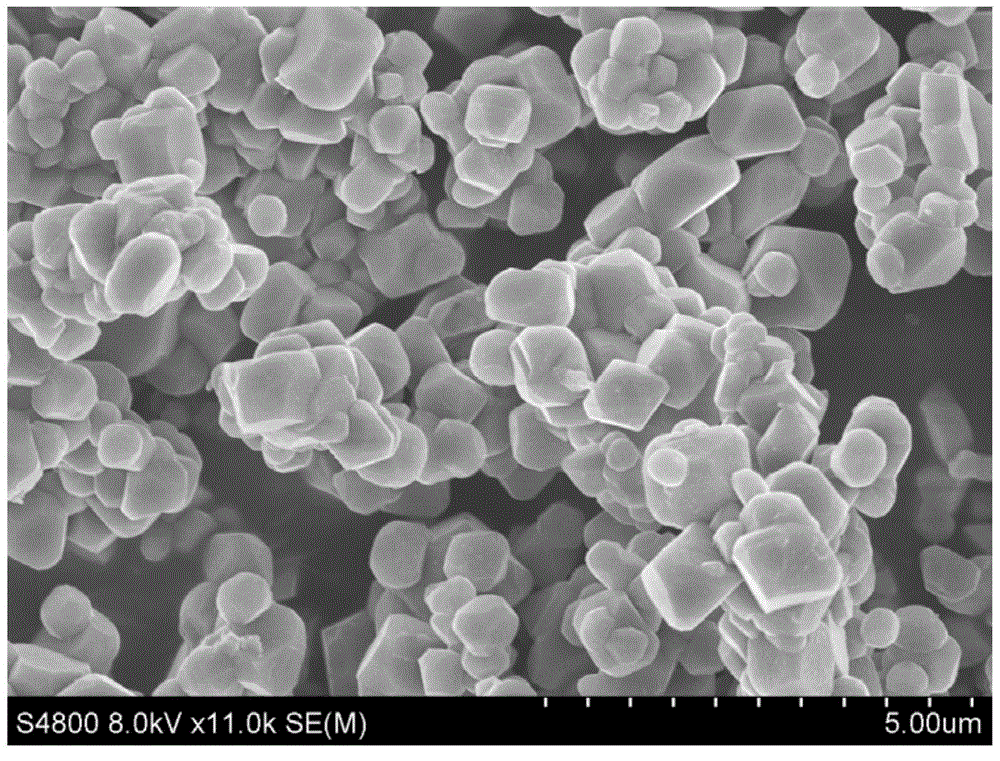

Ternary cathode material, precursor thereof, and preparation method of ternary cathode material and precursor

ActiveCN107585794AHigh activityShorten the diffusion pathCell electrodesSecondary cellsLayered structureSeed crystal

The invention provides a ternary precursor with a composite hetero-structure. The molecular formula of the ternary precursor is Ni<1-a-b>CoM(OH)2@Ni<1-x-y>Co<x>M<y>O<z>, wherein 0<a<1, 0<b<1, 0<a+b<1, 0<x<1, ,0<y<1, 0<x+y<1, 1<z<1.5, and M represents Mn or Al. The ternary precursor comprises a ternary oxide precursor and a ternary hydroxide precursor. The ternary hydroxide precursor is coated on the surface of the ternary oxide precursor. The molecular formula of the ternary oxide precursor is Ni<1-x-y>Co<x>M<y>O<z>, and the molecular formula of the ternary hydroxide precursor is Ni<1-a-b>CoM(OH)2. The invention further provides a preparation method of the ternary precursor. According to the preparation method, a spray pyrolysis method and a co-precipitation method are combined, the ternary oxide precursor obtained by spray pyrolysis is taken as the seed crystal, then a layer of ternary hydroxide precursor is coated on the surface of the ternary oxide precursor through theco-precipitation method to obtain the ternary precursor, and the ternary precursor and lithium salts are mixed and sintered to prepare the ternary cathode material. The ternary cathode material has the advantages of good layered structure, high initial efficiency, high specific capacity, and excellent circulating ratio performance.

Owner:CENT SOUTH UNIV

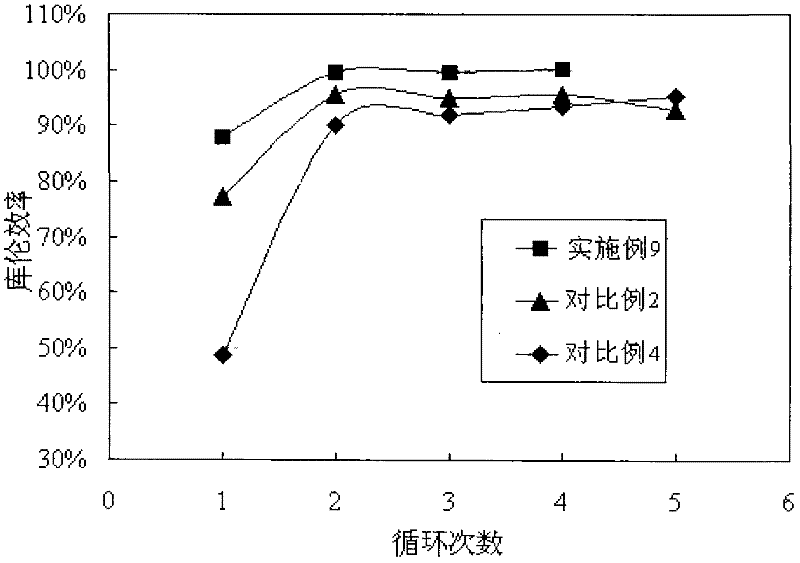

Electrochemical energy storage device and preparation method hereof

ActiveCN105047986AImprove first-time efficiencyIncrease energy densityCell electrodesFinal product manufactureLithiumElectrical battery

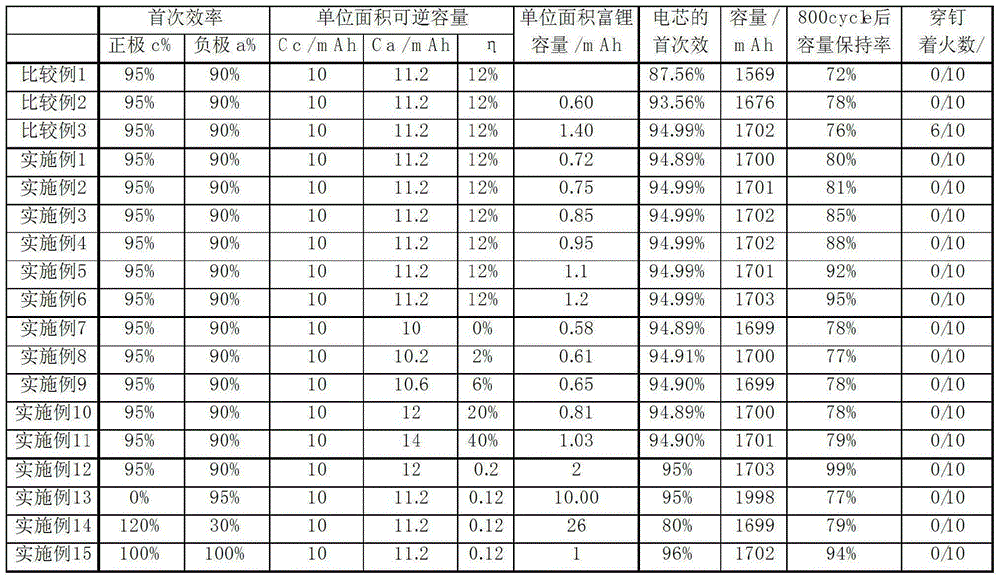

The invention belongs to the technical field of electrochemical energy storage, and particularly relates to an electrochemical energy storage device. The electrochemical energy storage device comprises a cathode plate, an anode plate, an isolating membrane, electrolyte and an outer package, wherein the initial coulomb efficiency of a cathode active substance on the cathode plate is c%; the reversible capacity of the cathode plate in unit area is Cc mAh; the initial coulomb efficiency of an anode active substance on the anode plate is a%; the reversible capacity of the anode plate in unit area is Ca mAh; the anode capacity excess rate eta in unit area is (Ca-Cc) / Cc*100%; electrode plates are subjected to lithium-rich treatment; and the lithium-rich capacity m in unit area is that: Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m. When lithium-rich treatment is carried out, the lithium-rich capacity m in unit area is that Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m; the first lithium loss of the anode can be supplemented; and excessive lithium can be used for supplementing lithium consumption in the cycling process, so that the cycle performance of the battery is improved.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Preparation method of lithium ion battery silicon-carbon anode material

InactiveCN107634208AImprove first-time efficiencyImprove cycle performanceCell electrodesSecondary cellsGraphiteLithium-ion battery

The invention discloses a preparation method of a lithium ion battery silicon-carbon anode material. The preparation method comprises following steps: 1, raw material silicon powder is subjected to ball milling so as to obtain nanoscale silicon powder; 2, the nanoscale silicon powder is mixed with a conductive agent via solid phase material mixing; 3, liquid phase coating is adopted so as to formamorphous carbon coating layers on the surfaces of the nanoscale silicon powder and the conductive agent; 4, an obtained coated material is subjected to high temperature sintering in a furnace under inert gas protection; 5, mechanical ball milling is adopted to prepare a silicon-carbon material with an appropriate particle size; and 6, the silicon-carbon material is mixed with commercial graphiteso as to obtain the lithium ion battery silicon-carbon anode material. The preparation method is capable of increasing the primary coulombic efficiency and the cycling performance of the lithium ion battery silicon-carbon anode material, the process is simple, efficiency is high, the preparation method is friendly to the environment, and is beneficial for large scale production of silicon-carbon anode materials.

Owner:赣州市瑞富特科技有限公司

Continuous lithium powder replenishing method for both sides of lithium ion battery negative plate

ActiveCN103208612AEvenly dispersedQuantitative dispersionCell electrodesElectric fieldMaterials science

The invention belongs to the technical field of lithium ion battery production methods, and particularly relates to a continuous lithium powder replenishing method for both sides of a lithium ion battery negative plate. The continuous lithium powder replenishing method includes placing a cold-pressed negative plate on an unwinding mechanism; starting a negative plate towing system, starting a first lithium replenishing system, and adding an electric field synchronously to enable the lithium powders to be absorbed on one surface of the negative plate, and then passing the negative plate through a first rolling system; and after passing the negative plate through a tension adjusting and tilting mechanism, starting a second lithium replenishing system and adding the electric field synchronously to enable the lithium powders to be absorbed on the other surface of the negative plate, and then passing the negative plate through a second rolling system to be wound. Compared with the prior art, the continuous lithium powder replenishing method has the advantages that the lithium powders can be distributed on the upper surface and the lower surface of the negative plate evenly, quantitatively and accurately, and the lithium powders can be prevented from sticking on rollers by the first rolling system and the second rolling system. And furthermore, the lithium powders are not pressed in entire processes, so that damages to soft powders such as the lithium powders can be effectively avoided.

Owner:DONGGUAN AMPEREX TECH

Conductive agent combined type lithium ion battery positive pole piece and manufacture method thereof

InactiveCN106207092AIncrease energy densityImprove Coulombic efficiencyCell electrodesSecondary cellsAgent CombinationSlurry

The invention discloses a conductive agent combined type lithium ion battery positive pole piece, which comprises a current collector and a positive pole film adhered to the current collector. The positive pole film comprises a positive pole active material, a conductive agent and a binding agent, wherein the conductive agent is a combination of CB and CNTs or CB and GNPs or CNTs and GNPs or CB, CNTs and GNPs. A manufacture method comprises the steps of (1) adding the binding agent into solvent and evenly stirring and mixing; (2) adding the conductive agent combination of two or three of CB, CNTs and GNPs into the solvent and evenly stirring and mixing; (3) adding the positive pole active material and evenly stirring and mixing to obtain positive pole slurry; (4) coating the positive pole slurry on the current collector and obtaining the lithium ion battery positive pole piece after roasting and rolling. The positive pole piece is high in energy density, low in expansion rate, high in coulombic efficiency and high in compaction.

Owner:APOWER ELECTRONICS CO LTD

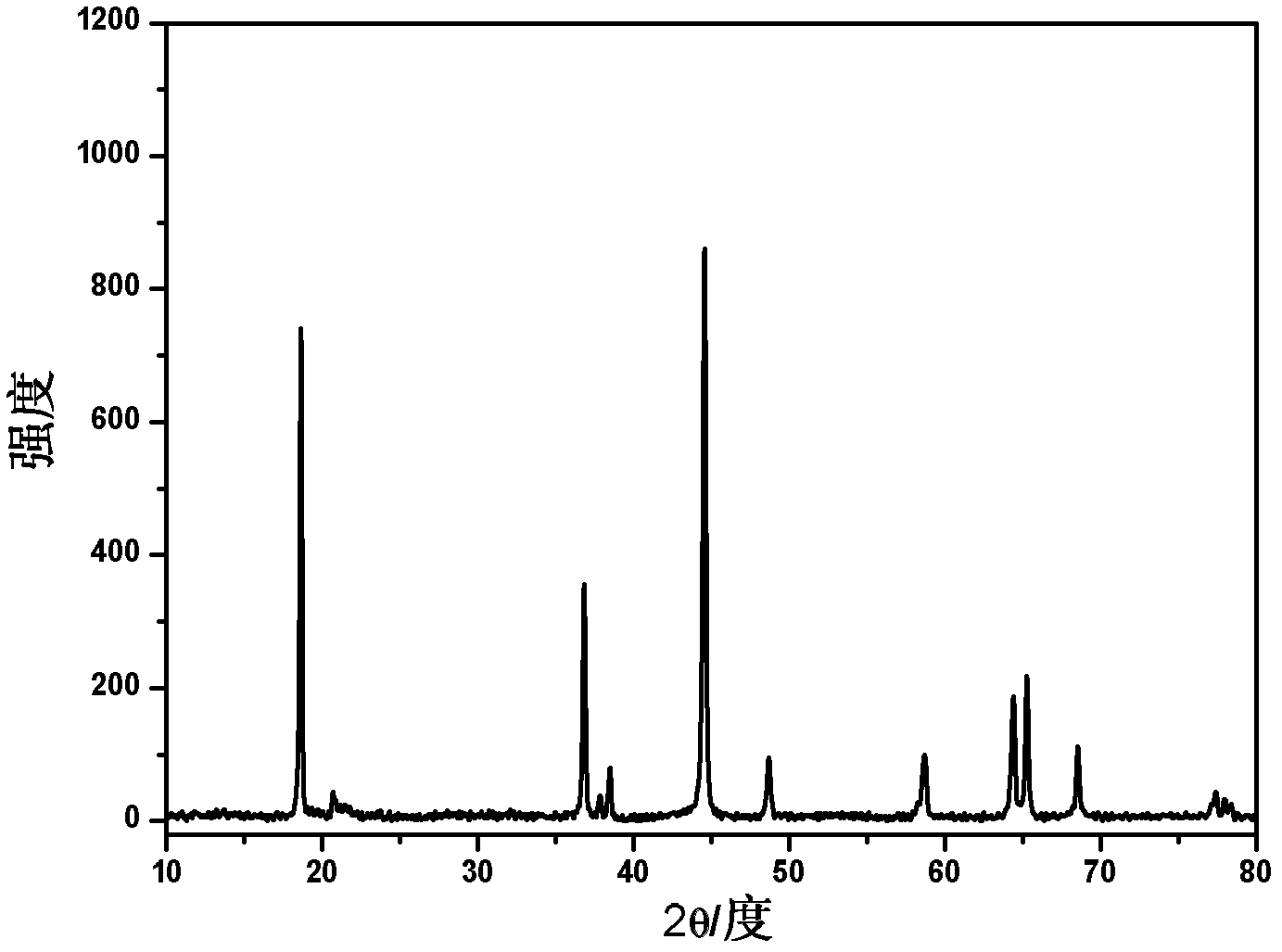

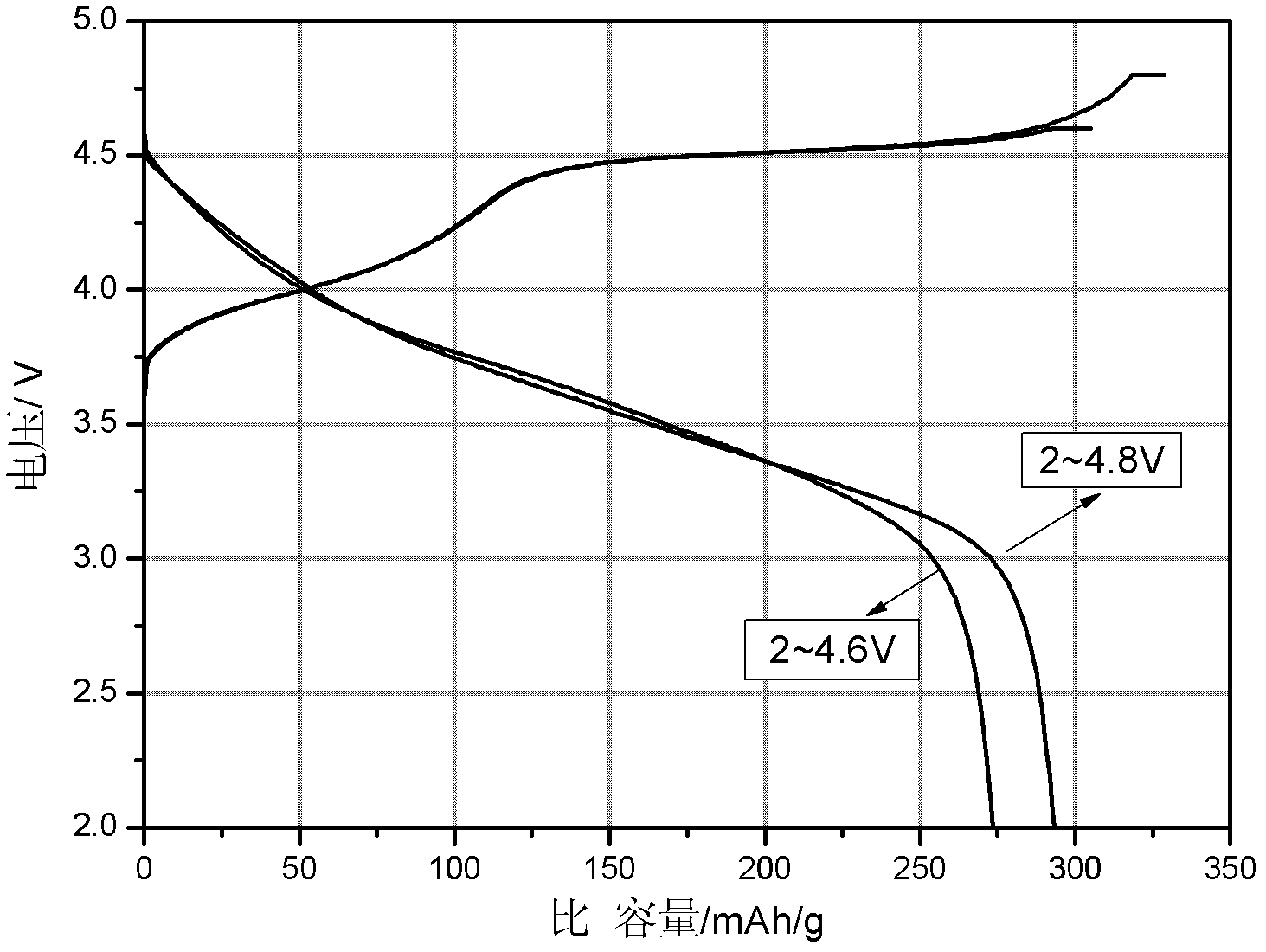

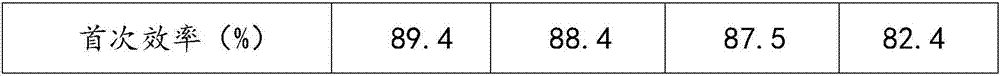

High-capacity lithium-rich cathode material and preparation method thereof

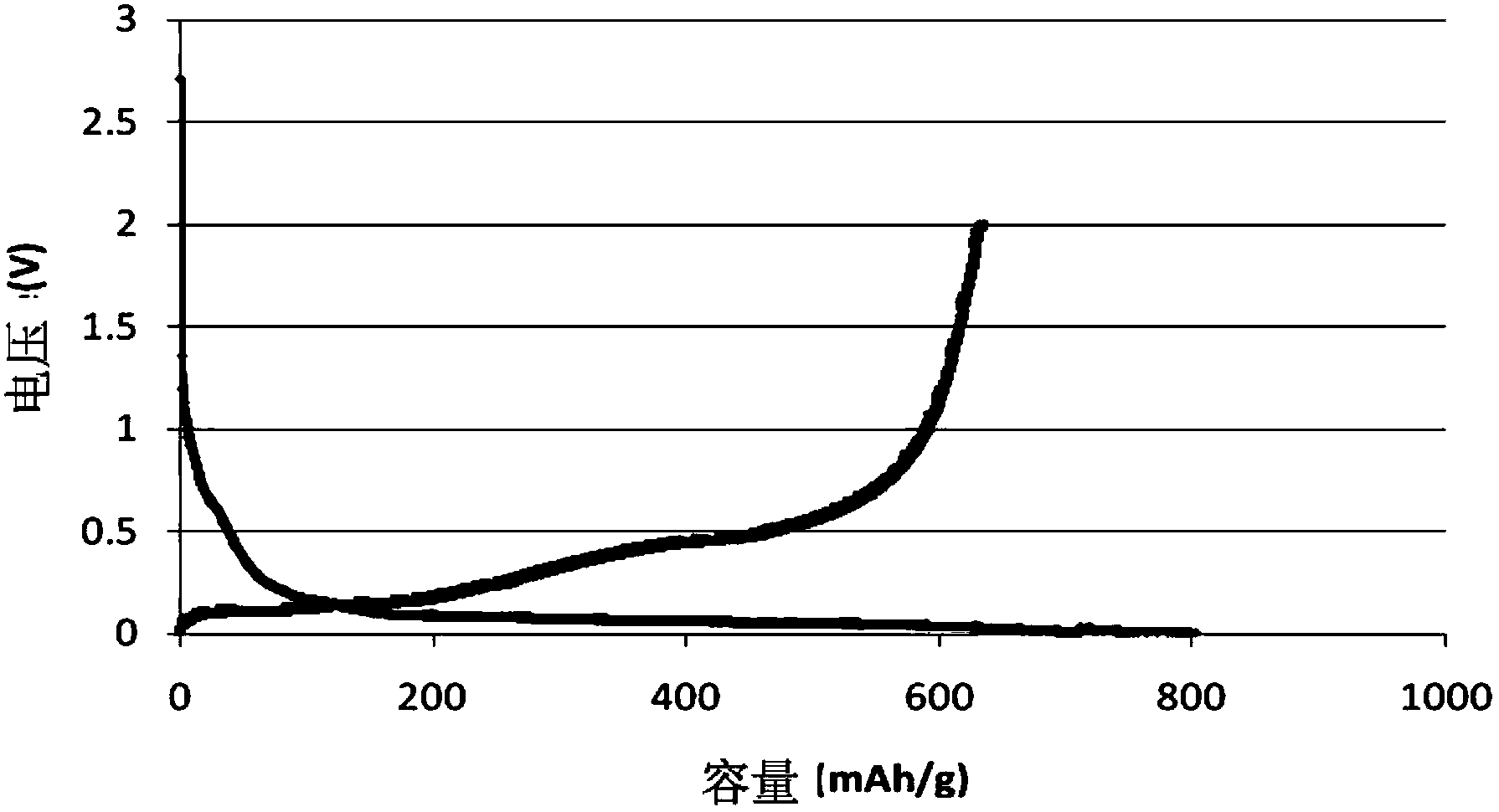

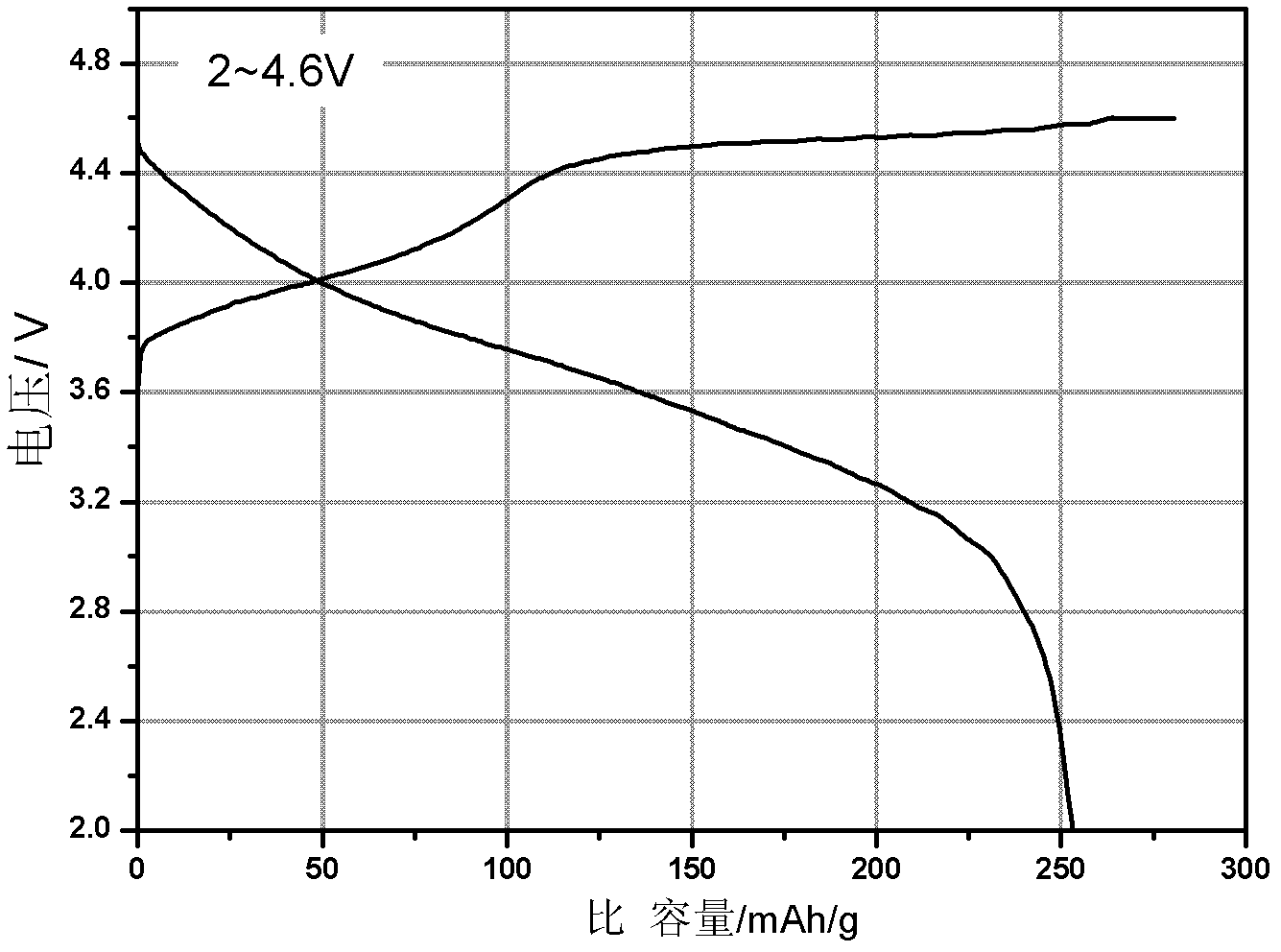

InactiveCN103035900AHigh specific capacityThe synthesis process is simpleCell electrodesMetallurgyCharge discharge

The invention discloses a high-capacity lithium-rich cathode material and a preparation method thereof. The general formula of the lithium-rich cathode material is Li[Lid(NiaCobMncMx)]O2, wherein M is one or more than one elements selected from Cu, Mg, Al, Y, Bi, Ti and Sn, a is more than or equal to 0.17 and less than or equal to 0.21, b is more than or equal to 0.09 and less than 0.13, c is more than or equal to 0.54 and less than or equal to 0.58, d is more than or equal to 0.10 and less than or equal to 0.15, x is more than or equal to 0 and less than or equal to 0.05, and the sum of a, b, c, d and x is 1. The high-capacity lithium-rich cathode material disclosed by the invention has the advantages of high specific capacity and high initial efficiency; initial discharge capacity can be 273mAh / g and the initial efficiency is higher than 89% during charge-discharge of 2-4.6V; and the initial discharge capacity can be 293mAh / g and the initial efficiency is higher than 87% during charge-discharge of 2-4.8V.

Owner:PULEAD TECH IND

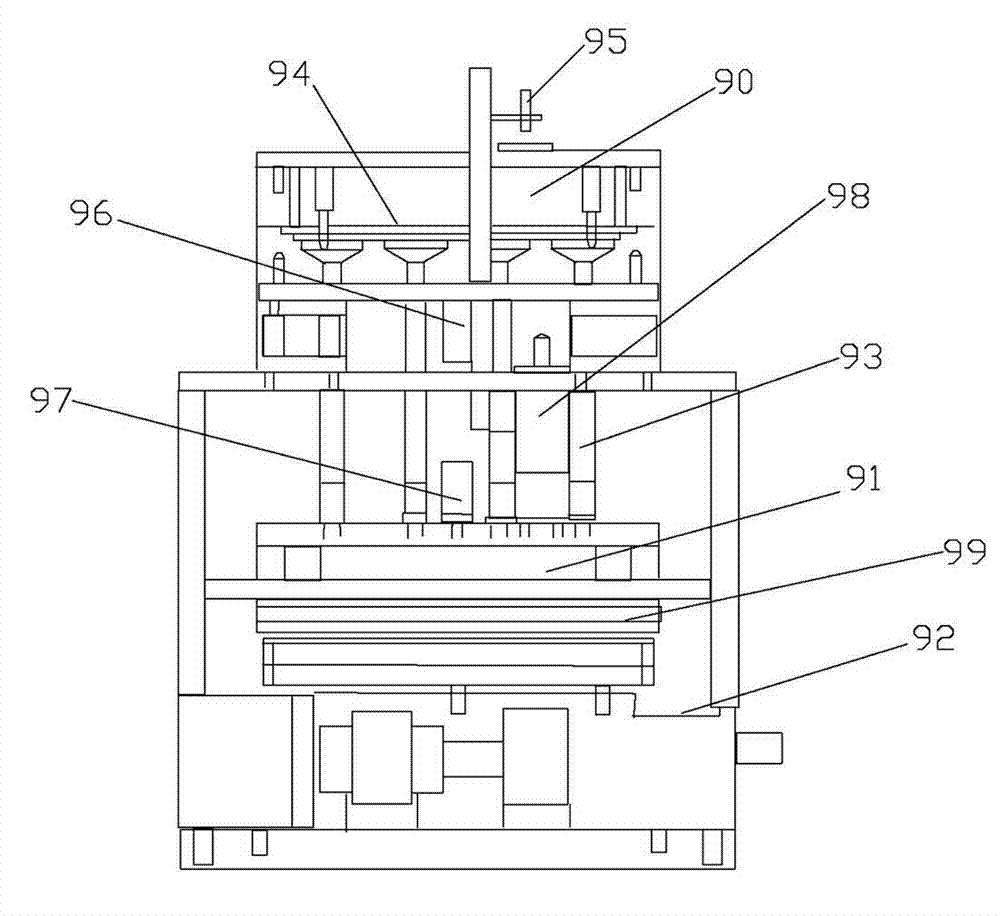

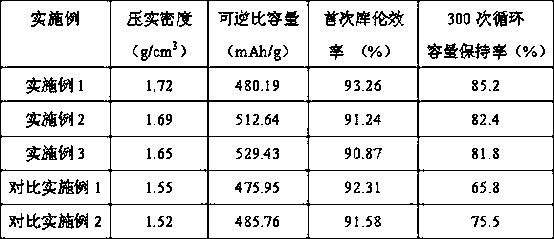

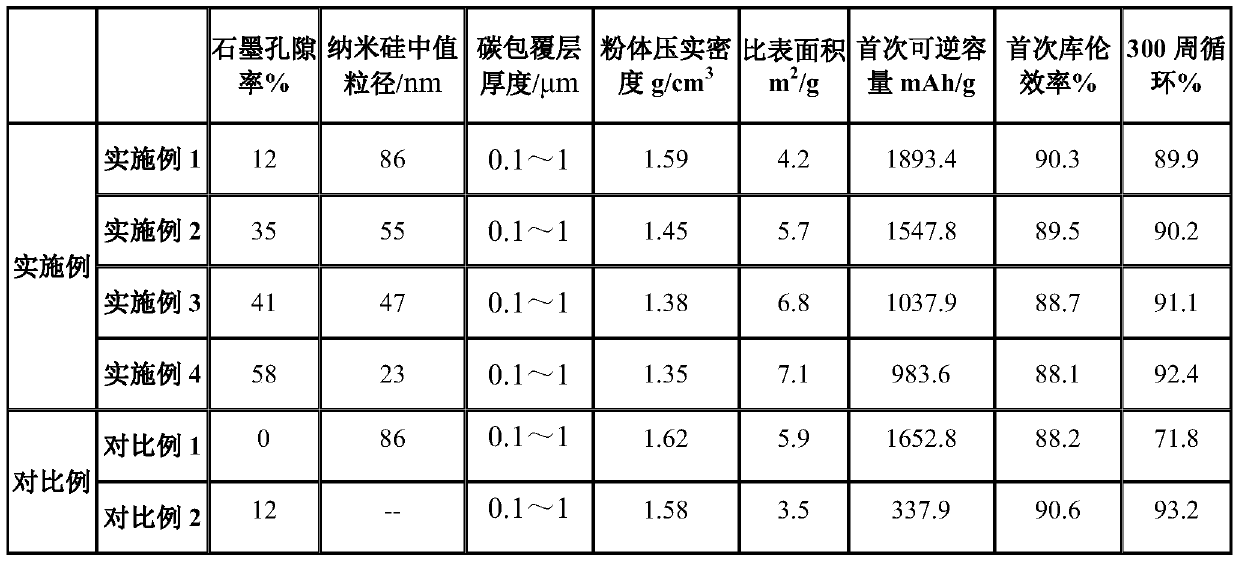

Preparation method of silicon-carbon negative electrode material for high-compaction-density lithium ion battery

ActiveCN108736007AImprove first-time efficiencyImprove cycle performanceMaterial nanotechnologyCell electrodesHigh energyCarbonization

The invention discloses a preparation method of a silicon-carbon negative electrode material for a high-compaction-density lithium ion battery. The preparation method comprises the following steps: (1) preparing nano-sized silicon powder; (2) preparing micron-sized porous natural graphite; (3) mixing the prepared nano-sized silicon powder with the porous natural graphite by ball milling; (4) adding a solution in which a carbon source precursor is dispersed into a mixture of the nano-sized silicon powder and the natural graphite for secondary ball milling; (5) coating and carbonizing integrateddevice with a graphite negative electrode material under inert gas protection for granulation and high-temperature carbonization to obtain a silicon-carbon materials with appropriate particle size; and (6) blending the prepared silicon-carbon material with commercial graphite to form a silicon-carbon negative electrode material. The preparation method not only guarantees the first coulomb efficiency and cycle performance of the silicon-carbon negative electrode material, but also significantly improves the compaction density, thereby laying a foundation for further preparation of a high-energy-density battery. In addition, the preparation process is fast and convenient; raw materials are easy to obtain; and large-scale production and application of the silicon-carbon negative electrode material are facilitated.

Owner:赣州市瑞富特科技有限公司

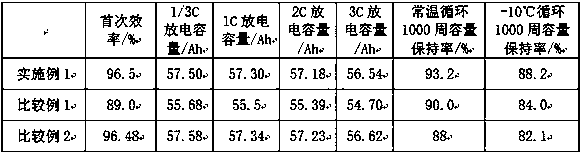

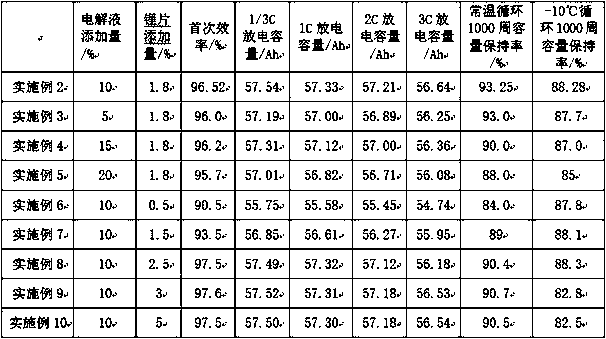

Negative electrode paste mixing process with pre-lithiation effect, and lithium battery

ActiveCN108417774AEasy to quantifyPromote formationElectrode manufacturing processesSecondary cellsConductive pasteNickel–lithium battery

The invention relates to a negative electrode paste mixing process with a pre-lithiation effect, and a lithium battery. In an environment with a dew point of minis 40 to minus 50 DEG C, a negative electrode active material, a conductive agent and other dry powder are stirred uniformly; next, conductive paste is added and then added into NMP in two times to be kneaded and mixed uniformly; and finally, a metal lithium sheet and a film-forming additive-containing electrolyte are added to carry out dispersion and pre-lithiation. The metal lithium sheet and the film-forming additive-containing electrolyte are added in the paste mixing process, so that quantification of the metal lithium sheet can be facilitated, formation of an SEI membrane can be promoted, and an obvious lithium supplementingeffect is realized; pre-lithiation is performed directly in the paste mixing process, and extra pre-lithiation equipment is not needed, so that production cost is lowered; and in the subsequent electrolyte injection of the lithium battery, the content of the additive in the electrolyte can be reduced, and electrical conductivity of the electrolyte can be improved, thereby improving safety, initialefficiency, rate capability and cycle performance of the battery.

Owner:江西安驰新能源科技有限公司

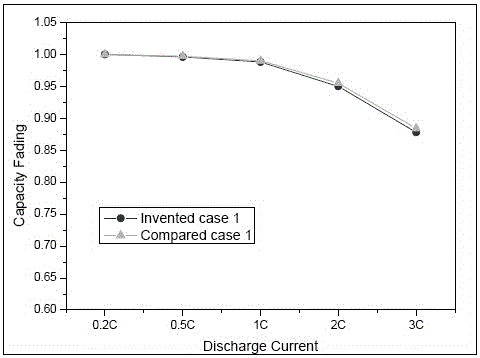

Silicon carbon anode material for lithium ion battery and preparation method thereof

InactiveCN110311125AAlleviate volume expansionIncrease transfer rateSecondary cellsNegative electrodesPorosityCarbon layer

The invention belongs to the technical field of lithium ion batteries and particularly relates to a silicon carbon anode material for a lithium ion battery and a preparation method thereof. The anodematerial is a core-shell structure, wherein the core comprises porous graphite and nano-silicon; the pores of the graphite are formed through strong base erosion; the nano-silicon is deposited in thepores of the graphite by CVD deposition; the shell is an organic cracked carbon layer; the porosity of the porous graphite is 10 to 60%; the median diameter of the nano-silicon is 20-100 nm; and a carbon coating layer has a thickness of 0.1 to 1[mu]m. Compared with the prior art, the silicon carbon anode material for the lithium ion battery prepared by the method uses the porous graphite to reserve a space for the volume expansion of the nano-silicon so as to greatly alleviate the volume expansion of the nano-silicon and increase ion and electron transport rates. The silicon carbon anode material for the lithium ion battery has excellent electrochemical performance and stable structure. The preparation method is simple in process, low in cost, and suitable for industrial production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +1

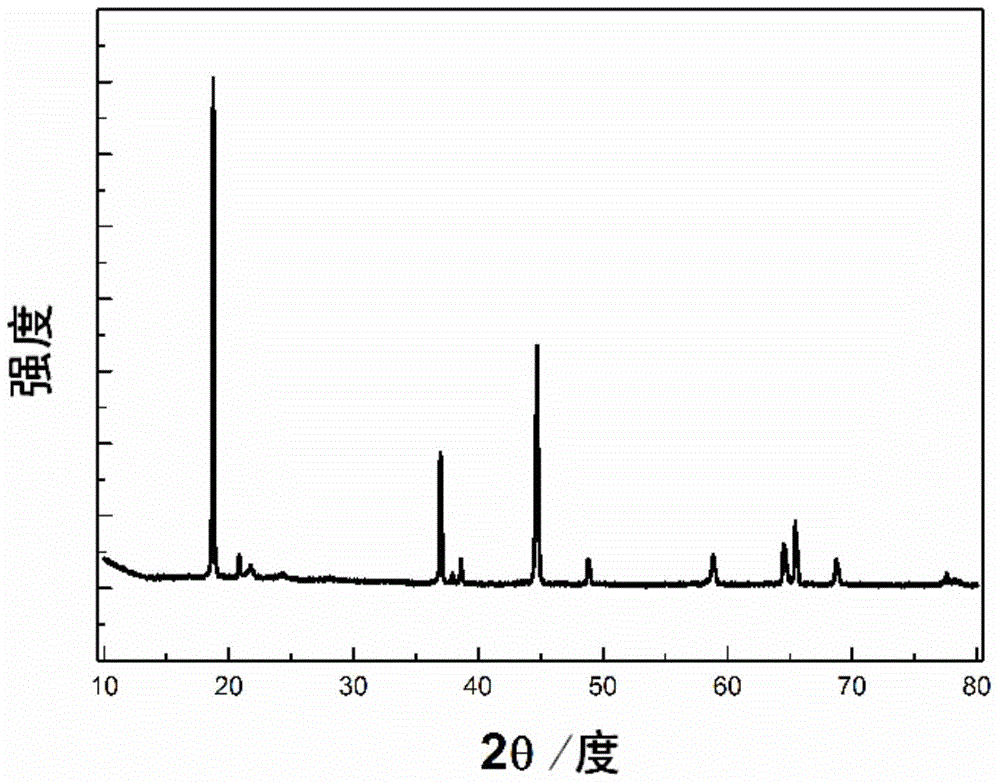

Lithium-rich manganese-based positive electrode material and preparation method thereof, and lithium ion battery

ActiveCN104966831AImprove cycle performanceHigh crystallinityCell electrodesSecondary cellsManganeseSodium-ion battery

The present invention provides a lithium-rich manganese-based positive electrode material and a preparation method thereof, wherein the general formula of the positive electrode material is Li(1+x)MnyMzO2, M is one or a plurality of materials selected from nickel, cobalt, iron, magnesium, titanium, aluminum and vanadium, x is more than 0 and is less than or equal to 0.5, y is more than 0.33 and less than 1, z is more than 0 and is less than 0.3, (x+y+z) is 1, and the primary particle diameter of the lithium-rich manganese-based positive electrode material is 400-3000 nm. According to the present invention, the lithium-rich manganese-based positive electrode material has characteristics of large primary particle diameter, low specific surface area and good crystallinity so as to improve the cycle performance and the first efficiency of the positive electrode material; and the cladding layer can be obtained through the surface modification and has the high ion conductivity so as to effectively improve the rate capability of the material. The present invention further provides a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lithium battery hard carbon microsphere cathode material with core-shell structure and preparation method thereof

The invention provides a lithium battery hard carbon microsphere cathode material with core-shell structure and a preparation method thereof. The lithium battery hard carbon microsphere cathode material with core-shell structure is formed by starch and a graphitized layer as coating. The surface of the material is subjected to catalytic graphitization treatment to form the graphitized layer, and the inside of the material maintains the hard carbon structure. The product is made by preparing a starch-based hard carbon microsphere and performing catalytic graphitization treatment. Owing to the highly-graphitized coating layer, the first charge / discharge efficiency of the prepared carbon microsphere with core-shell structure is higher than the conventional hard carbon-based materials; and owing to the hard carbon inner structure, the capacity is higher and the magnification property is excellent.

Owner:DONGFANG ELECTRIC CORP LTD

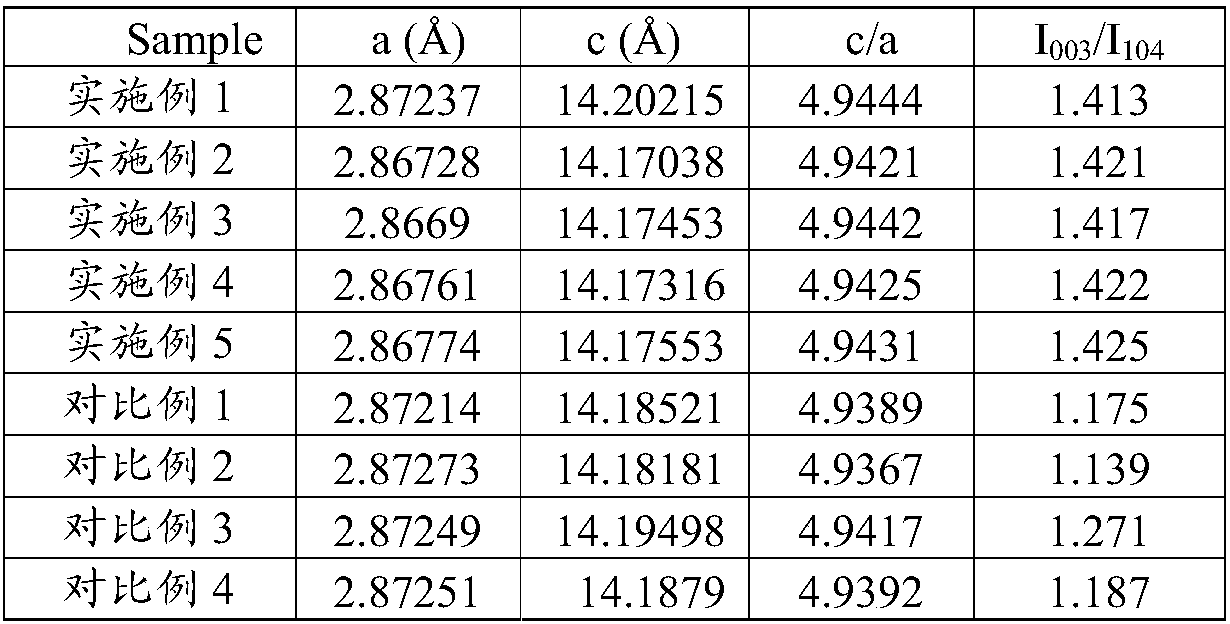

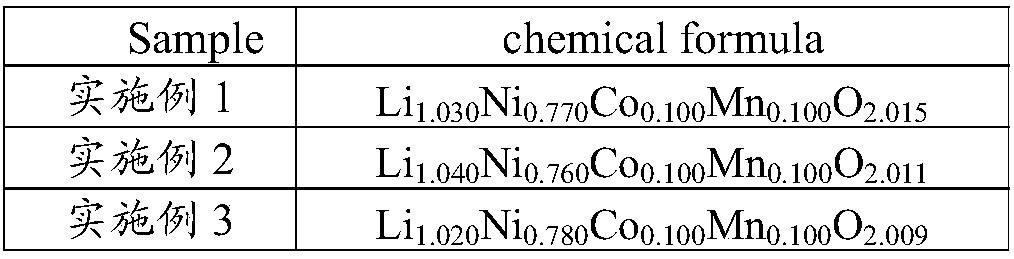

Preparation method of high-nickel ternary material

ActiveCN108346797AHigh crystallinityImprove structural stabilityElectrode thermal treatmentSecondary cellsLithiumMetallurgy

The invention provides a preparation method of a high-nickel ternary material. The high-nickel ternary material is Li<1+a>Ni<x>Co<y>M<z>O<2+b>, wherein a is greater than or equal to -0.10 and less than or equal to 0.50; x is greater than or equal to 0.8 and less than 0.9; y is greater than or equal to 0.1 and less than or equal to 0.25; z is greater than or equal to 0 and less than or equal to 0.25; b is greater than or equal to -0.05 and less than or equal to 0.10; M is at least one kind of Mn, Al, Ti, Ba, Sr, Mg, Cr, Zn, V and Cu; the preparation method comprises the steps of enabling a precursor and a lithium source to be mixed, and adding sintering auxiliaries to be mixed uniformly, and then performing sintering in a three-stage sintering mode, wherein the three-stage sintering mode iscarried out by performing sintering in the first stage, then performing sintering in the second stage and finally performing sintering in the third stage, and the sintering temperature in the secondstage is higher than that in the first stage and in the third stage. By adoption of the three-stage sintering mode, and by enabling the sintering temperature in the second stage to be higher than thatin the first stage and in the third stage, the prepared high-nickel ternary material is high in crystallinity and less in Li / Ni mixed arrangement, thereby realizing high structural stability, high initial efficiency and high power.

Owner:ZOLTRIX MATERIAL GUANGZHOU

Silicon-carbon composite electrode and preparation method thereof

InactiveCN107403920AHigh tap densityHigh densityCell electrodesSecondary cellsCarbon compositesSalt deposit

The invention discloses a silicon-carbon composite electrode and a preparation method thereof. The silicon-carbon composite electrode is of a shell-core structure, wherein a core contains silicon powder, a hollow carbon sphere and an inorganic lithium salt compound, the hollow carbon sphere is doped into the silicon powder, and the inorganic lithium salt compound is electrically deposited between the silicon powder and the hollow carbon sphere; and a shell is a high-molecular polymer. According to the silicon-carbon composite electrode prepared by virtue of the preparation method, by utilizing lithium salt deposited on the surface of silicon, the lithium ion transmission rate during charging and discharging is increased, sufficient lithium ions are provided for the formation of an SEI membrane, the initial efficiency can be obviously improved, the expansion rate of a silicon material can be decreased, and the cycle performance of the silicon material can be improved; and meanwhile, the silicon-carbon composite electrode has the characteristics of high stability and strong stability at 100-150 DEG C, the contact between the lithium salt material and air can be avoided, and the processability and the safety performance of the lithium salt material can be improved; and furthermore, the polymer has relatively good dissolving property with an electrolyte solvent, so that the polymer can serve as lithium salt, and the initial efficiency, safety performance and energy density of a cathode material are improved.

Owner:深圳市金牌新能源科技有限责任公司

Lithium ion battery positive plate capable of supplementing lithium and lithium ion battery

ActiveCN107248567AHigh cycle capacity retentionEasy to manufactureCell electrodesElectrolyte/reactants regenerationDischarge efficiencySilicon alloy

The invention discloses a lithium ion battery positive plate capable of supplementing lithium and a lithium ion battery containing this positive plate. This positive pate can provide the lithium source at the first charging, thereby placing the effect of compensating the lithium consumption when the positive and the negative form an SEI film, the first charging / discharging efficiency and the cycle performance are promoted, and the charging capacity and the energy density can be promoted, the lithium ion battery positive plate is especially suitable for the negative system with the low first charging / discharging efficiency, such as: the negative system containing silicon, silicon alloy, silicon oxide, or tin, tin alloy, and tin oxide.

Owner:安普瑞斯(无锡)有限公司

Coating modification method for improving performance of rich-lithium manganese-base positive electrode material

ActiveCN106784655AIncrease capacityImprove first-time efficiencyCell electrodesSecondary cellsPrecipitationLithium

The invention discloses a coating modification method for improving performance of a rich-lithium manganese-base positive electrode material. The rich-lithium manganese-base positive electrode material is arranged in the material, wherein the rich-lithium manganese-base material is Li[LixMn1-x-yMy]O2; praseodymium phosphate is arranged on a surface layer of the material; intermigration of a transition metal ion, a phosphate radical and a praseodymium ion exists in a coating process; and a new phase capable of conducting an ion and an electron is generated on an interface. The method comprises the following specific steps of ultrasonically dispersing the rich-lithium manganese-base material in secondary water or an organic solution to form a disperse and uniform suspension; dissolving praseodymate in the suspension; adding phosphoric acid or phosphate to allow a phosphate radical ion and the praseodymium ion to perform a precipitation reaction on the surface of the rich-lithium manganese-base material; generating an initial coating layer; obtaining slurry comprising the initial coating layer; and finally drying the obtained slurry and then calcinating the slurry to obtain the rich-lithium manganese-base anode composite powder material comprising a praseodymium phosphate coating layer. The rich-lithium manganese-base composite material comprising the praseodymium phosphate coating layer prepared by the method is low in cost, high in capacity, high in first efficiency, low in voltage drop, good in stability and good in rate performance.

Owner:UNIV OF SCI & TECH BEIJING

Composite graphite negative electrode material with high energy density, and preparation method and application thereof

InactiveCN103000867AIncrease energy densityImprove discharge capacityCell electrodesHigh energyLithium-ion battery

The invention relates to a graphite composite material with high energy density. The composite graphite material comprises artificial graphite, natural graphite and a coating. A mass ratio of the artificial graphite to the natural graphite is 15:1-1:5; a mass ratio of the coating to the composite graphite is 1:5 to 5:1; the composite graphite comprises the artificial graphite and the natural graphite; the coating material is one selected from middle-temperature coal pitch, high temperature coal pitch, secondary coal pitch, petroleum pitch and coal tar, and a combination thereof. The composite graphite negative electrode material provided by the invention has advantages of high energy density, high discharge capacity, high first discharge (388mAh / g), high first efficiency (higher than 95%), high compactness (1.79g / cm<3>) and good processing performance, and meets requirements of high energy density of lithium ion battery material by portable electronic products.

Owner:天津市贝特瑞新能源科技有限公司

High-capacity lithium ion battery positive material with core-shell heterostructure and preparation method of material

InactiveCN103762353AImprove cycle stabilityImprove first-time efficiencyCell electrodesSecondary cellsDischarge efficiencyManganese

The invention relates to a high-capacity lithium ion battery positive material. The high-capacity lithium ion battery positive material is a laminar composite material with a core-shell structure taking a lithium-rich phase material as a shell material and a spinel phase material as a core material. The preparation method comprises the following steps: performing coprecipitation reaction on nickel-manganese salt-mixture solution, ammonium hydroxide and sodium carbonate solution to obtain manganese carbonate nickel precursor; after uniformity mixing the precursor with a powdered lithium source, calcinating to obtain the powder granular core material with spinel structure; and calcinating after uniformity mixing the core material and Li2CO3, so as to obtain the target object. The high-capacity lithium ion battery positive material provided by the invention has the advantages that the positive material is high in specific capacity, cycling stability and first discharging efficiency, and the preparation technology of the material is good in controllability, low in manufacturing costs, and is suitable for large-scale production, so as to meet the demand on materials with high voltage and high specific capacity in the market.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

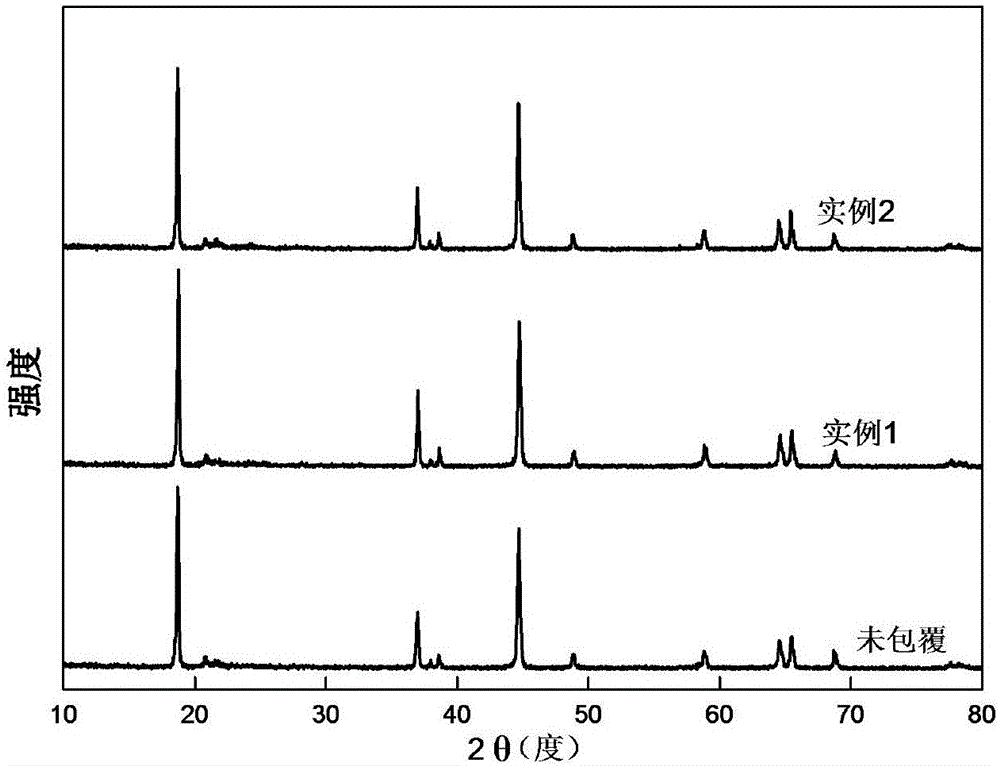

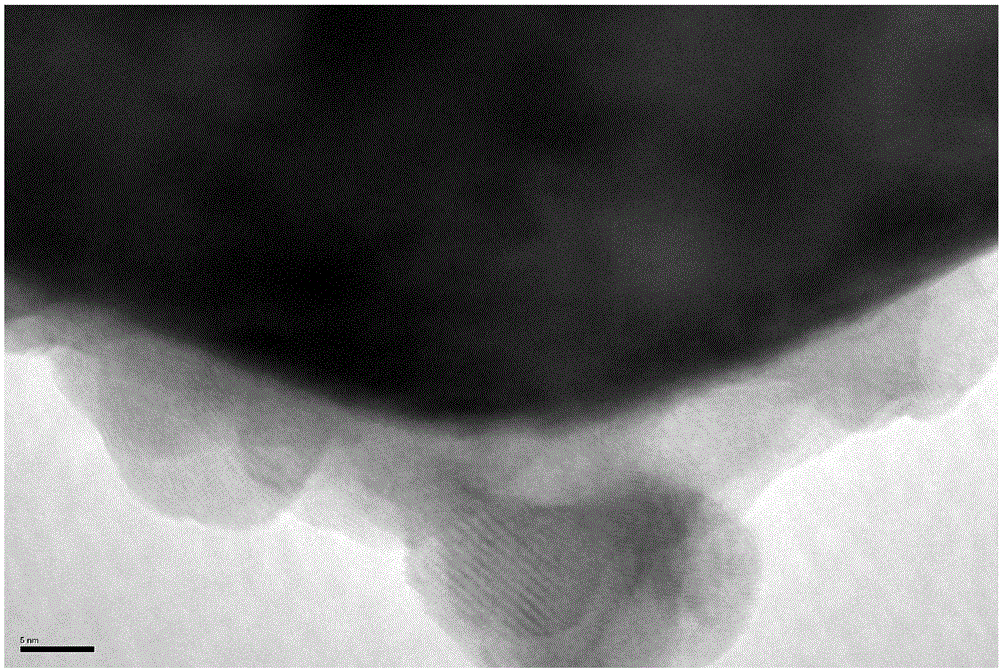

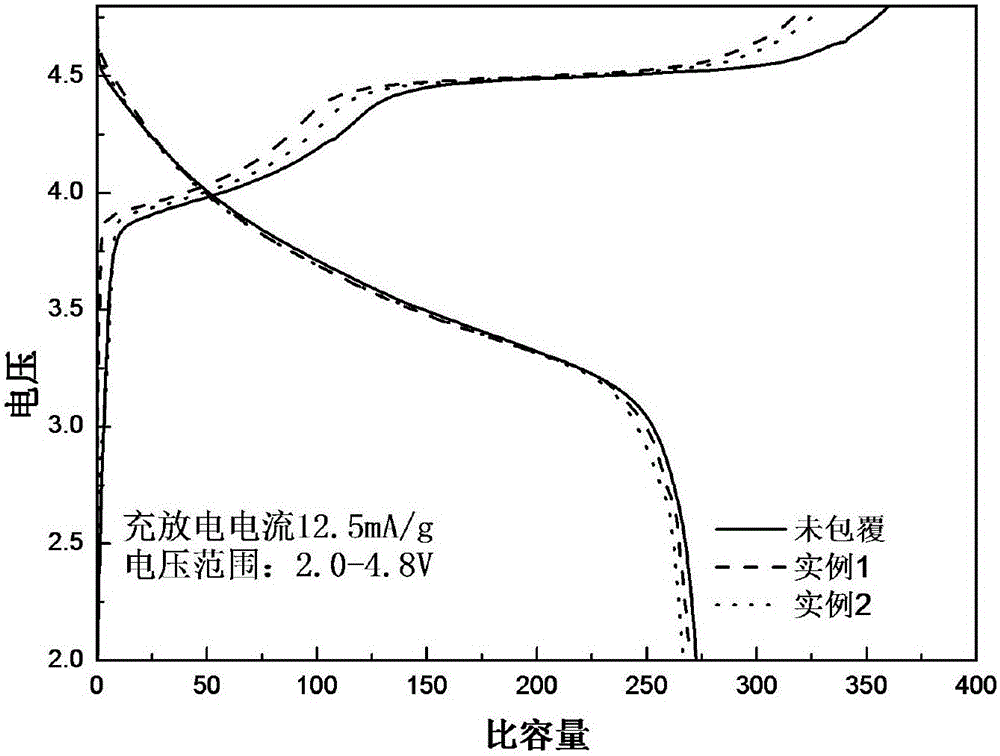

High-voltage lithium nickel manganese oxide/graphite lithium ion battery and manufacturing method thereof

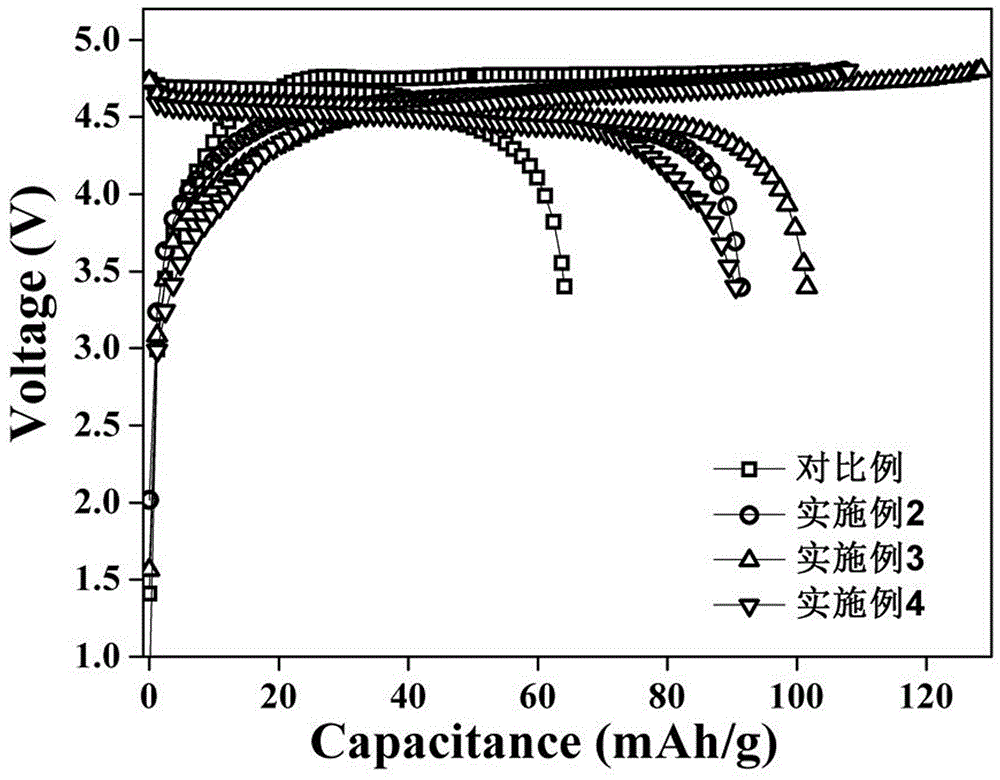

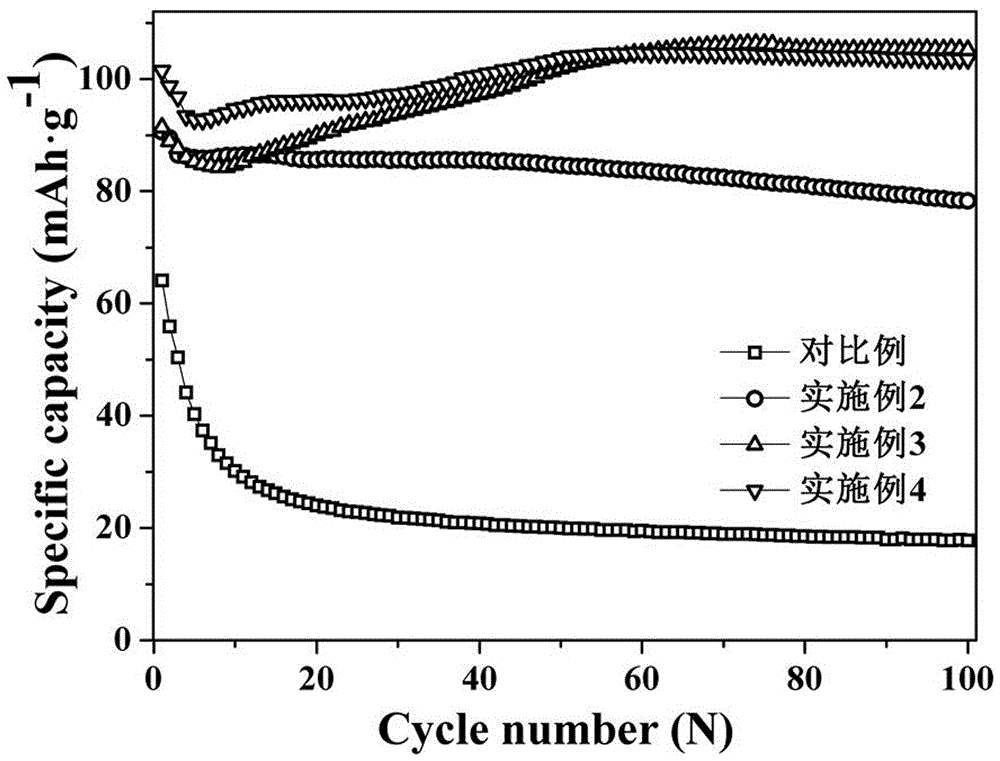

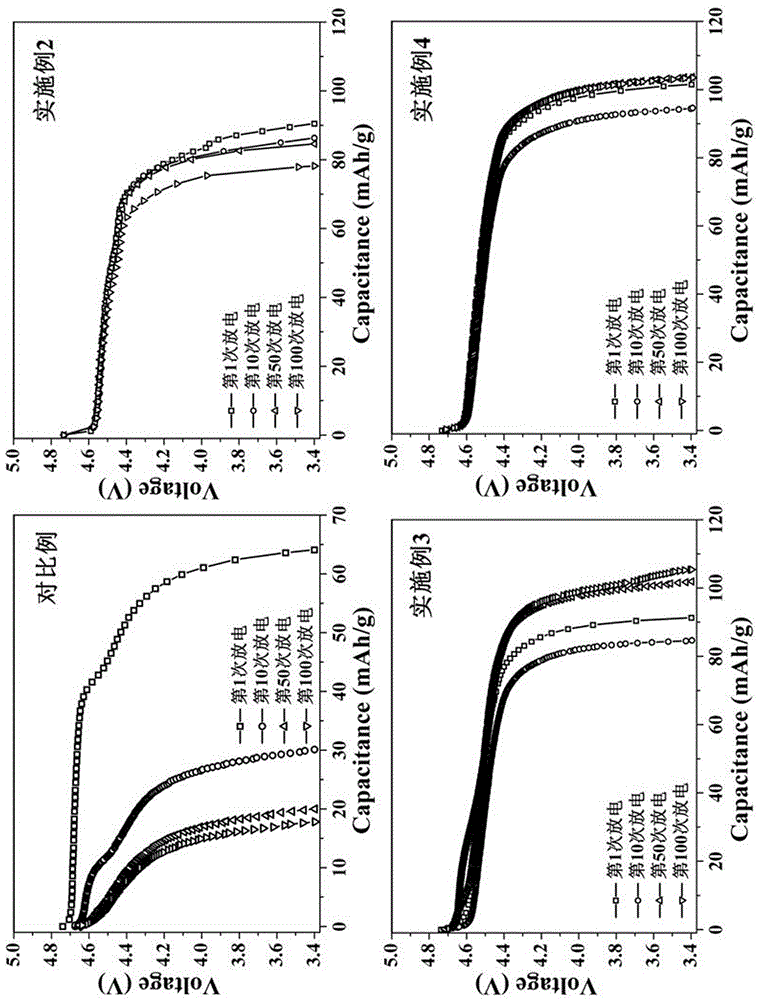

ActiveCN106159345AHigh specific capacityImprove first-time efficiencyCell electrodesFinal product manufactureManganese oxideOrganic acid

The invention discloses a lithium nickel manganese oxide (LNMO) / graphite lithium ion battery and a manufacturing method thereof. The surface of a negative electrode is modified through an organic acid ester and components of an SEI (Solid-Electrolyte Interface) film are changed; the stability of an electrolyte and electrode interface is enhanced, so that the sharp attenuation of a capacity is effectively stopped. By optimizing electrolyte and adding a functional additive into traditional organic electrolyte, the first-time efficiency of the battery is improved, the self discharge of the battery is inhibited, the specific capacity of the battery is improved, and the battery with a high specific capacity and a long cycle is realized. In order to further stabilize efficient running of the LNMO / graphite lithium ion battery with the high specific capacity and the long cycle and improve the stability of the battery, the invention further provides modification in the aspect of a positive electrode. An LNMO@LTO positive electrode material is prepared by covering LNMO by Li4Ti5O12 so that a covering layer can effectively avoid direct contact between the electrolyte and an active material body, the overflowing of Mn from the positive electrode material is reduced and the further catalysis effect on the SEI film by the Mn is reduced, and furthermore, the system becomes relatively stable.

Owner:GUANGXI NORMAL UNIV

Preparation method of silicon carbon composite anode material

InactiveCN104900843AIncrease compaction densityImprove first-time efficiencyCell electrodesSecondary cellsCarbon compositesHigh conductivity

The invention discloses a preparation method of a silicon carbon composite anode material. According to the anode material, a multiphase composite system is formed through combination of silicon, metal and carbon, the high capacity of the material is guaranteed, and the volume expansion and shrinkage effect in the charge-discharge process can be relieved; silicon and metal are dispersed in a carbon cracking system, metal can improve the conductivity, silicon has a high-capacity characteristic, the cracking carbon provides mechanical support, and accordingly, the material structure is stabilized. The silicon carbon composite anode material has high compaction density, good processing performance, high conductivity, high initial efficiency and excellent cycling stability. The preparation process of the anode material is simple, the cost of raw materials is low, and the anode material is environment-friendly, pollution-free and suitable for industrial production.

Owner:田东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com