Patents

Literature

1598results about How to "Improve Coulombic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

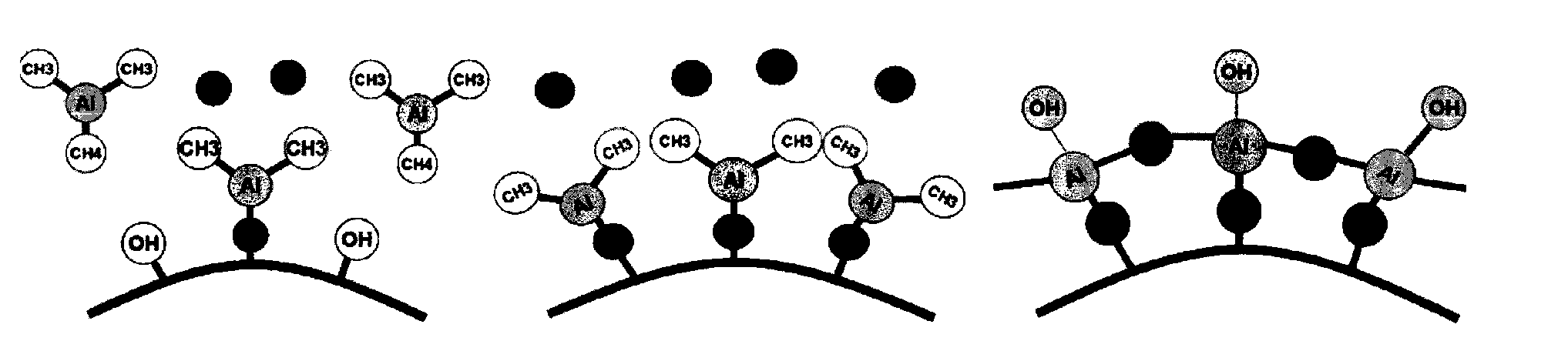

Method of producing lithium ion-storing/releasing material, lithium ion-storing/releasing material, and electrode structure and energy storage device using the material

InactiveUS20090162750A1Quickly chargeHigh charge and discharge efficiencyHybrid capacitor electrodesDouble layer capacitorsLithiumSilicon oxide

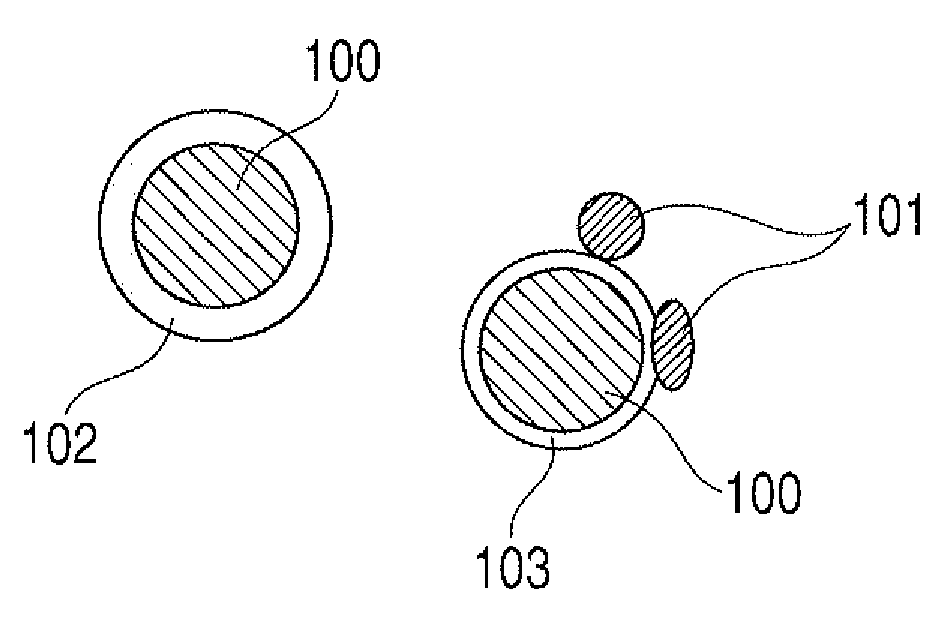

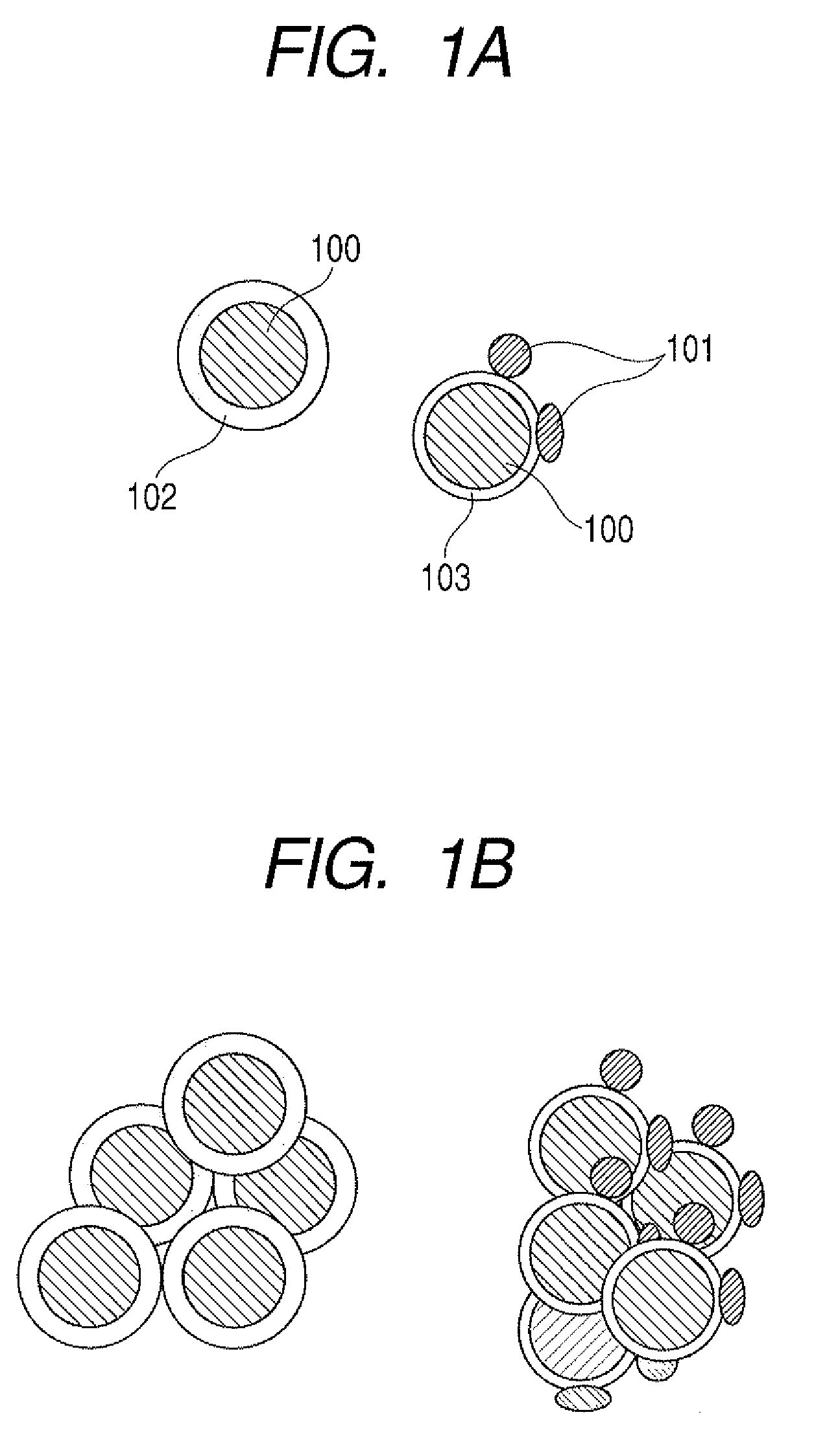

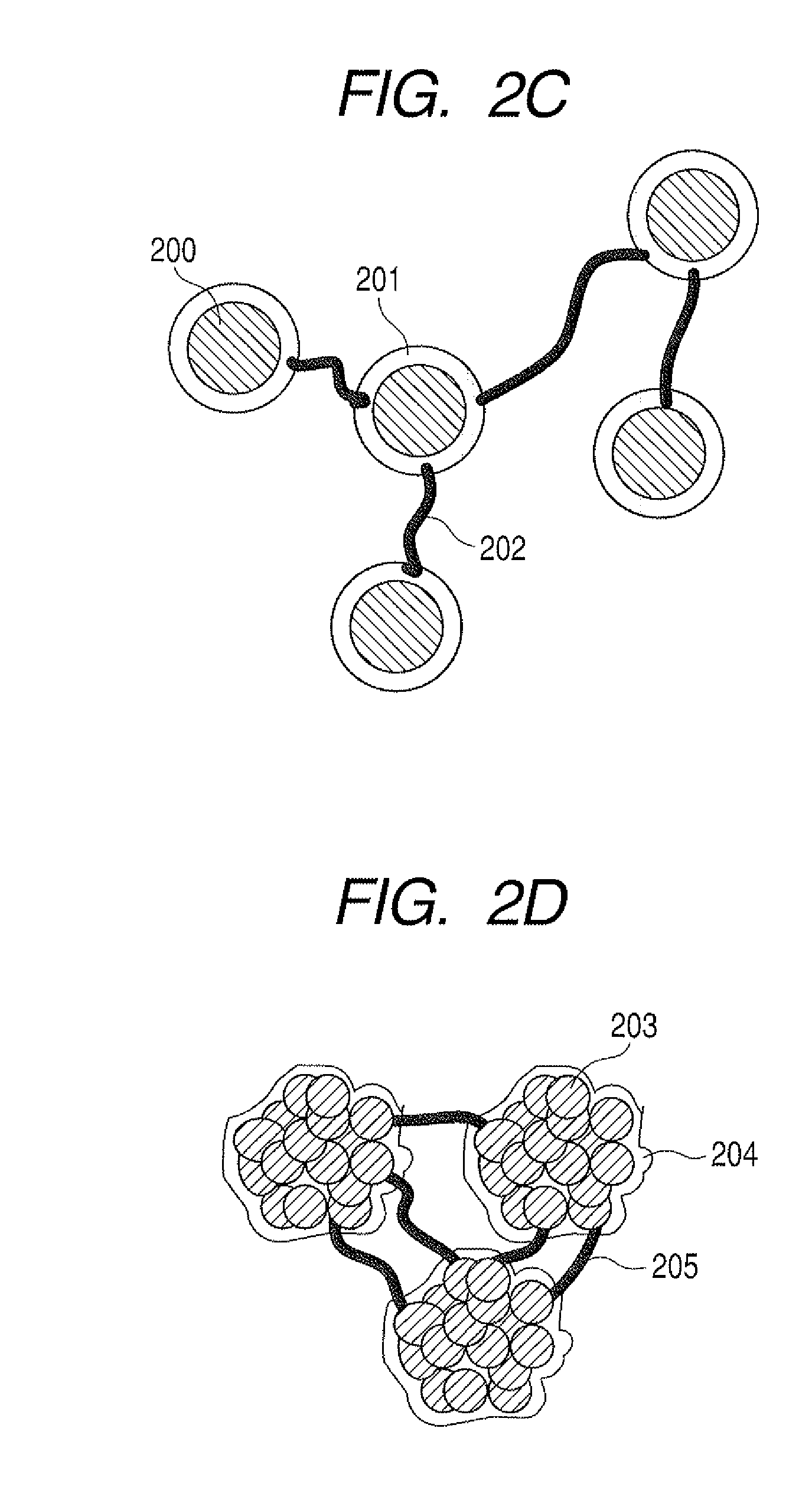

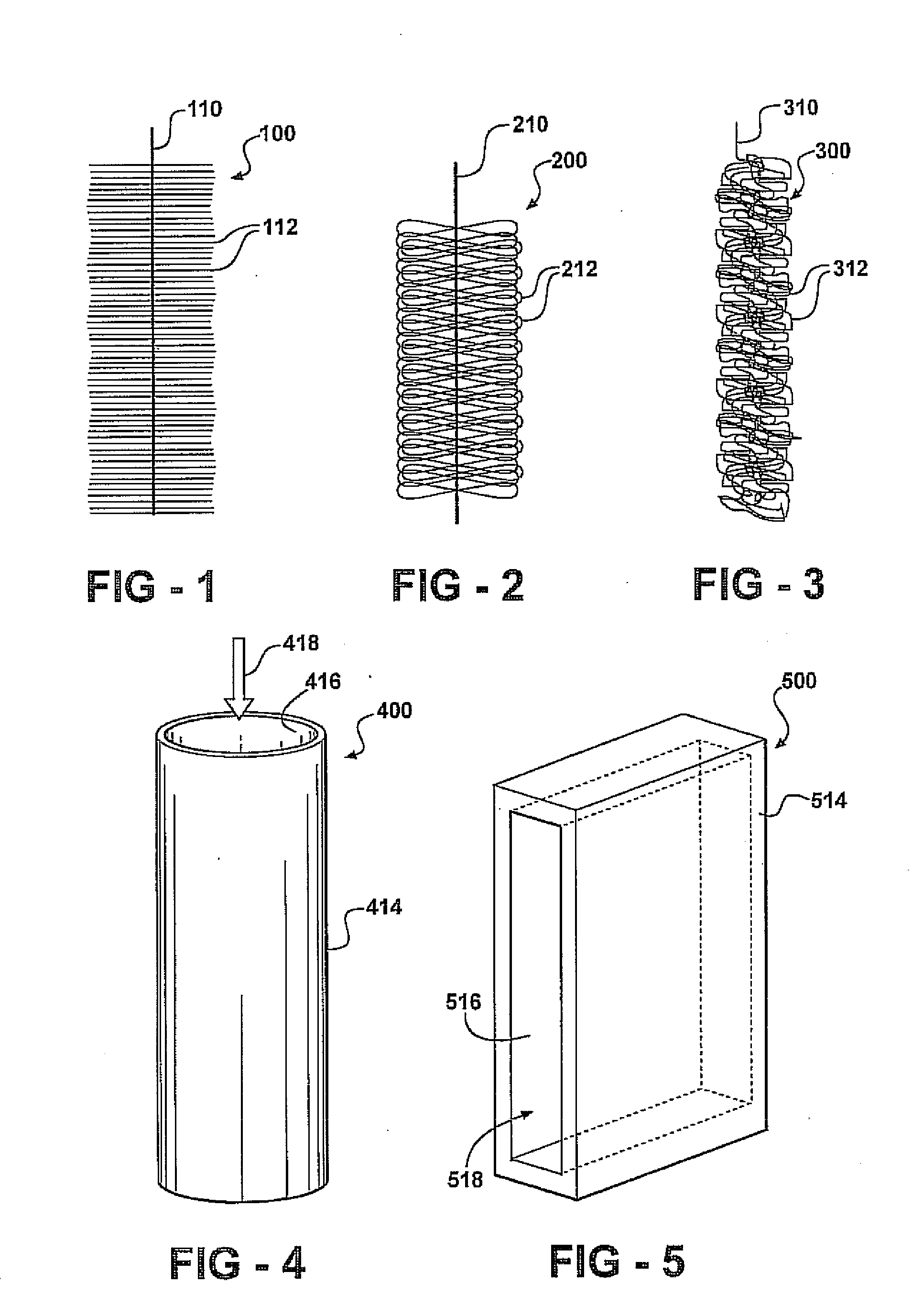

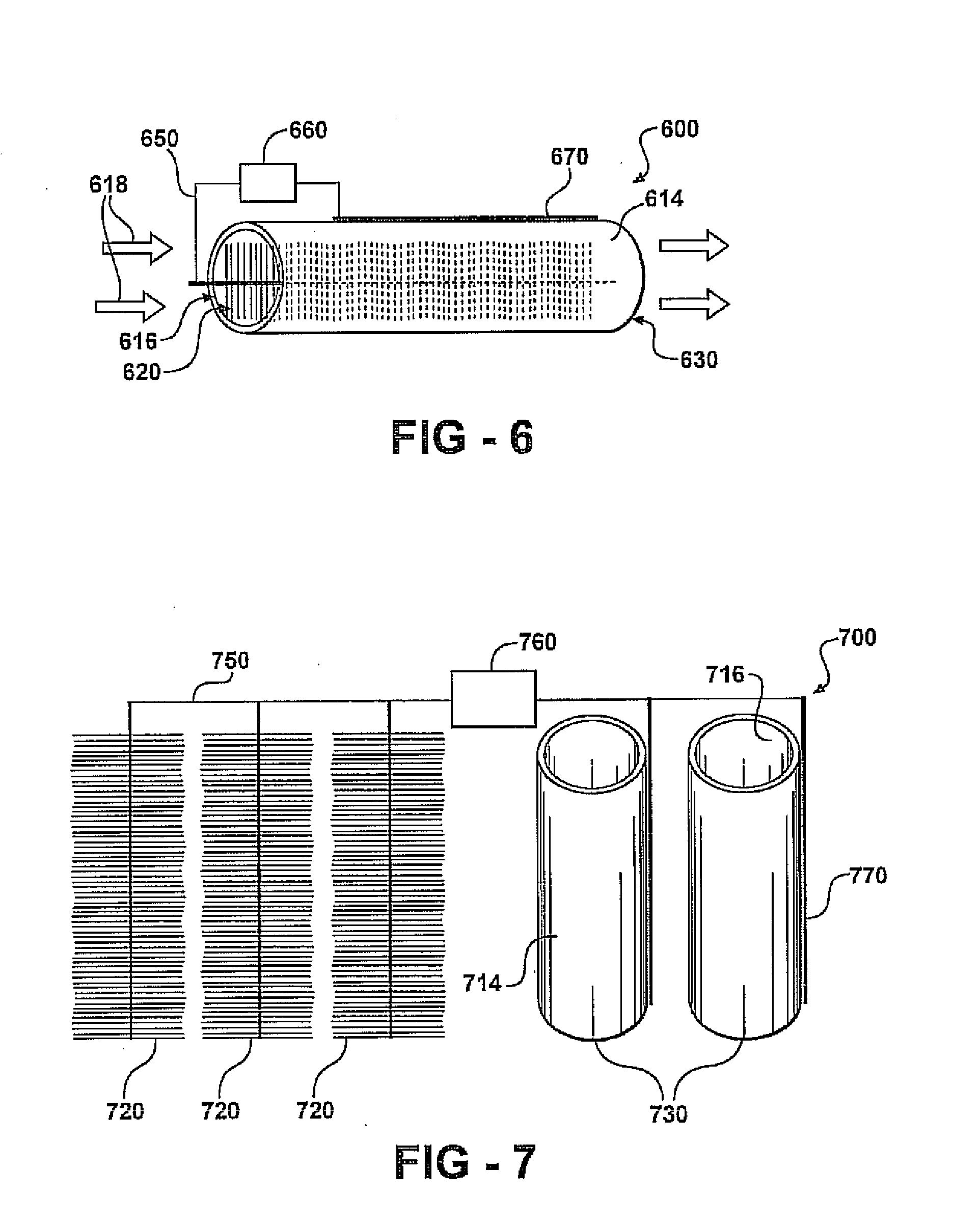

A method of producing a material capable of electrochemically storing and releasing a large amount of lithium ions is provided. The material is used as an electrode material for a negative electrode, and includes silicon or tin primary particles composed of crystal particles each having a specific diameter and an amorphous surface layer formed of at least a metal oxide, having a specific thickness. Gibbs free energy when the metal oxide is produced by oxidation of a metal is smaller than Gibbs free energy when silicon or tin is oxidized, and the metal oxide has higher thermodynamic stability than silicon oxide or tin oxide. The method of producing the electrode material includes reacting silicon or tin with a metal oxide, reacting a silicon oxide or a tin oxide with a metal, or reacting a silicon compound or a tin compound with a metal compound to react with each other.

Owner:CANON KK

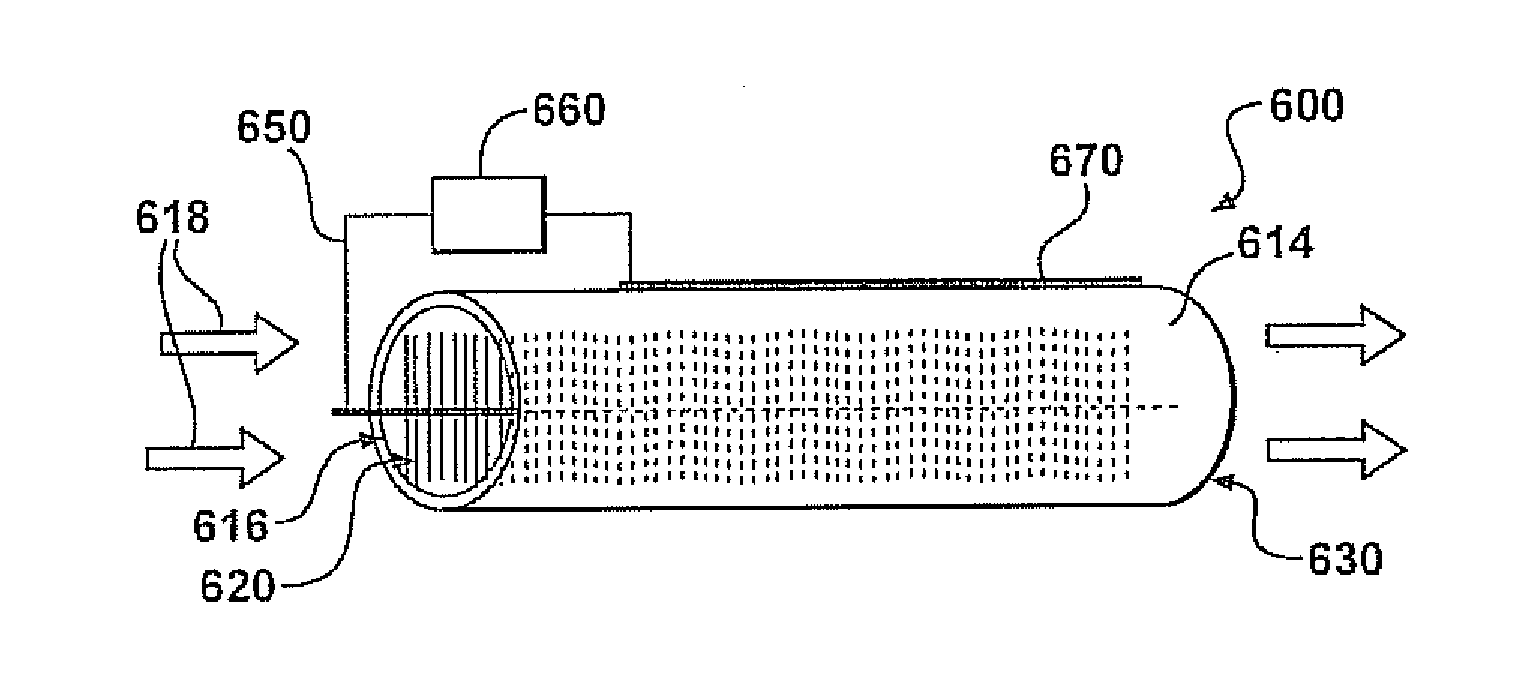

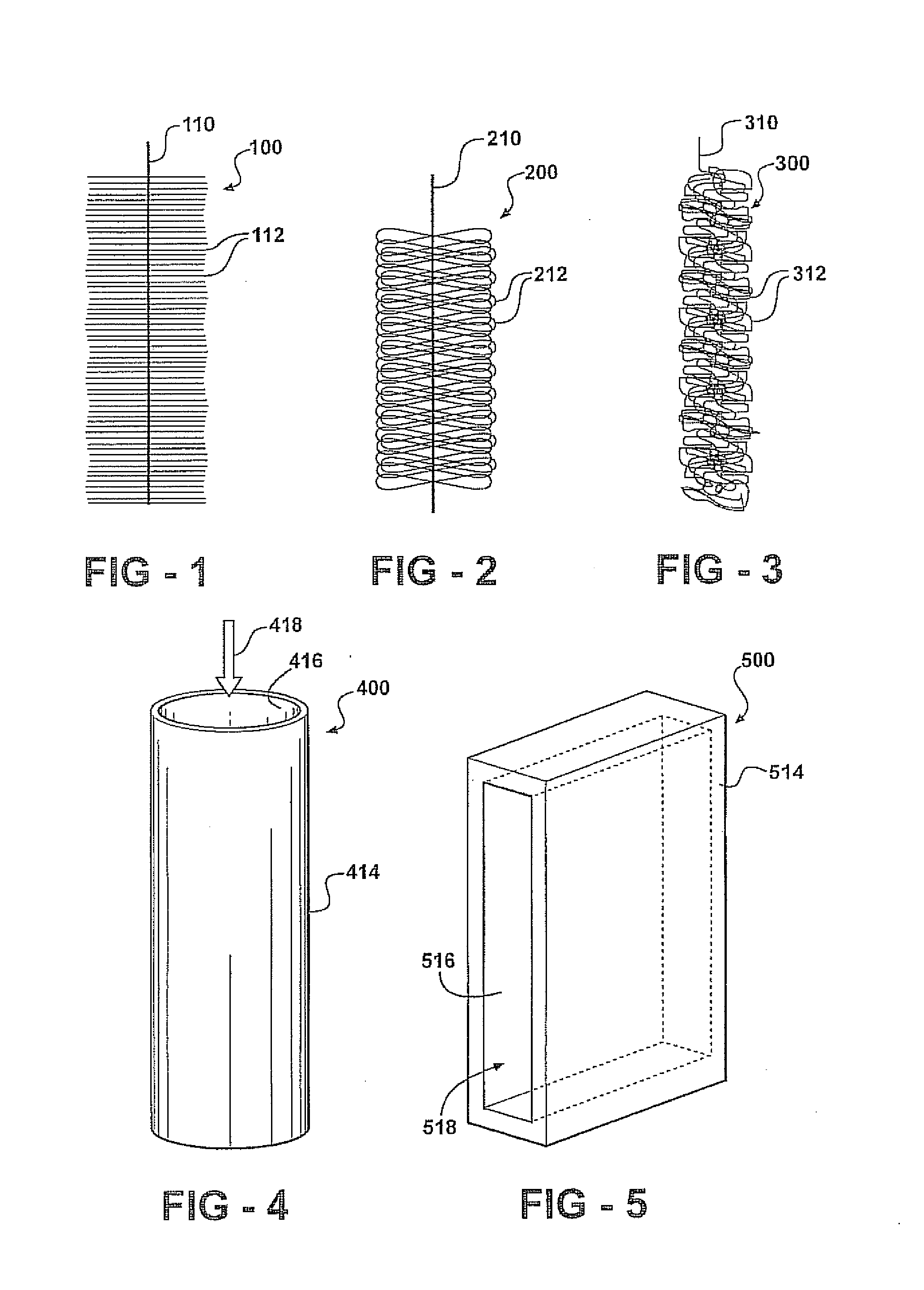

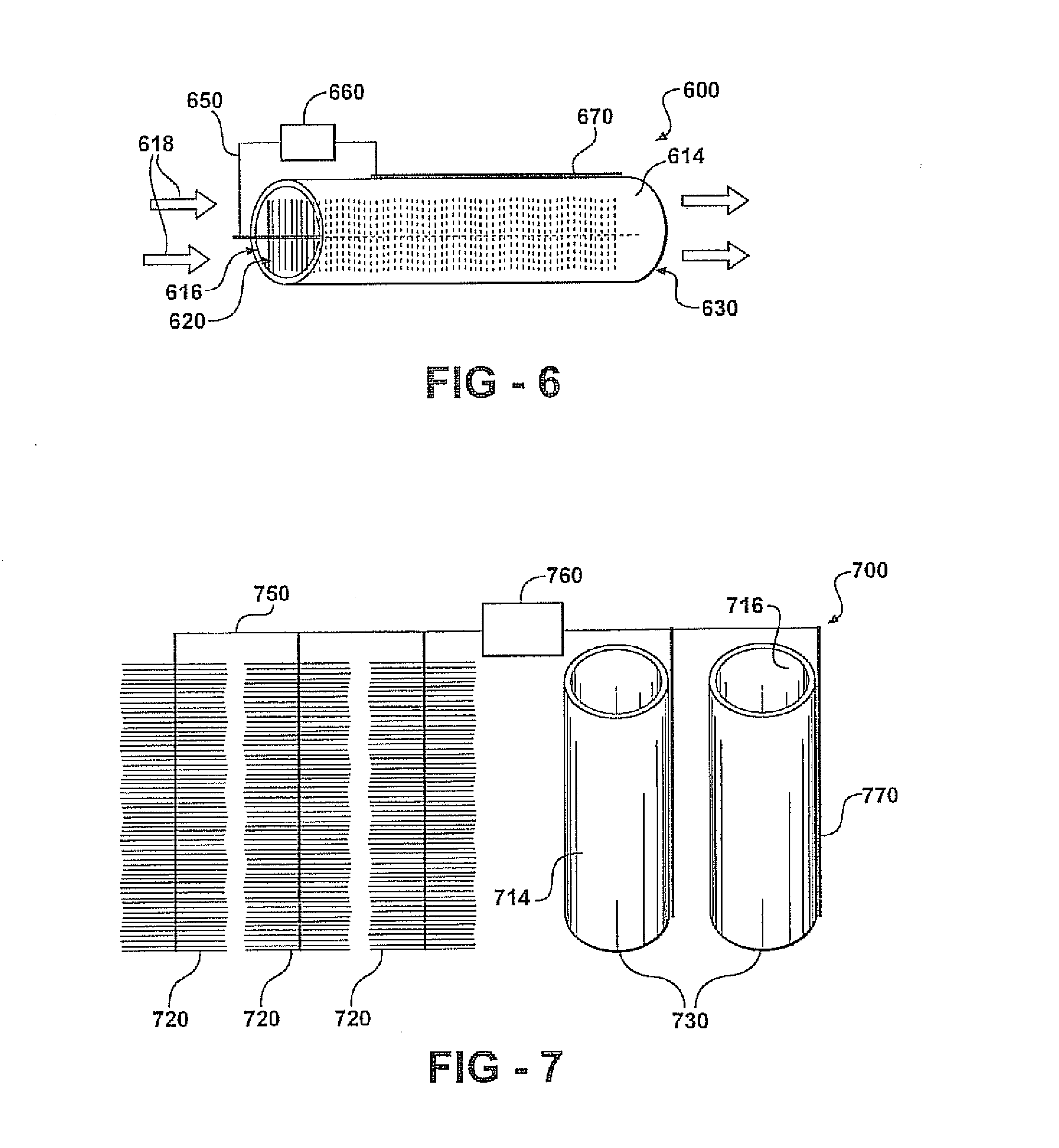

Electrodes and methods for microbial fuel cells

InactiveUS20080292912A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

Negative electrode active material and use of secondary lithium battery

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Graphite powder suitable for negative electrode material of lithium ion secondary batteries

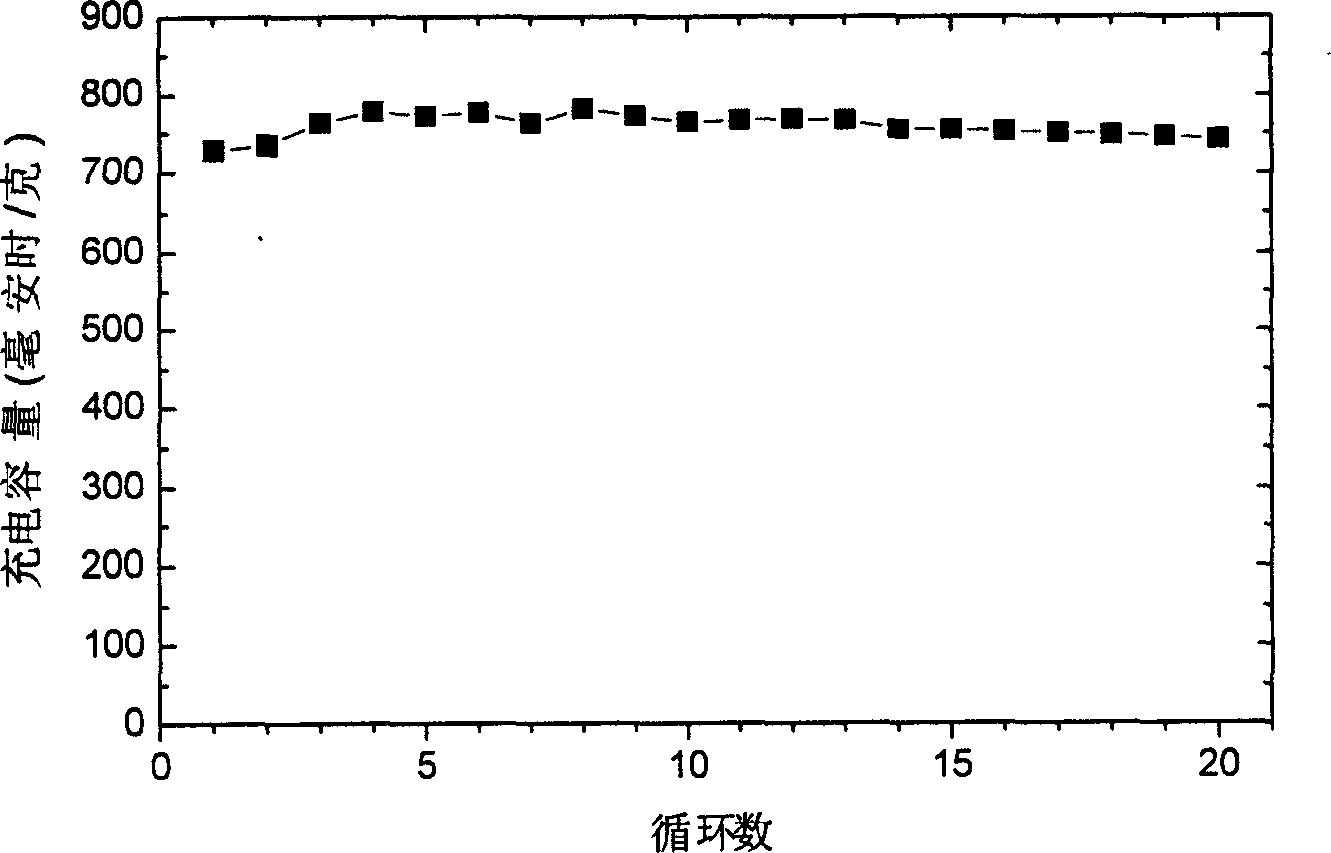

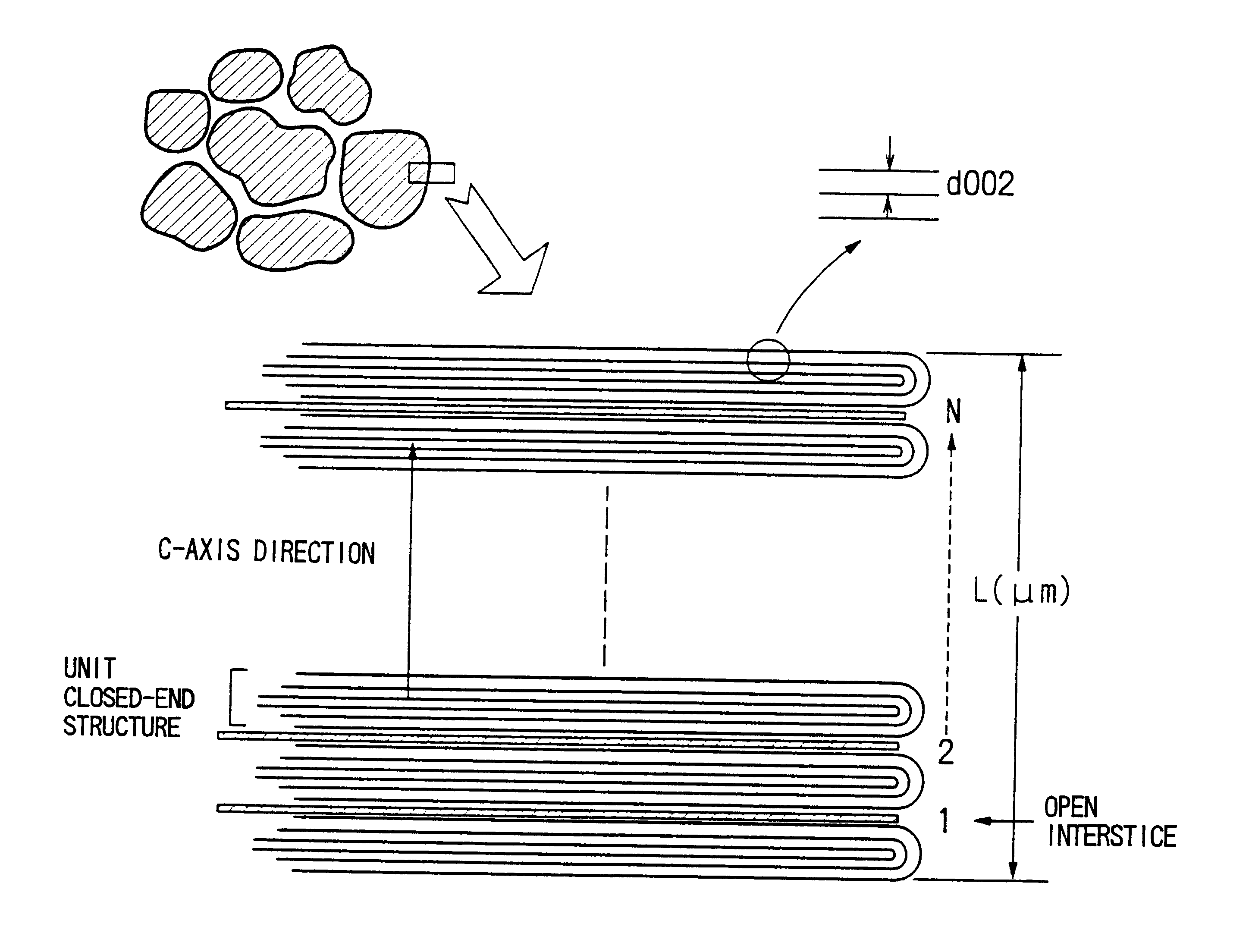

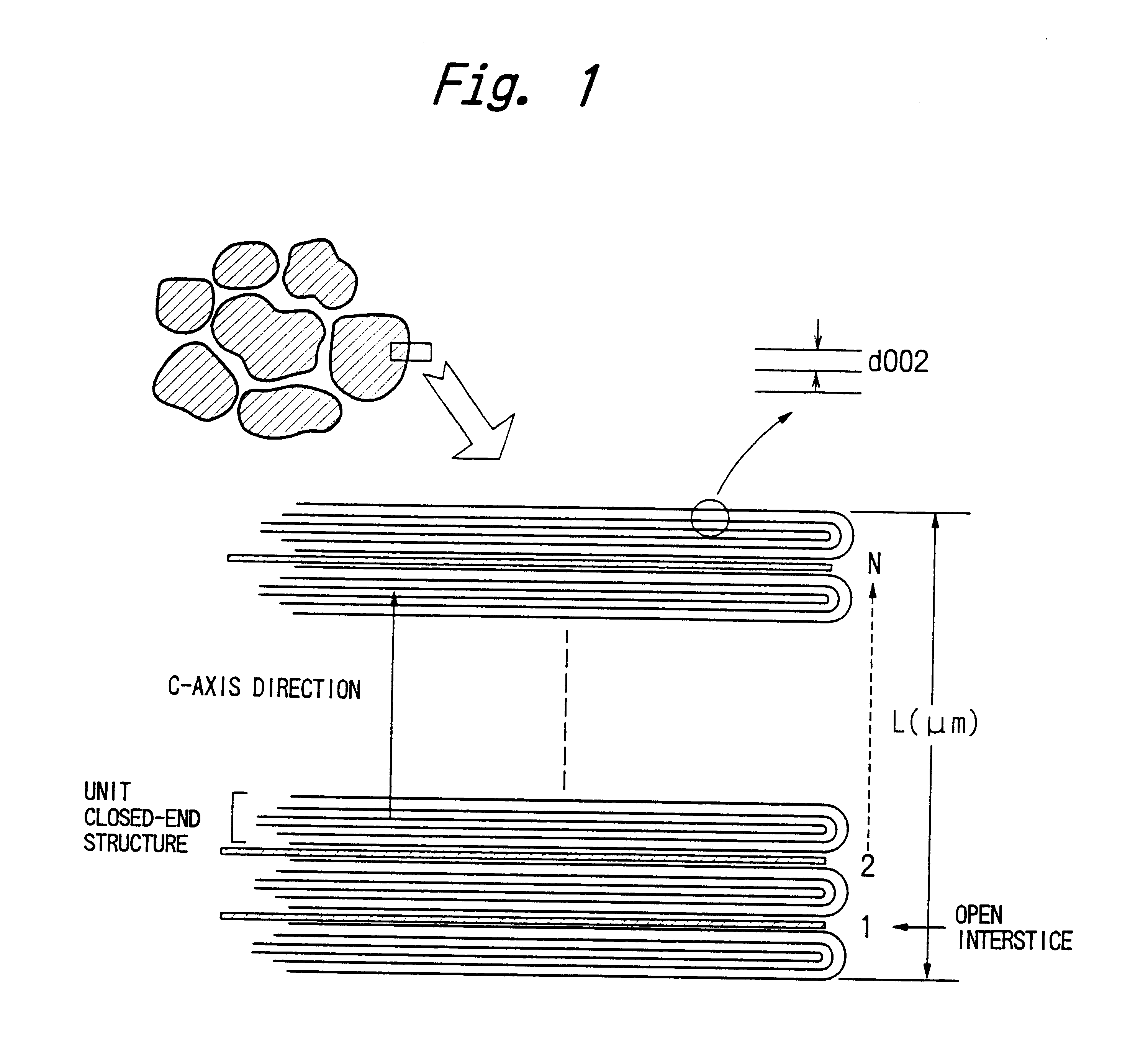

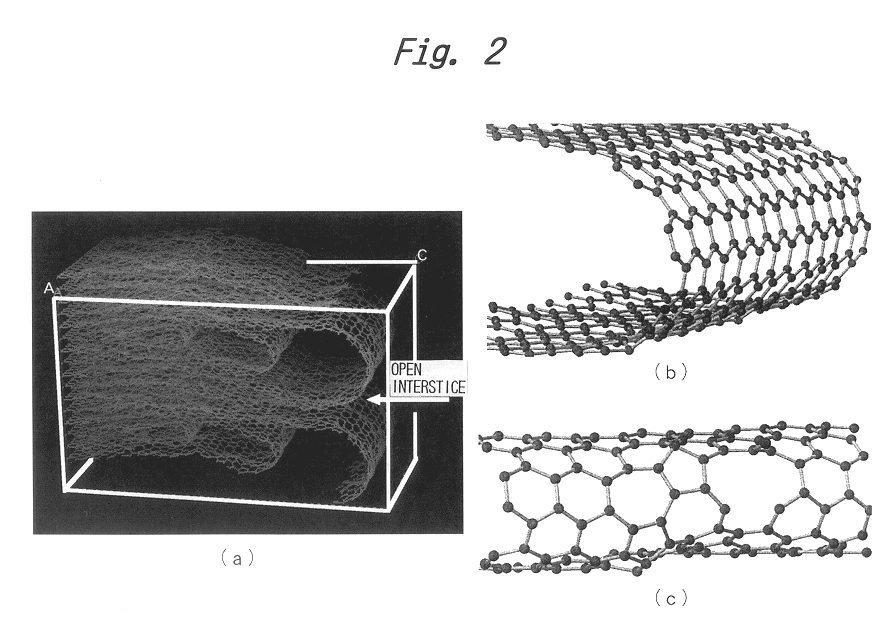

InactiveUS6576369B1Improve discharge capacityImprove Coulombic efficiencyNon-aqueous electrolyte accumulatorsGraphiteLithiumMicrometer

A graphite powder has surface closed-end structures in which the graphite c-plane layers of the graphite layer crystal lattices have closed-ends on the surface of the graphite powder by linking the ends of one or more pairs of the c-plane layers, leaving interstices which are open on the surface of the graphite. The number of open interstices is at least 100 and at most 1500 per micrometer in a c-axis direction of the graphite. Preferably, the graphite powder has a specific surface area of 1.0 m2 / g or less. Such a graphite powder can be prepared either by graphitizing a carbon material, which has been pulverized at a high speed under well-controlled conditions before and / or after the carbonization, or by subjecting a carbon material, which has been pulverized under well-controlled conditions before and / or after the carbonization, to graphitization and then to oxidative heat treatment at a temperature of 600-800° C. and finally to heat treatment at a temperature of 800° C. or higher in an inert gas. The graphite powder can be used to produce negative electrodes of lithium ion secondary batteries having a high discharge capacity of at least 320 mAh / g and a high charge / discharge coulombic efficiency of at least 90%.

Owner:NIPPON DENKO CO LTD +1

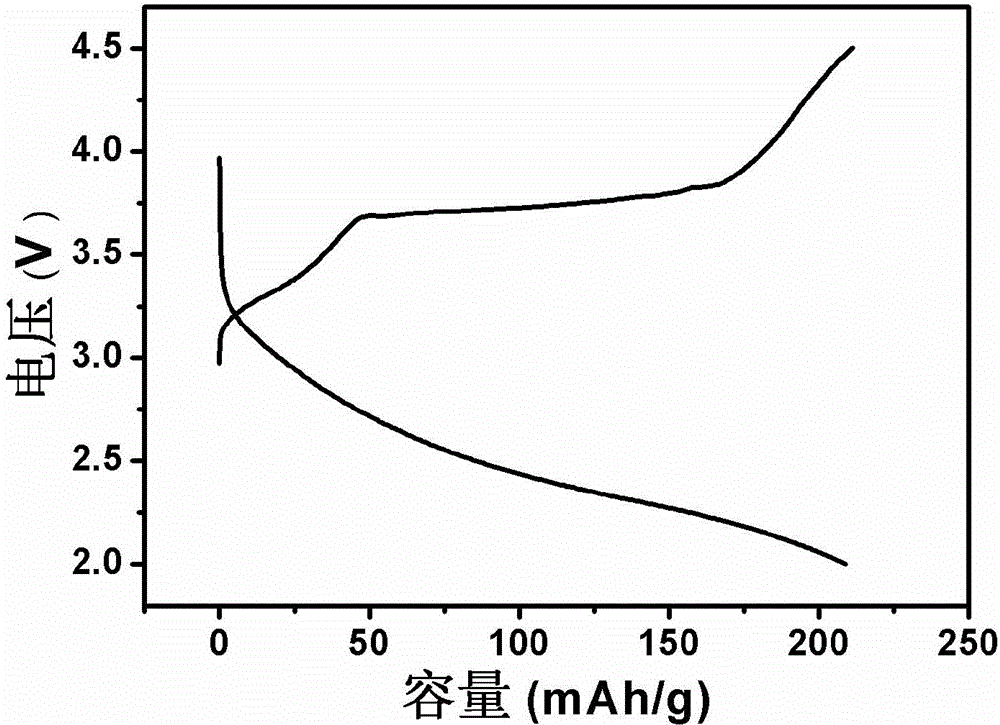

Electrolyte additives for lithium sulfur rechargeable batteries

ActiveUS9160036B2Improve Coulombic efficiencyAvoid reactionLi-accumulatorsLithium–sulfur batteryLithium sulfur

An electrolyte solution for a lithium sulfur battery contains a lithium oxalatoborate compound in a 0.05-2 M solution in conventional lithium sulfur battery electrolyte solvents, optionally with other lithium compounds. Examples of solvents include dimethoxyethane (DME), dioxolane, and triethyleneglycol dimethyl ether (TEGDME). Electrochemical cells contain a lithium anode, a sulfur-containing cathode, and a non-aqueous electrolyte containing the lithium oxalatoborate compound. Lithium sulfur batteries contain a casing enclosing a plurality of the cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

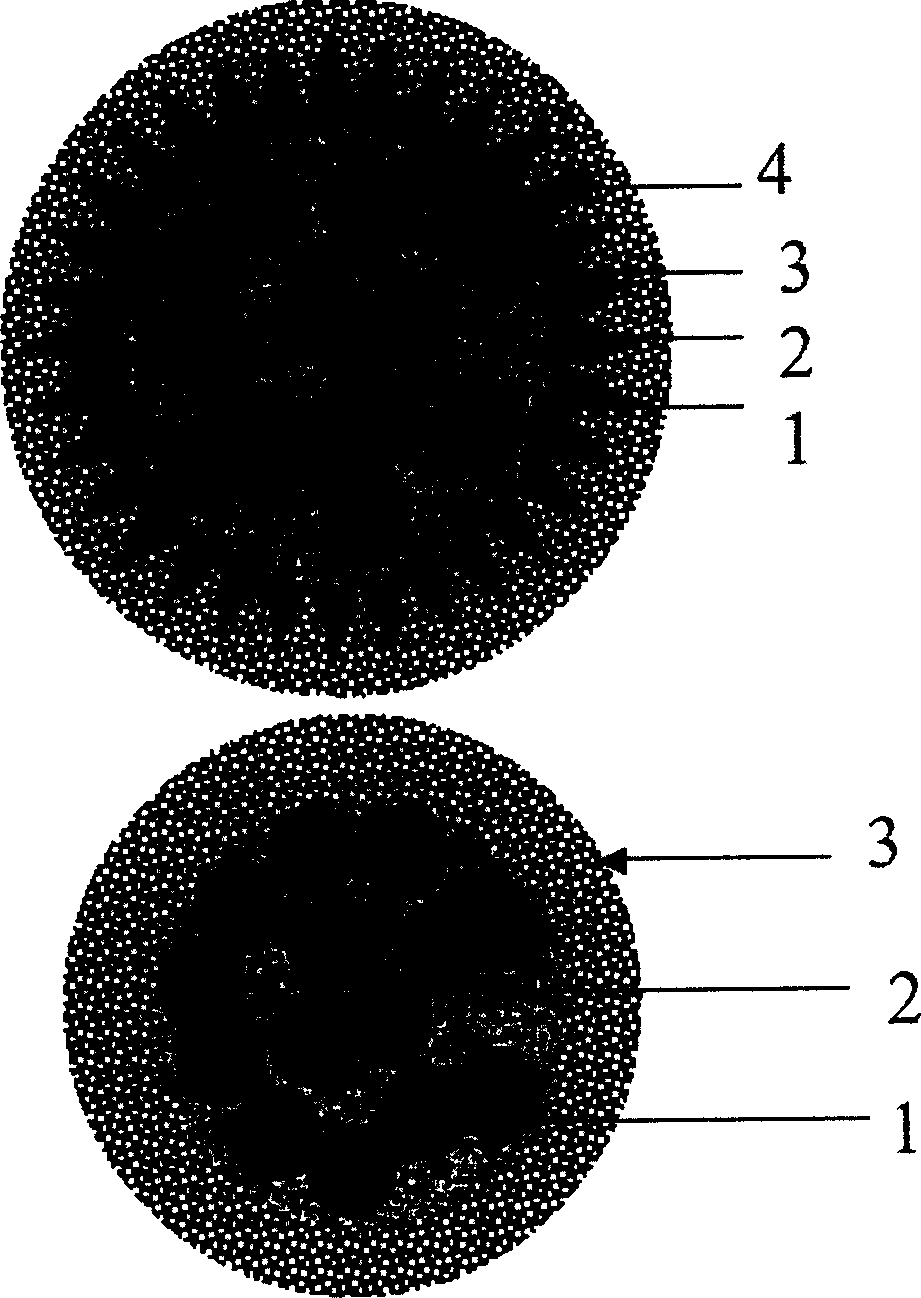

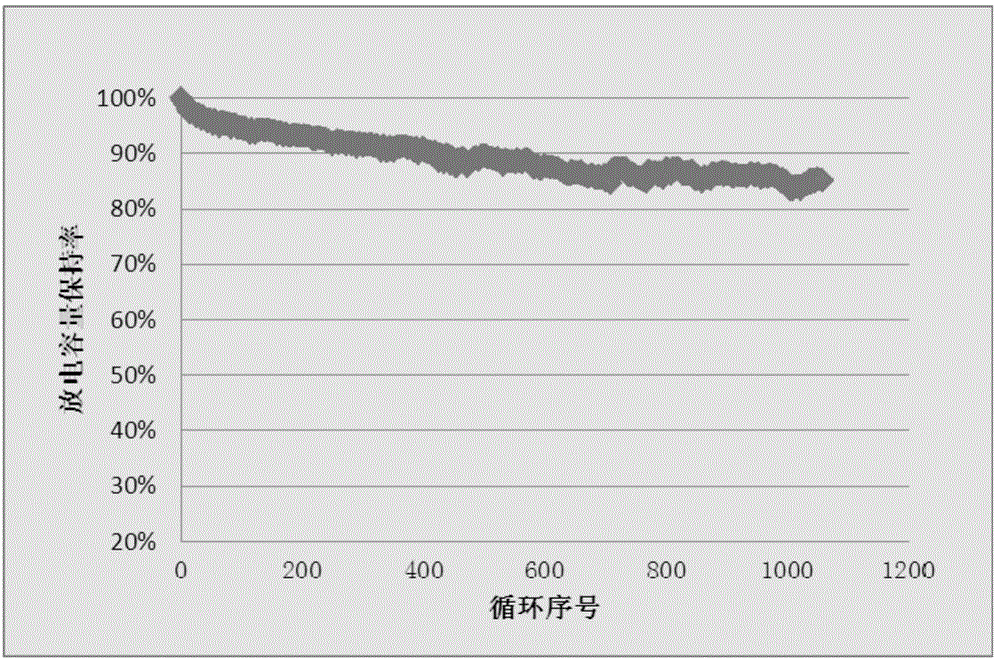

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

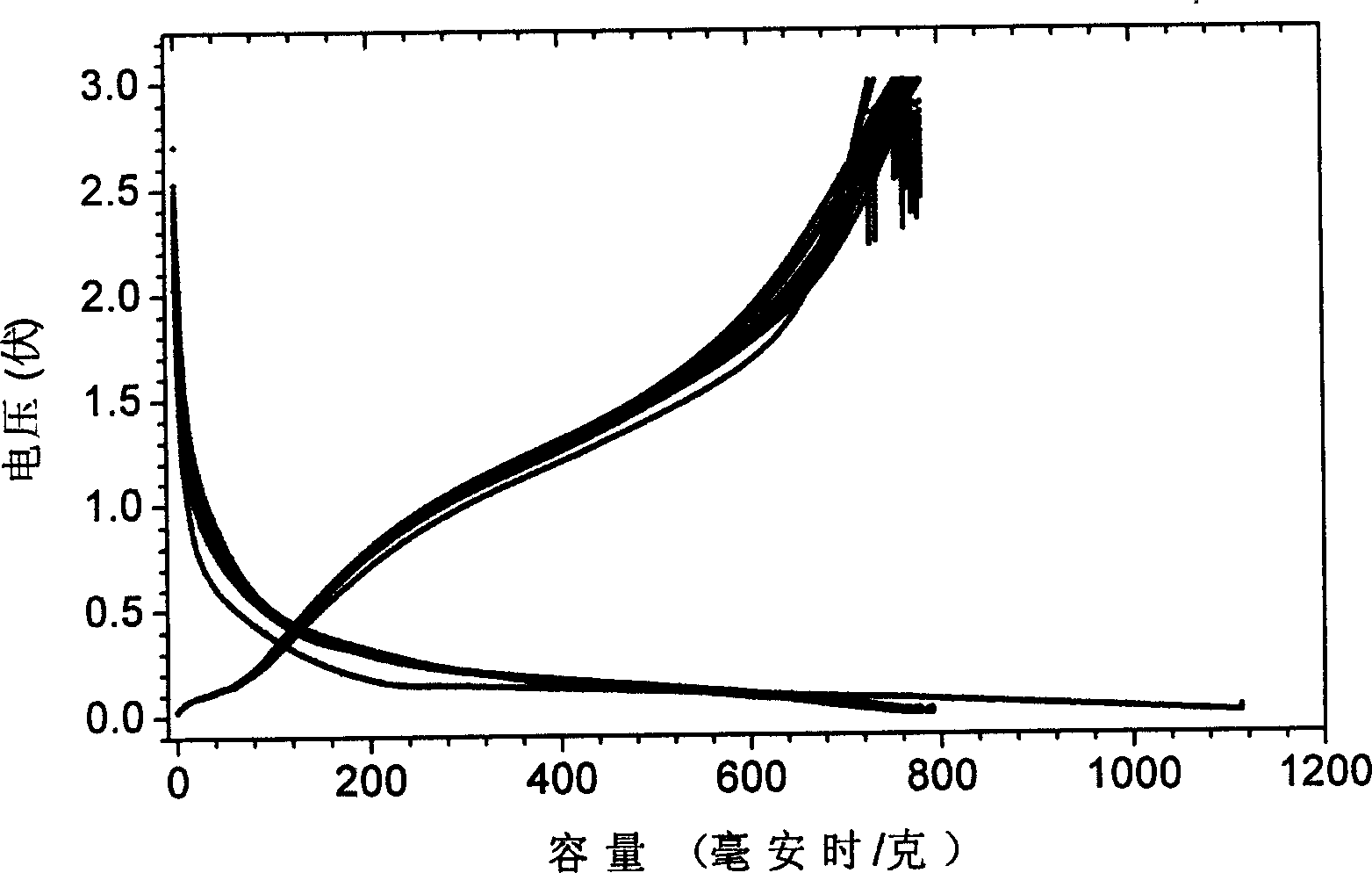

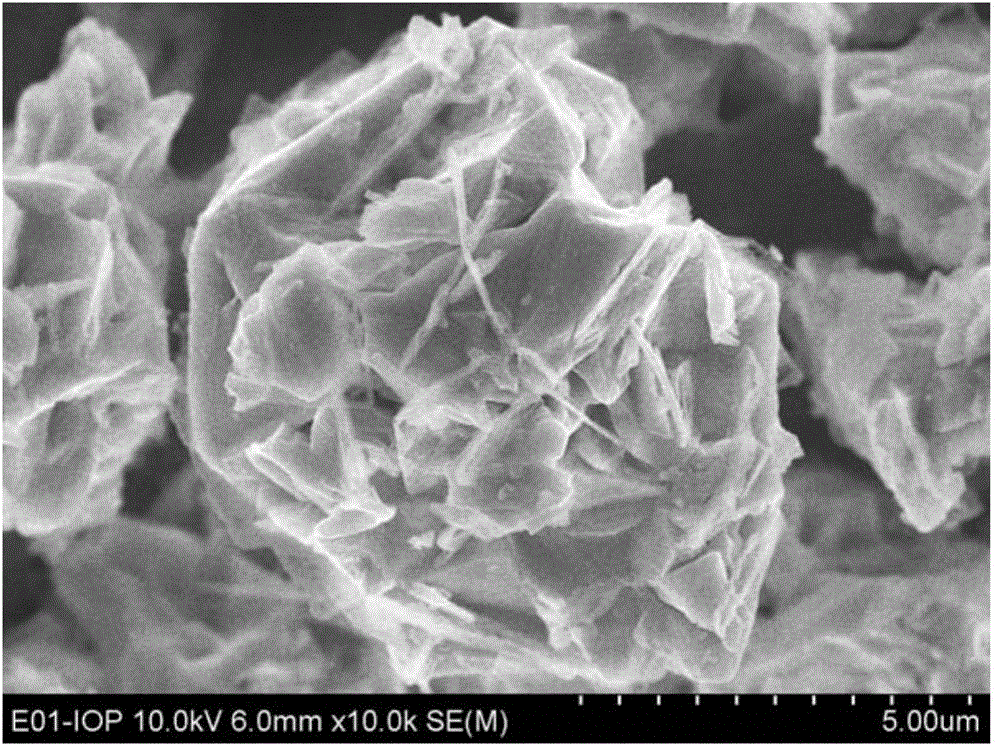

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

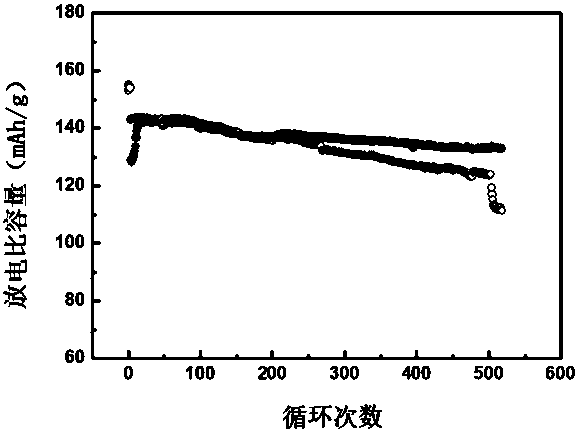

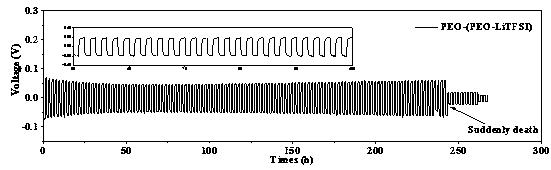

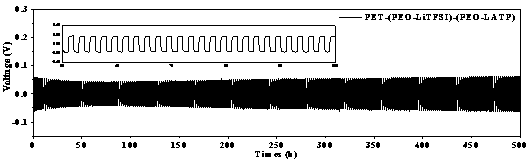

Lithium anode with inorganic protective coating and preparation method thereof

InactiveCN108565398AEasy to operateLow costNon-aqueous electrolyte accumulator electrodesElectrical conductorInorganic compound

The invention discloses a lithium anode with an inorganic protective coating and a preparation method thereof. The lithium anode includes a lithium anode active substance and an inorganic protective coating that covers the same, wherein the lithium anode active substance is lithium metal or lithium alloy; the inorganic protective coating is prepared from a binder and a lithium ion conductor inorganic compound or an inorganic compound that may generate a lithium ion conductor in situ on the surface of the lithium anode. A layer of stable compact inorganic protective film is prepared on the surface of the lithium anode active material by means of direct coating which is simple and low in cost, side reaction between the lithium anode active material and electrolyte is inhibited, uniform deposition of lithium ion is promoted, growth of lithium dendrite is slowed, and safety of the lithium anode is improved. The lithium anode prepared herein has excellent cycle performance, and a new concept for the application of the lithium anode is provided.

Owner:HARBIN INST OF TECH

SiO<x>/C composite cathode material, method for preparing same and application of SiO<x>/C composite cathode material

ActiveCN105655564AImprove conductivityIncrease capacityCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention provides an SiO<x> / C composite cathode material, a method for preparing the same and application of the SiO<x> / C composite cathode material. The SiO<x> / C composite cathode material is of a core-shell structure. A shell layer of the SiO<x> / C composite cathode material is a carbon layer, a core of the SiO<x> / C composite cathode material comprises a plurality of silicon carbon composite material particles, the silicon carbon composite material particles include SiO<x> particles and amorphous conductive carbon layers, the amorphous conductive carbon layers cover the surfaces of the SiO<x> particles, and free spaces are reserved between the silicon carbon composite material particles. The SiO<x> / C composite cathode material, the method and the application have the advantages that the SiO<x> / C composite cathode material is excellent in conductivity, firm in structure and stable in capacity, the coulomb efficiency and the cycle performance can be greatly improved, technological conditions for the method are controllable, the SiO<x> / C composite cathode material prepared by the aid of the method is stable in performance and high in production efficiency, and the production cost can be reduced.

Owner:王凤鸣

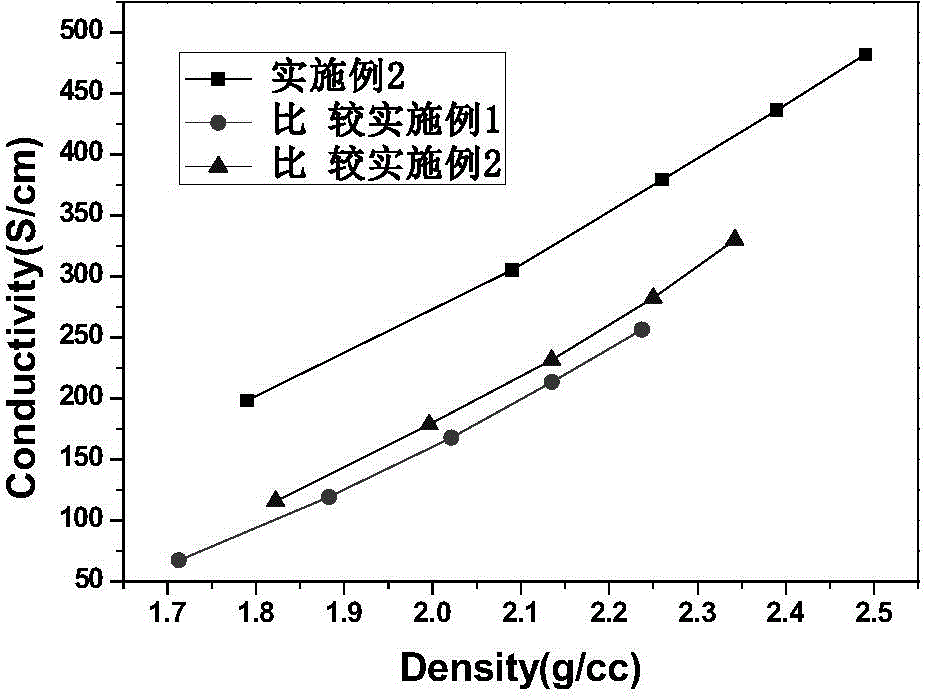

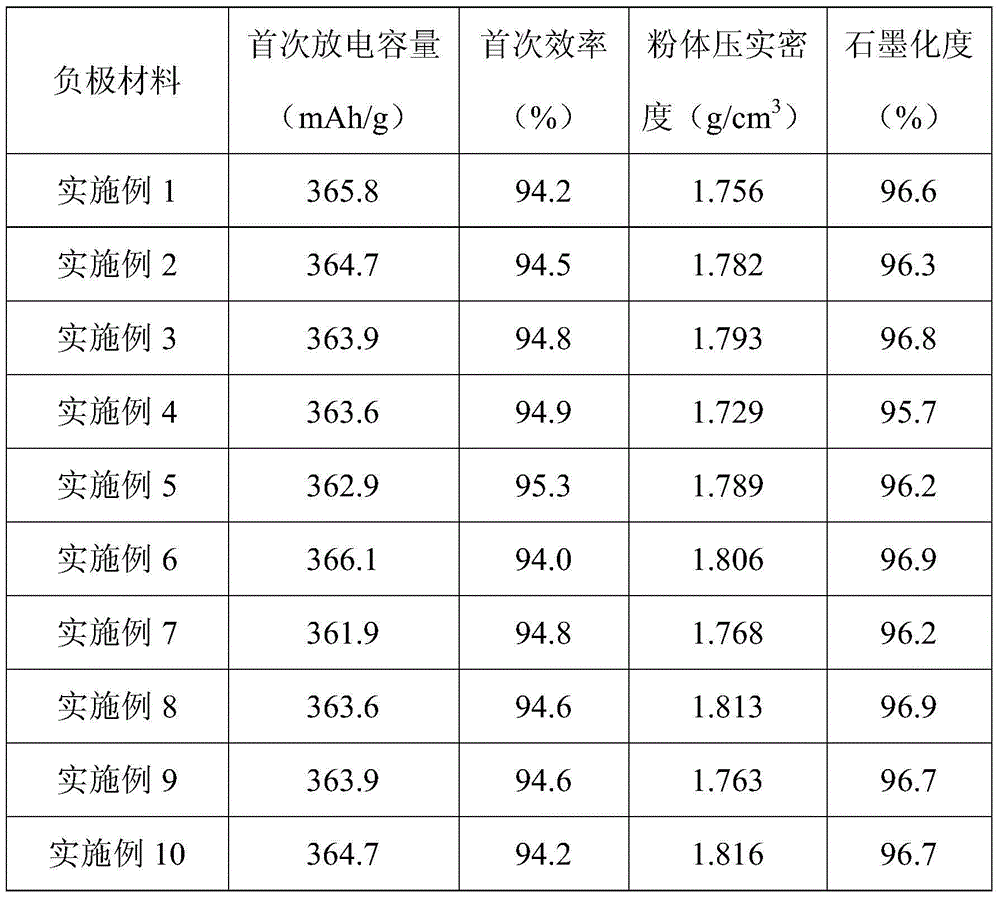

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

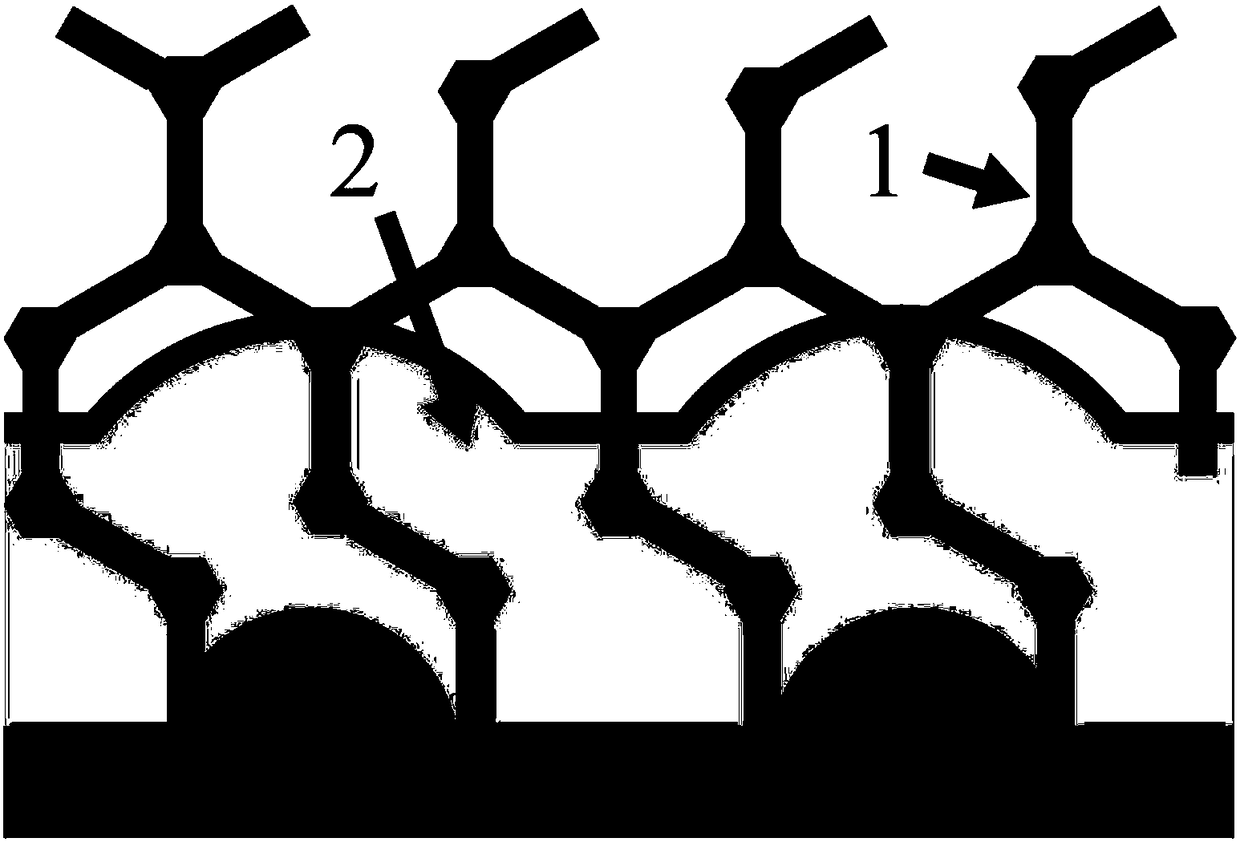

Anode material for lithium metal battery as well as preparation method and application of anode material

PendingCN108232117AImprove Coulombic efficiencyImprove securityCell electrodesLi-accumulatorsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses an anode material for a lithium metal battery. The anode material comprises a current collector and a carrier which is in tight fit with the current collector, wherein the carrier has a three-dimensional framework structure; a gap of the three-dimensional framework structure is filled with lithium metal; the carrier is selected from at least one of polymelamine, polyacrylonitrile, polyaniline, polyimide, polyvinylidene fluoride and polytetrafluoroethylene. The anode material disclosed by the invention has the advantages that a nonconductive polymer with the three-dimensional framework structure is used as the carrier, and stable deposition of lithium ions is realized by using interaction of functional groups contained in the carrier and the lithium ions; meanwhile,volumetric expansion is inhibited, internal stress of the battery is relieved, and thereby the aim of inhibiting growth of lithium dendrites is achieved. The coulombic efficiency, the safety of the lithium ion battery obtained by assembling the anode material prepared disclosed by the invention is remarkably improved and cycle life is obviously prolonged.

Owner:ZHEJIANG UNIV

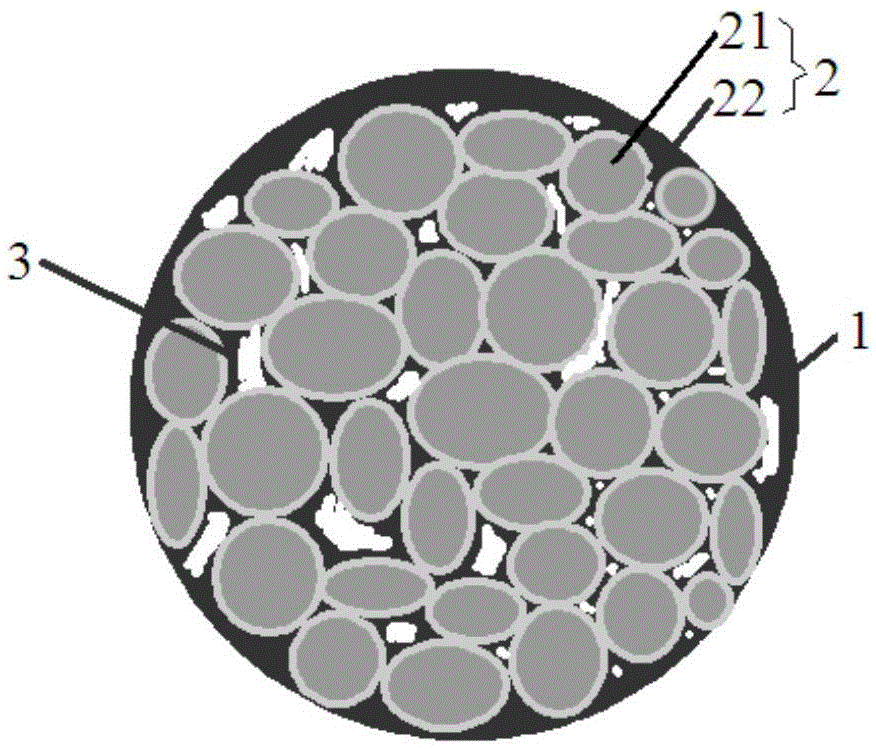

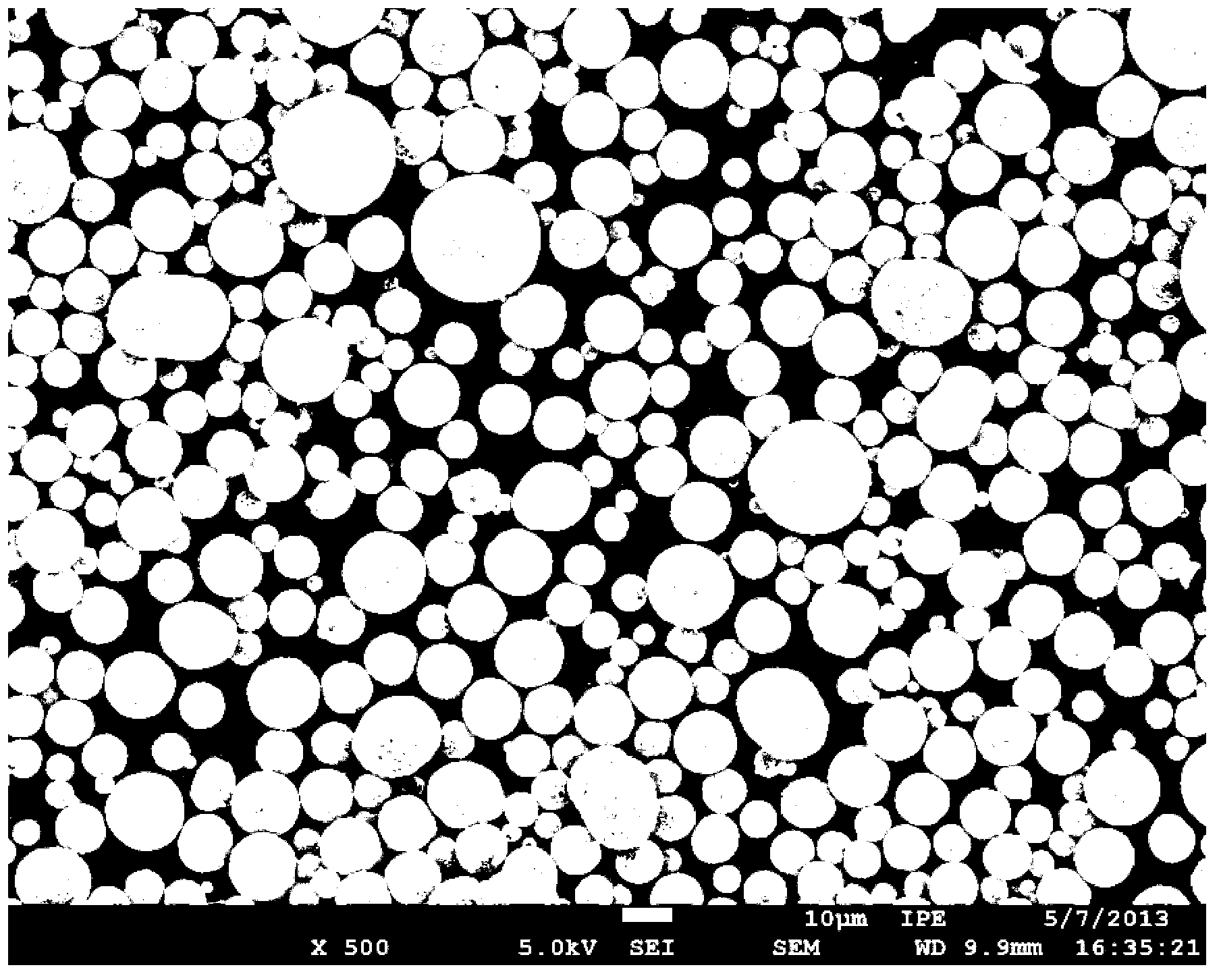

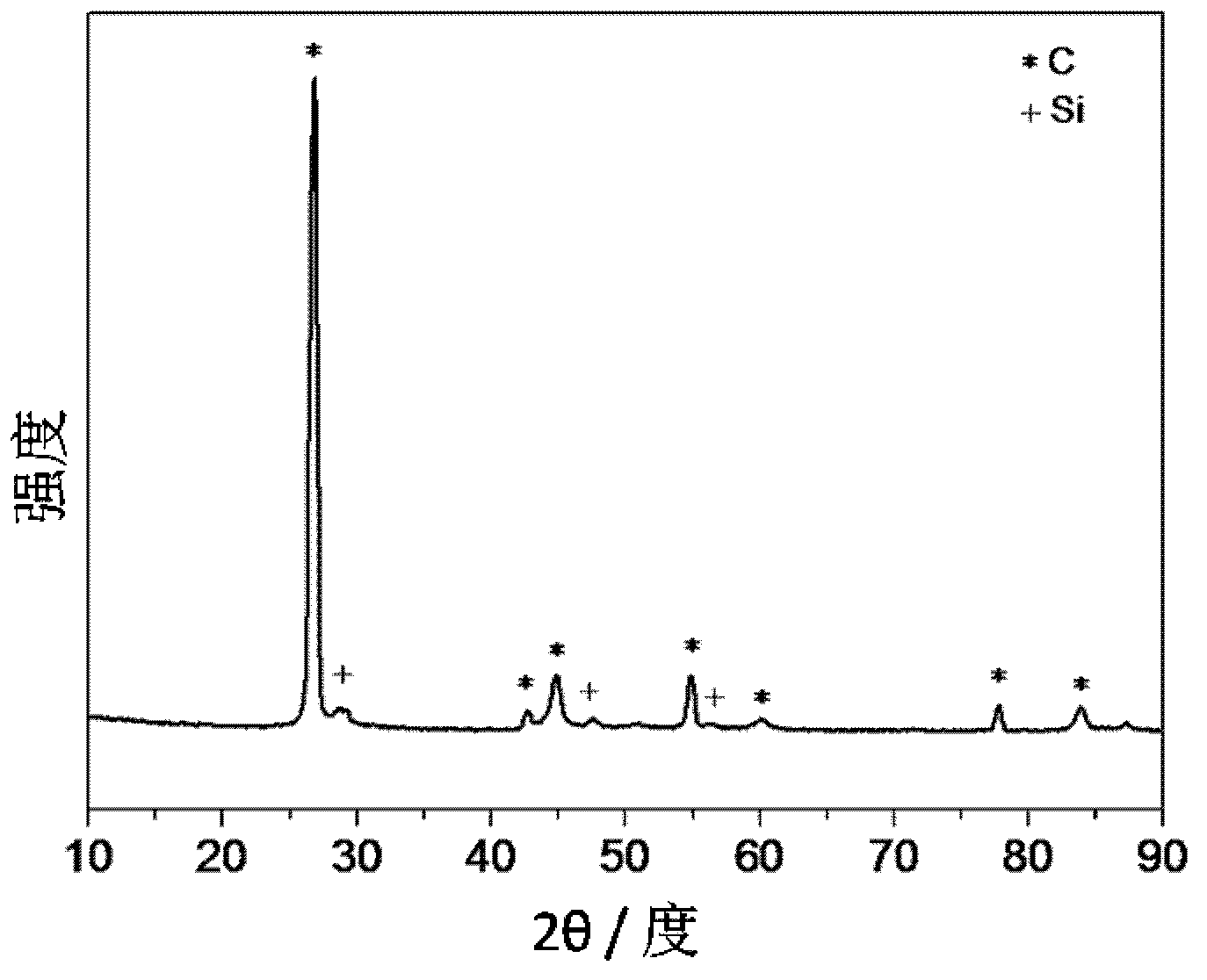

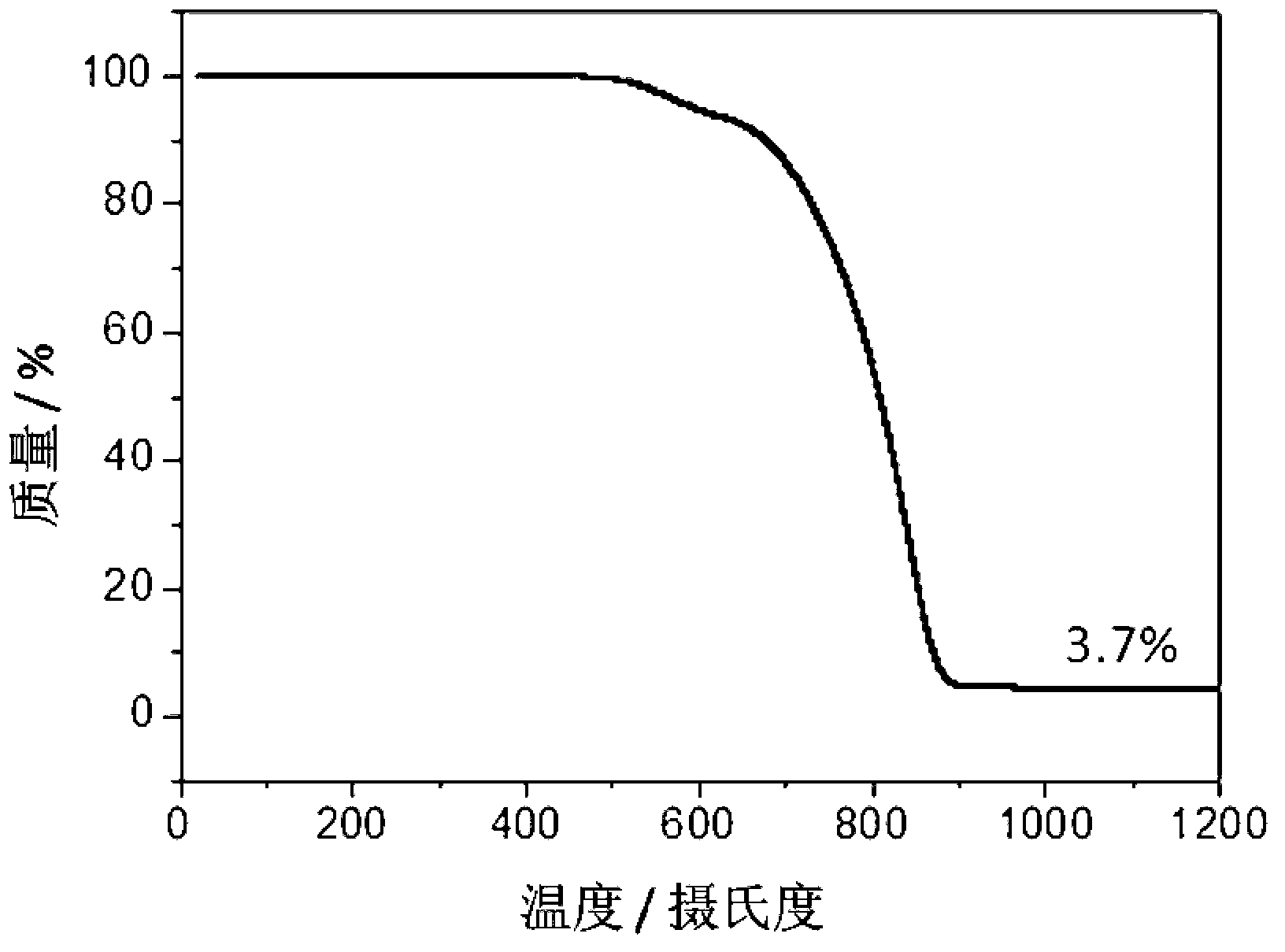

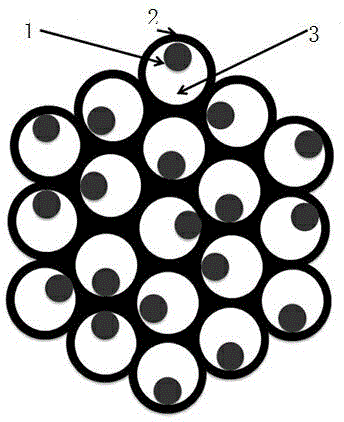

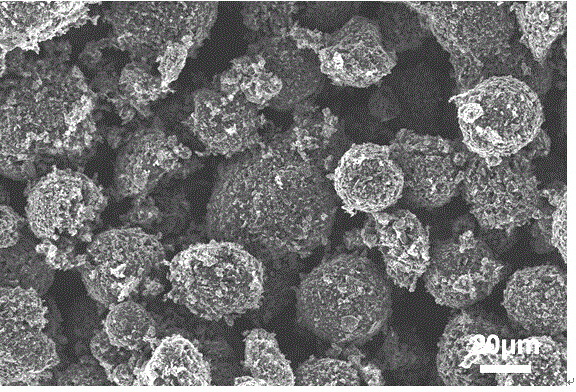

Silicon/carbon composite microsphere negative electrode material as well as preparation method and application for same

ActiveCN103311522AStable structureImprove charge and discharge cycle lifeCell electrodesSolventCarbon black

The invention relates to a silicon / carbon composite microsphere negative electrode material as well as a preparation method and an application for the same. The silicon / carbon composite microsphere negative electrode material is silicon / carbon composite microspheres internally provided with pore structures; and each microsphere comprises a matrix material of hard carbon, and an active material of silicon powder. The preparation method for the silicon / carbon composite microsphere negative electrode material comprises the following steps of: uniformly mixing silicon powder, soft carbon, carbon black, a soluble carbon-containing organic adhesive and a solvent with formula amounts to obtain a slurry; and performing spray-drying and carbonization on the slurry to obtain the silicon / carbon composite microsphere negative electrode material. The silicon / carbon composite microsphere negative electrode material provided by the invention has the advantages of being high in tap density, high in reversible capacity, good in cyclicity, good in rate capability, safe and reliable, and high in first-week coulombic efficiency; the preparation method provided by the invention is simple in process, environment-friendly, low in energy consumption and cost, and easy to realize large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

InactiveCN106159213ASimple preparation processLow costCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention relates to the battery field, and in particular relates to a silicon-carbon composite material and a preparation method thereof and application thereof in lithium ion battery. The following problems exist in the application of silicon-based materials in the lithium ion battery: 1. first coulombic efficiency of the lithium ion battery is low; 2, cycle life of the lithium ion battery is short; 3, the rate performance is poor; 4, the materials are low in production efficiency, and not conducive to large-scale industrial production. In order to solve the problems, the silicon-carbon composite material is provided, secondary-particles comprise a plurality of first particles containing core-shell structures, the core-shell structure comprises a carbon shell layer and silicon core particles which are completely wrapped by the carbon shell layer, and a gap is between the carbon shell layer and the silicon core particles. The preparation method of the silicon-carbon composite material and the application of the silicon-carbon composite material in the lithium ion battery are also provided.

Owner:BERZELIUS (NANJING) CO LTD

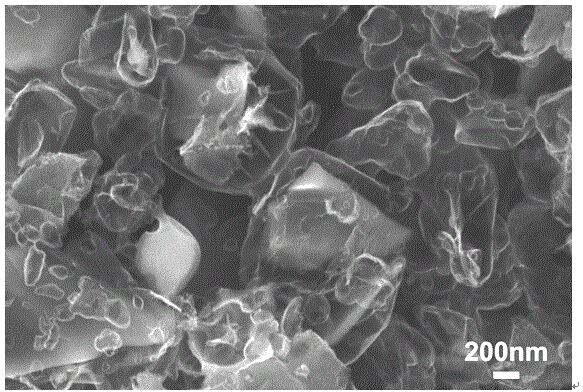

Inorganic-organic nano composite solid electrolyte membrane and preparation method and application thereof

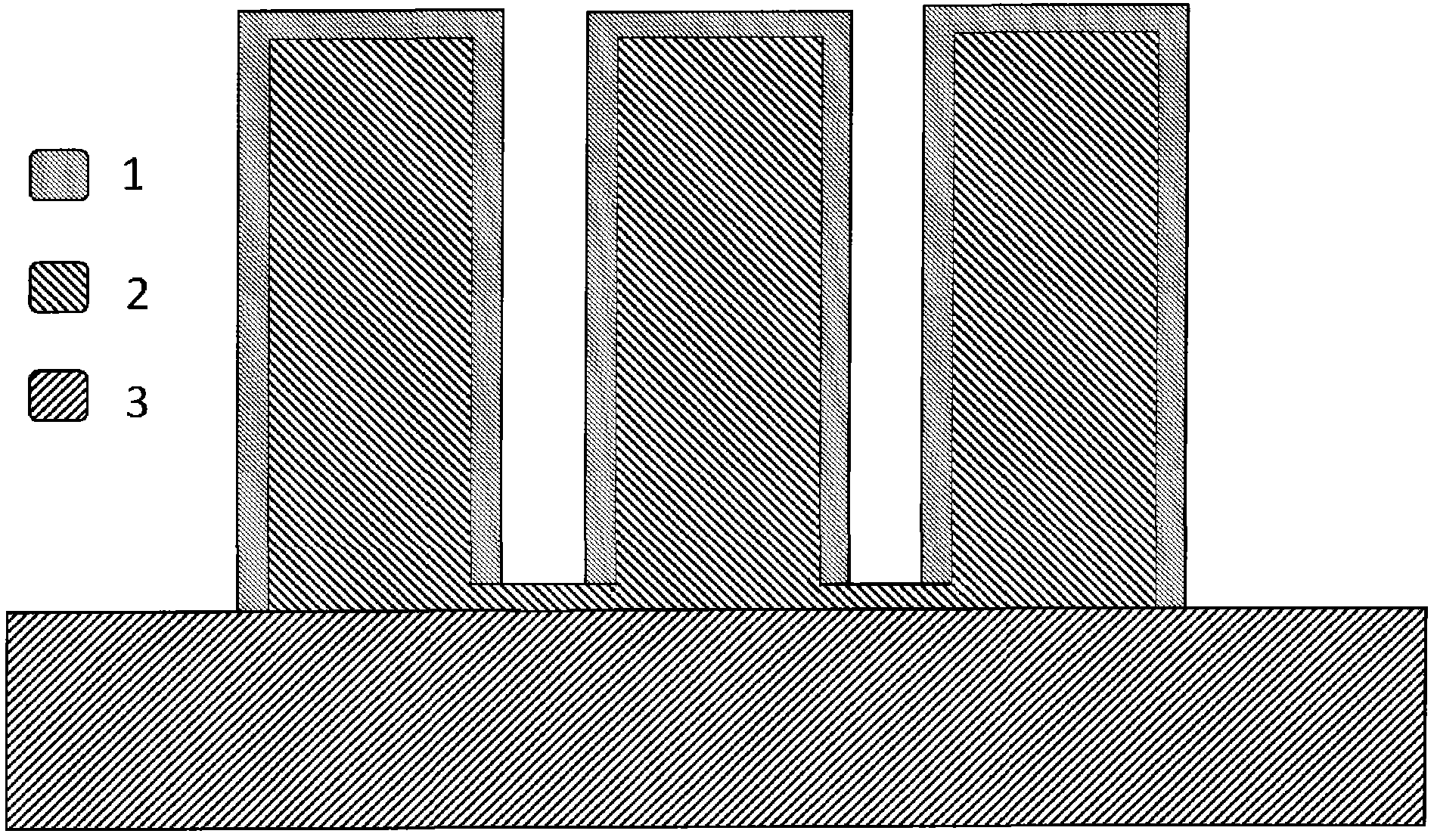

ActiveCN109638349AImprove compatibilityEasy transferSolid electrolytesFinal product manufactureSolid state electrolyteHigh energy

The present invention discloses an inorganic-organic nano composite solid electrolyte membrane and a preparation method and application thereof. The composite solid electrolyte is a novel inorganic-organic nanocomposite combining the respective advantages of inorganic ceramic solid electrolyte and organic polymer electrolyte and is composed of a negative electrode protective layer, a support layerand a positive electrode interface layer. The support layer plays a supporting role, and the main component of the negative electrode protective layer is the inorganic solid electrolyte with good mechanical properties, which can effectively inhibit the growth of lithium dendrite; and the positive electrode interface layer is mainly composed of organic polymer electrolyte with good flexibility, ensures good contact with active materials and provides a continuous ion transport channel. In the present invention, the composite solid electrolyte with good interface compatibility is prepared by coating on both sides of the support layer, and the process is simple and efficient. The composite solid electrolyte can effectively inhibit dendritic crystal and reduces interface resistance so that a solid lithium metal battery has higher energy density and longer cycle life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

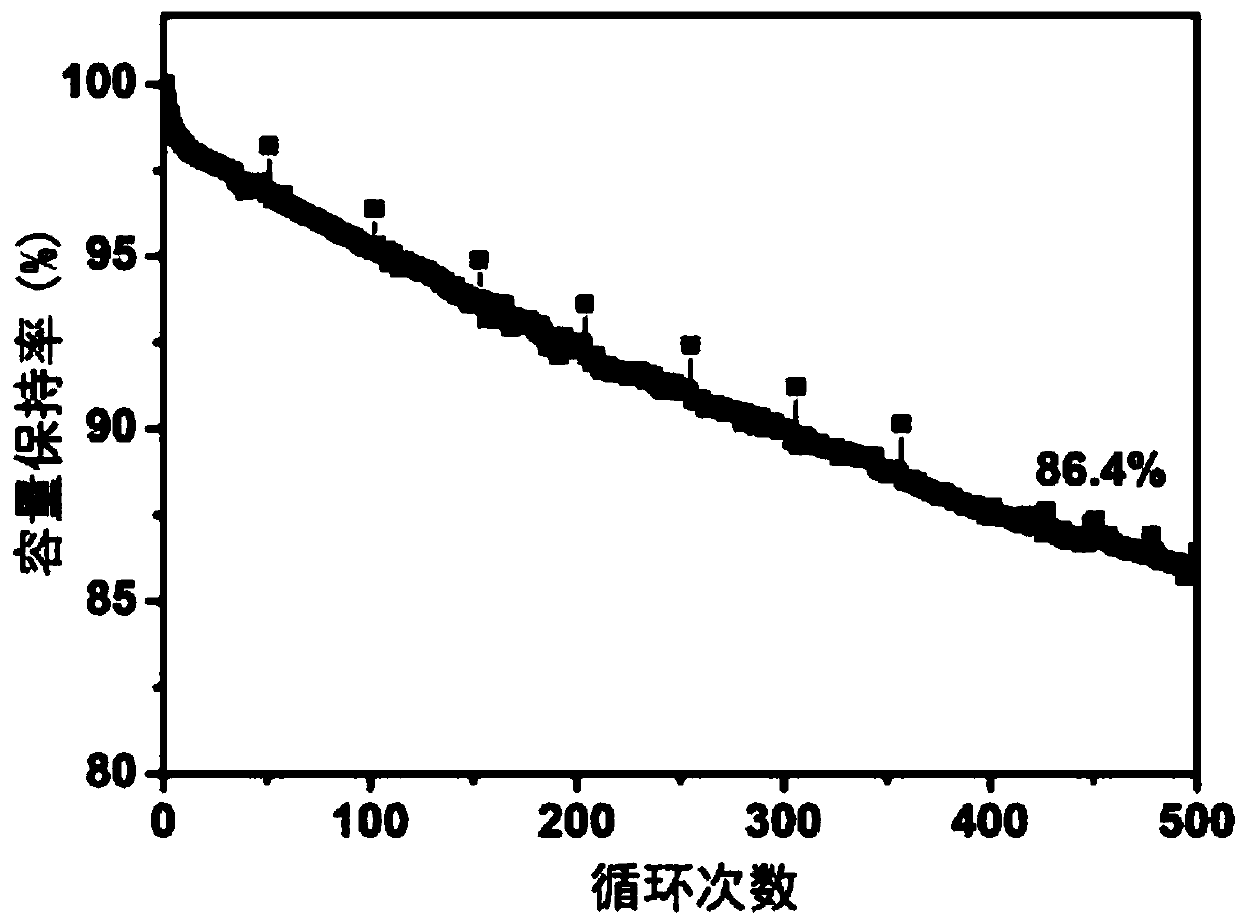

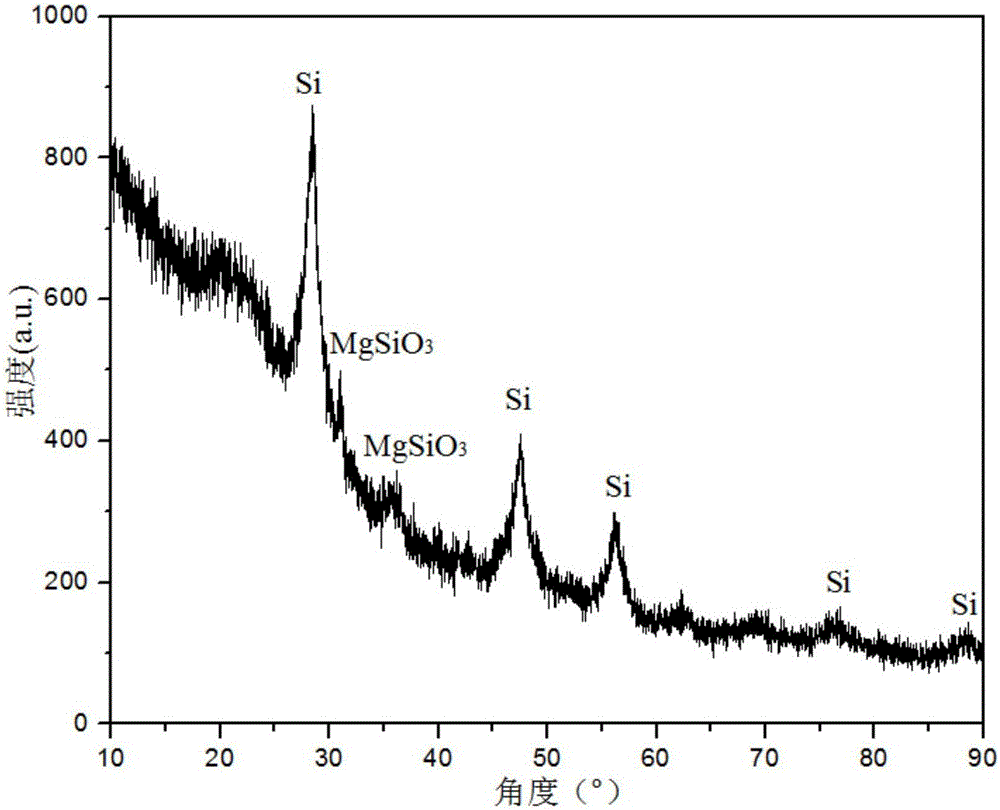

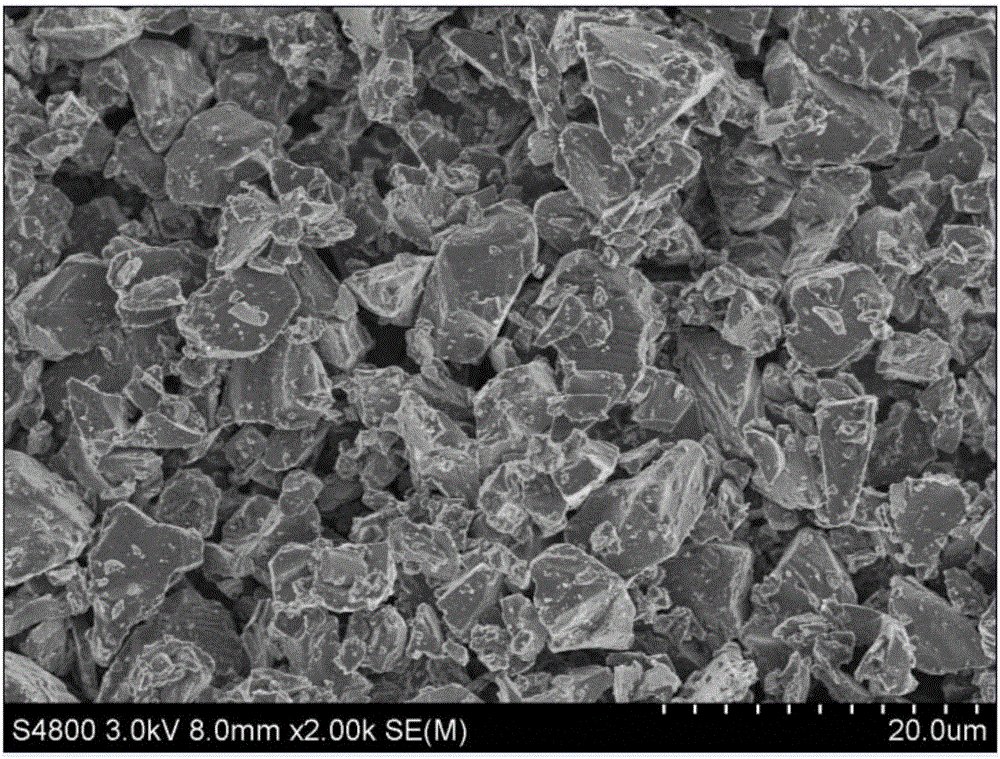

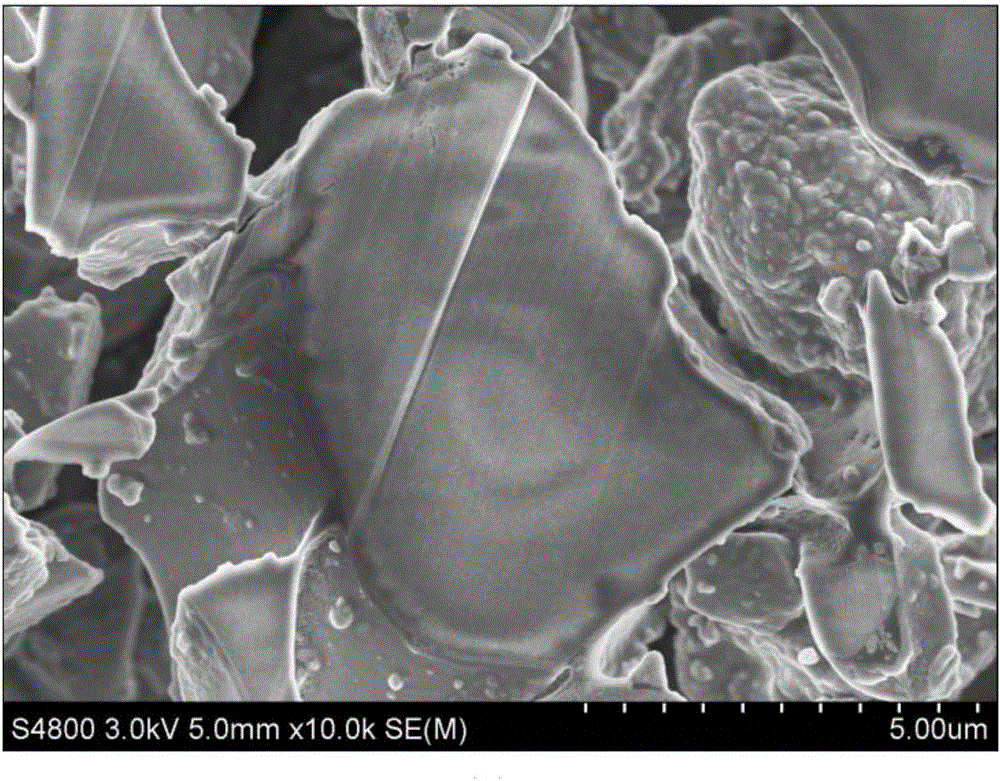

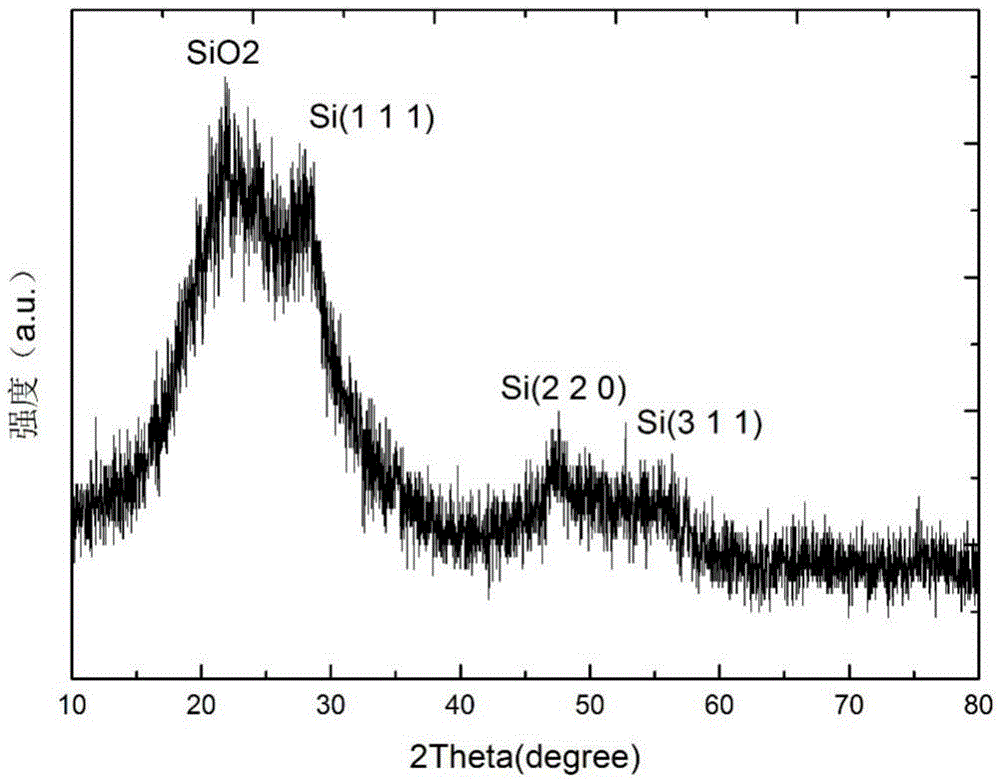

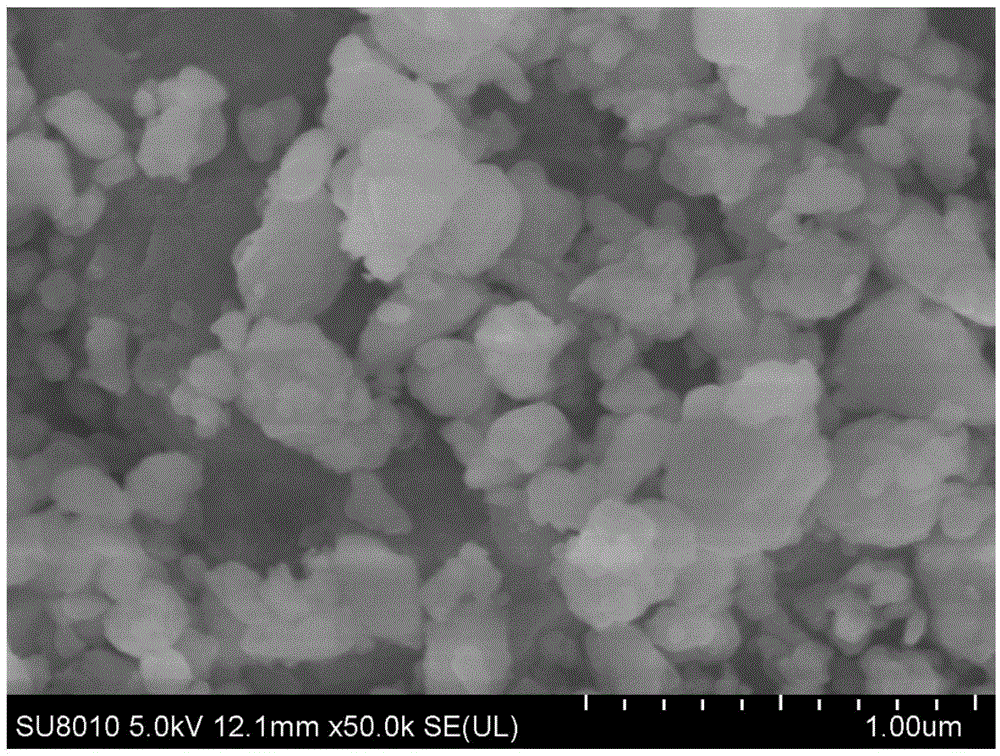

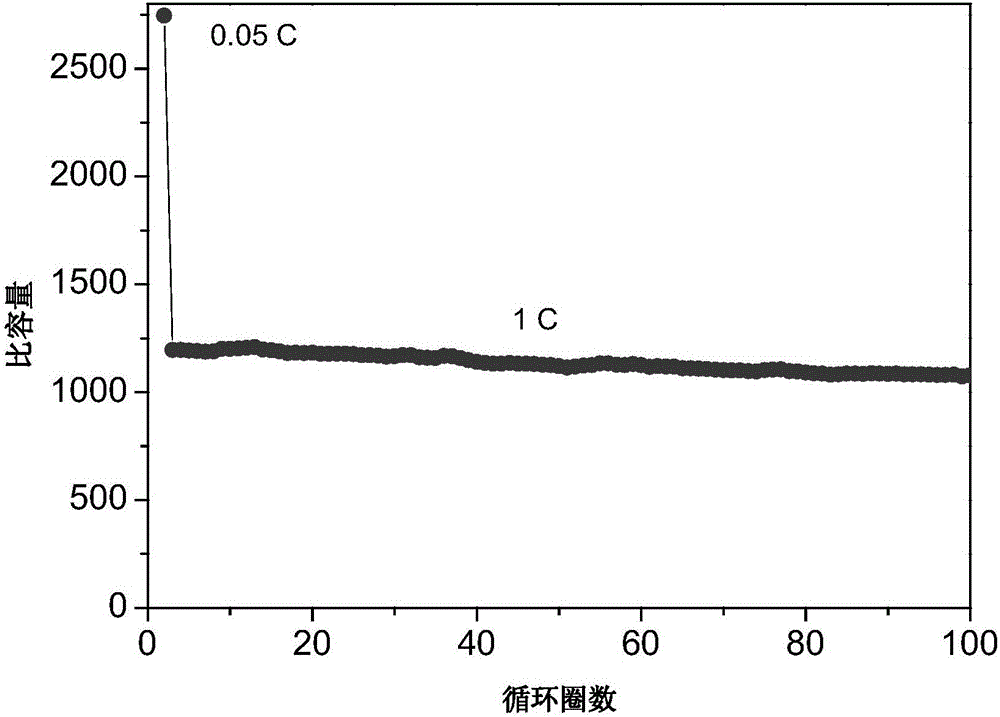

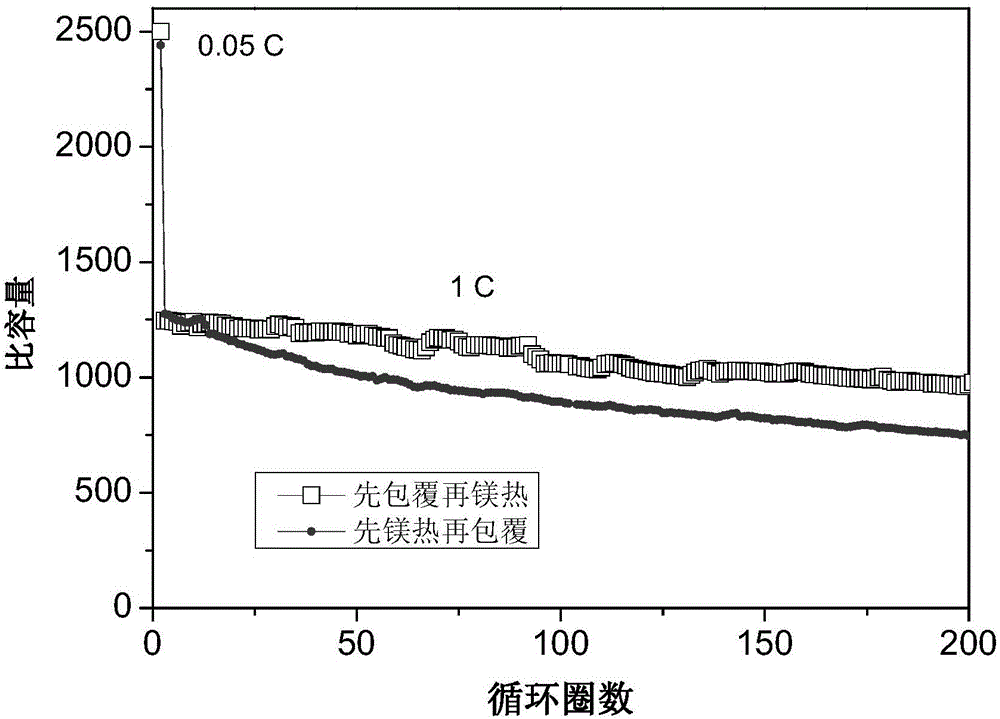

Method for preparing silicon/carbon composite material with magnesiothermic reduction process

InactiveCN106374088AThe process method is simpleLow costCell electrodesSecondary cellsSolventPorous composite

The invention discloses a method for preparing a silicon / carbon composite material with a magnesiothermic reduction process, and belongs to the technical field of composite material preparation. The method comprises the following steps: (1) mixing a silicon dioxide source, an organic carbon source and a solvent, carrying out ball-milling to prepare a uniformly pulpous mixture, and obtaining a silicon dioxide-carbon precursor composite material through drying; (2) mixing the silicon dioxide-carbon precursor composite material with magnesium powder to carry out a magnesiothermic reduction reaction, collecting products and carrying out acid pickling and washing, and drying to obtain the silicon / carbon composite material. According to the method, silicon dioxide reduction and high temperature carbonization are completed by using a one-step process, and the method has the advantages of simple technical process, low cost and large-scale production; the prepared composite material effectively maintains the appearance of porous silicon, so that the composite material has preferable capability for bearing volumetric strain; the porous composite material is applied to a lithium battery, so that the lithium-ion de-intercalation depth is small, the ion diffusion path is short, the reversible capacity and coulombic efficiency of the lithium battery are effectively improved, and the cycle life is prolonged.

Owner:TIANNENG SAFT ENERGY JOINT CO

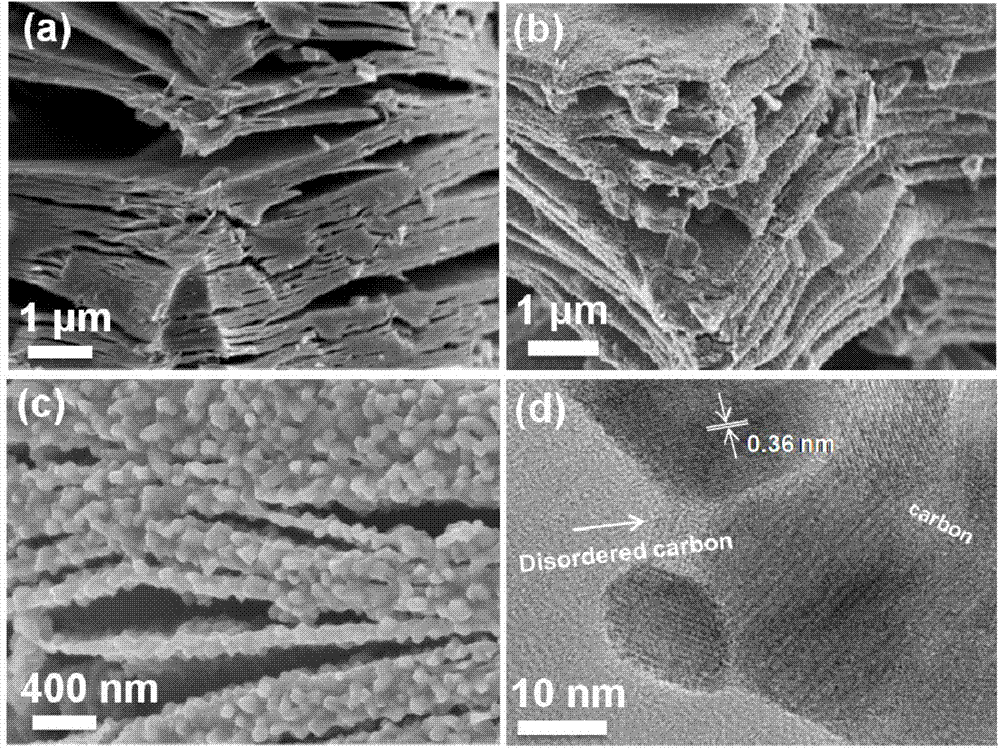

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

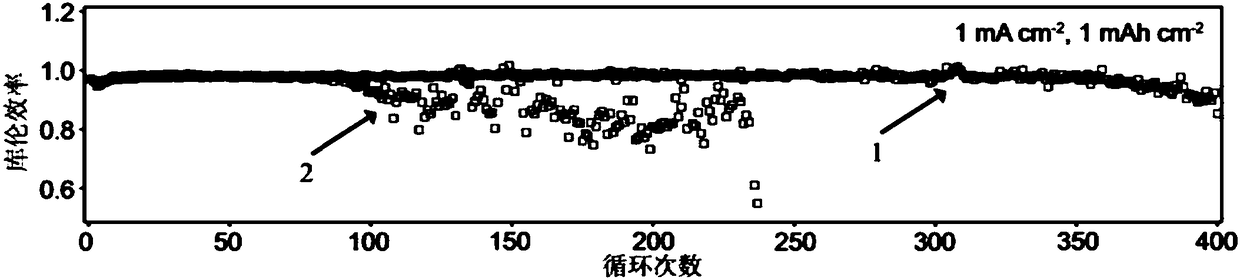

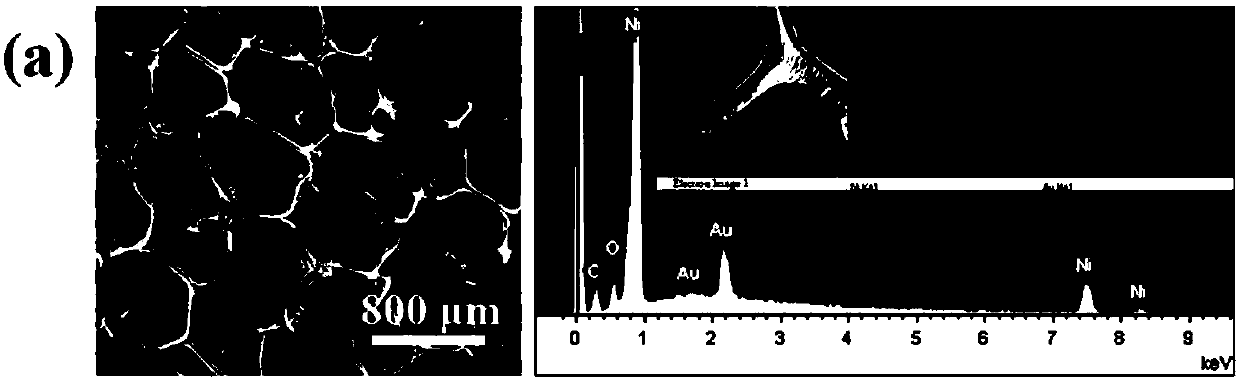

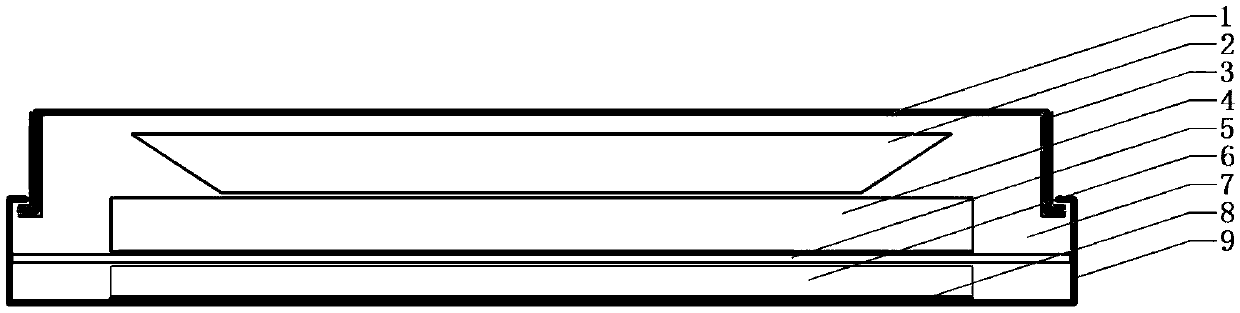

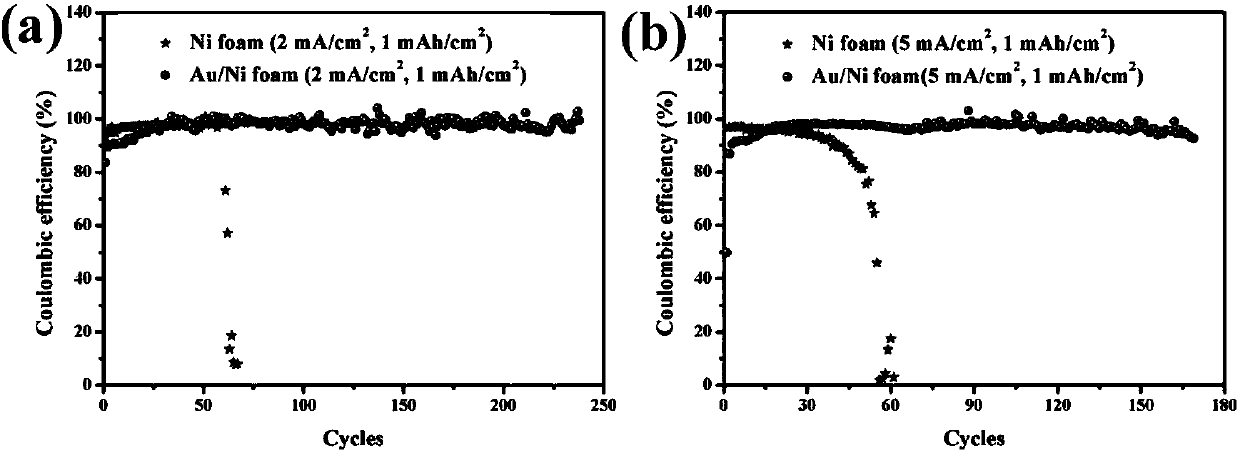

Lithium metal negative electrode for secondary battery, preparation method and application of lithium metal negative electrode

ActiveCN107910496AAvoid cloggingHigh specific surface propertiesMaterial nanotechnologyElectrochemical processing of electrodesLithium dendriteCurrent collector

The invention discloses a lithium metal negative electrode for a secondary battery. The lithium metal negative electrode comprises a three-dimensional porous current collector, a lithium metal activesubstance dispersed into pores of the current collector, and a lithium deposition induction layer compounded on any plane of the current collector. Furthermore, the invention further discloses a preparation method and application of the negative electrode, and a lithium-ion secondary battery obtained through assembly of the negative electrode. The lithium metal negative electrode has the unique advantage that the lithium deposition induction layer is deposited on one plane of the current collector, so that unexpected improvement of the stability, especially the stability at high current density (for example, 3-5mA / cm<2>), of the negative electrode is facilitated. According to the method, the problems of pore plugging and lithium dendrite growth caused by preferential deposition of lithiumon the surface of the electrode in the three-dimensional porous lithium negative electrode are effectively solved, the charge-discharge coulomb efficiency of a lithium positive electrode is improved and the cycle life of the lithium positive electrode is prolonged.

Owner:CENT SOUTH UNIV

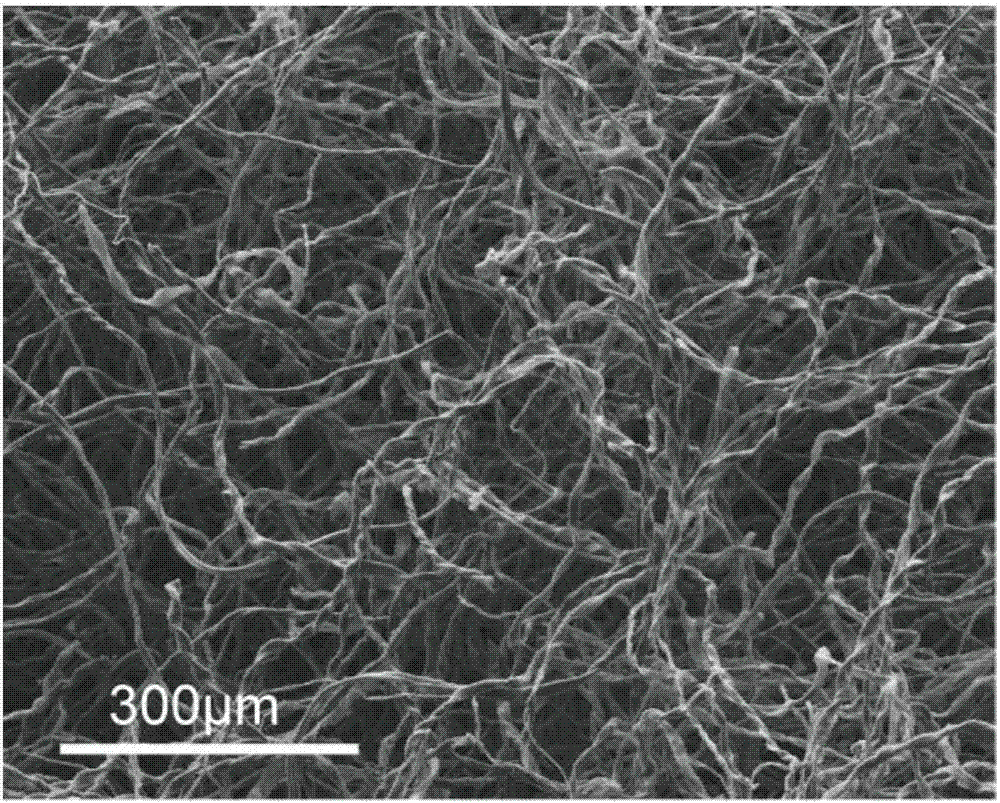

Doped carbon-sulfur species nanocomposite cathode for li-s batteries

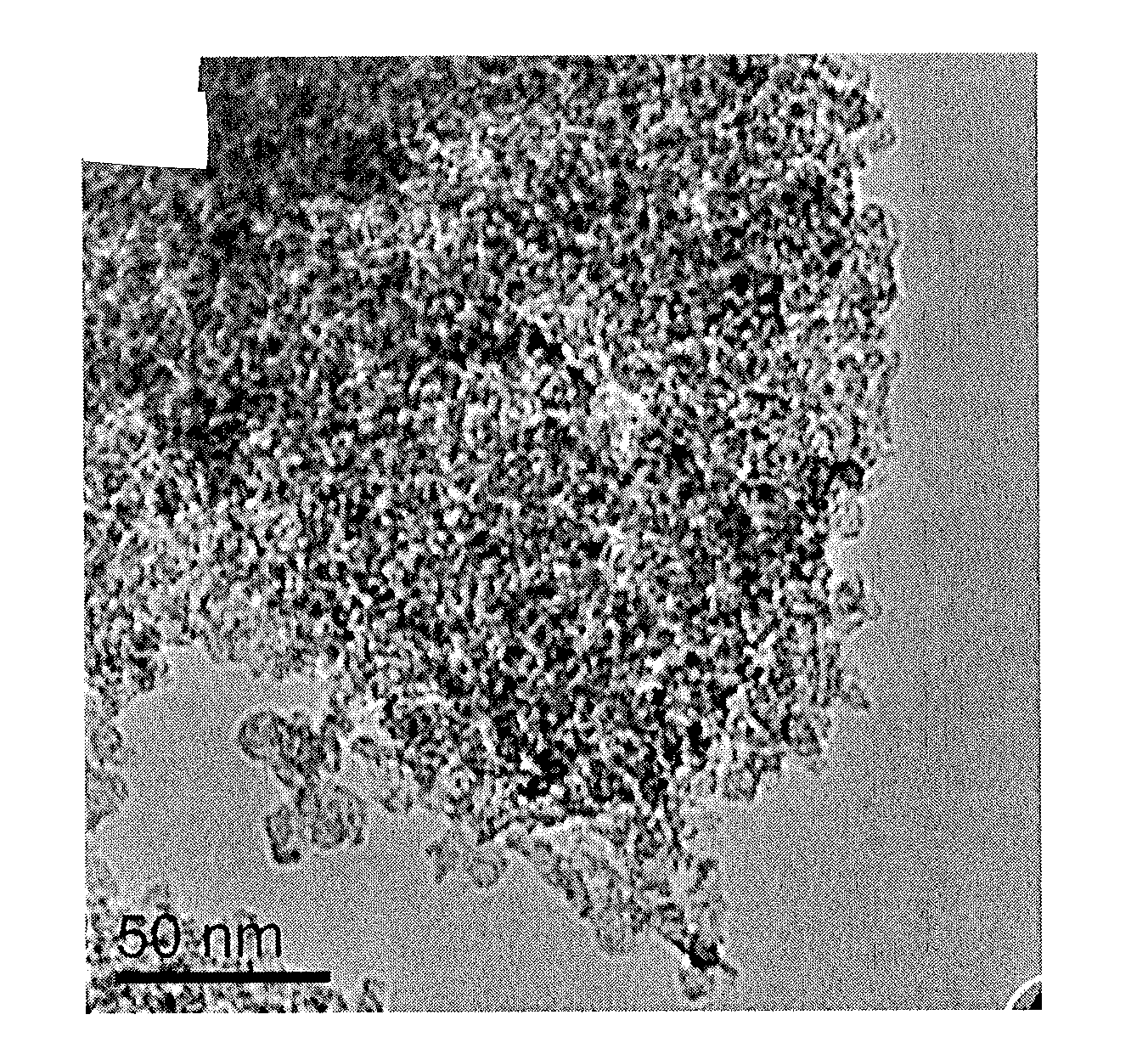

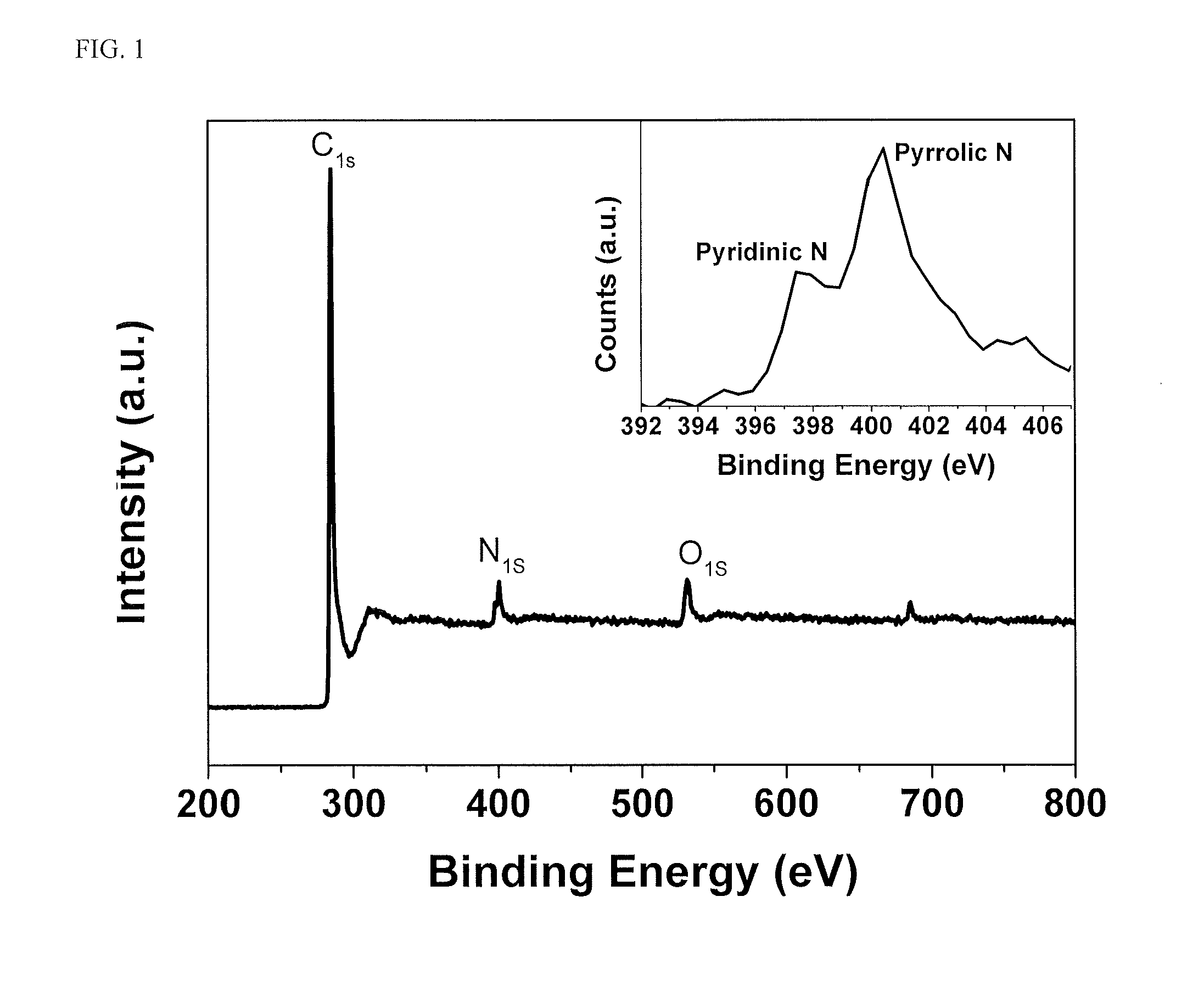

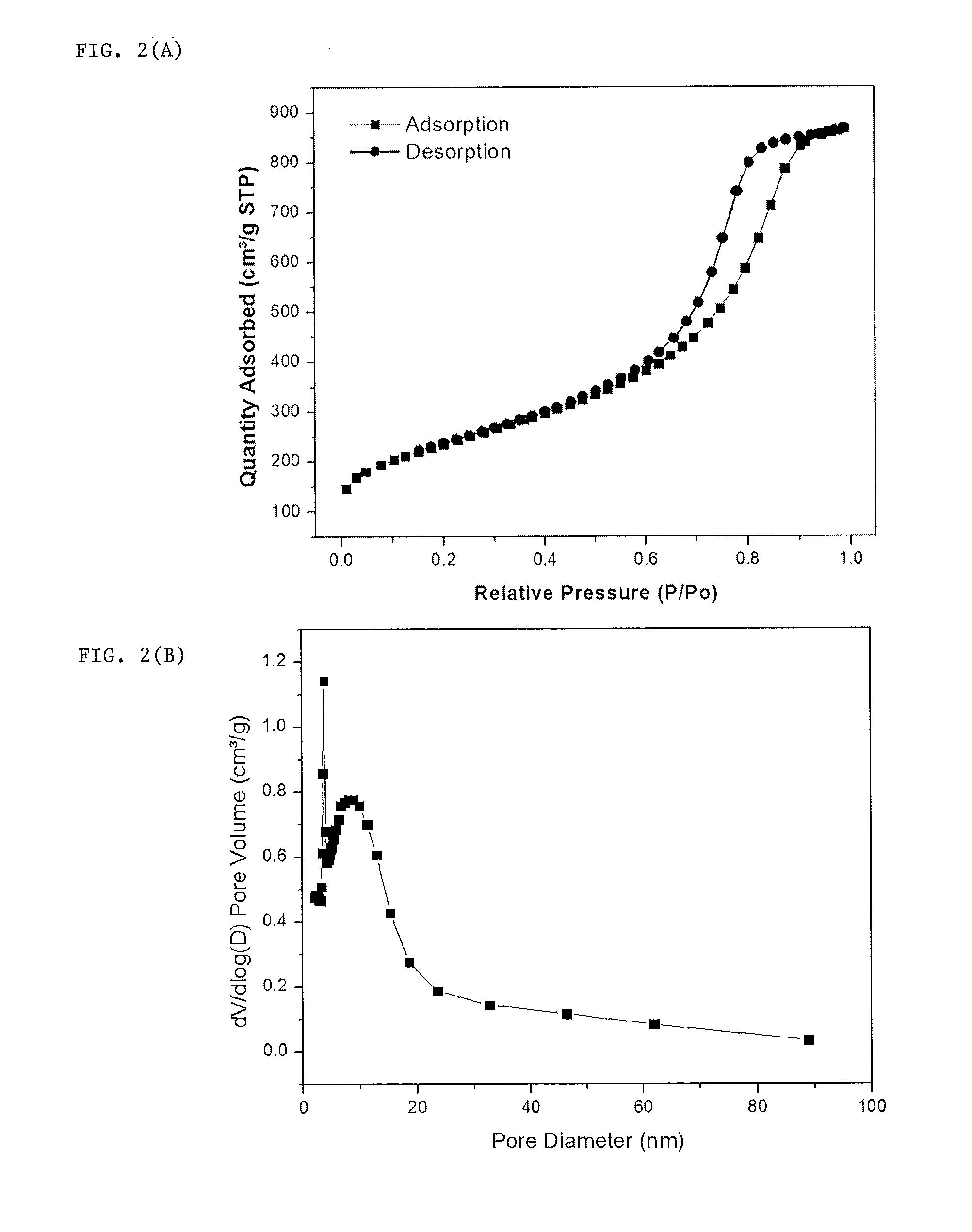

ActiveUS20140017569A1Reduced diffusion lossImprove Coulombic efficiencyConductive materialOrganic conductorsLithium sulfurHeteroatom

We report a heteroatom-doped carbon framework that acts both as conductive network and polysulfide immobilizer for lithium-sulfur cathodes. The doped carbon forms chemical bonding with elemental sulfur and / or sulfur compound. This can significantly inhibit the diffusion of lithium polysulfides in the electrolyte, leading to high capacity retention and high coulombic efficiency.

Owner:PENN STATE RES FOUND

Negative electrode material used for lithium battery and preparation method and application thereof

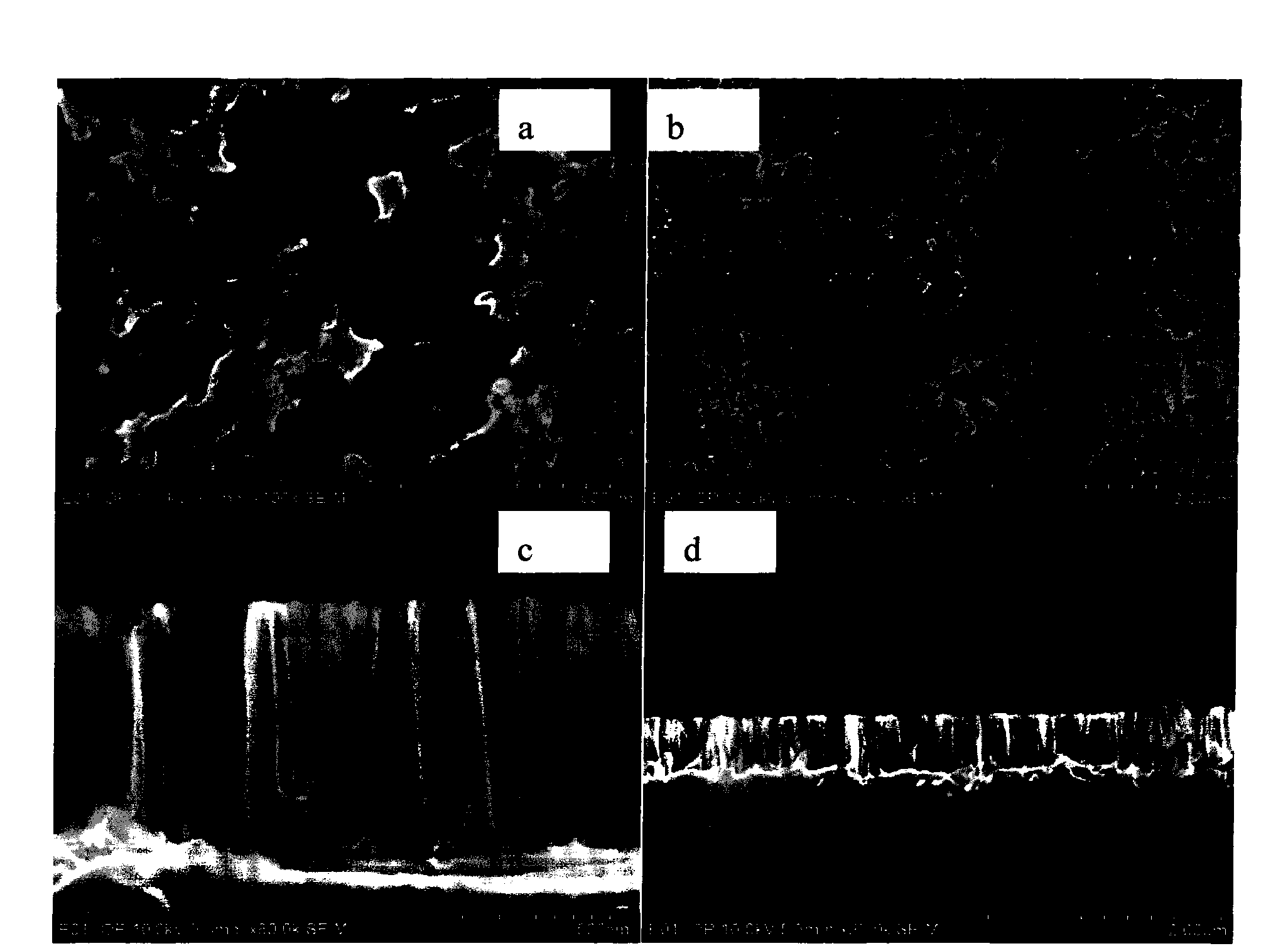

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

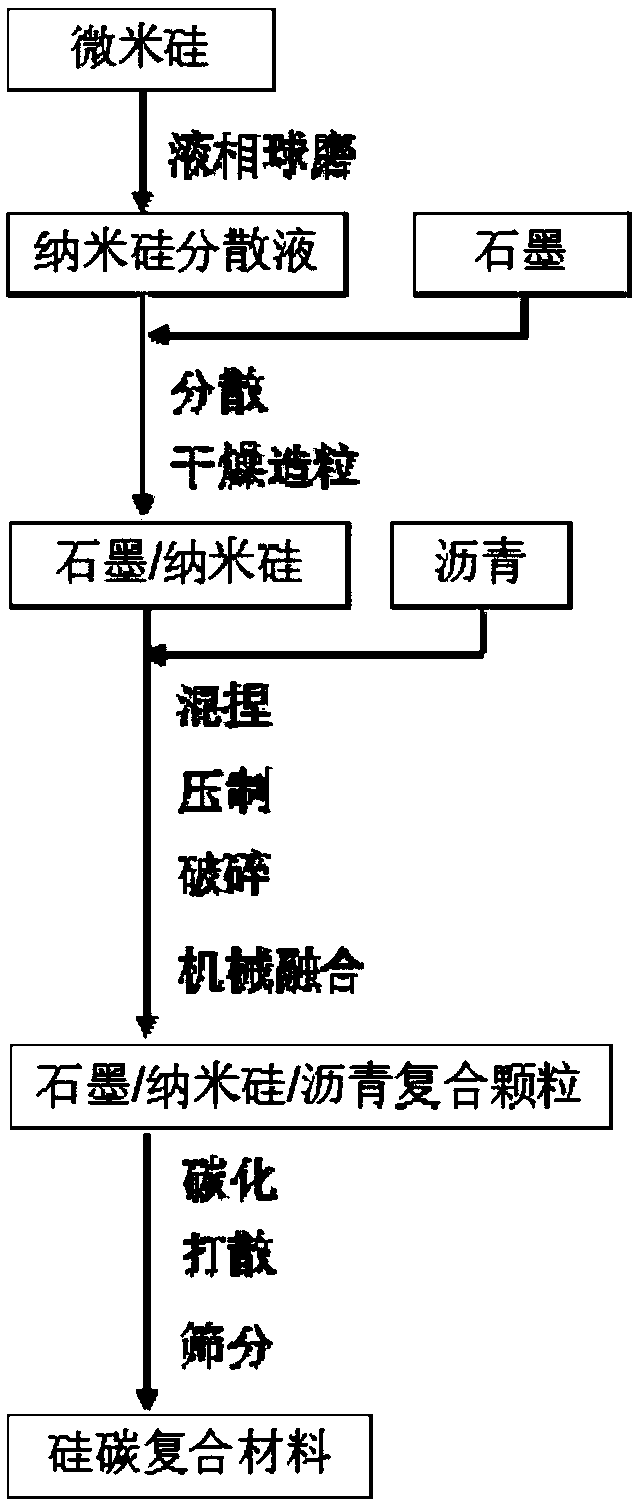

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

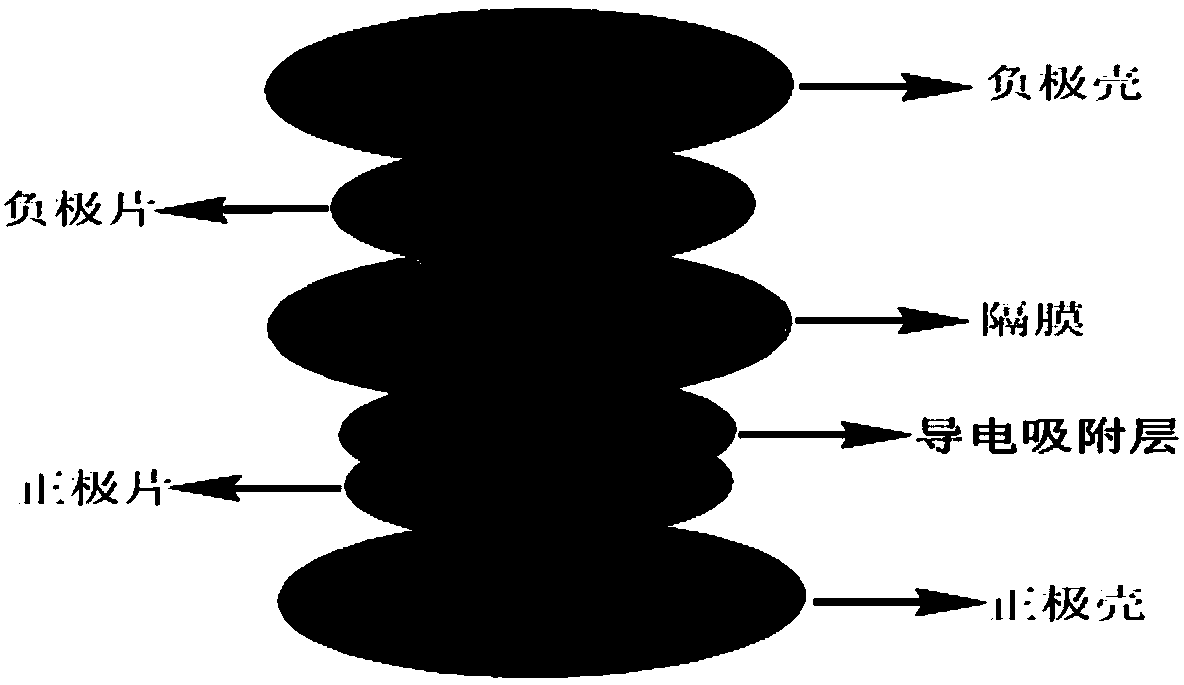

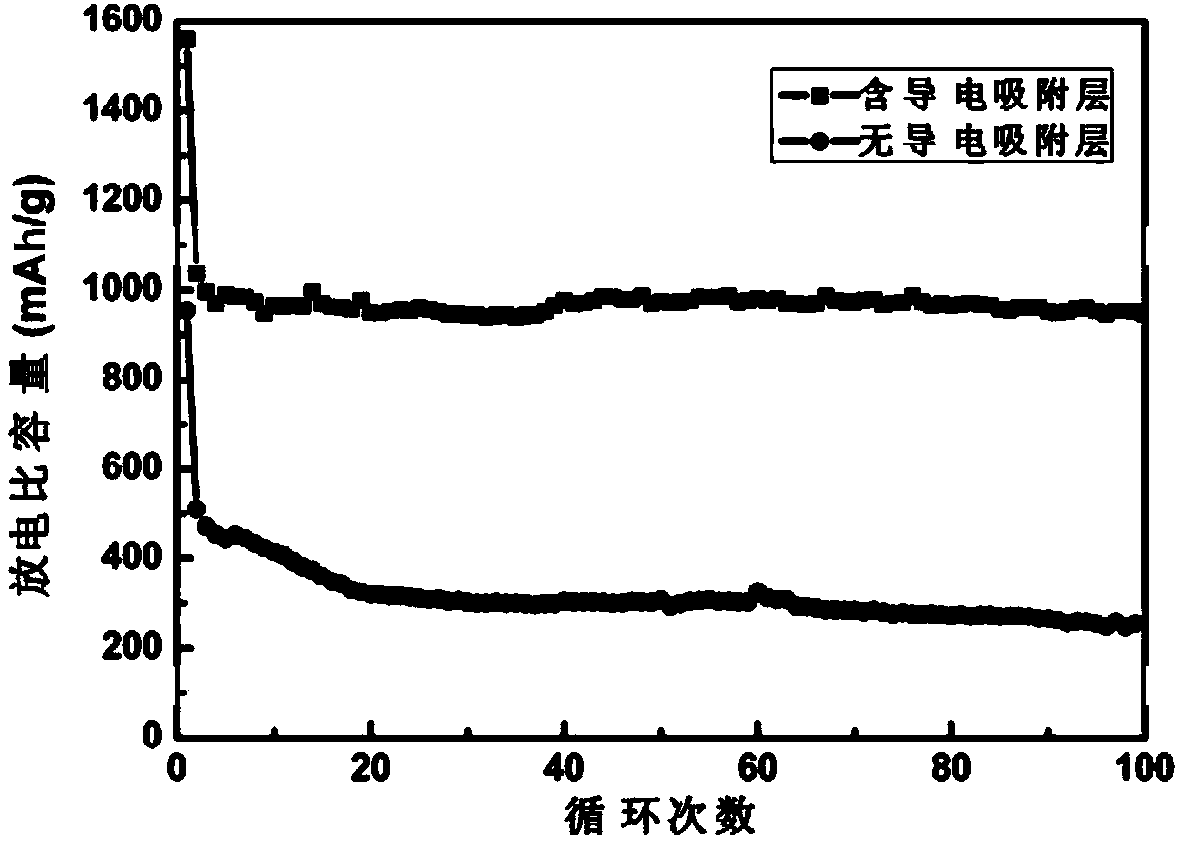

Lithium-sulfur battery with conductive adsorption layer, and application of conductive polymer film

InactiveCN103515646AEnhance electrical conductivityInhibition of the shuttle effectElectrode carriers/collectorsLi-accumulatorsChemistryAdhesive

The invention discloses a lithium-sulfur battery with a conductive adsorption layer, and an application of a conductive polymer film. The lithium-sulfur battery comprises a sulfur-containing positive electrode sheet, a separation film, and a lithium negative-electrode sheet. A conductive absorption layer is arranged between the sulfur-containing positive electrode sheet and the separation film. The application comprises that the conductive polymer film prepared from a conductive polymer, a conductive agent, and an adhesive is arranged as a conductive absorption layer between the sulfur-containing positive electrode sheet and the separation film of the lithium-sulfur battery, such that the lithium-sulfur battery is prepared. The prepared lithium-sulfur battery has the characteristics of high specific capacity, high coulombic efficiency, and long service life. The conductive polymer film has the advantages of low raw material cost, simple preparation method, and suitability for industrialized productions.

Owner:CENT SOUTH UNIV

Double-effect composite membrane used for lithium sulphur battery and preparation method thereof

ActiveCN108461694AImprove the utilization rate of active substancesImprove stabilityCell component detailsHigh energyLithium–sulfur battery

The invention provides a double-effect composite membrane used for a lithium sulphur battery and a preparation method thereof. The membrane is composed of a functional composite layer and porous insulating film. The functional composite layer is a composite of conductive carbon base materials, polar materials and a binder, wherein the mass fraction of the conductive carbon base materials and polarmaterials is 5%-90% and 5%-90% respectively. The preparation method comprises the steps that the conductive carbon base materials and the polar materials are used for preparing the functional composite layer, the functional composite layer is loaded on the porous insulating film, and surface loading capacity of the functional composite layer is 0.1-3.0 mg cm-2. The composite membrane in the lithium sulphur battery regulates and controls reaction and deposition behaviors of active substances in different charge-discharge stages and significantly improves the utilization and stability of the active substances of the lithium sulphur battery. Compared with ordinary commercial polymer battery membranes, the composite membrane prolongs the cycle life of the lithium sulphur battery and improvesspecific energy, positive discharge capacity and coulombic efficiency. The method is simple in operation, is beneficial to large-scale preparation, and facilities wide commercial application of the high-energy density lithium sulphur battery.

Owner:TSINGHUA UNIV

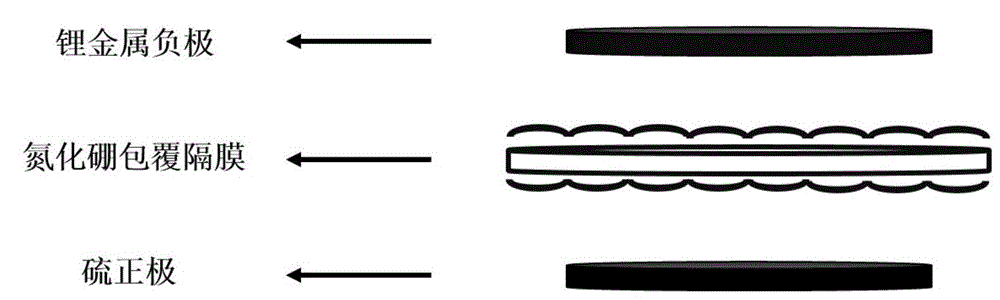

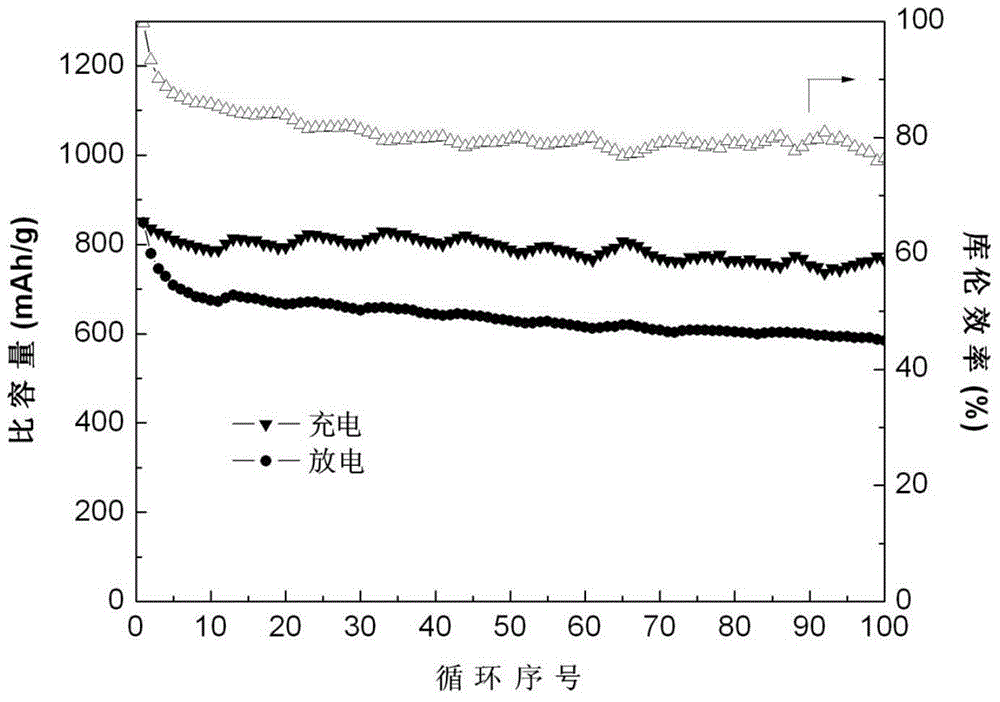

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

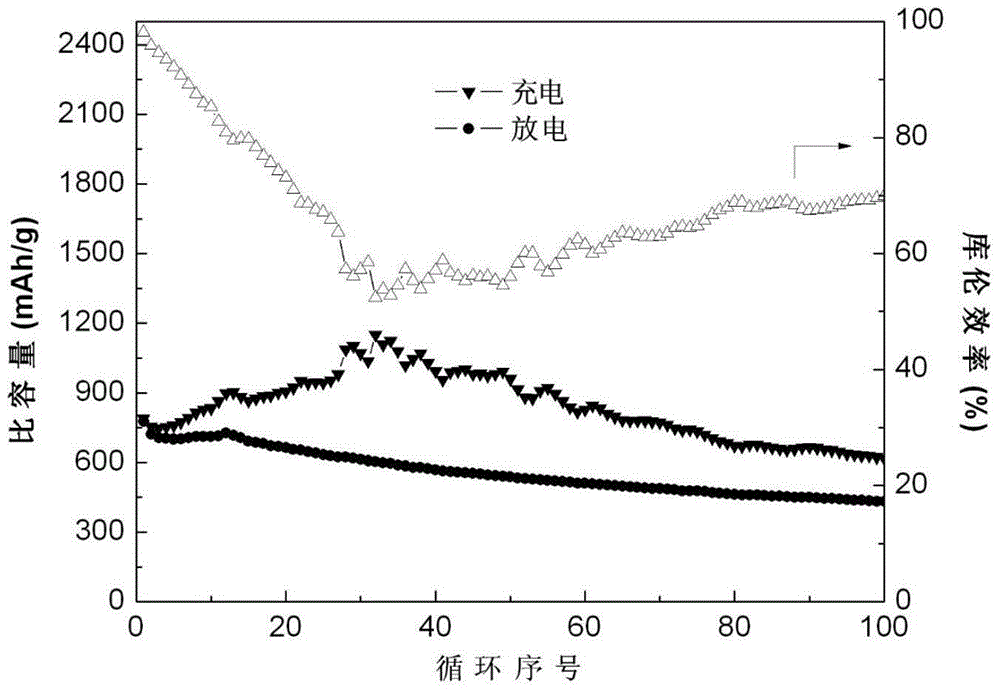

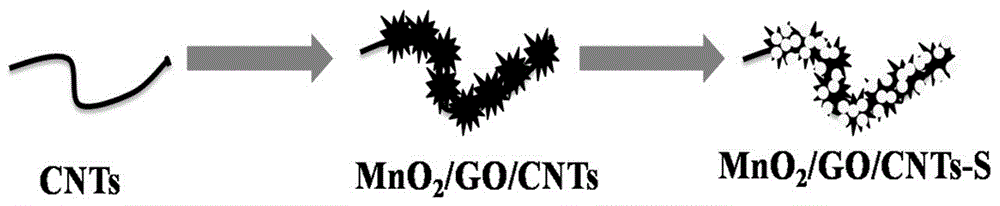

Cathode material for long-circulation lithium-sulfur battery and preparation method thereof

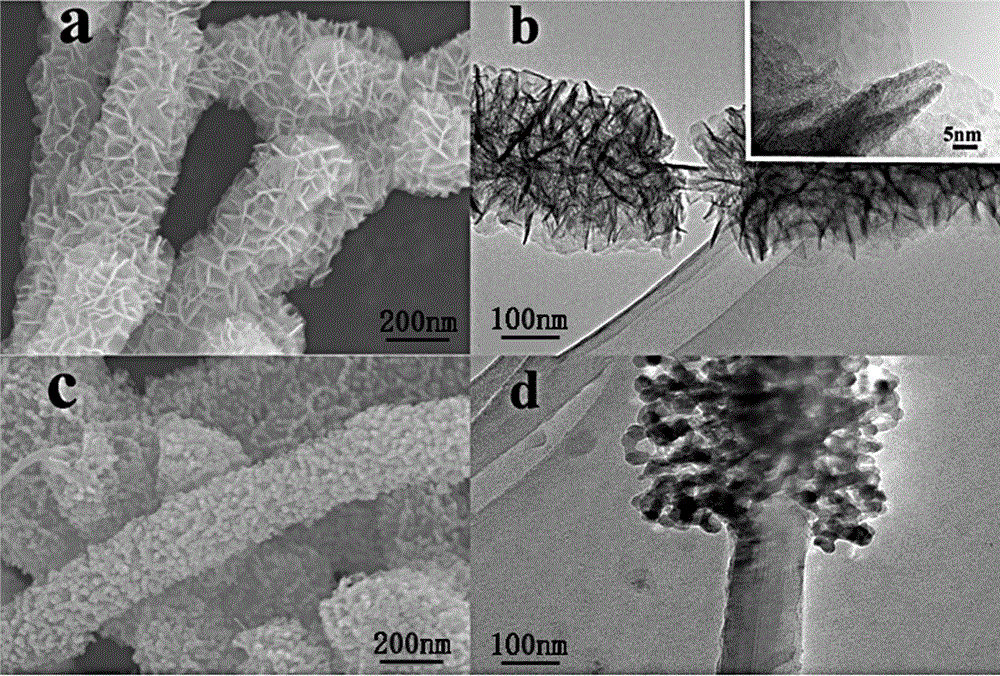

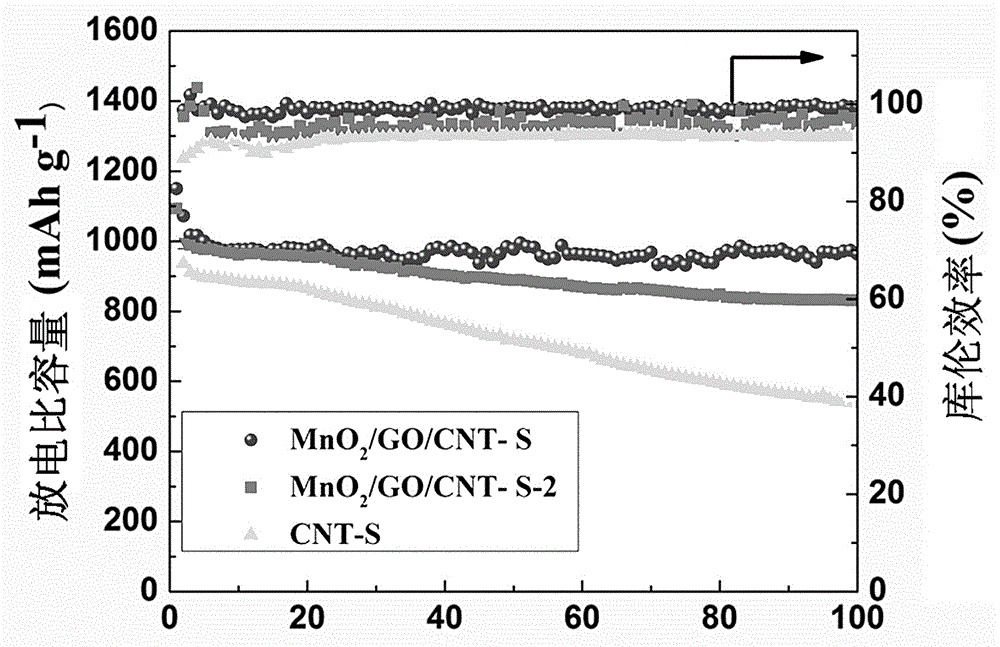

InactiveCN106374087AImprove conductivityImprove mechanical propertiesMaterial nanotechnologyCell electrodesOxideCarbon composites

The invention discloses a cathode material for a long-circulation lithium-sulfur battery and a preparation method thereof. The cathode material is compounded from the following materials: a three-dimensional metallic oxide or metallic sulfide / carbon composite material and a sulfur-containing material, wherein the three-dimensional metallic oxide or metallic sulfide / carbon composite material is compounded from the following materials: a metallic oxide or metallic sulfide, and a carbon composite material. The carbon composite material is a nanocarbon composite material, with a two-dimensional structure, compounded by a one-dimensional material and a two-dimensional material. The sulfur-containing material is elemental sulfur or a polysulfide containing a -Sm- structure in which m is greater than 2. The cathode material for the long-circulation lithium-sulfur battery prepared in the invention has high conductivity and a three-dimensional space structure, the coulombic efficiency and cycle performance of the lithium-sulfur battery can be improved effectively, and meanwhile the cathode material has excellent rate capability.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Carbon material for battery electrode and production method and use thereof

InactiveUS20070092428A1Less deformation/orientationLarge discharge capacityGraphiteSecondary cellsPolymer scienceSource material

The invention provides a carbon material for a battery electrode, which comprises a carbon powder material as a composite of carbonaceous particles and an a carbon material derived from an organic compound prepared by allowing the organic compound serving as a polymer source material to deposit onto and / or permeate into the carbonaceous particles to thereby polymerize the polymer material and then heating at 1,800 to 3,300° C., and which has an intensity ratio of 0.1 or more for peak intensity attributed to a (110) plane to peak intensity attributed to a (004) plane determined through X-ray diffraction spectroscopic analysis on a mixture of the carbon material and a binder resin when pressed at 103 kg / cm2 or higher. The carbon material which undergoes less deformation / orientation due to application of pressure, has high discharge capacity and small irreversible capacity and exhibiting excellent coulombic efficiency, cycle characteristics and leakage-current load characteristics.

Owner:SHOWA DENKO KK

Reduction of the loss of zinc by its reaction with oxygen in galvanized steel and batteries

InactiveUS20070125644A1Improve Coulombic efficiencyMinimal porosityMachining electrodesFuel and primary cellsElectrochemical responseChemical reaction

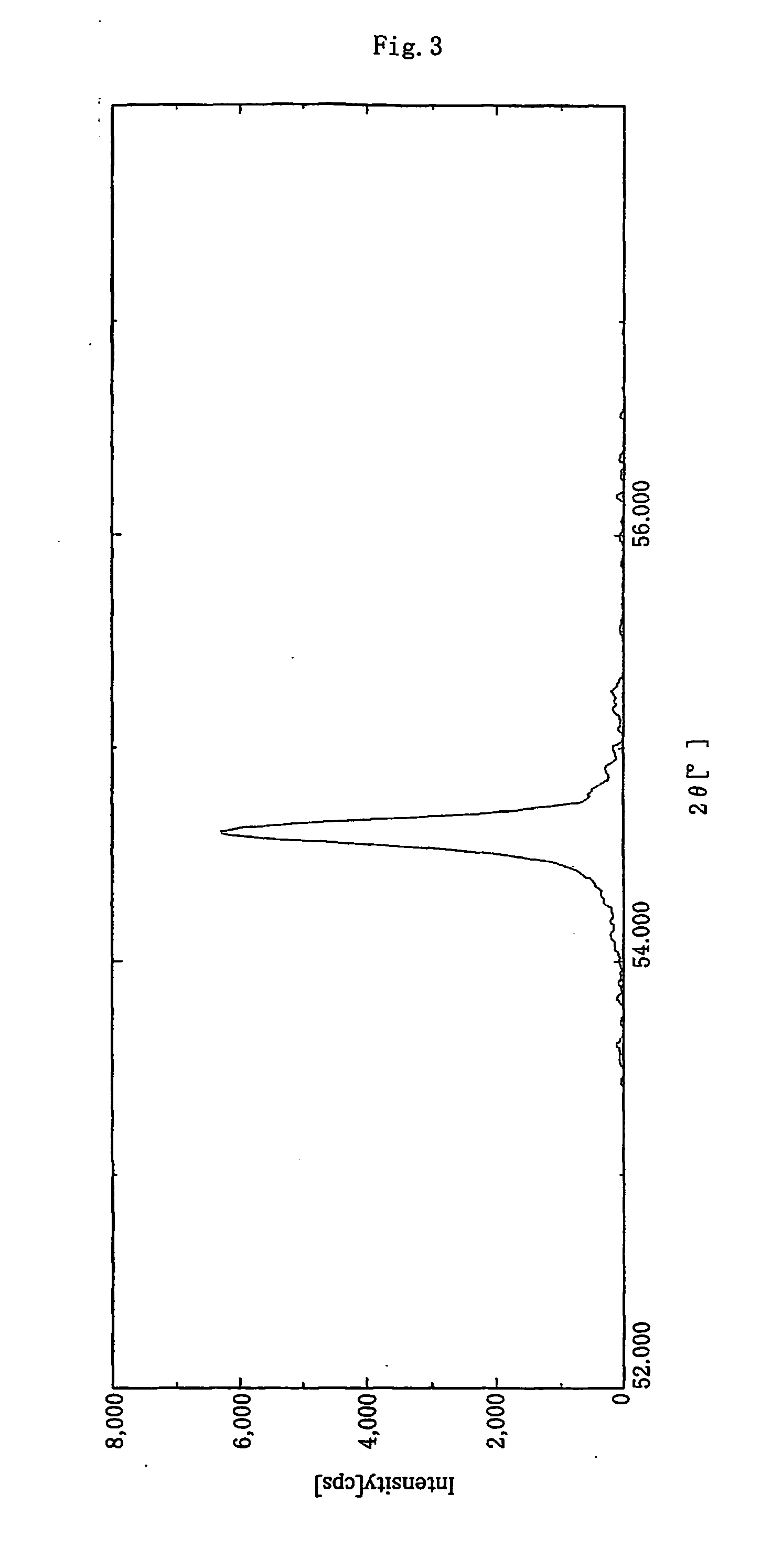

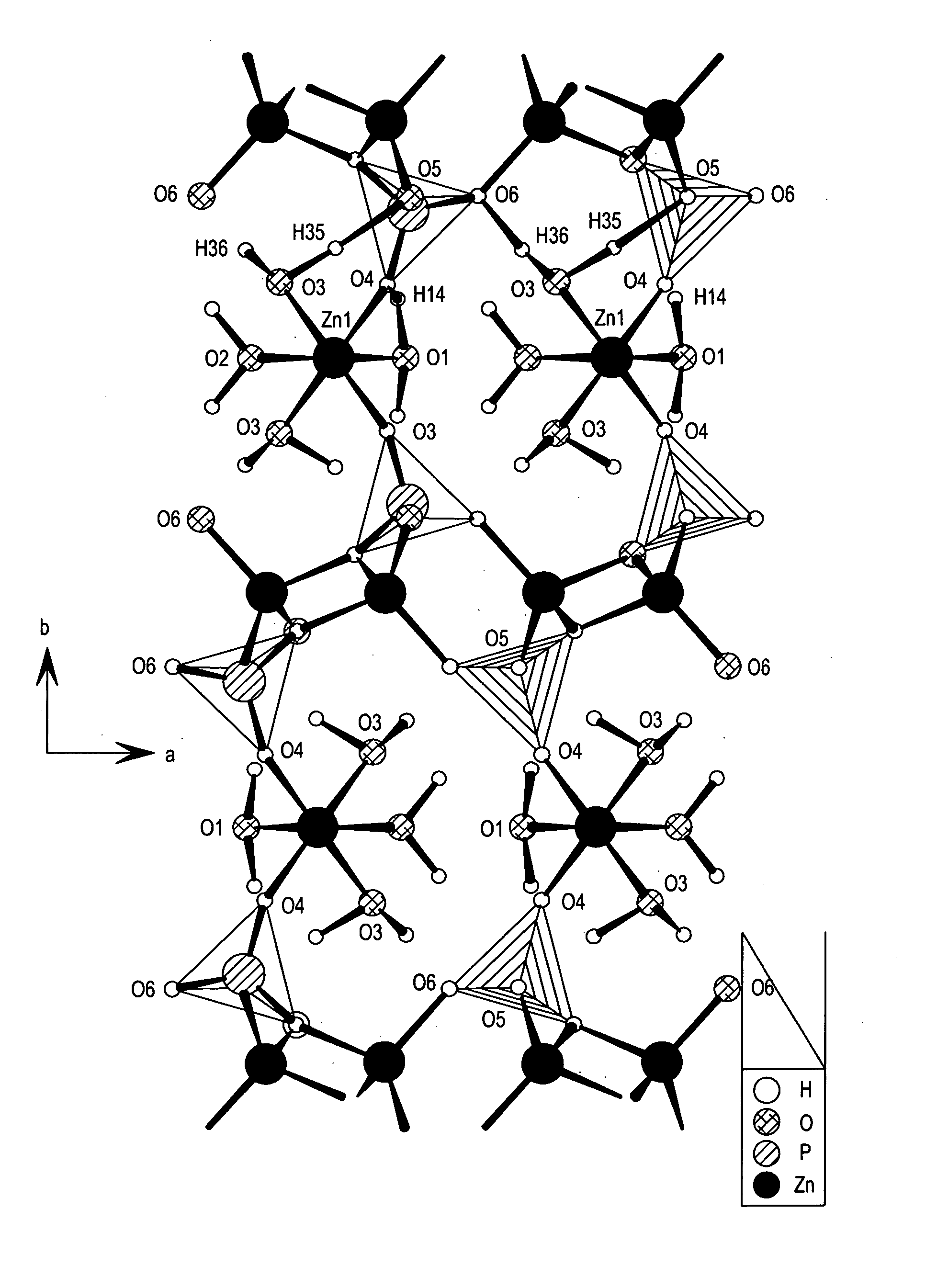

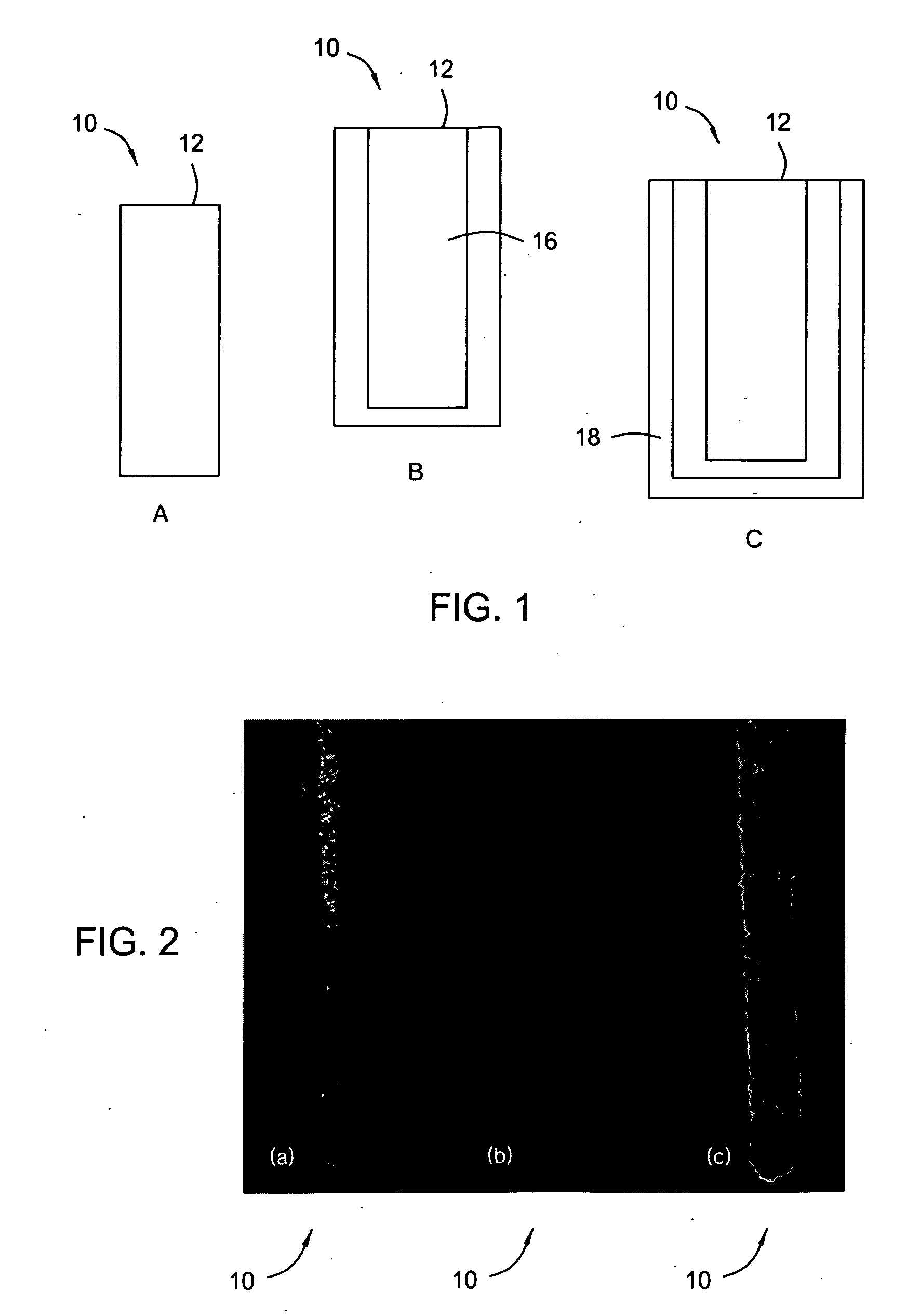

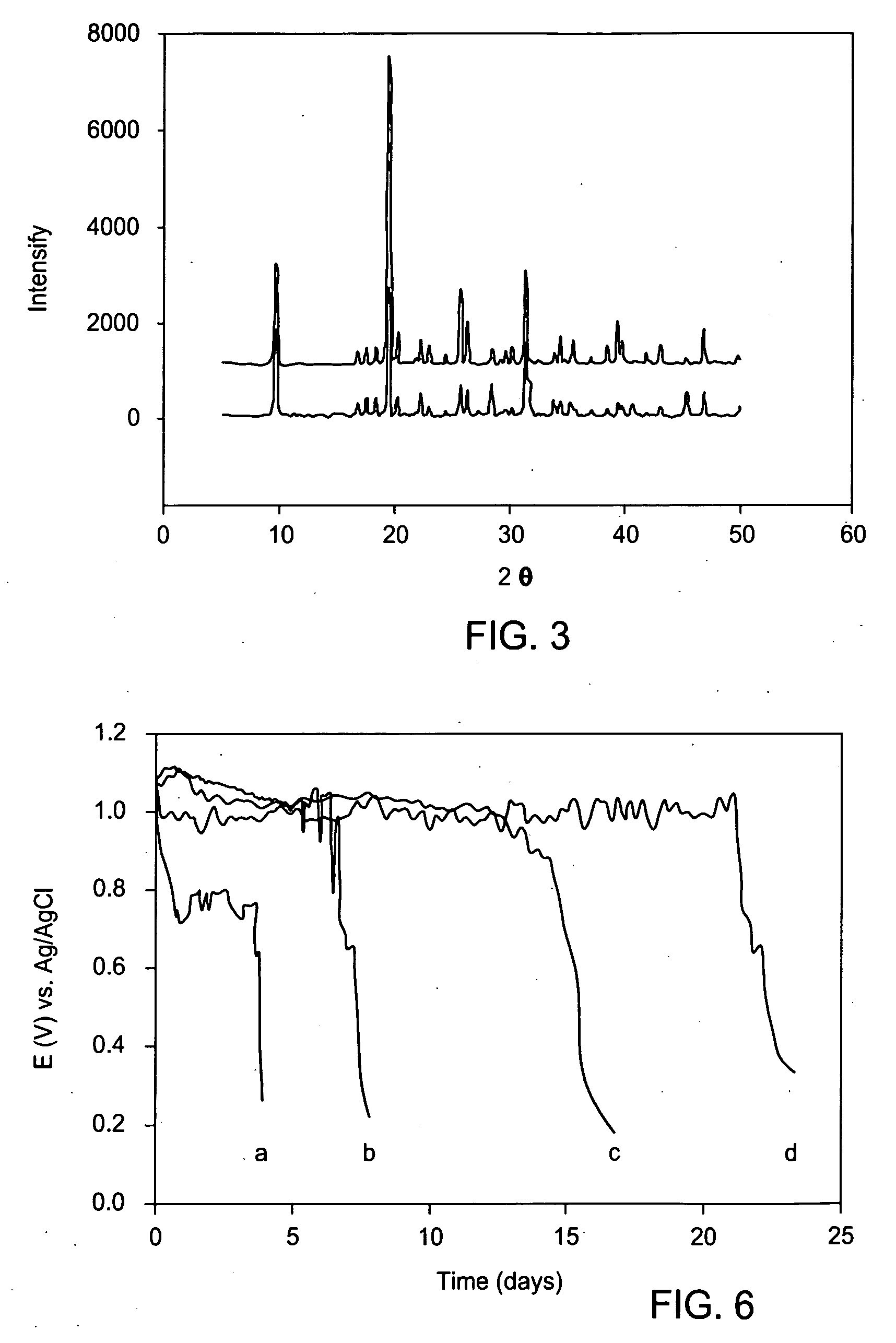

A non-porous Zn2+ conducting inorganic lamellar layer is formed on the zinc coating of galvanized steel or on a zinc anode of an electrochemical cell. The layer reduces the rate of the unwanted chemical reaction of zinc and oxygen but allows desired electrochemical reactions underlying the cathodic protection of the steel and the efficient utilization of zinc anodes in electrochemical cells, e.g., a physiological buffer solution or serum as their electrolytes. The ion conducting non-porous lamellar layer having a hopeite phase Zn3(PO4)2.4H2O may be formed spontaneously on, e.g., NAFION® coated zinc anodes discharged in neutral pH saline phosphate solutions.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Electrodes and methods for microbial fuel cells

InactiveUS20100151279A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

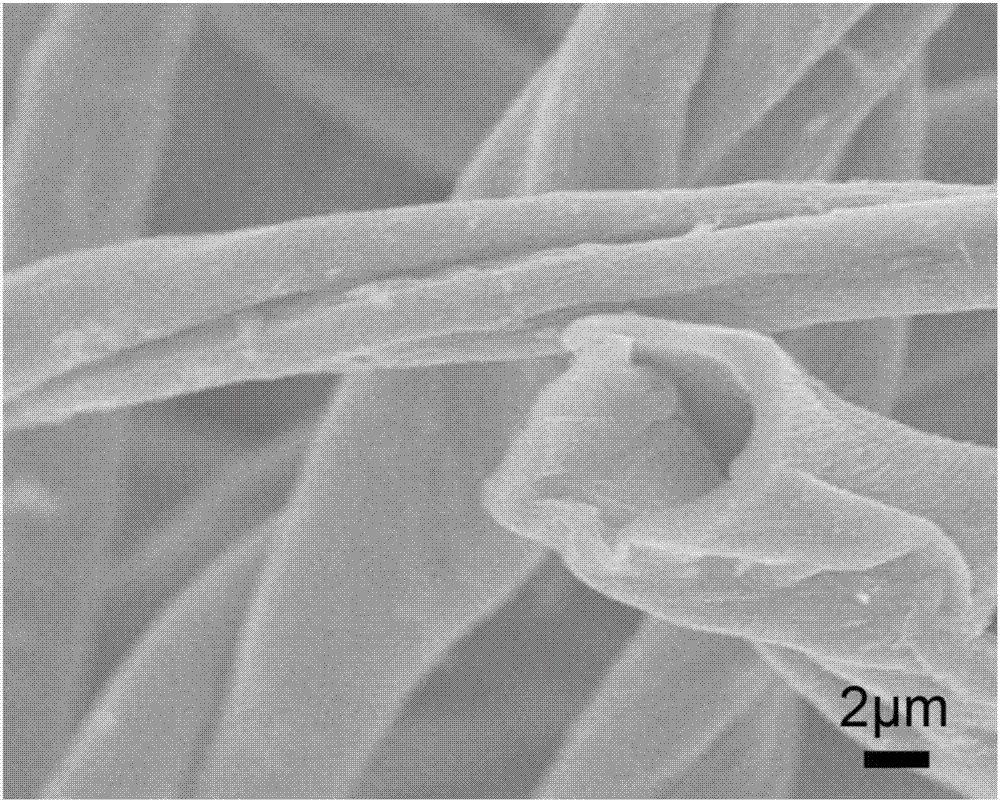

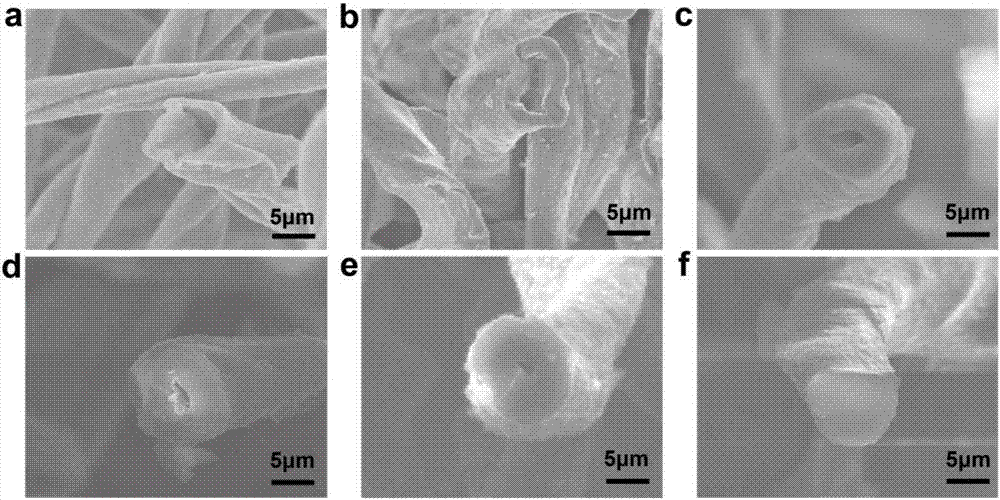

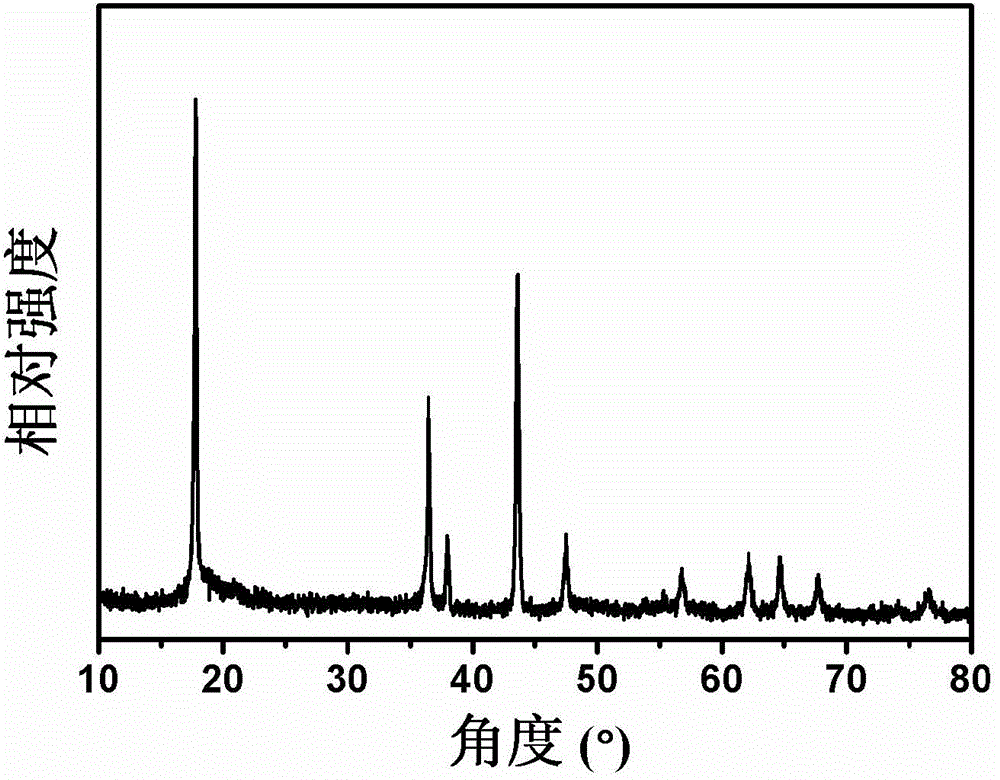

Three-dimensional current collector for metal secondary battery anode and preparation and application thereof

ActiveCN106898778ALarge electroactive surface areaReduce current densityElectrochemical processing of electrodesElectrode carriers/collectorsFiberHollow fibre

The invention provides a three-dimensional porous current collector serving as a metal secondary battery anode current collector; the current collector is a three-dimensional porous hollow carbon fiber current collector having both hollow fiber tubular structure and porous structure. Compared with the traditional flat current collectors, the three-dimensional porous hollow carbon fiber current collector is capable of inhibiting dendritic crystal that occurs during metal deposition / separation, the safety of a metal anode is improved greatly, improved coulombic efficiency and longer cycle life can be achieved, and voltage polarization can be decreased. A method to prepare the three-dimensional porous hollow carbon fiber bobbin current collector is simple and easy, the raw materials are low in price and easy to obtain, and the collector is suitable for large-scale production and has high practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Lithium molybdate serving as secondary battery electrode material

InactiveCN104577088AImprove cycle performanceImprove securityCell electrodesSecondary cellsMetallurgyLithium molybdate

The invention discloses lithium molybdate serving as a secondary battery electrode material. In an execution mode, a chemical formula of the electrode material is Li (2-x)MoyMzO(3-u), wherein x is larger than or equal to minus 2 and smaller than or equal to 2, y is larger than 0 and smaller than or equal to 5, z is larger than or equal to 0 and smaller than or equal to 9, u is larger than or equal to minus 9 and smaller than or equal to 3, and M comprises one element selected from C, N, F, Na, Mg, Al, Si, P, S, Cl, K, Ca, Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Tc, Ru, Rh, Pd, Cd, In, Sn, Sb, Te, I, Cs, Ba, Ta, W, Re, Os, Ir, Pt, Au, Hg, Pb, Bi, Po, At, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu or combination of the elements. The electrode material is characterized by having very high specific capacity, excellent cycle performance, rate capability and safety.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

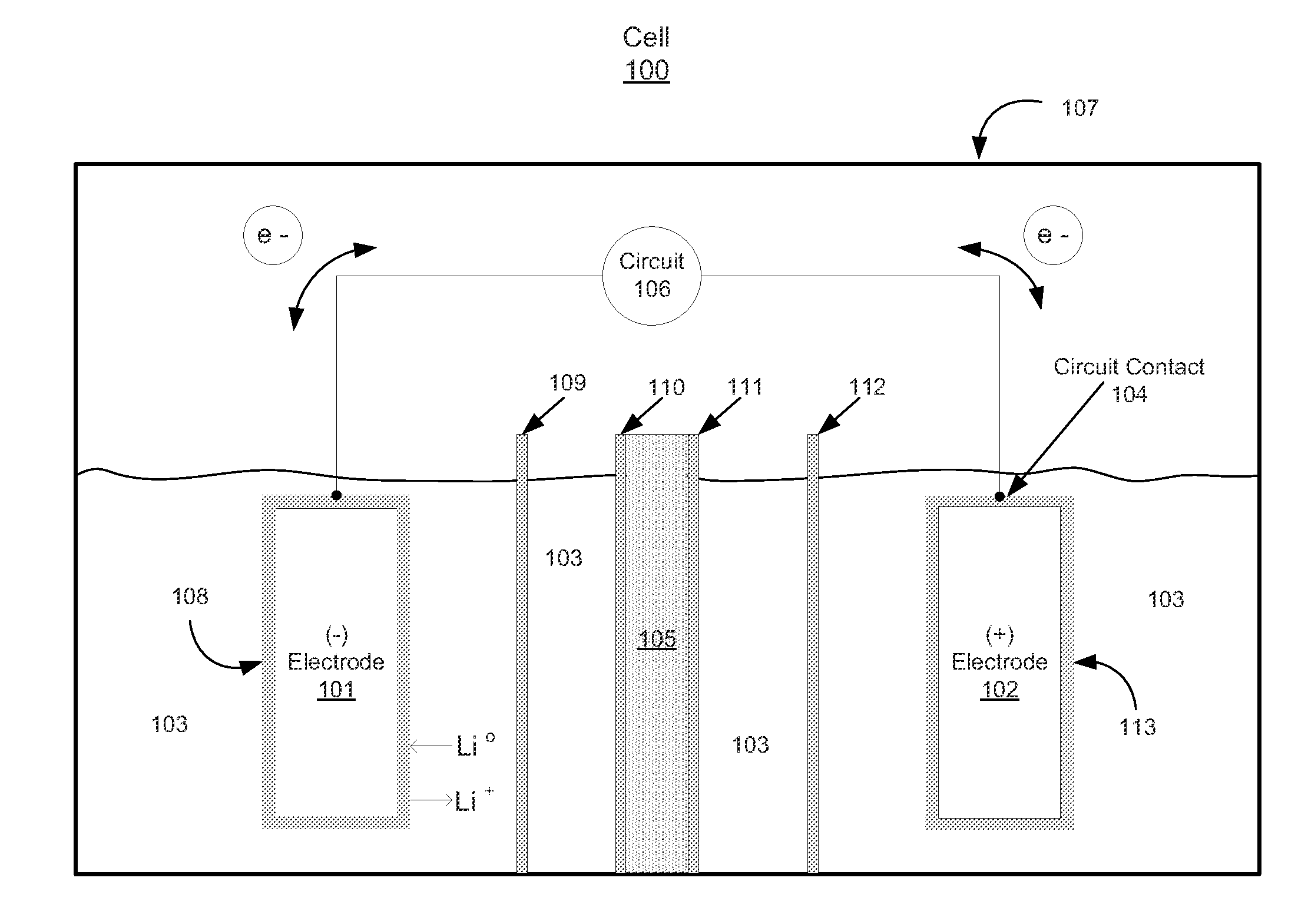

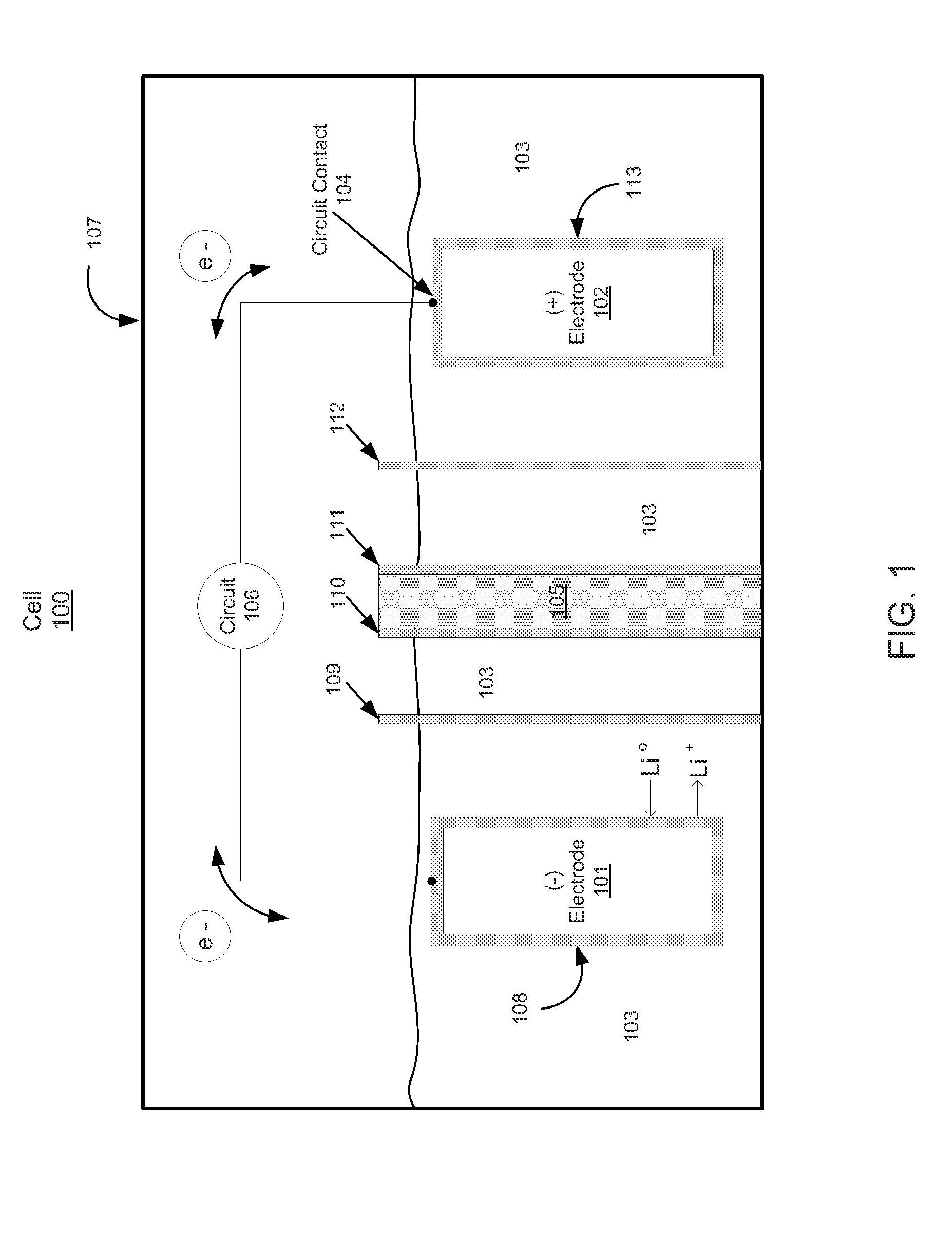

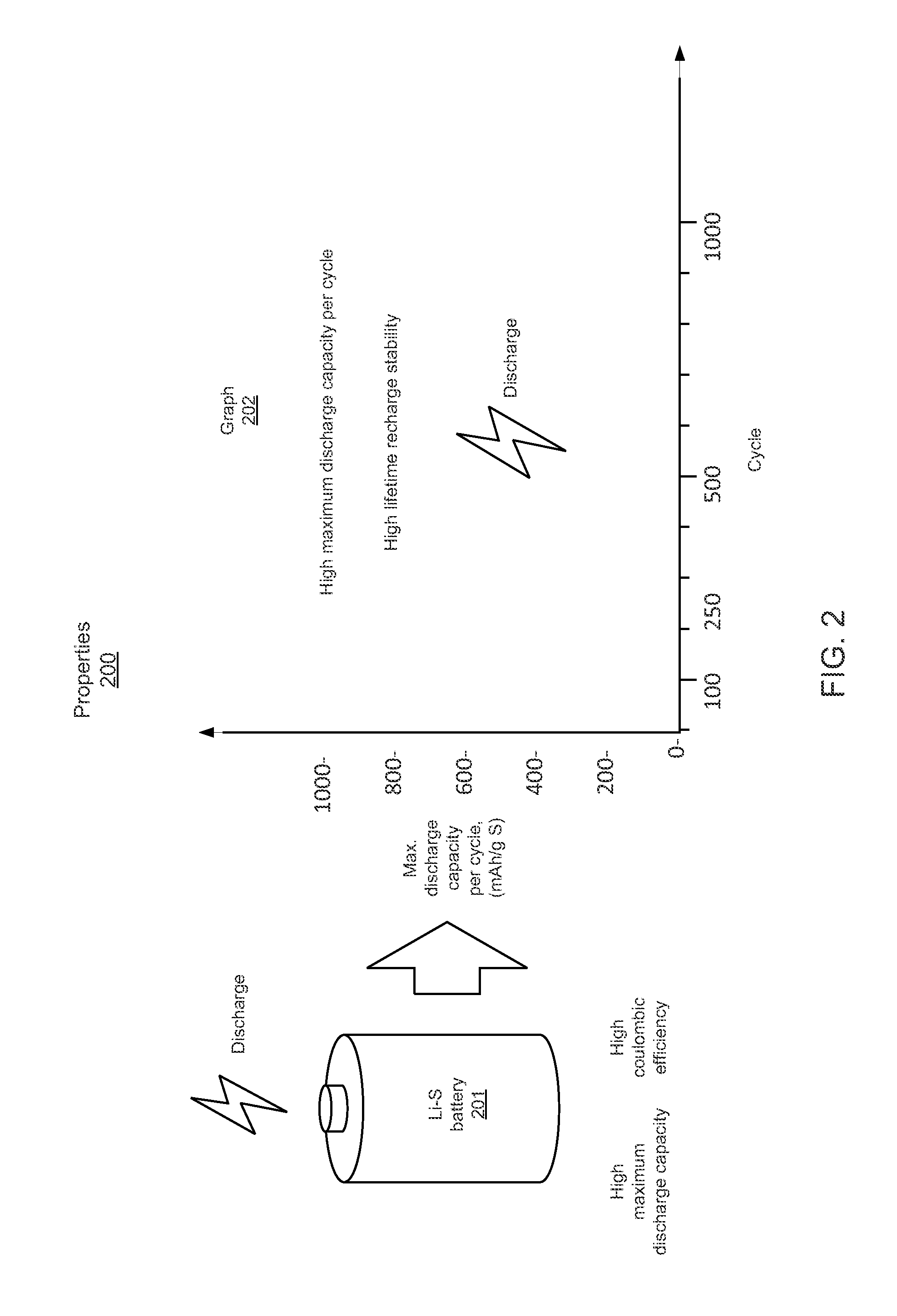

Additives with ionomer articles, methods for making and methods for using

InactiveUS20150171469A1Improve Coulombic efficiencyIncrease the maximum discharge capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureIonomerLithium

There are cells comprising a sulfur-containing first electrode. The cells also comprise a lithium-containing second electrode associated with a total amount of electrode lithium, including electrochemically utilized electrode lithium. The cells also includes a circuit coupling the first electrode with the second electrode, an article comprising an ionomer and an electrolyte medium comprising at least one additive selected from one or more of the groups consisting of nitrogen-containing additives, sulfur-containing additives, and organic peroxide additives. There are also associated methods of making and methods of using the cells.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com