Patents

Literature

1337 results about "Expansion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

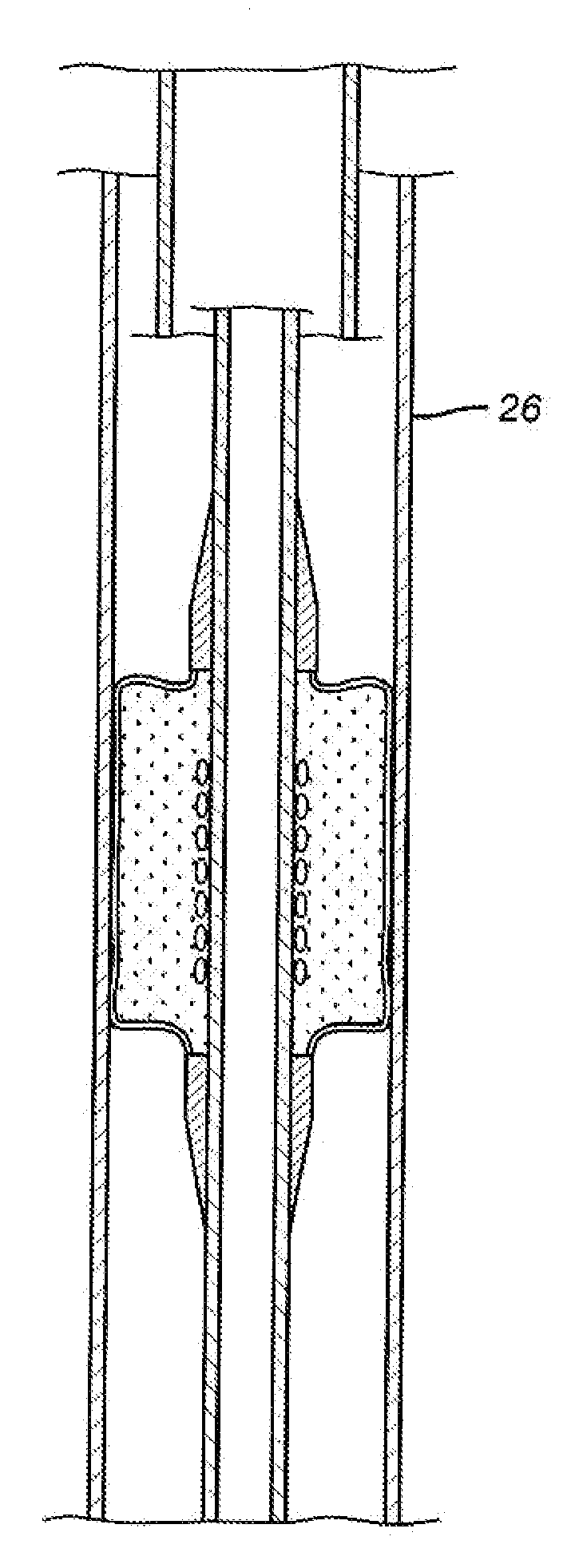

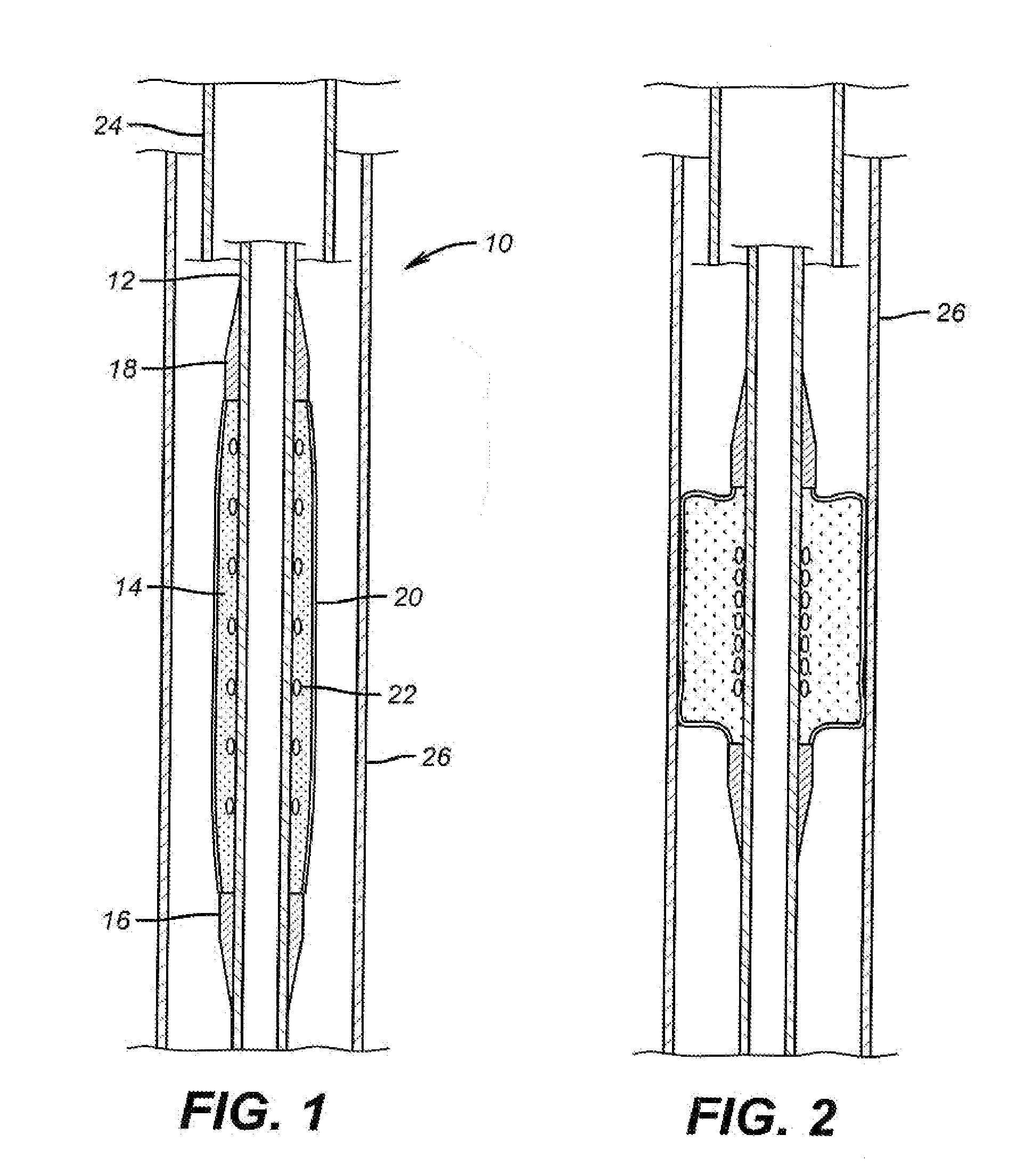

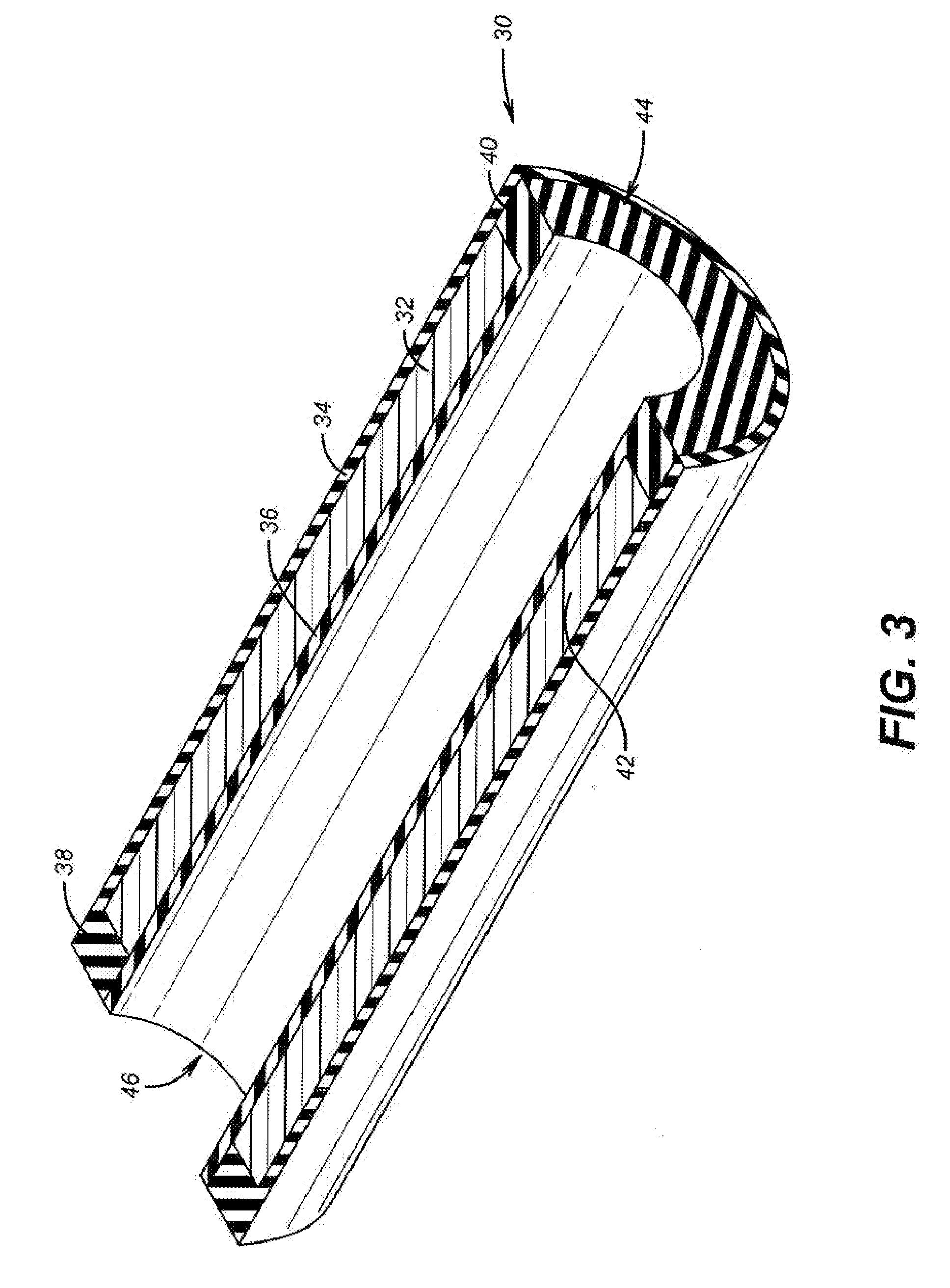

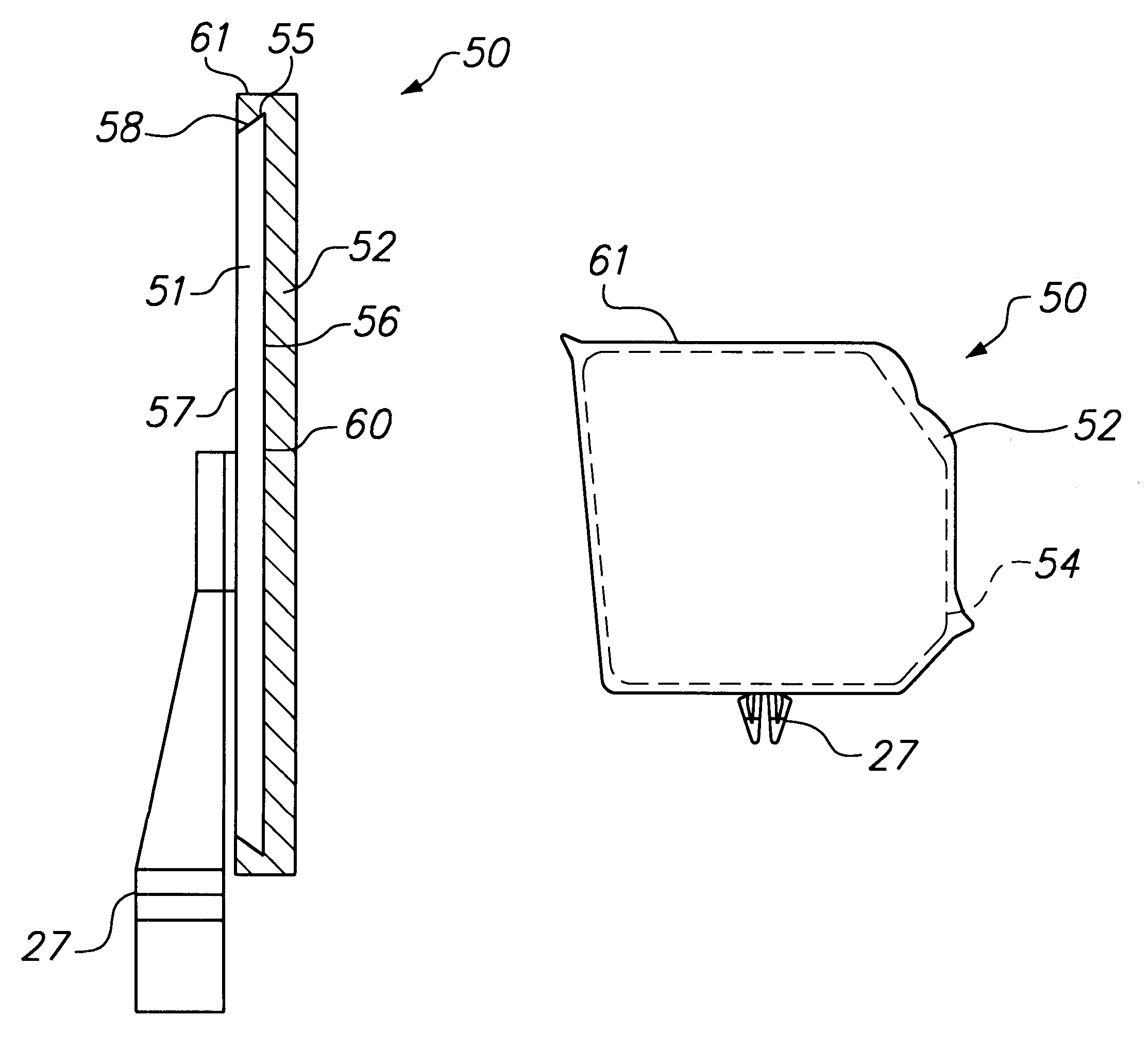

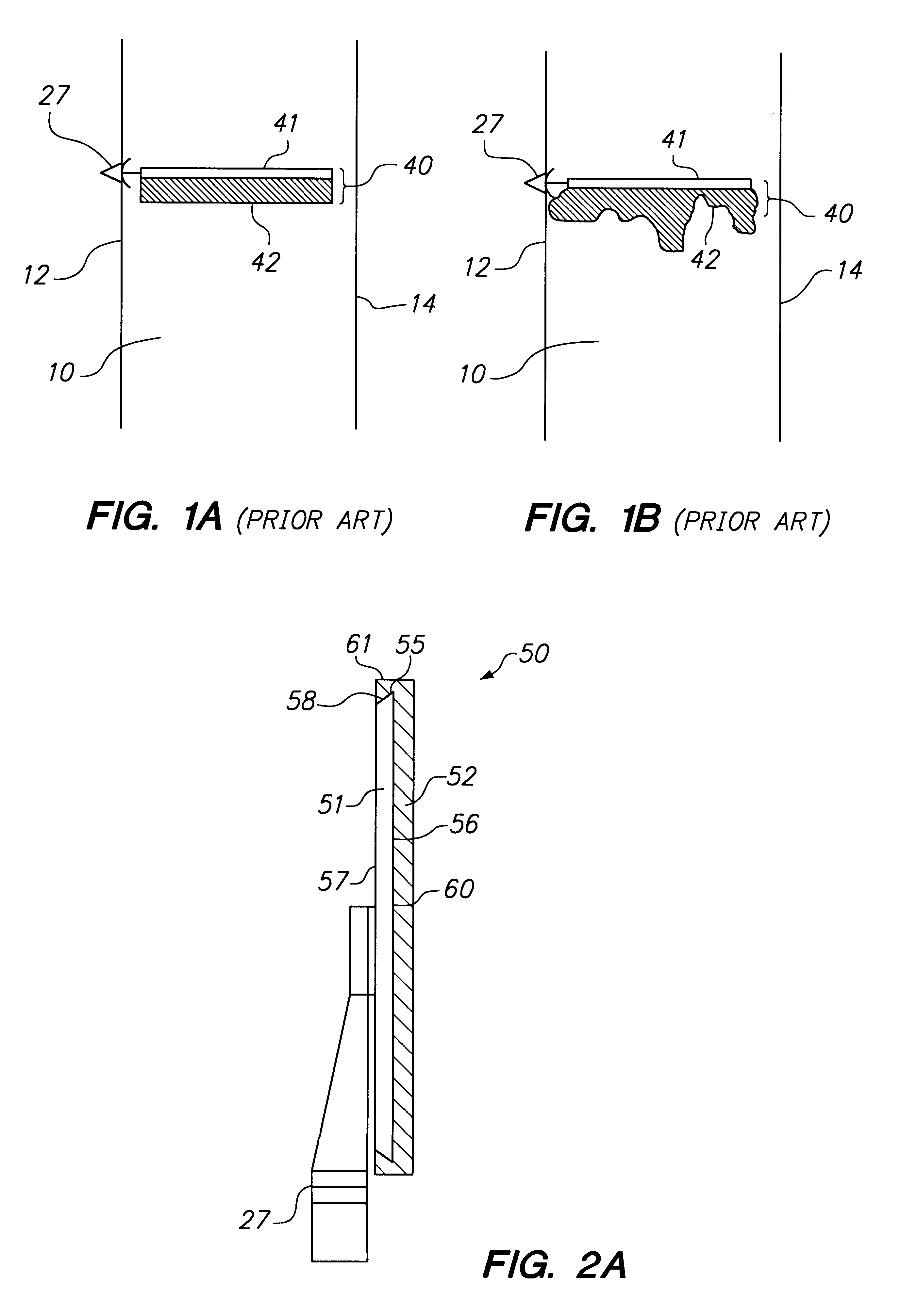

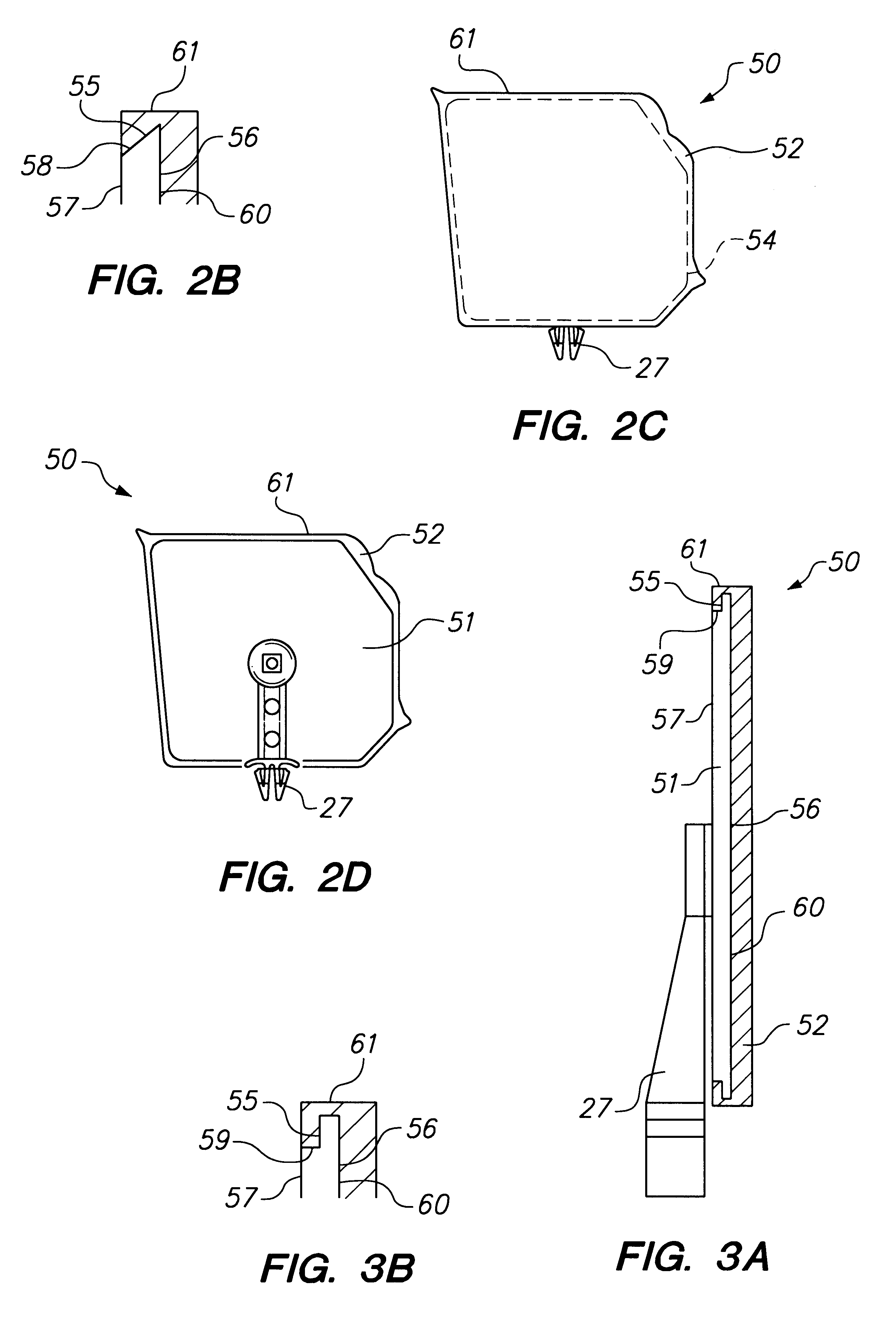

Packer sealing element with shape memory material

A packer or bridge plug uses a sealing element made from a shape memory polymer (SMP). The packer element receives heat or other stimulus to soften the SMP while the element is compressed and retained. While so retained, the heat or other stimulus is removed to allow the SMP to get stiff so that it effectively seals a surrounding tubular. High expansion rates are possible as the softness of the material under thermal input allows it to be reshaped to the surrounding tubular or to the surrounding open hole from a smaller size during run in and to effectively retain a sealed configuration after getting stiff on reduction in its core temperature while longitudinally compressed. The SMP or equivalent material whose modulus is changeable can be covered on the outside, the inside or both with an elastic material that protects the SMP and enhances the seal in the wellbore and against the mandrel.

Owner:BAKER HUGHES INC

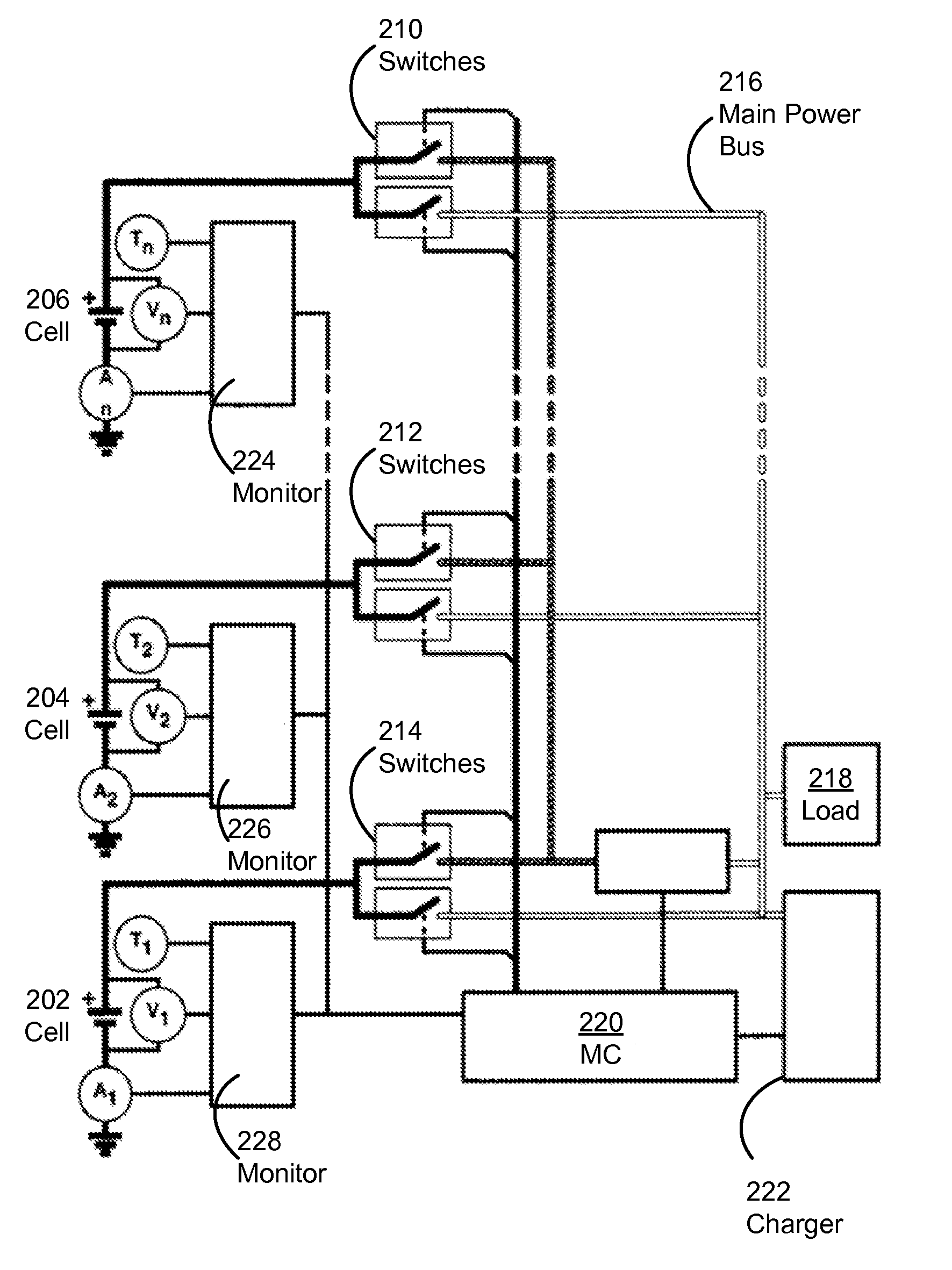

Managing Cycle and Runtime in Batteries for Portable Electronic Devices

InactiveUS20130257382A1Prolong lifeIncrease ratingsSecondary cells charging/dischargingElectric powerResting timeUser input

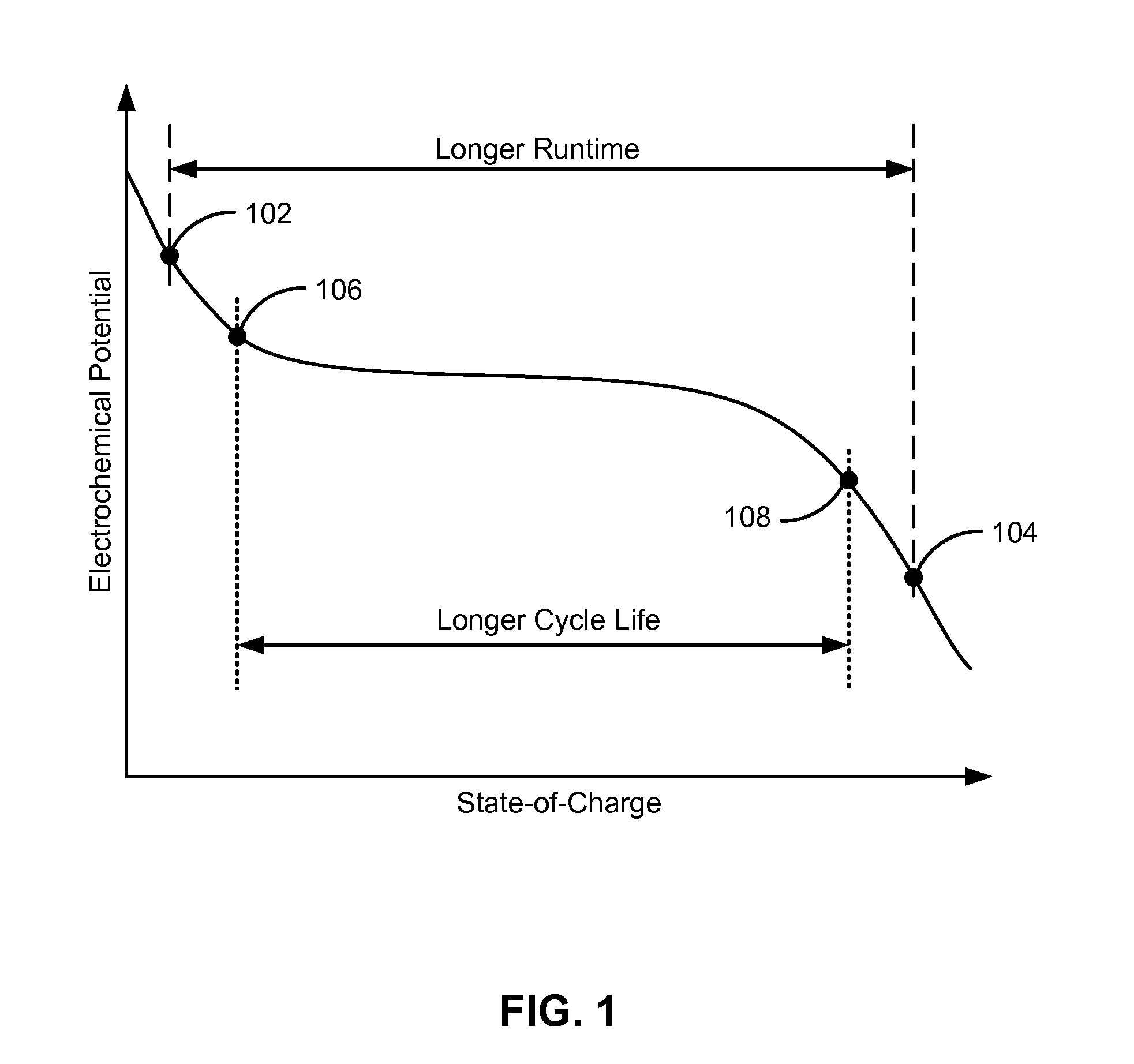

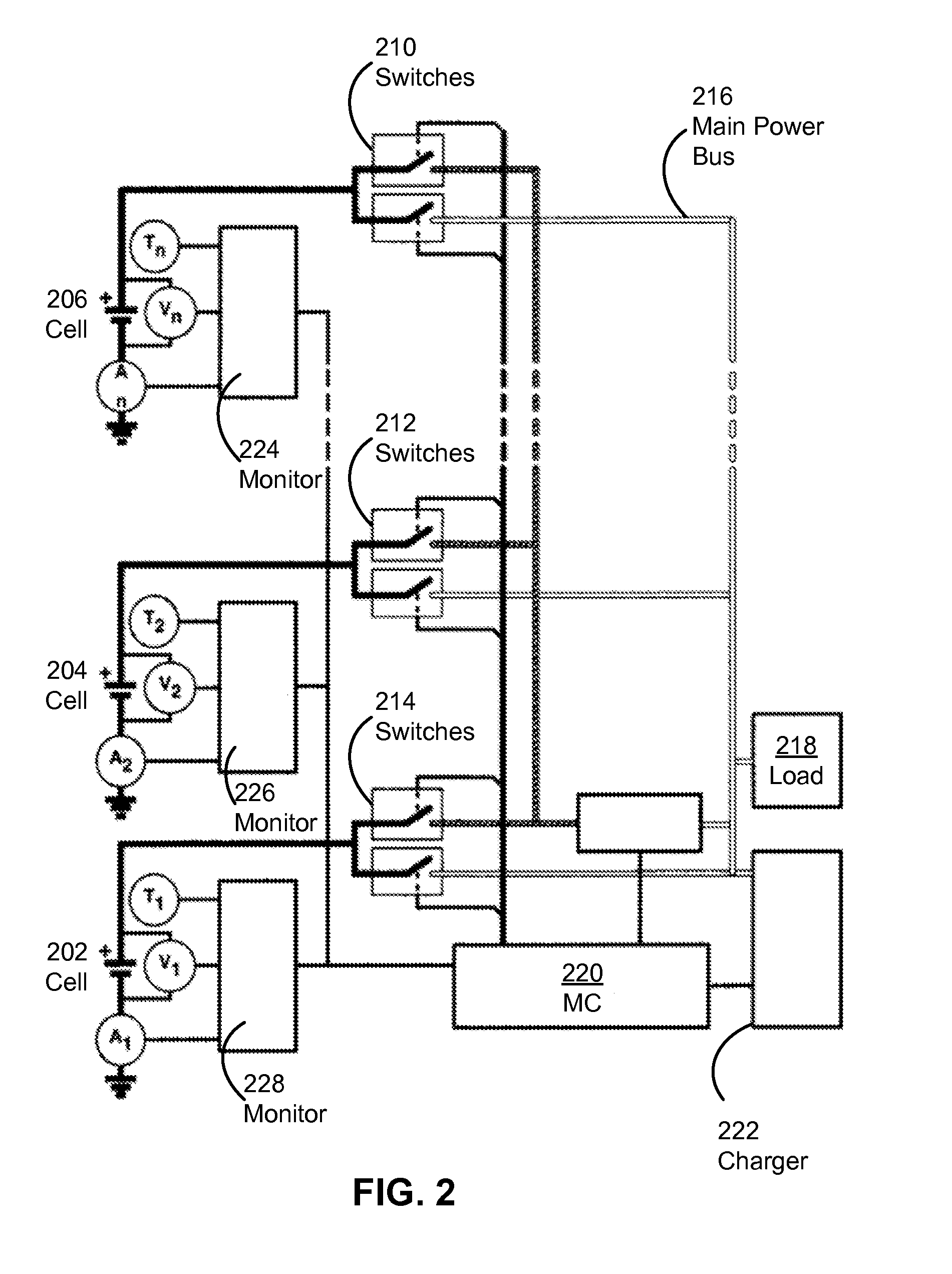

The disclosed embodiments provide a system that manages use of a battery in a portable electronic device. The system includes a monitoring mechanism that monitors one or more battery-usage parameters of the battery during use of the battery with the portable electronic device. The battery-usage parameters may include a battery age, a resting time, a swell rate, a temperature, a cell balance, a voltage, a current, usage data about how the battery has been cycled, and / or user input. The system also includes a management apparatus that adjusts a charge-termination voltage or a discharge-termination voltage of the battery based on the battery-usage parameters to manage a cycle life of the battery, the swell rate, and / or a runtime of the battery.

Owner:APPLE INC

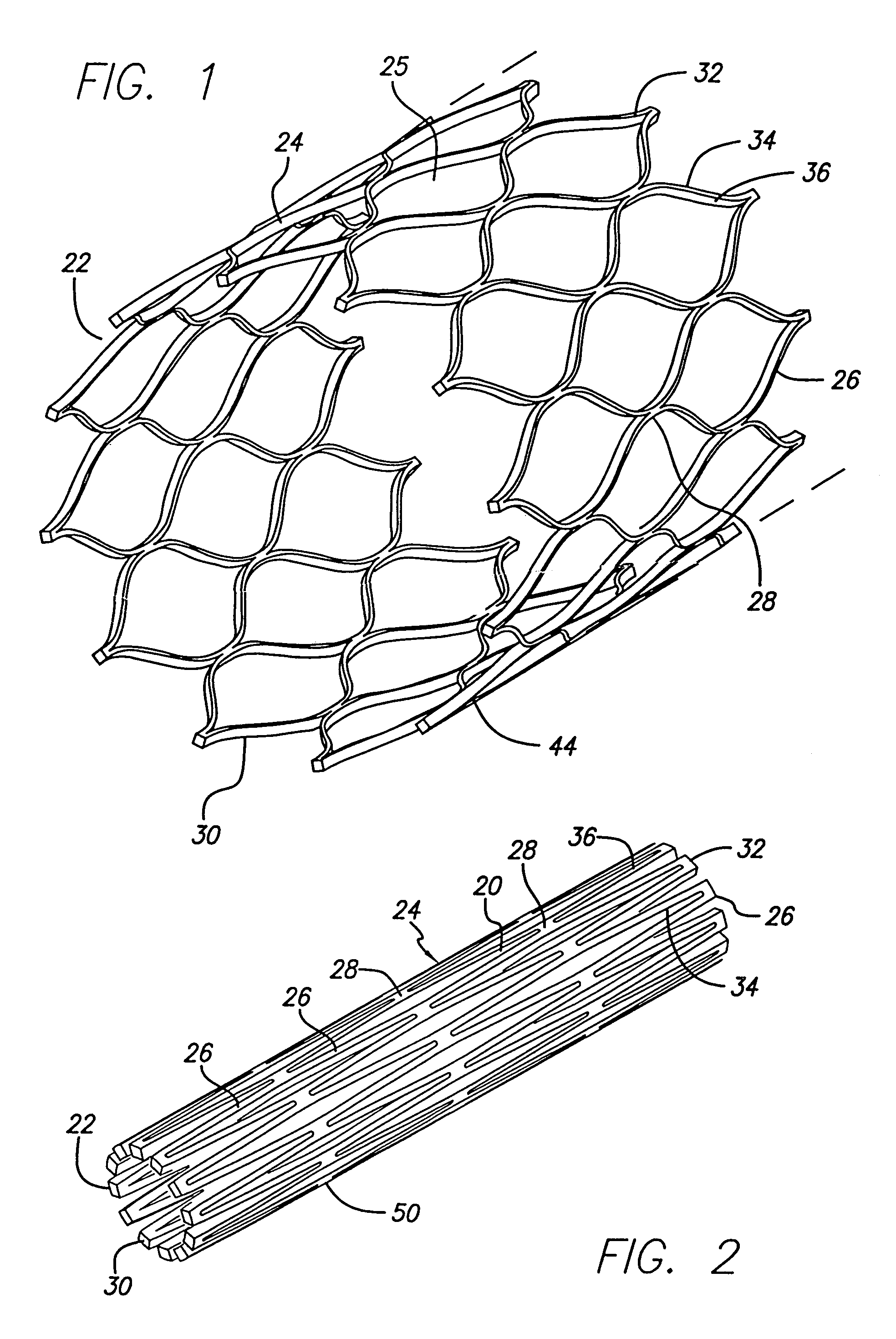

Reduced profile AAA device

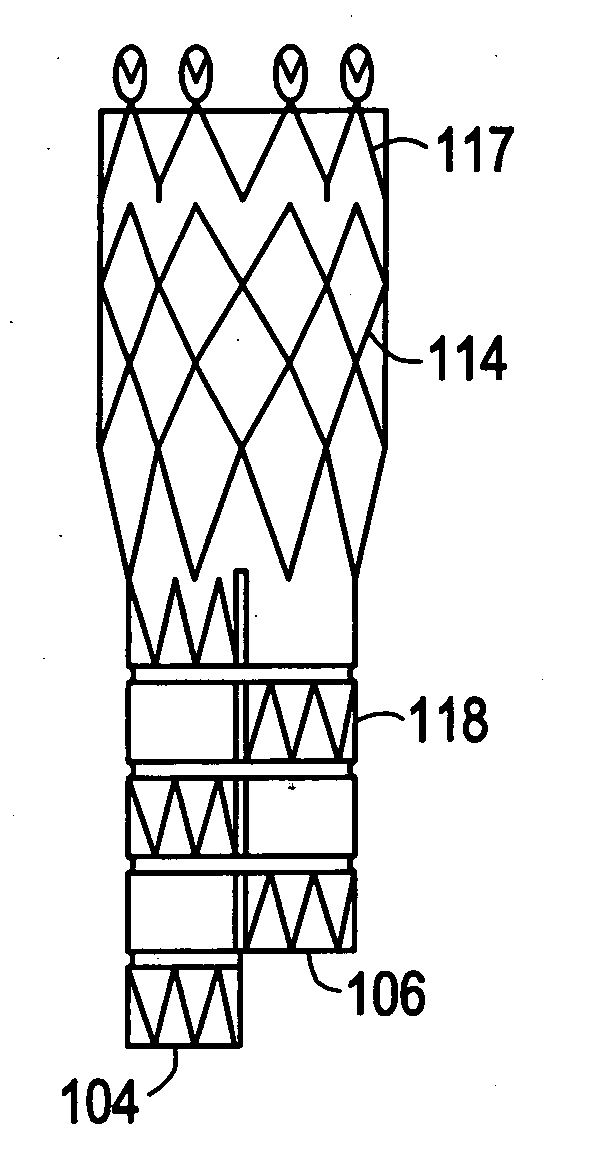

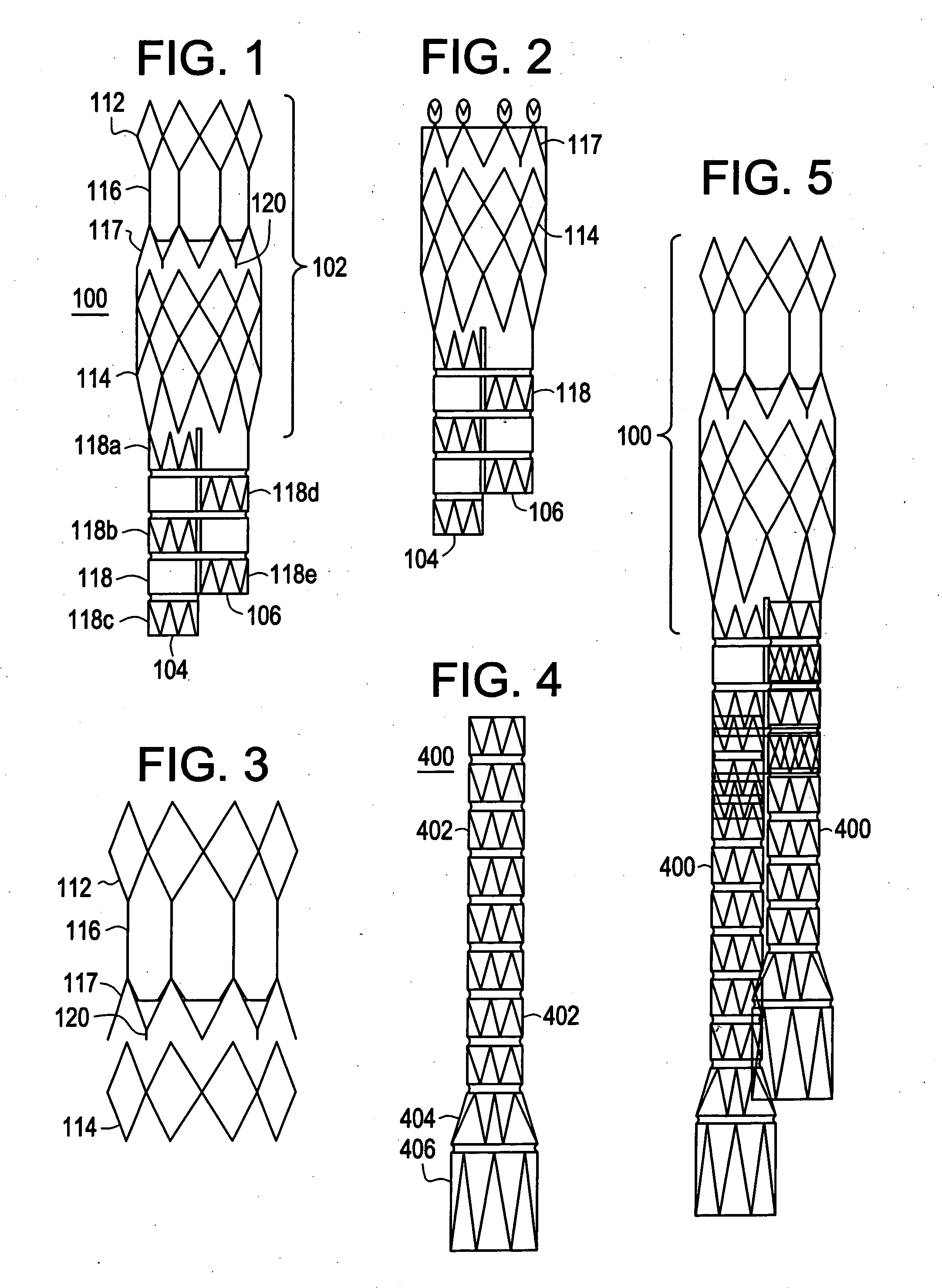

An abdominal aortic aneurysm endoprosthesis having a reduced profile for percutaneous delivery of the endoprosthesis. The endoprosthesis provides a cranial section supported by a stent, and a bifurcated caudal section having at least two legs each of which are supported by individual stents. The individual stents of each leg of the caudal section are staggered so as not to line up with one another. Altering the lengths of the legs permits nesting of the endoprosthesis. Optimizing the expansion ratio and radial strength of the endoprosthesis is achieved by altering the dimensions of the starting material from which the stent segments are fabricated, by altering the final austentite temperature of the starting materials, or by changing the structural configuration of the stent segments. A graft material is attached to at least a portion of the cranial section and to all of the caudal section of the endoprosthesis.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

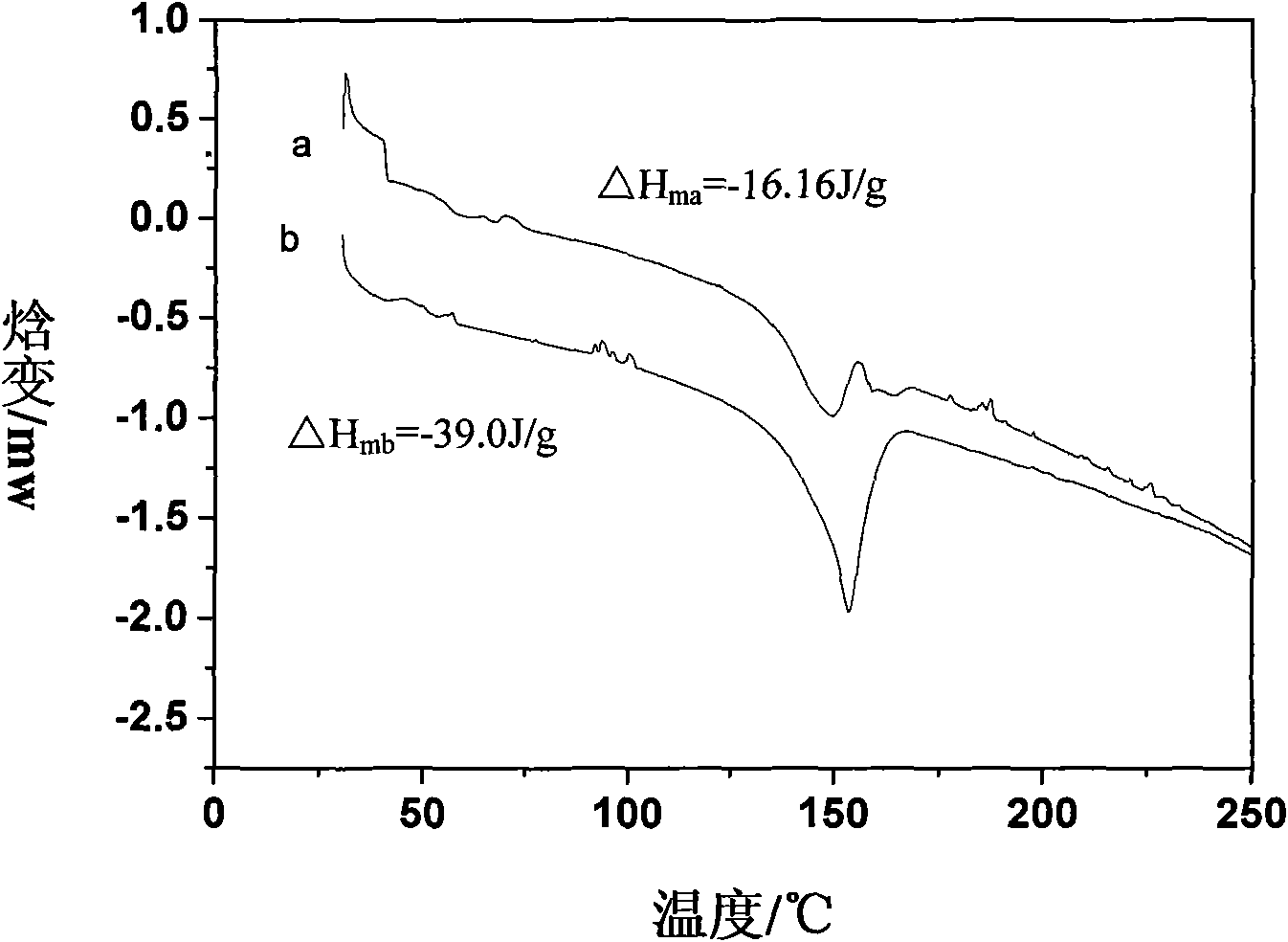

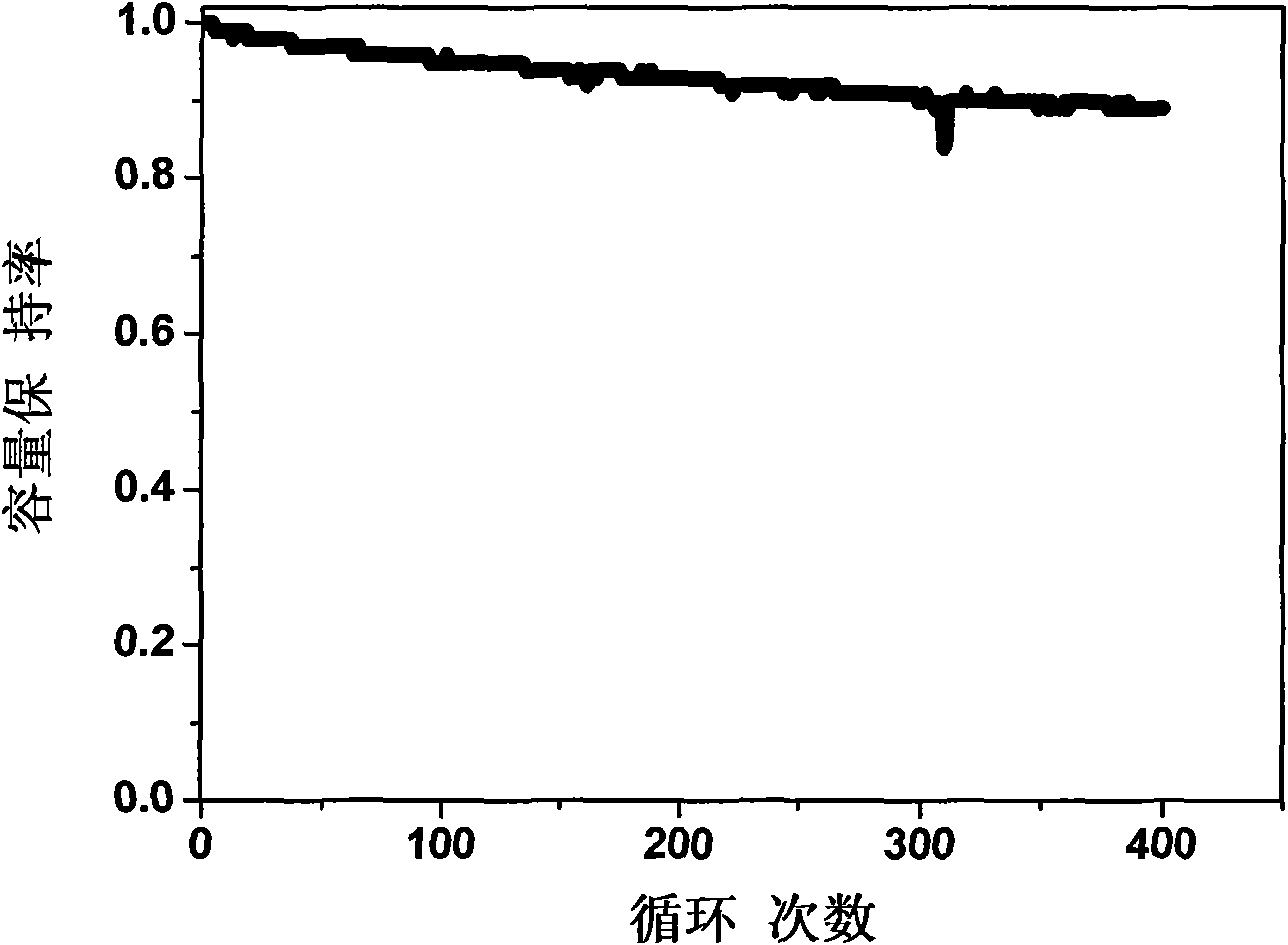

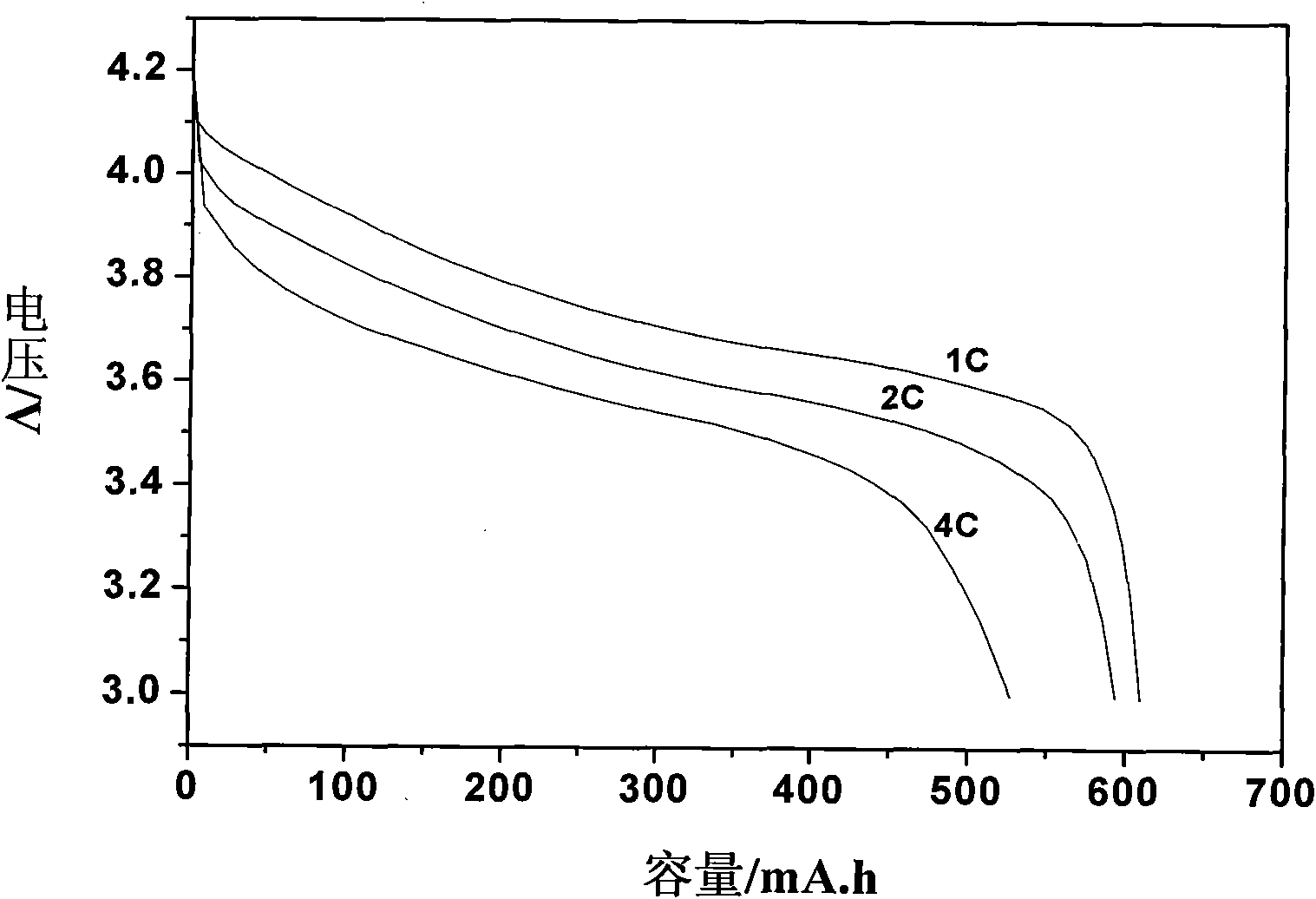

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

Cavity sealing article having improved sag resistance

Conventional foamable cavity sealing articles are susceptible to sagging when expanded in a vertical orientation with the foaming material facing downwards, because of gravitational drag on the molten material during expansion. The problem is particularly pronounced in foaming materials formulated to have high expansion ratios and low melt viscosities. A solution to the problem is presented in the form of a cavity sealing article having a planar holder and a foamable sealer, the foamable sealer circumscribing the edge of the support member. This construction creates a gripping effect which prevents sagging of the sealing member during expansion.

Owner:TYCO INT PA +2

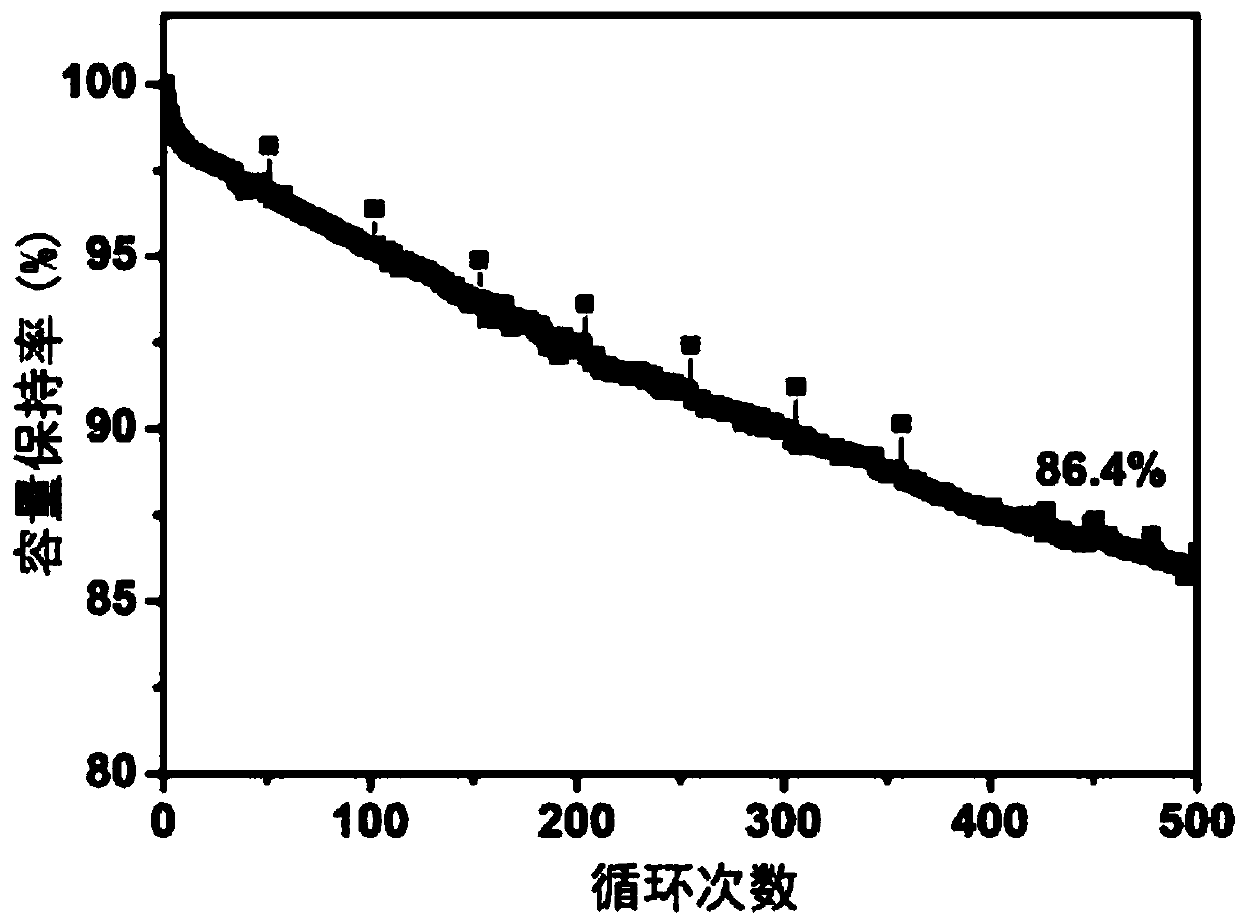

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

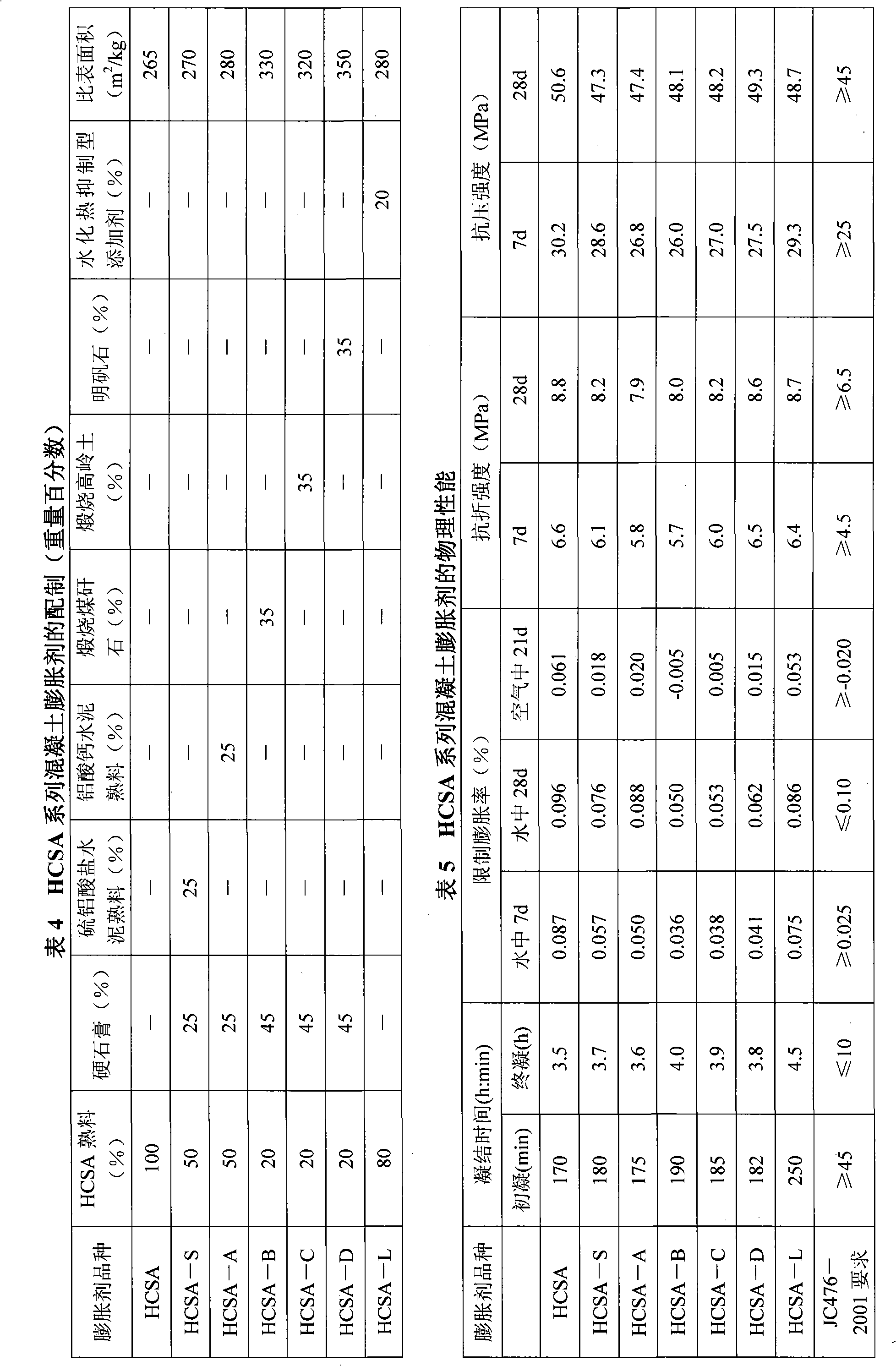

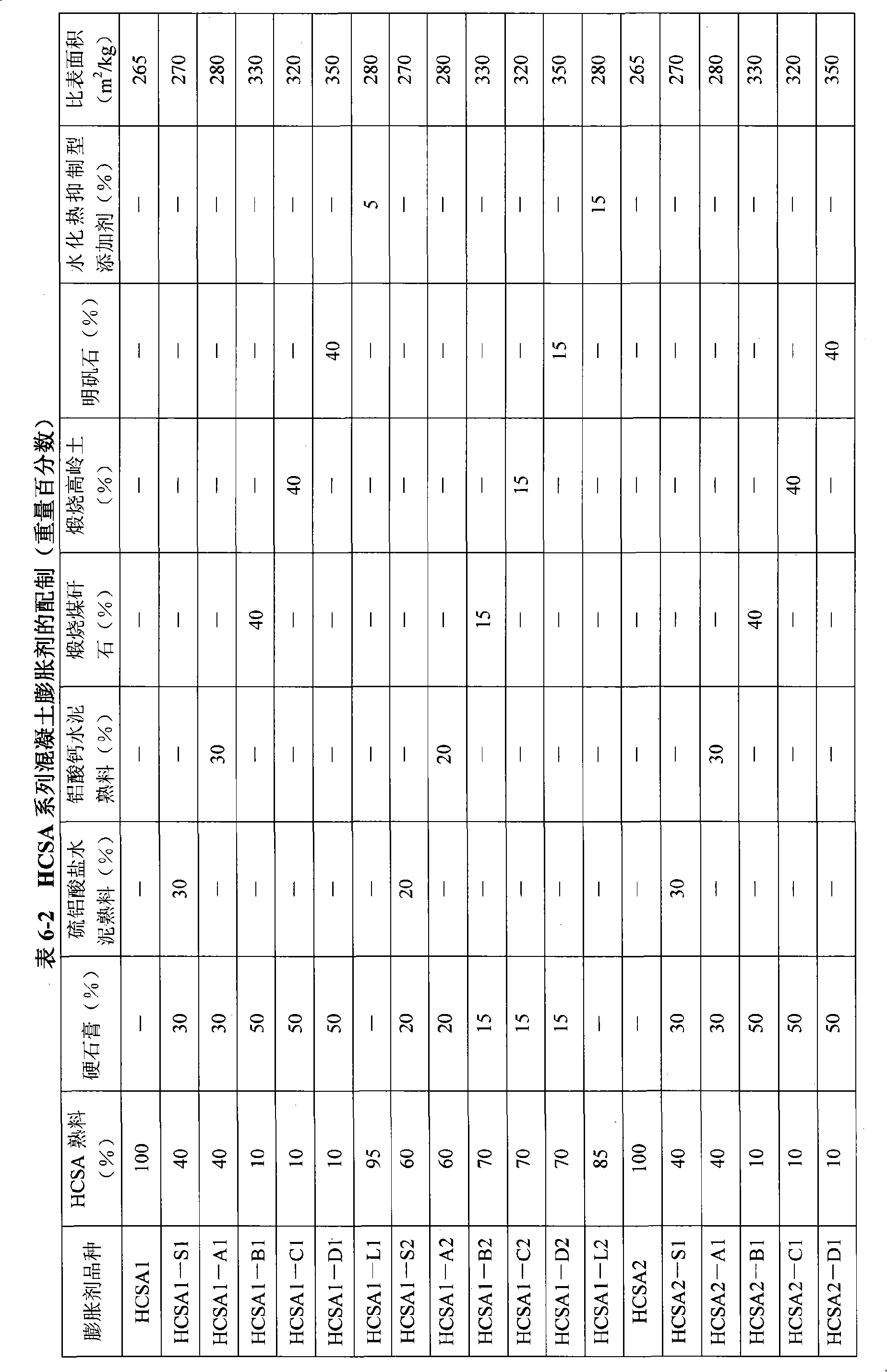

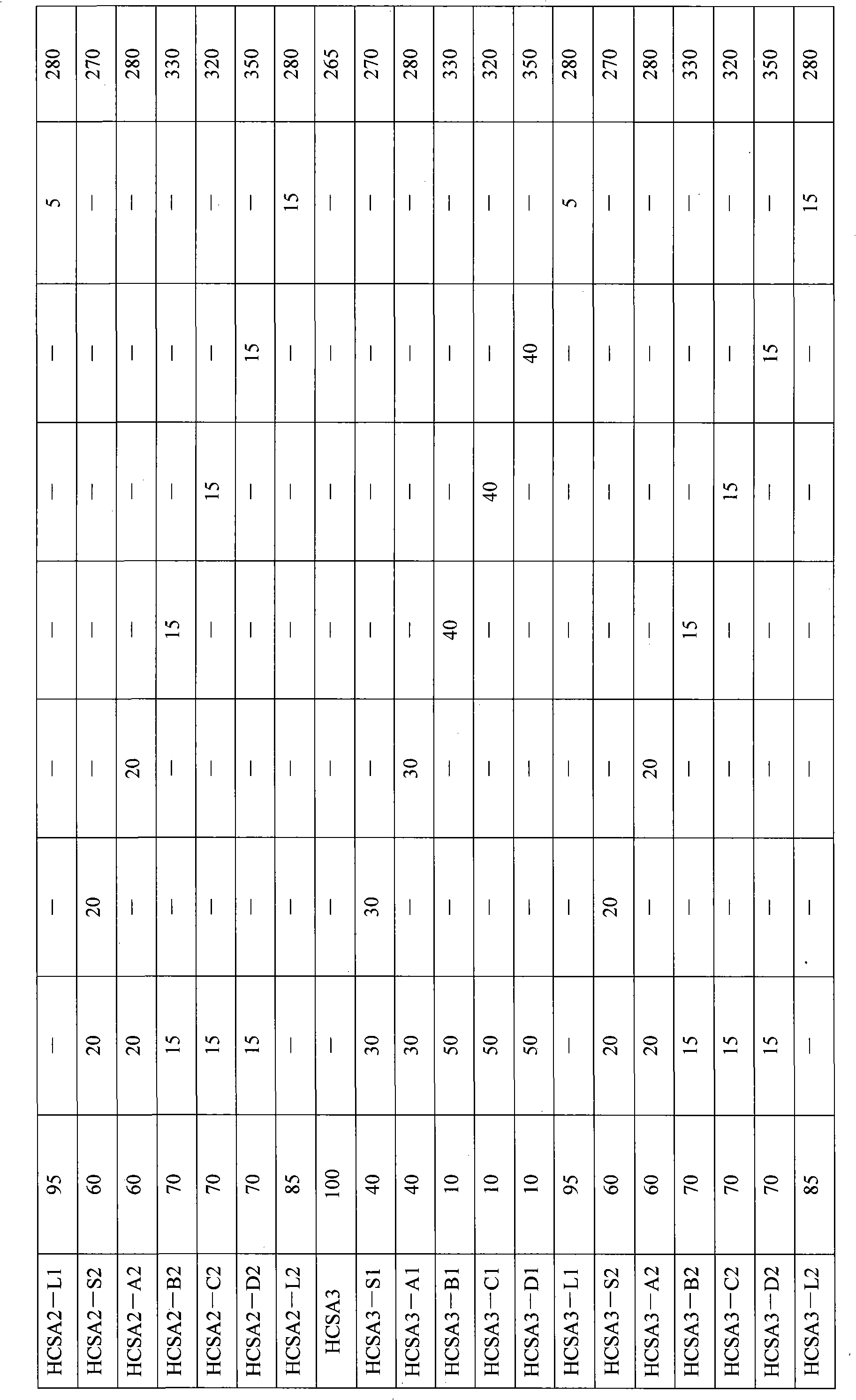

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

SiOx based composite negative electrode material, preparation method and battery

ActiveCN103647056AGood dispersionQuick blend effectCell electrodesLi-accumulatorsCarbon coatingSilicon oxide

The invention relates to a high-capacity SiOx based composite negative electrode material, a preparation method and a battery, wherein the negative electrode material comprises a silicon oxide material, a carbon material and an amorphous carbon coating layer; the silicon oxide material is silicon oxide or silicon oxide material modified in a carbon coating manner; surfaces of carbon material particles are coated with the silicon oxide material. A preparation method of the high-capacity SiOx based composite negative electrode material comprises the steps of performing physical processing or carbon coating modification on a silicon oxide raw material, thus obtaining a micron-sized silicon oxide material; and then mechanically fusing, coating with a solid phase and sintering at a high temperature to obtain the high-capacity negative electrode material. Through the high-capacity SiOx based composite negative electrode material, the effect of uniform dispersing and coating of the micron-sized silicon oxide particles on the surfaces of the carbon material particles can be achieved by virtue of the combination of mechanical fusion and solid-phase coating processes. The silicon oxide particles are well dispersed on the surface of the carbon material particle; the strength of bonding between the silicon oxide particles and the carbon material particles is high; the recycling performance of the material can be greatly improved; and meanwhile, the high-capacity SiOx based composite negative electrode material is high in first efficiency (breaking through the theoretical efficiency of SiOx), low in expansion rate, long in service life, environmental-friendly, pollution-free and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD

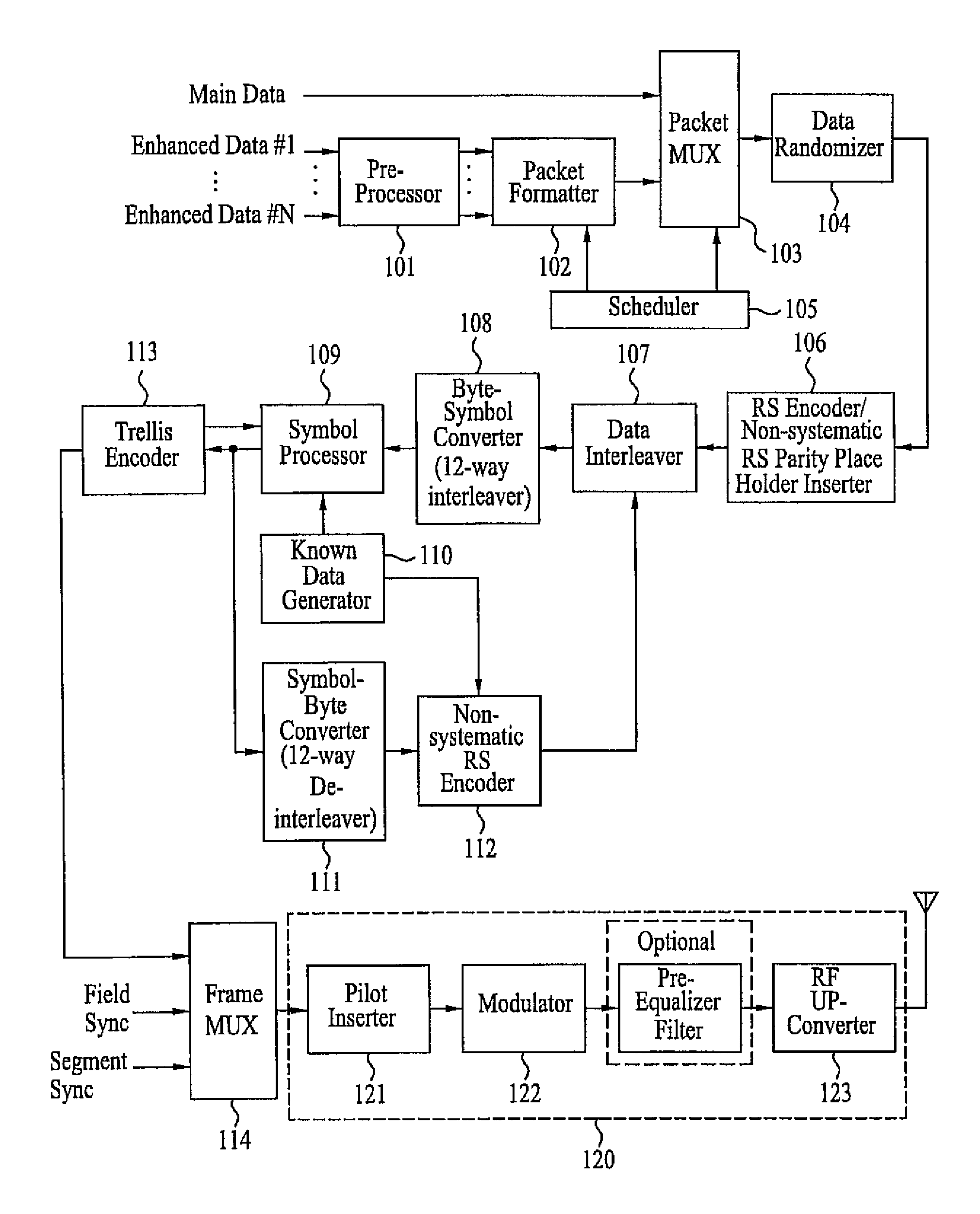

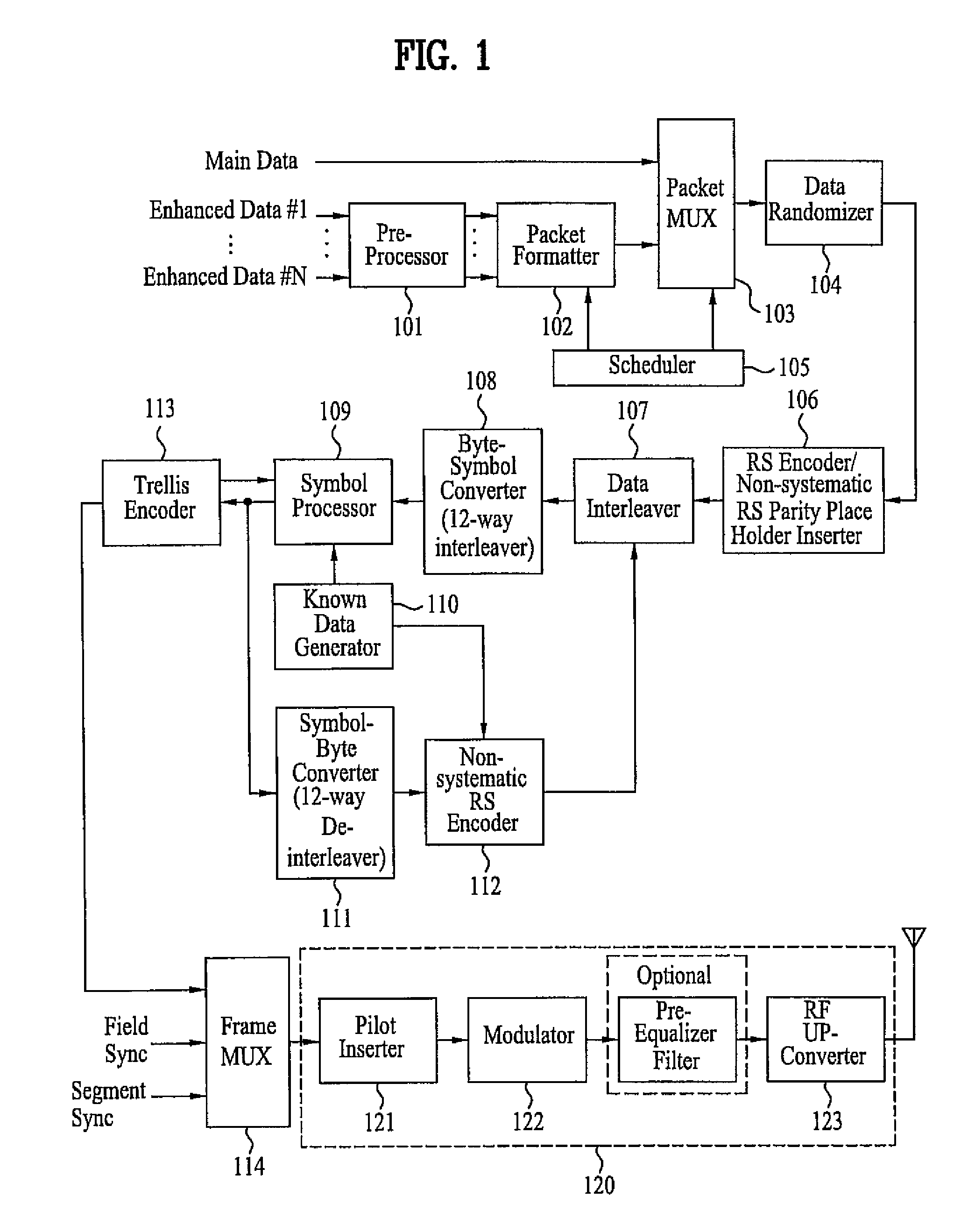

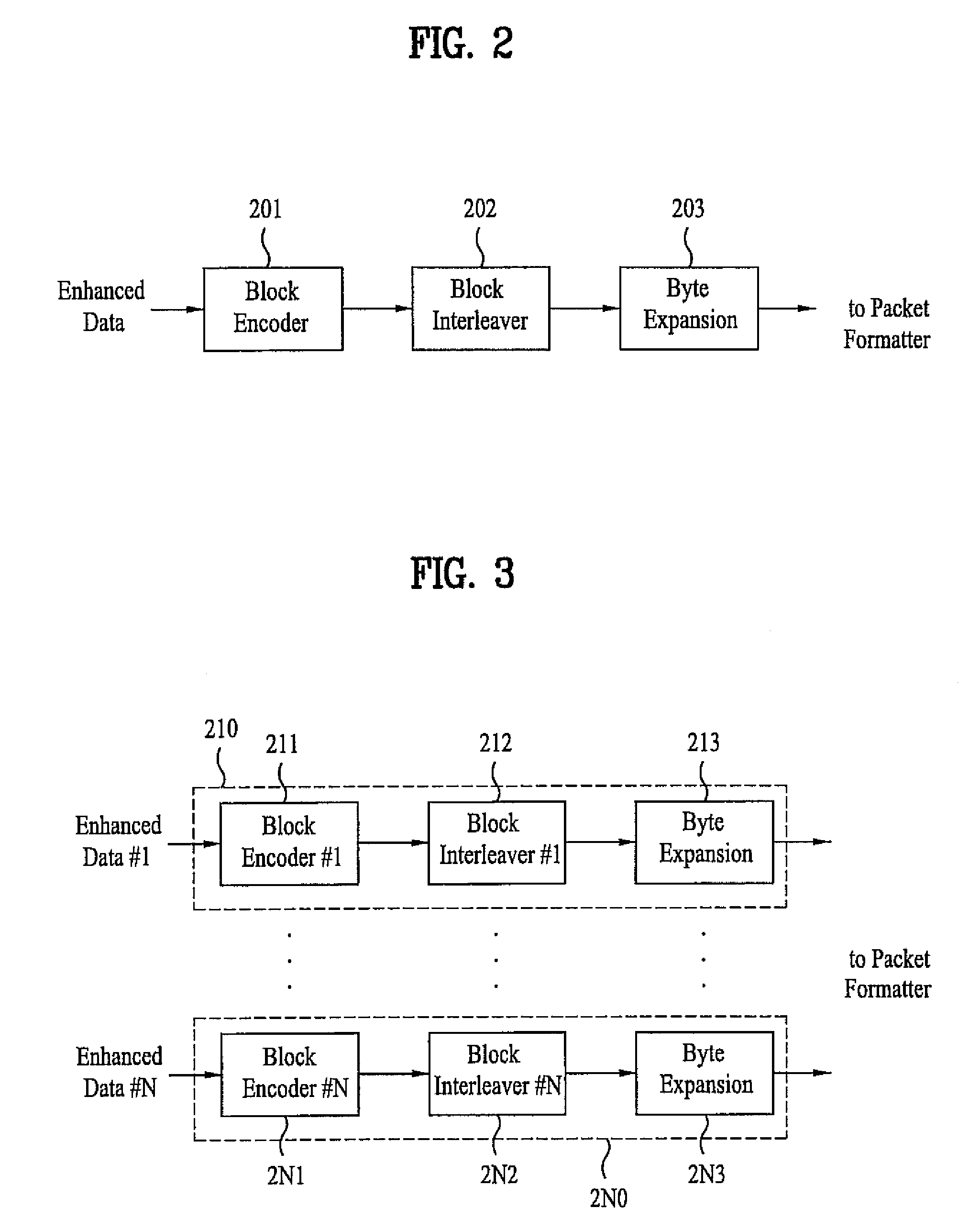

DTV transmitting system and receiving system and method of processing broadcast signal

InactiveUS7840882B2Improve reception performanceTelevision system detailsData representation error detection/correctionMultiplexerForward error correction

A DTV transmitting system includes a first pre-processor for coding first enhanced data having a high priority for forward error correction (FEC) at a first coding rate and expanding the first enhanced data at a first expansion rate, and a second pre-processor for coding second enhanced data having a low priority for FEC at a second coding rate and expanding the second enhanced data at a second expansion rate. The receiving system further includes a data formatter for generating enhanced data packets, a multiplexer for multiplexing the enhanced data packets with main data packets, an RS encoder for RS-coding the multiplexed data packets, and a data interleaver for interleaving the RS-coded data packets and outputting a group of interleaved data packets having a head, a body, and a tail.

Owner:LG ELECTRONICS INC

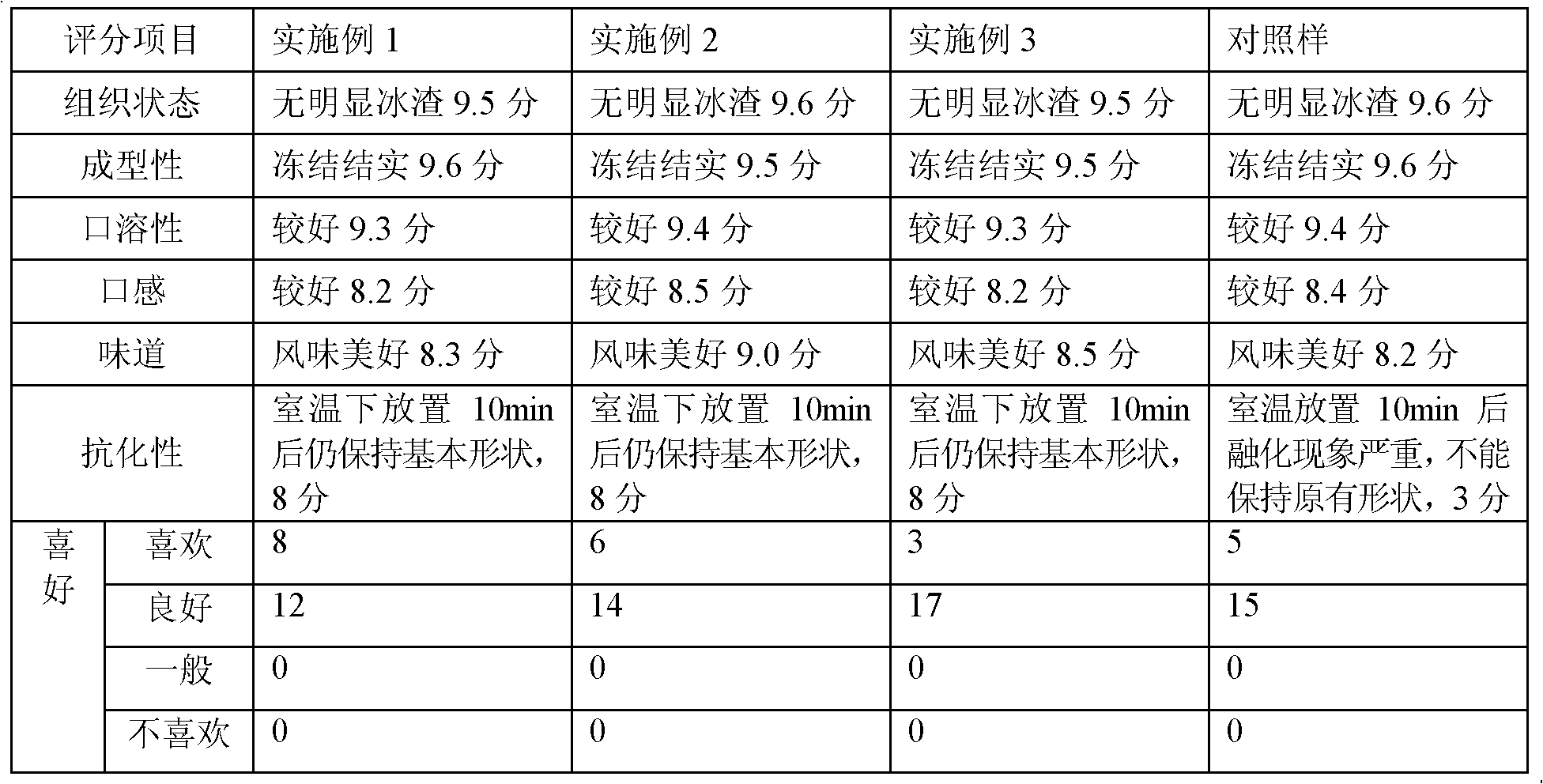

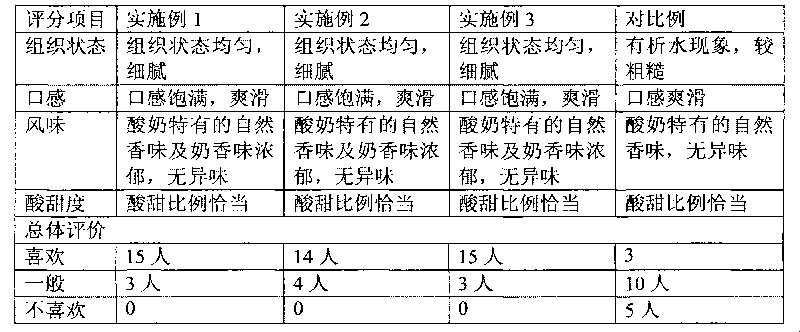

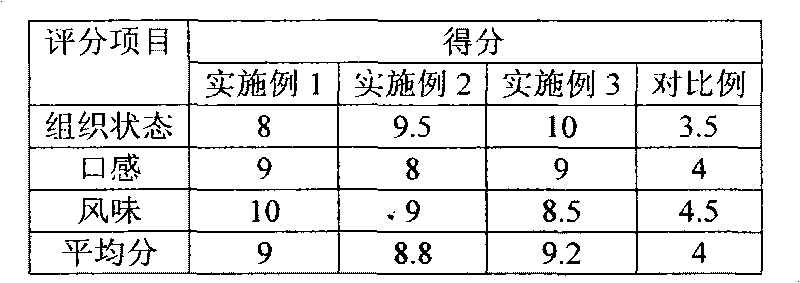

Self-expanding ice-cream and production method thereof

The invention provides self-expanding ice-cream and a production method thereof. The self-expanding ice-cream comprises, by total weight, 35%-80% of light cream, 0.1-5% of thickener, and 0.1%-5% of super absorbent polymer, wherein the thickener is from one or a plurality of gelatin, sodium alginate and carrageen, and the super absorbent polymer is from one or a plurality of locust bean gum, xanthan gum, gellan gum and guar gum. In addition, milk fat content of the ice-cream is 15%-25%. The production method of the self-expanding ice-cream includes: whipping light cream of the ice-cream ingredients until expansion rate of the light cream reaches 60%-85%; mixing the light cream with other ingredients to make ice-cream liquid; and pouring the ice-cream liquid into a mould prior freezing into the finished ice-cream. The ice-cream can have certain expansion rate and good organization and taste with no coagulating needed in production of the self-expanding ice-cream, and the ice-cream is excellent in forming performance, oral thawing performance and thawing resistance.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

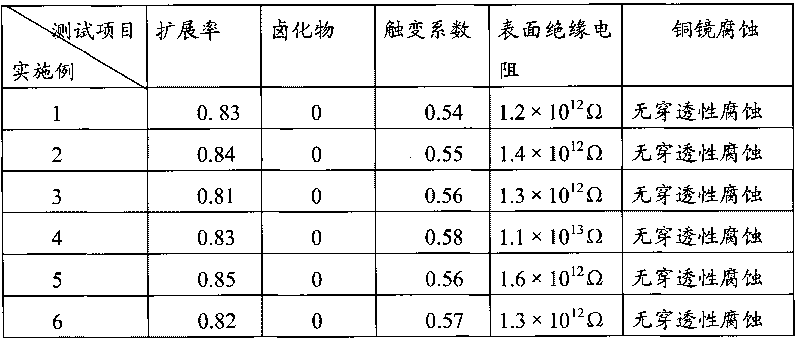

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

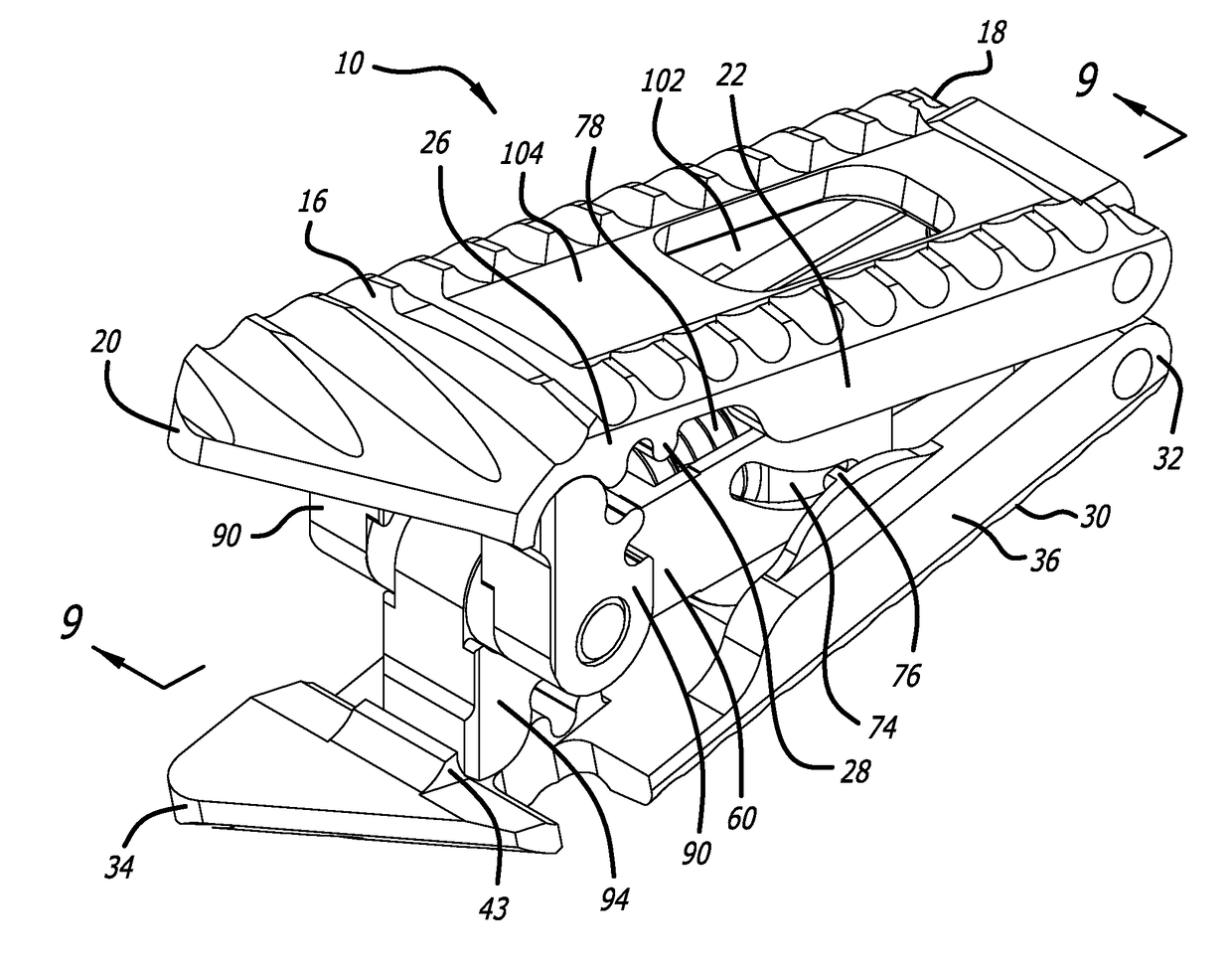

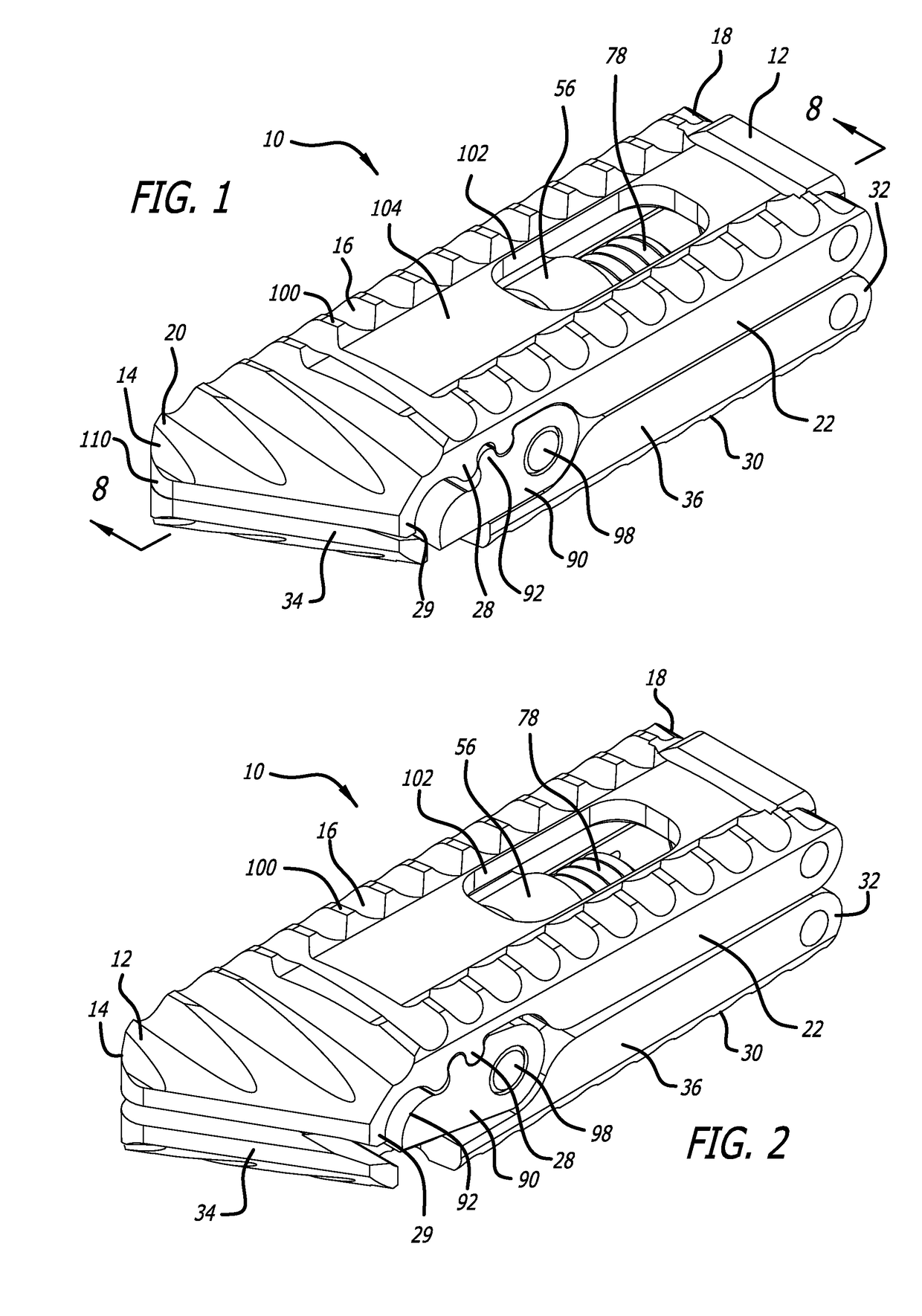

Geared cam expandable interbody implant and method of implanting same

A geared cam expandable spinal implant. Rotational motion of a rotating portion is translated into linear motion of a yoke, which moves geared cams at the distal end of the implant to mate with, and walk along, teeth of corresponding racks. The walking of the gear cam teeth along the rack teeth creates a regular rate of implant expansion, reduces initial excessive expansion force applied to the implant, and provides fine adjustment of the expansion rate and force.

Owner:WARSAW ORTHOPEDIC INC

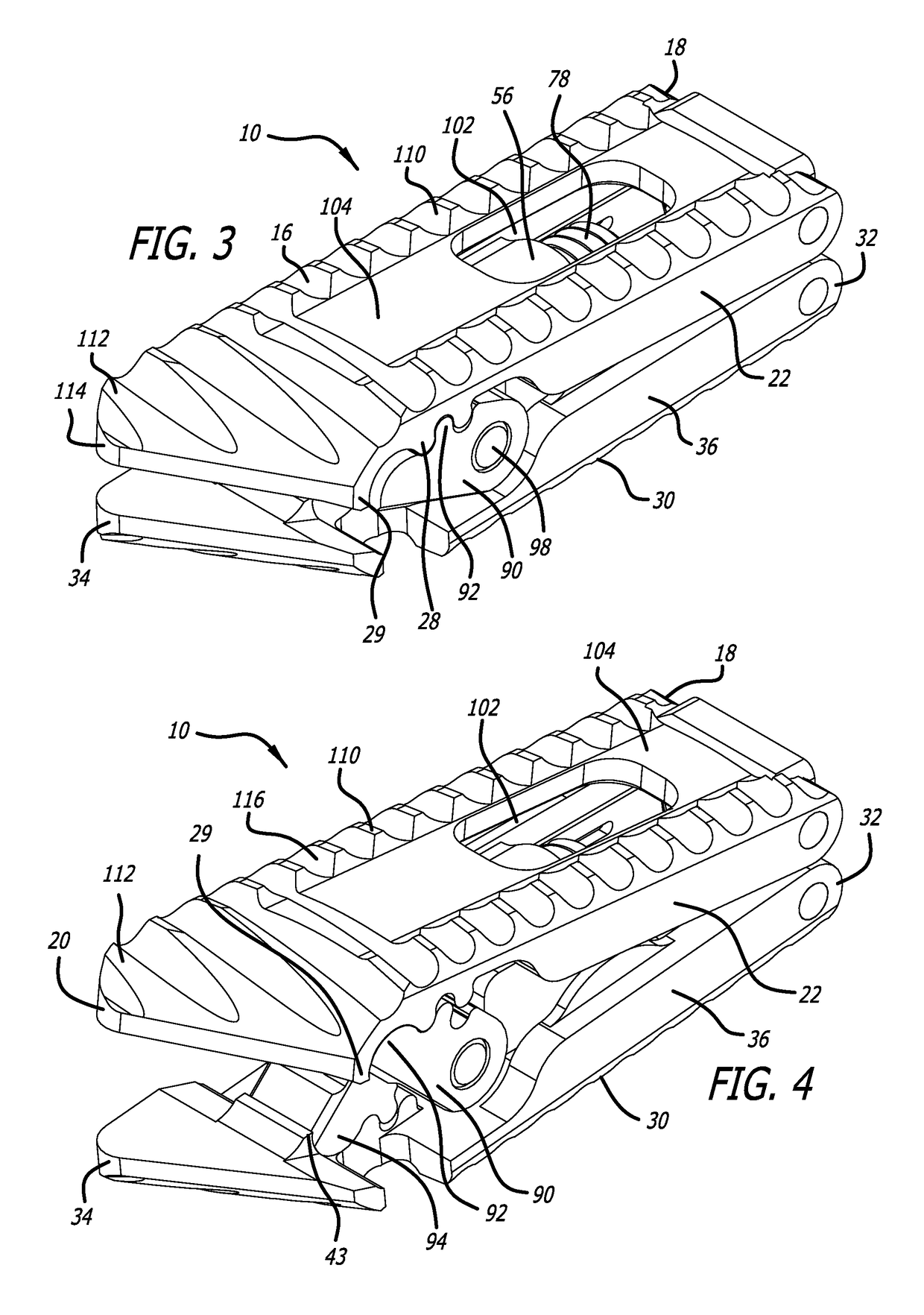

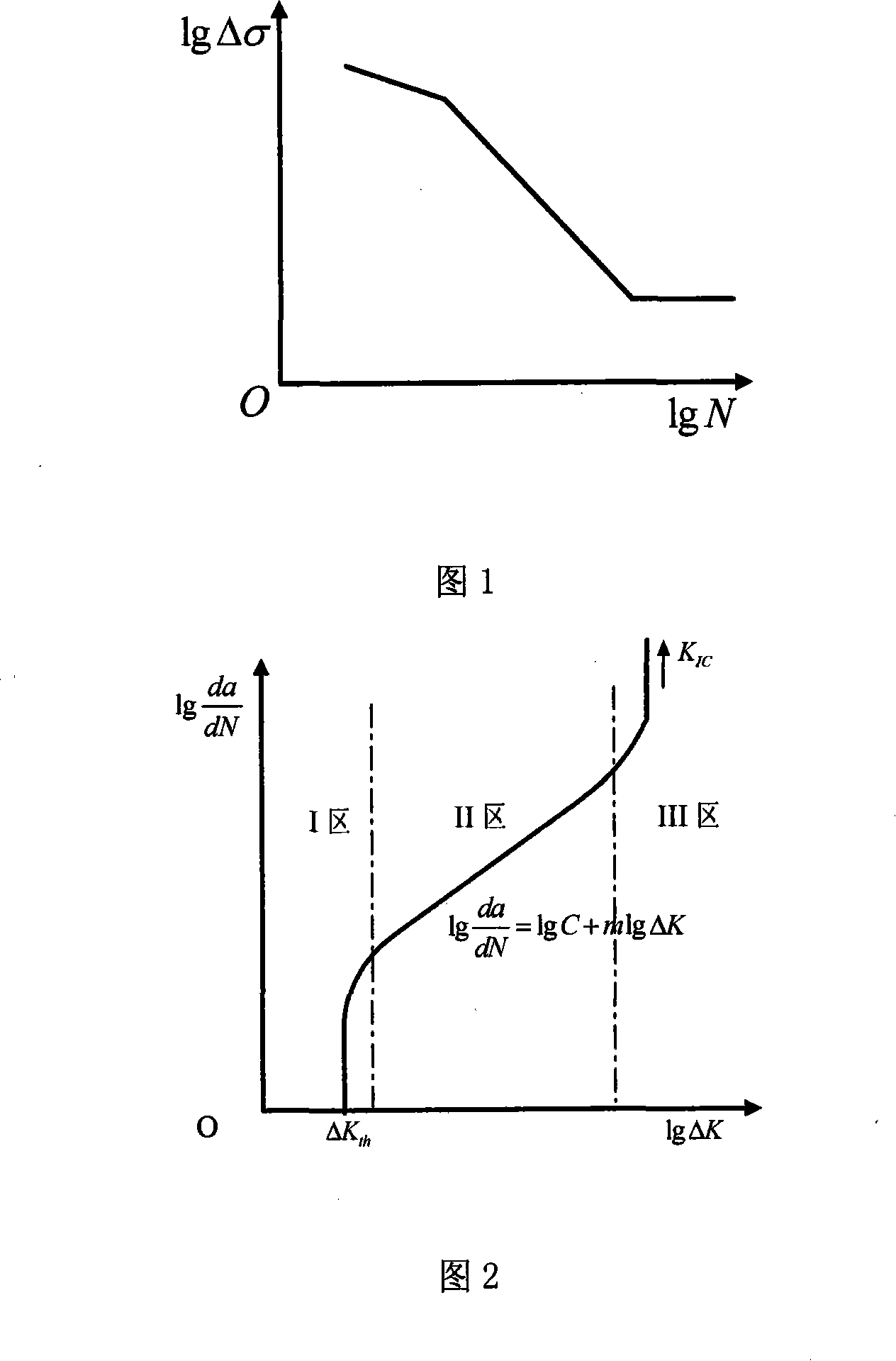

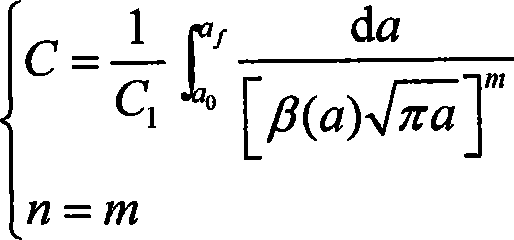

Mechanical structure crack expansion rate and crack expansion life span predication method

InactiveCN101122560ASave moneyShorten the development cycleUsing mechanical meansComplex mathematical operationsHysteresisCrazing

A crack growth rate and crack growth life prediction method for a mechanical structure belongs to a calculation method for fatigue crack growth rate and crack growth length of the mechanical structure. At first, a relationship between S-N and P-S-N curve expressions (power function form) and a crack growth rate curve expression (Paris formula) is built up in the method. A determination method of the crack growth rate under the conditions of block spectrum load, overload hysteresis load and random load is proposed. And a determination method of Paris curve parameters is provided when the S-N and P-S-N curves cannot be expressed in power function form. And a method for improving the prediction precision of the crack growth rate and the crack growth life is proposed. The S-N and P-S-N curves are used by the method to predict the crack growth rate and the crack growth life. Therefore, the method has the advantages of little dependence on tests and high precision and can shorten the product development period and save much manpower, material resources and financial resources.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

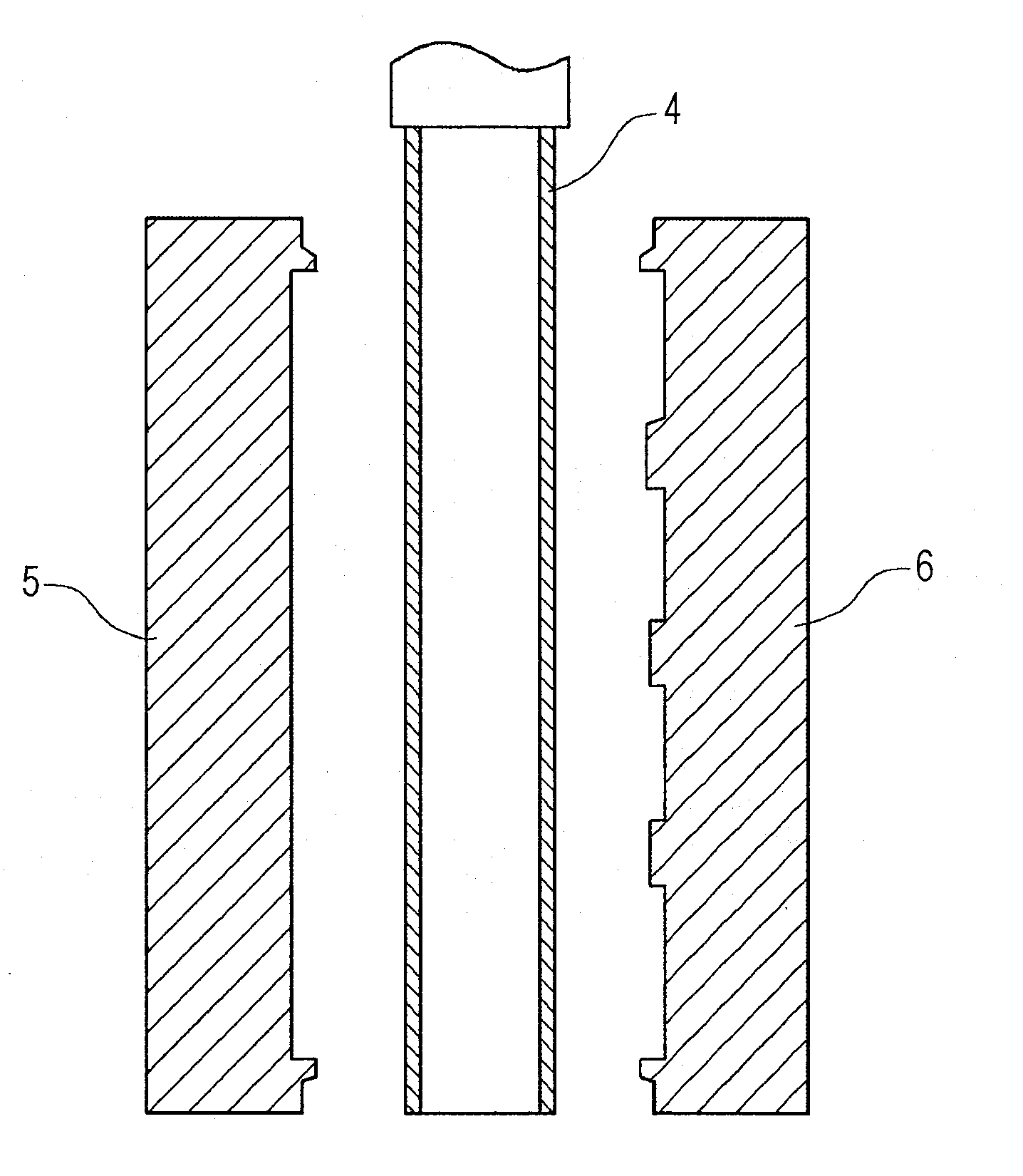

Method for molding molded foam, and molded foam

ActiveUS20110104414A1High expansion rateReduce weightClosuresLayered productsFoaming agentPolypropylene

The invention provides a molded foam molding method capable of obtaining a molded foam in which pinholes may not be formed with ease even when a blow ratio is high and which has a high expansion ratio. The invention also provides a molded foam which includes no pinholes, is reduced in weight, and is excellent in heat insulating property. The molding method includes blending a polypropylene-based resin having an equilibrium compliance from 2.0 to 6.0 (10−3×Pa−1) with a foaming agent and kneading the blend in an extruder. The extruded foamed resin is molded so as to be fit along a mold by a pressurized fluid. Moreover, the molded foam is formed by the method described above, and has an expansion ratio from 1.5 to 5.0 times and an impact strength of not less than 30 kg·cm.

Owner:KYORAKU CO LTD

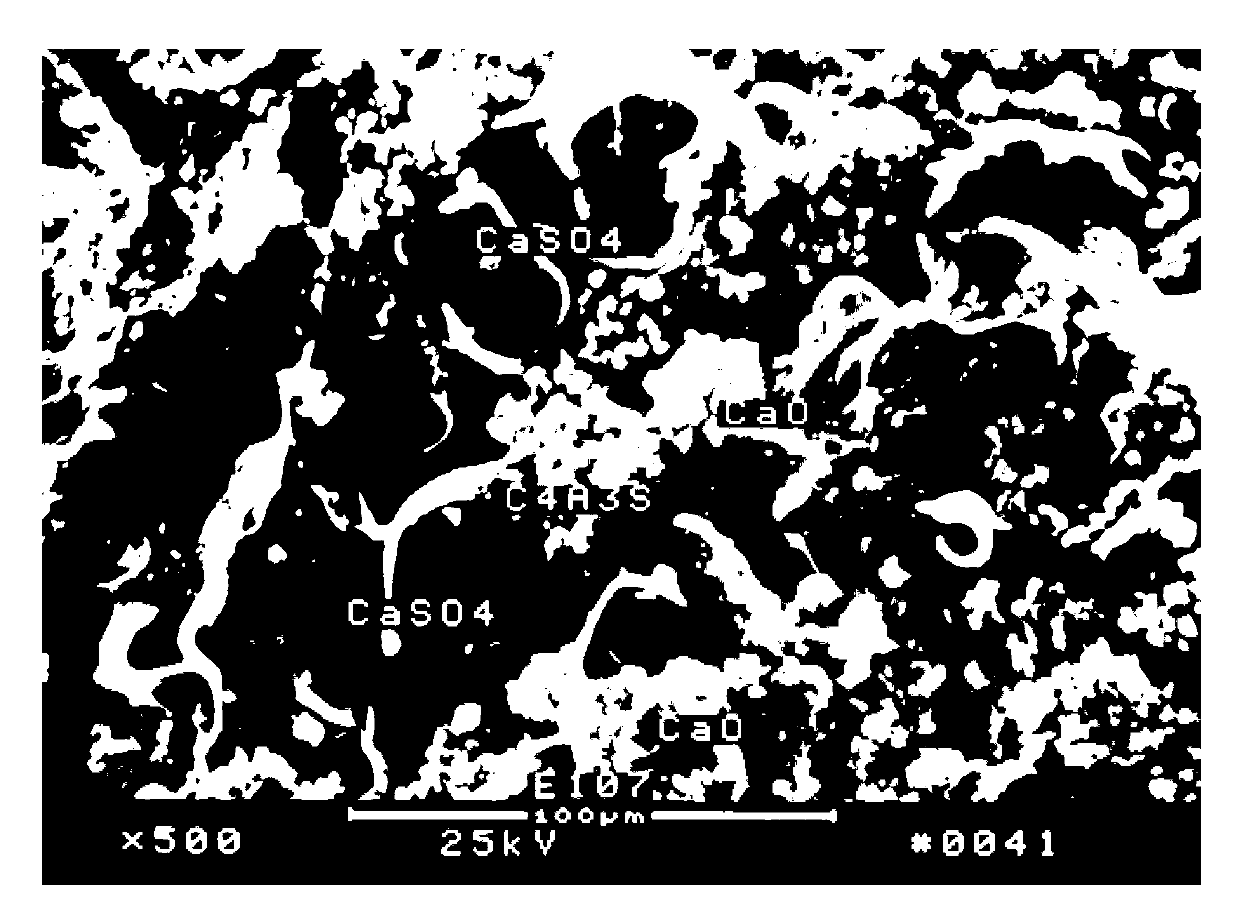

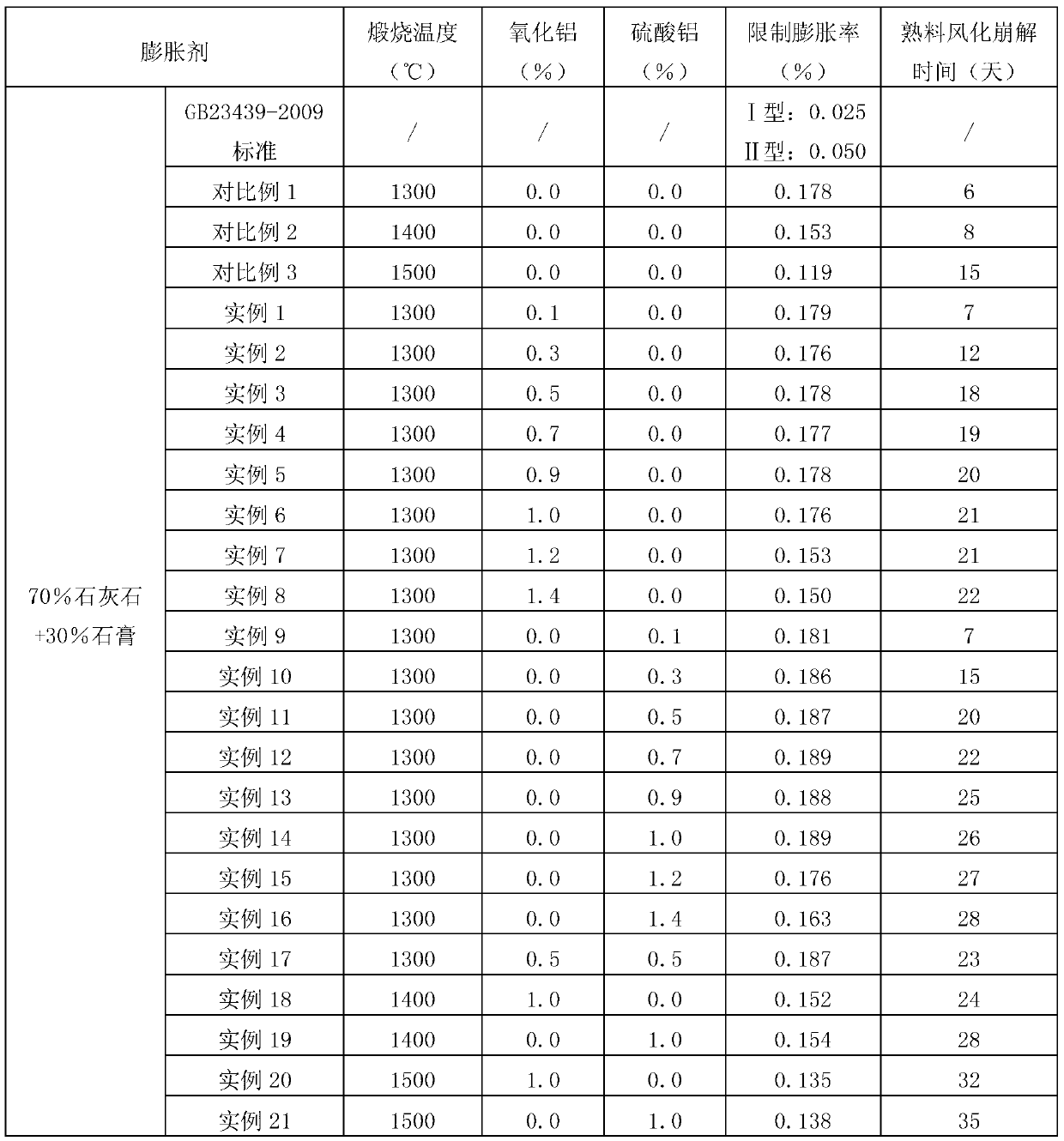

Gypsum and calcium oxide melt inclusion expansion clinker, concrete expansion agent, and preparation method and application thereof

The invention relates to a gypsum and calcium oxide melt inclusion expansion clinker, a concrete expansion agent, and a preparation method and application thereof, belonging to the field of construction materials. The expansion clinker provided by the invention is prepared by mixed grinding and high-temperature burning of limestone, gypsum and aluminum oxide and / or aluminum sulfate. The concrete expansion agent is prepared by grinding the expansion clinker together with a calcium sulphoaluminate cement clinker, calcium stearate or / and triethanolamine until the specific surface area is 140-400 m<2> / kg. According to the invention, the expansion clinker has high restrained expansion rate and high clinker weathering resistance; the concrete expansion agent has the functions of cracking resistance, seepage resistance, shrinkage compensation and the like, and has the advantage of long product shelf life (up to 6 months). The concrete expansion agent can be used for cracking resistance and seepage resistance of a common concrete structure, and can greatly enhance the durability of the concrete.

Owner:CHINA BUILDING MATERIALS ACAD

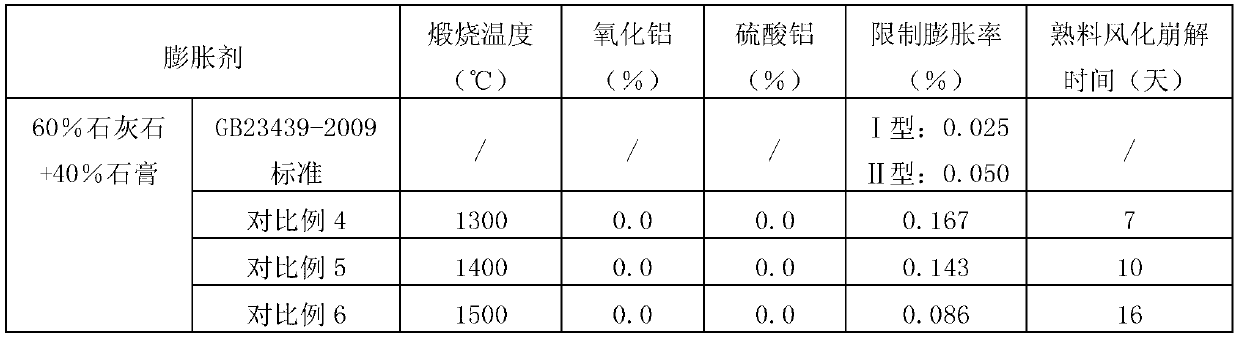

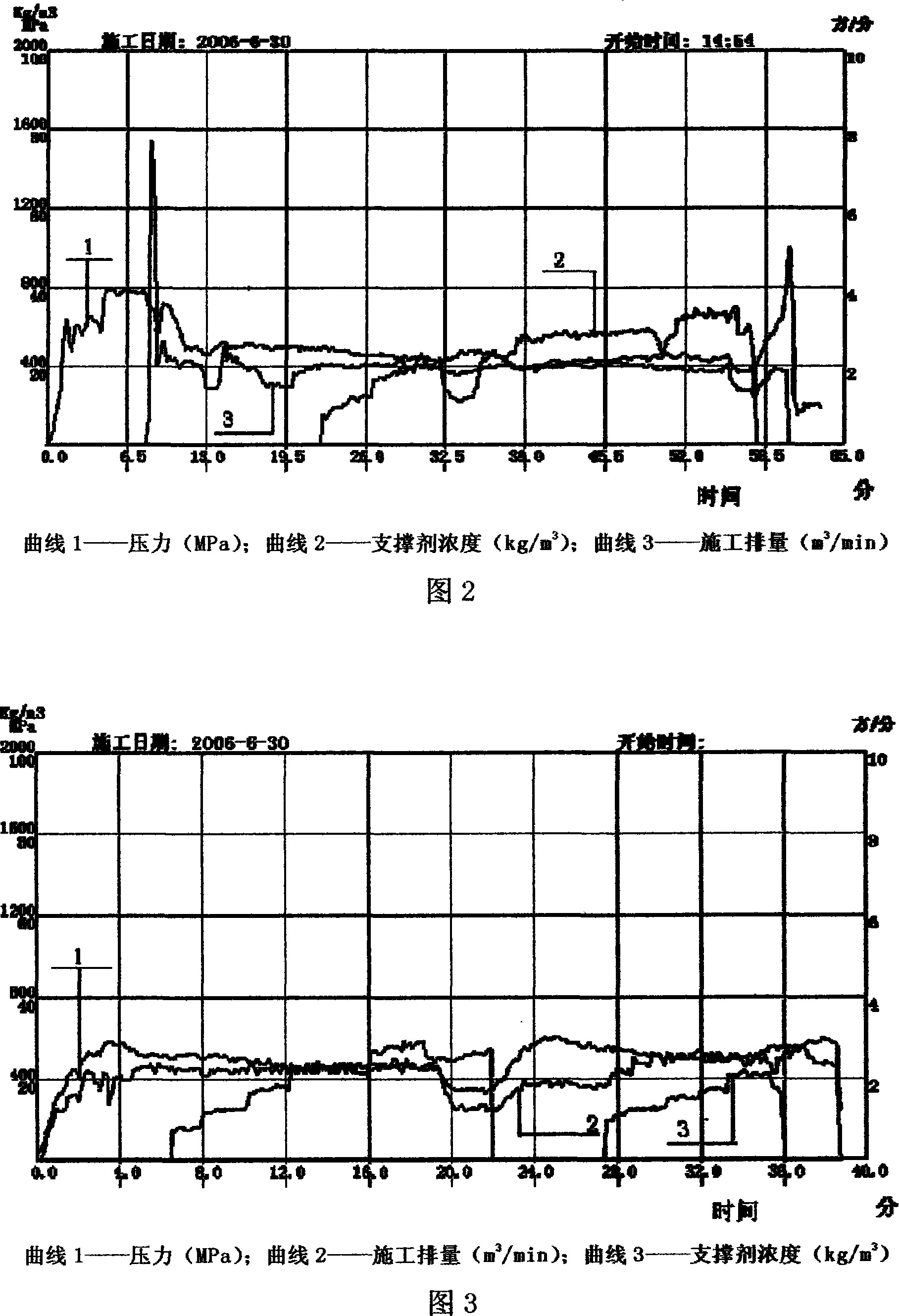

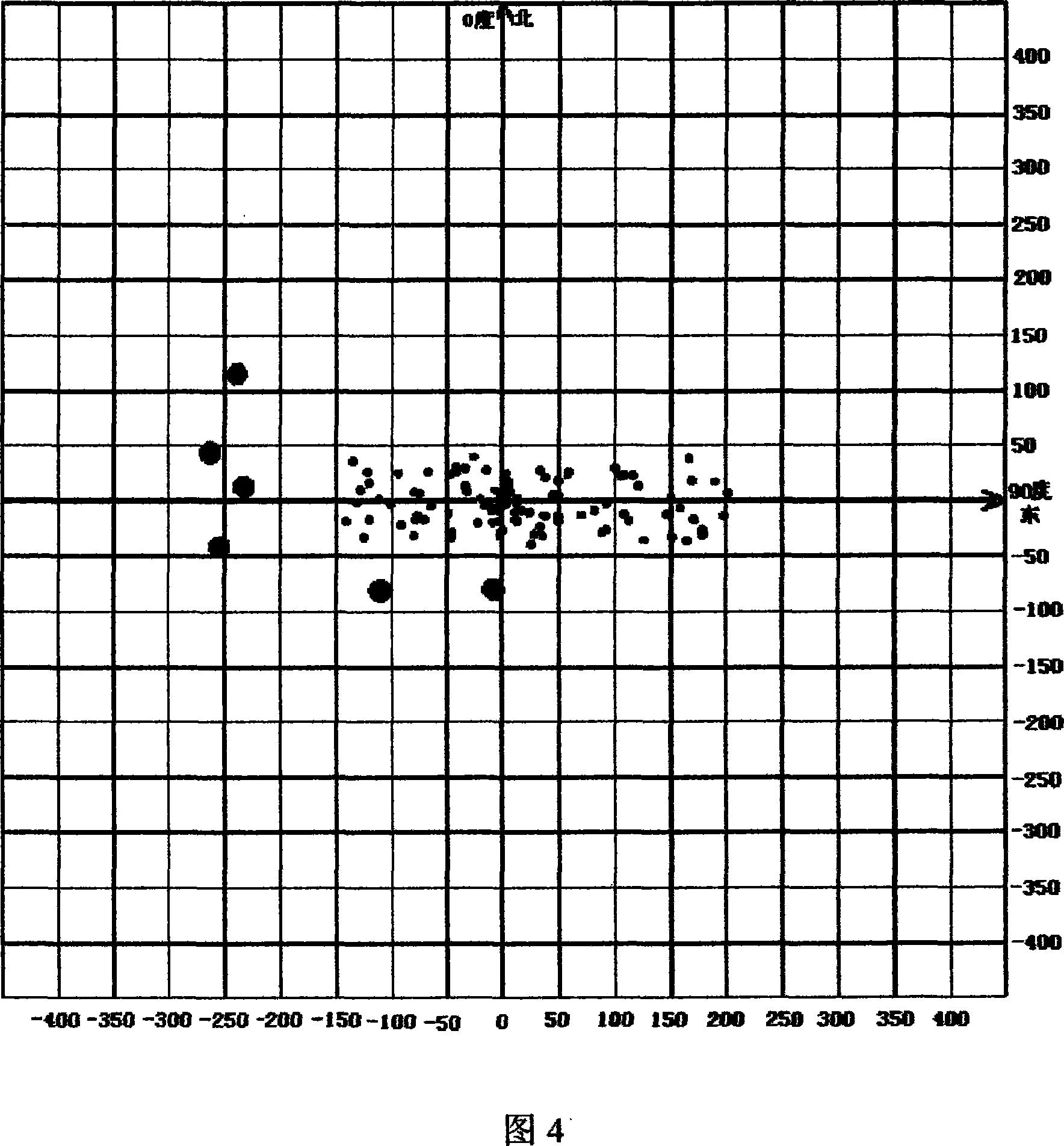

Fracturing process for enhancing low permeability reservoir deliverability

ActiveCN101113669AGuaranteed permeabilityIncreased productivity after pressingFluid removalAcid fracturingClay minerals

The invention relates to an oil field production technique, in particular to a fracturing method applied under the oil well to improve new well production capacity of low permeability reservoir before being brought into production. The fracturing reformation course at least comprises common fracturing technique and is characterized in that the method uses a compound application of more than two techniques of the use of acid fracturing liquid, or diversion agent or acid liquid and diversion agent by adopting high-energy gas fracturing technique; the upper sealed fracturing pipe is adopted during the working of hydraulic fracturing; the acid liquid is adopted during a pad fluid stage as the working liquid; the diversion agent is added for one or more times to seal fractured cracks; an increasing working flow rate is adopted before and after the adding of the diversion agent. The method of the invention can increase oil discharging area after fracturing, reduce expansion rate of clay minerals in fractured reservoir and improve completion of oil well reformation, fracturing effect and production capacity of low permeability reservoir after fracturing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Recomposed bamboo board producing process

ActiveCN103496024AHigh hardnessHigh strengthFlat articlesDomestic articlesHardnessVolumetric Mass Density

The invention relates to the field of bamboo production, in particular to recomposed bamboo board producing process. The recomposed bamboo board producing process uses renewable bamboo as raw materials, the utilization rate of bamboo is high and can reach more than 90%, and resource waste is reduced. The density of recomposed bamboo boards manufactured in the recomposed bamboo board process is high as 1200kg / m<3> and is more than 1.6 times of the density of ordinary bamboo floors. The recomposed bamboo boards have the advantages of being high in hardness, high in strength, high impact toughness and wearproof. The recomposed bamboo boards manufactured in the recomposed bamboo board producing process further have the advantages of being capable of resisting to water absorption, free of deformation and the like. Tests show that the thickness expansion rate is only 0.4% after the recomposed bamboo boards absorb water for 24 hours and is far better than and smaller than the European standard of 2.0%. The free formaldehyde emission of the recomposed bamboo boards manufactured in the recomposed bamboo board producing process is below 0.4mg / L, so that harm of formaldehyde to people is reduced.

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

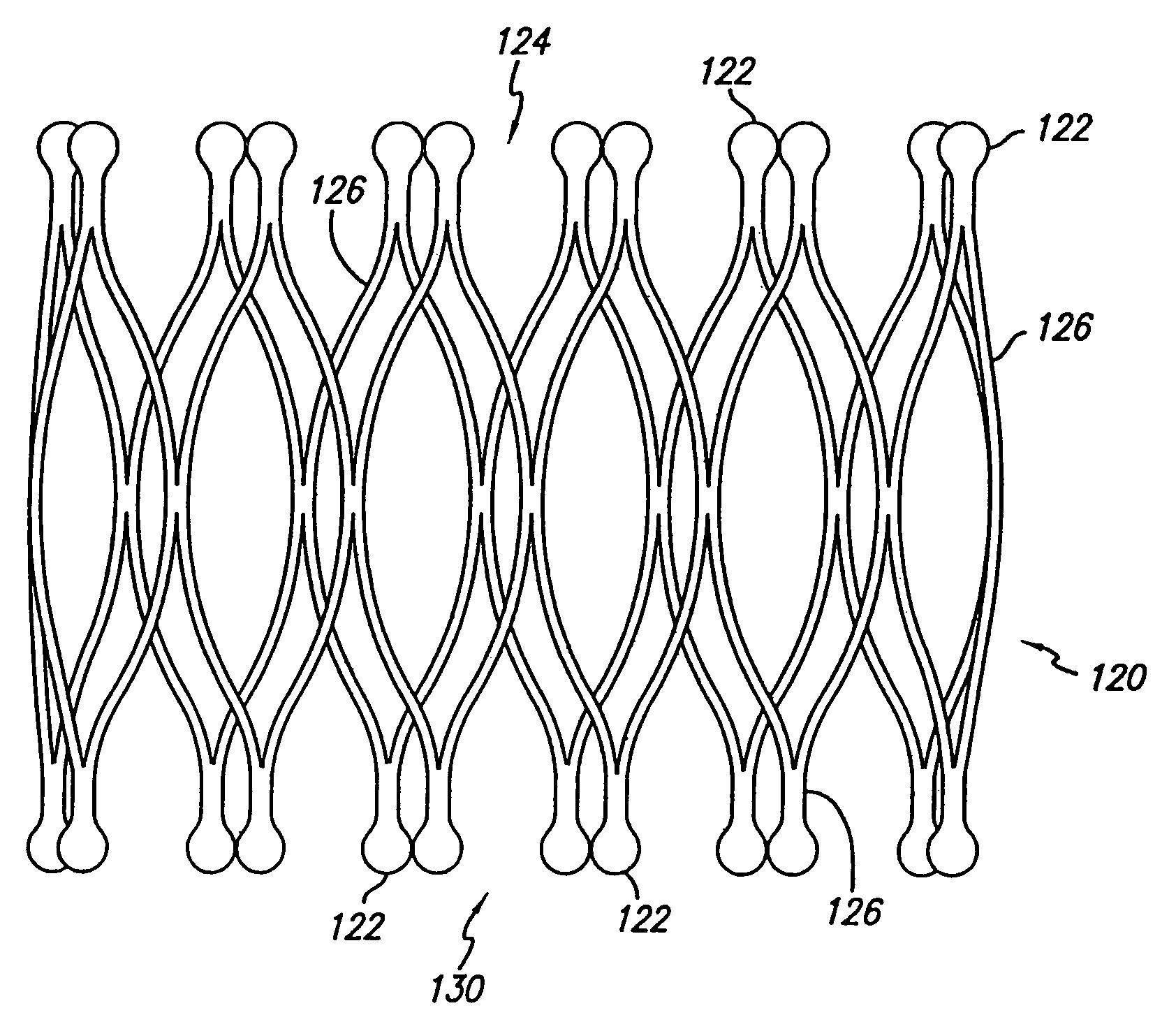

Single-piece endoprosthesis with high expansion ratios and atraumatic ends

A new endoluminal prosthesis for use in sealing a vascular graft to corporeal lumen provides for a flattened bulbous tail at the end of each cell of the prosthesis. The flattened bulbous tails reduce the amount of wear between the prosthesis and the softer material of the vascular grafts or corporeal lumen walls. A method of manufacturing a stent from a flat sheet of material is also included.

Owner:ENDOVASCULAR TECH

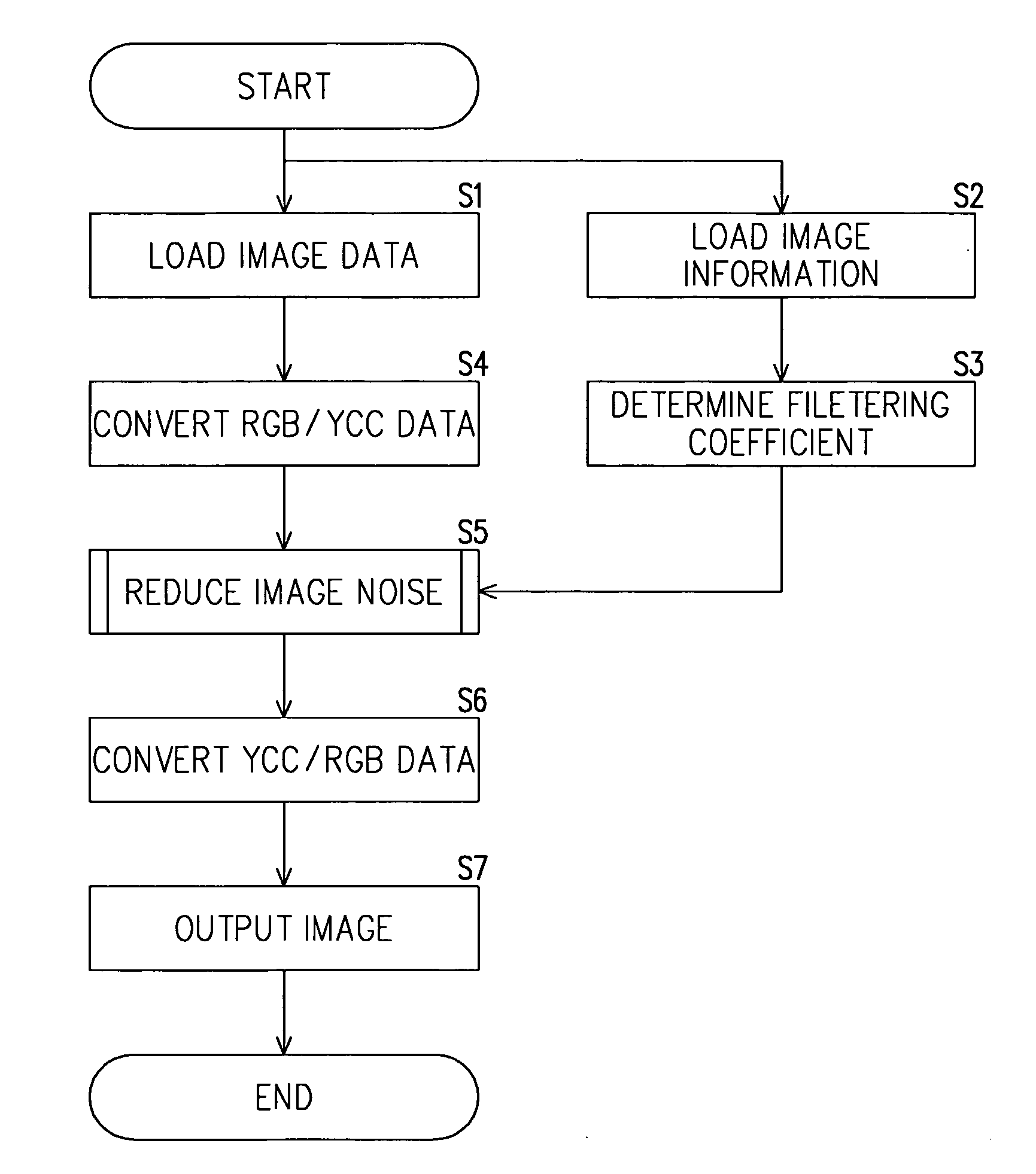

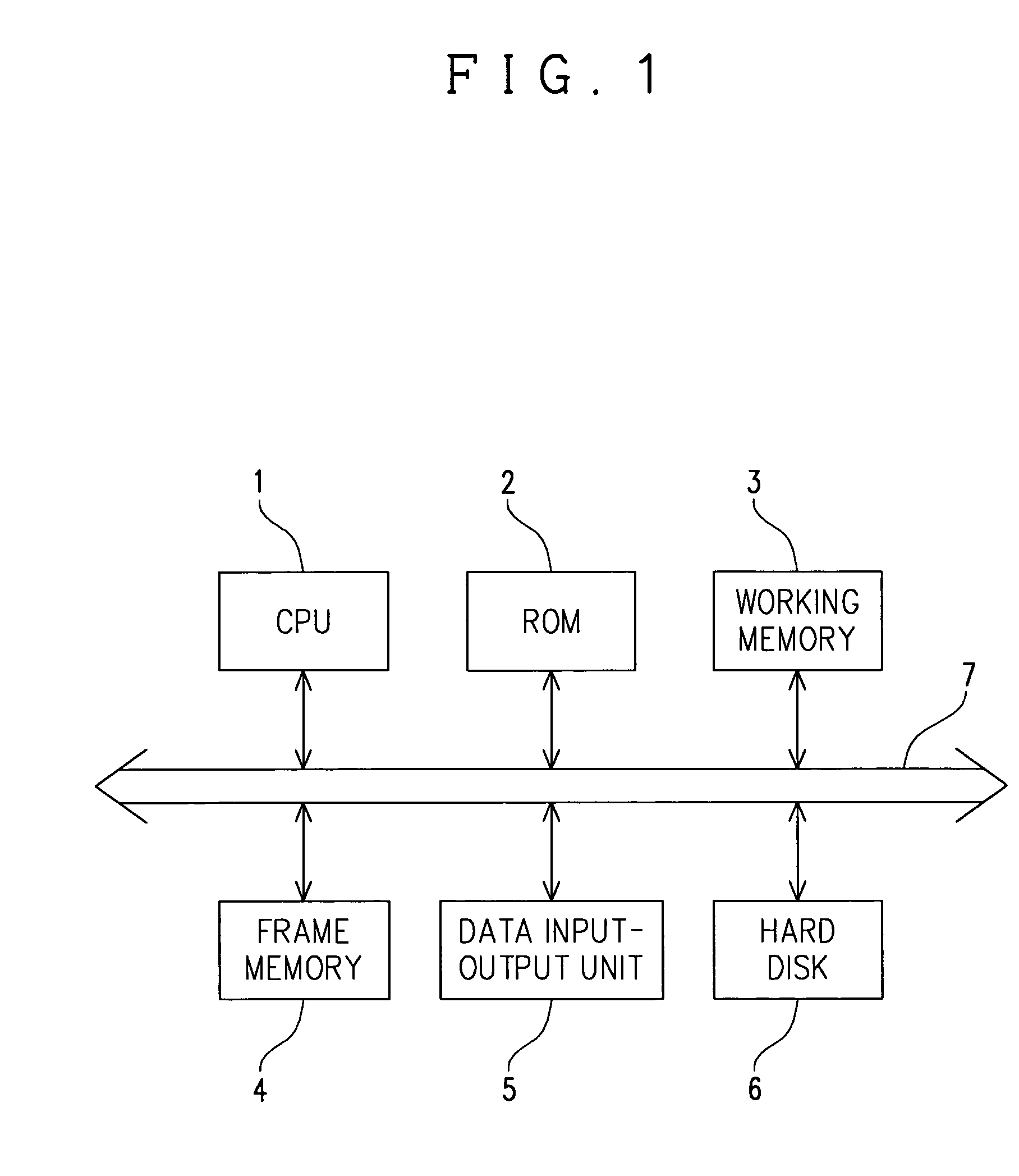

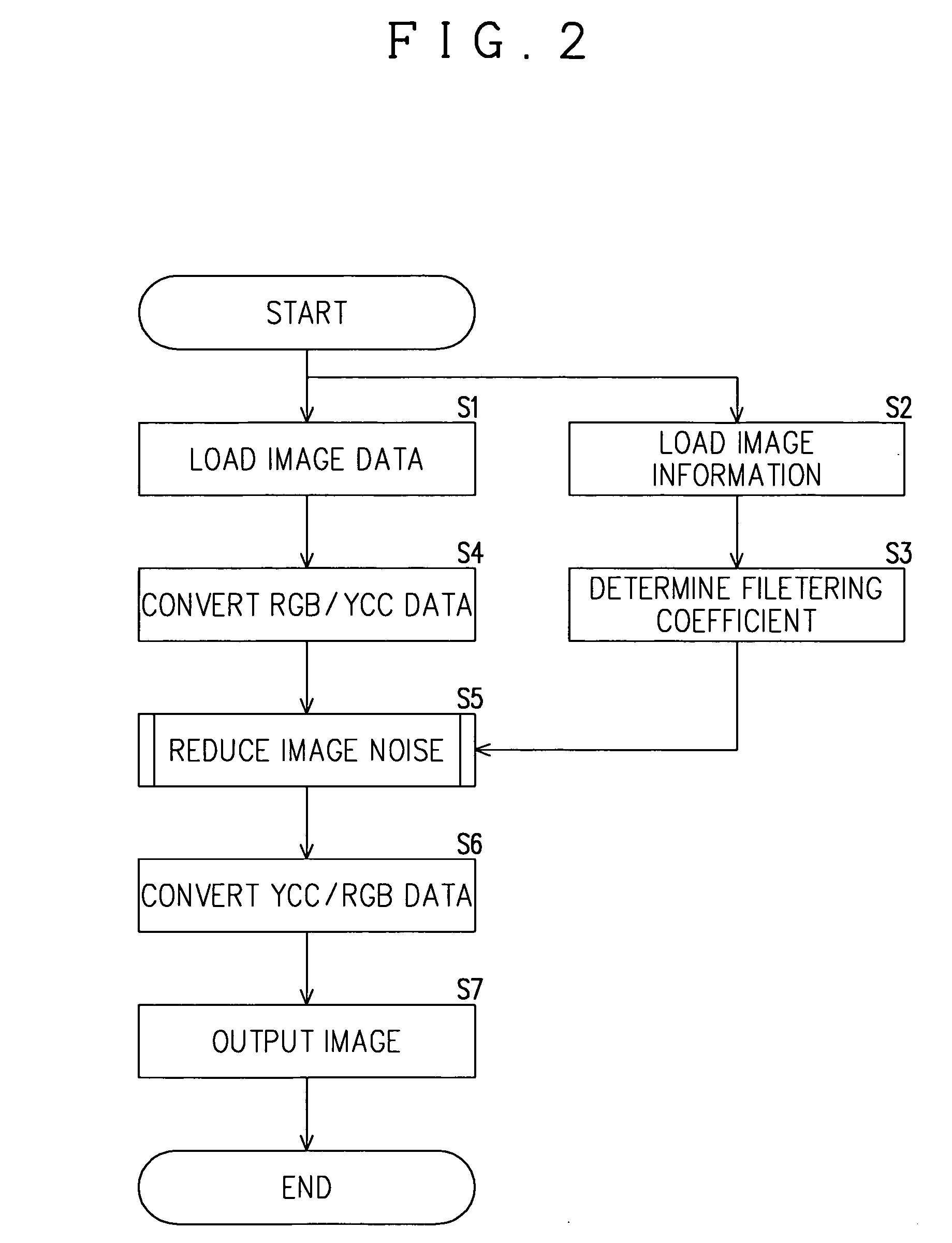

Method for reducing noise in images

InactiveUS20060104538A1Small luminance differenceDeterioration of image qualityImage enhancementTelevision system detailsPattern recognitionImage denoising

There is provided a method of reducing block noise, mosquito noise and other image noises in an image by a filtering process using a smoothing filter, which block noise, mosquito noise and other image noises being caused at the time of decoding encoded, compressed image data on a block-by-block basis. The method includes changing the extent or intensity of the image noise reduction in the filtering process in a continuous or stepwise manner according to an output size or expansion rate of an image to be outputted to printer paper, photographic paper or other output media, thereby allowing the extent or intensity of the image noise reduction to be increased as the output size or expansion rate of the image increases. This method is capable of allowing the extent of the image noise reduction applied to image data to be perceived in a similar fashion, irrespective of the output size.

Owner:NORITZ CORP

Polypropylene composite material for automobile bumper and prepn. thereof

InactiveCN1834145AImprove performanceReduce surface defectsBumpersHeat deflection temperaturePolypropylene composites

This invention discloses a kind of polypropylene composite materials for automobile bumpers and its preparation method. This kind of materials comprises 93.3~56.5wt% polypropylene, 0.2~1.5wt% thermo-stabilizers, 0.3~1wt% photo-stabilizers, 0.2~1% auxiliary reagents, 1~20wt% activating and reinforcing masterbatches and 5~20wt% stuffing masterbatches. The product in this invention has high surface activity, low thermo expansion rate and high thermo expansion temperature. The surface tension is 40mN / m, the linear thermo expansion rate is 10 to the power -6 to 10 to the power -7 mm per mm per deg. C, the thermo deformation temperature is 55 deg. C and some other technological indices all reach or exceed current standards for automobile materials. Thanks to the high surface tension and strong paint-adhesion of the bumpers made of this kind of materials, paints can be directly sprayed rather than flame processing. The thermo expansion rate is low, and therefore, loosening due to significant deformation might not occur with large temperature variation. Besides, it also has the advantages of high the thermo resistant temperature, short baking time and high production efficiency.

Owner:SHANGHAI KINGFA SCI & TECH

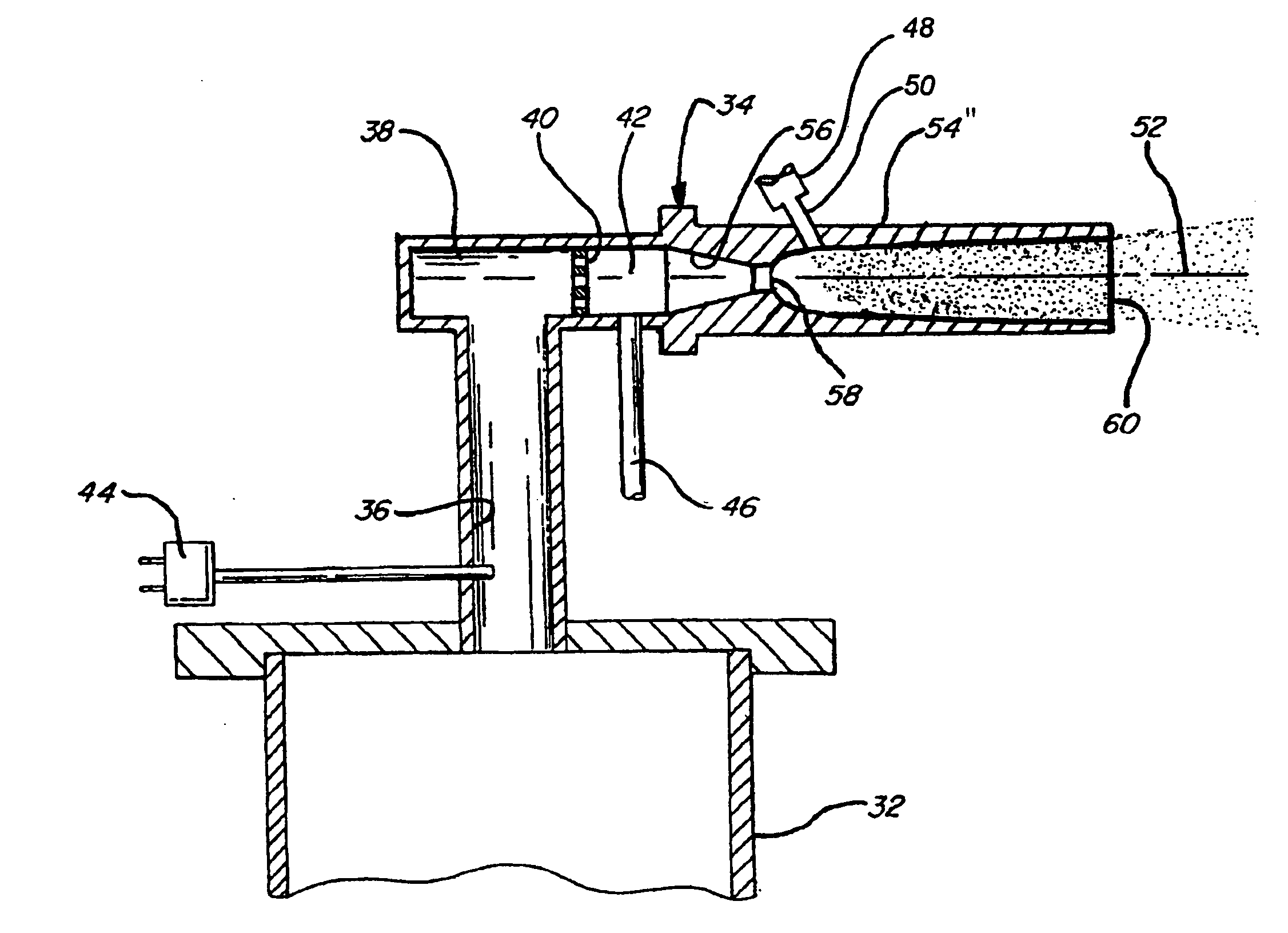

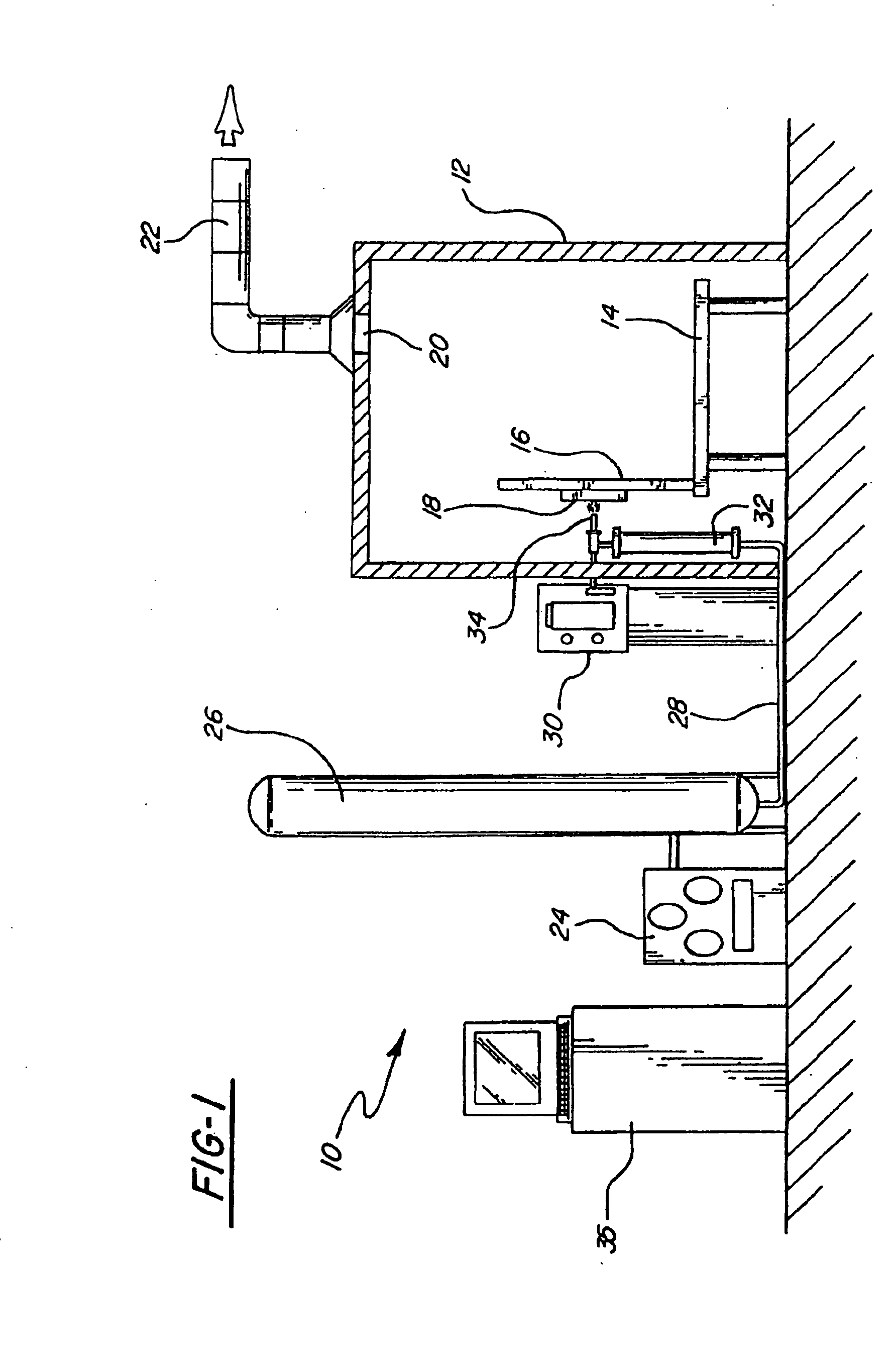

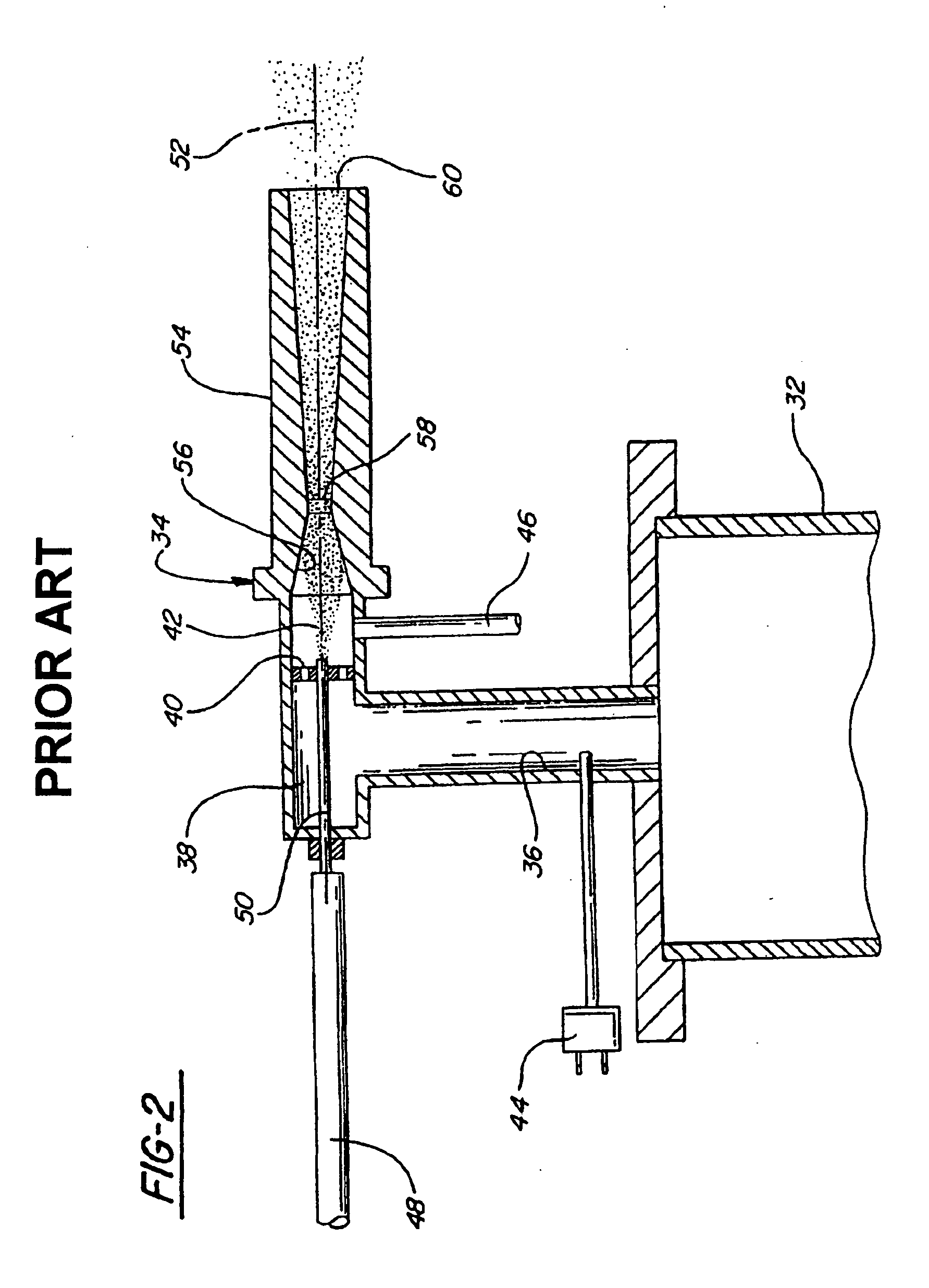

Modified high efficiency kinetic spray nozzle

A modified high efficiency kinetic spray nozzle is disclosed. The modified nozzle has a rapid expansion rate in the diverging region relative to prior art nozzles, which enables one to achieve much higher particle velocities without an increase in the main gas temperature. Preferably, the expansion rate of the supersonic nozzle in a portion of the diverging region is at least 1 mm2 per millimeter, more preferably 2 mm2 per millimeter, more preferably 5 mm2 per mm, with a most preferable expansion rate being 10 mm2 per millimeter.

Owner:FLAME SPRAY IND

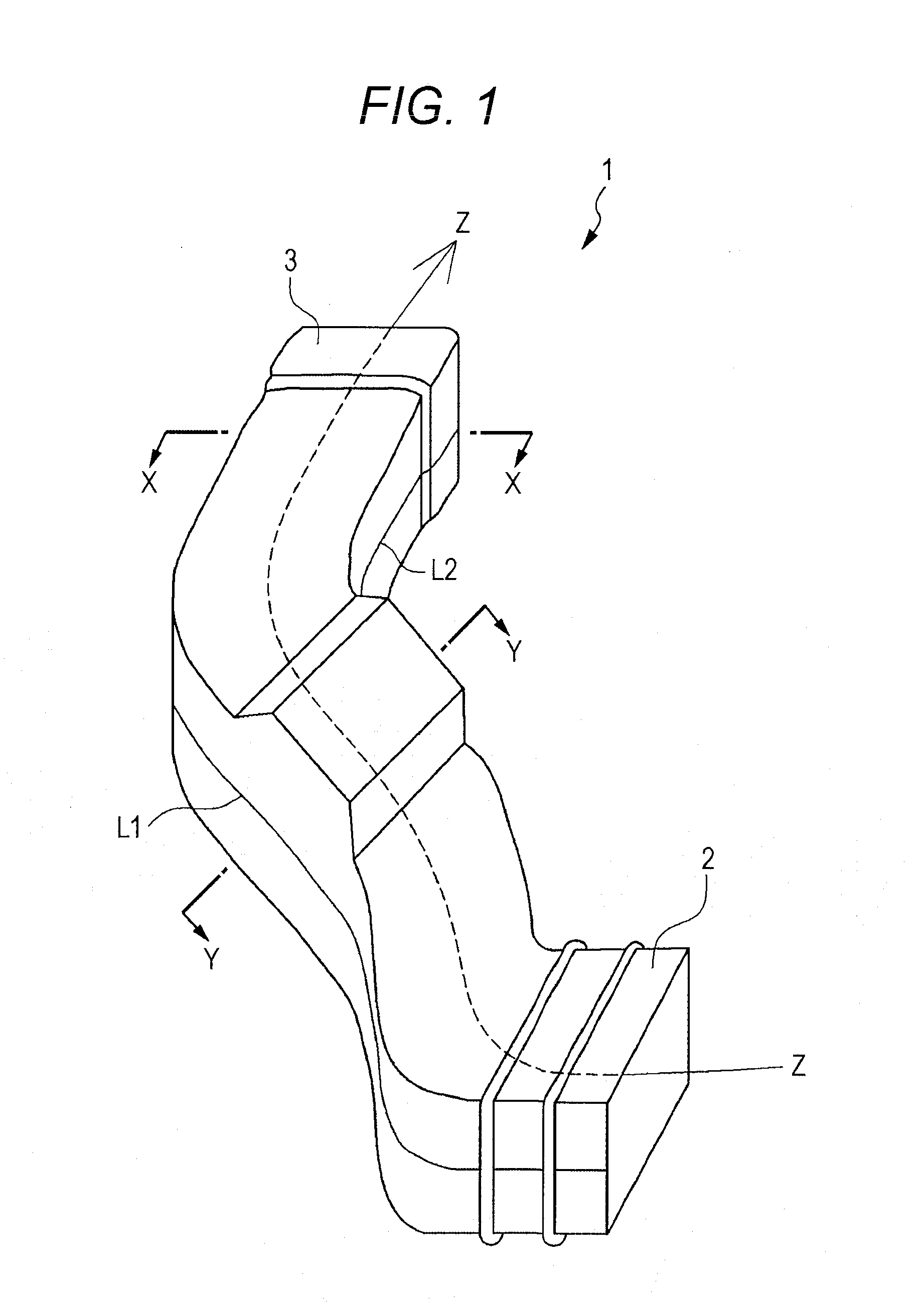

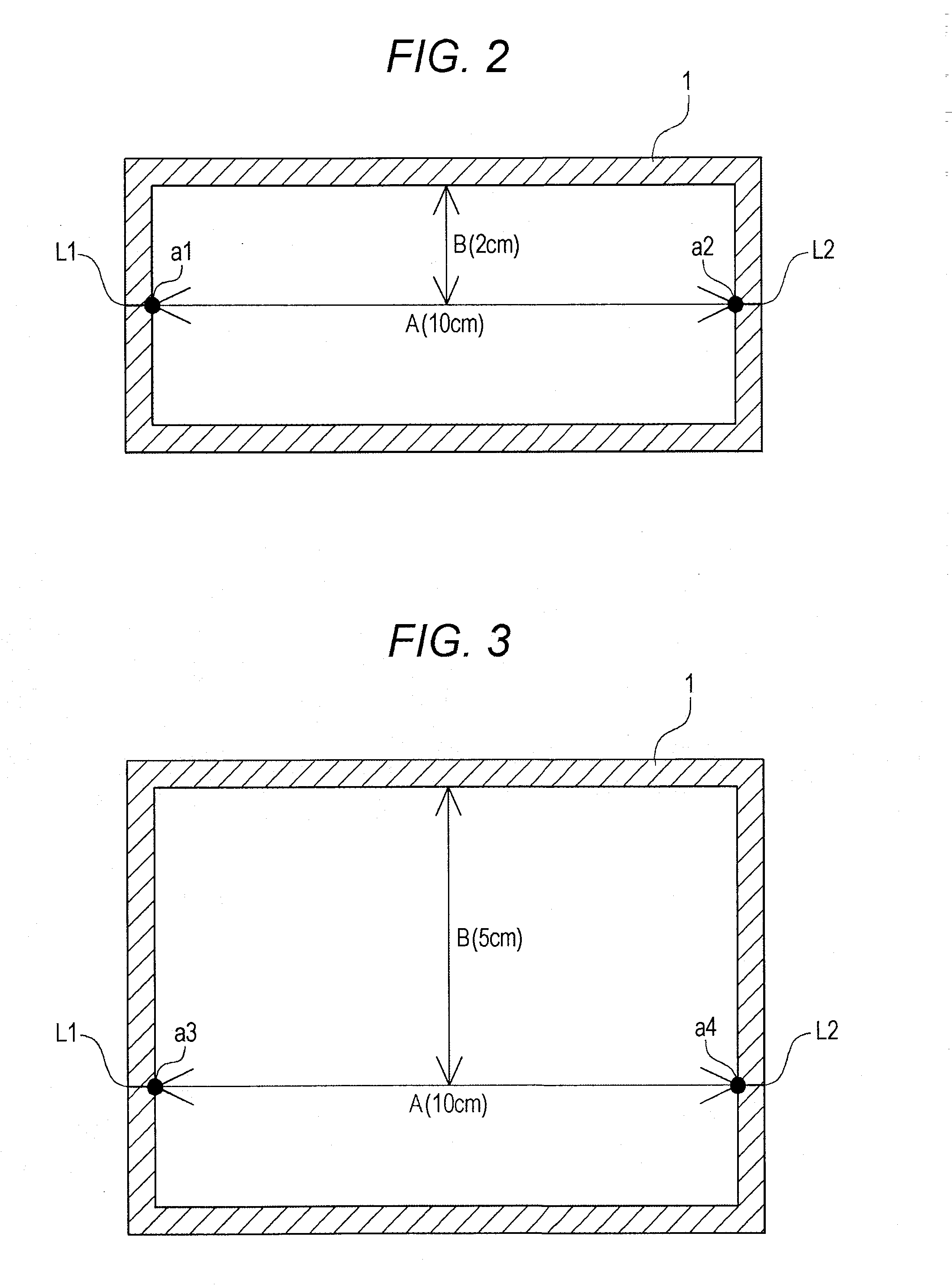

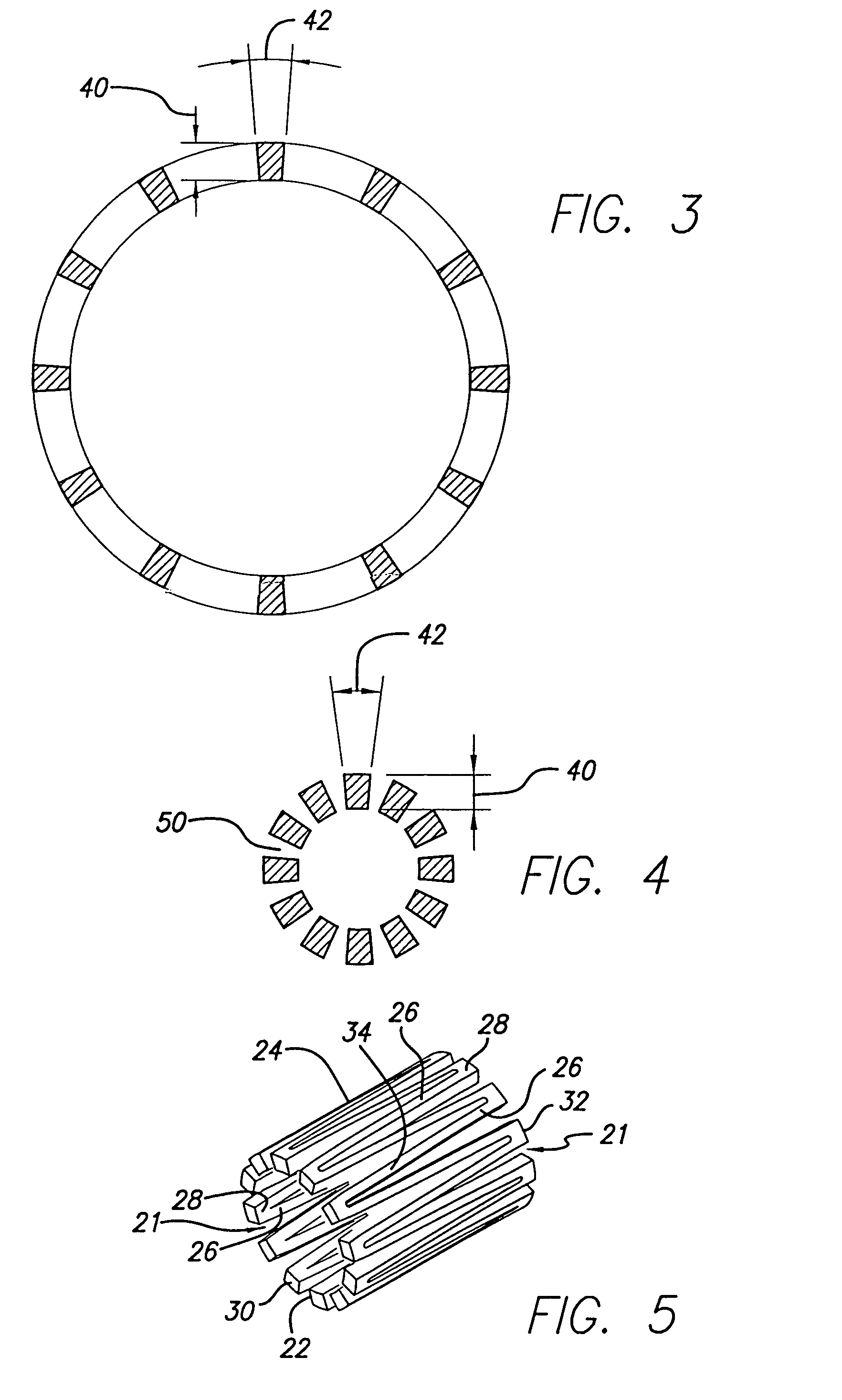

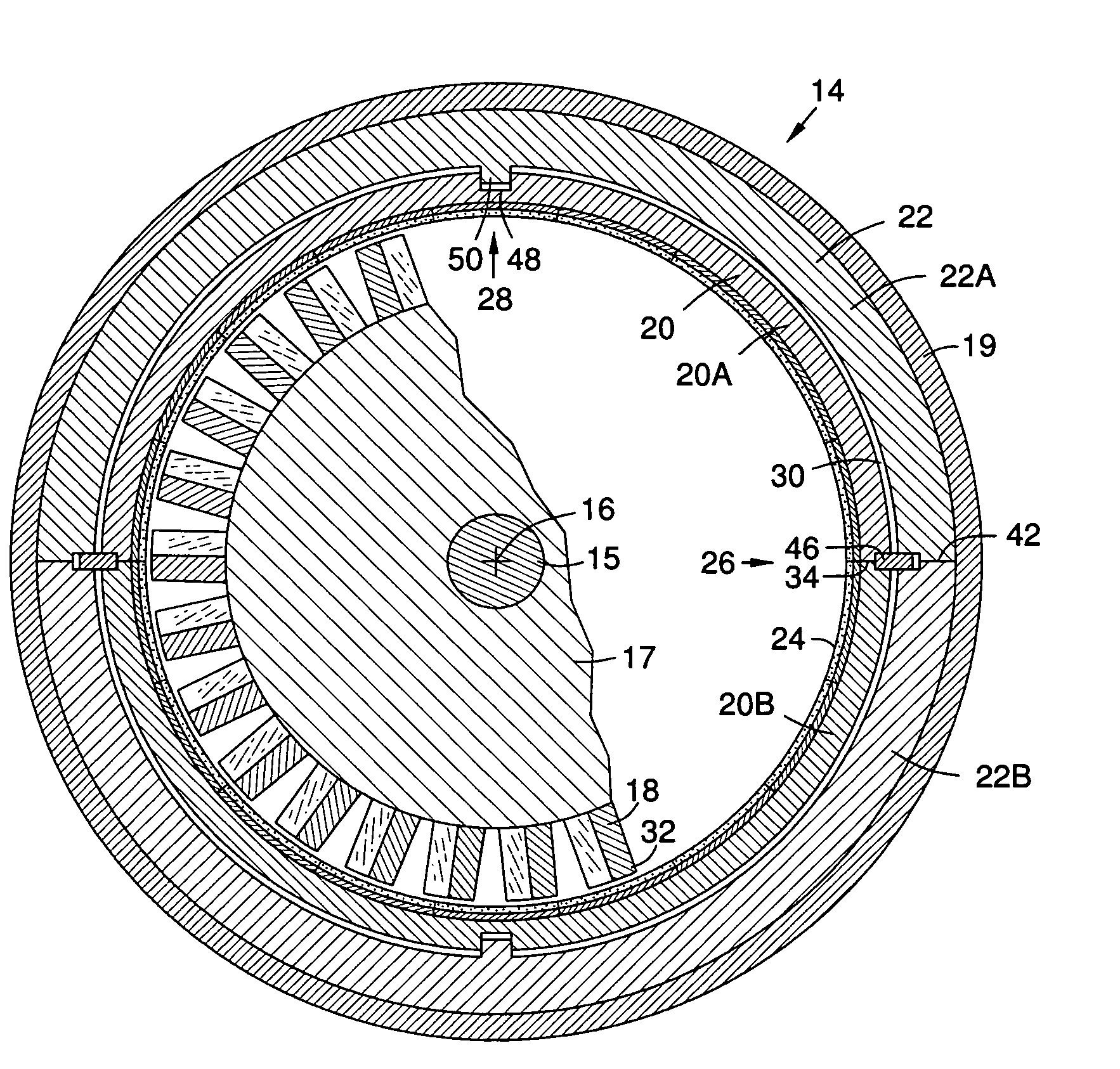

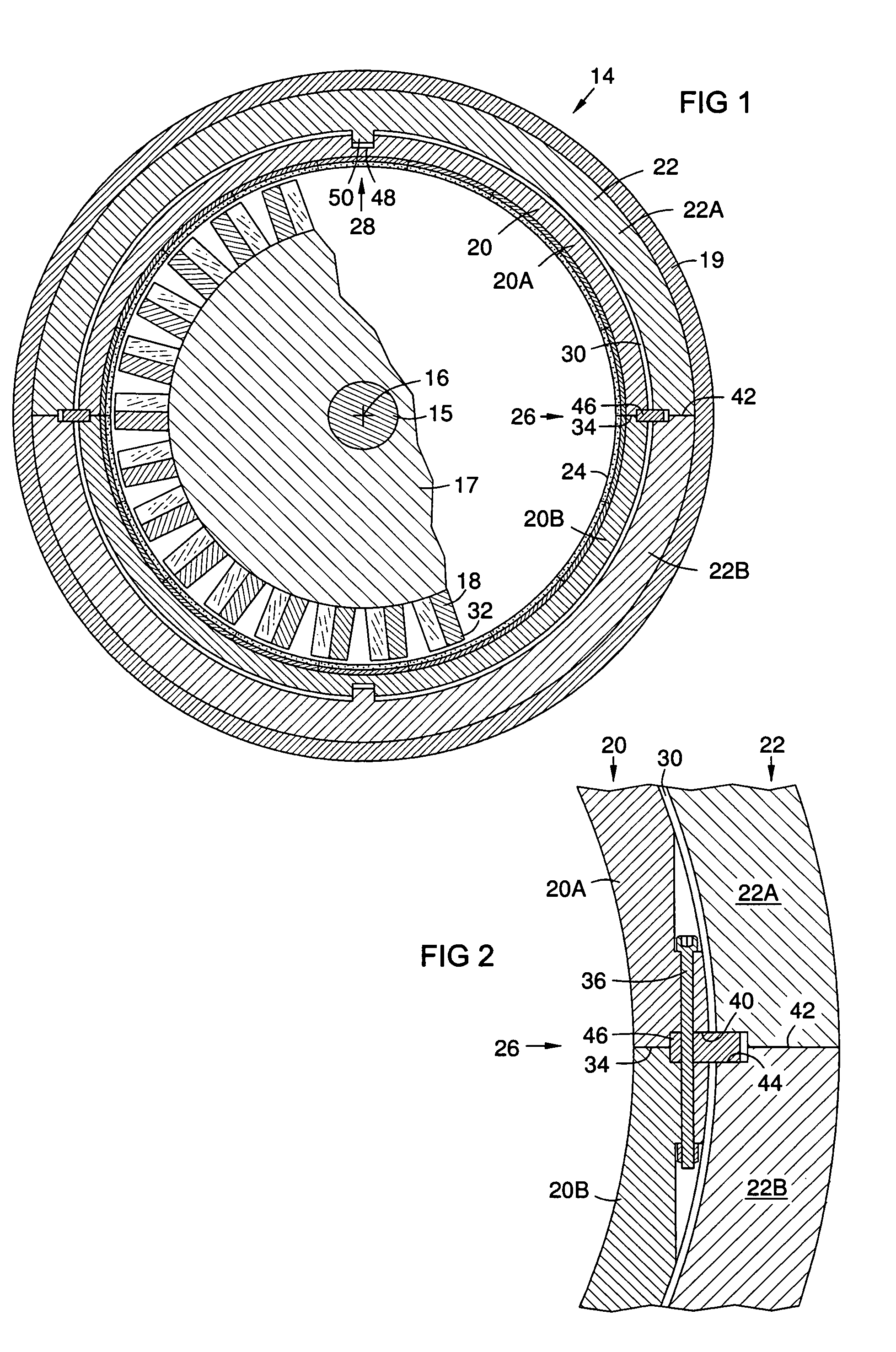

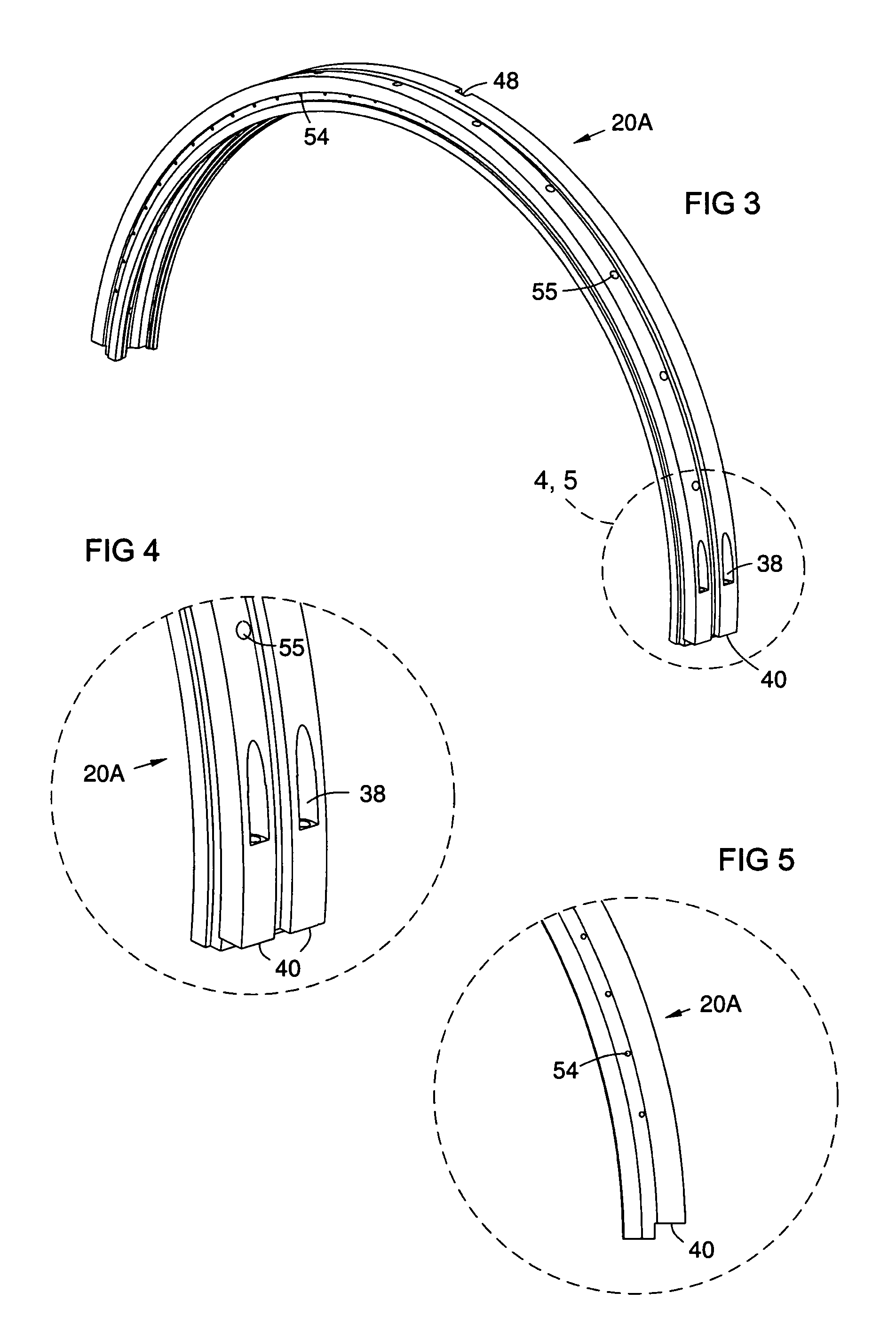

Inner ring with independent thermal expansion for mounting gas turbine flow path components

An inner mounting ring (20) for gas turbine flow path components such as shroud ring segments (24). The inner ring (20) may be mounted to an outer ring (22) on radially slidable mounts (26, 28) that maintain the two rings (20, 22) in coaxial relationship, but allows them to thermally expand at different rates. This allows matching of the radial expansion rate of the inner ring (20) to that of the turbine blade tips (32), thus providing reduced clearance (33) between the turbine blade tips (32) and the inner surface of the shroud ring segments (24) under all engine operating conditions. The inner ring (20) may be made of a material with a lower coefficient of thermal expansion than that of the outer ring (22).

Owner:SIEMENS ENERGY INC

Cross-linked hyaluronic acid cell-scaffold material and preparation method and application

ActiveCN104225677APromote regenerationProvide temporary protectionOrganic active ingredientsSurgical drugsCross-linkFreeze-drying

The invention relates to a cross-linked hyaluronic acid cell-scaffold material and its preparation method and application. The cross-linked hyaluronic acid cell-scaffold material is obtained by crosslinking of high-molecular hyaluronate and low-molecular hyaluronate. The proportion of hyaluronate disaccharide molecules which take part in the crosslinking is 0.5%-20%, and expansion rate of the hyaluronate disaccharide molecules in an isotonic solution is 80%-110%. The preparation method of the cell-scaffold material comprises two freeze drying steps. Hyaluronate mixed with a cross-linking agent is formed firstly; after a heating reaction, water is added for swelling to form gel; and freeze drying is then carried out to obtain the porous scaffold material. The scaffold has abundant pores, has a certain mechanical strength and pore size and has good hydroscopicity and biocompatibility. The scaffold can be used as a tissue engineering cell-scaffold in promoting cartilage injury repairing and also can be used for preparing a haemostasis anti-adhesion material.

Owner:INST OF BIOPHARM OF SHANDONG PROVINCE

Preparation method of calcium oxide expansion agents

The invention relates to a preparation method of calcium oxide expansion agents. The method comprises the following steps: mixing and grinding lime stone and composite mineralizer to obtain raw material, calcining at 1100-1300 DEG C to obtain calcium oxide expansion agent chamotte, and mixing and grinding the chamotte with disperse carrier to obtain the calcium oxide expansion agents, wherein composite mineralizer is composed of 50-70wt% of gypsum and 30-50wt% of copper slag, the weight ratio of composite mineralizer to lime stone is 5:95-10:90, and the weight ratio of calcium oxide expansion agent chamotte to disperse carrier is 75:25-90:10. The calcining heat of the calcium oxide expansion agents of the invention is relatively lower, calcium oxide is not easy to overheat; the water requirement of hydrated product is small, the expansion efficiency is high, the expansion rate is high; and cement concrete can realize effective expansion in dry environment.

Owner:JIANGSU SOBUTE NEW MATERIALS

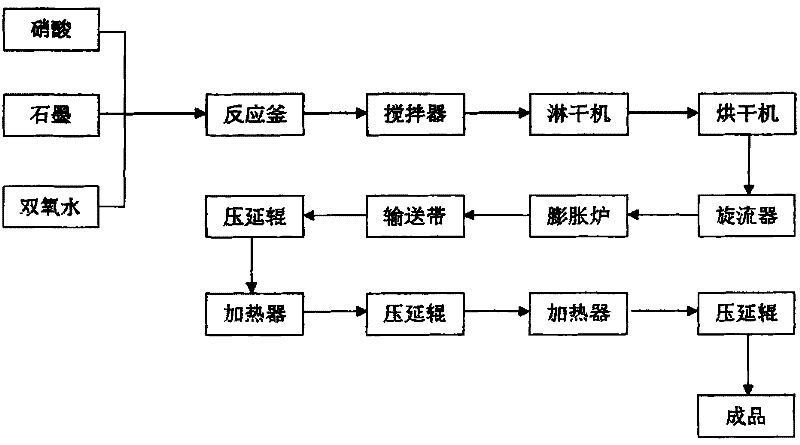

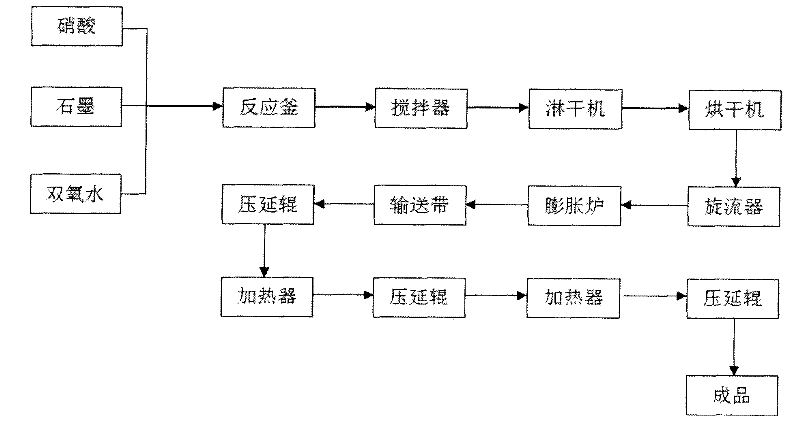

Ultrathin graphite paper radiating fin and manufacturing method thereof

The invention relates to a manufacturing method of an ultrathin graphite paper radiating fin. In the presence of nitric acid and hydrogen peroxide, graphite can stirred to be prepared into an expanded graphite product with the expansion ratio of 300 times, the expanded graphite product is dehydrated by a draining machine, dried by a drying oven and screened by a machine; the obtained graphite product is sent to an expansion furnace at a temperature of 950 DEG C for heating and expanding via a swirler, the expanded vermicular graphite is extracted from the expansion furnace and is sent to a stock bin; and according to different thickness requirements, vermicular graphite is subjected to repeated rolling until the thickness of final ultrathin graphite paper is reached. The thickness of the graphite paper radiating fin is equal to or greater than 0.04mm, the sulphur content is less than 1000ppm, and the thermal conductivity is more than 300W / moK. The invention, the obtained graphite paper radiating fin is thinnest, the miniaturization and ultra thin of the final product are realized, the service life of the product is improved, the problem of rapidly radiating at high temperature is solved, the cost of raw materials for producing the graphite paper radiating fin is lowered, rare graphite resources are protected and the uses of irregular shape products can be satisfied.

Owner:肖云凯

Polyamine strong inhibitor for drilling fluid, and preparation method thereof

InactiveCN103087691AEnhanced inhibitory effectReduced tendency to absorb waterFlushingDrilling compositionSodium BentoniteInstability

The invention relates to a polyamine strong inhibitor for a drilling fluid. The polyamine strong inhibitor is prepared through the following step that: an amine compound and an epoxy compound are subjected to a reaction at a temperature of 90-110 DEG C in the presence of an alkali metal catalyst to synthesize the polyamine strong inhibitor for the drilling fluid, wherein the amine compound is polyether amine, alkyl amine, ether amine, tetraethylenepentamine, pentaethylenehexamine or polyethylene polyamine, and the epoxy compound is propylene oxide or ethylene oxide. According to the present invention, based on high temperature strong water sensitivity easy-instability stratum, special molecular structure design is adopted, such that the inhibitor has strong inhibition, and mud making of clay and hydration expansion of shale can be inhibited; and the inhibitor provides a stabilization effect for dynamic cutting force when the Xuanhua bentonite addition amount is up to 30%, wherein a debris rolling recovery rate can be more than 90%, a 8 h shale linear expansion rate is less than or equal to 10%, a temperature resistance performance is more than or equal to 180 DEG C, biological toxicity is low, and a LC50 value is more than 38010 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

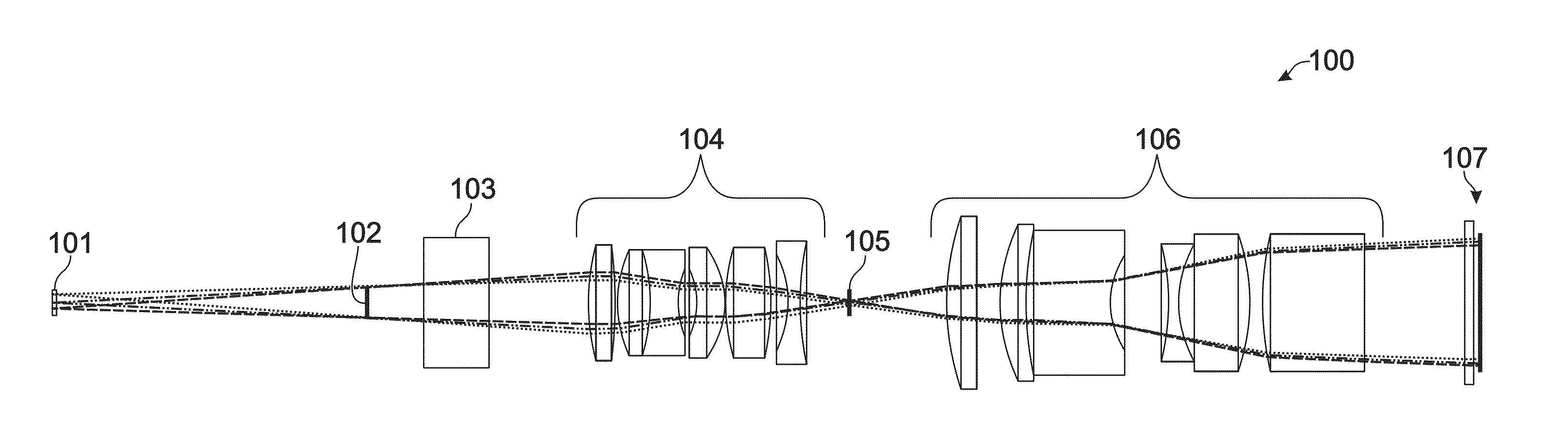

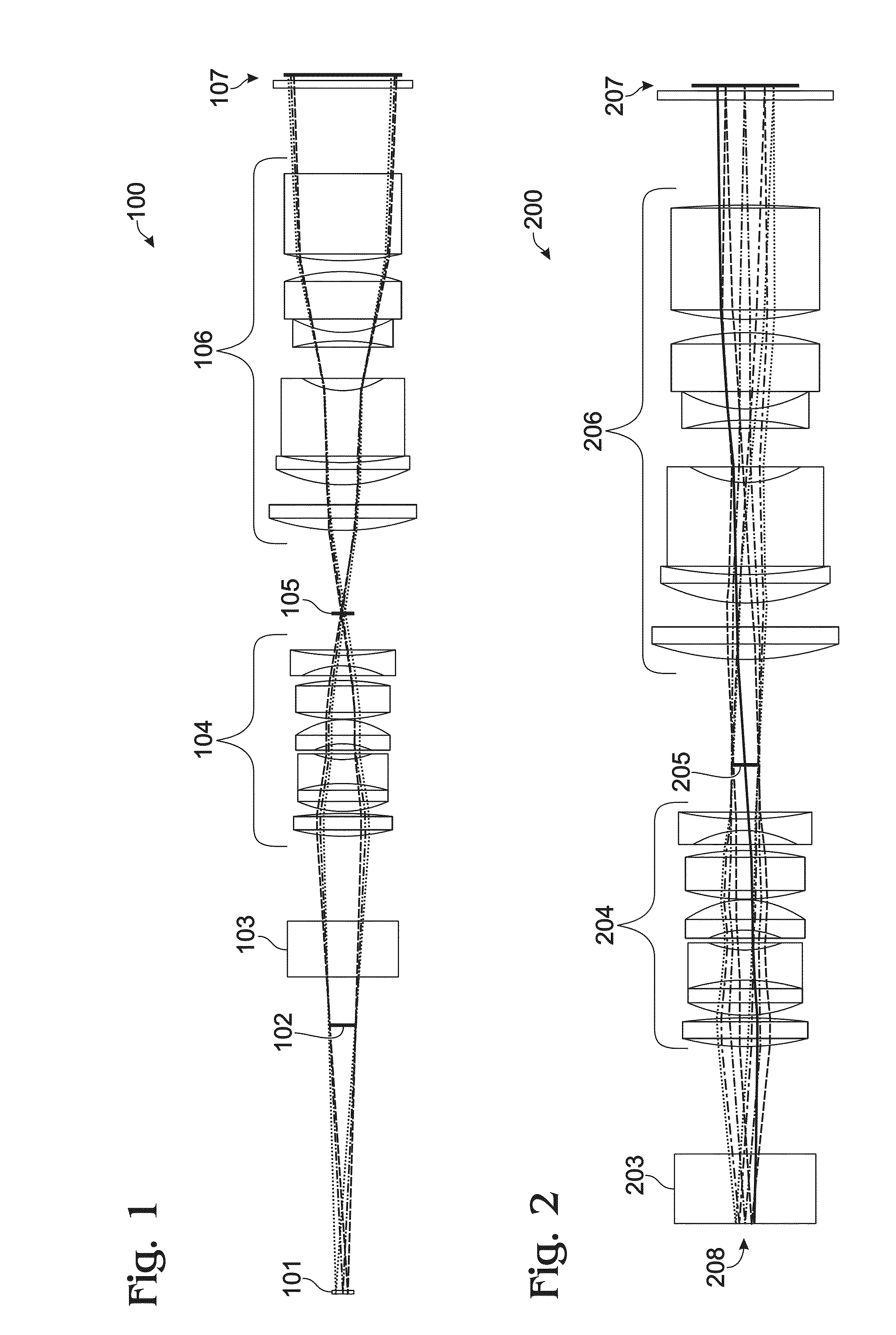

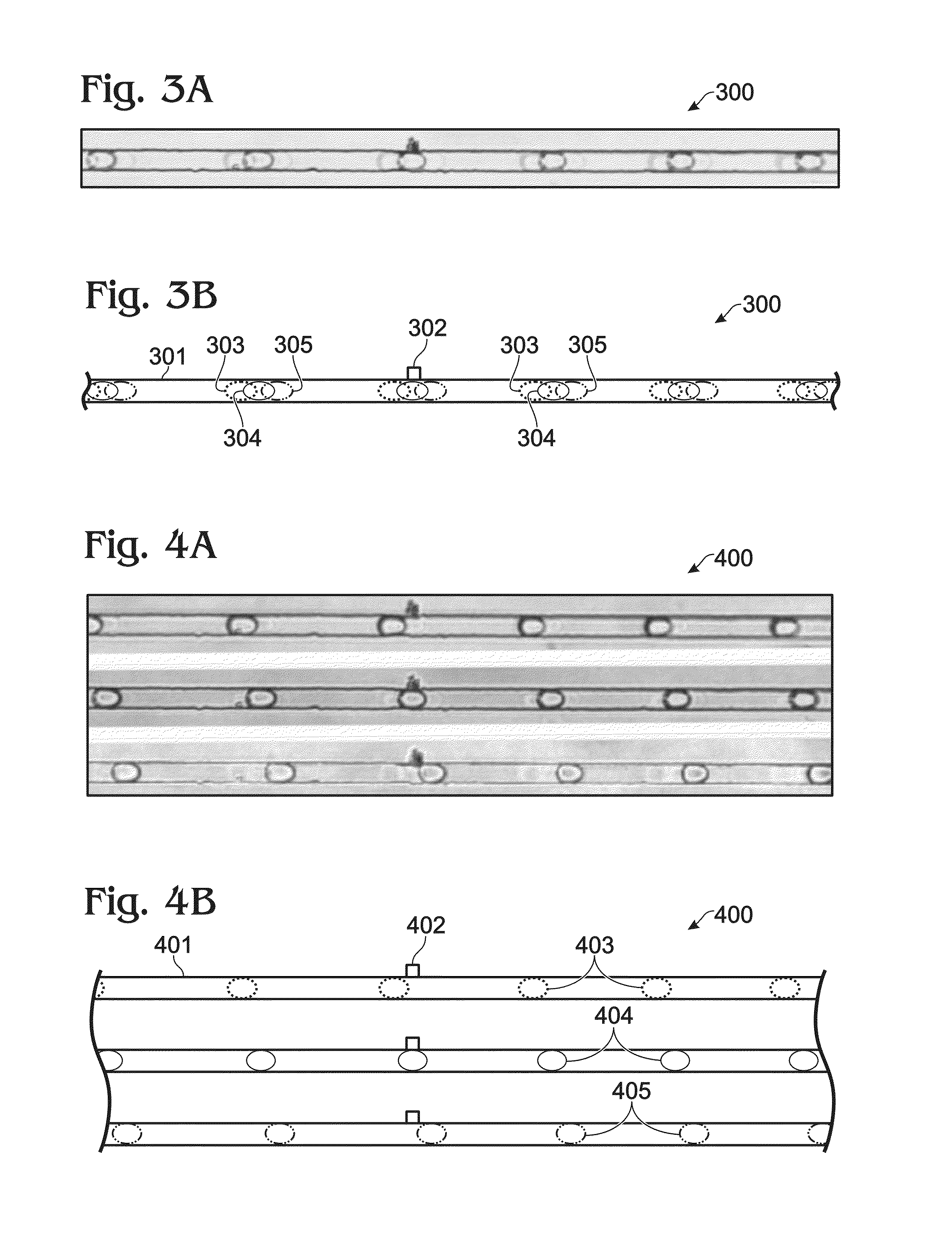

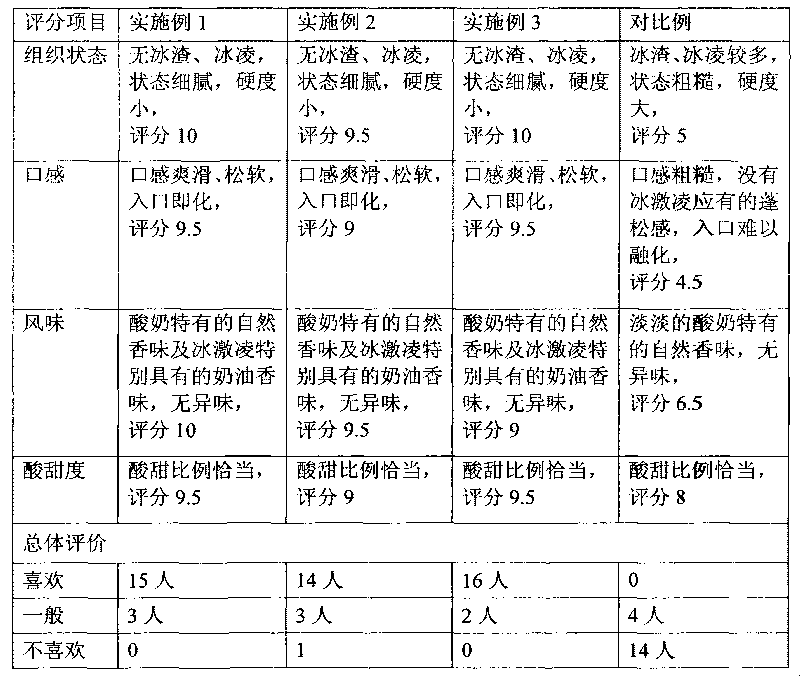

Low cost optical high speed discrete measurement system

ActiveUS20140354795A1Volume measurement apparatus/methodsVolume/mass flow measurementLength waveMicrofluidic channel

Systems and methods are provided for determining a velocity or an inflation rate of a droplet in a microfluidic channel. The droplet is exposed to two or more temporally separated flashes of light, each flash including light of one wavelength band, and imaged using a detector configured to distinguish light in the wavelength bands. Two or more images of the droplet are acquired, each corresponding to one of the flashes, and all within a single video frame or photographic exposure. The images can be processed separately and the position or size of the droplet in each image is calculated. A velocity or inflation rate is then determined by dividing the change in position or size by the amount of time allowed to pass between the flashes.

Owner:BIO RAD LAB INC

Frozen sour milk and manufacturing method thereof

The invention provides frozen sour milk and a manufacturing method thereof. Among the ingredients of the frozen sour milk, total solid matters account for 25 to 34 percent; fat matters account for 8 to 15 percent and non-fat milk solid accounts for 10 to 12 percent. And the ingredients of the frozen sour milk include a sweetner which offers a sweetness that can also be achieved by adding 12 to 13 percent of sucrose the ingredients, wherein the sweetner contains corn syrup which accounts for 2.5 to 3.5 weight percent of the ingredients. The frozen sour milk of the invention is prepared by mixing the ingredients of the frozen sour milk, homogenizing, sterilizing and cooling the mixture, inoculating an actic acid bacterium ferment for fermentation, freezing the resulting product and controlling a certain expansion rate. In the invention, due to reasonable selection and mixing ratio of the formula of the frozen sour milk and the proper control of a production process, the produced frozen sour milk product has an excellent flavor, mouth feel and stability and the product quality can keep almost constant during repeated freezing. Thus, the frozen sour milk can satisfy the needs of consumers for different eating modes.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Al and Al alloy soft braze welding metal displaced type unleaded welding soldering flux

InactiveCN101204762AWith corrosion protectionImprove matchWelding/cutting media/materialsSoldering mediaSurface-active agentsSolder paste

The invention discloses a soldering metal replacement no lead welding scaling powder for aluminum and aluminum alloy, which is composed of the following weight proportions: 5 to 50 percent of metal salt that can be reduced by the aluminum, 10 to 15 percent of stripper, 3 to 40 percent of wetting agent, 3 to 20 percent of activating agent, 1 to 15 percent of surface active agent, 2 to 20 percent of inhibiter and a carrier with the rest percent. The invention has an extremely excellent matching effect with a lead-free solder in the welding temperature and is suitable for being made into a welding stick or a welding paste with the lead-free solder. After welding, the invention has a high welding intensity and a good expansion rate, belongs to an environment protection scaling powder, and has the function of inhibition protection on the aluminum and aluminum alloy as well as a simple and practical preparing method. Undoubtedly, the embodiment can also be used for the no lead soldering on the materials like stainless steel, galvanized iron, copper and copper alloy, etc., and bear the same effects as well.

Owner:昆山成利焊锡制造有限公司

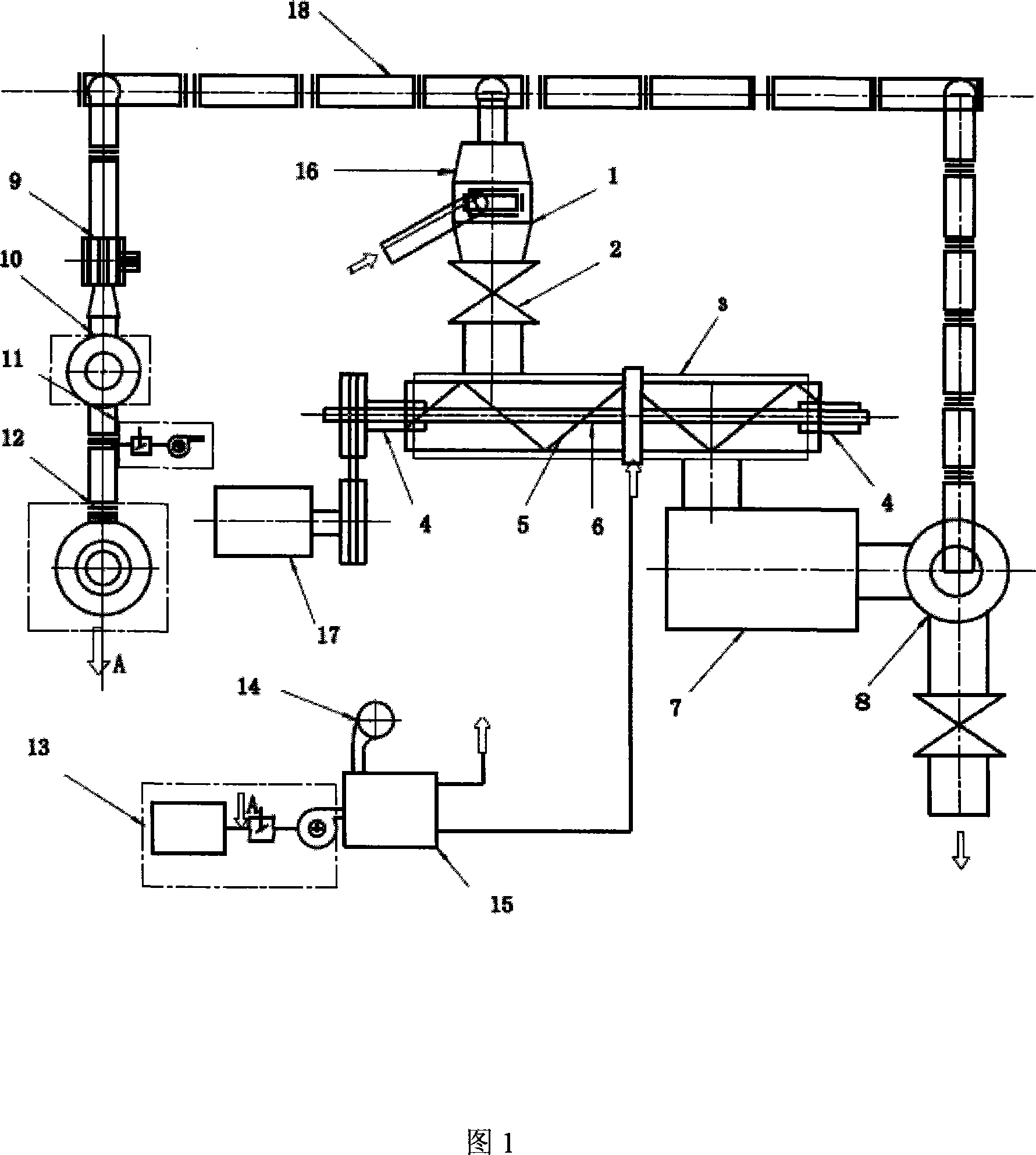

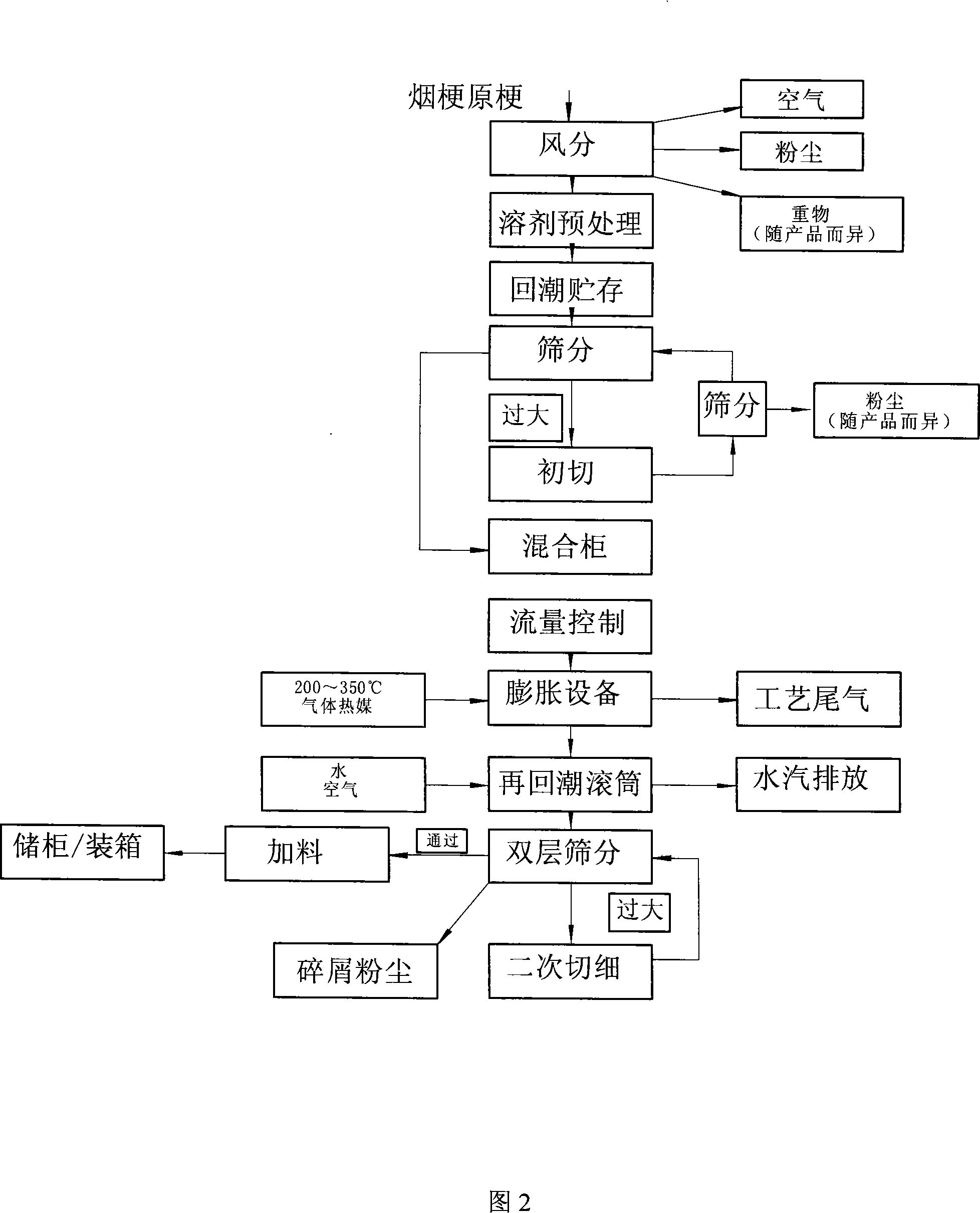

Method and equipment for pretreatment cabo

ActiveCN101214086AImprove uniformityHigh expansion rateTobacco preparationTobacco treatmentGas solidPretreatment method

The invention relates to a pretreatment method of tobacco stem which is preheated through gas heat medium and is treated with microwaves in the gas heat medium environment and equipment which adopts the method. The tobacco stem which is required to be processed is treated: preheating the raw materials to be 100-170 DEG C; heating the gas heat medium to be 150-350 DEG C; mixing the tobacco stem and the gas heat medium and implementing the gas-solid separation after the microwave field action to obtain solid expanded tobacco stem which is treated completely. Then,granular expanded tobacco stem is obtained after the moisture regaining, the screening, the fine shearing, etc. The equipment includes a gas heat medium preheating mechanism, a microwave complex expansion treatment mechanism, etc. With the process and the equipment of the invention, the breakage during the expansion process is small; the pressure used by the process is close to the normal pressure; the pressure resistance requirement for the equipment is not high; the production process is simple and easy; the most fundament lies in that through the gas heat medium with low oxygen content used for preheating the tobacco stem, the evenness and the expansion ration of the tobacco stem and the aspiration quality of the tobacco stem materials are obviously improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com