Patents

Literature

37 results about "Strong inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strong-inhibition strong-blocking drilling fluid

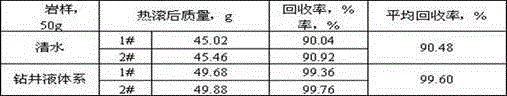

InactiveCN102863947AReduce harmNo pollution in the processDrilling compositionHigh concentrationAbsorption capacity

The invention relates to the technical field of drilling fluid for petroleum drilling, particularly to high-inhibition strong-blocking drilling fluid. The drilling fluid comprises, by weight, 0.5%-15% of a strong inhibitor, 0.5%-7% of a strong blocking agent, 0.5%-5% of bentonite and 0.2%-6% of a fluid loss agent. The drilling fluid has strong inhibiting effect on hydration of strong water-sensitive mud shales through high concentration K+ generated after dissolution of the strong inhibitor; simultaneously, anions generated after the dissolution of the strong inhibitor take the absorption action with the surface of clay through the absorption capacity so as to form protective films on the surface of the clay, and therefore the hydration of the clay is prevented; and the strong blocking agent can achieve strong blocking to strong water-sensitive mud shale stratums with micro-cracks to form isolating films in the real sense, and therefore instability of well walls of the strong water-sensitive mud shale stratums is prevented. The drilling fluid has the advantages of being good in blocking, strong in inhabitation, good in lubricity, stable in high temperature property, small in damage to reservoir stratums, free of pollution and capable of improving the production efficiency.

Owner:CNPC XIBU DRILLING ENG

Polyamine strong inhibitor for drilling fluid, and preparation method thereof

InactiveCN103087691AEnhanced inhibitory effectReduced tendency to absorb waterFlushingDrilling compositionSodium BentoniteInstability

The invention relates to a polyamine strong inhibitor for a drilling fluid. The polyamine strong inhibitor is prepared through the following step that: an amine compound and an epoxy compound are subjected to a reaction at a temperature of 90-110 DEG C in the presence of an alkali metal catalyst to synthesize the polyamine strong inhibitor for the drilling fluid, wherein the amine compound is polyether amine, alkyl amine, ether amine, tetraethylenepentamine, pentaethylenehexamine or polyethylene polyamine, and the epoxy compound is propylene oxide or ethylene oxide. According to the present invention, based on high temperature strong water sensitivity easy-instability stratum, special molecular structure design is adopted, such that the inhibitor has strong inhibition, and mud making of clay and hydration expansion of shale can be inhibited; and the inhibitor provides a stabilization effect for dynamic cutting force when the Xuanhua bentonite addition amount is up to 30%, wherein a debris rolling recovery rate can be more than 90%, a 8 h shale linear expansion rate is less than or equal to 10%, a temperature resistance performance is more than or equal to 180 DEG C, biological toxicity is low, and a LC50 value is more than 38010 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of treating a patient with a cyp3a4 substrate drug

ActiveUS20180333409A1Reduce morbidityAvoid and reduce incidenceNervous disorderHydroxy compound active ingredientsReduced dosePosaconazole

The present disclosure provides for methods of treating a patient with a CYP3A4 substrate drug contraindicated for concomitant administration with a strong CYP3A4 inhibitor, wherein the patient is treated with multiple doses of posaconazole, stops posaconazole treatment, and then is treated with the CYP3A4 substrate drug. In some embodiments, treatment with the CYP3A4 substrate drug is delayed for about 2-21 after stopping posaconazole. In some embodiments, the patient is treated with or prescribed a reduced dose of the CYP3A4 substrate drug for about 2-21 after stopping posaconazole.

Owner:BOW RIVER LLC

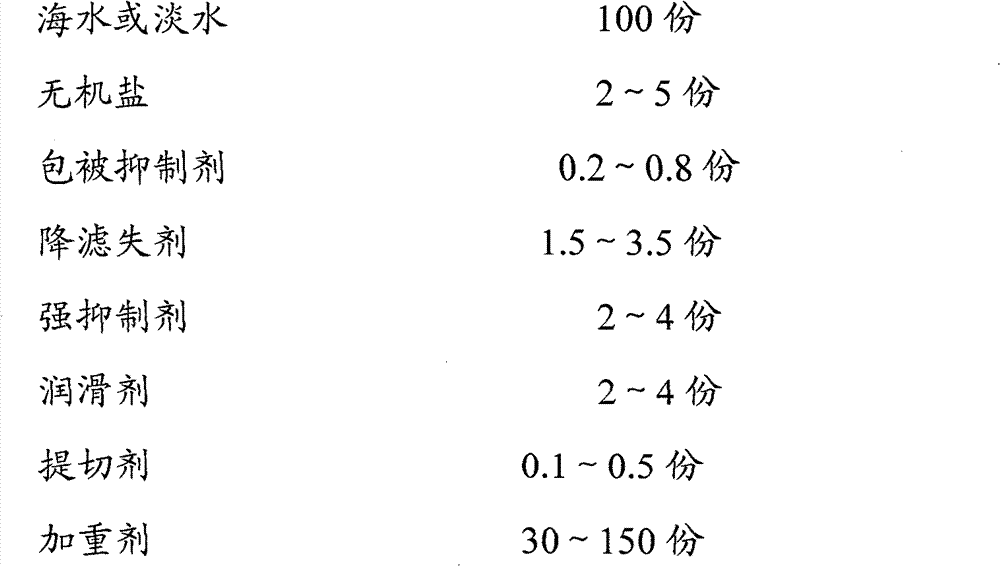

High-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage

ActiveCN101717624AEnhanced inhibitory effectImprove rheologyDrilling compositionWater basedInorganic salts

The invention discloses a high-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage, which comprises the following components: 100 parts of seawater or fresh water, 2-5 parts of inorganic salt, 0.2-0.8 part of coating inhibitor, 1.5-3.5 parts of fluid loss additive, 2-4 parts of strong inhibitor, 2-4 parts of lubricant, 0.1-0.5 part of shear strength improving agent and 30-150 parts of weighting agent. The well drilling fluid has strong inhibition and has good rheological property and stable system performance during the whole well drilling process,even a large quantity of highly easily hydrated and dispersed cuttings exist for invasion of sewage, the viscosity of the well drilling fluid is basically controlled to be about 50s.

Owner:CHINA NAT OFFSHORE OIL CORP +1

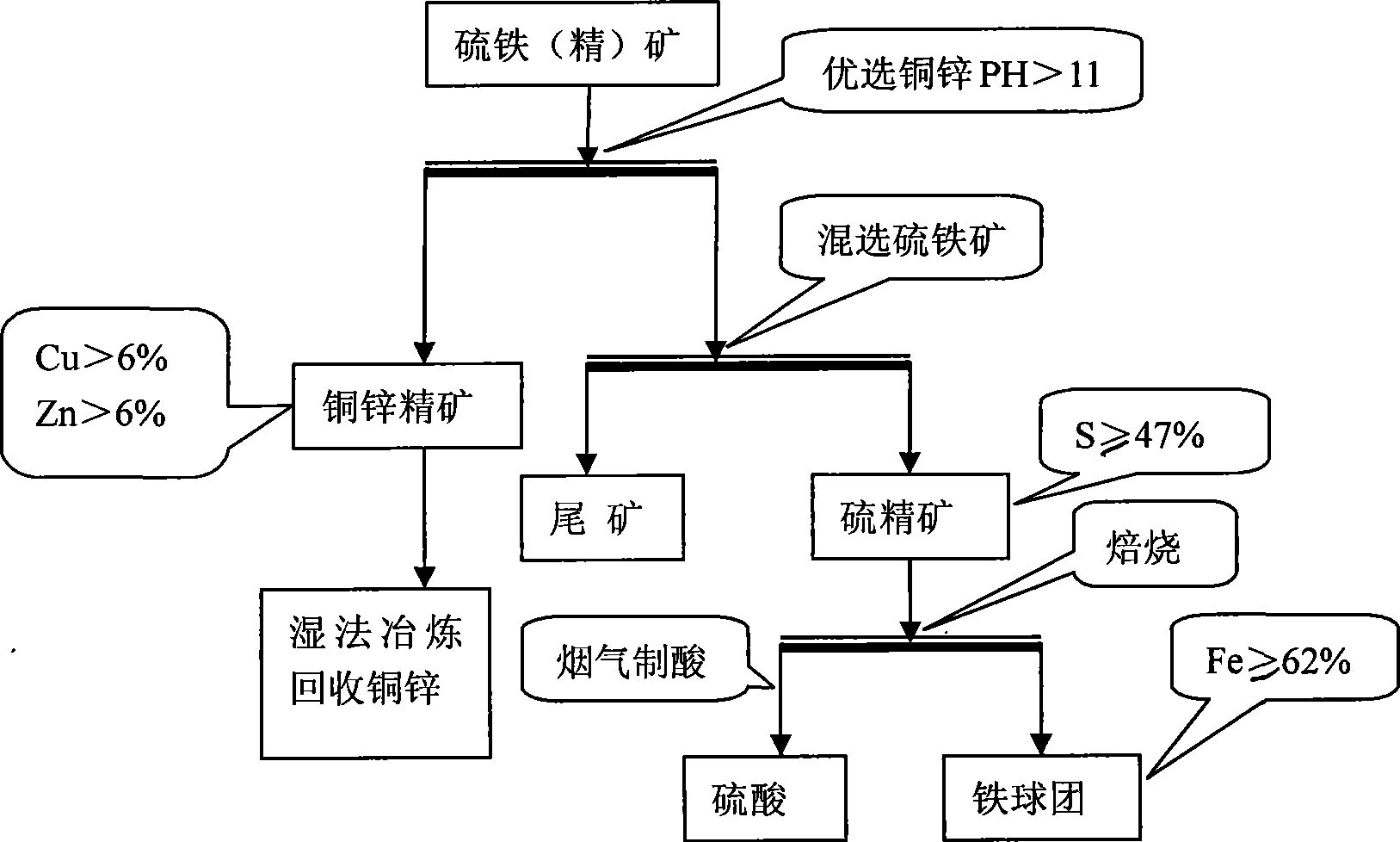

Comprehensive recovery method for ferro-sulphur ore containing copper, zinc and iron multi-metal

The invention discloses a method for comprehensively recovering polymetallic sulfurous iron ores containing copper, zinc and iron, which comprises the following steps: adding a strong inhibitor into the sulfurous iron ores first, controlling the pH value to be more than or equal to 11, adding a collector and a foaming agent into the mixture, and preferably performing flotation on copper and zinc; and activating tailings by an activator, adding the collector and the foaming agent into the tailings for floatation of sulfur, guaranteeing sulfur concentrate S is more than or equal to 47 percent, performing roasting, using flue gas to prepare a sulfuric acid, and directly using roasted sulfate slag to manufacture iron pellets. The method not only widens the application scope of copper-zinc bulk concentrate treatment grade but also recovers useful elements in the ores with low cost and high quality, not only recovers the copper with high yield but also recovers the zinc with high yield, avoids resource waste, greatly improves the surrounding environment, and eliminates zinc pollution. The tailings are activated by the activator, and the collector and the foaming agent are added into the tailings for flotation of the sulfur; the sulfur concentrate S is guaranteed to be more than or equal to 47 percent and roasted at a temperature of between 900 and 1,150 DEG C; the flue gas is used for preparing the sulfuric acid; and Fe in the roasted sulfate slag is more than or equal to 62 percent, and the roasted sulfate slag can be directly manufactured into the iron pellets which are then sold to iron mills, so that the aim of comprehensive recycle is achieved.

Owner:LINGBAO CITY JINYUAN MINING

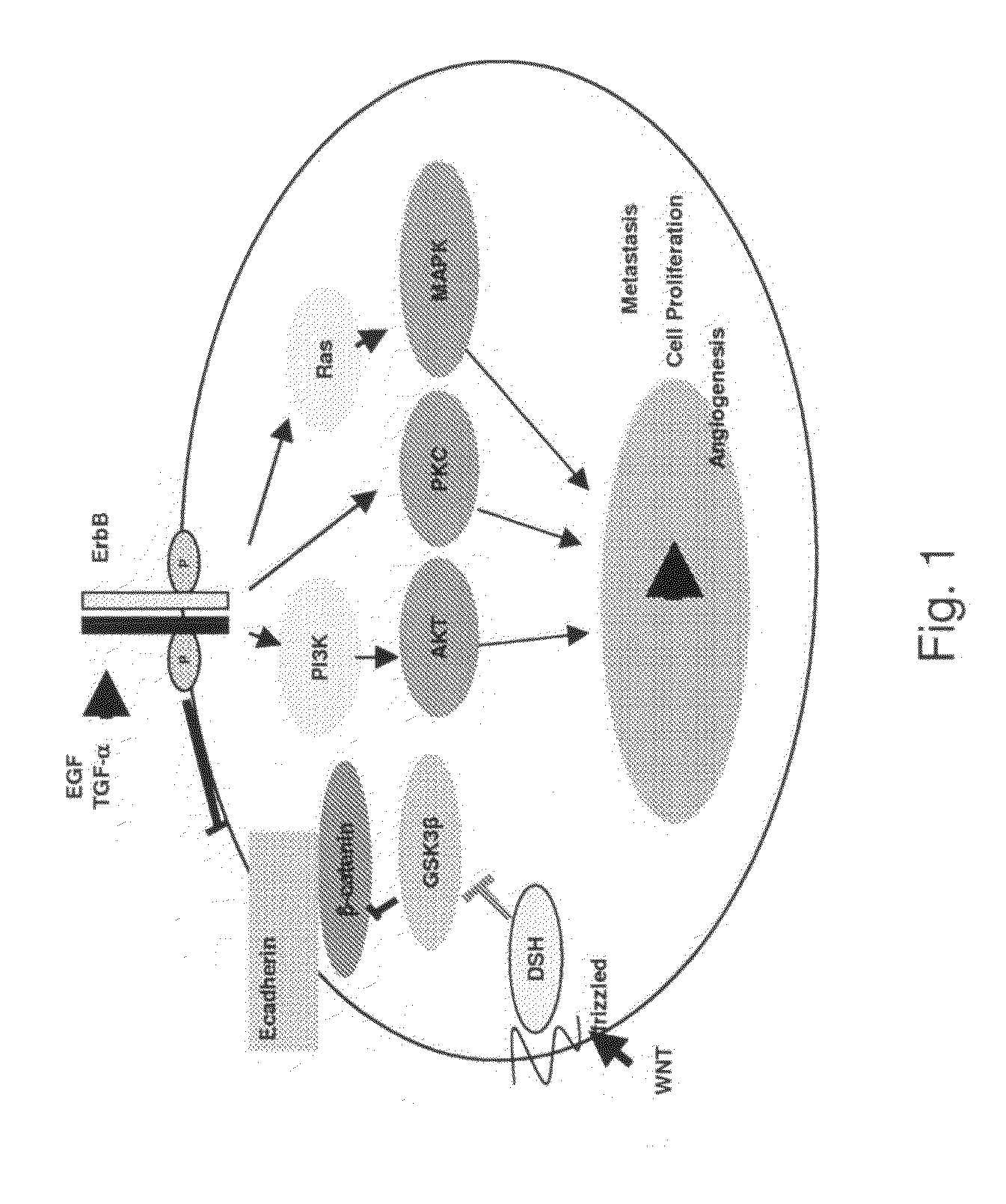

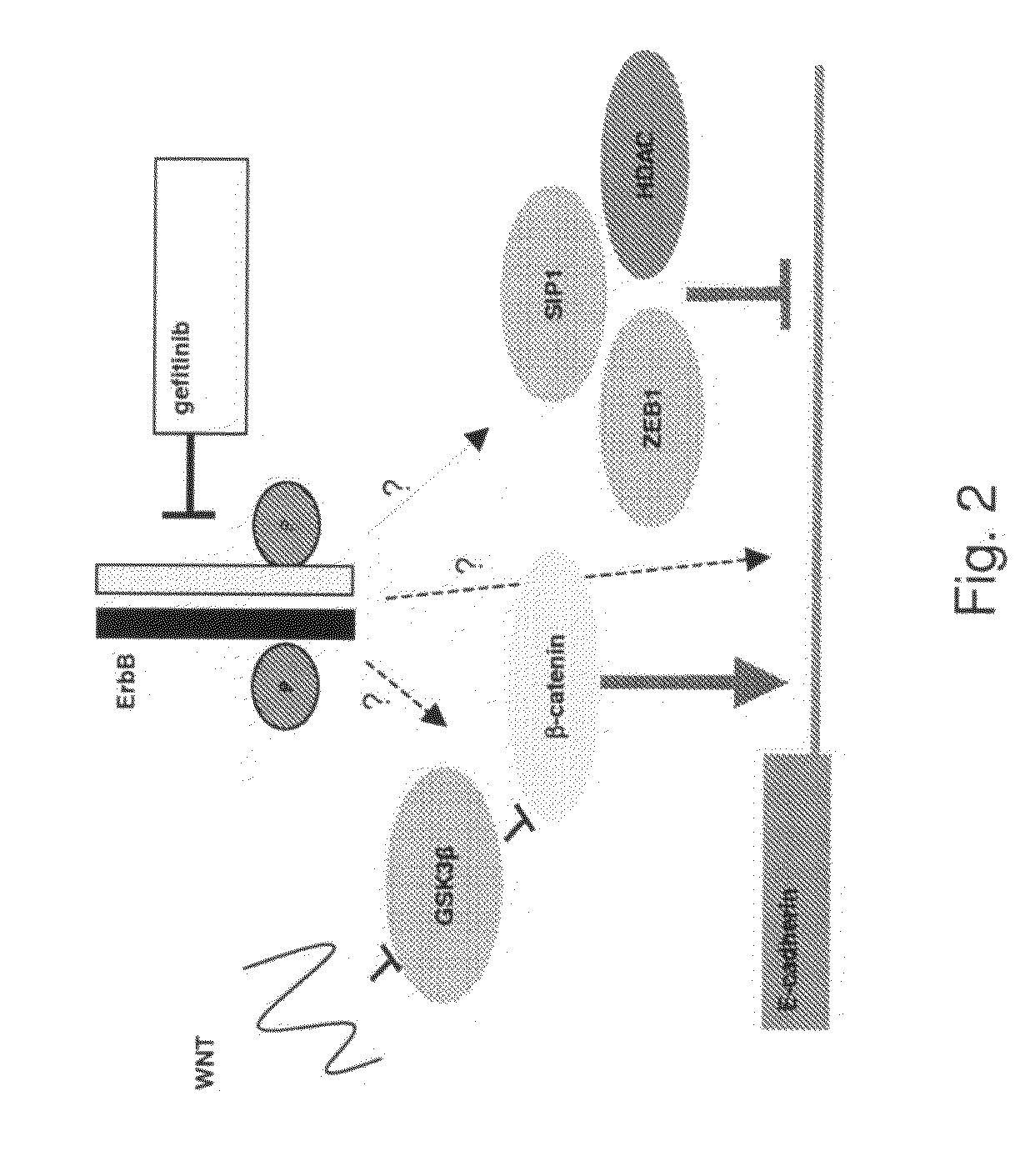

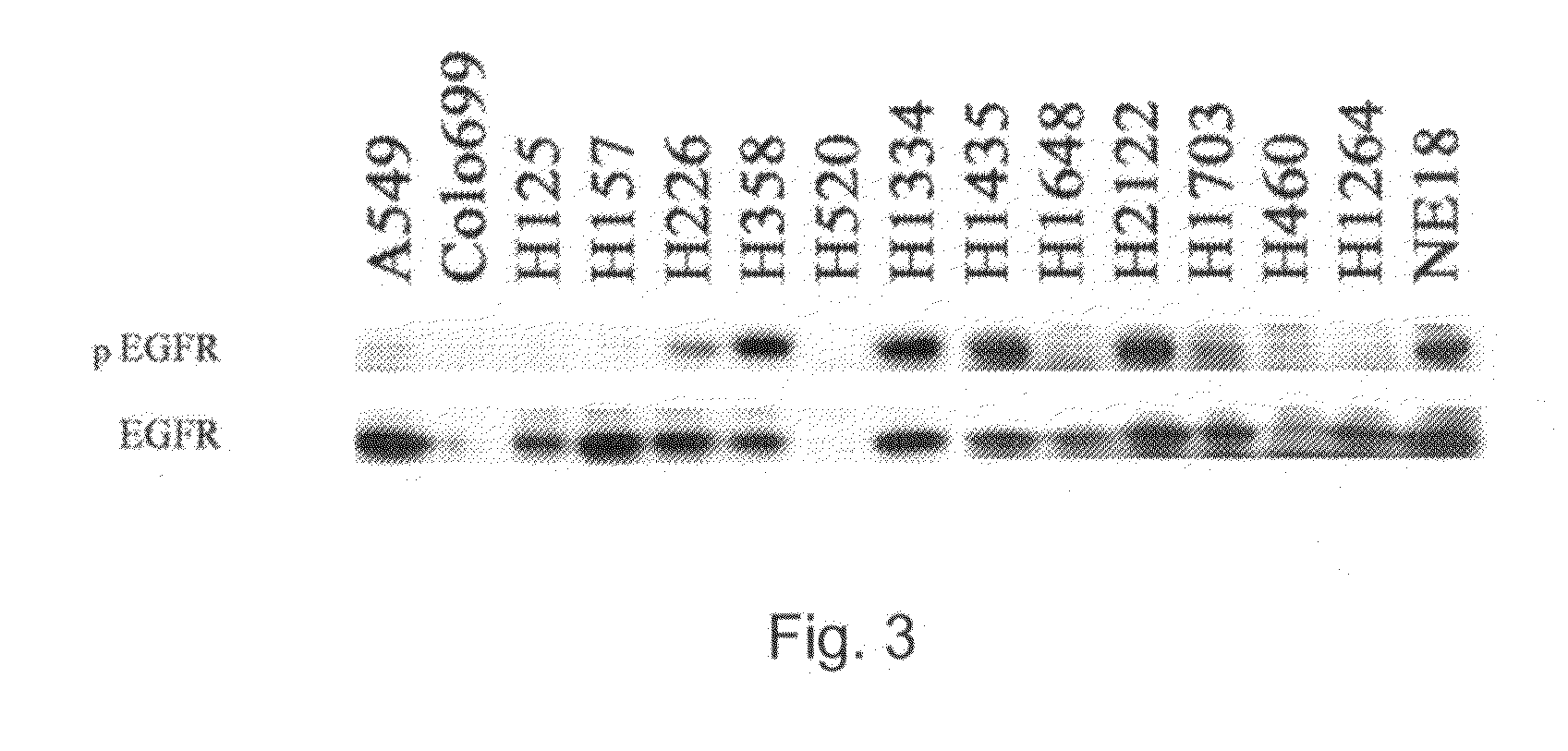

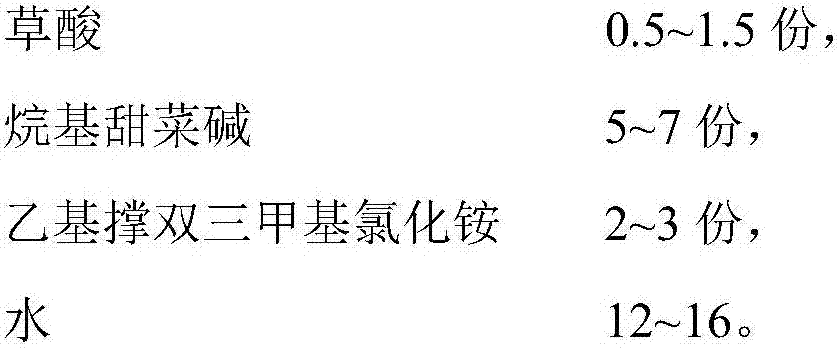

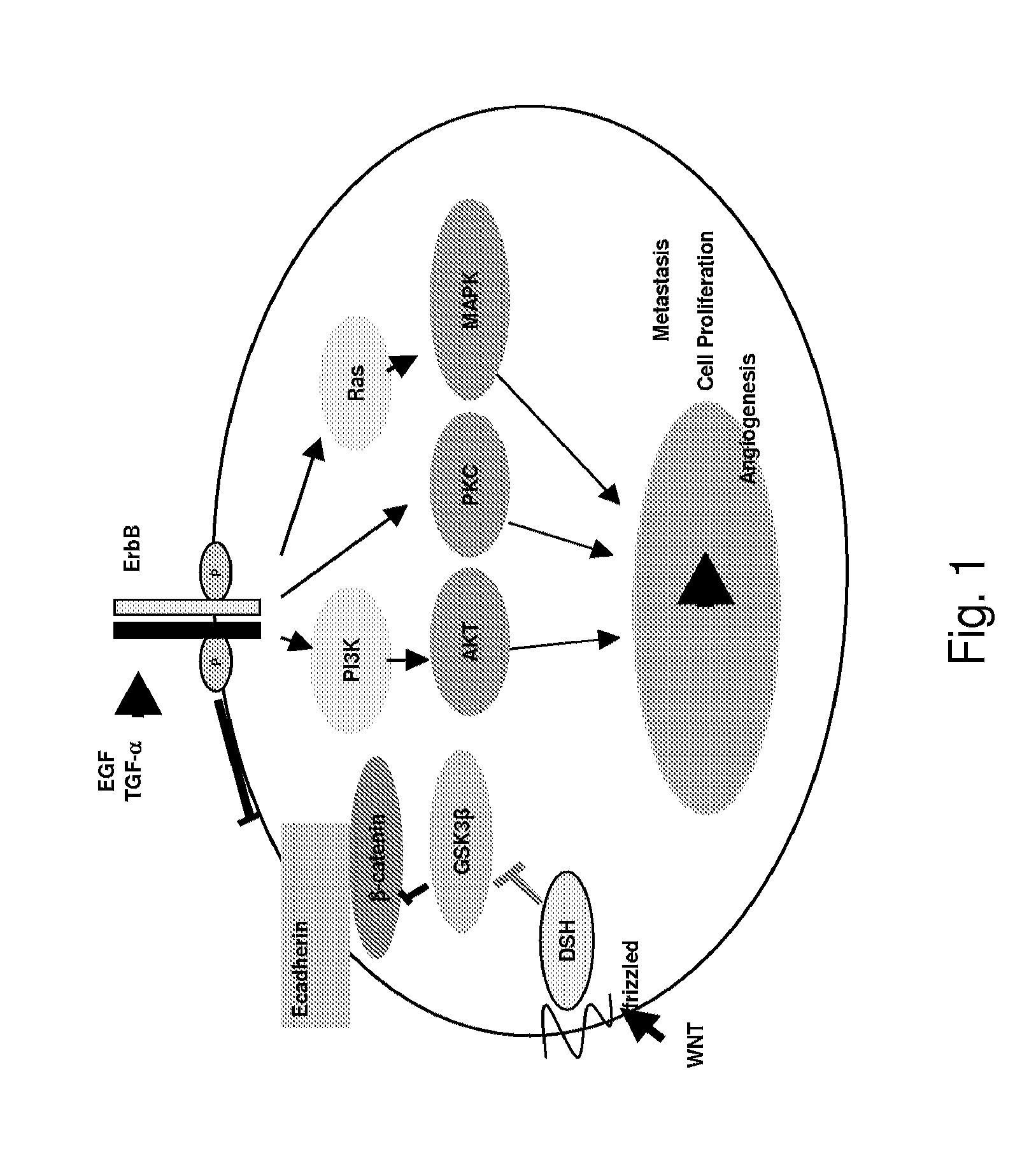

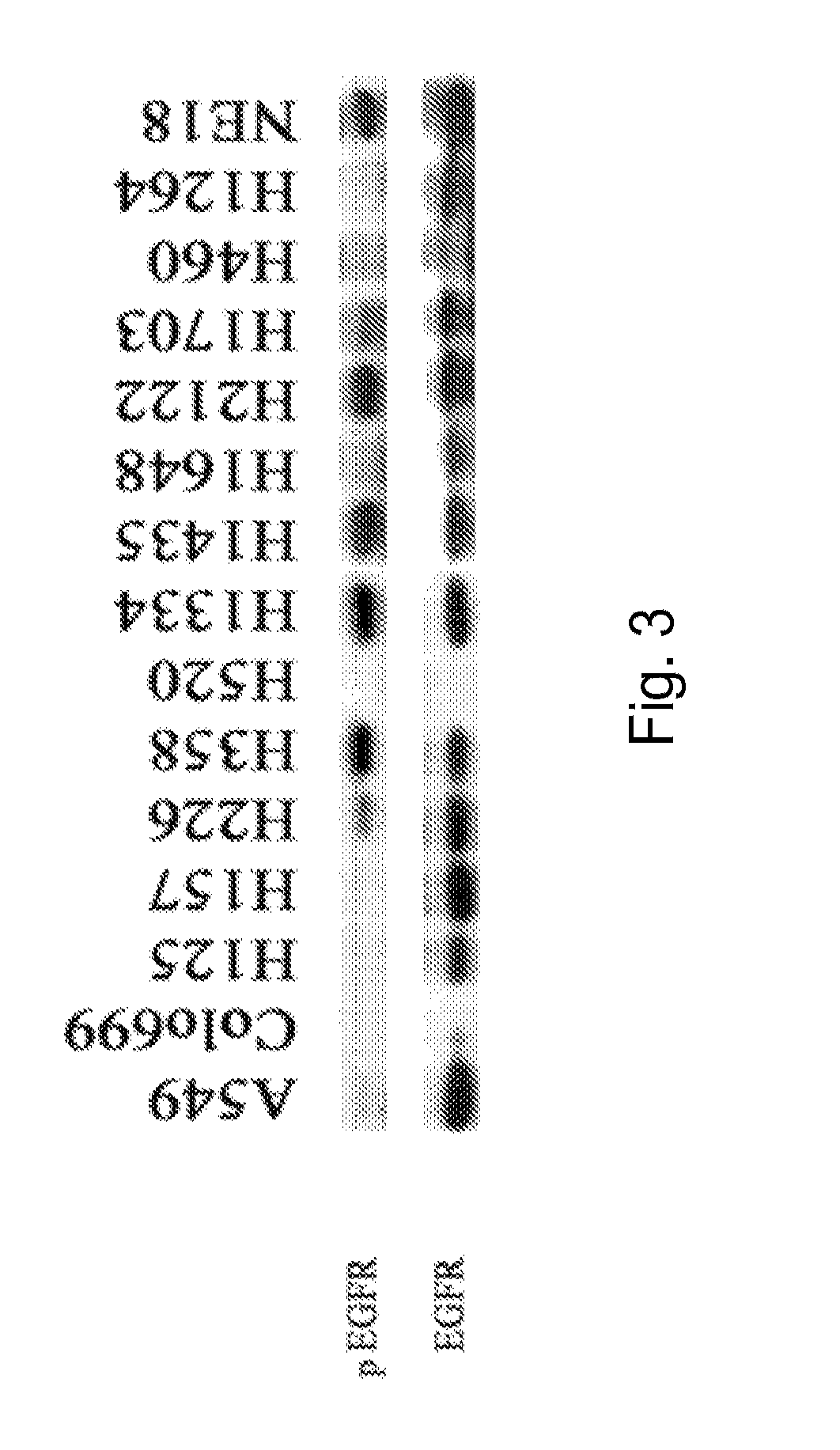

Gefitnib Sensitivity-Related Gene Expression and Products and Methods Related Thereto

Disclosed is the identification, provision and use of a panel of biomarkers that predict sensitivity or resistance to EGFR inhibitors, and products and processes related thereto. In one embodiment, a method is described for selecting a cancer patient who is predicted to benefit from therapeutic administration of an EGFR inhibitor, an agonist thereof, or a drug having substantially similar biological activity as EGFR inhibitor. Also described is a method to identify molecules that interact with the EGFR pathway to allow or enhance responsiveness to EGFR inhibitors, as well as a plurality of polynucleotides or antibodies for detection of the expression of genes that are indicative of sensitivity or resistance to EGFR inhibitors, an agonist thereof, or a drug having substantially similar biological activity as EGFR inhibitors. A method to identify a compound with the potential to enhance the efficacy of EGFR inhibitors is also described.

Owner:UNIV OF COLORADO THE REGENTS OF

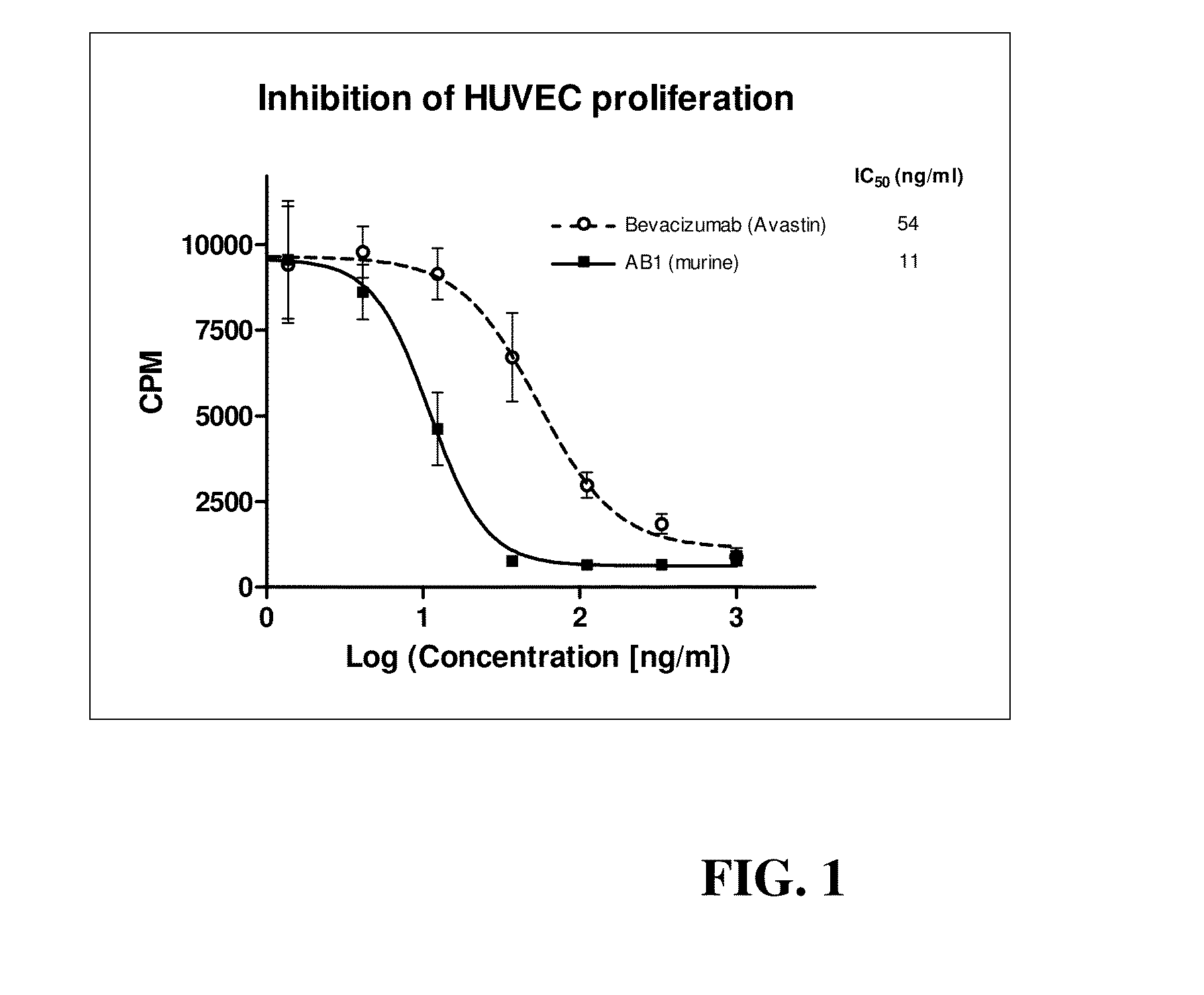

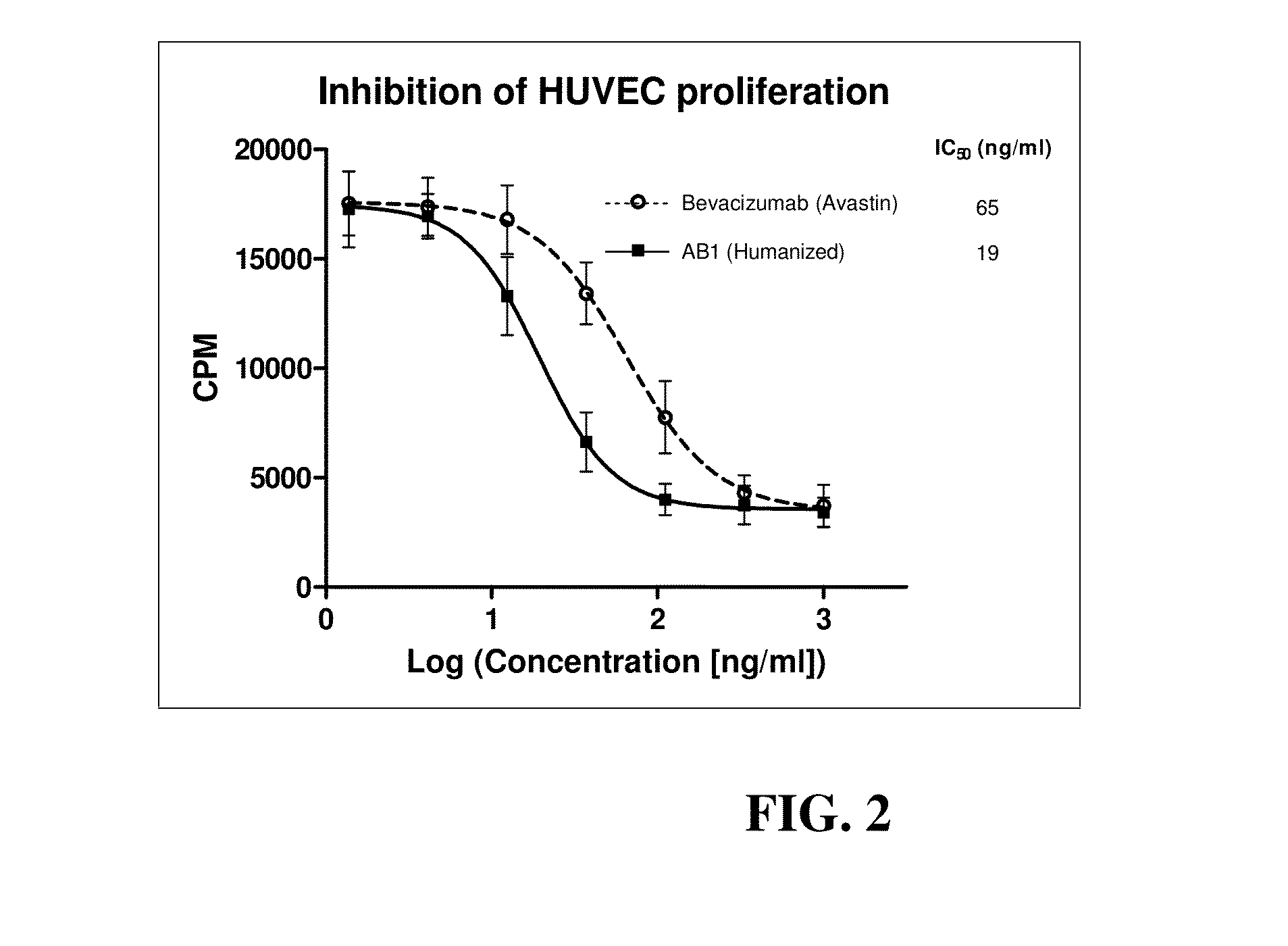

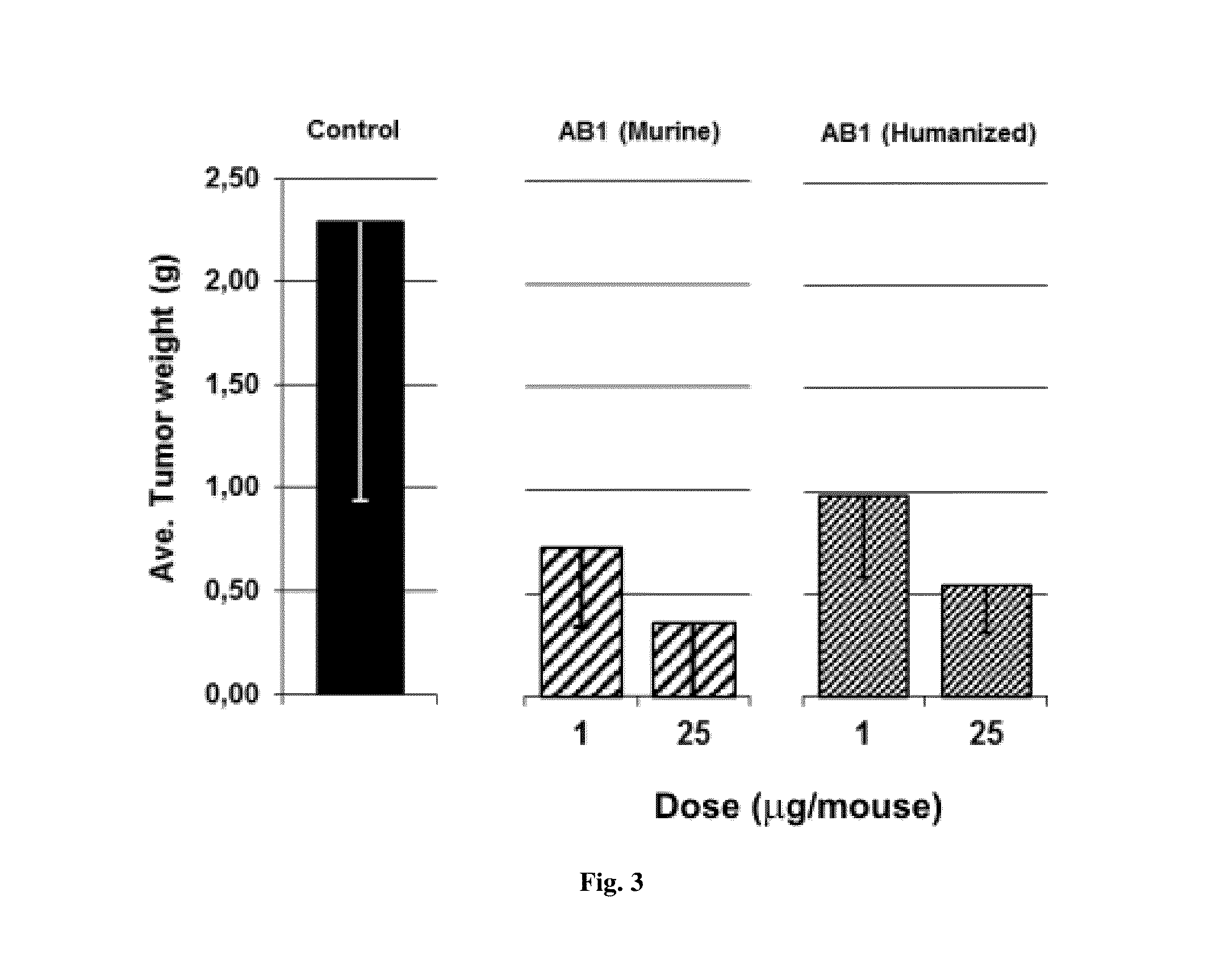

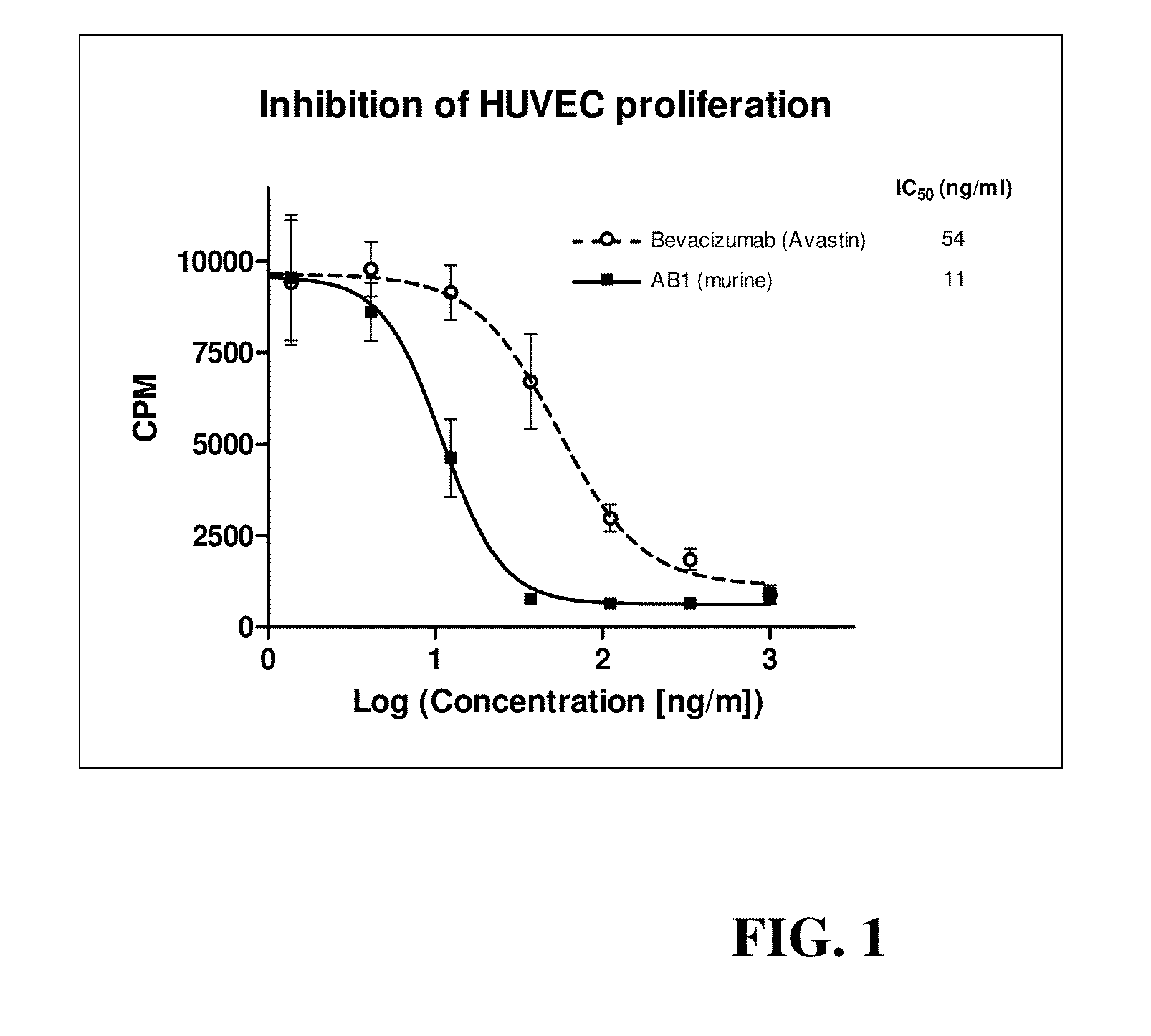

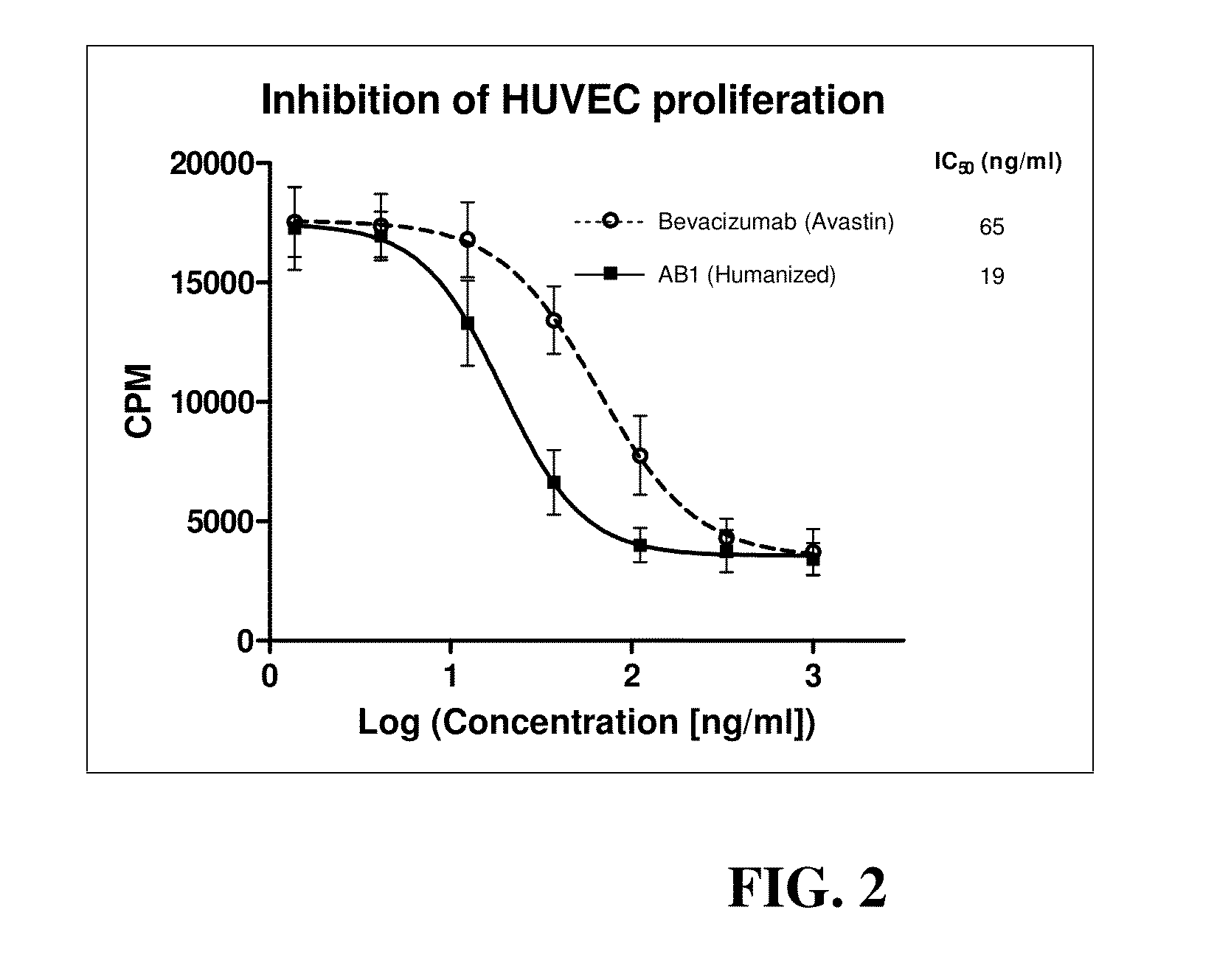

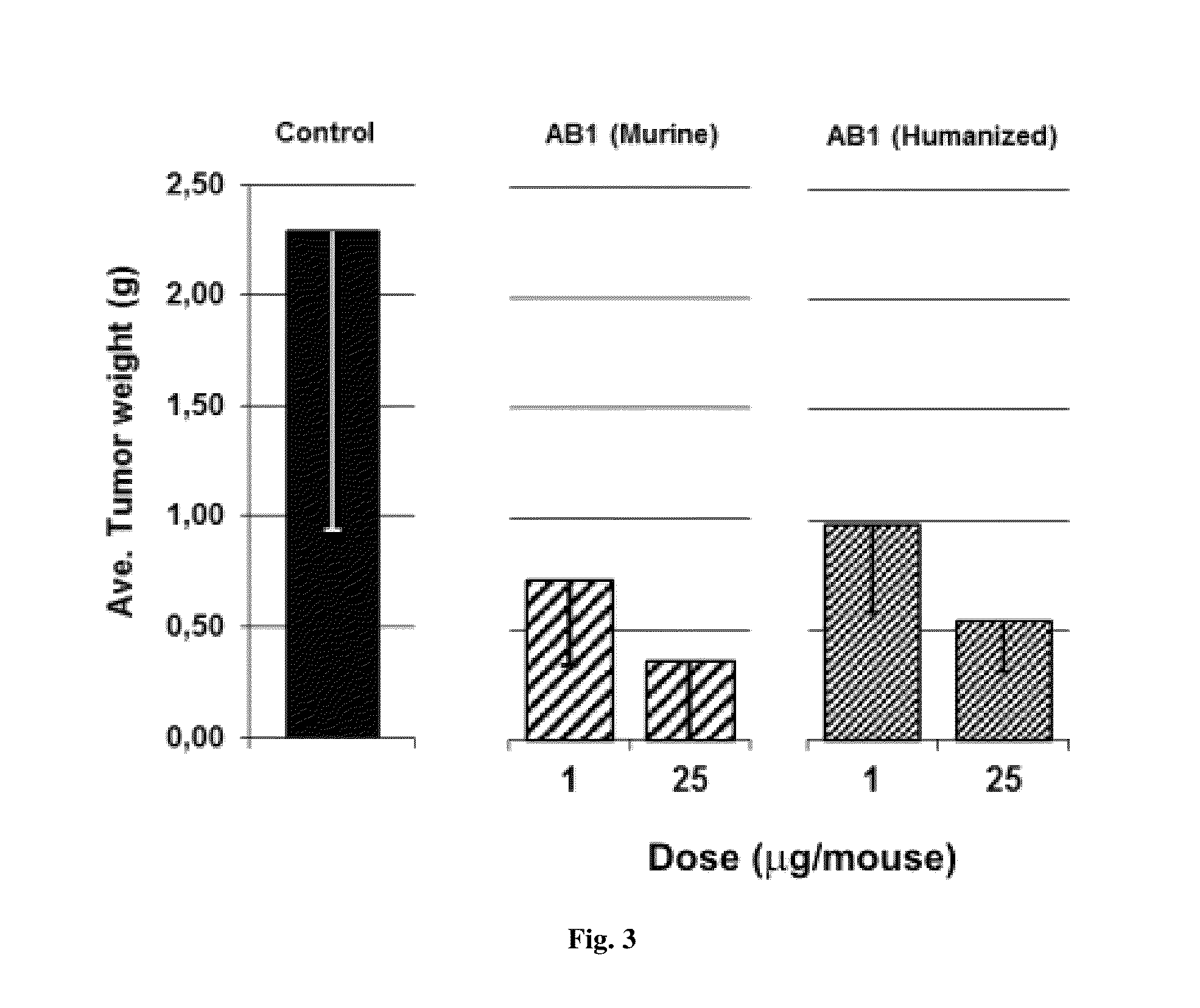

Anti-human VEGF antibodies with unusually strong binding afinity to human VEGF-a and cross reactivity to human VEGF-b

ActiveUS20150315270A1High homologyHigh affinityOrganic active ingredientsSenses disorderNeoplasmStrong inhibitor

Murine and humanized anti-human VEGF antibodies and uses are disclosed. The anti-human VEGF antibodies of the invention have higher binding affinity for human VEGF-A, are stronger inhibitors of the VEGF-A induced proliferation of endothelial cells in culture as compared with anti-human VEGF antibodies in the art. Moreover, these antibodies cross react with human VEGF-B. The antibodies of the invention inhibit tumor growth in vivo in greater extent than Bevacizumab (Avastin™) when administered at the same dosage

Owner:CONSEJO NACIONAL DE INVESTIGACIONES CIENTIFICAS Y TECNICAS CONICET 99 +1

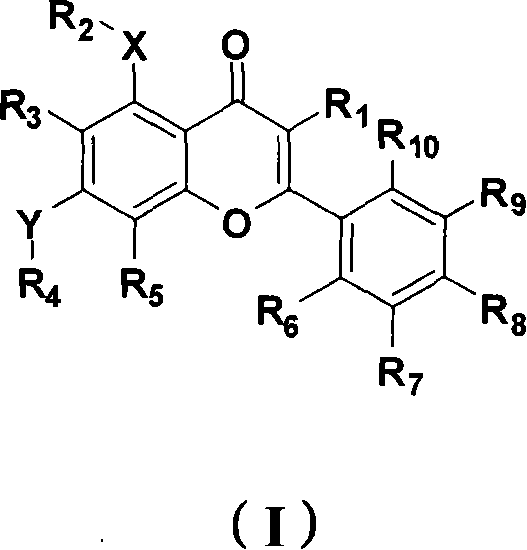

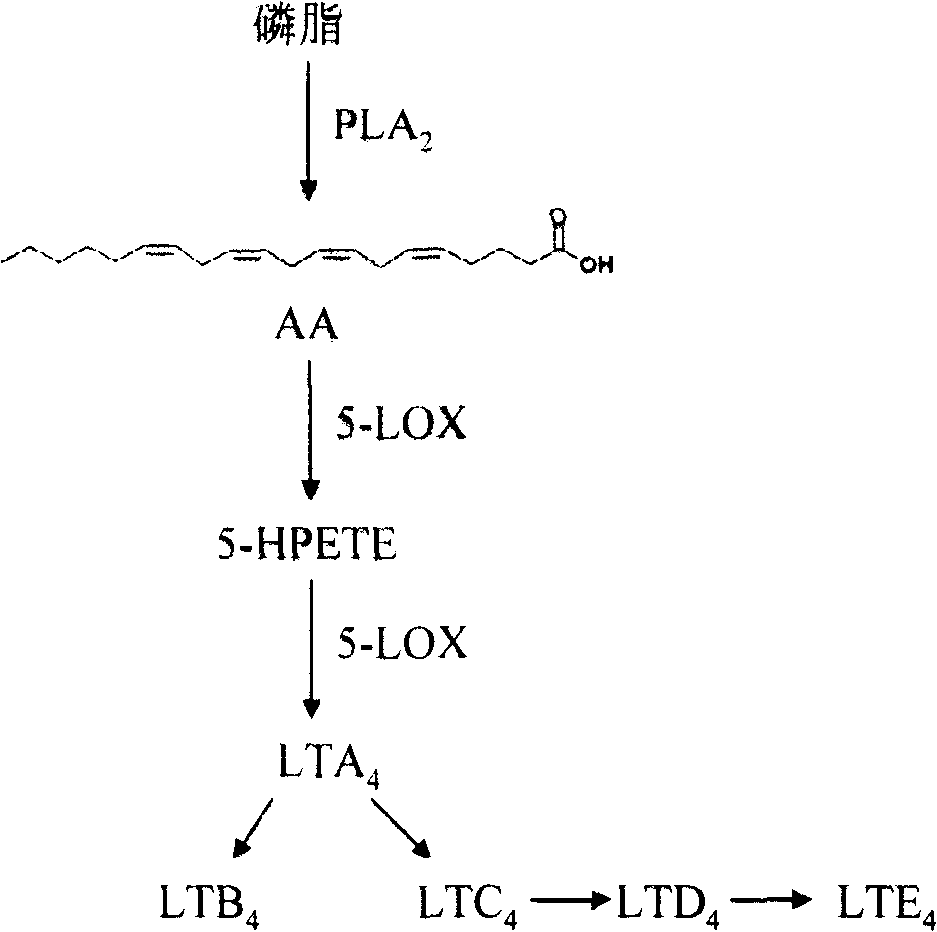

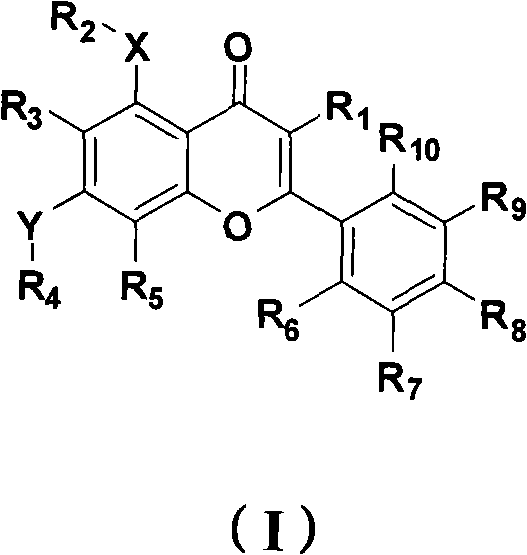

Substituted flavonoids and preparation method, application and pharmaceutical composition thereof

InactiveCN101265250AOrganic active ingredientsOrganic chemistryStrong inhibitorImmunological diseases

The invention provides a substituted flavonoid in formula (I), and pharmaceutically acceptable salt, solvate and hydrate thereof, wherein the definitions of R1-R10, X and Y are described in specification. Pharmacological experiment indicates that the compound is 5-lipoxidase strong inhibitor. Therefore, the flavonoid is expected to be applied in the preparation of drugs for preventing and / or treating inflammation diseases, immunological diseases such as asthma, anaphylaxis, etc., and cardiovascular disease. The invention also provides the preparation method of the flavonoid.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

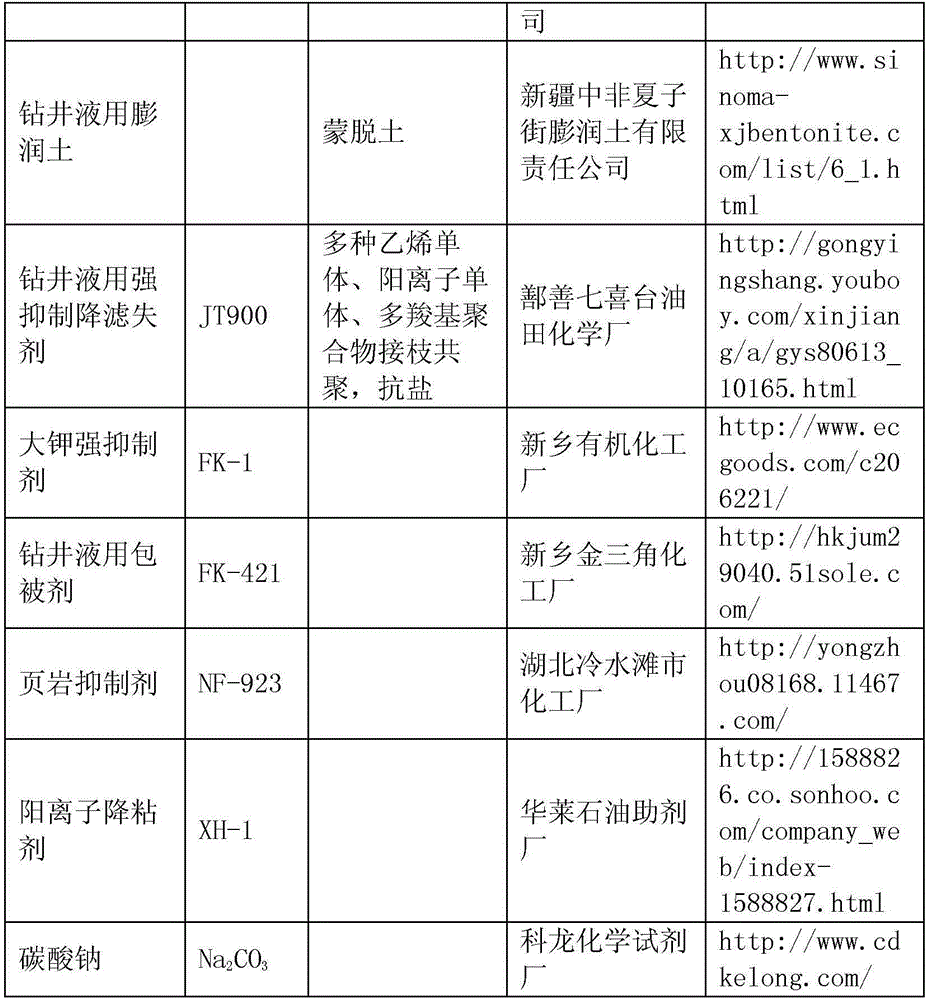

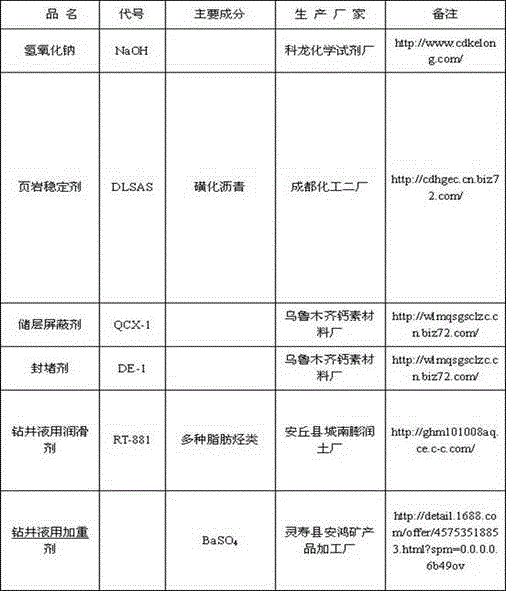

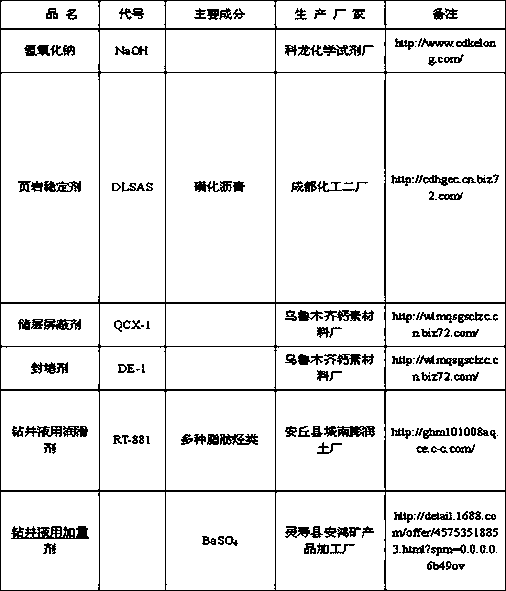

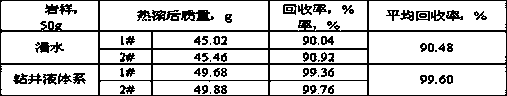

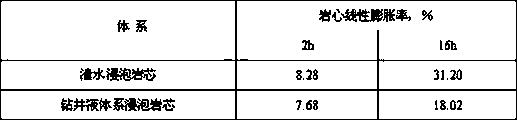

Strong inhibitive drilling fluid for drilling shale

The invention relates to a strong inhibitive drilling fluid for drilling shale for shale gas development and solves the problem of wellbore instability, and hydration collapse of the shale stratum is inhibited. The technical scheme of the strong inhibitive drilling fluid is that the the drilling fluid is prepared from the compositions of, by mass unit, 900-1,000 g of tap water, 30-60 g of bentonite for drilling fluid, 2-4 g of Na2CO3, 0.3-1 g of strong inhibitive filtrate reducer JT900 for drilling fluid, 0.5-1 g of potassium strong inhibitor FK-1, 2-5 g of coating agent FK-421 for drilling fluid, 1-1.5 g of shale inhibitor NF-923, 1-2 g of positive ion viscosity reducer XH-1, 2-3 g of shale stabilizer DLSAS, 4-6 g of reservoir shielding agent QCX-1, 2-4 g of blocking agent DE-1 and 0.5-1 g of lubricant RT-881 for drilling fluid; finally, the alkali liquor with the mass percentage concentration of 40% is prepared by adding water to NaOH, the system PH is adjusted to be 8.5, the drilling fluid weighting agent baryte is used for weighting the the system density to be 1.8-2.0 g / cm<3>, and the drilling liquid is prepared. The drilling fluid system has small environment pollution, and the drilling liquid has excellent rheological property and high sealing capacity and is used for drilling the shale.

Owner:SOUTHWEST PETROLEUM UNIV

Medicine combination for overcoming drug resistance of liver cancer and kidney cancer tumors and application of medicine combination

ActiveCN111420059AIncreased sensitivityImprove efficacyOrganic active ingredientsAntineoplastic agentsHepatocellular carcinomaRenal clear cell carcinoma

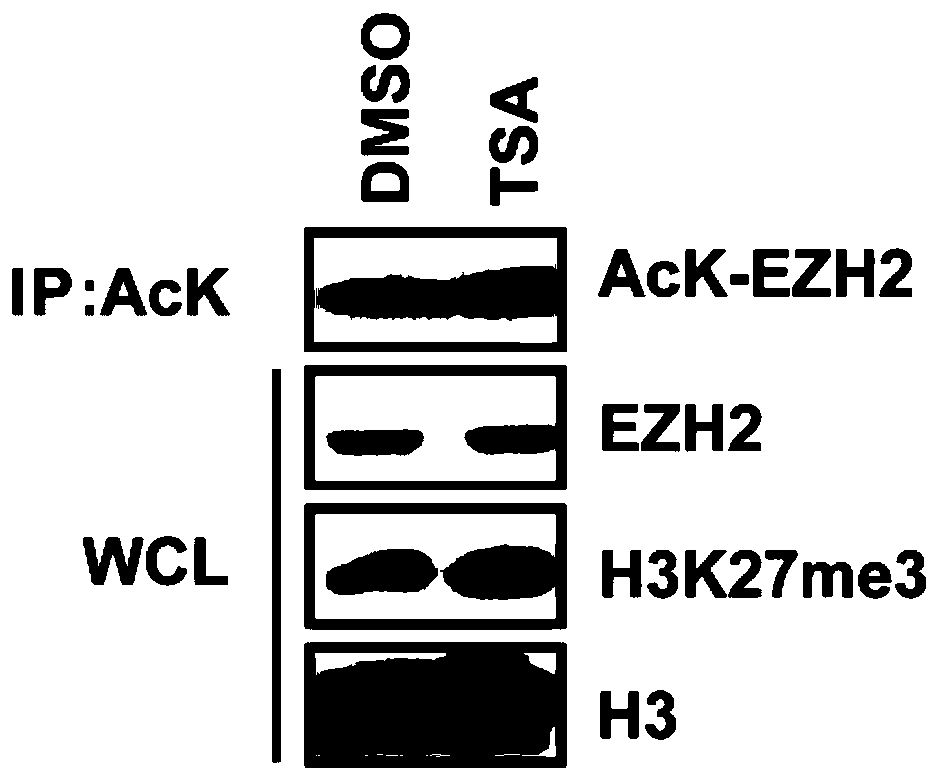

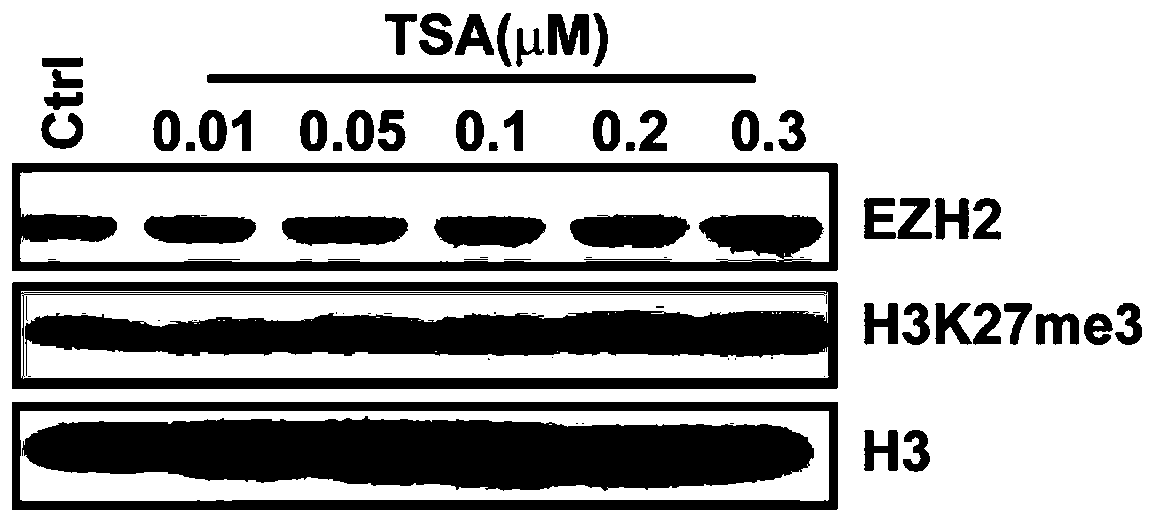

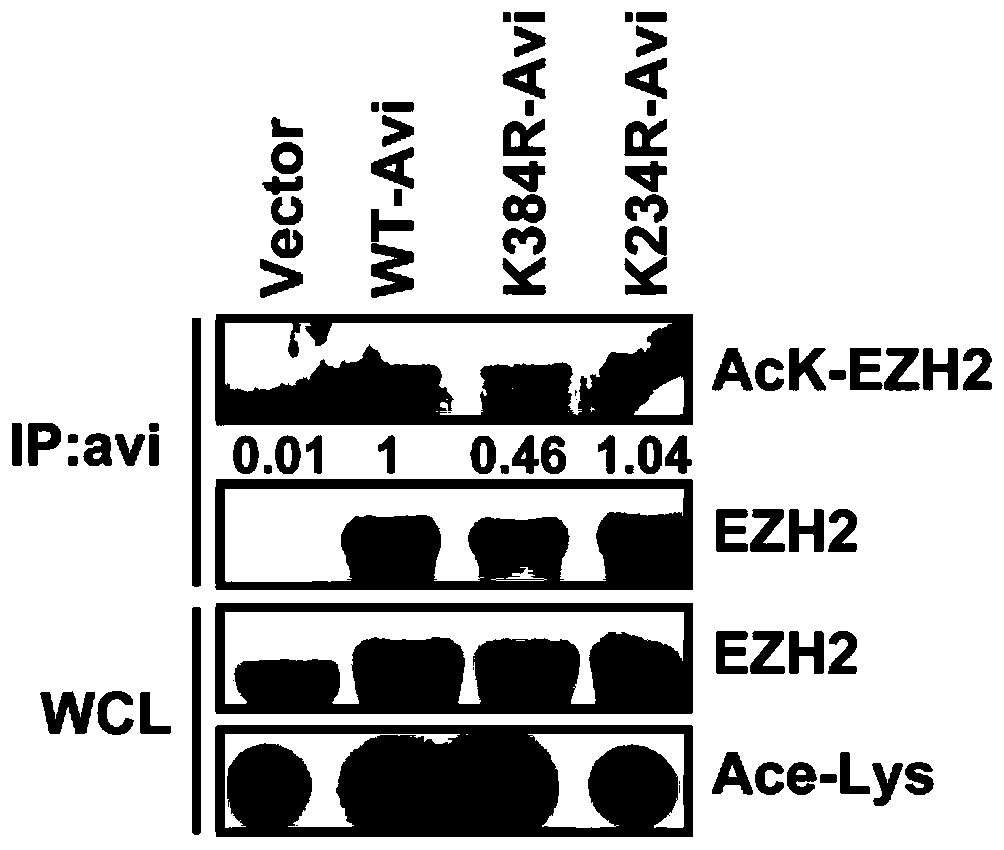

The invention discloses a medicine combination for overcoming drug resistance of liver cancer and kidney cancer tumors and an application of the medicine combination. The research of the invention shows that through combined use of an acetylase inhibitor anacardic acid (AA) and an EZH2 inhibitor GSK-126, tumor sensitivity of the EZH2 inhibitor is enhanced from two aspects of reducing stability ofthe EZH2 and inhibiting activity of the EZH2, the effect is obvious, and a new method and a new idea are provided for improving the drug effect and the application range of the EZH2 inhibitor. Experiments show that combined use of the acetylase inhibitor and the EZH2 inhibitor has strong killing effect on hepatocellular carcinoma and renal clear cell carcinoma cells, and the effect of combined useis obviously superior to the effect of single use of the EZH2 inhibitor, so that combined use of the acetylase inhibitor and the EZH2 inhibitor can really exert a synergistic effect, and a new methodis provided for improving the drug effect and application range of the EZH2 inhibitor.

Owner:SUN YAT SEN UNIV

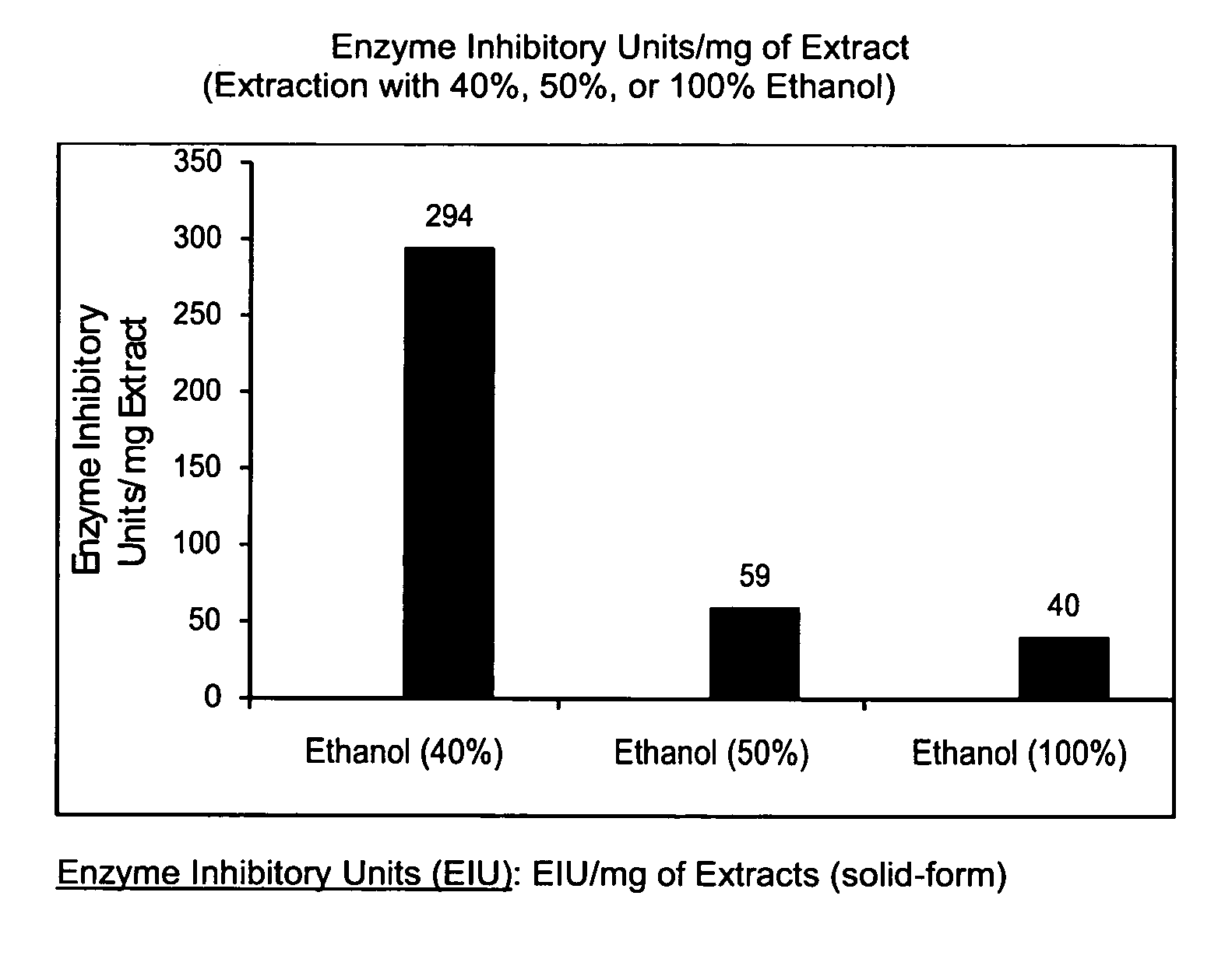

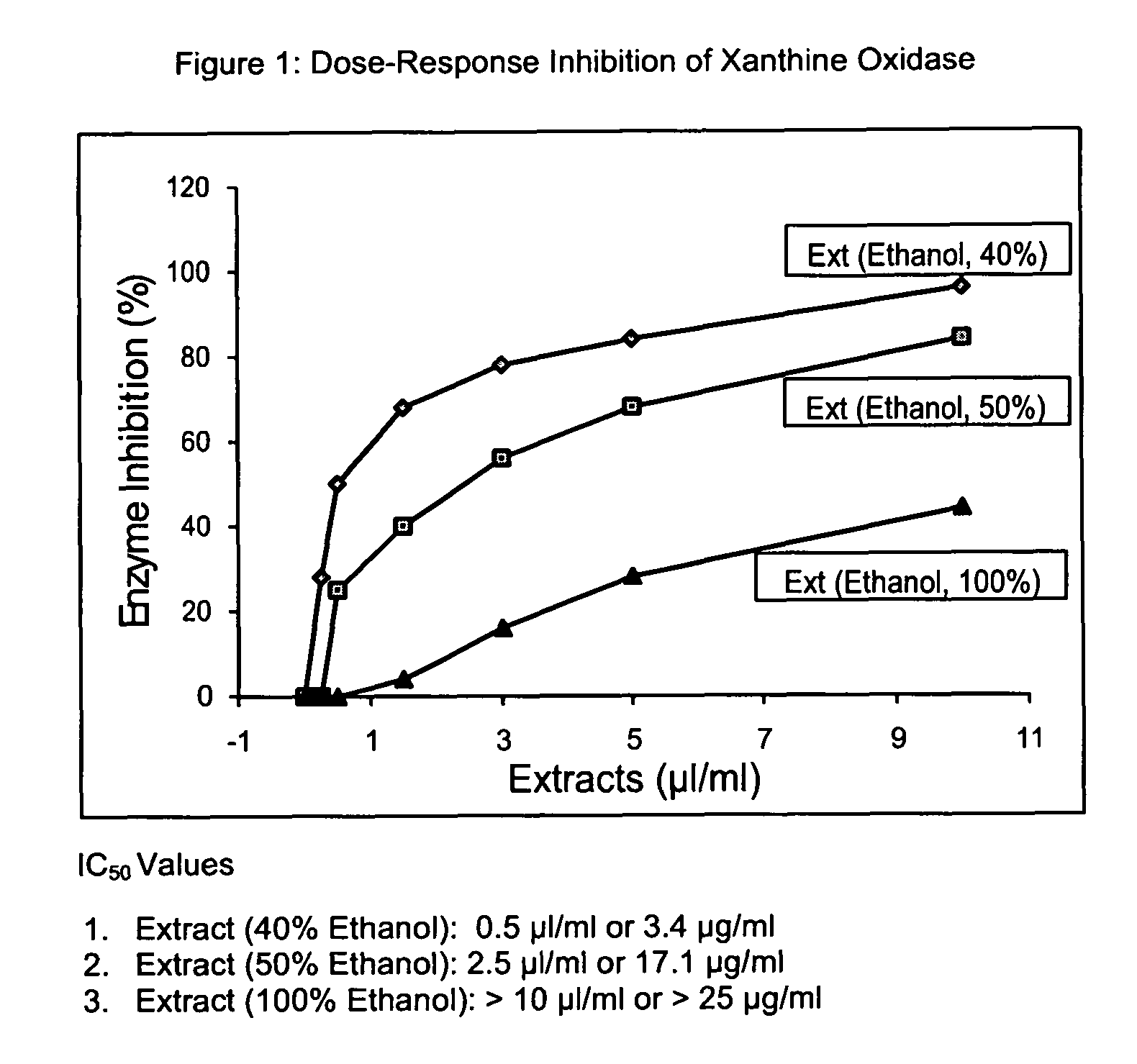

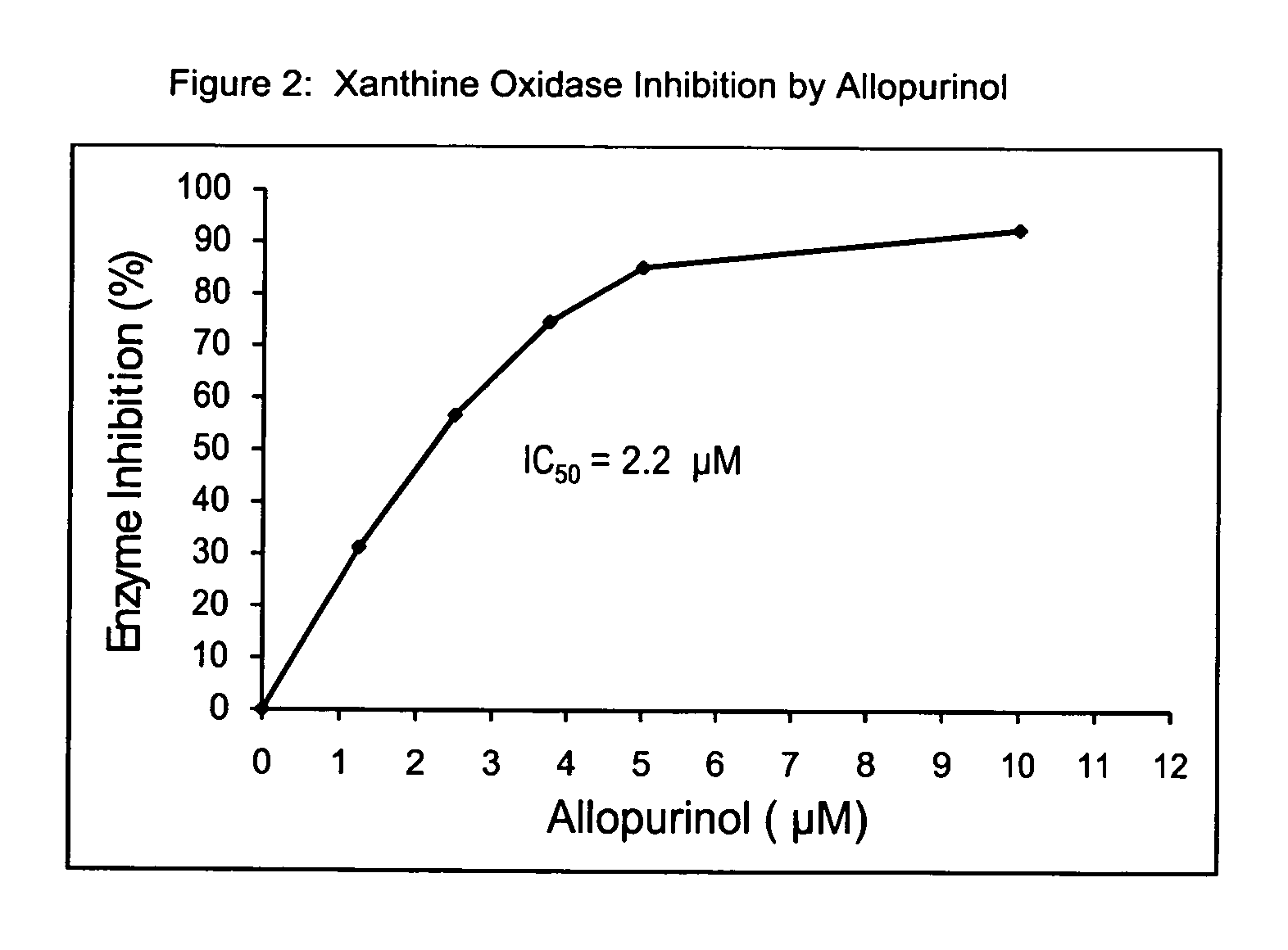

Development of biochemically standardized extracts from fresh rhizomes of turmeric (Curcuma longa) for treatment of diseases caused by hyperuricemia

InactiveUS8808768B2Prevent degradationAvoid tissue damageBiocideAnimal repellantsDiseaseIndian saffron

The present invention demonstrates the ethanol extracts of fresh rhizome of turmeric (Curcuma longa) strongly inhibit xanthine oxidase, a key biological enzyme responsible for the production of uric acid and superoxide radicals. The dose-response data demonstrate the turmeric extracts prepared with 40% and 50% ethanol are much stronger inhibitors of xanthine oxidase than curcumin. Based on the enzyme-inhibitory data (IC50 values), a biochemical method is developed to standardize turmeric extracts / products as Enzyme-Inhibitory Units (EIU), which has many commercial and biological applications, including, identification and development of pharmacologically effective turmeric products; use of turmeric extracts / products with EIU values >50 per mg to prevent the production of harmful uric acid and superoxides in diseases caused by hyperuricemia and gout; determination of the stability (shelf-life) of turmeric products stored at the retail stores by comparing their EIU values.

Owner:AGARWAL KAILASH CHANDRA

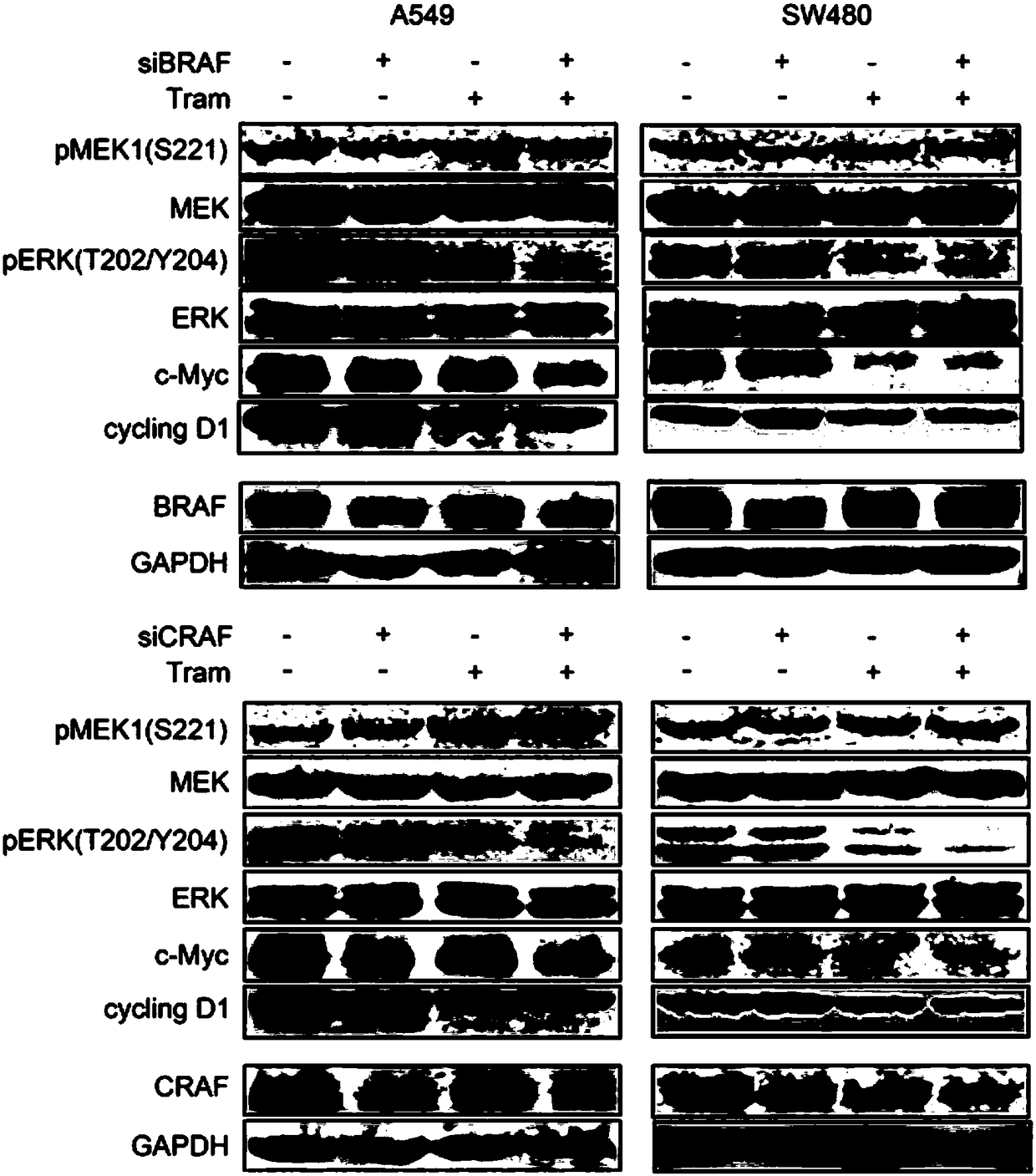

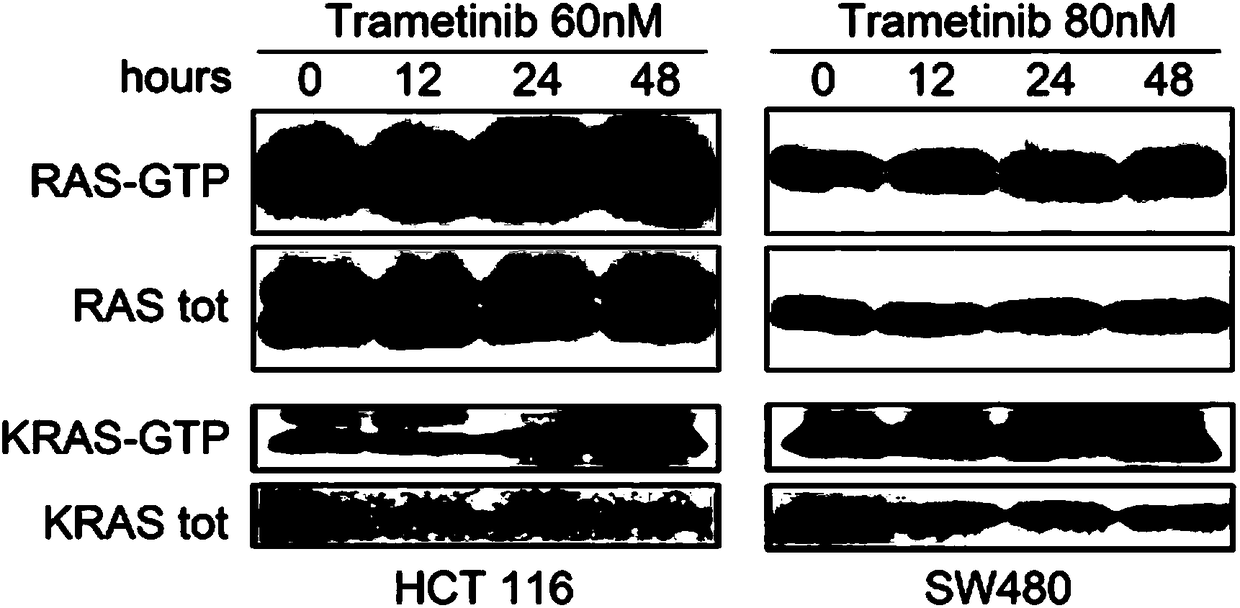

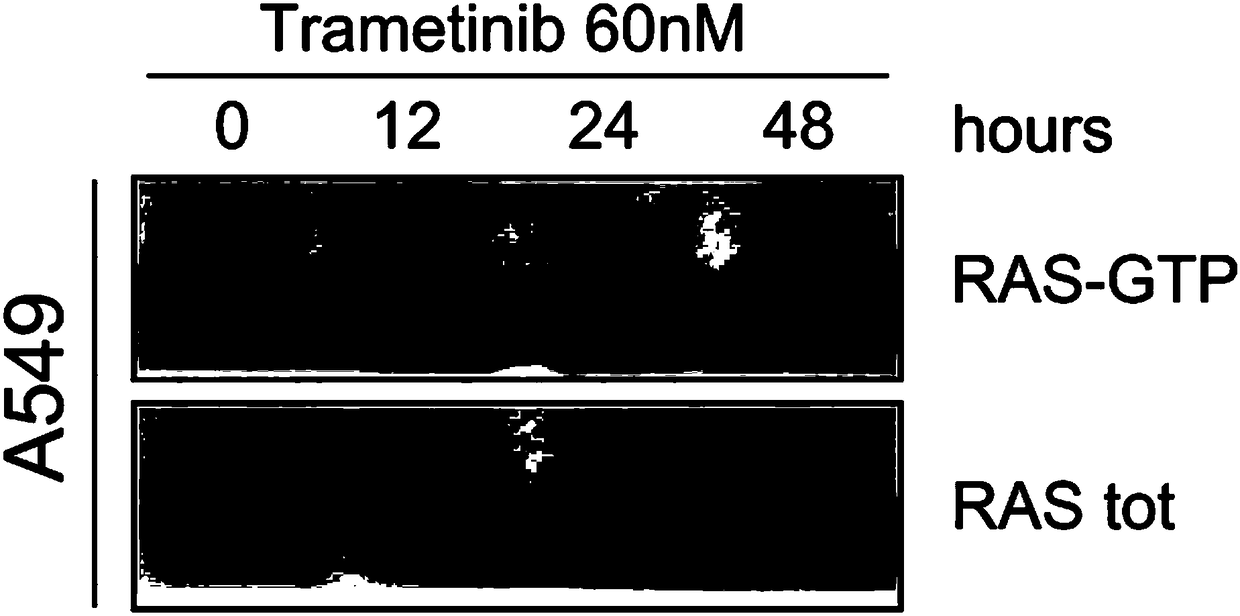

Combined drug for treating tumors

ActiveCN108452310AHigh cytotoxicityGood killing effectOrganic active ingredientsAntineoplastic agentsCo medicationMEK inhibitor

The invention discloses a combined drug for treating tumors, concretely discloses a use of an RAS inhibitor in the preparation of a drug for enhancing the KRAS mutant tumor inhibition effect of an MEKinhibitor, and also discloses a combined drug for treating KRAS mutant tumors. The combined drug for treating KRAS mutant tumors contains different specifications of unit preparations for simultaneously or separately giving an RAS inhibitor and an MEK inhibitor, and a pharmaceutically acceptable carrier. The combined drug can effectively treat the KRAS mutant tumors, has an obviously better effect than the MEK inhibitor and the RAS inhibitor used alone, and has a good clinical application prospect.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

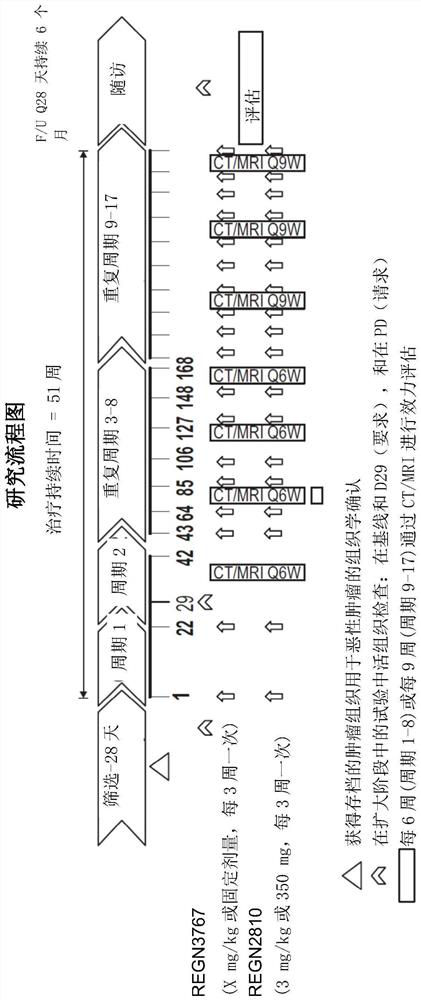

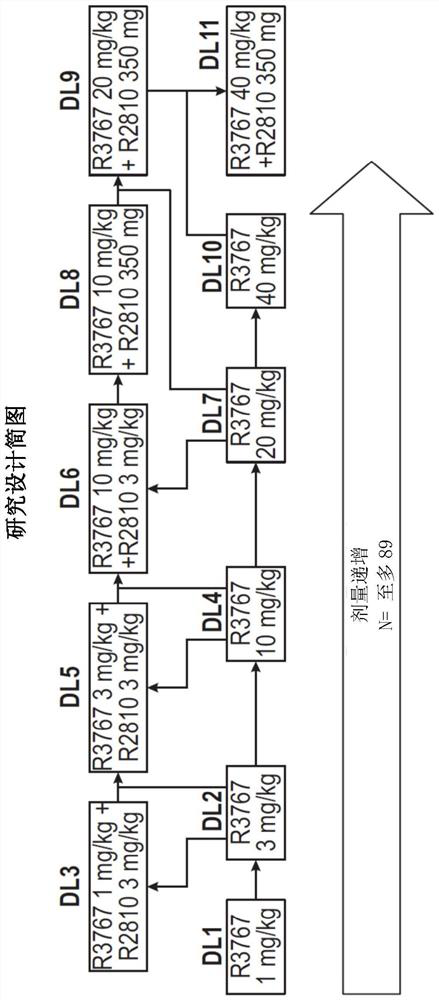

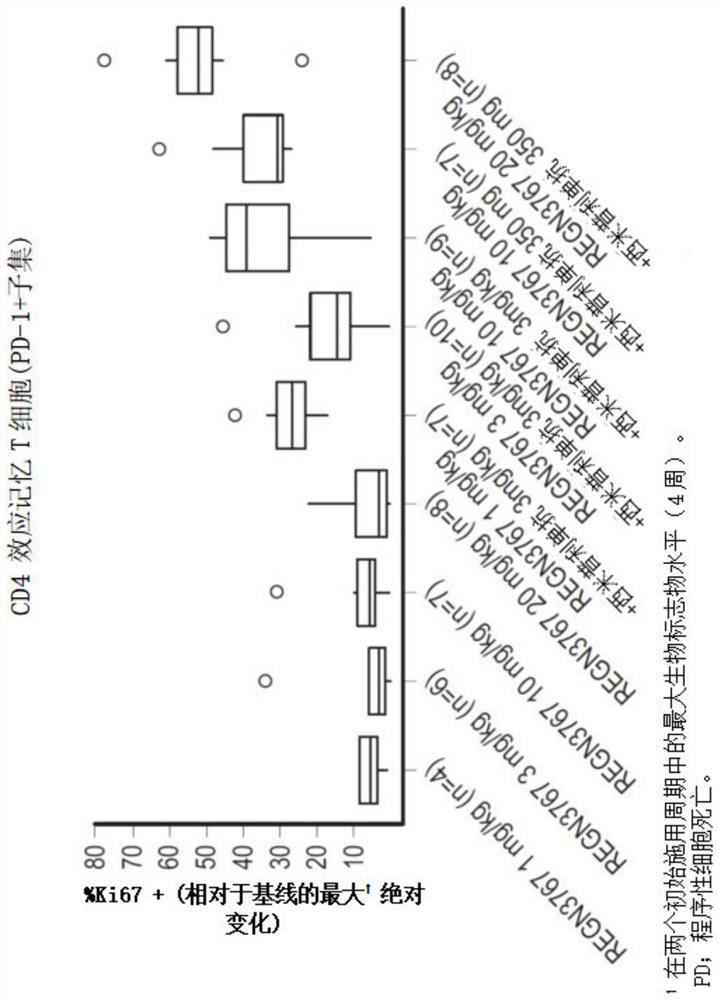

Combination of pd-1 inhibitors and lag-3 inhibitors for enhanced efficacy in treating cancer

PendingCN113825527ABacterial antigen ingredientsPeptide/protein ingredientsAntiendomysial antibodiesAntigen Binding Fragment

The present disclosure provides methods for treating or inhibiting the growth of cancer comprising selecting a patient with cancer and administering a therapeutically effective amount of a LAG-3 inhibitor in combination with a therapeutically effective amount of a PD-1 inhibitor (e.g., an anti-PD-1 antibody or antigen-binding fragment thereof). In certain embodiments, the administration of the PD-1 inhibitor enhances the efficacy of a LAG-3 inhibitor (e.g., an anti-LAG-3 antibody or antigen-binding fragment thereof) in inhibiting the growth of cancer.

Owner:REGENERON PHARM INC

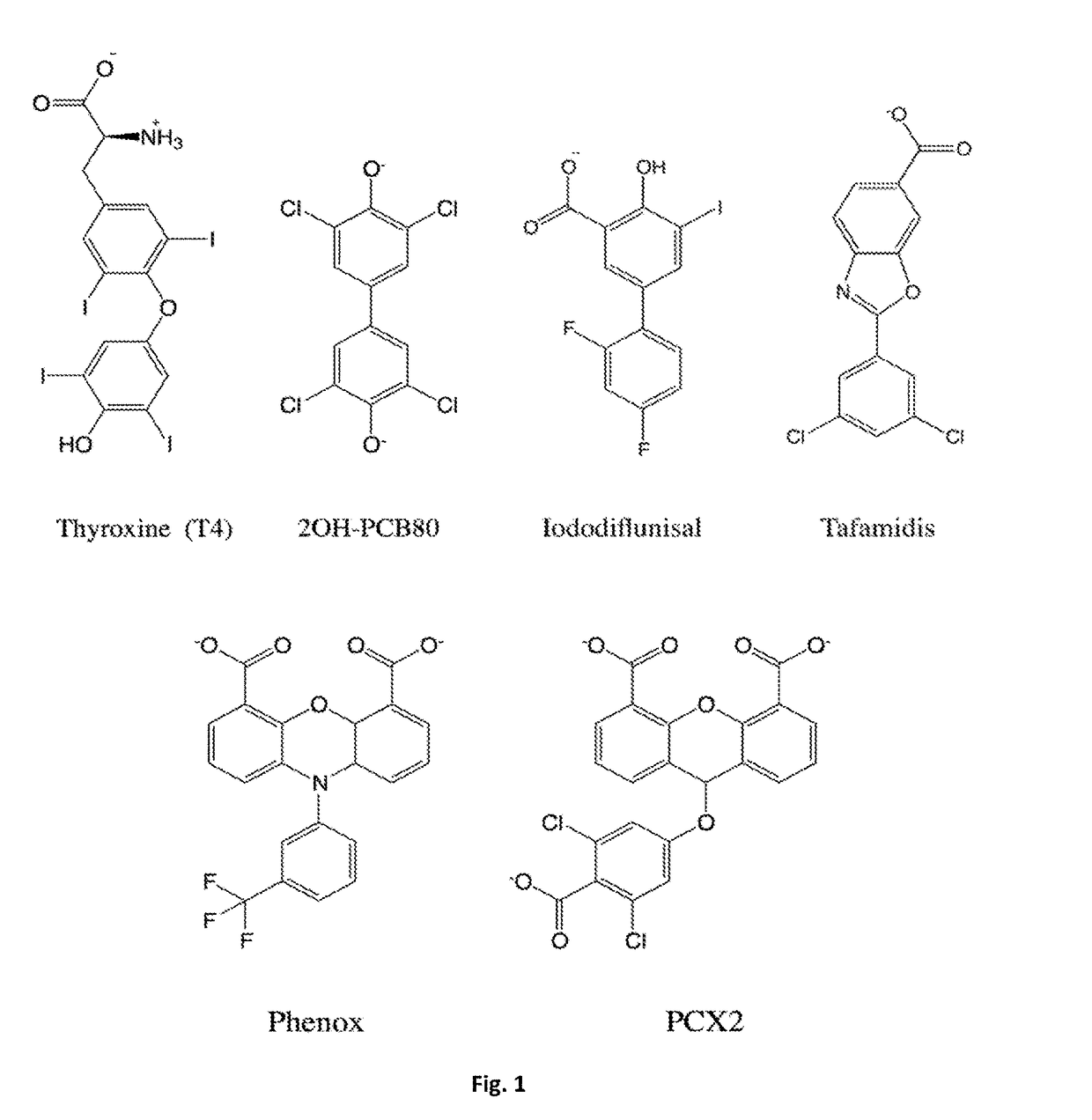

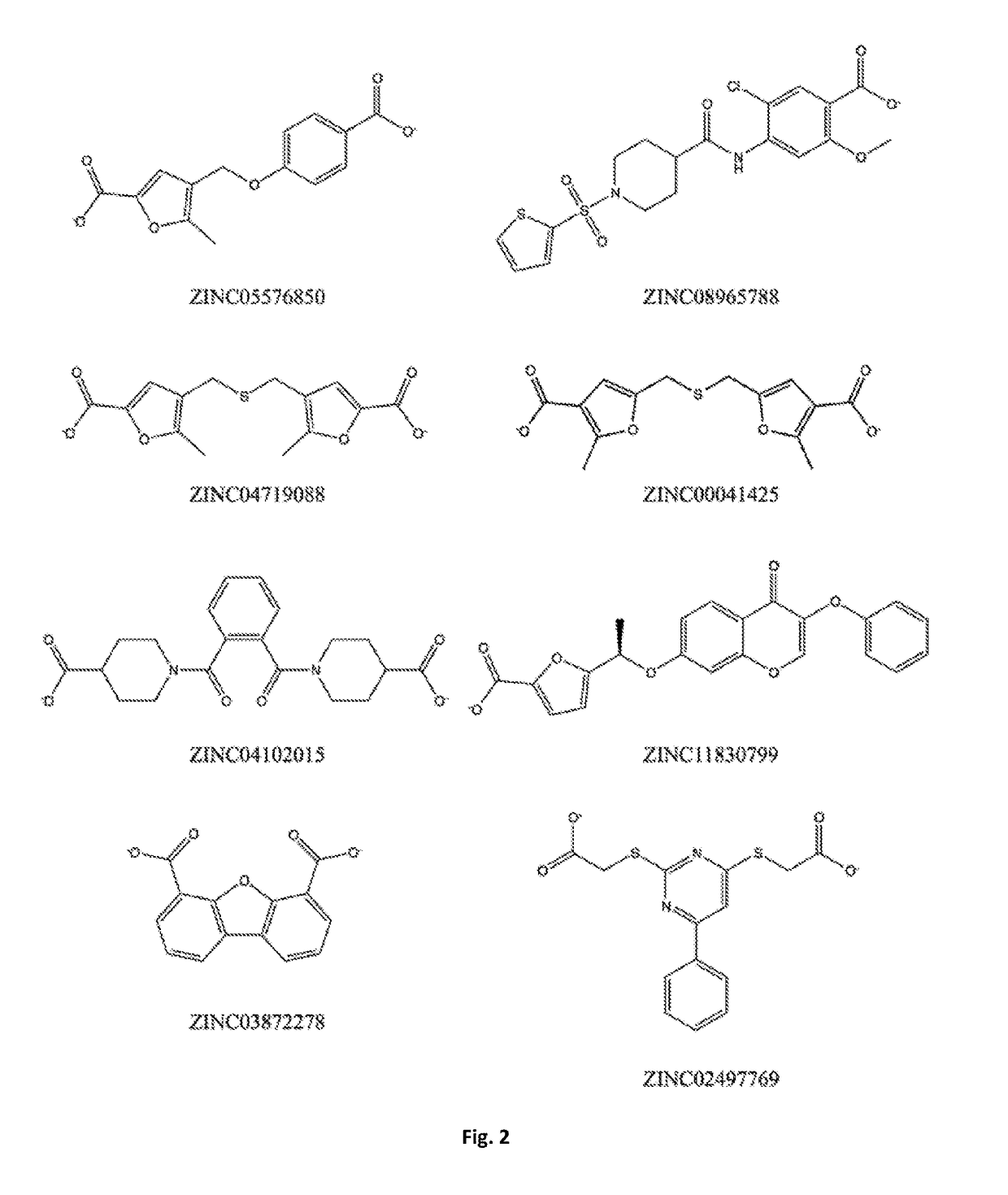

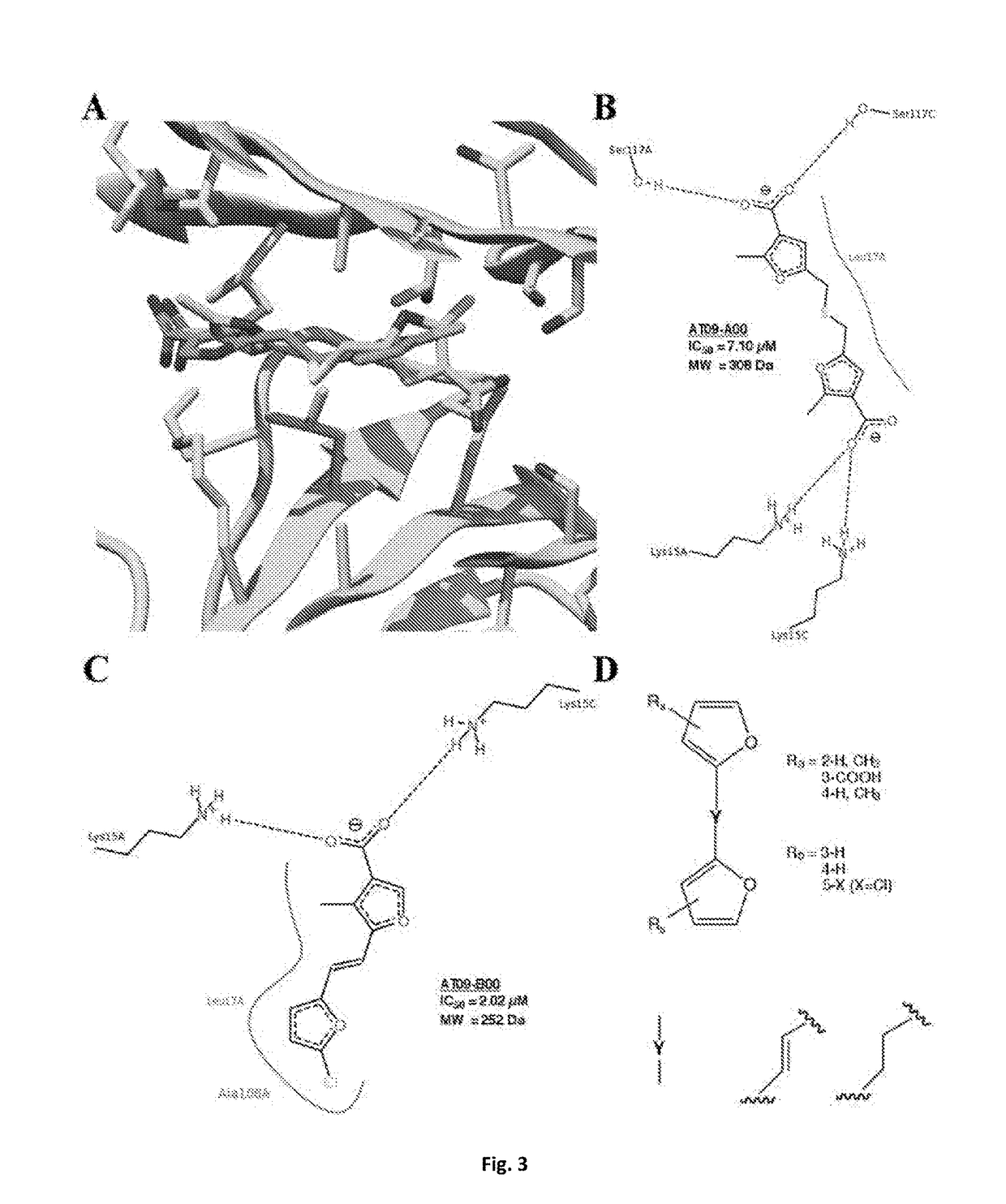

Bis-furan derivatives as transthyretin (TTR) stabilizers and amyloid inhibitors for the treatment of familial amyloid polyneuropathy (FAP)

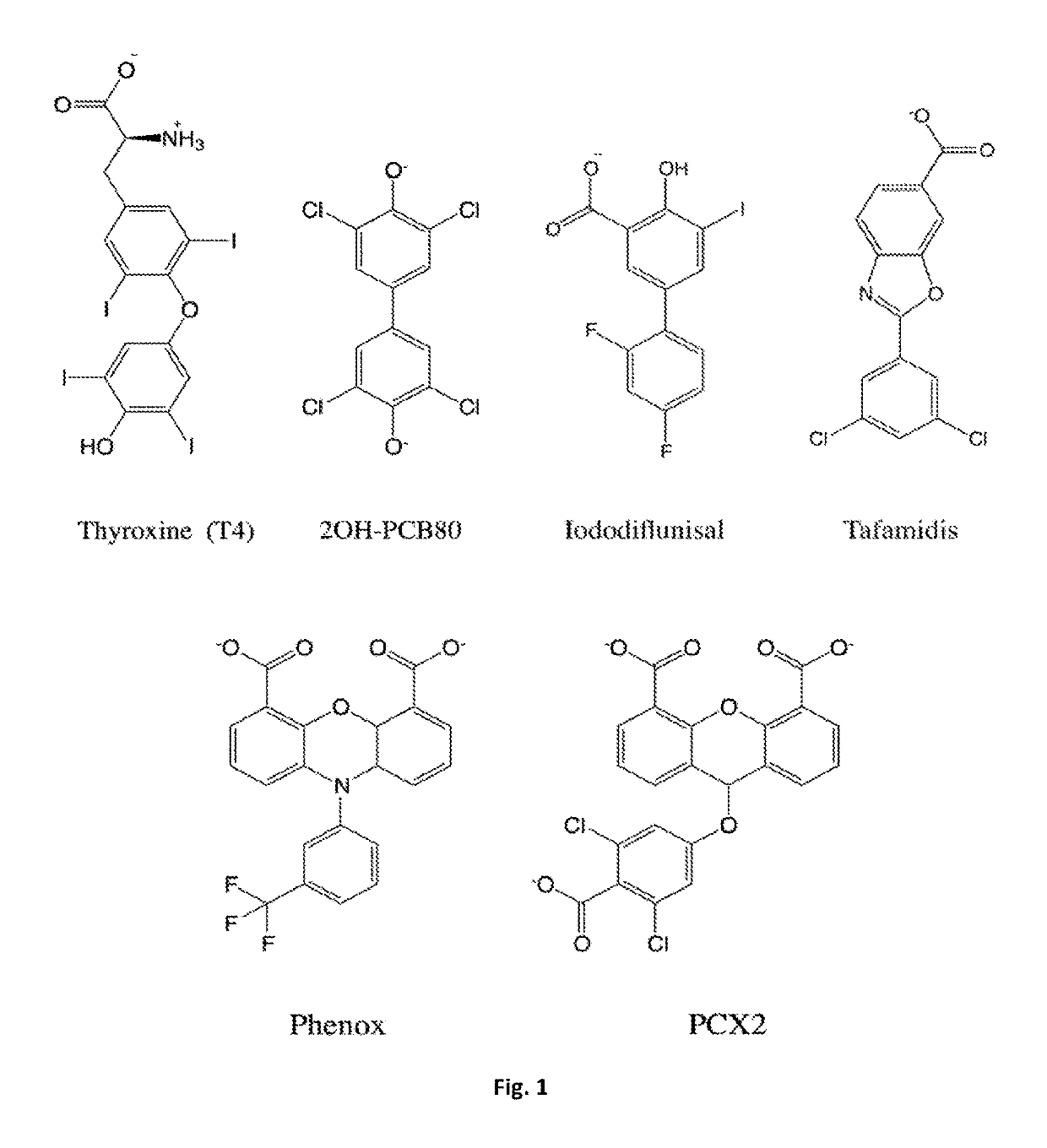

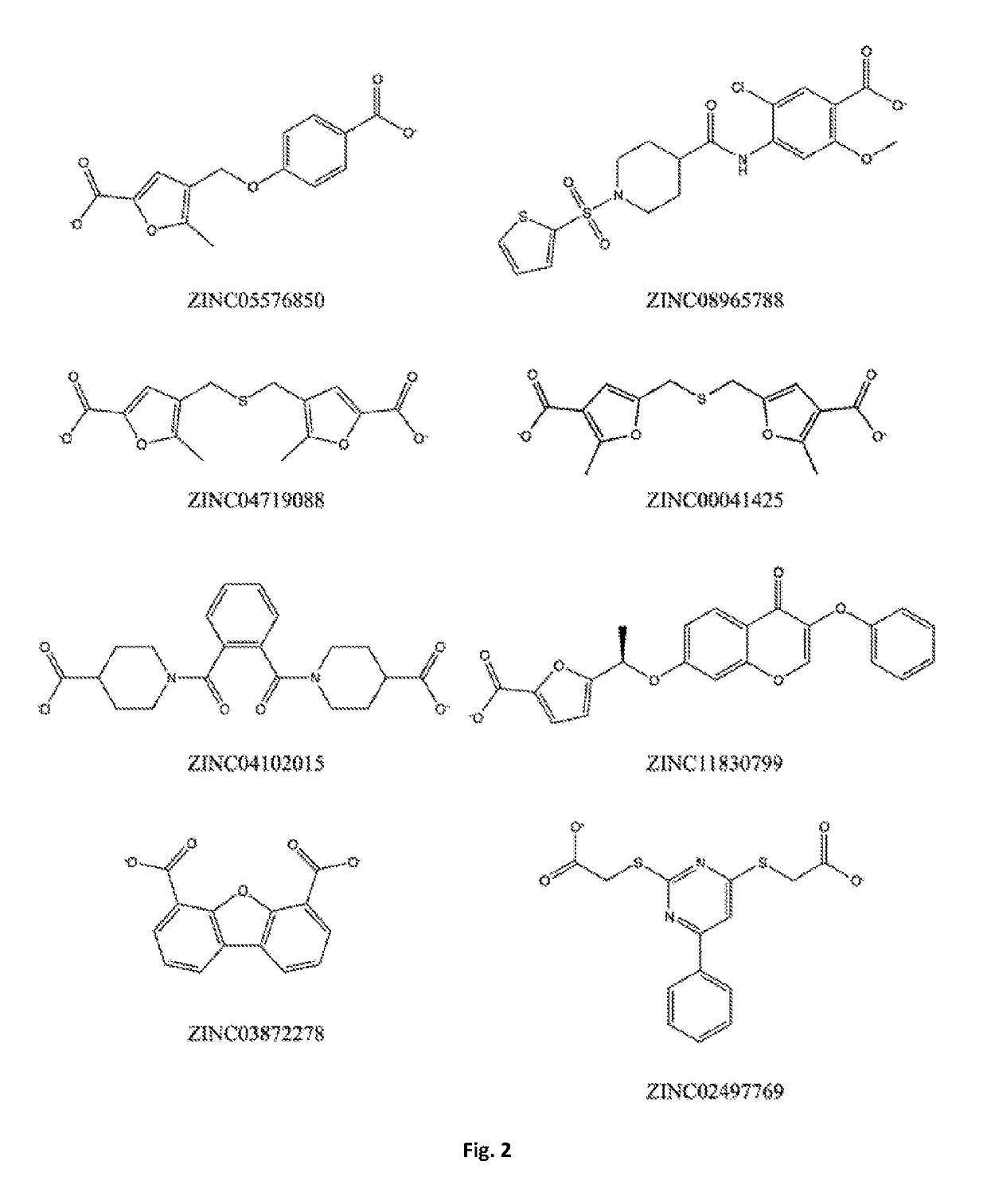

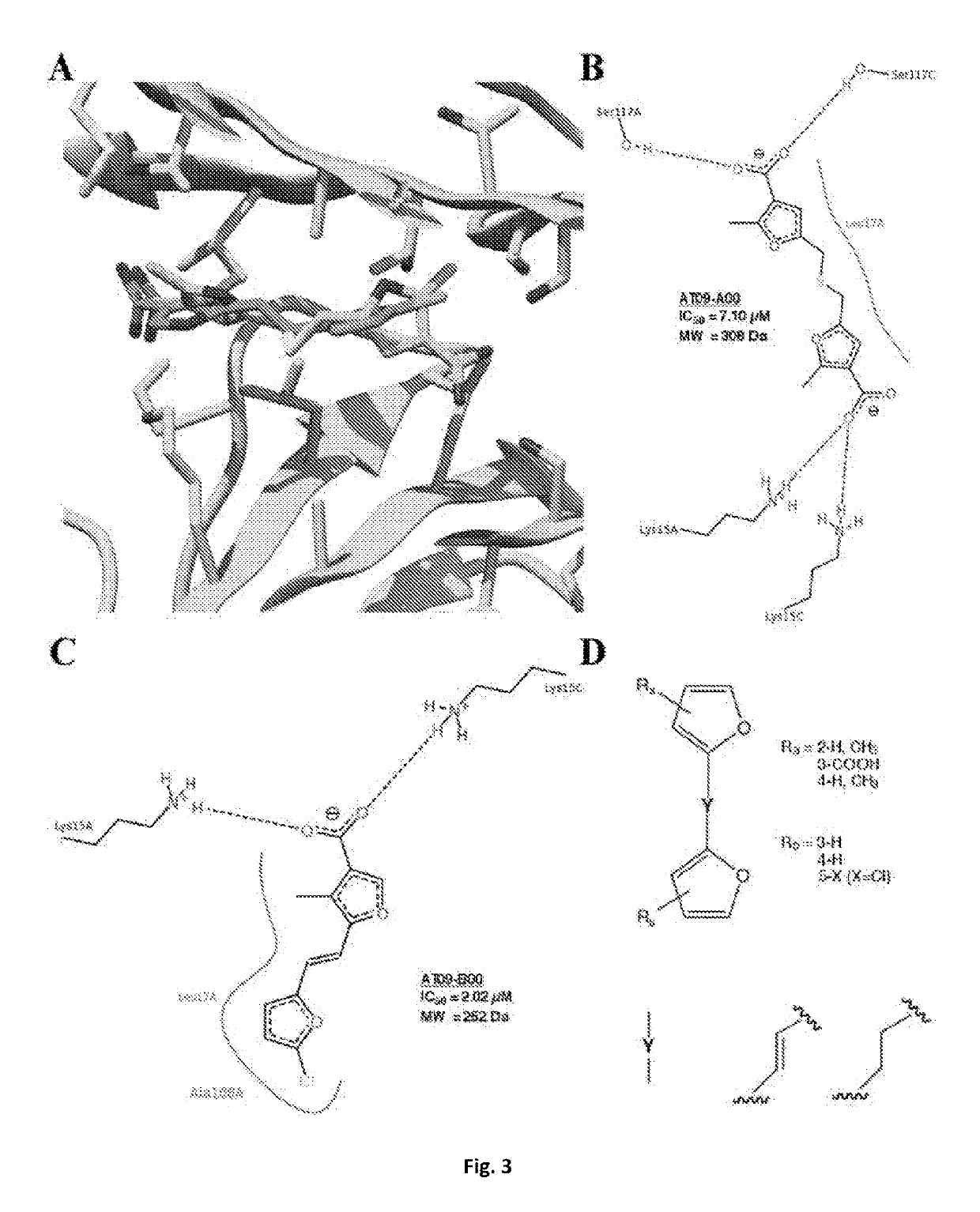

ActiveUS20180208570A1Reduce deliveryImprove stabilityOrganic active ingredientsNervous disorderFuranDisease

The design and synthesis of a novel bis-furan scaffold tailored for high efficiency at inhibiting transthyretin amyloid formation is reported. In vitro results show that the discovered compounds are more efficient inhibitors of amyloid formation than tafamidis, a drug currently used in the treatment of familial amyloid polyneuropathy (FAP), despite their lower molecular weight and lipophilicity. Moreover, ex vivo experiments with the strongest inhibitor in the series, conducted in human blood plasma from normal and FAP Val30Met-transthyretin carriers, disclose remarkable affinity and selectivity profiles. The promises and challenges facing further development of this compound are discussed under the light of increasing evidence implicating transthyretin stability as a key factor not only in transthyretin amyloidoses and several associated co-morbidities, but also in Alzheimer's disease.

Owner:BSIM2 BIOMOLECULAR SIMULATIONS SA

Bis-furan derivatives as transthyretin (TTR) stabilizers and amyloid inhibitors for the treatment of familial amyloid polyneuropathy (FAP)

ActiveUS10377729B2Reduce deliveryImprove stabilityOrganic active ingredientsNervous disorderFuranDisease

The design and synthesis of a novel bis-furan scaffold tailored for high efficiency at inhibiting transthyretin amyloid formation is reported. In vitro results show that the discovered compounds are more efficient inhibitors of amyloid formation than tafamidis, a drug currently used in the treatment of familial amyloid polyneuropathy (FAP), despite their lower molecular weight and lipophilicity. Moreover, ex vivo experiments with the strongest inhibitor in the series, conducted in human blood plasma from normal and FAP Val30Met-transthyretin carriers, disclose remarkable affinity and selectivity profiles. The promises and challenges facing further development of this compound are discussed under the light of increasing evidence implicating transthyretin stability as a key factor not only in transthyretin amyloidoses and several associated co-morbidities, but also in Alzheimer's disease.

Owner:BSIM2 BIOMOLECULAR SIMULATIONS SA

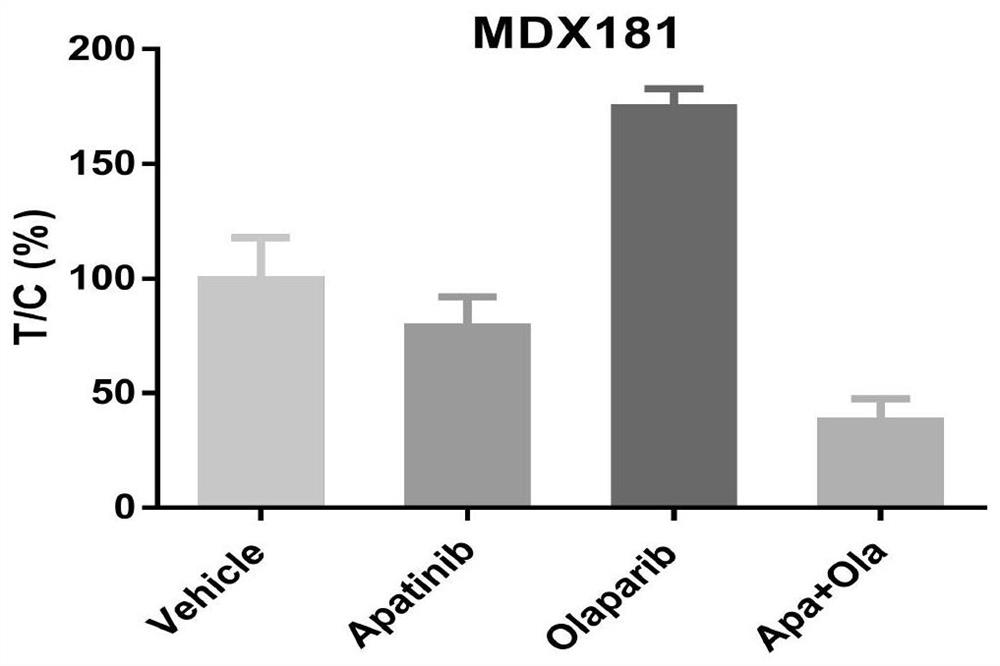

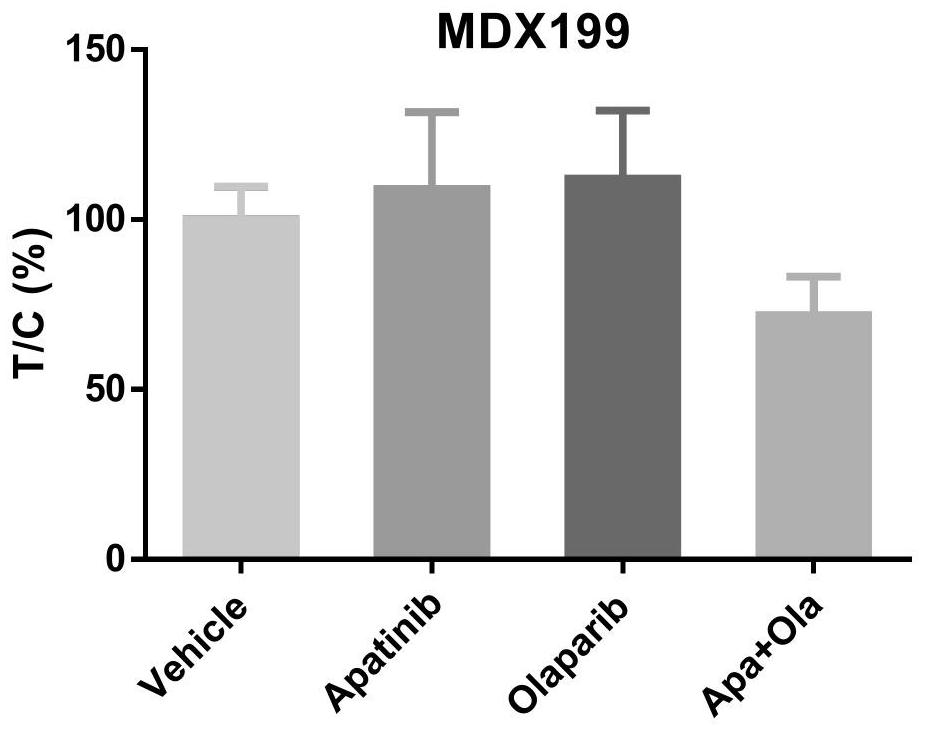

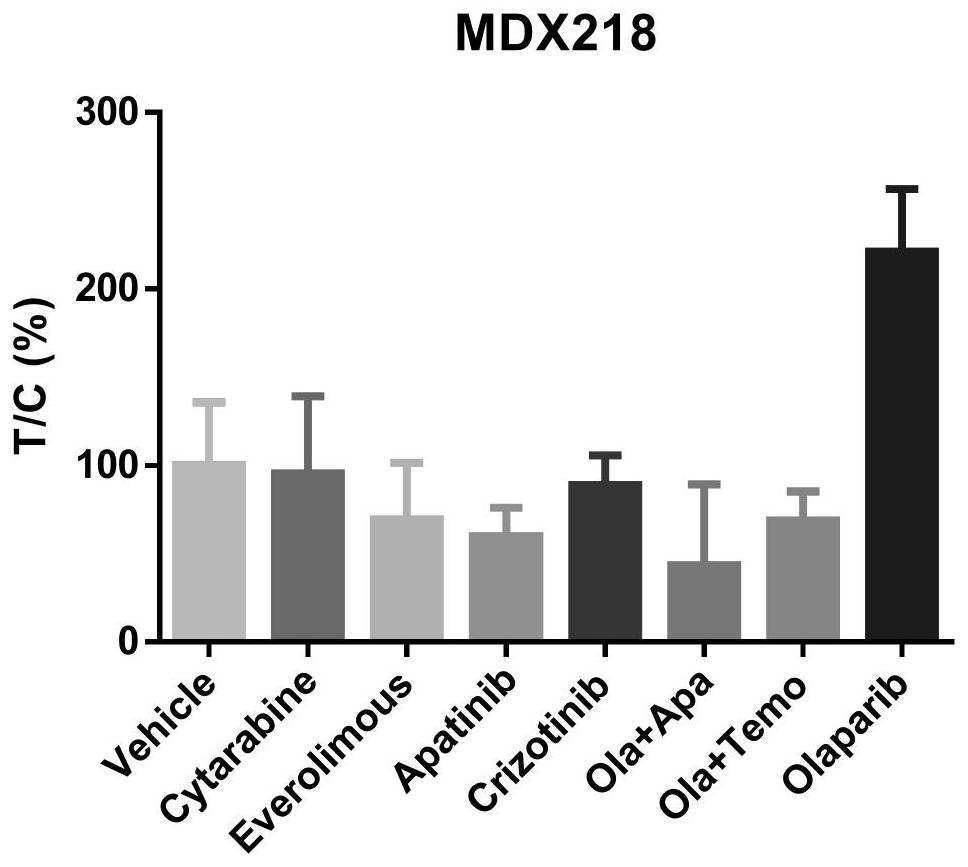

Medicine for treating advanced refractory solid tumors with TP53 mutation and application

PendingCN112316149AGood treatment effectThe curative effect is miraculousOrganic active ingredientsAntineoplastic agentsRAD51Therapeutic effect

The invention belongs to the technical field of precision medicine, and discloses a medicine for treating advanced refractory solid tumors with TP53 mutation and application. The medicine for treatingthe advanced refractory solid tumors with TP53 mutation comprises apatinib and olaparib. AN anti-angiogenesis medicine is combined with a PARP inhibitor to treat the advanced solid tumors with TP53 mutation, and magical curative effects are achieved. The anti-angiogenesis medicine combined with the PARP inhibitor shows a certain anti-cancer curative effect in preclinical research. The anti-angiogenesis medicine can down-regulate homologous recombination repair related genes such as BRCA and RAD51, can make cells in a hypoxic state, and can enhance the treatment effect of the PARP inhibitor.

Owner:王海涛

High-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage

The invention discloses a high-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage, which comprises the following components: 100 parts of seawater or fresh water, 2-5 parts of inorganic salt, 0.2-0.8 part of coating inhibitor, 1.5-3.5 parts of fluid loss additive, 2-4 parts of strong inhibitor, 2-4 parts of lubricant, 0.1-0.5 part of shear strength improving agent and 30-150 parts of weighting agent. The well drilling fluid has strong inhibition and has good rheological property and stable system performance during the whole well drilling process, even a large quantity of highly easily hydrated and dispersed cuttings exist for invasion of sewage, the viscosity of the well drilling fluid is basically controlled to be about 50s.

Owner:CHINA NAT OFFSHORE OIL CORP +1

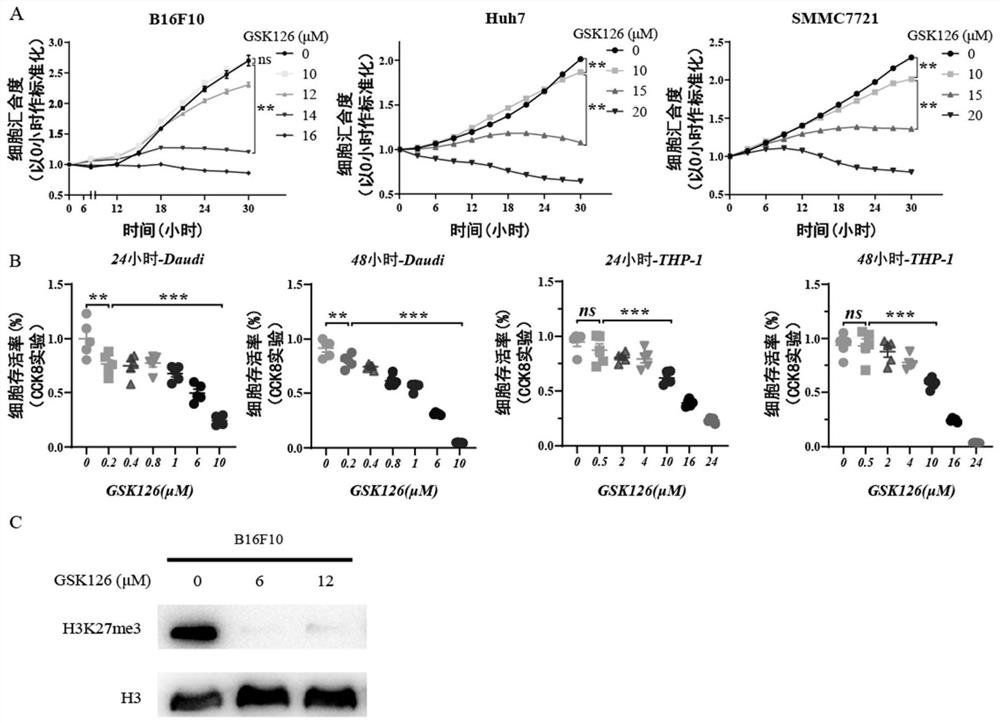

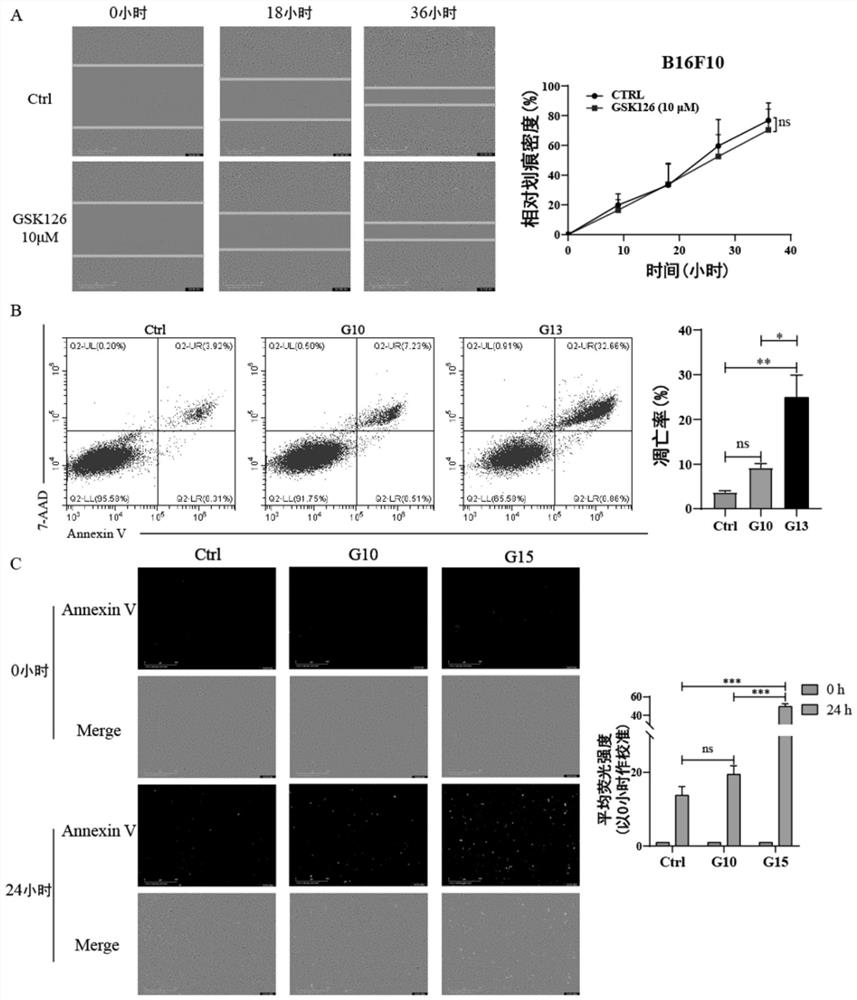

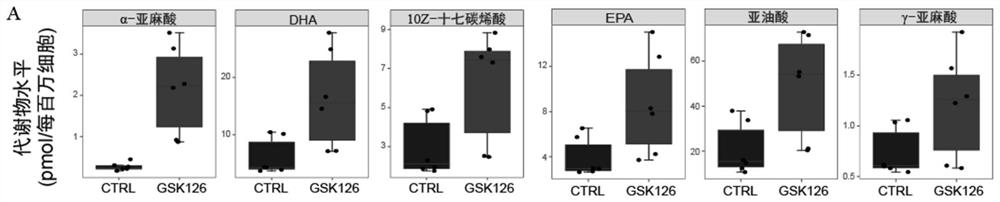

Anti-tumor pharmaceutical composition containing EZH2 inhibitor and SCD1 inhibitor and application of anti-tumor pharmaceutical composition

ActiveCN114177299AGood curative effectImprove anti-tumor effectOrganic active ingredientsAntineoplastic agentsPharmaceutical drugStrong inhibitor

The invention belongs to the field of medicine, and provides a pharmaceutical composition for enhancing the anti-tumor effect of an EZH2 inhibitor, the pharmaceutical composition comprises the EZH2 inhibitor and an SCD1 inhibitor, and the SCD1 inhibitor enhances the anti-solid tumor effect of the EZH2 inhibitor. The invention also provides a related preparation of the pharmaceutical composition and application of the pharmaceutical composition in preparation of antitumor drugs. Experimental results show that the EZH2 inhibitor GSK126 and the SCD1 inhibitor MF-438 are combined for treating B16F10 and SMMC7721 cells, and it is found that the inhibition effect of the GSK126 on cell proliferation can be obviously enhanced by combining the EZH2 inhibitor GSK126 and the SCD1 inhibitor MF-438. The invention provides a new thought for safely, effectively, conveniently and economically treating solid tumors by using the EZH2 inhibitor clinically, and has a good clinical application prospect.

Owner:PEKING UNIV THIRD HOSPITAL

Anti-human VEGF antibodies with unusually strong binding affinity to human VEGF-A and cross reactivity to human VEGF-B

Murine and humanized anti-human VEGF antibodies and uses are disclosed. The anti-human VEGF antibodies of the invention have higher binding affinity for human VEGF-A, are stronger inhibitors of the VEGF-A induced proliferation of endothelial cells in culture as compared with anti-human VEGF antibodies in the art. Moreover, these antibodies cross react with human VEGF-B. The antibodies of the invention inhibit tumor growth in vivo in greater extent than Bevacizumab when administered at the same dosage.

Owner:CONSEJO NACIONAL DE INVESTIGACIONES CIENTIFICAS Y TECNICAS CONICET 99 +1

A kind of strong inhibitory drilling fluid for drilling shale

The invention relates to a strong inhibitive drilling fluid for drilling shale for shale gas development and solves the problem of wellbore instability, and hydration collapse of the shale stratum is inhibited. The technical scheme of the strong inhibitive drilling fluid is that the the drilling fluid is prepared from the compositions of, by mass unit, 900-1,000 g of tap water, 30-60 g of bentonite for drilling fluid, 2-4 g of Na2CO3, 0.3-1 g of strong inhibitive filtrate reducer JT900 for drilling fluid, 0.5-1 g of potassium strong inhibitor FK-1, 2-5 g of coating agent FK-421 for drilling fluid, 1-1.5 g of shale inhibitor NF-923, 1-2 g of positive ion viscosity reducer XH-1, 2-3 g of shale stabilizer DLSAS, 4-6 g of reservoir shielding agent QCX-1, 2-4 g of blocking agent DE-1 and 0.5-1 g of lubricant RT-881 for drilling fluid; finally, the alkali liquor with the mass percentage concentration of 40% is prepared by adding water to NaOH, the system PH is adjusted to be 8.5, the drilling fluid weighting agent baryte is used for weighting the the system density to be 1.8-2.0 g / cm<3>, and the drilling liquid is prepared. The drilling fluid system has small environment pollution, and the drilling liquid has excellent rheological property and high sealing capacity and is used for drilling the shale.

Owner:SOUTHWEST PETROLEUM UNIV

Organosilicate semi-permeable membrane agent

InactiveCN106318341APrevent collapseReduce complicationsDrilling compositionSilicic acidPotassium hydroxide

The invention relates to the technical field of semi-permeable membrane agents, and especially relates to an organosilicate semi-permeable membrane agent. The agent comprises the following components in parts by mass: 15-19 parts of alkylamidoamine, 20-30 parts of sulfoisophthalic acid, 5-12 parts of diethylenepolyamine, 10-20 parts of glycerin, 15-32 parts of silicic acid, 4-10 parts of potassium hydroxide, 15-20 parts of sodium 2-hydroxybenzenesulfonate, and 100-130 parts of deionized water. The formula is employed, the organosilicate semi-permeable membrane agent has high inhibition effects for hydration swelling and dispersion of shale, and the agent is a strong inhibitor with excellent performance and can prevent collapse of borehole walls and reduce complex downhole conditions. In addition, the agent does not pollute environment, and the agent has low cost with less energy consumption.

Owner:刘夕平

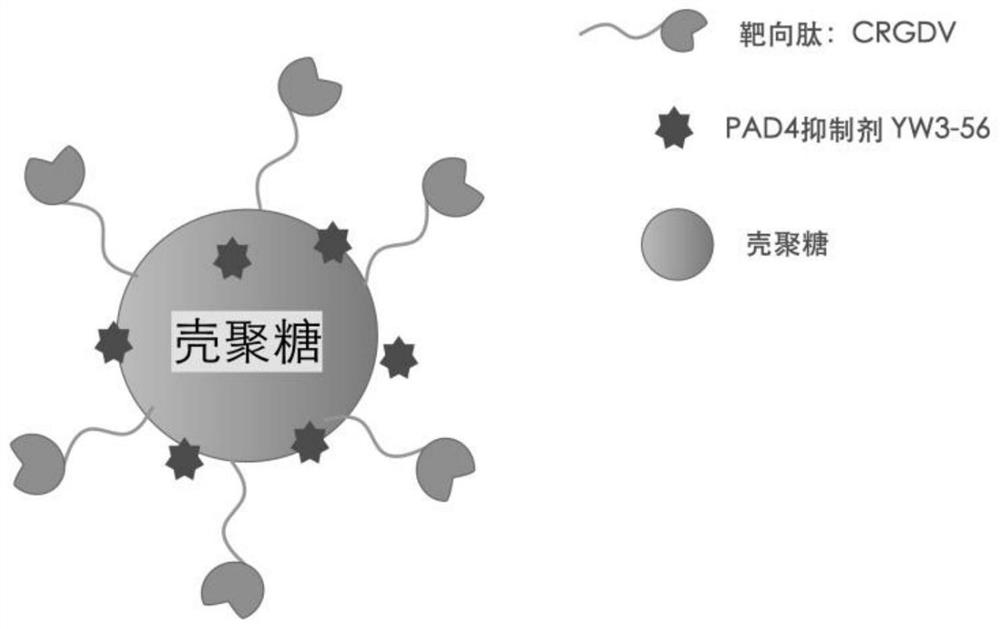

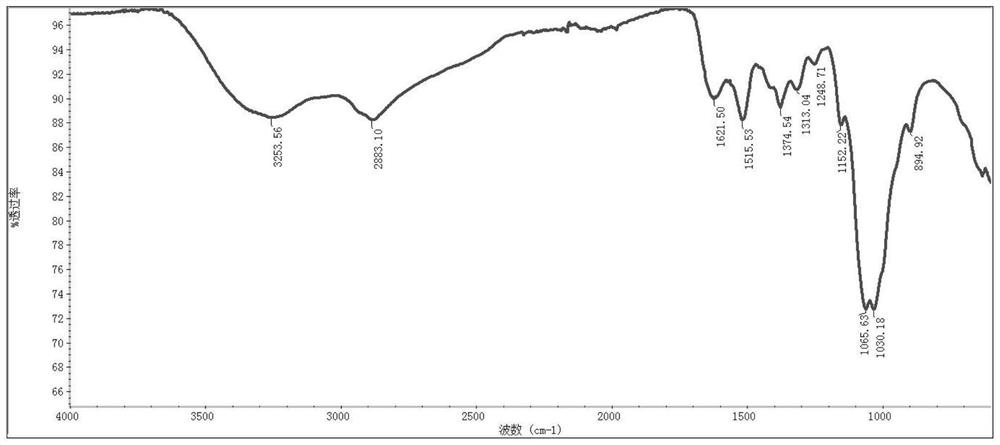

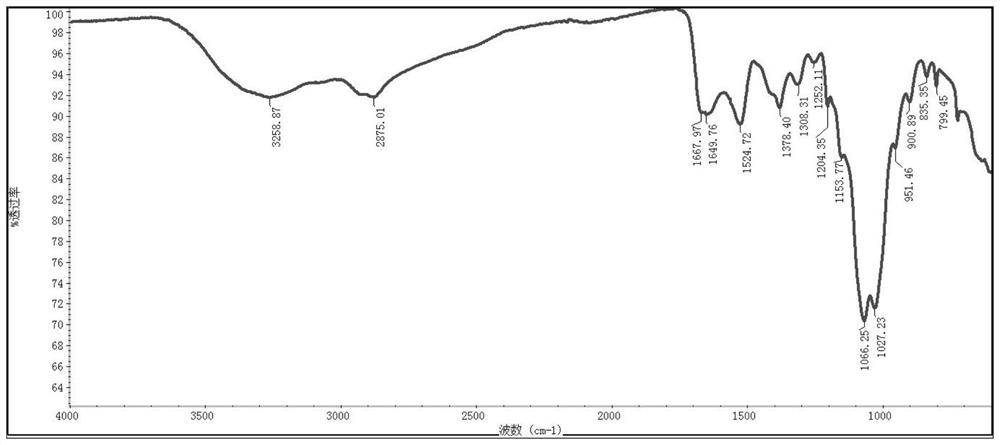

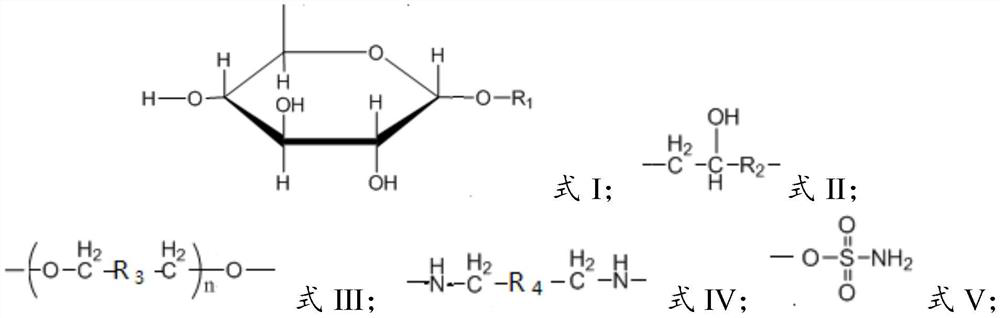

CRGD sequence peptide modified chitosan loaded PAD4 inhibitor and preparation method and application thereof

ActiveCN113350296AEasy to operateEasy to achieve industrial mass productionBoron compound active ingredientsPharmaceutical non-active ingredientsReceptorTumor cells

The invention provides a CRGD sequence peptide modified chitosan loaded PAD4 inhibitor and a preparation method and application thereof, and belongs to the technical field of antitumor drugs. According to the CRGD sequence peptide modified chitosan loaded PAD4 inhibitor and the preparation method and application thereof, CRGD sequence peptide modified chitosan is used as a drug carrier, wherein the chitosan has good biocompatibility and biodegradability, RGD sequence peptide in CRGD sequence peptide can be specifically combined on a corresponding receptor overexpressed by target cells, and the targeting effect achieved by targeting delivery of drugs to a target area can be achieved by using specific combination of the receptor on the surface of tumor cells and a ligand of a targeting preparation. According to the CRGD sequence peptide modified chitosan loaded PAD4 inhibitor and the preparation method and application thereof, the CRGD sequence peptide modified chitosan is used for loading the PAD4 inhibitor, the selectivity of the PAD4 inhibitor to the target tumor cells can be enhanced, adverse drug reactions are reduced, and the PAD4 inhibitor has good antitumor activity.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

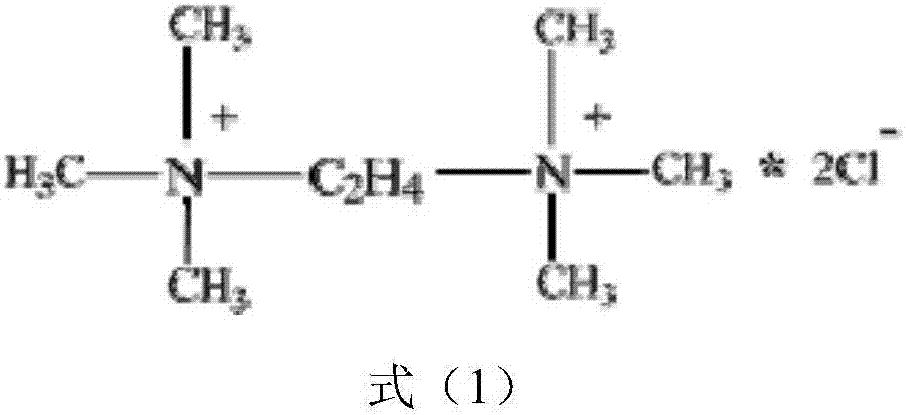

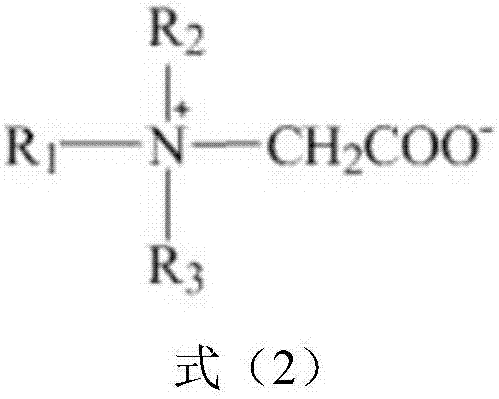

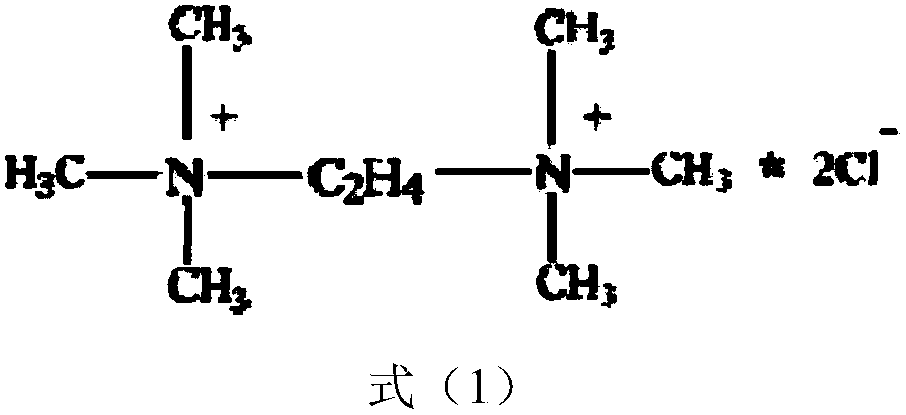

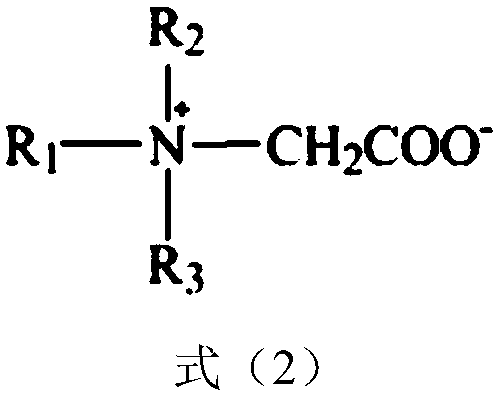

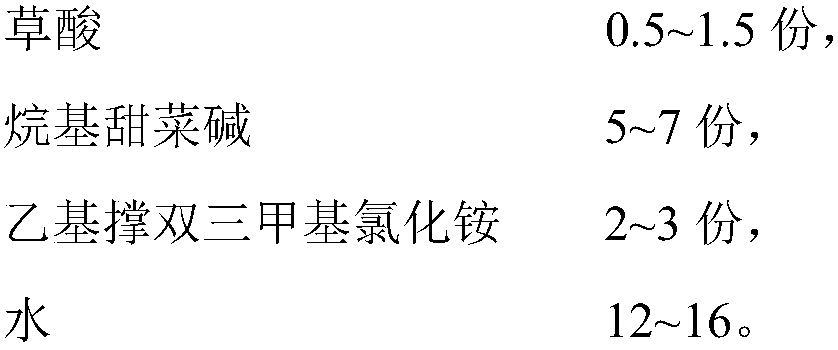

Strong inhibitor organic salt for drilling fluid, and drilling fluid

ActiveCN107384338ANo pollution in the processEnhanced inhibitory effectOrganic compound preparationAmino-carboxyl compound preparationInorganic saltsBetaine

The invention discloses strong inhibitor organic salt for drilling fluid, and the drilling fluid, and belongs to the related technical field of the drilling fluid. The main raw material components of the strong inhibitor organic salt for the drilling fluid comprise oxalic acid, alkyl betaine and ethylated bistrimethyl ammonium chloride, preferably, water is included. In addition, the invention also provides the drilling fluid containing the organic salt. In the organic salt system, cation is a quaternary ammonium ion, anion is an organic carboxylic acid ion containing an organic amine cation group, the inhibition effect of the organic salt is more excellent than that of inorganic salt potassium chloride, and the pH value is more than or equal to 6 when the concentration is 5.0 percent by weight; in the solution of 30 percent by weight, the recovery rate of rock debris is more than or equal to 70 percent; the Cl<-> content is less than or equal to 1 percent and the performance is excellent; the chloridion is not contained, environmental pollution is avoided, the preparation method is simple, the condition is mild, the production cost is low and a wide application prospect is achieved.

Owner:北京培康佳业技术发展有限公司

Gefitnib Sensitivity-Related Gene Expression and Products and Methods Related Thereto

Owner:SYNDAX PHARM INC

Strong inhibitor organic salt for drilling fluid and drilling fluid

ActiveCN107384338BNo pollution in the processEnhanced inhibitory effectOrganic compound preparationAmino-carboxyl compound preparationInorganic saltsBetaine

The invention discloses strong inhibitor organic salt for drilling fluid, and the drilling fluid, and belongs to the related technical field of the drilling fluid. The main raw material components of the strong inhibitor organic salt for the drilling fluid comprise oxalic acid, alkyl betaine and ethylated bistrimethyl ammonium chloride, preferably, water is included. In addition, the invention also provides the drilling fluid containing the organic salt. In the organic salt system, cation is a quaternary ammonium ion, anion is an organic carboxylic acid ion containing an organic amine cation group, the inhibition effect of the organic salt is more excellent than that of inorganic salt potassium chloride, and the pH value is more than or equal to 6 when the concentration is 5.0 percent by weight; in the solution of 30 percent by weight, the recovery rate of rock debris is more than or equal to 70 percent; the Cl<-> content is less than or equal to 1 percent and the performance is excellent; the chloridion is not contained, environmental pollution is avoided, the preparation method is simple, the condition is mild, the production cost is low and a wide application prospect is achieved.

Owner:北京培康佳业技术发展有限公司

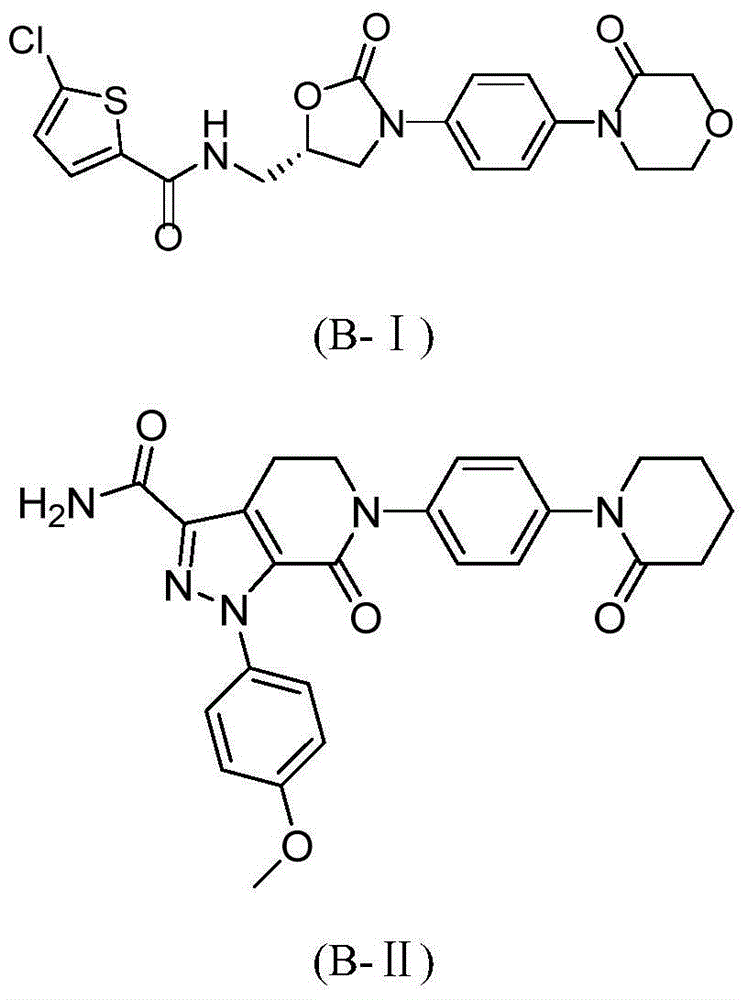

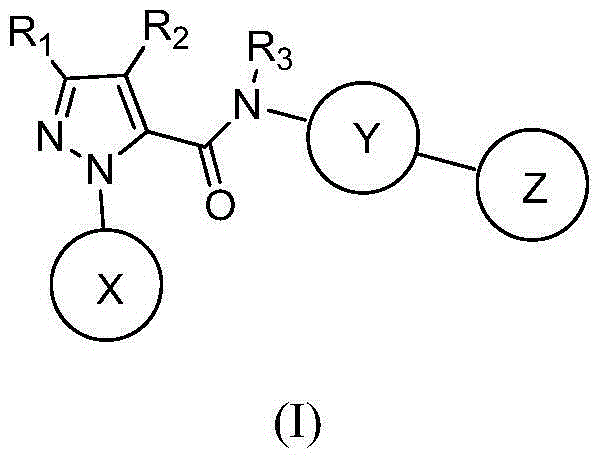

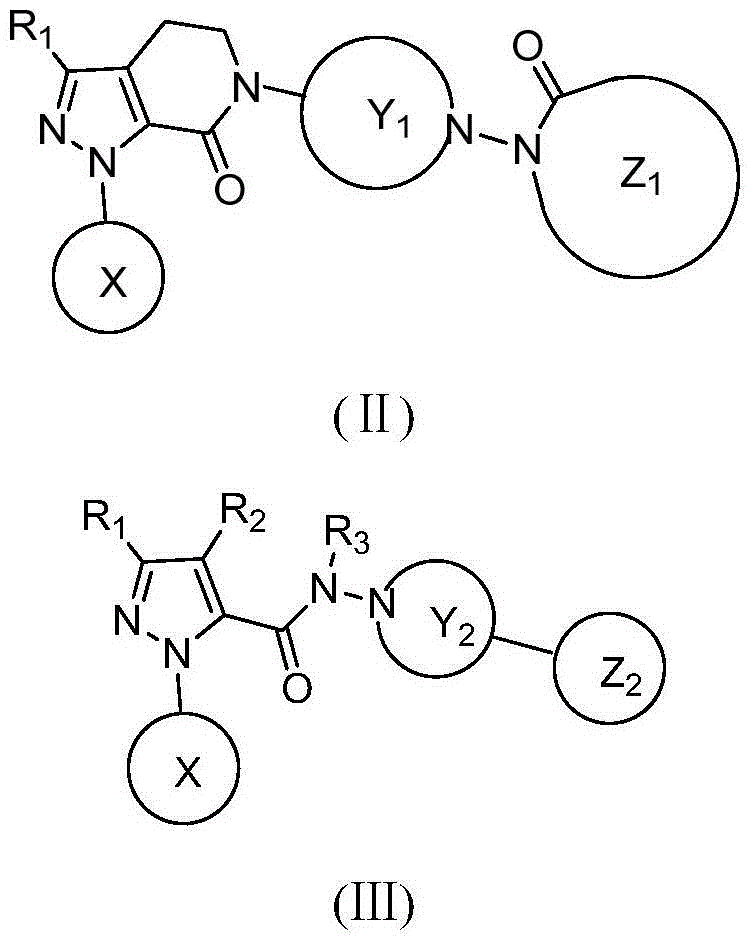

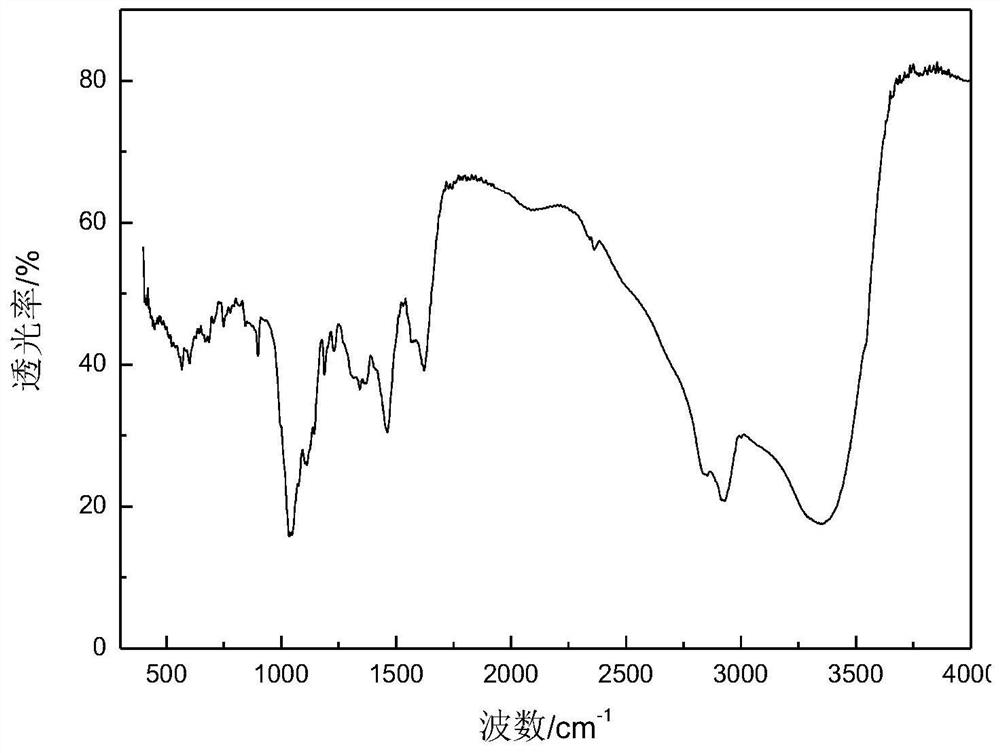

Hydrazide compound as blood coagulation factor Xa inhibitor

ActiveCN105085515AGood water solubilityGood curative effectOrganic active ingredientsOrganic chemistryDiseaseBenzene

The invention relates to a new compound represented by formula (I) or a pharmaceutically acceptable salt thereof. In the formula (I), X is selected from a 3-9-membered carbon ring or a benzo ring thereof and a 4-10-membered heterocyclic ring or a benzo ring thereof; Y and Z are respectively independently selected from 4-9-membered saturated heterocyclic rings; and R1-3 are respectively independently selected from H, F, Cl, Br, I, CN, OH, SH, NH2, CHO and COOH, or are selected from R01 substituted C1-10 alkyl or heteroalkyl groups, C3-C10 cycloalkyl or heterocycloalkyl groups, and C3-10 cycloalkyl or heterocycloalkyl group substituted C1-10 alkyl or heteroalkyl groups. The compound can be used as an anticoagulant for treating and preventing thrombus abnormity diseases. The strong blood coagulation factor Xa inhibitor is provided to meet practical demands of selectivity and the strong inhibitor of the blood coagulation factor Xa.

Owner:NORTH CHINA PHARMA COMPANY

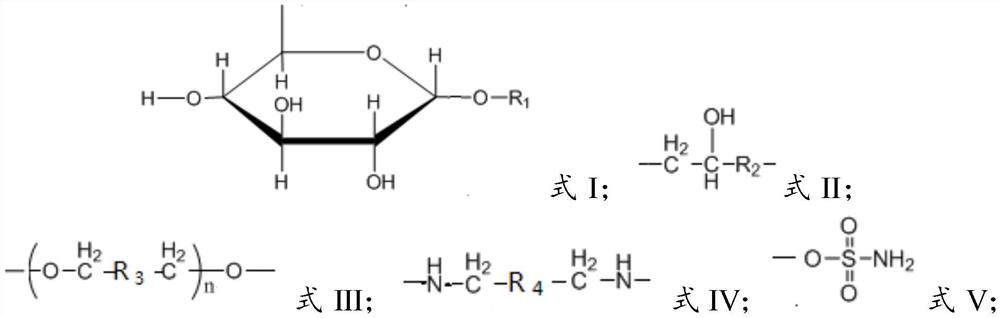

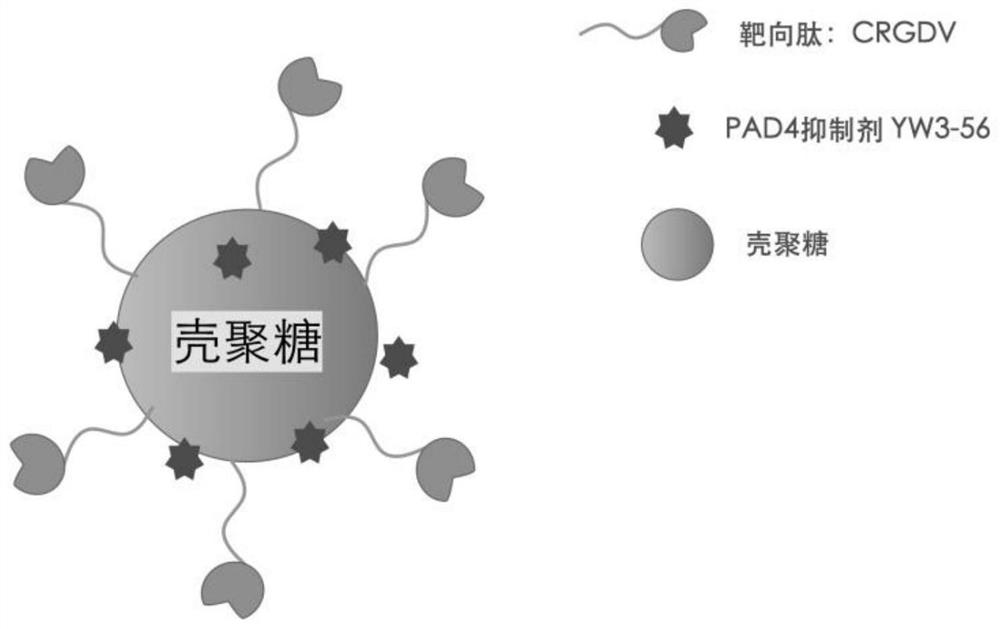

Modified alkyl glycoside high-temperature-resistant inhibitor as well as preparation method and application thereof

PendingCN113929899AImprove anti-slump performanceEase of field applicationDrilling compositionGlycosidePtru catalyst

The invention belongs to the technical field of oilfield chemical drilling fluid treating agents, and provides a modified alkyl glycoside high-temperature-resistant strong inhibitor and a preparation method and application thereof. The preparation method comprises the following steps: subjecting halogenated epoxide, polymeric glycol and alkyl glycoside to reacting under catalysis of an acid catalyst so as to obtain halogenated alcohol polyether alkyl glycoside; subjecting the halogenated alcohol polyether alkyl glycoside to reacting with organic amine to obtain amino polyether alkyl glycoside; and subjecting the amino polyether alkyl glycoside to reacting with sulfamic acid serving as a sulfonating agent to generate the modified alkyl glycoside high-temperature-resistant strong inhibitor. The modified alkyl glycoside provided by the invention comprises an alkyl glycoside group, a hydroxyalkyl group, a polyether group, an amido group and a sulfonic acid group, and has a relatively good collapse inhibition effect under a high-temperature condition. In addition, the modified alkyl glycoside provided by the invention has no biotoxicity. The modified alkyl glycoside provided by the invention can be applied to drilling fluids, is suitable for drilling construction of formations such as deep wells and ultra-deep wells with relatively high formation temperature and with shale easy to collapse, and meets the requirements for well wall stability and environmental protection of high-temperature formations.

Owner:中石化石油工程技术服务有限公司 +2

A kind of crgd sequence peptide modified chitosan-loaded pad4 inhibitor and its preparation method and application

ActiveCN113350296BEasy to operateEasy to achieve industrial mass productionBoron compound active ingredientsPharmaceutical non-active ingredientsReceptorPharmaceutical Substances

The invention provides a PAD4 inhibitor loaded with CRGD sequence peptide modified chitosan and a preparation method and application thereof, belonging to the technical field of antitumor drugs. The present invention uses CRGD sequence peptide modified chitosan as a drug carrier, wherein chitosan has good biocompatibility and biodegradability, and the RGD sequence peptide in the CRGD sequence peptide can be specifically combined in target cells for overexpression On the corresponding receptors of the tumor cells, the targeting effect achieved by the specific binding of the receptors on the tumor cell surface and the ligands of the targeting preparations to deliver the drugs to the target area can be achieved. The invention uses the CRGD sequence peptide to modify the chitosan to load the PAD4 inhibitor, which can enhance the selectivity of the PAD4 inhibitor to the target tumor cells, reduce the adverse drug reactions, and make it have good anti-tumor activity.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

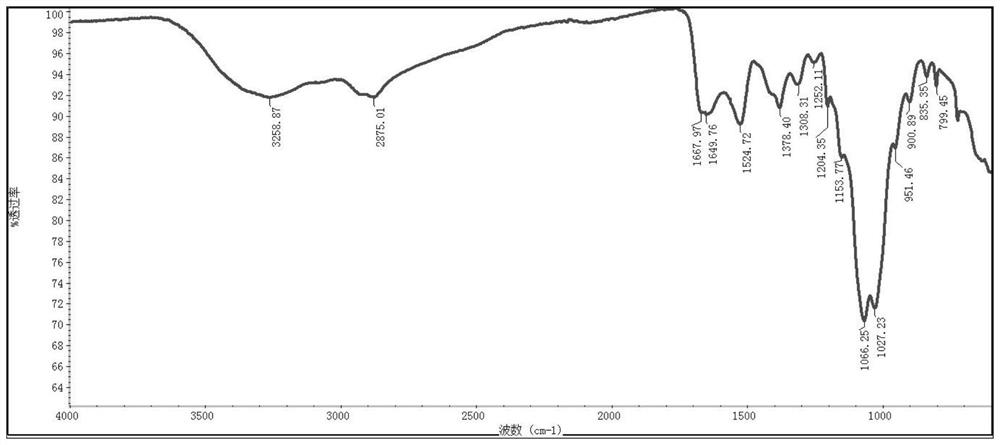

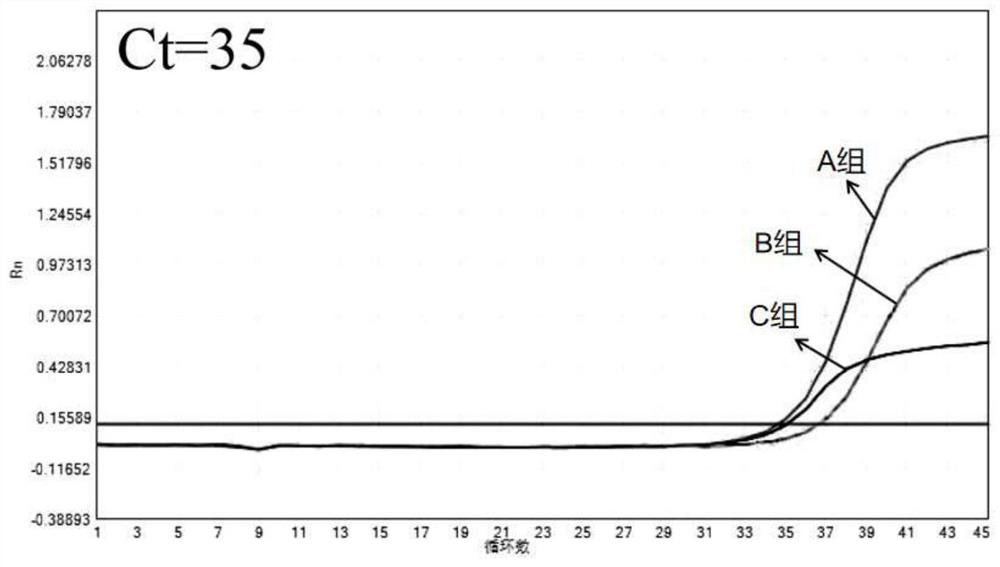

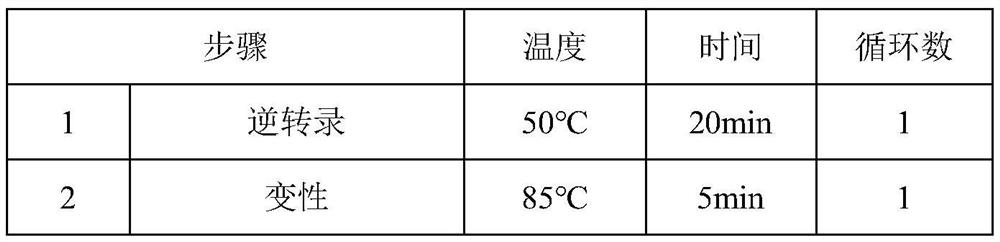

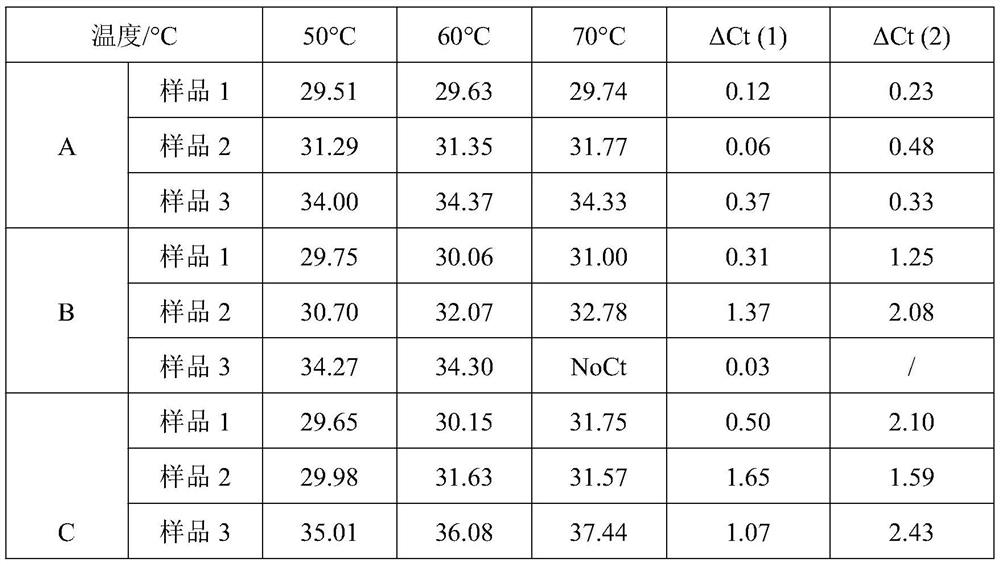

M-MLV reverse transcriptase mutant and application thereof

ActiveCN113355303AReduce distractionsNot affected littleBacteriaMicrobiological testing/measurementTranscriptase activityWild type

The invention discloses an M-MLV reverse transcriptase mutant and application thereof. The amino acid sequence of the M-MLV reverse transcriptase mutant is shown as SEQ ID NO.2 in a sequence table. The reverse transcriptase provided by the invention is obtained through site-specific mutagenesis rational design screening on the basis of wild type M-MLV reverse transcriptase in combination with the existing structural characteristics of reverse transcriptase structure research progress and fusion of a plurality of mutants, the reverse transcriptase mutant has very strong inhibitor tolerance, the interference of an inhibitor on cDNA synthesis is reduced. In the reaction process of a sample added with whole blood and sputum, the activity of the mutant reverse transcriptase is not influenced or is slightly influenced. Meanwhile, the reverse transcriptase mutant provided by the invention can tolerate a high temperature of 70 DEG C, has relatively high reaction sensitivity and accuracy while having relatively good thermal stability, and has a very strong application prospect.

Owner:ZYBIO INC

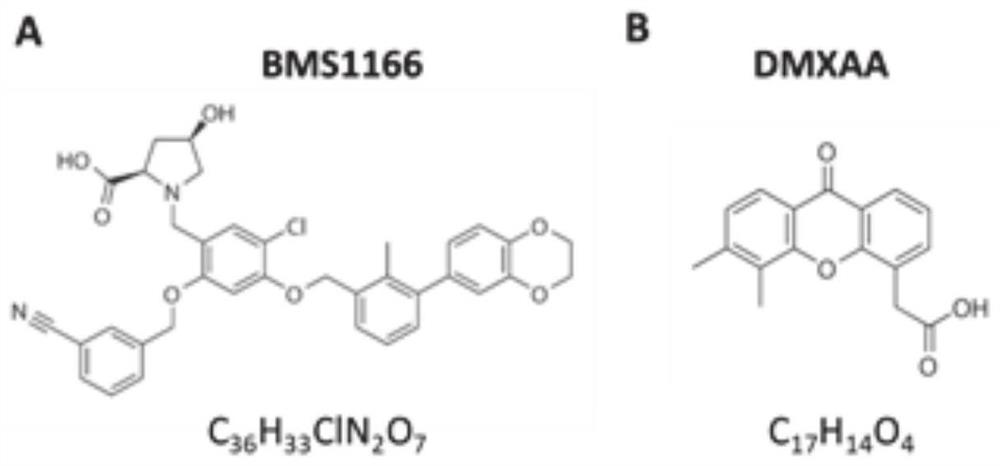

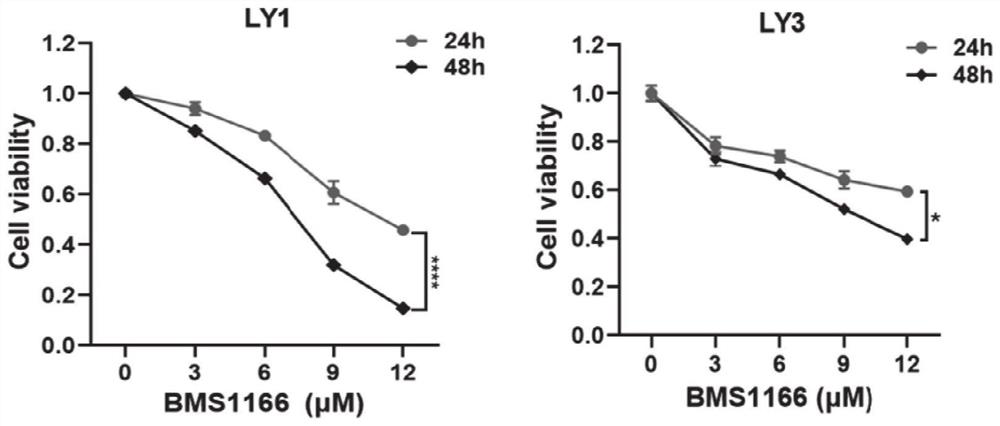

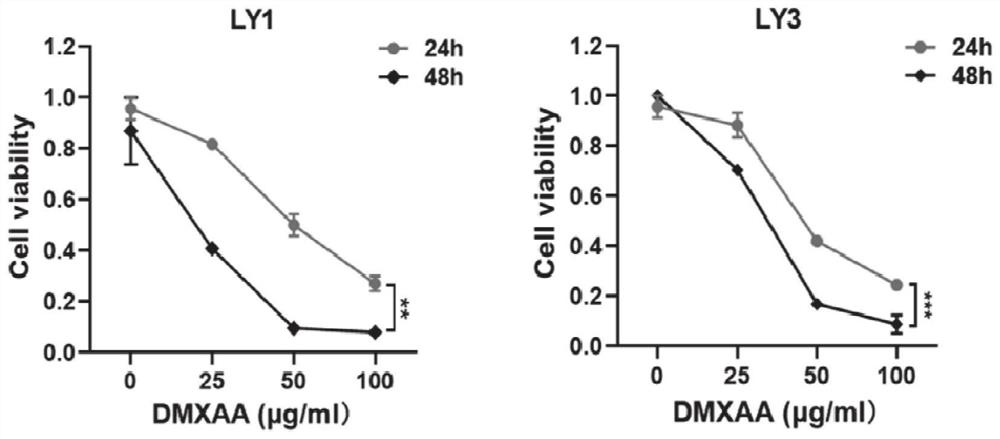

Application of combination of PD-1 inhibitor and STING agonist in tumor treatment

PendingCN114159429AInhibition of activationPrevent proliferationOrganic active ingredientsAntineoplastic agentsCell activityTumor therapy

The invention provides application of a PD-1 inhibitor combined with an STING agonist in tumor treatment, and belongs to the technical field of medicines. According to the application disclosed by the invention, the research finds that both the PD-1 inhibitor (BMS1166) and the STING agonist (DMXAA) can be used for effectively inhibiting the proliferation of DLBCL cells. The DMXAA induces the activation of a cGAS / STING pathway, and promotes the DLBCL cells to highly express STING. The expression of PD-L1 can be promoted by increasing the expression of STING, so that the inhibition of BMS1166 on cell viability is enhanced. Therefore, when the BMS1166 and the DMXAA are combined for use, a synergistic effect can be generated, and a more remarkable anti-tumor effect can be achieved. The invention provides a technical support for enhancing the treatment reaction of the PD-1 inhibitor in DLBCL and optimizing the treatment scheme of the PD-1 inhibitor.

Owner:SHANDONG PROVINCIAL HOSPITAL AFFILIATED TO SHANDONG FIRST MEDICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com