Patents

Literature

234results about How to "Easy to achieve industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cannabis sailve extract rich in cannabidiol and preparation method of cannabis sailve extract

ActiveCN105535111AImprove extraction efficiencyHigh in CBDPlant ingredientsActivated carbonChemistry

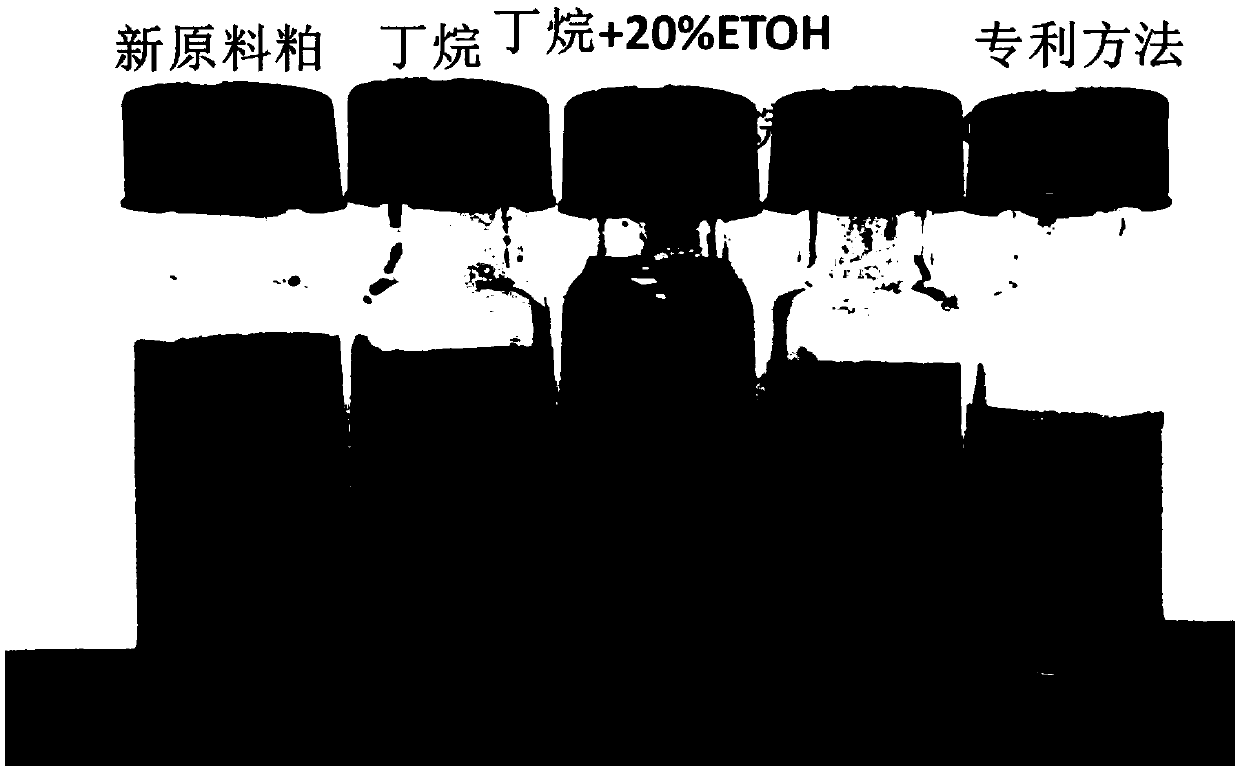

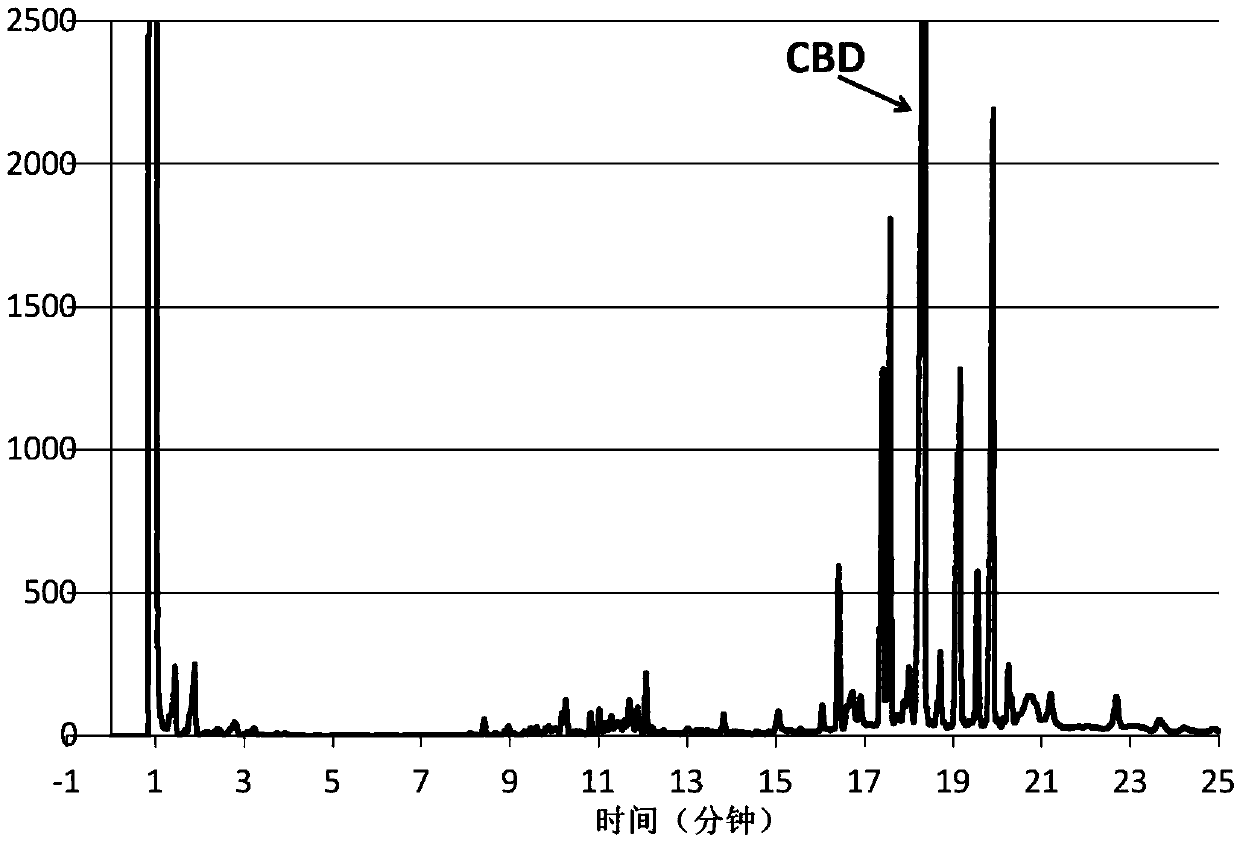

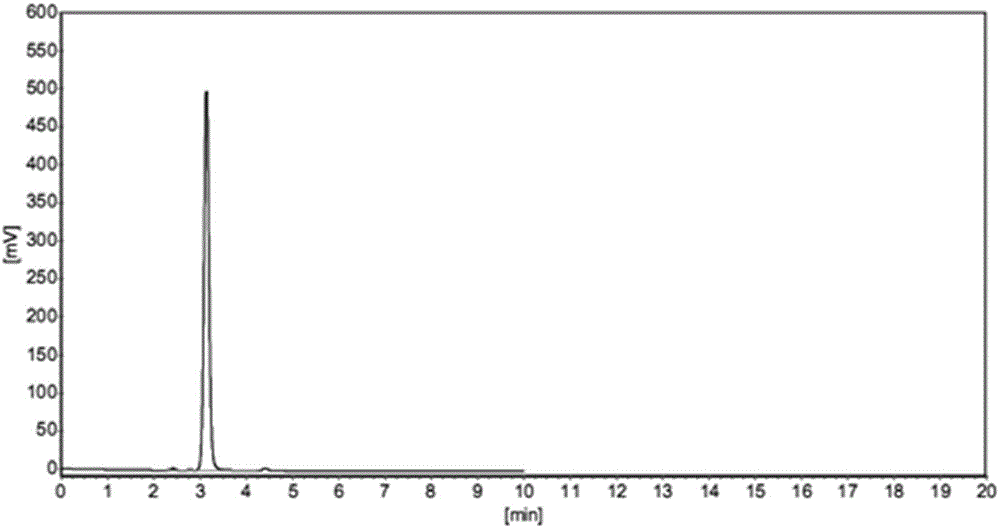

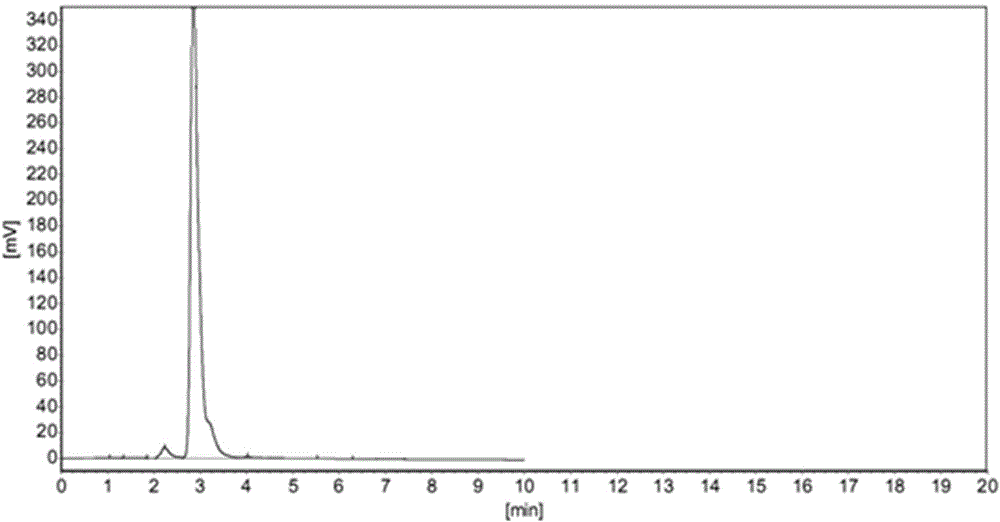

The invention discloses cannabis sailve extract which is extracted from flowers and leaves of industrial cannabis sailve and rich in cannabidiol (CBD) and a preparation method of the cannabis sailve extract. The preparation method includes the steps that firstly, heat dry treatment is conducted on the flowers and leaves of cannabis sailve, then a subcritical butane extraction technology is adopted, ethyl alcohol serves as entrainer, and crude extract which is rich in cannabidiol is obtained; the crude extract is dissolved in an ethanol solution of a certain proportion, and low-temperature odstearynowanie is conducted; centrifugation is conducted through a centrifugal machine, or filtering is conducted through a filtering machine to remove waxiness; activated carbon is added to liquid supernatant, and decolorization and filtration are conducted; finally, filtrate is subjected to rotary evaporation to remove ethyl alcohol, and the cannabis sailve extract rich in CBD can be obtained. The obtained cannabis sailve extract is high in CBD content and good in color and has a good physiological property. The method is simple in process, industrialized application is achieved easily, and development and utilization of high value-added products of Cannabis sailve are promoted.

Owner:山西汉麻生物科技有限公司

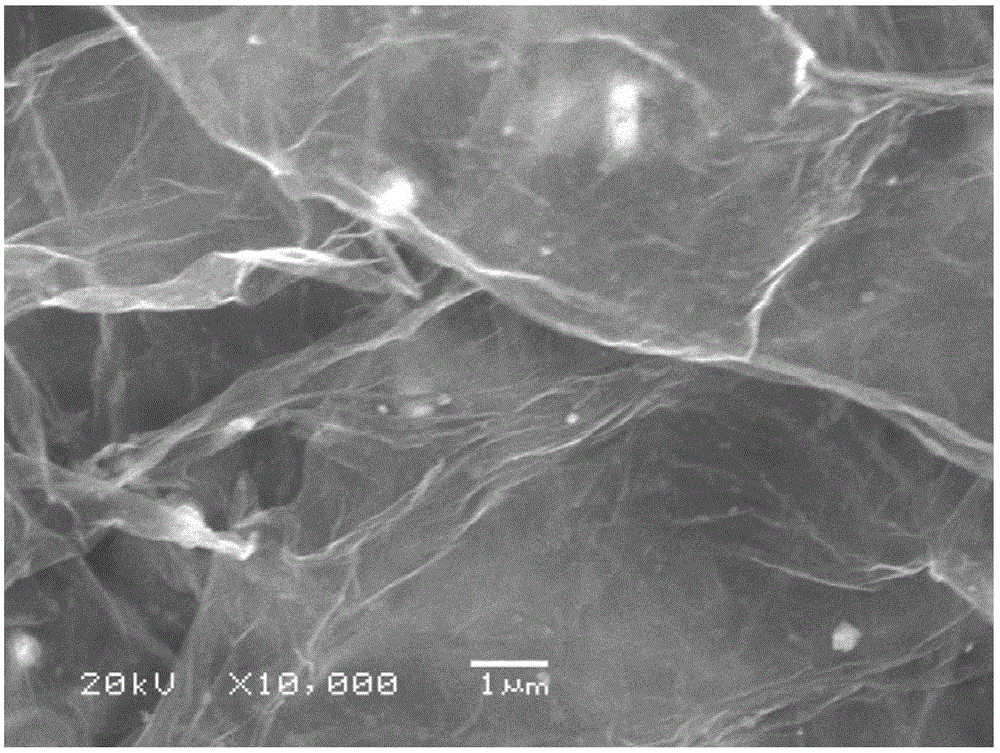

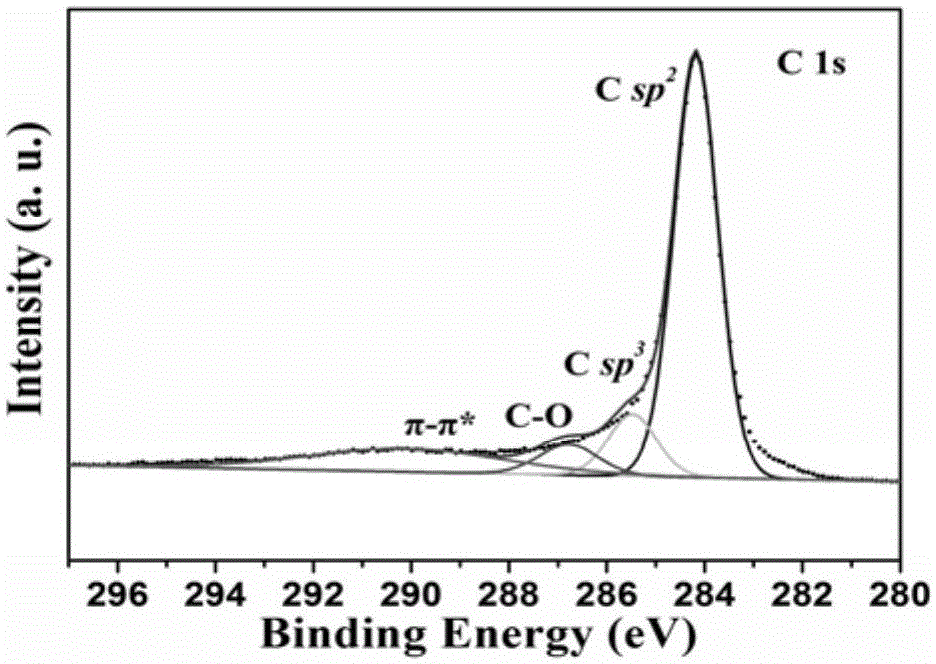

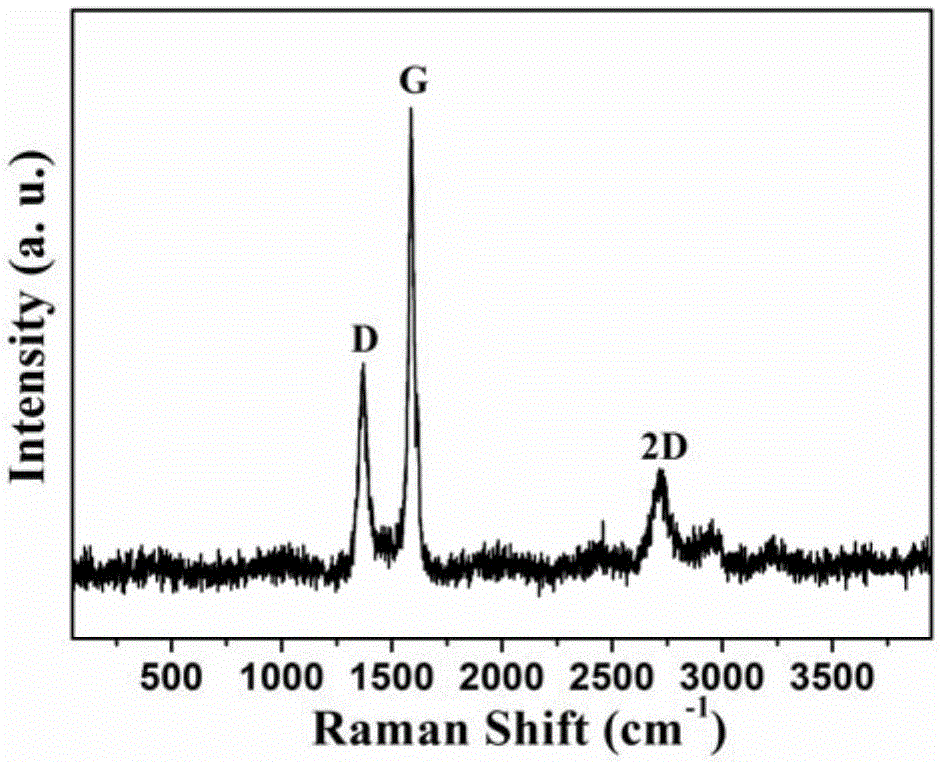

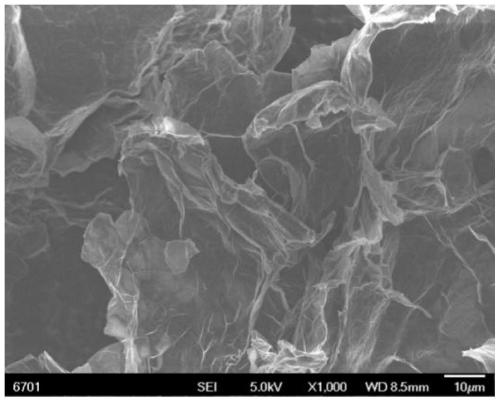

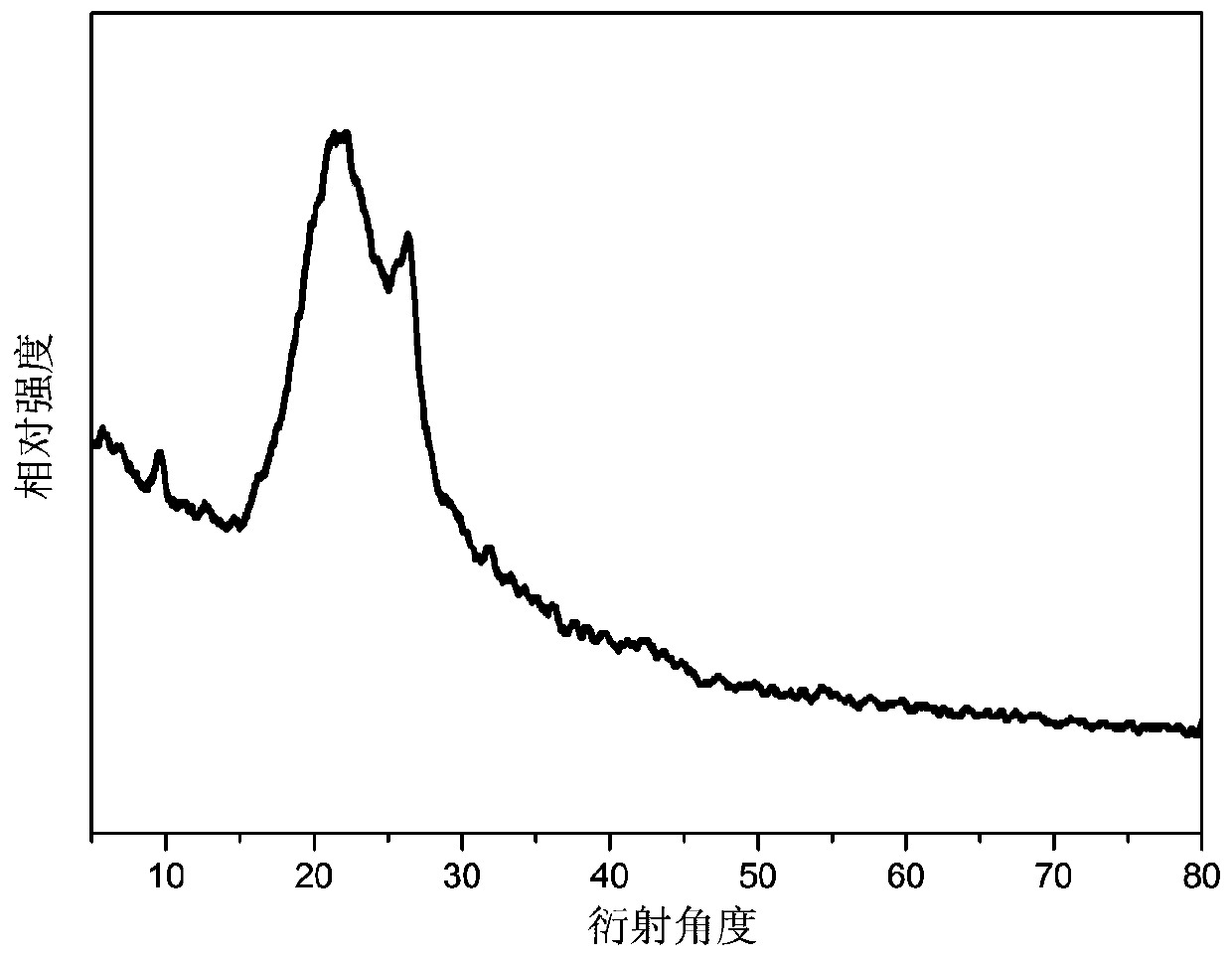

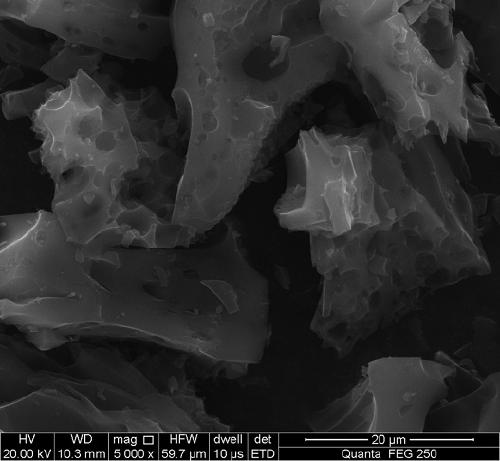

Preparation method of fewer-layer graphene

The invention discloses a preparation method of fewer-layer graphene, which comprises the following steps of: putting graphite into solution containing a tetraalkyl-substituted quaternary ammonium cation and OH- for ultrasonic treatment in combination with a liquid phase intercalation technology and a microwave irradiation technology, so that the tetraalkyl-substituted quaternary ammonium cation is inserted into the middle of a graphite layer to form an intercalation layer, and the spacing of the graphite layer is increased; then carrying out microwave irradiation on the treated graphite, so that the graphite intercalation layer is decomposed to generate a large quantity of gas and further increase the spacing of the graphite layer; successively dispersing the treated graphite in a low-polarity organic solvent for ultrasonic treatment, so that the graphite is stripped to generate the grapheme; and finally carrying out centrifugal treatment to obtain upper-layer liquid after treatment, i.e. fewer-layer graphene dispersion liquid. The preparation method has the advantages of simplicity in operation, short time consumption, low cost, high grapheme yield, good repeatability and easy realization of industrialized mass production; and the fewer-layer graphene prepared by the preparation method is below 10 in quantity of layers and has the advantages of fewer defects, fewer oxygen-contained groups and high conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing graphene from biomass waste

ActiveCN105060288AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerCarbonization

The invention discloses a method for preparing graphene from biomass waste, which comprises the following steps: pretreating biomass waste with white lime to obtain a biomass residue; and carrying out desilication hydrolysis, carbonization and carbonization material decalcification impurity removal on the biomass residue, and quickly heating to perform high-temperature graphitization. The prepared graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The prepared biomass fewer-layer graphene has a certain mesoporous structure, and is especially suitable to be used in the fields of lithium ion batteries, supercapacitors and the like. The method is simple in technique and convenient to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production.

Owner:CENT SOUTH UNIV

Method for extracting cannabidiol-containing hemp extract

InactiveCN107898826AImprove extraction efficiencyHigh in CBDPlant ingredientsFood scienceActivated carbonCentrifugation

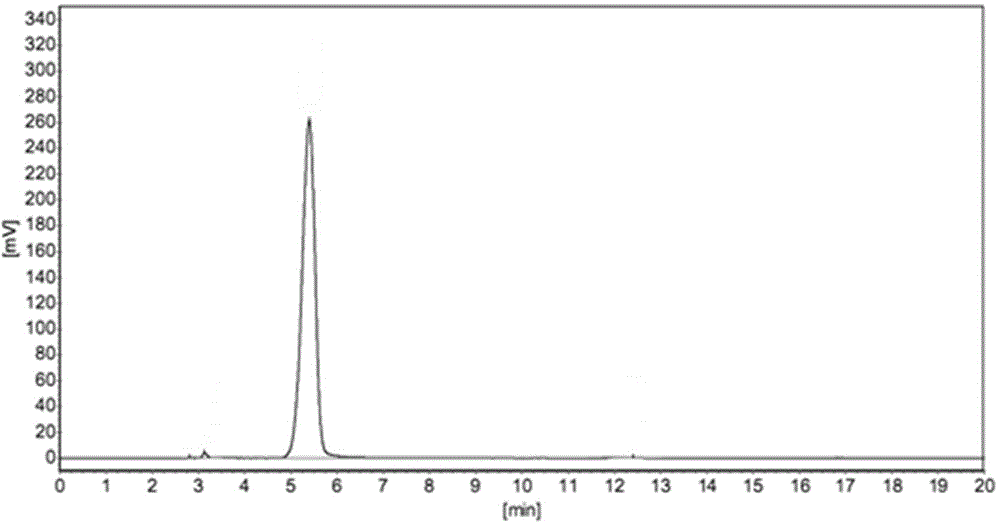

The invention discloses a method for preparing cannabidiol-containing hemp extract. The method comprises the following steps: taking mature industrial hemp seeds, drying the hemp seeds, removing impurities, and crushing the hemp seeds for later use; carrying out extraction on the crushed hemp seeds with ethanol with the concentration being 95-100% (V / V) according to a solid-liquid ratio of 1:5 to1:20; filtering the obtained extract, and carrying out reduced pressure concentration to obtain industrial hemp seed extract; dissolving the obtained hemp seed extract in ethanol, and carrying out low-temperature winterization; centrifuging the obtained winterized suspension by using a centrifuge or a filtration technique; decolorizing a supernatant obtained after the centrifugation by using activated carbon, and filtering the supernatant; and carrying out rotary evaporation on a filtrate obtained after the filtration to obtain the cannabidiol-containing hemp extract. The product obtained in the invention has the advantages of high CBD content, good color and good physiological characteristics. The method has the advantages of simple process, easiness in industrial application, and promotion of the development and utilization of high added value products of hemp.

Owner:云南谷益美农业开发有限公司

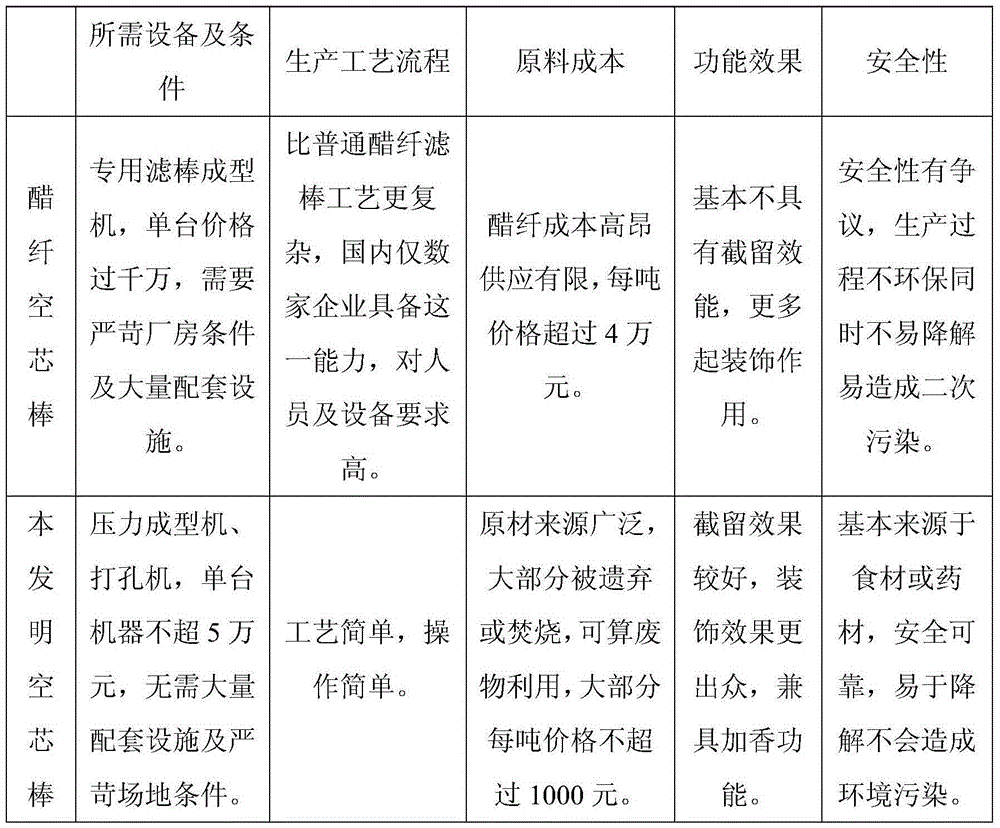

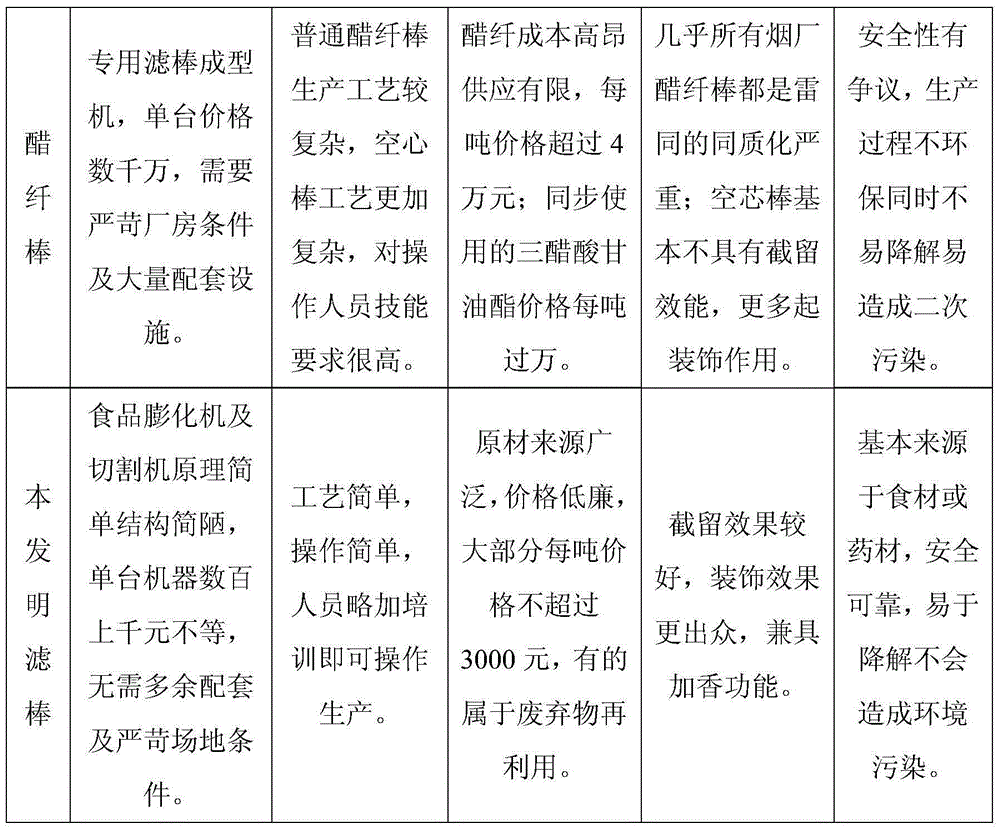

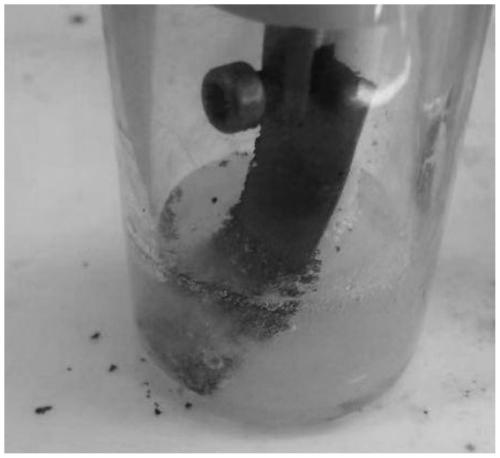

Natural plant material hollow cigarette filter rod as well as preparation method and application thereof

InactiveCN105982350AExtensive sources of raw materialsLow priceTobacco smoke filtersCigarette filterEngineering

The invention discloses a natural plant material hollow cigarette filter rod as well as a preparation method and application thereof. The hollow cigarette filter rod is prepared by the following steps: uniformly mixing a natural plant particle material with a binder; squeezing into a cake by moulding equipment; mechanically cutting and grinding the obtained cake into a cylinder; and further perforating the cylinder along a central axis. The preparation method has the advantages of low equipment requirements, simplicity in operation, cheap raw materials and low production cost; and the prepared hollow cigarette filter rod has high safety performance, is environment-friendly, has the adsorption interception function of a common acetate fiber hollow filter rod, and can realize an aroma enhancement effect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

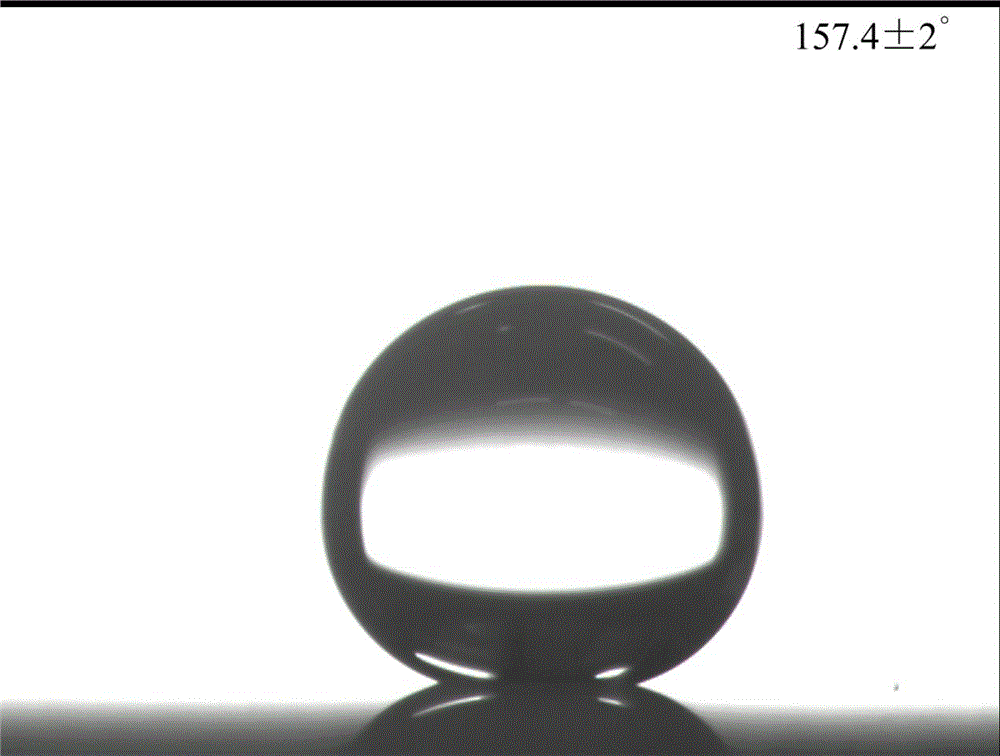

Super-hydrophobic modified nanofiber membrane as well as preparation method and application thereof

ActiveCN106984194AGuaranteed StrengthImprove hydrophobicityMembranesSeawater treatmentPorosityNanoparticle

The invention discloses a preparation method of a super-hydrophobic modified nanofiber membrane. The preparation method comprises the following steps: mixing a hydrophobic high polymer, electrolyte and a solvent A to obtain high polymer spinning solution, and carrying out electrostatic spinning, so that a nanofiber membrane is obtained; dispersing carbon nanofibers and nanocarbon particles into a solvent B to respectively obtain carbon nanofiber dispersion and nanocarbon particle dispersion, sequentially coating the nanofiber membrane, and drying, so that a precursor is obtained; and finally carrying out hot pressing, so that the super-hydrophobic modified nanofiber membrane is obtained. The invention discloses the preparation method of the super-hydrophobic modified nanofiber membrane, a number of nodes are avoided from being produced as the nanoparticles are directly doped into electrostatic spinning solution, the method is simple and convenient, the prepared modified nanofiber membrane has good hydrophobic property and is high in porosity, high in flux and extremely high in retention rate, and membrane requirements in a membrane distillation process are met.

Owner:ZHEJIANG UNIV

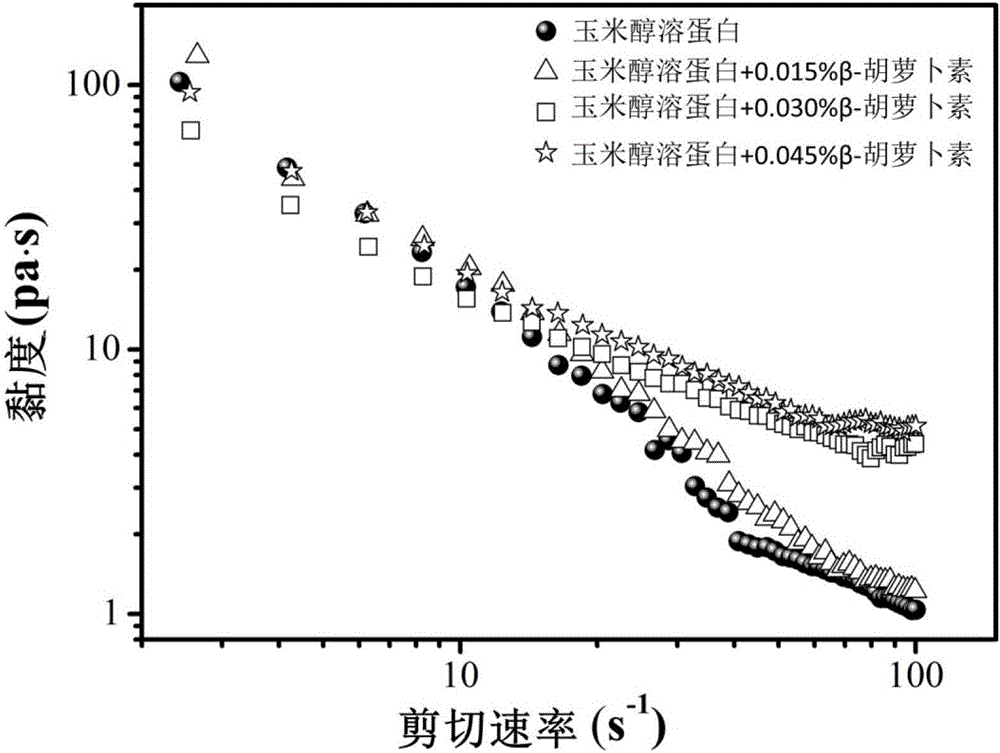

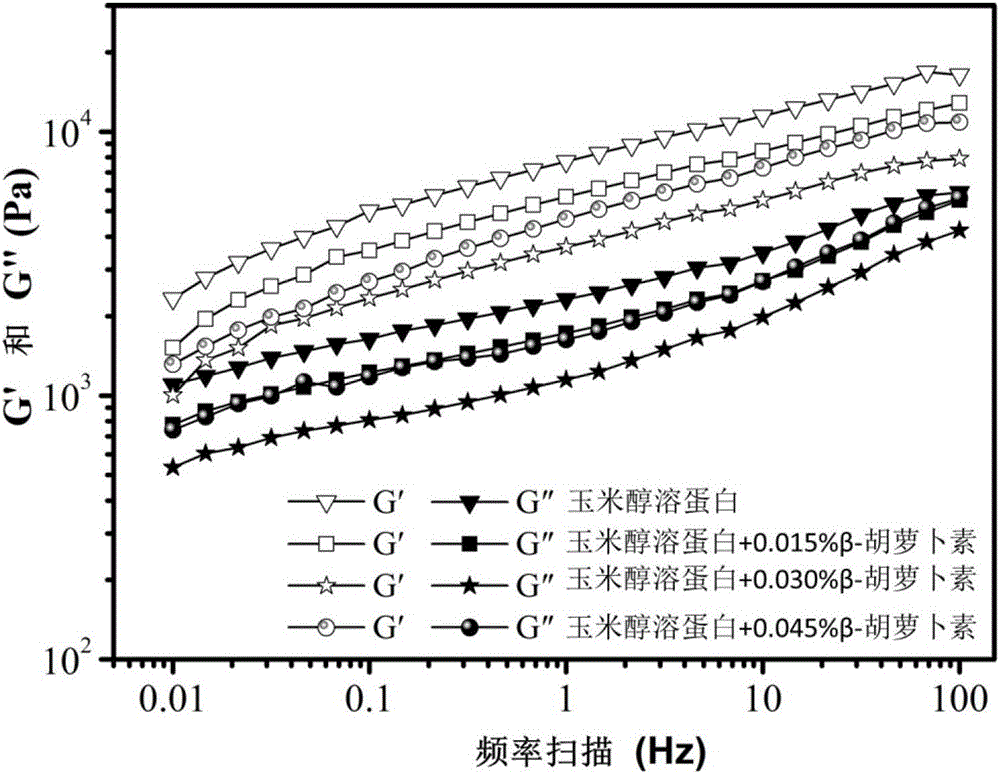

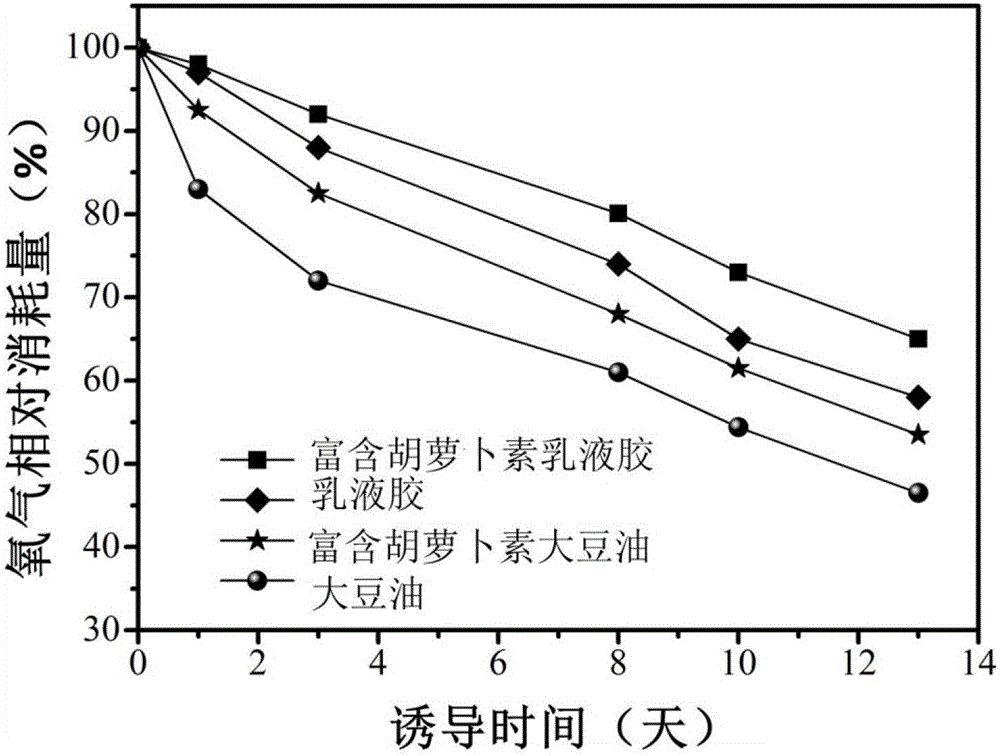

Cereal protein-based carotenoid emulsion gel and preparation method thereof and application

The invention discloses a cereal protein-based carotenoid emulsion gel and a preparation method thereof and application. The preparation method comprises the steps of dissolving cereal protein and insoluble carotenoid in heated glycerin, causing the heating temperature to be 40-180 DEG C, and forming a clear transparent mixed dispersion liquid with stirring; preheating edible oil at 40-120 DEG C; adding the preheated edible oil dropwise into the glycerin mixed liquid of the cereal protein and carotenoid, performing shearing and homogenization, and obtaining the cereal protein-based carotenoid emulsion gel. The cereal protein-based carotenoid emulsion gel not only is simple in process, needs no complex device and is low in cost and controllable in process, but also is safe and environmentally friendly; the product is luminous yellow, and the flavor is good. The cereal protein-based carotenoid emulsion gel can be used for various foods, the sensory value, edible value and nutritional value are enhanced, and the cereal protein-based carotenoid emulsion gel can particularly serve as smearing oil and shortening to be applied to baked foods such as breads, cakes and biscuits and become a novel healthy food ingredient.

Owner:SOUTH CHINA UNIV OF TECH

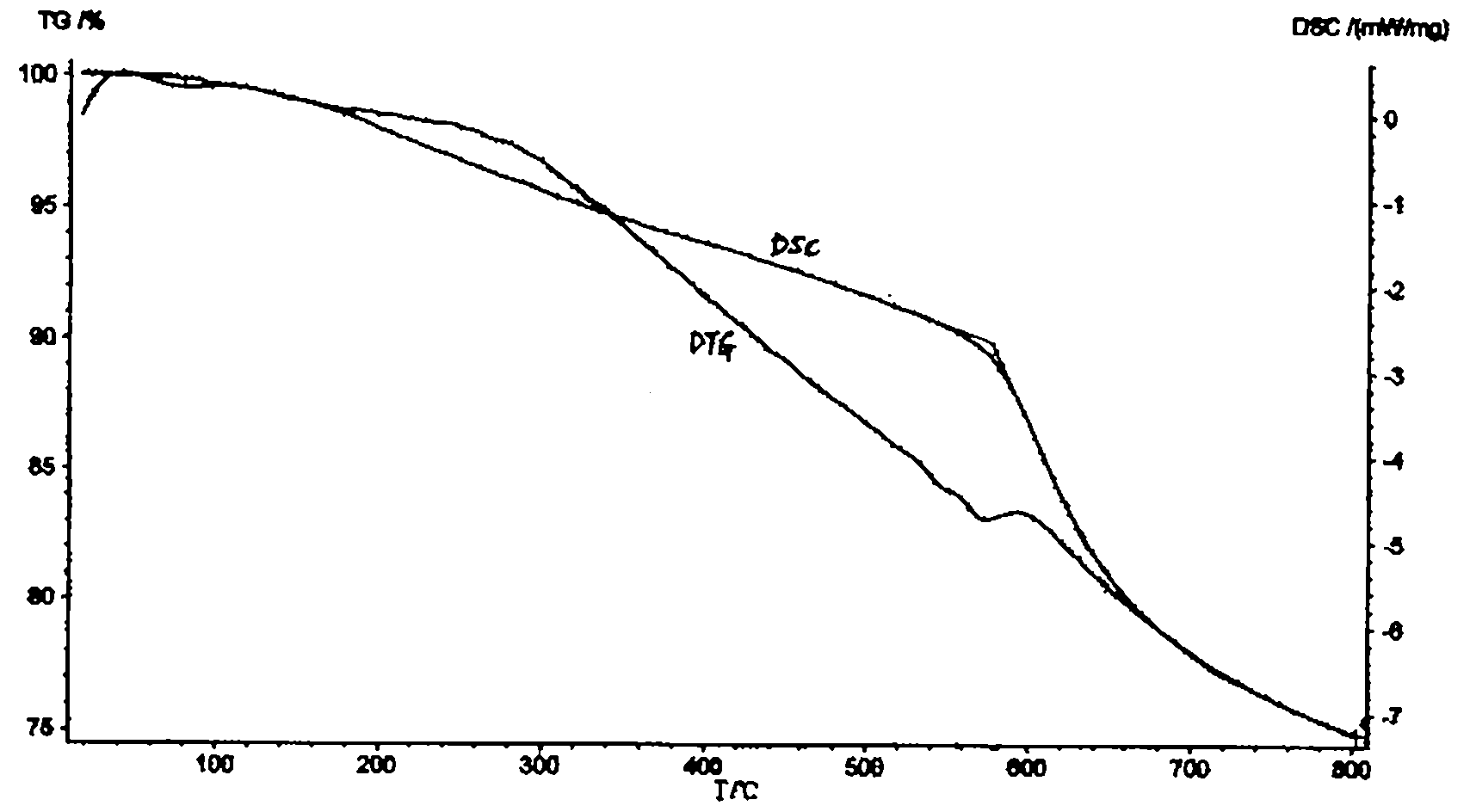

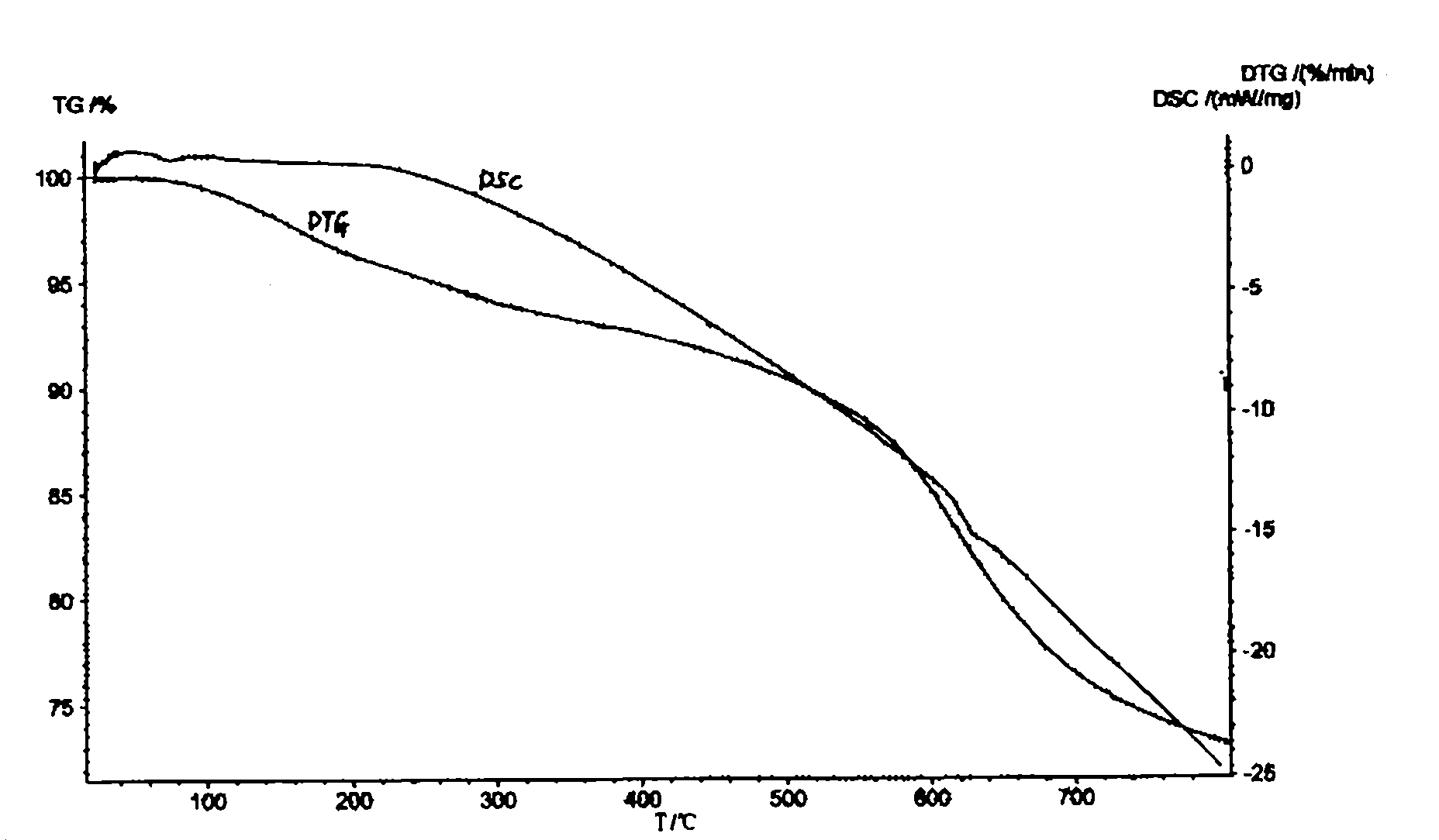

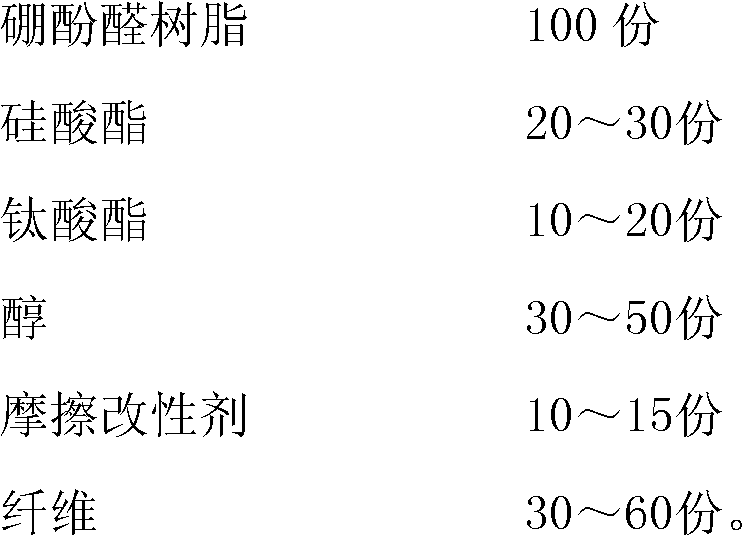

Organosilicon and titanium modified boron containing phenolic resin composite material and preparation method thereof

ActiveCN102329474AExcellent friction and wear resistanceImprove high temperature resistanceFiberOperability

The invention discloses an organosilicon and titanium modified boron containing phenolic resin composite material and a preparation method thereof. The composite material comprises 100 parts of boron containing phenolic resin, 20 to 30 parts of silicate ester, 10 to 20 parts of titanate, 30 to 50 parts of alcohol, 10 to 15 parts of friction modifier and 30 to 60 parts of fiber. A special raw material formula is adopted and the prepared composite material has excellent frictional wear resistance, high temperature resistance, moisture resistance and self-lubricating property; a preparation process for the modified phenolic resin is stable, high in operability and easy for industrial production; the composite material prepared from the modified phenolic resin is suitable for water scraping plates, sliding plates and the like in hot rolling and cold rolling production lines in the steel industry, friction plates in the fields of automobiles and high-speed rails, and other fields of high-temperature and low-temperature brake; and a manufacturing process is simple and is suitable for large-scale industrial production.

Owner:太仓力达莱特精密工业有限公司

High-heat-conductivity high-corrosion-resistance cast aluminum alloy and preparation method thereof

The invention discloses high-heat-conductivity high-corrosion-resistance cast aluminum alloy and a preparation method thereof. The high-heat-conductivity high-corrosion-resistance cast aluminum alloycomprises the raw material components of, by weight, 7-9% of Si, 0.6-1.0% of Fe, 0.2-0.6% of Zn, 0.1-0.5% of Co, 0.05-0.15% of B, 0.2-0.5% of RE, 0.05-0.2% of Sr and the balance Al. In the preparationprocess, the aluminum alloy containing the elements of Si, Fe and Co is melted at the high temperature at first, and then is subjected to still standing and cooled; pure Zn, Al-RE intermediate alloy,Al-B intermediate alloy and Al-Sr intermediate alloy are added into the melt for further alloying; and the melt is subjected to refining and slag removal, and molding is achieved through casting. According to the alloy preparation process, the technology effect is remarkable, the Co, B, Sr and RE multi-element compound synergistic effect is sufficiently realized, and thus, the alloy casting piecehas the excellent heat conductivity, high mechanical property and good corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

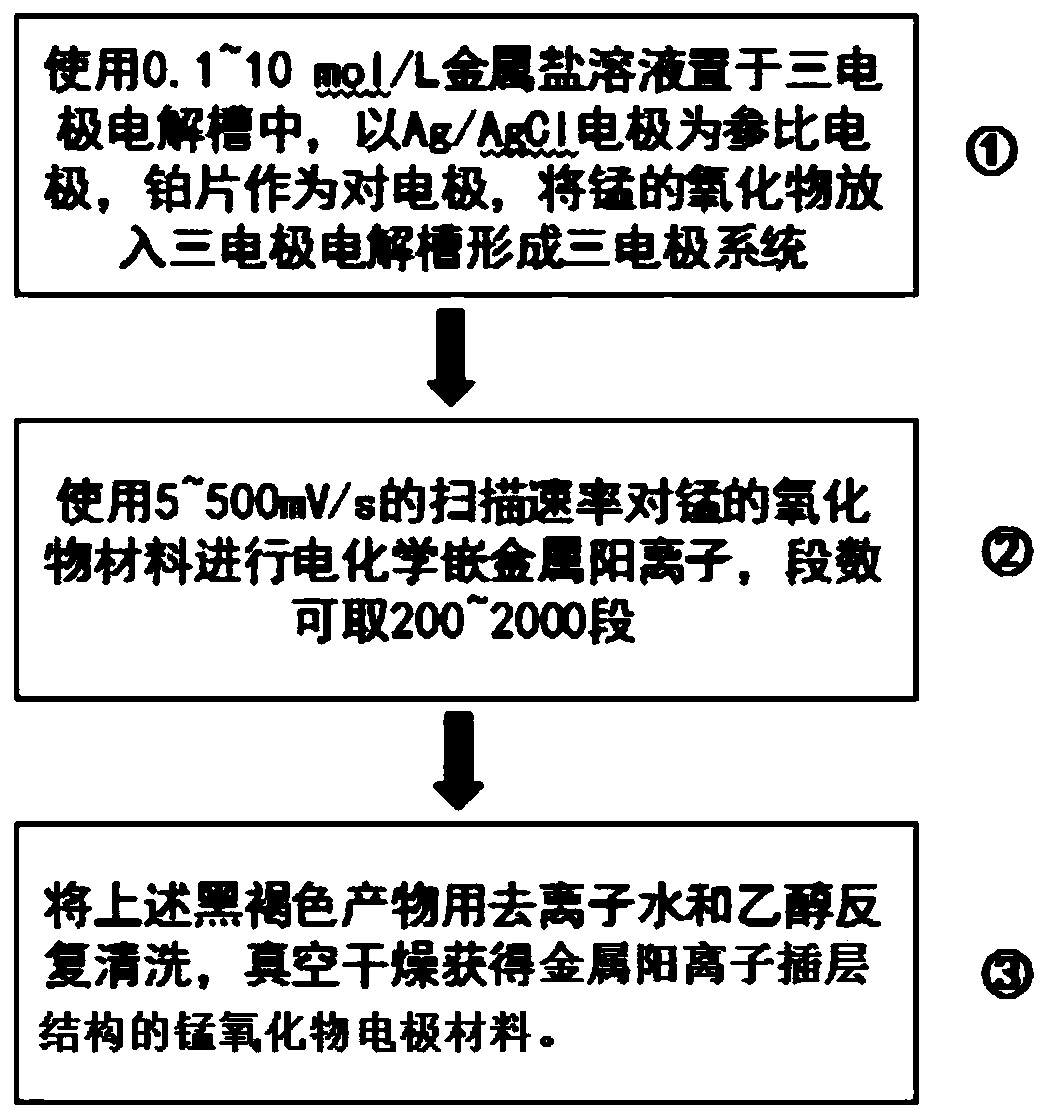

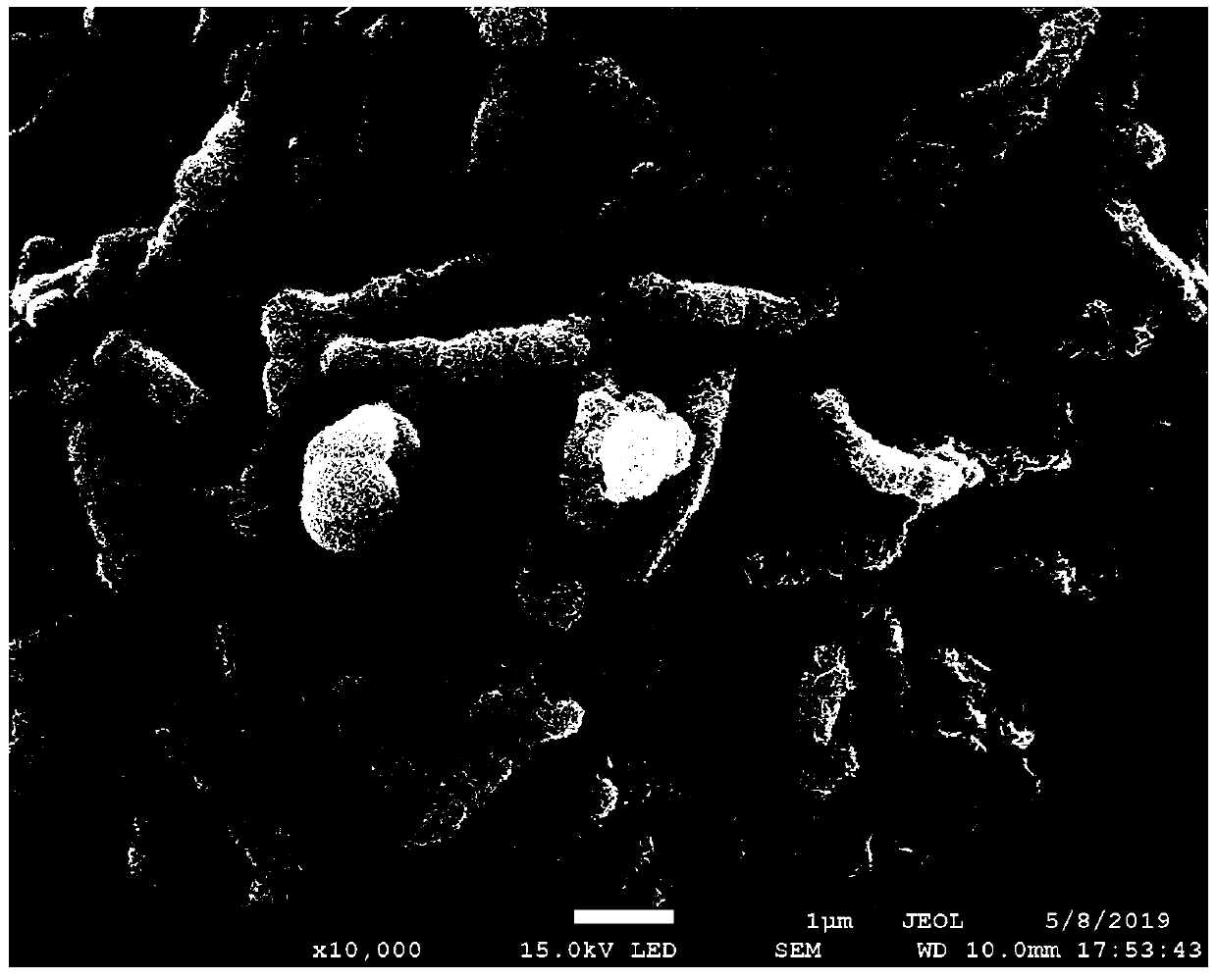

Manganese oxide electrode material with metal cation intercalation structure and preparation method and application thereof

ActiveCN110729462AThe shape of the array has little effectGood ion interface and transport channelsHybrid capacitor electrodesCell electrodesManganese oxideCharge and discharge

The invention discloses a manganese oxide electrode material with a metal cation intercalation structure. In the material, metal cations are inserted between the layers of the original manganese oxide, and a metal nano sheet is also grown on the surface. The insertion of the cations increases the layer spacing so as to facilitate insertion and removal of the ions in the electrolyte during the charging and discharging process. The increase of the specific surface area provides larger contact sites for the ions in the electrolyte. The preparation method of the electrode material is as follows: 1), placing 0.1-10mol / L metal salt solution in a three-electrode electrolytic cell, taking the Ag / AgCl electrode as a reference electrode and the platinum sheet as a counter electrode and putting the manganese oxide into the three-electrode electrolytic cell to form a three-electrode system; 2), using the scanning rate of 5-500mV / s to electrochemically embed the metal cations into the manganese oxide material, wherein the number of segments can be 200-2000 segments; and 3) repeatedly cleaning the black-brown product and vacuum drying.

Owner:HUBEI UNIV

Method for preparing biomass fuel by taking cow dung as raw material

The invention discloses a method for preparing a biomass fuel by taking the cow dung as the raw material, comprising the following steps: (1) treating the fresh cow dung until the water content is decreased to 60-75%; (2) mixing the fresh cow dung with a composite microbial inoculum, and fermenting for 10-20 days until the water content of the product of fermentation is less than 42%; and (3) feeding the product of fermentation into a granulating workshop, grinding, screening, granulating, and airing until water content is less than 30% to obtain the biomass fuel. The stickiness of cow dung is made to decrease by the biological activity of the microbial inoculum so that the solid and the liquid are separated naturally, the COD concentration of the sewage separated out is reduced significantly compared with that of the cow dung liquid mechanically squeezed out and is generally about 500mg / l, and the sewage can enter a sewage treating system of the pasture so as to be treated without generating impact load. The temperature of the cow dunghill rises ceaselessly to about 70 DEG C at most so that various harmful microorganisms in the cow dung can be killed effectively. The content of crude fiber in the product of fermentation enriches gradually, and the calorific value increases correspondingly to more than 2,500kcal.

Owner:太仓东浔生物科技有限公司

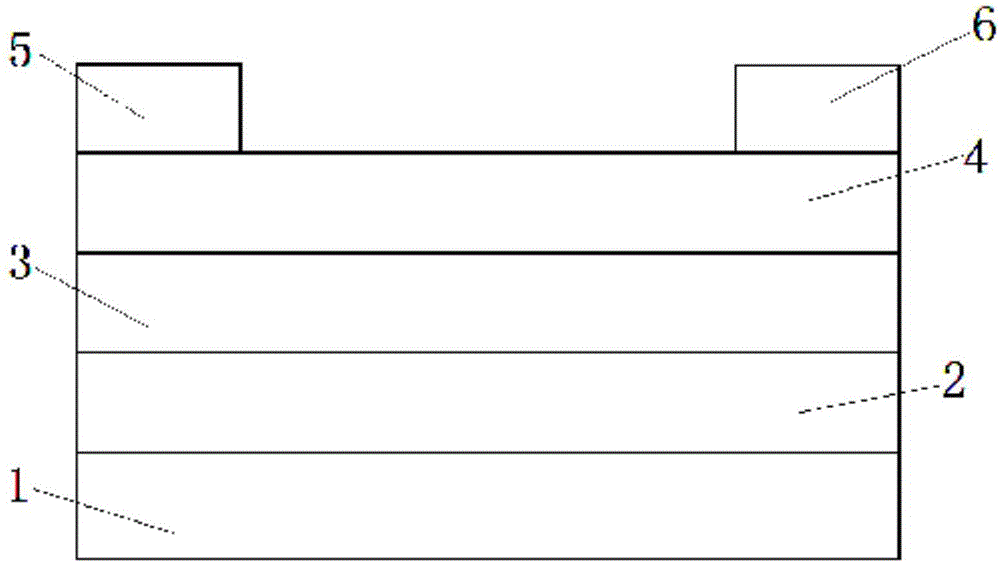

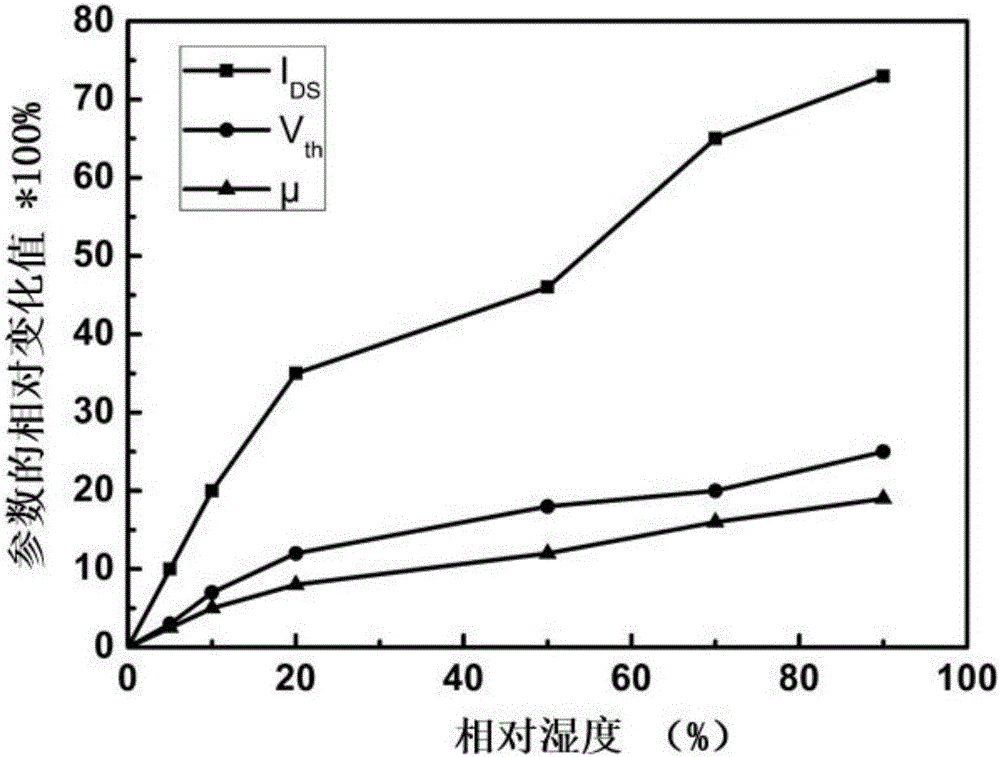

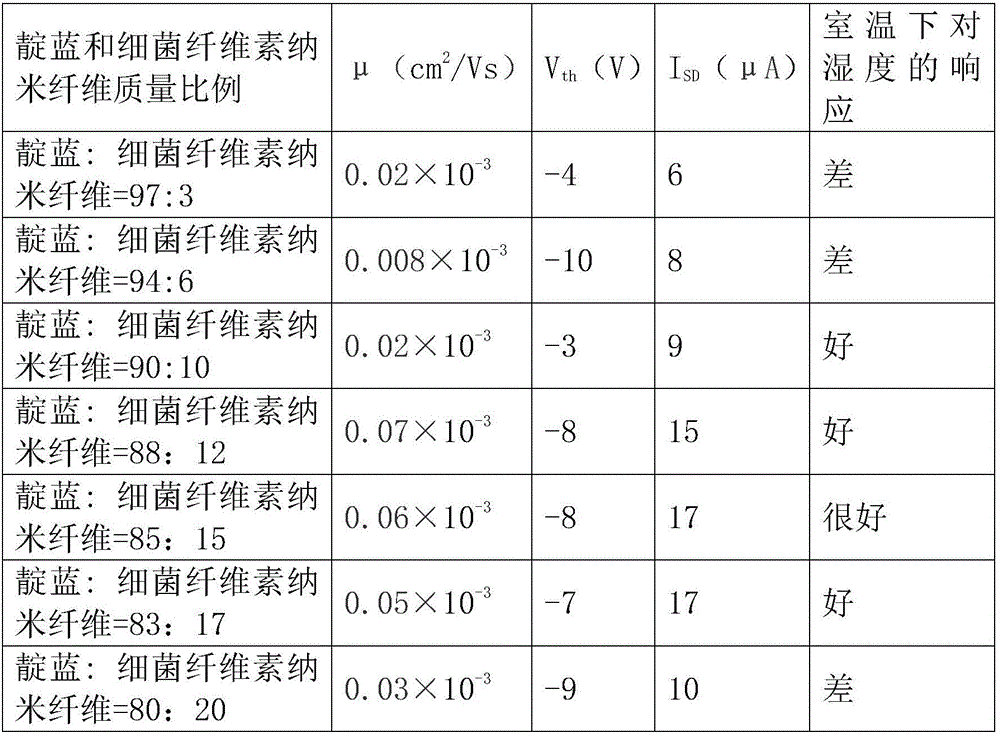

Humidity sensor based on organic field effect transistor and preparing method thereof

InactiveCN106198635AImprove response rateLow detection limitMaterial analysis by electric/magnetic meansFiberInsulation layer

The invention discloses a humidity sensor based on an organic field effect transistor and a preparing method thereof. The humidity sensor comprises a substrate, a gate electrode, a gate insulation layer, an organic semiconductor layer and source and drain electrodes from bottom to top in sequence, wherein the organic semiconductor layer is formed by mixing of one or more of indigo blue or indigo blue derivatives and bacterial cellulose nanofiber, and the mass percentage of bacterial cellulose nanofiber is 3-20%. By means of high orientation property of bacterial cellulose nanofiber, the morphology of an organic semiconductor film and the size of organic material crystalline grains are controlled precisely, water adsorbability of the semiconductor film is improved, and mechanical strength and flexibility of electronic devices are effectively improved; furthermore, indigo blue or indigo blue derivatives and bacterial cellulose nanofiber have high biocompatibility and biodegradability, so that the problem of ecological pollution caused by electronic waste can be effectively solved, and the humidity sensor can be widely applied to the field of portable wearable flexible sensors.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Novel spirofluorene xanthene organic electroluminescent material and preparation method thereof

InactiveCN103666455ASimple methodMild reaction conditionsOrganic chemistrySolid-state devicesOrganic solar cellOrganic laser

The invention provides a novel spirofluorene xanthene organic electroluminescent material and a preparation method thereof. The material is synthesized by connecting a functional group to the 2 position of spirofluorene xanthenes as a center unit, and has a structure represented by a general formula in the specification; and in the general formula, R represents a secondary amino group, a pyrryl group, an indolyl group, a carbazyl group, a benzimidazolyl group, or derivative groups of the above groups. The compound has the advantages of simple synthetic method, easy processing, easy purification and low cost. The above organic electroluminescent compound emits blue light, can be used in luminescent materials, can be used as a hole transport material or an electron transfer material, and is hopeful to be widely used in organic light-emitting diode devices, organic electrical storage devices, organic solar batteries, organic laser diode devices and organic field effect transistors.

Owner:方圆环球光电技术盐城有限公司 +1

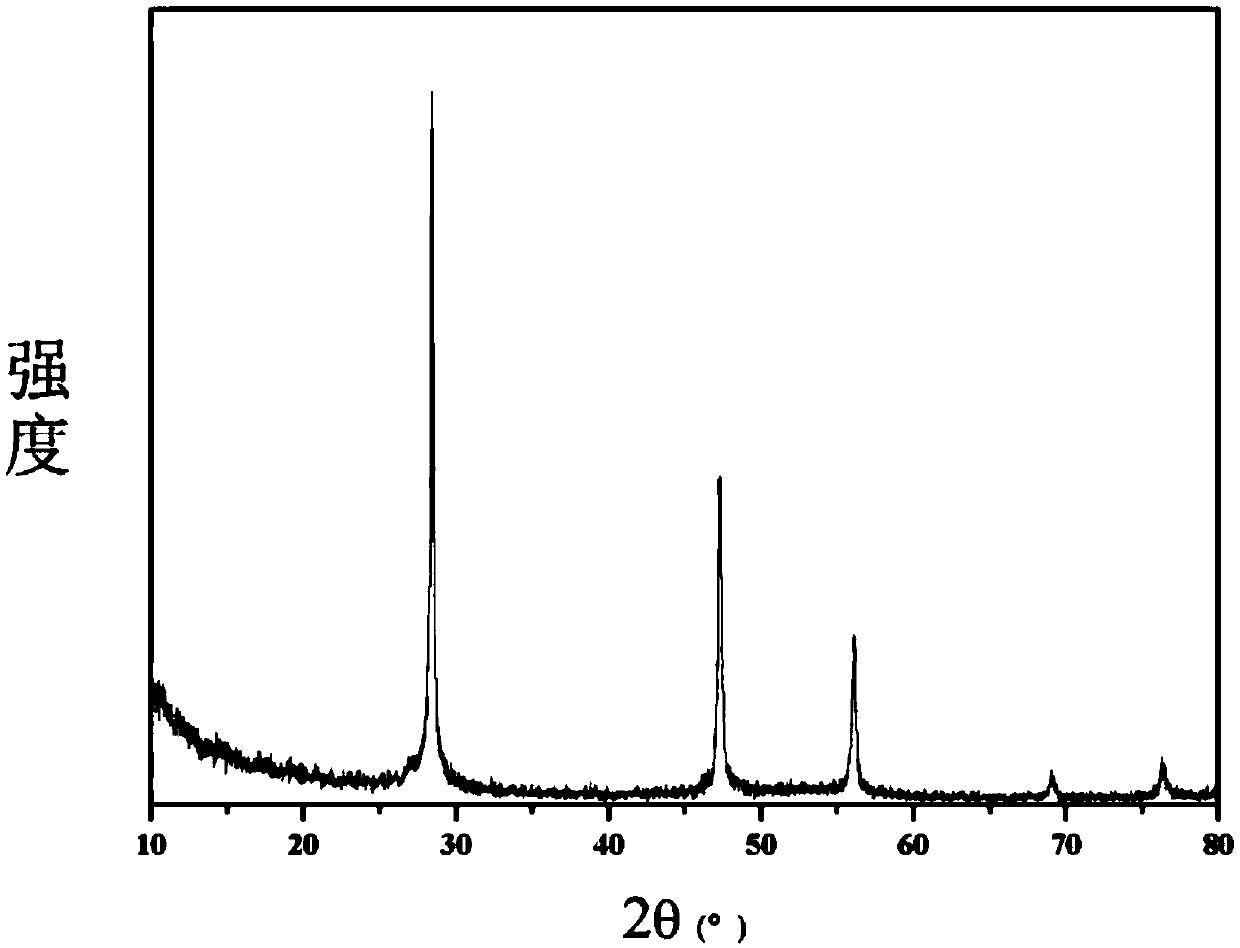

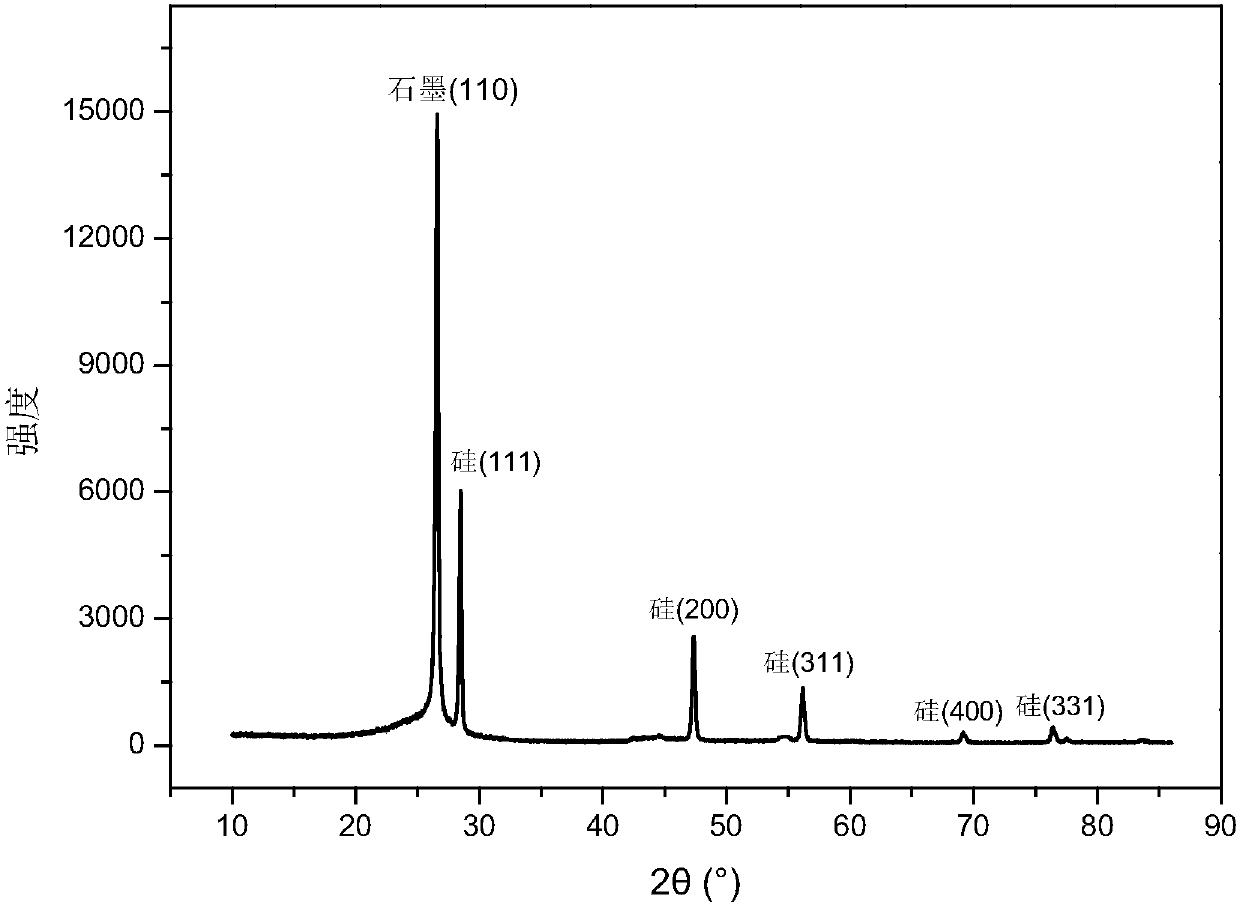

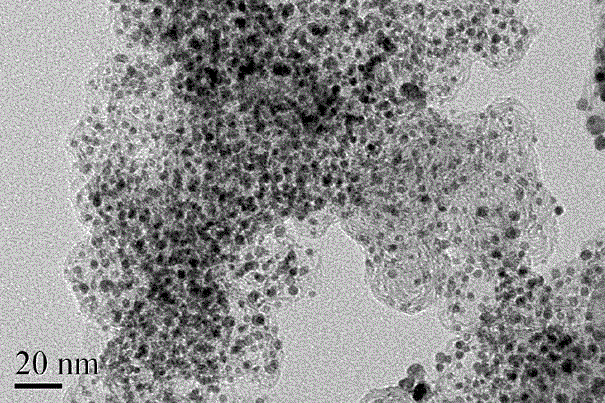

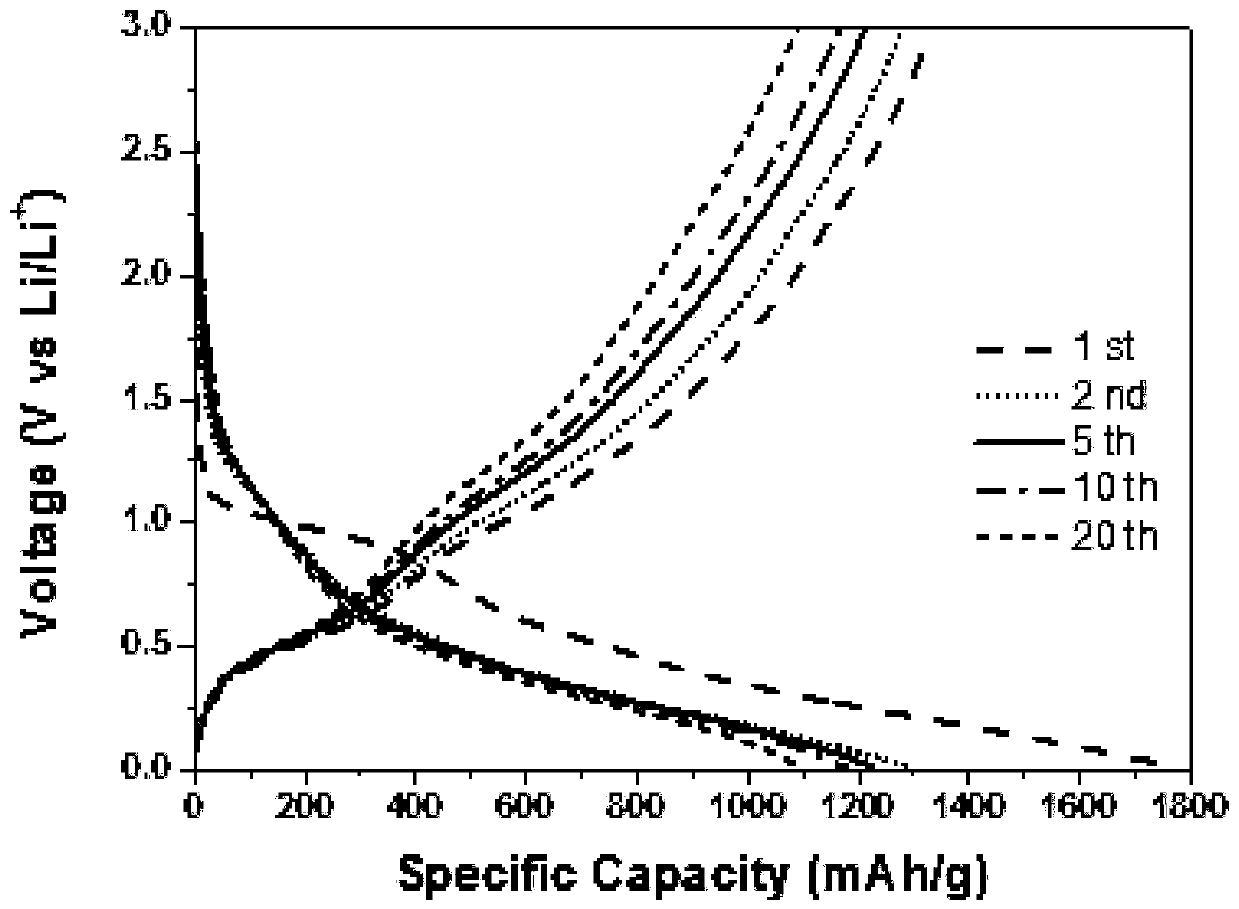

Nano silicon, preparation method thereof and application of nano silicon in silicon carbon composite cathode material and lithium ion battery

InactiveCN107634199AImprove electronic conductivityBuffer volume effectCell electrodesSecondary cellsCarbon compositesCyclic process

The invention provides nano silicon, a preparation method thereof and an application of the nano silicon in a silicon carbon composite cathode material and a lithium ion battery. The invention provides a method for preparing the pure silicon component nano silicon by a low-temperature molten salt method, the obtained nano silicon is the secondary particles with a particle size being 80-120 nm formed by assembling the primary silicon particles, which is very suitable for preparing the silicon carbon composite cathode material, the silicon carbon composite cathode material is employed for preparing the silicon carbon material by a machinery fusion and high-temperature pyrolysis method, the electronic conductivity of the silicon material is improved, the volume effect generated during an alloying and dealloying process of the silicon cathode can be effectively buffered, and the structural stability of the material during a cycle process is increased. The silicon carbon cathode material has the advantages of high initial coulomb efficiency, good cycle performance, high compacted density, and stable electrode structure, and the preparation process of the nano silicon and the silicon carbon composite cathode material is environment friendly and pollution-free.

Owner:EVE ENERGY CO LTD

Manufacturing method of all-solid-state sodium ion battery and all-solid-state sodium ion battery

InactiveCN110429329AFlexibleImprove securityFinal product manufactureElectrolyte accumulators manufactureAll solid stateSolid state electrolyte

The invention belongs to the sodium ion battery technology field and especially relates to a manufacturing method of an all-solid-state sodium ion battery. The method comprises the following steps ofmixing sodium salt, an organic solvent, an additives and an initiator to obtain a liquid mixture; coating on a surface of a positive pole sheet and / or a negative pole sheet to form a solid electrolytelayer; packaging to obtain a sodium ion cell; baking the sodium ion cell and injecting into the liquid mixture, and standing; heating the sodium ion cell to obtain an unactivated solid sodium ion battery; and carrying out formation, degassing and vacuum packaging on the solid-state sodium ion battery so as to obtain the all-solid-state sodium ion battery. The liquid mixture is used to fully wet asolid electrolyte layer and fill gaps in the pole sheets and the gaps in the solid electrolyte layer, and then the liquid mixture is polymerized in situ at a high temperature to form a polymer solidelectrolyte so as to form the all-solid-state sodium ion battery. Ionic conductivity of the solid electrolyte layer is improved, and rate performance of the all-solid-state sodium ion battery is improved.

Owner:SO-FUN TECH CORP LTD

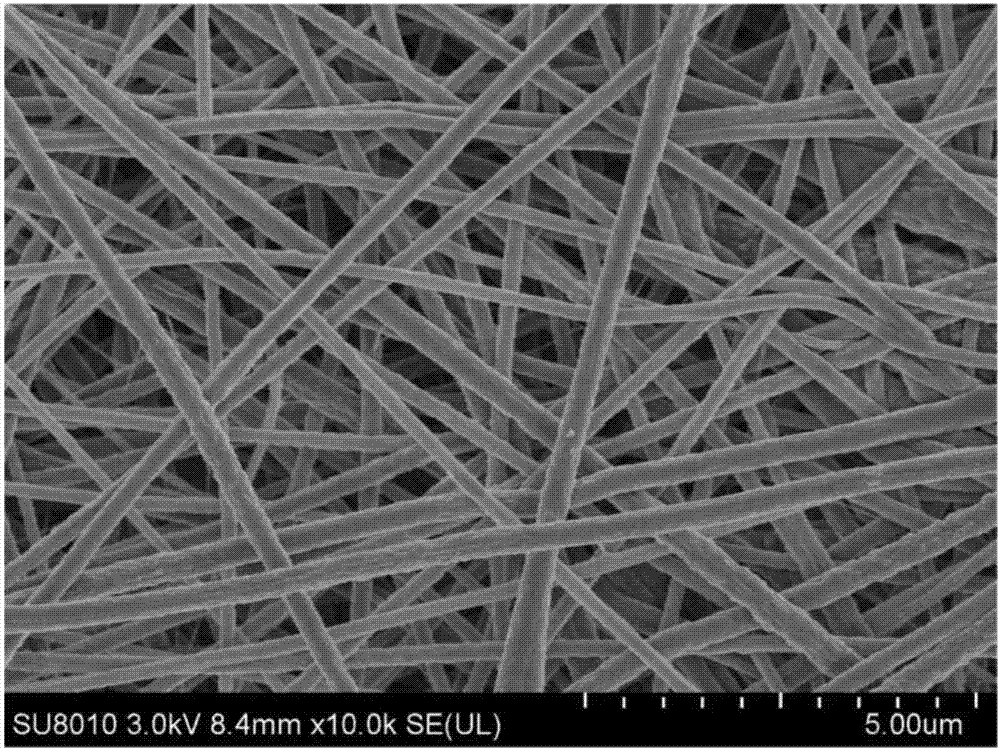

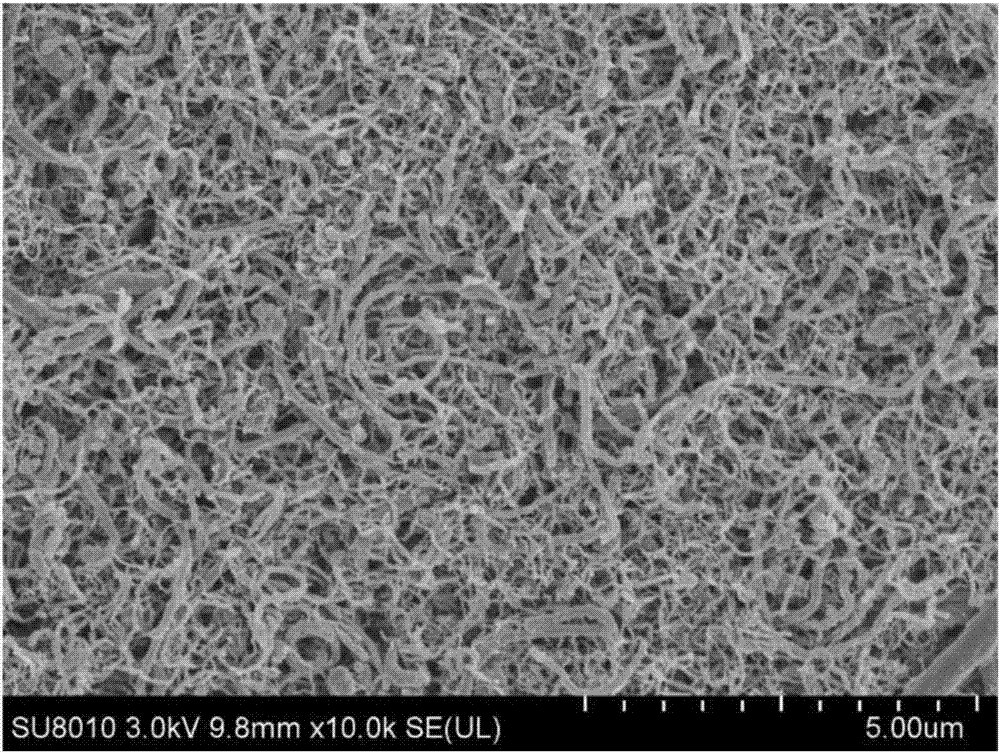

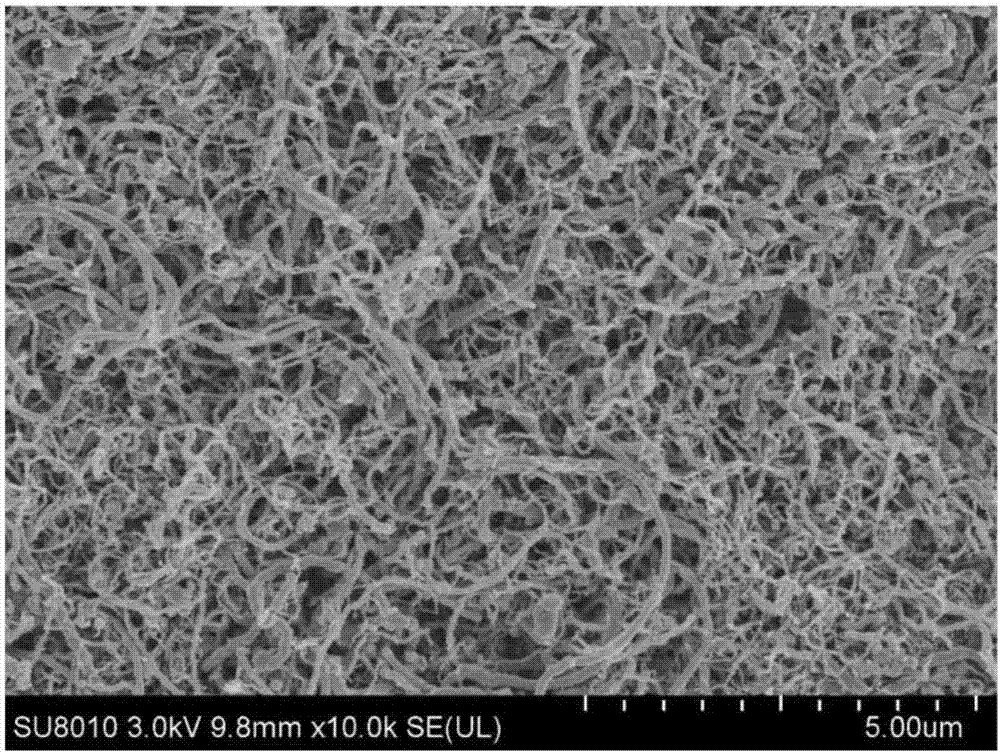

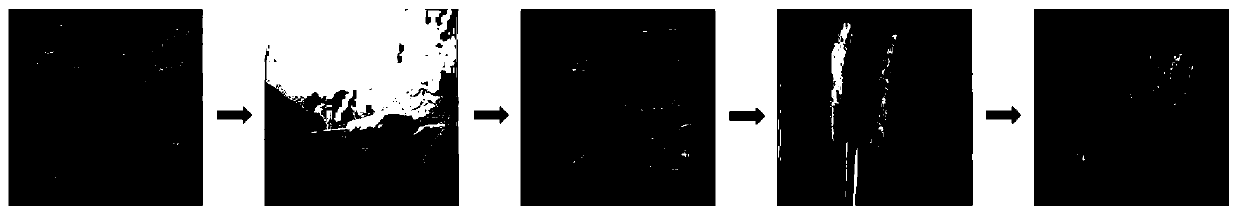

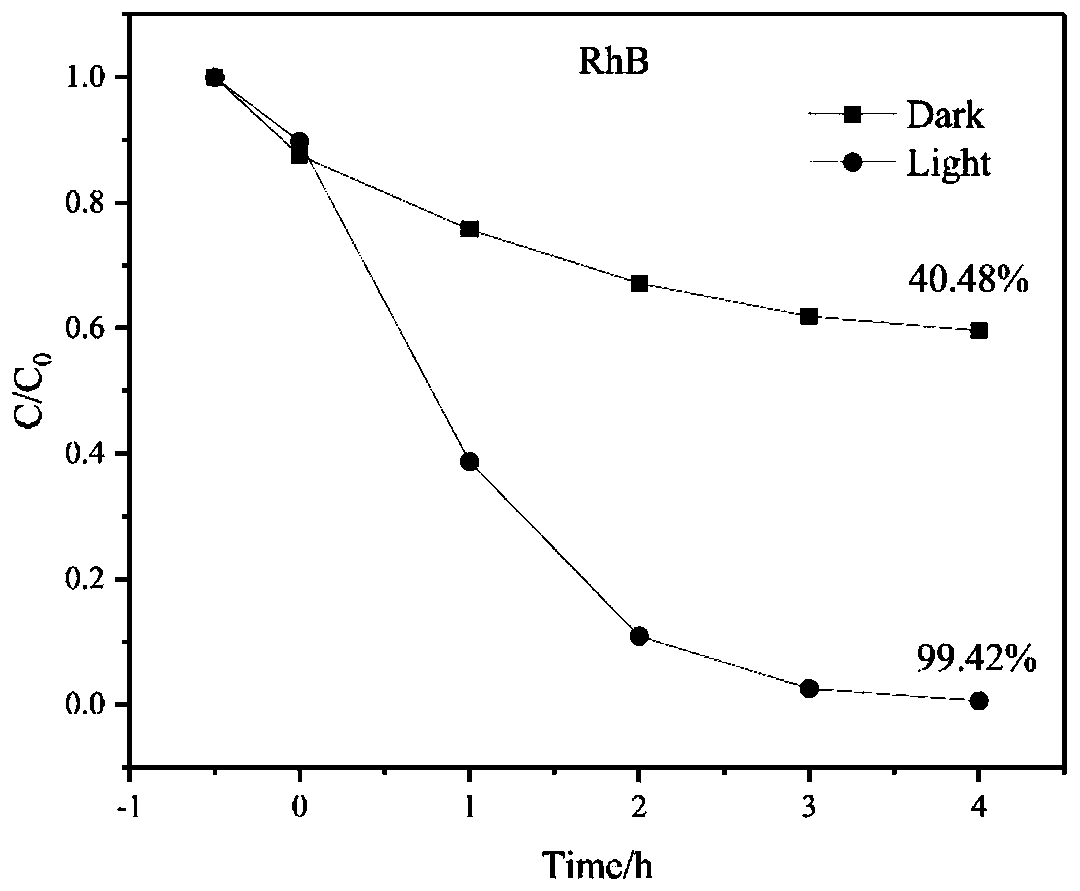

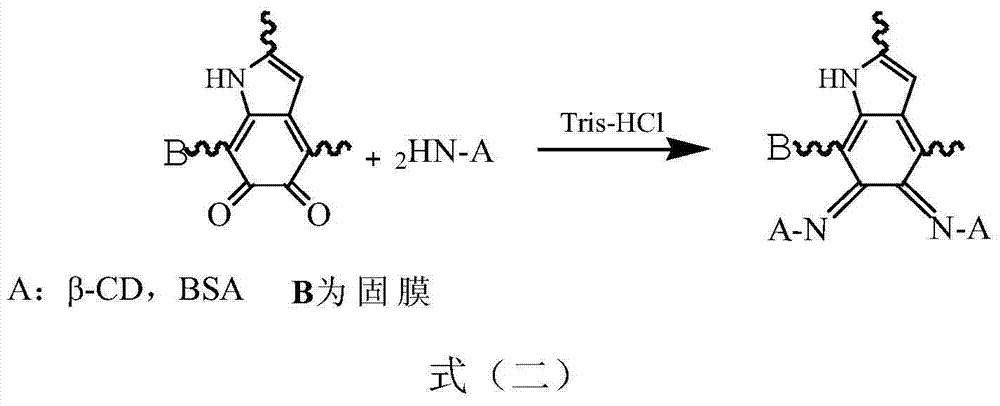

Superhydrophobic modified electrostatically-spun membrane and preparation method and application thereof

ActiveCN106894165ASimple manufacturing processEasy to achieve industrial mass productionNon-woven fabricsPorosityHydrophobic polymer

The invention discloses a preparation method of a superhydrophobic modified electrostatically-spun membrane, comprising the steps of mixing a hydrophobic polymer, electrolyte and solvent A into a polymer spinning dope, and performing electrostatic spinning to obtain an electrostatically-spun membrane; dispersing carbon nanotubes in solvent B to obtain carbon nanotube dispersion, coating the electrostatically-spun membrane with the dispersion, and drying to obtain a precursor; hot-pressing at last to obtain the superhydrophobic modified electrostatically-spun membrane. The preparation method disclosed herein prevents mass nodes due to carbon nanotubes being doped directly in an electrostatic spinning dope, the method is simple and convenient, and the prepared modified electrostatically-spun membrane has good hydrophobicity, high porosity and flux as well as high retention rate, and meets the requirement for membrane application in membrane distillation process.

Owner:ZHEJIANG UNIV

Bismuth tungstate/tungsten oxide/polymer composite nanofiber membrane for high-energy ray protection and preparation method of membrane

ActiveCN110438664ASimple structureHave mechanical strengthWater/sewage treatment by irradiationWater treatment compoundsHigh energyGamma ray

The invention discloses a bismuth tungstate / tungsten oxide / polymer composite nanofiber membrane for high-energy ray protection and a preparation method of the membrane, and belongs to the technical field of ray protection material preparation. Firstly, a tungsten oxide nanorod seed crystal is prepared by hydrothermal synthesis, secondly, the tungsten oxide nanorod seed crystal is mixed with polymer solution to prepare electrospinning precursor solution, the nanofiber membrane is prepared by an electrostatic spinning process, and then a flexible heterogeneous composite nanofiber is prepared bya subsequent two-step hydrothermal process. Owing to physicochemical properties of tungsten and bismuth oxide and structural characteristics of nanofibers, the nanofiber membrane has high protective effects on X and gamma rays and can keep low density, a continuous nanofiber material solves the problem of agglomeration of powder materials, interference of electromagnetic shielding effects in radiocommunication is avoided by introduction of non-conductive materials, the nanofiber membrane can be used for photocatalytic degradation of organic pollutants after the life cycle of the nanofiber membrane serving as a high-energy ray protection is ended, and the nanofiber membrane is a novel nano-material with a good application prospect.

Owner:JILIN UNIV

Method for separating alpha-ketoglutaric acid from conversion solution

ActiveCN104529755ARealize multiple recyclingAchieve recyclingOrganic compound preparationChemical industryUltrafiltrationSulfate

The invention discloses a method for separating alpha-ketoglutaric acid from a conversion solution, which comprises the following steps: sequentially carrying out ceramic filtration, ultrafiltration and reverse osmosis on the conversion solution to obtain an alpha-ketoglutaric acid concentrated solution; reacting the obtained concentrated solution with calcium superchloride, and filtering to obtain alpha-ketoglutarate; adding the alpha-ketoglutarate and ethanol into a reaction kettle, slowly and dropwisely adding sulfuric acid, stopping adding the acid when the pH value of the ethanol solution is 1.3-1.5, stirring to react to generate a calcium sulfate precipitate, filtering, and collecting the filtrate which is a ketoglutaric acid ethanol solution; eluting the residual alpha-ketoglutaric acid from the calcium sulfate with ethanol, and collecting the eluting solution; and mixing the filtrate and eluting solution, and heating and concentrating under reduced pressure to precipitate the alpha-ketoglutaric acid crystal. The membrane filtration technique is adopted to avoid abundant water evaporation; and thus, the method has the advantages of energy saving, high production yield, favorable crystal form, light color of the crystal grain, and stable product quality, and can easily implement industrialized large-scale production.

Owner:JING JING PHARMA

Environment-friendly cigarette filter rod as well as preparation method and application thereof

InactiveCN105982348AExtensive sources of raw materialsLow costTobacco smoke filtersFiberFood material

The invention discloses an environment-friendly cigarette filter rod as well as a preparation method and application thereof. The preparation method of the environment-friendly cigarette filter rod comprises the following steps: adding a high-starch food material and a high-fiber plant material into a popcorn machine, and extruding; performing extrusion moulding through a mould; and mechanically cutting to obtain a solid filter rod or hollow filter rod. The preparation method has the advantages of low equipment requirements, simplicity in operation, cheap raw materials and low production cost; and the prepared solid filter rod and hollow filter rod have high safety performance, are environment-friendly and have certain adsorption interception functions and aroma enhancement effects.

Owner:CHINA TOBACCO HUNAN INDAL CORP

High-concentration organic saline solution-based method for preparing graphene through electrochemical intercalation

ActiveCN110316729AInhibit rapid decompositionContinuous controllable intercalationGrapheneIonCvd graphene

The invention provides a high-concentration organic saline solution-based method for preparing graphene through electrochemical intercalation, and belongs to the technical field of graphene preparation. In the preparation method, a high-concentration organic saline solution is used as an electrolyte, graphite is used as an anode, an inert conductive precious metal material is used as a cathode, and an electrochemical intercalation reaction is carried out to obtain graphene aggregates. By using the high-concentration organic saline solution as the electrolyte, quick decomposition of water can be inhibited, and continuous controllable intercalation of the graphite can be achieved. Fluorine-containing macromolecular organic salt is adopted in the method, under the action of voltage, the organic salt still has a stable structure, in the electrochemical intercalation reaction, the chemical reaction of intercalation ions and the graphite can be effectively avoided, the crystal structure of the graphite is protected from being damaged, and therefore, the high-quality graphene is prepared. The preparation method is short in preparation period, low in cost, environmentally friendly and simple, no acid liquid is generated, and massive industrial production is easily achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

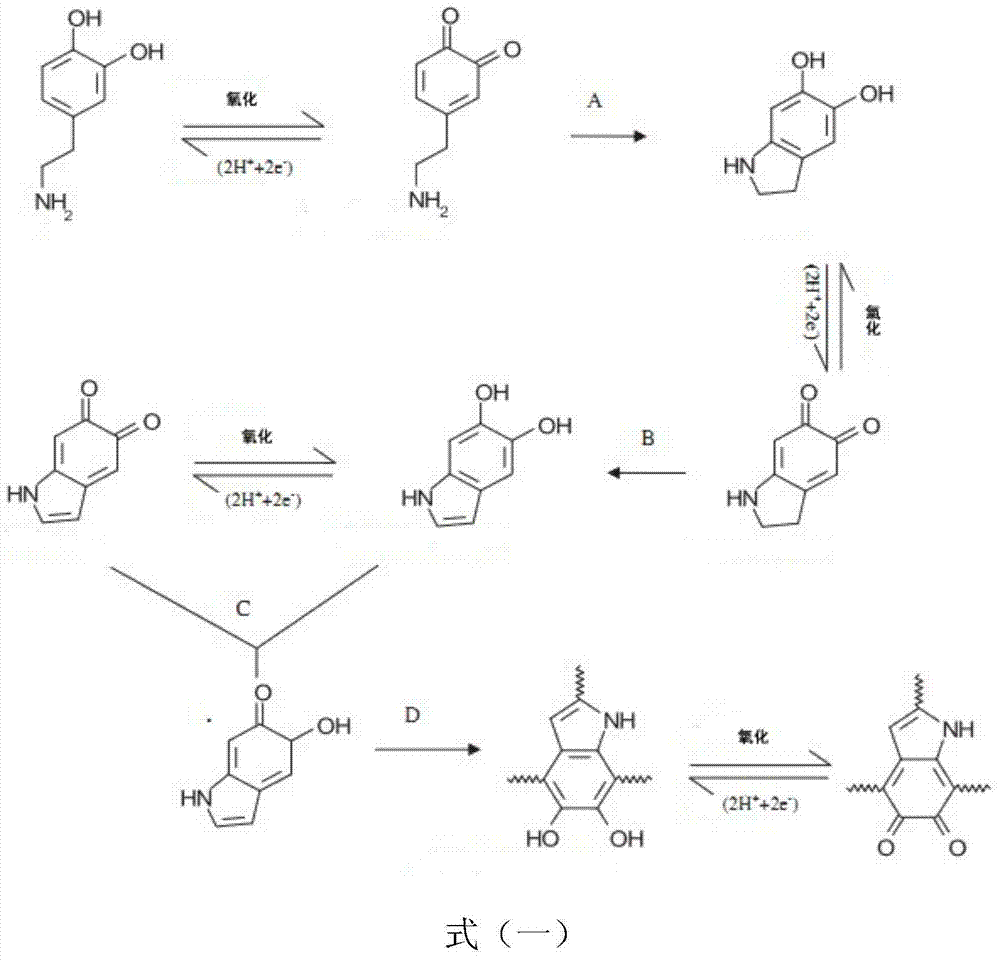

Chiral-separation solid membrane grafted by chiral identification body through dopamine pretreatment, and making method thereof

ActiveCN103585903AEasy to chemically modifyImprove hydrophilicitySemi-permeable membranesOptically-active compound separationPre treatmentDopamine

The invention belongs to the technical field of polymer membrane materials, and discloses a chiral-separation solid membrane grafted by a chiral identification body through dopamine pretreatment, and a making method and an application thereof. The method includes the following concrete steps: 1, immersing a solid membrane in a dopamine solution, stirring for reacting, and flushing with clear water; and 2, immersing the flushed solid membrane in a solution of the chiral identification body, heating for reacting, washing, and carrying out vacuum drying to obtain the chiral-separation solid membrane grafted by the chiral identification body through dopamine pretreatment. Firm and stable fctive function groups comprising -NH2, -OH and -C=O are introduced to the surface of the solid membrane through the above immersion technology; and chiral recognition sites are introduced to the surface of the solid membrane through the above immersion technology without influencing the structure or performances of the membrane, so the chiral-separation solid membrane grafted by the chiral identification body through dopamine pretreatment can be used for the effective separation of racemes The making method has the advantages of realization of the implementation of above reactions in an aqueous solution for a whole course, and mild and unharsh reaction conditions, development of the modification selectivity of the solid membrane, simple process, and easy realization of the industrialized batch production.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

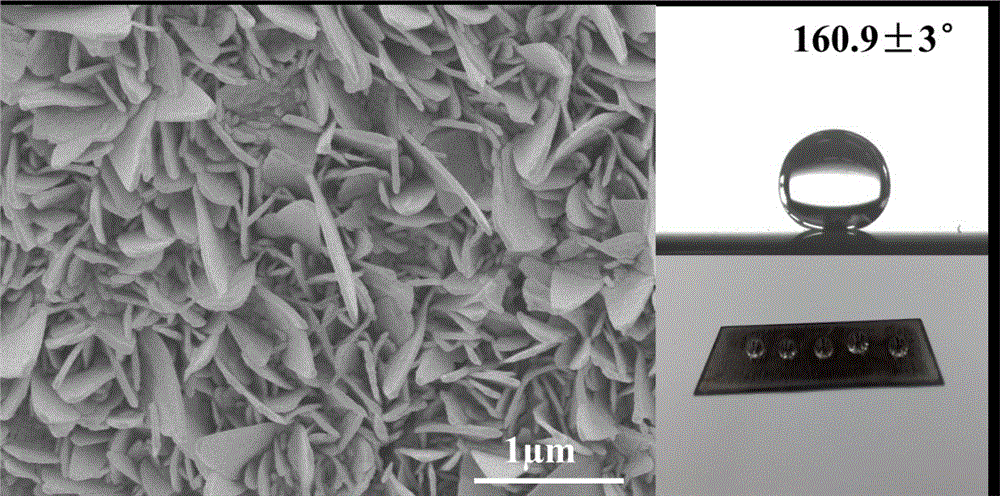

Manufacturing method for super-hydrophobic metal surface

InactiveCN105689237AImprove friendlinessNo pollution in the processPretreated surfacesSpecial surfacesPre treatmentThermal treatment

The invention discloses a manufacturing method for a super-hydrophobic metal surface. A super-hydrophobic material is manufactured through grinding pretreatment, thermal treatment and low-surface-energy matter modification. A base body surface having roughness is obtained through grinding pretreatment; a metal oxide layer is generated through thermal treatment; and the super-hydrophobic surface is manufactured through low-surface-energy matter modification. The technological method is simple and controllable, and industrial production is easy to achieve.

Owner:SICHUAN UNIV

Steamed bun zymophyte, preparation method thereof and application of steamed bun zymophyte

The invention relates to steamed bun zymophyte, a preparation method thereof and application of the steamed bun zymophyte, and belongs to the field of biotechnology and food. The steamed bun zymophyte comprises the following raw materials in percent by weight: 5.00-15.00% of steamed bun yeast powder, 5.00-15.00% of lactobacillus plantarum powder, 0.10-5% of lactobacillus casei powder, 0.10-5.00% of lactobacillus acidophilus powder and 60.00-89.80% of edible glucosum anhydricum. The preparation method comprises the following steps of pre-mixing the lactobacillus plantarum powder, the lactobacillus casei powder and the lactobacillus acidophilus powder; adding the lactobacillus plantarum powder, the lactobacillus casei powder and the lactobacillus acidophilus powder in the edible glucosum anhydricum; and uniformly blending the mixture so as to obtain the steamed bum zymophyte. 2-10g steamed bun zymophyte is added in 1Kg of flour. By using the steamed bun zymophyte, the flavor and the quality of steamed buns are improved, the problem that the quantity of steamed bun processing zymophyte is insufficient is solved, and the shortcoming that the feature and the flavor of steamed buns fermented by using the existing zymophyte are not obvious is overcome.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

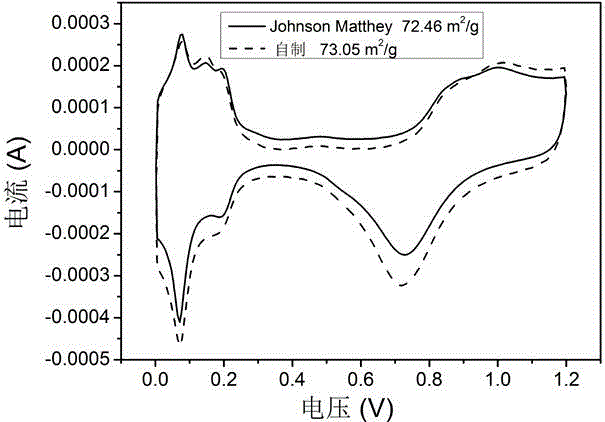

Preparation method for proton exchange membrane fuel cell catalyst

InactiveCN104588001APlay a role in purificationIncreased mesopore volumeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumProcess efficiency

The invention discloses a preparation method for a proton exchange membrane fuel cell catalyst. The adoption of a surfactant and a stabilizer is avoided, the preparation method is easy to operate, safe and convenient, and the preparation efficiency is greatly improved; acid is added as a precipitant, so that the precipitation time of the catalyst is greatly shortened, and the process efficiency is improved; a drying process of the catalyst is rapidly finished by a spray drying technology, and materials sprayed in the drying process are instantaneously heated by high temperature only when being sprayed into spray particles, so that the phenomenon of agglomeration of the catalyst is reduced, and the electrochemical activity of the platinum-carbon catalyst is kept high after the catalyst is dried; moreover, by the spray drying technology, the preparation time of the catalyst is further reduced, and the preparation method is easy to realize industrial production, and has broad market prospect.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

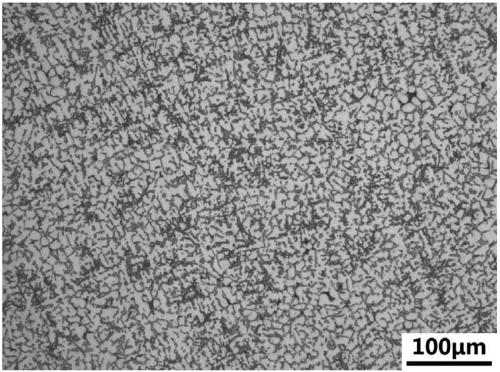

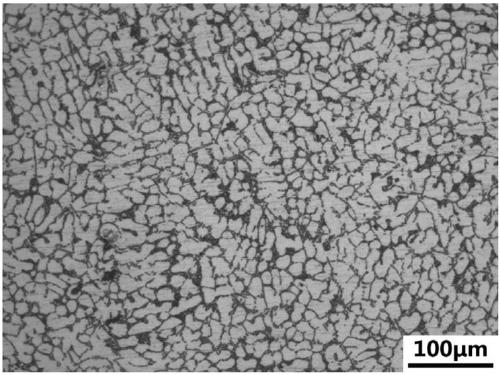

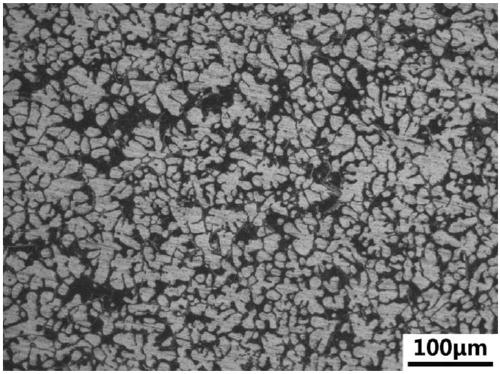

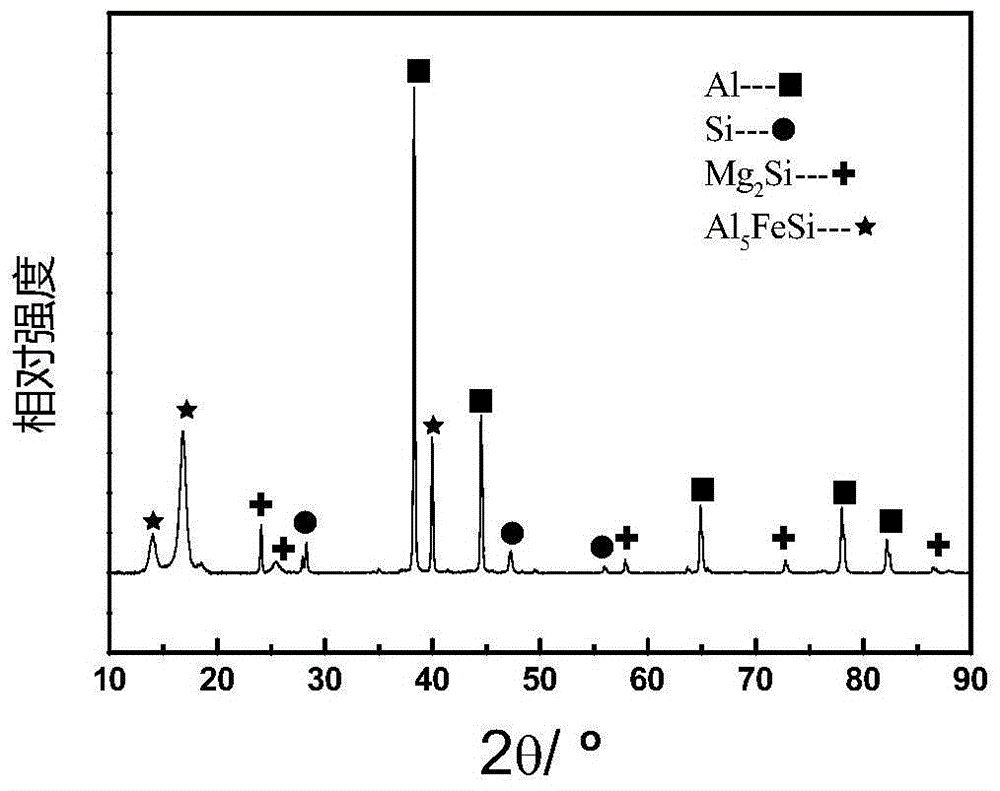

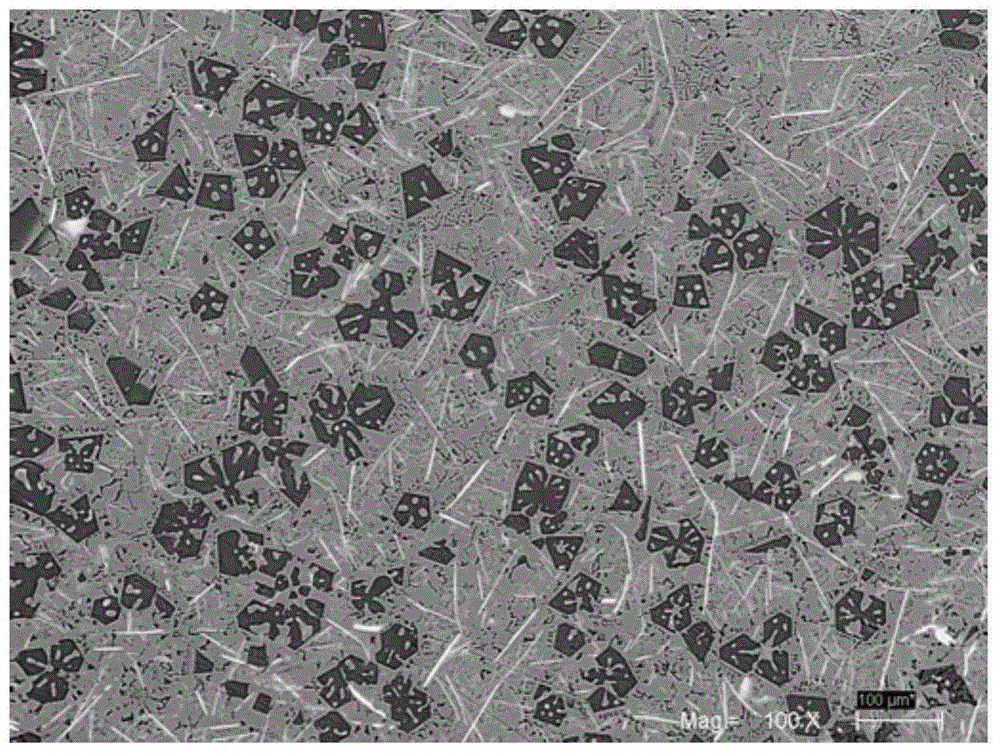

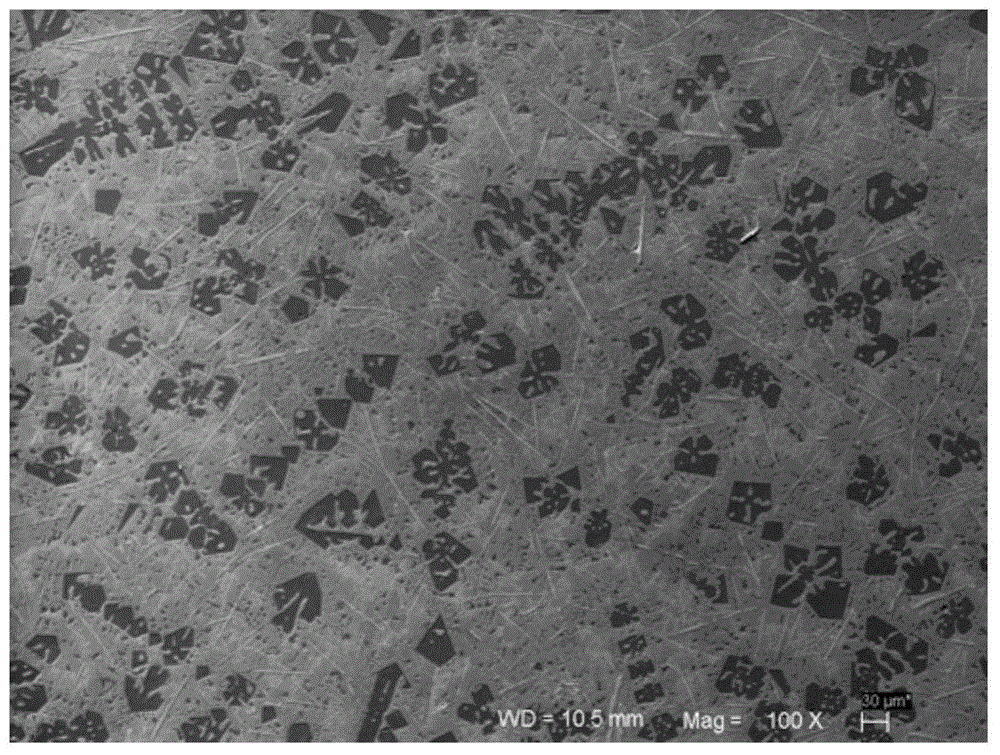

Combined treating method for modified Mg2Si/Fe-rich aluminum matrix composite texture

The invention discloses a combined treating method for modified Mg2Si / Fe-rich aluminum matrix composite texture. The combined treating method comprises the following steps that firstly, melt of a Mg2Si / Fe-rich aluminum matrix composite is prepared, and heat preservation is carried out at 700-750 DEG C; secondly, a refining modificator is put into the melt, heat preservation is continued for 10-20 min at 700-750 DEG C, and stirring is carried out, wherein the refining modificator comprises Cr and B, the adding amount of Cr accounts for, by mass, 0.8-1.5% of the Mg2Si / Fe-rich aluminum matrix composite, and the adding amount of B accounts fro, by mass, 0.2-0.4% of the Mg2Si / Fe-rich aluminum matrix composite; and thirdly, degassing, purifying and refining molding are carried out on the melt obtained in the second step. According to the combined treating method, the synchronous refining modification of the Fe-phase and the Mg2Si-phase in the Mg2Si / Fe-rich aluminum matrix composite is achieved, and the combined treating method is simple in technology, easy to operate, obvious in modification effect and free of pollution.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation and application of boat-fruited sterculia seed residue based sulfur-doped porous carbon

ActiveCN109704307AEasy accessLow priceMaterial nanotechnologyOther chemical processesPorous carbonCombined method

The invention provides preparation and application of boat-fruited sterculia seed residue based sulfur-doped porous carbon. The preparation comprises the following steps: subjecting tea-made boat-fruited sterculia seed residues, which serve as a raw material, and a sulfur dopant to high-temperature carbonization in an inert atmosphere so as to obtain sulfur-doped carbon, and then, carrying out physical activating treatment, thereby obtaining the sulfur-doped porous carbon. According to the preparation and the application, the sulfur-doped porous carbon is prepared by adopting a high-temperature carbonization and physical activation combined method, the method is simple in operation, the process is easy to control, washing is not required after activation, the production cost is reduced, the carbon yield is relatively high, and the method is environmentally friendly; and the prepared sulfur-doped porous carbon is of a nanosheet structure, is controllable in specific surface area and pore size distribution, high in electric conductivity and adjustable in sulfur content and is particularly suitable for being applied to the fields of heavy-metal wastewater treatment, printing and dyeing wastewater adsorption, lithium-sulfur batteries, lithium-ion batteries, sodium-ion batteries, supercapacitors, catalyst loading and the like.

Owner:HENAN INST OF ENG

Preparation method of porous carbon skeleton tin-coated composite electrode material

ActiveCN109786711ALower charge transfer impedanceImprove conductivityCell electrodesSecondary cellsWater solubleCarbon source

The invention discloses a preparation method of a porous carbon skeleton tin-coated composite electrode material, and belongs to the technical field of electrode material preparation. A water-solubletin source, acrylamide, a cross-linking agent and an initiator are adopted to prepare a gel precursor solution, and polymerization is performed to form gel of a three-dimensional network structure, and then low-temperature carbonization treatment is carried out on the gel to obtain the tin-based carbon composite electrode material. The polyacrylamide gel composite tin source is prepared and effectively dispersed, and a carbon skeleton formed by low-temperature carbonization can be used for fixing tin dioxide nanoparticles, so that the phenomena of large volume expansion and easy pulverizationof the tin-based material in a charging or discharging process are improved; moreover, polyacrylamide is doped with nitrogen atoms in situ while providing a carbon source, so that the material conductivity is improved; the particle size of generated tin dioxide is less than 10 nm, so that chemical reaction sites can be added, and high specific capacity, high energy density and good rate performance are presented; and compared with an existing process, the preparation method has the advantages of simple preparation process, low preparation temperature and low process cost, and is easy for industrial large-scale production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

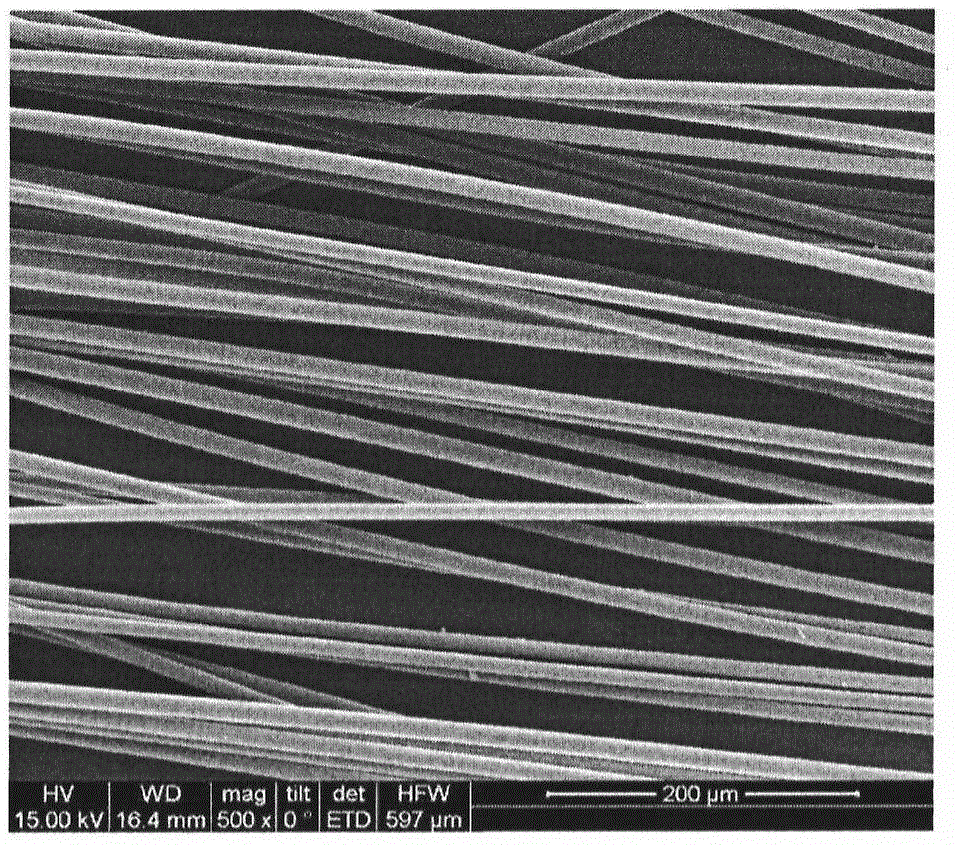

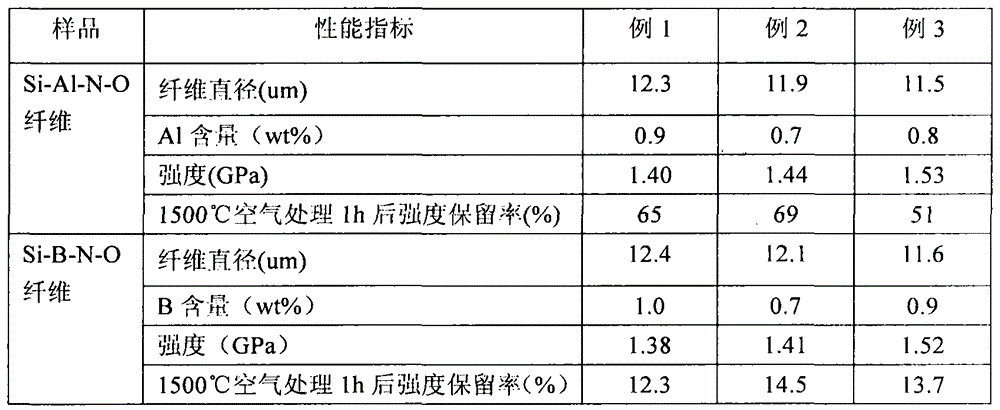

Preparation method for aluminum-containing continuous silicon nitride fibers

InactiveCN104988603AOvercoming the problem of sharp drop in strengthAvoid water resistanceFibre chemical featuresFiberDecomposition

The invention discloses a preparation method for aluminum-containing continuous silicon nitride fibers. The method includes the steps that 1, air curing treatment is performed on aluminum-containing polycarbosilane fibers; 2, nitrogenization is performed on the aluminum-containing infusible polycarbosilane fibers under the atmosphere of pure ammonia gas or a nixed atmosphere of ammonia gas, nitrogen gas and argon gas; 3, high-temperature sintering is performed under the atmosphere of nitrogen gas or argon gas. The aluminum-containing continuous silicon nitride fibers prepared through the method solve the problem that B2O3 volatilization happens on B-containing continuous silicon nitride fibers at the temperature above 1500 DEG C in an aerobic environment, holes are formed, and consequently the strength of the fibers is sharply reduced; compared with a precursor method, the problems that materials are not resistant to water and air and prone to decomposition are solved, and the aluminum-containing continuous silicon nitride fibers have better high temperature resistance and high-temperature oxidation resistance; in addition, the preparation process and equipment are simple, the cost is low, and industrial volume production is easy to achieve.

Owner:SUZHOU IND PARK HIGH PERFORMANCE CERAMIC FIBER ENG CENT CO LTD

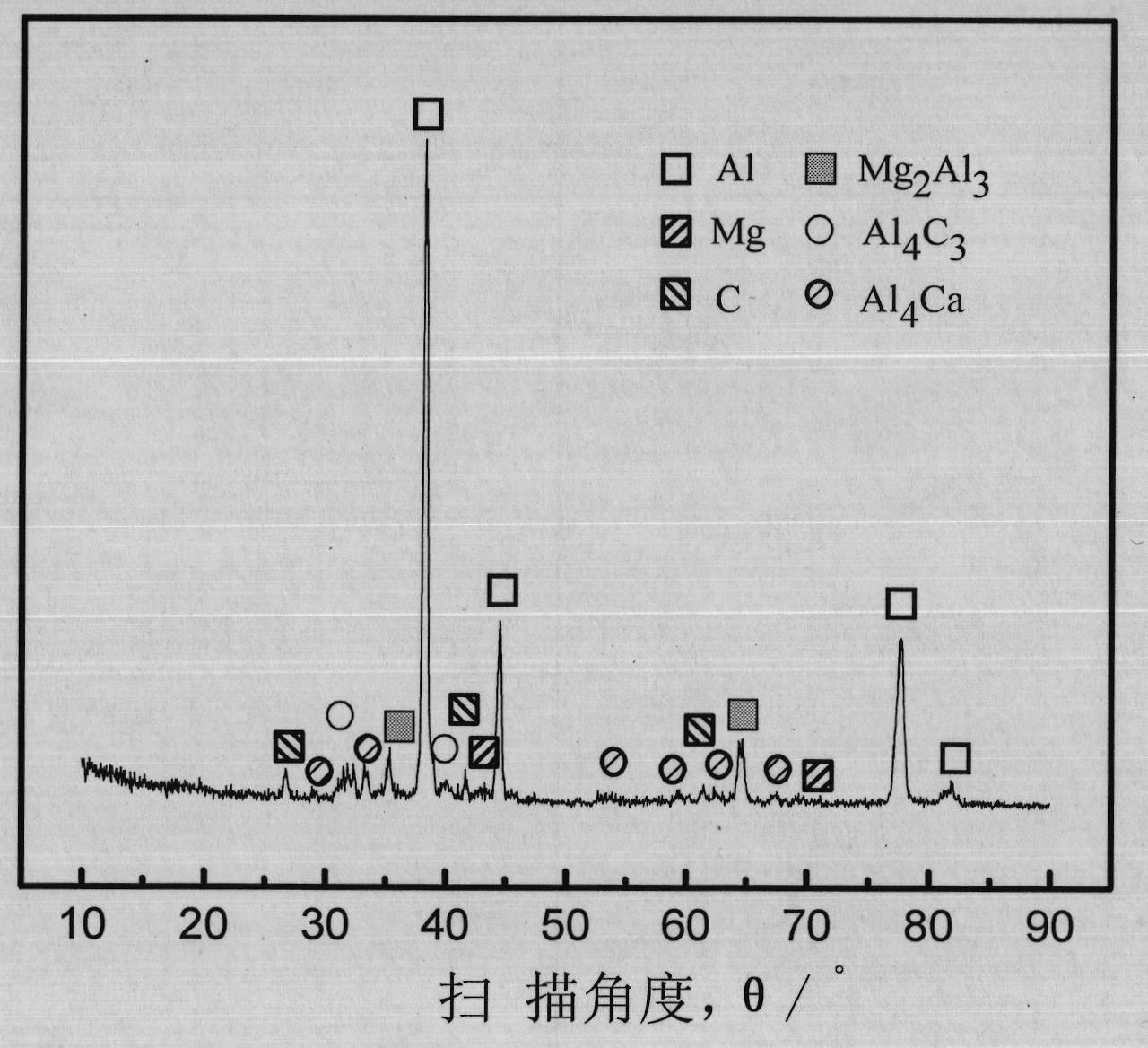

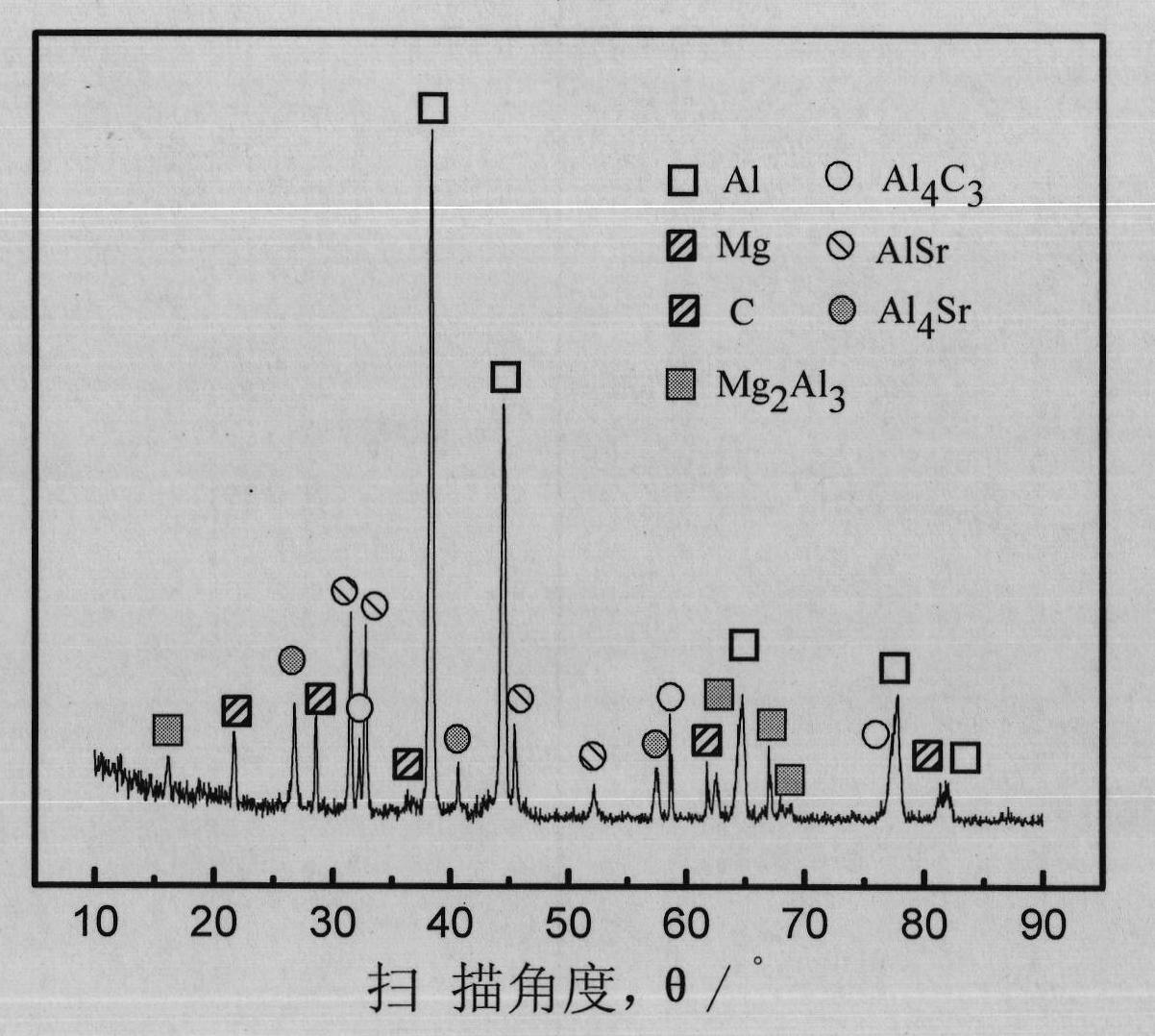

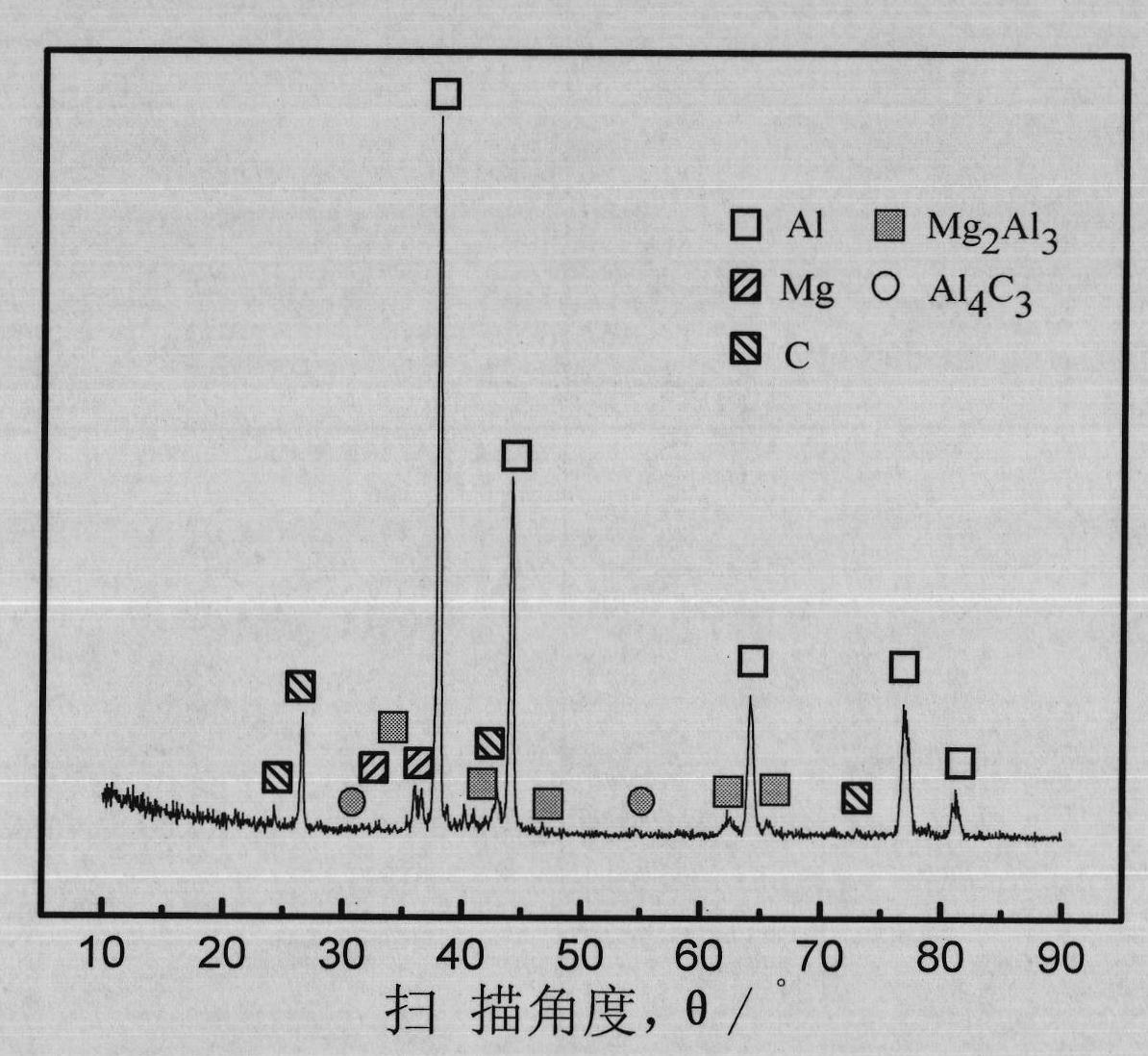

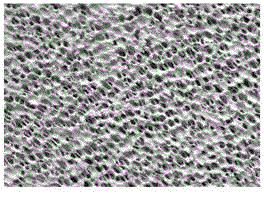

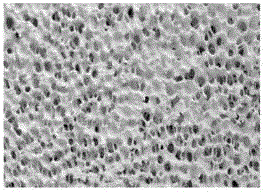

Composite grain finer for Mg-Al alloy and preparation method thereof

The invention discloses a composite grain finer for Mg-Al alloy and a preparation method thereof. The composite finer comprises the following components: 50-60 percent of Al, 1-5 percent of C, 5-10.5 percent of Ca or 5-10.5 percent of Sr, and the balance of Mg. The preparation method comprises the following steps of: melting pure Al under 700-800 DEG C, adding Mg-CA or Mg-Sr intermediate alloy according to the formula, and compensating the insufficient Mg with pure Mg to obtain Al-Mg-Ca or Al-Mg-Sr intermediate alloy melt, cooling the melt to 600-650 DEG C, uniformly dispersing graphite powder into the melt by using a semi-solid stirring method, and casting to obtain the composite grain finer. The finer has the advantages of simple preparation method, easy batch production, easy control of the addition amount, no discharge of pollutant and particularly remarkable fining effect for the Mg-Al alloy with low Al content.

Owner:SOUTH CHINA UNIV OF TECH

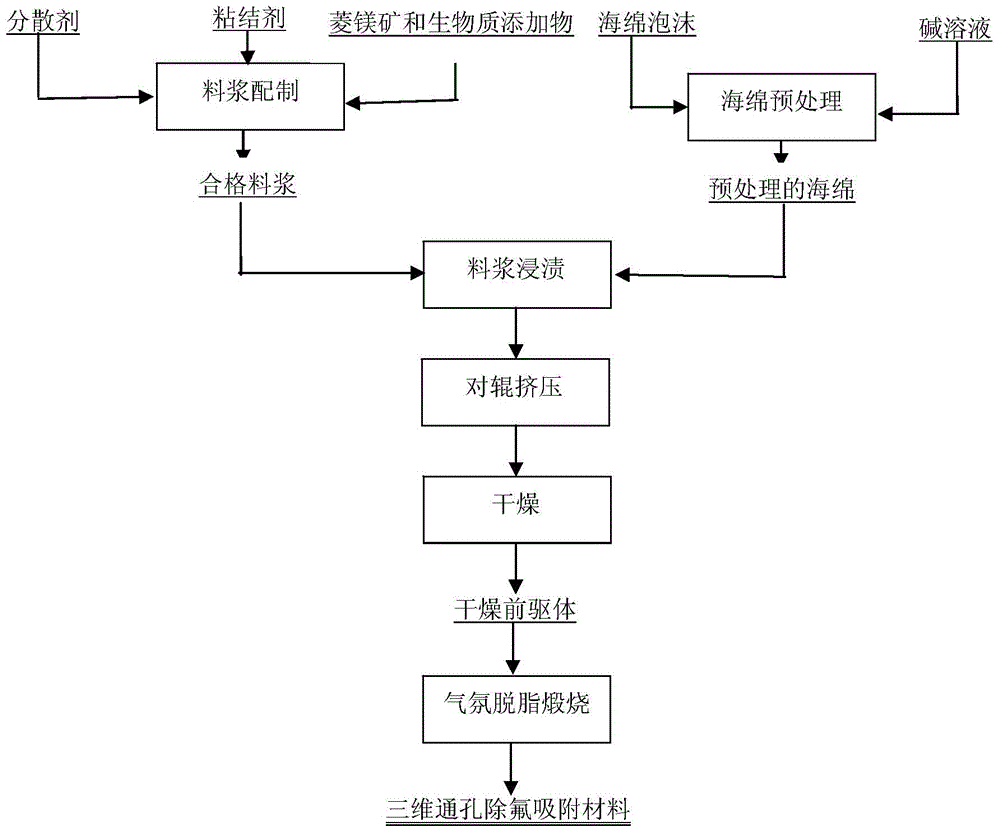

Preparation method of defluorination and adsorption material by taking magnesite as raw material

InactiveCN104874368ALarge specific surface areaOvercome the disadvantage of easy to produce large bed resistanceOther chemical processesWater contaminantsAdditive ingredientSlurry

The invention provides a method for preparing a defluorination material with a three-dimensional through hole structure by taking magnesite as a raw material. The method comprises the following steps: mixing ground and sieved natural magnesite and a biomass additive at a certain ratio, and uniformly dispersing a solution containing a binding agent to form slurry; filling the slurry into through hole polyurethane sponge foams; and rolling, molding, drying, degreasing and calcining to obtain a defluorination adsorption material with the three-dimensional through hole structure. The defluorination adsorption material keeps a honeycomb pore structure of the polyurethane sponge foams, and a plurality of micro-pores, which are remained by volatilizing organic matters including the binding agent, polyurethane sponge and the like, are formed in the surface, so that the specific surface area is large. Furthermore, the material sufficiently utilizes characteristics of magnesium-rich ingredients of natural magnesite; degreasing and active calcining are carried out at the same time; and the adsorption material which takes active magnesium oxide as the main ingredient is obtained and can be widely applied to purification treatment of fluorine-containing sewage. The preparation method of the defluorination adsorption material is simple, the raw material cost and the equipment cost are low, the operation is easy and the industrial large-scale production is easy to realize.

Owner:北京绿洁美科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com