Patents

Literature

1660 results about "Tin dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin(IV) oxide, also known as stannic oxide, is the inorganic compound with the formula SnO₂. The mineral form of SnO₂ is called cassiterite, and this is the main ore of tin. With many other names, this oxide of tin is an important material in tin chemistry. It is a colourless, diamagnetic, amphoteric solid.

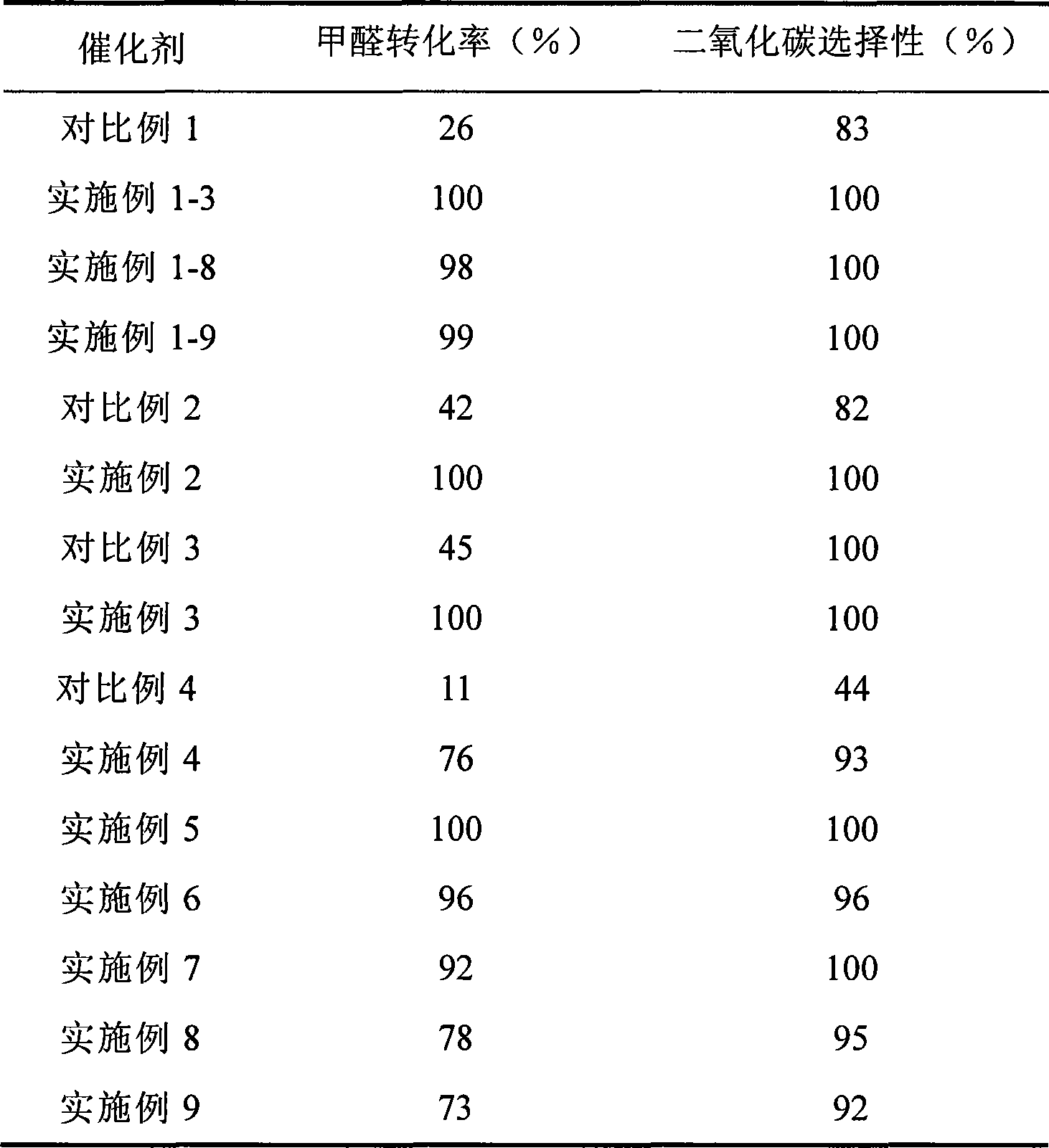

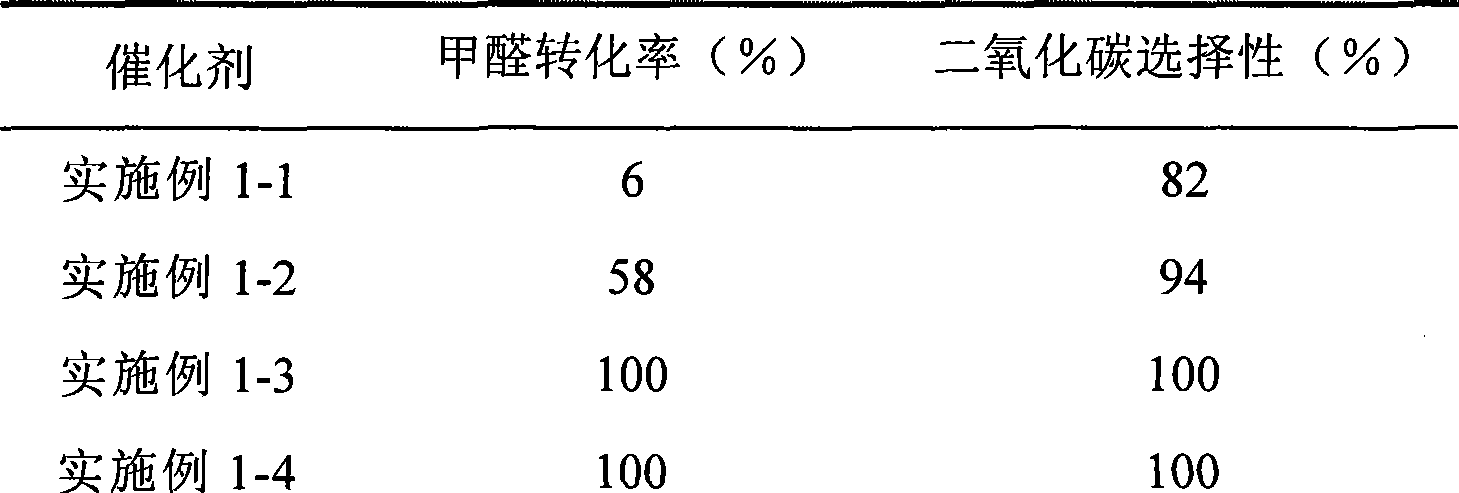

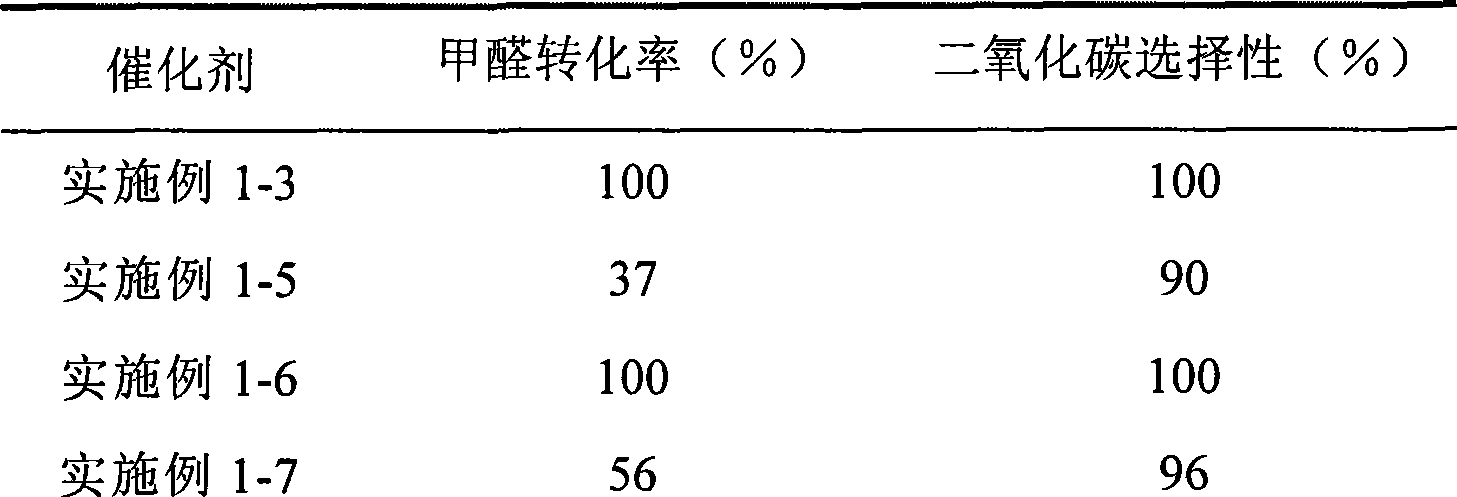

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

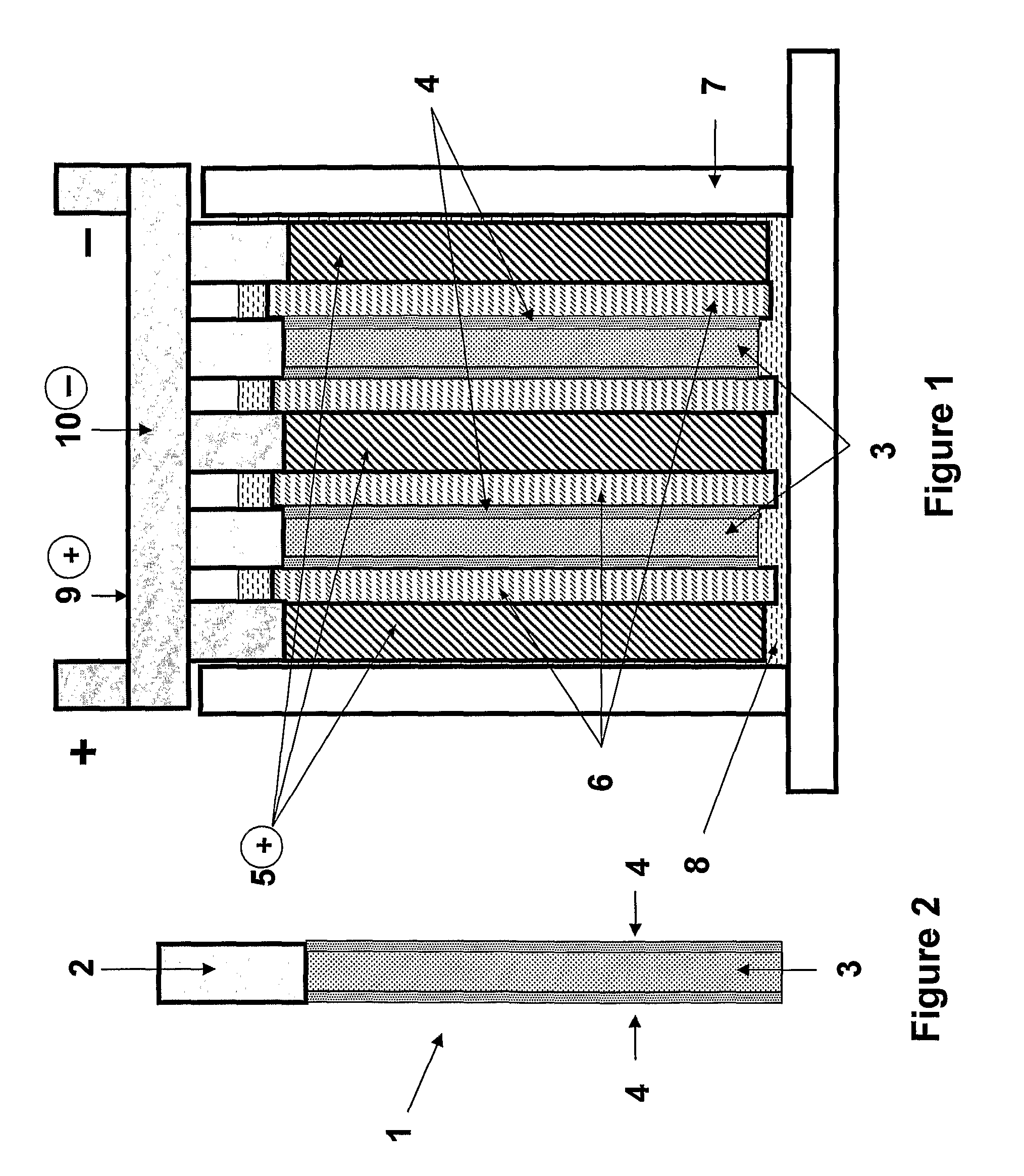

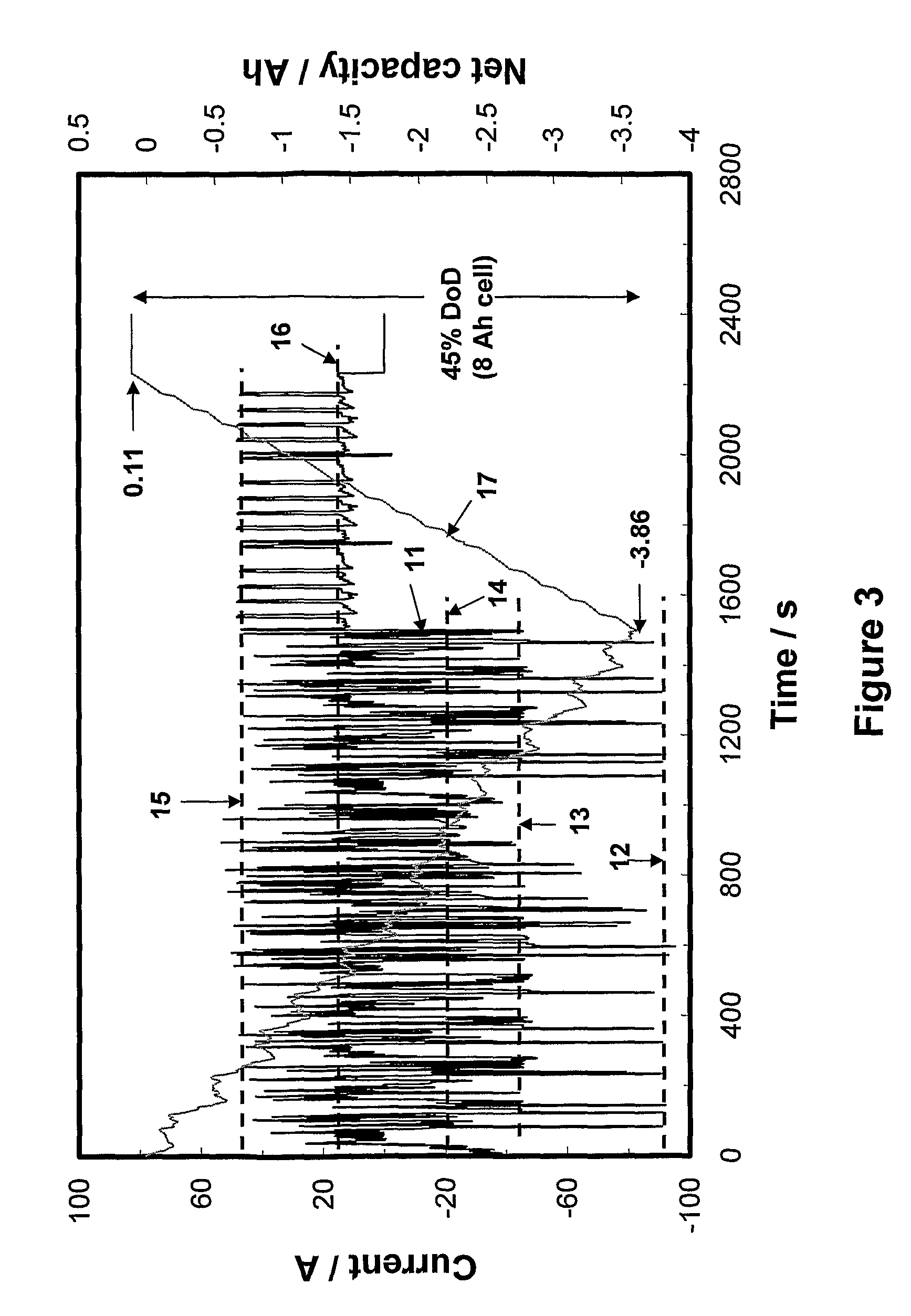

Energy storage device

ActiveUS20100203362A1Reduce heatImprove conductivityLead-acid accumulatorsCapacitor and primary/secondary cellsTin dioxideConductive materials

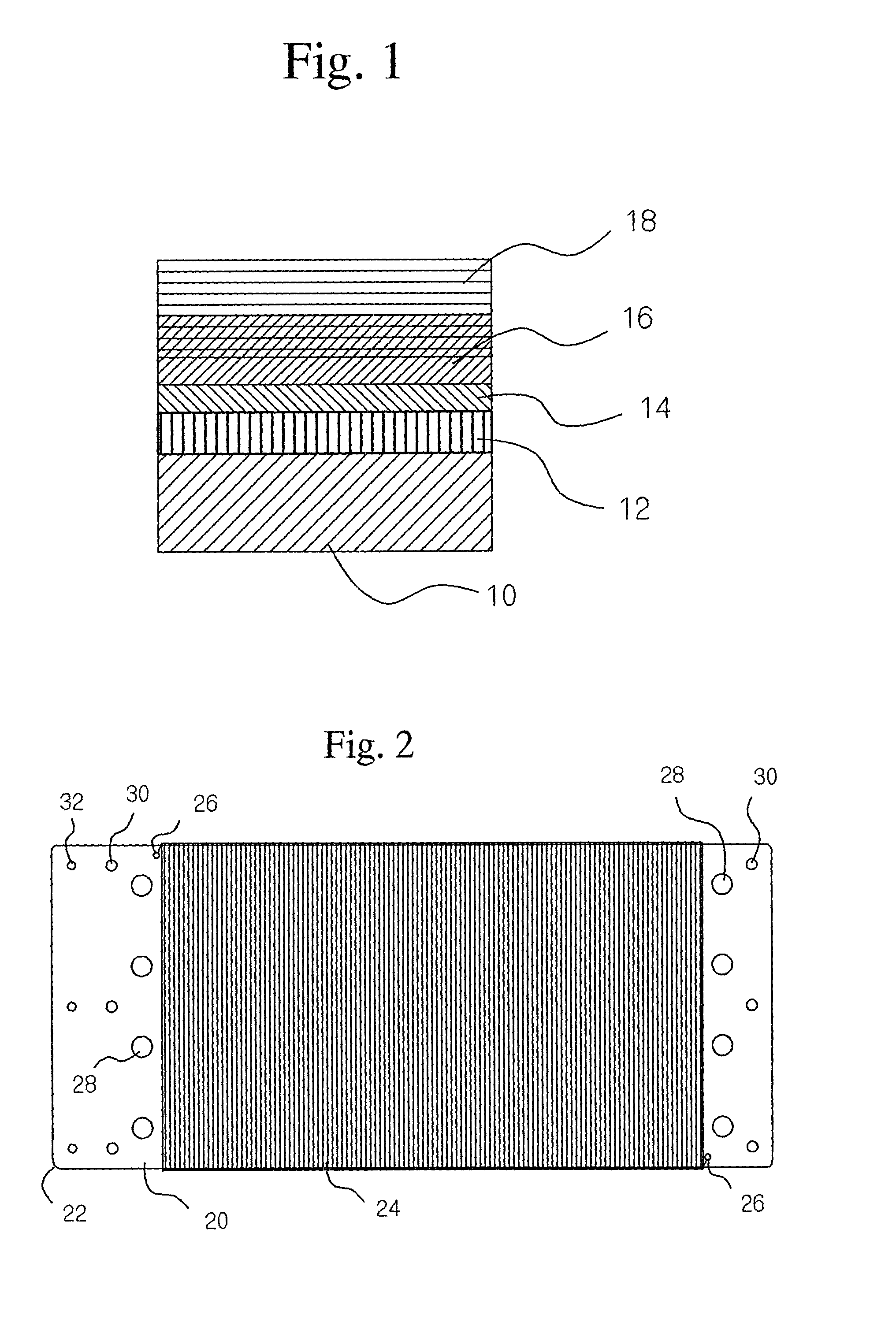

An energy storage device comprising at least one negative electrode, wherein each negative electrode is individually selected from (i) an electrode comprising negative battery electrode material; (ii) an electrode comprising capacitor electrode material; (iii) a mixed electrode comprising either—a mixture of battery and capacitor electrode material or—a region of battery electrode material and a region of capacitor electrode material, or—a combination thereof, and wherein the energy storage device either comprises at least one electrode of type (iii), or comprises at least one electrode of each of types (i) and (ii),—at least one positive electrode, wherein the positive electrode comprises positive battery electrode material and a charging ability-increasing additive, such as one or a mixture of: (a) carbon nanomaterial, vapour grown carbon fibre, fullerene, or a mixture thereof, and (b) tin dioxide conductive materials.

Owner:COMMONWEALTH SCI & IND RES ORG +1

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

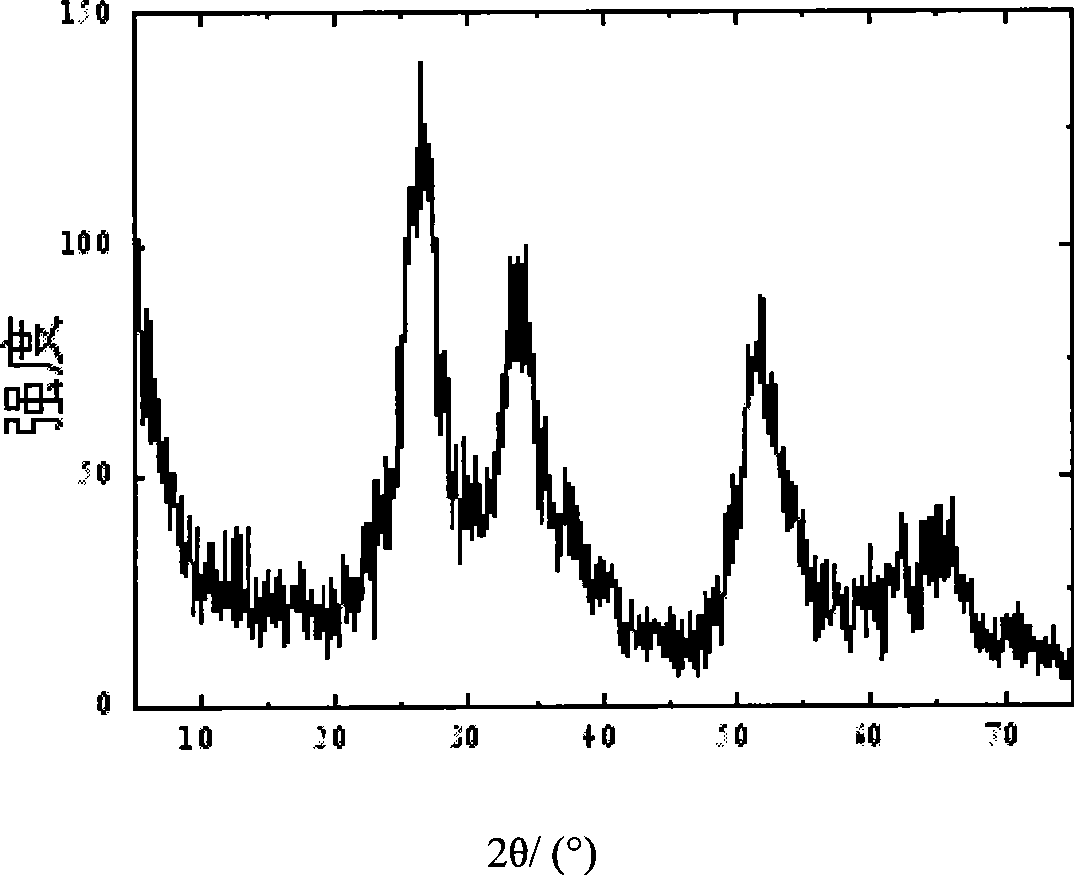

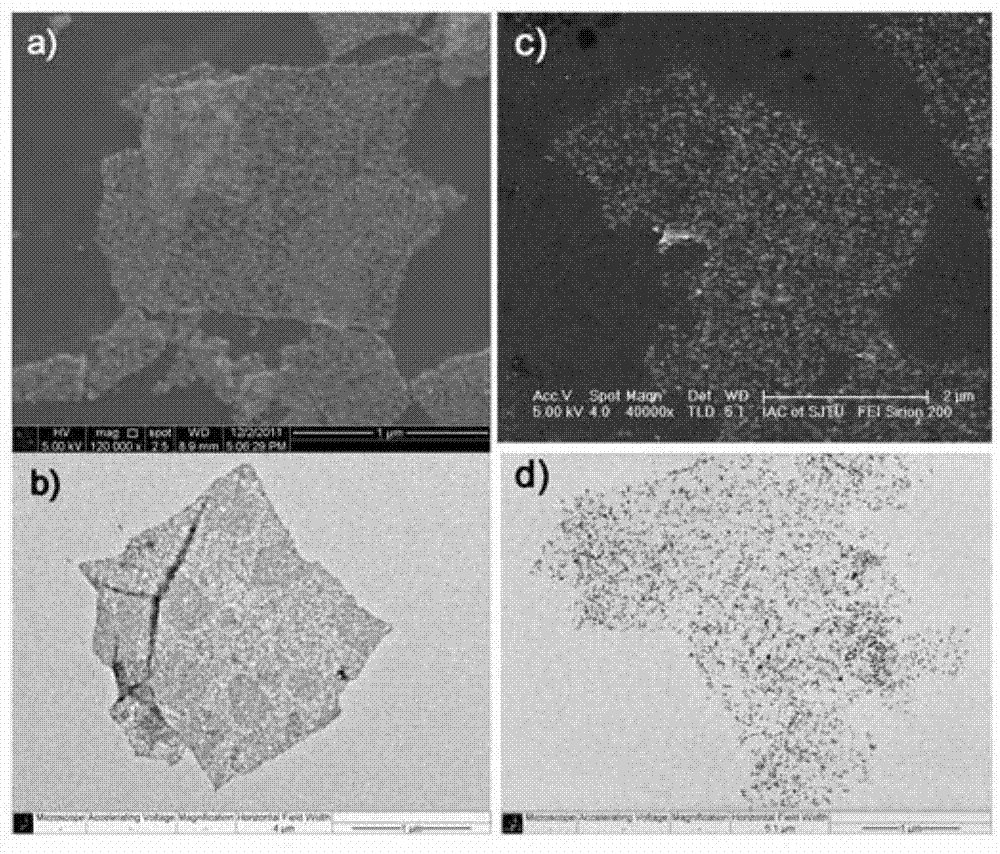

Negative pole material for lithium ionic cell and preparation process thereof

InactiveCN101478043AImprove cycle performanceSimple methodElectrode manufacturing processesTin dioxideLithium

The invention discloses a negative electrode material of a Li-ion battery and a preparation method thereof. The negative electrode material is a load-type negative electrode material, i.e. tin dioxide loaded with grapheme nanometer sheet. The negative electrode material has the advantages of higher electron and ion conductivity, large reaction area, large free expansion space, adaptability to various environments with large charge / discharge rate, and can endow the battery with high cycle performance, high specific capacity and quick charge / discharge capability; and the reversible specific capacity of the battery can be kept at a value larger than 600 mAh.g during charge / discharge with a current of 300 mAh.g. The preparation method of the negative electrode material is simple and feasible and suits industrial production.

Owner:SHANGHAI JIAO TONG UNIV

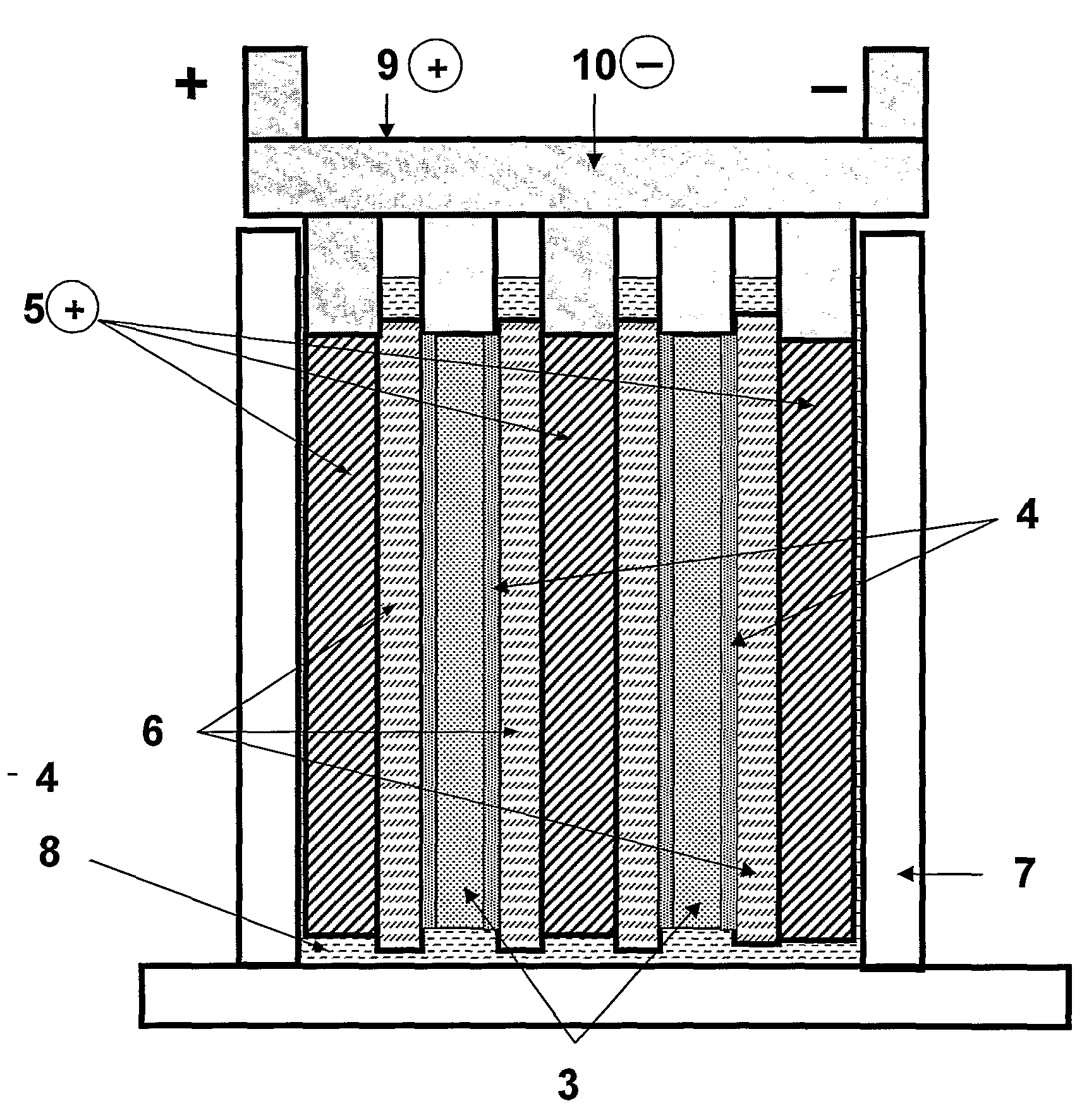

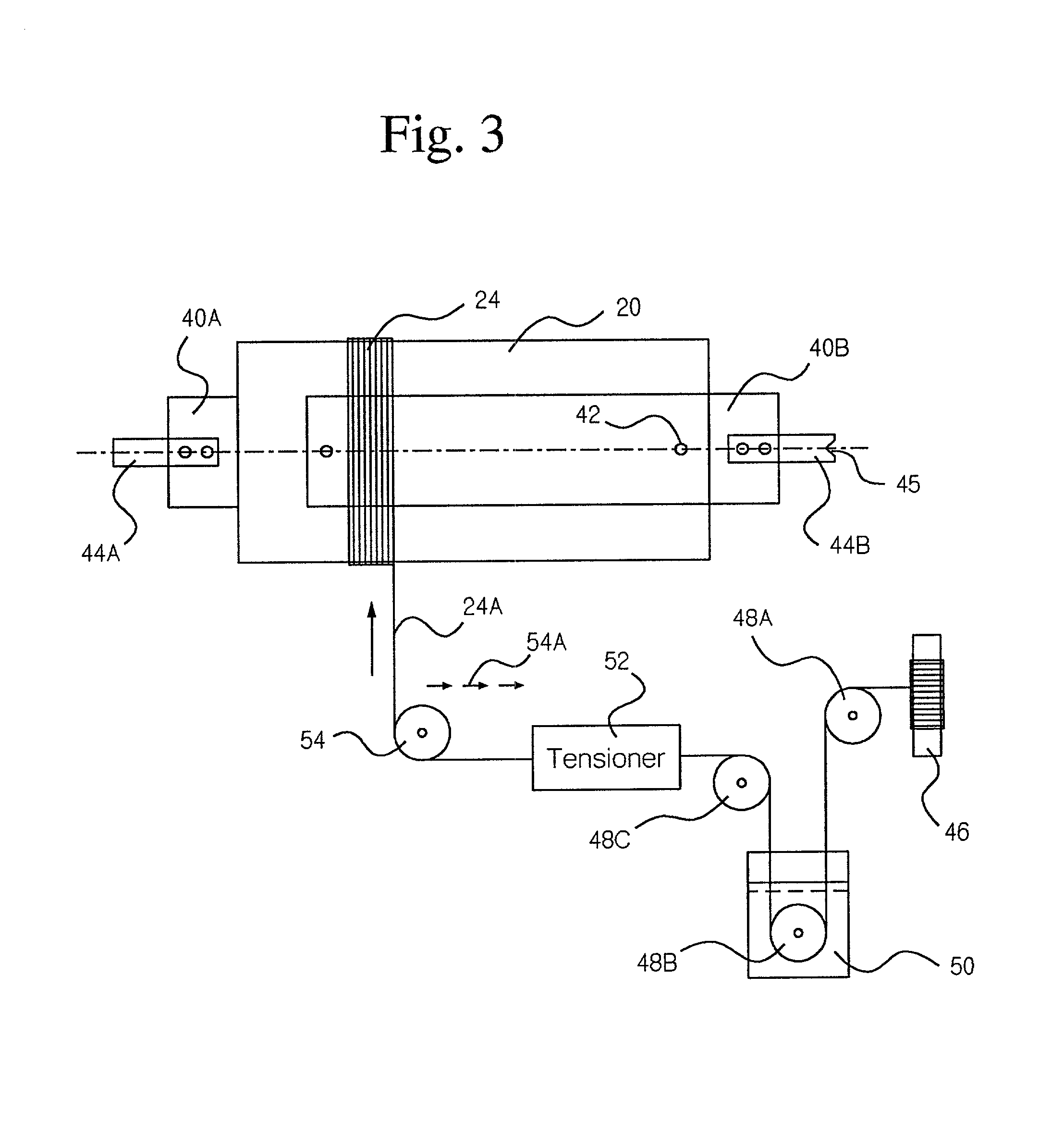

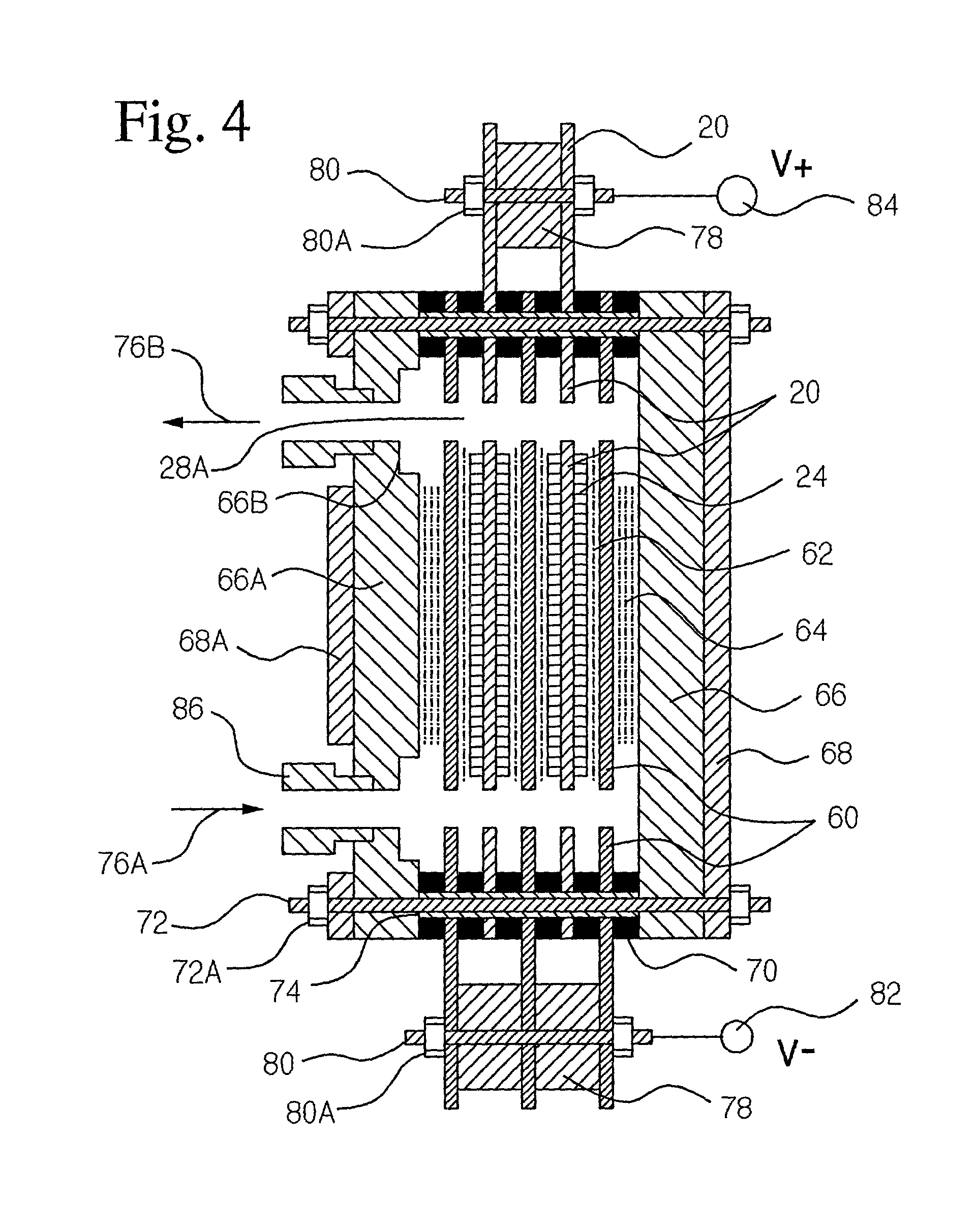

Electrode and electrochemical cell for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

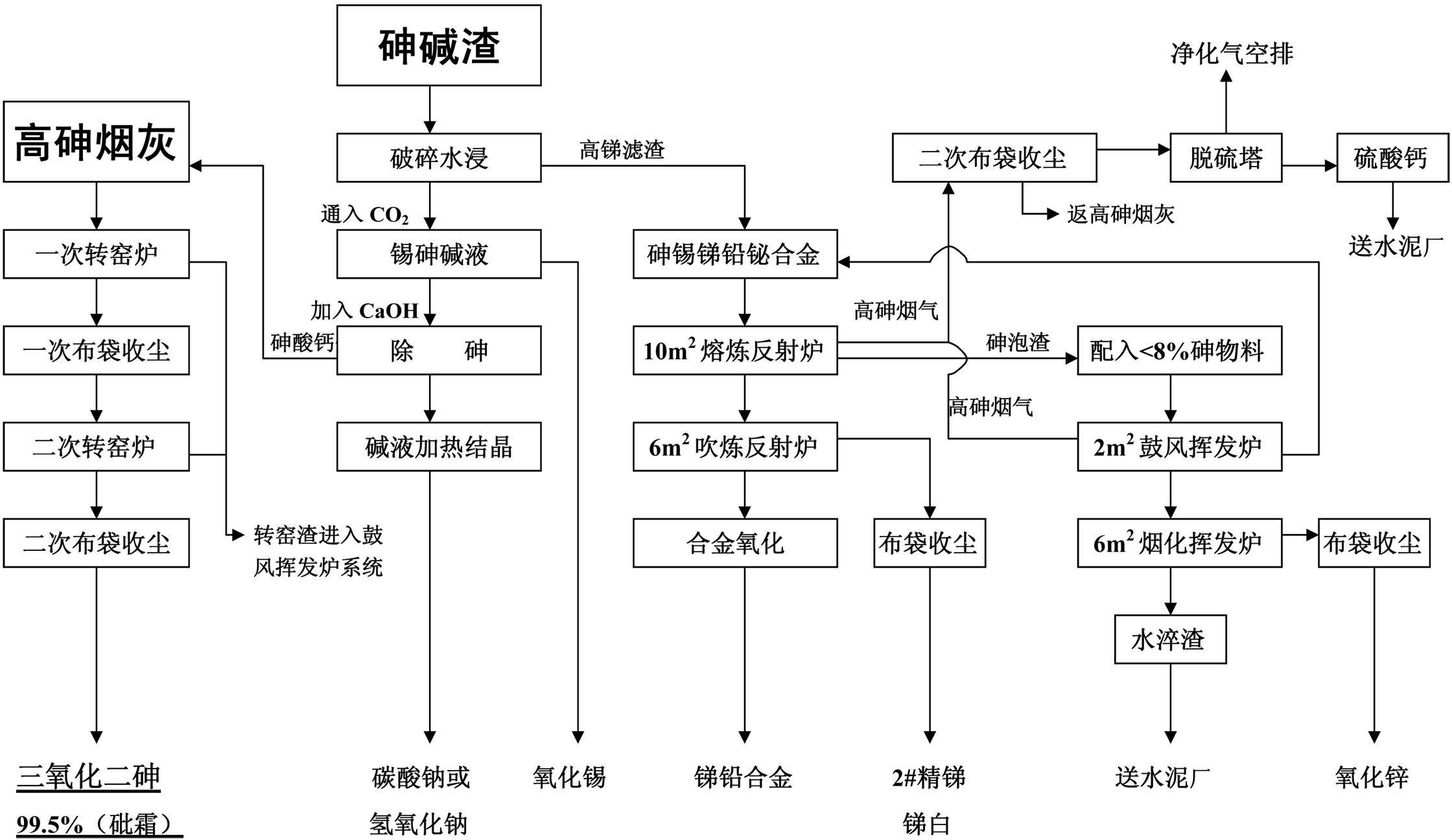

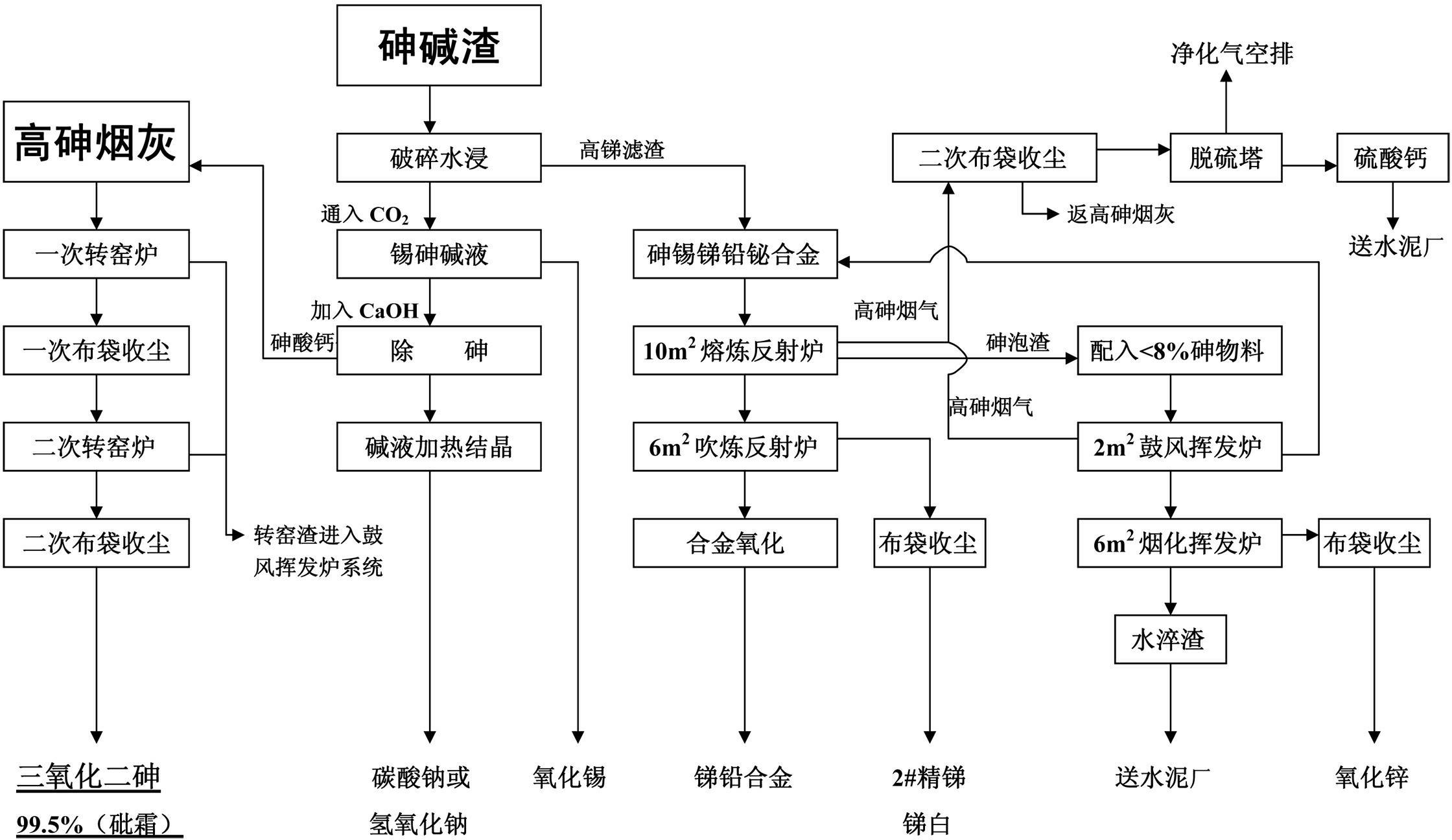

A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

ActiveCN102286665ANo pollutionCement productionProcess efficiency improvementRecovery methodTin dioxide

Disclosed is a comprehensive recovery method for a complex material containing arsenic and valuable metal slags, comprising passing the materials containing arsenic through a primary rotating kiln to volatilize the arsenic, and through a secondary rotating kiln to purify the arsenic, so that an arsenic product containing 99.5% As 2 O 3 is produced; reduction smelting slags from the primary and secondary rotating kilns in a blowing volatilization furnace, with the resultant highly arsenious dust being returned to the primary rotating kiln for treatment, and the slags being used as a raw material in a cement manufactory and a raw material for zinc after undergoing strongly reductive dearsenization and volatilization of zinc in a fuming furnace; the resultant alloy containing arsenic being subjected to basic oxidizing refinement, and the oxidized / refined alloy after dearsenizations containing Pb > 72%, Sb > 12%, As 2 O 3 <0.02%, being sold as a lead-antimony alloy; the basic slags from the refinement, containing As 2 O 3 10%-20%, being subjected to crushing, dissolution in base, and filtration, with the slags thereof being returned to a blowing volatilization furnace for treatment; precipitating tin from the basic solution containing tin and arsenic by blowing in CO 2 , with the filtered tin oxide being sold as a raw material for tin; adding Ca(OH) 2 into the basic filtrate containing arsenic to precipitate arsenic, returning the filtered slags of calcium arsenate to the primary rotating kiln for treatment, and evaporating the remaining basic solution to concentrate and recover the base.

Owner:LEIYANG YANXIN NON FERROUS METALS

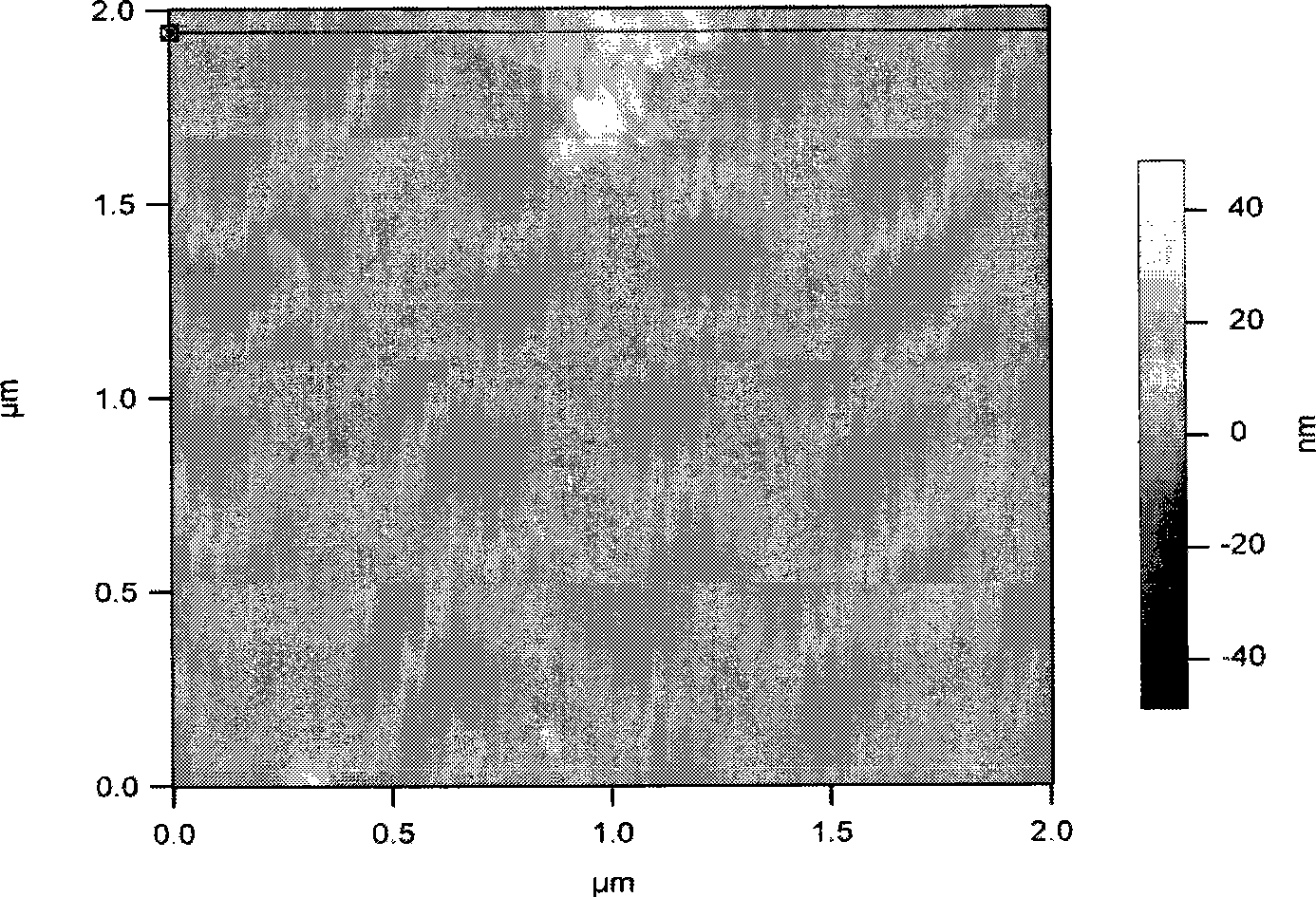

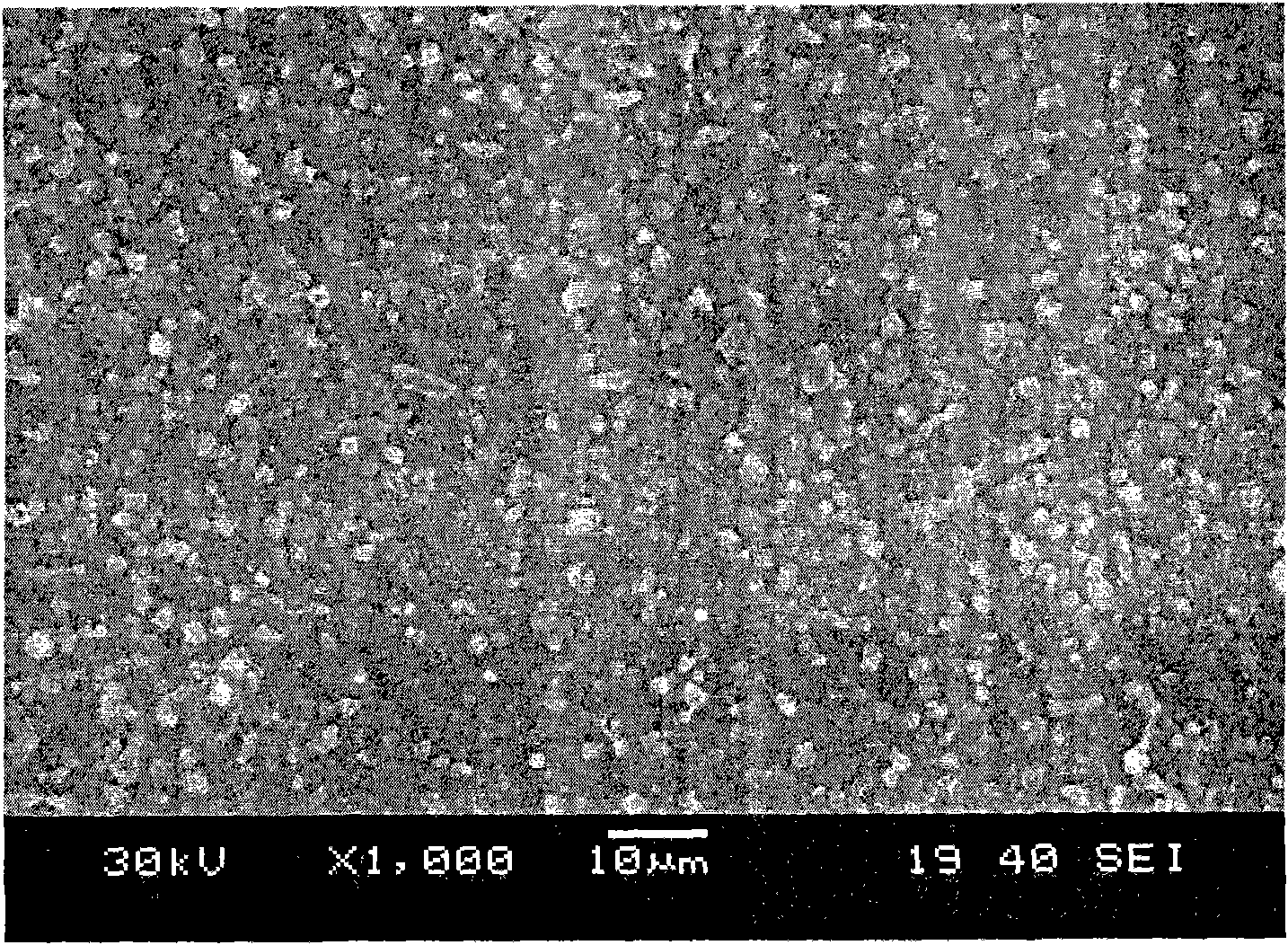

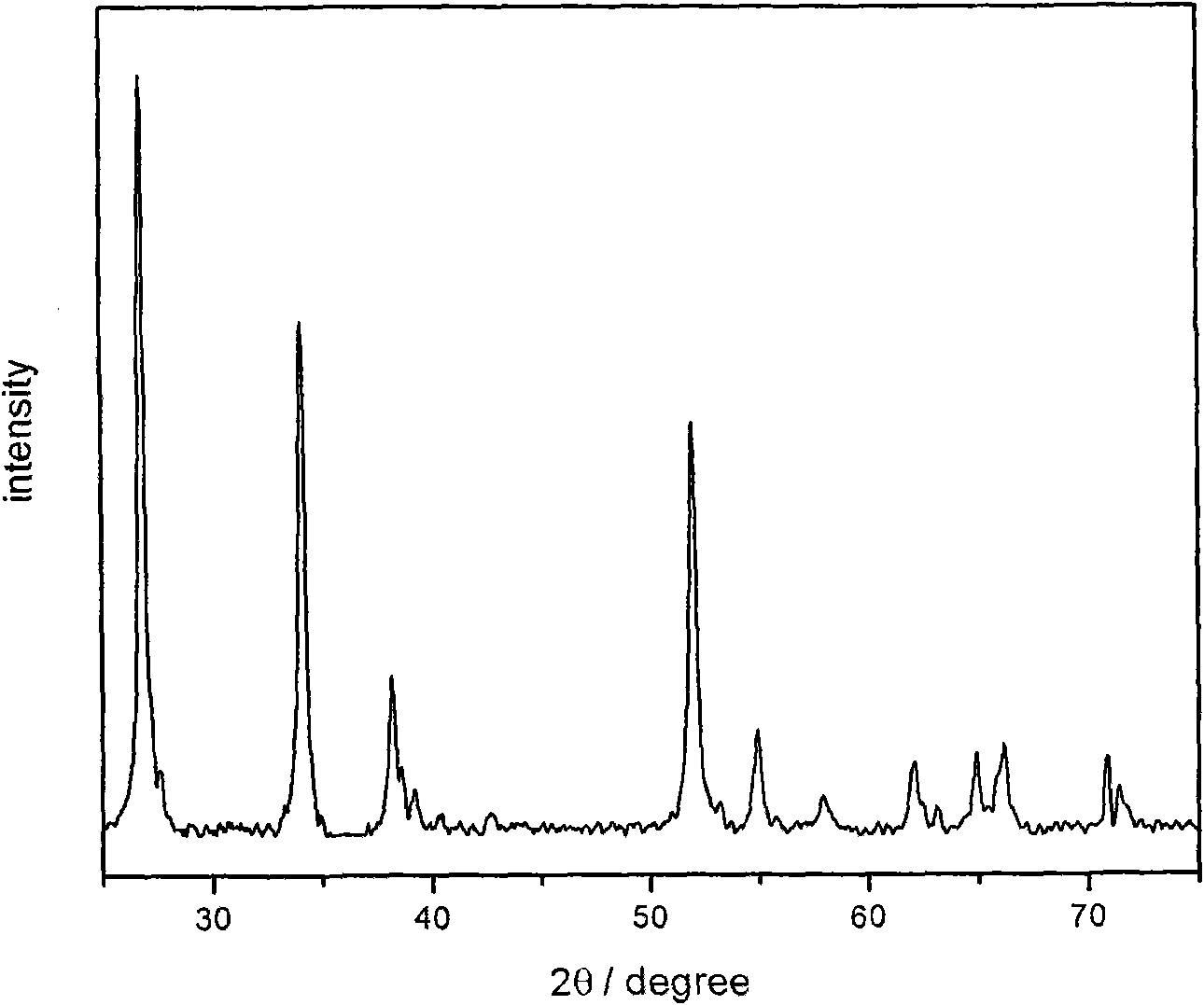

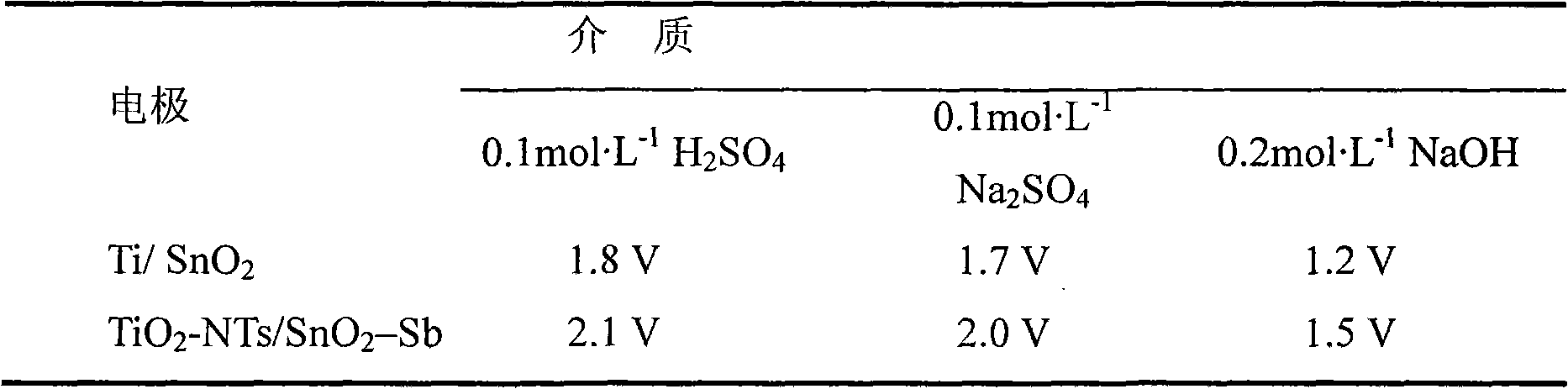

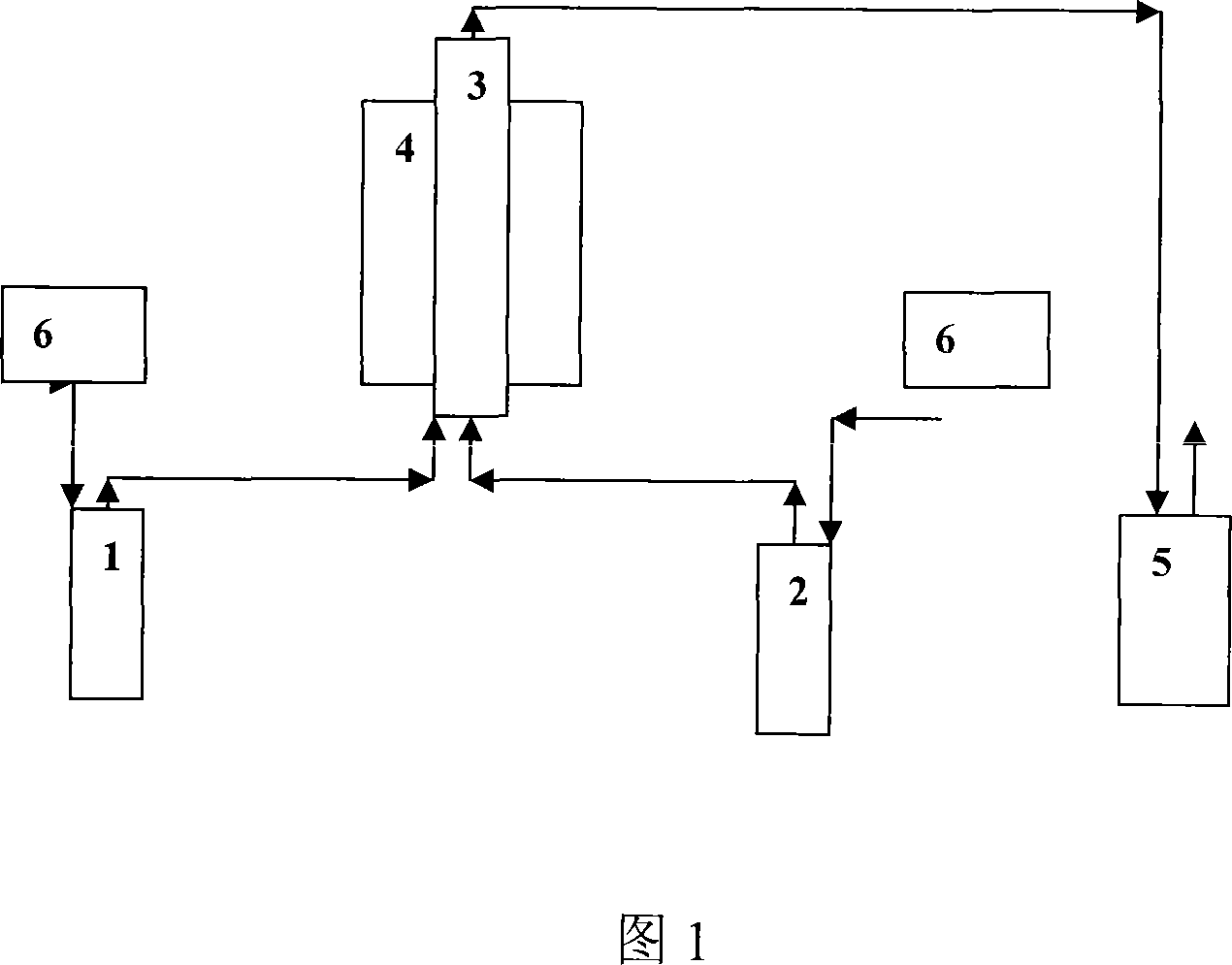

Preparation method of titanium-based titanium dioxide nanotube stannic oxide electrode

ActiveCN101857288AOrderly rowsHigh specific surface areaWater/sewage treatmentAnodic oxidationTin dioxide

The invention relates to a preparation method of a titanium-based titanium dioxide nanotube stannic oxide electrode, belonging to the technical field of electro-catalysis electrode preparation. The method comprises the following steps: firstly adopting an anodic oxidation method to prepare a titanium dioxide nanotube on a titanium matrix, thus improving the specific surface area of the titanium matrix; and depositing stibium and tin in the titanium dioxide nanotube by an electro-deposition method successively, and performing thermal oxidation to lead the stibium doped stannic oxide to be bonded firmly with the titanium dioxide nanotubes directly connected with the titanium matrix. The stannic oxide crystal particles prepared by the electro-deposition method are dispersed evenly, and the electrode surface is compact and has no crack. The method overcomes the defect that crack is generated on the surface of the electrode prepared by the traditional brush coating thermal decomposition method. The electrode prepared by the invention has high potential for oxygen evolution, high electric catalytic activity and long service life and the like; the preparation process is easily controlled, has low cost and lower equipment requirements; and the prepared electrode can effectively treat pollutants that are poorly biodegradable.

Owner:NANJING UNIV OF SCI & TECH

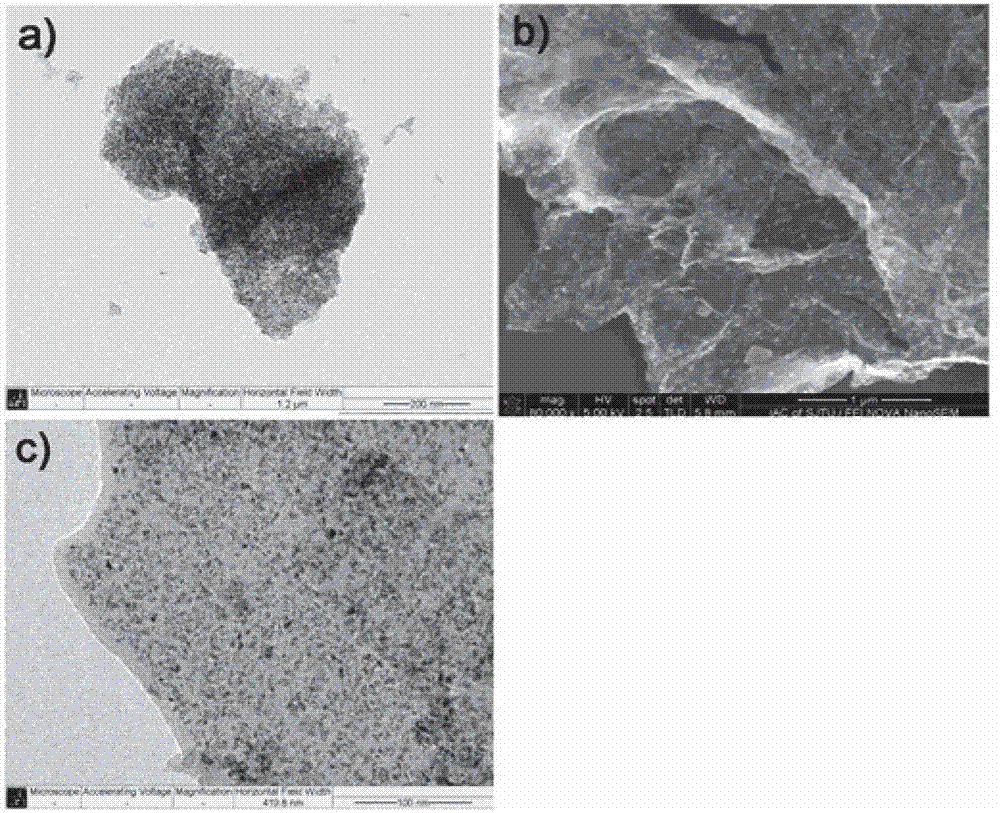

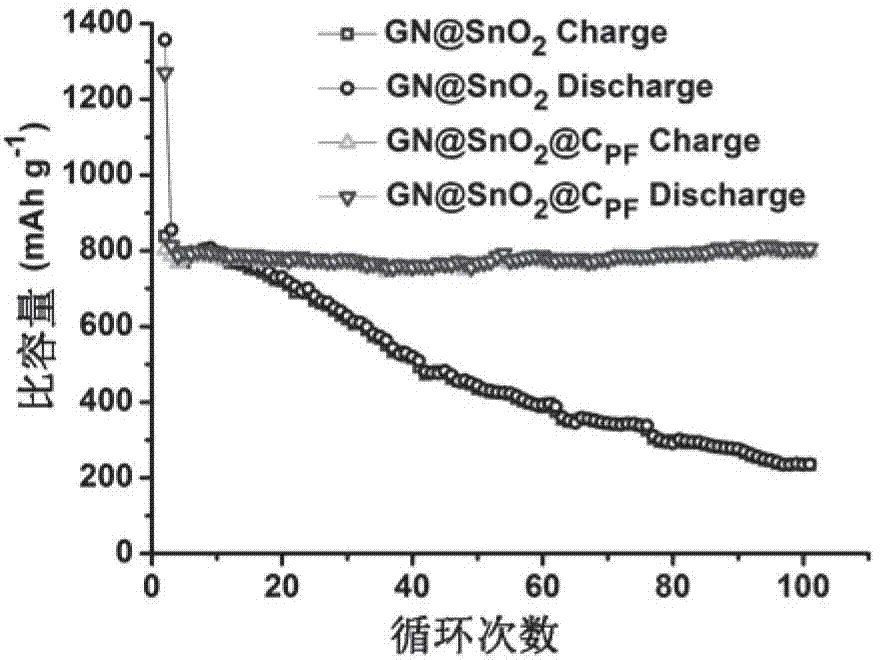

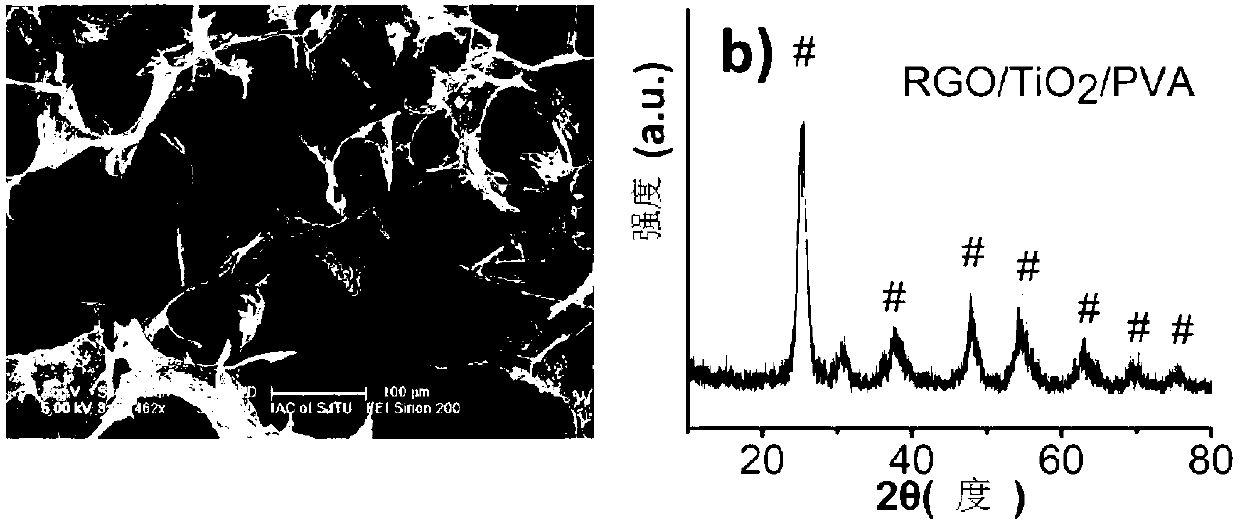

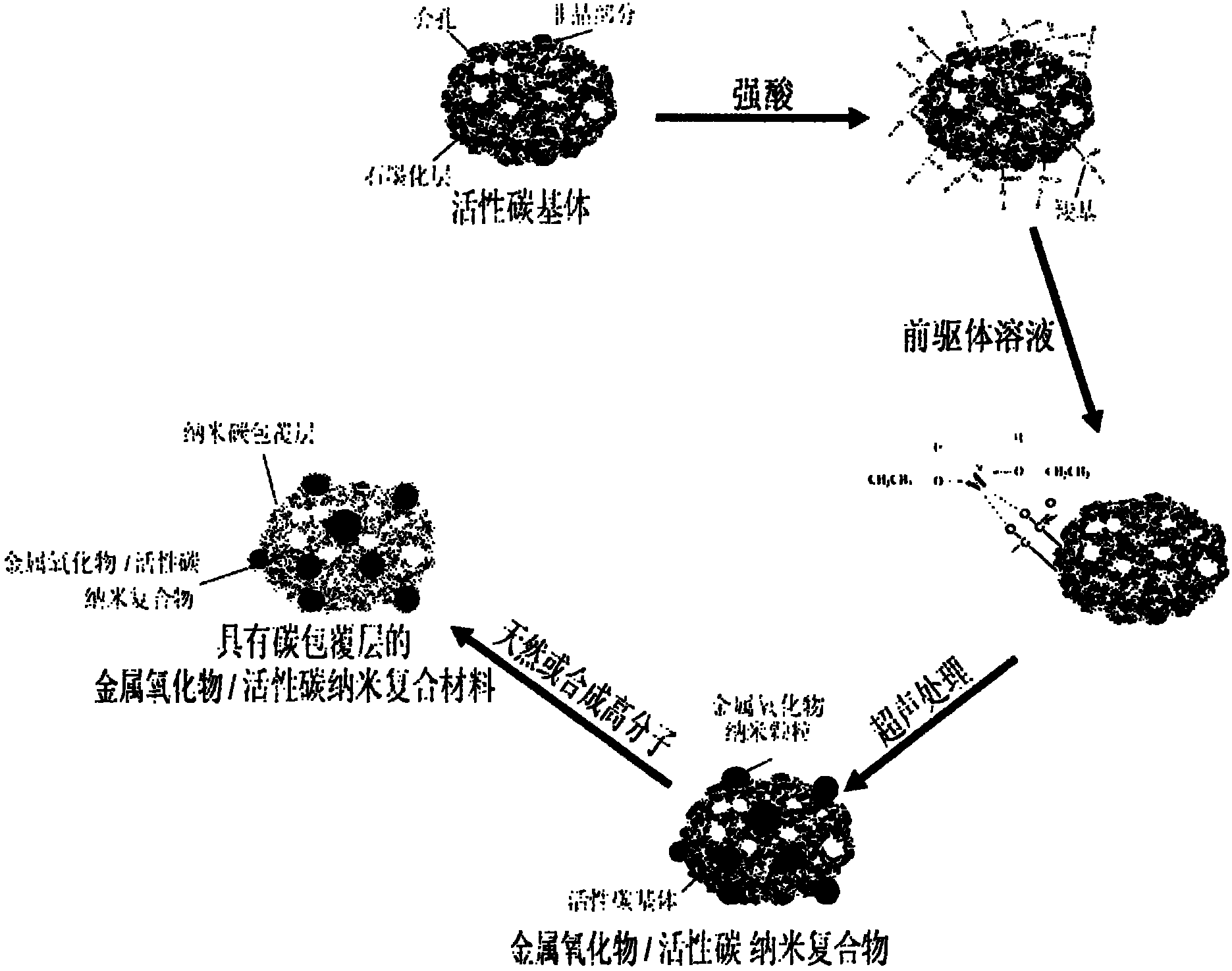

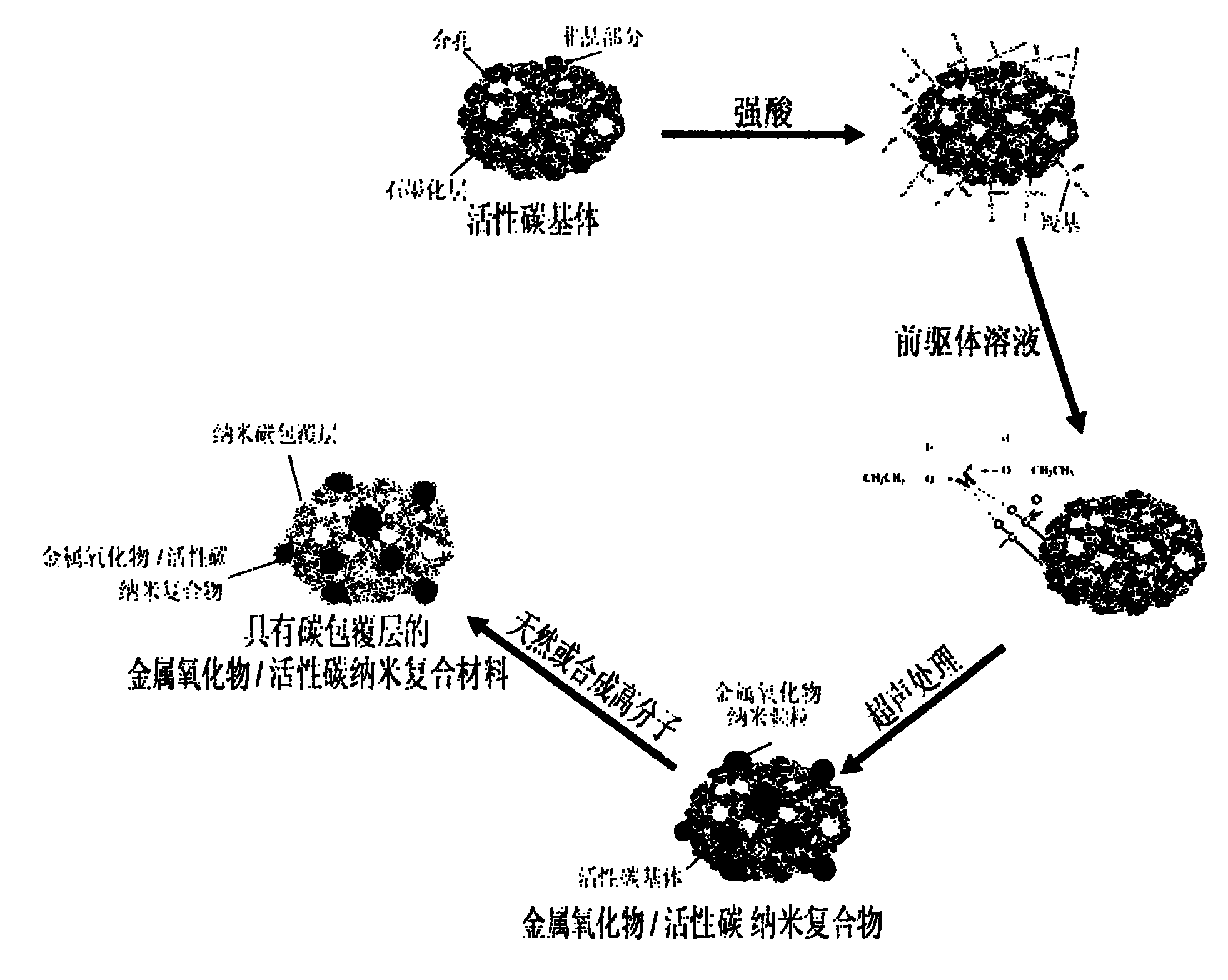

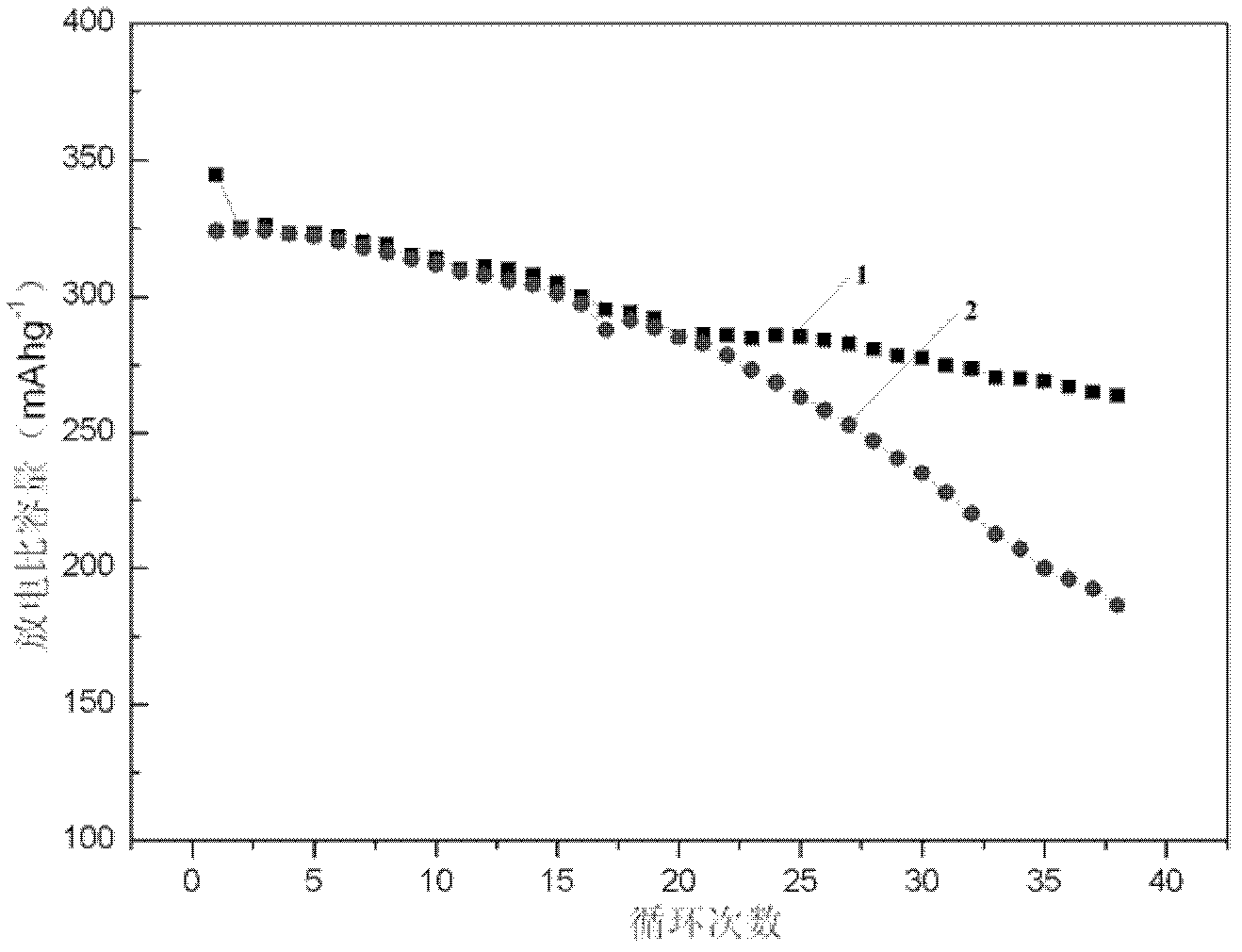

Preparation method and application of carbon-coated grapheme-based metal oxide composite

InactiveCN102881898AImprove cycle stabilityExcellent rate performanceCell electrodesTin dioxideMetal oxide nanoparticles

The invention discloses a preparation method and application of a carbon-coated grapheme-based metal oxide composite in a two-dimensional core-shell structure. The carbon-coated grapheme-based metal oxide composite in the two-dimensional core-shell structure is prepared by taking the two-dimensional grapheme in a single-layer carbon atom structure as a carrier and the phenolic resin or polysaccharide as the carbon source precursor. The metal oxide nanoparticles obtained by the method are uniformly loaded on a graphene sheet and well coated in the carbon-coated layer. The preparation method has the advantages of simple process, mild condition and low cost. The Electrochemical tests prove that the carbon-coated grapheme-based metal oxide composite in the two-dimensional core-shell structure has excellent cycle stability and rate properties. The experiments prove that: under the charge and discharge current of 200mAhg<-1>, the tin dioxide material has the discharge capacity of 200mAhg<-1>, and the ferroferric oxide material has the discharge capacity of 930mAhg<-1>. Therefore, better experimental data and theoretical support are provided for the research and the application of the metal oxide in the field of electrochemistry.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of self-cleaning ceramic nanometer glass antireflective coating material and preparation method of reflection deducting coating

InactiveCN102061111AWith self-cleaning effectHas surface antistatic propertiesCoatingsWater basedTin dioxide

The invention discloses a preparation method of a self-cleaning ceramic nanometer glass antireflective coating material and a coating preparing technique thereof. The reflection deducting coating is formed by coating a composite of amorphous porous silicon dioxide and one or a plurality of titanium dioxide, zirconium dioxide, tin dioxide, ceria, yttria, and the like on the surface of photovaltic glass or common float glass, the reflection deducting coating coated on the surface of the glass has the characteristics of self-cleaning effect, high ceramic hardness and wear resistance. surface antistatic property of dust protection, aging resistance and zero-decrement, can be used for 25 years; and within 250nm-2500nm, the degree of transparency of the photovoltaic glass coated with the reflection deducting coating can be improved by 2.5%-3.5%, and the degree of transparency of the common glass coated with the reflection deducting coating can be improved by 2.8%-3.8%. The nanometer antireflective coating material provided by the invention is a water-based paint, the three wastes are not generated in the preparing course, the preparation method is simple, and the cost is low; and the coating preparing technical process is low in requirement and simple and easy to operate, the energy is saved, thereby being suitable for industrial production in large scale.

Owner:中山市旌旗纳米材料科技有限公司

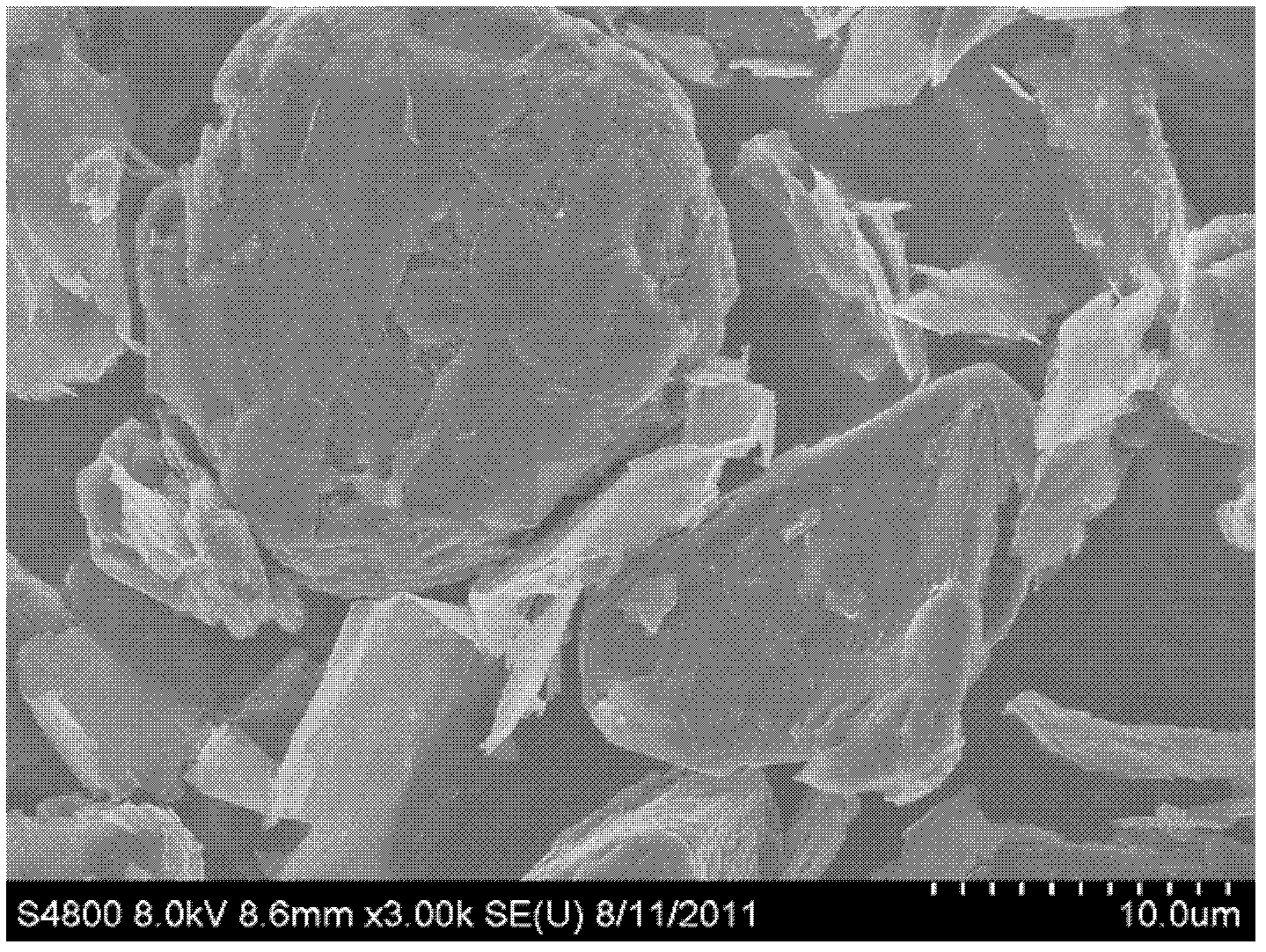

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

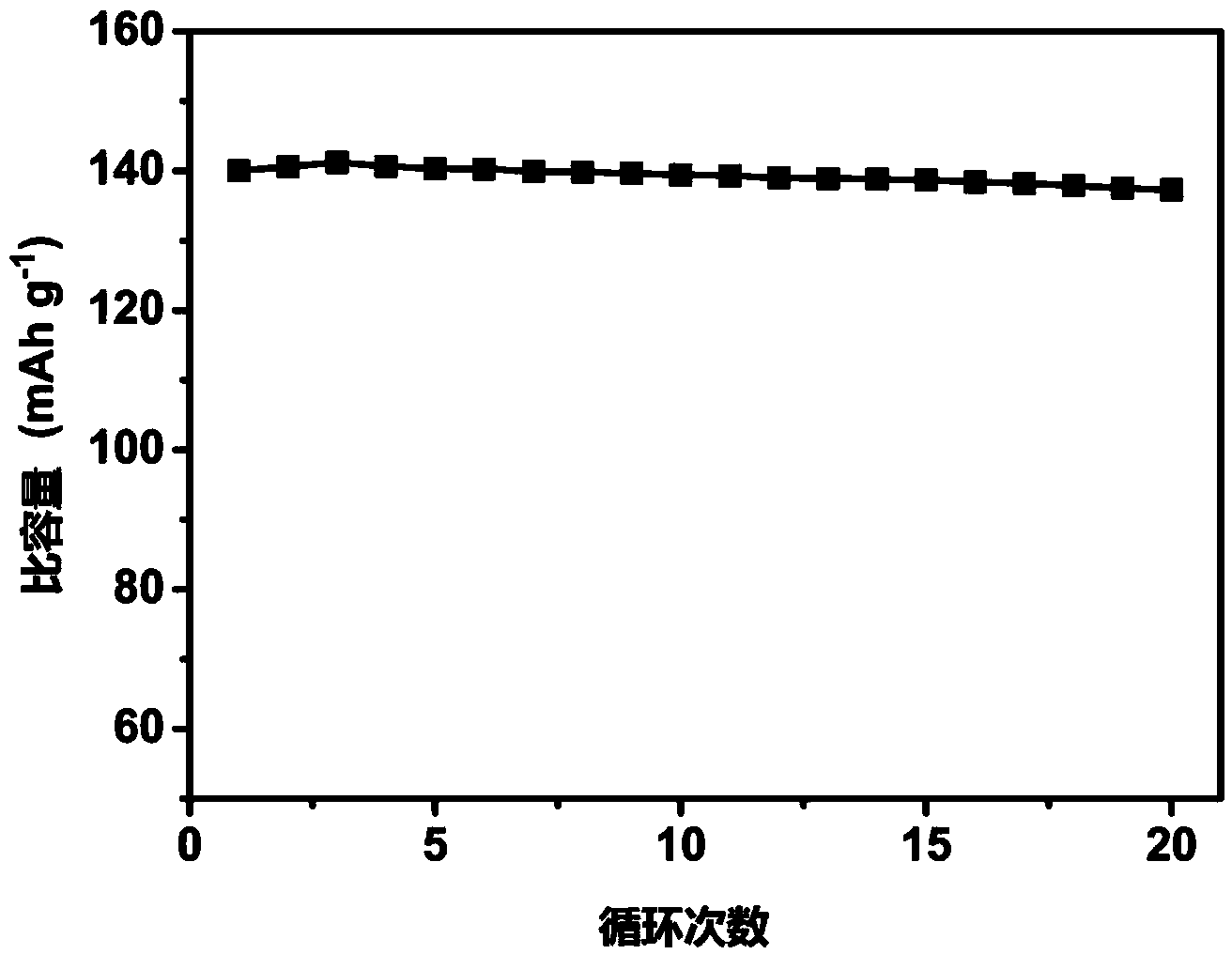

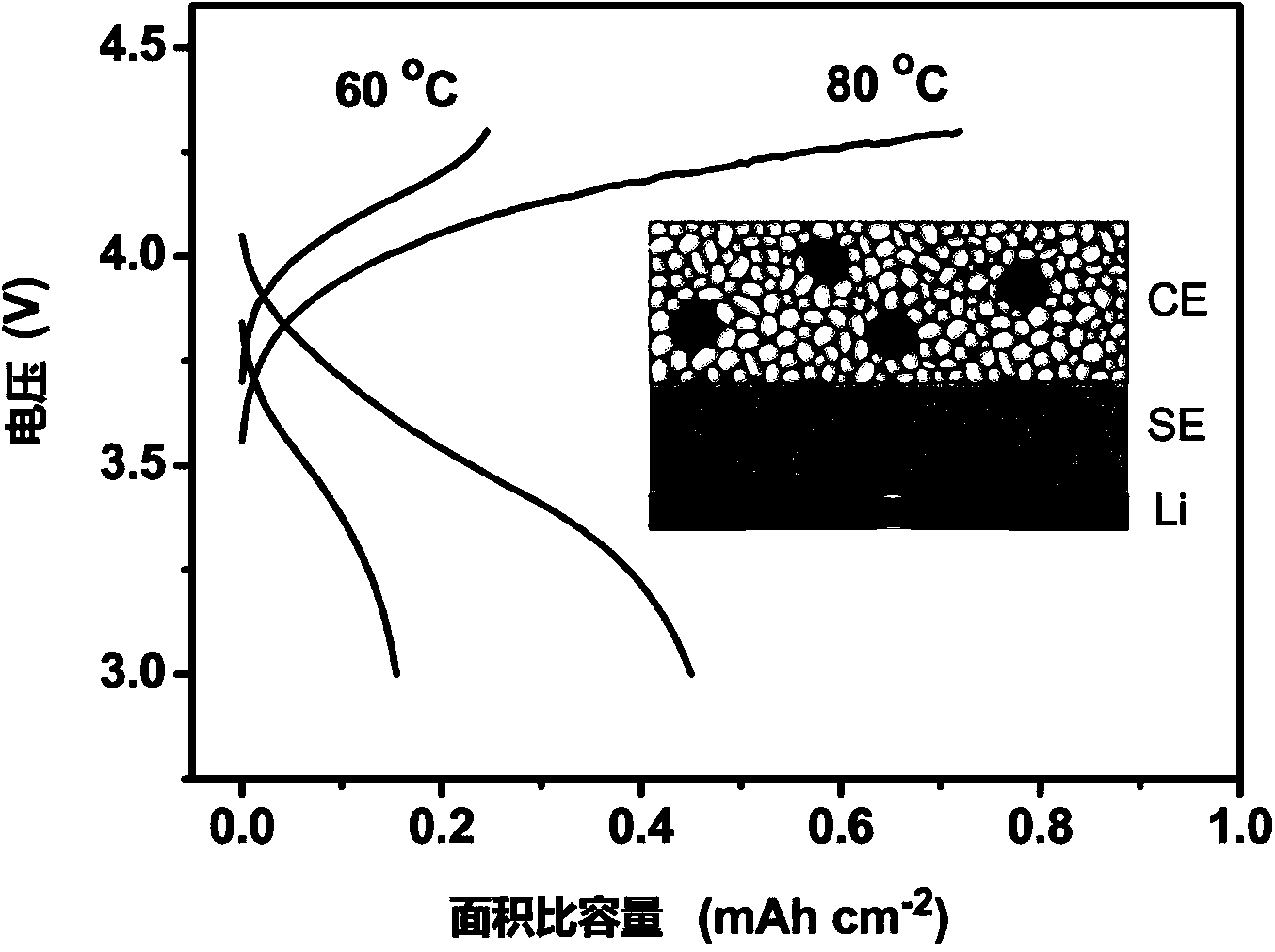

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

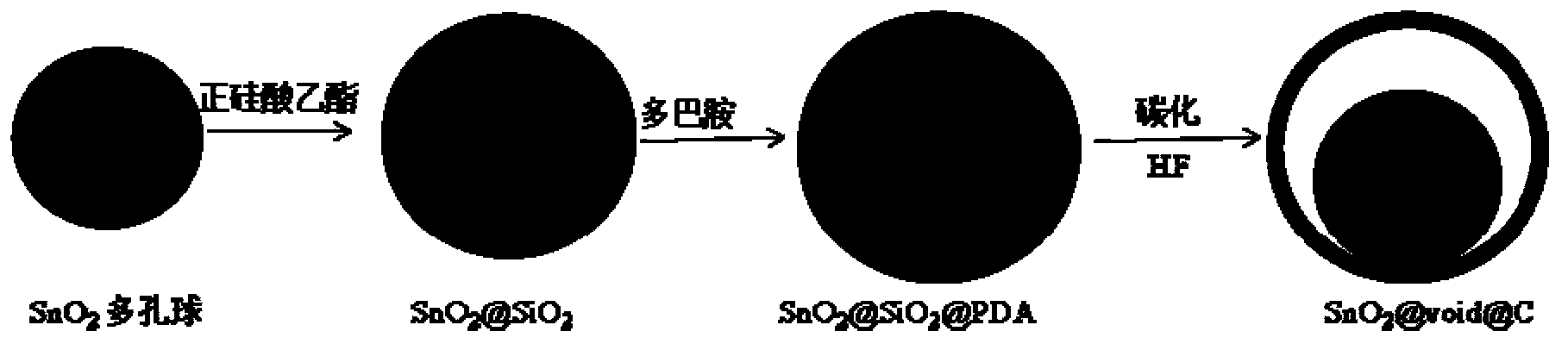

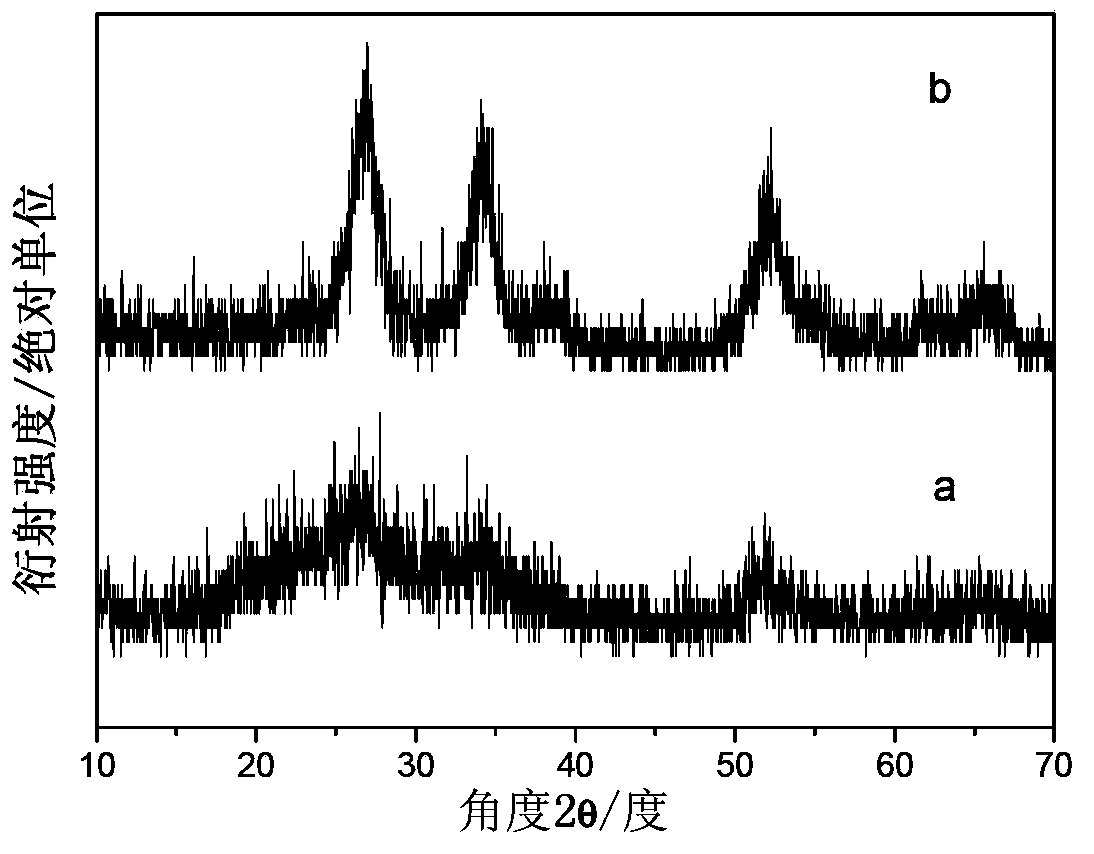

Yolk-shell structure tin dioxide-nitrogen-doped carbon material and preparation method thereof

ActiveCN103367719AImprove conductivityImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesTin dioxideYolk

The invention relates to a yolk-shell structure tin dioxide-nitrogen-doped carbon material and a preparation method thereof, belonging to the technical field of lithium ion battery electrode material. The yolk-shell structure SnO2@void@N-C material takes porous submicron tin dioxide SnO2 as a core and has the diameter of 200-400 nanometers; nitrogen-doped carbon (N-C) is taken as a shell, and the thickness of the shell is 15-20 nanometers; a cavity has the inner diameter of 300-500 nanometers; in the N-C shell, the mass percent of N element is 8-12%. The porous SnO2 core shortens the lithium ion diffusion path; the volume change of SnO2 can be effectively buffered by a gap between the SnO2 core and a carbon layer in the charge-discharge process, and the N-C can effectively improve the electrical conductivity of the material, so that the yolk-shell structure tin dioxide-nitrogen-doped carbon material has excellent electrochemical cycle stability. The thickness of the carbon layer can be regulated and controlled by controlling the concentration of dopamine or the auto-agglutination time, and the size of the gap can be regulated and controlled by controlling the quantity of tetraethoxysilane; the preparation method can well control the structure of the material, and is simple in technology and convenient to operate.

Owner:BEIJING UNIV OF CHEM TECH

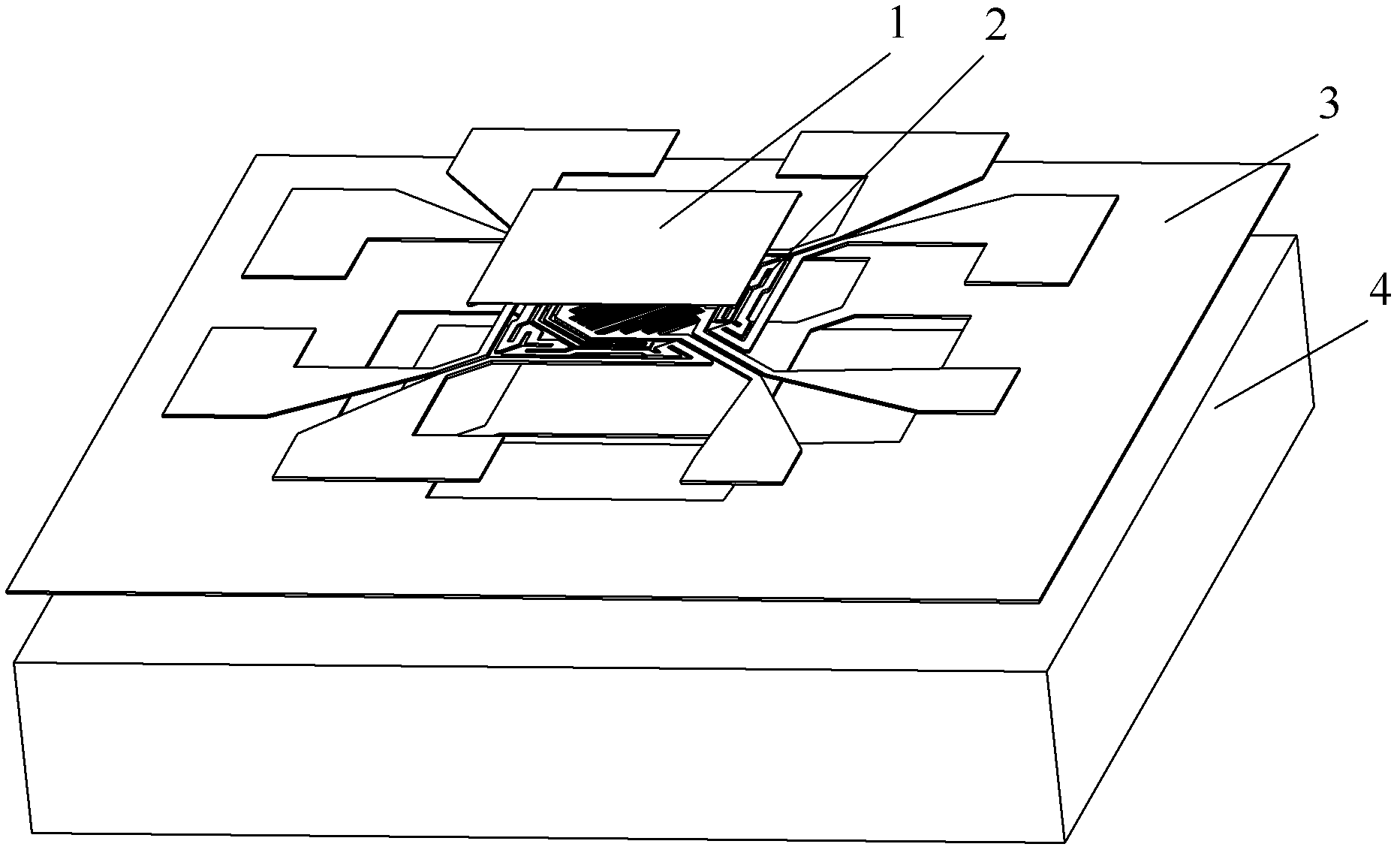

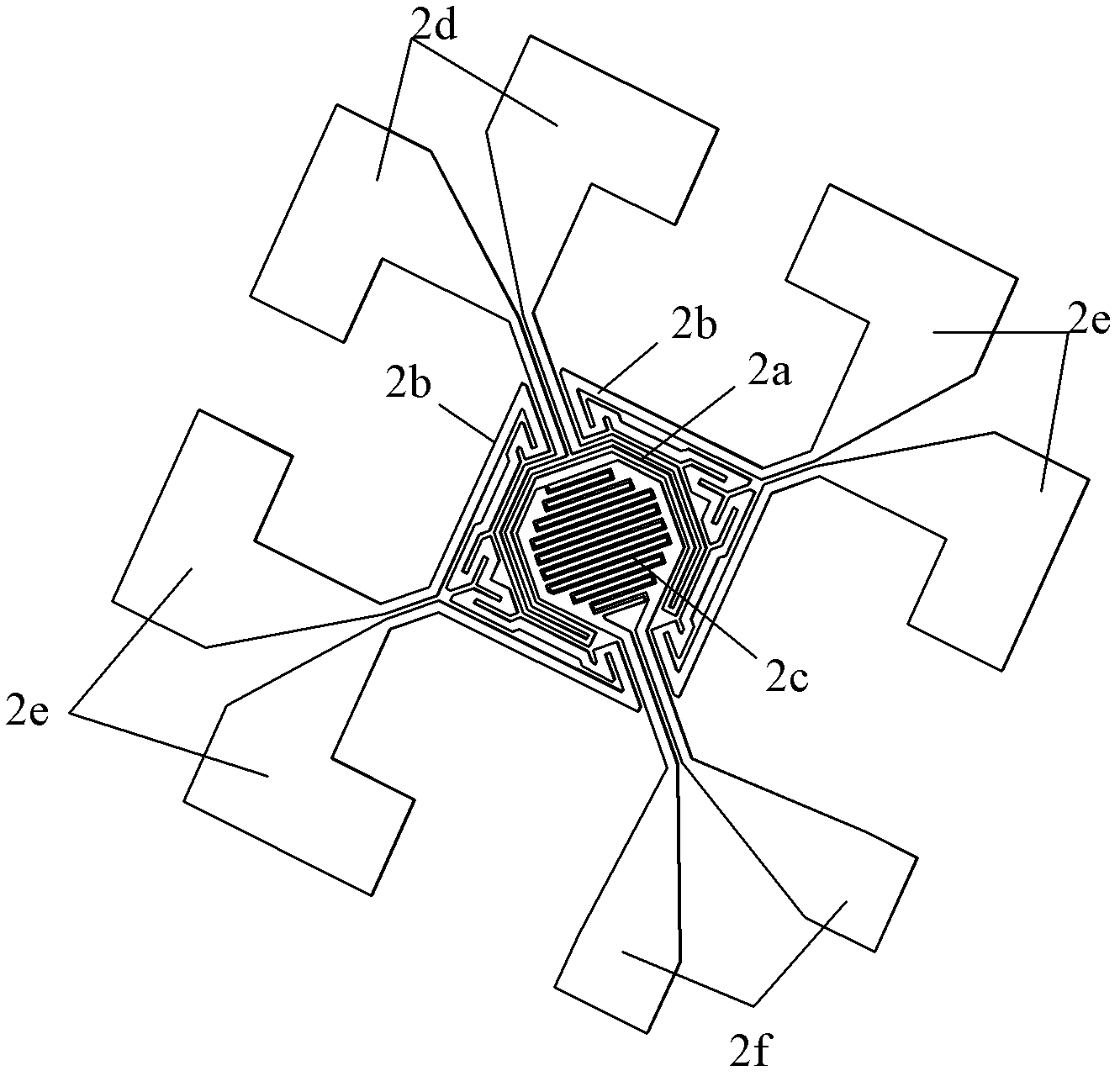

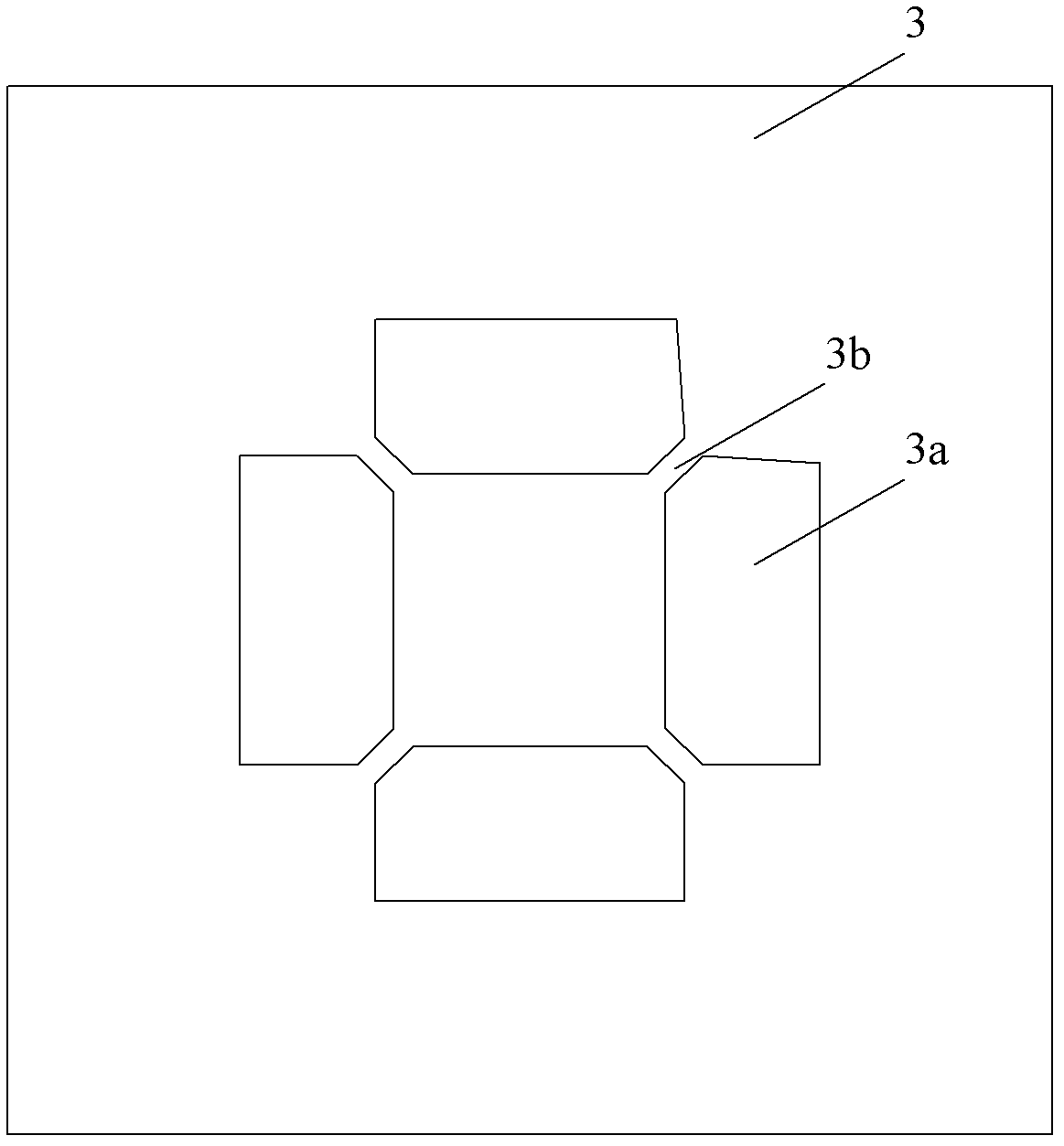

Gas sensor and manufacturing technique thereof

InactiveCN102426176ADecrease the resistance value to measure the change in resistanceReduce volumeDecorative surface effectsMaterial analysis by electric/magnetic meansTin dioxideHeat transmission

The invention discloses a gas sensor and a manufacturing technique of the gas sensor; the gas sensor comprises a silicon substrate, a silicon dioxide heat insulation stop layer, an interdigital signal electrode, a temperature measurement electrode and a heating electrode, wherein the silicon substrate is provided with a structure of a through hole; the upper surface of the silicon substrate comprises a silicon dioxide layer arranged on the top of the through hole; and the silicon dioxide layer is processed into a cantilever structure by a surface technique. The upper surface of the silicon dioxide layer is provided with an electrode group formed by the interdigital signal electrode, the temperature measurement electrode and the heating electrode, and the upper surface of the electrode group is provided with a tin dioxide layer. The technique disclosed by the invention leads the heating electrode, the interdigital signal electrode and the temperature measurement electrode to be manufactured in the same layer, so that the manufacturing complexity is reduced, and the yield is reduced; and the silicon dioxide layer of the sensor is corroded so as to form the cantilever structure, and a heat transmission channel is reduced, so that the power consumption of the sensor is lower.

Owner:NANJING UNIV OF TECH

Metal oxide blended silver-tin dioxide electric contactor material and its preparing method

The present invention belongs to the preparation techonlogy of electric alloy material. The electric contactor material consists of Ag 85-90 wt%, SnO2 5-20 wt% and blended metal oxide 0.5-8 wt%. The blended metal oxide is ZrO2, ZnO, TiO2, MnO2, WO3 or Sb2O3. The electric contactor material is prepared through coating oxide through chemical plating with plating liquid with dispersant, mixing the coated pwoder and silver powder, pressing, sintering, hot extruding, cold drawing or cold rolling, and making rivet or punched product. The present invention has the features of homogeneous oxide dispersion, good fusion welding resistance, high arc corrosion resistance and less electric transfer. The production process is simple, practical, low in cost and suitable for large scale production.

Owner:TIANJIN UNIV

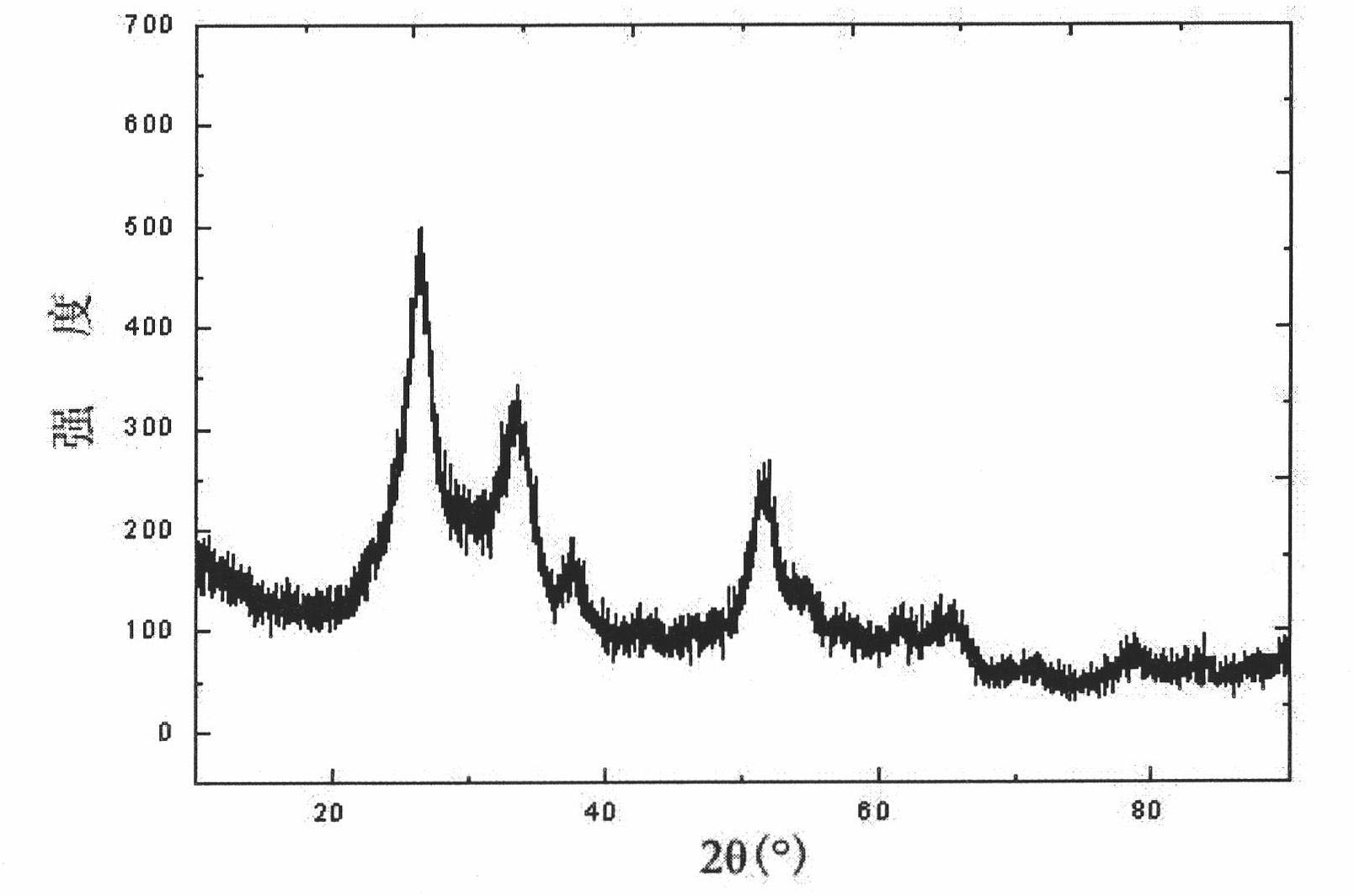

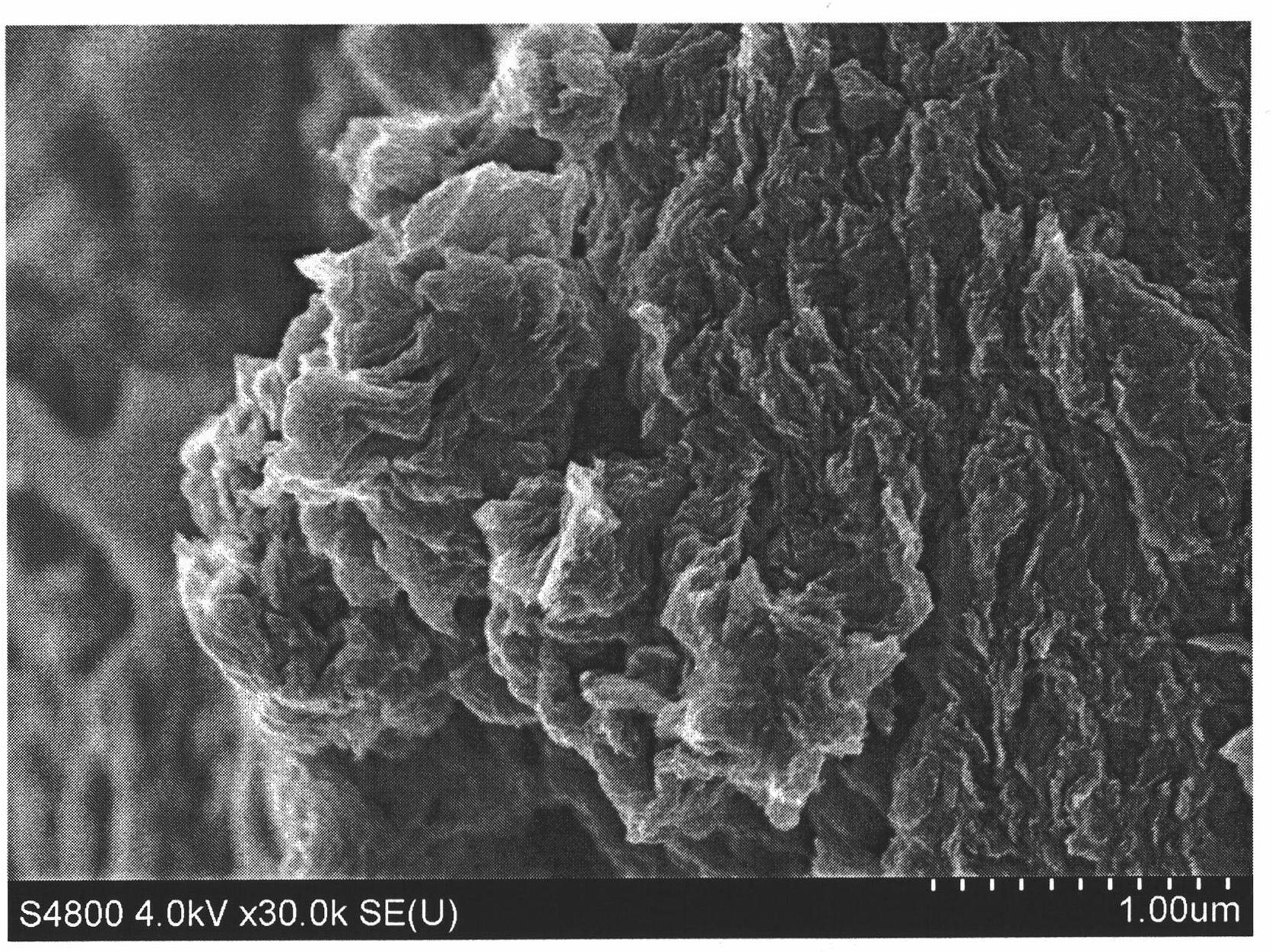

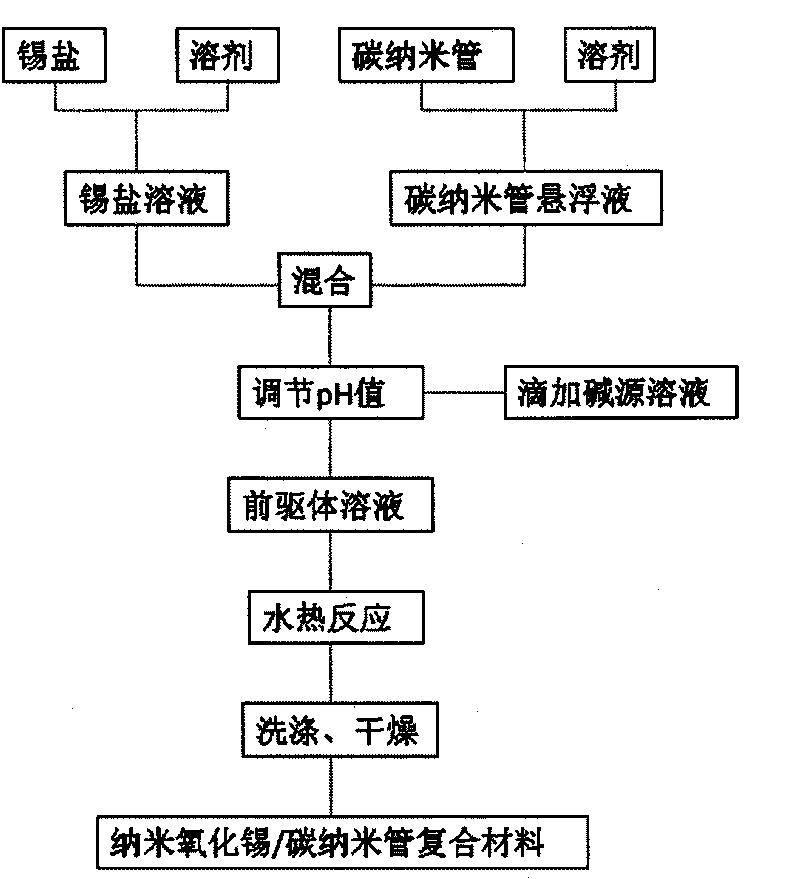

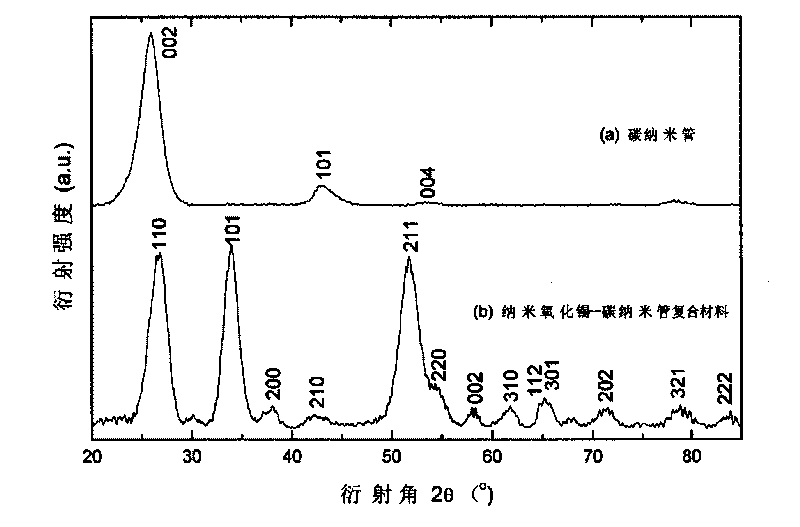

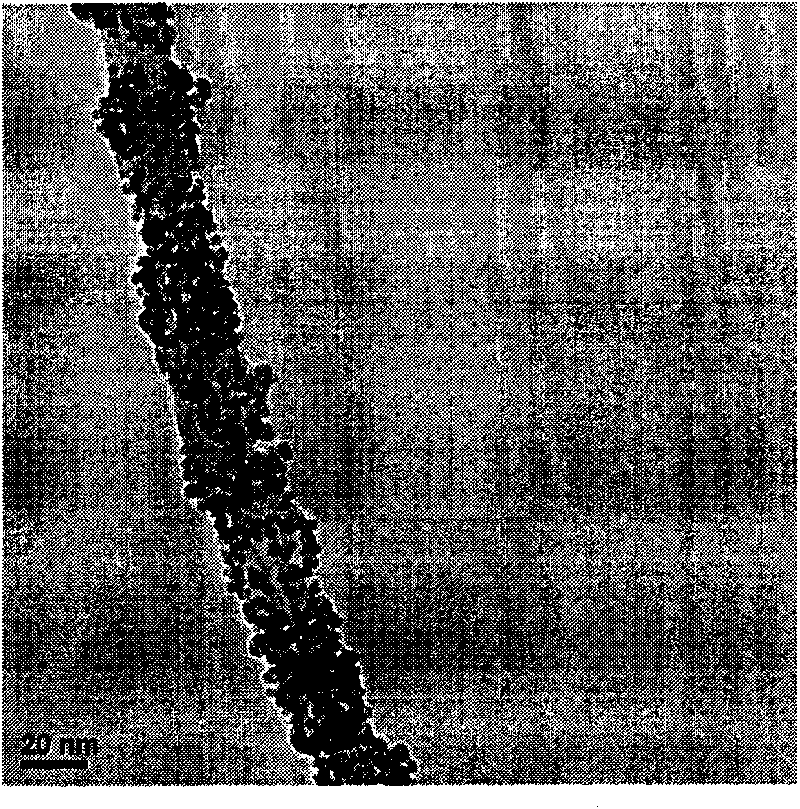

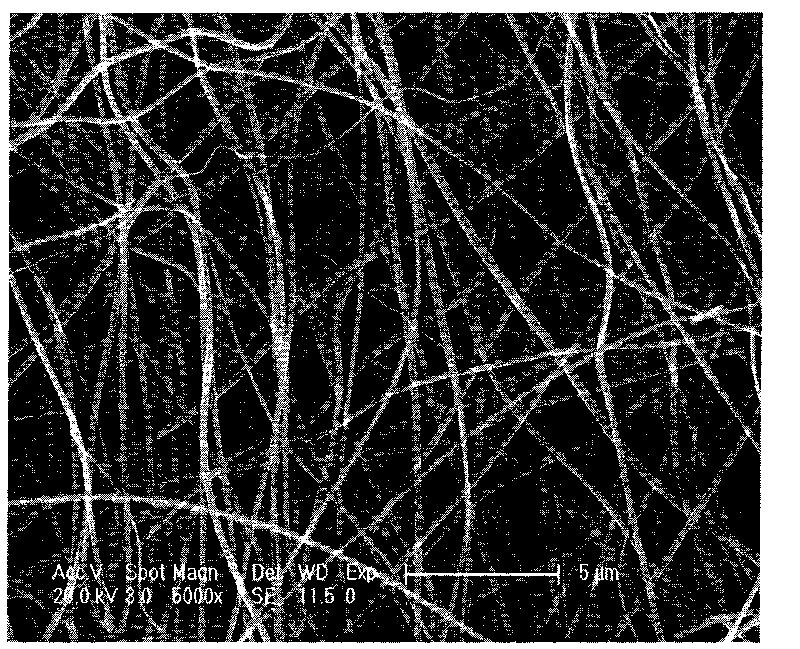

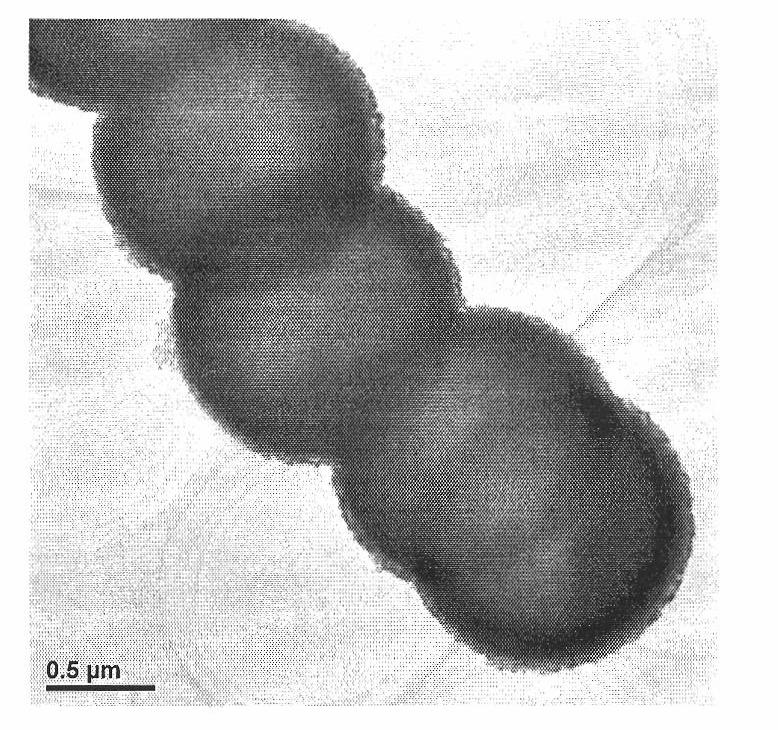

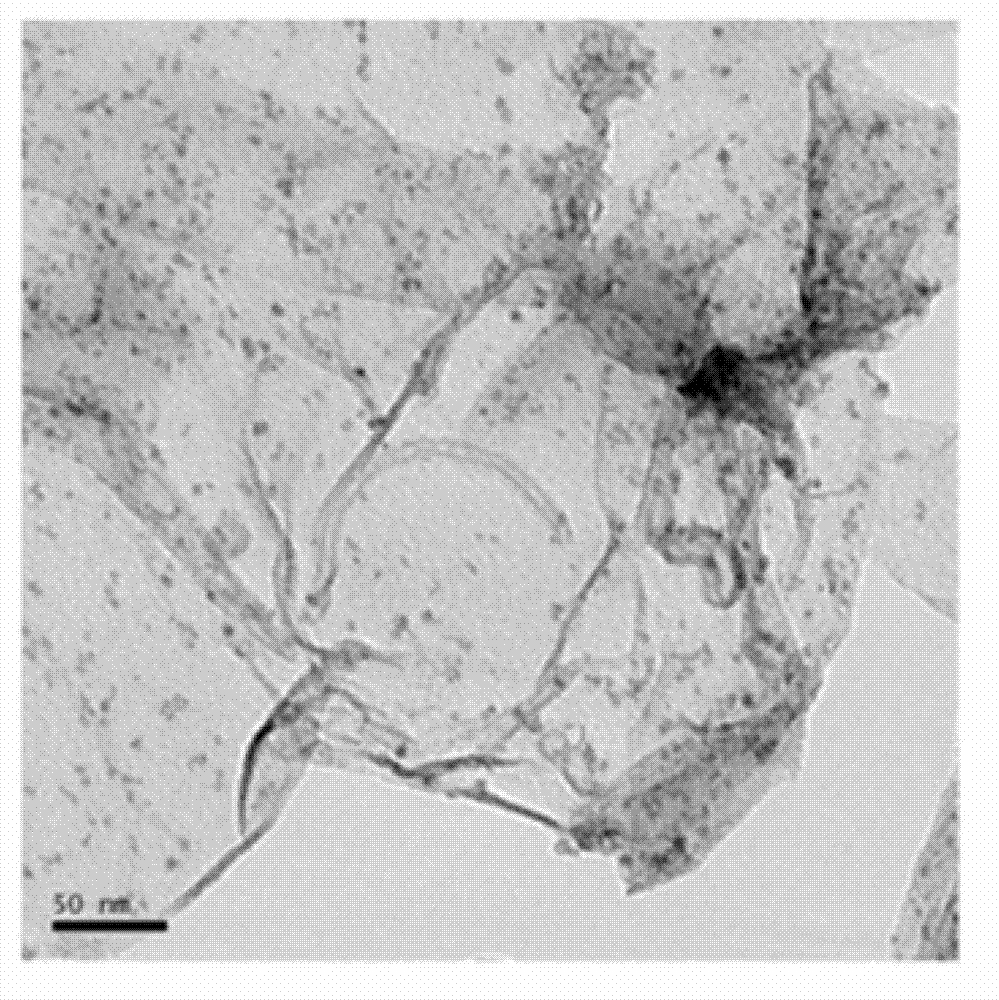

In-situ synthesis method for nano tin dioxide/carbon nano tube composite material

InactiveCN101704504AControllable particle sizeShape is easy to controlNanostructure manufactureTin dioxideSynthesis methods

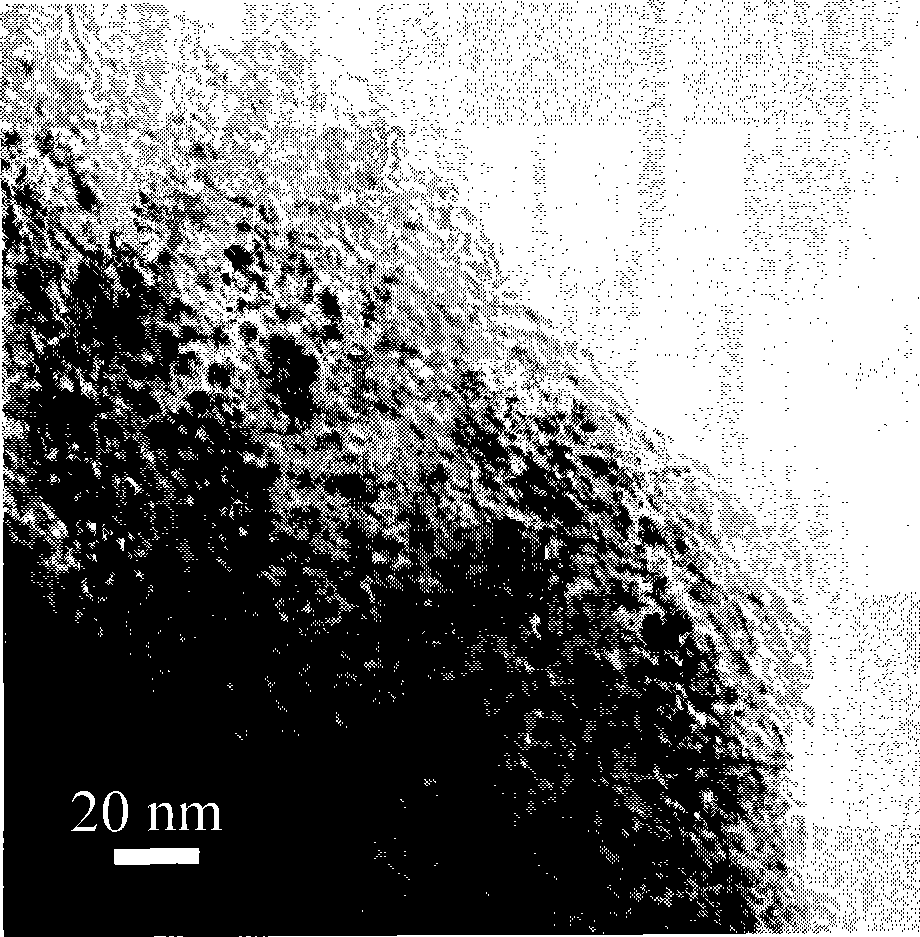

The invention discloses an in-situ synthesis method for a nano tin dioxide / carbon nano tube composite material, which mainly uses an inorganic tin salt, a carbon nano tube and an alkali source as raw materials. The experimental process mainly comprises the steps of precursor preparation, hydrothermal reaction, precipitate washing and drying and the like. The in-situ synthesis method for the nano tin dioxide / carbon nano tube composite material has the advantages that: a hydrothermal method is adopted to realize the in-situ deposition and the growth of the nano tin dioxide on the surface of the carbon nano tube; the obtained SnO2 nano particles have small and uniform particle size (less than 10nm), are well-crystallized, are uniformly coated on the surface of the carbon nano tube, and are tightly combined with the carbon nano tube; the composite material has potential application prospect in the aspects of a gas sensor material, an anode material of a lithium ion battery and the like. The method has no addition of any surface active agent, has simple and easily-obtained materials, simple process without pollution, short preparation period, mild reaction condition and low cost, and is suitable for large-scale production, so the method is an environment-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

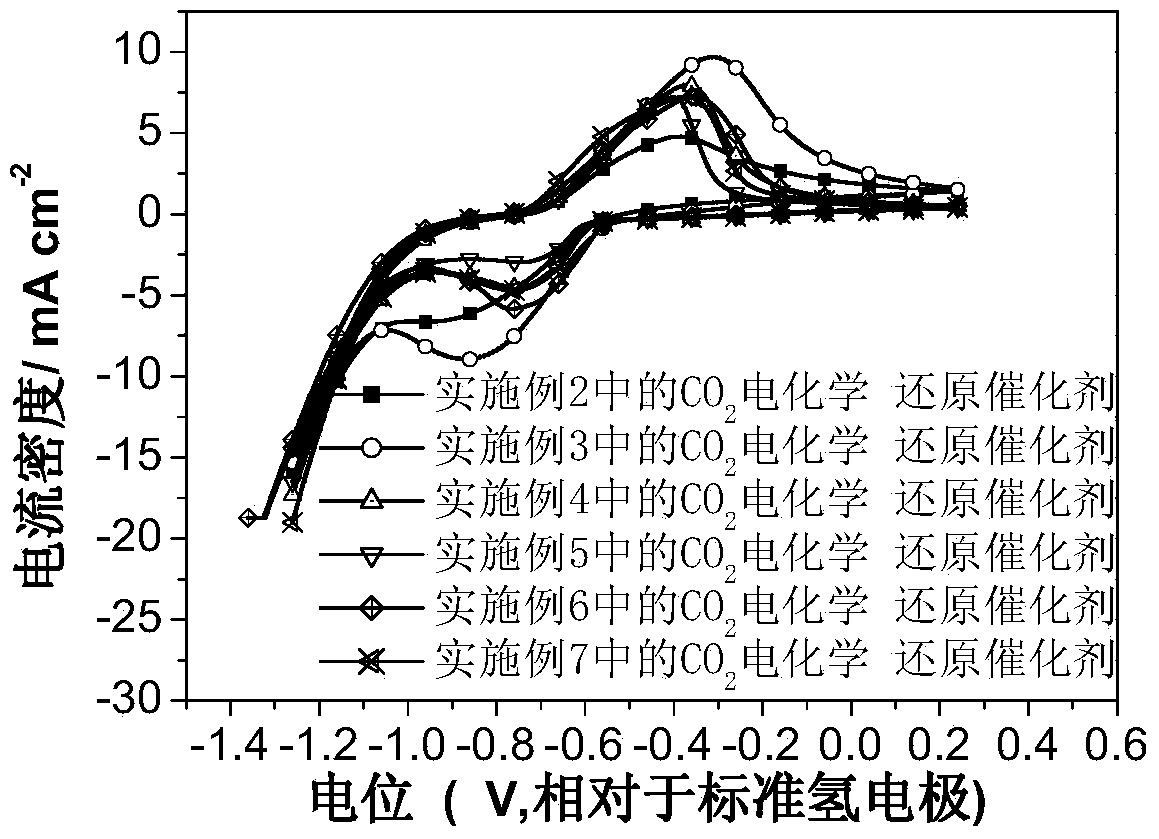

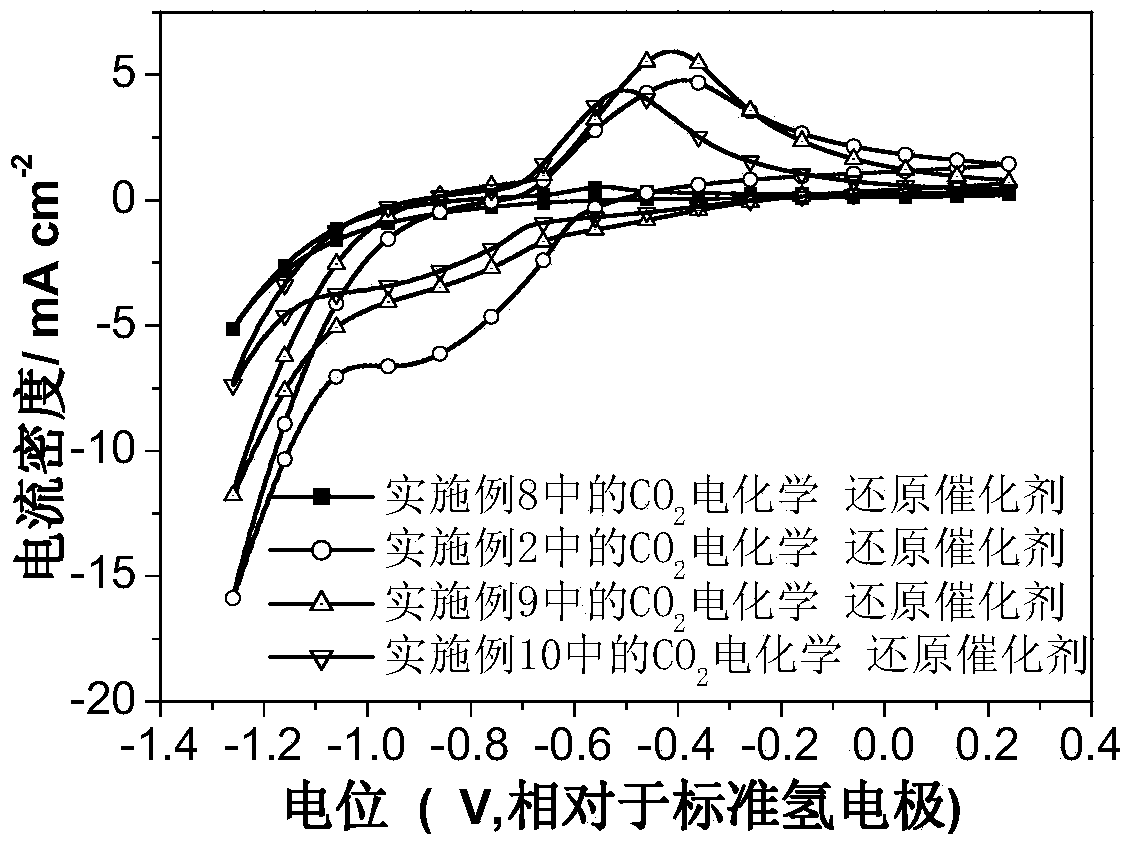

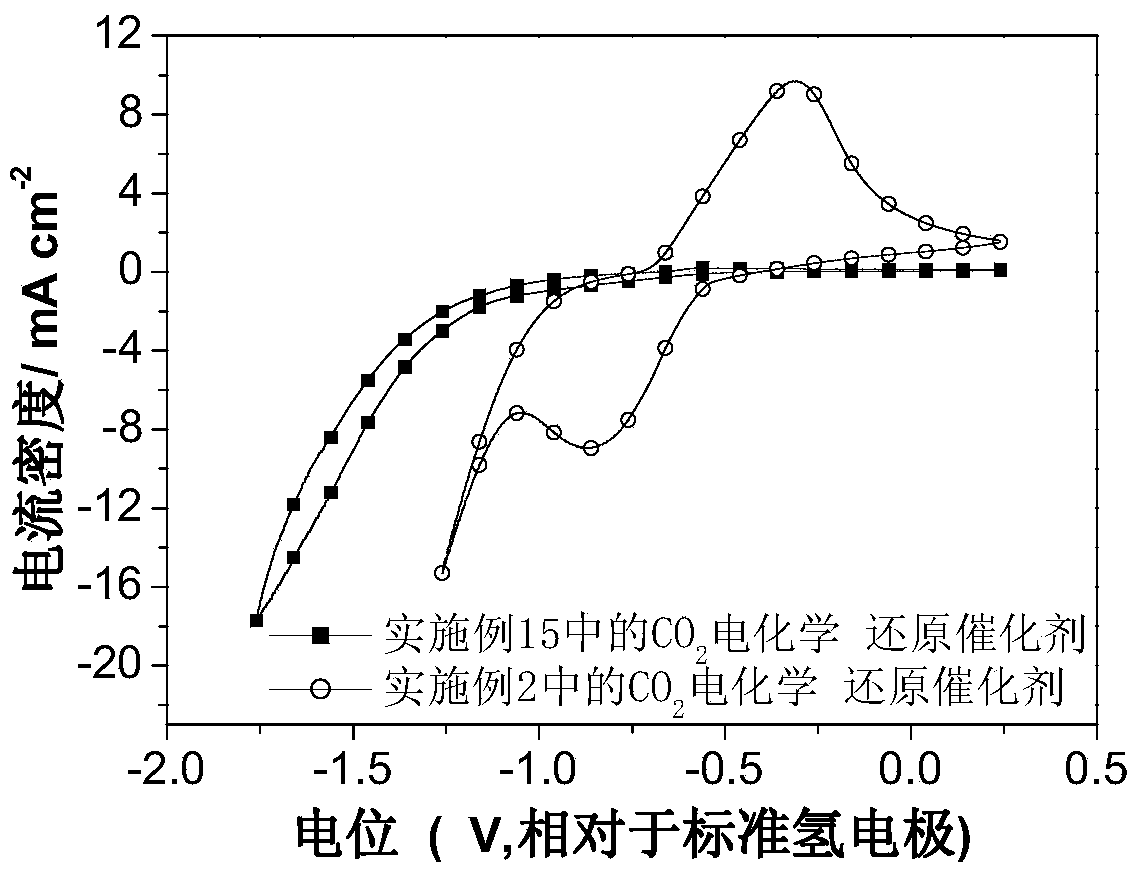

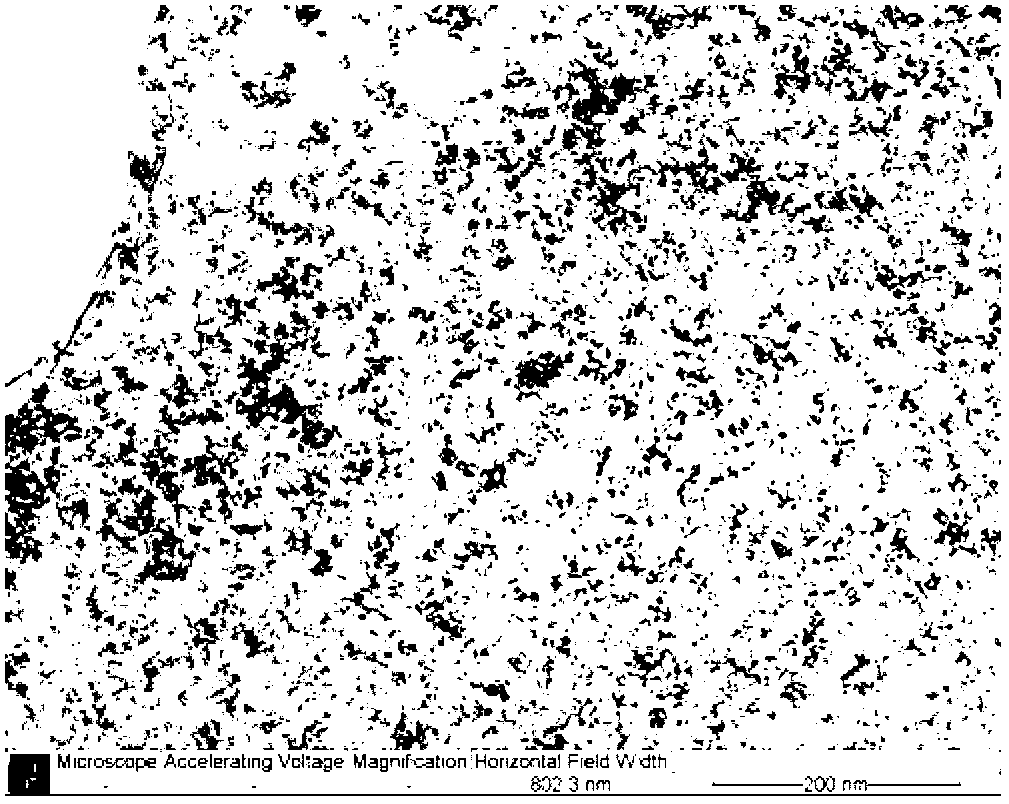

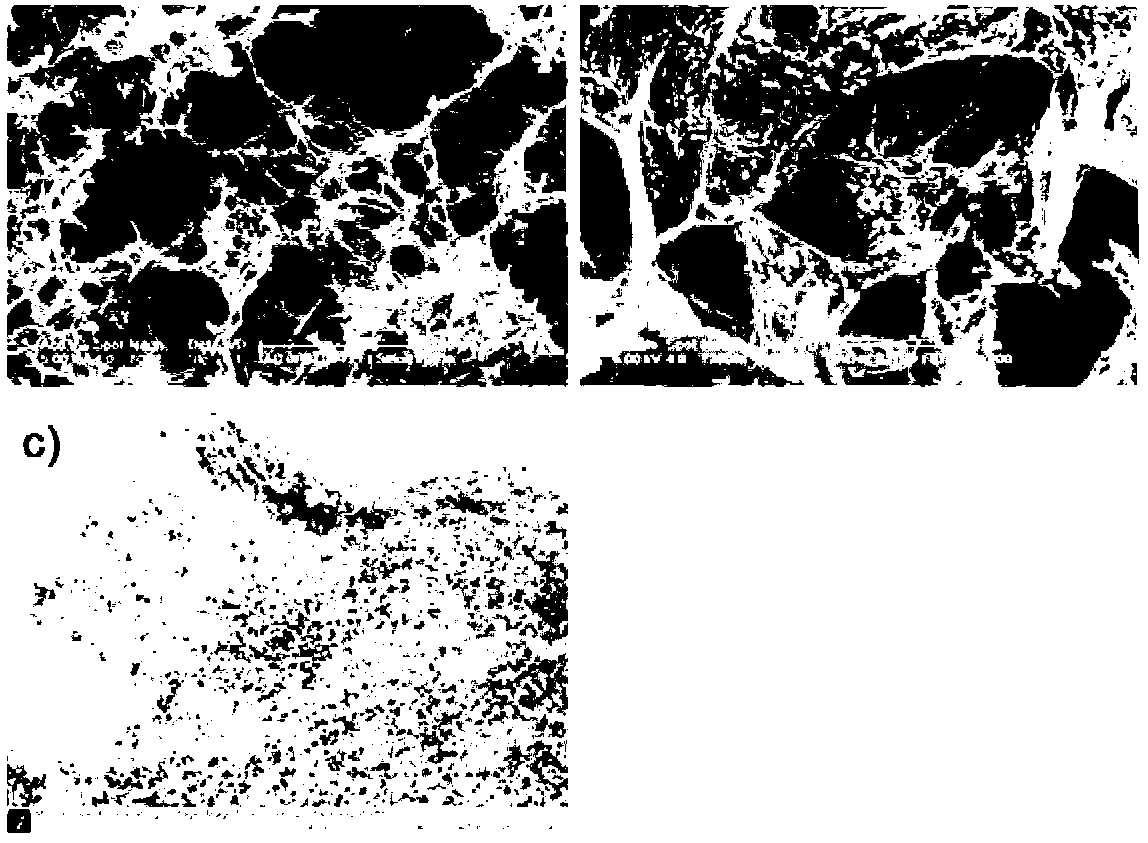

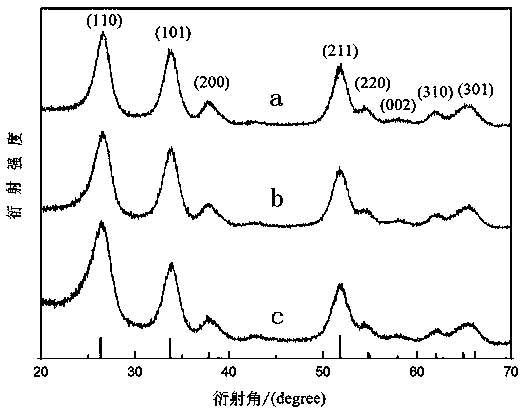

Carbon dioxide electrochemical reduction catalyst as well as preparation method and application thereof

InactiveCN103715436AIncrease the number of active sitesThe synthesis method is simpleMaterial nanotechnologyCell electrodesTin dioxideTrisodium citrate

The invention relates to a carbon dioxide electrochemical reduction catalyst as well as a preparation method and an application thereof. The carbon dioxide electrochemical reduction catalyst comprises tin dioxide nanoflower, wherein the tin dioxide nanoflower is synthesized through hydrothermal reaction and comprises the synthesis raw materials including 0.1-0.5M of tin dioxide, 1-5M of trisodium citrate mixed solution and 0.1-0.5M of sodium hydroxide. The carbon dioxide electrochemical reduction catalyst is applied to a carbon dioxide electrochemical reduction catalyst gas diffusion electrode. The carbon dioxide electrochemical reduction catalyst has the advantages that the specific surface area of the catalyst is enlarged, the electrochemical reduction catalytic activity of the catalyst for carbon dioxide reduction is improved, the hydrogen evolution reaction is effectively inhibited, and the selectivity of formic acid in a product is improved.

Owner:DONGHUA UNIV +1

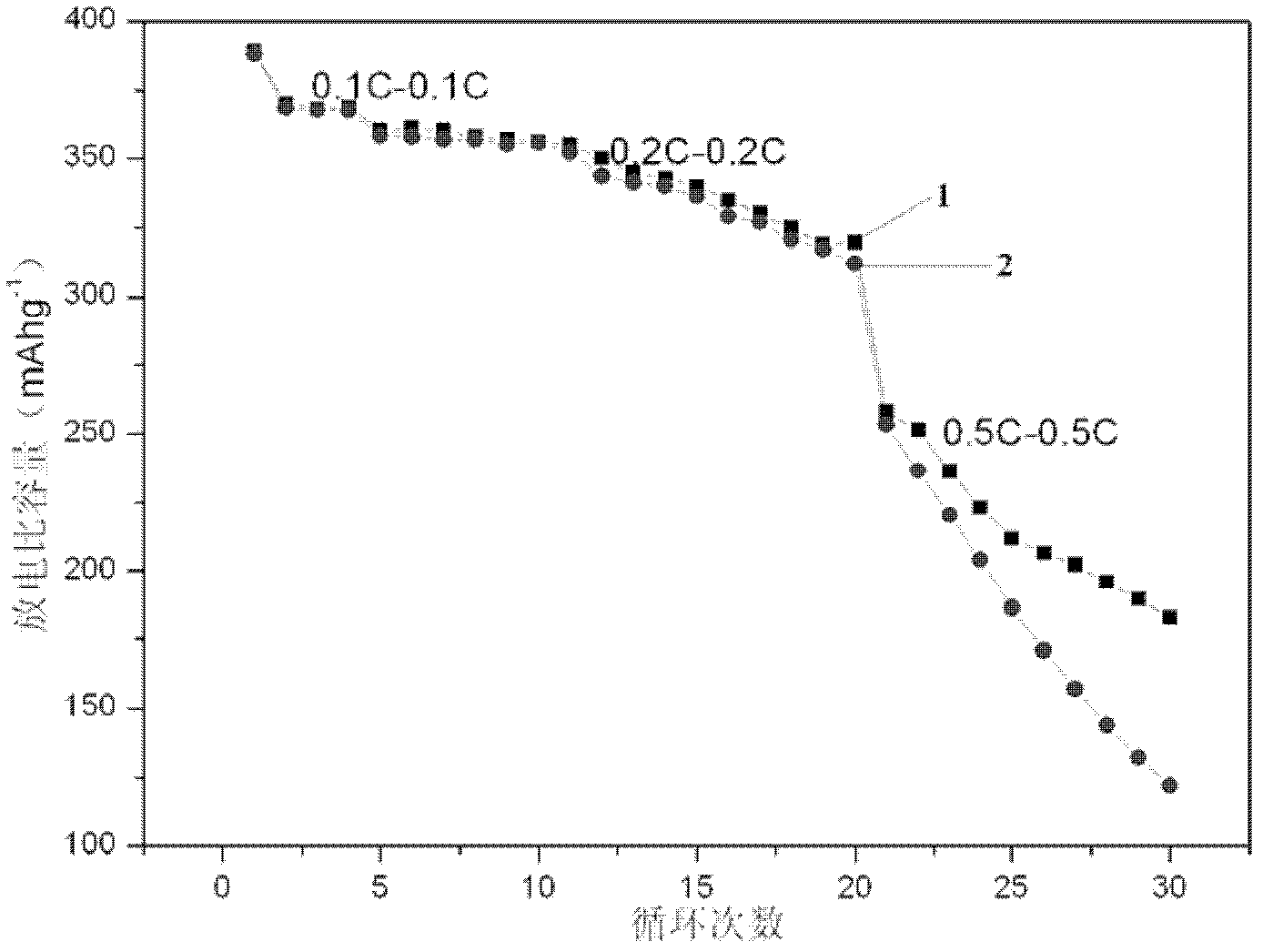

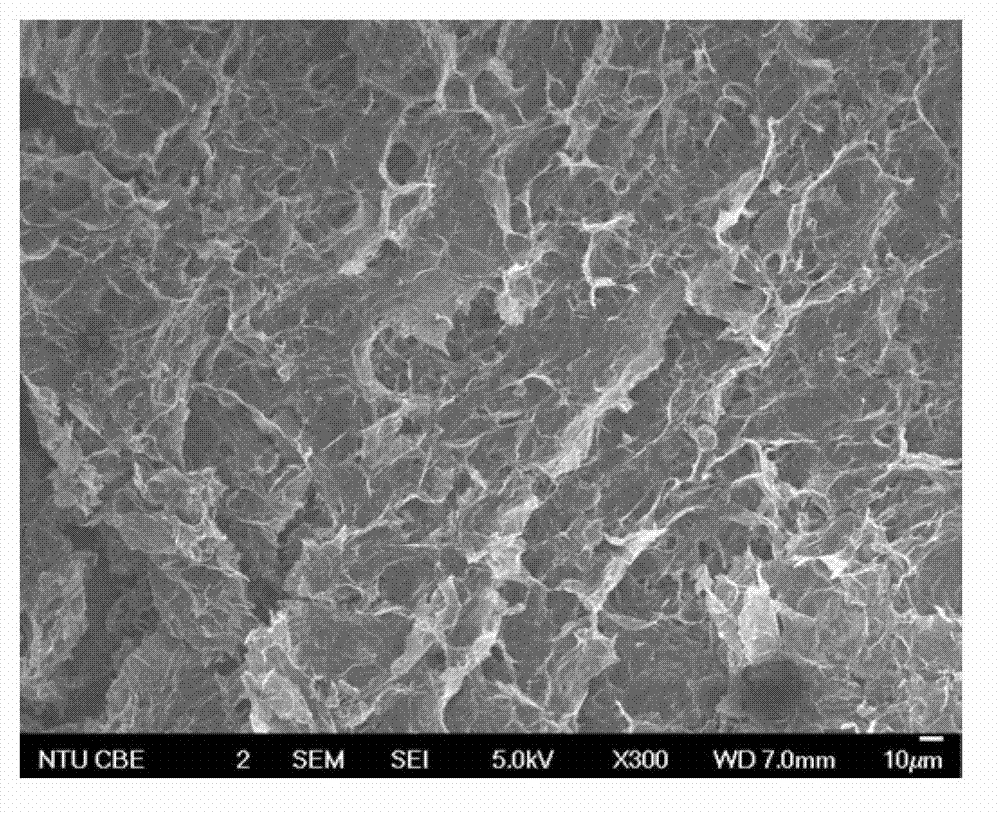

Preparation method and application of three-dimensional-structure graphene-base metal oxide composite material

InactiveCN103346301AInhibition of agglomerationSuppress crushingCell electrodesNanotechnologyTin dioxideFreeze-drying

The invention discloses a preparation method and application of a three-dimensional-structure graphene-base metal oxide composite material. According to the preparation method disclosed by the invention, the three-dimensional-structure graphene-base metal oxide composite material is prepared by a hydrothermal freeze-drying method by using single-layer carbon-atom-structure graphene as a carrier and some high molecular polymers as an auxiliary crosslinking agent. The three-dimensional aerogel obtained by the method has high metal oxide carrying capacity. The electrochemical test proves that the three-dimensional aerogel graphene-base metal oxide composite material obtained by the preparation method has excellent loop stability and rate capability. The experiment proves that the discharge capacity of the tin dioxide material can reach 1050 mAhg<-1> under the charging / discharging current of 100 mAg<-1>, and the discharge capacity of the titanium oxide material can reach 150 mAhg<-1> under the charging / discharging current of 50 mAg<-1>.

Owner:SHANGHAI JIAO TONG UNIV

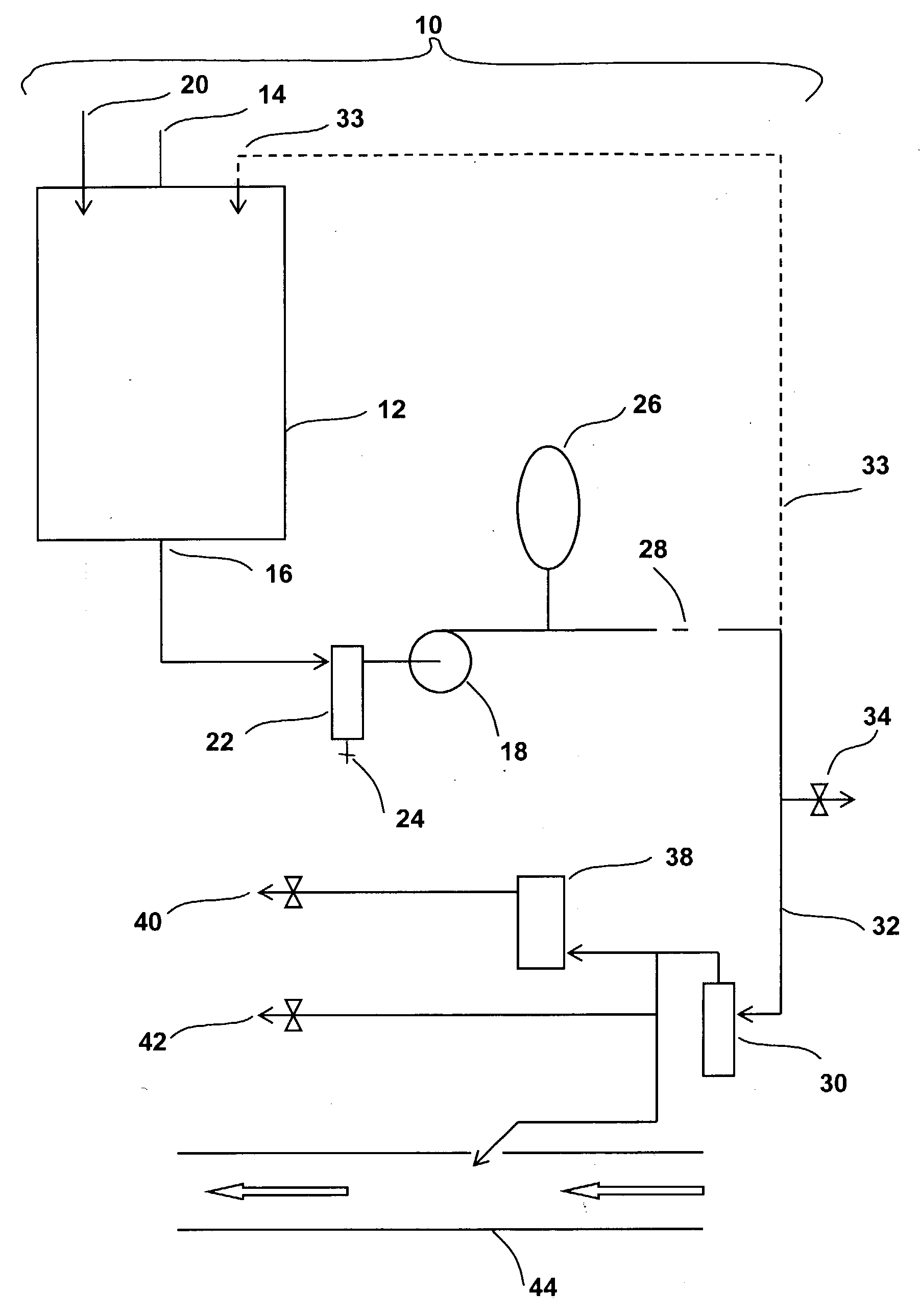

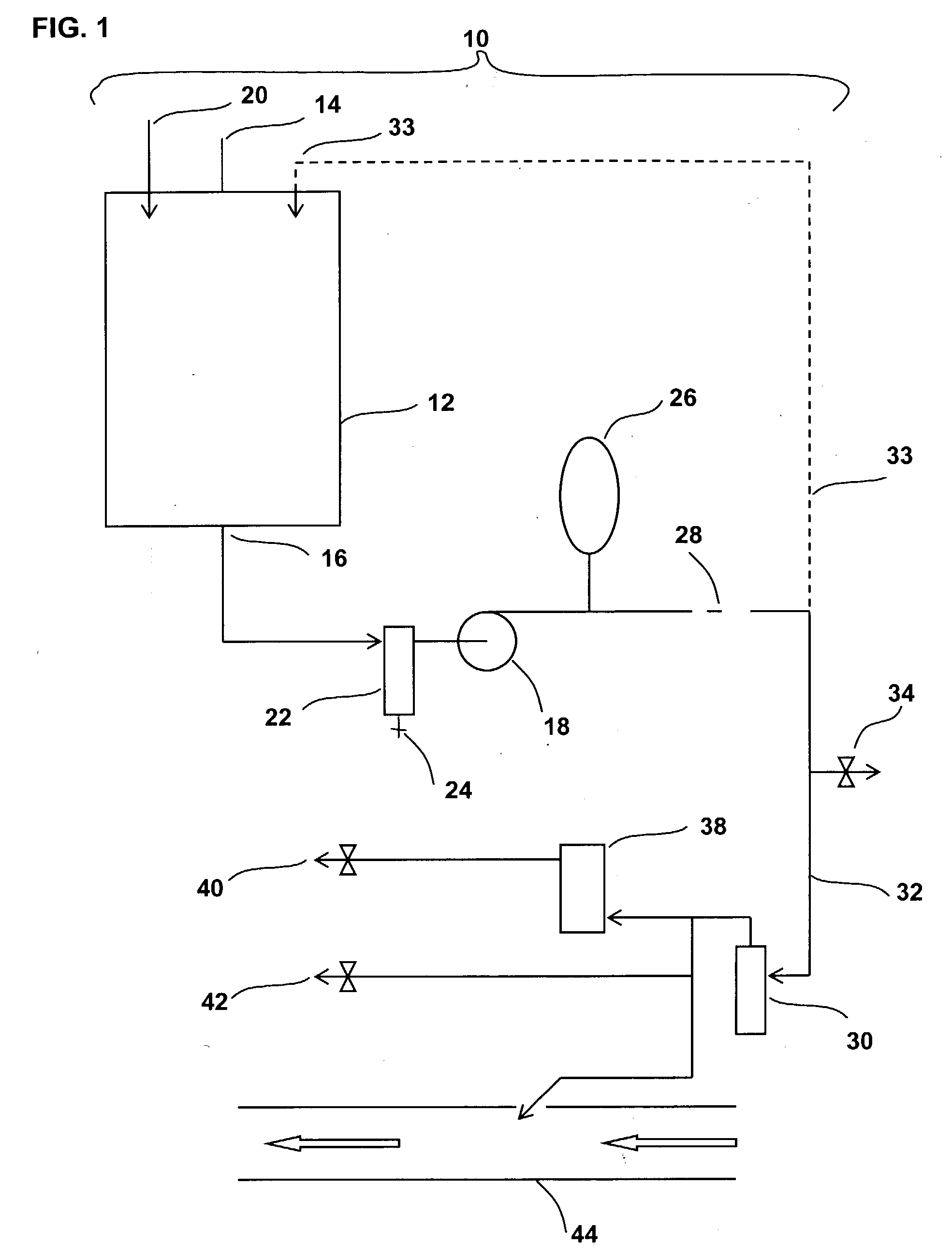

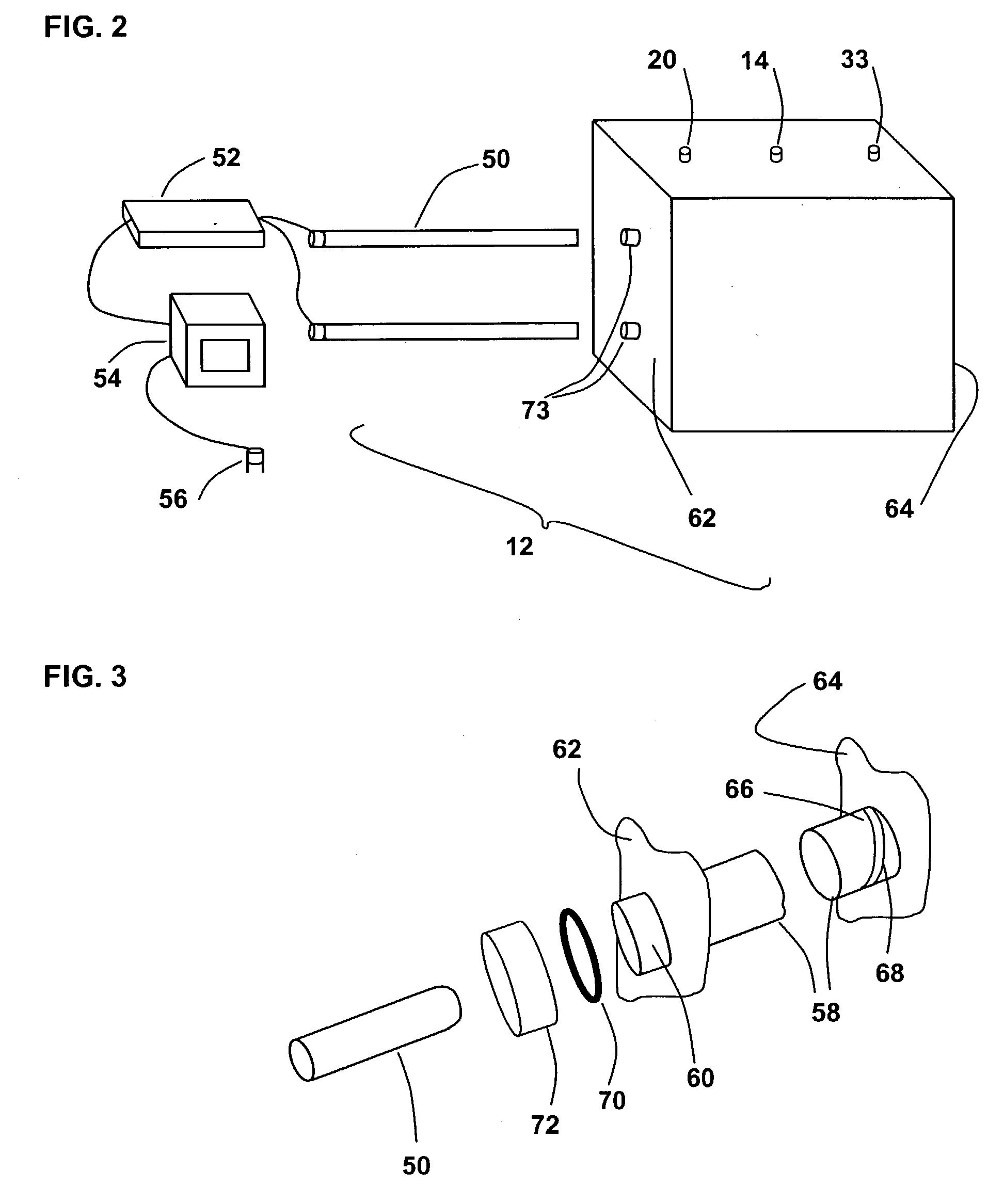

Internal UV treatment of potable water systems

InactiveUS20050000911A1Reduce eliminate buildupIncrease the number ofWater treatment parameter controlWater/sewage treatment by irradiationTin dioxideWater filter

A disinfectant treatment for self-contained potable water systems. A lamp or lamps within the interior of at least one component system in which water is resident. During operation of the system. As the water tank, water heater, water filter, or other component which holds a volume of water. By putting a radioactive and a microbial effect in response to exposure to UV radiation may be formed of the vessel or other component. The radioactive material may be tin dioxide, titanium dioxide, or other material that produces hydroxyl ions in response to UV exposure. The hydroxyl ions flow from the vessel or other component into the piping and other components so as to attack / inhibit microbial action throughout the system. The lamps are mounted within quartz sleeves for immersion in water or other components. The quartz sleeves to prevent vibration damage. May also be used to of the system so as to prevent friction freeze damage.

Owner:THORPE GEORGE W

Method for preparing nano-carbon coated lithium battery anode material

ActiveCN102082262AGuaranteed channels for circulation and exchangeEasy transferCell electrodesCarbon layerTin dioxide

The invention discloses a method for preparing a nano-carbon coated lithium battery anode material. An active carbon material which is highly graphitized and has a porous structure is prepared from waste crops, and serves as a substrate; uniformly dispersed nano tin dioxide particles are loaded on the substrate subjected to simple treatment, natural or synthetic polymer is used as a carbon source, and a carbon layer coats the nano tin dioxide particles so as to fulfill the aim of combining the regulation function of nano dispersion of the nano particles on volume expansion of the tin dioxide with the restraint and buffer function of the coated carbon layer on the tin dioxide particles; therefore, higher battery capacity and cycle stability can be achieved.

Owner:QINGDAO HAIYUAN IND

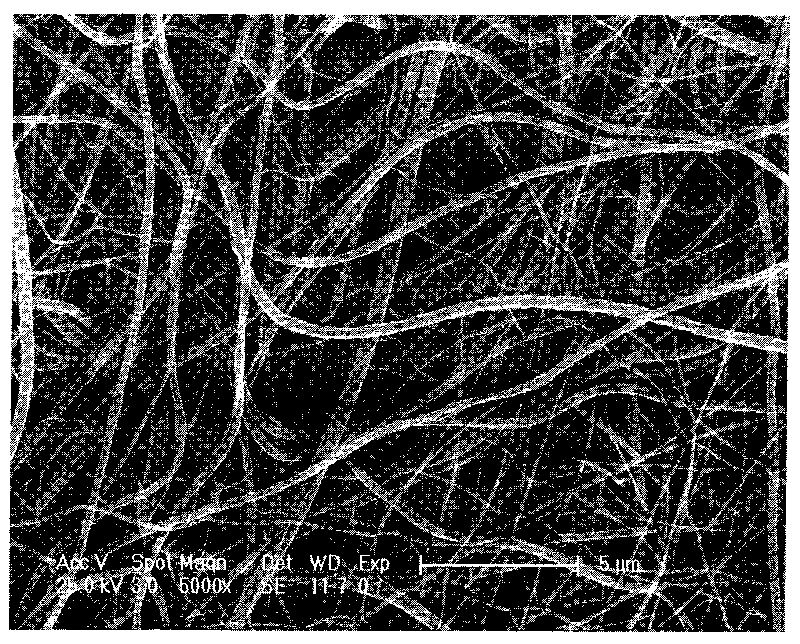

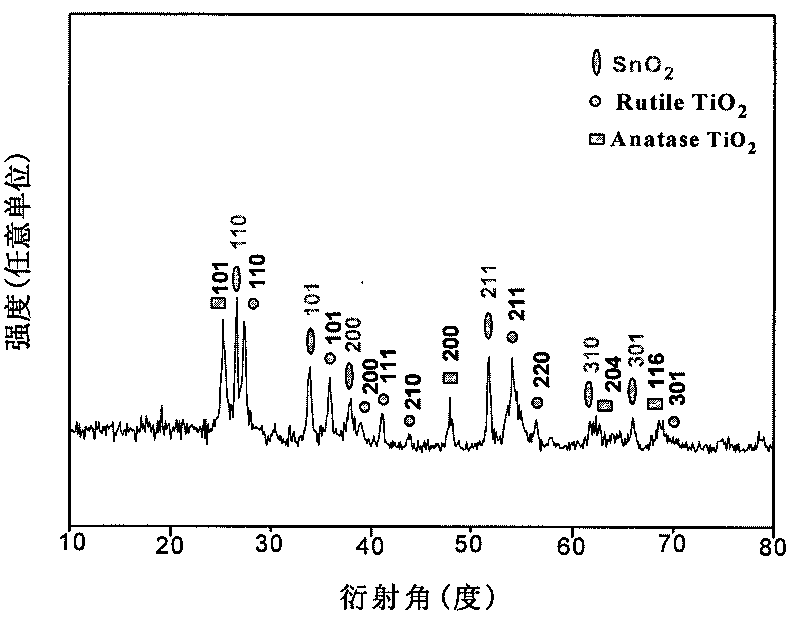

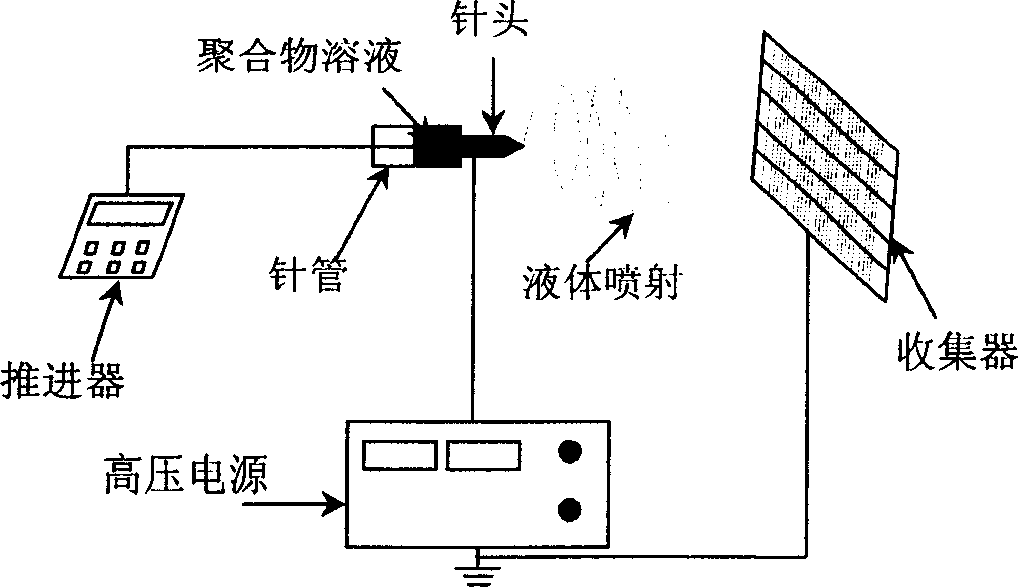

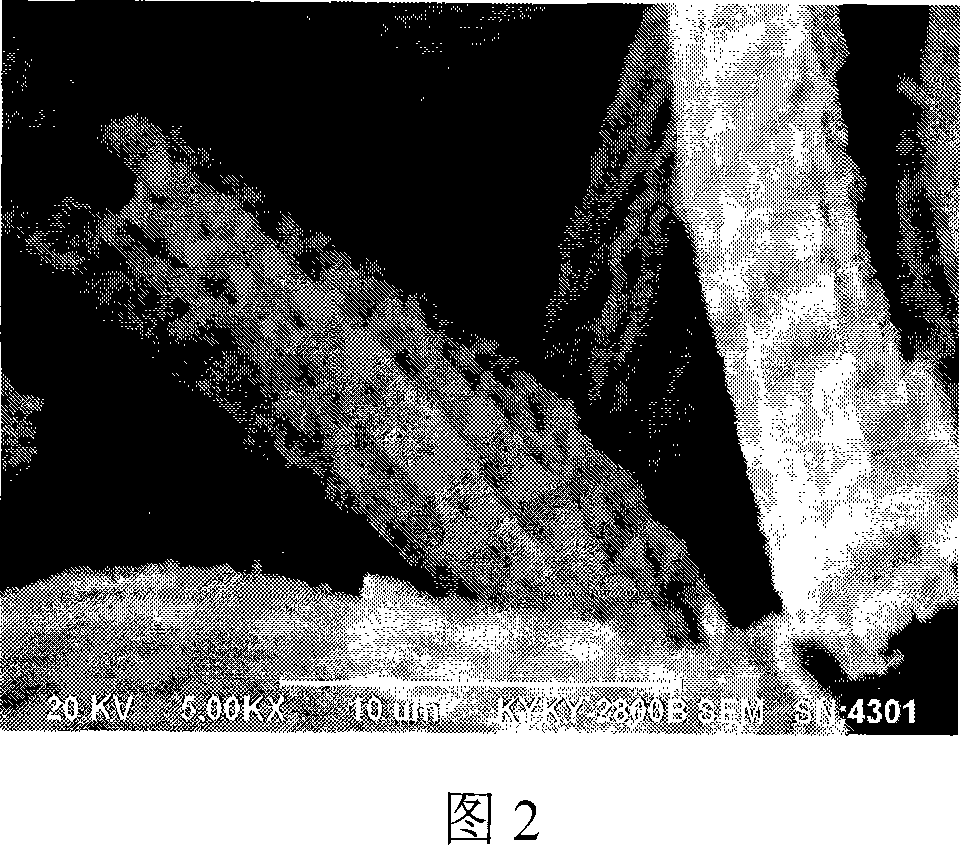

Method for preparing tin dioxide and titanium dioxide nano cable

The invention relates to a method for preparing a tin dioxide and titanium dioxide nano cable, which belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparation of spinning solution, adding stannic chloride and polyvinylpyrrolidone (PVP) into a mixed solvent of N, N-dimethylformamide and glycerin so as to prepare a core layer of the spinning solution, and adding PVP into a mixed liquid of butyl titanate and absolute ethyl alcohol so as to prepare a shell layer of the spinning solution; (2) preparation of (PVP+SnC14) and [PVP+Ti(OC4H9)] composite nano fiber by a coaxial electrostatic spinning technology under the condition that the voltage is 11.5-15 kV, the curing distance is 10-15 cm, the room temperature is 20-25 DEG C and the relative humidity is 45-50 percent; (3) preparation of SnO2 an TiO2 nano cable: carrying out heat treatment on the composite nano fiber to obtain the cable with cable diameter of 300-340 nm, core layer diameter of 200-220 nm, the shell layer thickness of 50-60 nm and length of more than 300 mu m.

Owner:CHANGCHUN UNIV OF SCI & TECH

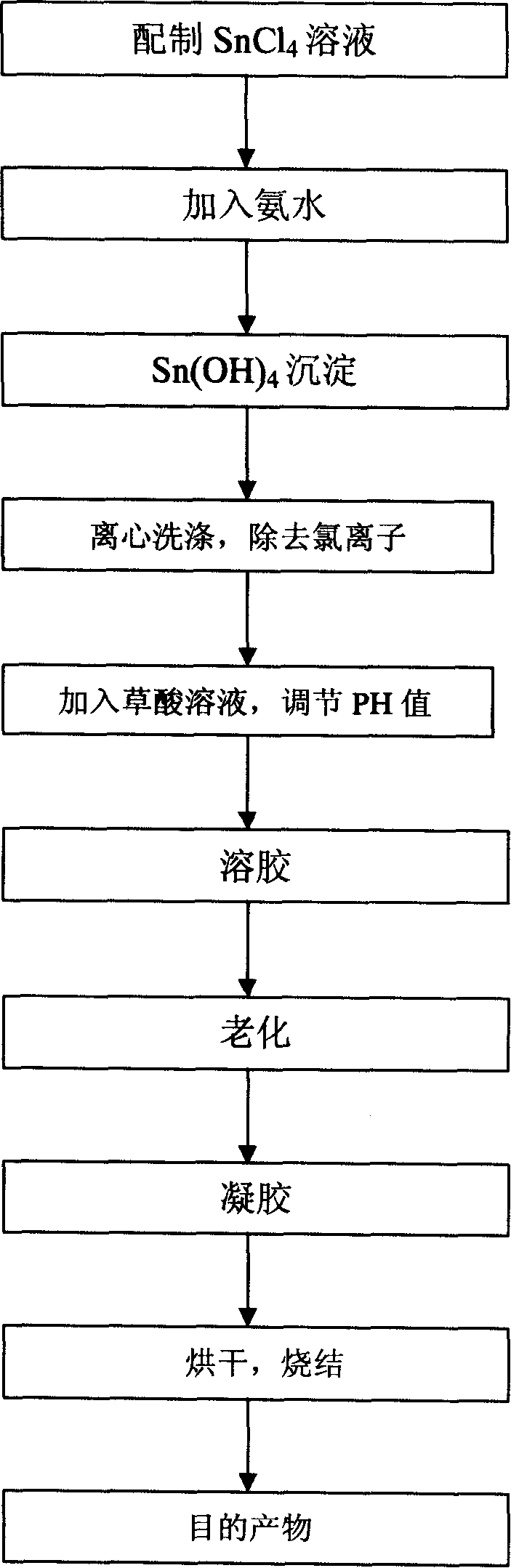

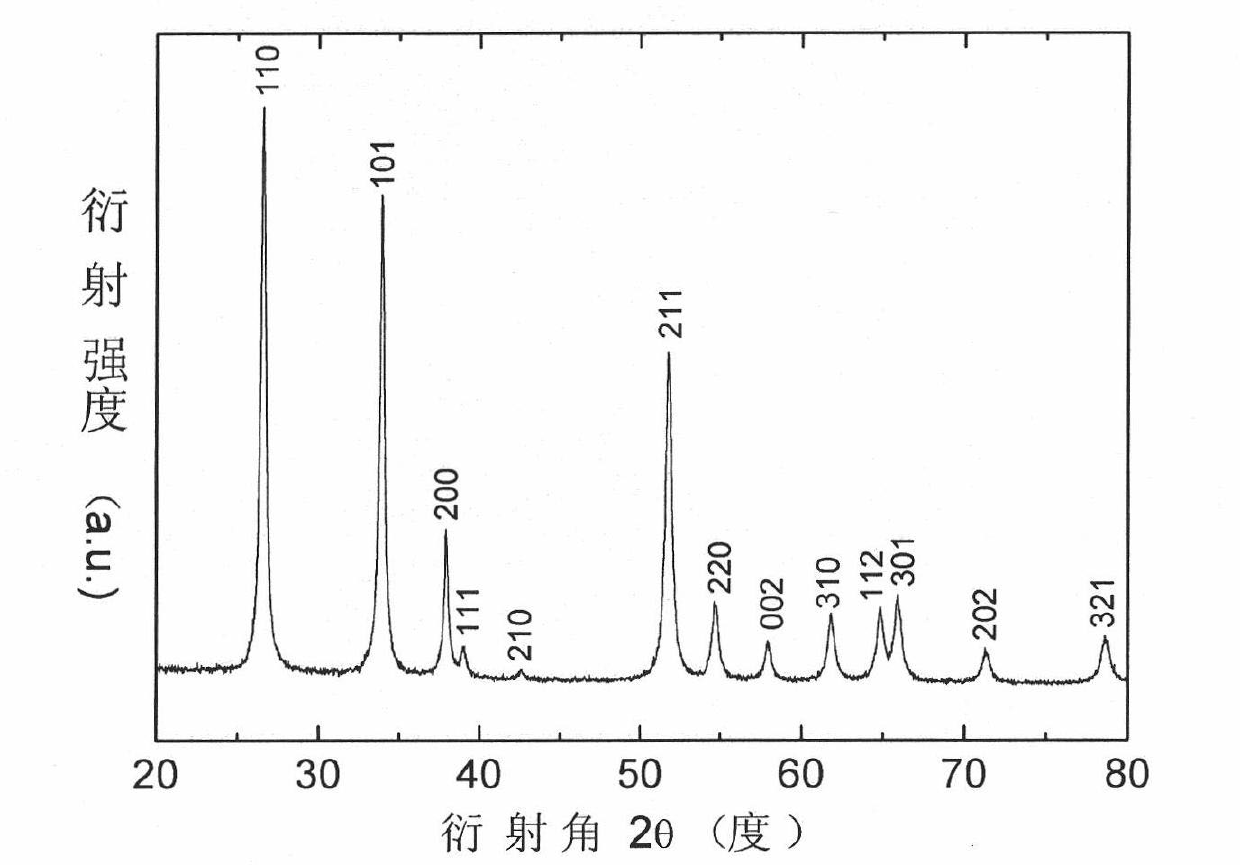

Process for preparing one-dimensional nano tin dioxide material

InactiveCN1724383ALow costSimple preparation processNanostructure manufactureTin oxidesOxalateTin dioxide

A process for preparing one-dimension nano-SnO2 material used for high-sensitivity gas sensor or transparent electrode includes such steps as preparing solution of SnCl4 * 5H2O, adding ammonia water, depositing, centrifugal washing for removing Cl ions, adding oxalic acid to generate sol, ageing to become gel, drying and sintering.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Cathode composite material of lithium ion battery and preparation method thereof

InactiveCN102569750AEasy to prepareRaw materials are easy to getCell electrodesTin dioxideMicrosphere

The invention provides a cathode composite material of a lithium ion battery. The cathode composite material comprises graphene and an electrode active material, wherein the electrode active material is one or more of intermediate-phase bituminous coal microspheres, silicon, lithium titanate, titanium dioxide, tin dioxide and graphite. According to the invention, the graphene and the electrode active material are mixed with water to obtain a mixed solution, which is dried to obtain the cathode composite material of the lithium ion battery. According to the invention, the graphene is adopted as an electroconductive additive, has favorable electroconductive performance, mechanical strength and huge specific surface area, can be favorably attached to the surface of the electrode active material, and is beneficial for shortening the diffusion path of lithium ions, so that the ionic conductivity of the cathode composite material of the lithium ion battery is increased; in addition, the addition of the graphene is beneficial to the enhancement of the full contact between the cathode material of the battery and a current collector, so that the cyclic performance and the multiplying power of the lithium ion battery can be improved in a better way; and the cathode composite material of the lithium ion battery, provided by the invention, has better electric properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

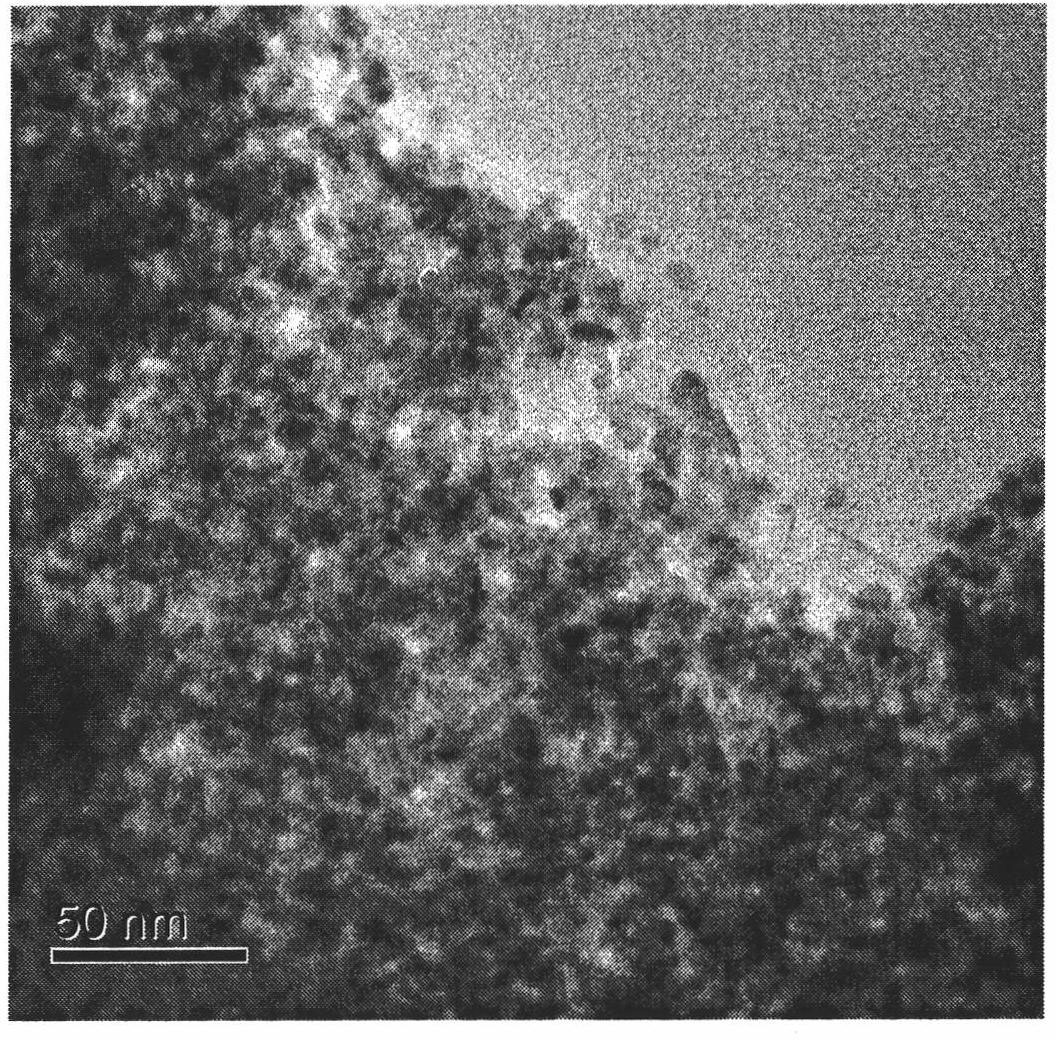

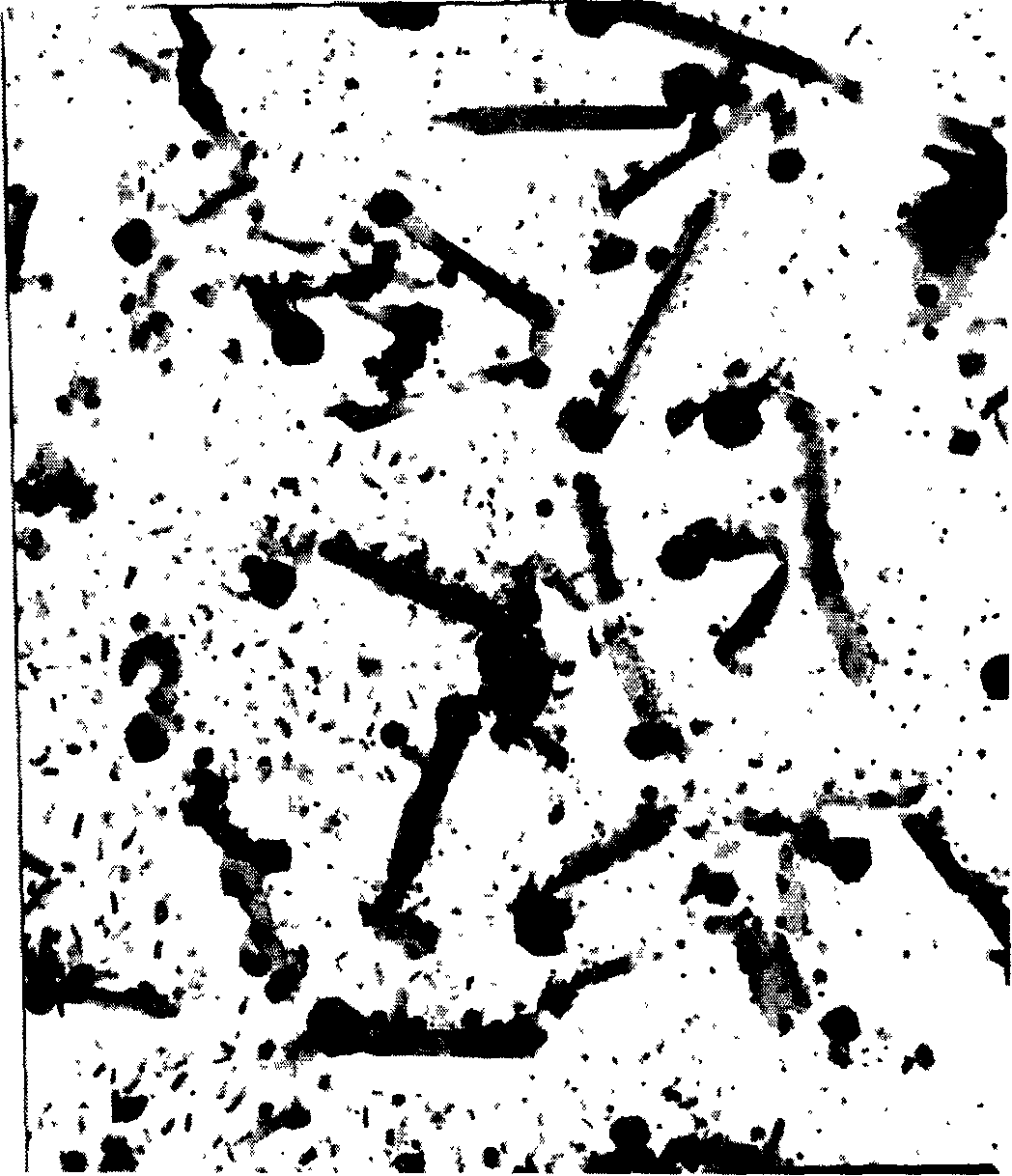

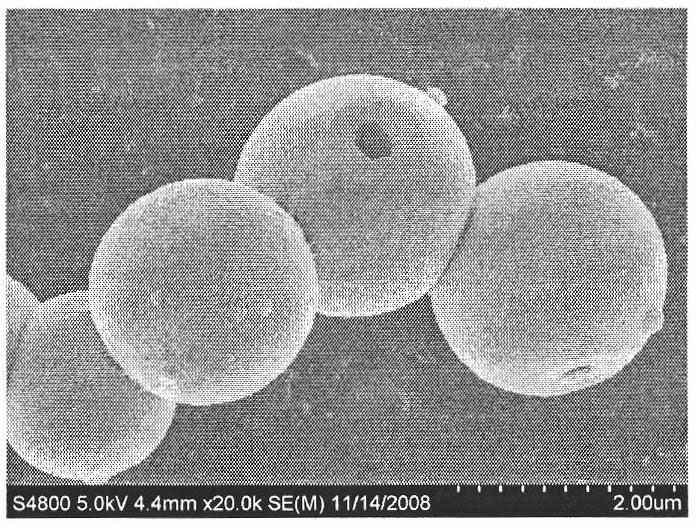

Method for preparing hollow spherical stannic oxide nano powder

InactiveCN102086044AAvoid destructionEasy to makeNanostructure manufactureTin oxidesTin dioxidePrill

The invention provides a method for preparing hollow spherical stannic oxide nano powder and belongs to the technical field of preparation of nano materials. The preparation method mainly comprises the steps of: respectively preparing tin salt and an alkali source into solution; uniformly dripping the solution of the alkali source into the solution of tin salt with stirring of a magnetic force, and stirring to obtain uniform precursor solution; performing hydrothermal treatment on the precursor solution in a reaction kettle; washing and drying the hydrothermal product to obtain the hollow spherical powder consisting of nano SnO2 particles. The prepared SnO2 hollow spheres have uniform size, regular shape, good crystallization and uniform thickness of a spherical shell. In the method, an expendable template is not needed, the process is simple and reaction conditions are mild, and the method has the characteristics of short preparation period, high product quality, high yield, low costand the like, and is an environmentally-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

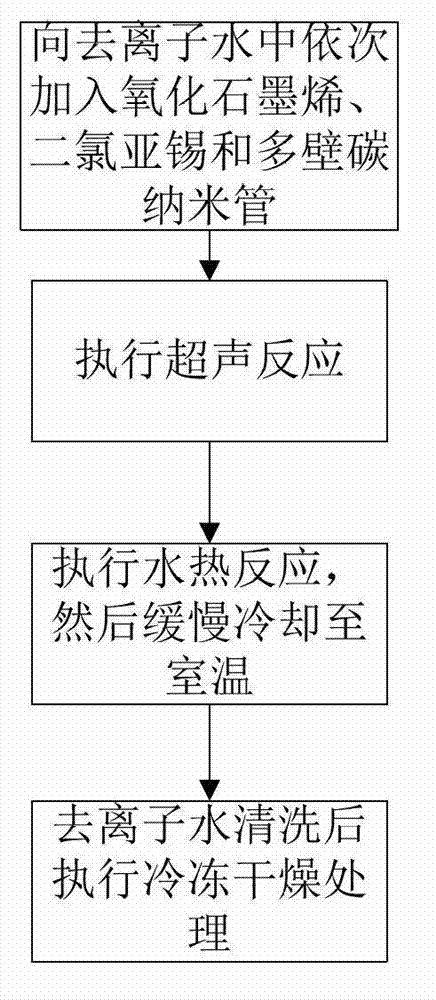

Preparation method of graphene-carbon nanotube-nano tin dioxide three-dimensional composite material and product thereof

InactiveCN103112846ALarge specific surface areaLight in massMaterial nanotechnologyCarbon compoundsTin dioxideCarbon nanotube

The invention discloses a preparation method of a graphene-carbon nanotube-nano tin dioxide three-dimensional composite material, which comprises the following steps: (a) by using deionized water as a solvent, sequentially adding graphene oxide, stannous dichloride and multiwall carbon nanotubes as solutes, and mixing; (b) performing ultrasonic reaction on the mixed solution at 25-40 DEG C under the ultrasonic power of 100-300W for 1-2 hours; and (c) transferring the solution subjected to ultrasonic reaction into a hydrothermal kettle, performing hydrothermal treatment at 120-300 DEG C for 6-72 hours, and slowly cooling to room temperature, thereby obtaining the three-dimensional-structure graphene-carbon nanotube-nano tin dioxide composite material product. The invention also discloses a corresponding product and application thereof. The method disclosed by the invention can be used for preparing the three-dimensional-structure graphene composite material in an economic environment-friendly and convenient-operation mode; and the graphene-carbon nanotube-nano tin dioxide three-dimensional composite material has the characteristics of high specific surface area, porousness, light weight, long cycle life and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

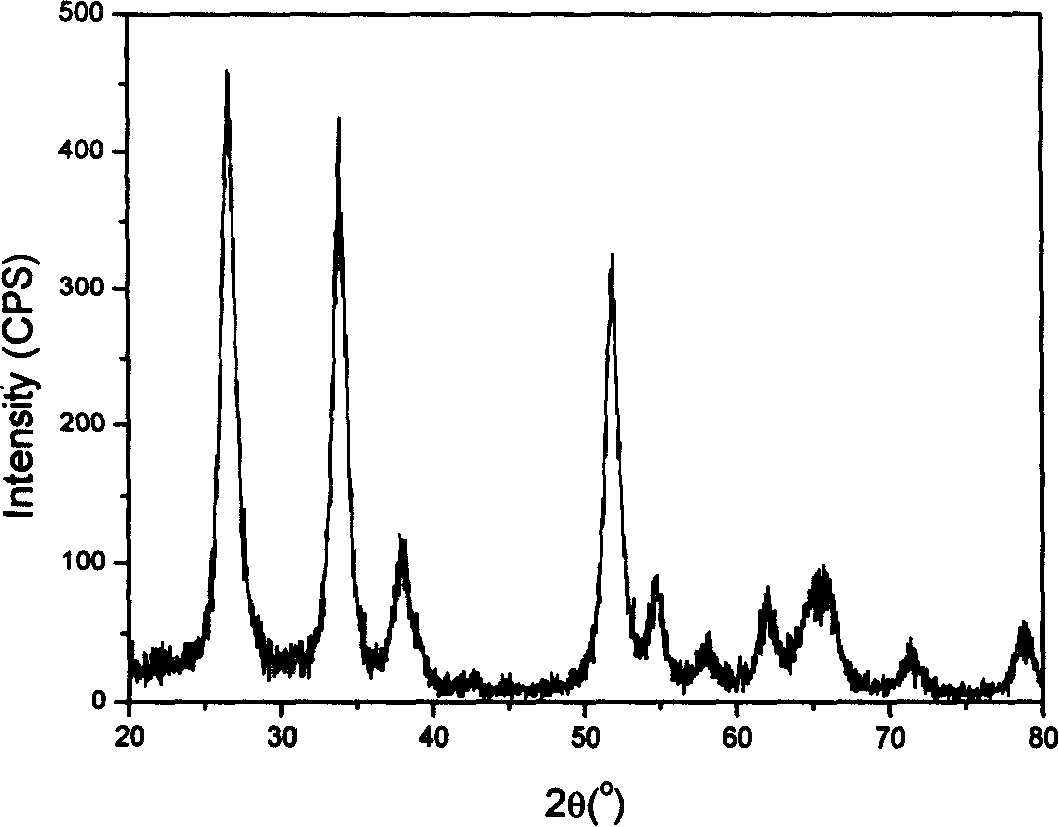

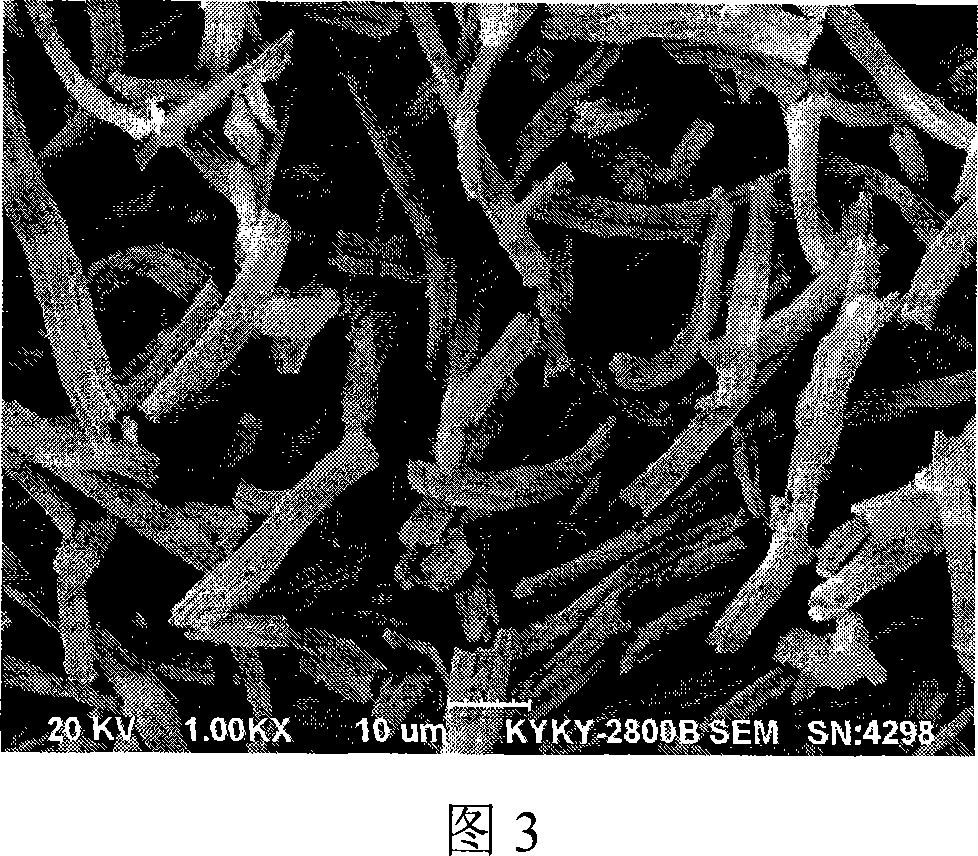

Preparing low density porous tin dioxide nano fiber laser target material by electro-static spinning method

InactiveCN1858308AHigh porosityChemical composition is easy to controlInorganic material artificial filamentsFilament/thread formingTin dioxideVolumetric Mass Density

The electrostatic spinning process for preparing low density porous nanometer SnO2 fiber as laser target material is fast, efficient and simple. The electrostatic spinning process includes compound spinning solution with polyvinyl pyrrolidone, absolute ethyl alcohol, tin tetrachloride in certain weight proportion through mixing at room temperature; electrostatic spinning through spraying the spinning solution with spinning jet to an accepting screen 5-30 cm apart from the jet while applying electric field of 0.1-1 kv / cm, controlling the spraying time and the motion of the accepting screen to obtain fiber of different density and deposited in different areas; and roasting at 450-550 deg.c to obtain the nanometer SnO2 fiber.

Owner:SOUTHEAST UNIV

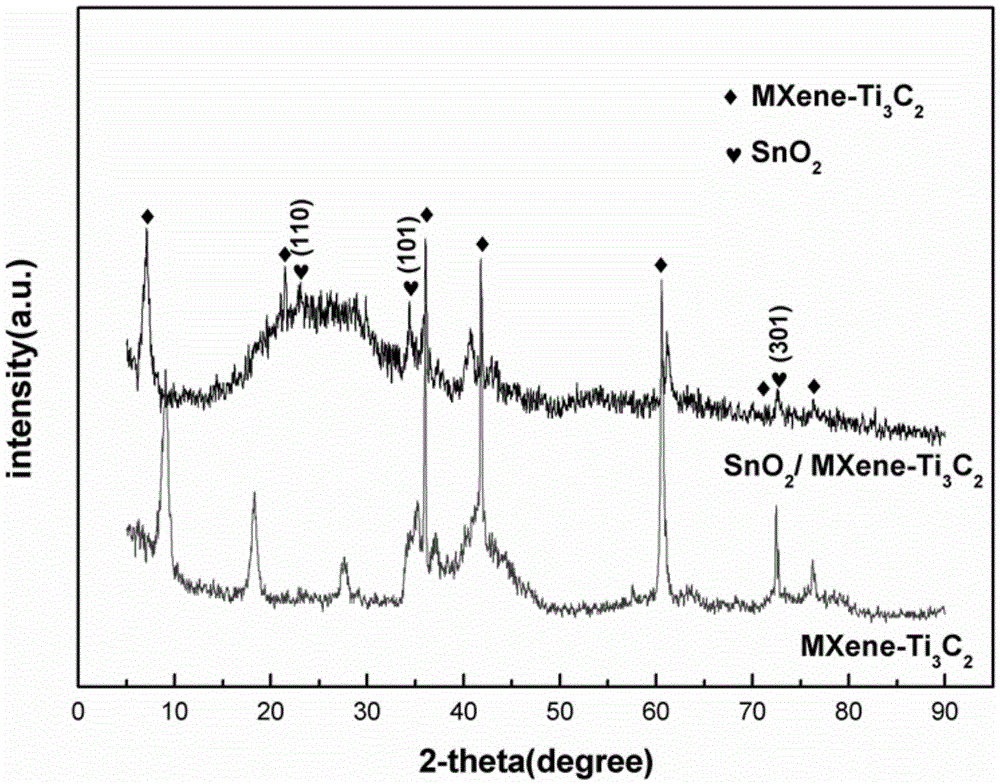

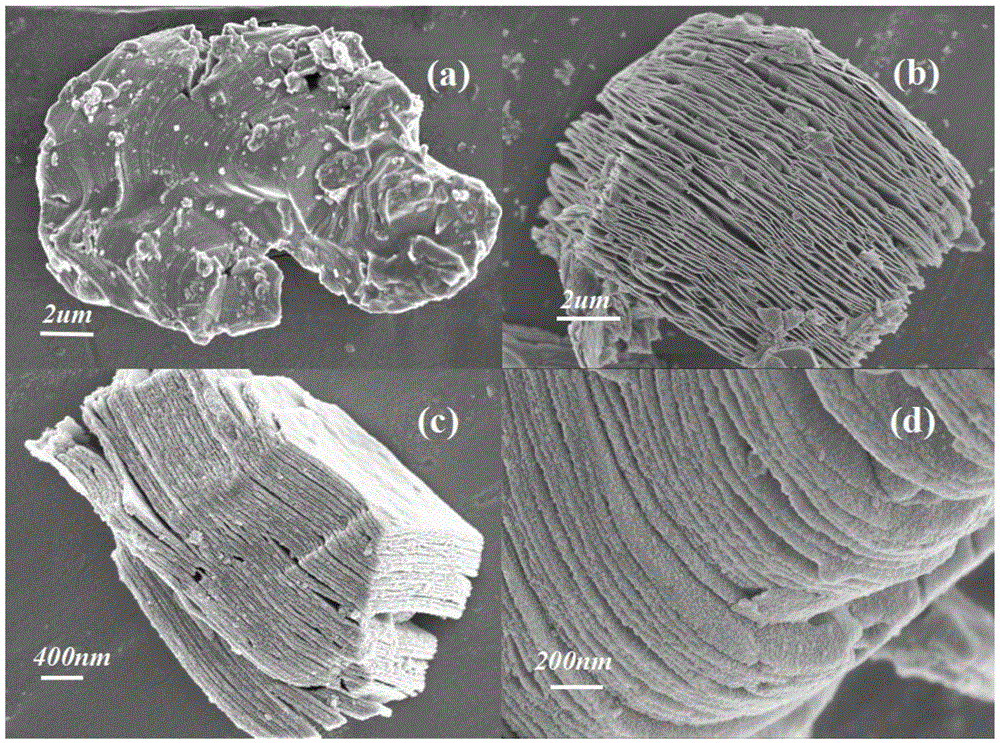

Preparation method of granular tin dioxide/two-dimensional nano titanium carbide composite material

ActiveCN105470486AImprove electrochemical performanceImprove thermal conductivityHybrid capacitor electrodesCell electrodesTin dioxideTitanium carbide

The invention provides a preparation method of a tin dioxide / two-dimensional nano titanium carbide composite material. The preparation method comprises: carrying out ball milling on ternary layered Ti3AlC2 ceramic powder; immersing the obtained product in hydrofluoric acid solution to perform the reaction for 6h to 120h; stirring, centrifugally cleaning a corrosion product by using deionized water, and drying an obtained solid sample to obtain a two-dimensional layered nano material MXene-Ti3C2; and mixing SnCl4.5H2O, glucose and the two-dimensional nano MXene-Ti3C2, using ethanol as a solvent, adjusting PH to 12 to 14, stirring with a magnetic force for 2h, performing the reaction at 120 DEG C for 6h, and after naturally cooling to a room temperature, carrying out centrifuging and drying to obtain a SnO2 / MXene-Ti3C2 composite material. The material obtained by the preparation method can effectively alleviate a volume effect of SnO2 nano particles, and the SnO2 / MXene-Ti3C2 nano composite material has an excellent application prospect in the field of an anode material field of a high storage germanium lithium ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing graphene aerogel loaded tin dioxide composite material

InactiveCN104143631AHigh charge and discharge capacityImproved magnification performanceMaterial nanotechnologyCell electrodesElectrolytic agentTin dioxide

The invention relates to a method for preparing a graphene aerogel loaded tin dioxide composite material, belonging to the technical field of electrode materials of lithium ion batteries. The method mainly comprises the following steps: stirring and performing ultrasonic treatment on oxidized graphene and water-soluble tin salt in a mass ratio of (2:1)-(1:3), adding 0.1-2mL of an organic amine solution, transferring into a hydrothermal kettle, keeping for 6-24 hours at 80-180 DEG C, subsequently taking out a columnar product, and performing freeze-drying on the product so as to obtain the graphene aerogel loaded tin dioxide composite material. According to the graphene aerogel loaded tin dioxide composite material prepared by using the method, and thin graphene is cross-linked to form micron-order ducts, and the surface of the graphene is uniformly loaded with 3-6nm of tin dioxide grains. By adopting a three-dimensional structure, very good electrolyte wettability is achieved, the excellent conductivity of graphene is brought into full play, the growth of the tin dioxide grains is controlled, the negative effects caused by size increase are avoided, and the structural stability and the circulation property of the composite material as a negative electrode material are improved.

Owner:SHANGHAI UNIV

A kind of copper red glaze and its production method and the method for making ceramic product with it

The invention discloses copper red glaze and a production method thereof, and a method for preparing a ceramic product therefrom. The copper red glaze is prepared from parent glaze, a coloring agent and a stabilizing agent, wherein the parent glaze is prepared from the following components in parts by weight: 26 to 32 parts of quartz, 24 to 30 parts of feldspar, 10 to 14 parts of limestone, 12 to16 parts of barium carbonate, 4 to 8 parts of clay, 0 to 4 parts of zinc oxide and 0 to 4 parts of sodium borate; the coloring agent is one or a mixture of a plurality of copper oxide, cuprous oxide and copper carbonate, and the adding amount of the coloring agent is 1 to 4 parts by weight; the stabilizing agent is one or a mixture of a plurality of stannic oxide, ferric oxide, lead oxide and silicon carbide, and the adding amount of the stabilizing agent is 3 to 6 parts by weight. According to the invention, the copper red glaze is bright crimson red, the ceramic product produced from the copper red glaze has high yield and low cost, and can be used for producing domestic ceramic and display art ceramic products.

Owner:广东文化长城集团股份有限公司

N-doped porous carbon nano-fiber@tin dioxide lithium-ion battery negative electrode material and preparation method thereof

The invention discloses an N-doped porous carbon nano-fiber@tin dioxide lithium-ion battery negative electrode material and a preparation method thereof. The preparation method is characterized by comprising the following steps: firstly, preparing nano-fibers containing ZIF-8 through an electrostatic spinning method and carrying out high-temperature calcination under the protection of inert gas toprepare porous carbon nano-fibers CNF; then covering outer surfaces of the porous carbon nano-fibers CNF with one layer of SnO2 nanoparticles through a hydrothermal method, so as to obtain a CNF@SnO2nano composite material; finally, covering the outer surface of the composite material with one layer of polypyrrole PPy and carrying out the high-temperature calcination to obtain an N-doped CNF@SnO2 nano composite material used as the lithium-ion battery negative electrode material. The N-doped porous carbon nano-fiber@tin dioxide lithium-ion battery negative electrode material disclosed by theinvention is the chargeable and dischargeable lithium-ion battery negative electrode material; the problems that the stability and the electrical conductivity of the metal SnO2 nanoparticles are poorin a charging / discharging process of a battery are effectively solved, and the circulating performance and the rate performance of the battery are improved; the preparation method disclosed by the invention is simple and is hopeful to realize large-scale production, so that the preparation method has a very good application prospect.

Owner:HEFEI UNIV OF TECH

Method of preparing titanium dioxide, stannum dioxide and doping composite fiber material thereof

InactiveCN101033082AGood lookingSimple structureNanostructure manufactureTitanium dioxideTin dioxideNitrogen gas

This invention relates to a method for preparing fiber TiO2, SnO2 and its doped compound material characterizing in utilizing a fiber material as a template, taking TBT, titanium tetrahalide, tin tetrachloride or a mixture as a precursor, which is carried by nitrogen or argon and enters into a reactor with a gas containing ammonia for chemical gaseous phase deposition, in which, the gas flow, deposition temperature and the sinter atmosphere and temperature are controlled, the inert gas is heated to get load-type fiber material to be sintered under the atmosphere of oxidation and reaction to remove the fiber template and form an oxide fiber material, and utilize the active carbon fiber template and ignition process to form porous fiber or tubular fiber material.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com