Method for preparing hollow spherical stannic oxide nano powder

A hollow spherical, nano-powder technology, applied in tin oxide, nano-structure manufacturing, nano-technology, etc., can solve problems such as pollution, environment, and high heat treatment temperature, and achieve the effect of no pollution in the process, simple raw materials, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a) 1.3539g SnCl 2 .2H 2 O is dissolved in 20ml of absolute ethanol, then stirred until forming the clear solution of tin protochloride of 0.3mol / l; The NaOH of 0.8g is dissolved in 50ml deionized water, then stirred until forming the clear solution of NaOH of 0.4mol / l;

[0033] b) under strong stirring, NaOH solution is evenly added dropwise to the tin salt solution until the pH value is between 11 and 13, and then stirred for 10 minutes to form a uniform milky white precursor solution;

[0034] c) Transfer the above precursor solution to a hydrothermal reactor, conduct a hydrothermal treatment at 180° C. for 12 hours, and then naturally cool to room temperature;

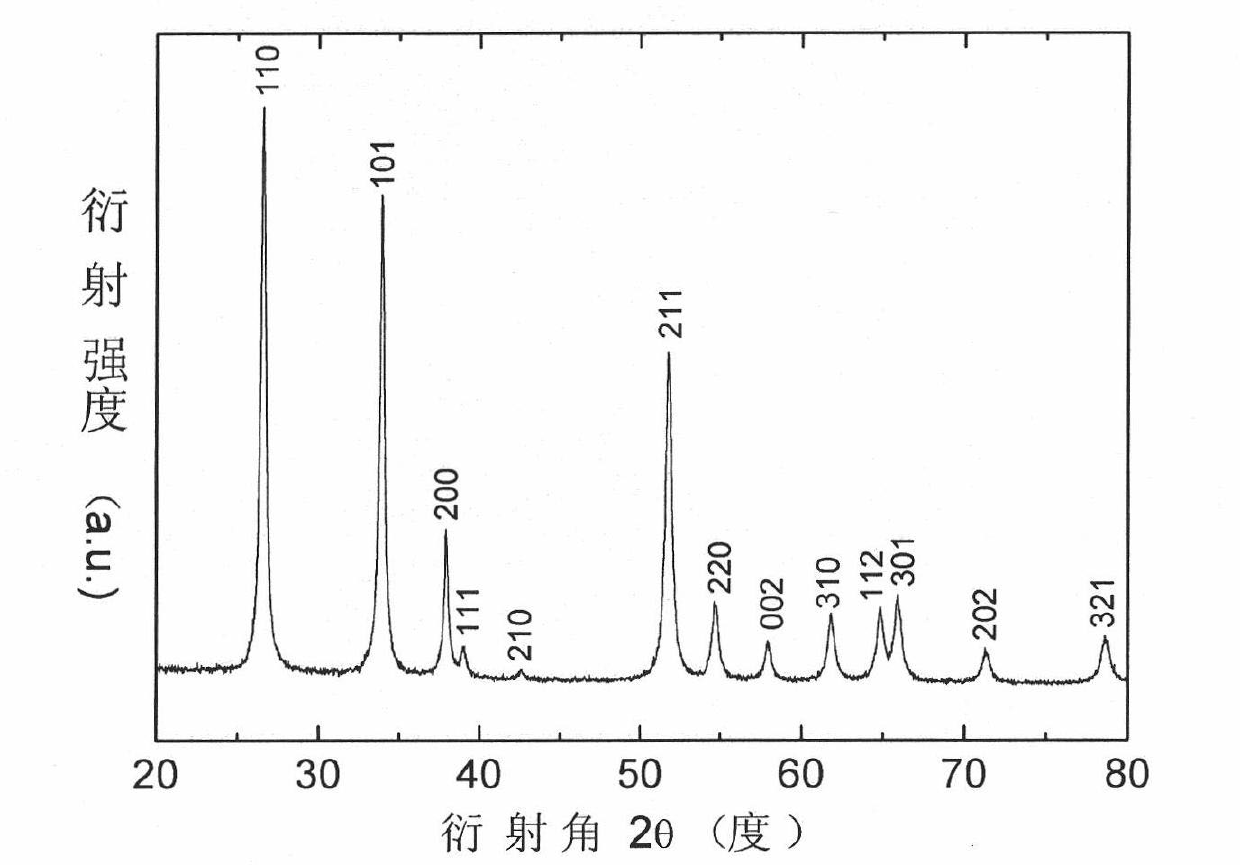

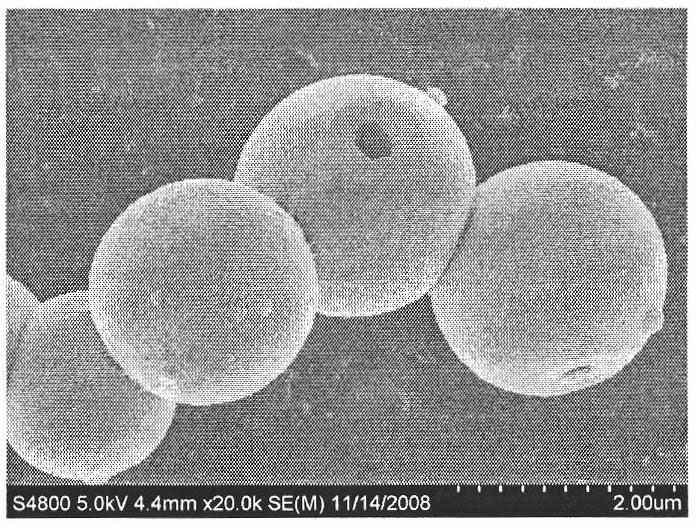

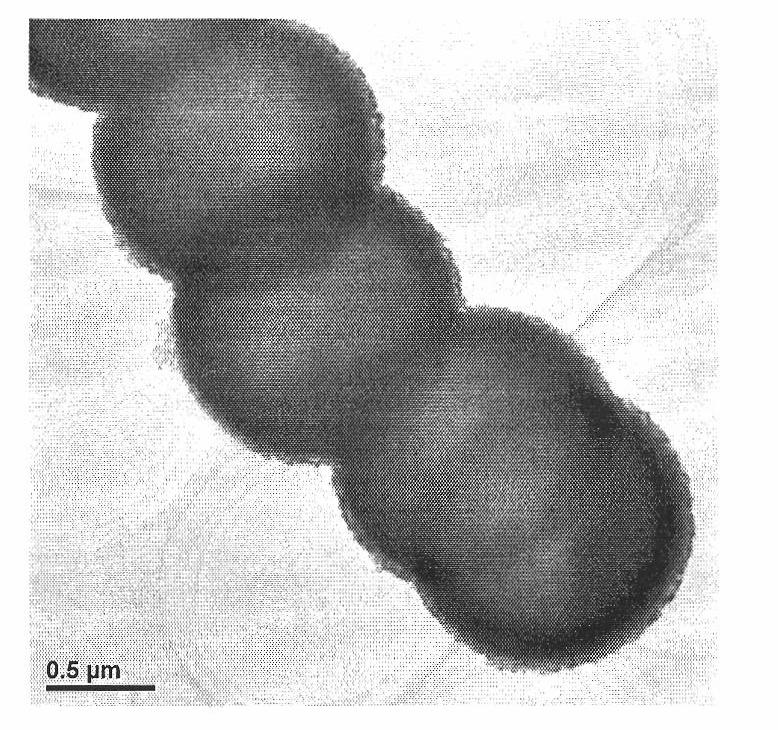

[0035] d) Wash the hydrothermal product several times with deionized water and absolute ethanol in sequence until the soluble ions are completely removed, and dry at 70°C for 2 hours under vacuum to obtain white hollow spherical SnO 2 Nano powder. by SnO 2 SnO composed of nanoparticles 2 The diameter of ...

Embodiment 2

[0038] a) 1.8052g SnCl 2 .2H 2 O is dissolved in 20ml of absolute ethanol, then stirred until forming the clear solution of stannous chloride of 0.4mol / l; the NaOH of 0.4g is dissolved in 20ml deionized water, then stirred until forming the clear solution of NaOH of 0.5mol / l;

[0039] b) Under strong stirring, evenly drop NaOH solution into the tin salt solution until the pH value is between 11 and 13, and then stir for 15 minutes to form a uniform milky white precursor solution;

[0040] c) Add 10ml of ethylene glycol to the above precursor solution, and then stir for 30min to form a uniform solution;

[0041] d) Transfer the above solution to a hydrothermal reaction kettle, perform hydrothermal treatment at 180° C. for 12 hours, and then naturally cool to room temperature;

[0042] e) Wash the hydrothermal product several times with deionized water and absolute ethanol in sequence until the soluble ions are completely removed, and dry at 90°C for 1 h under vacuum to obtain w...

Embodiment 3

[0044] a) 1.0518g SnCl 4 .5H 2 O is dissolved in 10ml of deionized water, then stirred until forming a 0.3mol / l tin chloride solution; 0.8g of NaOH is dissolved in 40ml of deionized water, then stirred until forming a 0.5mol / l clear solution of NaOH;

[0045] b) under strong stirring, NaOH solution is evenly added dropwise to the tin salt solution until the pH value is between 11 and 13, and then stirred for 10 minutes to form a uniform milky white precursor solution;

[0046] c) Transfer the above precursor solution to a hydrothermal reaction kettle, hydrothermally treat at 160°C for 16h, and then naturally cool to room temperature;

[0047] d) Wash the hydrothermal product several times with deionized water and absolute ethanol in sequence until the soluble ions are completely removed, and dry at 60 °C for 3 h under vacuum to obtain white hollow spherical SnO 2 Nano powder. by SnO 2 SnO composed of nanoparticles 2 The diameter of the hollow sphere is about 1 μm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com