Patents

Literature

66467results about How to "No pollution in the process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

an air purifier

InactiveCN103861421BLarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

Owner:QINGDAO CHUANSHAN NEW MATERIALS

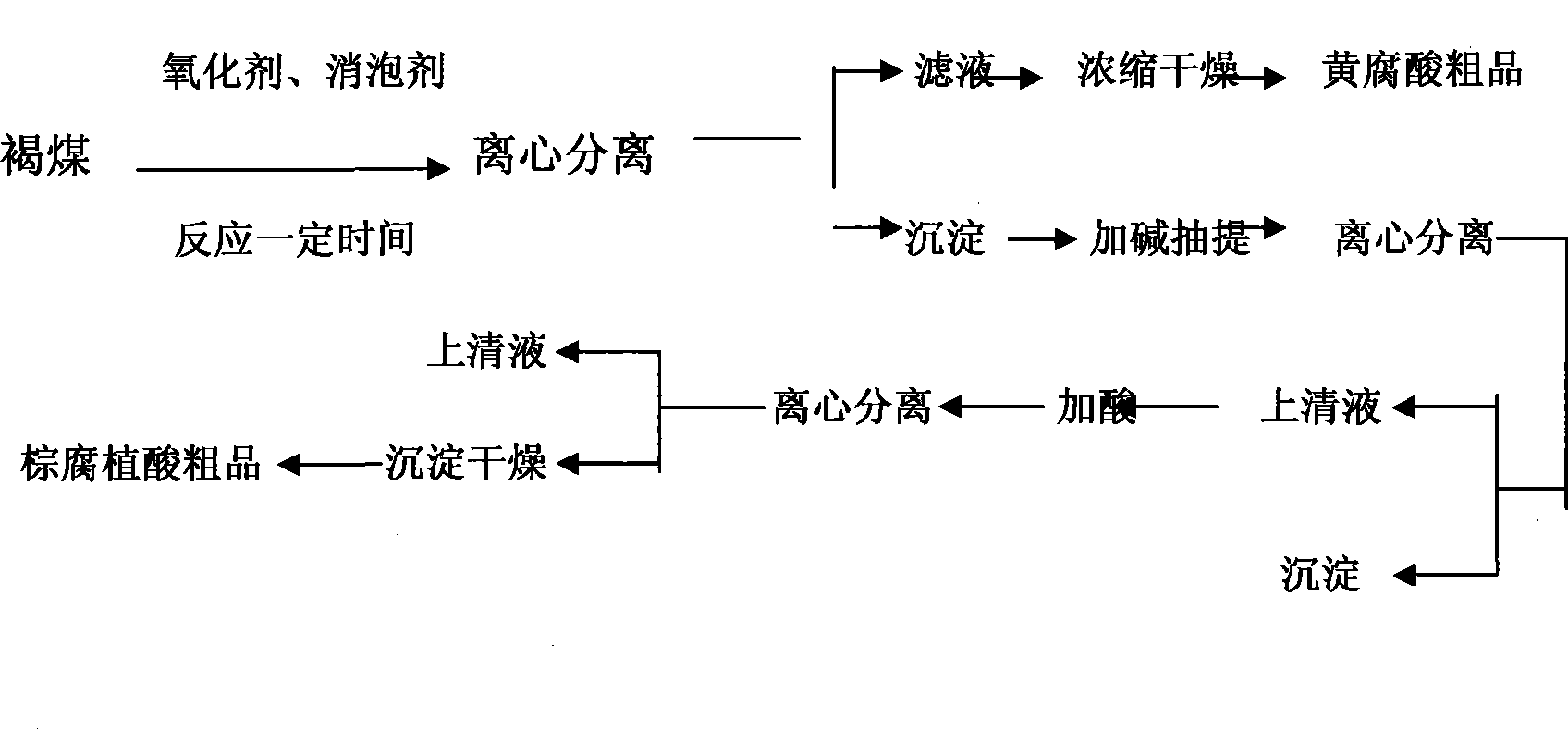

Method for preparing humic acid and salt thereof by oxidation and degradation of brown coal

The invention discloses a method for producing humic acid and salt thereof through the oxidative degradation of young lignite. The method comprises the following steps: carrying out the oxidation reaction of the lignite containing the humic acid and aqueous hydrogen peroxide solution; after the reaction, obtaining water soluble fulvic acid through centrifugal separation, supernatant filtration, concentration and drying; adding alkali into the fulvic acid to prepare a fulvic acid salt product; carrying out the alkaline extraction and centrifugal separation of the residue deposit of the production of the fulvic acid, adding acid into the supernatant till the pH value is 1 to 2, carrying out a reaction at an increased temperature or room temperature, carrying out centrifugal separation after the reaction is finished, and obtaining purified ulmic acid after precipitation and drying; and directly concentrating and drying the supernatant in the previous step to obtain the humate. The method can improve the yield of the fulvic acid and total humic acid in the young lignite, and simultaneously increase the active group in the humic acid. The method can be used for producing fulvic acid, fulvic acid salt, ulmic acid and ulmic acid salt products. In particular, the method puts an end to the environmental pollution caused by the nitric acid which is taken as an oxidation degradation agent. In addition, the method has a short technological line, low cost, simple requirements on equipment, and moderate conditions. The method which can be applied to the industrialized production has good application prospect.

Owner:KUNMING UNIV OF SCI & TECH +4

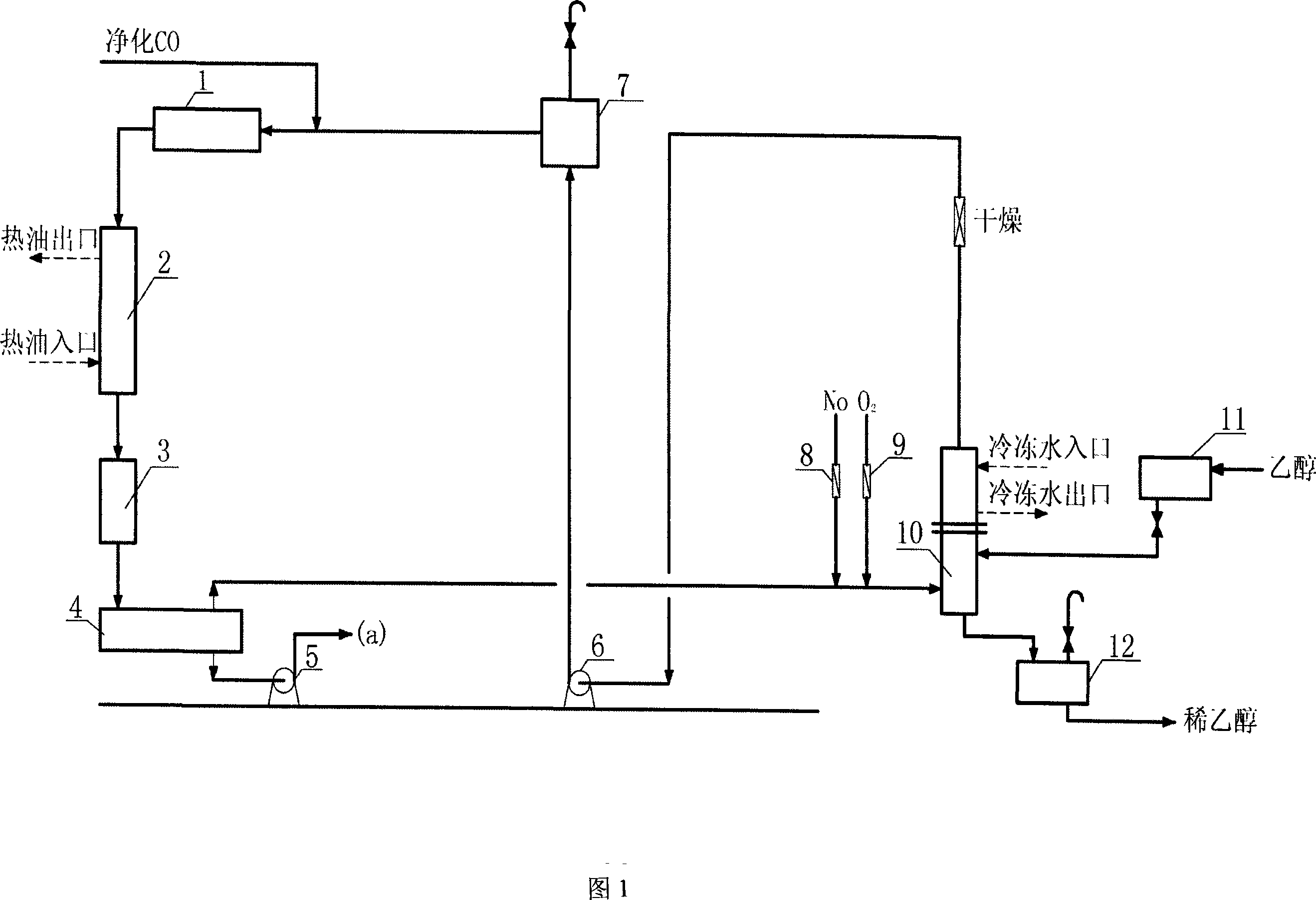

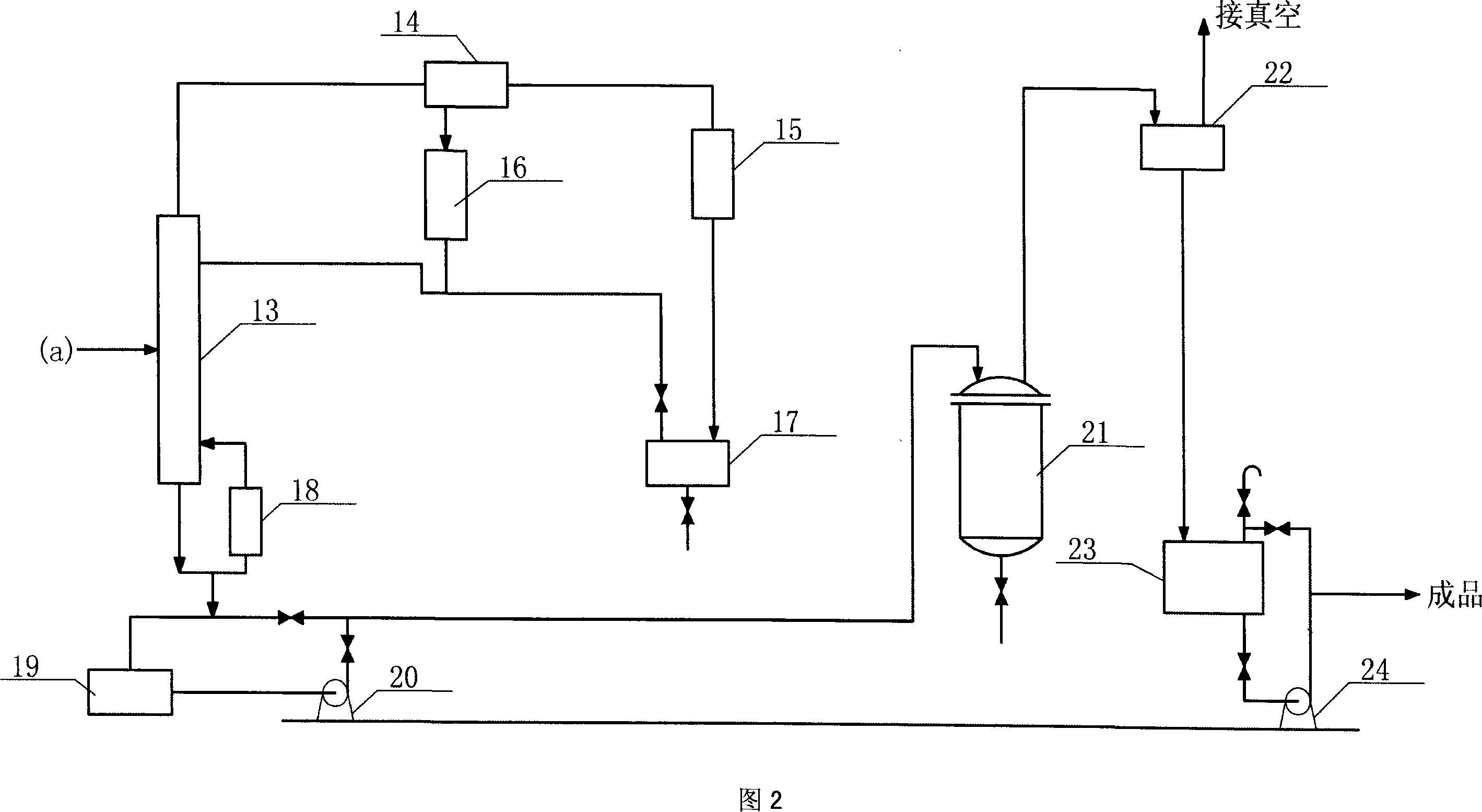

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

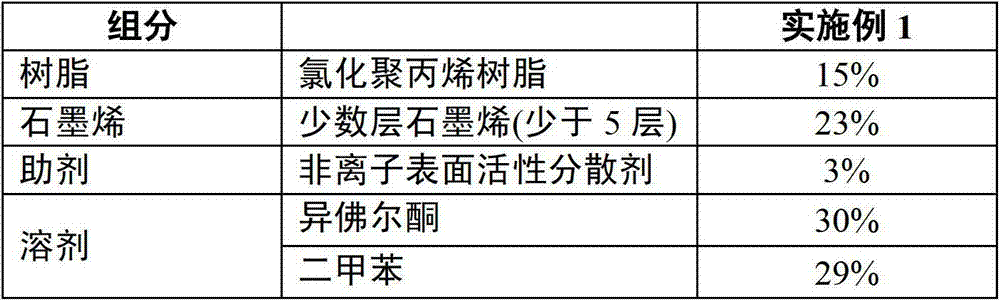

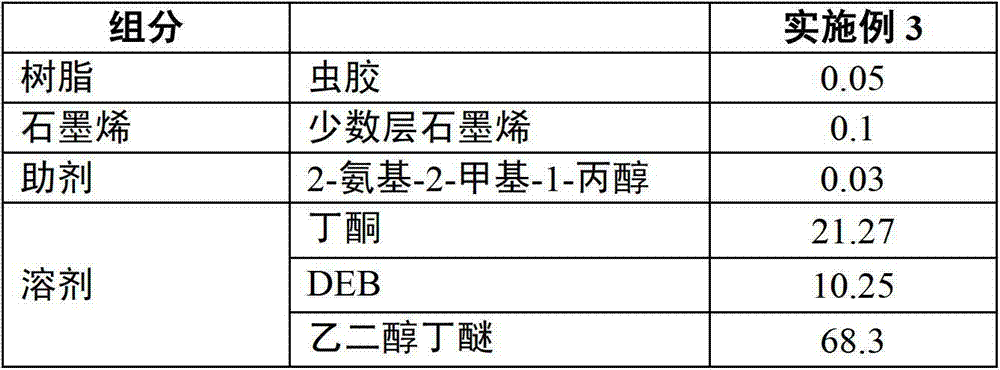

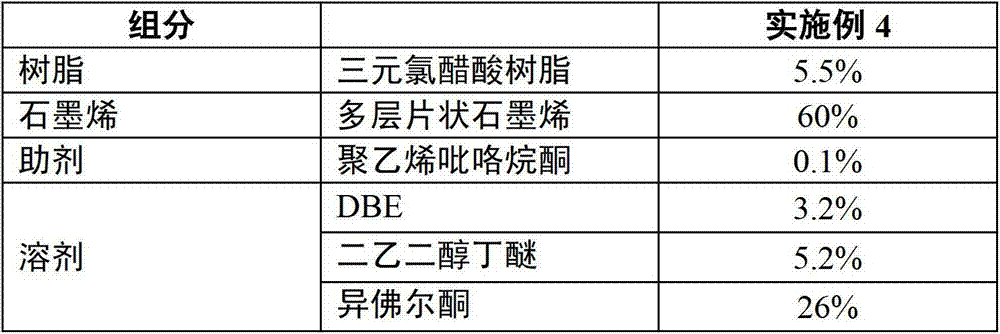

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

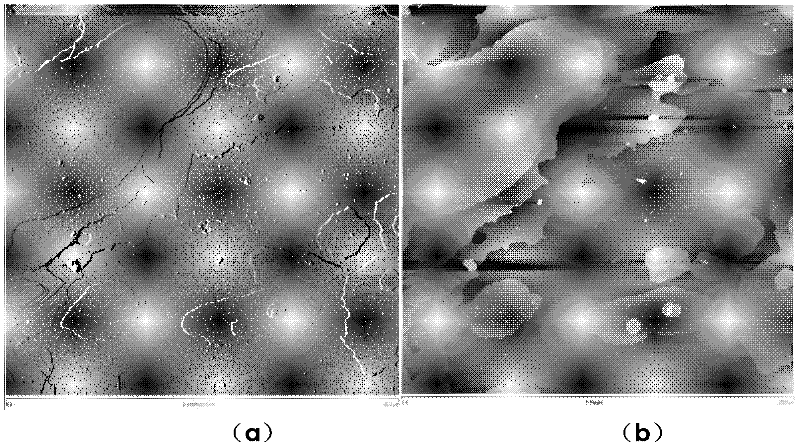

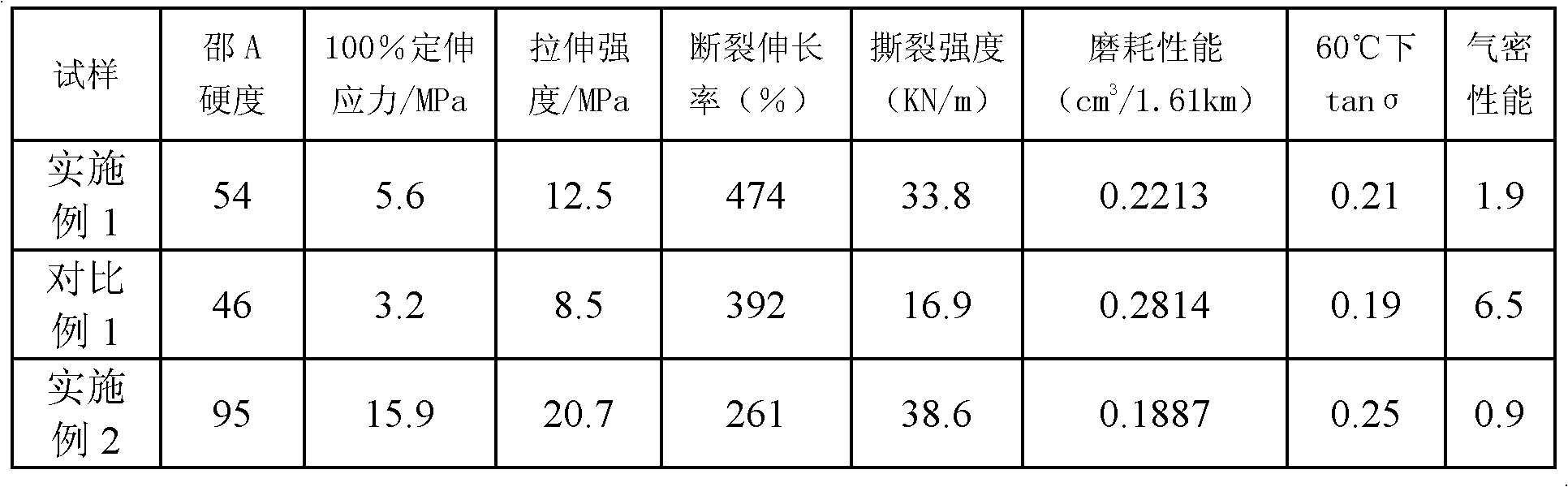

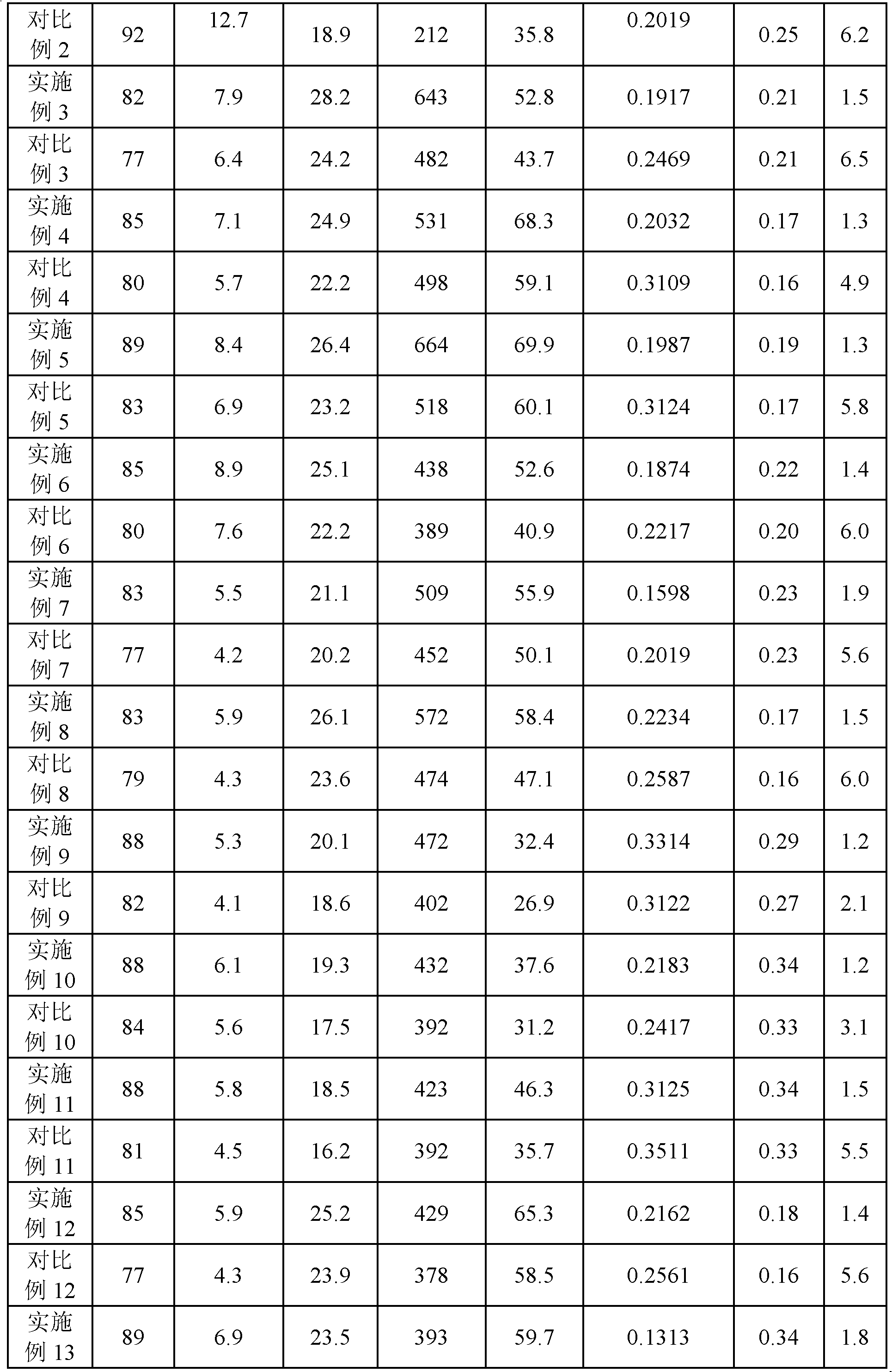

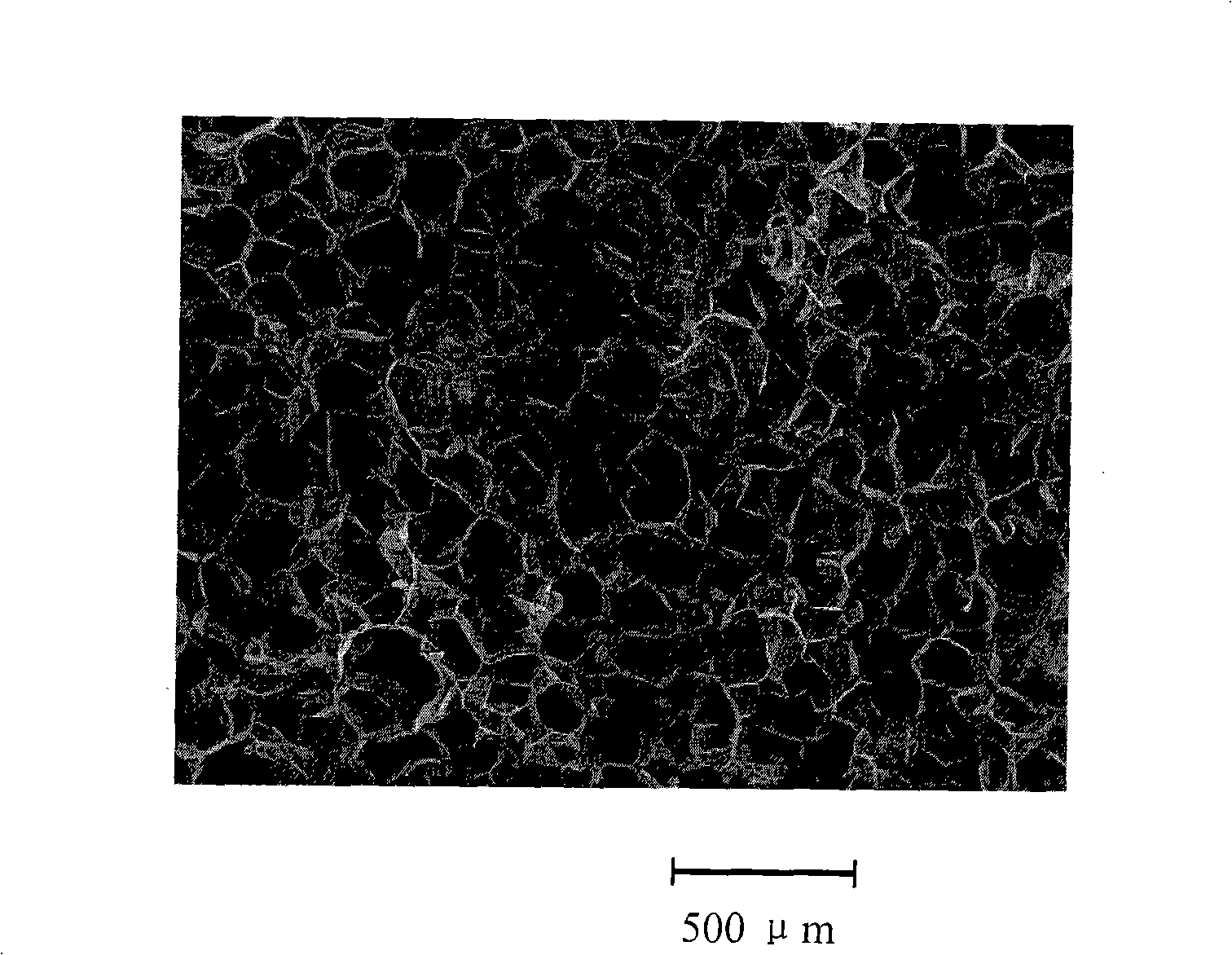

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

Method for synthesizing epoxypropane

ActiveCN101279959AHigh selectivityExtend your lifeOrganic chemistryBulk chemical productionAlcoholReaction temperature

The invention discloses a method to synthesize propylene oxide, which is characterized in that alcohol with low content of carbon, propylene and oxydol(mol ratio 1-15:0.5-5:1) are put into a reactor which is fed with catalyzer; the propylene and the oxydol react and produce propylene oxide, and the condition for the reaction includes: temperature 30-90 DEG C, pressure 0.5-4.5MPa, ph value of the solution 5,0-8.0, and airspeed of the solution 0.1-7h-1; wherein the temperature and ph value of the solution in the whole process are adjusted according to the conversion rate of the oxydol, and once the conversion rate of the oxydol drops to 88.5%, the ph value and the temperature of the solution are increased. The method is simple in process, mild in condition, the conversion rate of the oxydol is high and the propylene oxide is of selectivity; meanwhile, the life of the catalyzer is prolonged to over 1200h through the adjustment of the ph value and the temperature of the solution.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD +2

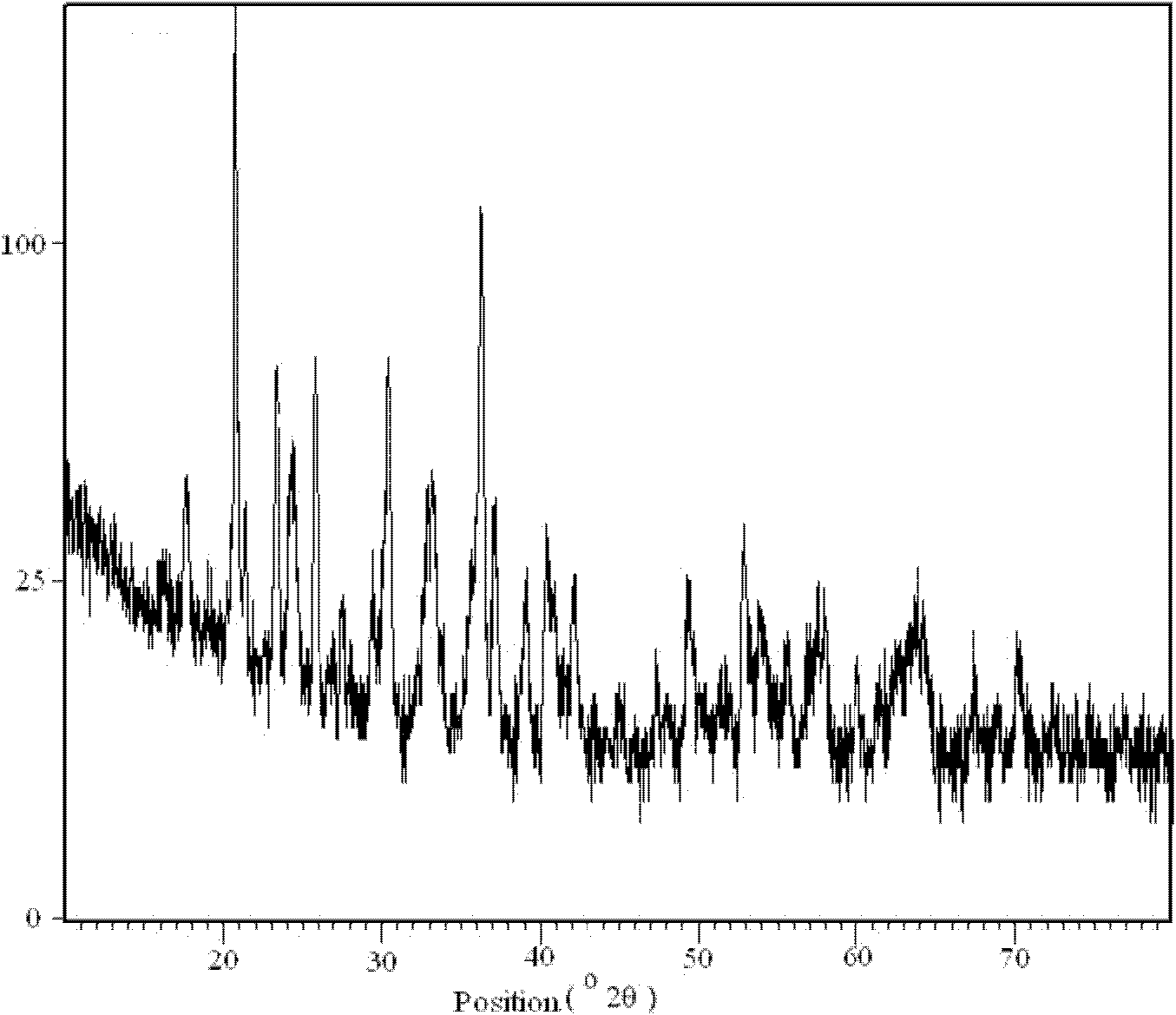

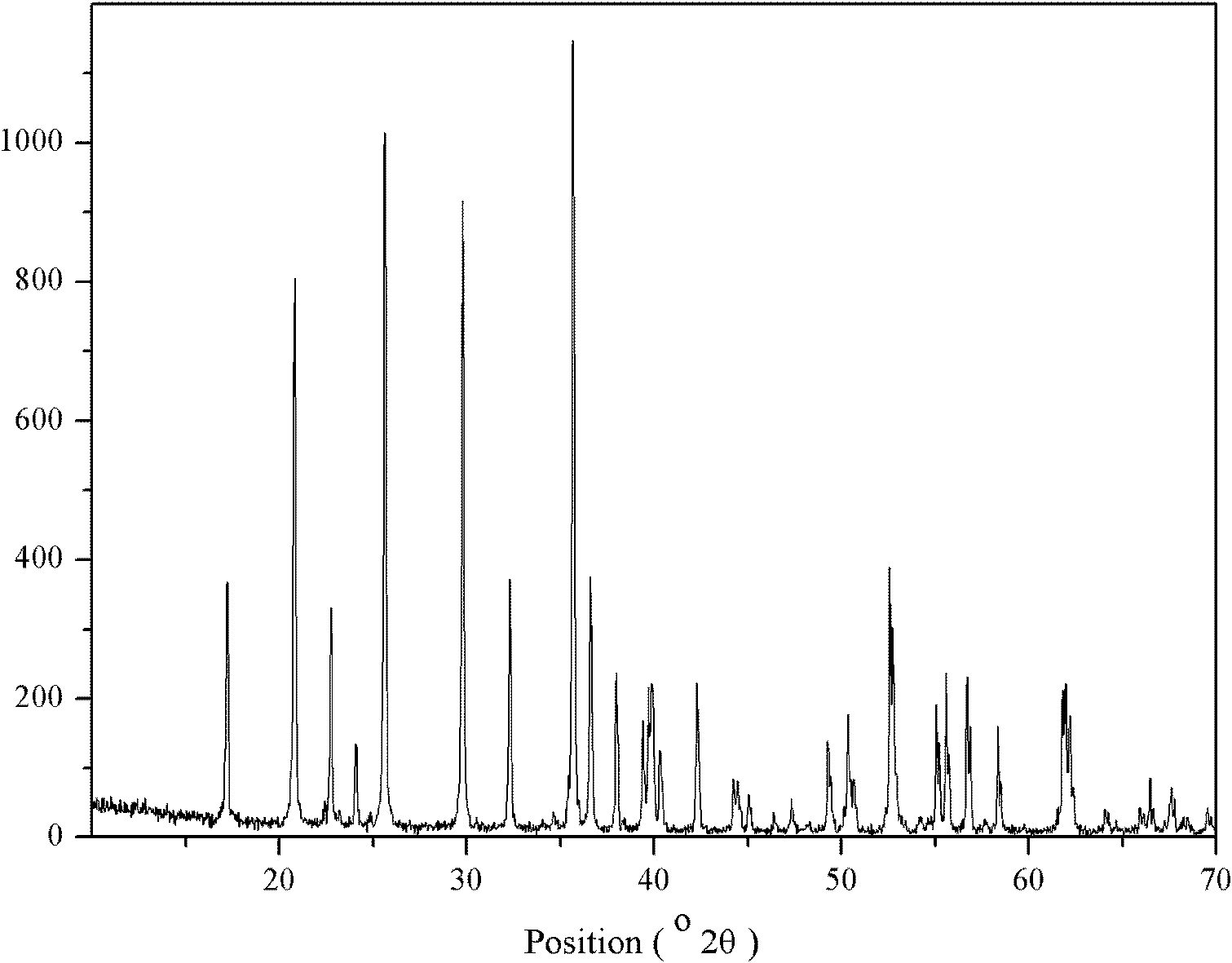

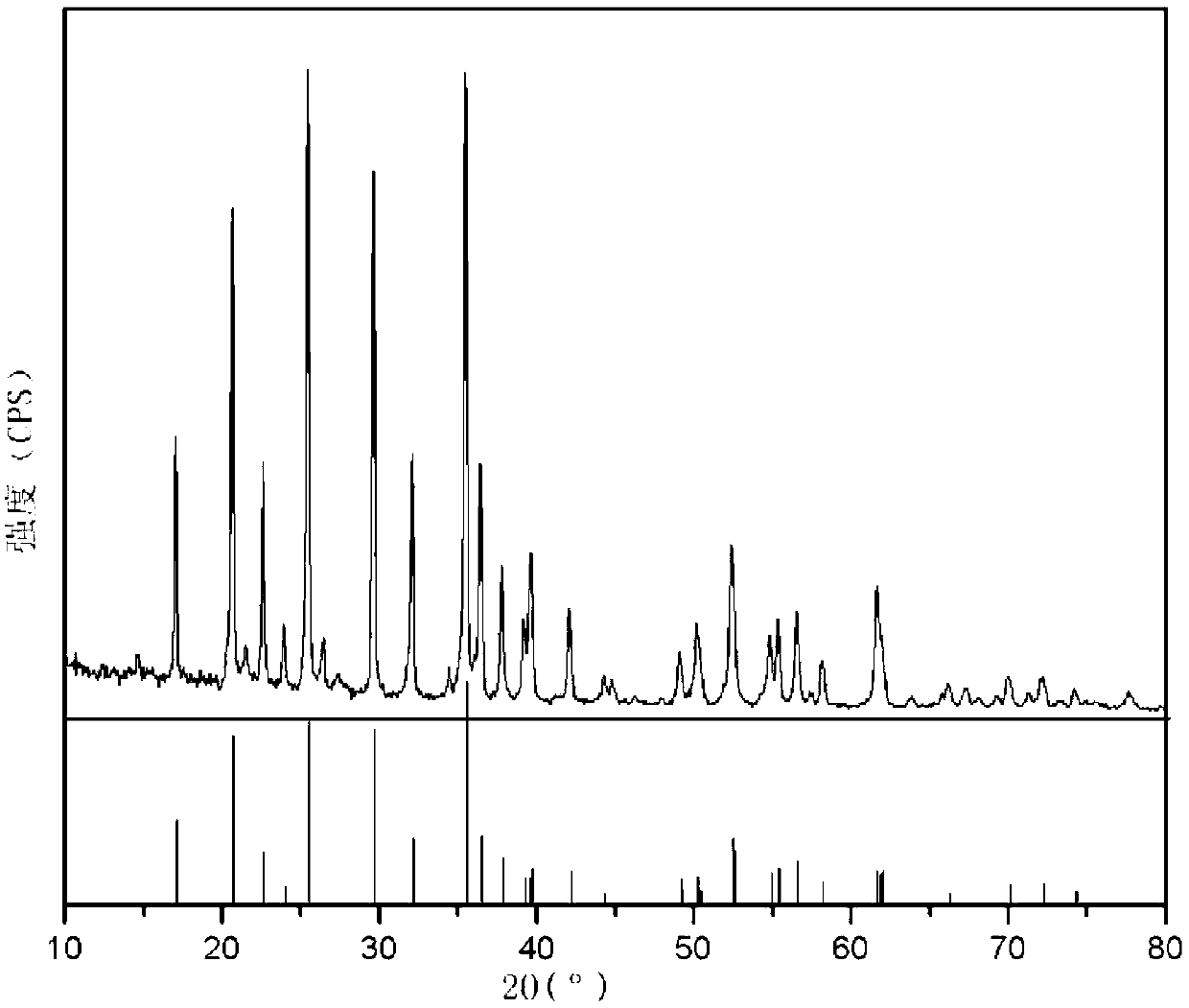

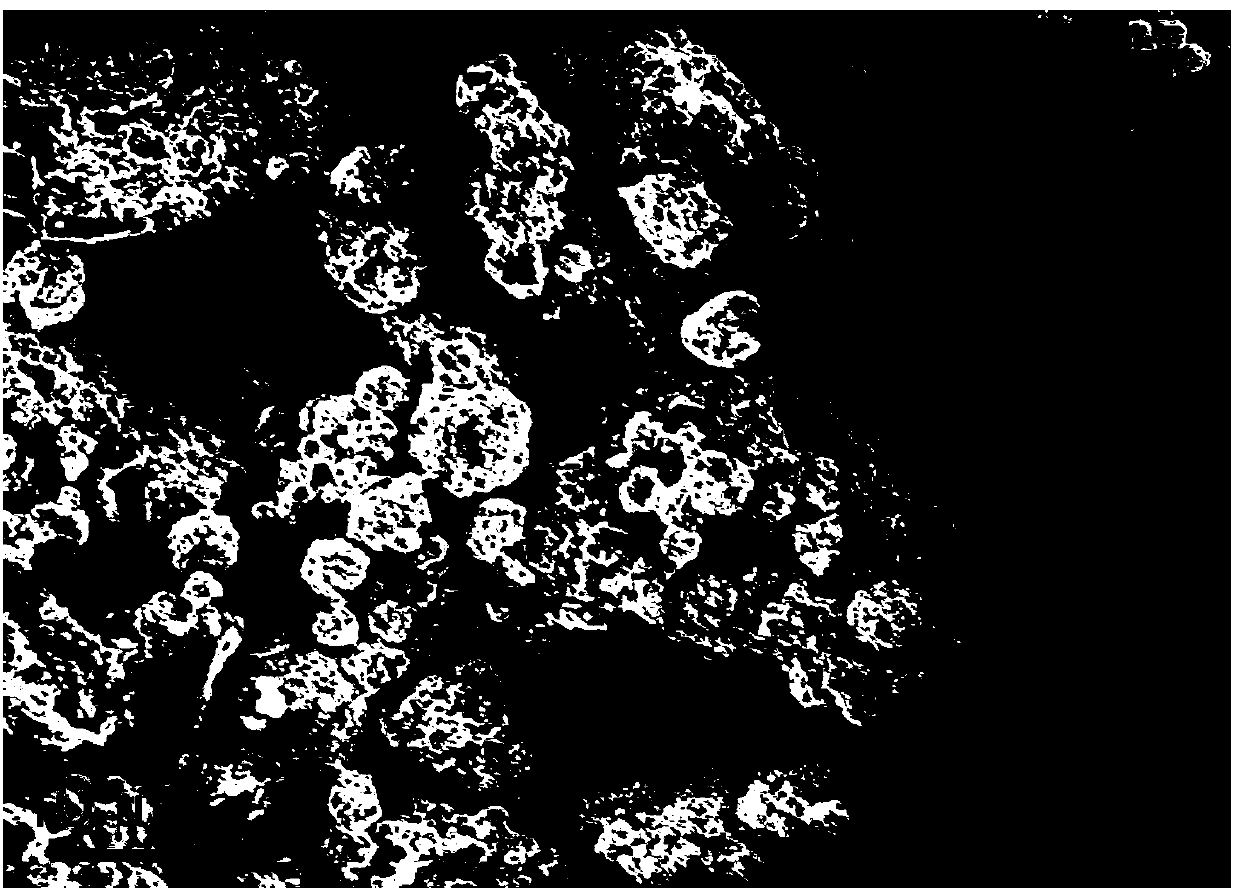

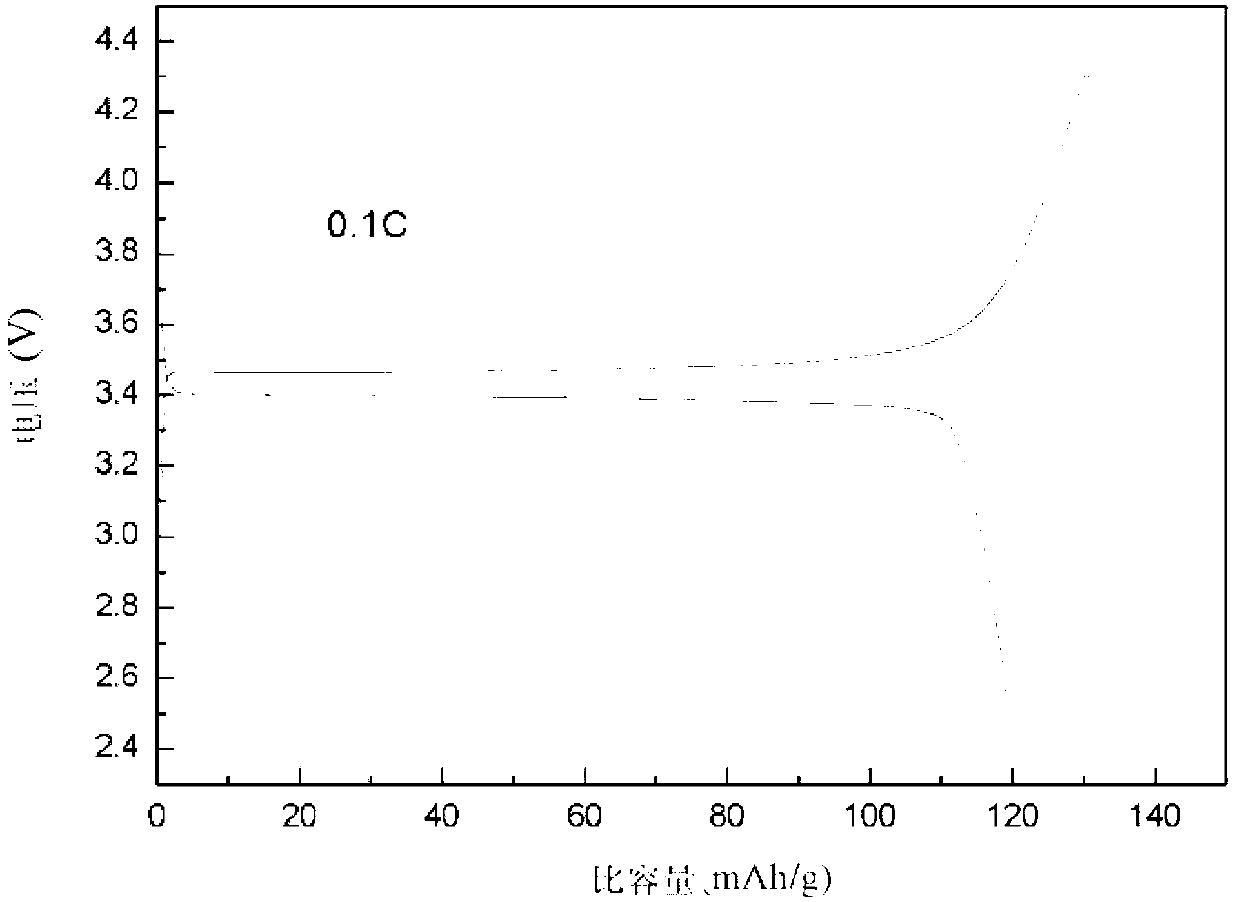

Recycling treatment method of waste and old lithium iron phosphate battery anode materials

InactiveCN102208706ANo pollution in the processEasy to operateSolid waste disposalWaste accumulators reclaimingLithium iron phosphateHigh energy

The invention discloses a recycling treatment method of waste and old lithium iron phosphate battery anode materials, which comprises the following steps of: firstly, scattering waste and old lithium iron phosphate batteries and stripping and collecting anode materials in the waste batteries; heating the collected anode materials at high temperature and removing carbon and an adhesion agent to obtain solid powder; adding a lithium source compound and a carbon source into the solid mixture; ball-milling the mixture through a high-energy wet method; and finally, charging the ball-milled powder into a non-oxide atmosphere and roasting at high temperature to obtain the qualified lithium iron phosphate anode materials. The recycling method disclosed by the invention has the advantages of simple process, convenience for operation and high recovery rate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

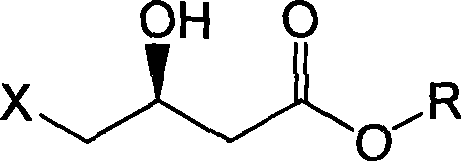

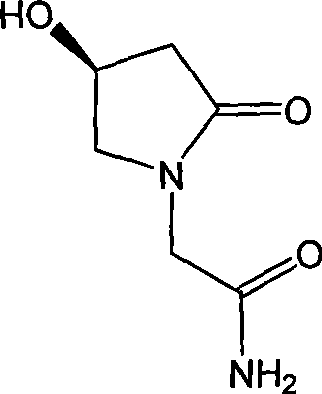

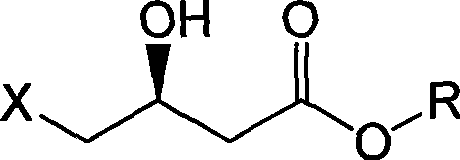

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

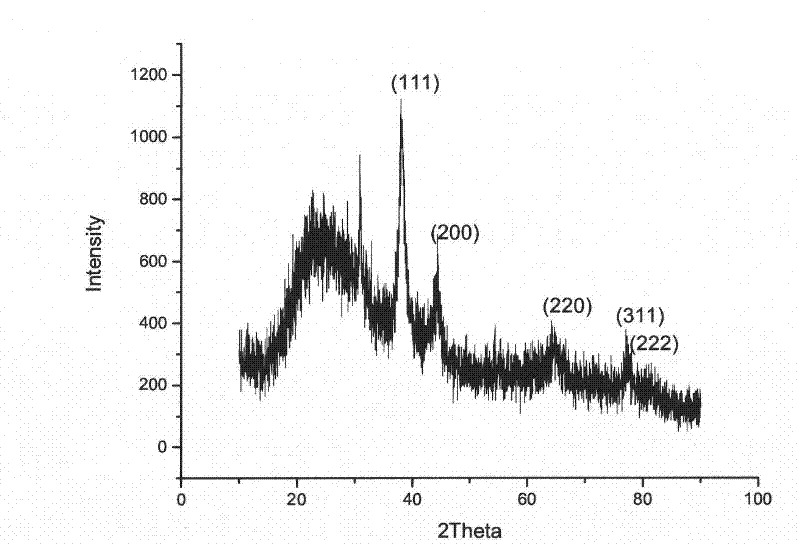

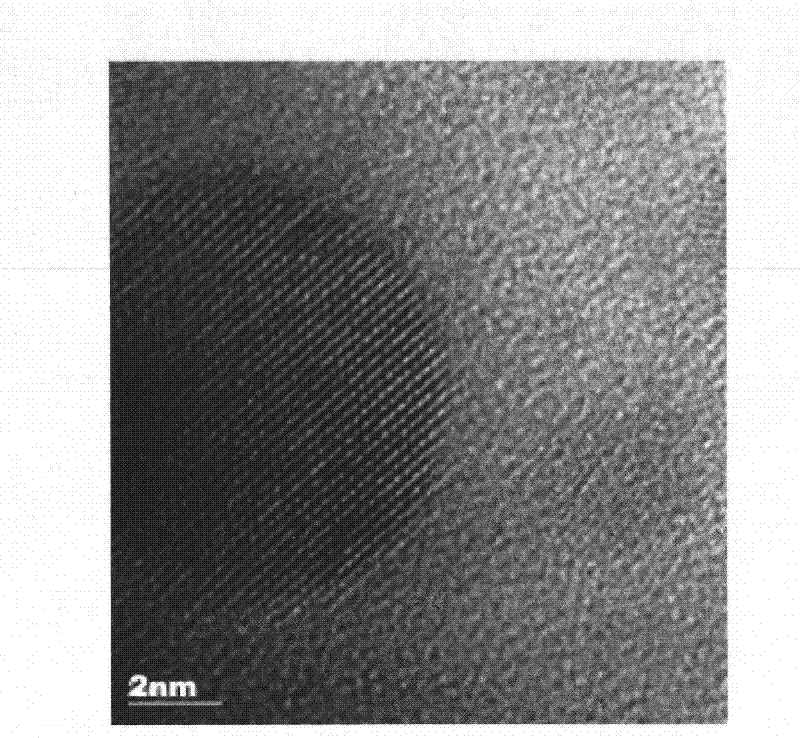

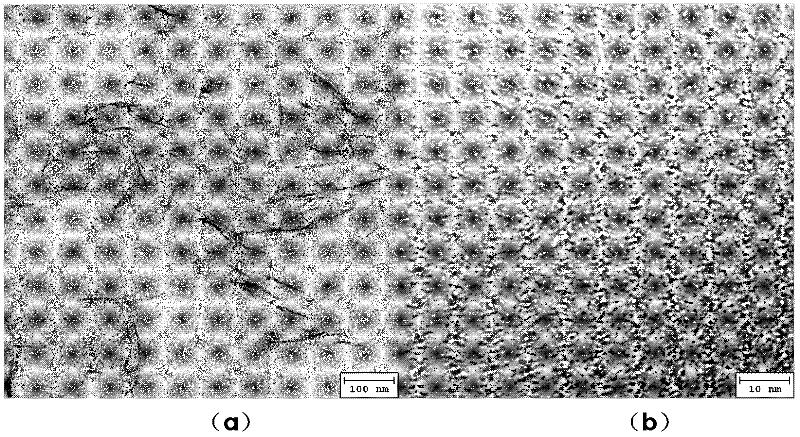

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

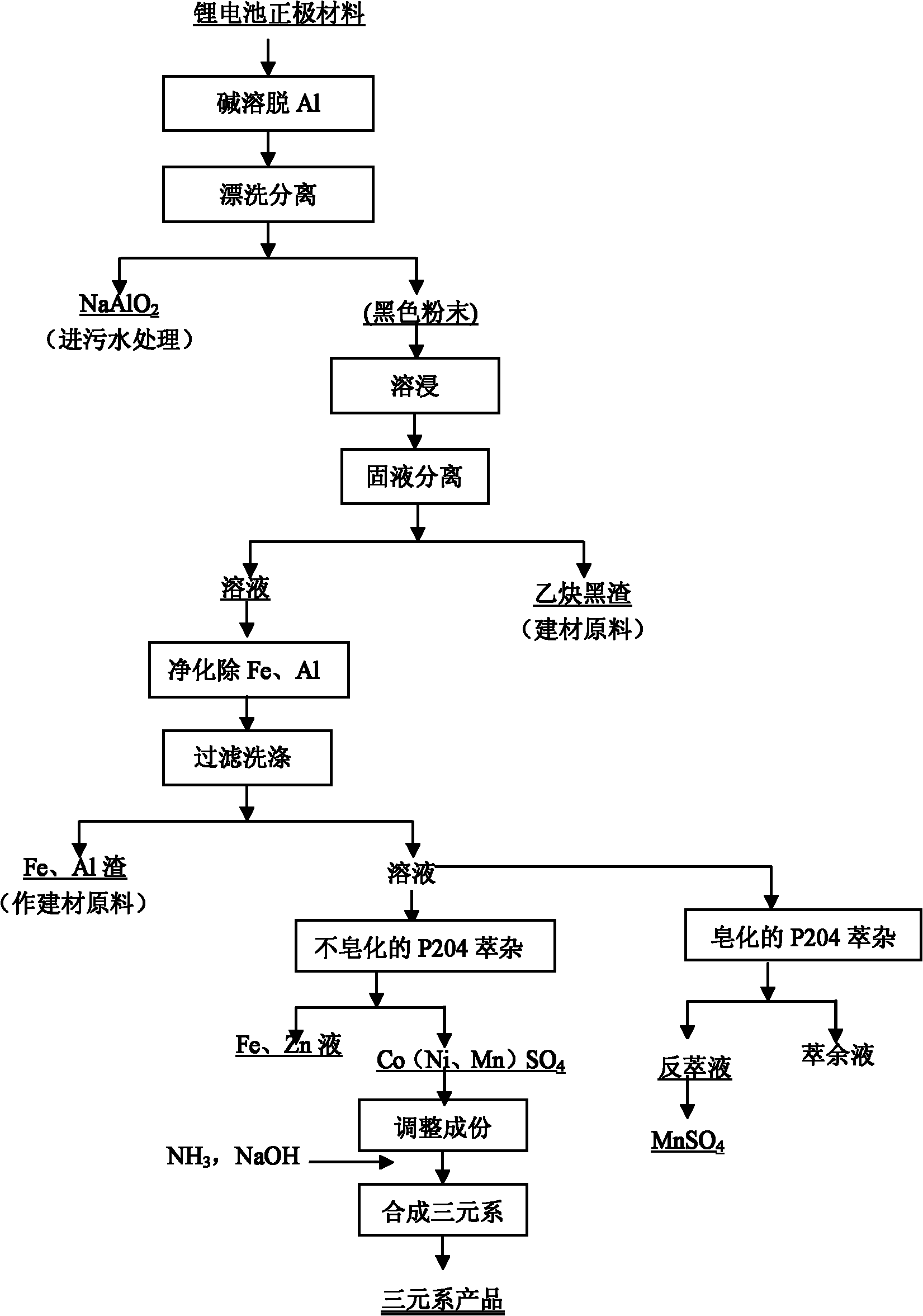

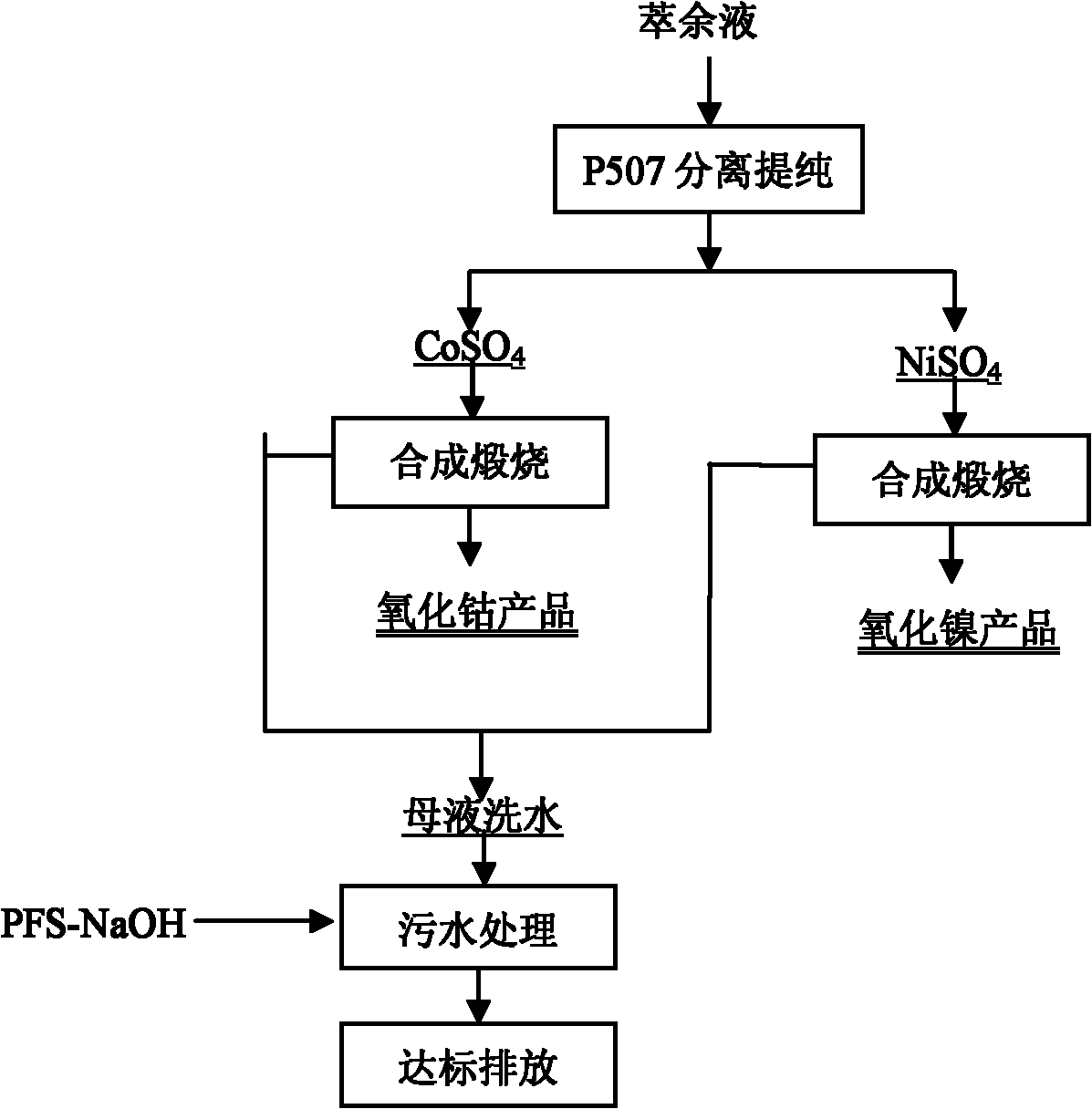

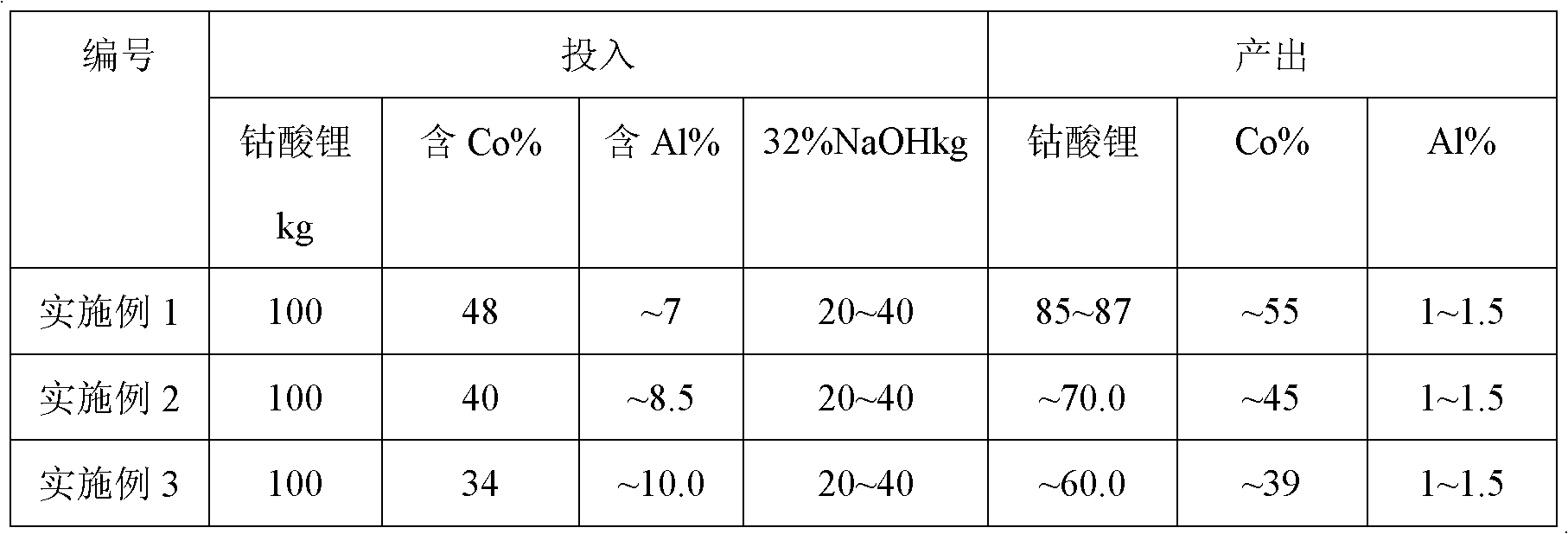

Method for recovering cobalt, nickel and manganese from waste lithium cells

ActiveCN101871048ANo pollution in the processReduce consumptionProcess efficiency improvementRecovery methodAlkaline earth metal

The invention discloses a method for recovering cobalt, nickel and manganese from waste lithium cells. Most of the conventional recovery methods can hardly guarantee the product quality. The technical scheme adopted by the invention is as follows: (1) the anode materials of waste lithium cells are immerged in low-concentration alkali solution, and because the anode materials do not react with the alkali solution, the anode materials shed from aluminum sheets to become black powder; (2) for the black powder, dilute sulfuric acid is first adopted for low-acid dissolution, Na2SO5 or Na2SO3 or Fe powder added with concentrated sulfuric acid is then adopted for reduction and dissolution, and finally, 3 to 6mol / L of sulfuric acid is adopted for high-acid dissolution; (3) solid-liquid separation is carried out on the substance obtained in step 2; (4) reagent is adopted for precipitating and deeply removing alkaline earth impurities. The method has the advantages of simple operation, low auxiliary material consumption, high product purity, high metal yield and no environment pollution, and is an ideal method for recovering cobalt, nickel and manganese from waste lithium cells.

Owner:ZHEJIANG HUAYOU COBALT +1

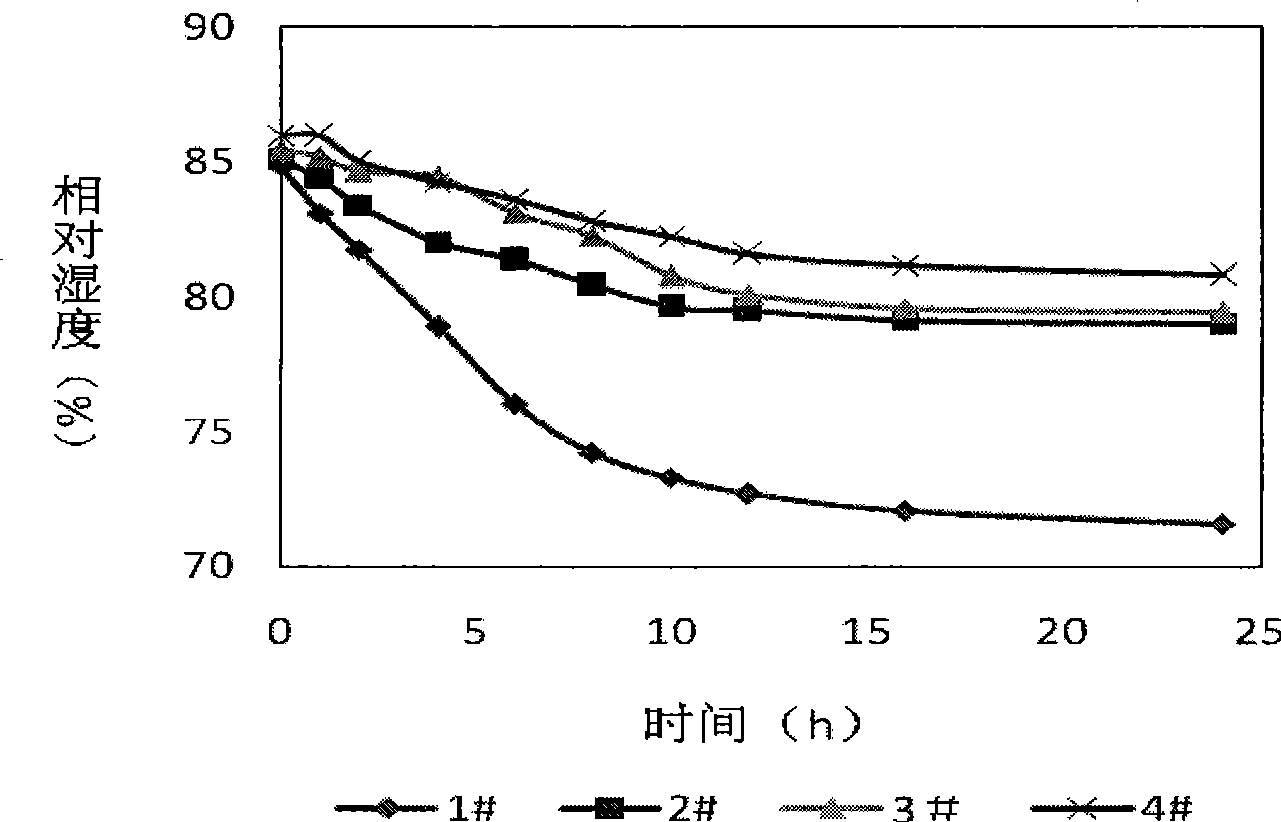

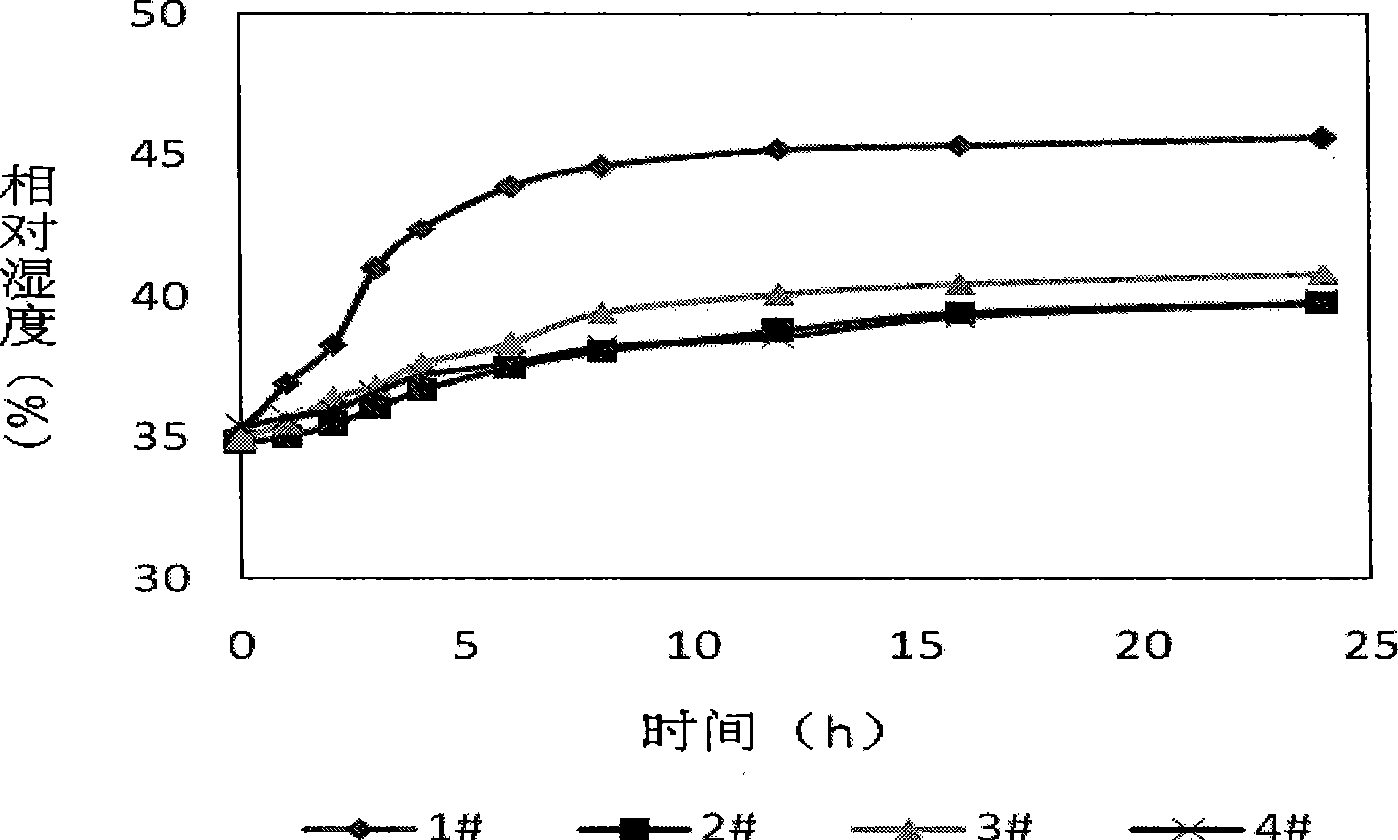

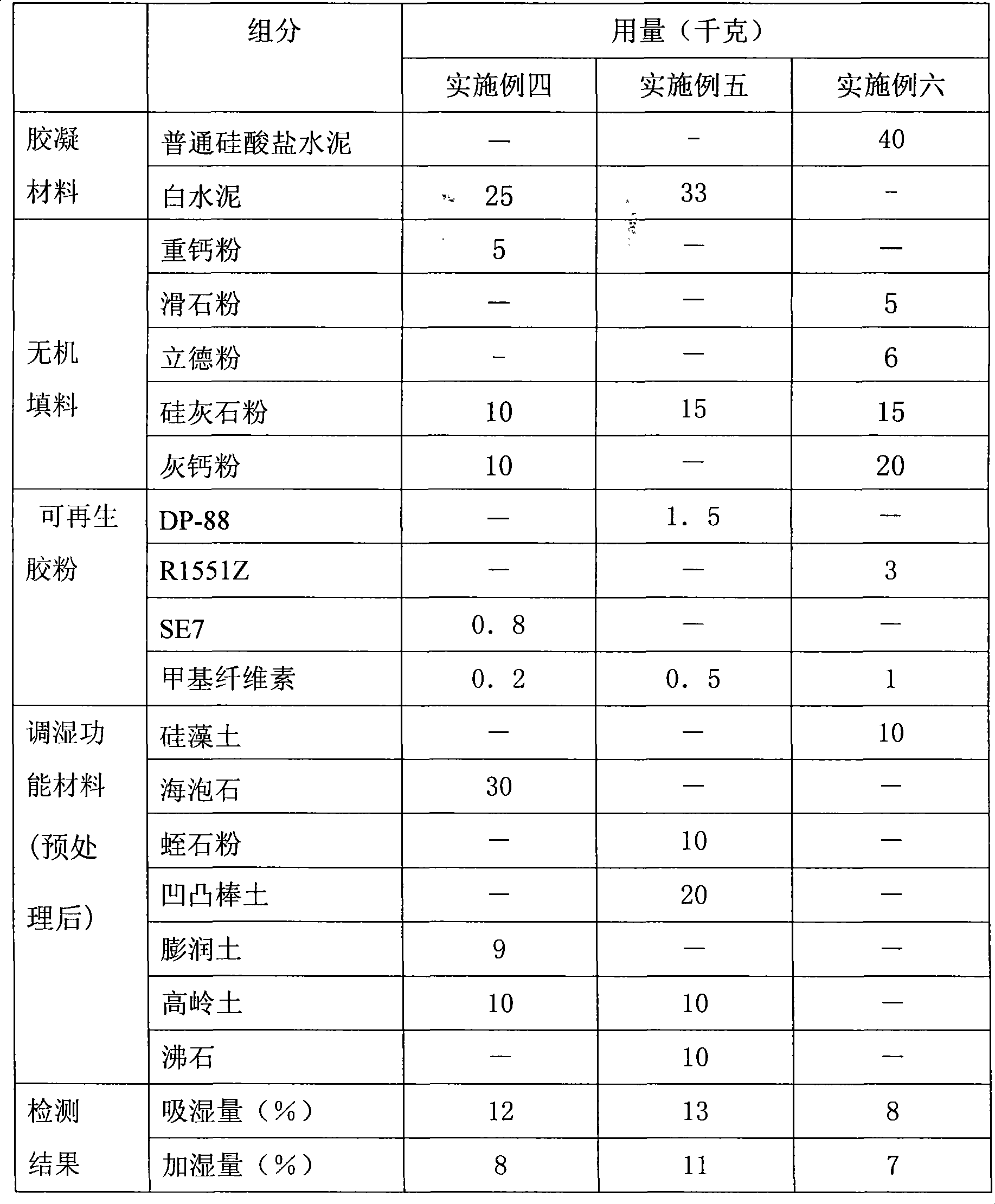

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

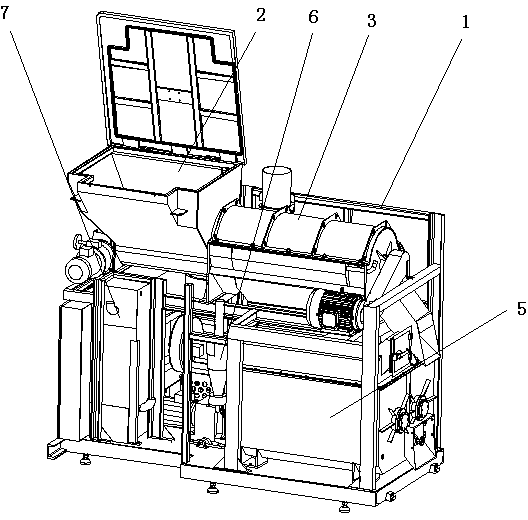

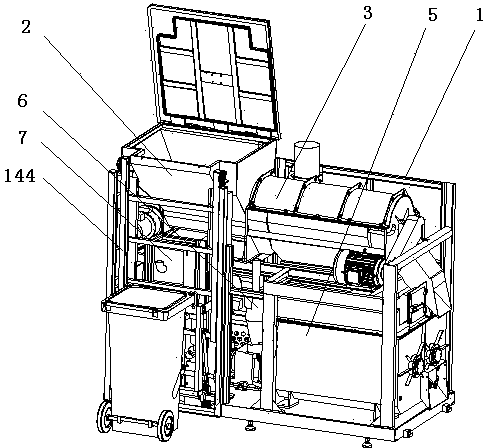

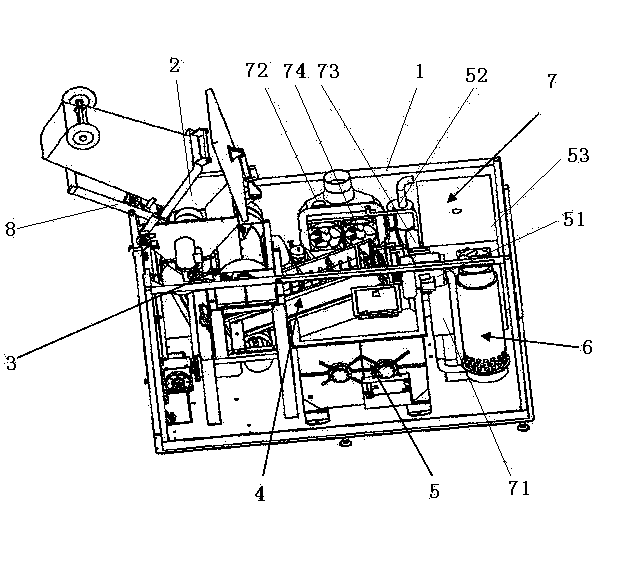

Kitchen waste pretreatment device

ActiveCN103464449ADeodorization up to standardWith automatic sortingSolid waste disposalControl systemOil water

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a closed shell and a control system. The kitchen waste pretreatment device is characterized in that the upper end of the shell is provided with a feeding funnel and a feeding motor; the shell is internally provided with an automatic sorting device, a biological fermentation drying device, an oil-water separation device, an ionization deodorization device and a gas condensation device; the feeding funnel is communicated with a kitchen waste charge hole of the automatic sorting device through a discharge hole; the automatic sorting device is communicated with a charge hole of the biological fermentation drying device through a kitchen waste outlet; the automatic sorting device is communicated with the oil-water separation device through a liquid outlet; the biological fermentation drying device is communicated with the gas condensation device through a gas exhaust opening; the gas condensation device is communicated with the ionization deodorization device, so that the effects of automatic sorting, rapid fermentation treatment speed, uniform fermentation, rapid heating speed, capability of oxygenating in fermentation, standard gas deodorization and environment protection and no pollution are achieved.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

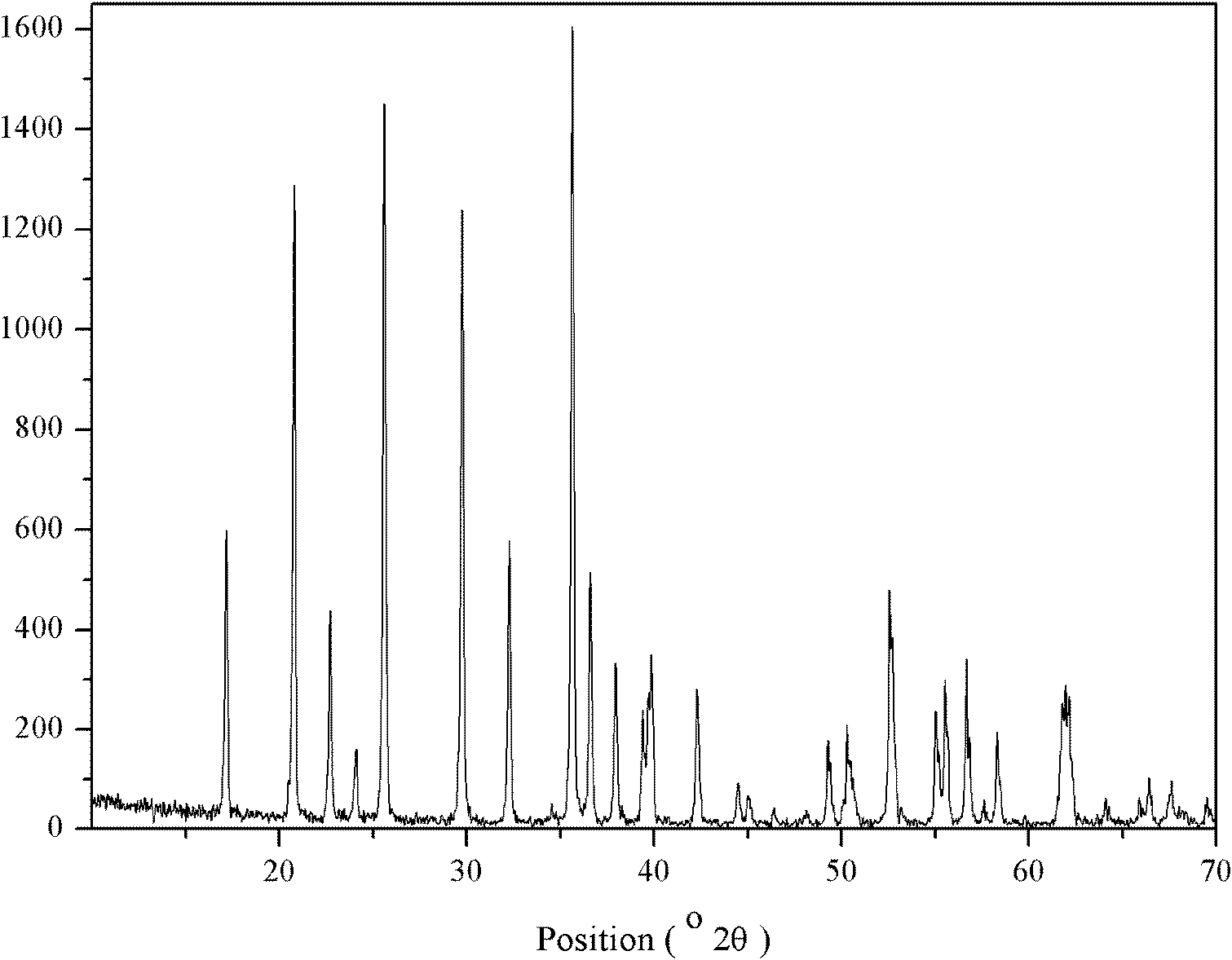

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

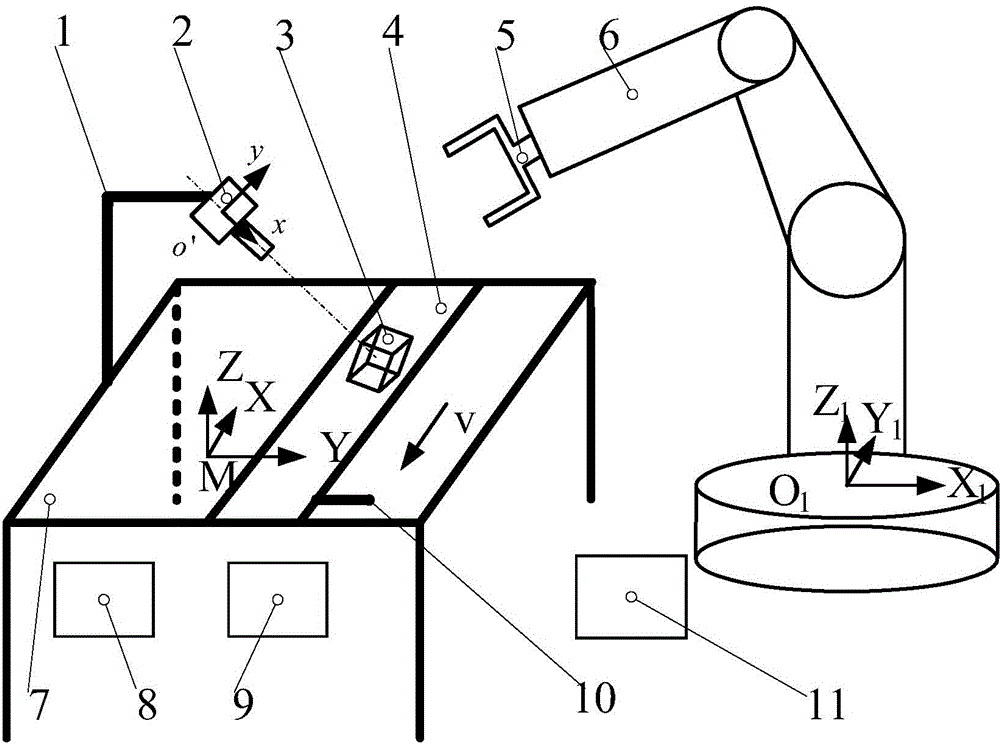

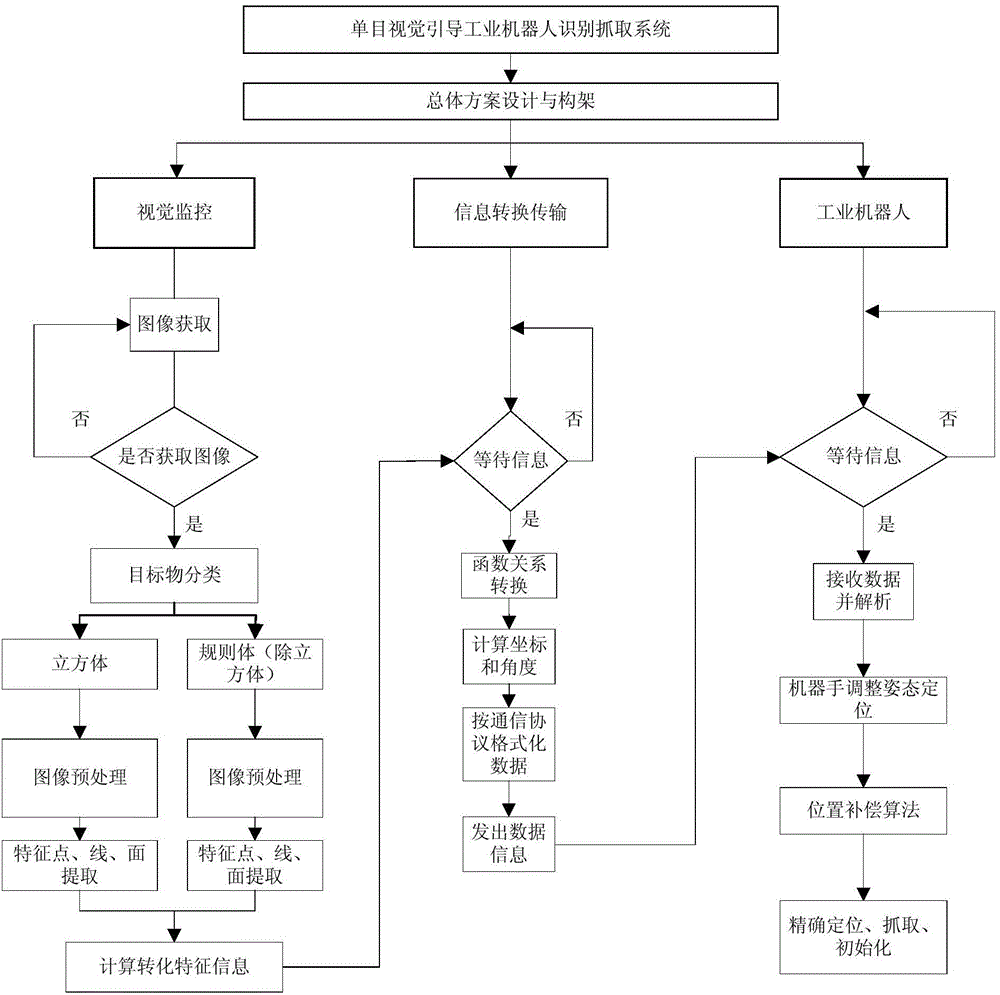

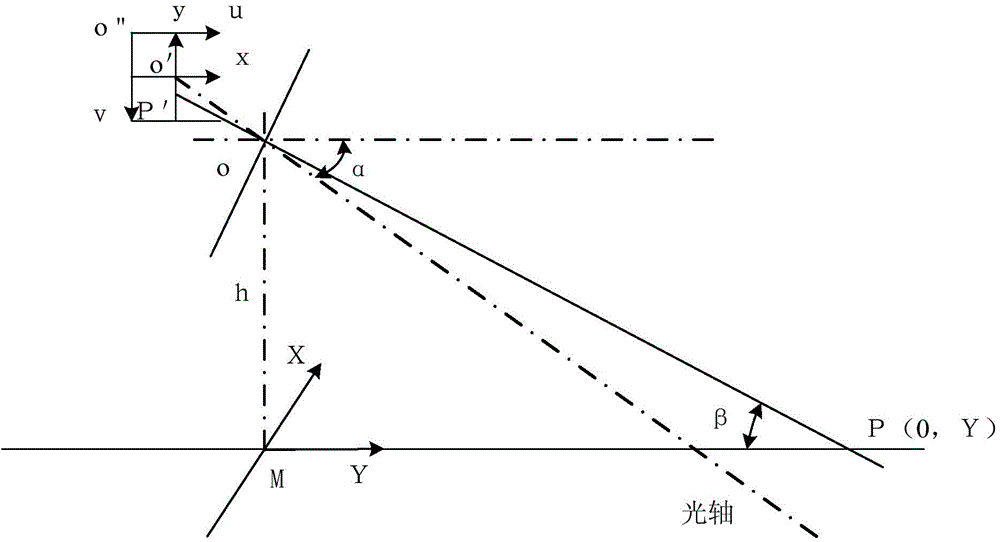

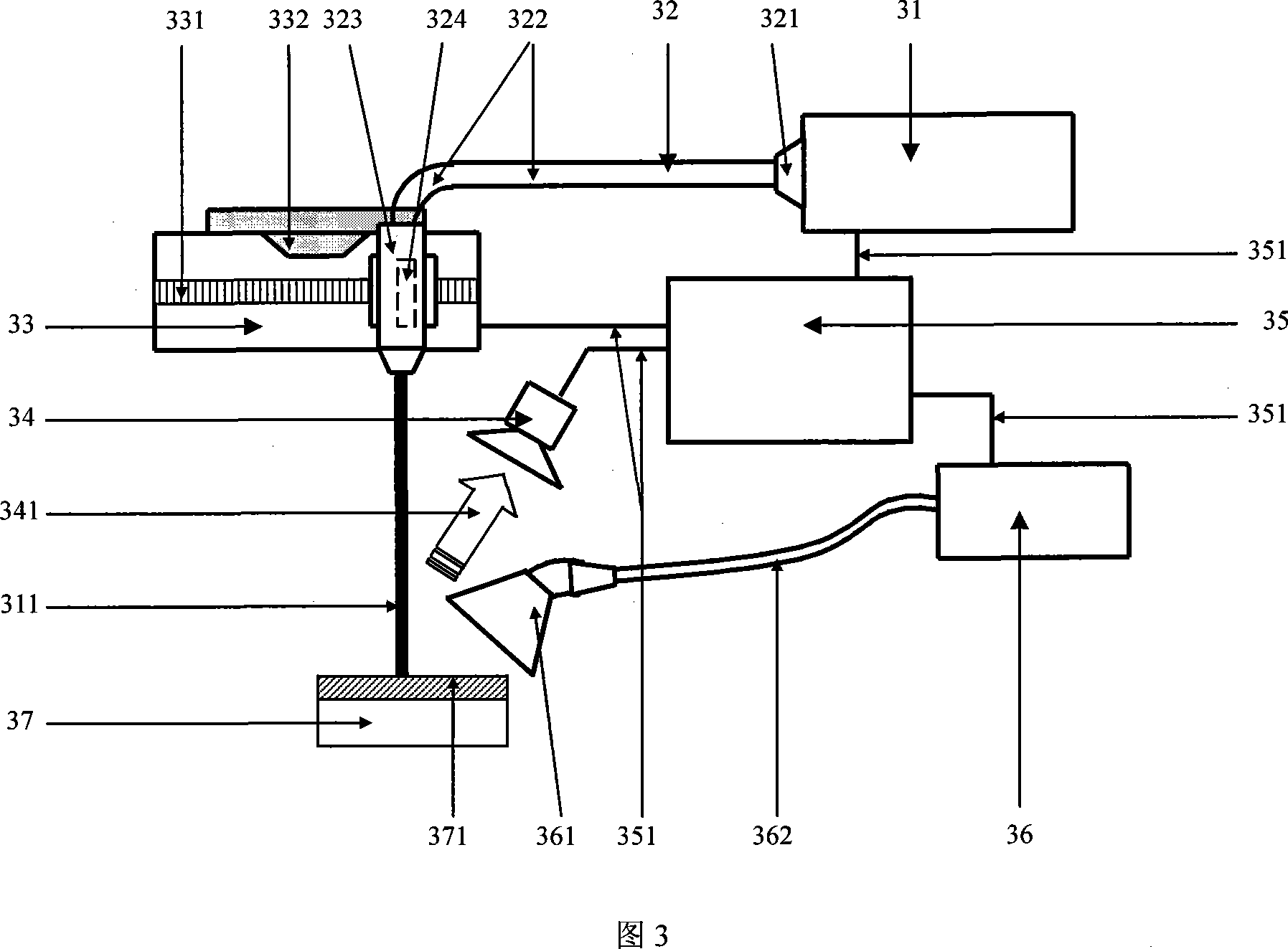

Posture and moving track positioning system and method of robot grabbing online workpiece

The invention discloses a posture and moving track positioning system and method of robot grabbing an online workpiece. The device comprises a camera support, an industrial camera, the tested workpiece, a workpiece conveying belt, a tail end executer, a robot system, a workbench, an image processor and the like. The method comprises the steps that a depth positioning model of a plane point in an absolute coordinate system in the vertical direction, a depth positioning model of a space point in the absolute coordinate system in the vertical direction, an X-axis positioning model of the plane point in the absolute coordinate system in the horizontal direction and an X-axis positioning model of the space point in the absolute coordinate system in the horizontal direction are established, three-dimensional coordinates of imaging points in all the cameras can be solved through combination of the priori knowledge of the workpiece, accordingly, and a robot can be guided to adopt the accurate tail end executer posture and movement track to intelligently grab the workpiece accurately. The posture and moving track positioning system and method have the advantages that the grabbing precision is high, the structure is simple, and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

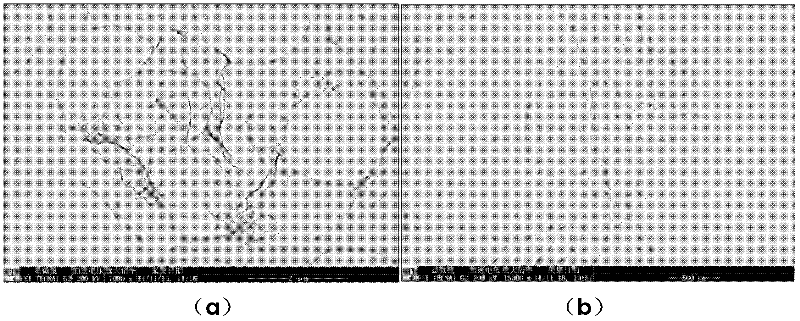

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

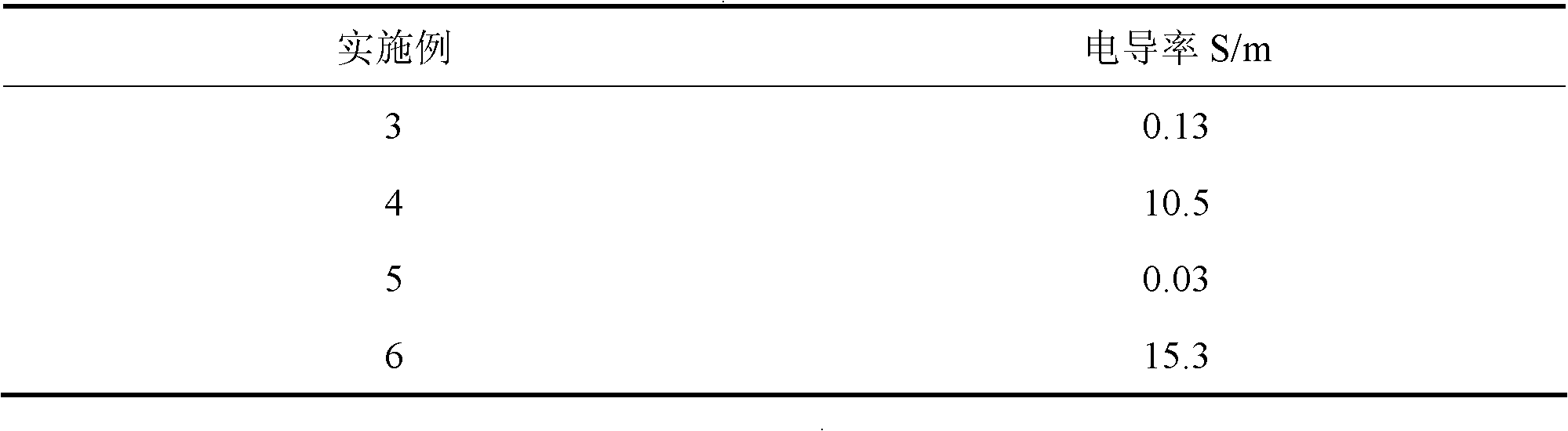

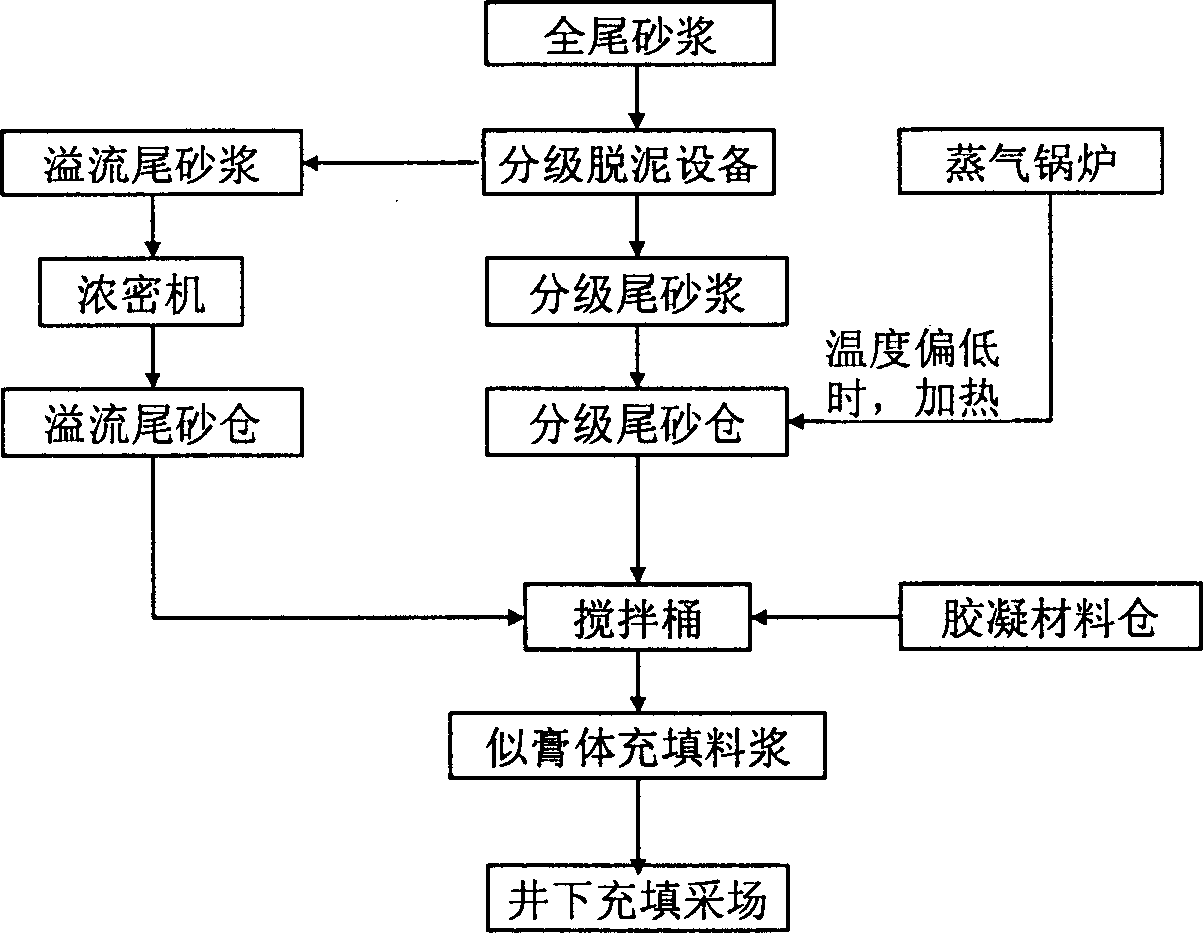

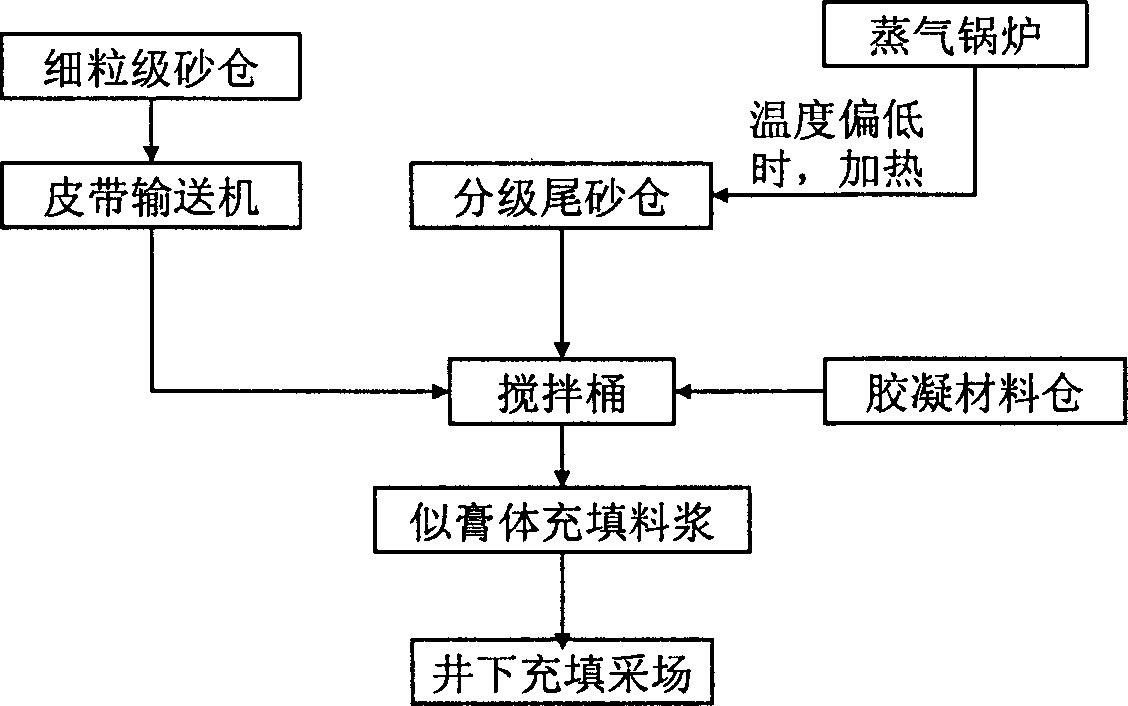

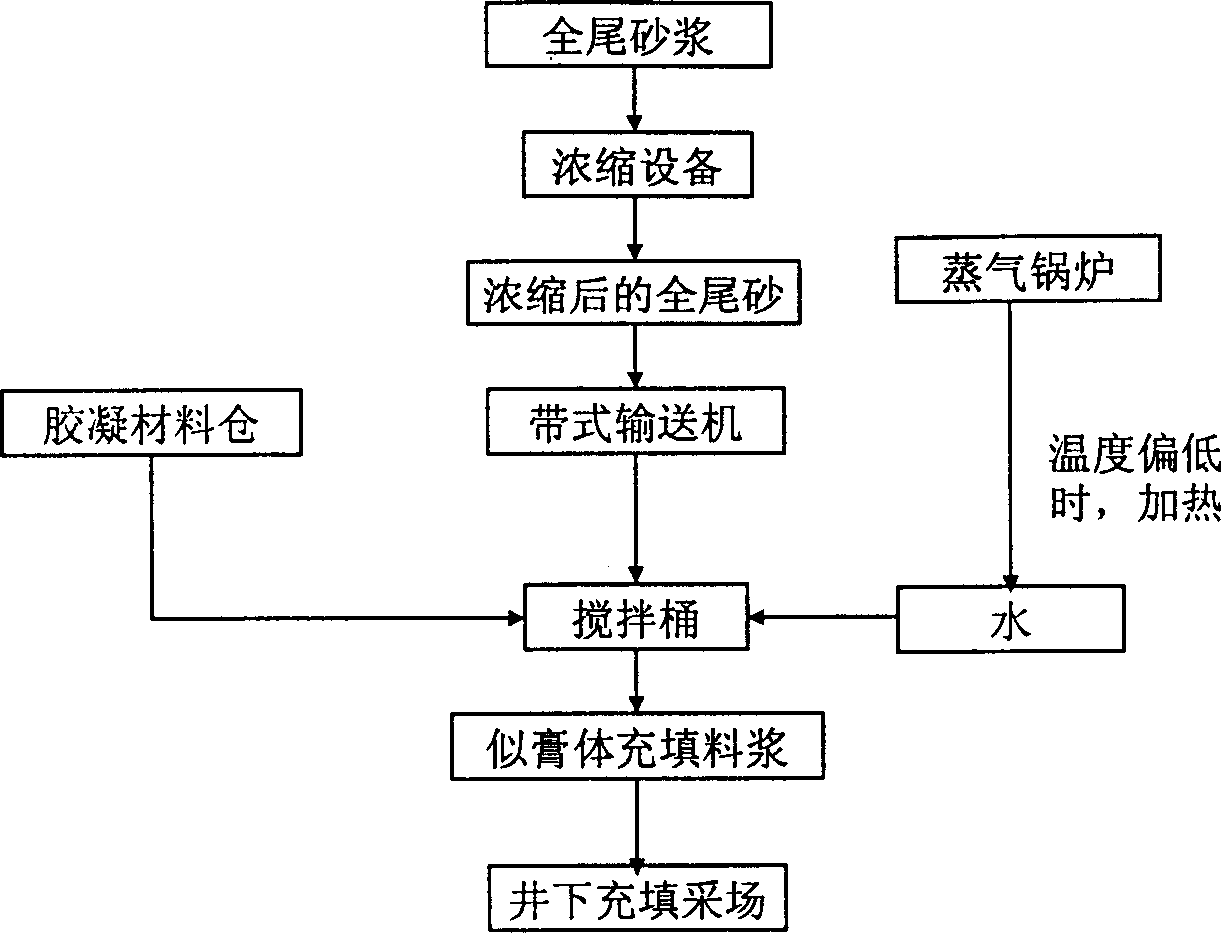

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

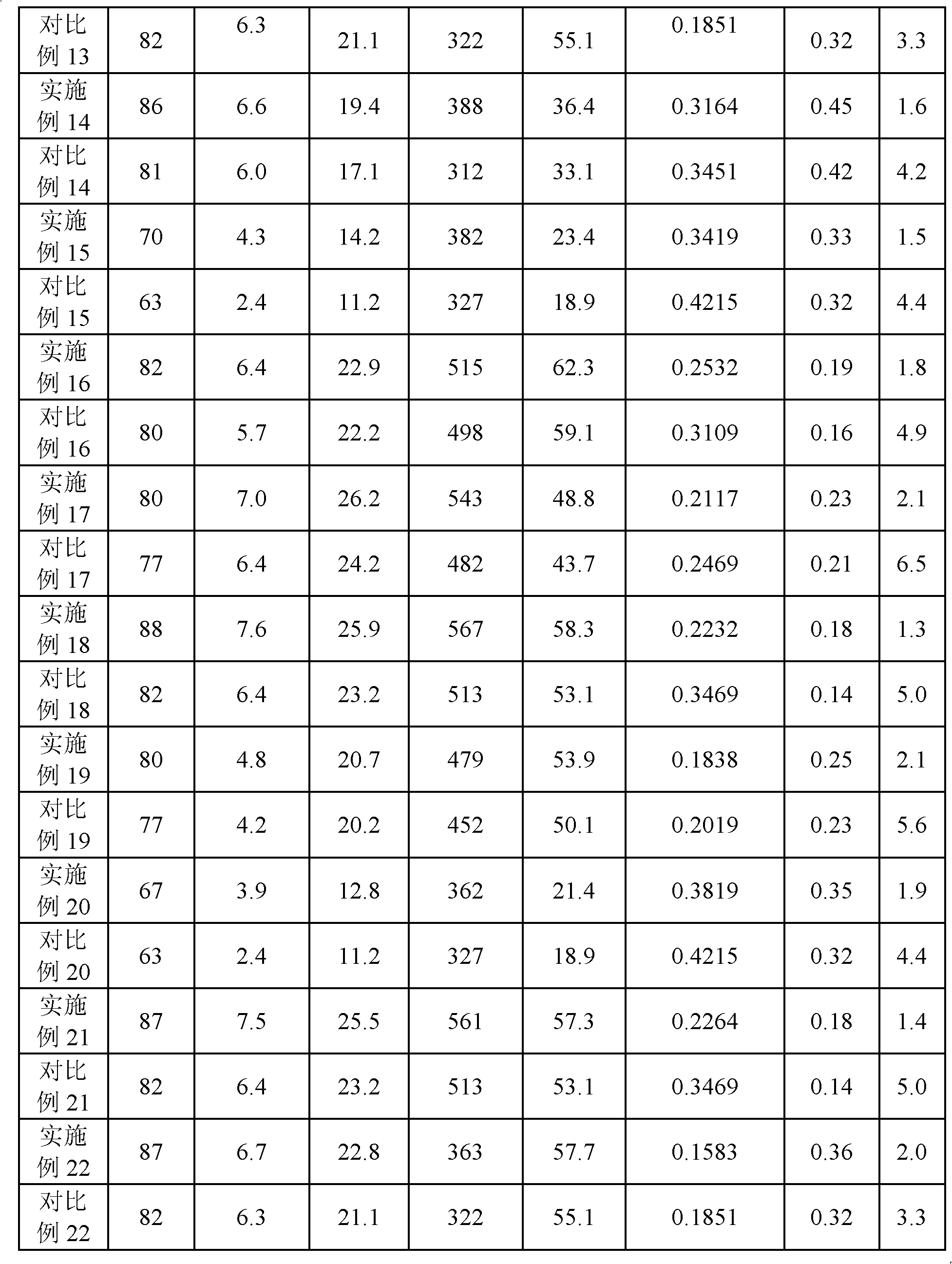

Low-temperature ceramic permeable bricks and production method thereof

InactiveCN101289310ASolve pollutionLow costCeramic materials productionClaywaresNatural resourceState of art

The invention relates to a low temperature ceramics non-watertight brick made of solid waste slag and a manufacture method thereof, belonging to the technical field of building materials. The mixture ratio by weight of the components of the low temperature ceramics non-watertight brick is that waste slag gelled material to waste slag skeletal material to porogenic agent to activating agent to addition agent to paint to water is equal to 100:200-800:0.1-40:13-50:0.2-3.0:0.1-7.0:1-20. After the process, mixture, vibrating forming and maintenance process for the raw materials, the raw materials are prepared into the low temperature ceramics non-watertight brick with a filled pore by taking the low temperature ceramics mineral as the matrix phase and taking the inorganic waste slag particle as the wild phase. Compared with the prior art, the low temperature ceramics non-watertight brick has the advantages of high strength, good permeability of water, high salvage value, simple process, low cost, environment protection and natural resources reservation, etc. which can be widely applied to the laying of urban highways.

Owner:KUNMING UNIV OF SCI & TECH

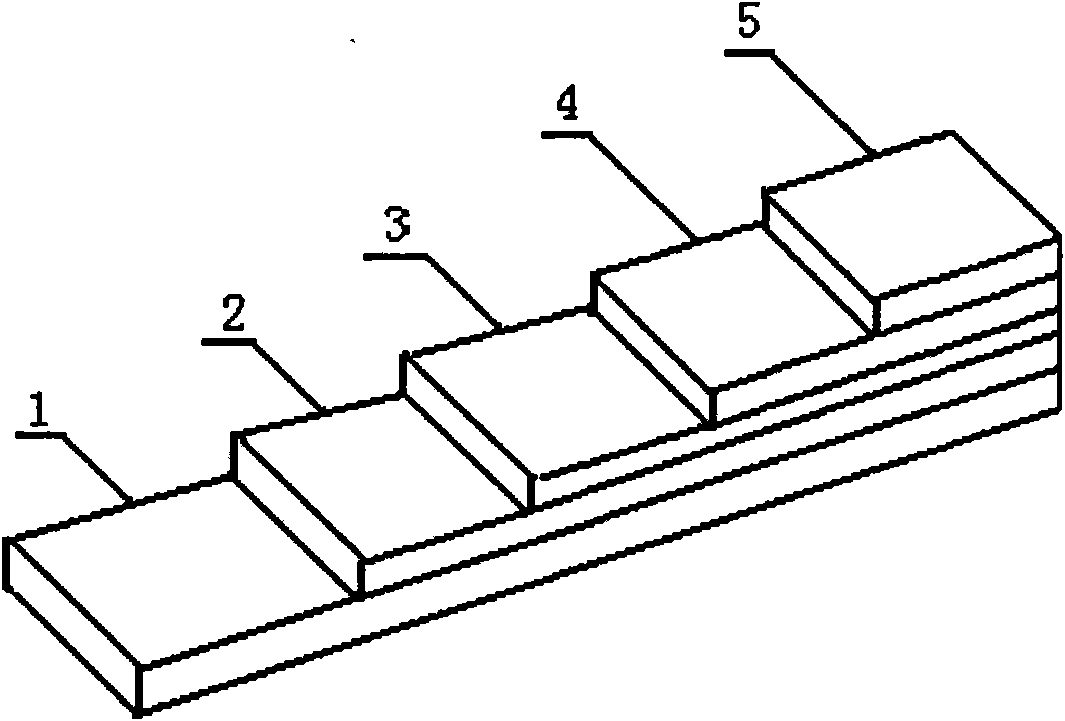

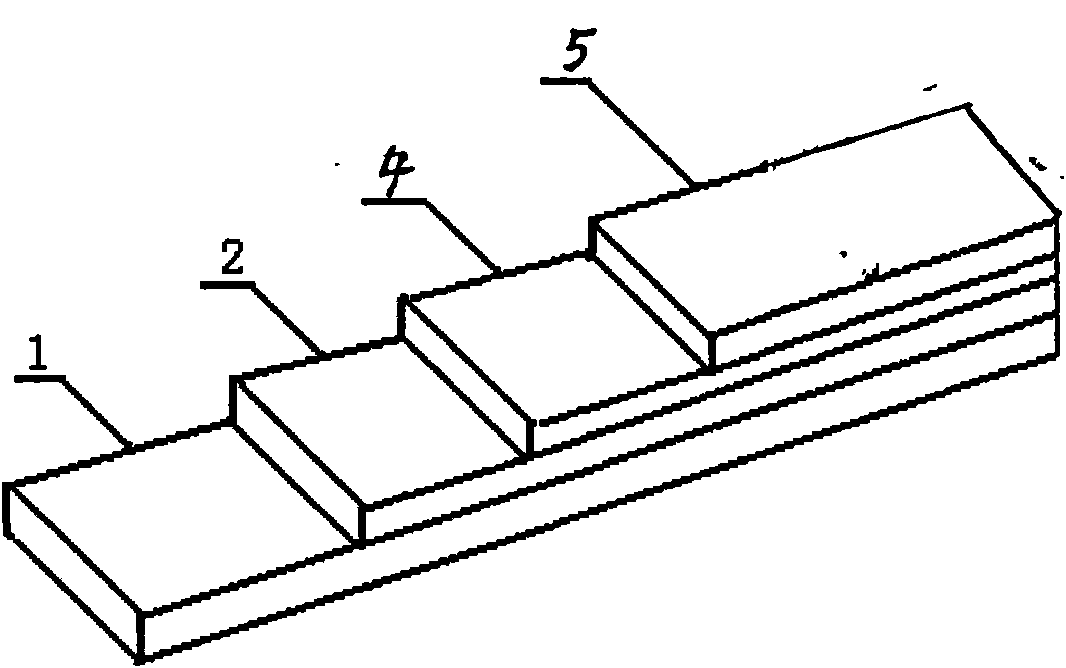

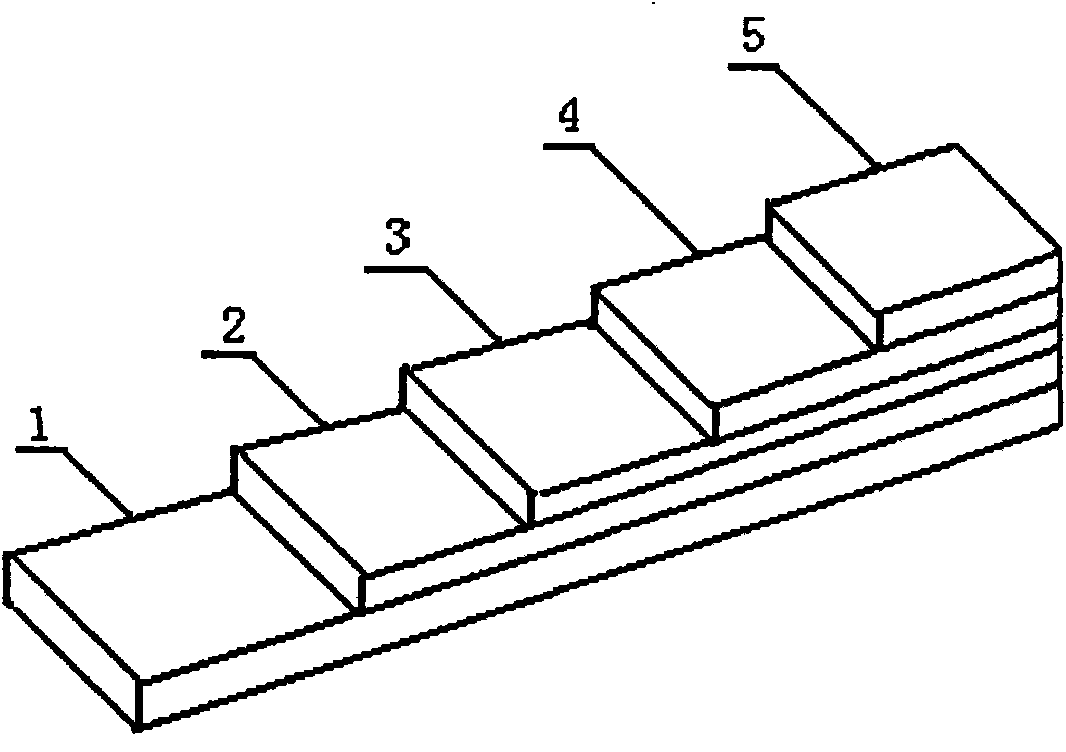

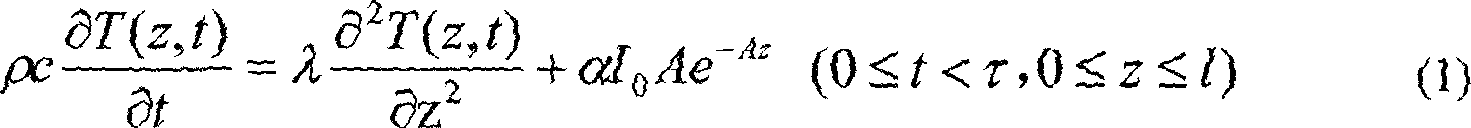

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Polypropylene foaming material and production method thereof

The invention discloses a polypropylene foaming material. The polypropylene foaming material comprises the following components according to proportioning by weight: 60-99 parts of polypropylene resin; 0.1-10 parts of nucleating agent; 0.1-5 parts of antioxidant; 0-5 parts of colorant; 0-5 parts of lubricant; and 0-20 parts of filling material; and the melt index of the polypropylene resin is 0.1-20 g / 10 min, and the foaming process adopts supercritical fluid as the foaming agent, i.e. 0.1-20 parts of supercritical fluid (proportioning by weight). The invention also discloses a production method of the foaming material. Compared with the prior art, the invention has the advantages that the universal polypropylene can be adopted as a base material, no polymer is provided, the cross-linking reaction does not occur, the foaming process is free from environmental pollution, and the production method is safe; the quality of the obtained foaming material is stable, the foaming percentage and the cell density are high, the distribution is uniform, and the invention is suitable for the industrial production at a large scale; and meanwhile, the overall production method is simple, the operation is easy, and the production cost is relatively lower.

Owner:合肥朗润中科材料有限公司

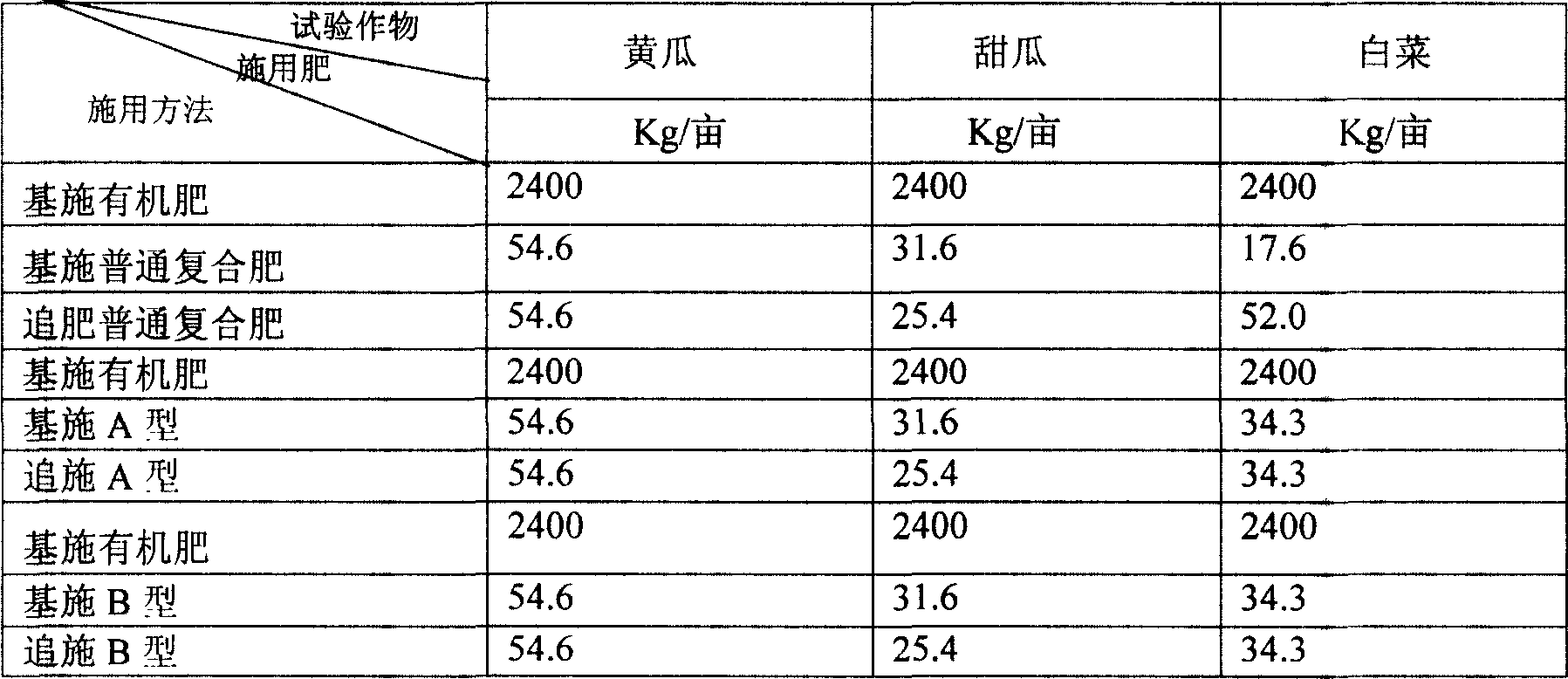

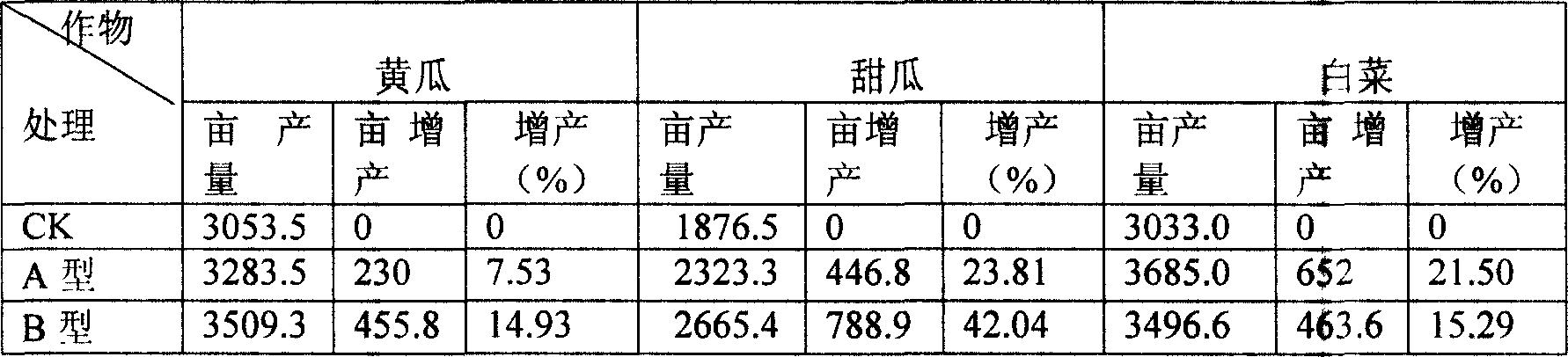

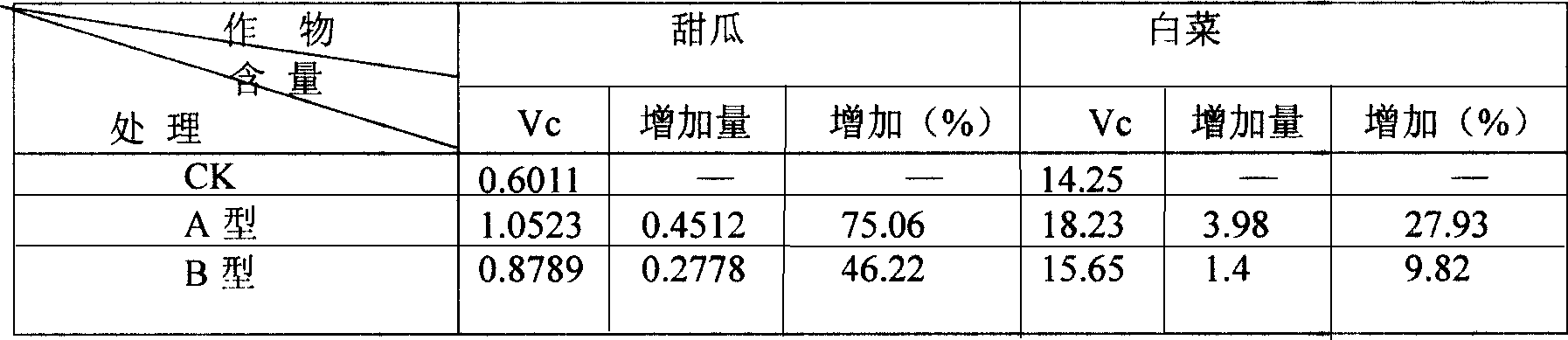

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

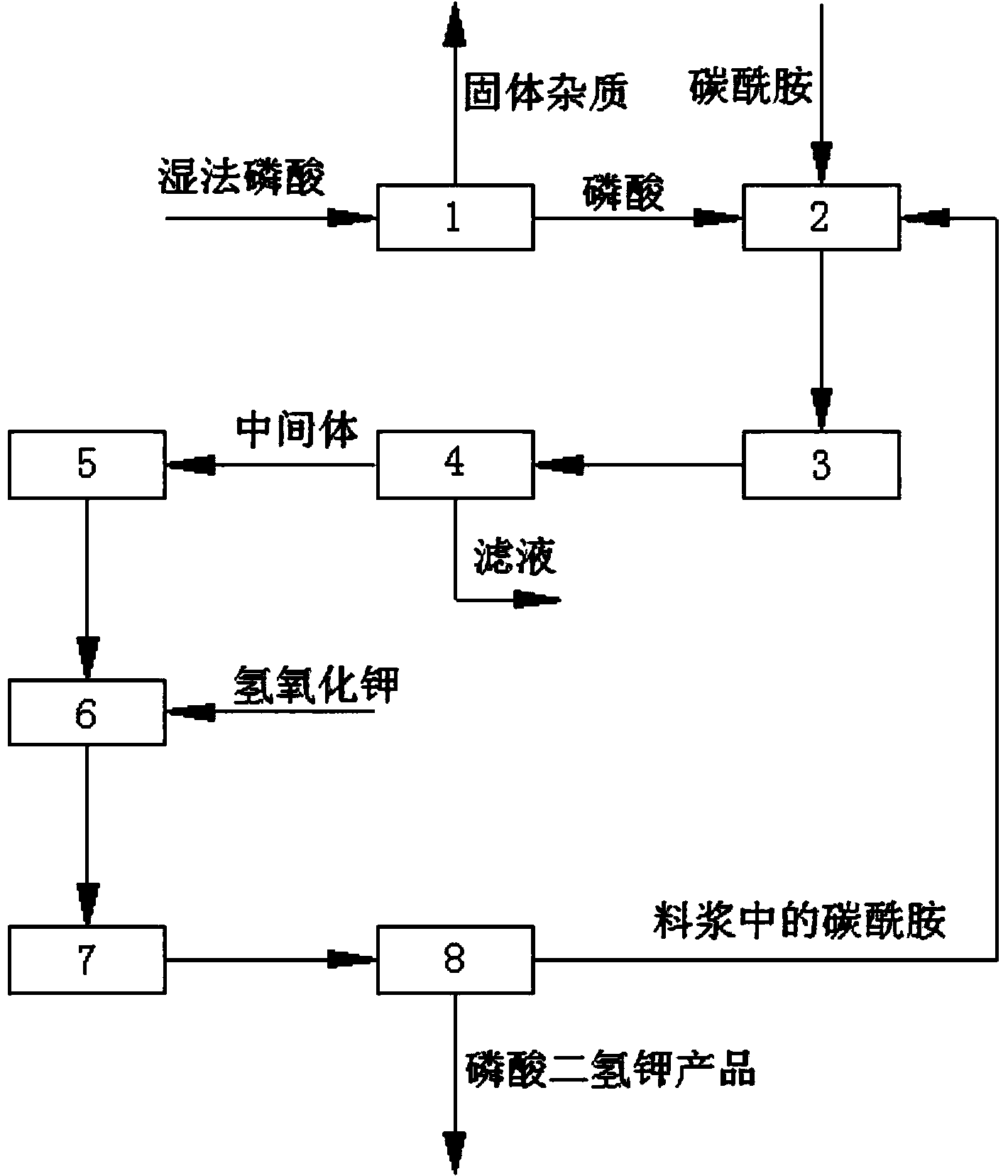

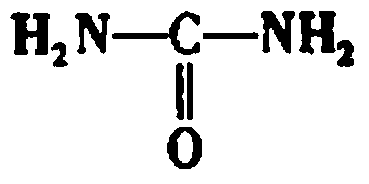

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

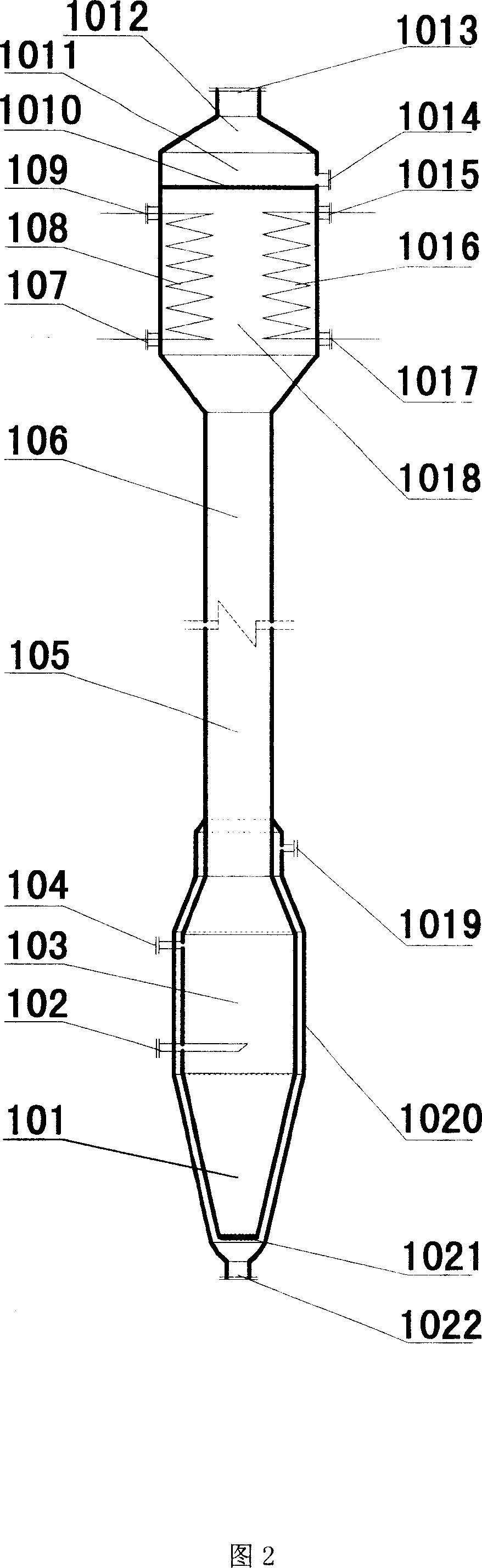

Ultrasonic detection narrow pulsewidth laser sludge remover and its sludge removing method

InactiveCN101143364AWon't happenGood decontamination effectAnalysing solids using sonic/ultrasonic/infrasonic wavesDirt cleaningShock waveAutomatic control

An ultrasonic detection narrow pulse wide laser cleaner includes a narrow pulse wide laser device (1), a beam adjustment transmission device (2), a moving platform device (3), an ultrasonic detection device (4), an automatic control device (5), a dust absorption recovery device (6) and an ultrasonic detection narrow pulse wide laser filth clearing method. A cleaned object surface is irradiated with narrow pulse wide lasers. And a strong vibration shock wave is produced in short time to remove filths from the medium surface. At the same time, an instrument device is used to monitor and analyze ultrasonic waves caused by the vibration during the cleaning process to ensure the good medium surface and realize the automatic cleaning process. The cleaner is used to remove various filths of oxides, corrosion matters, paint, grease marks, residues, etc. of the media surfaces of metals, semiconductors, buildings, etc. The cleaner has the advantages of good effect, non-damages, high efficiency, automation, etc.

Owner:NANKAI UNIV

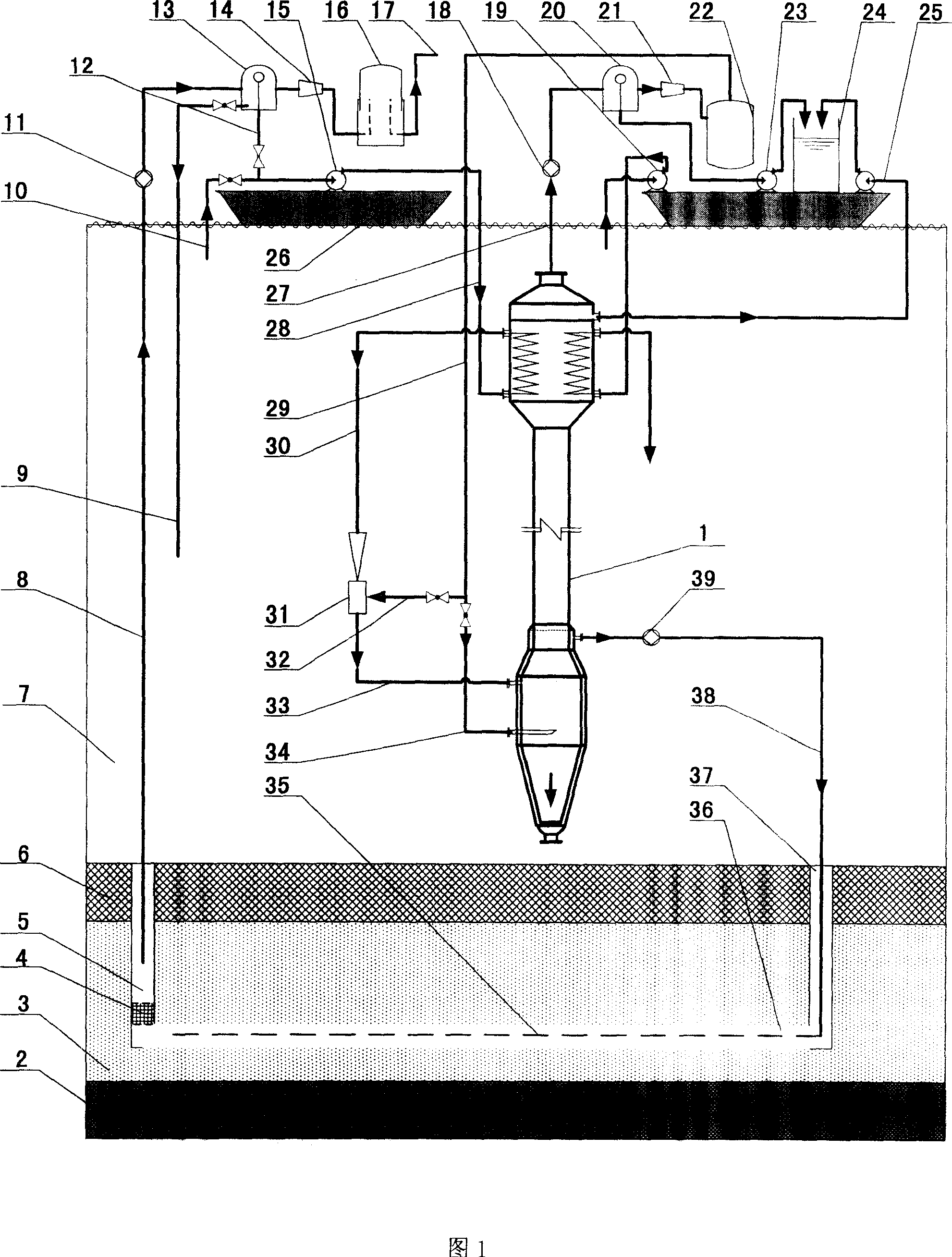

Method for exploiting natural gas hydrates and device thereof

ActiveCN101016841AImprove energy efficiencySimplify mining processConstructionsMineral miningSaline waterSalt water

The invention discloses a method for developing natural gas hydrate, which comprises that building developing well, horizontal well and collecting well, building floating platform and natural gas hydrate developer on sea, building sea concentration heater, preparing hot salt water, decomposing natural gas hydrate and collecting natural gas. And the inventive device comprises a sea floating platform, a developing well, a collecting well, a horizontal well, a hydrate recycling system, a fresh water groove, a hot salt water tube, a hot salt water pump, and a seawater concentrating heater. The invention has simple process, low energy consumption and low cost, without pollution.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

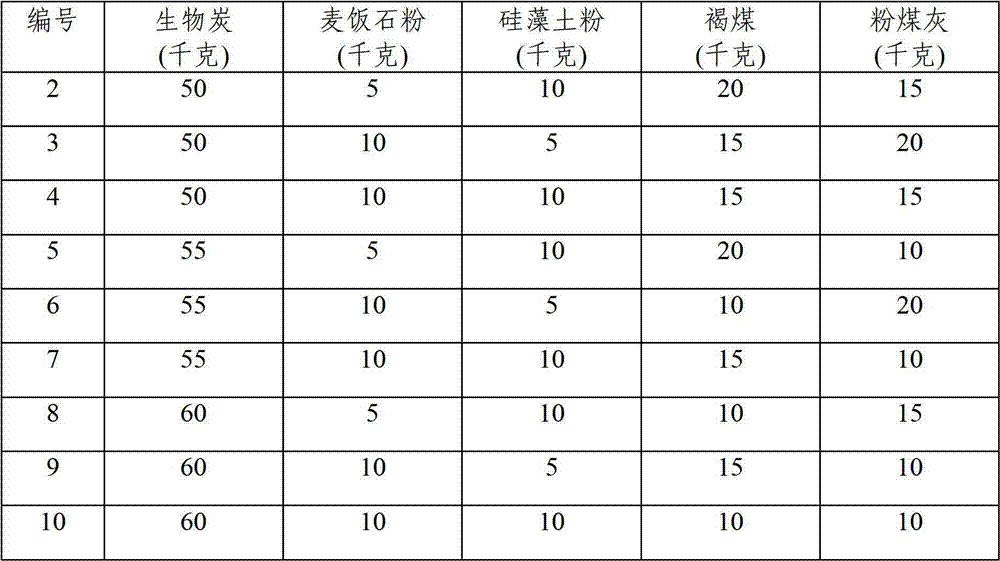

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872ASimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsBiochar

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

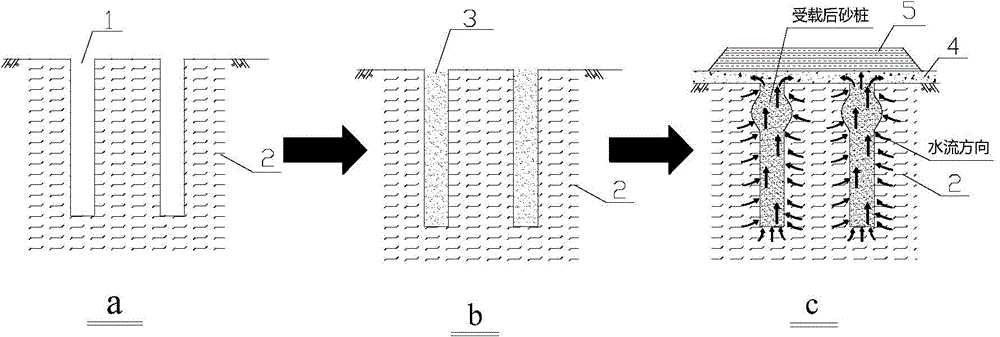

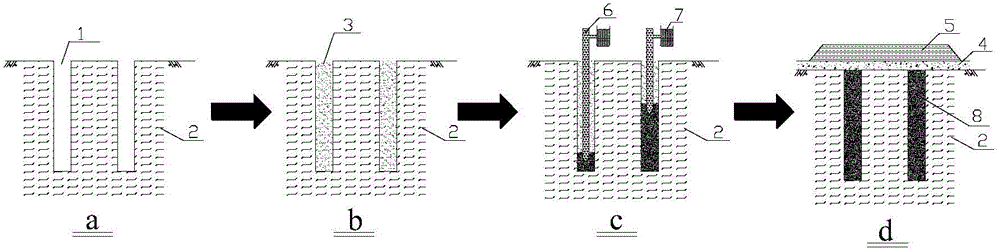

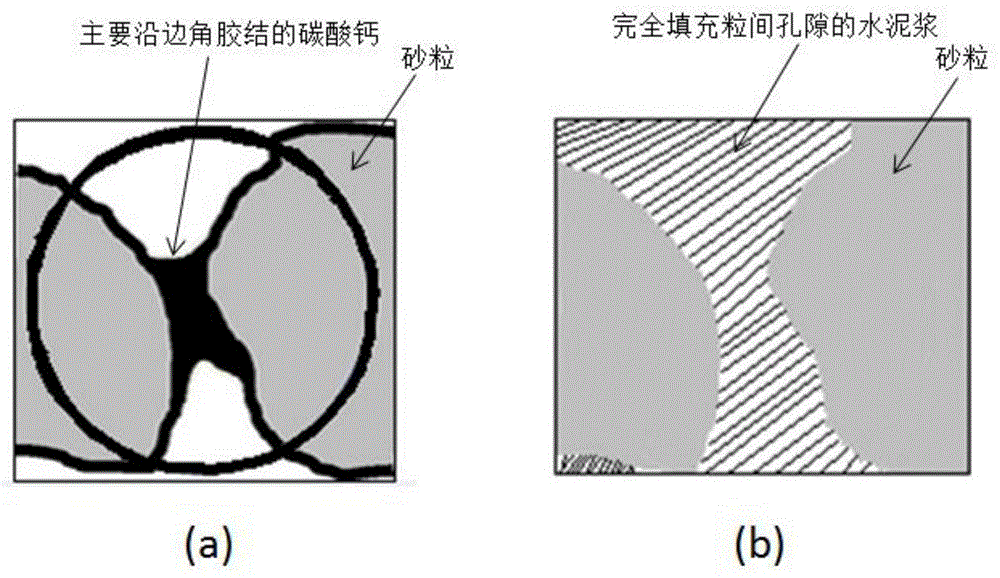

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com