Patents

Literature

23935results about How to "Good weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

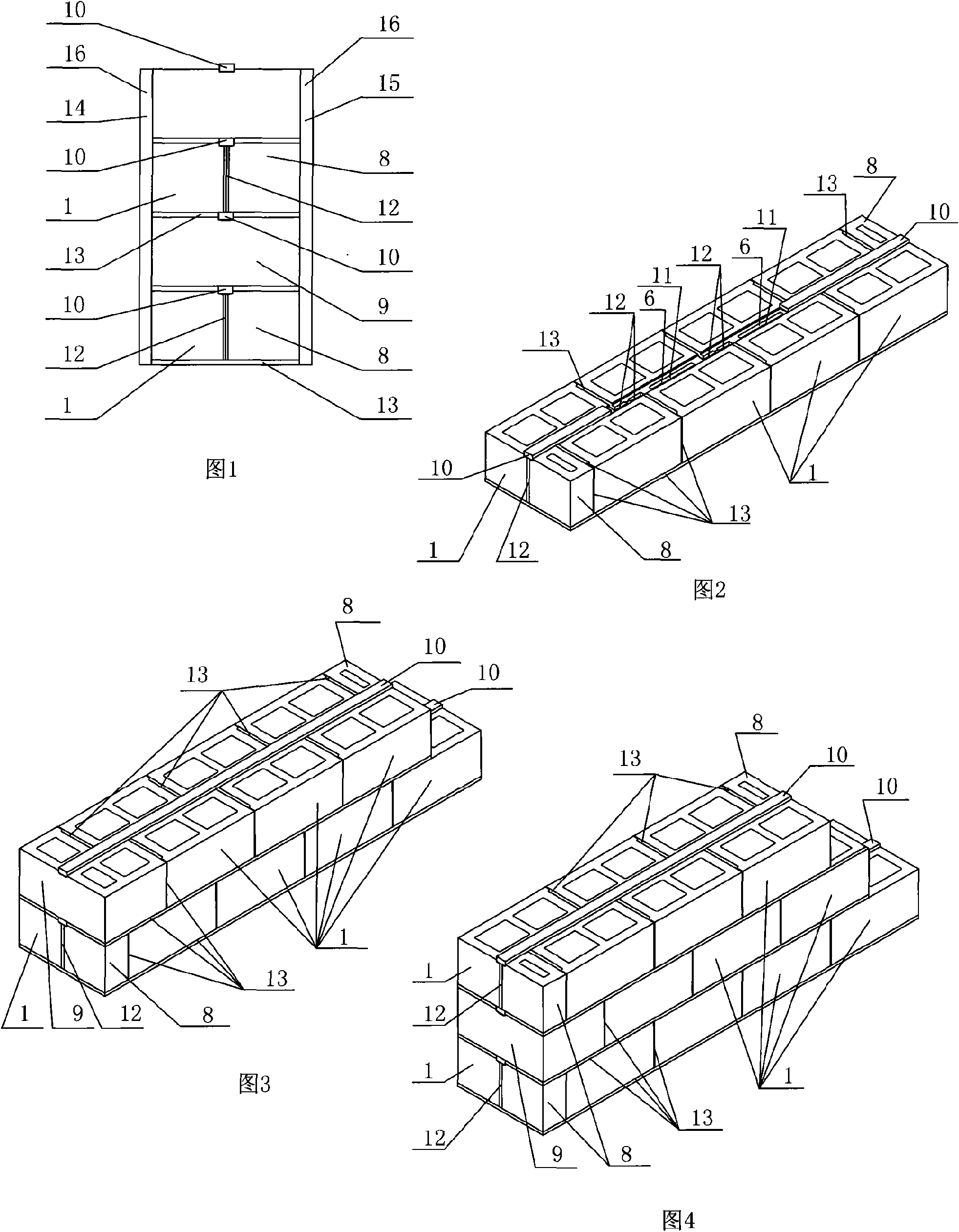

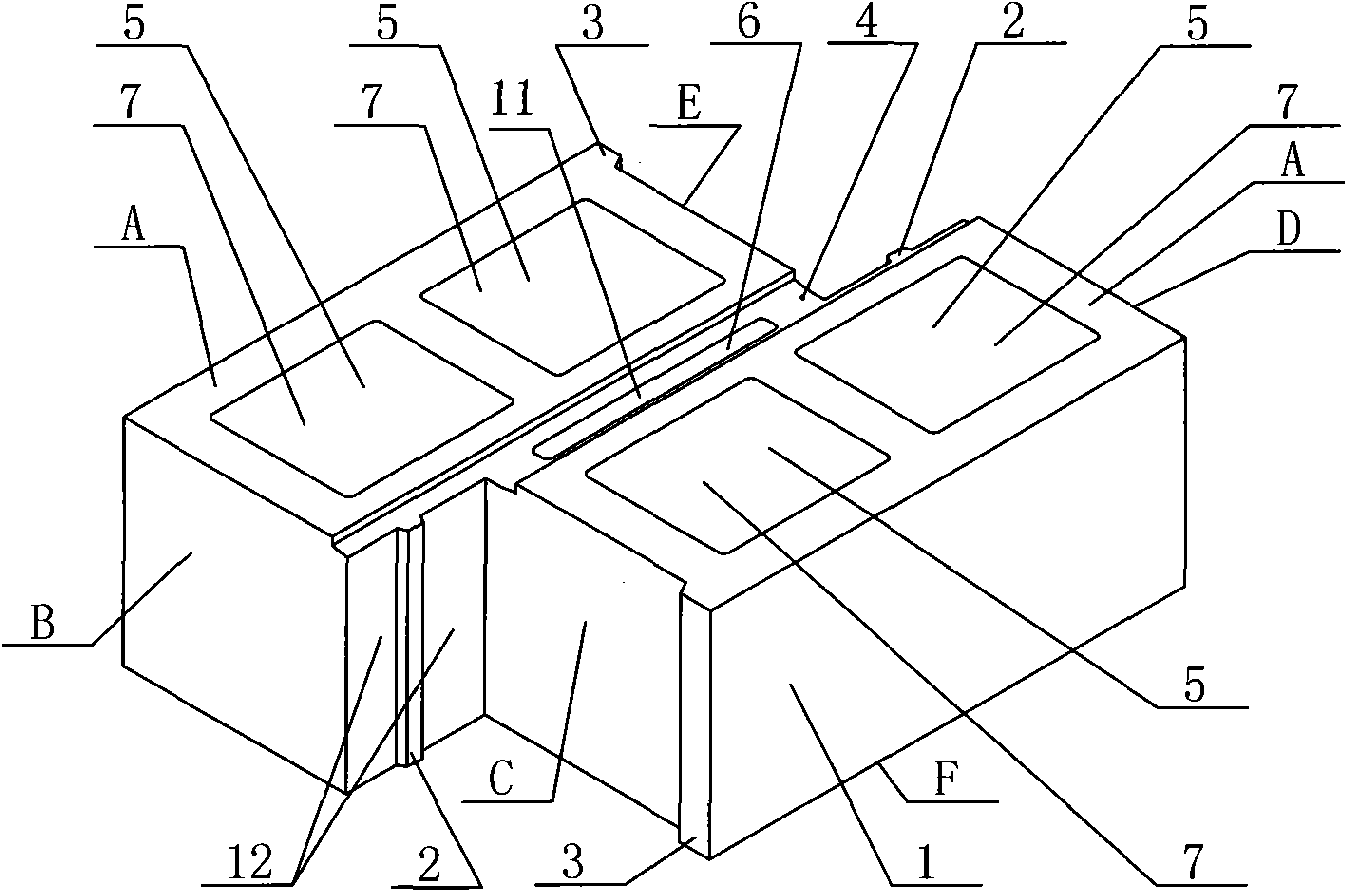

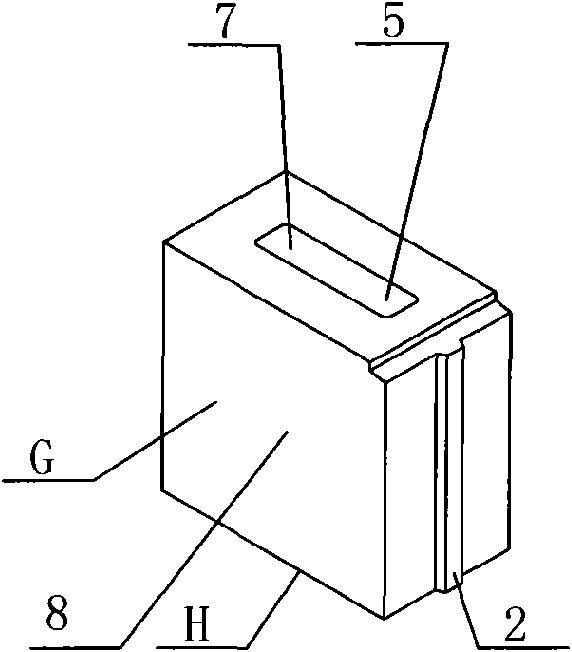

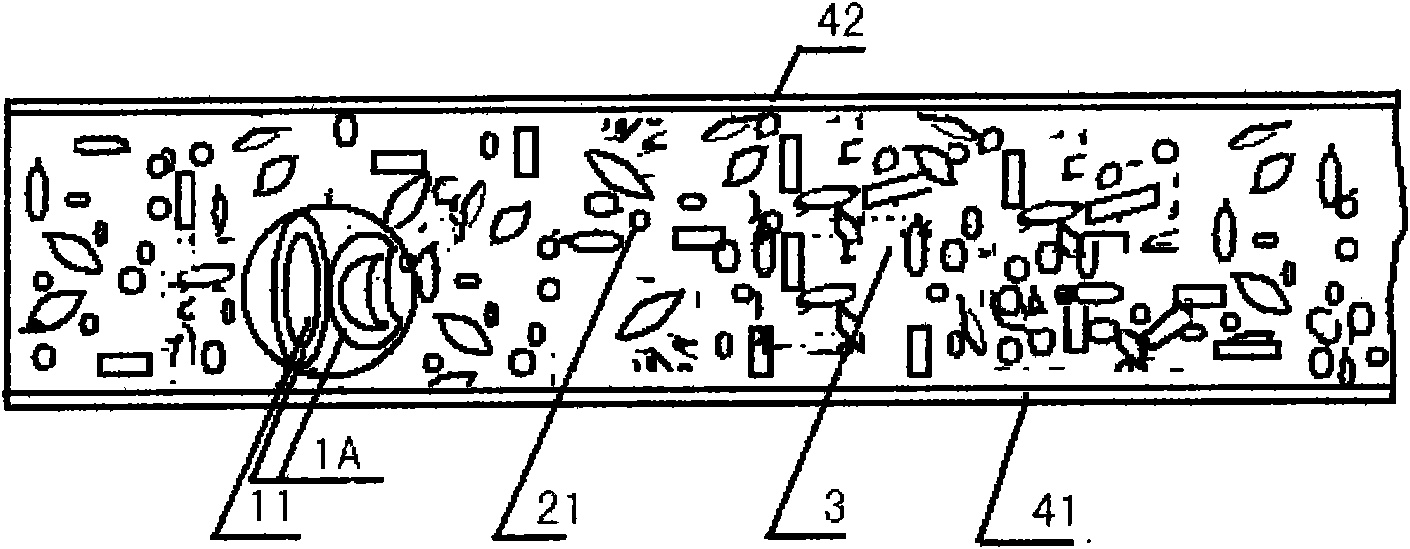

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

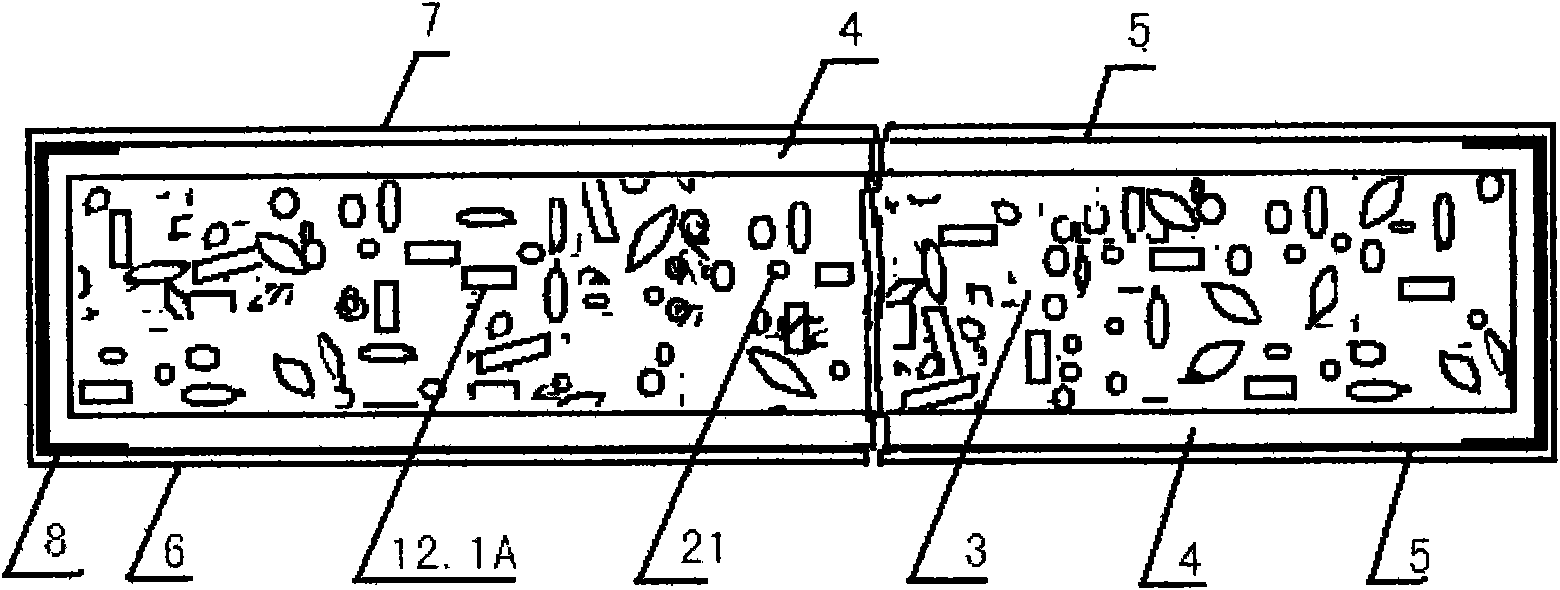

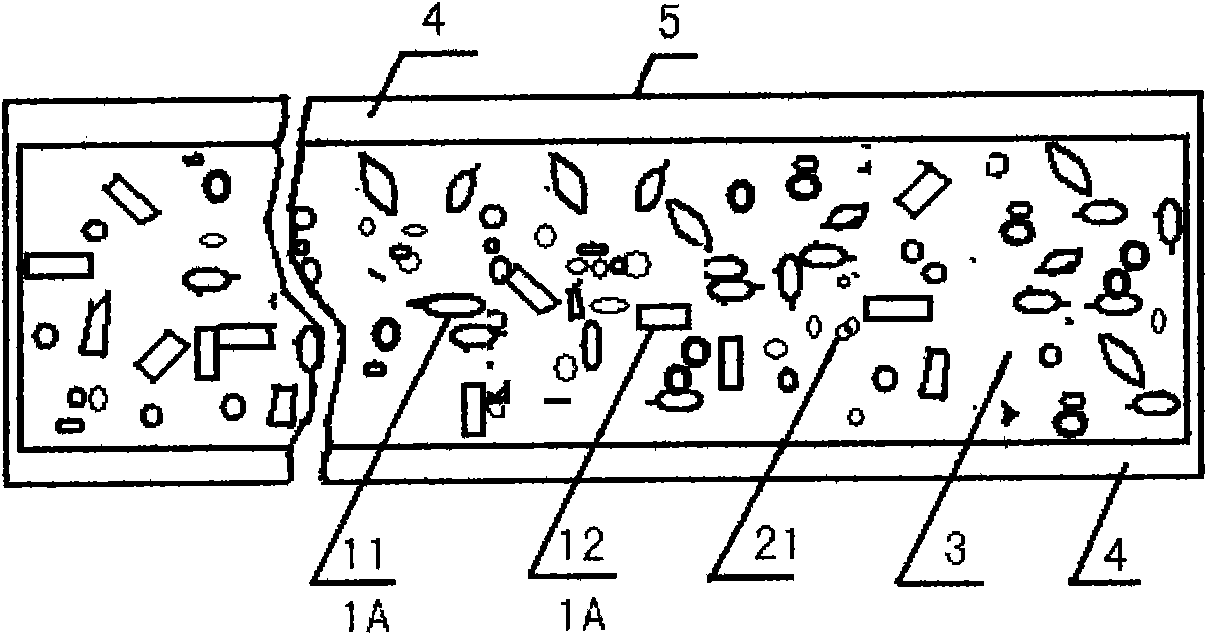

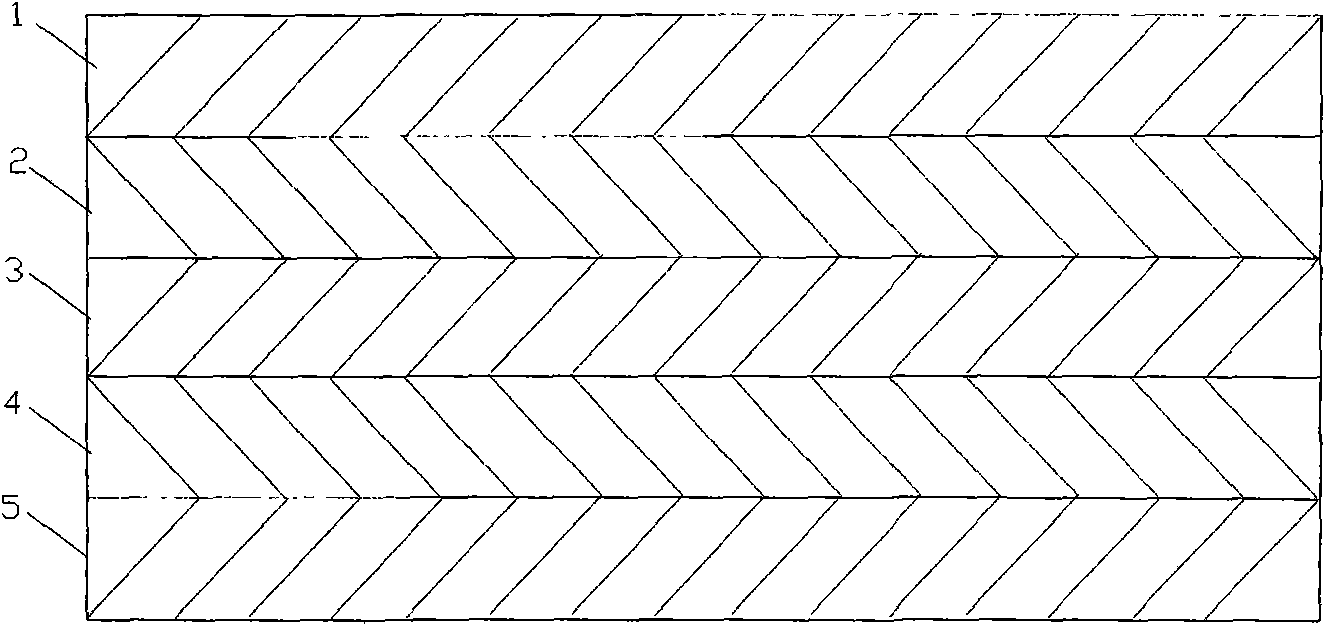

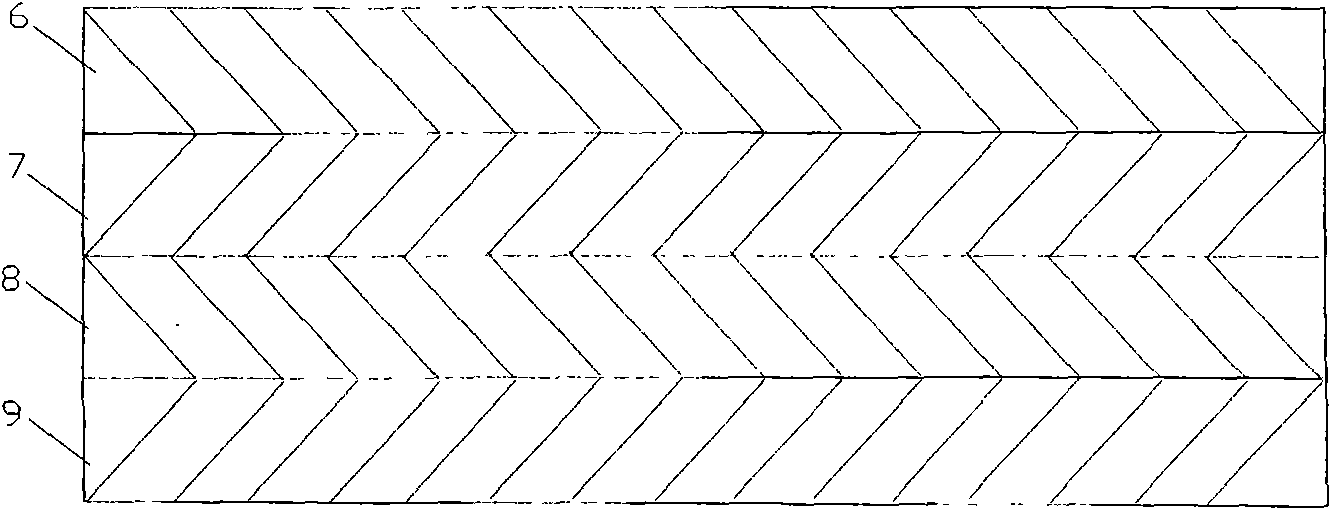

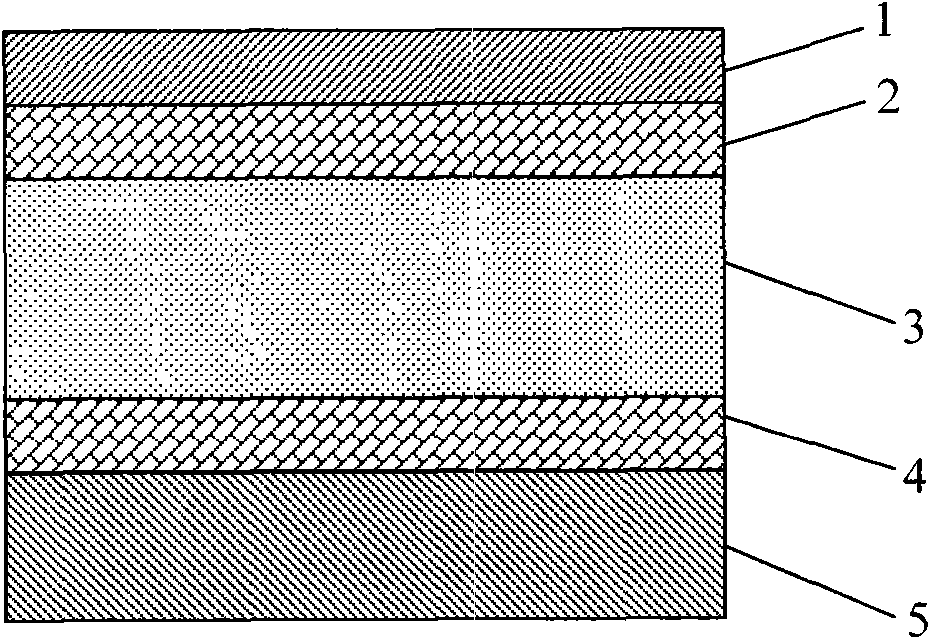

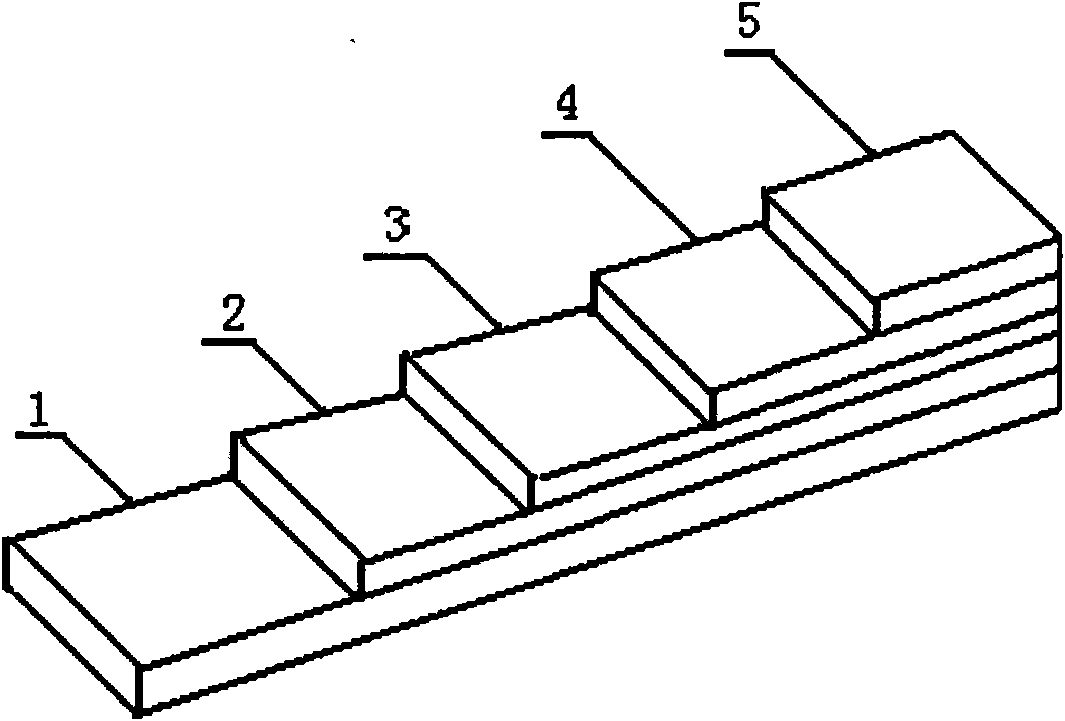

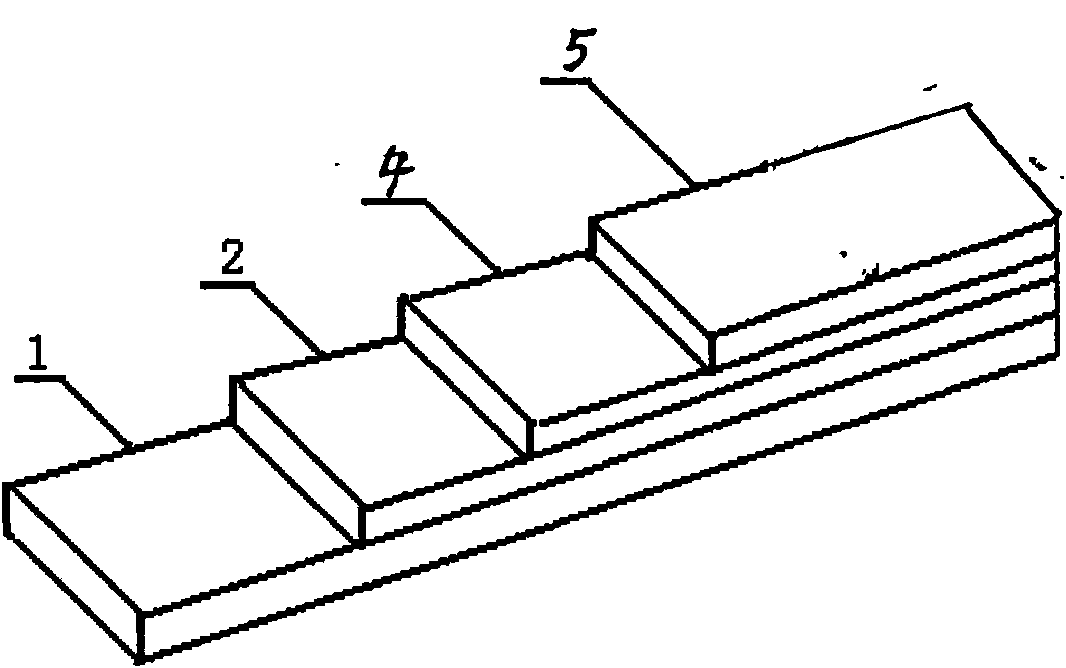

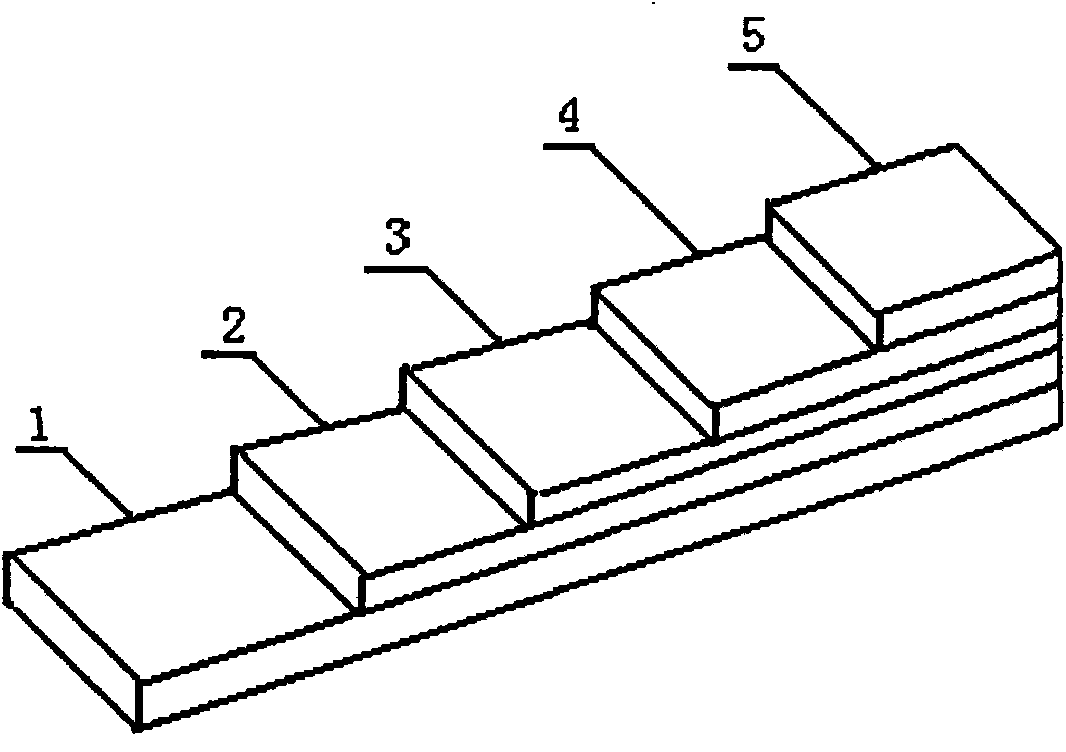

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

Antireflection film, polarizing plate, method for producing them, liquid cryatal display element, liquid crystal display device, and image display device

ActiveUS20070146887A1Reduce weightLow costLiquid crystal compositionsSynthetic resin layered productsSilica particleLiquid-crystal display

To provide an antireflection film which is easily and inexpensively producible and which has an antireflection property, a scratch resistance and a stain resistance in a sufficient level, and a polarizing plate and a liquid crystal display device utilizing the antireflection film of such excellent ability, the antireflection film includs a transparent support and a low-refractive index layer having a lower refractive index than the transparent support, wherein the low-refractive index layer is an outermost layer, and the low-refractive index layer contains a hollow silica particle and a compound that reduces a surface free energy of the outermost layer.

Owner:FUJIFILM CORP

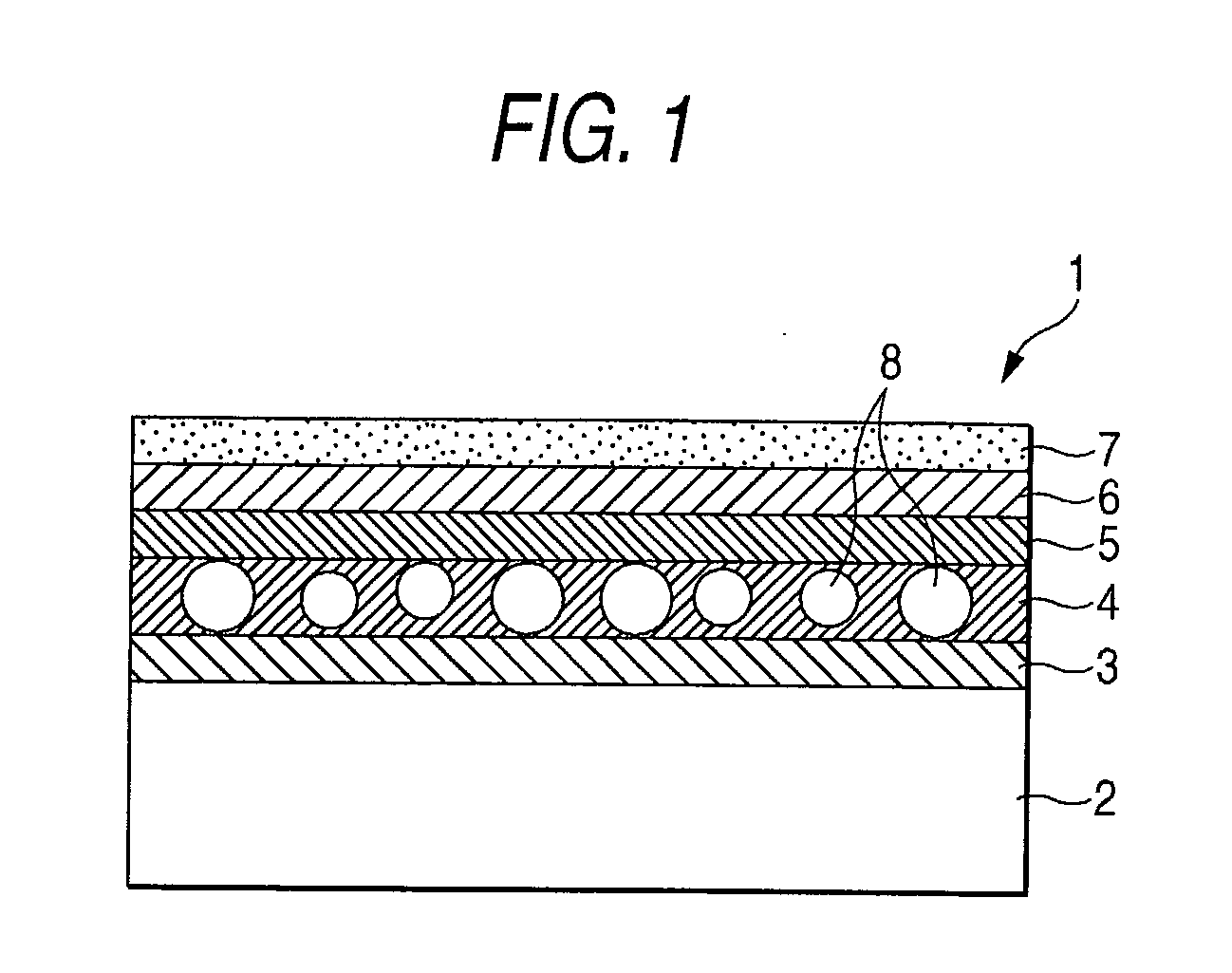

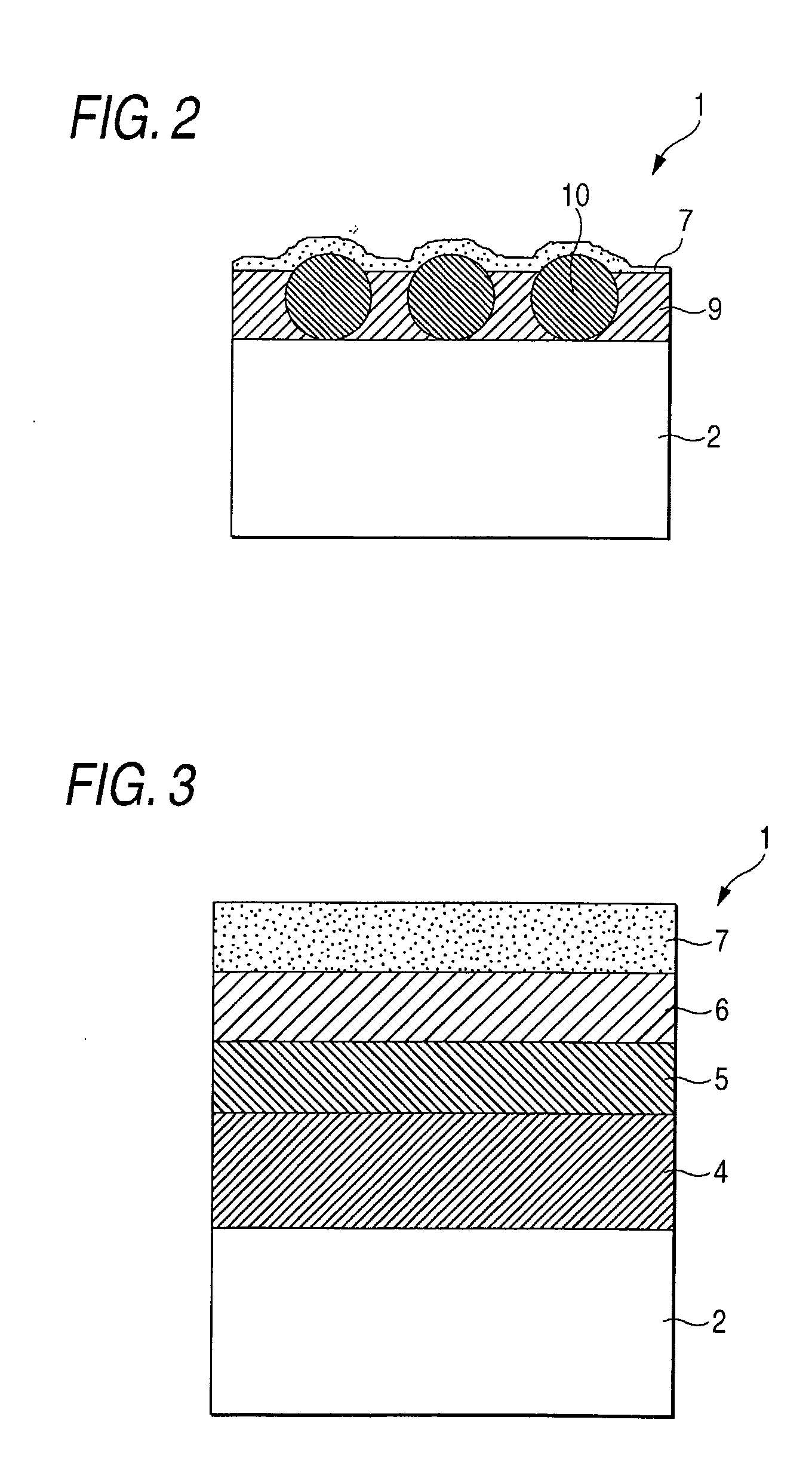

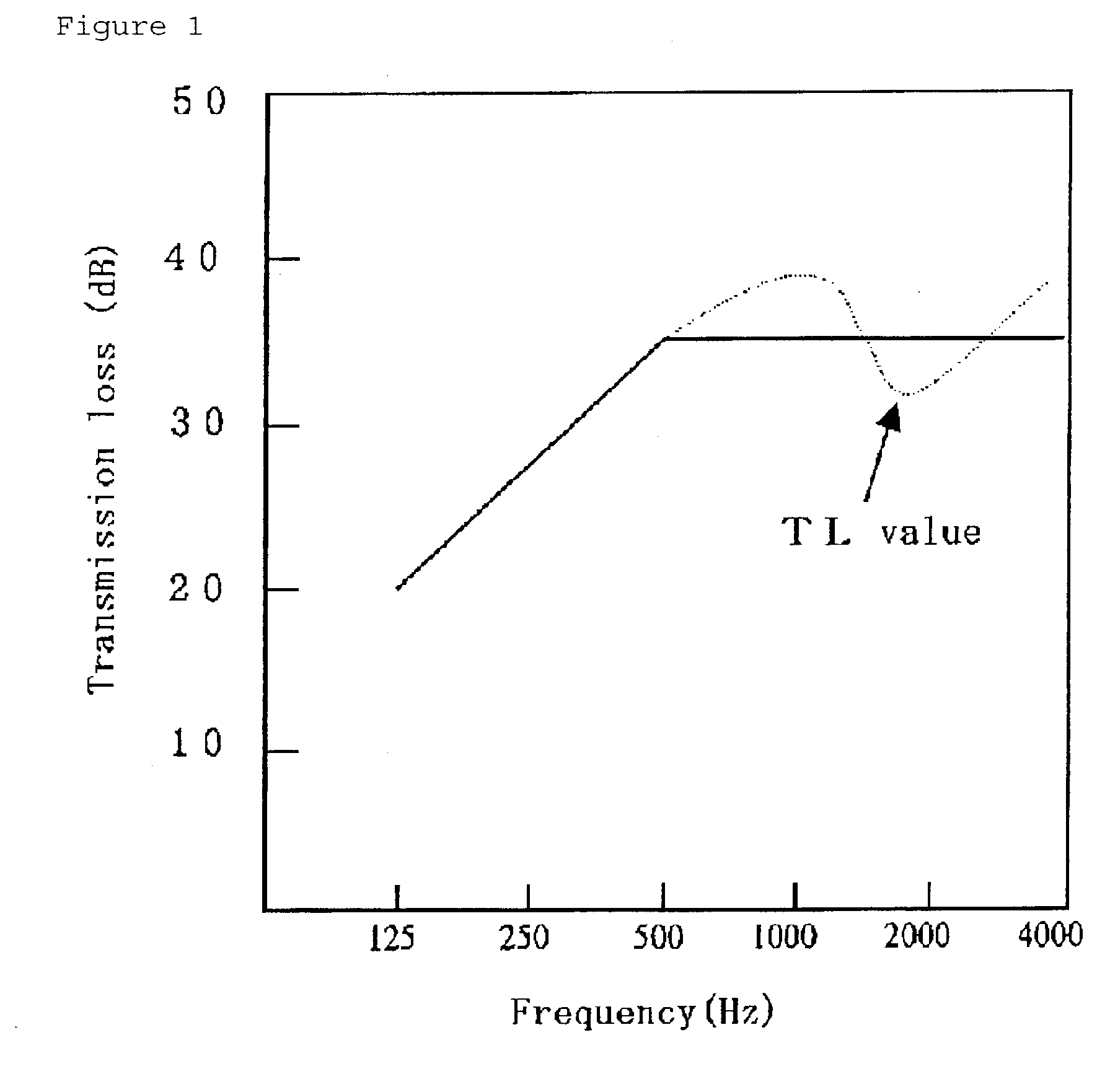

Interlayer film for laminated glass and laminated glass

InactiveUS20030139520A1Improve adhesionHigh transparencyNon-fibrous pulp additionFibre treatmentChemistryUltrasound attenuation

The invention provides an interlayer film for a laminated glass and a laminated glass, which are protected against a slump in TL value through attenuation of said coincidence effect and adapted to display an outstanding sound insulation performance over a broad temperature range. An interlayer film for a laminated glass comprising a plasticizer and a polyacetal resin, which is a blend of a polyacetal resin having an average polymerization degree of 1,000 to 3,000 and a polyacetal resin having an average polymerization degree of 3,000 to 5,000, and which has an acetalization degree of 60 to 85 mol % and an acetyl group content of 8 to 30 mol %. An interlayer film for a laminated glass which shows a temperature dependence of loss tangent in which the lowest-temperature side maximum of loss tangent appears at 30° C. or lower when examined for dynamic viscoelasticity.

Owner:SEKISUI CHEM CO LTD

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

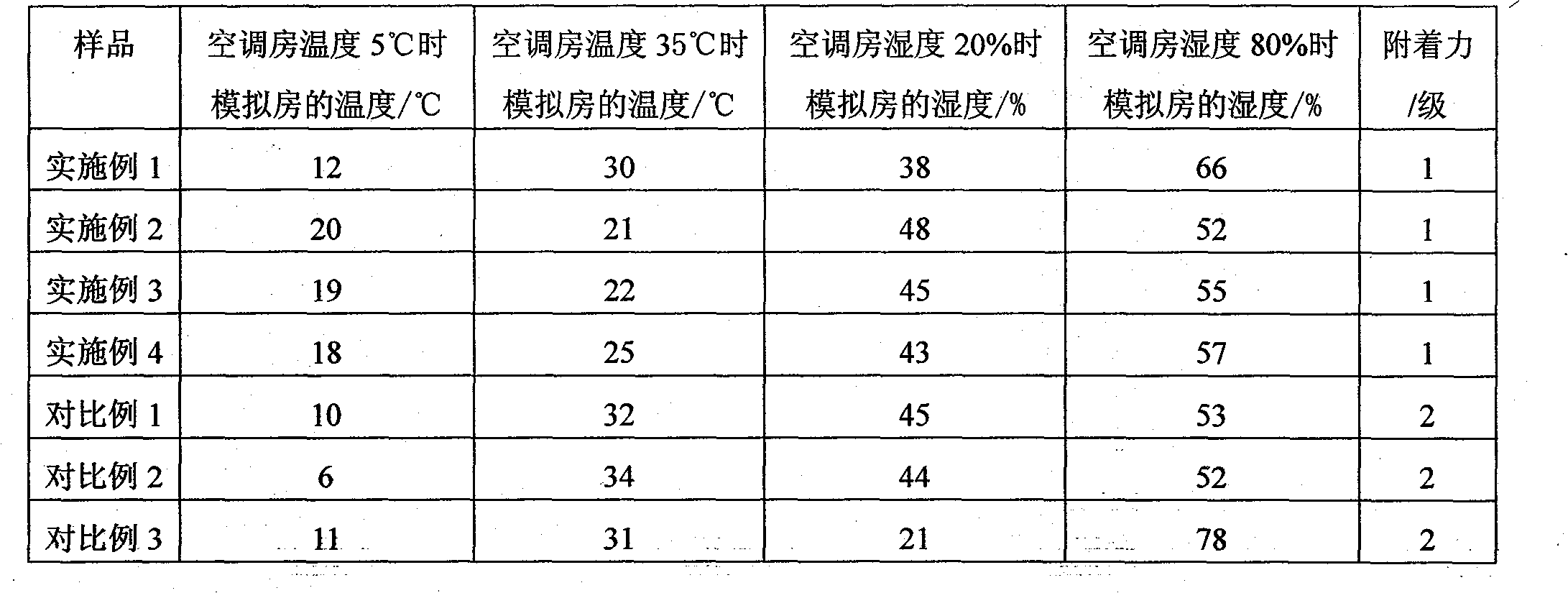

Temperature adjusting humidity adjusting coating and preparation method thereof

InactiveCN103159437ALower room temperatureTurn up the room temperatureEnvironmental resistanceThermal insulation

The invention relates to temperature adjusting humidity adjusting coating and a preparation method thereof. The temperature adjusting and humidity adjusting coating comprises thermal insulation undercoat, phase transition energy storage intermediate coat and heat conduction humidity adjusting finish. The undercoat insulates heat, and the phase transition energy storage intermediate coat transmits indoor energy through the finish and stores energy through the phase transition, and thereby effectively adjusting indoor temperature. The phase transition energy storage intermediate coat and the humidity adjusting function of the finish impart the whole coating temperature adjusting and humidity adjusting function. In addition, the temperature adjusting and humidity adjusting coating has the advantages of being fireproof, waterproof, antifouling, mechanical, capable of eliminating peculiar smell, sterilizing, insulating heat, removing sound, protecting environment and the like. The temperature adjusting and humidity adjusting coating is applicable to various kinds of constructional coating.

Owner:LUNAN RES INST OF COAL CHEM

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

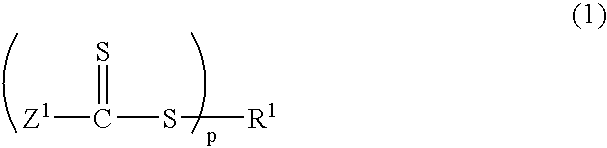

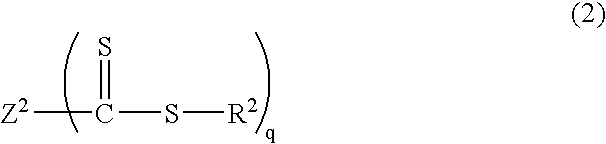

Curable resin composition

The object of the present invention is to provide a novel acrylic-modified silyl-terminated polyether resin composition which is advantageous not only in terms of the availability of raw materials and the ease of synthetic reaction, but also in fast-curing, good storage stability, good weatherability, high adhesiveness, thus promising high potentials of industrial utilization. Further, the object of the present invention is also to develop an environment-friendly curable composition which is a major social consideration. The composition is a curable composition comprising an oxyalkylene polymer (A) containing silyl functional group capable of crosslinking by forming a siloxane bond and a copolymer (B) having a molecular chain comprising alkyl acrylate and / or alkyl methacrylate monomer units and containing silyl functional group capable of crosslinking by forming a siloxane bond, said copolymer (B) having both dialkoxysilyl and trialkoxysilyl groups as said silyl functional group.

Owner:KANEKA CORP

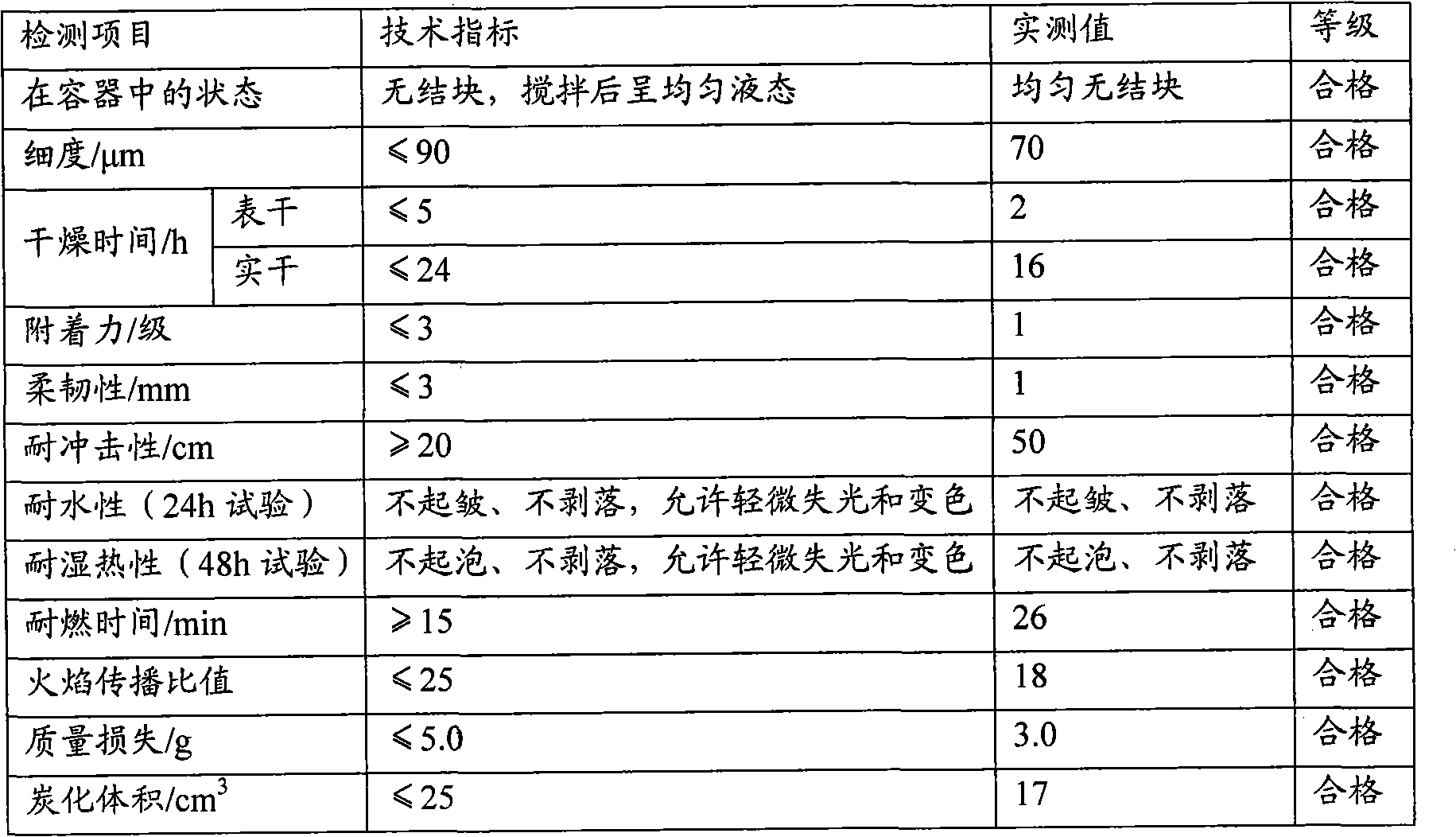

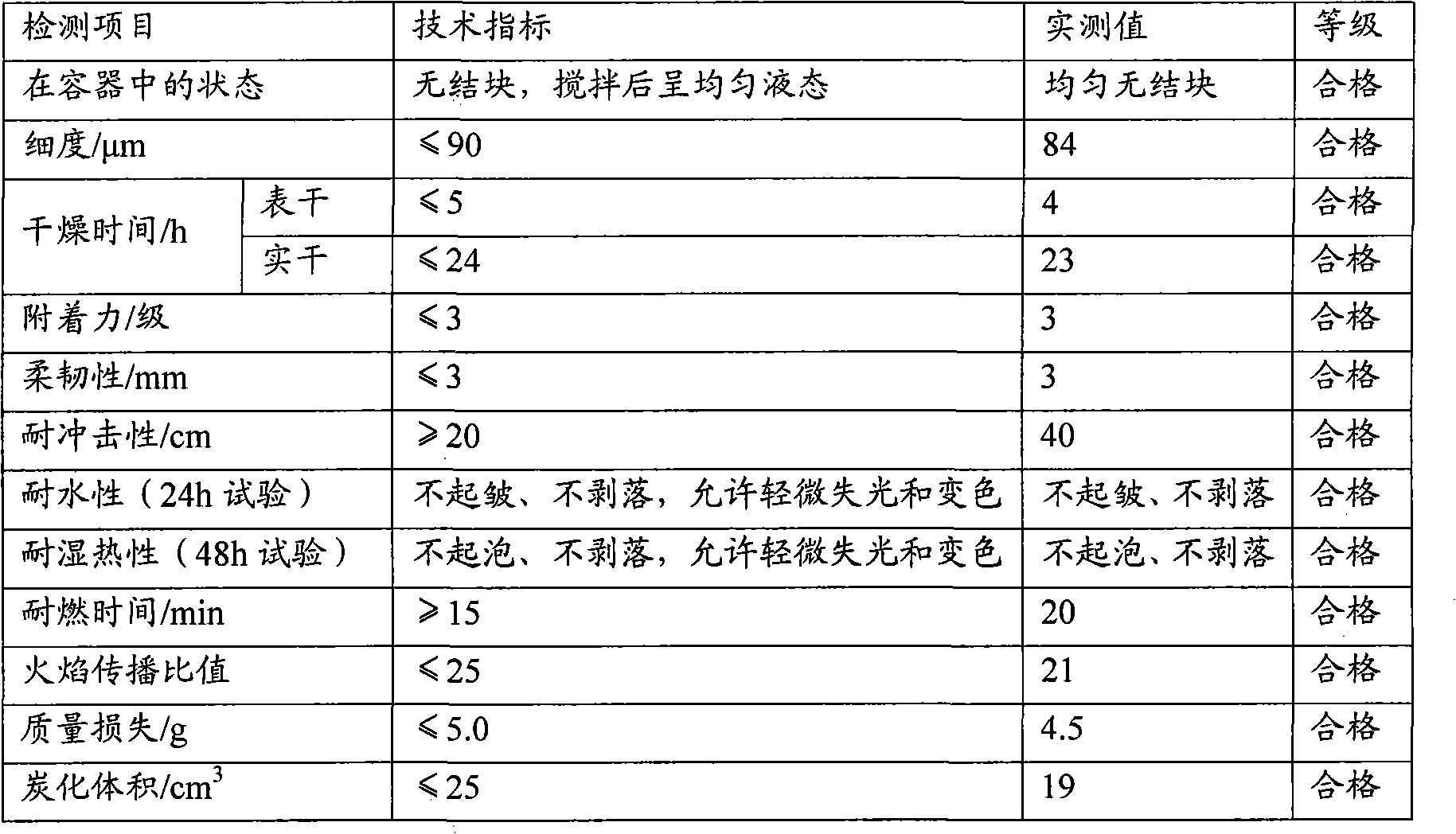

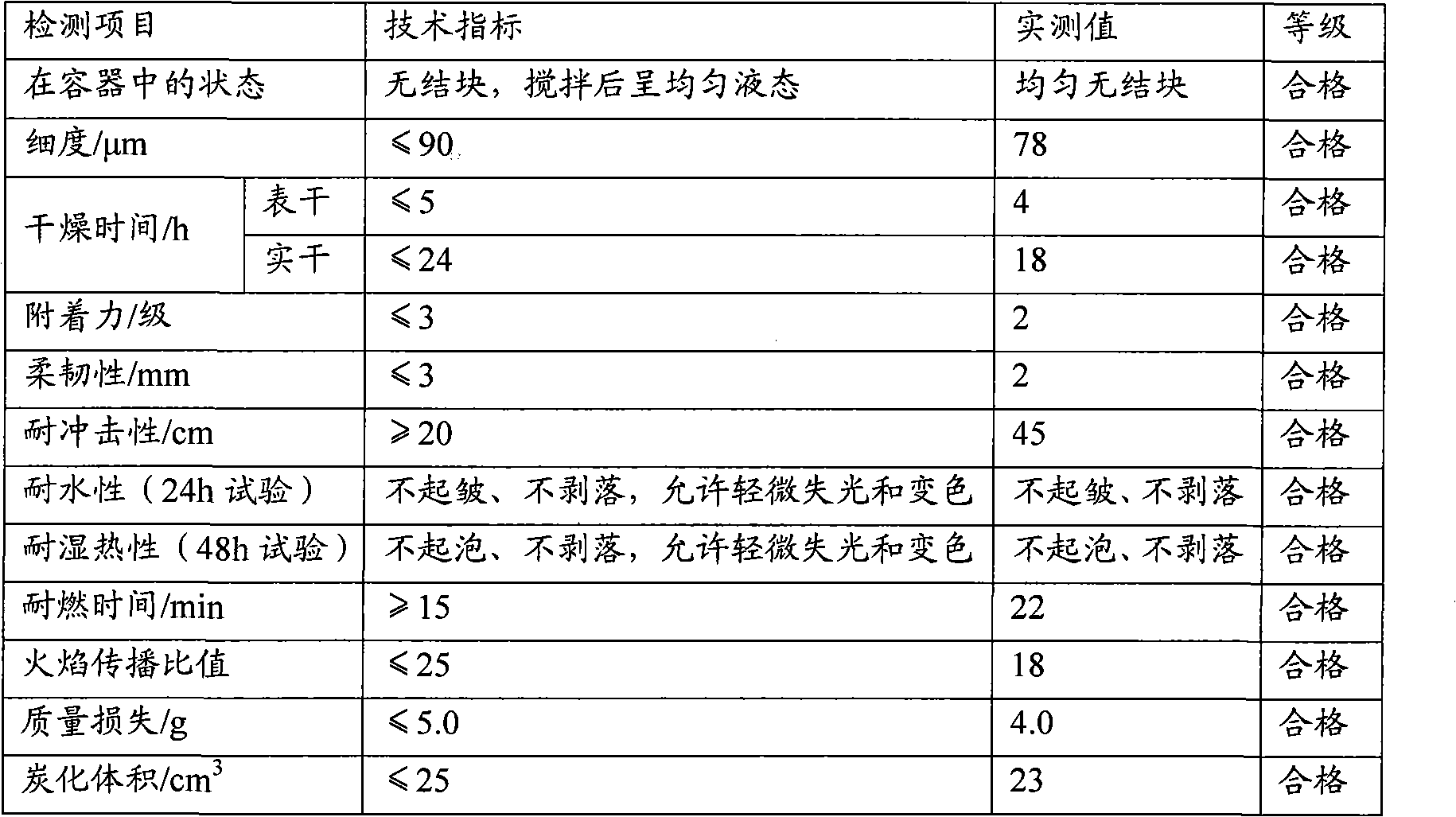

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

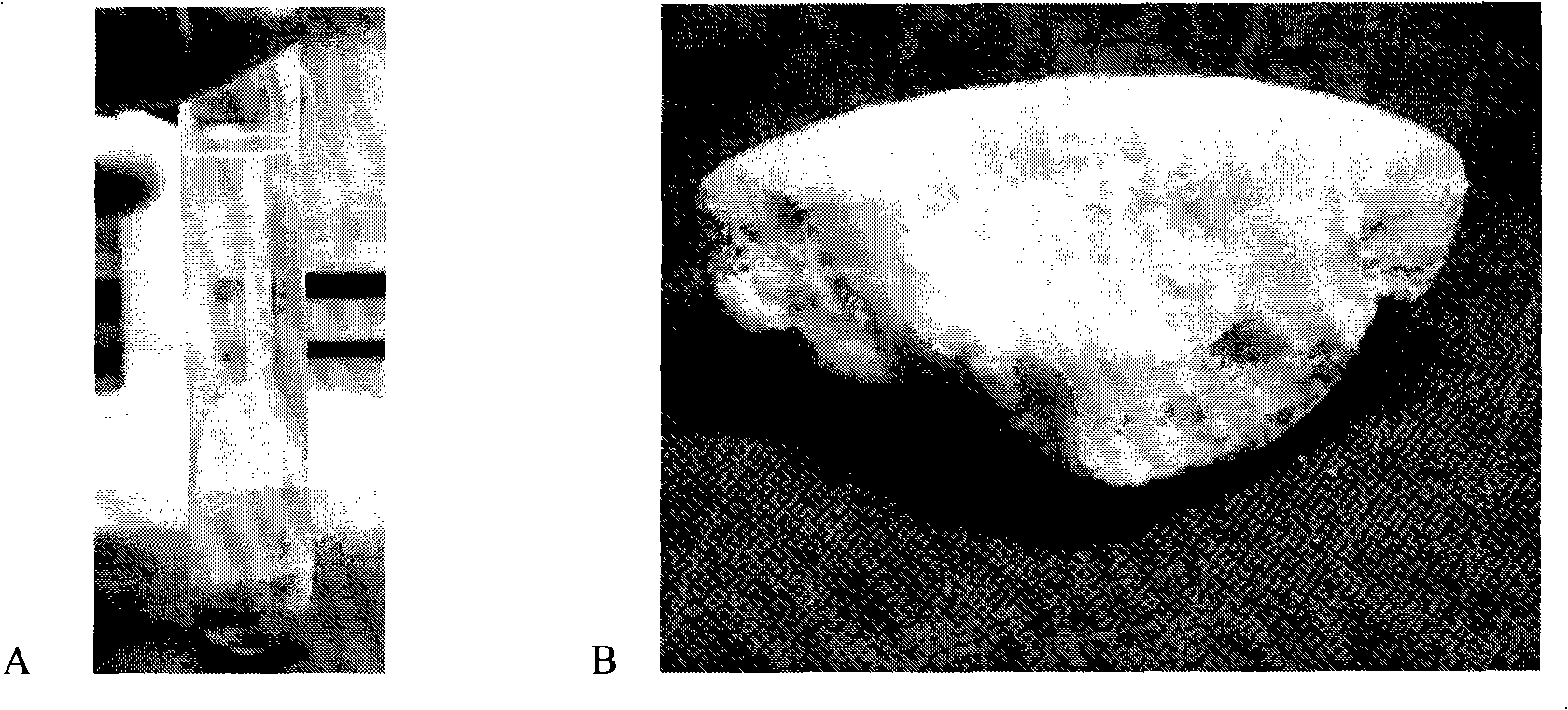

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

High-performance water-based anticorrosion paint and preparation method thereof

InactiveCN102134410AReduce heavy metal contentImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsAviationWater based

The invention relates to a preparation method of high-performance water-based anticorrosion paint. The high-performance water-based anticorrosion paint comprises 30-60 parts of inorganic material resin, 0.5-30 parts of polyaniline-based nano composite material, 0-30 parts of curing agent, 0.1-1 part of defoaming agent, 0.1-1 part of dispersant and 0.1-1 part of leveling agent. Since the high-performance water-based anticorrosion paint does not contain organic resin or organic solvent, the paint has the advantages of heat resistance, wear resistance, weather resistance, oil resistance, fire resistance and environmental protection; the paint also has the advantages of simple preparation technique, strong binding force with metal, and low cost, can be cured at normal temperature, and can be widely used for corrosion protection in the fields of aviation, navigation, chemical engineering, electronics and the like.

Owner:济宁市产品质量监督检验所

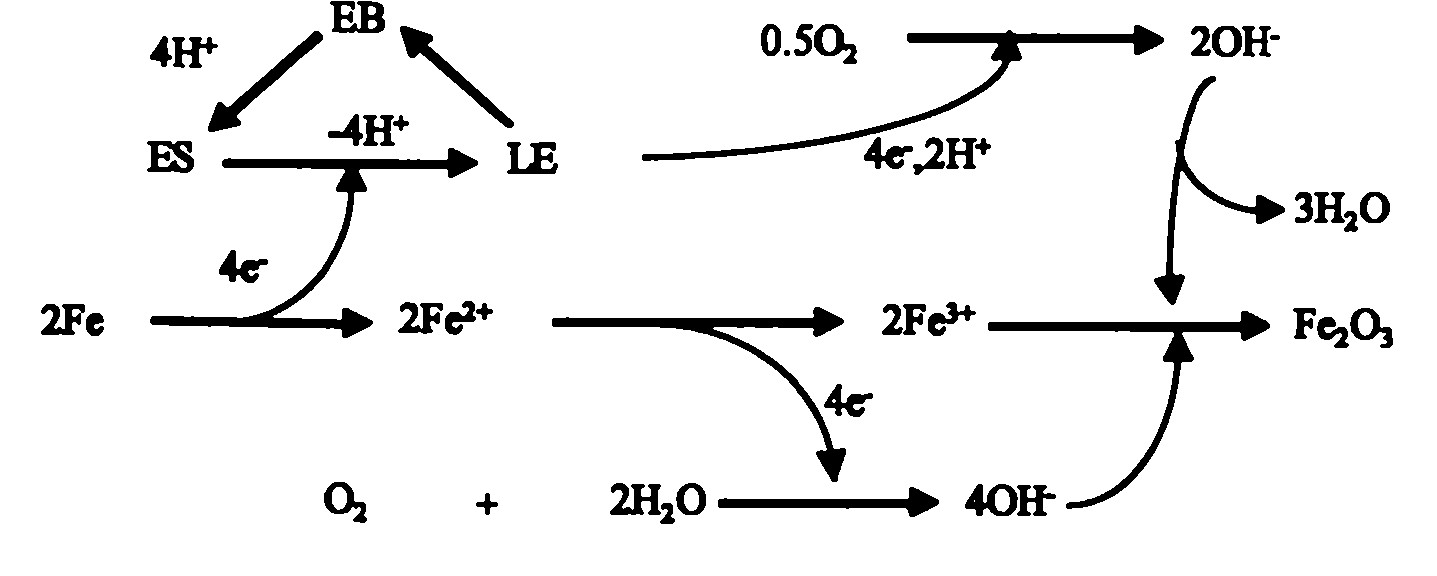

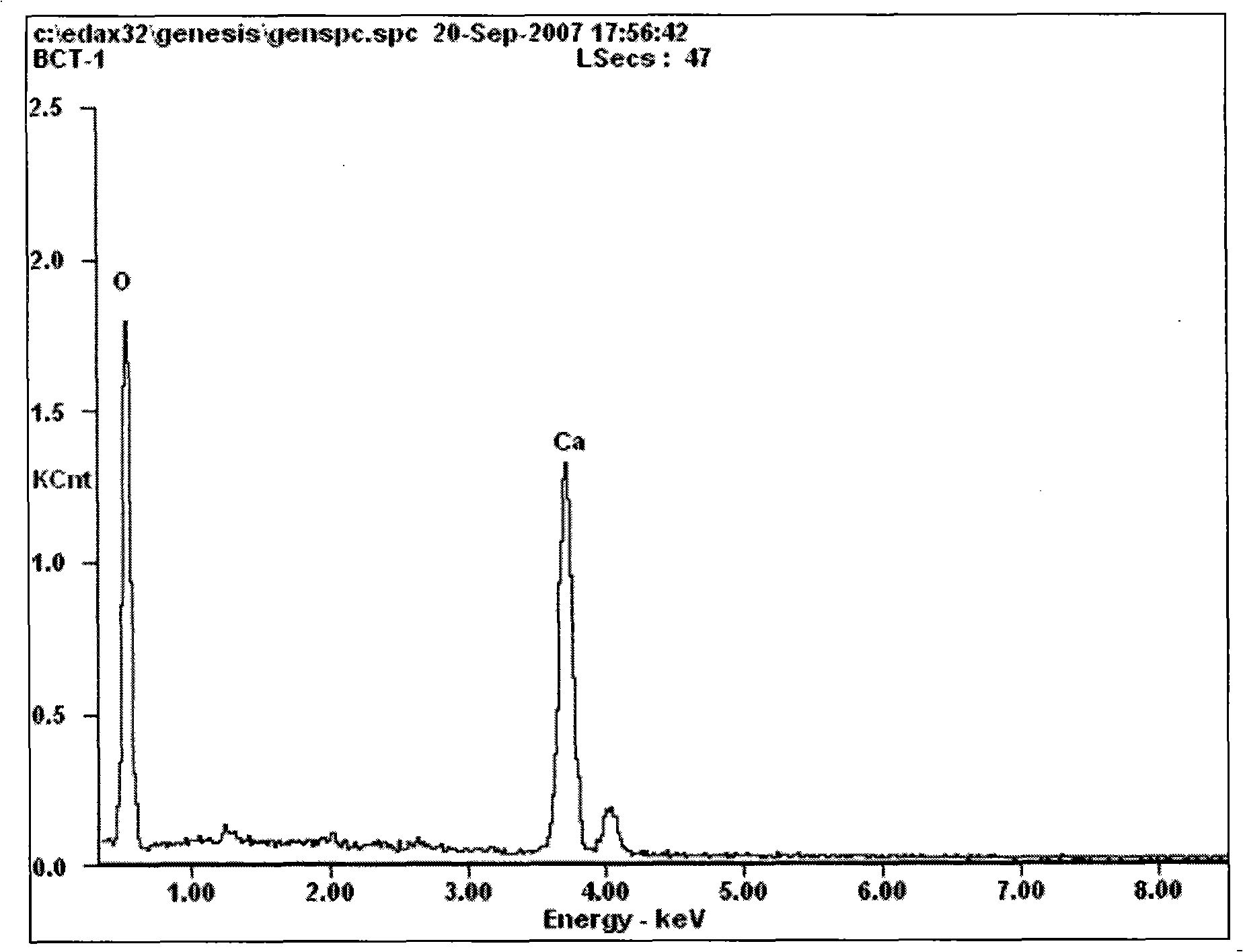

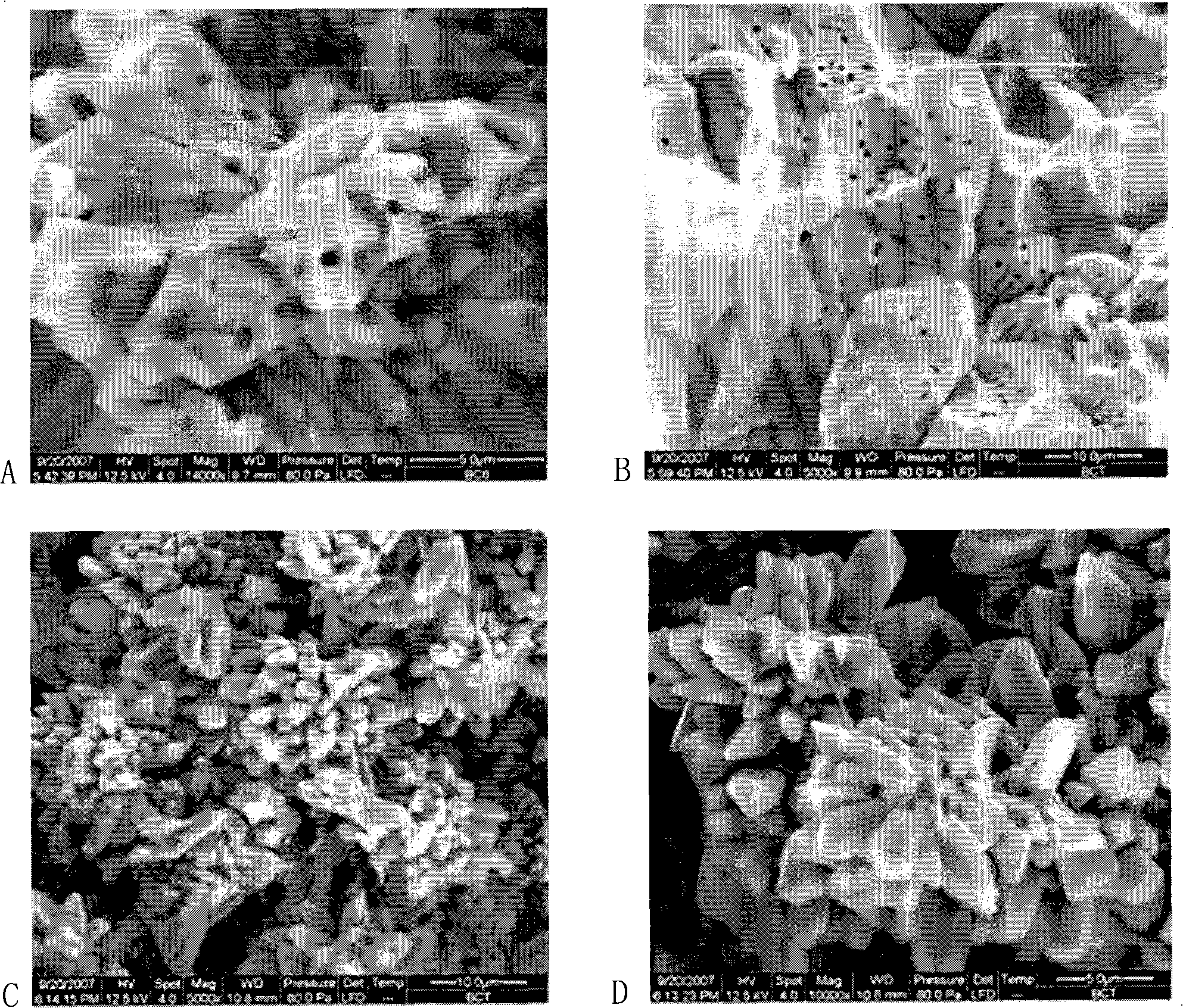

Microorganism cause concrete or concrete, producing method and application thereof

InactiveCN101270369ADoes not hinder precipitationApplicable treatmentBacteriaMicroorganism based processesMicroorganismEnvironmental hazard

The invention discloses a microbiogenic cement and concrete and a production method thereof, which mainly mixes the Bacillus pasteurii solution for producing urease and an admixture of containing urea and mineral calcium salt and obtains the microbiogenic cement after reacting in a certain condition; adds admixture such as sand etc. into the mixture of mixing the bacterial solution and the mixture and reacts to generate the microbiogenic concrete. The microbiogenic cement or concrete of the invention can be used on protection and restoration of masonry ancient architectures and repair of cracks on concrete building or treatment of liquescent sandy soil. The invention provides a permanent method of safety, effectiveness and without environmental hazard for repair and strengthening technology of large quantity of civil architecture and structure; the invention has the advantages of the good effects, the good weatherability, the good permeability of gas and the good permeability of water and being especially suitable for treatment of the sandy soil; the invention is safe and environmental-friendly, and belongs to the environmental-friendly restoring material.

Owner:TSINGHUA UNIV

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

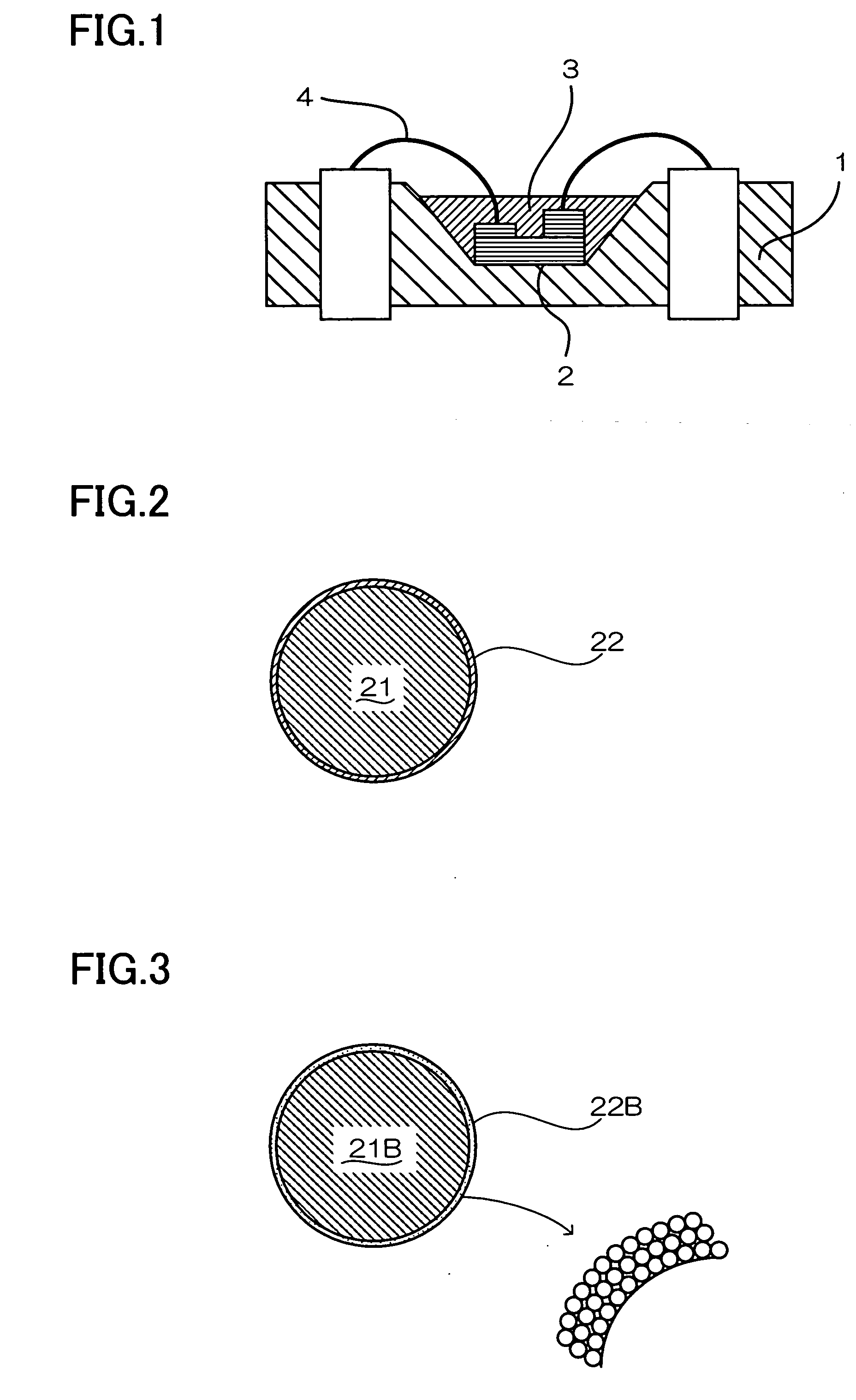

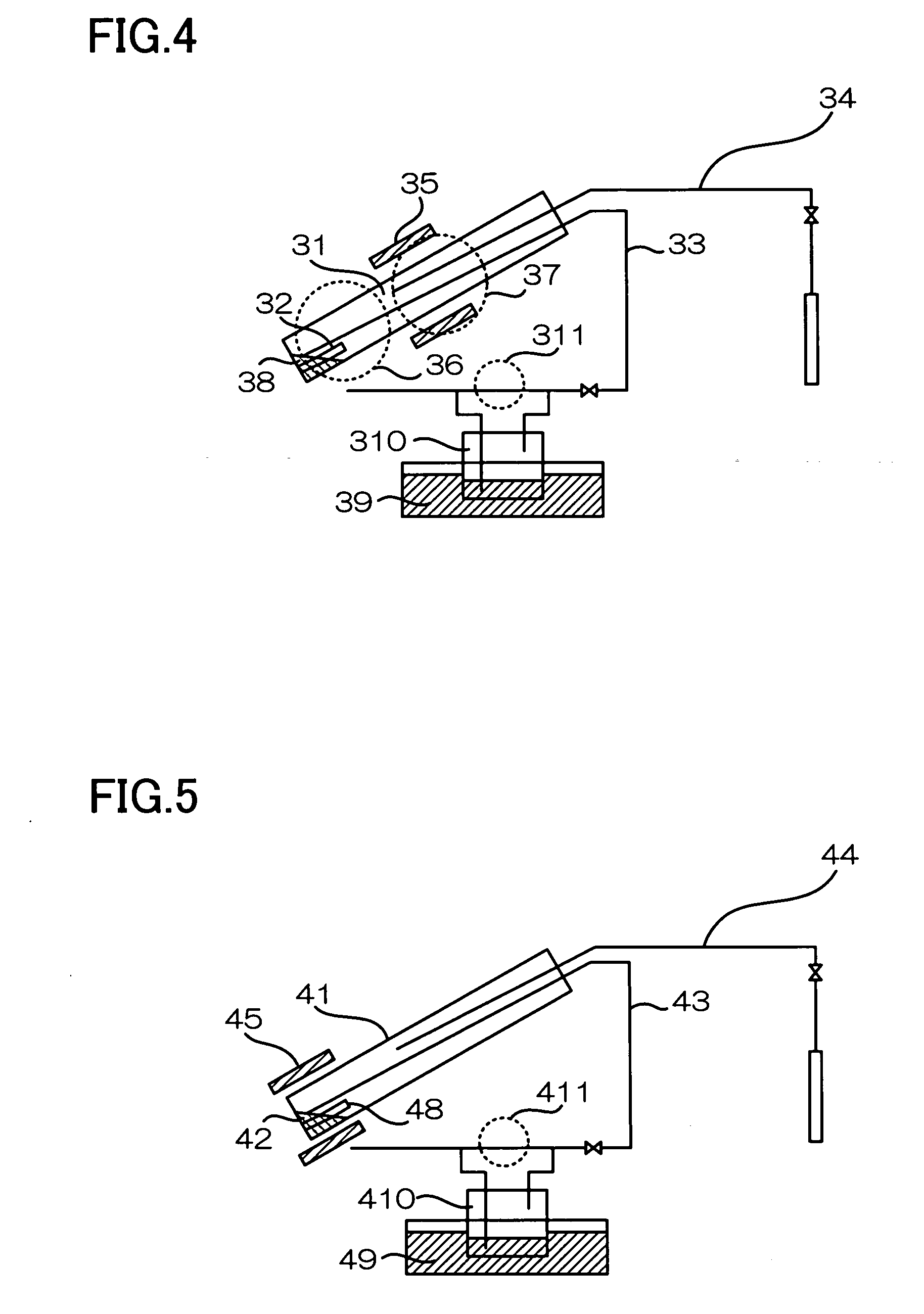

Light emitting device, phosphor, and method for preparing phosphor

ActiveUS20060001352A1Solve the lack of lifeIncrease thermal resistanceGas-filled discharge tubesDischarge tube luminescnet screensRare-earth elementOxygen

The surface of a phosphor is coated with a coating member made of a material different from the phosphor in chemical vapor-phase reaction. The coating member is made of any of metal oxide, metal nitride and metal oxynitride. The coating member coats the surface of the phosphor whereby having a substantially smooth film, or is formed such that a large number of fine particles relatively smaller than the phosphor aggregate to coat the whole surface of the phosphor. The coating member contains at least one metallic element selected from the group consisting of Al, Si, and rare earth elements. In addition, the phosphor is a transparent water-soluble phosphor and is an alkaline-earth silicon-nitride phosphor, an alkaline-earth silicon oxynitride phosphor, or the like. The BET value of the coated phosphor is 1.0 to 10 times the BET value before coating. The average thickness of the coating is 10 nm to 500 nm.

Owner:NICHIA CORP

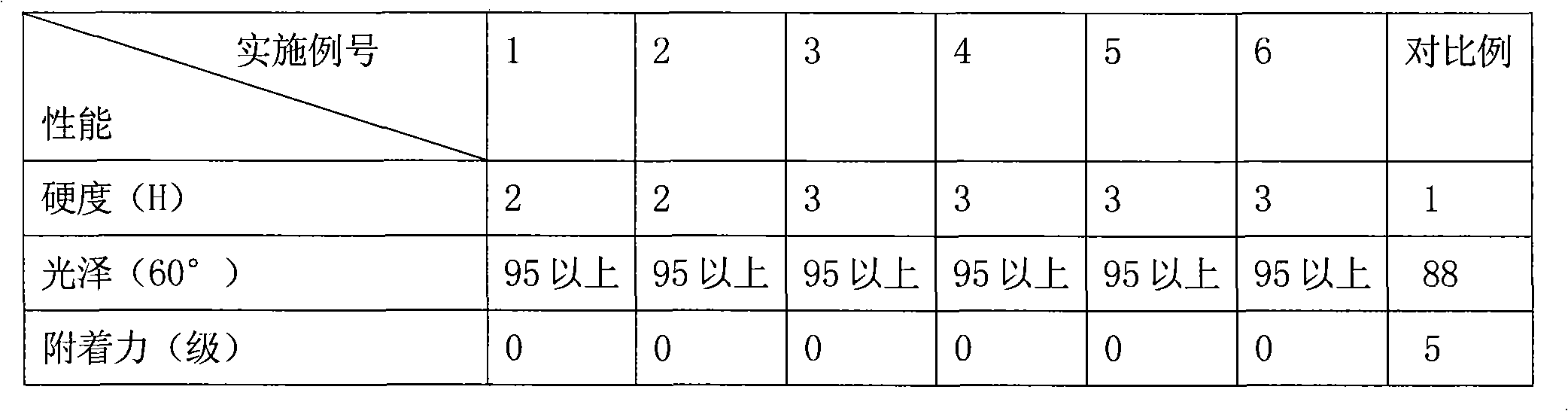

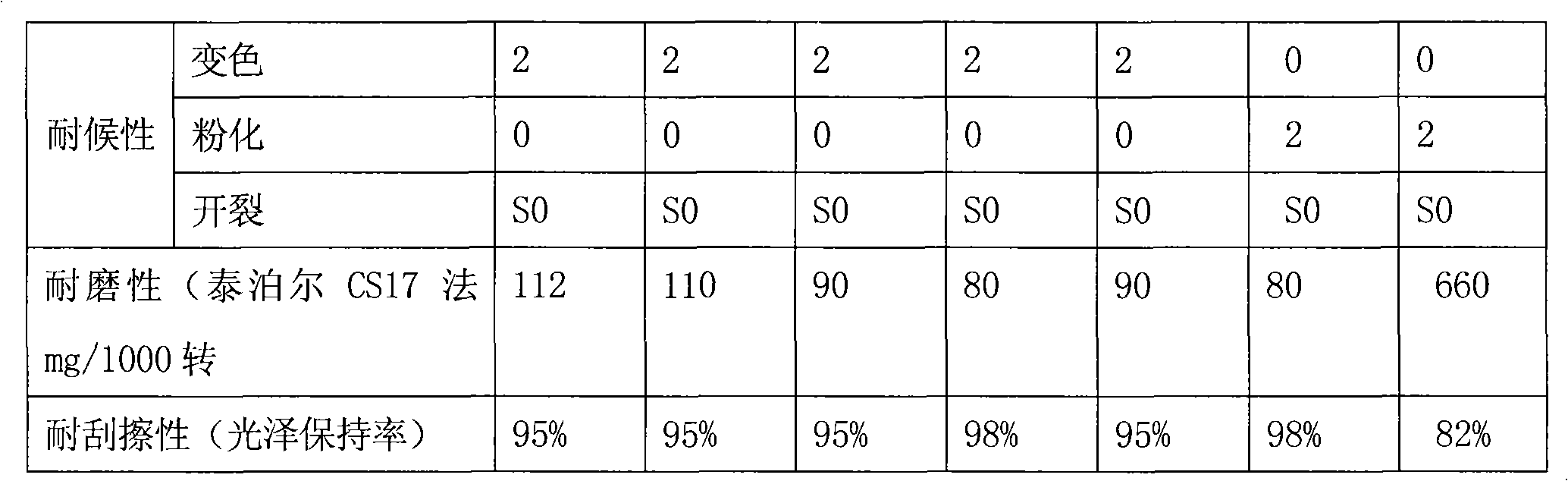

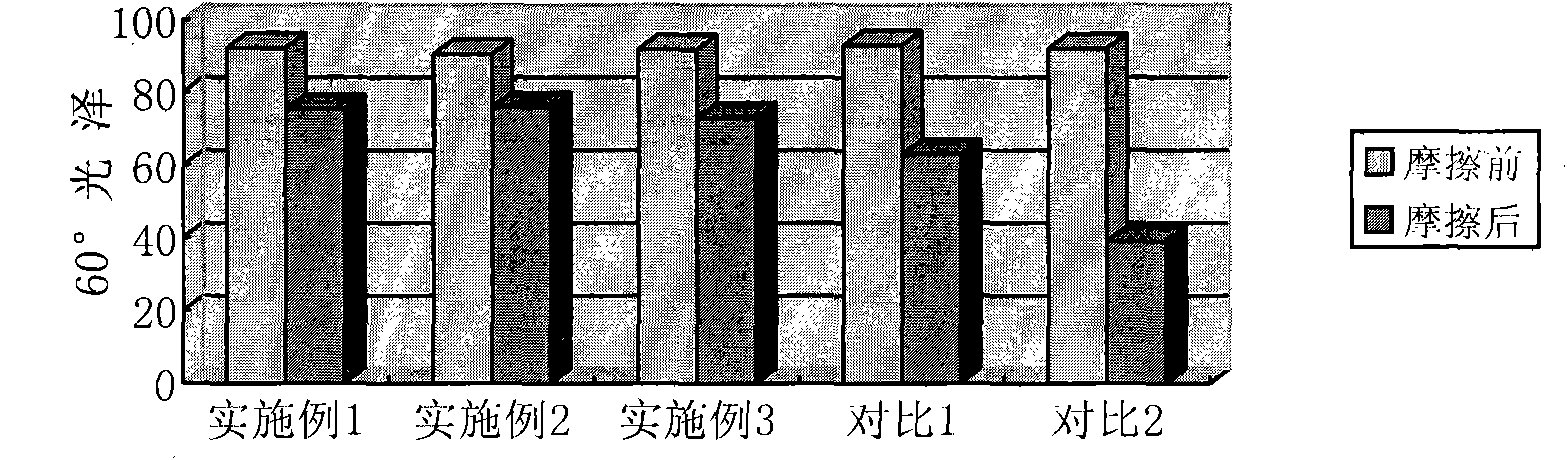

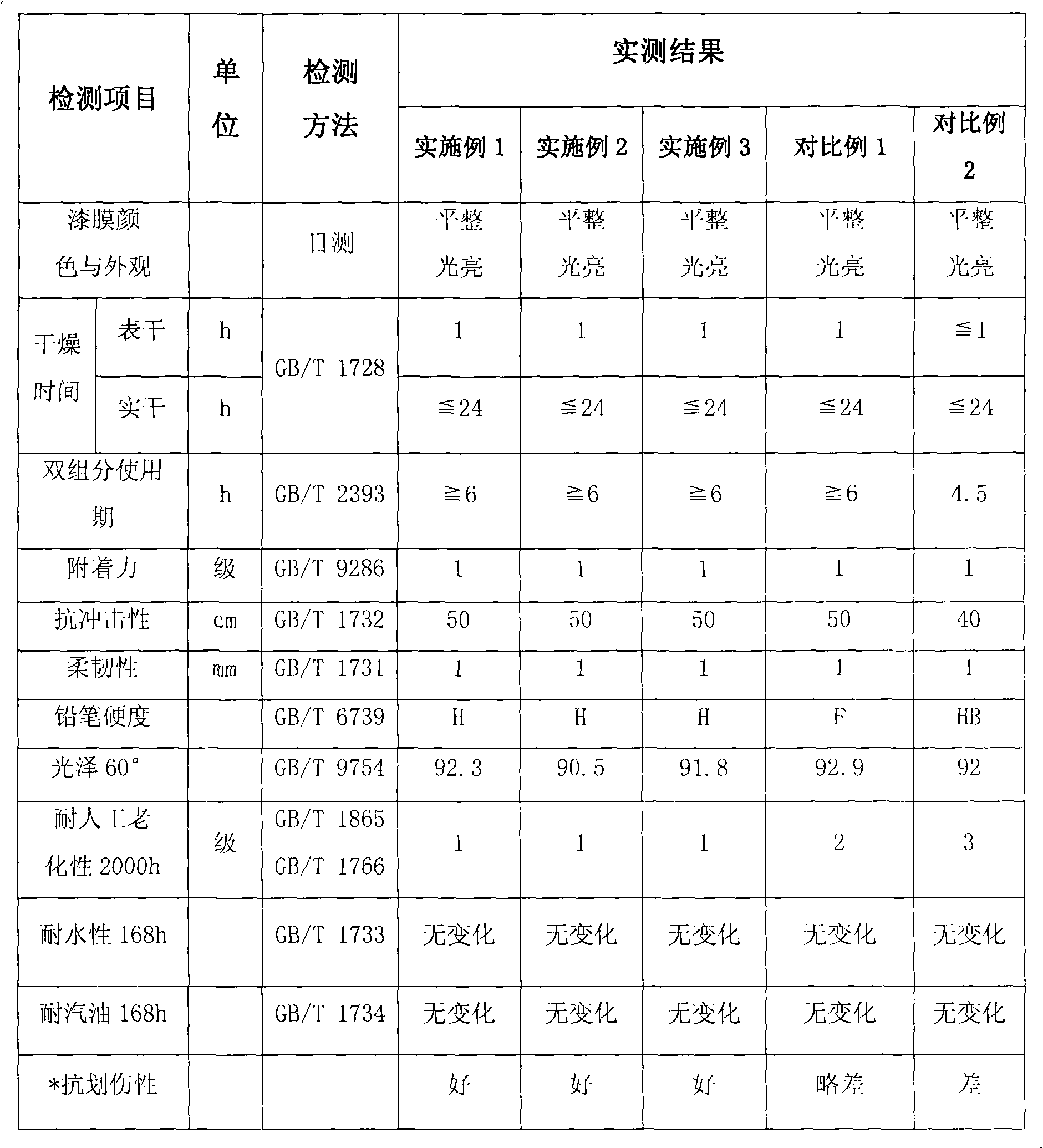

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Ultraviolet curable organic silicon-acrylic resin electronic adhesive and application thereof

InactiveCN101812278AFast curingIncrease elasticityOther chemical processesCoatingsNon toxicityAdhesive

The invention provides an ultraviolet curable organic silicon-acrylic resin electronic adhesive, which comprises the following components: (1) 100 parts of doublebond-containing acrylic monomers or prepolymer, (2) 5 to 500 parts of doublebond-containing organic silicon resin with a molecular weight of 1,000 to 10,000, (3) 1 to 100 parts of vinyl compound modified inorganic nano particle, (4) 1 to 50 parts of radical ultraviolet initiator, (5) 1 to 100 parts of organosilan, (6) 0 to 200 parts of inorganic reinforcing agent, and (7) 0 to 50 parts of auxiliary agent, wherein the ultraviolet curable organic silicon-acrylic resin is prepared by carrying out ultraviolet curing on the materials, and the solid content thereof is 100 weight percent. The product produced by the invention has the excellent characteristics of firm bonding with metal, glass and plastic materials and electronic devices, good optical property, good elasticity, good weather resistance, safety, non-toxicity, convenient construction and the like, can replace traditional solvent electronic adhesives, and is used for protective coatings, protective adhesives, packaging materials and the like of electronic devices, integrated circuits, printed circuits, LED chips and the like.

Owner:SHANGHAI XIYI NEW MATERIAL SCI & TECHCO

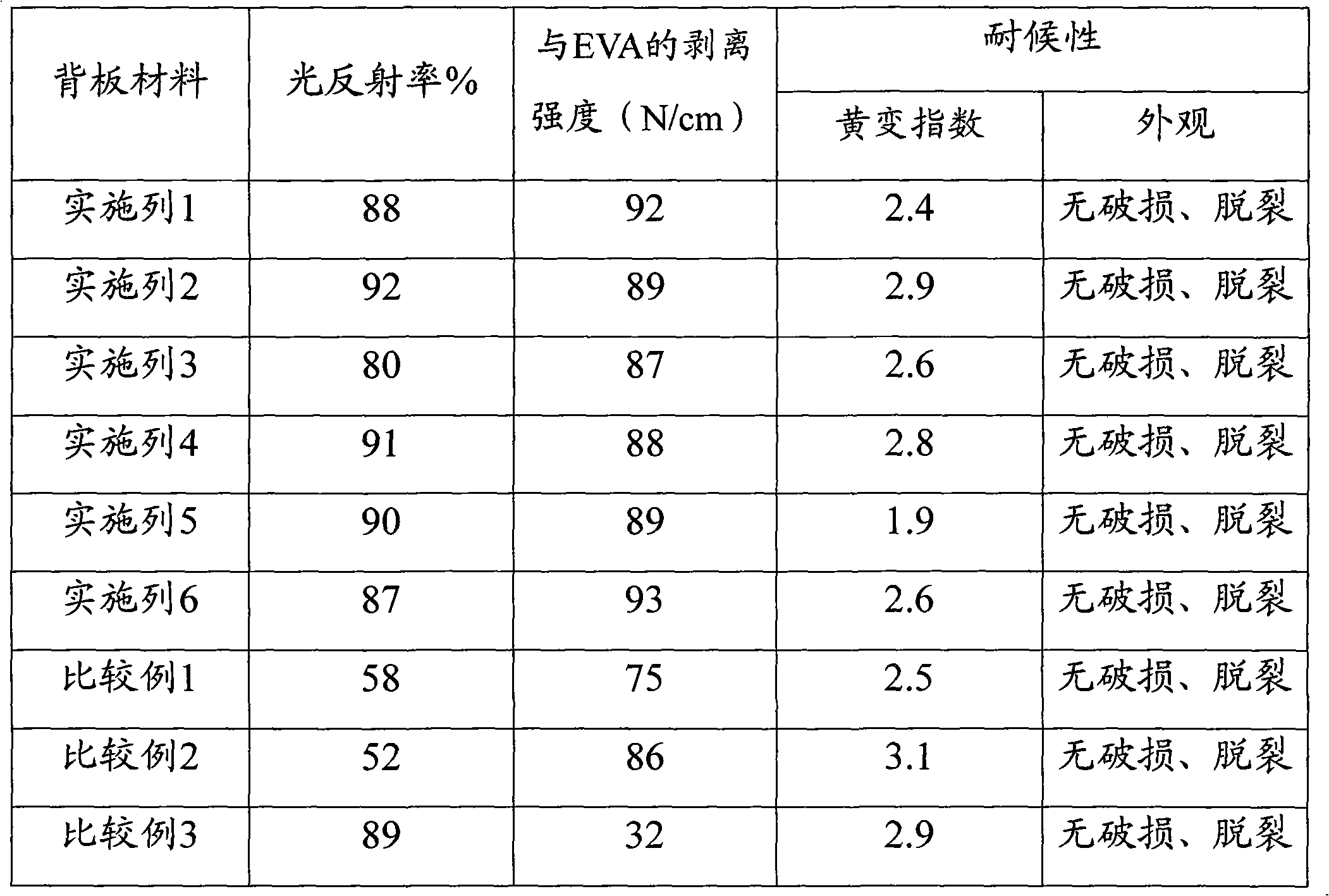

Solar cell module back veneer material

InactiveCN101645465AGood weather resistanceGood adhesionSynthetic resin layered productsPhotovoltaic energy generationSolar cellSolvent

A solar cell module back veneer material comprises a base coat layer having high adhesive strength with EVA, two layers of fluororesin-containing weather resistance coating films and an intermediate polymer basilemma between the two layers of fluororesin-containing resin weather resistance coating films, wherein at least one layer of fluororesin-containing resin weather resistance coating film hashigh light reflection performance, the base coat layer having high adhesive strength with EVA and the weather resistance coating film having high light reflection performance in the coating film arearranged at the side close to a cell sheet in an encapsulated cell module, the fluororesin-containing resin masking liquid has good coating uniformity and good adhesive force with the polymer basilemma, and contains high reflection filler component with the constituents as the follows according to parts by weight: 100 parts of fluororesin-containing resin, 3-20 parts of curing agent, 10-30 parts of high reflection filler, 0.0003-0.0001 part of catalyst, and 50-200 parts of solvent.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

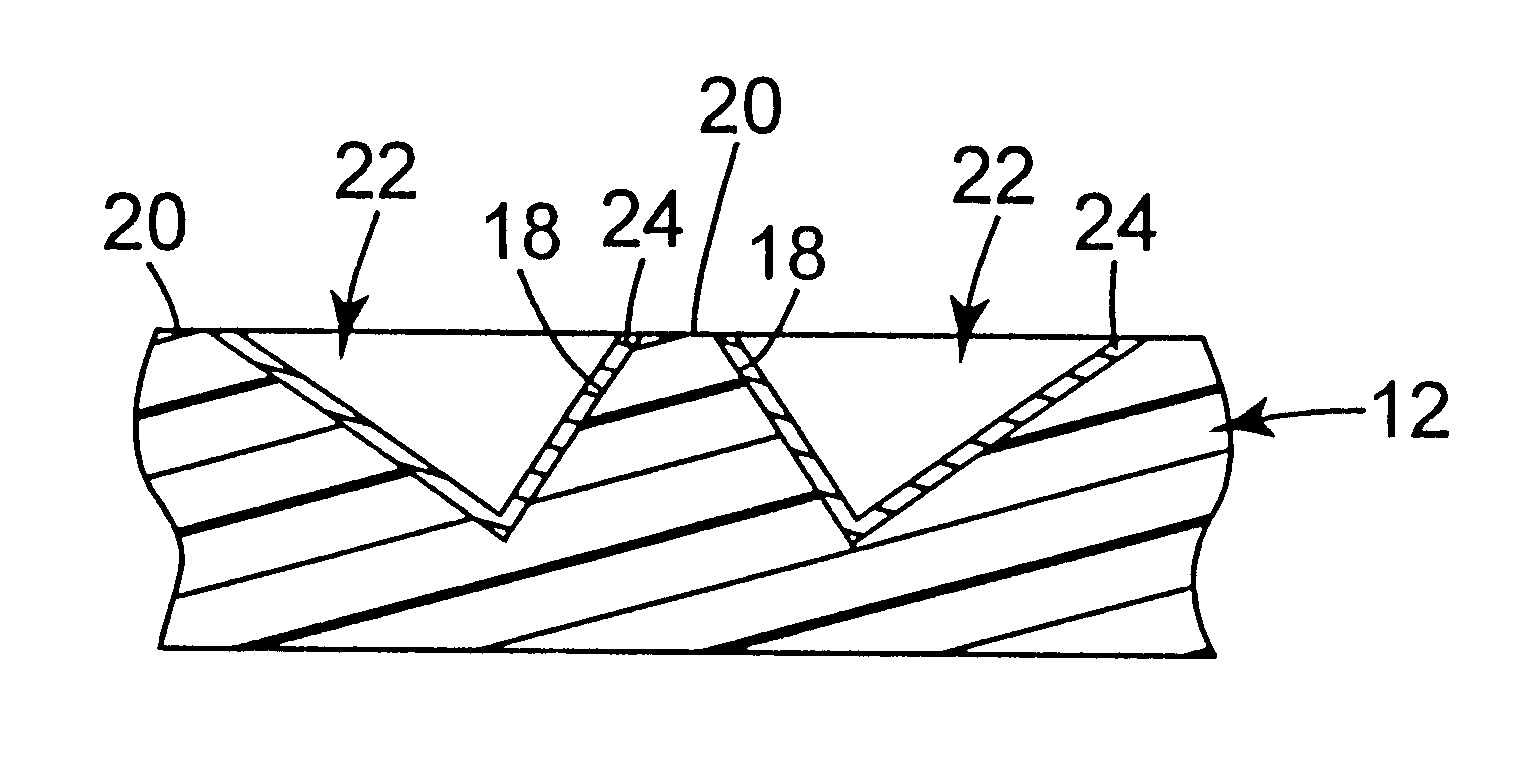

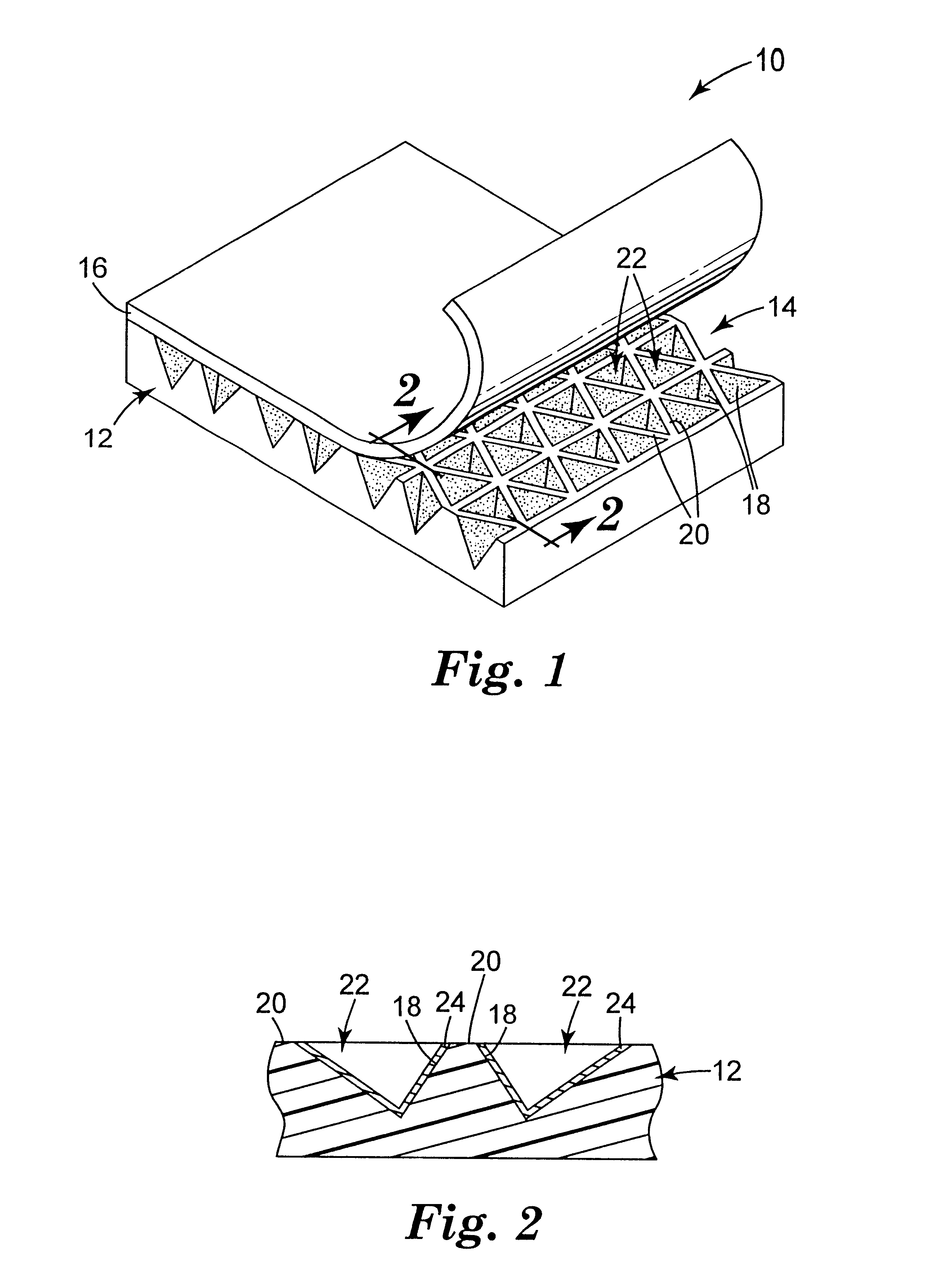

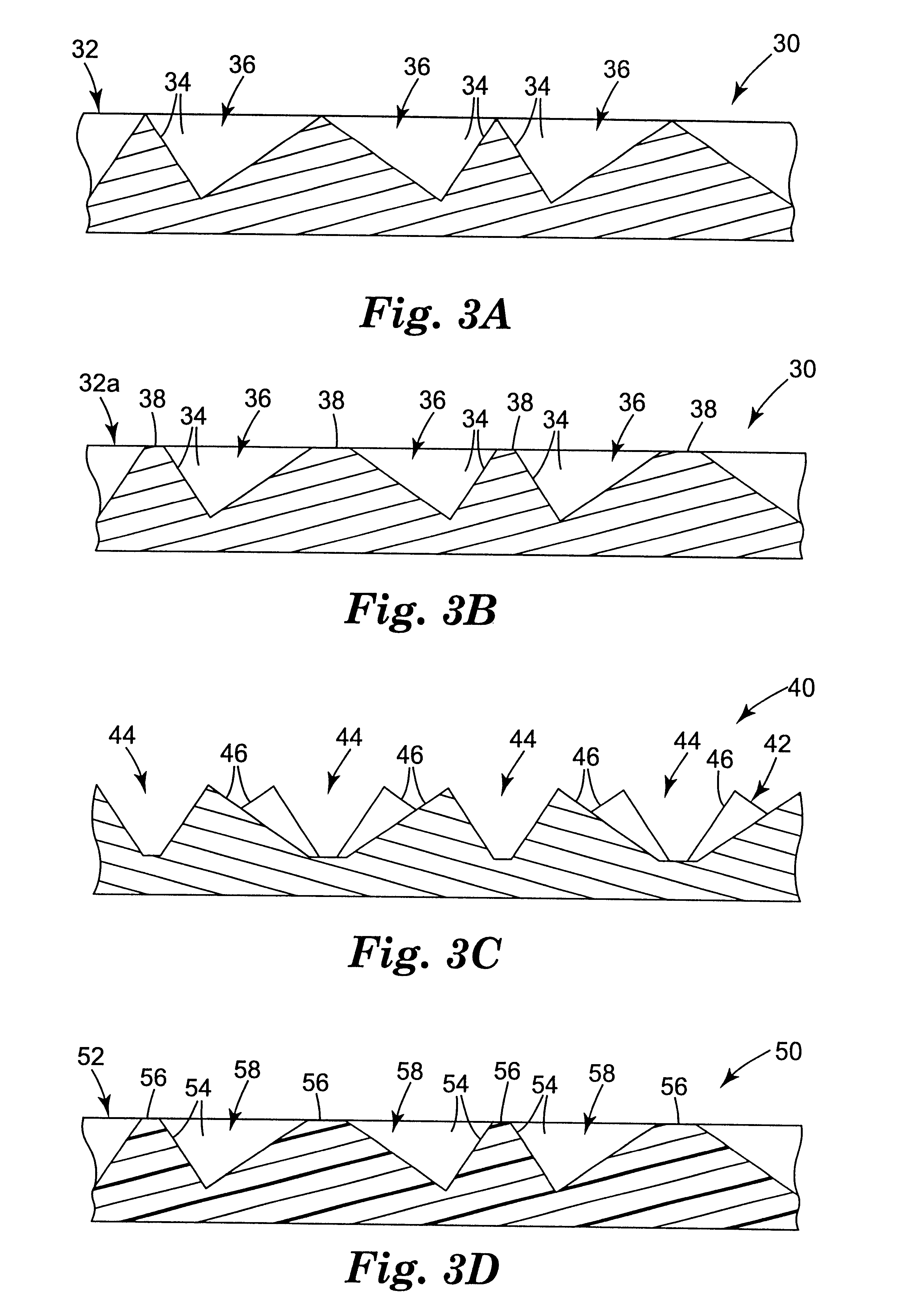

Cube corner cavity based retroreflectors and methods for making same

InactiveUS6287670B1High specular reflectivityEfficient retroreflectionMirrorsDiffusing elementsSurface finishEngineering

Retroreflective sheeting includes a body layer having a structured surface with recessed faces and top surfaces, the recessed faces forming cube corner cavities. The recessed faces have a high specular reflectivity, while the top surfaces have a low specular reflectivity. In some embodiments a substantially continuous film of reflective material covers the structured surface, and a masking substance is provided over the reflective material at the top surfaces. Alternatively, the top surfaces are given a non-smooth surface finish so that the film of reflective material on those portions has a diffuse reflectivity. In other embodiments the film of reflective material is discontinuous, disposed selectively on the recessed faces and not on the top surfaces. A cover layer is also provided, and can bond at least to the top surfaces. Keeping the top surfaces substantially free of reflective material inhibits corrosion and can enhance the bond integrity. The top surfaces are preferably flat, and diffusely reflective to enhance the daytime whiteness of the sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

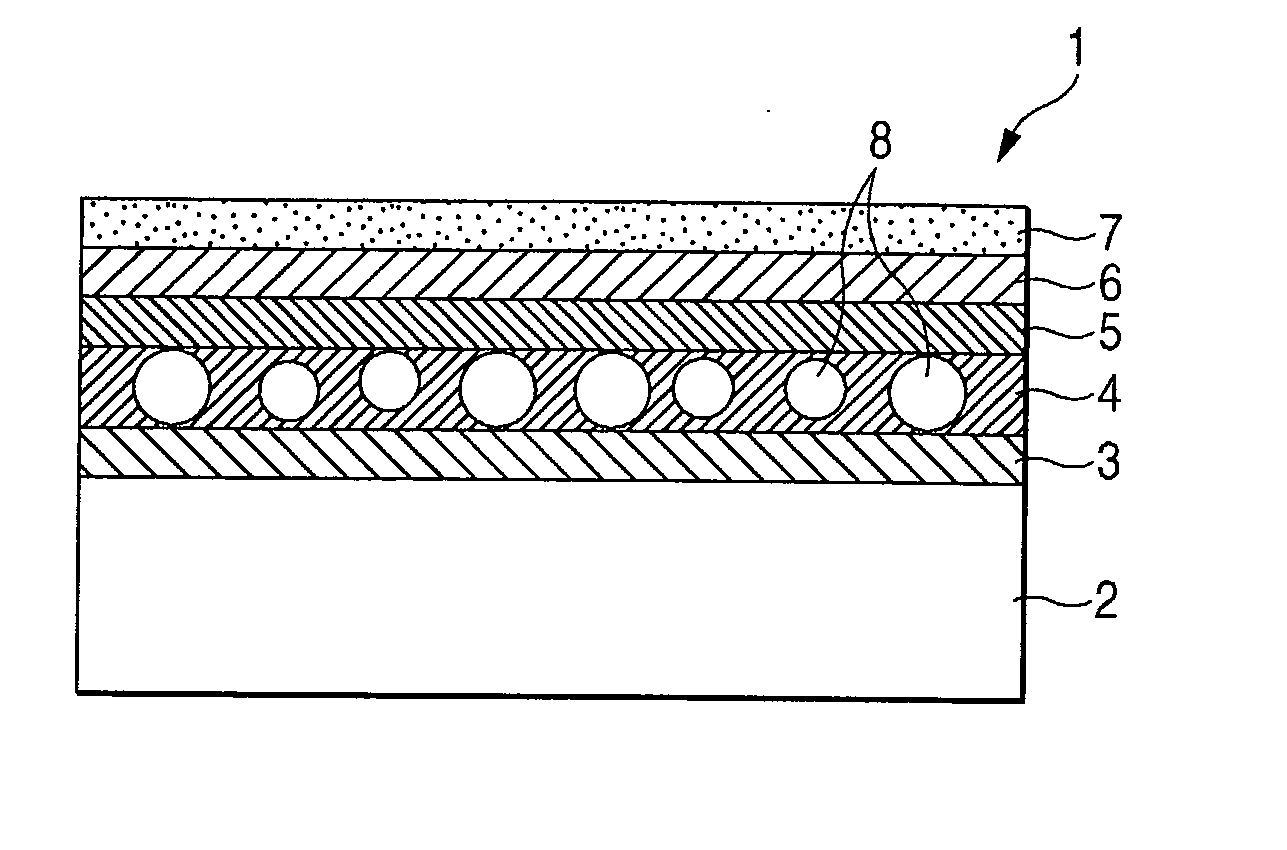

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Acicular constituent high strength weathering resistant steel and producing method thereof

InactiveCN1609257AThe ingredients are designed to be simpleGood weather resistanceWeather resistanceAlloy steel

The present invention relates to high strength high weather resistance steel with needle structure and its production process, and belongs to the field of low alloy steel making. The present invention adopts very low carbon content to result in normal temperature dissolvability in alpha-Fe not higher than 0.0218 wt%, adds Cu, Cr, Ni, Mo, Nb, Ti, Al, Zr, RE and Ca, and ensures the main structure is needle-like structure for excellent weather resistance. The steel of the present invention is produced by means of hot rolling technology and relaxation-separation control technology and has low production cost and short production period. It has excellent weather resistance, excellent toughness, and excellent weldability needing no preheating before welding and heat treatment after welding, and may be used widely in bridge, building, traffic facility, sea platform, etc.

Owner:武汉钢铁有限公司 +1

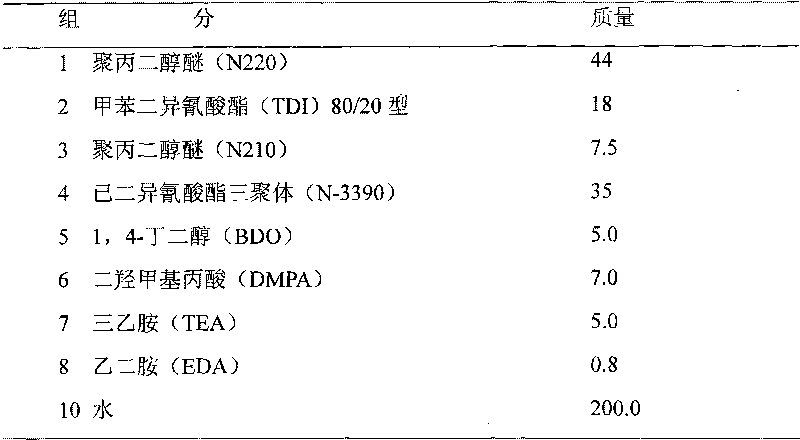

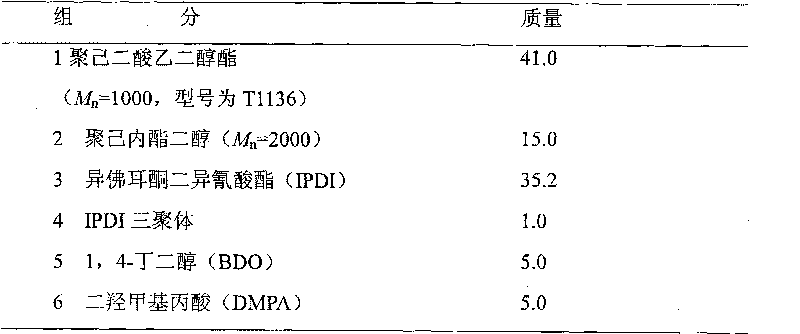

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

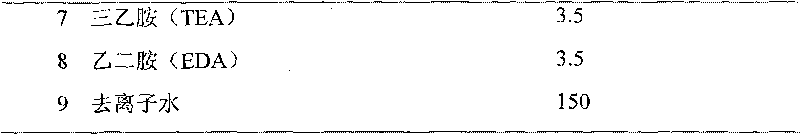

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

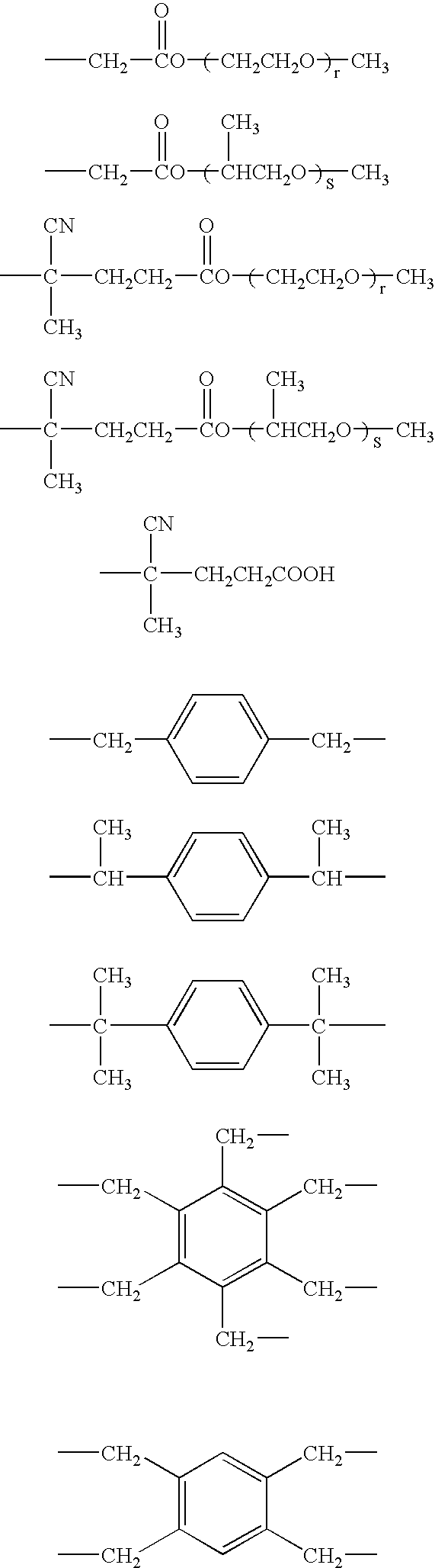

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

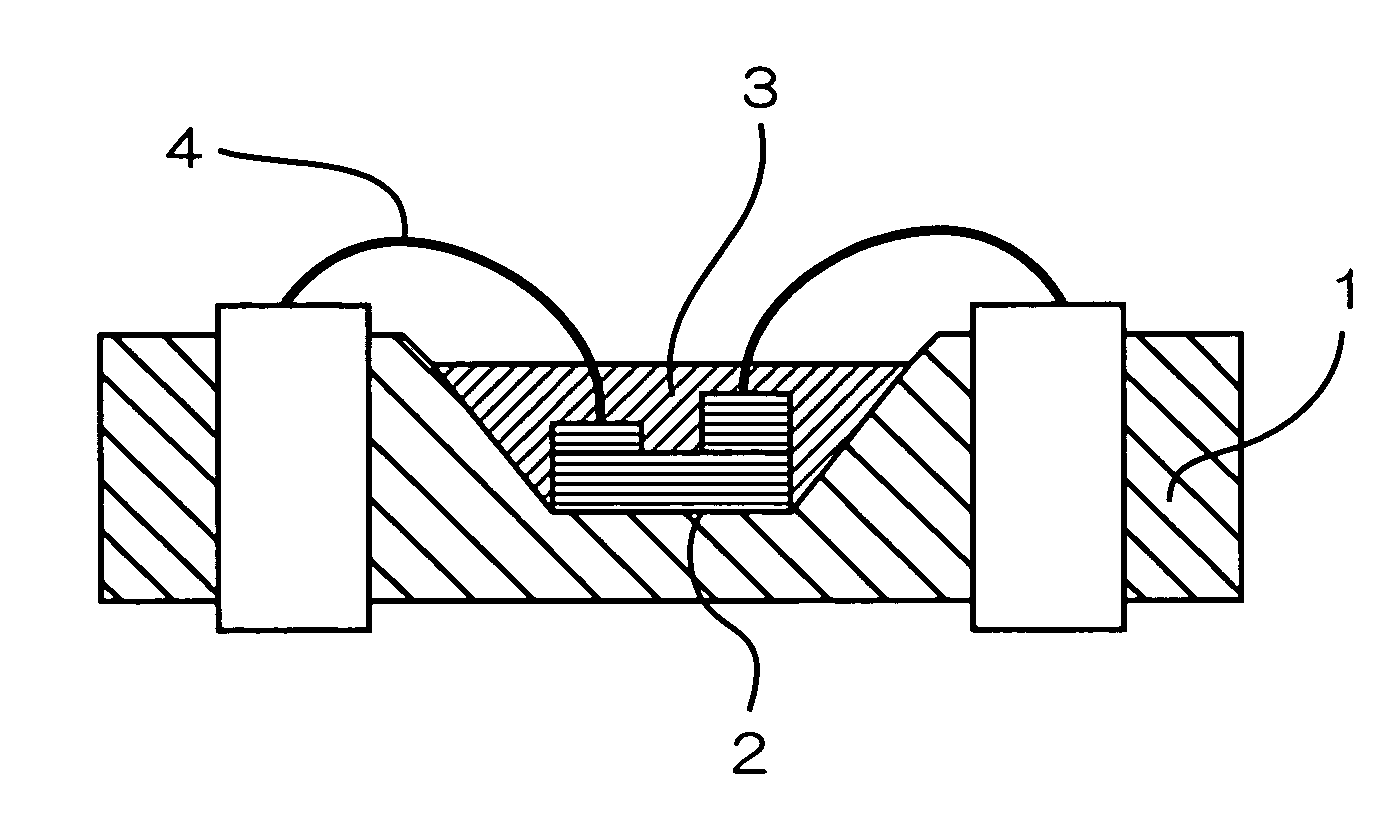

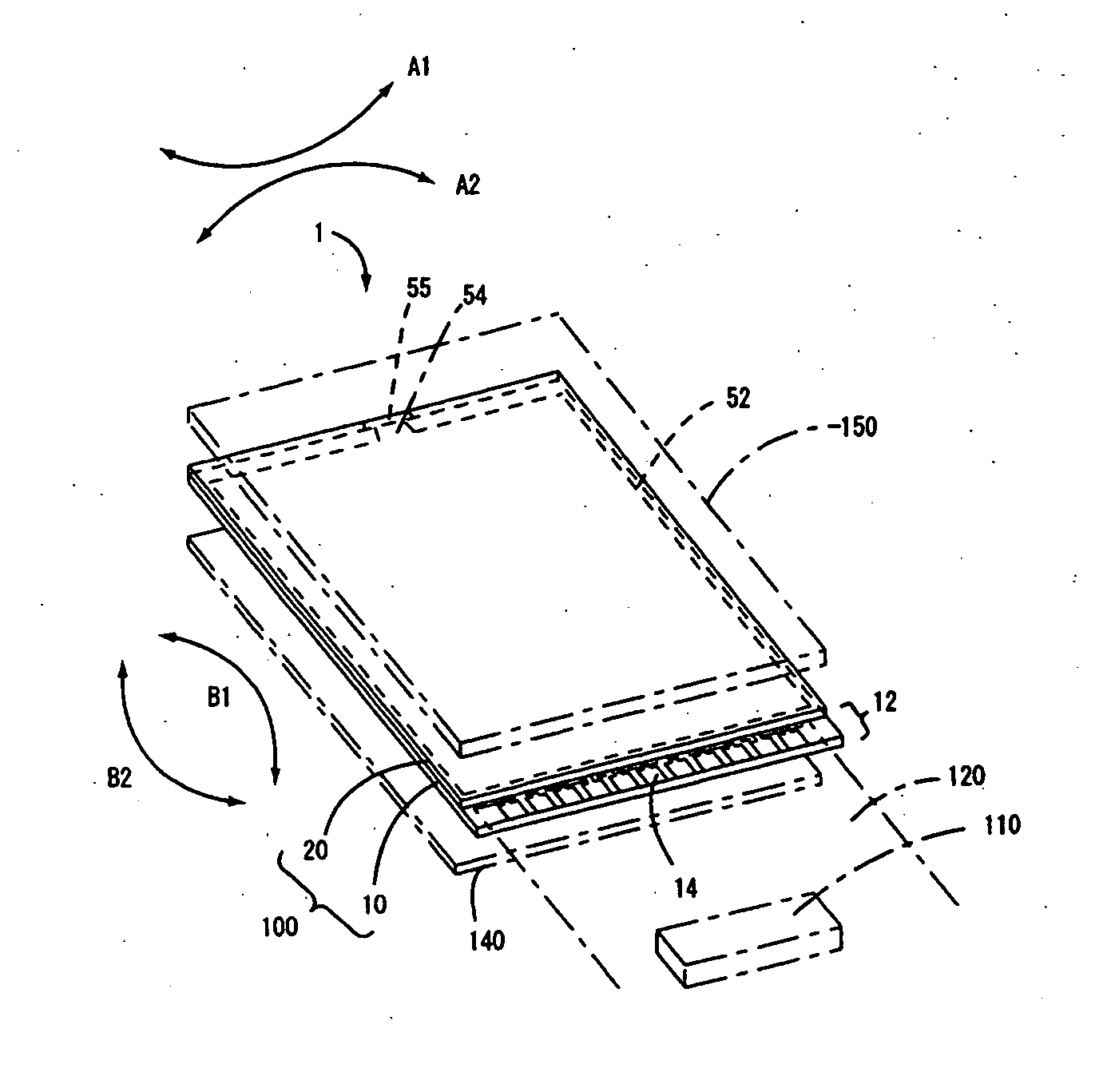

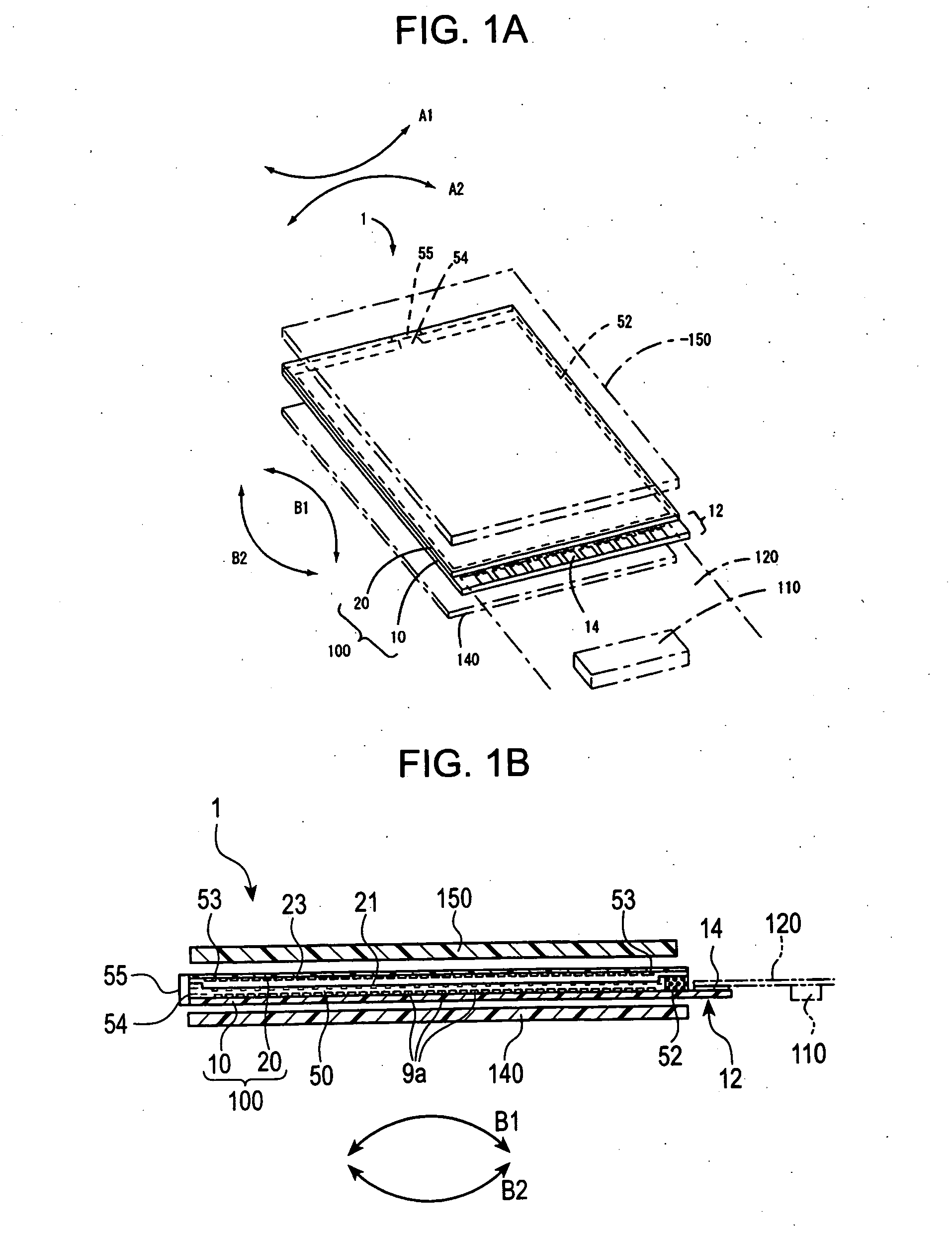

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS20050117197A1Uniform lightQuality improvementStatic indicating devicesOptical waveguide light guideEngineeringQuartz substrate

A method of manufacturing an electro-optical device having a curved display surface with high reliability is provided. A liquid crystal panel 100 comprising a TFT array substrate 10 and a counter substrate 20, each composed of a glass substrate or a quartz substrate, is thinned down to, for example, a thickness of 25 μm by a polishing process or an etching process. Subsequently, a first polarizing plate 140, first spacers 260, the liquid crystal panel 100, second spacers 270, and a second polarizing plate 150 are superposed on a base 210 having a curved surface 220 in this order, and then the outer circumference of the second polarizing plate 150 is pressed against the base 210 while curving the second polarizing plate 150 along the curved surface 220 of the base 210. Then, in order to maintain such a curved state, the second polarizing plate 150 is fixed to the base 210 by a double-faced tape 280.

Owner:SEIKO EPSON CORP

Phosphate film-coated powder and preparation method thereof

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

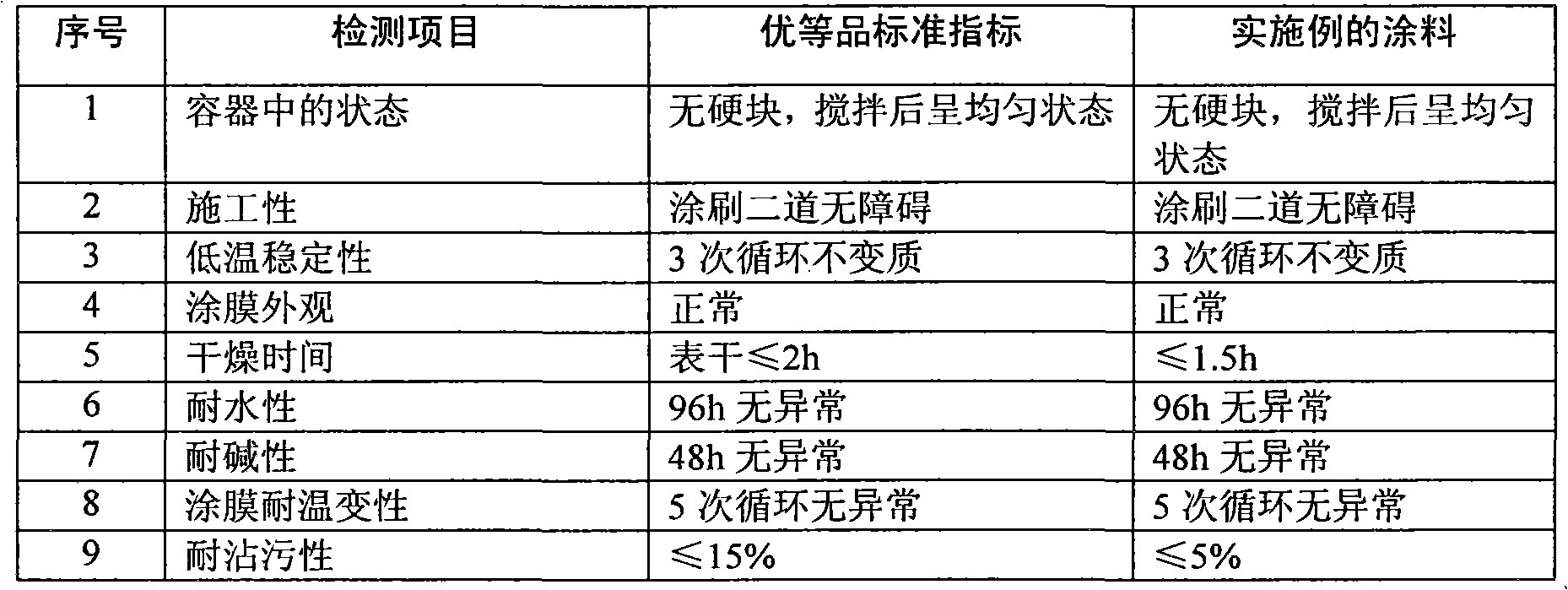

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

Modified, weather resisting polypropylene material

This invention discloses a modified polypropylene material used as elements of home appliances, such as outdoor hulls of air-conditioners and panels of automobiles. The modified polypropylene material comprises: polypropylene resin 65-85 wt.%, toughening modifier 1-18 wt.%, mineral reinforcer 0-25 wt.%, coupler 0.1-0.8 wt.%, processing auxiliary 0.2-2 wt.%, photostabilizer 0.2-2 wt.% and colorant 0.1-1.5 wt.%. Compared with present polypropylene material, the modified polypropylene material has improved weathering resistance and anti-aging property.

Owner:CGN JUNER NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com