Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

A process method and self-insulation technology, applied to walls, building components, buildings, etc., can solve problems such as high cost, poor durability, and complicated construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

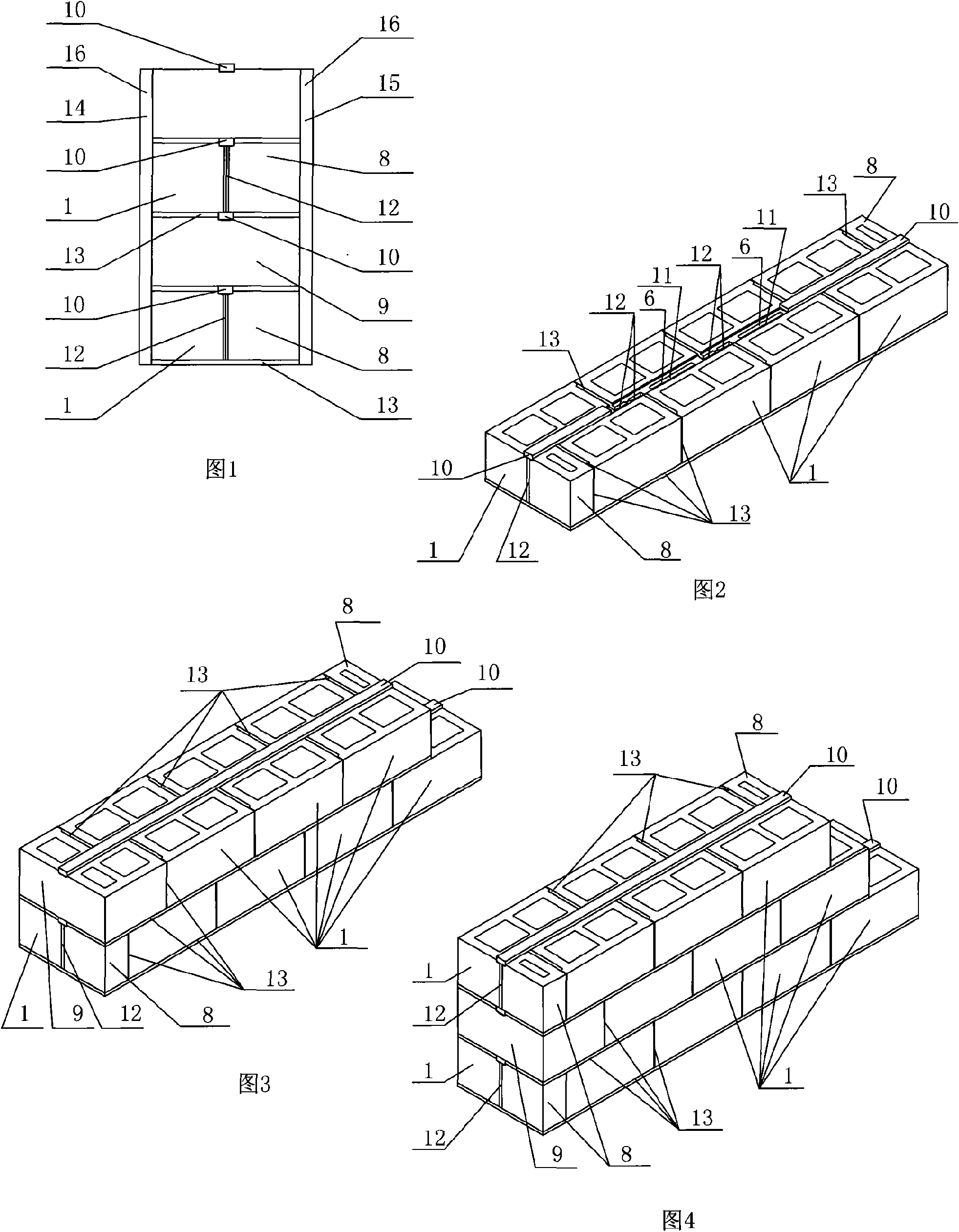

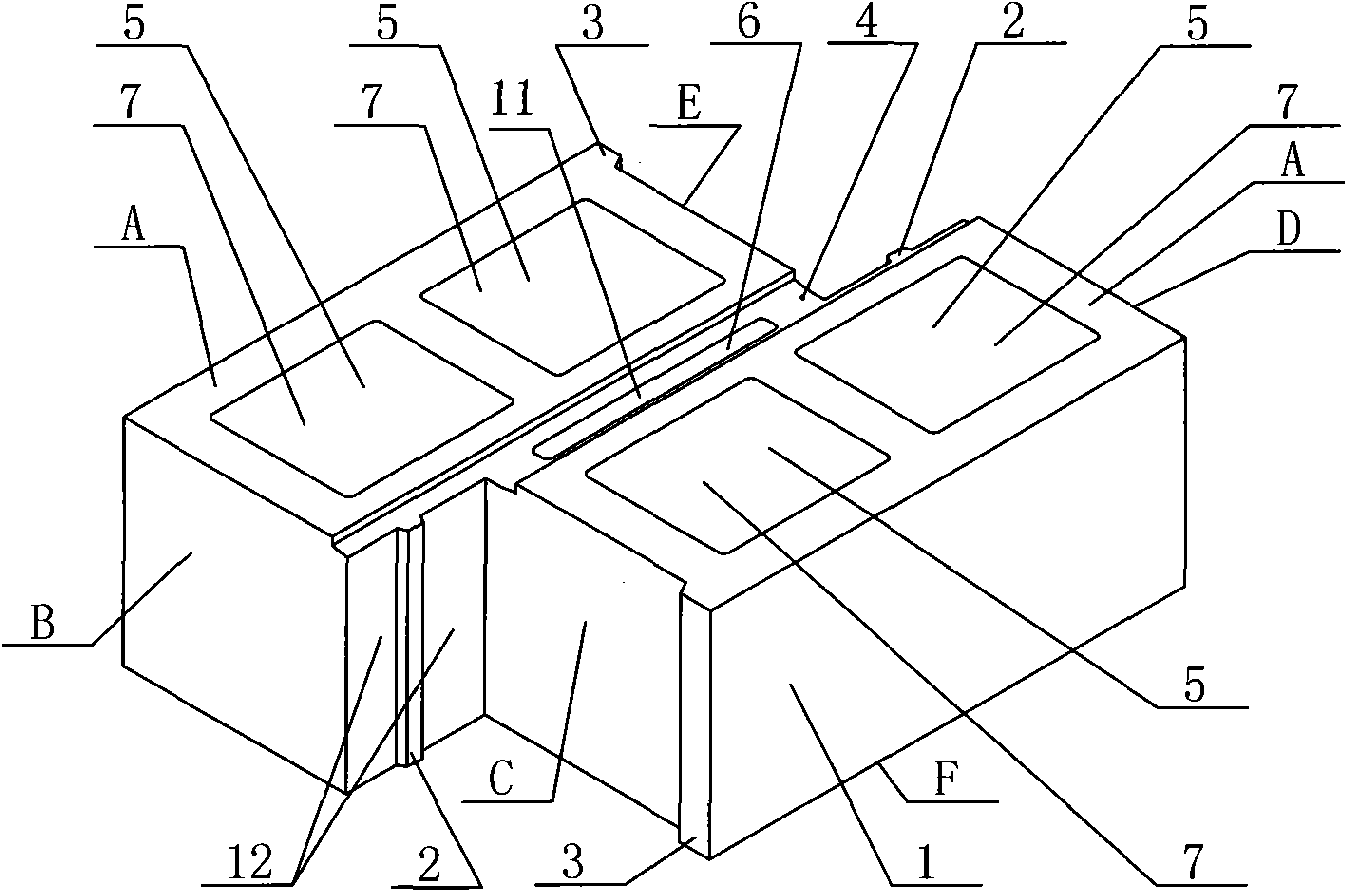

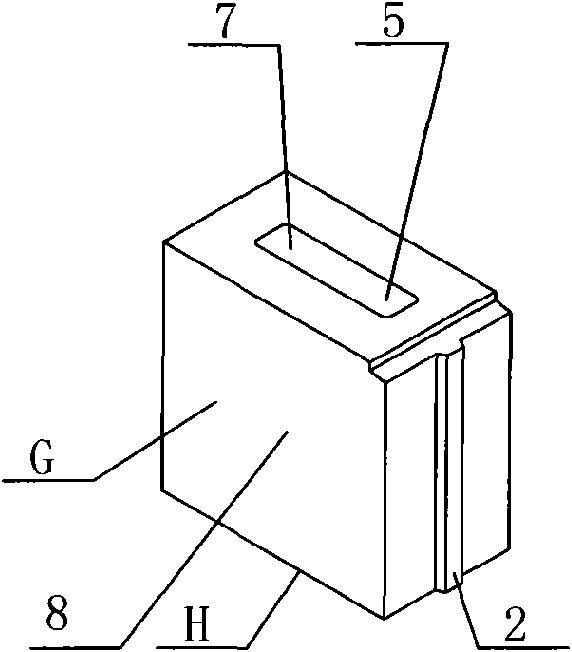

[0023] Z-shaped energy-saving block 1 is built by masonry and is combined with broken bridge insulation board 10, long groove static air layer 11, crack-resistant masonry mortar 13, inorganic thermal insulation decorative board 16, external wall crack-resistant plastering mortar 14, and inner wall anti-crack mortar. The combined static air layer 12 formed by the plastering mortar 15 can automatically cut off the thermal bridge of the horizontal masonry joints and vertical masonry joints;

[0024] The specific method is as follows:

[0025] The first skin brick for masonry self-insulation and energy-saving walls:

[0026] (1), lay one deck of 8-10mm thick anti-cracking masonry mortar 13 by wall thickness on the foundation or the foundation beam upper surface, the lower surface of the anti-cracking masonry mortar 13 is bonded with the foundation or the foundation beam upper surface;

[0027] (2) Take the first Z-shaped energy-saving block 1, apply 10mm thick anti-cracking mason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com