Patents

Literature

4629 results about "H shaped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

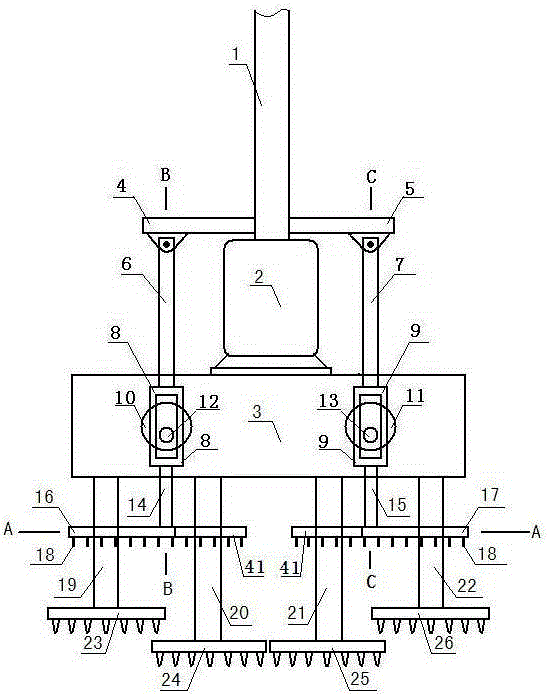

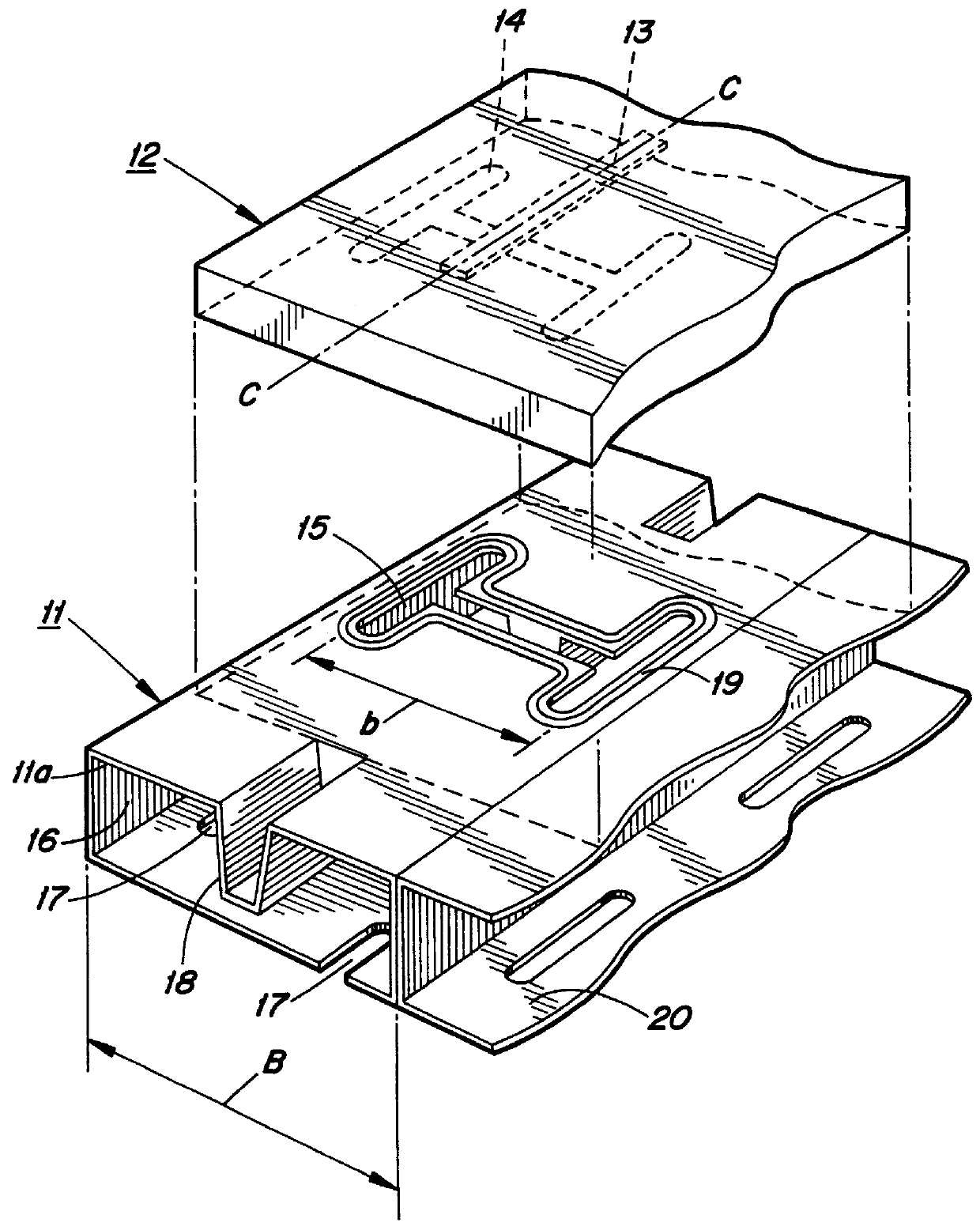

H-shaped mixing pile equipment

Disclosed is H-shaped mixing pile equipment. Mixing arms are fixed to the front portion and the rear portion of the right portion of a first large square frame respectively, a plurality of second tool teeth are arranged in the direction, facing a second mixing shaft, of the two mixing arms respectively, and the lower portions of the two mixing arms are each provided with a plurality of first tool teeth. Mixing arms are fixed to the front portion and the rear portion of the left portion of a second large square frame respectively, a plurality of second tool teeth are arranged in the direction, facing a third mixing shaft, of the two mixing arms respectively, and the lower portions of the two mixing arms are each provided with a plurality of first tool teeth. A plurality of second tool teeth are arranged in a frame body of the first large square frame, and a plurality of first tool teeth are arranged on the lower portion of the frame body of the first large square frame. A plurality of second tool teeth are arranged in a frame body of the second large square frame, and a plurality of first tool teeth are arranged on the lower portion of the frame body of the second large square frame.

Owner:朱艳菊

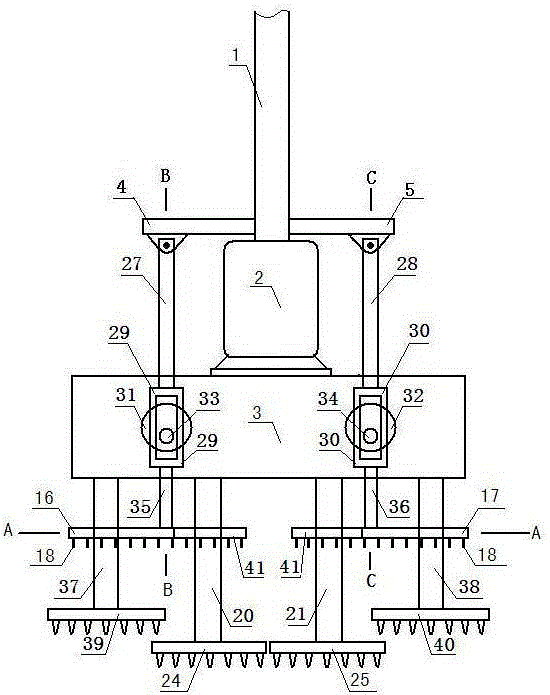

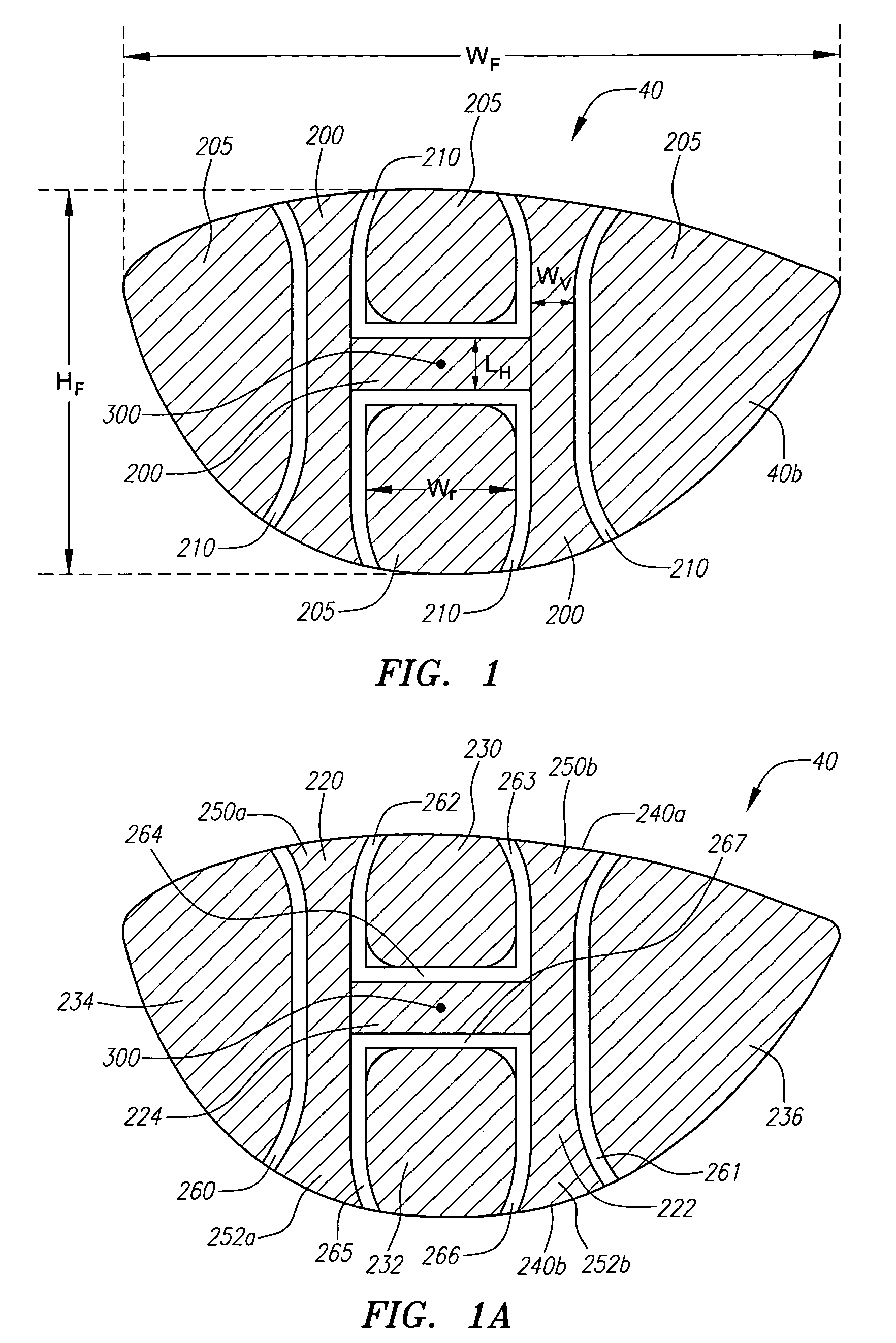

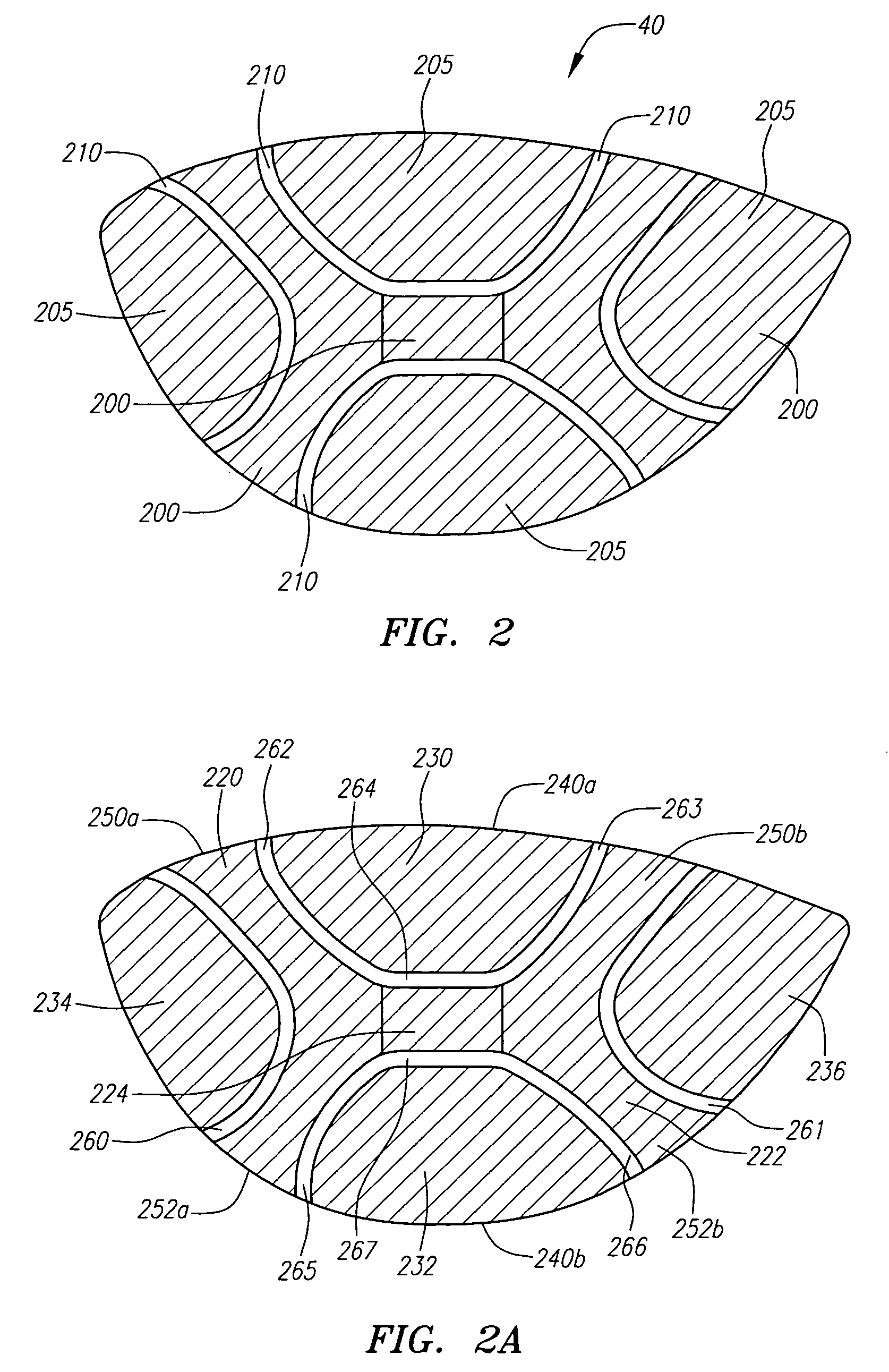

Golf club head with variable face thickness

A face or face insert (40) for a golf club head (20) is disclosed herein. The face (40) has an interior surface (40a) with a first thickness section (200) and a second thickness region (205). The first thickness section (200) preferably has a thickness that is at least 0.025 inch greater than the thickness of the second thickness region (205). In a most preferred embodiment, the first thickness section (205) has an H shape. The face or face insert (40) with variable thickness allows for a face or face insert (40) with less mass in a golf club head (20) that conforms to the United States Golf Association regulations.

Owner:TOPGOLF CALLAWAY BRANDS CORP

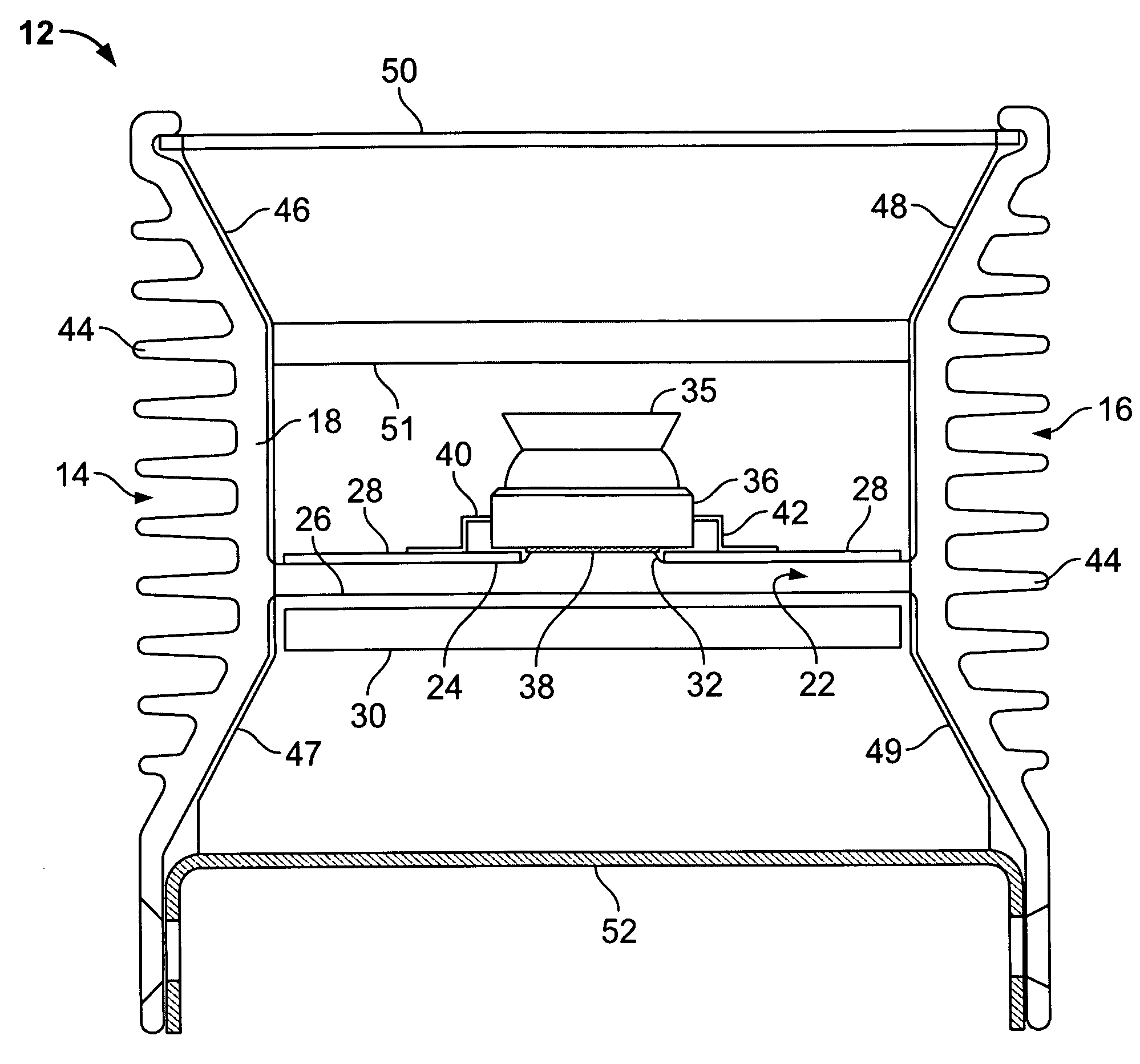

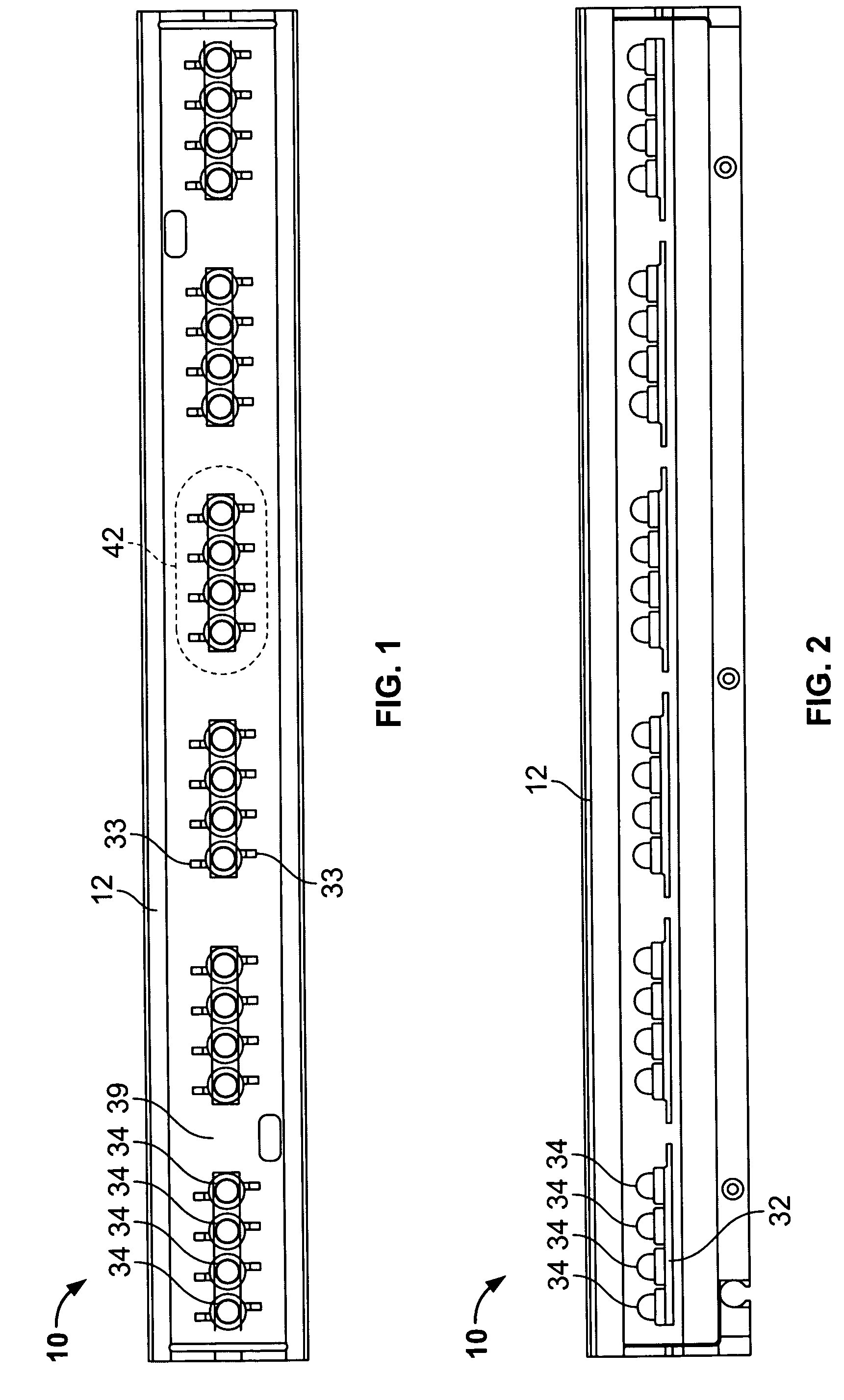

Light fixture for an LED-based aircraft lighting system

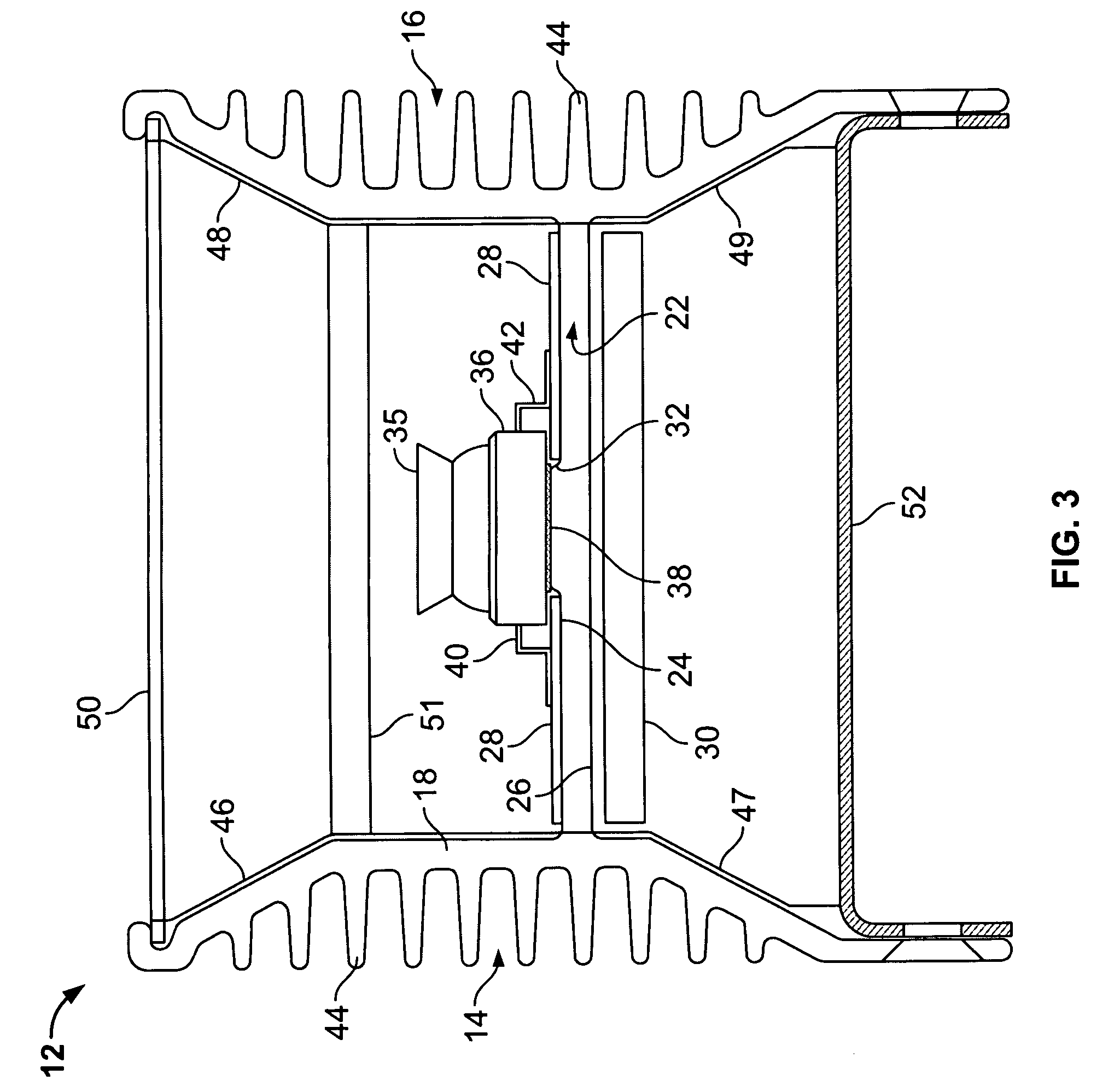

A light fixture for housing LED units is provided. The light fixture has a housing that has a substantially H-shaped cross section. The housing has a crossbar with a series of mesas defined on its upper surface. A group of LED units is attached to each of the series of mesas, each LED unit being attached with a thin layer of adhesive. The LED units are electrically insulated from the housing by either the adhesive, which may be electrically insulating, or by an electrically insulating coating on the housing.

Owner:BE AEROSPACE INCORPORATED

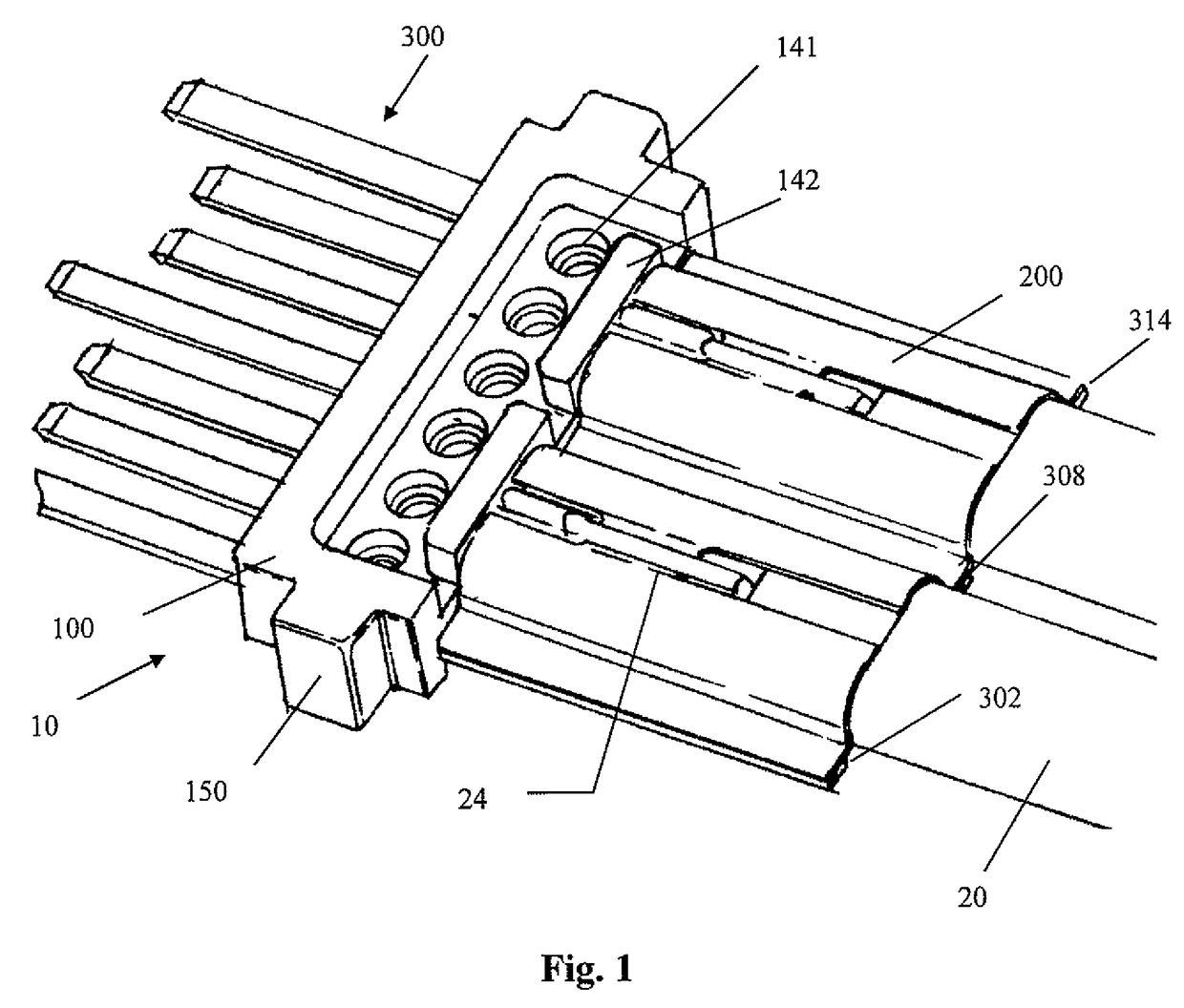

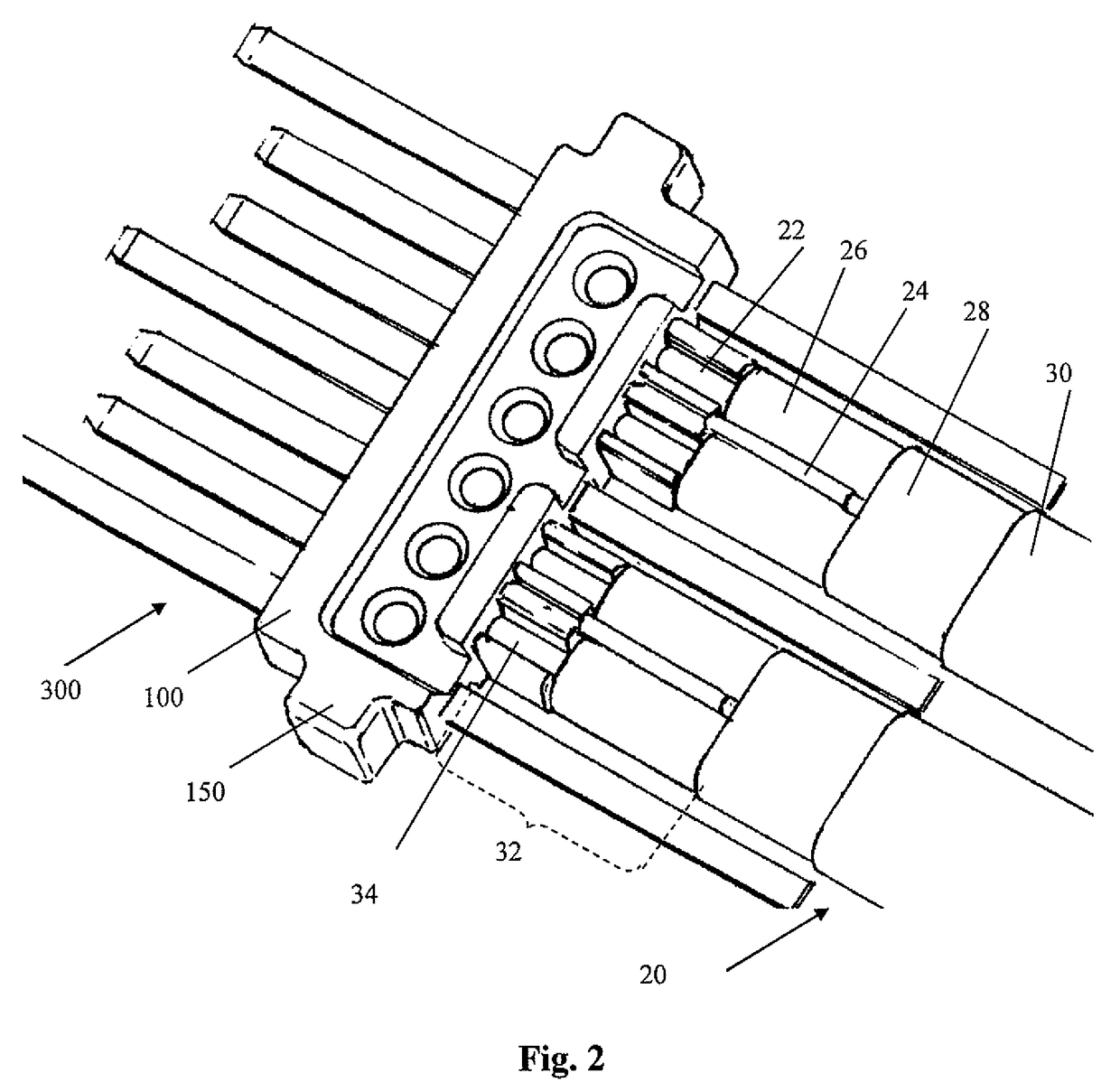

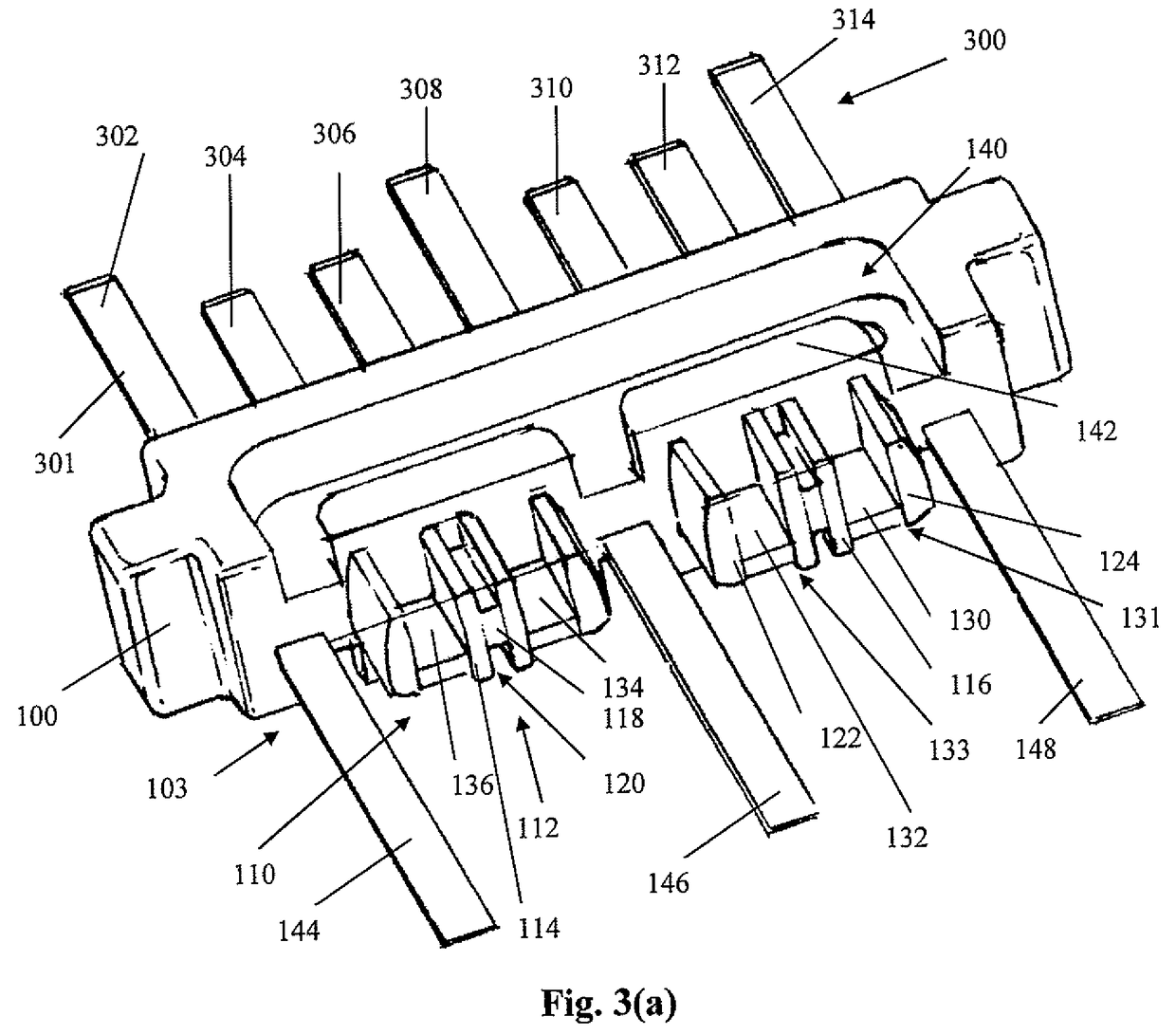

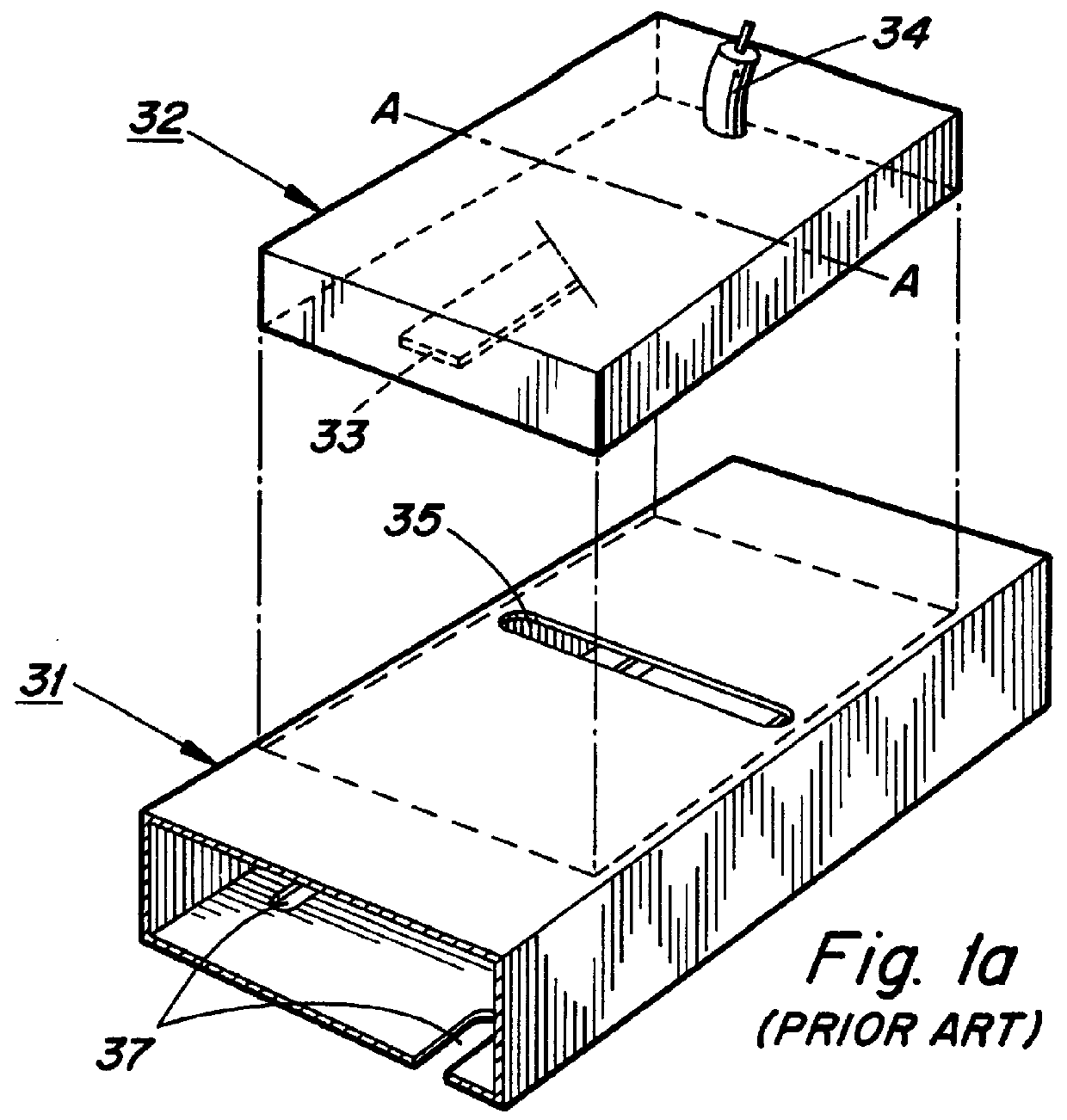

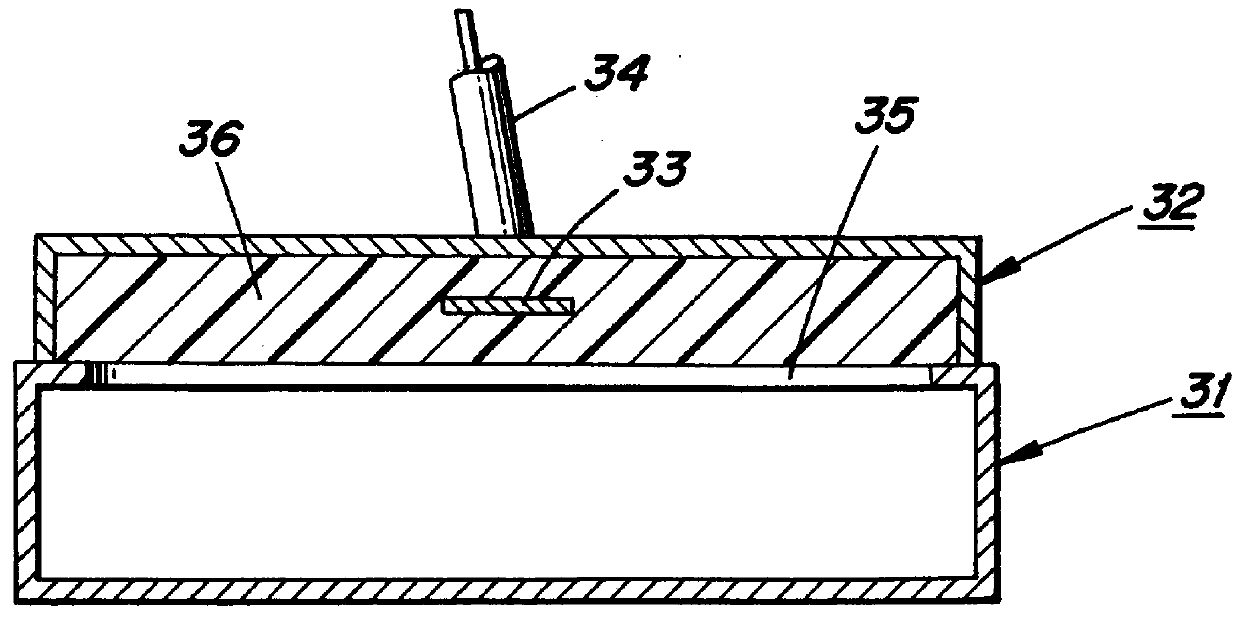

Ground sleeve having improved impedance control and high frequency performance

A waferized connector connects to two twinax cables. The connector includes a molded lead frame, ground sleeve, twinax cable, and overmolded strain relief. The lead frame is molded to retain a lead frame containing both differential signal pins and ground pins. Termination sections are provided at the rear of the lead frame to terminate each of the signal wires of the cables to respective signal lands. The ground sleeve has two general H-shape structures connected together by a center cross-support member. Each of the H-shaped structures having curved legs, each of which fits over the signal wires of one of the twinax cables. The wings of the ground sleeve are terminated to the ground lands of the lead frame and the drain wire of the cable is terminated to the ground sleeve to terminate the drain wire to a ground reference. The ground sleeve controls the impedance in the termination area of the cables, where the twinax foil is removed to expose the wires for termination to the lands. The ground sleeve also shields the cables to reduce crosstalk between themselves and adjacent wafers when arranged in a connector housing. A conductive slab member is formed over the sleeve to provide a capacitive coupling with the conductive foil of the signal cable.

Owner:AMPHENOL CORP

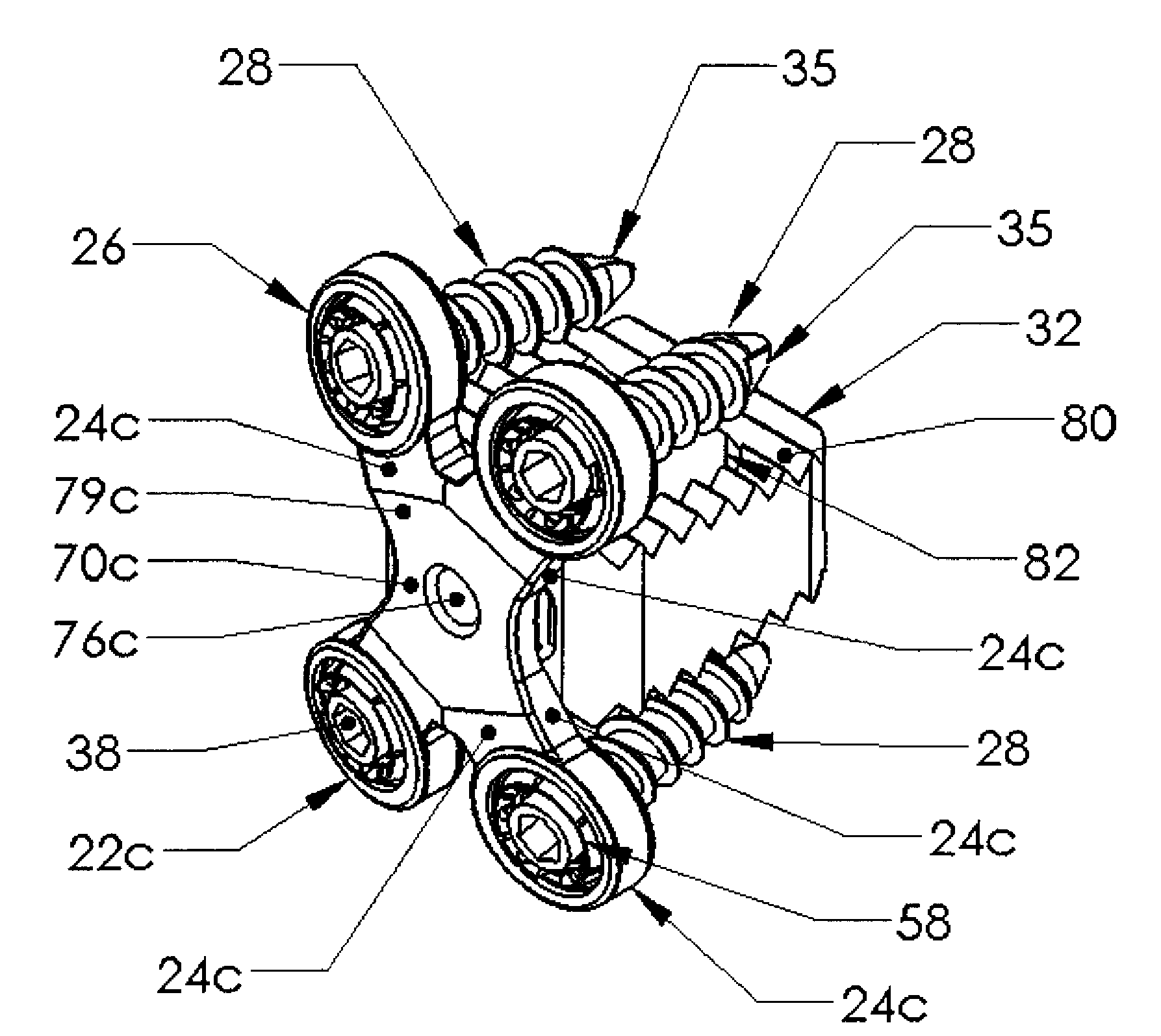

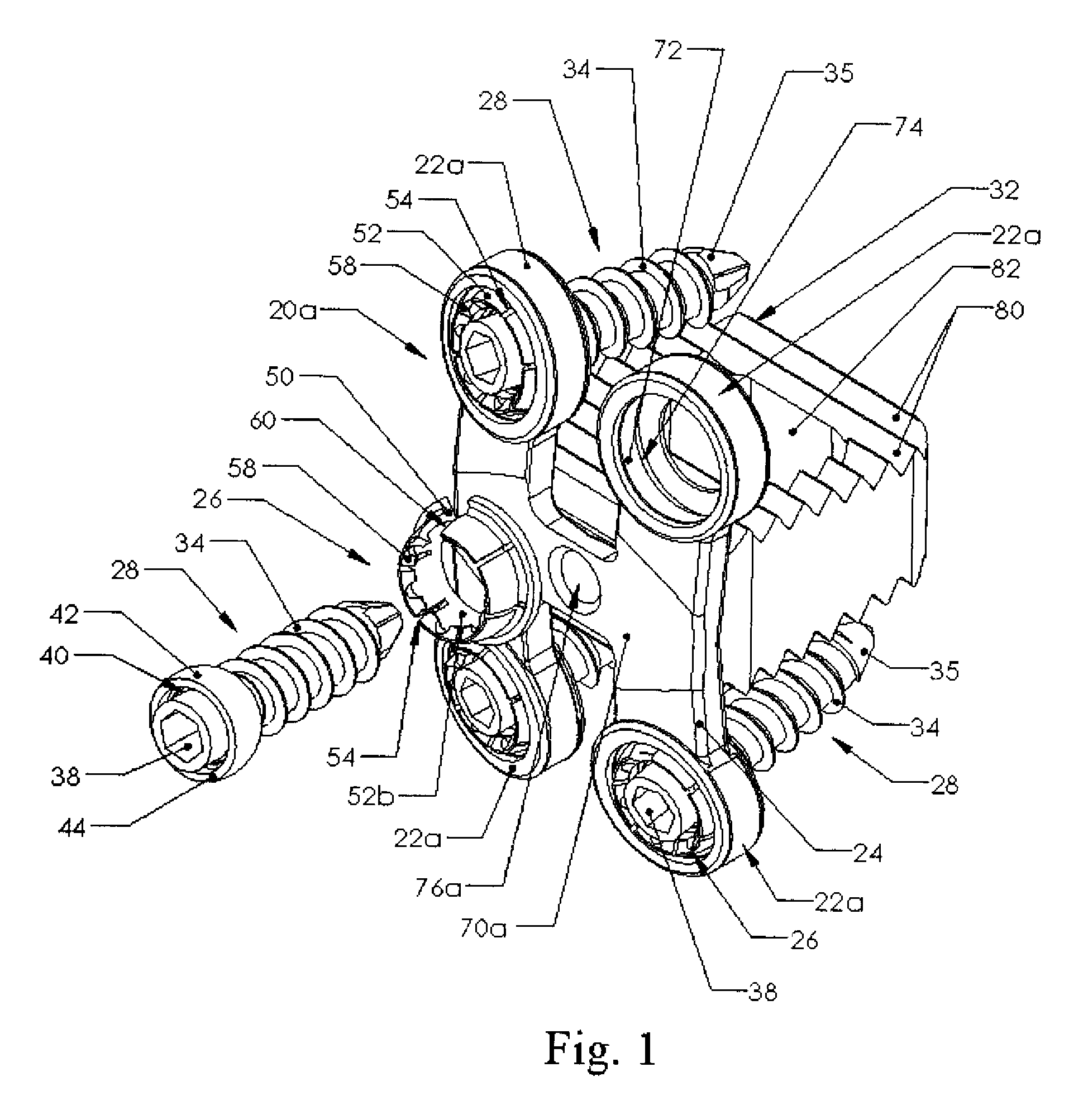

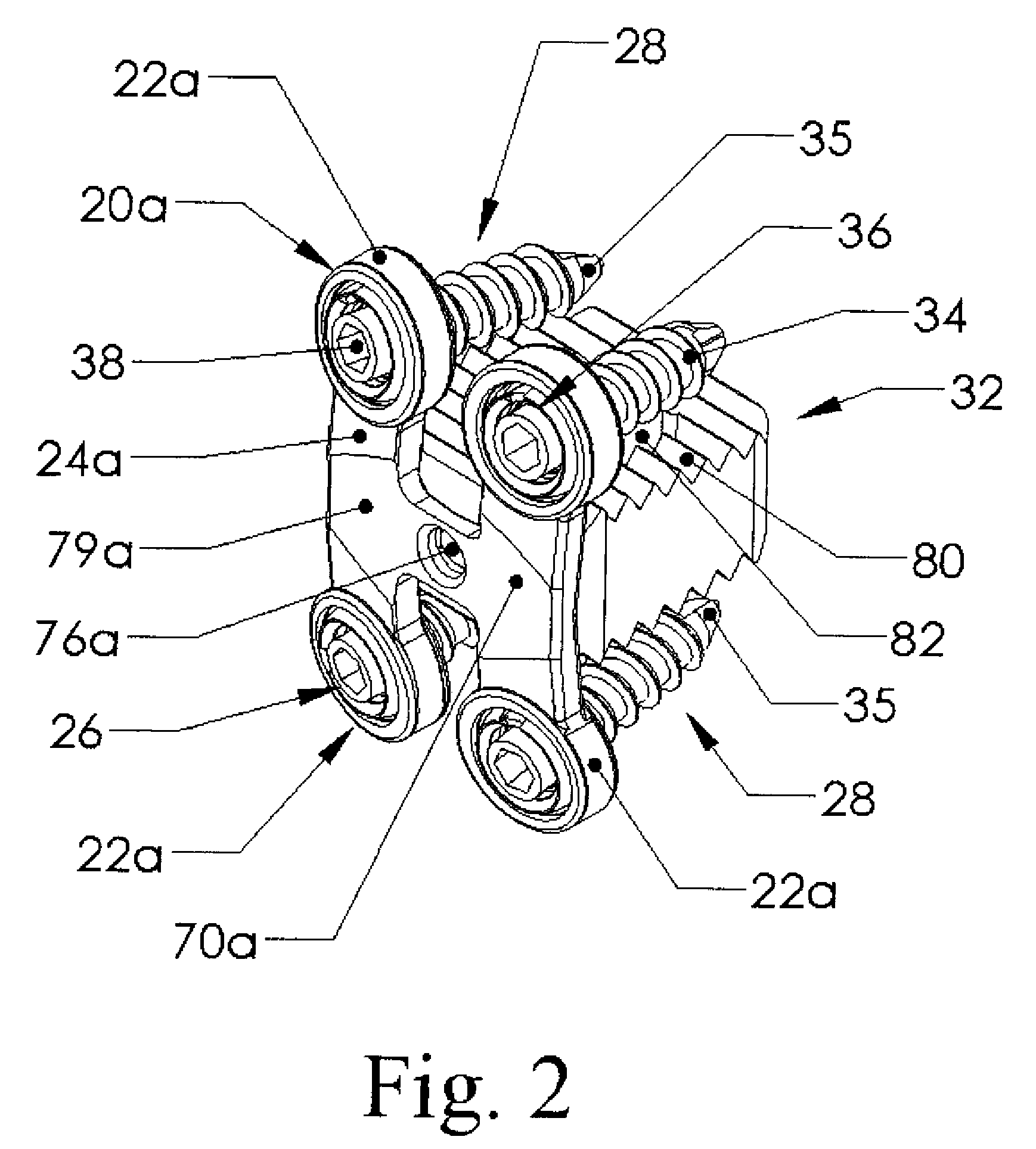

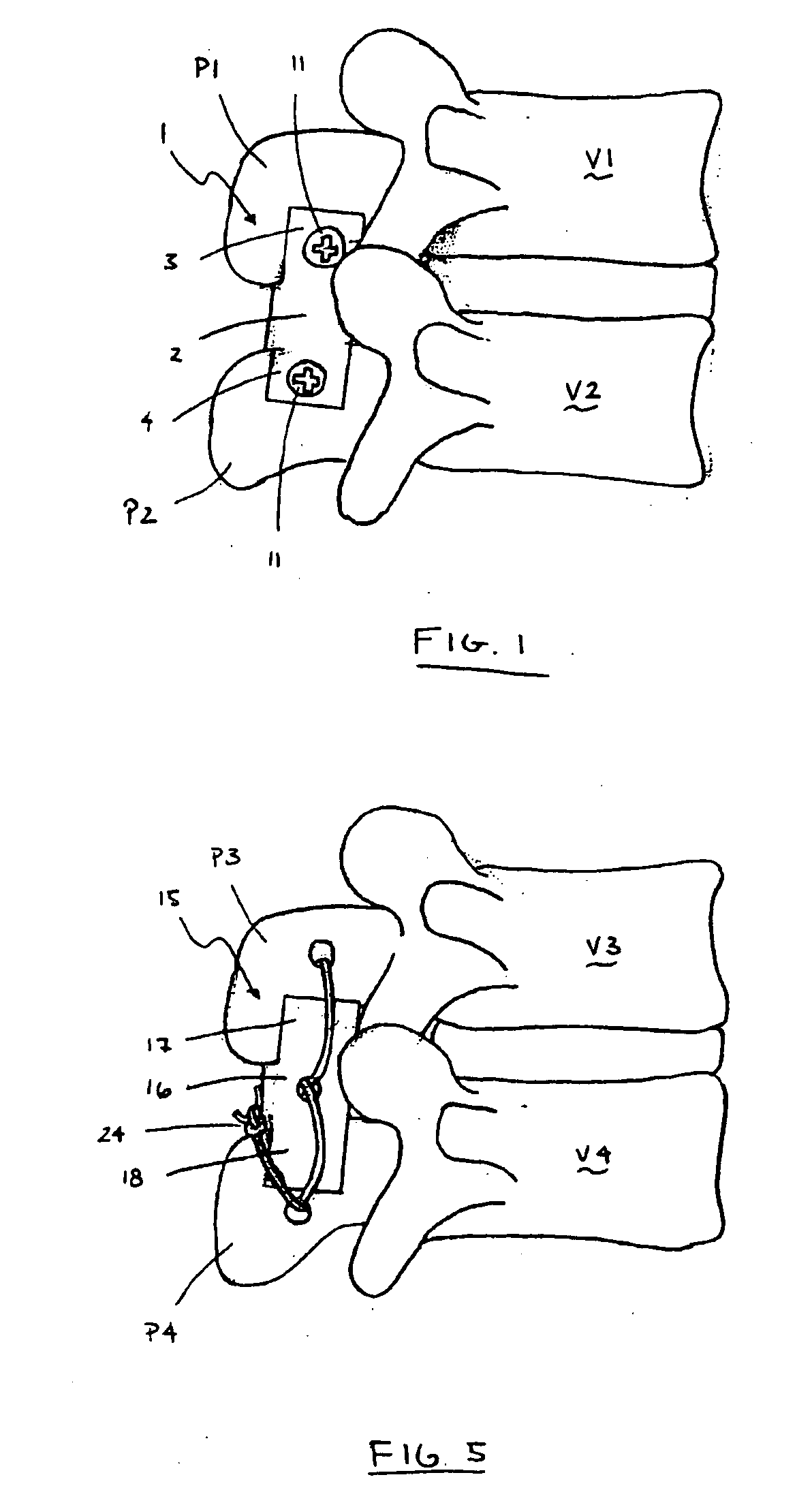

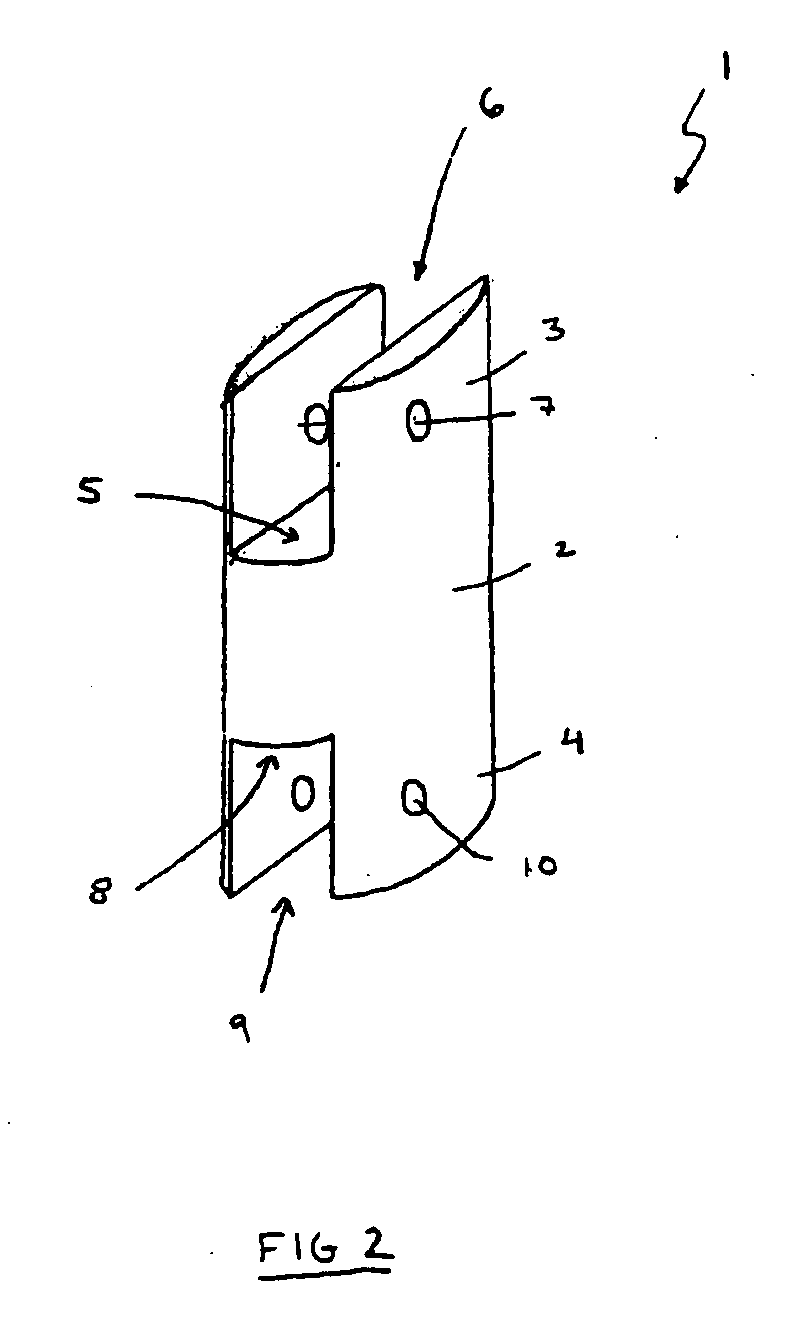

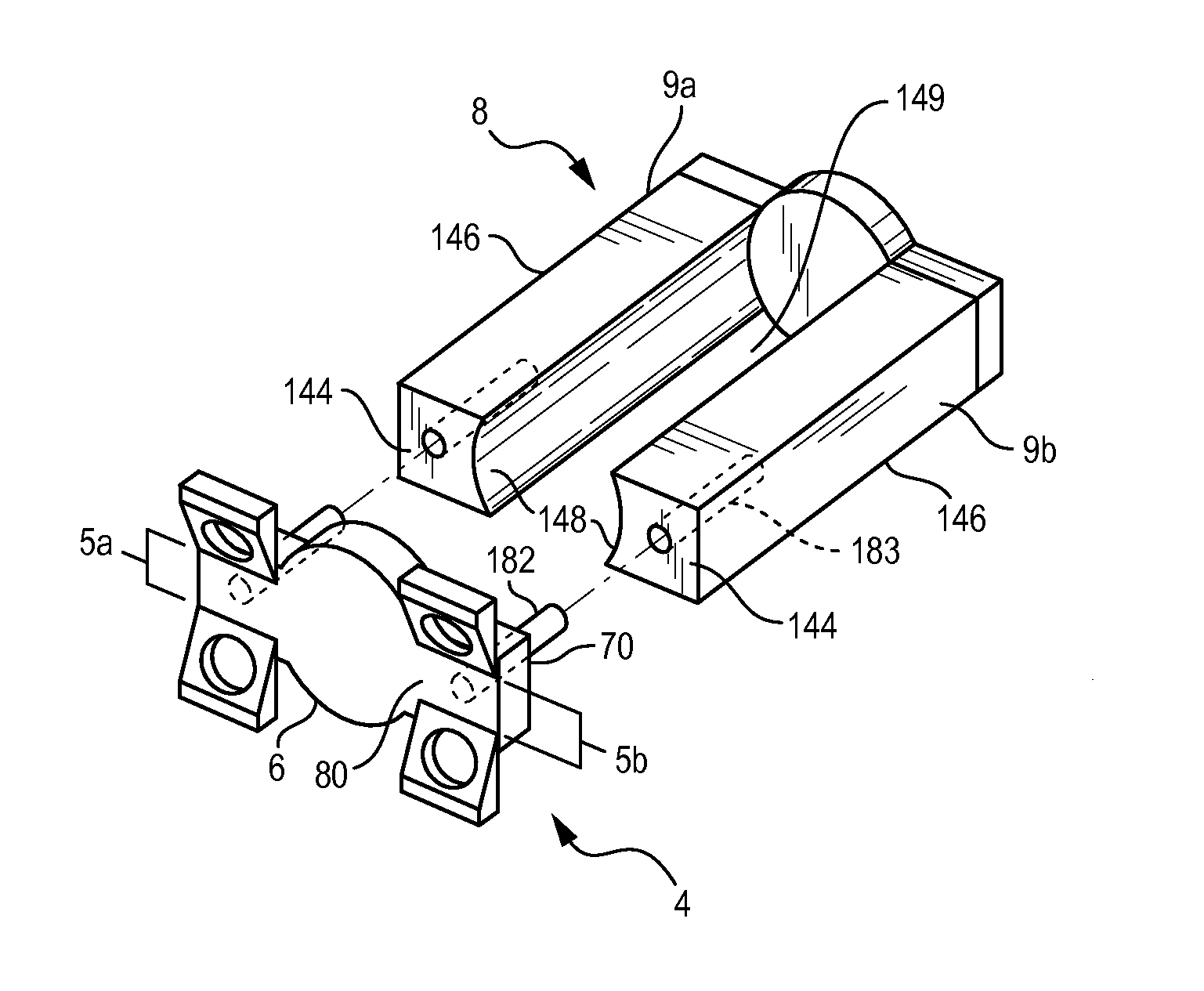

Spinal fixation device

ActiveUS20090326580A1Reduce stimulationAdjustable flexibilitySuture equipmentsInternal osteosythesisIliac screwBiomedical engineering

A spinal fixation assembly has a bone screw with head having a continuously curved spherical outer surface. The curved surface nests in a split annular bushing having a plurality of segments curving around the screw head. The bushing has an outward extending flange that fits into a recess in a socket in a fixation plate. The plate has at least three legs which extend from ends of a cross-member to form one of an H shaped, X shaped or A shaped configuration. Each socket is curved to rotatably receive rotation of the bushing. The socket recess is larger than the bushing flange to allow the bushing to tilt a predetermined amount depending on a thickness of the outward extending flange.

Owner:WESTMARK MEDICAL

Spinal distraction device and methods of manufacture and use

InactiveUS20070093823A1Overcomes drawbackInternal osteosythesisJoint implantsDistractionBiomedical engineering

A spinal distraction device is provided having a generally H-shaped cross section that maintains a desired space between adjacent spinous processes. The distraction device includes a body and two pairs of parallel sidewalls. The sidewalls create channels for receiving respective spinous processes. The distraction device is fused to the spinous processes with fixation devices.

Owner:NUVASIVE

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

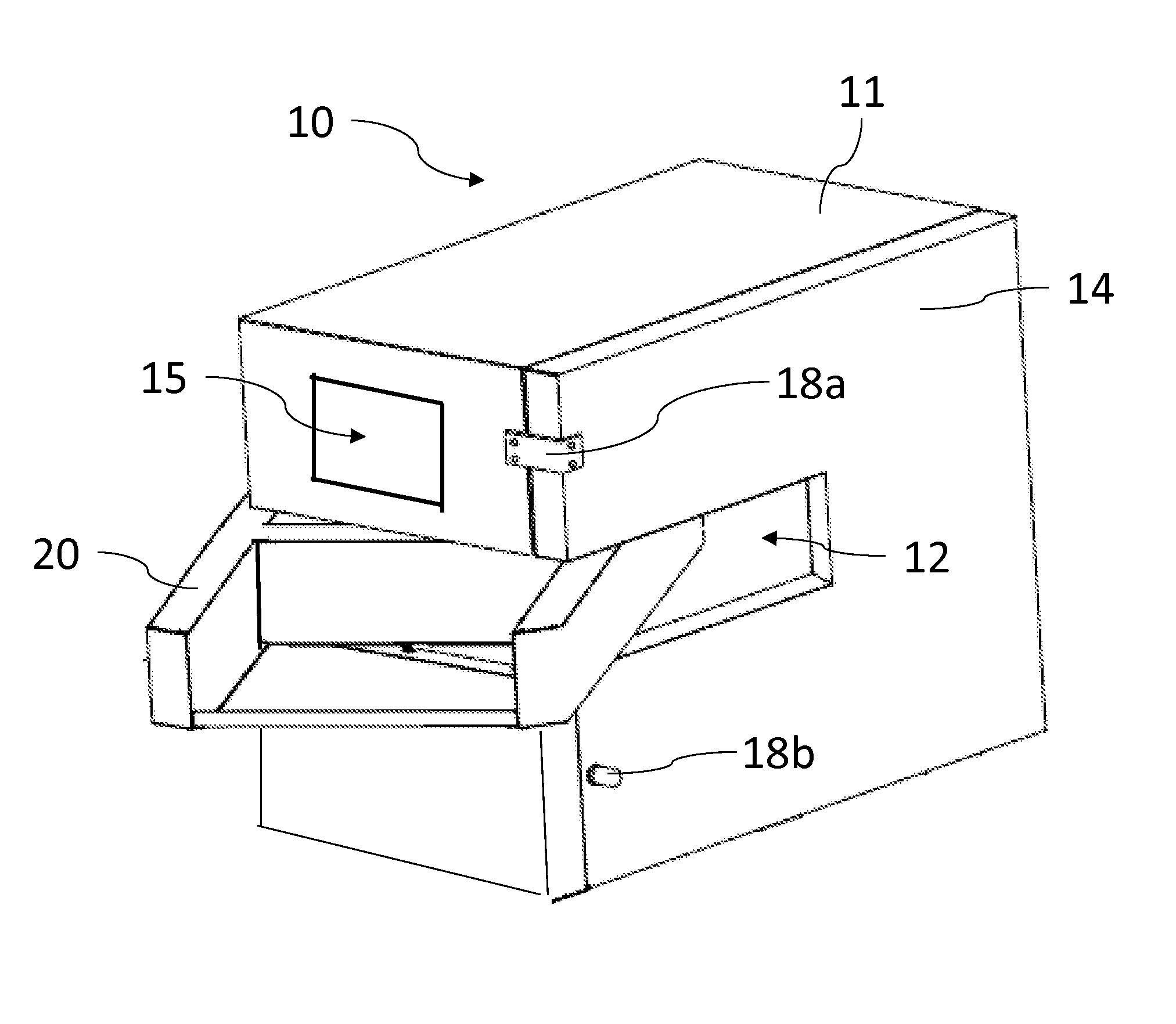

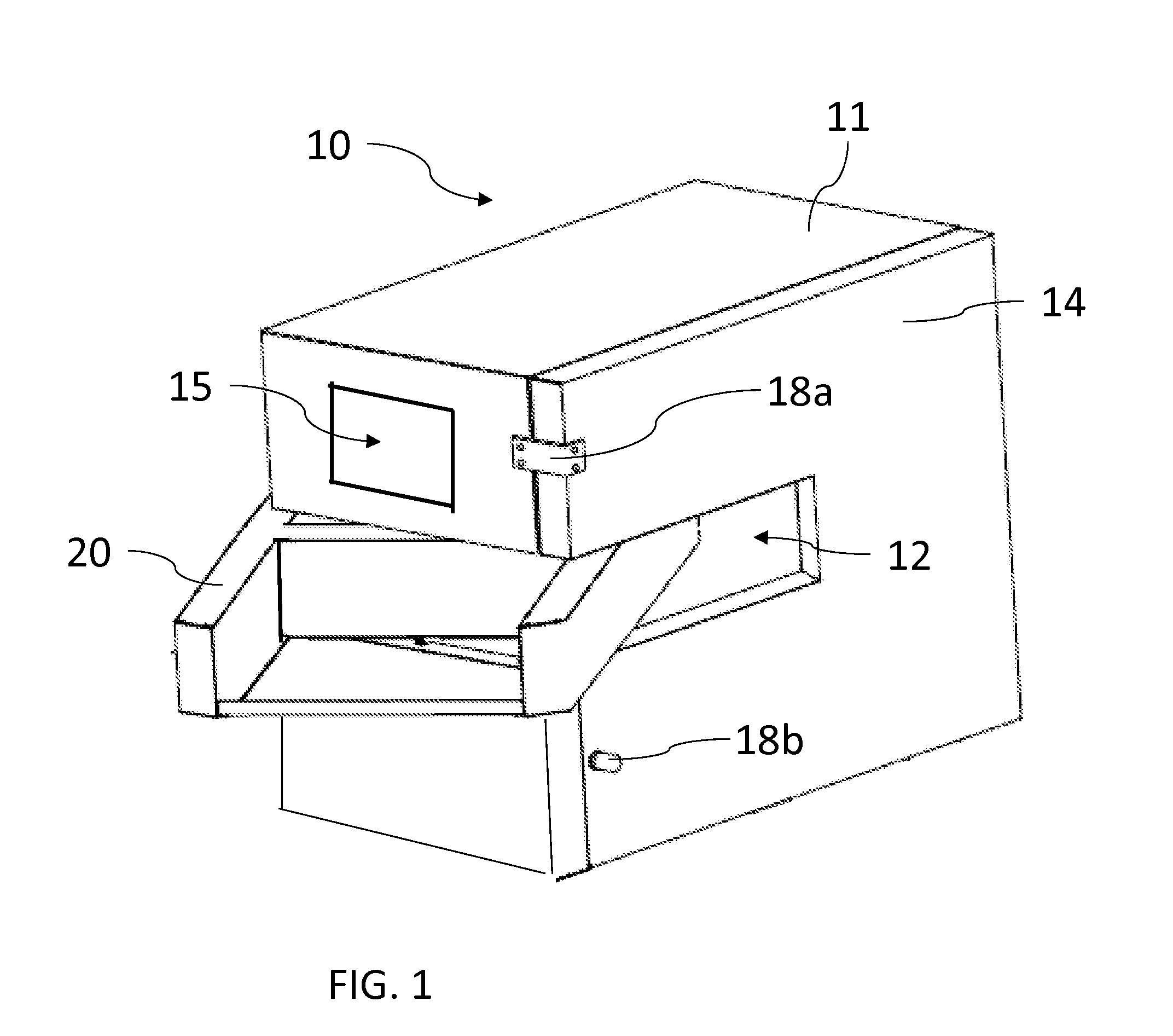

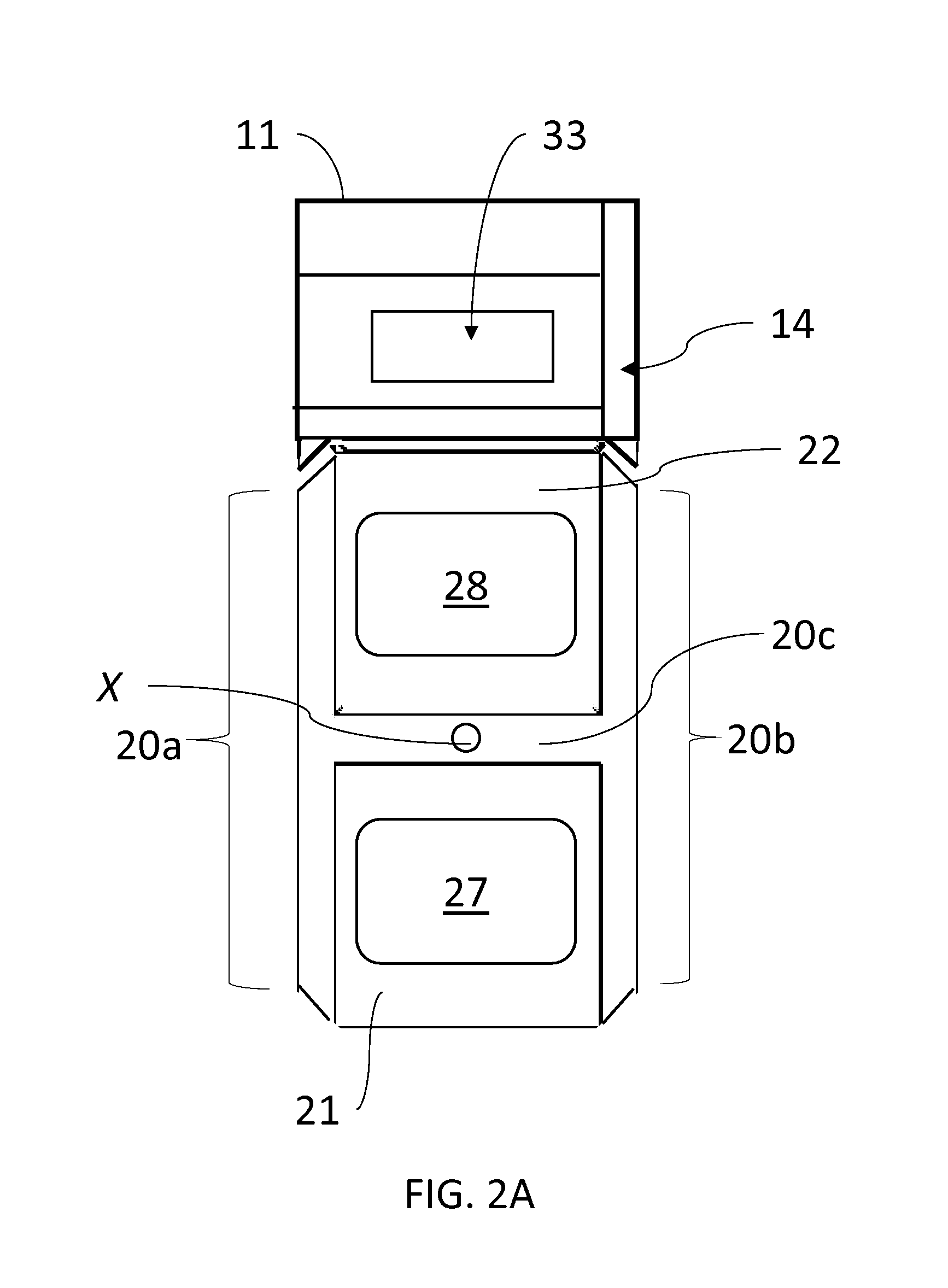

Oven having an H-shaped rotating door

ActiveUS9480364B2Prevent escapeDomestic stoves or rangesStoves/ranges shelves or racksMechanical engineeringFood item

An oven comprising a housing, a cavity, an H-shaped rotating door, a motor and a heat source is disclosed. The cavity, which includes an opening, is located within the housing. The H-shaped rotating door, which can be rotated by the motor, includes a first food loading section and a second food loading section. The H-shaped rotating door also serves as a cover to prevent heat within the cavity from escaping through the opening. The heat source provides heat to the cavity to heat up any food item placed on one of the food loading sections located within the cavity.

Owner:OVENTION

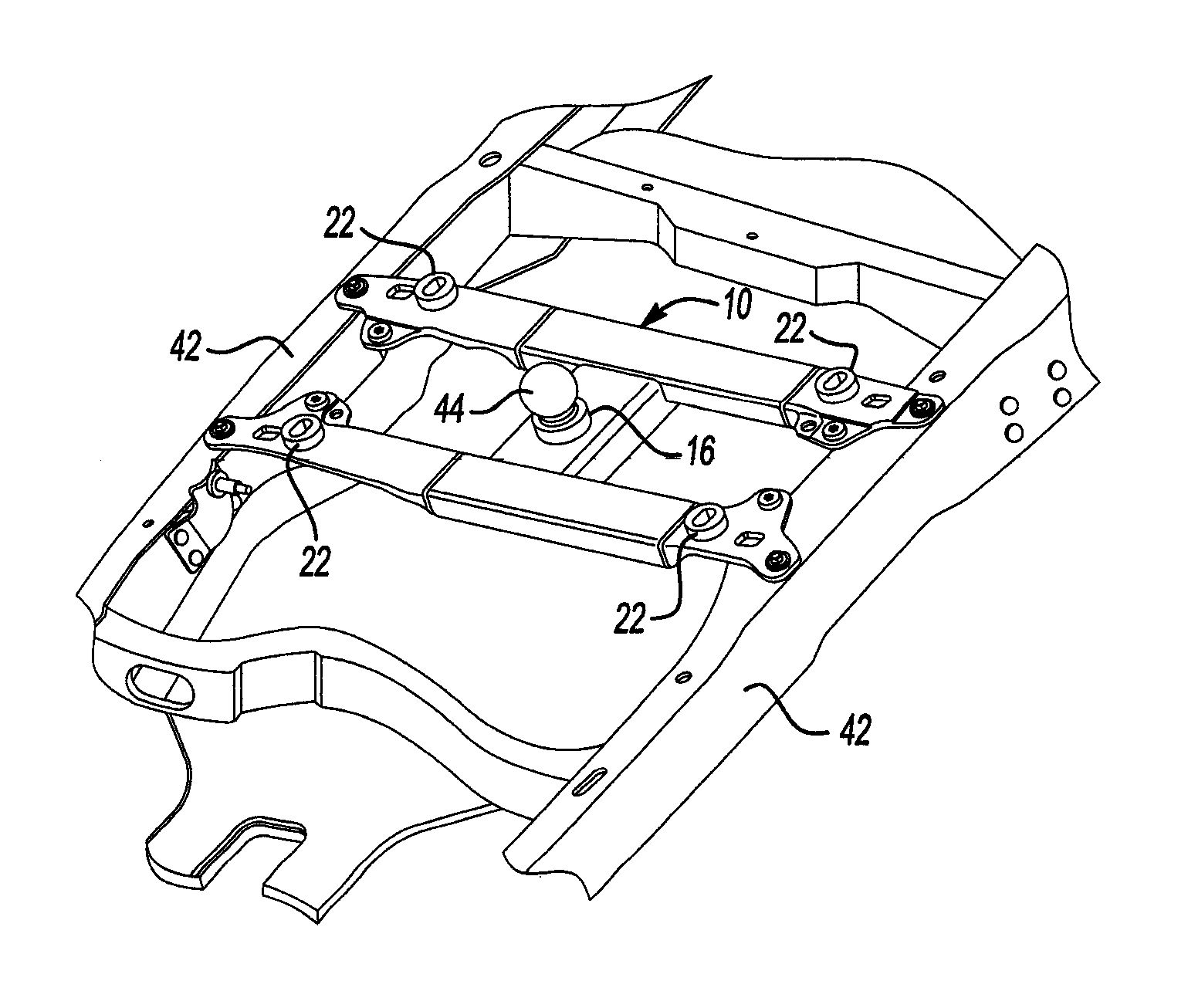

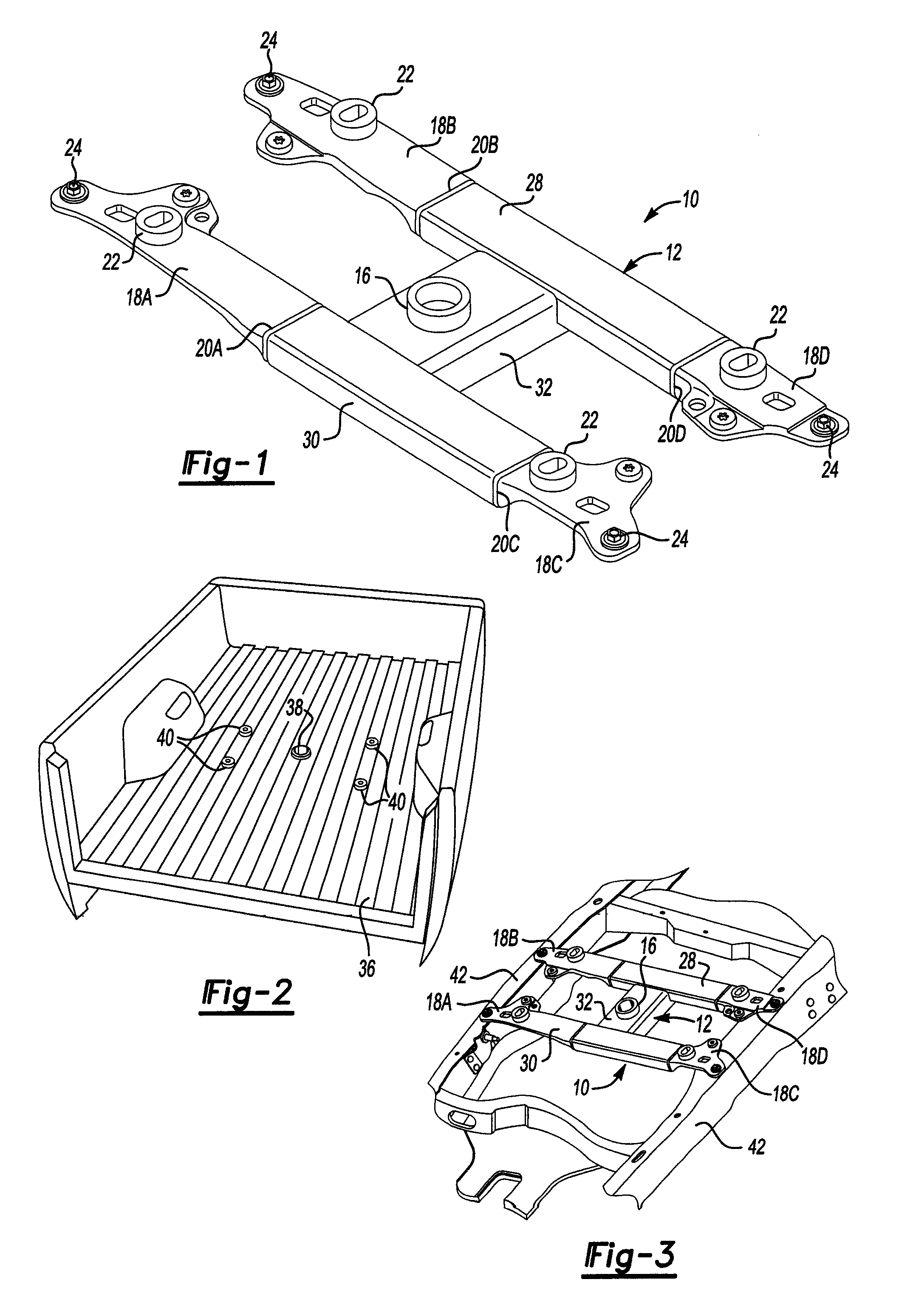

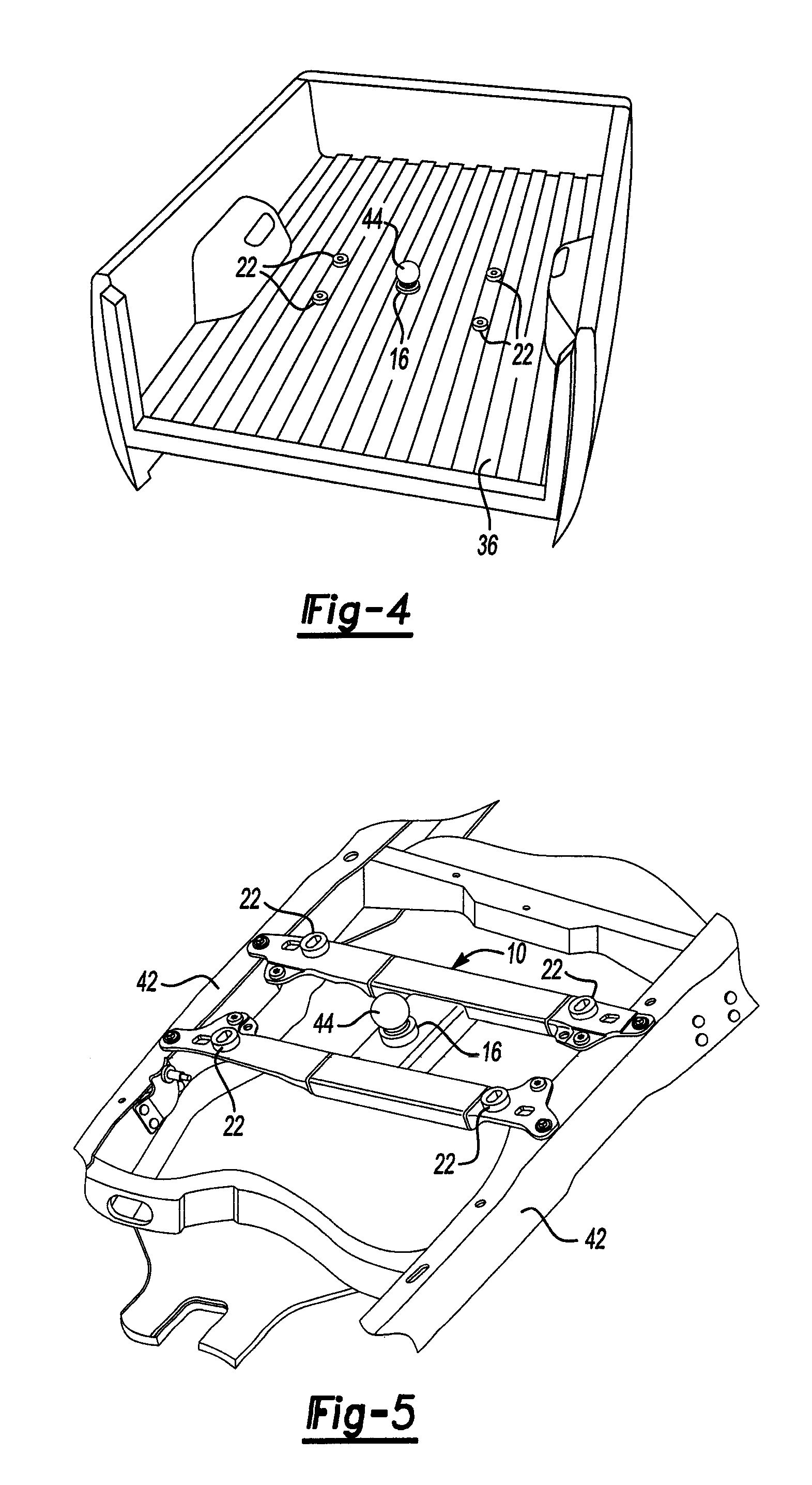

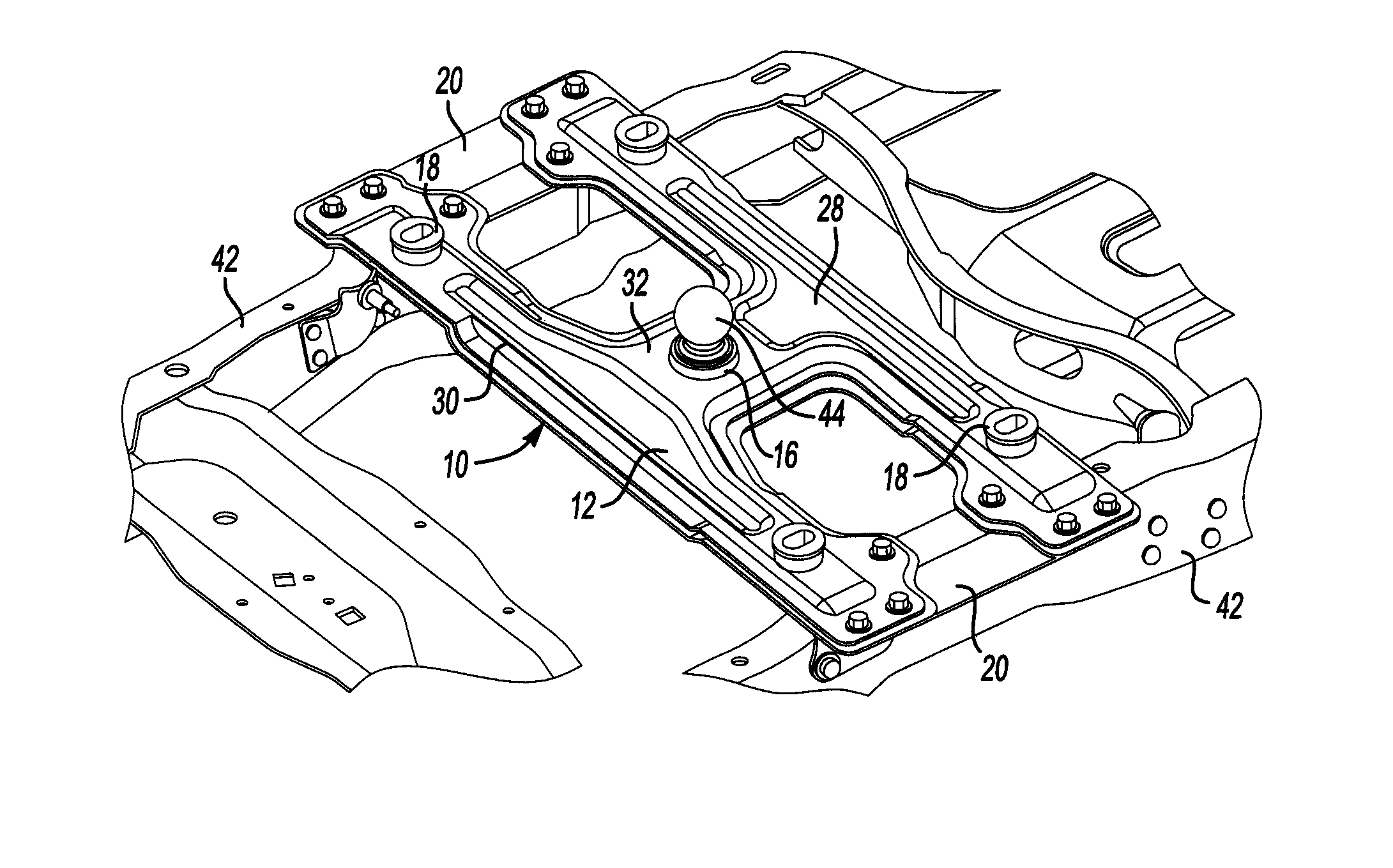

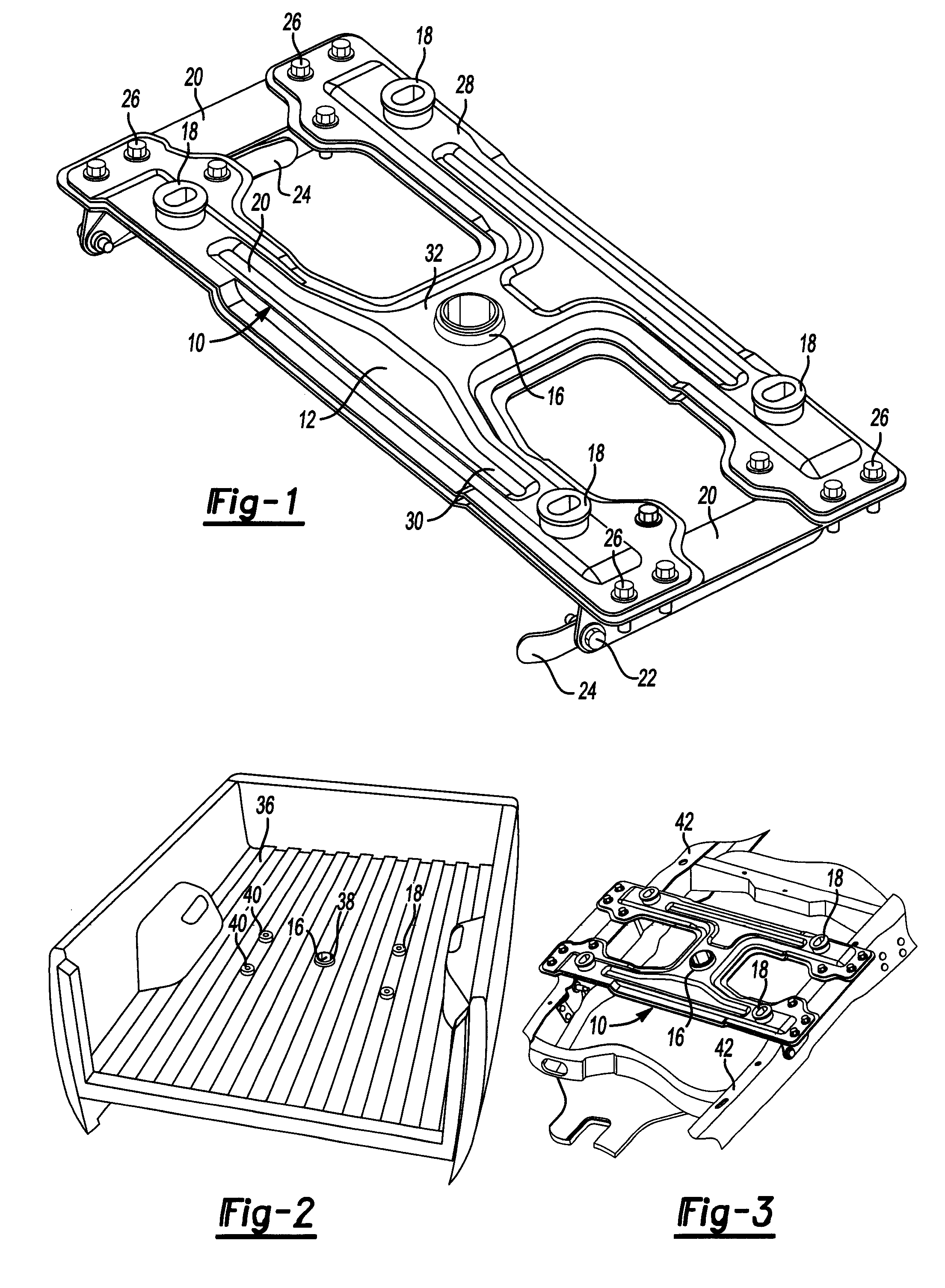

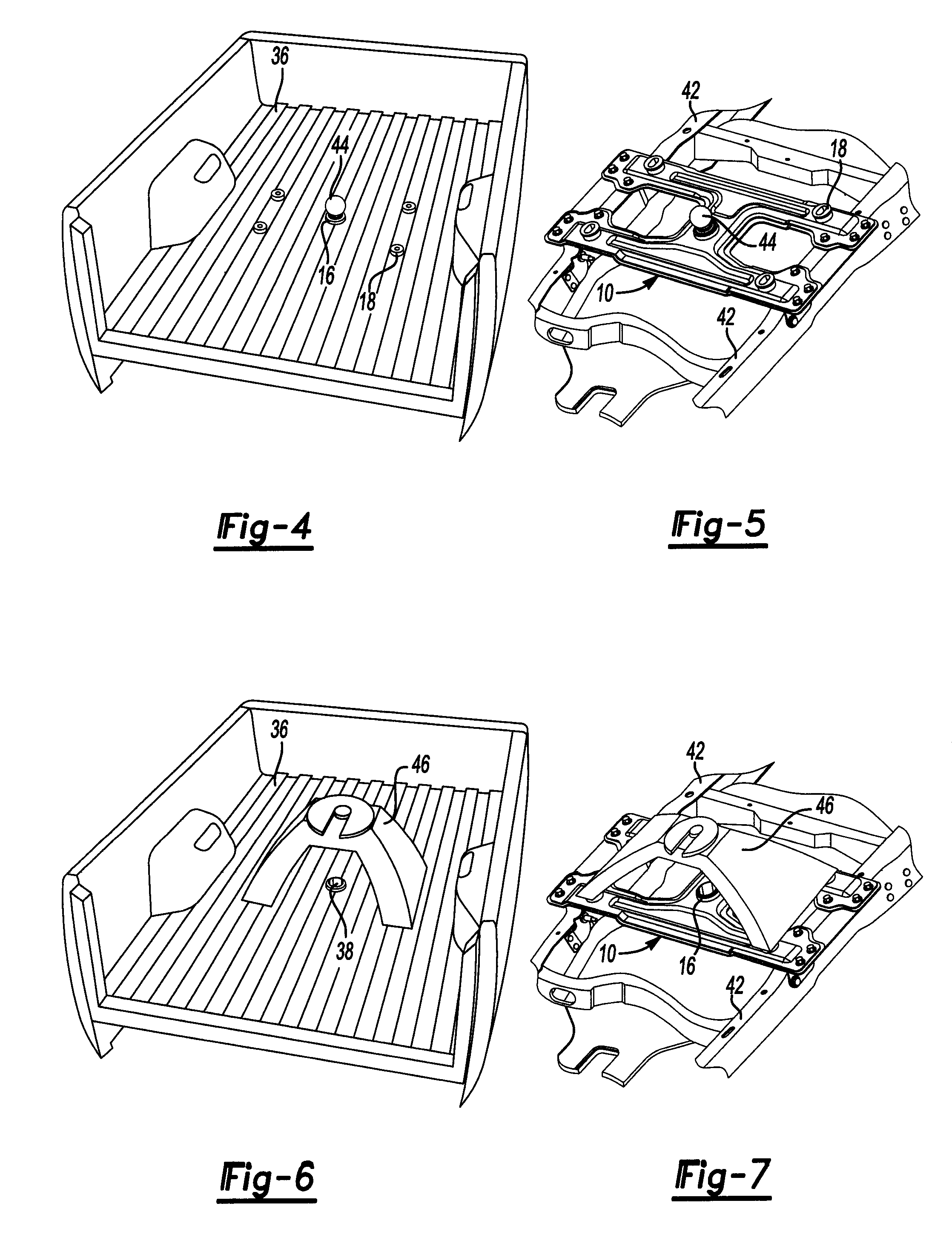

Integrated support structure for either a fifth wheel hitch or a gooseneck trailer hitch

An integrated support structure apparatus is provided for attaching either a fifth wheel trailer hitch or a gooseneck trailer hitch to a truck bed. The integrated support structure comprises an H-shaped body that is attached to at least one truck frame rail below the truck bed. A gooseneck ball receiver is attached to a central portion of the body and aligned with a gooseneck opening in the truck bed. A plurality of mounting pads are formed integrally as part of a plurality of end inserts that are assembled to the body.

Owner:FORD GLOBAL TECH LLC

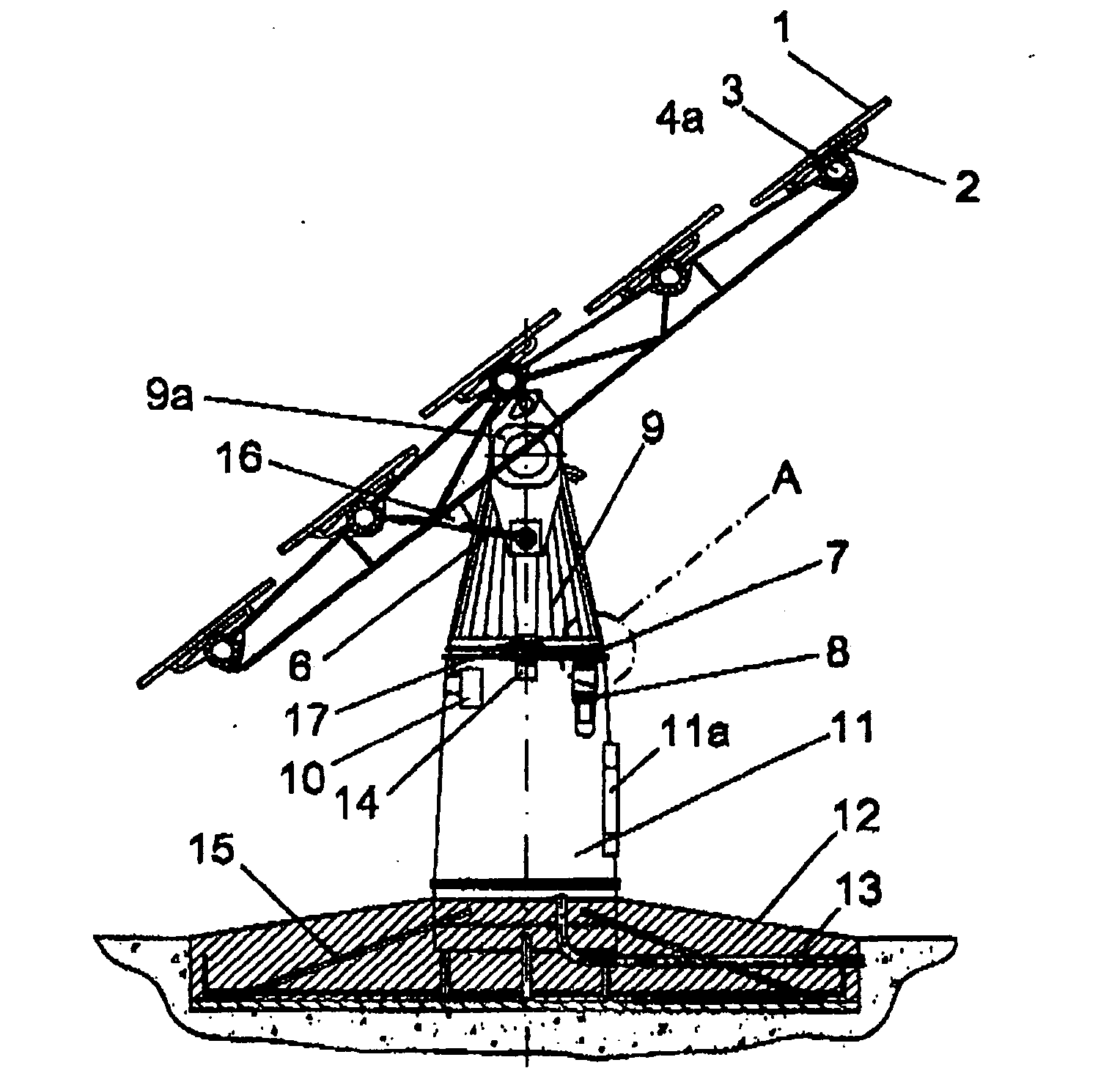

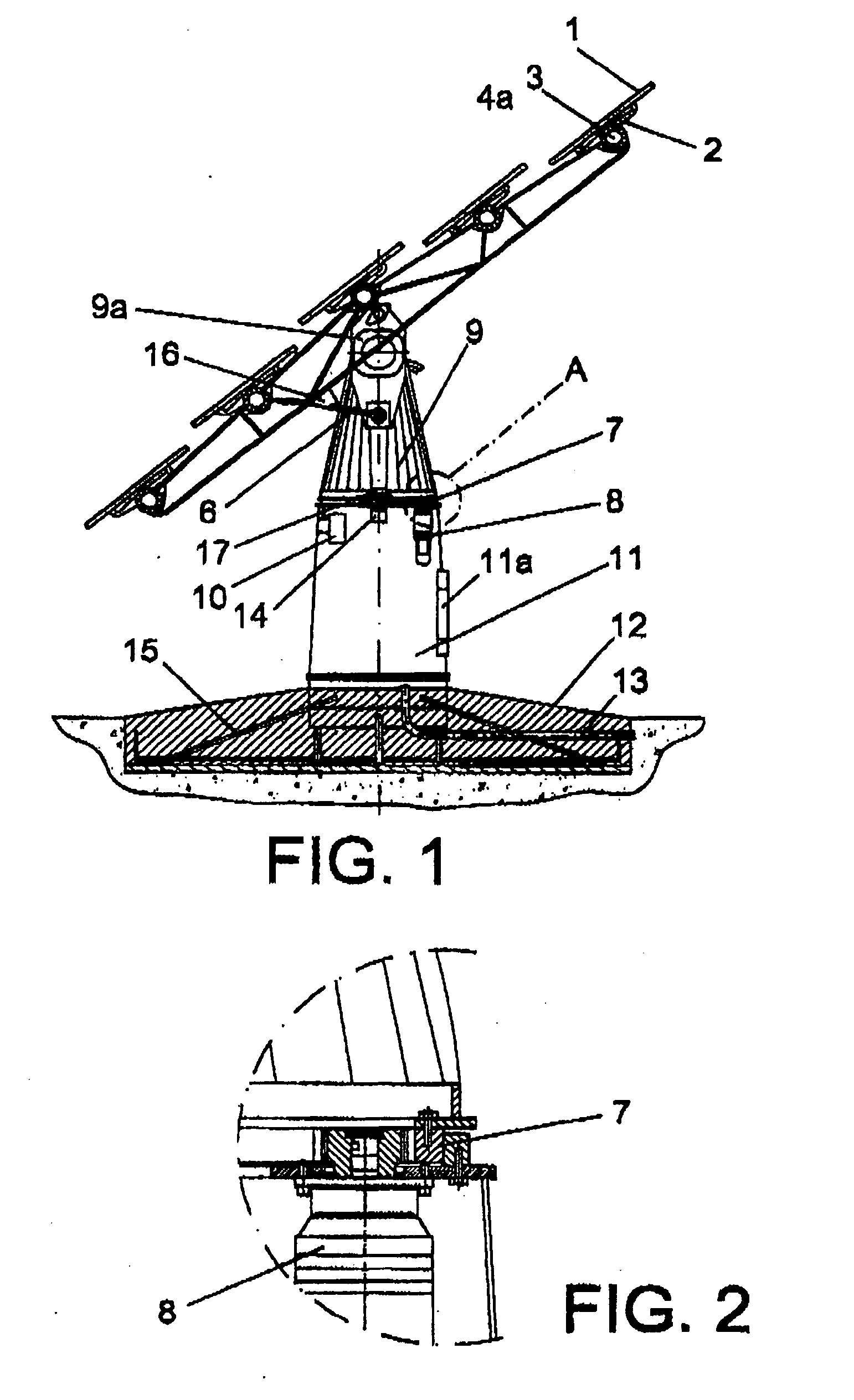

Solar tracker

The invention relates to a solar tracker characterized by having photovoltaic panels arranged in spaced rows at different levels and two slopes, favouring their ventilation and the expansion of the frame; the panels being fixed by means of yokes and clips to a support (3) anchored to the H-shaped frame (4) resting on swivelling supports of a tower having little height supporting the entire structure, its tilt being variable by means of a tension device, the side longitudinal beams (4a) being extendible to house more rows of panels (1) since the remaining structural components, tower, bearings, column and base have been oversized for that purpose.

Owner:ROMEO MANUEL LAHUERTA

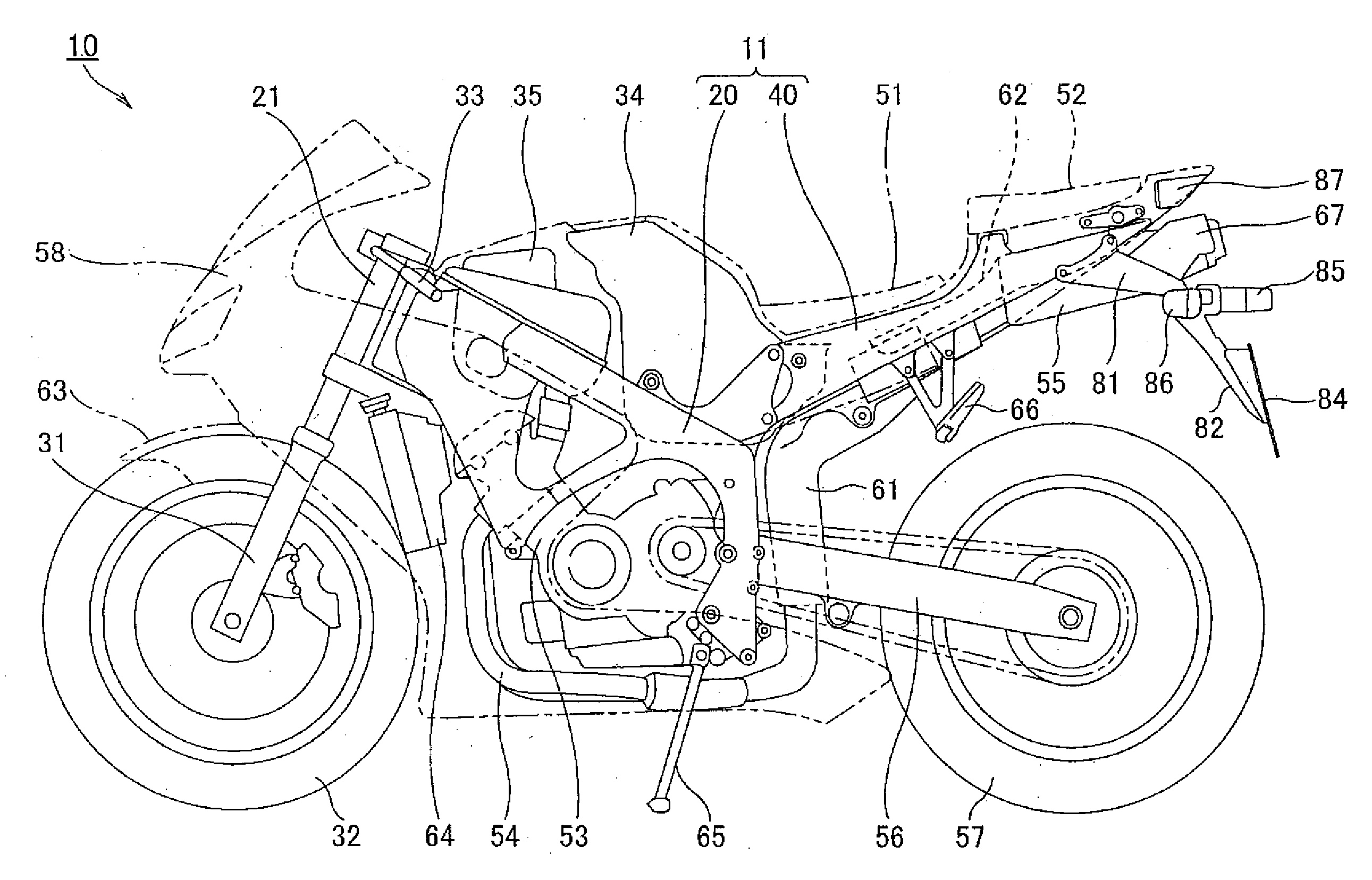

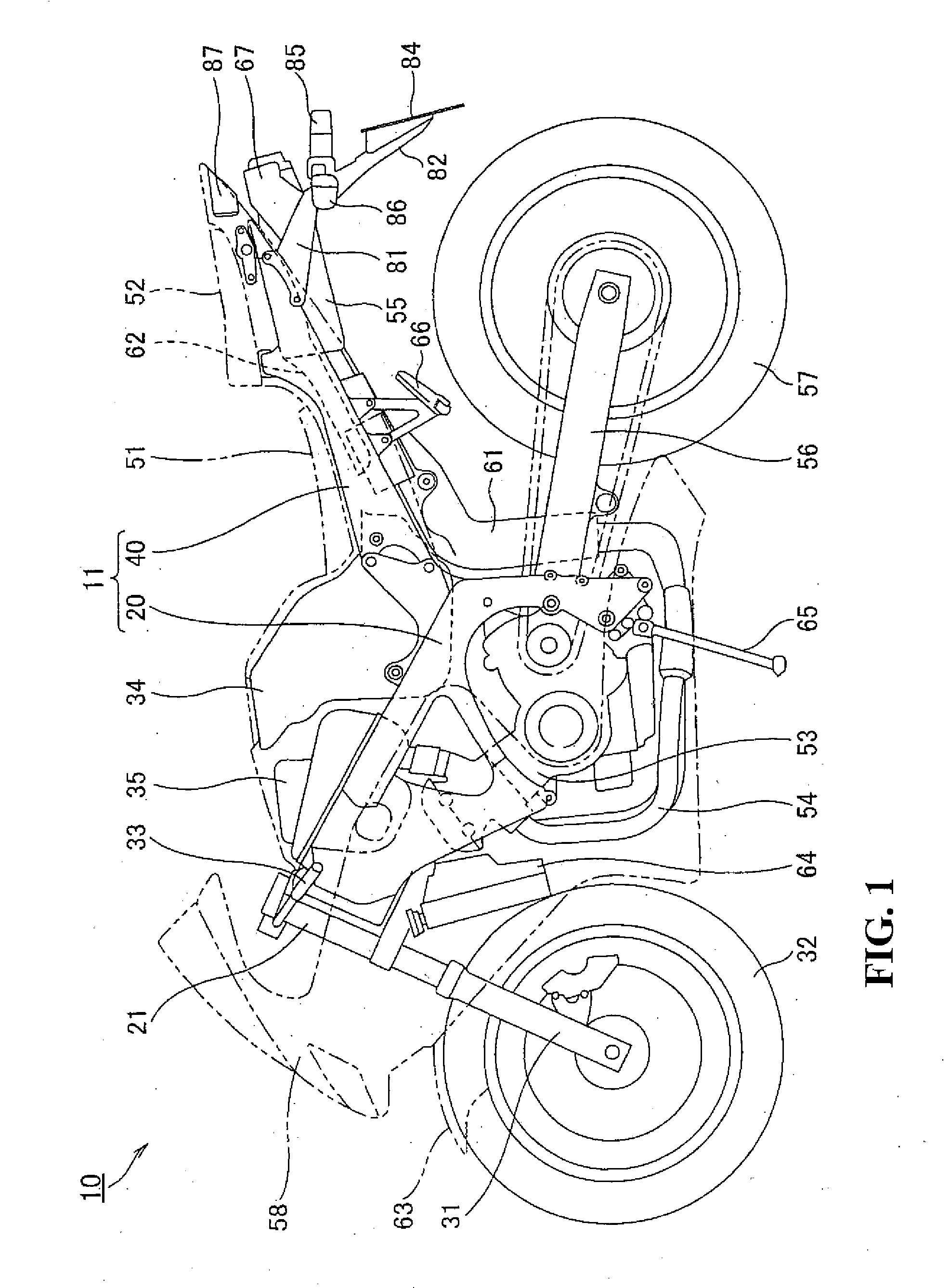

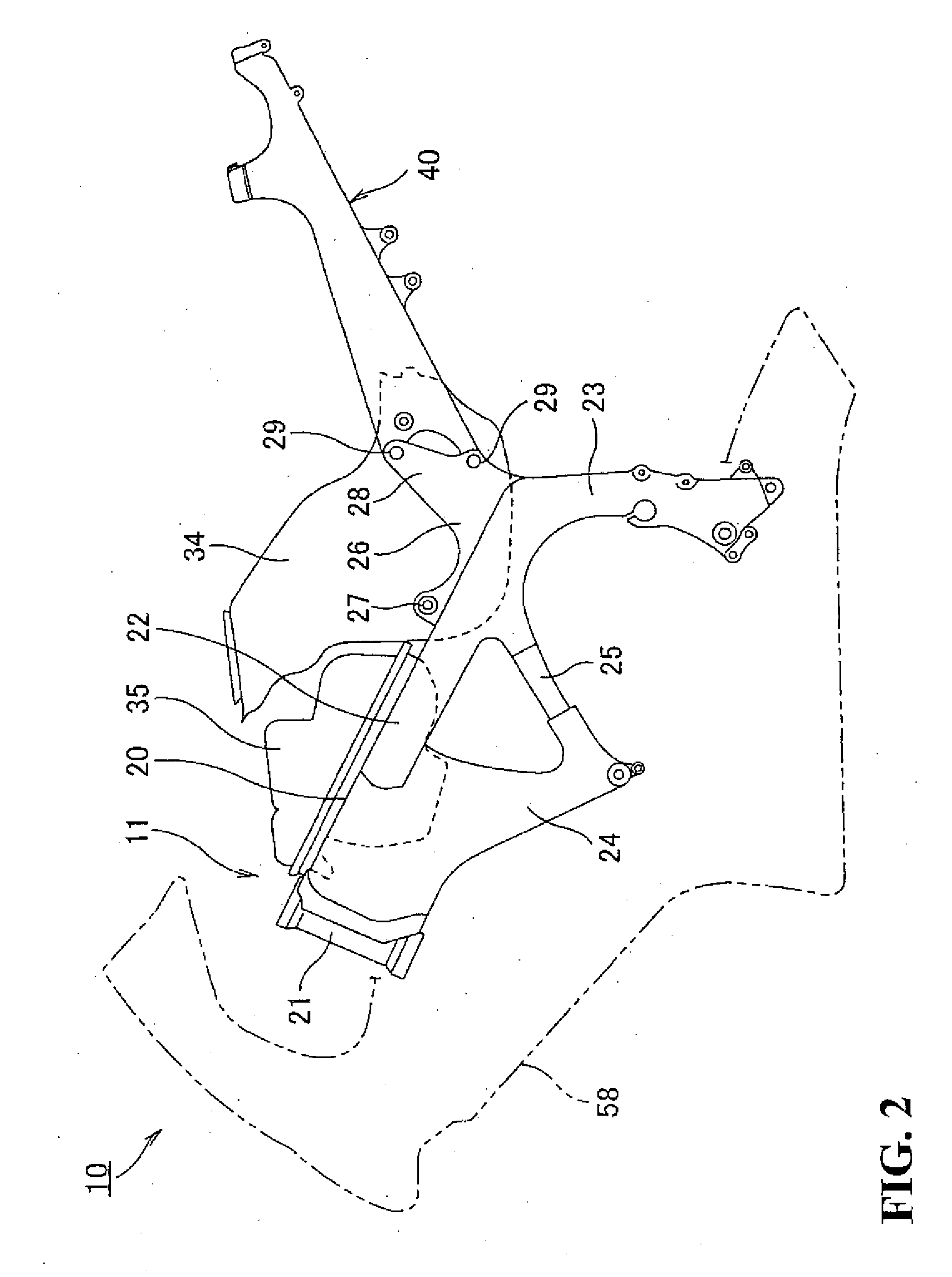

Seat rail structure of motorcycle

InactiveUS20080277980A1Improve productivityHigh strengthMotorcyclesCycle saddlesDie castingEngineering

A seat rail structure for a motorcycle having sufficient strength and rigidity while achieving a weight reduction of a vehicle body. A seat rail structure of a motorcycle includes a main frame and a seat rail formed of magnesium alloy to be secured to the main frame. The seat rail includes a pair of left and right side wall portions extending rearwardly from the main frame, and a plurality of connecting portions formed into a substantially angular C-shape in cross section or into a substantially H-shape in cross section for connecting the left and right side wall portions. At least part of the connecting portions are connected at a level flush with or above the upper surface of the side wall portions. The side wall portions and the connecting portions are integrally formed by die casting.

Owner:HONDA MOTOR CO LTD

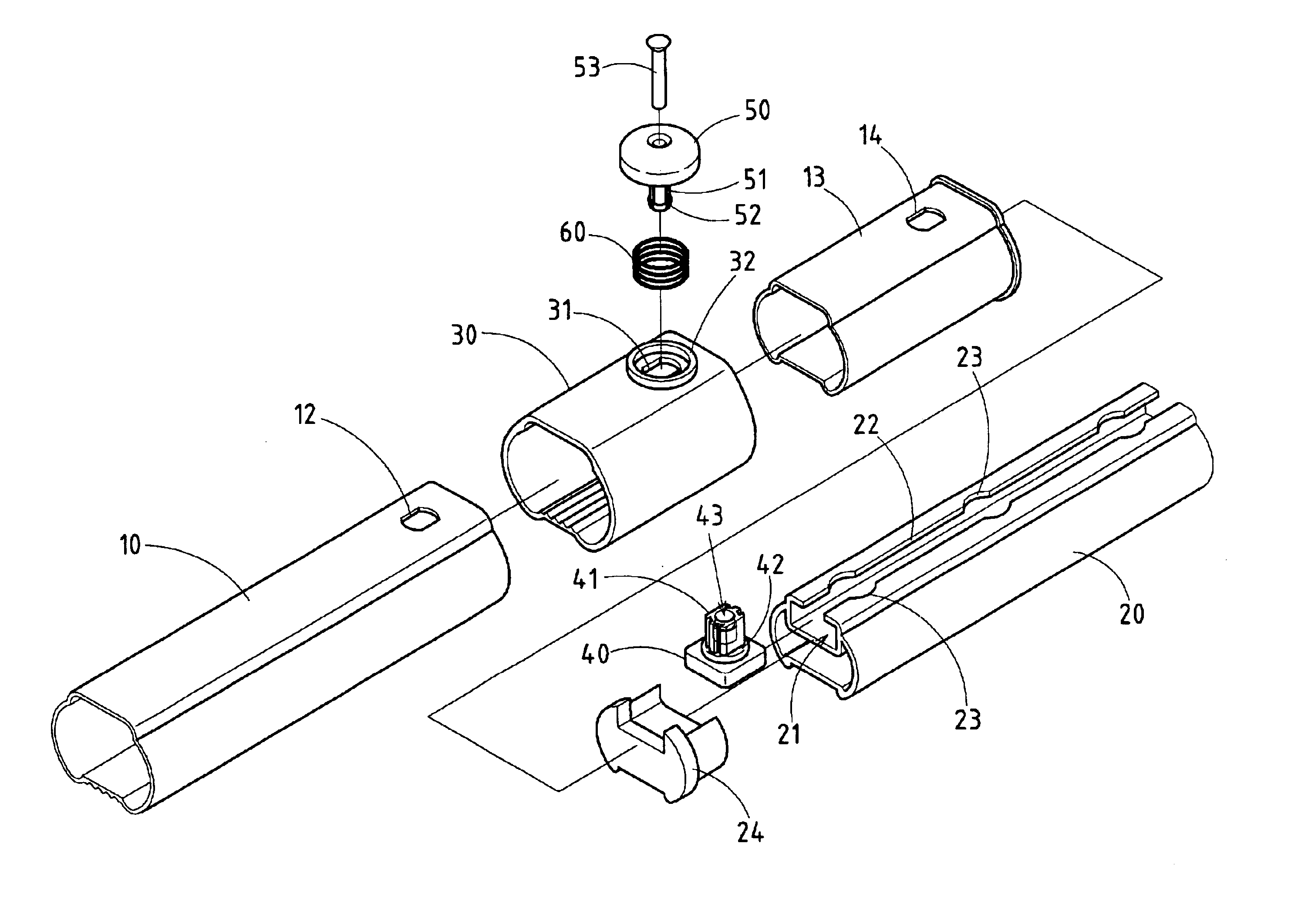

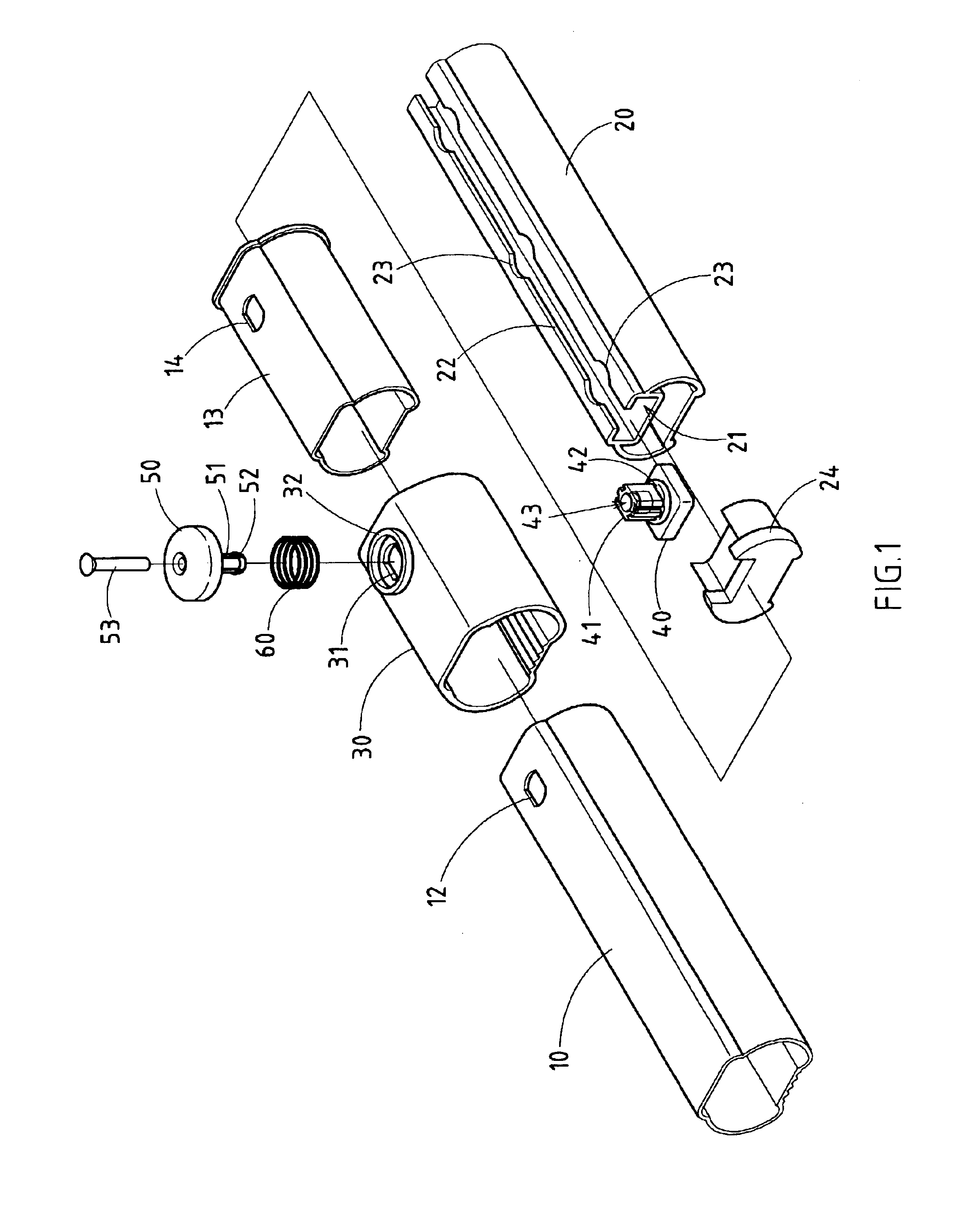

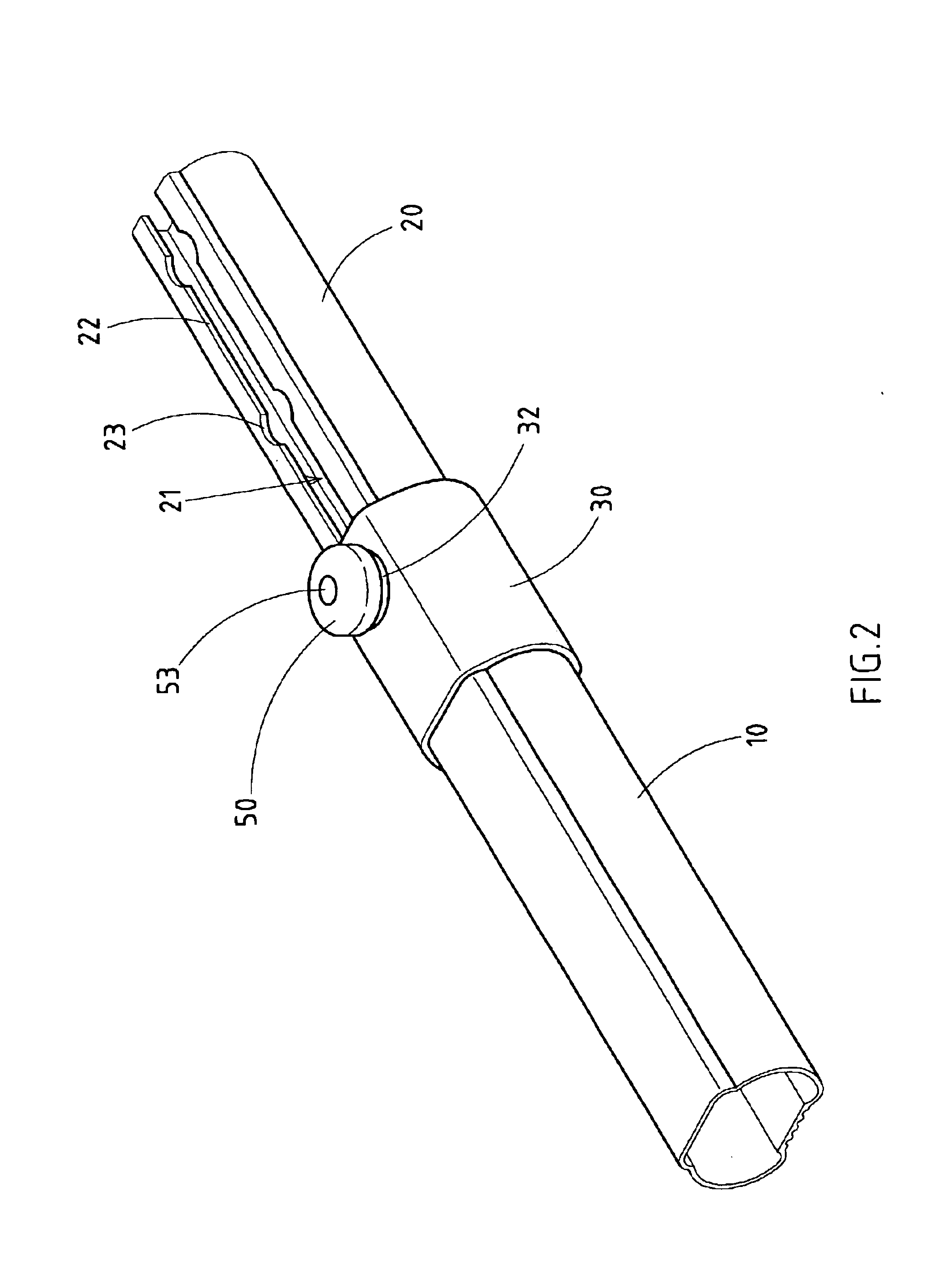

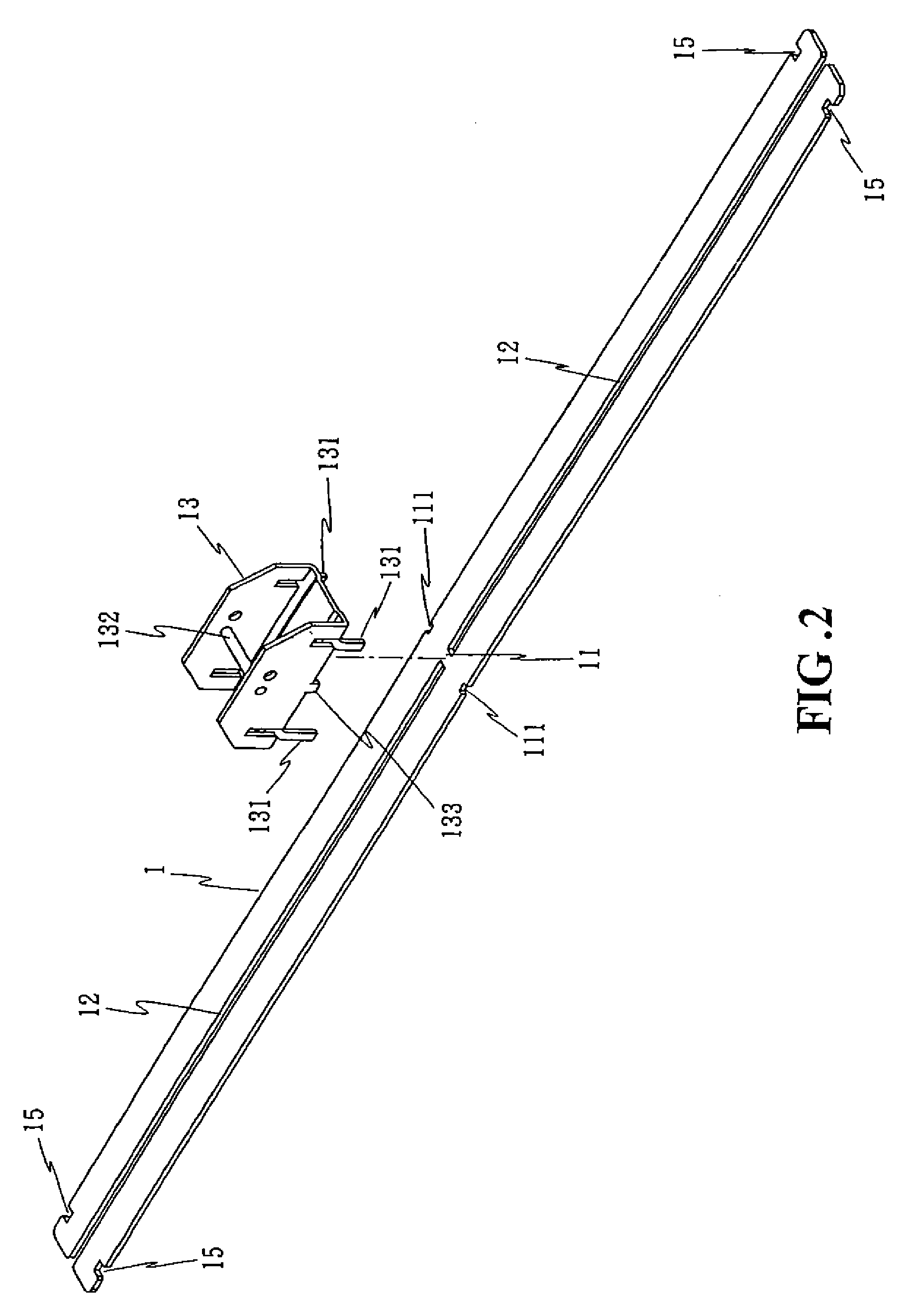

Hedge shear extendable handle enhanced structure

This innovation provides a hedge shear extendable handle enhanced structure focusing on resolving the operating inconvenience and physical deficiencies such as bending and deformation resulting from the operations of legendary hedge shear. The main structure of the enhancement is a pivot joint formation of an inner and outer tube. The main feature is the H-shape profile structure of the inner tube with a slide way built with an internal diffusion slot and a perforation slot. The perforation slot has a few interleaved positioning fillisters along the slide way. The positioning fillisters in the inner tube will park the sliding block when it shifted upward and matching with the locating block on the top pillar while moving upward. A press button assembles on top of the pillar and remains in an upward position with the sliding block under normal condition with the help of a spring. The main functionality is retaining the convenience of the press button operation while maintaining ruggedness and endurance of the product using such technique.

Owner:HUANG YAO CHUNG

Quadrifilar helical antenna

A quadrifilar helical antenna comprising two pairs of filars having unequal lengths and phase quadrature signals propagating thereon. A conductive H-shaped impedance matching element matches a source impedance to an antenna impedance. The impedance matching element having a feed terminal at the center thereof from which current is supplied to the two filars of each filar pair disposed about an edge of the impedance matching element and symmetric with respect to a center of the impedance matching element. The impedance matching element further comprises a reactive element for matching the antenna and source impedances.

Owner:SKYCROSS INC

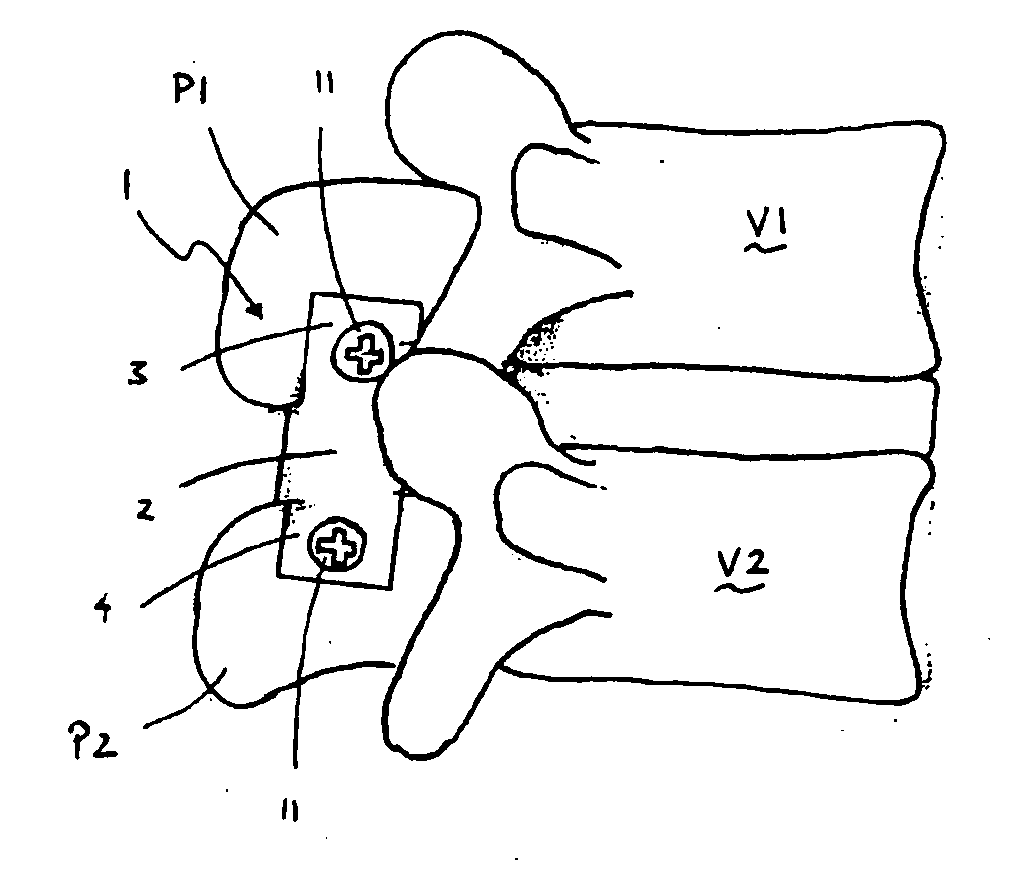

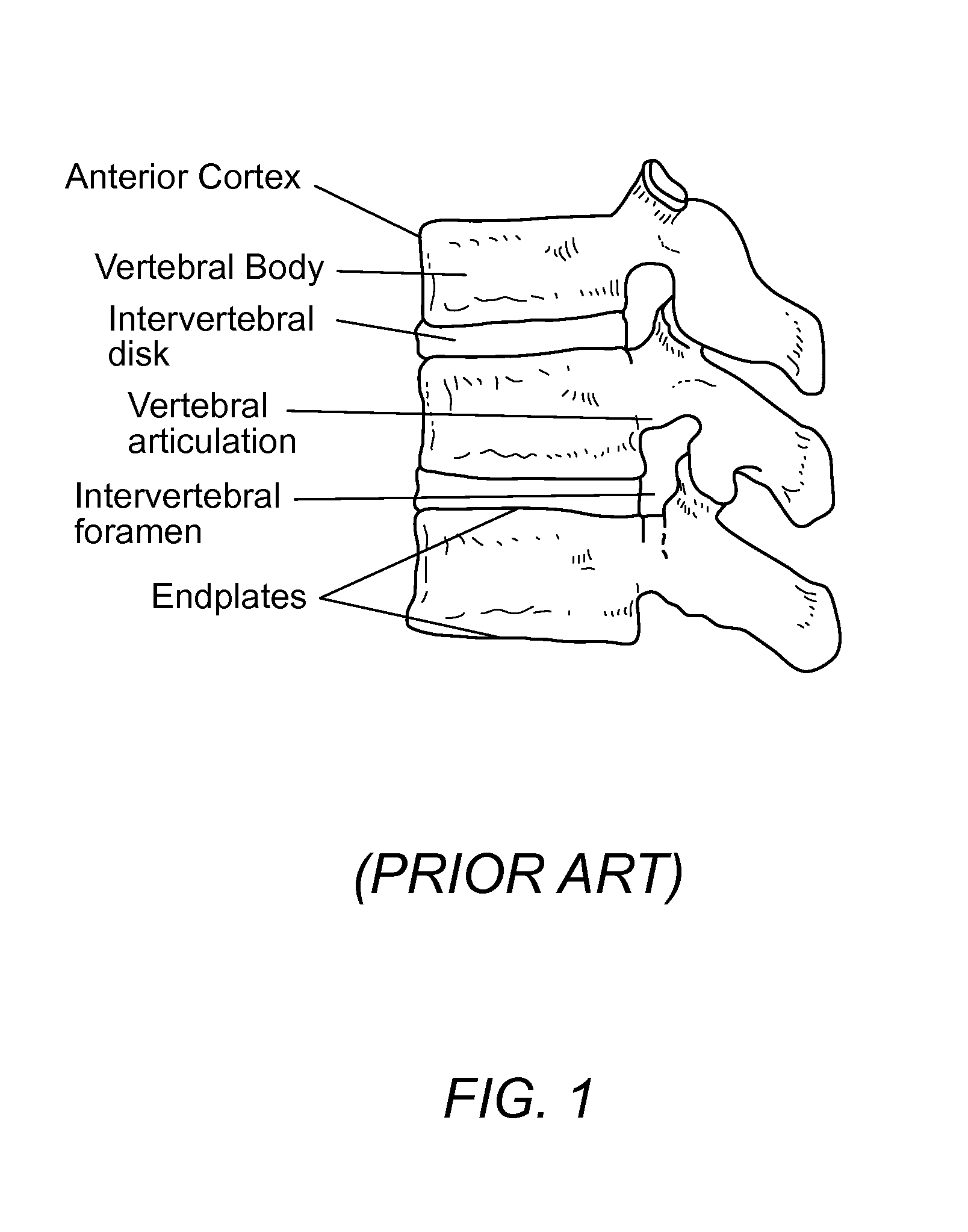

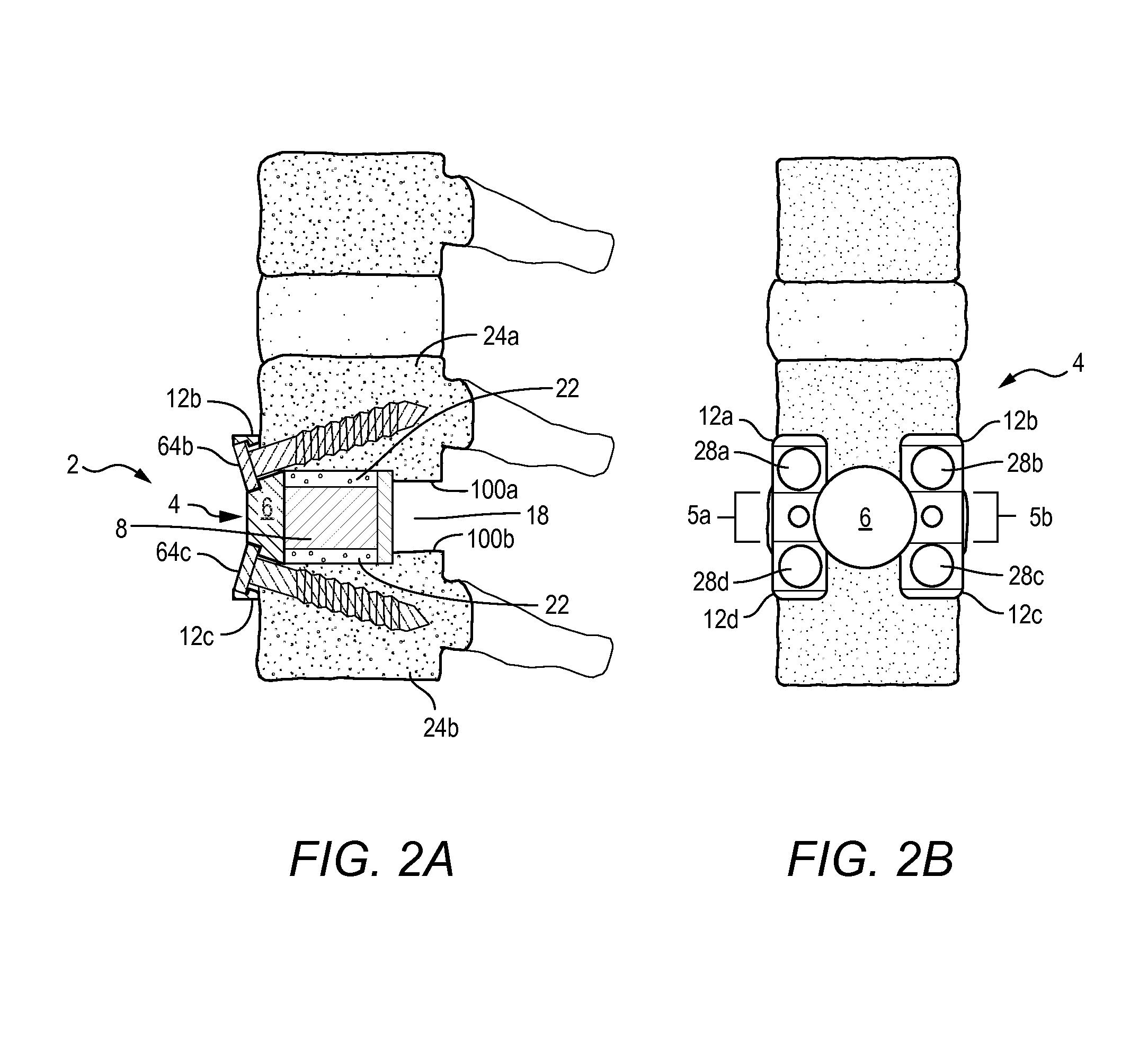

Anterior intervertebral spacer and integrated plate assembly and methods of use

InactiveUS8932358B1Easy to fuseImprove stabilityBone implantSpinal implantsAnterior cortexIntervertebral spaces

A precisely size matched intervertebral plate and spacer assembly for ensuring a tight fit within a disc space to promote spinal fusion, comprising: a “U-shaped” spacer configured to fit within the intervertebral space; and, a matching countersunk low profile “H-shaped” anterior plate joined perpendicularly to the spacer. The plate further comprises: a plurality of anchor members configured to attach to the junctions of the anterior cortex faces and the endplates; and, channels individually traversing through the anchor members for inserting screws into the vertebral bodies' cortical bone. The spacer comprises a hollow three-sided U-shaped member, comprising two opposing parallel side walls, and a perpendicular posterior wall, while lacking a superior, inferior, and anterior wall. The exterior walls of the plate and spacer are planar, while the interior walls of the spacer are curved to house a precisely fitting cylindrical graft, or other insert such as DBM, bone dust, bone paste, bone dowel with direct contact to the endplates to promote fusion.

Owner:NEHLS DANIEL

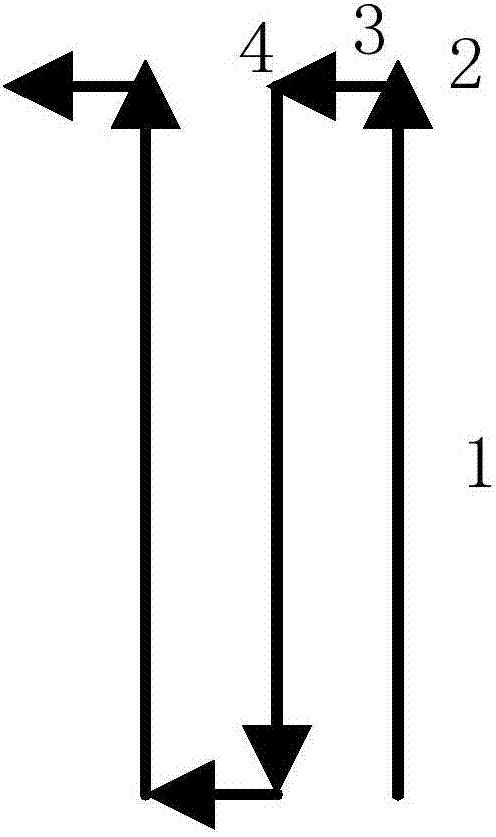

Intelligent robot route planning method

ActiveCN107340768AReduce mistakesValid recordProgramme-controlled manipulatorAutonomous decision making processReal time analysisSimulation

The invention discloses an intelligent robot route planning method. The intelligent robot route planning method comprises steps of (1) dividing an operation space into a plurality of n-meter*m-meter rectangle virtual zones, (2) controlling the intelligent robot to transverse every virtual zone in an H-shaped movement, (3) constructing a grid map with distance information, angle information, collision information and obstacle information in a H-shaped movement of the intelligent robot, and marking a passing point, an obstacle point and a collision point, (3) realizing a map in real time, determining whether a whole operation space finishes traversing, if yes, entering the step (4), if no, returning to the step (2), and (4) controlling the intelligent robot to perform one time of an along-the-border behavior and marking the along-the-border behavior points on the constructed map. The intelligent robot route planning method can construct an effective grid map with errors in a controllable range according to the distance information, angle information, collision information and obstacle information of the robot behavior and realizes a low cost and efficient robot route planning.

Owner:AMICRO SEMICON CORP

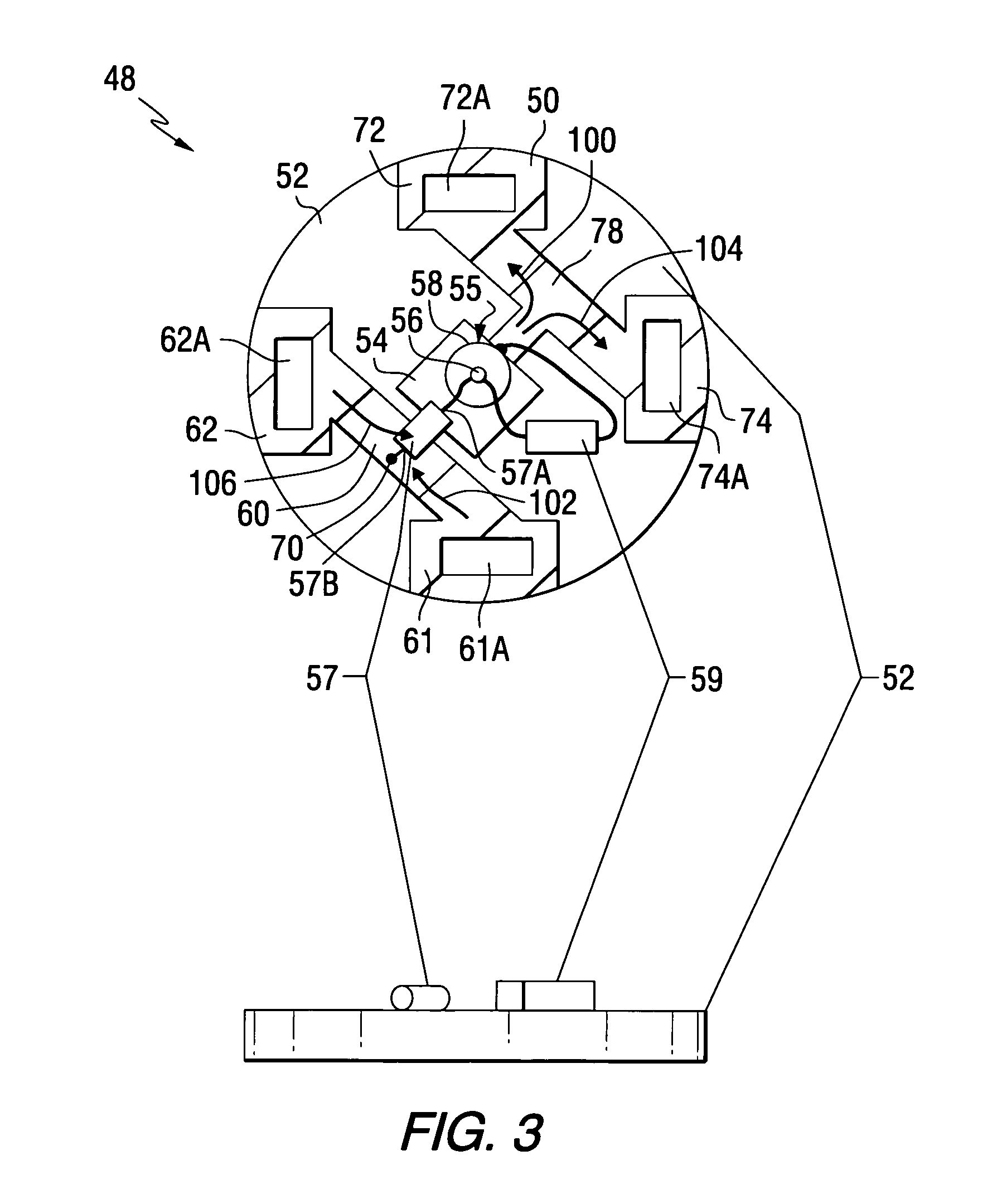

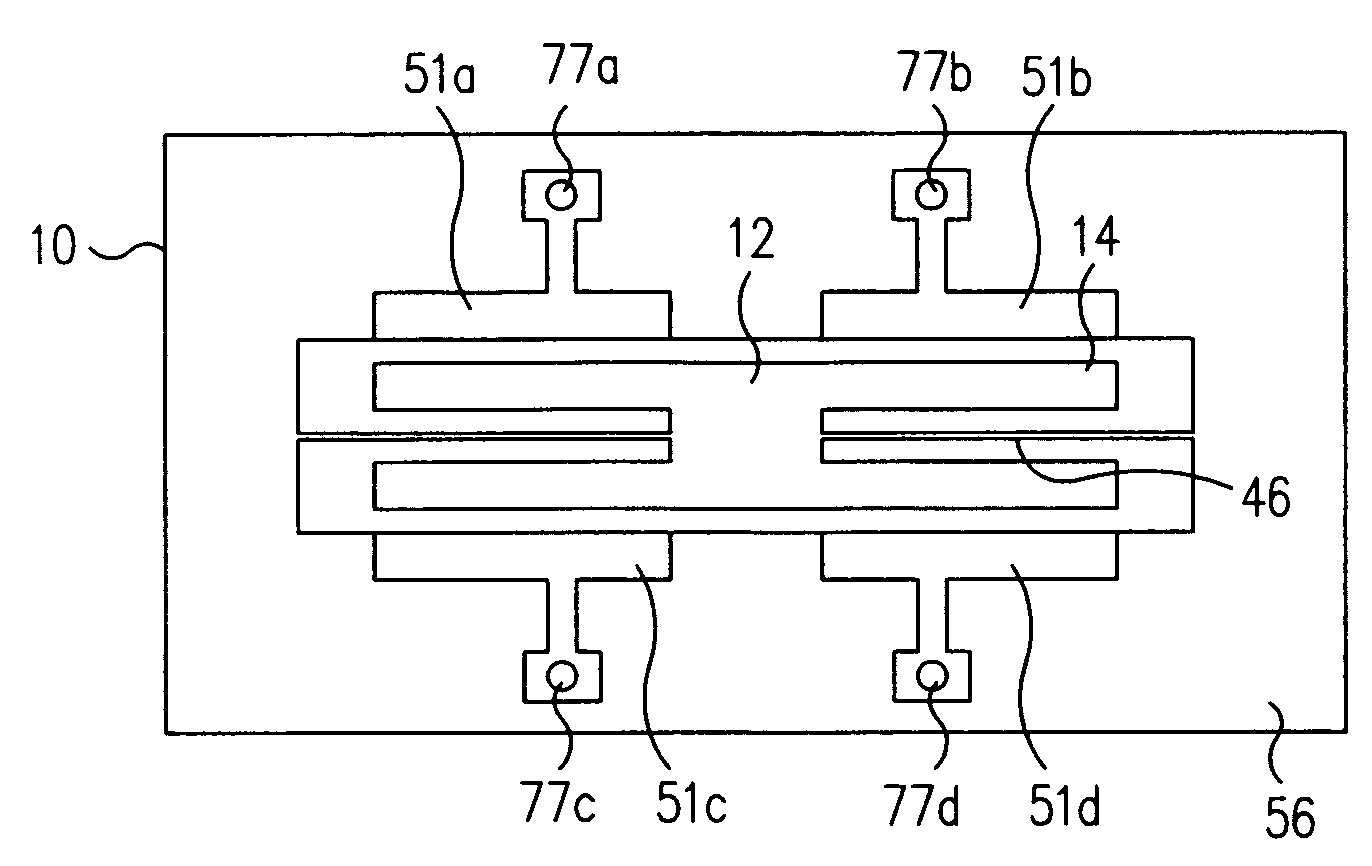

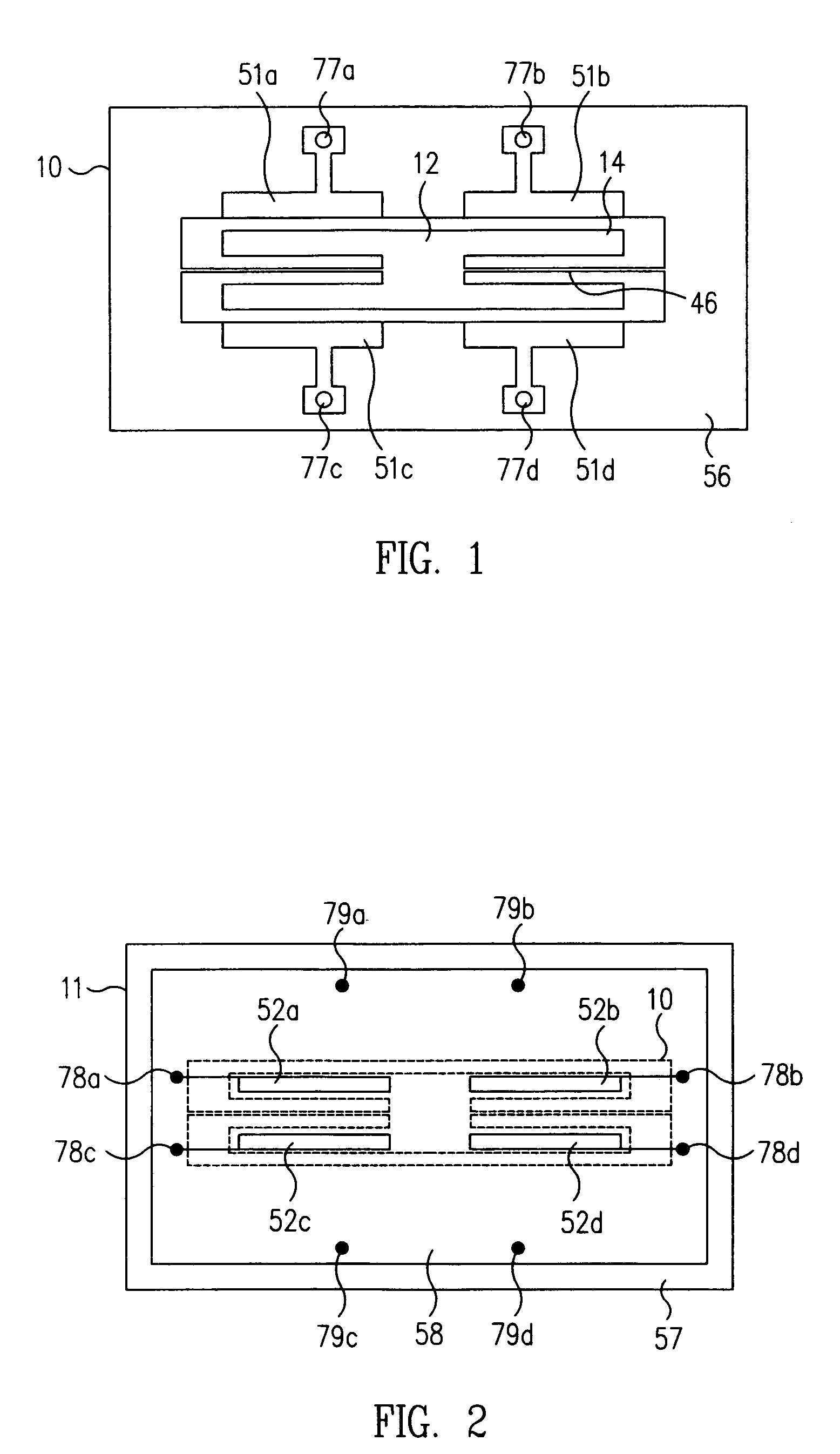

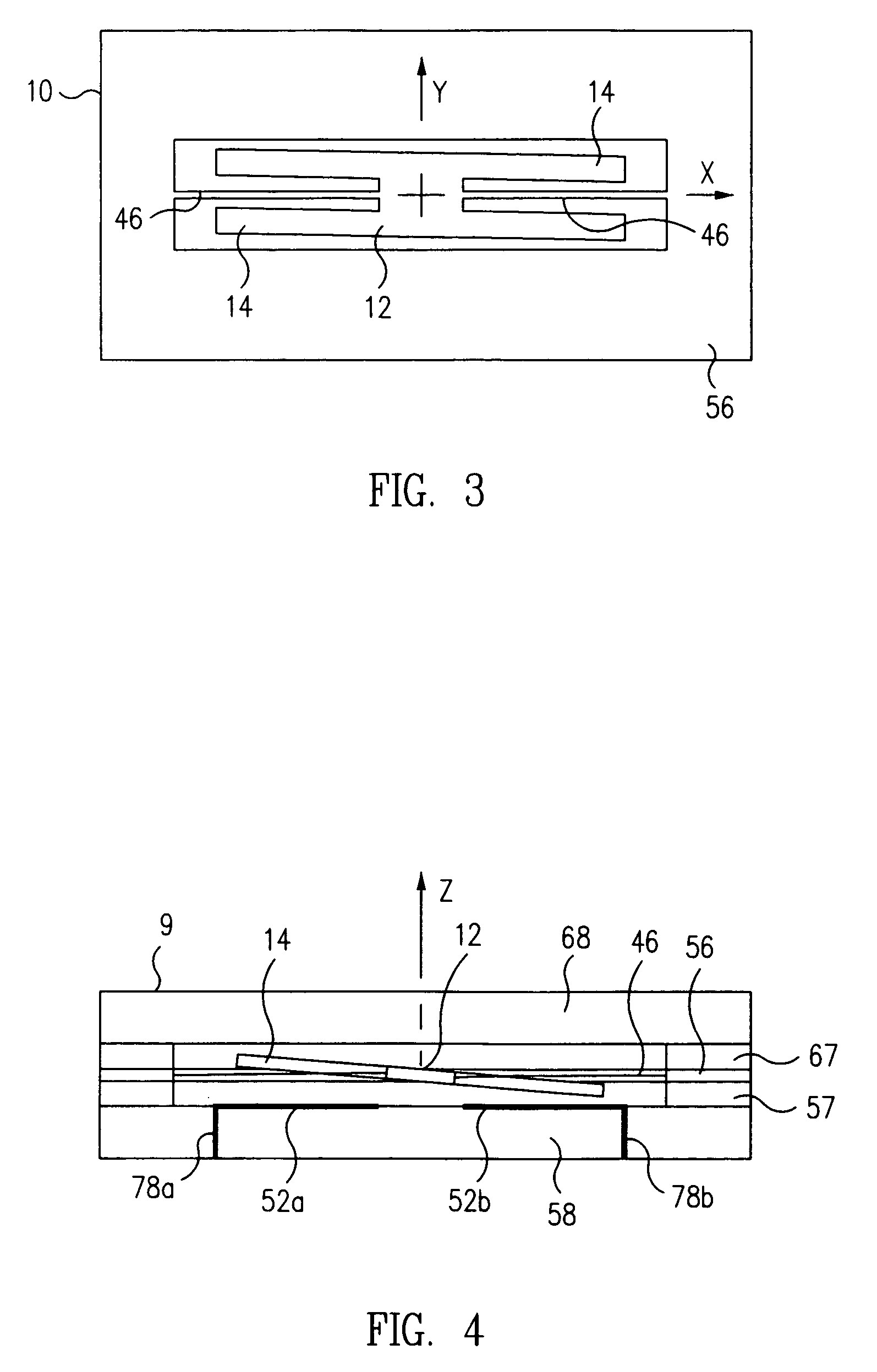

Micro-electromechanical system inertial sensor

InactiveUS7640803B1Easy to manufactureHigh aspect ratioAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSquare cross sectionAccelerometer

A micro-machined MEMS resonator gyroscope and accelerometer is fabricated from an epilayer semiconductor wafer to incorporate a substantially planar, H-shaped resonator mass suspended from a support plate by two opposed elongated springs that couple to the relatively short crossbar member of the H. The masses are harmonically oscillated relative to the support plate and a baseplate portion, and two orthogonal modes of the structure corresponding to the two nearly degenerate fundamental torsional modes thereof are used for sensing angular rate about one axis, and linear acceleration along two axes, of the sensor. The H-shaped mass advantageously incorporates a relatively high length-to-width aspect ratio, and in one embodiment, the springs may advantageously incorporate either a square cross-section, such that the structure can be tuned to substantially match the fundamental frequencies of the two resonance modes of the structure by removing, e.g., by an etching process, a small amount of material from the upper surfaces of the springs.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

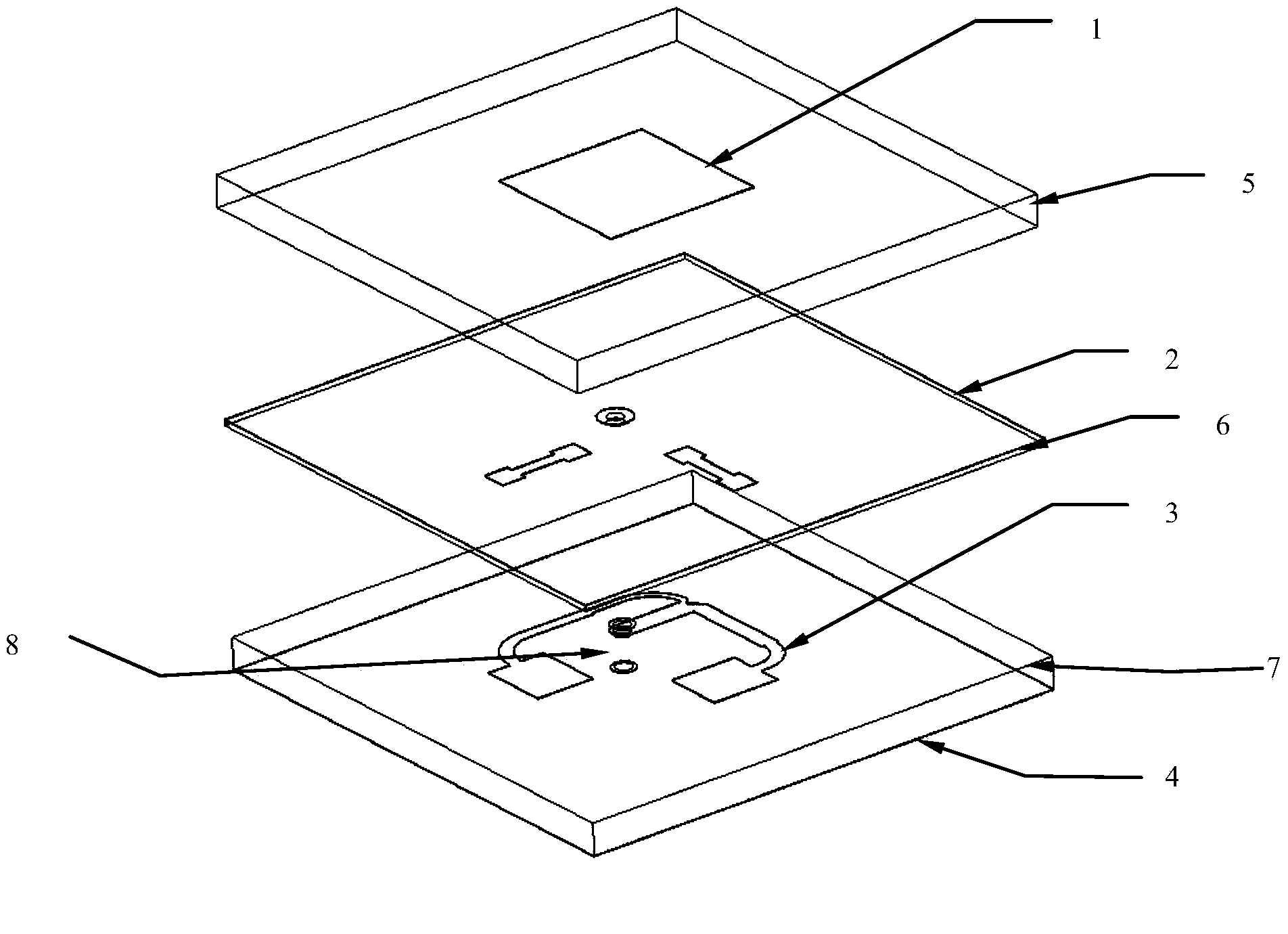

Low-cost microwave- and millimeter-wave polarized antenna of multi-layer PCB (Printed circuit board) process

InactiveCN104103906AImproving Impedance BandwidthSmall structure sizeRadiating elements structural formsSlot antennasAxial ratioDielectric substrate

The invention discloses a low-cost microwave- and millimeter-wave polarized antenna of the multi-layer PCB (Printed circuit board) process. The polarized antenna is of a multi-layer structure and comprises a quadrate radiating metal patch, an upper dielectric substrate, a metal floor equipped with an H-shaped coupling gap, a medium dielectric substrate, a feed metal plate with power division network, a lower dielectric substrate and a bottom metal floor; the quadrate radiating metal patch is coupled with the floor equipped with the H-shaped coupling gap to realize feed; the feed network of a microstrip line structure is positioned below the floor; the metal floor equipped with the H-shaped coupling gap is connected with the bottom metal floor through a metal through hole; the feed metal plate with the power division network is connected with the bottom metal floor through a second metal through hole to form a coaxial microstrip line conversion structure by which feeding from the bottom part of the antenna is realized. The antenna has the characteristics that the frequency band is wide, the size is small, the cost is low, the manufacturing and processing are simple, and the axial ratio feature is great.

Owner:SOUTHEAST UNIV

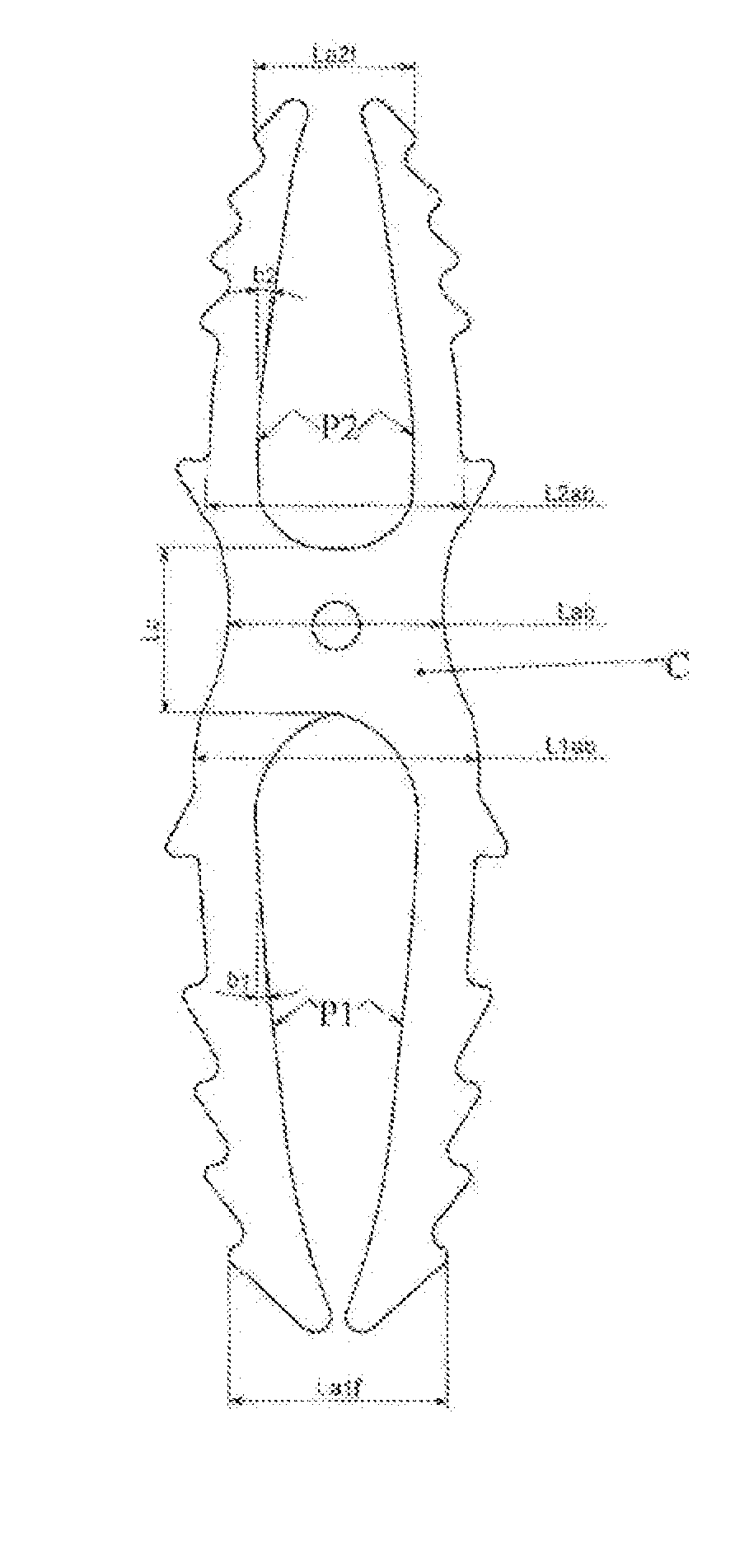

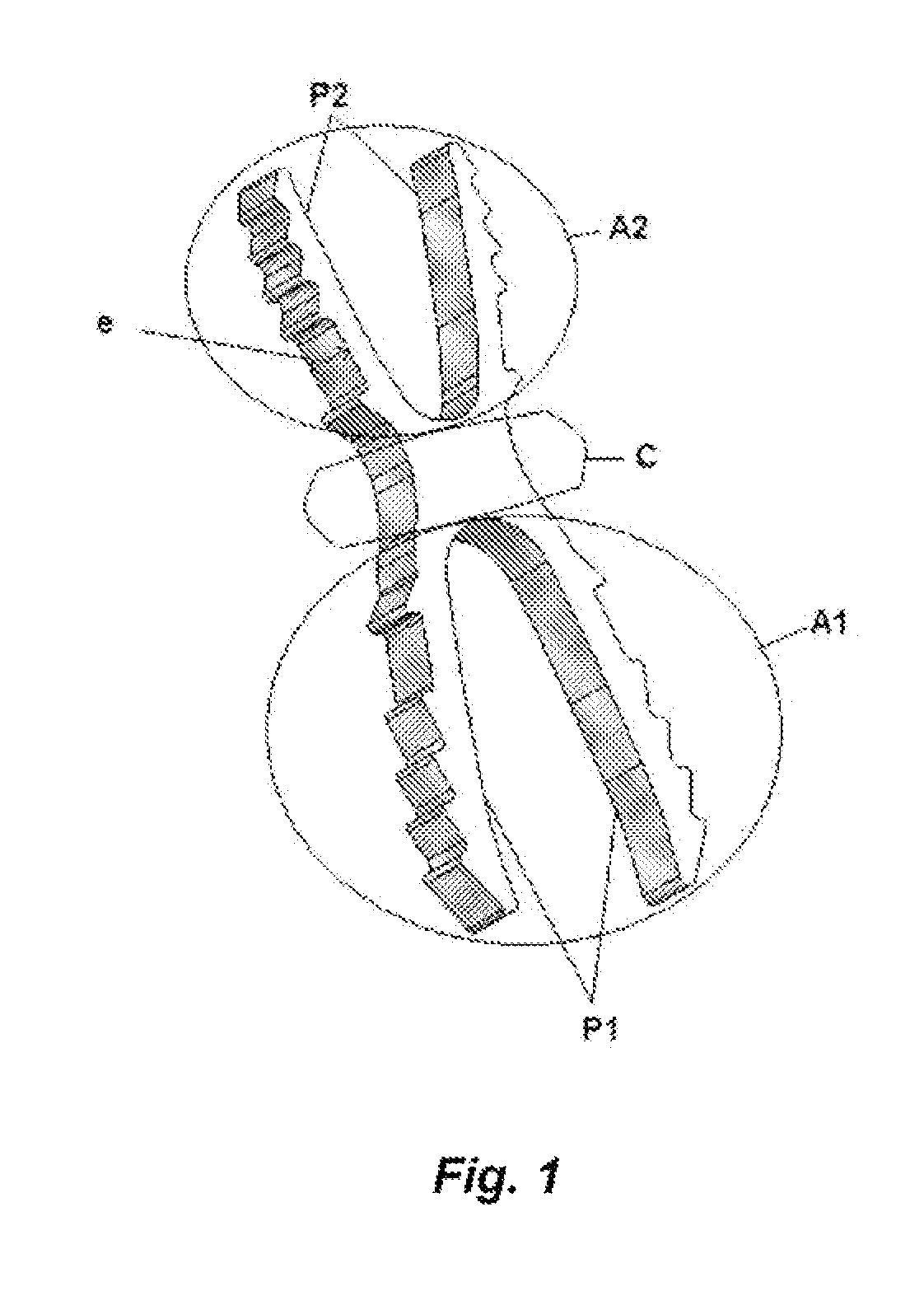

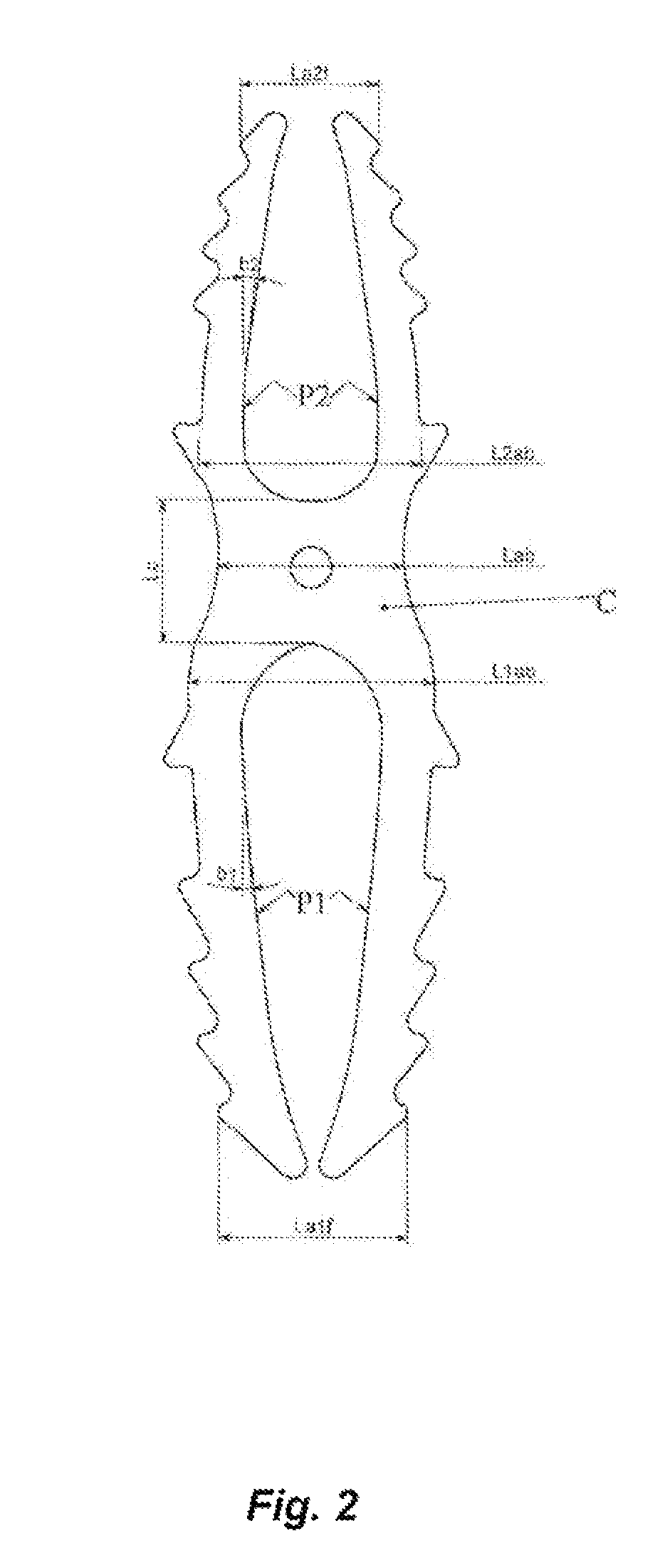

Osteosynthesis device

ActiveUS8394097B2Efficient and effectiveHigh deformationSuture equipmentsFinger jointsBiomedical engineeringH shaped

Intramedullary osteosynthesis device is capable of adopting a profiled H-shape in a closed introductory state in order to be easily implantable and an X-shape in an open implanted state for good fixation in the bone.

Owner:STRYKER EURO OPERATIONS HLDG LLC

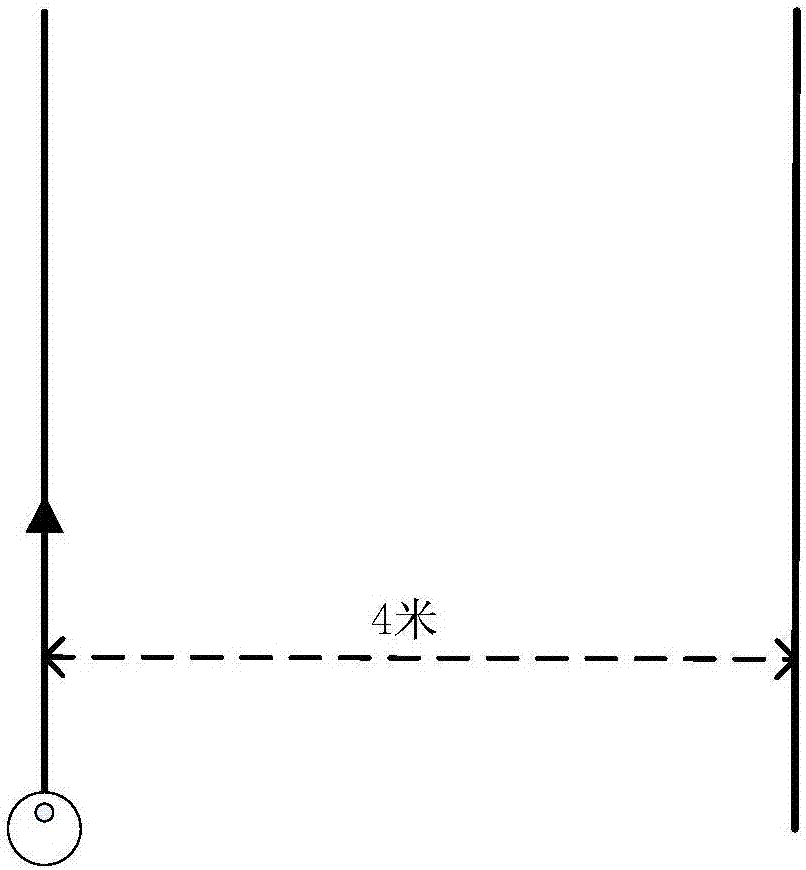

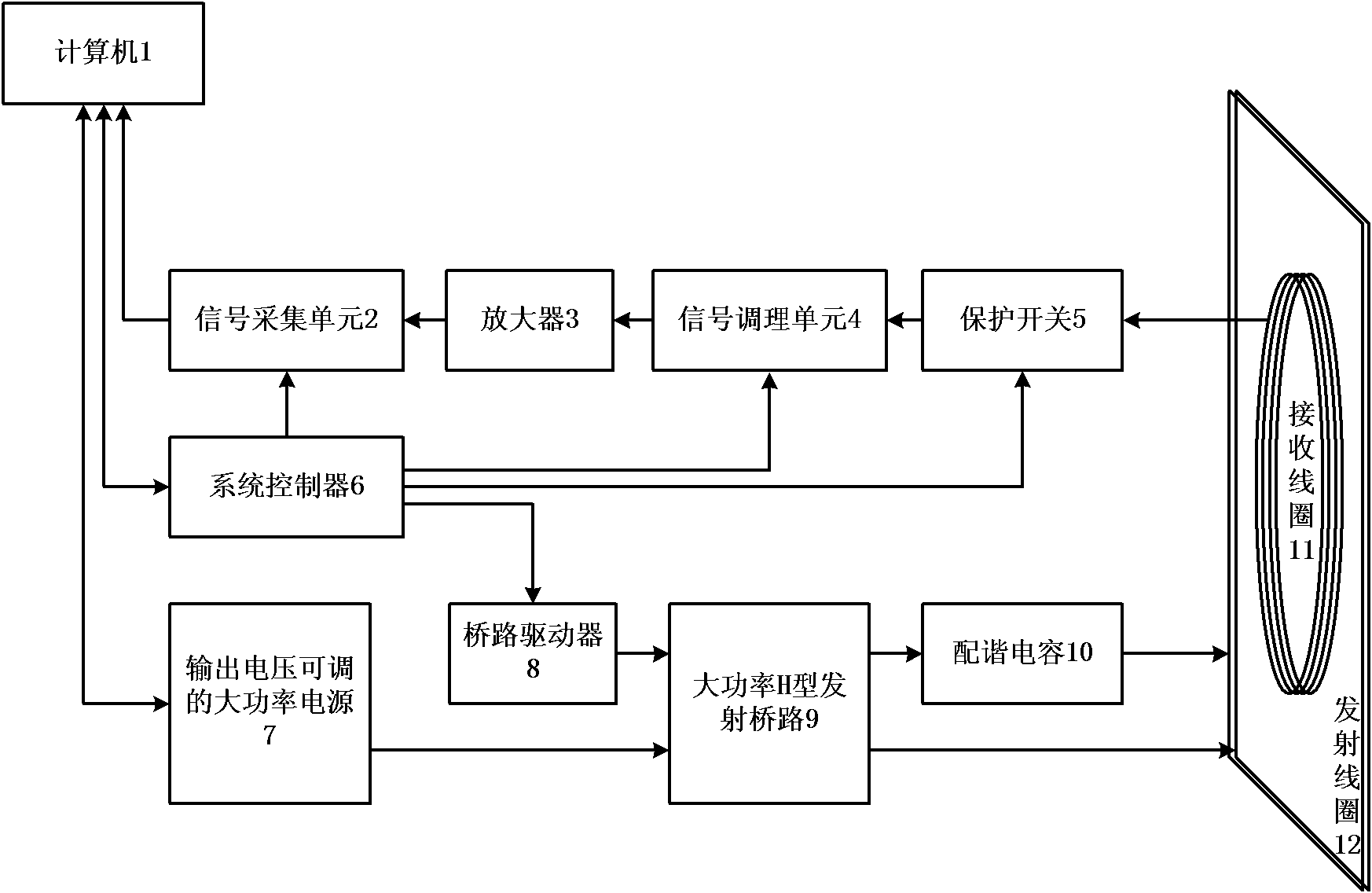

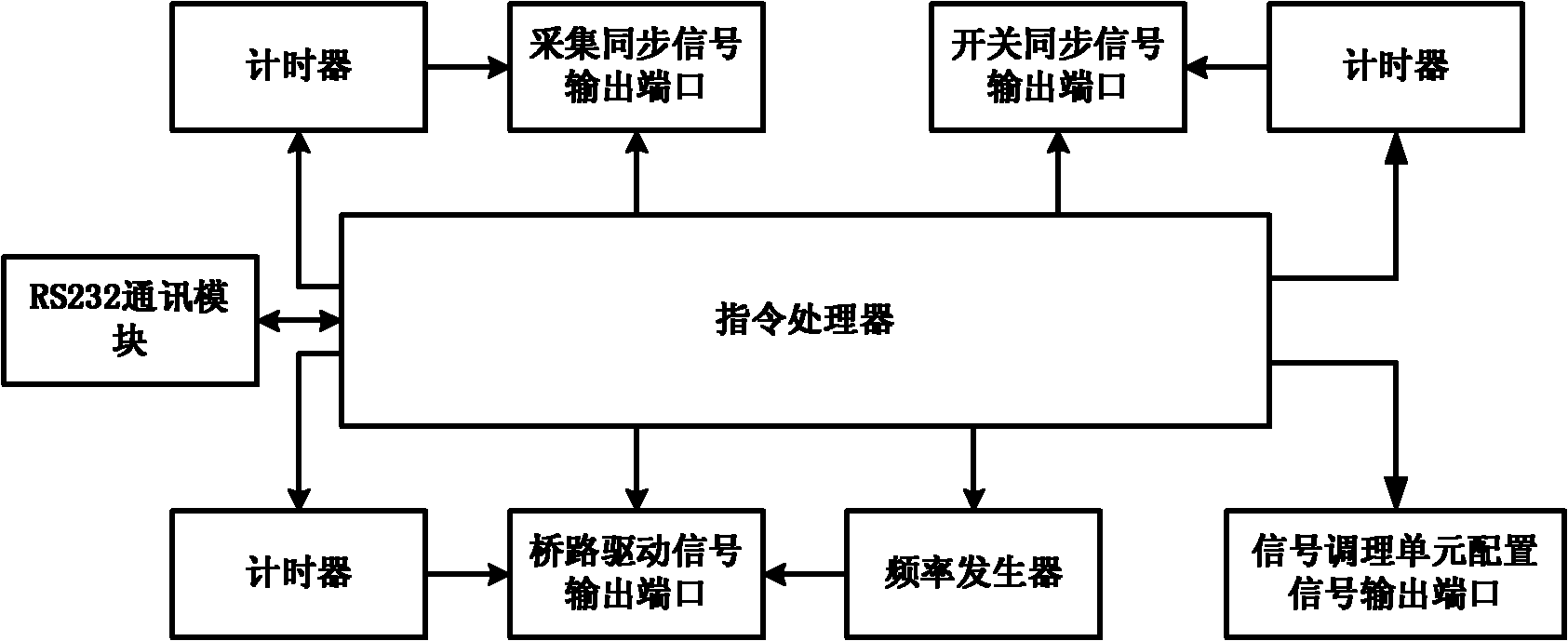

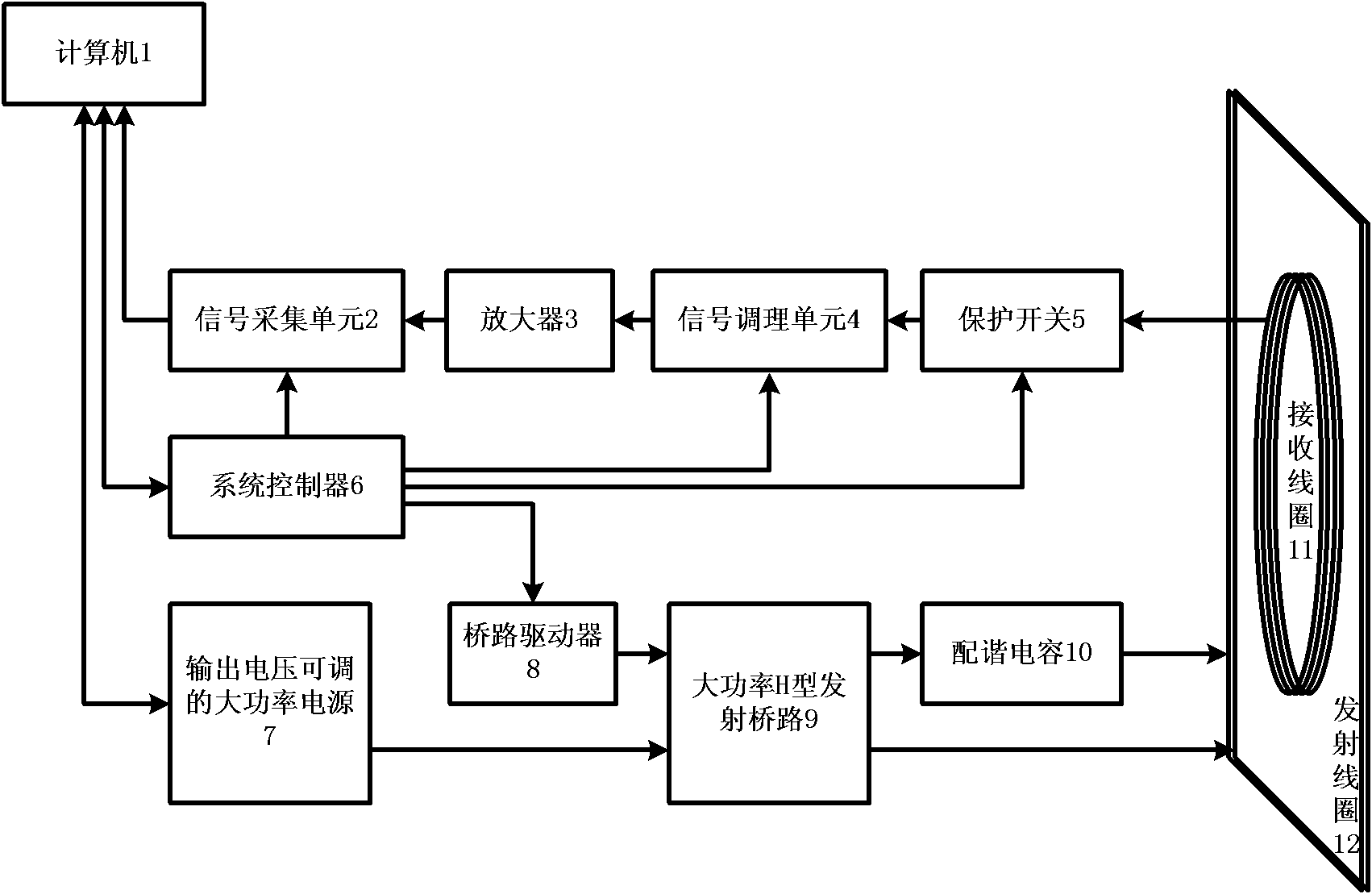

Nuclear magnetic resonance detection device and method for advanced detection of water bodies in front

ActiveCN102062877ASmall footprintEnsure construction safetyDetection using electron/nuclear magnetic resonanceCapacitanceEngineering

The invention relates to a nuclear magnetic resonance detection device and a nuclear magnetic resonance detection method for the advanced detection of a water bodies in the front. In the device, a computer is connected with a system controller, a high-power power supply and a signal acquisition unit by a serial port bus respectively; and the system controller is formed by connecting a bridge circuit driver, a high-power H-shaped transmitting bridge circuit, a resonant capacitor and a transmitting coil. Compared with the prior art, the device can detect important information such as the existence of water-bearing bodies in the front, the water content of the water-bearing bodies and the like accurately and effectively. The occupied area of the coil is reduced effectively by a mode of arranging the coil vertically, so that the device can perform exploration in narrow space. The device can detect the underground geological condition within a certain distance in the front directly and accurately in production fields of coal fields and mines or construction sites of tunnels so as to reduce mine accidents caused by geological disasters such as water burst, mud gushing and the like due to unclear geological conditions in the front or various incidents caused by the geological disasters in the process of tunnel construction.

Owner:长春国地探测仪器工程技术股份有限公司

Microwave antenna transmission device having a stripline to waveguide transition via a slot coupling

InactiveUS6081241AImprove efficiencySmall demand on spaceOne-port networksCoupling devicesLeveling effectElectrical conductor

A device for the power transmission of microwaves between a strip-line and a number of parallel cavity waveguides arranged in a group antenna. The strip-line includes H-shaped slots. These slots are centered with respect to a central conductor. Opposite each of the slots, a corresponding slot is arranged through the wall of the cavity waveguide. Electrically conducting seals are arranged to follow immediately outside the contours of the slots. The strip-line is fixedly fastened to the seals and the ridge waveguide, whereby good electrical coupling is achieved. Simultaneously, small cavities are formed between the slots. These cavities have a leveling effect such that the demands on mechanical precision is appreciably lowered, such that the tolerance to placement of the slots opposite to each other is increased substantially as compared to the case of the waveguides directly abutting the strip-line.

Owner:TELEFON AB LM ERICSSON (PUBL)

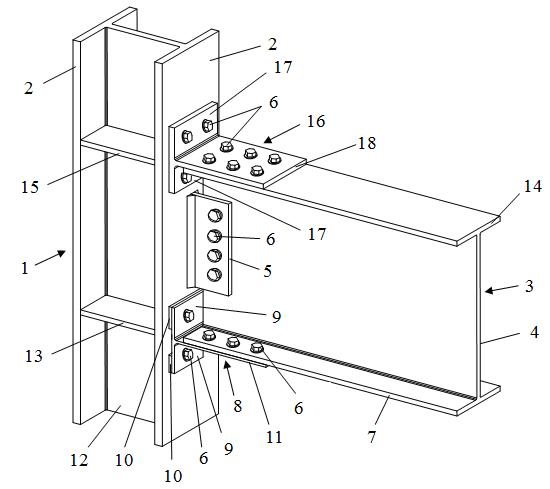

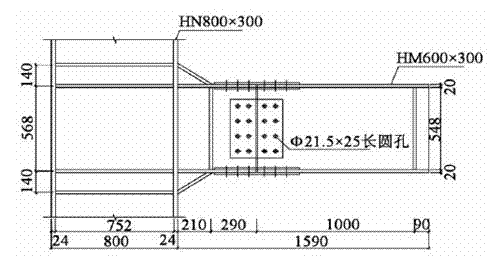

Easily repaired steel-structure beam-column node

InactiveCN101812872ASolve the lack of ductilitySolve the problem prone to brittle failureShock proofingHigh intensitySteel columns

The invention relates to an easily repaired steel-structure beam-column node, in particular to an easily repaired steel-structure beam-column node which is applied in the field of structural engineering and particularly used in high-intensity earthquake-proof areas. The node comprises an upright H-shaped steel column and an H-shaped steel beam of which the end part is vertically connected on a side wing plate of the H-shaped steel column, and is characterized in that: connecting ends of a belly plate of the H-shaped steel beam and the side wing plate of the H-shaped steel column are connected by a reinforced connecting plate closely contacted with the belly plate of the H-shaped steel beam and high-strength bolts penetrating the reinforced connecting plate, the reinforced connecting plate is in welding connection with the side wing plate of the H-shaped steel column, and both sides of the connecting end of a bottom side wing plate of the H-shaped steel beam are in locked connection with the H-shaped steel column by a T-shaped connecting plate and penetrating high-strength bolts respectively; and the T-shaped connecting plate is transversely arranged, upper and lower ends of the T-shaped connecting plate in the vertical direction are in locked connection with the side wing plate of the H-shaped steel column by a washer and the penetrating high-strength bolts respectively, a transverse plate of the T-shaped connecting plate is supported on the lower part of the bottom side wing plate of the H-shaped steel beam and locked by the penetrating high-strength bolts. The structure can effectively avoid brittle failure, has good ductile fracture characteristic, and can be widely applied to structures of earthquake areas, particularly the high-intensity earthquake-proof areas; and the easily repaired steel-structure beam-column node of the invention also has the advantages of convenient construction and convenient after-earthquake repairing.

Owner:FUZHOU UNIV

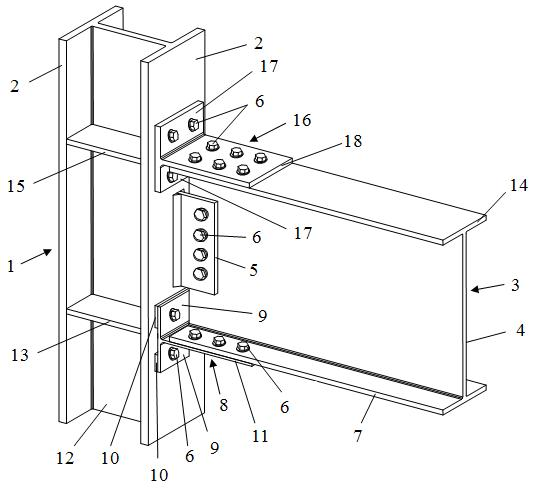

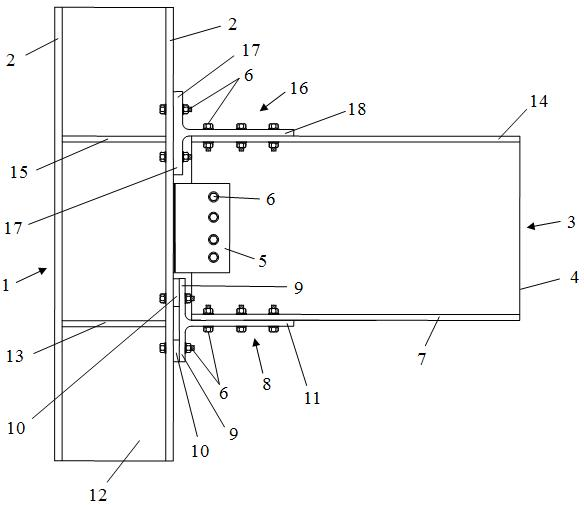

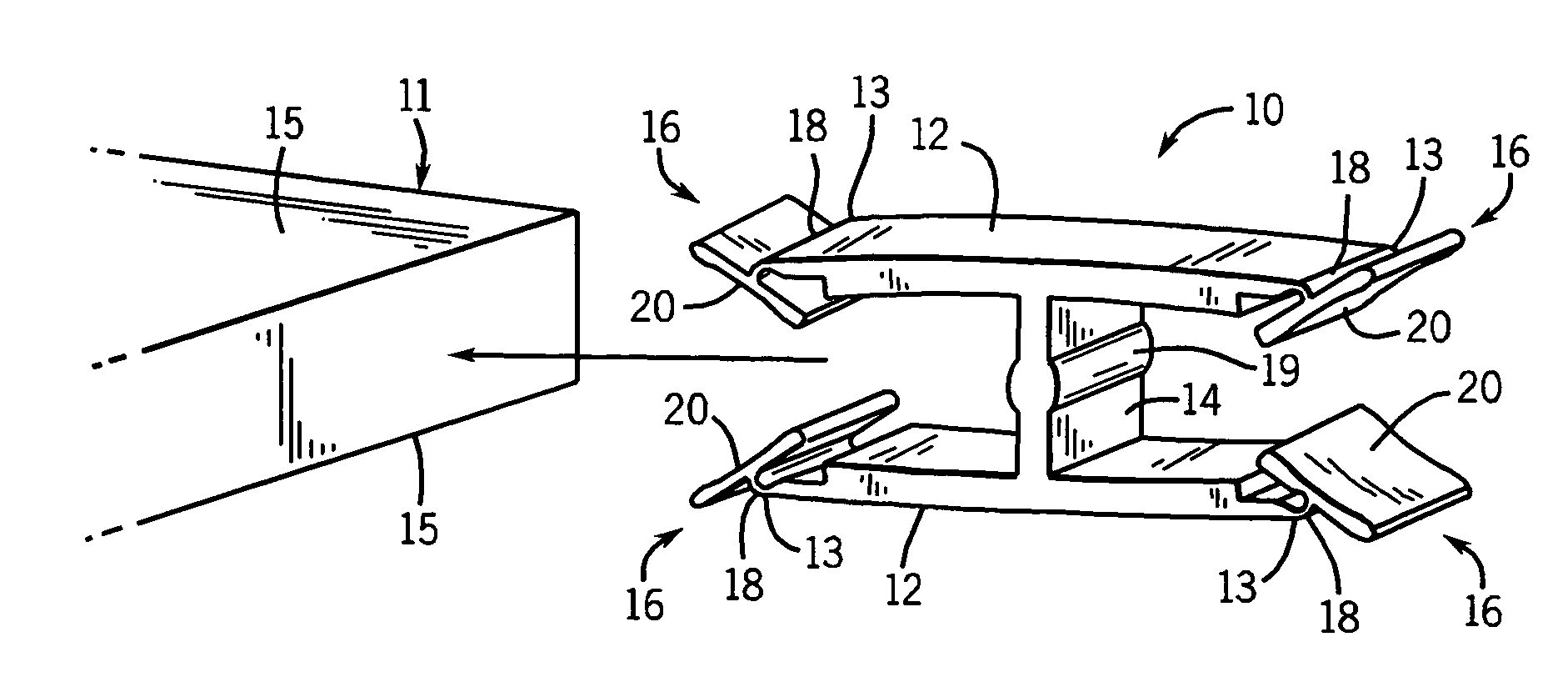

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

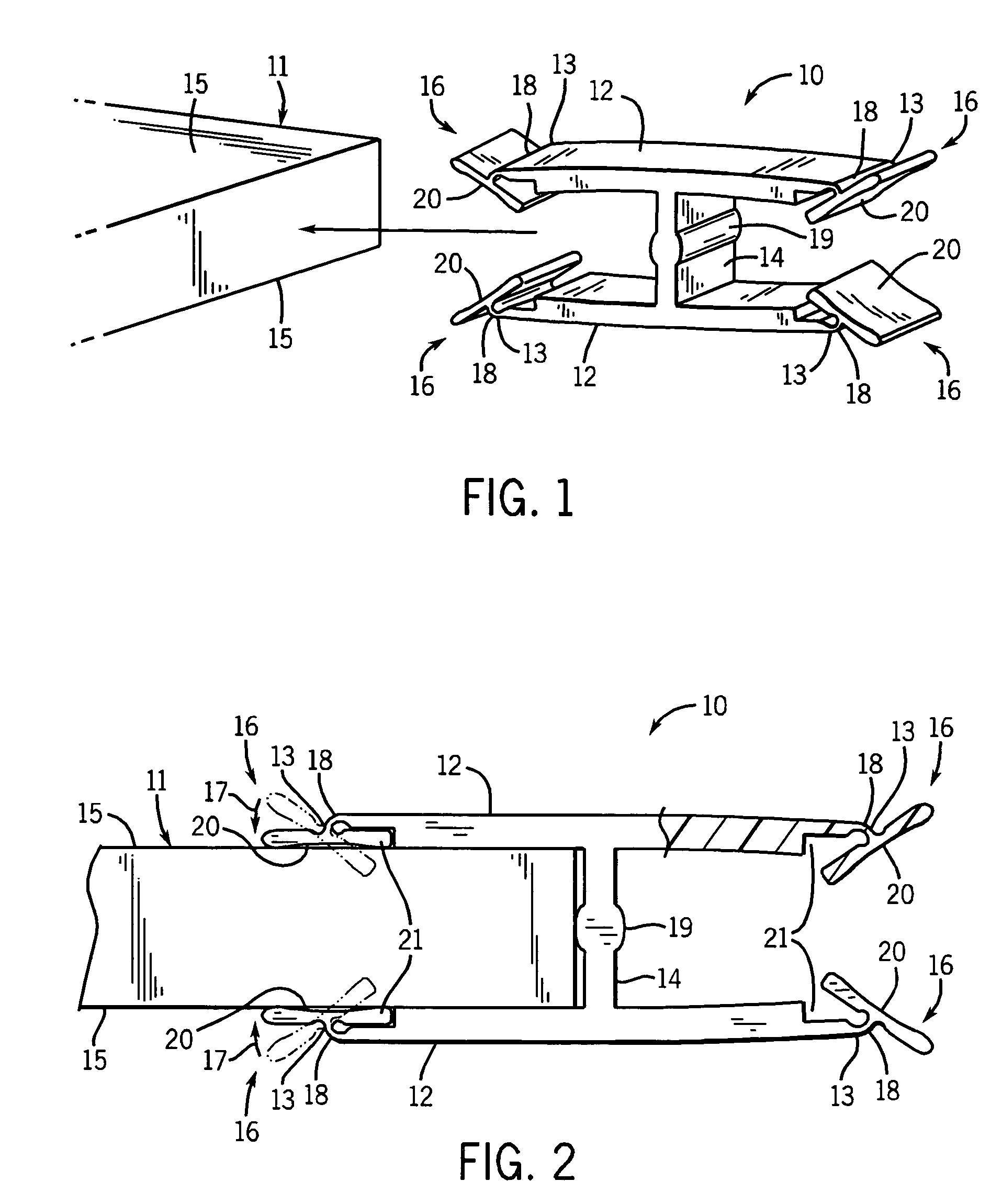

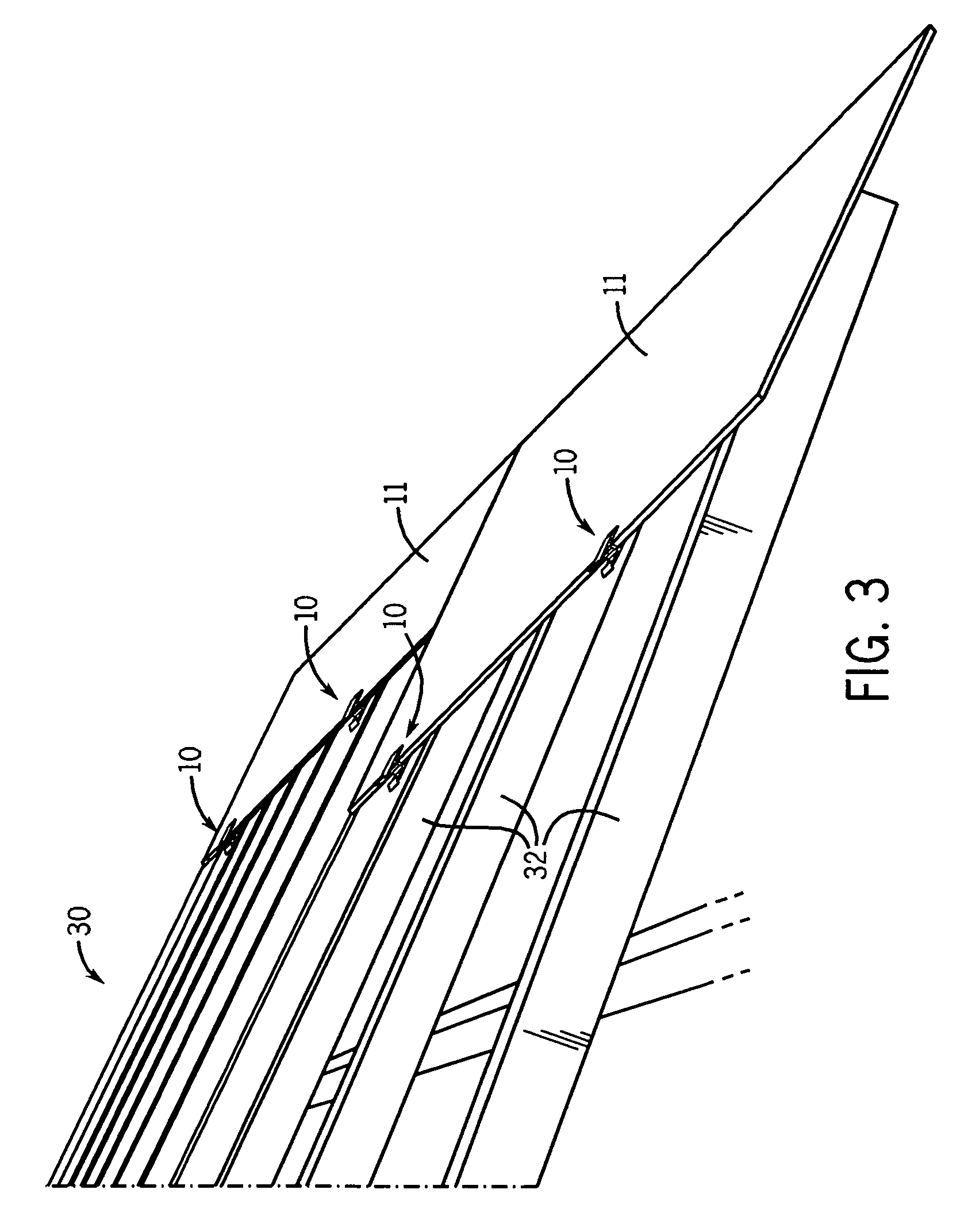

H clip

ActiveUS7444792B2Easy and quick insertionEasy to slipSnap fastenersGirdersEngineeringMechanical engineering

An H-shaped clip is used to connect two pieces of building material such as plywood, roofing sheath, wafer board or other materials quickly, easily and securely. The H clip includes two tapered arms connected by a spacing bar, where each arm ends in a ski-shaped lead-in having a contoured face and a living hinge.

Owner:M&O PRODS +1

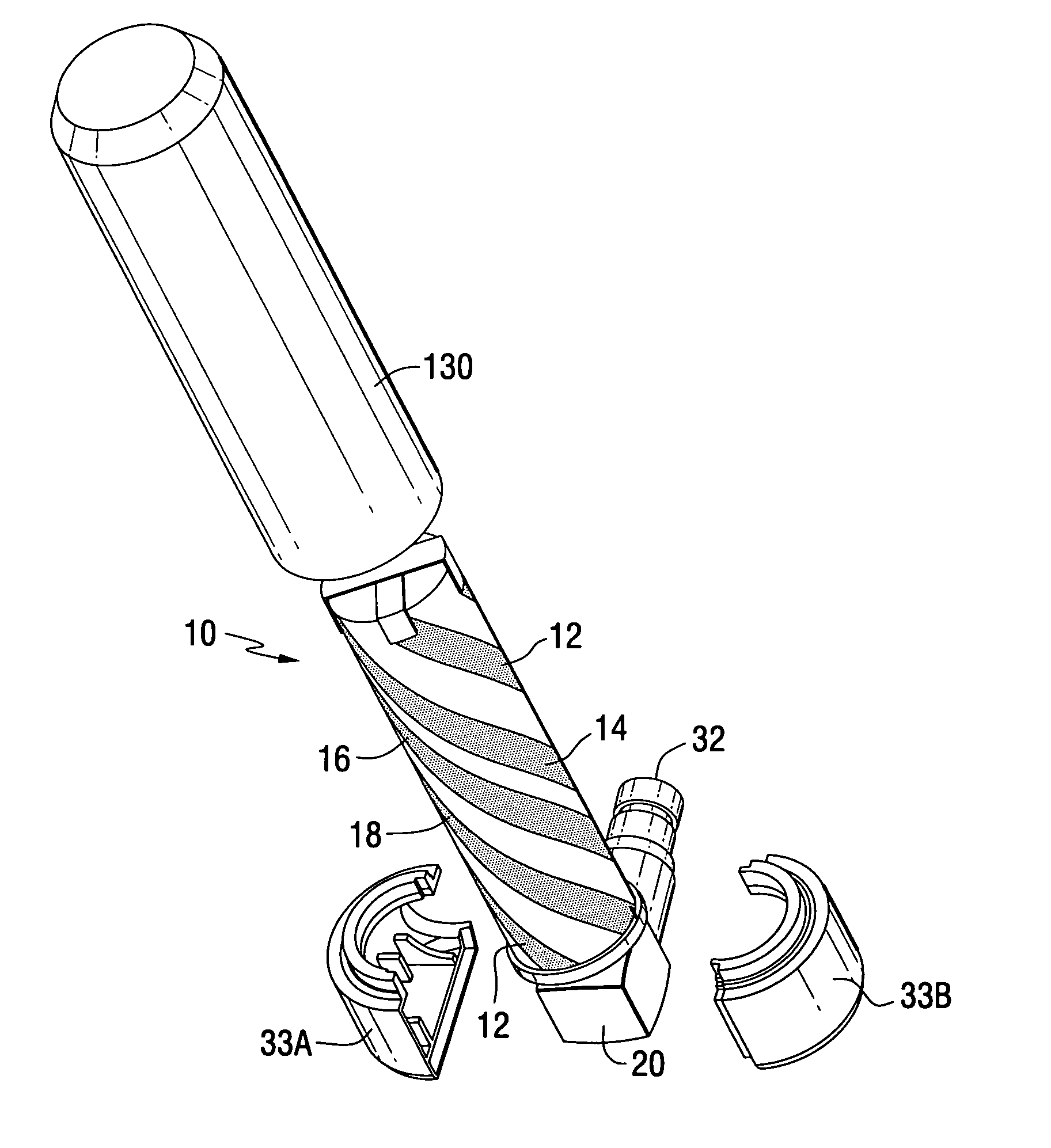

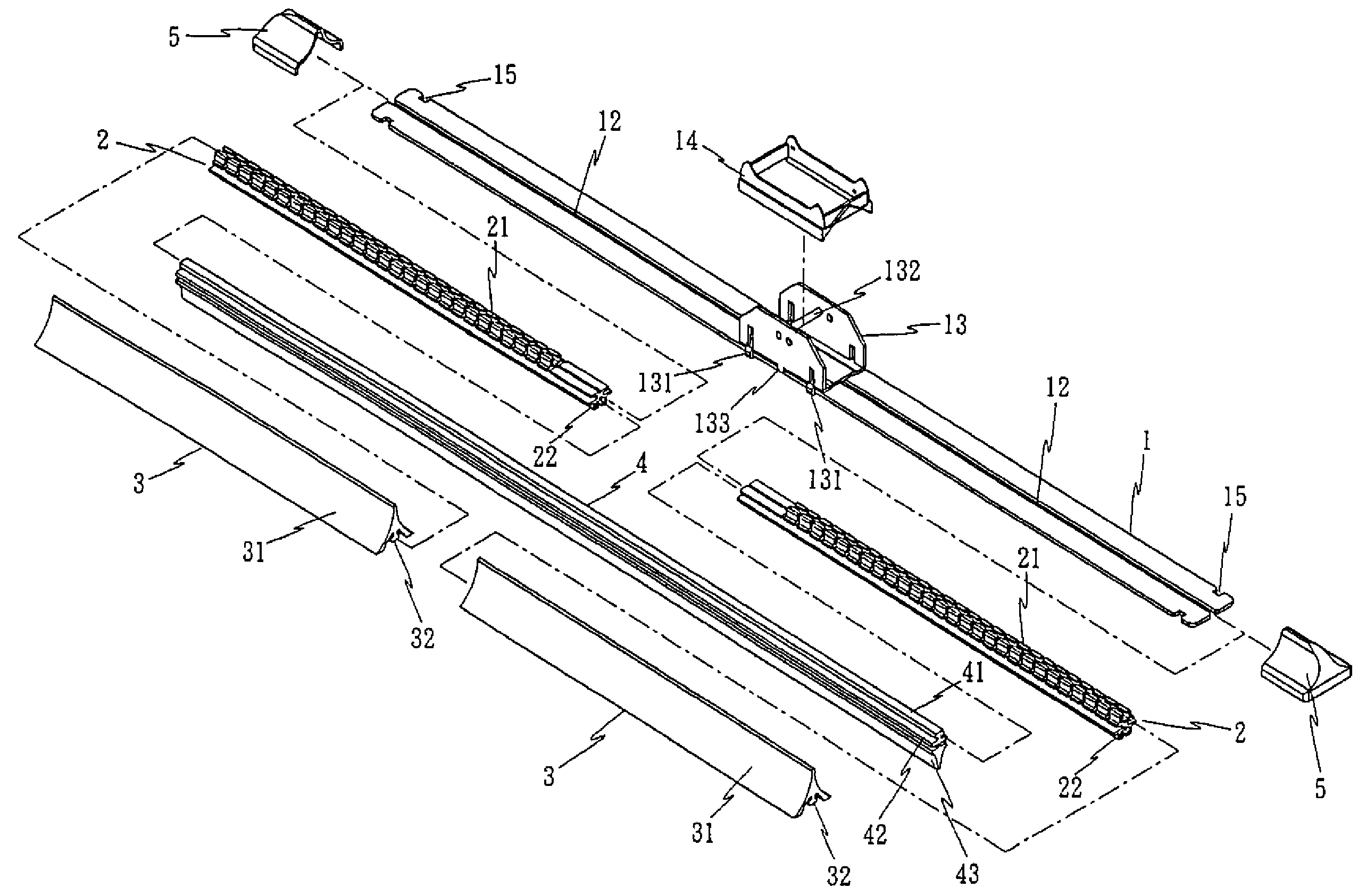

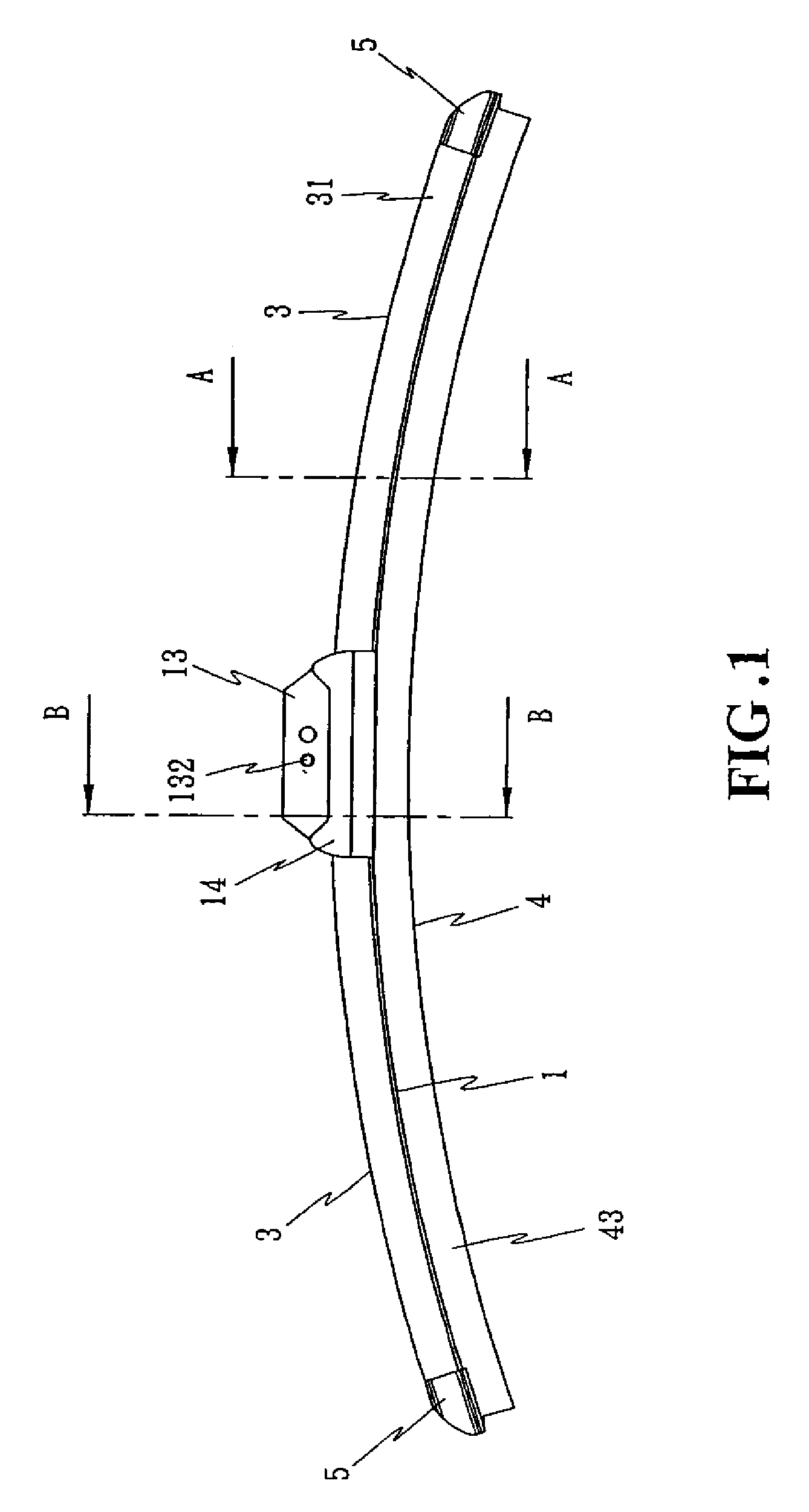

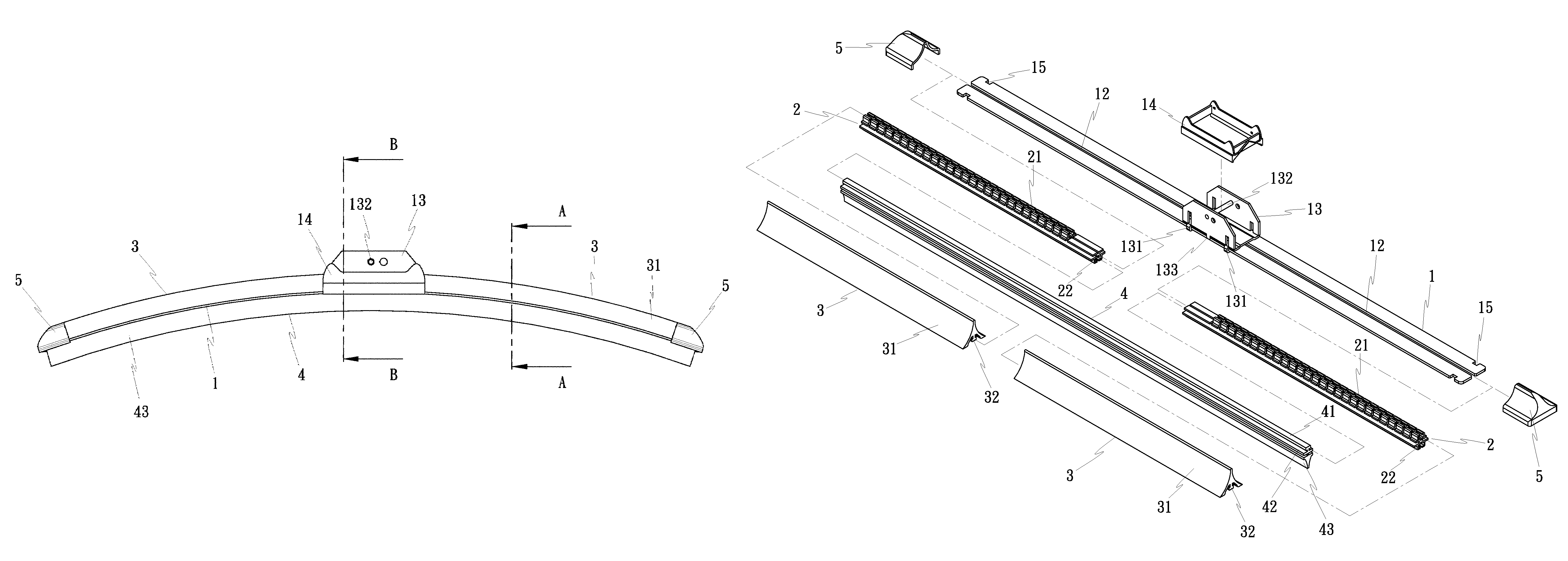

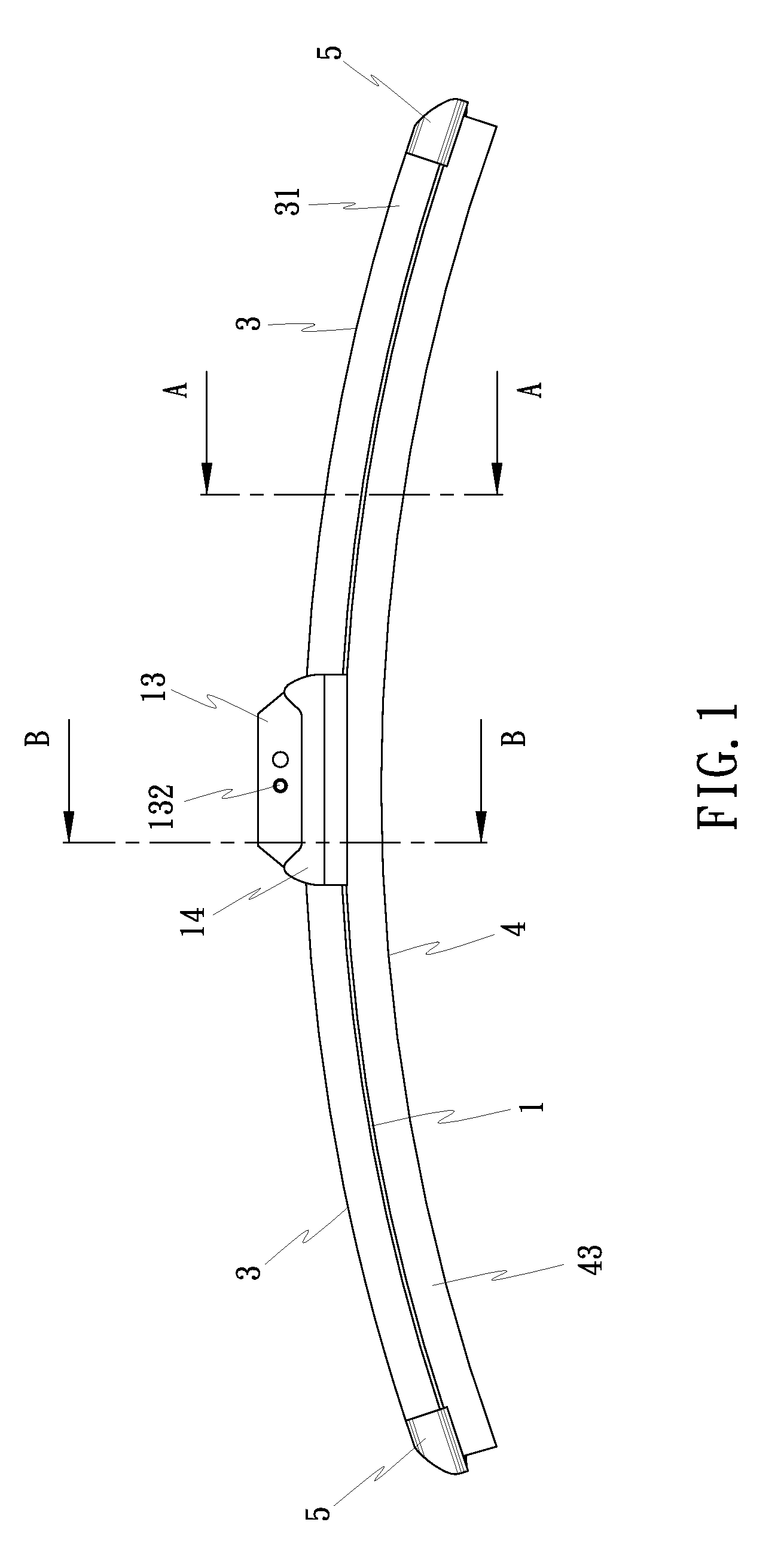

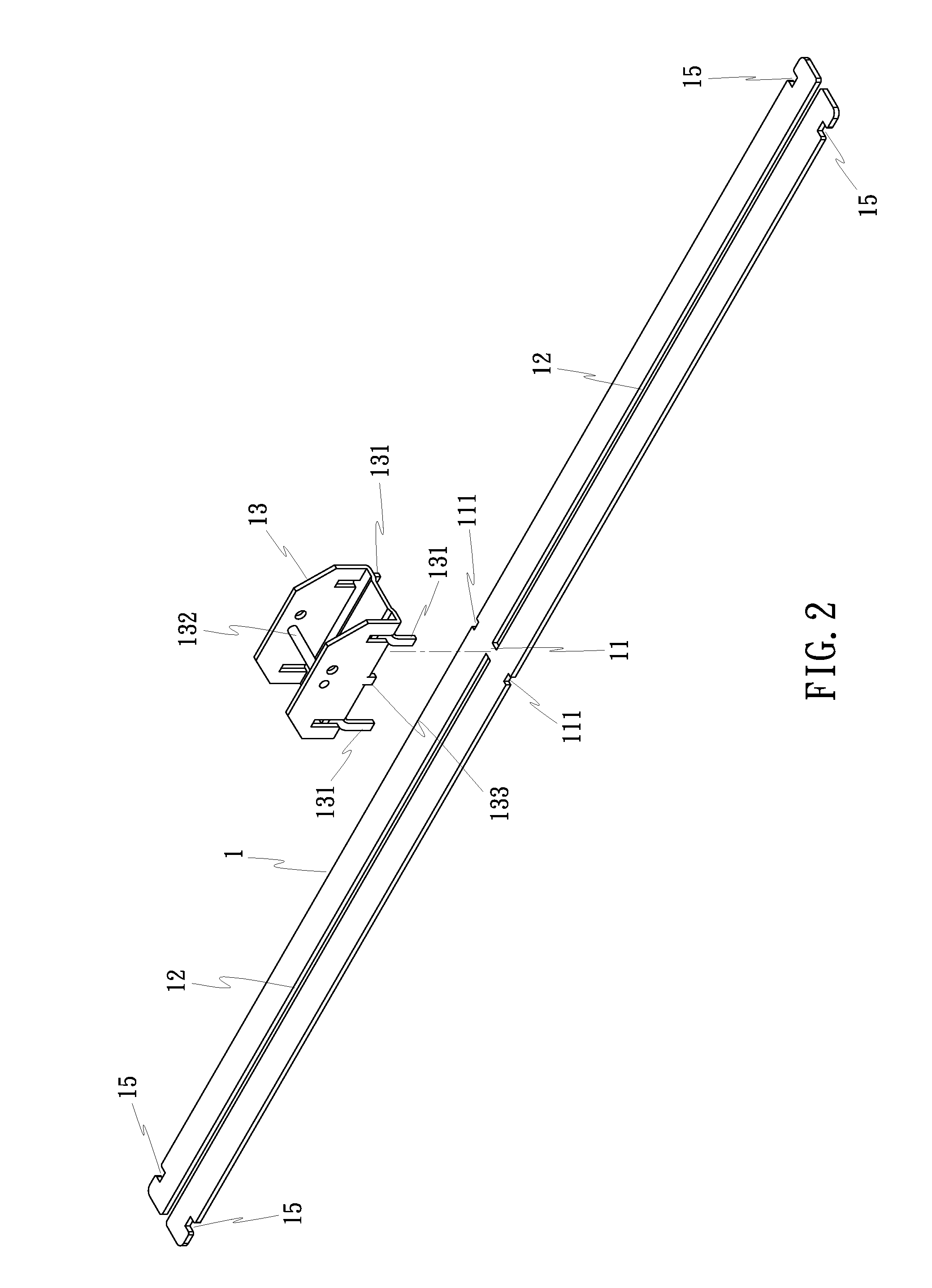

Frameless windshield wiper structure

InactiveUS20100024151A1Simple structureRiveting is eliminatedWindow cleanersVehicle cleaningEngineeringLower face

A frameless windshield wiper includes a curved resilient metal plate, two flexible bars, two rubber back covers, a rubber wiping strip, and two end closure caps. The resilient metal plate is an elongate plate having an H-shape including a central connection section connecting between two strips defining therebetween elongate slits so that the metal plate assumes a fork-like configuration having opposite fork-like open ends. The central section is riveted to a coupler over which a plastic protective cap is fit. The flexible bars have upper and lower faces respectively forming upper and lower retainers to which the rubber back covers and the rubber wiping strip are respectively fit. The end caps are fit to opposite ends of the metal plates. Thus, an automobile windshield wiper that can be efficiently and easily assembled is provided.

Owner:KU YUAN CHIN

Integrated support structure for either a fifth wheel hitch or a gooseneck trailer hitch

An integrated support structure apparatus is provided for attaching either a fifth wheel trailer hitch or a gooseneck trailer hitch to a truck bed. The integrated support structure comprises an H-shaped body that is attached to at least one truck frame rail below the truck bed. A gooseneck ball receiver is attached to a central portion of the body and aligned with a gooseneck opening in the truck bed. A plurality of receptacles are attached to the body in an array and are aligned with a corresponding plurality of pedestal access openings in the truck bed.

Owner:FORD GLOBAL TECH LLC

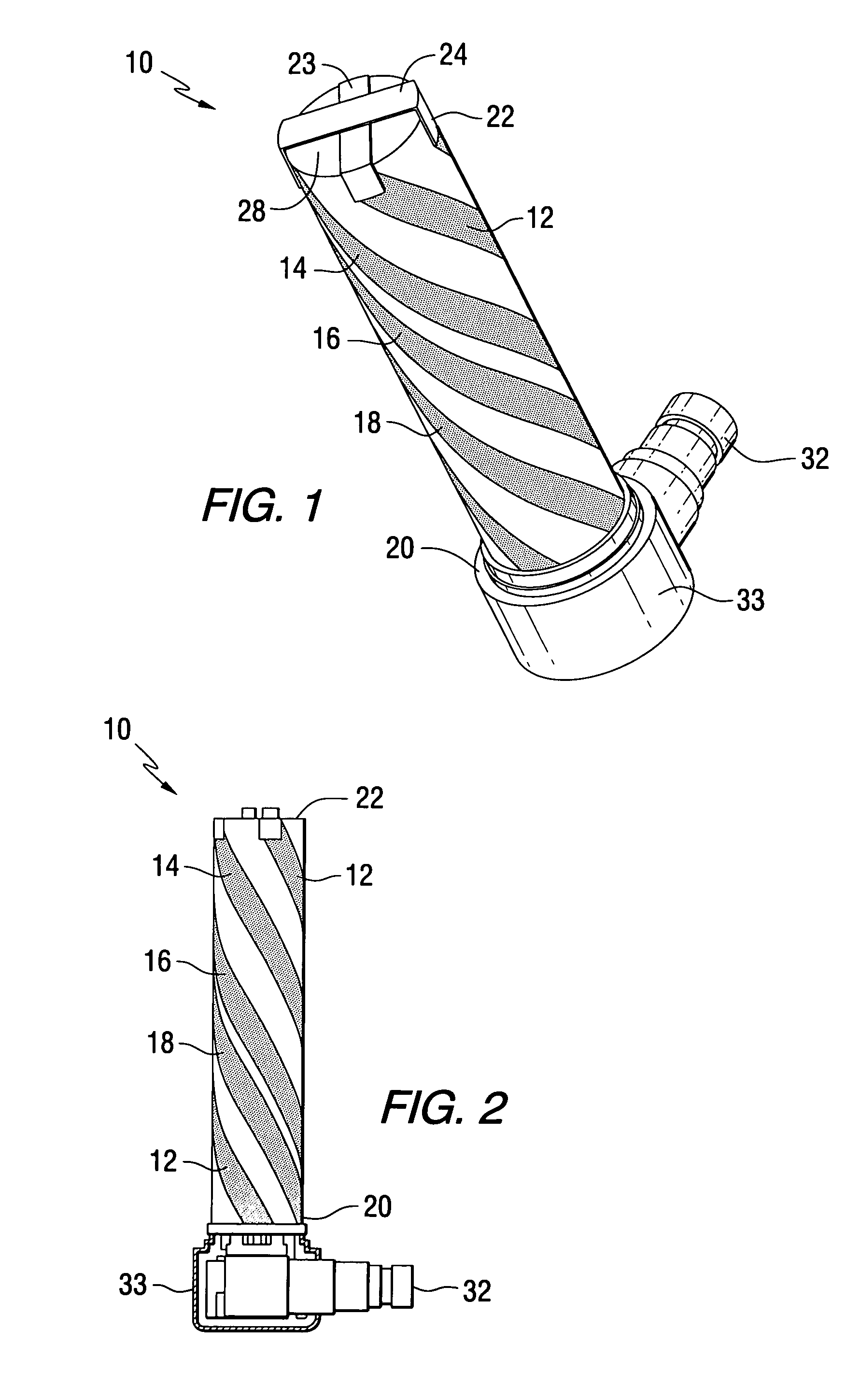

Non-bracket windshield wiper

ActiveUS7503095B2Save much material costDifficult to assembleWindow cleanersVehicle cleaningElastomerEngineering

A non-bracket windshield wiper includes an H-shaped and smoothly arched elastic metal bow strip having a middle neck and two longitudinal crevices at two sides of the neck, a holder frame mounted with a packing member and riveted to the middle part of the elastic metal bow strip for mounting to a windshield, two holding strips respectively coupled to the longitudinal crevices of the elastic metal bow strip, two back rubber strips respectively coupled to two top engagement structures of the holding strips, a rubber wiper blade coupled to two bottom engagement structures of the holding strips, and two end caps respectively capped on the two ends of the elastic metal bow strip.

Owner:LIN SALLY

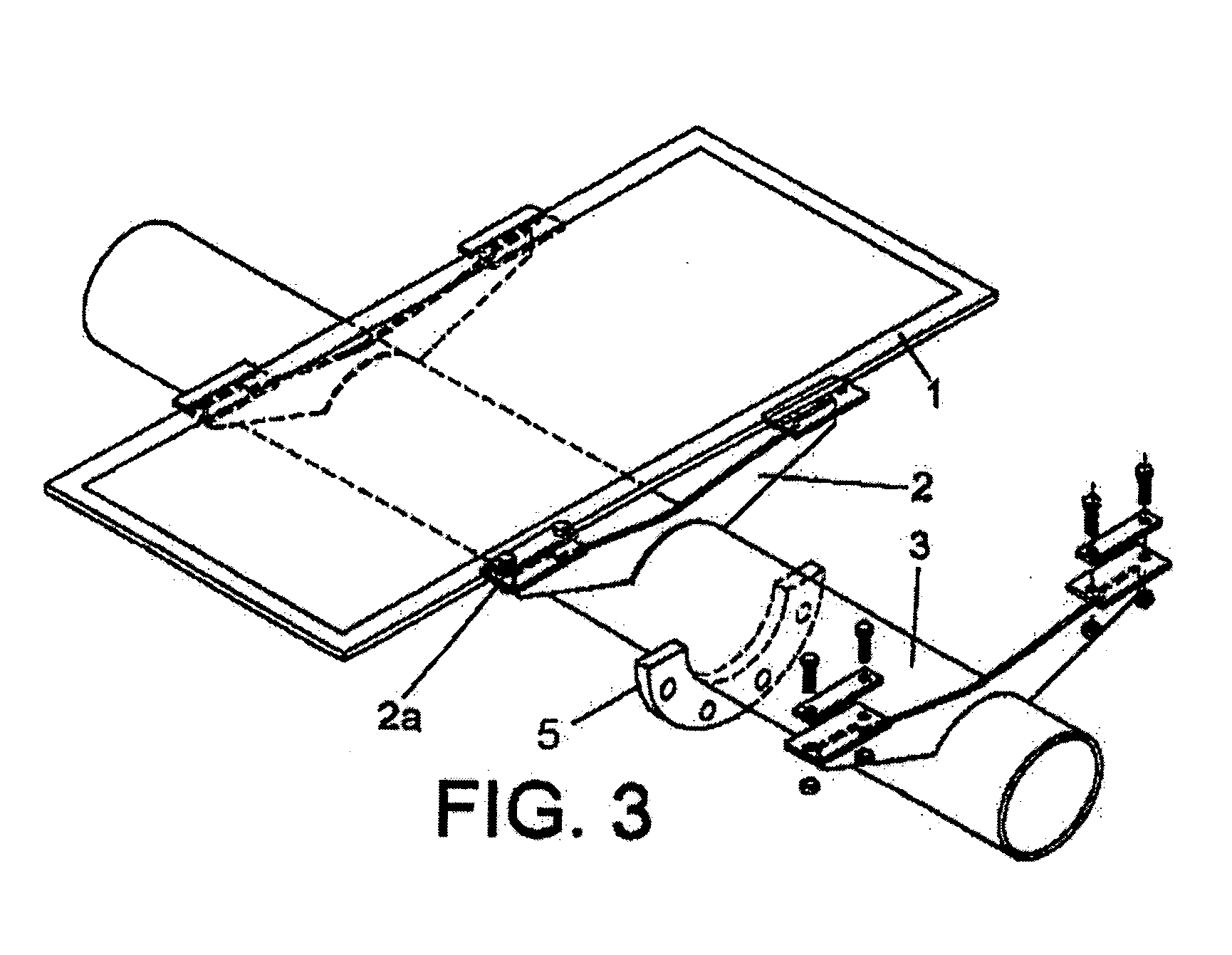

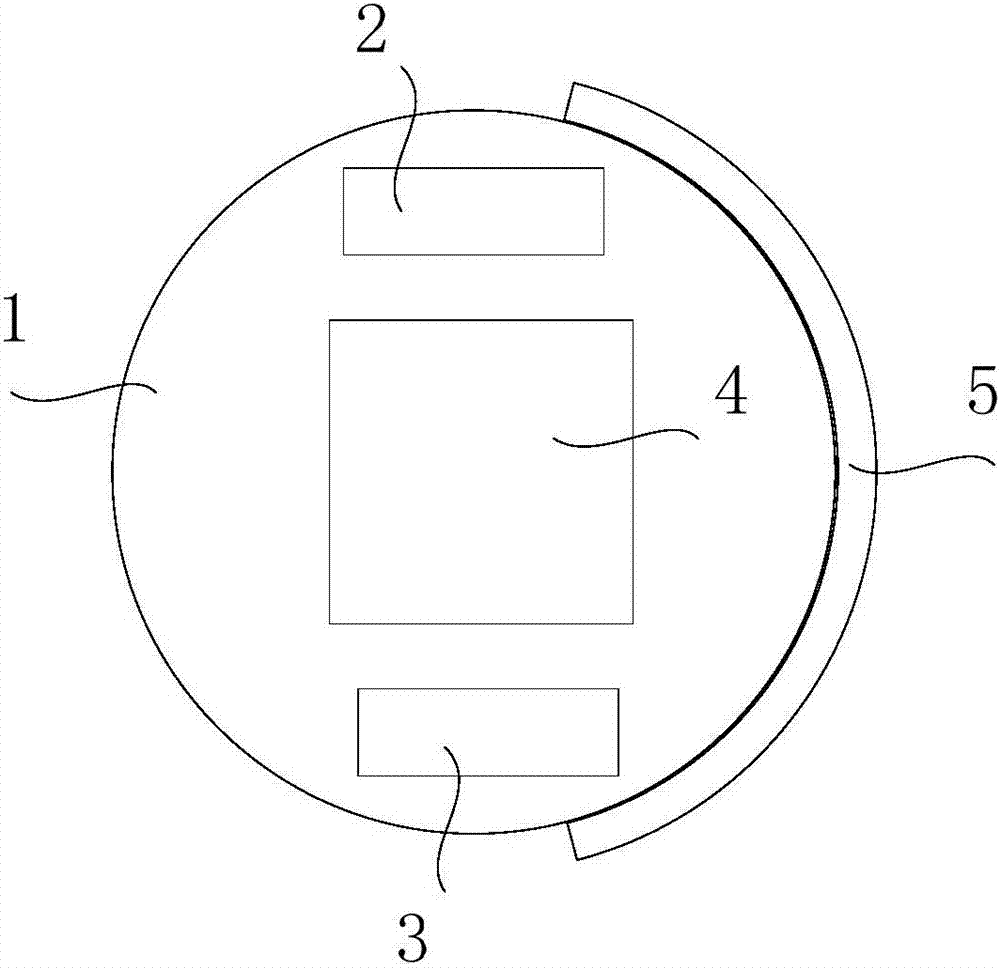

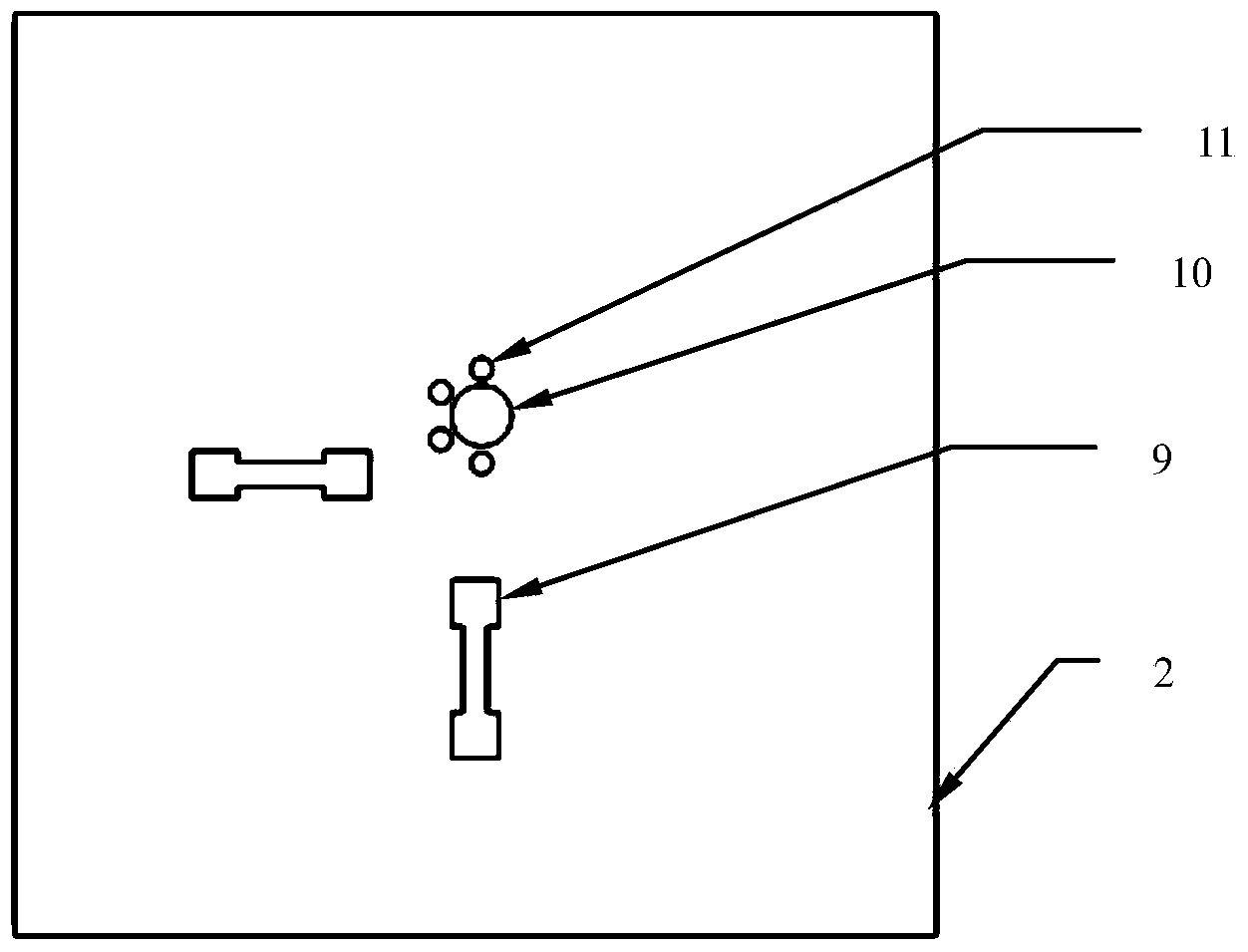

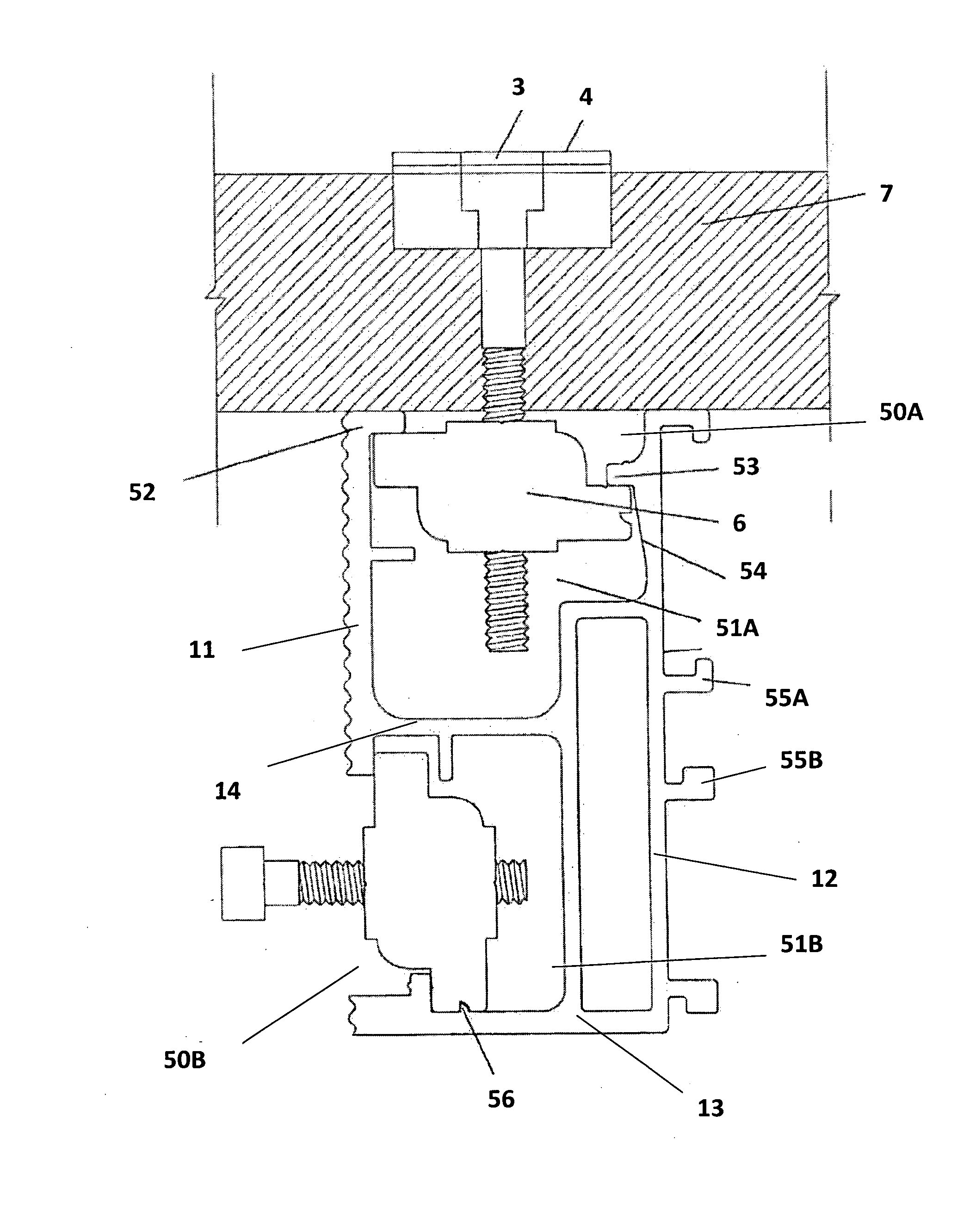

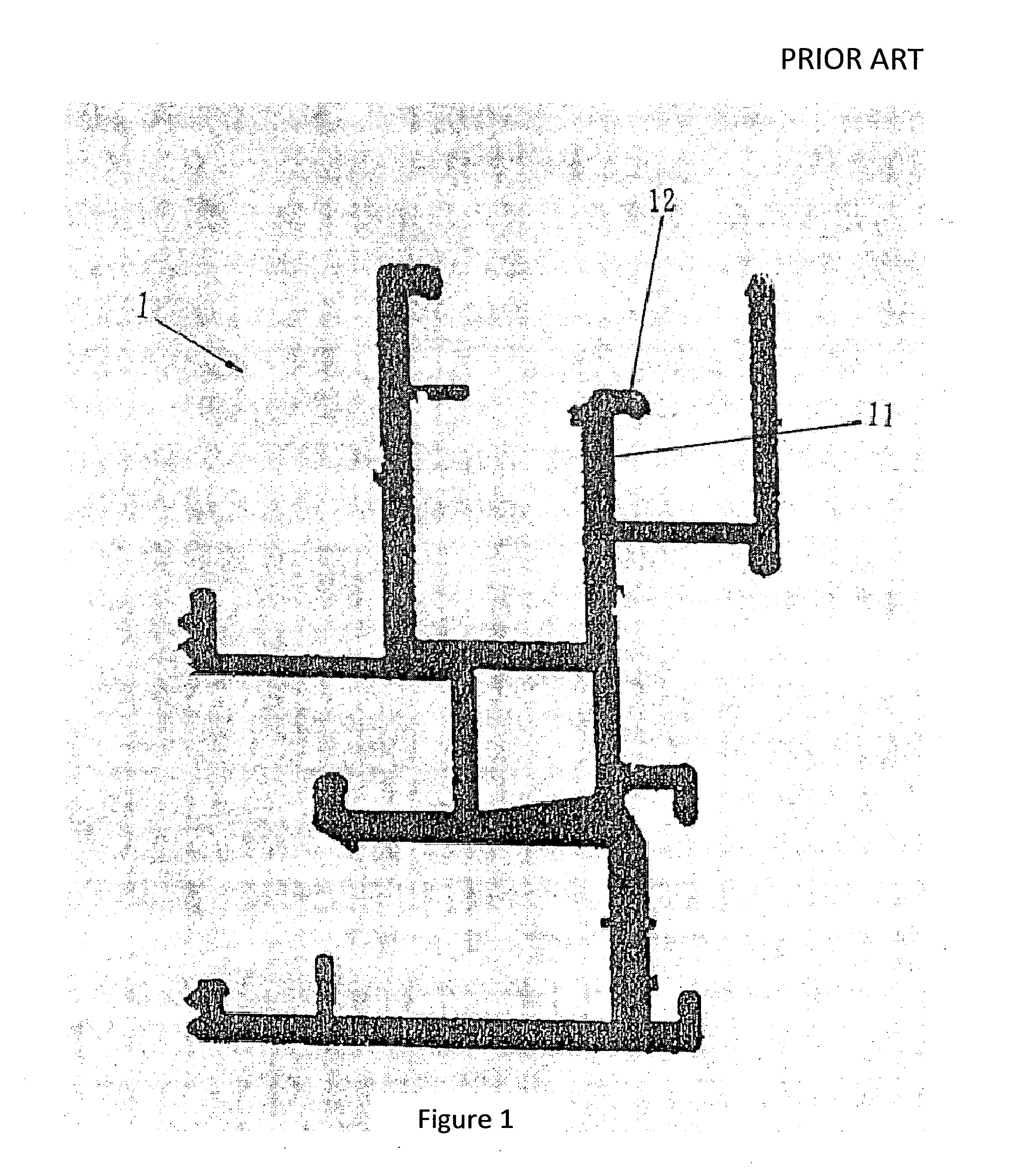

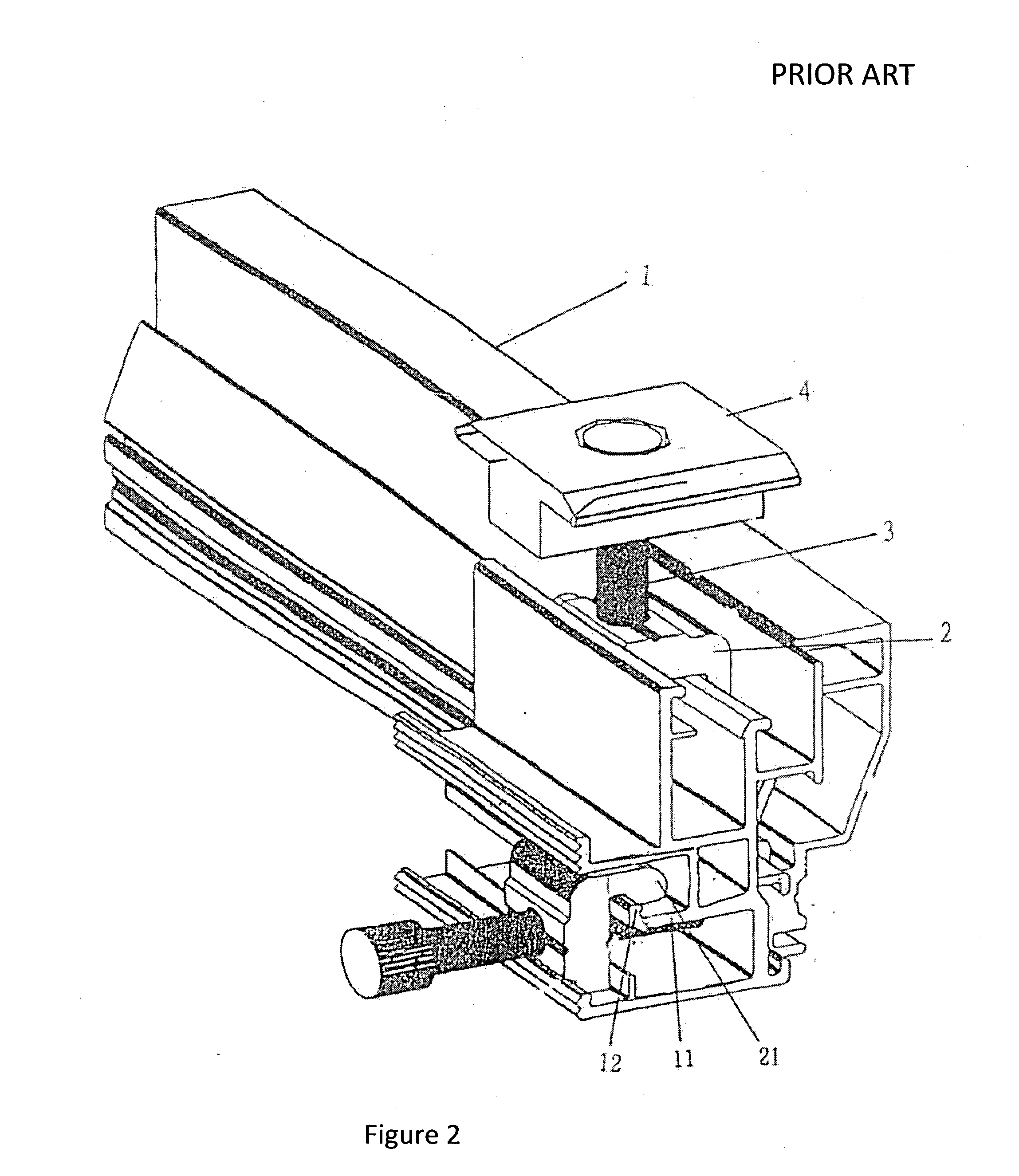

Mounting device

InactiveUS20110126881A1Optimize locationImprove structural strengthPhotovoltaic supportsSolar heating energyComputer moduleEngineering

A photovoltaic module mounting system having a rack structure, which includes a mounting rack structure having a rail (5) and two clamps (6) for holding a photovoltaic module (7) by a bolt (3) extending from a press plate (4) on an outer side of the module (7) to one of the clamps (6) mounted in an upper input space (51A) in the rail (5). Entrances (50A and 50B) are provided relatively for each of the two input spaces (51A and 51B) each providing a space to input one of the at least two clamps (6), which are mutual perpendicular. The longitudinal input space (51A) in the upper section of the substantially H shape rail is used to hold the clamp (6) to fix the photovoltaic module (7). The lateral input space (51B) is used to hold the clamp (6) to fix the rail (5) to the pre-location. It has an excellent function on lateral and longitudinal location. And the structure is simple, compact, efficient, adaptable and saves on material.

Owner:KERRYJ INVESTMENT

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

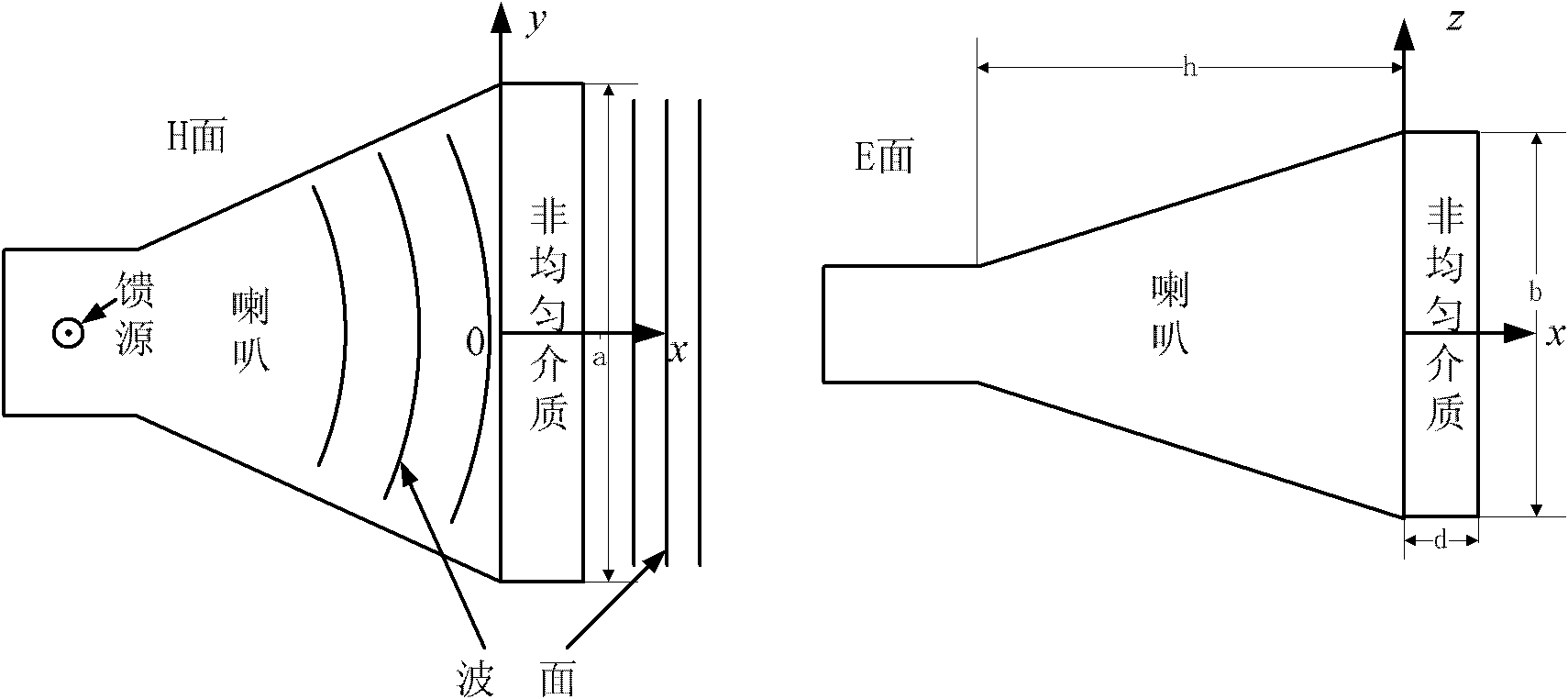

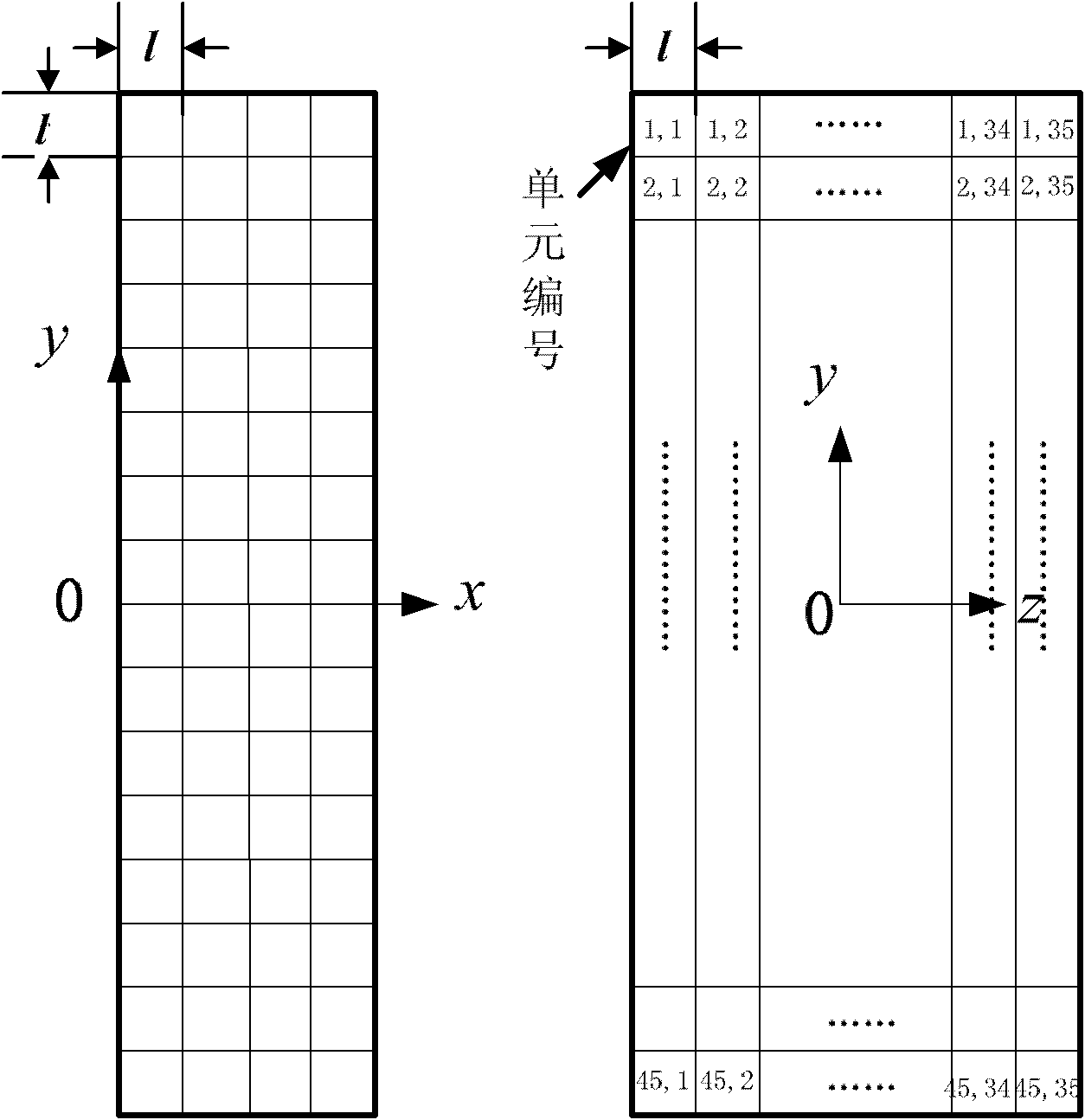

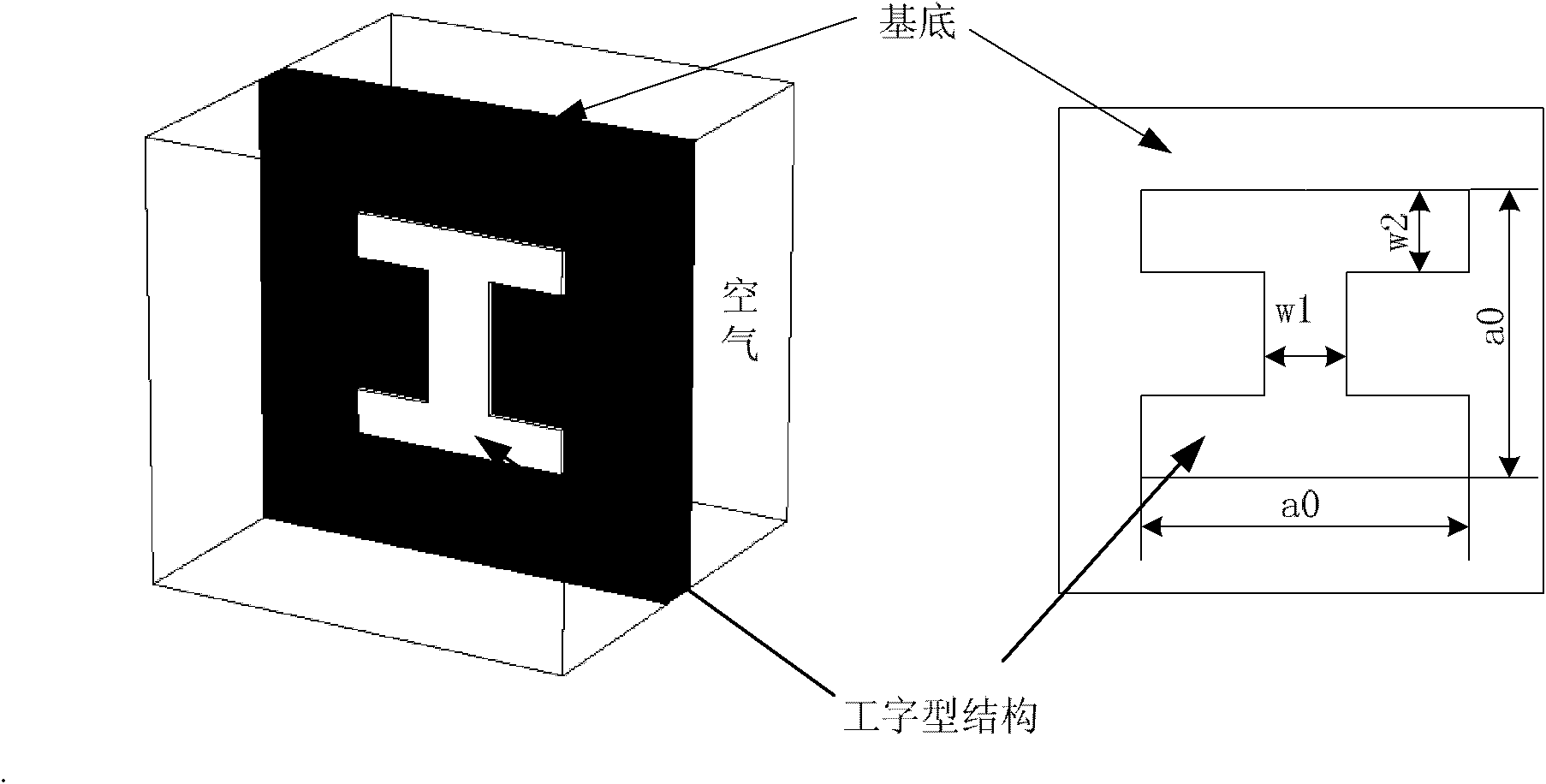

High-gain horn antenna based on inhomogeneous medium

The invention discloses a high-gain horn antenna based on an inhomogeneous medium, which is made by the following steps of: (1) determining a central frequency f for the operation of the antenna; (2) designing the ordinary horn antenna operated in the central frequency according to a general designing method for the horn antenna, wherein the aperture of an H side of the antenna is a, the aperture of an E side is b, and the length of a horn is h; (3) determining a refractive index profile n (x, y) of the inhomogeneous medium placed on a mouth surface of the horn; and (4) building the inhomogeneous medium with refractive indexes distributed according to the n (x, y) by using a reverse H-shaped sub-wavelength artificial structural material, and evaluating the structural size of a reverse H-shaped sub-wavelength artificial structural material unit corresponding to each refractive index in a mode of emulation by finite element software.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

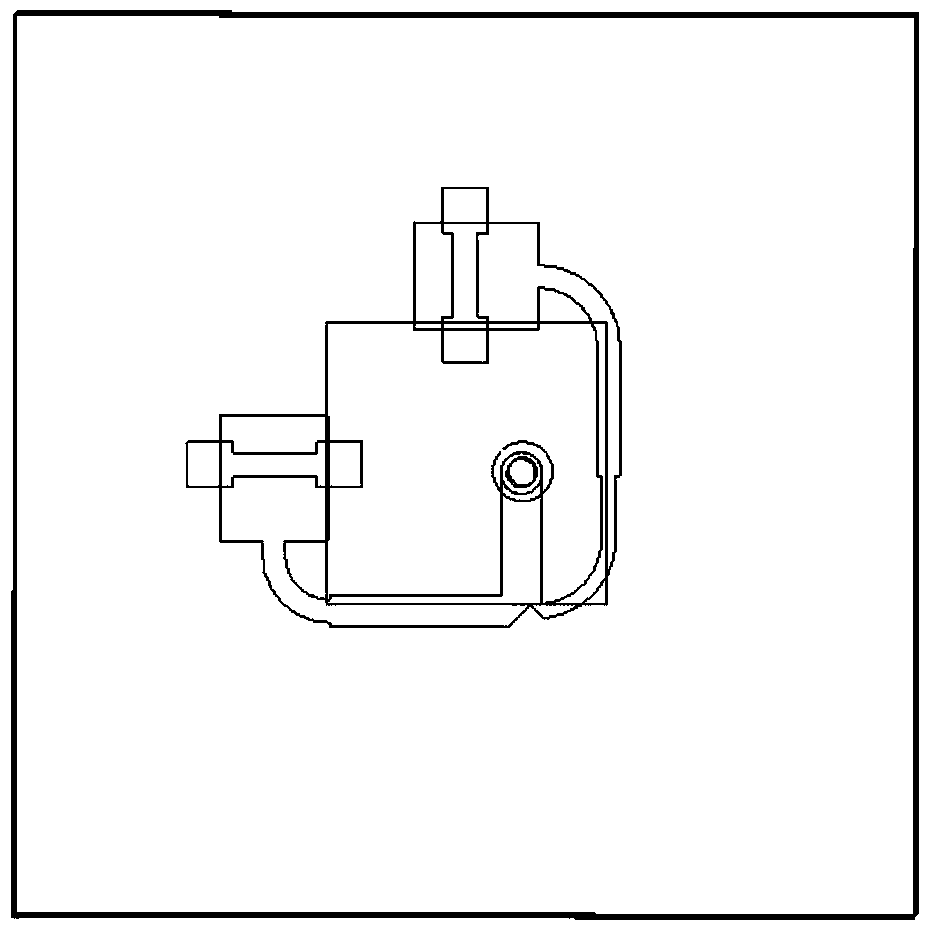

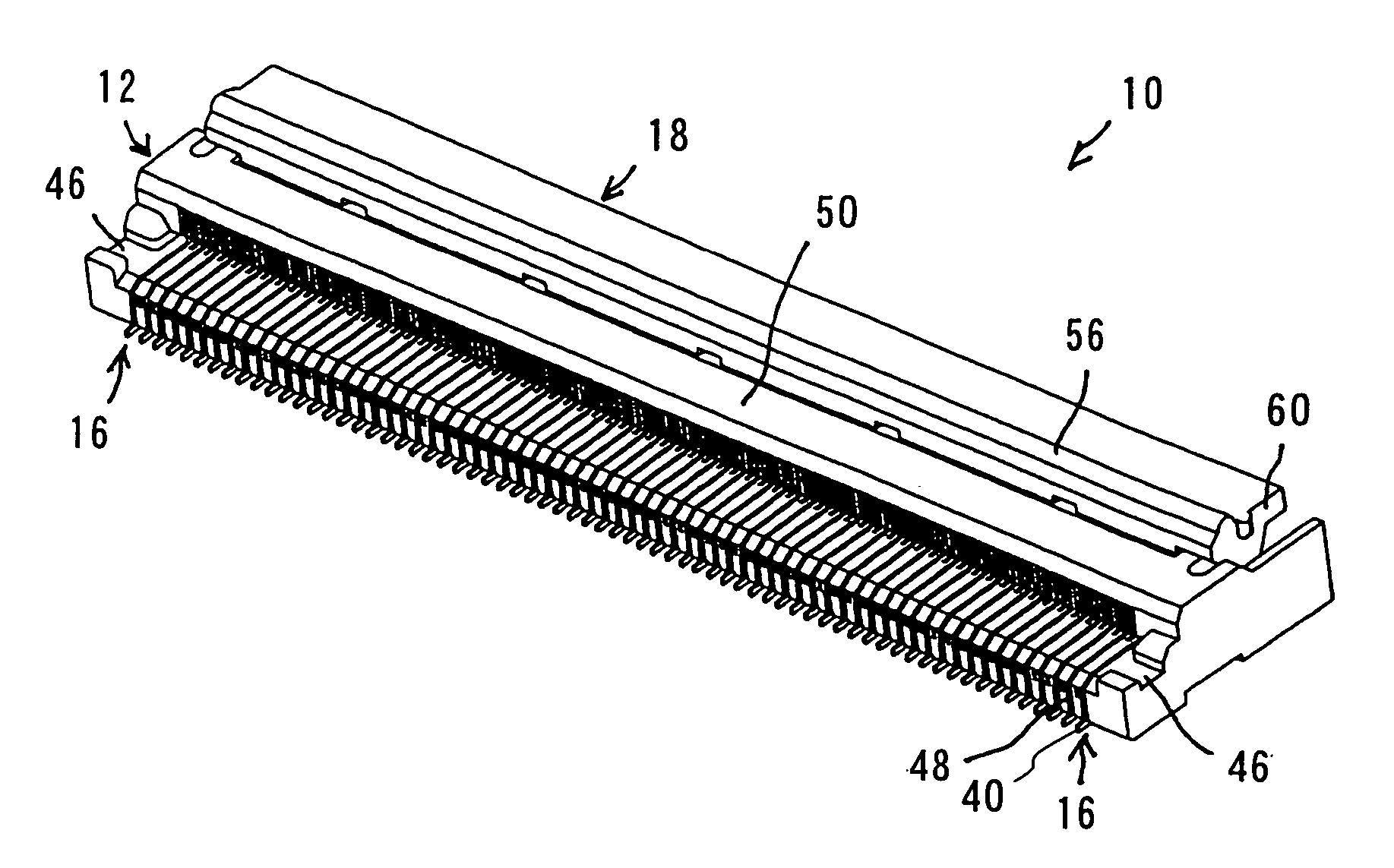

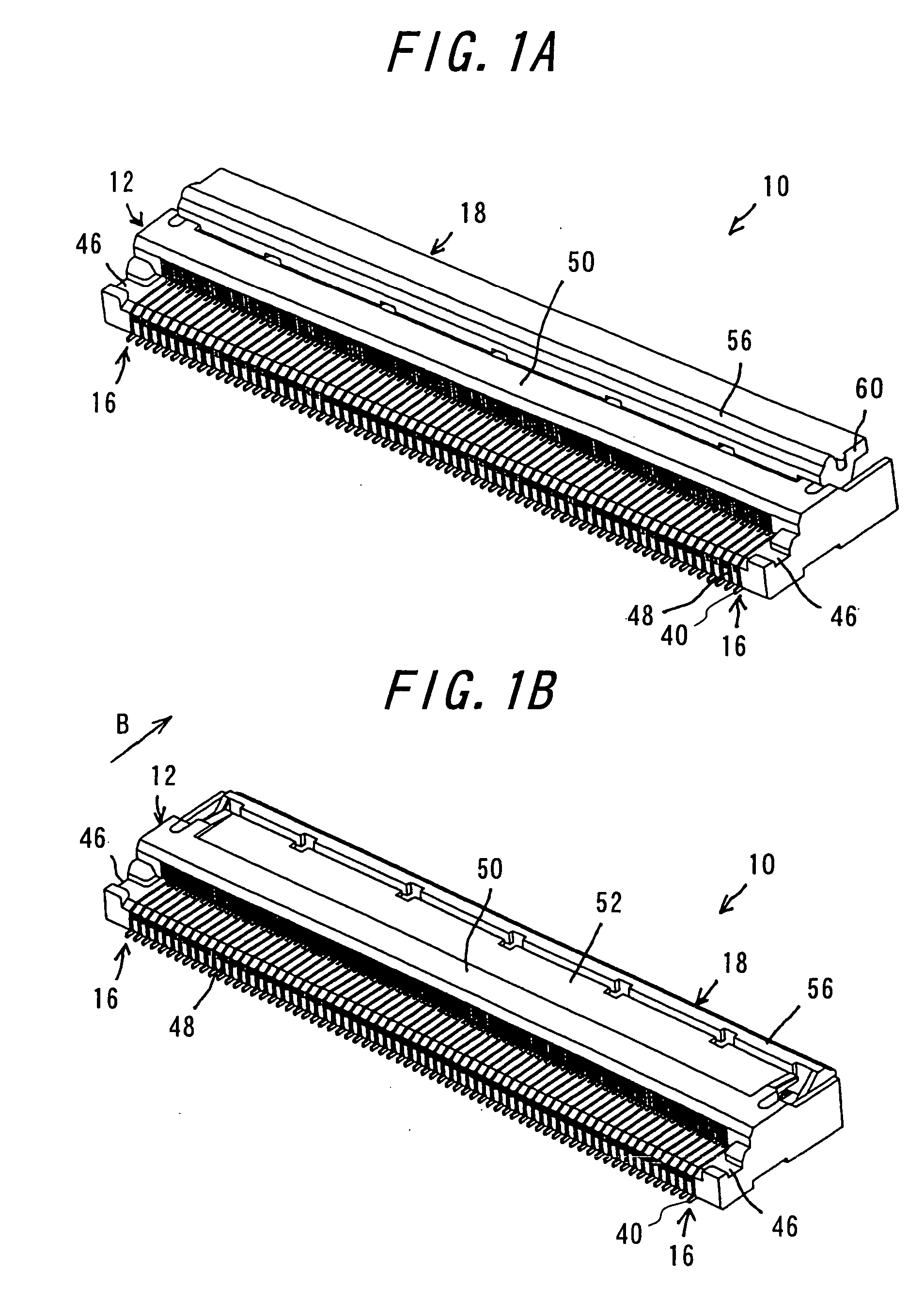

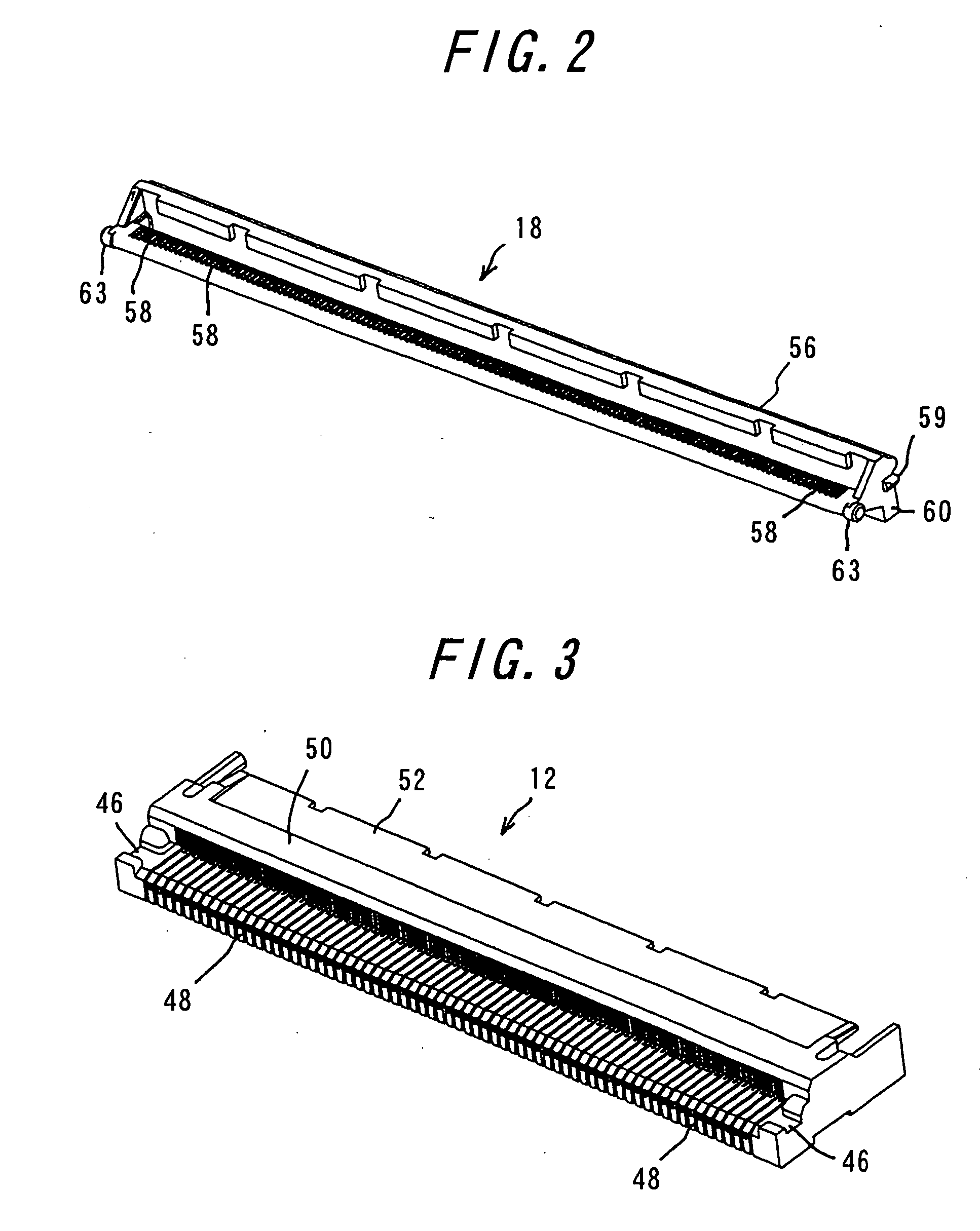

Connector

InactiveUS20060089036A1Improve propertiesOvercome disadvantagesEngagement/disengagement of coupling partsCoupling contact membersEngineeringMechanical engineering

A connector includes a required number of contacts, a housing, and a pivoting member. The contacts are substantially H-shaped and each includes at least a contact portion, a connection portion, a fulcrum portion, a connecting portion and a pressure receiving portion. The urging portions of the pivoting member are pivotally moved between the connection portions and the pressure receiving portions to bring the contact portions of the contacts into contact with a connecting object. The housing has a ceiling portion covering the contact portions of the contacts, and an upper wall covering the pressure receiving portions. The pivoting member includes an actuating portion, the urging portions, anchoring holes, and a cover portion for covering tail portions of the contacts upon pivotal movement of the pivoting member. The connecting object can be inserted into the connector with a slight force and dust proofing property can be improved.

Owner:DDK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com