Patents

Literature

427 results about "Metalworking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metalworking is the process of working with metals to create individual parts, assemblies, or large-scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills, processes, and tools.

Threading insert with cooling channels

A metalworking apparatus includes a threading insert with a channel-less chip breaker and a holder for holding the threading insert. The threading insert includes (i) one cooling channel disposed on the top side of the threading insert for each crest and each valley, which terminates near the cutting region, and (ii) a ceramic coating on at least the cutting region of crests and valleys, with each cooling channel being uncoated.

Owner:SIDERCA S A L C ARGENTINA

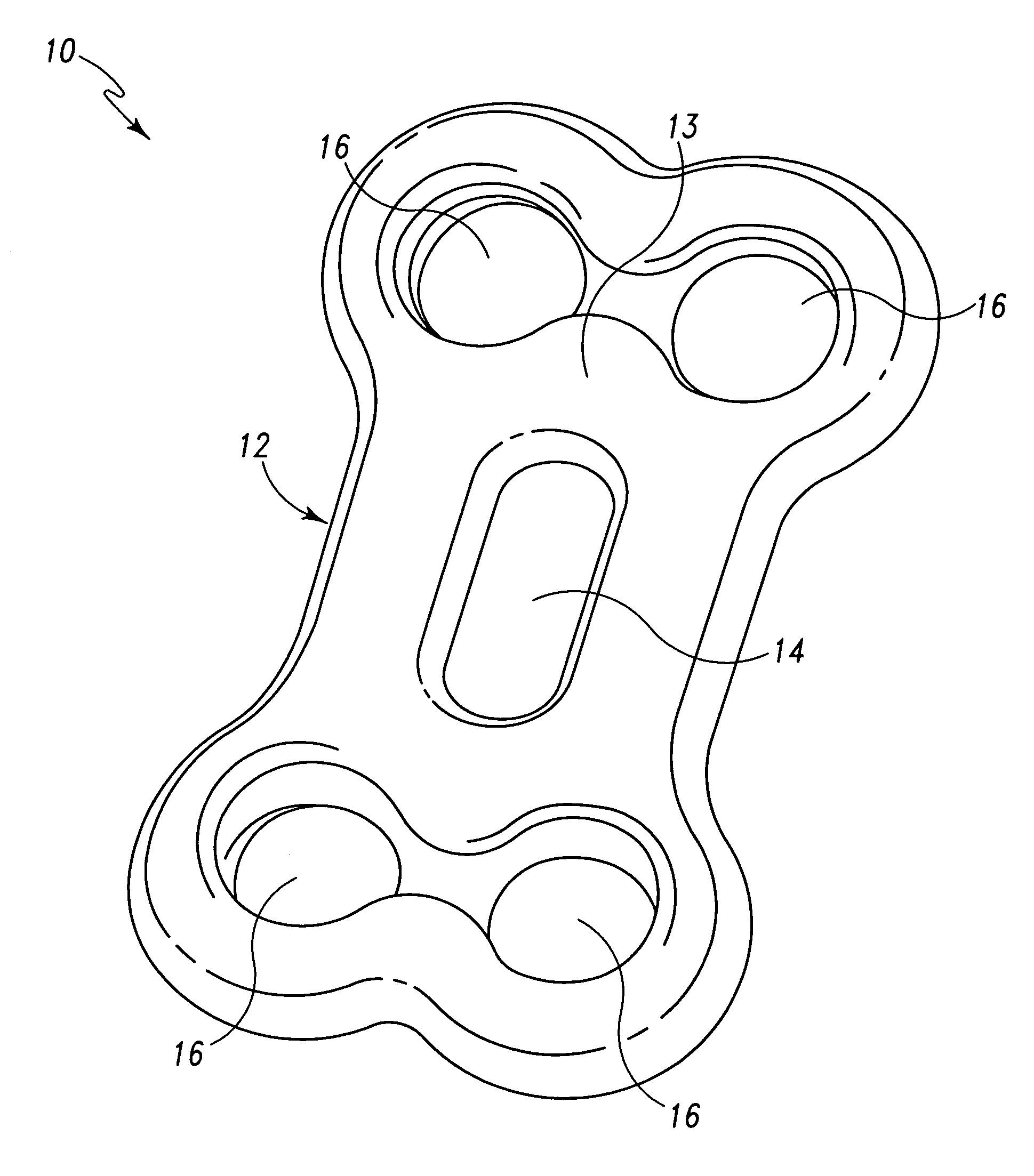

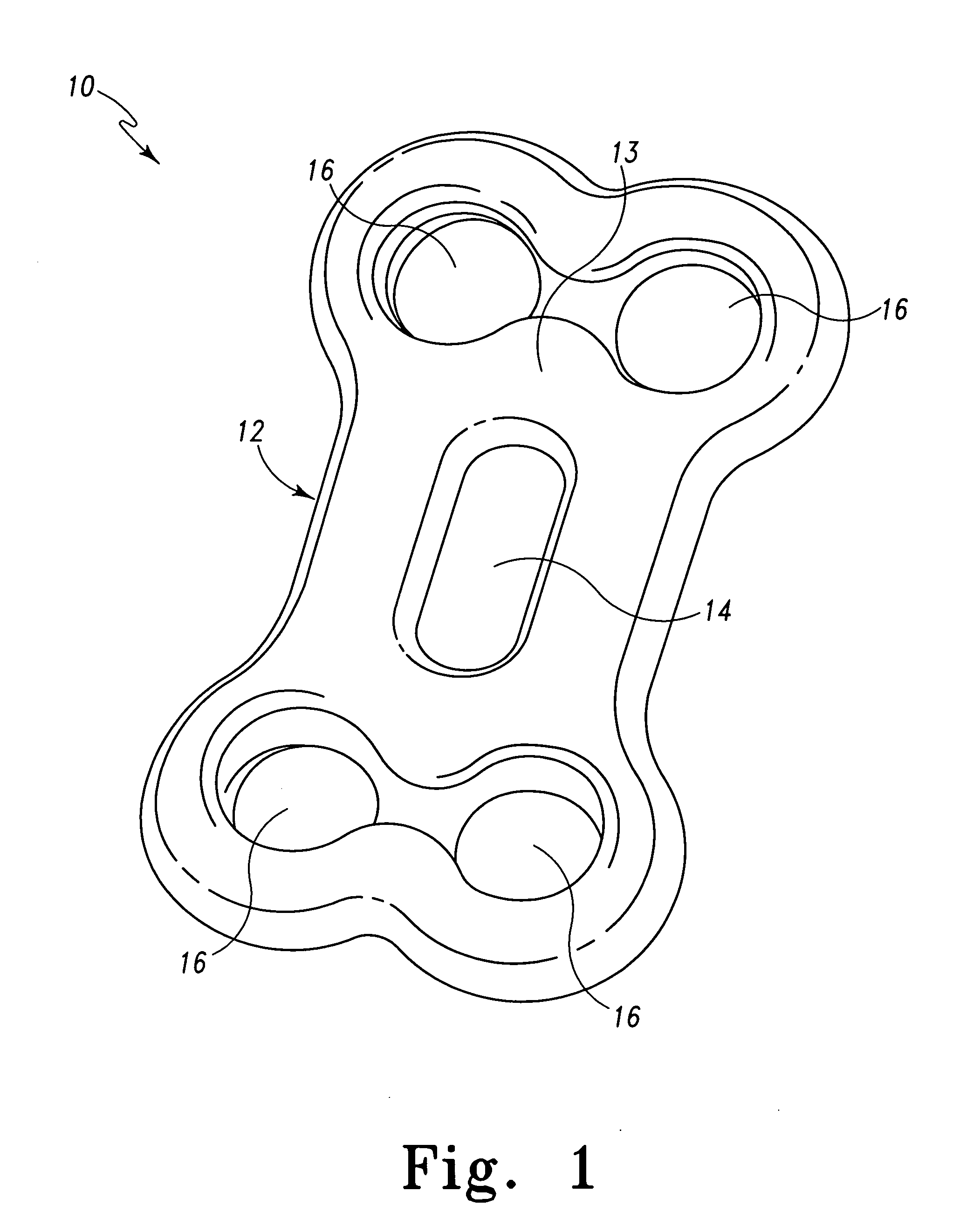

Shweel

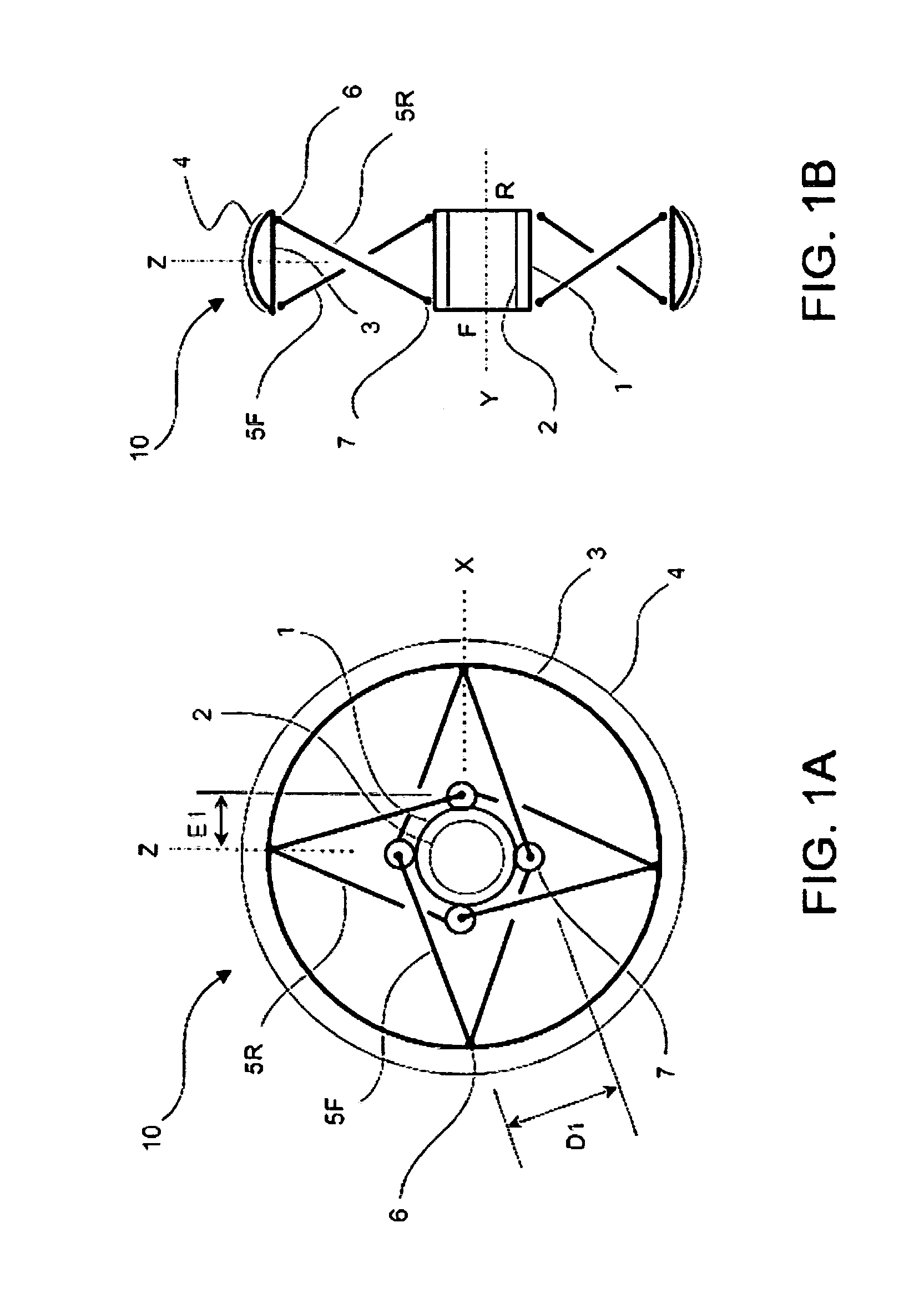

InactiveUS20130340902A1Quiet and comfortable rideReduce rolling resistanceHigh resiliency wheelsMetalworkingRolling resistance

Shock-absorbers used as wheel-spokes between wheel-hub and rigid rim, which may be lined with threaded rubber or having gripping features otherwise. It reduces rolling resistance, saving fuel. It improves drivability. The compliance of the shocks is commensurate with that of a comparable inflated tire, but optimized passively or actively circumferentially, vertically and laterally. Rubber-bushing or spoke-inclination enhances driving stability. Giant field assembled mining-truck-wheels may be produced and deployed and field-assembled quickly by common metalworking shops at fractional cost and weight. It is environmentally friendly, for hardly using or not using rubber. The gas or liquid of the shock spokes may be interconnected and cooled. Soft and hard driving may be controlled manually or by computer on the fly. It is suitable for applications ranging from bicycle wheels to aircraft landing gears. It is fireproof, bulletproof, airless and silent. It cannot bounce or skid at jumpstart or braking and on ice.

Owner:KEMENY ZOLTAN A

Multifunctional hydrocarbon oil composition

ActiveUS20090111723A1Improve working environmentReduce odorOrganic chemistryOrganic non-surface-active detergent compositionsElectric dischargeMetalworking

A multifunctional, high-performance hydrocarbon composition is demanded. Concretely, a metalworking oil composition having high workability even under a severer lubricating condition while resisting to high productivity, and further capable of suppressing deterioration of working environments or degradation of quality of a product without rise of lubricant cost, a metalworking oil composition for minimal quantitative lubrication system, which is excellent in characteristics as a water-insoluble lubricant for nonferrous metalworking and also in characteristics as a lubricant for cutting / grinding by minimal quantitative lubrication method, and can attain improvement in working efficiency and a further extended tool life, an electric discharge machining oil improved in working environments such as odor or skin roughness and further improved in processing rate, particularly processing rate in high-level finish, a rust preventing oil composition improved in resin compatibility, and a detergent excellent in adaptability with organic material are demanded.Therefore, metalworking oil which contains, as hydrocarbon base oil, hydrocarbon base oil having a density at 15° C. of 0.7 to 0.8 g / cm3, and including a n-paraffin content of 10 to 90% by mass, an aromatic content of 0 to 3% by volume, and a naphthene content of 0 to 20% by volume, a metalworking oil including the above-mentioned base oil and ester oil, and electric discharge machining oil, rust preventing oil, and a detergent composition including the above-mentioned base oil are provided.

Owner:NIPPON OIL CORP

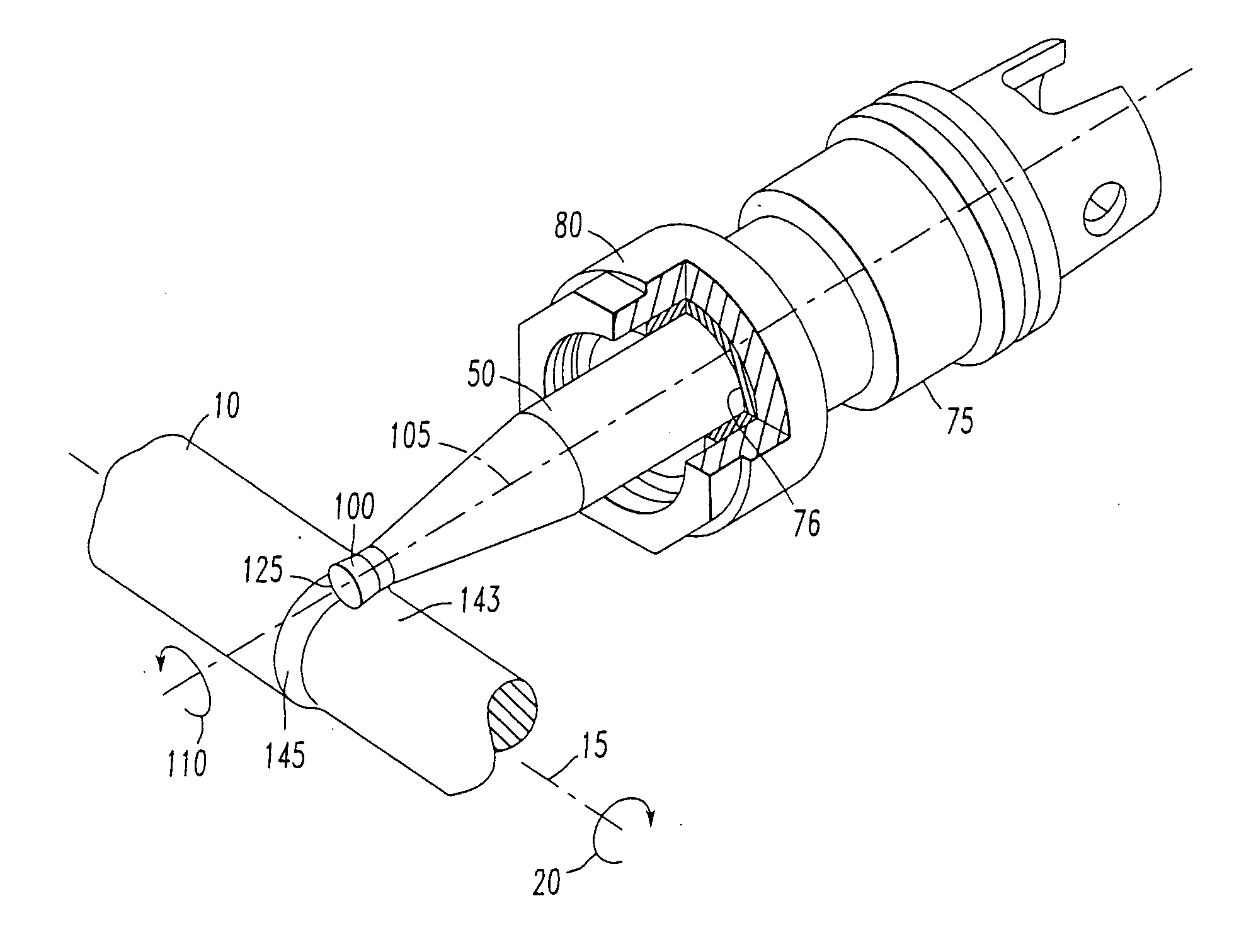

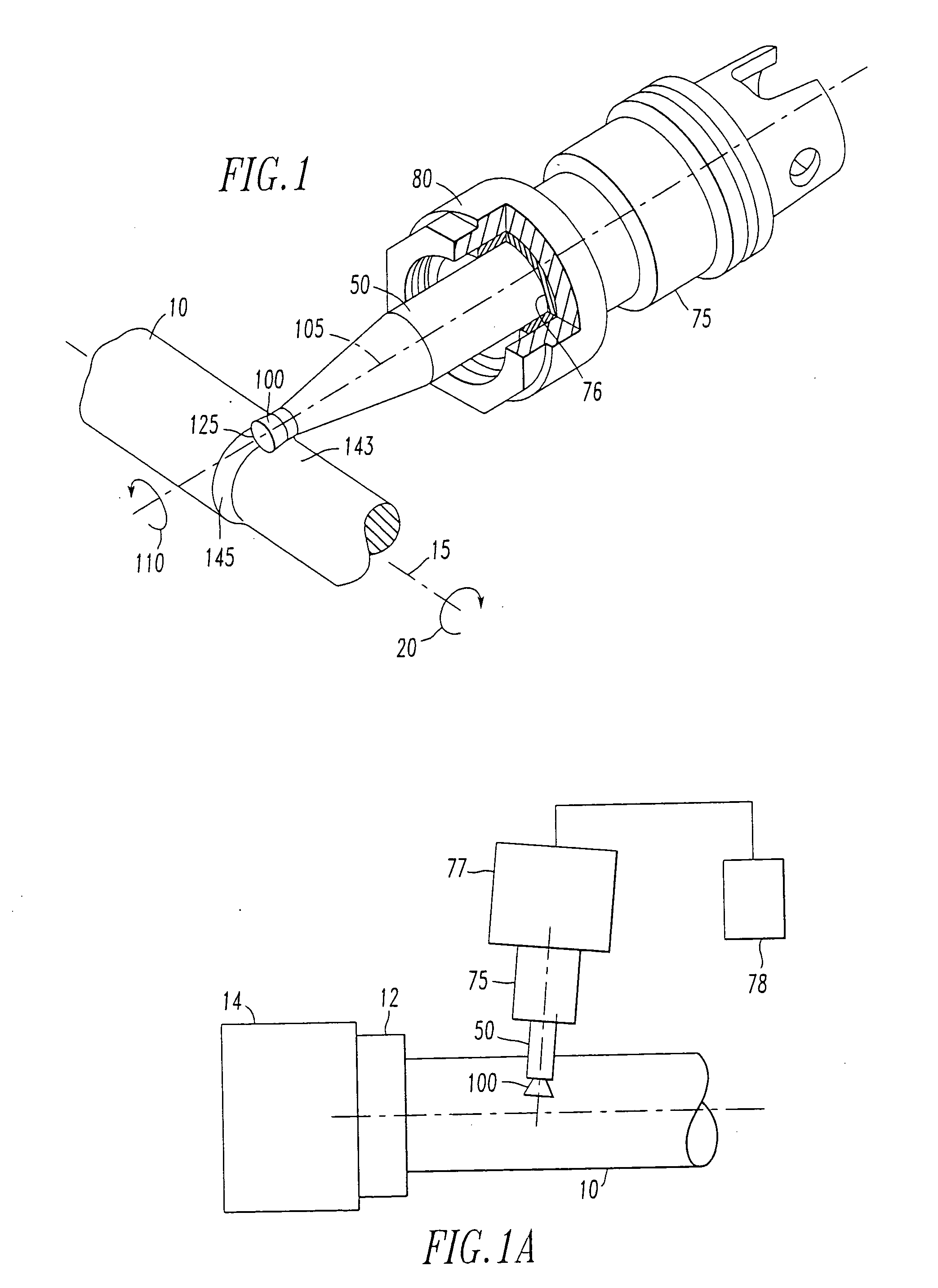

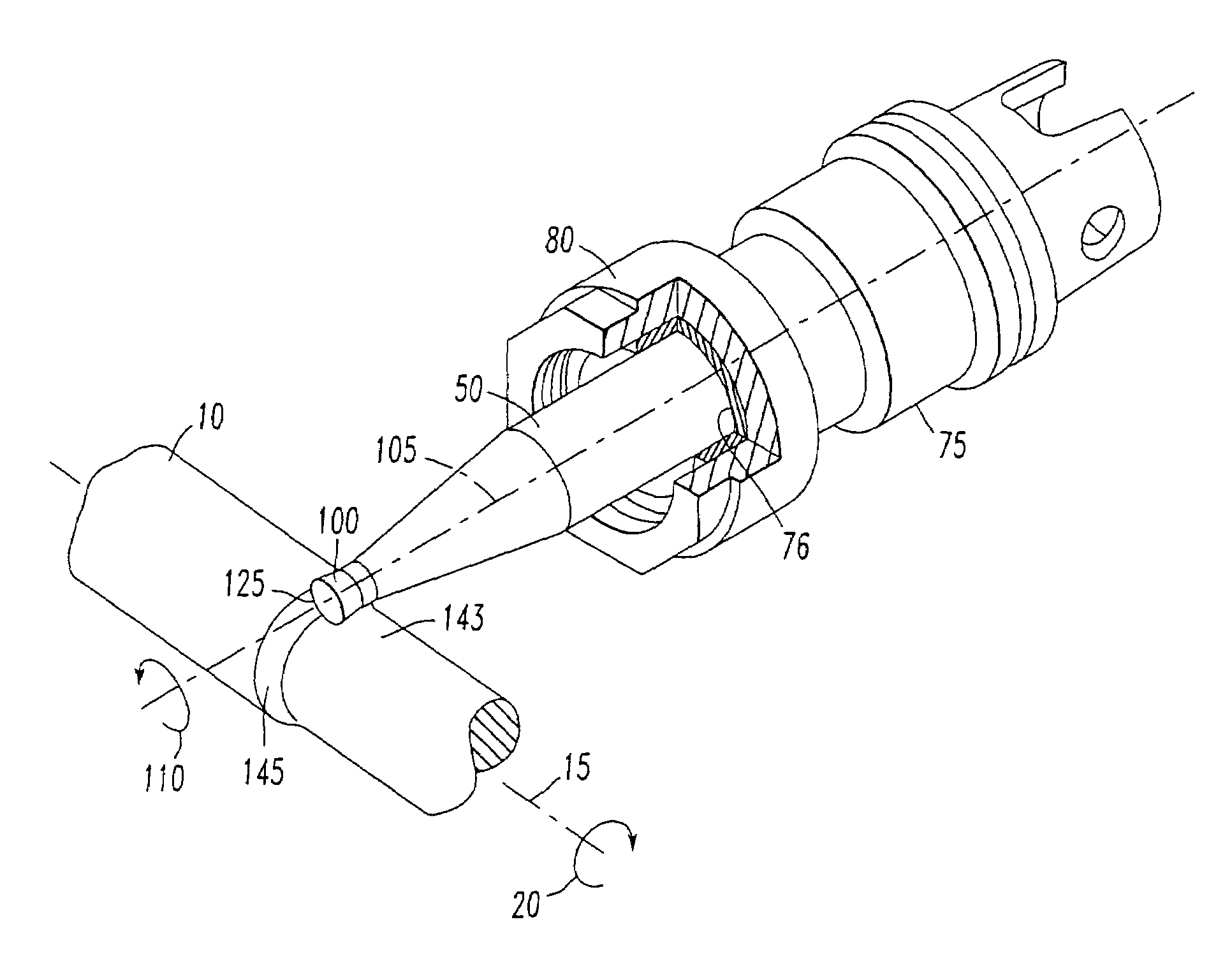

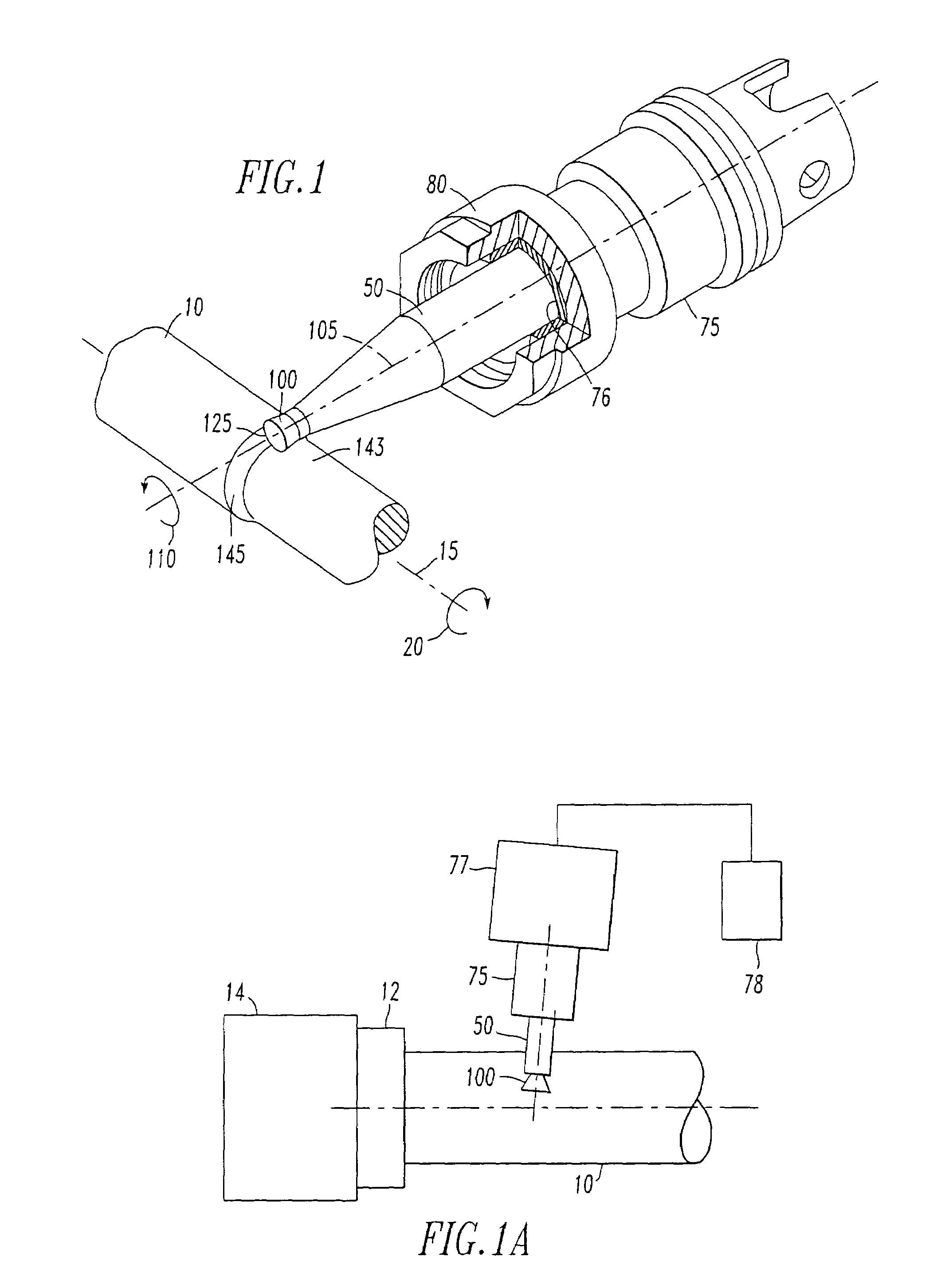

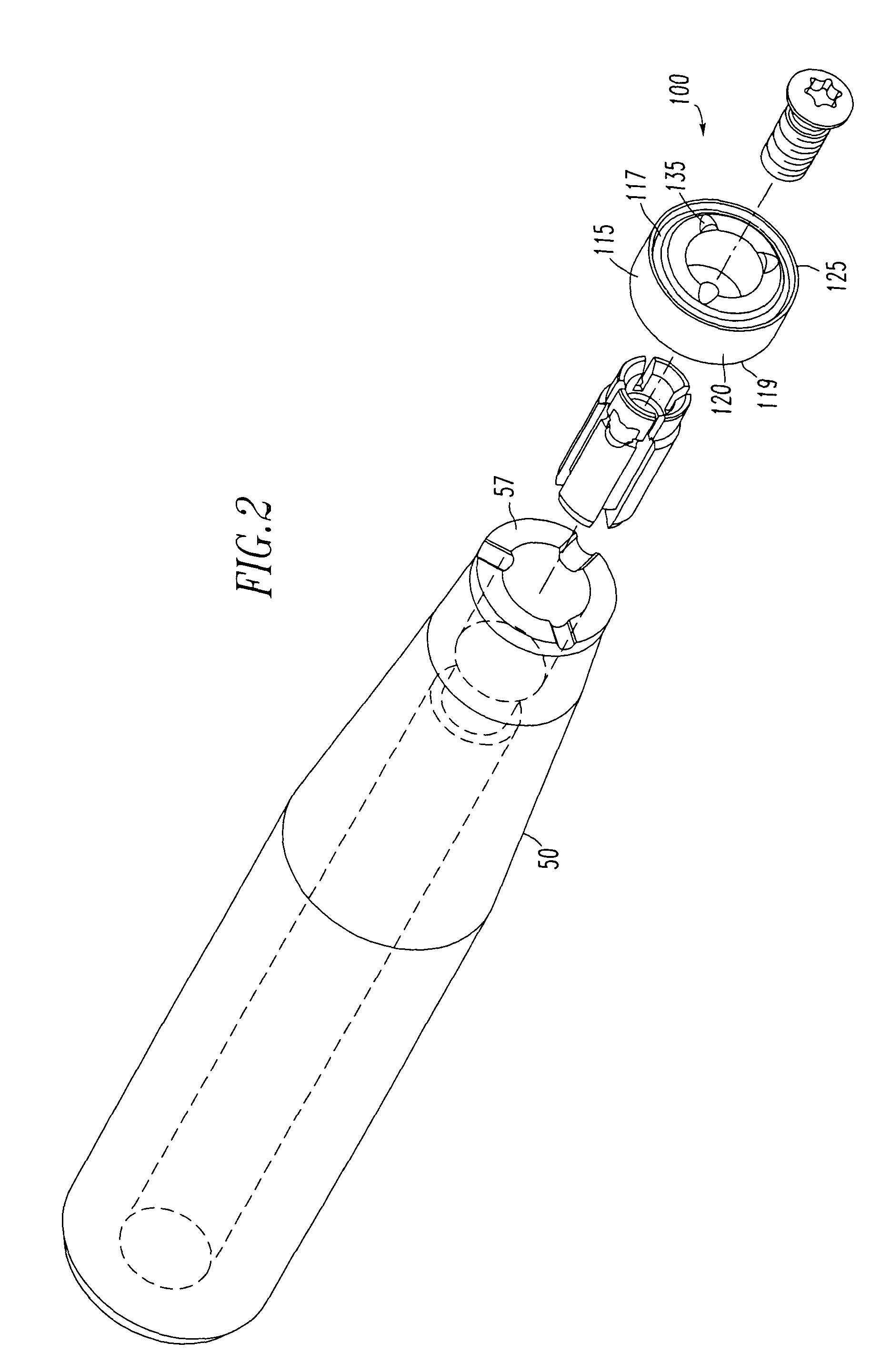

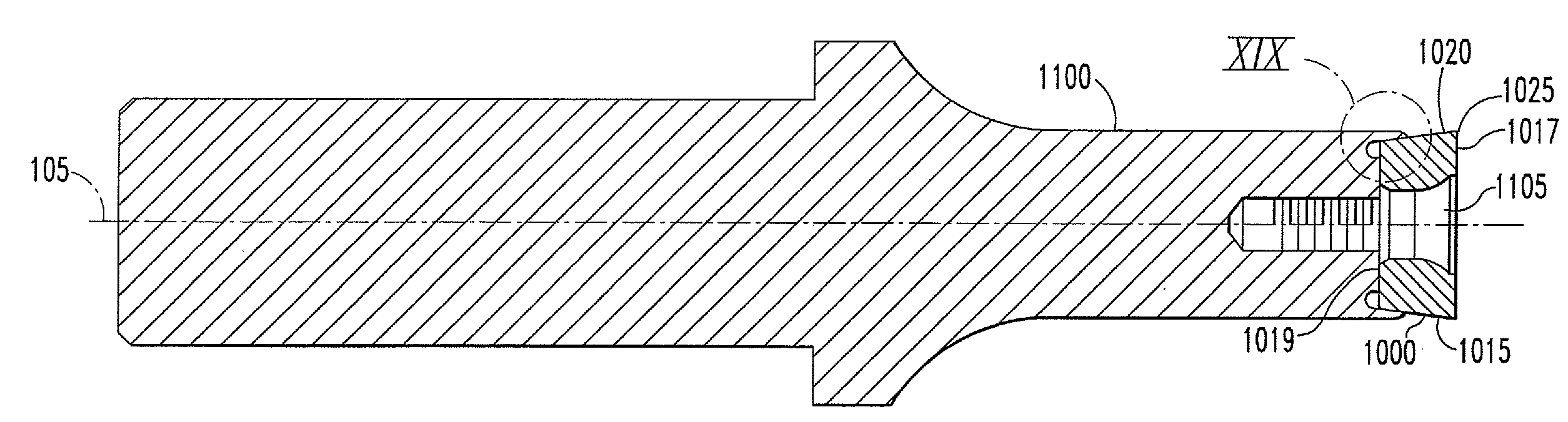

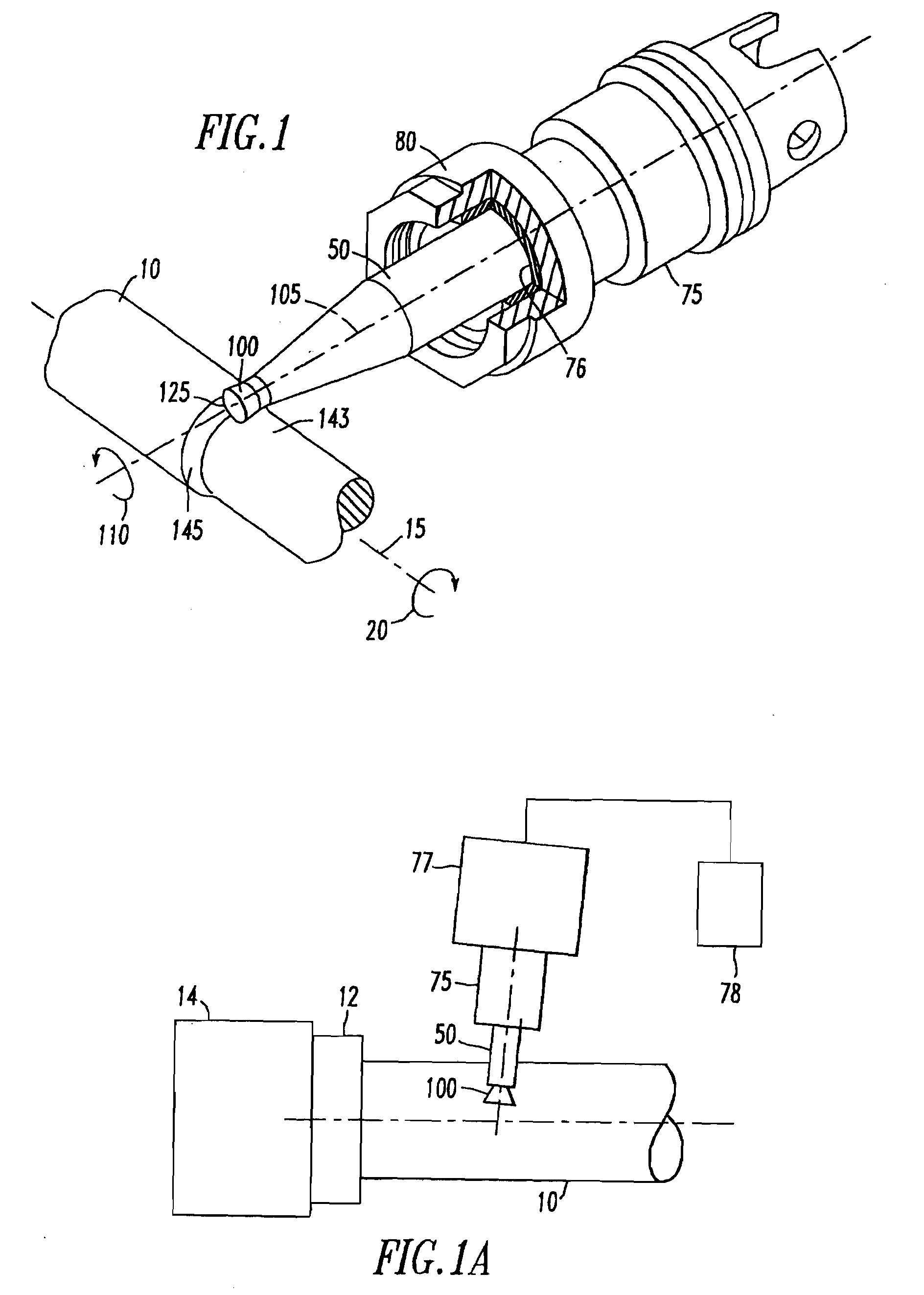

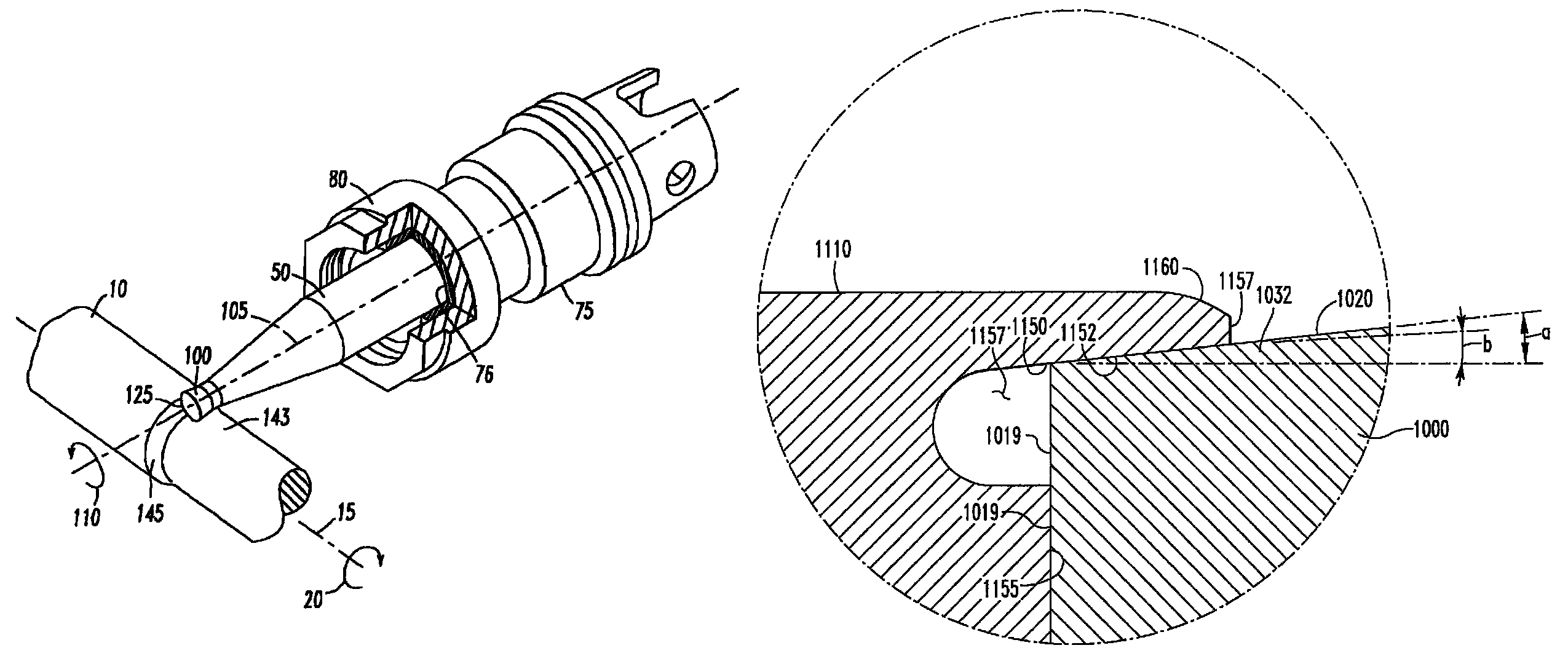

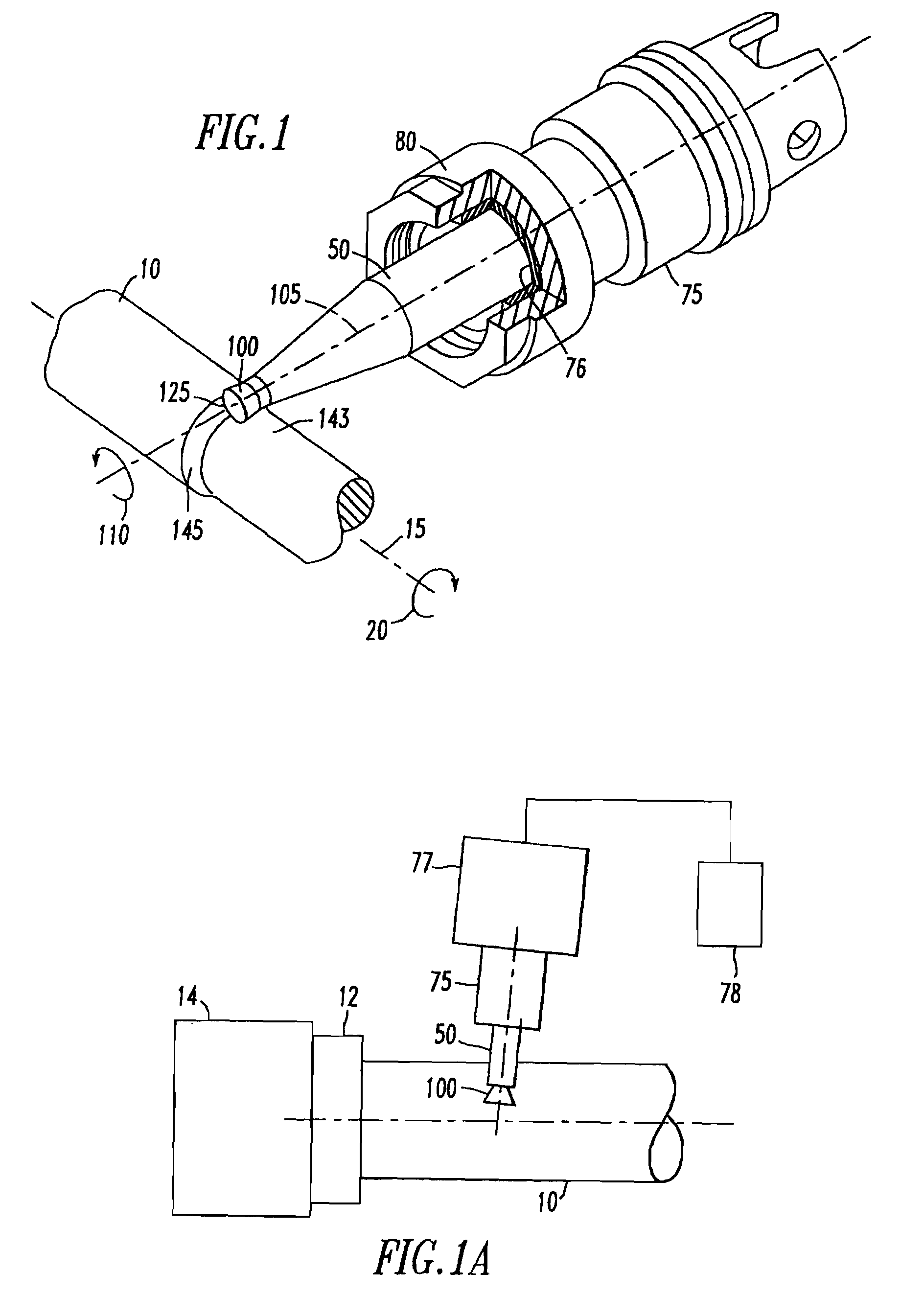

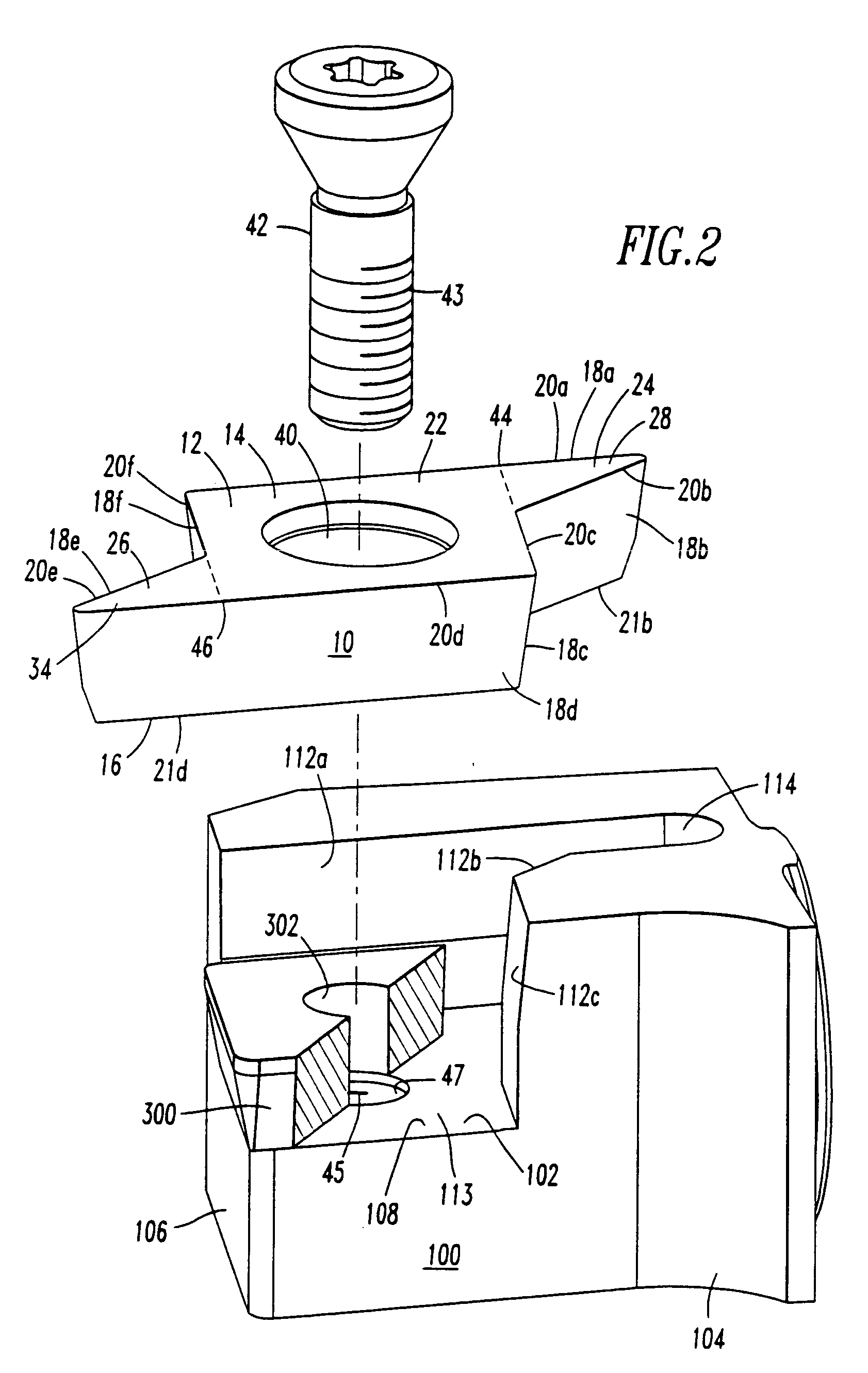

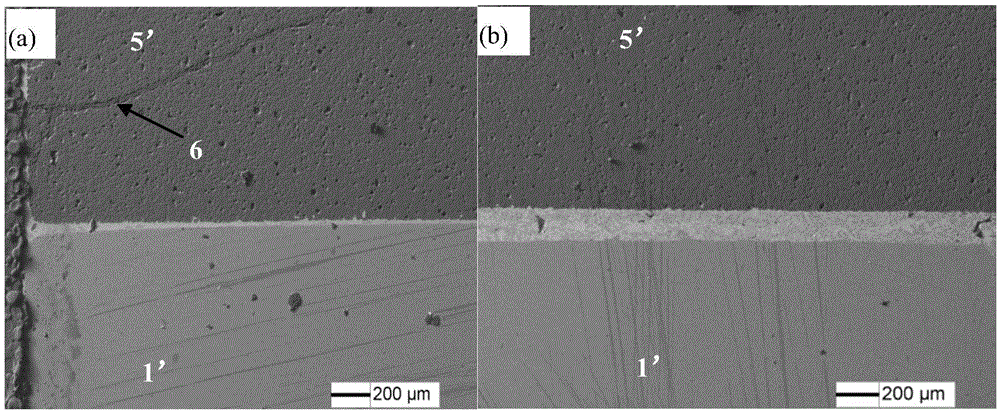

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

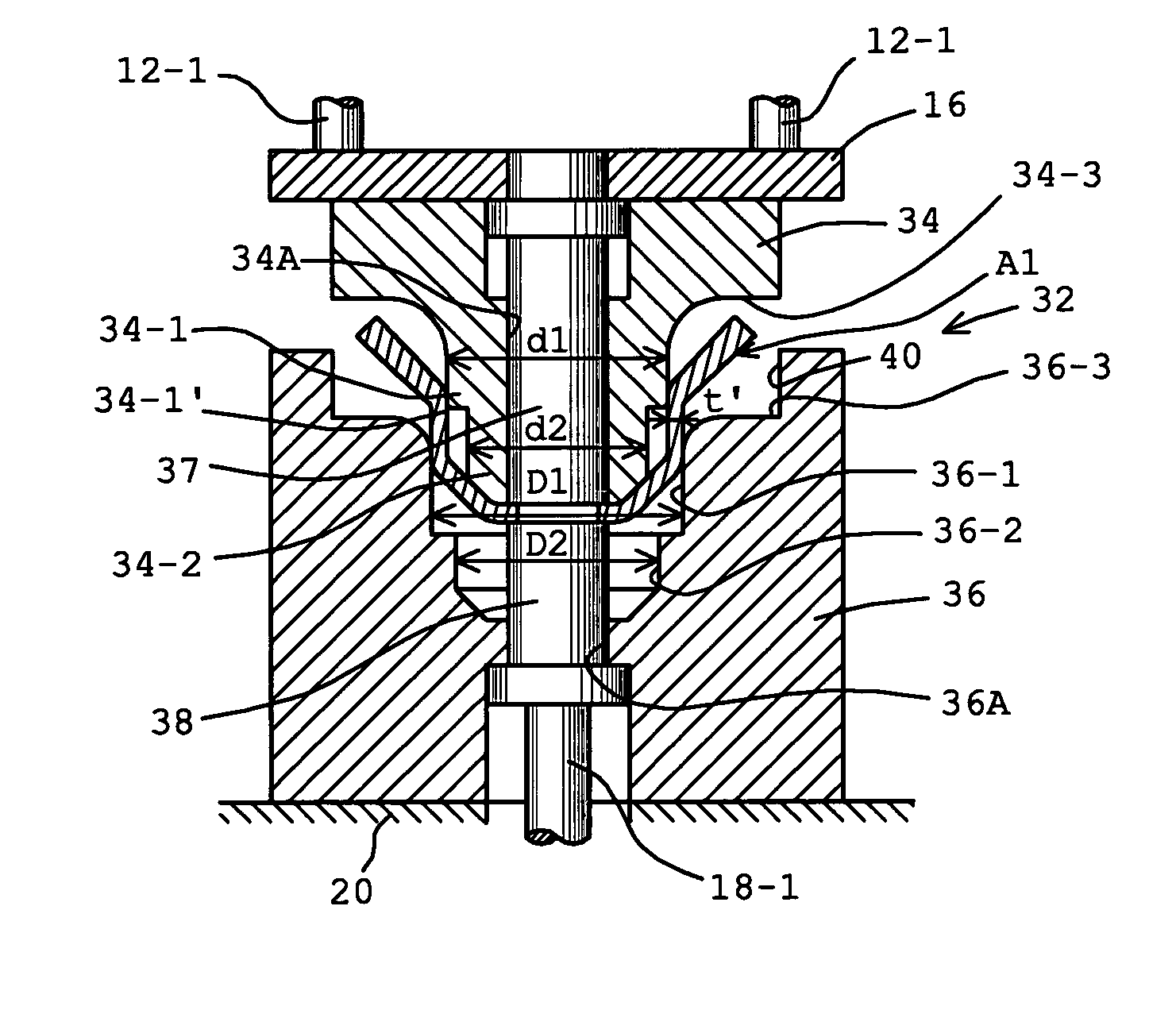

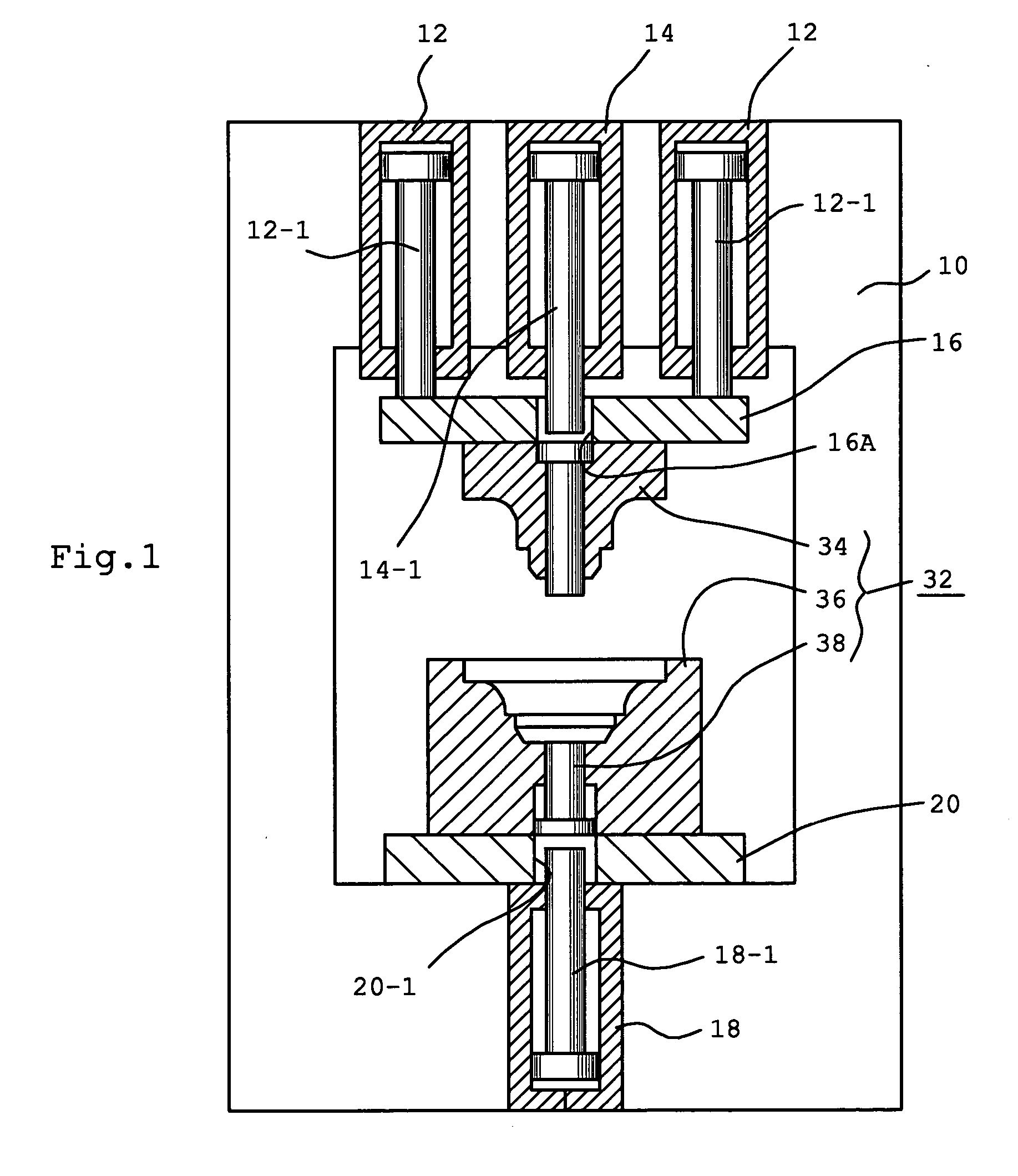

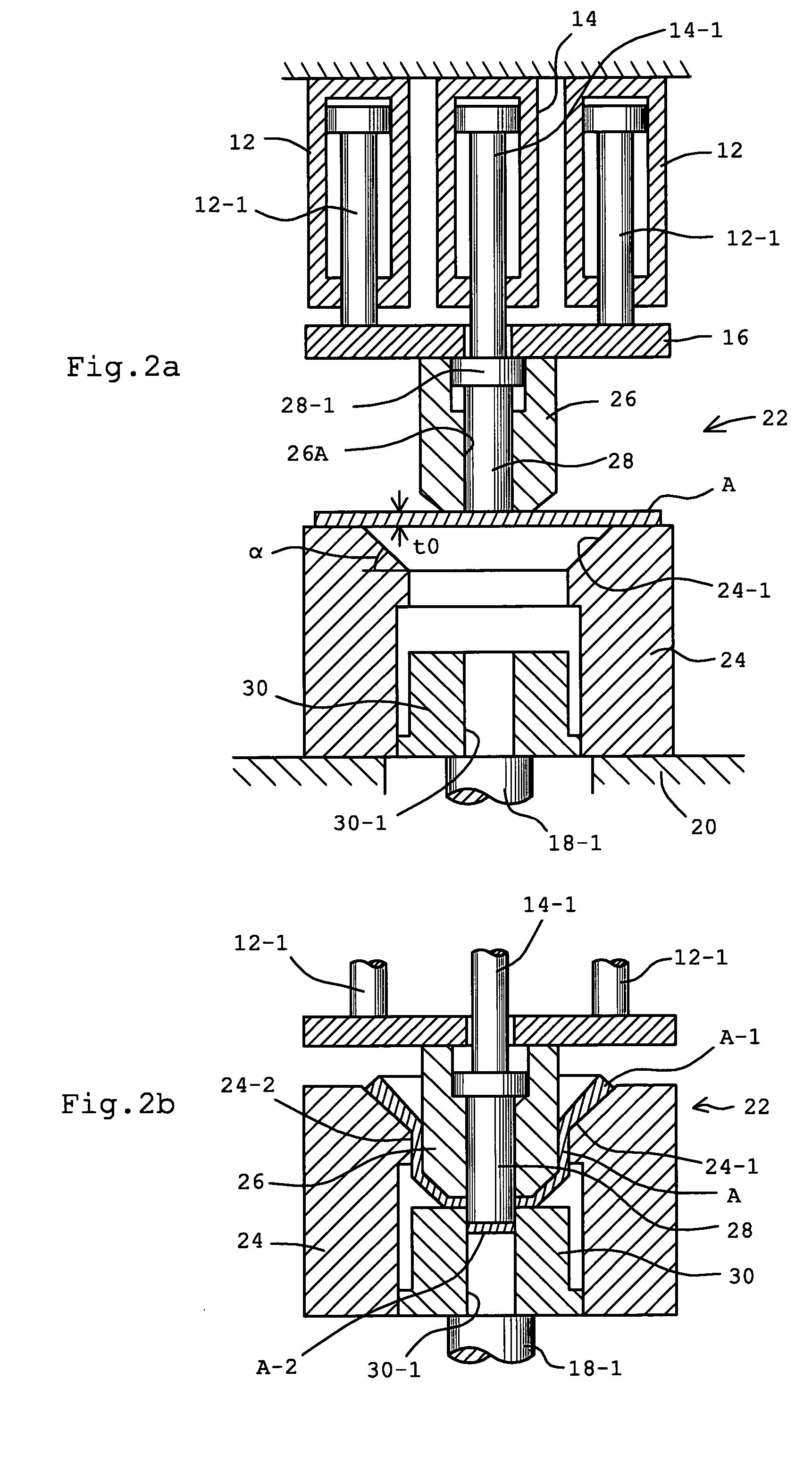

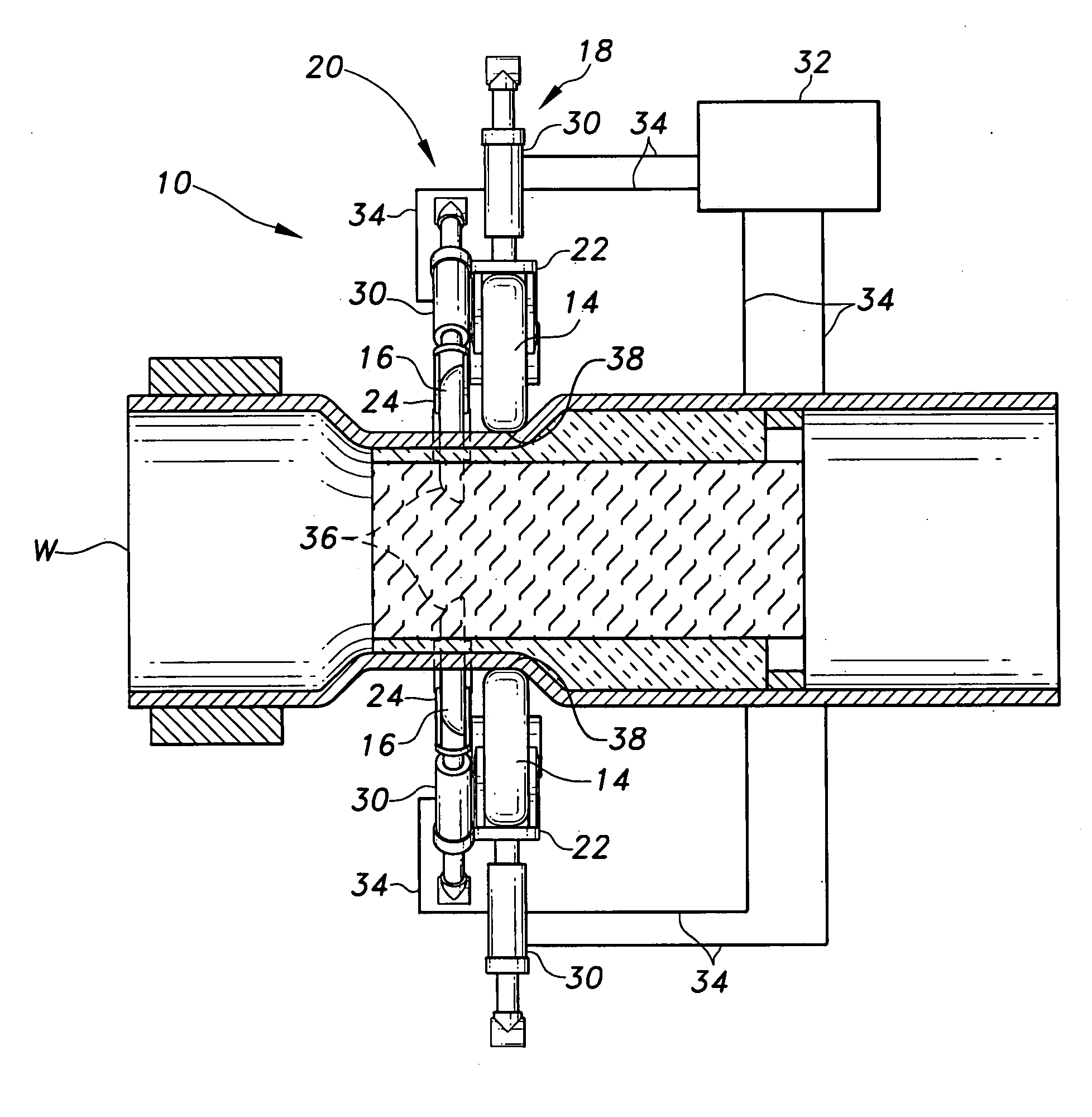

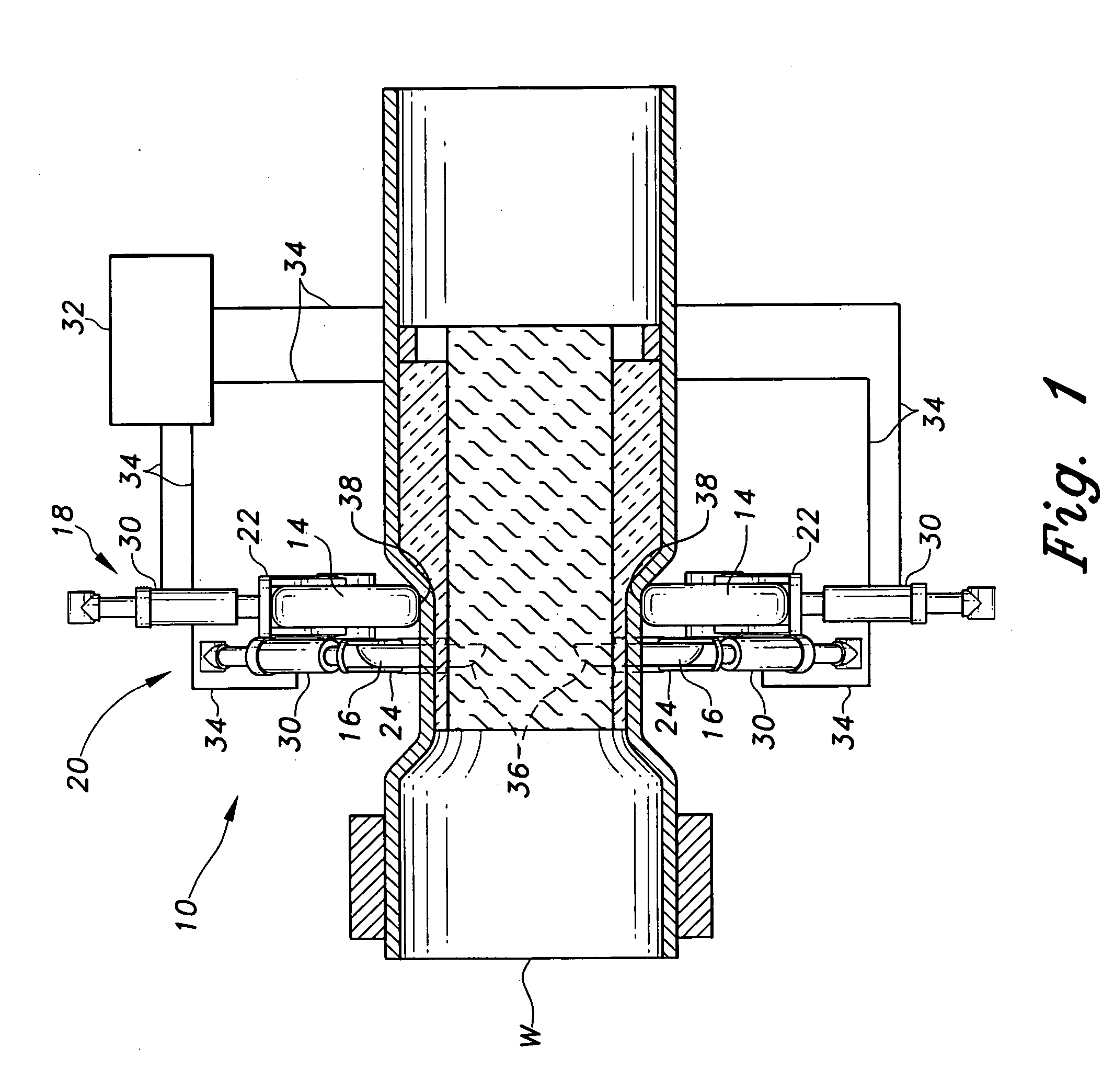

Method and apparatus for producing thin walled tubular product with thick walled flange

InactiveUS20040244459A1Forging/hammering/pressing machinesDomestic articlesMetalworkingWork in process

Method and apparatus for producing a thin walled tubular product with thickened flange. A first stage metalworking (drawing) of a circular plate material A is done by using a first die set 22 having a conical die 24 and a drawing punch 26 is done in a manner that the end of the blank plate is remained on the conical surface 24-1 of the die, so that a semi-finished tubular product A1 with a inclined flange A1-1 is obtained. Then, a second stage metalworking (drawing) of the semi-finished tubular product A1 is done by a second die set 32 having a shaping punch 34 and a restraint die 36. The semi-finished tubular product A1 is held by the restraint die 36 and the shaping punch 34 is introduced into the semi-finished tubular product A1 for effecting a wall thickness reduction under ironing principle while forming a stepped portion. Simultaneous with the execution of the second stage drawing, a flattening of the flange is done while restriction diameter expansion by a wall 40, thereby obtaining a thickened flattened flange A2-3.

Owner:MATSUOKA MINAKO +2

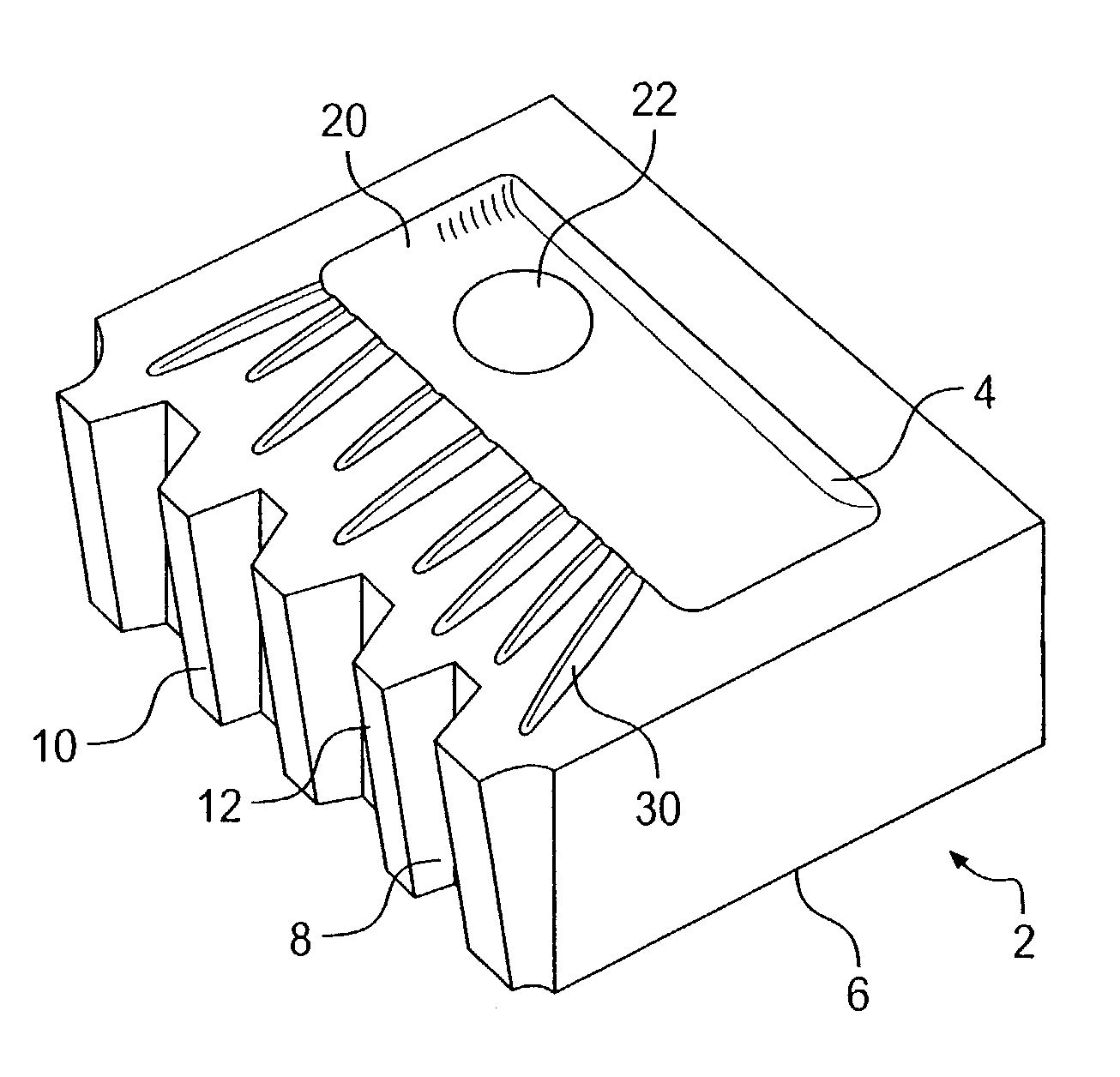

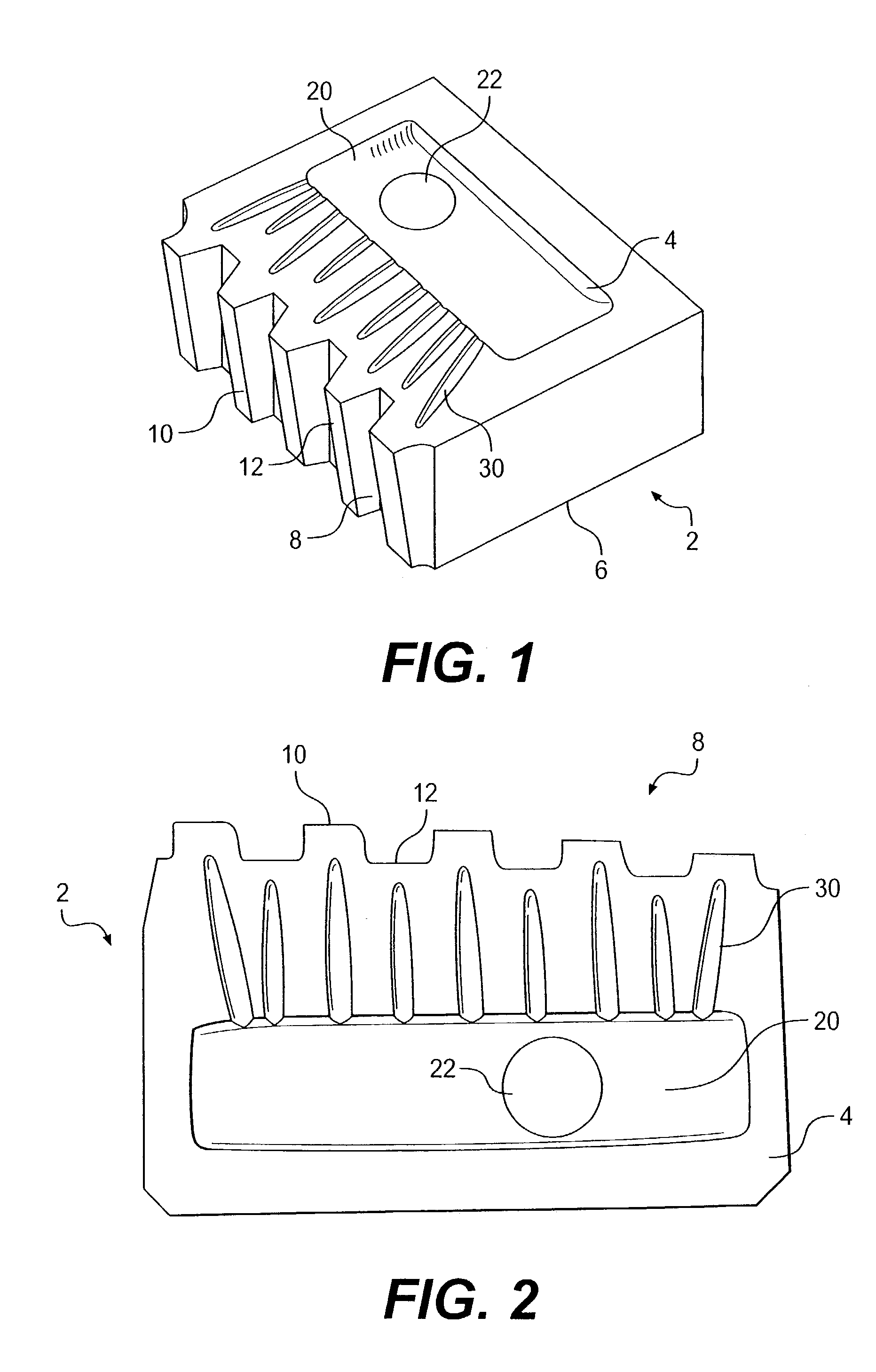

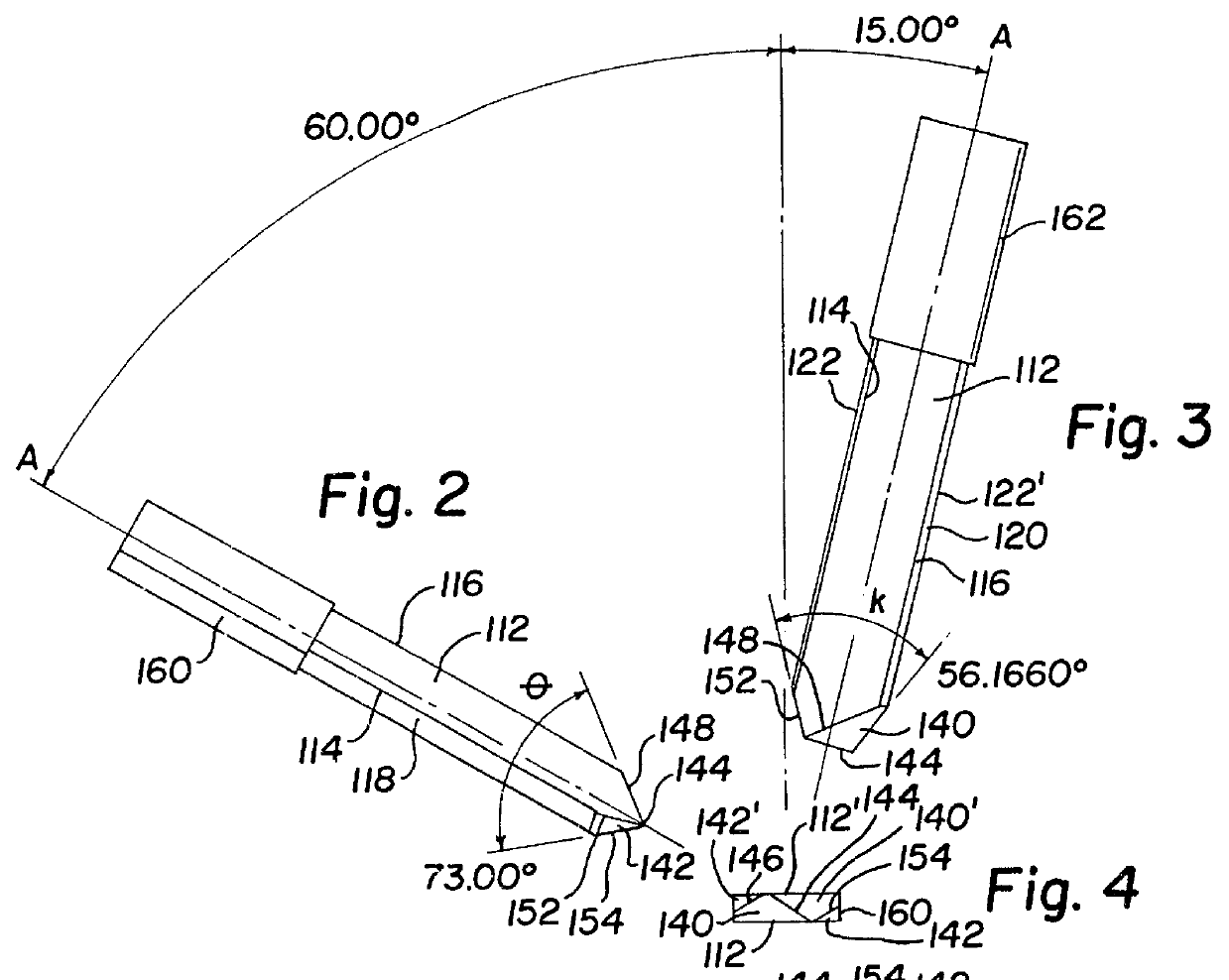

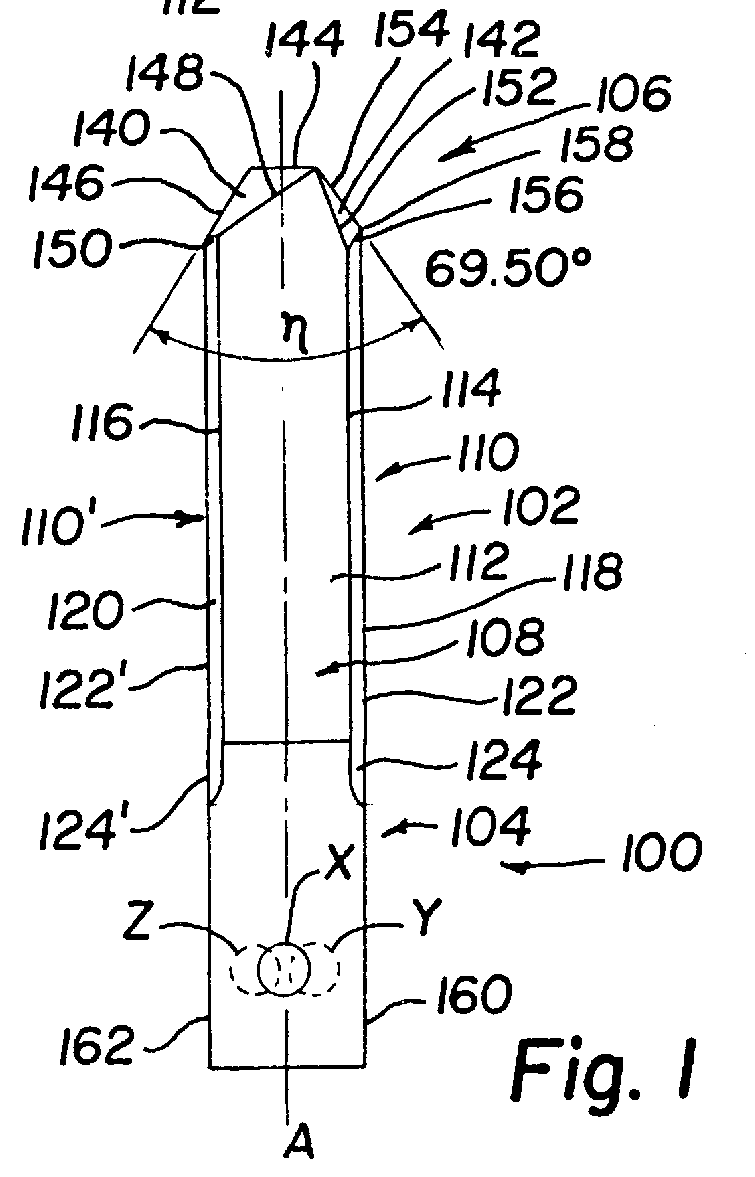

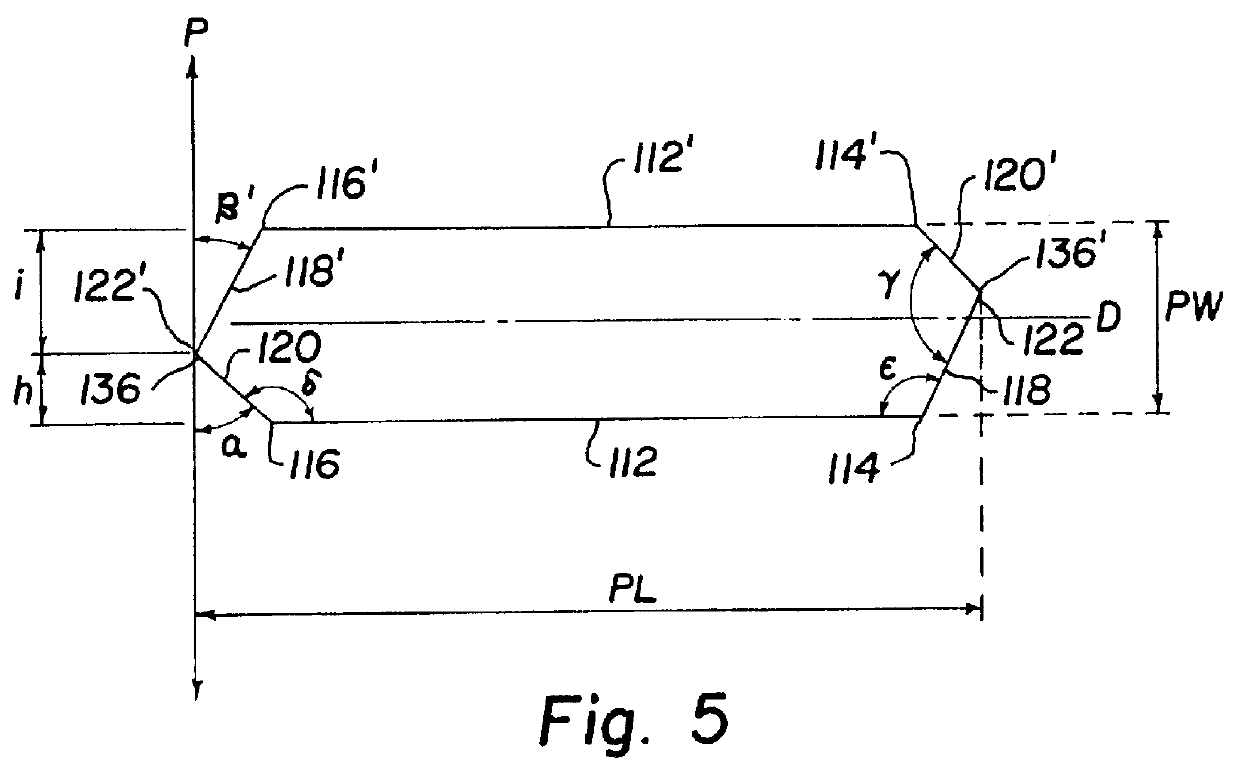

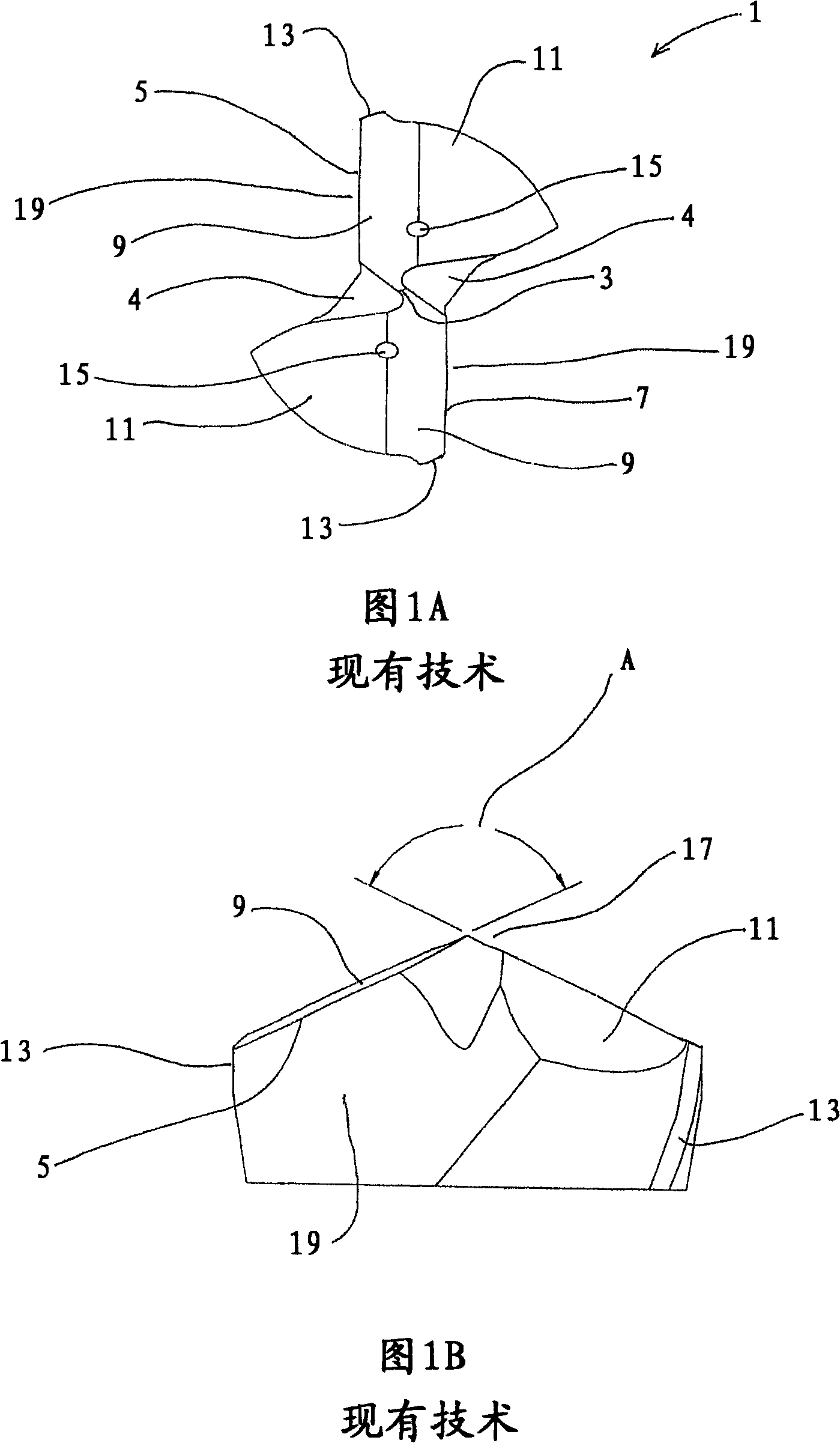

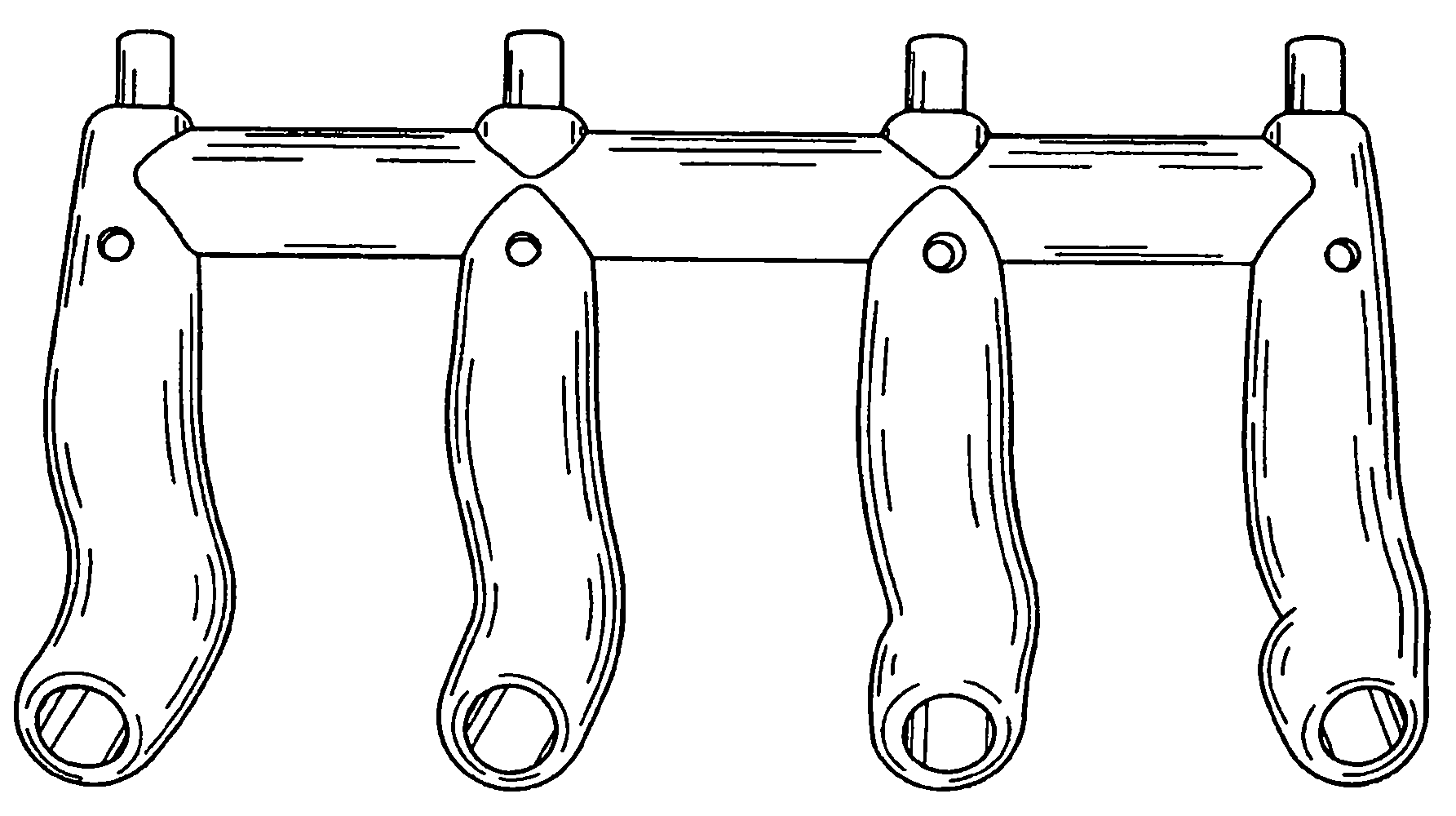

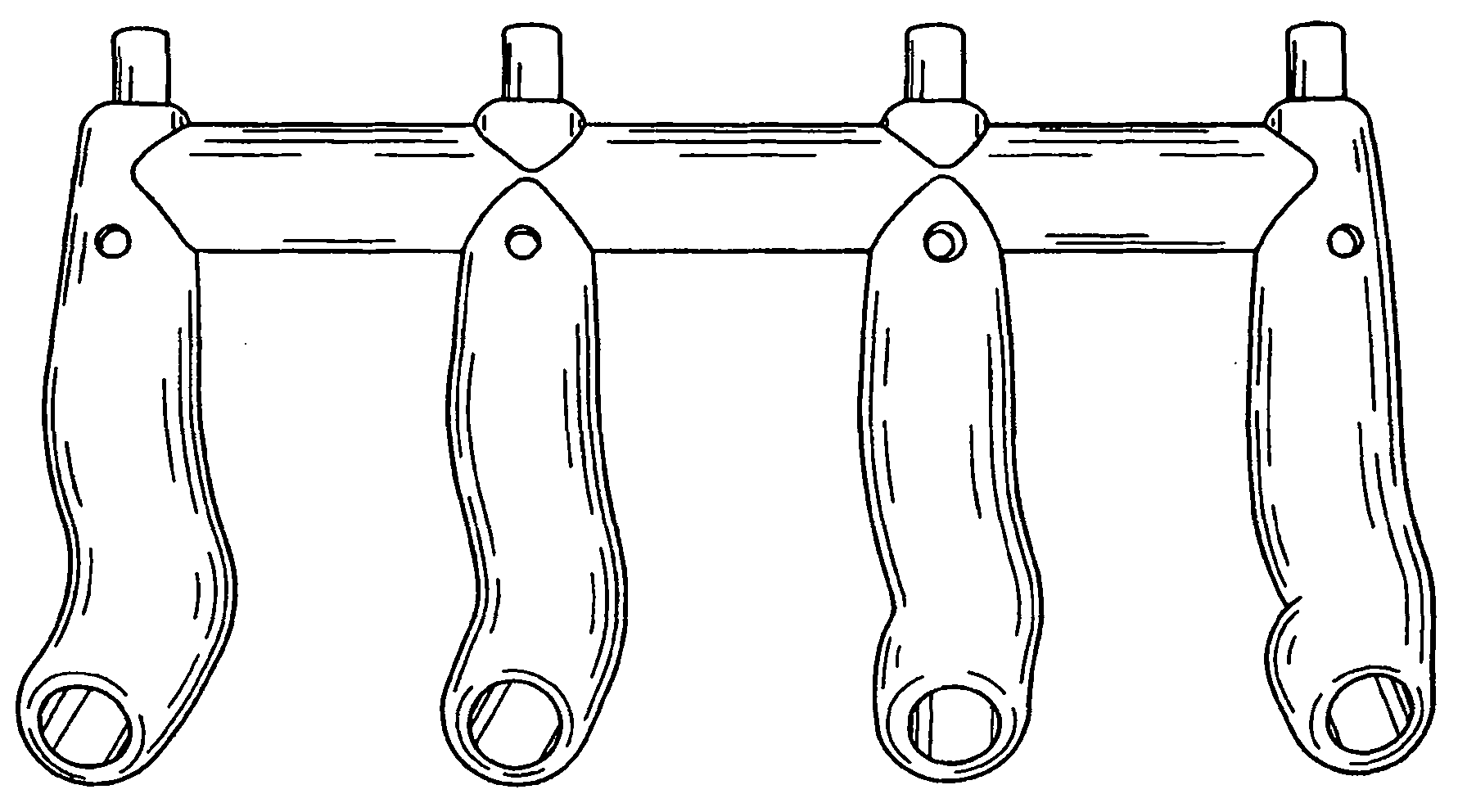

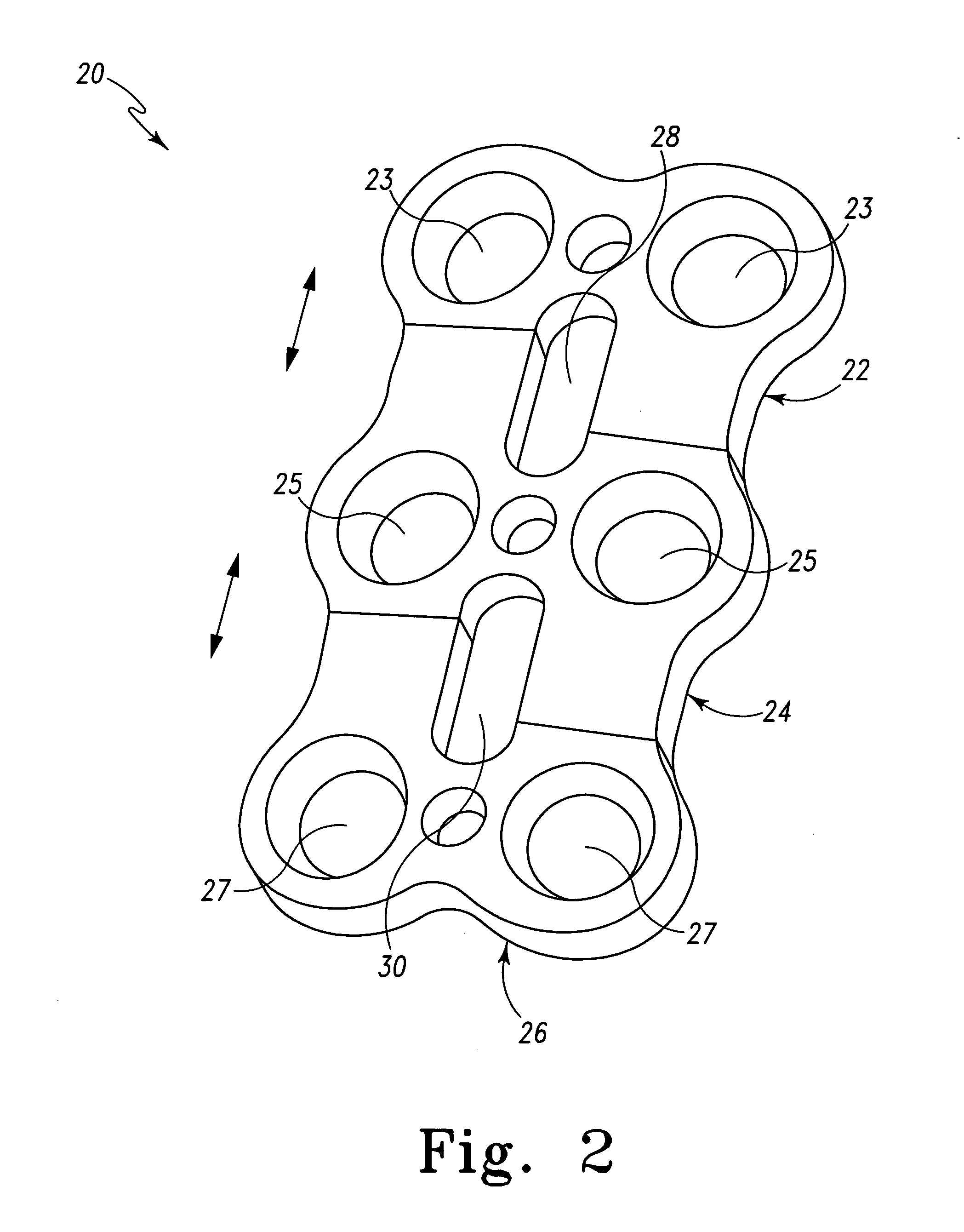

Punch and die for producing connector plates

A blade punch for forming teeth in a connector plate, the blade punch comprising an elongated blade having a metal working tip at one end and a shank at the other end. The blade has an elongated cross-section defined by opposing parallel spaced planar side walls and opposing ends. Each end comprises a major end wall and a minor end wall which converge to end wall intersections, where the end wall intersections are eccentric to a plane parallel to and midway between said side walls. Each end wall intersects a side wall at an obtuse angle. The metal working tip has opposed air cut faces abutting one another along an air cut edge and opposed first and second forming faces, each of the forming faces abutting one of the air cut faces along an exterior edge. Each of the air cut faces is bordered by a portion of one of the minor end walls, a portion of one of the side walls, the air cut edge, and one of the exterior edges. Each of the forming faces is bordered by a portion of one of the major end walls, a portion of one of the minor end walls, a portion of one of the side walls, and one of the exterior edges. A forming angle between 50 DEG and 60 DEG is formed between the first forming face and the exterior edge bordering the second forming face in a plane normal to the first forming face.

Owner:ILLINOIS TOOL WORKS INC

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

Rapid analysis of functional fluids

ActiveUS20050227369A1Quick analysisAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorCombustionMetalworking

The invention relates to a method to analyze the condition of a functional fluid comprising: (1) obtaining a sample of the used fluid; (2) placing the sample of the fluid to a test medium; (3) reacting the fluid with an indicator in the test medium; (4) analyzing visually the results of the reactor resulting in the determination of the condition of the fluid. Further an apparatus for analyzing functional fluids is disclosed in the form of a test medium consisting of an absorbent or nonabsorbent material which has been treated with a chemical indicator, marker substance or a developer or detector reagent upon which a sample of the fluid to be tested is placed. The components in the treated test medium react with components in the test fluid providing a visual indication, for example a color change, to judge the condition, the presence of a marker substance or another parameter of the fluid. The functional fluid may be a lubricant, fuel or other functional fluid of innumerable sources, including internal combustion engines, turbines, transmissions, differentials, pumps, metalworking operations, cooling systems, etc, and be either organic solvent or aqueous based.

Owner:THE LUBRIZOL CORP

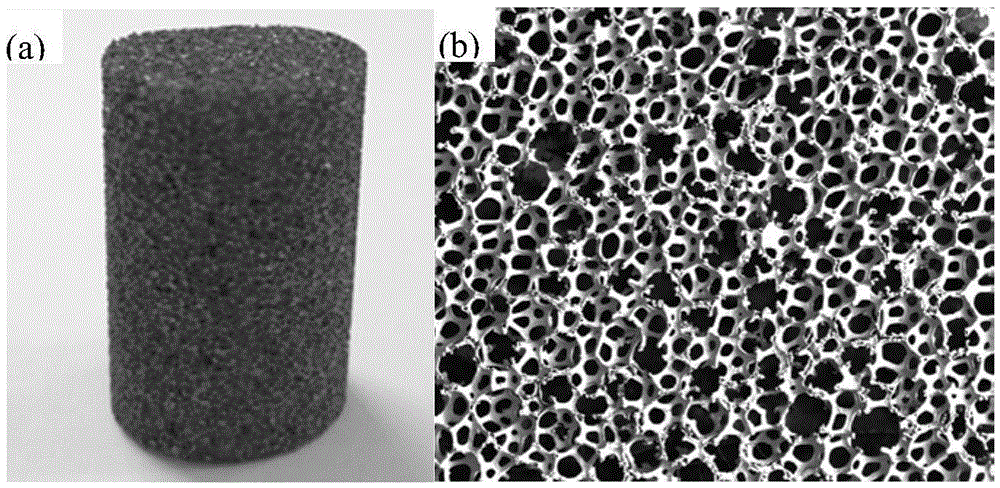

Abrasive particles with metallurgically bonded metal coatings

InactiveUS20020069592A1Improve solubilityGood metallurgical bondPigmenting treatmentOther chemical processesBorideRhenium

An abrasive composite particle comprising a cubic abrasive core particle encapsulated within a deposit of hexagonal metallurgical bond forming material comprising at least about 50 volume percent rhenium, ruthenium, osmium or mixtures thereof. The metallurgical bonds serve to retain the core particle in a matrix / binder very strongly. Metallurgical bonds are formed by the encapsulating material taking into solution, at the interface with the cubic abrasive core particle, some element or compound from the abrasive particle such as, for example, carbon or cubic boron nitride, from the core particle. Chemical bonds are not formed between the abrasive particle and the deposit. Suitable abrasive core particles include diamond, cubic carbides, cubic borides, cubic nitrides, cubic oxides, and the like. Conventional fabrication procedures such as chemical vapor deposition are employed to form the metallurgical bond forming deposit on the core particle. The composite abrasive particles are useful in forming articles according to conventional powdered metal processing operations. The articles so formed are useful for their hardness as well as their abrasiveness.

Owner:POWDERMET

Abrasive particles with metallurgically bonded metal coatings

InactiveUS6540800B2Improve solubilityGood metallurgical bondPigmenting treatmentOther chemical processesBorideRhenium

Owner:POWDERMET

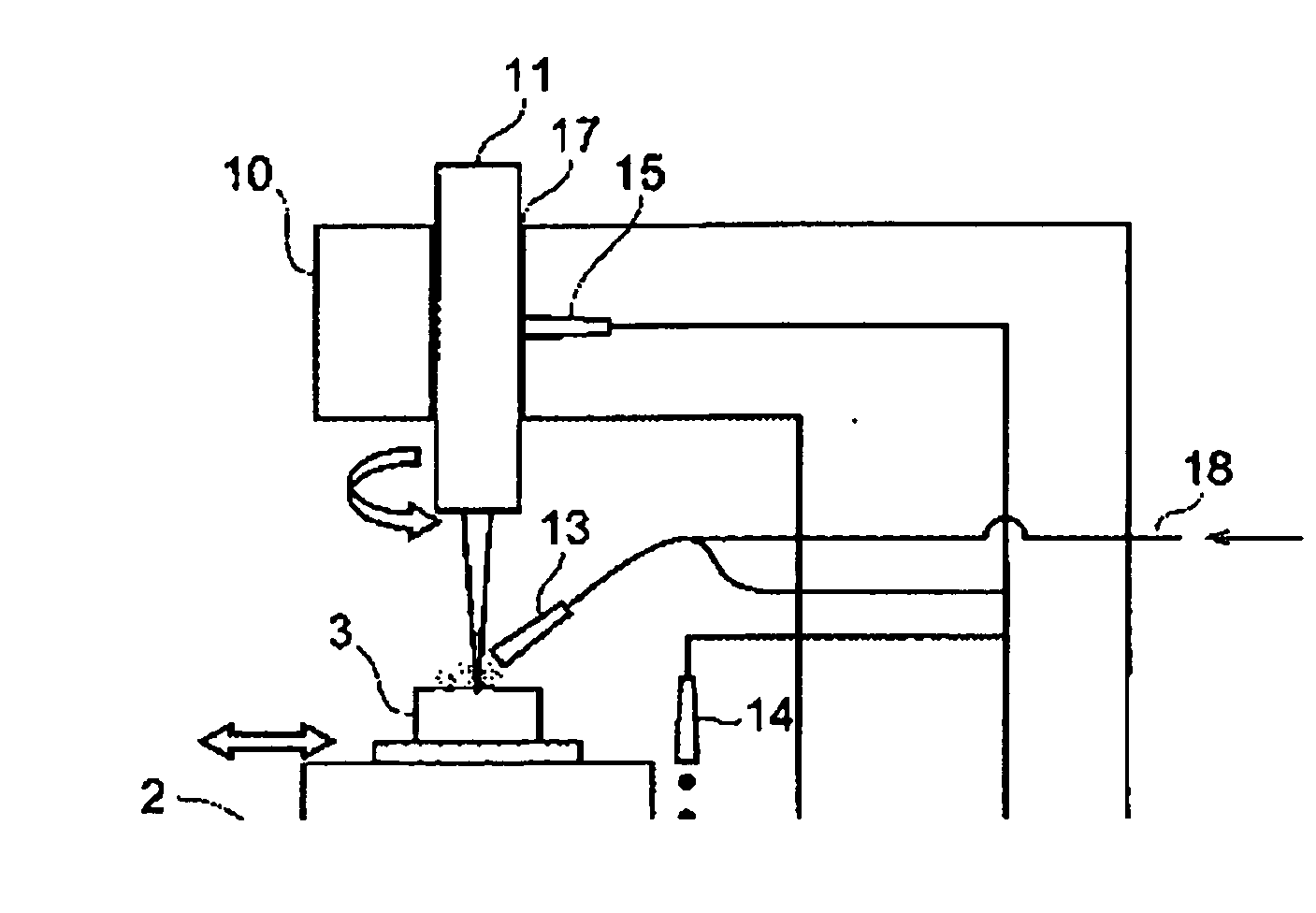

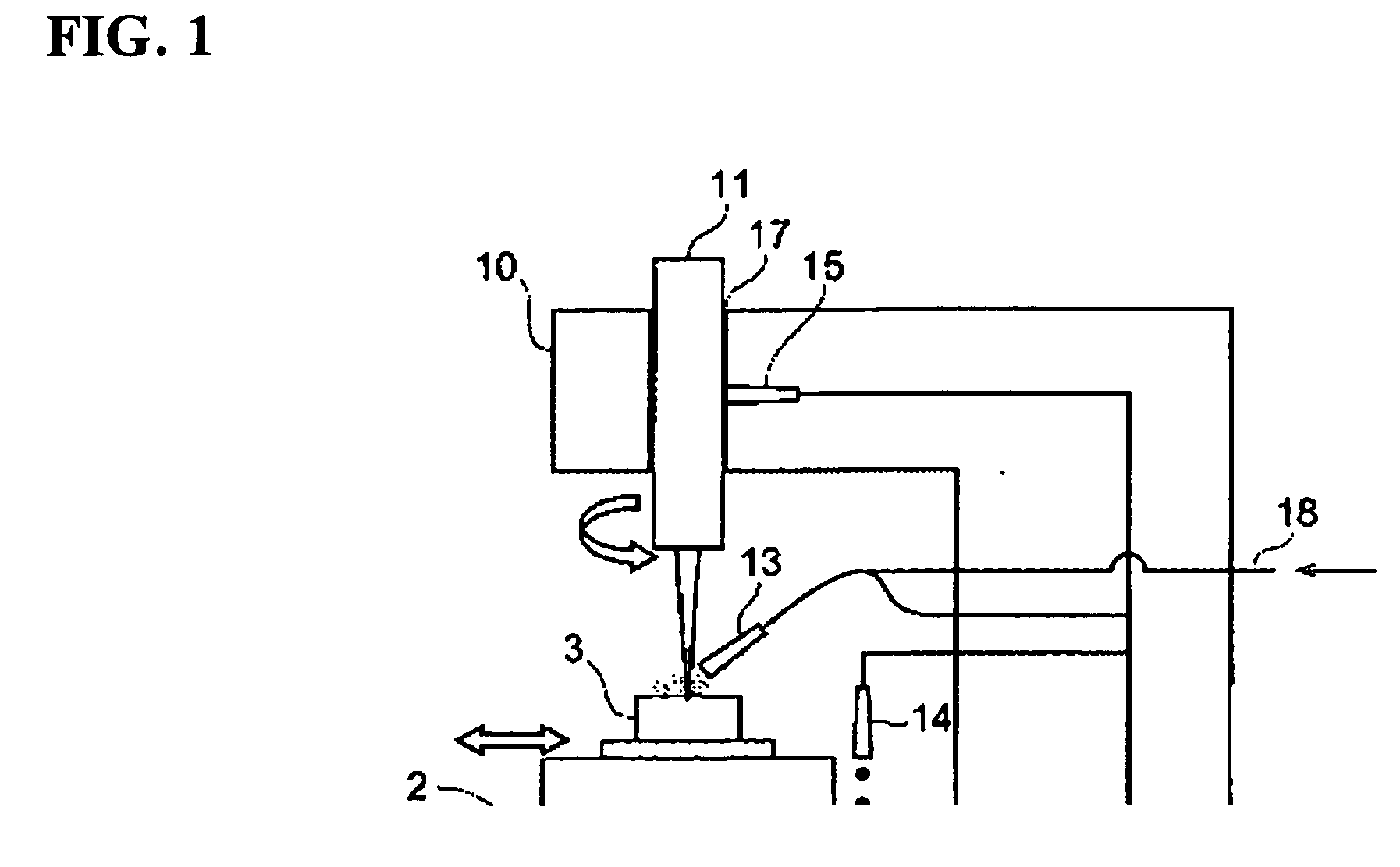

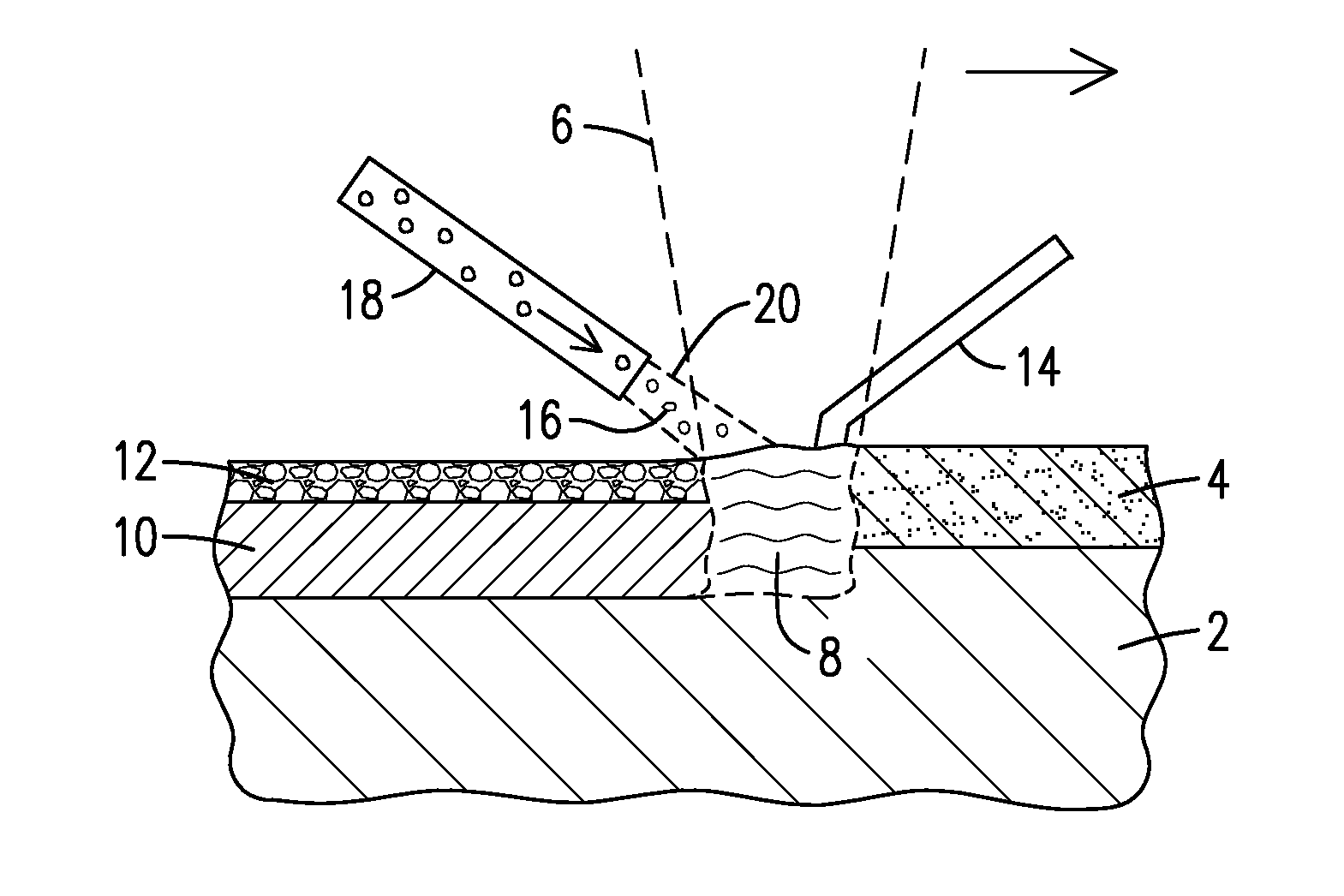

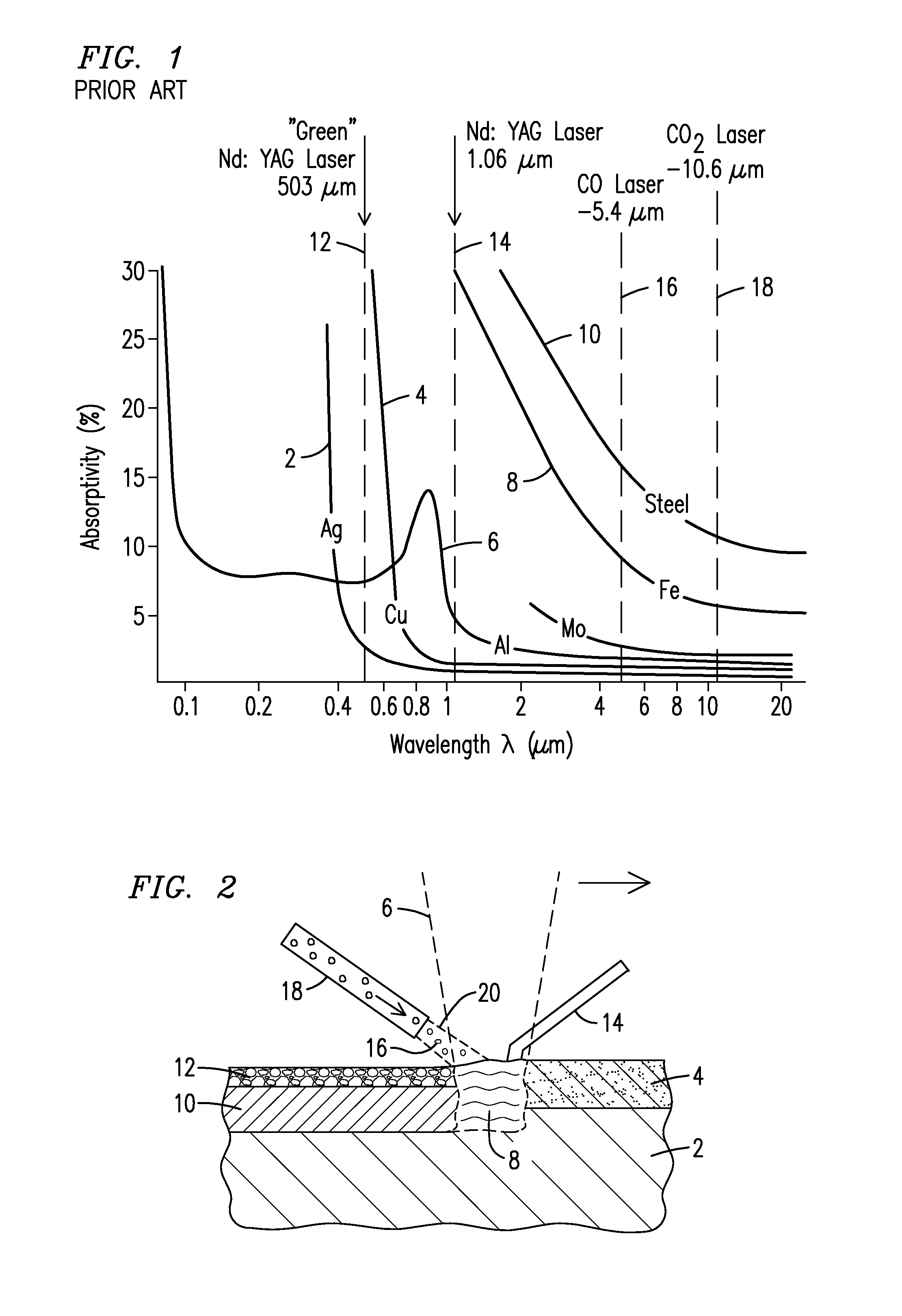

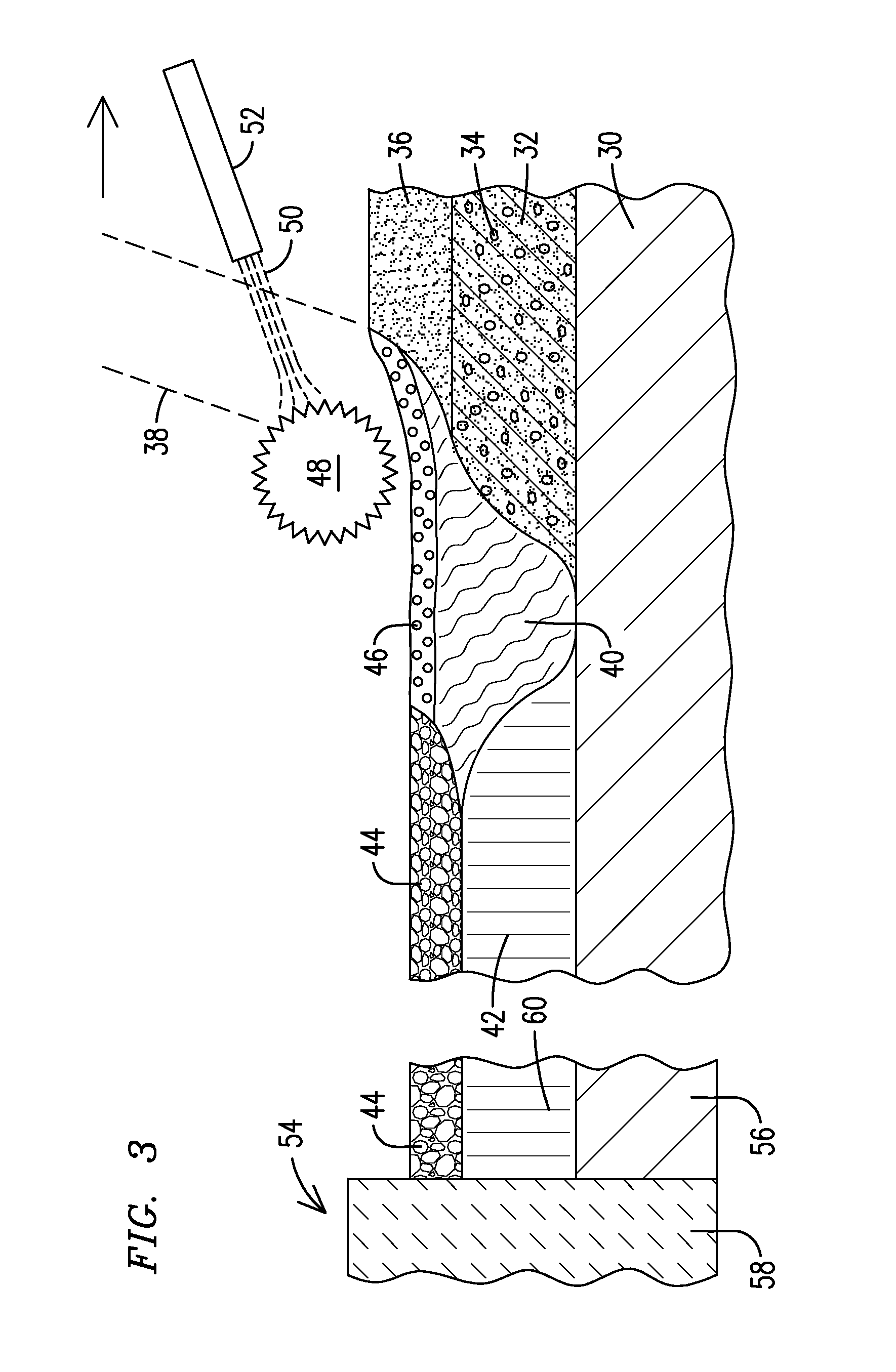

Laser metalworking of reflective metals using flux

Methods for laser processing of reflective metals. A reflective metal (2) is heated by applying a laser beam (6) to a layer of flux (4) in contact with the reflective metal, in which the flux is a powdered flux composition. The laser beam (38) may be applied to a powdered flux composition (36) such that thermal energy absorbed from the laser beam is transferred to a reflective-metal filler material (32) situated on a support material (30), and the powdered flux composition and the reflective-metal filler material melt to form a melt pool (40) which solidifies to form a metal layer (42) covered by a slag layer (44).

Owner:SIEMENS ENERGY INC

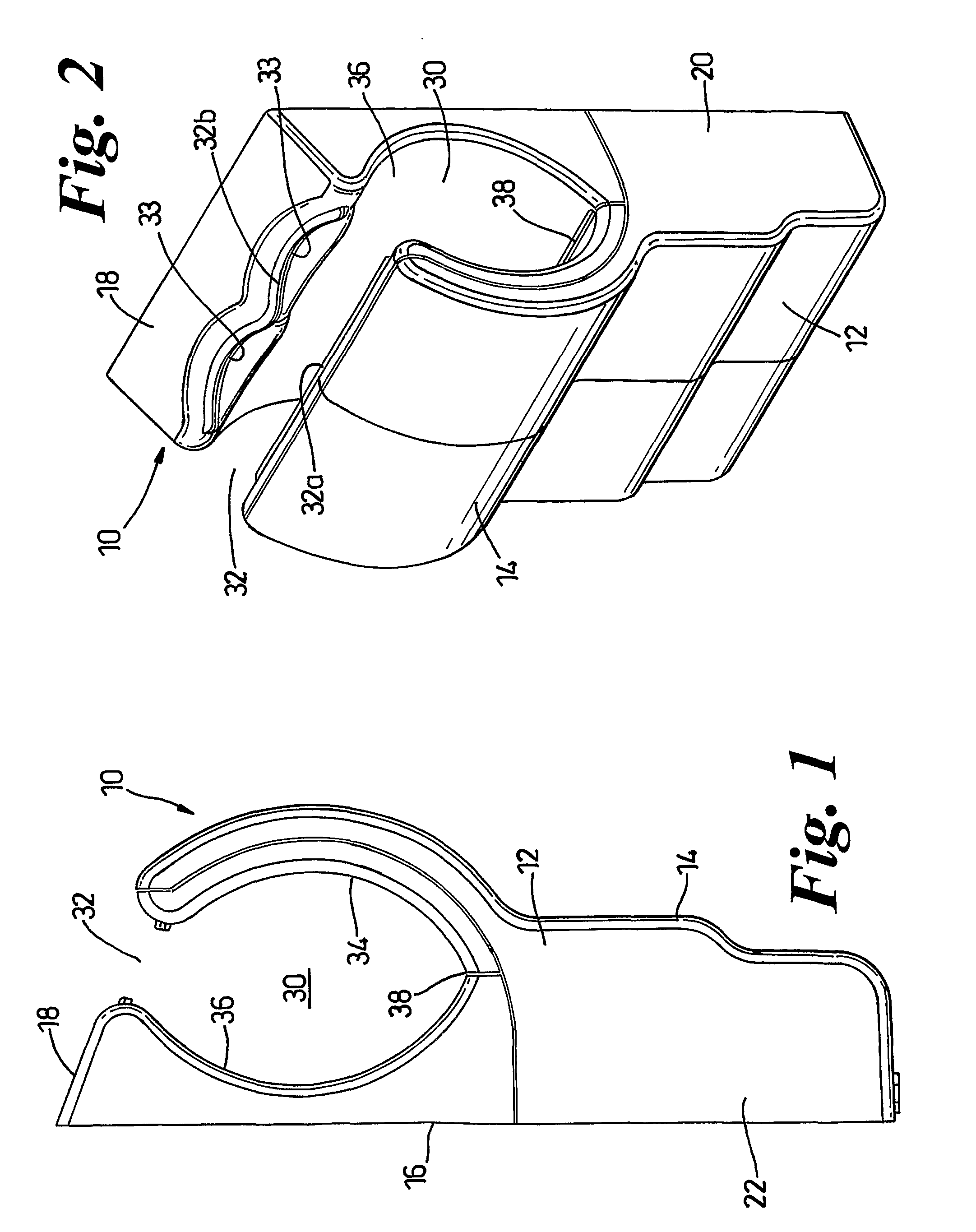

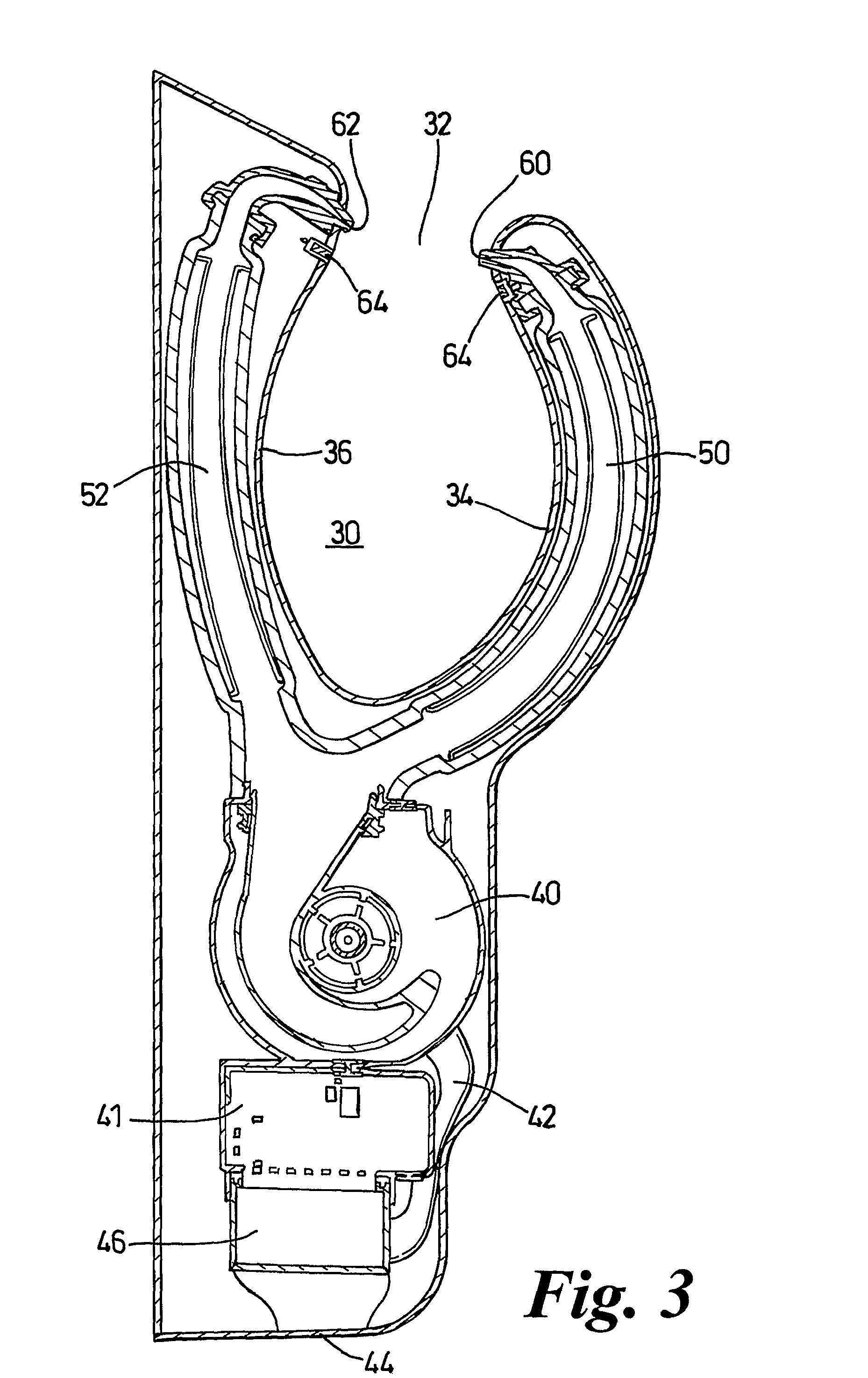

Dryer

ActiveUS20080216343A1Minimizing introductionReduce manufacturing costDrying solid materials with heatWash-standsMetalworkingPlastic materials

A drying apparatus has a casing, a cavity formed in the casing for receiving an object, and a fan located in the casing and creating an airflow. At least one slot-like opening communicates with the fan and is arranged in the casing so as to direct an airflow transversely across the cavity. The slot-like opening is formed between opposing walls which are manufactured from a thermosetting plastics material. By manufacturing the walls of the slot-like opening from a thermosetting plastic material such as melamine, the walls of the slot-like opening can be molded economically instead of machined from metal. The thermosetting plastic material is dimensionally stable when moulded, thermally resistant and impact resistant.

Owner:DYSON TECH LTD

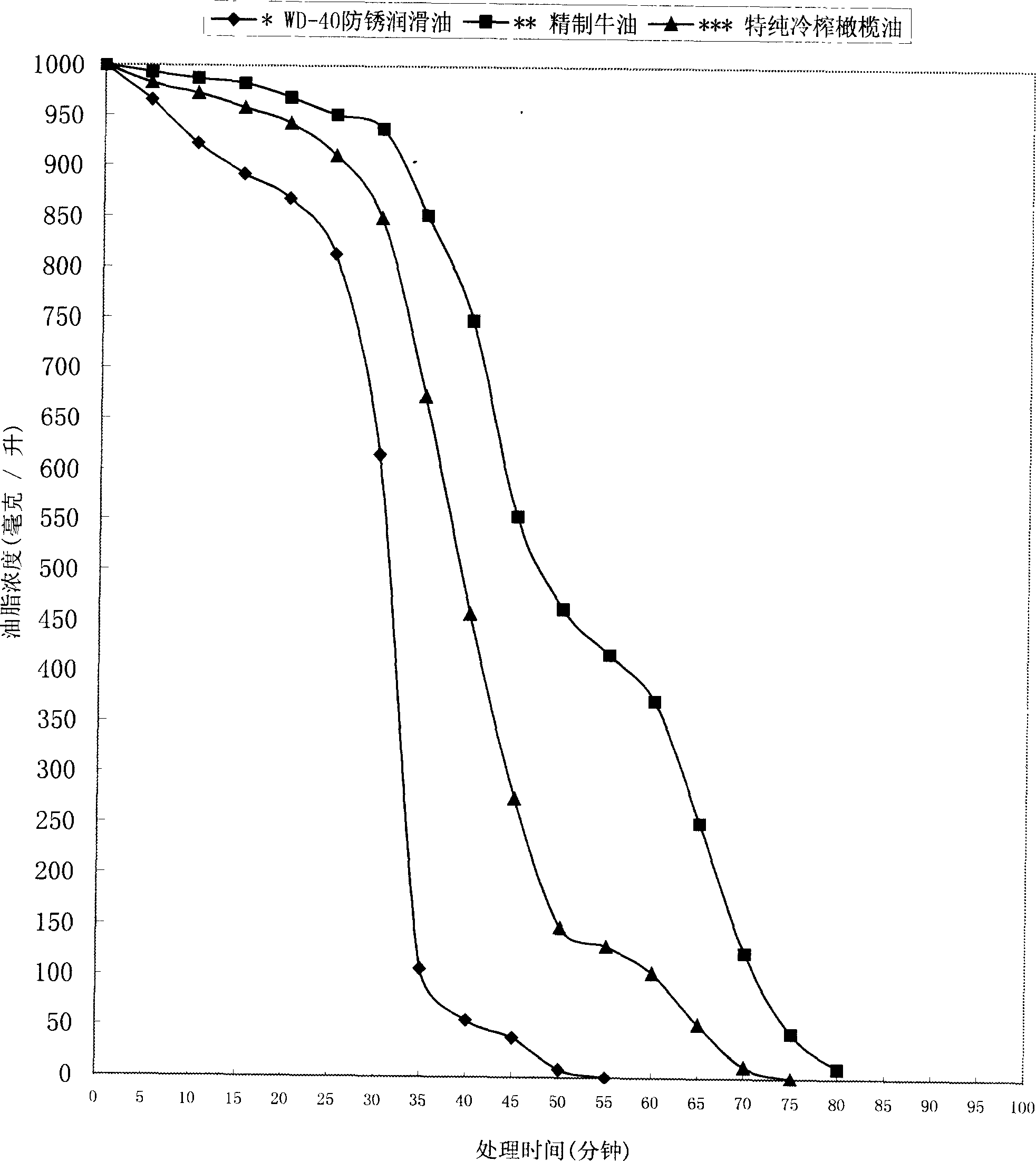

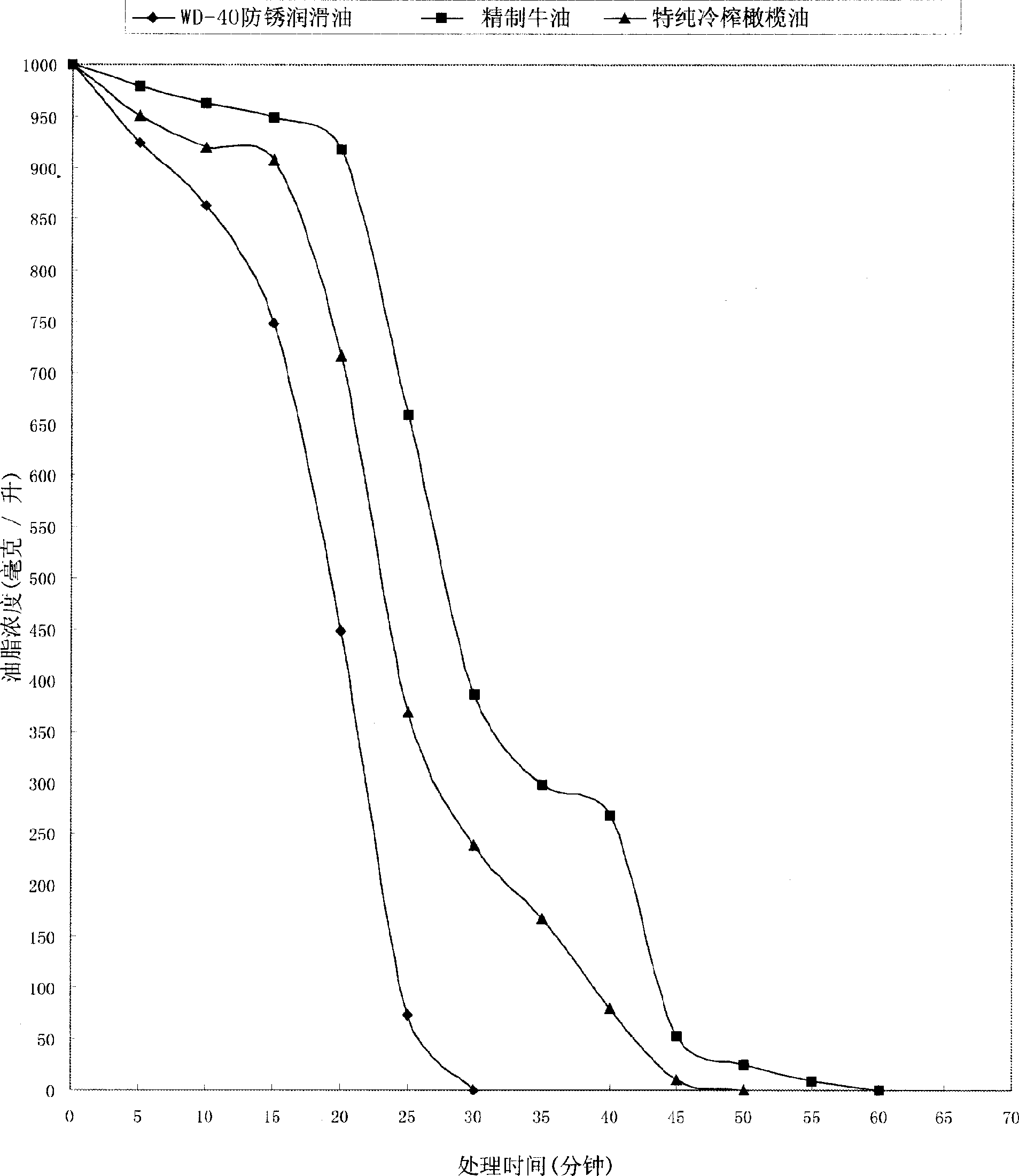

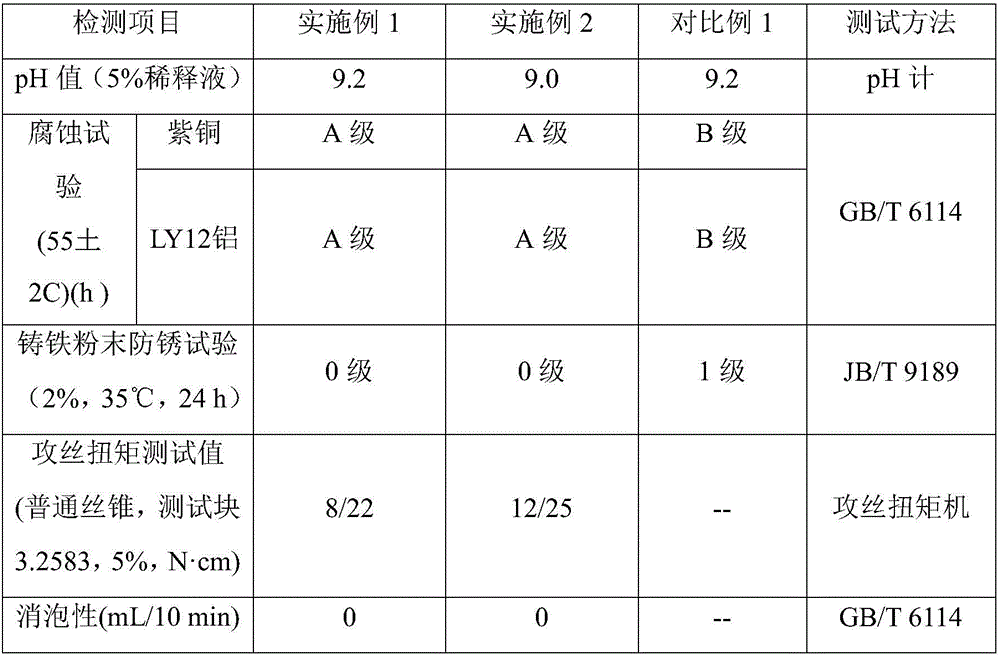

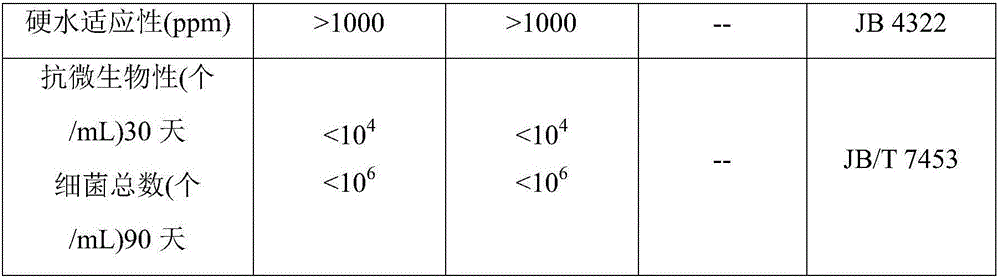

Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

The invention discloses a biological degreaser for degreasing pretreatment in metal processing industry and method for processing greasy dirt on metal surfaces, which integrates the two independent processes of grease removing and greasy dirt decomposing, the biological degreaser containing oil-degraded microorganisms can not only scale off greasy dirt from metal surfaces, but also decompose the greasy dirt simultaneously.

Owner:TANTZ ENVIRONMENTAL TECH

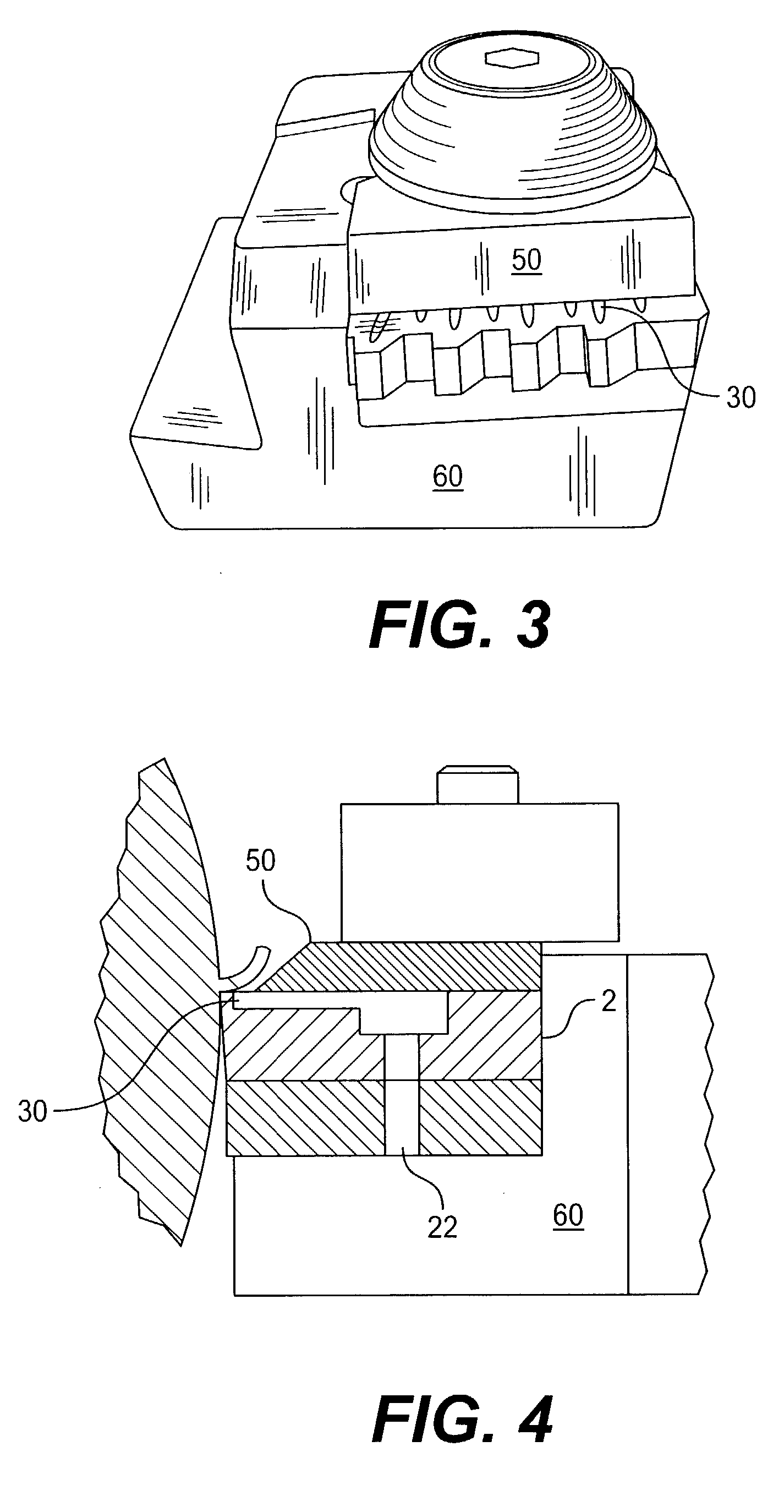

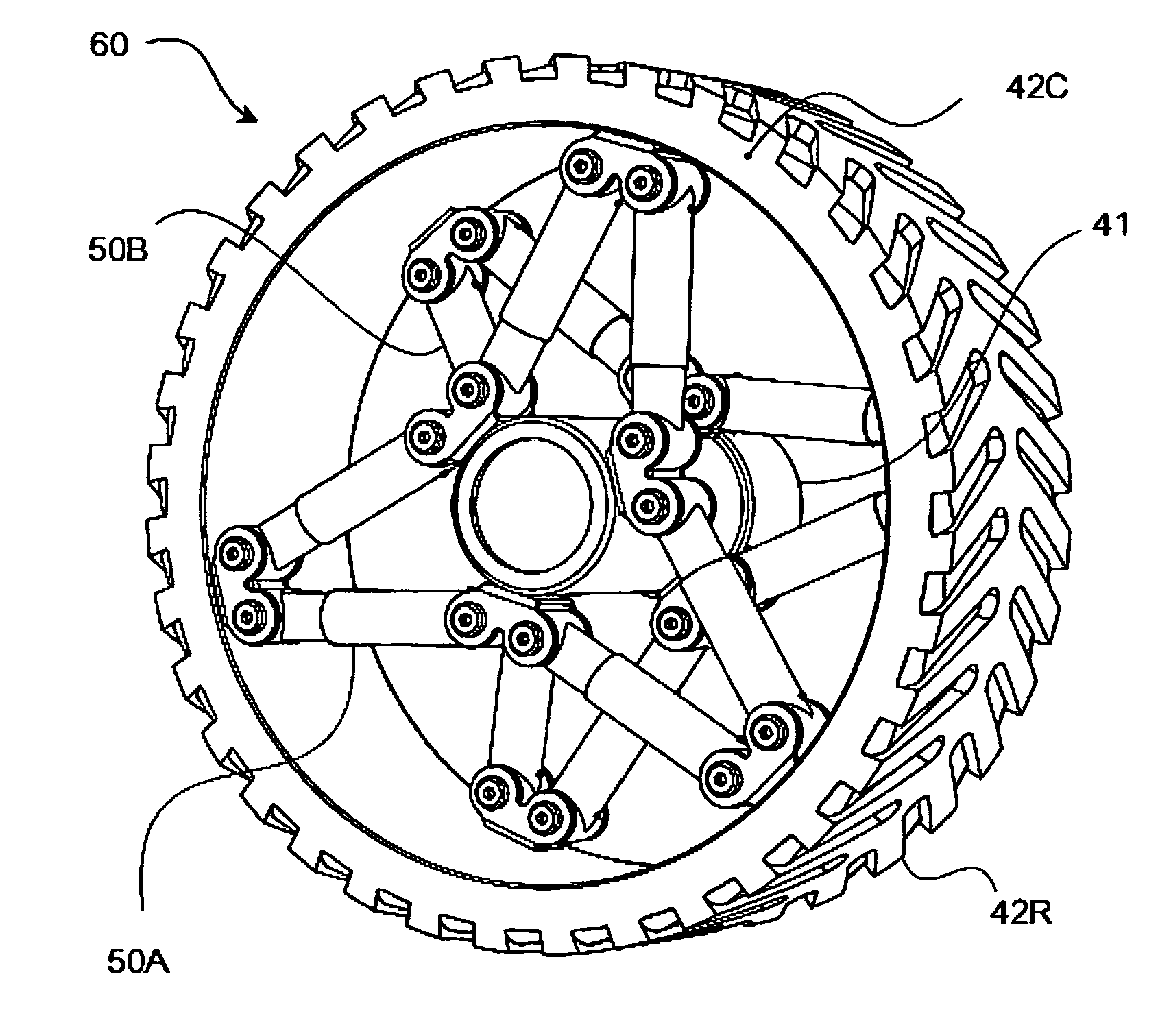

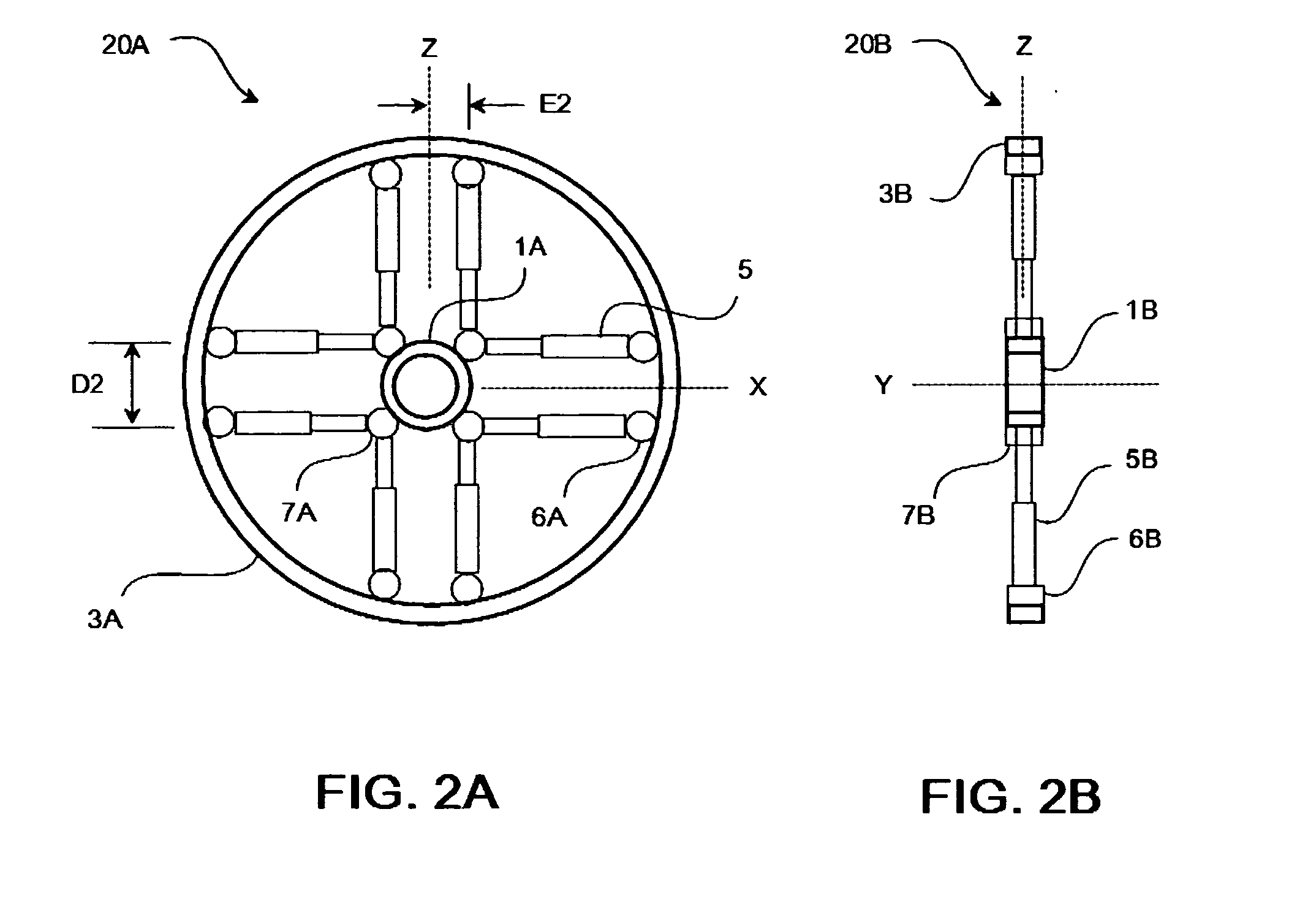

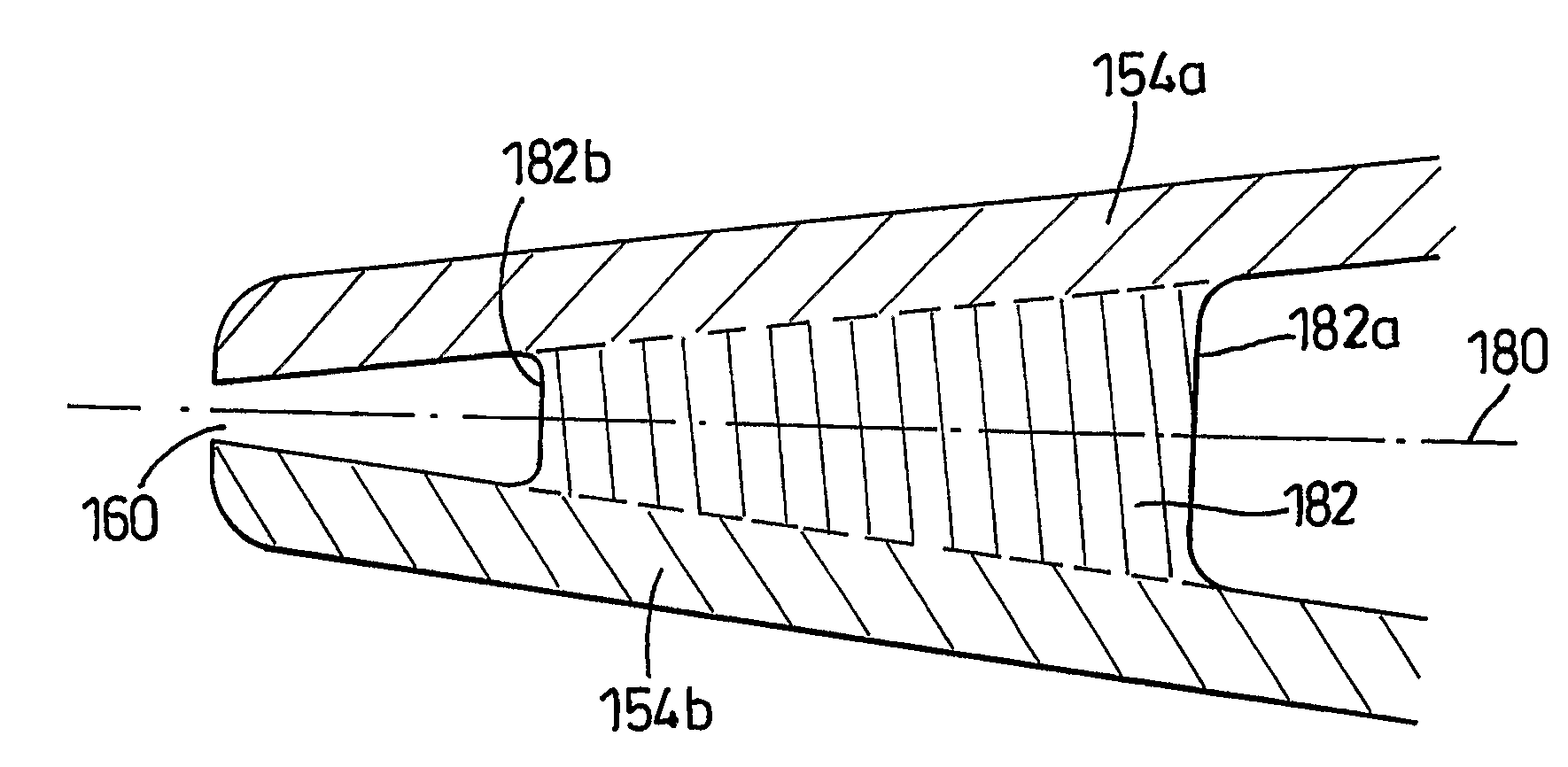

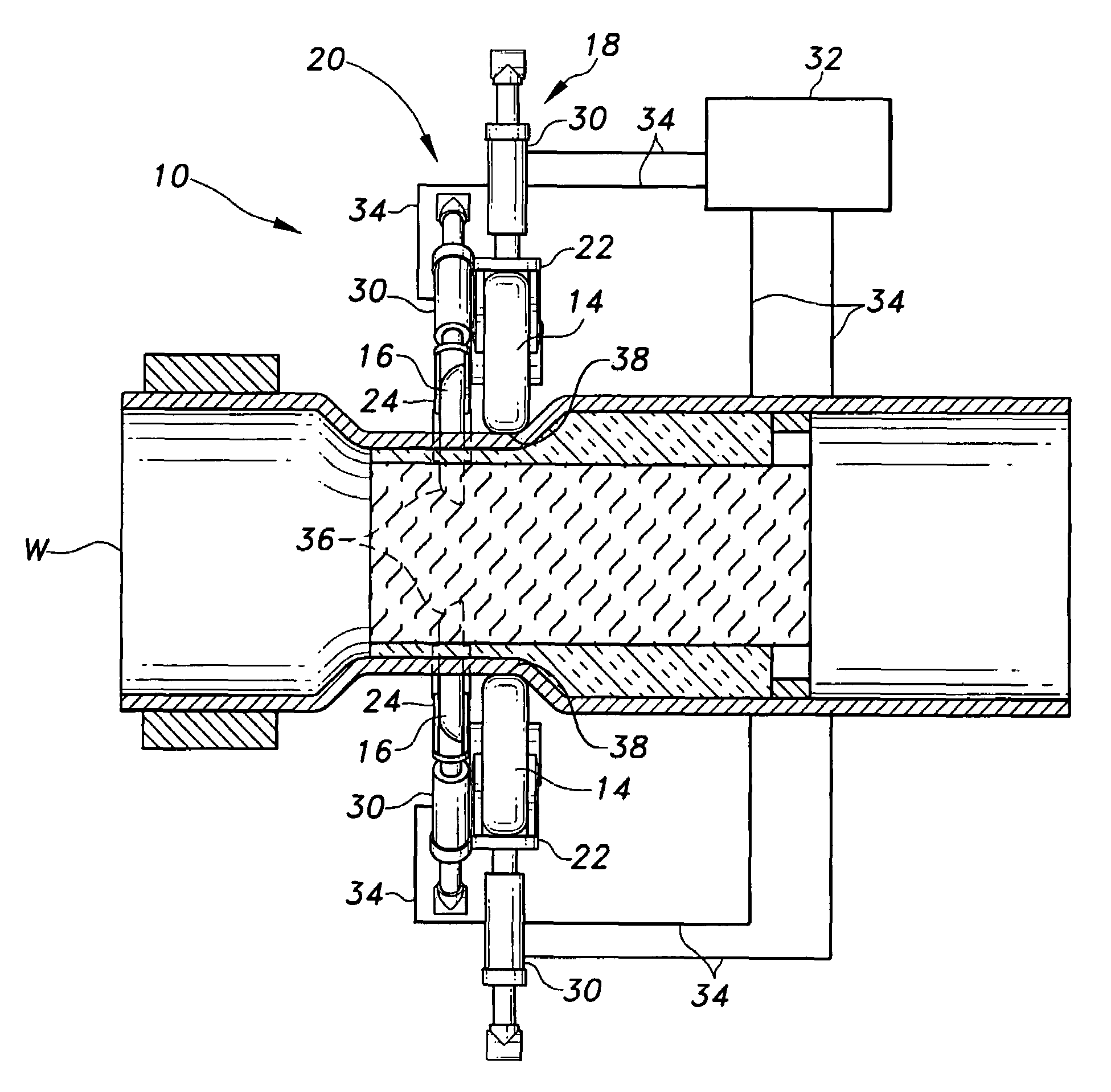

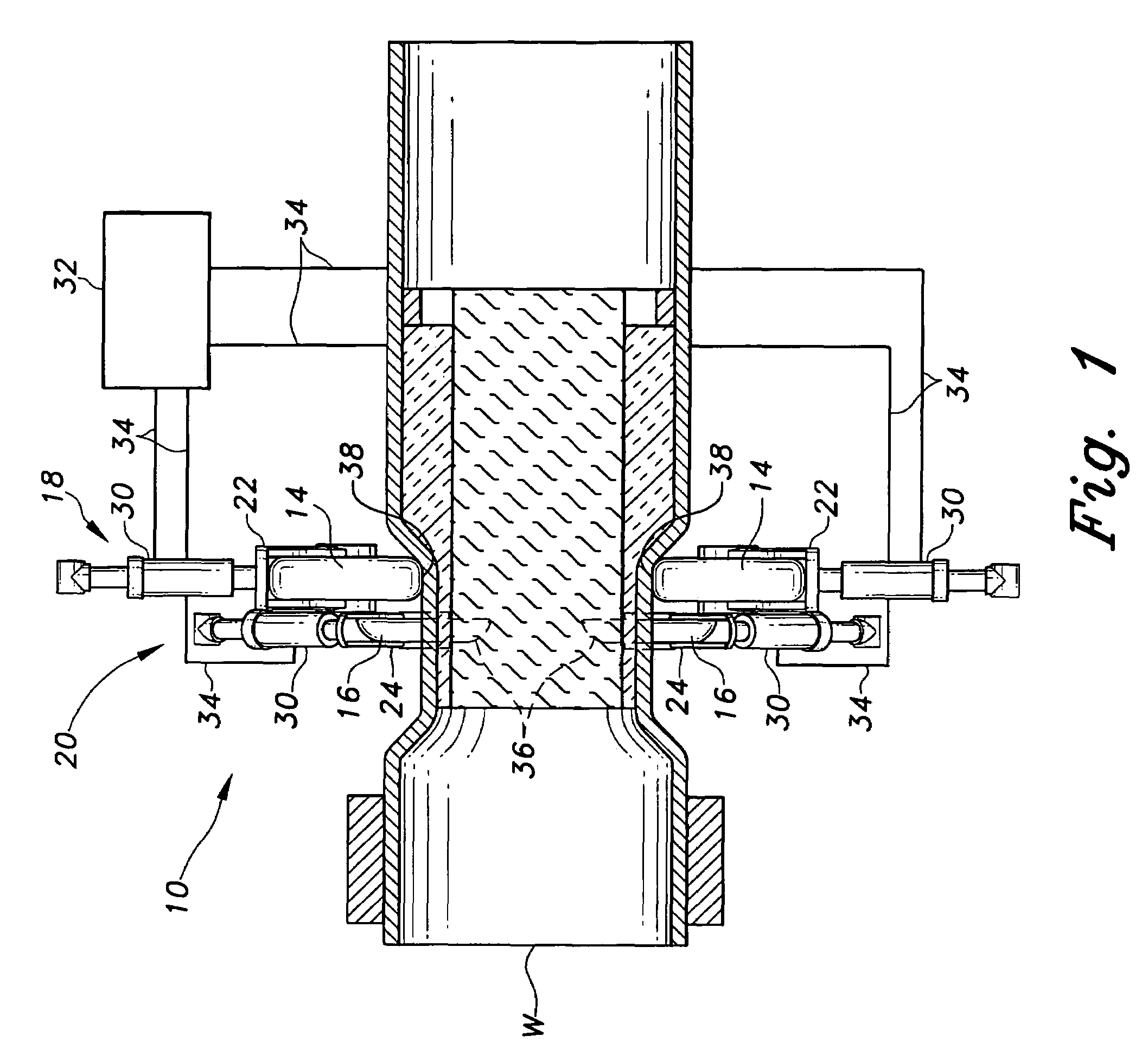

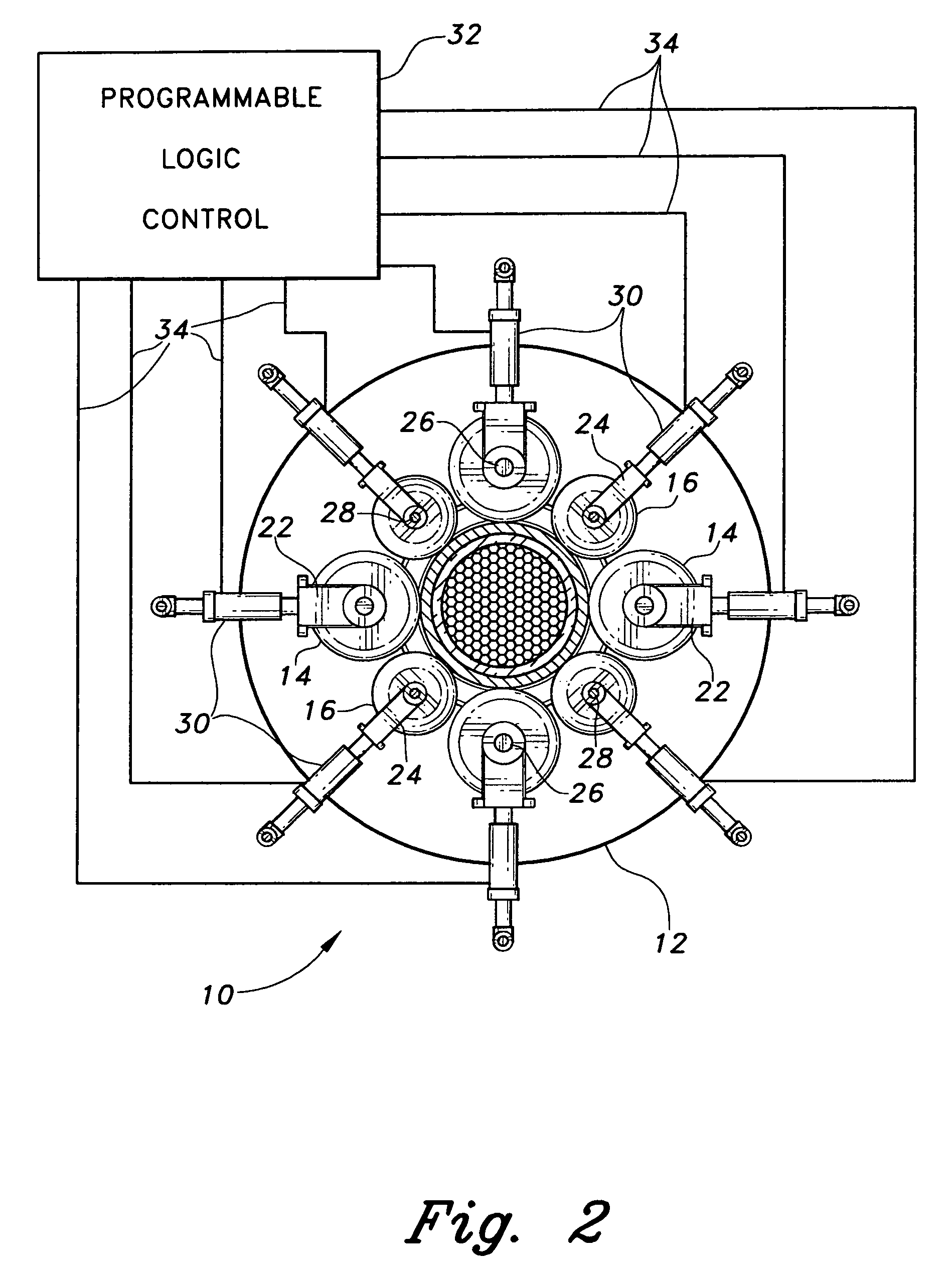

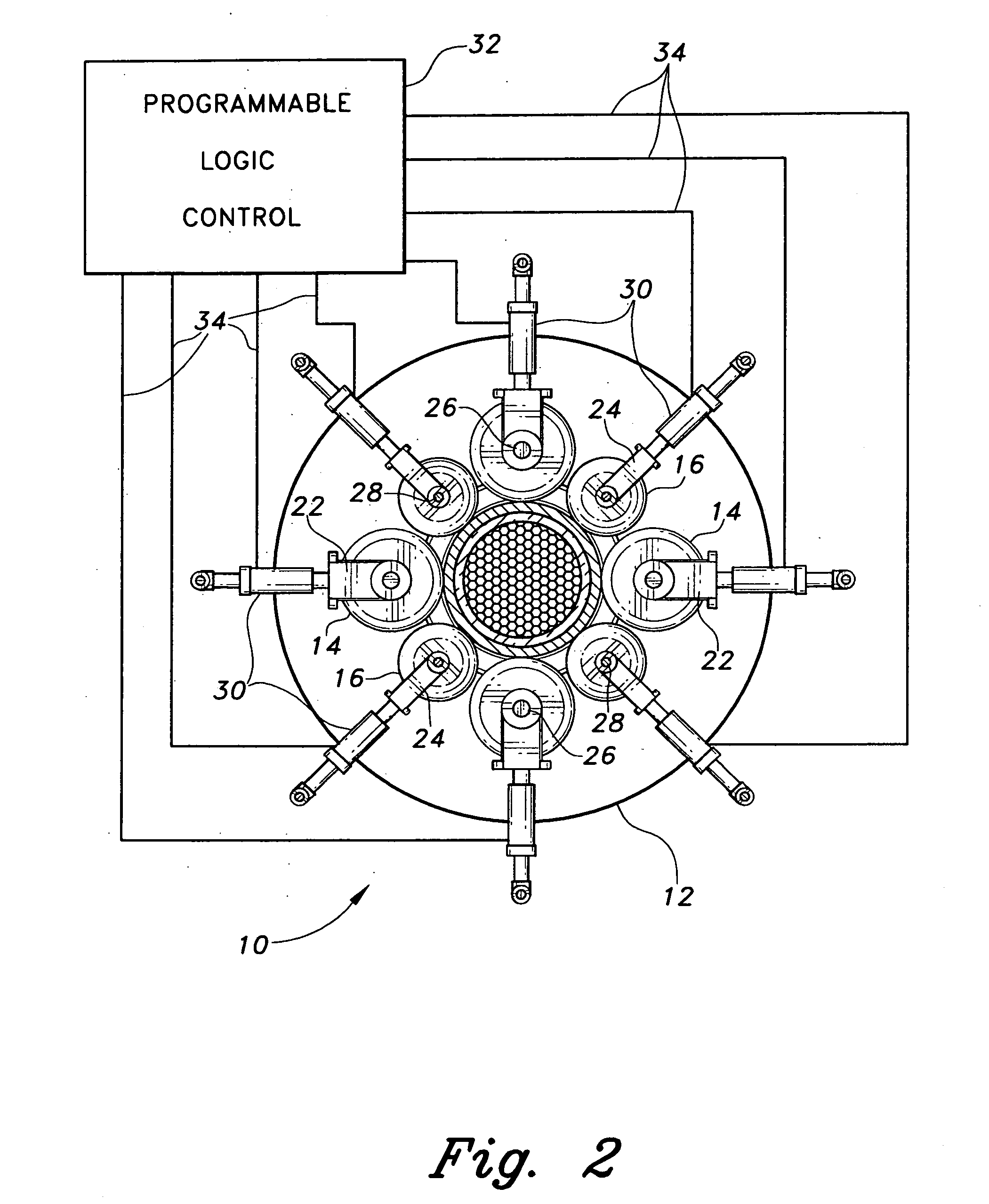

Metal spin forming head

InactiveUS7316142B2Rapid and accurate spin formingStart fastMetalworkingProgrammable logic controller

The present metal spin forming head includes two sets of rollers, with each set having a series of individual metal working rollers therein. The rollers of each set are circumferentially spaced evenly about the head, with each of the rollers of the second set being evenly positioned between corresponding rollers of the first set. The second roller set may be in a non-coplanar relationship with the first roller set. The first roller set comprises rollers having relatively broad widths, for forming the general contours of the workpiece. The second roller set comprises rollers having relatively narrow rims for forming circumferential grooves in the workpiece, resulting in corresponding beads within the workpiece for securing an article therein. The rollers are controlled independently of one another by a programmable logic control capable of driving the rollers cyclically as the workpiece (or spin forming head) rotates to form non-cylindrical shapes.

Owner:SCHALLER & CO

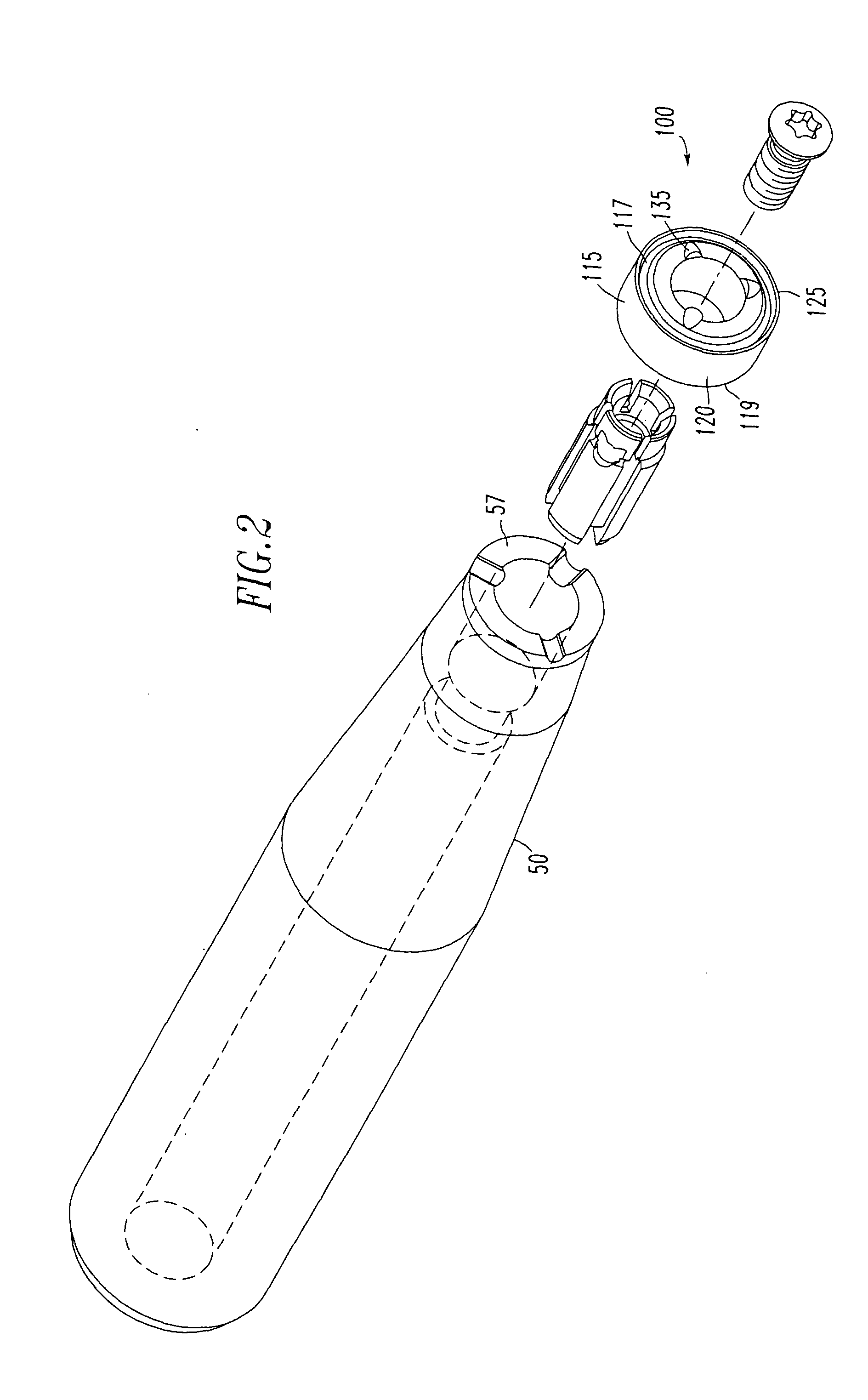

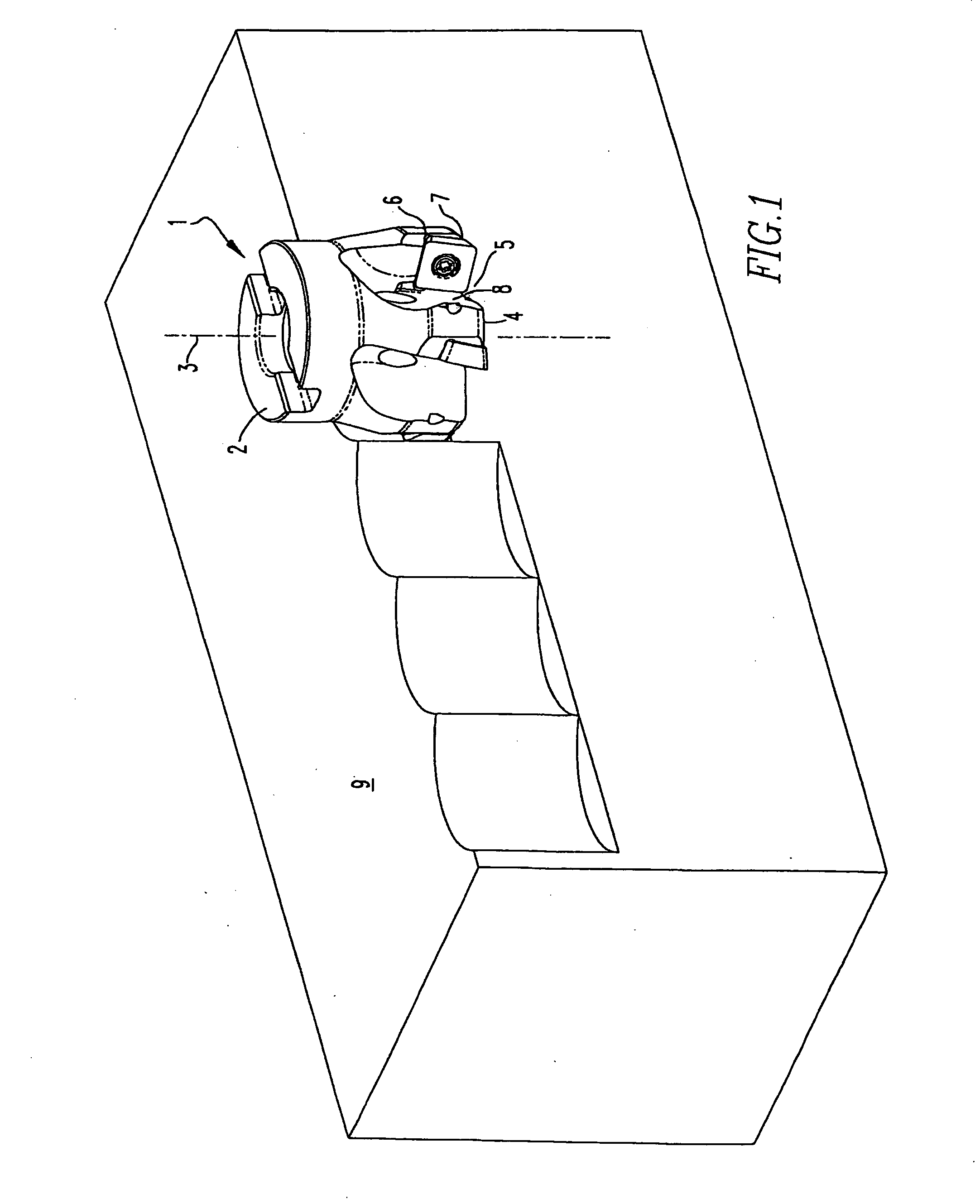

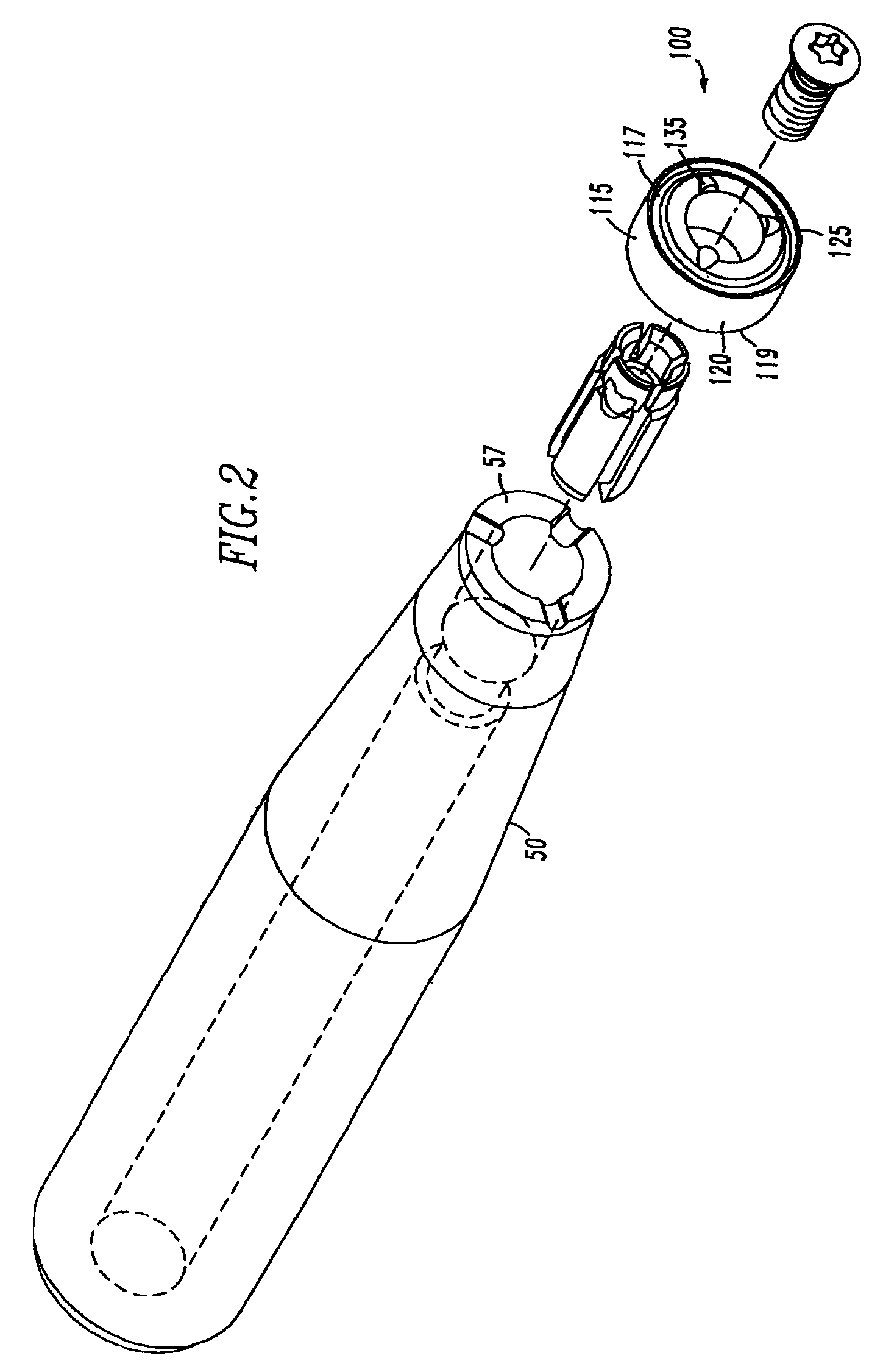

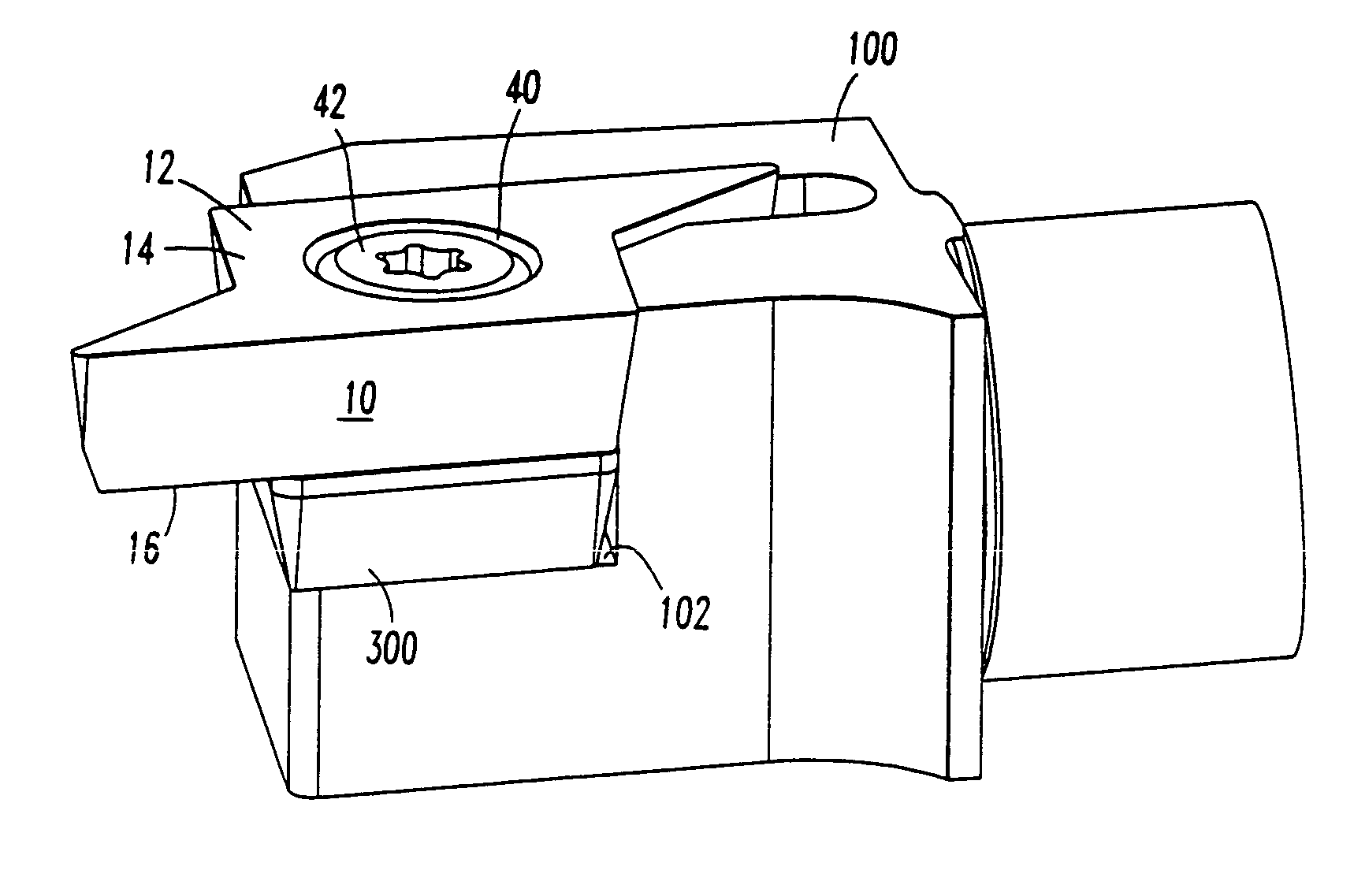

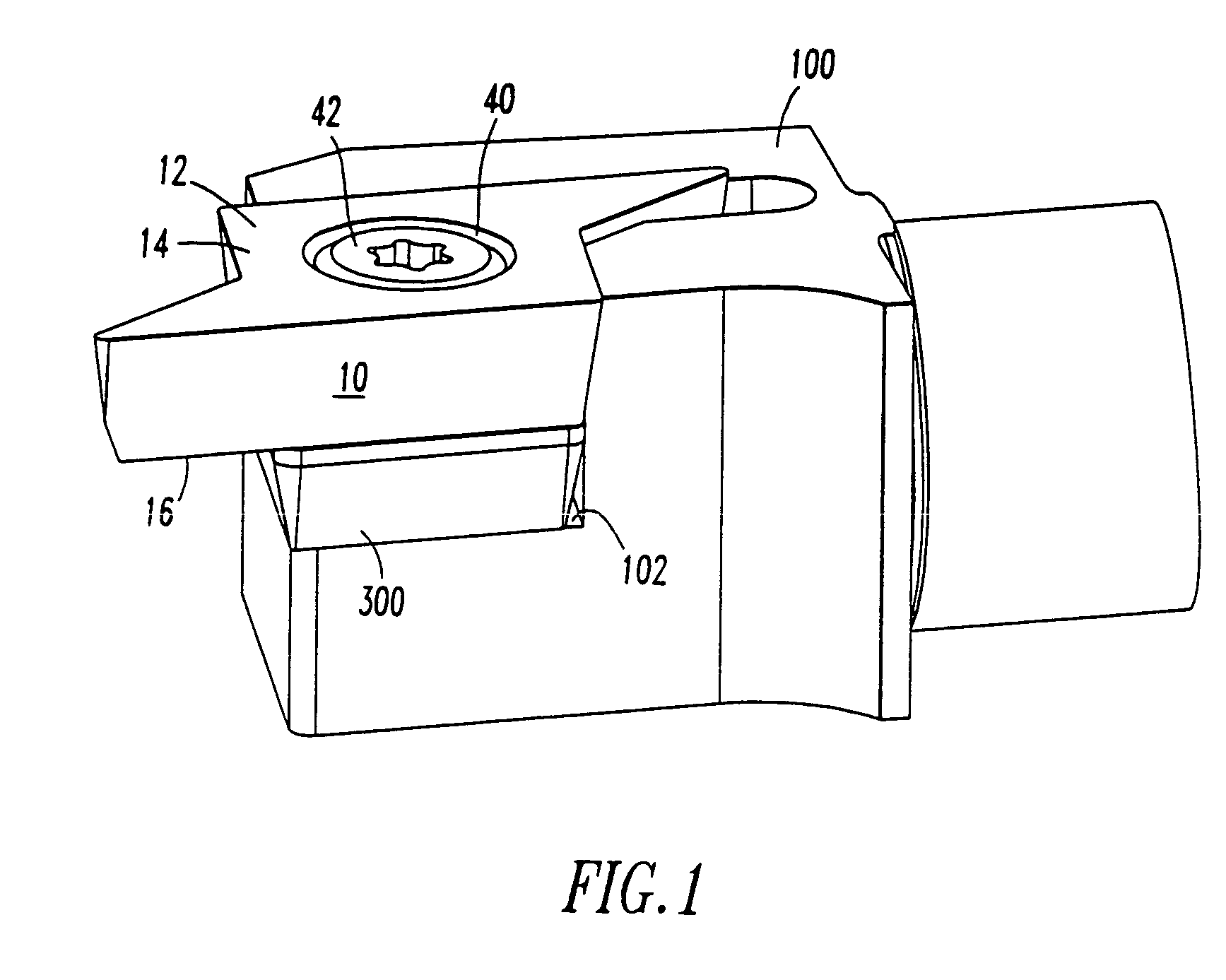

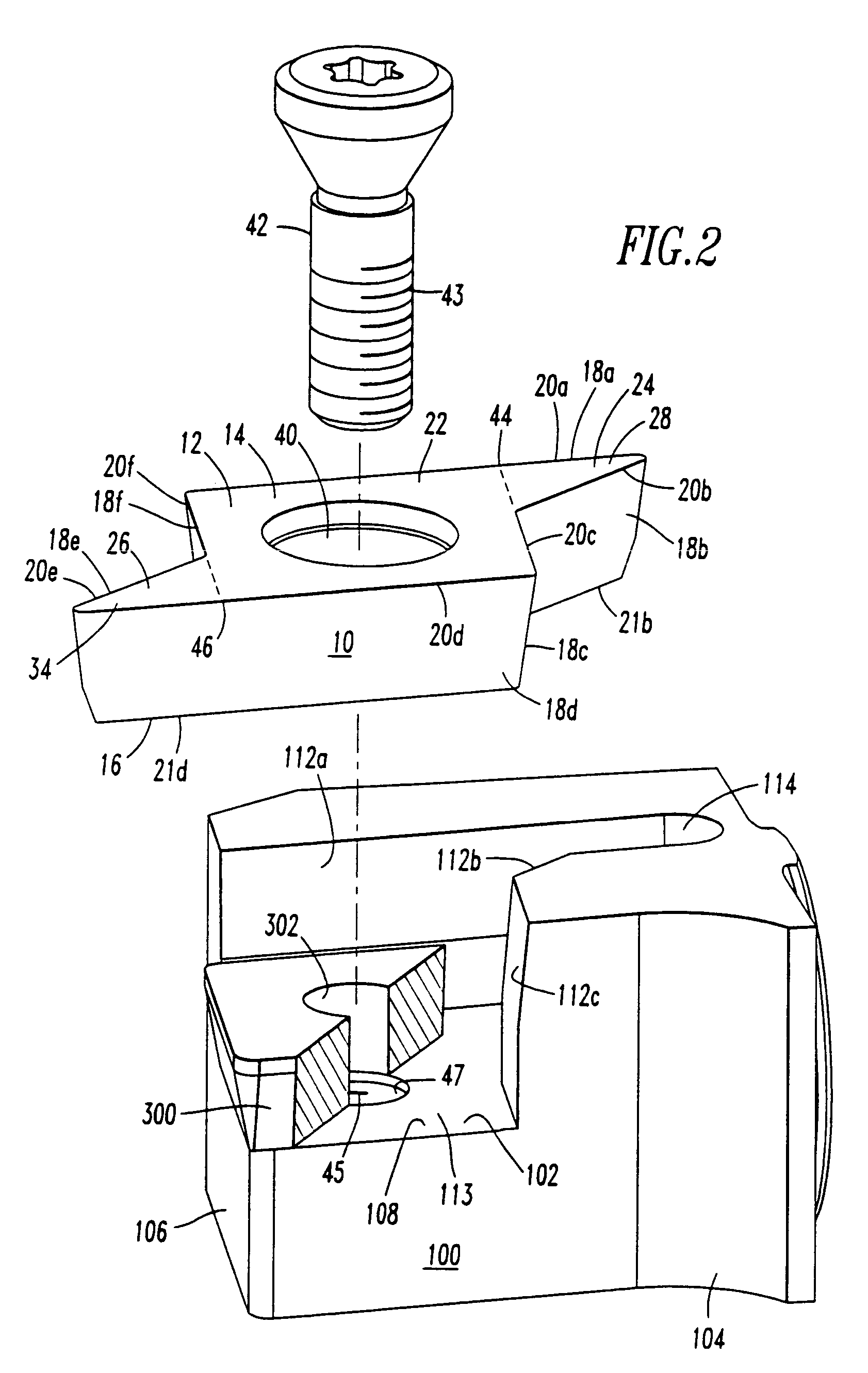

Assembly For Rotating A Cutting Insert During A Turning Operation And Inserts Used Therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. The cutting insert is secured within a toolholder having features to secure the insert but at the same time make for efficient removal of the insert from the toolholder.

Owner:KENNAMETAL INC

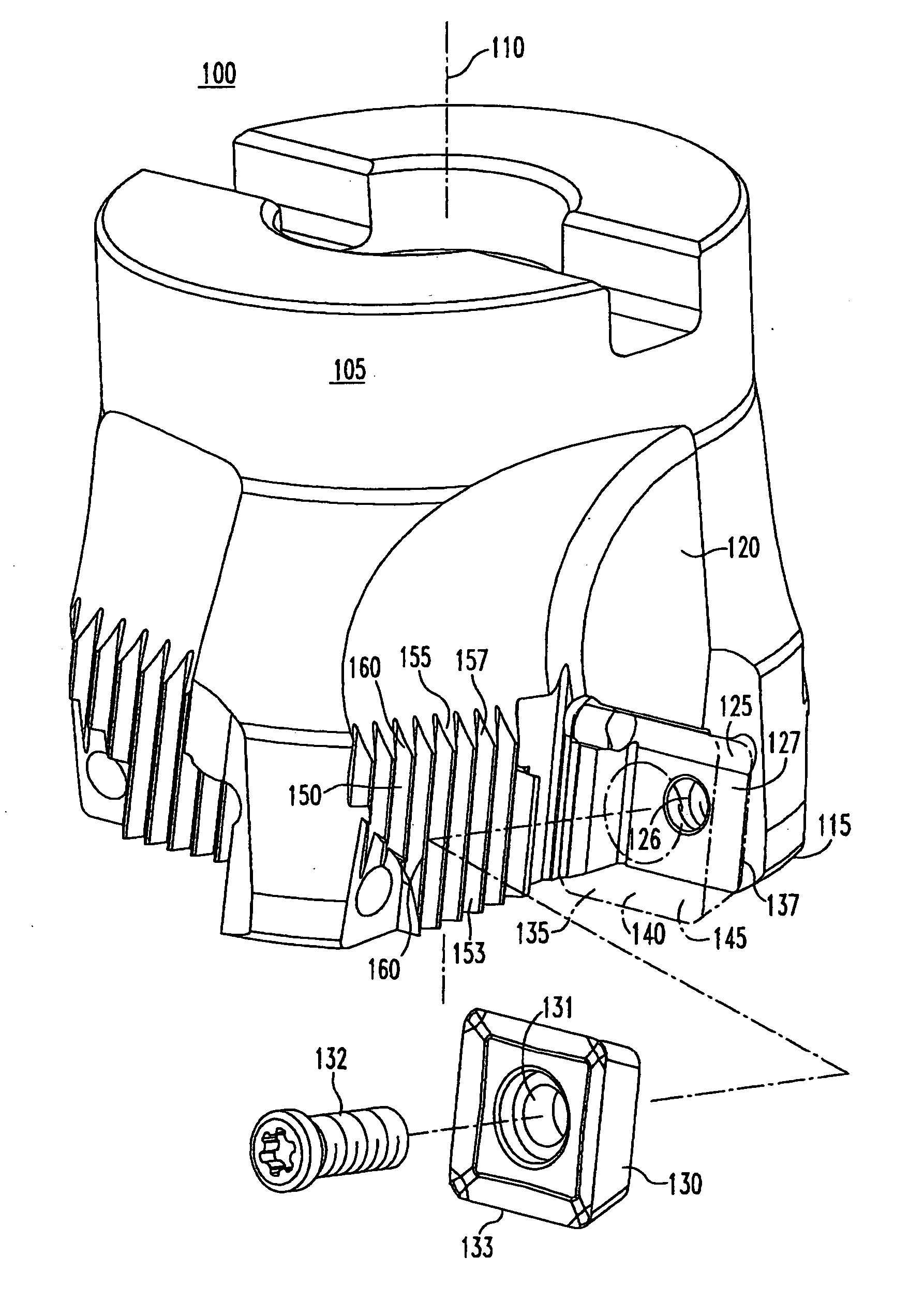

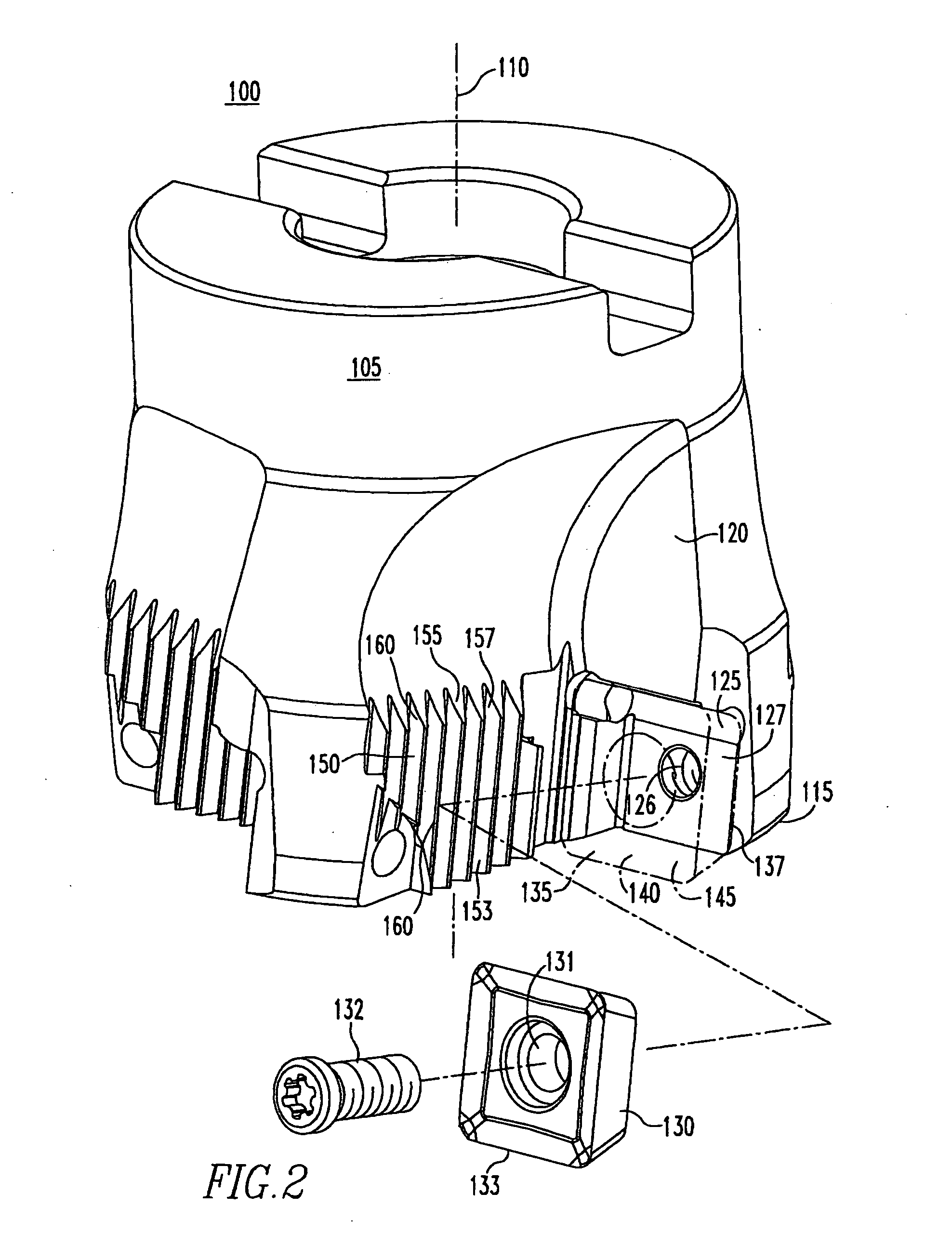

Toolholder with chip ejection segment thereupon

A toolholder for use in a metalworking operation, with a body extending along a longitudinal axis and a recess extending within the first end of the body. Adjacent an insert pocket adapted to receive a cutting insert in the recess is at least one wall with a portion having a surface with multiple interruptions to form a chip ejection segment. The chip ejection segment may be an integral part of the toolholder body or may be a discrete piece removably attached to the toolholder body. A method of imparting to a toolholder such a chip ejection segment is also disclosed.

Owner:KENNAMETAL INC

Assembly for rotating a cutting insert during a turning operation and inserts used therein

Owner:KENNAMETAL INC

Metal spin forming head

The present metal spin forming head includes two sets of rollers, with each set having a series of individual metal working rollers therein. The rollers of each set are circumferentially spaced evenly about the head, with each of the rollers of the second set being evenly positioned between corresponding rollers of the first set. The second roller set may be in a non-coplanar relationship with the first roller set. The first roller set comprises rollers having relatively broad widths, for forming the general contours of the workpiece. The second roller set comprises rollers having relatively narrow rims for forming circumferential grooves in the workpiece, resulting in corresponding beads within the workpiece for securing an article therein. The rollers are controlled independently of one another by a programmable logic control capable of driving the rollers cyclically as the workpiece (or spin forming head) rotates to form non-cylindrical shapes.

Owner:SCHALLER & CO

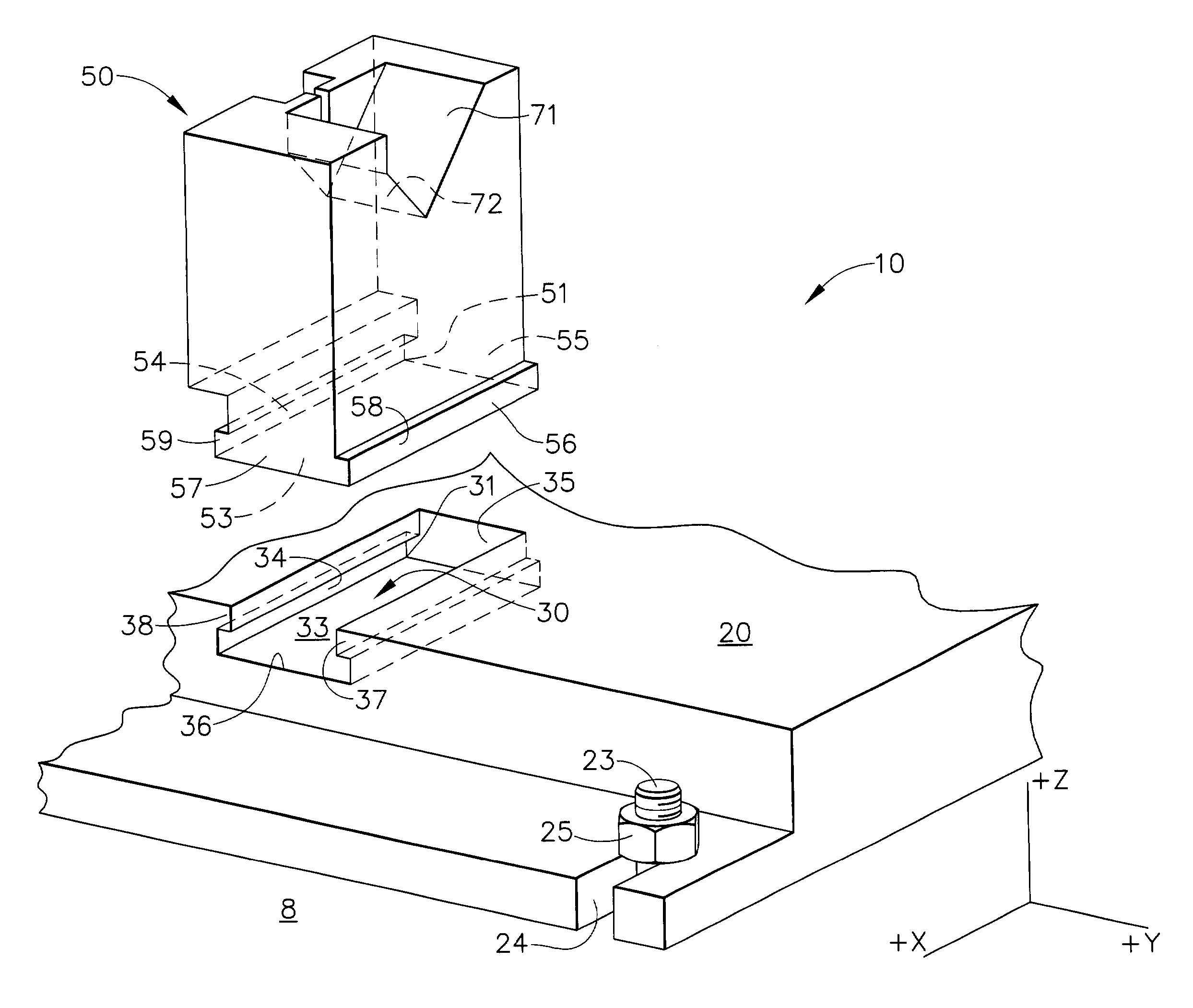

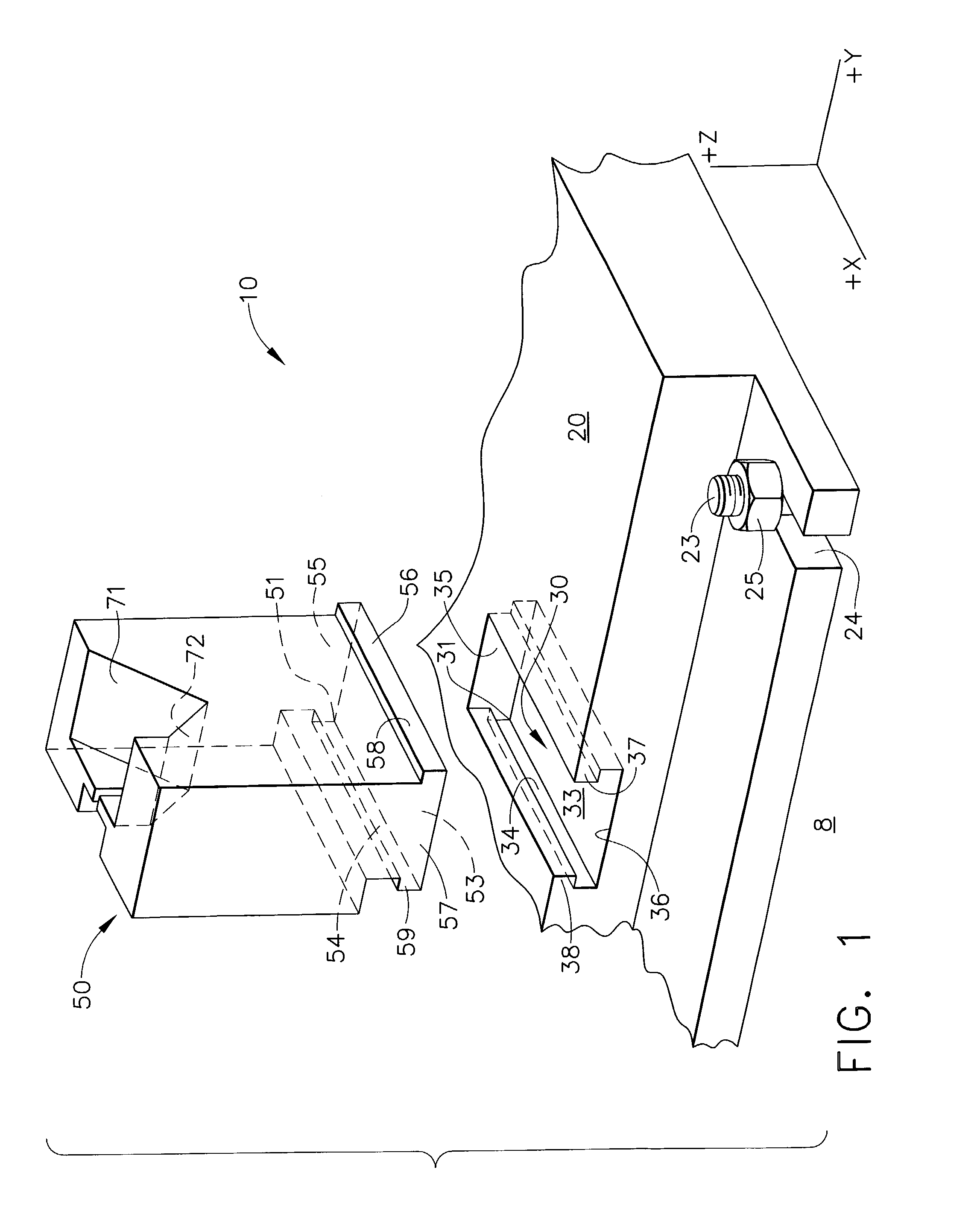

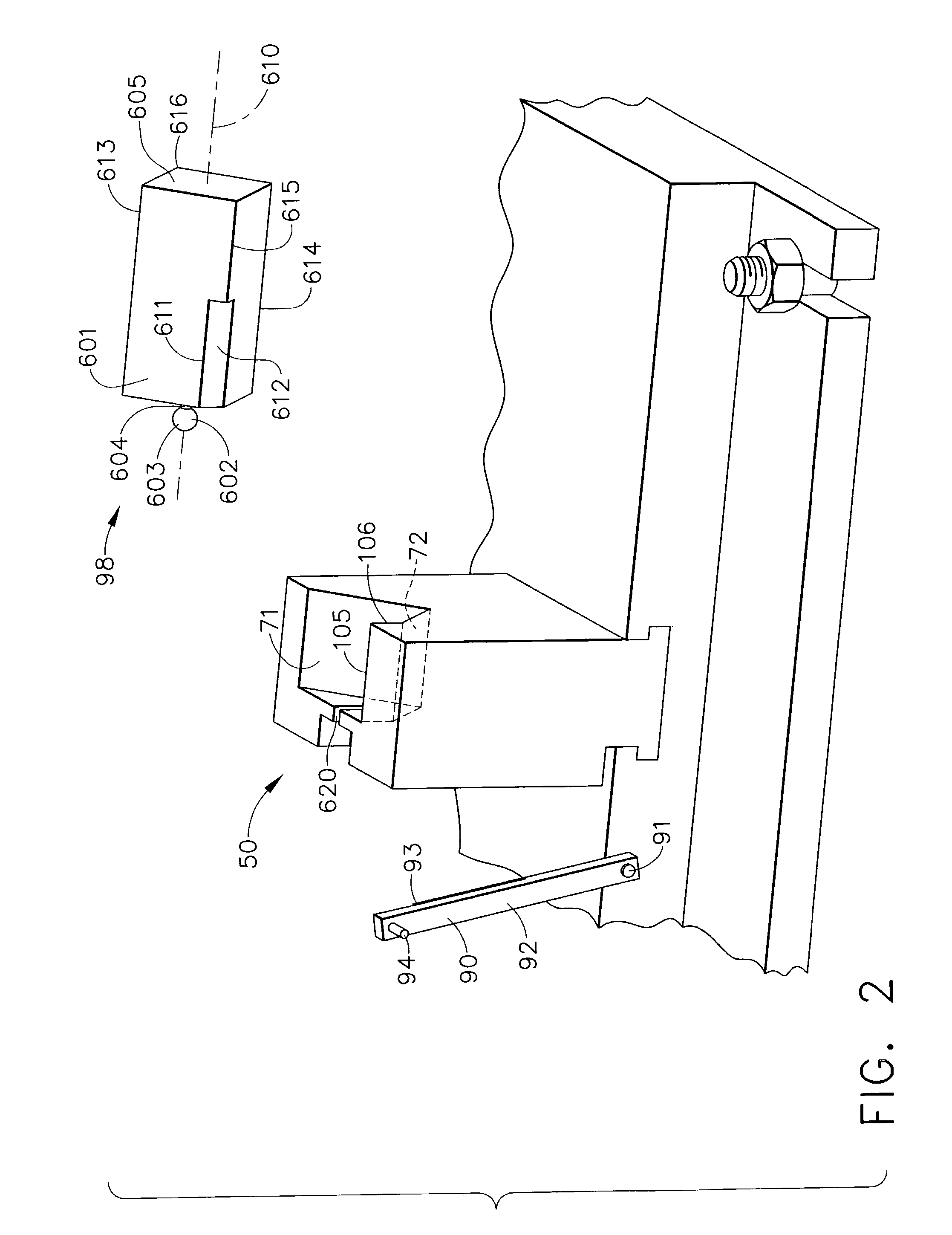

Manufacturing cell using tooling apparatus

A manufacturing cell having a plurality of work stations, where at least one of the work station comprises a metalworking machine, and where at least one metalworking machine is provided with a modular tooling apparatus. The modular tooling apparatus consists of a base having one or more attachment surfaces, and one or more inserts that can be inserted semi-permanently to the attachment surfaces. The attachment surface is typically a pocket in the surface of the base. The insert has a workpiece support feature that can support and / or secure the workpiece into the proper position and orientation for machining. The base, pockets and inserts are configured to provide a characteristic location and orientation for the workpiece relative to the base, and to the metalworking machine. The modular tooling apparatus permits machining a family of workpiece members that are related but different in detail, by inserting an insert member from the family of inserts to properly position and orient the corresponding workpiece member, without needing to change, disconnect, or move the base tooling. The invention also provides a process for performing a plurality of metalworking operations on workpieces, employing the manufacturing cell described hereinabove.

Owner:GENERAL ELECTRIC CO

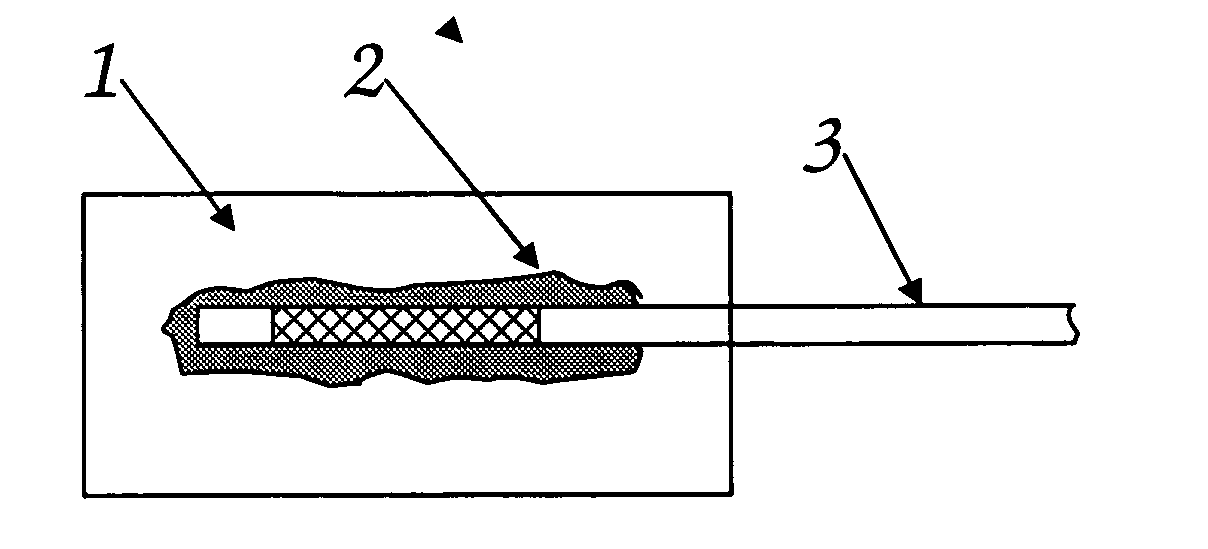

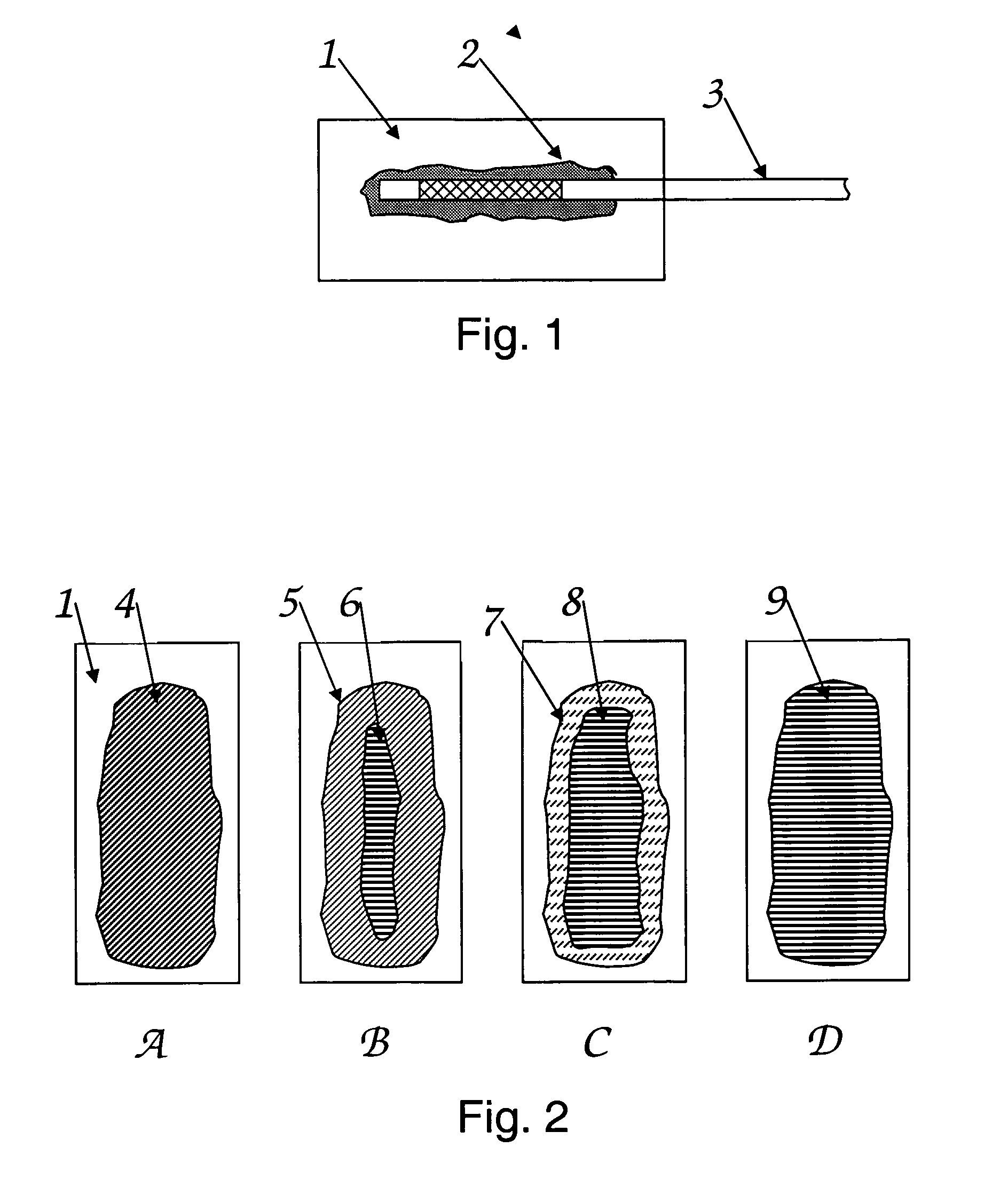

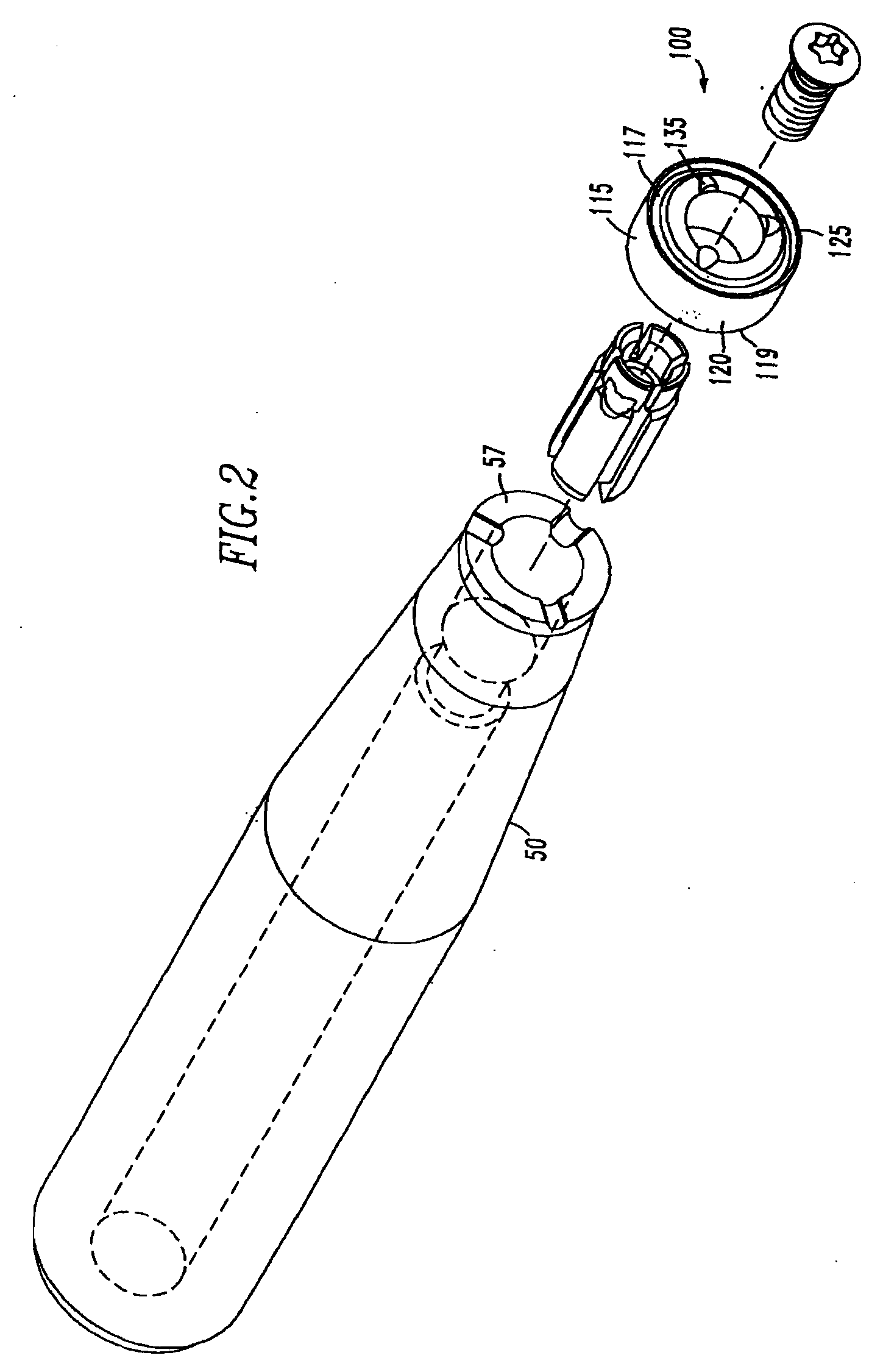

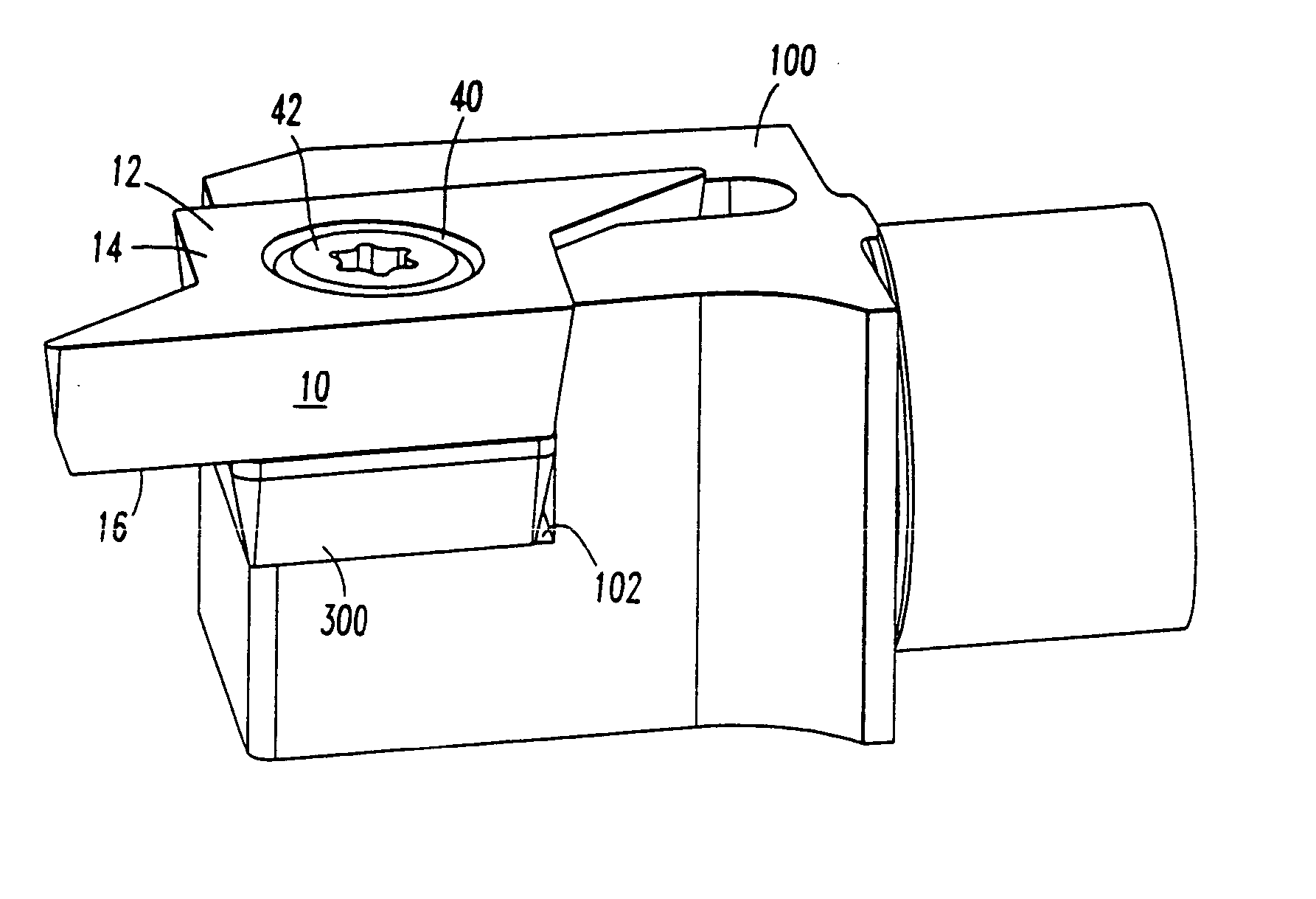

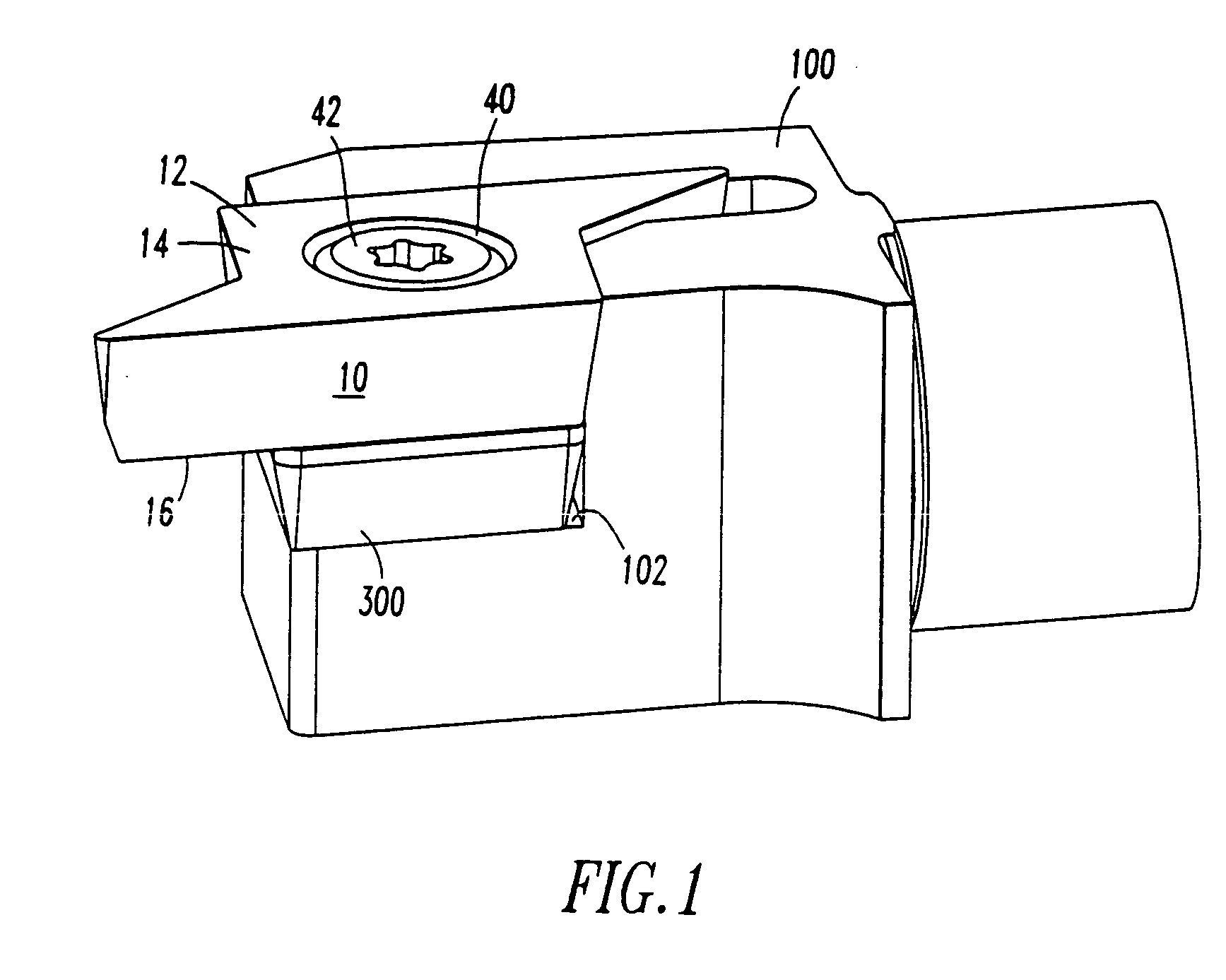

Cutting insert and toolholder for holding the same

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

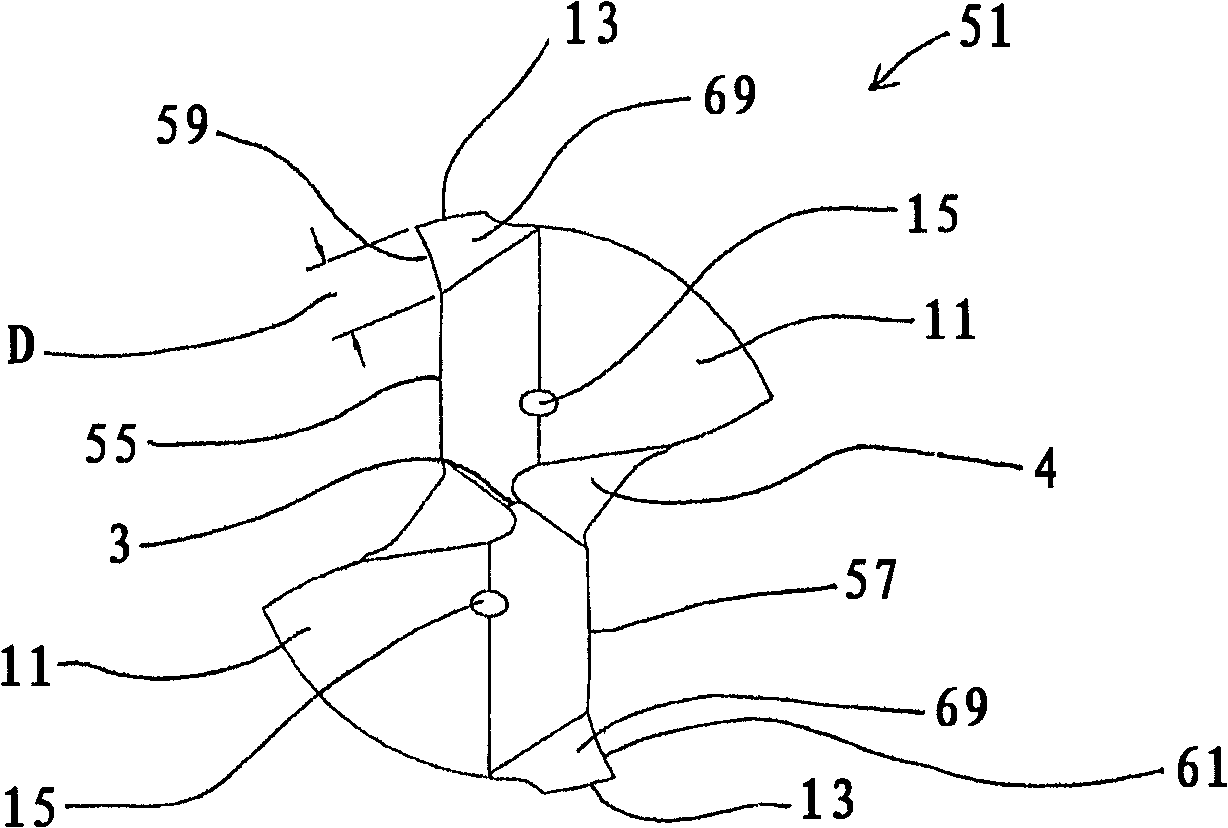

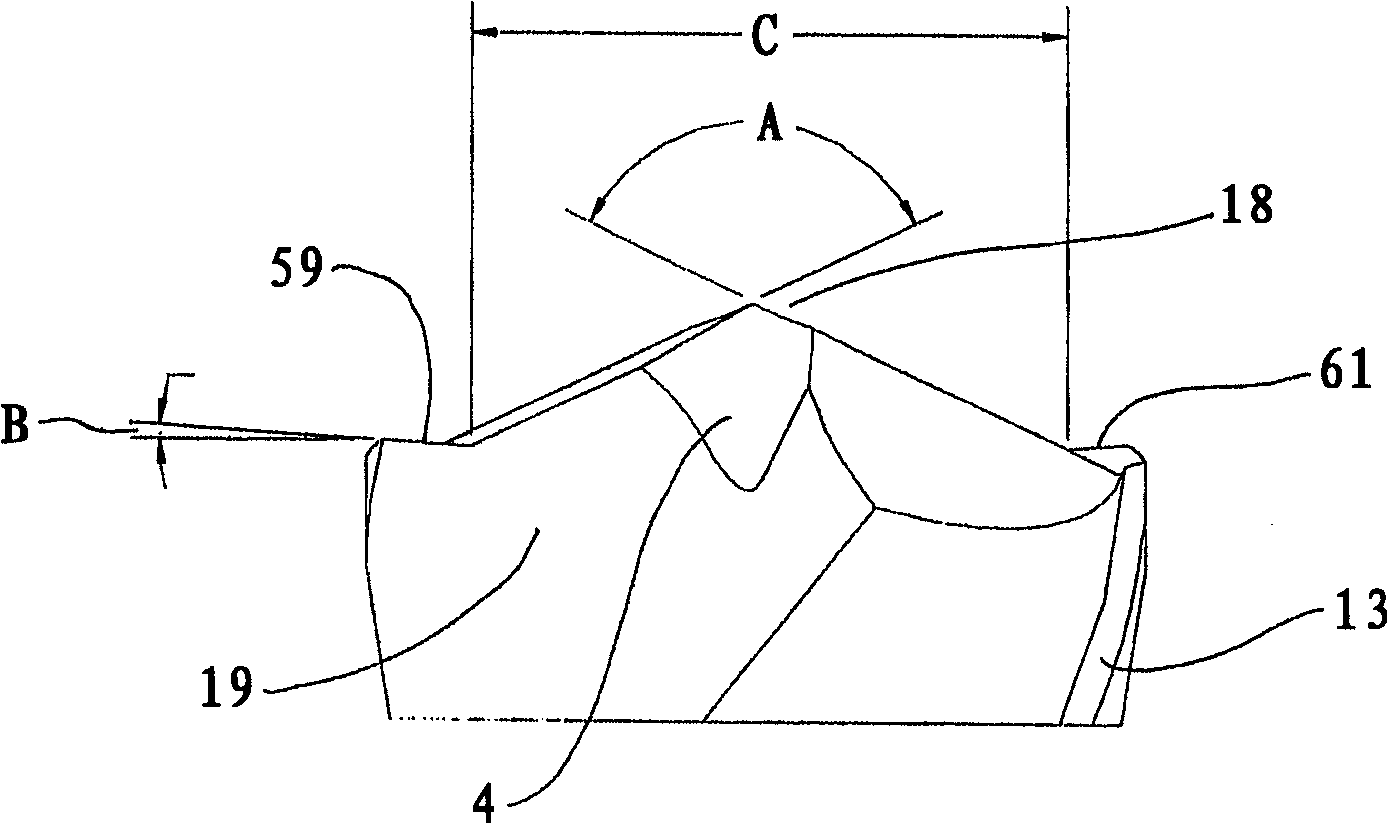

Twist drill

ActiveCN101282806ARelieve pressureReduce the temperatureWorkpiecesTurning toolsBurr heightMetalworking

A metal-working twist drill is provided with inner cutting edges that form a point (18) having an angle, A, of 130 degrees . An outer, peripheral, part of each cutting edge (55, 57) forms an outer cutting portion (59, 61). The outer cutting portions slope in the opposite direction to the corresponding inner cutting edges and form an angle B, of 3 degrees with respect to a plane normal to the axis of rotation of the twist drill. The width of the outer cutting portion, D as measured at the cutting edge, is 10.5% of the diameter of the twist drill. The metal-working twist drill produces bores having a reduced exit burr height.

Owner:天窗工具有限公司

Cutting insert and toolholder for holding the same

InactiveUS20050019112A1Minimization requirementsCutting insertsTurning toolsDiamond cuttingMetalworking

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

Mould material mixture having improved flowability

InactiveCN101842175AImprove liquidityImprove stabilityFoundry mouldsFoundry coresMetalworkingParticulate metal

The invention relates to a mould material mixture for producing casting moulds for metal processing, a process for producing casting moulds, casting moulds which can be obtained by the process and their use. The production of the casting moulds is carried out using a refractory base moulding material and a binder based on water glass. A proportion of a particulate metal oxide selected from the group consisting of silicon dioxide, aluminium oxide, titanium oxide and zinc oxide is added to the binder, with particular preference being given to using synthetic amorphous silicon dioxide. The mould material mixture contains a surface-active material as further significant constituent. The addition of the surface-active material enables the flowability of the mould material mixture to be improved, which makes it possible to produce casting moulds having a very complicated geometry.

Owner:ASHLAND SUEDCHEM KERNFEST

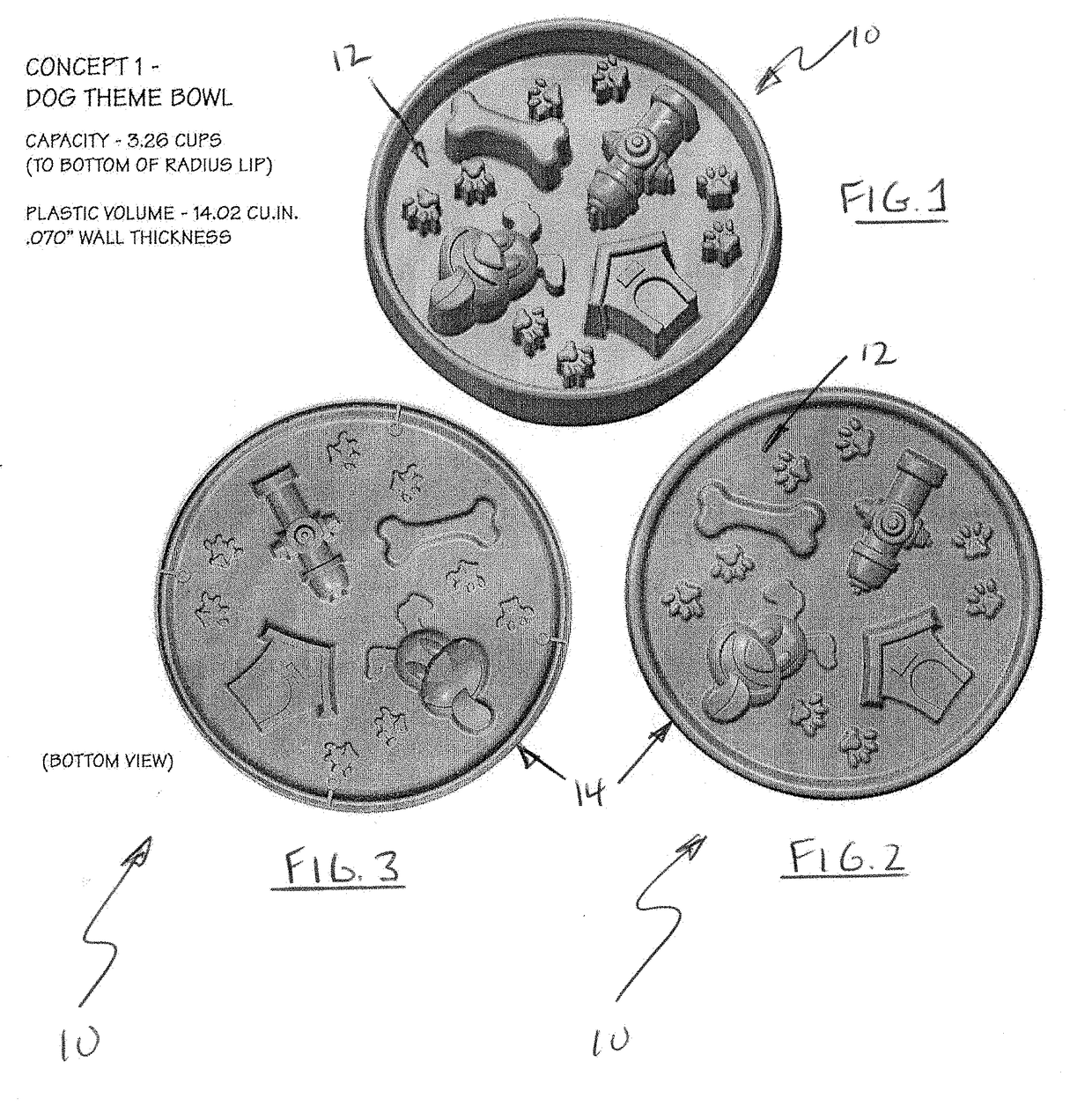

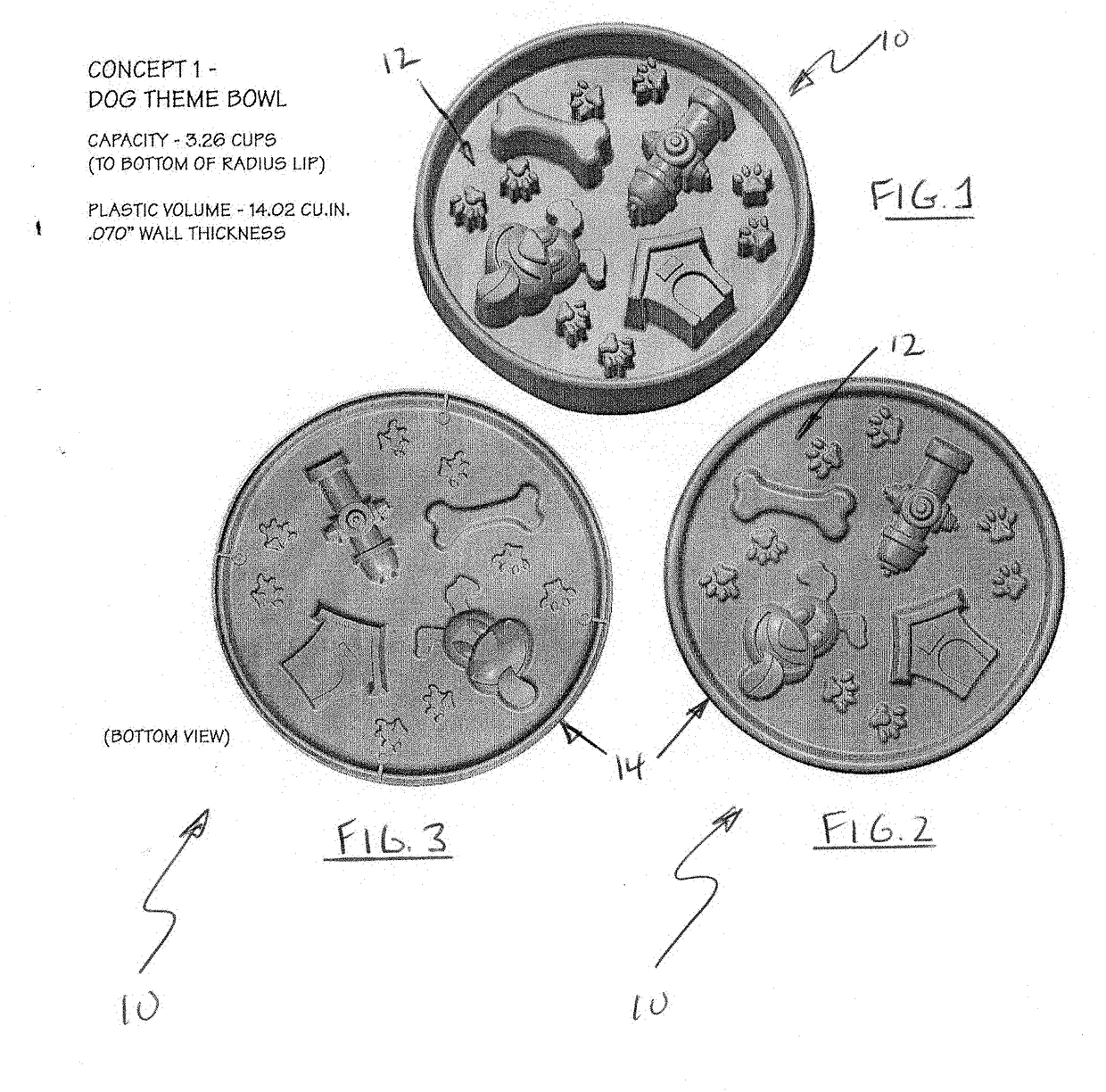

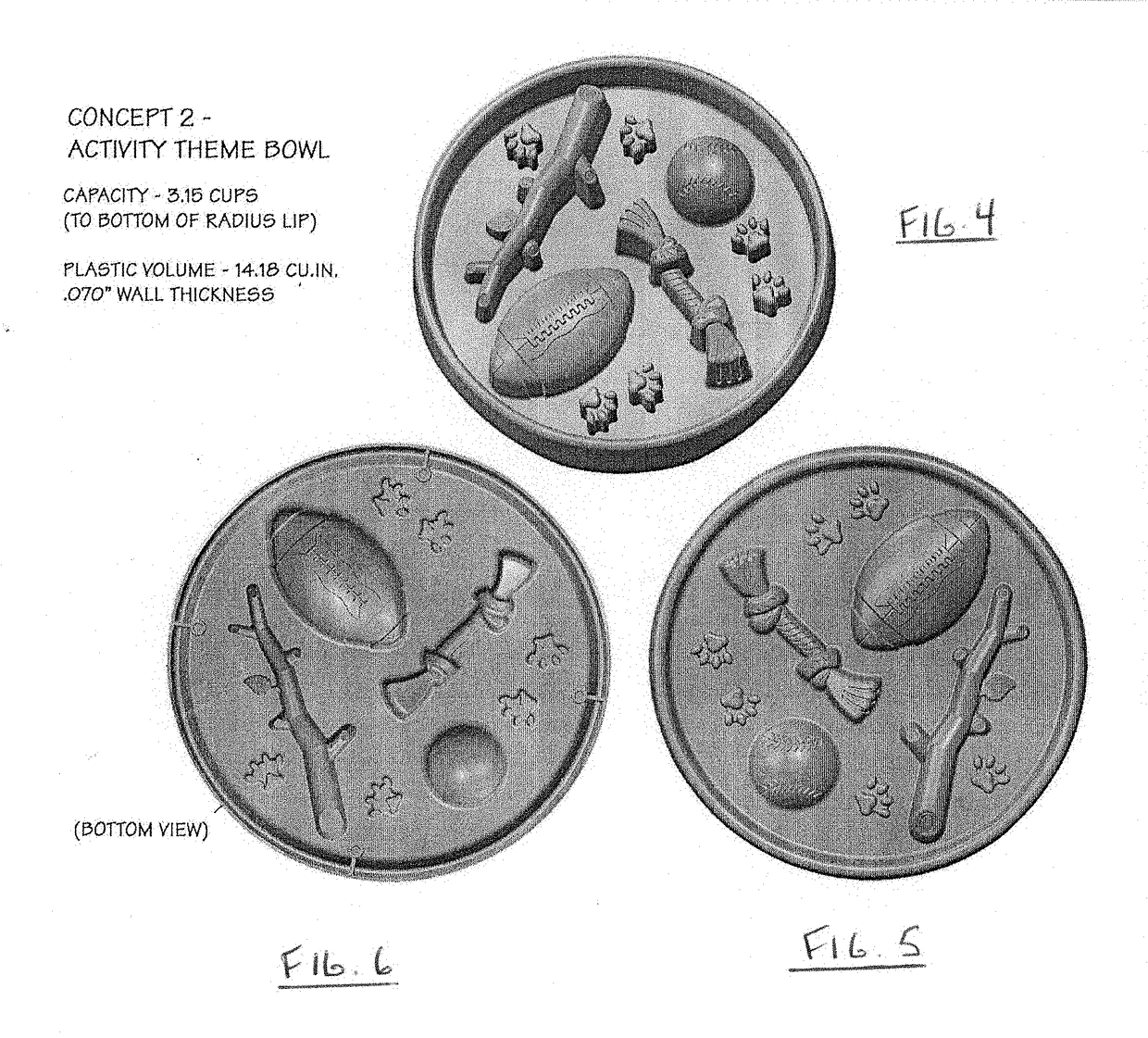

Metallized Plastic Pet Product

InactiveUS20180133991A1Not be readily and shapedMetallic coatingAnimal watering devicesAnimal feeding devicesBlow moldingSurface finish

A variety of pet related products are provided formed initially of plastic and finalized with a metallized surface finish. The pet product is molded using injection molding, rotational molding, vacuum forming, blow molding, compression molding, thermoforming or other plastic forming techniques that can provide a structure having a shape that cannot be readily or economically shaped by metal stamping or other conventional metalworking method. The semi finished plastic part is then subjected to a metallizing process in an individualized non-contiguous manner, where a thin metallic layer is deposited on at least one of the product surfaces. The resultant pet product item simulates the appearance metal, and may provide the durability, cleanability and the general antimicrobial nature resulting metal surfaces.

Owner:OUR PETS

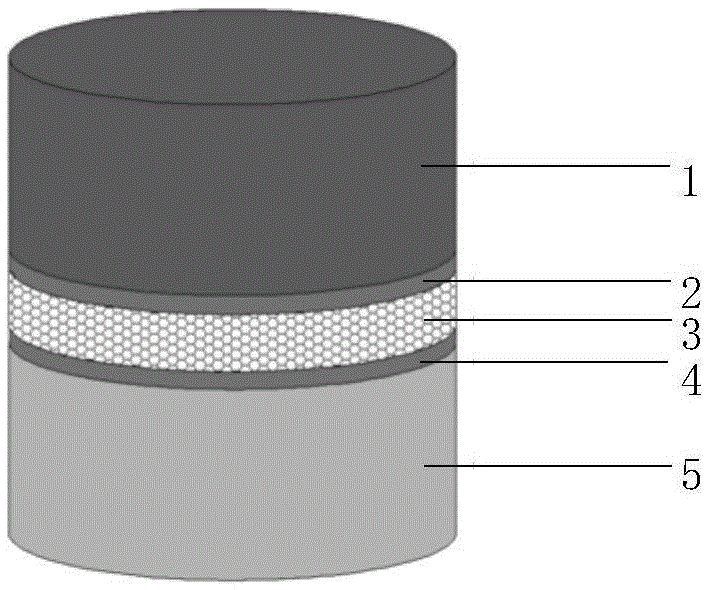

Ceramic and metal brazing composite component and preparing method thereof

InactiveCN105537712AHigh strengthImprove thermal fatigue performanceSoldering apparatusWelding/soldering/cutting articlesMetalworkingThermal fatigue

The invention provides a ceramic and metal brazing composite component. The composite component comprises metal, ceramic and a middle layer formed between to-be-welded faces of the ceramic and the metal; the middle layer comprises upper layer brazing filler metal, foam metal and lower layer brazing filler metal. The invention further provides a preparing method of the composite component. The preparing method comprises the steps that the upper layer brazing filler metal, the lower layer brazing filler metal and the foam metal are machined into an upper brazing filler metal layer, a lower brazing filler metal layer and a foam metal layer with the areas close to the area of the to-be-welded faces; the lower brazing filler metal layer, the foam metal layer, the upper brazing filler metal layer and to-be-welded metal are sequentially placed on the to-be-welded ceramic surface, and a certain pressure is applied to complete assembling; and an assembled sample is heated under the vacuum condition, is subject to heat preservation for a certain time, and then is cooled. The composite component has the excellent strength and thermal fatigue performance. According to the preparing method, existing materials can be directly used, complex pretreatment is avoided, and firm bonding between ceramic and metal can be achieved.

Owner:BEIHANG UNIV

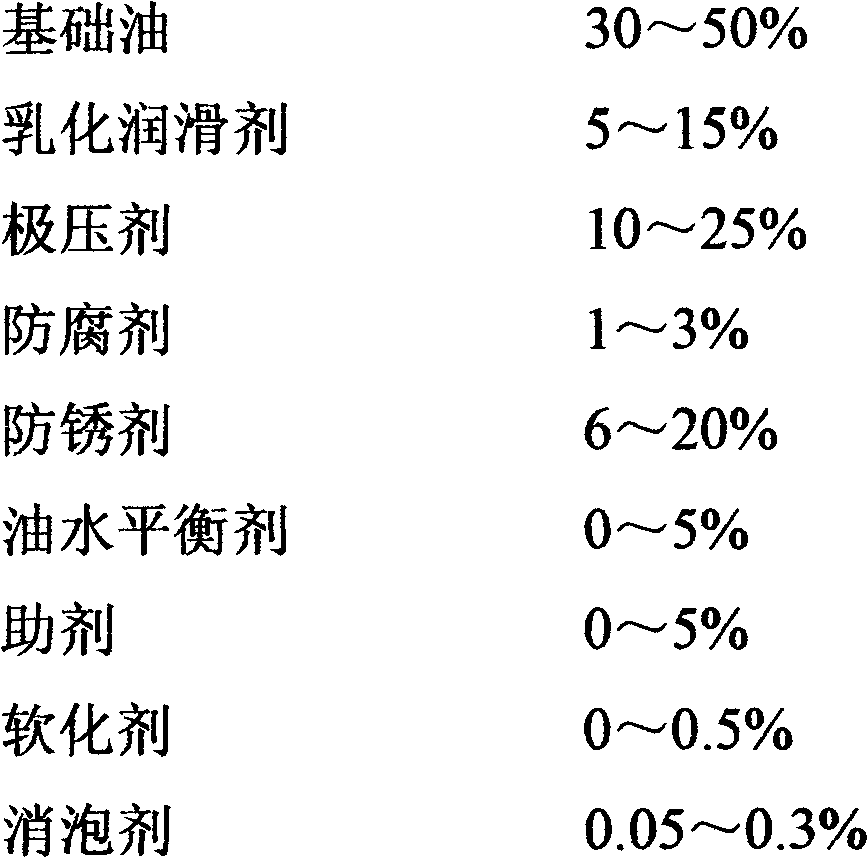

Extreme-pressure metalworking liquid and its preparation method

InactiveCN102787006AReduce pollutionSolve the shortcomings of narrow bactericidal spectrumLubricant compositionMetalworkingBenzisothiazolone

The invention discloses an extreme-pressure metalworking liquid. The extreme-pressure metalworking liquid uses recovered oil as base oil, which not only enables cost to be saved but also allows environmental pollution to be reduced; the chlorine-containing extreme pressure agent chlorinated paraffin S52 and the sulfur-containing extreme pressure agent RC4801 are used as extreme pressure agents for the metalworking liquid, so the extreme-pressure metalworking liquid is suitable for machining with a great processing temperature range; benzisothiazolone and 3-iodine-2-propenyl-butylcarbamate are used as antiseptics, which enables the service life of a product to be prolonged. The metal processing liquid provided by the invention is suitable for a wide variety of machining, such as complex processing technologies like cutting, turning, drilling, grinding, boring and milling.

Owner:NEUFTECH BIOTECH HEFEI

Method of fabricating medical devices and medical devices made thereby

A method of fabricating medical devices and medical devices made from the method of fabricating a medical device, the medical device, without being exhaustive, may be a medical instrument, an implant, a prosthetic, a body support structure or the like. The method includes work-hardening a work-hardenable metal to achieve a desired microstructure of the metal, then fabricating a medical device in accordance with the desired microstructure utilizing the work-hardened metal. In one form, the desired microstructure is an elongated grain structure. The medical device is created from the grain-elongated metal such that the medical device is oriented relative to the plane of grain elongation. In a particular form of the invention, the medical device is a curved spine plate wherein elongated grains of the work hardened metal are oriented in a plane normal to a curvature of the spine plate. Work-hardening includes forging, cold rolling or hot rolling, and annealing prior to use in medical device fabrication. This creates a metal implant stock that has more strength and flexibility in compression and bending than without undergoing the present work-hardening. These properties are exploited in medical device design, fabrication, fabrication orientation and / or the like to create medical devices such as super strong implants.

Owner:LIFE SPINE INC

Water-soluble lubricating oil

InactiveCN1575330AImprove machinabilityGood stamping performanceDischarging arrangementOther chemical processesOil and greaseMetalworking

The water-soluble lubricating oil composition of this invention contains animal fats and oils and / or plant fats and oils, and the nonionic surfactant of polyoxyethylene sorbitol fatty acid ester. The water-soluble lubricating oil composition of this invention is excellent in emulsion stability, and it can reduce environmental pollution. It is suitably as metal processing oils such as cutting oil and plastic working oils, and release agent such as asphalt mixture adhesion prevention agent and concrete release agent.

Owner:THE NISSHIN OILLIO GRP LTD

Method for processing liquid fuel oil by using waste oil

InactiveCN101805644AMeet the use requirementsWell mixedTreatment with plural serial refining stagesLiquid carbonaceous fuelsMetalworkingAntioxidant

The invention relates to a method for processing liquid fuel oil by using waste oil. The method comprises the following steps of: in part by weight, weighing 40 to 50 parts of waste metal processing oil, 20 to 30 parts of waste emulsifying oil and 20 to 40 parts of waste lubricating oil, and stirring the components uniformly and sufficiently to obtain mixed oil; adding a cationic surfactant and concentrated sulfuric acid into the mixed oil, performing emulsion breaking, and filtering the mixture to eliminate heavy metals and other impurities; adding diatomaceous earth into the mixture to perform adsorption bleaching, and performing filter pressing to separate liquid and a solid mixture; adding isopropanol to separate out oil and water; and adding a flash point modifier and an antioxidant into the separated oil, and modulating the mixture to obtain the liquid fuel oil. The method has a simplified process, can be performed at normal temperature and generates fewer waste products; the waste oil can be combusted sufficiently after being processed, and an exhaust gas contains few harmful gases; and the fuel oil can be widely used as a fuel for power generation by electric power plants, ship boilers, heating furnaces, metallurgical furnaces and other industrial furnaces. The method realizes the full utilization of the waste oil and has good economic and social benefits.

Owner:GONGYI OASIS WASTE TREATMENT

Long-life and low-foam emulsion for aluminium alloy cutting

InactiveCN106281616AImprove the lubrication effectHigh surface finishLubricant compositionMaterials science6111 aluminium alloy

The invention relates to a long-life and low-foam emulsion for aluminium alloy cutting, belonging to the technical field of metal processing media. The emulsion has the beneficial effects that the lubricating capacity of cutting fluid and the surface finish of workpieces are improved by adopting combination of extreme pressure lubricants and oily lubricants; the alkali retention capacity and pH stability of the cutting fluid are improved by adopting optimized alcohol amine combination and through cooperation of monoethanolamine, triethanolamine and special alcohol amines; the requirements of different aluminium alloys for aluminium corrosion inhibition are achieved by adopting compound aluminium corrosion inhibitor combination and combining the characteristics of phosphorus-containing aluminium corrosion inhibitors and silicon-containing aluminium corrosion inhibitors; the stability of the cutting fluid primary fluid and a diluent is enhanced and adverse effects on machine tool paint are avoided by adopting special coupling agent combination; control of foam in a high pressure fluid supply system and a high precision filtering system is achieved by adopting the foam inhibition properties of the systems and the defoaming properties of defoaming agents.

Owner:NANJING KERUN LUBRICANTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com