Patents

Literature

705 results about "Forming face" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of semiconductor device

ActiveUS20110003433A1Increase productionImprove productivitySemiconductor/solid-state device detailsSolid-state devicesForming faceResist

A disclosed device includes a manufacturing method of semiconductor device including preparing a semiconductor substrate including semiconductor chip forming regions, scribing regions surrounding these regions, and cutting regions formed in the scribing regions and narrower than the scribing regions, forming check patterns and semiconductor chips, forming a resist film, forming through grooves narrower than the scribing regions and wider than the check patterns and the cutting regions, removing the check patterns with a wet blast process using the resist film and collectively forming grooves at portions of a protection film and the semiconductor substrate facing the through grooves, removing the resist film, forming internal connection terminals on the contacting faces, forming an insulating resin layer, forming a wiring forming face by removing until connecting faces are exposed, forming wiring patterns, and cutting the semiconductor substrate, the insulating resin layer, and a solder resist layer to separate into individual semiconductor devices.

Owner:SHINKO ELECTRIC IND CO LTD

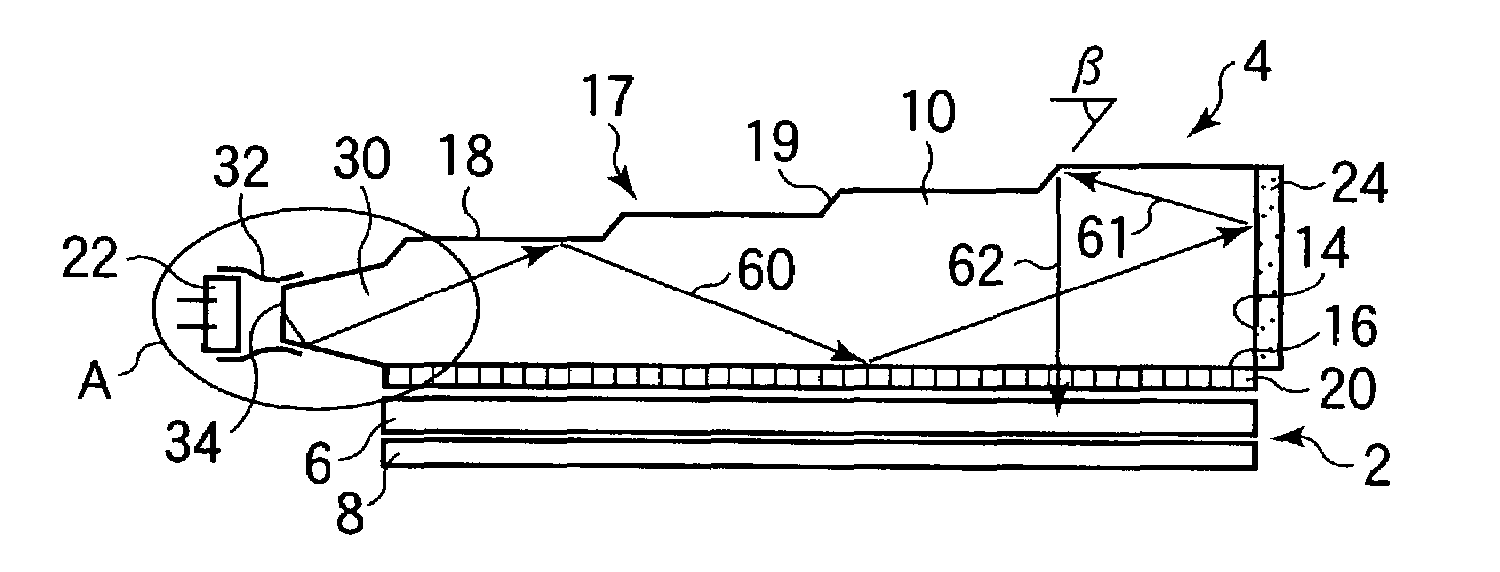

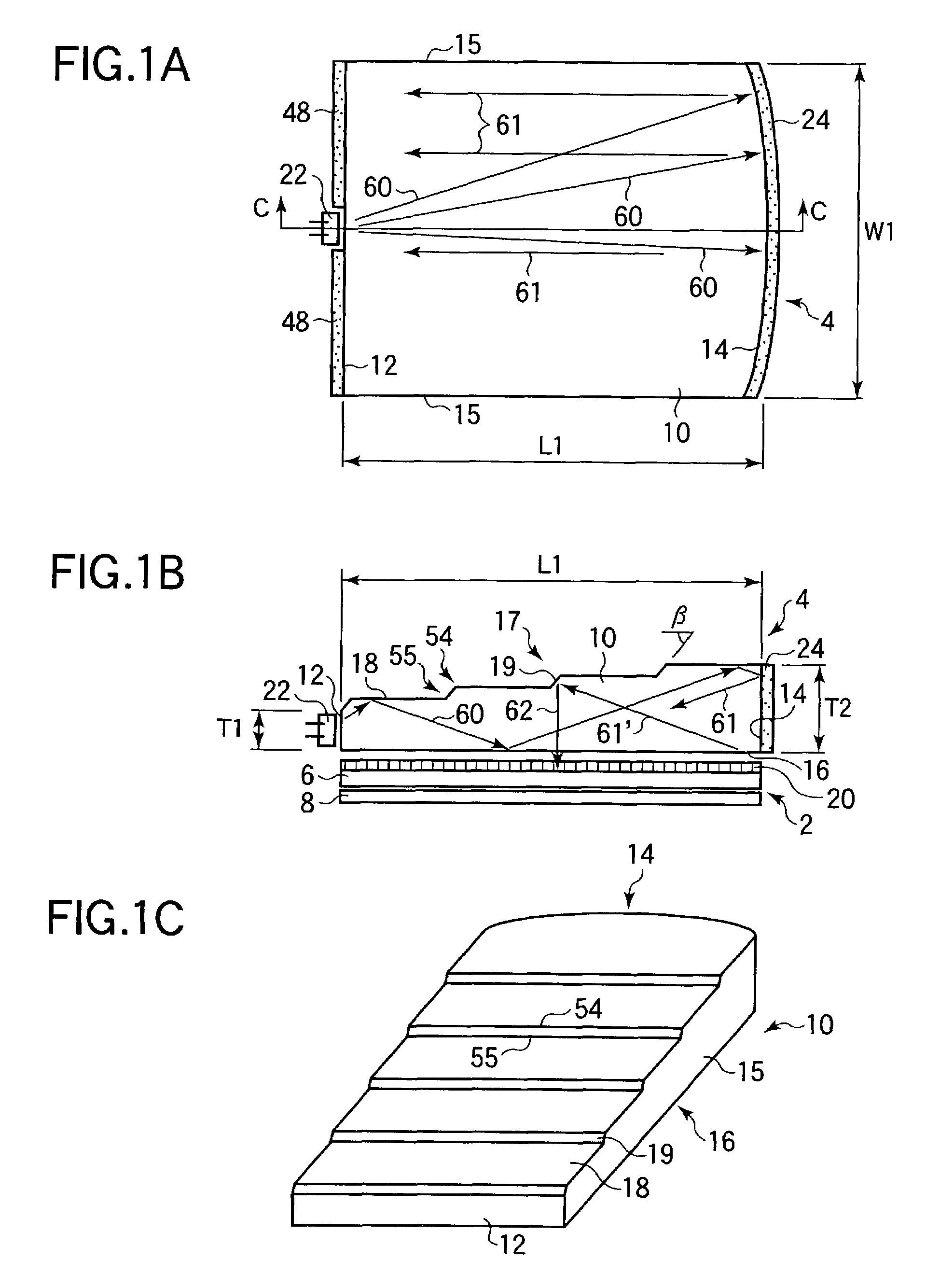

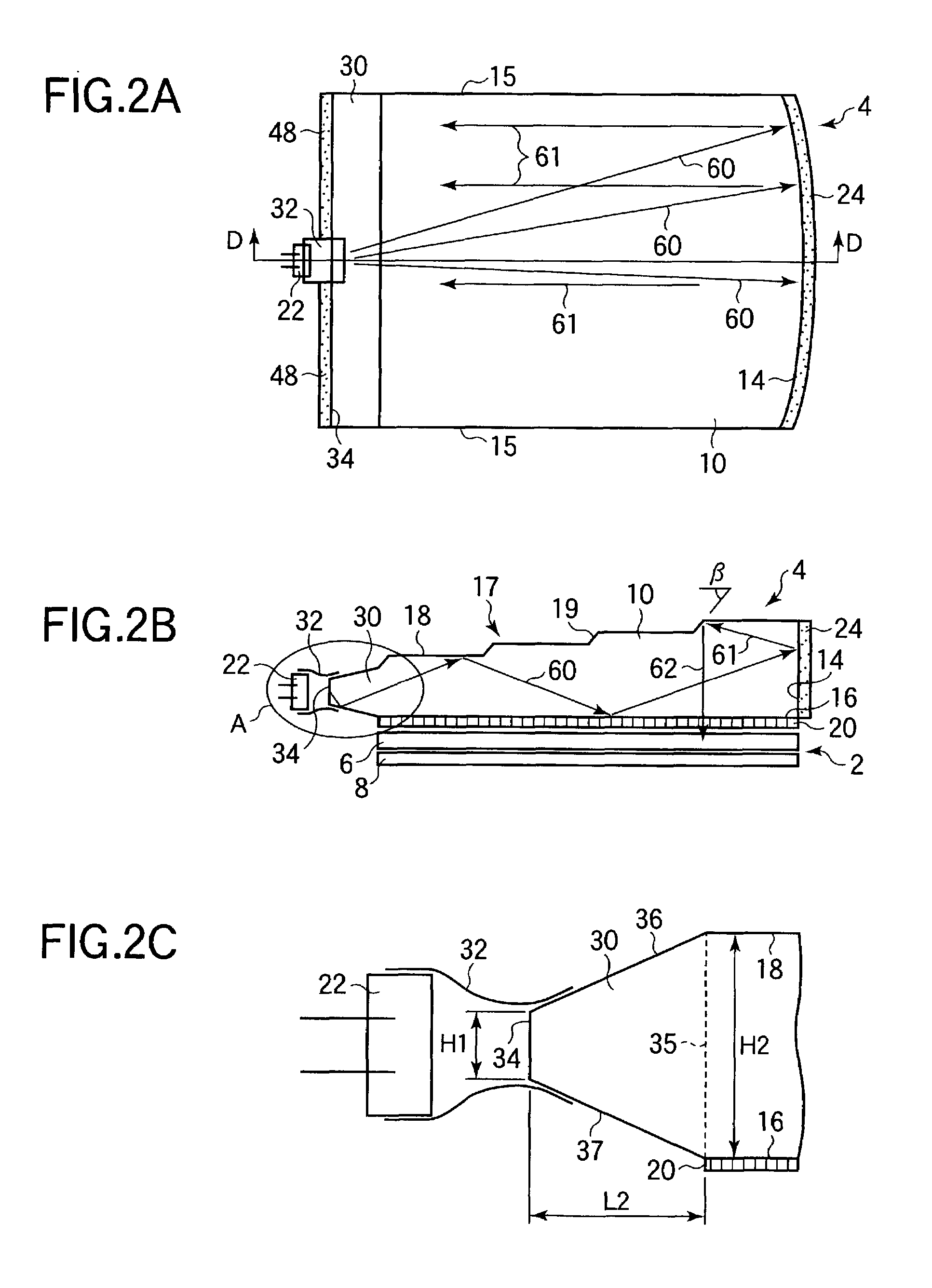

Light guide plate, light source device equipped therewith and display device

InactiveUS7073933B2Dispersion suppressionIncrease contrastPoint-like light sourceMeasurement apparatus componentsForming faceLight guide

A display device used for a display unit of portable electronic equipment, a light source device therefor and a light guide plate, suppressing dispersion in the brightness and featuring a high contrast and a good display quality. The constitution includes a light incidence surface on where light emitted from an LED falls, a light reflection surface formed facing the light incidence surface and reflects light from the light incidence surface, a light outgoing surface arranged between the light incidence surface and the light reflection surface, and has a circularly polarizing plate intimately adhered onto the surface thereof, and an opposing surface formed facing the light outgoing surface and in which there are alternately arranged first opposing surfaces for guiding the incident light to the light outgoing surface as well as to the light reflection surface, and second opposing surfaces for emitting the light reflected by the light reflection surface through the light outgoing surface.

Owner:SHARP KK

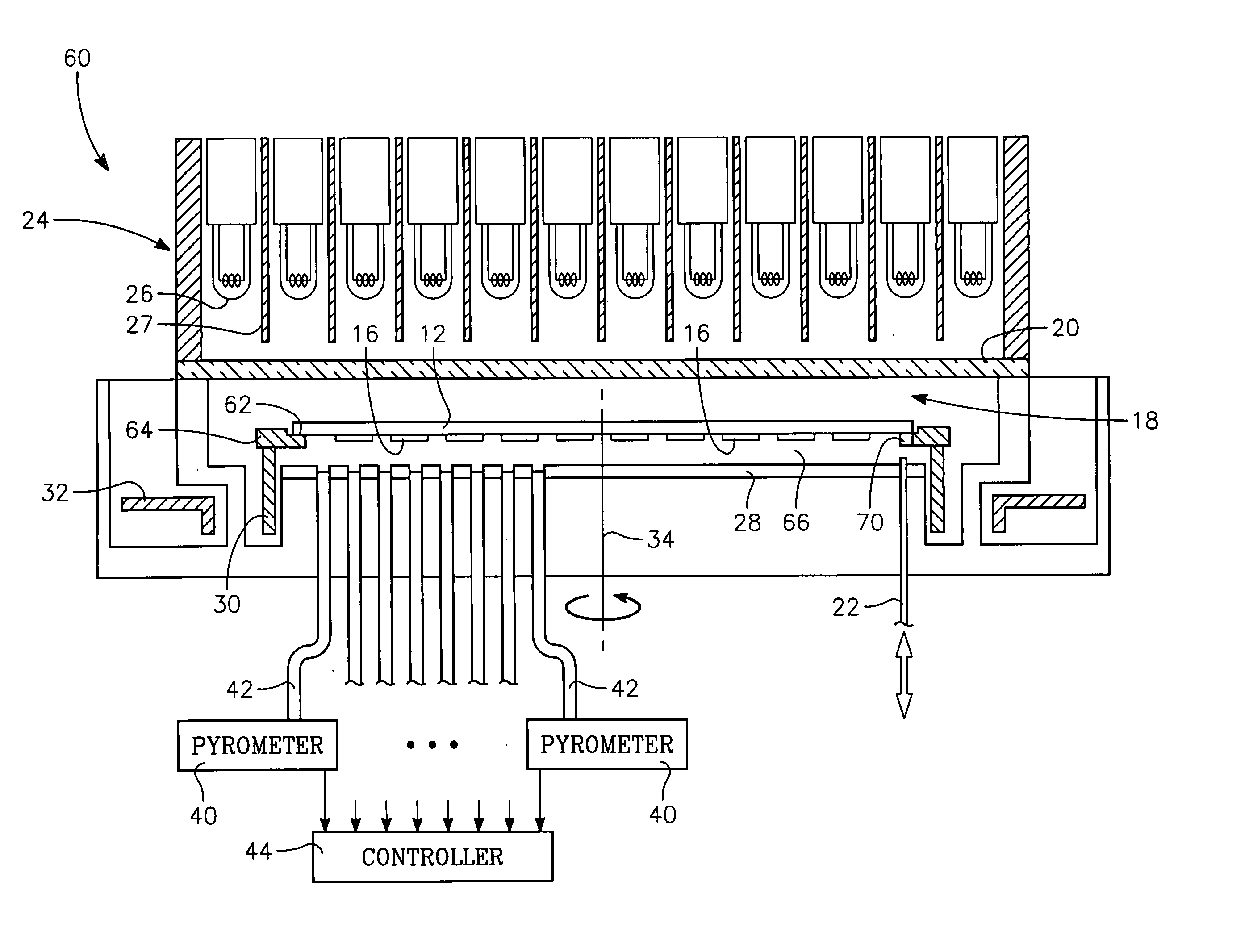

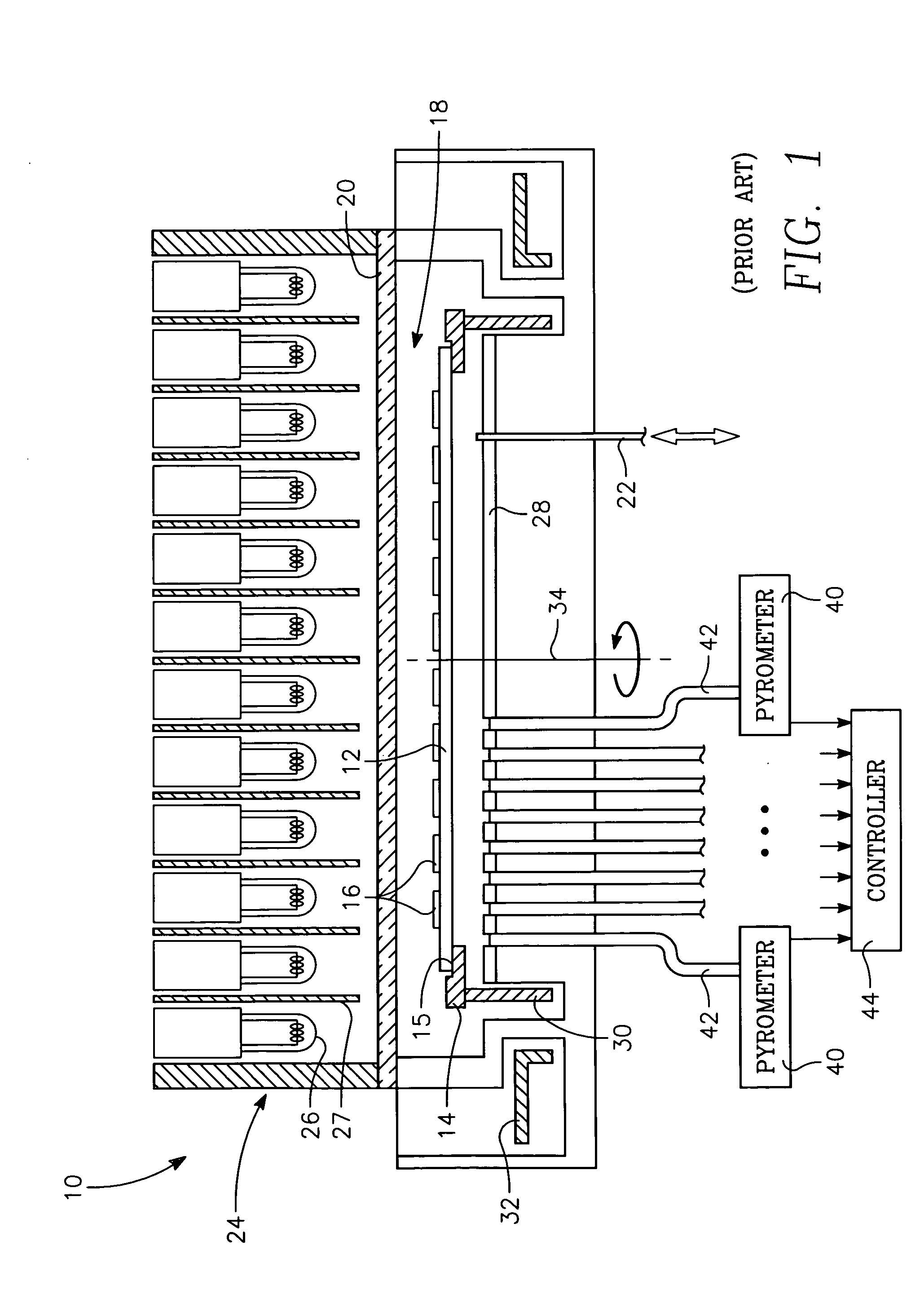

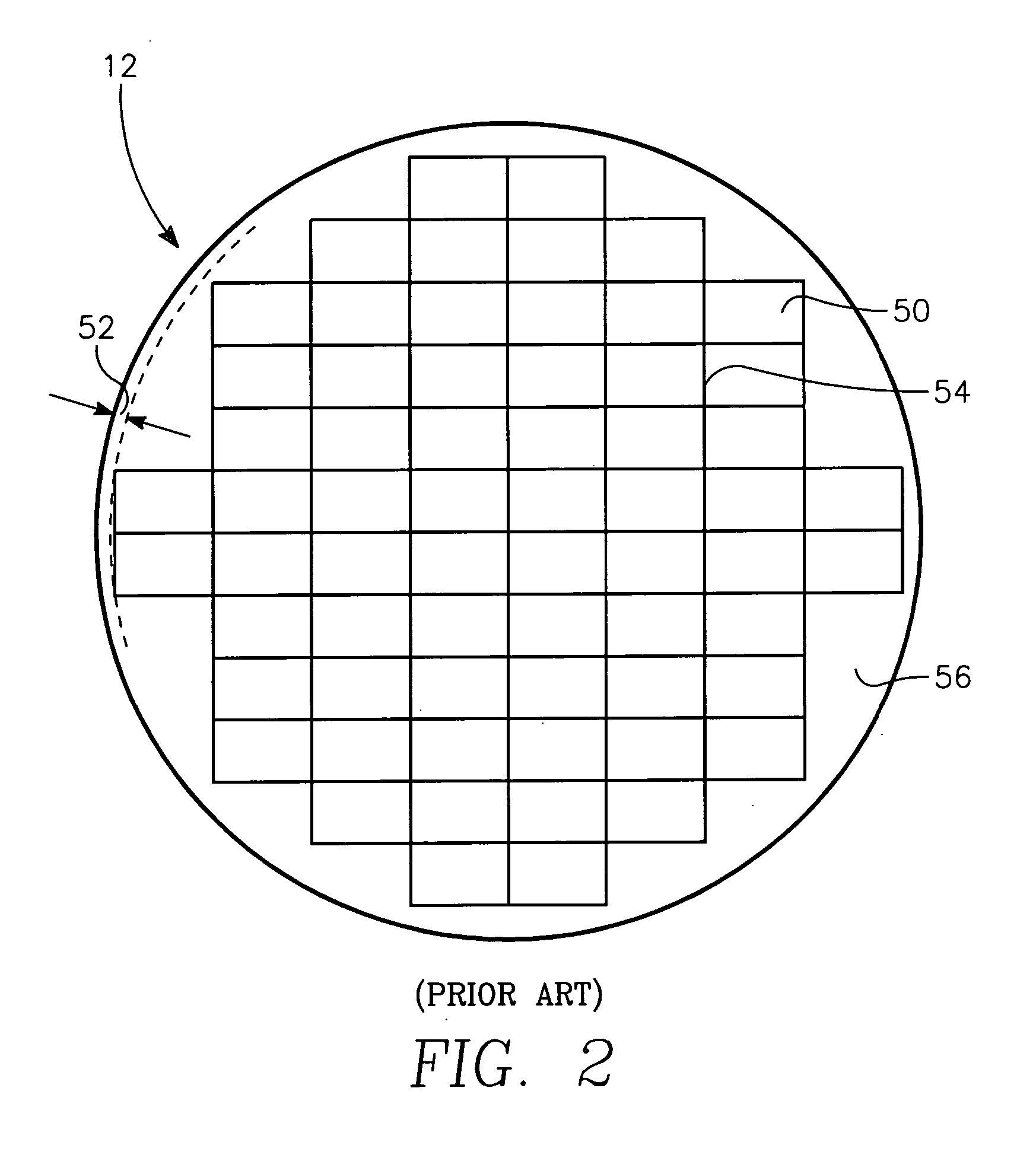

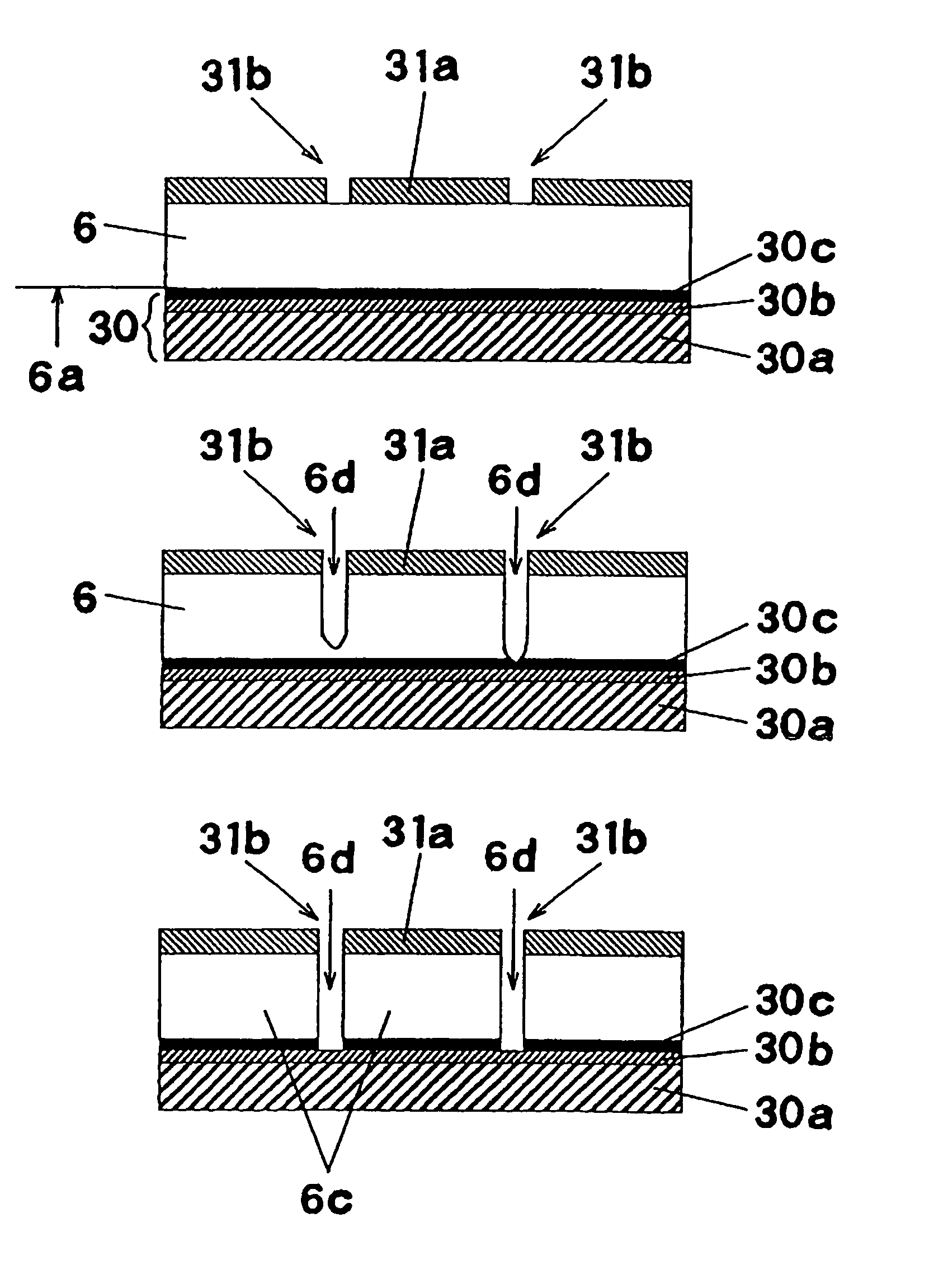

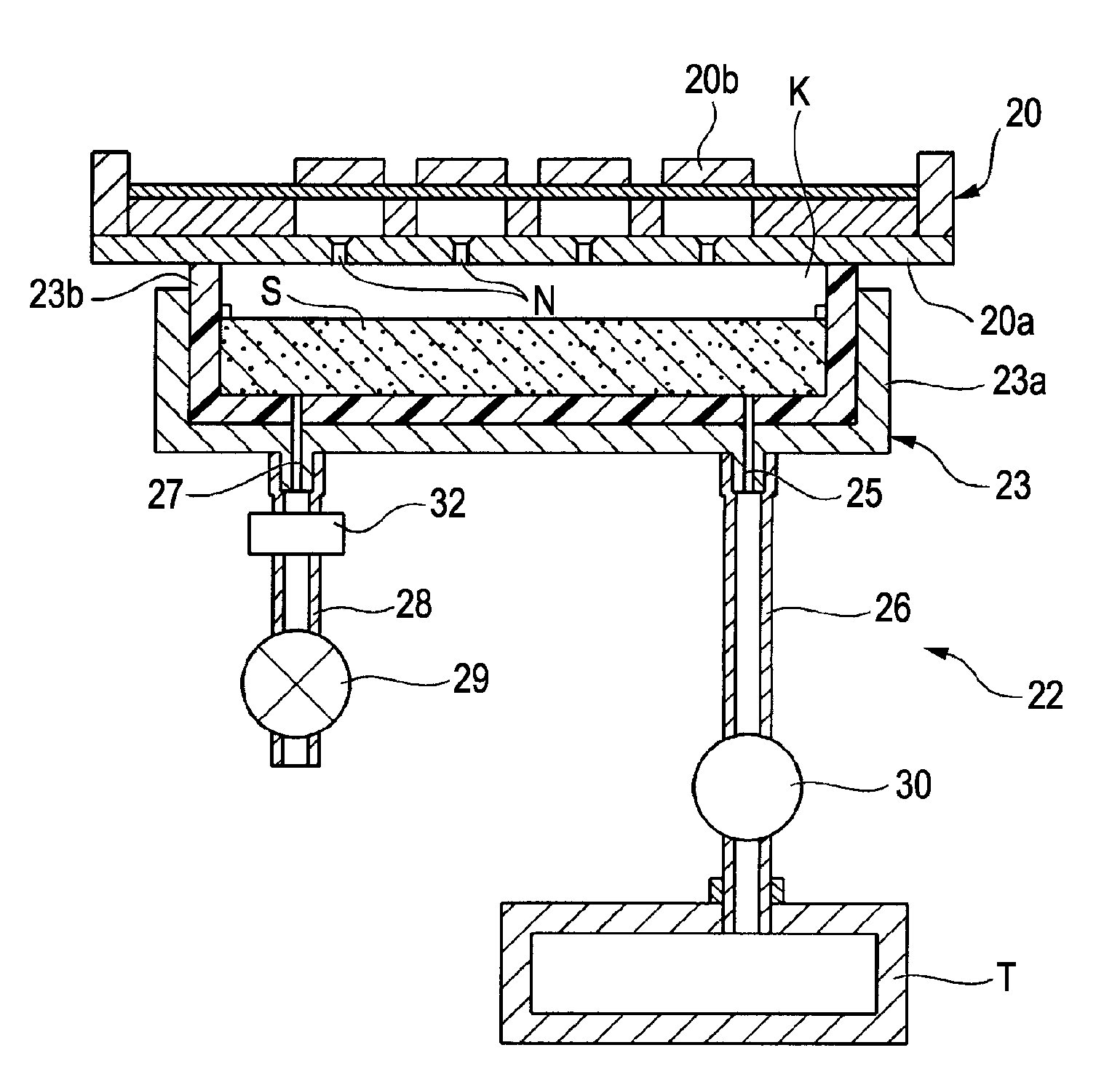

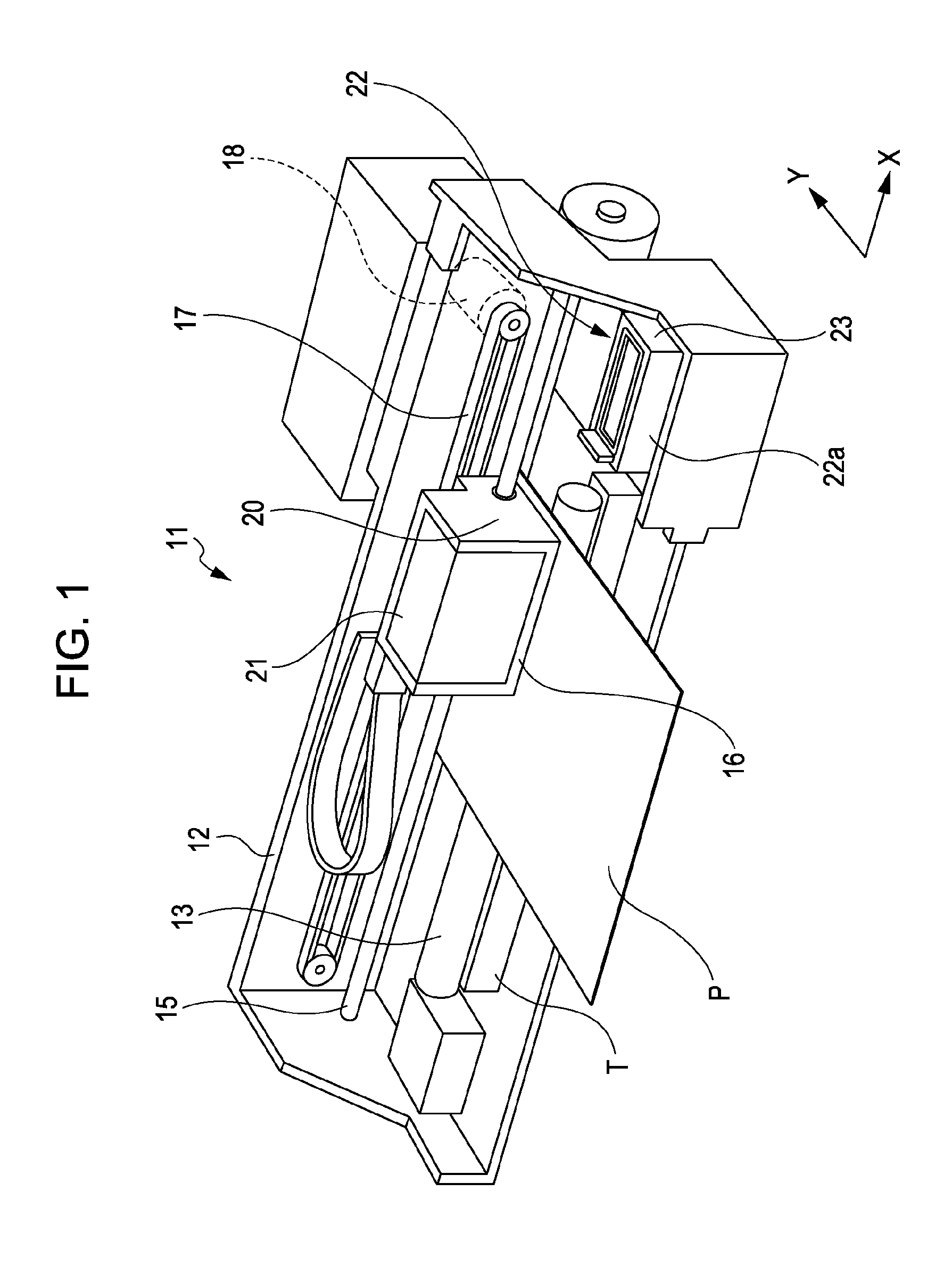

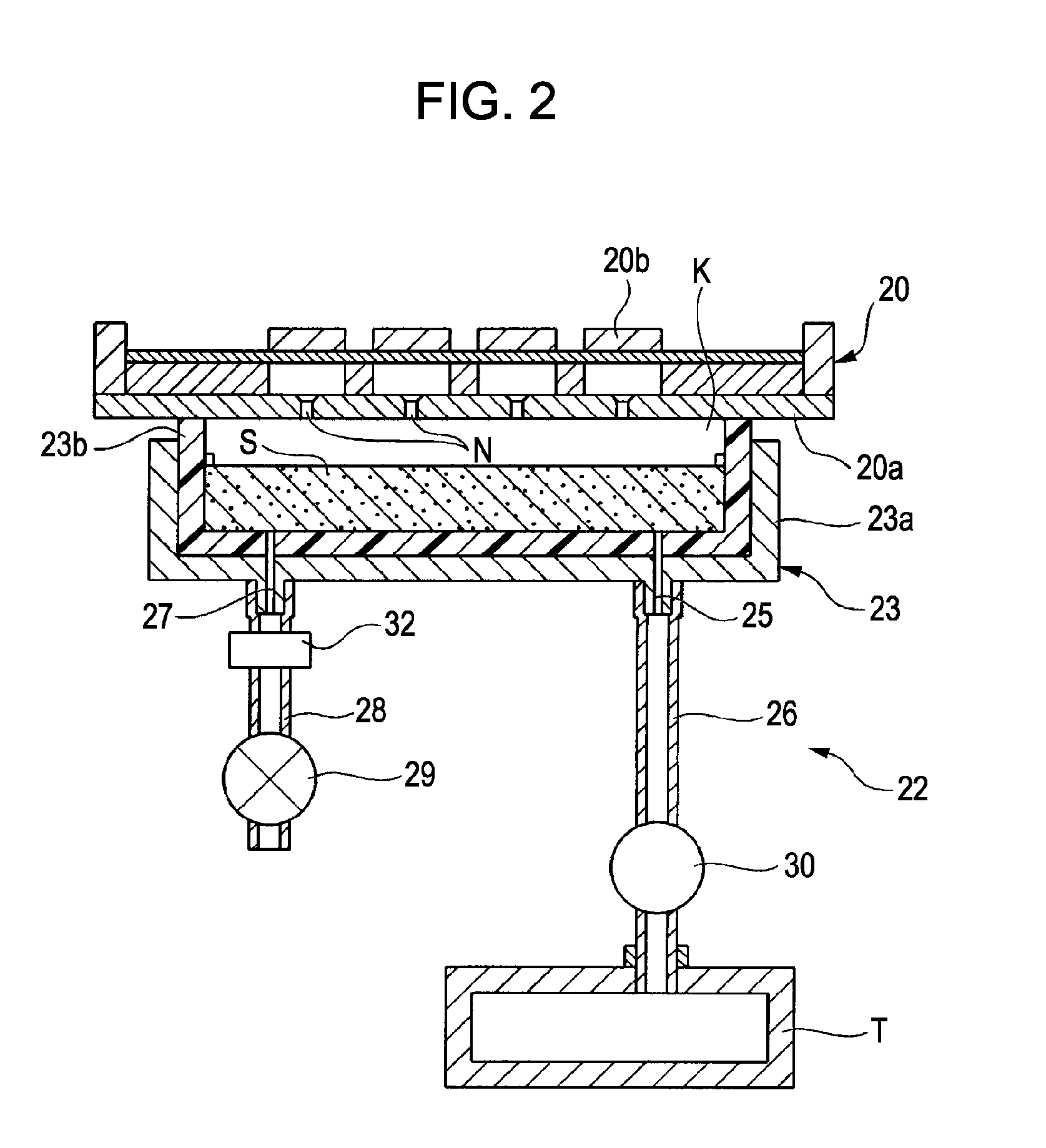

Backside rapid thermal processing of patterned wafers

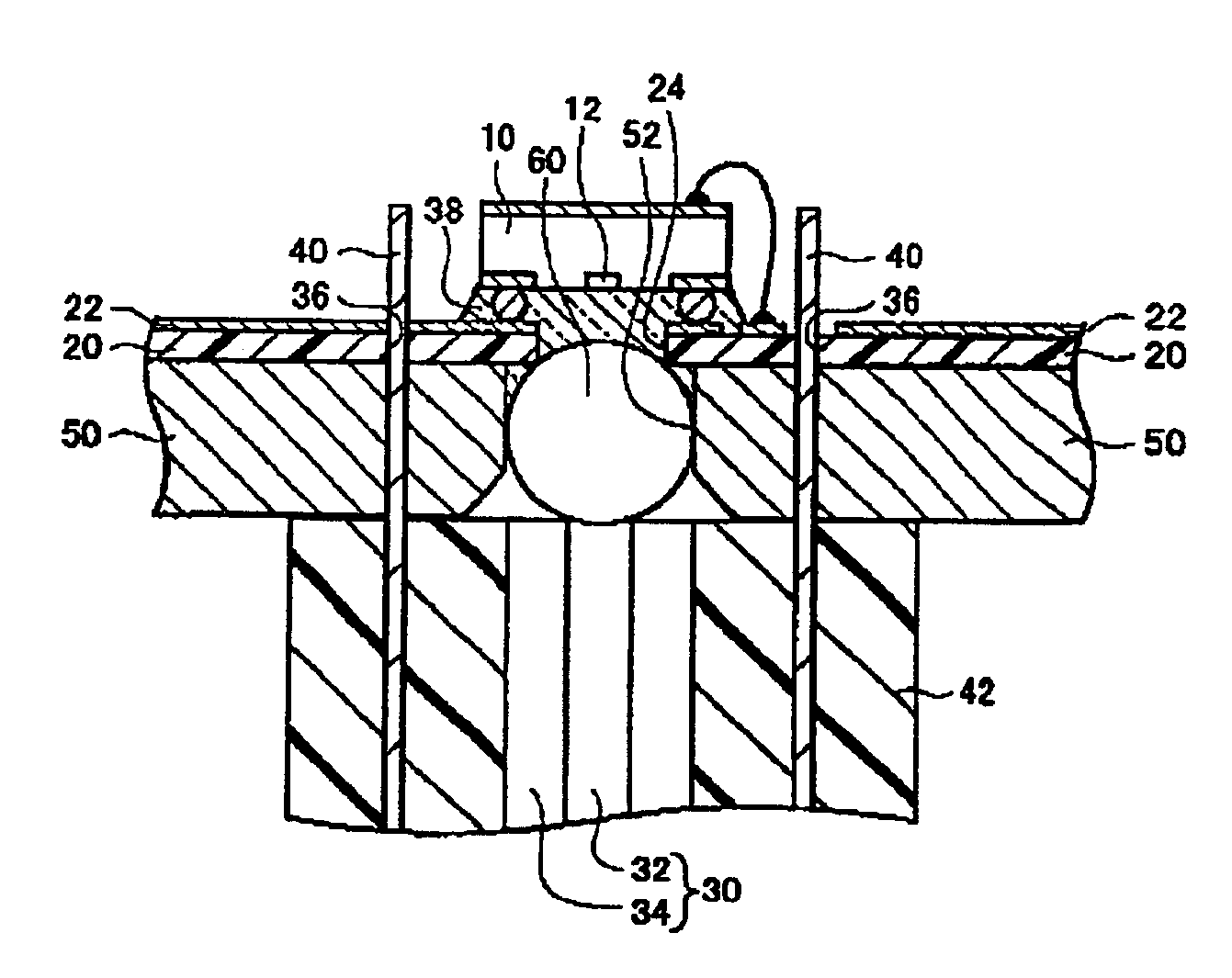

A apparatus and method of thermally treating a wafer or other substrate, such as rapid thermal processing (RTP). An array of radiant lamps directs radiation to the back side of a wafer to heat the wafer. The front side of the wafer on which the patterned integrated circuits are being formed faces a radiant reflector. The wafer is thermally monitored for temperature and reflectivity from the side of the reflector. When the lamps are above the wafer, an edge ring supports the wafer in its edge exclusion zone. Alternatively, a reactor includes upwardly directed lamps and a reflector above and facing the front side of the wafer.

Owner:APPLIED MATERIALS INC

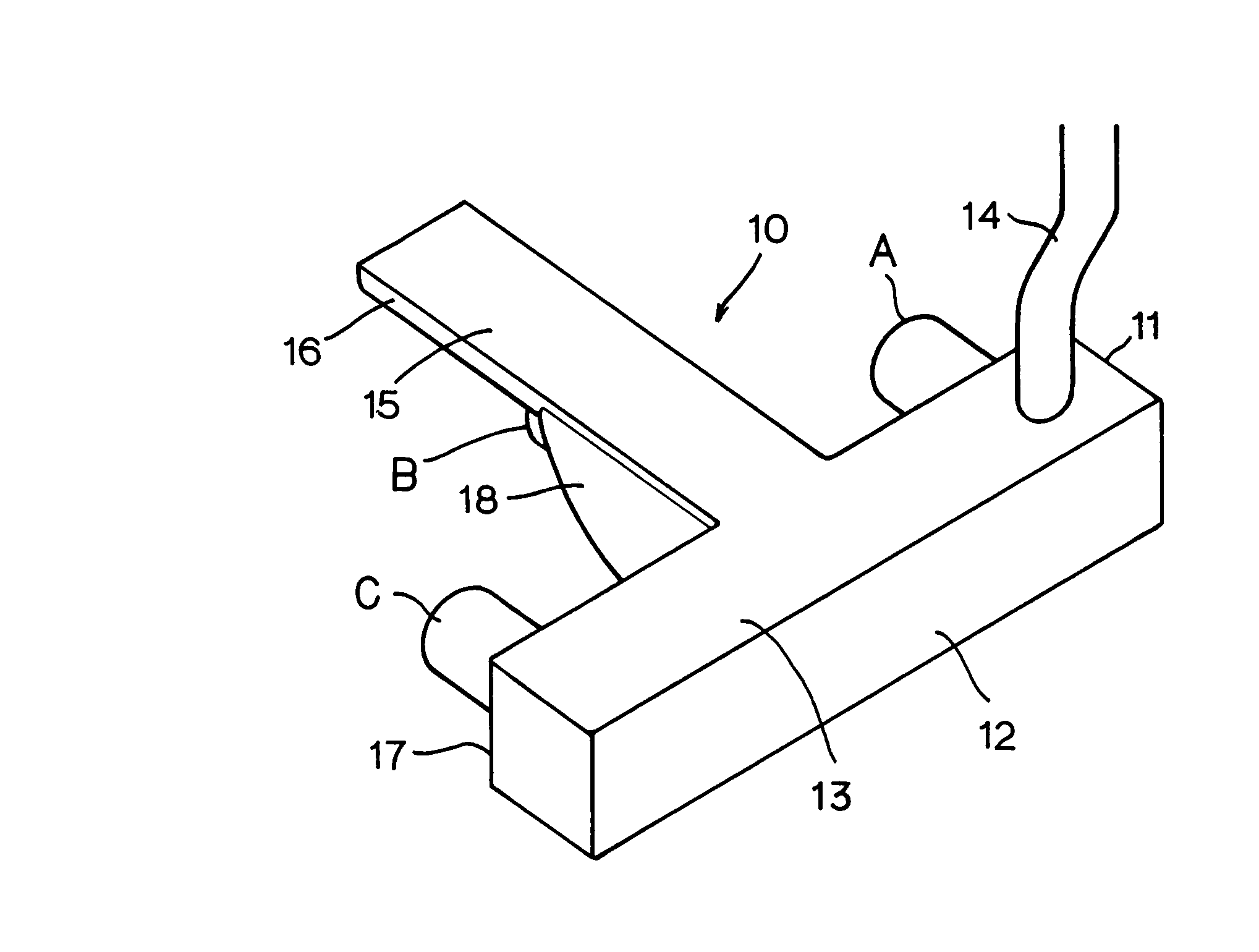

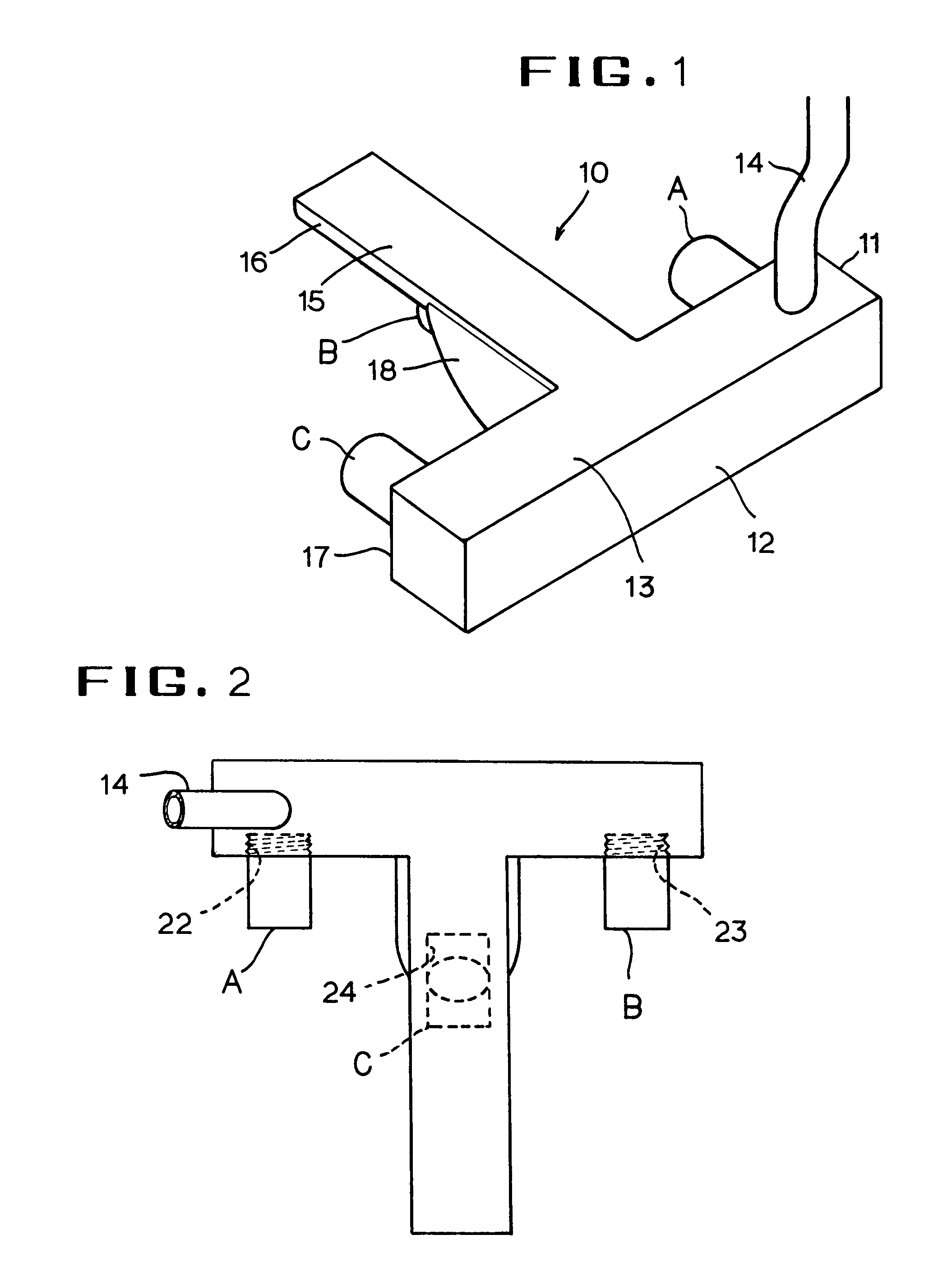

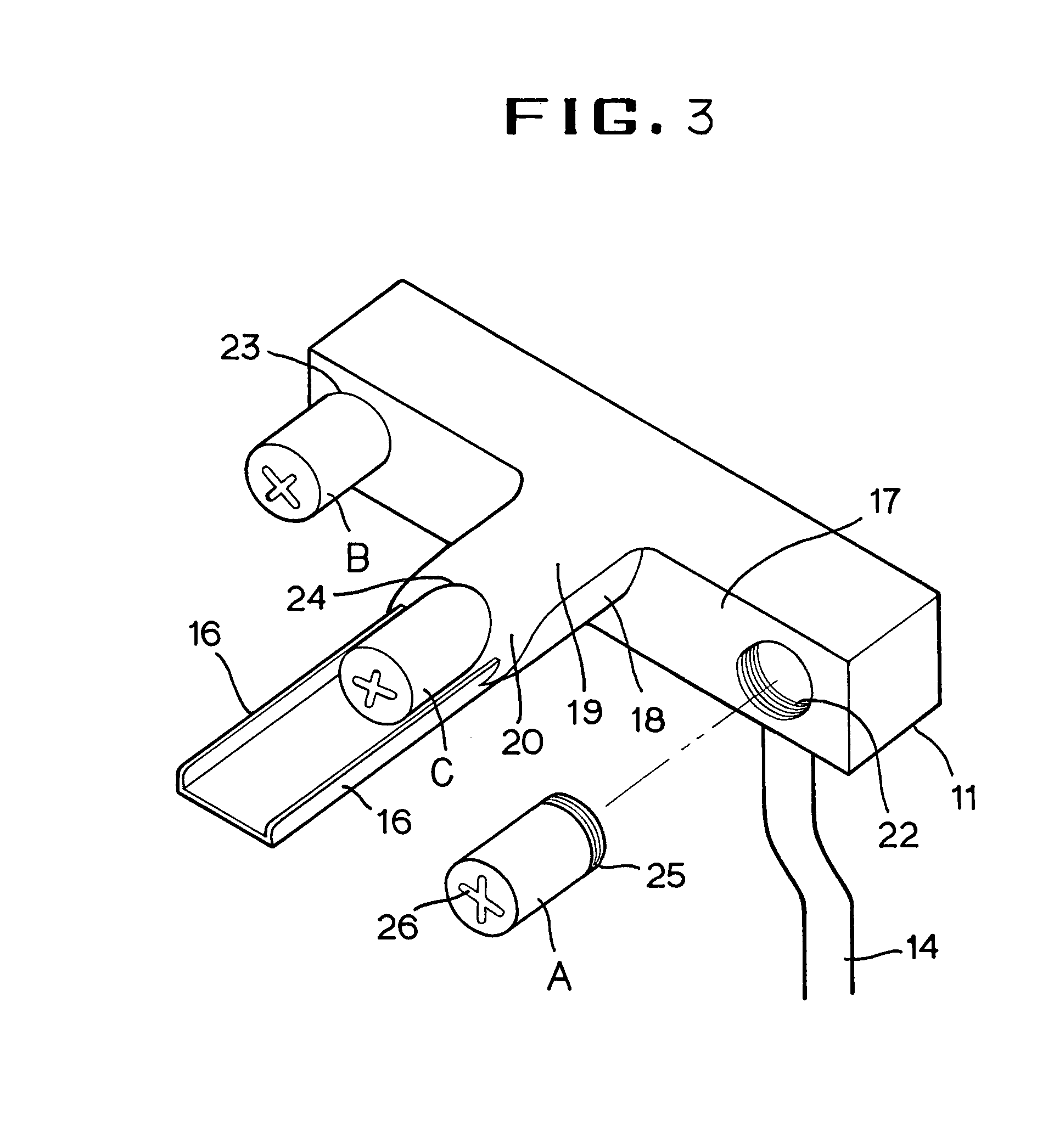

Weight interchangeable putter

A weight interchangeable golf putter is provided having a T shaped head. The head has a main body constituting the main weight and a striking face. From the trailing edge of the top surface a center tail extends rearward to form the T shape of putter plane. At the sides of the tail there are formed end fins with their free ends opened rearward to better guide the putter head through the air during the stroking address. The top of the back weight extends to near midway of the length of the tail and merges with the bottom of the tail. The back weight has a bottom surface in flush with the corresponding bottom of the main body and terminates with an end wall tapered gradually toward the main body to avoid hitting the ground when strokes are made. Three cylindrical bores are formed facing the same backward direction in the common 90-degree angle from the rear wall to receive different metal screws. When the screws are in their initial positions the putter with its face balanced neutralizes the leftward pulling or rightward pushing in the putting of the right-handed golfer who tends to show more pulling problems. Balance adjusting at the day's practice rounds or putting will be rightfully done with ease and no special tool thanks to the protruding screw design which provides an extra visual aid as well as a structural indicator of the invisible sweet spot to improve the actual approach of the ball into the hole cup.

Owner:JUNG MAN YOUNG

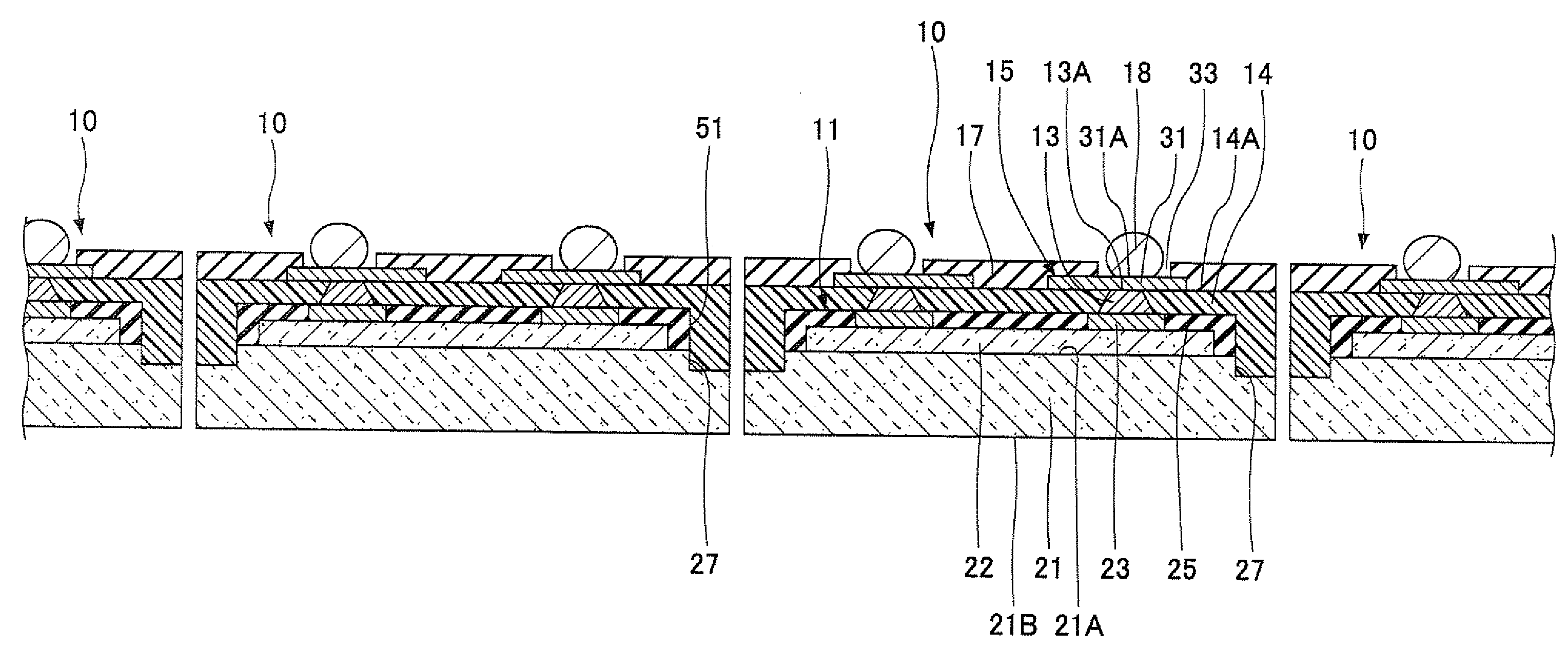

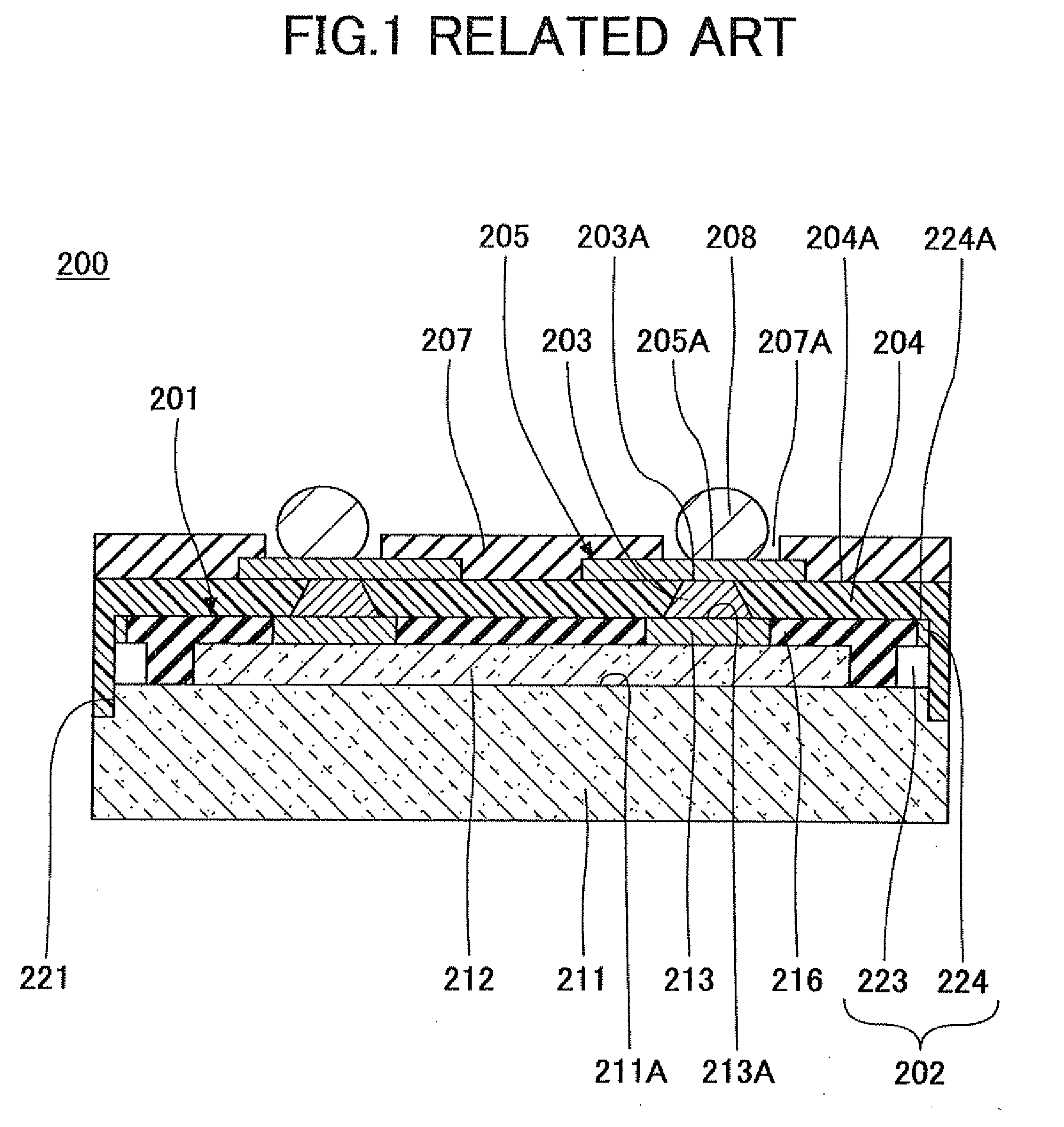

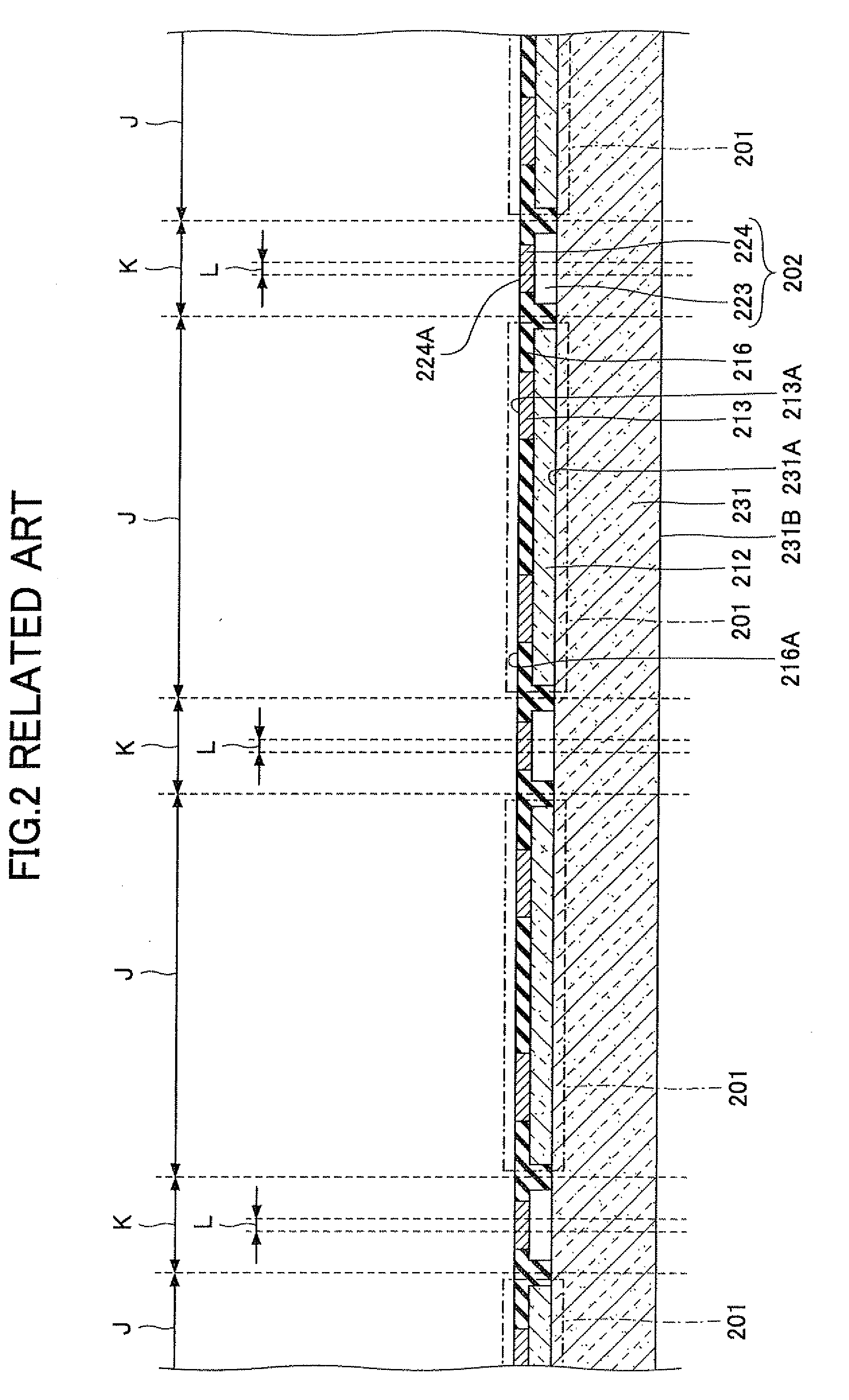

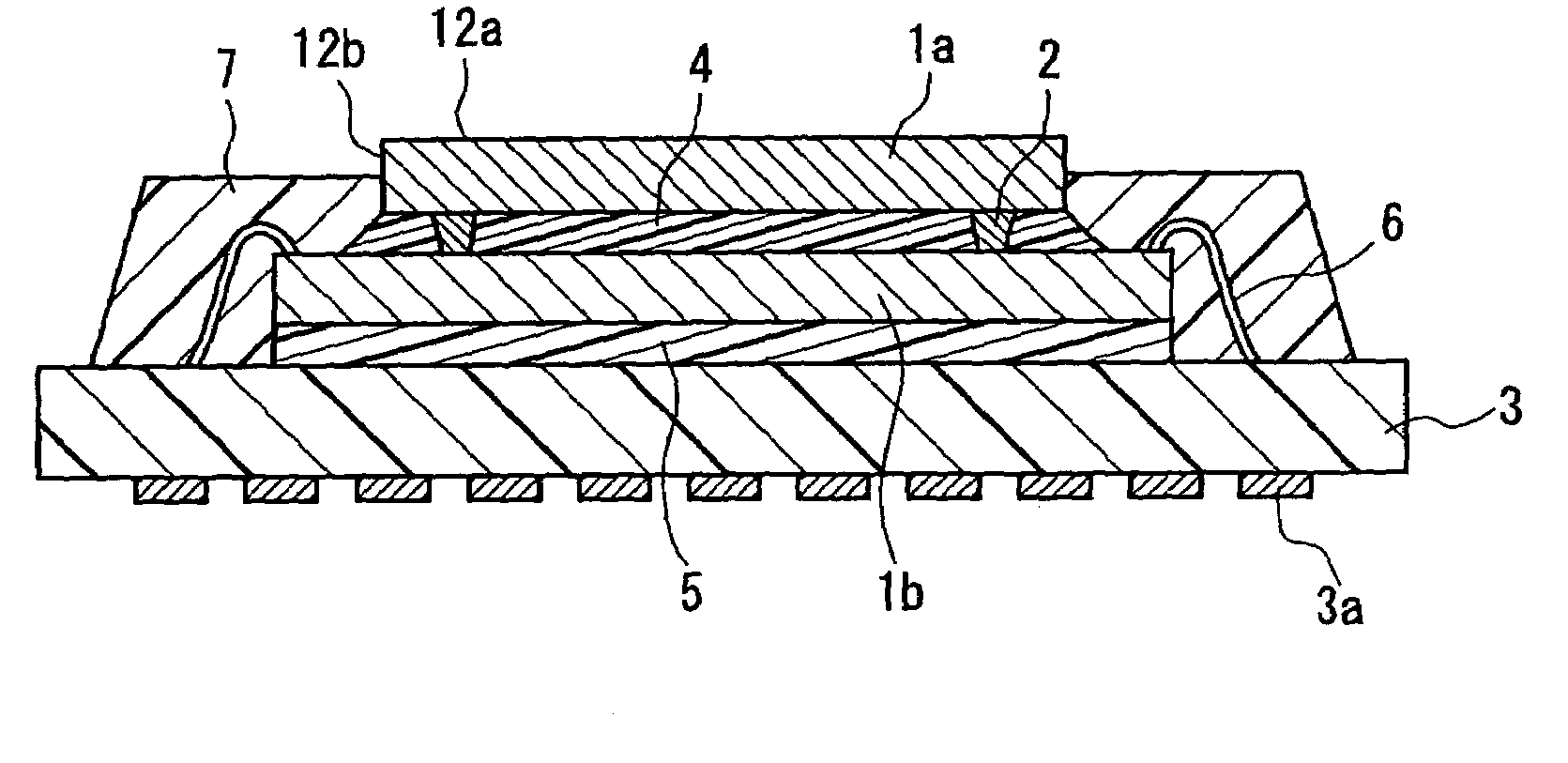

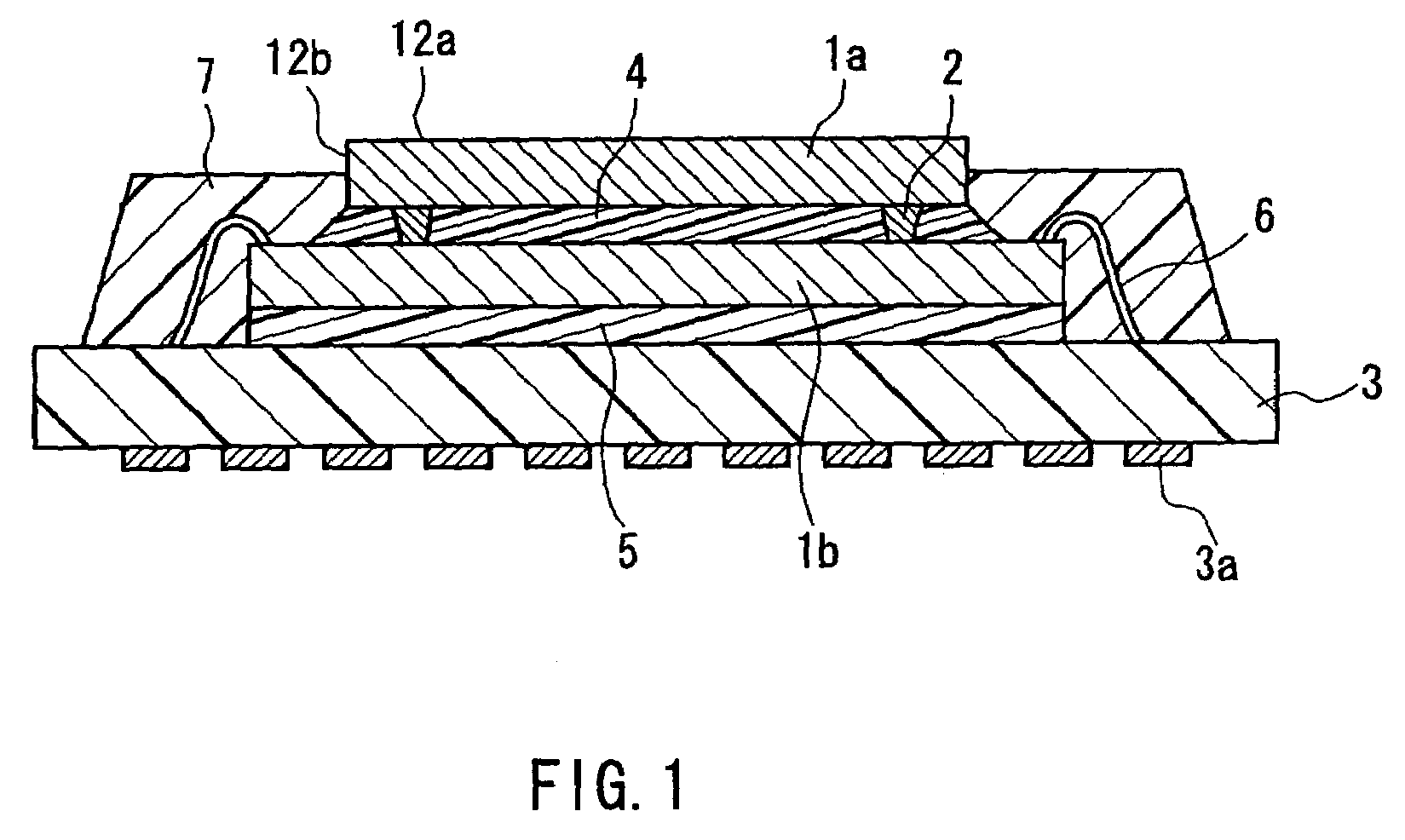

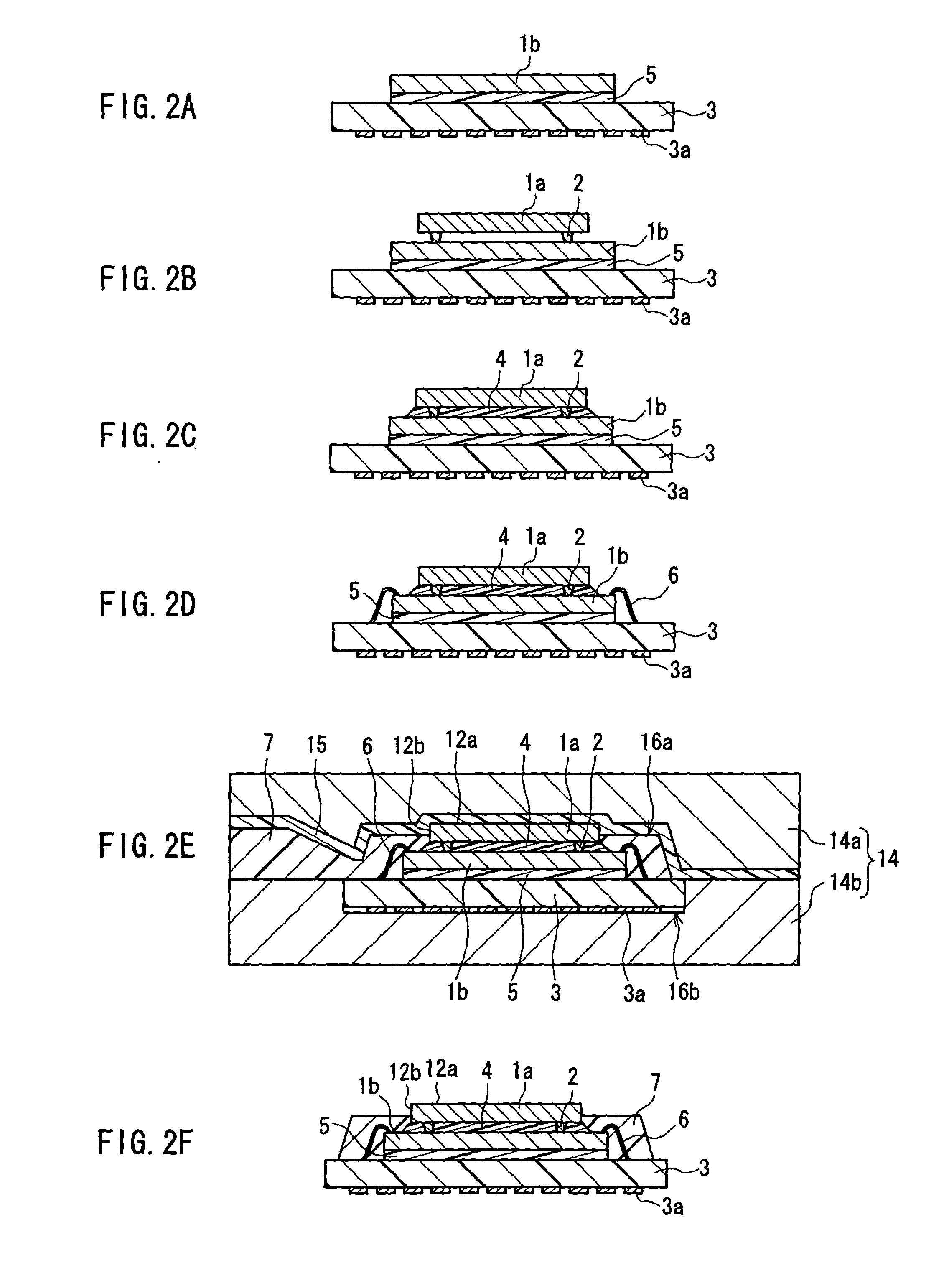

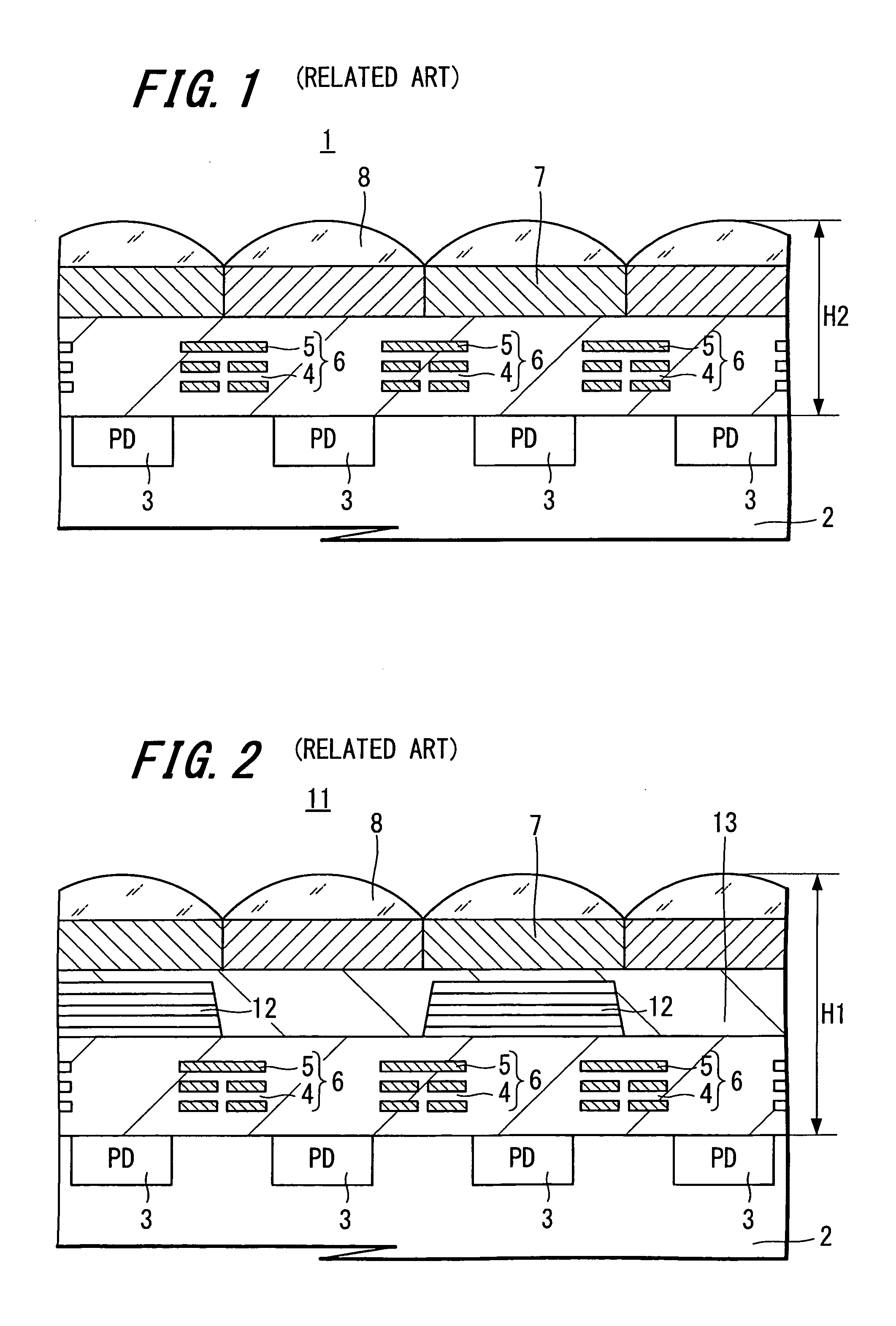

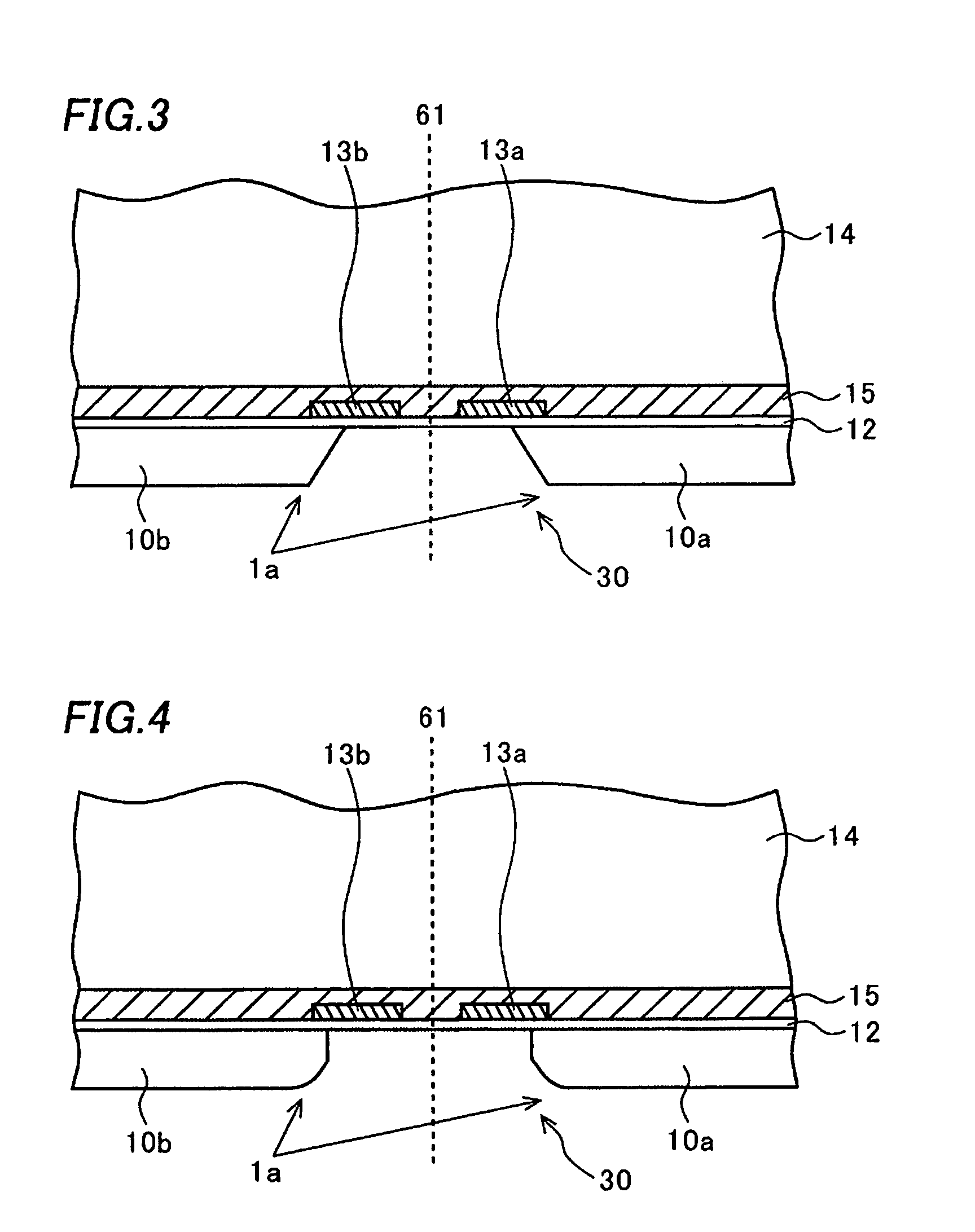

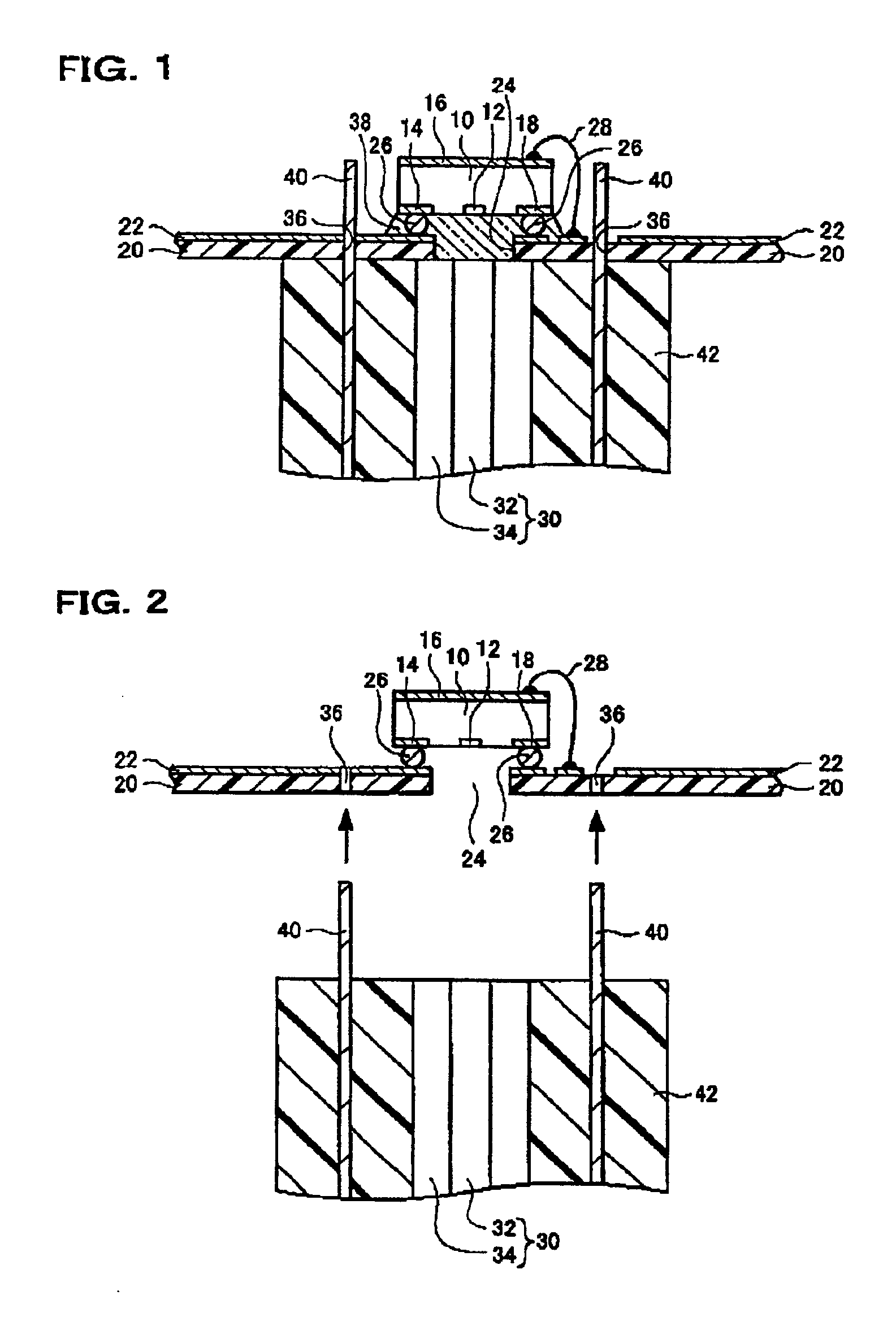

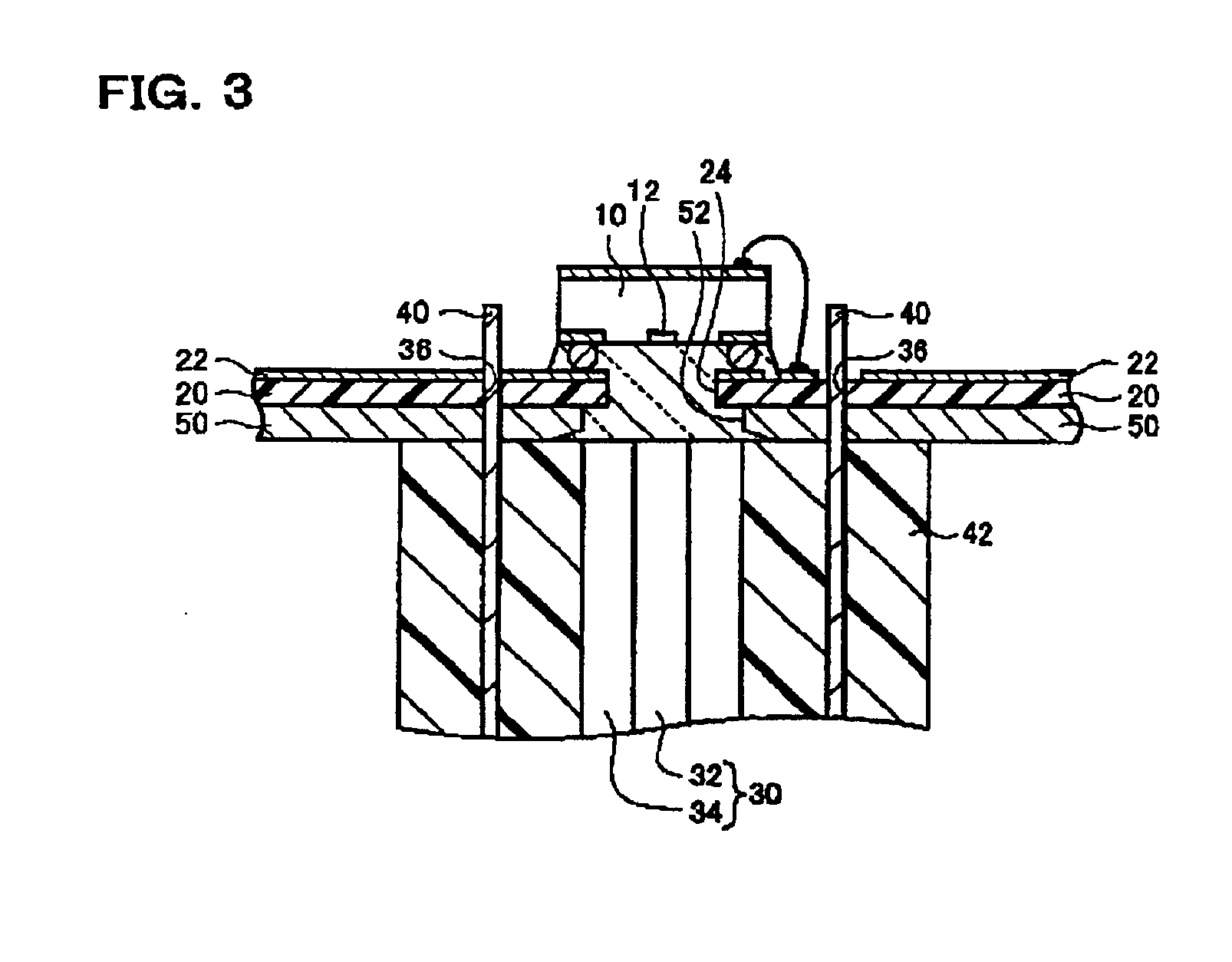

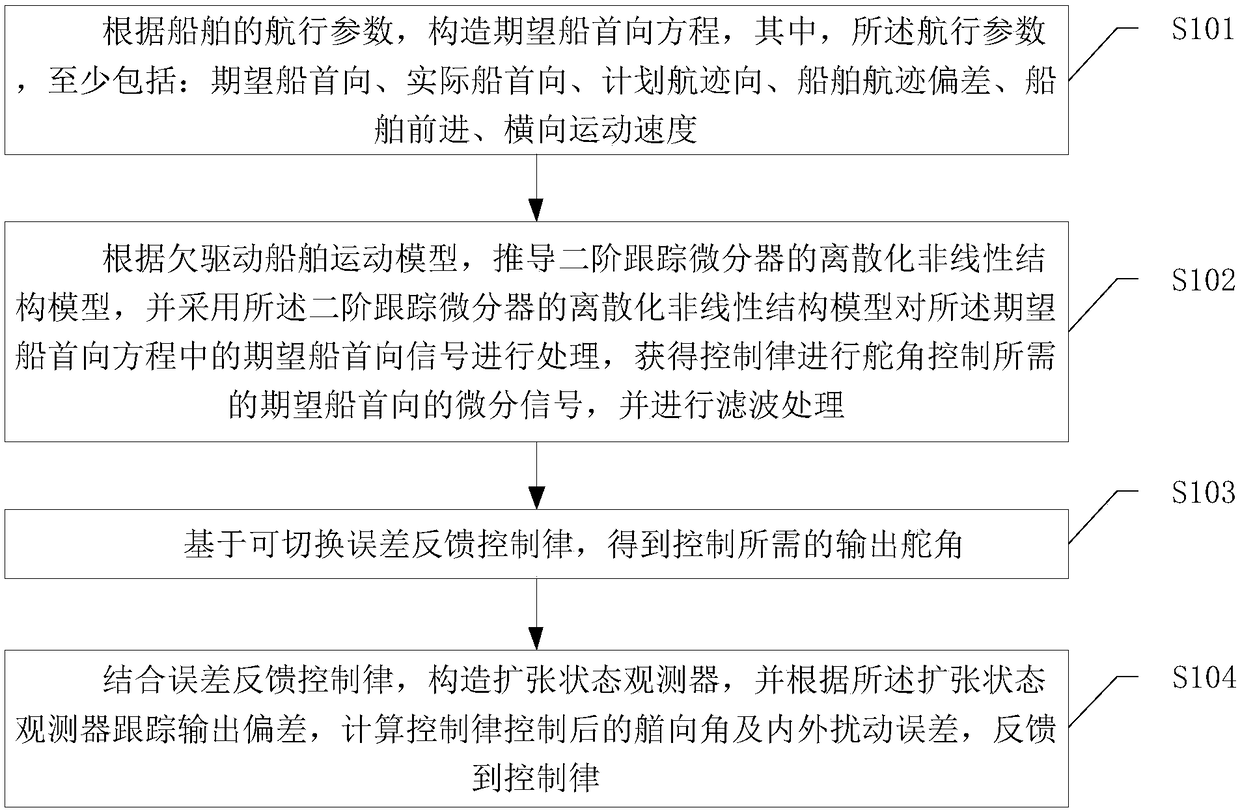

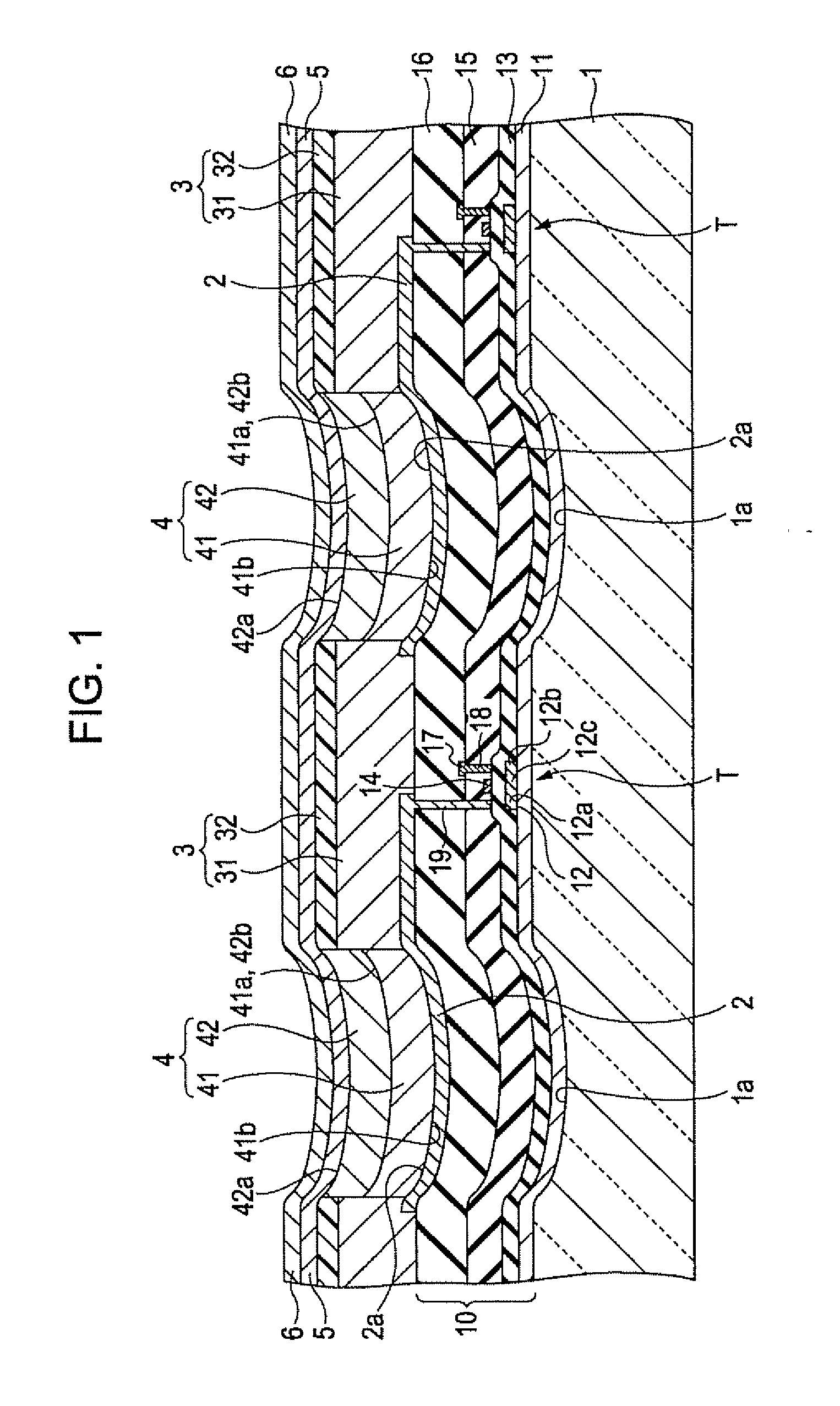

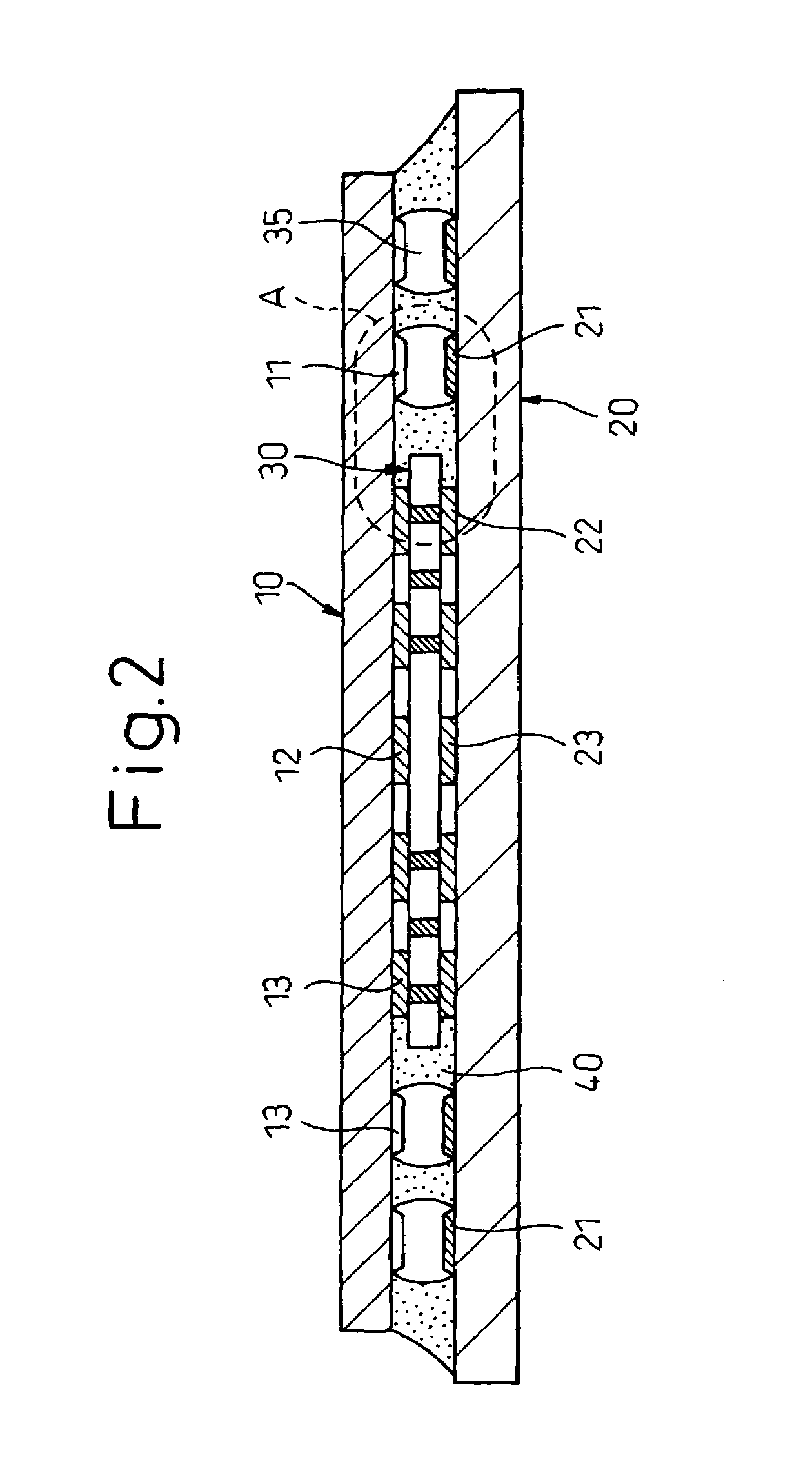

Semiconductor device and method for manufacturing the same

ActiveUS7138706B2Good heat dissipationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesForming faceSemiconductor chip

A semiconductor device with excellent heat dissipation characteristics that can achieve a high reliability when mounted in electronic equipment such as a cellular phone or the like and a method for manufacturing the same are provided. The semiconductor device includes a substrate, a plurality of semiconductor chips mounted on the substrate by stacking one on top of another, and an encapsulation resin layer made of encapsulation resin. Among the plurality of semiconductor chips, a first semiconductor chip as an uppermost semiconductor chip is mounted with a surface thereof on which a circuit is formed facing toward the substrate, and the encapsulation resin layer is formed so that at least a surface of the first semiconductor chip opposite to the surface on which the circuit is formed and a part of side surfaces of the first semiconductor chip are exposed to the outside of the encapsulation resin layer.

Owner:TESSERA ADVANCED TECH

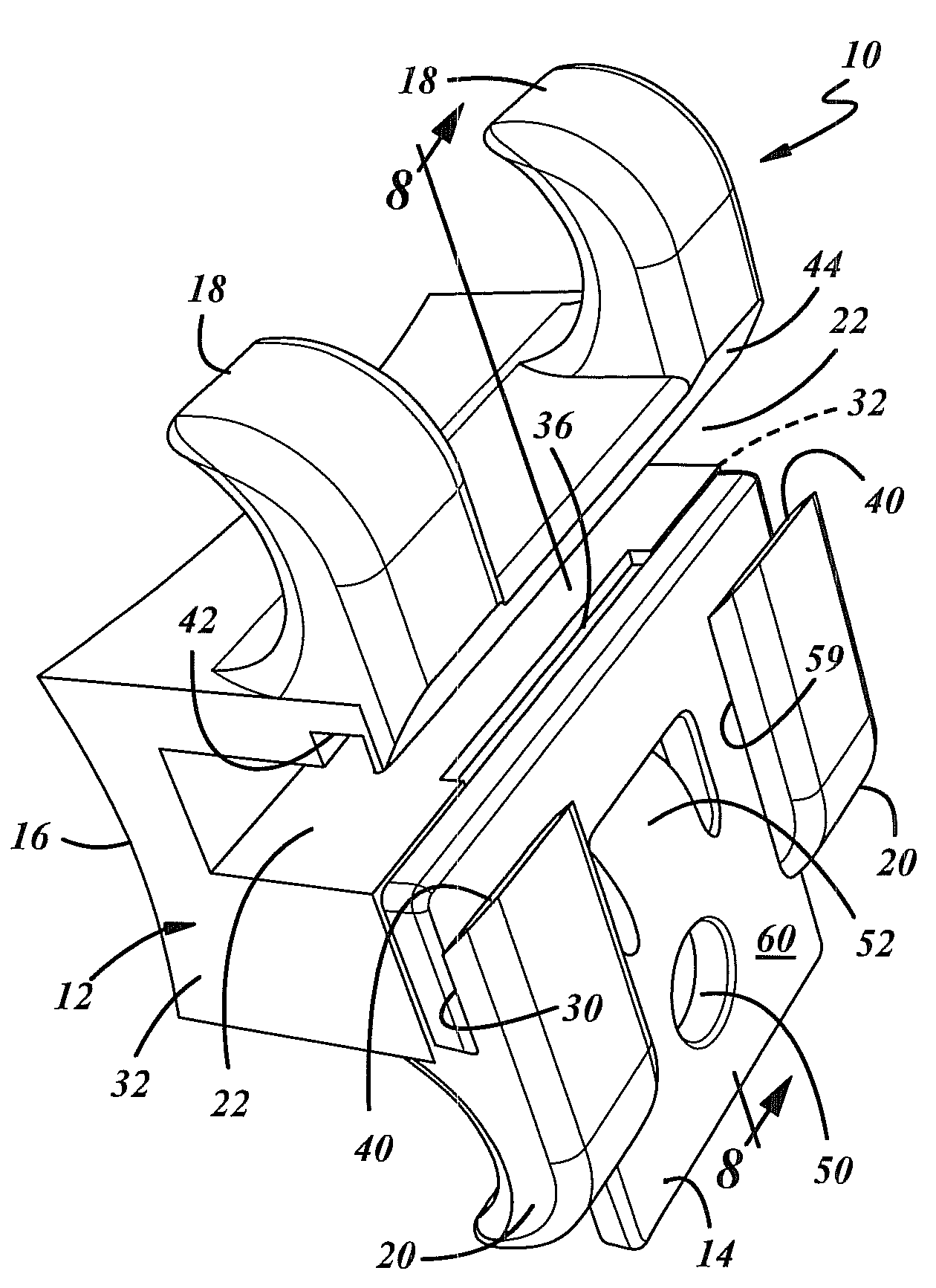

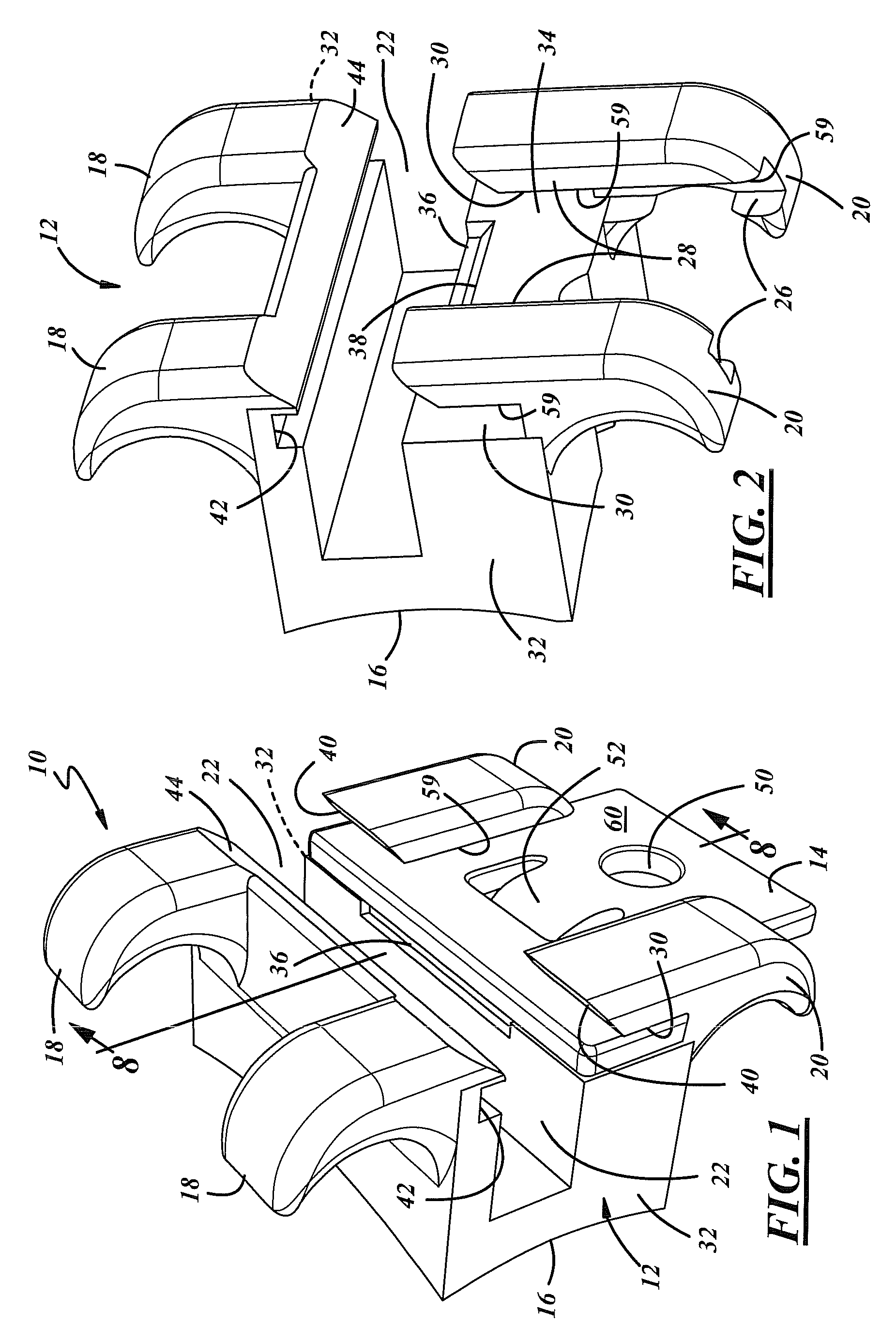

Self-ligating orthodontic bracket

According to one embodiment of the invention, a self-ligating orthodontic bracket apparatus has a body with an archwire slot, a lingual surface for mounting to a tooth and a guide track. The body and guide track form facing surfaces. A clip is engaged between the facing surfaces and is slideably movable in the guide track between an open position such that the archwire slot can receive an archwire and a closed position in which the clip can retain the archwire in the slot. The clip is dimensioned to extend the entire length and height of the slot in the bracket when in the closed position.

Owner:LOKAR ROBERT

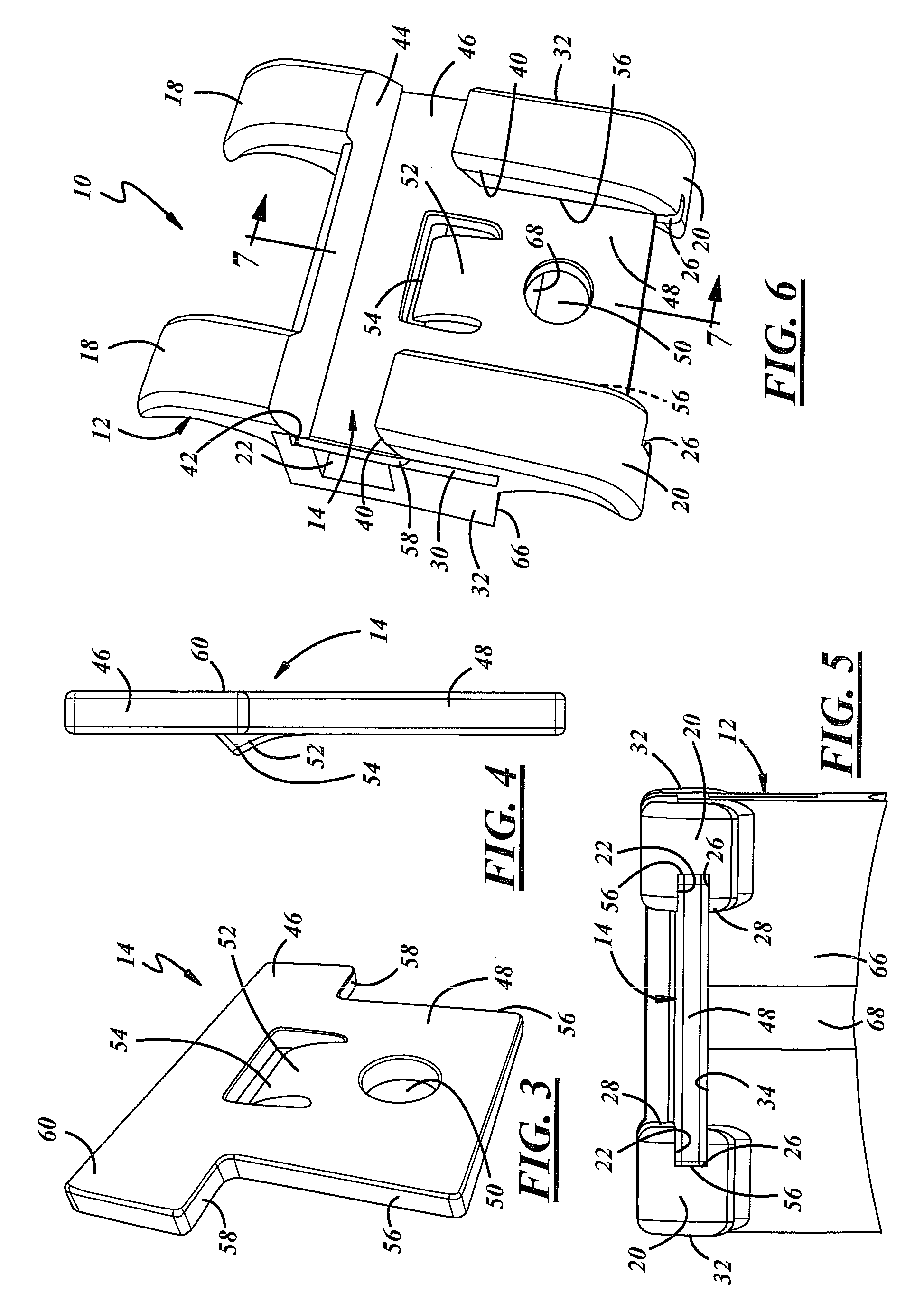

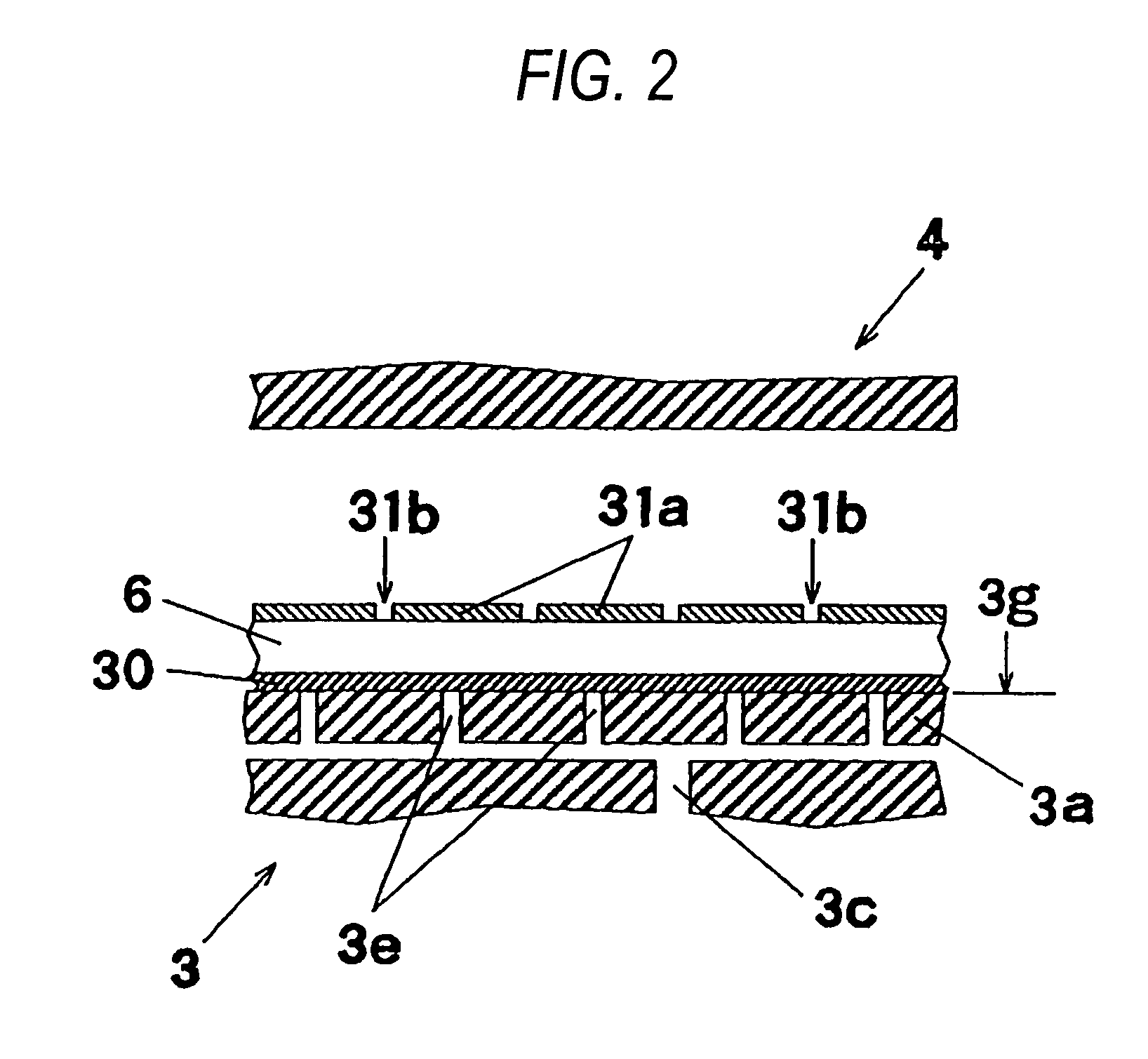

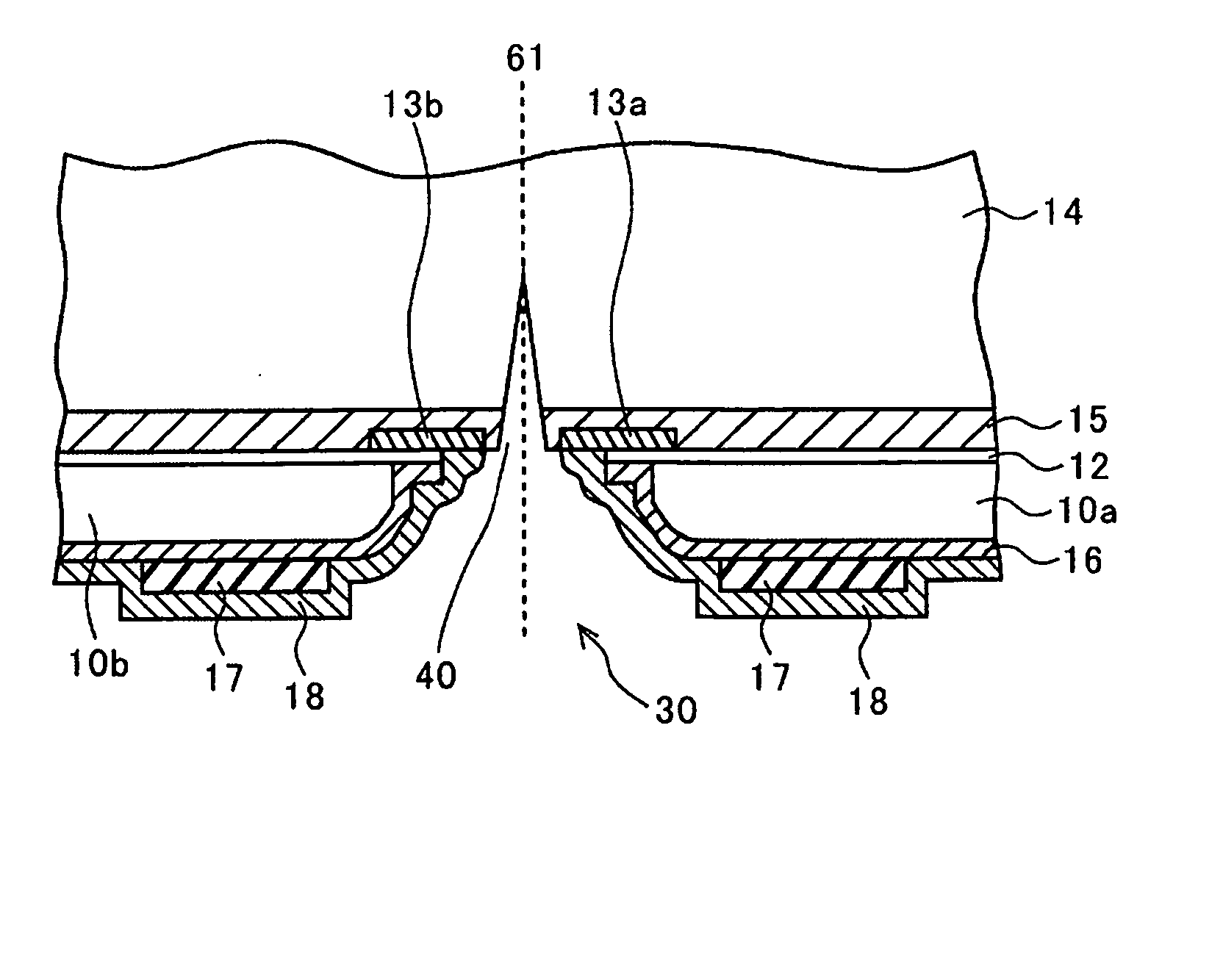

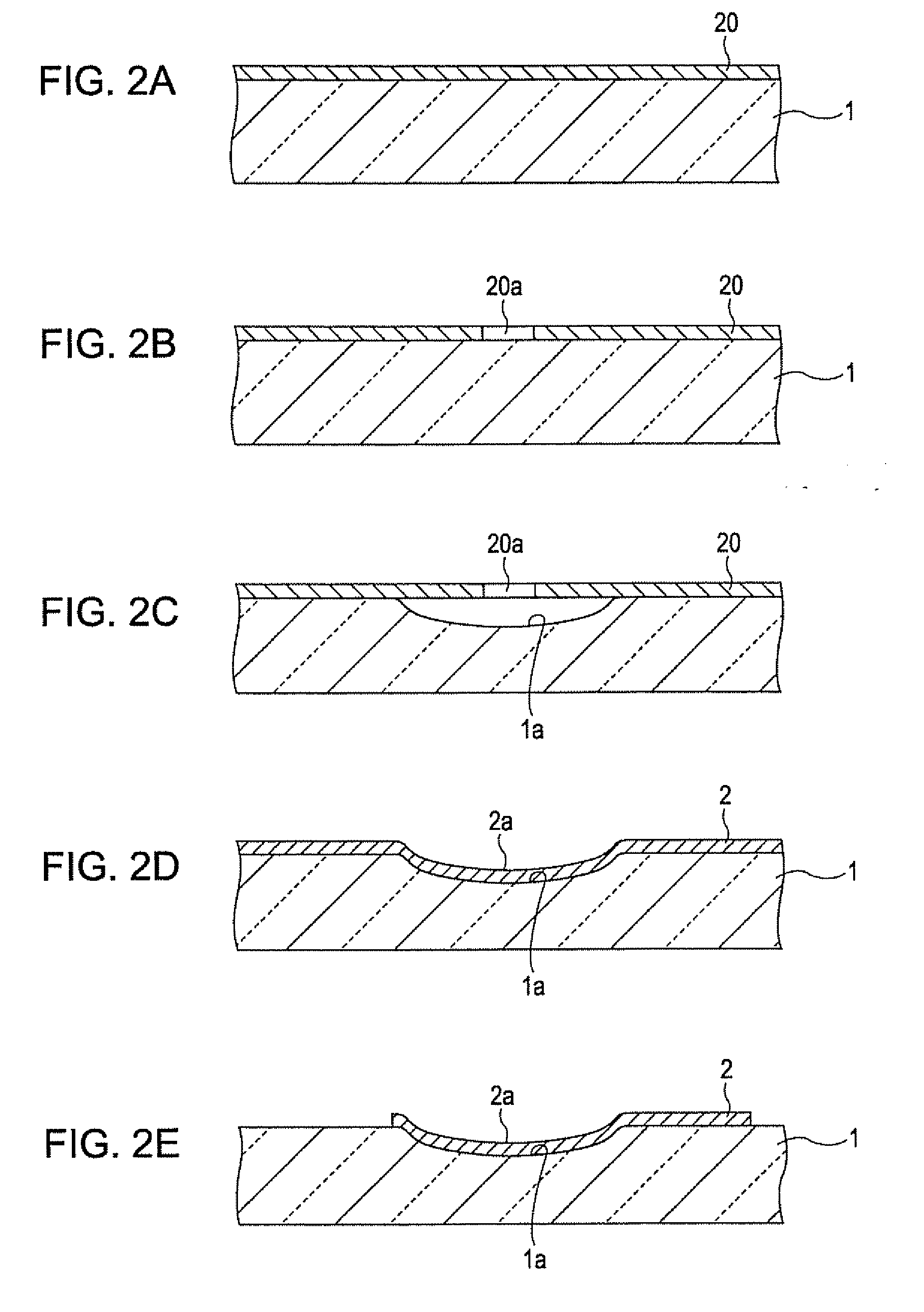

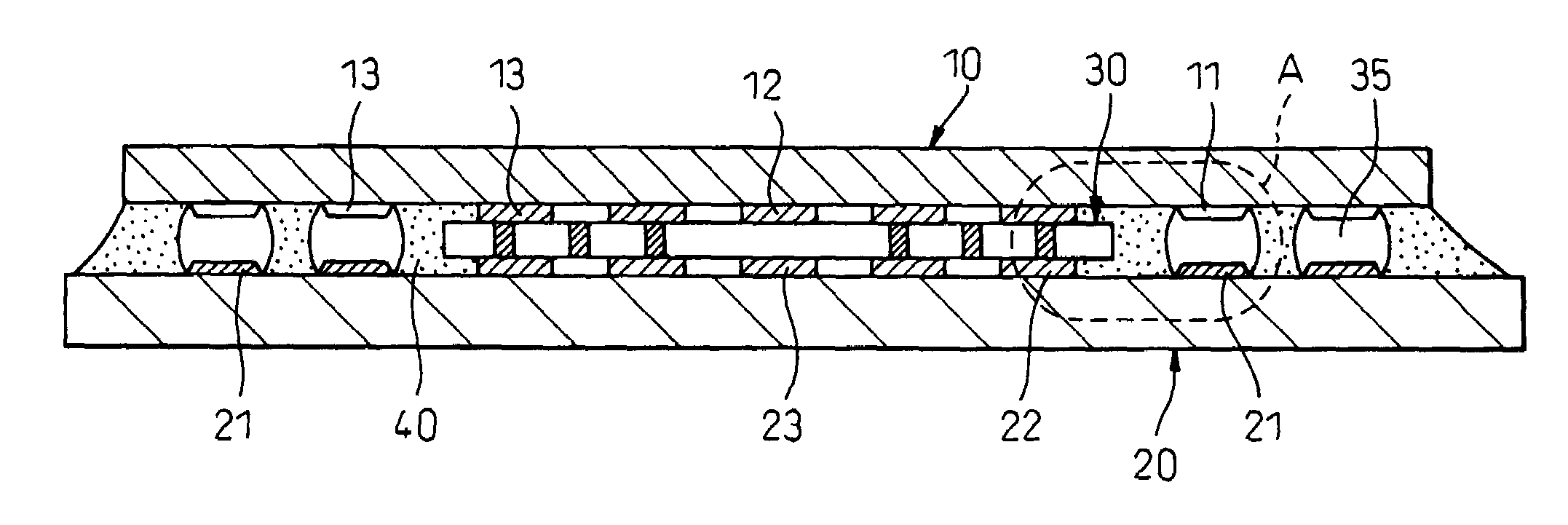

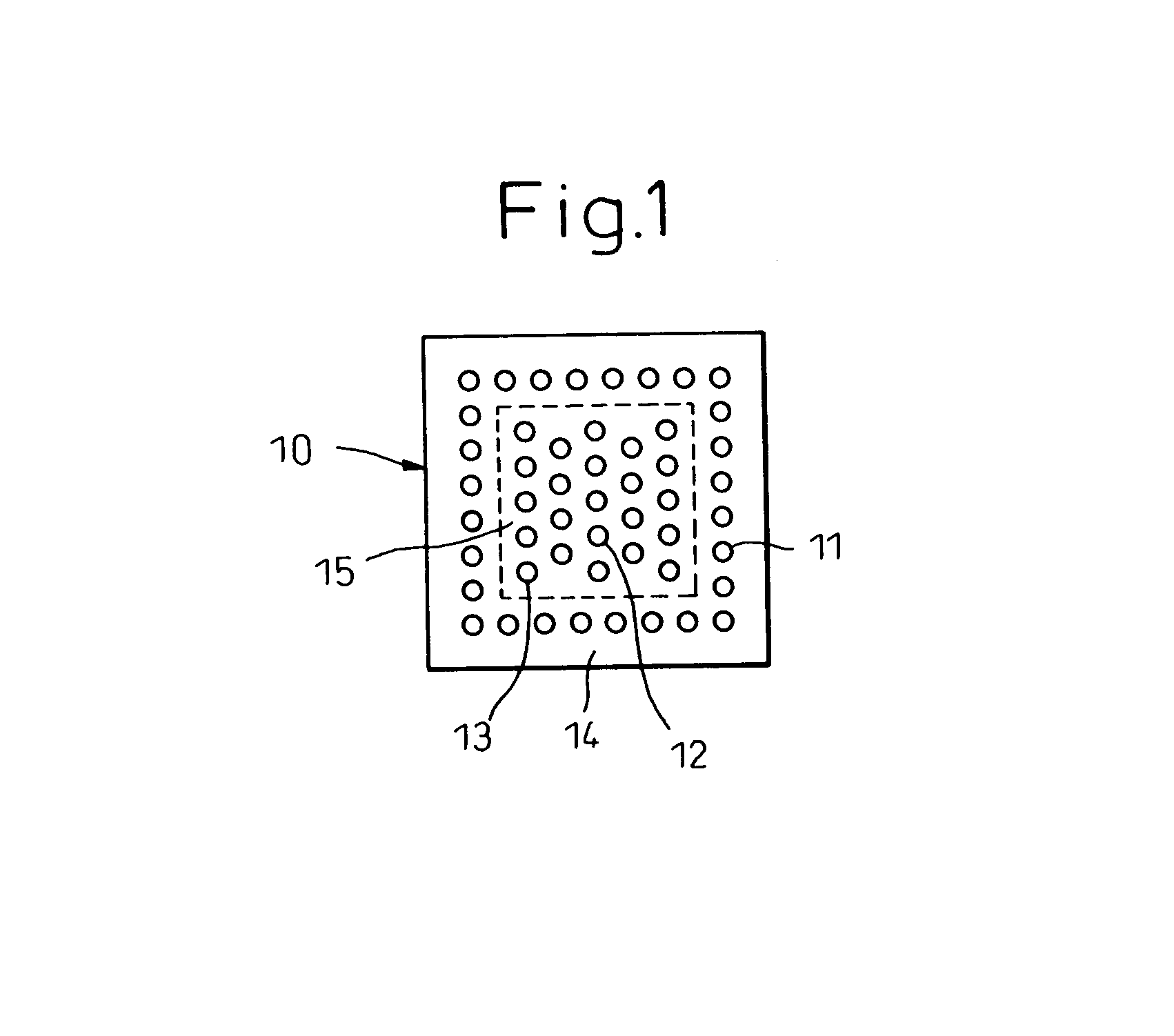

Method of cutting semiconductor wafer and protective sheet used in the cutting method

InactiveUS7060531B2Suppressing progressInhibit progressFilm/foil adhesivesSemiconductor/solid-state device detailsForming faceResist

In a method of cutting a semiconductor wafer in which the semiconductor wafer 6 is cut by plasma etching, a protective sheet 30 on which a metallic layer 30b, a plasma etching rate of which is low, is formed on one face of an insulating sheet 30a is stuck on to a circuit forming face 6a by an adhesive layer 30c, and plasma is exposed onto an opposite side to the circuit forming face 6a from a mask side which is formed by covering regions except for cutting lines 31b with a resist film 31a so as to conduct plasma etching on portions of the cutting lines. Due to the above structure, it is possible to use the metallic layer as an etching stop layer for suppressing the progress of etching. Therefore, fluctuation of the progress of etching can be avoided and heat damage caused on the protective sheet can be prevented.

Owner:PANASONIC CORP

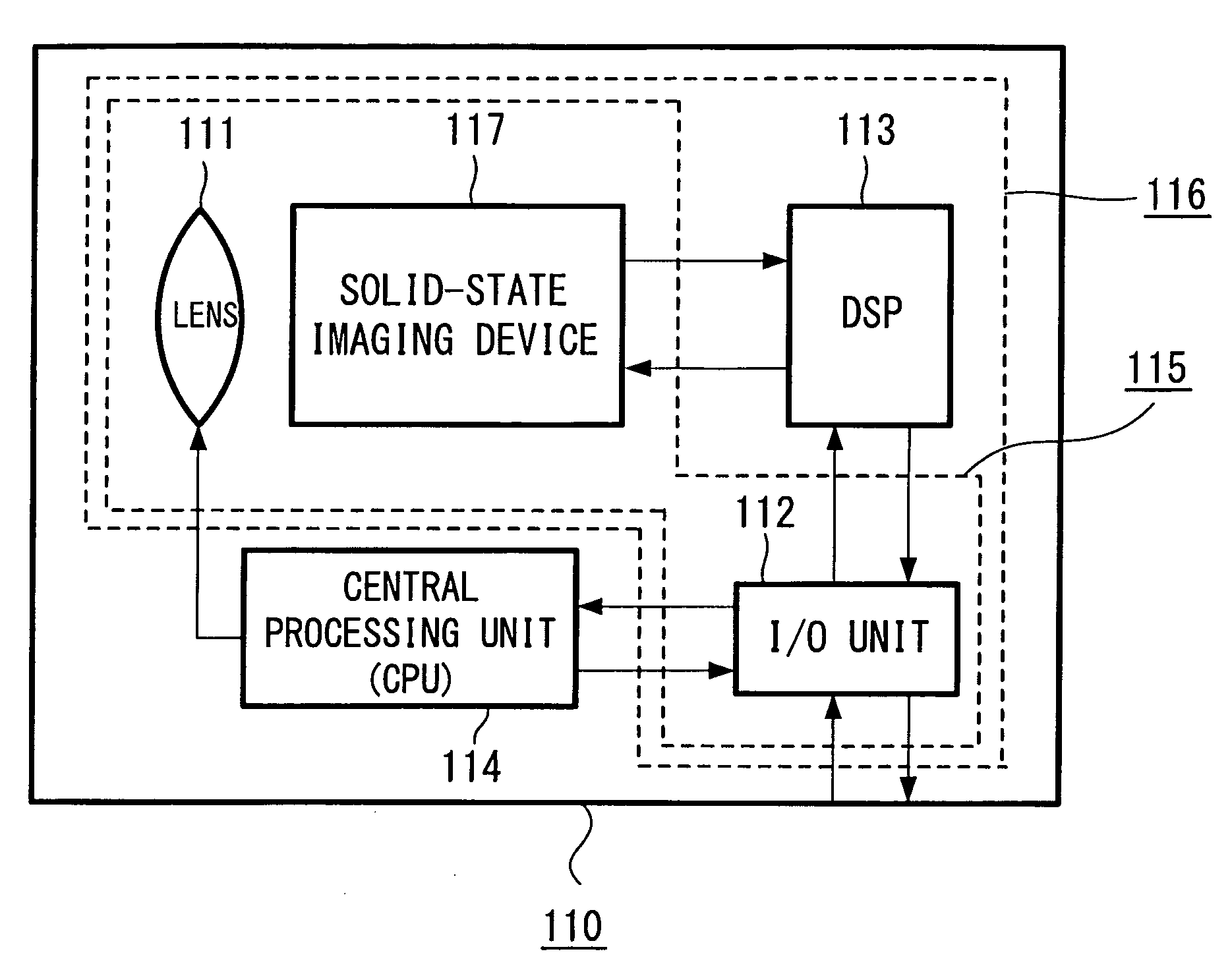

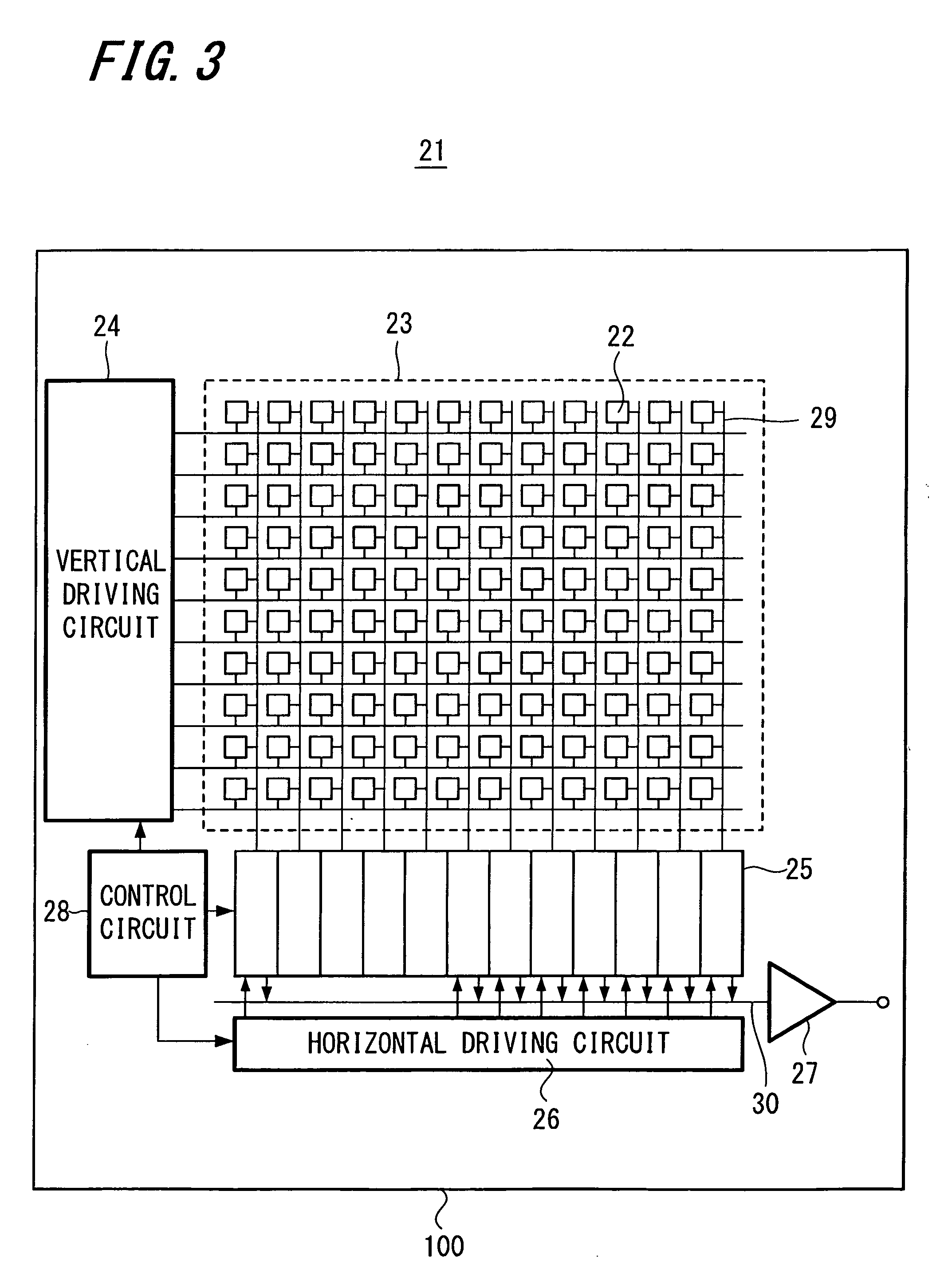

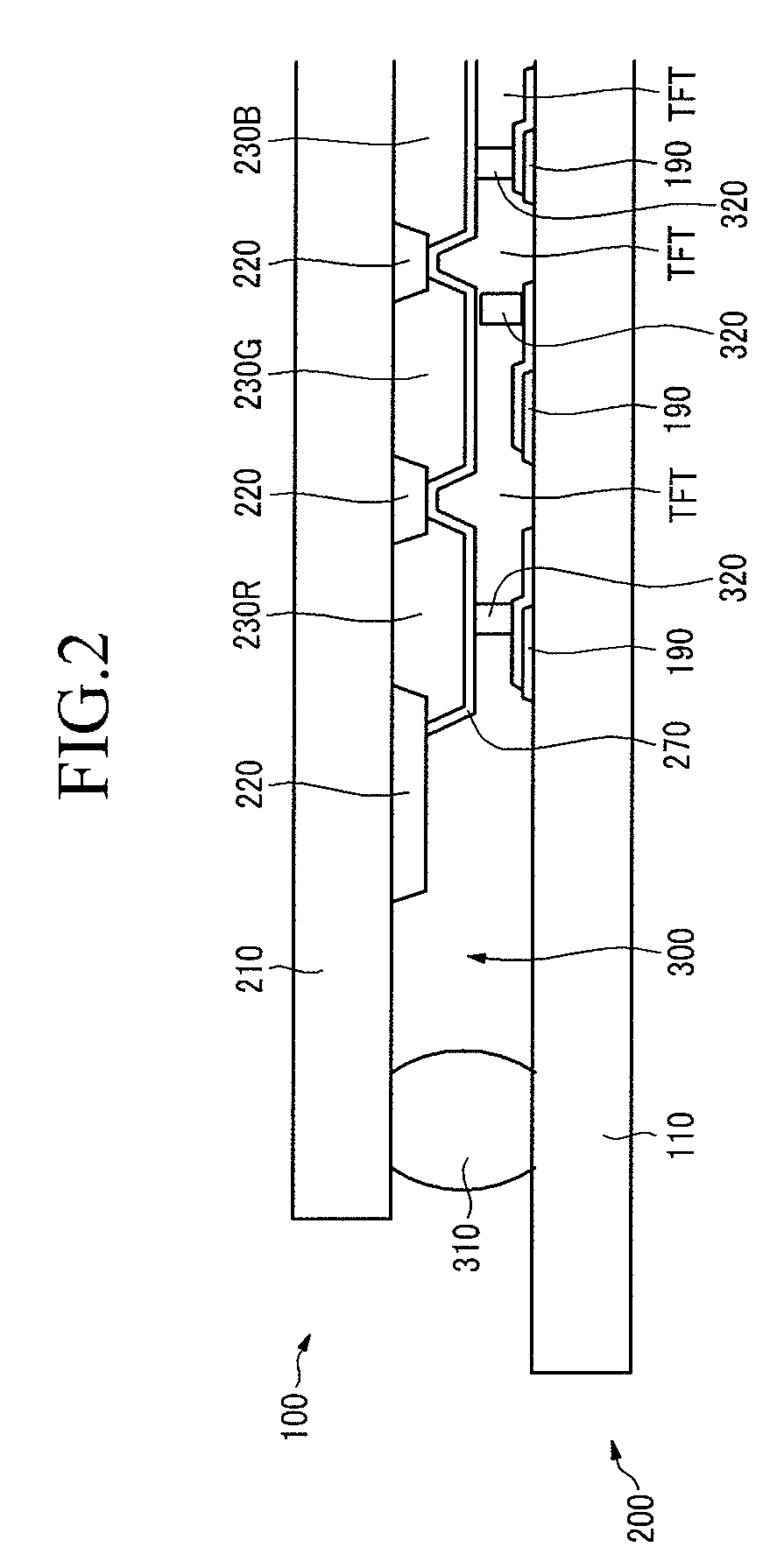

Solid-state imaging device and camera module

ActiveUS20090002531A1High quality imagingOccurrence can be suppressedTransistorTelevision system detailsForming facePhotoelectric conversion

A solid-state imaging device is provided. The solid-state imaging device includes a plurality of arrayed pixels, an optical inner filter layer, and a light-blocking side wall. The plurality of arrayed pixels each includes a photoelectric conversion portion and a pixel transistor. The optical inner filter layer is provided for blocking infrared light and formed facing toward a light-receiving surface of the photoelectric conversion portion of a desired pixel among the arrayed pixels. The light-blocking side wall is formed on a lateral wall of the optical inner filter layer.

Owner:SONY CORP

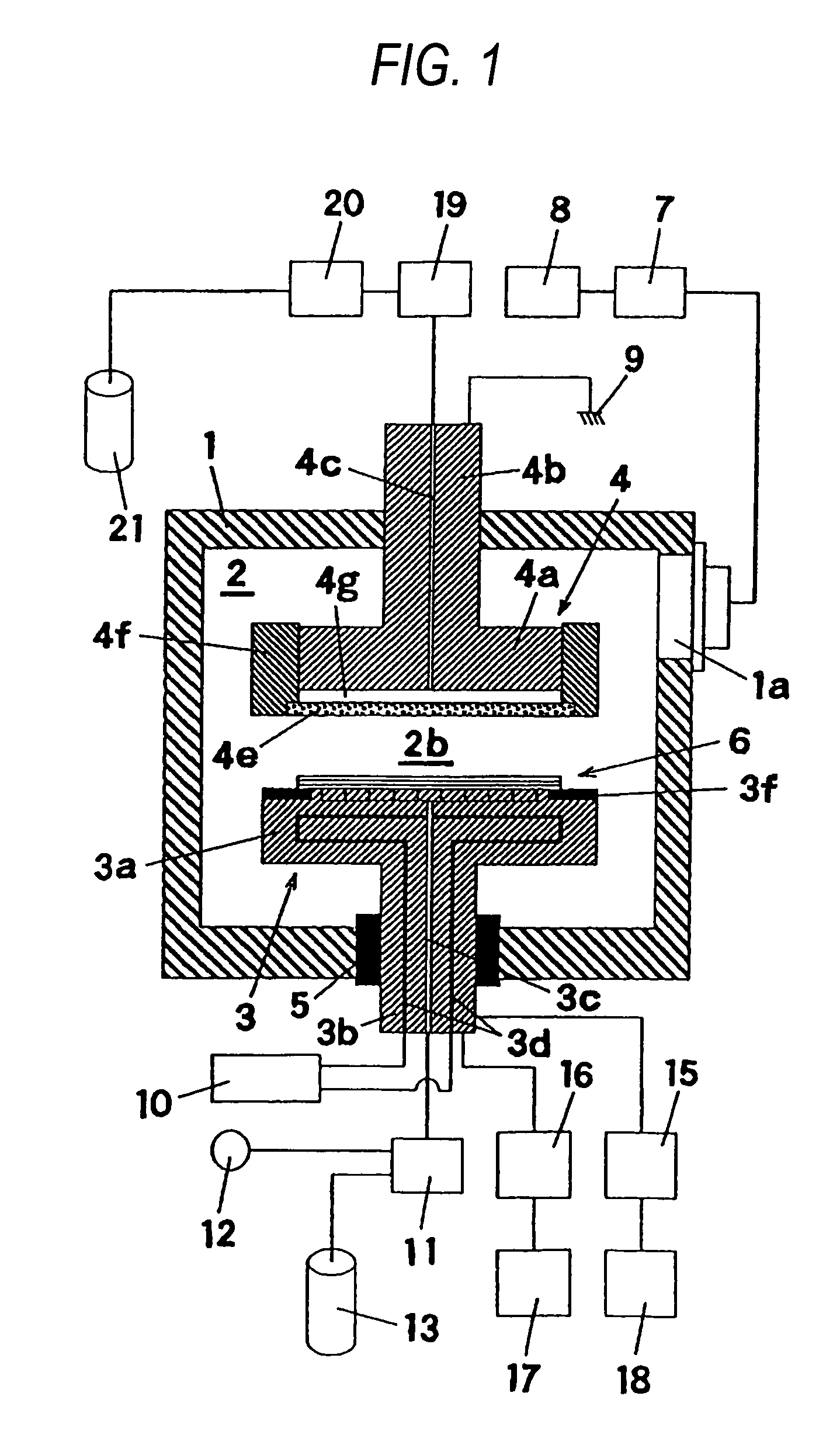

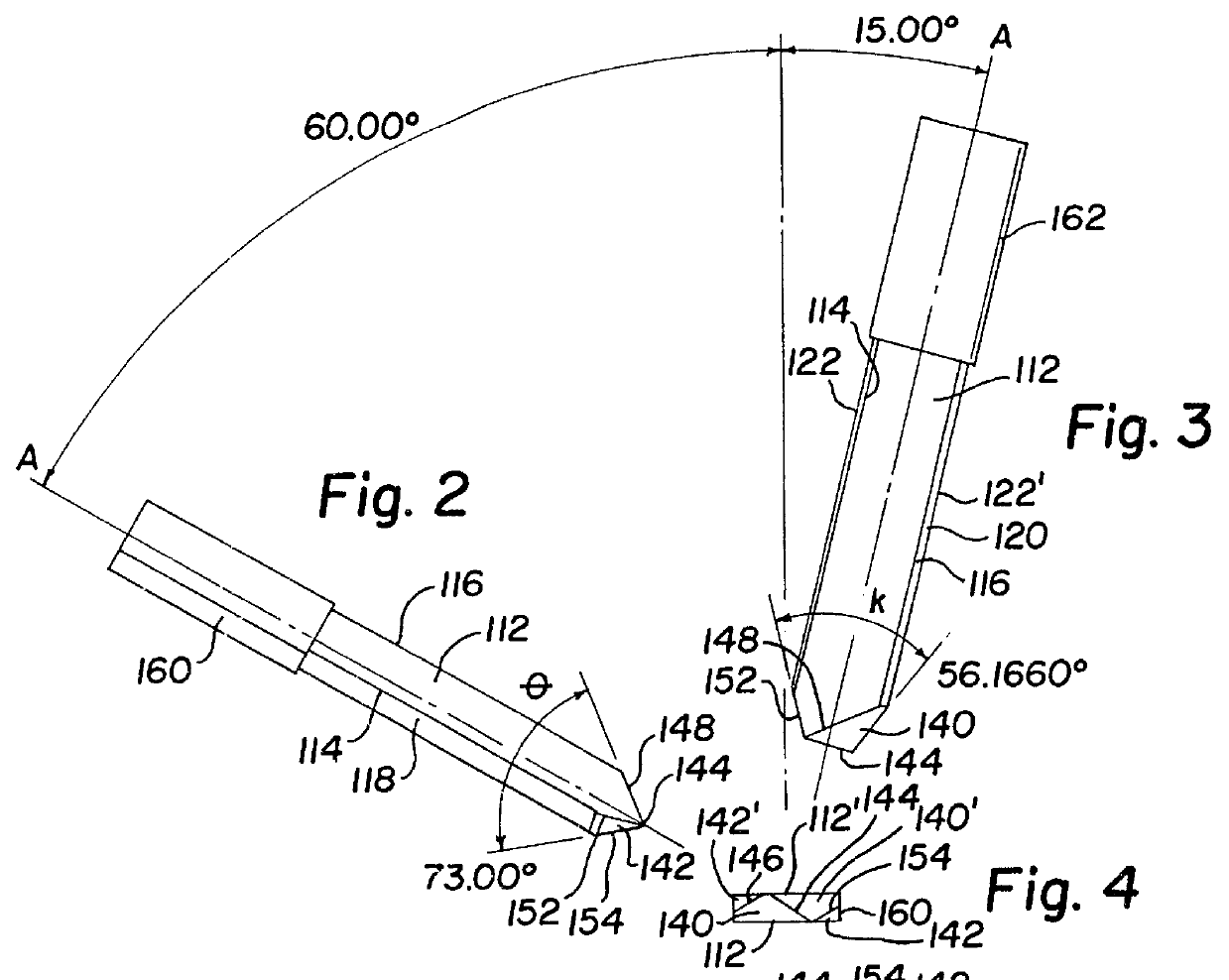

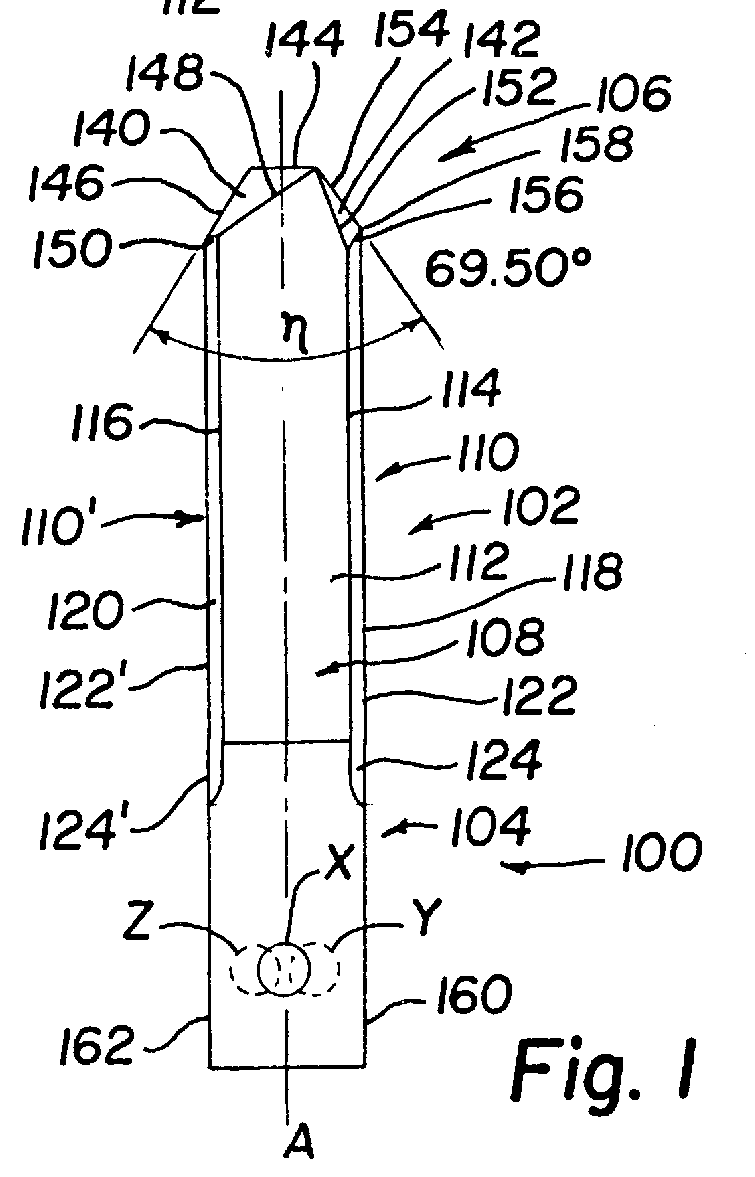

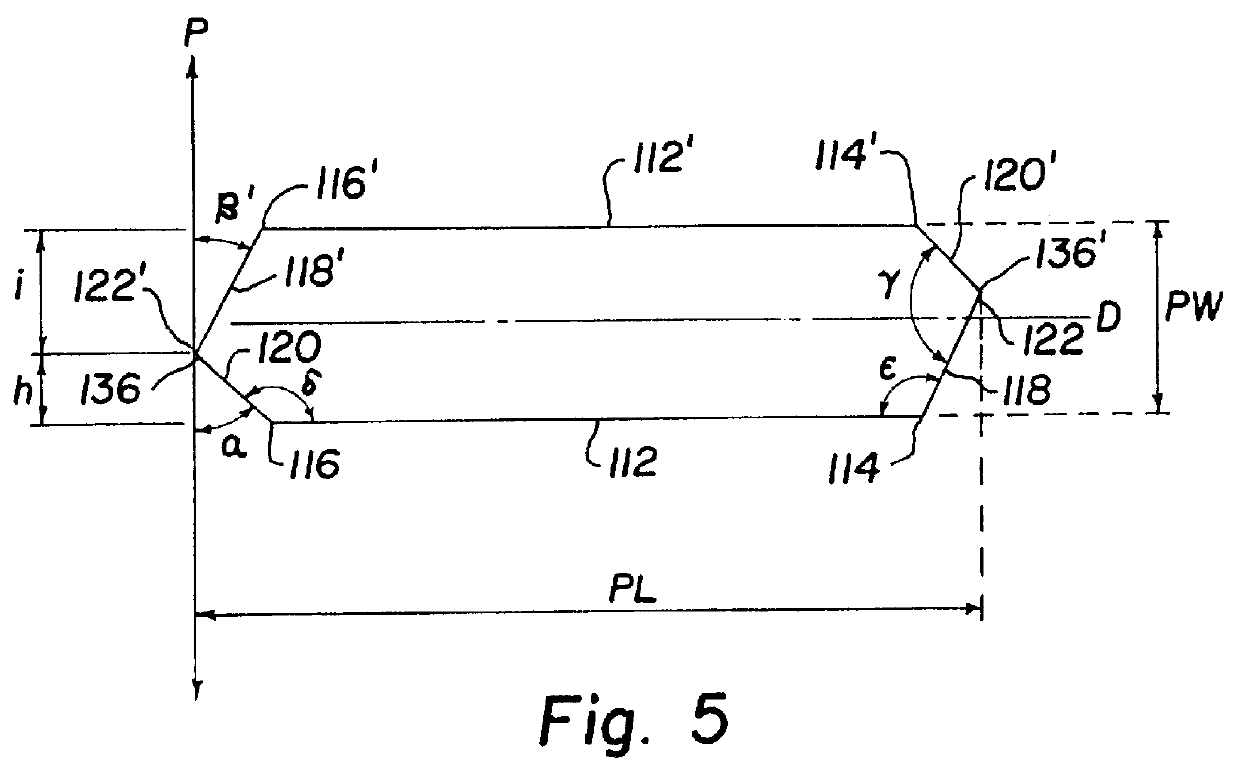

Punch and die for producing connector plates

A blade punch for forming teeth in a connector plate, the blade punch comprising an elongated blade having a metal working tip at one end and a shank at the other end. The blade has an elongated cross-section defined by opposing parallel spaced planar side walls and opposing ends. Each end comprises a major end wall and a minor end wall which converge to end wall intersections, where the end wall intersections are eccentric to a plane parallel to and midway between said side walls. Each end wall intersects a side wall at an obtuse angle. The metal working tip has opposed air cut faces abutting one another along an air cut edge and opposed first and second forming faces, each of the forming faces abutting one of the air cut faces along an exterior edge. Each of the air cut faces is bordered by a portion of one of the minor end walls, a portion of one of the side walls, the air cut edge, and one of the exterior edges. Each of the forming faces is bordered by a portion of one of the major end walls, a portion of one of the minor end walls, a portion of one of the side walls, and one of the exterior edges. A forming angle between 50 DEG and 60 DEG is formed between the first forming face and the exterior edge bordering the second forming face in a plane normal to the first forming face.

Owner:ILLINOIS TOOL WORKS INC

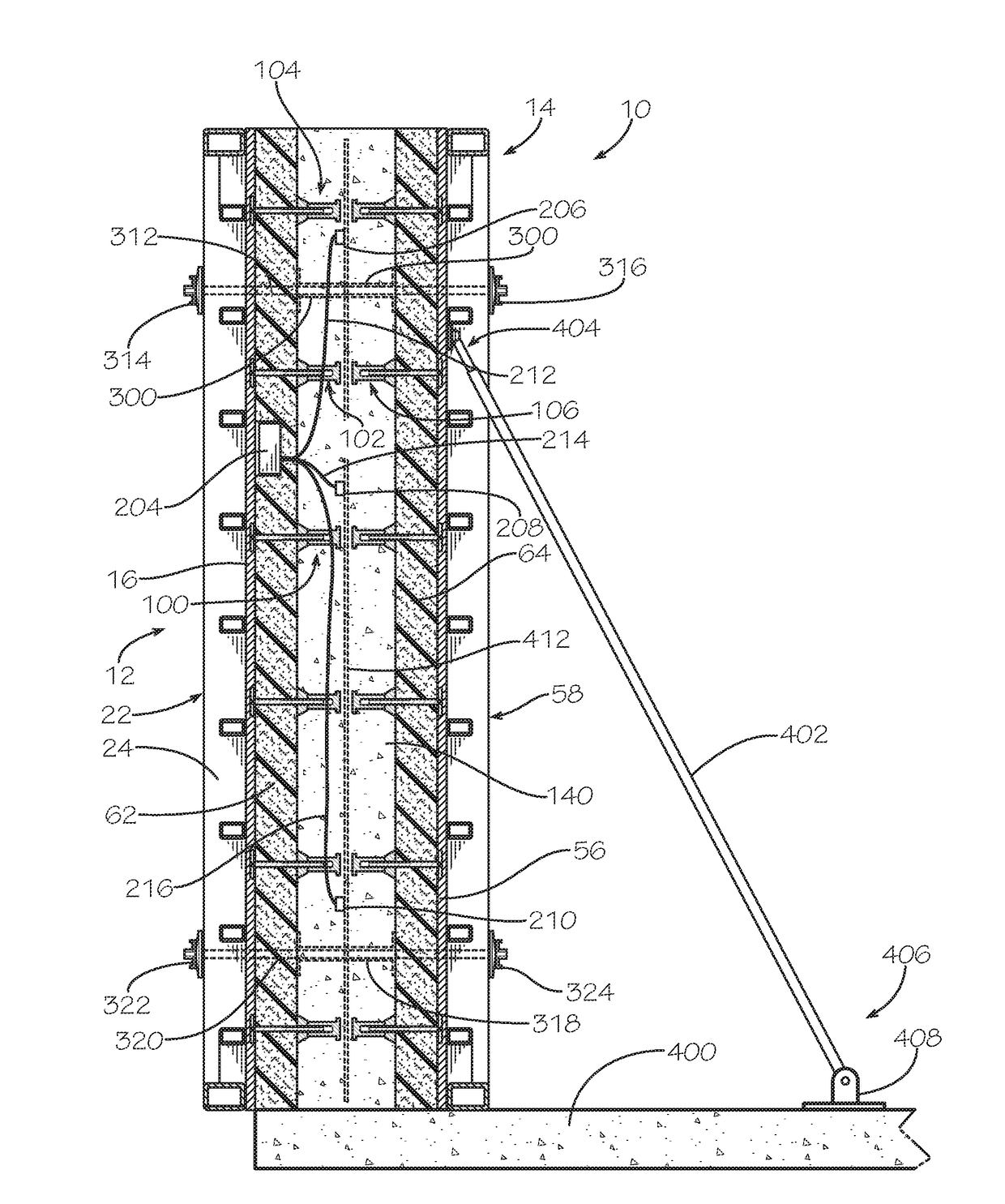

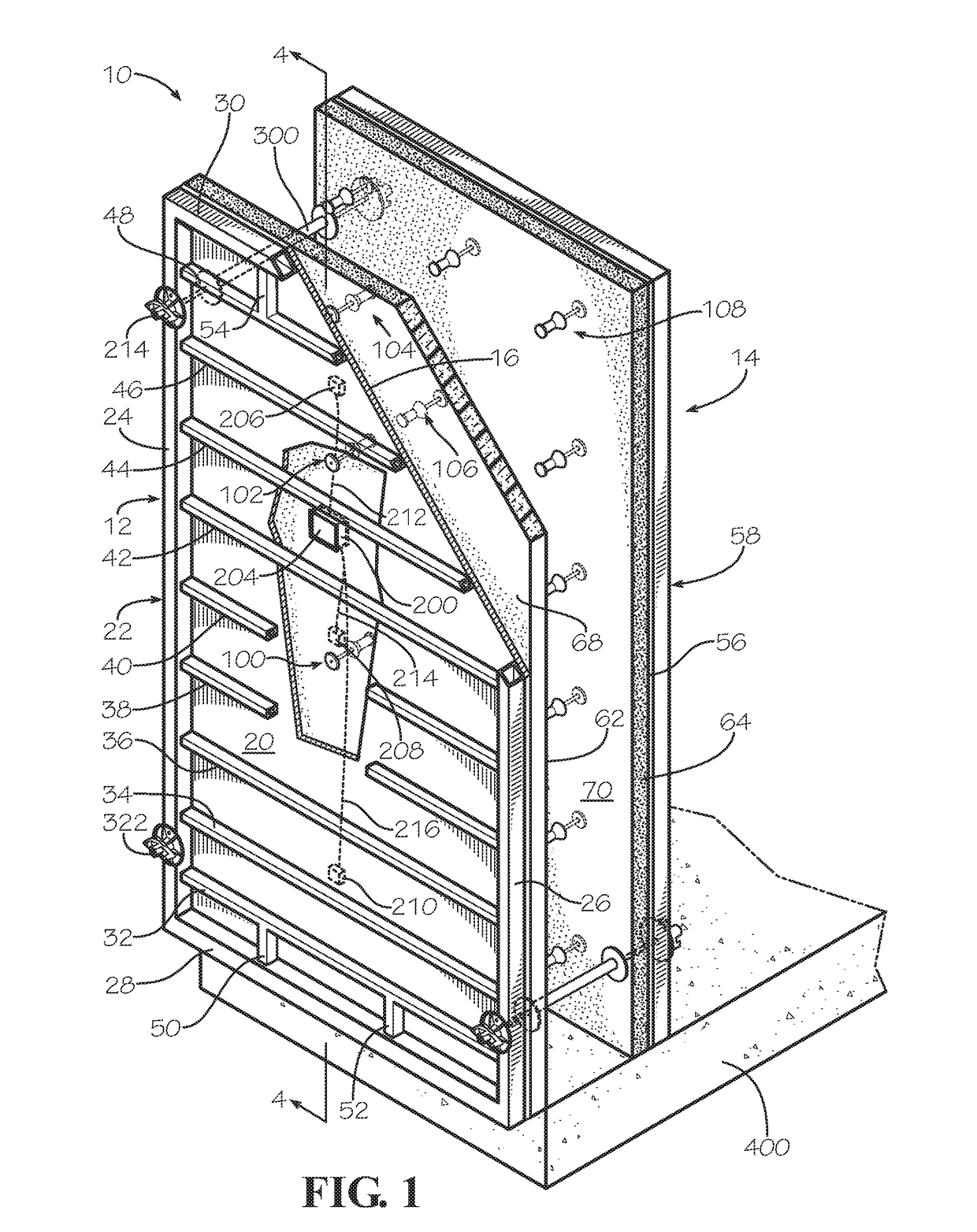

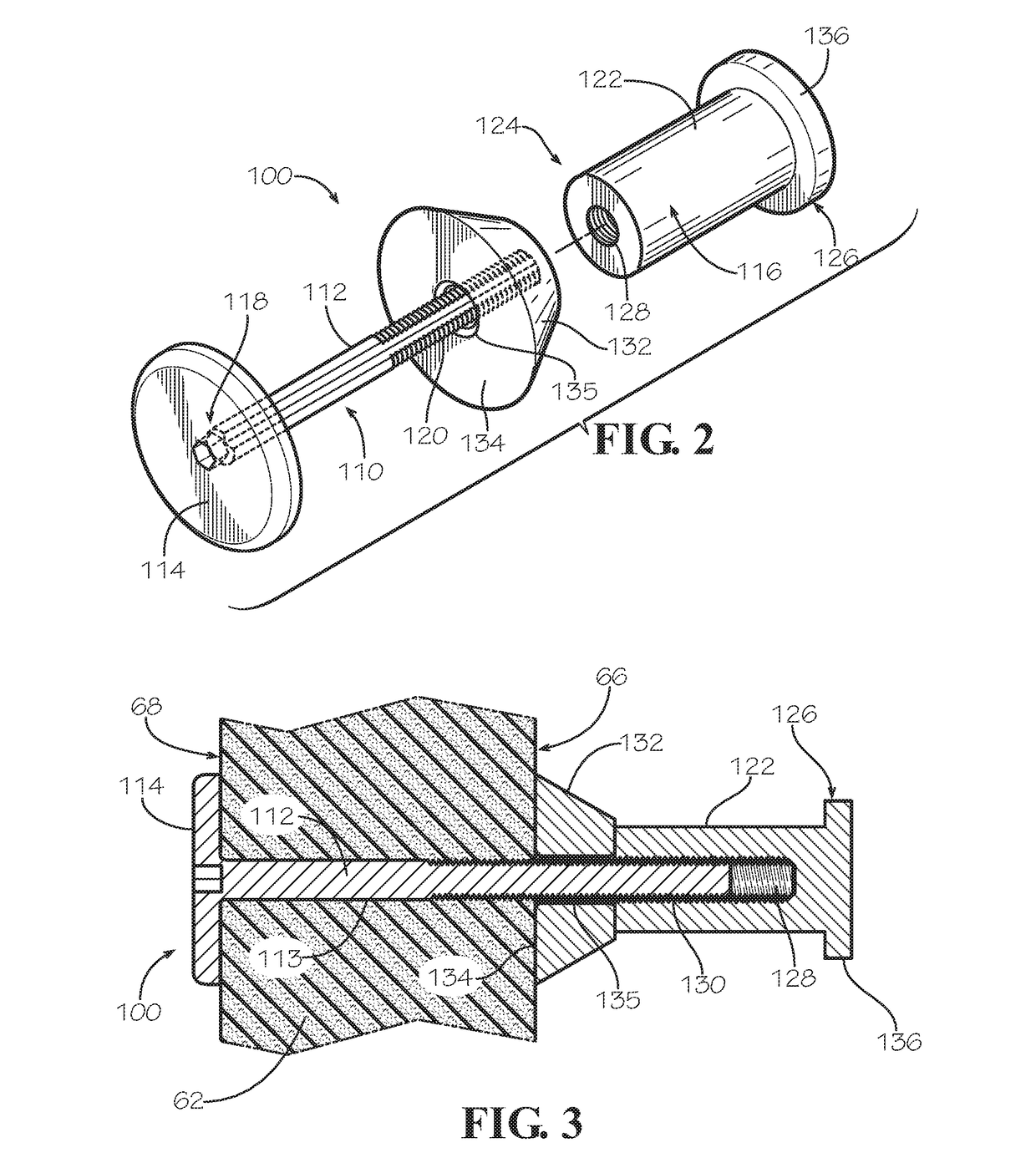

Self-annealing concrete, self-annealing concrete forms, temperature monitoring system for self-annealing concrete forms and method of making and using same

ActiveUS20170218614A1Improved curing environmentAvoid insufficient heatingConstruction materialWallsForming faceTemperature monitoring

The invention comprises a product. The product comprises a first removable concrete form having a concrete forming face and a first insulating panel insert having a first primary surface and an opposite second primary surface, wherein the second primary surface of the first insulating panel insert contacts the concrete forming face of the first removable concrete form. The product also comprises an elongate anchor member having an enlarged portion and an elongate portion, the elongate portion having a first end and an opposite second end, wherein the enlarged portion is disposed adjacent the first end and contacts the second primary surface of the first insulating panel insert and wherein the elongate portion extends through the first insulating panel insert and extends outwardly from the first primary surface of the first insulating panel insert. A method of using a removable insulated concrete form system is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

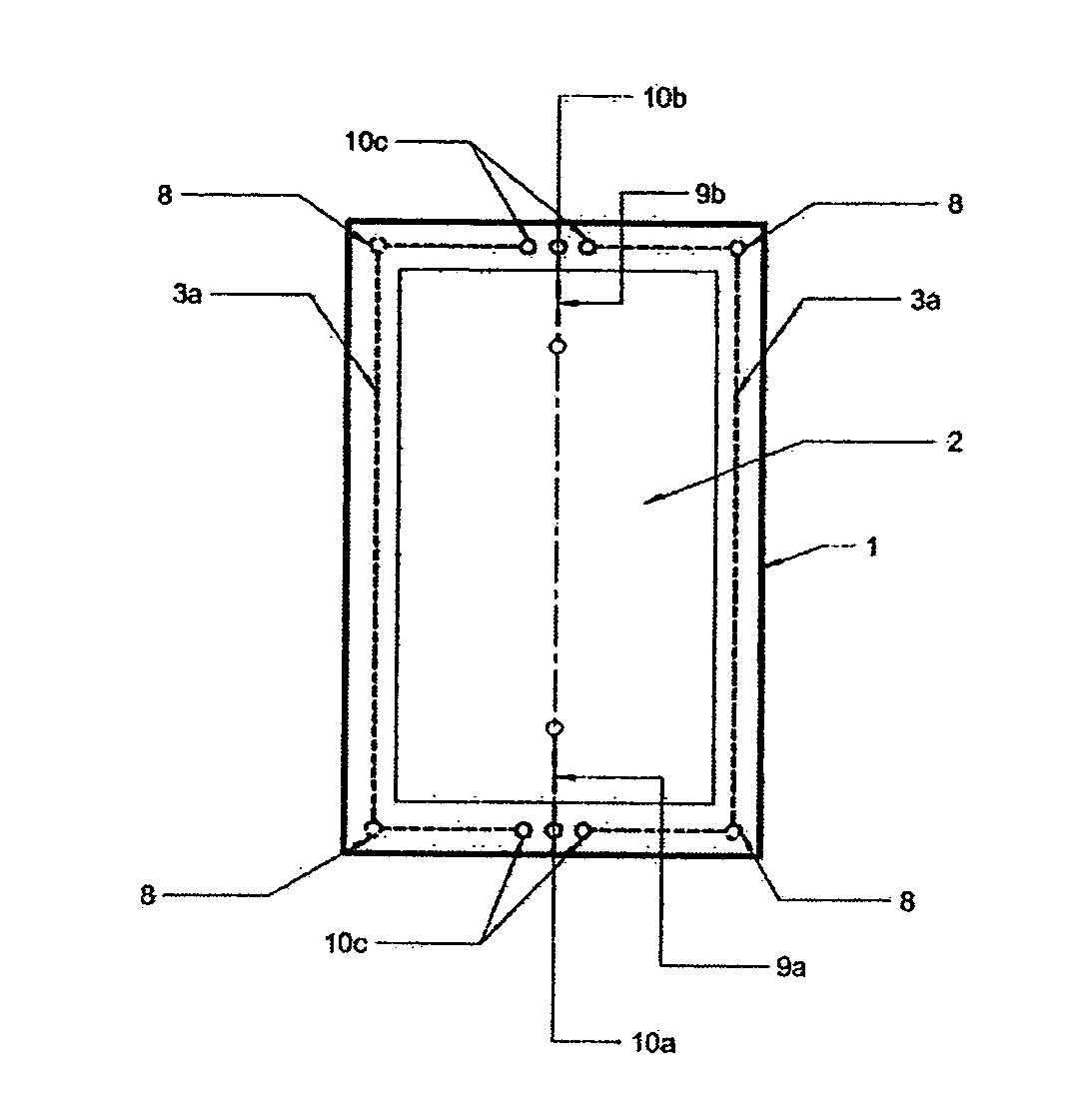

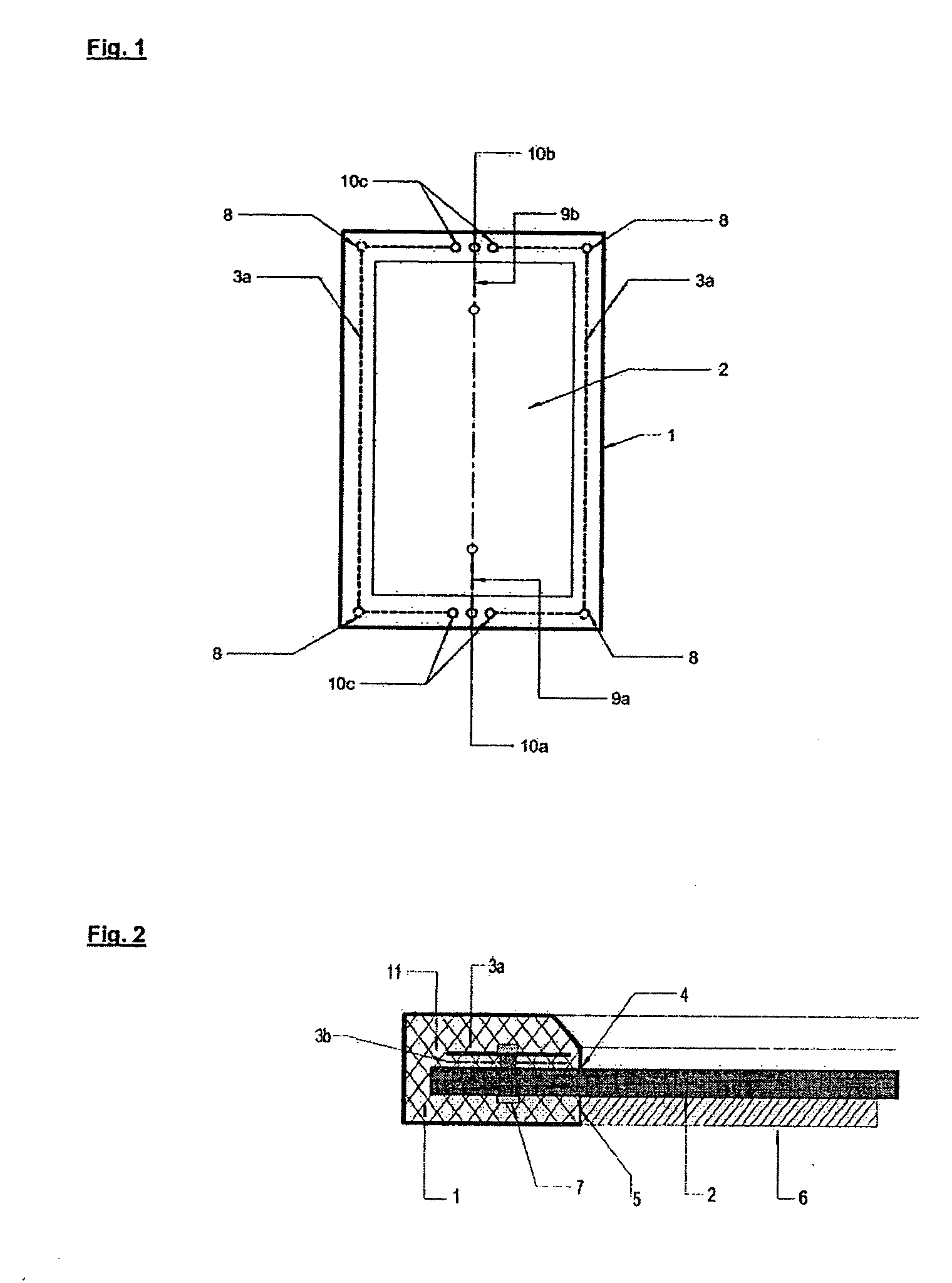

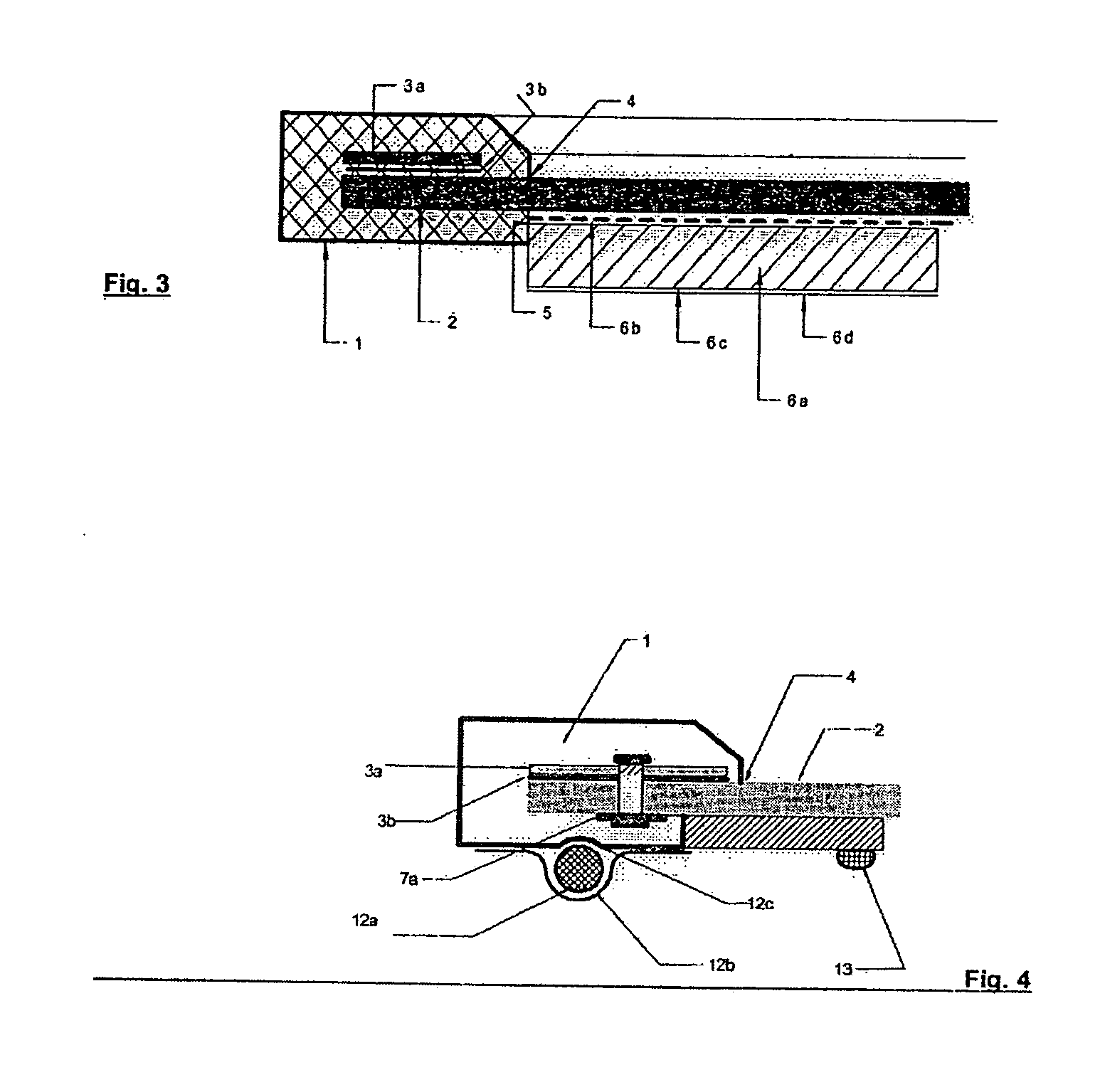

Flexible solar power module with a current lead integrated in the frame

The invention refers to a non-glass and flexible solar power module and the method for its manufacture where the module is provided with a circumferential and flexible frame having integrated through-wiring and socket parts, which are formed face-side into the frame, for module interconnection by means of plug-in connectors. The solar module is thoroughly and completely sealed off on its rear side and has a full-surface smooth texture which is established by the insertion of a thin flexible panel, preferably made of plastic, together with the laminate into the form for the manufacture of the frame by means of RIM (reaction injection moulding). The modules are mounted on the building, preferably by means of bonding / cementing to practically any random roof materials, as well as to curved surfaces and without a backward cable lead.

Owner:BAYER MATERIALSCIENCE AG

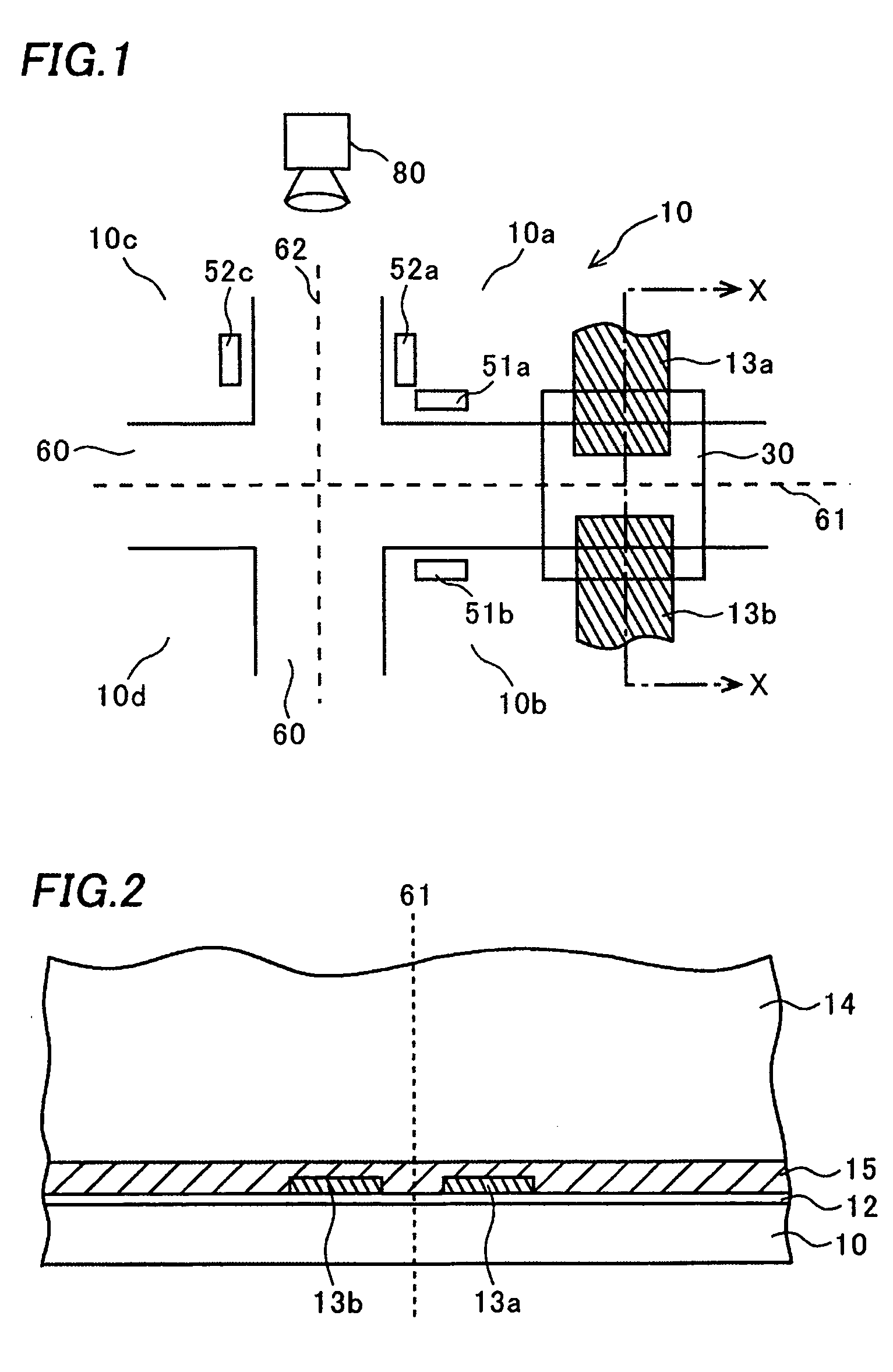

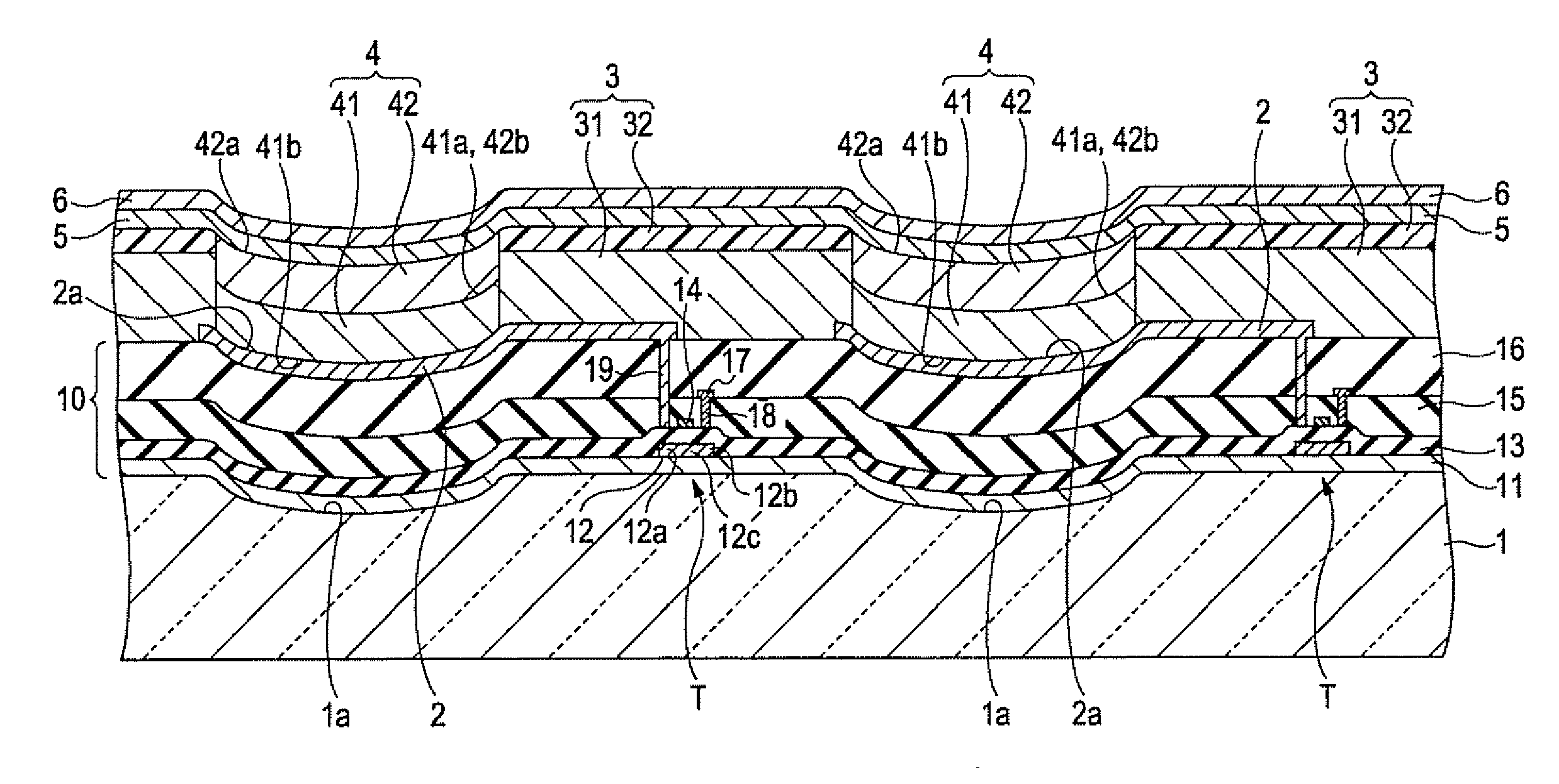

Semiconductor device and manufacturing method of the same

ActiveUS20050208735A1Semiconductor/solid-state device testing/measurementCannulasForming faceDevice material

The invention is directed to an improvement of cutting accuracy in a cutting process when a semiconductor device attached with a supporting member is manufactured. The invention provides a manufacturing method of a semiconductor device where a semiconductor wafer attached with a glass substrate is cut with moving a rotation blade along a dicing region and has following features. A pair of alignment marks is formed facing each other over the dicing region on the semiconductor wafer. Then, when the rotation blade is to be aligned on a center of the dicing region, that is, on a centerline thereof in the cutting process, positions of the alignment marks are detected by a recognition camera, the centerline is calculated based on the detection result, and the rotation blade is aligned on the centerline to perform cutting.

Owner:SEMICON COMPONENTS IND LLC

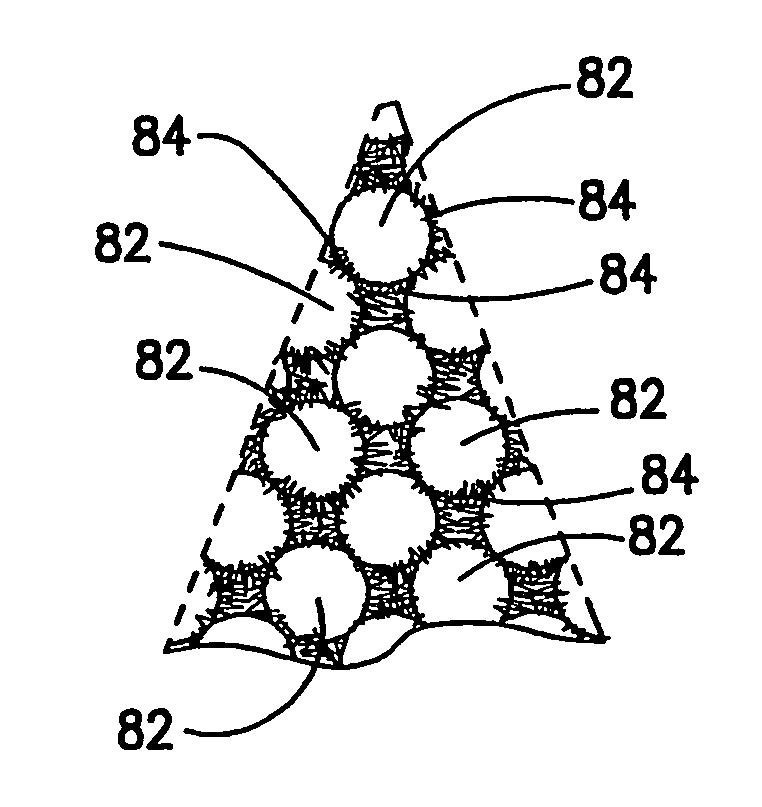

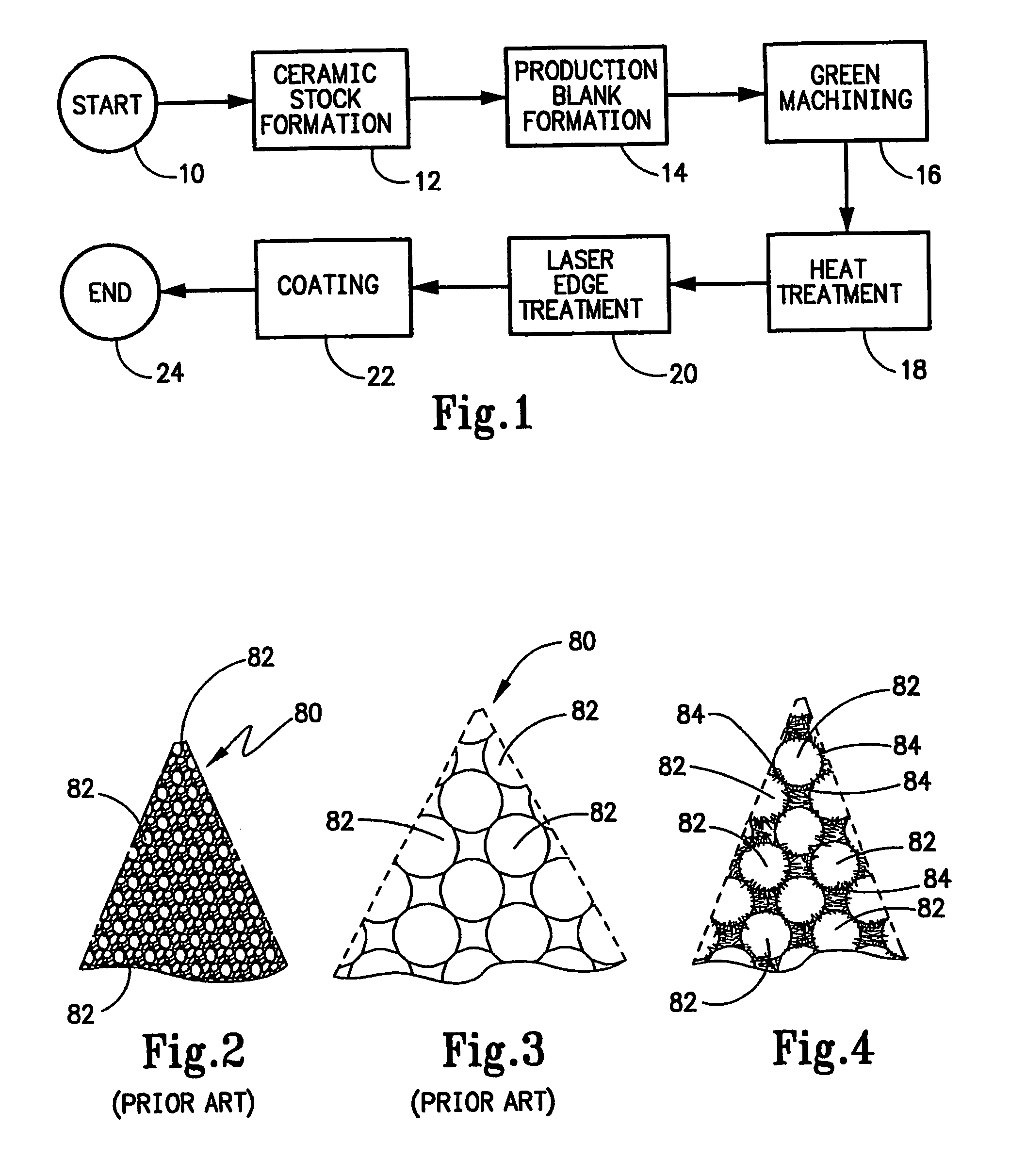

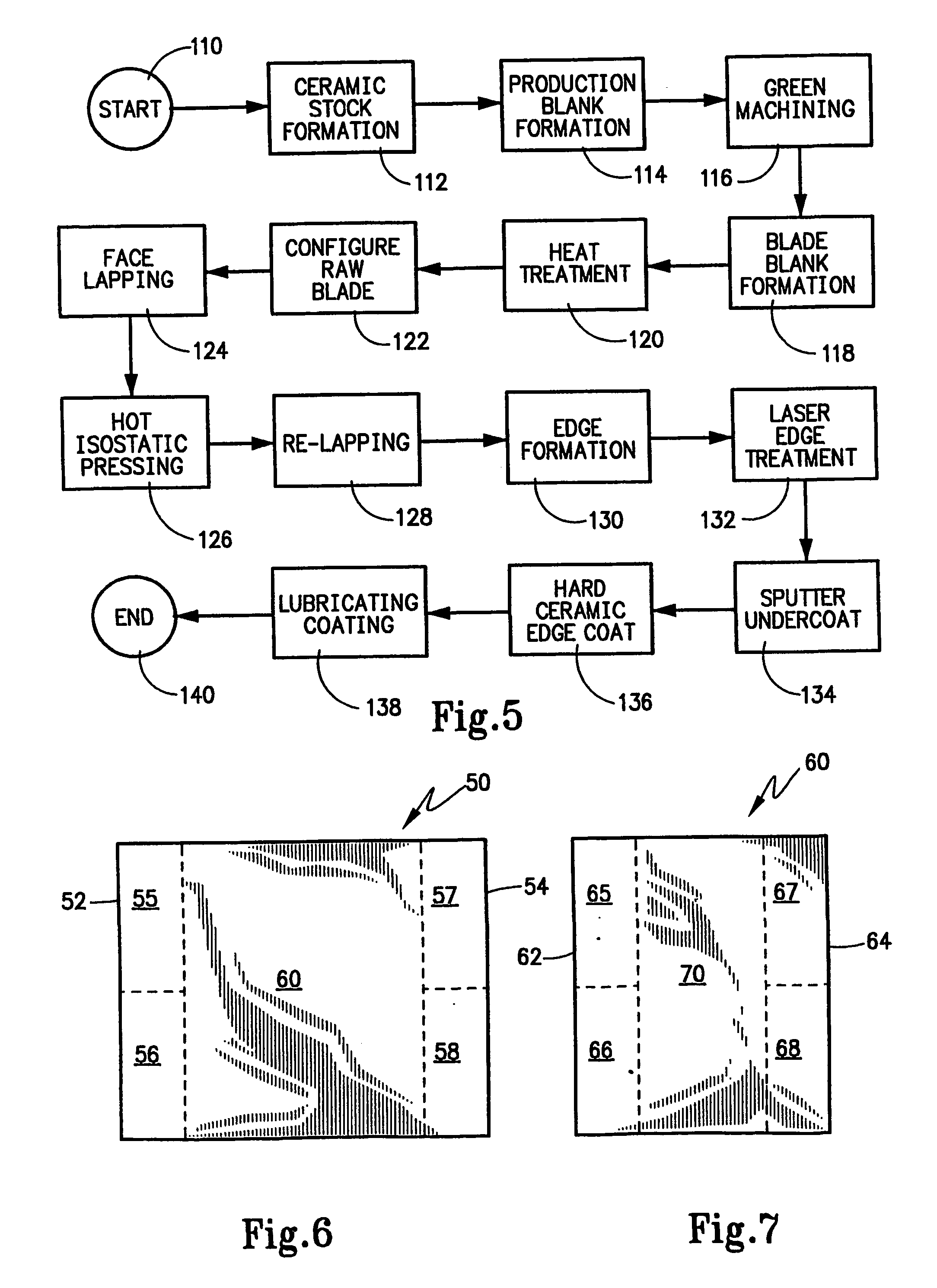

Ceramic blade and production method therefor

InactiveUS7140113B2Enhanced cutting edgeDurable edgeMetal working apparatusCutleryForming faceCeramic coating

A blade of ceramic material is treated to enhance the strength and sharpness of the cutting edge. In one embodiment, ceramic particles along at least one margin of an edge-forming face are fused, such as by a laser treatment. The edge mardin can have a hard ceramic coating of a different ceramic material such as a nitride of chromium, zirconium, titanium, titanium carbon or boron. The hard ceramic coating can be used alone or in conjunction with the laser treatment. The invention includes the methods of treating the edge, both to form the hard ceramic coating and to fuse the particles by scanning with laser, such as an ultraviolet laser.

Owner:LAZORBLADES

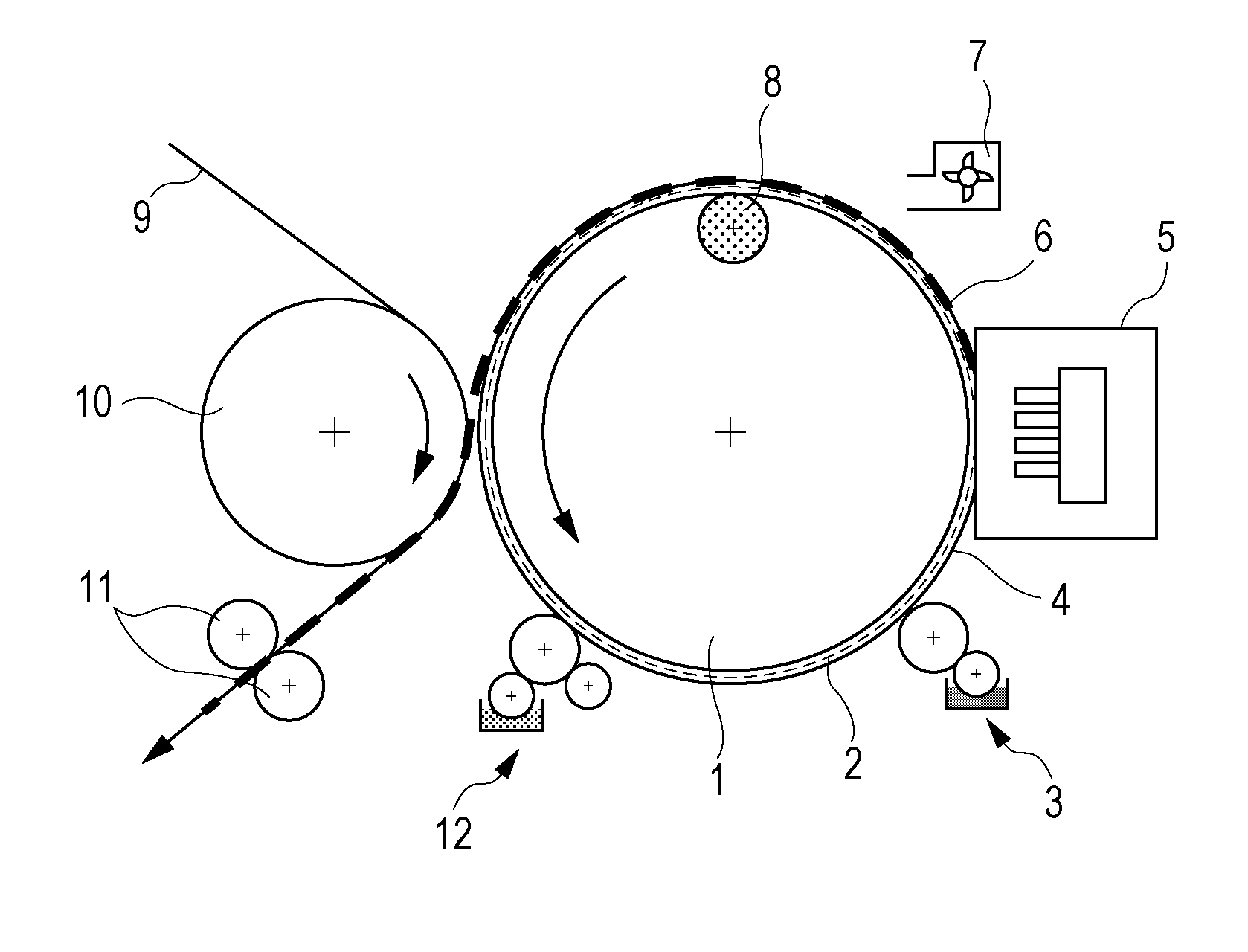

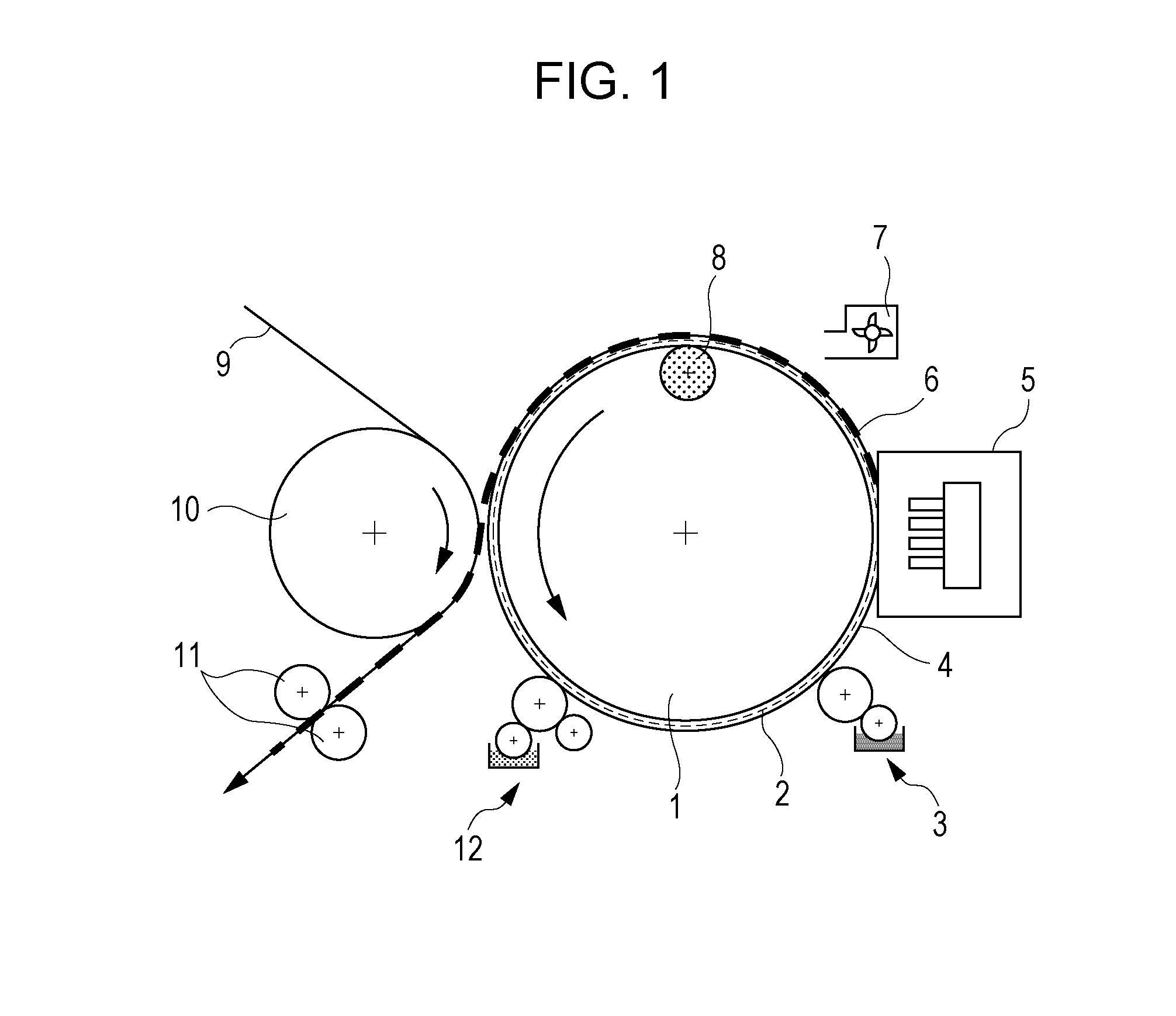

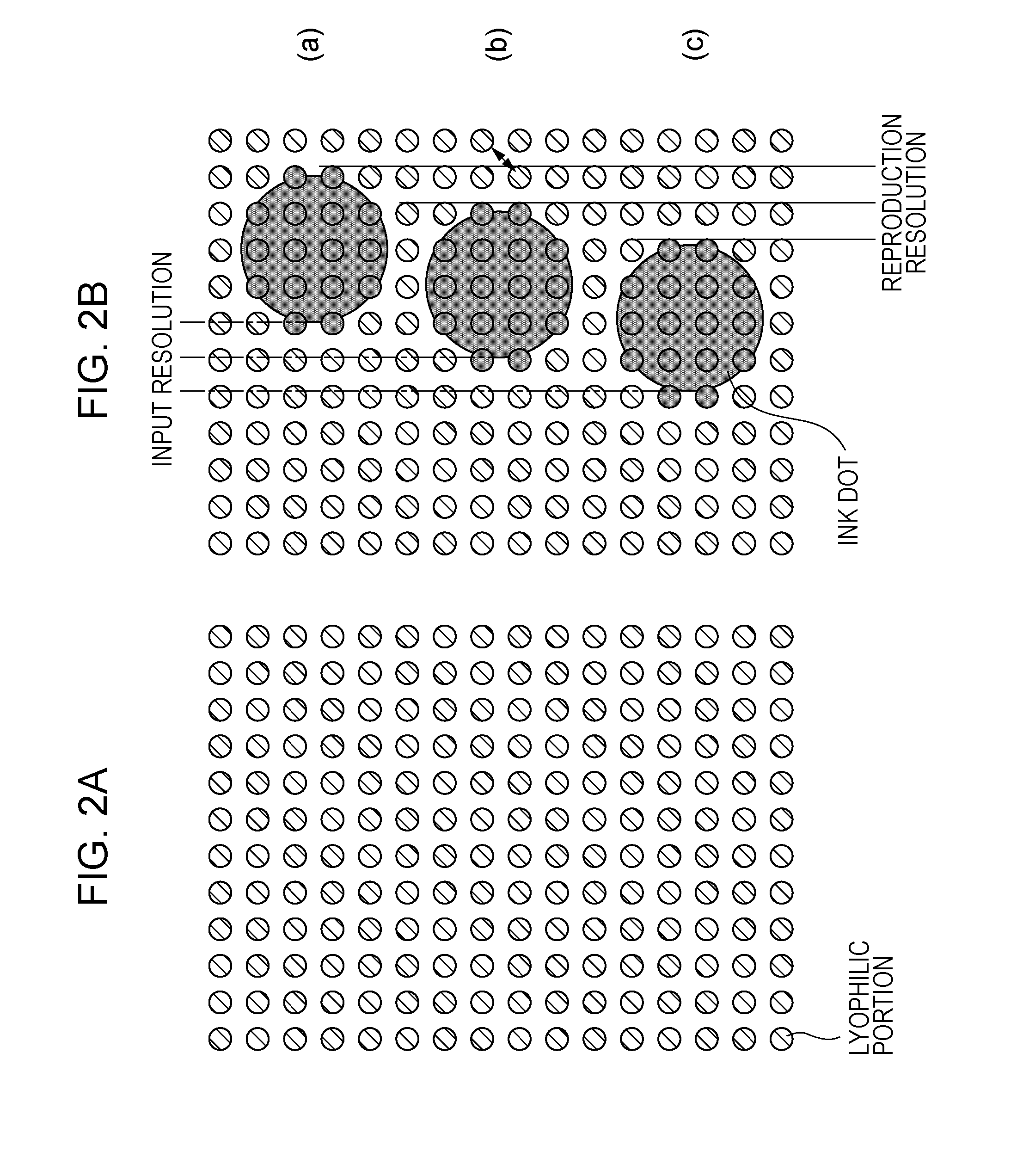

Transfer inkjet recording method

InactiveUS20120105561A1Avoid deformationPrevent of in in imagePrintingForming faceIntermediate image

A transfer inkjet recording method includes the step of applying an aggregating agent onto an image-forming face of an intermediate transfer member, having a pattern including lyophilic portions and a lyophobic portion, the step of forming an intermediate image by applying an ink onto the image-forming face, and the step of transferring the intermediate image to a recording medium from the image-forming face. The lyophilic portions include at least two types of portions having different areas.

Owner:CANON KK

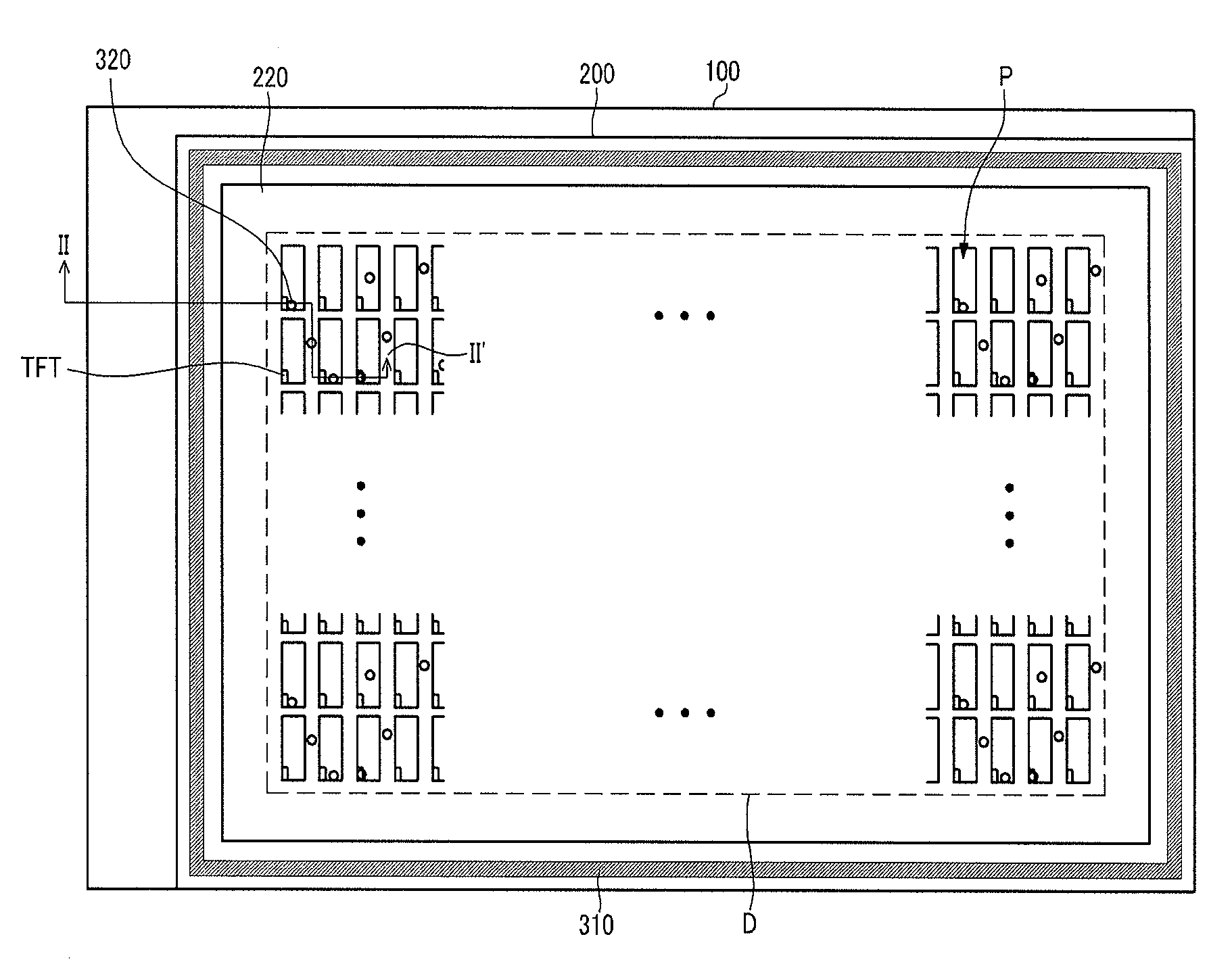

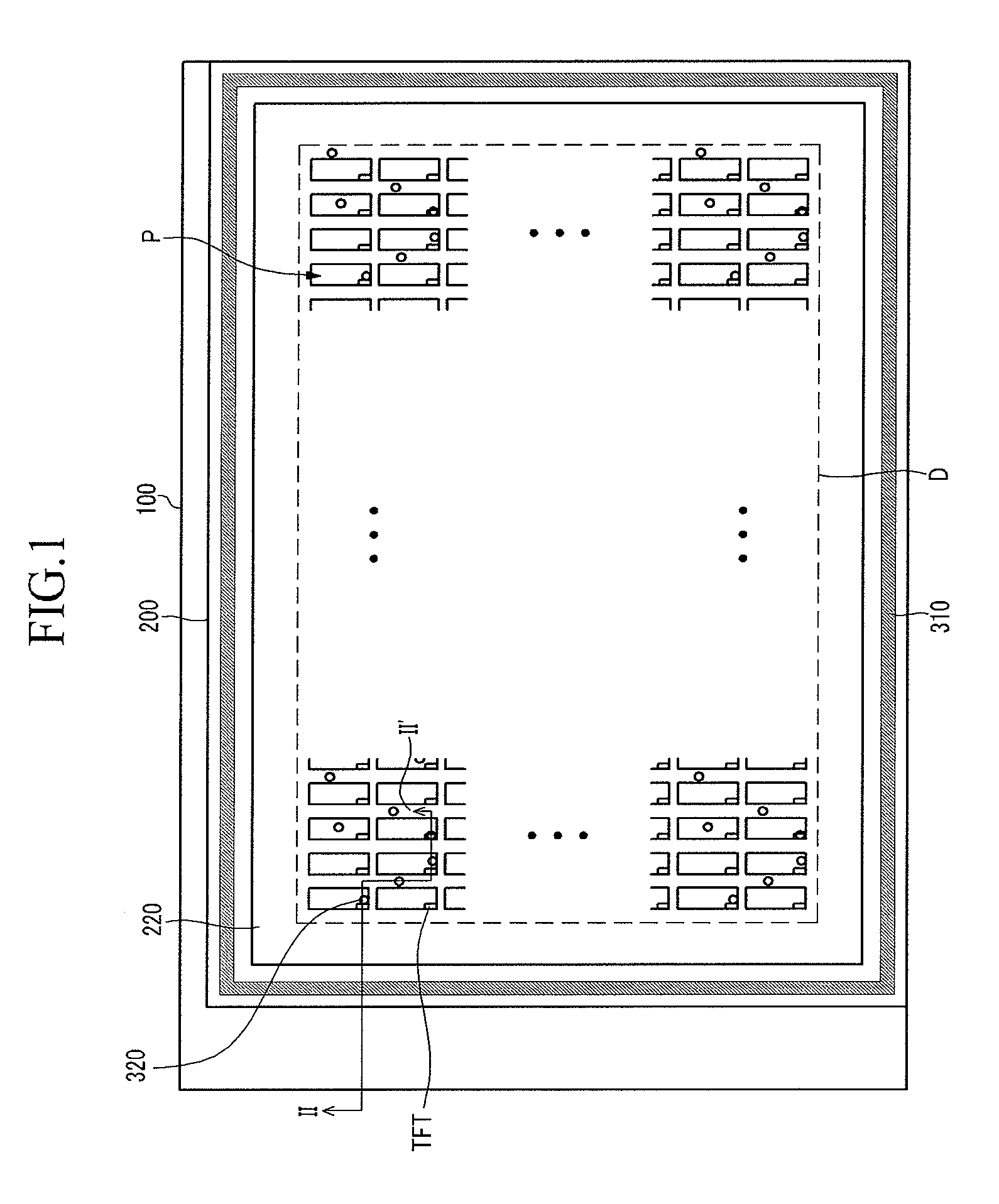

Liquid Crystal Display

InactiveUS20080174726A1Eliminates cell gapMinimise concentrationOther chemical processesNon-linear opticsForming faceSilica particle

A liquid crystal display (LCD) includes a first substrate, a pixel electrode formed on the first substrate, a second substrate formed facing the first substrate, a common electrode formed on the second substrate, and a spacer disposed between the first and second substrates. The spacer is circular cylinder shaped or hexahedral-shaped. The spacer may be formed by dissolving a block copolymer that includes a hydrophilic group and a hydrophobic group in an acid aqueous solution including a silica particle precursor or an alkali aqueous solution including a silica particle precursor.

Owner:SAMSUNG ELECTRONICS CO LTD

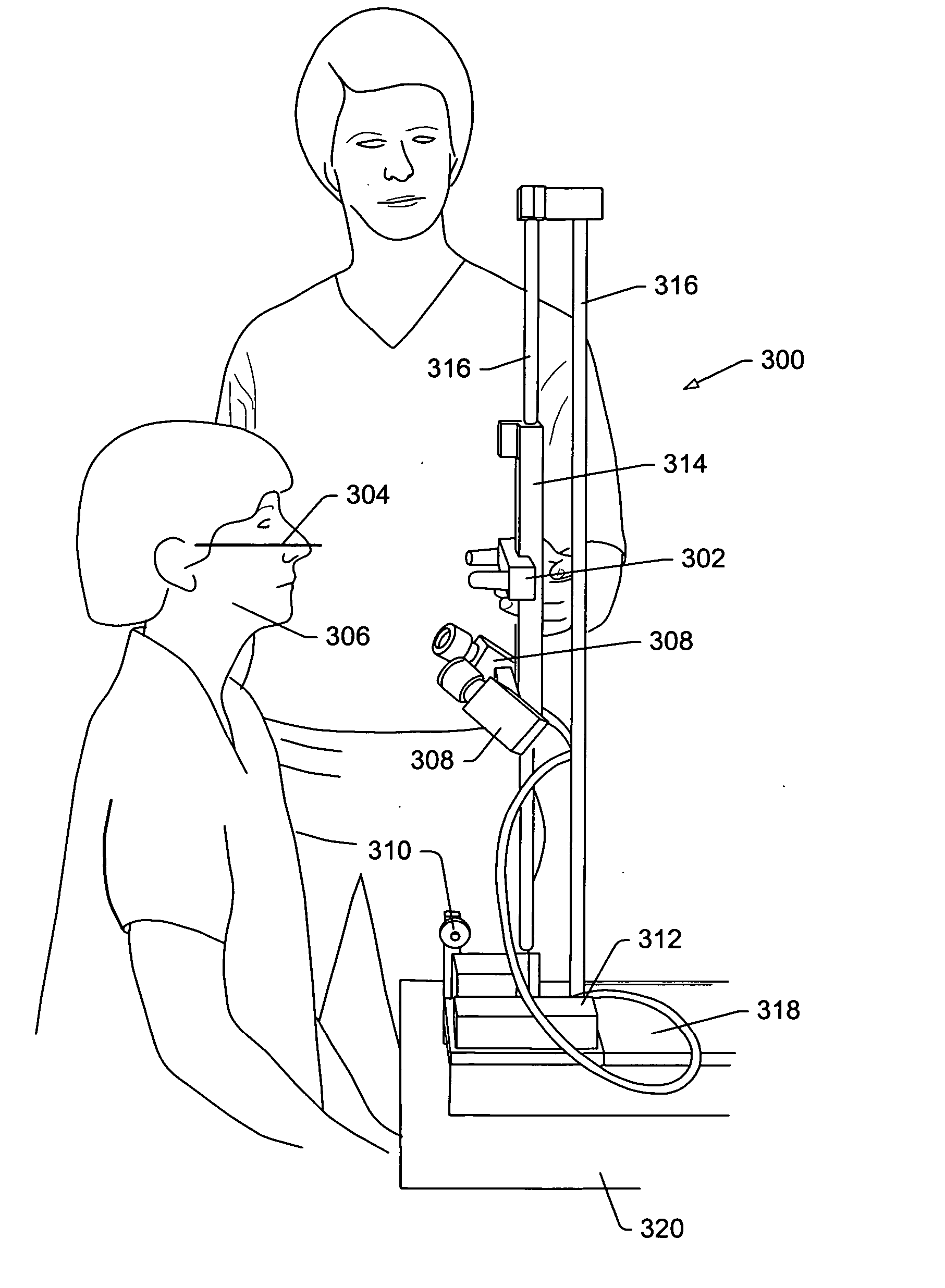

System and method for design and manufacture of custom face masks

Methods and systems for forming face masks are disclosed. Embodiments may utilize computer-aided design and computer-aided manufacturing to form custom fitted face masks. System software may be configured to acquire facial topography information, design a mask based on the topography information, and send mask information to a computerized manufacturing device. The software may communicate with a scanning device for facial topography acquisition and a milling machine for pattern fabrication. In an embodiment, the scanning device may include a linear scan non-contact laser imager. In an embodiment, the scanning device may be manually moved with respect to an individual being scanned, thereby eliminating the need for motive apparatus. In such embodiments, position information may be determined based on data from a position sensor coupled to the scanning device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

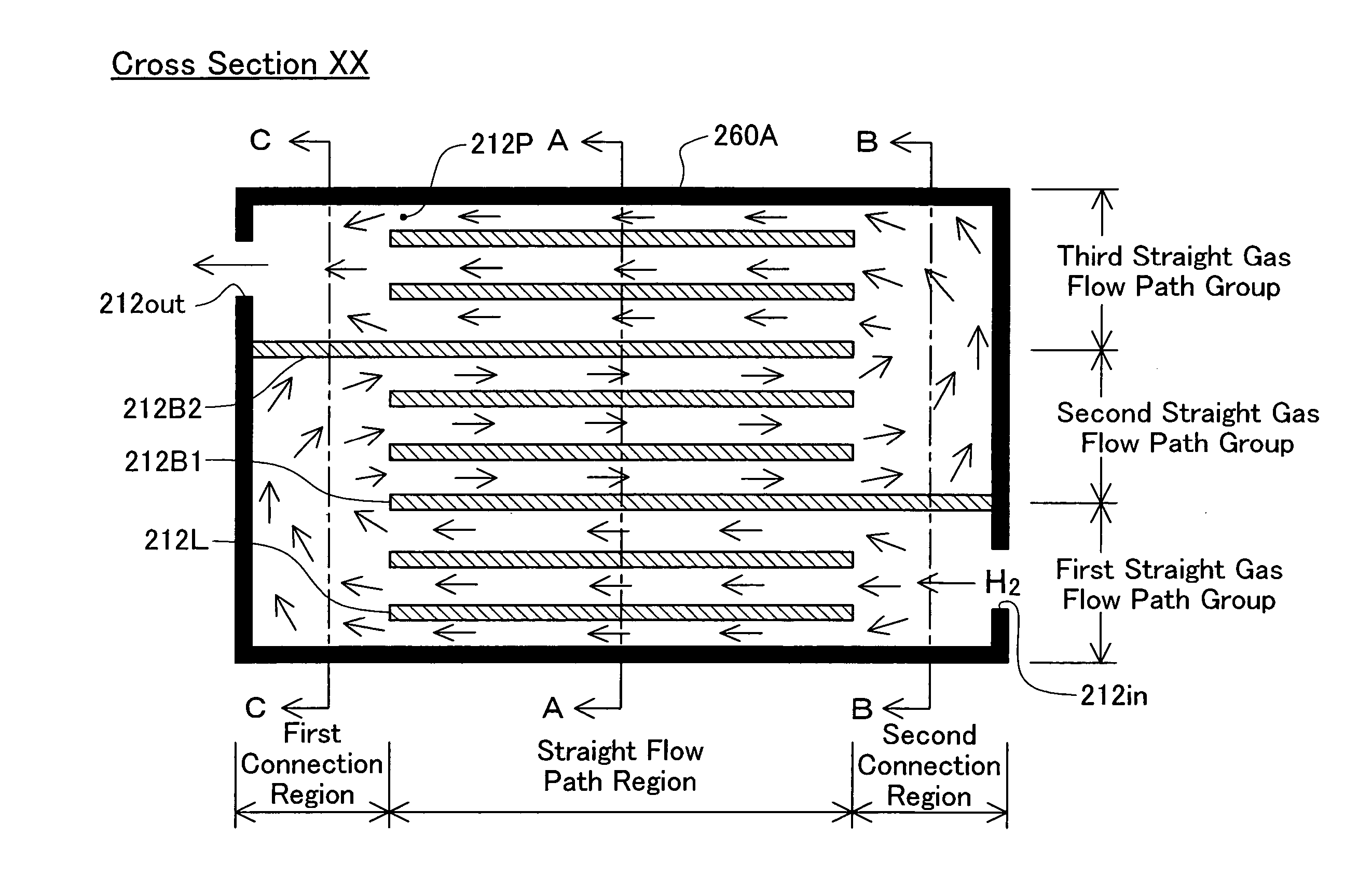

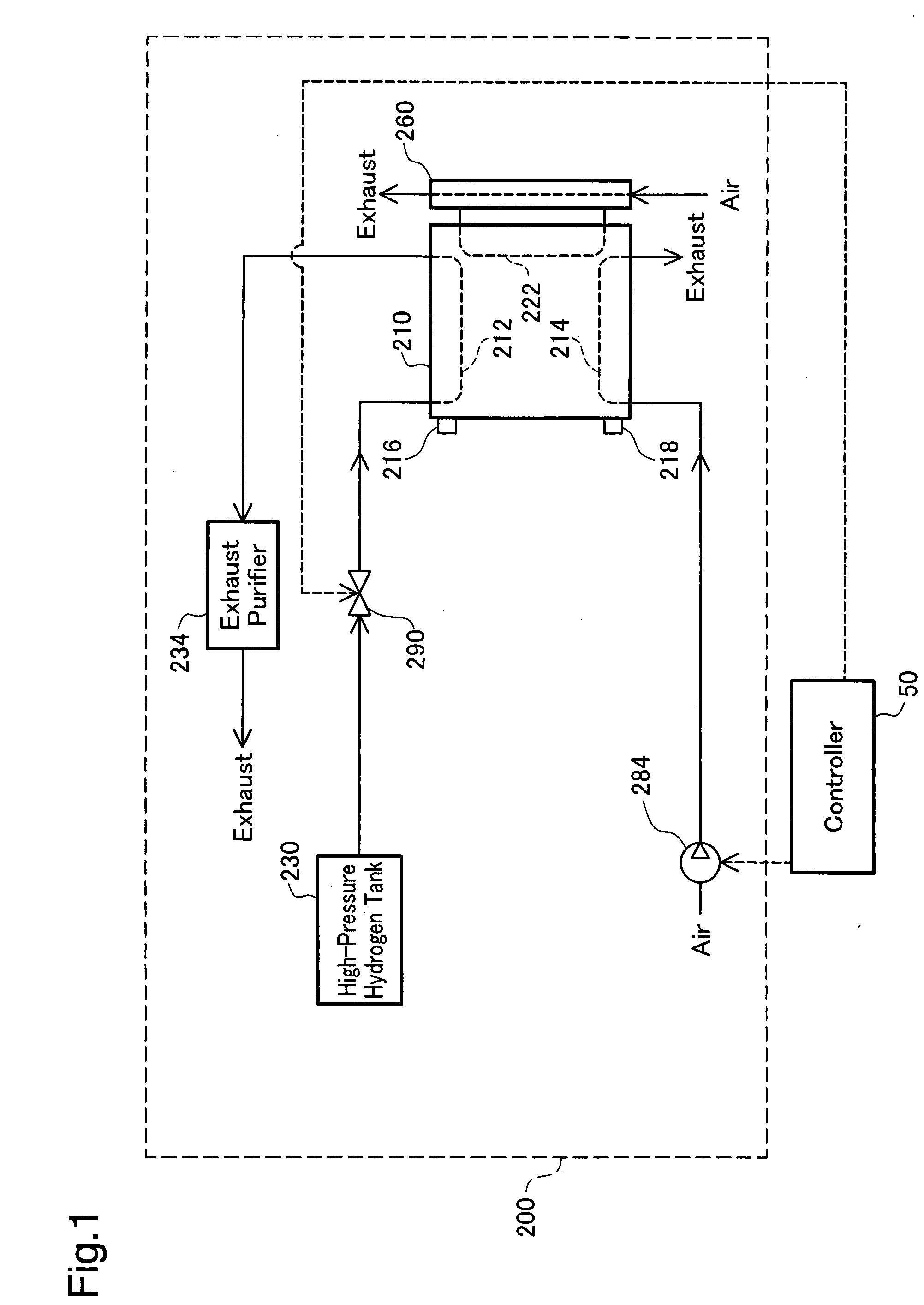

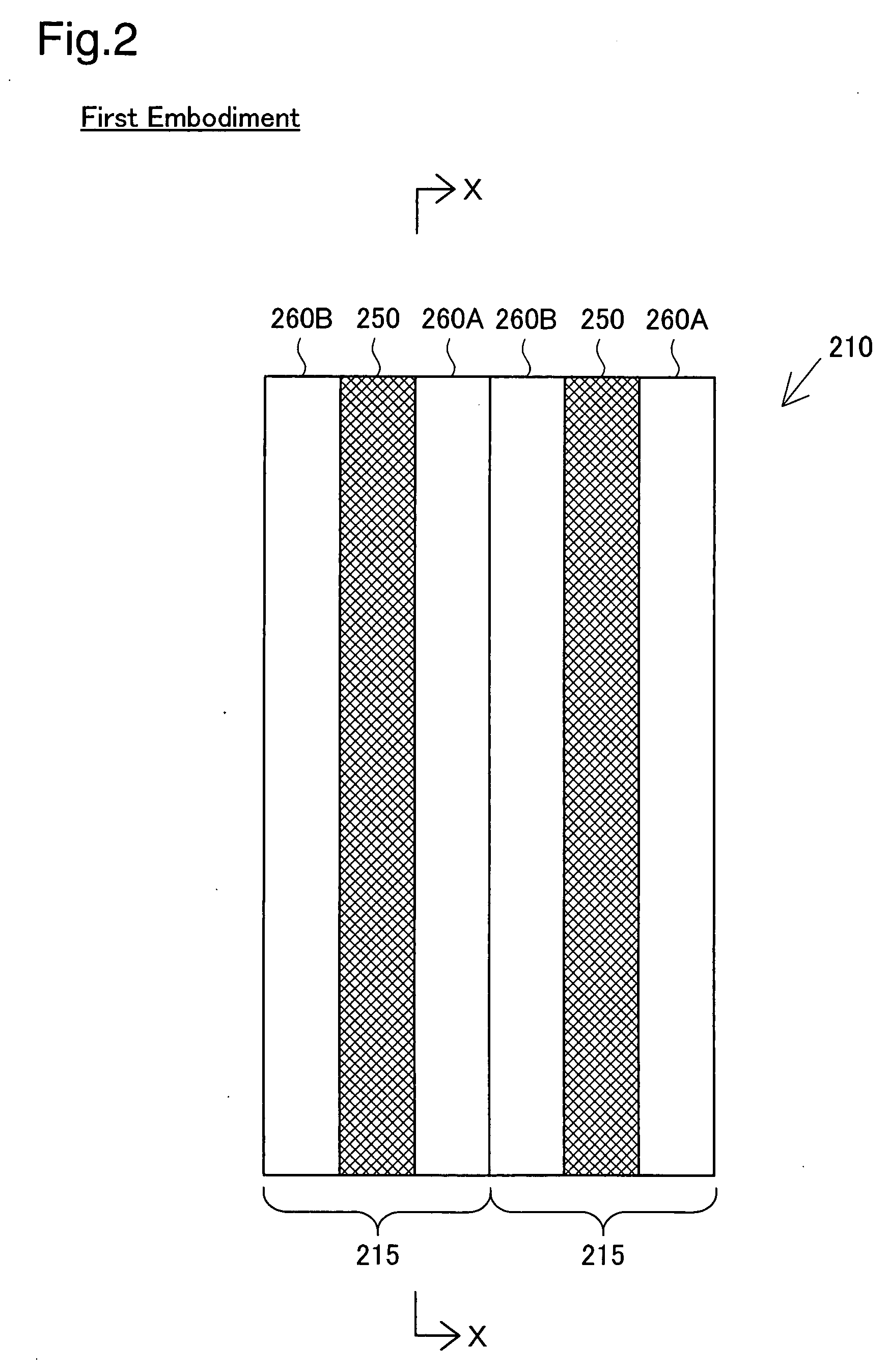

Fuel Cell And Fuel Cell Separator

ActiveUS20070298308A1Drawback can be obviatedElectrolyte moving arrangementsFuel cells groupingForming faceFuel cells

The fuel cell of the invention includes an electrolyte assembly, and a separator having one face as a gas flow path-forming face with a gas flow path formed thereon to allow flow of a reactive gas and the other face, which is reverse to the one face, as a refrigerant flow path-forming face with a refrigerant flow path formed thereon to allow flow of a refrigerant. The gas flow path-forming face of the separator has multiple linear gas flow paths that are arranged in parallel to one another, and a gas flow path connection structure that divides the multiple linear gas flow paths into plural linear gas flow path groups and connects at least part of the plural linear gas flow path groups in series. The refrigerant flow path-forming face has multiple linear refrigerant flow paths that are formed as a reverse structure of the multiple linear gas flow paths on the gas flow path-forming face, and a refrigerant flow path connection structure that is formed as a reverse structure of the gas flow path connection structure on the gas flow path-forming face to connect the multiple linear refrigerant flow paths in parallel.

Owner:TOYOTA JIDOSHA KK

Optical module and method of manufacturing the same, and optical transmission device

A method of manufacturing an optical module includes the steps of mounting an optical device onto a substrate with a surface on which an optical part is formed facing the substrate, and aligning an optical fiber with the optical part through the substrate. An aligning guide is provided at an end portion of the optical fiber except an end surface facing the optical part. The guide is attached to a guide receiving section, the position of which is determined relatively with the optical device.

Owner:SEIKO EPSON CORP

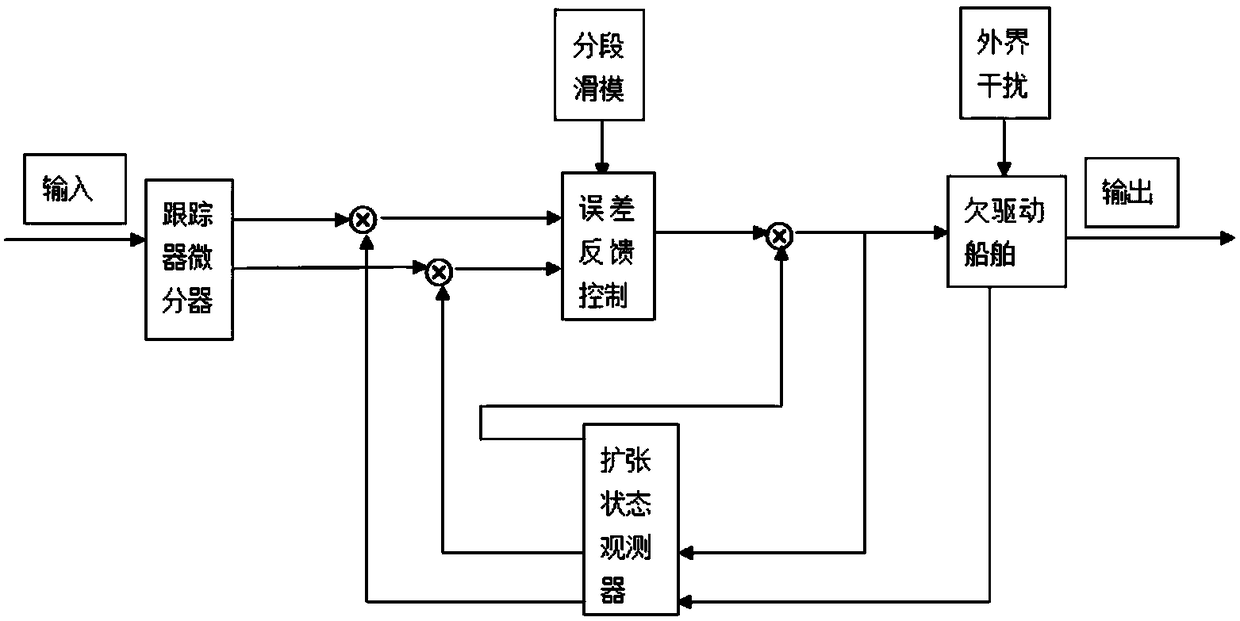

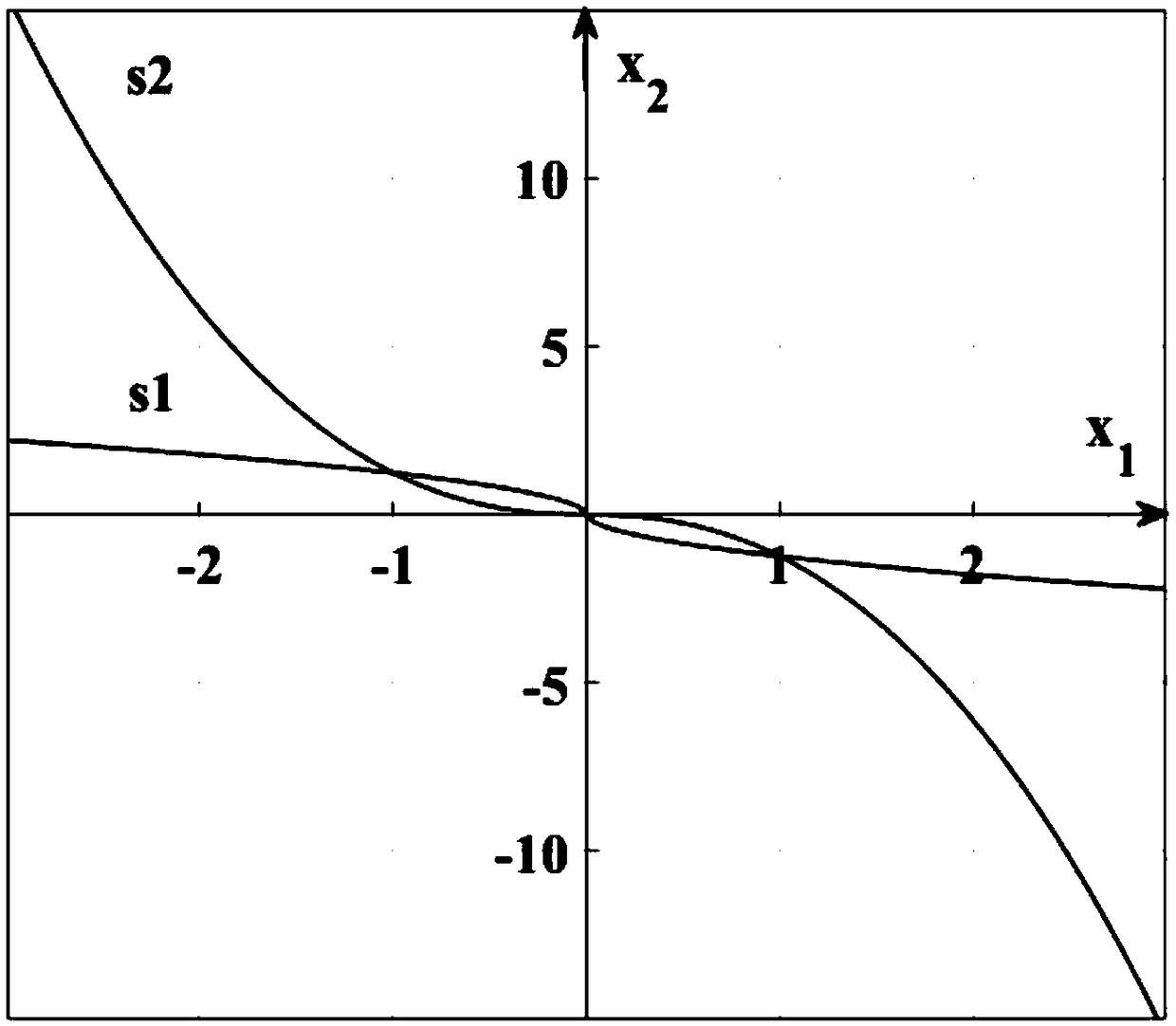

Ship track active-disturbance-rejection control method based on slip form of multi-modal nonsingular terminal

ActiveCN109460043AImprove performanceFast convergenceAutonomous decision making processSustainable transportationForming faceDifferentiator

The invention provides a ship track active-disturbance-rejection control method based on the slip form of a multi-modal nonsingular terminal. The method includes the steps of constructing an expectedship heading equation according to navigational parameters of a ship, deducing a discretization nonlinear structural model of a two-order differentiator, processing expected ship heading signals in the expected ship heading equation to obtain expected ship heading differential signals required for controlling the rudder angle by the control law, obtaining the output rudder angle on the basis of the switchable error feedback control law, constructing an expanded state observer in combination with the error feedback control law, tracking the output deviation according to the expanded state observer, estimating the heading angle and inner and outer disturbance errors controlled by the control law, and feeding the heading angle and the inner and outer disturbance errors back into the control law. By improving the expanded state observer, a linear function and a nonlinear function can be switched in real time; the switchable segmented slip form face is designed; through the segmented slip form face, the switchable error feedback control law is designed, and the under-actuated ship track control is well realized.

Owner:SHANGHAI MARITIME UNIVERSITY

Electroluminescent device, method of manufacturing the device, electronic device, thin-film structure, and method of forming thin film

InactiveUS20080238295A1Uniform thicknessImprove finenessDischarge tube luminescnet screensLamp detailsForming faceFilm material

An electroluminescent device includes a substrate having a bank-forming face on one surface thereof, a bank formed on the bank-forming face, and a thin-film layer constituting an electroluminescent element at a region surrounded by the bank. The thin-film layer is formed by filling the region surrounded by the bank with a thin-film material liquid and solidifying the liquid. The bank-forming face and a contact face with the thin-film layer have curved surfaces so that the central portions thereof are convexed toward the substrate side.

Owner:SEIKO EPSON CORP

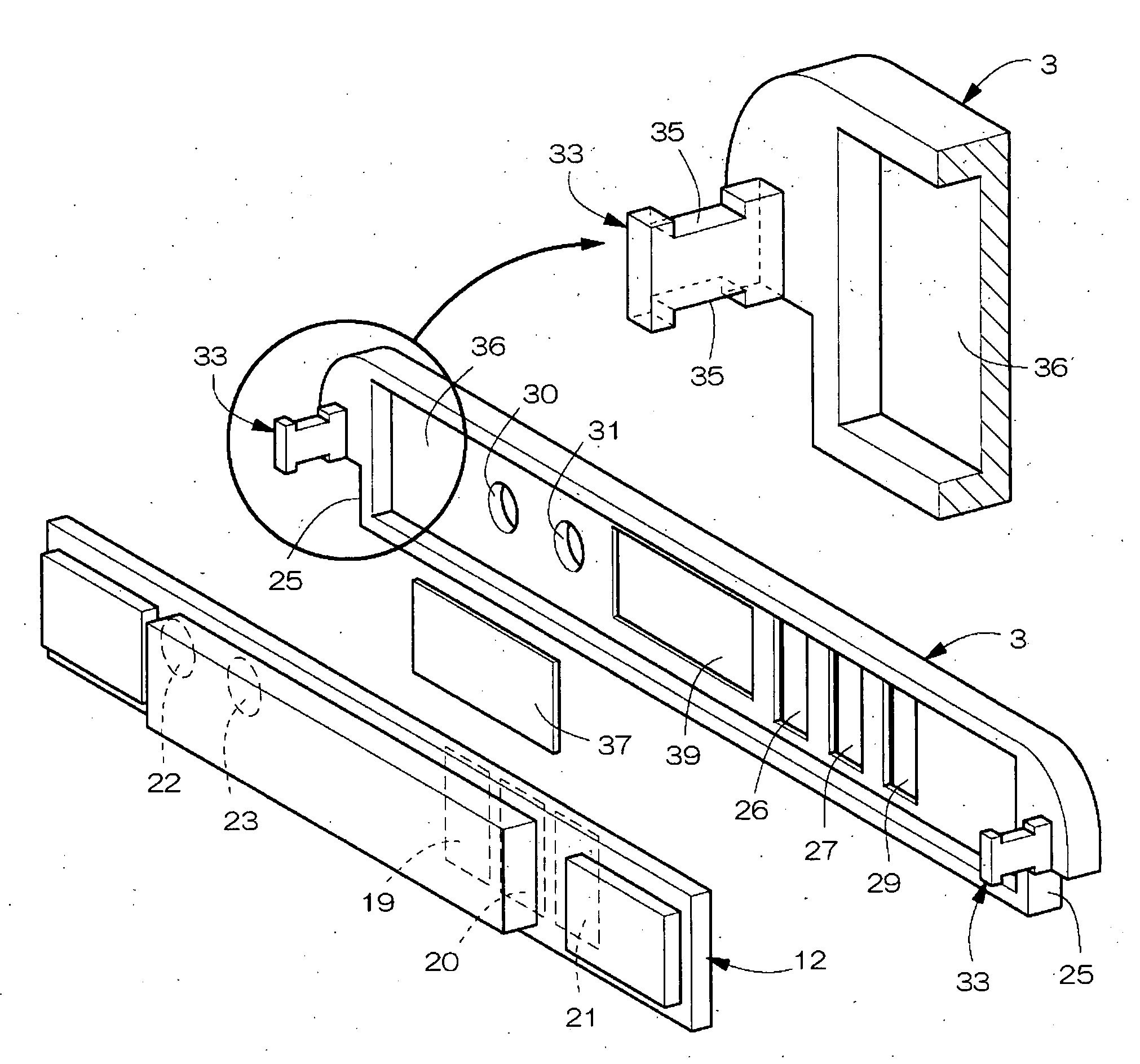

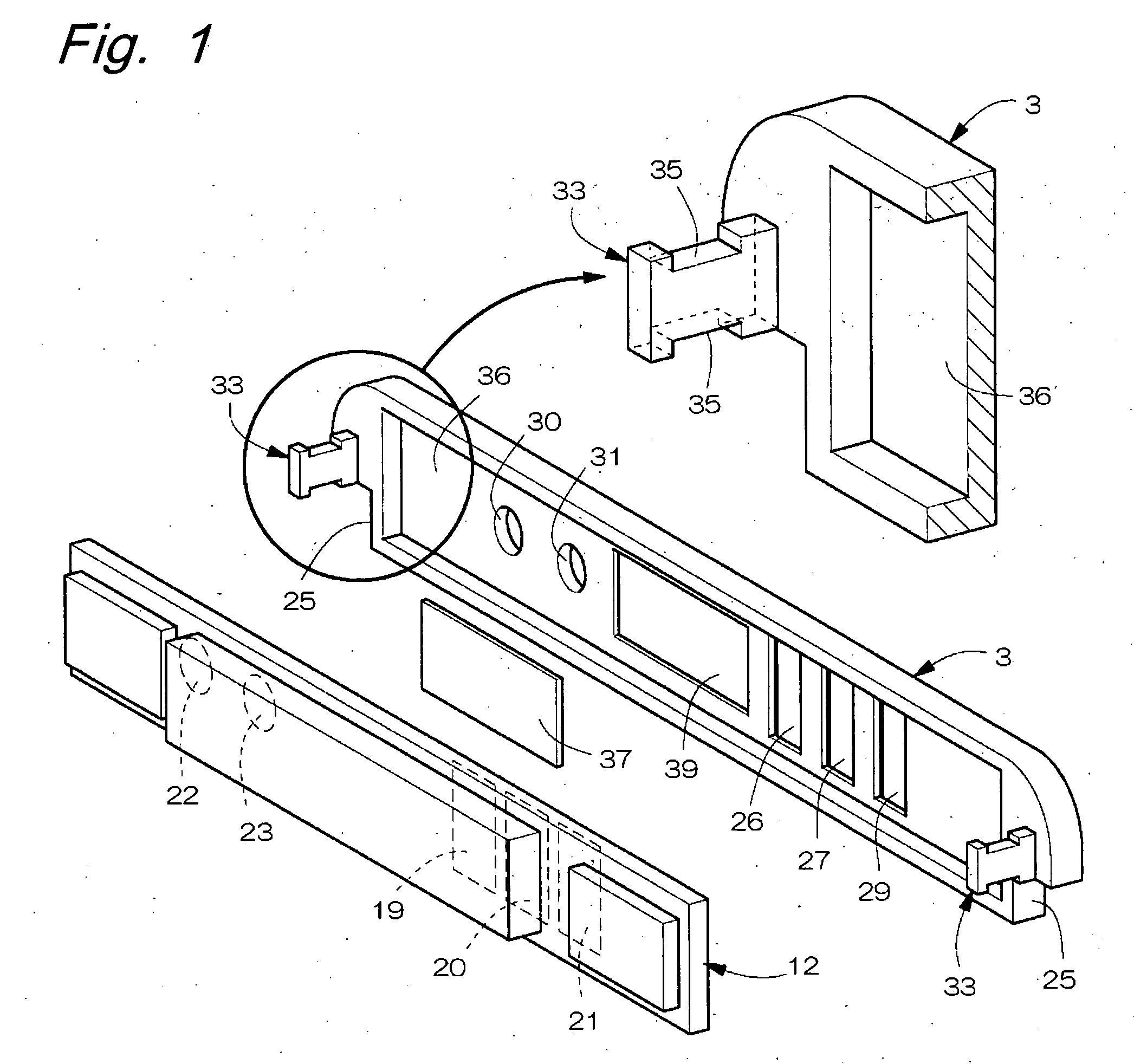

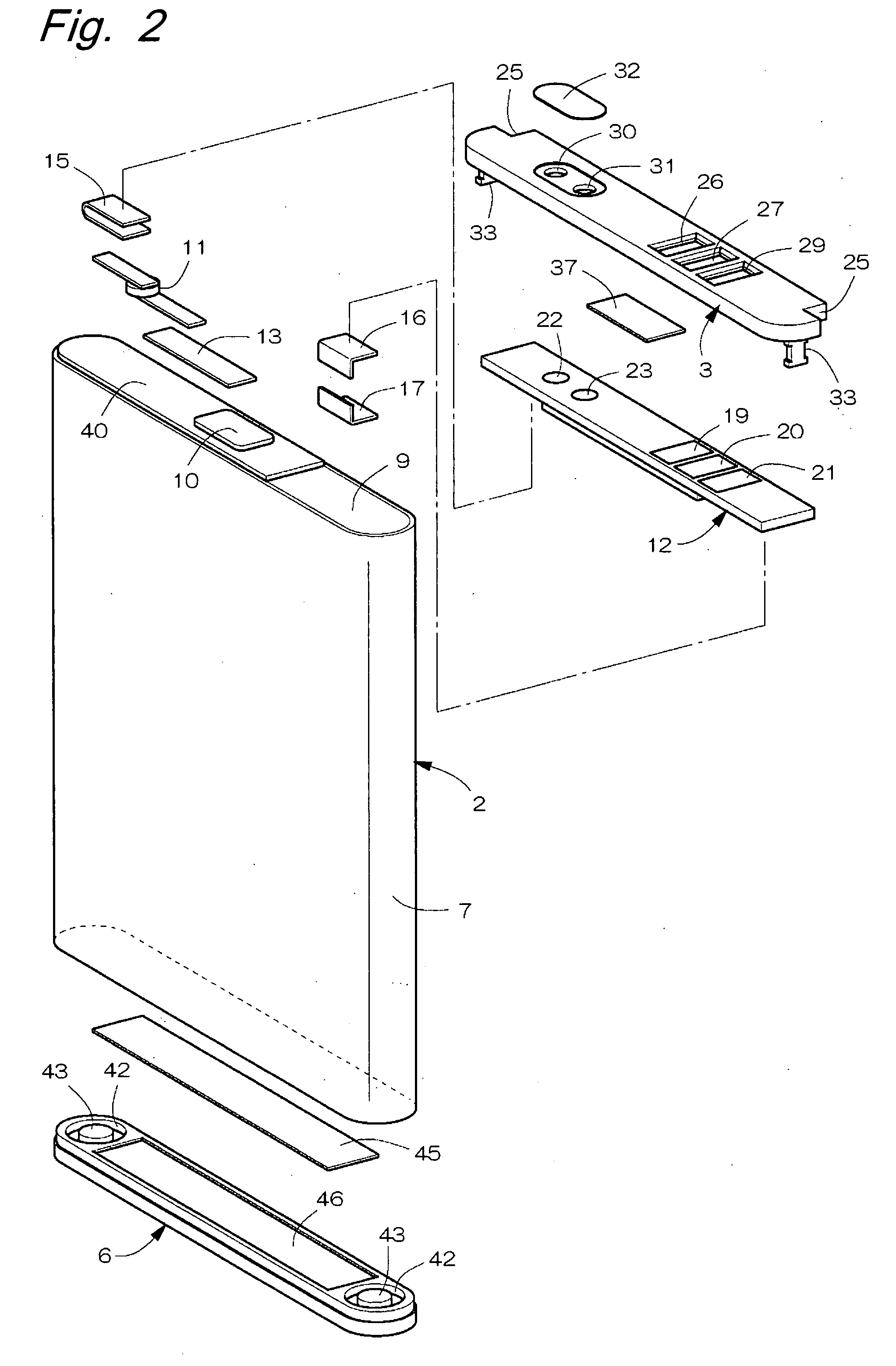

Battery Pack

InactiveUS20100143793A1Reliably securedAvoid contactPrimary cell to battery groupingCell component detailsForming faceBattery pack

The battery pack of the present invention includes a circuit board placed on the upper side of a unit cell, an upper cover placed on the upper side of the circuit board, and a resin mold that is formed in between the upper cover and the upper surface of the unit cell and integrates the circuit board and the upper cover with the upper surface of the unit cell. External connection terminals for connection with the contact terminals of external equipment are placed on the upper surface of the circuit board, and the upper cover has a window that is provided in a penetrating form facing the external connection terminals. In order to regulate a spacing between the upper cover and the upper surface of the unit cell, a positioning projection is provided directed downward at both right and left ends on the lower surface of the upper cover, and a board fitting portion in which the circuit board is fit is formed on the lower surface of the upper cover.

Owner:HITACHI MAXELL ENERGY LTD

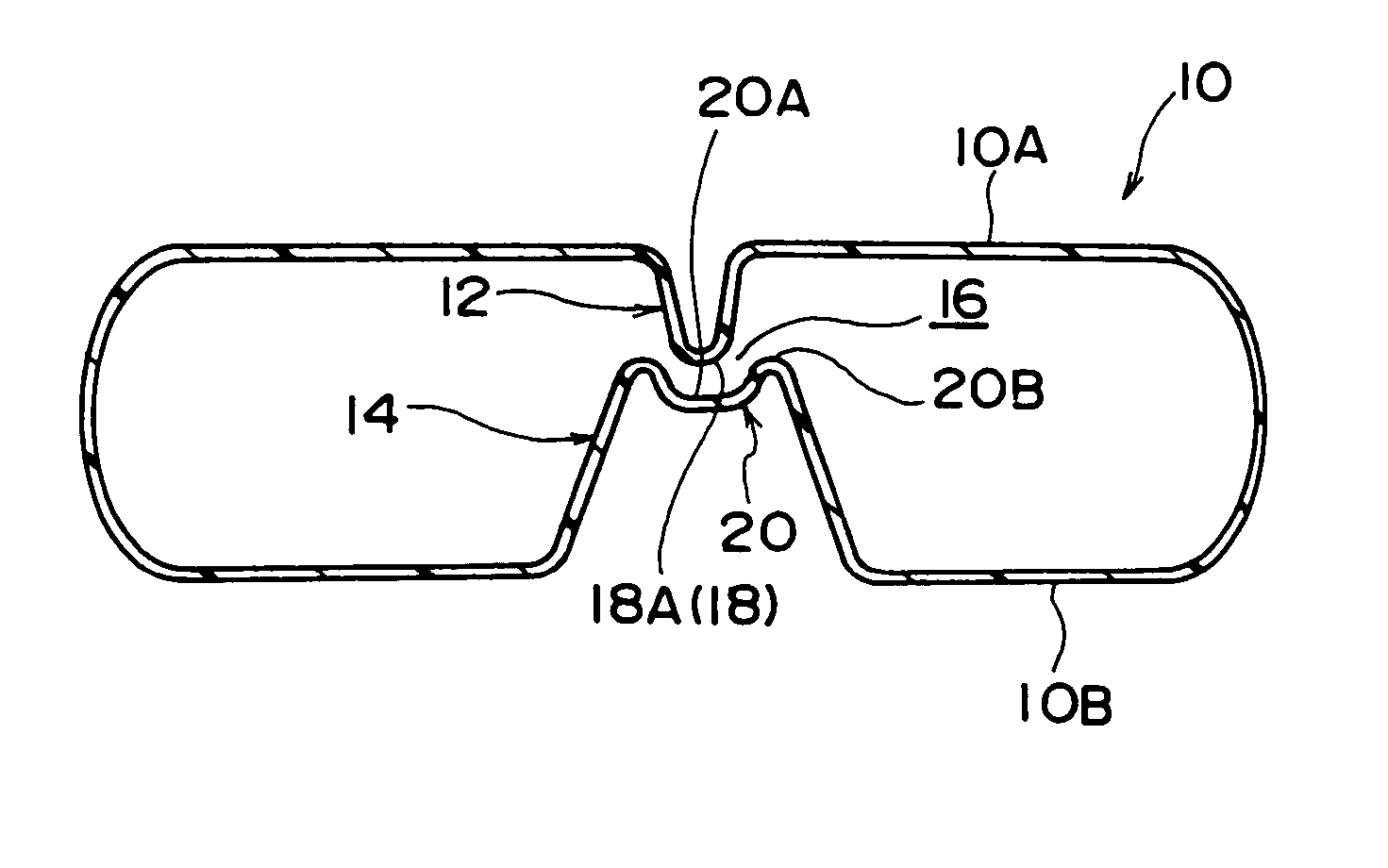

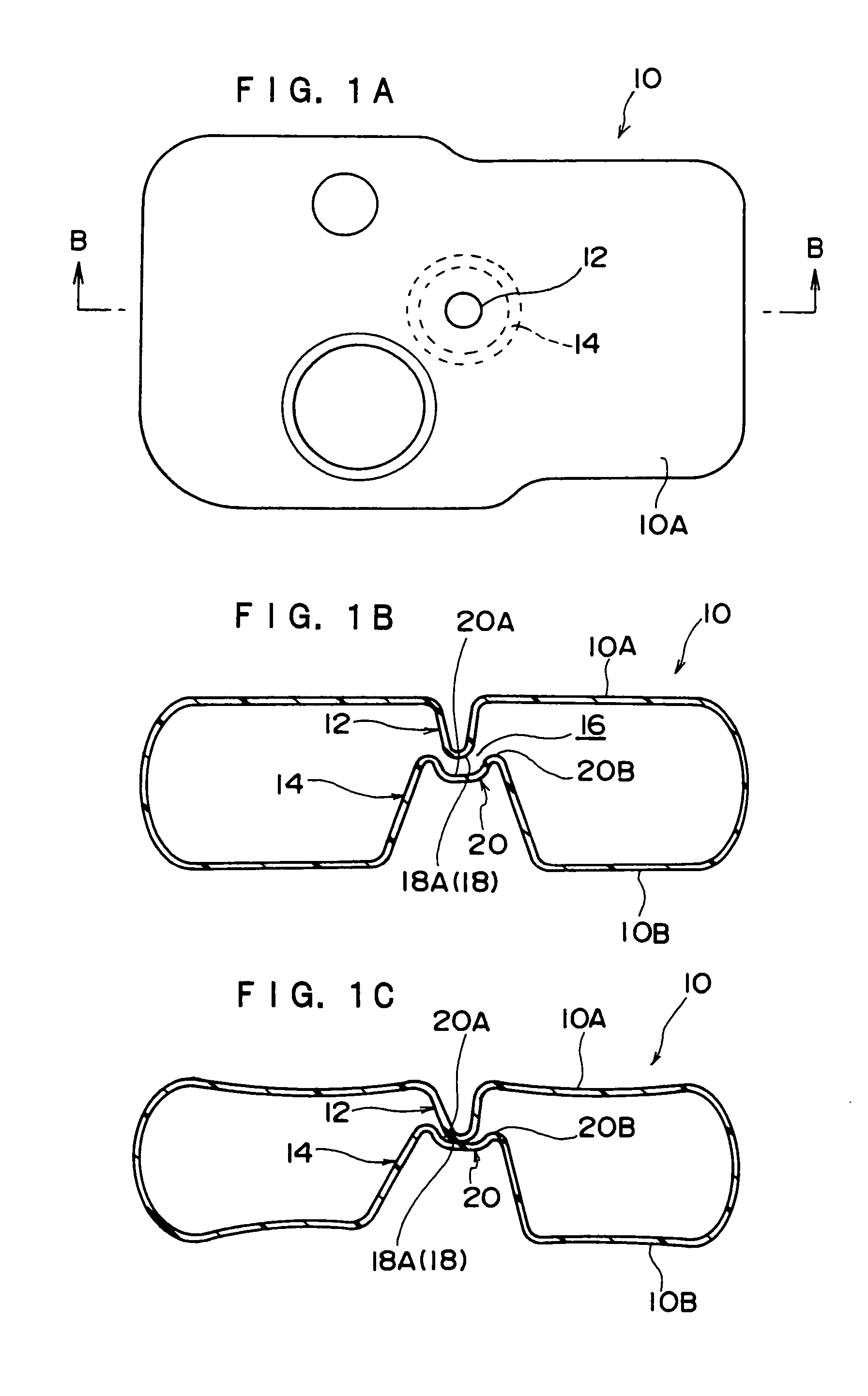

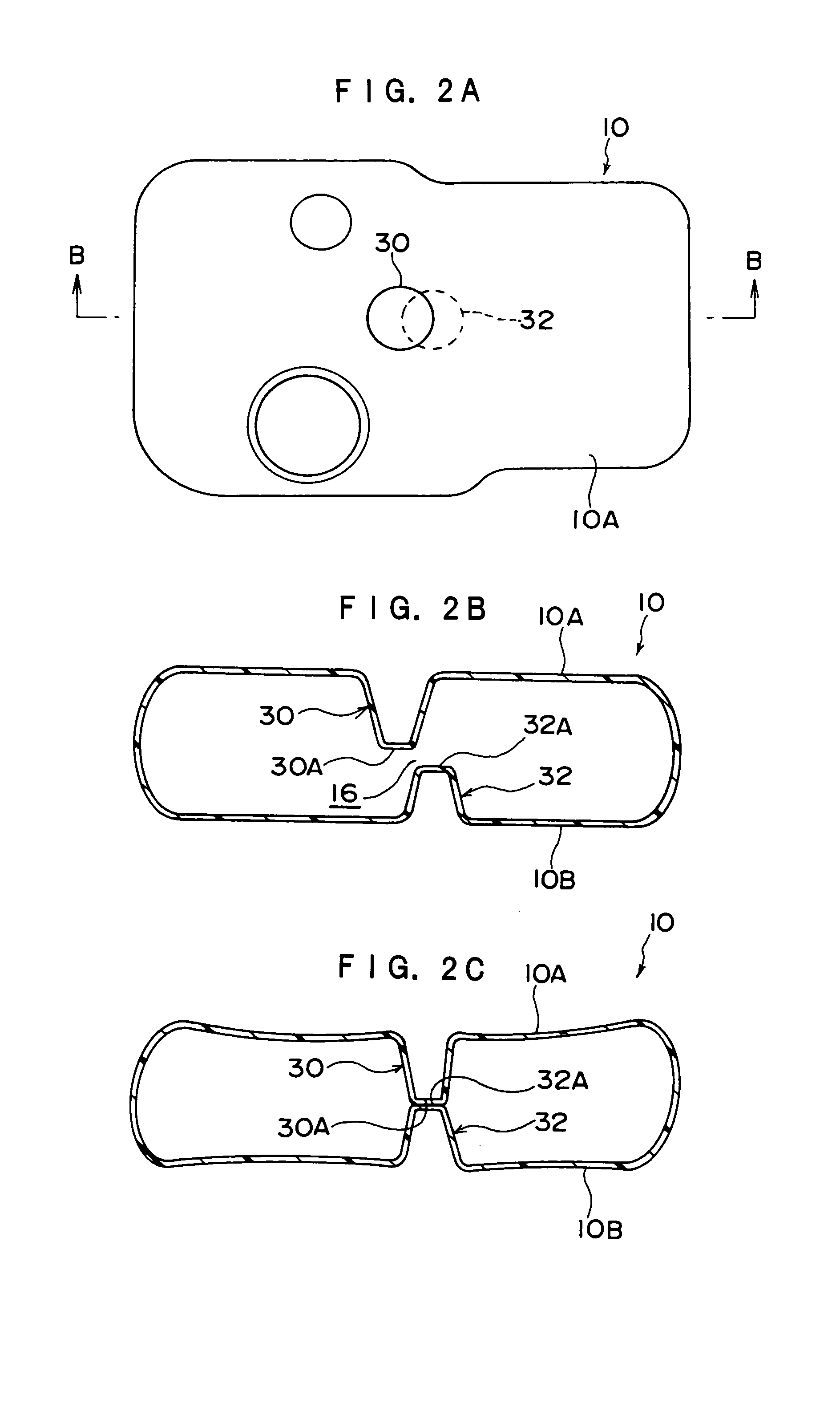

Fuel tank structure

InactiveUS20060207991A1Avoid deformationInterfere with stateLarge containersItem transportation vehiclesForming faceFuel tank

The present invention provides a fuel tank structure capable of securely suppressing deformation of a fuel tank by mutual contact of a pair of upper and lower interference sections at the time of deformation of tank by negative pressure. On a peak wall and a bottom wall of the fuel tank, an upper stand-off and a lower stand-off are formed face to face vertically with a certain interval therebetween. The lower stand-off is larger in diameter than the upper stand-off, and includes a general surface for contacting a projecting end of the upper stand-off during application of negative pressure, and an annular rib for preventing dropping of the projecting end. Therefore, at the time of application of negative pressure, deformation of the fuel tank can be securely suppressed.

Owner:TOYOTA JIDOSHA KK

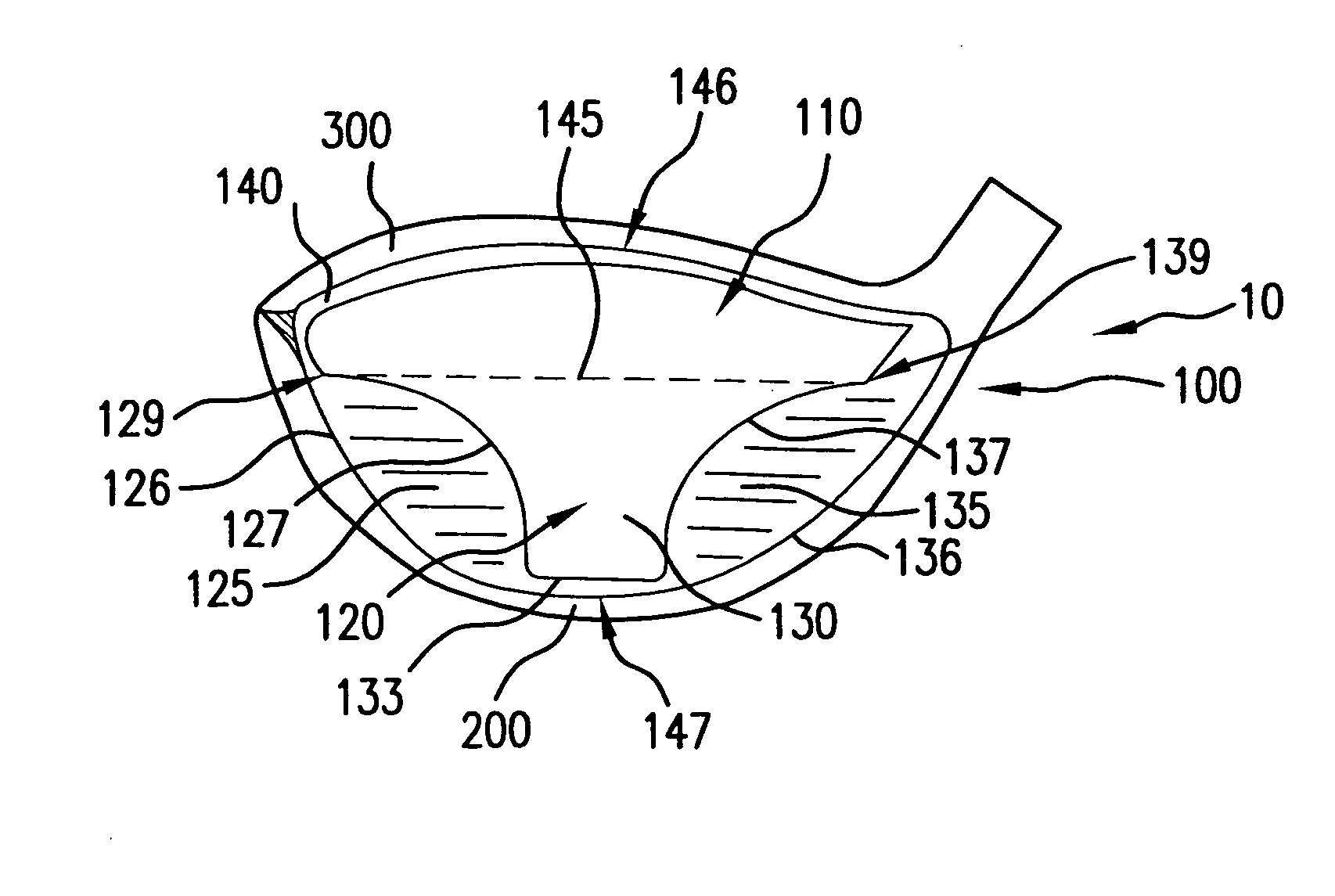

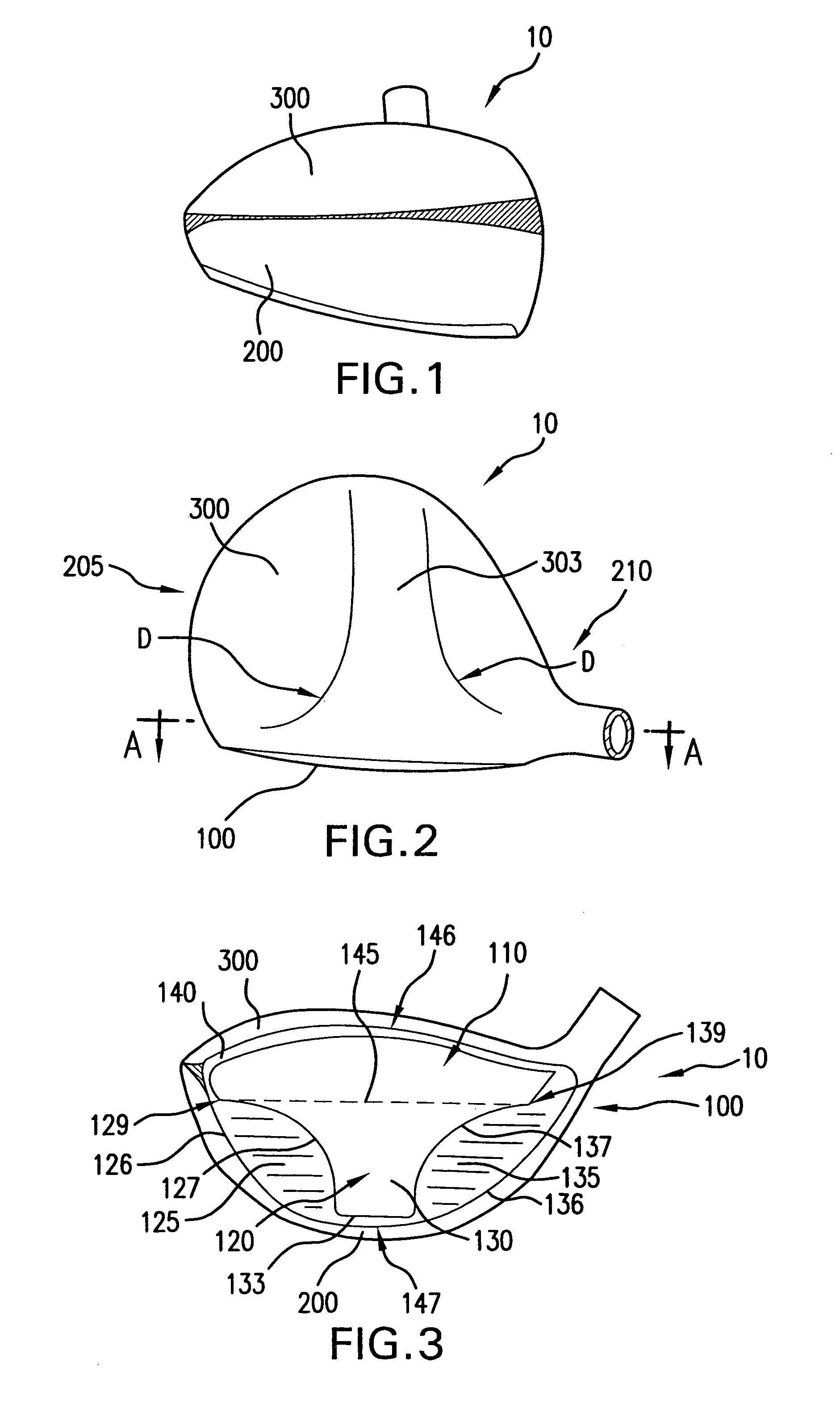

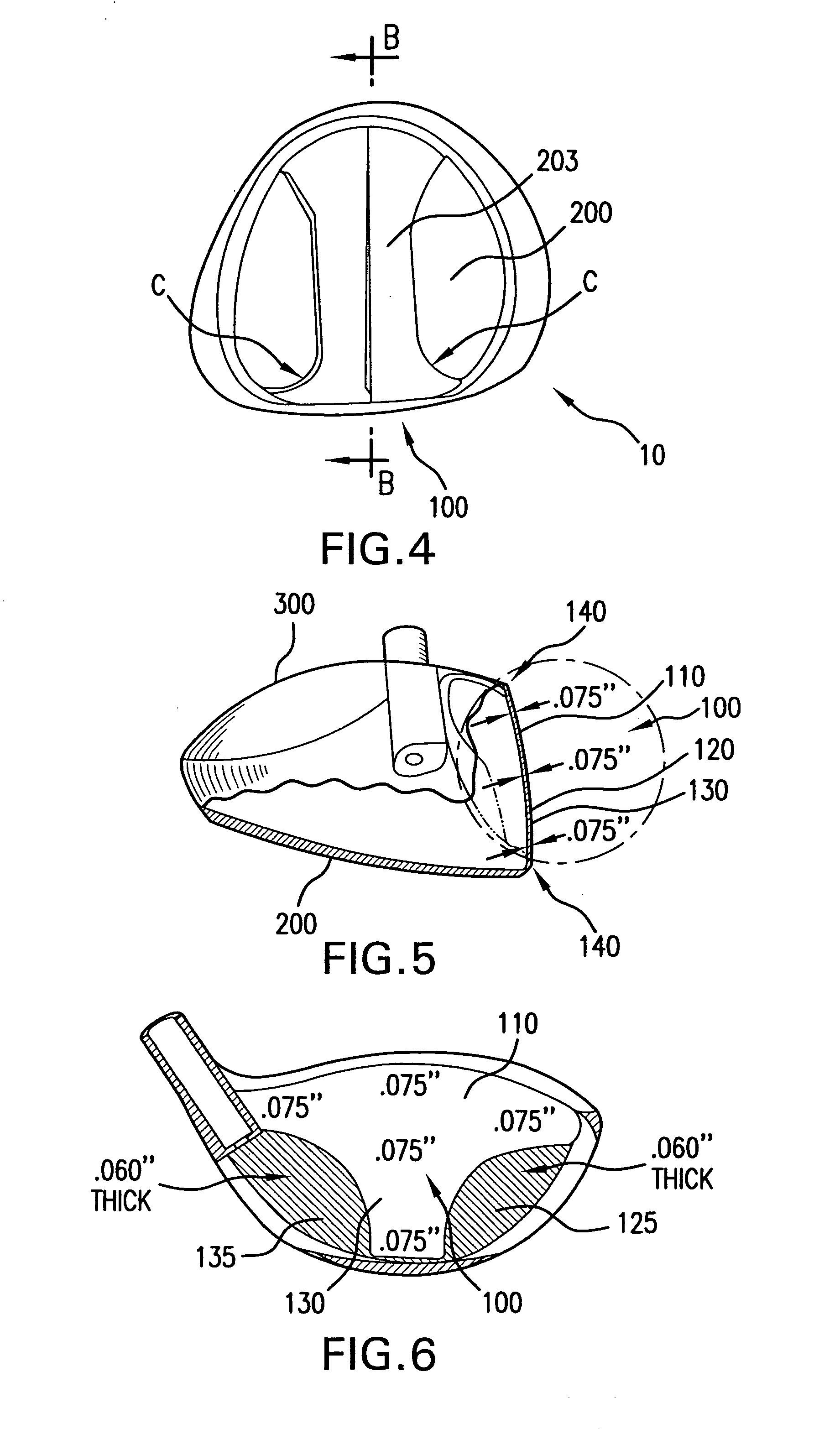

Golf club head

The present invention, in one embodiment, provides a method for making a wood-type golf club head. The method includes the steps of: forming a face portion of the golf club head from a piece of sheet metal consisting essentially of a titanium alloy; and after forming the face portion, attaching the formed face portion to a crown and a sole of the golf club head. The step of forming the face portion includes pressing the piece of sheet metal into a die at about 70 tons psi.

Owner:KNUTH DEAN L

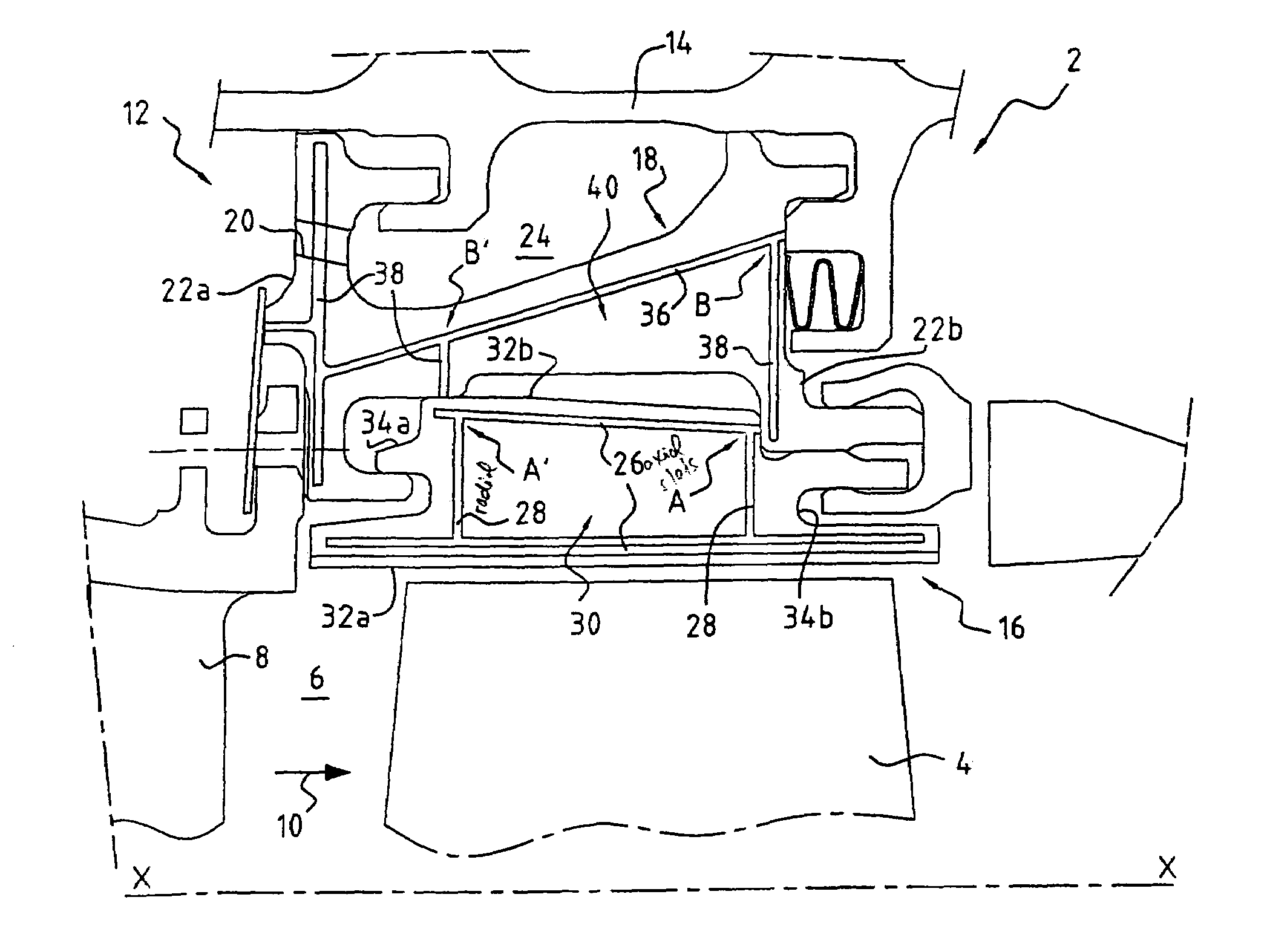

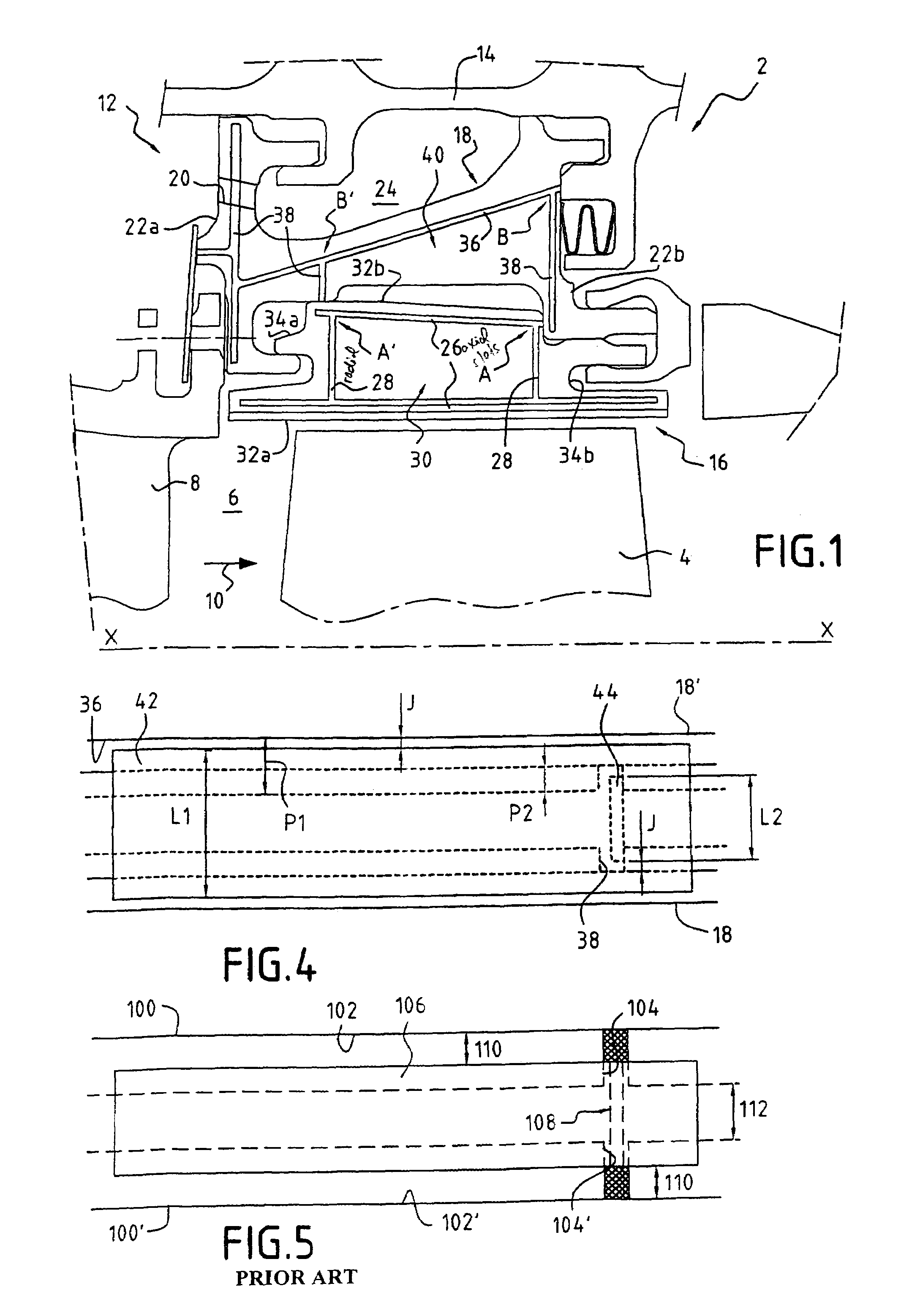

Stationary ring assembly for a gas turbine

A stationary ring assembly forming a rotor shroud for a gas turbine including a plurality of segments having adjacent side faces that are placed end to end with sealing means interposed therebetween. The sealing means include at least one axial sealing strip and at least one radial sealing strip respectively received in axial slots and in radial slots formed facing one another in the adjacent side faces of the segments. At least one end of each radial slot opens out into the corresponding axial slot, each axial slot of a segment presents a depth that is greater than the depth of the corresponding radial slot, and the axial sealing strip presents a width that is greater than the width of the radial strip.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

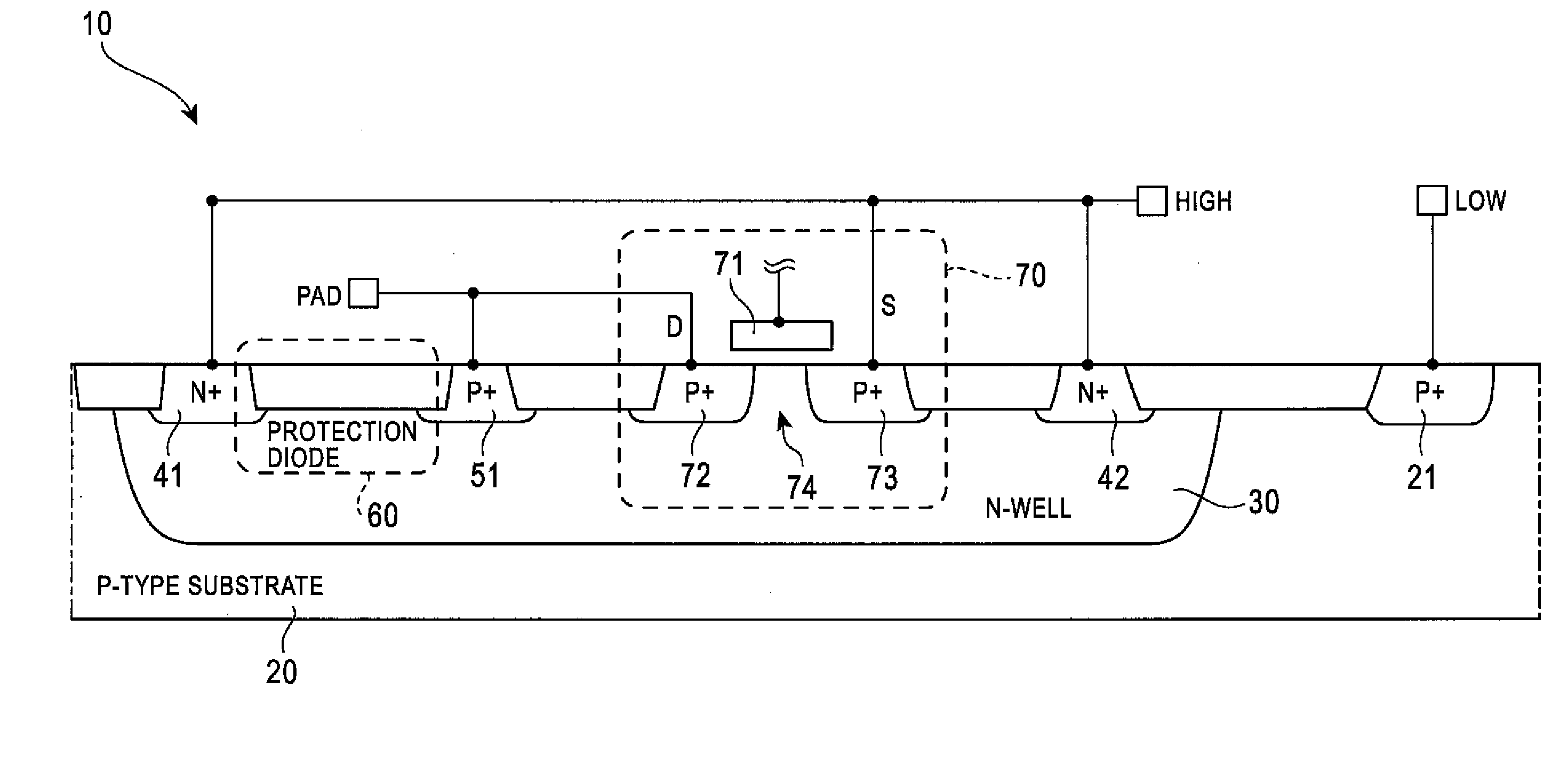

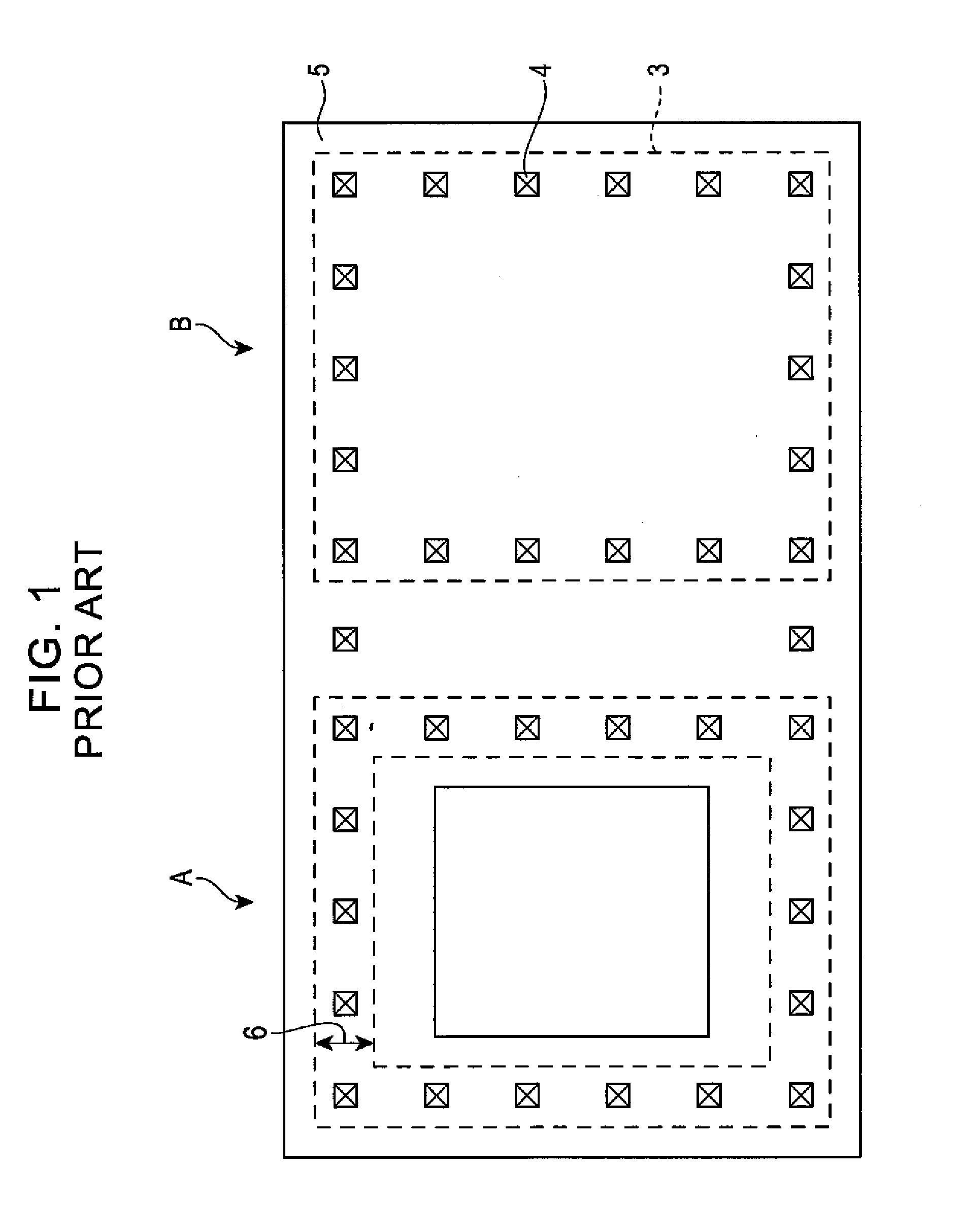

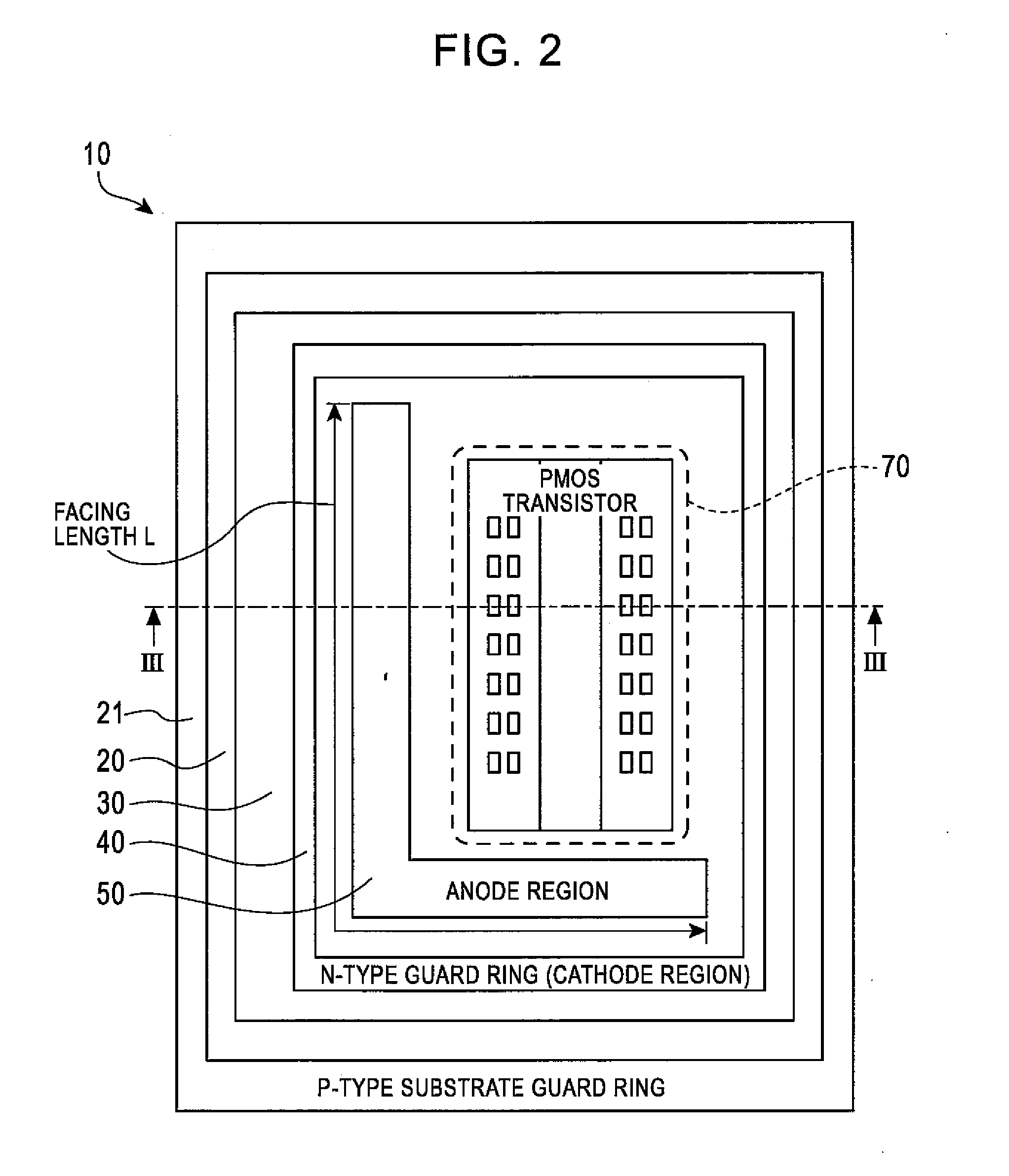

Semiconductor integrated circuit device

InactiveUS20080073721A1Reduce areaAppropriate protection performanceTransistorSemiconductor/solid-state device detailsForming faceSemiconductor

A semiconductor integrated circuit device includes at least one MOS transistor that is formed in a main region of the circuit device. The main region has one conductivity type. The semiconductor integrated circuit device also includes a guard ring region formed surrounding the MOS transistor and in contact with the main region. The guard ring has the same conductivity type as the main region. The semiconductor integrated circuit device further includes an anode region formed facing the guard ring region and in contact with the main region. The anode region has the opposite conductivity type to the main region. The semiconductor integrated circuit device also includes a cathode region having at least a portion of the guard ring region. The anode region, the main region, and the cathode region form a diode.

Owner:LAPIS SEMICON CO LTD

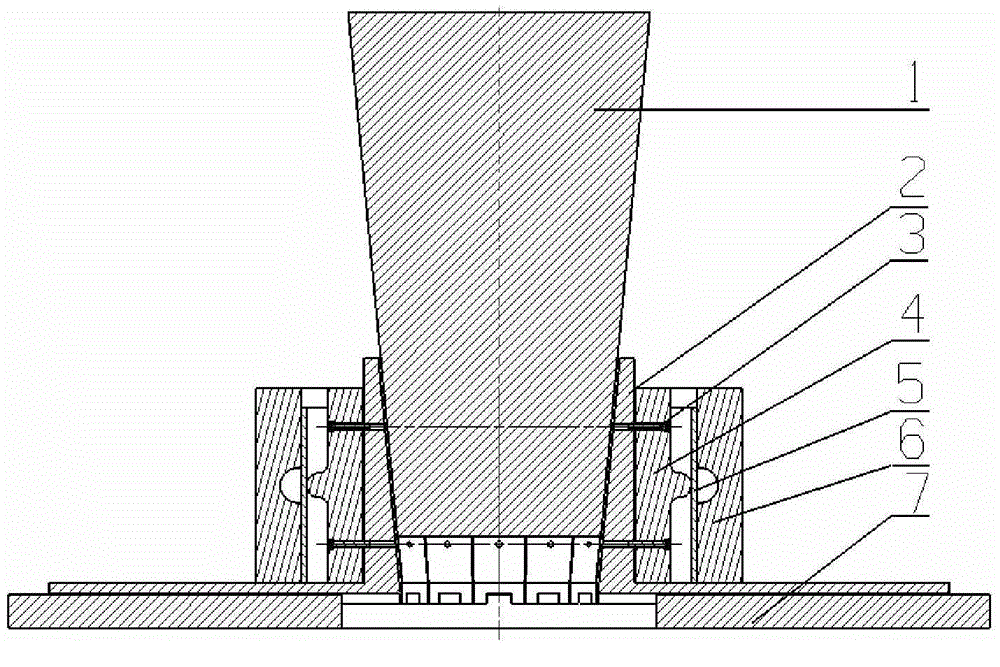

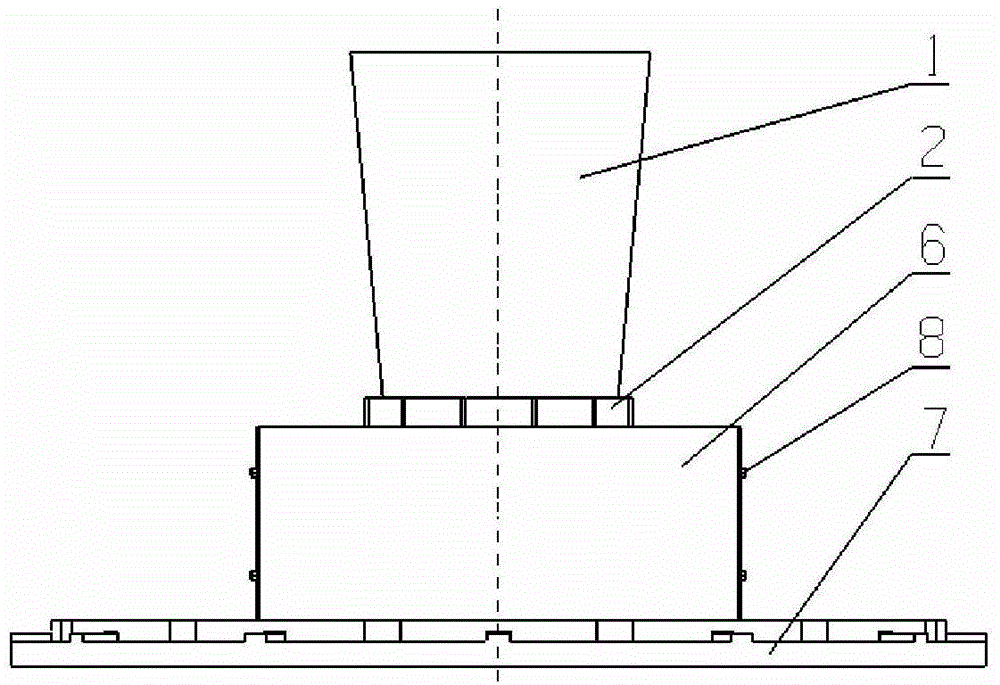

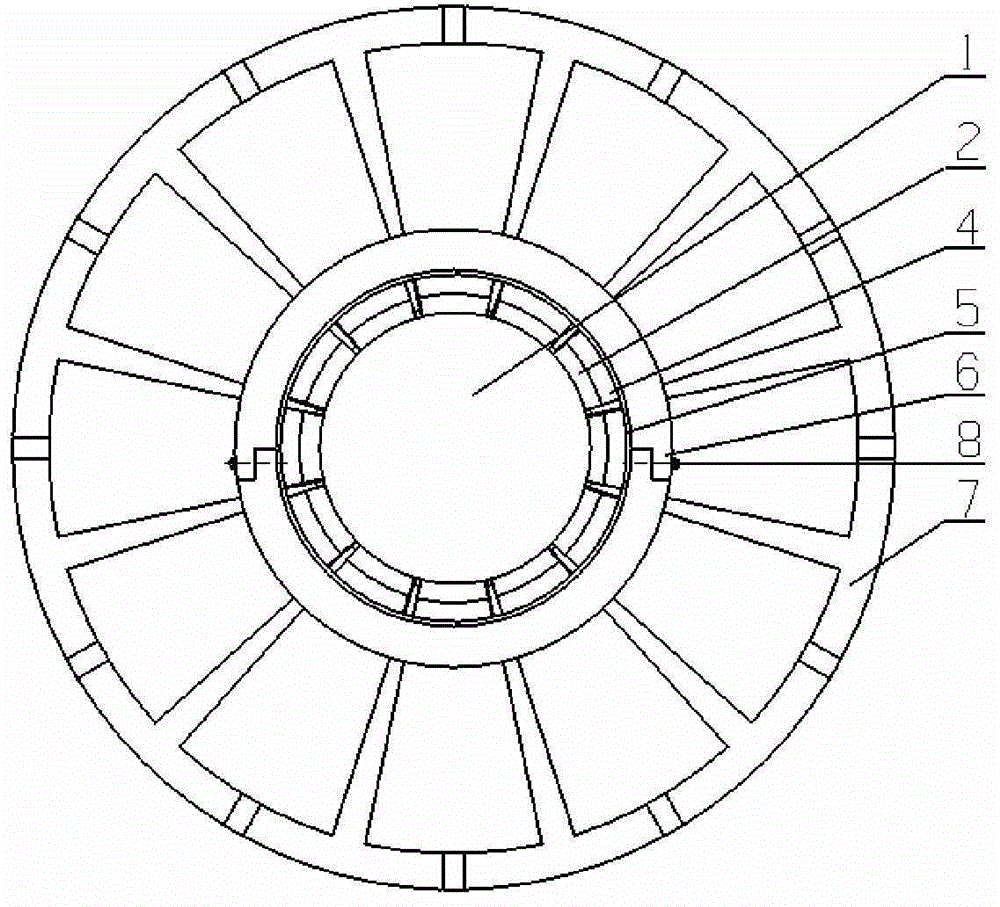

Bulging die for titanium-alloy thin-walled complicated irregular annular workpieces

ActiveCN104801598AImprove shape and position accuracyHigh precisionShaping toolsForming faceEngineering

The invention relates to a bulging die for titanium-alloy thin-walled complicated irregular annular workpieces. The bulging die comprises a core shaft, n brackets, n male dies, female dies and a base, wherein n sliding rails are uniformly distributed on the upper surface of the base, and all brackets are respectively embedded in all the sliding rails so as to form a circular assembly; the small-diameter end of the core shaft is located in the assembly and is fit with the internal surfaces of all the brackets; the n male dies are fixedly arranged on all the brackets respectively; each circular female die is formed through folding corresponding two semicircular female die clacks and sleeves the external surface of the corresponding male die; the internal surfaces of the female dies and the external surfaces of the male dies are workpiece forming faces. According to the bulging die, the forming of the irregular annular workpieces mainly relies on the plastic forming of a material, so that the surface wear resistance of parts is improved, the service lives of the parts are prolonged, and the material is saved; the accuracy of the annular workpieces can be corrected; during continuous repeated machining, the consistency of size and accuracy of the parts can be guaranteed.

Owner:丹东丰能工业股份有限公司

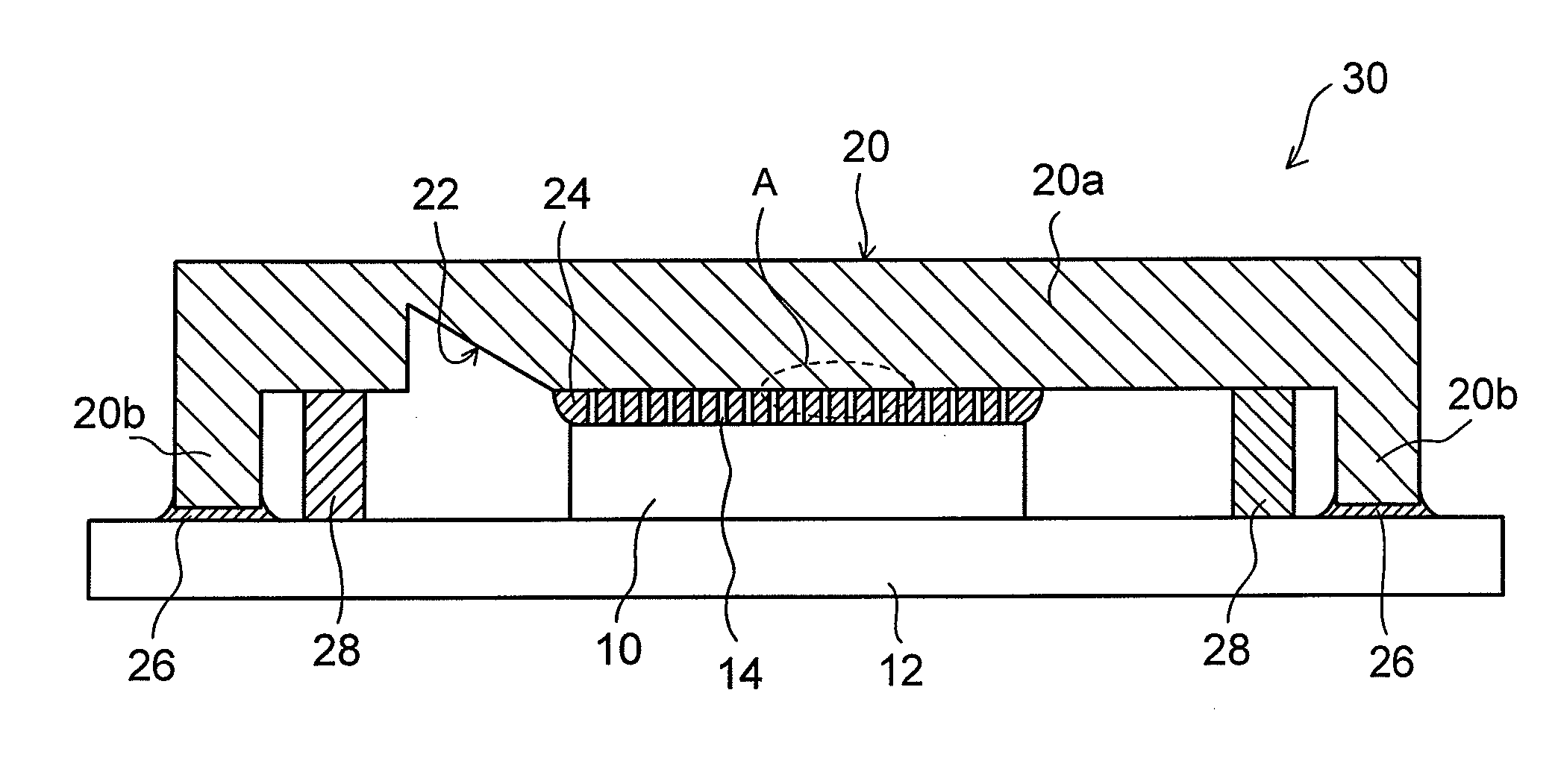

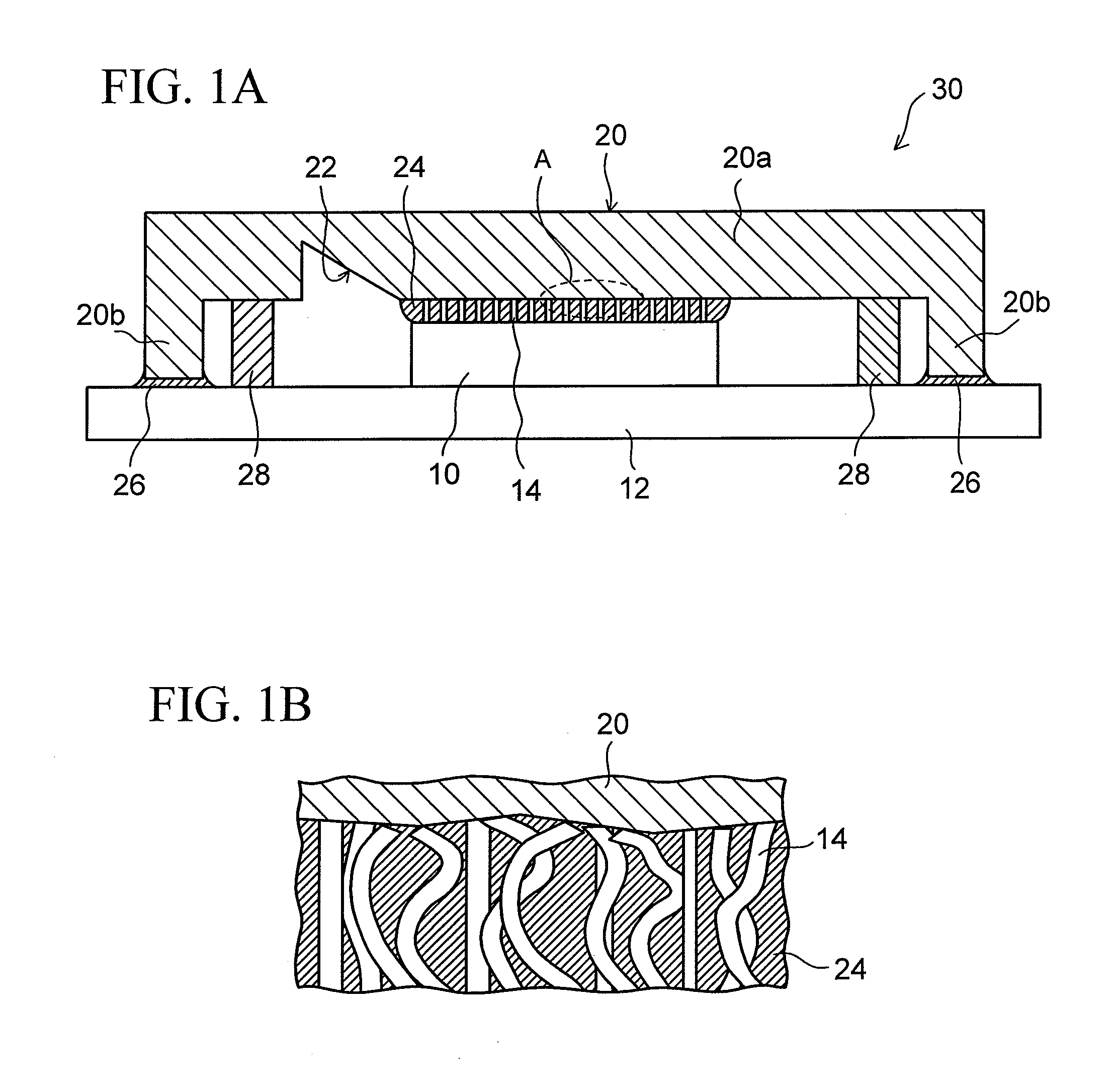

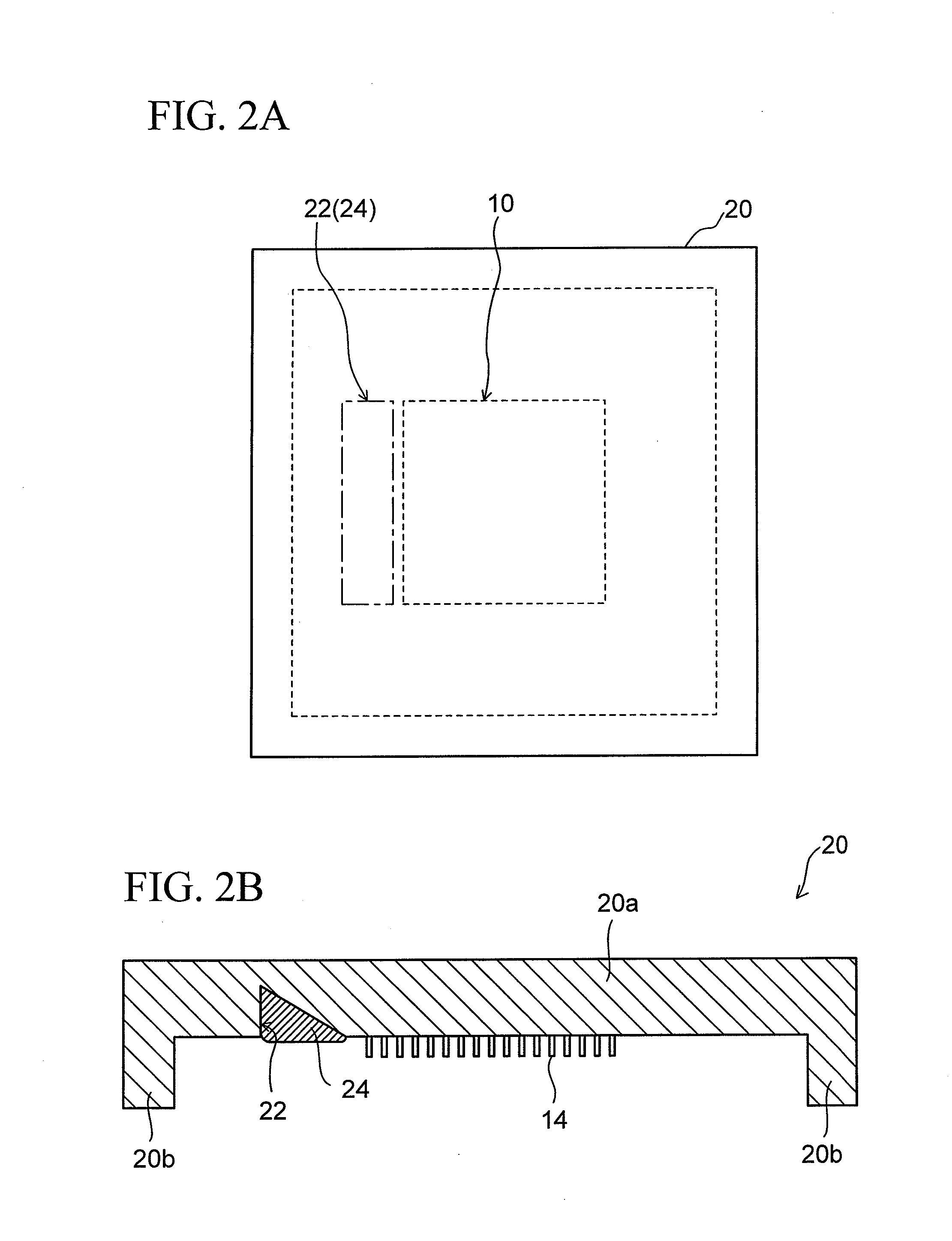

Semiconductor device having additional functional element and method of manufacturing thereof

ActiveUS7005747B2Reduce intensityImprove processing speedSemiconductor/solid-state device detailsSolid-state devicesForming faceCapacitor

A capacitor is arranged at the closest position to a semiconductor element and the generation of switching noise is reduced as low as possible by increasing the processing speed, arranging the components highly intensively and reducing the operation voltage. One face of the capacitor is connected to an electrode of the electrode forming face of the semiconductor element and the other face of the capacitor is connected to the connection pads on the wiring board so that the capacitor is interposed between the electrode forming face of the semiconductor element and the semiconductor mounting face of the wiring board, the other face of the capacitor is connected to the connection pads on the wiring board, and at the same time, flip-chip connection is conducted on the connection pads on the wiring board via the solder bumps connected to the electrodes of the semiconductor element.

Owner:SHINKO ELECTRIC IND CO LTD

Method of manufacturing electronic component device

ActiveUS20100299918A1Improve thermal conductivityStable thermal couplingPrinted circuit assemblingSemiconductor/solid-state device detailsForming faceEngineering

A recessed portion is formed in a predetermined position in a heat-spreading component. A thermoplastic resin serving as a thermal interface material (TIM) is stored in the recessed portion. Meanwhile, a large number of filamentous thermo-conductive elements serving as the TIM are arranged to stand side by side on a surface of the heat-spreading component in which the recessed portion is formed (or on an exposed surface of an electronic component). Then, the heat-spreading component is fixed onto a board in such a manner that the surface of the heat-spreading component in which the recessed portion is formed faces the board and that a clearance is adjusted between the electronic component and the heat-spreading component. Thereafter, the resin is heated to a softening point thereof into a fluidized state, and the resin is flowed and filled into the clearance between the electronic component and the heat-spreading component.

Owner:SHINKO ELECTRIC IND CO LTD

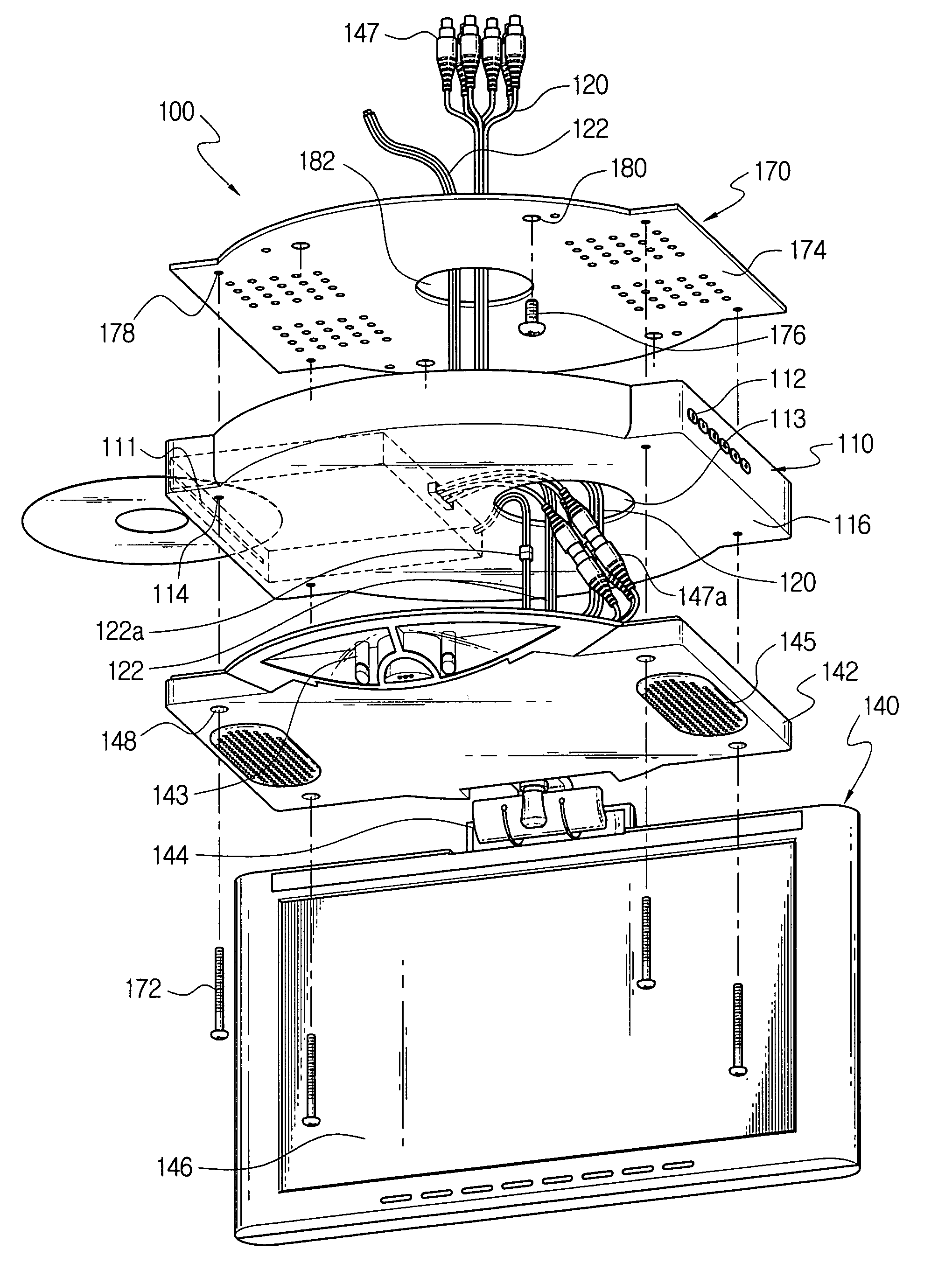

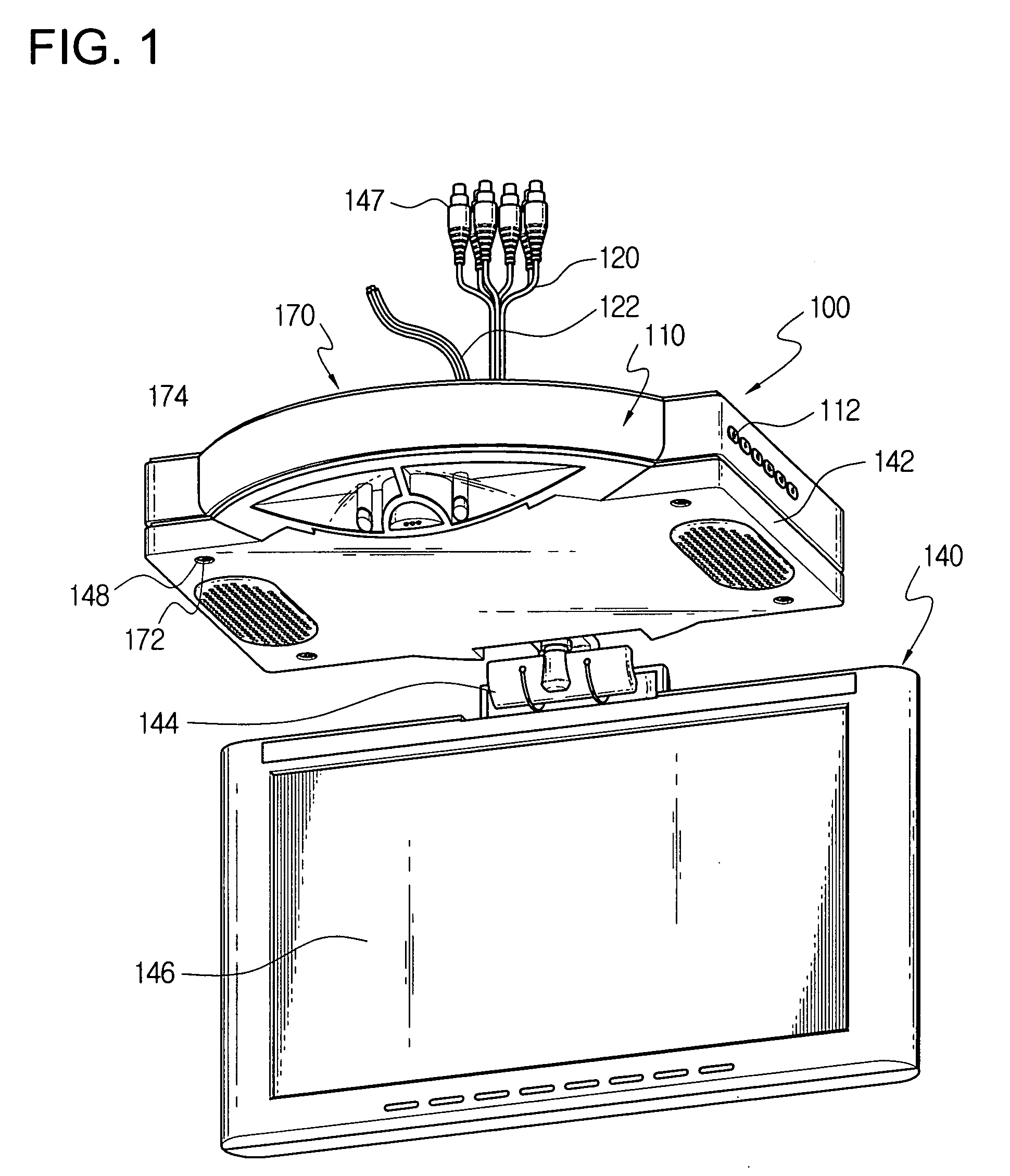

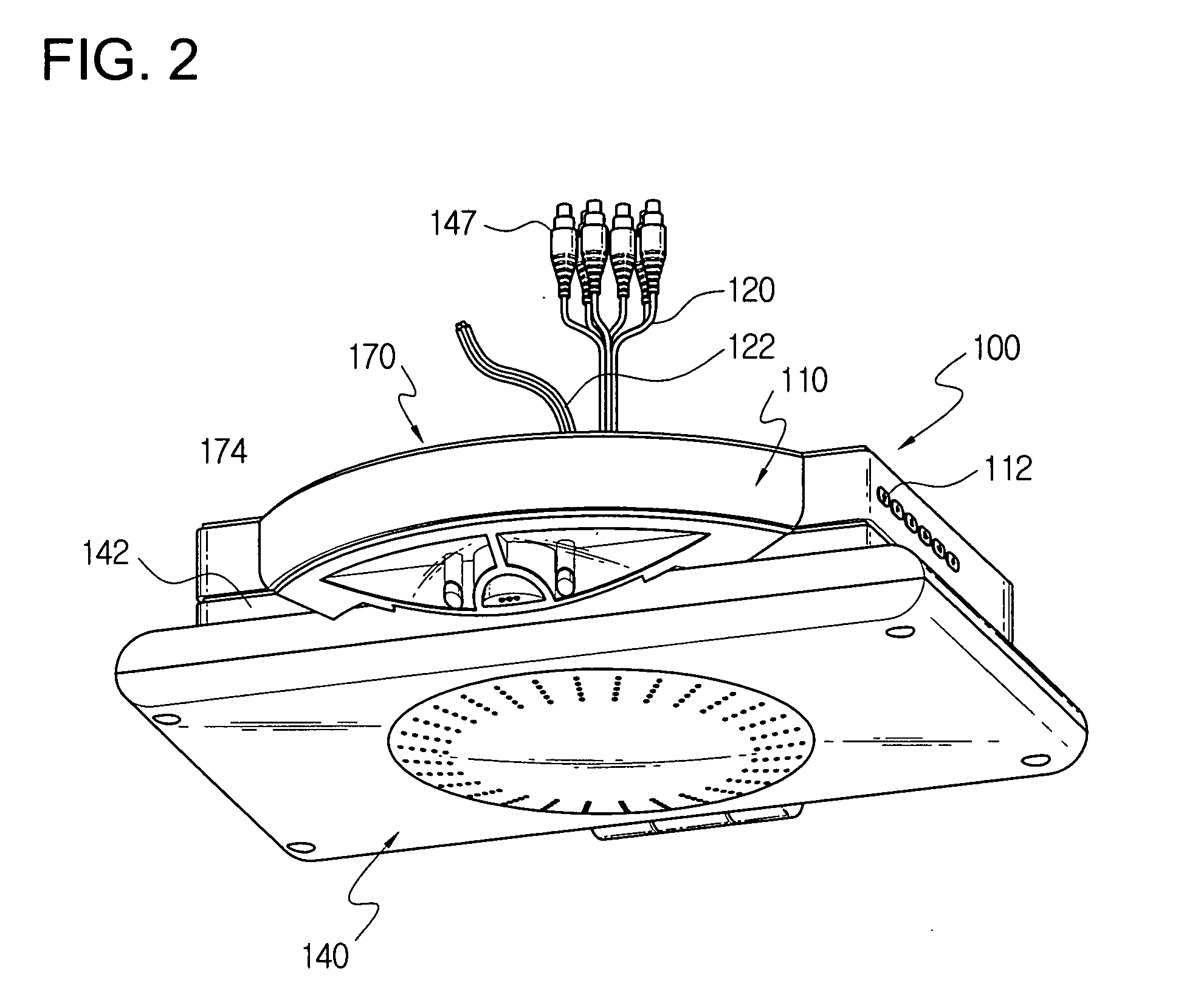

Display apparatus for vehicles

InactiveUS20050122670A1Easy to replaceTelevision system detailsDigital data processing detailsForming faceDisplay device

A display apparatus for vehicles is provided. The display apparatus for vehicles comprises a disc player comprising a display mounting unit, wherein a connection plate of a display unit is coupled to the bottom surface of the display mounting unit in a stacked form, or separated from the bottom surface; the display unit which comprises the connection plate having second fixing parts enabling the display unit to be coupled with the display mounting unit in a stacked form facing each other, and a screen unit which is installed on the connection plate through a hinge so as to rotate about the hinge, is capable of being folded and unfolded; and fixing components which allow the disc player and / or the display unit to be fixed to the ceiling of the vehicle. The display apparatus allows a purchaser to select a disc player as an option item and easily replace only a defective part. Particularly, the display apparatus has an advantage of easy installation and separation.

Owner:KOREA TECH IND

Fluid ejecting apparatus

A fluid ejecting apparatus includes a fluid ejecting head with a nozzle forming face having formed thereon a plurality of nozzles for ejecting fluid, a cap that is able to form a sealed space together with the nozzle forming face by being in contact with the nozzle forming face, a decompressing unit that is coupled to the cap so as to decompress the sealed space via a first channel, an ambient air ventilating unit that is coupled to the cap so as to open the sealed space to ambient air via a second channel, and a check valve that is provided on the second channel between the cap and the ambient air ventilating unit.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com