Patents

Literature

21951 results about "Interconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In telecommunications, interconnection is the physical linking of a carrier's network with equipment or facilities not belonging to that network. The term may refer to a connection between a carrier's facilities and the equipment belonging to its customer, or to a connection between two (or more) carriers.

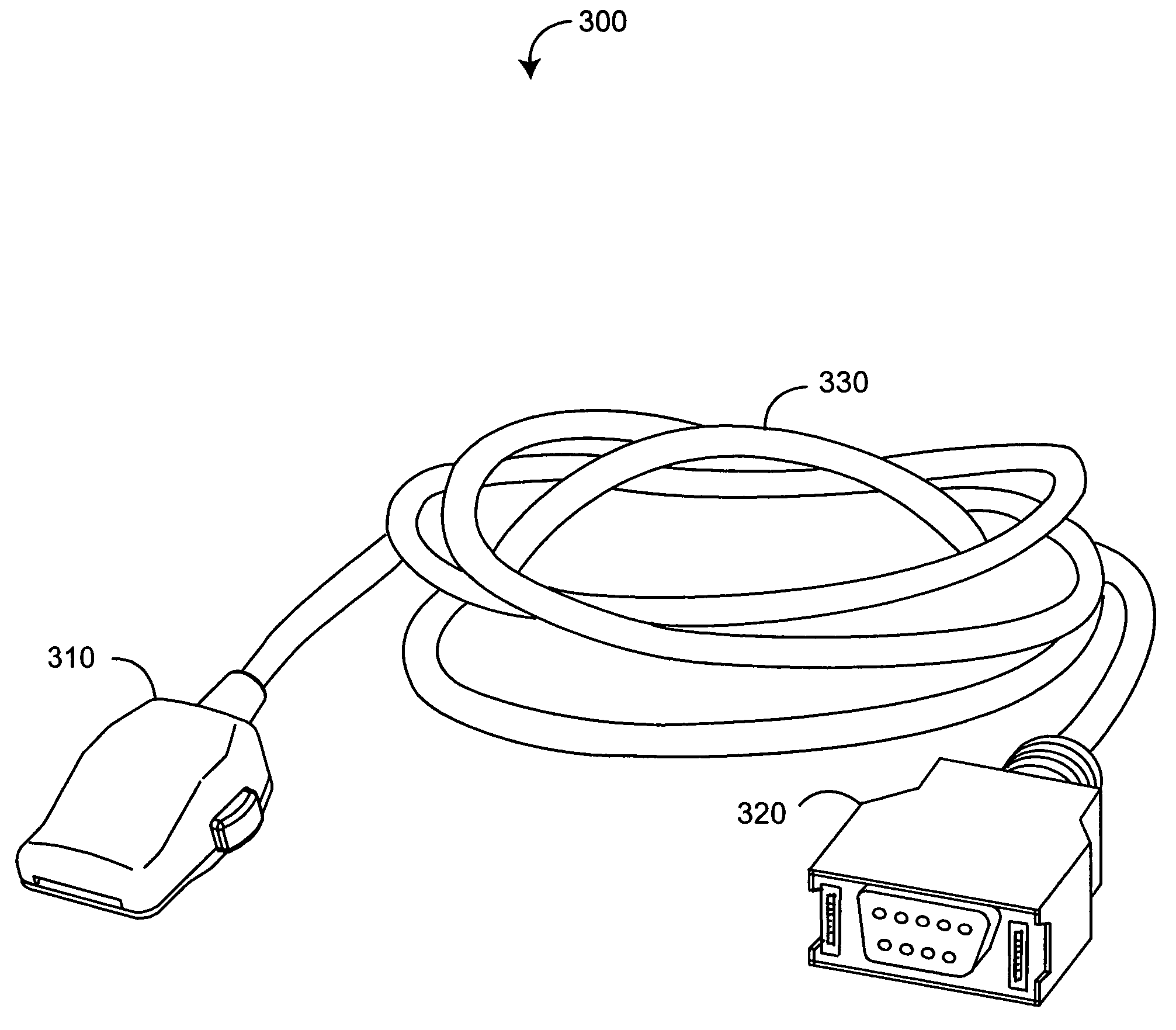

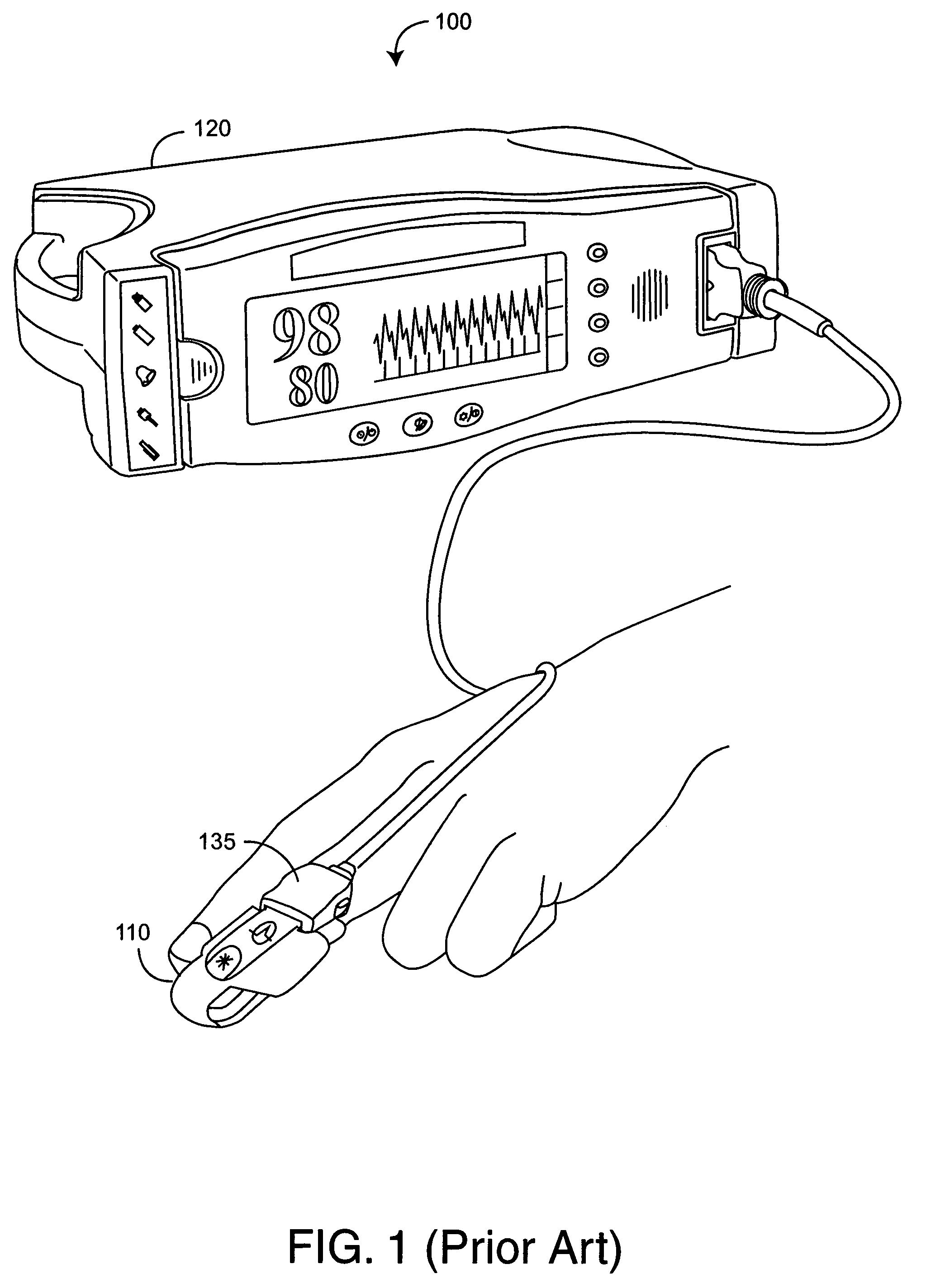

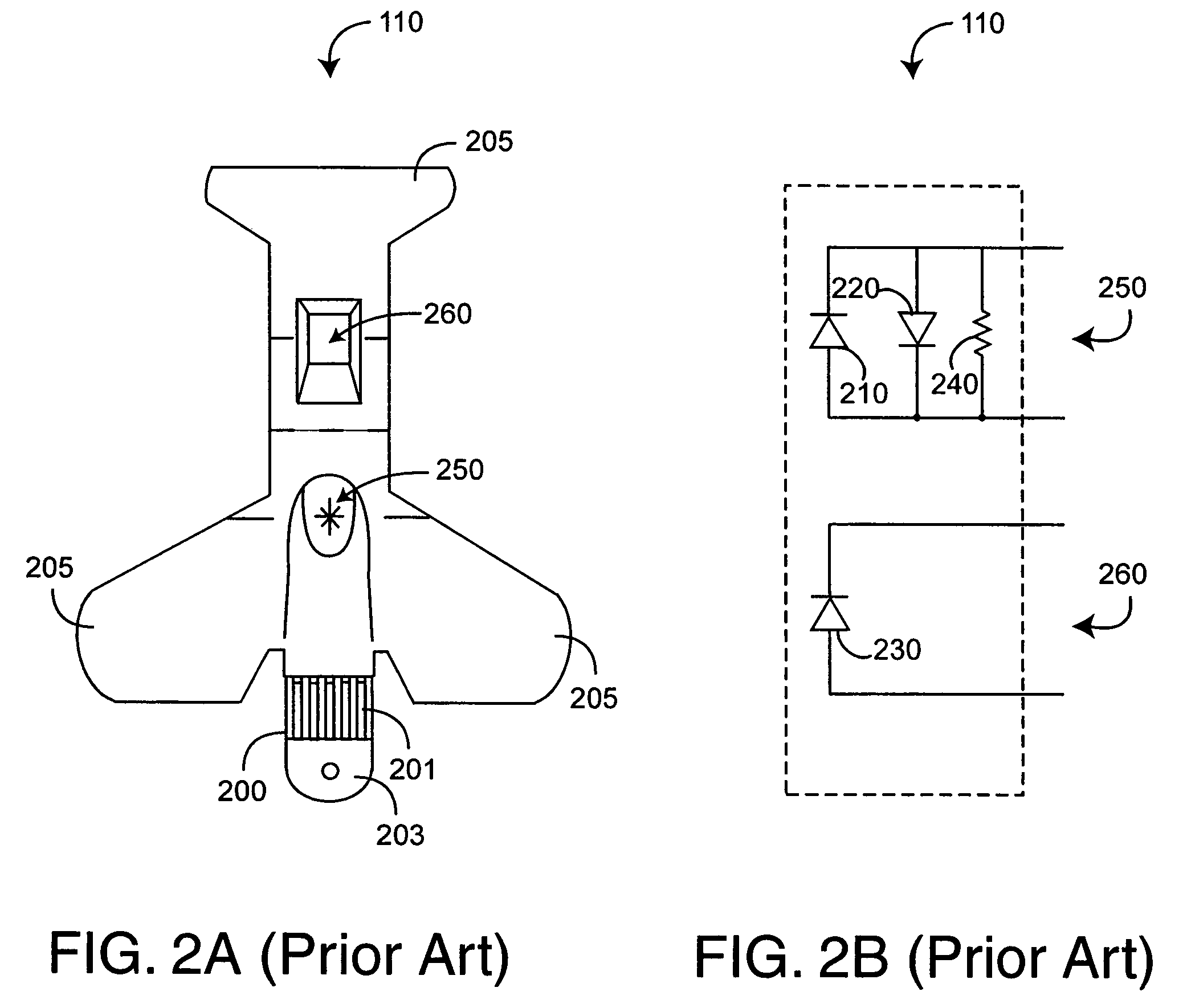

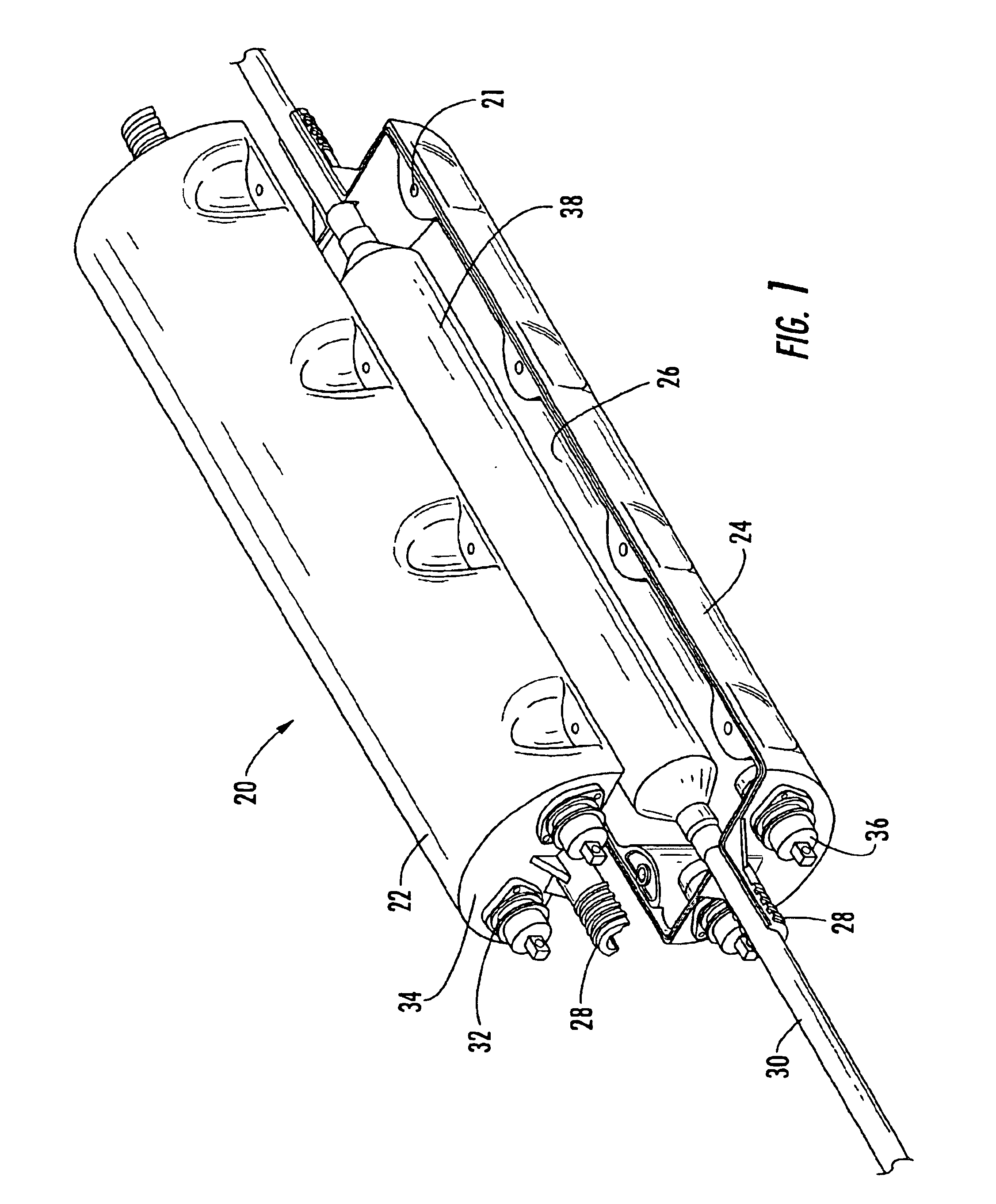

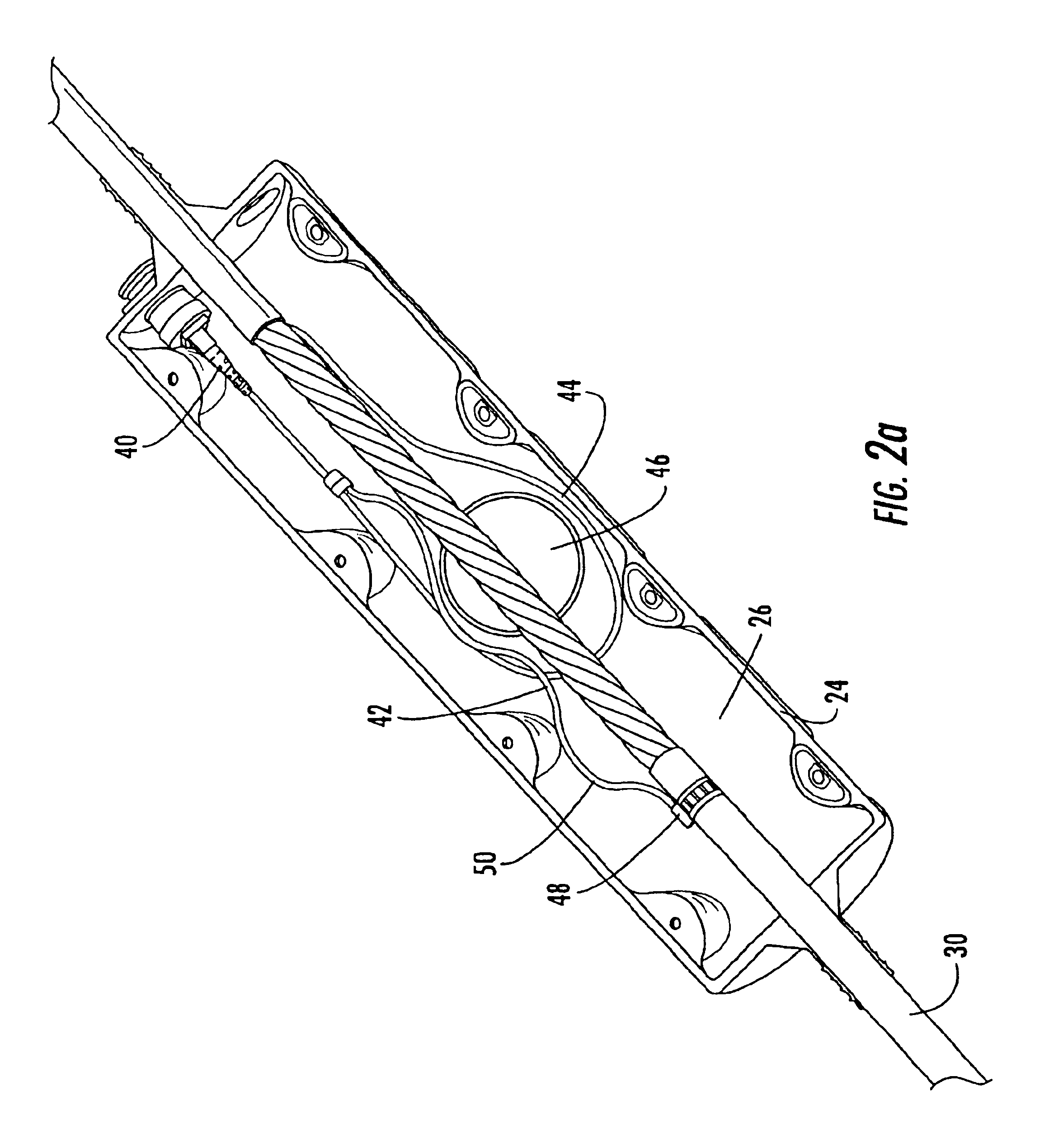

Pulse oximetry sensor adaptor

InactiveUS6993371B2Avoid complex processCost of very criticalDiagnostic recording/measuringSensorsAudio power amplifierPulse oximetry

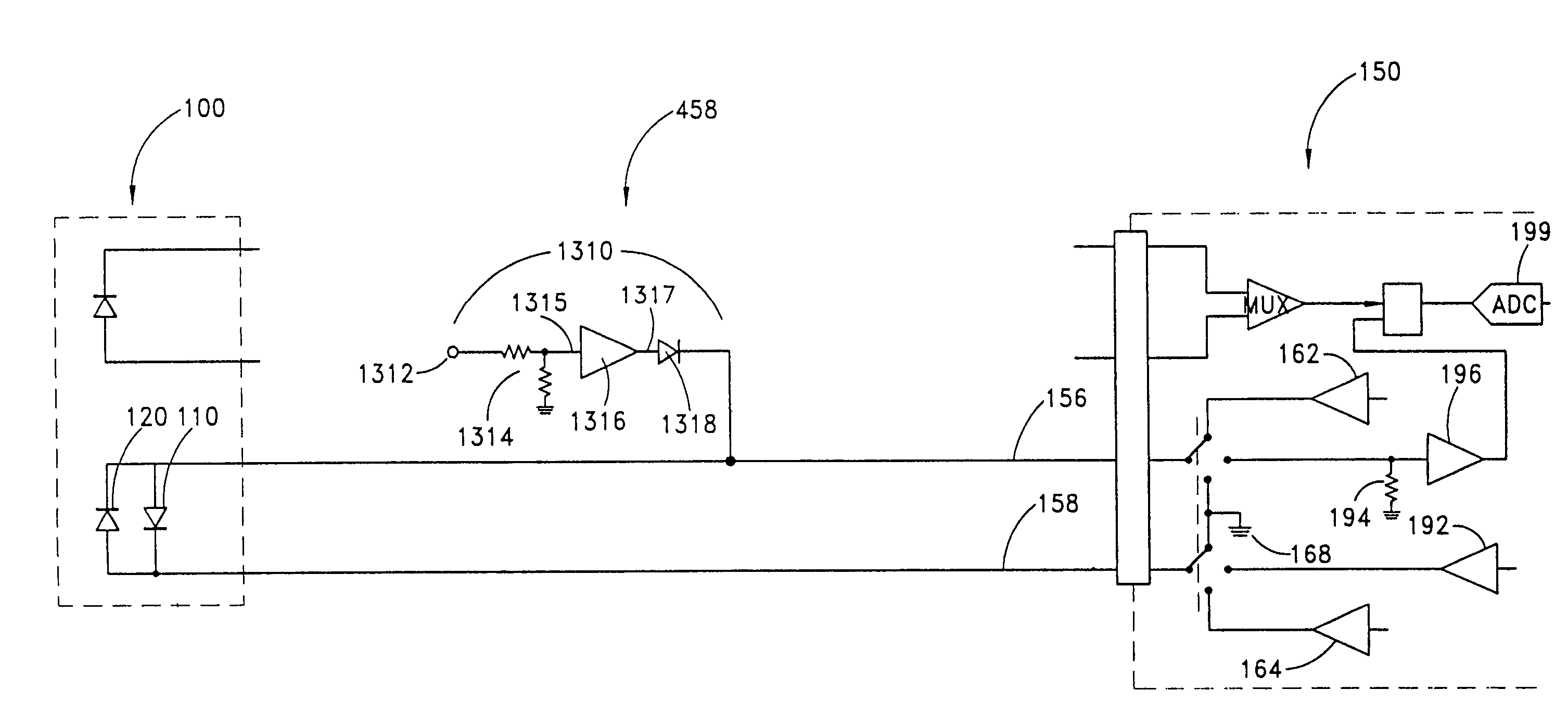

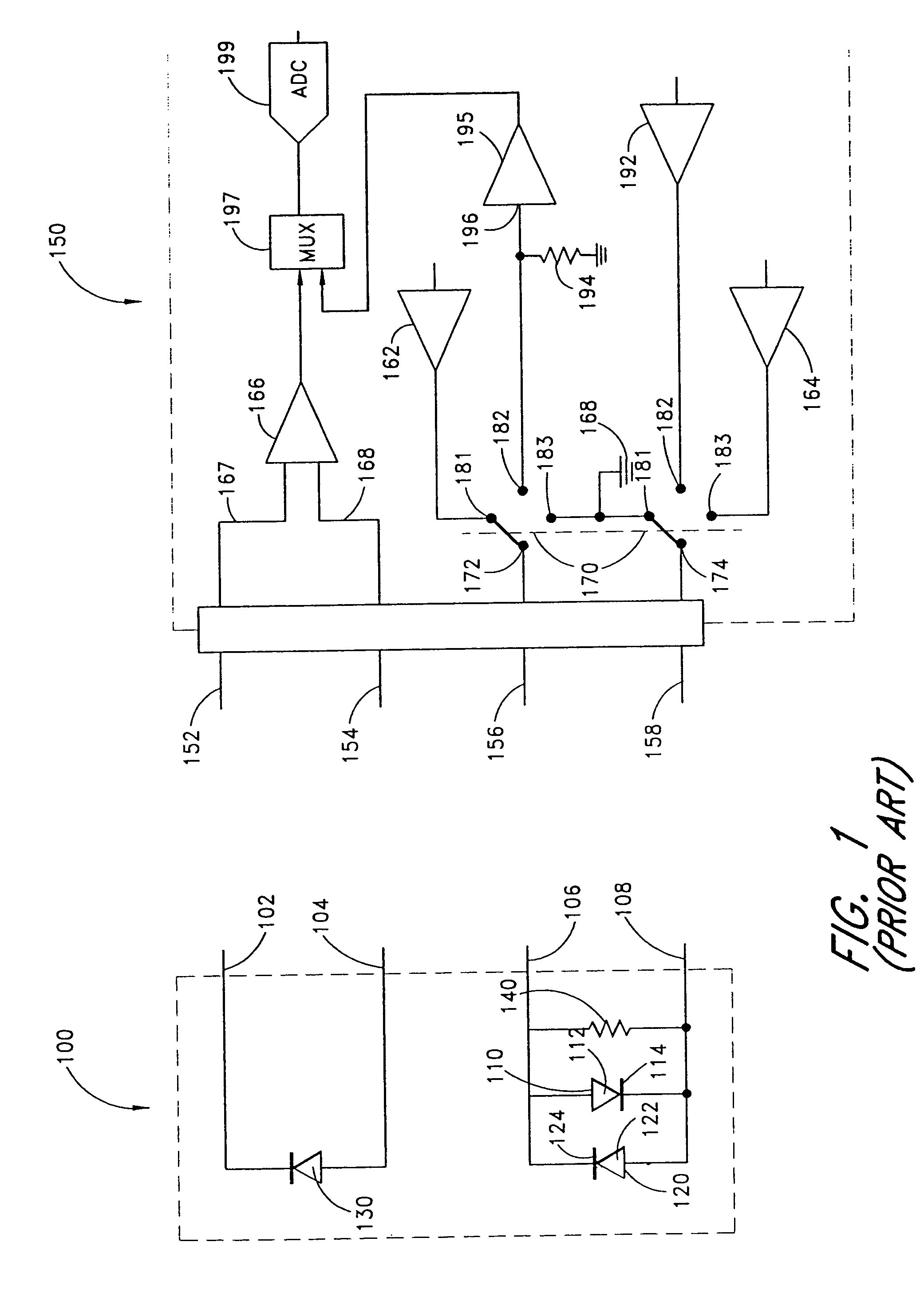

An adapter allows the interconnection of a sensor originating from one manufacturer to be coupled with conventionally incompatible monitors originating from other manufacturers to form a properly functioning pulse oximetry system. The adapter matches a sensor driver in a monitor to the current requirements and light source configuration of a sensor. The adapter also matches a sensor's light detector signal level to the dynamic range requirements of a monitor preamplifier. Further, the adapter provides compatible sensor calibration, sensor type and security information to a monitor. The adapter may have a self-contained power source or it may derive power from the monitor, allowing both passive and active adapter components. The adapter is particular suited as an adapter cable, replacing a conventional patient cable or sensor cable as the interconnection between a sensor to a monitor in a pulse oximetry system.

Owner:JPMORGAN CHASE BANK NA

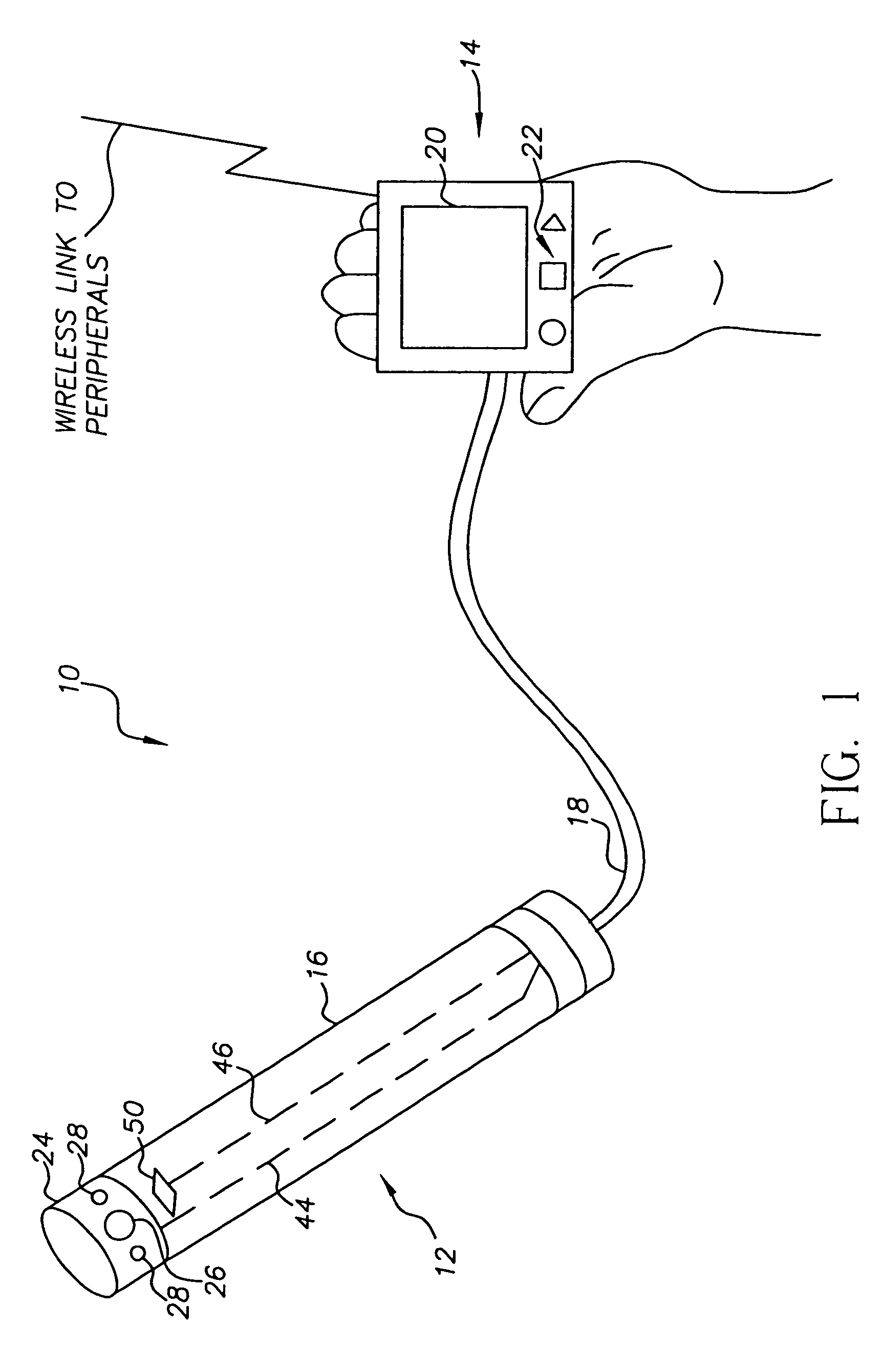

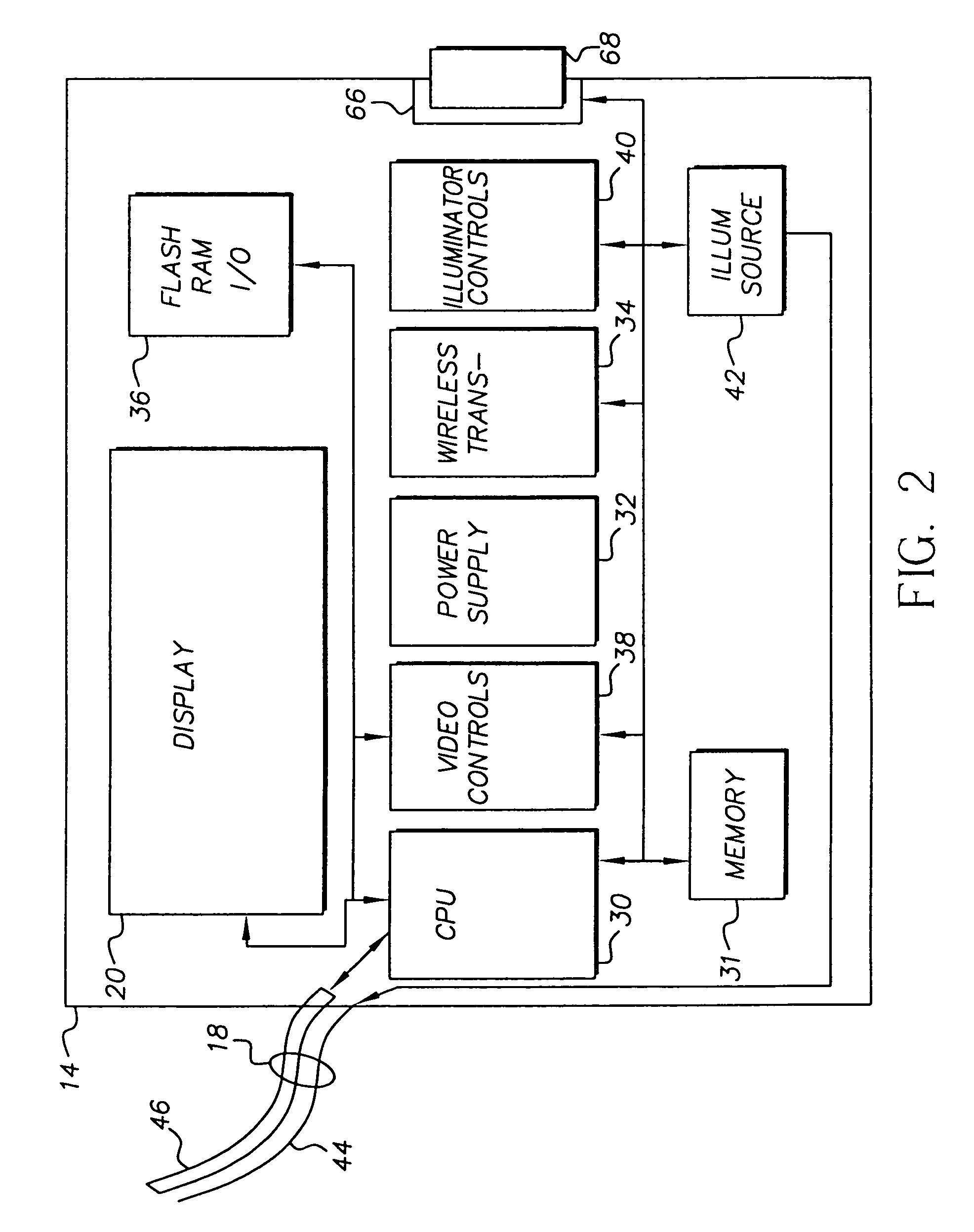

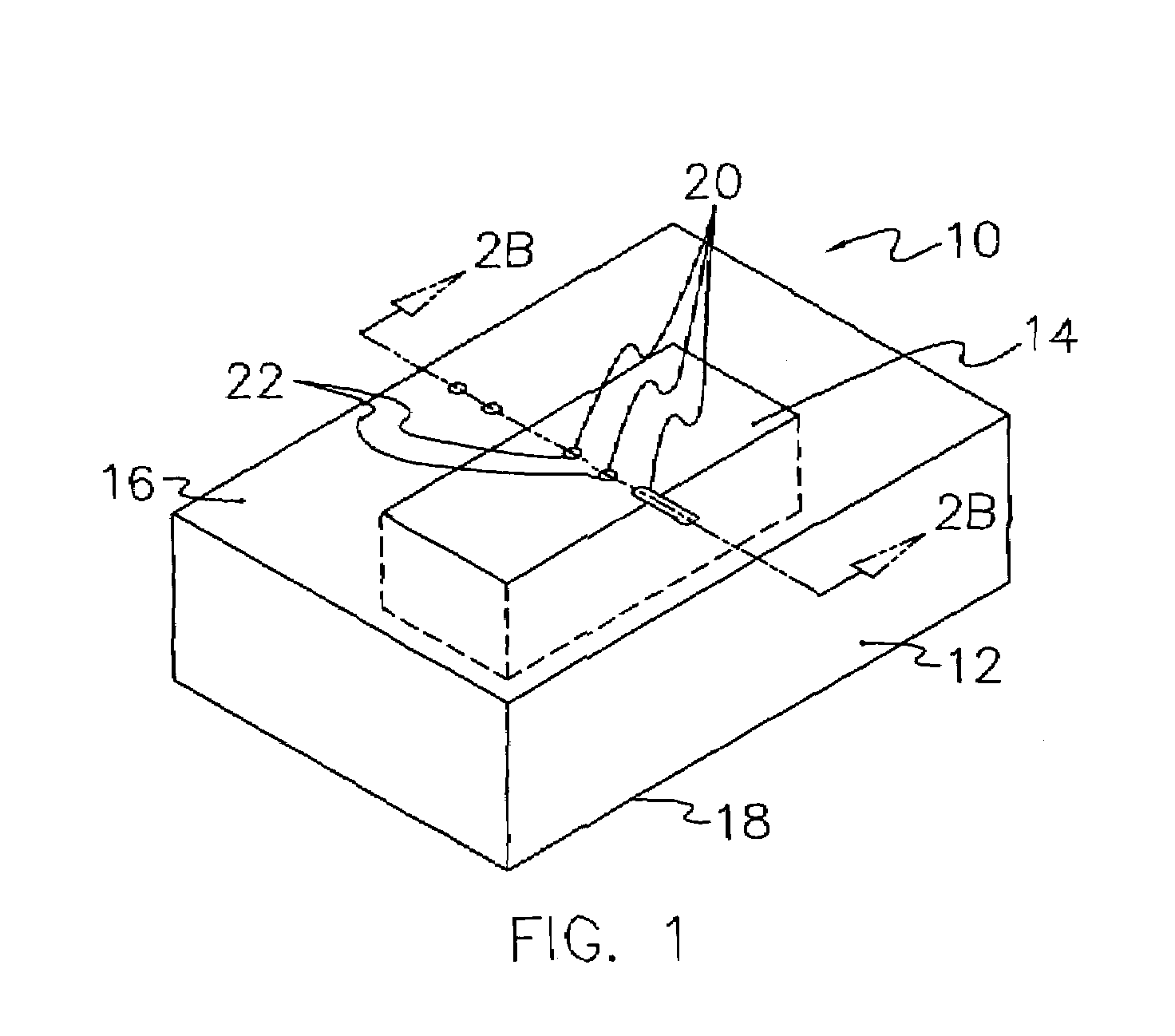

Intra-oral camera system with chair-mounted display

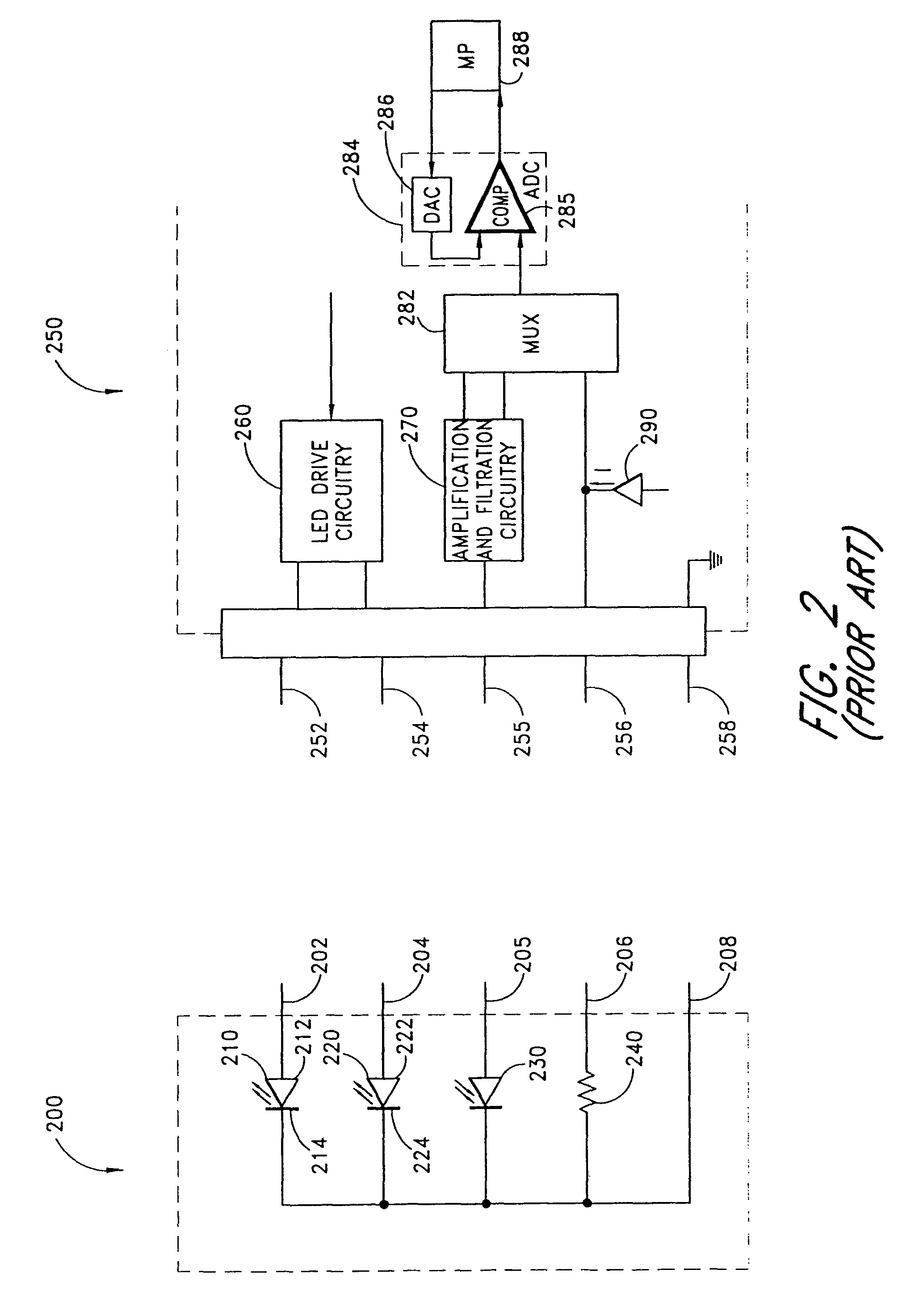

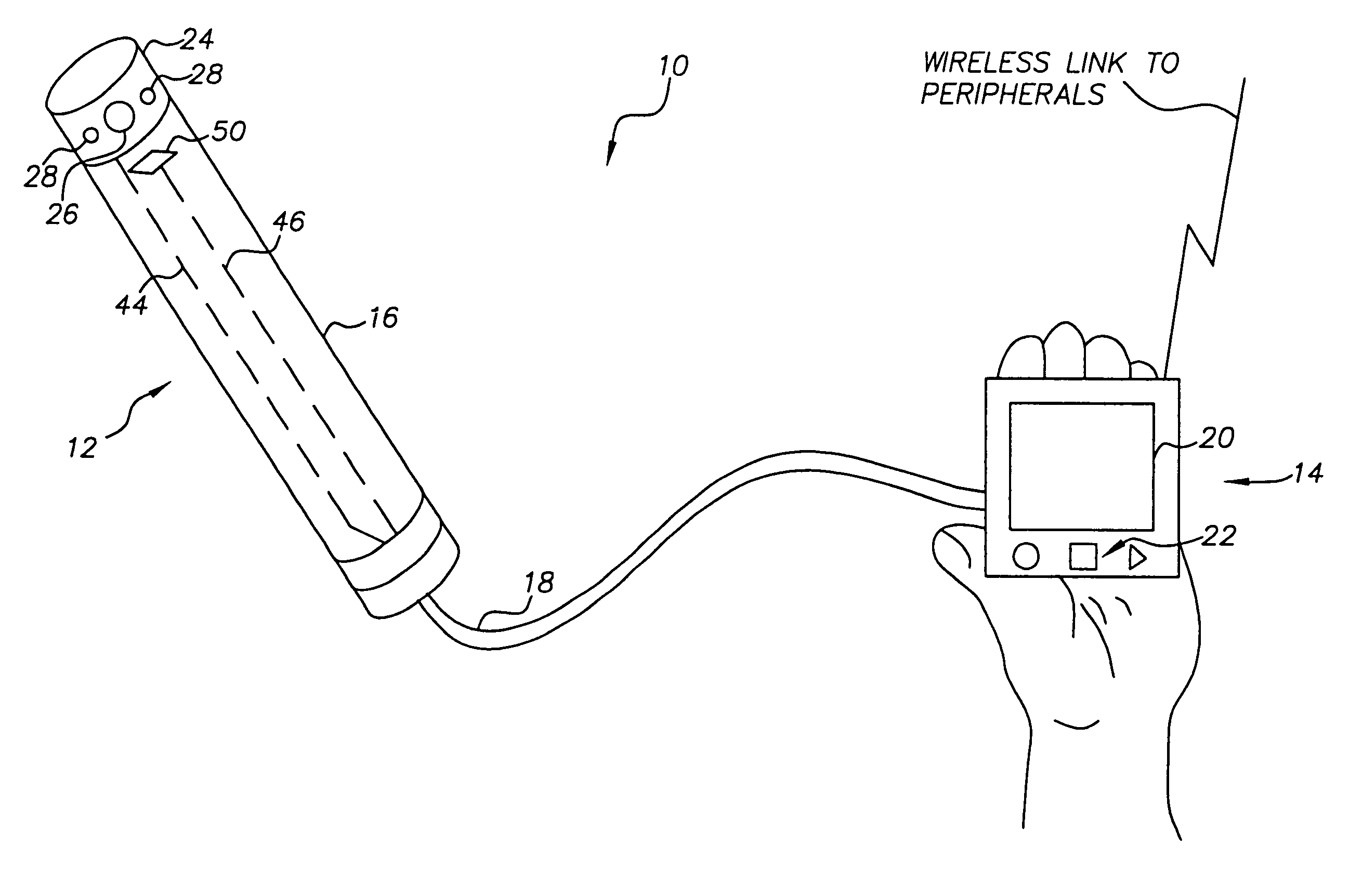

A portable intra-oral capture and display system, designed for use by a dental practitioner in connection with a patient seated in a dental chair, includes: a handpiece elongated for insertion into an oral cavity of the patient, where the handpiece includes a light emitter on a distal end thereof for illuminating an object in the cavity and an image sensor for capturing an image of the object and generating an image signal therefrom; a monitor interconnected with the handpiece, where the monitor contains electronics for processing the image for display and a display element for displaying the image, where the interconnection between the monitor and the handpiece includes an electrical connection for communicating the image signal from the image sensor in the camera to the electronics in the monitor; and a receptacle on the dental chair for receiving the monitor, wherein the receptacle conforms to the monitor such that the monitor may be withdrawn from the receptacle in order to allow the display element to be seen by the dental practitioner or the patient.

Owner:CARESTREAM HEALTH INC

Connector switch

An interconnection between a sensor and a monitor has a cable, an information element and a switch. The cable has conductors providing electrical communication between a sensor connector and a monitor connector. The information element is readable by the monitor and mounted in the sensor connector, the monitor connector or the cable. A switch is mounted in the sensor connector and is responsive to the sensor connecting to and disconnecting from the sensor connector so as to alter the readability of said information element.

Owner:JPMORGAN CHASE BANK NA

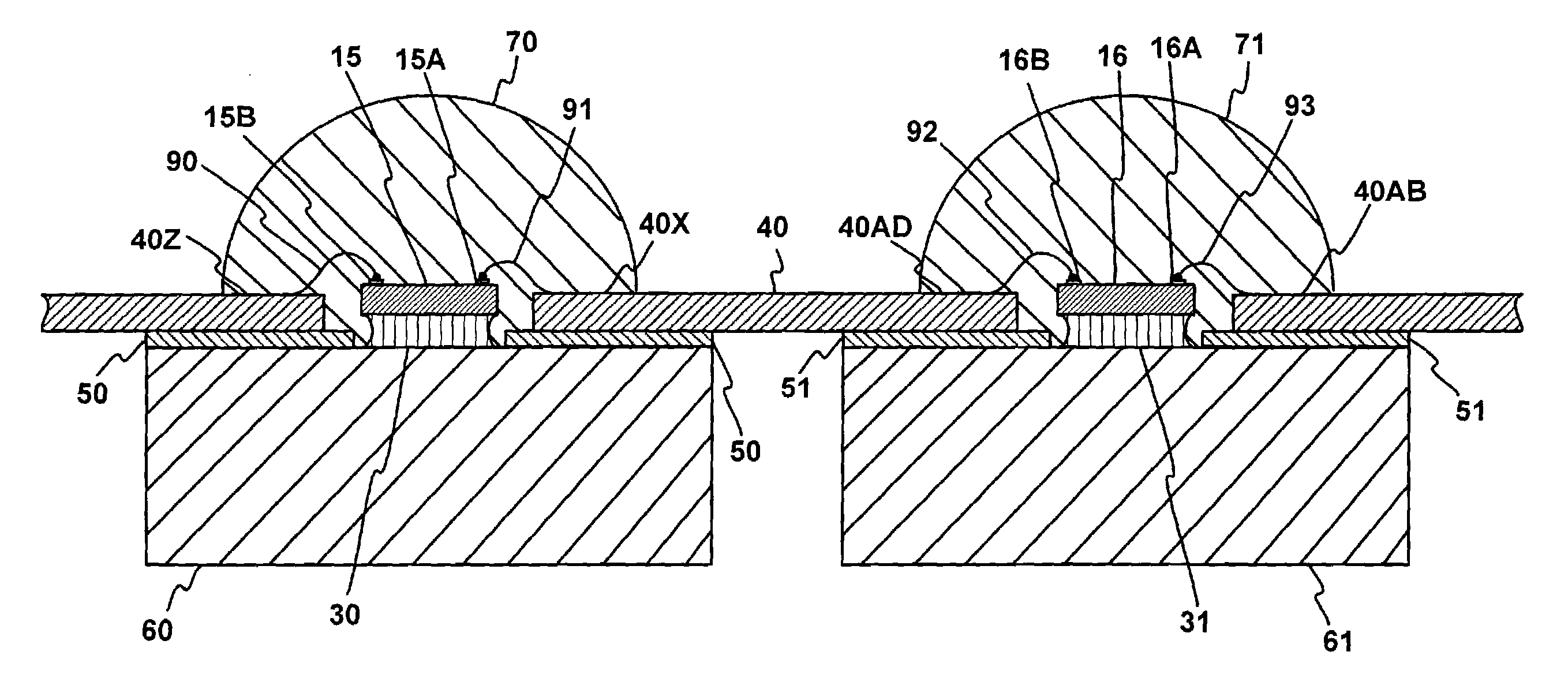

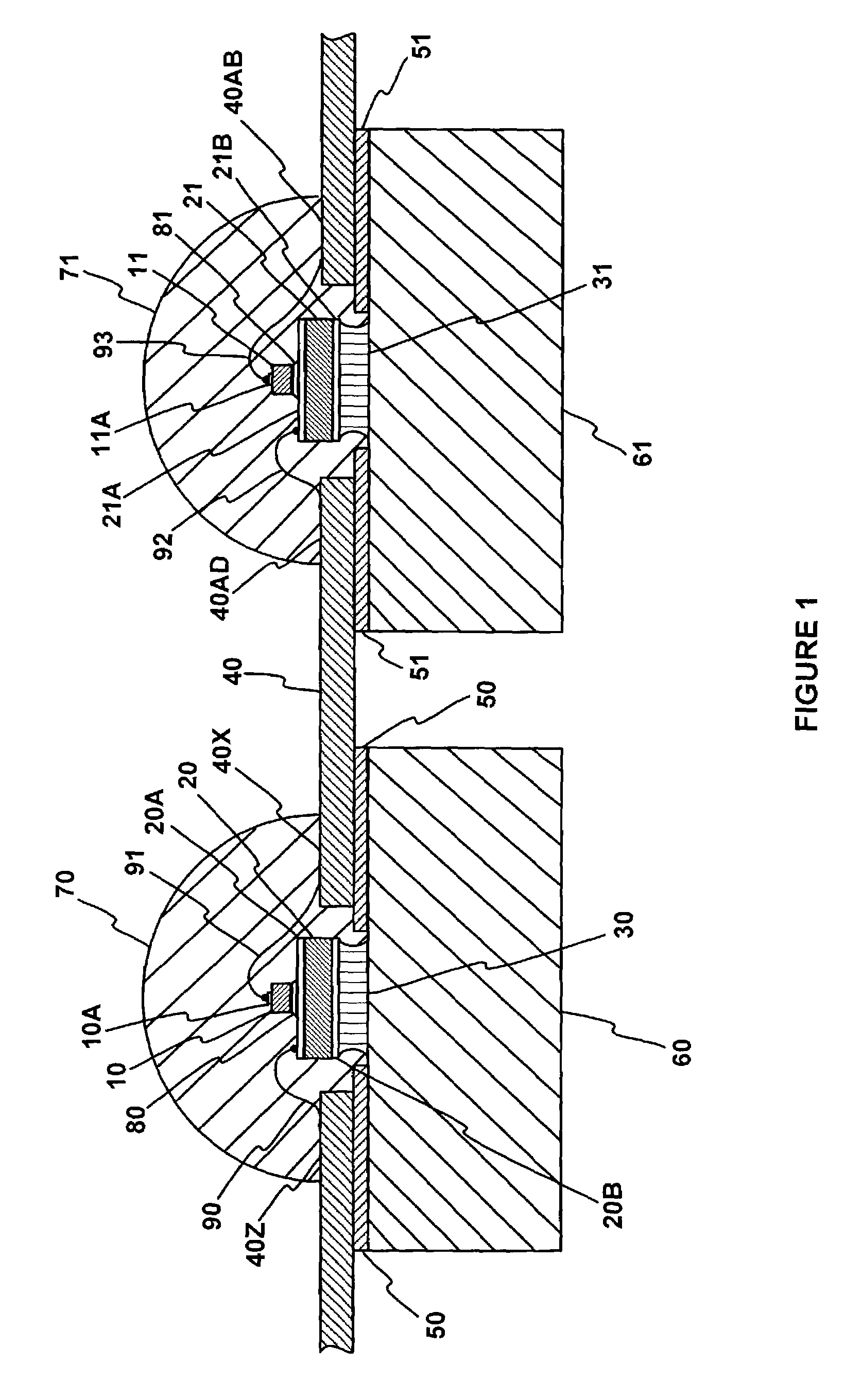

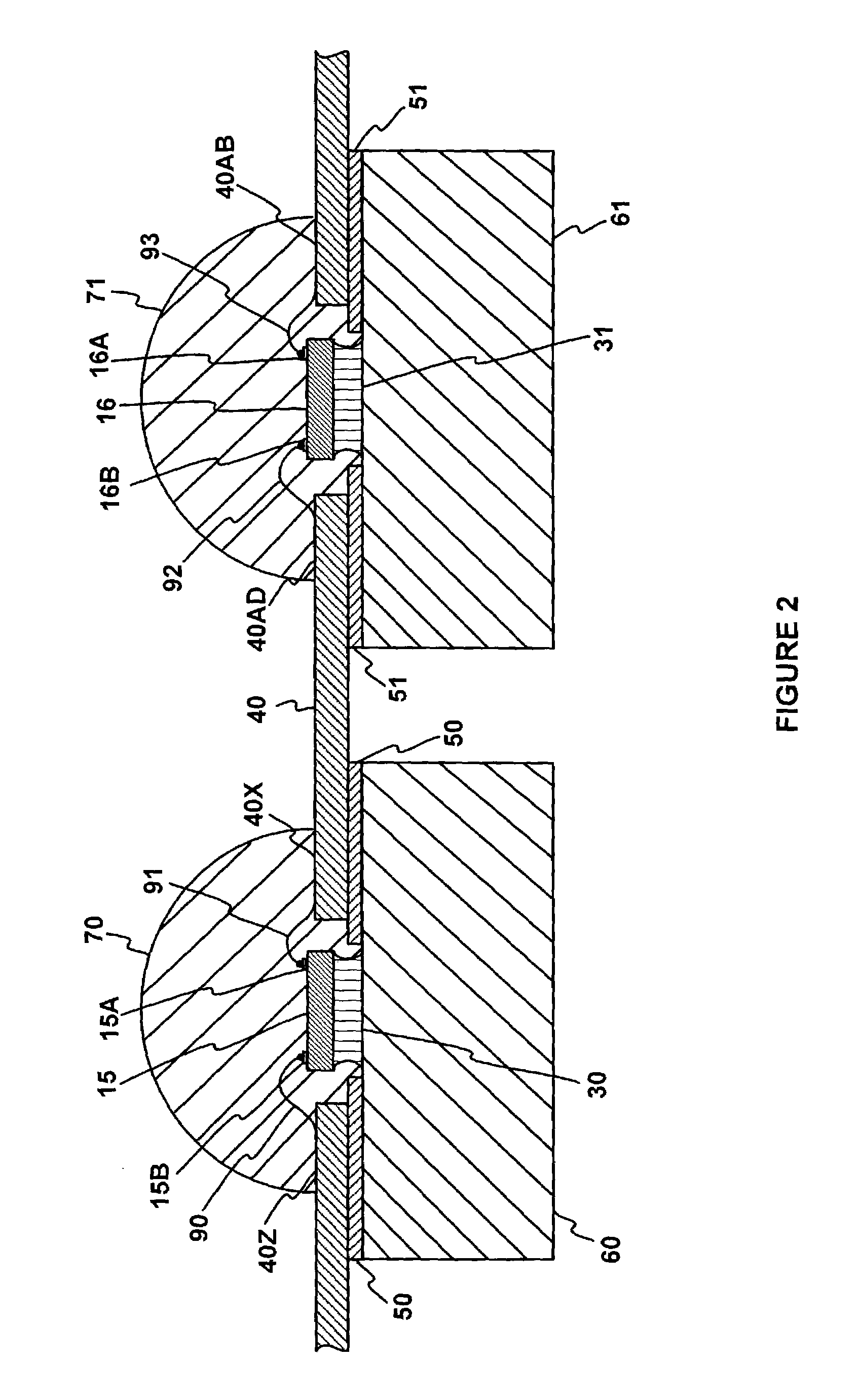

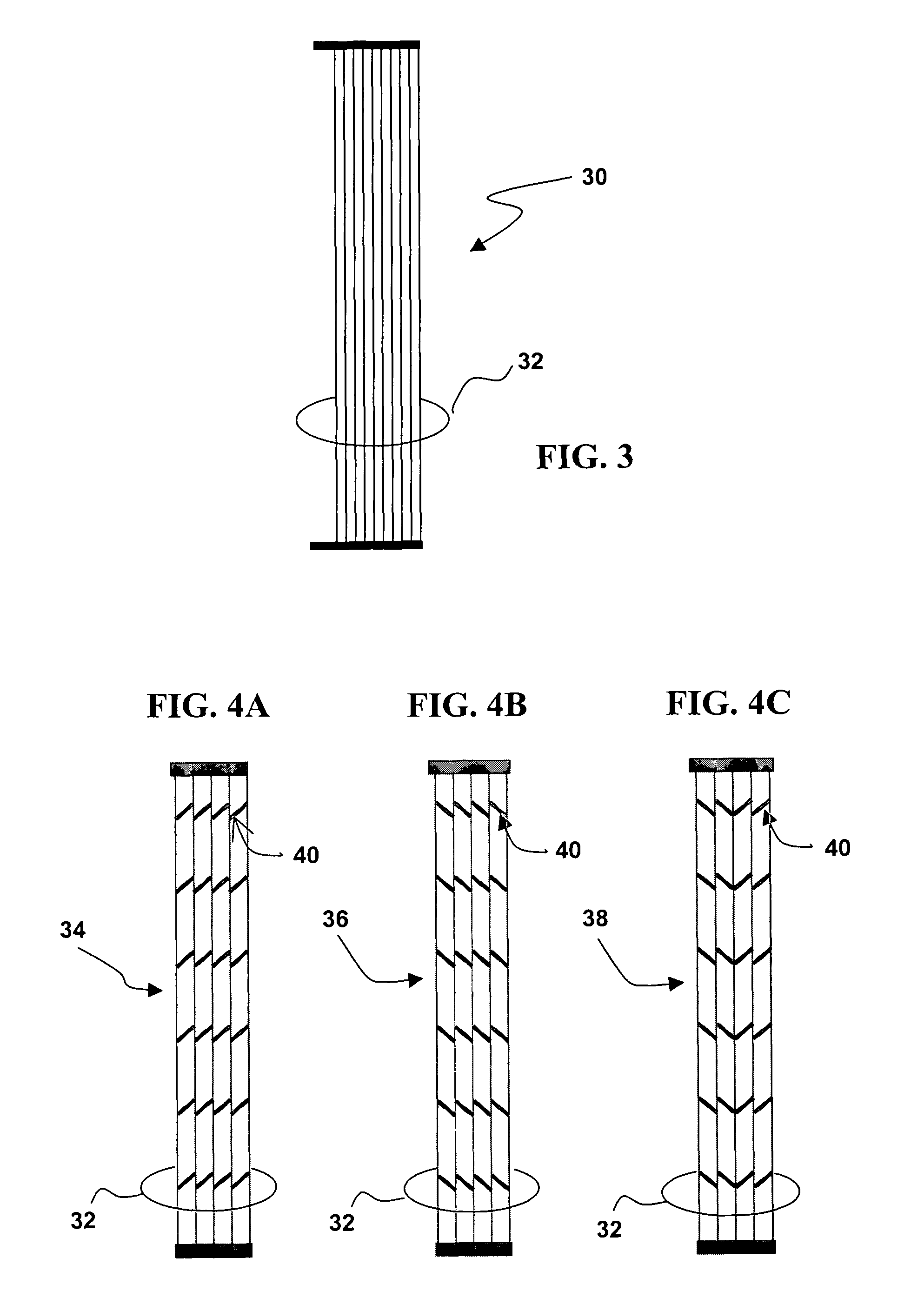

Bendable high flux LED array

ActiveUS6936855B1Easily variableWell formedSolid-state devicesSemiconductor devices for light sourcesLed arrayHigh flux

A bendable light emitting diode (LED) array in accordance with the present invention includes heat spreaders, dielectric material disposed above each heat spreader, and a bendable electrical interconnection layer disposed above these heat spreaders and electrically insulated from these heat spreaders by the dielectric material. At least one via passes through the dielectric material above each heat spreader, and at least one LED die is disposed above each via. The bendable electrical interconnection layer may be a lead frame comprising metal pathways that electrically interconnect some or all LED dice in series, in parallel, in anti-parallel, or in some combination of these configurations. Each via contains a thermally conductive material in thermal contact with the corresponding heat spreader below it and in thermal contact with the corresponding LED die above it. The LED dice may be thermally and electrically coupled to submounts disposed above corresponding heat spreaders in some embodiments.

Owner:EPISTAR CORP

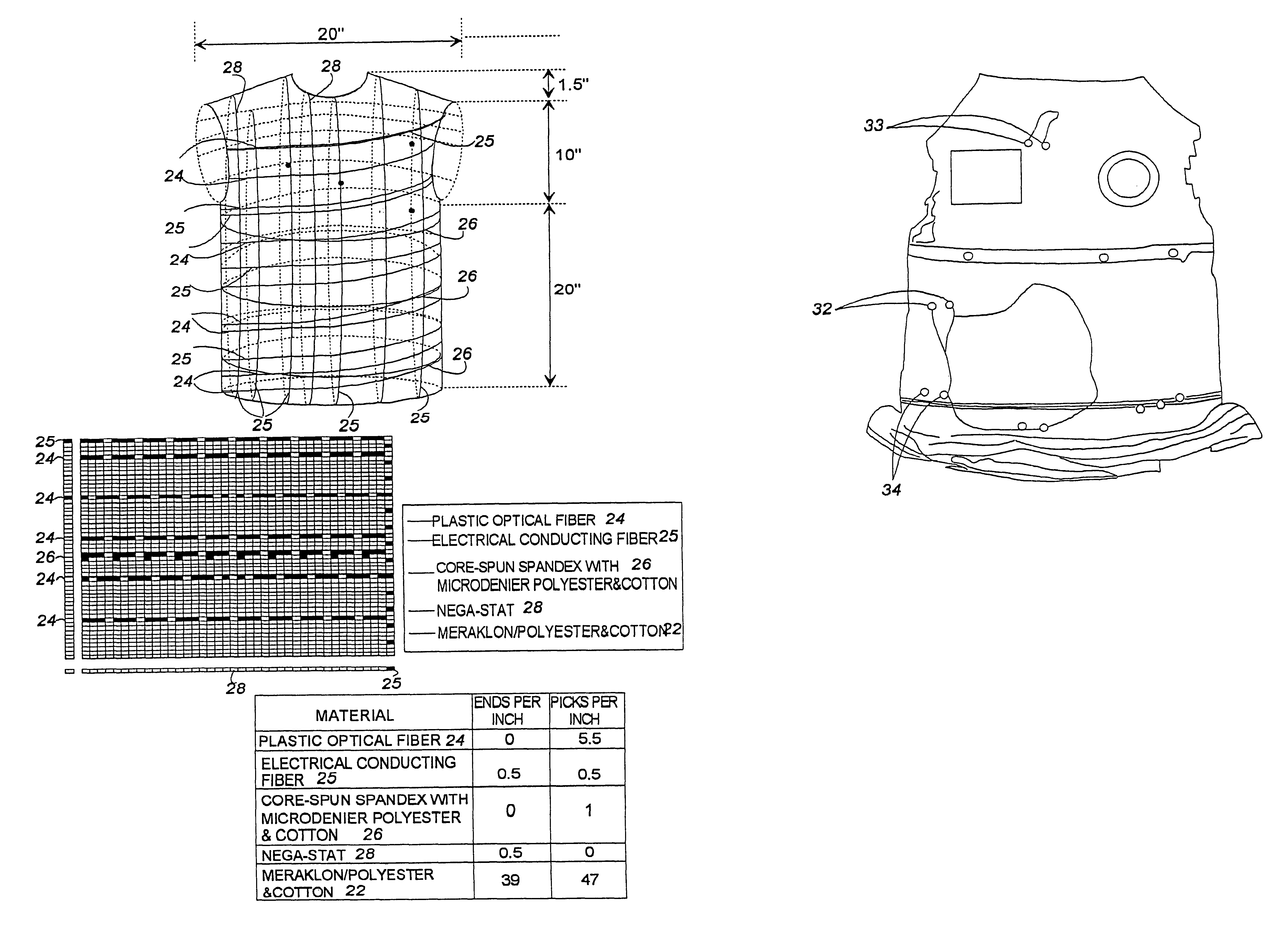

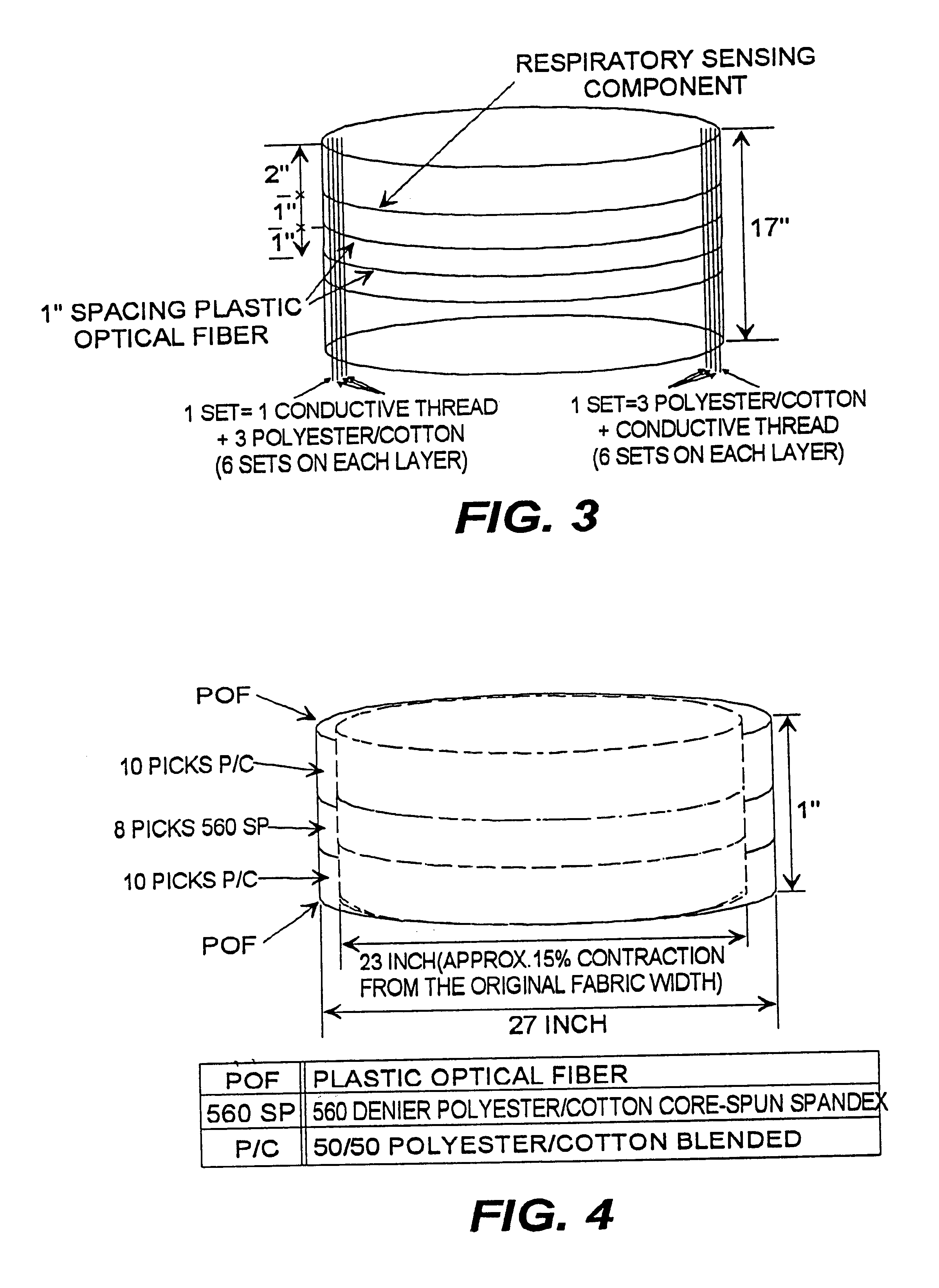

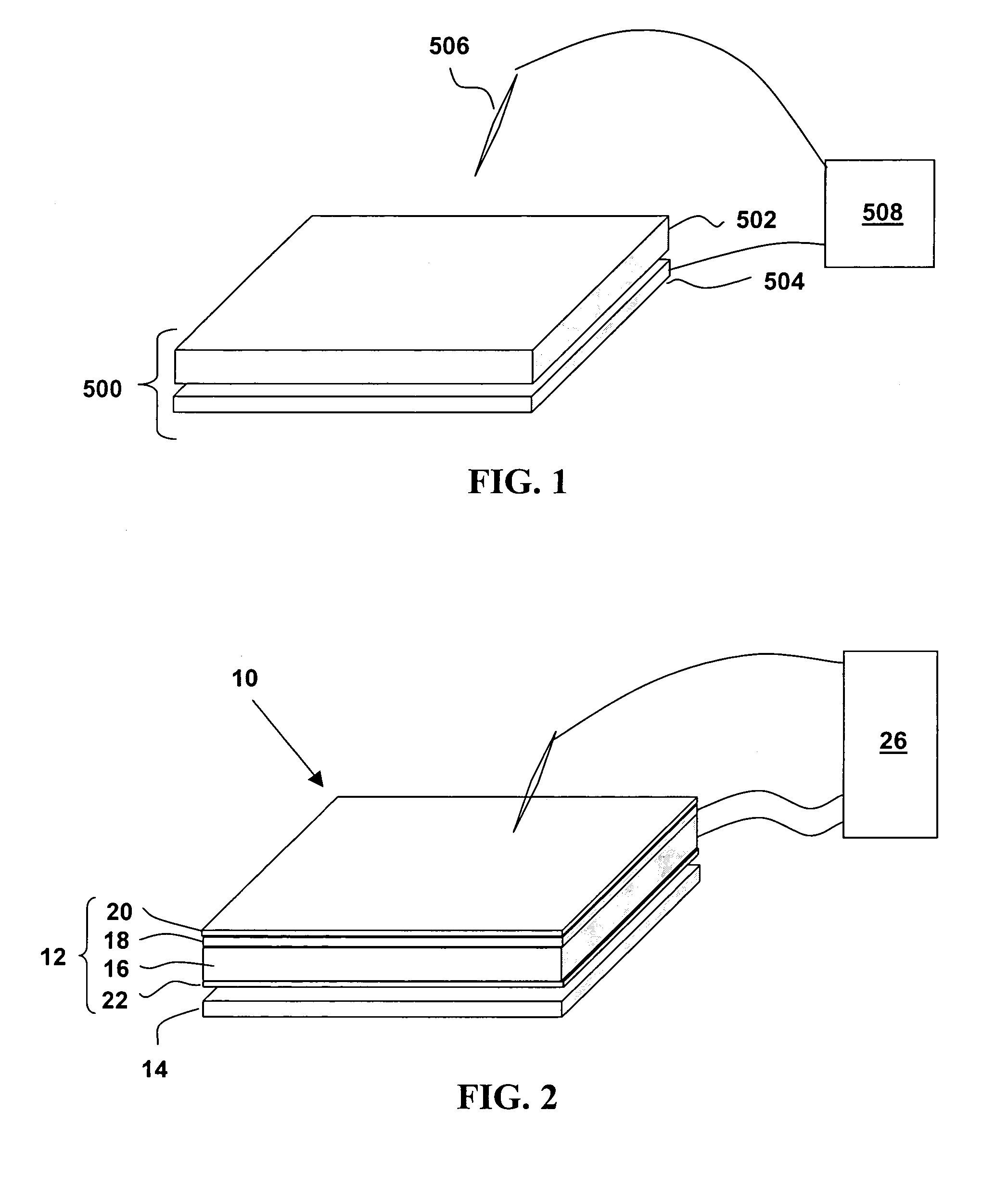

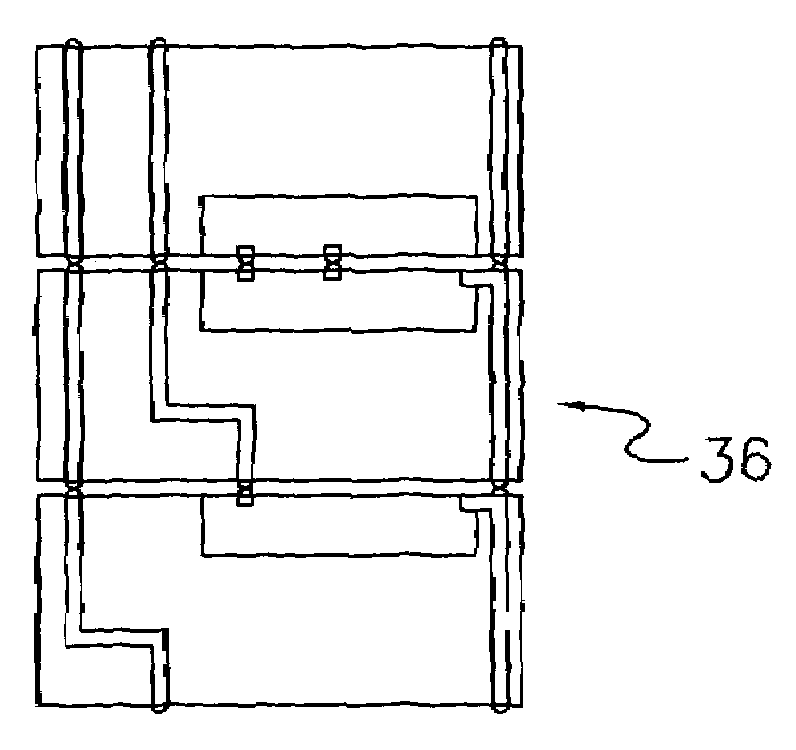

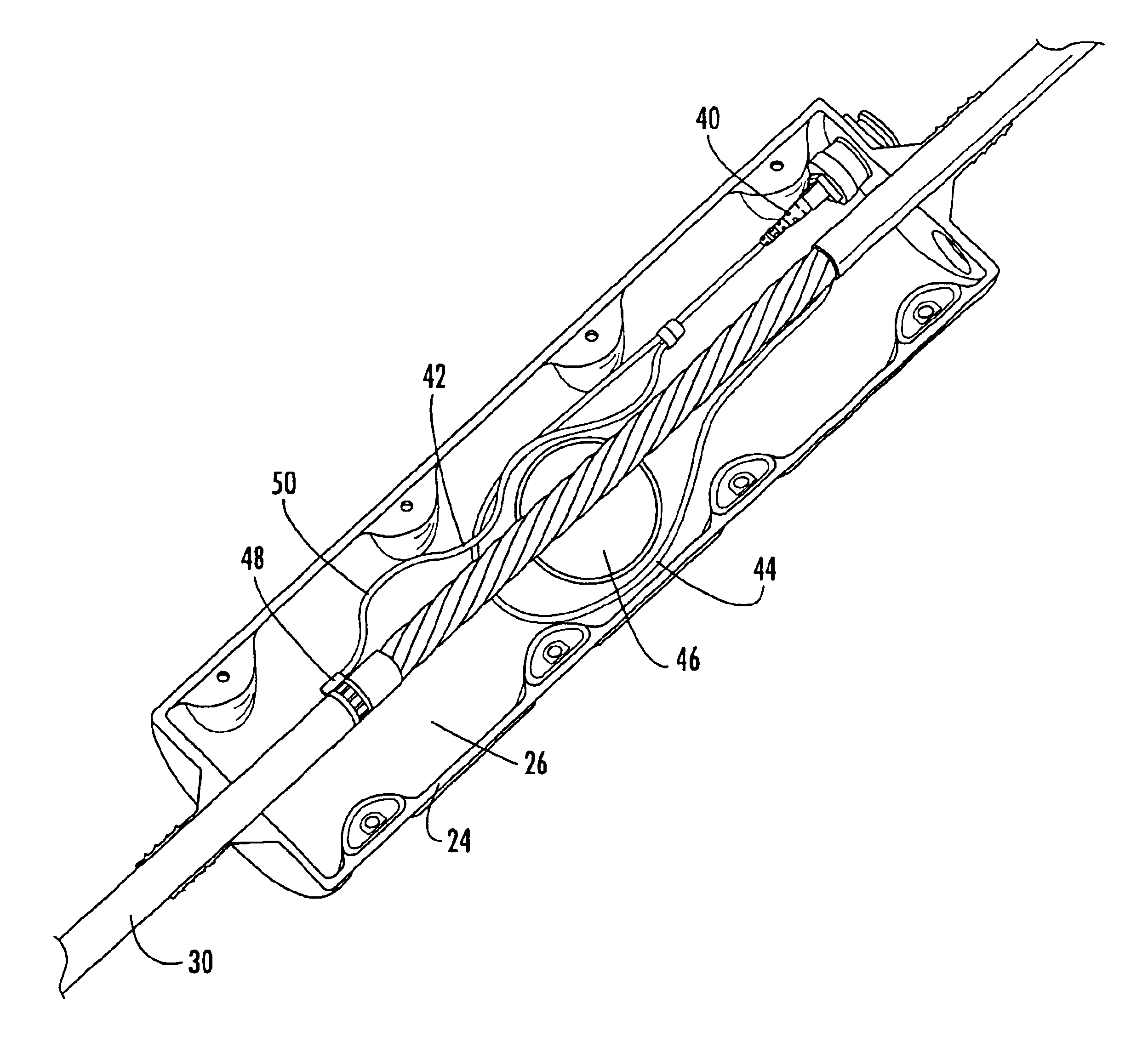

Fabric or garment with integrated flexible information infrastructure

InactiveUS6381482B1Raise the ratioImprove high temperature stabilityWeft knittingOrnamental textile articlesInformation processingEngineering

A fabric, in the form of a woven or knitted fabric or garment, including a flexible information infrastructure integrated within the fabric for collecting, processing, transmitting and receiving information concerning-but not limited to-a wearer of the fabric. The fabric allows a new way to customize information processing devices to "fit" the wearer by selecting and plugging in (or removing) chips / sensors from the fabric thus creating a wearable, mobile information infrastructure that can operate in a stand-alone or networked mode. The fabric can be provided with sensors for monitoring physical aspects of the wearer, for example body vital signs, such as heart rate, EKG, pulse, respiration rate, temperature, voice, and allergic reaction, as well as penetration of the fabric. The fabric consists of a base fabric ("comfort component"), and an information infrastructure component which can consist of a penetration detection component, or an electrical conductive component, or both. The preferred penetration detection component is a sheathed optical fiber. The information infrastructure component can include, in addition to an electrically conductive textile yarn, a sensor or a connector for a sensor. A process is provided for making an electrical interconnection between intersecting electrically conductive yarns. Furthermore, a process is established for sheathing the plastic optical fiber and protecting it.

Owner:GEORGIA TECH RES CORP

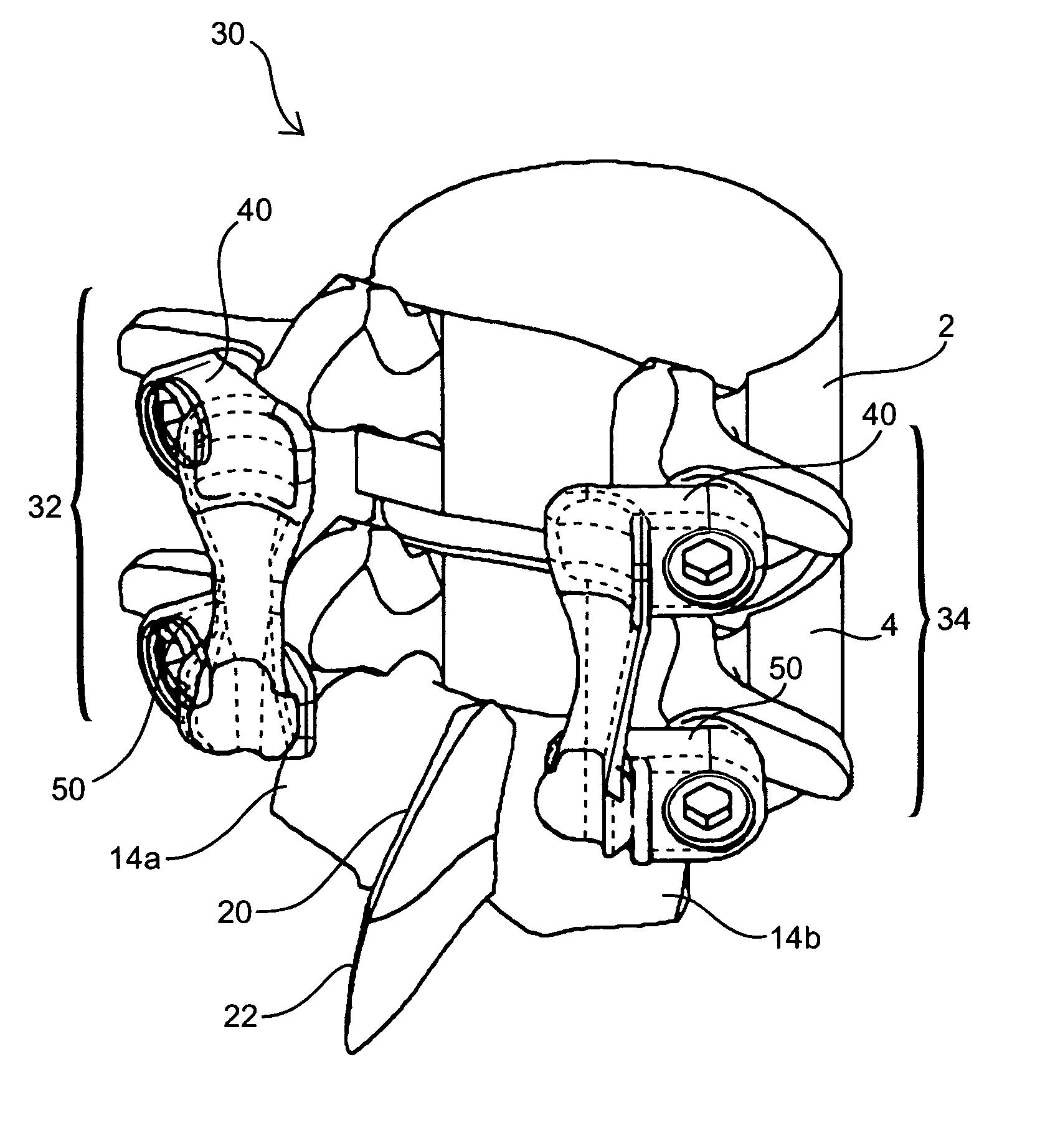

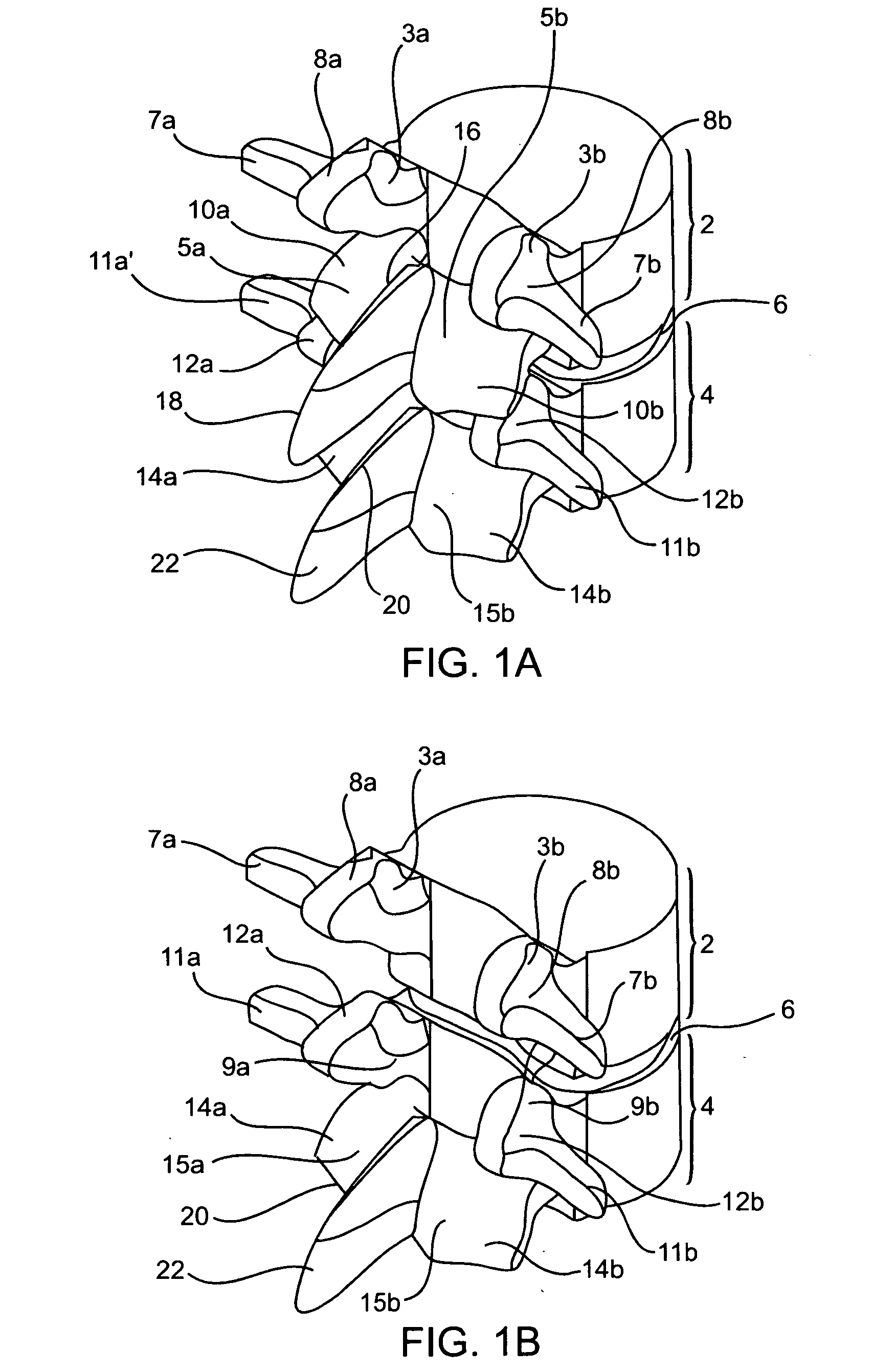

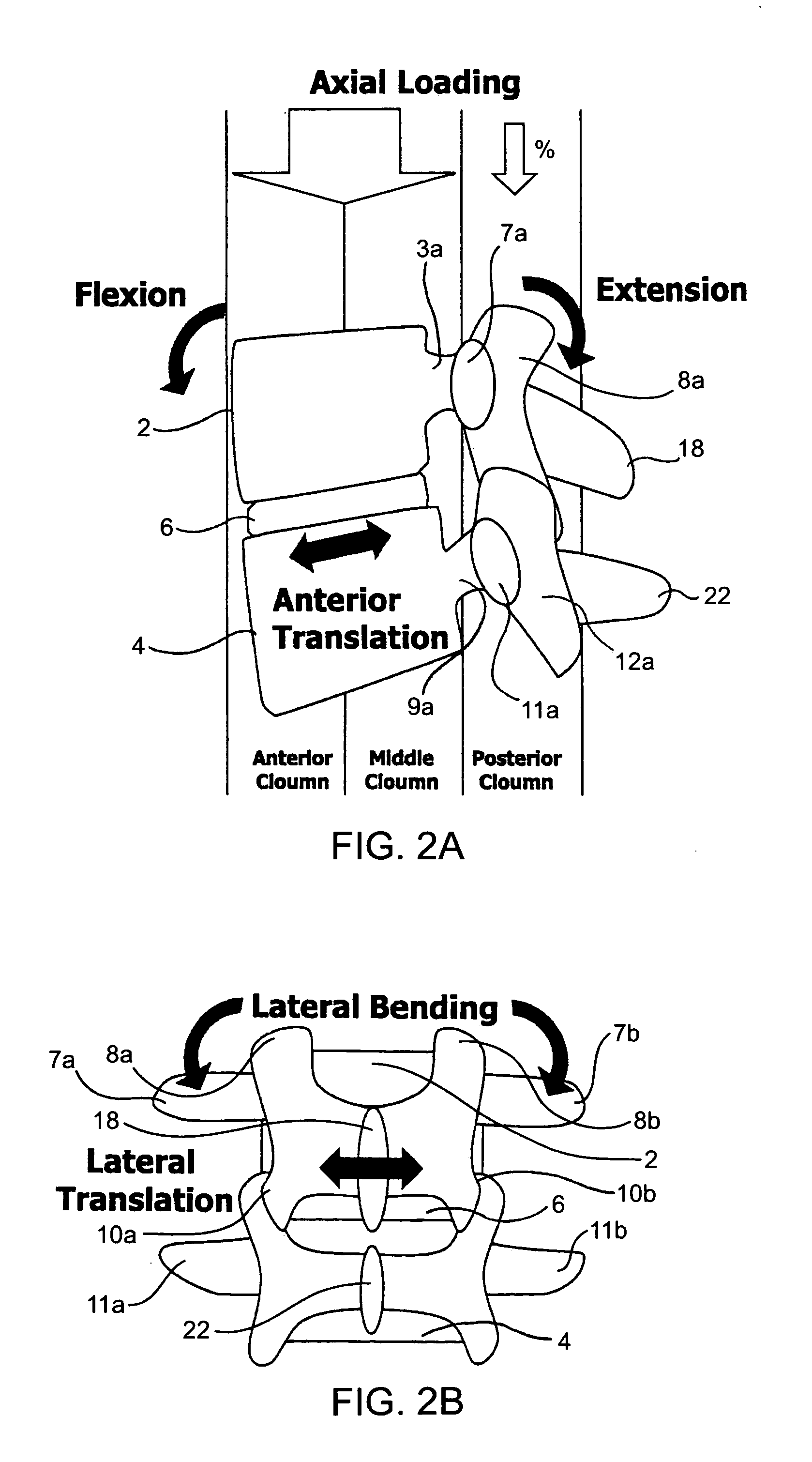

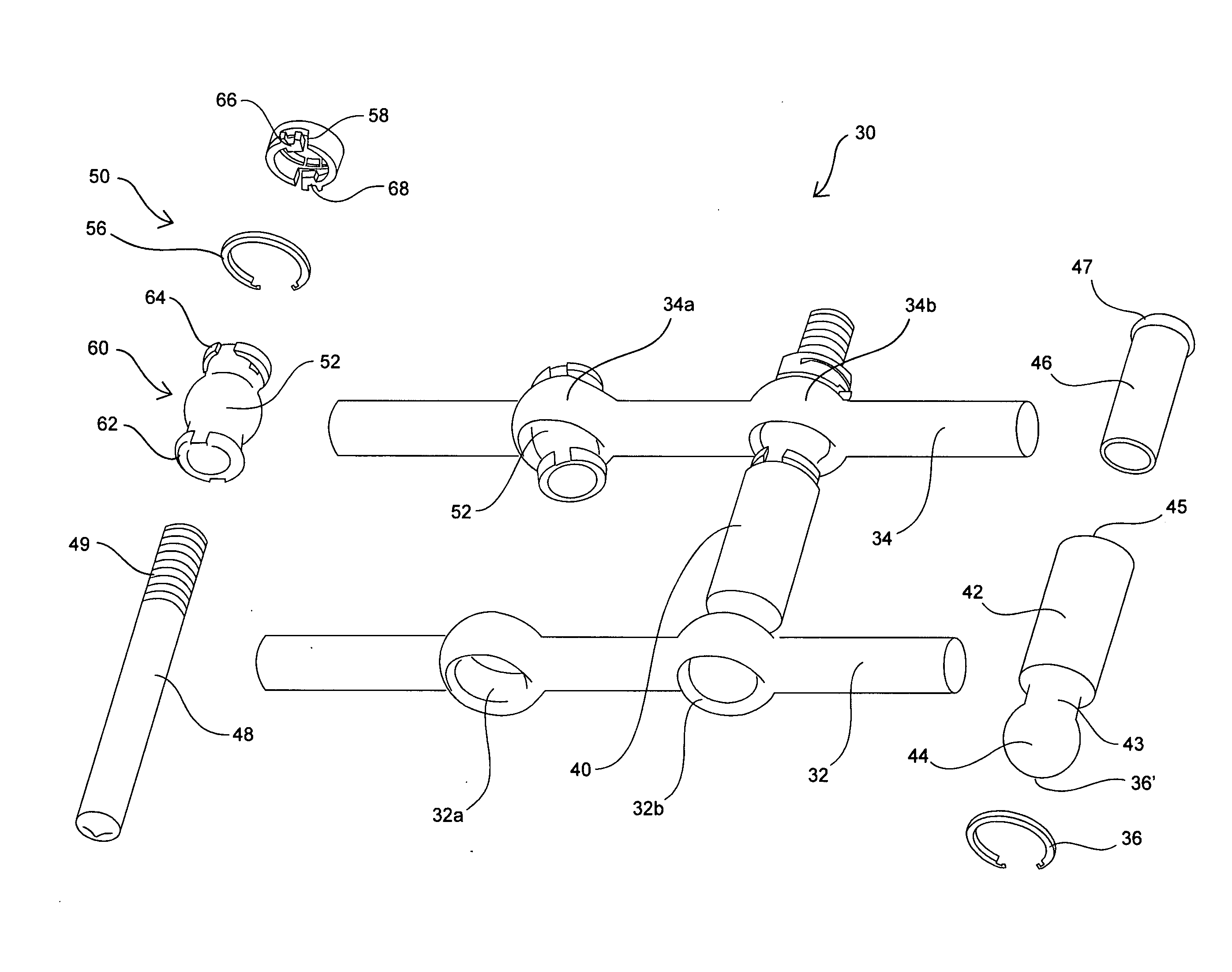

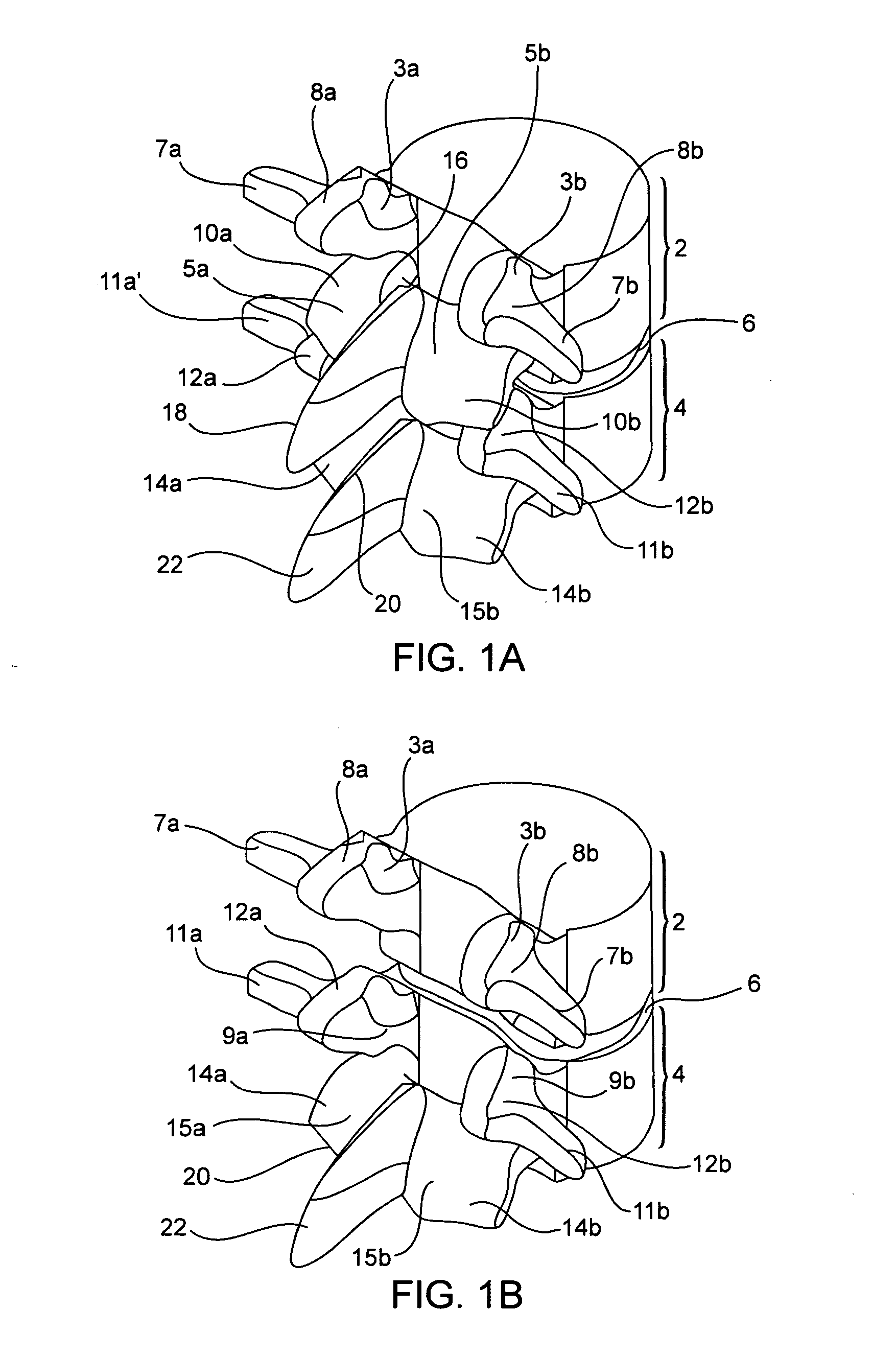

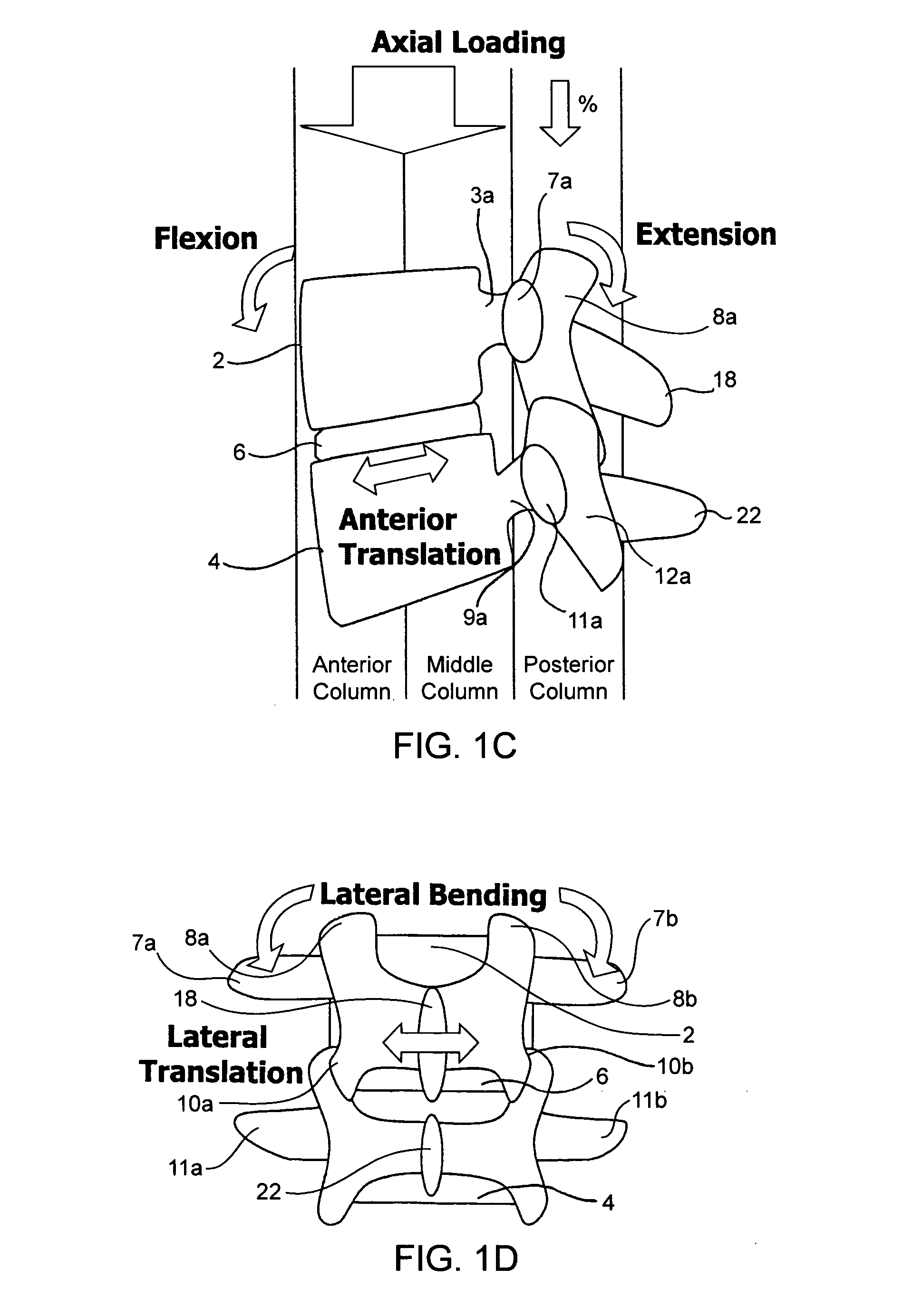

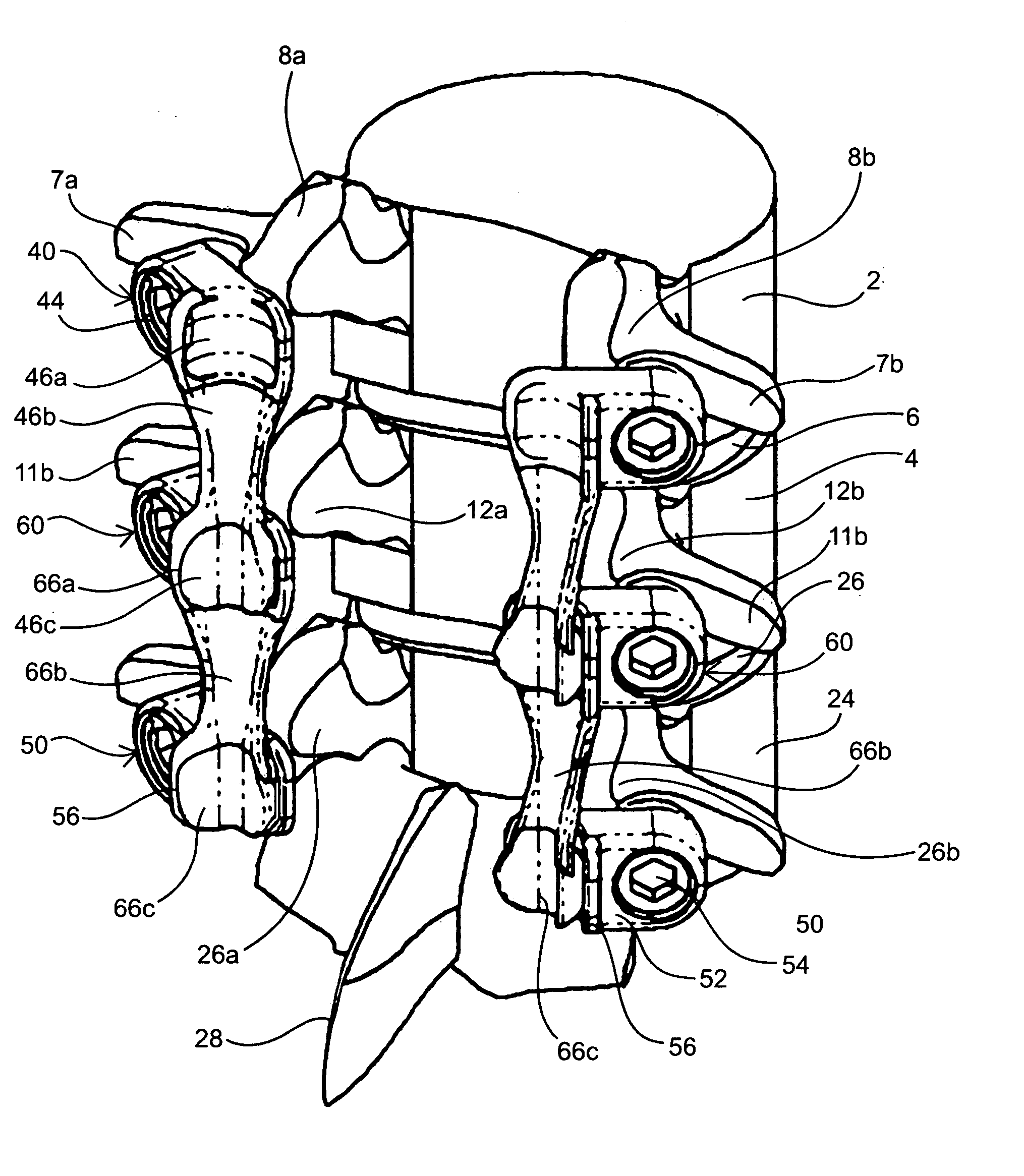

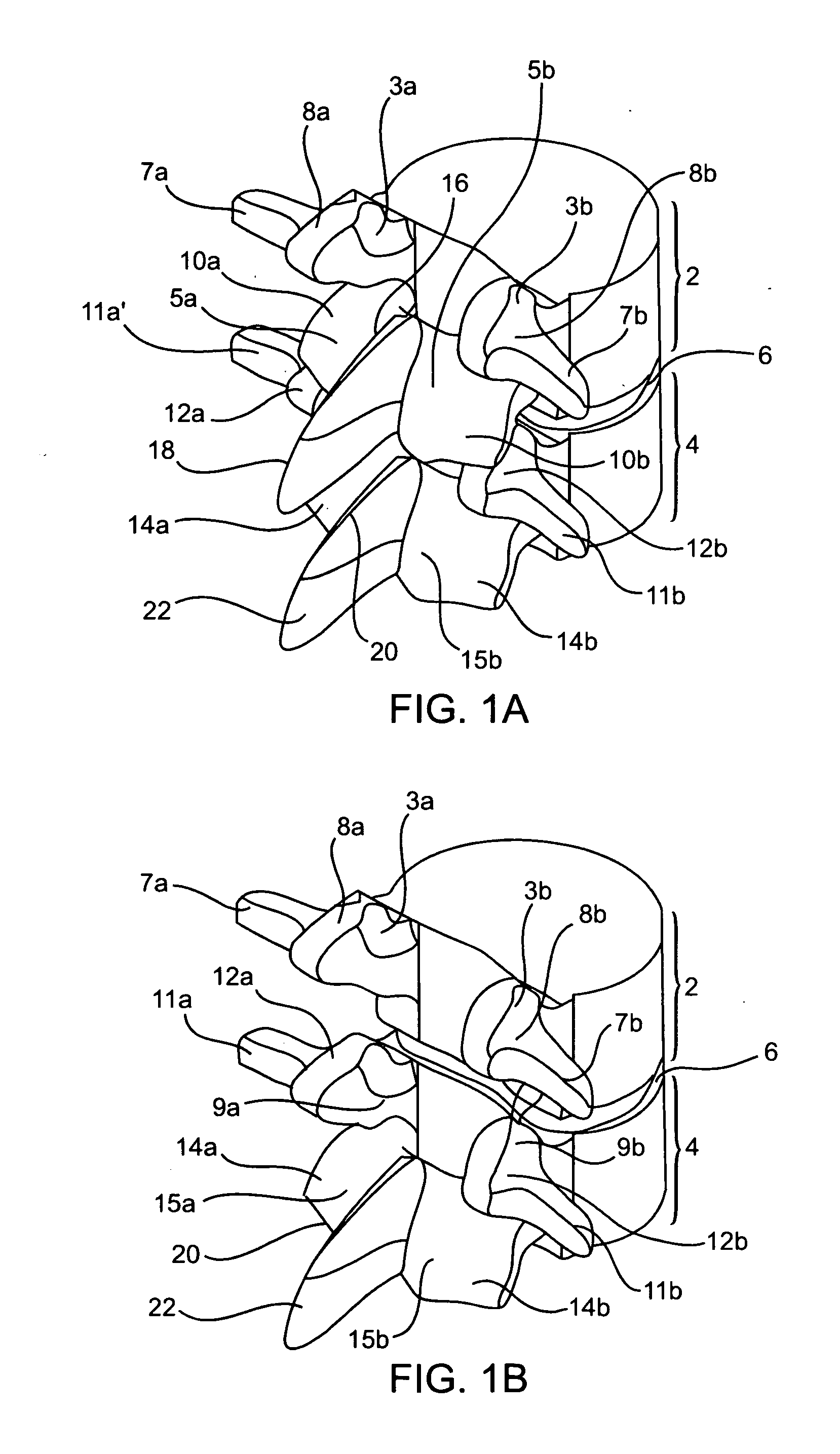

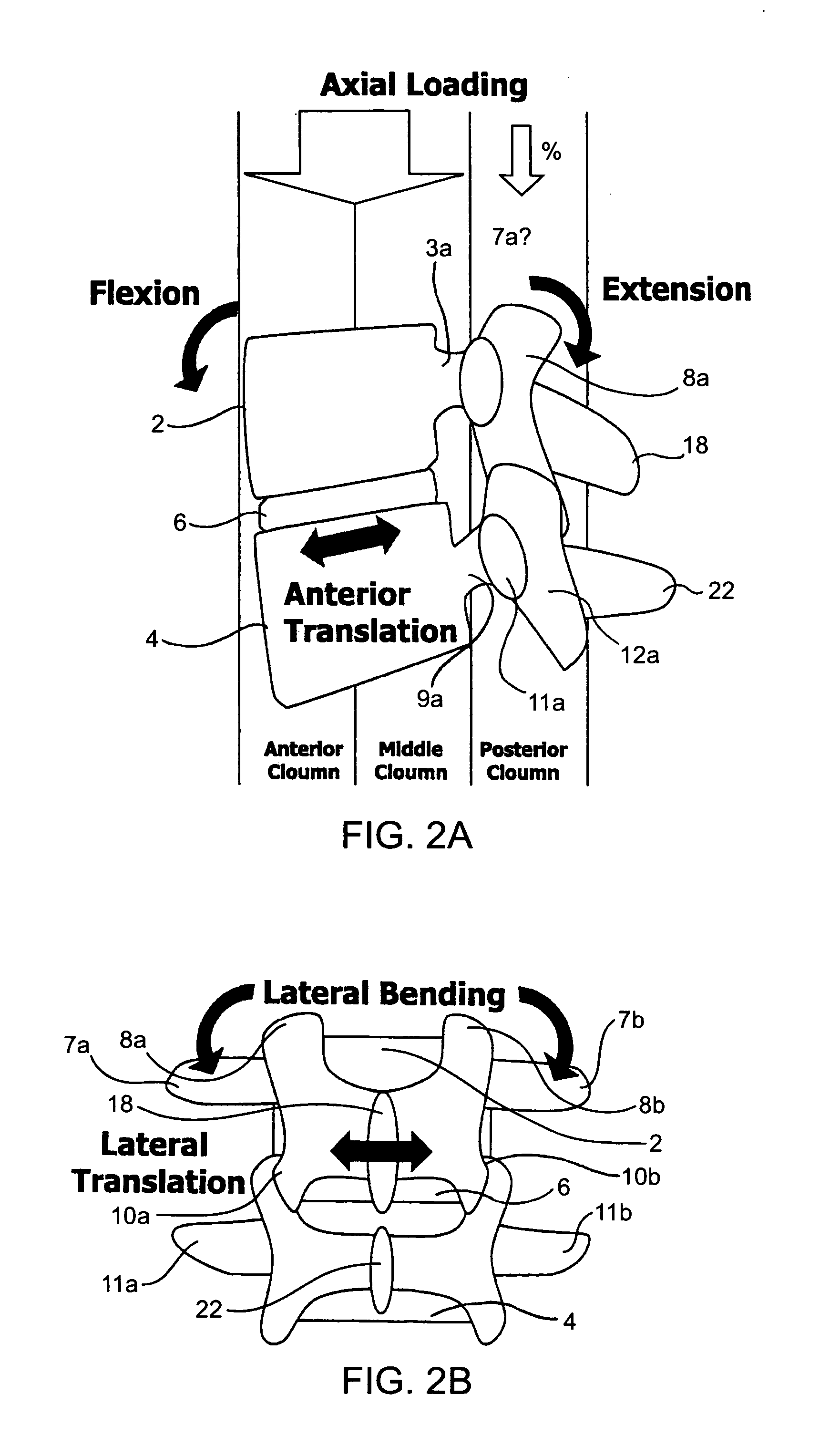

Systems and methods for posterior dynamic stabilization of the spine

ActiveUS20060084987A1Adjustable lengthShape adjustableInternal osteosythesisJoint implantsInterconnectionSpinal locomotion

Systems and devices for dynamically stabilizing the spine are provided. The systems include a superior component for attachment to a superior vertebra of a spinal motion segment and an inferior component for attachment to an inferior vertebral of a spinal motion segment. The interconnection between the two components enables the spinal motion segment to move in a manner that mimics the natural motion of the spinal motion segment. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

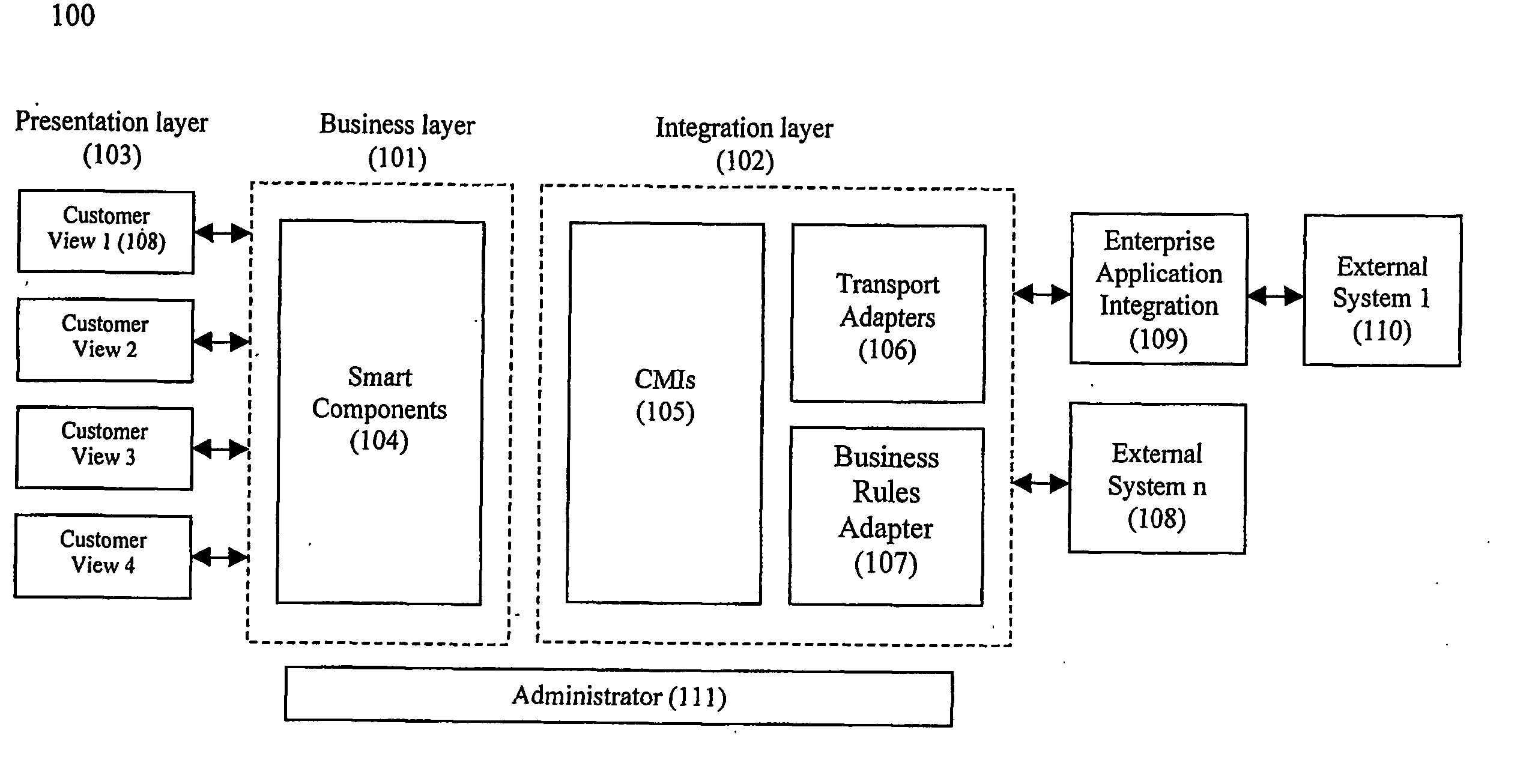

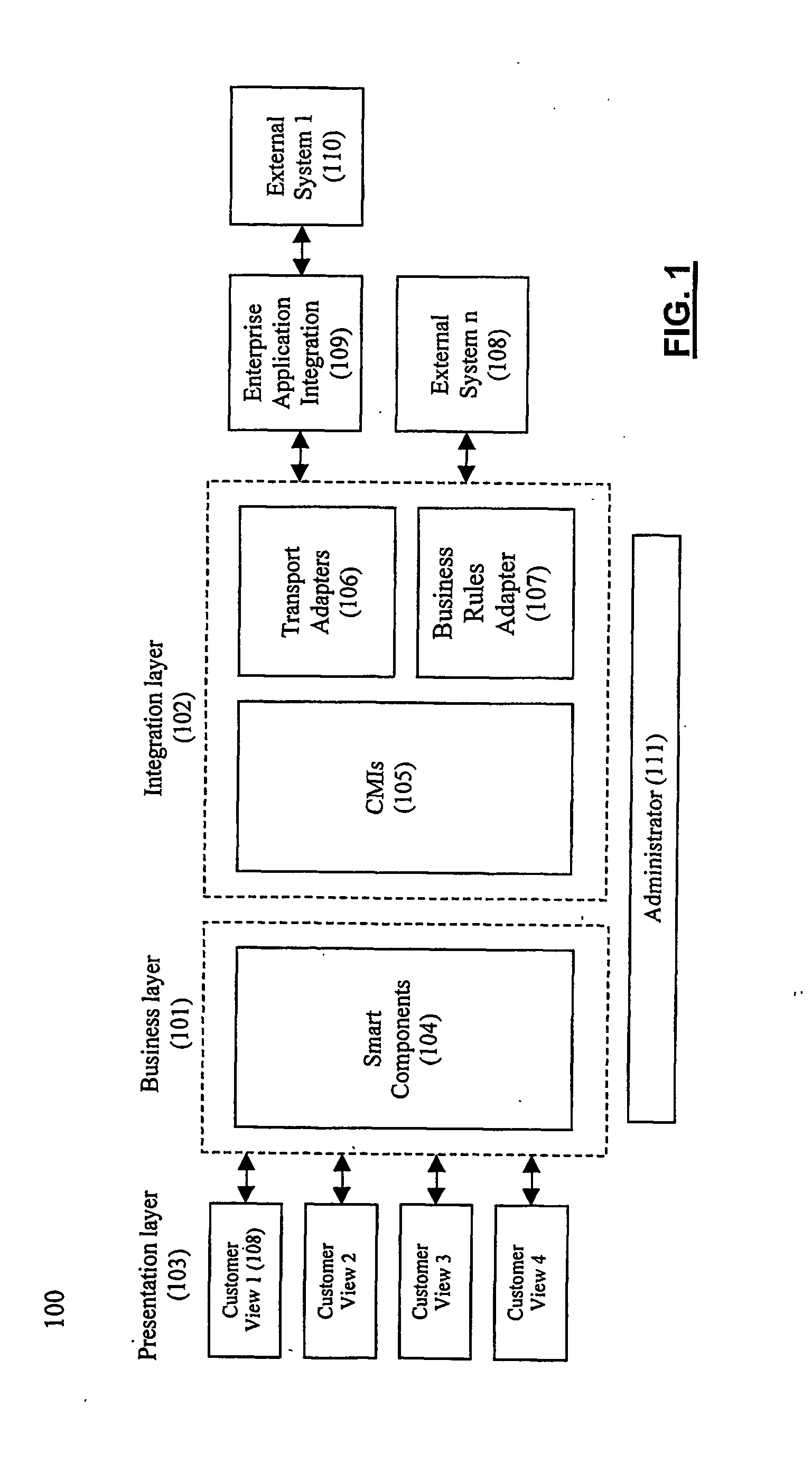

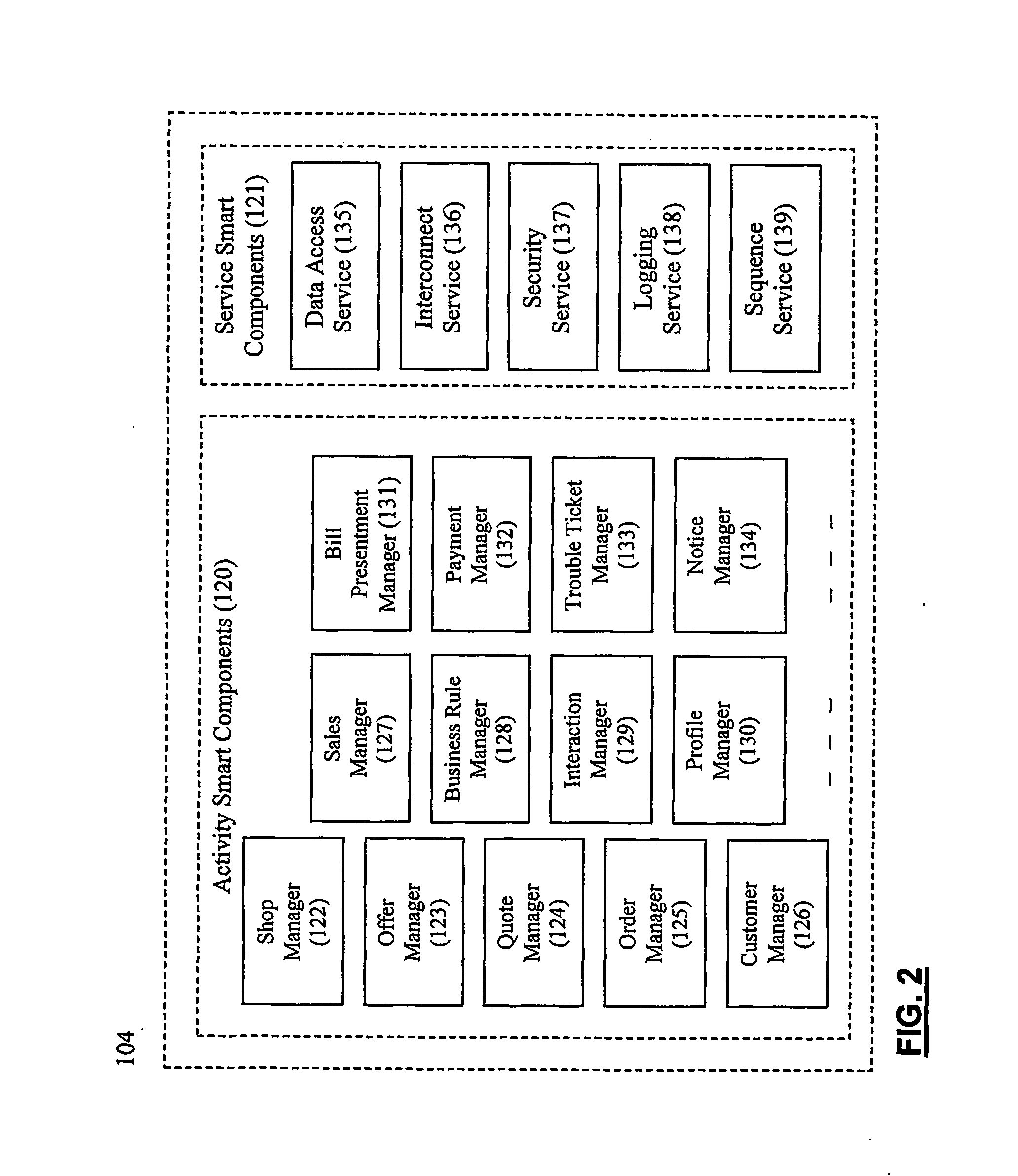

System and method for establishing eletronic business systems for supporting communications servuces commerce

ActiveUS20060059107A1Easy to addEasy to liftPayment protocolsBilling/invoicingEnterprise application integrationSupporting system

Owner:NETCRACKER TECH SOLUTIONS

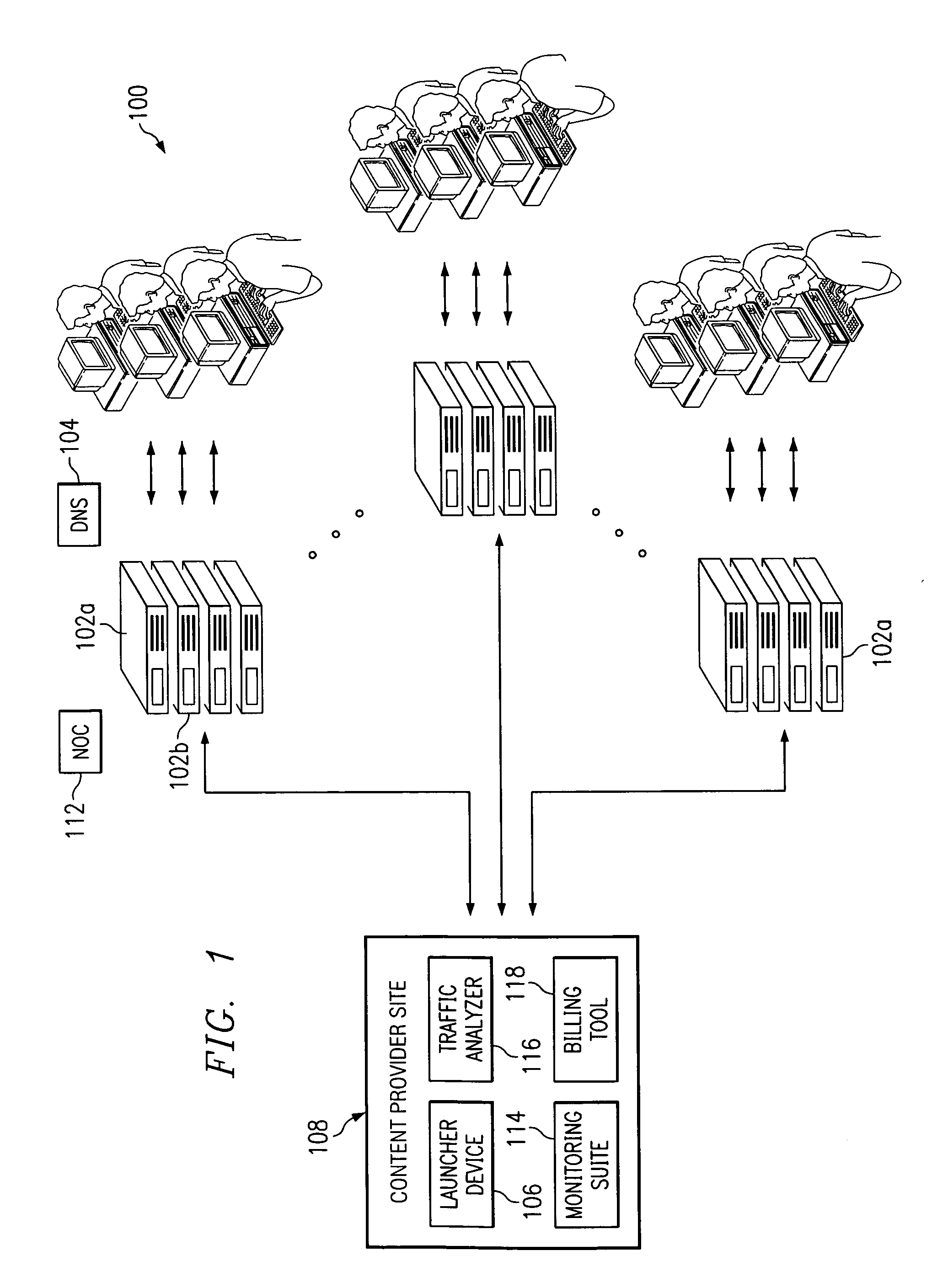

Internet content delivery service with third party cache interface support

InactiveUS7010578B1Increase reachImprove performanceDigital data information retrievalMultiple digital computer combinationsThird partyOff the shelf

Third party cache appliances are configured into a content delivery service to enable such devices to cache and serve content that has been tagged for delivery by the service. The invention enables the content delivery service to extend the reach of its network while taking advantage of high performance, off-the-shelf cache appliances. If the third party caches comprise part of a third party content delivery network, the interconnection of caches to the CDS according to the present invention enables the CDS and the third party network to share responsibility for delivering the content. To facilitate such “content peering,” the CDS may also include a traffic analysis mechanism to provide the third party network with preferably real-time data identifying the content delivered by the CDS from the third party caches. The CDS may also include a logging mechanism to generate appropriate billing and reporting of the third party content that is delivered from the cache appliances that have been joined into the CDS.

Owner:AKAMAI TECH INC

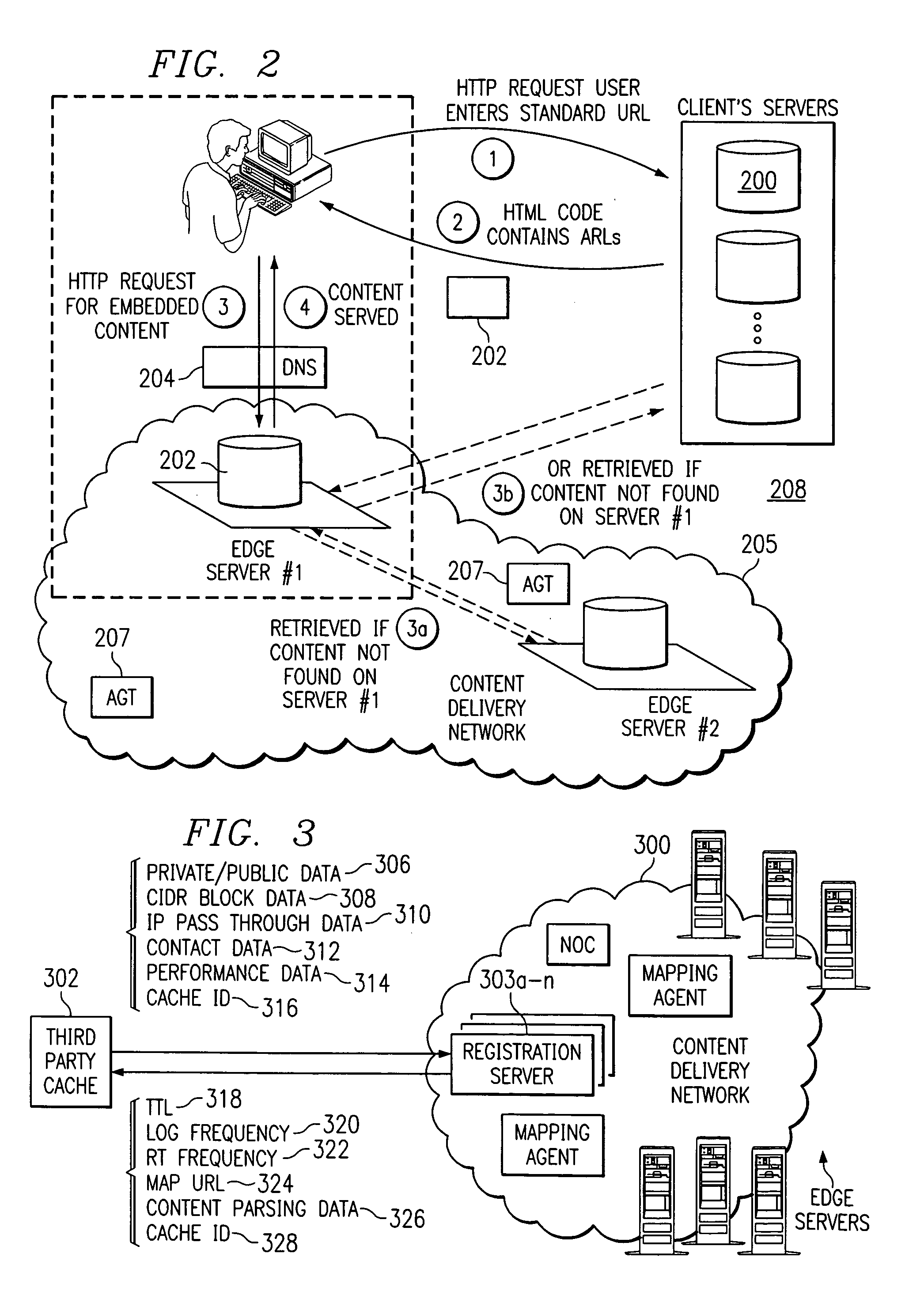

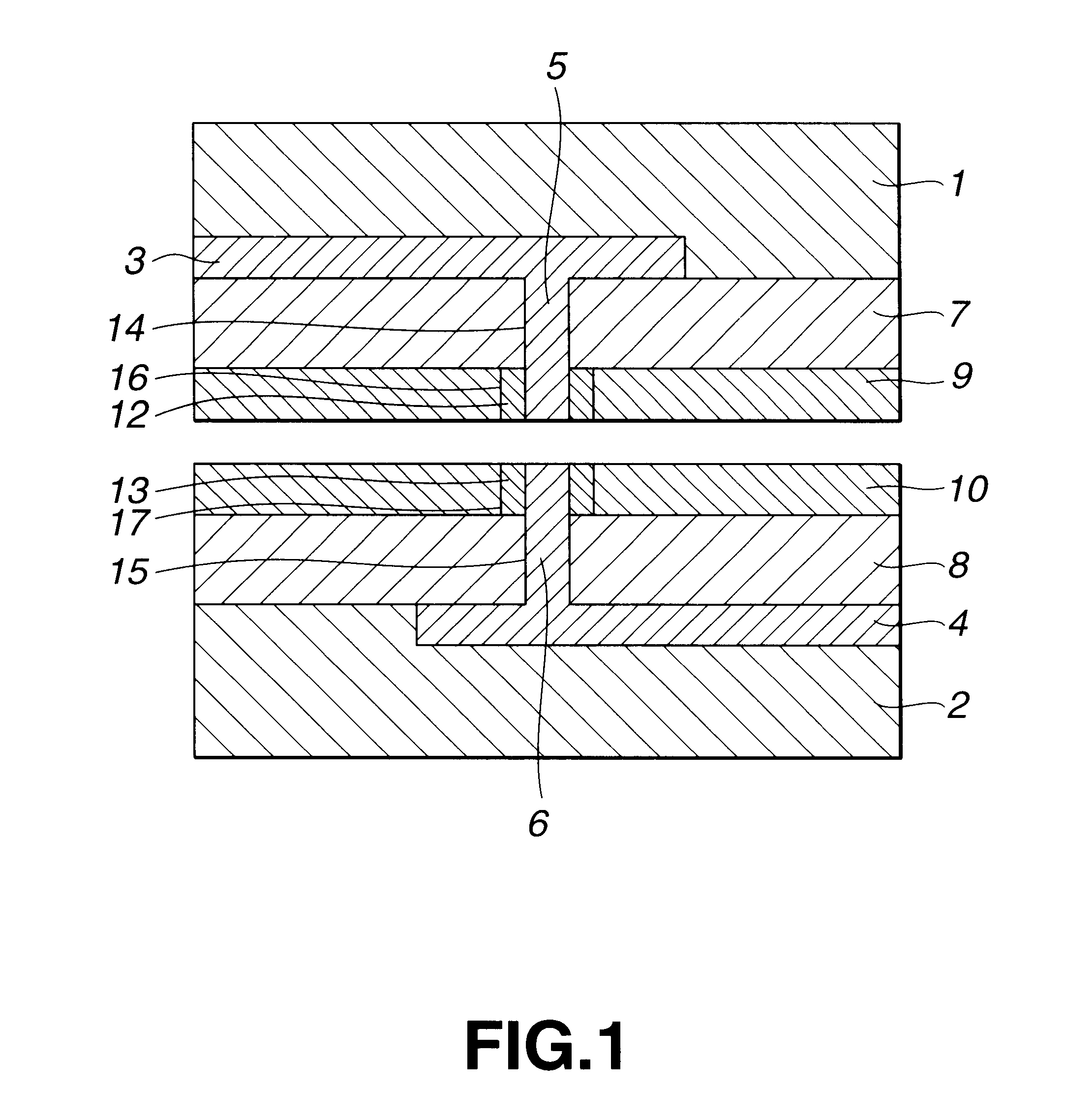

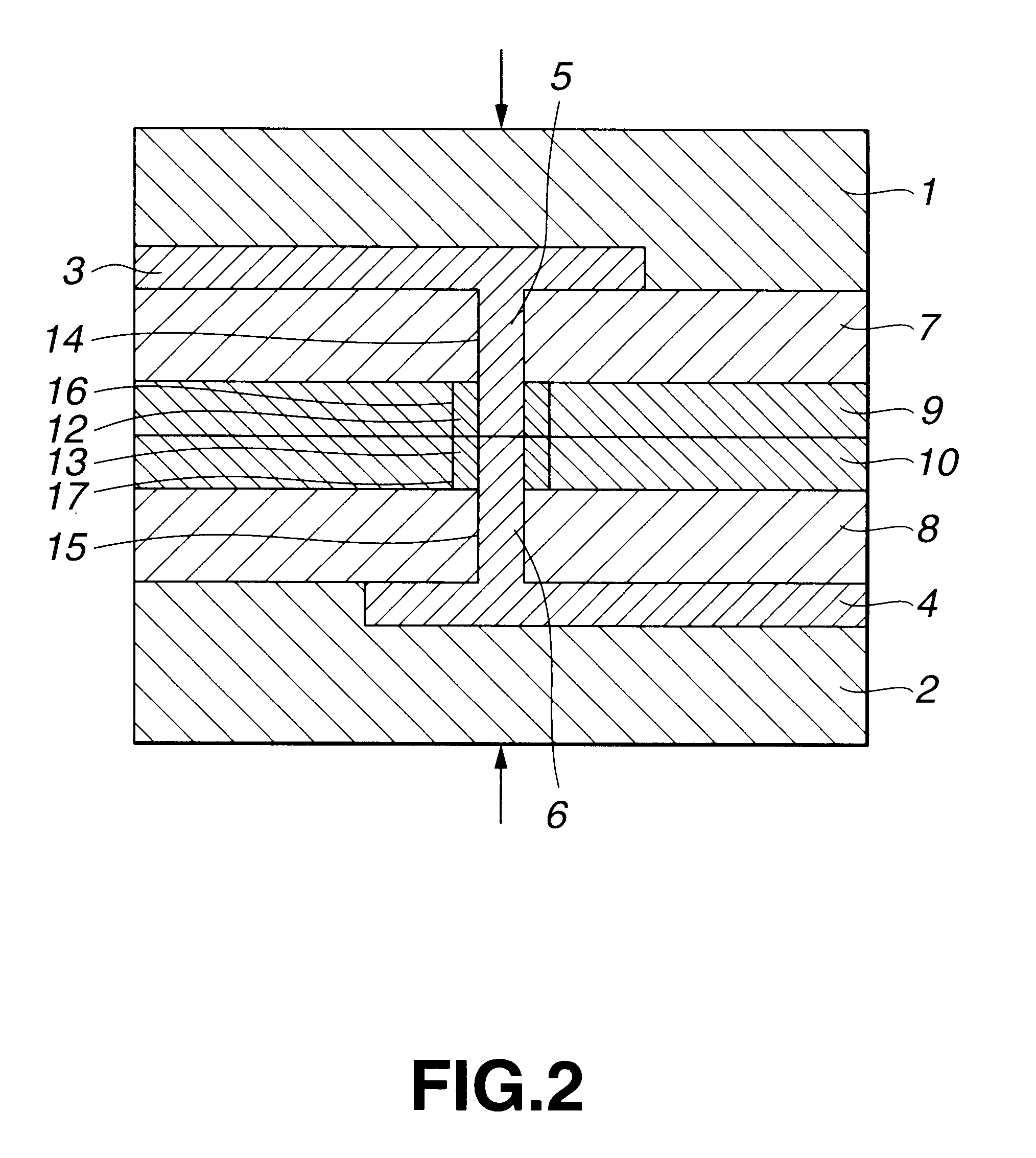

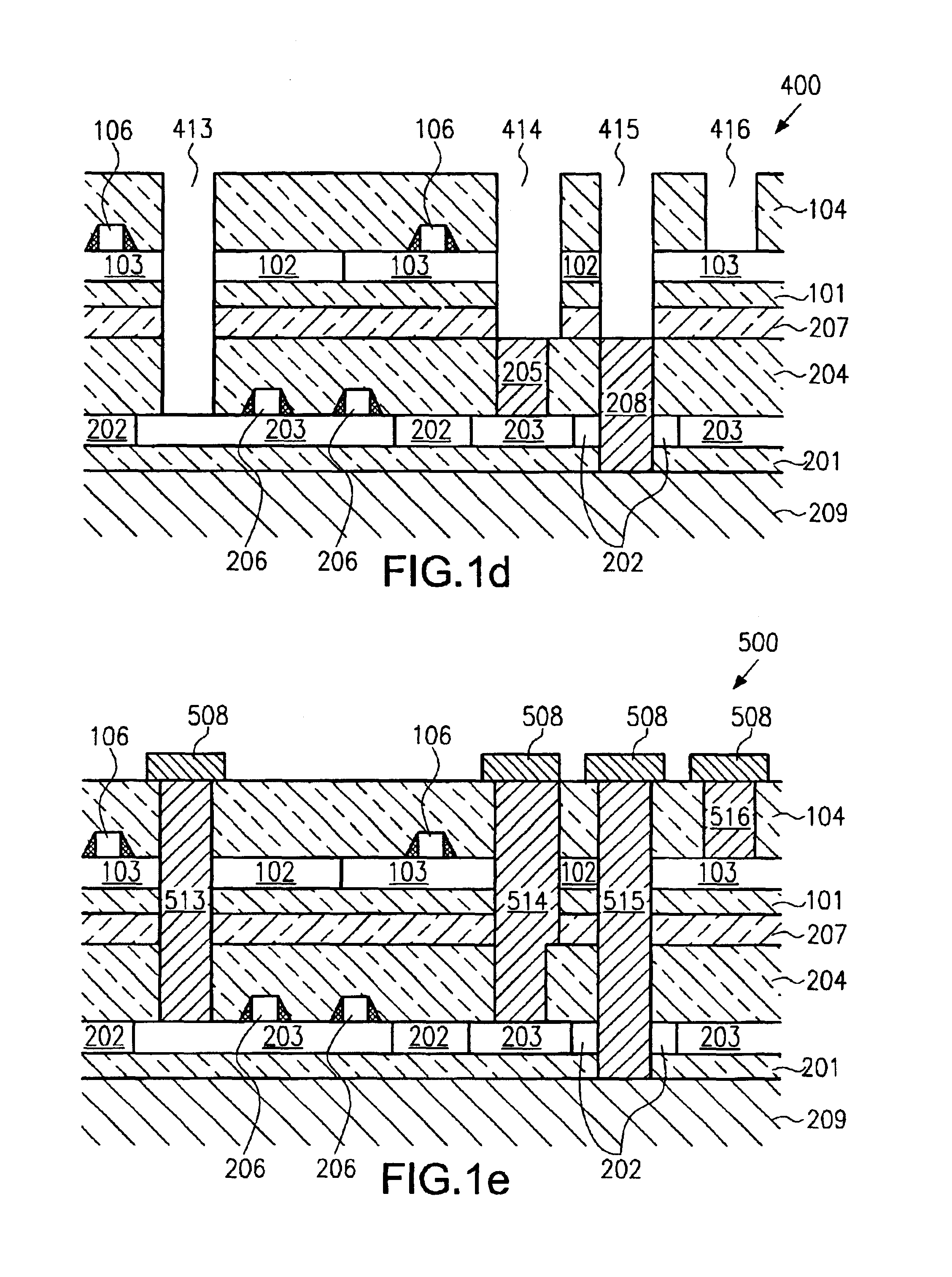

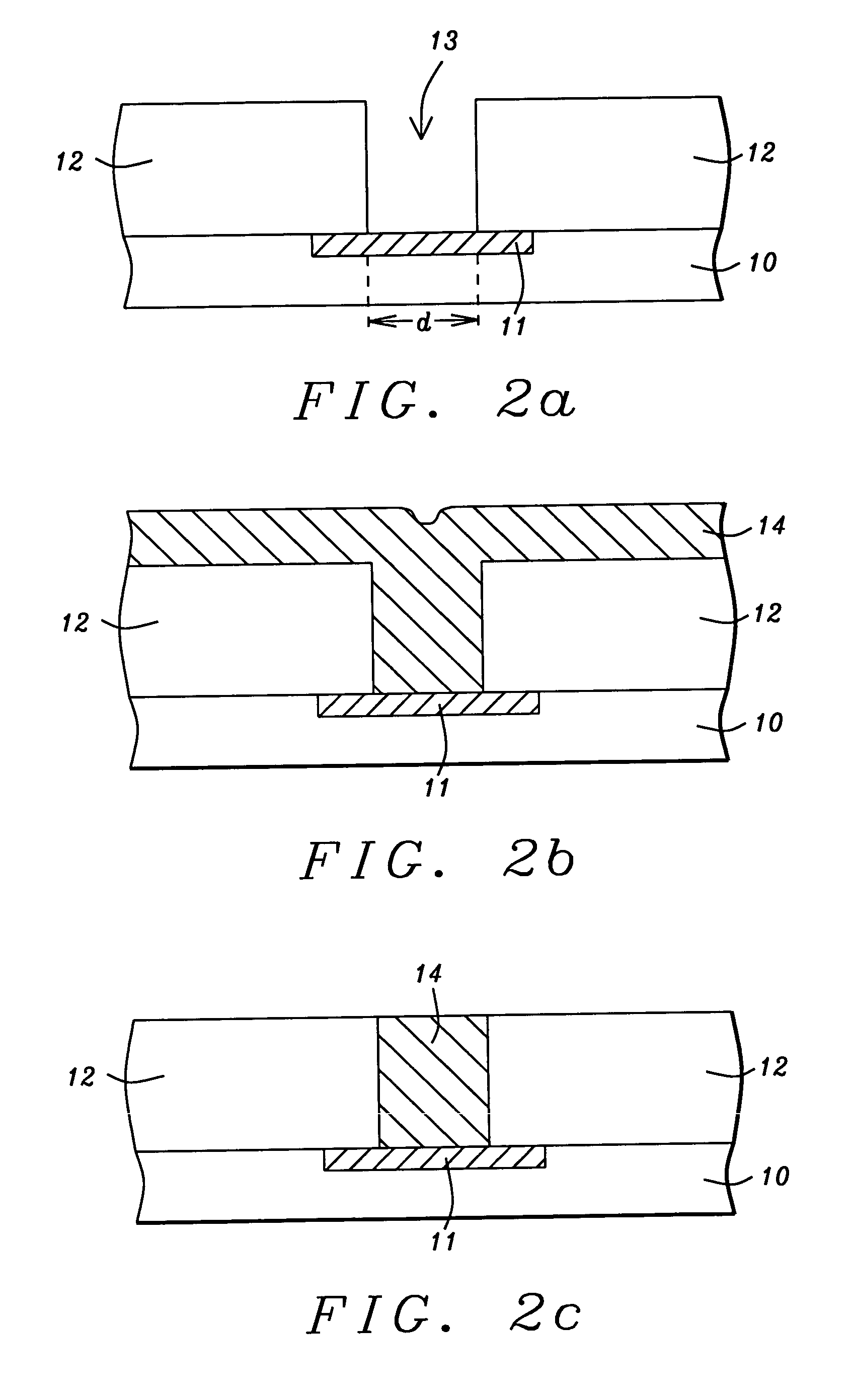

Interconnect structure for stacked semiconductor device

InactiveUS6465892B1Shorten the line lengthEasy to produceSemiconductor/solid-state device detailsSolid-state devicesDevice materialInterconnection

In a multi-layer interconnection structure, the wiring length is to be reduced, and the interconnection is to be straightened, at the same time as measures need to be taken against radiation noise. To this end, there is disclosed a semiconductor device in which plural semiconductor substrates, each carrying semiconductor elements, are bonded together. On each semiconductor substrate is deposited an insulating layer through which is formed a connection wiring passed through the insulating layer so as to be connected to the interconnection layer of the semiconductor element. On a junction surface of at least one of the semiconductor substrates is formed an electrically conductive layer of an electrically conductive material in which an opening is bored in association with the connection wiring. The semiconductor substrates are bonded together by the solid state bonding technique to interconnect the connection wirings formed on each semiconductor substrate.

Owner:LAPIS SEMICON CO LTD +9

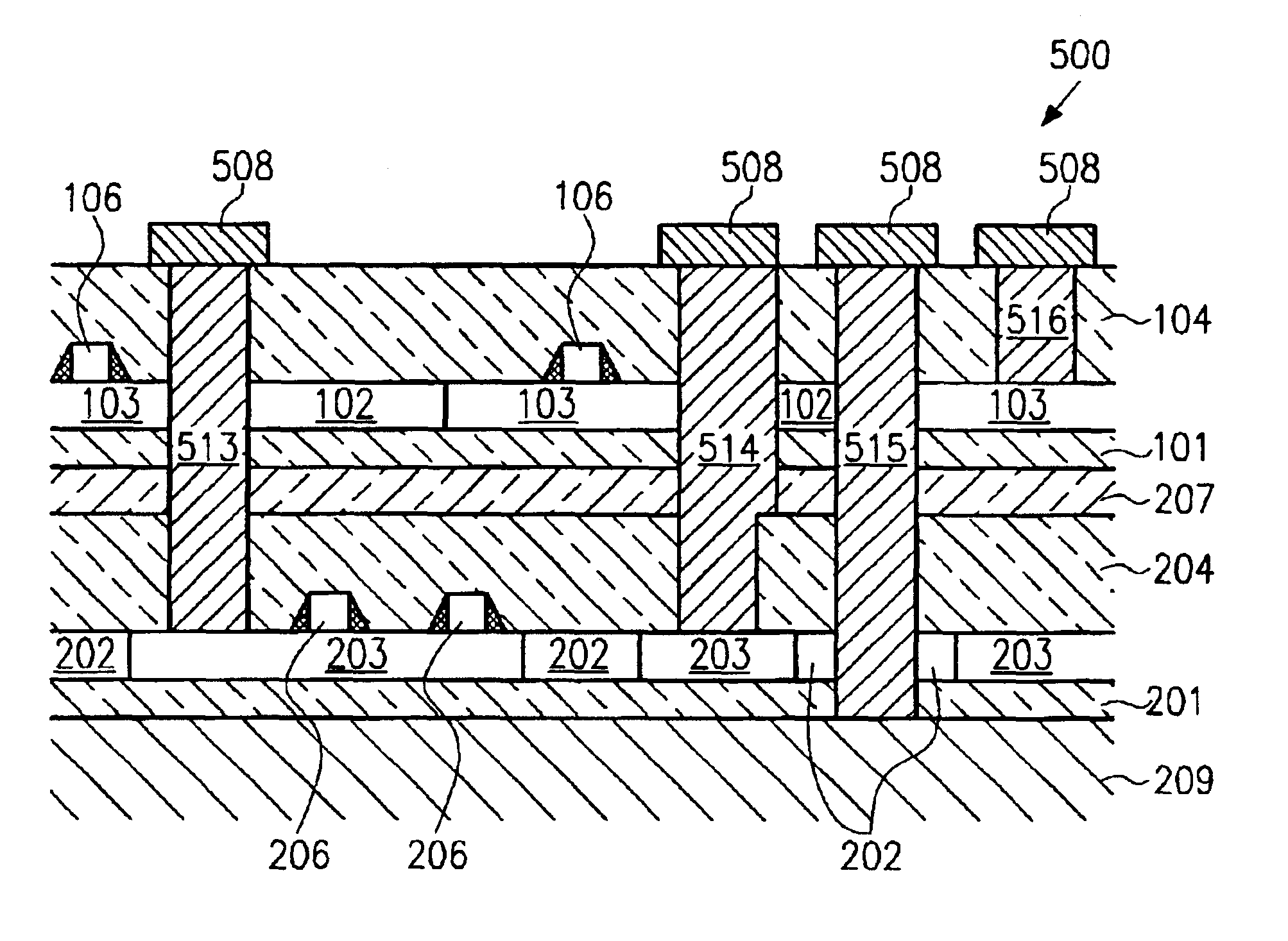

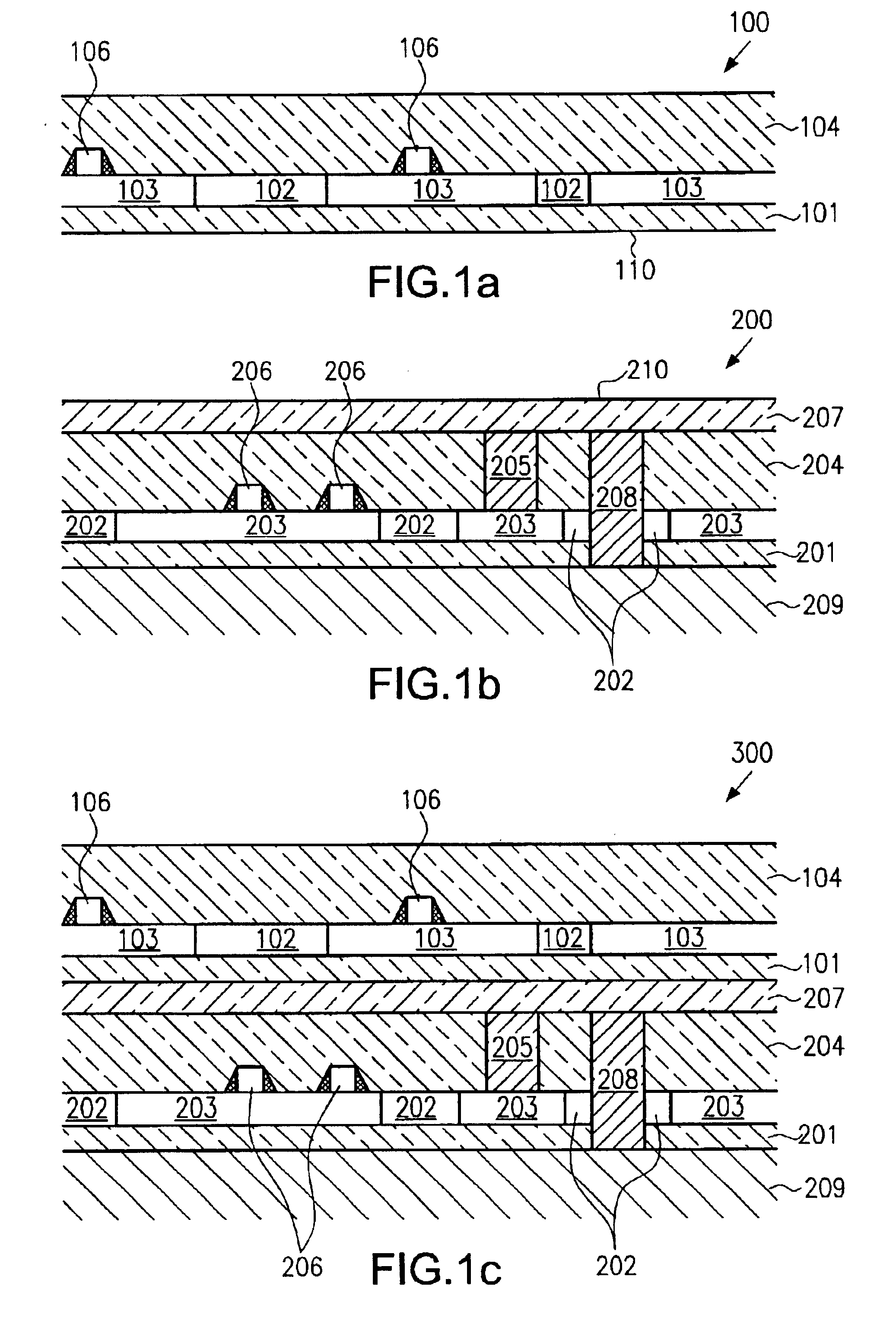

Three-dimensional integrated semiconductor devices

InactiveUS6943067B2Semiconductor/solid-state device detailsSolid-state devicesBonding processEngineering

The present invention describes a process for three-dimensional integration of semiconductor devices and a resulting device. The process combines low temperature wafer bonding methods with backside / substrate contact processing methods, preferably with silicon on insulator devices. The present invention utilizes, in an inventive fashion, low temperature bonding processes used for bonded silicon on insulator (SOI) wafer technology. This low temperature bonding technology is adopted for stacking several silicon layers on top of each other and building active transistors and other circuit elements in each one. The back-side / substrate contact processing methods allow the interconnection of the bonded SOI layers.

Owner:ADVANCED MICRO DEVICES INC

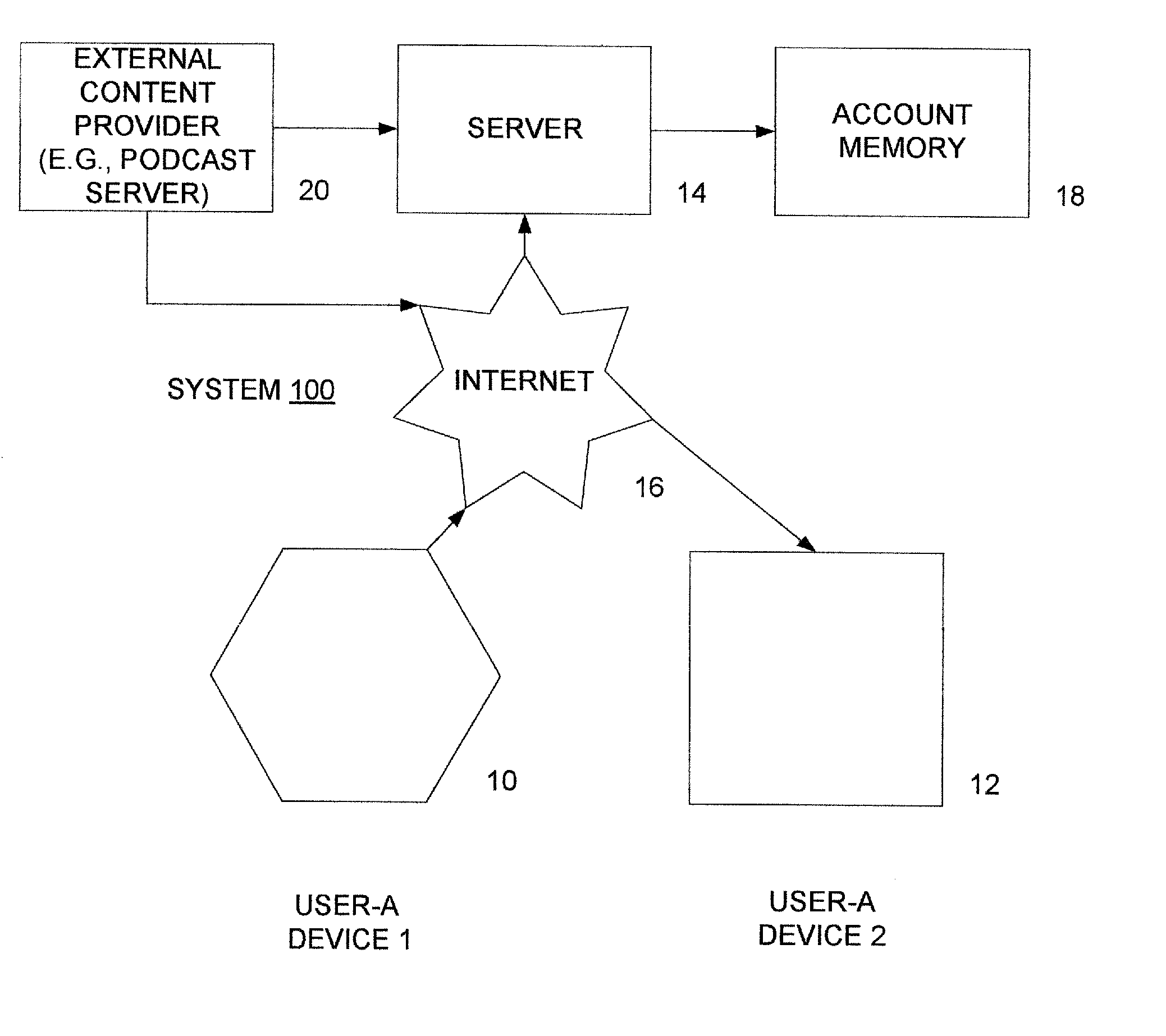

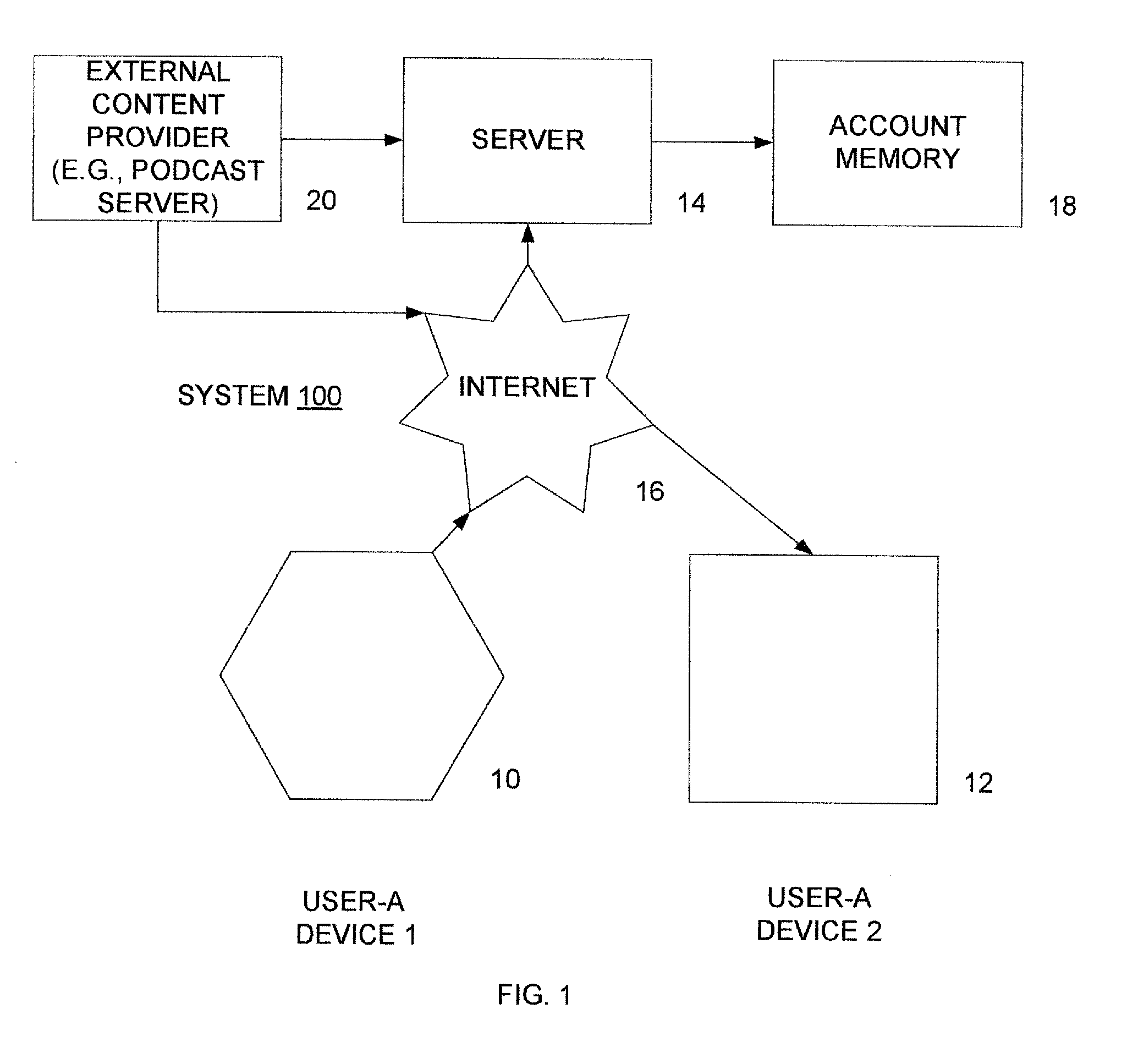

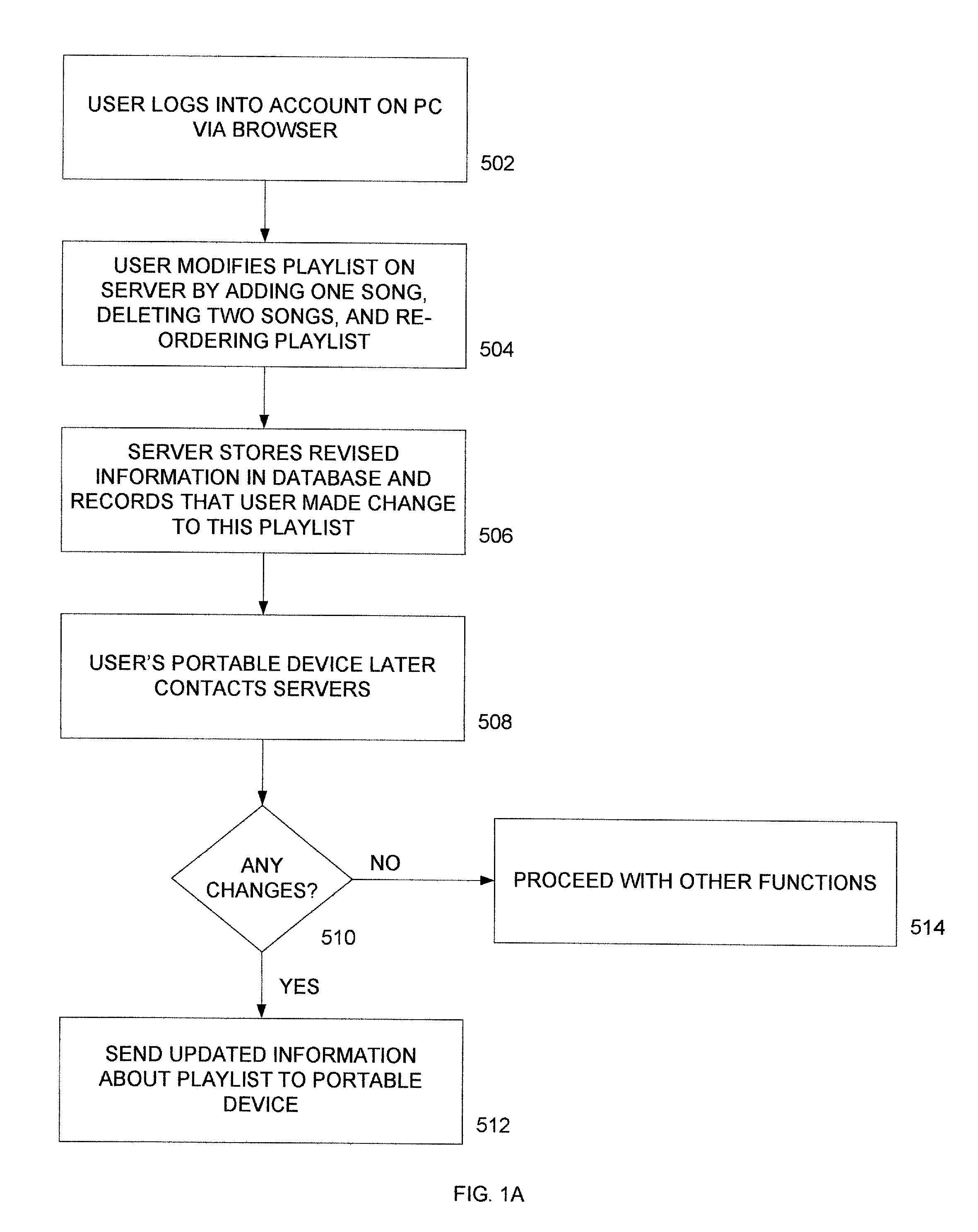

Audio visual player apparatus and system and method of content distribution using the same

InactiveUS20080010372A1None of methods is secureDigital data information retrievalElectronic editing digitised analogue information signalsWi-FiContent distribution

A system is presented providing content to a plurality of handheld devices (including musical selections). The devices can access a server over the Internet via a Wi-Fi or other similar wireless interconnection and can download songs requested by a user from the server or from other users using, e.g., a P2P protocol. All downloads may be governed by applicable DRM rules. Content and playlists may also be pushed by a server from other sources and means including, e.g., podcasting, based on predetermined rules, favorite preferences of users, and other criteria.

Owner:SANDISK TECH LLC

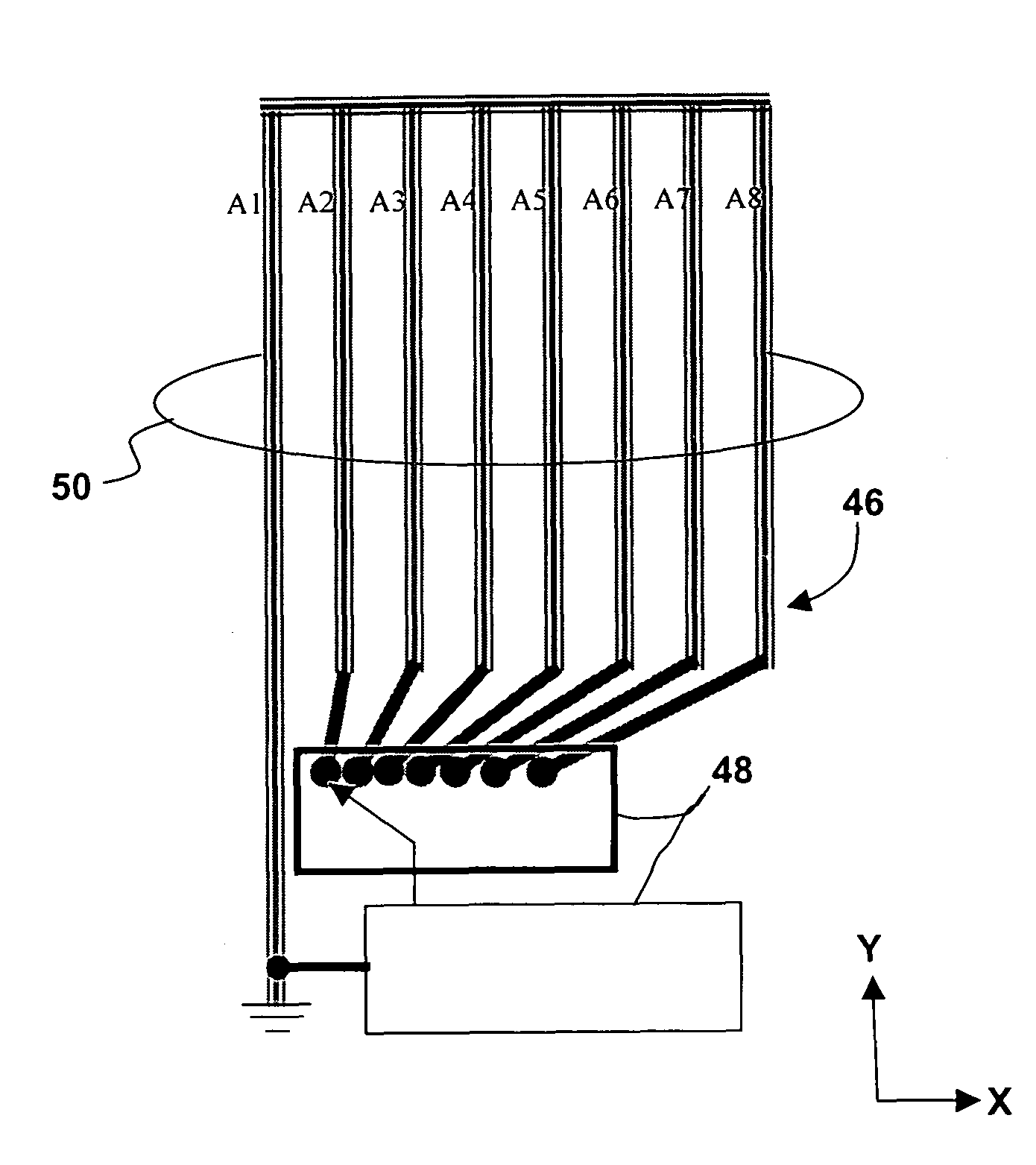

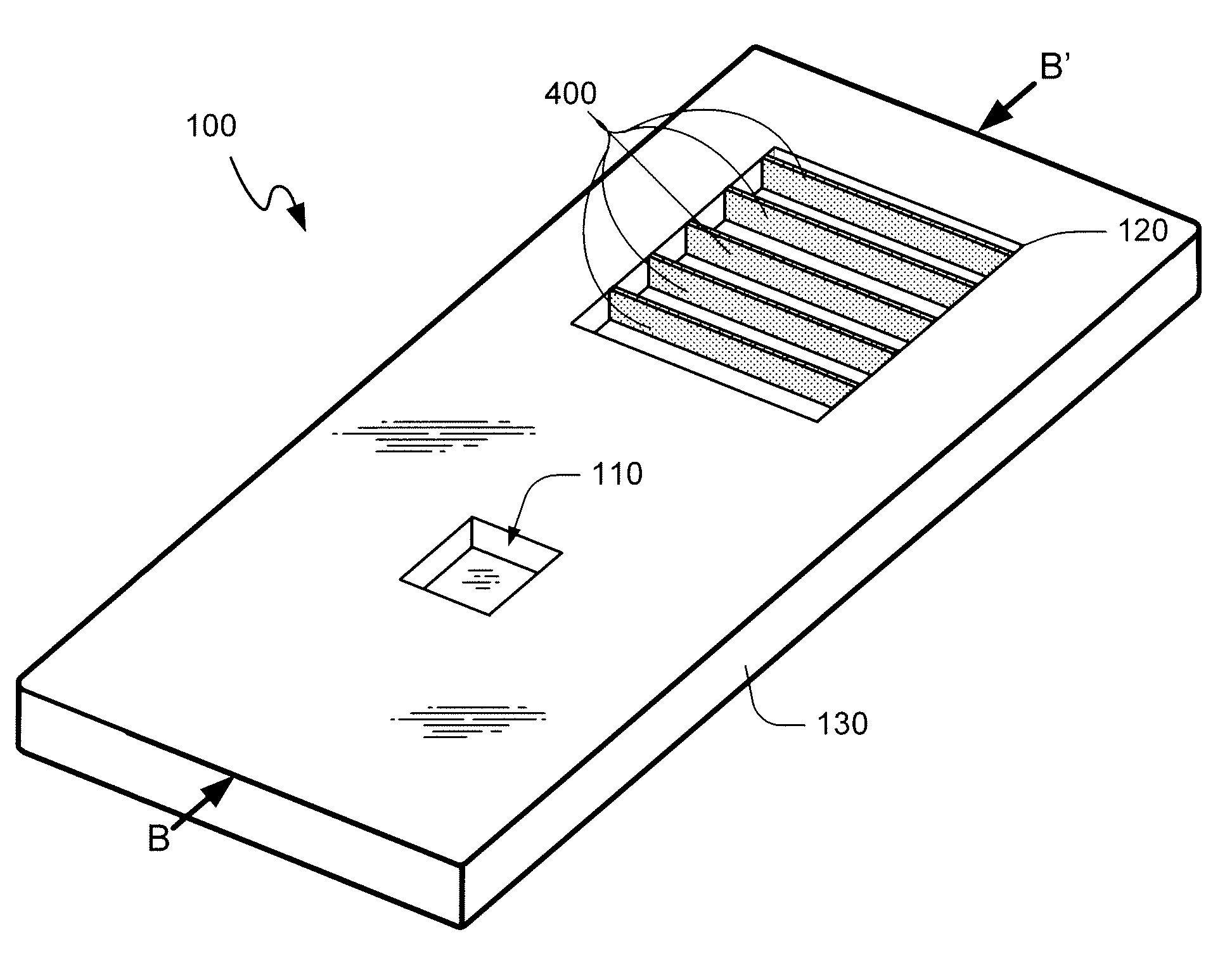

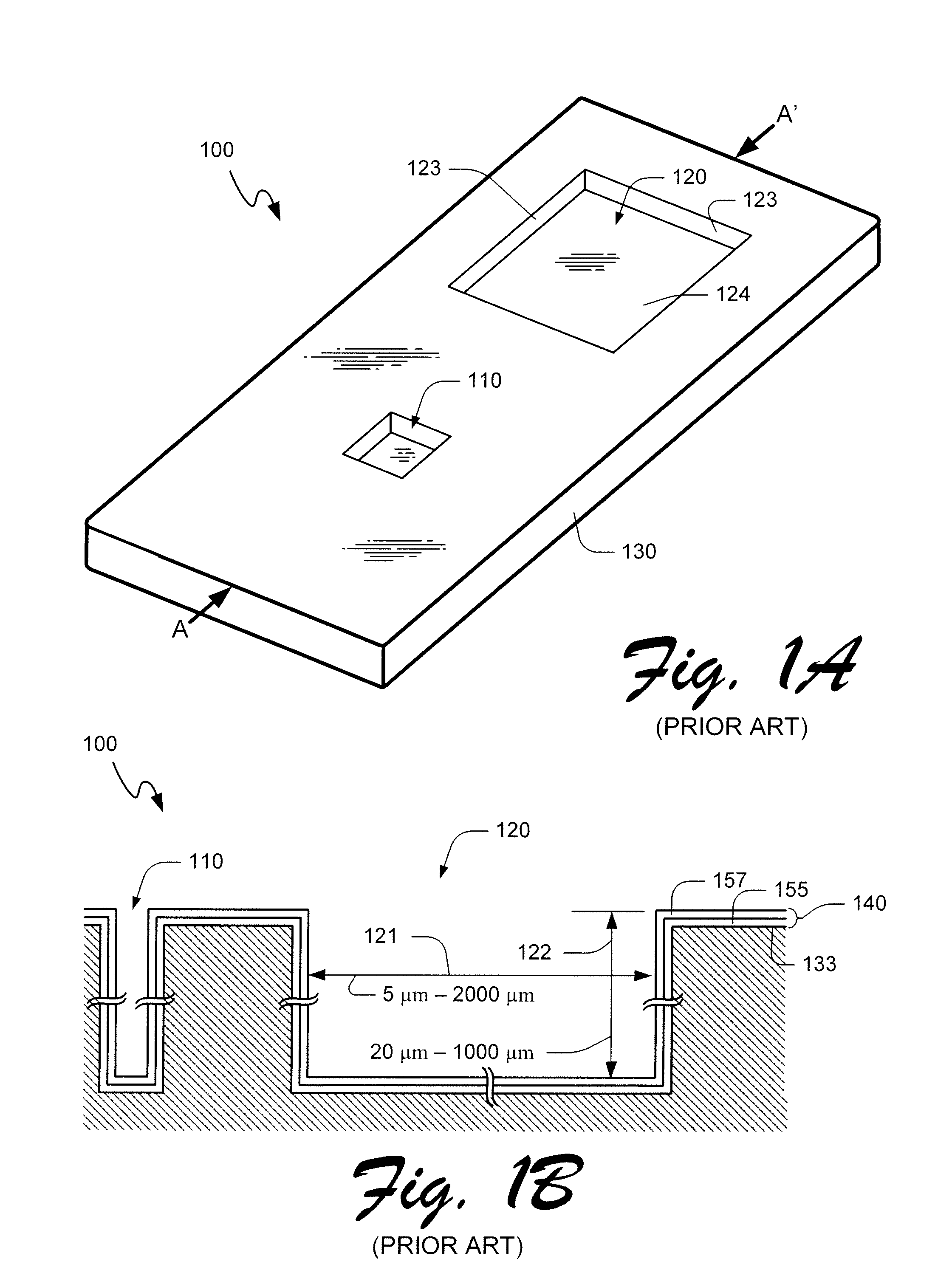

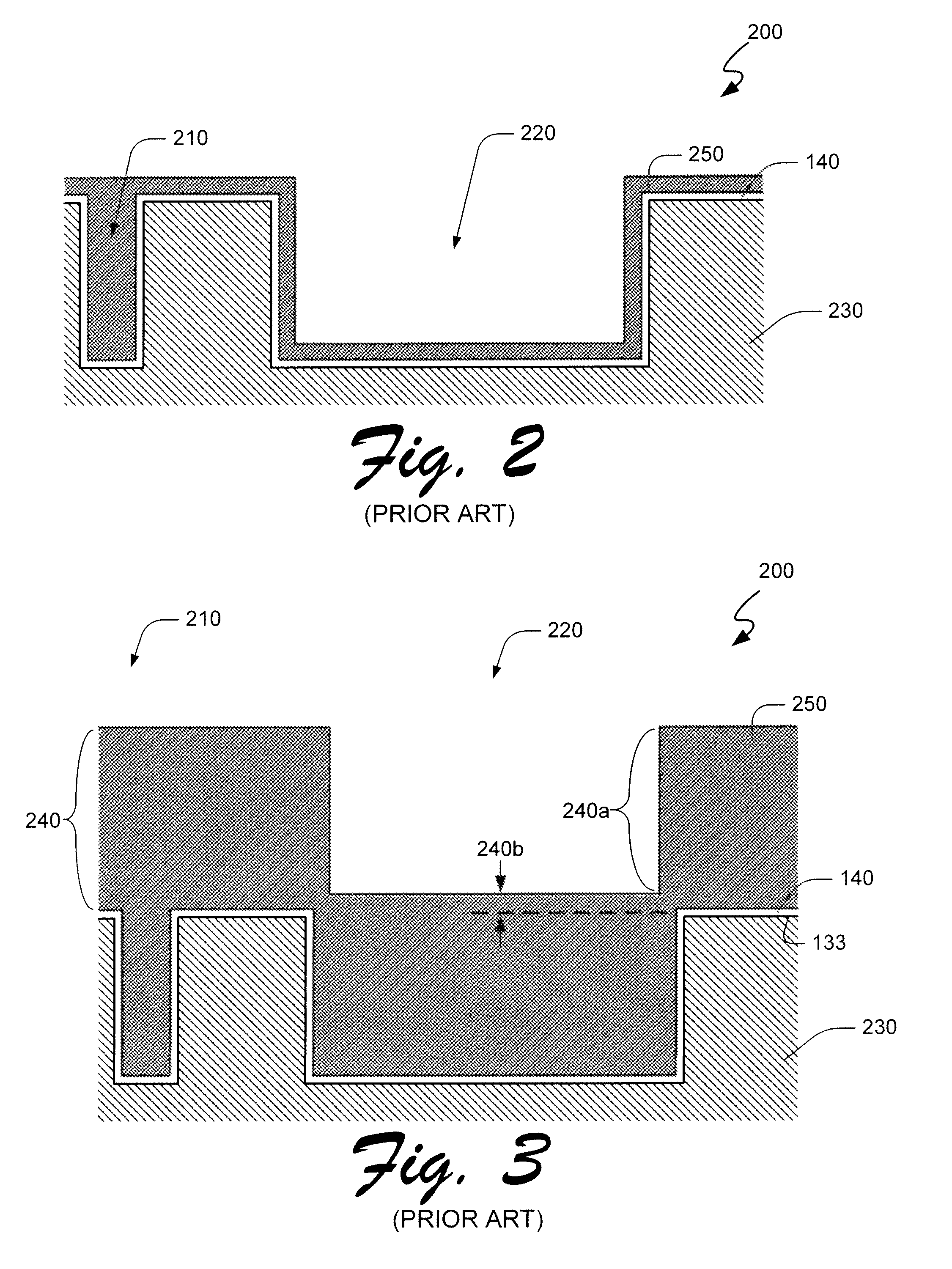

Electromagnetic digitizer sensor array structure

ActiveUS7875814B2Overcomes drawbackHigh sensitivityTransmission systemsGraph readingSensor arrayMiniaturization

Owner:INNOLUX CORP

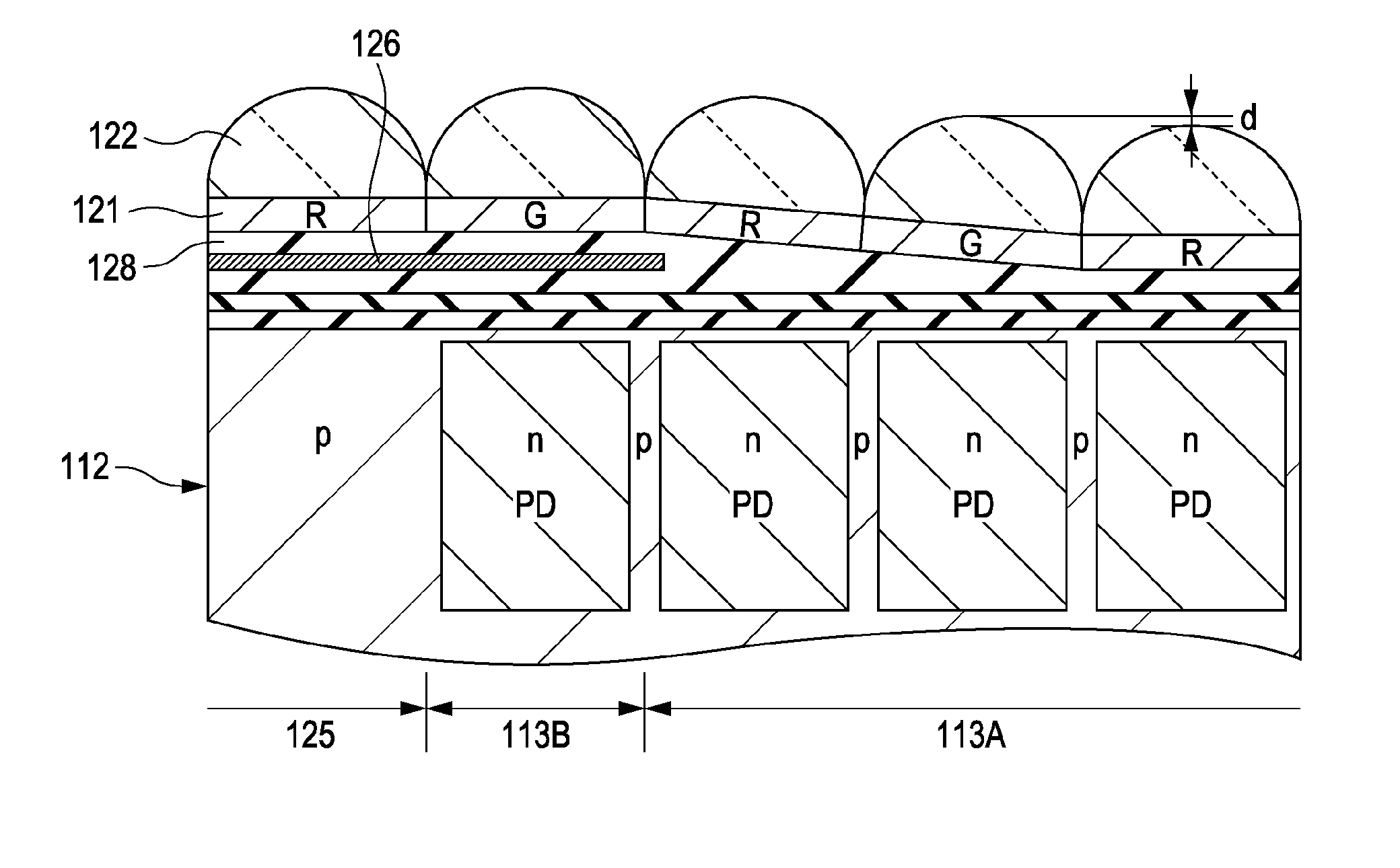

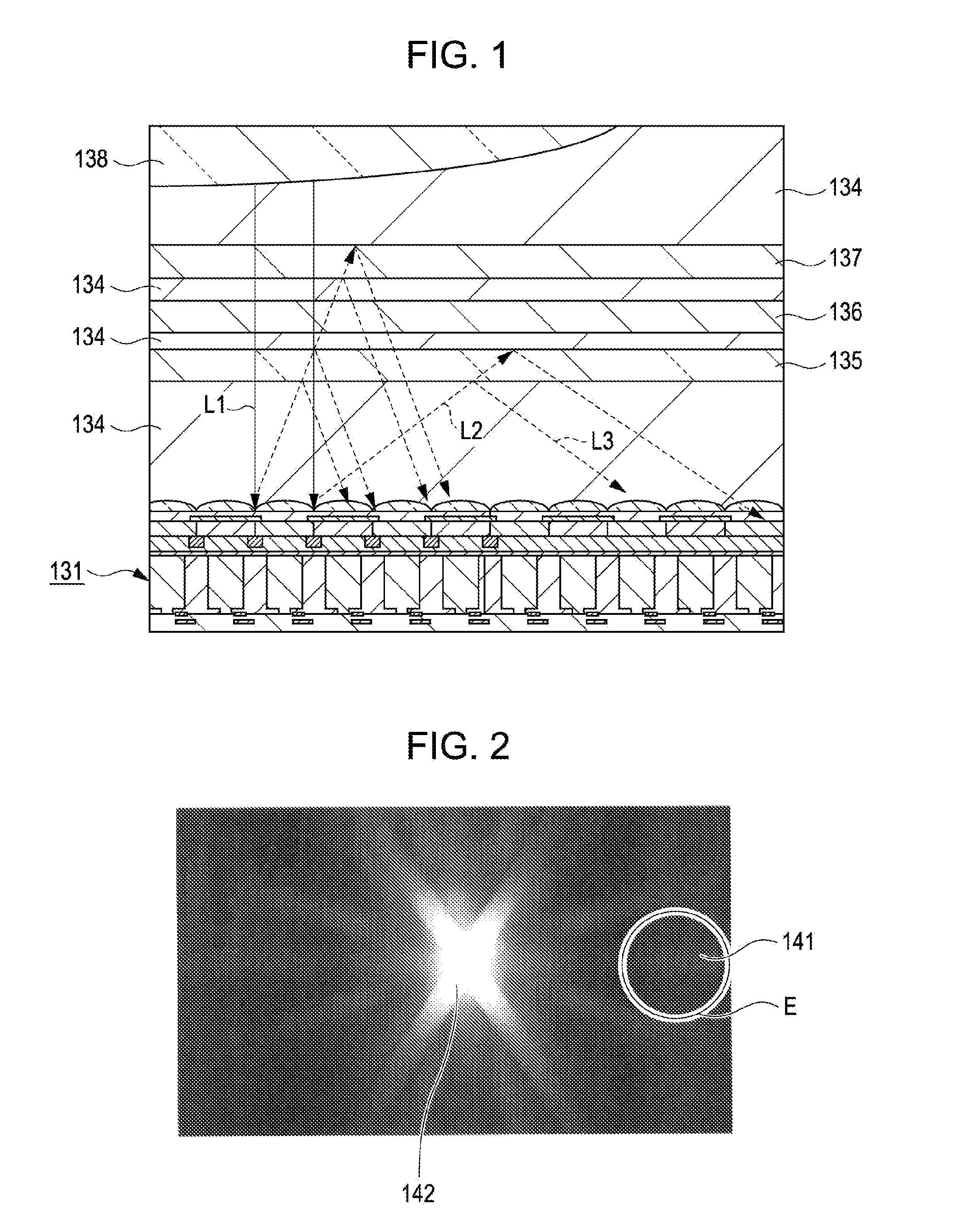

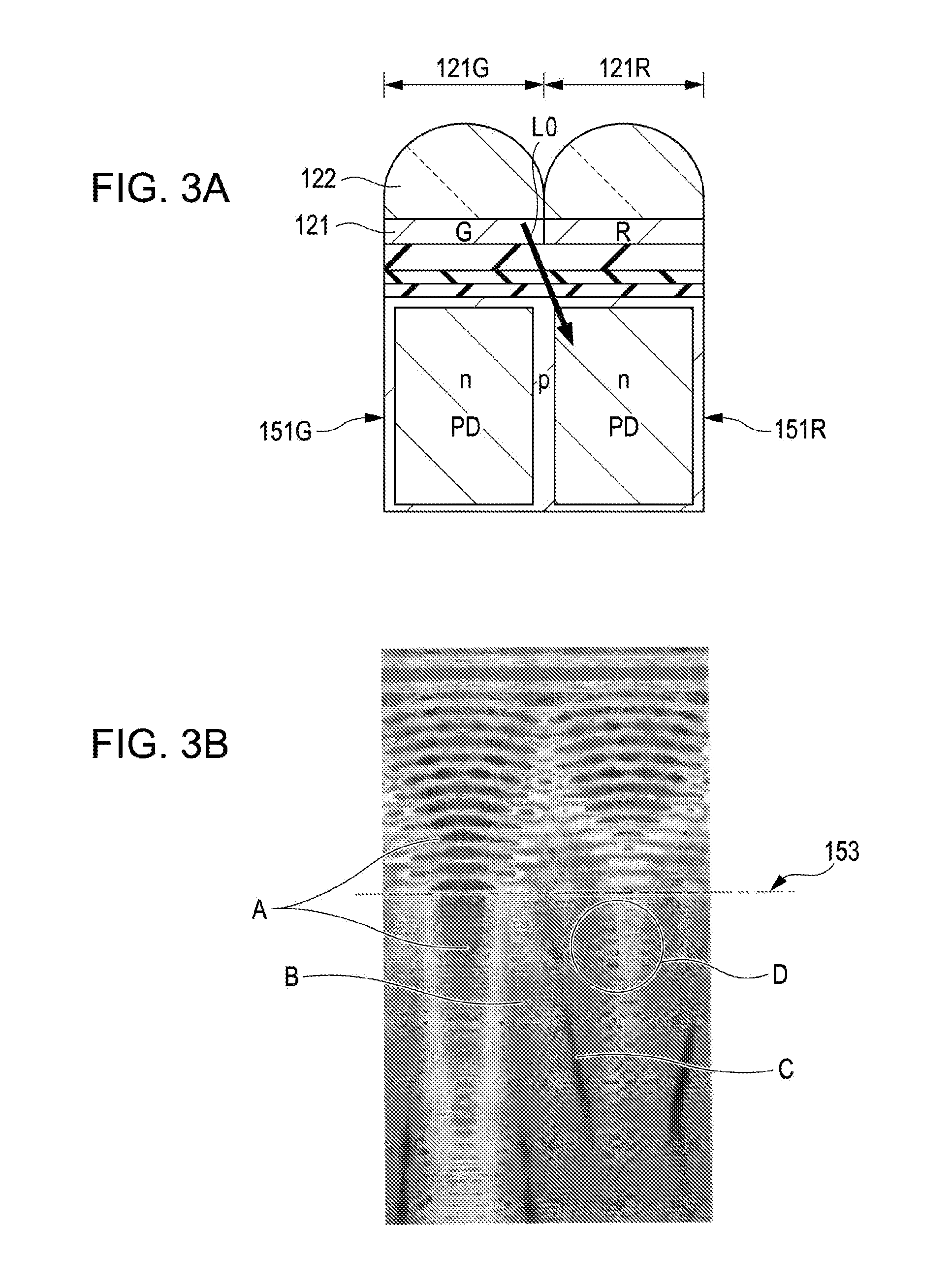

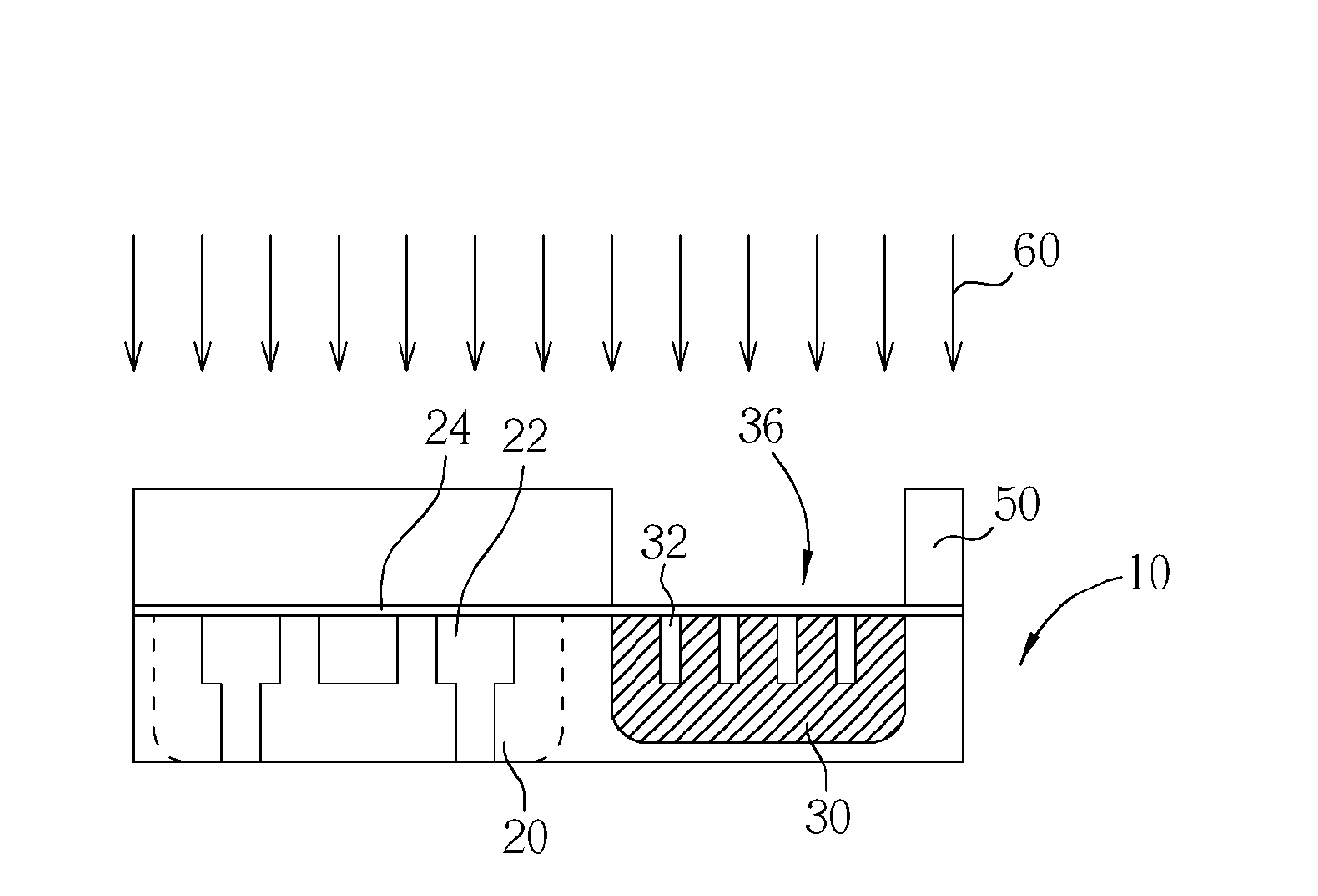

Solid-state imaging device, method of manufacturing the same, and electronic apparatus

ActiveUS20100201834A1Improve image qualityReduce colorTransistorTelevision system detailsInterconnectionPhotoelectric conversion

A solid-state imaging device includes: a pixel region in which a plurality of pixels composed of a photoelectric conversion section and a pixel transistor is arranged; an on-chip color filter; an on-chip microlens; and a multilayer interconnection layer in which a plurality of layers of interconnections is formed through an interlayer insulating film. The solid-state imaging device further includes a light-shielding film formed through an insulating layer in a pixel boundary of a light receiving surface in which the photoelectric conversion section is arranged.

Owner:SONY CORP

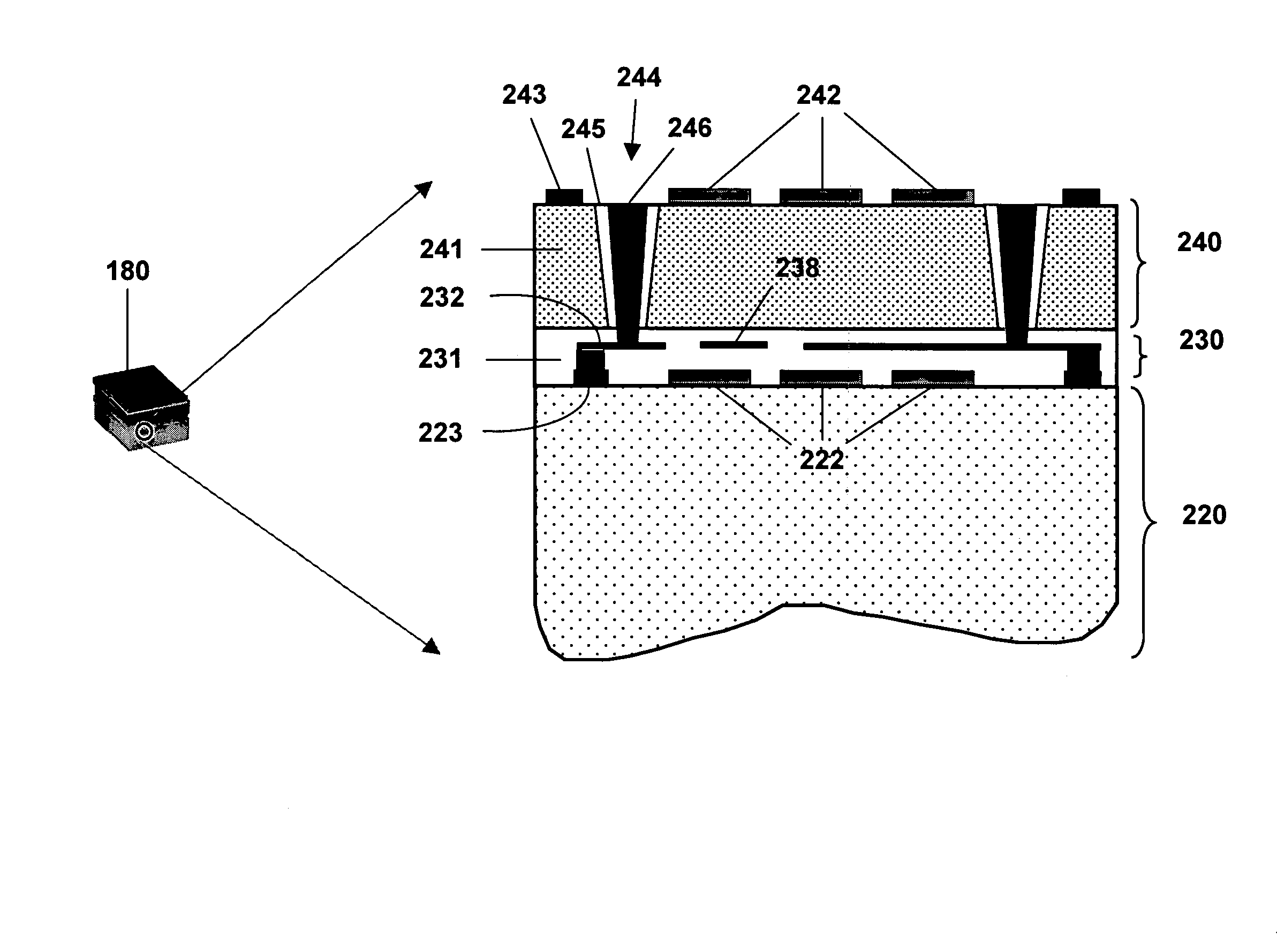

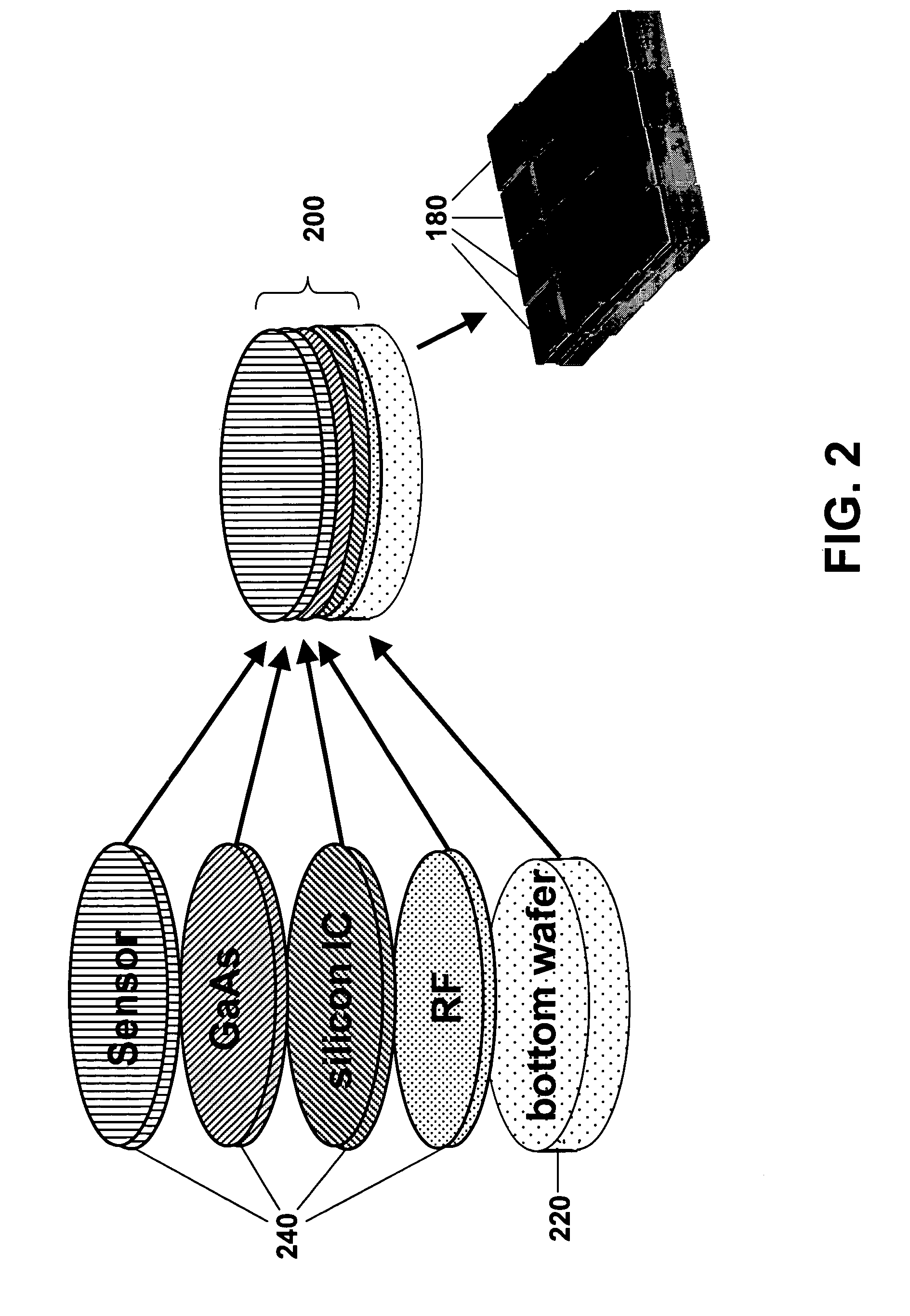

Heterogeneously integrated microsystem-on-a-chip

ActiveUS7335972B2Electronic circuit testingSemiconductor/solid-state device detailsMiniaturizationInterconnection

A microsystem-on-a-chip comprises a bottom wafer of normal thickness and a series of thinned wafers can be stacked on the bottom wafer, glued and electrically interconnected. The interconnection layer comprises a compliant dielectric material, an interconnect structure, and can include embedded passives. The stacked wafer technology provides a heterogeneously integrated, ultra-miniaturized, higher performing, robust and cost-effective microsystem package. The highly integrated microsystem package, comprising electronics, sensors, optics, and MEMS, can be miniaturized both in volume and footprint to the size of a bottle-cap or less.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

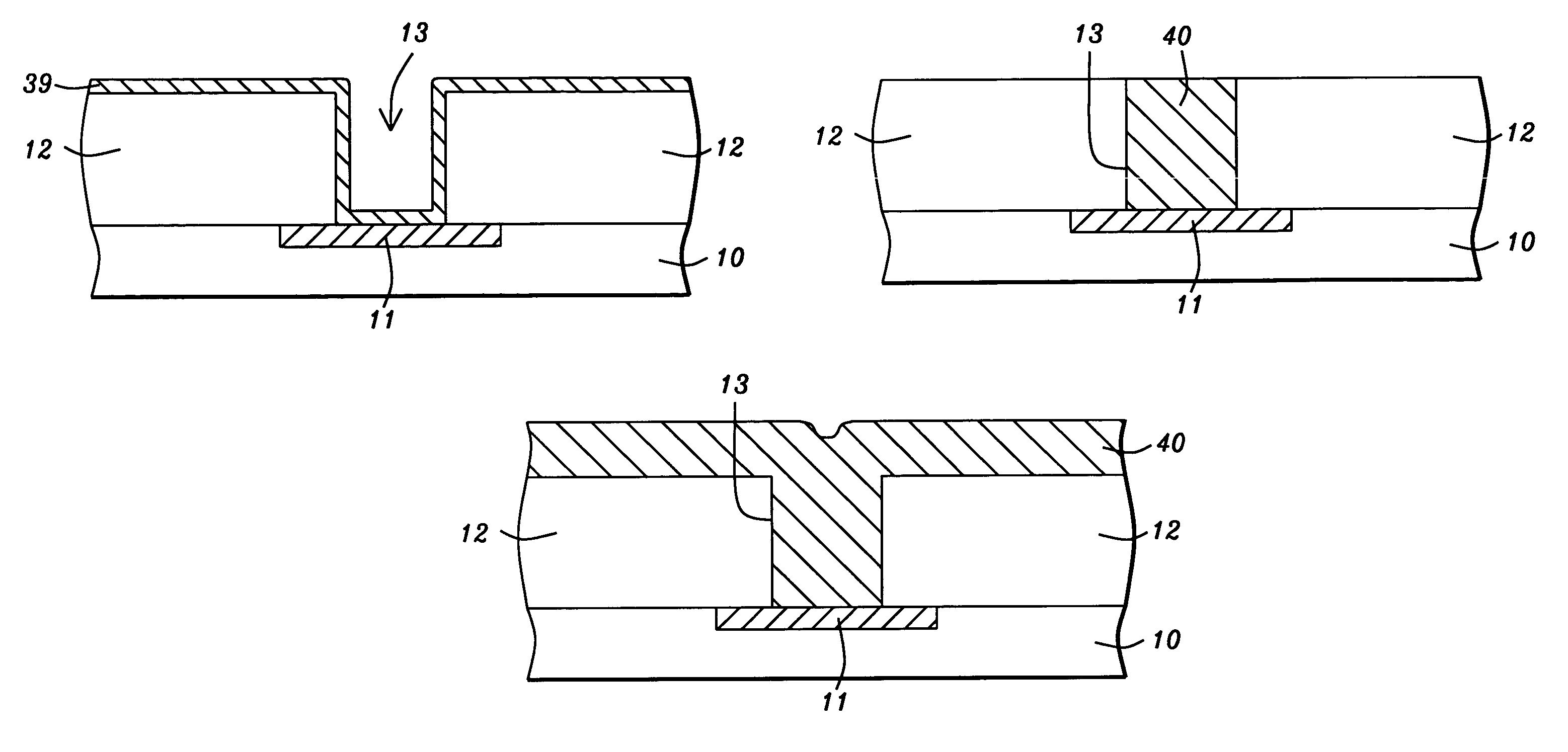

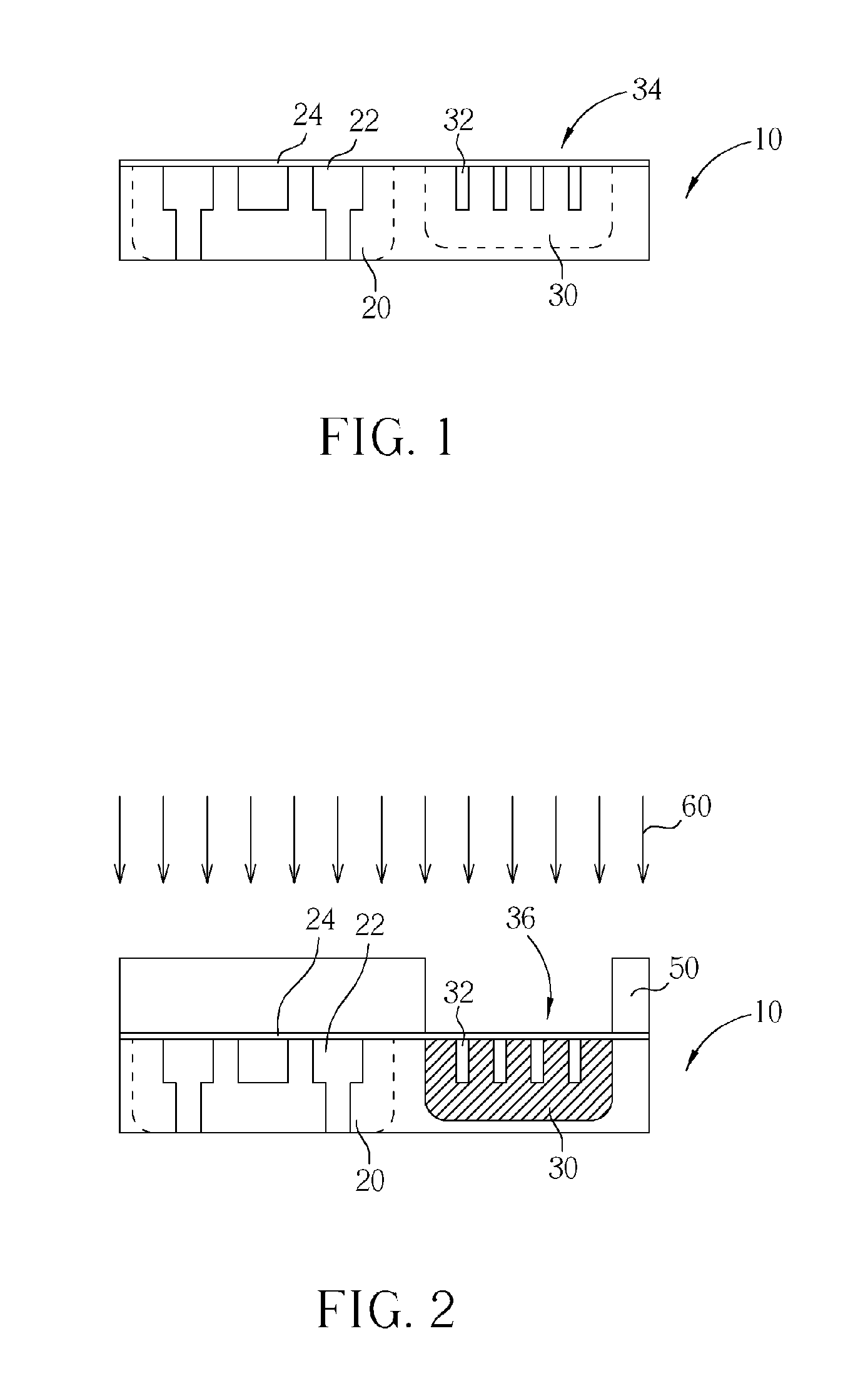

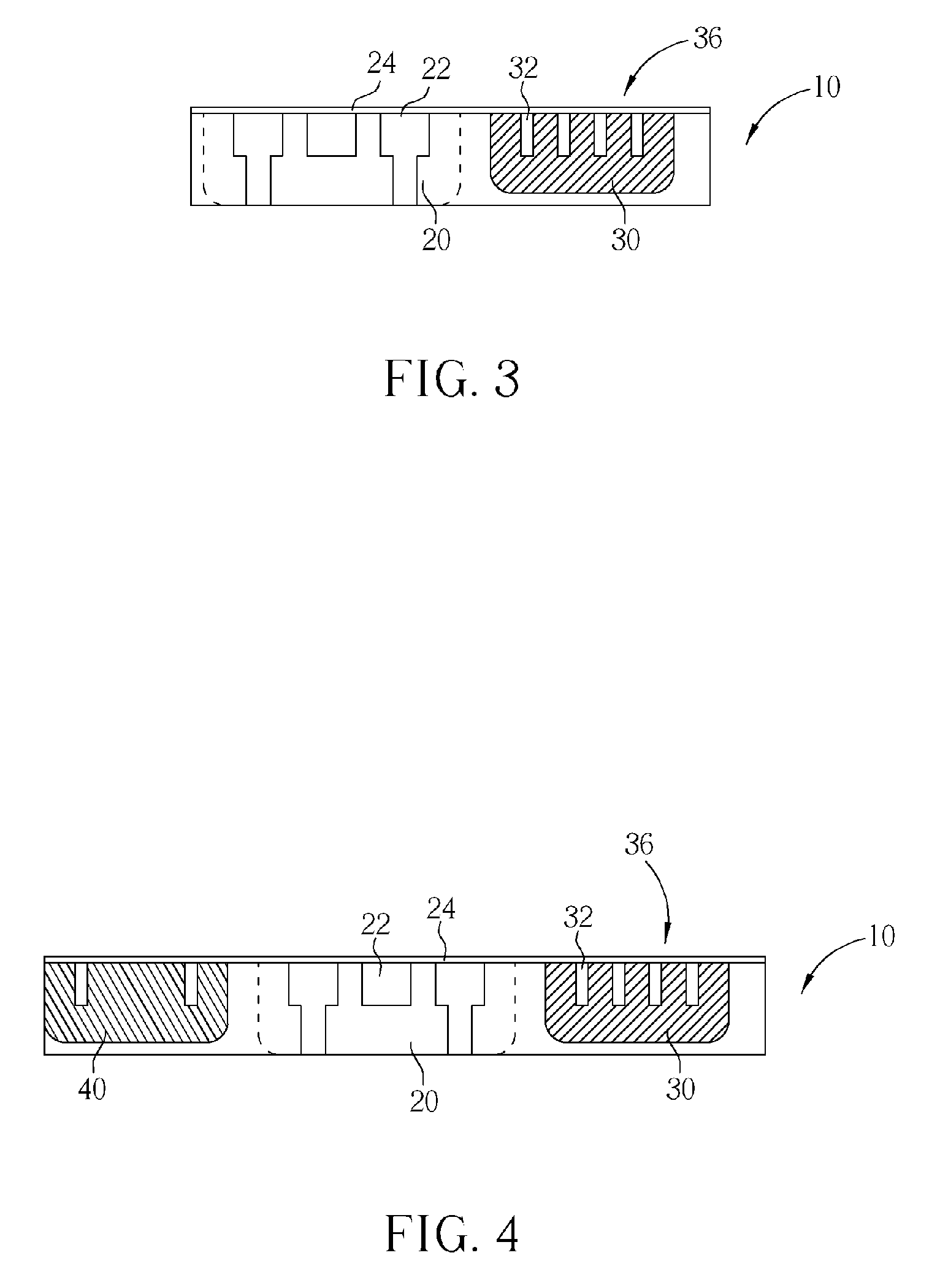

Method and apparatus for 3D interconnect

ActiveUS8076237B2Improve adhesionInhibited DiffusionSemiconductor/solid-state device detailsPrinted circuit aspectsConductive materialsEngineering

The present invention discloses methods for depositing a material, particularly a conductive material, in cavities of a substrate and forming bonding contacts or pads thereon. An intracavity structure may be utilized in conjunction with embodiments of the present invention to provide efficient filling of diverse cavities within the substrate. Also provided are embodiments for interconnection structures using filled cavities, along with electrically conductive or reactive structures which may include capacitors fabricated within a substrate.

Owner:ASM NUTOOL

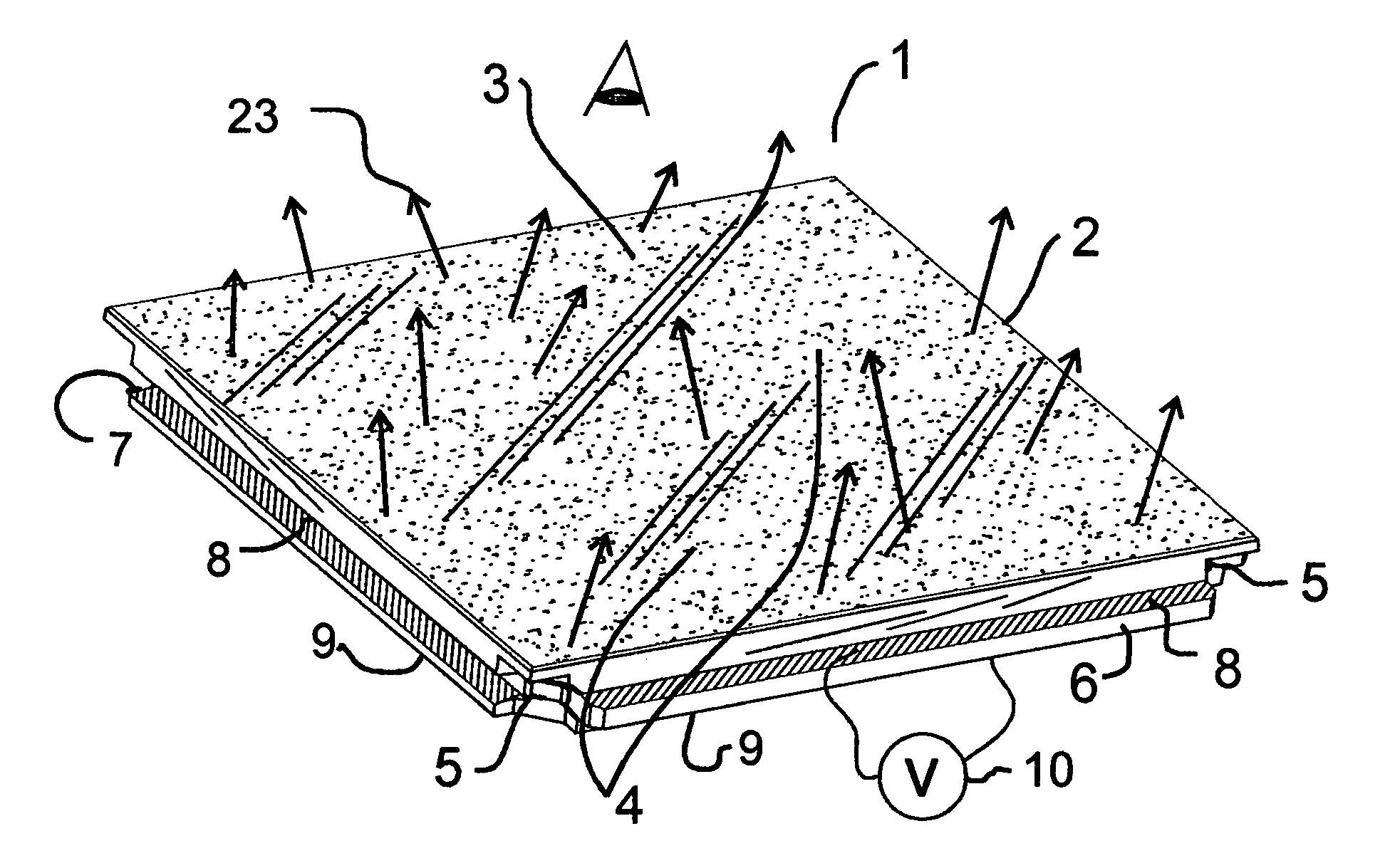

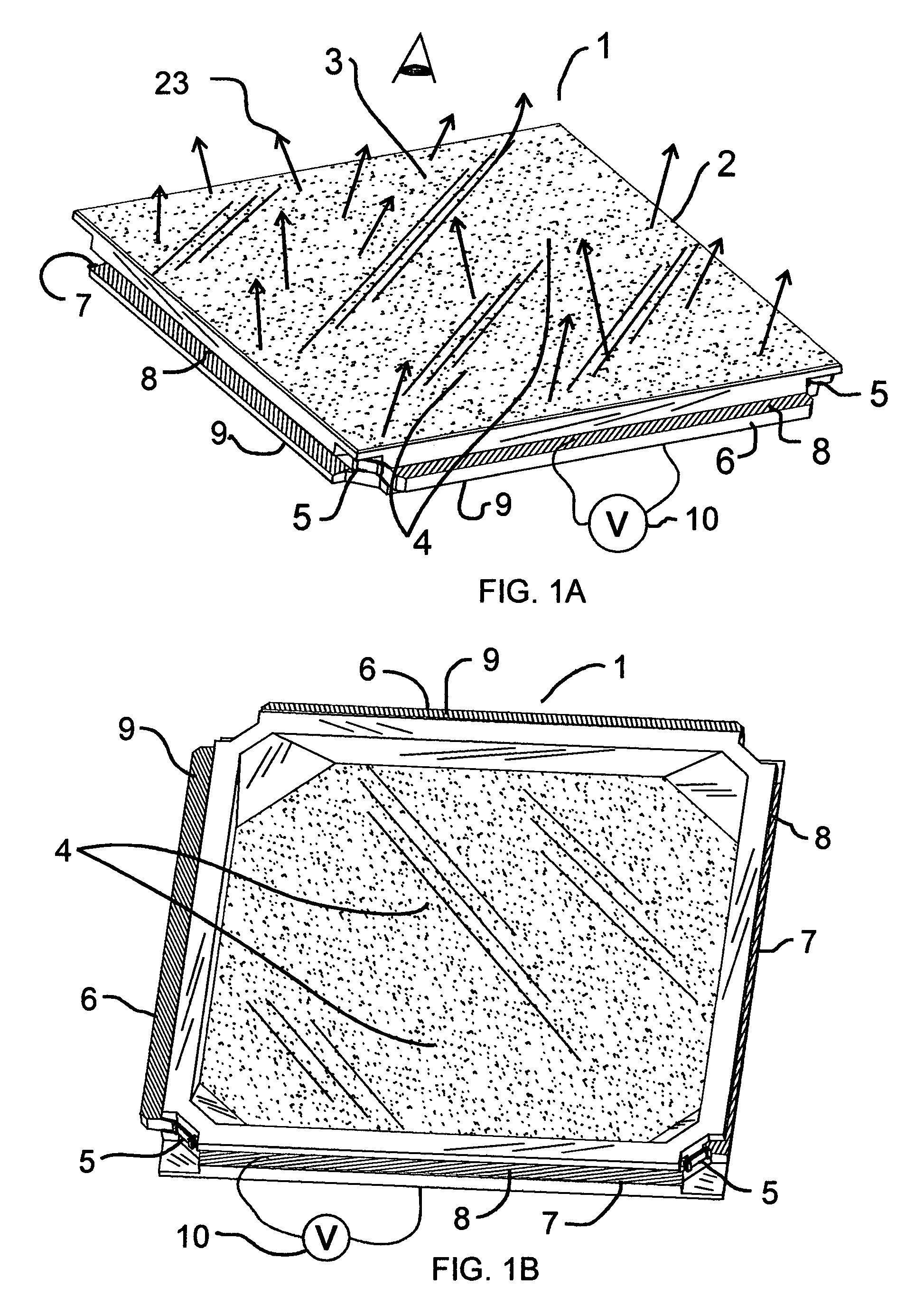

Lightguide tile modules and modular lighting system

A modular illumination system includes light emitting tile modules, each module comprising a light guide substrate, at least one source of illumination optically coupled to a light guiding substrate and interconnection means to connect one light emitting tile module to another light emitting tile module. The interconnection means may include mechanical and / or electrical elements. A plurality of modules may be connected to create an extended continuous extended illuminating system without significant gaps or seams. In one embodiment, the light guiding substrate of one module extends over the source of illumination of an adjacent module. In a further embodiment, the light guiding substrate may be textured to create a patterned area with higher light extraction. In a further embodiment, the source of illumination may be included in a separate electrical member. The illumination sources may include LEDs directed into an edge of the light guiding substrate.

Owner:RUDISILL CHARLES A

Electrochromic rearview mirror incorporating a third surface metal reflector

InactiveUS6064508AEconomical and reliableLow costMirrorsSolid-state devicesEpoxyElectrical conductor

An electrochromic variable reflectance mirror for a vehicle includes a reflector / electrode on the third surface of the mirror. This reflector / electrode forms an integral electrode in contact with the electrochromic media, and may be a single layer of a highly reflective material or may comprise a series of coatings. When a series of coatings is used for the reflector / electrode, there should be a base coating which bonds to the glass surface and resists any adverse interaction, e.g., corrosive action, with the constituents comprising the electrochromic media, an optional intermediate layer (or layers) which bonds well to the base coating and resists any adverse interaction with the electrochromic media, and at least one highly reflective layer which directly contacts the electrochromic media and which is chosen primarily for its high reflectance, stable behavior as an electrode, resistance to adverse interaction with the materials of the electrochromic media, resistance to atmospheric corrosion, resistance to electrical contact corrosion, the ability to adhere to the base or intermediate layer(s) (if present) and to the epoxy seal, and ease of cleaning. If a base layer is deposited it preferably covers the entire third surface; however, when this is done the highly reflective layer may optionally only coat the central portion of the third surface and not the perimeter edge portion. The third surface reflector / electrode provides of improved electrical interconnection techniques used to impart a voltage drive potential to a transparent conductor on the mirror's second surface.

Owner:GENTEX CORP

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

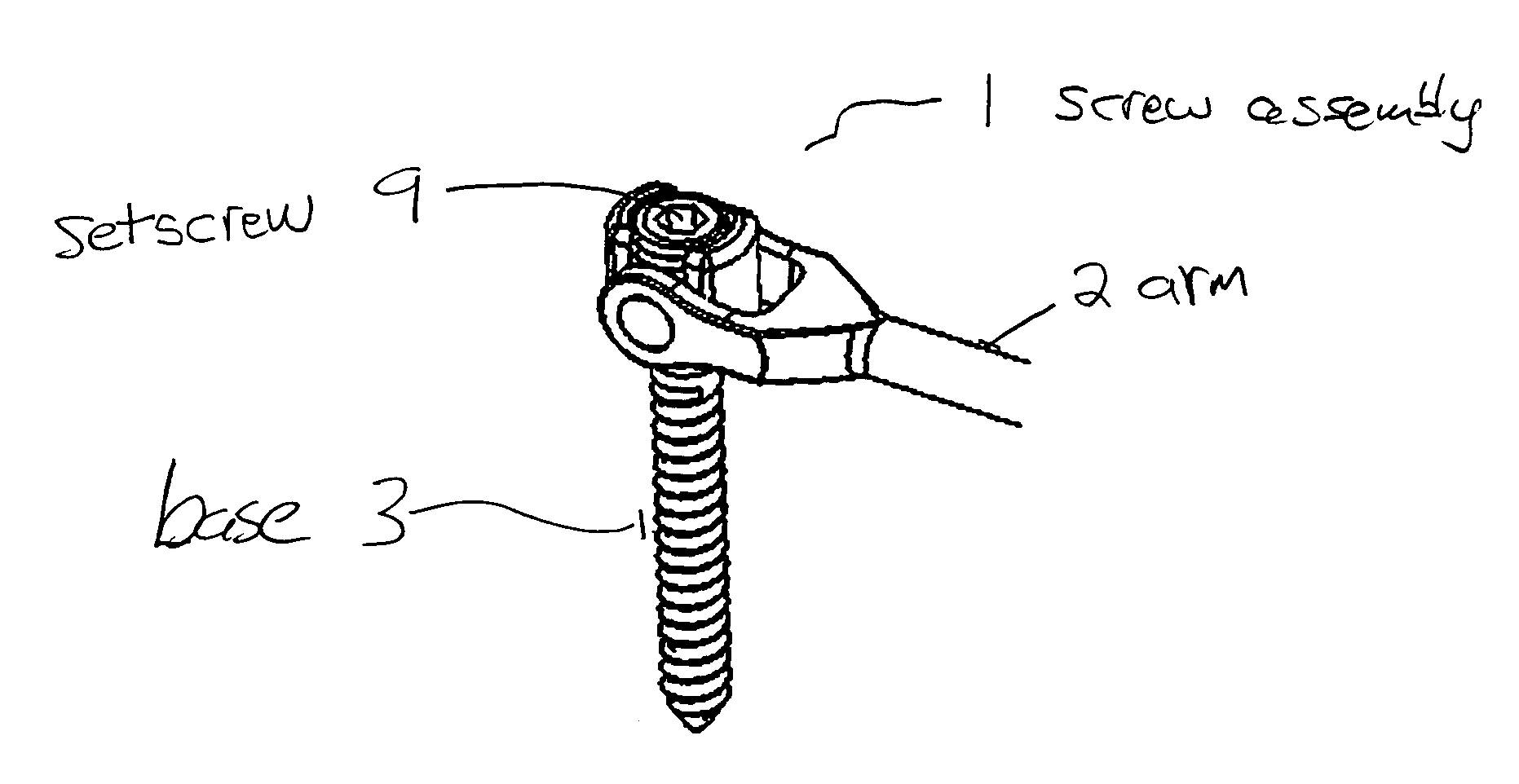

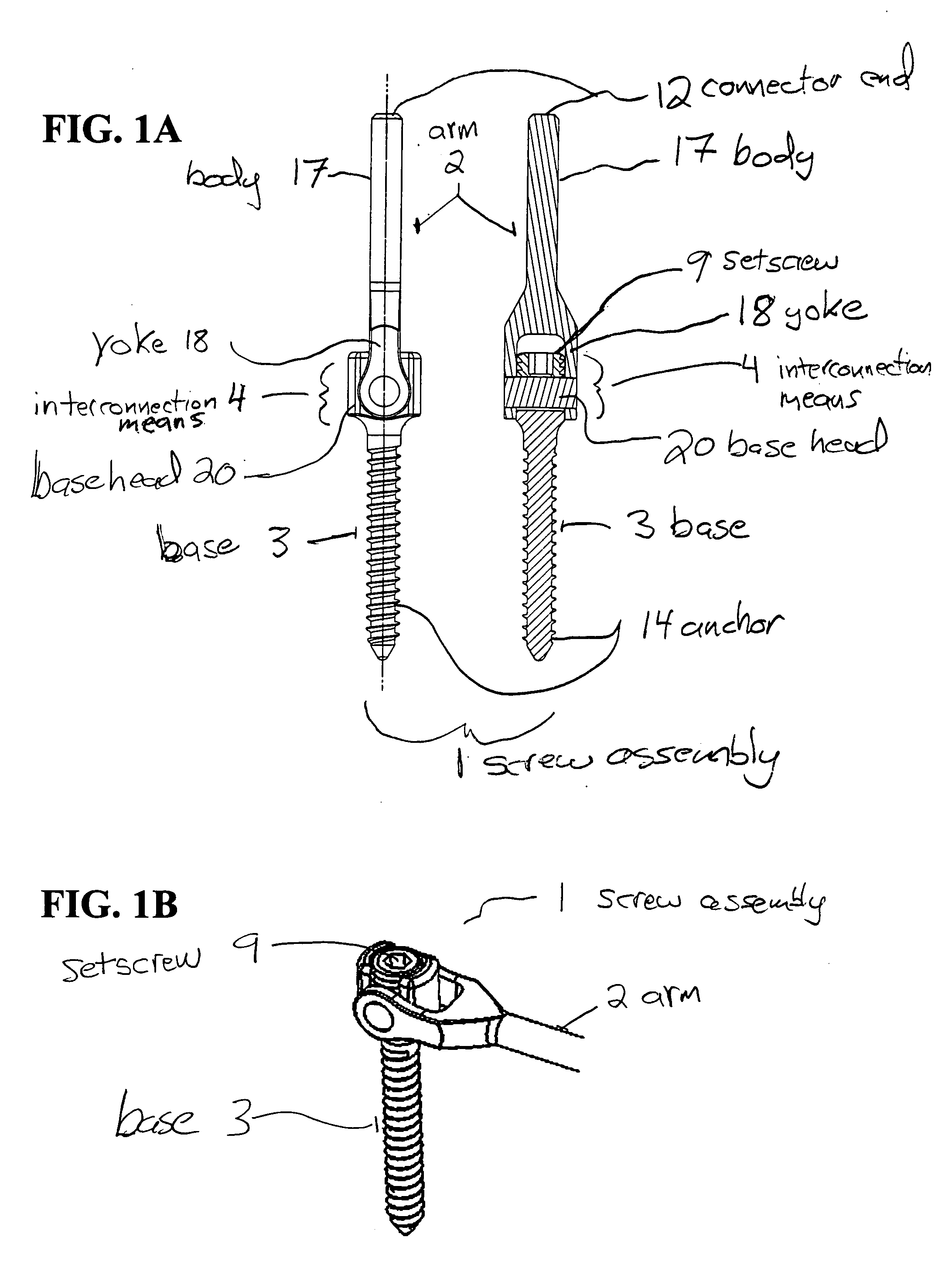

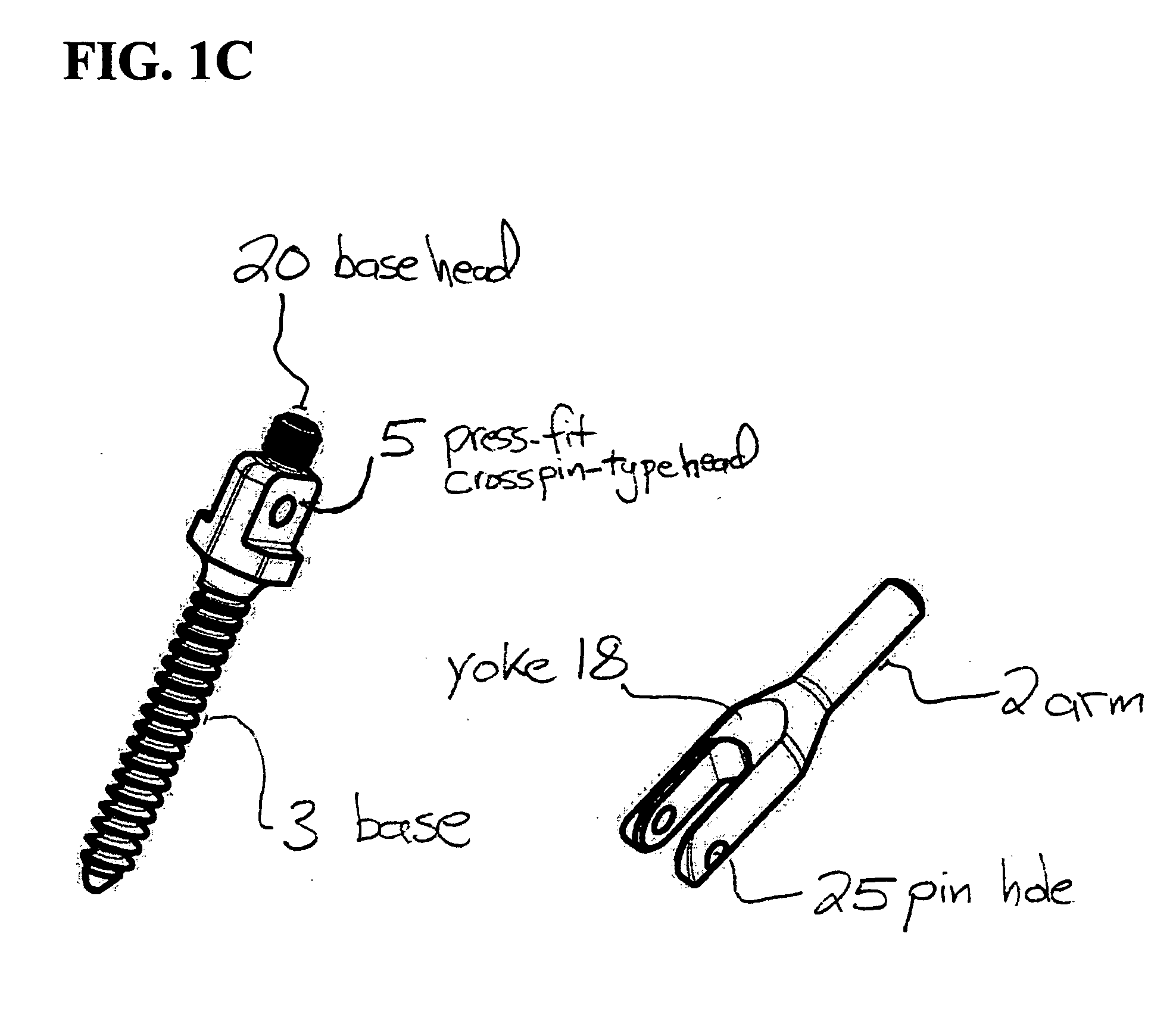

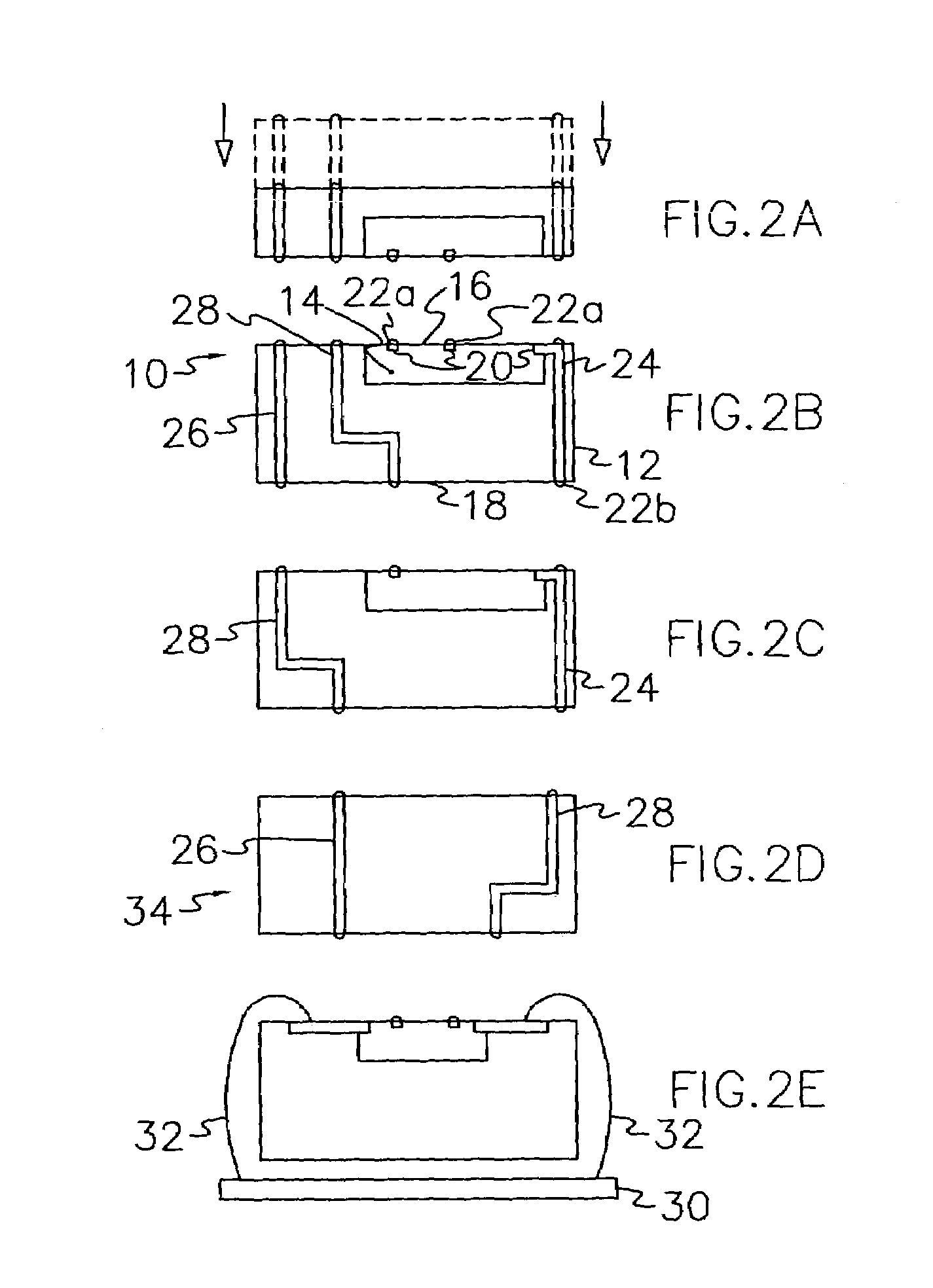

Pedicle screw assembly

A medical device and methods of use thereof are provided for supporting a structure (e.g., bone). A screw assembly is provided that is comprised of a base, an arm, and an interconnection means for coupling the base to the arm. The interconnection means allows the arm to be positionable in a first position that is parallel to a long axis of the base and positionable in a second position that is perpendicular to the long axis of the base. The base is configured for attachment to a structure and the arm configured for attachment to a support structure. A support structure is provided that includes one or more receivers having locking means, which can be configured as an open-ended saddle for attachment to a medical device (e.g., a screw assembly). The support structure is configured to receive one or more medical devices and lock the medical devices to the support structure after installation in a patient.

Owner:KYPHON

Space-saving packaging of electronic circuits

InactiveUS7071546B2Simplifies electrical connectionsMinimized volumeSemiconductor/solid-state device detailsSolid-state devicesInterior spaceSurface mounting

An apparatus and packaging method for stacking a plurality of integrated circuit substrates, i.e., substrates having integrated circuits formed as integral portions of the substrates, which provides interconnection paths through the substrates to simplify electrical connections between the integrated circuits while facilitating minimization of the volume and customization of the three dimensional package size to conform to the available internal space within a housing, e.g., one used in an implantabie device where package volume is at a premium. Furthermore, an internal cavity can be created by the stacked formation that is suitable for mounting of a surface mount device, e.g., a crystal or the like.

Owner:ALFRED E MANN FOUND FOR SCI RES

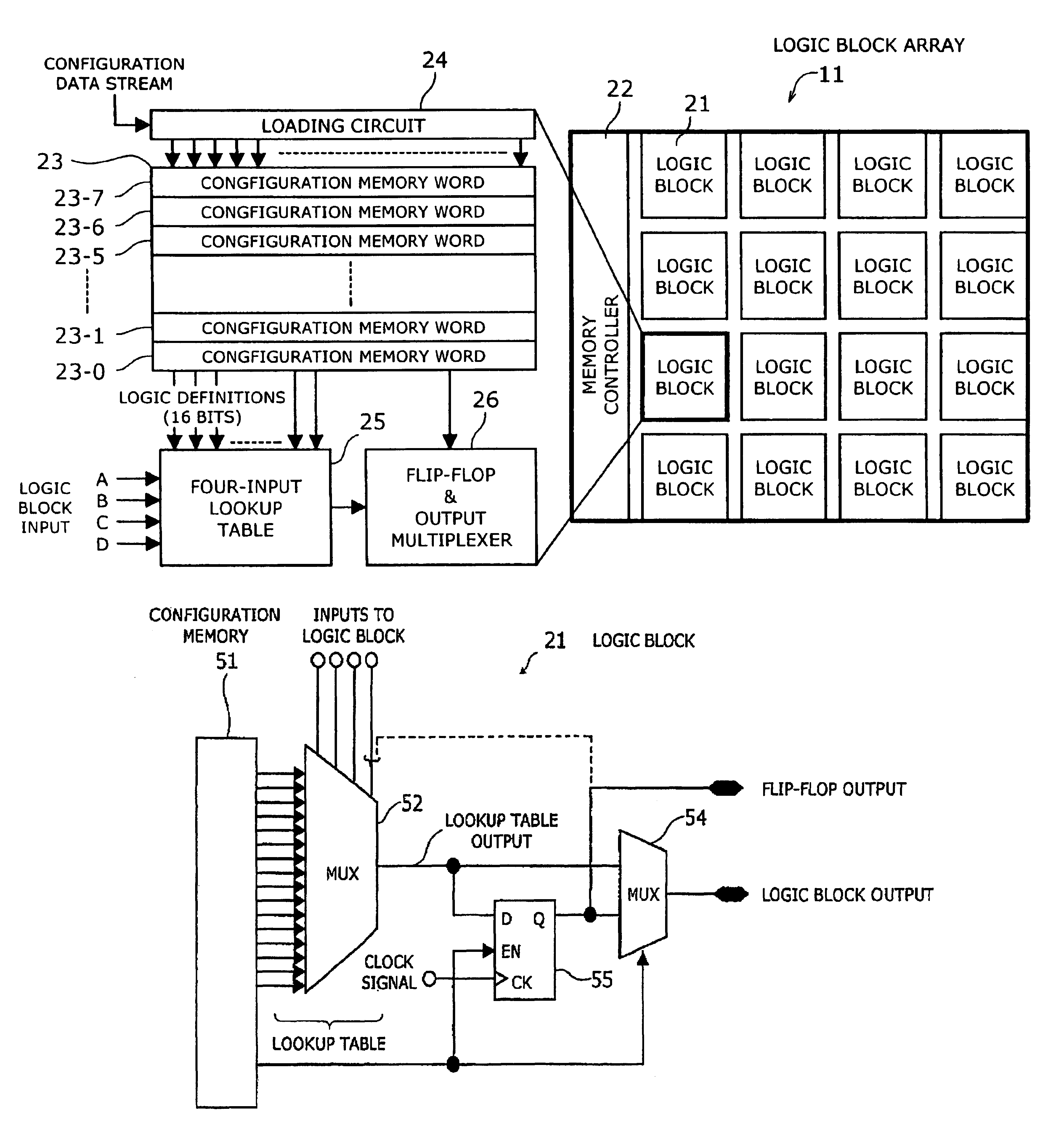

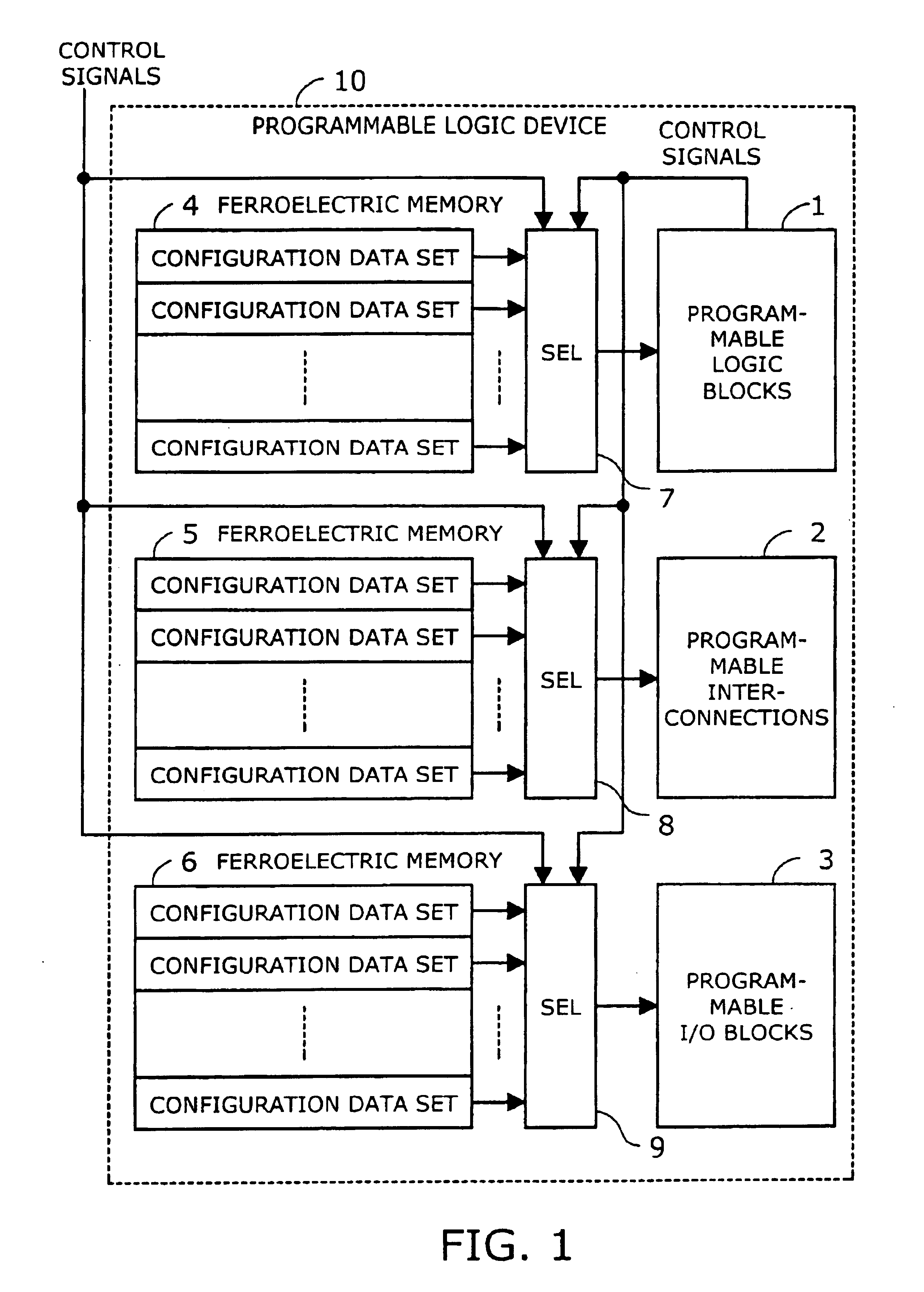

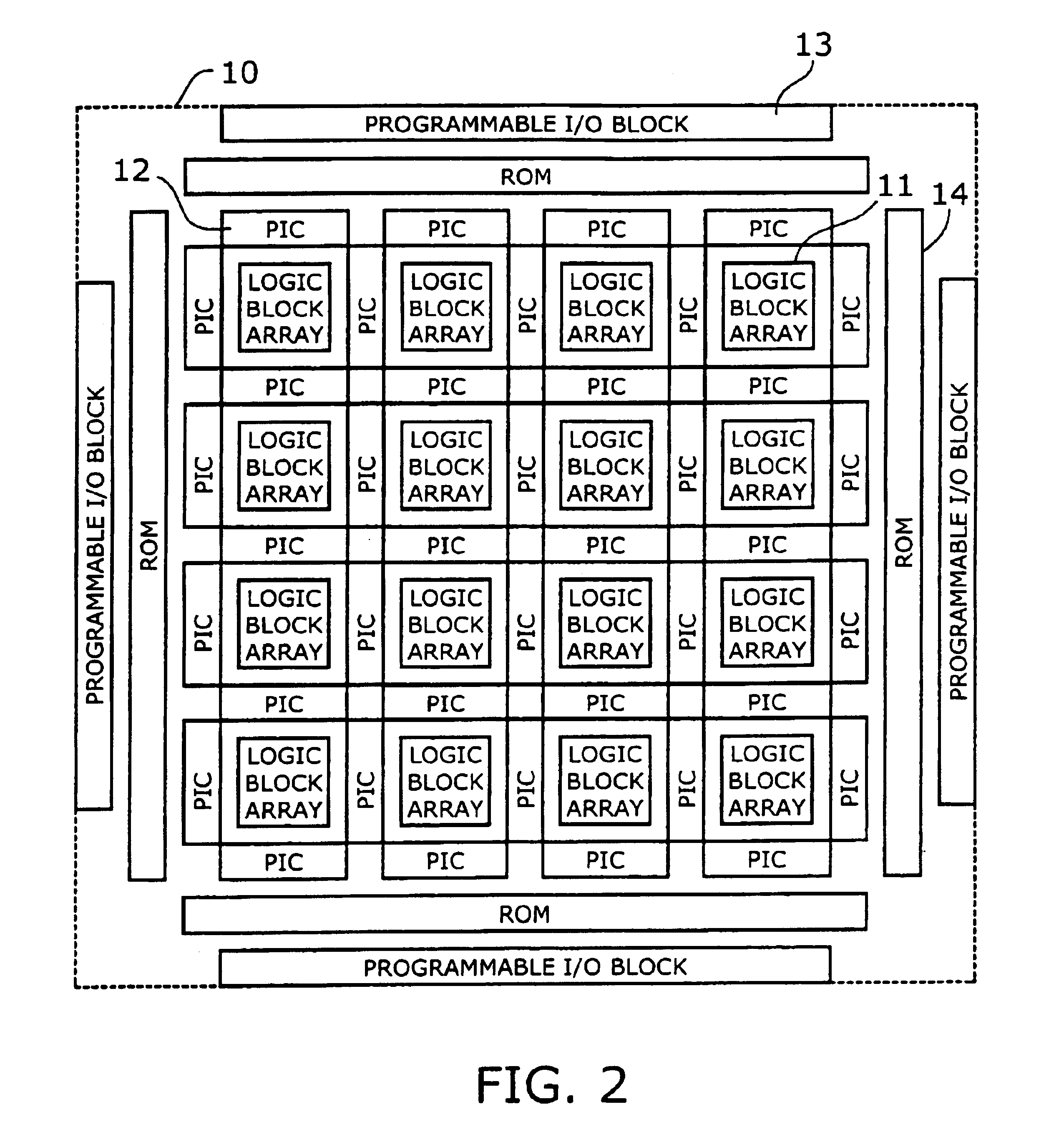

Programmable logic device with ferroelectric configuration memories

InactiveUS6924663B2Increase the effective amountEfficient architectureDigital storageInternal/peripheral component protectionElectricityData stream

A programmable logic device with ferroelectric configuration memories storing multiple configuration data sets. The device has programmable logic blocks, interconnections, and I / O blocks to provide desired logic functions. Those building blocks can be dynamically reconfigured by changing the selection of configuration data stored in the device's integral configuration memories. The configuration memories are divided into groups, so that they can be loaded concurrently with multiple configuration data streams. To protect the content of configuration memories from unauthorized access, the device employs an authentication mechanism that uses security IDs stored in the configuration memories. The device has a memory controller to provide an appropriate power supply sequence for ferroelectric memory cells to ensure the reliable data retention when the device is powered up or shut down.

Owner:FUJITSU SEMICON LTD

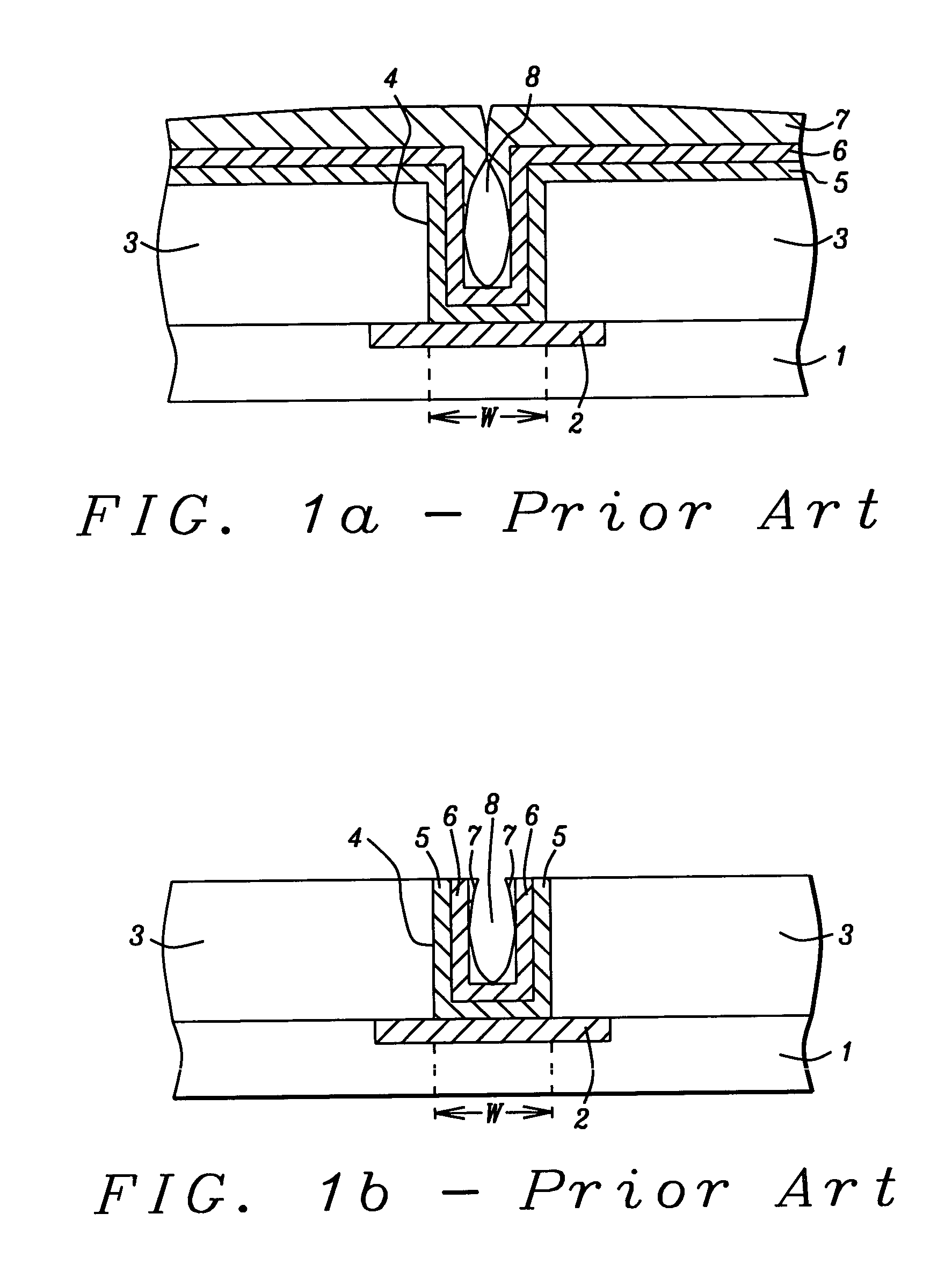

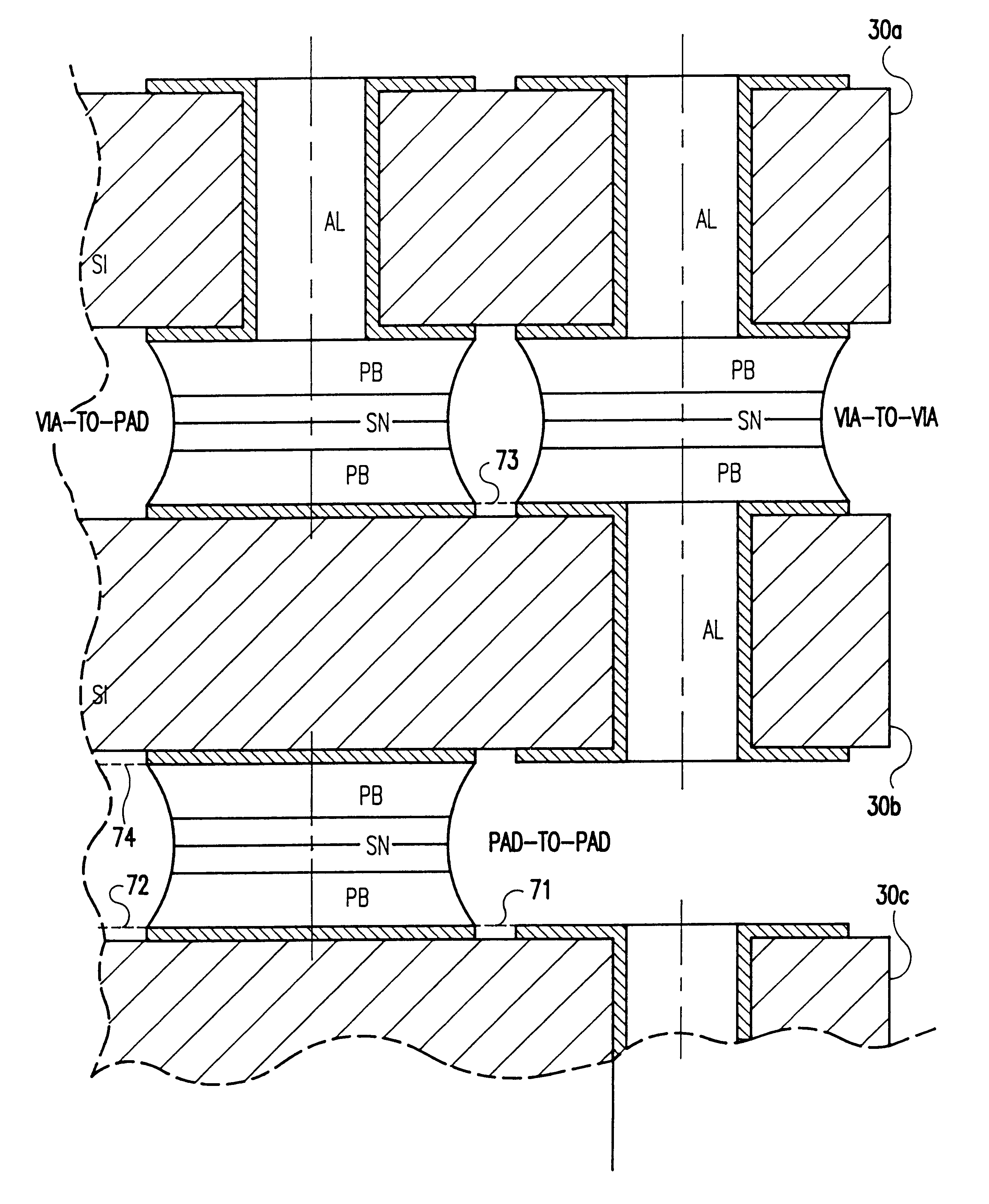

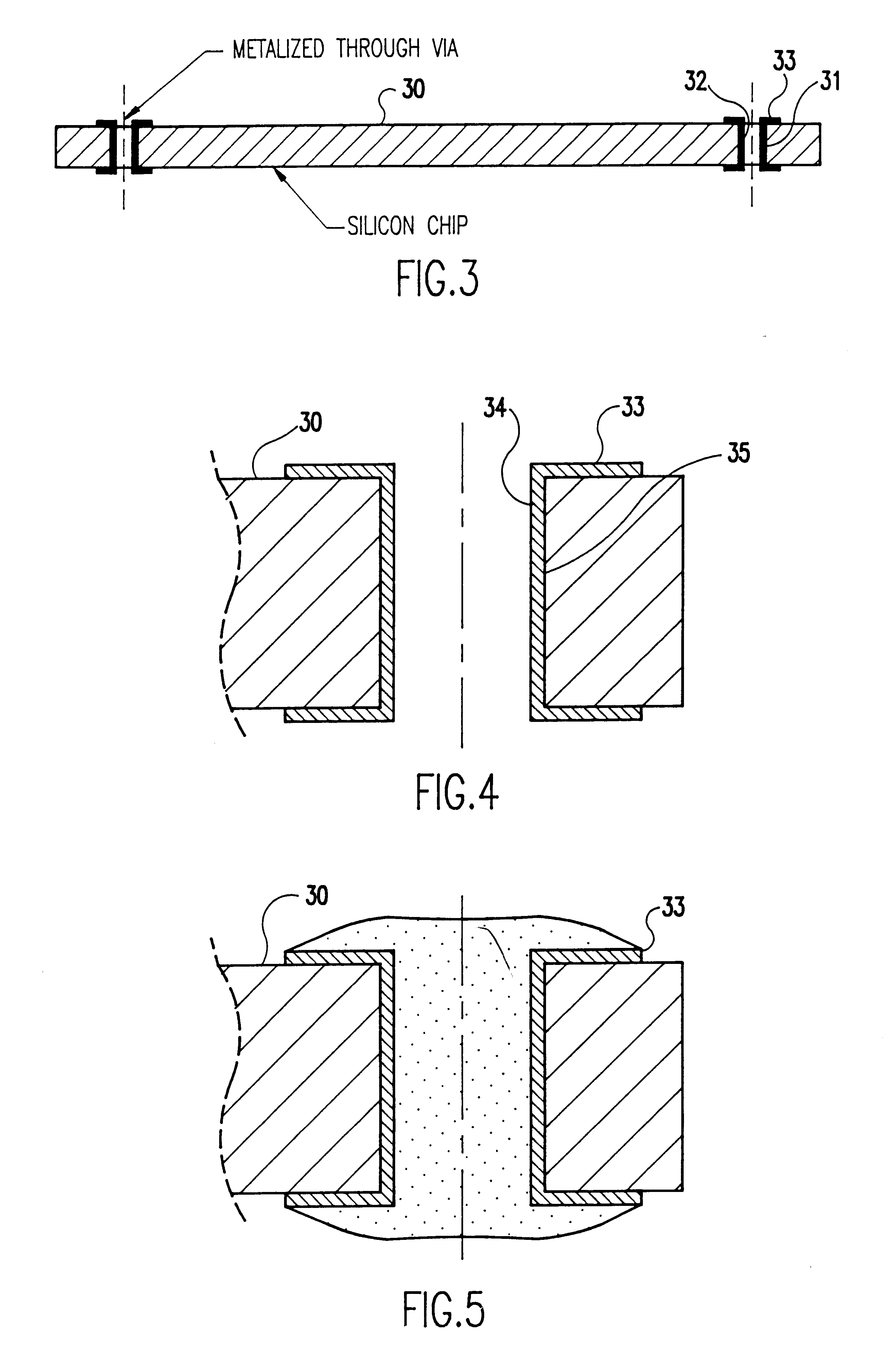

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

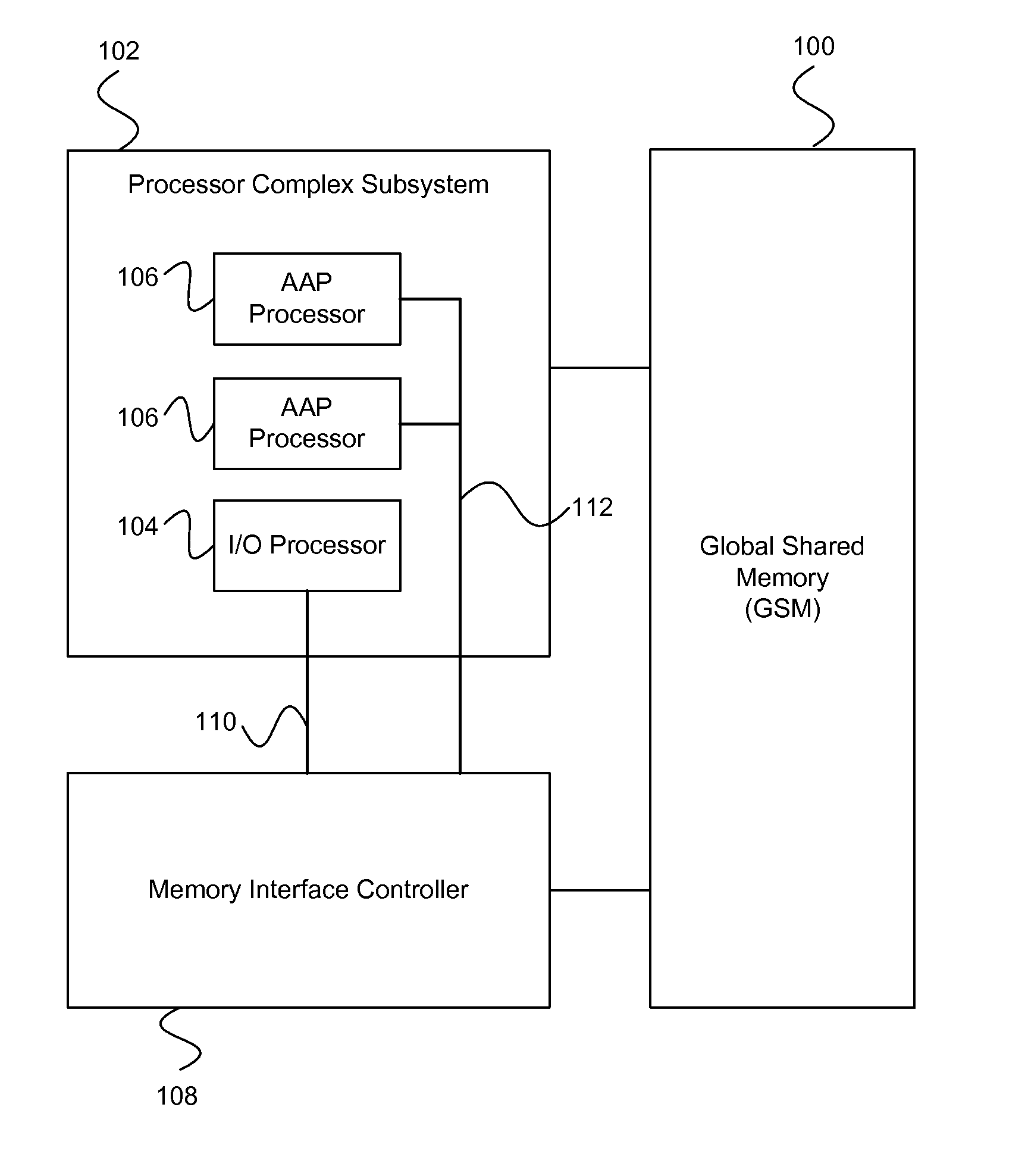

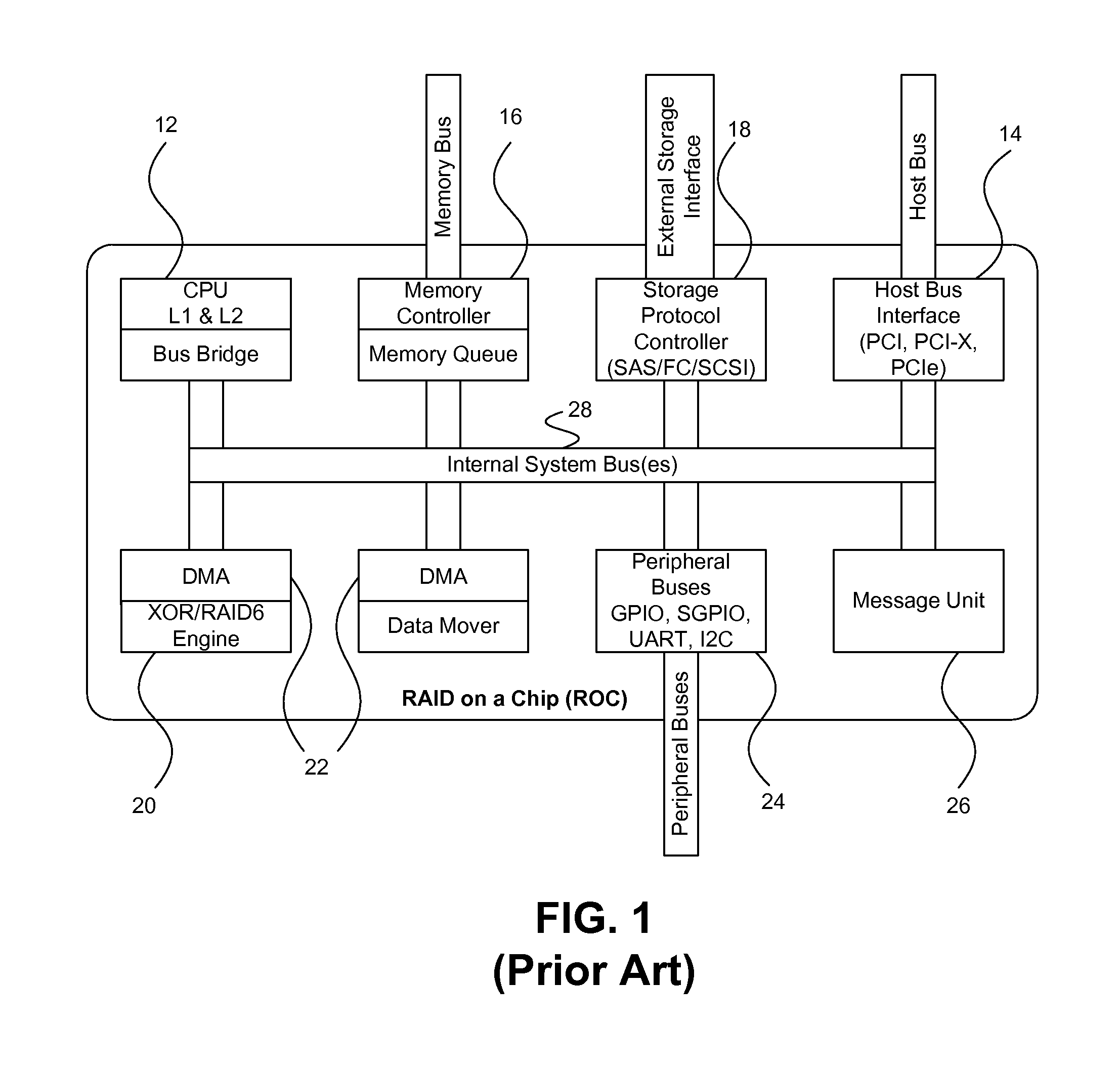

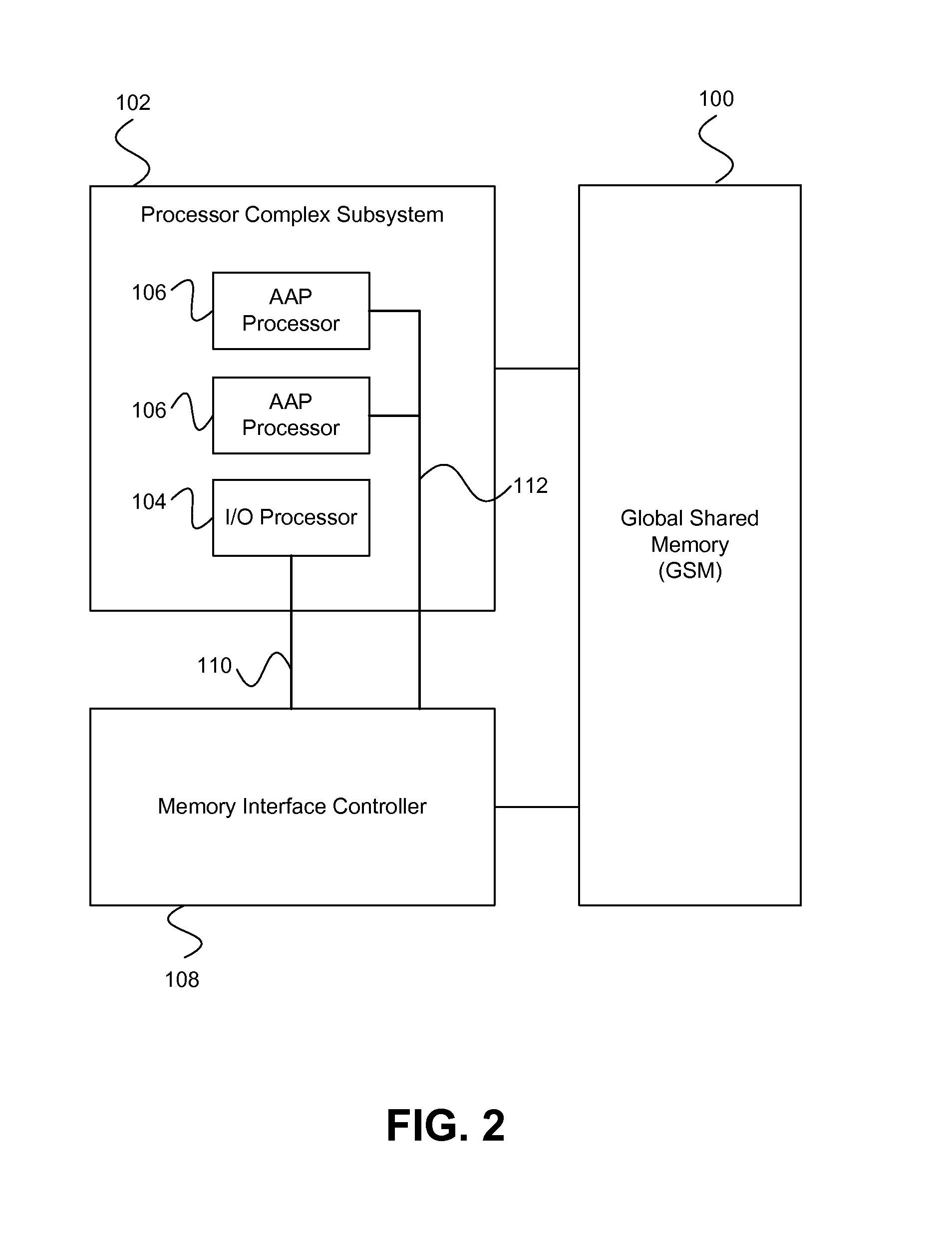

On-chip shared memory based device architecture

ActiveUS7743191B1Reduce disadvantagesLow costRedundant array of inexpensive disk systemsRecord information storageExtensibilityRAID

A method and architecture are provided for SOC (System on a Chip) devices for RAID processing, which is commonly referred as RAID-on-a-Chip (ROC). The architecture utilizes a shared memory structure as interconnect mechanism among hardware components, CPUs and software entities. The shared memory structure provides a common scratchpad buffer space for holding data that is processed by the various entities, provides interconnection for process / engine communications, and provides a queue for message passing using a common communication method that is agnostic to whether the engines are implemented in hardware or software. A plurality of hardware engines are supported as masters of the shared memory. The architectures provide superior throughput performance, flexibility in software / hardware co-design, scalability of both functionality and performance, and support a very simple abstracted parallel programming model for parallel processing.

Owner:MICROSEMI STORAGE SOLUTIONS

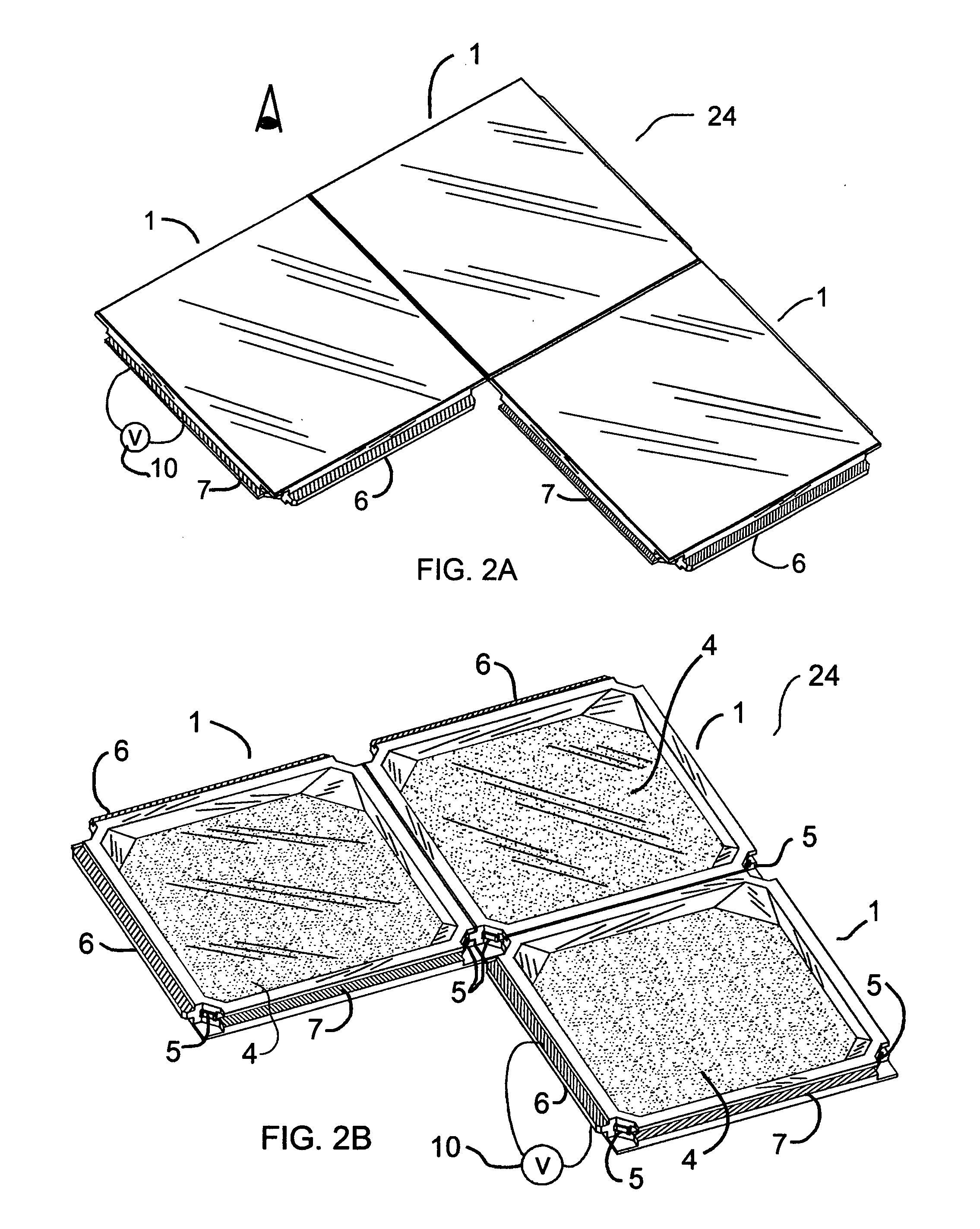

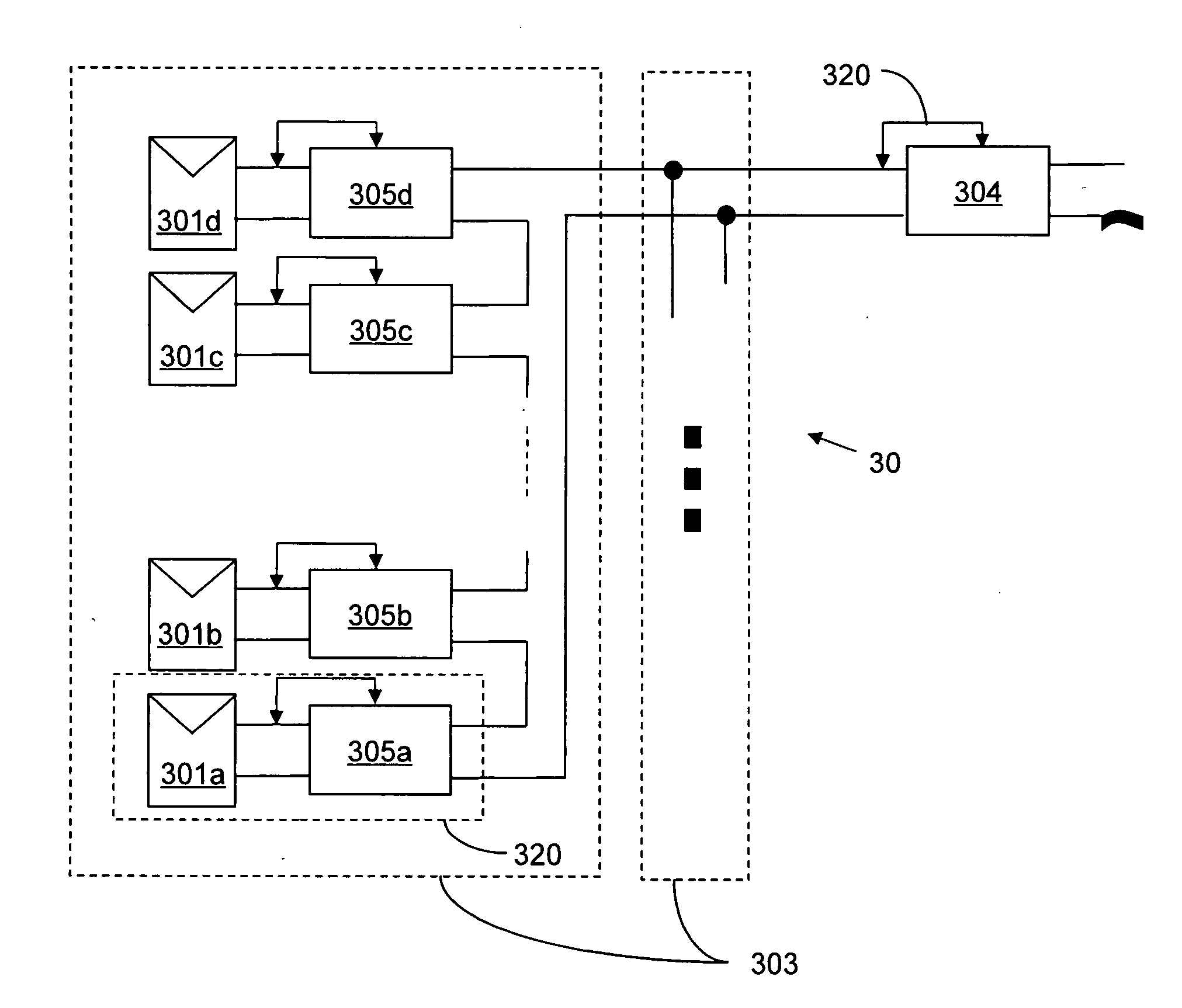

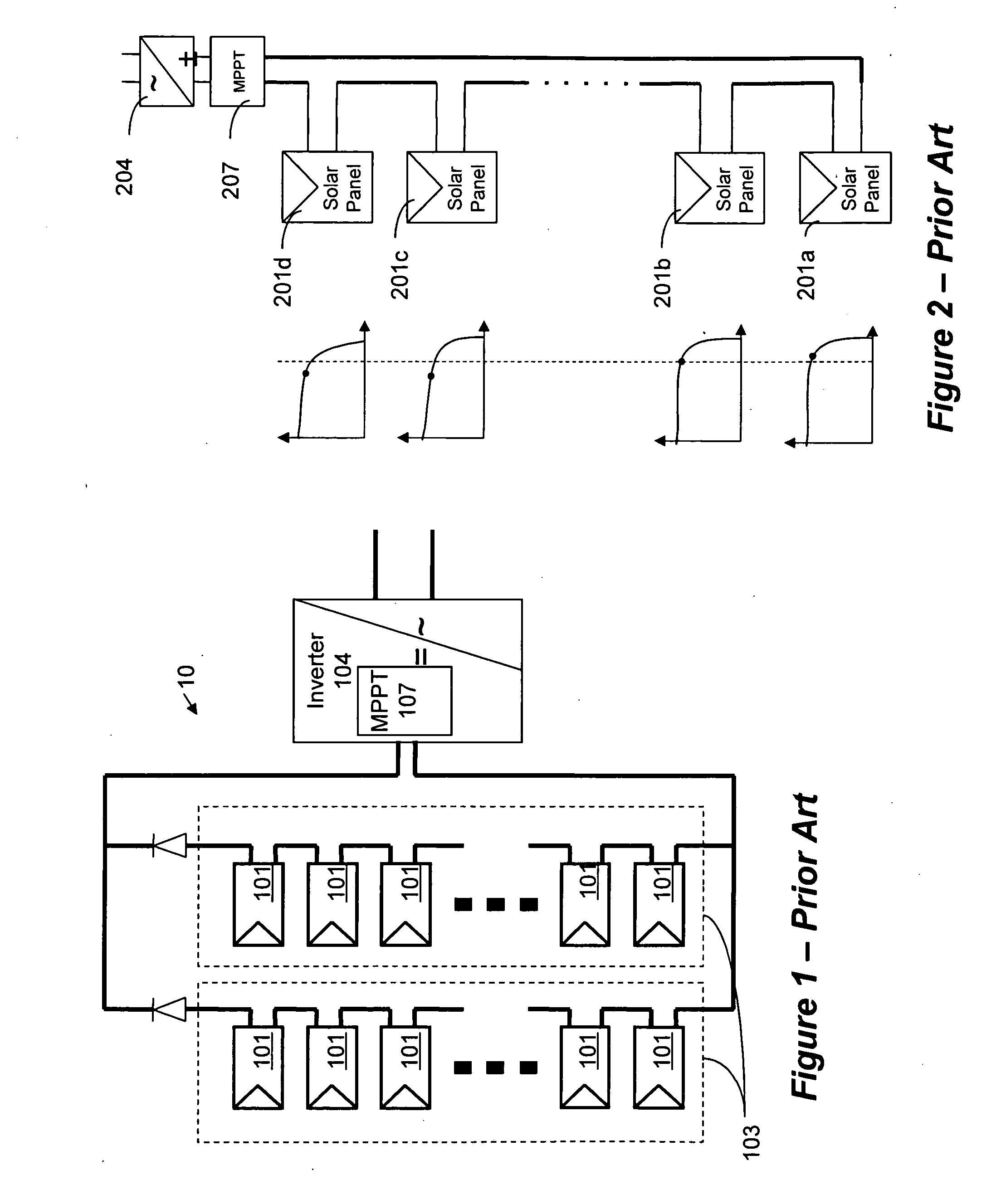

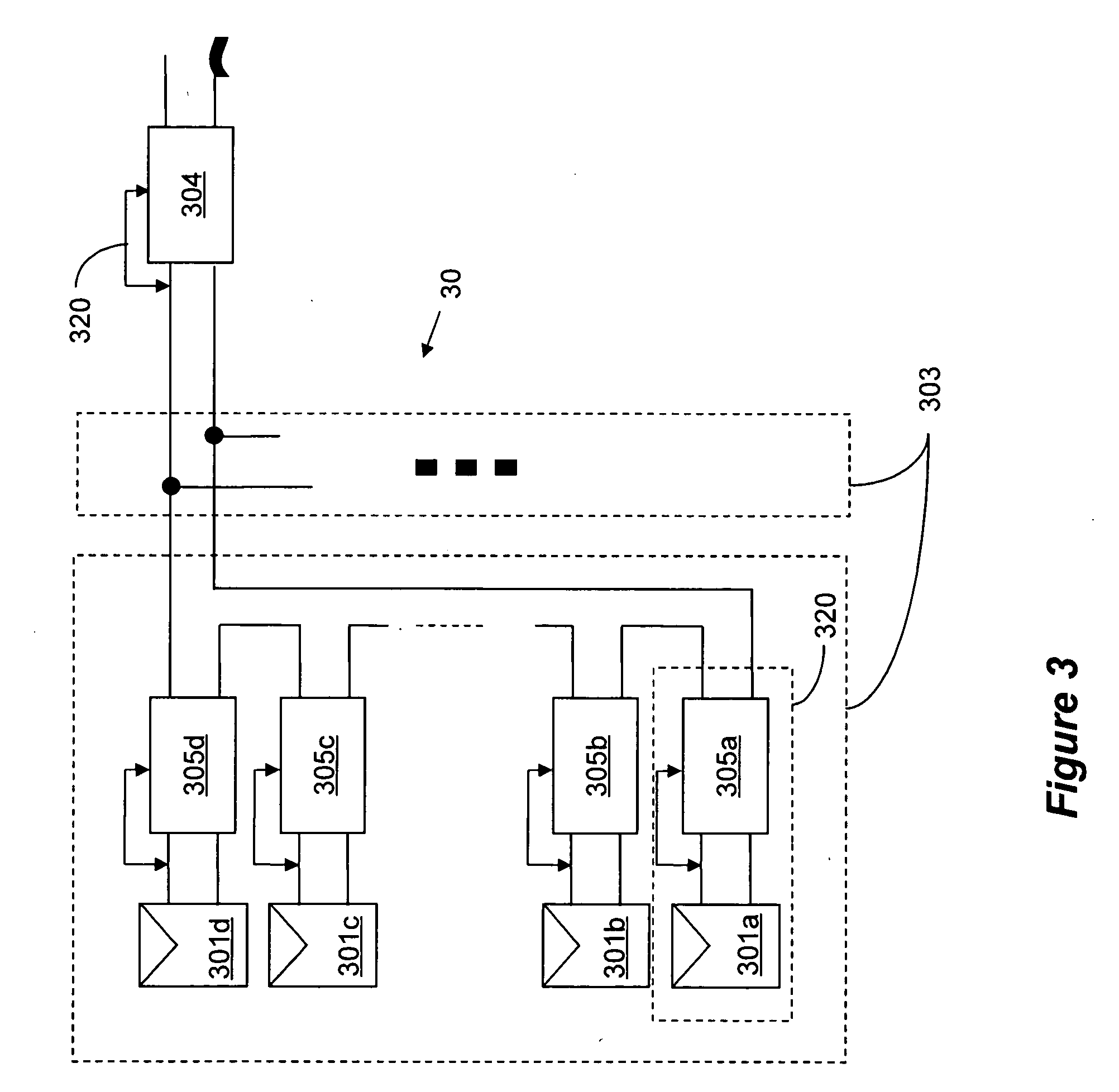

Distributed power harvesting systems using DC power sources

ActiveUS20090206666A1Improve reliabilitySafe operating voltageCoupling device detailsPhotovoltaicsEngineeringInterconnection

A distributed power harvesting system including multiple direct current (DC) power sources with respective DC outputs adapted for interconnection into a interconnected DC power source output. A converter includes input terminals adapted for coupling to the interconnected DC power source output. A circuit loop sets the voltage and current at the input terminals of the converter according to predetermined criteria. A power conversion portion converts the power received at the input terminals to an output power at the output terminals. A power supplier is coupled to the output terminals. The power supplier includes a control part for maintaining the input to the power supplier at a predetermined value. The control part maintains the input voltage and / or input current to the power supplier at a predetermined value.

Owner:SOLAREDGE TECH LTD

Metal capacitor and method of making the same

ActiveUS8114734B2Increase capacitanceAvoid delaySemiconductor/solid-state device detailsSolid-state devicesCapacitanceInterconnection

A method of making a metal capacitor includes the following steps. A dielectric layer having a metal interconnection and a capacitor electrode is provided. Then, a treatment is performed to increase the dielectric constant of the dielectric layer surrounding the capacitor electrode. The treatment can be UV radiation, a plasma treatment or an ion implantation. Accordingly, the metal capacitor will have a higher capacitance and RC delay between the metal interconnection and the dielectric layer can be prevented.

Owner:MARLIN SEMICON LTD

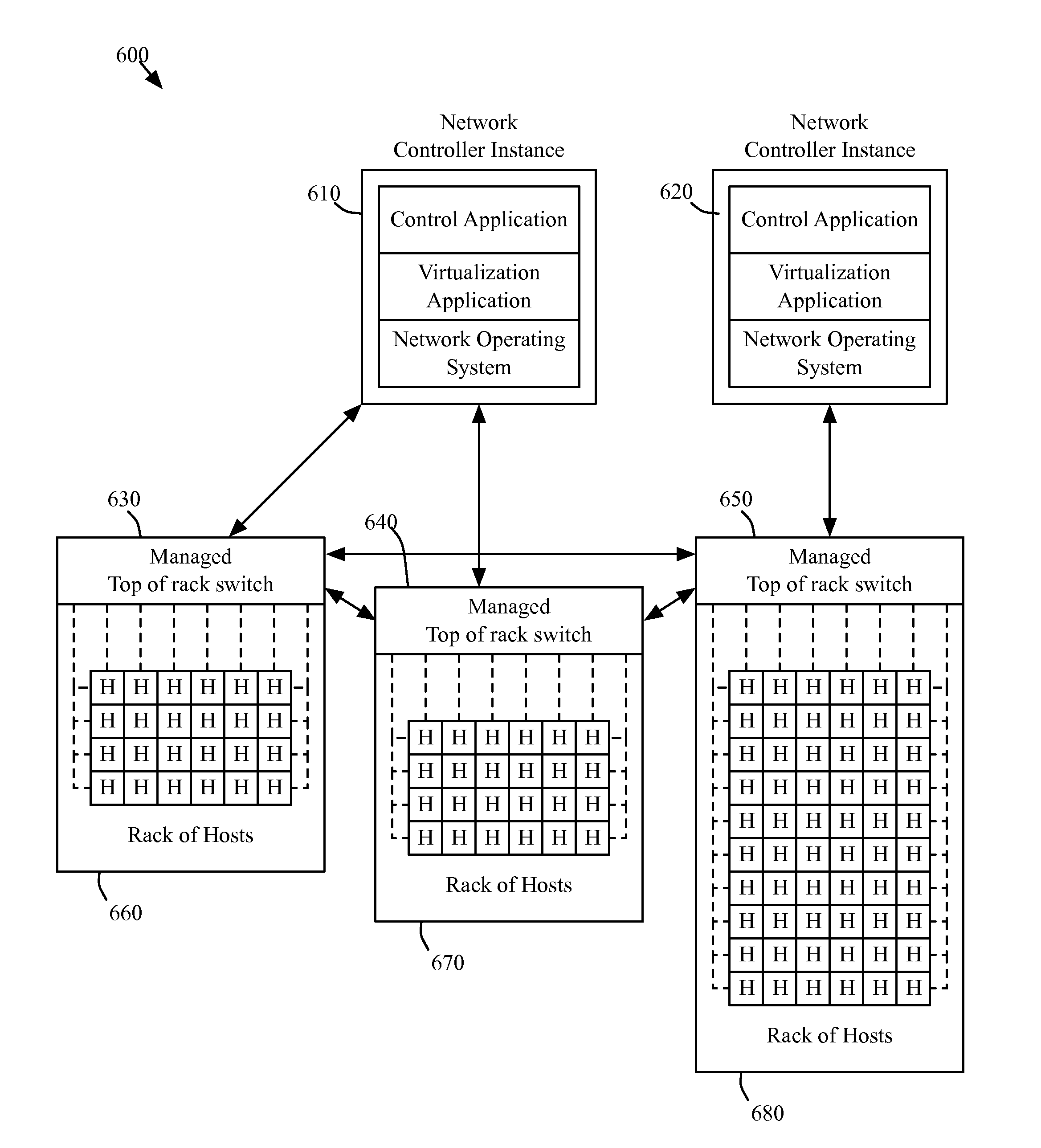

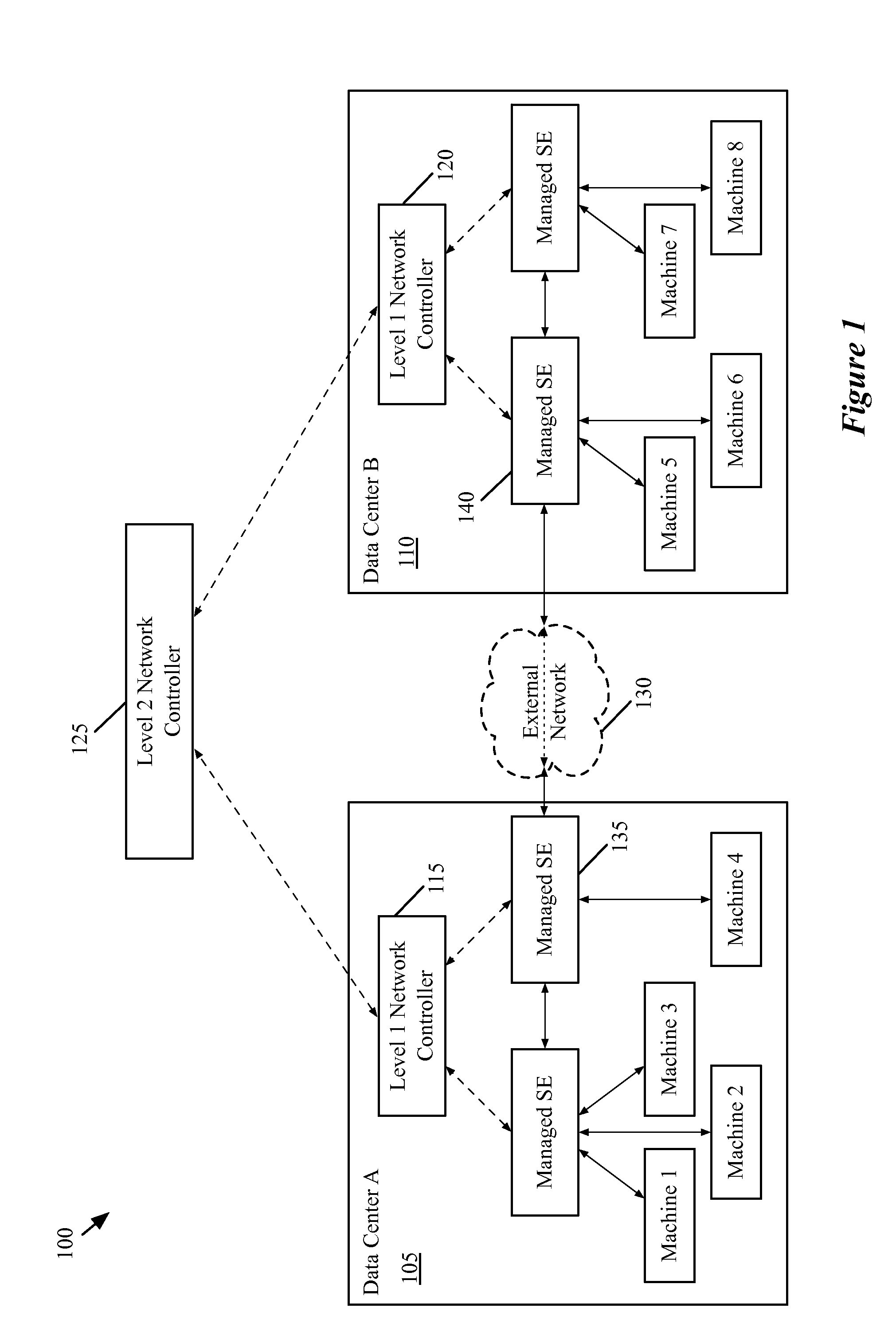

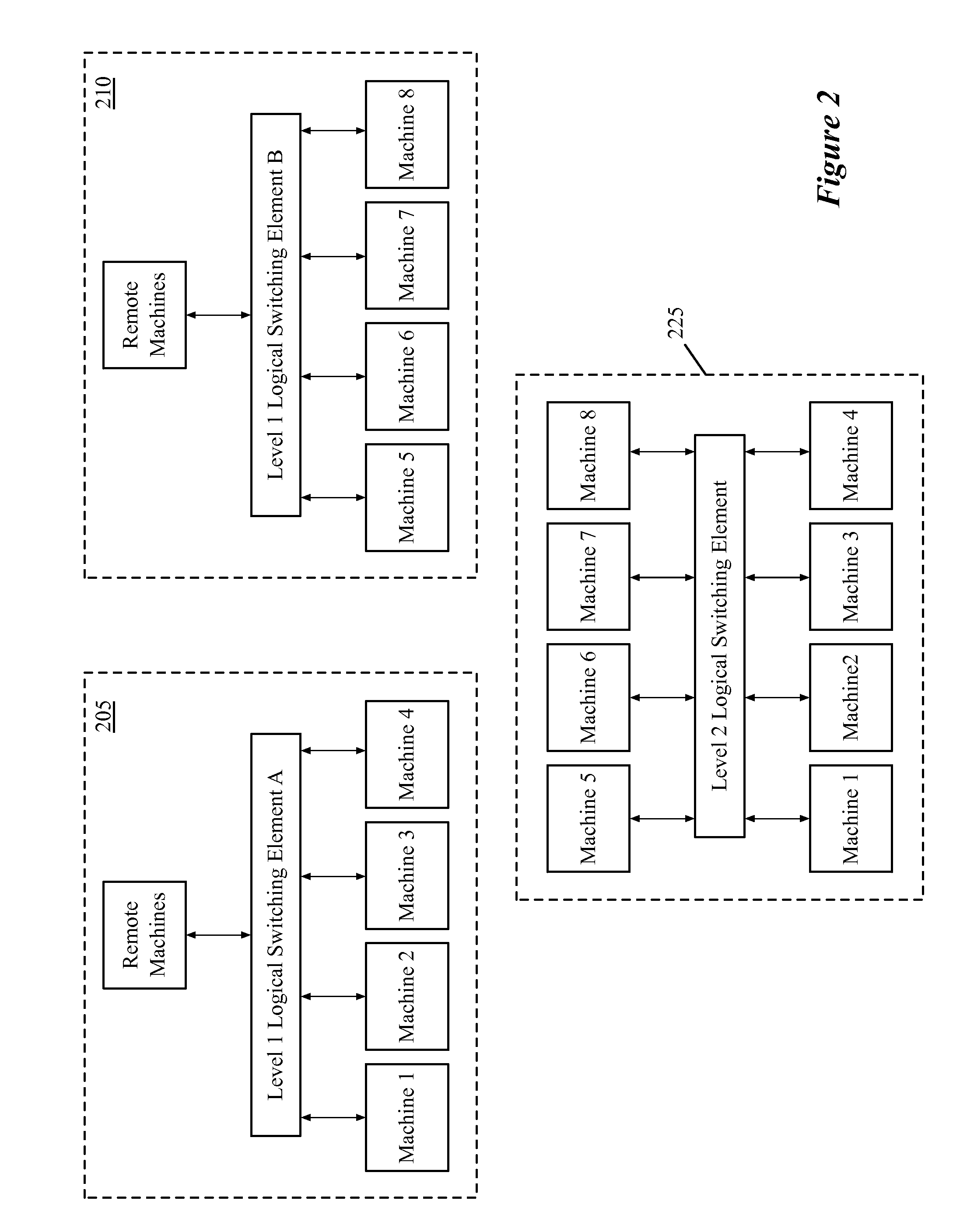

Federating interconnection switching element network to two or more levels

ActiveUS20130044641A1Data switching by path configurationNetwork connectionsControl systemNetwork control

A network control system for interconnecting several separate networks. The system includes i) several interconnection switching elements, each of which is for connecting one of the separate networks to a common interconnecting network, ii) a first set of network controllers for managing a first set of the interconnection switching elements at a first set of separate networks in order for machines at different networks within the first set to communicate with each other, iii) a second set of network controllers for managing a second set of interconnection switching elements at a second set of separate networks in order for machines at different networks within the second set to communicate with each other, and iv) a third set of network controllers for managing the first and second sets of network controllers in order for machines at networks in the first set to communicate with machines at networks in the second set.

Owner:NICIRA

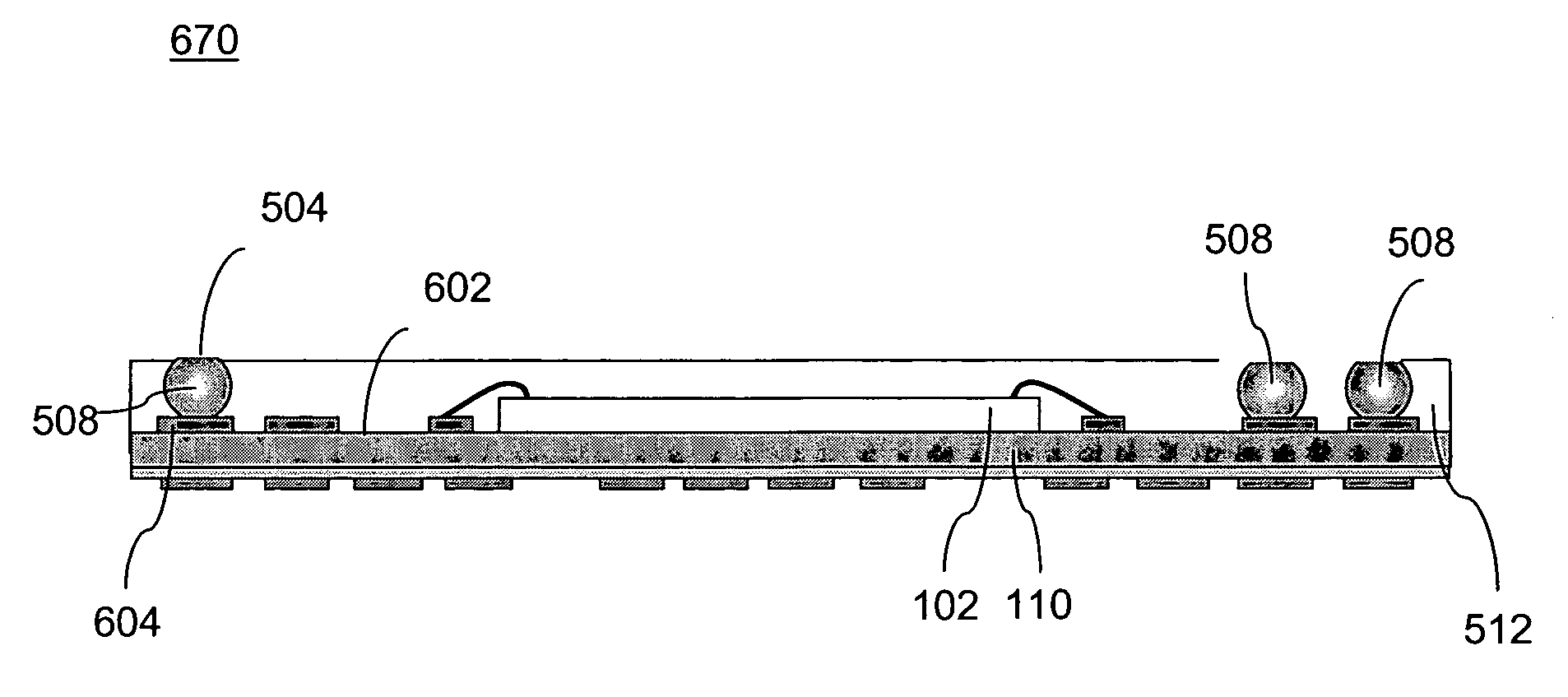

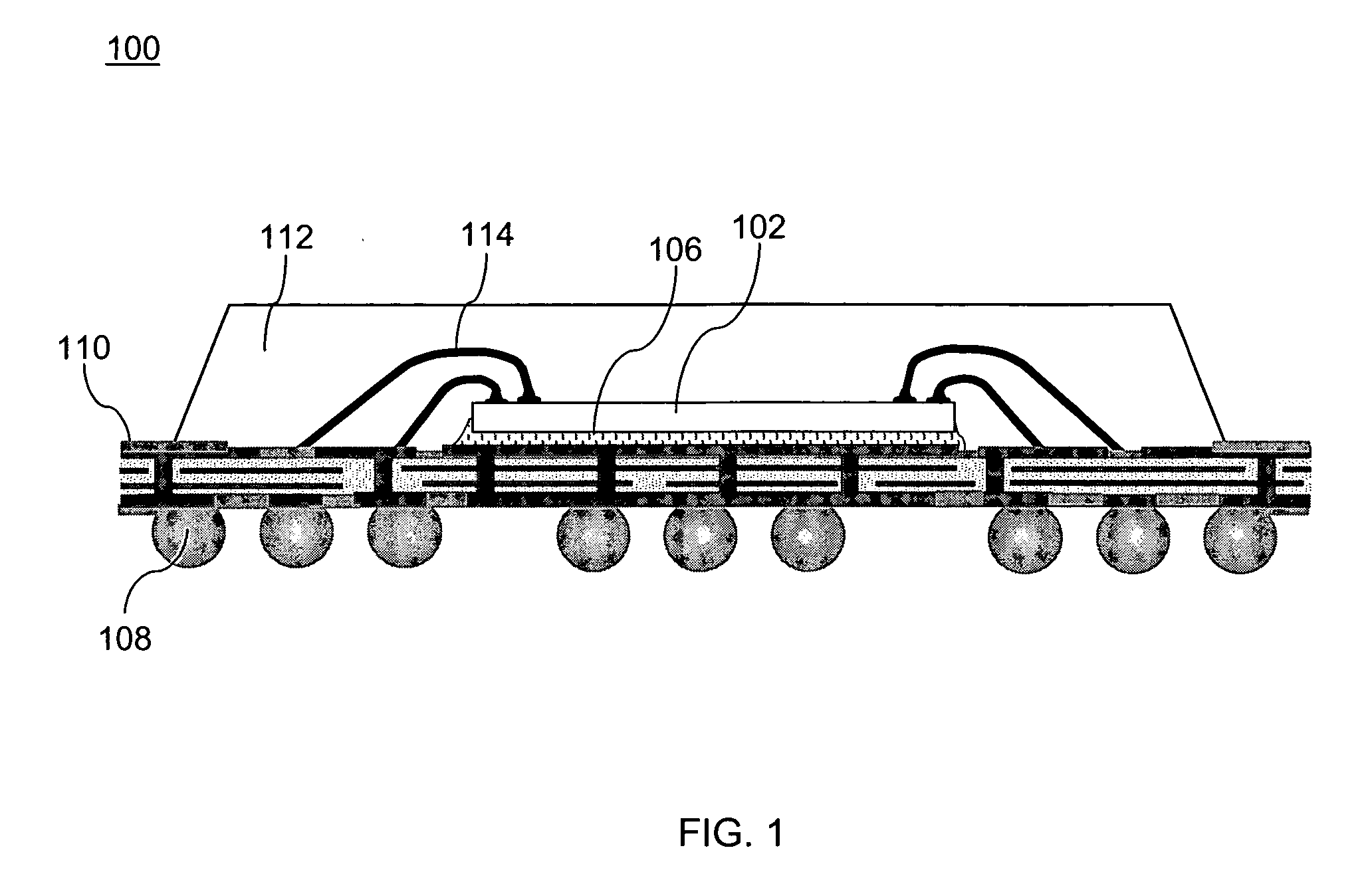

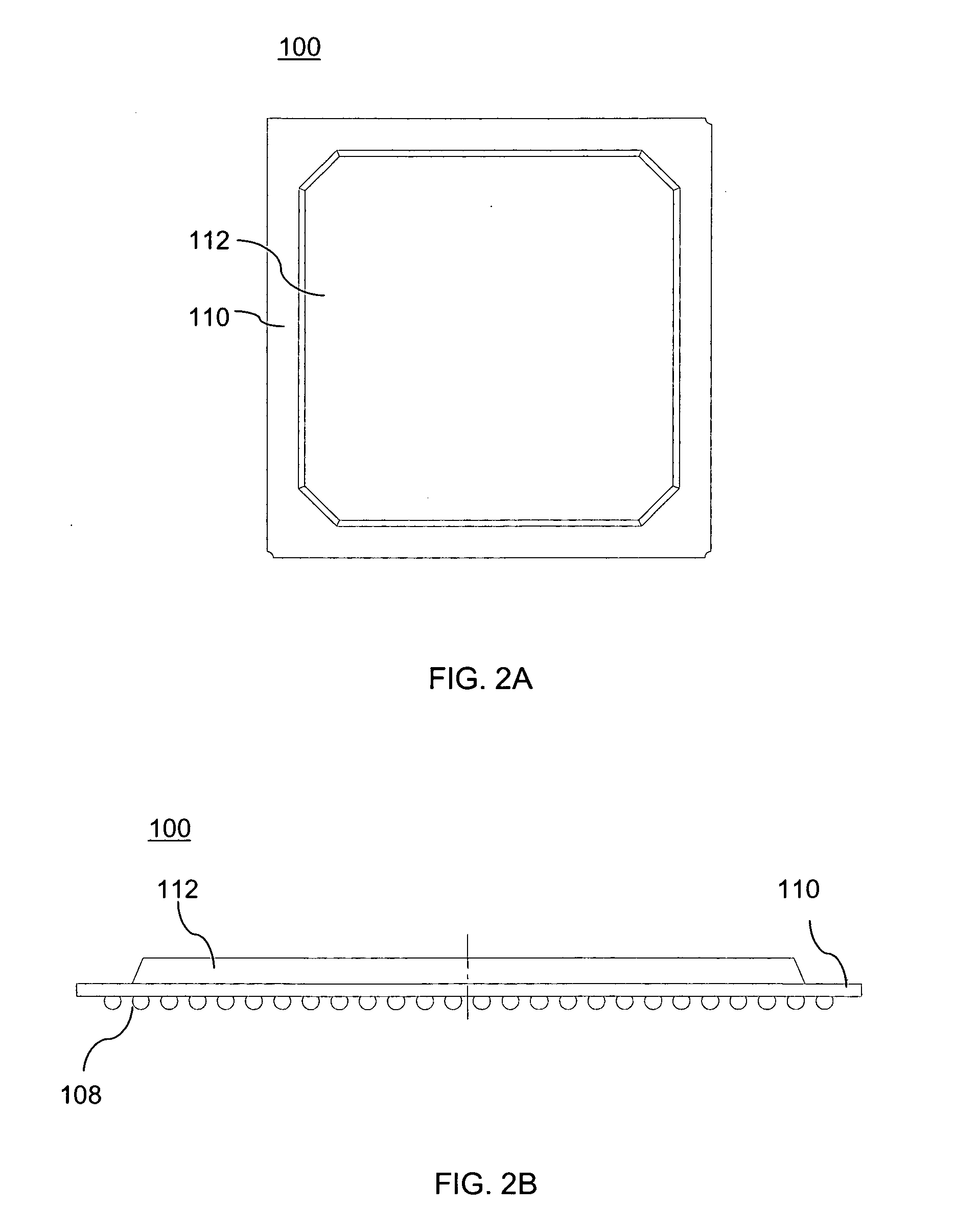

Integrated circuit (IC) package stacking and IC packages formed by same

ActiveUS20070290376A1Semiconductor/solid-state device detailsSolid-state devicesContact padSolder ball

Methods, systems, and apparatuses for integrated circuit (IC) package vertical interconnection are described herein. In an aspect of the invention, an IC package includes an IC die with contact pads. The IC package also includes interconnect members which are coupled to the die at the contact pads. An encapsulating material encapsulates the IC die and the interconnect members such that a contact surface of each interconnect member is accessible at a surface of the encapsulating material. A second IC package is coupled to the first IC package through the plurality of interconnect members of the first IC package. In an example, solder balls attached to a bottom of the second IC package are coupled to the contact surfaces of the interconnect members to couple the first IC package and the second IC package.

Owner:AVAGO TECH INT SALES PTE LTD

Systems and methods for posterior dynamic stabilization of the spine

InactiveUS20080097441A1Reduces and eliminates facet painLiquidityInternal osteosythesisJoint implantsSpinal columnInterconnection

Systems and devices for dynamically stabilizing the spine are provided. The systems include a superior component for attachment to a superior vertebra of a spinal motion segment and an inferior component for attachment to an inferior vertebral of a spinal motion segment. The interconnection between the two components enables the spinal motion segment to move in a manner that mimics the natural motion of the spinal motion segment while substantially offloading the facet joints of the spine. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:EXACTECH INC

Interconnection enclosure having a connector port and preterminated optical connector

InactiveUS6856748B1Maintaining bend radius controlReduce riskCoupling light guidesFibre mechanical structuresEngineeringInterconnection

An interconnection enclosure comprising at least one connector port operable for receiving a connector pair and a preterminated optical connector received in the at least one connector port, wherein the preterminated optical connector is adapted to be withdrawn from the exterior of the enclosure without entering the enclosure. The enclosure further comprising a tether means, a bend radius control means and a sealing means. An interconnection enclosure comprised of two halves held together by a fastening means, the enclosure defining an end wall and defining at least one connector port opening through the end wall for receiving a preterminated optical connector, the enclosure housing further defining an opening for receiving a distribution cable extending therethrough, wherein the preterminated optical connector is adapted to be withdrawn from the exterior of the enclosure without entering the enclosure.

Owner:CORNING OPTICAL COMM LLC

Systems and methods for posterior dynamic stabilization of the spine

InactiveUS20060084984A1Adjustable lengthShape adjustableInternal osteosythesisJoint implantsSpinal columnMedicine

Systems and devices for dynamically stabilizing the spine are provided. The systems include a superior component for attachment to a superior vertebra of a spinal motion segment and an inferior component for attachment to an inferior vertebral of a spinal motion segment. The interconnection between the two components enables the spinal motion segment to move in a manner that mimics the natural motion of the spinal motion segment. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com