Patents

Literature

3023 results about "Microlens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A microlens is a small lens, generally with a diameter less than a millimetre (mm) and often as small as 10 micrometres (µm). The small sizes of the lenses means that a simple design can give good optical quality but sometimes unwanted effects arise due to optical diffraction at the small features. A typical microlens may be a single element with one plane surface and one spherical convex surface to refract the light. Because micro-lenses are so small, the substrate that supports them is usually thicker than the lens and this has to be taken into account in the design. More sophisticated lenses may use aspherical surfaces and others may use several layers of optical material to achieve their design performance.

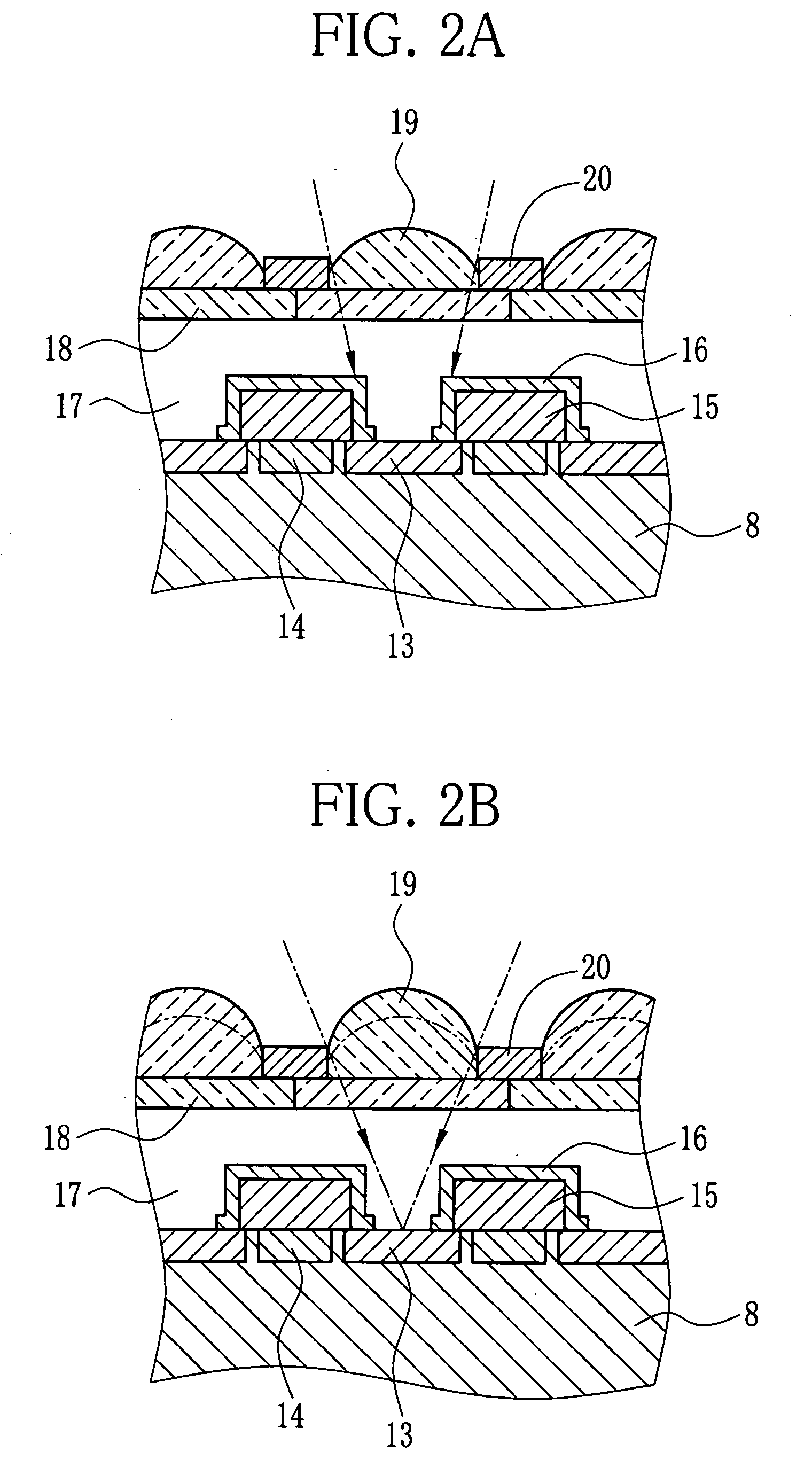

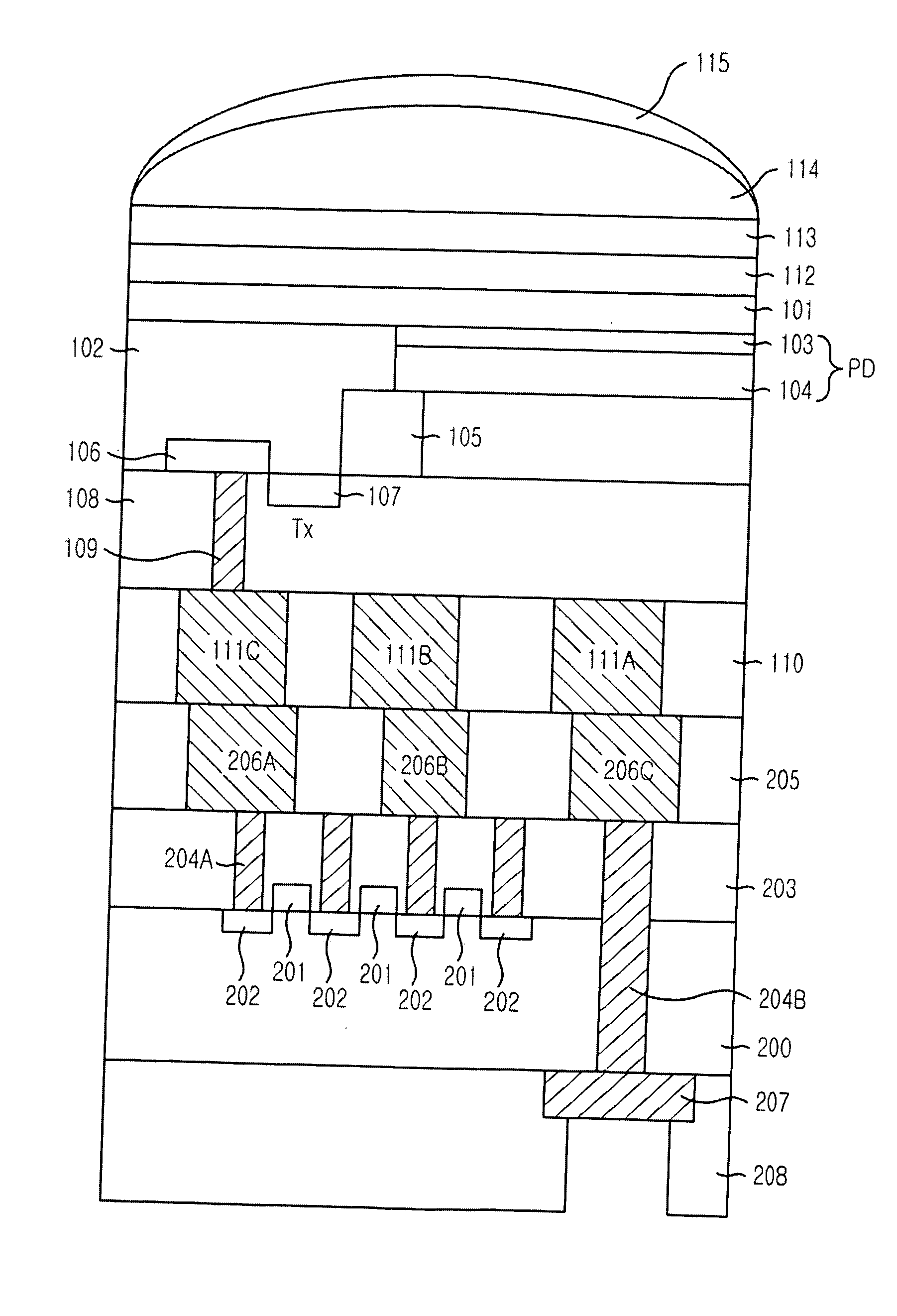

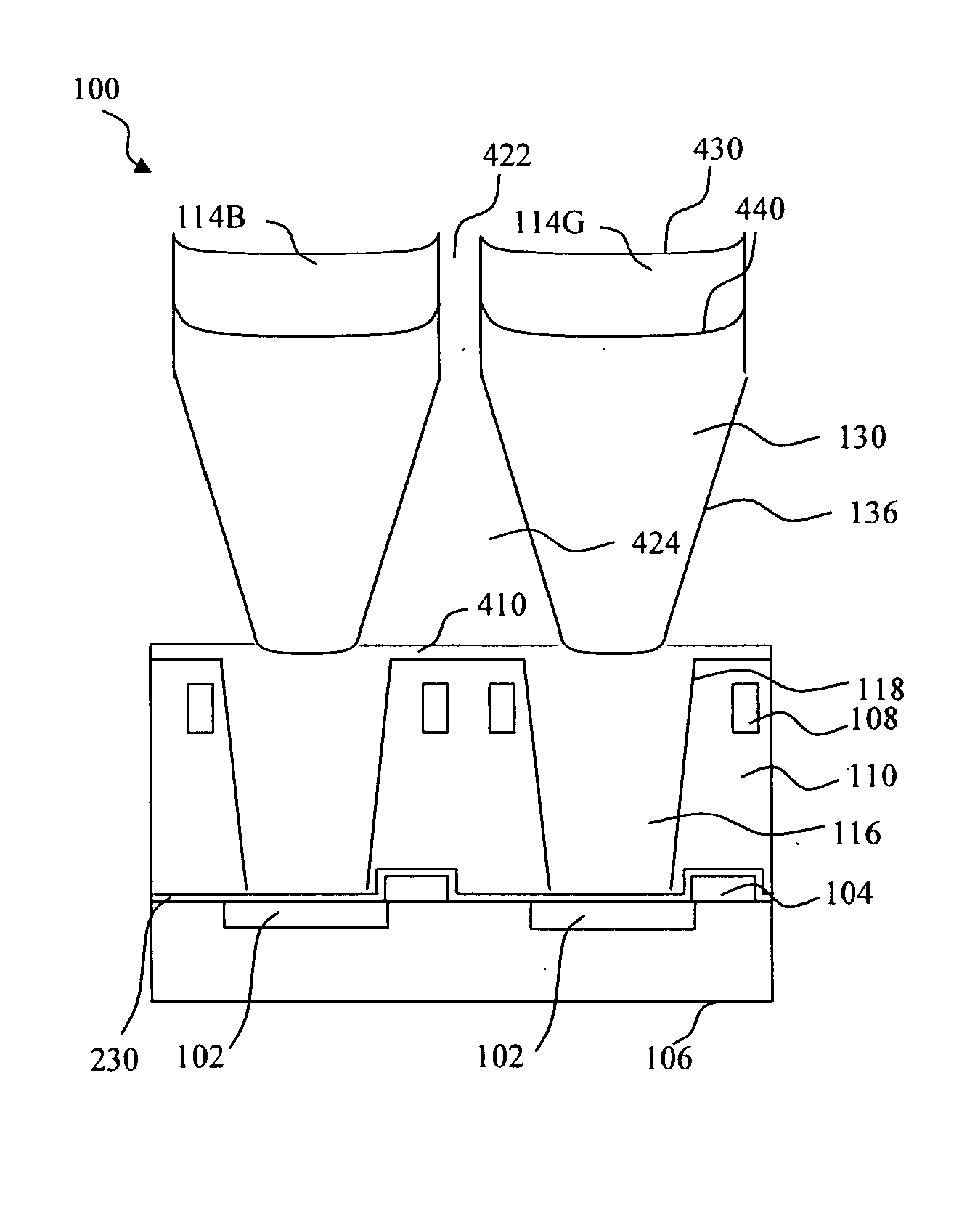

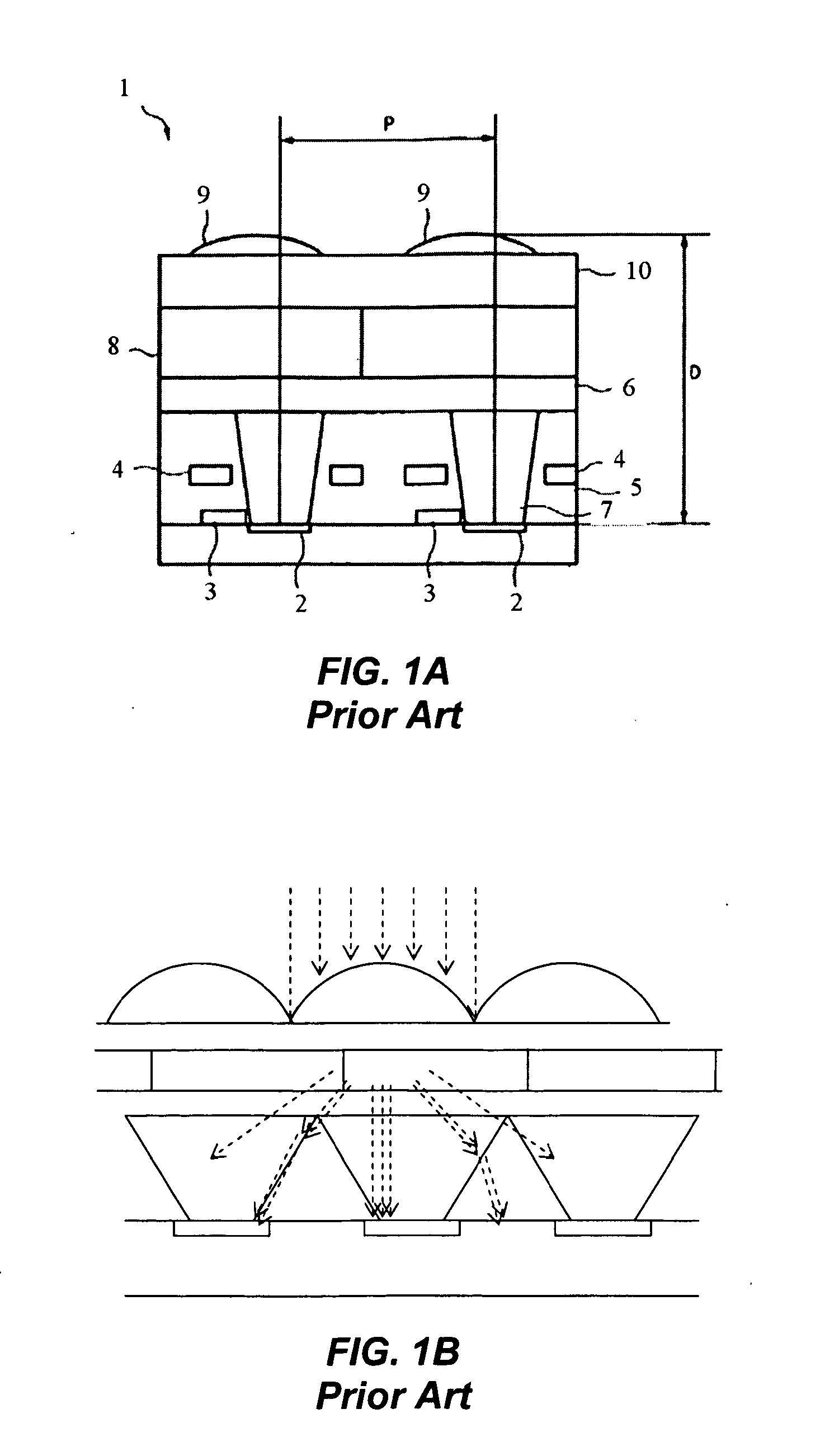

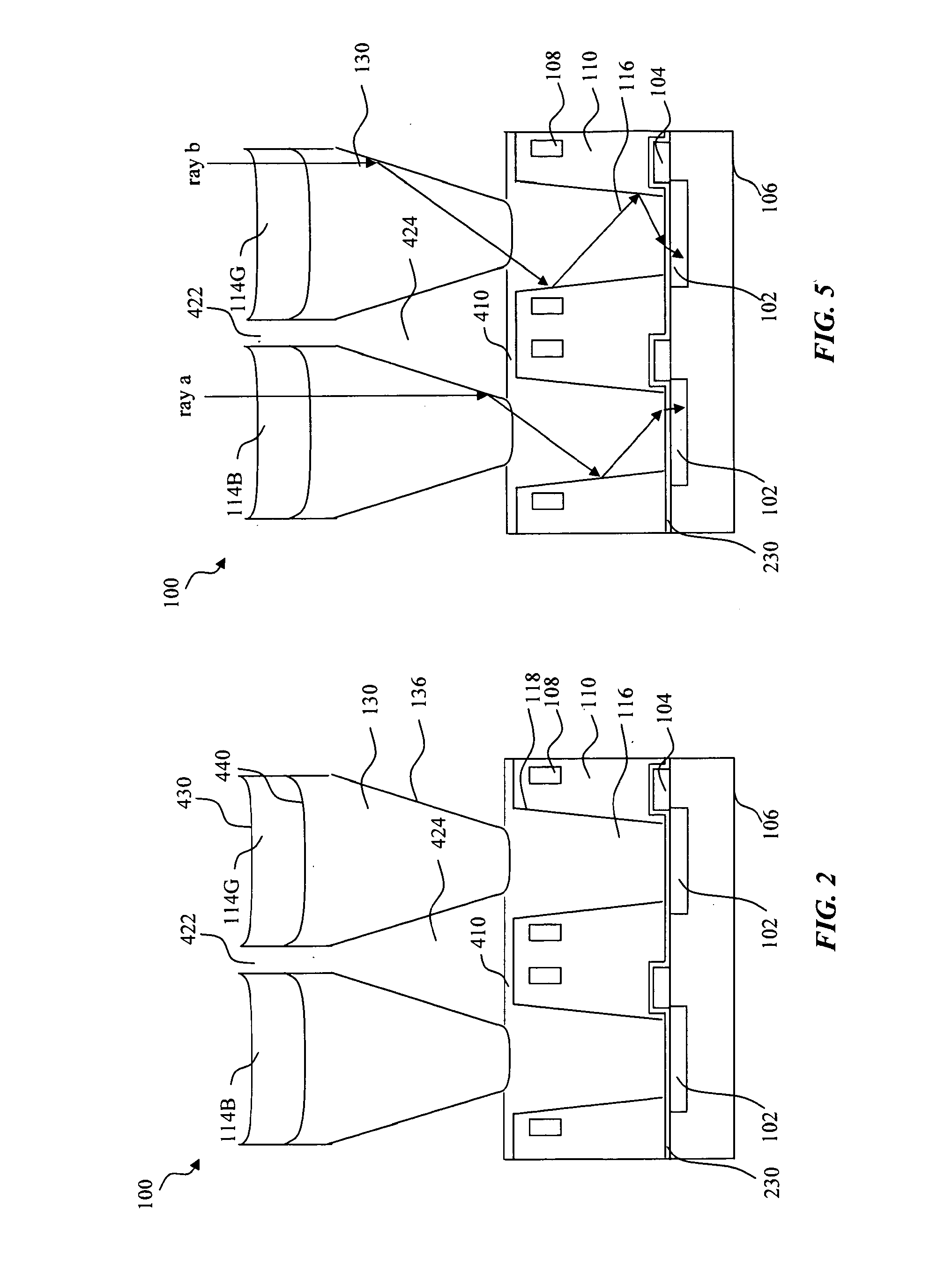

Solid-state imaging device, method of manufacturing the same, and electronic apparatus

ActiveUS20100201834A1Improve image qualityReduce colorTransistorTelevision system detailsInterconnectionPhotoelectric conversion

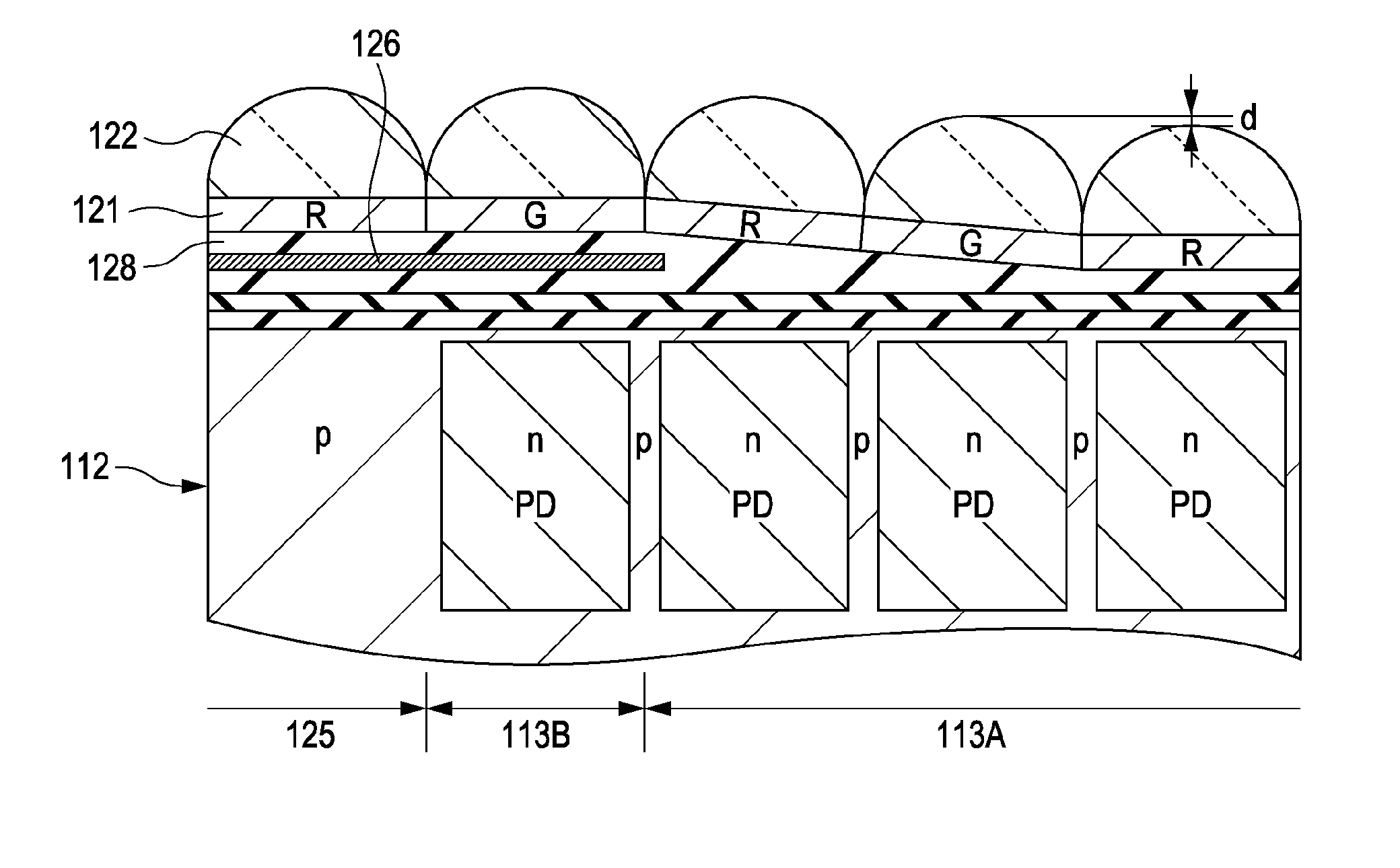

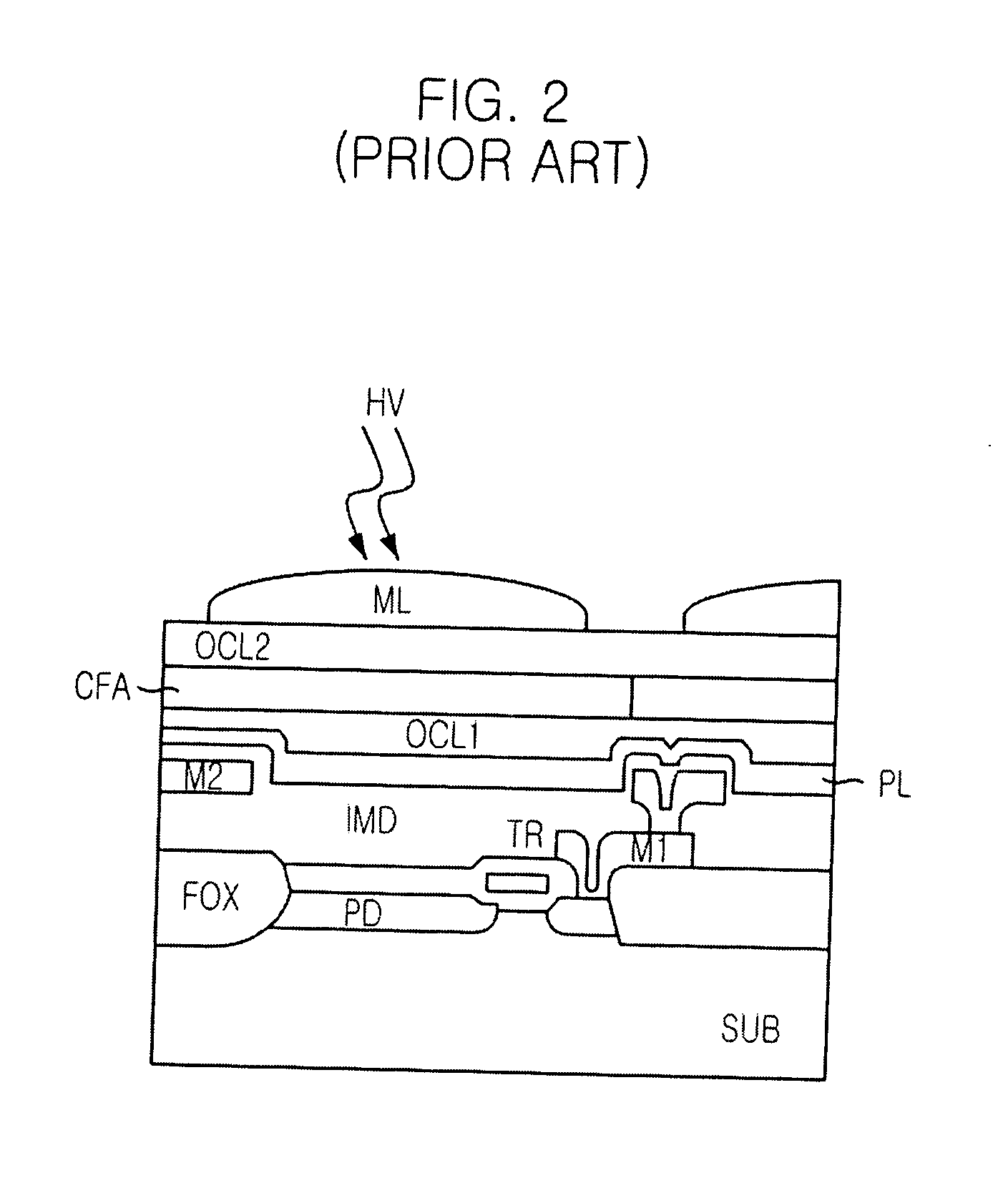

A solid-state imaging device includes: a pixel region in which a plurality of pixels composed of a photoelectric conversion section and a pixel transistor is arranged; an on-chip color filter; an on-chip microlens; and a multilayer interconnection layer in which a plurality of layers of interconnections is formed through an interlayer insulating film. The solid-state imaging device further includes a light-shielding film formed through an insulating layer in a pixel boundary of a light receiving surface in which the photoelectric conversion section is arranged.

Owner:SONY CORP

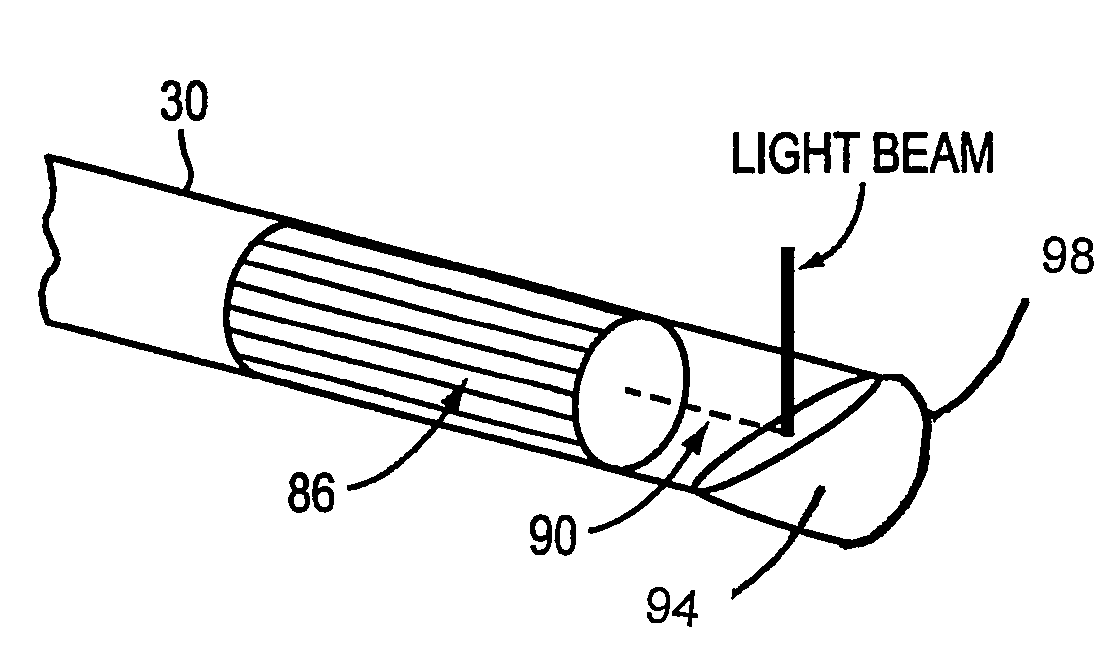

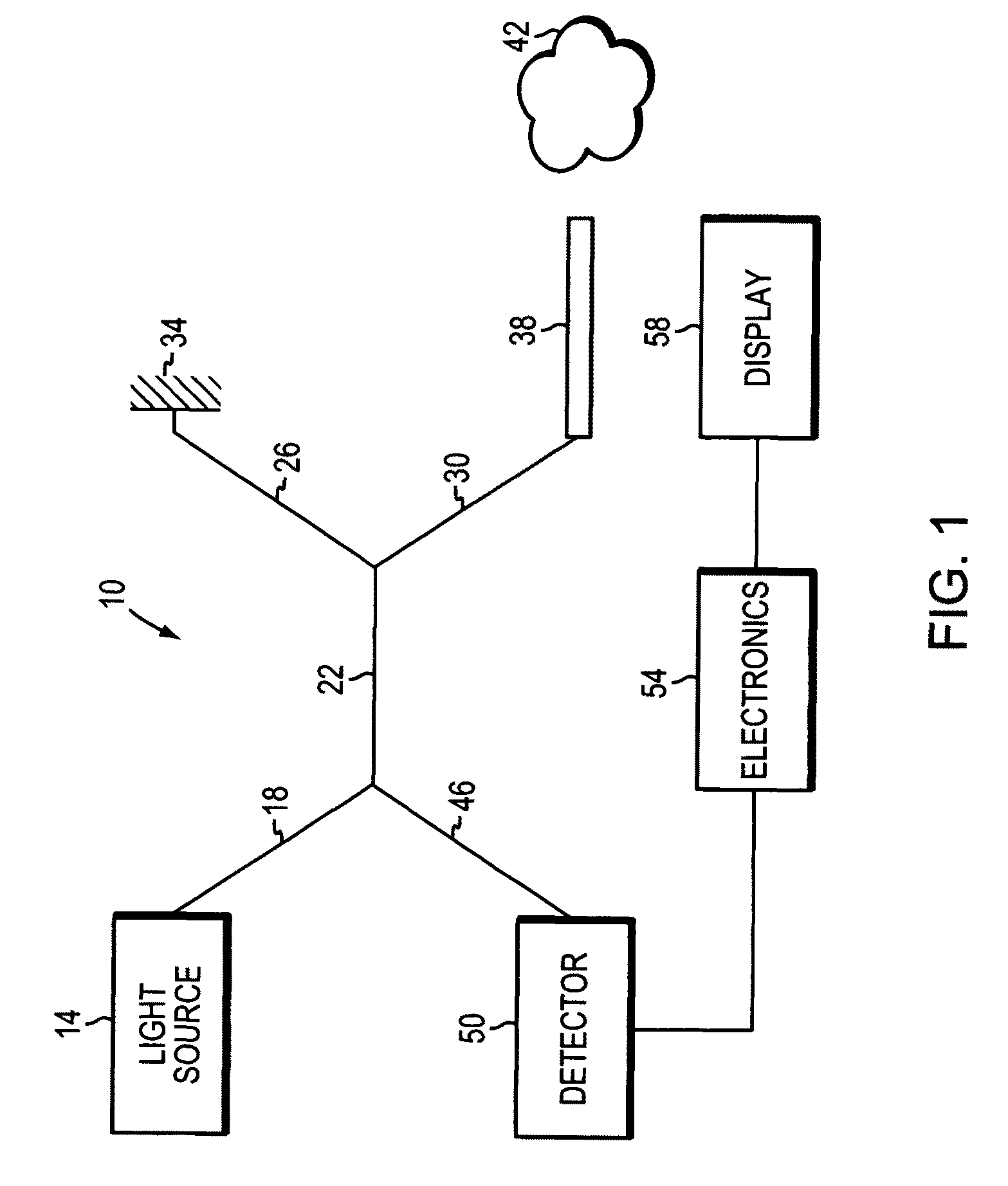

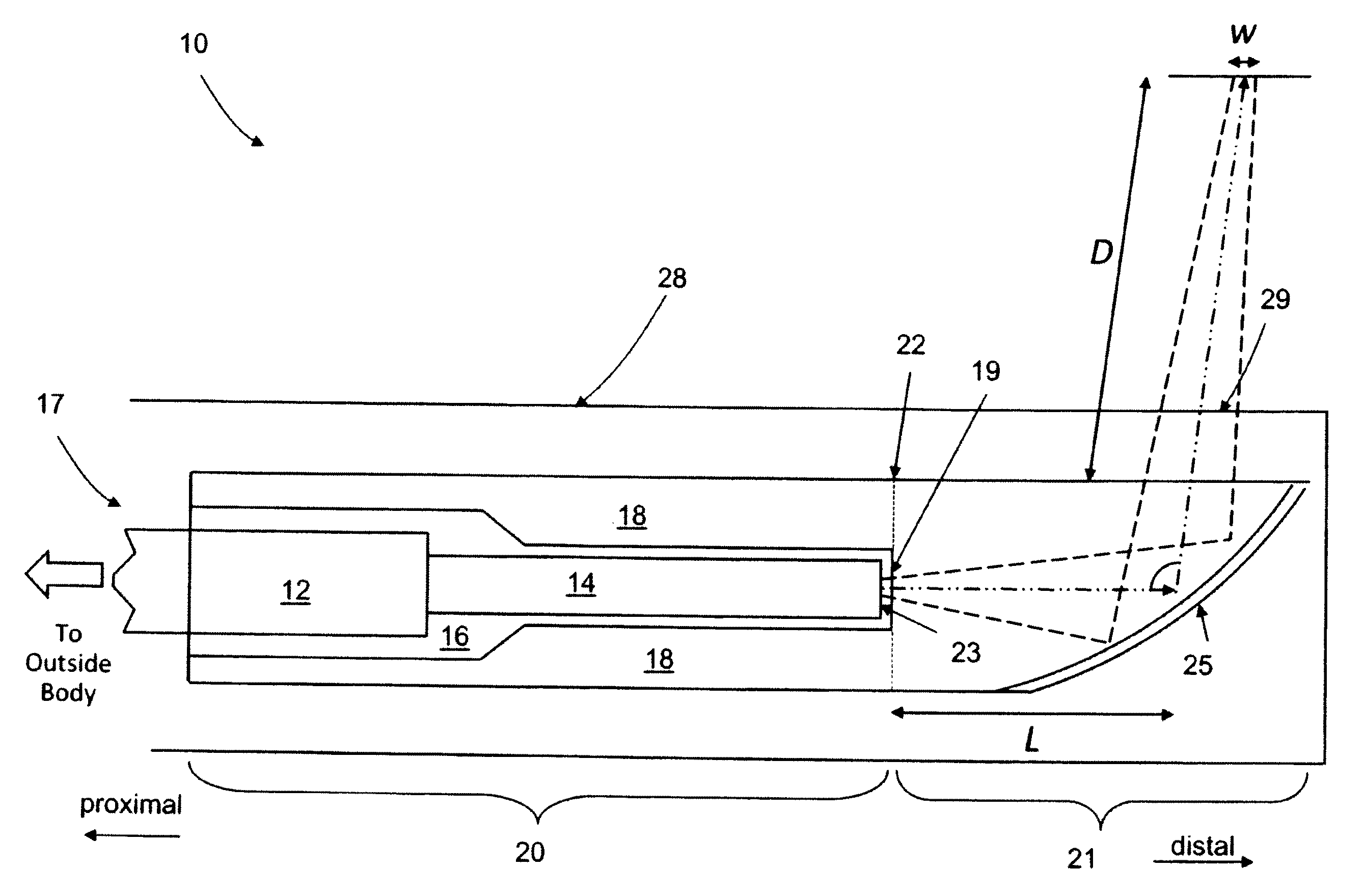

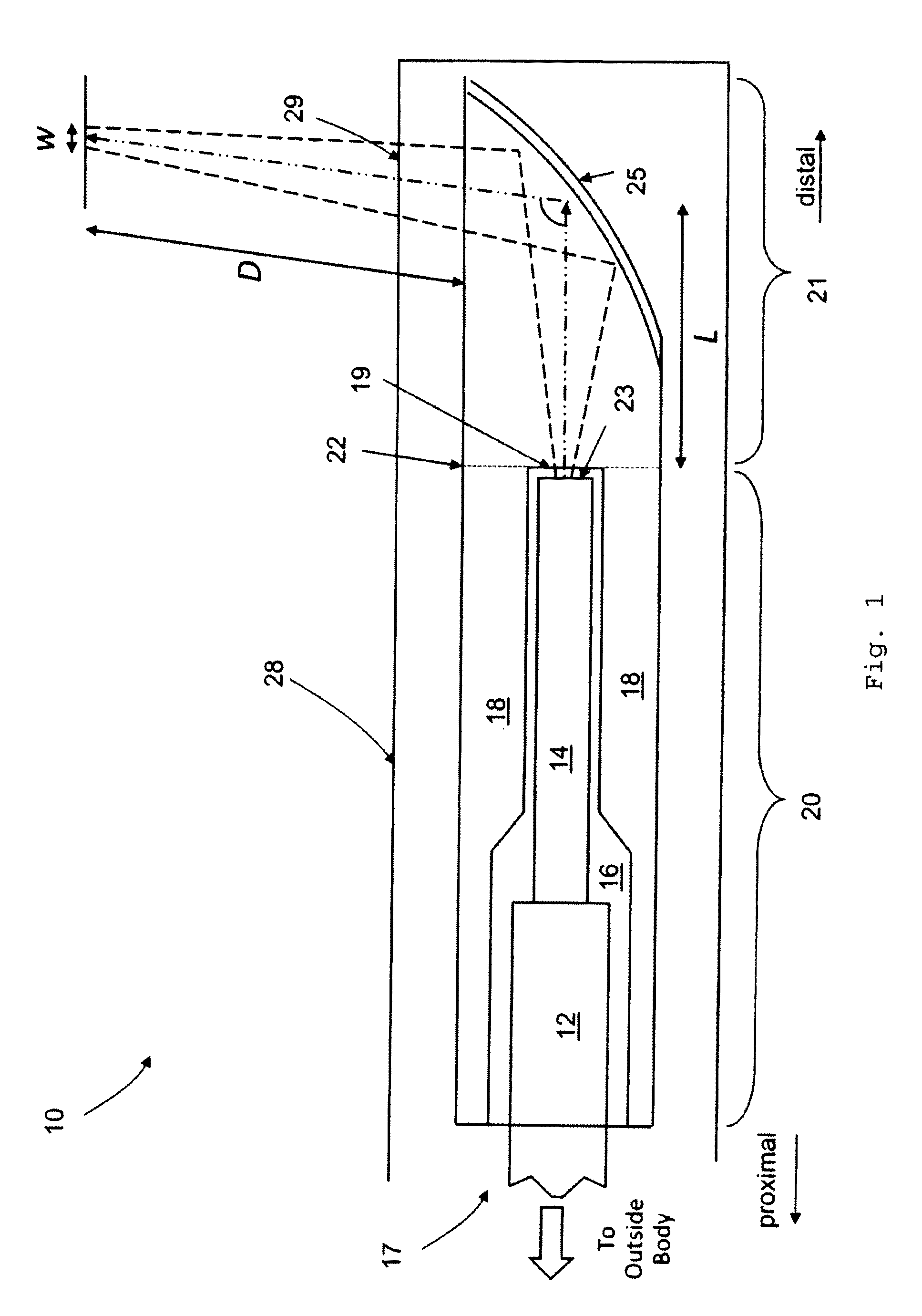

Imaging catheter with integrated reference reflector

In part, the invention relates to a lens assembly. The lens assembly includes a micro-lens; a beam director in optical communication with the micro-lens; and a substantially transparent film. The substantially transparent film is capable of bi-directionally transmitting light, and generating a controlled amount of backscatter. In addition, the film surrounds a portion of the beam director.

Owner:LIGHTLAB IMAGING

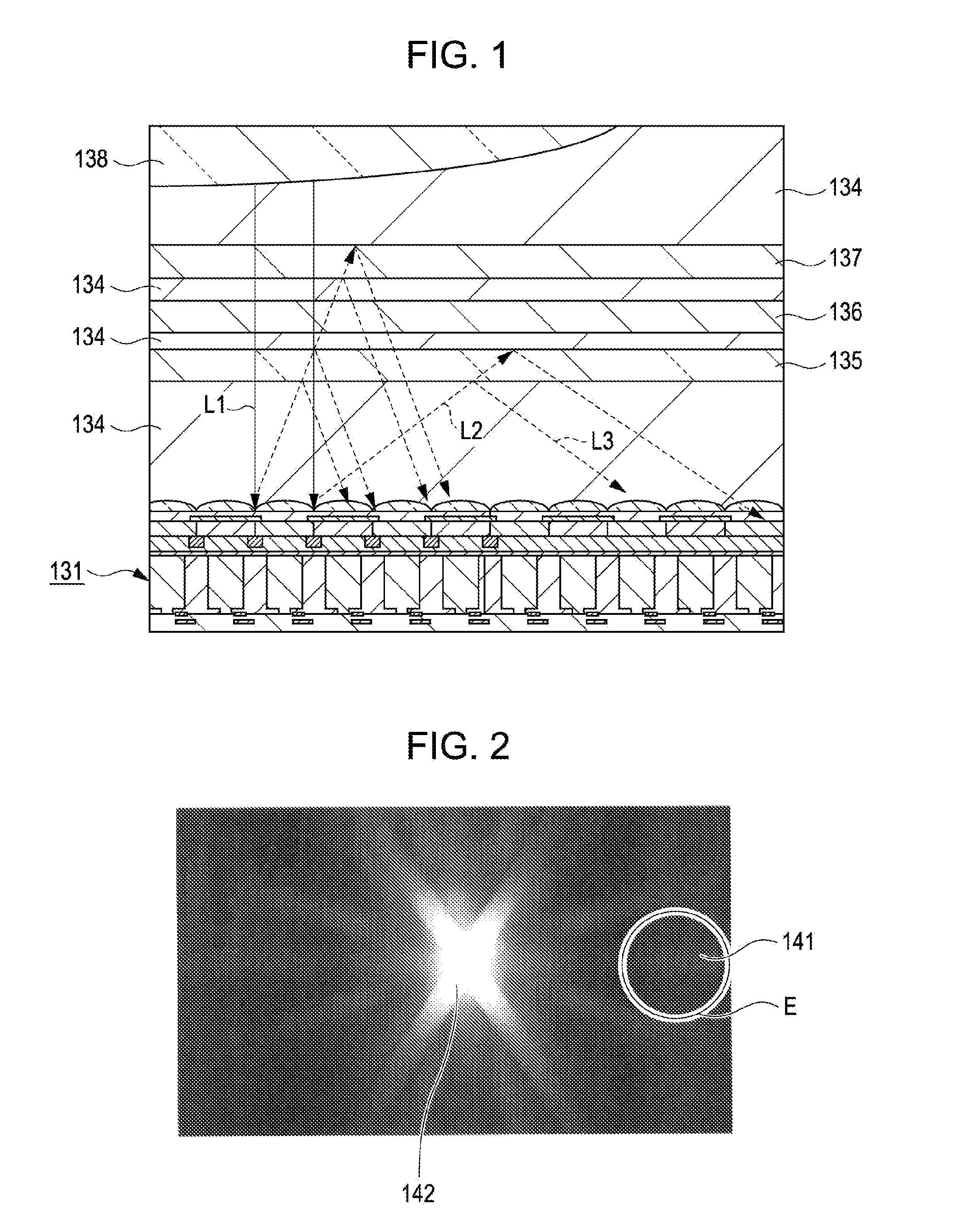

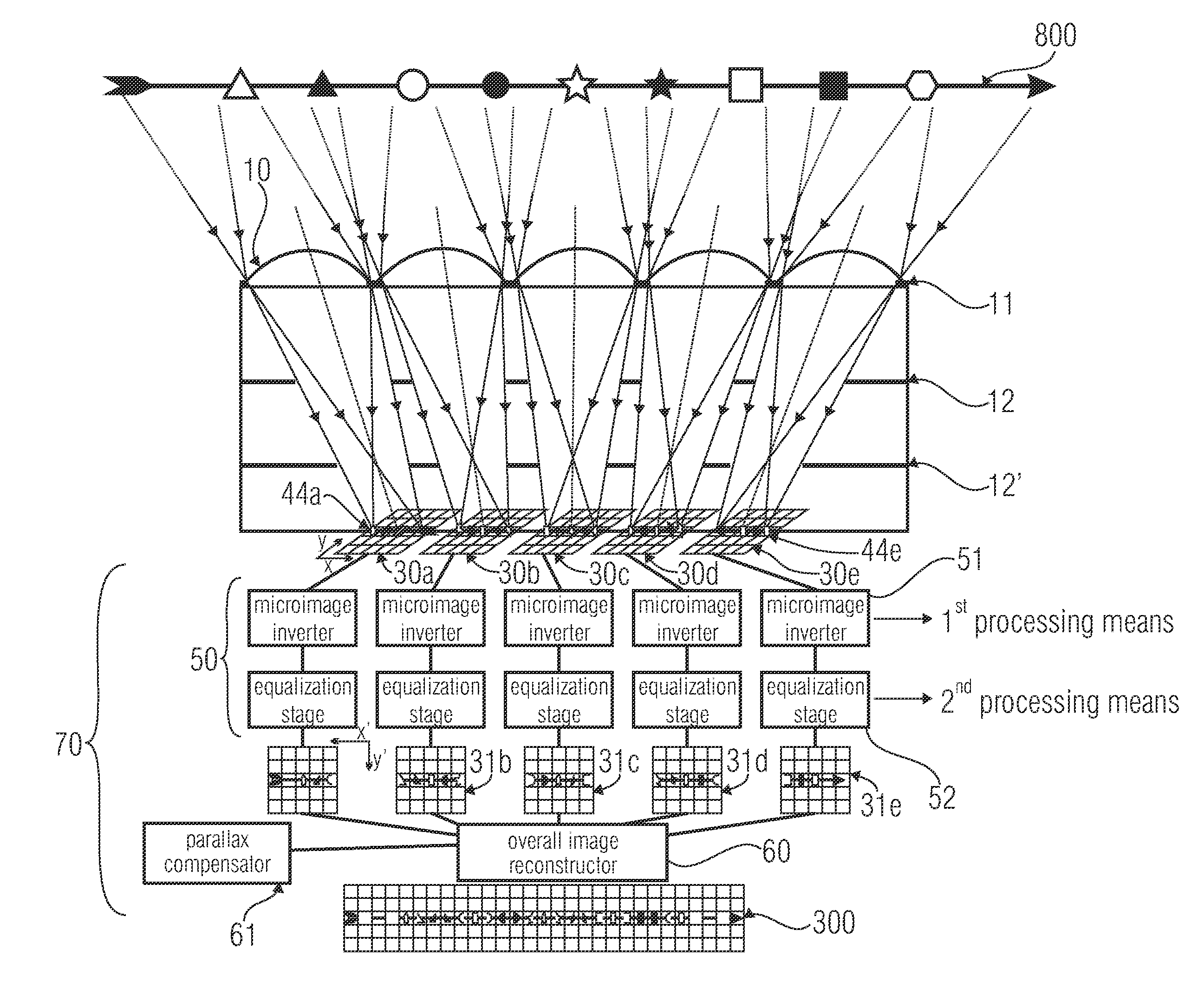

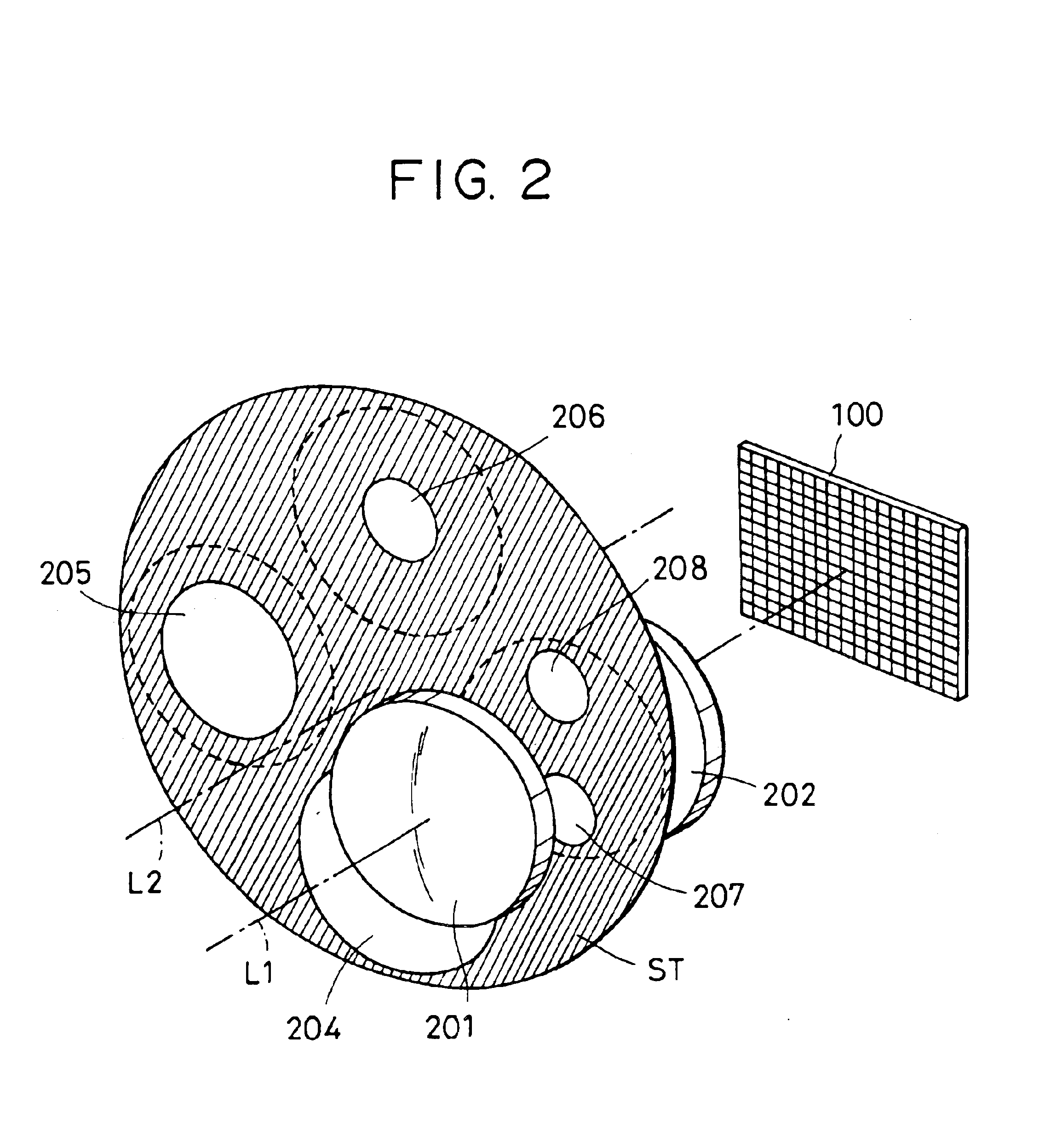

Device, image processing device and method for optical imaging

ActiveUS20110228142A1Short focal lengthShorten build lengthTelevision system detailsSolid-state devicesImaging processingGrating

An optical device for imaging is disclosed having at least one micro lens field with at least two micro lenses and one image sensor with at least two image detector matrices. The at least two image detector matrices each include a plurality of image detectors and there is an allocation between the image detector matrices and the micro lenses, so that each micro lens together with an image detector matrix forms an optical channel. The center points of the image detector matrices are shifted laterally by different distances, with respect to centroids, projected onto the image detector matrices, of the micro lens apertures of the associated optical channels, so that the optical channels have different partially overlapping detection areas and so that an overlapping area of the detection areas of two channels is imaged onto the image detector matrices offset with respect to an image detector raster of the image detector matrices. Further, an image processing device and a method for optical imaging are described.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

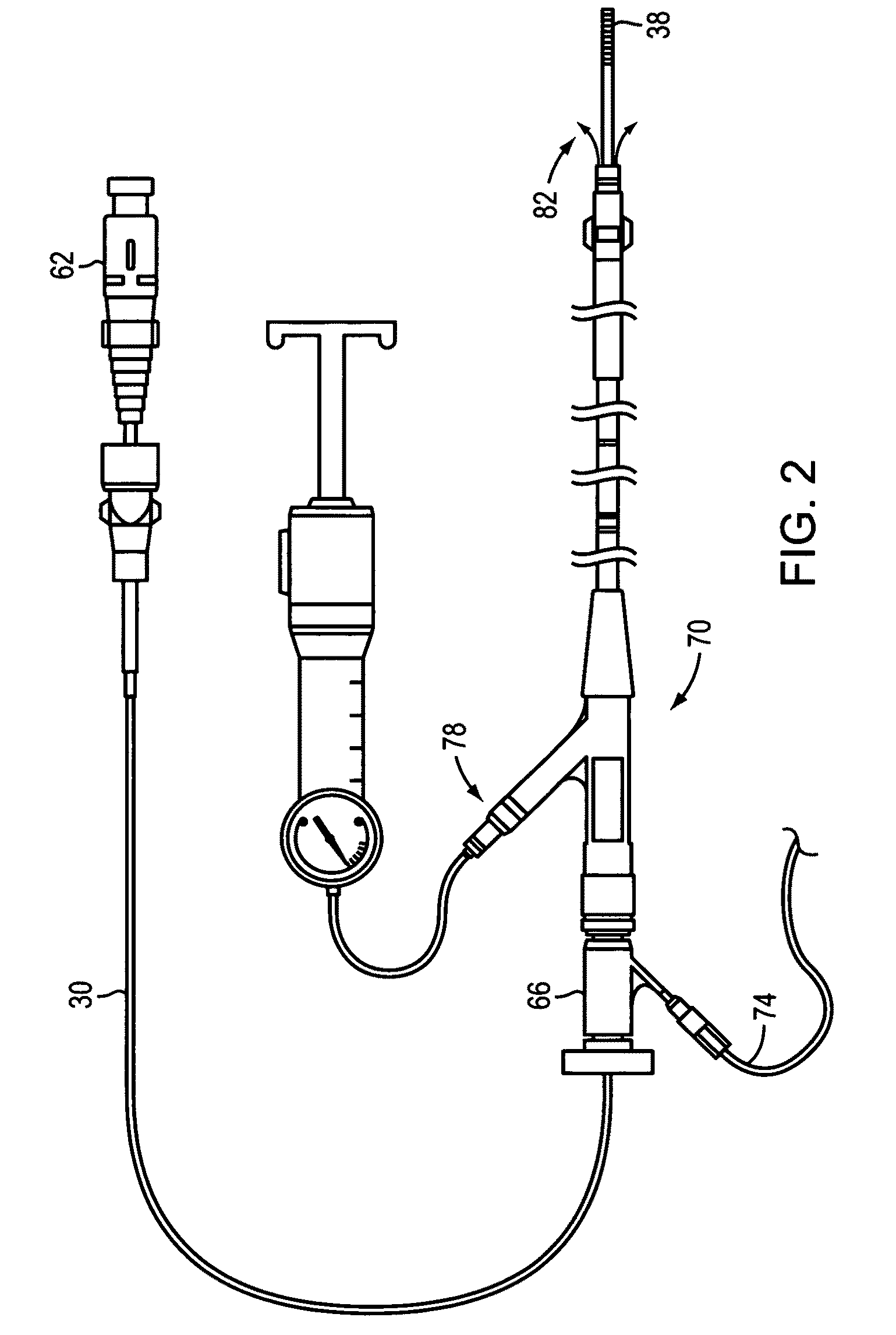

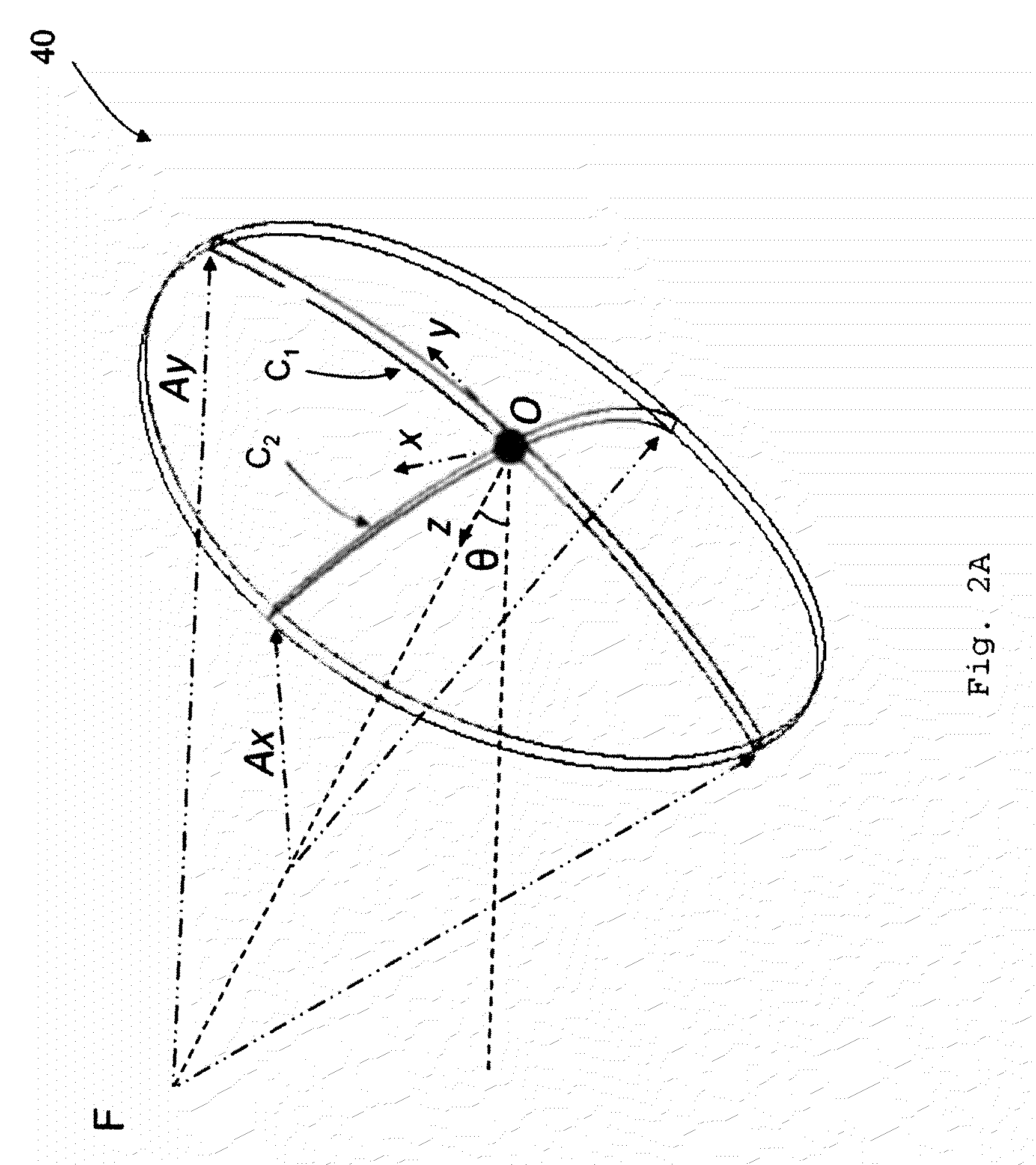

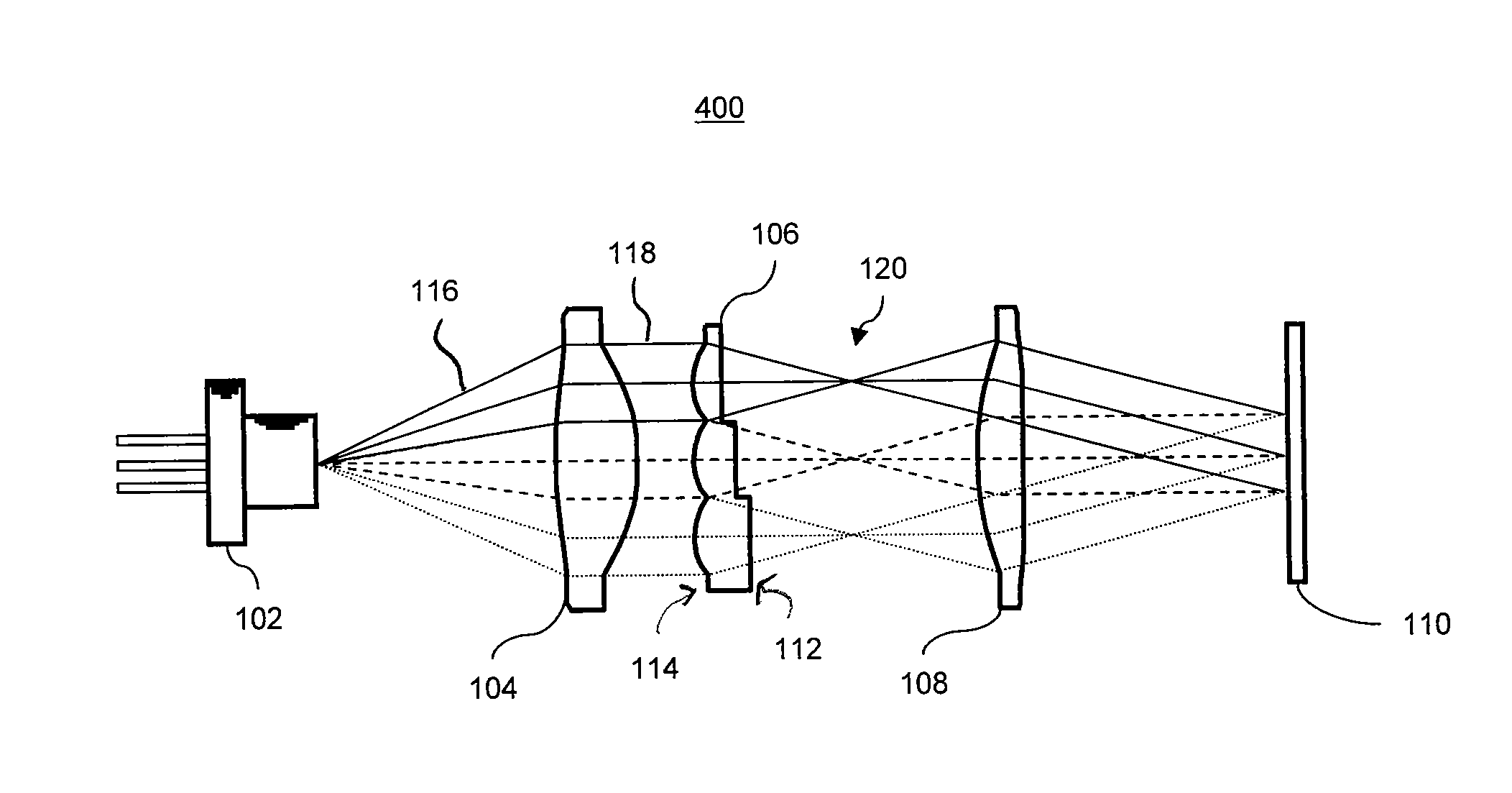

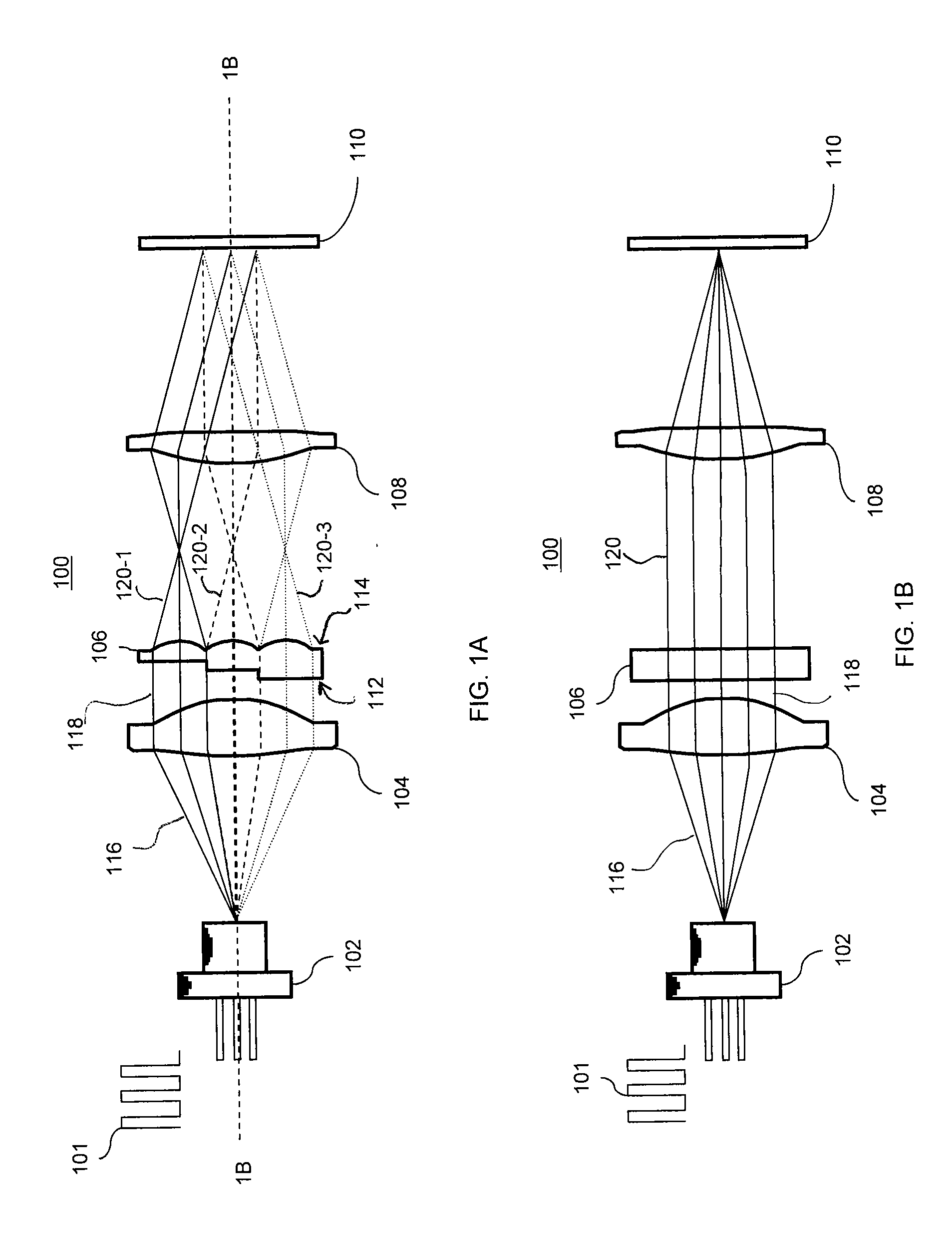

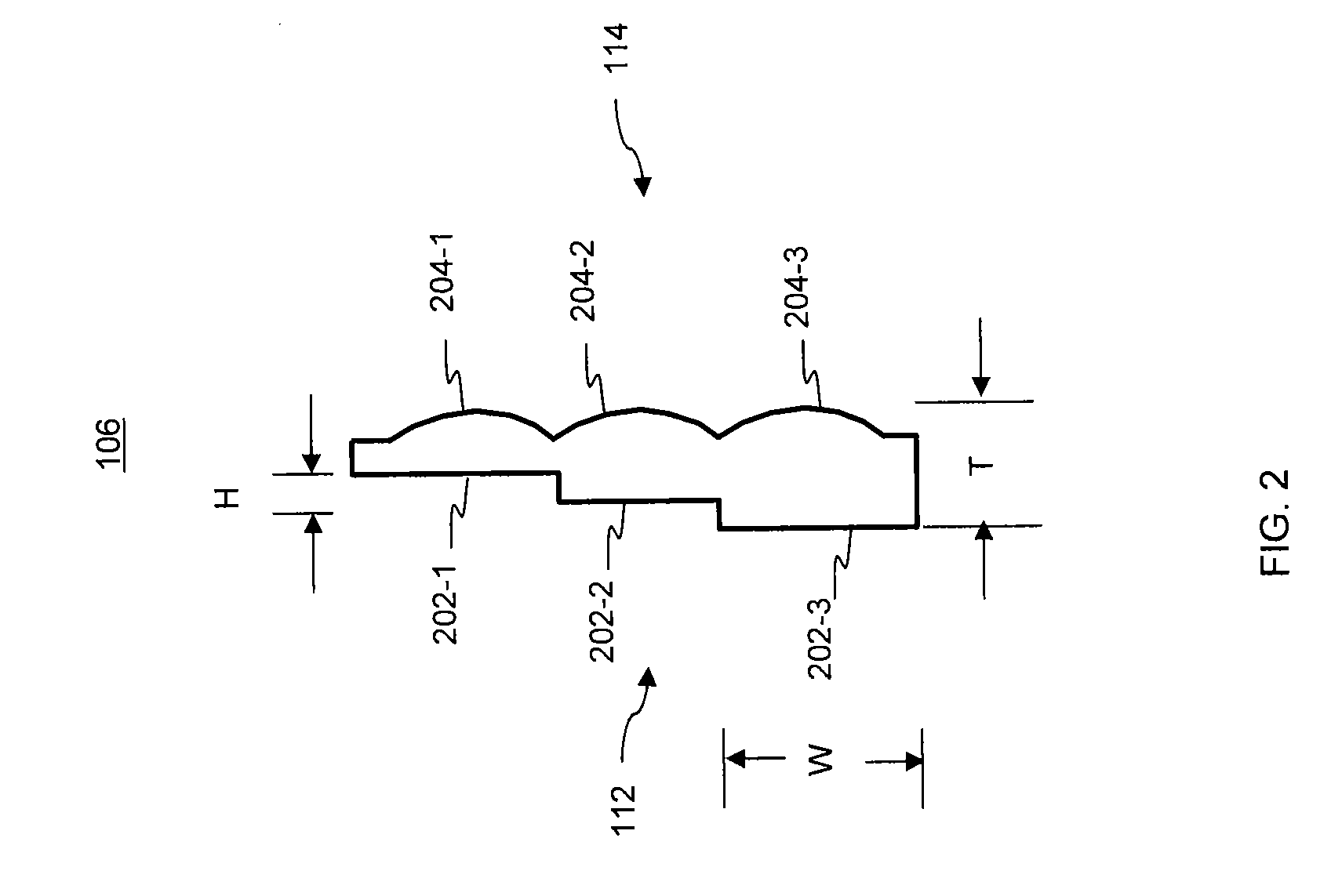

Miniature Optical Elements for Fiber-Optic Beam Shaping

ActiveUS20100253949A1Avoid disruptionAvoid damageMirrorsEndoscopesFiberDiagnostic Radiology Modality

In part, the invention relates to optical caps having at least one lensed surface configured to redirect and focus light outside of the cap. The cap is placed over an optical fiber. Optical radiation travels through the fiber and interacts with the optical surface or optical surfaces of the cap, resulting in a beam that is either focused at a distance outside of the cap or substantially collimated. The optical elements such as the elongate caps described herein can be used with various data collection modalities such optical coherence tomography. In part, the invention relates to a lens assembly that includes a micro-lens; a beam director in optical communication with the micro-lens; and a substantially transparent film or cover. The substantially transparent film is capable of bi-directionally transmitting light, and generating a controlled amount of backscatter. The film can surround a portion of the beam director.

Owner:LIGHTLAB IMAGING

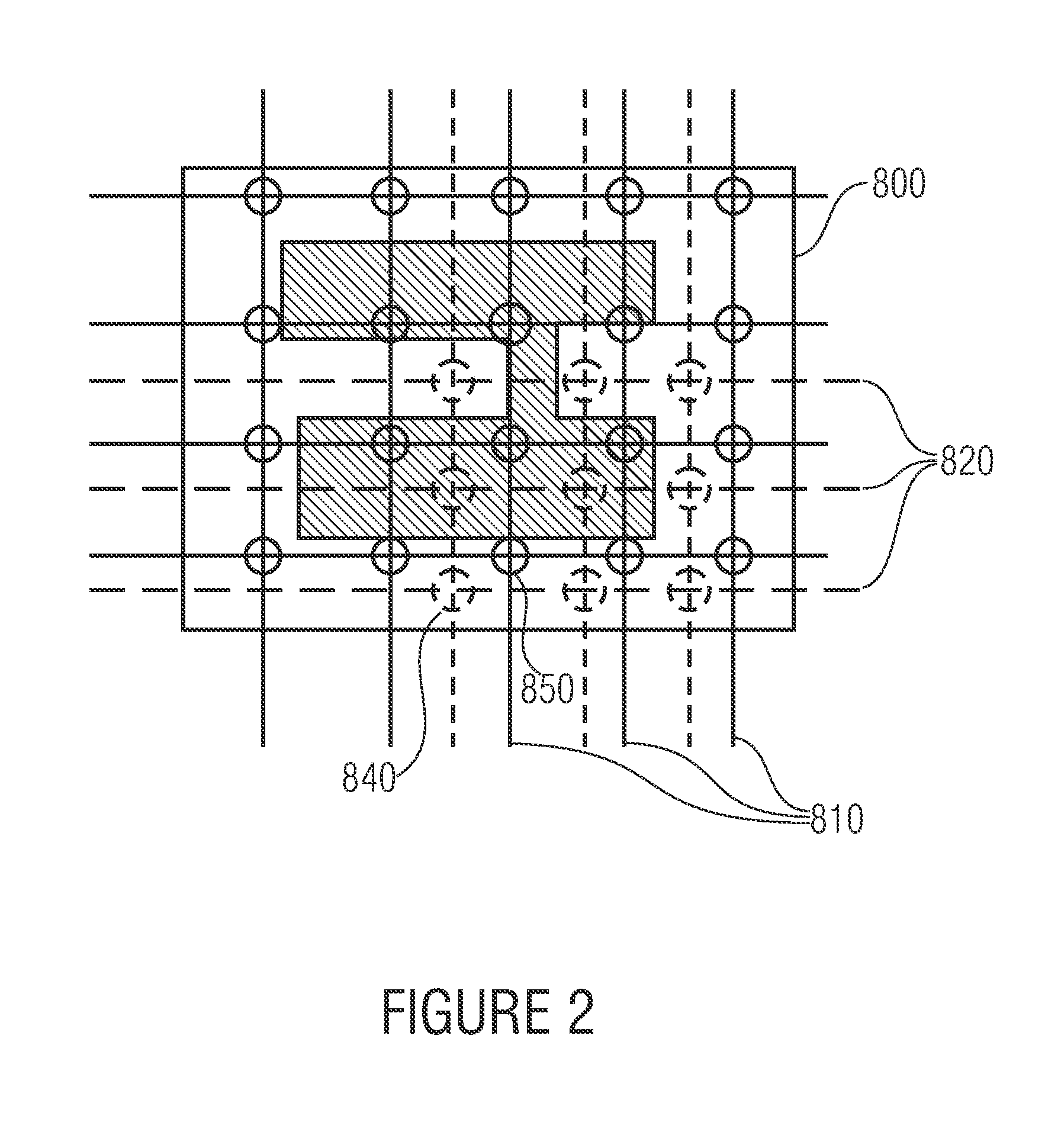

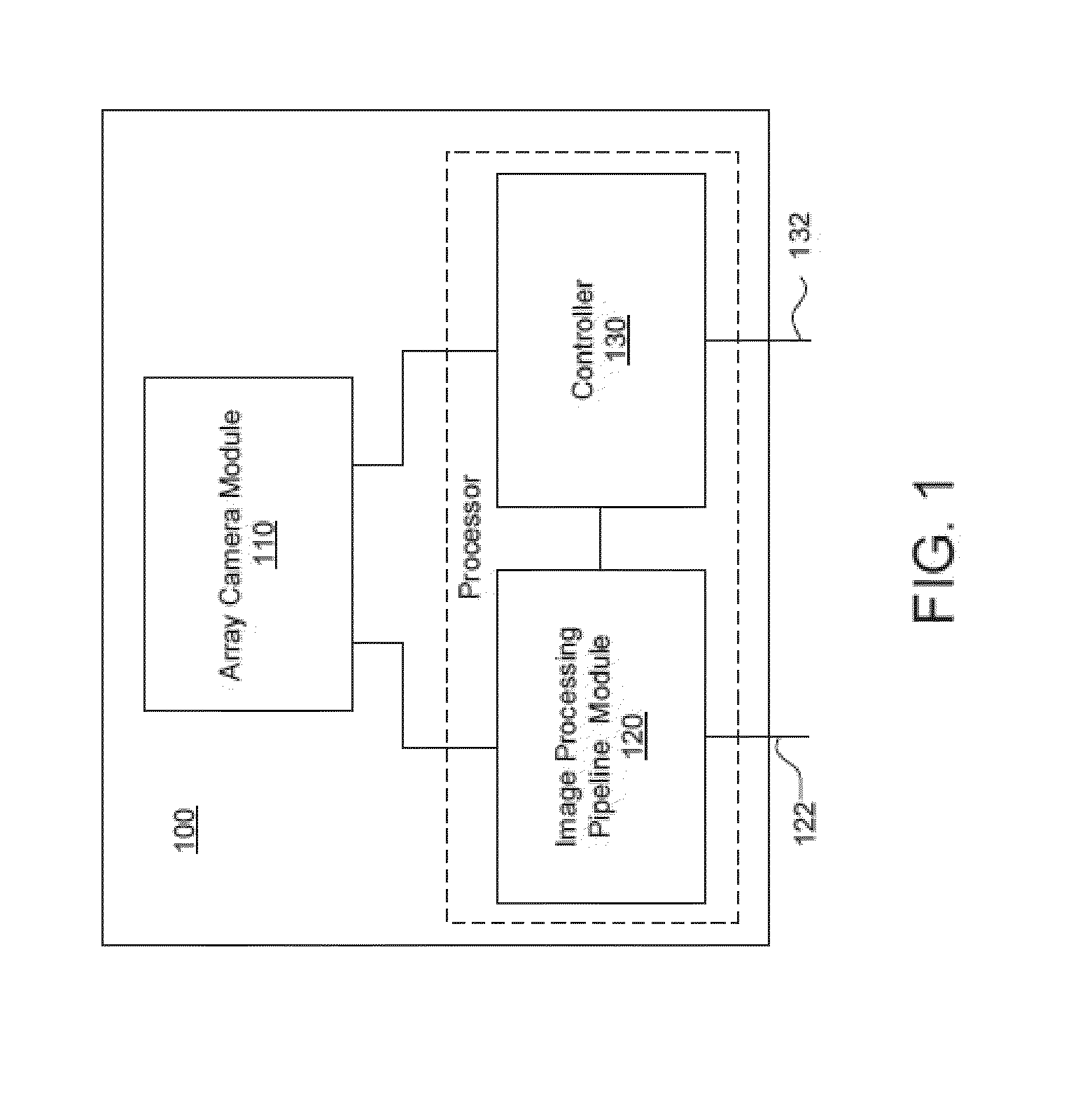

Systems and methods for controlling aliasing in images captured by an array camera for use in super-resolution processing

ActiveUS20140267890A1Television system detailsTelevision system scanning detailsImage resolutionCamera module

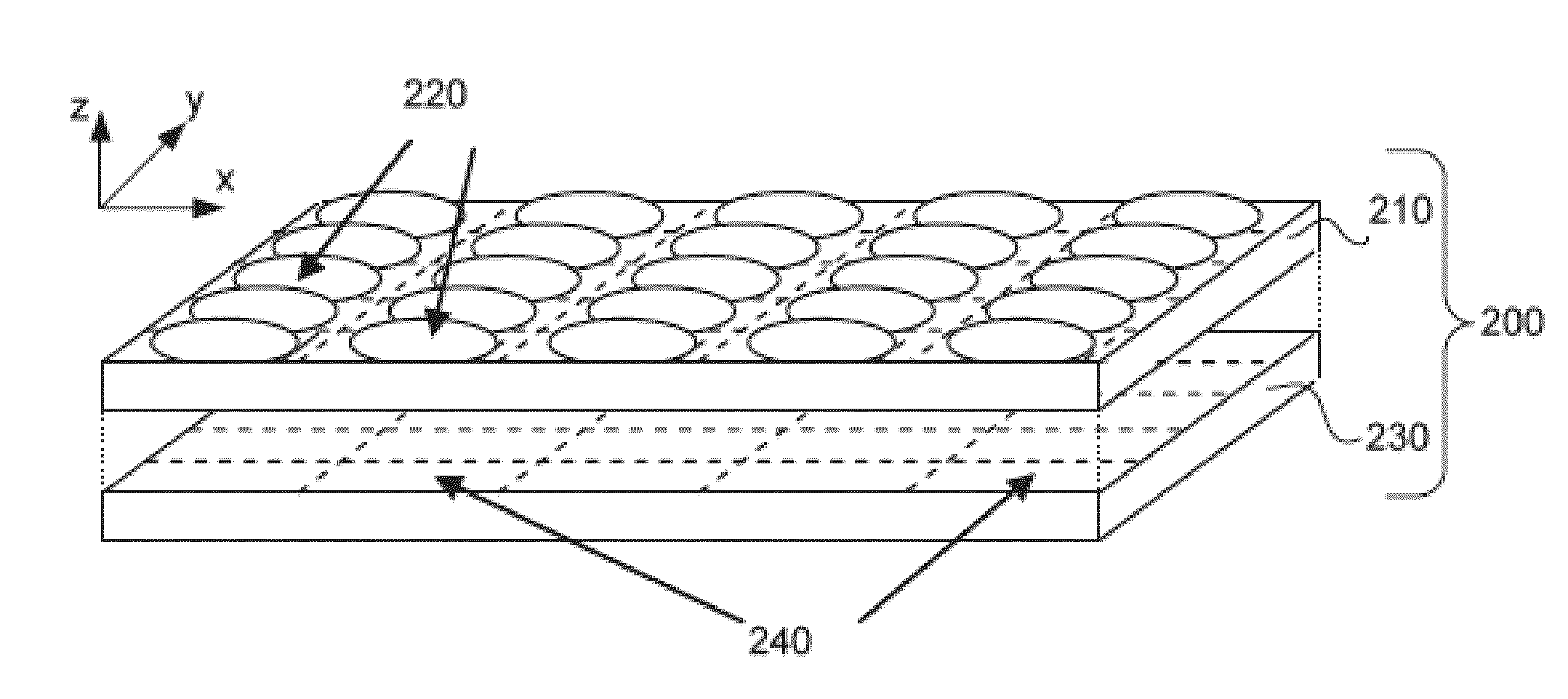

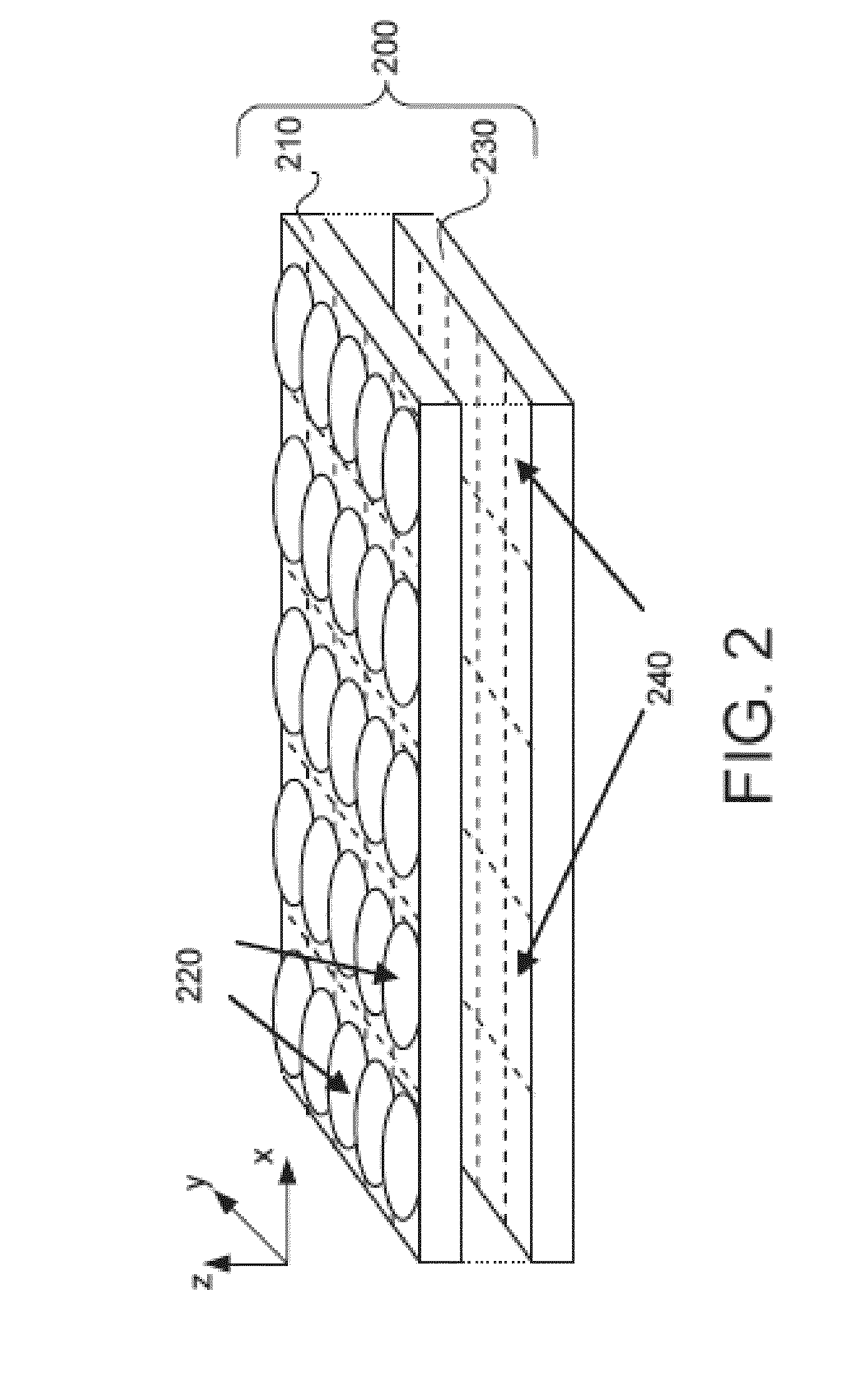

Imager arrays, array camera modules, and array cameras in accordance with embodiments of the invention utilize pixel apertures to control the amount of aliasing present in captured images of a scene. One embodiment includes a plurality of focal planes, control circuitry configured to control the capture of image information by the pixels within the focal planes, and sampling circuitry configured to convert pixel outputs into digital pixel data. In addition, the pixels in the plurality of focal planes include a pixel stack including a microlens and an active area, where light incident on the surface of the microlens is focused onto the active area by the microlens and the active area samples the incident light to capture image information, and the pixel stack defines a pixel area and includes a pixel aperture, where the size of the pixel apertures is smaller than the pixel area.

Owner:FOTONATION LTD

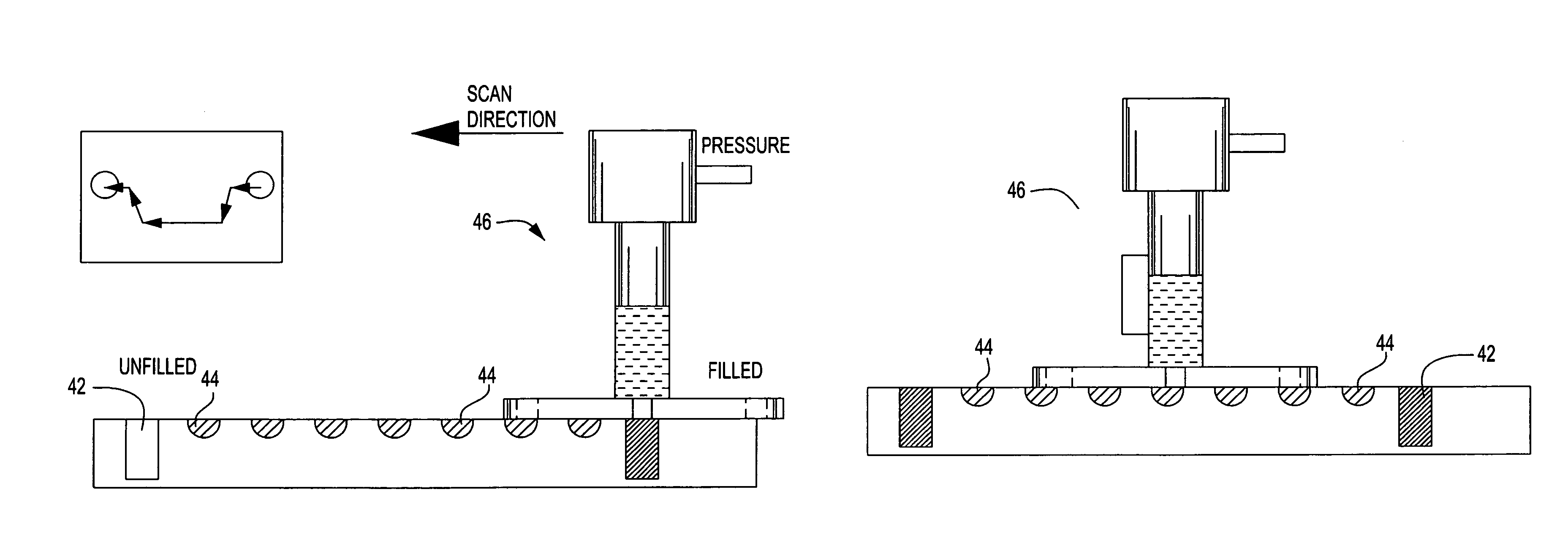

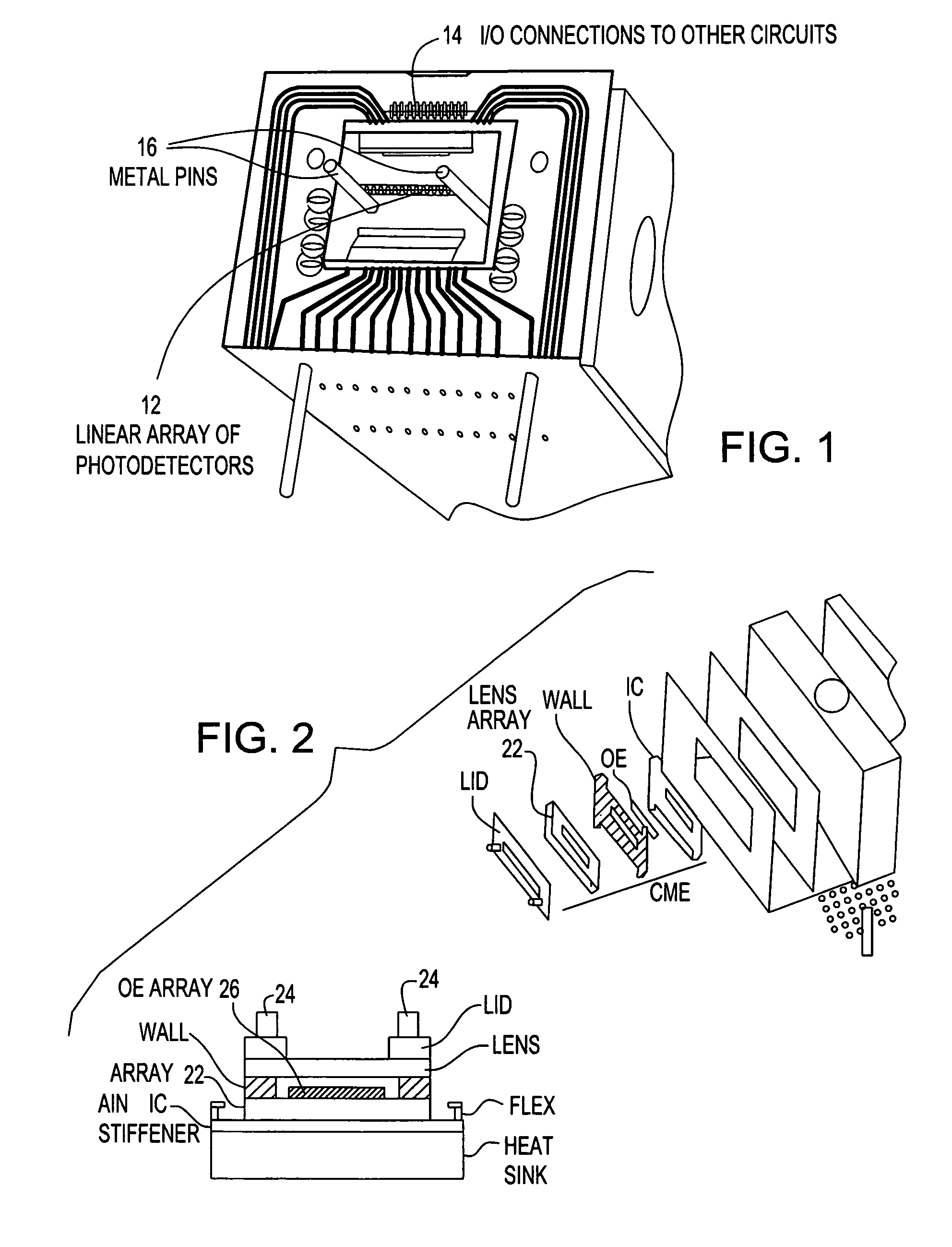

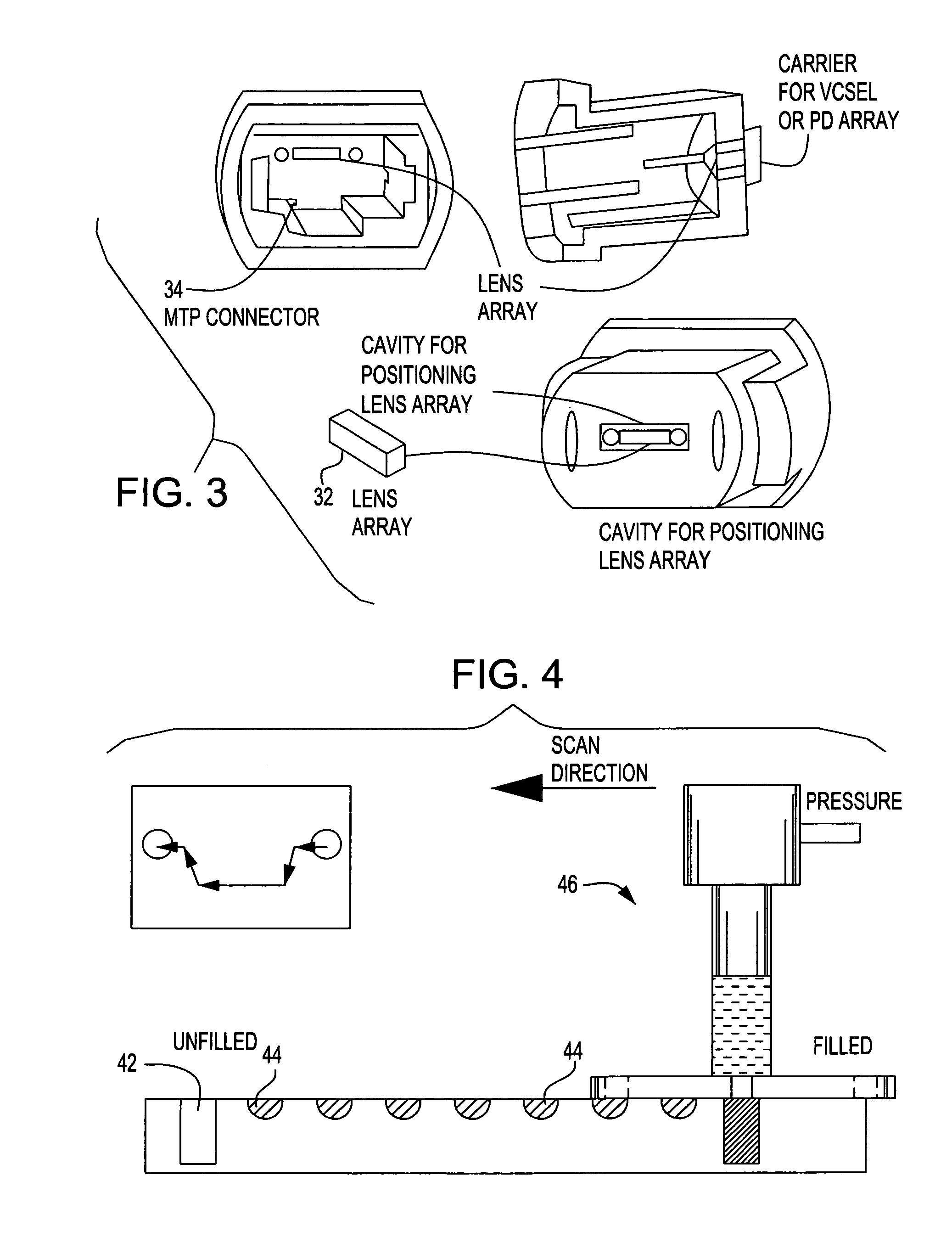

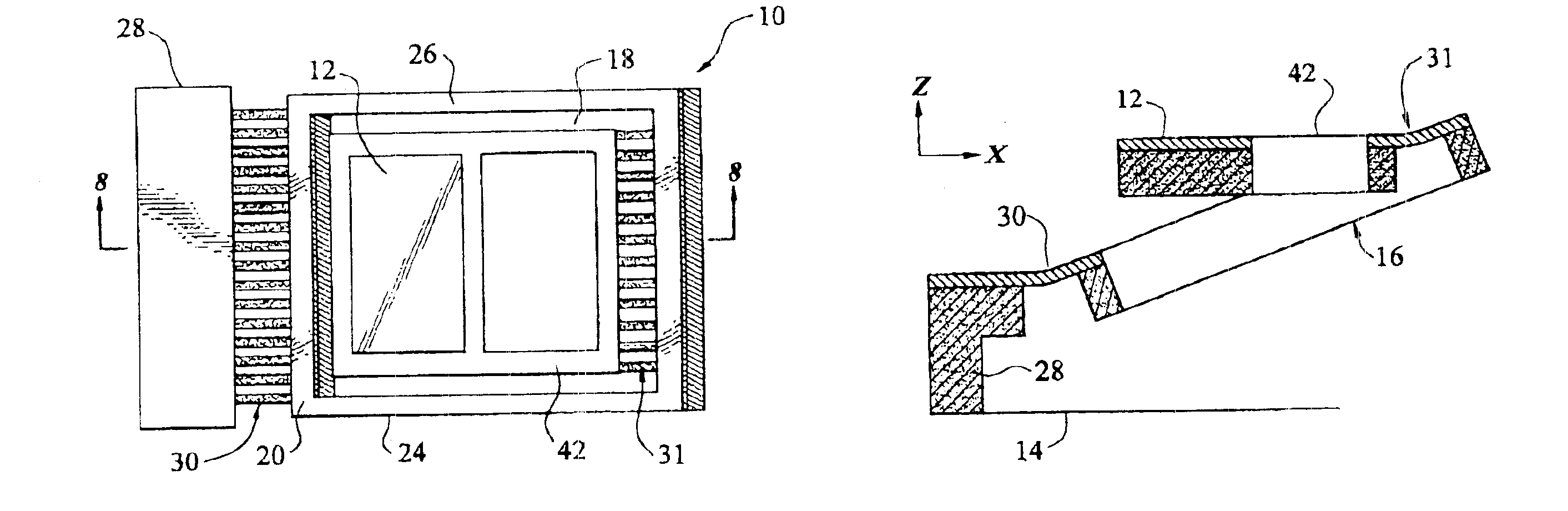

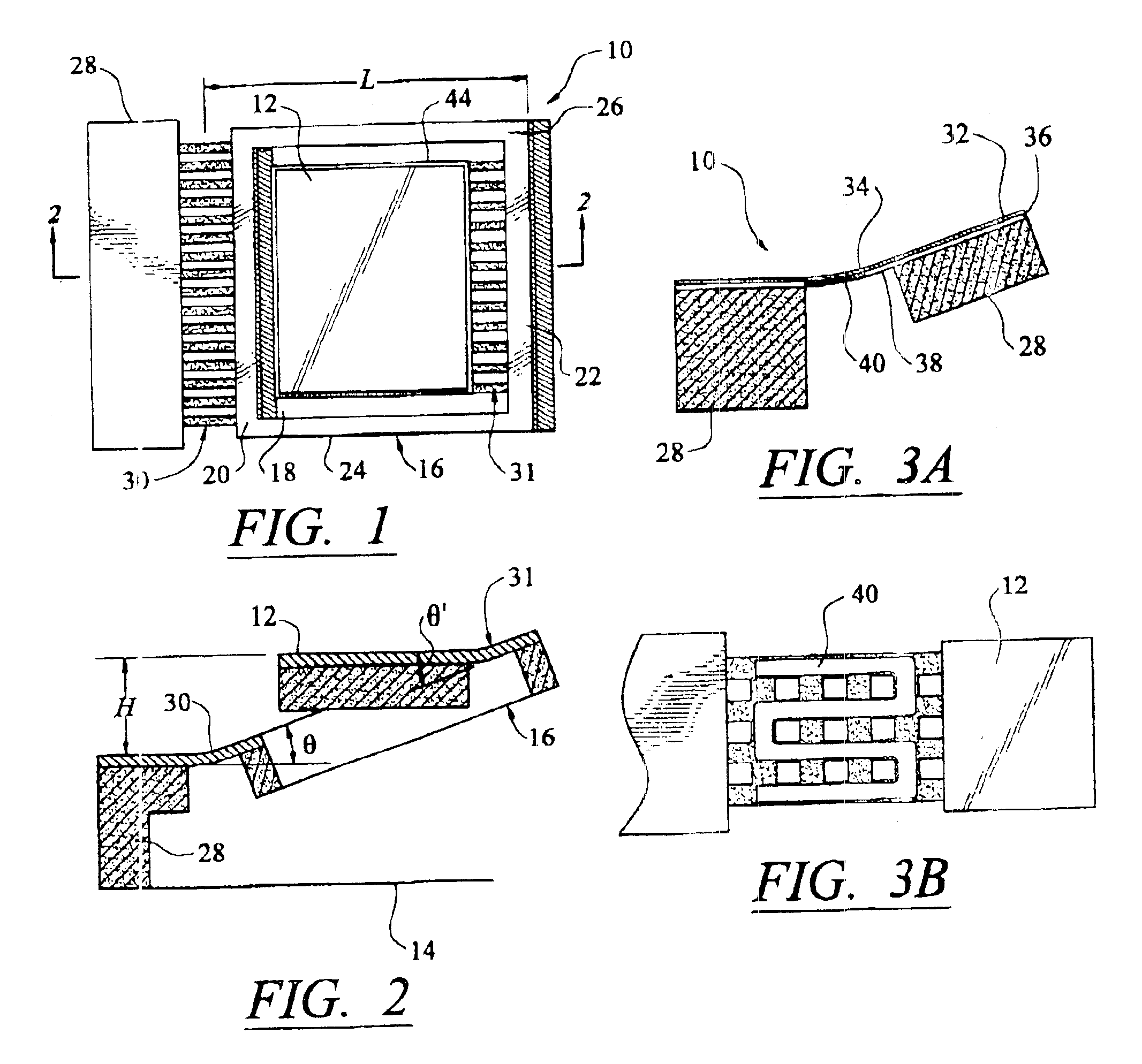

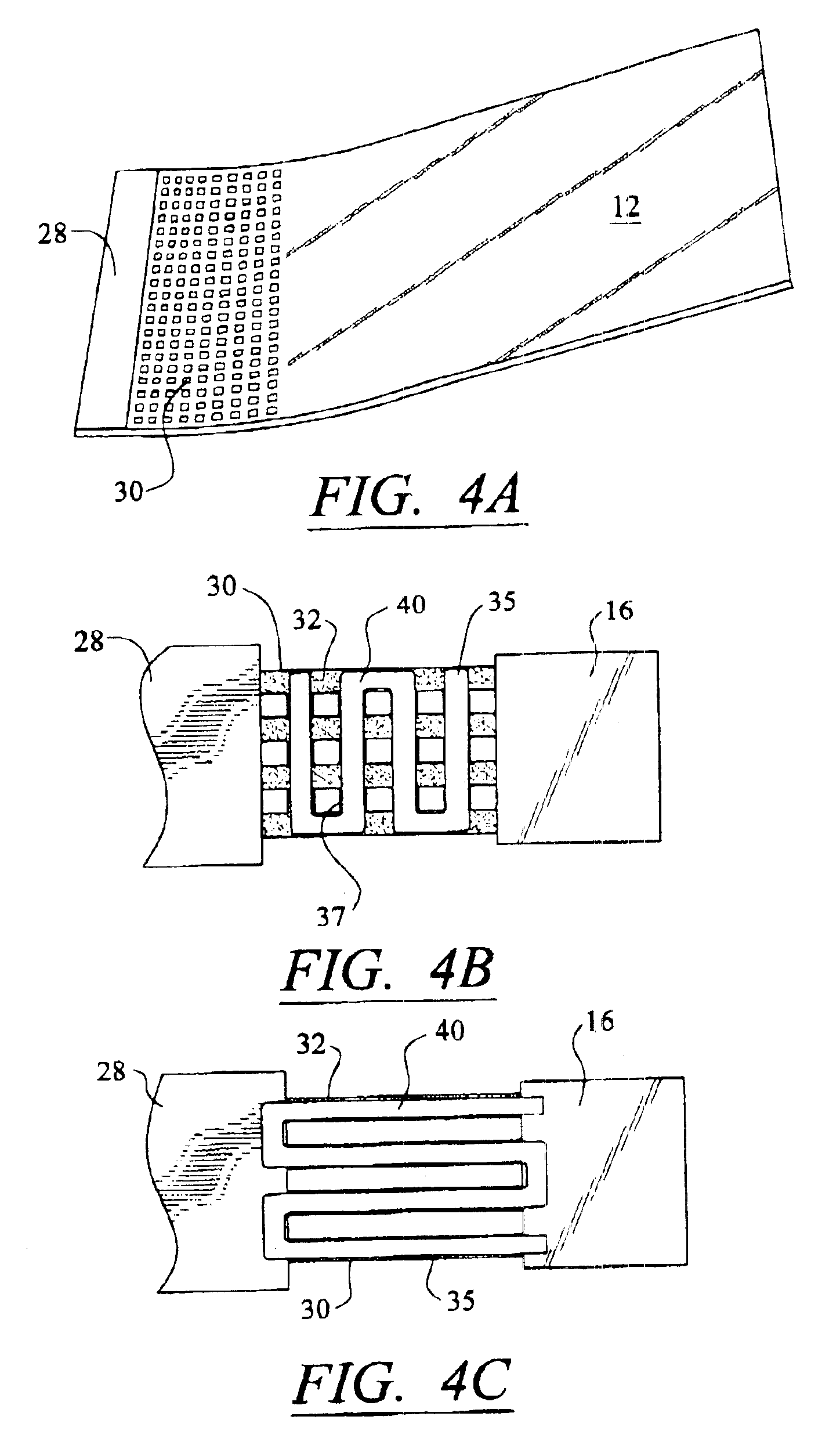

Hybrid optical/electronic structures fabricated by a common molding process

InactiveUS7391572B2Improve thermal performanceEasy alignmentOptical articlesGlass shaping apparatusElectricityElectronic structure

Owner:INT BUSINESS MASCH CORP

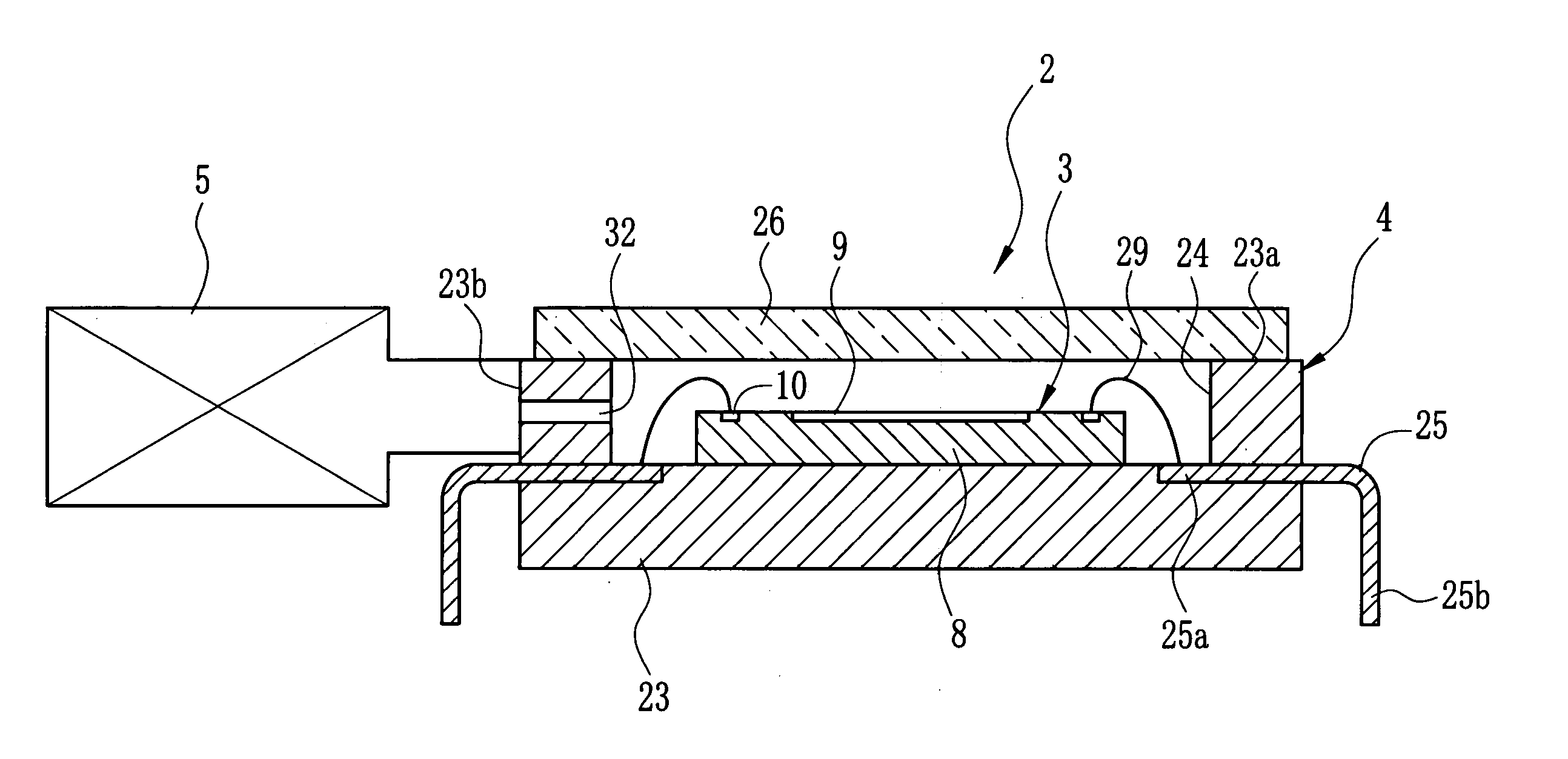

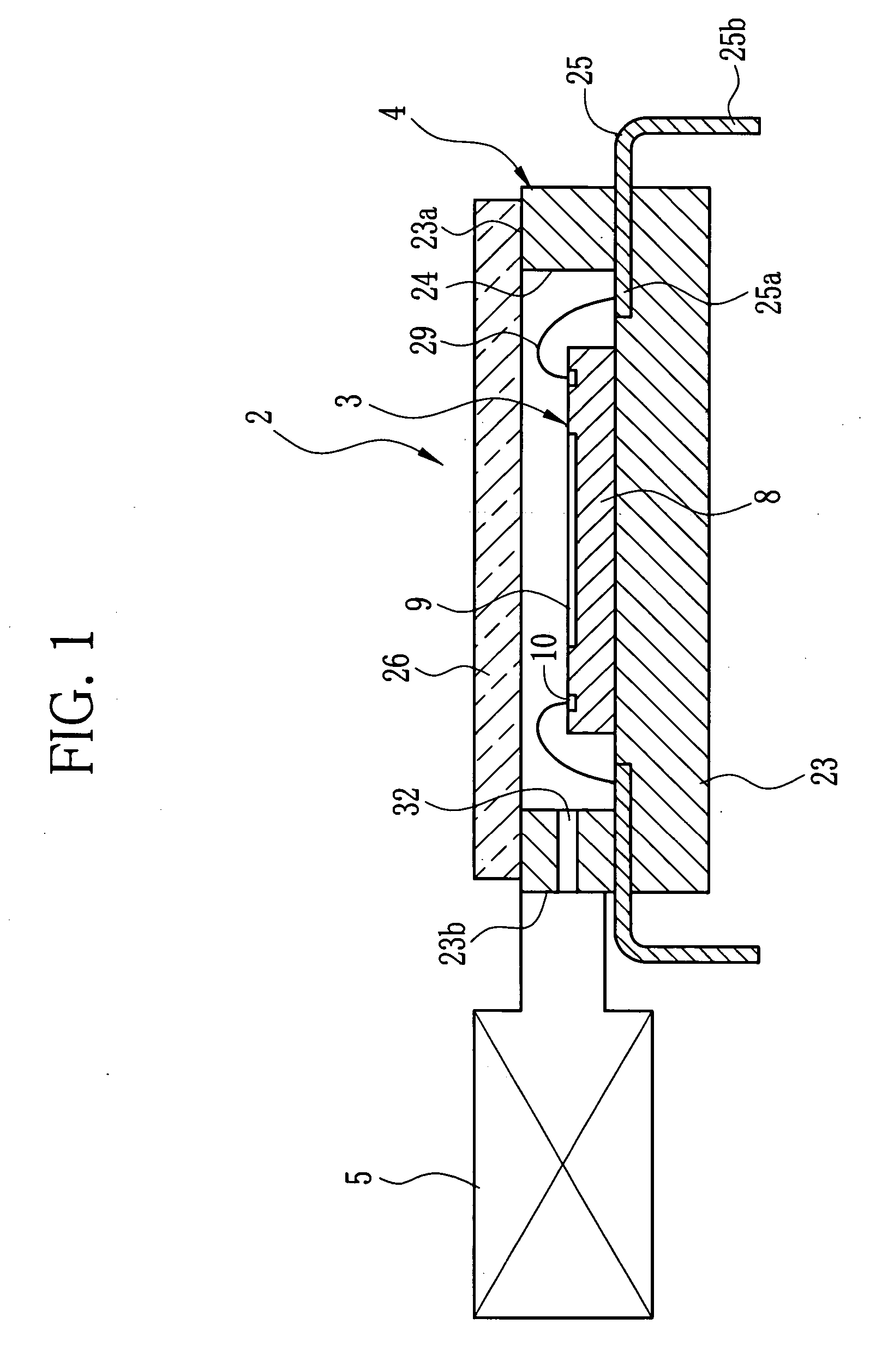

Imaging device and digital camera

InactiveUS20060279648A1Quantum efficiencyHigh imaging sensitivityTelevision system detailsTelevision system scanning detailsEngineeringAtmospheric pressure

An imaging device includes an image sensor chip and a package for containing the image sensor chip. Formed in the package is a vent hole that is connected to an air pump. In a light receiving area of the image sensor chip, there are photodiodes and microlenses above them. The microlenses are made of a gel-like transparent material. When the internal air pressure of the package is changed by the air pump, each microlens transforms in response to the change of the internal air pressure, and thereby changes the surface curvature thereof.

Owner:FUJIFILM CORP

Image sensor and method for manufacturing the same

An image sensor and manufacturing process thereof are provided. An image sensor according to an embodiment comprises a first wafer formed with a photodiode cell without a microlens and a second wafer formed with a circuit part including transistor and a capacitor. The first wafer is stacked on the second wafer such that a connecting electrode can be used to electrically connect the photodiode cell of the first wafer to the circuit part of the second wafer.

Owner:INTELLECTUAL DISCOVERY CO LTD

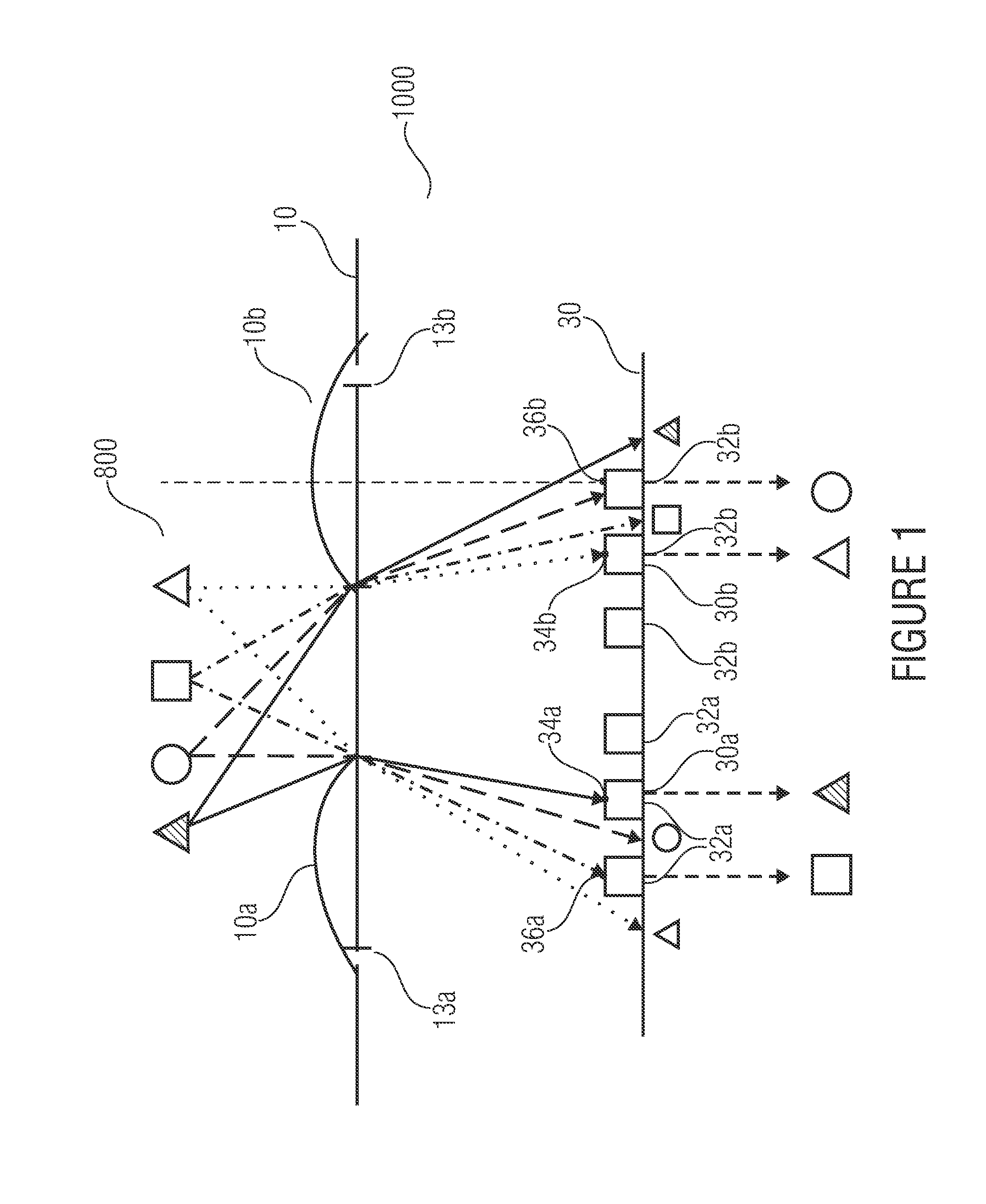

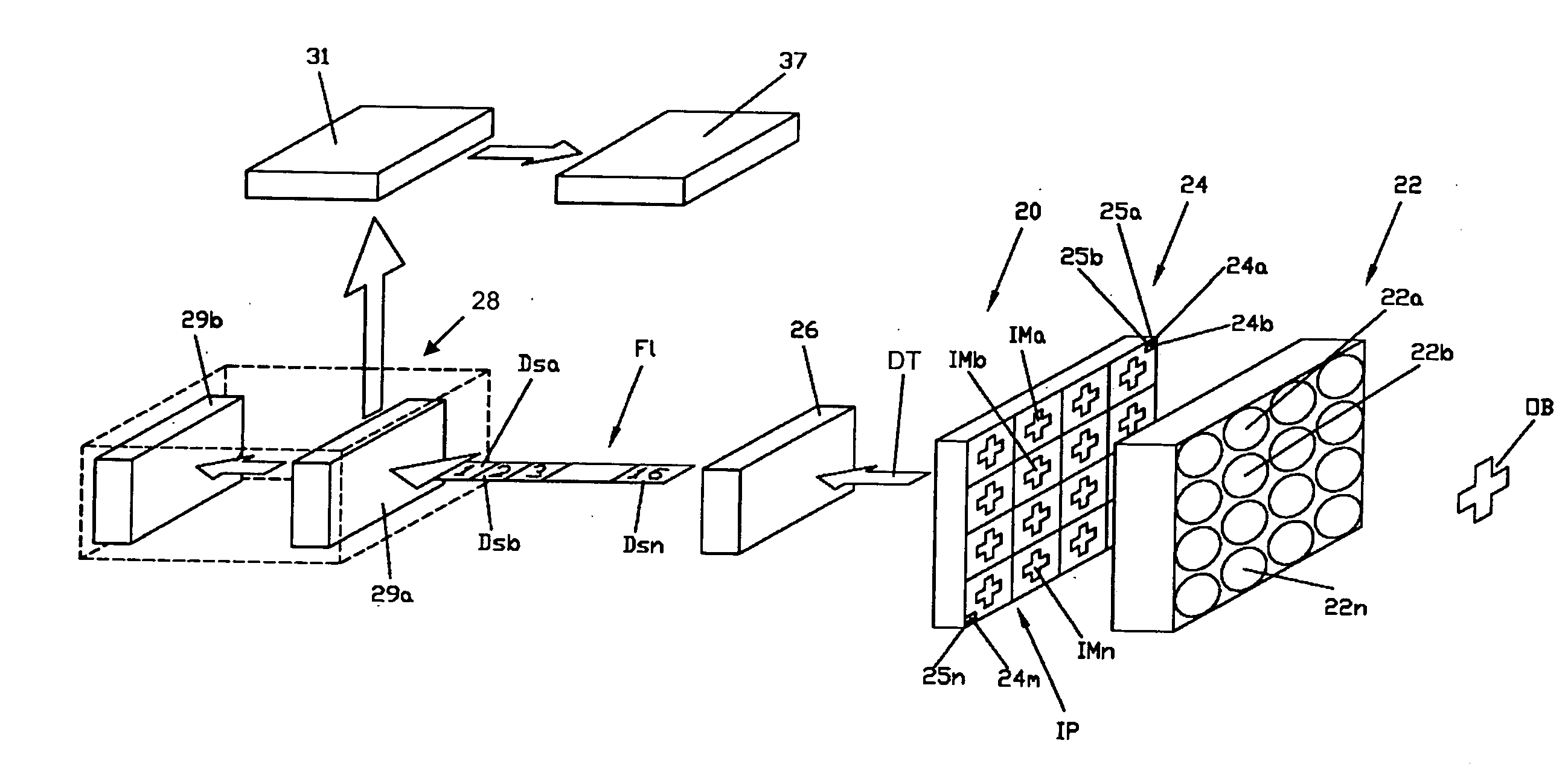

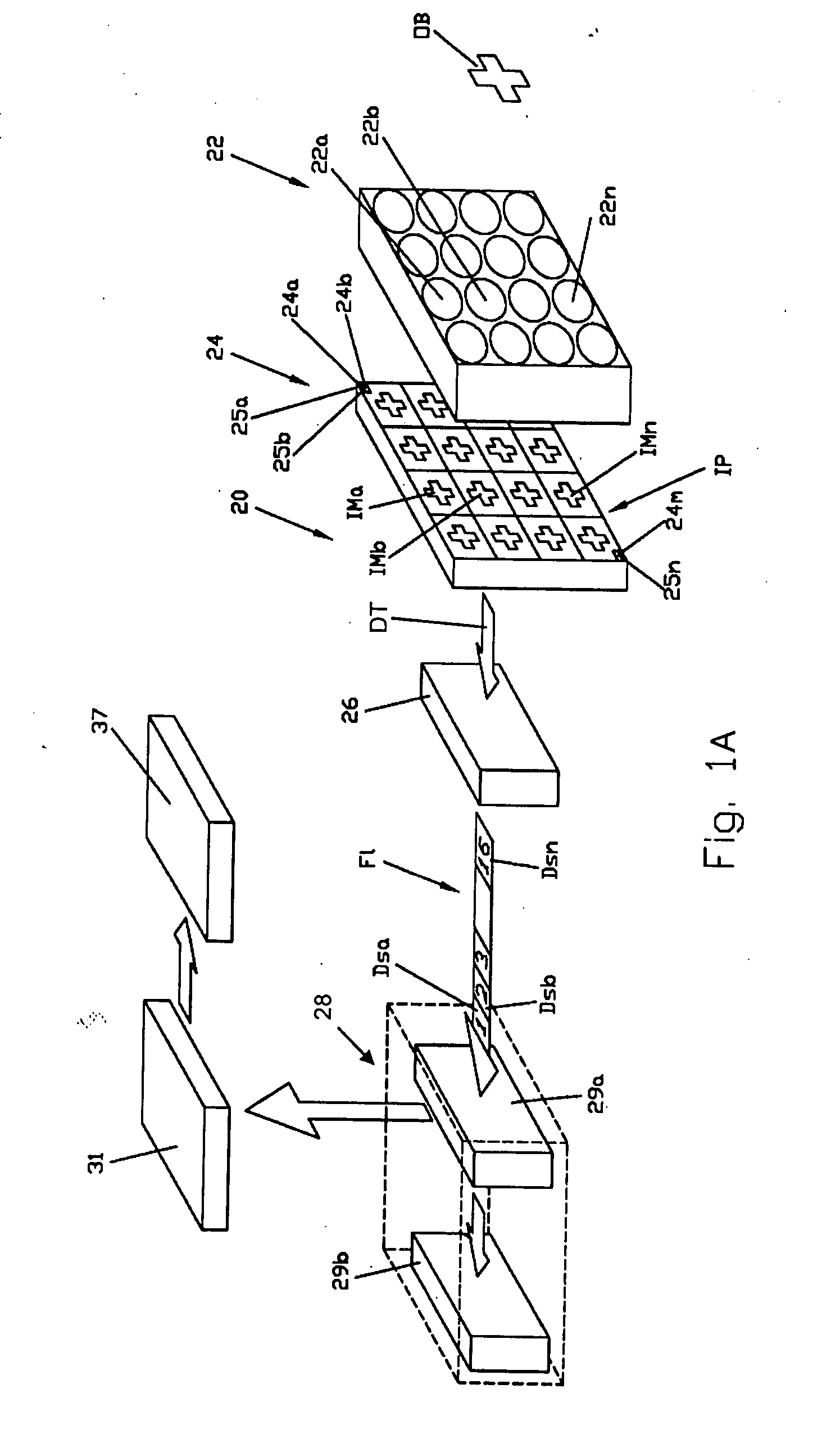

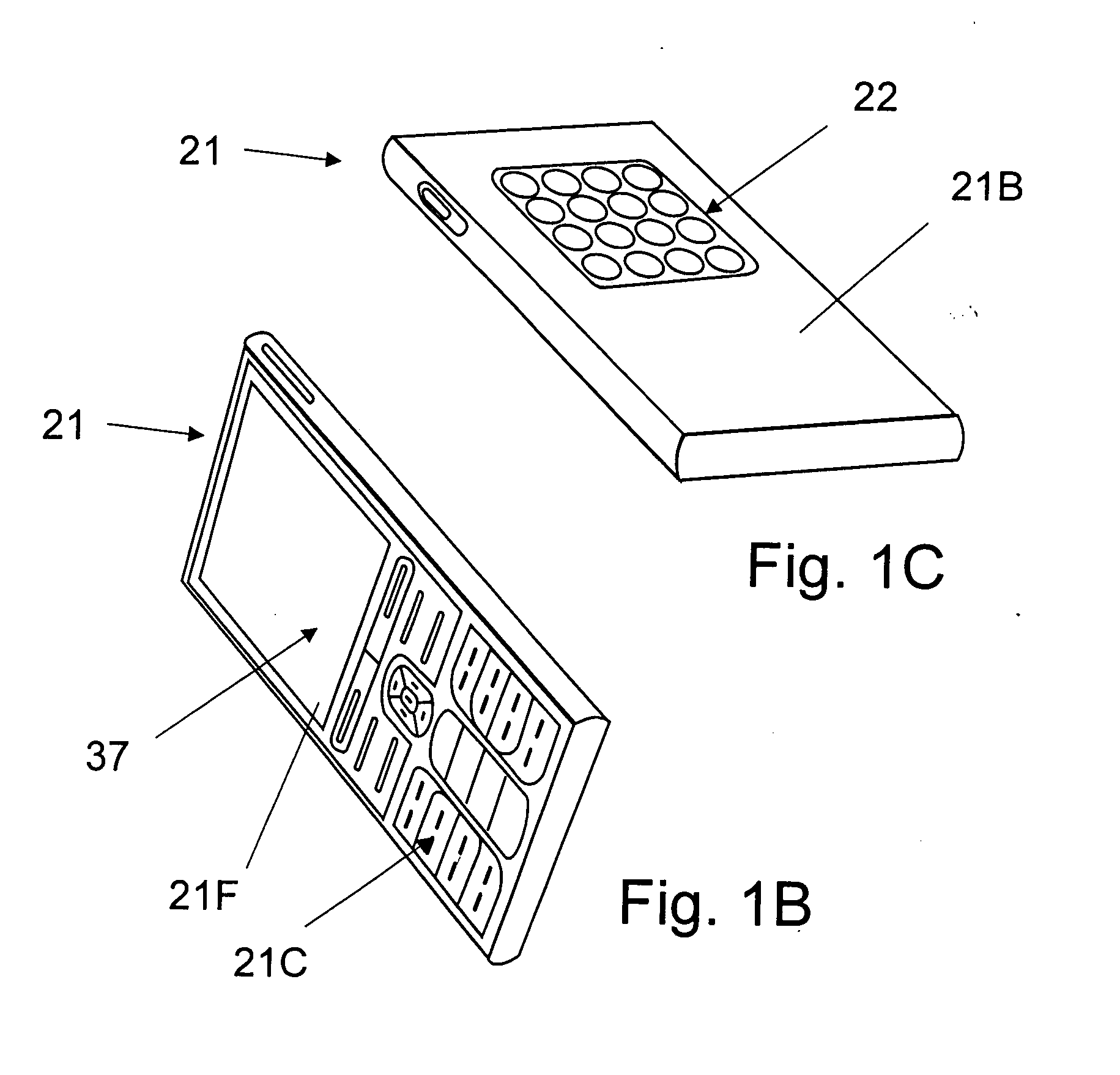

Ultra-thin digital imaging device of high resolution for mobile electronic devices and method of imaging

InactiveUS20070263114A1Enhance the imageCompact integrationTelevision system detailsColor television detailsDigital imagingData set

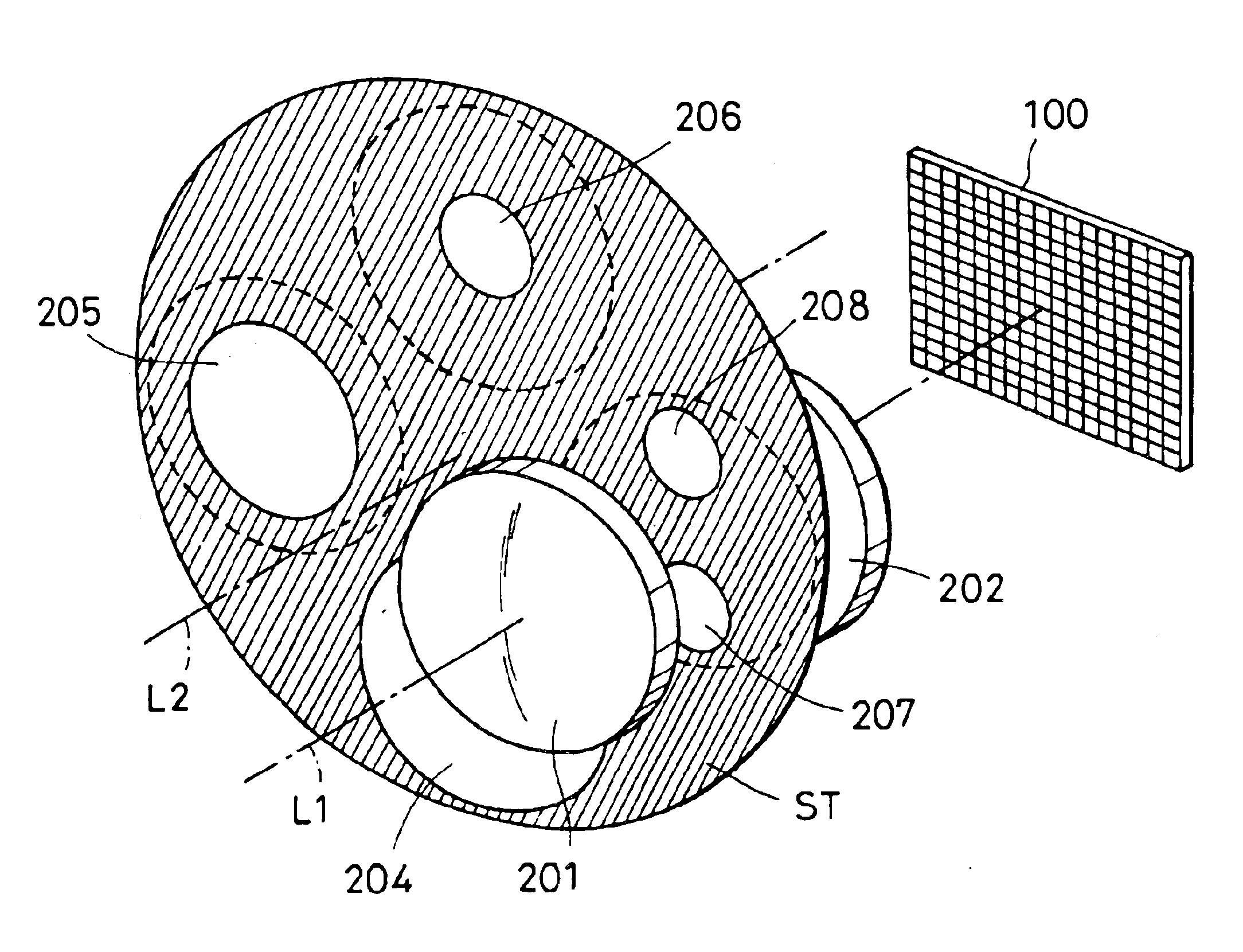

An ultra-thin digital imaging device has a thickness of several millimeters and is capable of producing data for creating images of 3 Mp and higher. The device comprises a multi-channel imaging unit that contains a plurality of optical channels formed by microlens objectives and a pixilated image sensor unit with a plurality of sensing elements. Each individual identical image obtained through each optical channel is pixilated and converted into electrical signals that are processed into data sets which can be stored in the imaging device and either reproduced on the display of the device or transmitted to an external image-reproducing device where the obtained data of individual images are transformed into a single, high-resolution megapixel image by means of a technique known in the art.

Owner:MICROALIGN TECH

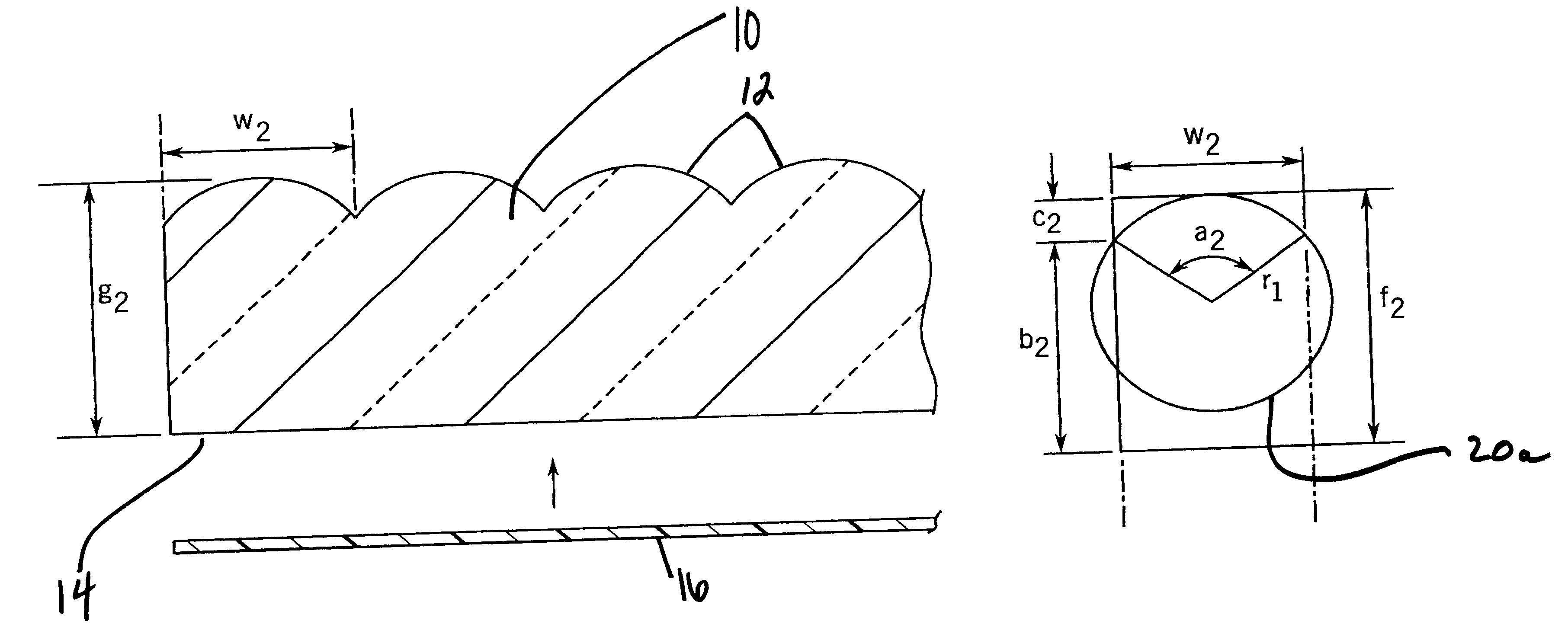

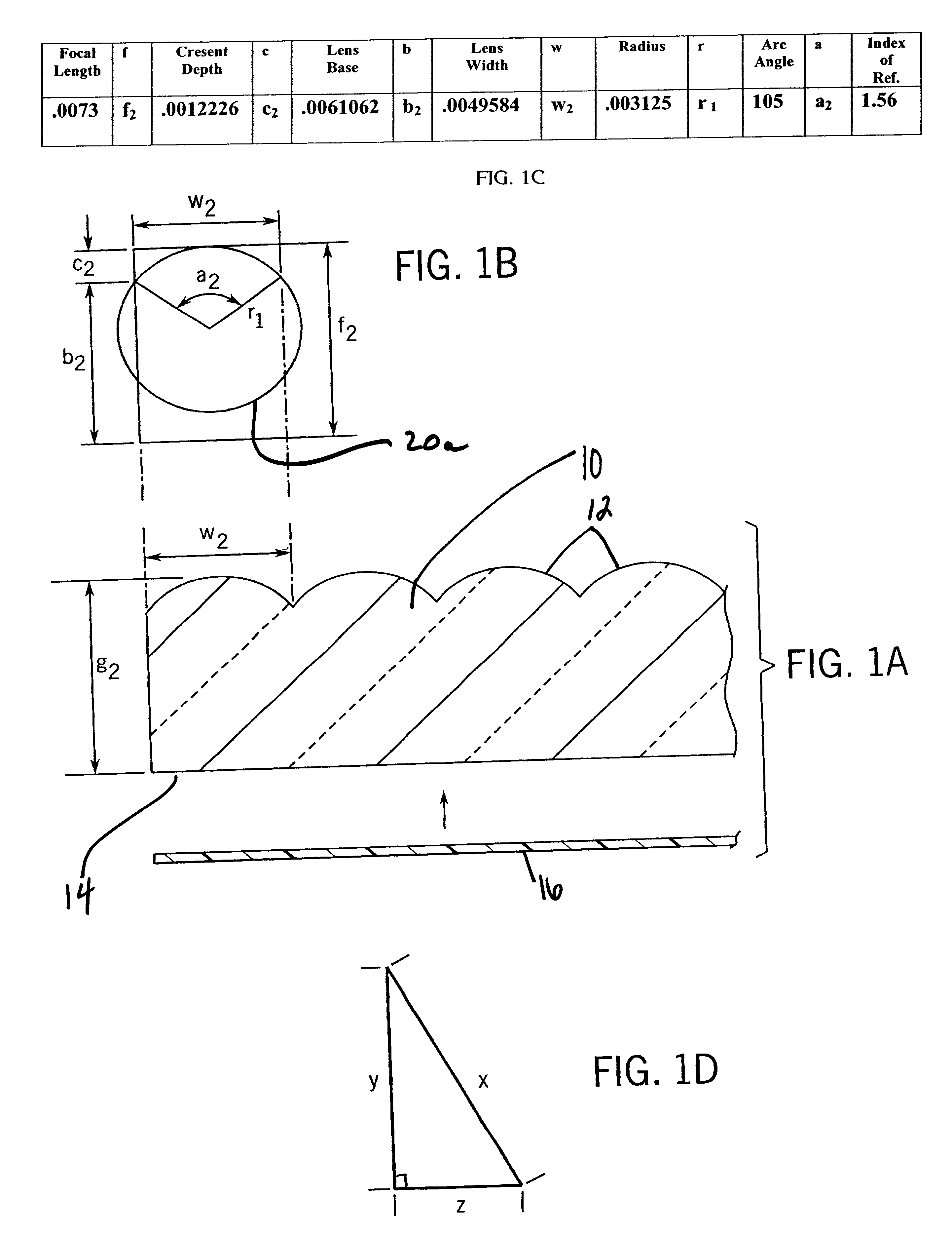

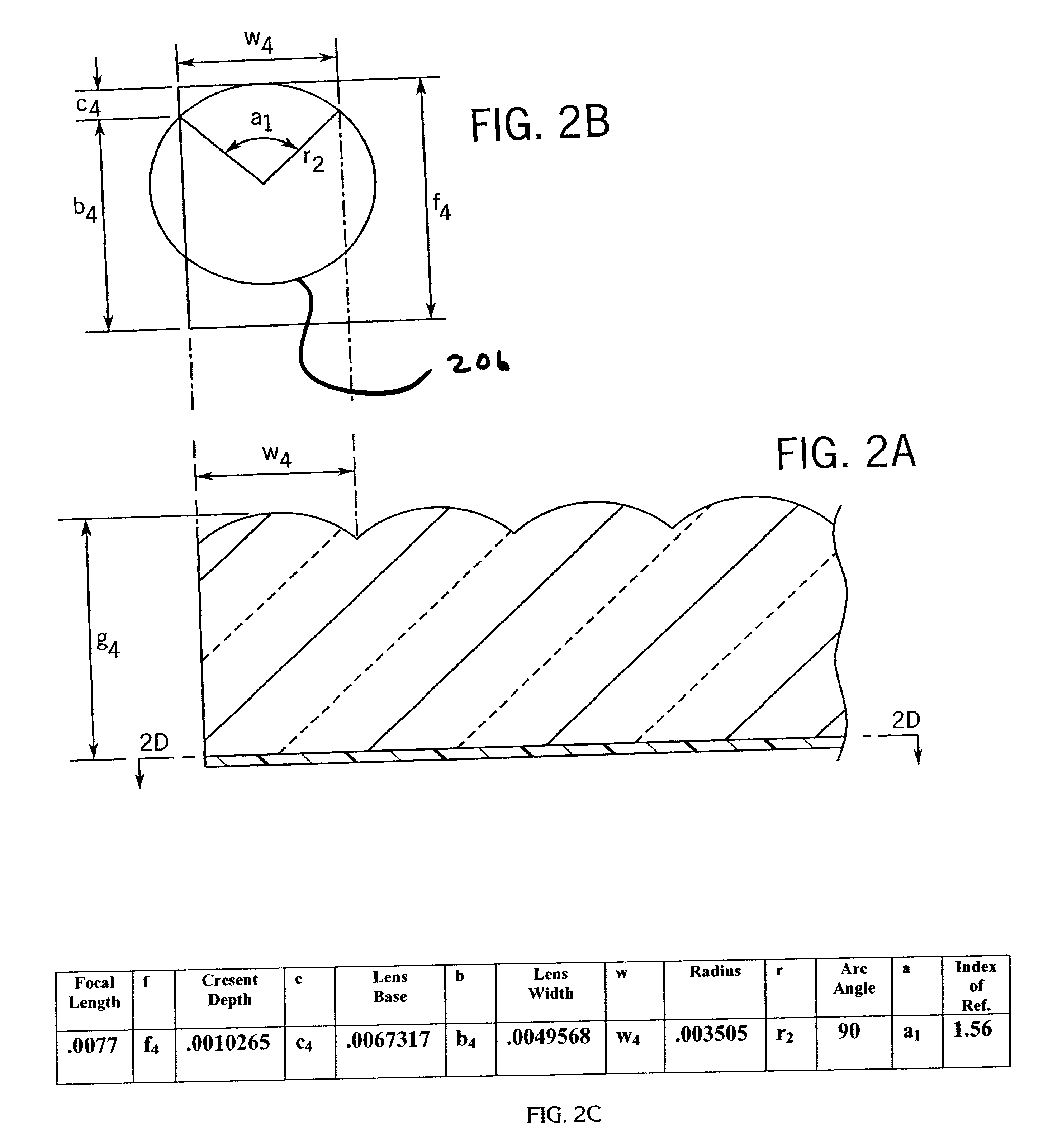

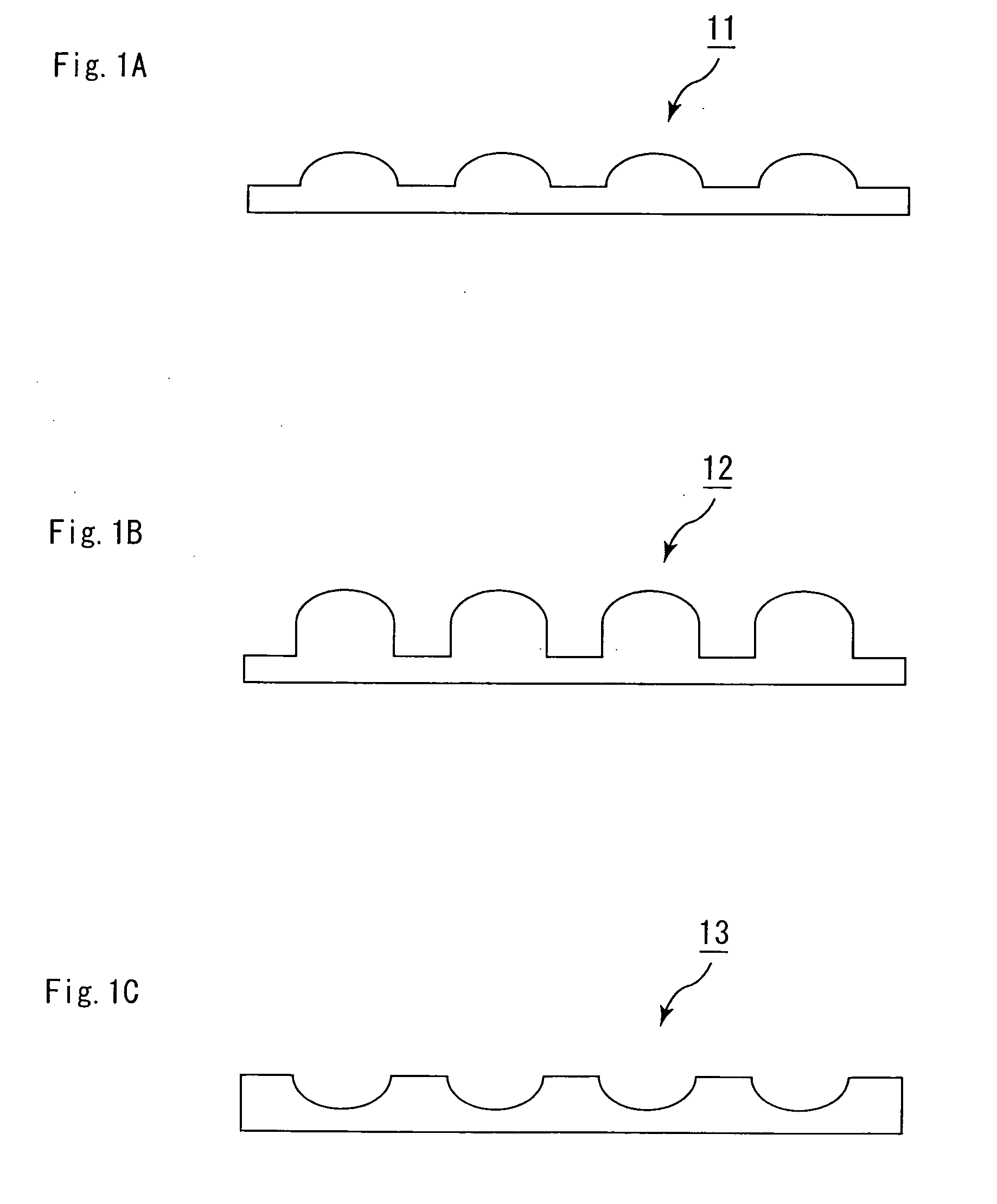

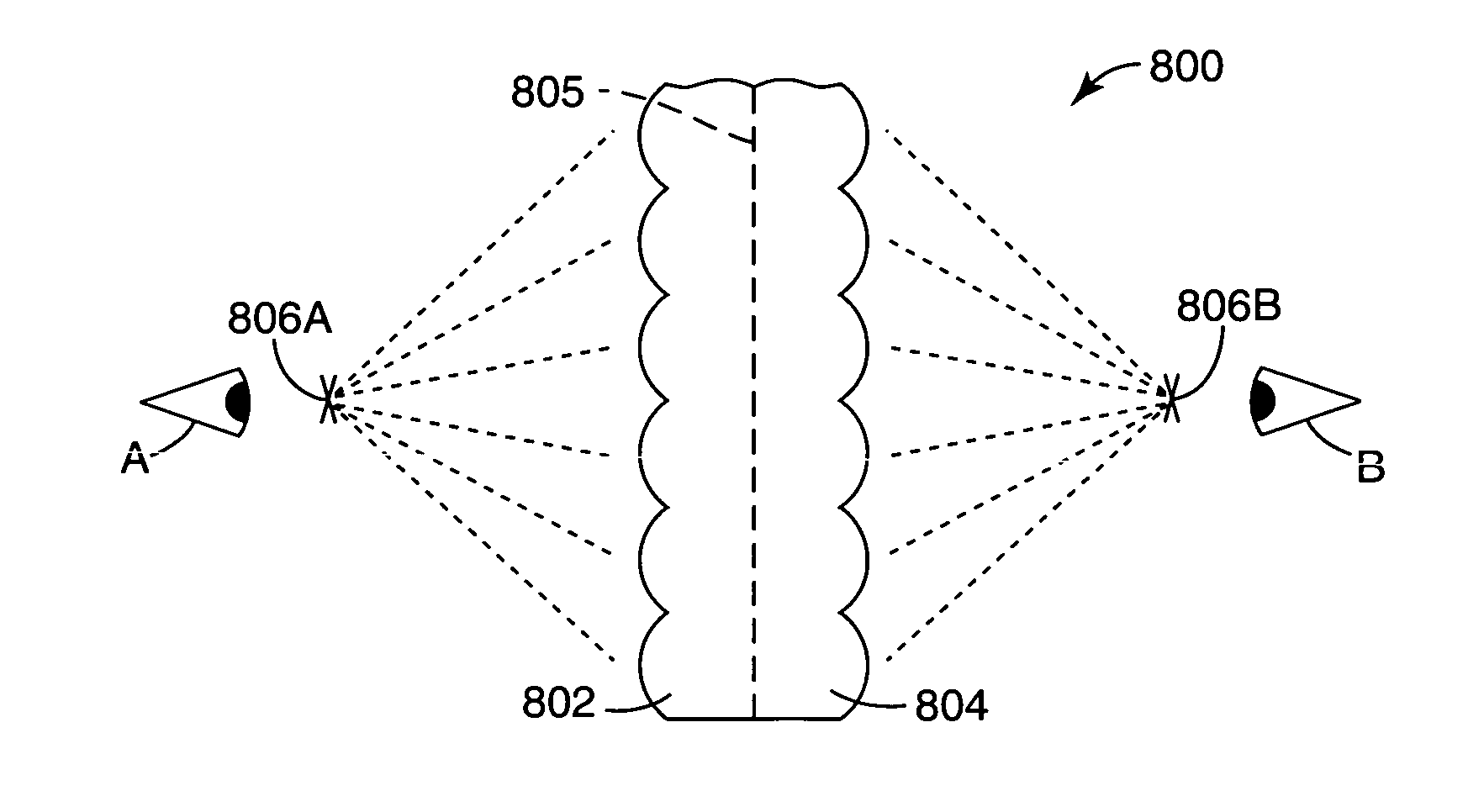

High definition lenticular lens

Disclosed herein is a high definition lenticular lens and a high definition lenticular image. The high definition lenticular lens can comprise a front surface having a plurality of lenticules and a substantially flat back surface opposite the front surface. Each lenticule has characteristic parameters that include a focal length, an arc angle, and a width. The arc angle is greater than about 90 degrees and the width is less than about 0.0067 inches. The lens has a gauge thickness that is equal to or substantially equal to the focal length. The high definition lenticular image comprises a precursor image joined to the high definition lenticular lens.

Owner:PACUR LLC

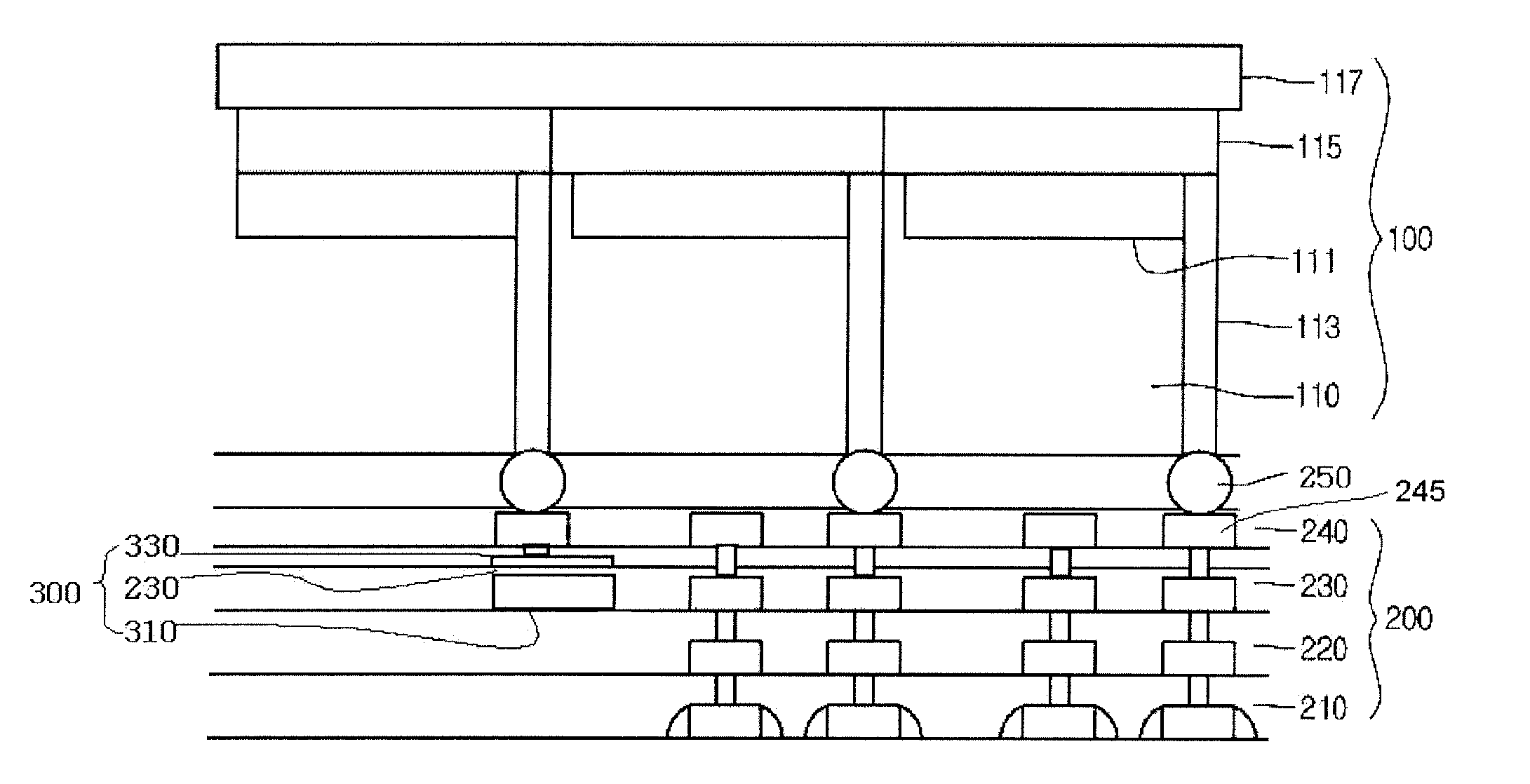

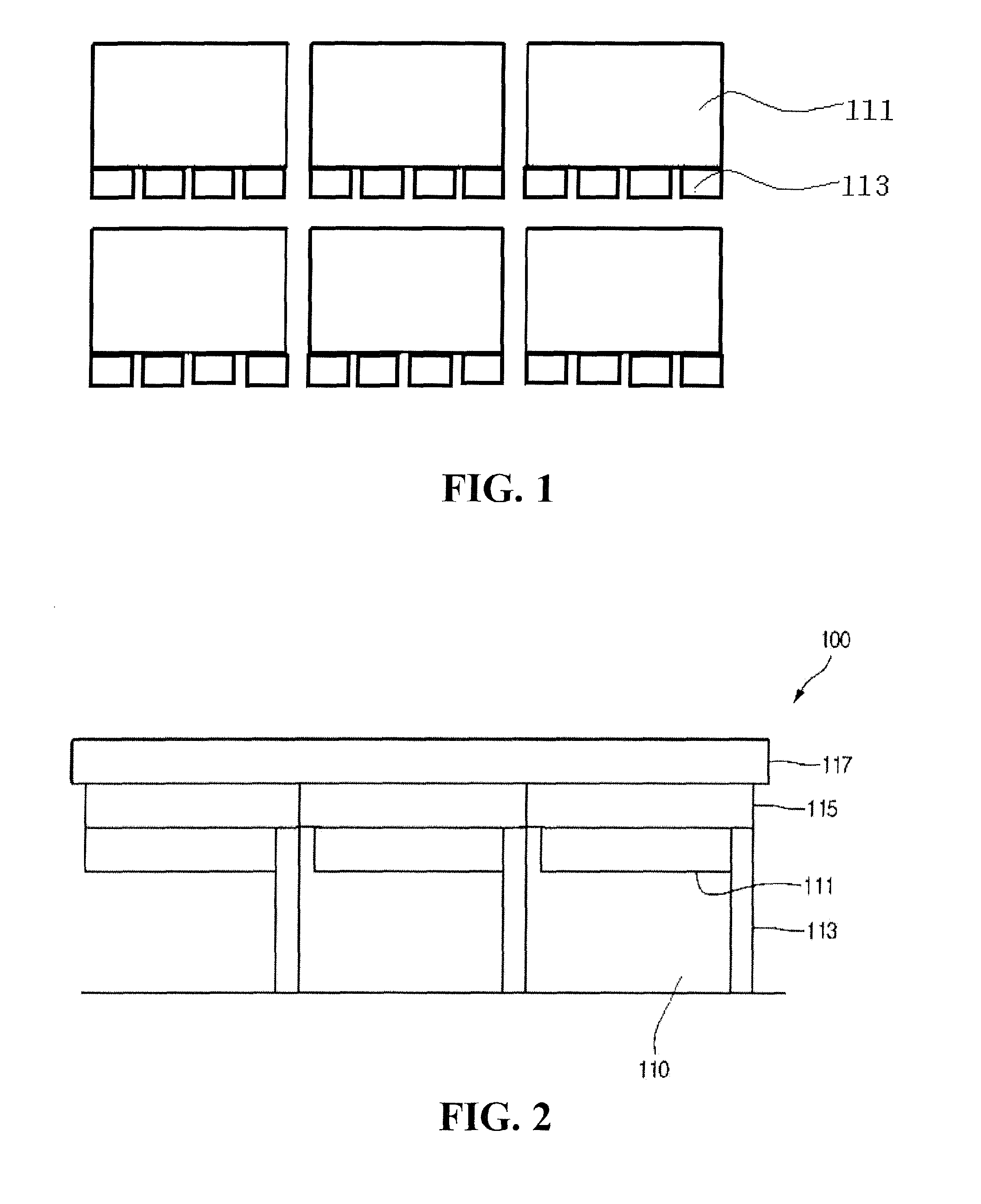

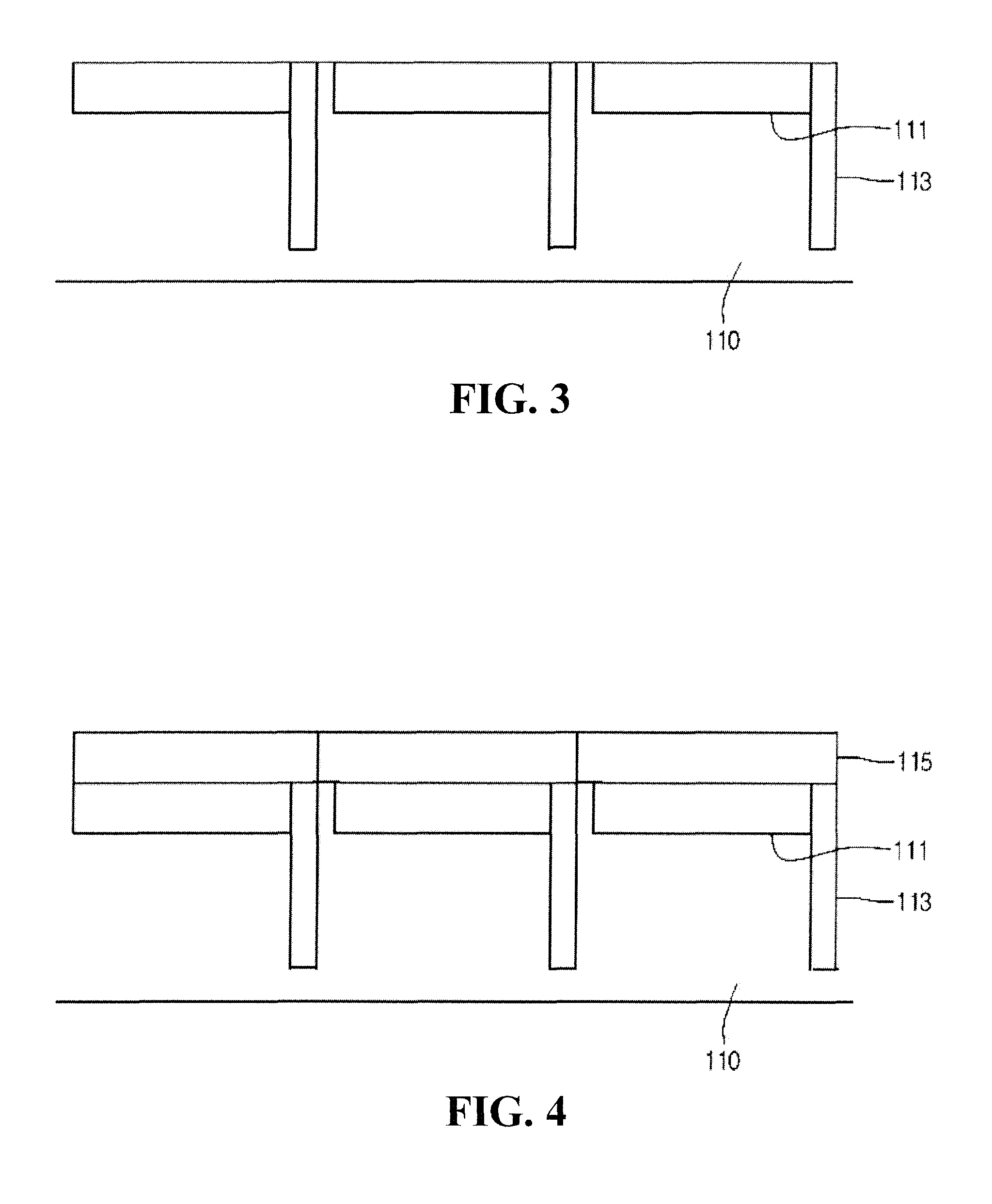

Image sensor with enlarged photo detection area and method for fabricating the same

ActiveUS20060146233A1Maximizing detection regionSolid-state devicesSemiconductor/solid-state device manufacturingCMOSThree dimensional integration

A complementary metal oxide semiconductor (CMOS) device with a three dimensional integration structure and a method for fabricating the same are provided. An image sensor includes a first substrate in which a photo detection device is formed; a second substrate in which a peripheral circuit is formed, wherein the first substrate and the second substrate are bonded through a plurality of bonding pads formed on both the first substrate and the second substrate, and a back side of the first substrate is turned upside down; and a microlens formed on a top portion of the back side of the first substrate.

Owner:INTELLECTUAL VENTURES II

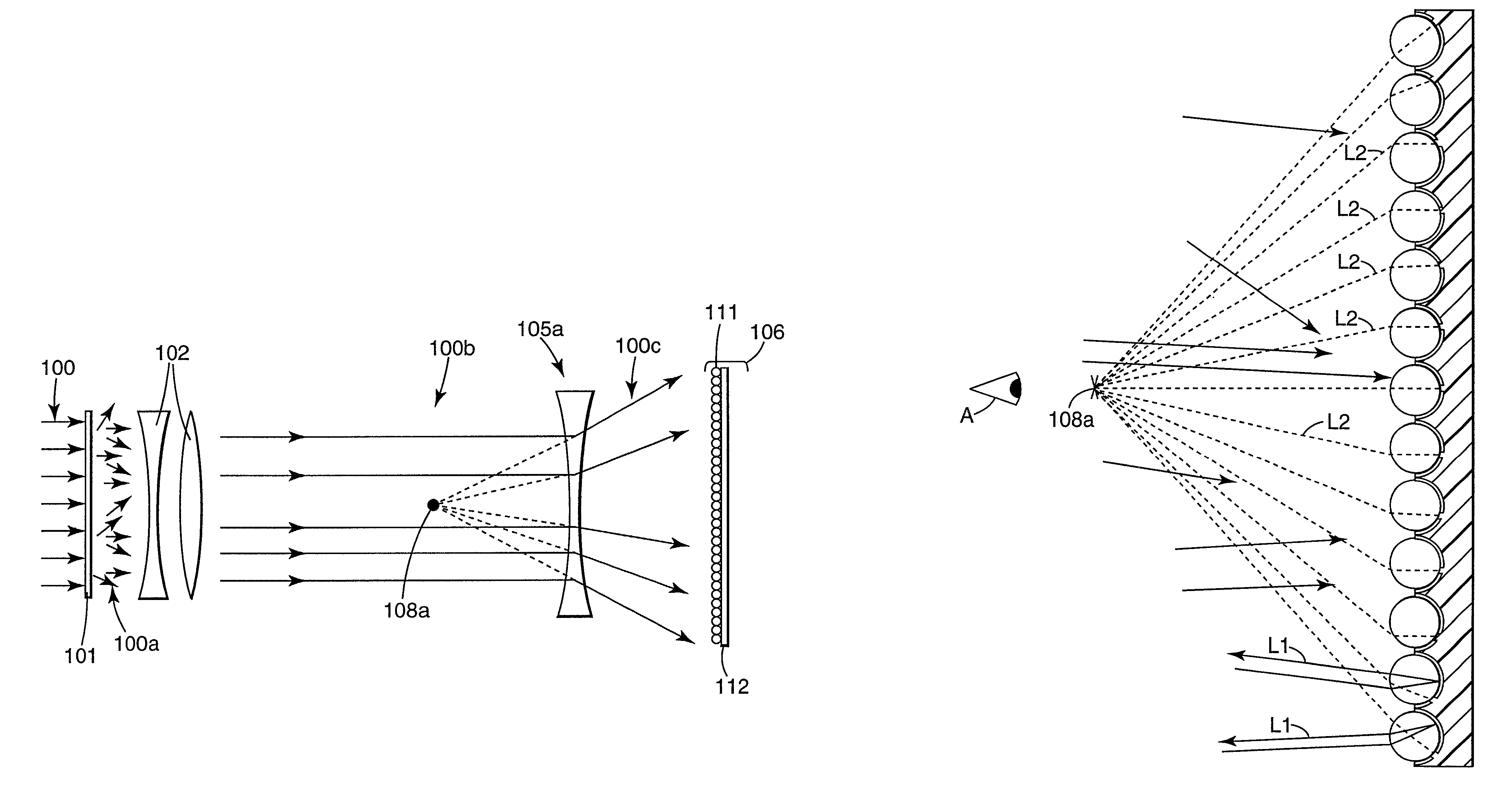

Laser illuminating device and image display device

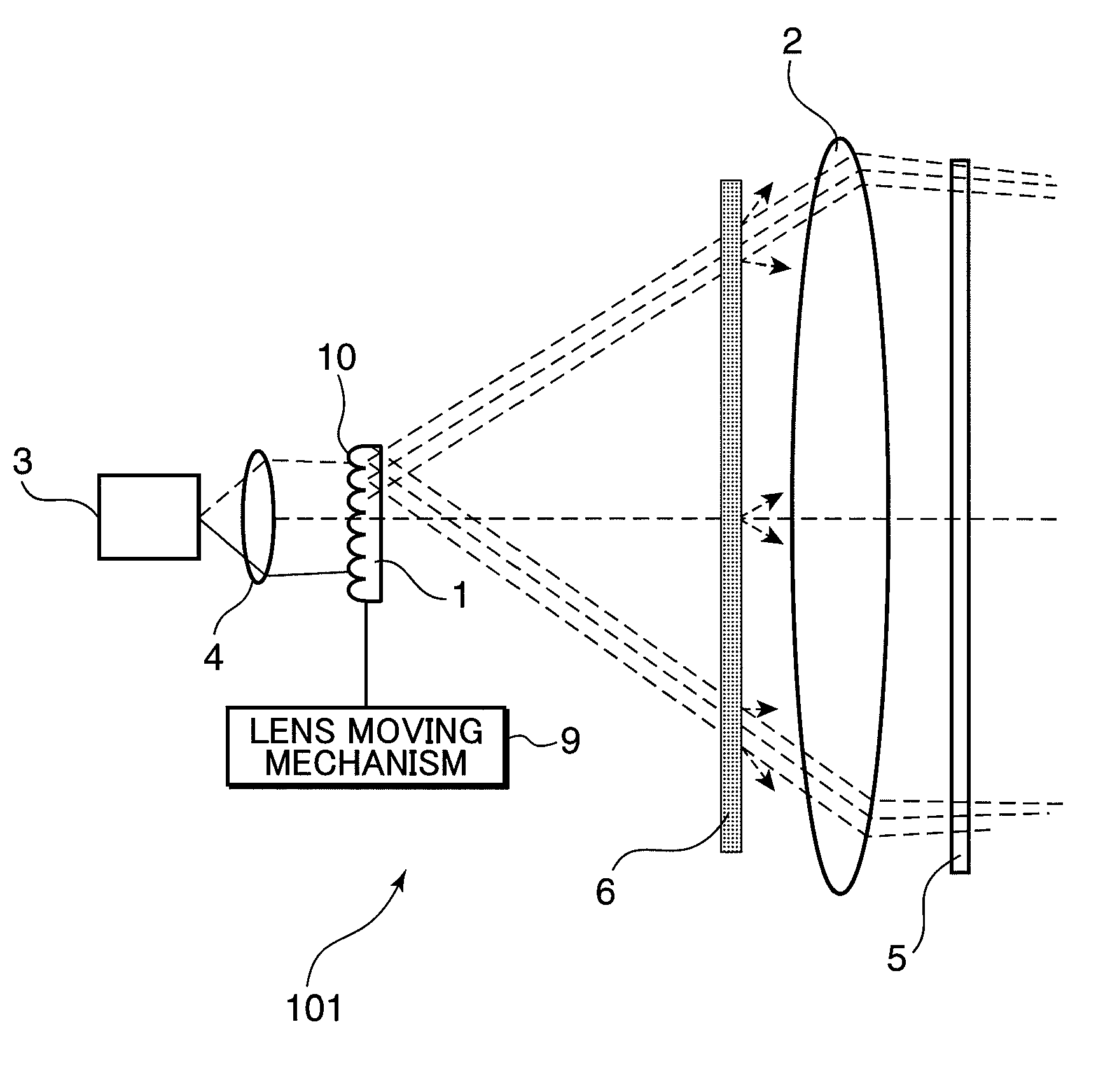

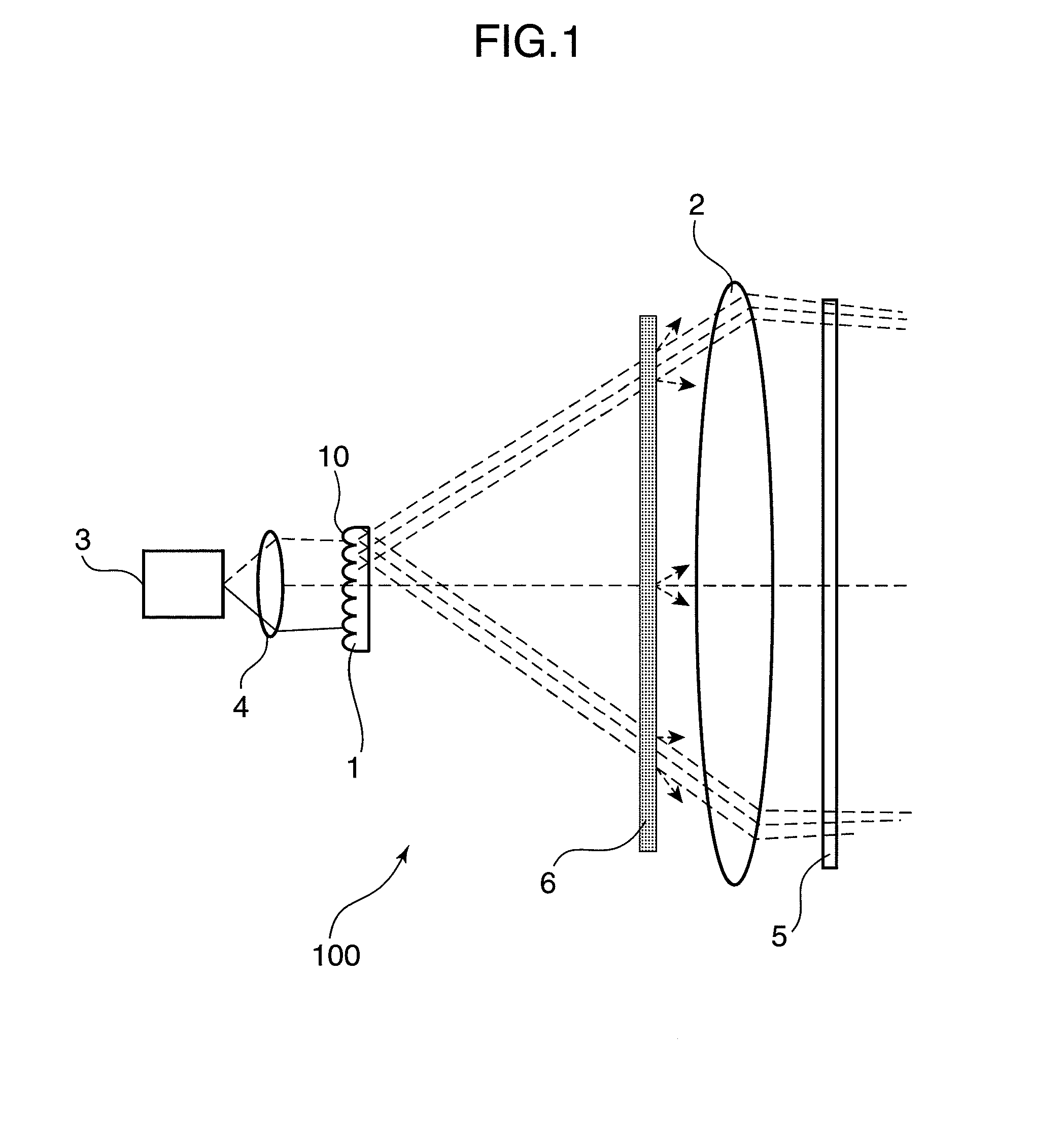

InactiveUS20100053565A1Remove speckle noiseUniform lightDiffusing elementsProjectorsDivergence angleLaser light

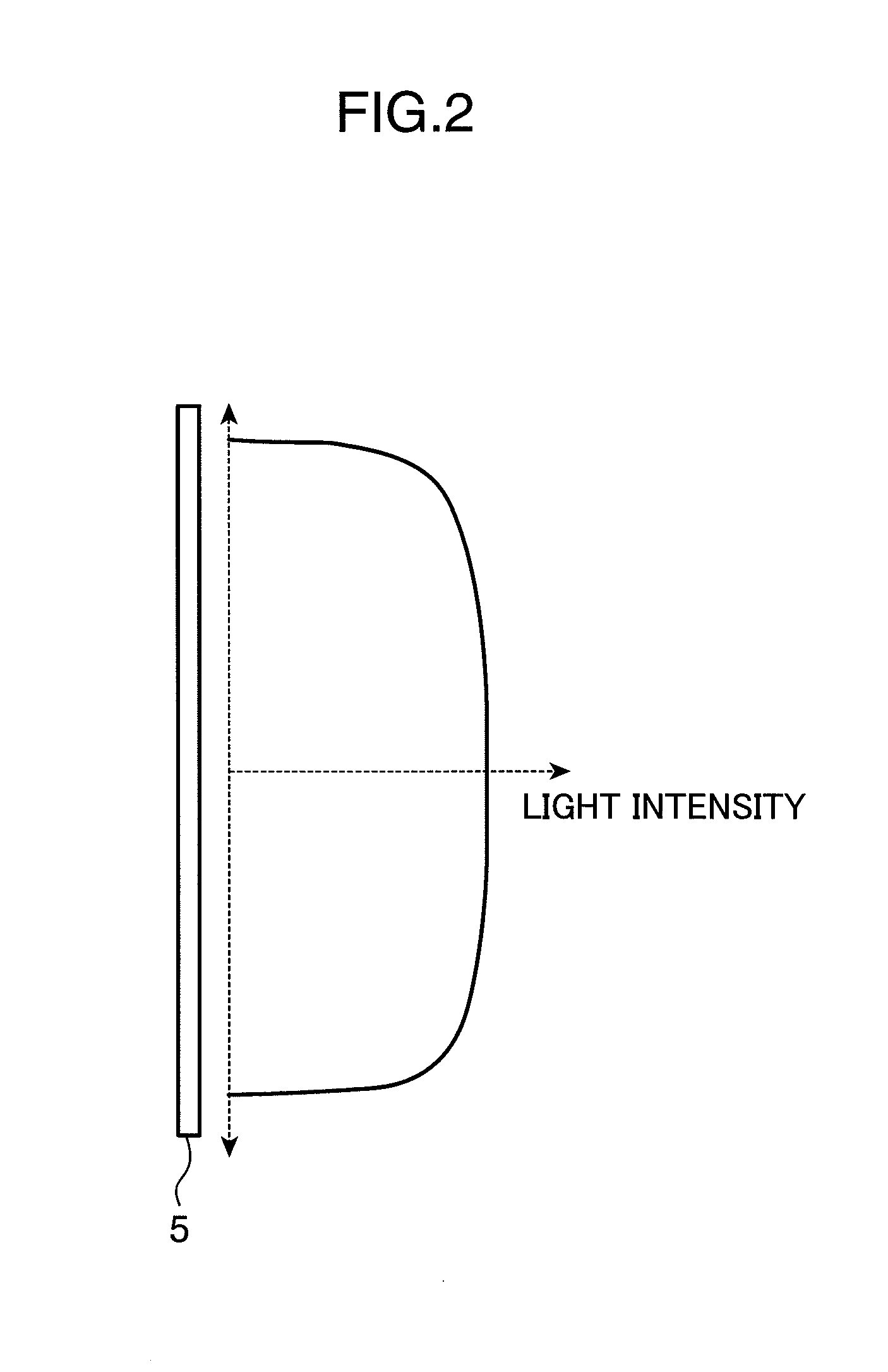

An object of the invention is to provide a laser illuminating device and an image display device that enable to remove speckle noises in a diffraction field and an image field, uniformly illuminate an illumination plane, and realize miniaturization. A laser illuminating device 100 includes a laser light source 3, a first lens 1 including a plurality of microlenses 10 each having a predetermined numerical aperture in an in-plane direction, each of the microlenses 10 being adapted to expand laser light emitted from the laser light source 3 to thereby superimpose the laser light transmitted through each of the microlenses 10; and a second lens 2 having an effective diameter larger than an effective diameter of the first lens 1, and for compensating for a divergence angle of the laser light expanded by each of the plurality of the microlenses 10.

Owner:PANASONIC CORP

Self-packaged optical interference display device having anti-stiction bumps, integral micro-lens, and reflection-absorbing layers

InactiveUS20070020948A1Reduce reflectionStatic indicating devicesVolume/mass flow measurementOptical propertyOptical cavity

An electronic device of an embodiment of the invention is disclosed that at least partially displays a pixel of a display image. The device includes a first reflector and a second reflector defining an optical cavity therebetween that is selective of a visible wavelength at an intensity. The device includes a mechanism to allow optical properties of the cavity to be varied such that the visible wavelength and / or the intensity are variably selectable in correspondence with the pixel of the displayable image. The device also includes one or more transparent deposited films, one or more absorbing layers, an integral micro-lens, and / or one or more anti-stiction bumps. The deposited films are over one of the reflectors, for self-packaging of the device. The absorbing layers are over one of the reflectors, to reduce undesired reflections. The integral micro-lens is over one of the reflectors, and the anti-stiction bumps are between the reflectors.

Owner:PIEHL ARTHUR +3

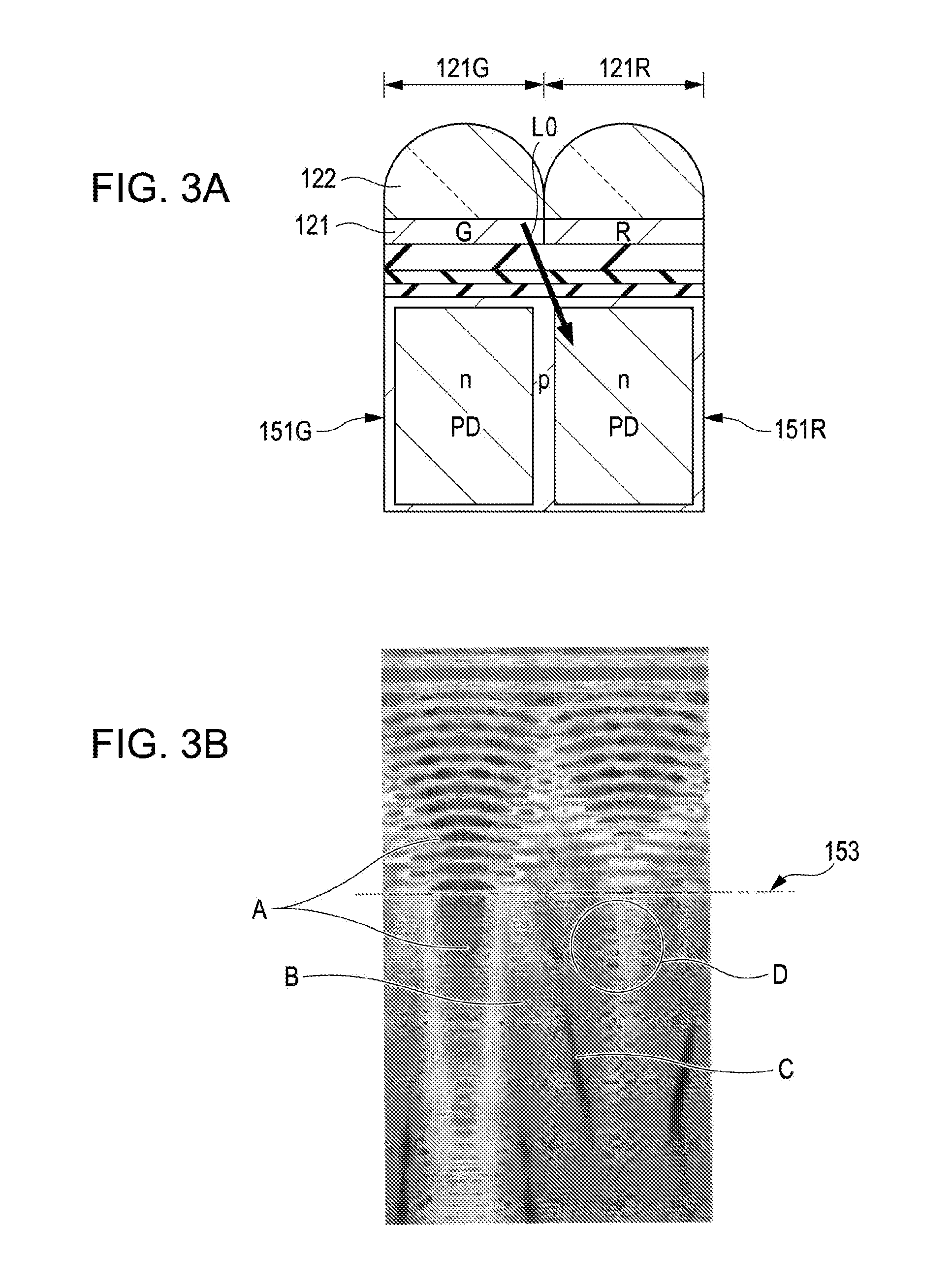

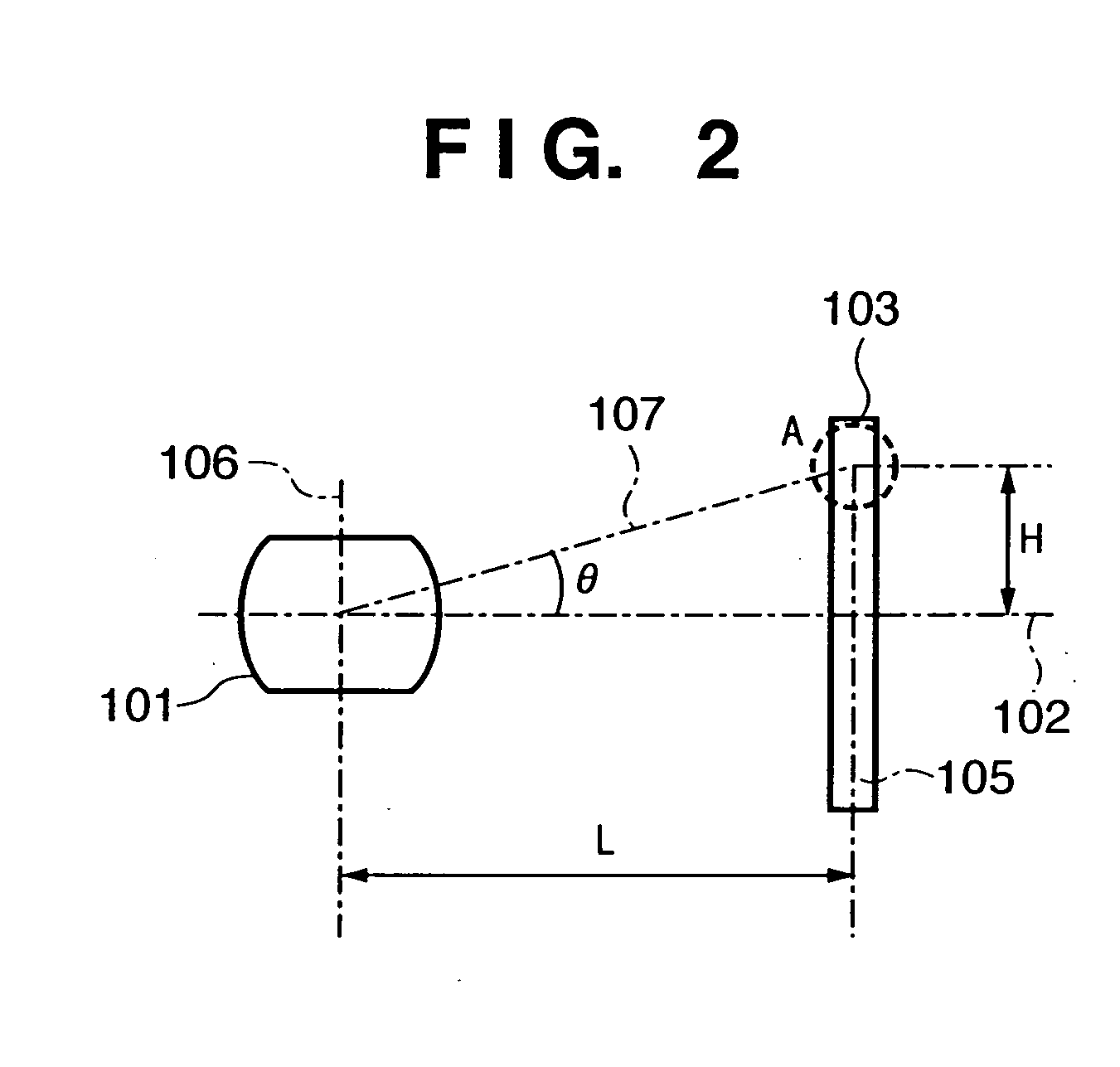

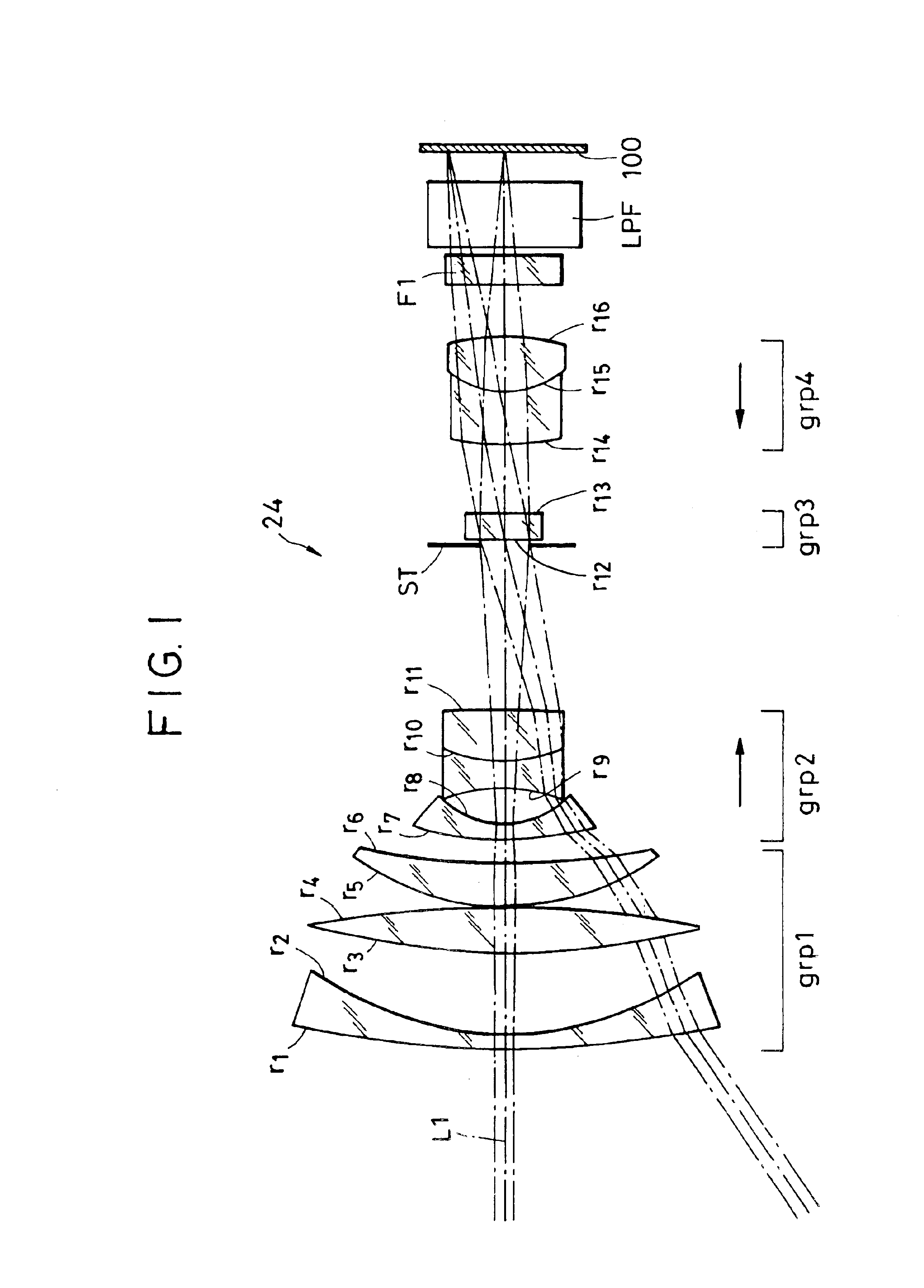

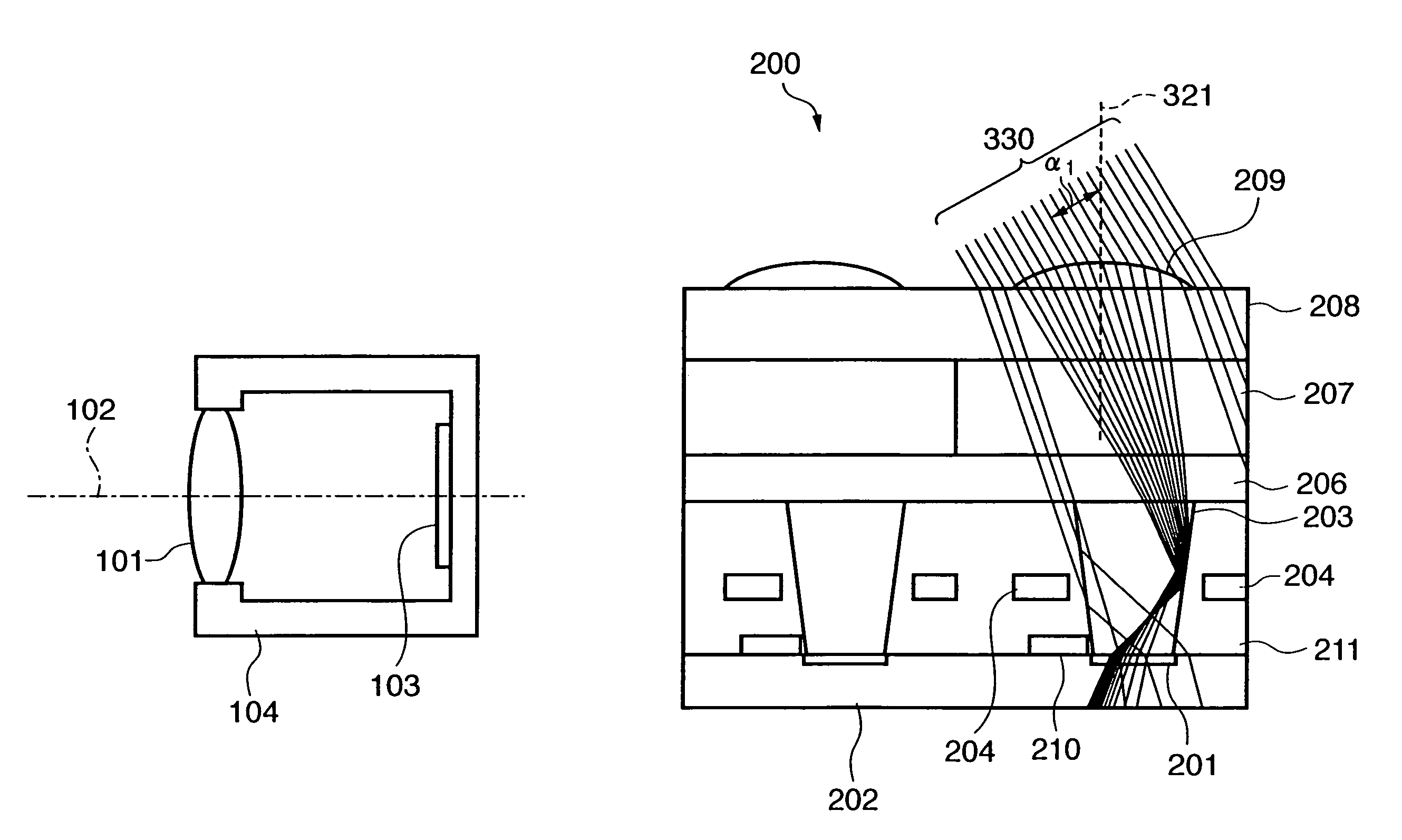

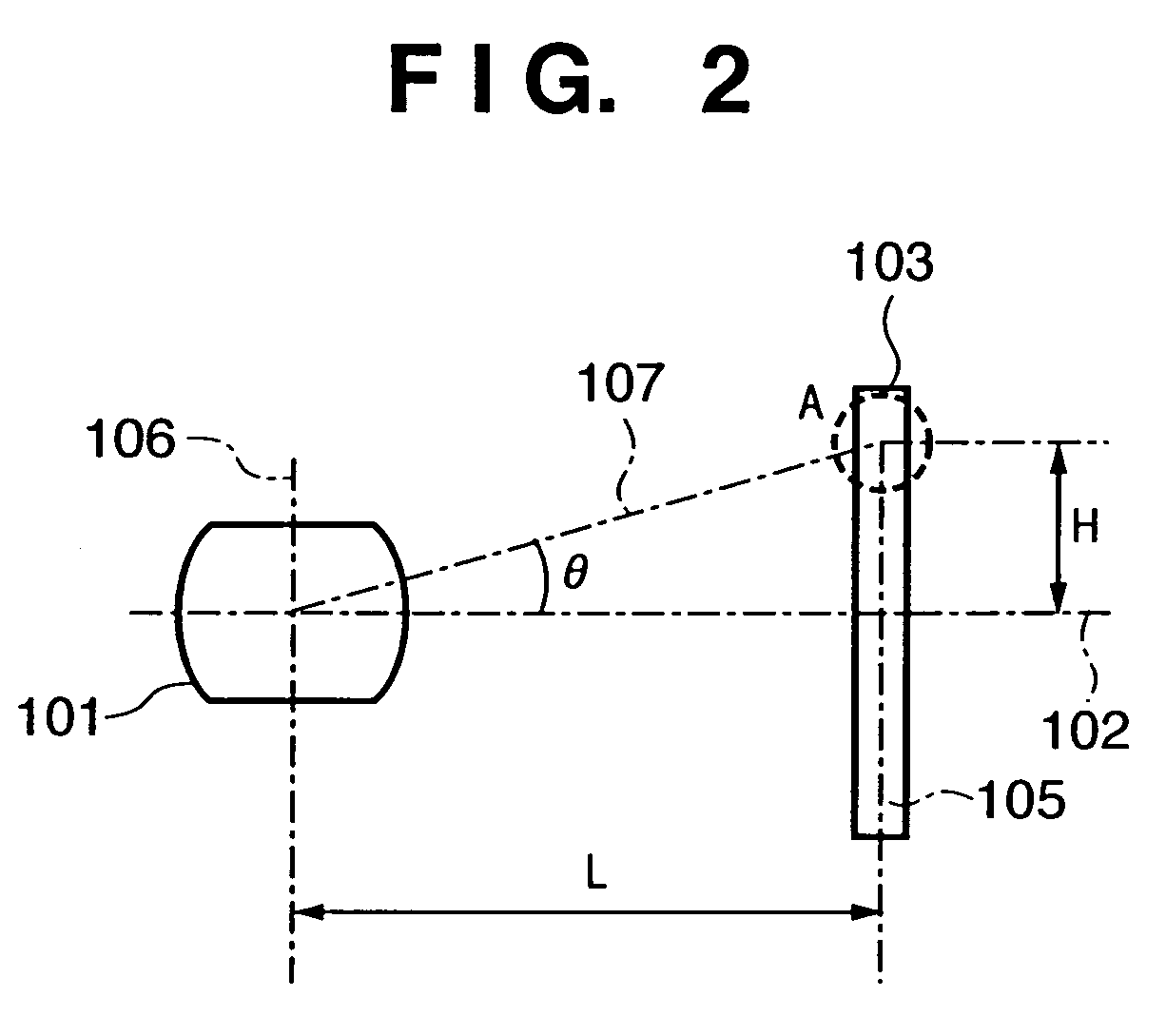

Solid-state image sensing element and its design support method, and image sensing device

ActiveUS20050236553A1Increase freedomImprove light collection efficiencyTelevision system detailsSolid-state devicesExit pupilLight guide

A solid-state image sensing element has a photoelectric conversion element which converts incoming light into an electrical signal in accordance with an amount of the light, a microlens which is arranged on an incident surface, a light guide which is arranged between the photoelectric conversion element and the microlens, and an insulating interlayer which is arranged around the light guide. The solid-state image sensing element located at a distance (H) satisfies: H·DL·P<a·NHNL for 0<a<1where L is the distance from an exit pupil of an image sensing optical system of an image sensing device, which mounts an image sensor formed by two-dimensionally arranging a plurality of the solid-state image sensing elements, H is the distance from a center of the image sensor to a position of the solid-state image sensing element on the image sensor, D is the height from the photoelectric conversion element to an apex of the microlens, P is the spacing between the plurality of solid-state image sensing elements, NH is the refractive index of the light guide, and NL is the refractive index of the insulating interlayer.

Owner:CANON KK

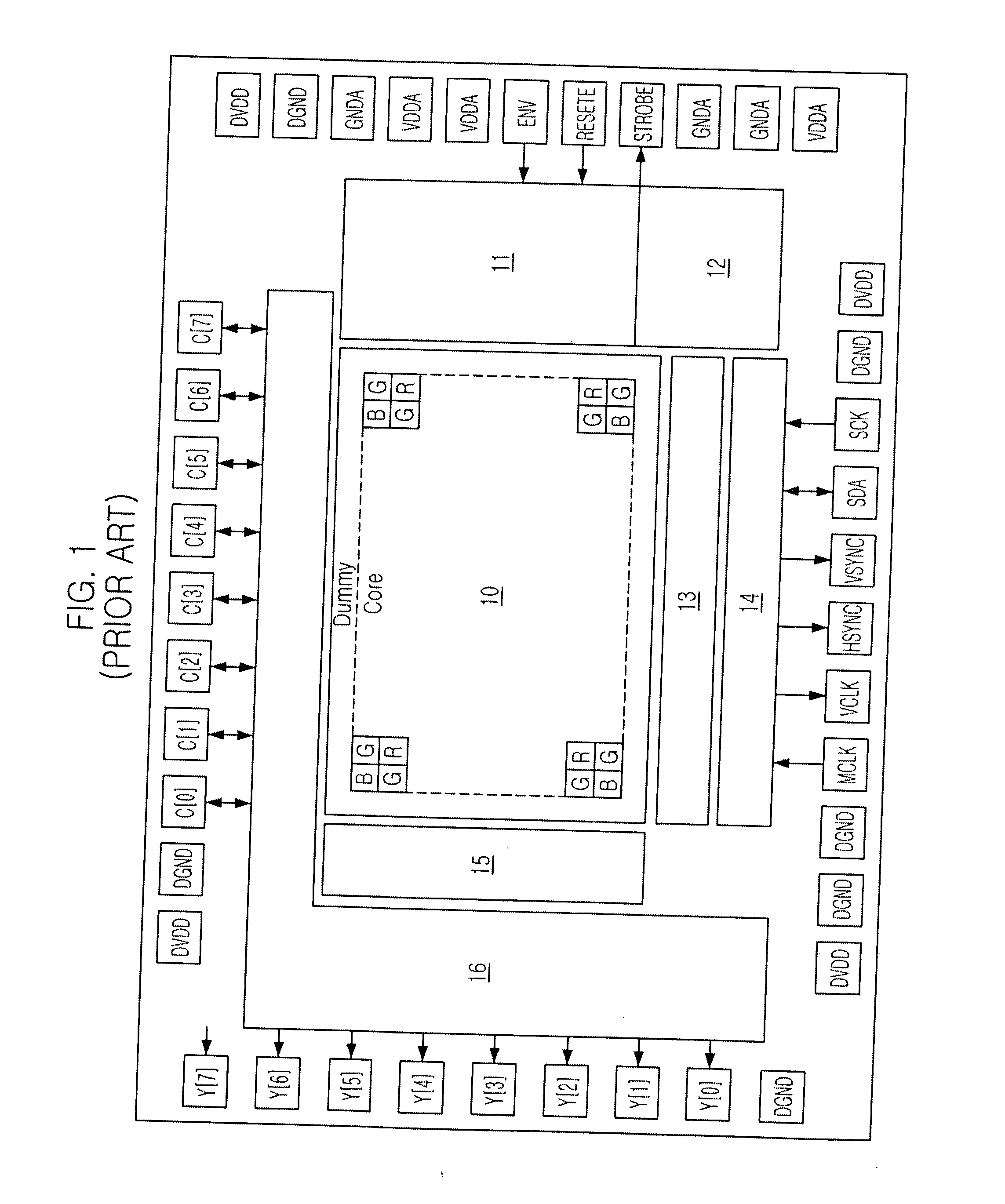

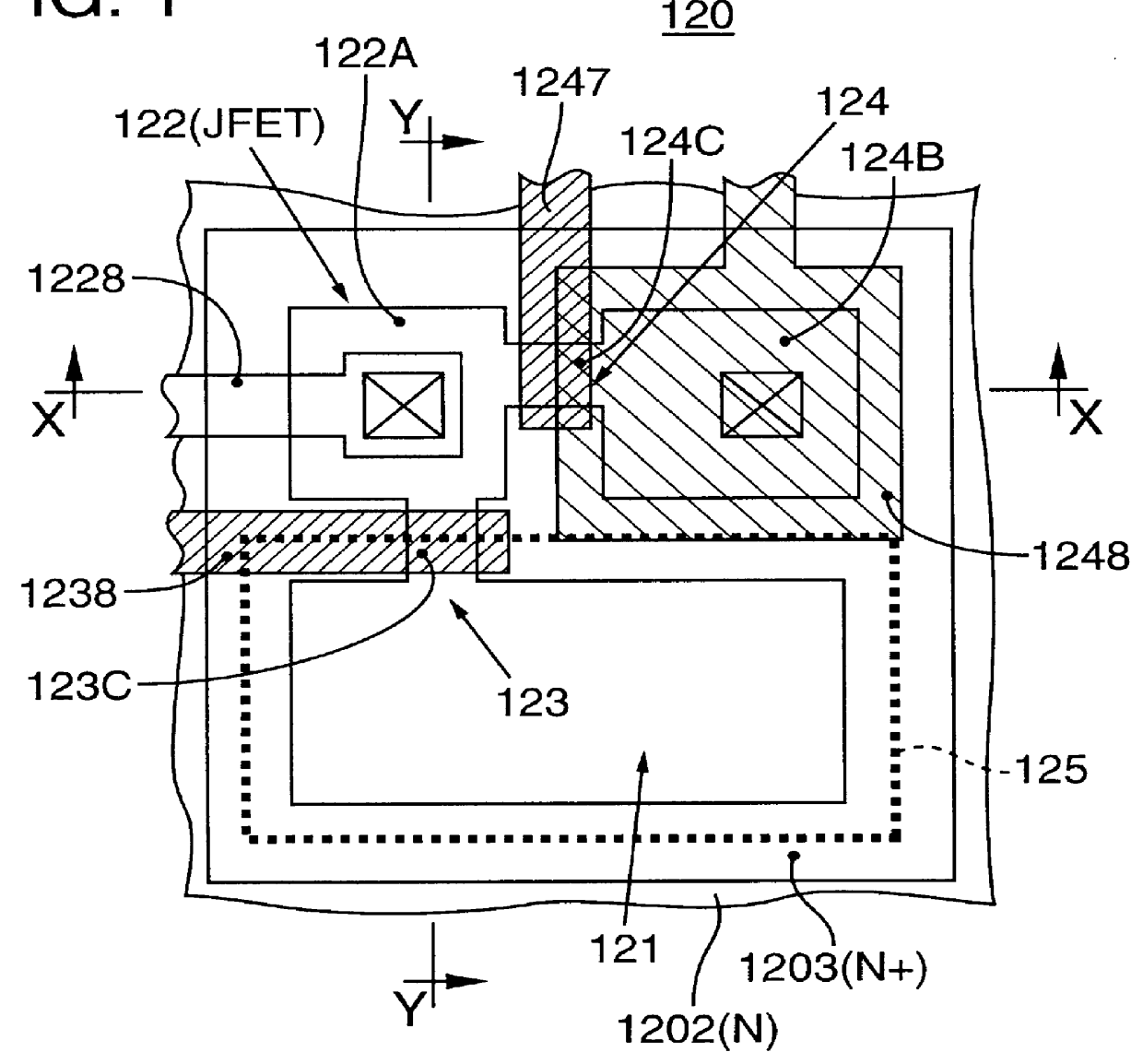

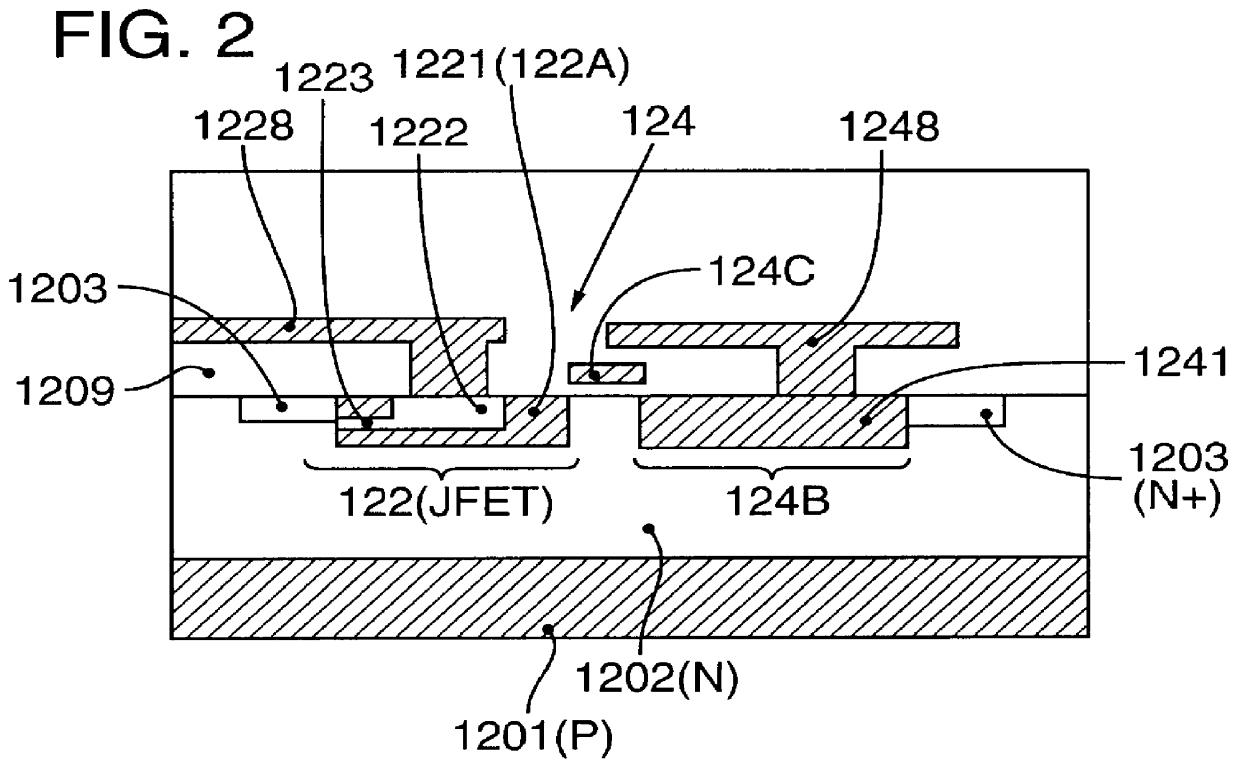

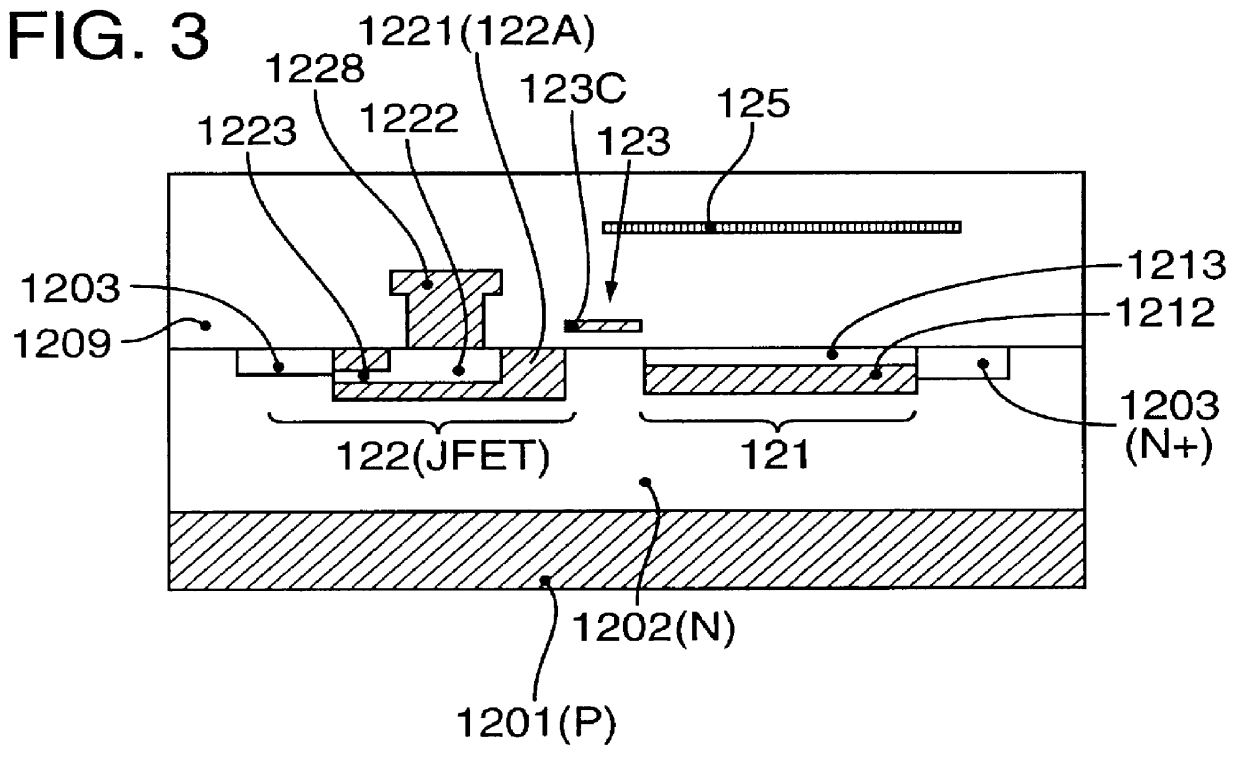

Solid-state imaging device

InactiveUS6046466ASharp image can be stably obtainedRealize automatic adjustmentTransistorTelevision system detailsSensor arrayMOSFET

A photoelectric conversion device suitable for use as an element of a photodetector array includes a photodiode for generating a first signal charge in response to incident light, an output unit including a JFET, and at least one transistor having an electrode that generates a second signal charge in response to incident light. The first and second signal charges may be output separately or combined. The second signal charge, or the first and second signal charges combined, may be monitored during an exposure time to determine the desired end of the exposure. An image sensor array may have one or more pixels with such light monitoring capability. The output signal for monitoring the light may be output over a reset drain interconnection, directly from the monitoring pixel or through other pixels via inter-pixel MOSFETS. Exposure time may be controlled, by timing a shutter or a strobe or the like, based on the monitored accumulation of signal charge during exposure. Microlenses may be provided on-chip to increase the effective aperture ratio of the array. The microlenses are designed to avoid interfering with the incident light used for monitoring. Resulting pixel-to-pixel variations in effective aperture ratio, if any, may be electronically compensated.

Owner:NIKON CORP

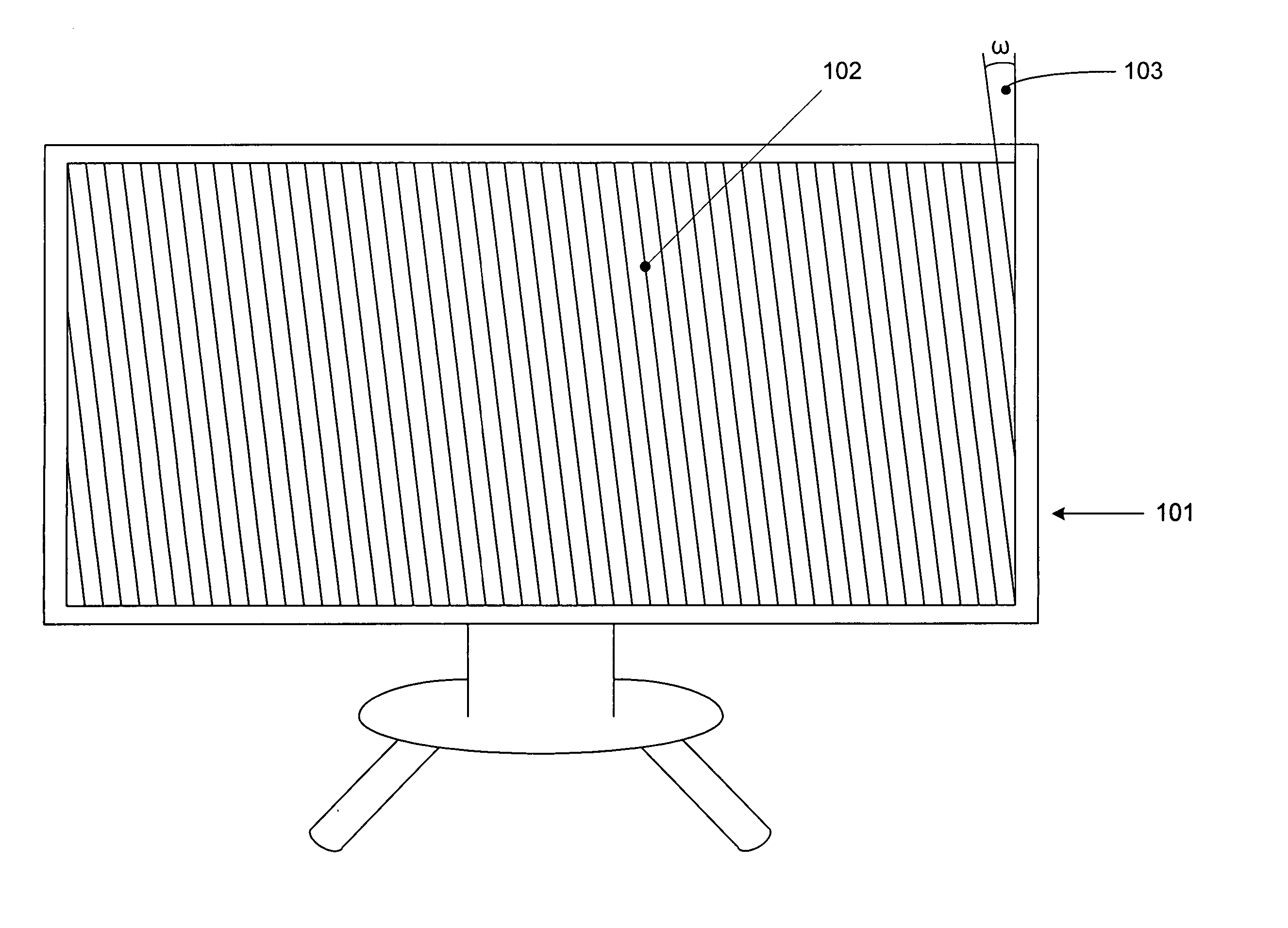

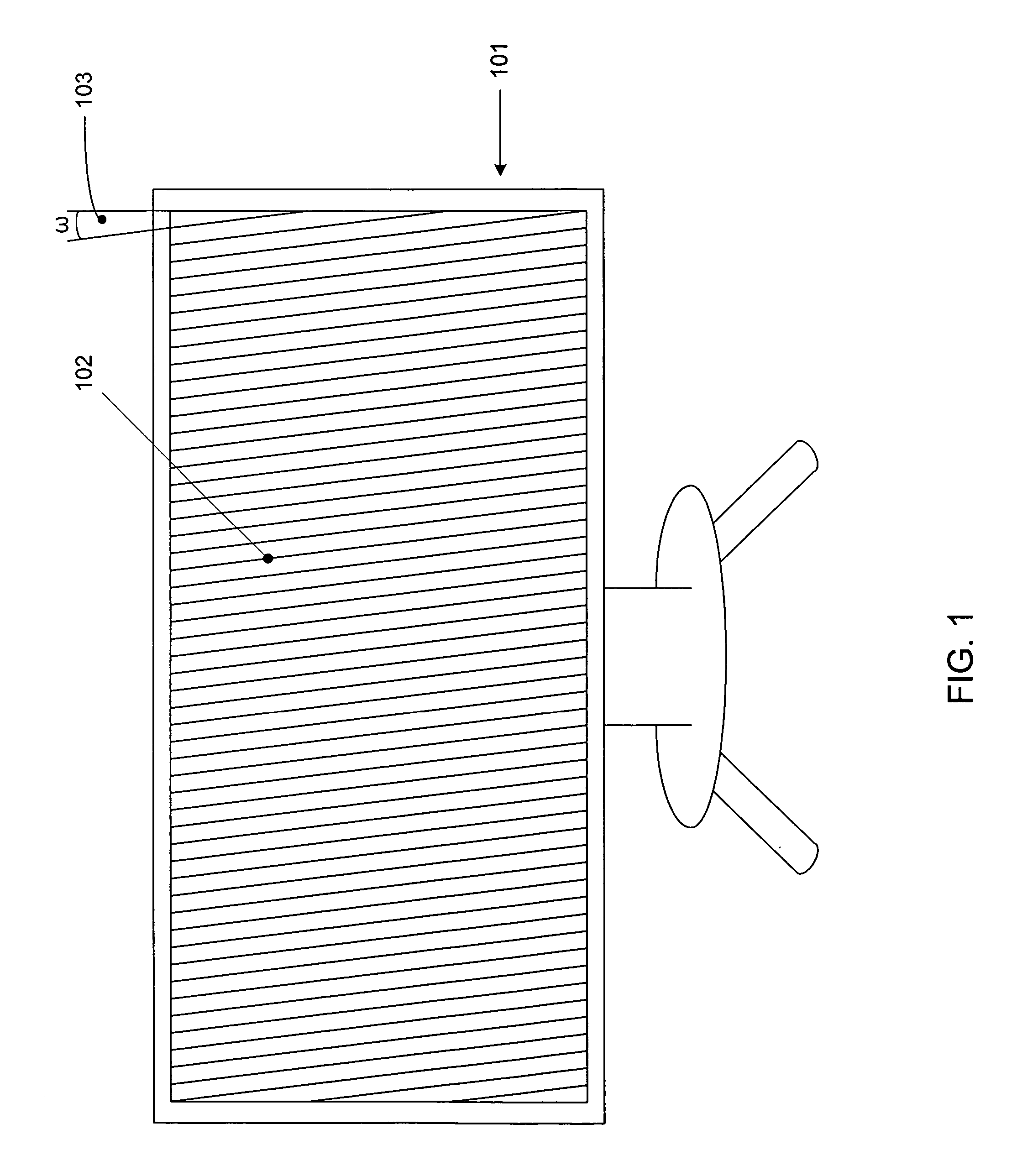

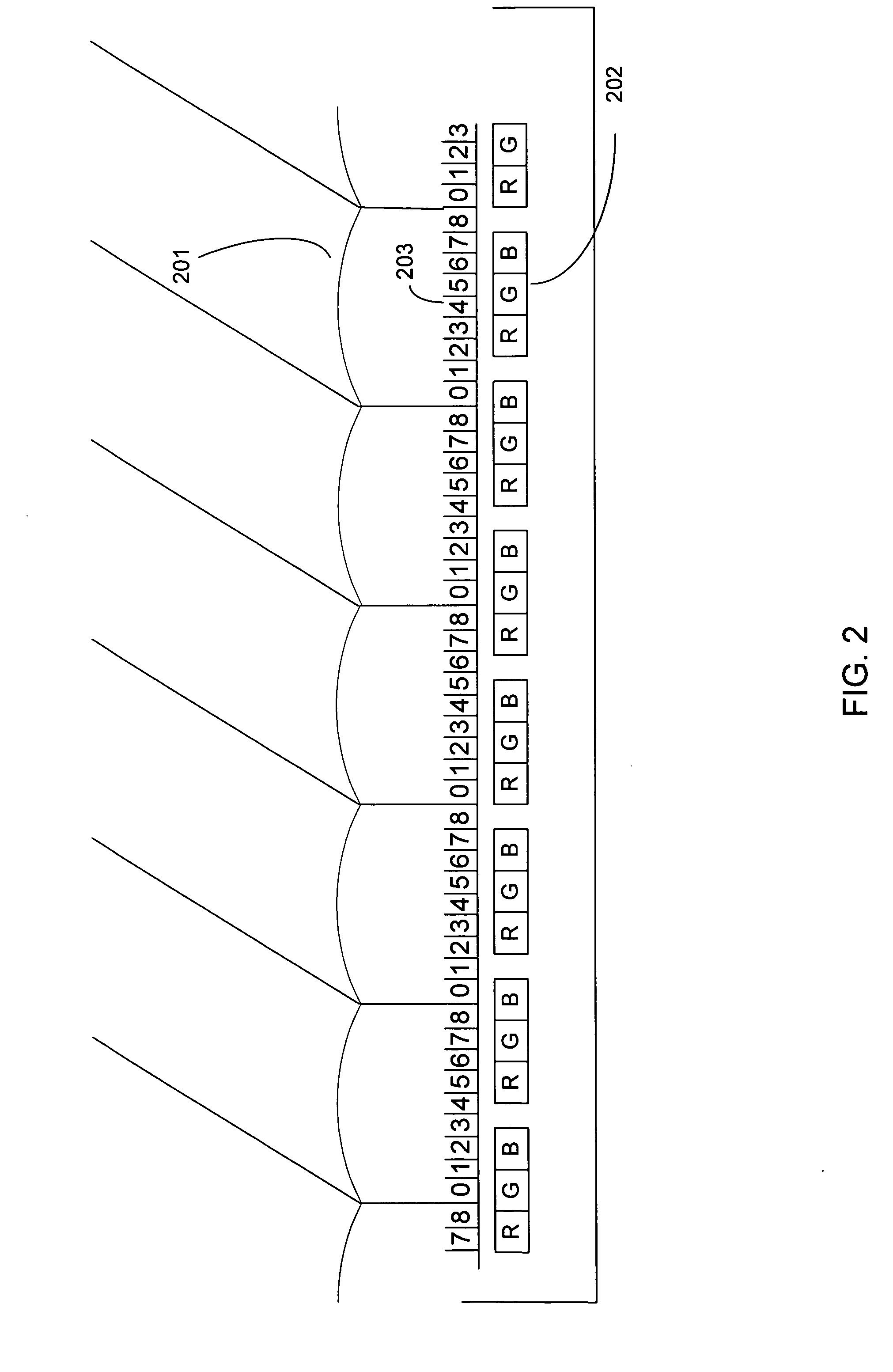

Autostereoscopic display with planar pass-through

InactiveUS20060284974A1Increase heightTelevision system detailsColor television detailsAutostereogramStereoscopic imaging

A method and system for presenting both autostereoscopic images and planar images in a single display is disclosed. The design comprises processing the planar images received in the form of planar image data. The processing comprises at least one from a group comprising selectively employing bleed-through processing to enhance the planar image data when viewed through a lens sheet comprising slanted lenticules, selectively introducing blurring into the planar image data, and selectively employing anti-alias processing to the planar image data. Certain super pixels may be computed that differ from standard pixels, and lenticules in the data sheet may be slanted at desired angles. The physical lenticules may cause bleed-through that may be processed. Resolution may be computed after processing, and the resolution implemented for display. Mode switching between planar and autostereoscopic imaging may be provided in the form of Metadata or visible flags.

Owner:REAID INC

Wide-angle variable focal length lens system

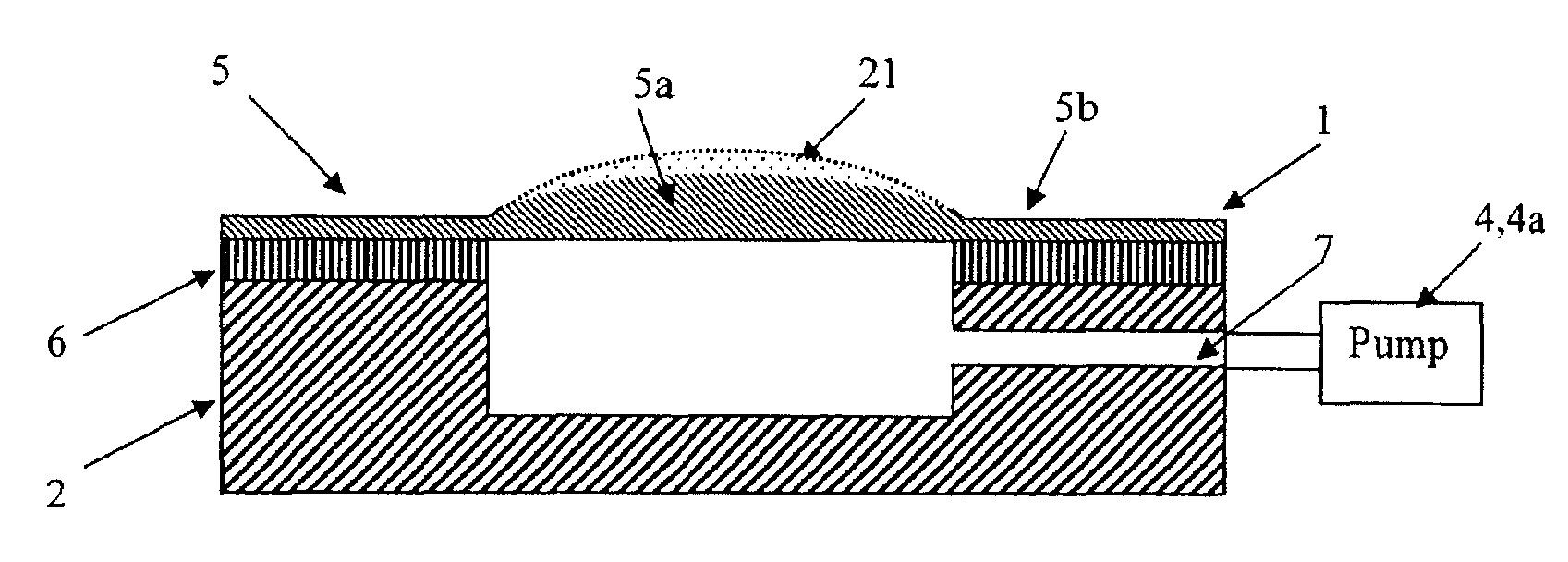

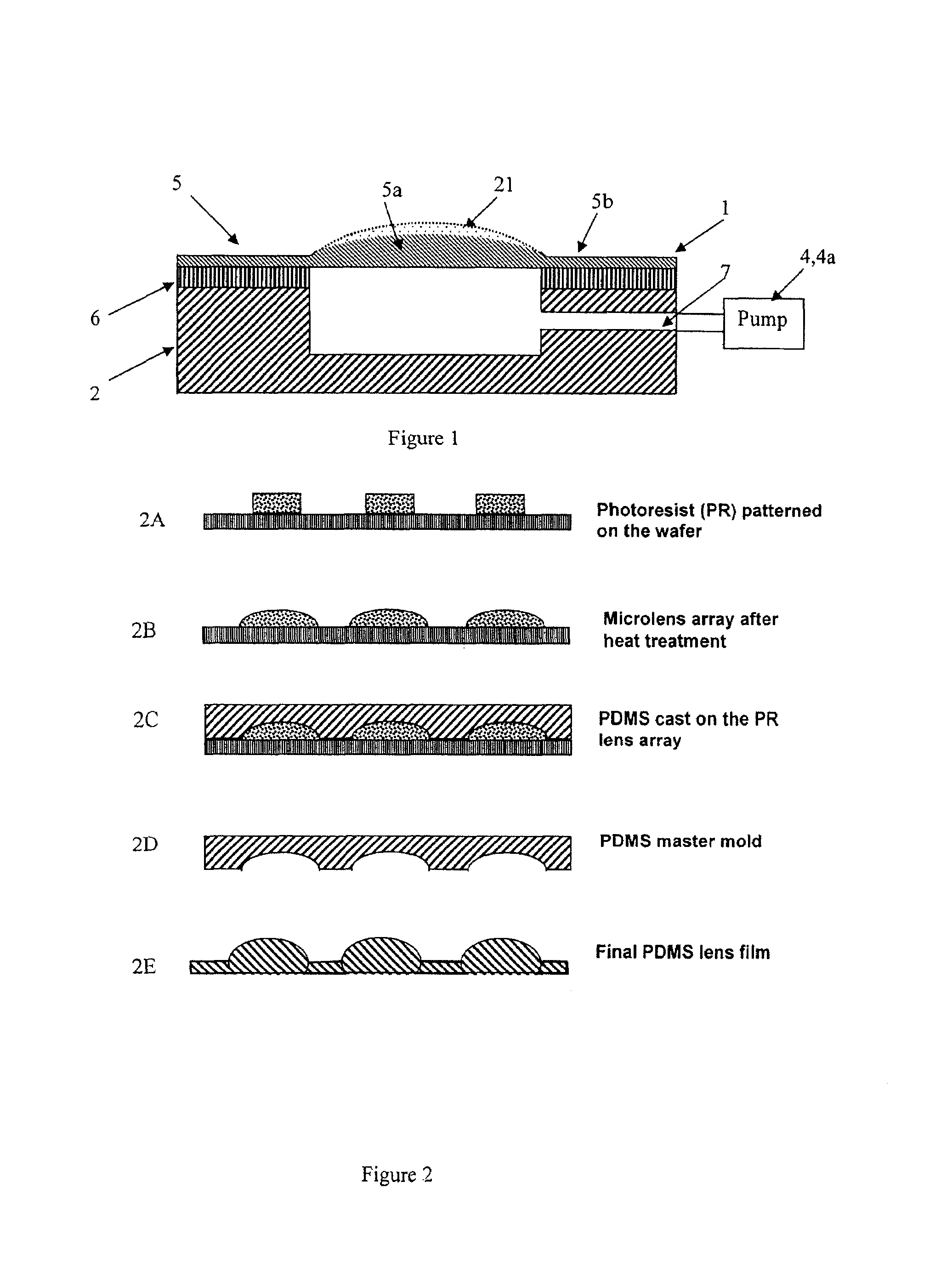

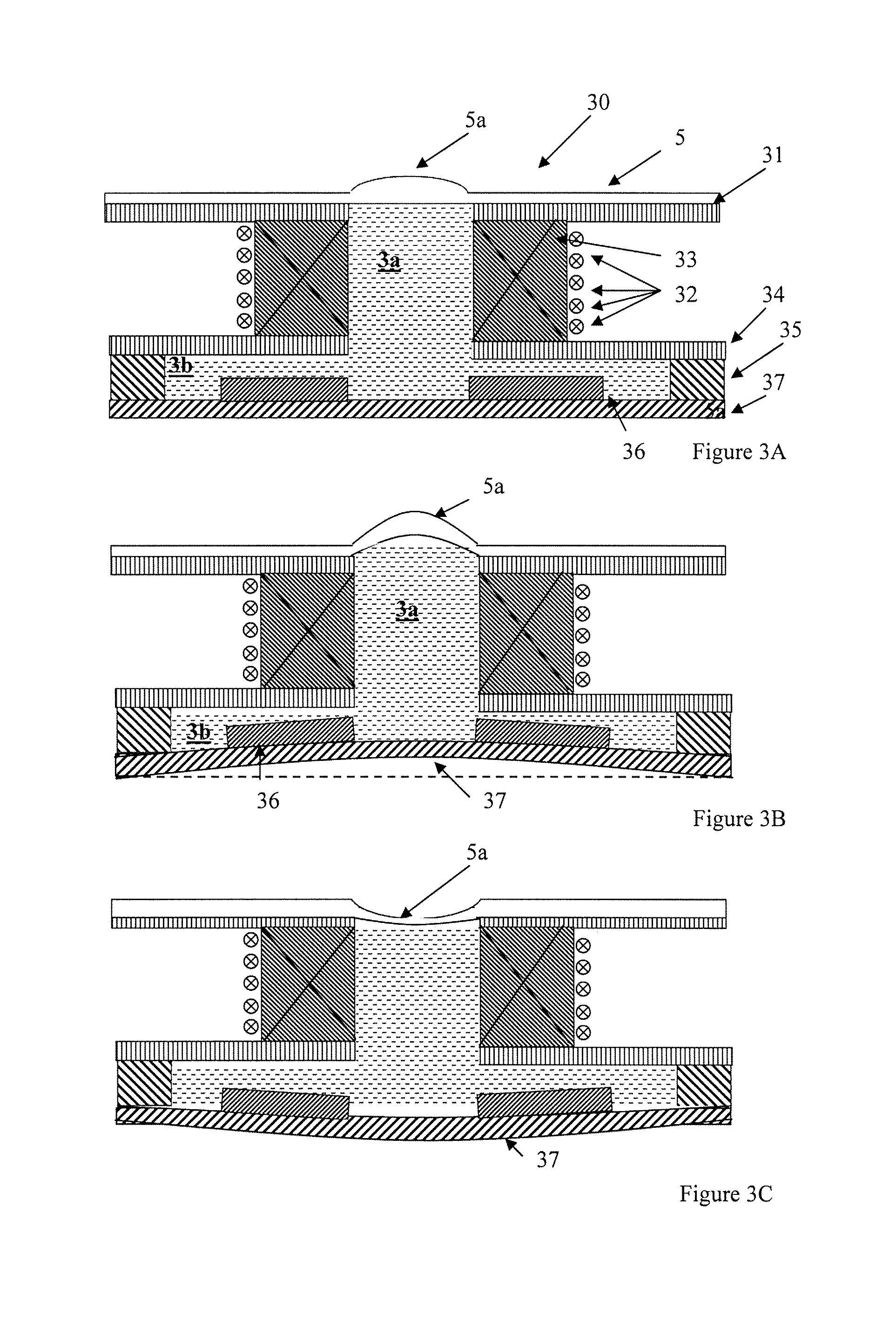

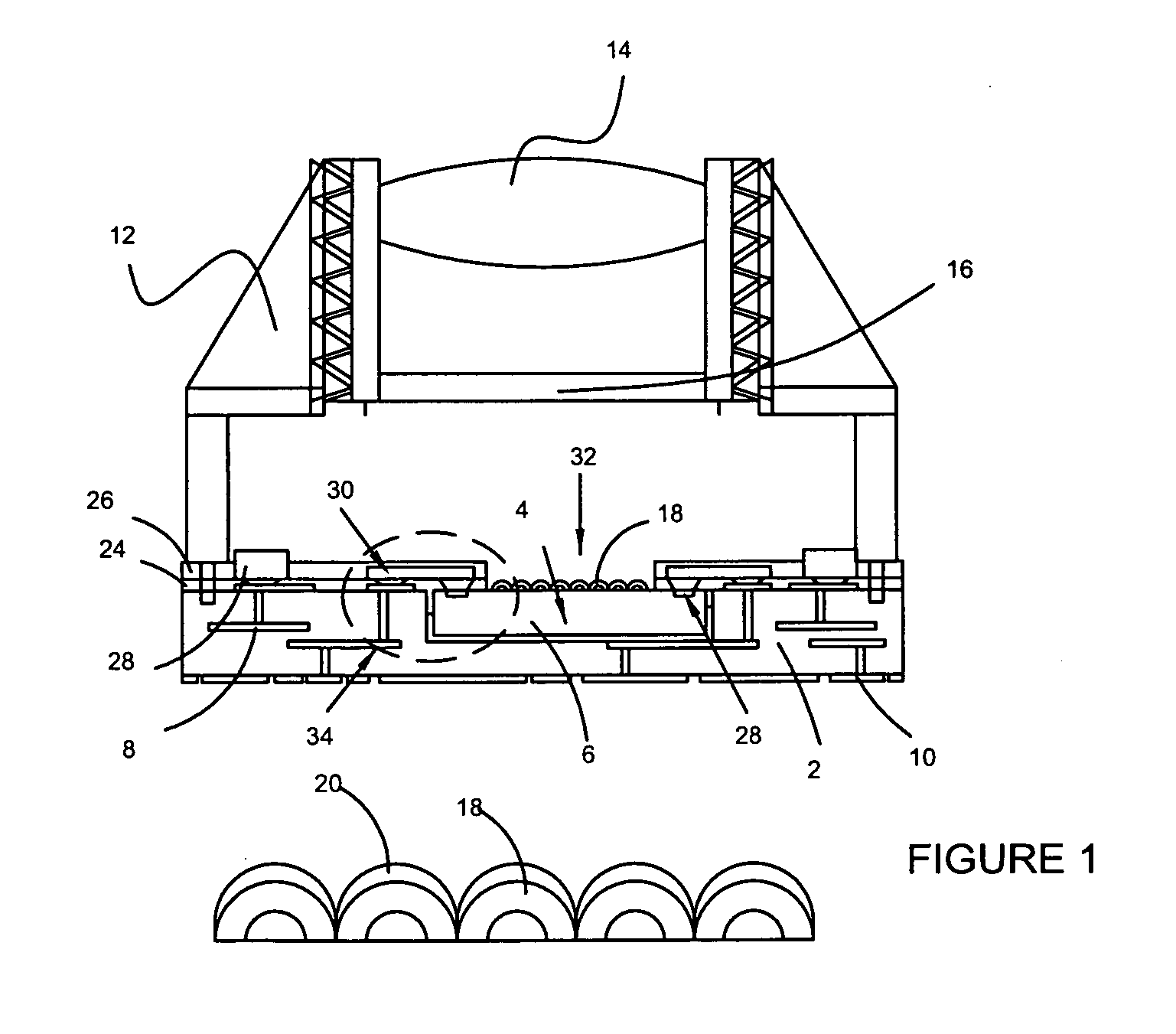

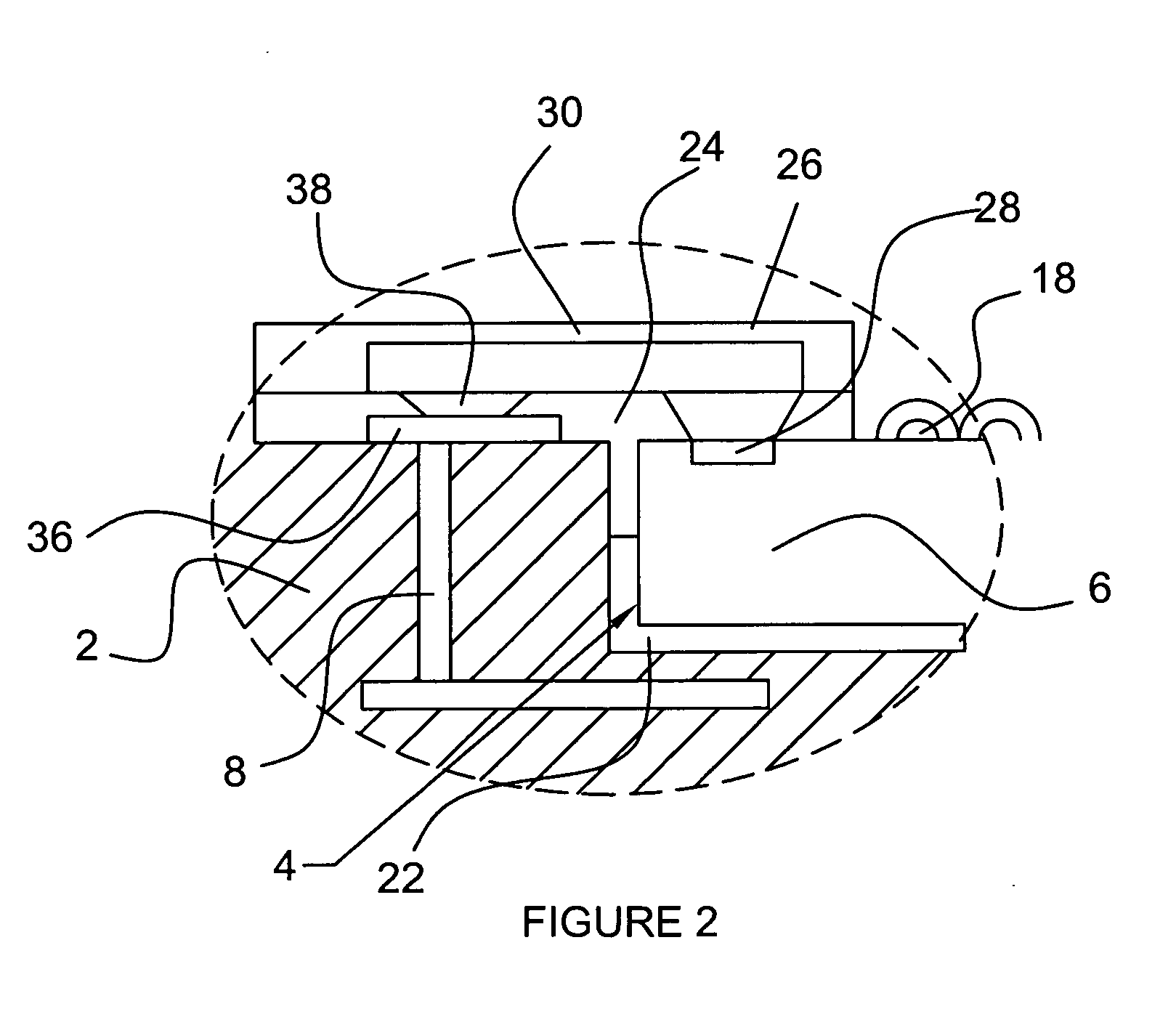

A variable focal length microlens system having a base section with a fluid chamber and a fluid pressurization mechanism. A flexible, substantially transparent polymer lens section is fixed above the fluid chamber and the lens section has a curvature providing an initial focal point when in an unstrained state. The fluid chamber is substantially sealed and the fluid pressurization mechanism includes a flexible wall in the base section. The flexible wall may be displaced by magnetic activation, PZT activation of another activating mechanism.

Owner:LOUISIANA TECH UNIV RES FOUND A DIV OF LOUISIANA TECH UNIV FOUND

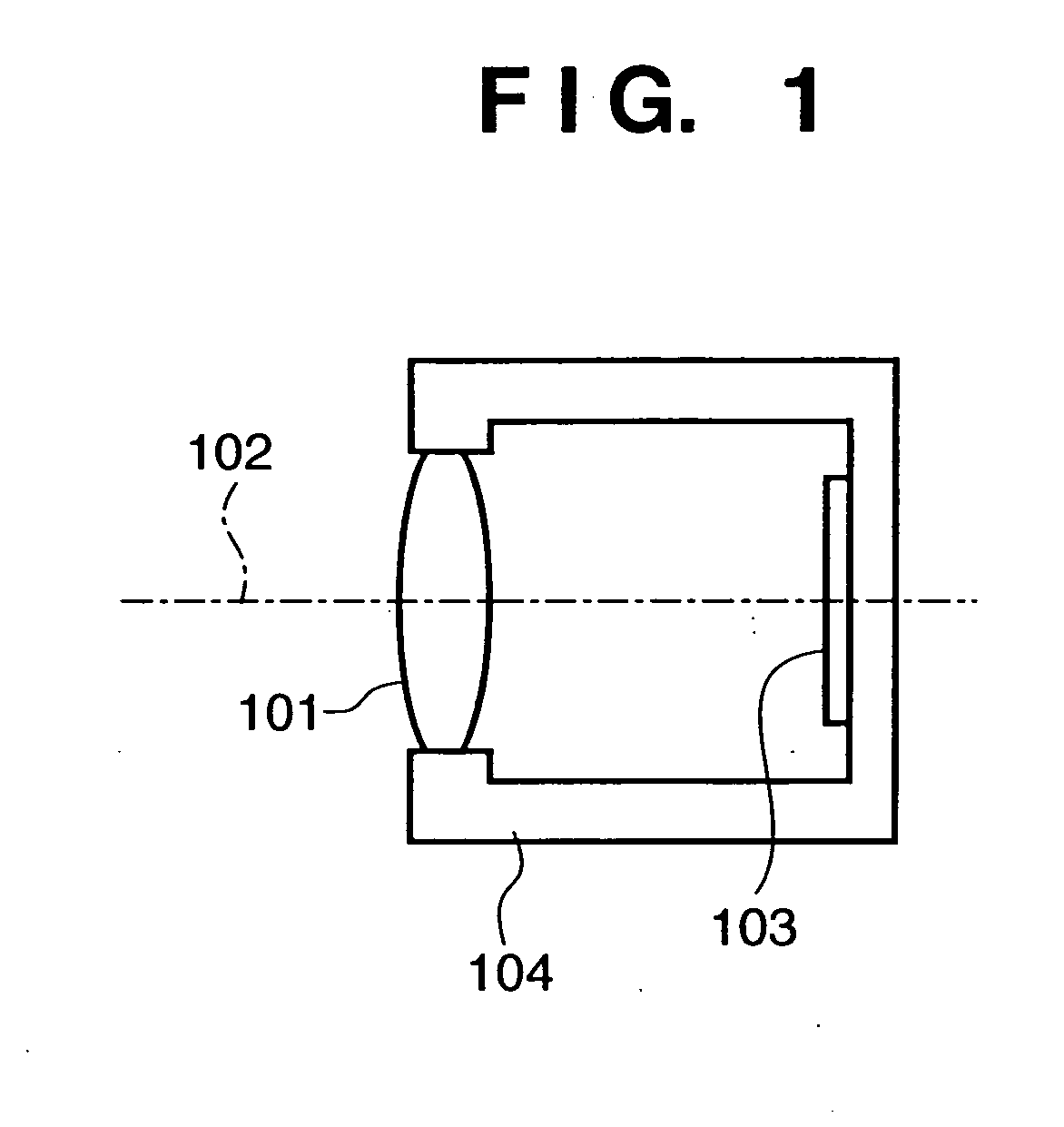

Focus detecting device with photoelectric conversion portion having microlens and with light blocking portion having first and second openings

A focus detecting device comprises a first photoelectric conversion section for performing photoelectric conversion of a light beam emitted from a first pupil area of a image pickup optical unit, a second photoelectric conversion section for performing photoelectric conversion of a light beam emitted from a second pupil area different from the first pupil area, a light intercepting section having openings for allowing passage of a portion of light in the first pupil area and for allowing passage of a portion of light in the second pupil area, and a detecting section for detecting a focus condition of the image pickup optical unit on the basis of photoelectric conversion outputs of the first photoelectric conversion means and the second photoelectric conversion sections. For example, when the image pickup optical unit has a large defocus quantity, the light intercepting section is set in an optical path for focus detection.

Owner:CANON KK

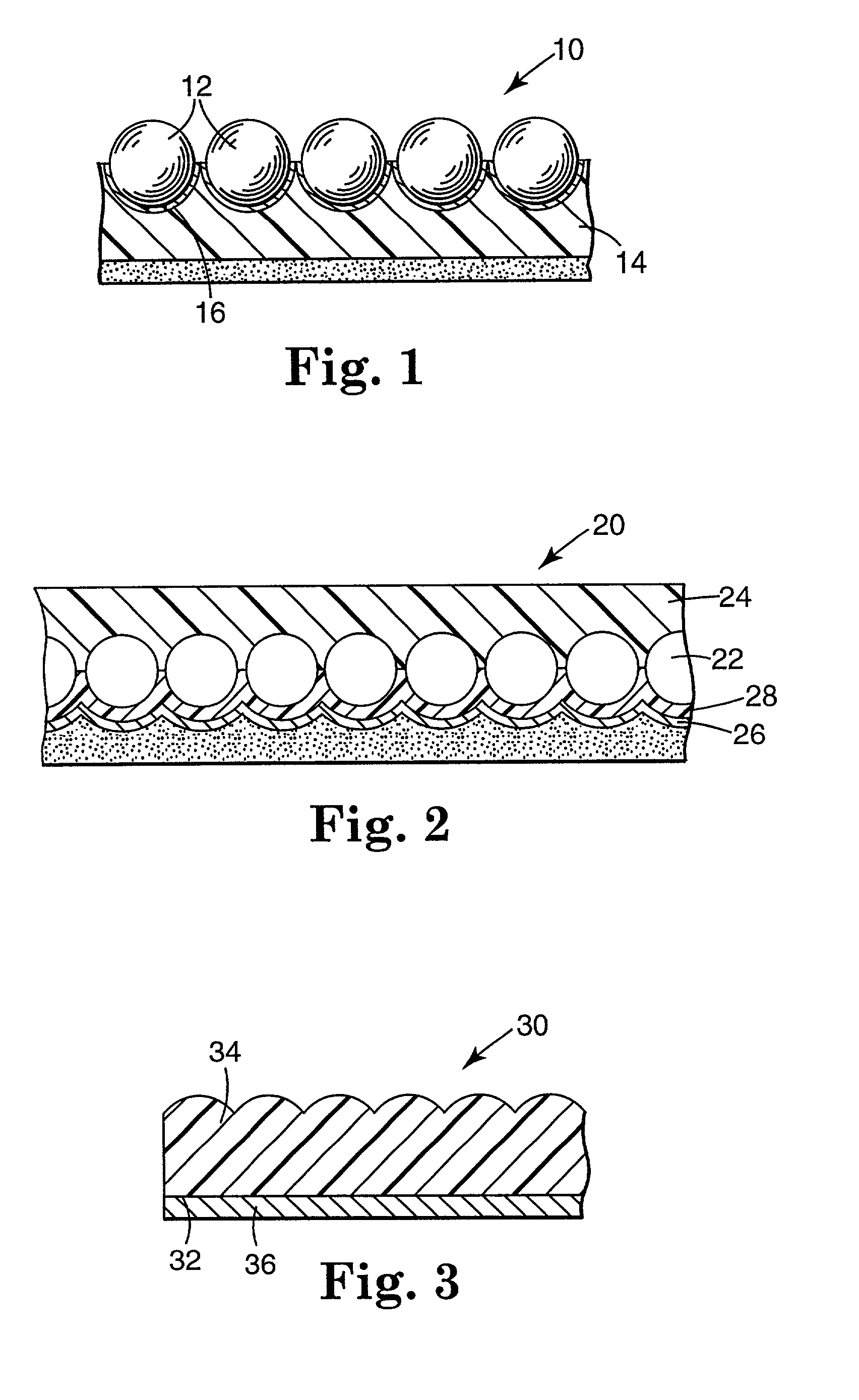

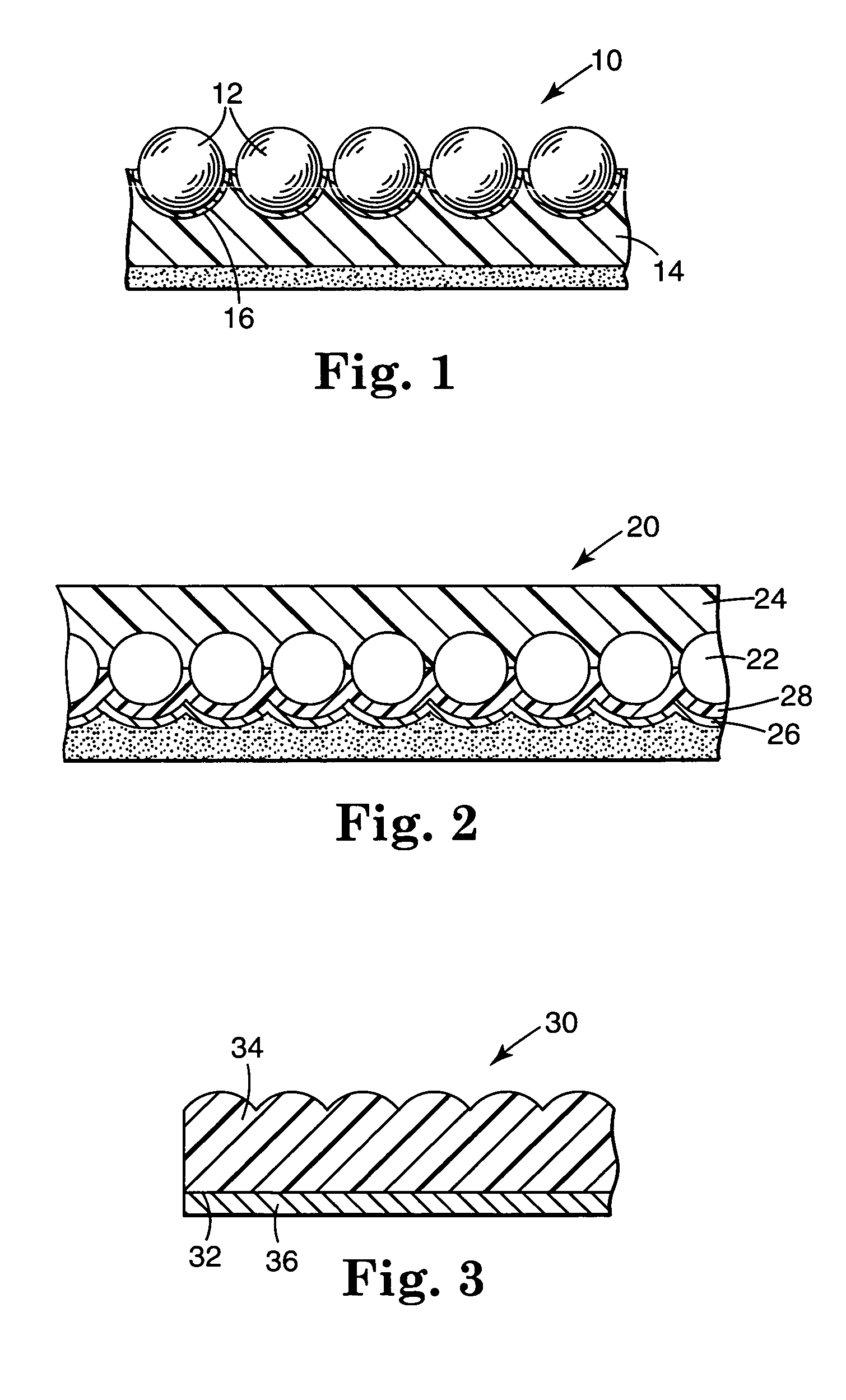

Sheeting with composite image that floats

Microlens sheetings with composite images are disclosed, in which the composite image floats above or below the sheeting, or both. The composite image may be two-dimensional or three-dimensional. Methods for providing such an imaged sheeting, including by the application of radiation to a radiation sensitive material layer adjacent the microlenses, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Light guide array for an image sensor

An image sensor pixel that includes a photoelectric conversion unit supported by a substrate and an insulator adjacent to the substrate. The pixel includes a cascaded light guide that is located within an opening of the insulator and extends above the insulator such that a portion of the cascaded light guide has an air interface. The air interface improves the internal reflection of the cascaded light guide. The cascaded light guide may include a self-aligned color filter having air-gaps between adjacent color filters. Air-gaps may be sealed from above by a transparent sealing film. The transparent sealing film may have a concave surface over the air-gap to diverge light that cross the concave surface into the air-gap away from the air-gap into adjacent color filters. These characteristics of the light guide eliminate the need for a microlens. Additionally, a portion of a support wall between a pair of color filters may have a larger width above than below to form a necking to hold down the color filters for better retention.

Owner:TAY HIOK NAM +1

Laser speckle reduction element

ActiveUS20120081786A1Reduce coherenceBroaden wavelength bandwidthPolarising elementsLight beamOptical pathlength

Owner:PANASONIC CORP

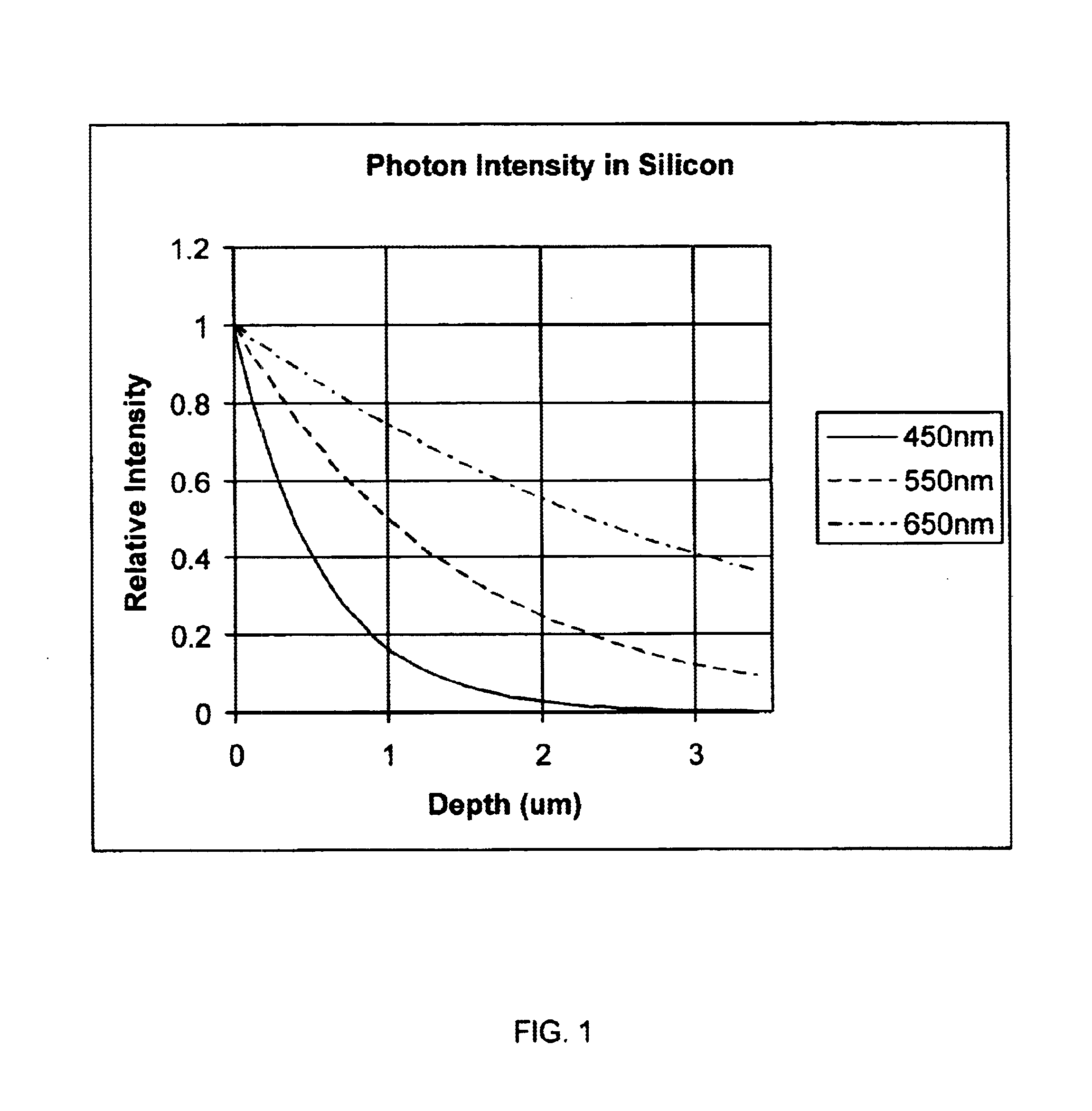

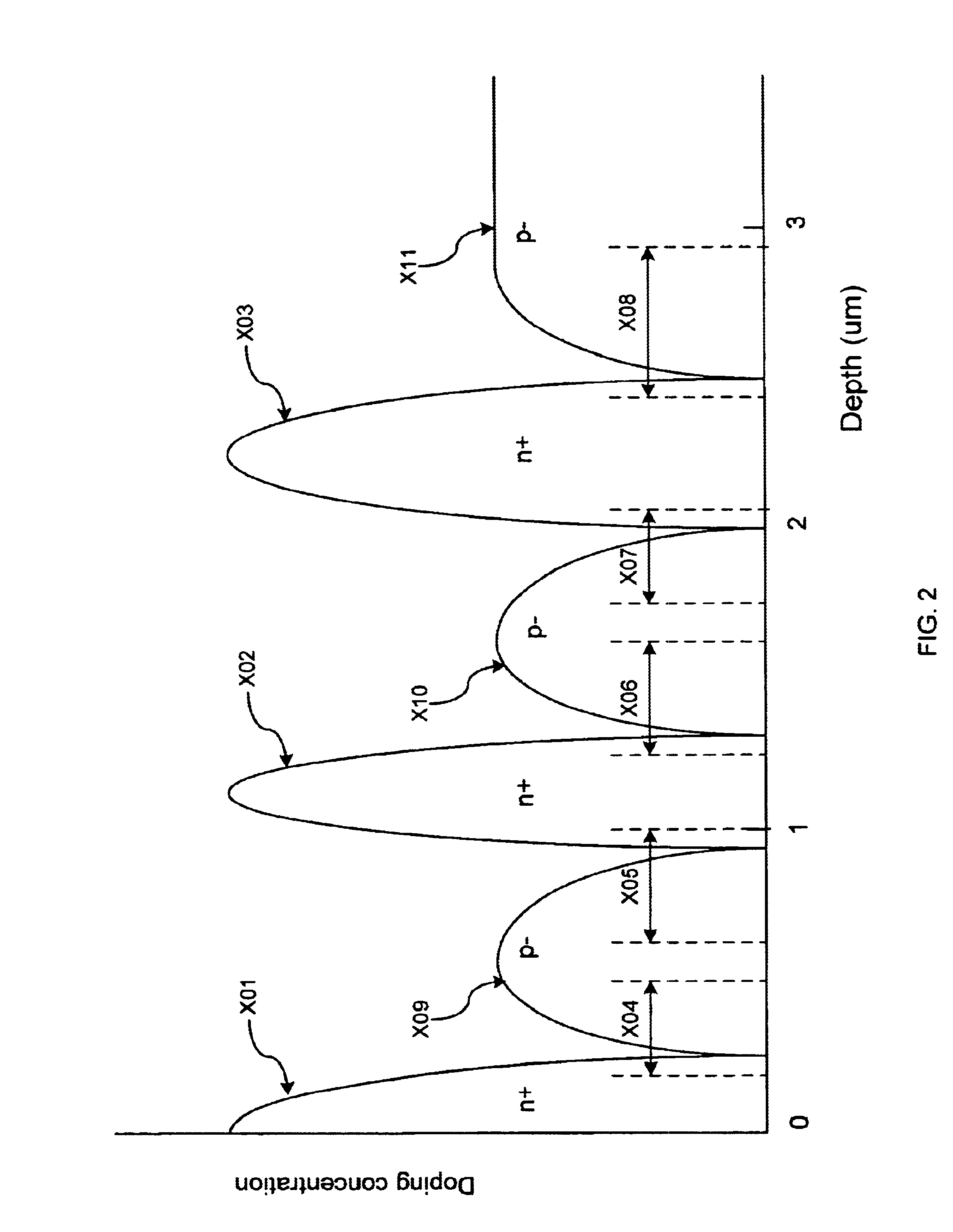

Vertical color filter sensor group with non-sensor filter and method for fabricating such a sensor group

InactiveUS6841816B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMicrolens

A vertical color filter sensor group formed on a substrate (preferably a semiconductor substrate) and including at least two vertically stacked, photosensitive sensors. In preferred embodiments, the sensor group includes at least one filter positioned relative to the sensors such that radiation that has propagated through or reflected from the filter will propagate into at least one sensor. Preferably, the filter is or includes a layer that has been integrated with the sensors by a semiconductor integrated circuit fabrication process. In other embodiments, the sensor group includes a micro-lens. Other aspects of the invention are arrays of vertical color filter sensor groups, some or all of which include at least one filter or micro-lens, and methods for fabricating vertical color filter sensor groups and arrays thereof.

Owner:FOVEON

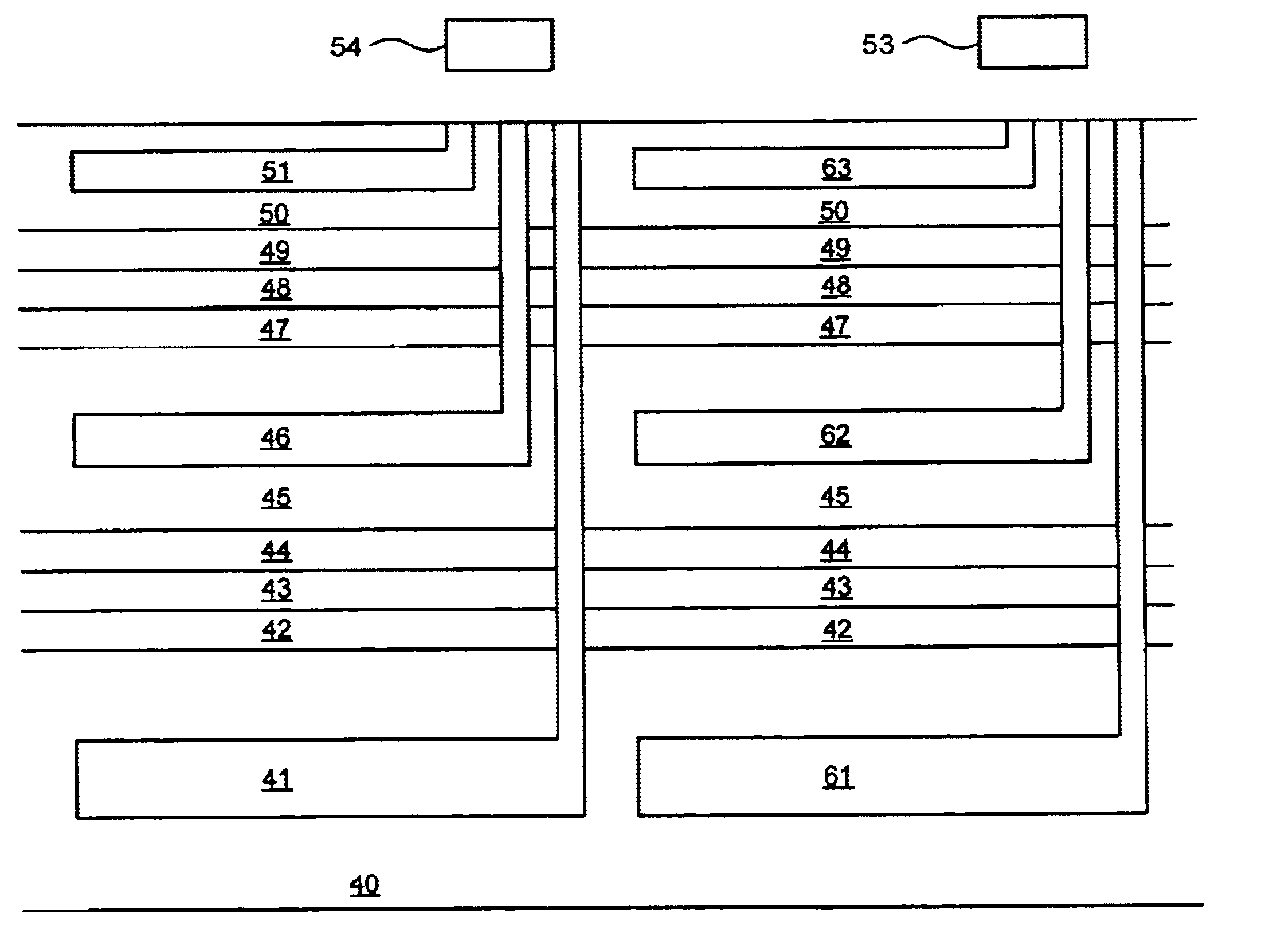

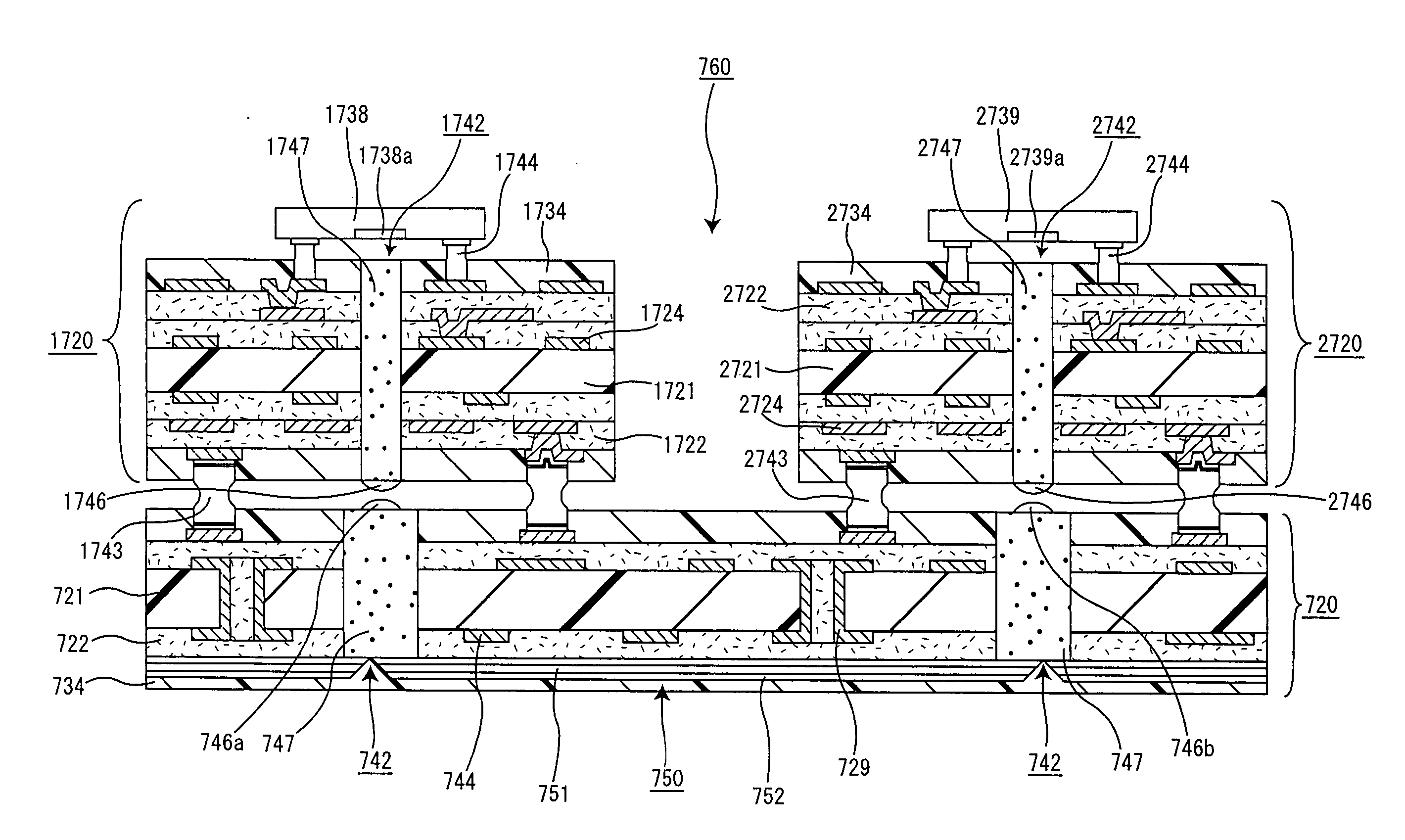

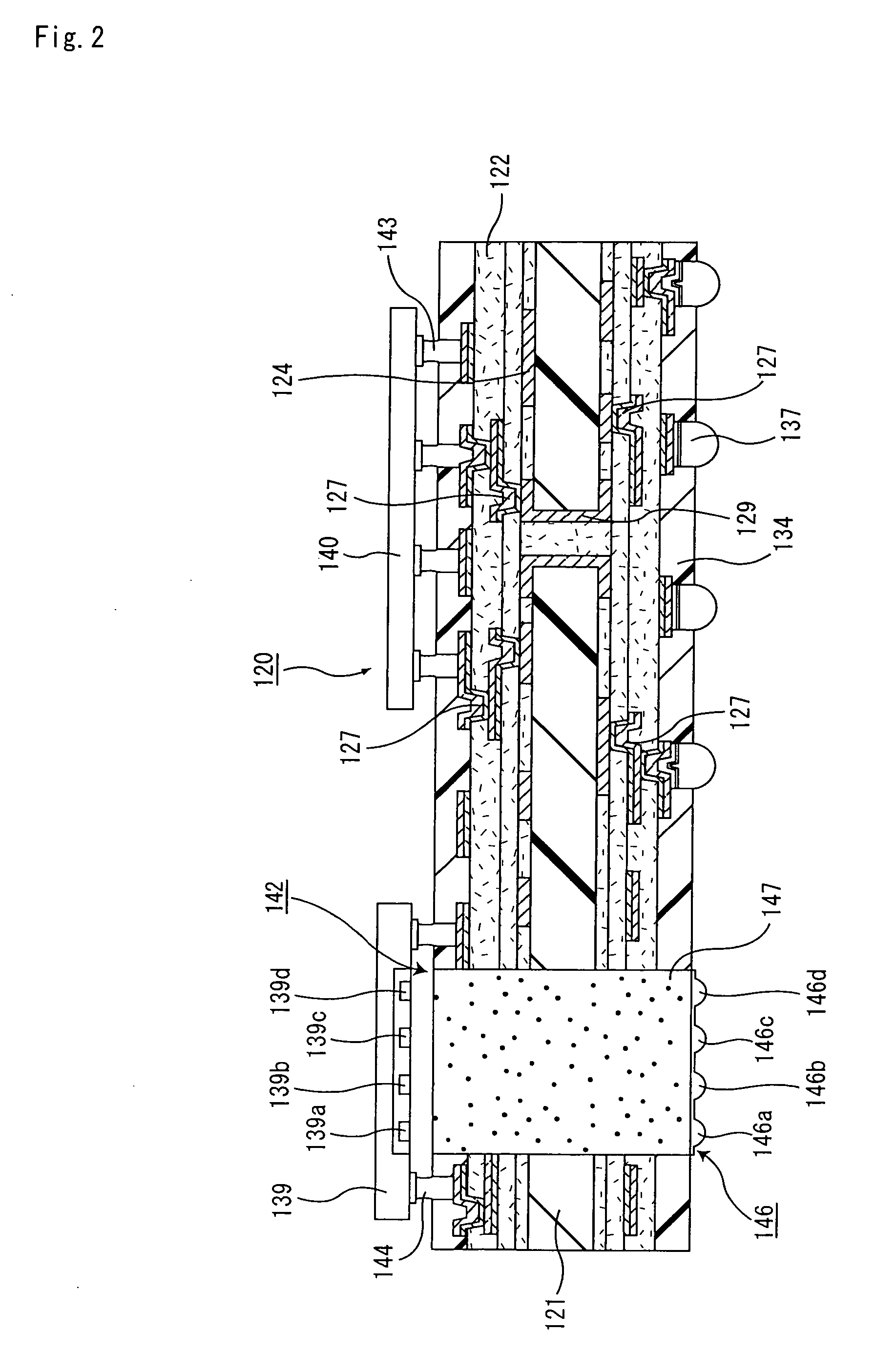

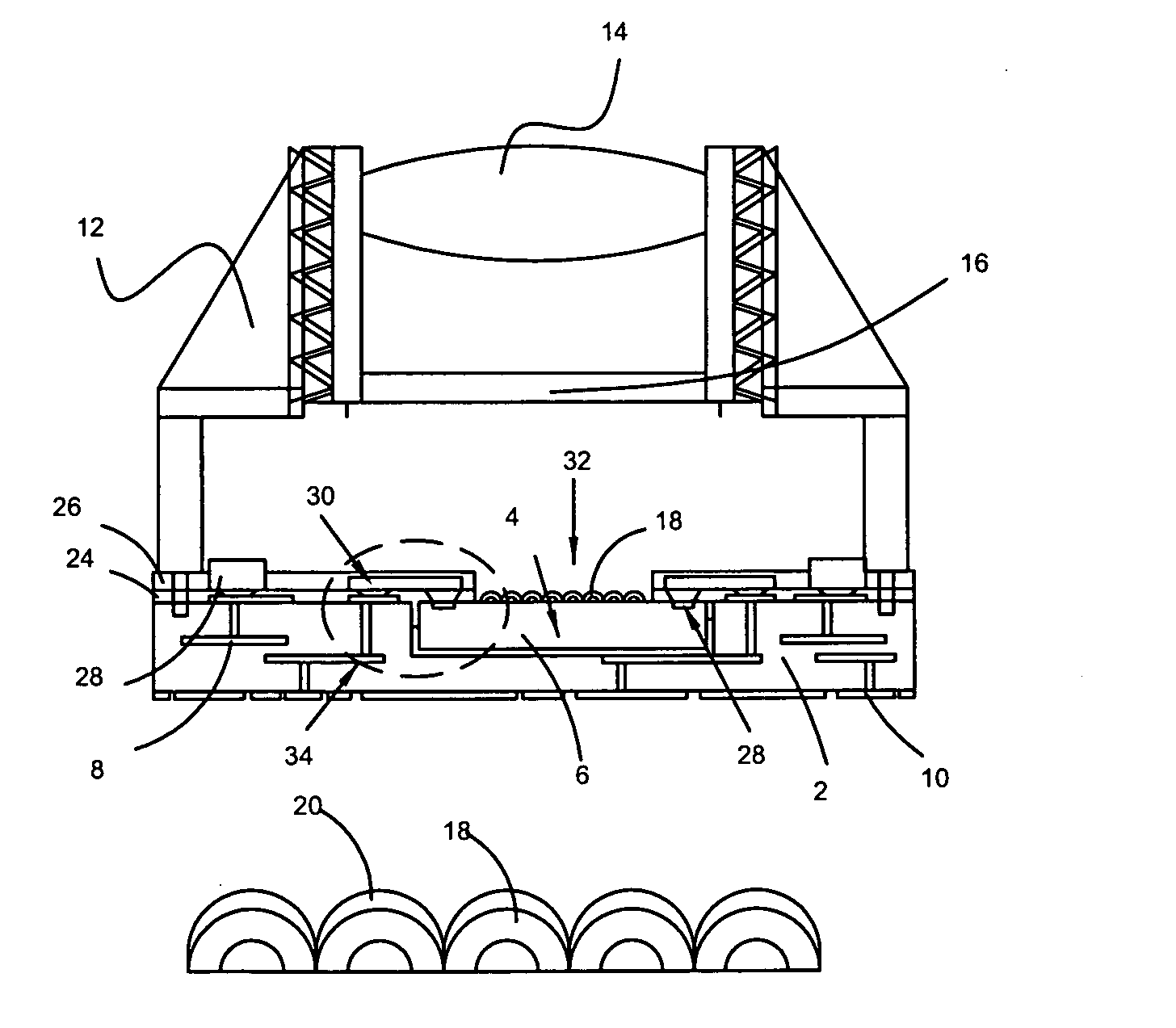

Substrate for mounting IC chip, substrate for motherboard, device for optical communication, manufacturing method of substrate for mounting IC chip, and manufacturing method of substrate for motherboard

ActiveUS20060263003A1Reduce transmission lossOptical signal can be suppressedCircuit optical detailsSolid-state devicesElectrical conductorEngineering

The present invention aims to provide a substrate for mounting an IC chip, on which an optical signal passing region is formed and which can suppress a transmission loss in an optical signal and transmit an optical signal more positively with high reliability. The substrate for mounting an IC chip according to the present invention is a substrate for mounting an IC chip, in which a conductor circuit and an insulating layer are laminated in alternate fashion and in repetition on both faces of a substrate and an optical element is mounted on the substrate. Herein, the substrate for mounting an IC chip includes an optical signal passing region, and a microlens arranged on an end portion of the optical signal passing region on the opposite side from the optical element.

Owner:IBIDEN CO LTD

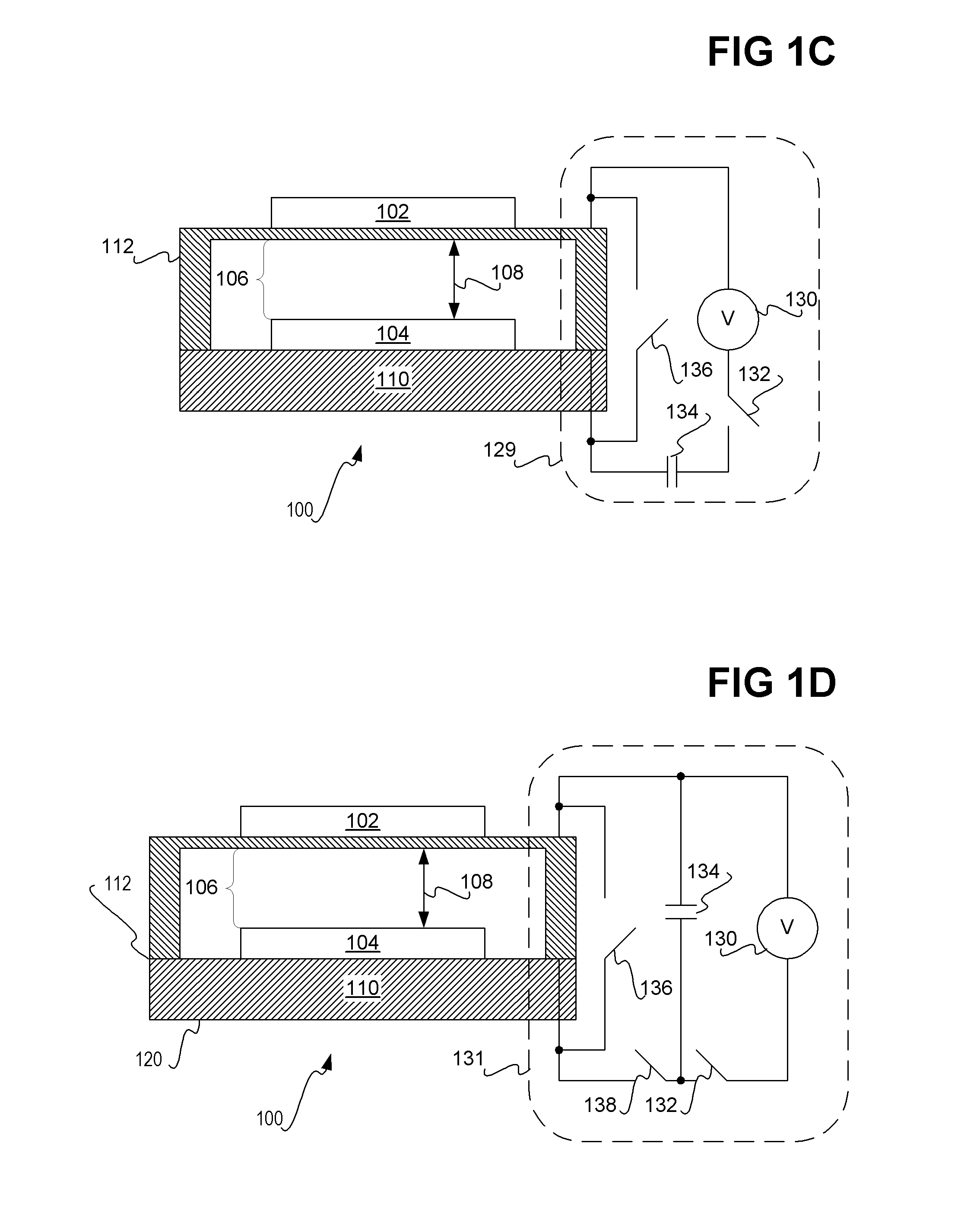

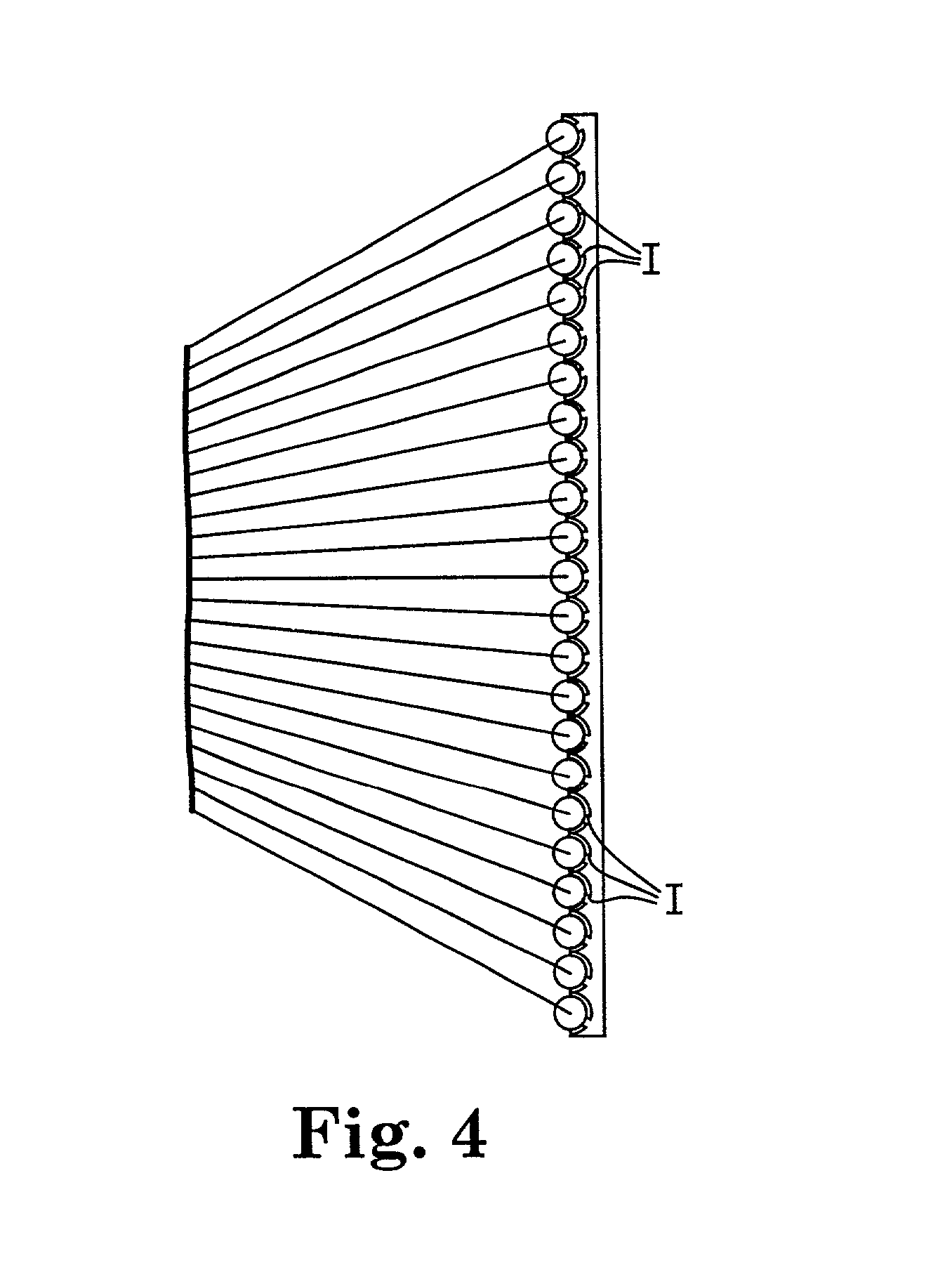

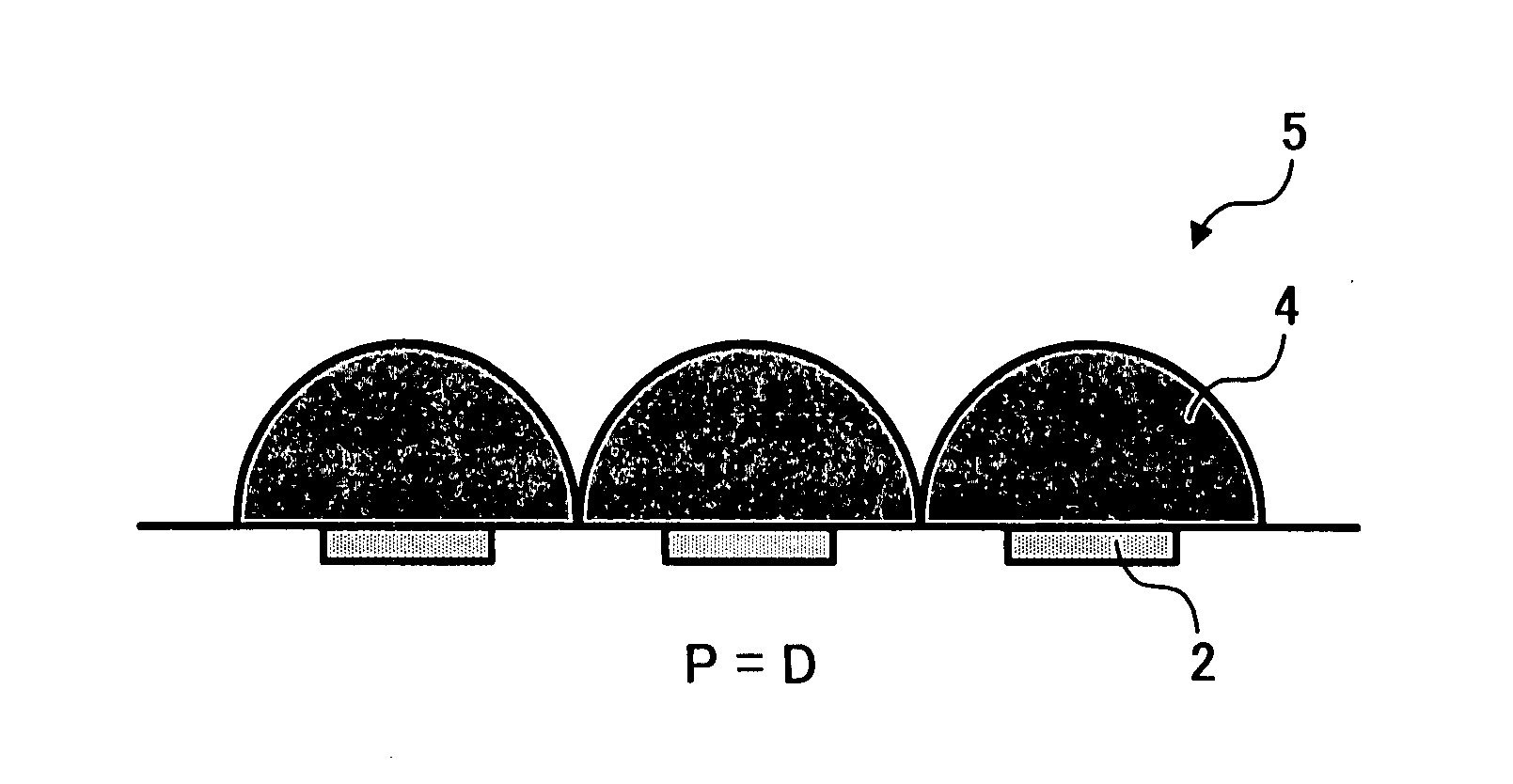

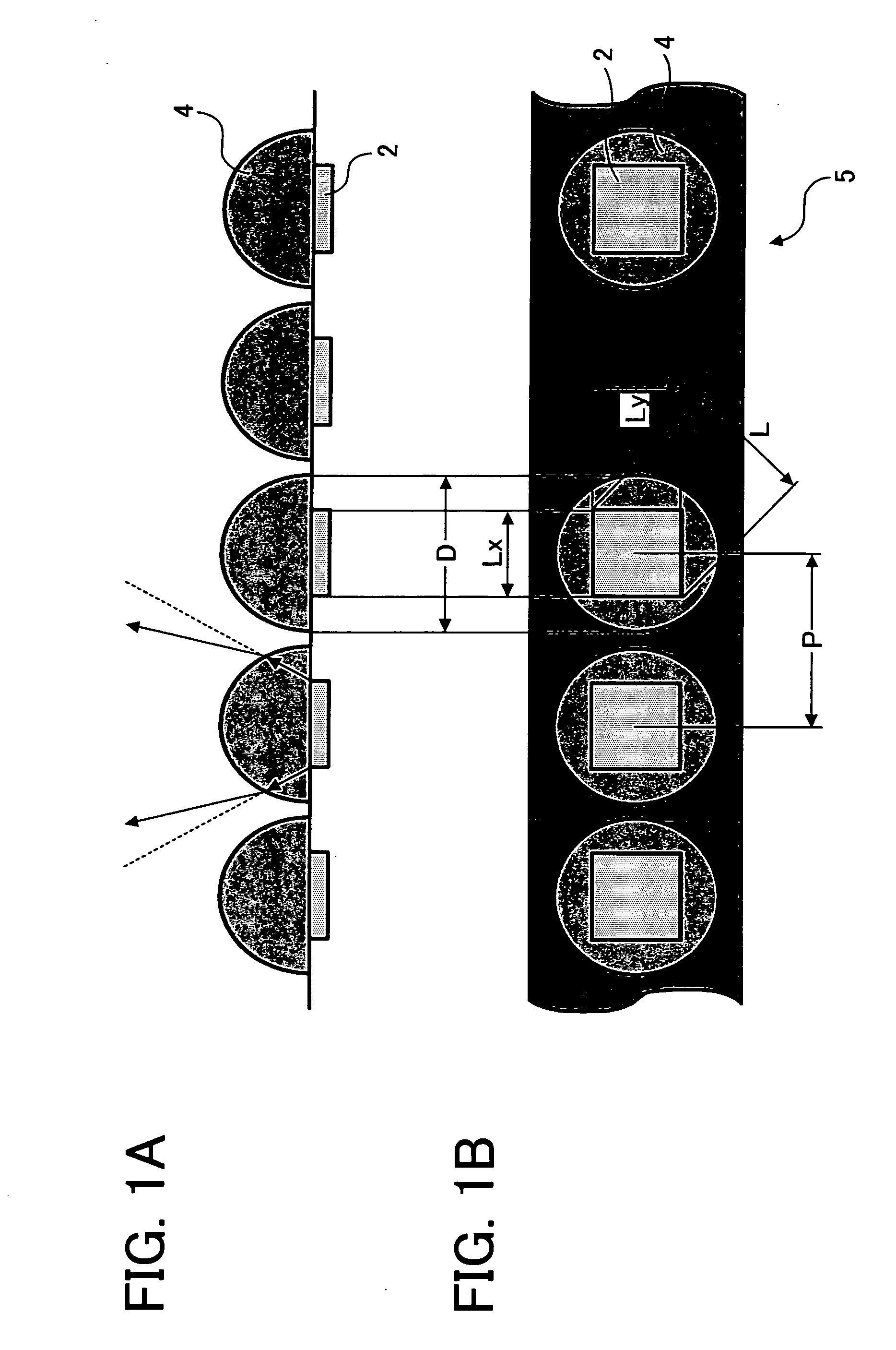

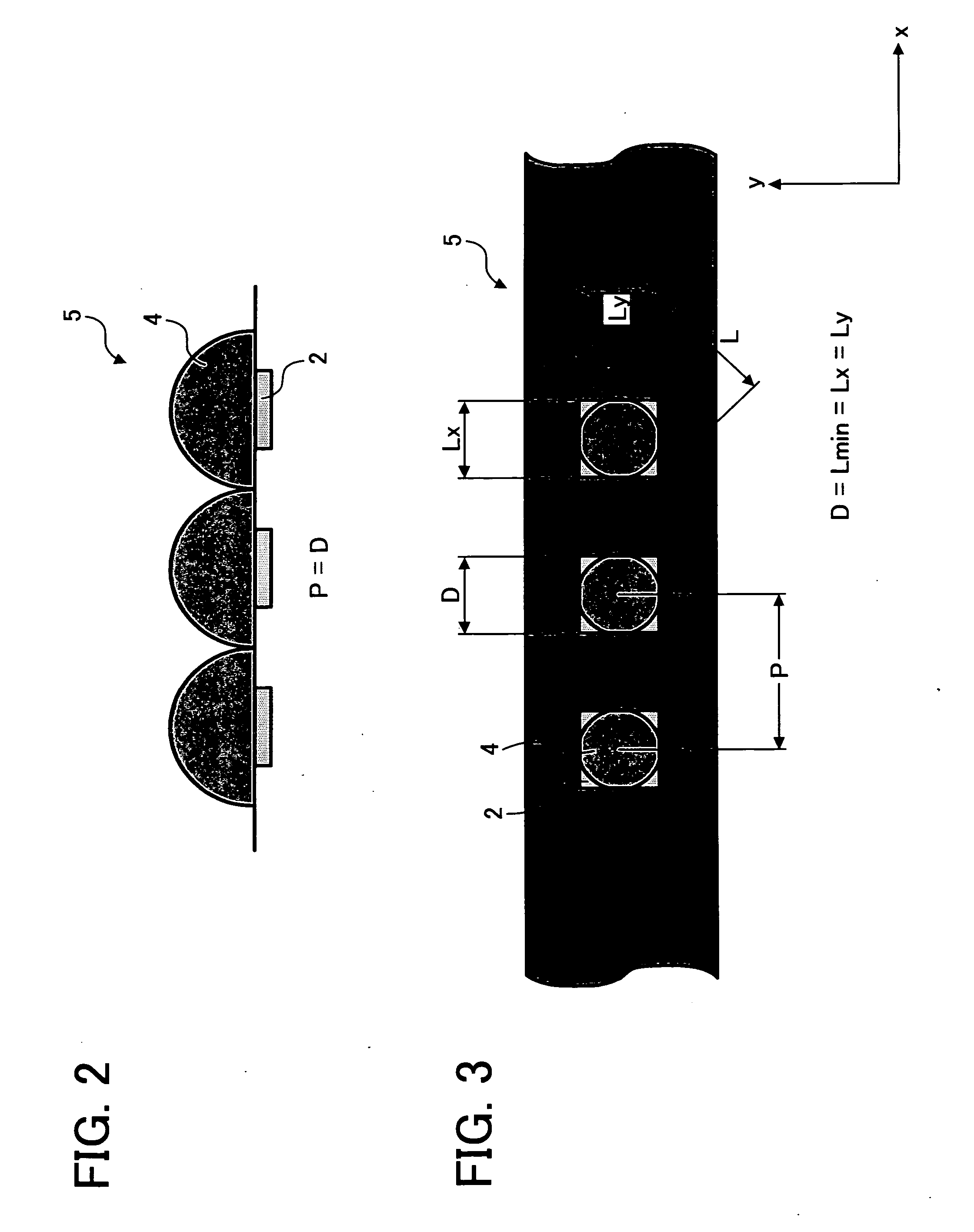

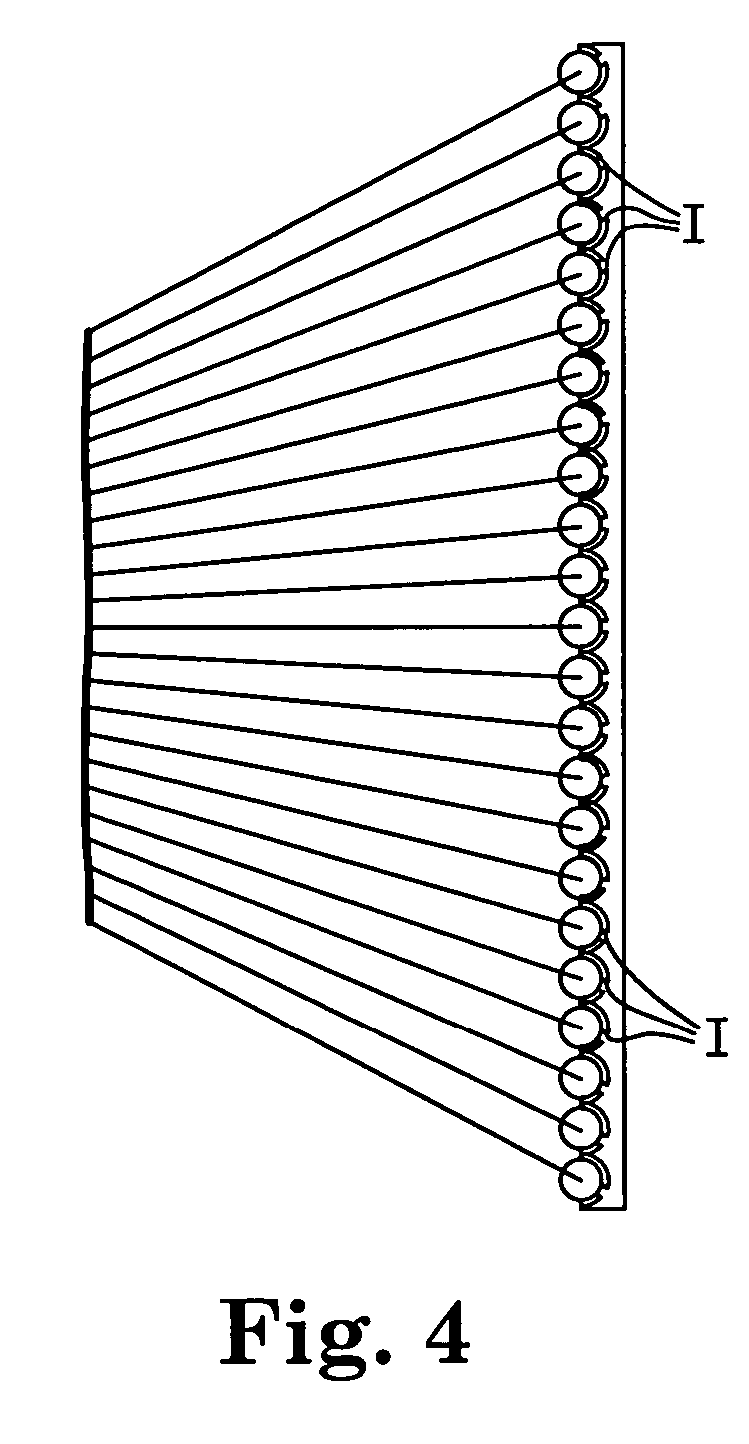

Light emitting array with improved characteristics, optical writing unit, and image forming apparatus

InactiveUS20050067944A1Good imaging propertiesIncrease speedSolid-state devicesDischarge tube main electrodesColor imageMonochromatic color

A light emitting array including at least a plurality of light emitting elements, each of which is provided thereon with a microlens in one-to-one correspondence. Light emitting portions of the light emitting element are provided having the shape of a rectangle and formed so as to satisfy the relational expression, Lmin≦D≦P, where Lmin is the length of the shorter side of the rectangle, P an alignment pitch of the light emitting elements, and D the diameter of microlens. In addition, light emitting elements are formed in line on a transparent thin film layer to satisfy the relationship, T1≦2·D2, where T1 is the thickness of the transparent thin film layer and D2 the diameter of each microlens. The light emitting array may suitably be included in the light source unit which is then incorporated into image forming apparatuses for forming mono-color or multiple-color images.

Owner:RICOH KK

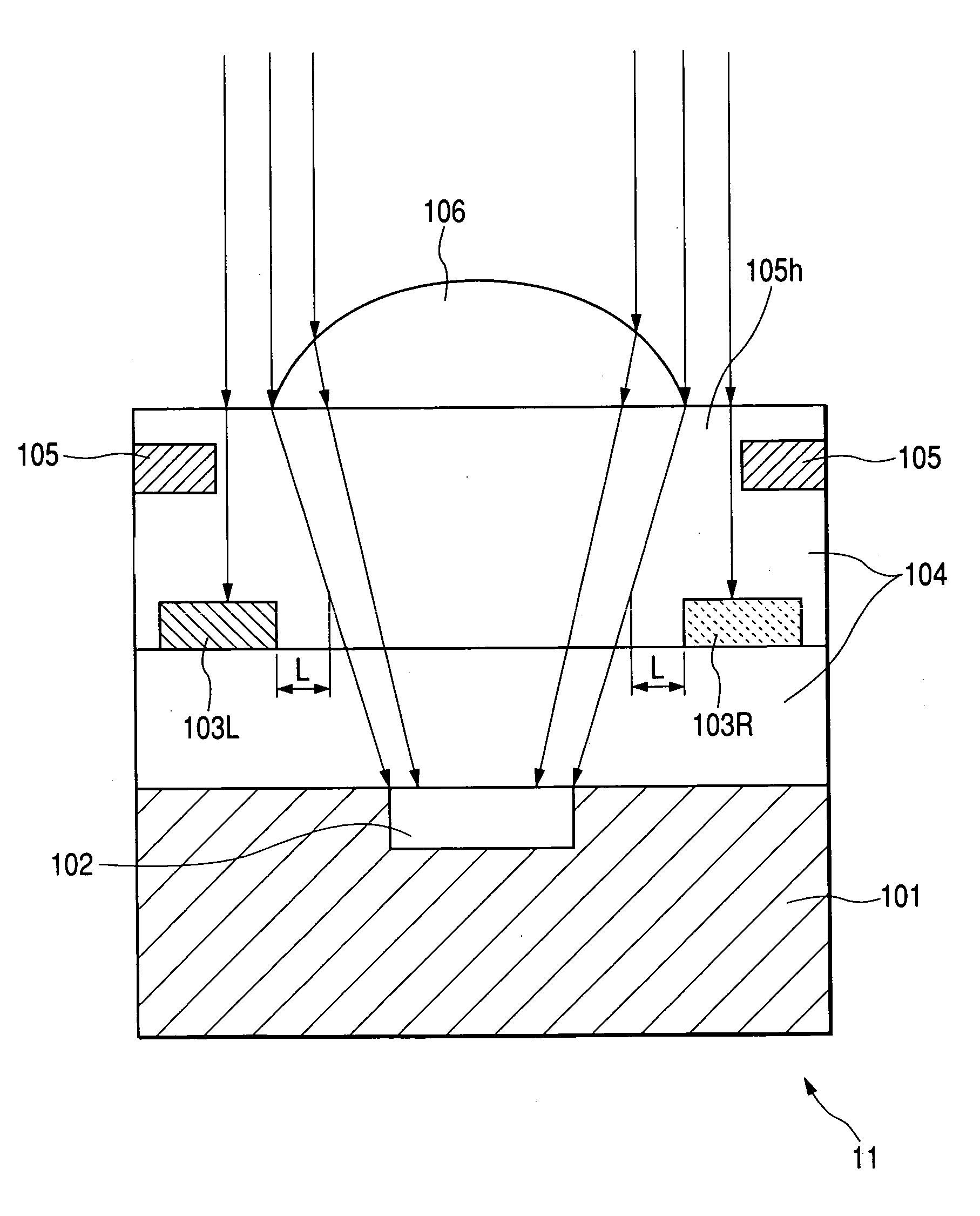

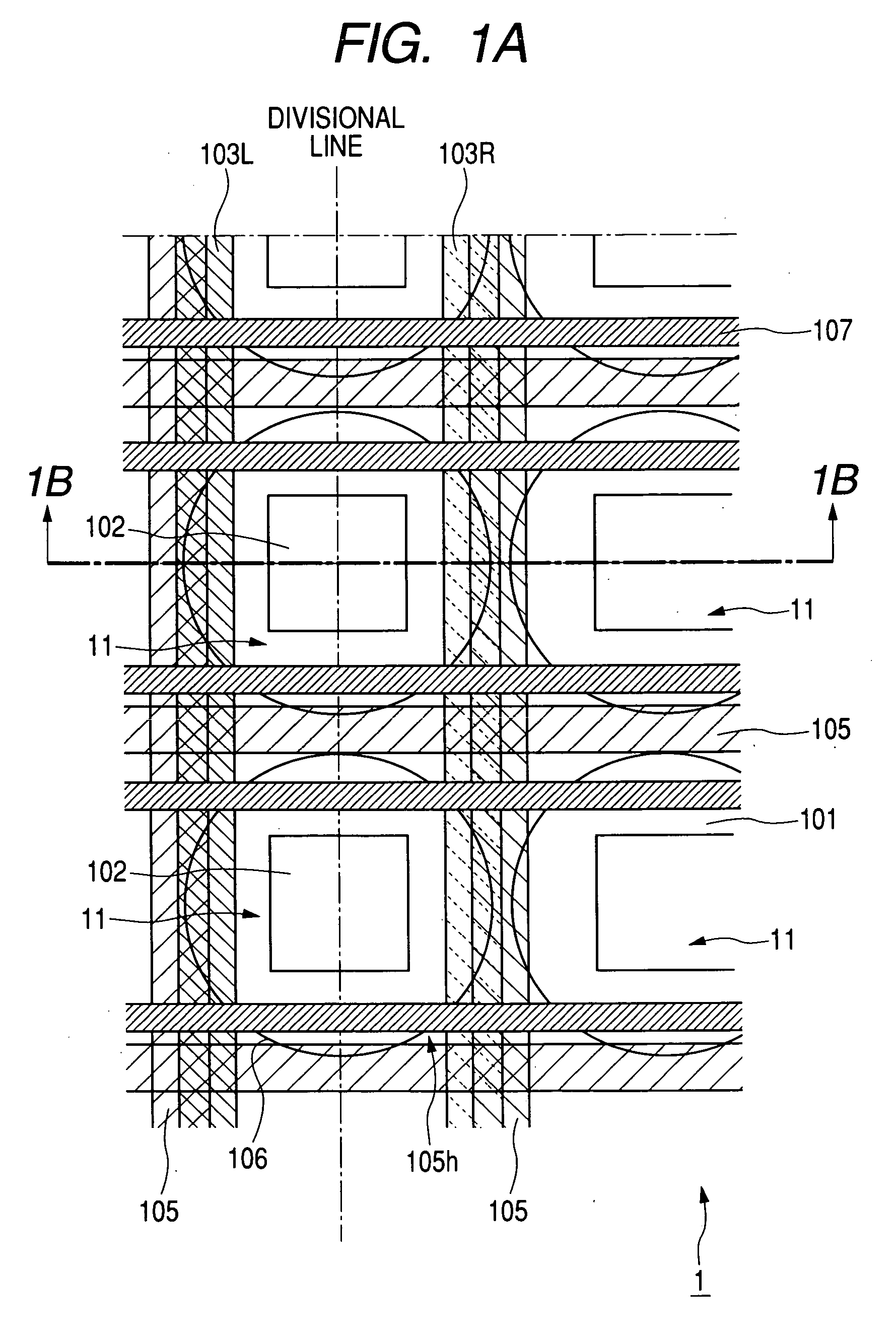

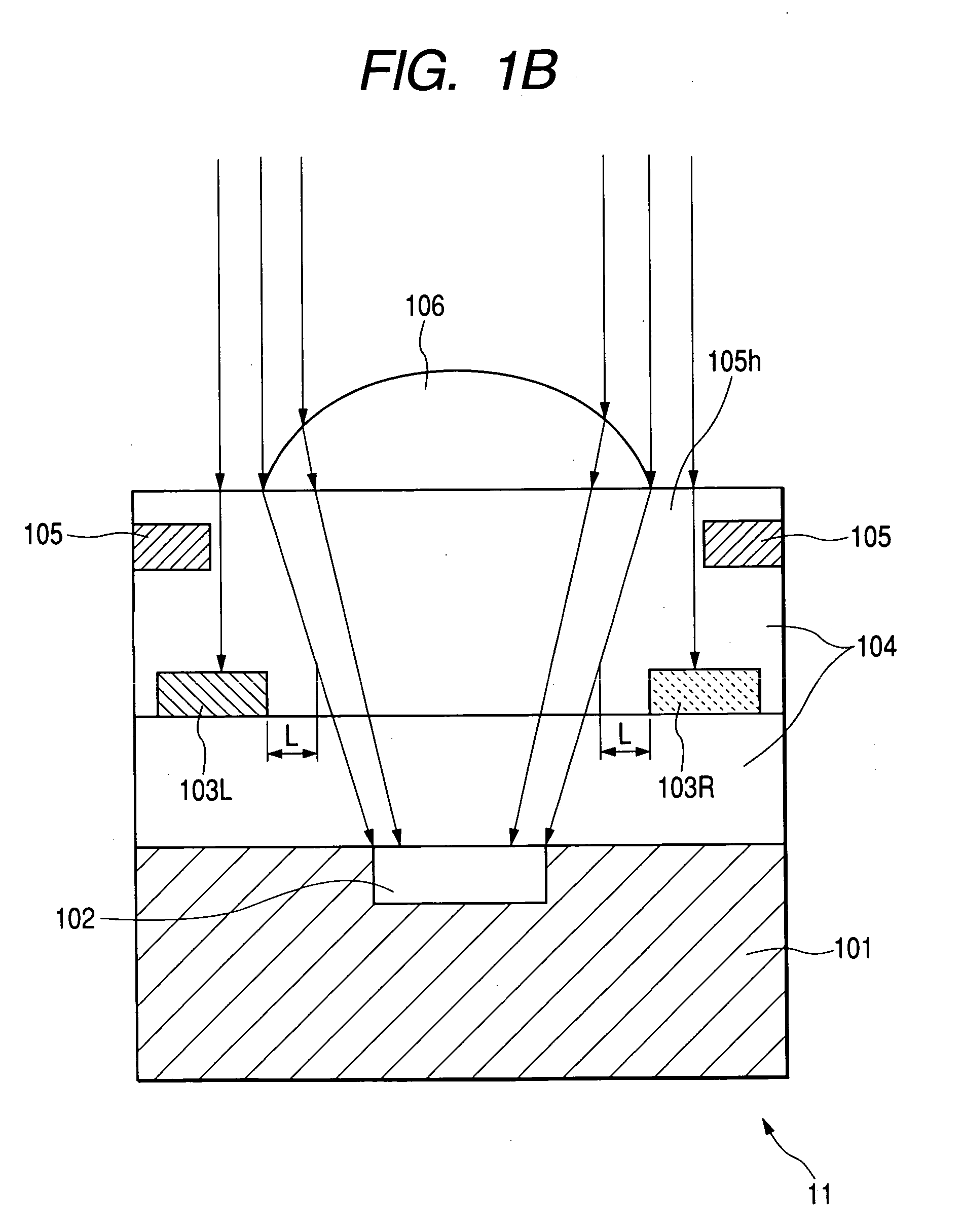

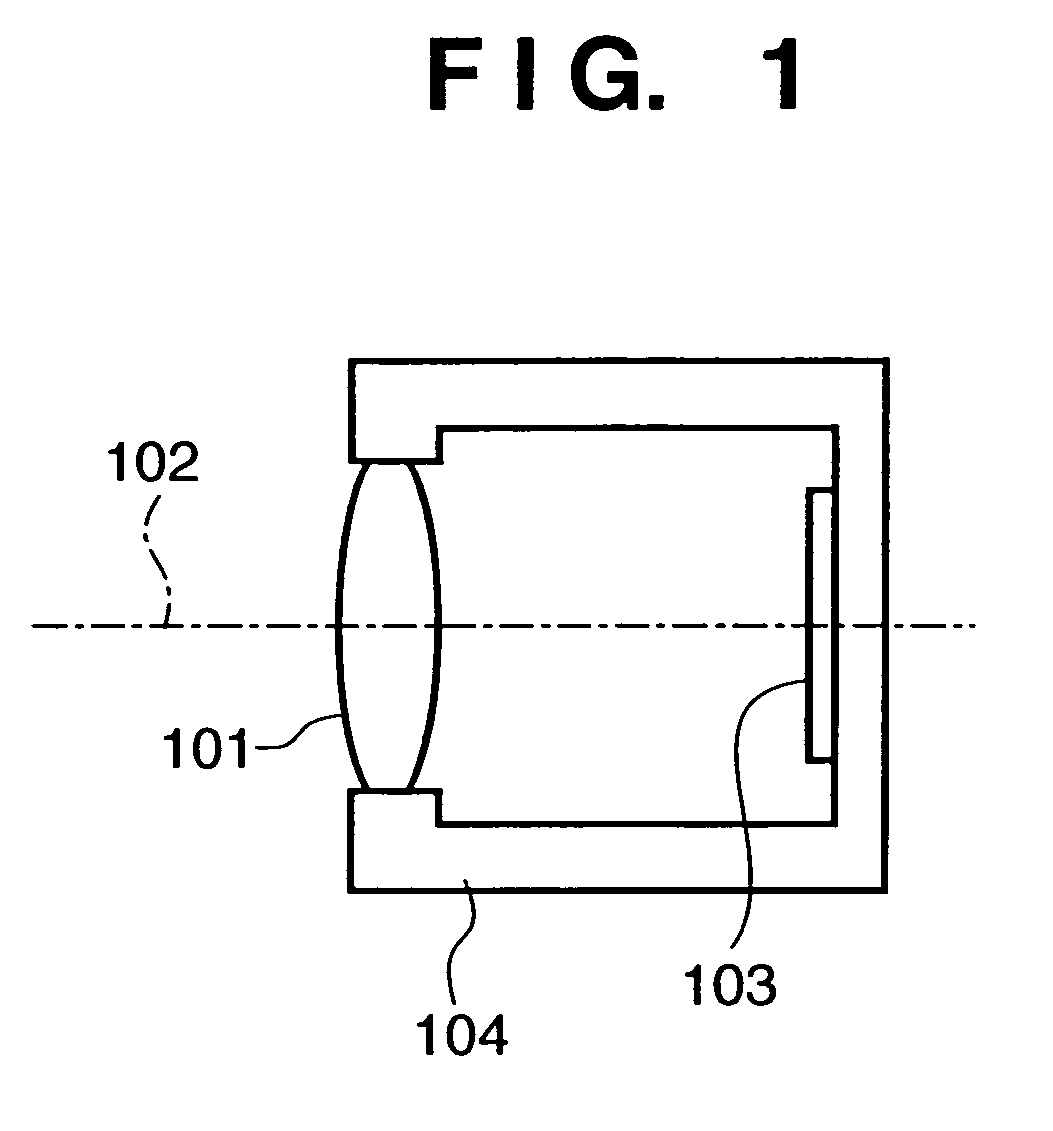

Solid state image pickup device, method for producing the same, and image pickup system comprising the solid state image pickup device

InactiveUS20050122418A1Good image dataReduce variationTelevision system detailsSolid-state devicesInsulation layerOptical axis

The present invention inhibits variations in sensitivity of an image pickup element formed in a jointed area in the image pickup element produced using exposure in a joined fashion. The image pickup element 11 has a light receiving area 102 formed on a substrate 101, an insulation layer 104 deposited on a light receiving area 102, and a microlens 106 formed on the insulation layer 104 and collecting incident light onto the light receiving area 102. A pattern 103L and a pattern 103R with an optical axis of the microlens 106 as a divisional line by exposure in a joined fashion in different exposure steps are arranged with an optical path for incident light collected by the microlens 106 held therebetween, and are provided so that a clearance from the optical path equals a distance L. The distance L is set to be larger than the alignment accuracy of an exposure device exposing the patterns 103L and 103R.

Owner:CANON KK

Solid-state image sensing element and its design support method, and image sensing device

ActiveUS7119319B2Increase freedomHigh light collecting efficiencyTelevision system detailsSolid-state devicesExit pupilLight guide

A solid-state image sensing element has a photoelectric conversion element which converts incoming light into an electrical signal in accordance with an amount of the light, a microlens which is arranged on an incident surface, a light guide which is arranged between the photoelectric conversion element and the microlens, and an insulating interlayer which is arranged around the light guide. The solid-state image sensing element located at a distance (H) satisfies:H·DL·P<a·NHNLfor0<a<1where L is the distance from an exit pupil of an image sensing optical system of an image sensing device, which mounts an image sensor formed by two-dimensionally arranging a plurality of the solid-state image sensing elements, H is the distance from a center of the image sensor to a position of the solid-state image sensing element on the image sensor, D is the height from the photoelectric conversion element to an apex of the microlens, P is the spacing between the plurality of solid-state image sensing elements, NH is the refractive index of the light guide, and NL is the refractive index of the insulating interlayer.

Owner:CANON KK

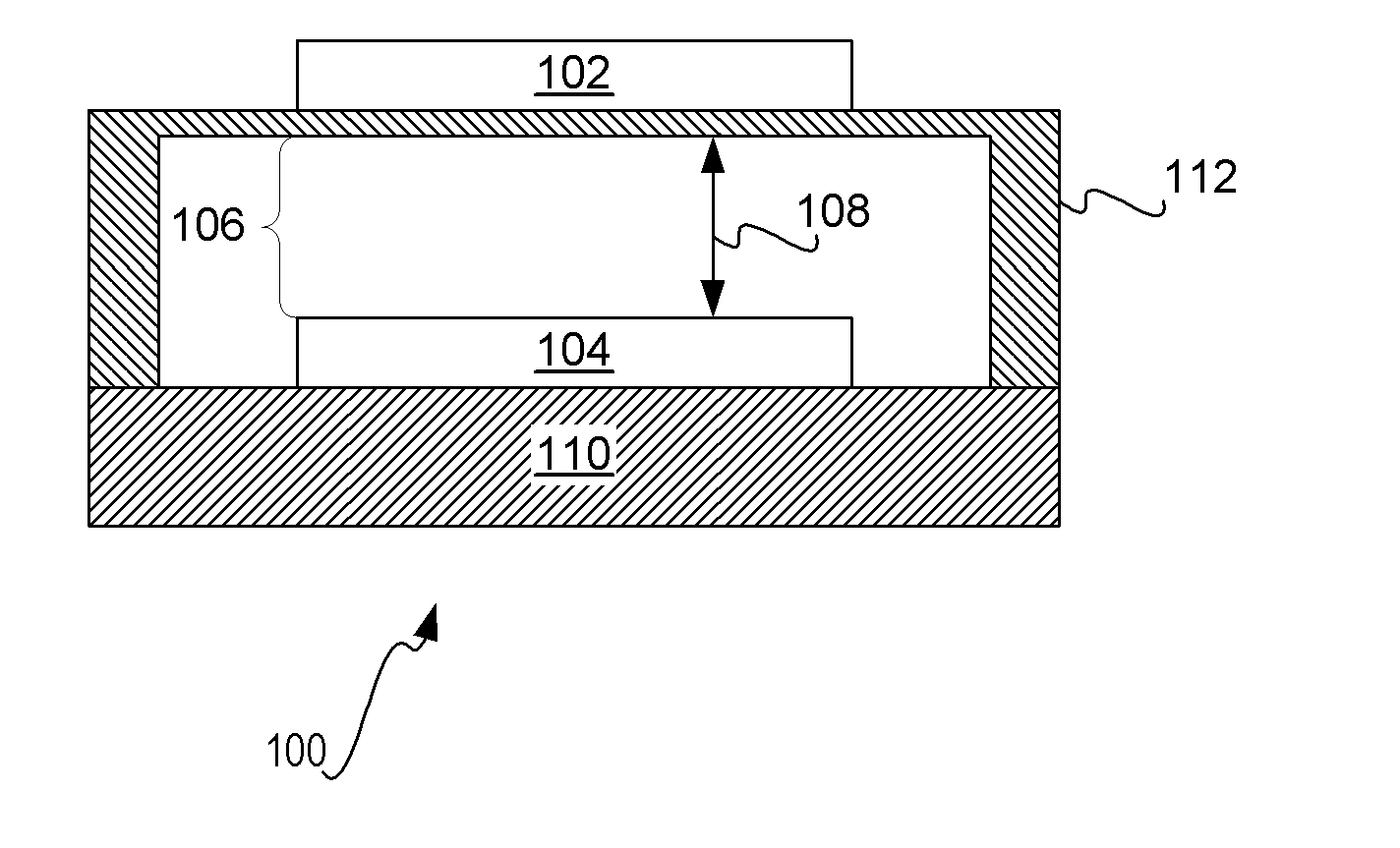

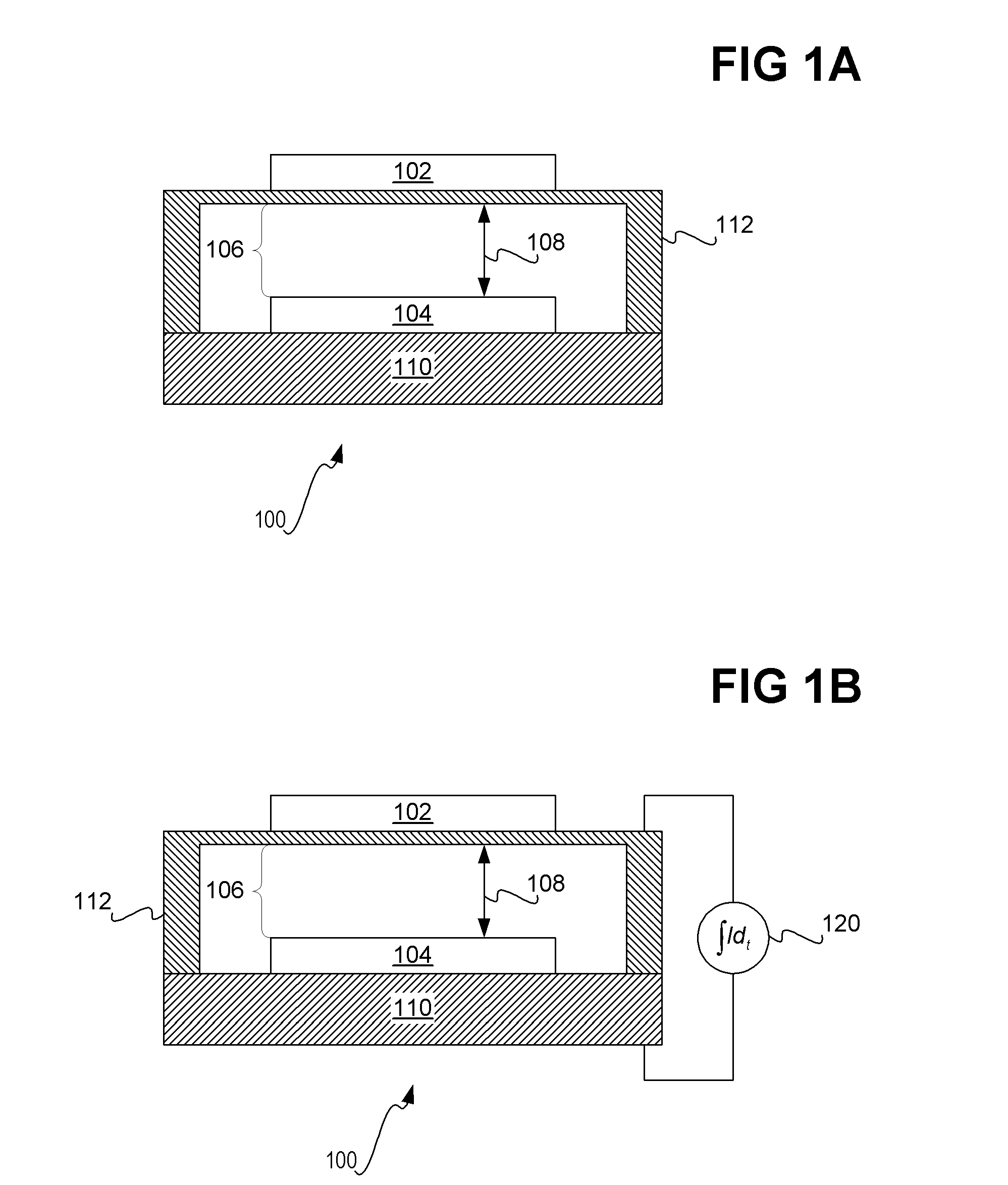

Vertical displacement device

A MEMS vertical displacement device capable of moving one or more vertically displaceable platforms relative to a base. In particular, the vertical displacement device may be capable of moving a vertically displaceable platform so that the vertically displaceable platform remains generally parallel to a base. The vertically displaceable platform may be, but is not limited to, a microlens, a micromirror, micro-grating, or other device. The vertical displacement device may also be included in optical coherence and confocal imaging systems.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Sheeting with composite image that floats

Translucent, transparent, or semi-translucent microlens sheetings with composite images are disclosed, in which a composite image floats above or below the sheeting, or both. The composite image may be two-dimensional or three-dimensional. The sheeting may have at least one layer of material having a surface of microlenses that form one or more images at positions internal to the layer of material, at least one of the images being a partially complete image. Additional layers, such as retroreflective, translucent, transparent, or optical structure layers may also be incorporated into the sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

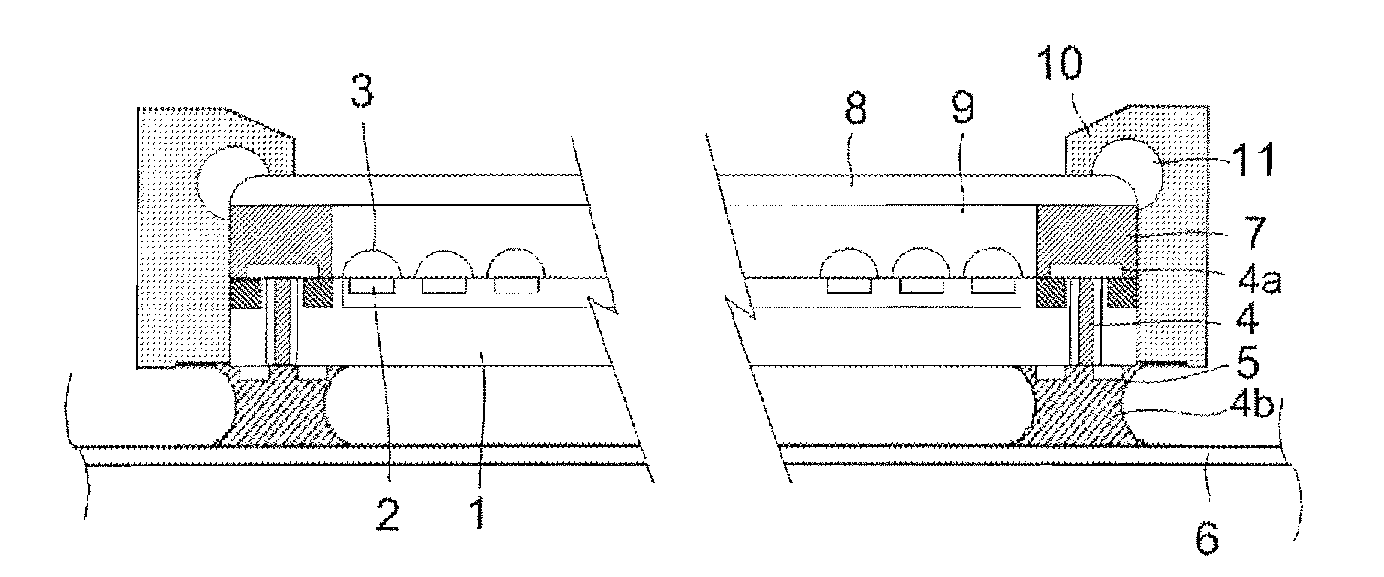

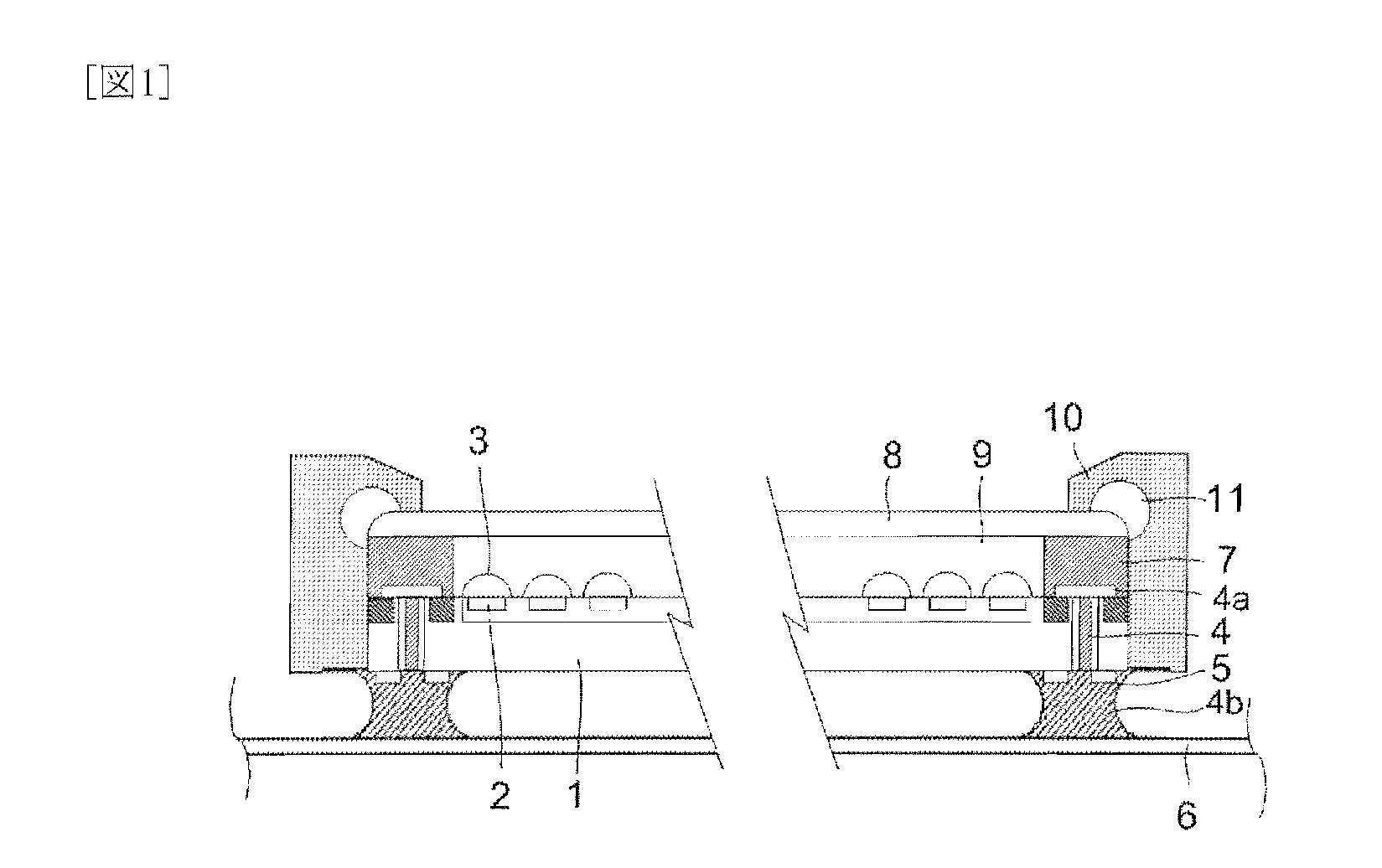

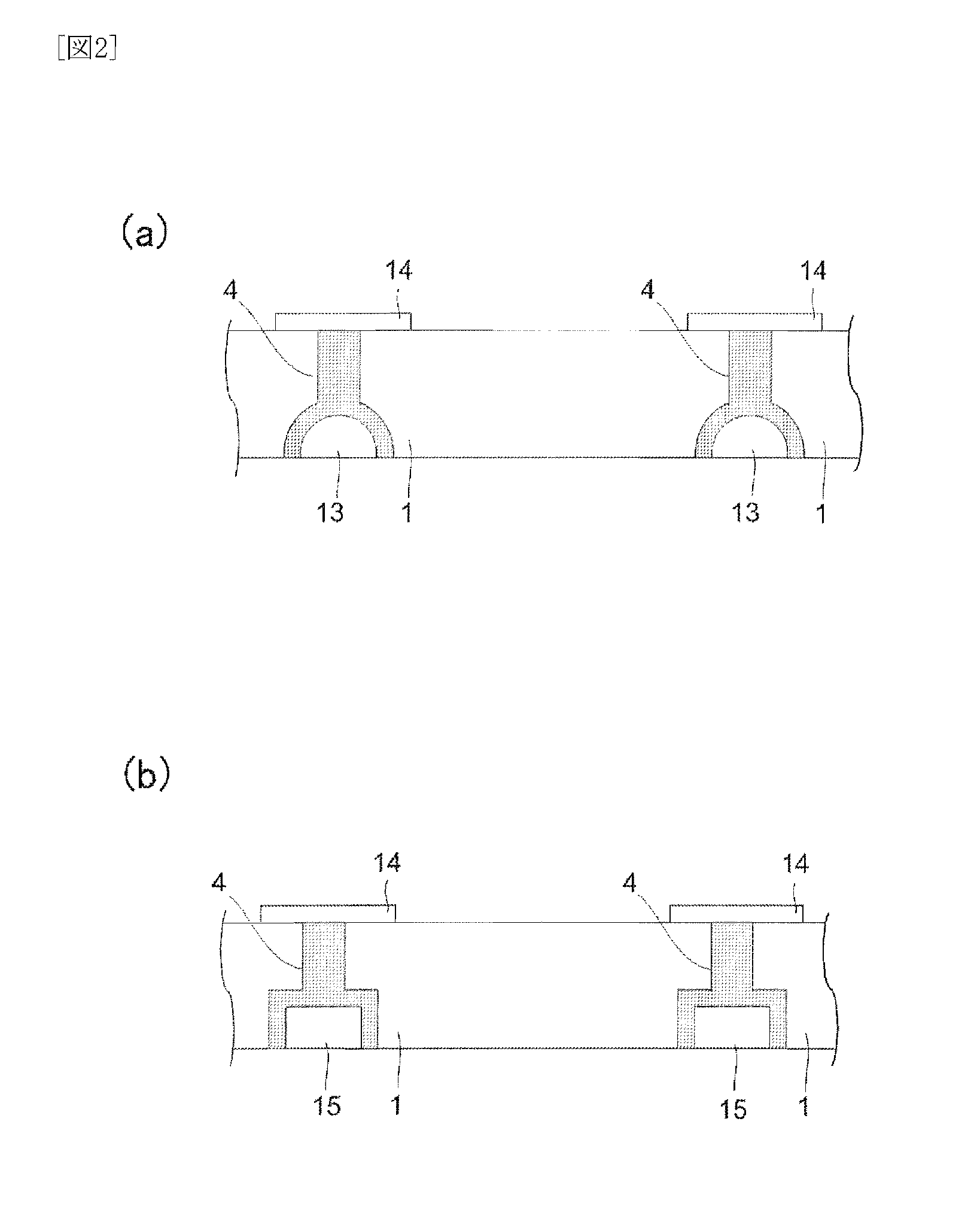

Solid-Stated Image Pickup Device And Method For Manufacturing Same

ActiveUS20080042227A1Reliability of device can be ensuredImprove production yieldTelevision system detailsSolid-state devicesEngineeringOptical glass

There are provided image pickup devices capable of significantly increasing production yield and ensuring long-term reliability and a method for manufacturing the image pickup devices. This invention is characterized in that it has a large number of light-receiving portions 2 formed at a surface portion of a wafer 1 and a microlens 3 formed for each of the light-receiving portions, through electrodes 4 for performing supply of power to the light-receiving portions 2 and passing and reception of an electrical signal are provided all over the periphery of the wafer 1, one end of each through electrode 4 is connected to an electrode pad 4a which is connected to a wire leading to a light-receiving element at the surface portion of the wafer 1, the other end is connected to a wire through a back electrode 5, a rib 7 which serves as a partition portion arranged to surround the microlenses 3 on four sides is provided on the surface of the wafer 1, a transparent plate 8 of optical glass or the like is bonded to an upper surface of the rib 7 with adhesive, and a protective frame 10 is provided at a junction between the rib 7 and the transparent plate 8.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

Image sensor module and the method of the same

InactiveUS20080173792A1Small foot printSimple processTelevision system detailsSolid-state devicesDielectric layerMicrolens

The present invention provides an image sensor module structure comprising a substrate with a die receiving cavity formed within an upper surface of the substrate and conductive traces within the substrate and a die having a micro lens disposed within the die receiving cavity. A dielectric layer is formed on the die and the substrate, a re-distribution conductive layer (RDL) is formed on the dielectric layer, wherein the RDL is coupled to the die and the conductive traces and the dielectric layer has an opening to expose the micro lens. A lens holder is attached on the substrate and the lens holder has a lens attached an upper portion of the lens holder. A filter is attached between the lens and the micro lens. The structure further comprises a passive device on the upper surface of the substrate within the lens holder.

Owner:ADVANCED CHIP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com