Patents

Literature

6543results about "Pattern printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

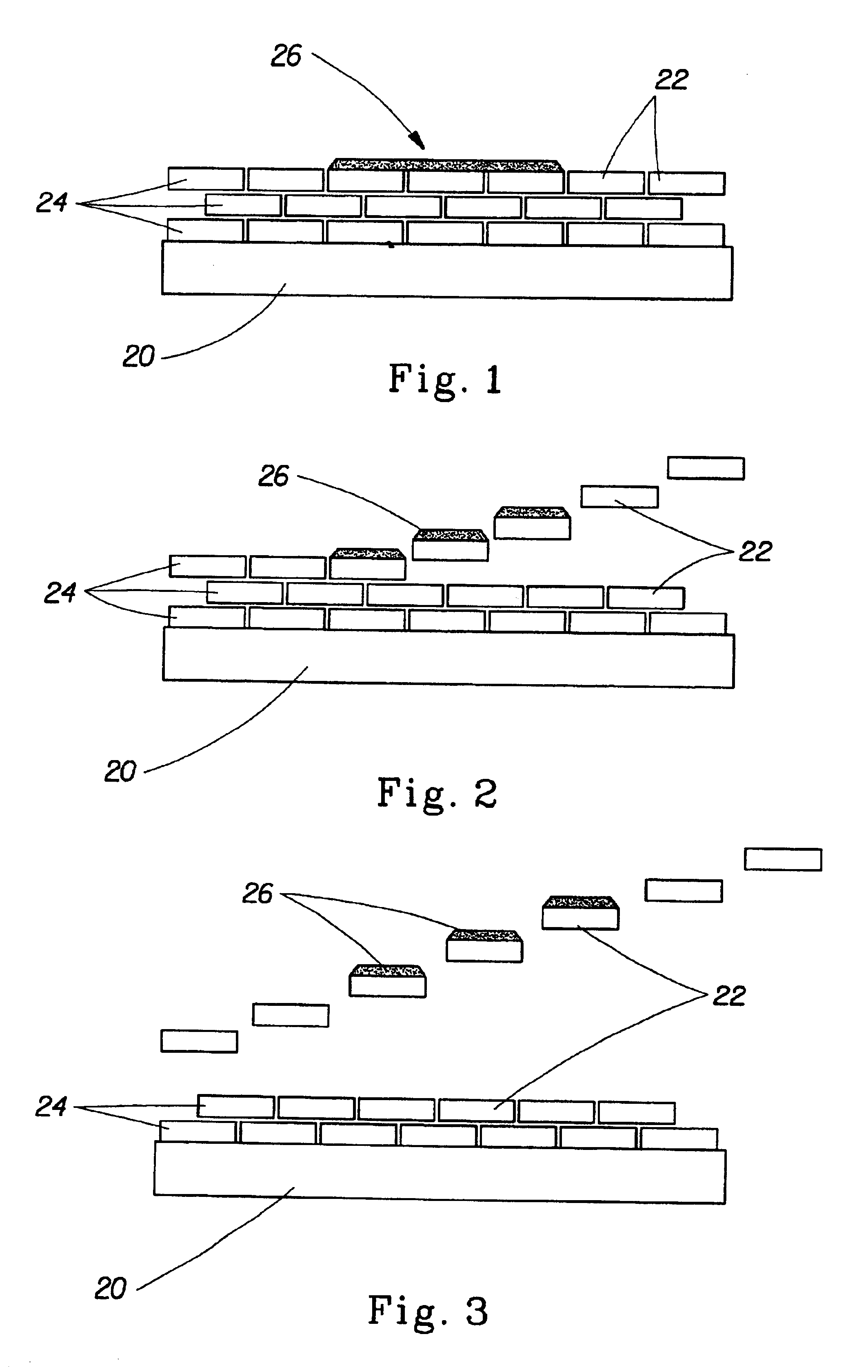

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

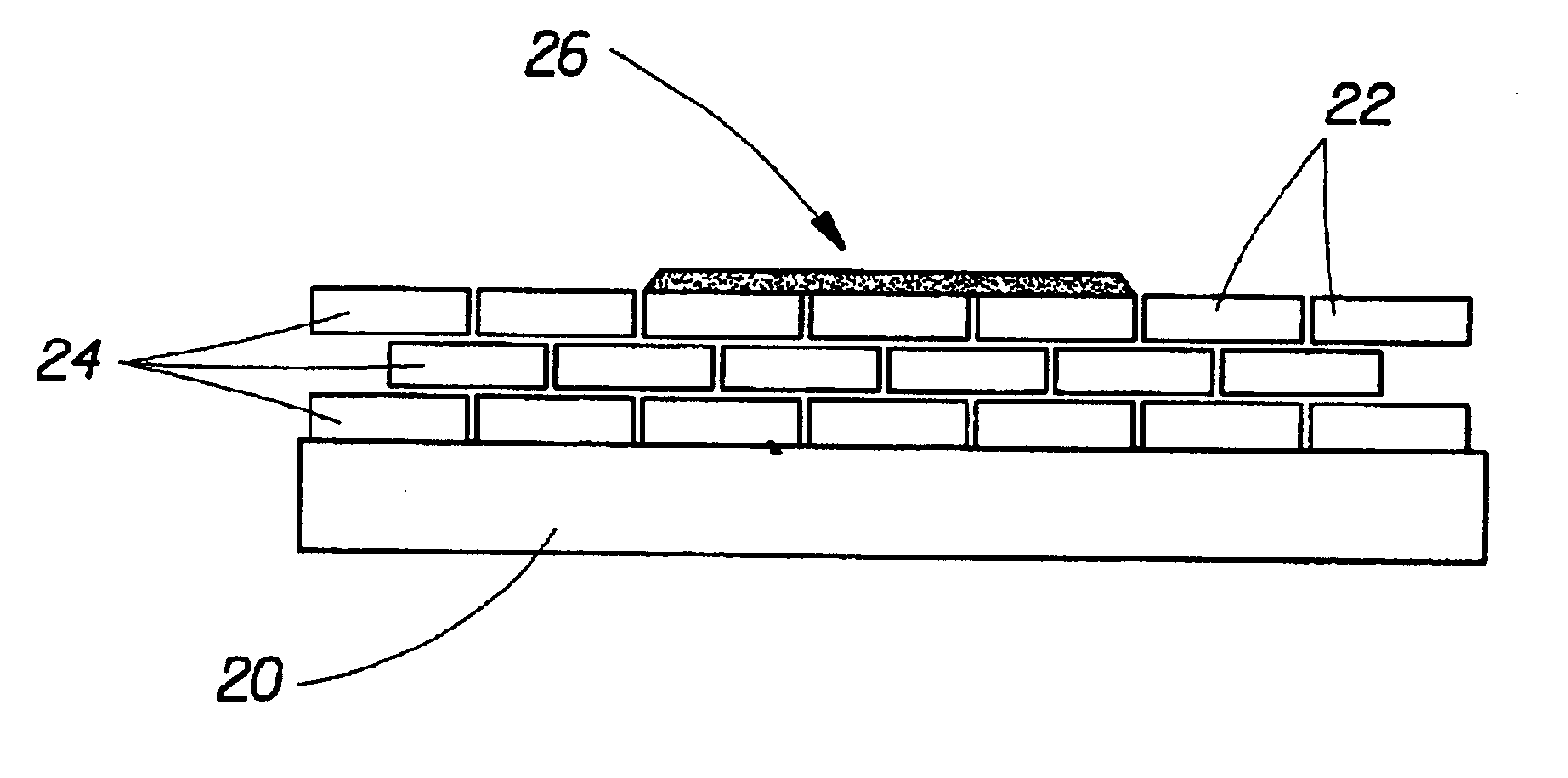

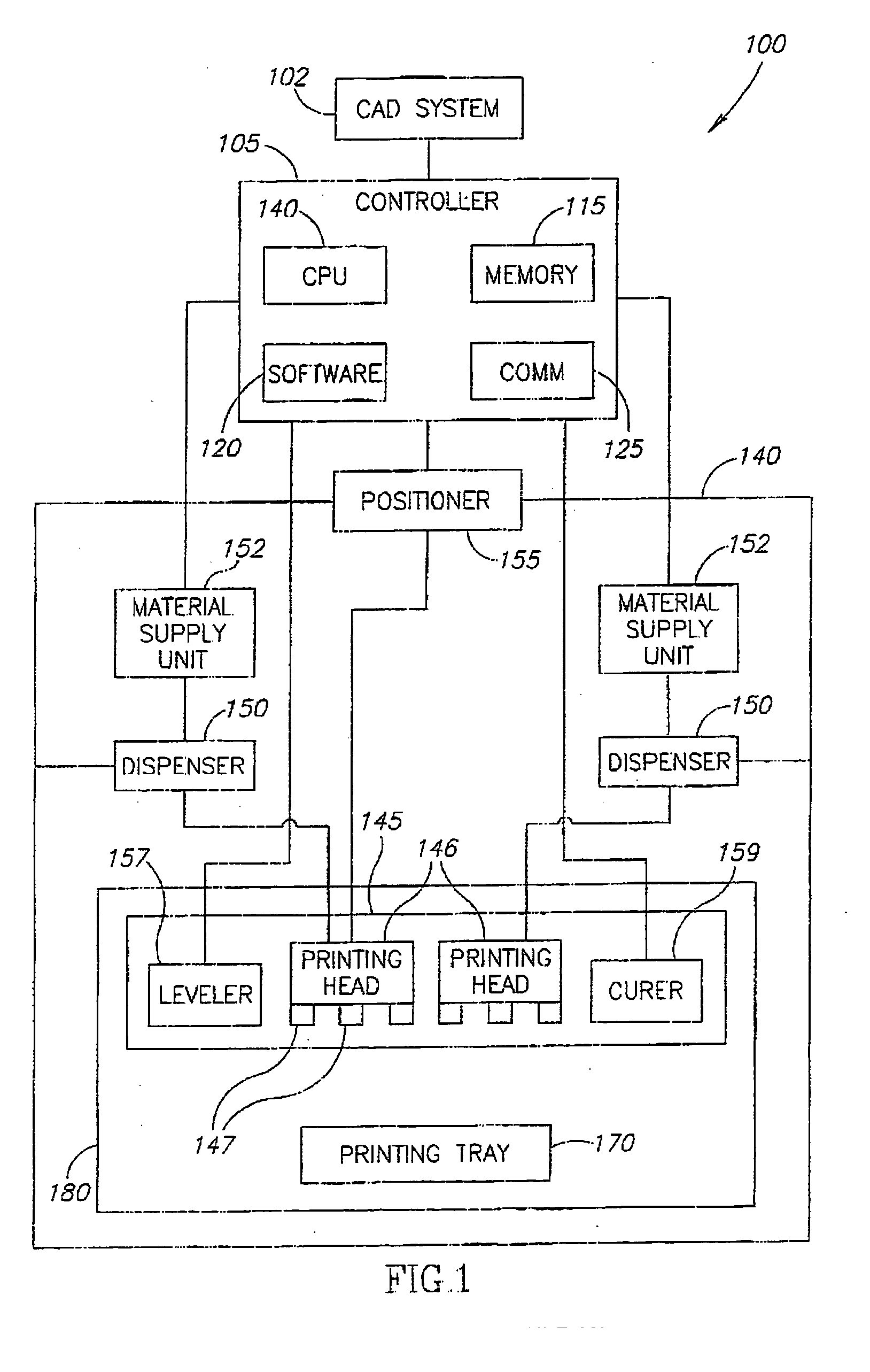

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

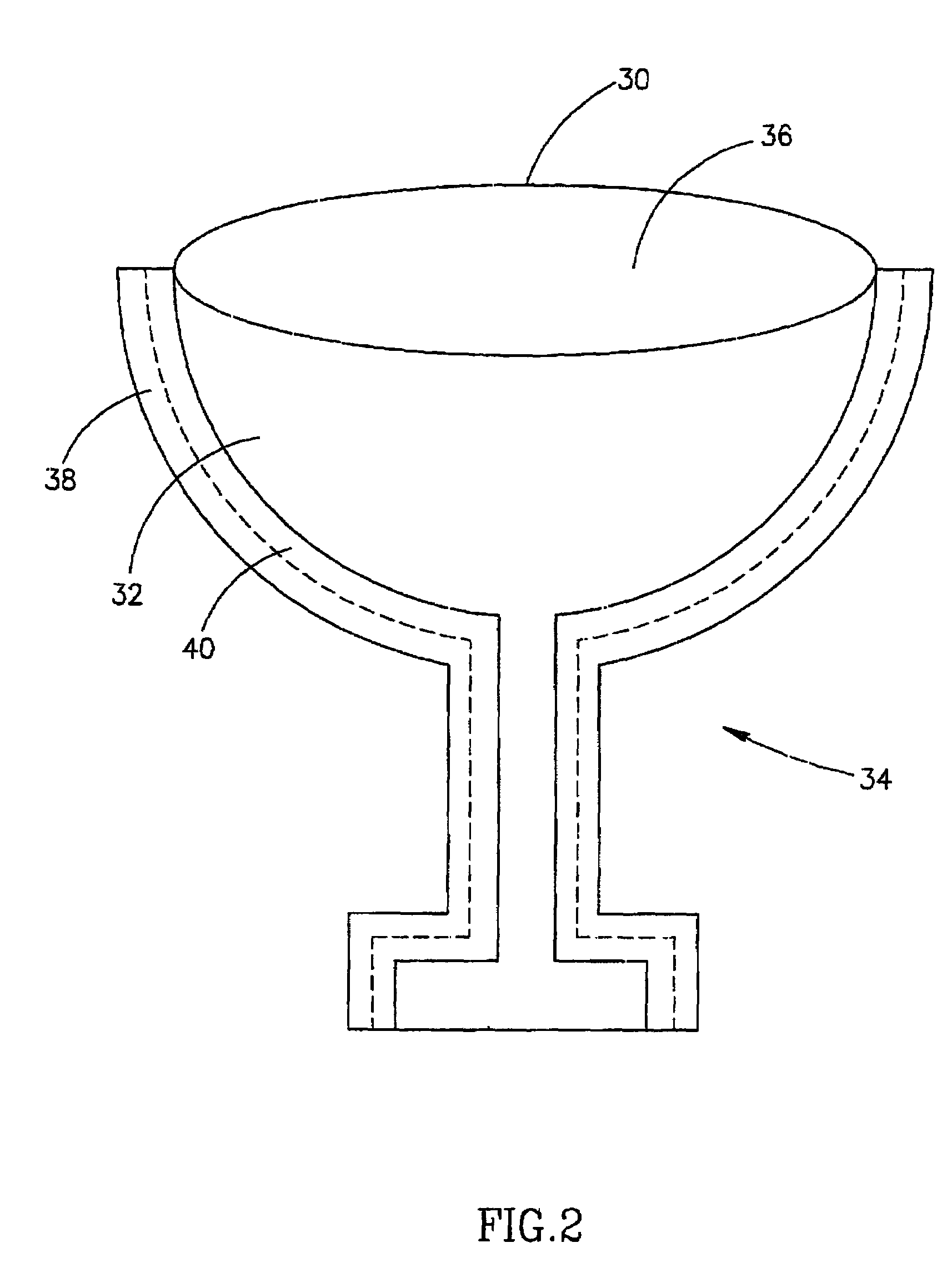

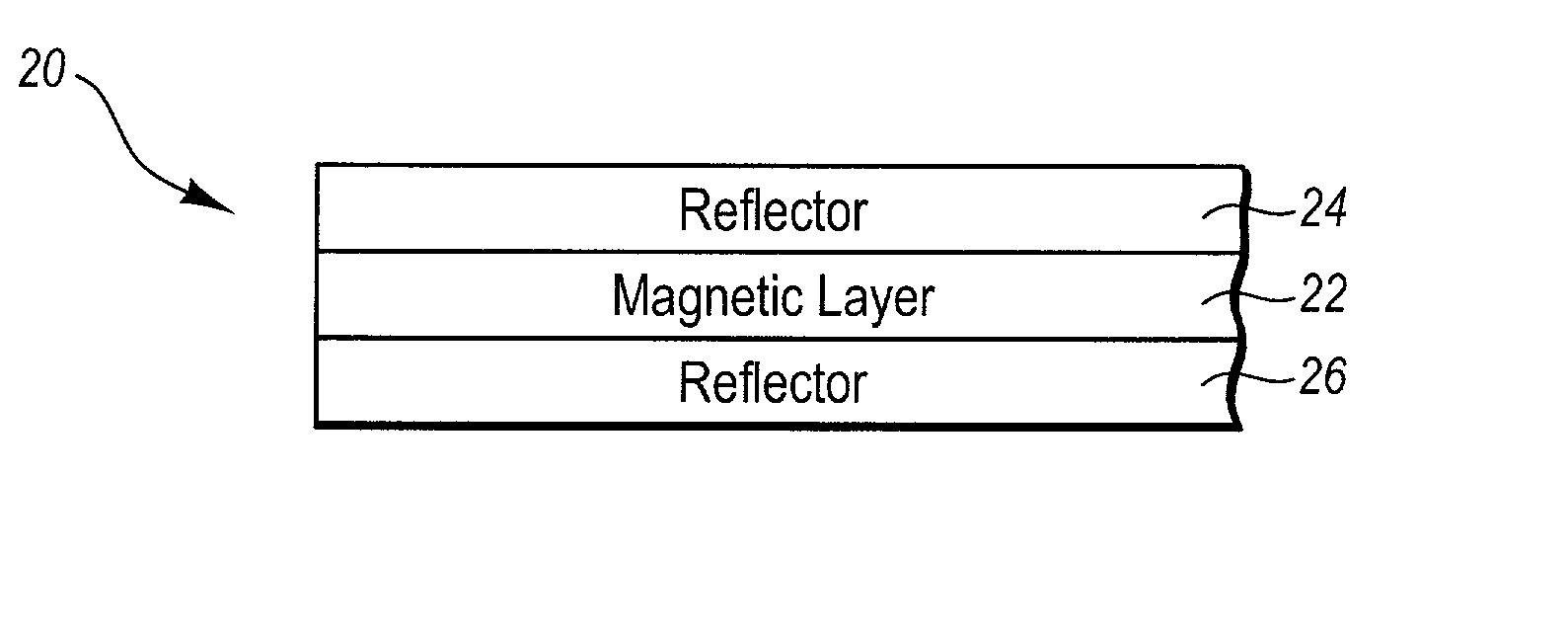

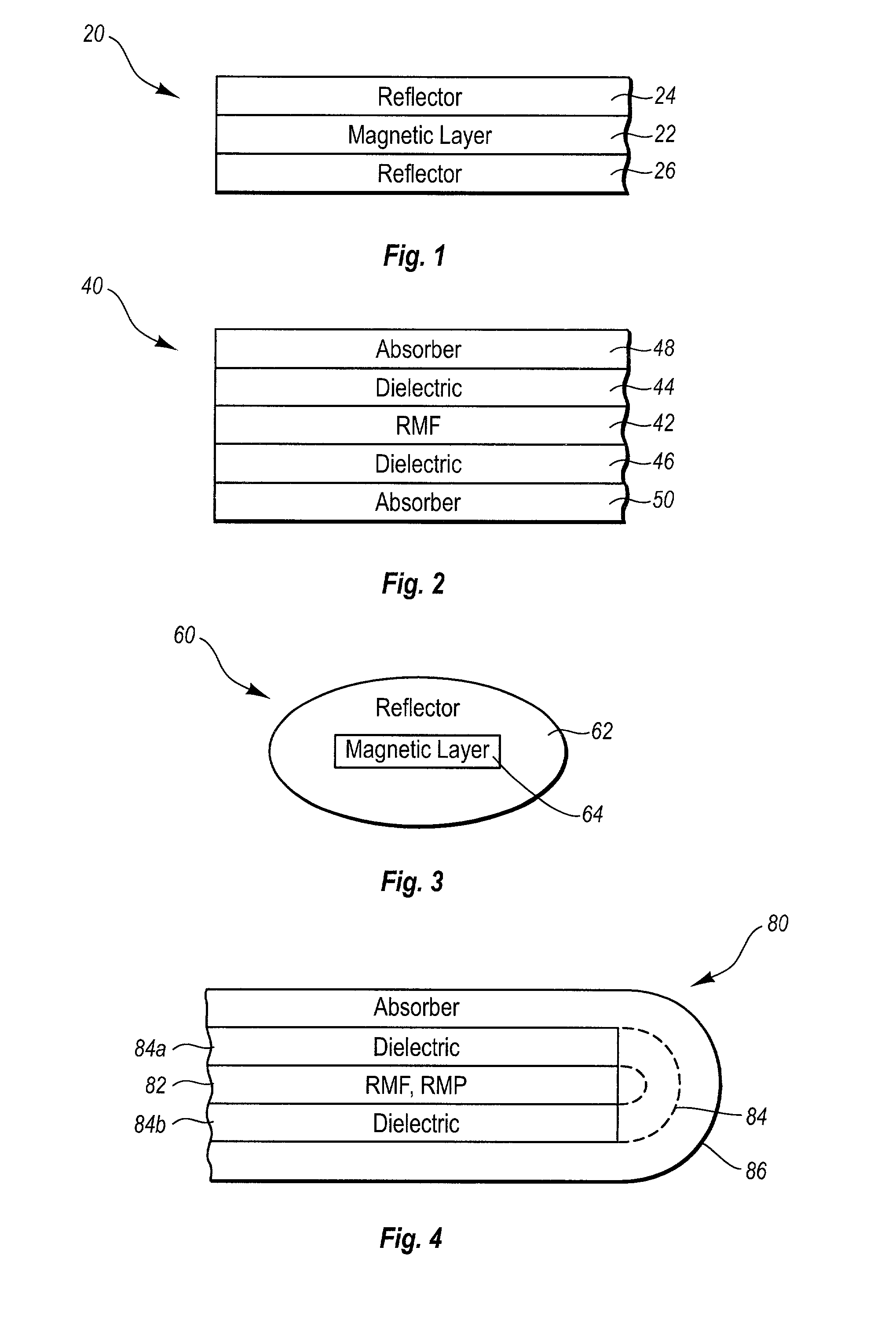

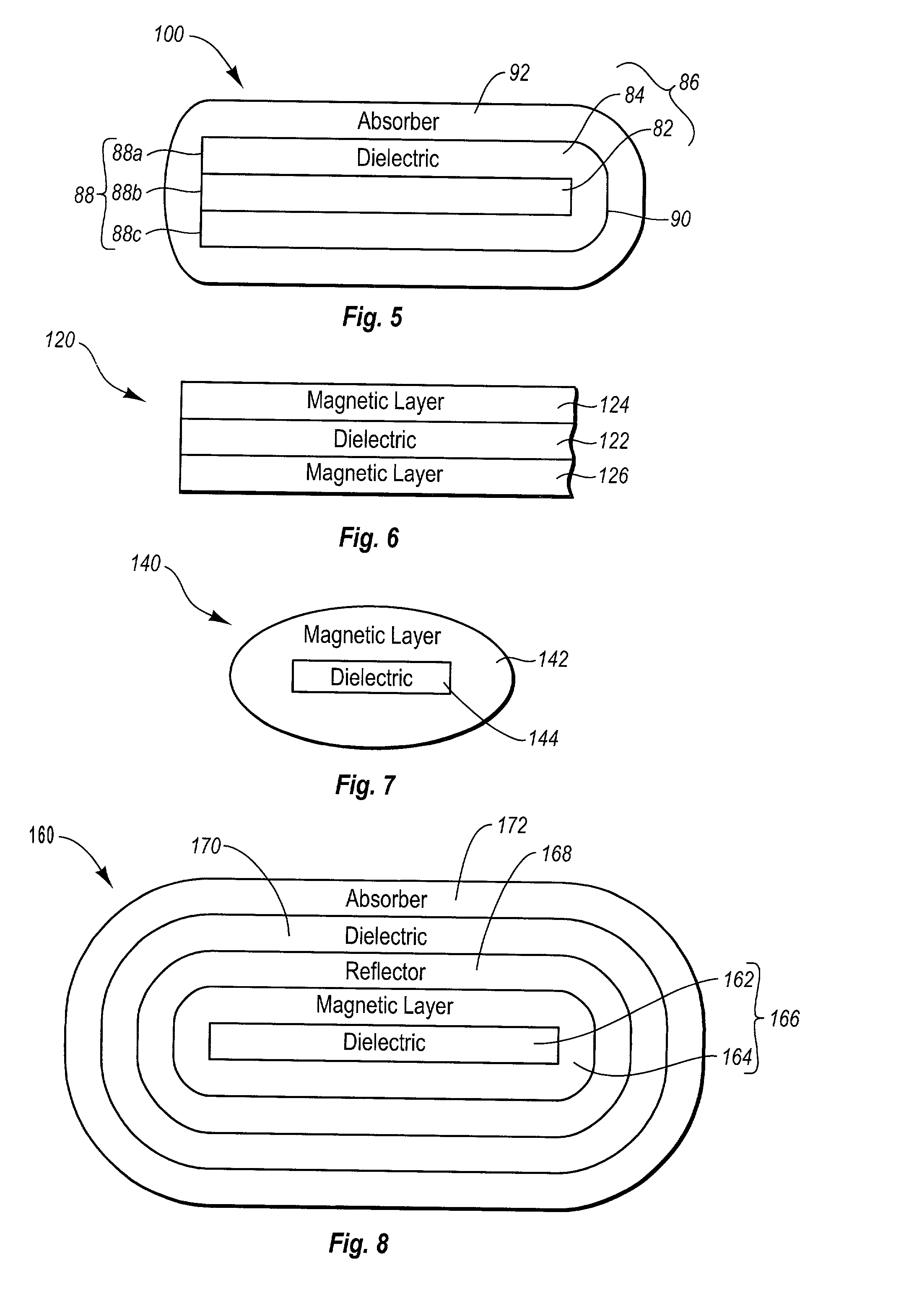

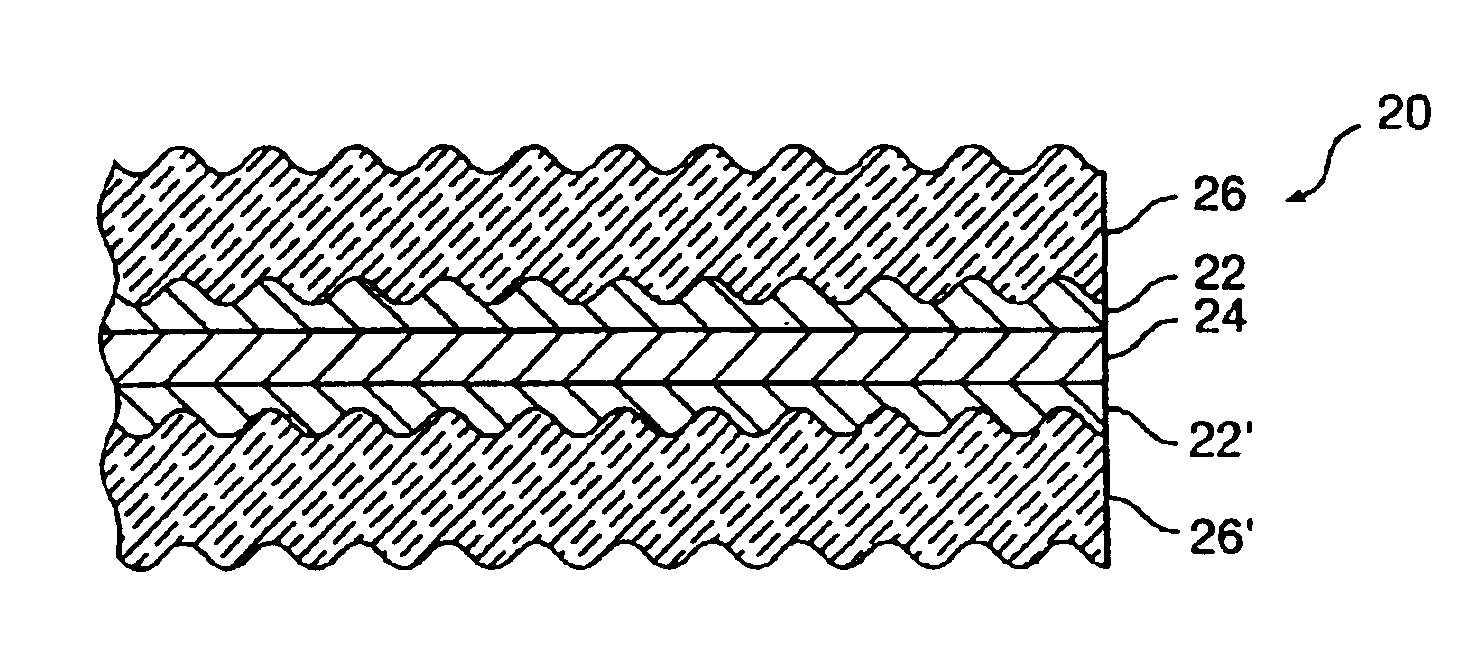

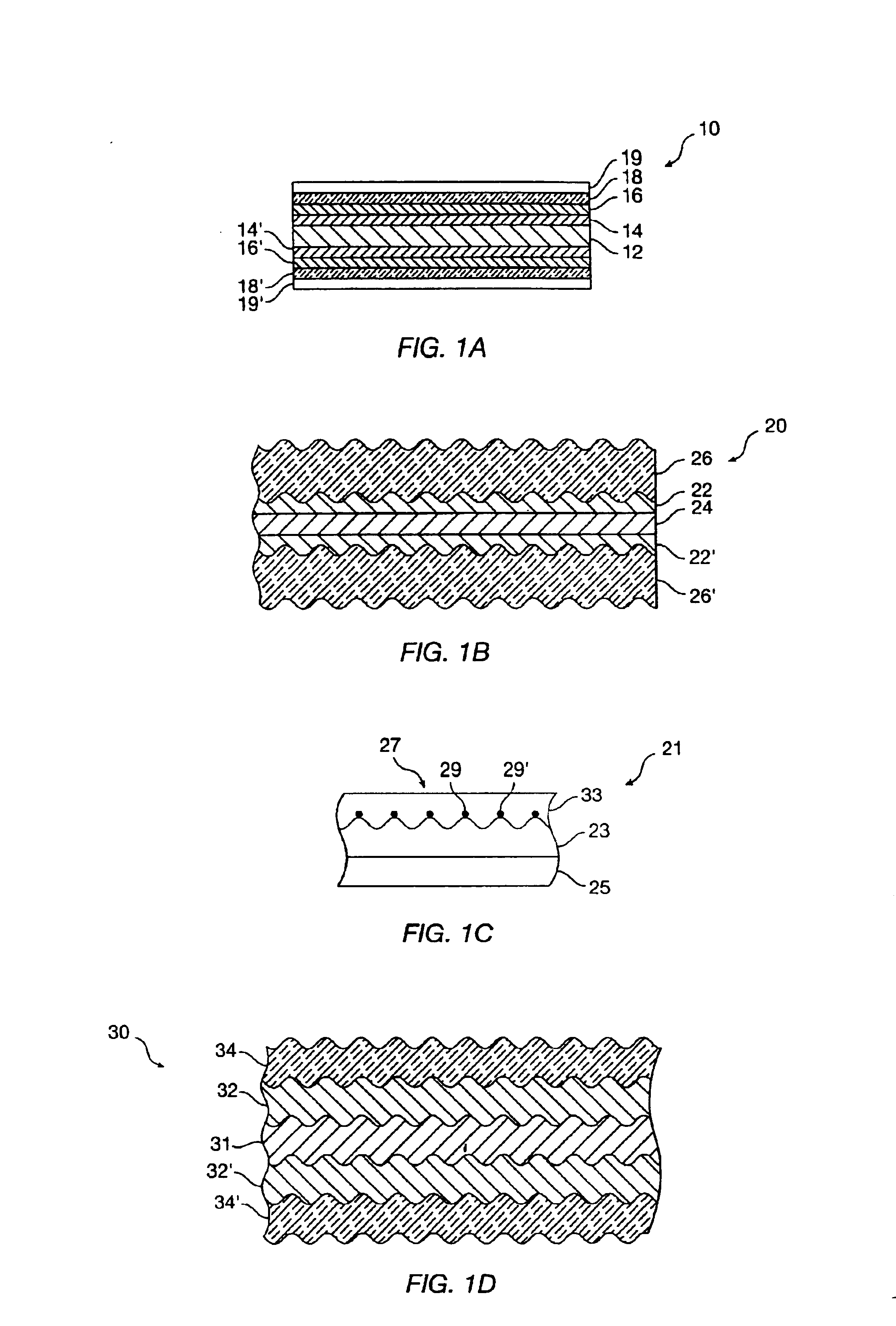

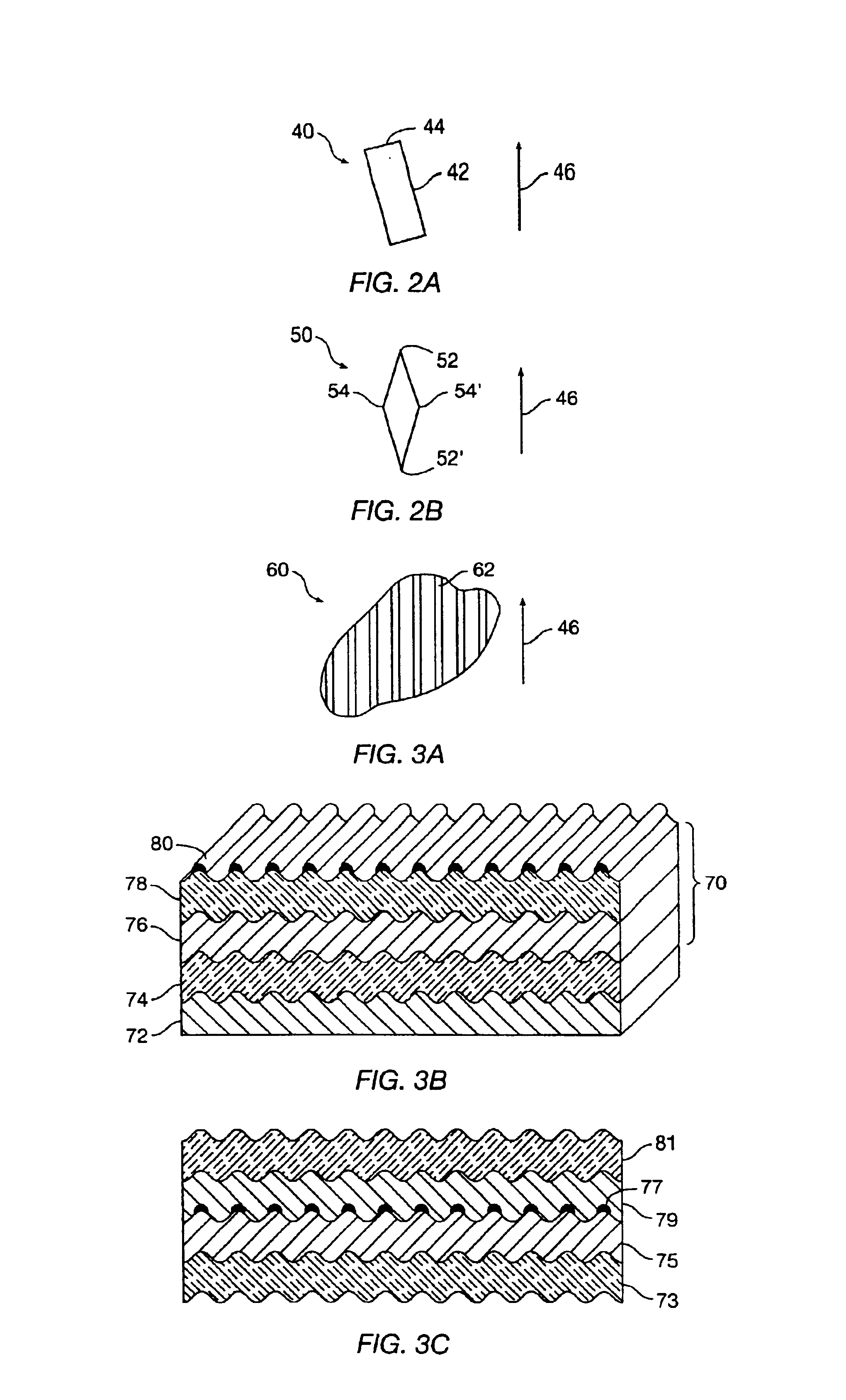

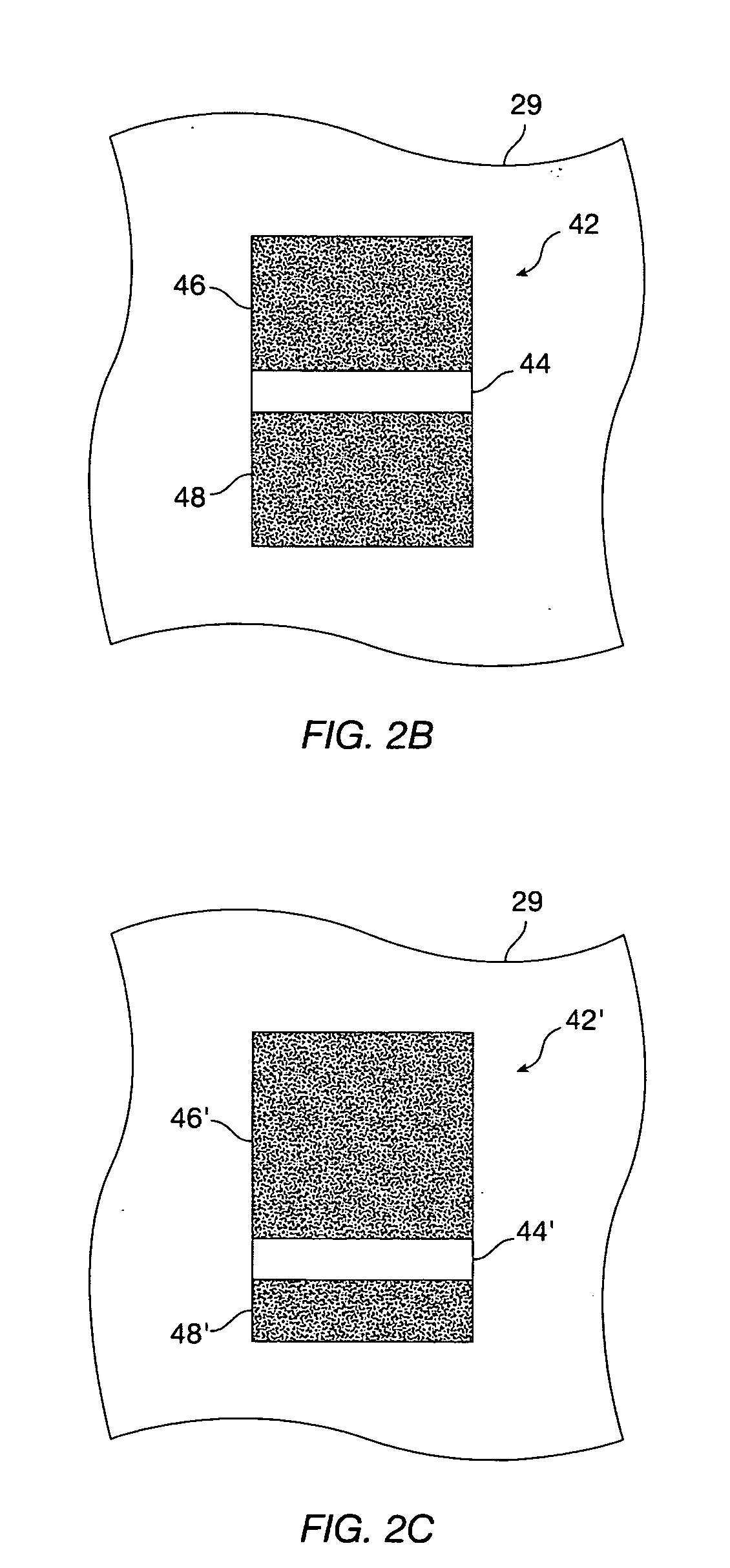

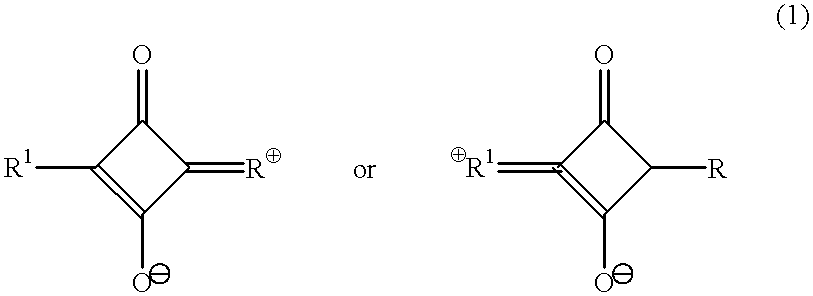

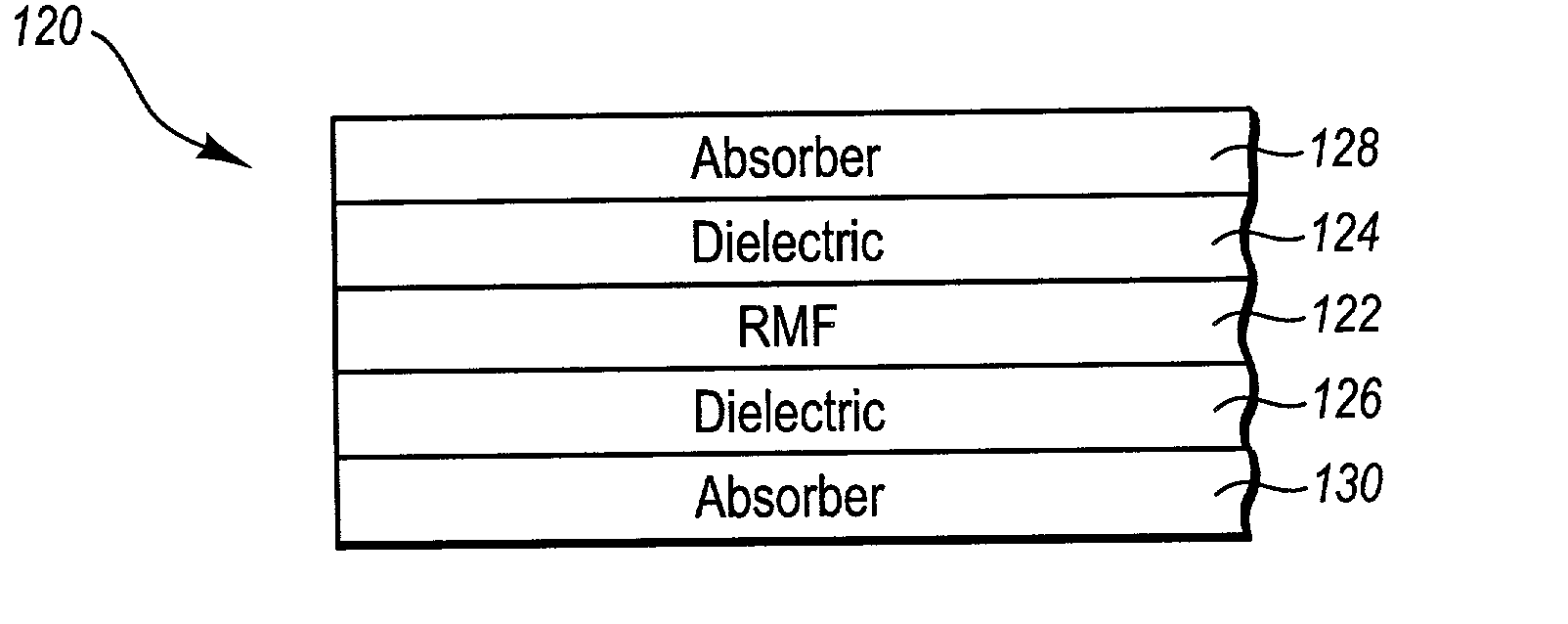

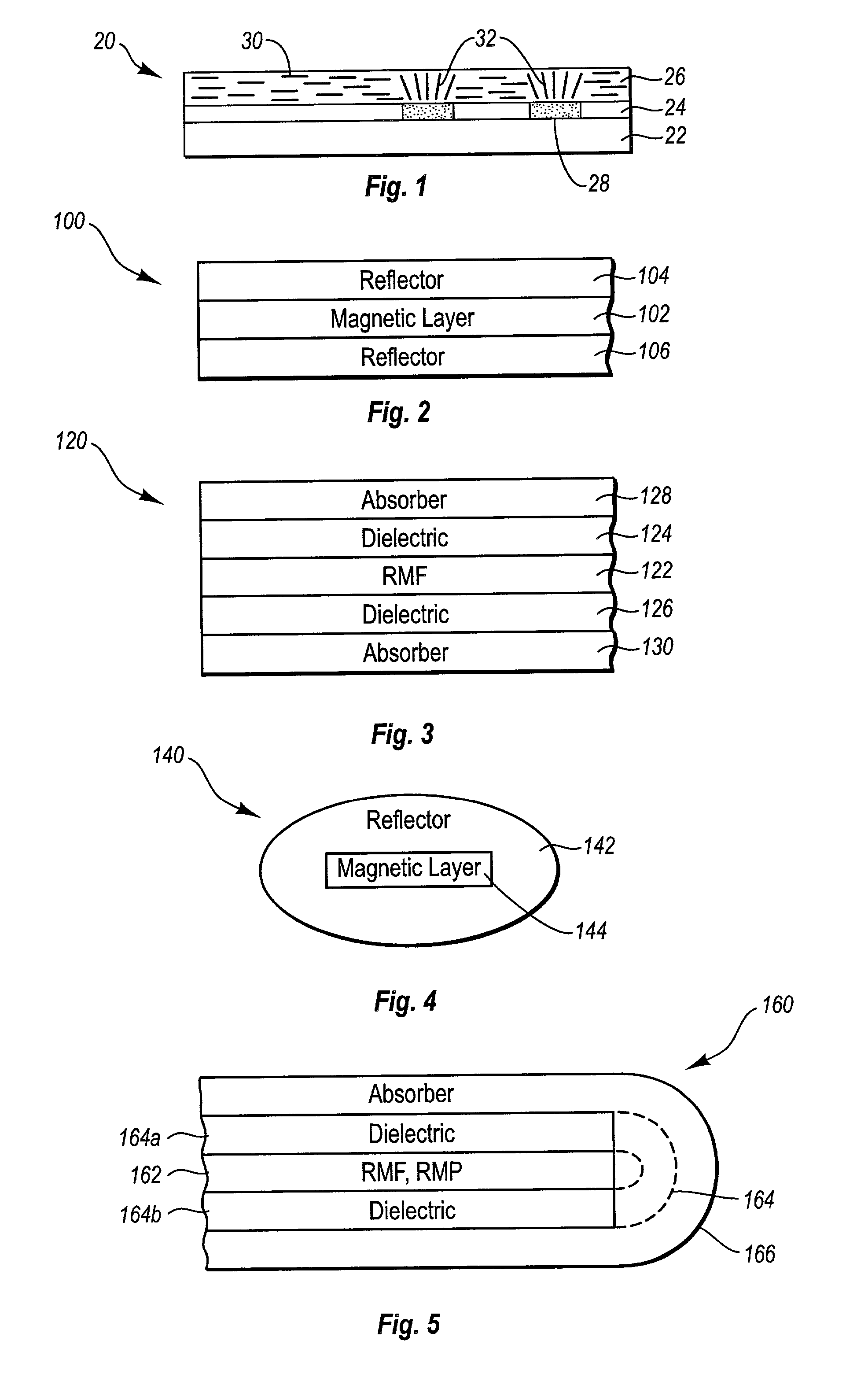

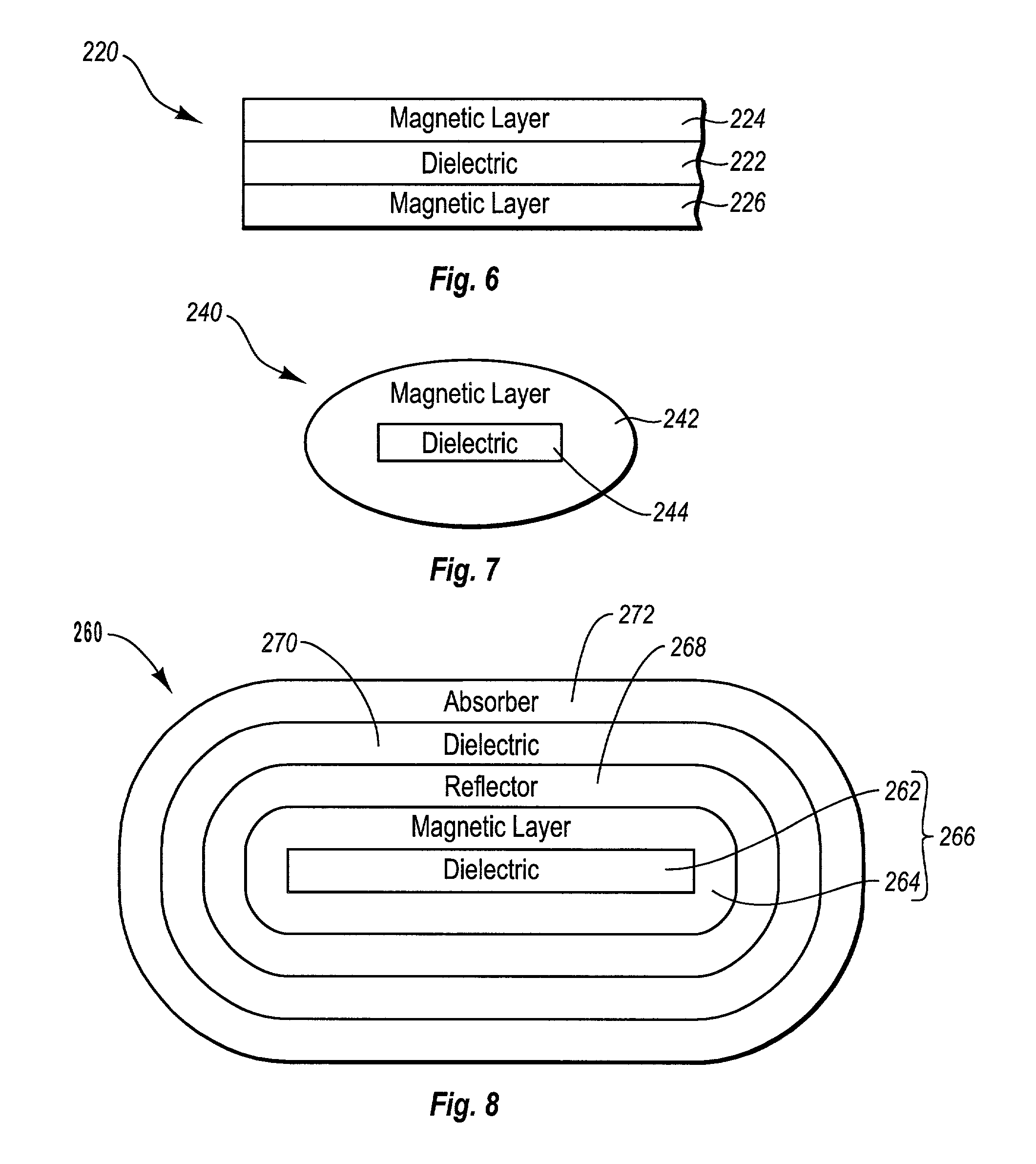

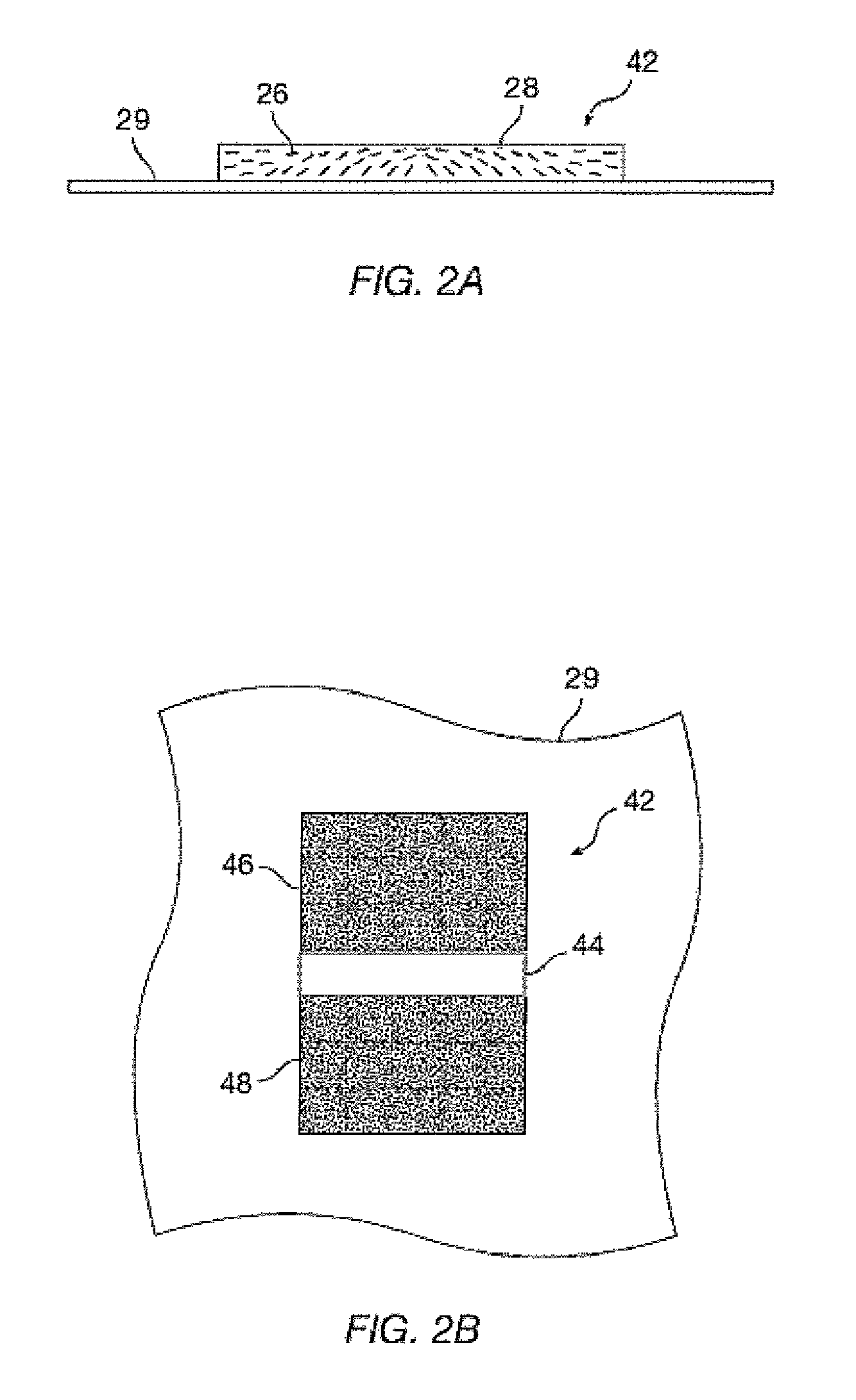

Multi-layered magnetic pigments and foils

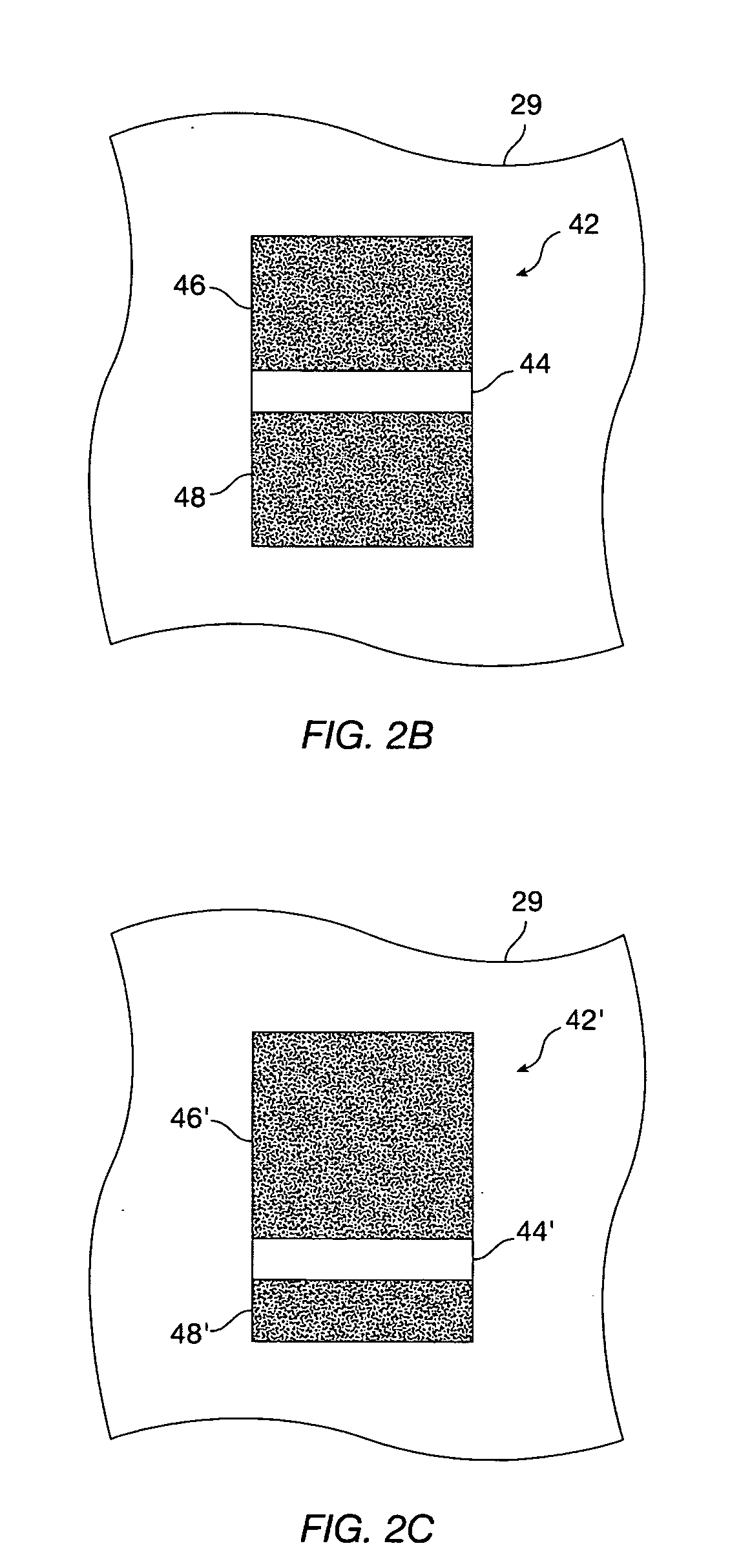

InactiveUS20020160194A1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:FLEX PRODUCTS INC

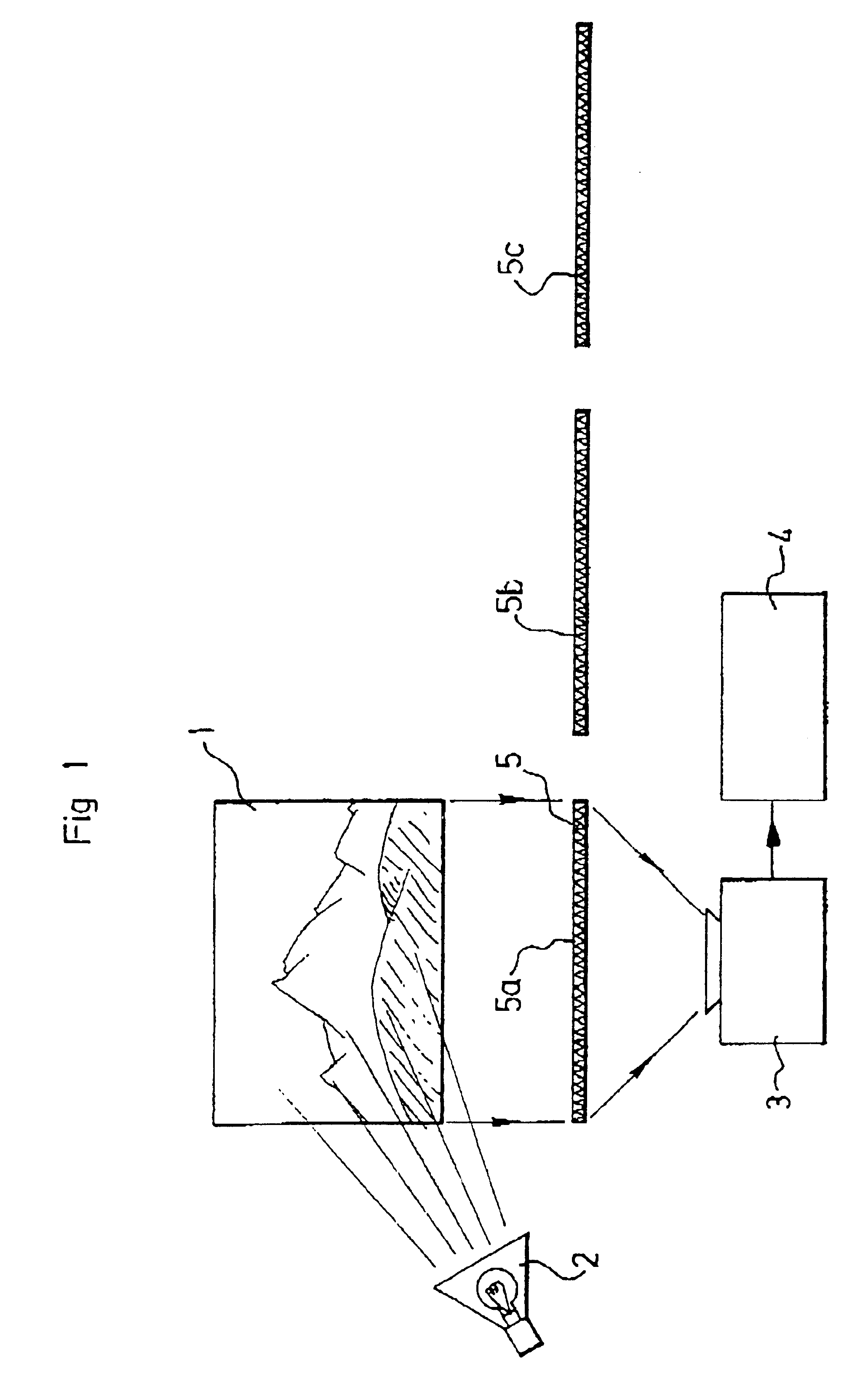

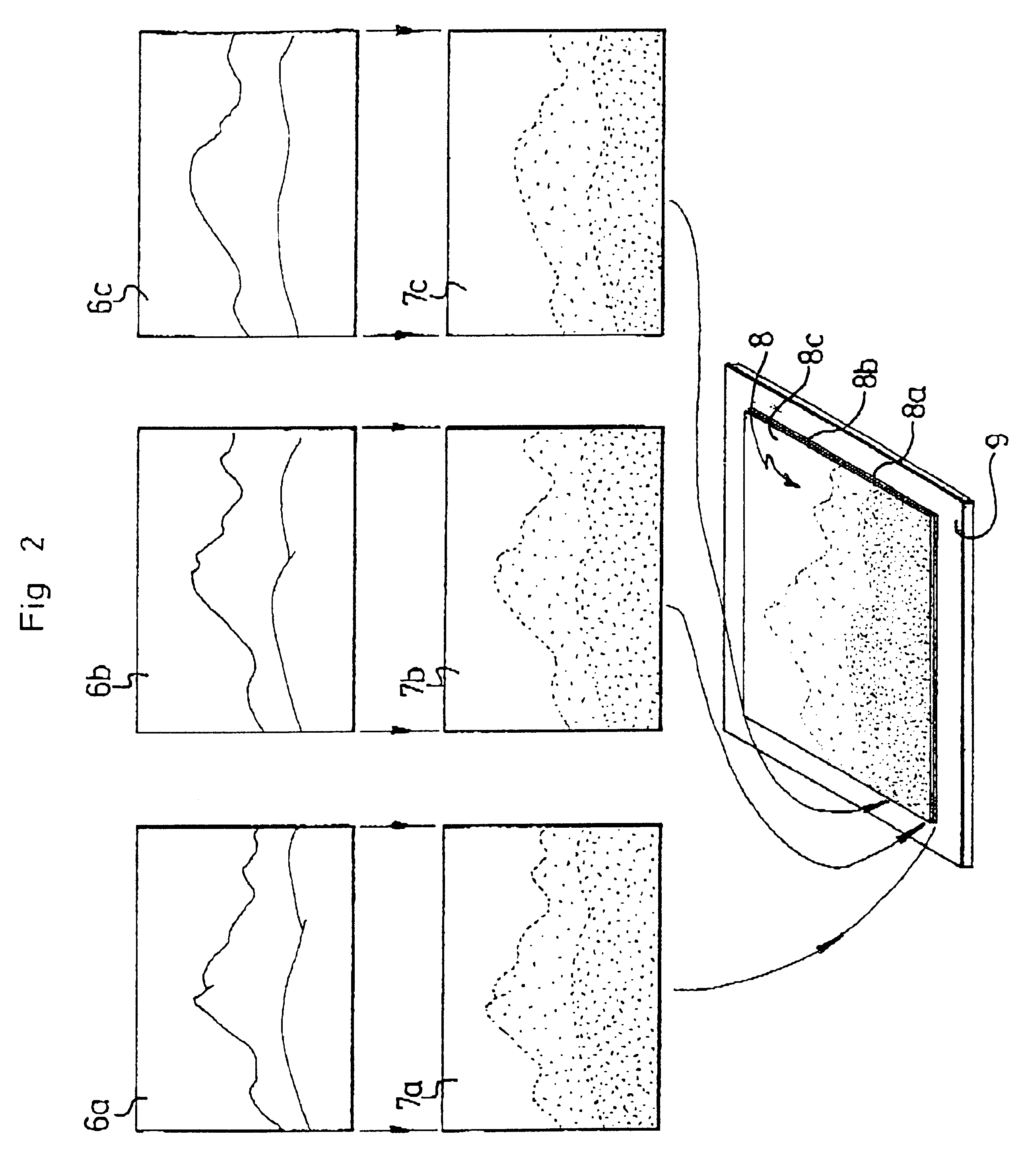

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

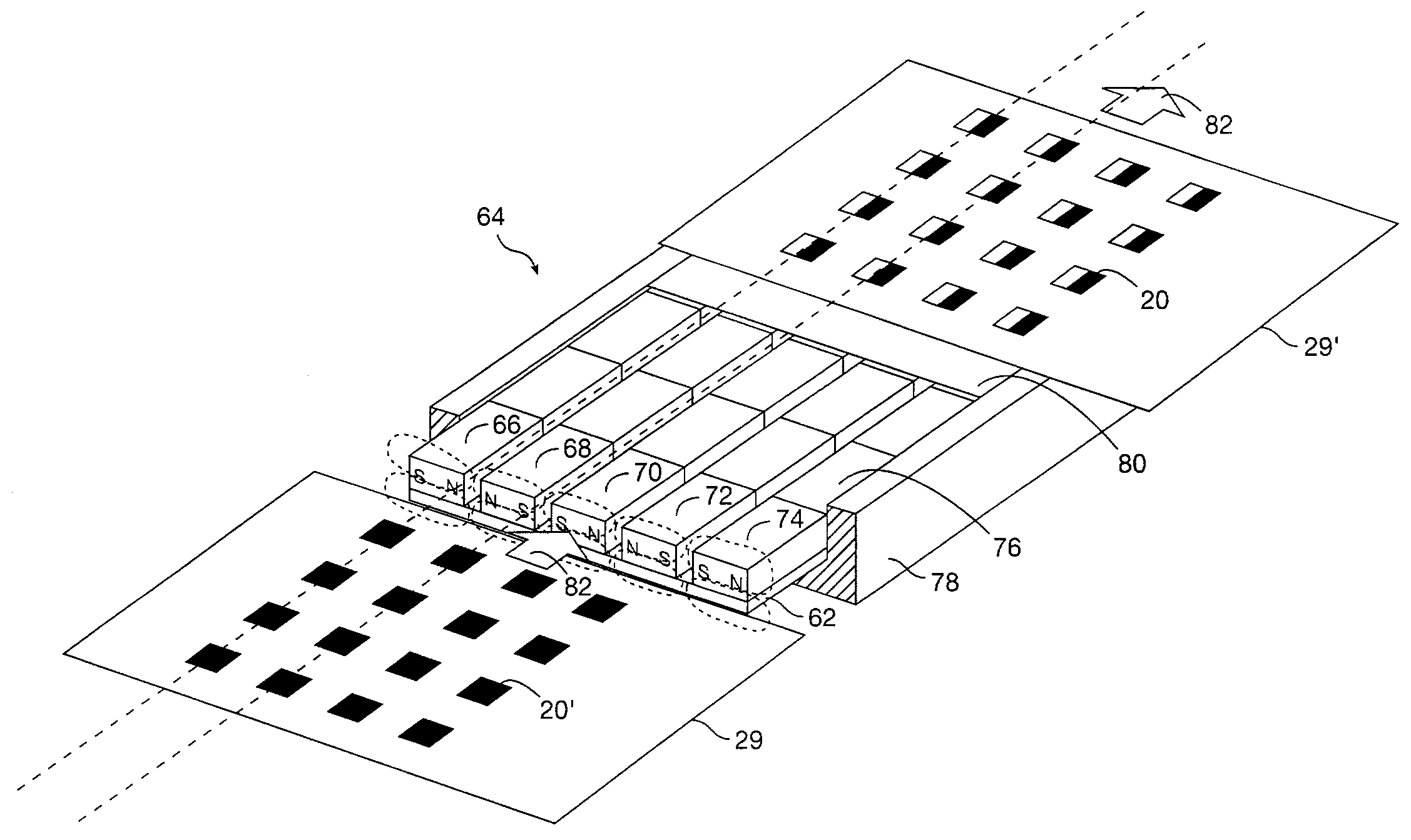

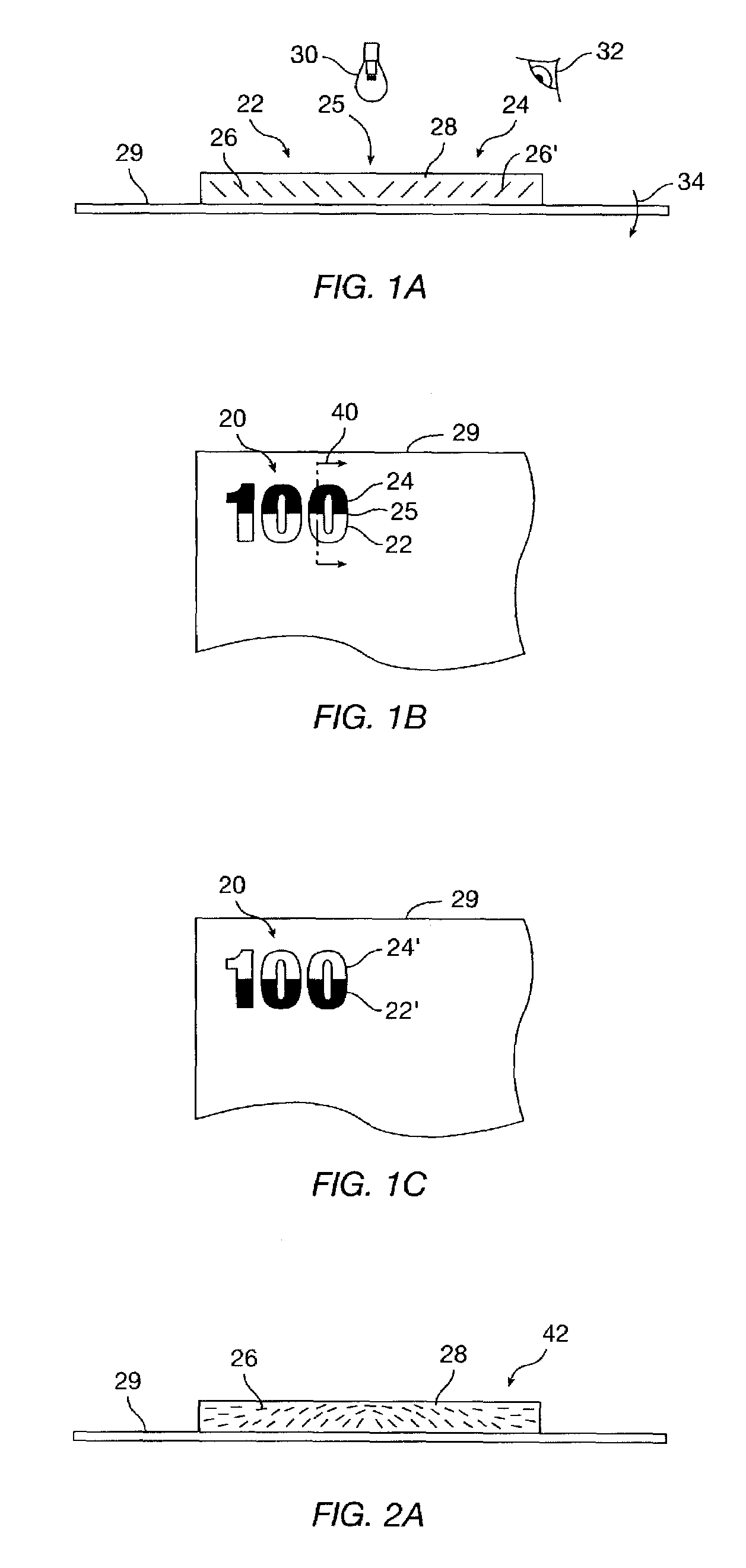

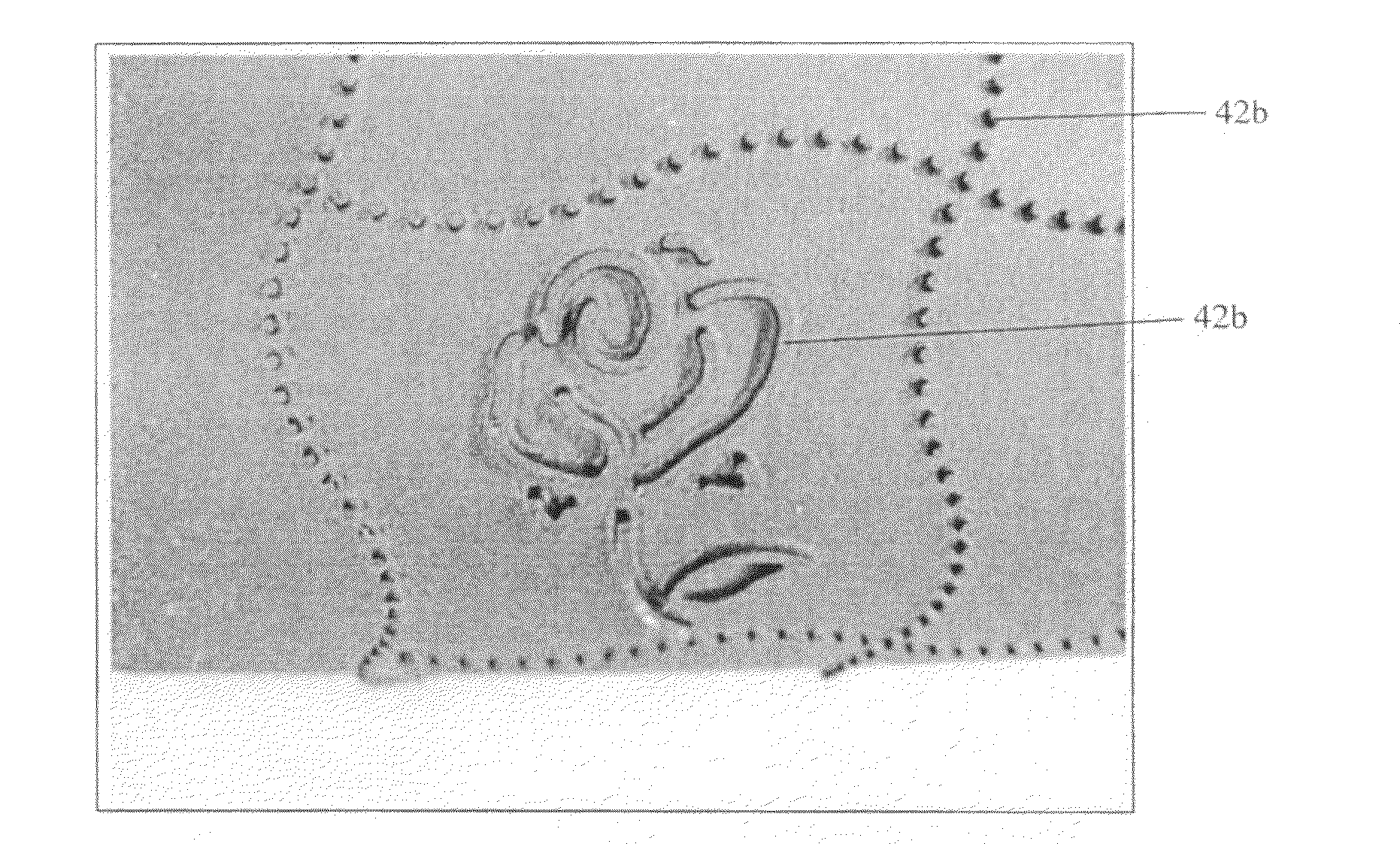

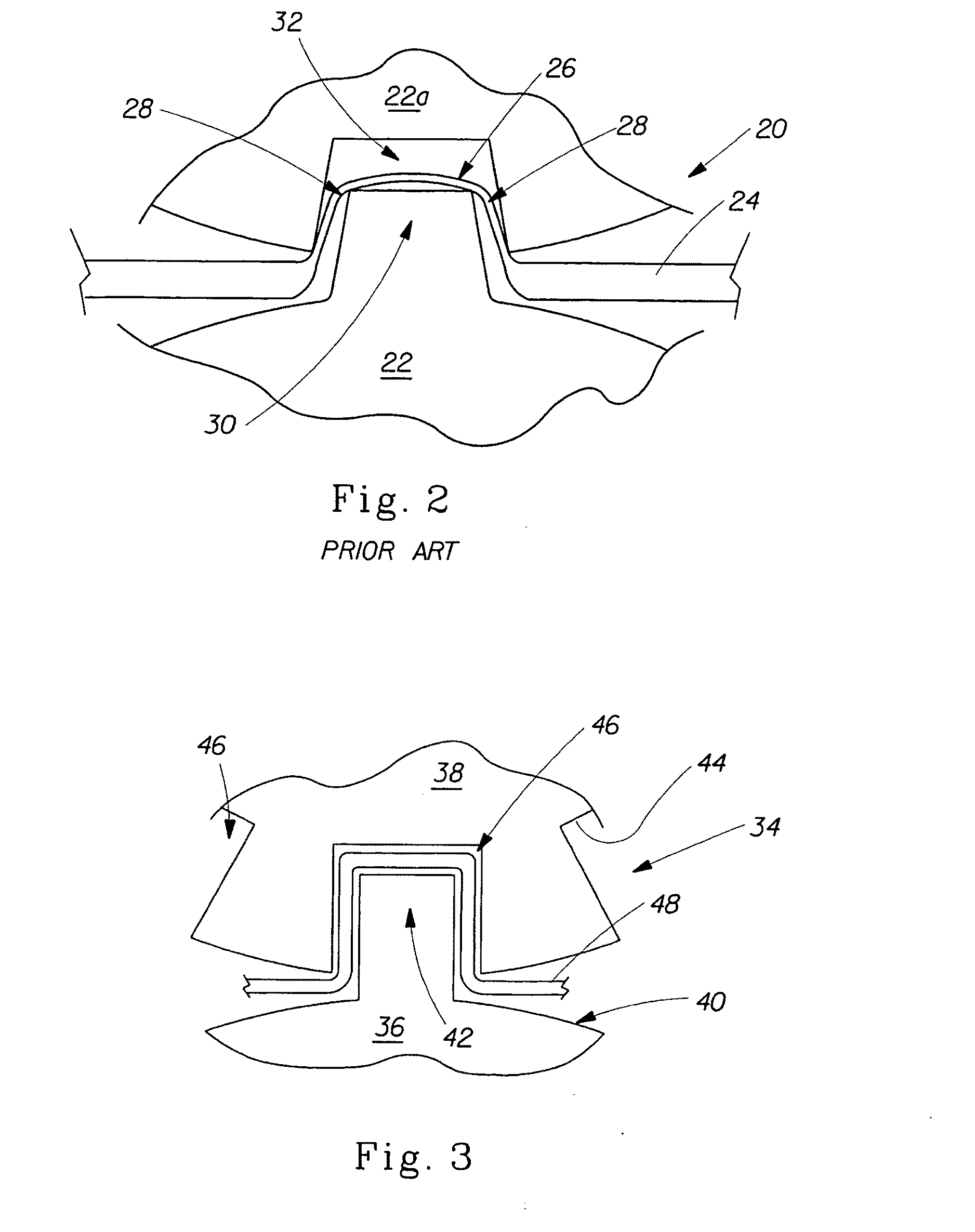

Method and apparatus for orienting magnetic flakes

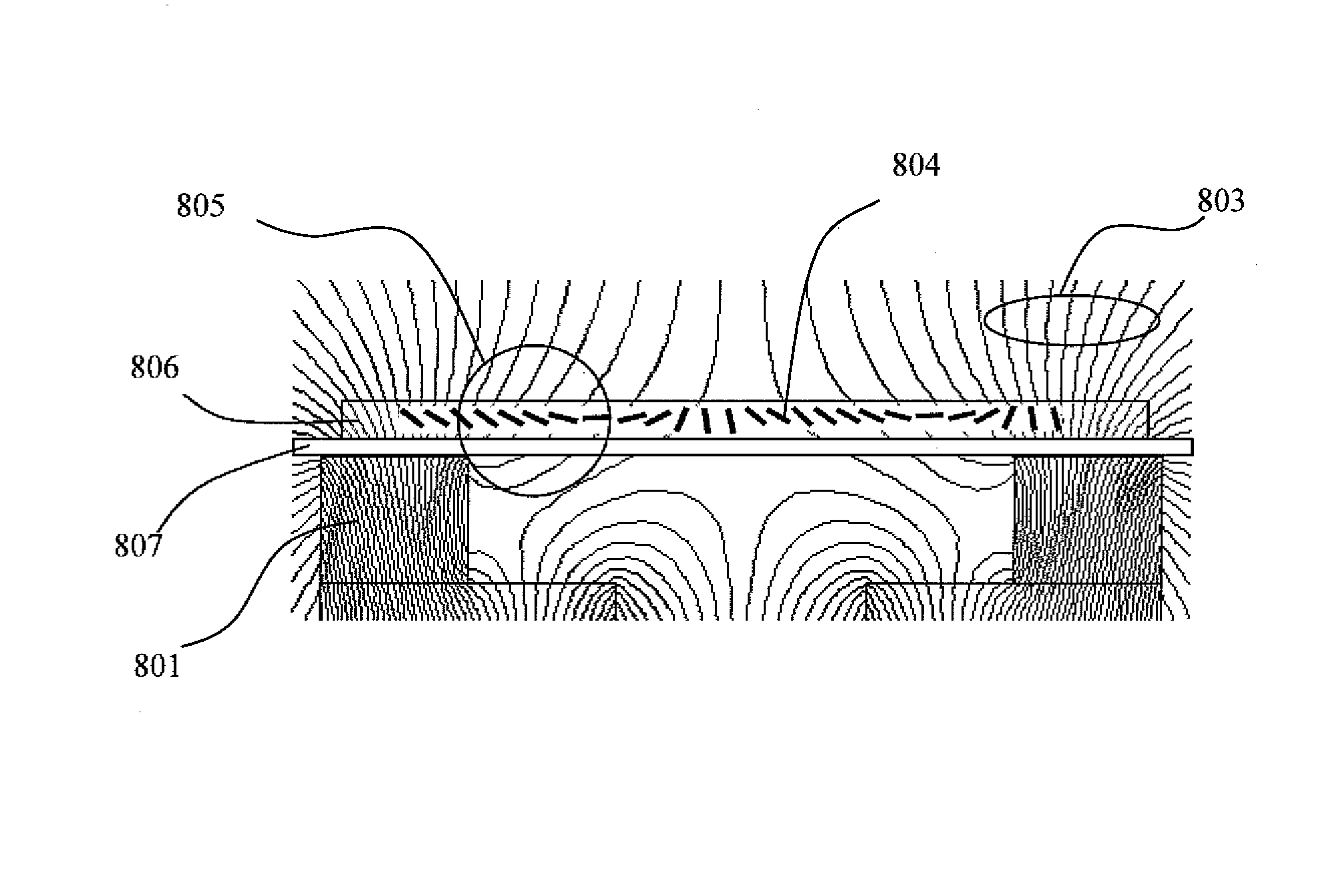

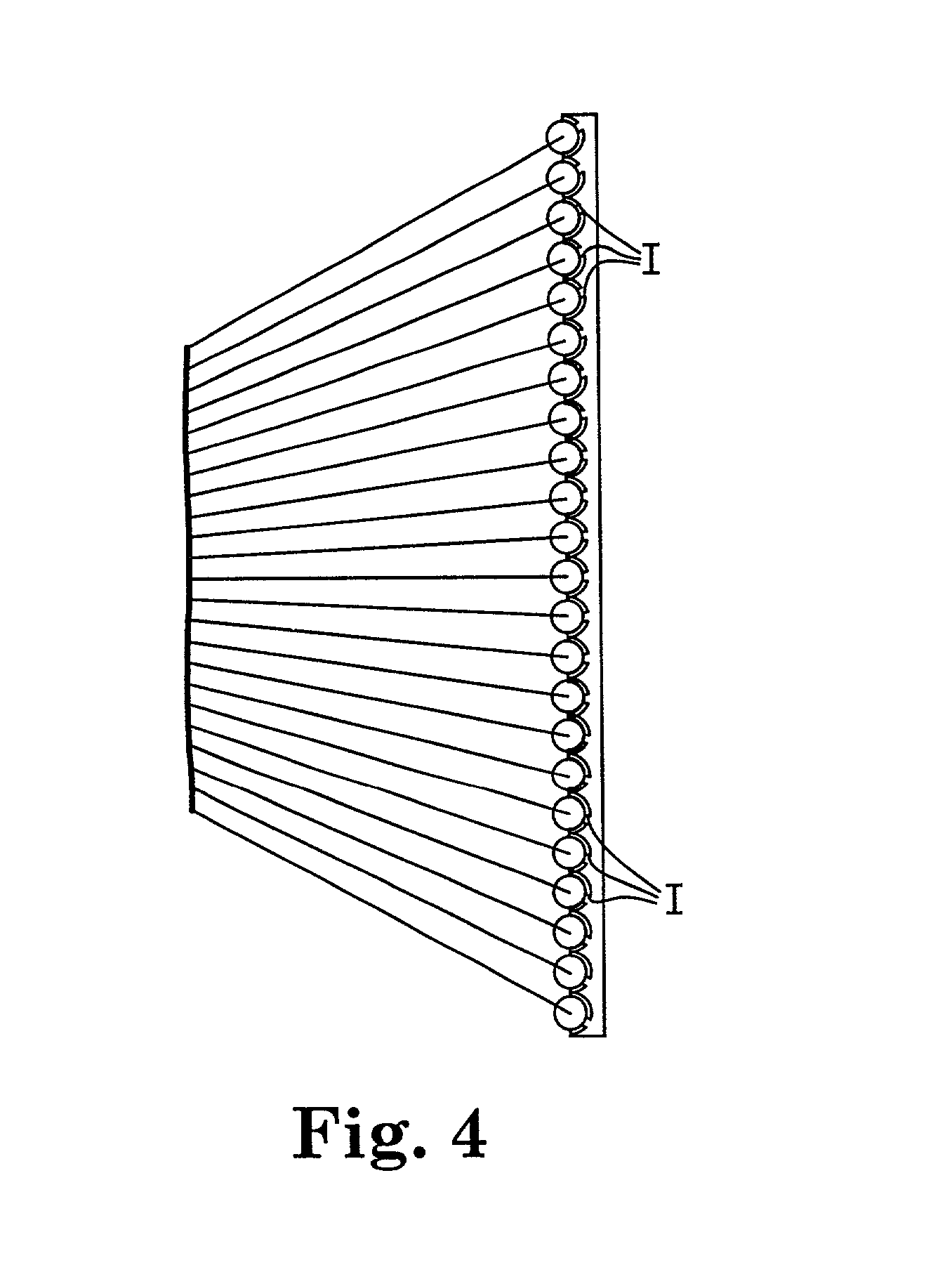

InactiveUS20050106367A1Non-fibrous pulp additionDecorative surface effectsPaper documentDocument preparation

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

Method and apparatus for orienting magnetic flakes

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

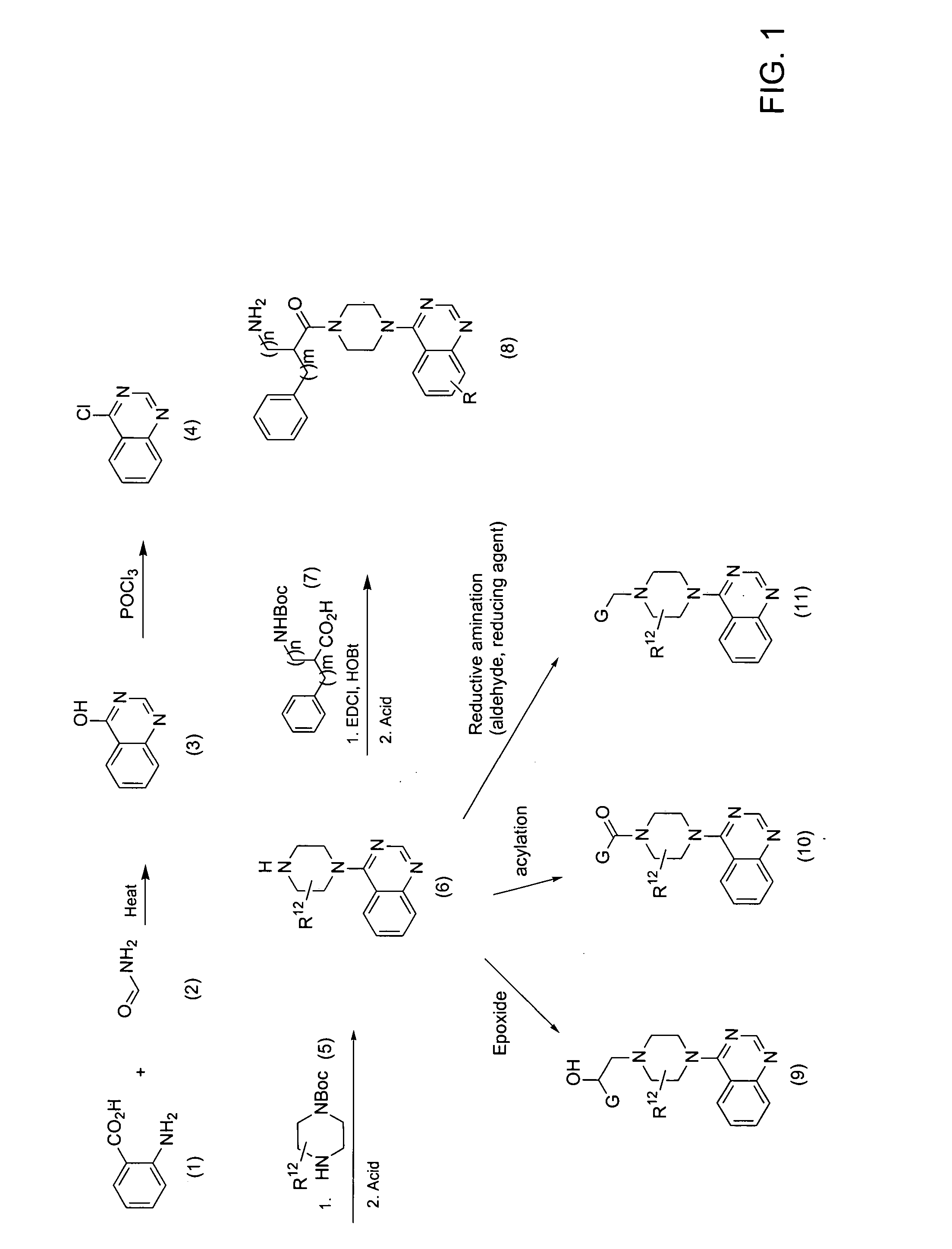

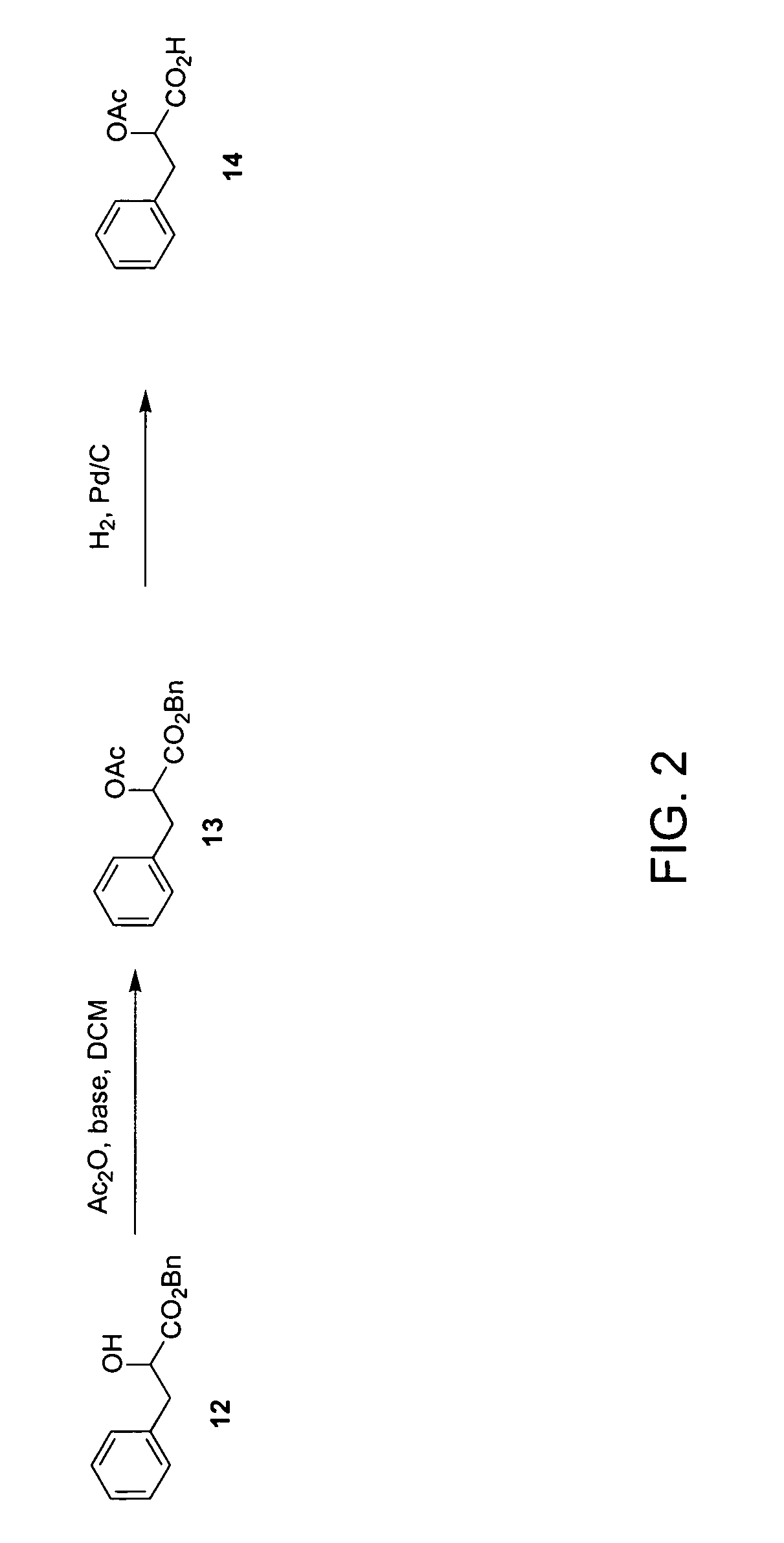

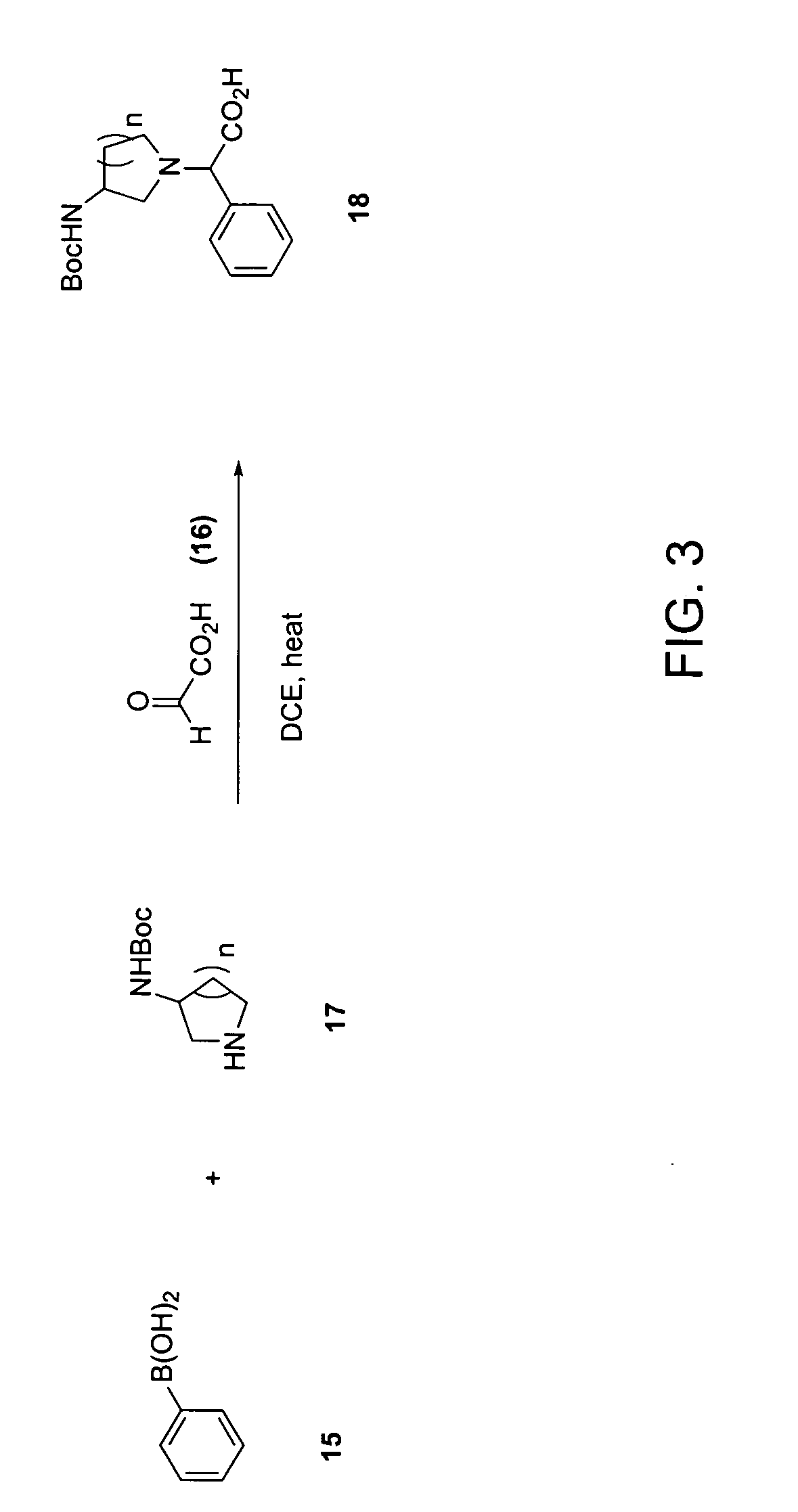

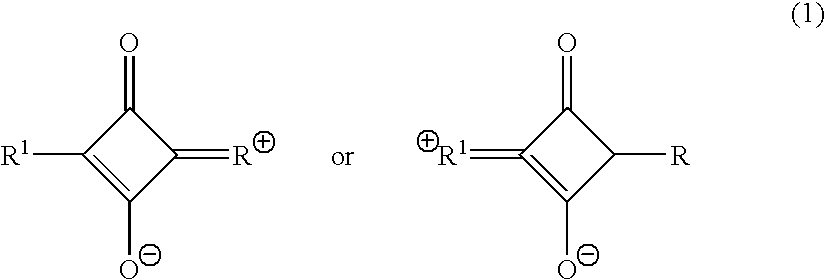

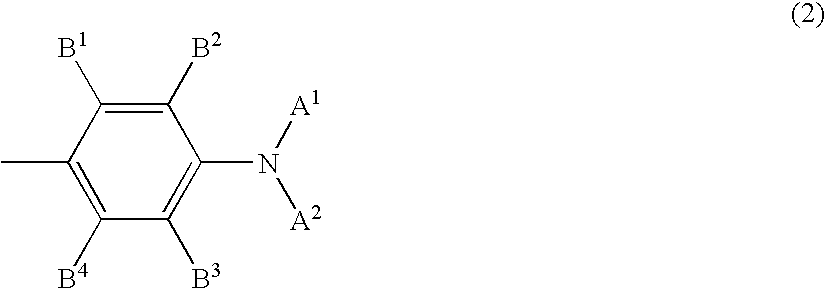

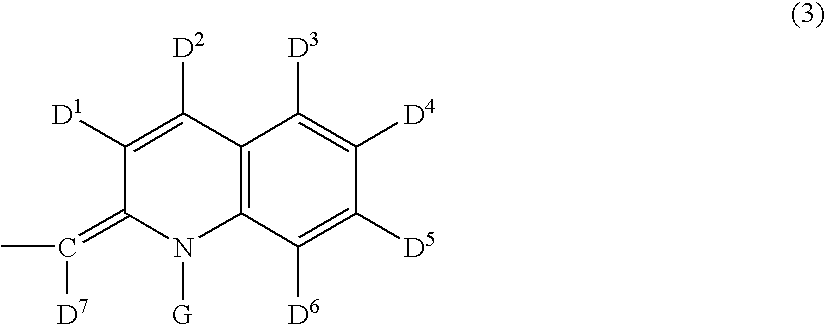

AKT protein kinase inhibitors

The present invention provides compounds, including resolved enantiomers, diastereomers, solvates and pharmaceutically acceptable salts thereof, comprising the Formula: A-L-CR where CR is a cyclical core group, L is a linking group and A is as defined herein. Also provided are methods of using the compounds of this invention as AKT protein kinase inhibitors and for the treatment of hyperproliferative diseases such as cancer.

Owner:ARRAY BIOPHARMA

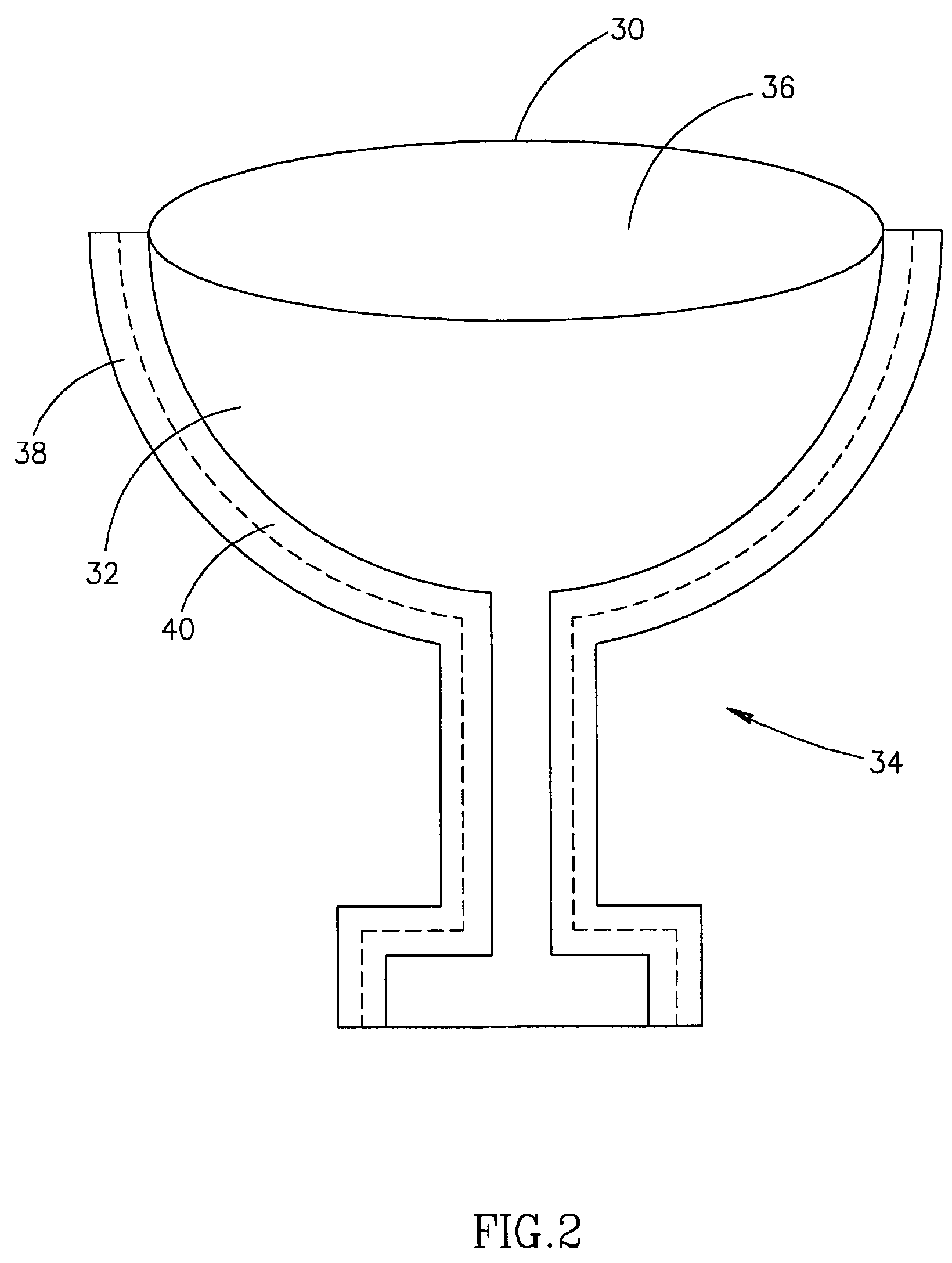

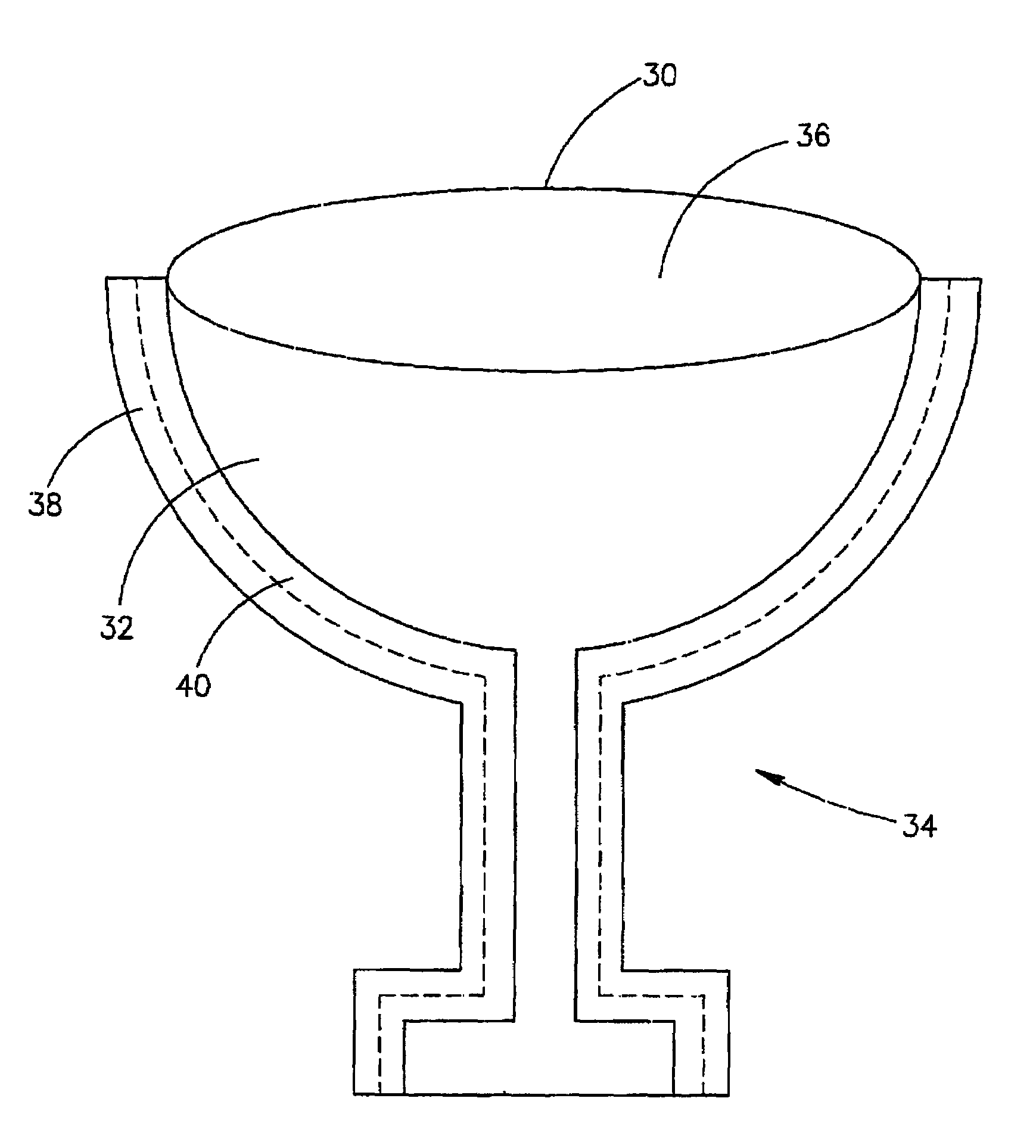

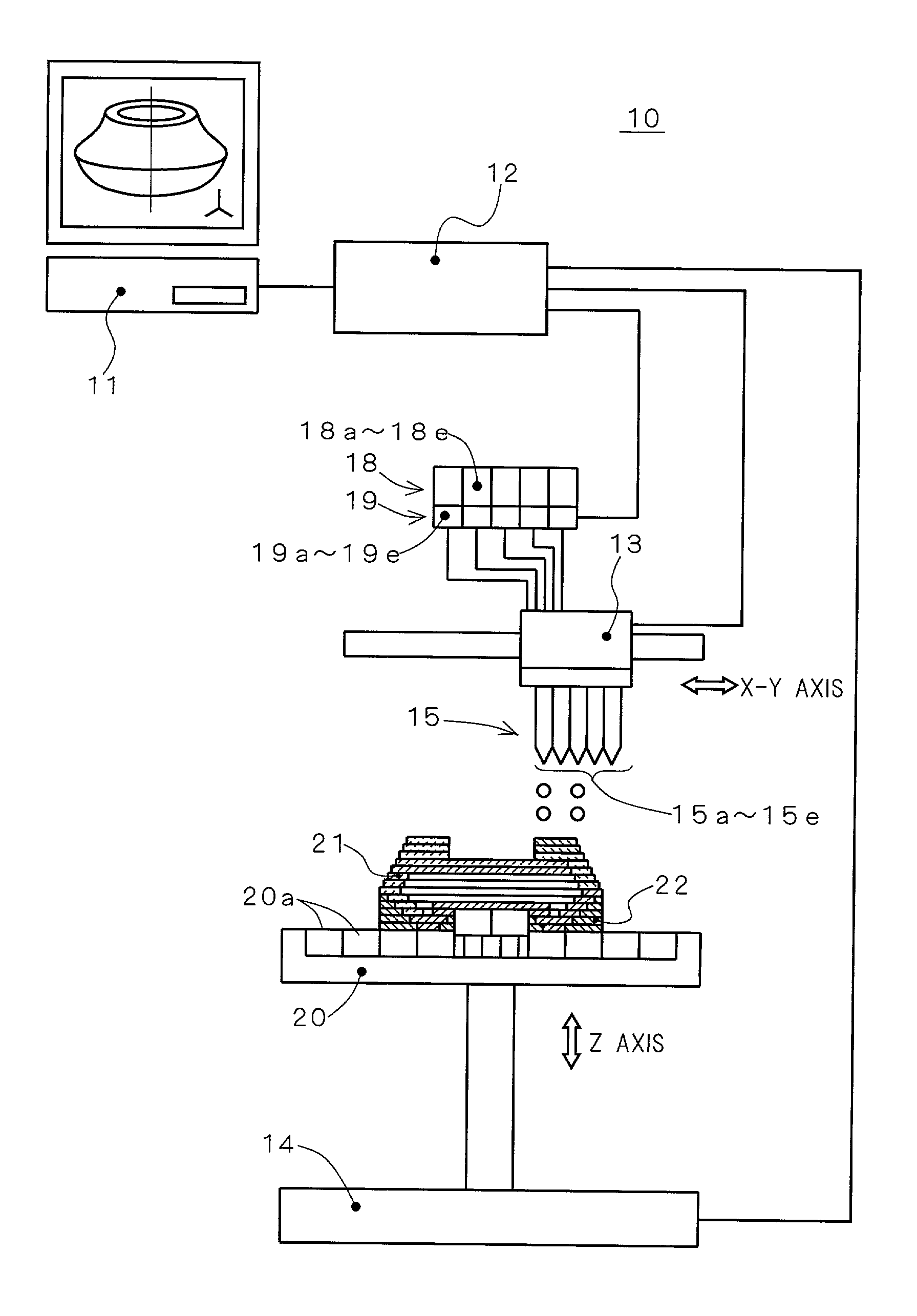

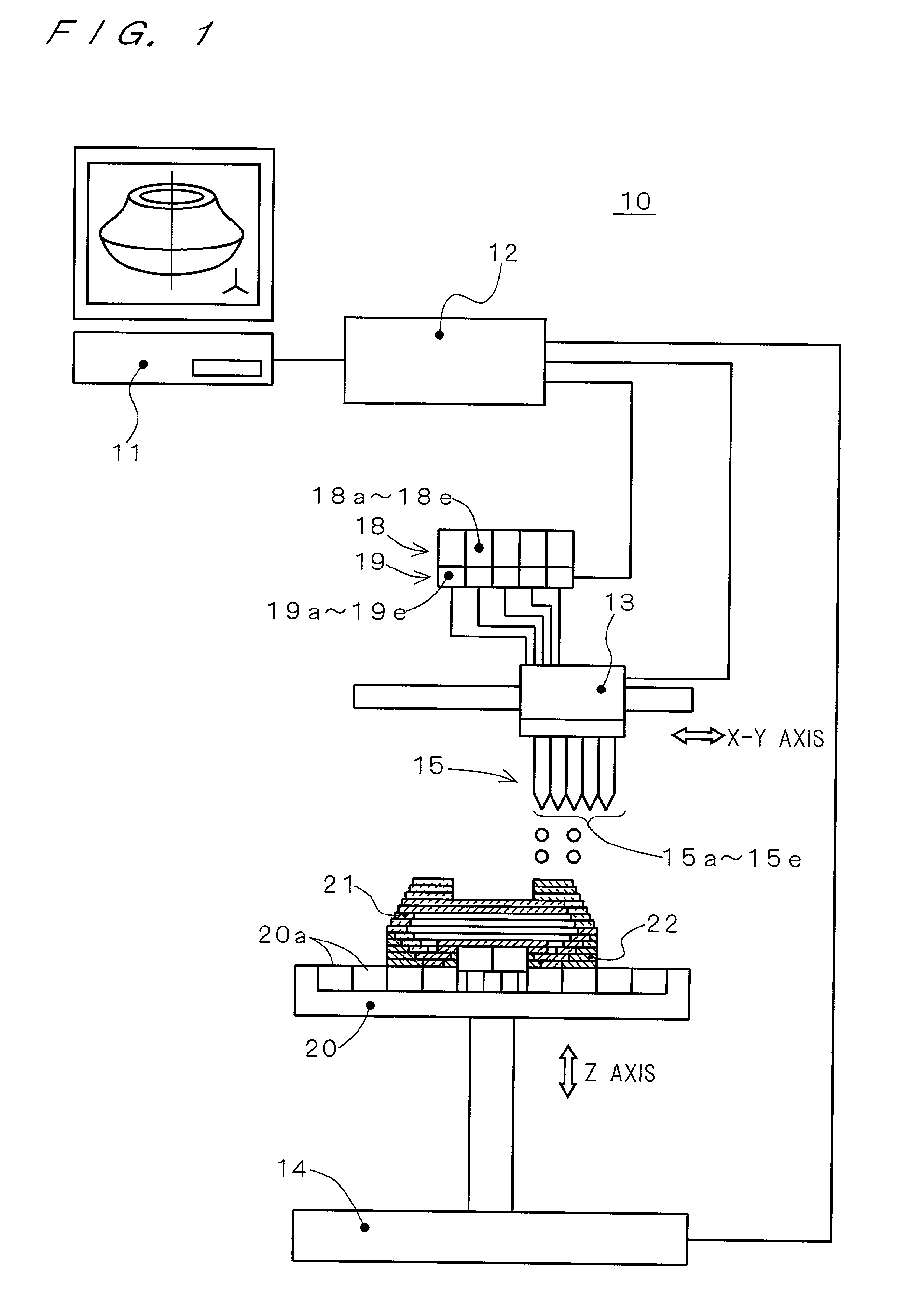

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

Method for producing a particular photoluminescent polychromatic printed image, resulting image and uses

InactiveUS6494490B1Inhibition of reproductionOther printing matterPattern printingPhotoluminescenceLength wave

Owner:FASVER TECH

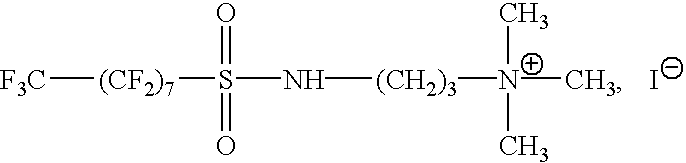

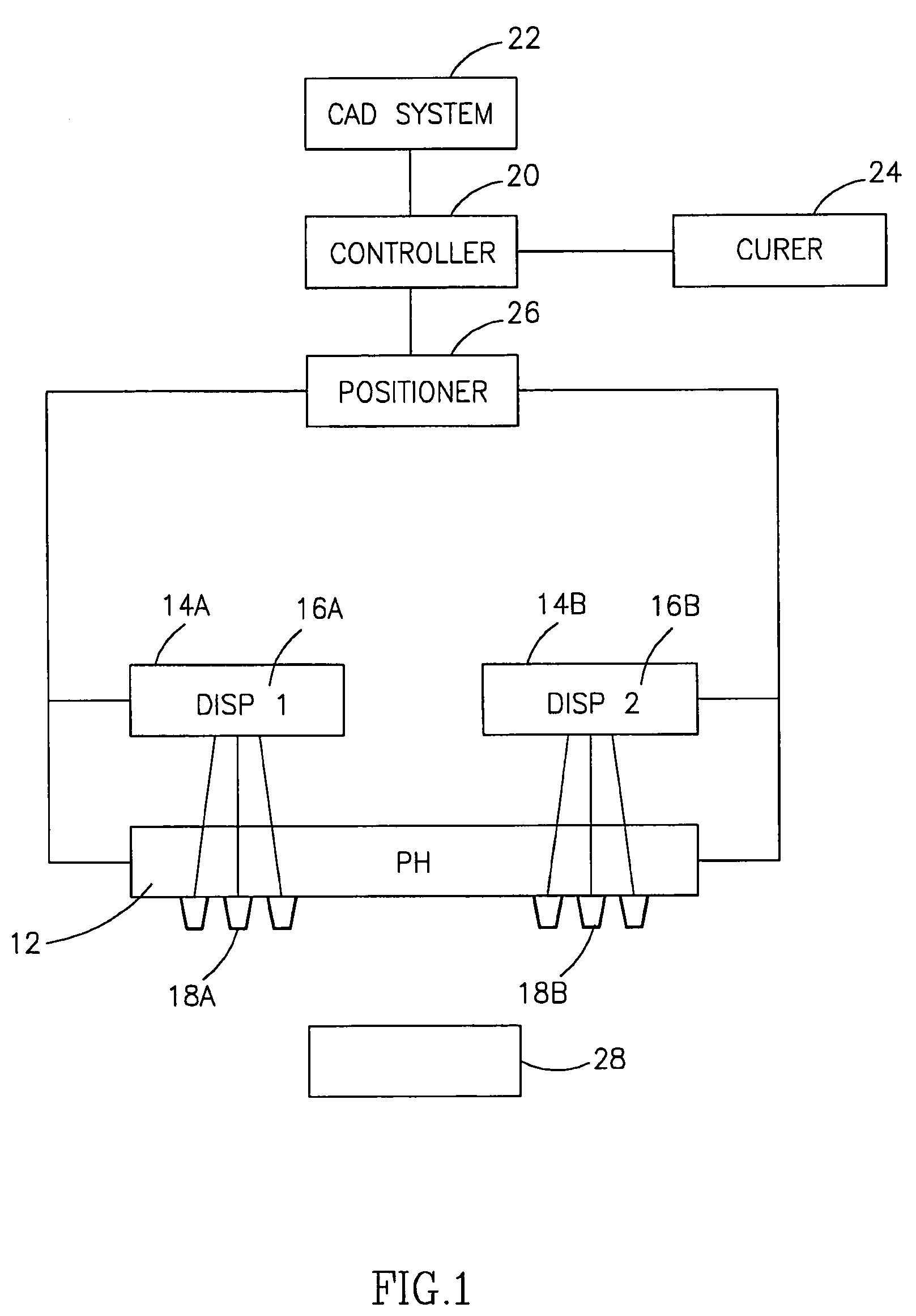

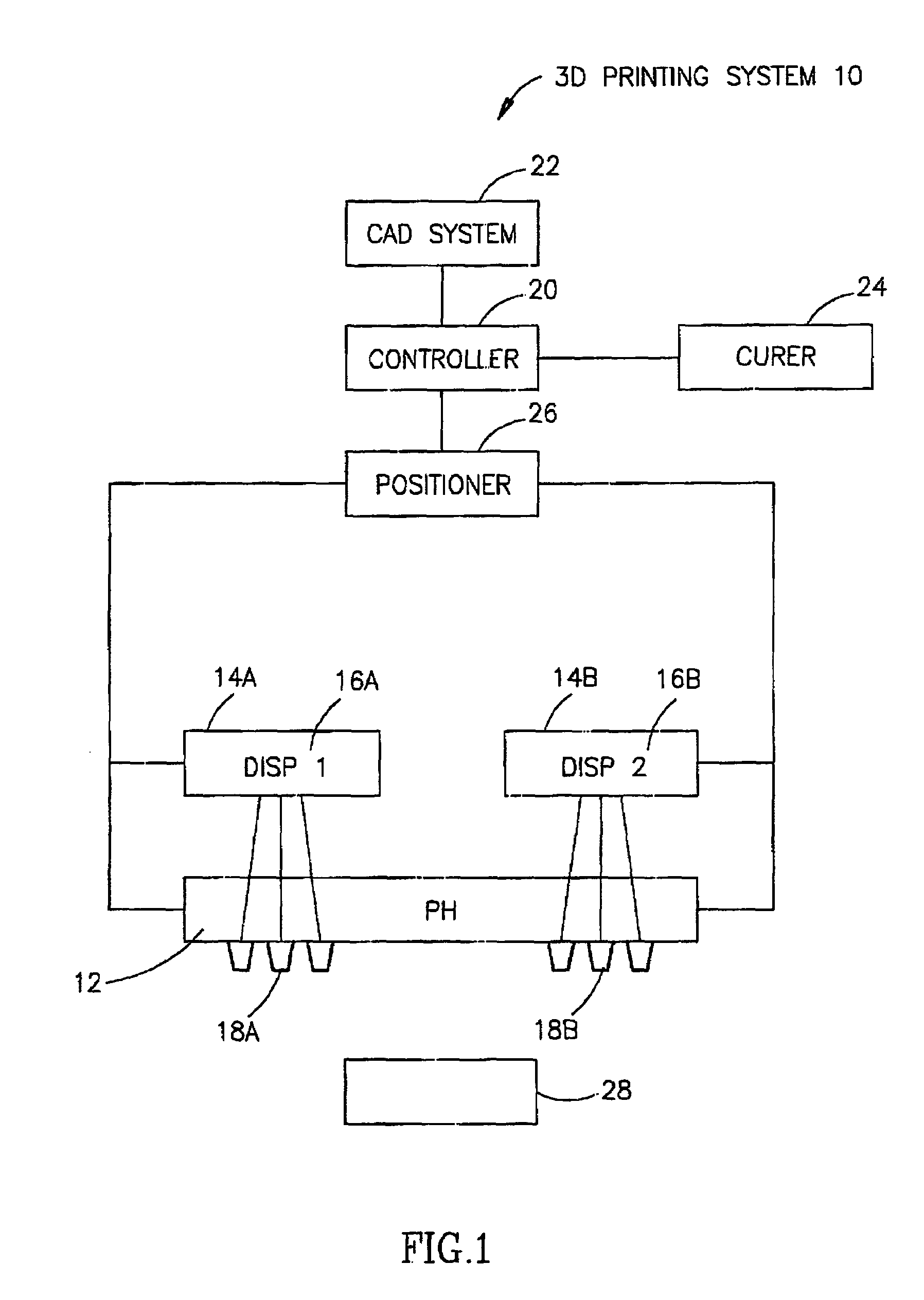

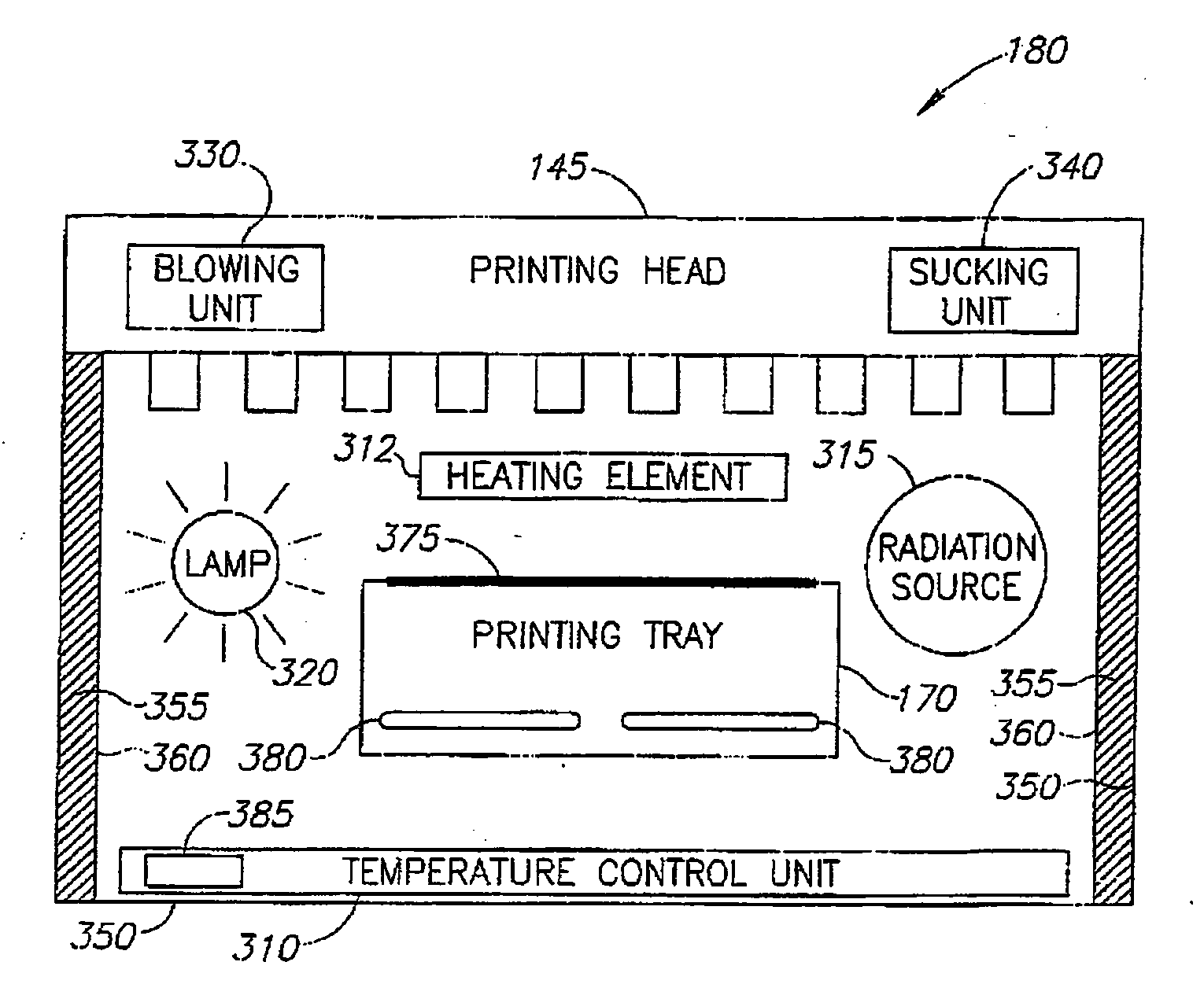

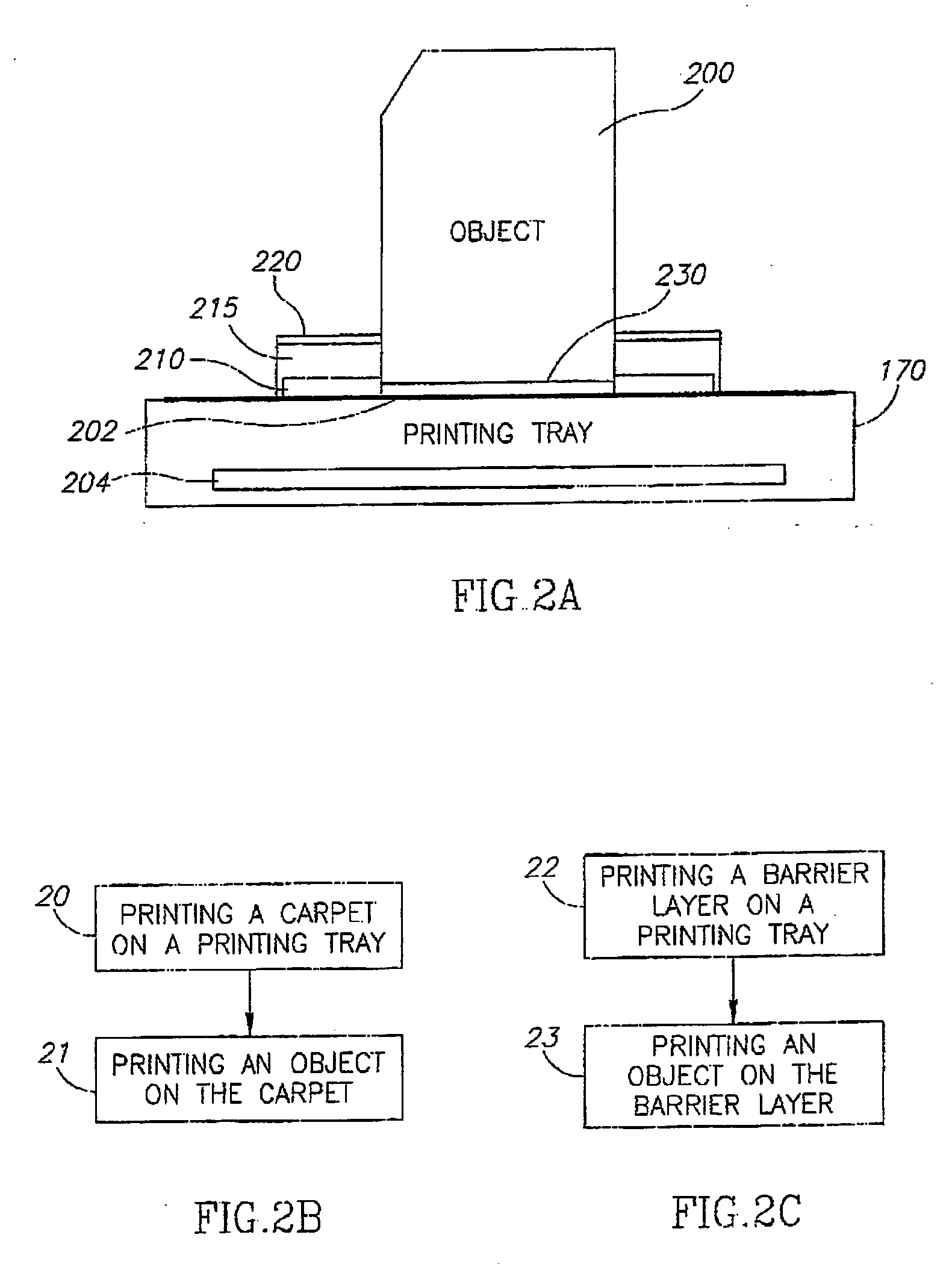

Process of and apparratus for three-dimensional printing

InactiveUS20060054039A1Low adhesion characteristicAvoid mechanical deformationManufacturing platforms/substratesPattern printingTemperature controlEngineering

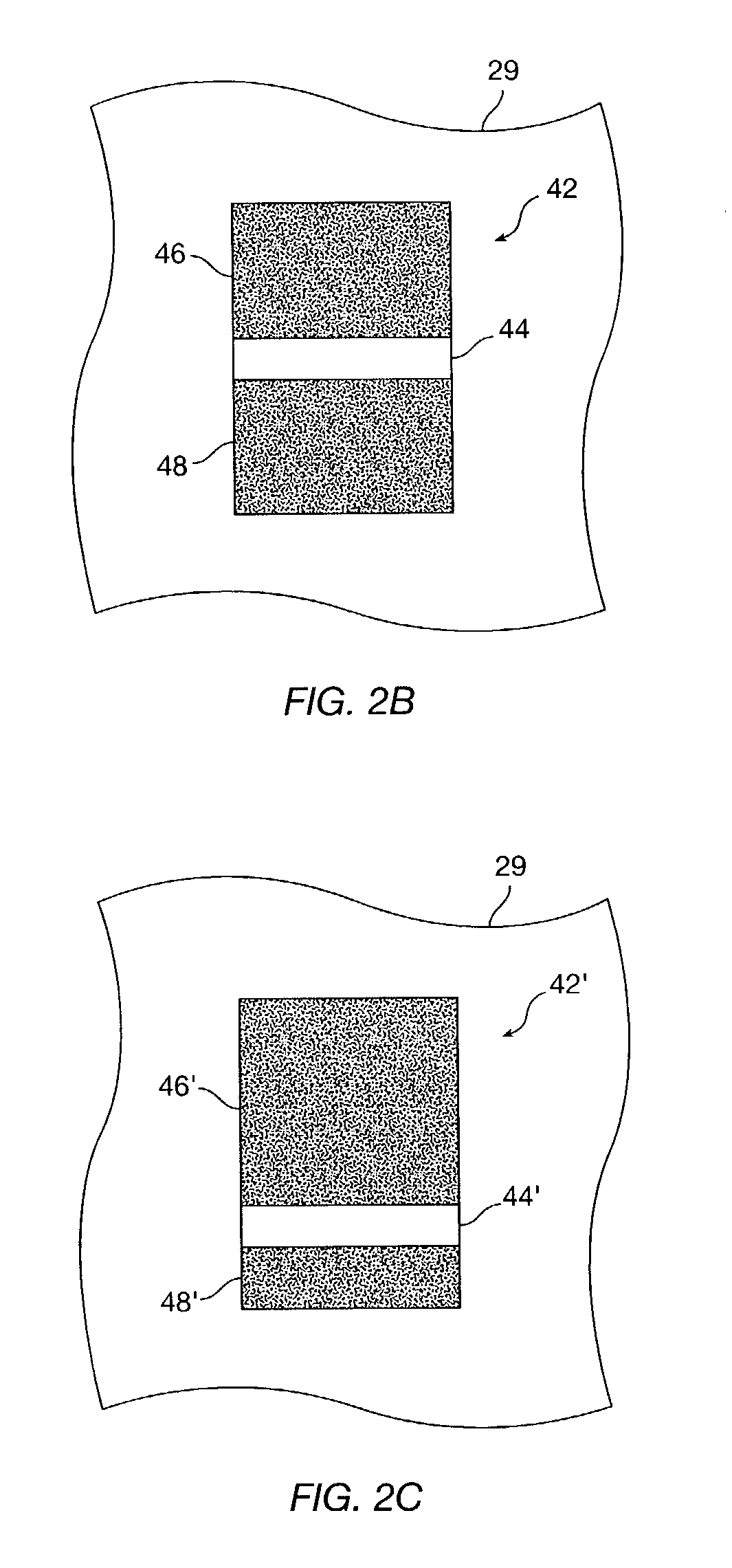

A process of, and apparatus for, three-dimensional printing of an object (200) from modeling material (220) including a printing tray (170) having a surface coating (202), a carpet (210), a support material (215), a support pedestal (210), a barrier layer (230) and a temperature control unit (204).

Owner:OBJET GEOMETRIES

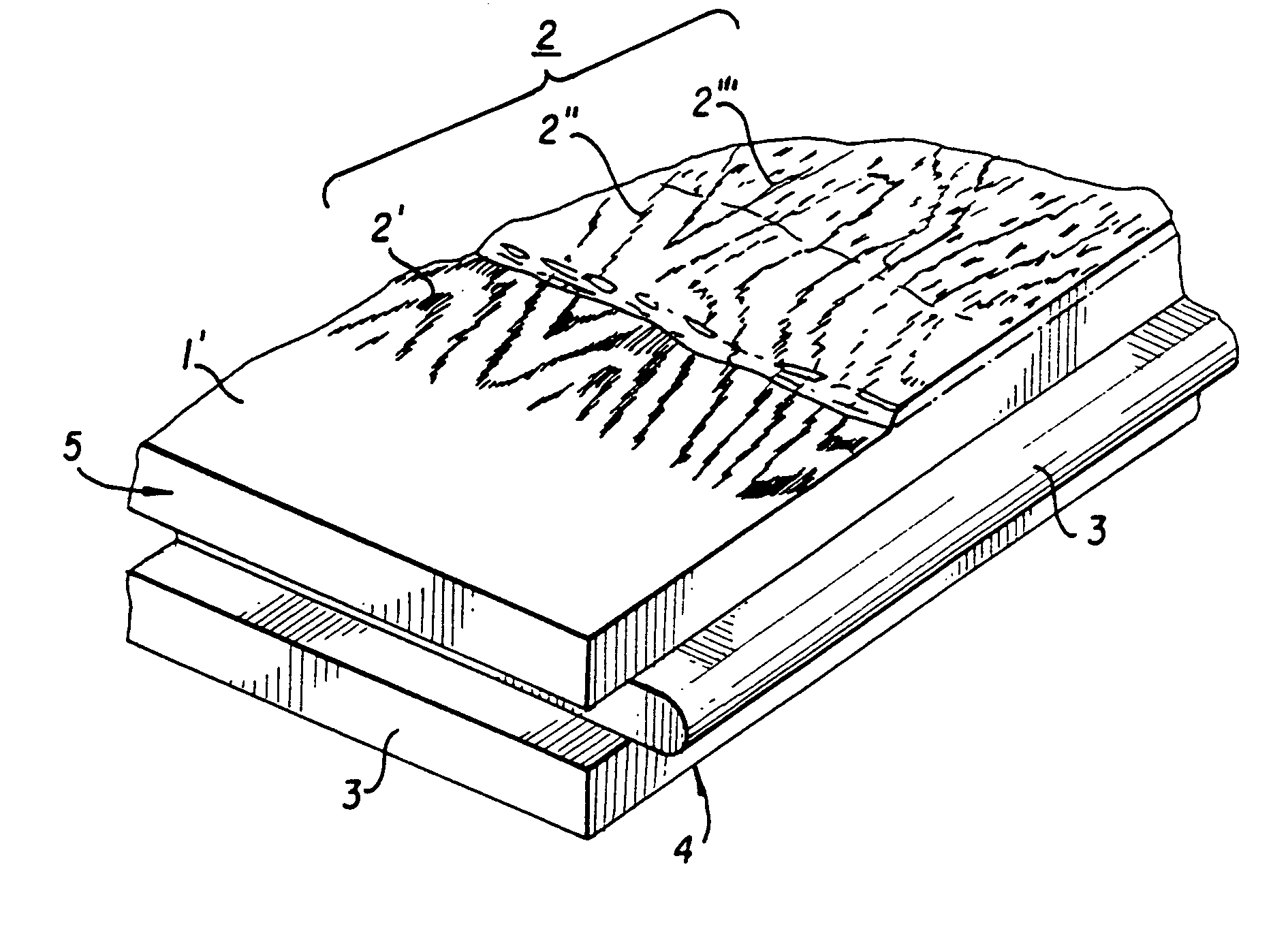

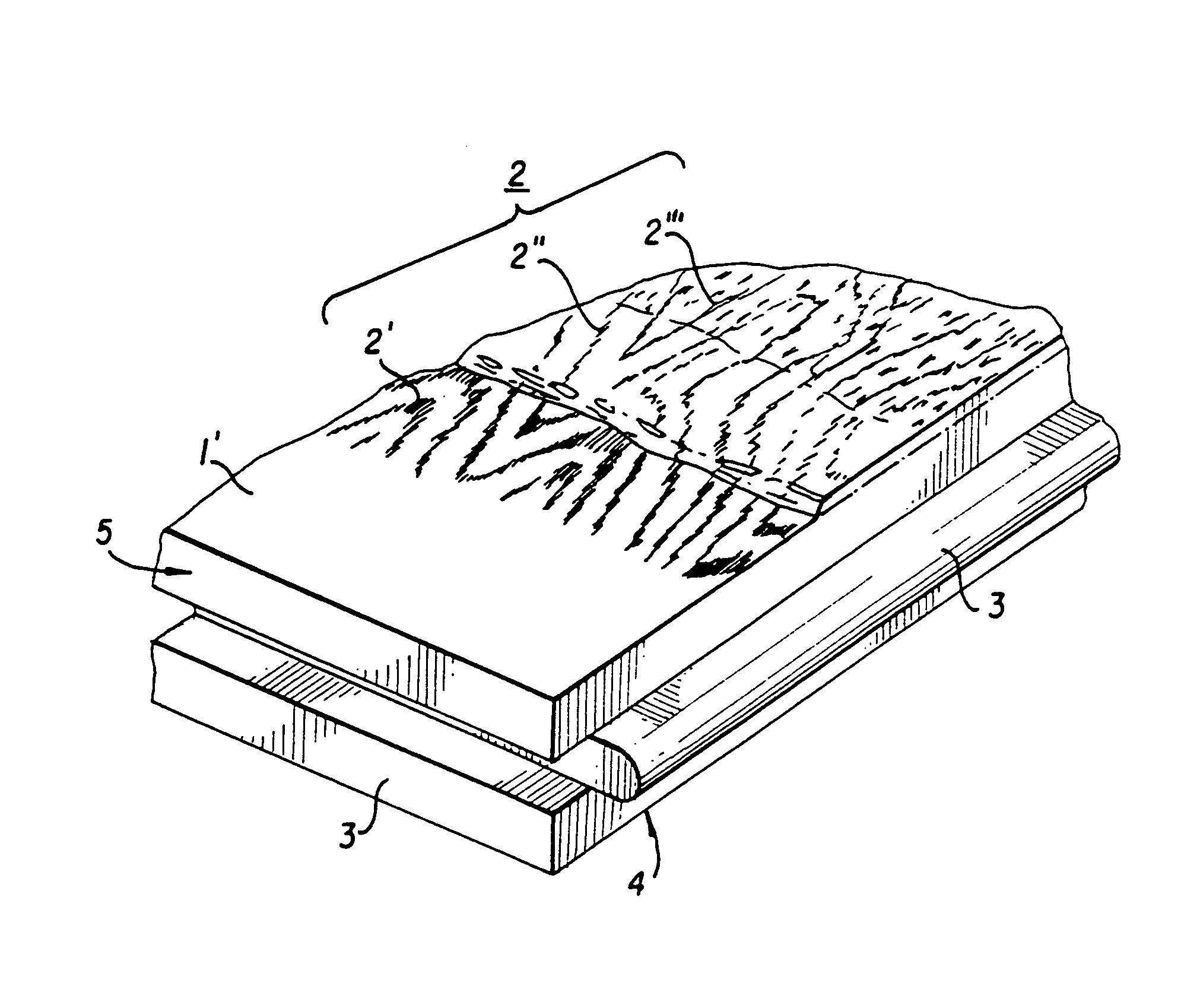

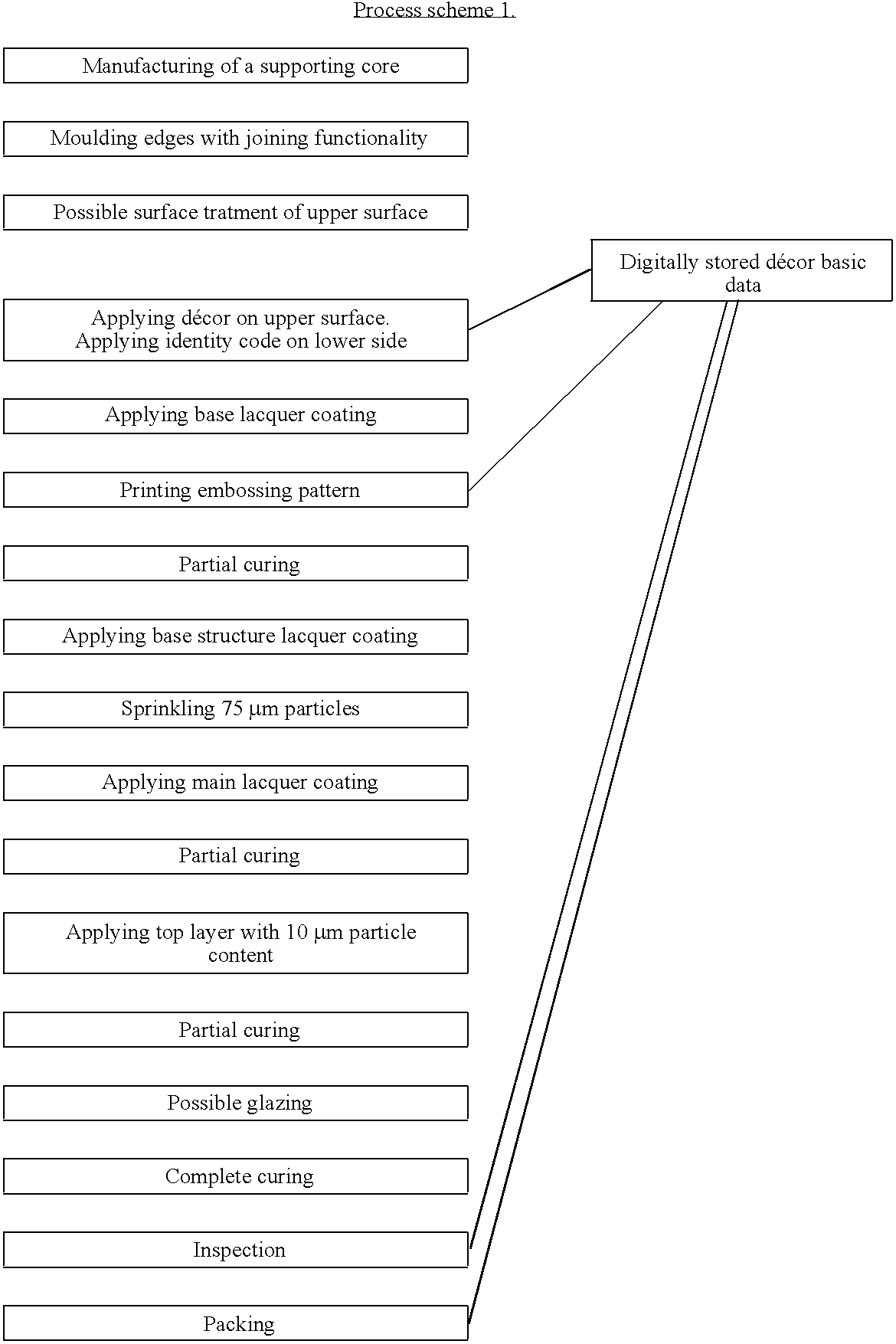

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

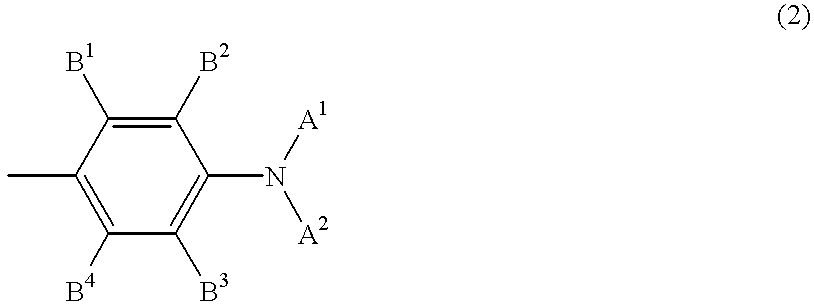

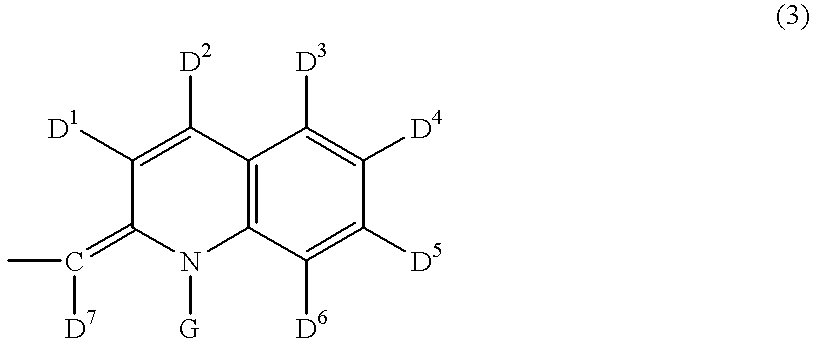

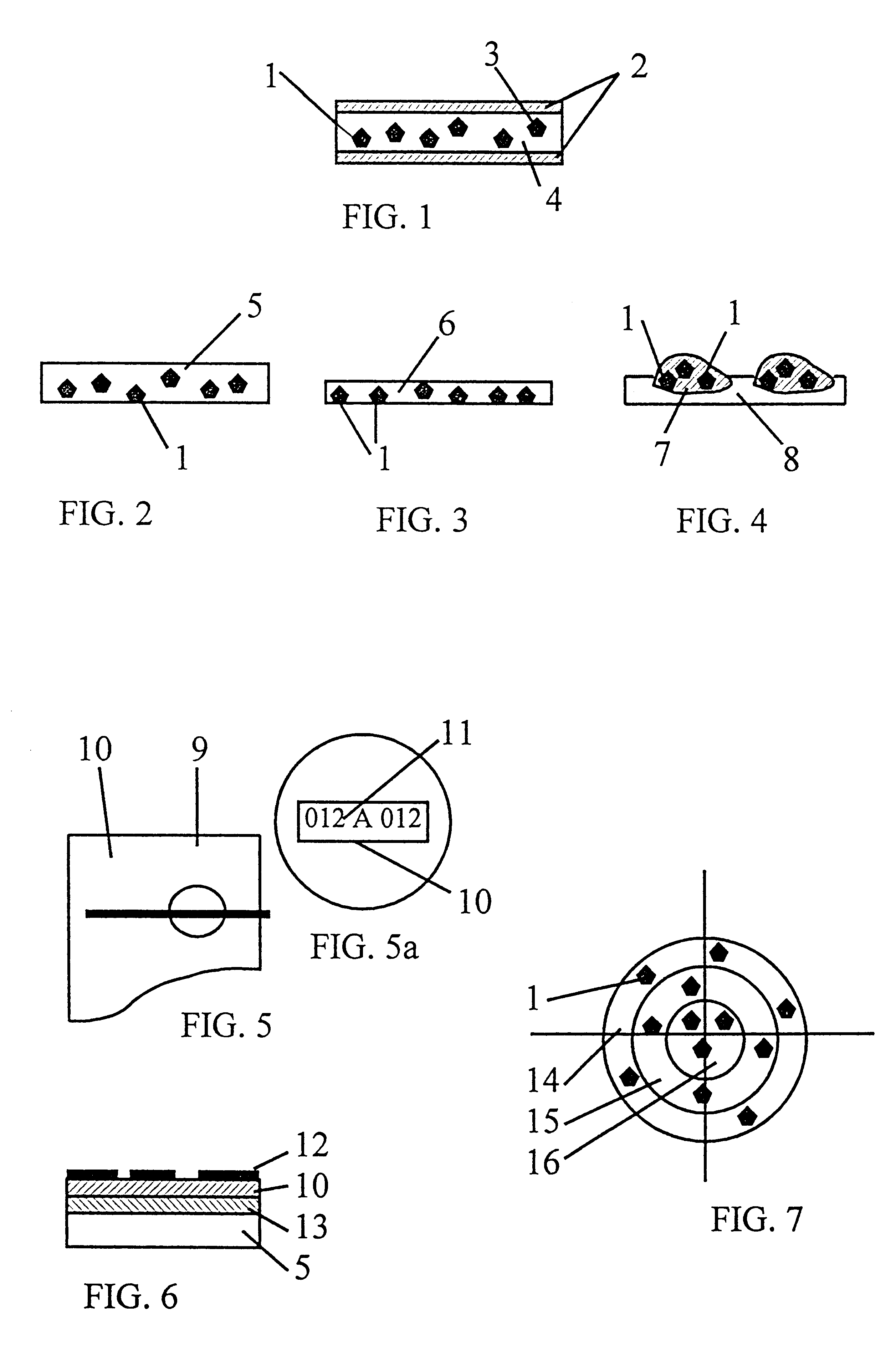

Raman-active taggants and their recognition

InactiveUS6610351B2Easy to useQuality improvementMaterial nanotechnologyRadiation applicationsMaximum dimensionActive component

An organic or organoelement, linear or branched, monomeric or polymeric composition of matter having a Raman-active component in the form of particles. The particles having a maximum dimension of 50 mum. The Raman-active compound is applied to a substrate. When the Raman-active compound is exposed to a laser light wavelength which is batochromically well beyond a spectral region of maximum absorbance of said Raman-active compound, Raman scattering can be detected.

Owner:QUANTAG SYST

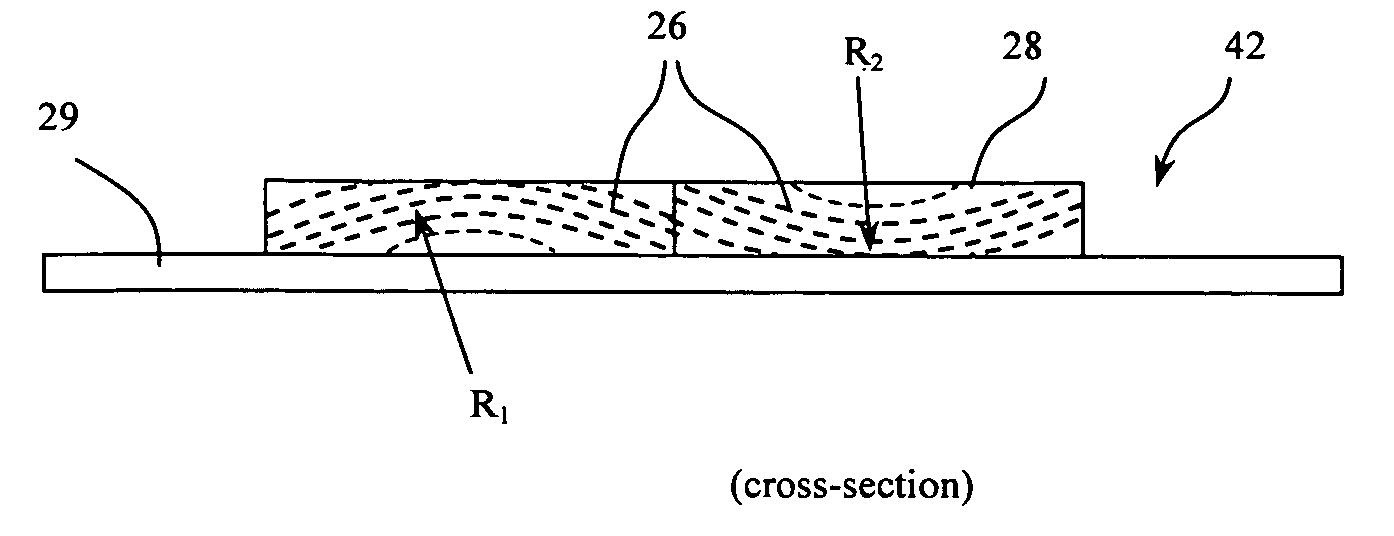

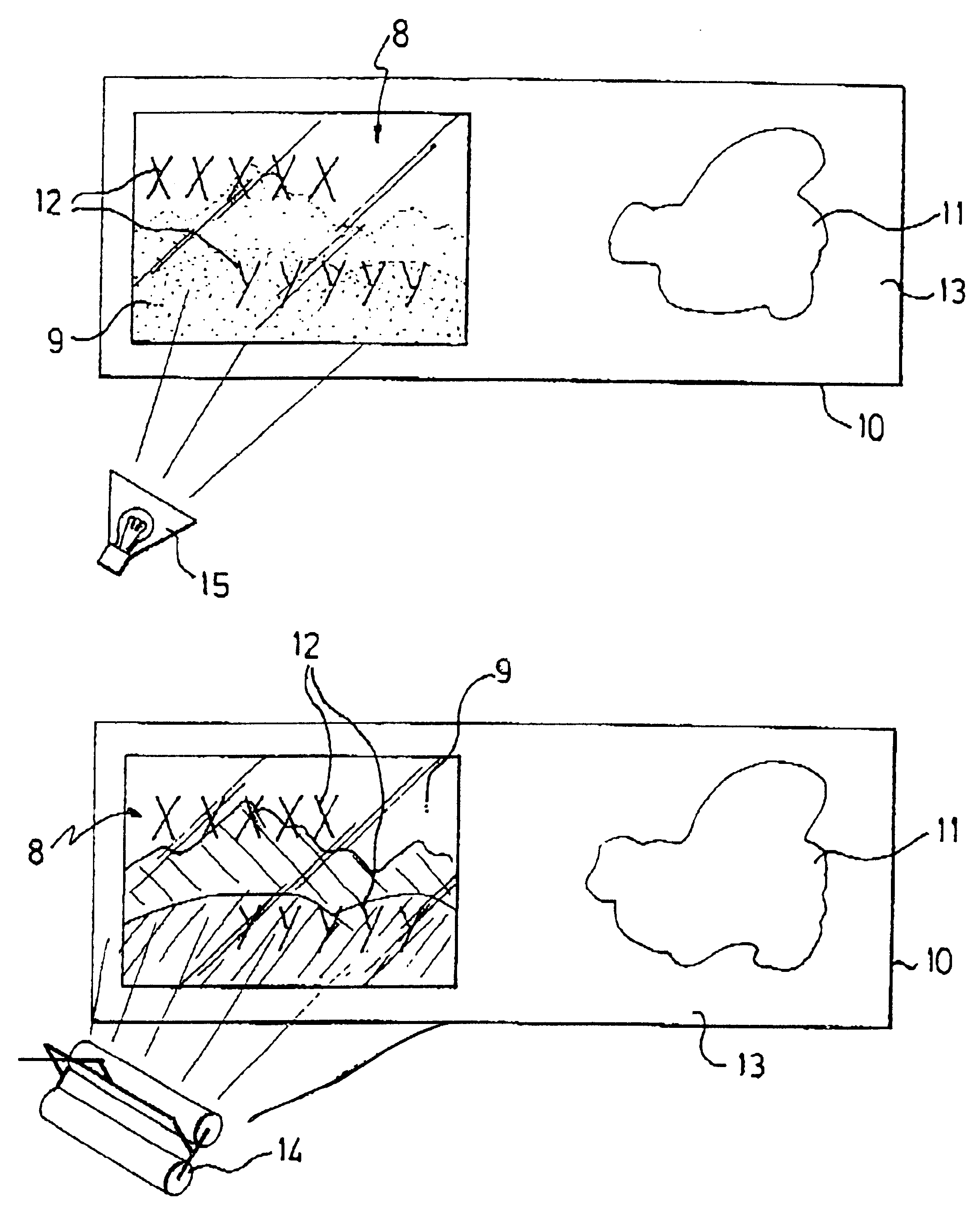

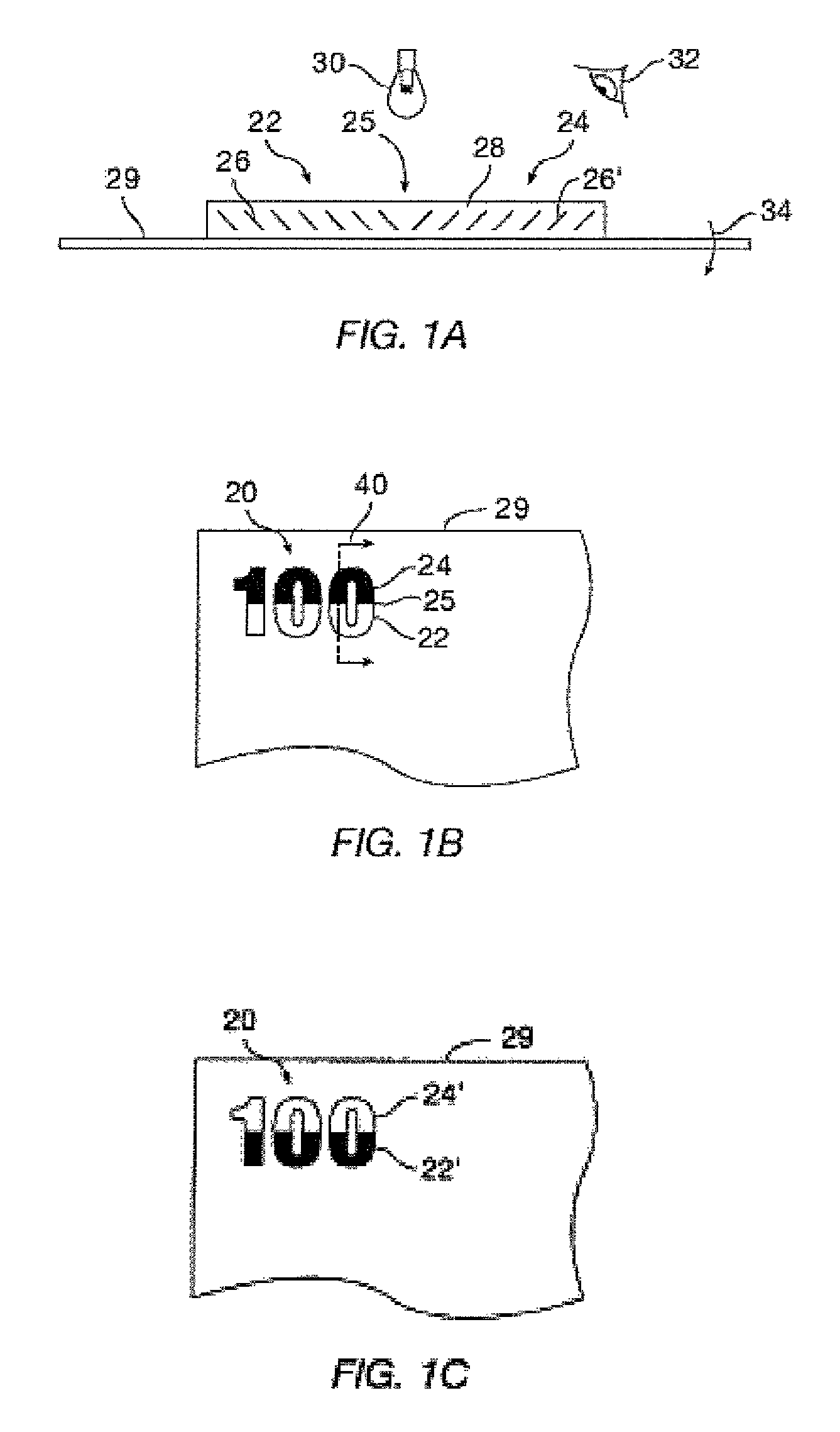

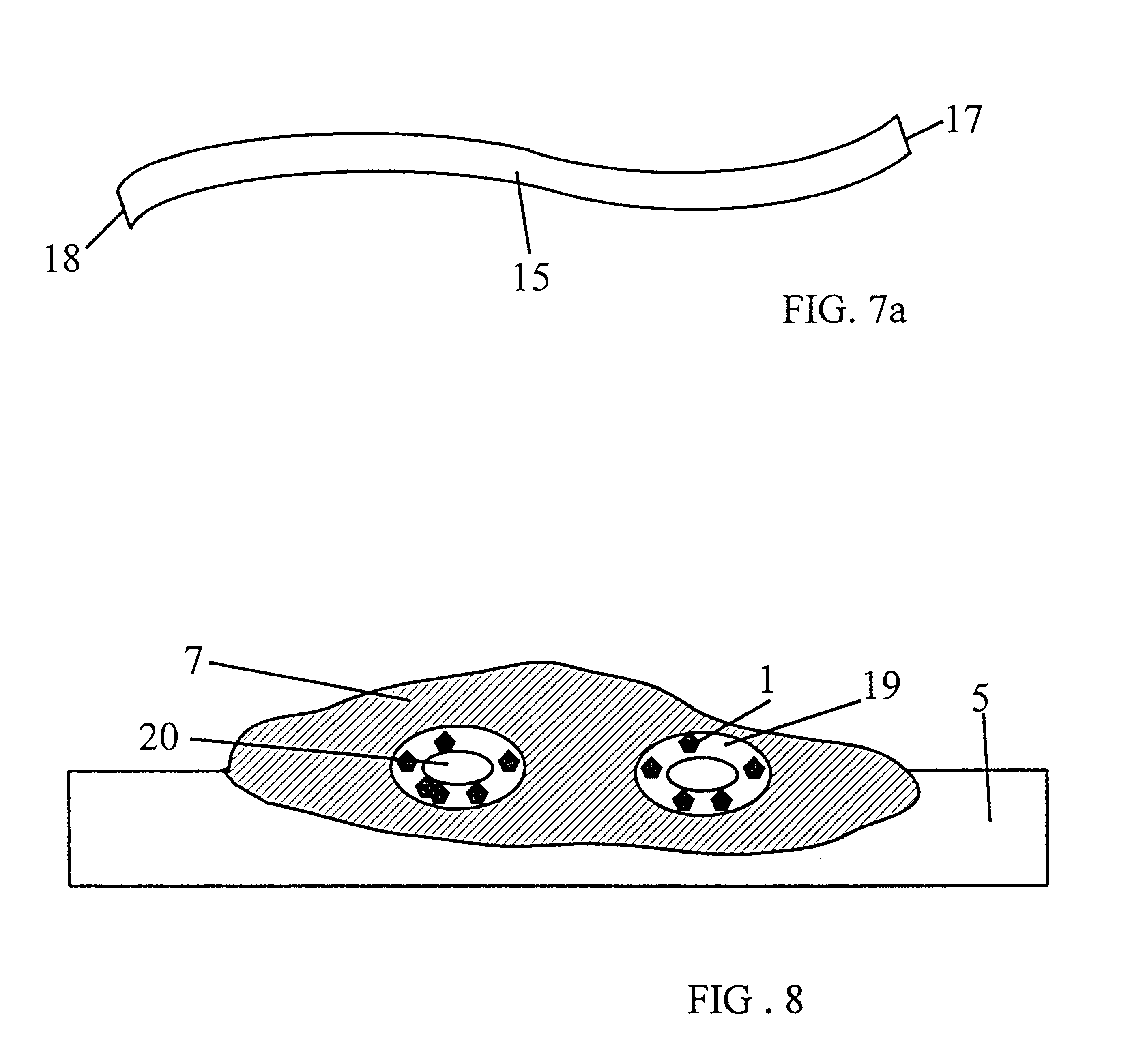

Methods for producing imaged coated articles by using magnetic pigments

InactiveUS20020182383A1Good colorGood optical performancePigmenting treatmentNon-fibrous pulp additionPigmentMagnetic field

Methods and devices for producing images on coated articles are provided. The methods generally comprise applying a layer of magnetizable pigment coating in liquid form on a substrate, with the magnetizable pigment coating containing a plurality of magnetic non-spherical particles or flakes. A magnetic field is then applied to selected regions of the pigment coating while the coating is in liquid form, with the magnetic field altering the orientation of selected magnetic particles or flakes. Finally, the pigment coating is solidified, affixing the reoriented particles or flakes in a non-parallel position to the surface of the pigment coating to produce an image such as a three dimensional-like image on the surface of the coating. The pigment coating can contain various interference or non-interference magnetic particles or flakes, such as magnetic color shifting pigments.

Owner:VIAVI SOLUTIONS INC

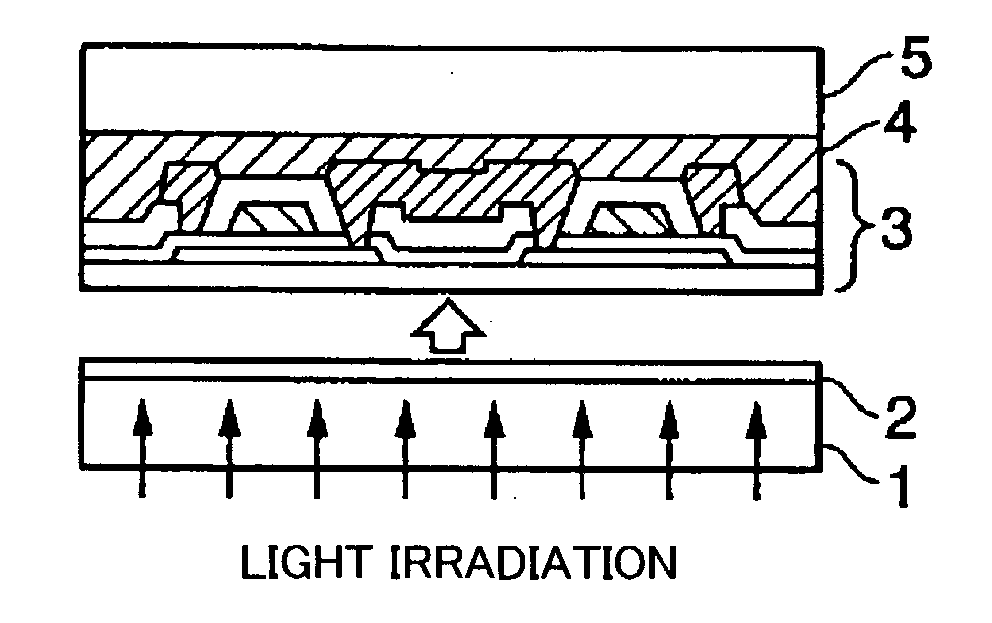

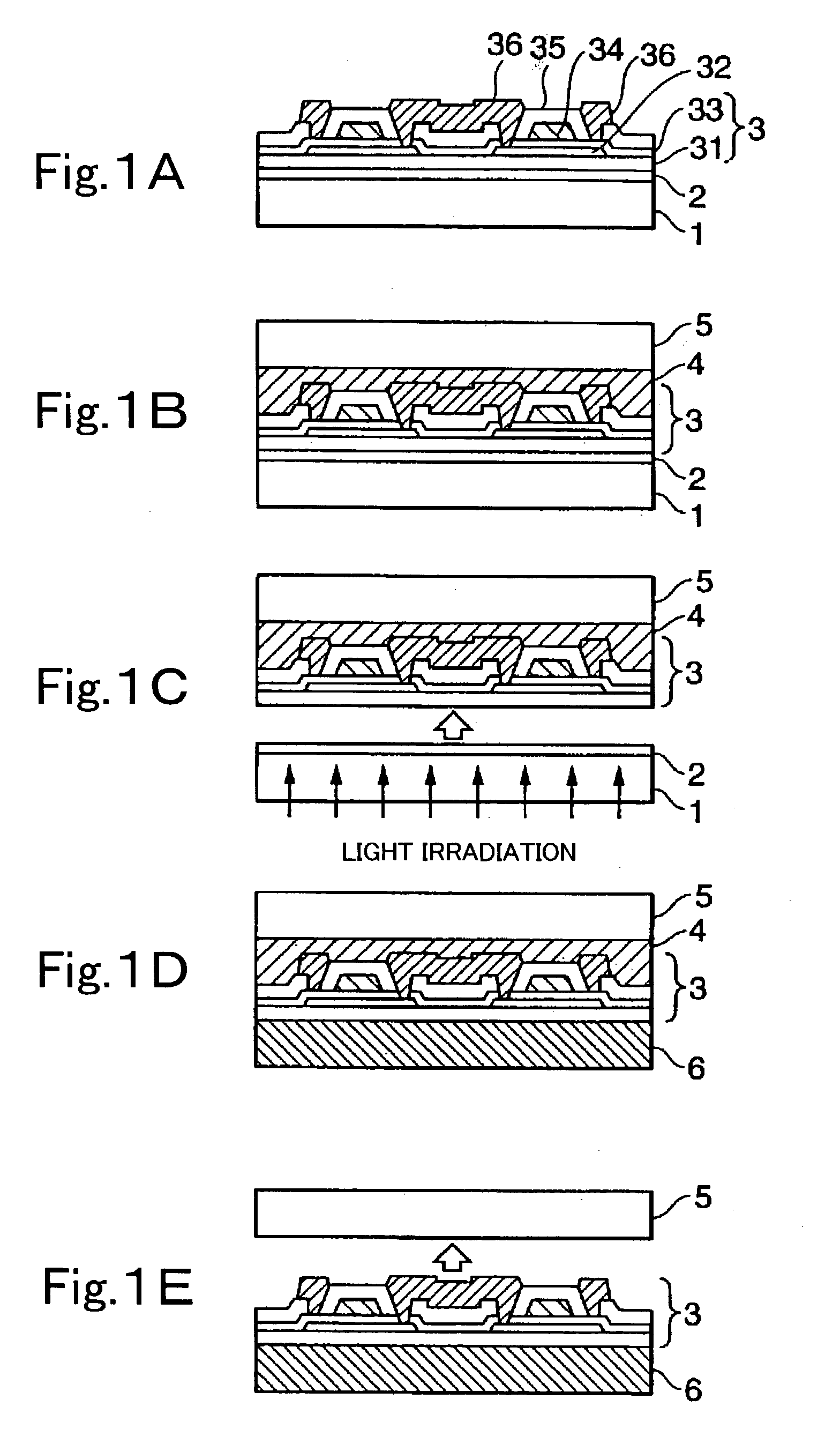

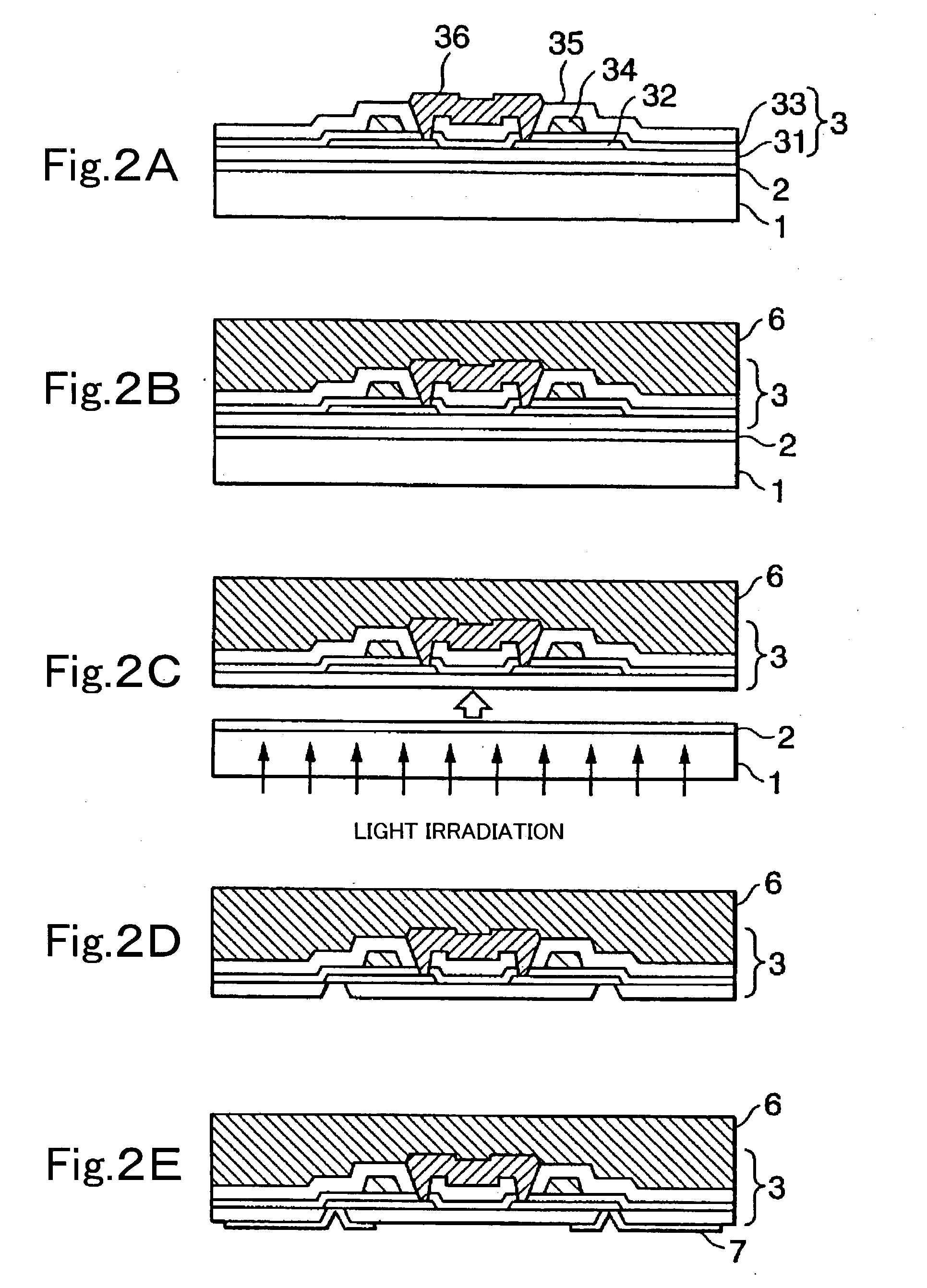

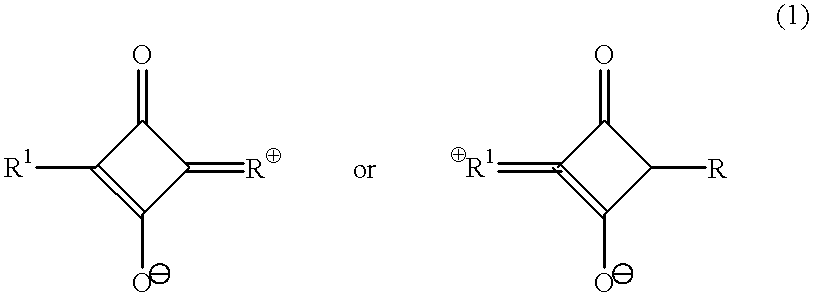

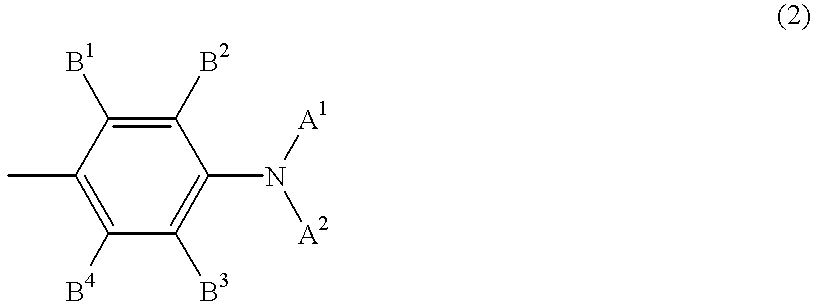

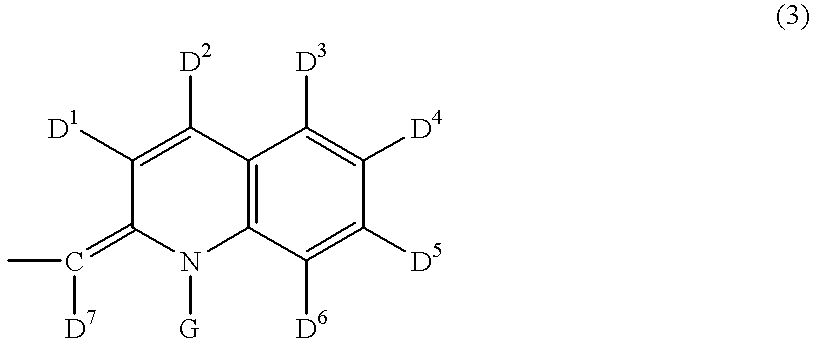

Method for transferring element, method for producing element, integrated circuit, circuit board, electro-optical device, IC card, and electronic appliance

InactiveUS20030024635A1Thinner semiconductor deviceMinimize cracksLamination ancillary operationsDecorative surface effectsDevice materialEngineering

A peeling layer 2 is formed on an element-forming substrate 1, an element-forming layer 3 including an electrical element is formed on the peeling layer, the element-forming layer is joined by means of a dissolvable bonding layer 4 to a temporary transfer substrate 5, the bonding force of the peeling layer is weakened to peel the element-forming layer from the element-forming substrate, the layer is moved to the temporary transfer substrate 5 side, a curable resin 6 is applied onto the element-forming layer 3 which has been moved onto the temporary transfer substrate 5, the resin is cured to form a transfer substrate 6, and the bonding layer 4 is dissolved to peel the temporary transfer substrate 5 from the transfer substrate 6, resulting in a structure in which a transfer substrate is formed directly on the element-forming layer 3. The separation and transfer technique can be used to form a substrate with better flexibility and impact resistance directly on a semiconductor element, without an adhesive layer on the semiconductor device that is produced.

Owner:SAMSUNG ELECTRONICS CO LTD

Raman-active taggants and their recognition

InactiveUS20020025490A1Easy to useQuality improvementOptical radiation measurementMaterial nanotechnologyLaser lightLasing wavelength

An organic or organoelement, linear or branched, monomeric or polymeric composition of matter having a Raman-active component in the form of particles. The particles having a maximum dimension of 50 mum. The Raman-active compound is applied to a substrate. When the Raman-active compound is exposed to a laser light wavelength which is batochromically well beyond a spectral region of maximum absorbance of said Raman-active compound, Raman scattering can be detected.

Owner:QUANTAG SYST

Dynamic appearance-changing optical devices (DACOD) printed in a shaped magnetic field including printable fresnel structures

Owner:VIAVI SOLUTIONS INC

Raman-active taggants and thier recognition

InactiveUS20040058058A1Easy to useQuality improvementMaterial nanotechnologyRadiation pyrometryLasing wavelengthLaser light

An organic or organoelement, linear or branched, monomeric or polymeric composition of matter having a Raman-active component in the form of particles. The particles having a maximum dimension of 50 mum. The Raman-active compound is applied to a substrate. When the Raman-active compound is exposed to a laser light wavelength which is batochromically well beyond a spectral region of maximum absorbance of said Raman-active compound, Raman scattering can be detected.

Owner:SHCHEGOLIKHIN ALEXANDER NIKITOVICH +4

Embossed fibrous structures and methods for making same

InactiveUS20100028621A1Good flexibilityHigh strengthMechanical working/deformationLayered productsFiberEngineering

Owner:THE PROCTER & GAMBLE COMPANY

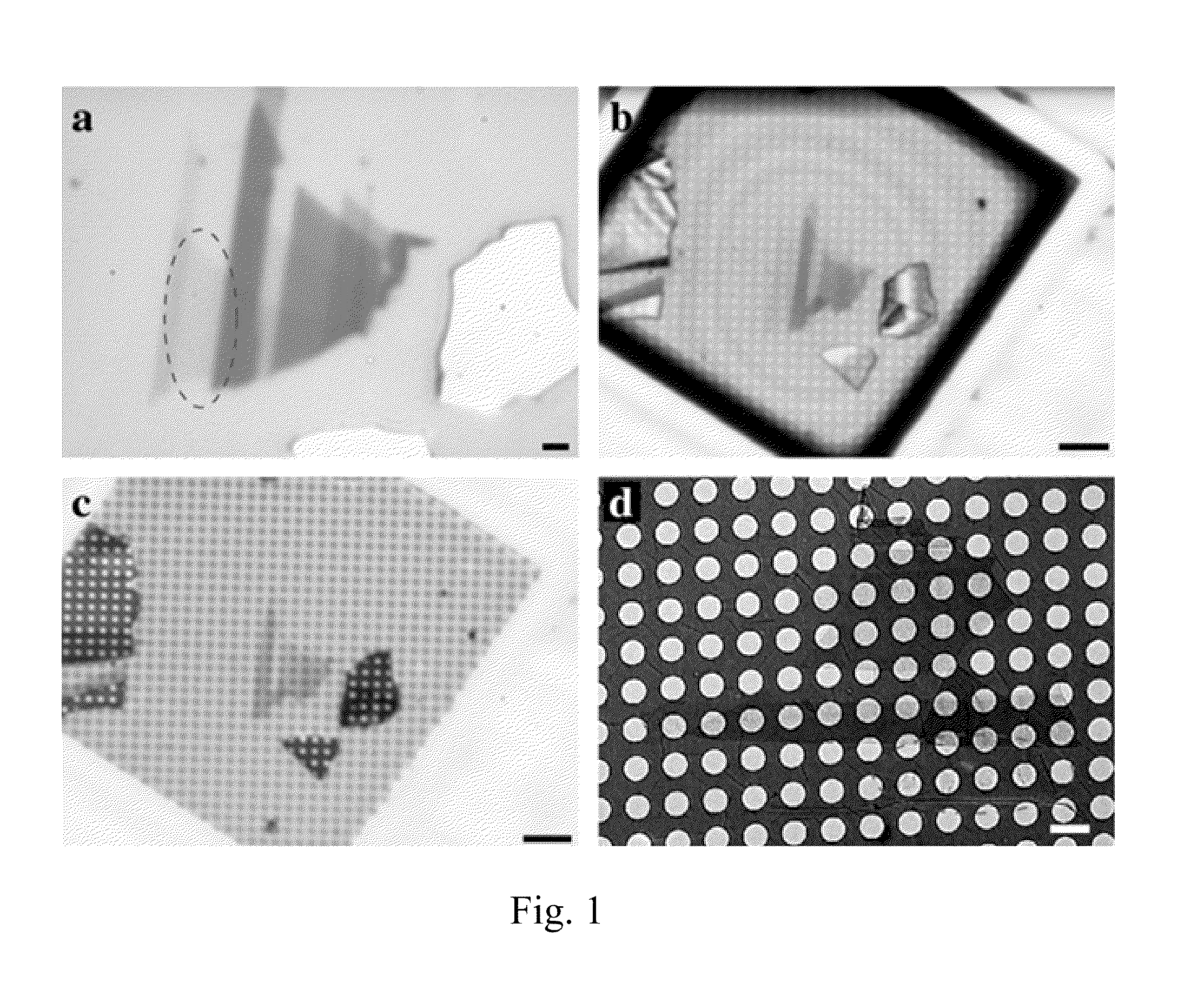

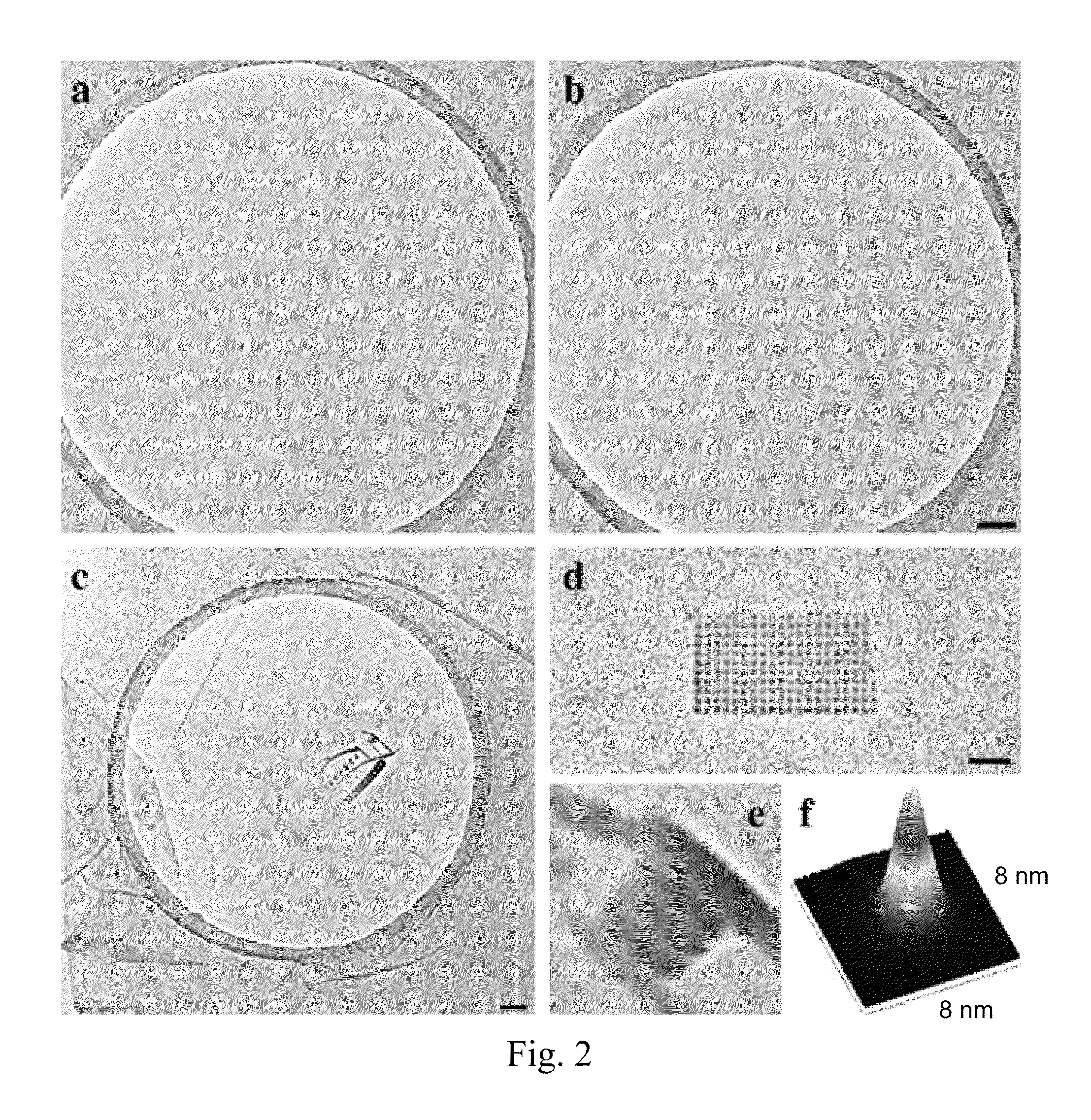

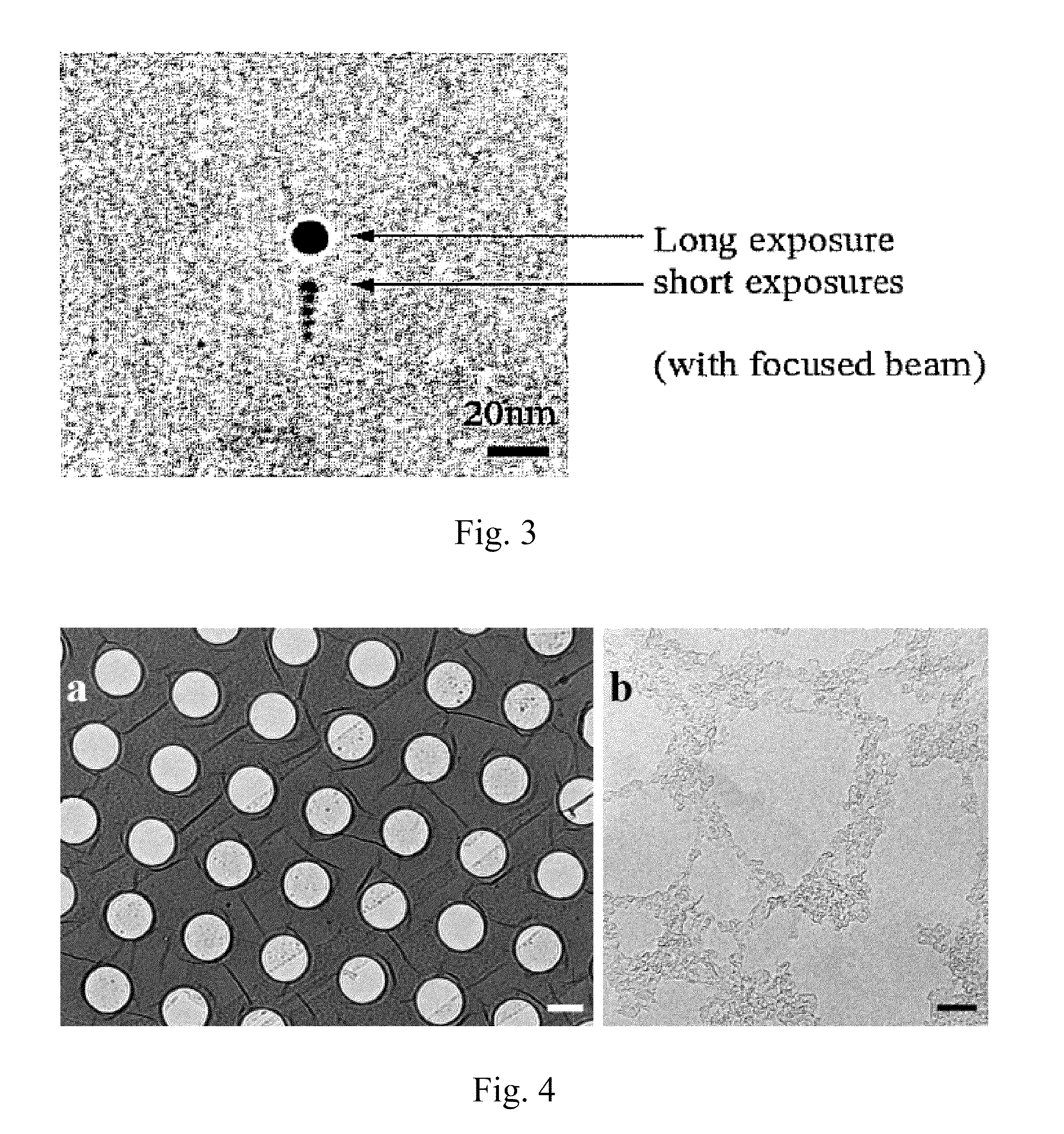

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

An embodiment of a method of suspending a graphene membrane across a gap in a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended across the gap in the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a graphene membrane suspended across a gap under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

Security document with a transparent pattern and a process for producing a security document with a transparent pattern

InactiveUS20080238086A1Obvious advantagesOther printing matterPhotosensitive materialsEngineeringPaper document

A security document comprising a plurality of self-supporting polymeric films and layers therebetween and thereon, said plurality of self-supporting polymeric films comprising a non-transparent microvoided axially stretched self-supporting polymeric film exclusive of foam and having a permanent transparent pattern; and a process for producing a security document with a permanent transparent pattern comprising the step of: image-wise application of heat optionally supplemented by the application of pressure to a security document precursor comprising a plurality of self-supporting polymeric films and layers therebetween and thereon, said plurality of self-supporting polymeric films comprising a non-transparent microvoided axially stretched self-supporting polymeric film exclusive of foam.

Owner:AGFA GEVAERT AG

Methods and systems for decorating bevel and other surfaces of laminated floorings

ActiveUS20070283648A1Eliminate needEnhance the imageCovering/liningsWallsEngineeringDigital printing

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

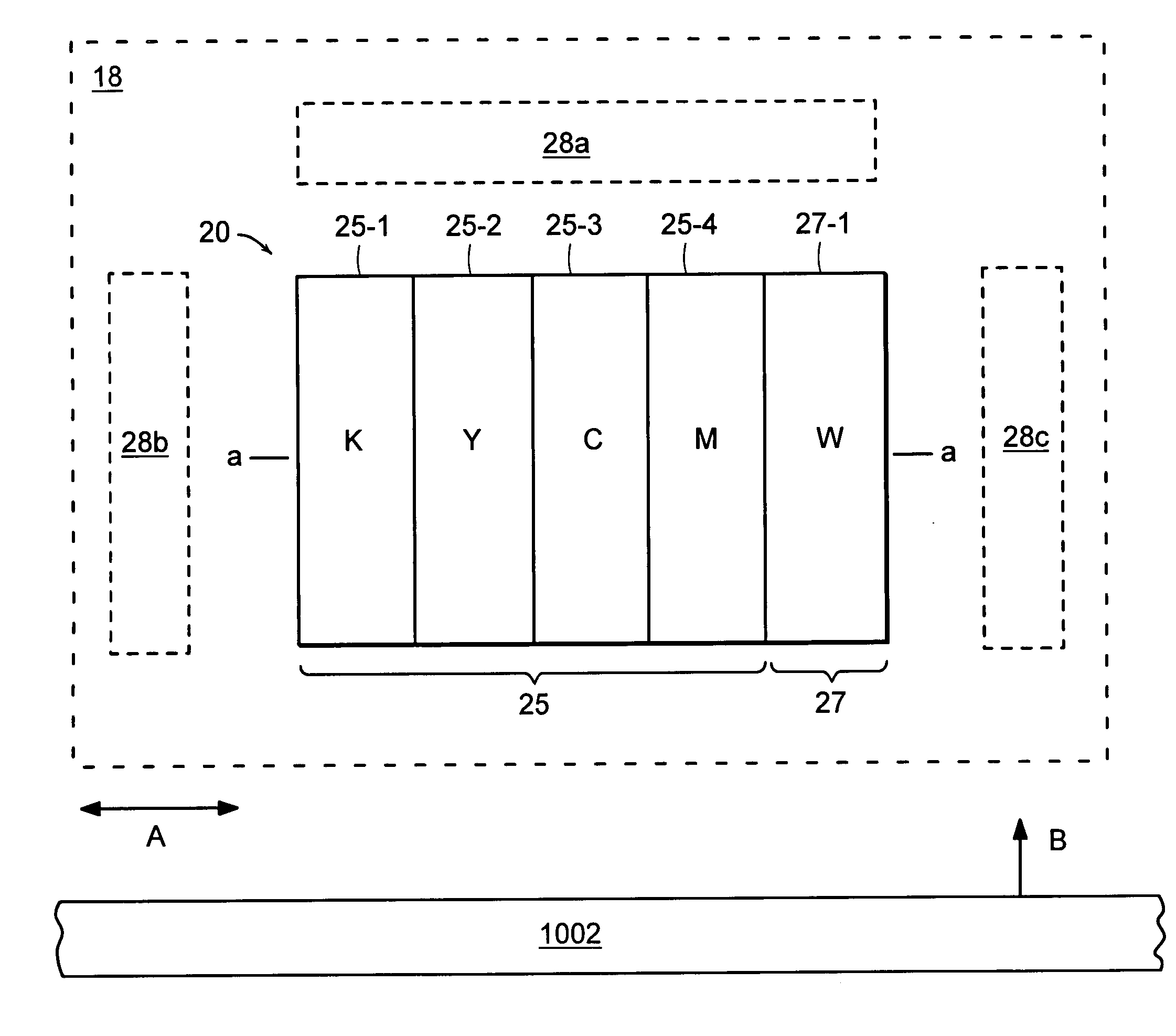

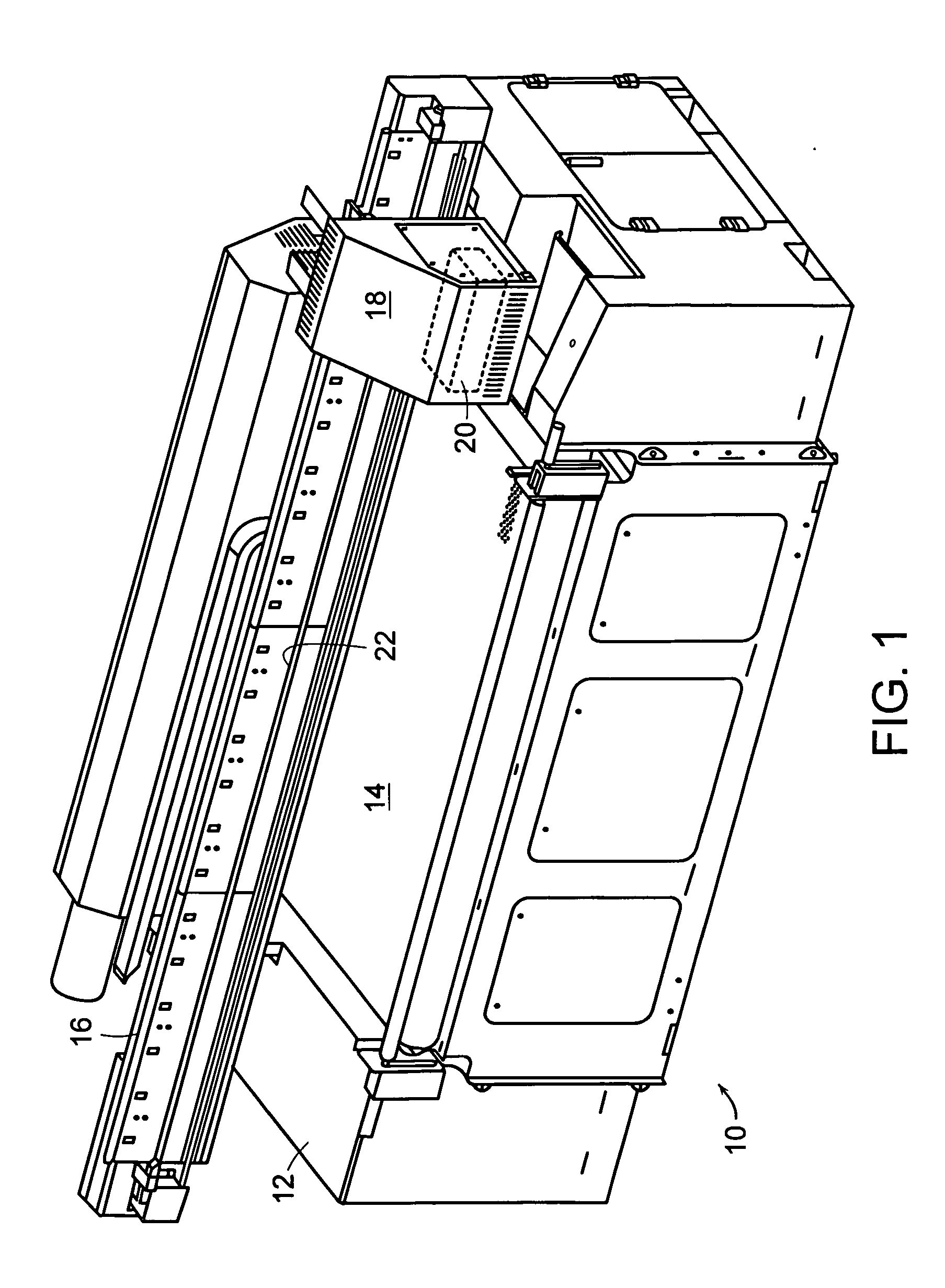

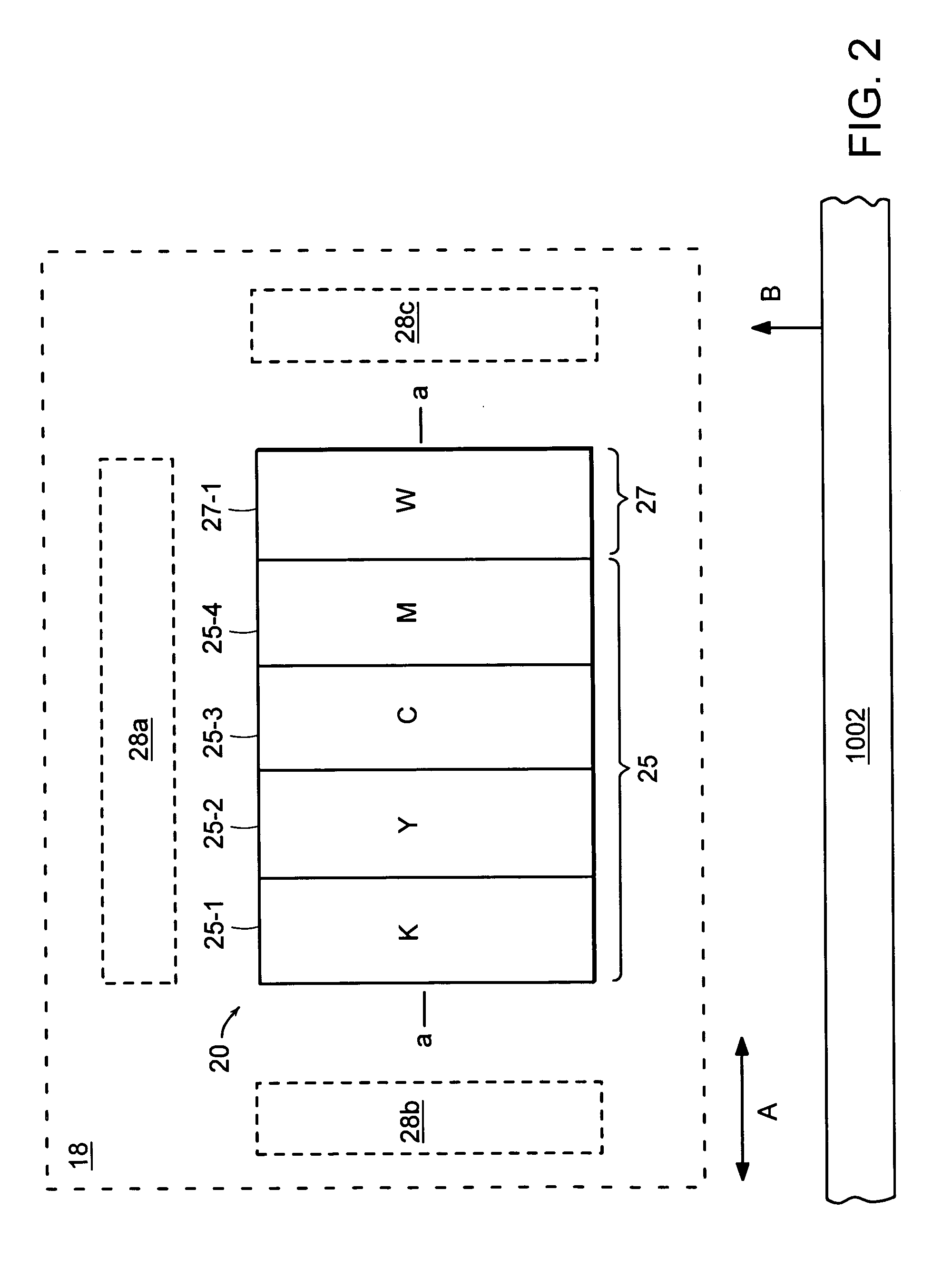

Method and system for multi-channel ink-jet printing

A printing apparatus having an array of printheads arranged along a single printhead axis, and capable of printing images and a coating layer on the substrate during a single printing operation. The coating layer can comprise a specialized printing fluid such as a layer of substantially white ink. The apparatus can perform a pre-coat printing operation, in which the coating layer is deposited first on the substrate, and the image is then printed over the coating layer. The apparatus can also perform a post-coat printing operation, in which the image is first printed onto the substrate, and the coating layer is then deposited over the image. The printhead array includes at least one printhead for printing inks to form the images, and at least one printhead for printing a specialized fluid to form the coating layer. Depending on the printing mode, a controller allocates certain nozzles of the array for printing inks and certain nozzles for printing the specialized fluid. As each section of a substrate advances under the array, it first receives a coating layer, and then an image layer; or it first receives an image layer and then a coating layer. The invention is particularly advantageous for printing on non-white and transparent substrates, as well as for printing backlit signs.

Owner:ELECTRONICS FOR IMAGING INC

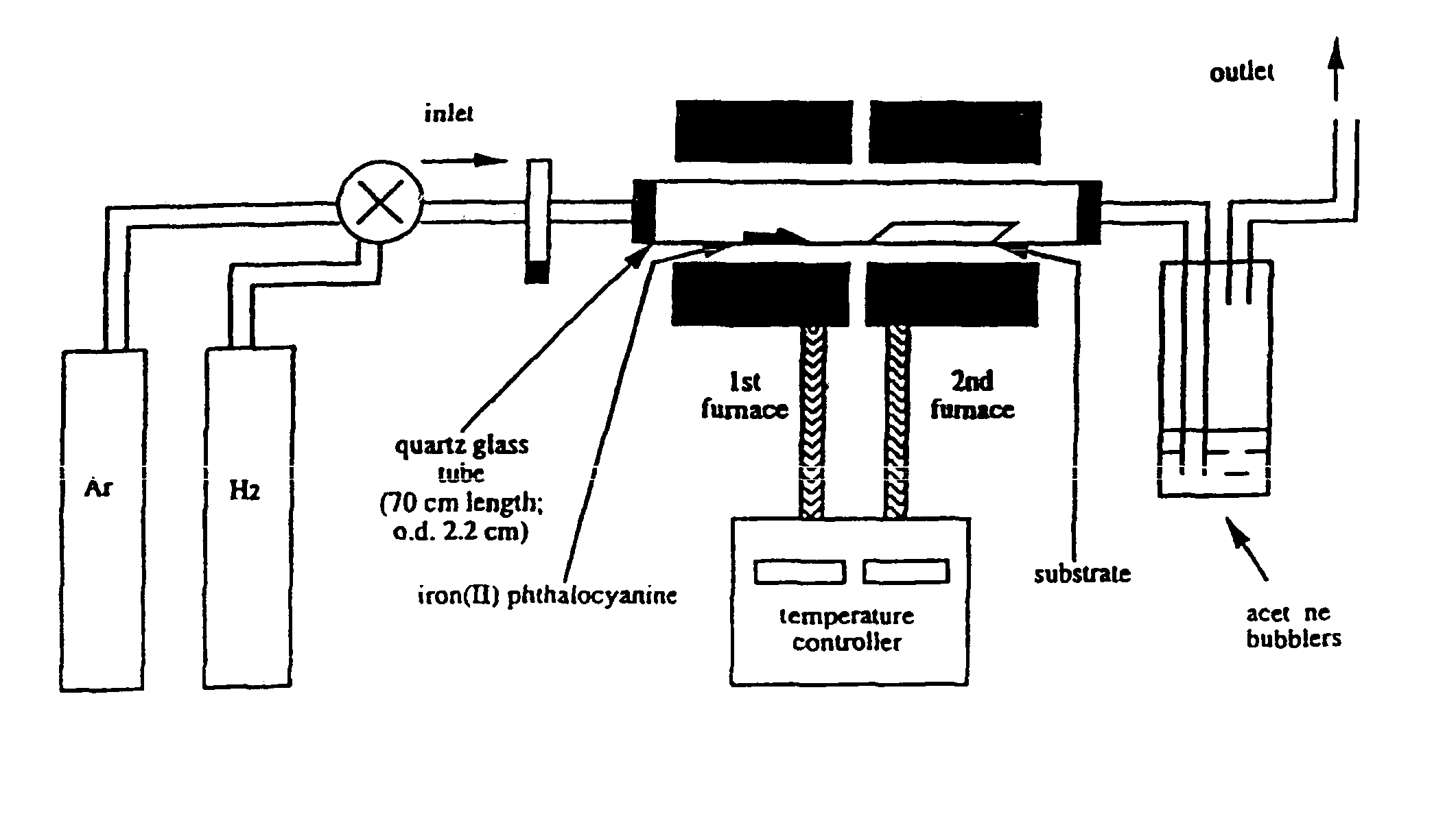

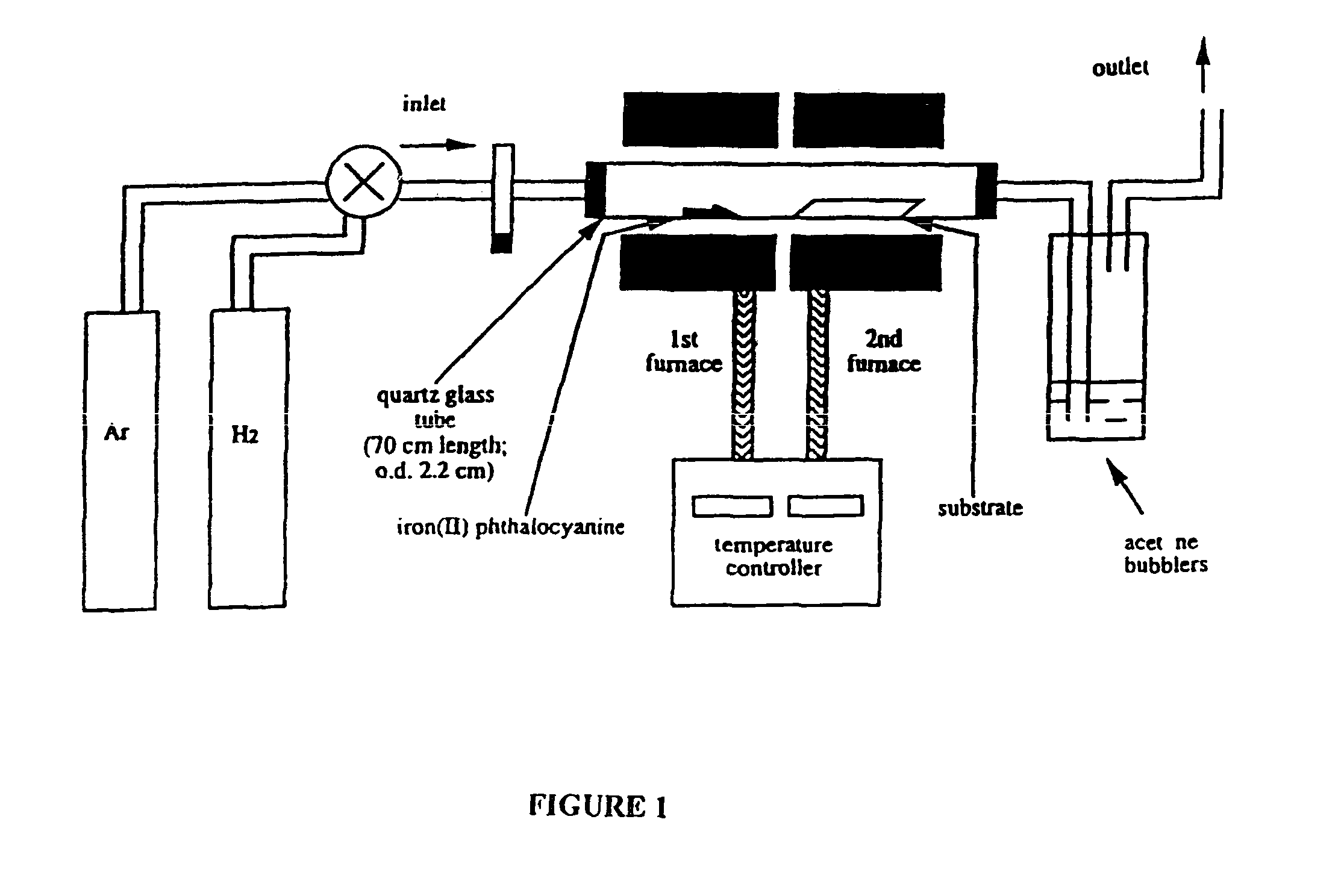

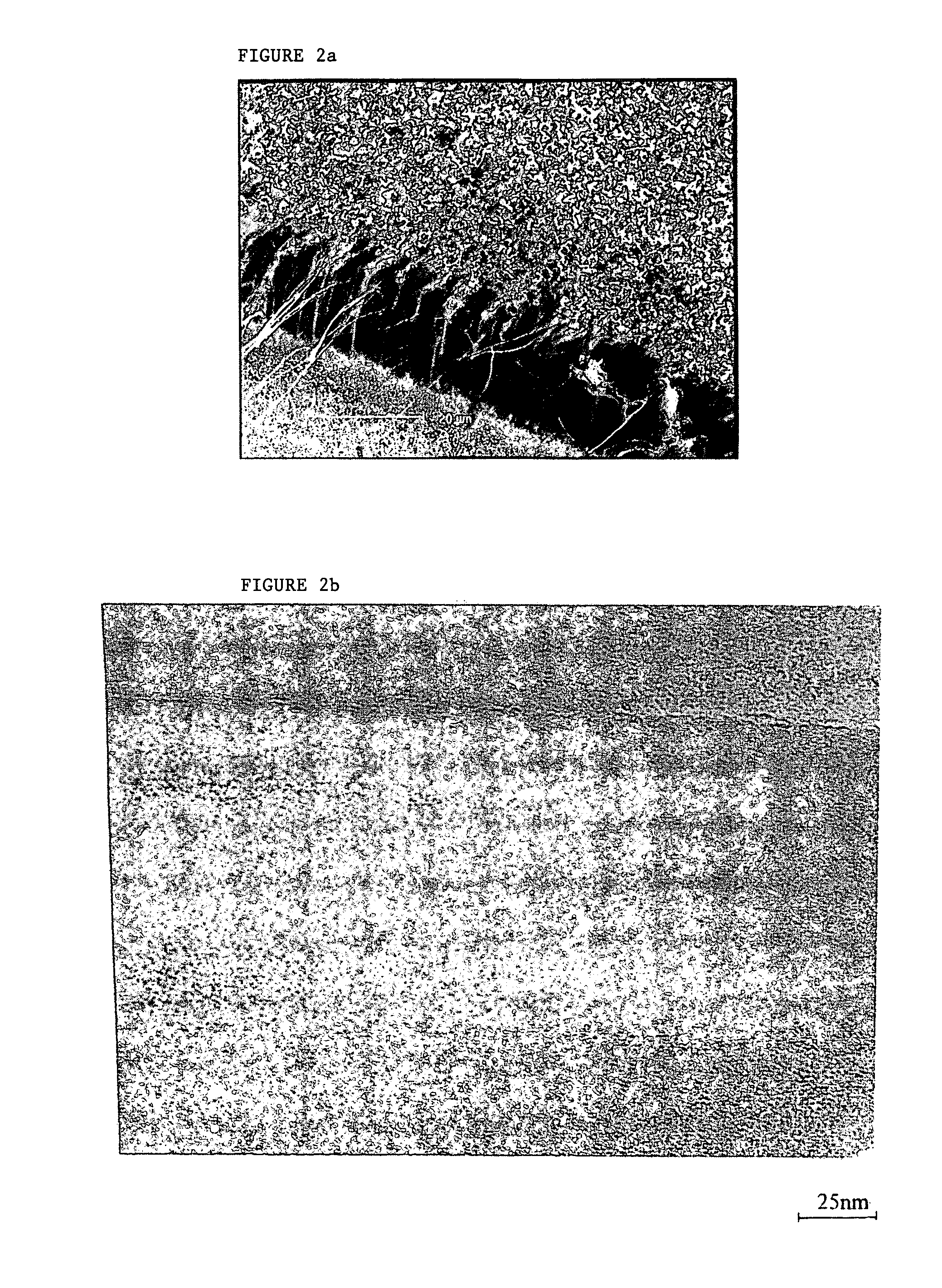

Substrate-supported aligned carbon nanotube films

InactiveUS7799163B1Conveniently routedIncreases potential applicationMaterial nanotechnologyCarbon compoundsNanotube

This invention relates to a process for preparing a substrate-supported aligned carbon nanotube film including: synthesizing a layer of aligned carbon nanotubes on the substrate capable of supporting nanotube growth, applying a layer of a second substrate to a top surface of aligned carbon nanotube layer, removing said substrate capable of supporting nanotube growth to provide an aligned carbon nanotube film supported on said second substrate.

Owner:UNIV OF DAYTON THE

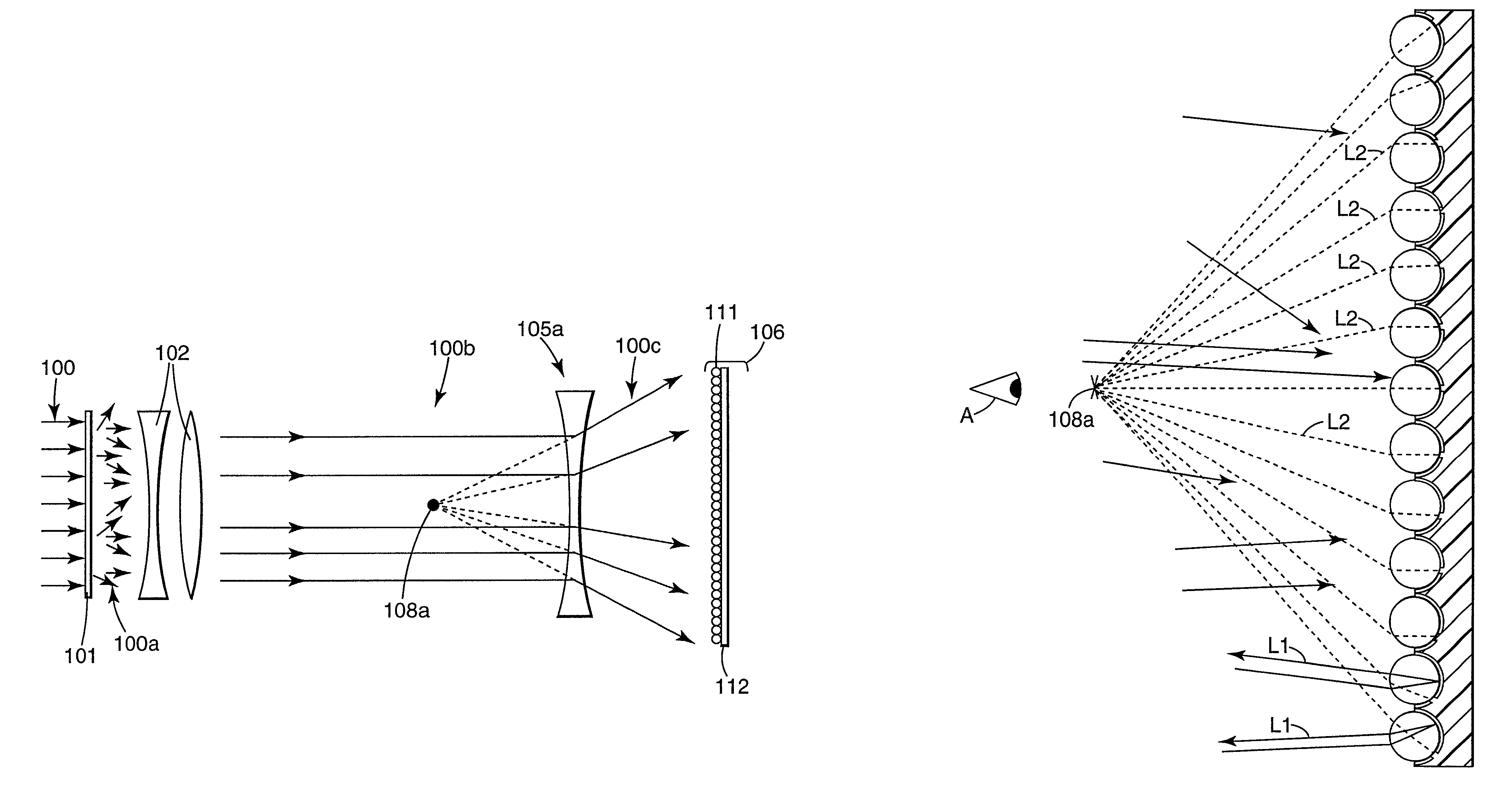

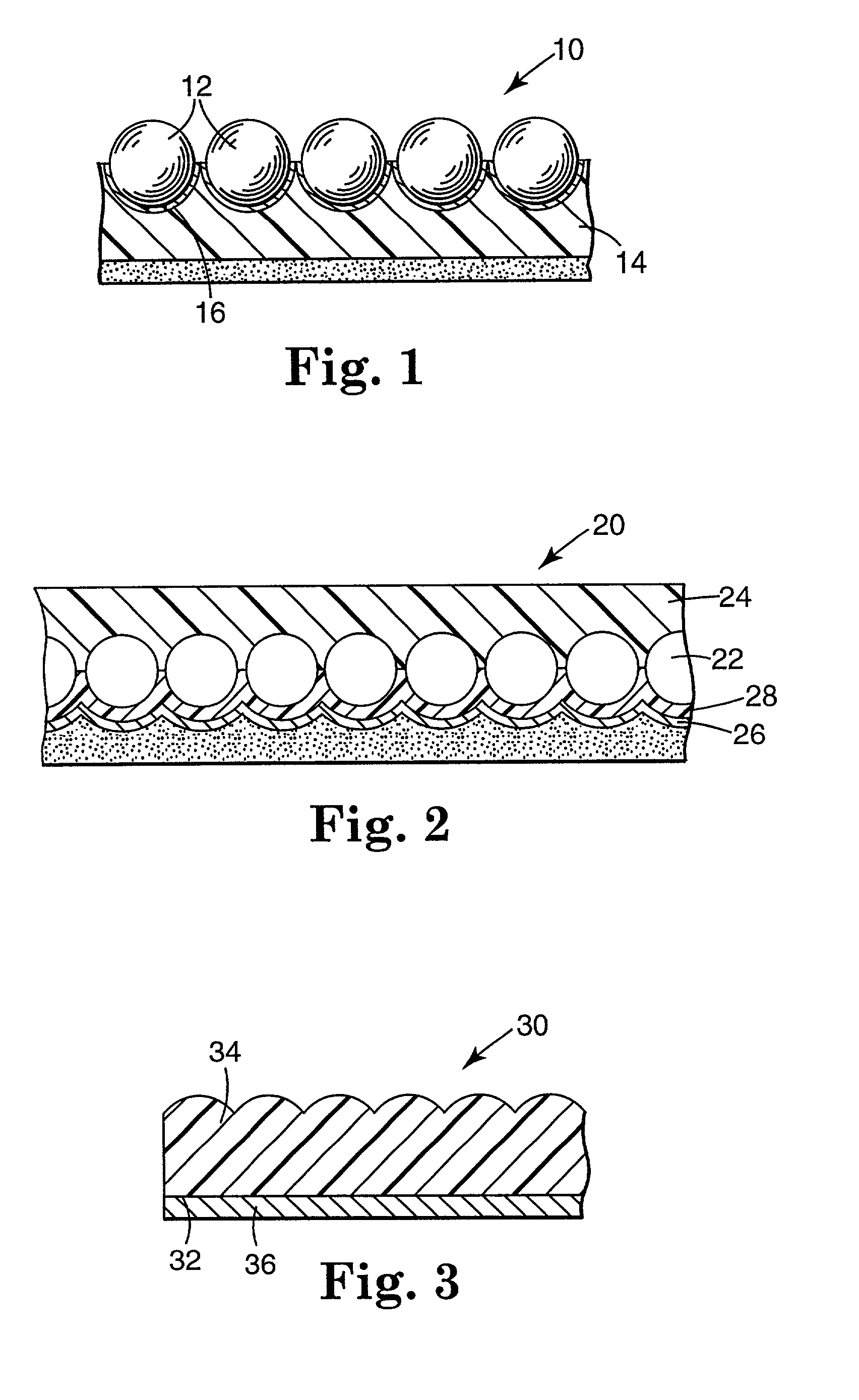

Sheeting with composite image that floats

Microlens sheetings with composite images are disclosed, in which the composite image floats above or below the sheeting, or both. The composite image may be two-dimensional or three-dimensional. Methods for providing such an imaged sheeting, including by the application of radiation to a radiation sensitive material layer adjacent the microlenses, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

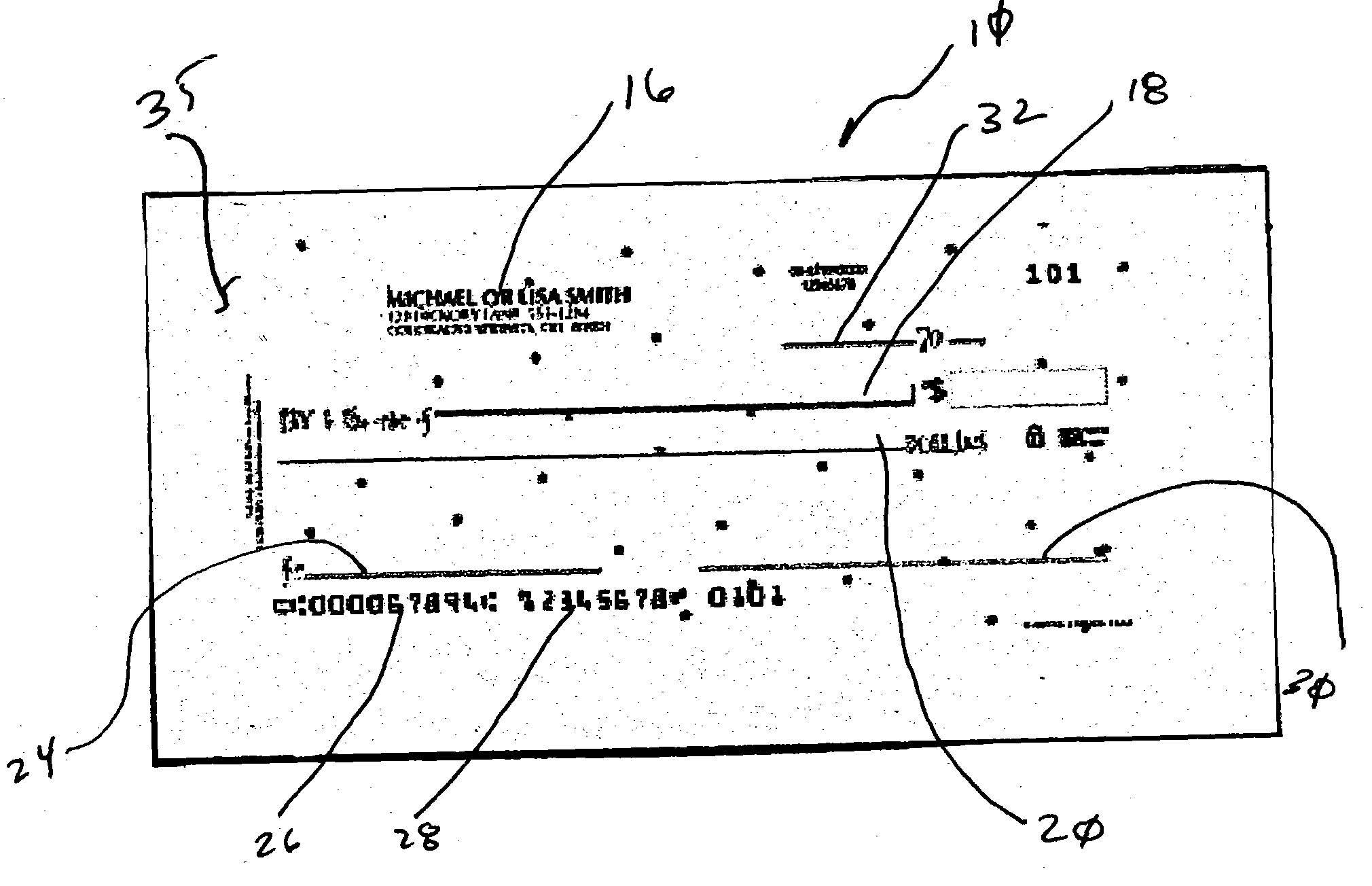

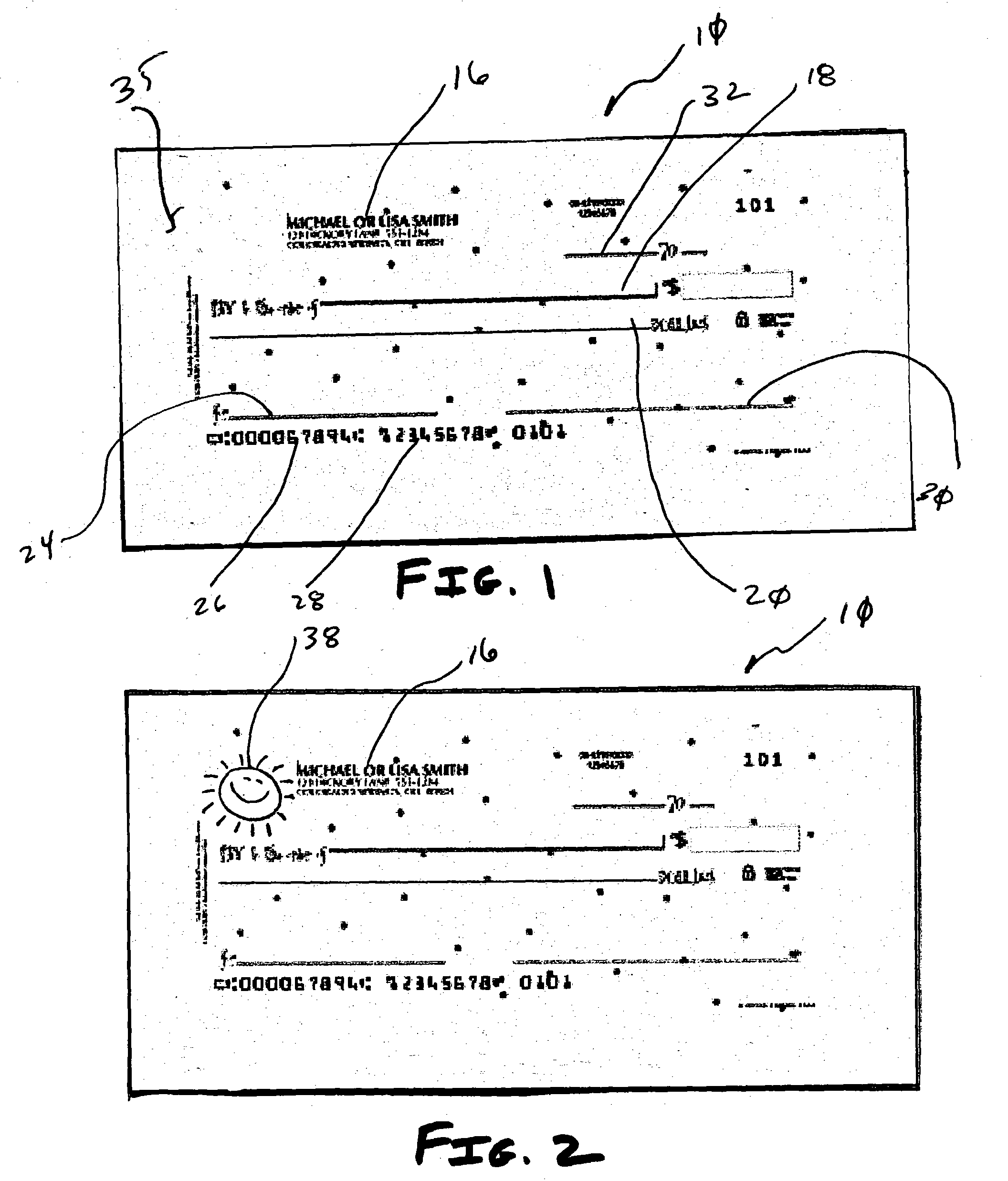

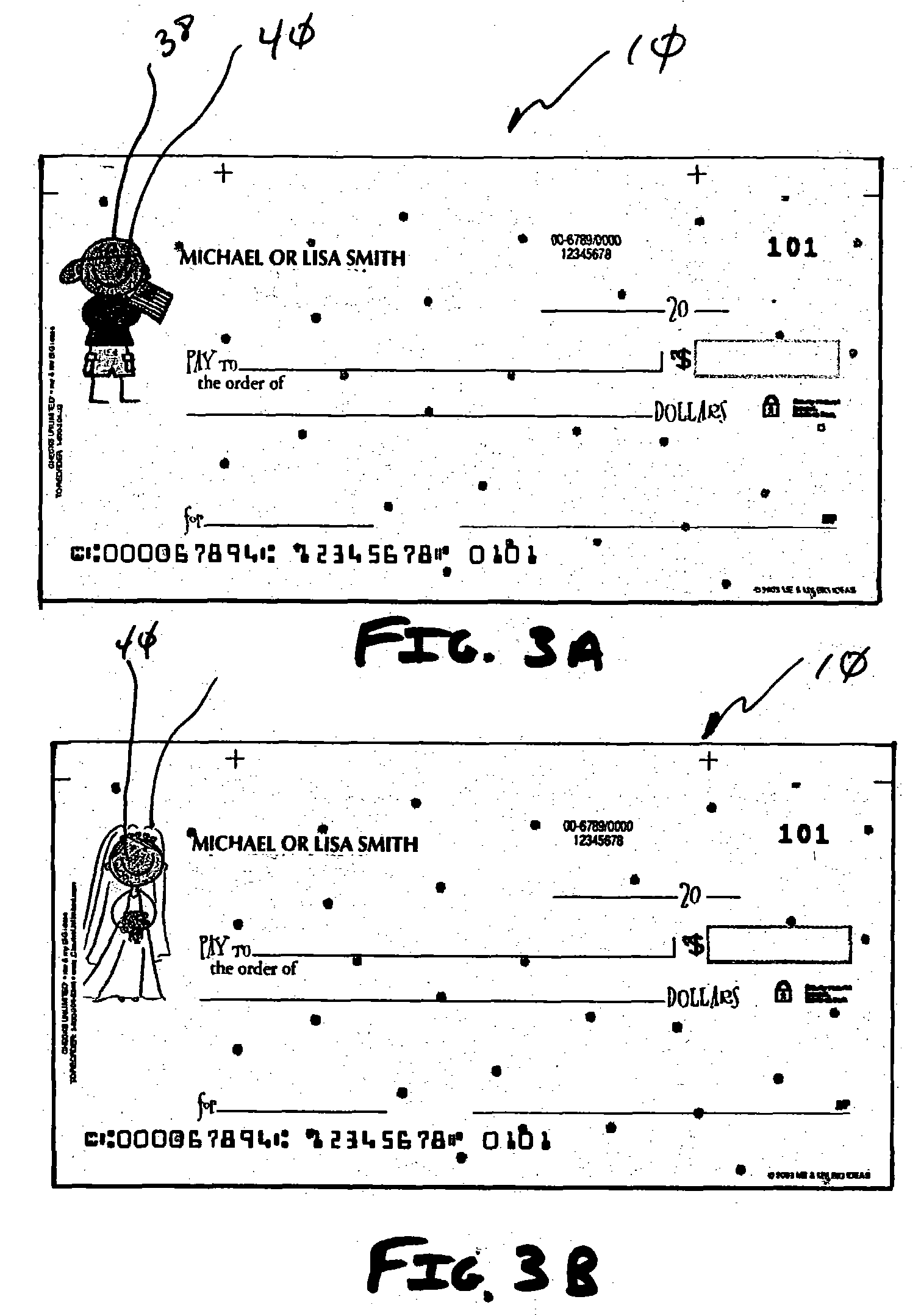

Method of customizing bank checks

InactiveUS20050001421A1Quality improvementDescribe wellOther printing matterPattern printingChequeComputer science

The present invention is related generally to the method of customizing personal checks. More specifically, a method is provided herein to alter a personal check in such a way as to add selective artistic customization. Preferably, the enhancements are done with an ink stamp and colored pencils, or with adhesive stickers, wherein the user will be able to selectively alter the check. It is envisioned that the images will convey a mood, an emotion, a feeling, or represent an occasion, a cause, or a holiday.

Owner:DIRECT CHECKS UNLIMITED

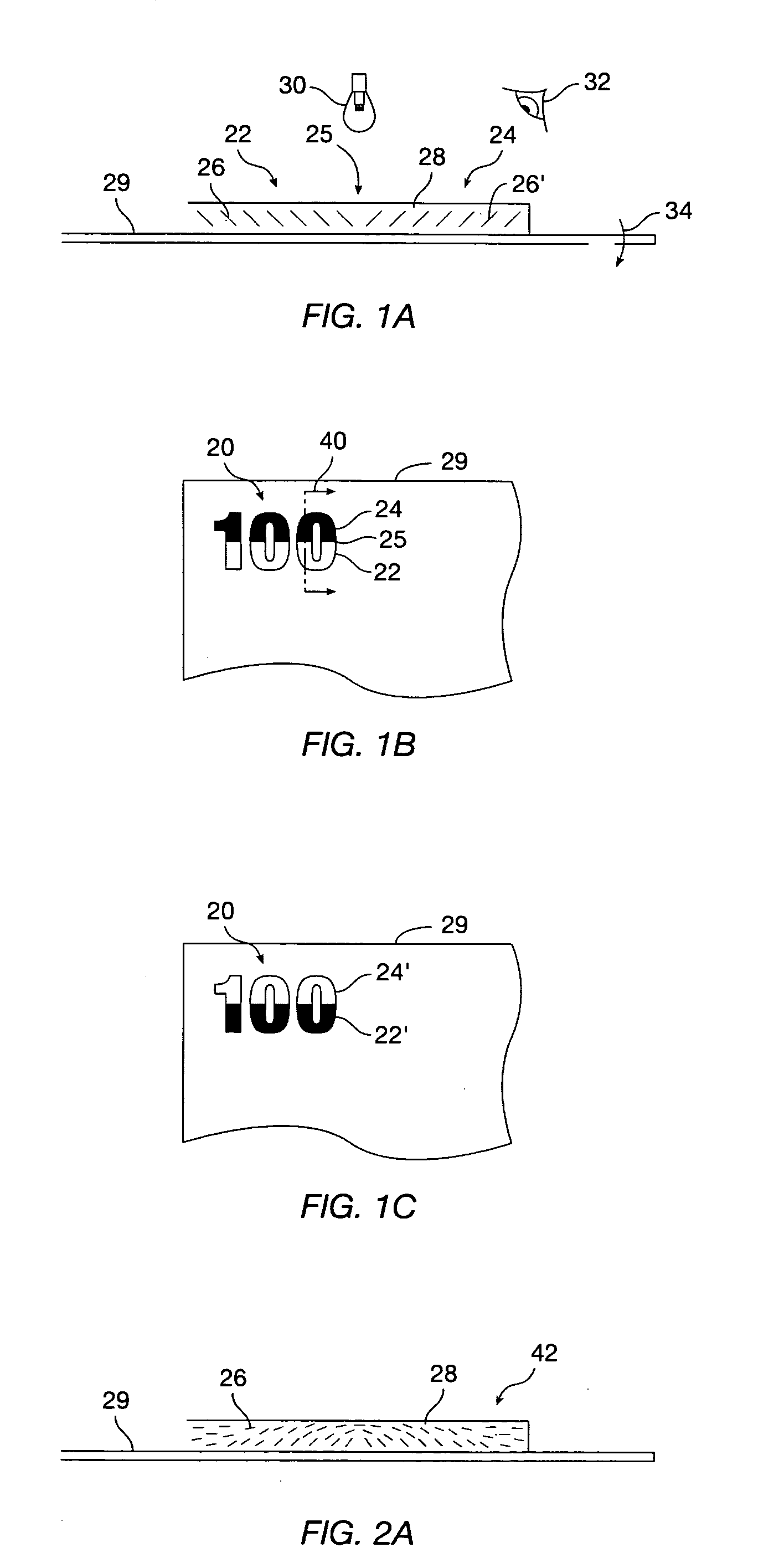

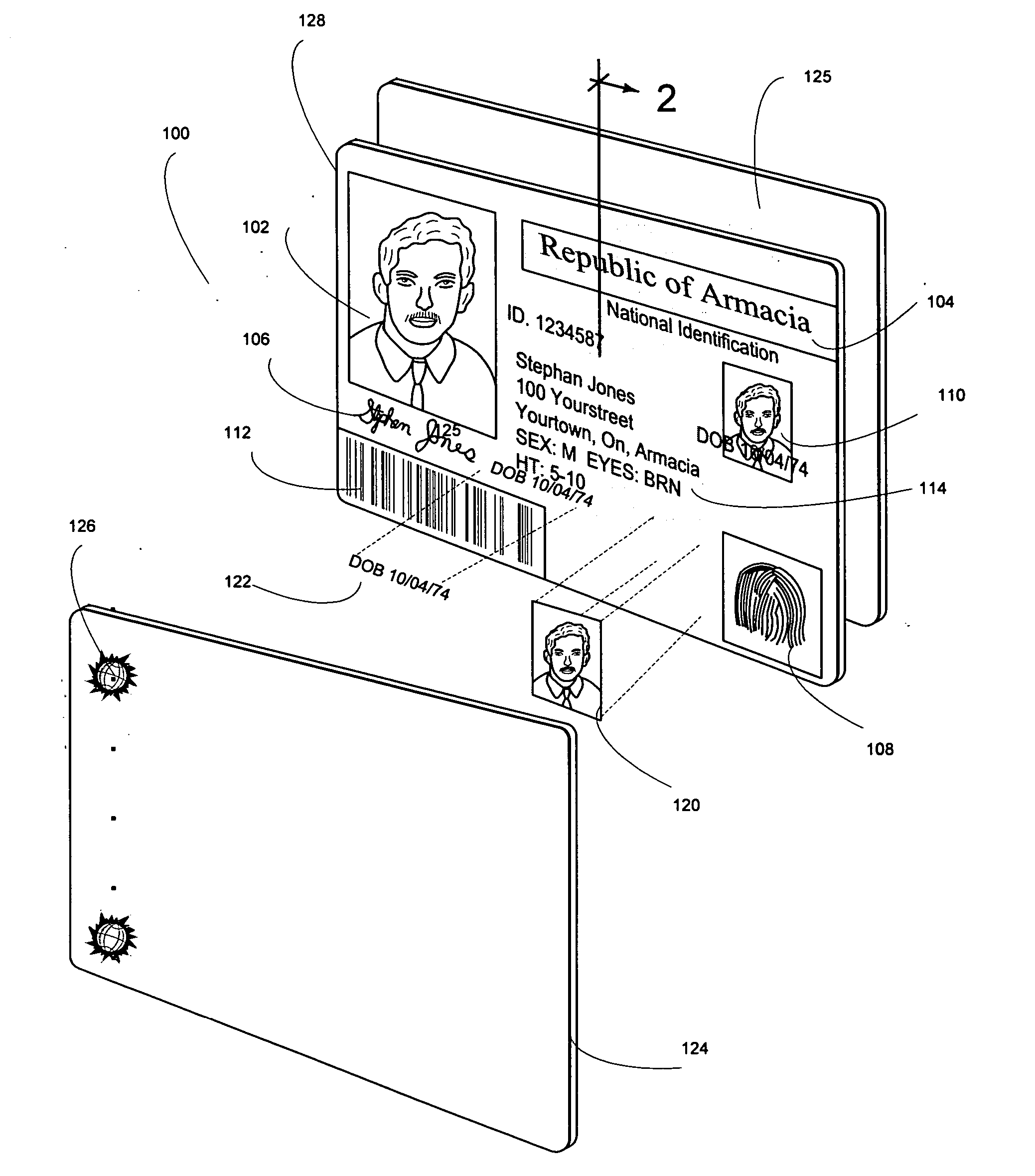

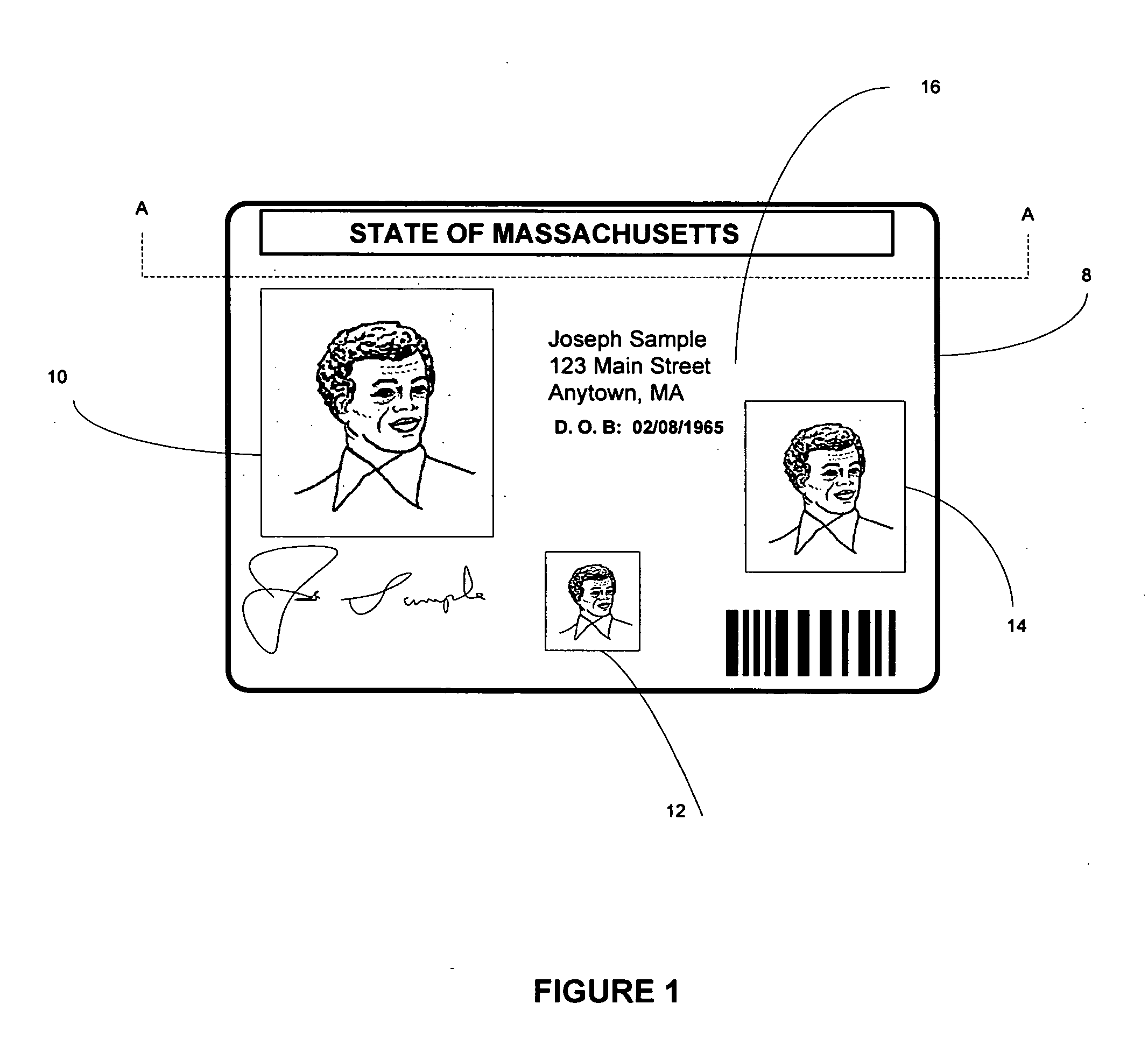

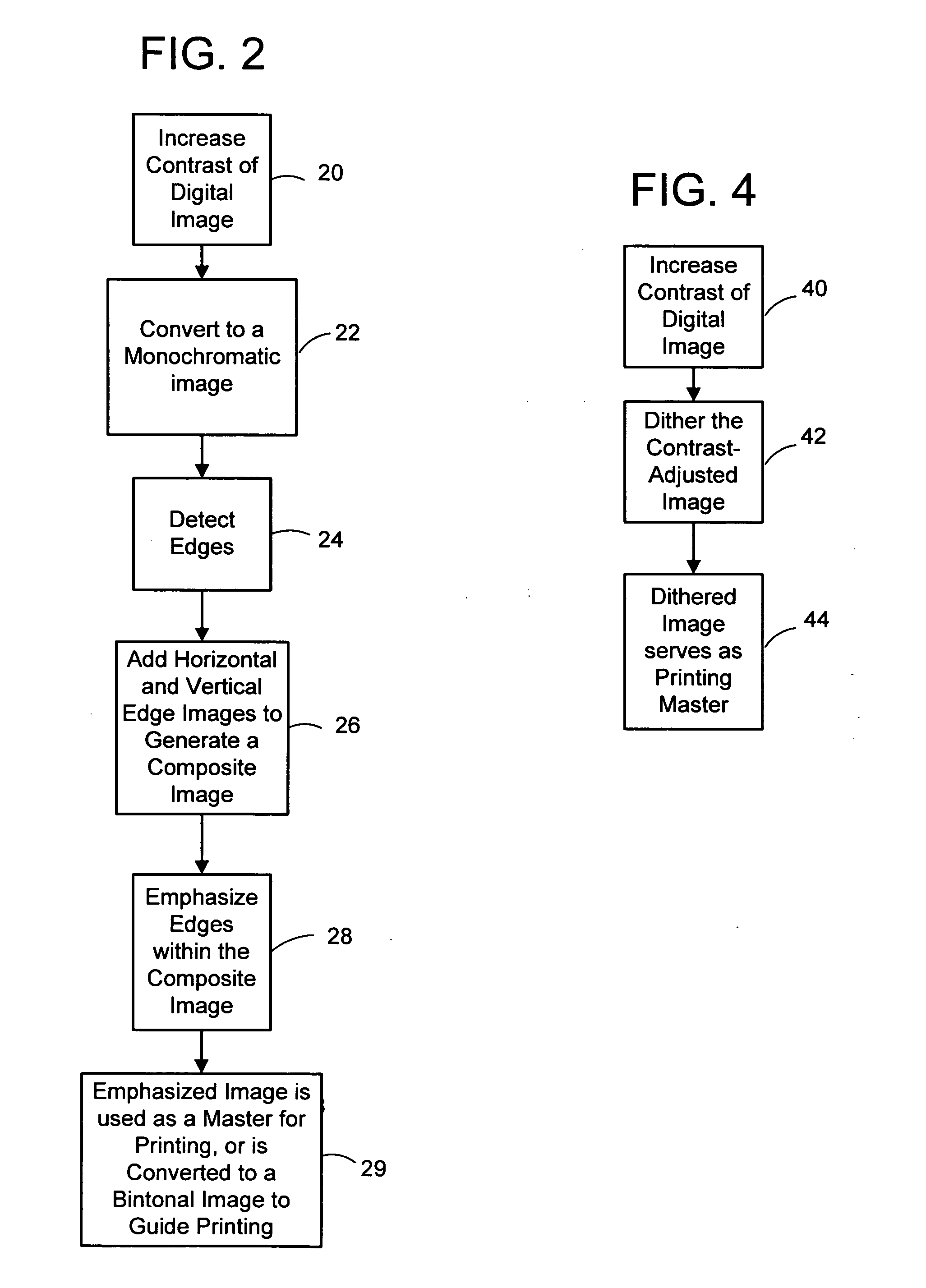

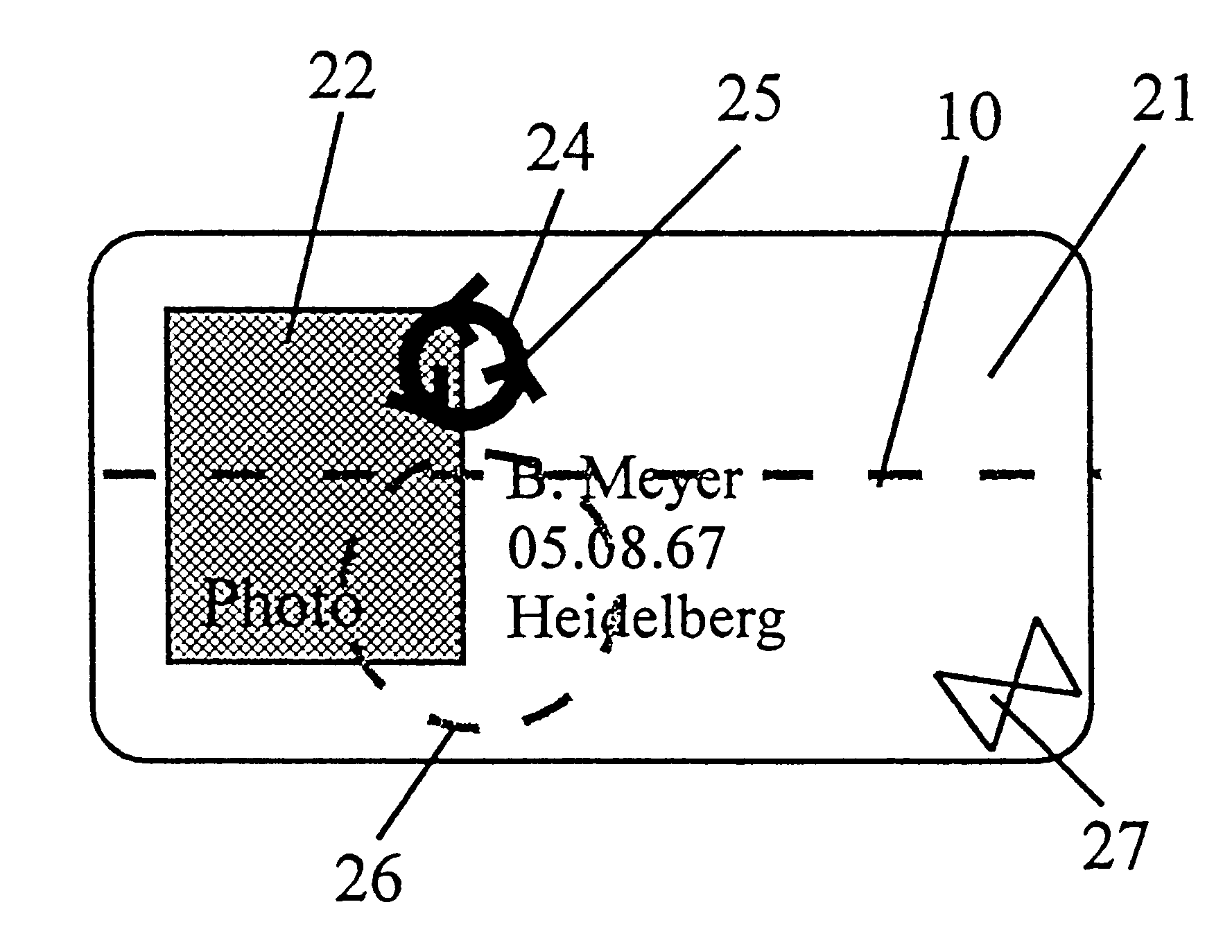

Optically variable personalized indicia for identification documents

The invention relates to identification documents, and in particular to providing optically variable personalized data to identification documents. In one implementation, we provide an identification document comprising a document layer and a first indicium. The document layer comprises a material capable of being printed by a thermally transferable optically variable ink. The first indicium is printed on the document layer and comprises personalized data and printed to the document layer by a thermally transferred optically variable ink. The first indicium may be printed to the document layer by disposing a thermally transferable optically variable ink in a mass transfer panel of a printer ribbon adapted for use in a dye diffusion thermal transfer printer, and printing the first indicium as part of a mass transfer printing process. The thermally transferred optically variable ink can be selected and printed such that the first indicium has at least one of a luster, shine, sheen, pearlescent appearance, iridescent appearance, and mirror-like appearance. This technology enables the creation of a halftone “mirror image” over a color ghost image to achieve a layered and linked multiple personalization scheme of ID documents.

Owner:L 1 SECURE CREDENTIALING

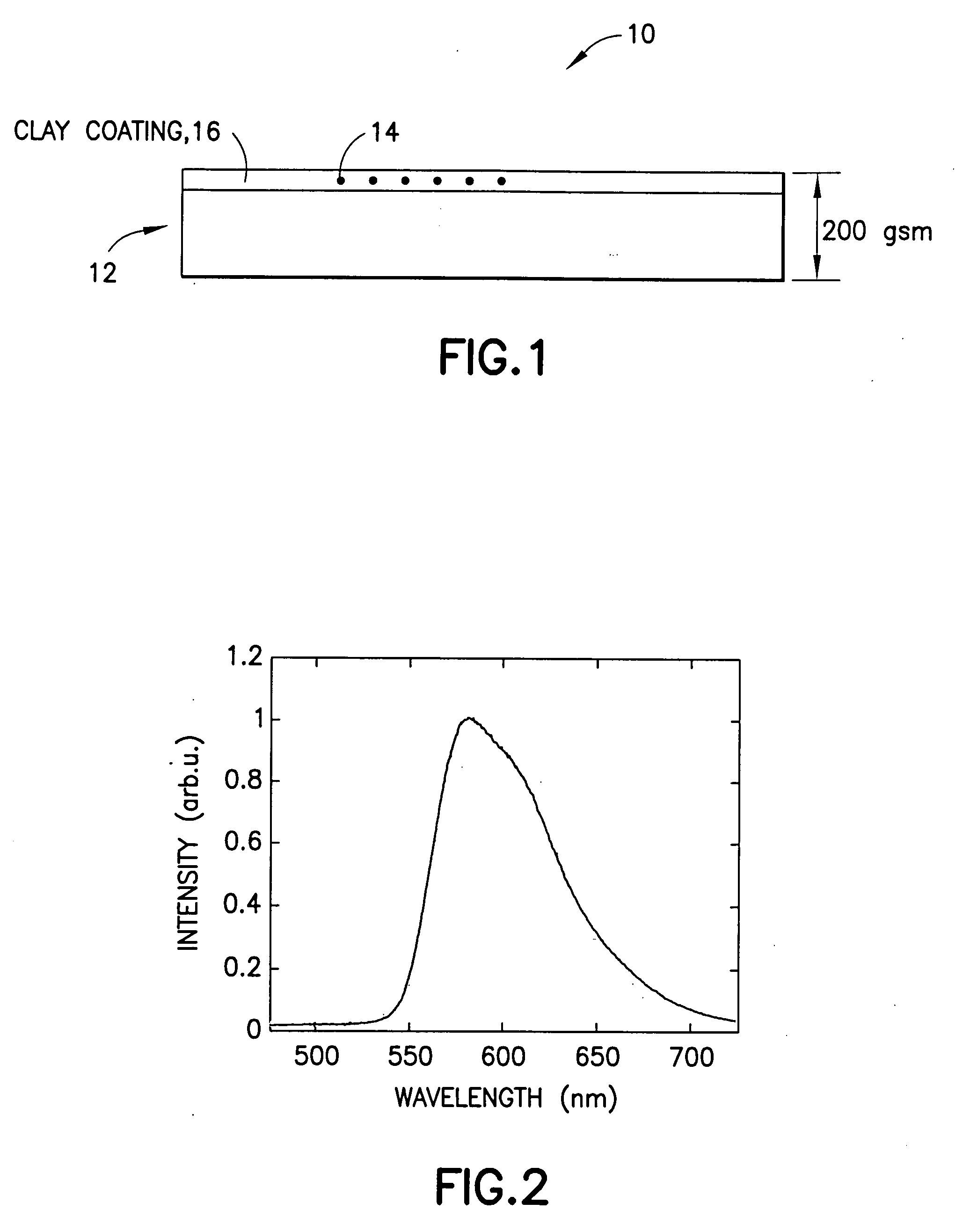

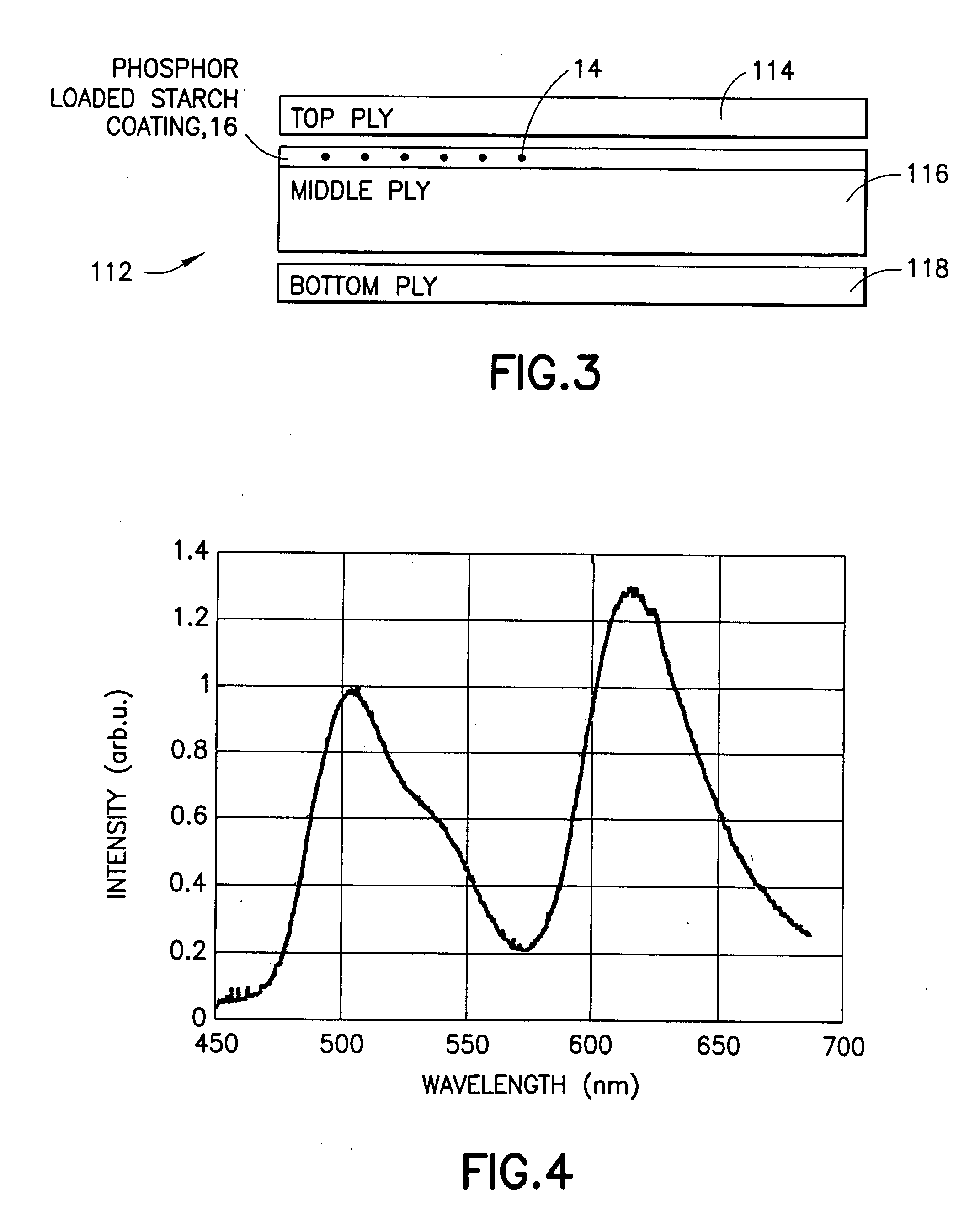

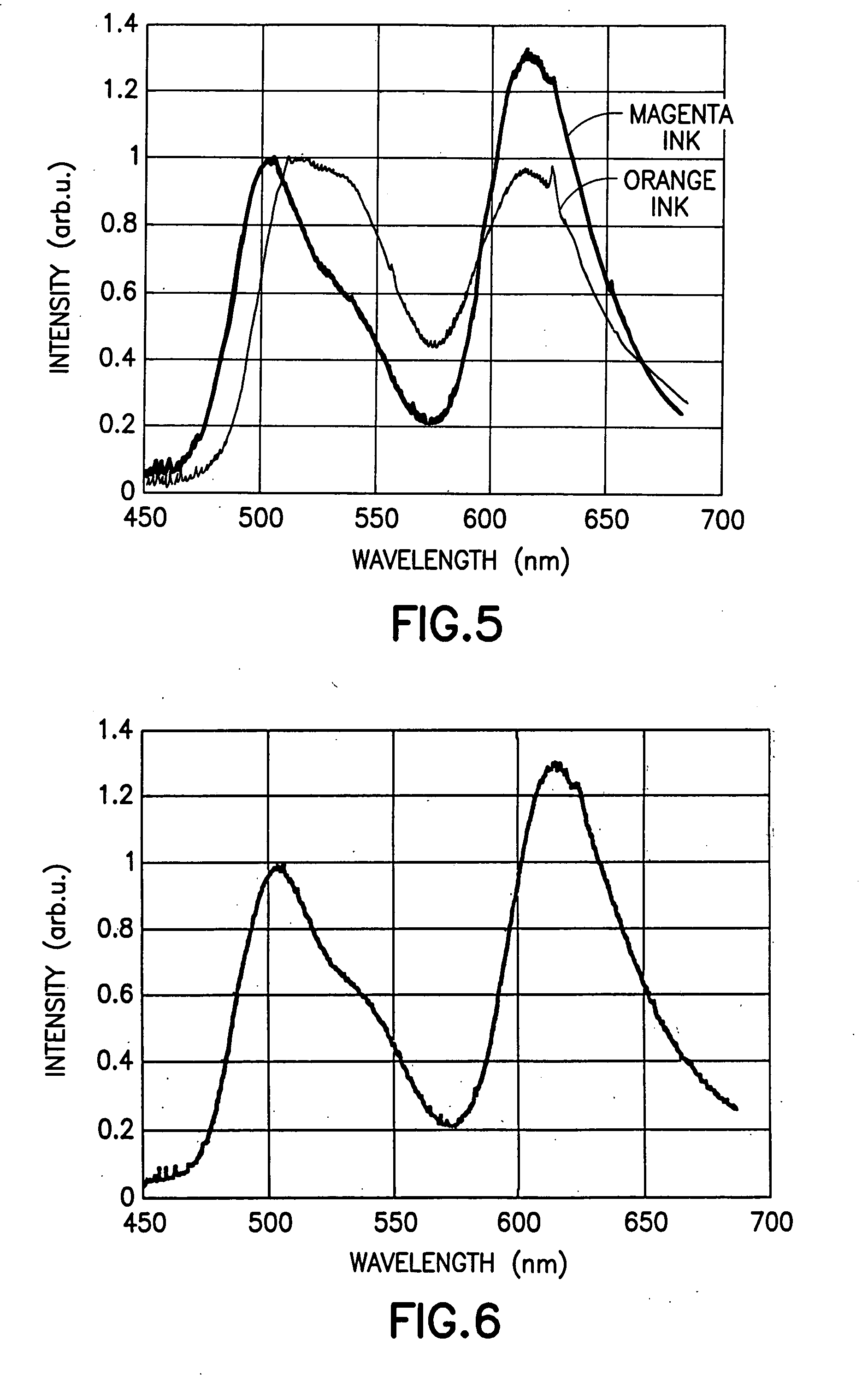

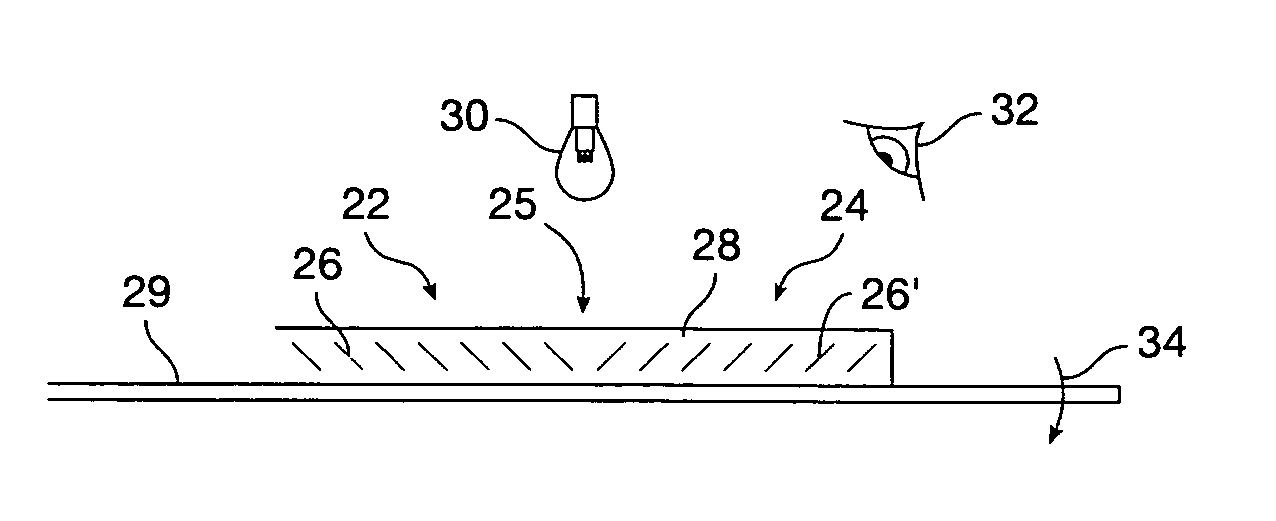

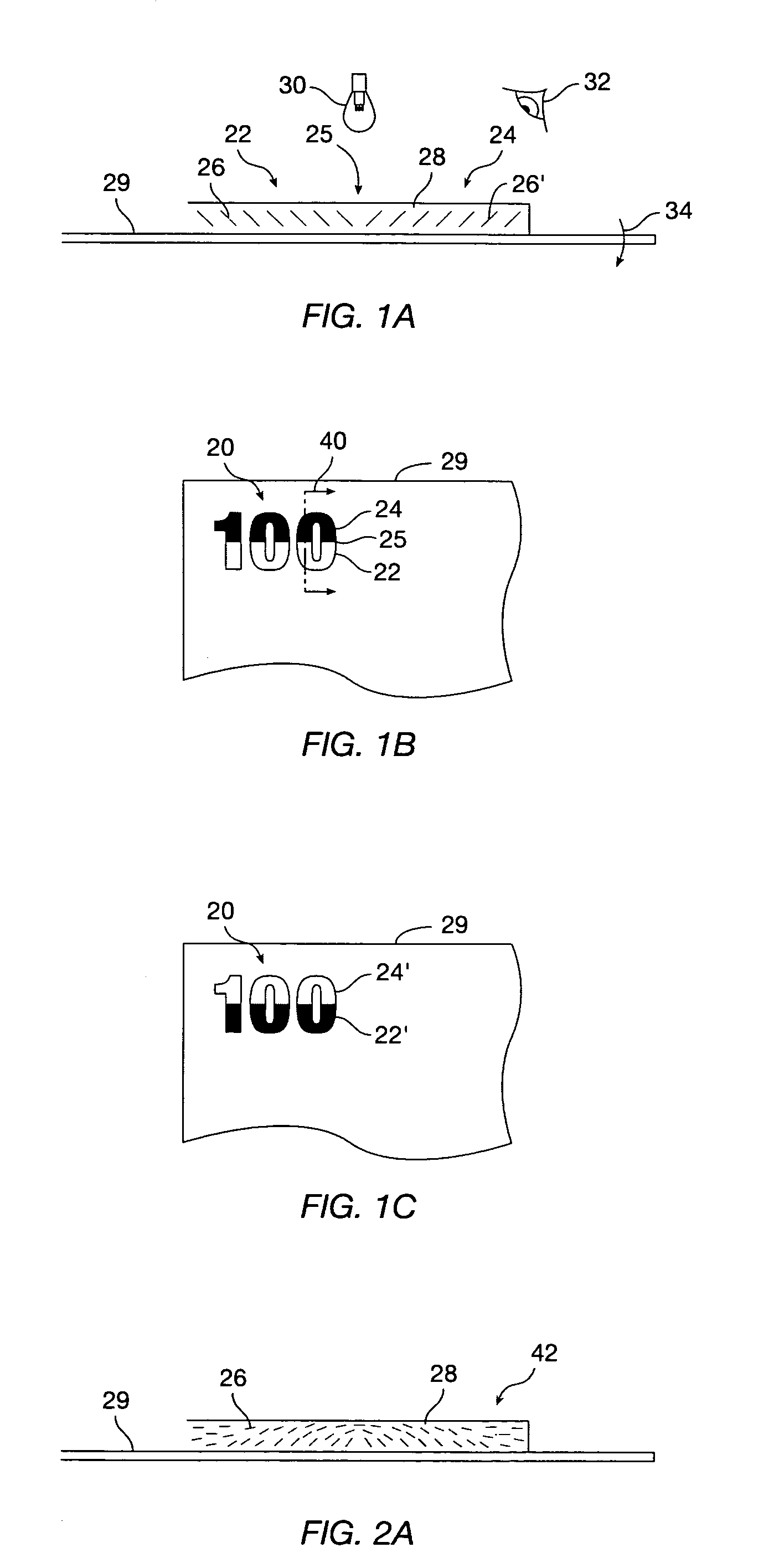

Taggant security system for paper products as a deterrent to counterfeiting

InactiveUS20050031838A1Difficult to duplicateNot easy to counterfeitNon-fibrous pulp additionOther printing matterPulp and paper industrySecurity system

A taggant security system for preventing the counterfeiting of goods associated with a paper product is provided. The taggant security system includes a paper product coating located on a paper product. The paper product coating is preferably one which is commonly used in the paper making industry. The taggant security system further includes one or more taggants incorporated within said paper product coating for authenticating said paper product. In preferred embodiments, the paper product coating is either a clay or starch coating. In addition, in preferred embodiments, the paper product is either a single or multi-ply packaging board or a label stock.

Owner:SPECTRA SYST CORP

Method and apparatus for orienting magnetic flakes

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

Security document with optically excitable dyes for authenticity check

InactiveUS6234537B1Reduce emission intensityIncrease intensityOther printing matterDuplicating/marking methodsEngineeringLaser

A security document with optically excitable dyes for authenticity checking. Dyes are applied to or embedded in the security documents. The dyes are advantageously embedded in a carrier material which in conjunction with the dyes forms a laser-active element. Certain optically excitable dyes are incorporated in a security document in such a way that when the security and / or sensitive document is optically excited, the dyes embedded in the security and / or sensitive document resonate with the material of the securities and secure documents, so that a well-defined narrow spectrum of all excited materials is emitted.

Owner:BUNDESDRUCKEREI GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com