Patents

Literature

5184 results about "Shell molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shell moulding, also known as shell-mould casting, is an expendable mold casting process that uses a resin covered sand to form the mold. As compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labor requirements. It is used for small to medium parts that require high precision. Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired part, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. Shell mold casting requires the use of a metal pattern, oven, sand-resin mixture, dump box, and molten metal.

Shape-memory, biodegradable and absorbable material

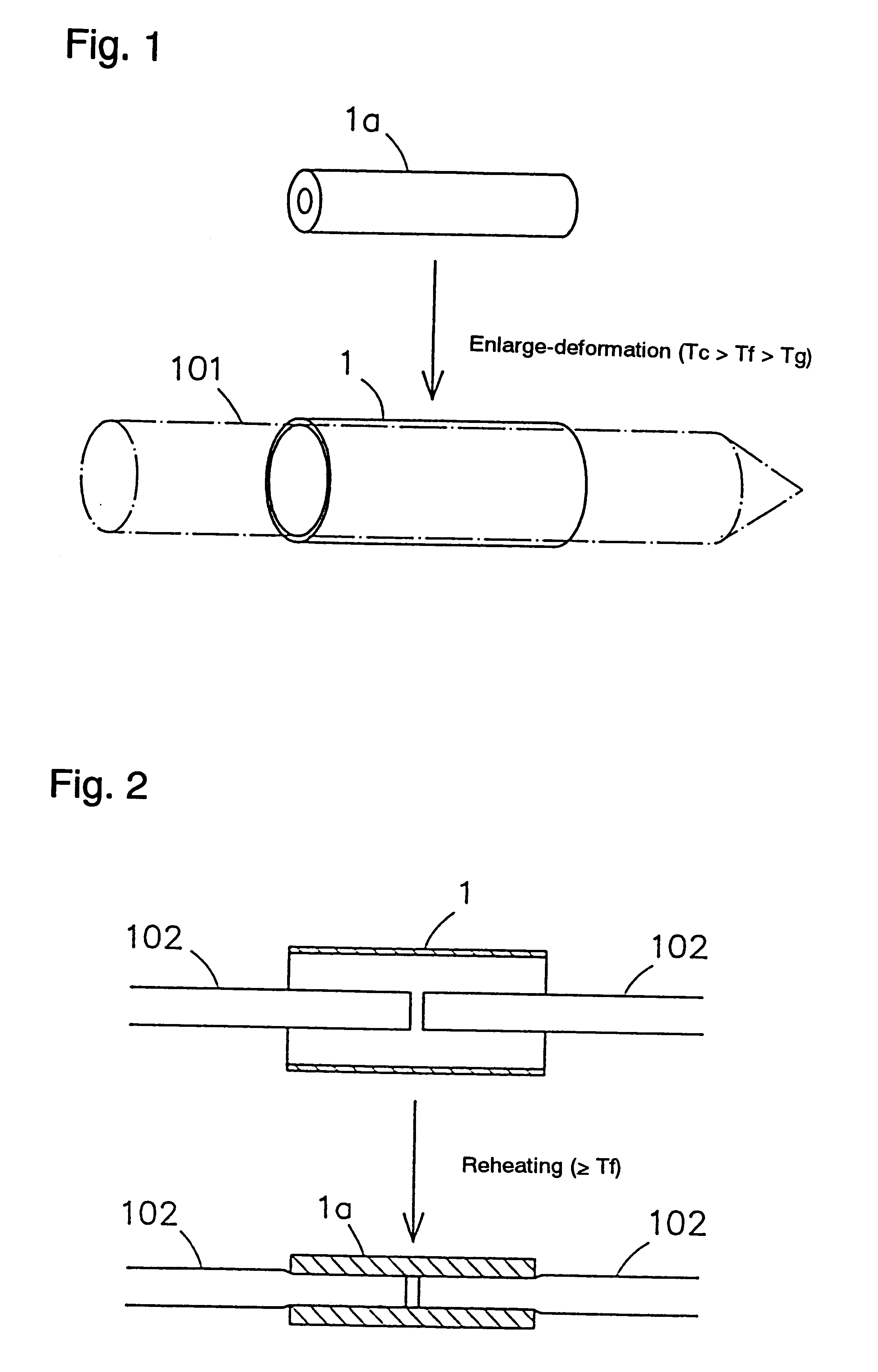

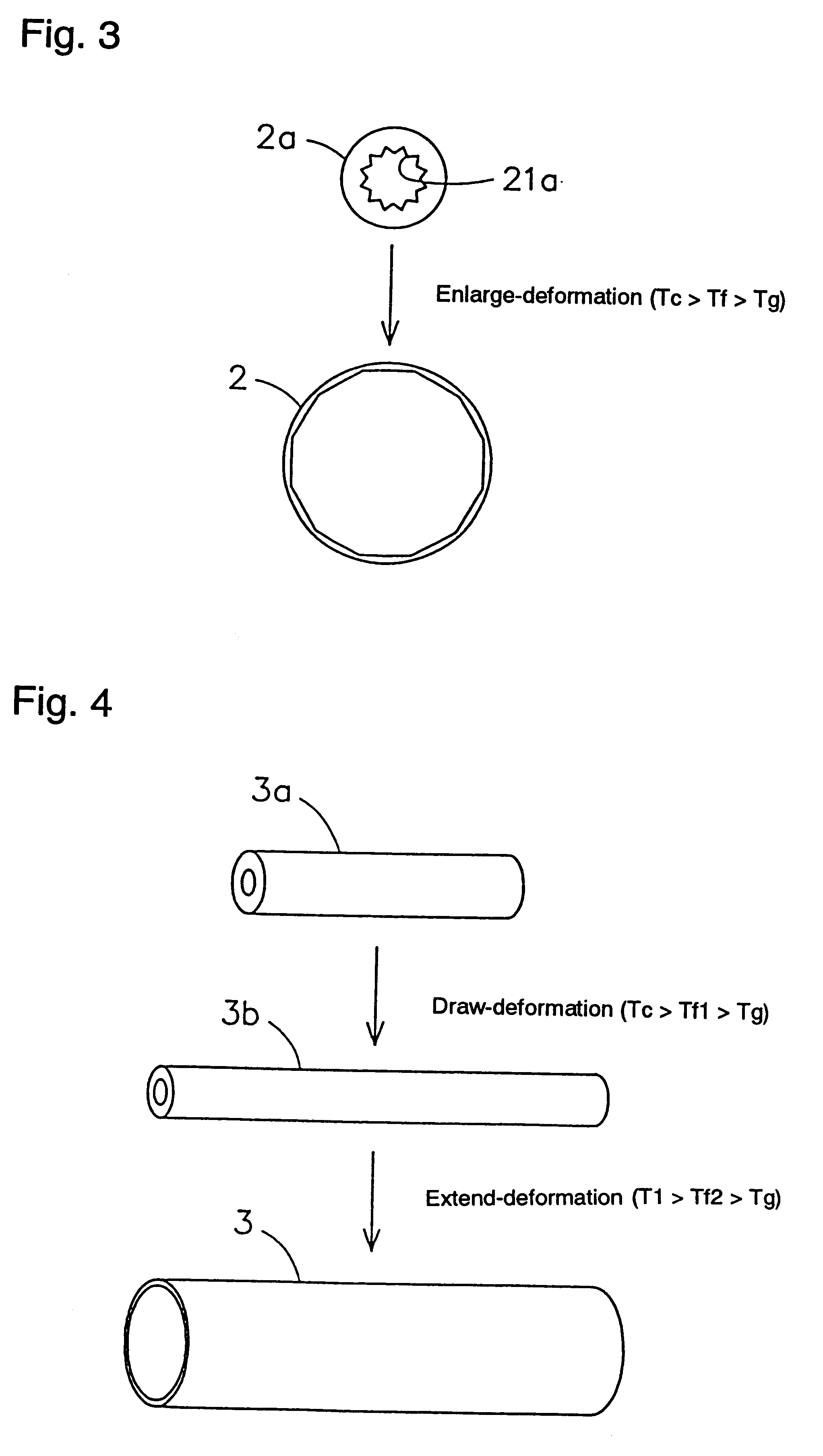

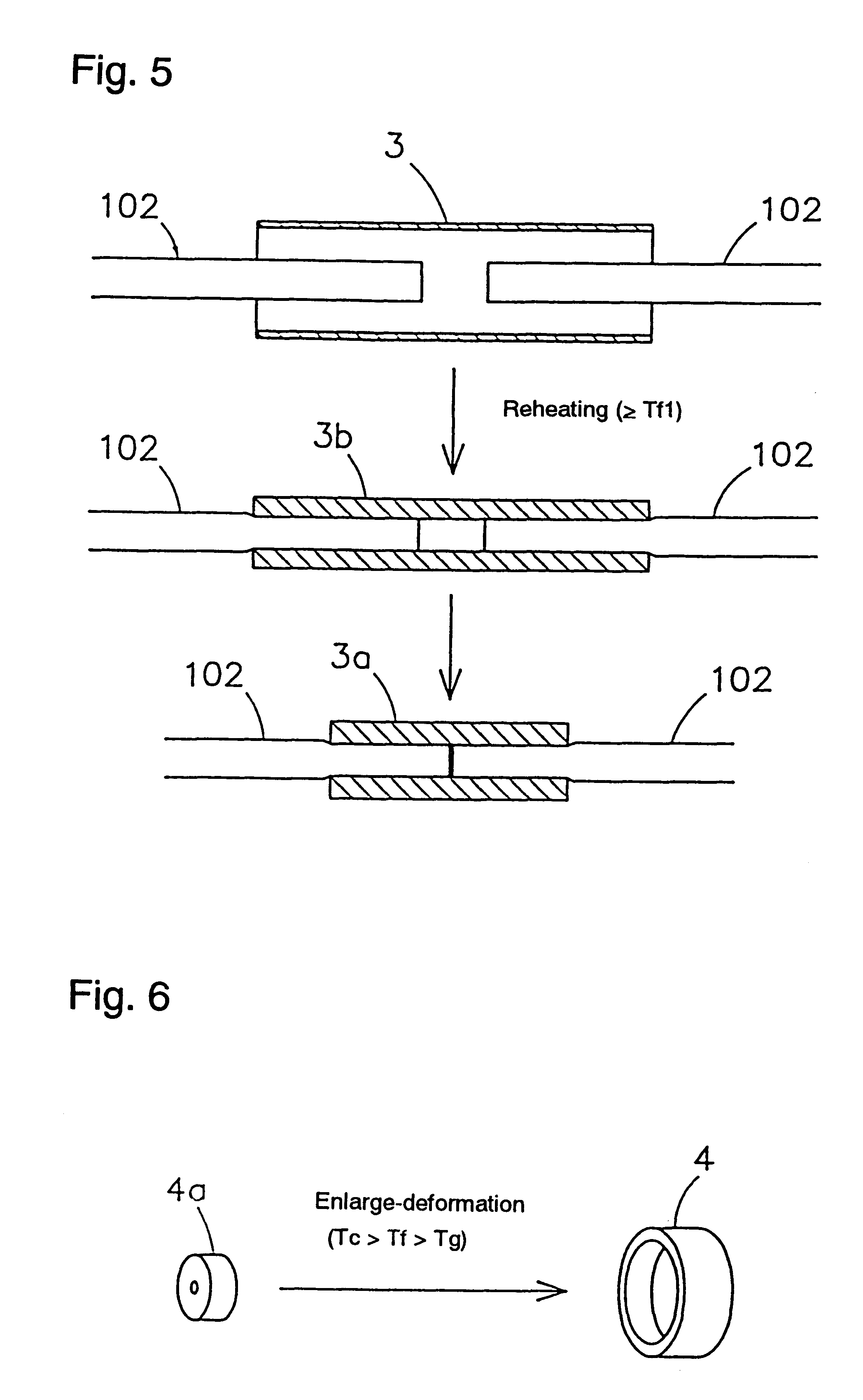

InactiveUS6281262B1Easily and surely performSuture equipmentsCosmetic preparationsVitrificationPolymer science

Shape-memory biodegradable and absorbable materials which make it possible to easily treat vital tissues by suture, anastomosis, ligation, fixation, reconstitution, prosthesis, etc. without causing burn. These materials never induce halation in MRI or CT and never remain in vivo. Such a shape-memory biodegradable and absorbable material is a material made of a molded article of lactic acid-based polymer and can be recovered to the original shape without applying any external force thereto but heating to a definite temperature or above. It is obtained by deforming a molded article (a primary molded article) made of a lactic acid-based polymer and having a definite shape into another molded article (a secondary molded article) having another shape at a temperature higher than the glass transition temperature thereof but lower than the crystallization temperature thereof (or 100.degree. C. when the molded article has no crystallization temperature) and then fixing said molded article to the thus deformed shape by cooling it as such to a temperature lower than the glass transition temperature. When this material is heated to the above-mentioned deformation temperature or above, it is immediately recovered to the original shape. The lactic acid-based polymer is hydrolyzed and absorbed in vivo.

Owner:TAKIRON CO LTD

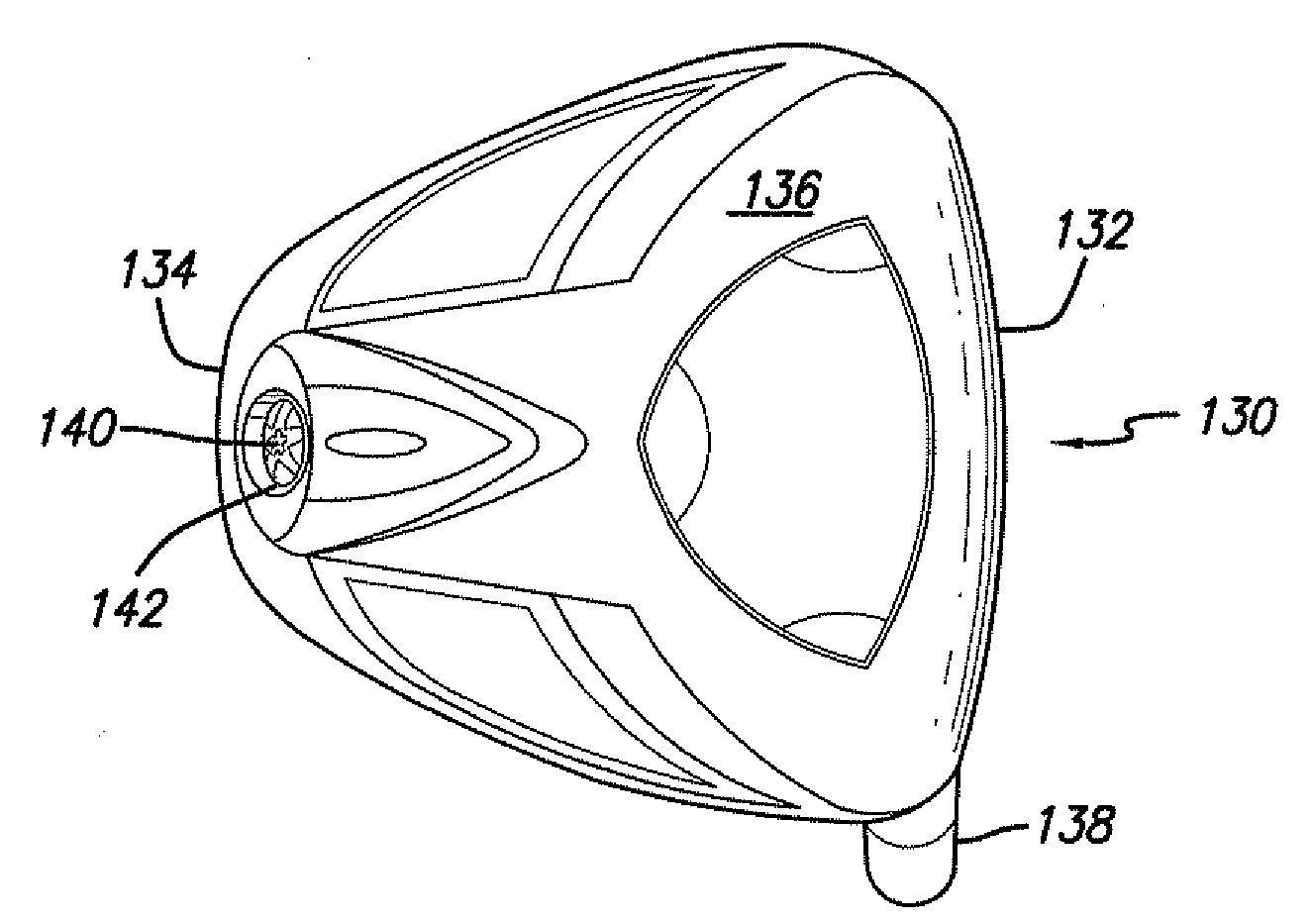

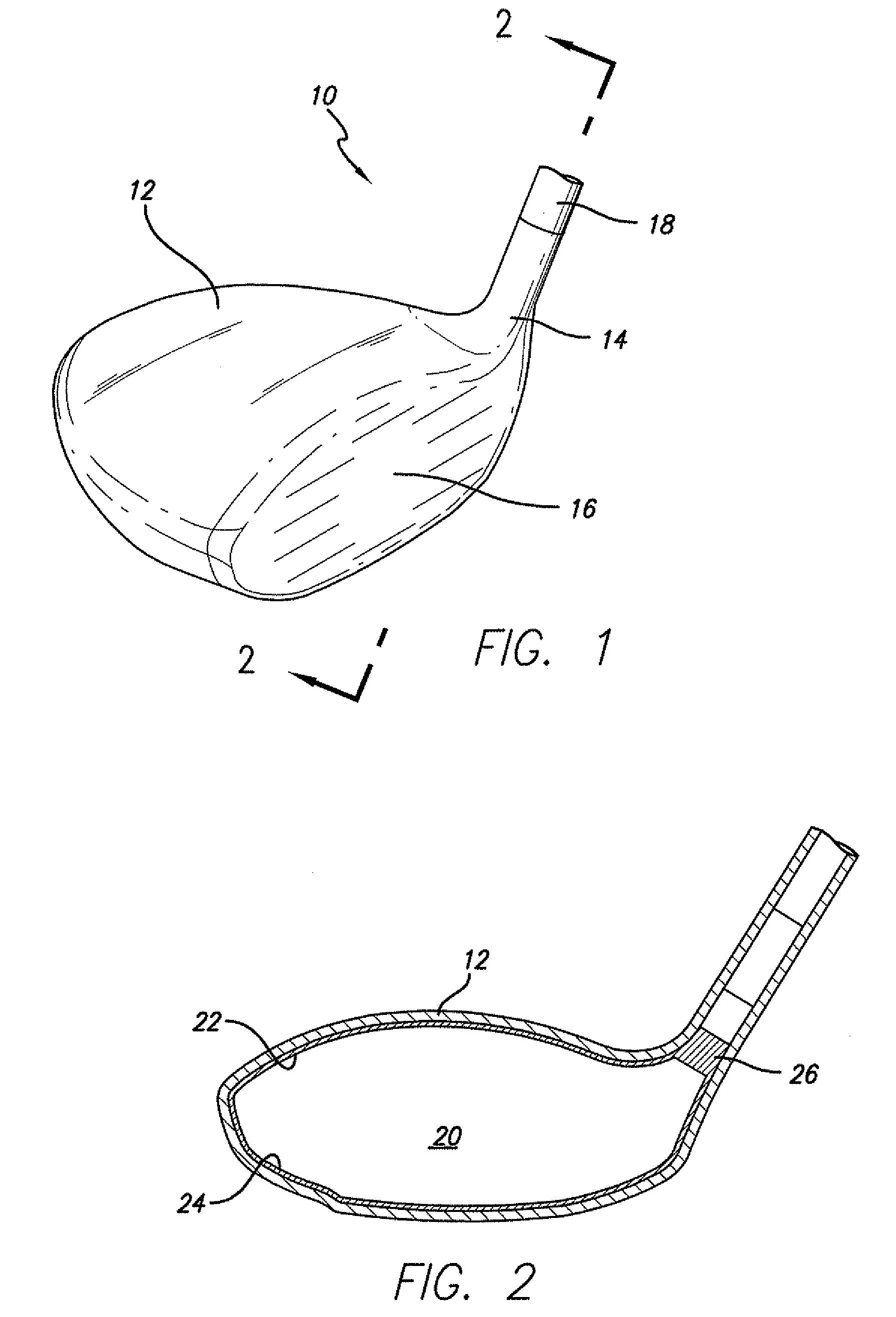

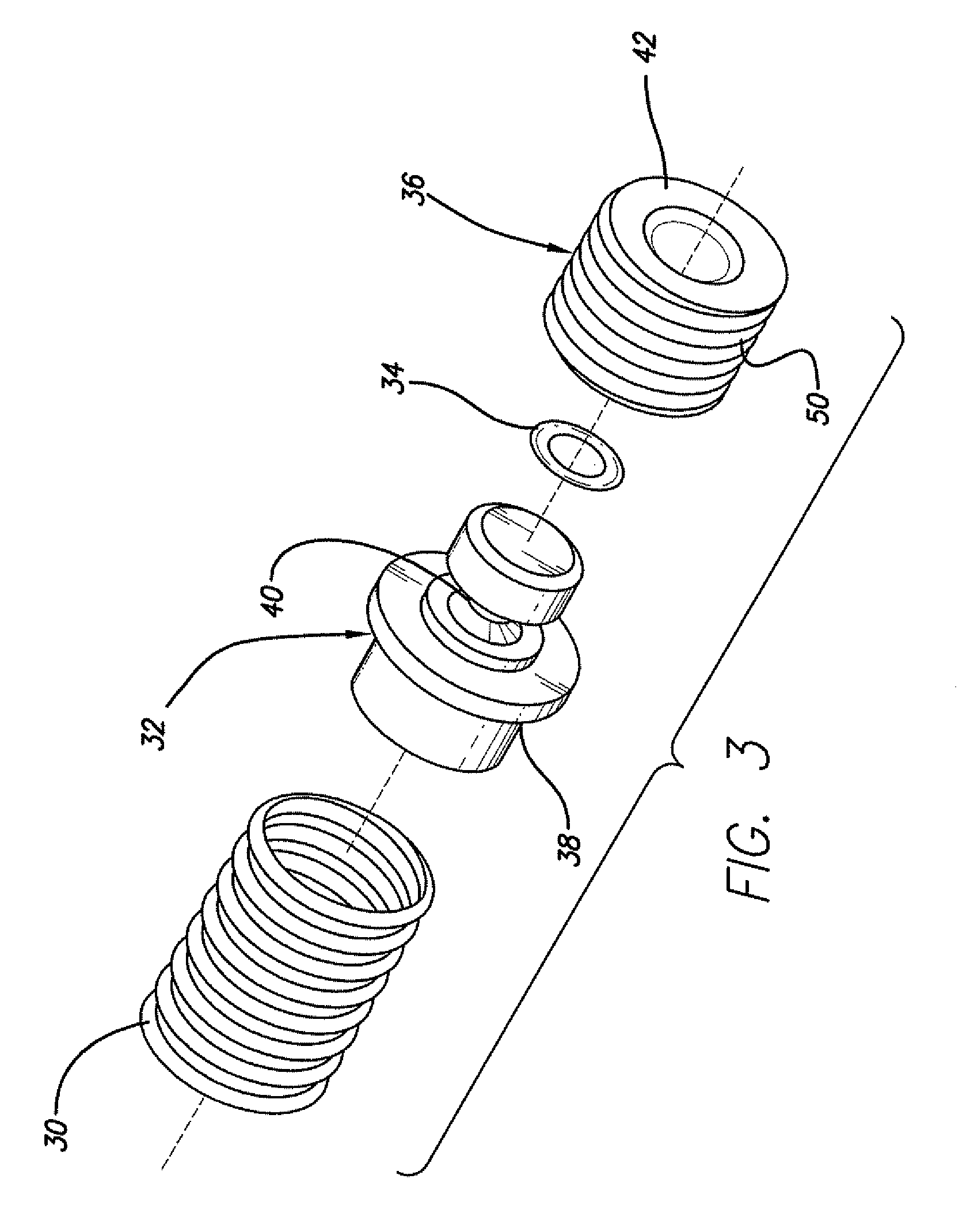

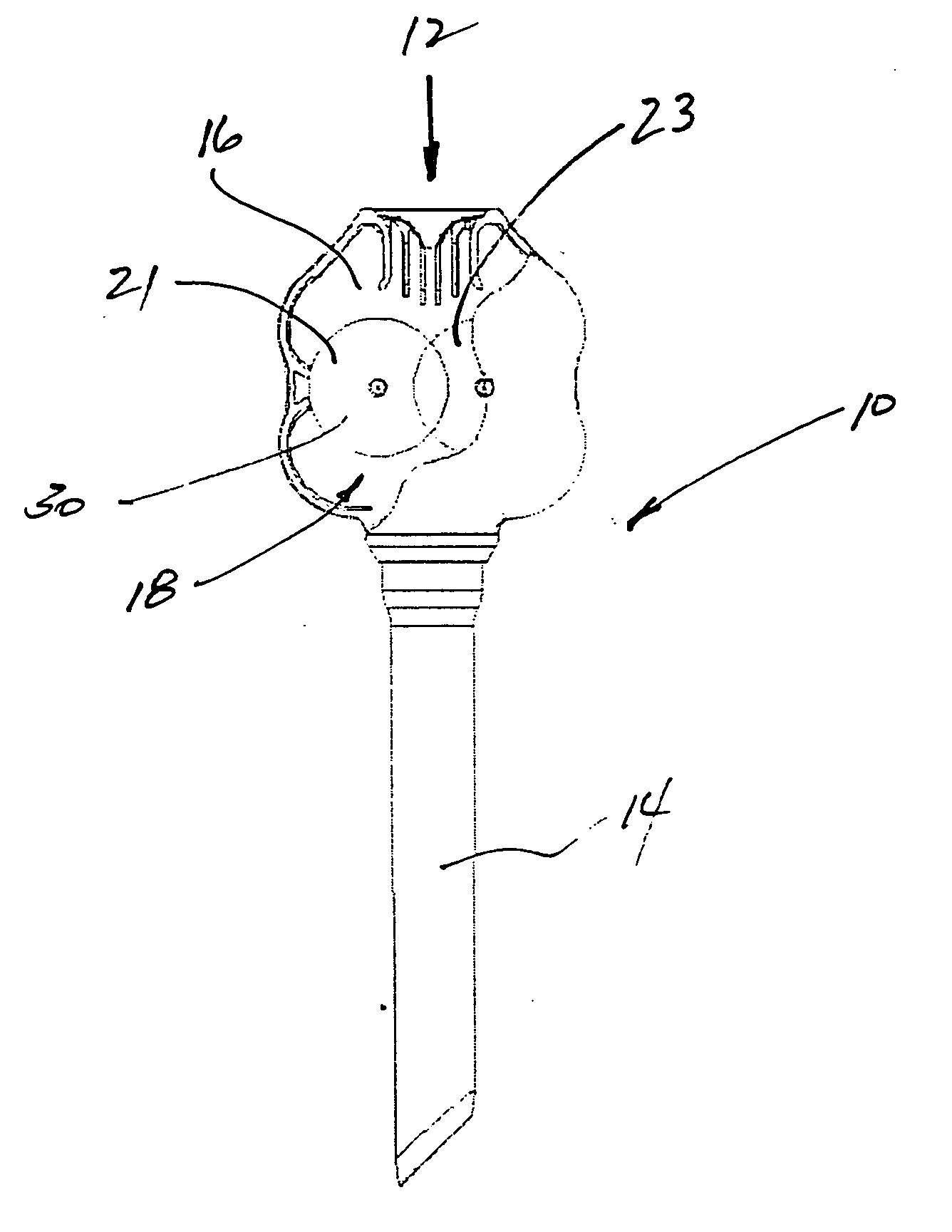

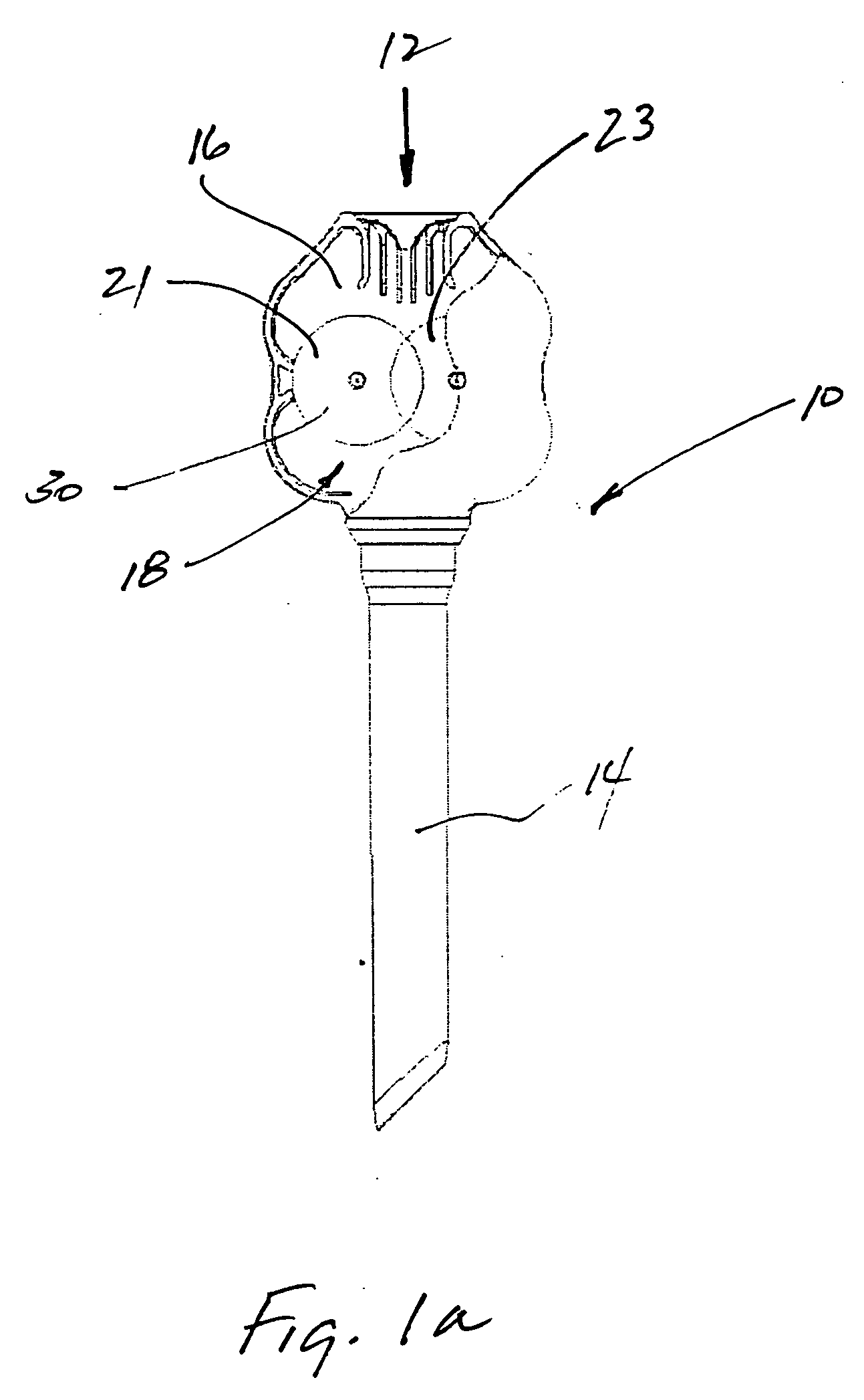

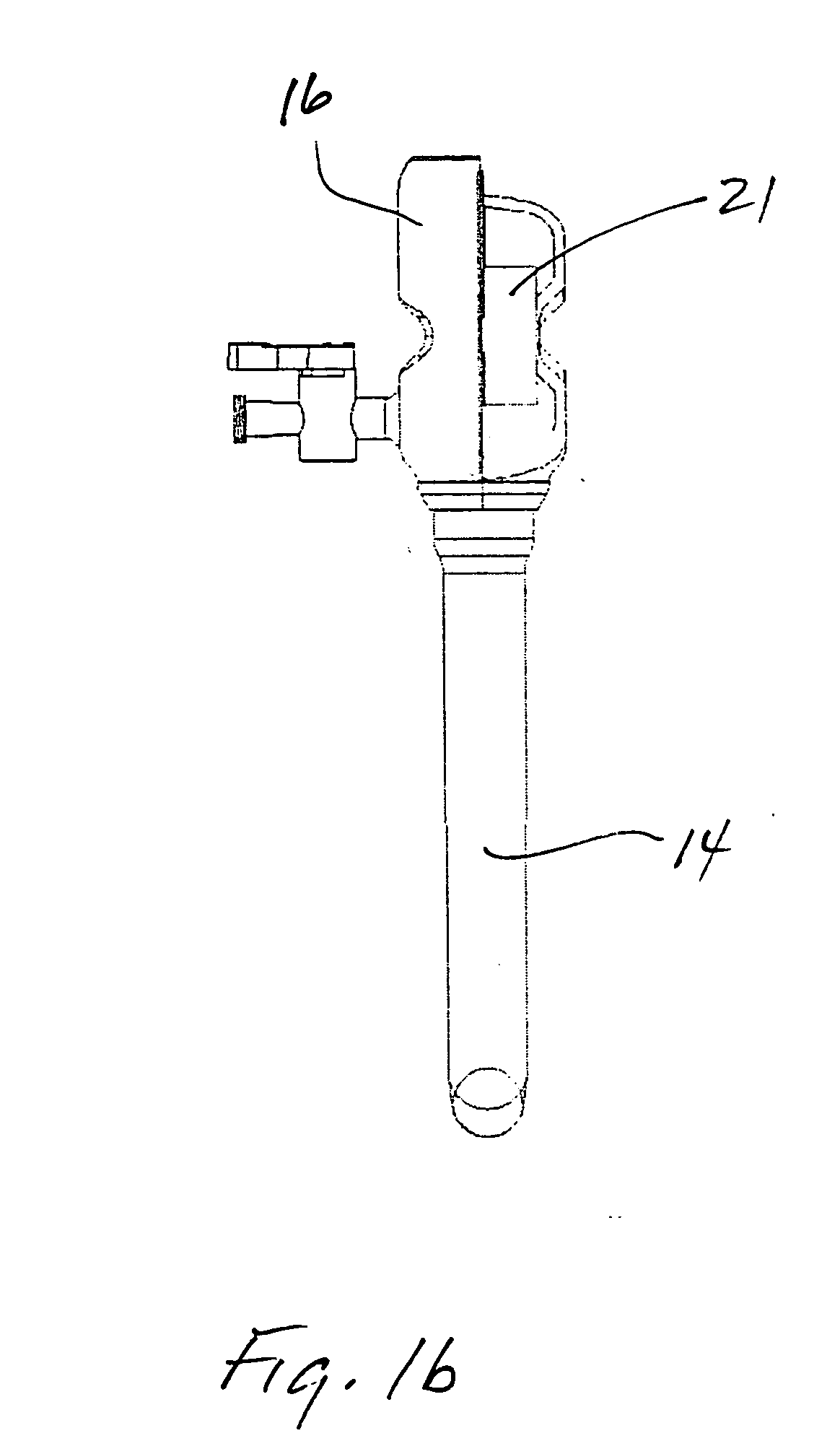

Golf club having a hollow pressurized metal head

ActiveUS20080188322A1Avoid passingPrevent escapeFilling using counterpressureMetal rolling stand detailsShell moldingPlastic materials

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

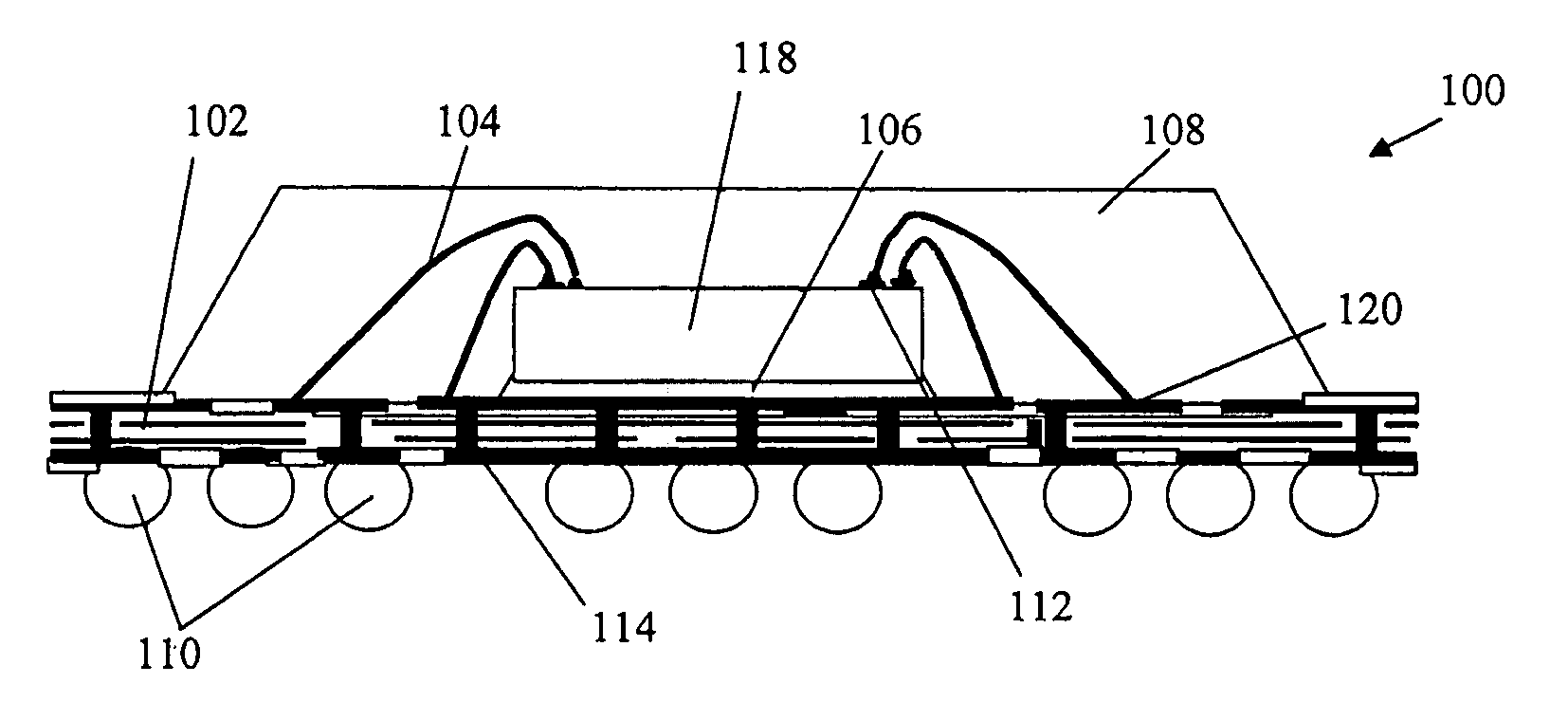

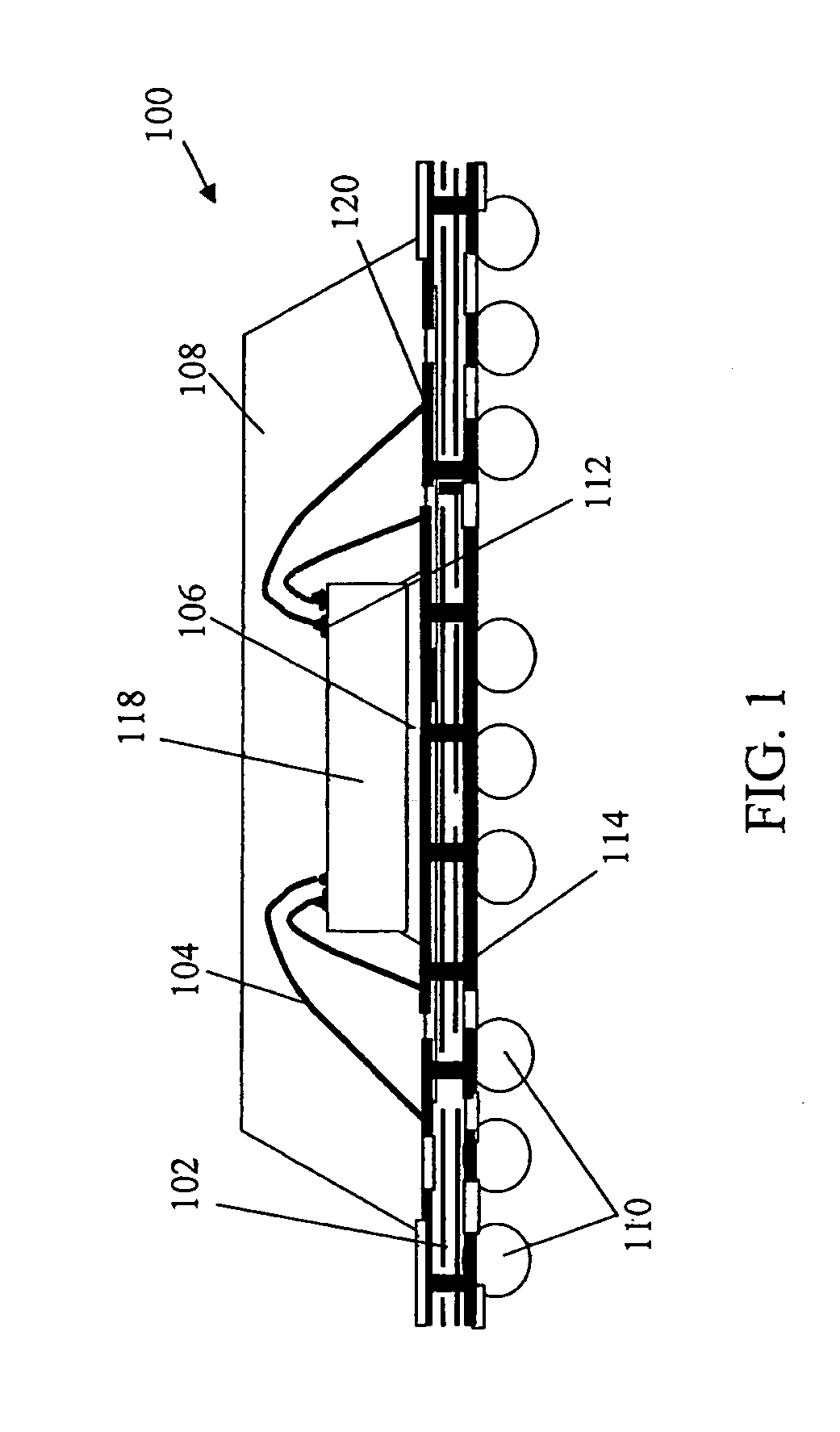

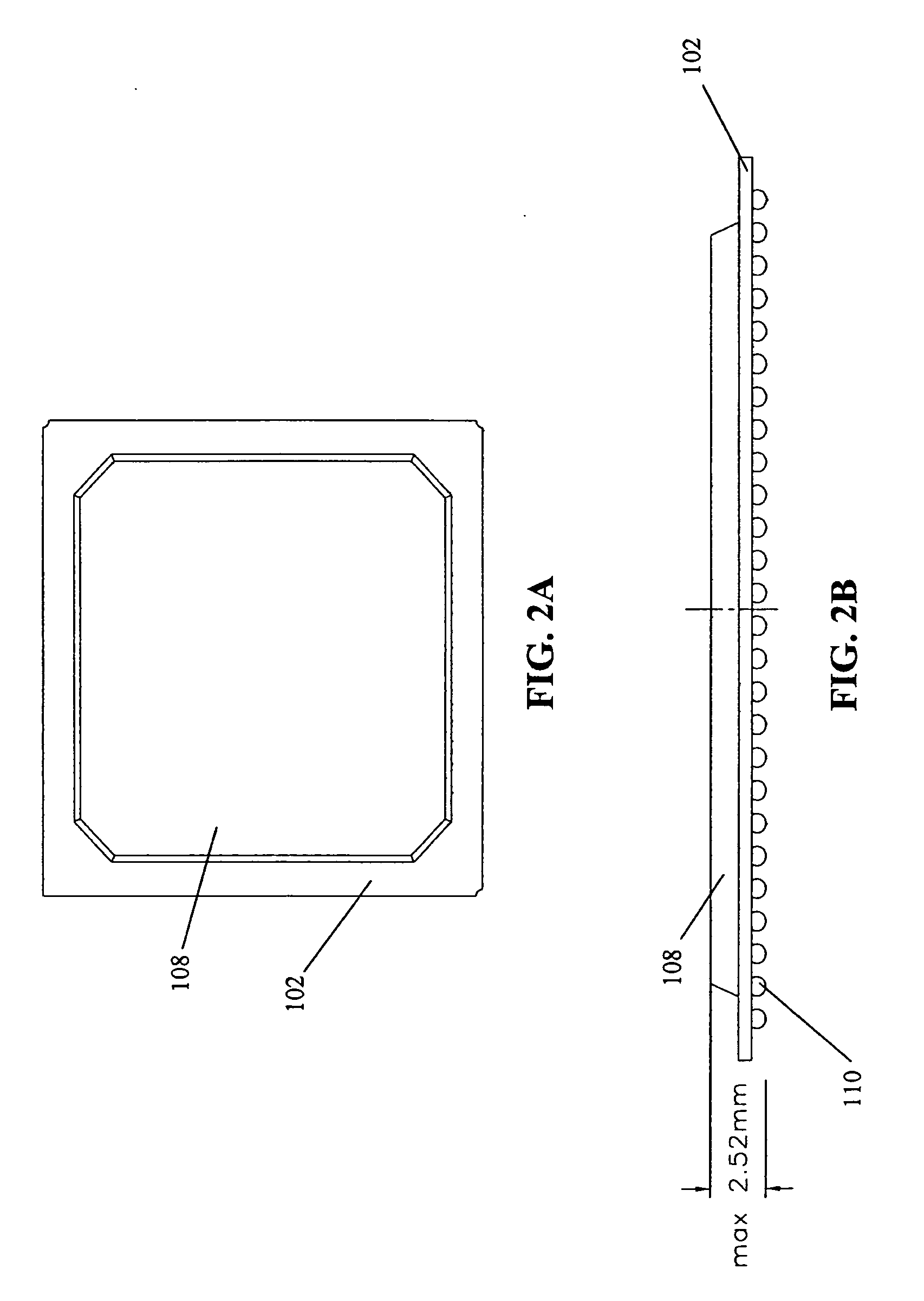

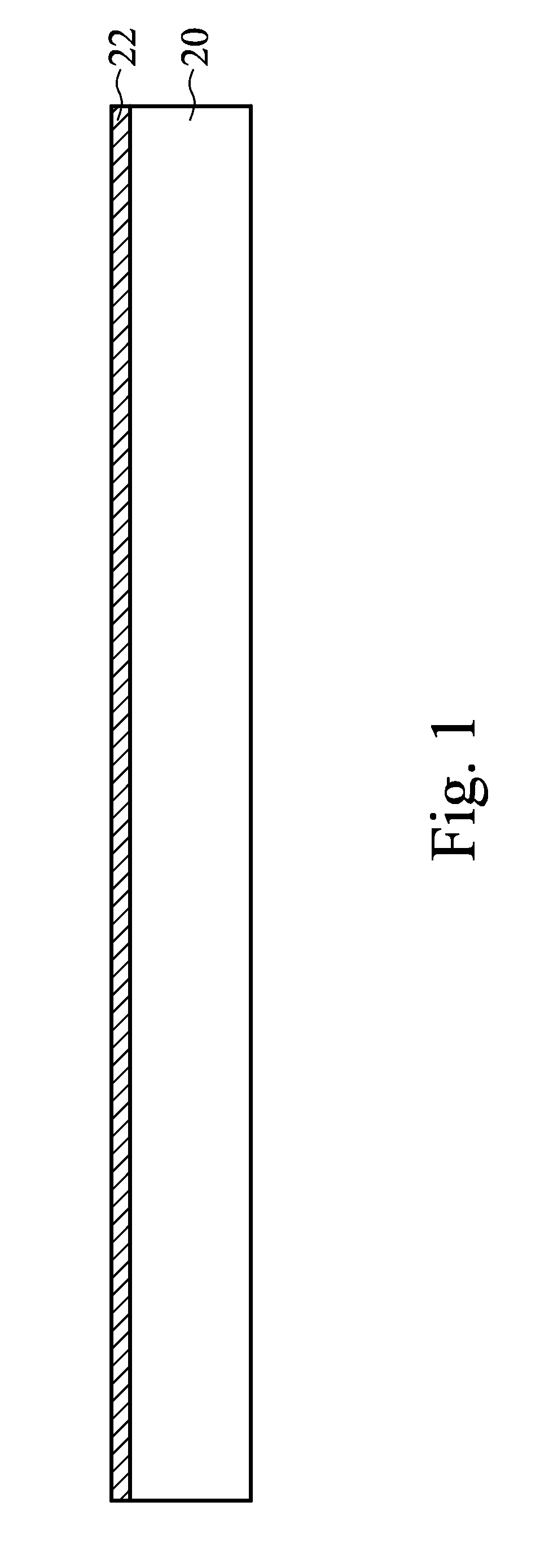

Interconnect structure and formation for package stacking of molded plastic area array package

ActiveUS20070273049A1Semiconductor/solid-state device detailsSolid-state devicesContact padShell molding

Apparatuses, methods, and systems for improved integrated circuit packages are described. An integrated circuit (IC) package includes a substrate having opposing first and second surfaces, an IC die, a plurality of conductive elements, and an encapsulating material. The substrate has a plurality of contact pads on the first surface that are electrically coupled to a plurality of electrically conductive features on the second surface. The plurality of conductive elements is formed on the first surface of the substrate. The IC die is located on the first surface of the substrate. The encapsulating material encapsulates the IC die and a portion of each element of the plurality of conductive elements.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

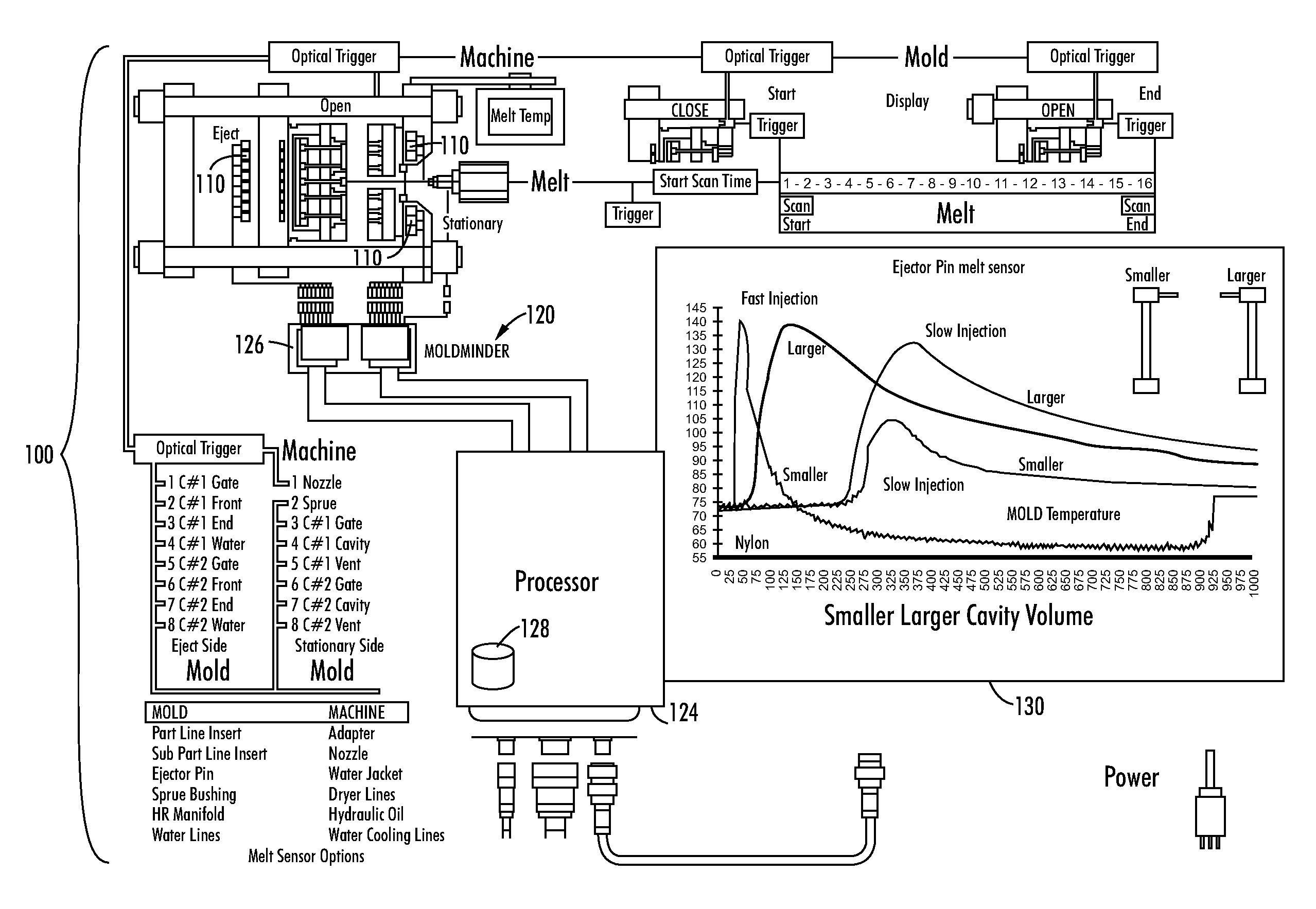

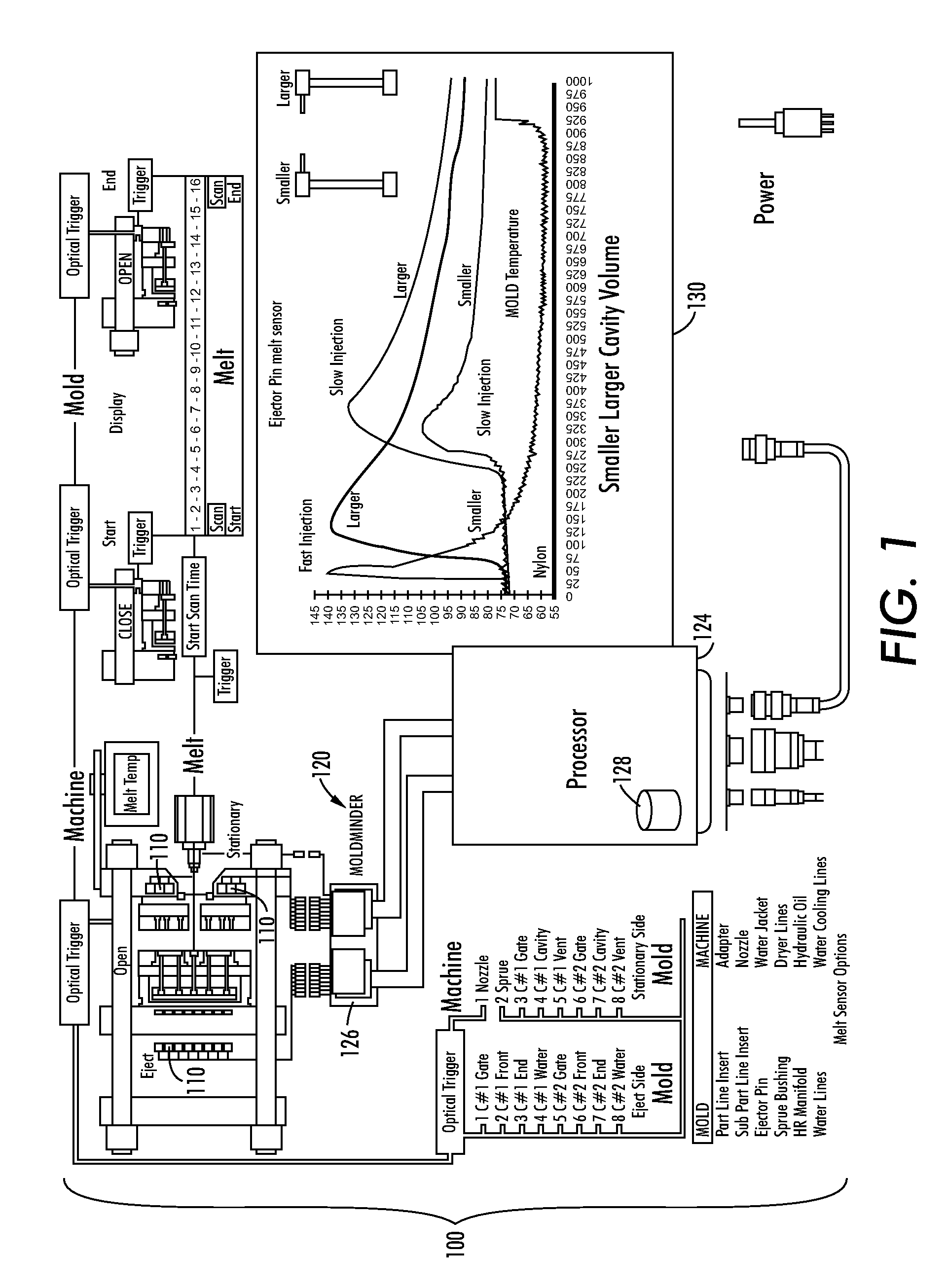

System for monitoring temperature and pressure during a molding process

Disclosed are systems and methods for the use of a micro-bead EMF junction in the sensing and control of an injection molding process, whereby the improved junction is able to reliably sense and indicate temperature and pressure changes in a molding process.

Owner:BUJA FREDERICK J

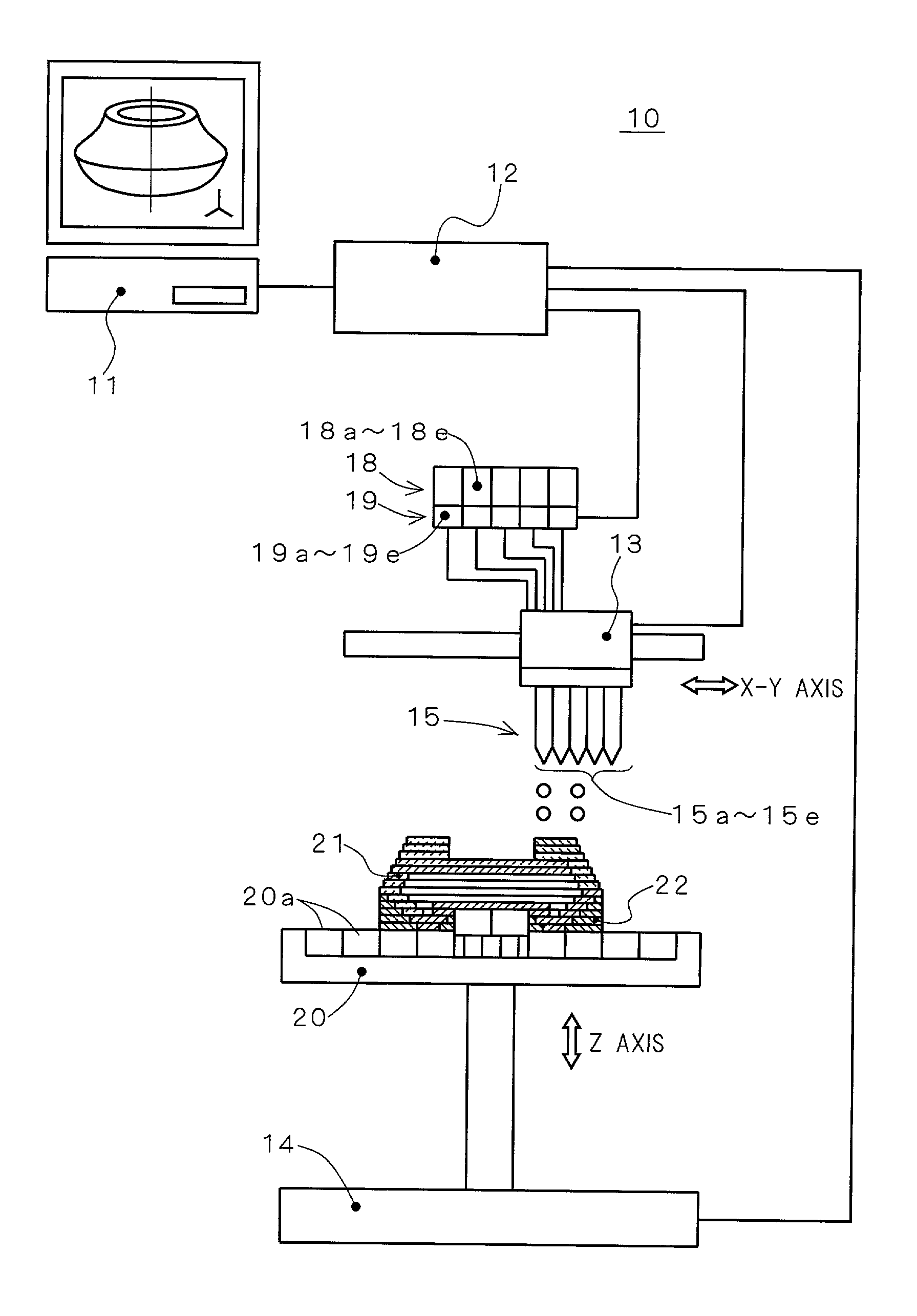

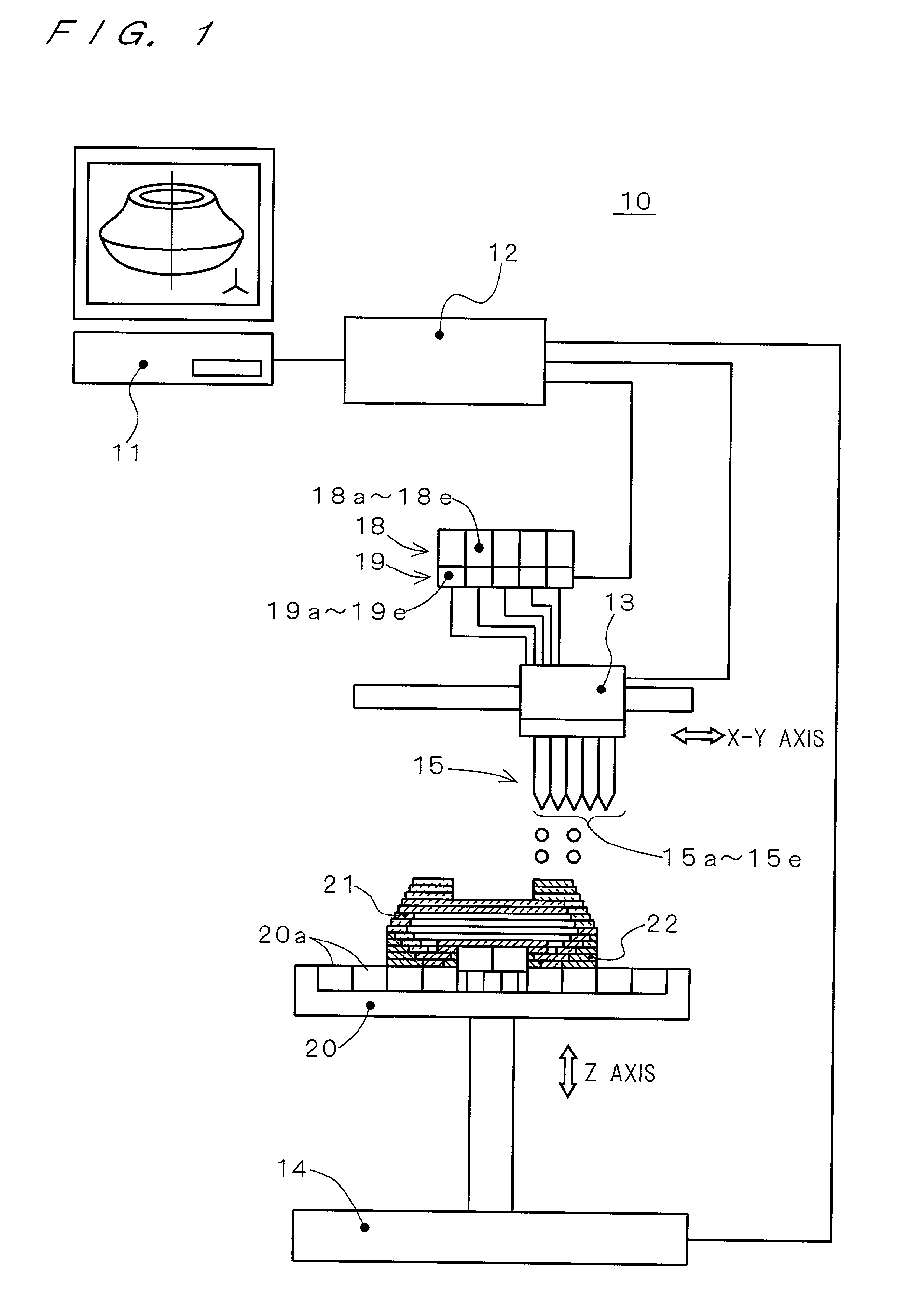

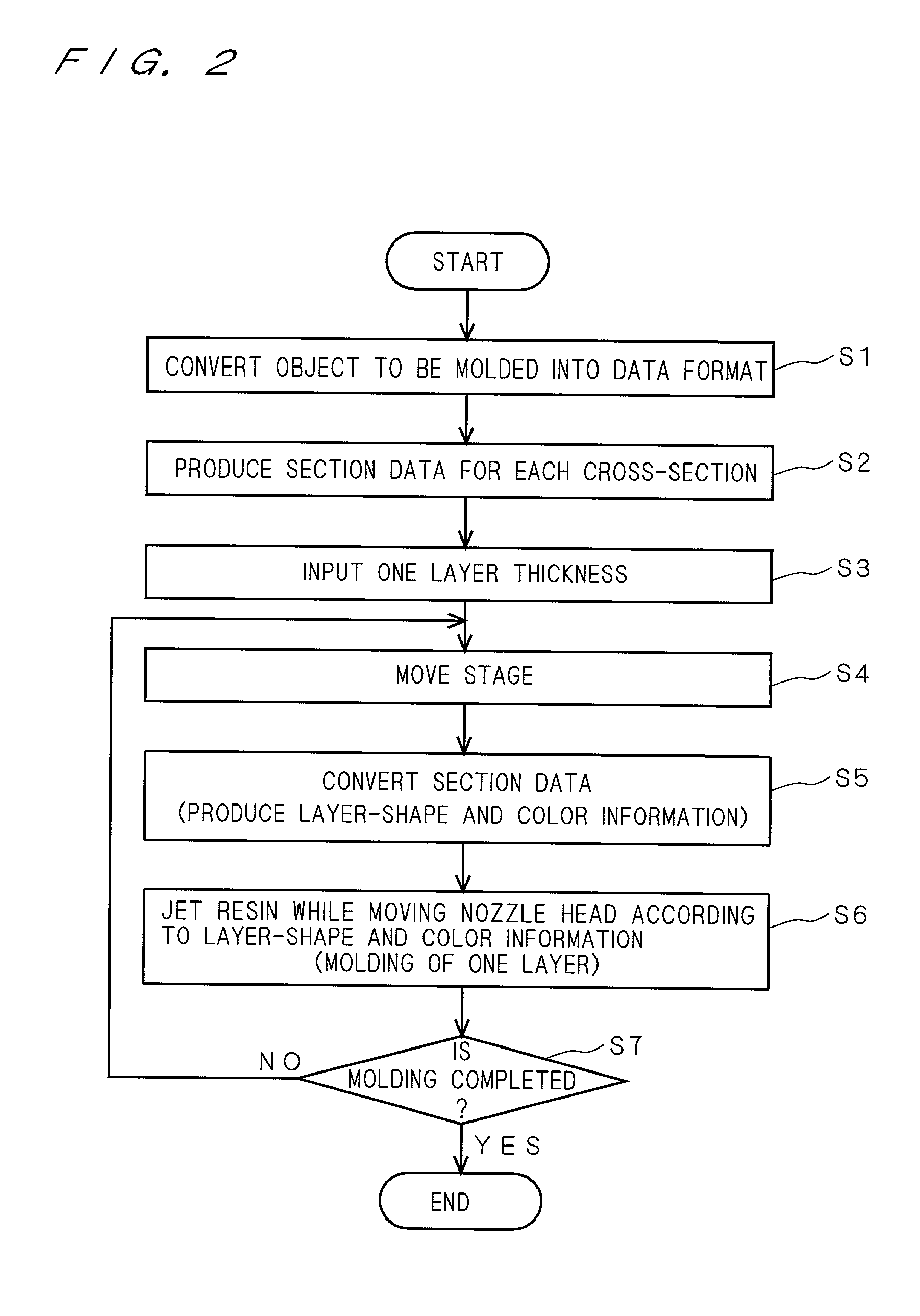

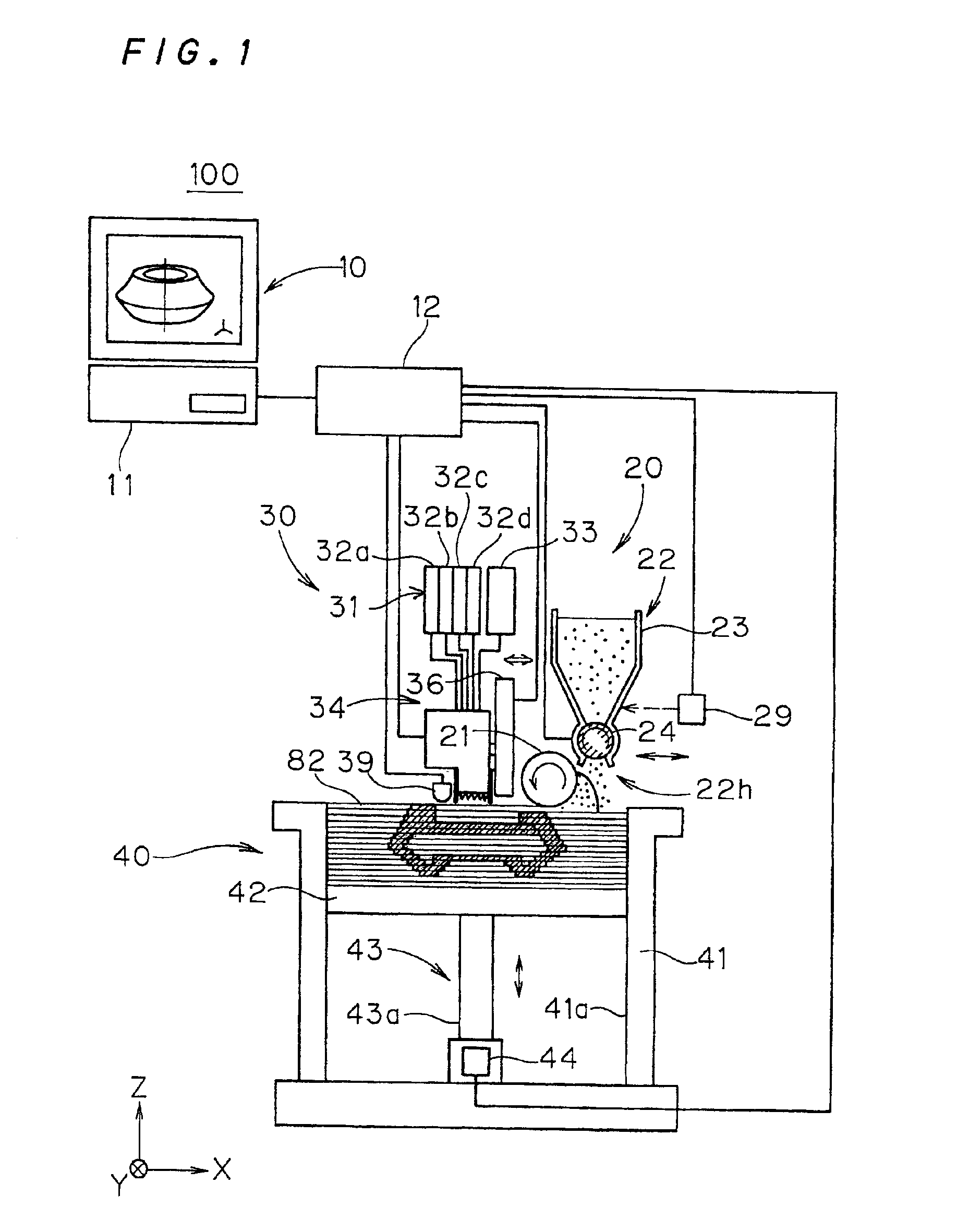

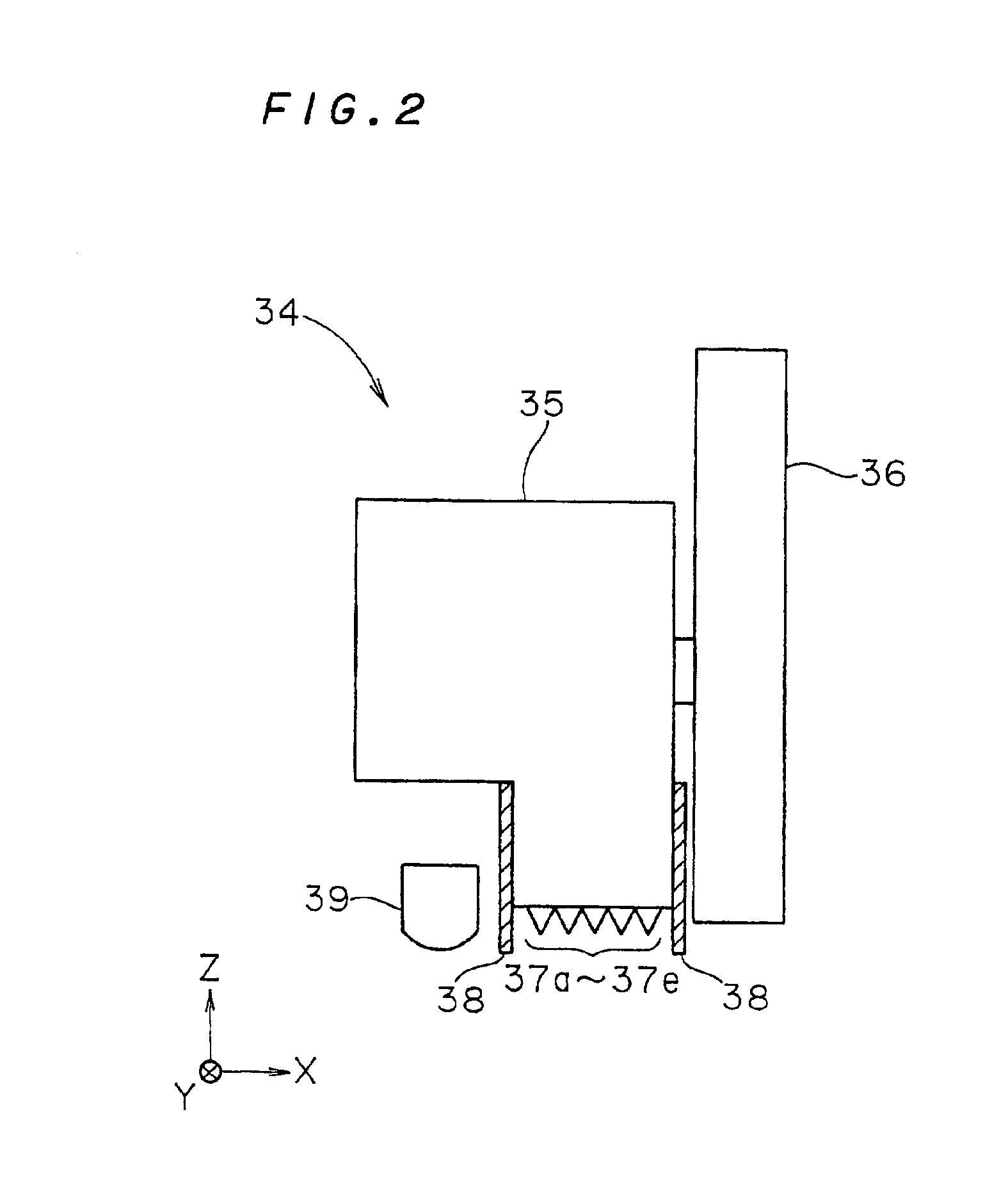

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

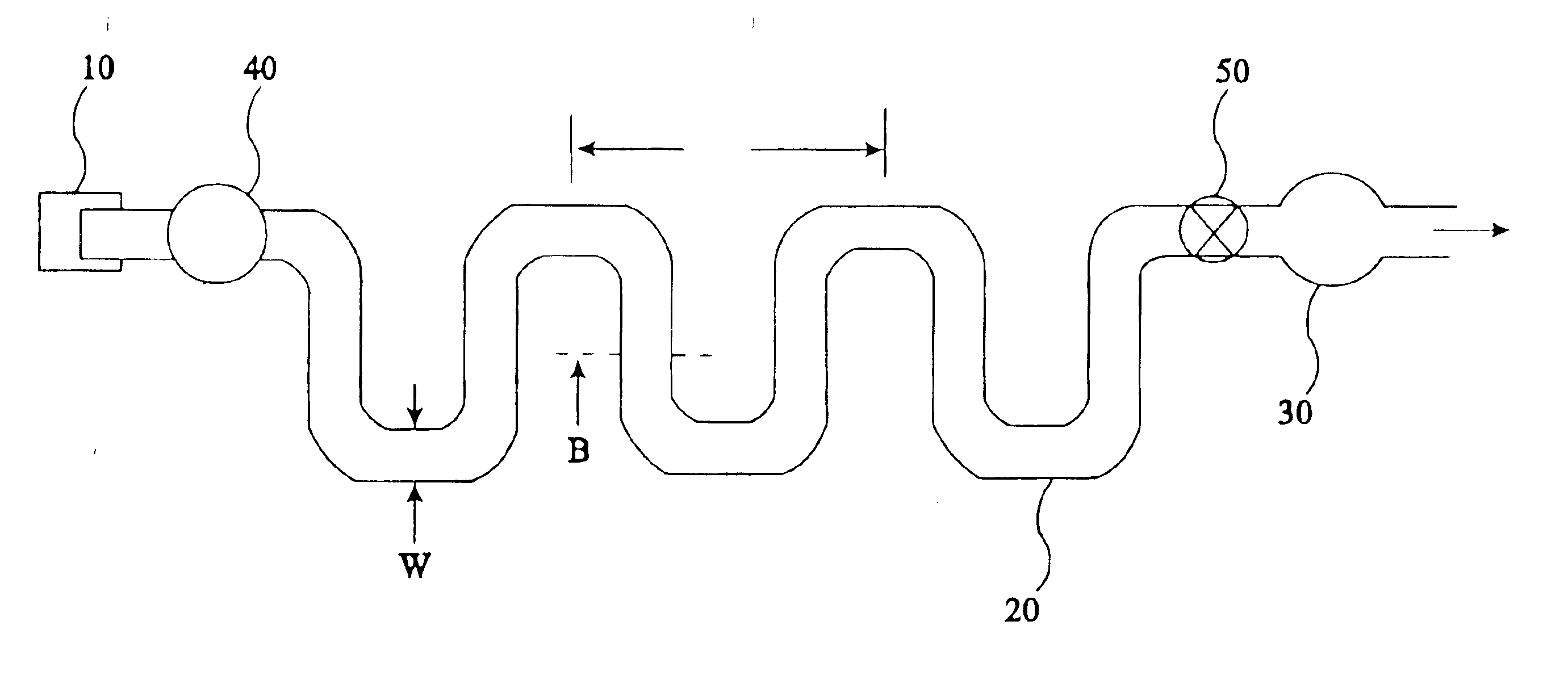

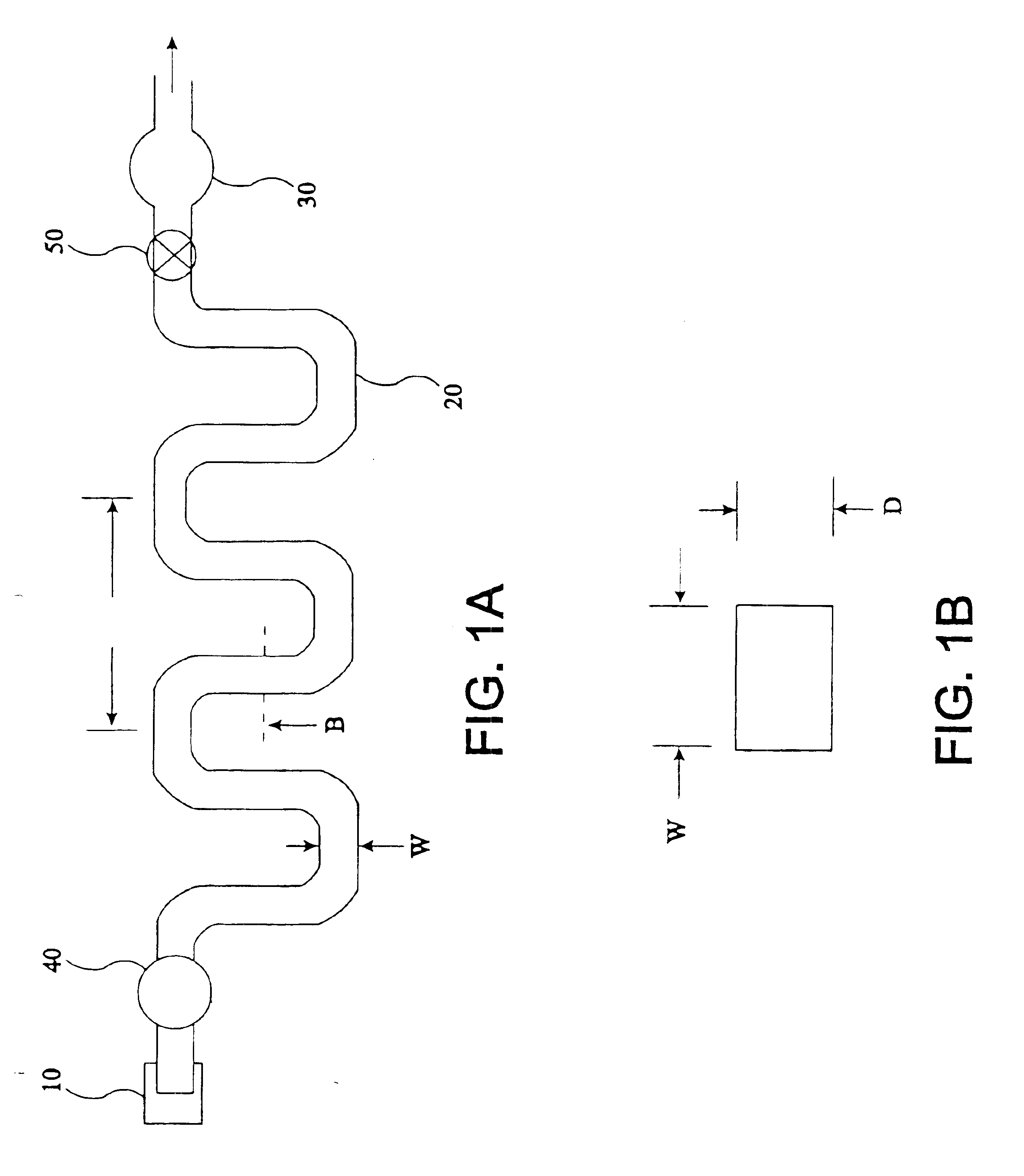

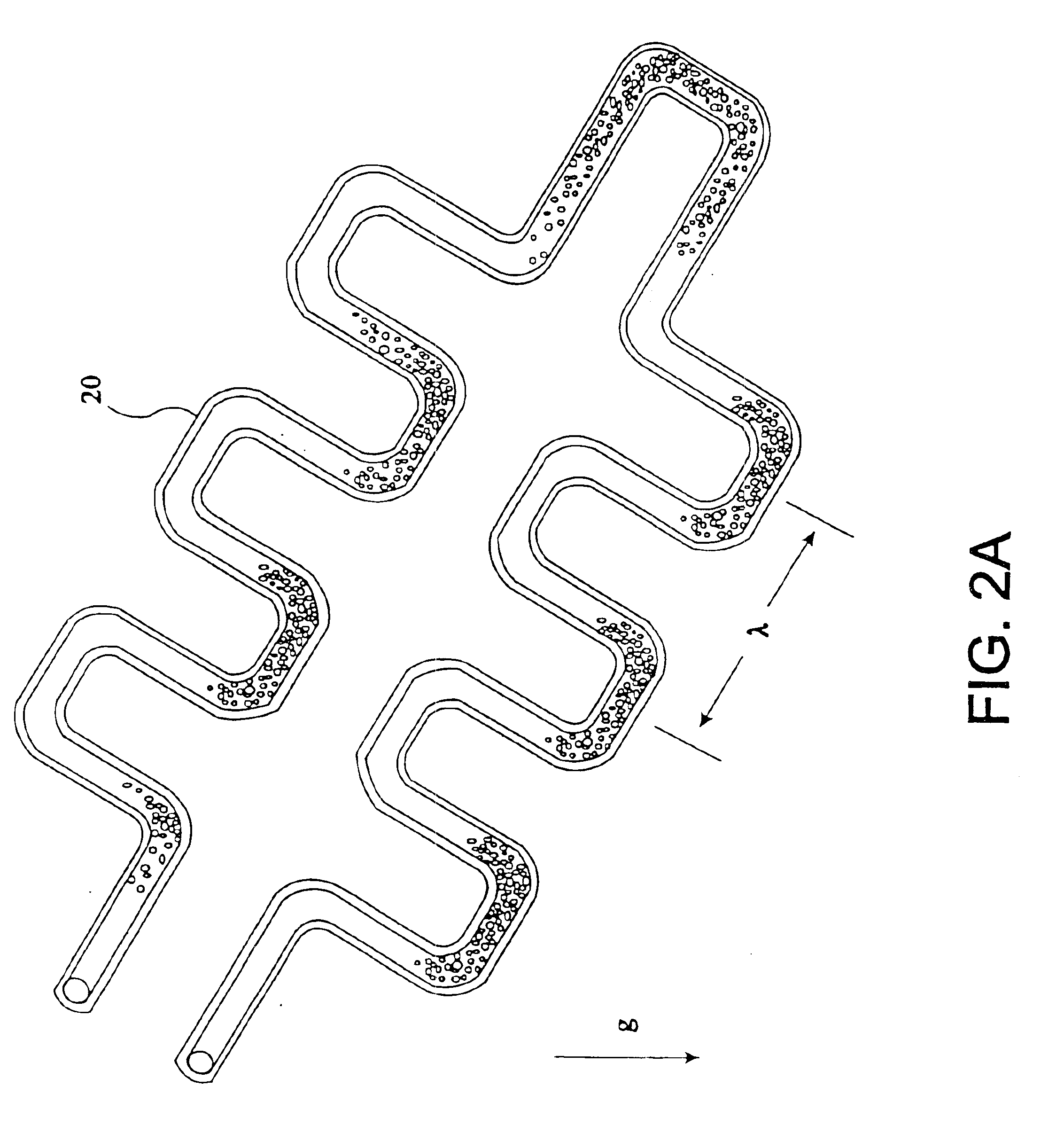

Liquid analysis cartridge

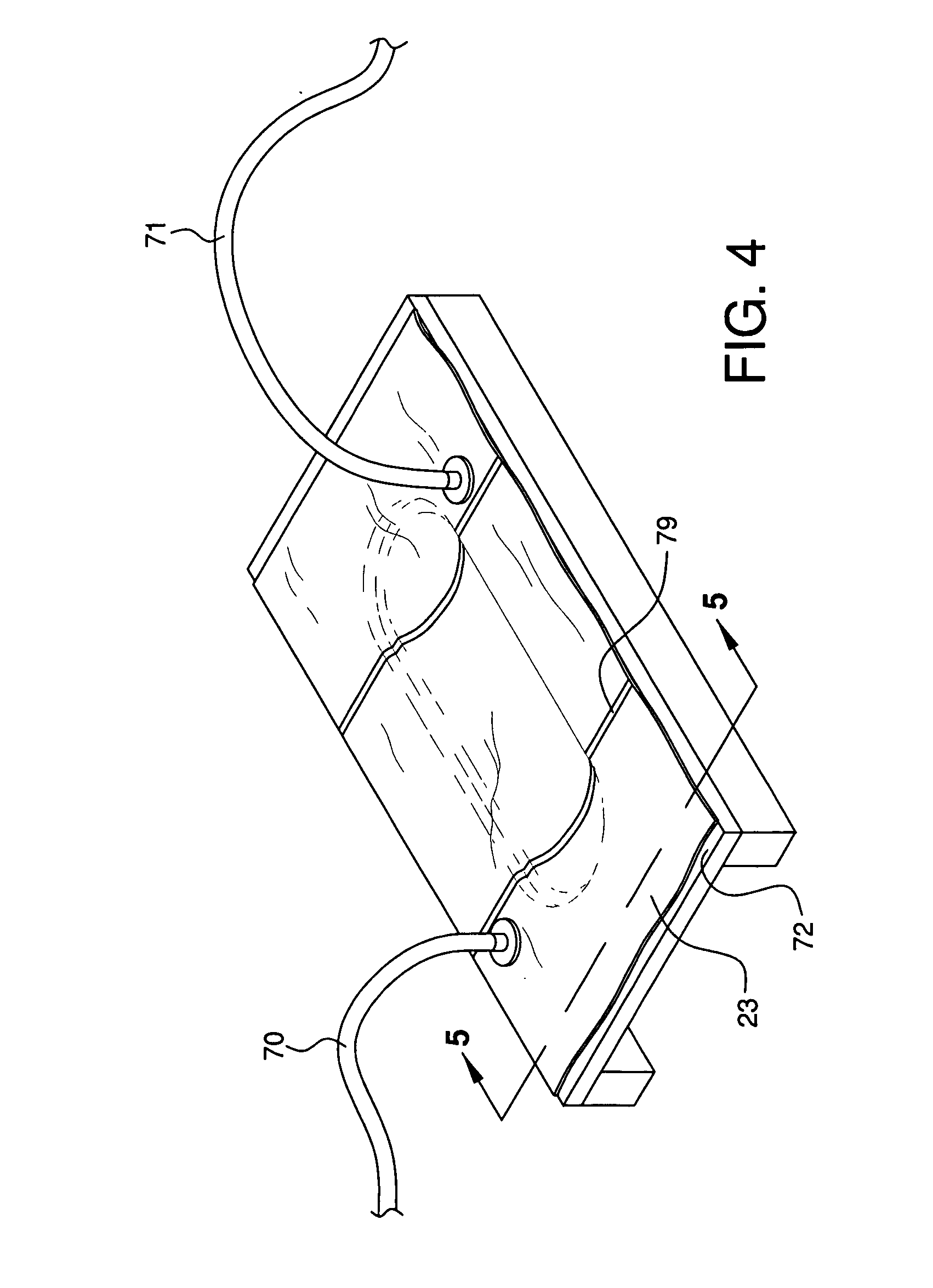

InactiveUS6852284B1Rapidly and effectively reconstituteEasy to reorganizeFlow mixersTransportation and packagingShell moldingDiluent

The present invention provides an apparatus and method for storing a particle-containing liquid. The storage apparatus comprises a microfluidic convoluted flow channel having a plurality of article capture regions. The storage channel is preferably an isotropic spatially periodic channel. Sedimented particles can be resuspended following storage. This invention further provides a microfluidic analysis cartridge having a convoluted storage channel therein. The sample analysis can use optical, electrical, pressure sensitive, or flow sensitive detection. A plurality of analysis channels can be included in a single cartridge. The analysis channels can be joined to reagent inlets for diluents, indicators or lysing agents. A mixing channel can be positioned between the reagent inlet and the analysis region to allow mixing and reaction of the reagent. The cartridge can include additional valves and pumps for flow management. The analysis cartridge can be a self-contained disposable cartridge having an integral waste storage container. This invention further provides a sheath flow assembly. The sheath flow assembly includes a sample channel and first and second sheath fluid channels positioned on either side of and converging with the sample channel. The assembly also includes upper and lower sheath fluid chambers positioned above and below and converging with the sample channel. The flow cartridges of this invention can be formed by molding, machining or etching. In a preferred embodiment they are laminated. This invention further provides a method of fabricating a laminated microfluidic flow device. In the method, flow elements are formed in rigid sheets and abutting surfaces of the sheets are bonded together.

Owner:UNIV OF WASHINGTON

Surgical device with tack-free gel and method of manufacture

InactiveUS20050033246A1Significant drag forceImprove complianceCannulasSurgical needlesMolten stateLow-density polyethylene

A process of making a tack-free gel is disclosed comprising the steps of providing a mold defining a mold cavity, the mold cavity comprising a plastic material; pouring or injecting a molten gel having a high molding temperature into the mold cavity; and forming the tack-free gel as a thin layer of plastic of the mold cavity is melted over the gel. The forming step further comprises cooling the gel from the molten state to a solidified state. The melting temperature of the plastic material is lower than the molding temperature of the gel; and the higher the temperature differential, the greater the melting of the plastic material and the thicker the layer of the plastic material on the surface of the gel. The mold may be formed of low-density polyethylene (LDPE). With the process of the invention, the heat of the molten gel at its molding temperature is transferred to the surface of the LDPE mold so as to melt a thin layer of the LDPE. The mold may comprise a mold base having a plurality of mold holes forming a plurality of mold cavities, each of the mold holes comprising an axial pin to mold an axial hole through a center of the gel, an LDPE cylinder providing a predetermined inside diameter for the mold, and an LDPE disc mounted on the axial pin and disposed at the bottom of each mold cavity in the mold base. The process may further comprise the step of dabbing the gel in a low-friction powder such as polytetrafluoroethylene (PTFE) and a lubricant. The mold may further comprise a mold top disposed axially of the mold base and comprises a plurality of holes forming a plurality of cavities, each of the mold top holes is adapted to receive the LDPE cylinder, and a second LDPE disc disposed at the top of each mold cavity of the mold top.

Owner:APPL MEDICAL RESOURCES CORP

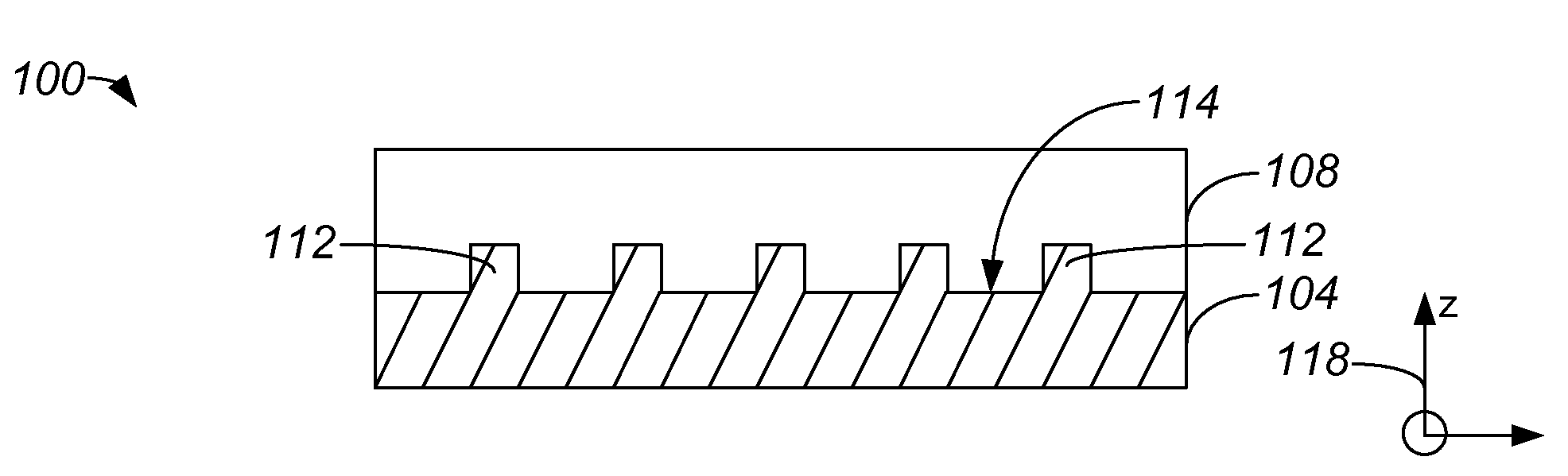

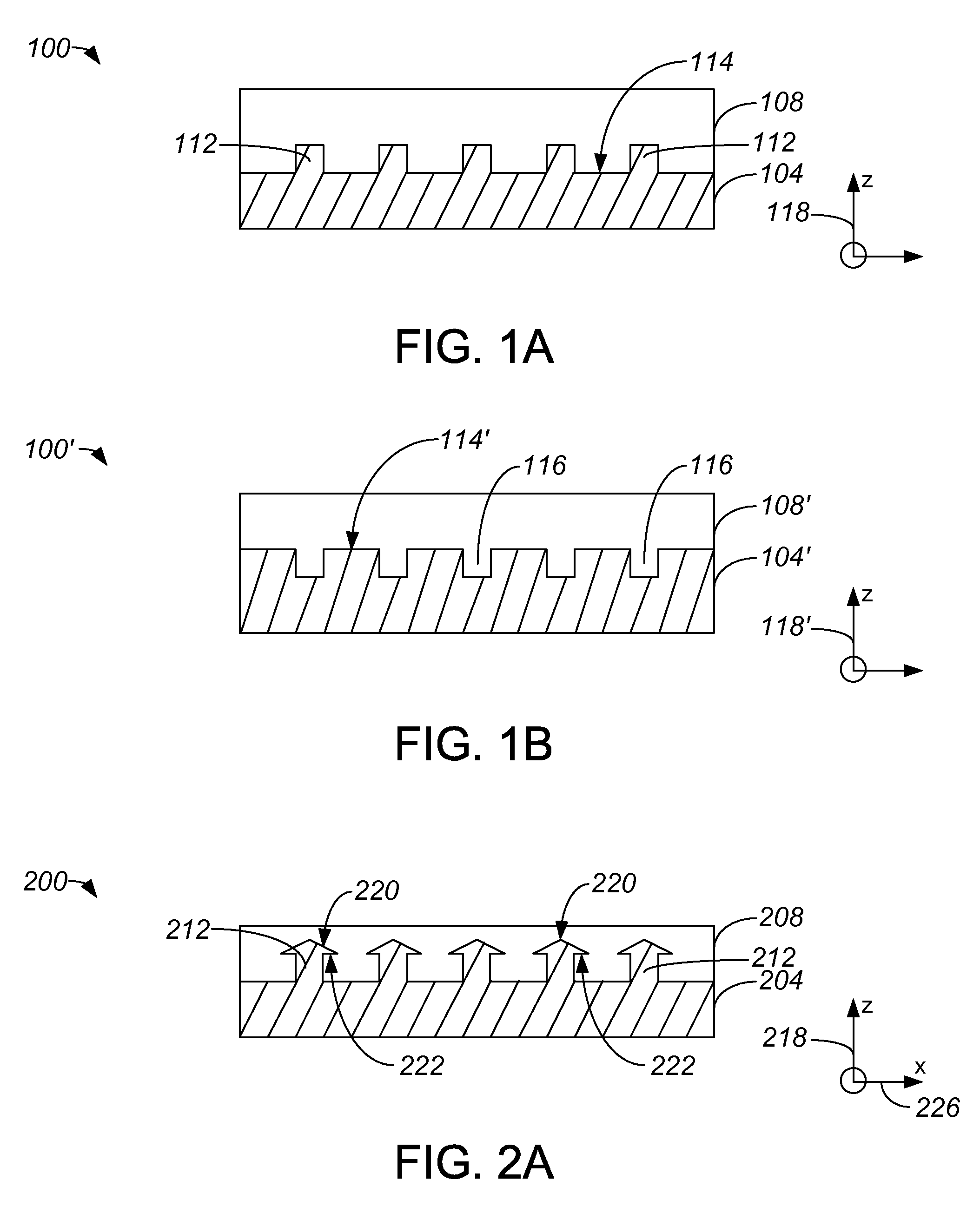

Imprint method and device

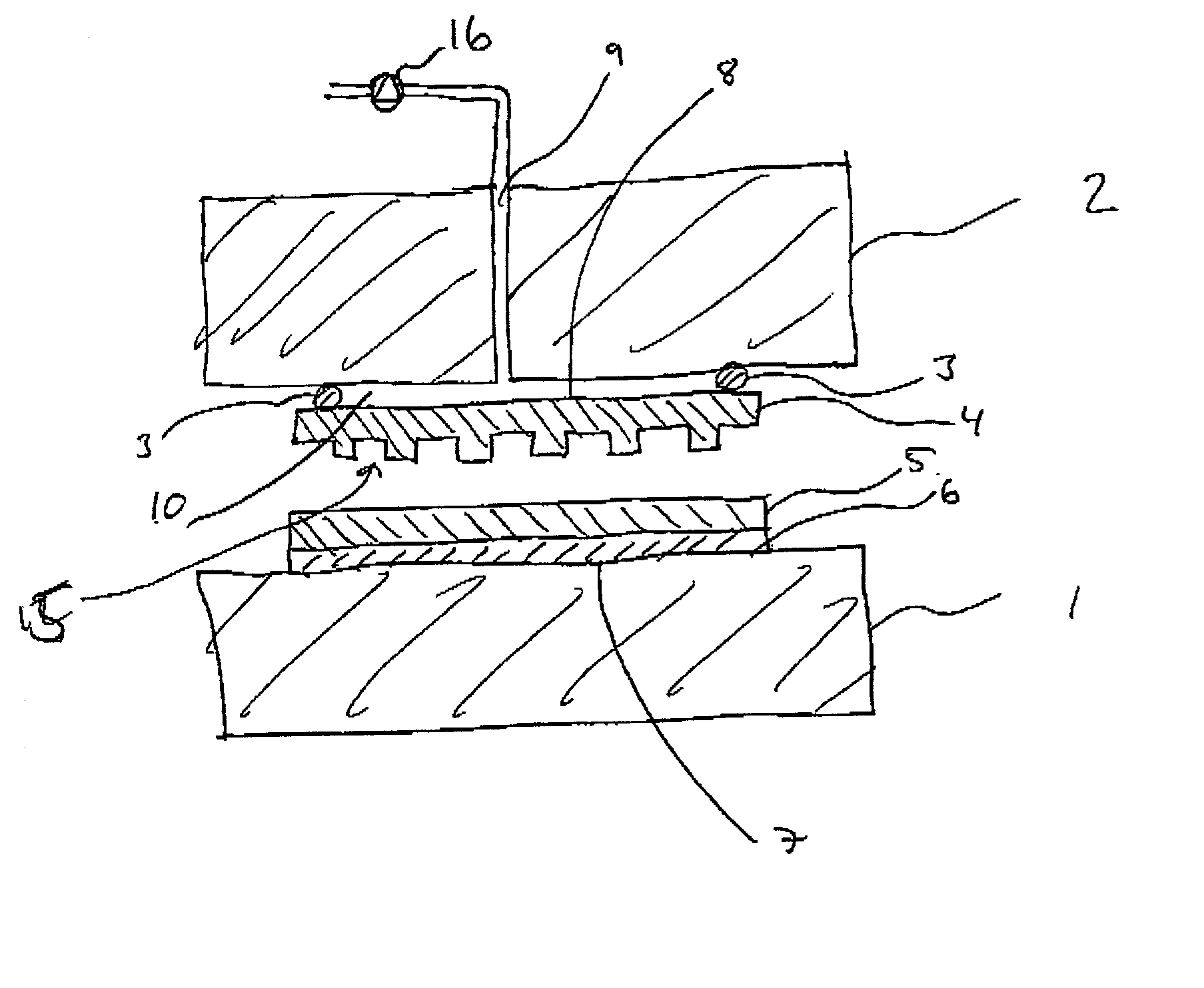

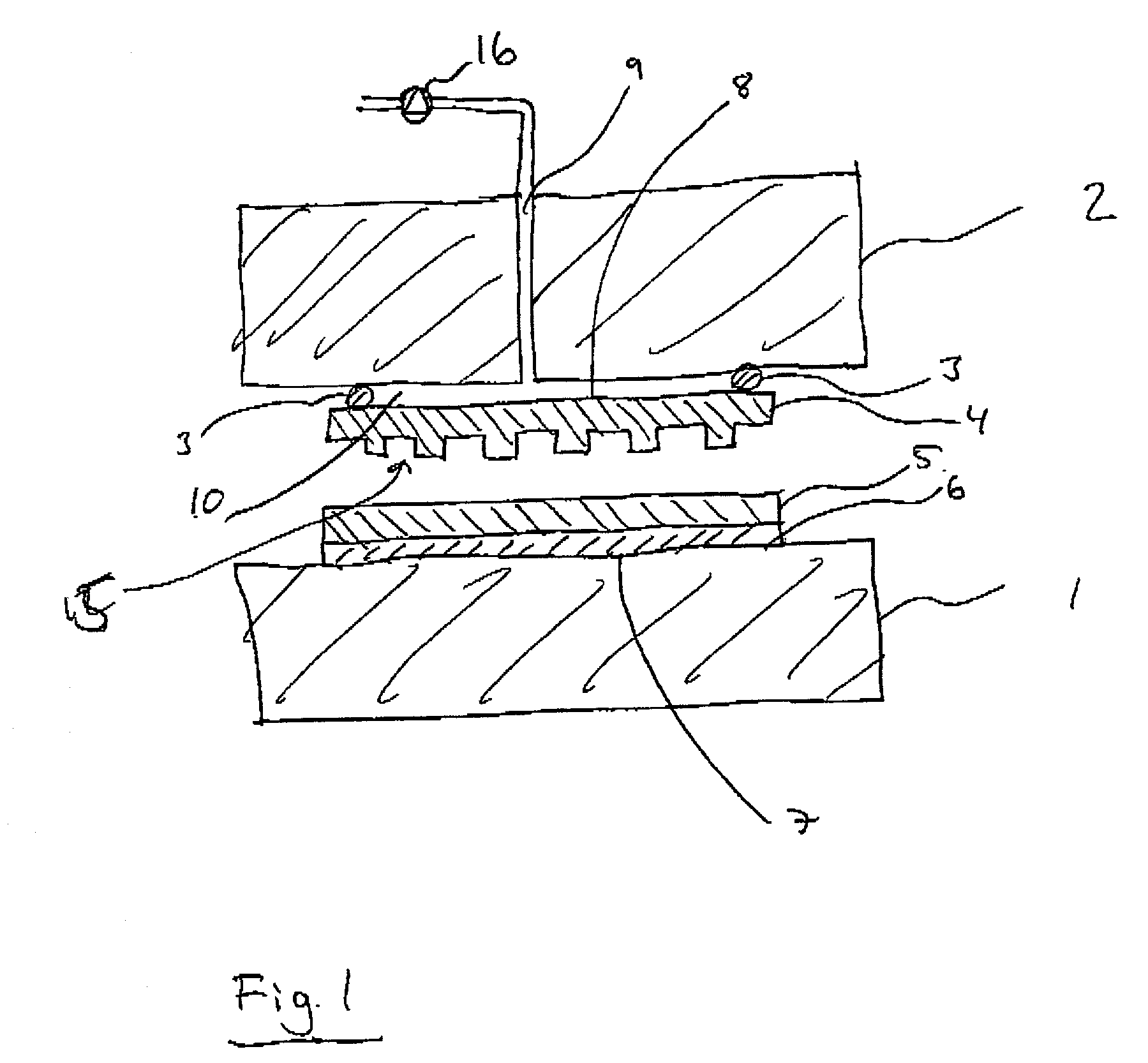

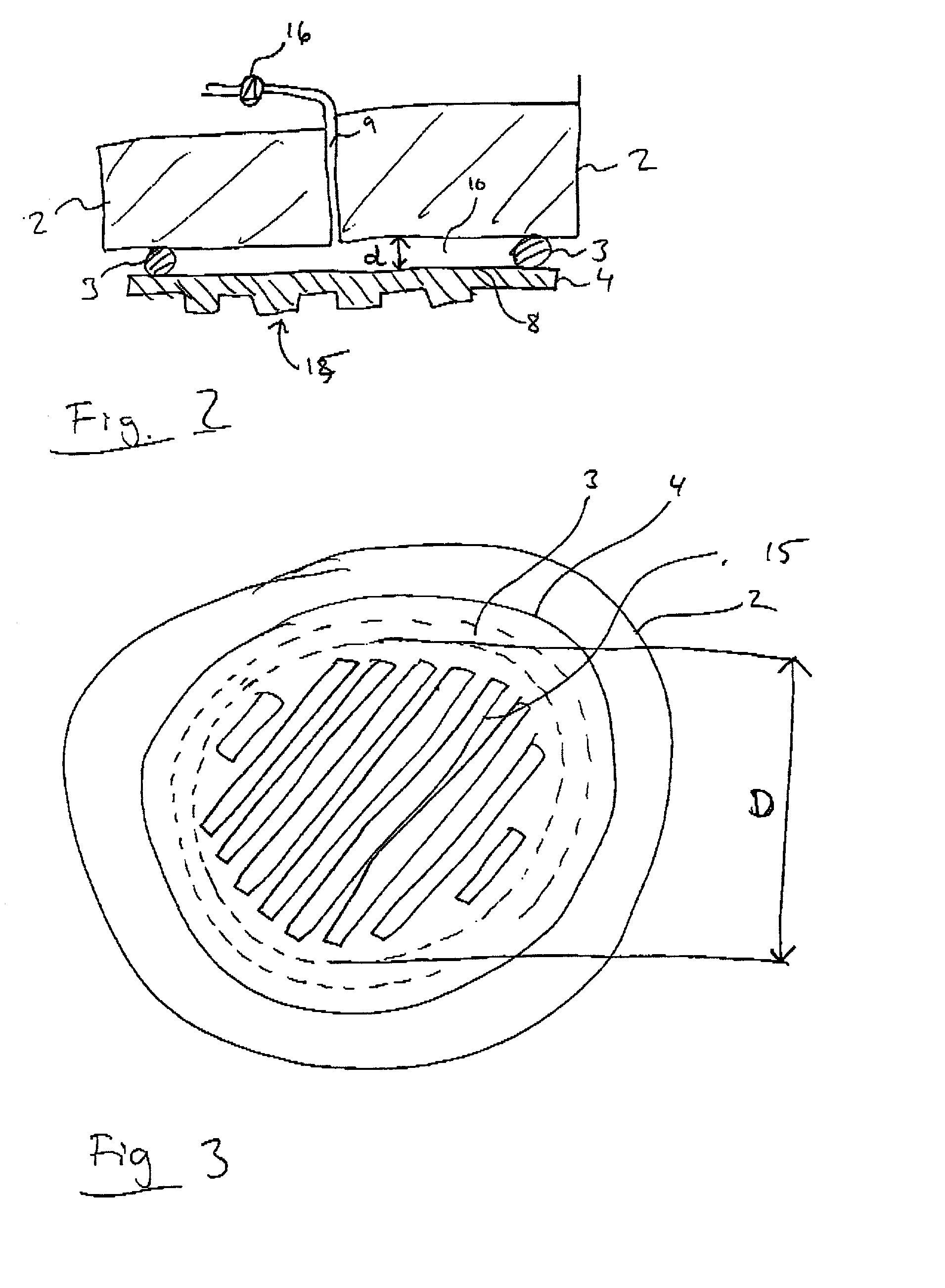

An imprint process comprises the step of aligning a substrate, supported on a first support member, with a template, supported on a second support member. The substrate has at least one essentially plane surface provided with a moldable film. The template has at least one essentially plane surface provided with a relief pattern. The relief pattern is adapted to interact with the moldable film. The process further comprises the step of arranging a sealing gasket between the template and the second support member, such that a pressure cavity is defined by the second support member, the template and the sealing gasket. The process also comprises the step of applying a static gas pressure to the pressure cavity, in order to provide a pressure between the template and the substrate. The pressure is sufficient to form a pattern in the moldable film. An imprint device is also disclosed.

Owner:OBDUCAT AB SE

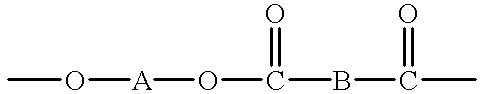

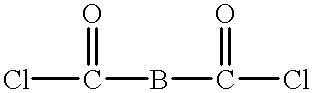

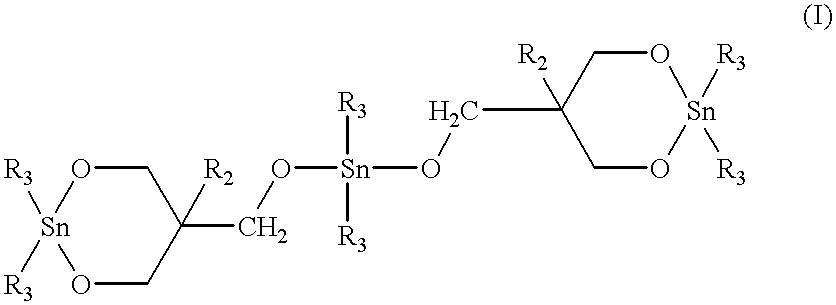

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

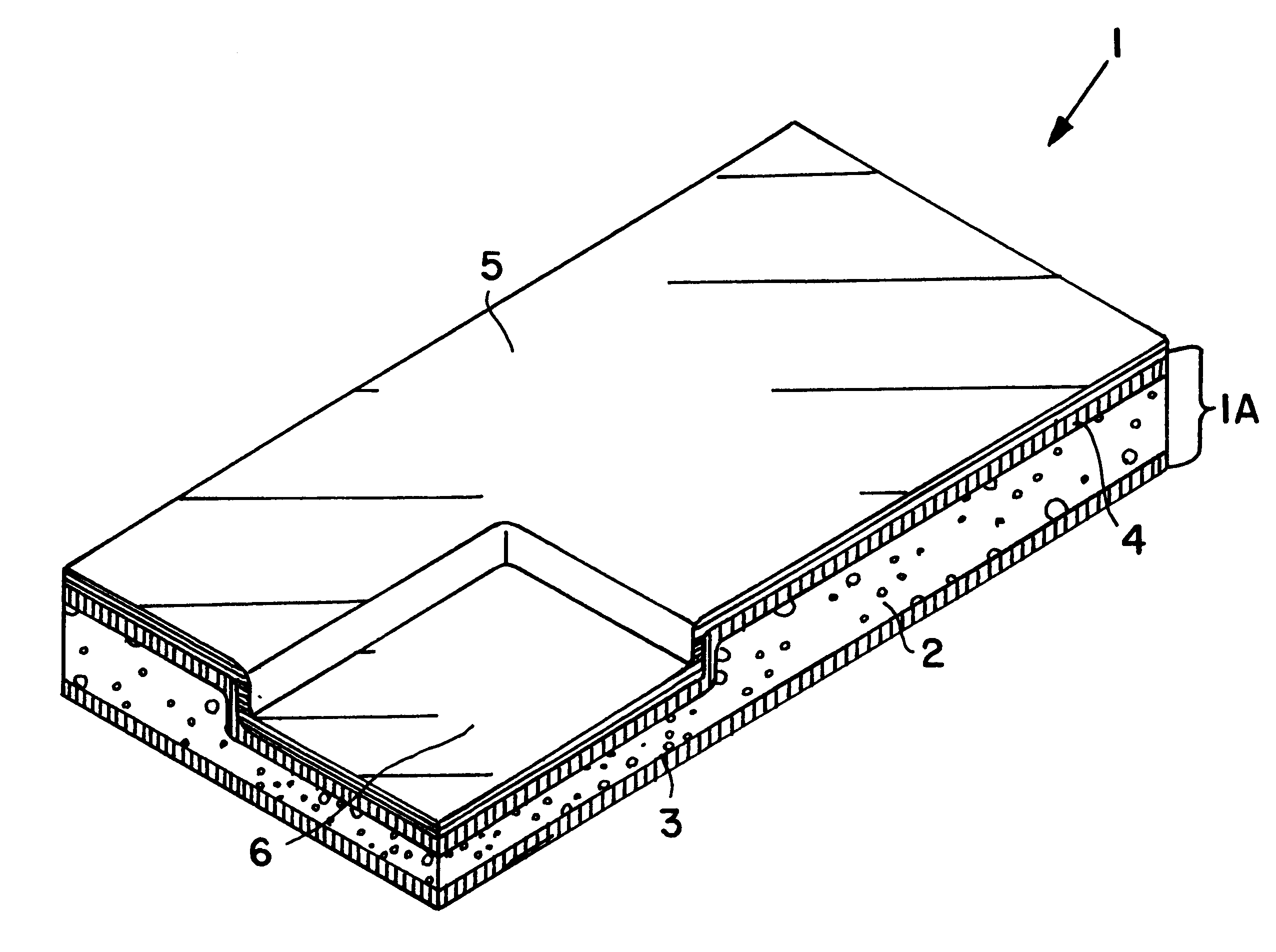

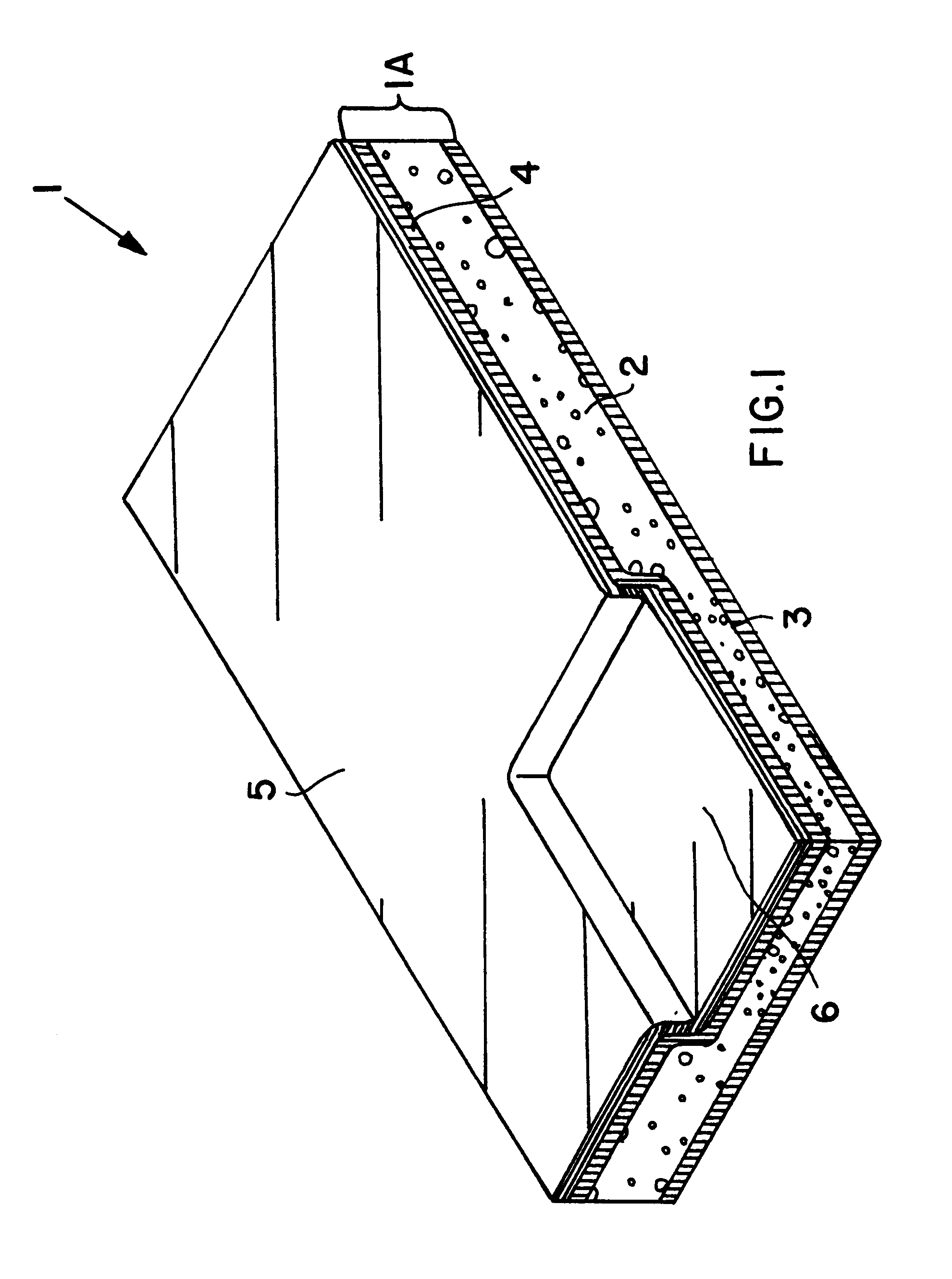

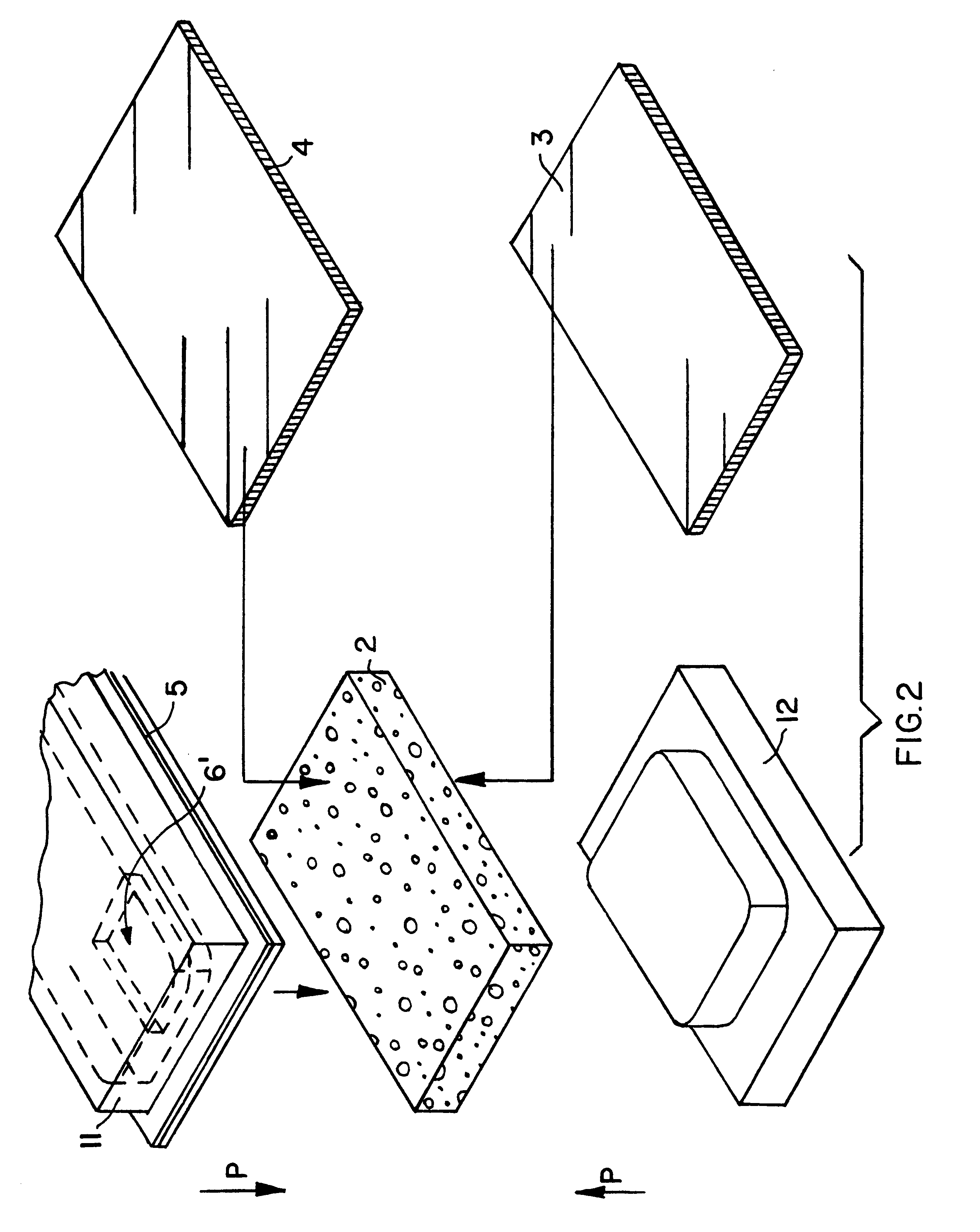

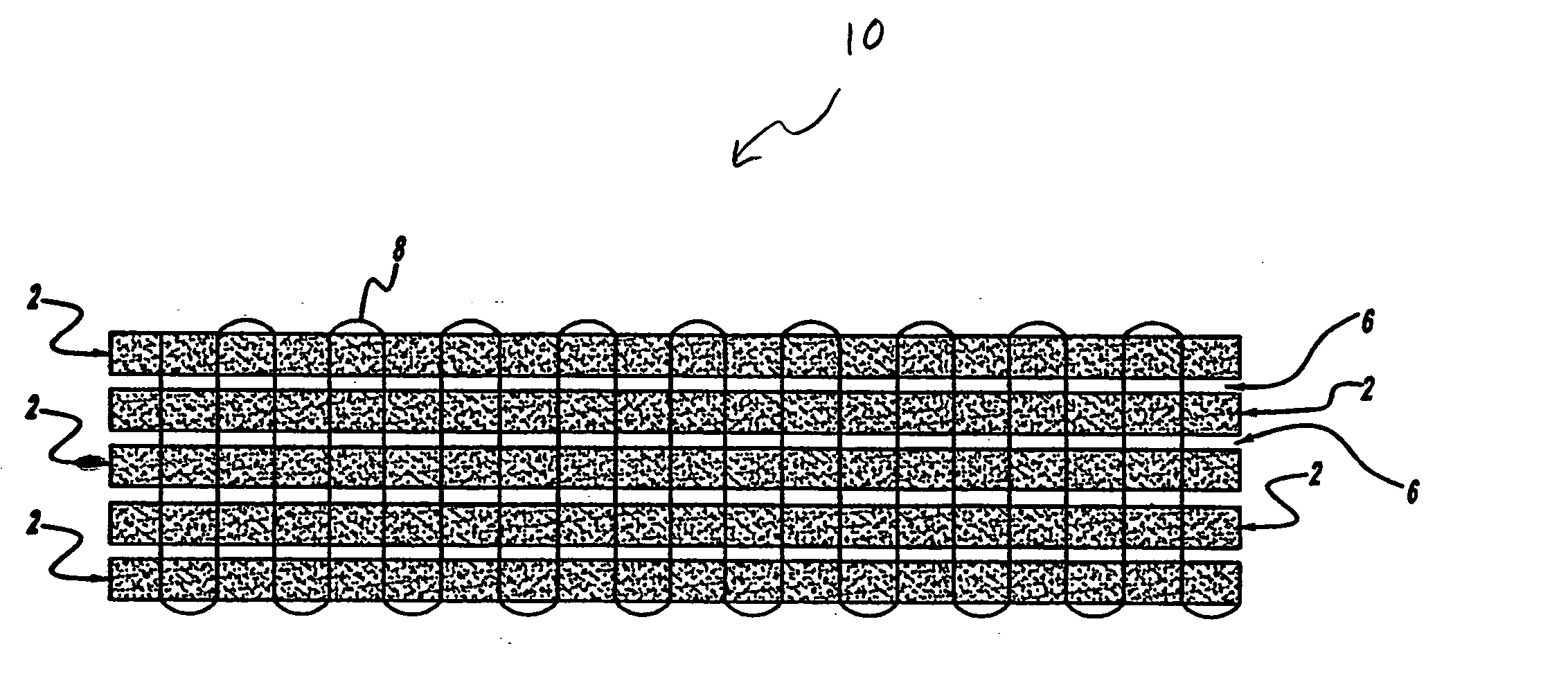

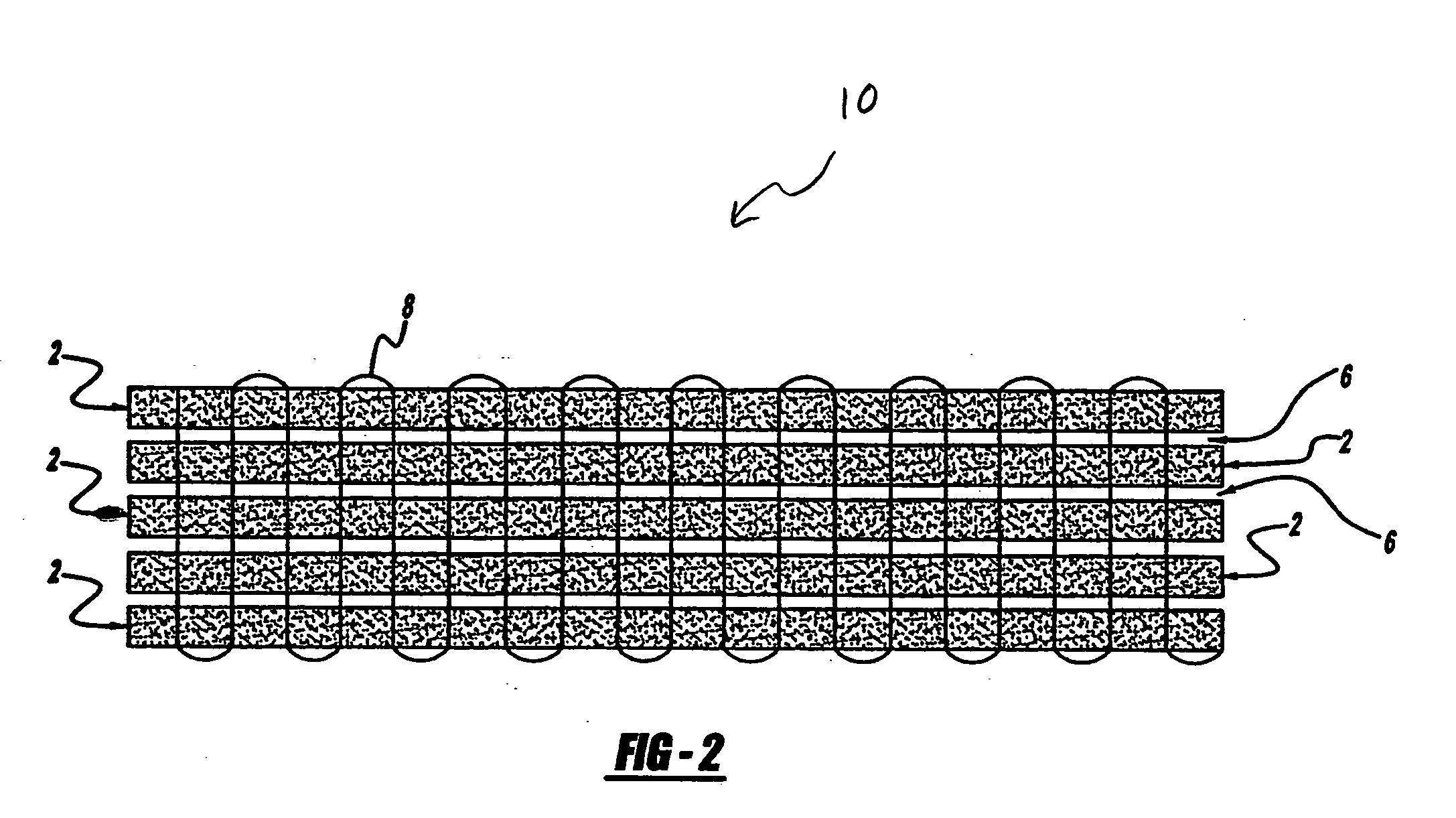

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

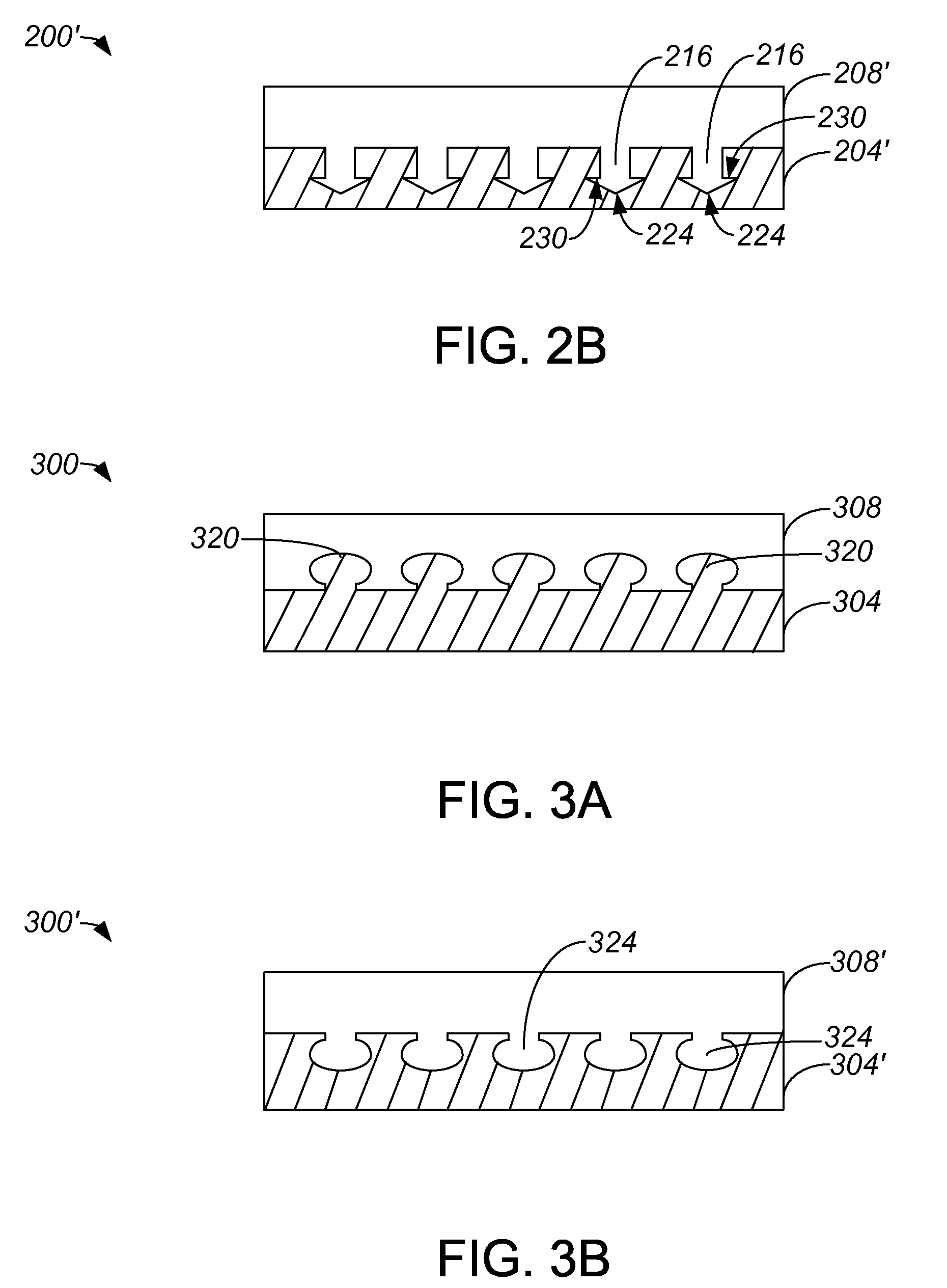

Methods and systems for forming a dual layer housing

ActiveUS20090017242A1Envelopes/bags making machinerySynthetic resin layered productsShell moldingMaterials science

Methods and apparatus for applying internal features or complex mechanical structures to a surface of a metal part are disclosed. According to one aspect of the present invention, a method for creating an assembly that includes a substrate and a molded piece involves obtaining the substrate, and forming at least one binding feature on a surface of the substrate. The method also includes molding on a surface of the binding feature and the surface of the substrate. Molding on the surface of the binding feature and the surface of the substrate mechanically binds the molded piece to the substrate.

Owner:APPLE INC

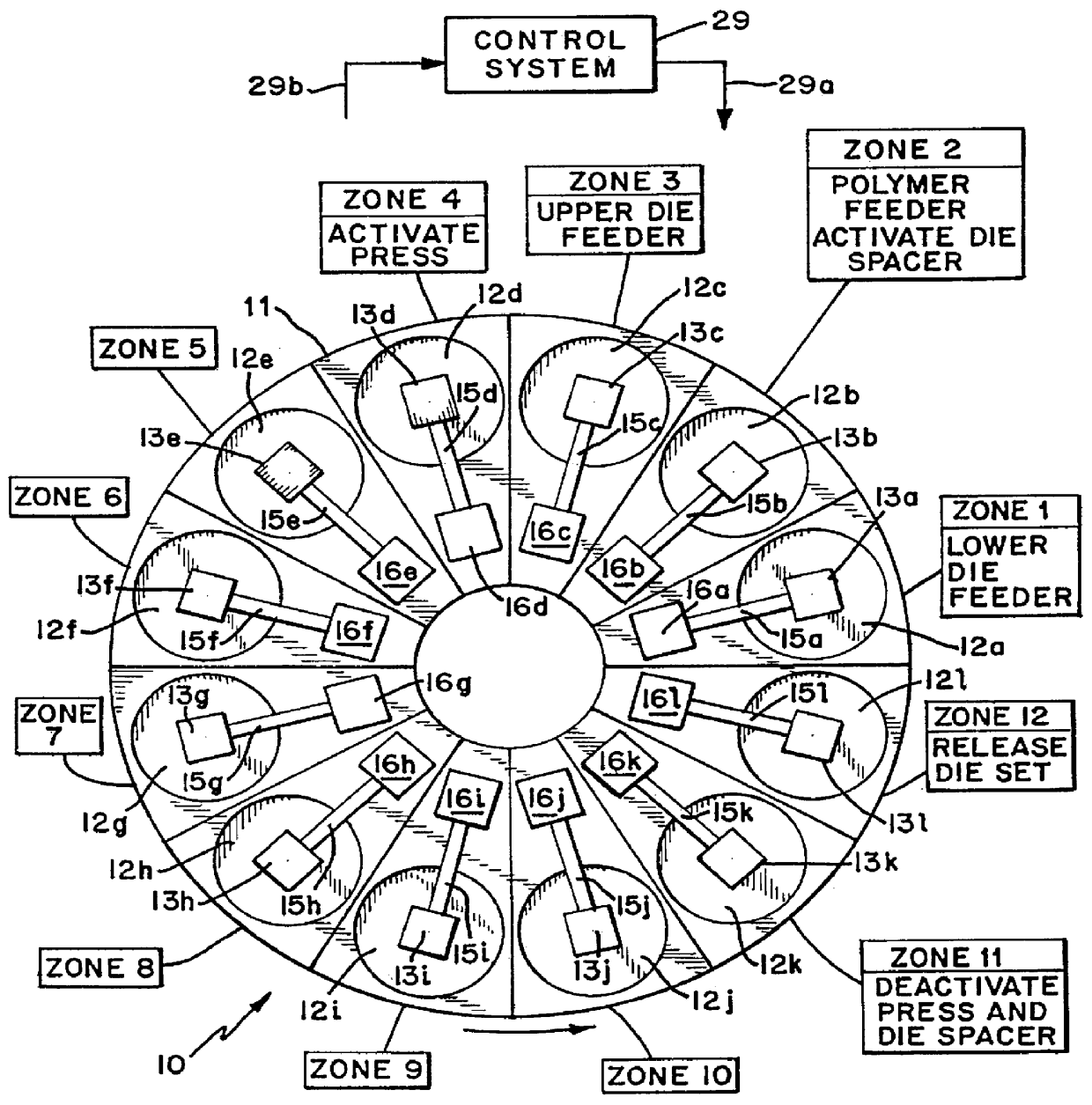

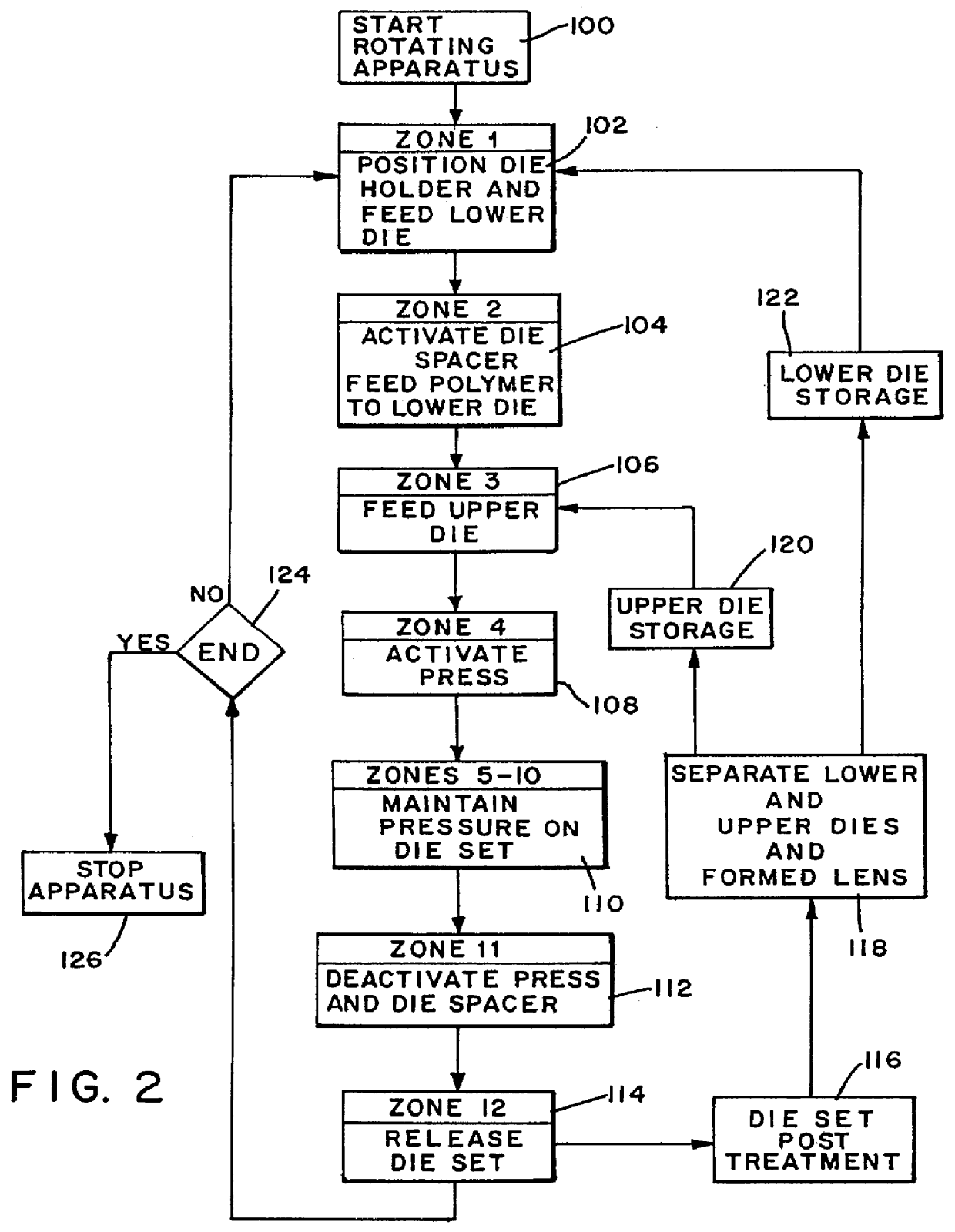

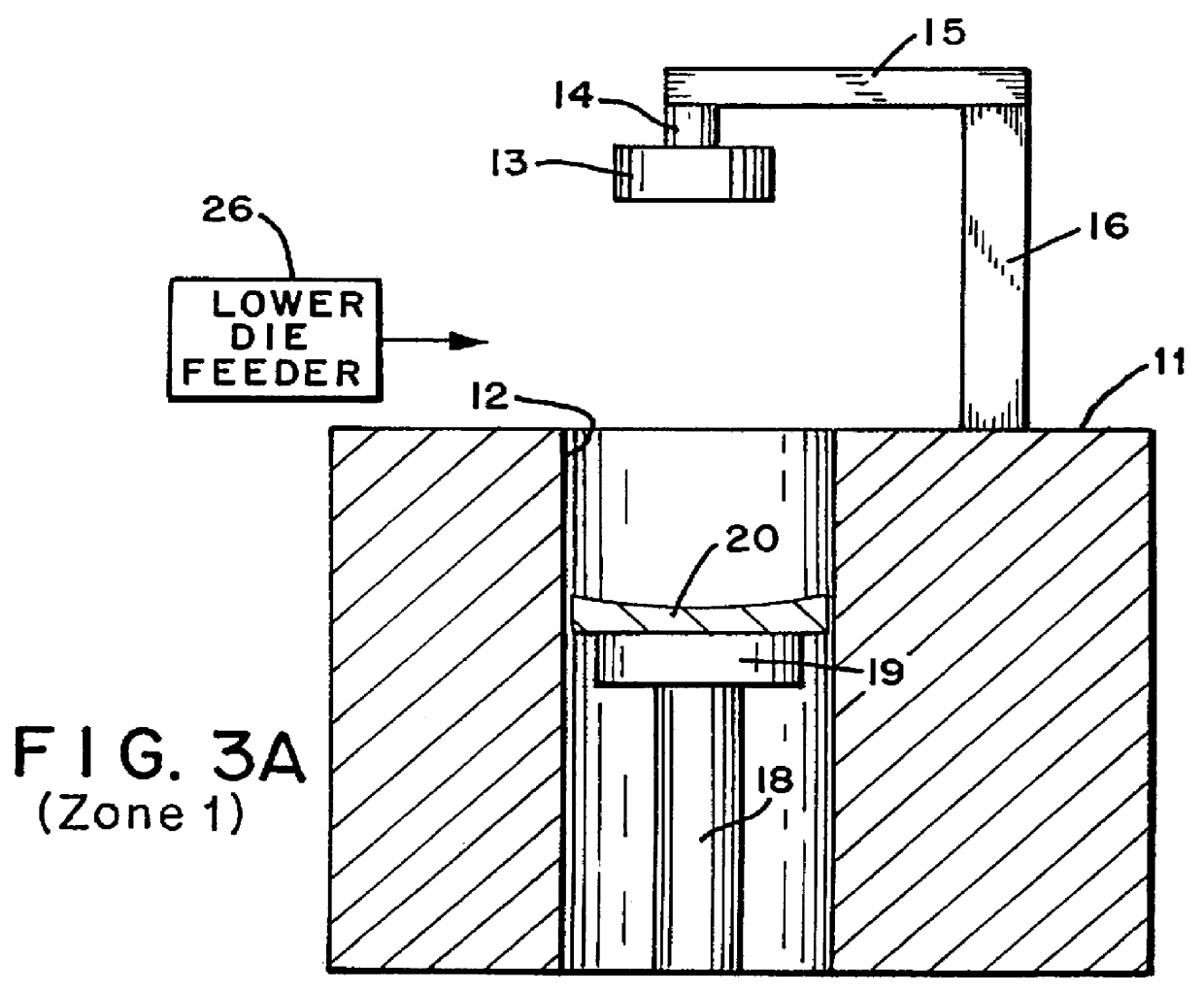

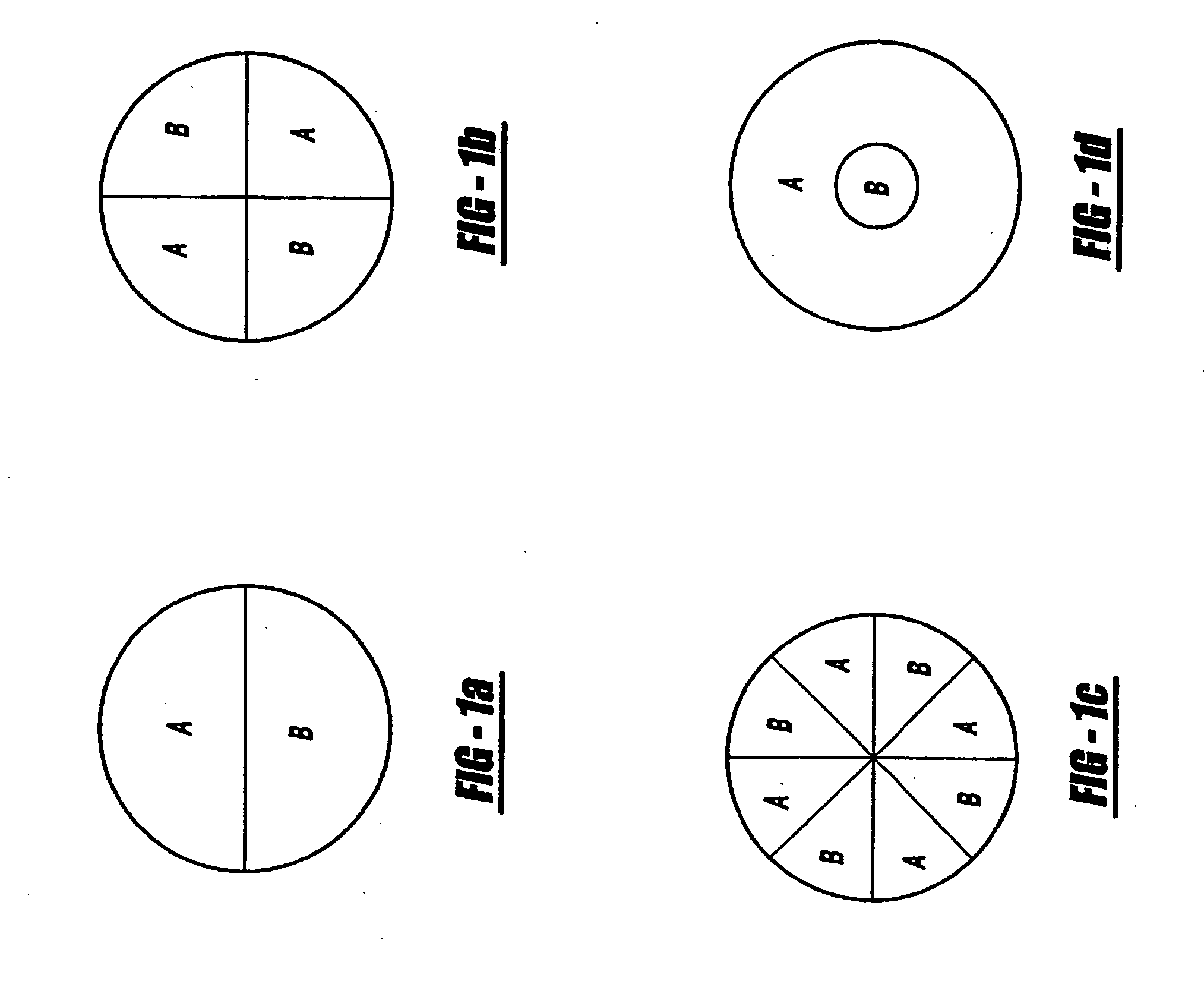

Continuous extrusion-compression molding process for making optical articles

InactiveUS6042754AEasy to processLong lastingRecord carriersConfectioneryCompression moldingShell molding

The present invention relates to making optical articles such as opthalmic lenses by molding and, in particular, to using a continuous extrusion-compression molding method to make plastic lenses whereby a polymer melt is fed from an extruder or melting apparatus to a first die of a plurality of rotating or conveyed sequentially processed compression die sets comprising a first die and a second die. The die sets are positioned on die supports on a rotating turntable or conveying system, the lenses formed by compressing the die sets with pressing means associated with each die support, the lenses separated from the dies and the dies recycled to die loading and the melt feed step of the process and the process repeated until the desired number of lenses or other optical articles such as compact disk substrates are produced.

Owner:FOREVER VISION

Reusable vacuum bag and methods of its use

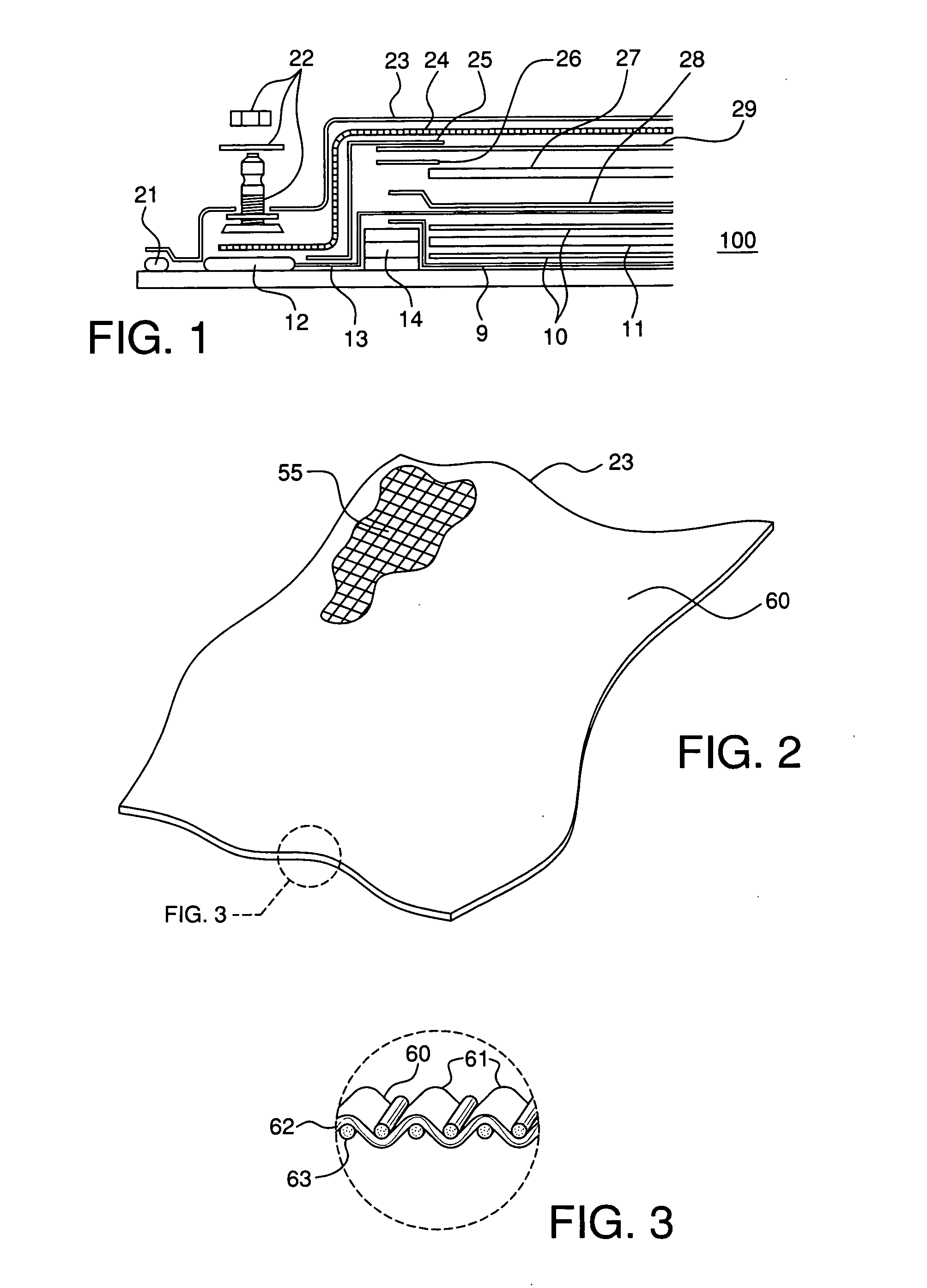

InactiveUS20050086916A1Eliminate disposableEliminate expenseDispersed particle filtrationConfectioneryFiberShell molding

Reusable vacuum bags are provided which include a fabric layer containing reinforcement fibers and a release surface disposed on at least the first side of the fabric layer. The vacuum bag is capable of withstanding multiple mold cycles of the vacuum of less than ambient pressure without significant leakage. In addition, the described vacuum bag can be used in resin transfer molding and standard bagging operations with commercial benefit.

Owner:SAINT GOBAIN BRUNSWICK TECH +1

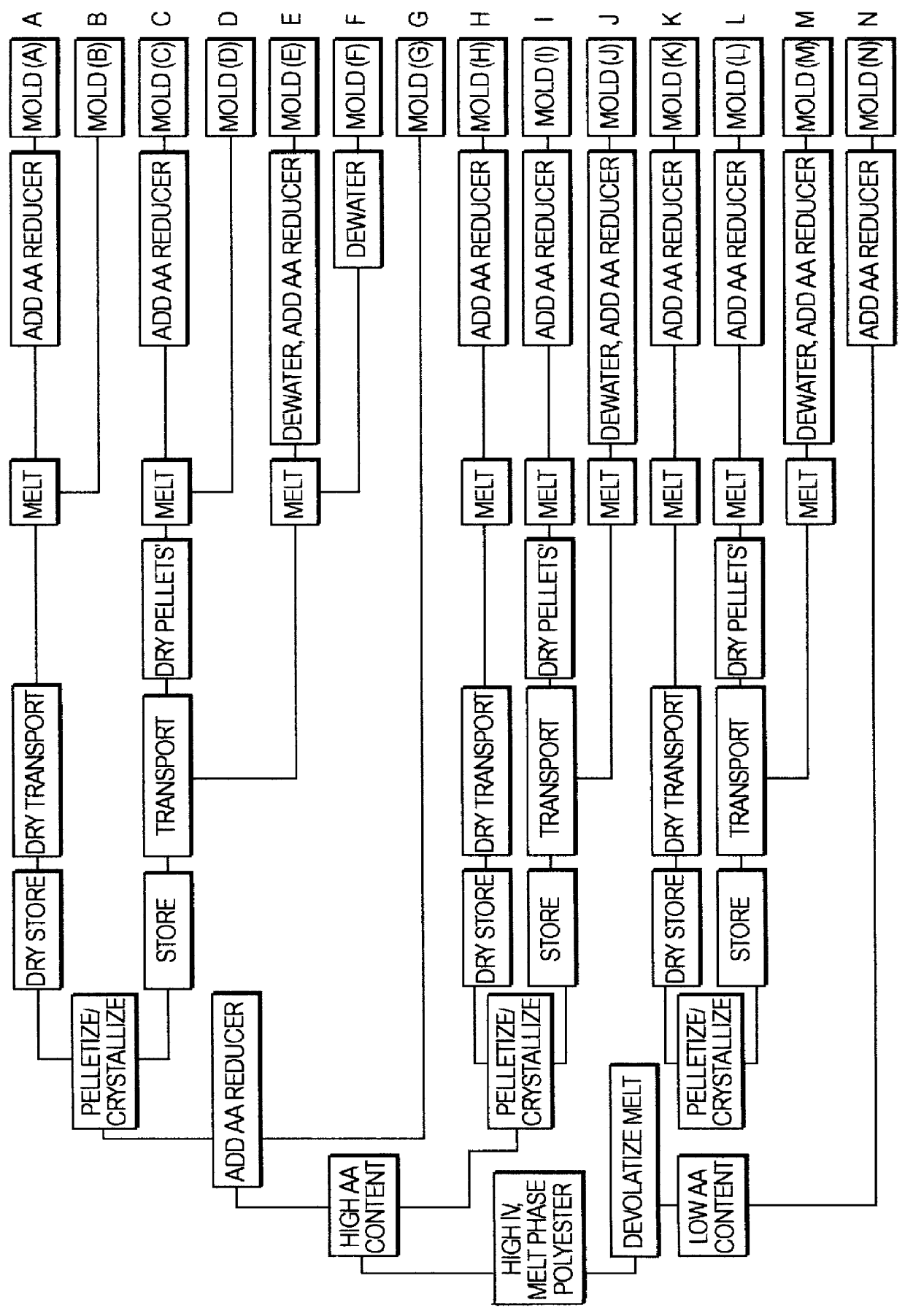

Process for producing pet articles with low acetaldehyde

The present invention discloses a process for producing molded, shaped or extruded articles comprising the steps of: a) melt reacting, in the presence of a catalyst which is substantially free of Co compounds, at least one glycol and at least one dicarboxylic acid to form a polyester having an I.V. of at least about 0.5 dL / g, wherein said at least one glycol is selected from the group consisting of glycols having up to 10 carbon atoms and mixtures thereof and said dicarboxylic is selected from the group consisting of alkyl dicarboxylic acids having 2 to 16 carbon atoms, aryl dicarboxylic acids having 8 to 16 carbon atoms and mixtures thereof; b) adding an acetaldehyde reducing additive to said polyester to form a reduced acetaldehyde polyester; and c) forming said reduced acetaldehyde polyester into articles directly from step b. Thus, the present invention provides a process for directly producing from the melt article having extremely low acetaldehyde content.

Owner:GRUPO PETROTEMEX DE C V

Methods and preforms for forming composite members with interlayers formed of nonwoven, continuous materials

ActiveUS20050059309A1Improve impact resistanceLayered productsWoven fabricsShell moldingMaterials science

Materials and methods are provided for producing preform materials for impact-resistant composite materials suitable for liquid molding. Interlayers formed of nonwoven, continuous fibers, such as spunbonded, spunlaced, or mesh fabric, are introduced between non-crimped layers of unidirectional reinforcing fibers to produce a preform for use in liquid-molding processes to produce a composite member. Curing of the preform provides increased impact resistance by increasing the amount of energy required to propagate localized fractures due to impact.

Owner:THE BOEING CO

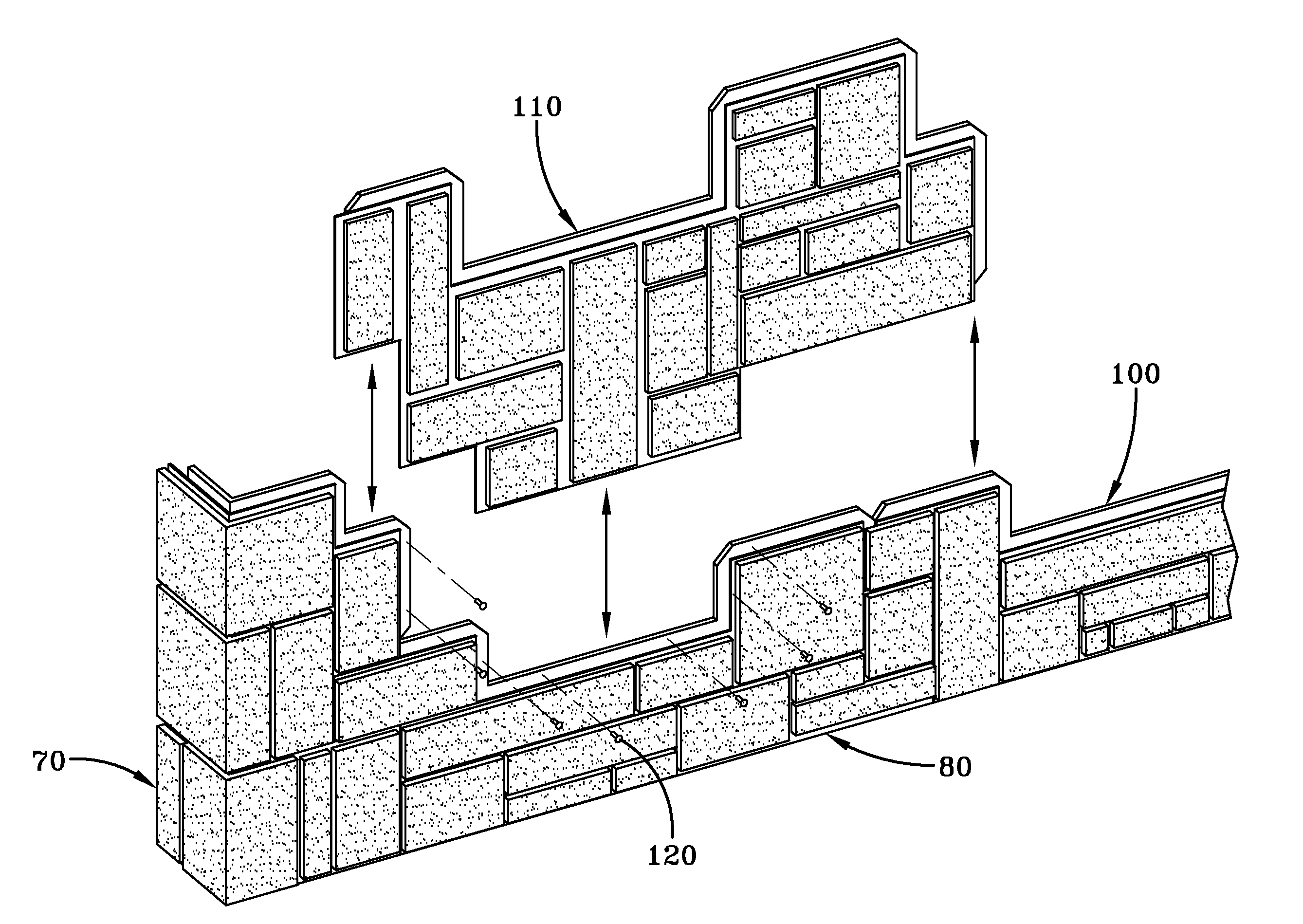

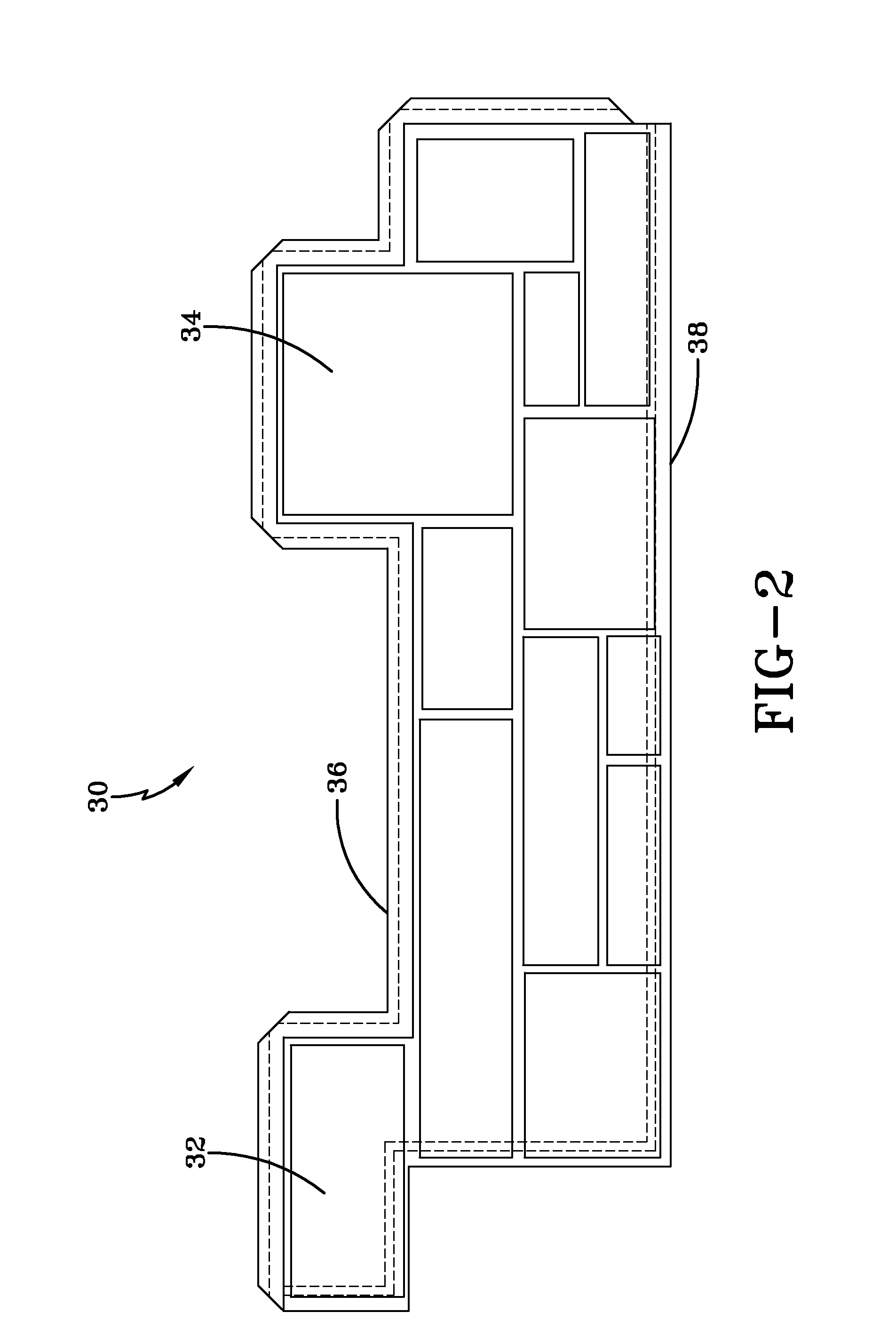

Foaming of simulated stone structures

InactiveUS20090056257A1Improve insulation performanceImprove sound insulationConstruction materialCovering/liningsBrickThermal insulation

Simulated stone, masonry, and brick textured products such as siding having a foam backing or with the hollow parts injected with foam or molded with foam in one or more steps, obtained when specially selected materials are properly admixed and formed via molding techniques. The foam backing is applied to the product in either a one or two step process. The foam backing may be used on panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearance of conventional building and construction materials including, but not limited to, stone, brick, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. The foam backing provides improves thermal insulation, improved sound reduction, improved rigidity, and improved dimensional stability. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

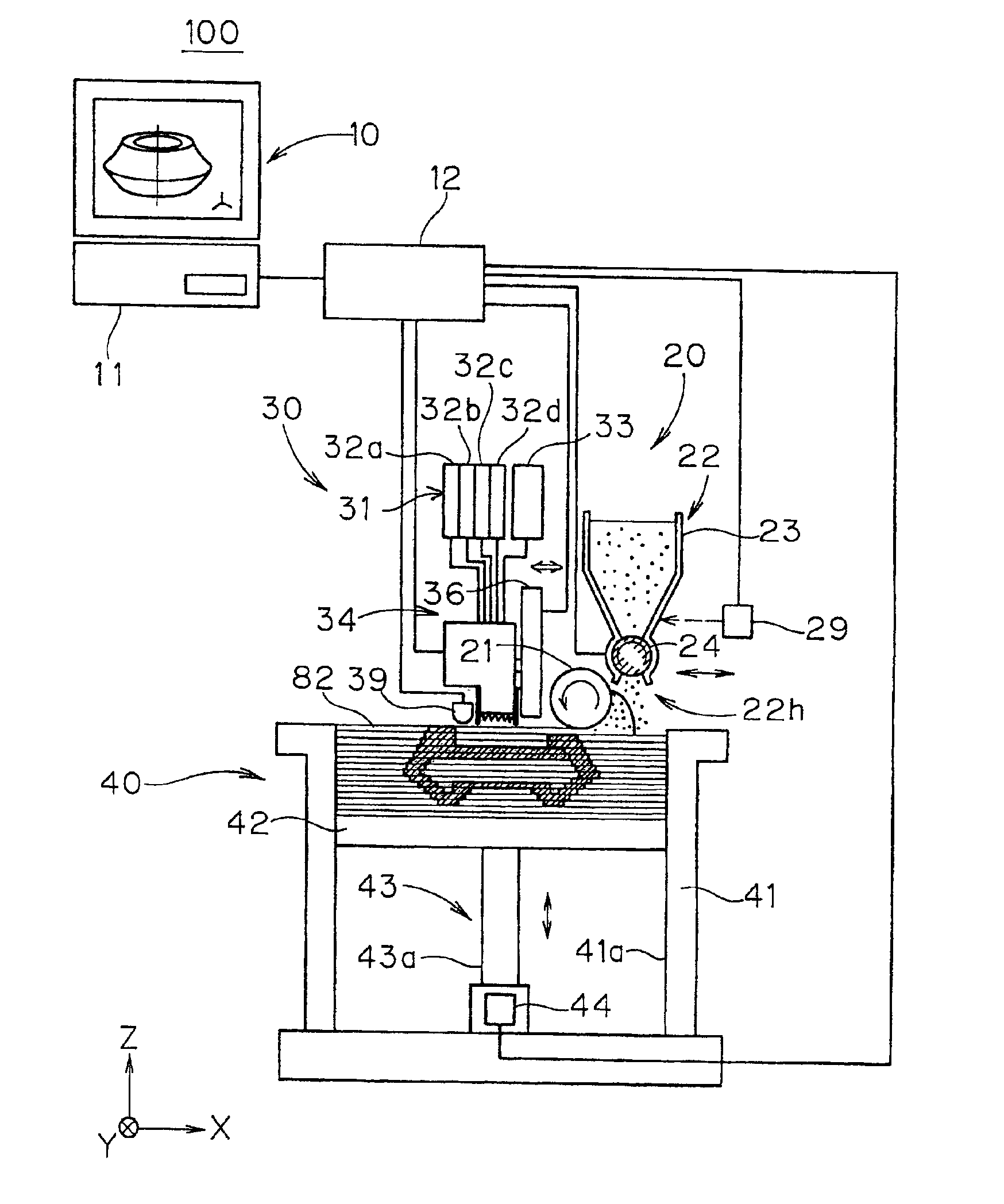

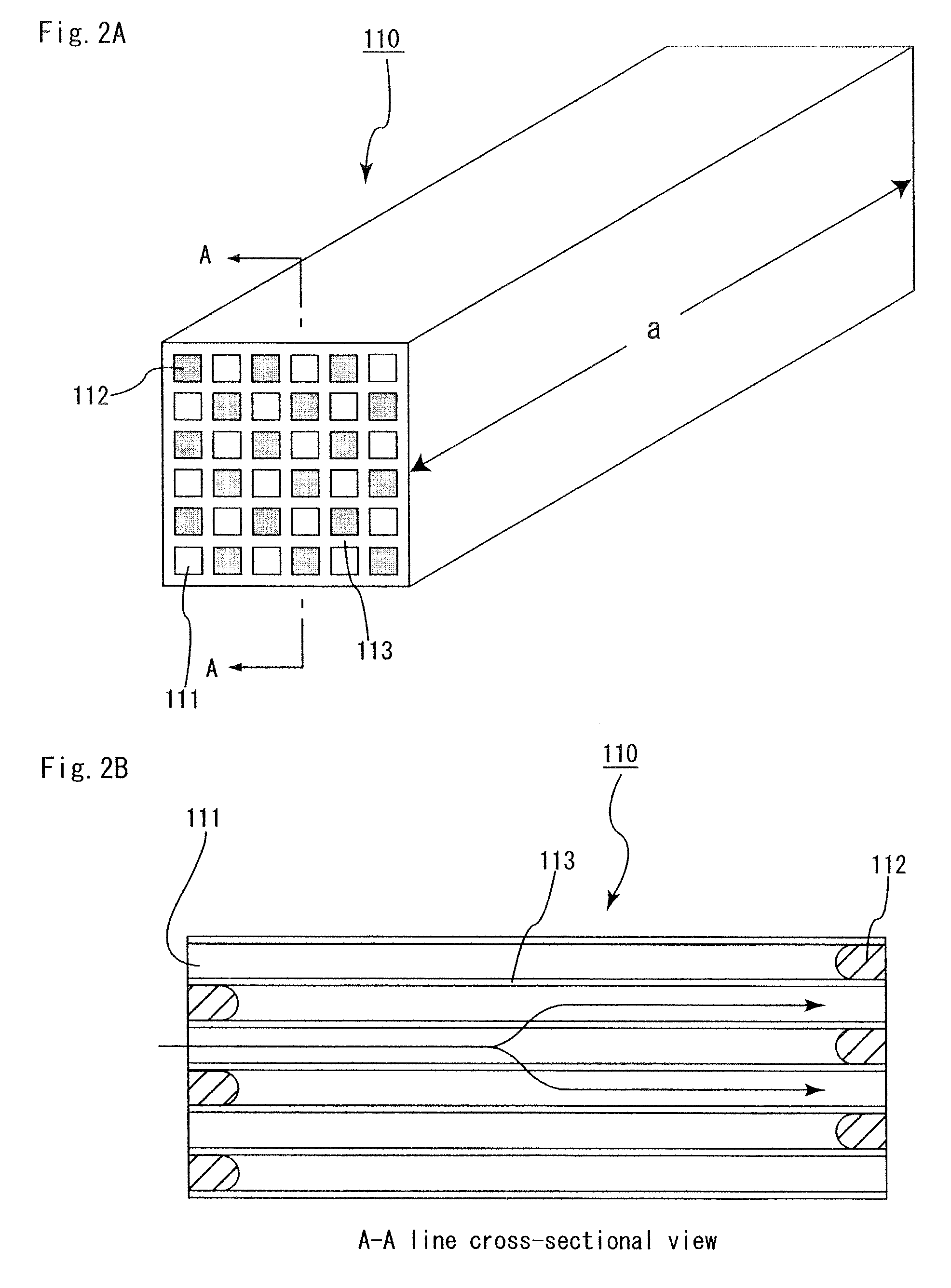

Three-dimensional molding apparatus and three-dimensional molding method

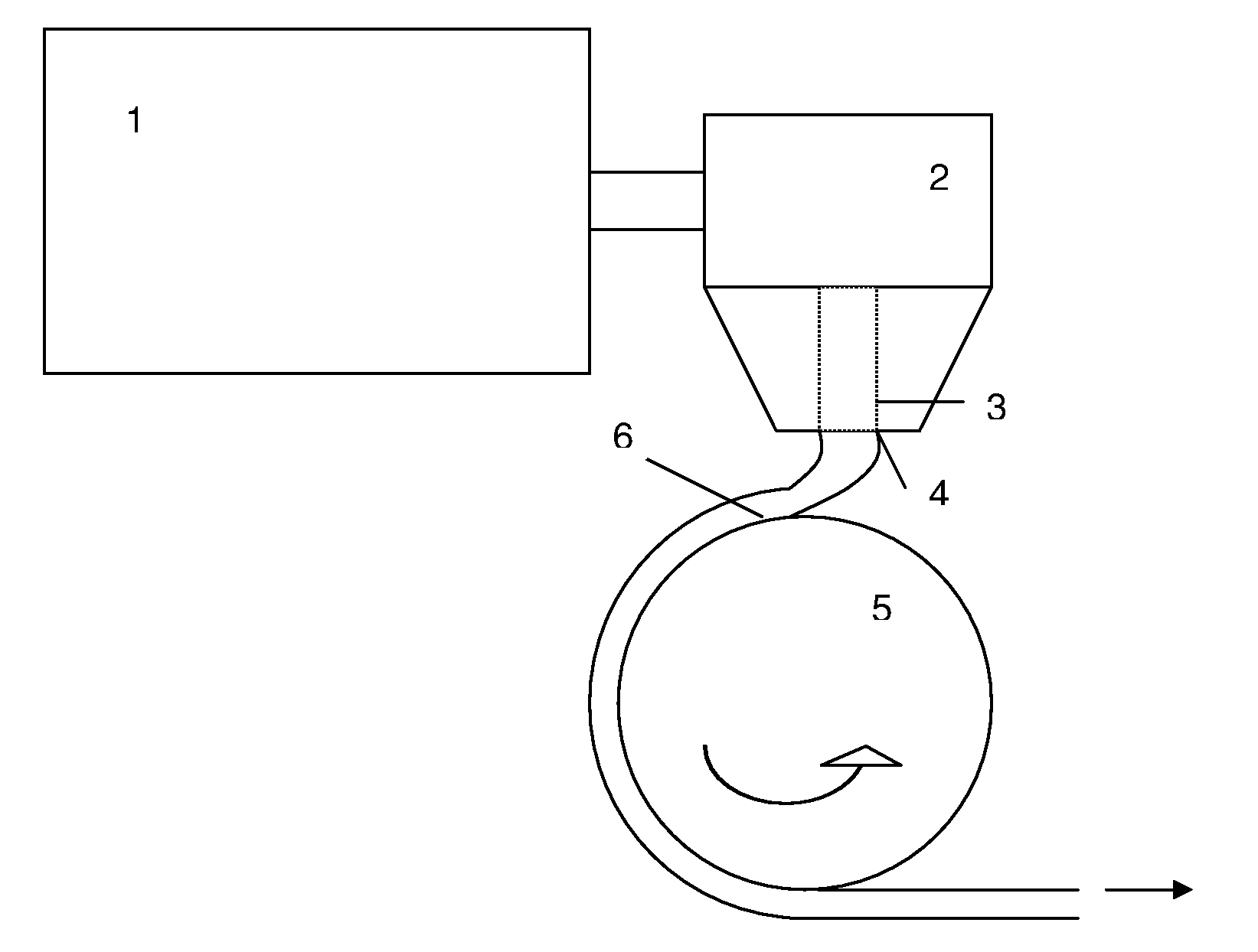

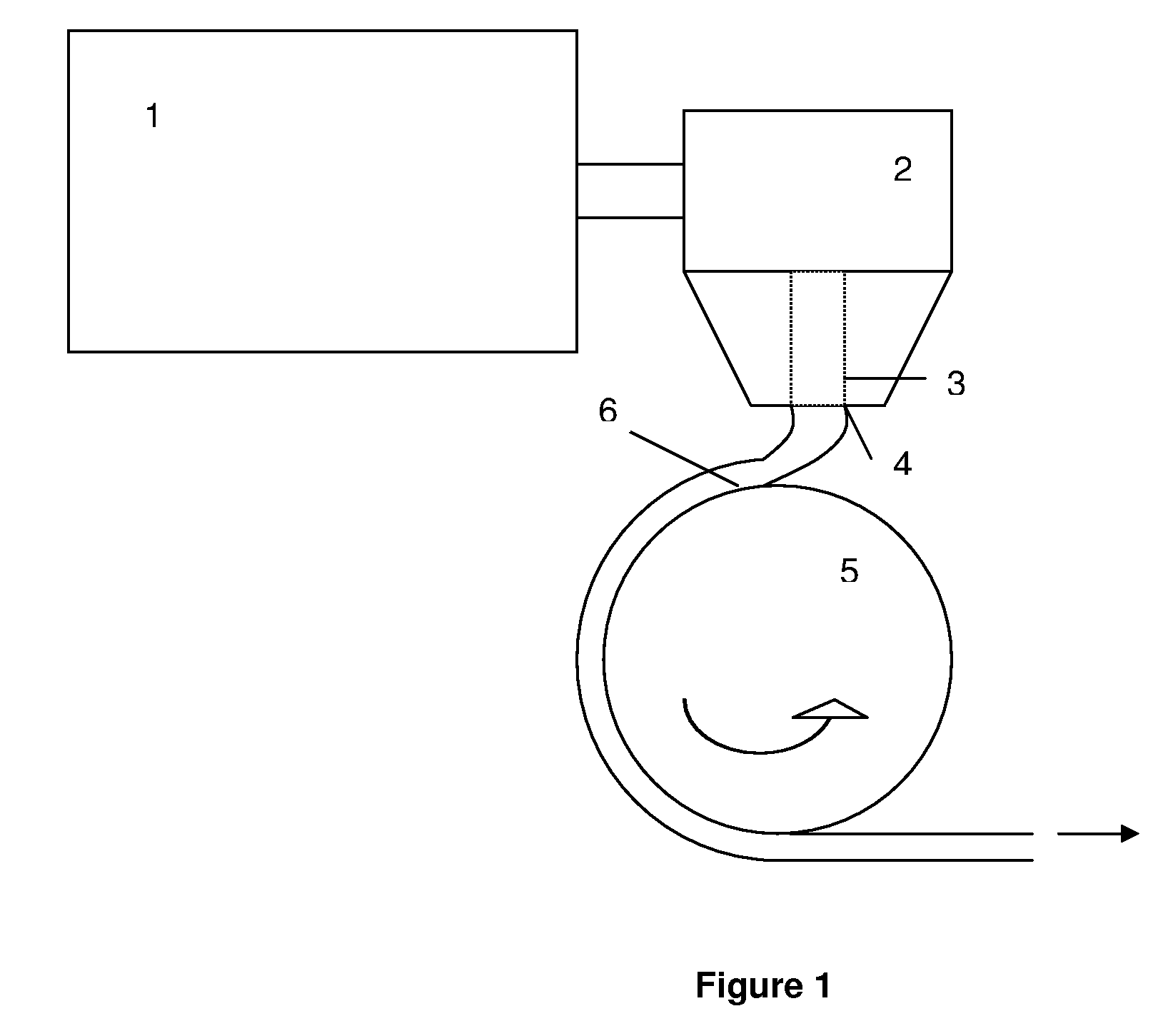

To provide a three-dimensional molding technique capable of generating a three-dimensional molded article in short time.In a three-dimensional molding apparatus, a powder material is allowed to drop via an opening while moving a thin layer formation section in the +X direction, thereby forming a powder layer on a molding stage. With respect to a selected region in the powder layer, a binder of ultraviolet-ray hardening resin is discharged from a head section. Then, the powder layer is irradiated with ultraviolet rays from an ultraviolet irradiation section, making the ultraviolet-ray hardening resin applied on the powder layer harden to thereby bind the powder material. By repeating this operation with respect to the powder layer which is sequentially formed, a three-dimensional molded article is formed. In this way, since an ultraviolet-ray hardening resin is used as a binder and a powder material can be bound rapidly by ultraviolet irradiation, it is possible to generate a three-dimensional molded article in short time.

Owner:MINOLTA CO LTD

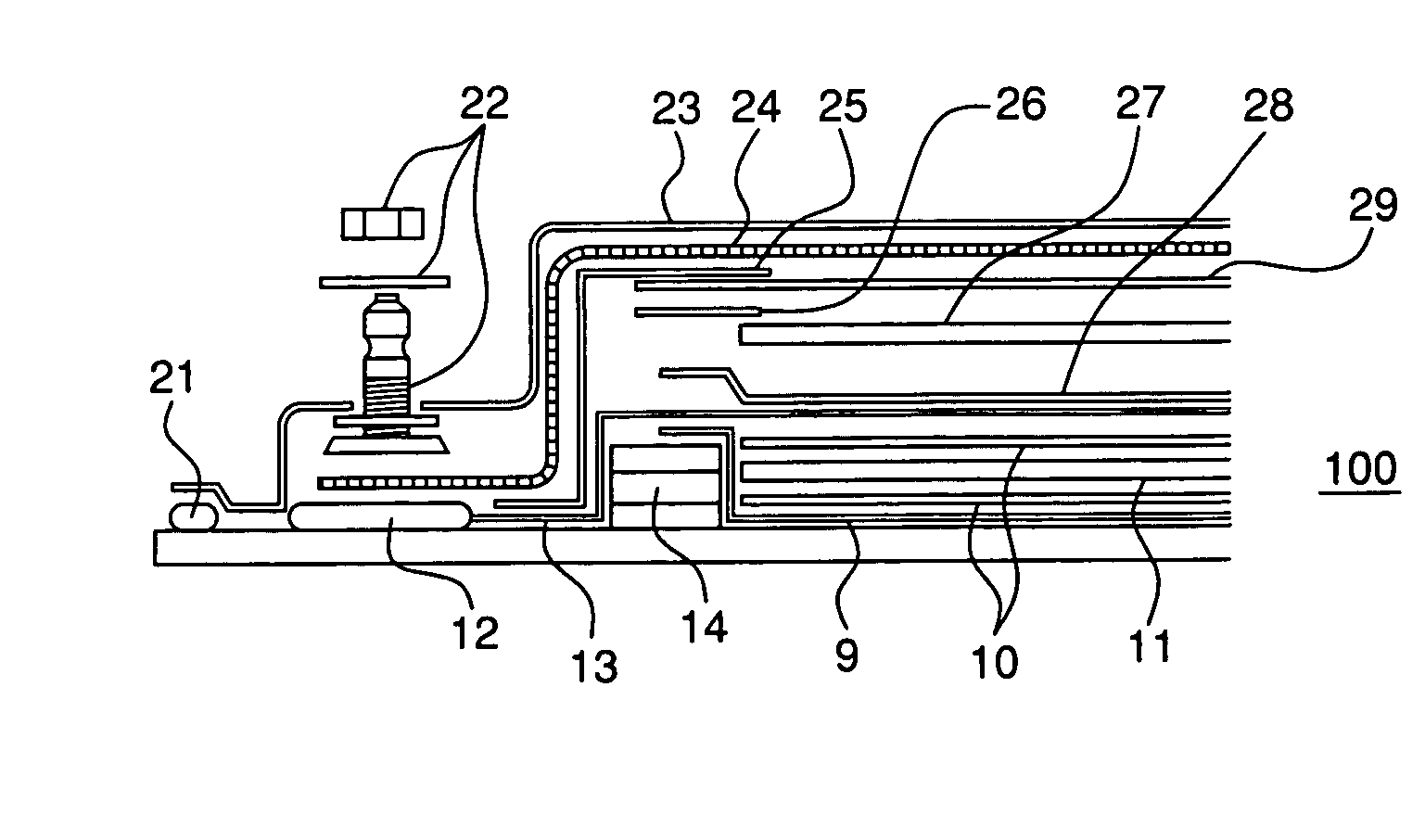

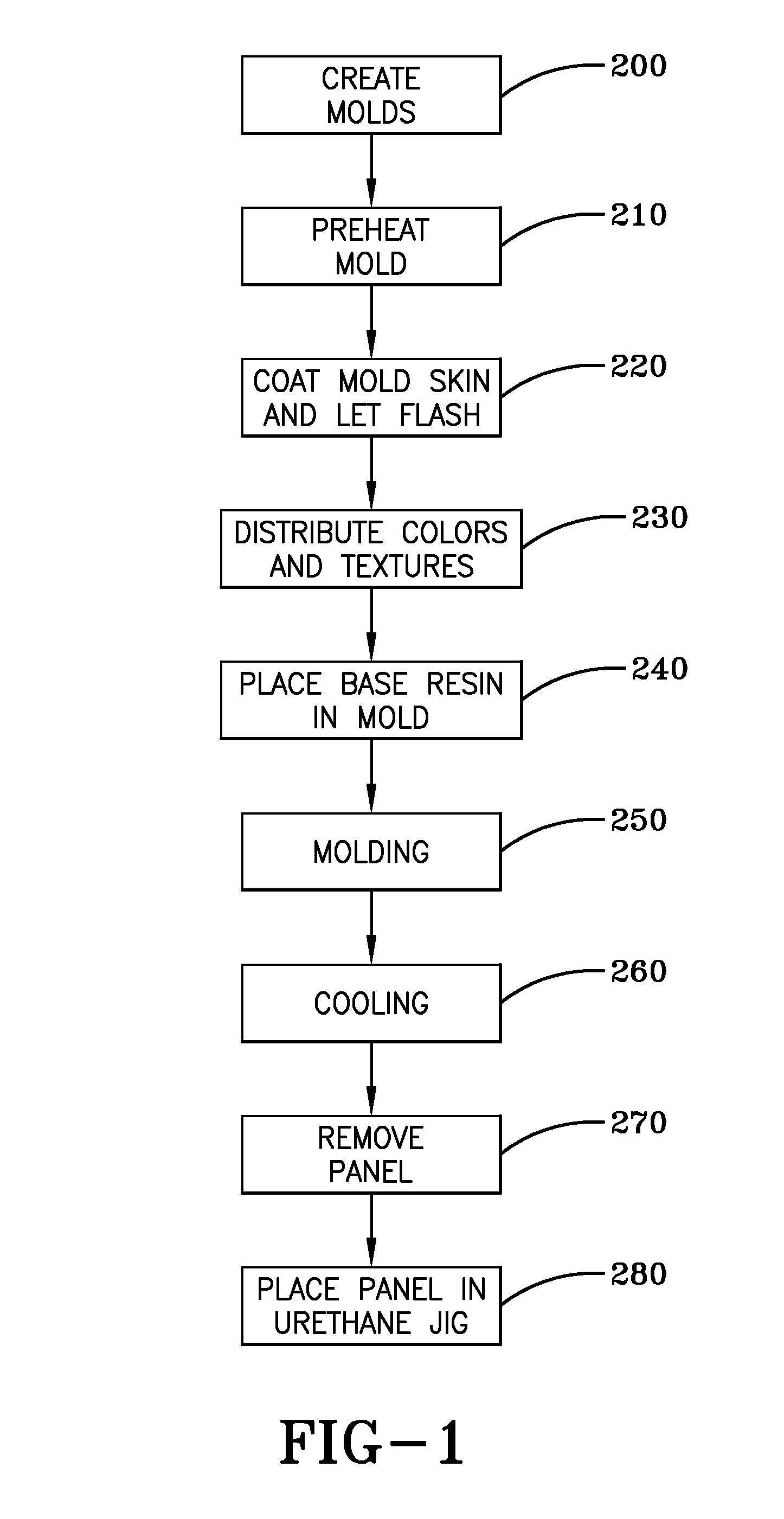

Vehicle interior trim panel with a soft-touch foam layer, and a method and apparatus for making the same

InactiveUS6136415ALow densityFlexible of partLamination ancillary operationsSynthetic resin layered productsDashboardPolyolefin

An interior trim component such as a vehicle dashboard includes a substantially rigid and form-stable substrate of polypropylene and natural fibers, a supporting halo skeleton and other frame components heat fused onto the backside of the substrate, and a polyolefin foam layer as well as a decorative polyolefin cover film laminated onto the front side of the substrate. The foam layer has an increased thickness and a decreased foam density at sharply contoured or curved areas of the trim component, in comparison to the flat surfacial areas. As a result, the trim component has a desirable soft-touch characteristic and impact absorbing properties at all areas including protruding curves and edges. A method for forming such a trim component involves steps of pre-molding the foam layer and cover film by vacuum thermoforming, pre-molding the substrate by vacuum thermoforming, and then heat laminating the pre-heated, pre-molded substrate onto the pre-molded foam layer and cover film. The sharply curved or contoured areas of the component are provided with a greater tolerance spacing between the substrate and the cover film, which are held to the respective mold contours by vacuum. Under the effect of heat and the applied vacuum, the foam layer expands to have a greater thickness and a lower density in these sharply contoured areas.

Owner:HERBERT OLBRICH

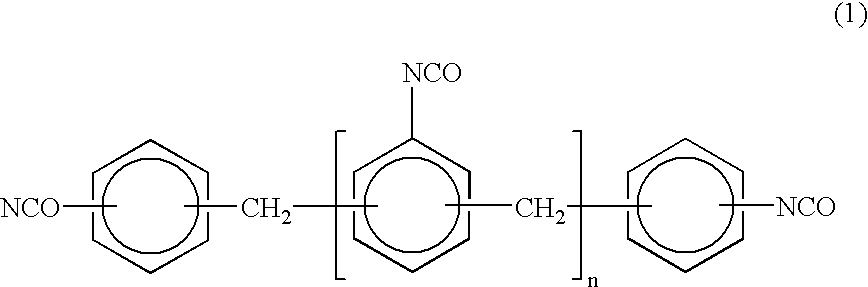

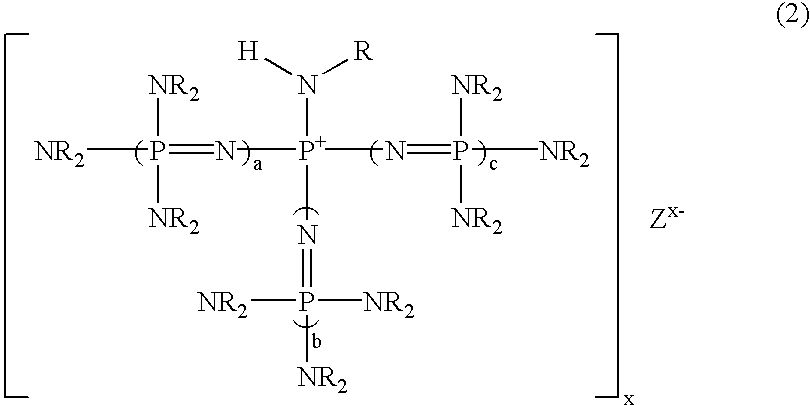

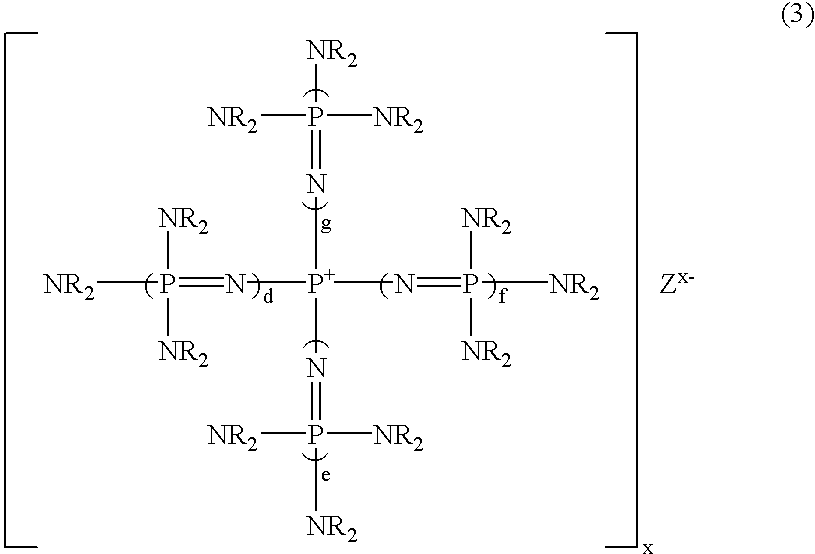

High-durability flexible polyurethane cold cure molded foam and process for producing the same

The high-durability flexible polyurethane cold cure molded foam of the invention has an overall density of not less than 35 kg / m3 and not more than 45 kg / m3 and a wet heat compression set of not more than 15%, and preferably has a hardness change ratio, as determined in a repeated compression test, of not more than 15%. This foam can be obtained by the process of the invention. The process of the invention is a process for producing a flexible polyurethane cold cure molded foam obtained from a polyol and / or a polymer polyol containing dispersed polymer microparticles obtained by radical polymerizing a compound having an unsaturated bond in the polyol, water, a catalyst and a polyisocyanate, wherein the polyol is a polyol synthesized by the use of a catalyst containing at least one compound selected from the group consisting of a compound having a nitrogen-phosphorus double bond, cesium hydroxide and rubidium hydroxide. The foam of the invention has a low density and is excellent in durability, particularly in hardness change ratio in a repeated compression test and wet heat compression set. According to the process of the invention, such a foam can be obtained.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

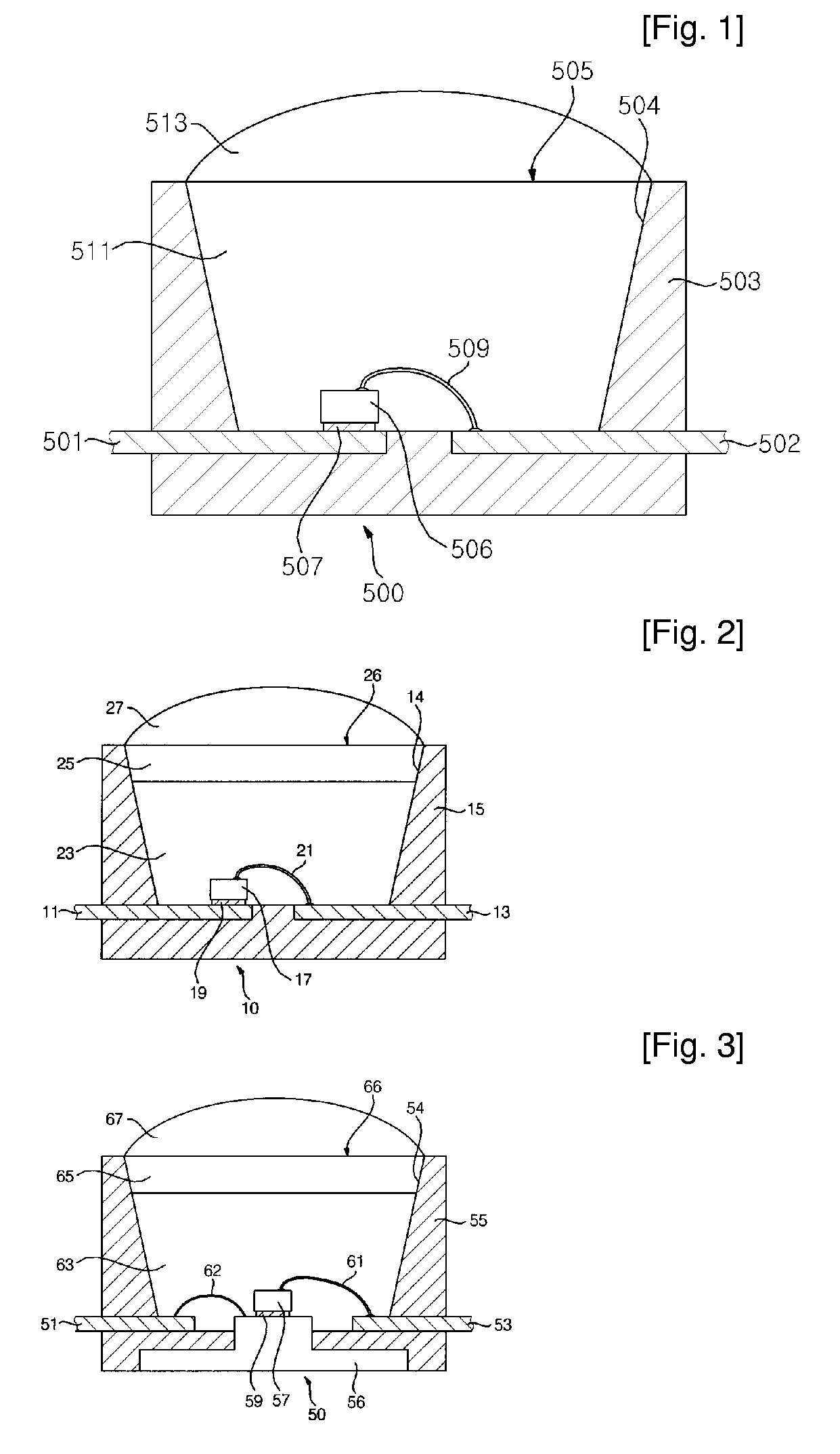

Light Emitting Diode Package Having Multiple Molding Resins

ActiveUS20080023721A1Avoid separationRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesShell moldingEngineering

Disclosed is a light emitting diode (LED) package having multiple molding resins. The LED package includes a pair of lead terminals. At least portions of the pair of lead terminals are embedded in a package main body. The package main body has an opening through which the pair of lead terminals is exposed. An LED die is mounted in the opening and electrically connected to the pair of lead terminals. A first molding resin covers the LED die. A second molding resin with higher hardness than the first molding resin covers the first molding resin. Therefore, stress to be imposed on the LED die can be reduced and the deformation of the molding resins can be prevented.

Owner:SEOUL SEMICONDUCTOR

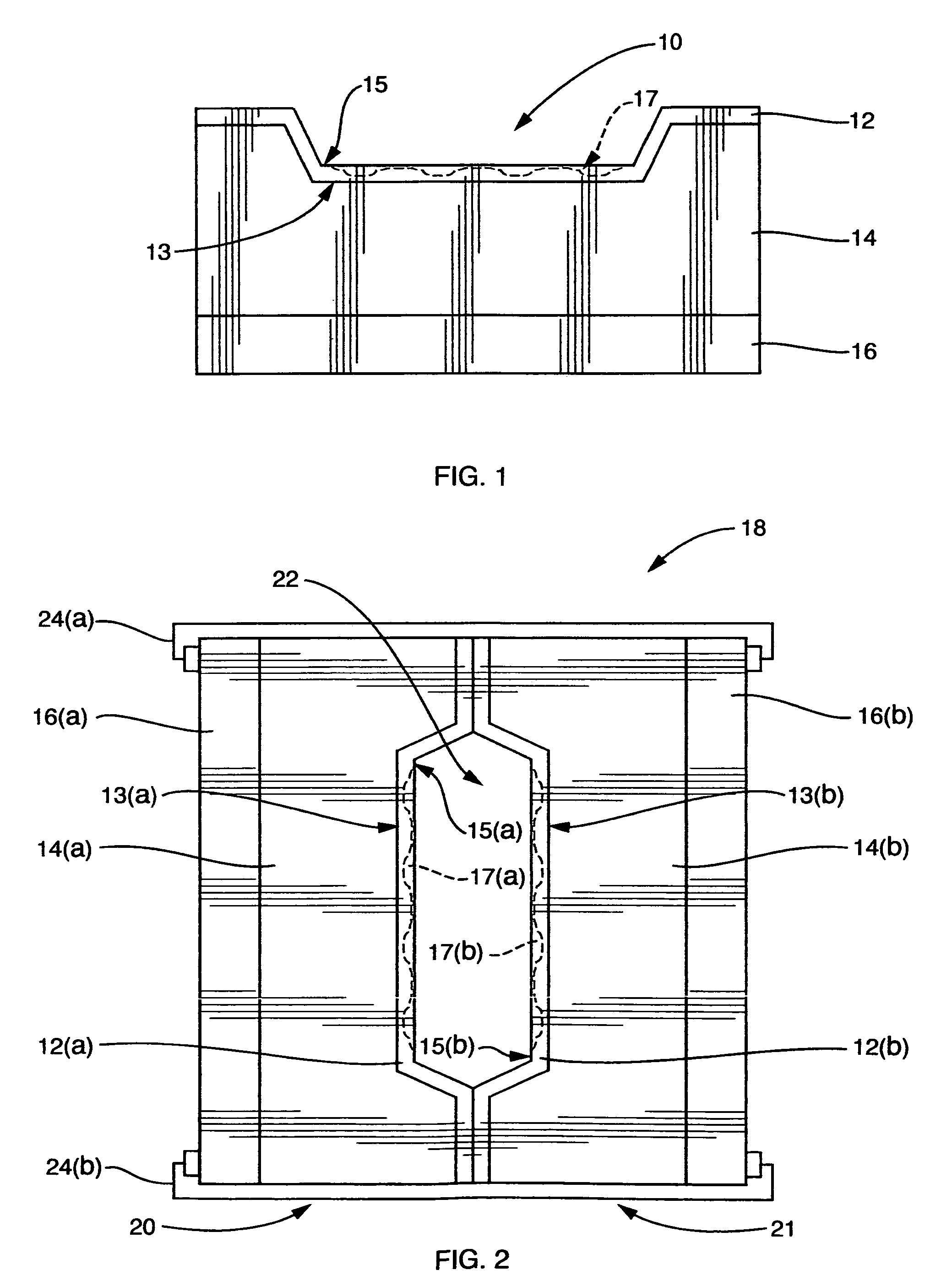

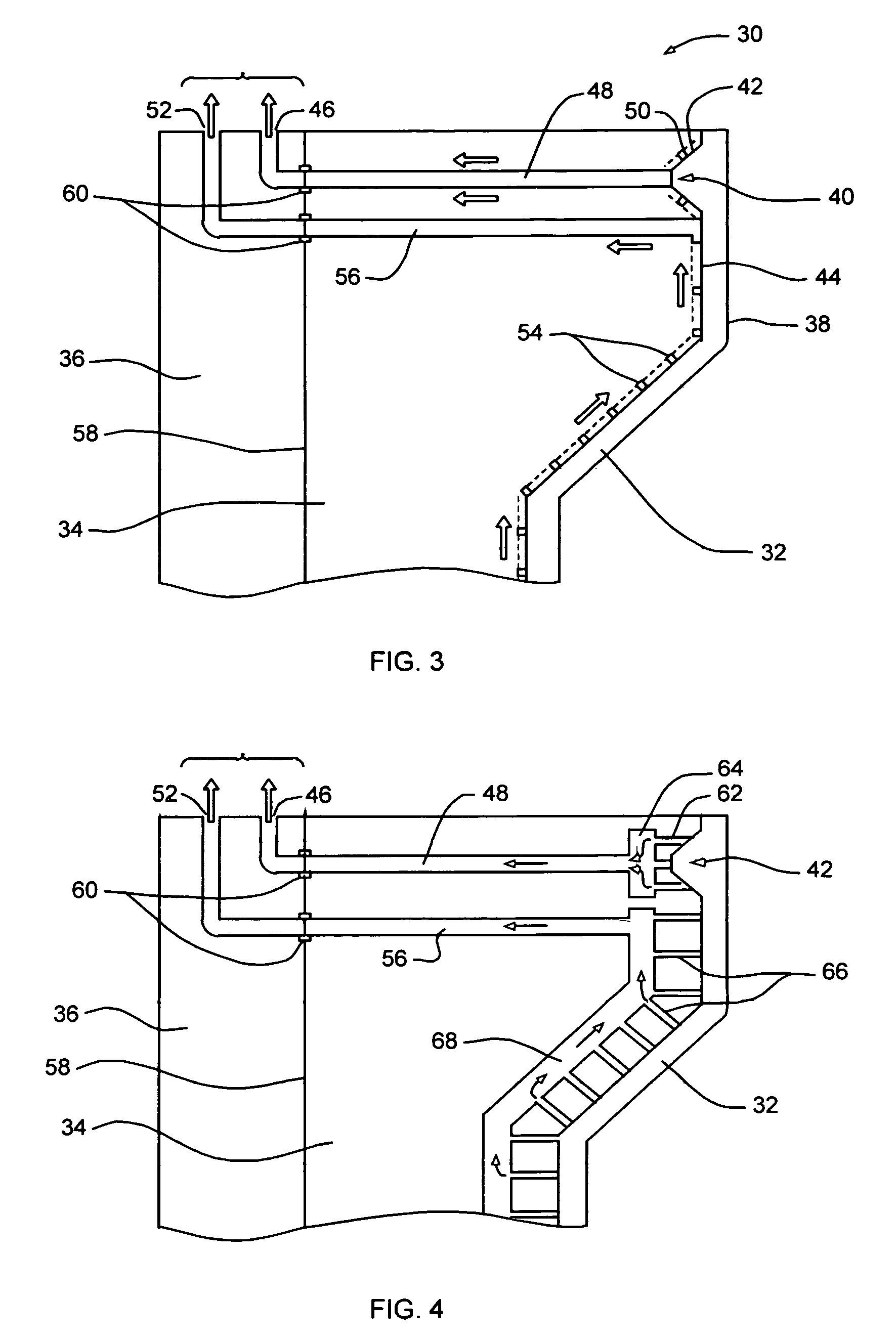

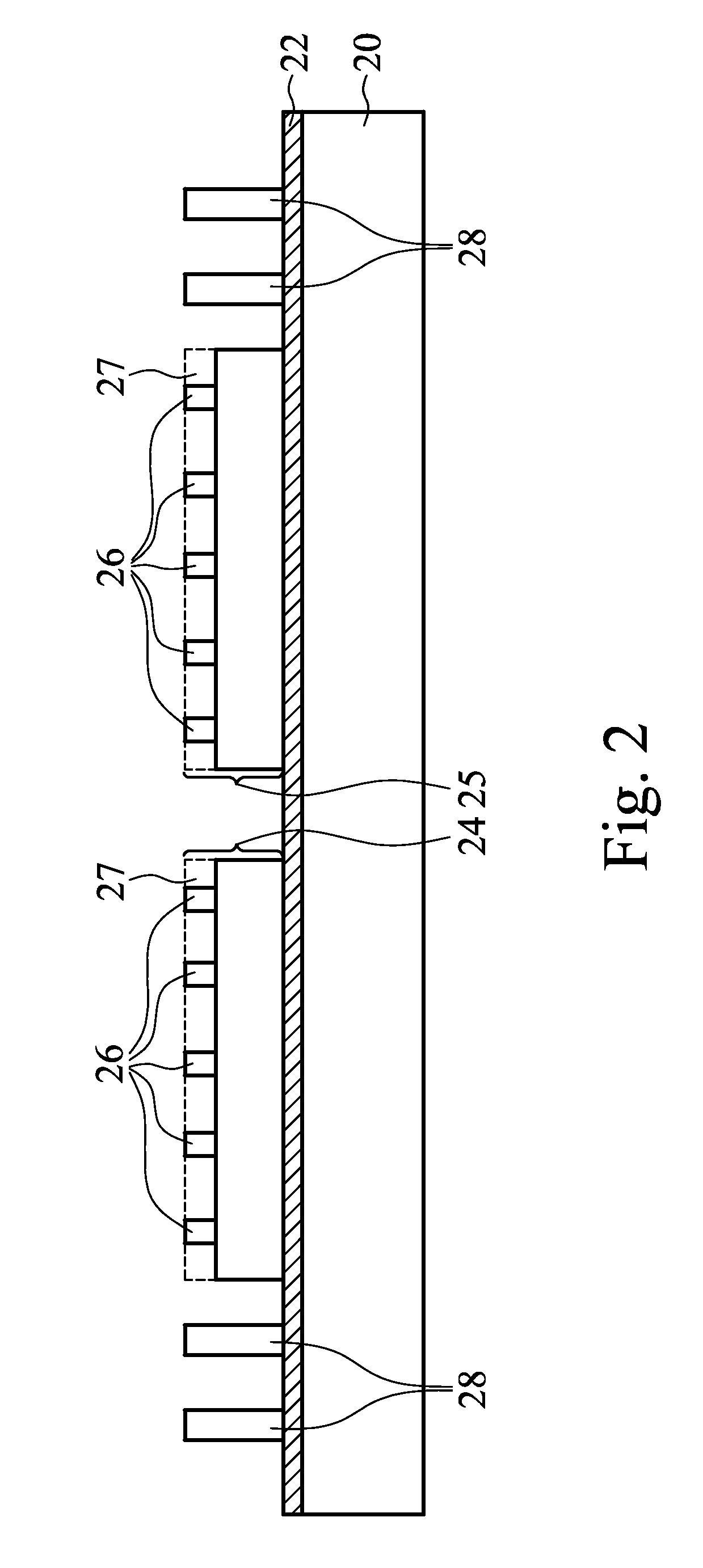

Compound tooling system for molding applications

ActiveUS7972129B2Easy to modifyEvenly heatedAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

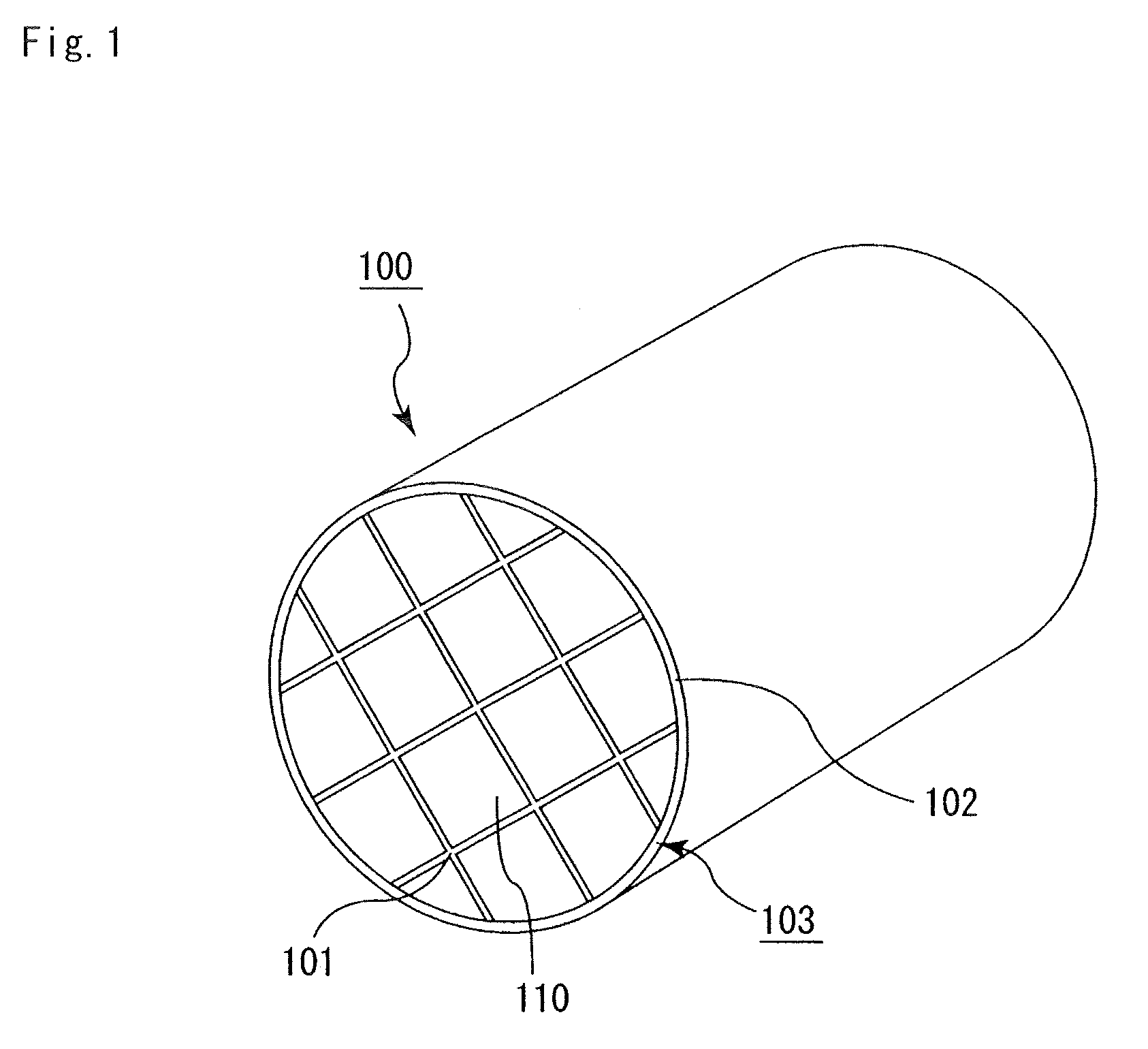

Method for manufacturing honeycomb structure and material composition for honeycomb fired body

The method for manufacturing a honeycomb structure includes preparing a material composition containing at least a silicon carbide powder, a binder and an additive; molding the material composition to form a pillar-shaped honeycomb molded body in which a number of cells are placed in parallel with one another in a longitudinal direction with a cell wall therebetween; carrying out a degreasing treatment on the honeycomb molded body; and carrying out a firing treatment on the honeycomb degreased body to manufacture a honeycomb fired body. The additive contains at least one kind selected from the group consisting of alumina, silica, titania, zirconia, magnesia, and a chemical composite containing any of alumina, silica, titania, zirconia and magnesia.

Owner:IBIDEN CO LTD

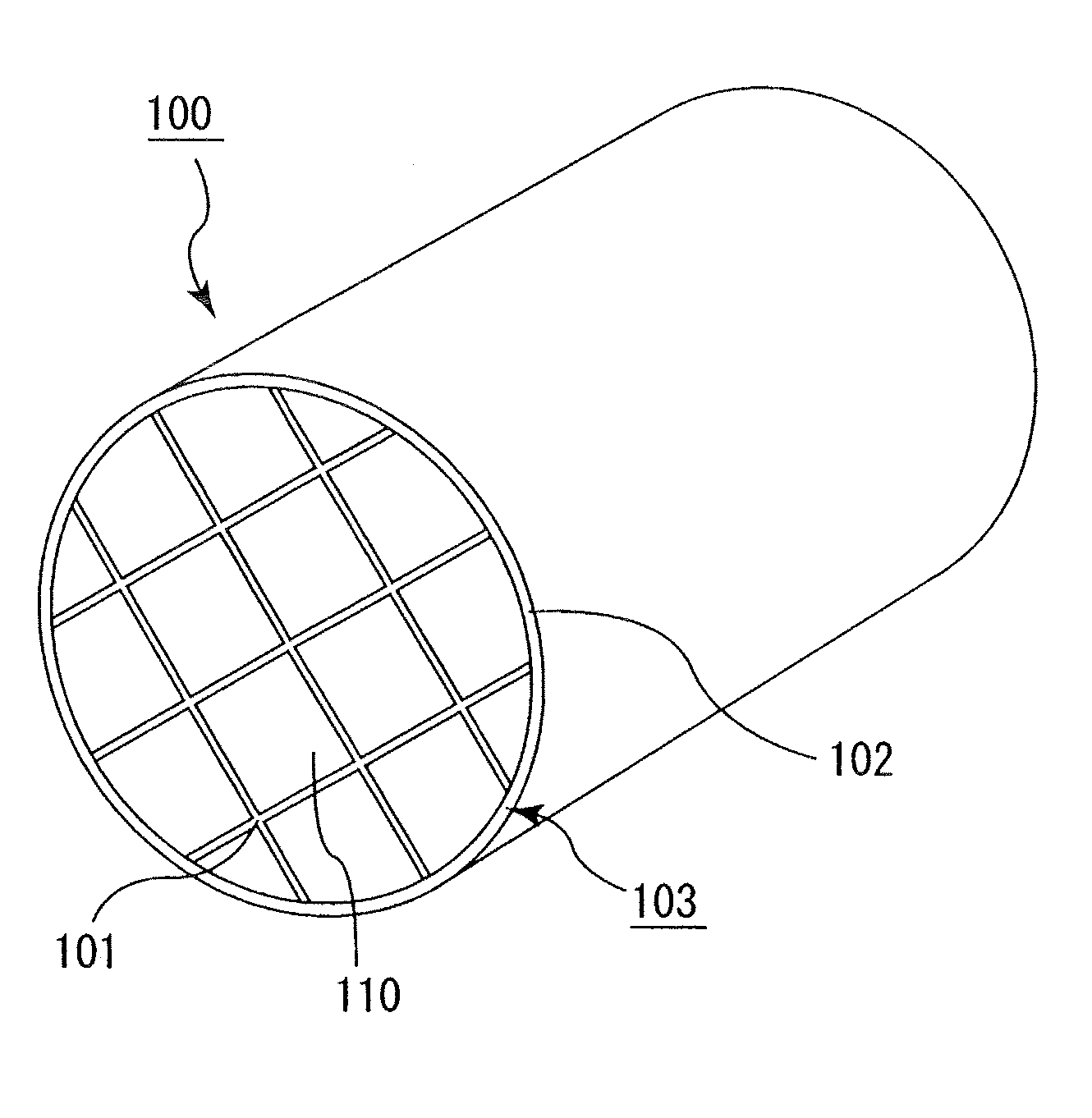

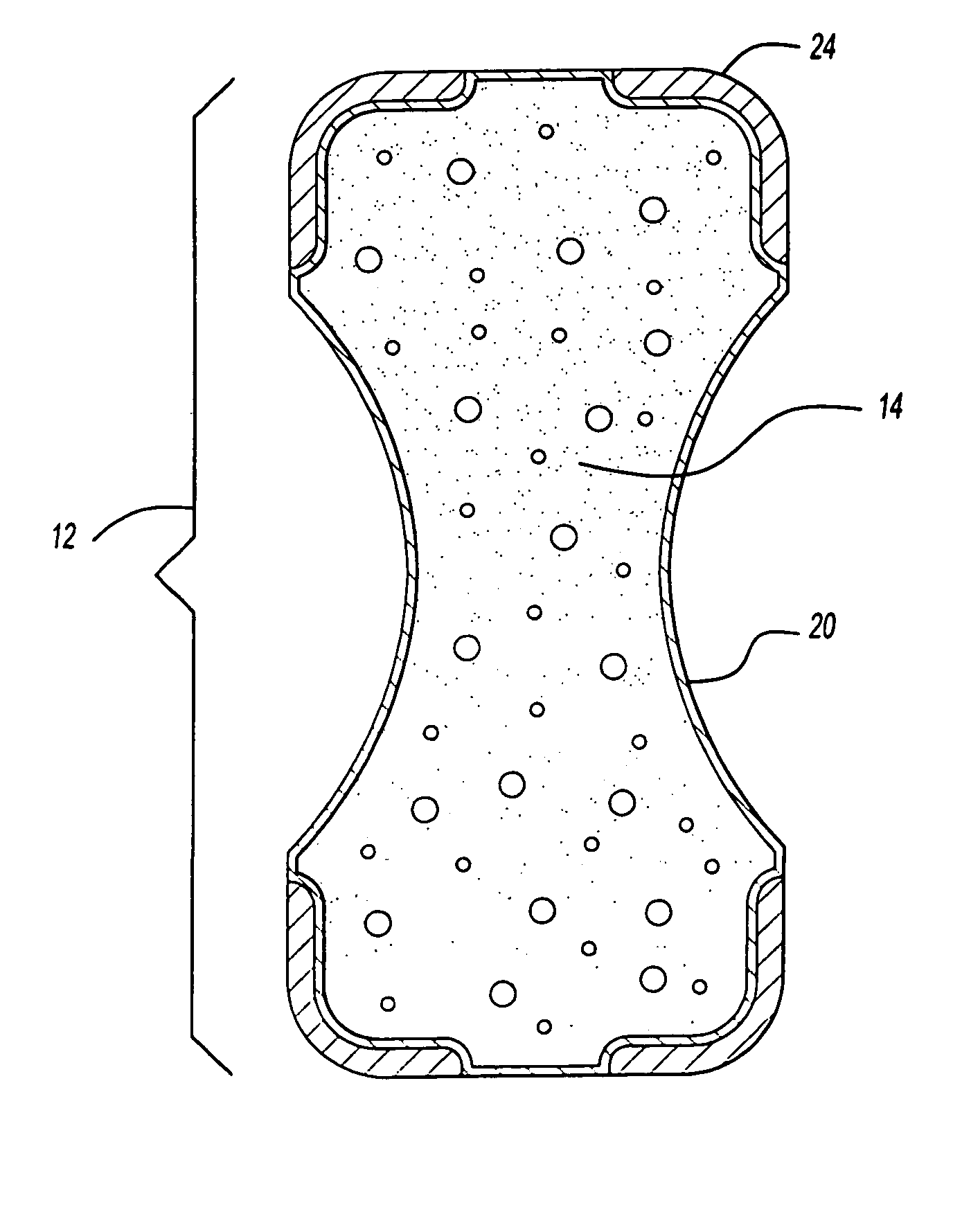

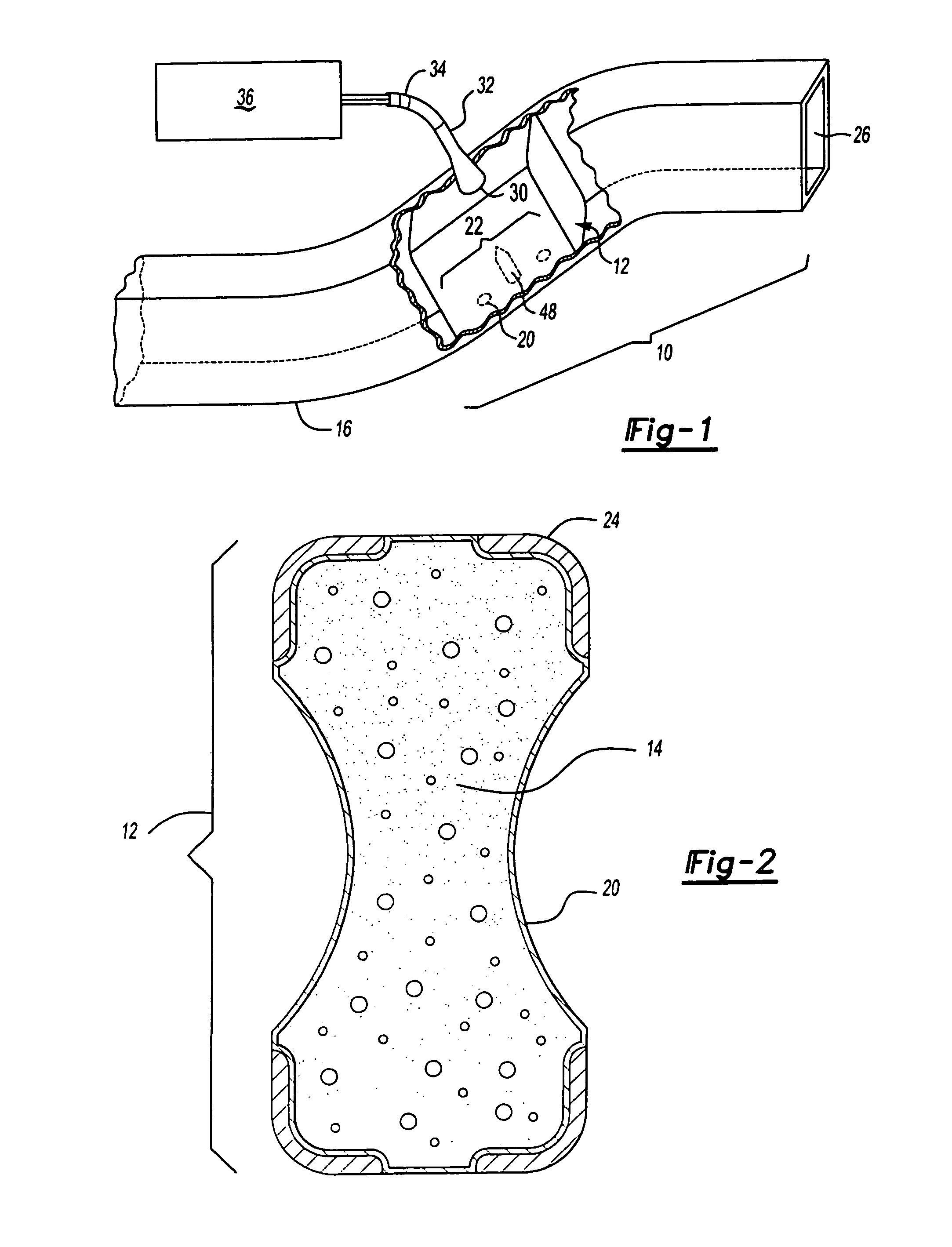

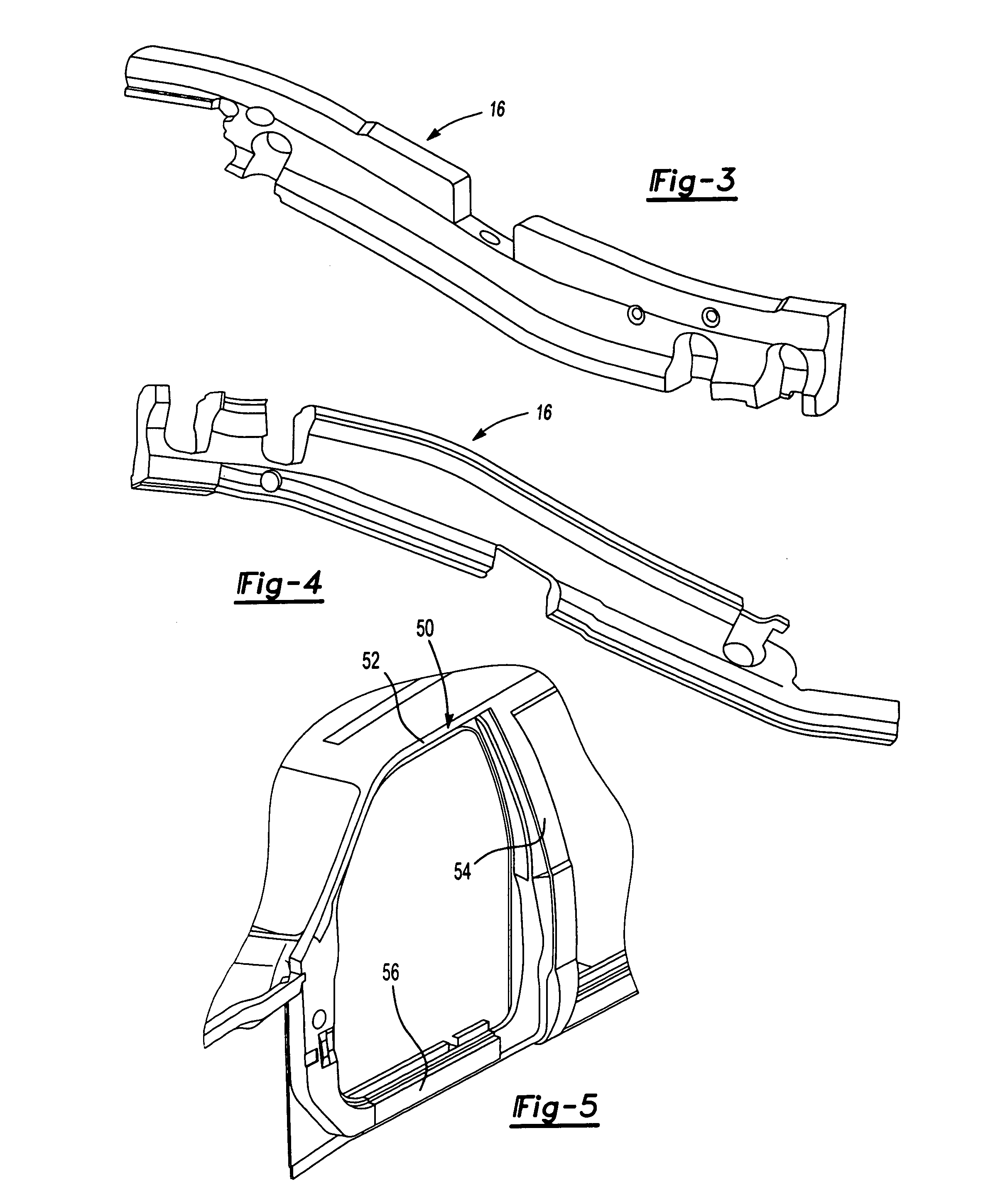

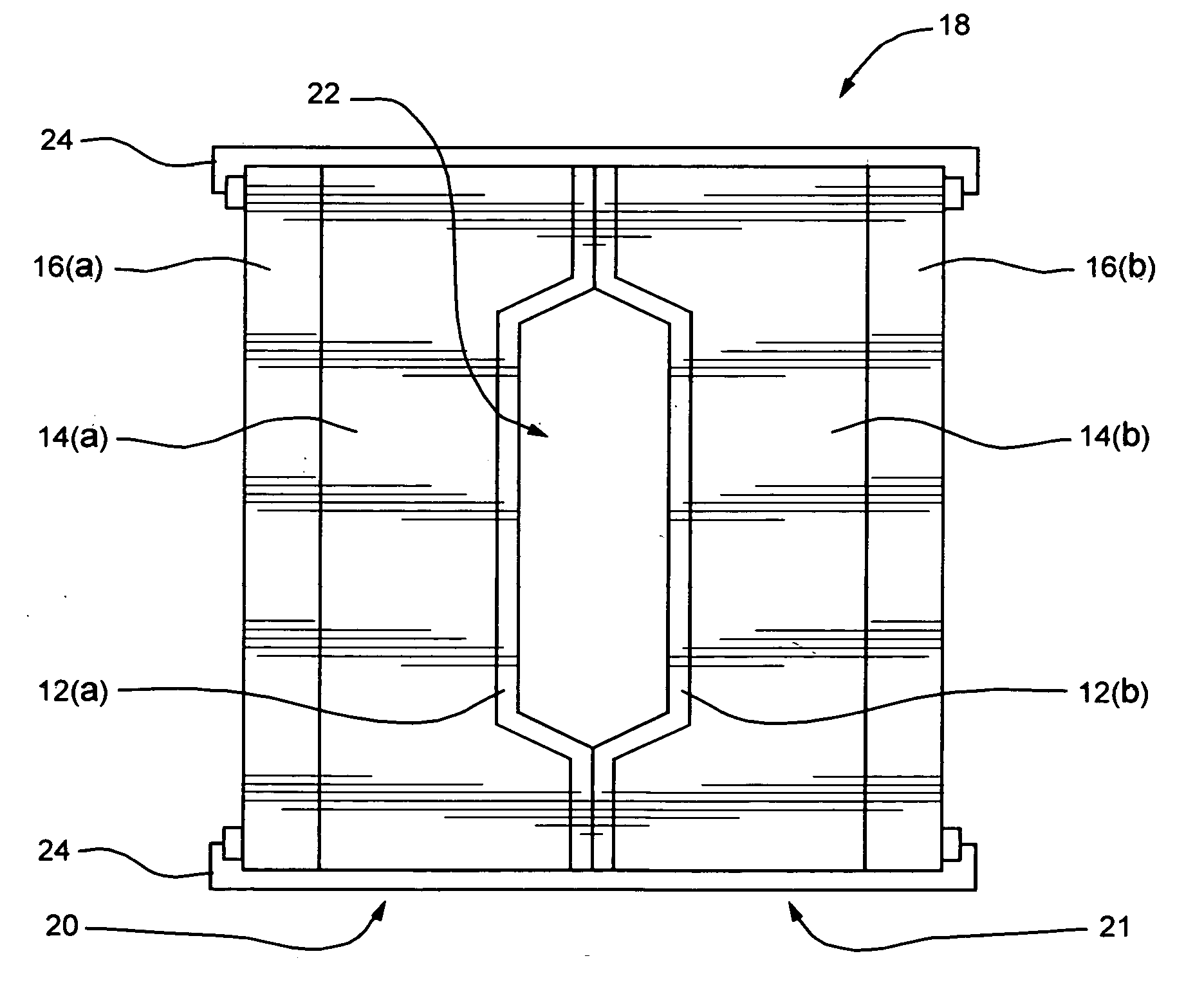

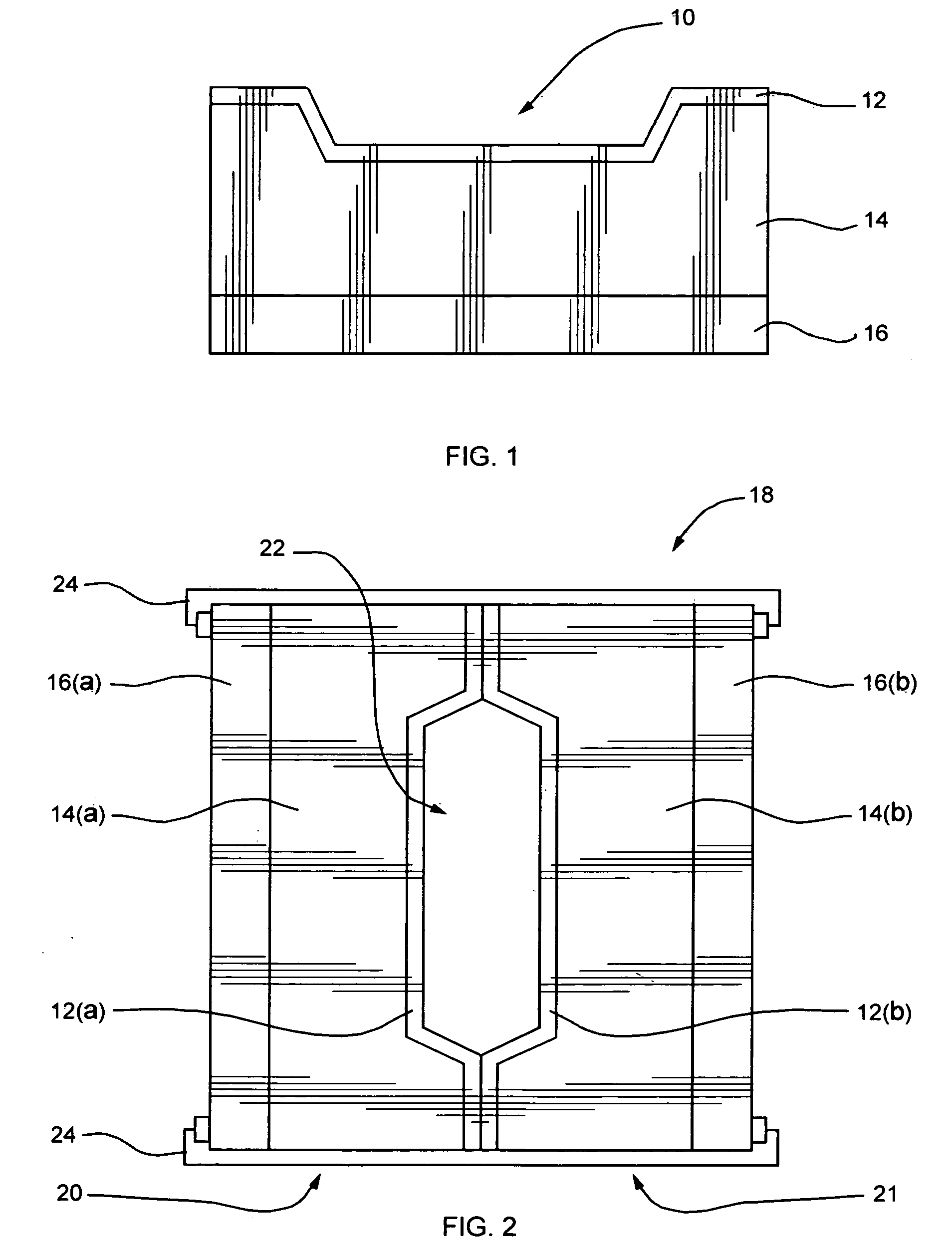

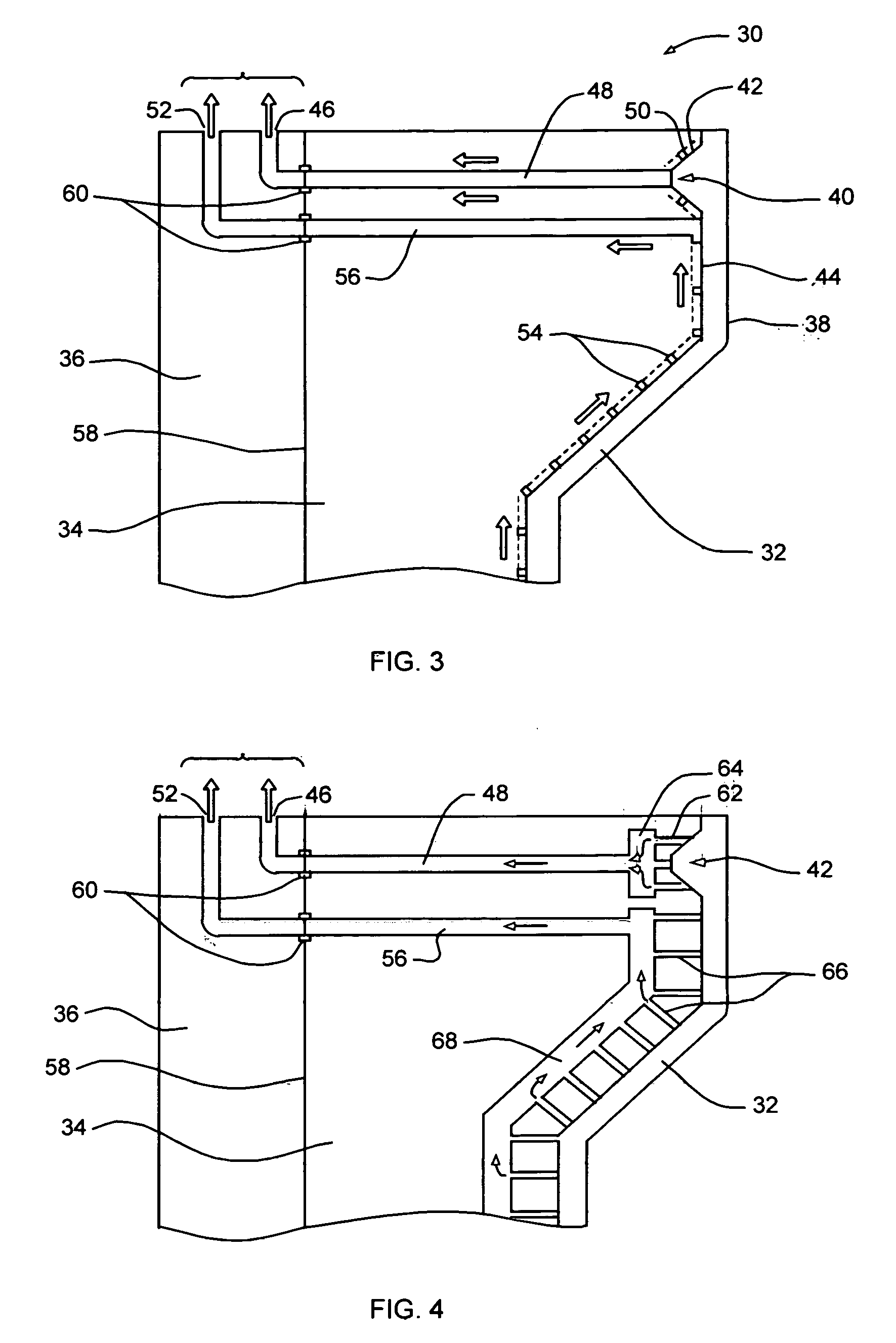

Reinforcement system utilizing a hollow carrier

ActiveUS7077460B2Reduce healthReduce cleanlinessVehicle seatsSynthetic resin layered productsBlow moldingShell molding

A system and method for reinforcing at least a portion of a structural member, including at least one hollow carrier, having an exterior shell and an interior portion, which substantially conforms to the dimensions and geometry of the structural member being reinforced; and a lightweight, low density material for filling the interior portion of one or more of the carriers. The material filling one or more of the carriers of the present invention can be a reinforcement material, self-curing material, or a heat activated expandable material. The carrier can be produced by blow molding or rotational molding and has an adhesive material disposed along at least a portion of the exterior shell used to place, adhere, and affix the carrier to a targeted portion of the structural member selected to be structurally reinforced.

Owner:ZEPHYROS INC

Heat resistant molded or extruded thermoplastic articles

InactiveUS20100029819A1Improve thermal stabilityFireproof paintsThin material handlingChemical compositionAlcohol

Disclosed is a molded or extruded thermoplastic article having high heat stability over at least 500 hours at least 170° C. including a thermoplastic composition including a thermoplastic resin; one or more polyhydric alcohols having more than two hydroxyl groups and a having a number average molecular weight (Mn) of less than 2000; one or more reinforcement agents; and optionally, a polymeric toughener; wherein 4 mm test bars prepared from said thermoplastic composition, and exposed at a test temperature at 170° C. for a test period of 500 hours, have, on average, a retention of tensile strength of at least 50 percent, as compared with that of an unexposed control of identical composition and shape. Further disclosed is a molded or extruded thermoplastic article, including a thermoplastic polyamide composition, wherein 4 mm test bars of said thermoplastic polyamide composition, when exposed at 210° C. for a test period of 500 hours, have a retention of tensile strength of at least 70 percent.

Owner:EI DU PONT DE NEMOURS & CO

Compound tooling system for molding applications

ActiveUS20070063378A1Accurate operationFacilitate partial removalAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

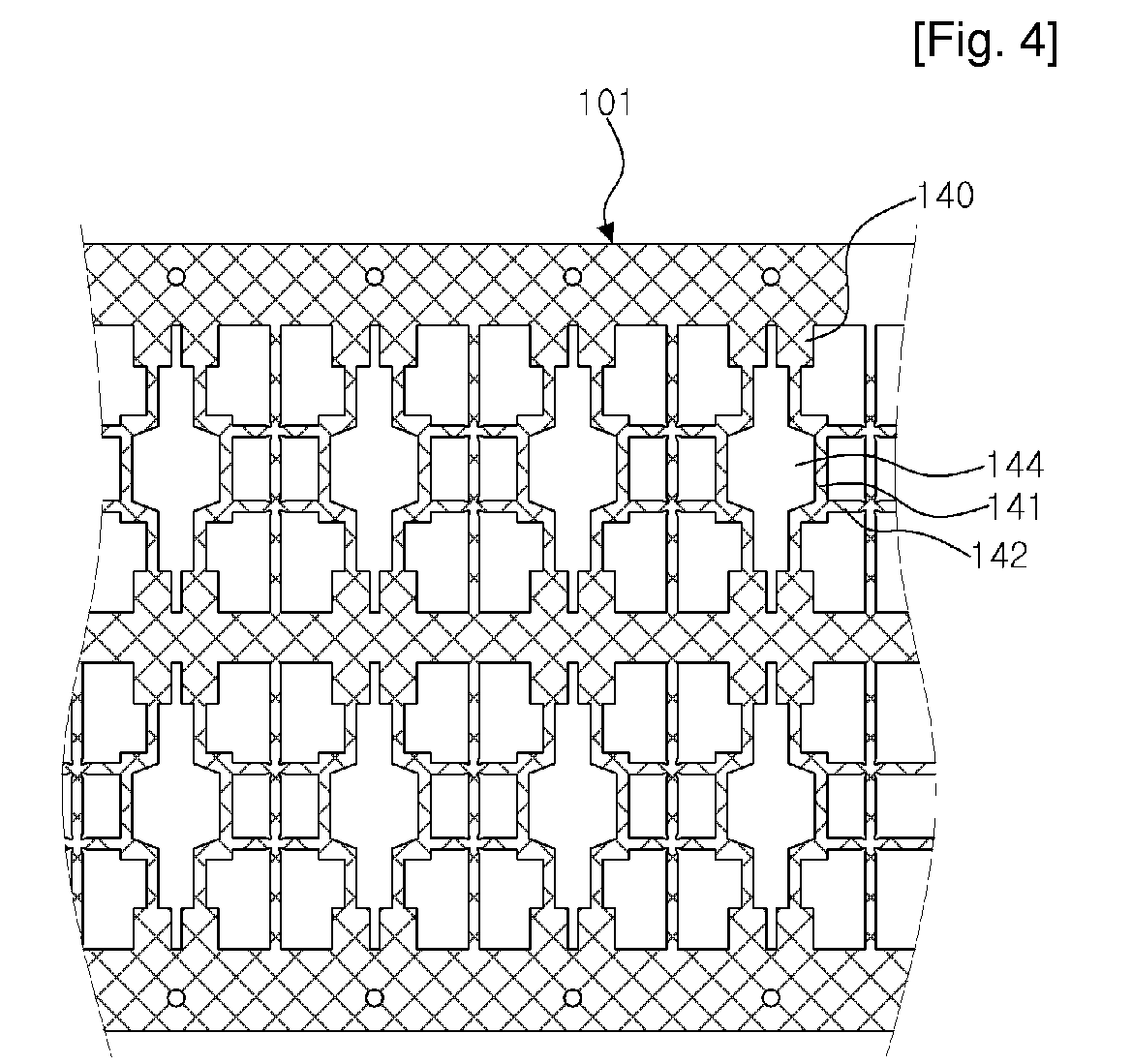

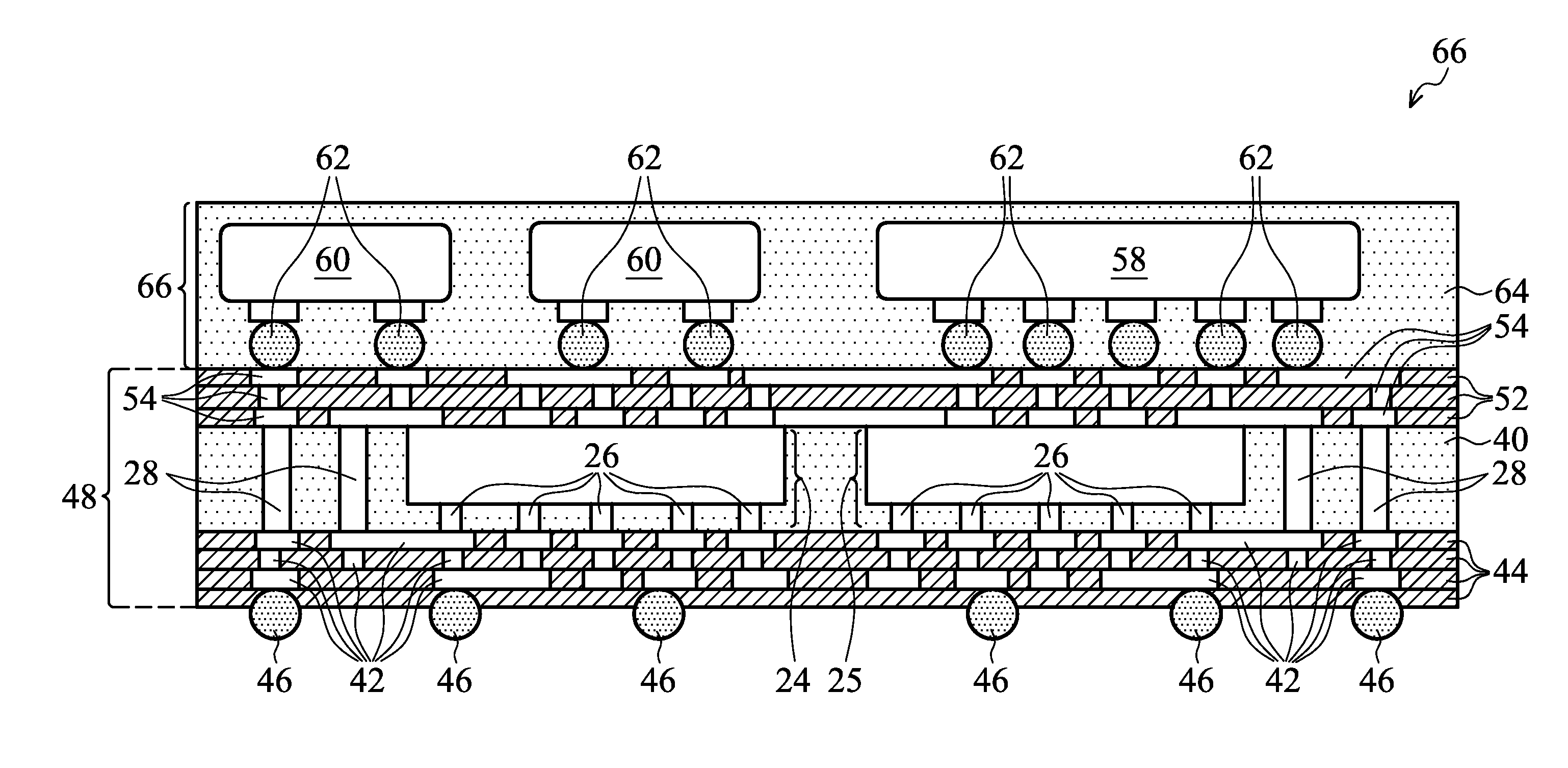

POP structures and methods of forming the same

ActiveUS8975726B2Increase the areaSemiconductor/solid-state device detailsSolid-state devicesShell moldingEngineering

A device includes a top package bonded to a bottom package. The bottom package includes a molding material, a device die molded in the molding material, a Through Assembly Via (TAV) penetrating through the molding material, and a redistribution line over the device die. The top package includes a discrete passive device packaged therein. The discrete passive device is electrically coupled to the redistribution line.

Owner:TAIWAN SEMICON MFG CO LTD

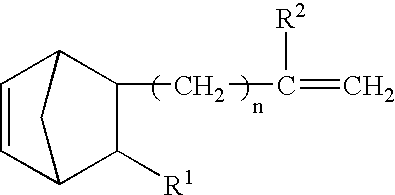

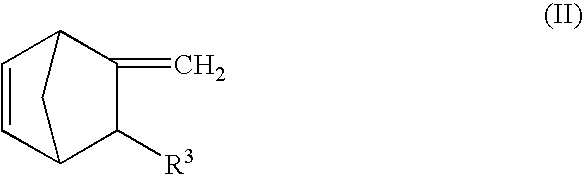

Crosslinkable rubber compositions and use thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

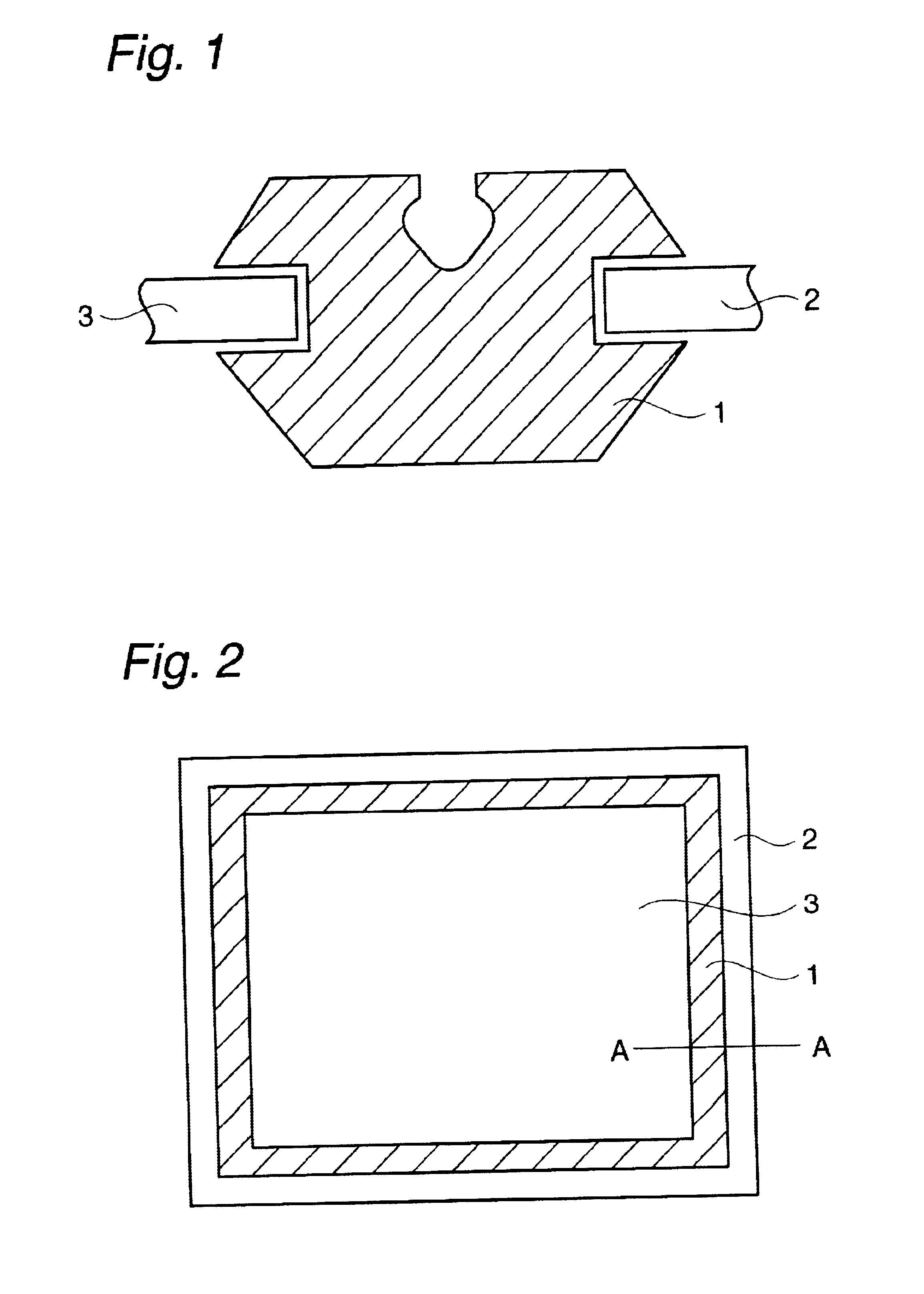

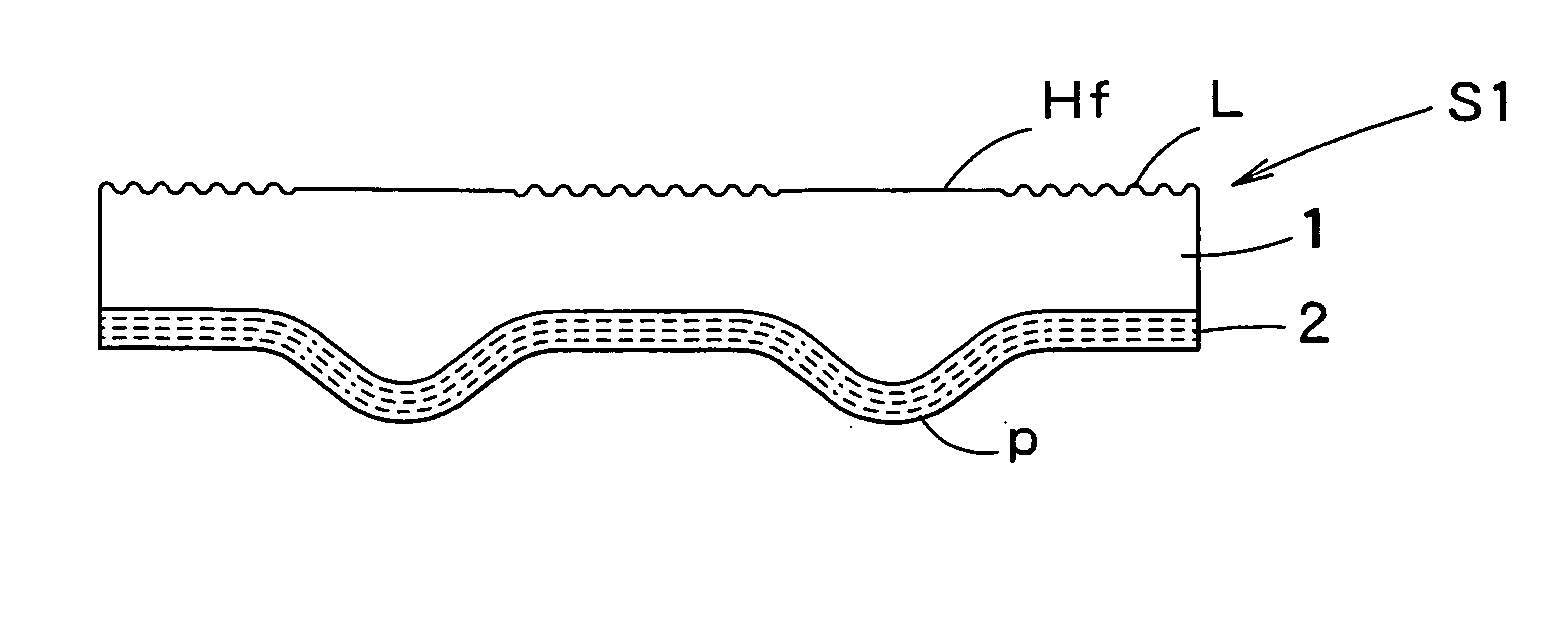

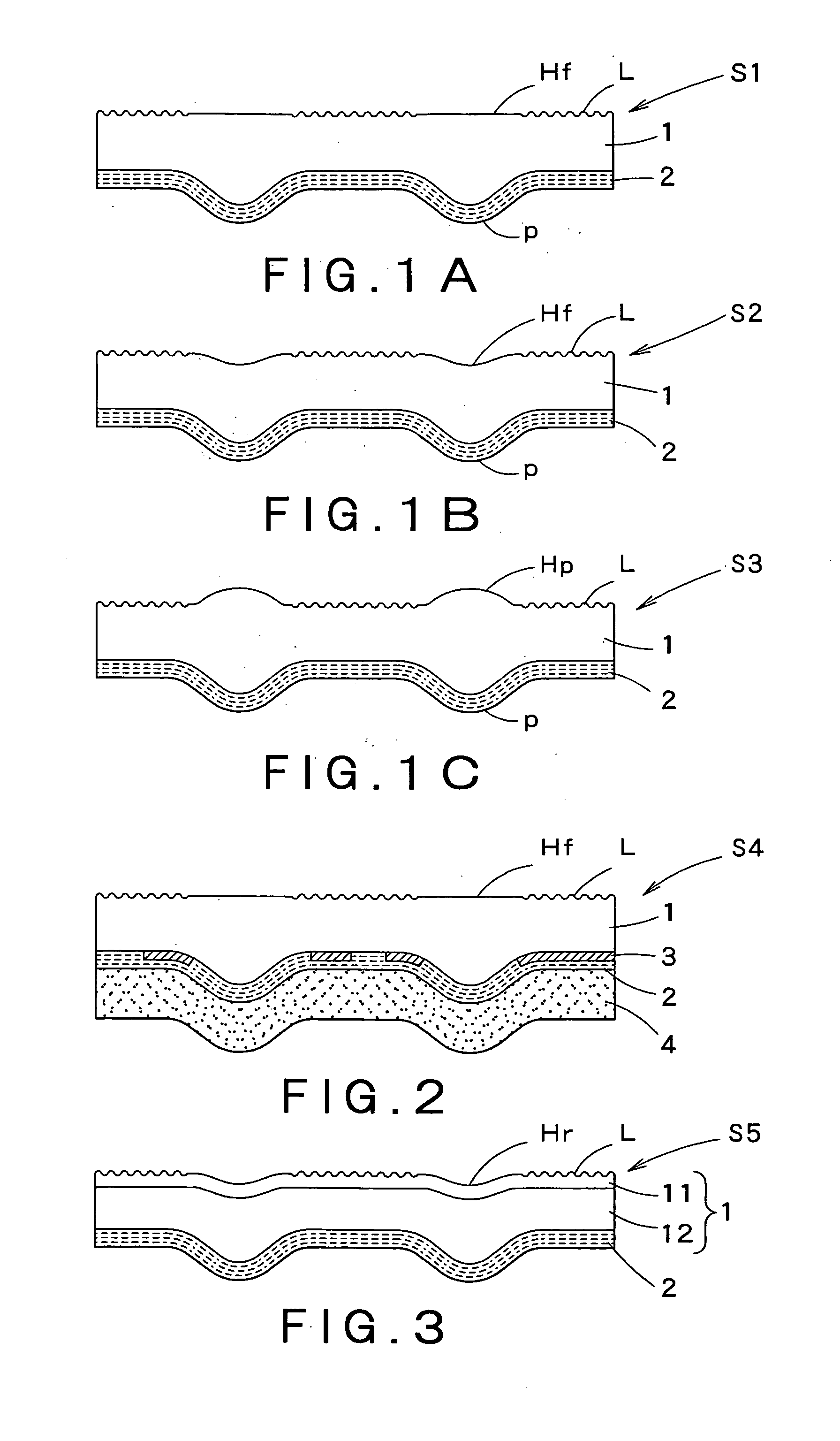

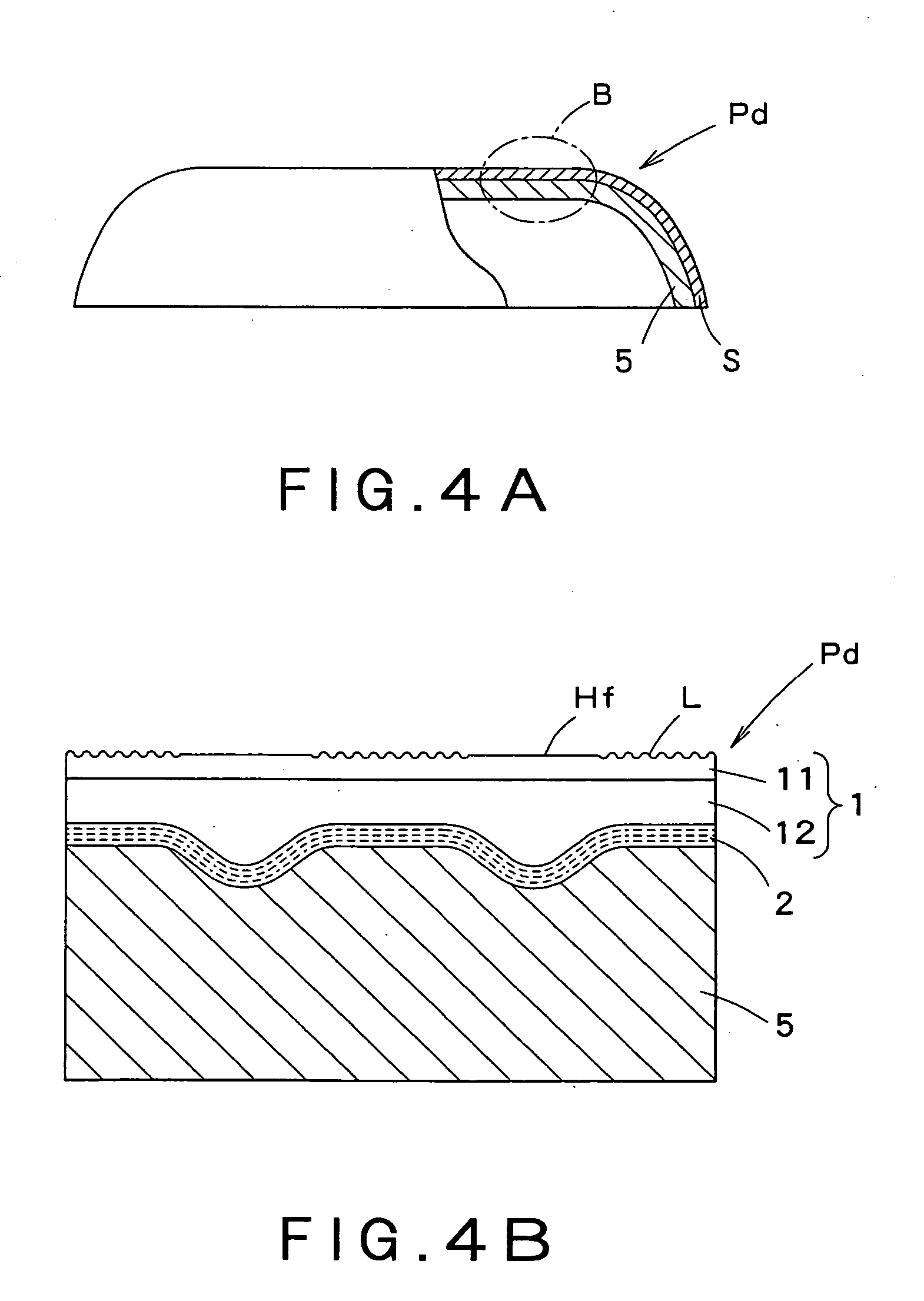

Decorating sheet, decorating molded article and in-mold decorating injection molding

ActiveUS20070026197A1Easy to manufactureOrnamental structuresSpecial ornamental structuresShell moldingEngineering

A decorating sheet comprises a transparent resin substrate sheet 1 and a glossy layer 2 laminated to the back surface of the transparent resin substrate sheet 1, and the front surface of the transparent resin substrate sheet 1 is divided into high-gloss portions H and low-gloss portions L. The transparent resin substrate sheet 1 is thick at the high-gloss portions and thin at the low-gloss portions, and, owing to these portions, the decorating sheet can provide a pattern that is visually sensed as if it were a three-dimensional pattern. This transparent resin substrate sheet 1 is composed of two layers, a crystalline resin layer 11 and a non-crystalline resin layer 12. A decorated molded product Pd can be obtained by laminating this decorating sheet to a resin molded product 5.

Owner:DAI NIPPON PRINTING CO LTD

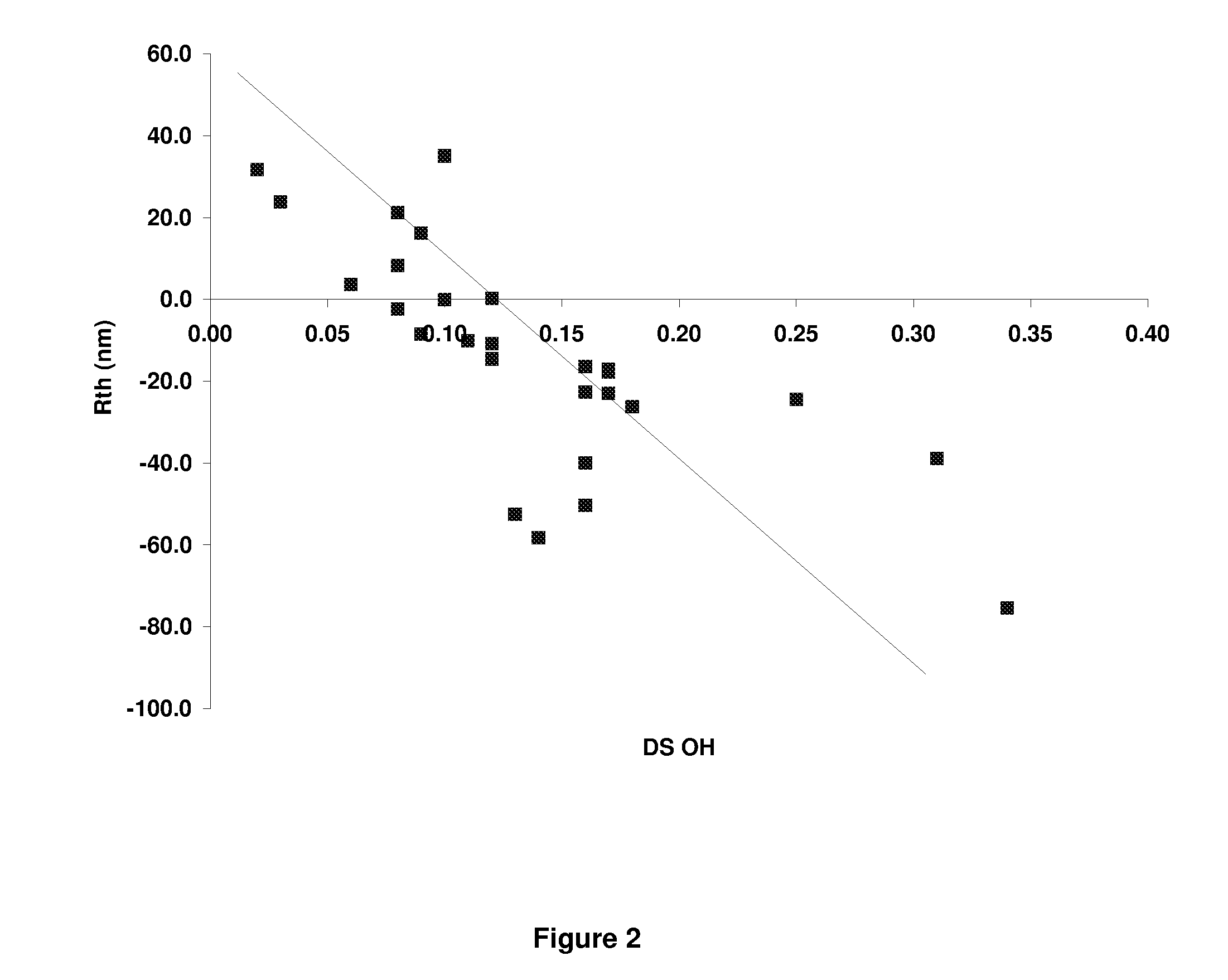

Cellulose Ester Compositions Having Low Bifringence and Films Made Therefrom Comprising a Plasticizer

The present invention relates to cellulose esters having low hydroxyl content for use in optical applications, such as liquid crystal display (LCD) films. Films made with low hydroxyl levels and a given ratio of non-acetyl ester to hydroxyl level have been found to have low intrinsic birefringence. Therefore, these films can be cast, molded, or otherwise oriented without an appreciable birefringence or optical distortion (i.e. retardation). Such features make these films useful in polarizer, protective, and compensator films as well as molded optical parts, such as lenses. Furthermore, it has also been found that resins of the present invention can also be made to have “+C plate” behavior either by melt or solvent based processing, a characteristic which is not typical of cellulose esters. Such +C behavior allows films to be produced having unique compensatory behavior. Other embodiments of the invention relate to methods melt casting films while minimizing birefringence formation. Another embodiment of the invention is directed to films made from the cellulose esters described herein further comprising a plasticizer.

Owner:EASTMAN CHEM CO

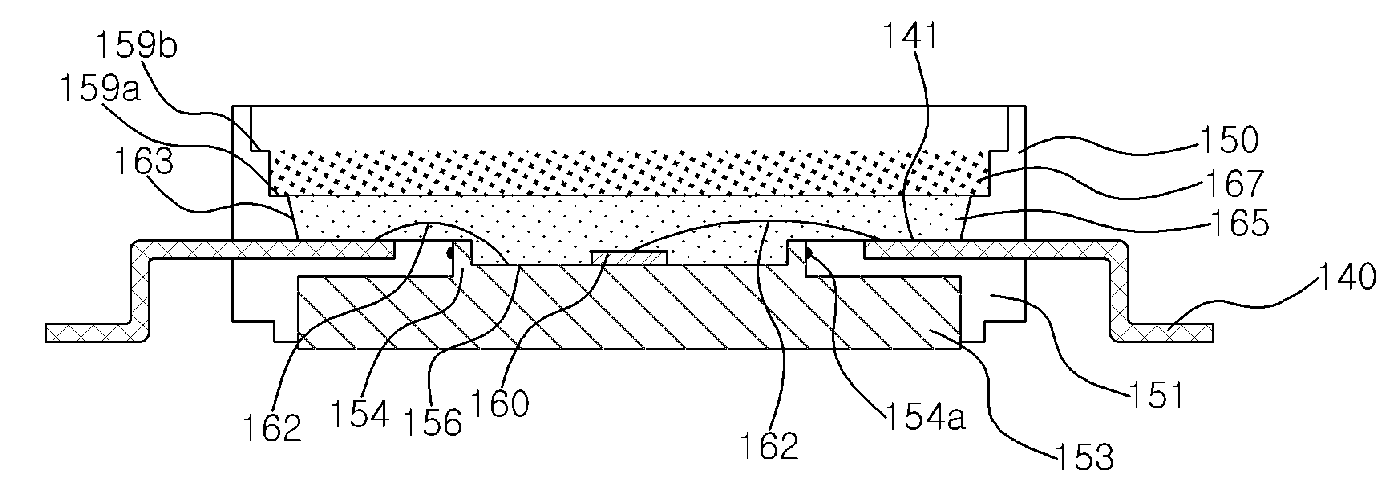

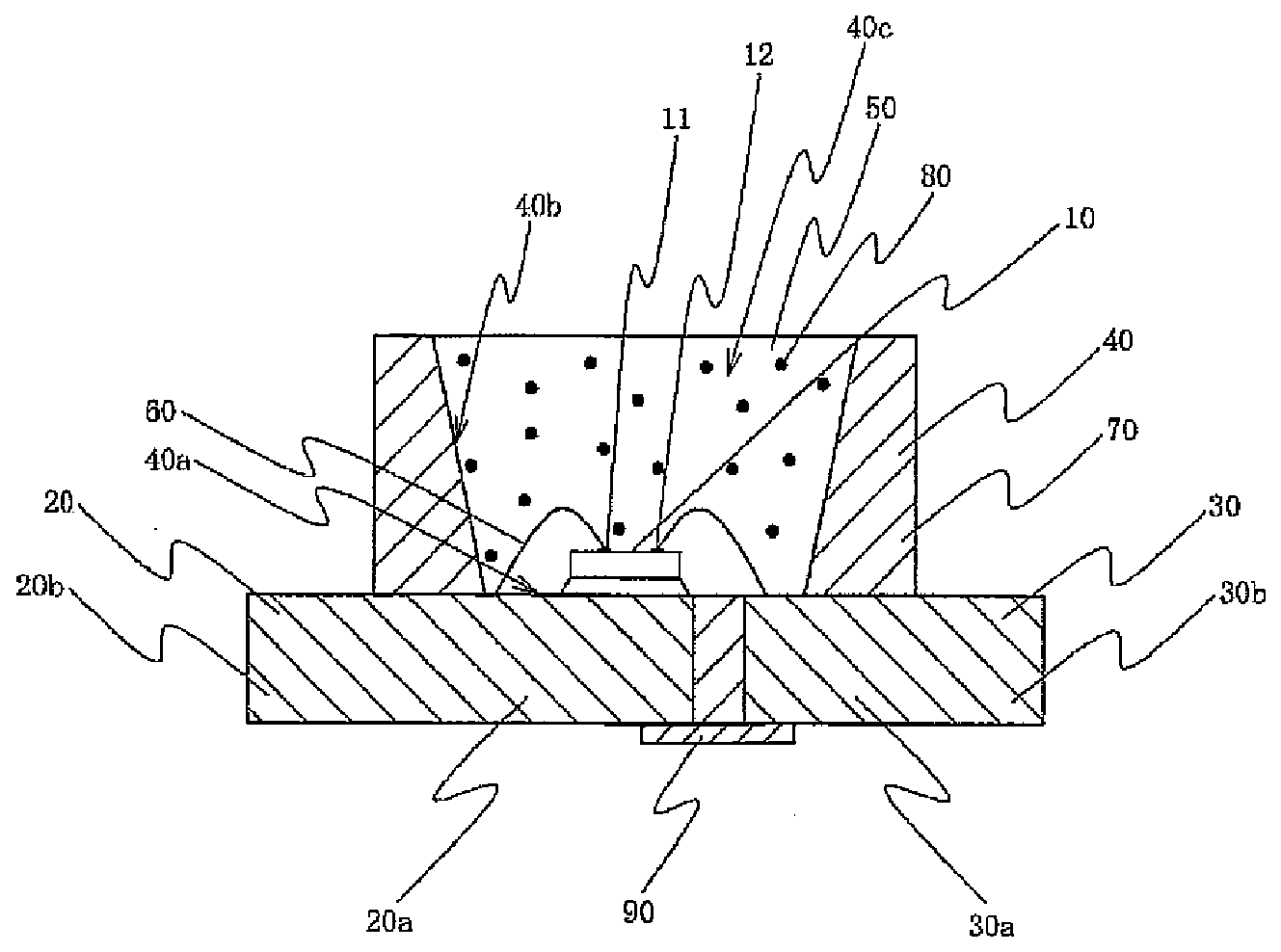

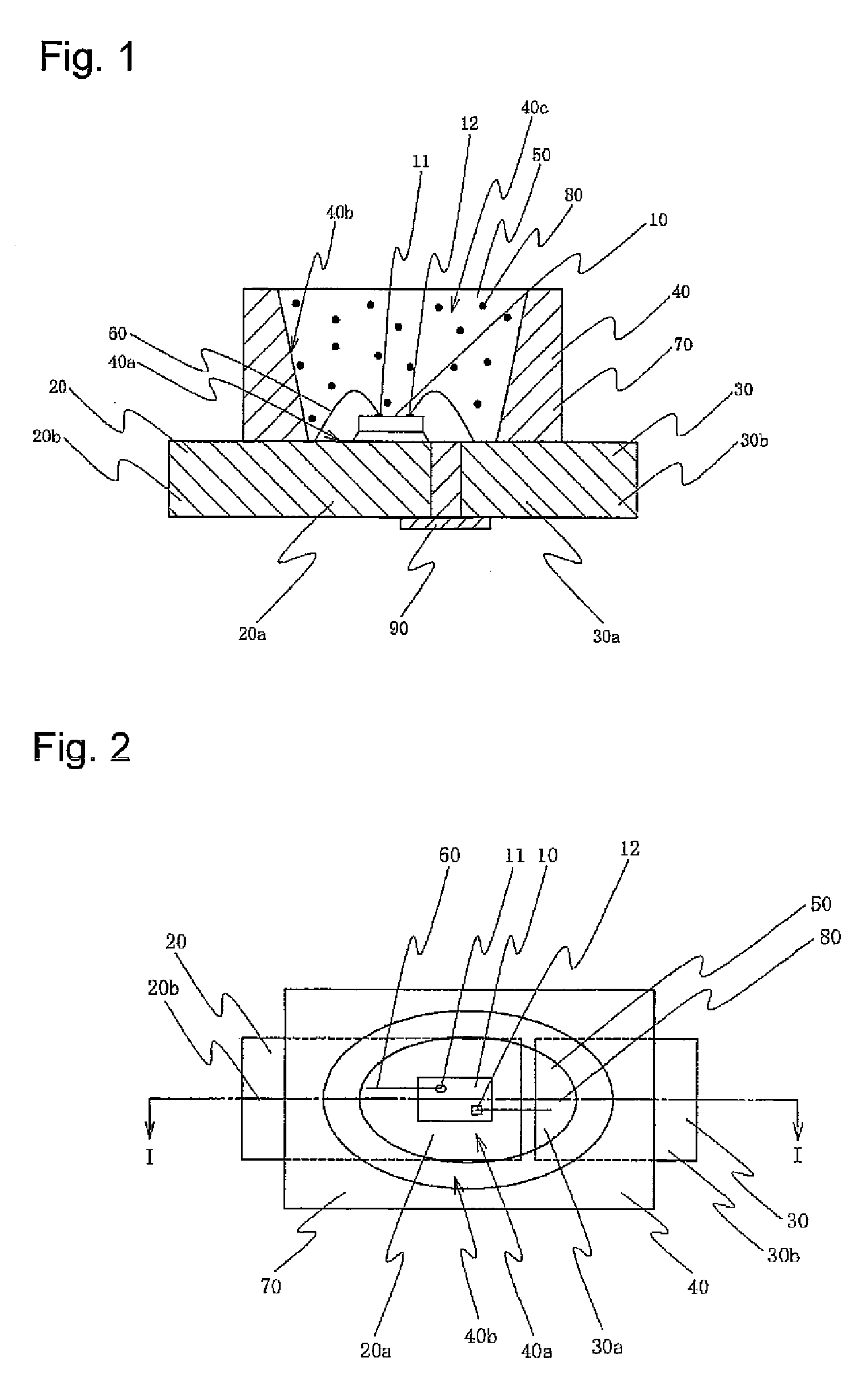

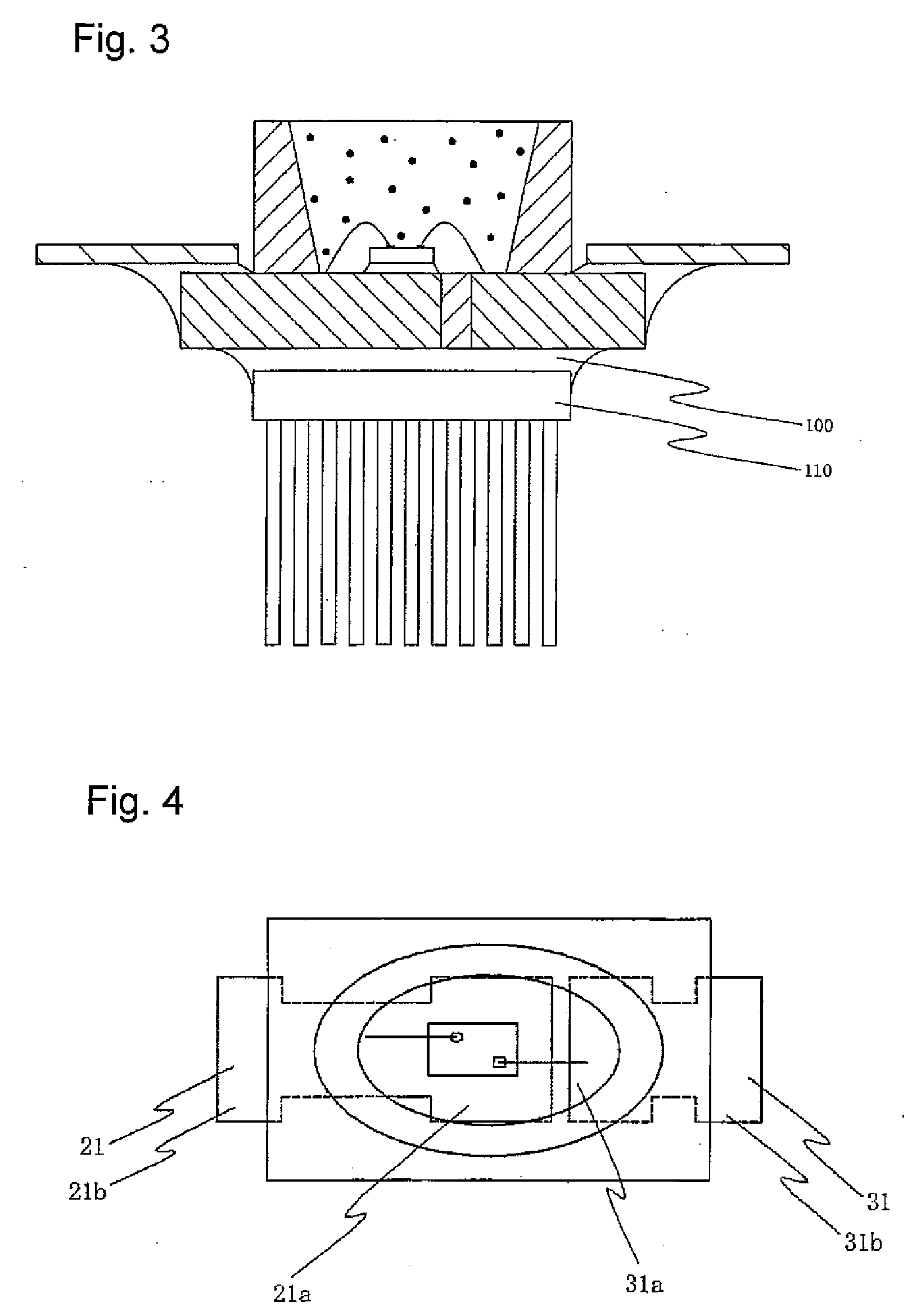

Resin molding, surface mounted light emitting apparatus and methods for manufacturing the same

ActiveUS20090050925A1Easy to useSuitable for mass productionSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyShell molding

The present invention provides a surface mounted light emitting apparatus which has long service life and favorable property for mass production, and a molding used in the surface mounted light emitting apparatus.The surface mounted light emitting apparatus comprises the light emitting device 10 based on GaN which emits blue light, the first resin molding 40 which integrally molds the first lead 20 whereon the light emitting device 10 is mounted and the second lead 30 which is electrically connected to the light emitting device 10, and the second resin molding 50 which contains YAG fluorescent material and covers the light emitting device 10. The first resin molding 40 has the recess 40c comprising the bottom surface 40a and the side surface 40b formed therein, and the second resin molding 50 is placed in the recess 40c. The first resin molding 40 is formed from a thermosetting resin such as epoxy resin by the transfer molding process, and the second resin molding 50 is formed from a thermosetting resin such as silicone resin.

Owner:NICHIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com