Patents

Literature

32551 results about "Plasticizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasticizers (UK: plasticisers) or dispersants are additives that increase the plasticity or decrease the viscosity of a material. These are the substances which are added in order to alter their physical properties. These are either liquids with low volatility or solids. They decrease the attraction between polymer chains to make them more flexible. Over the last 60 years more than 30,000 different substances have been evaluated for their plasticizing properties. Of these, only a small number – approximately 50 – are today in commercial use. The dominant applications are for plastics, especially polyvinyl chloride (PVC). The properties of other materials may also be modified when blended with plasticizers including concrete, clays, and related products. According to 2014 data, the total global market for plasticizers was 8.4 million metric tonnes including 1.3 million metric tonnes in Europe.

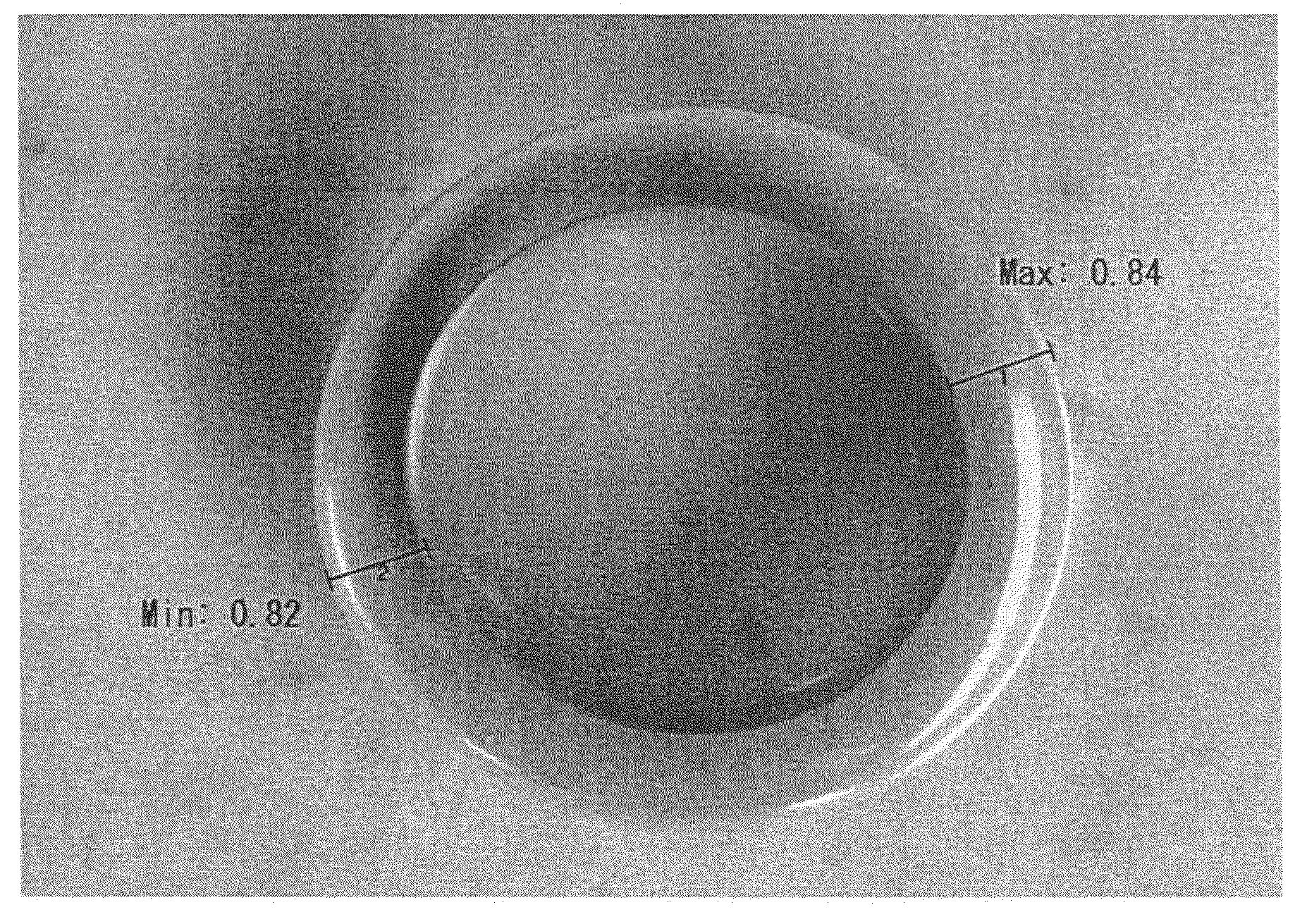

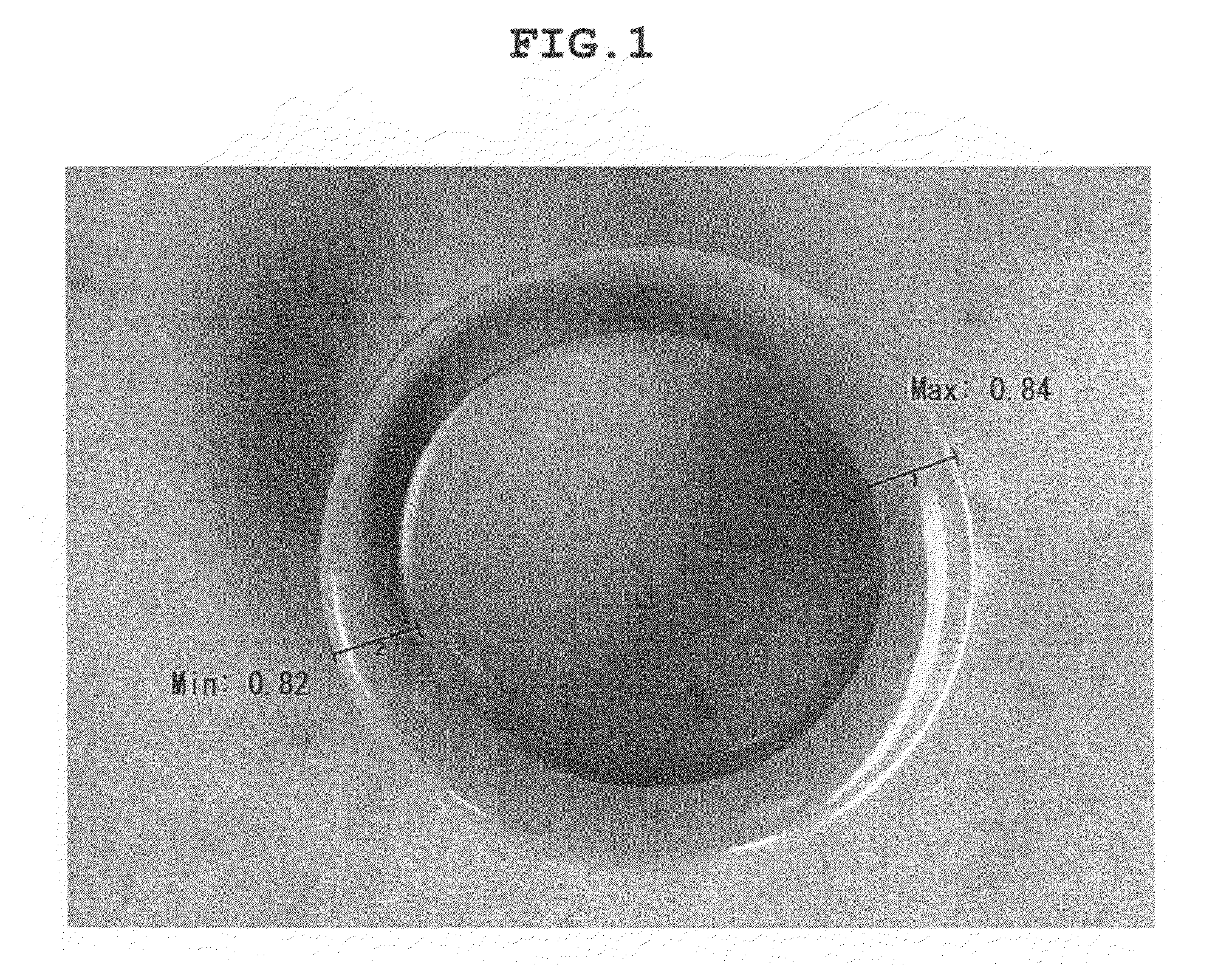

Colon targeted delivery system

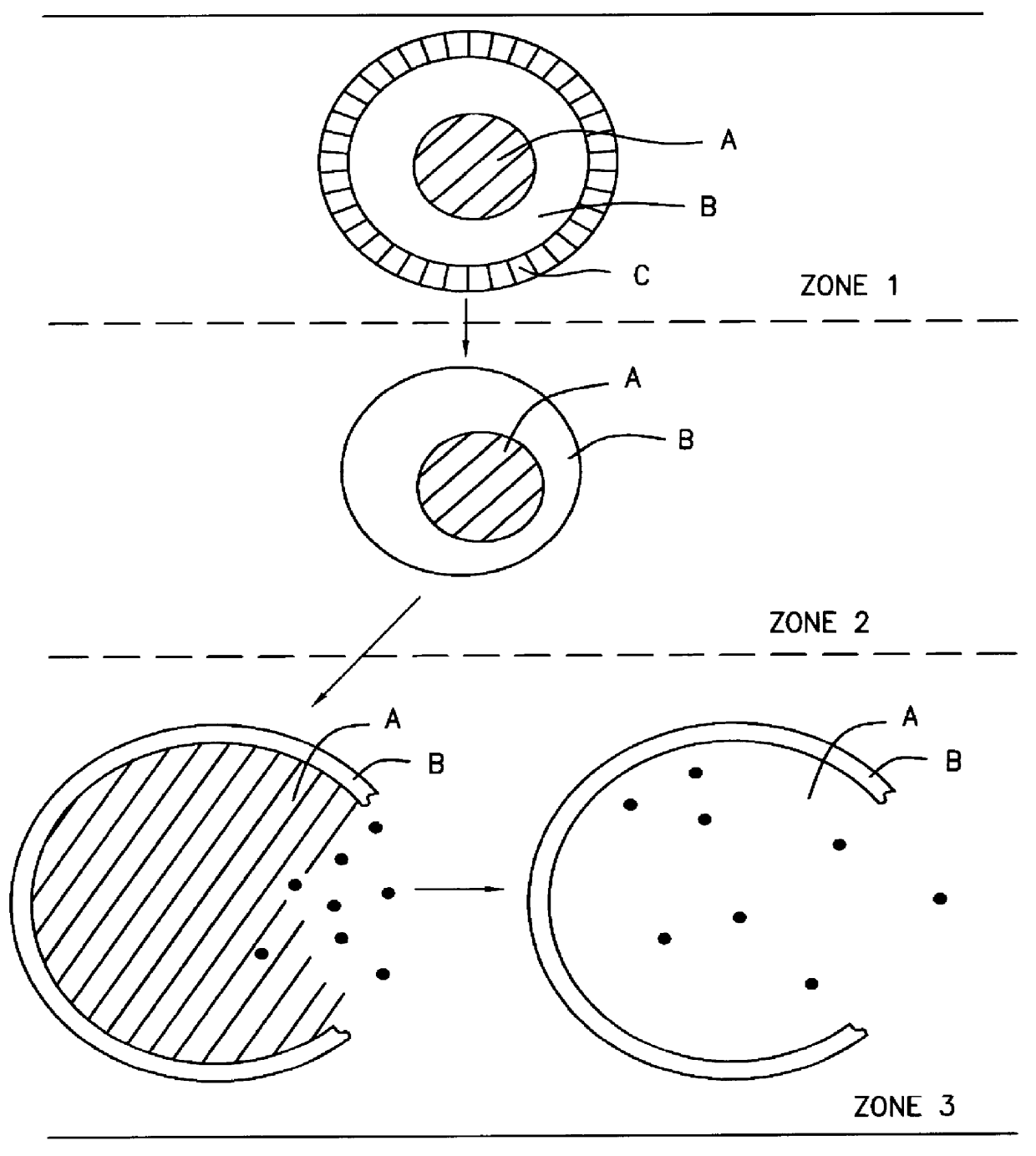

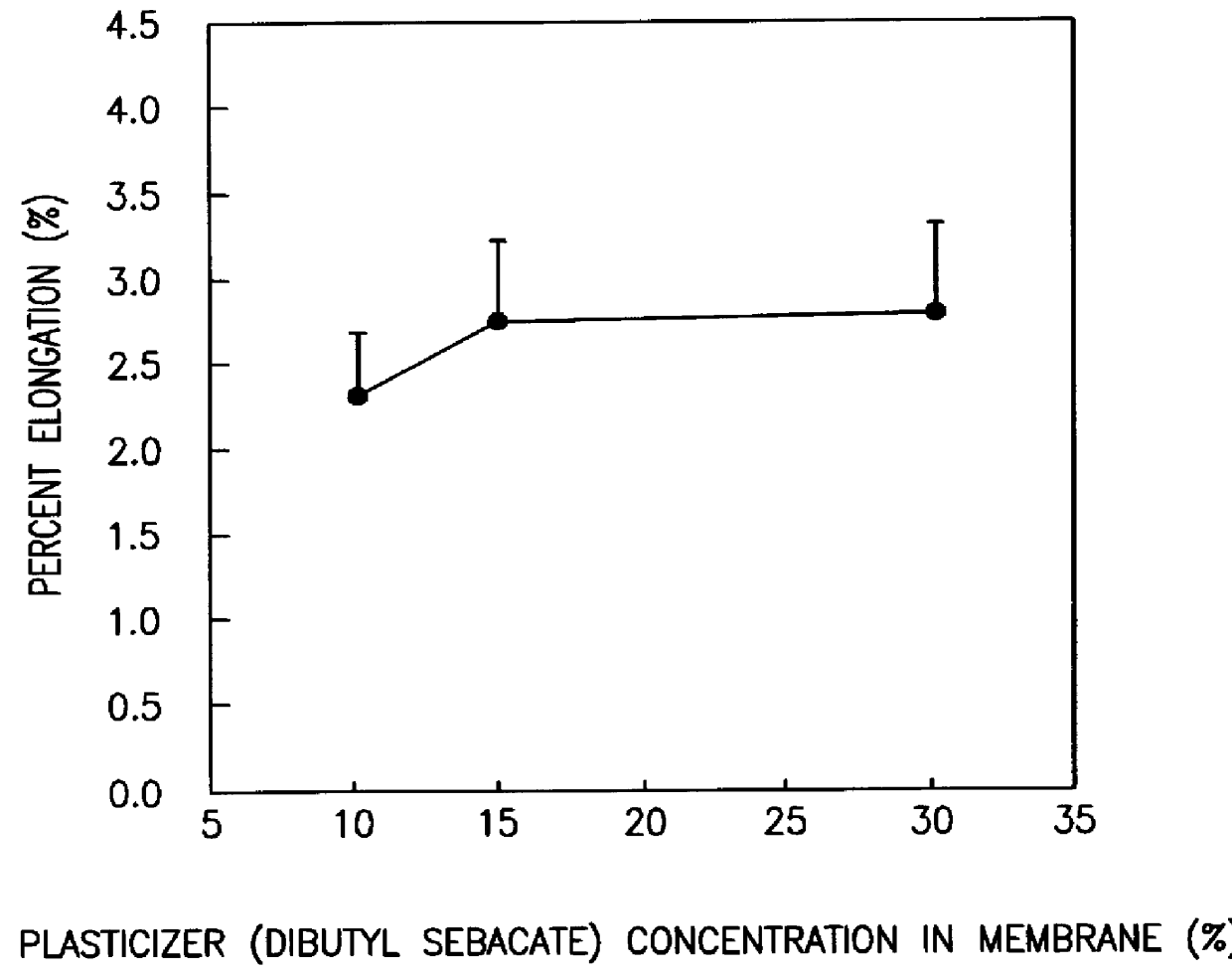

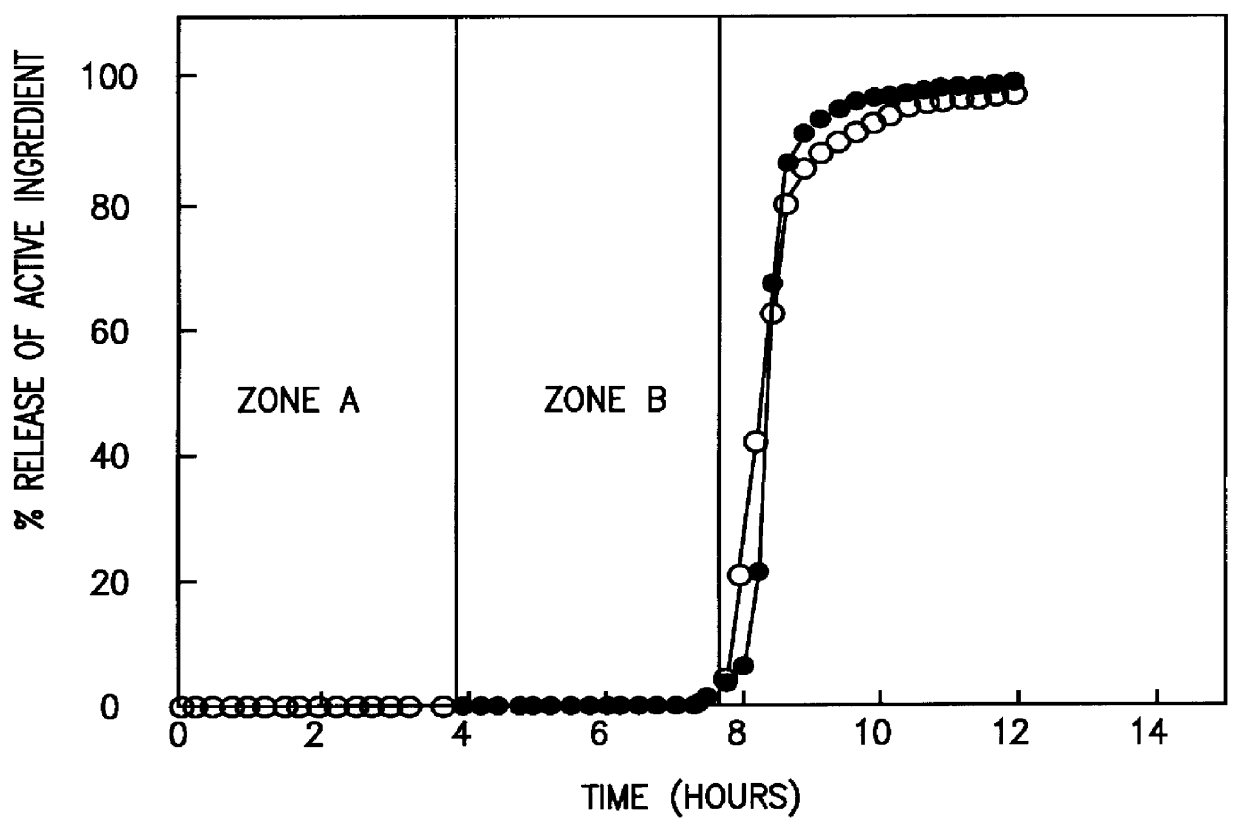

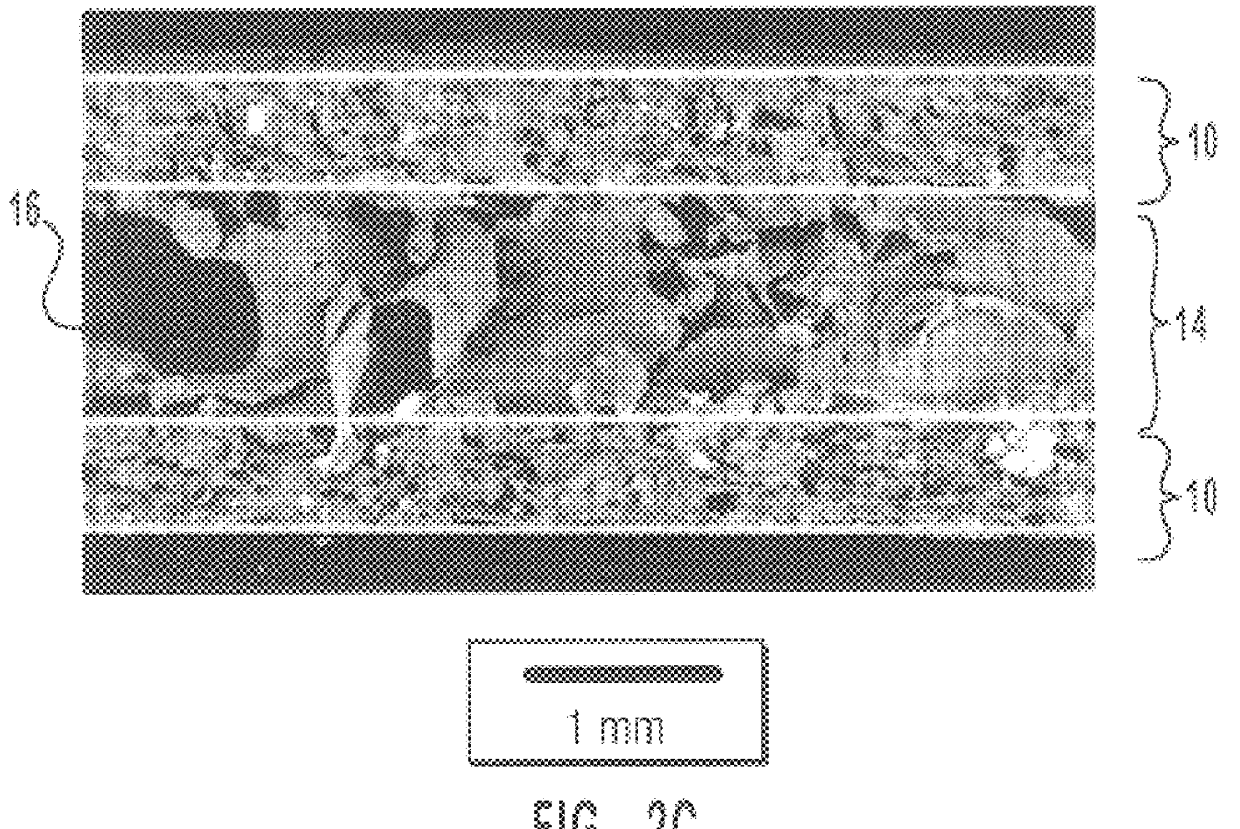

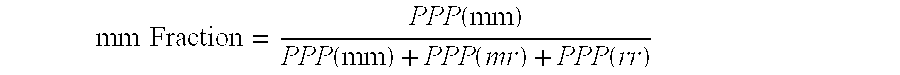

A novel delivery system for targeting drugs to the colon is herein described. The system is a tablet comprised of three parts: 1) an outer enteric coating, 2) an inner semi-permeable polymer membrane containing a plasticizer and 3) a central core comprising swelling excipients and an active ingredient. The novel dosage form described herein will release the drug consistently in the colon by a time-dependent explosion mechanism. This delivery system is particularly suitable for delivering viral protease inhibitors to the colon.

Owner:F HOFFMANN LA ROCHE & CO AG

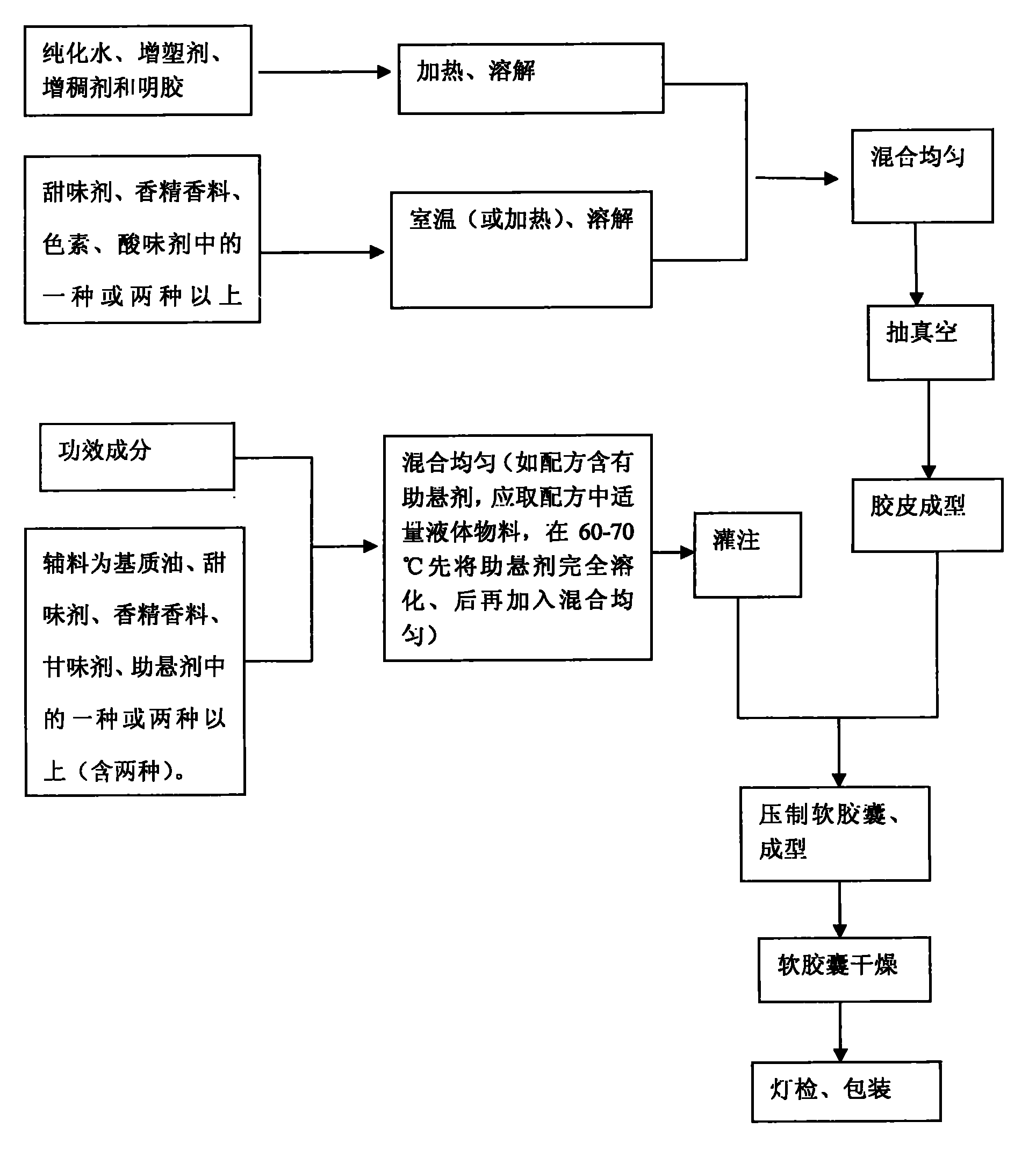

Chewable soft capsules and method for preparing same

ActiveCN101810336ADissolution stabilityRapid dissolutionFood shapingFood preparationFlavorPlasticizer

The invention discloses chewable soft capsules, which comprise capsule shells and contents sealed in the capsule shells. The chewable soft capsules are characterized by comprising the following raw materials in part by weight: 25 to 65 parts of glutin, 1 to 25 percent of thickening agent, 18 to 65 parts of plasticizer, 4 to 16 parts of water and a mixture containing one or more of 0.005 to 20 parts of sweetening agent, 0.005 to 2 parts of essence, 0.0001 to 10 parts of pigment and 0.0001 to 5 parts of acid additive. The invention also discloses a method for preparing the novel chewable soft capsules. The chewable soft capsules have the advantages of reasonable blending ratio, proper hardness, good temperature resistance, no adhesion, no deformation, stable storage, quick dissolution of effectively components and high chewiness; and when the chewing soft capsules are chewed, tastes of the capsule shells and the contents easily and uniformly spread in the mouth so as to cover up bad taste of raw materials.

Owner:SIRIO PHARMA CO LTD

Non-gelatin substitutes for oral delivery capsules, their composition and process of manufacture

Gelatin-free capsule for use in oral administration of medicines, cosmetic or bath applications, or dietary supplements can be prepared from compositions comprisinga) 8-50% by weight of water-dispersible or water-soluble plasticizer,b) 0.5 to 12% by weight kappa-carrageenan,c) 0 to 60% dextrins, andd) 1% to 95% by weight water,with the kappa-carrageenan comprising at least 50% by weight of all gums forming or contributing to formation of thermoreversible gels in the composition. A capsule for oral administration or cosmetic application may comprise a fill material to be administered to a patient or subject and a capsule, the capsule comprising an aqueous based film comprisinga) water-dispersible or water-soluble plasticizer, andb) carrageenan,with the carrageenan comprising at least 50% or 75% by weight of kappa-carrageenan, and the carrageenan comprising at least 50% or 75% by weight of all gums which form or contribute to the formation of thermoreversible gels. A process for forming the capsules may comprise heating the composition, casting or extruding the composition into a film, gelling the composition by cooling, associating a fill material with the gelled composition (usually as a film) and sealing the film about the fill material.

Owner:PATHEON SOFTGELS INC

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

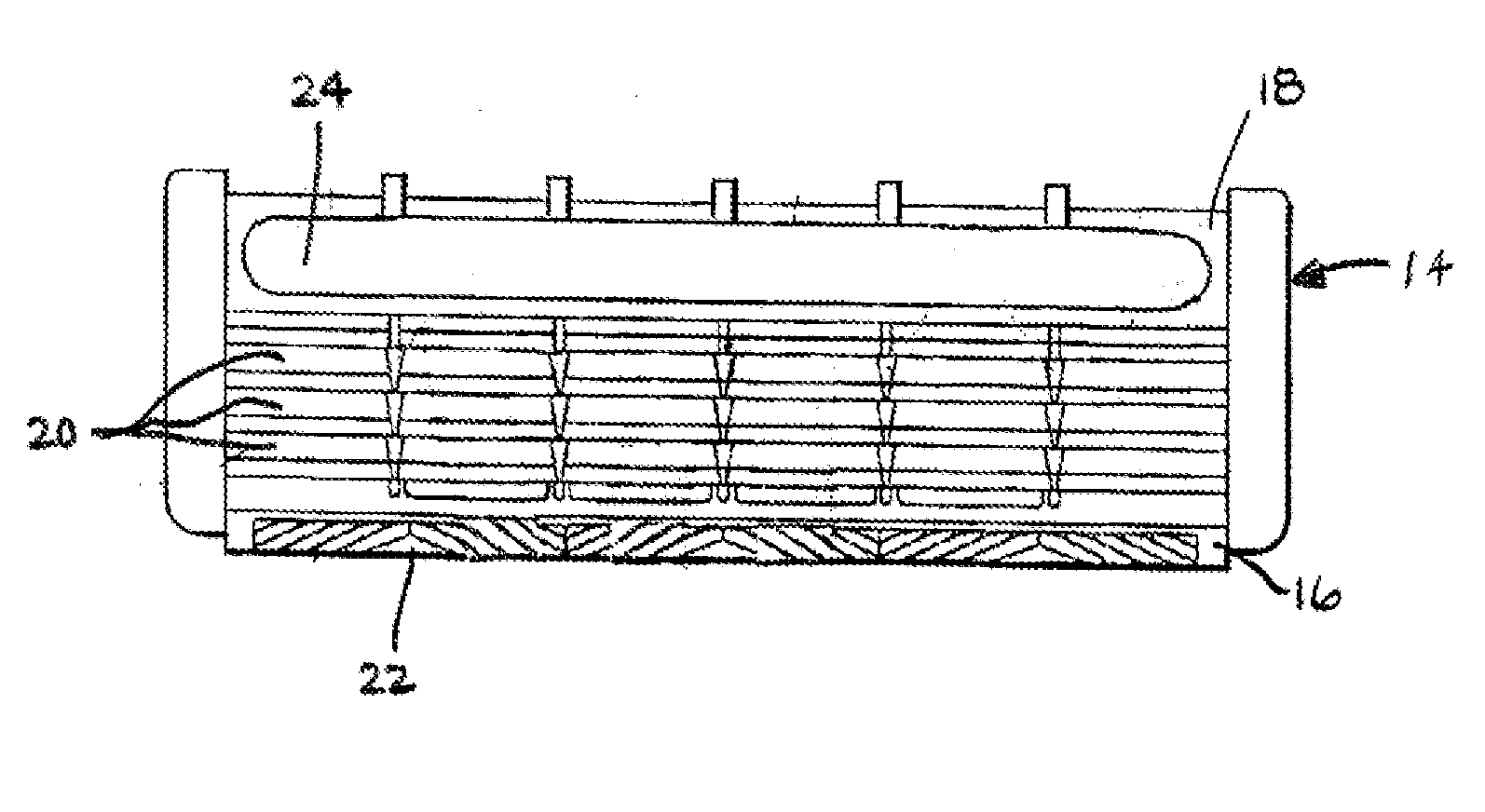

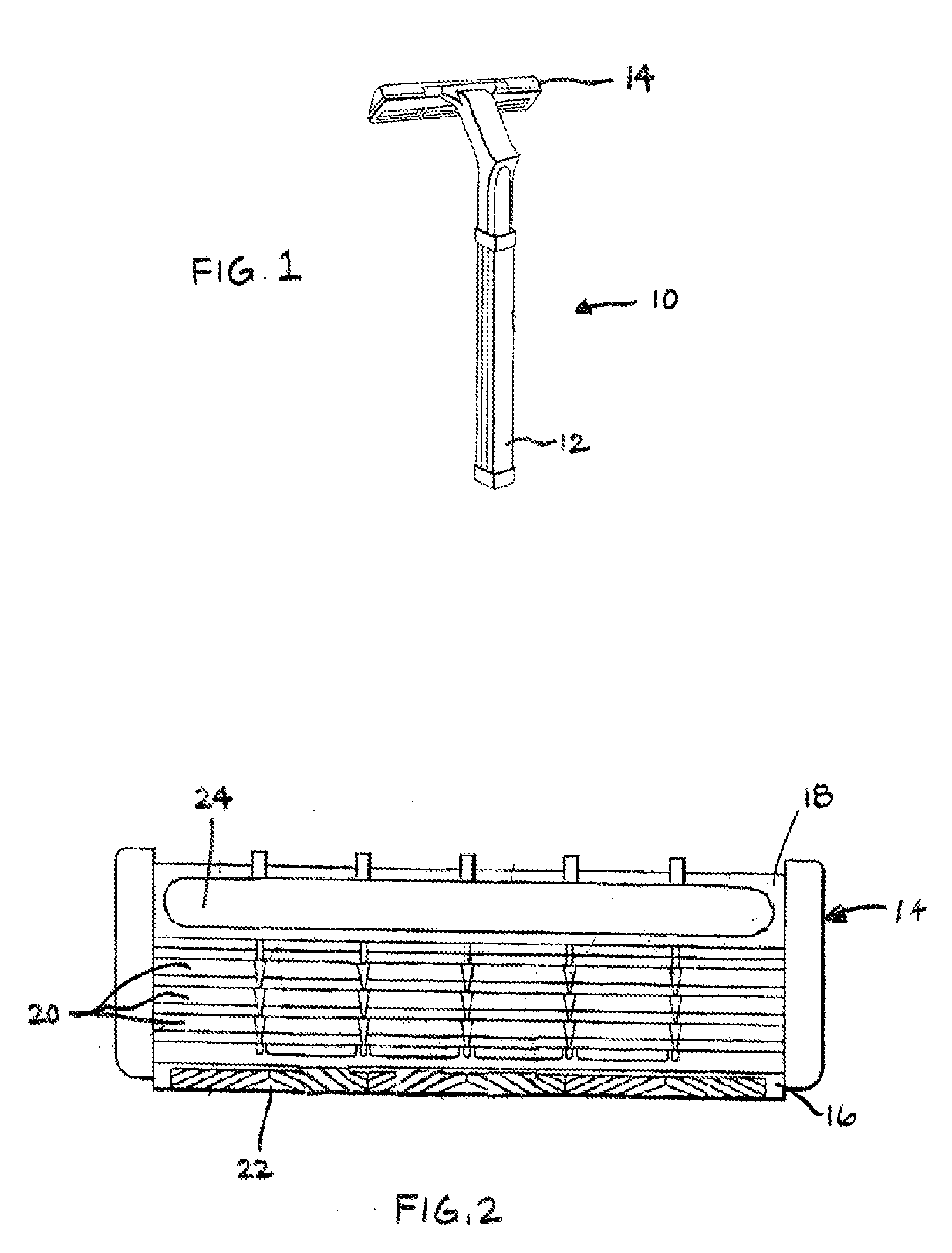

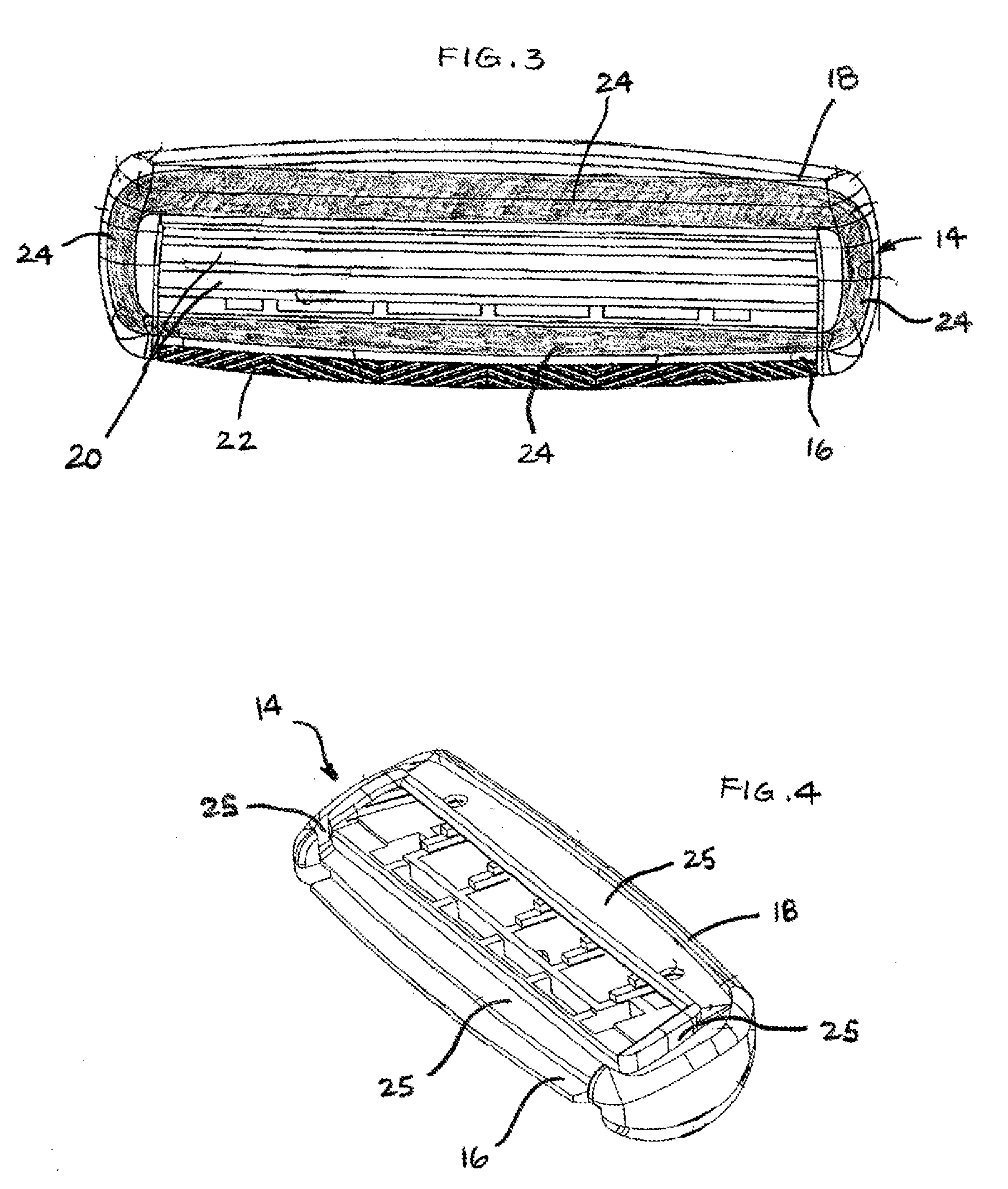

Shaving aid material

A shaving aid material is provided that includes a water-soluble lubricious shaving aid in combination with a water-insoluble erodable medium. In some embodiments, the shaving aid material further includes a water-soluble thermoplastic polymer, and may also include a plasticizer. Optional additional ingredients include emulsifiers, surfactants, skin conditioners, fragrances, depilatory agents, cleaning agents, medicinal agents, etc.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

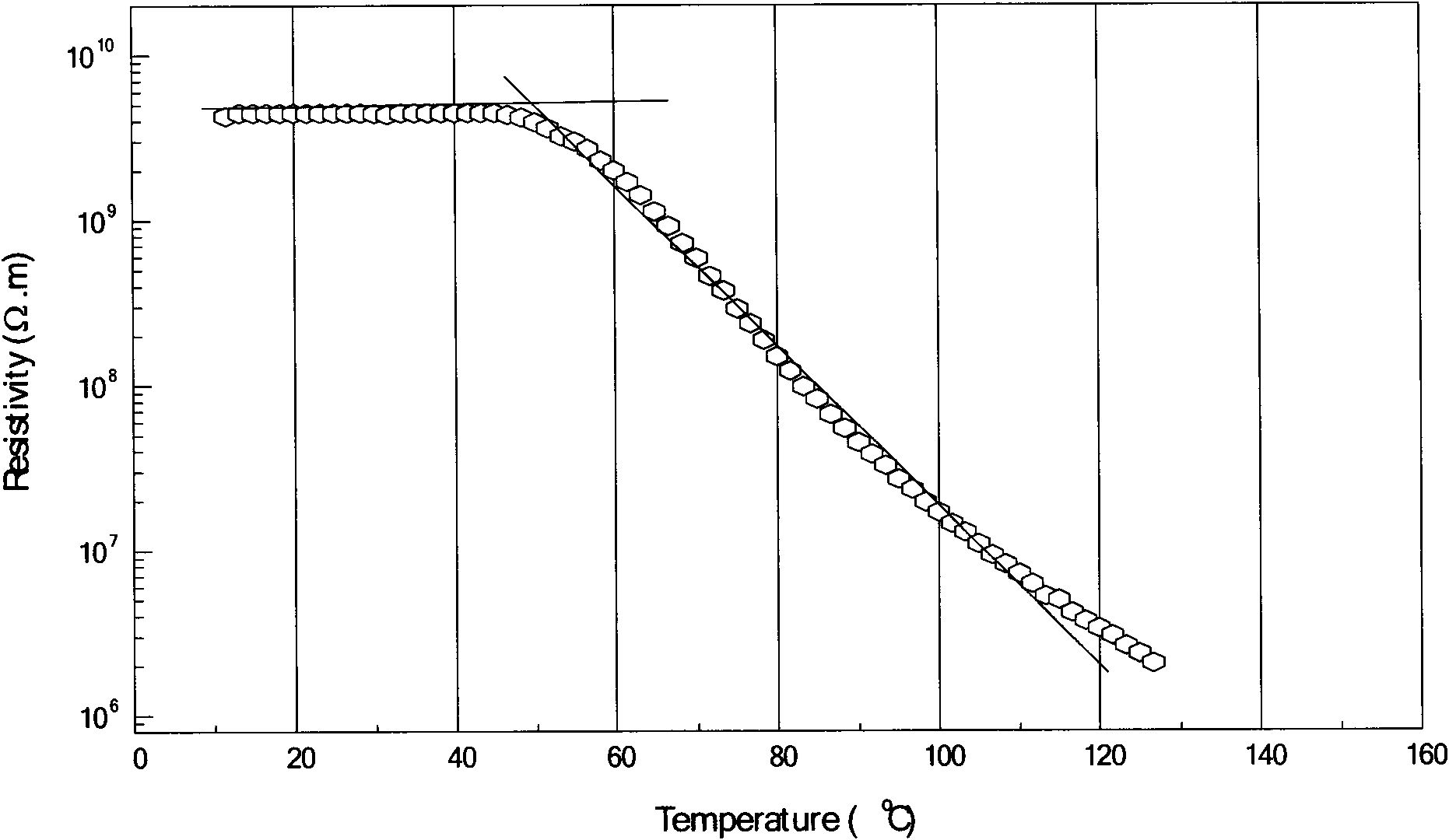

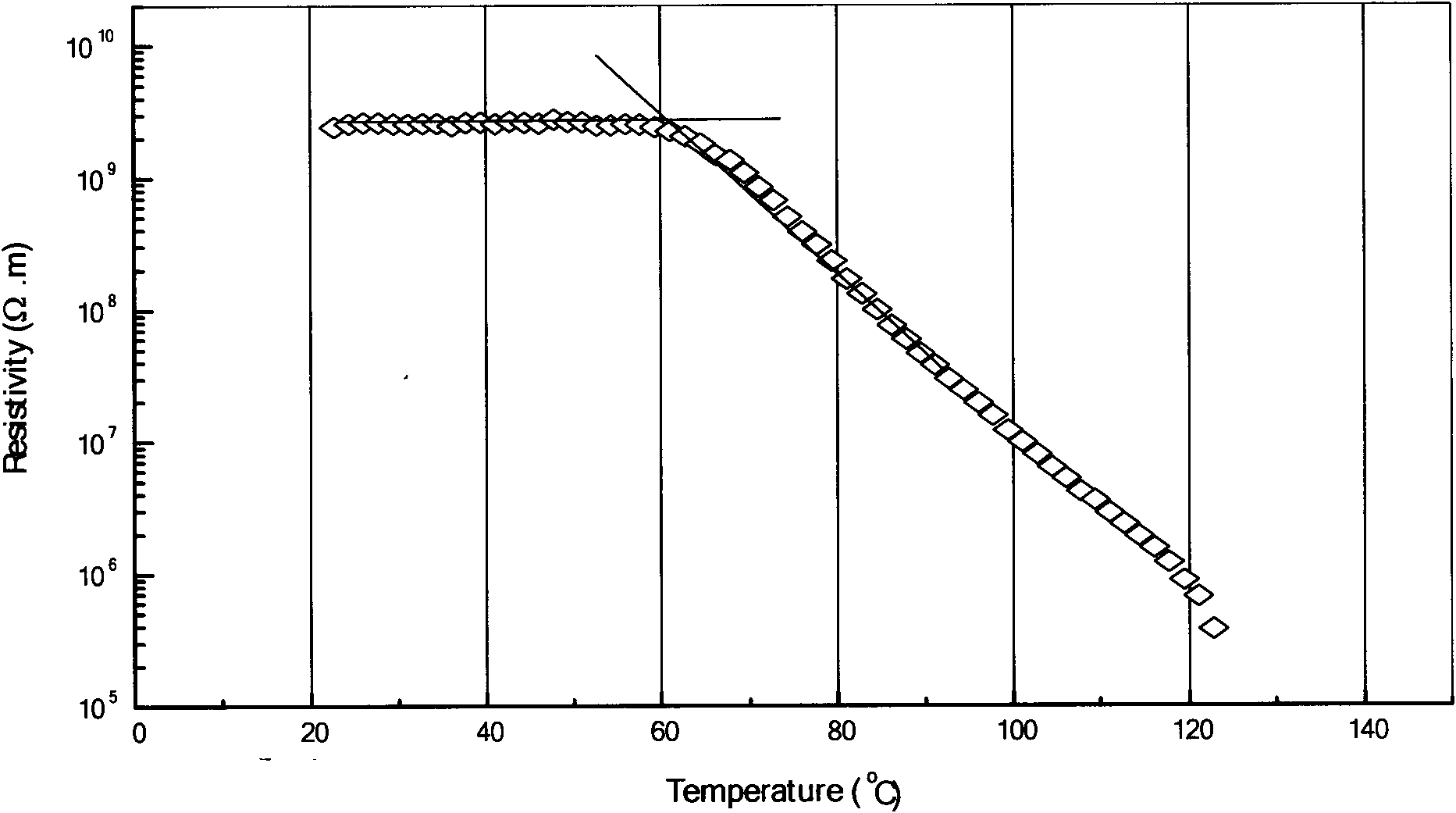

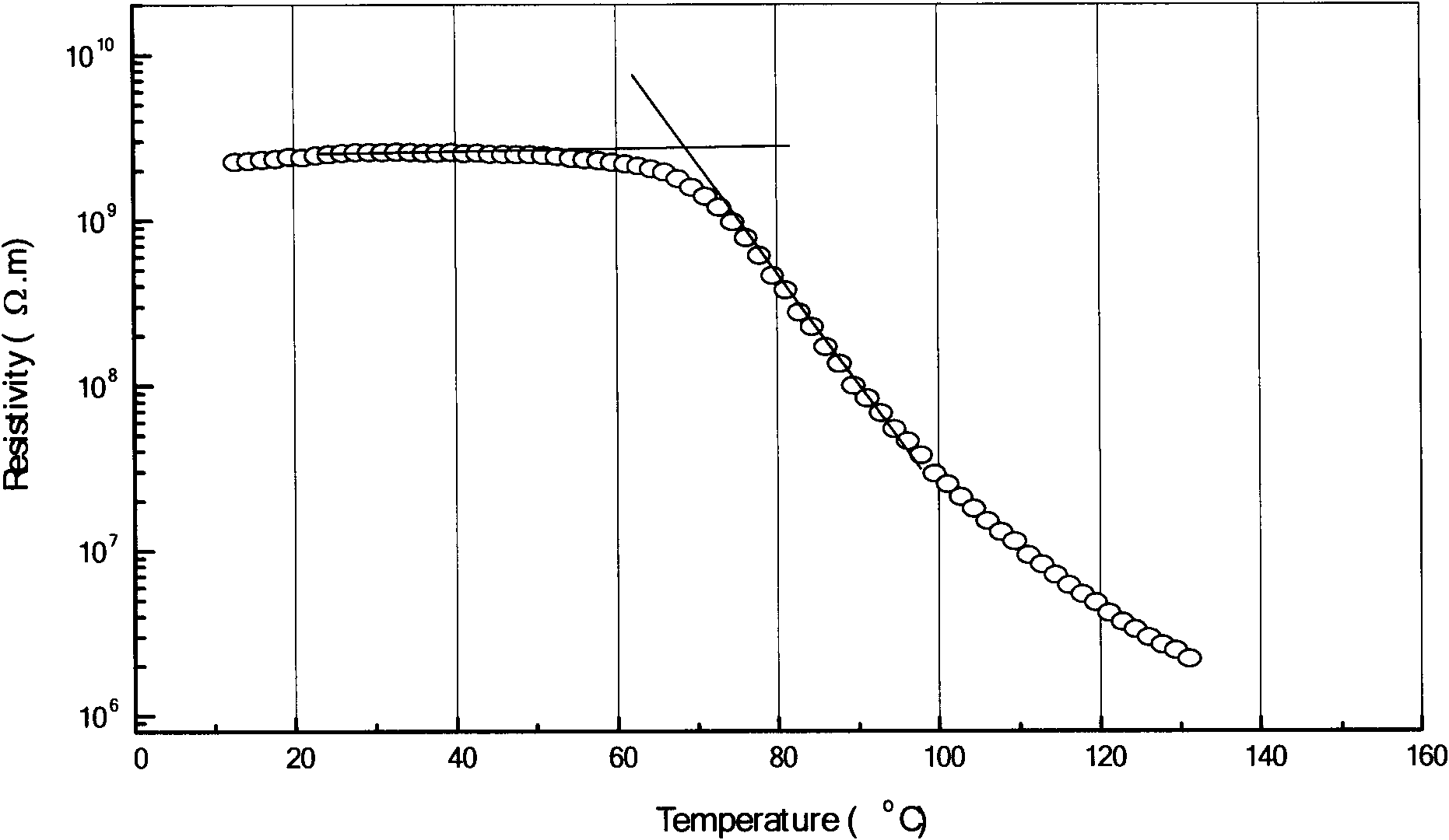

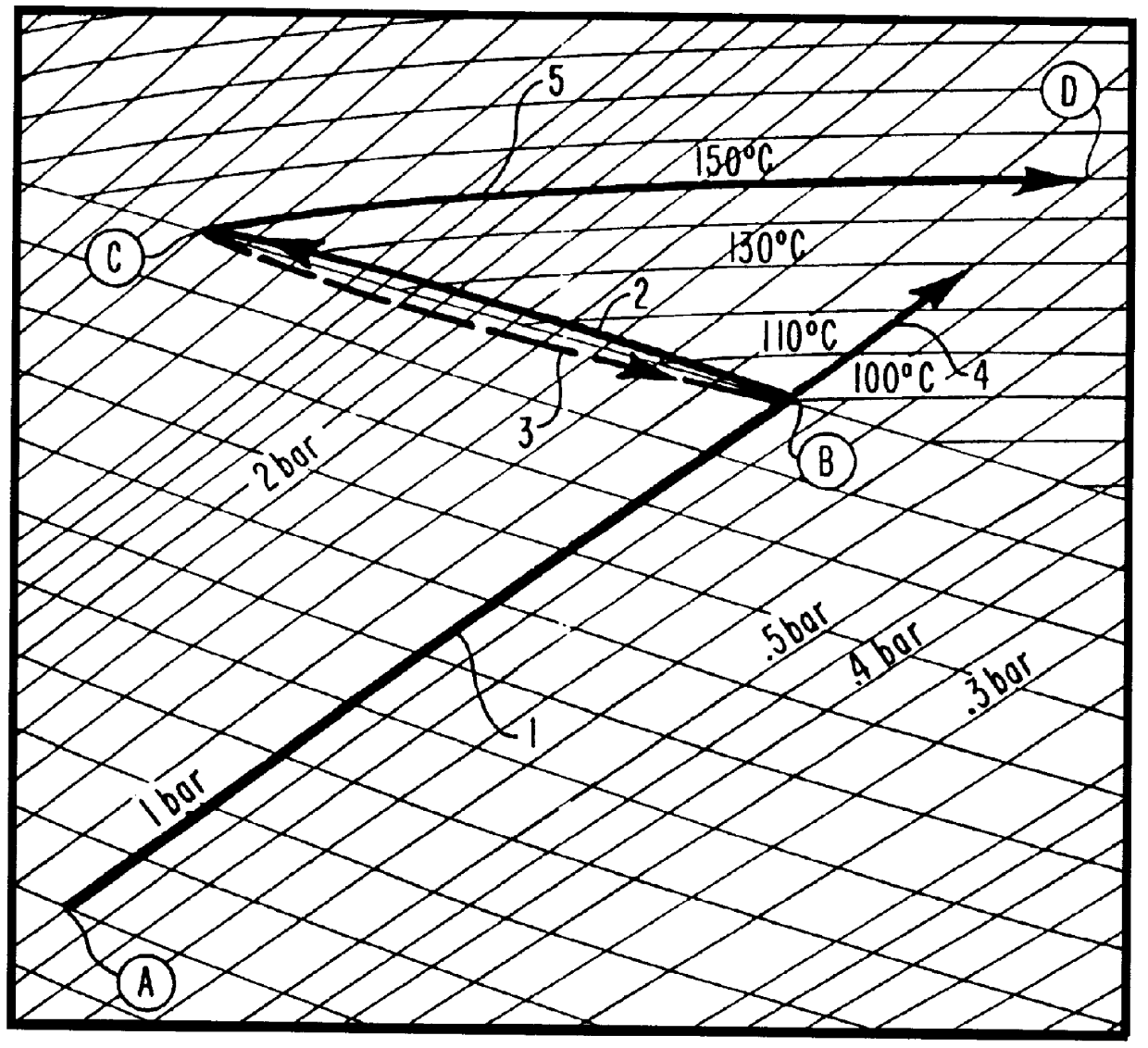

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

Sealants and potting formulations including mercapto-terminated polymers produced by the reaction of a polythiol and polyvinyl ether monomer

Sealant and potting formulations are provided which are prepared from components including ungelled mercapto-terminated polymer(s) prepared by reacting reactants comprising polyvinyl ether monomer(s) and polythiol material(s); curing agent(s) reactive with a mercapto group of the mercapto-terminated polymer; and additive(s) selected from the group consisting of fillers, adhesion promoters, plasticizers and catalysts.

Owner:PRC DE SOTO INT INC

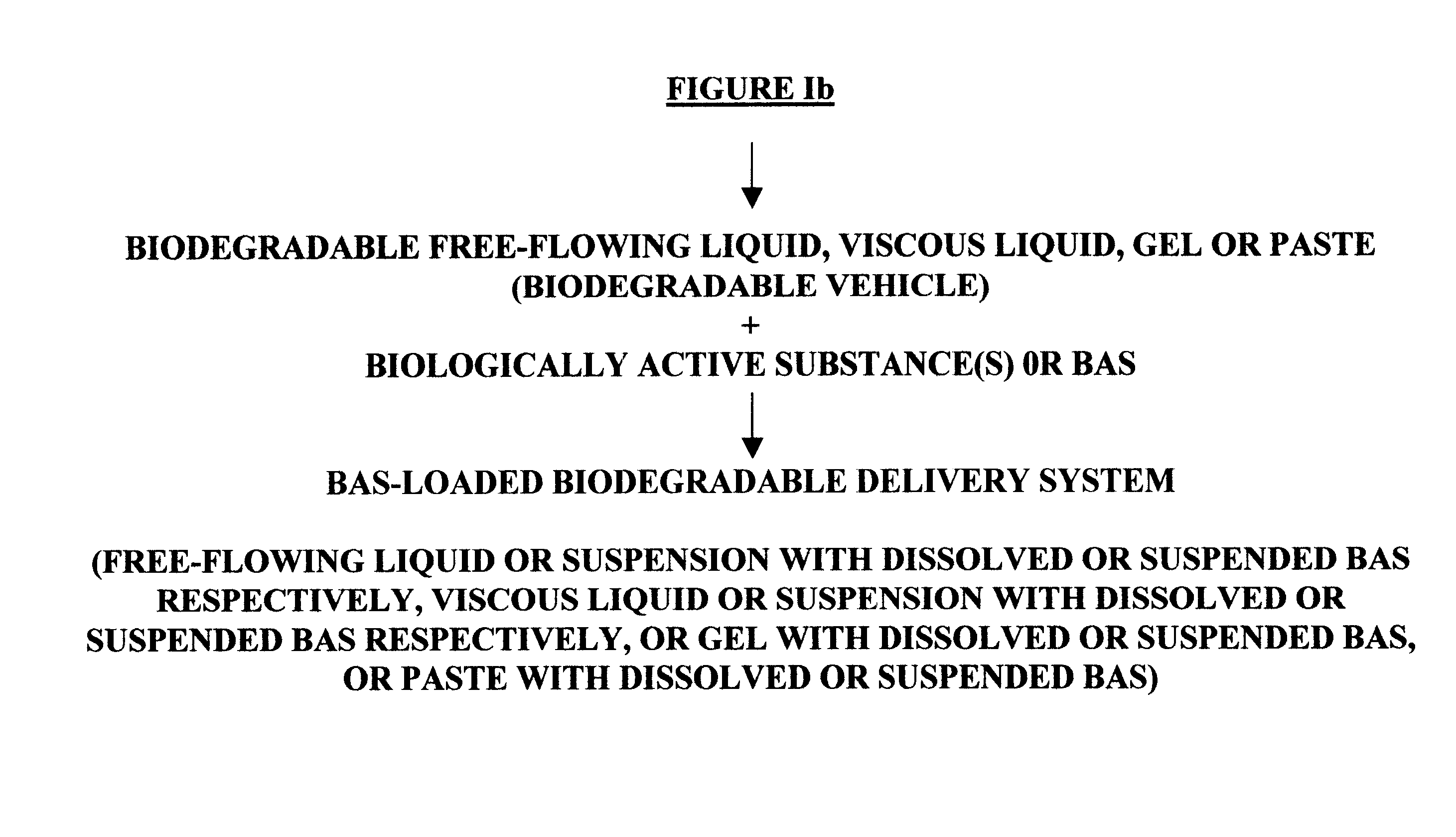

Biodegradable vehicle and filler

InactiveUS6432438B1Improve stabilityWell mixedOrganic active ingredientsPharmaceutical delivery mechanismPolymer sciencePlasticizer

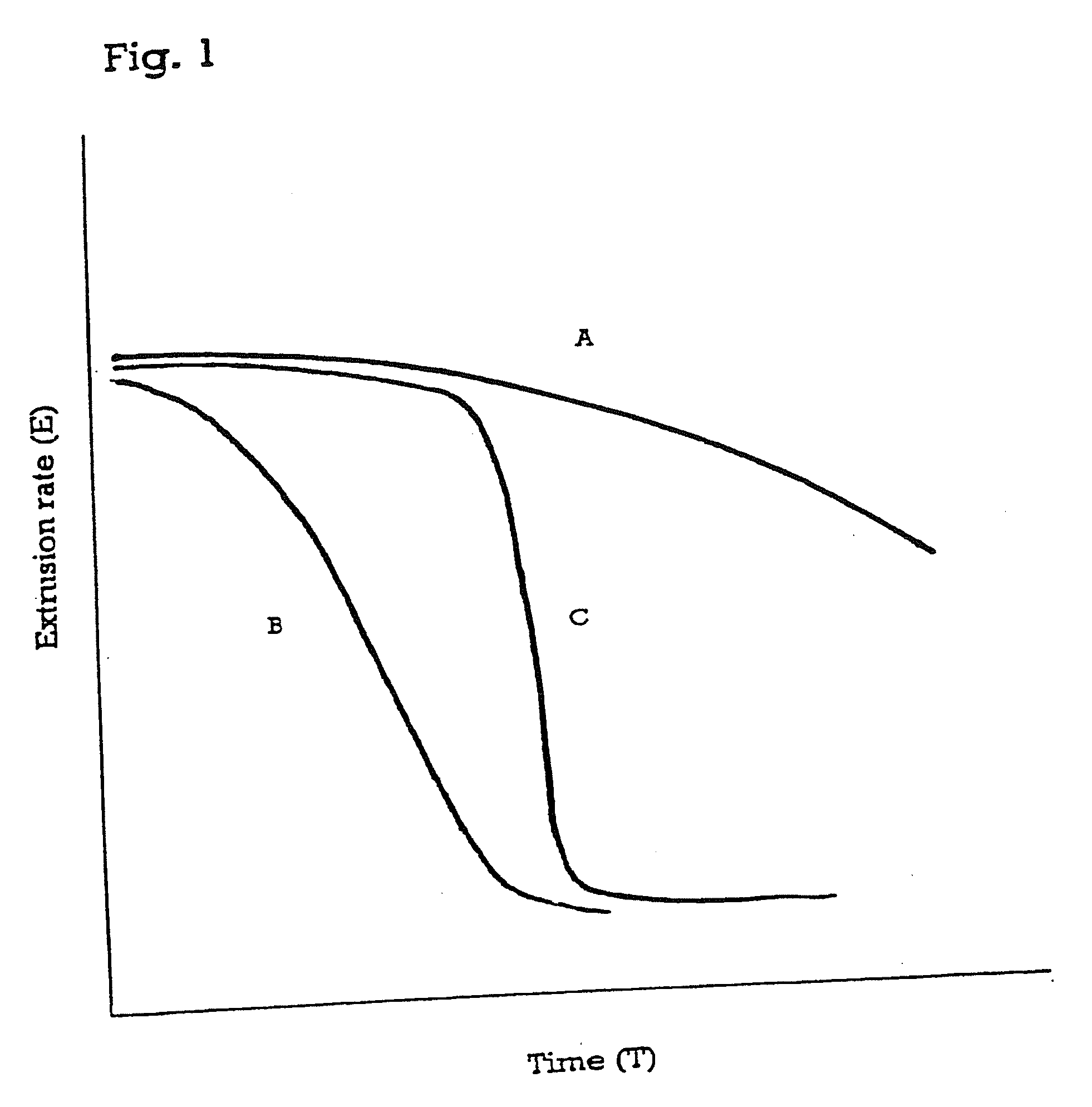

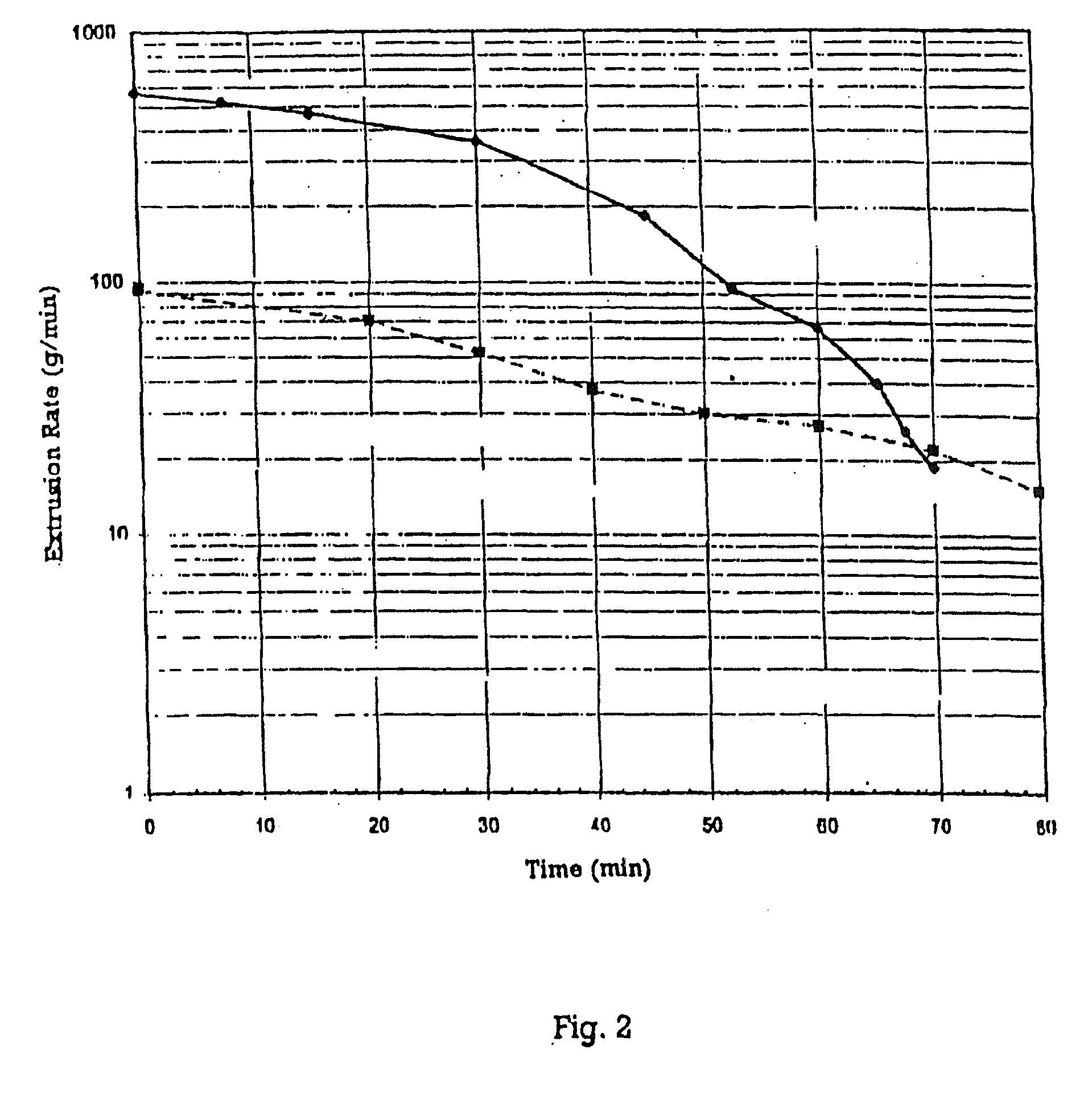

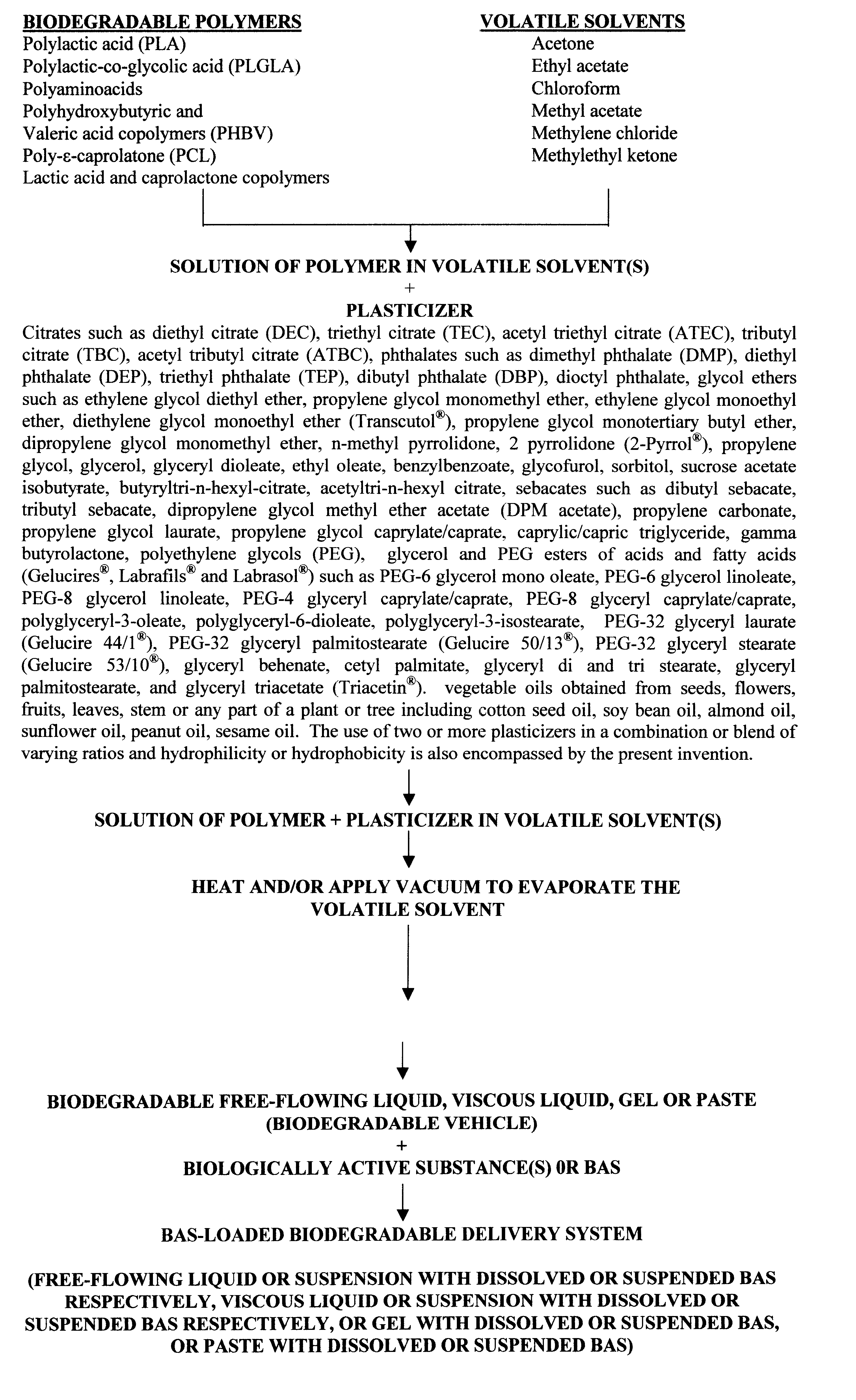

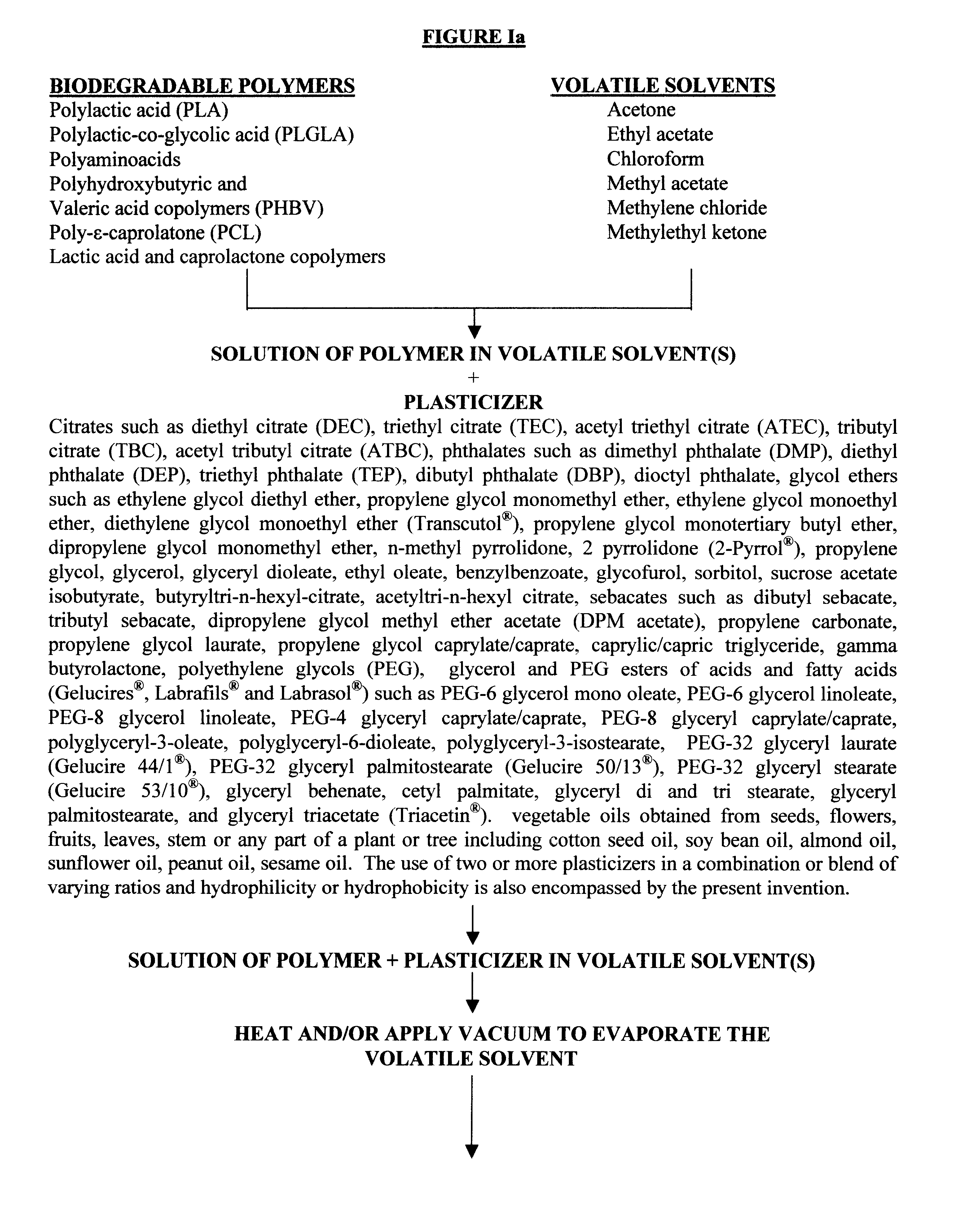

A biodegradable vehicle and filler (referred to in this invention as biodegradable vehicle), which can be mixed with one or more biologically active substances (BAS), or can be used as a biodegradable filler to fill in cavities or body tissues in animals, birds and humans. The consistency and rheology, hydrophilicity and hydrophobicity, and in vivo degradation rates of the biodegradable vehicle is controlled by modulating the molecular weight of polymers and copolymers, concentration of plasticizers, ratios of two or more plasticizer in the blends, types of polymers and copolymers, copolymer ratios, and ratios of blends of polymers with different molecular weights or different copolymers. The biodegradable vehicle is mixed with one or more BAS (which is separately stored away from the biodegradable vehicle in an appropriate container) just prior to use. Mixing of the BAS with the biodegradable vehicle can be accomplished by simply stirring the mixture with a stirring device, or by triturating the mixture or employing an ointment mill or a suitable device or apparatus or equipment that can be used for blending / mixing. Alternatively, a device, which resembles two syringes, attached together with a removable partition or a valve assembly can also be used to uniformly mix the BAS with the biodegradable vehicle. The mixing is performed in order to dissolve or uniformly suspend the BAS particles in the biodegradable vehicle. Modulating the polymer to plasticizer ratio, polymer molecular weight, copolymer ratio, and hydrophobicity and hydrophilicity of the plasticizer controls the release of the BAS from the biodegradable vehicle.

Owner:SHUKLA ATUL J

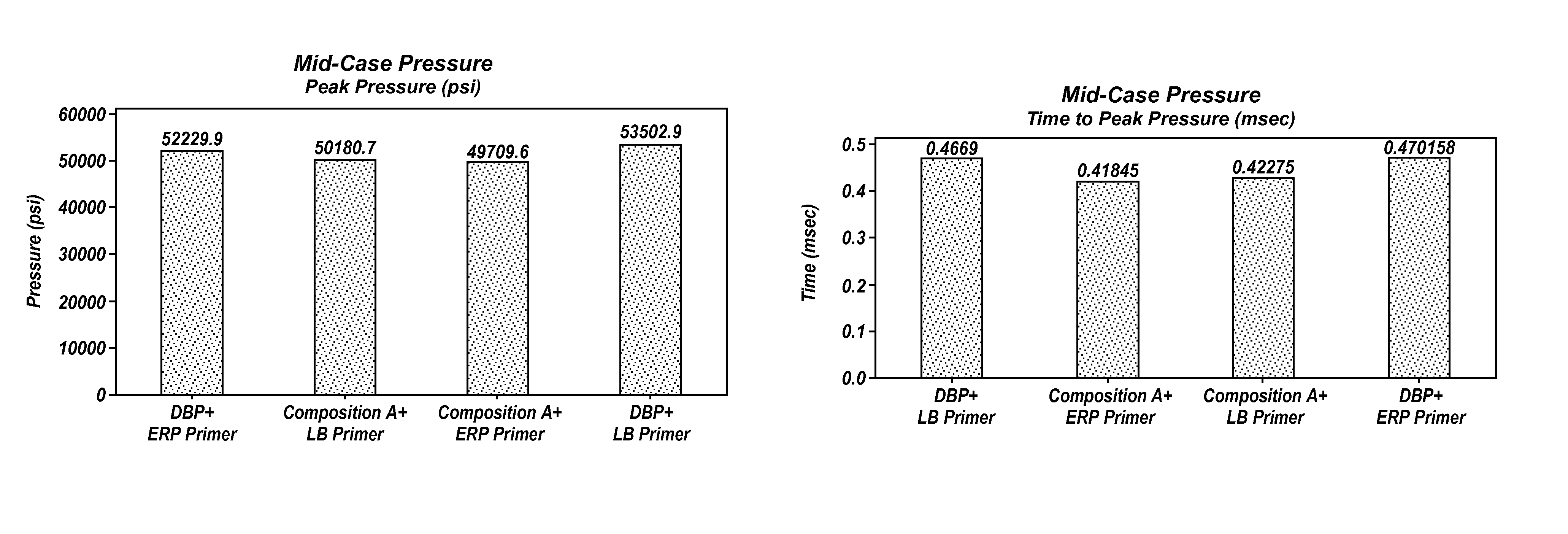

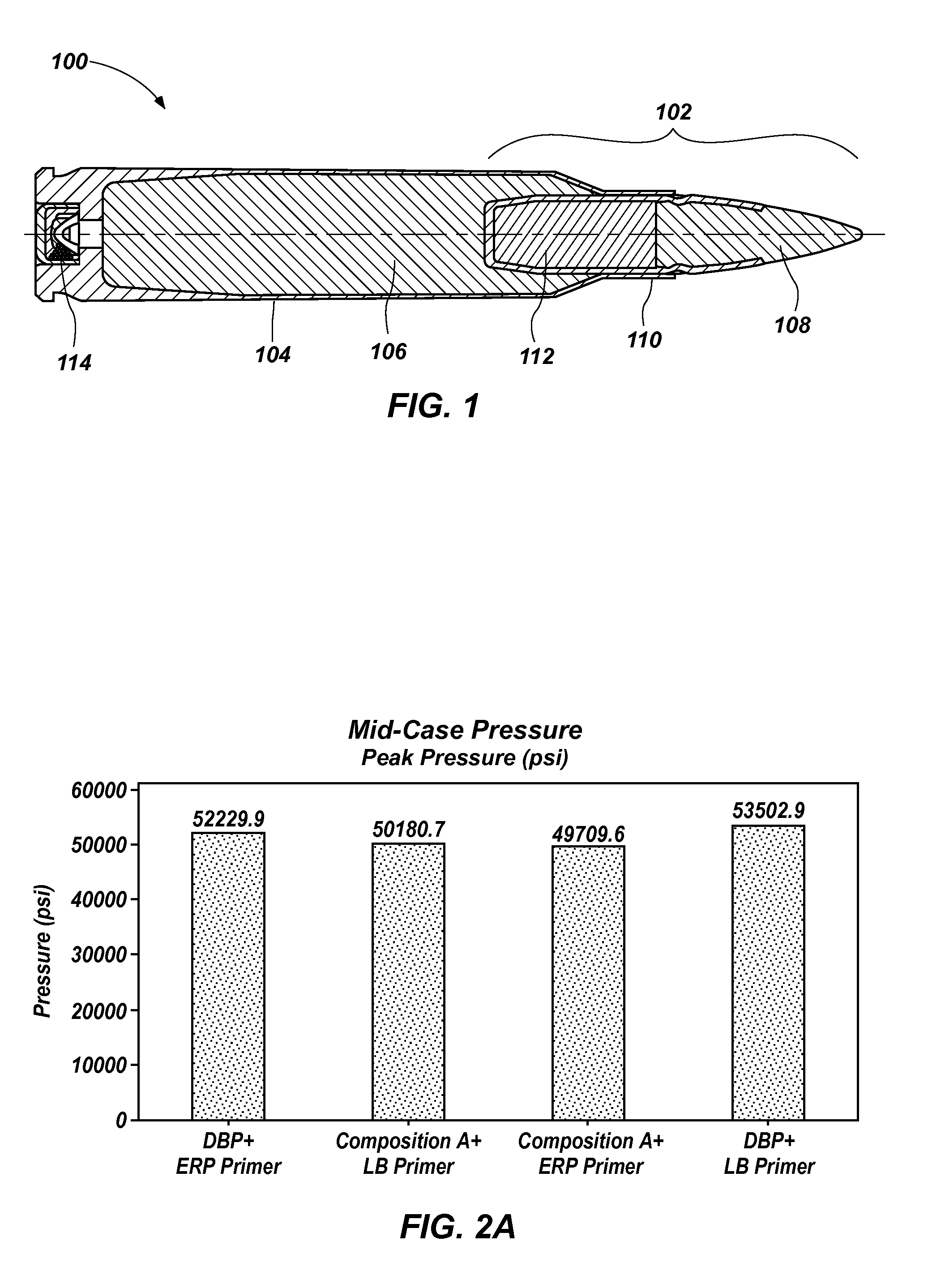

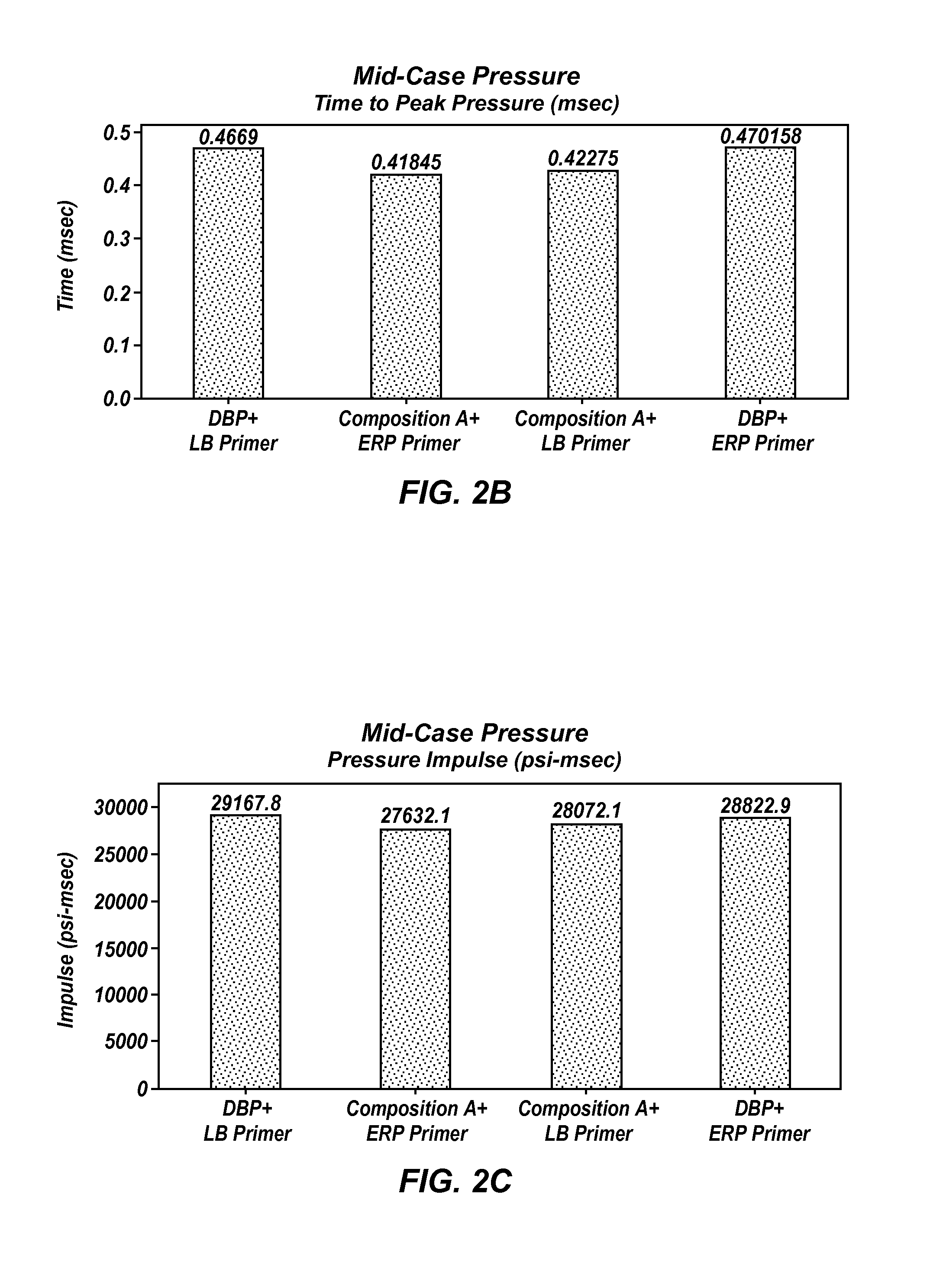

Propellant compositions including stabilized red phosphorus, a method of forming same, and an ordnance element including the same

Propellant compositions include an energetic binder, such as nitrocellulose, and a stabilized, encapsulated red phosphorous as a ballistic modifier. The propellant composition may additionally include an energetic plasticizer, such as nitroglycerine. For example, the propellant composition may be formed by mixing a double or multi base propellant that includes nitrocellulose plasticized with nitroglycerine with the stabilized, encapsulated red phosphorus. The propellant compositions may be substantially lead-free and may exhibit improved ballistic properties. Methods of forming such propellant compositions and an ordnance device including such propellant compositions are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

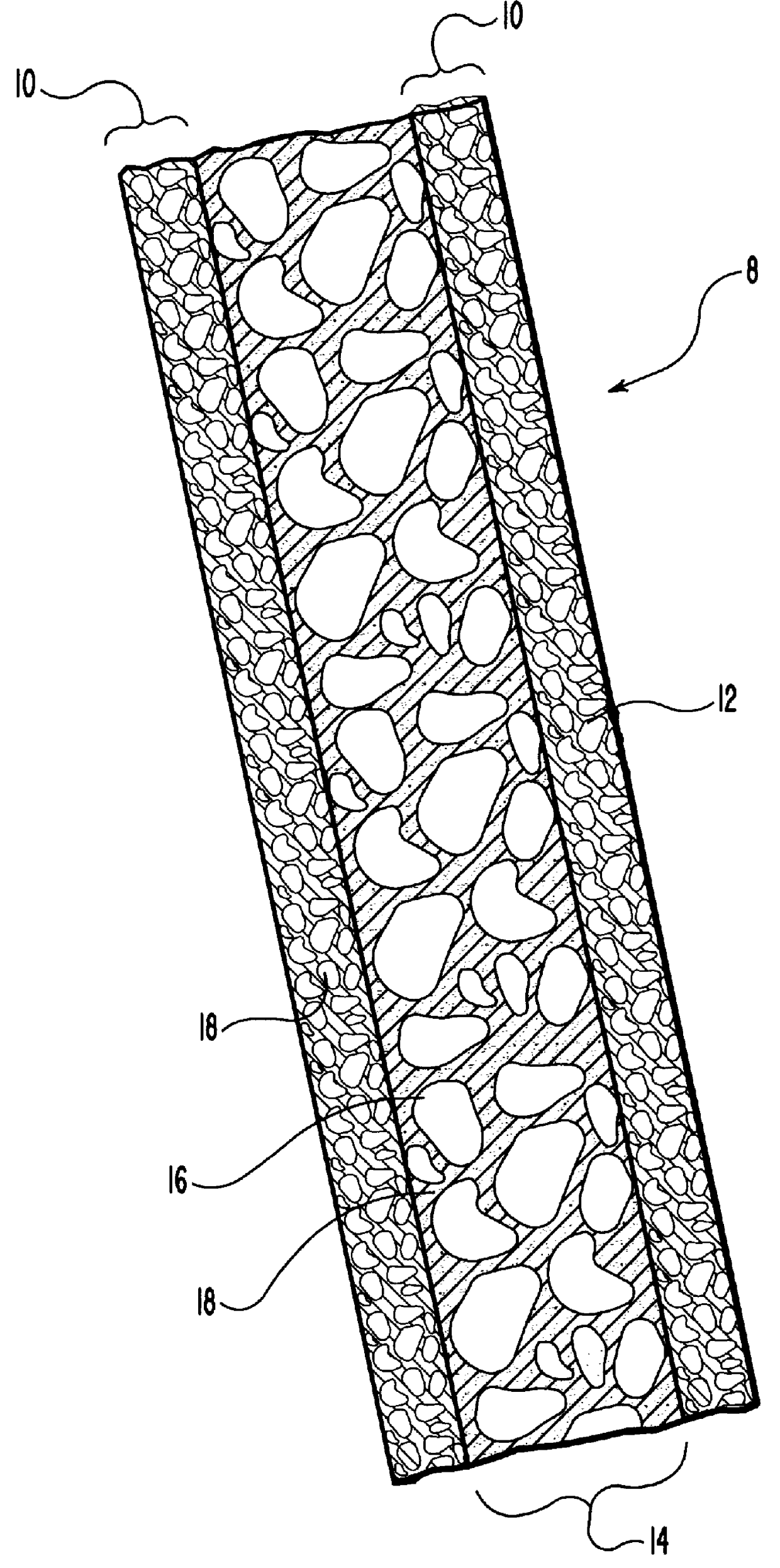

Gelled biopolymer based foam

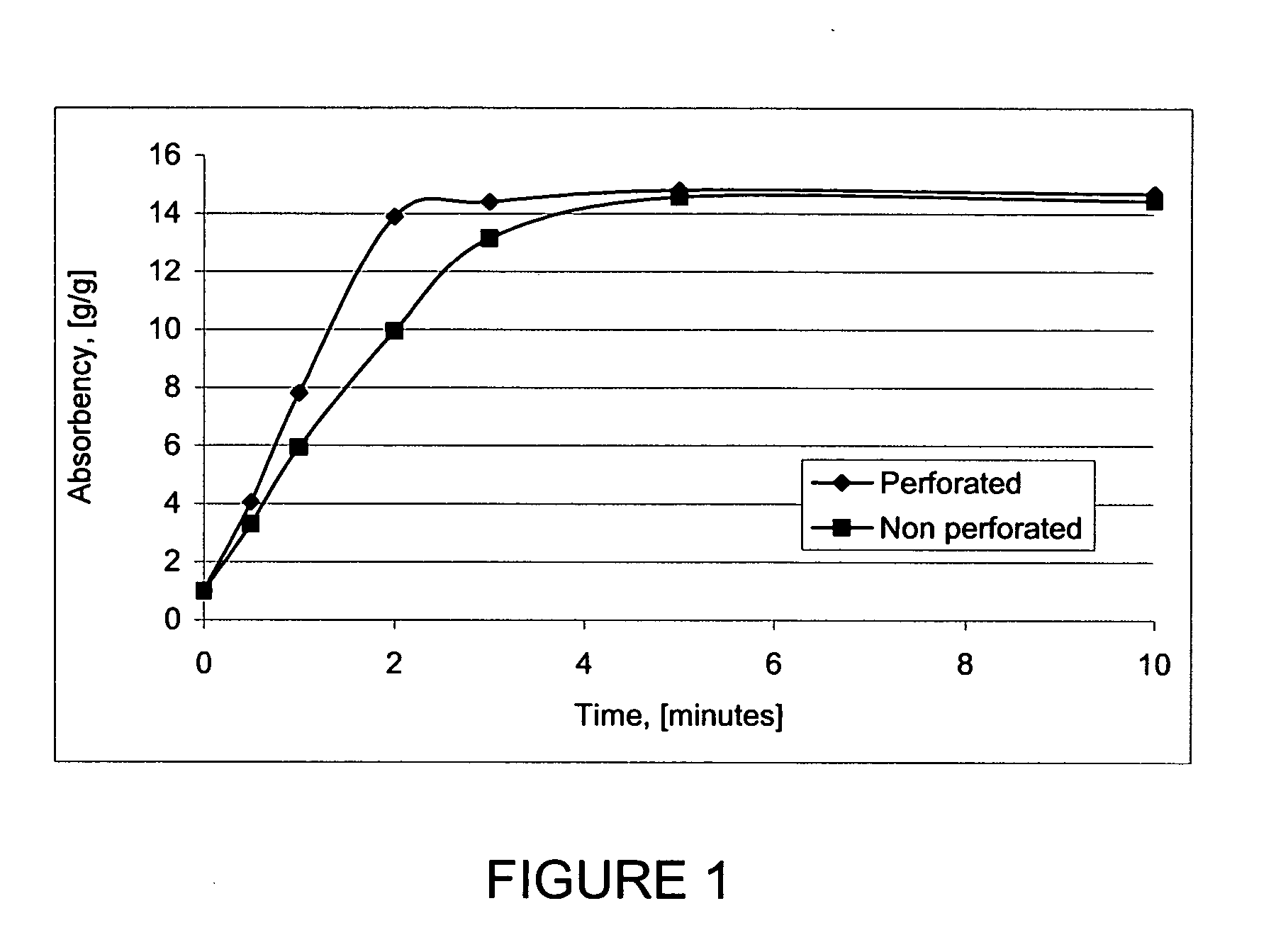

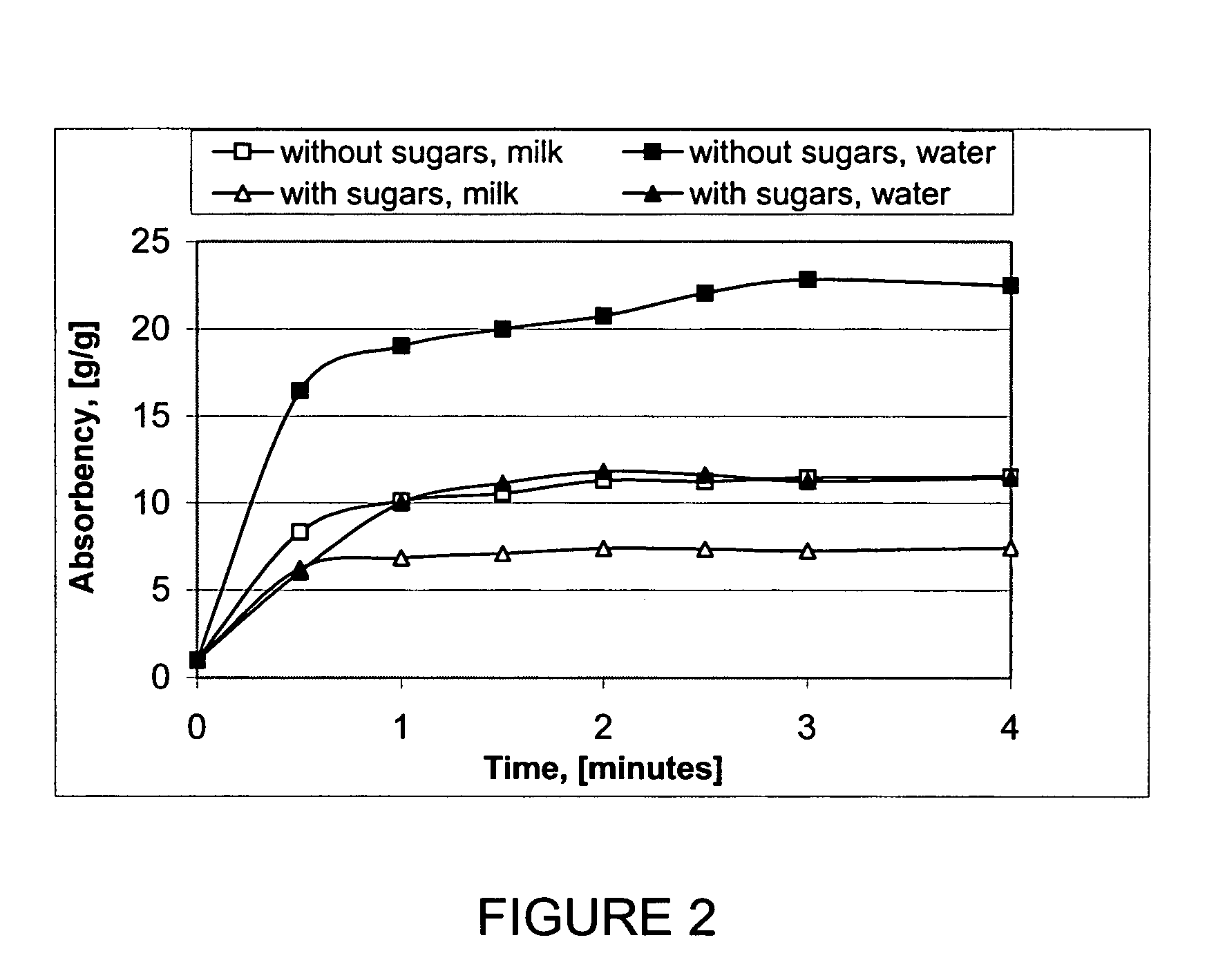

InactiveUS20050137272A1Improve water absorptionWet strengthCosmetic preparationsToilet preparationsPersonal careCross-link

Gelled biopolymer based foams are disclosed. The gelled foams comprise a cross-linked biopolymer, preferably alginate; optionally, a foaming agent such as hydroxy propyl methyl cellulose; and a plasticizer, preferably glycerin sorbitol, or a mixture thereof, that forms the predominant portion of the gelled foam. The foams are soft and pliable and have high absorbency. They are used as wound dressing materials, controlled release delivery systems, cell culture, barrier media for preventing tissue adherence, and bioabsorbable implants. They also have various personal care applications, especially in oral hygiene, and can be used in food applications.

Owner:FMC BIOPOLYMER AS

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Slow-release matrix pellets and the production thereof

InactiveUS6290990B1Simple and low-cost productionHigh content of active substancesPharmaceutical non-active ingredientsGranular deliveryMaximum diameterPlasticizer

Slow-release matrix pellets with a spherical or lenticular shape and uniform maximum diameters in the range from 0.5 to 4 mm, composed ofa) 0.1-87% by weight of at least one biologically active compound,b) 5-50% by weight of at least one water-insoluble polymer,c) 5-45% by weight of at least one lipophilic component as plasticizer for polymer b),d) 3-40% by weight of a natural or semisynthetic gel former,e) 0-50% by weight of one or more conventional formulation aids.

Owner:BASF AG

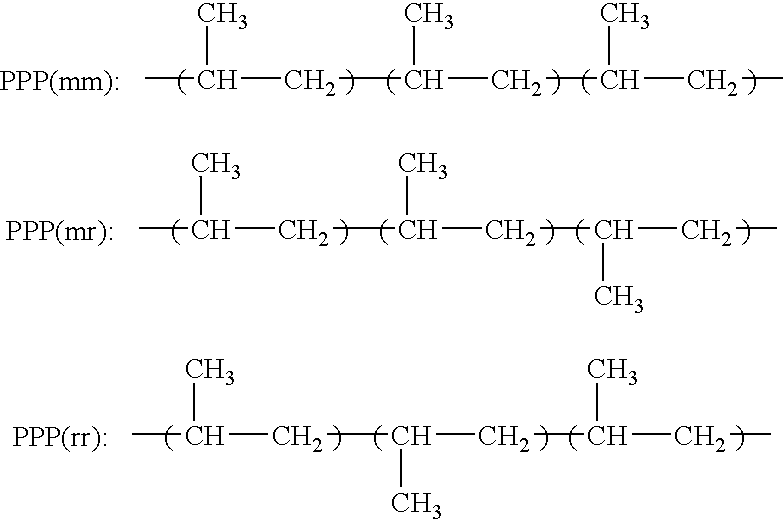

Plasticized polyolefin compositions

InactiveUS20060135699A1Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

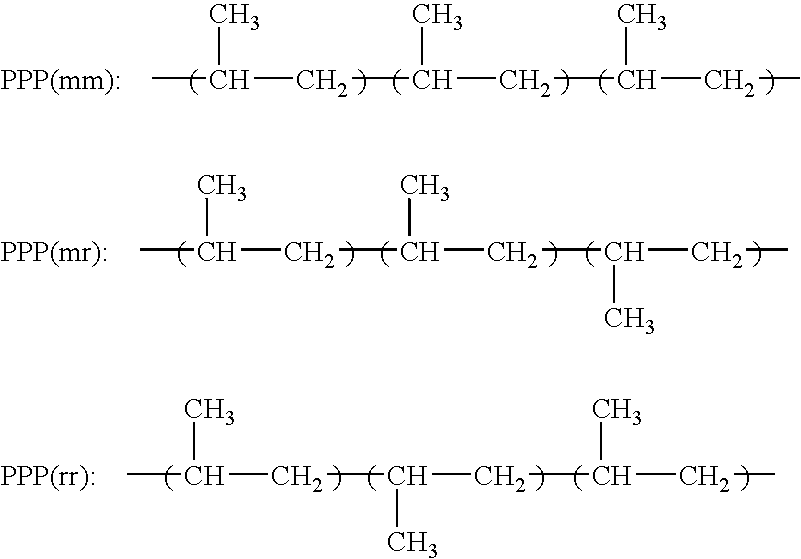

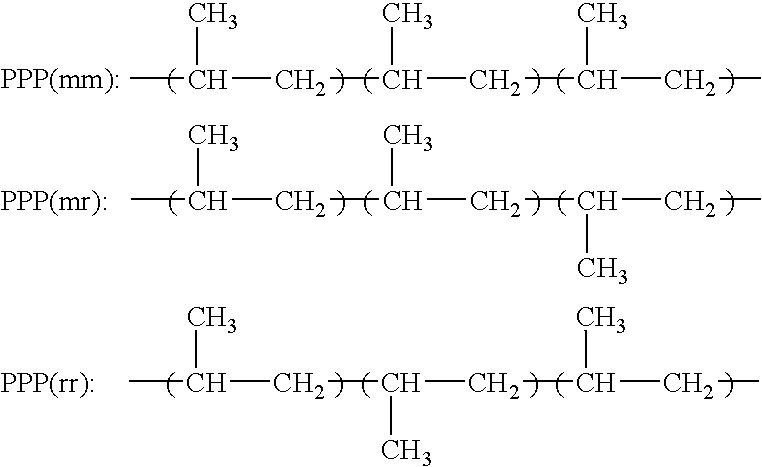

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

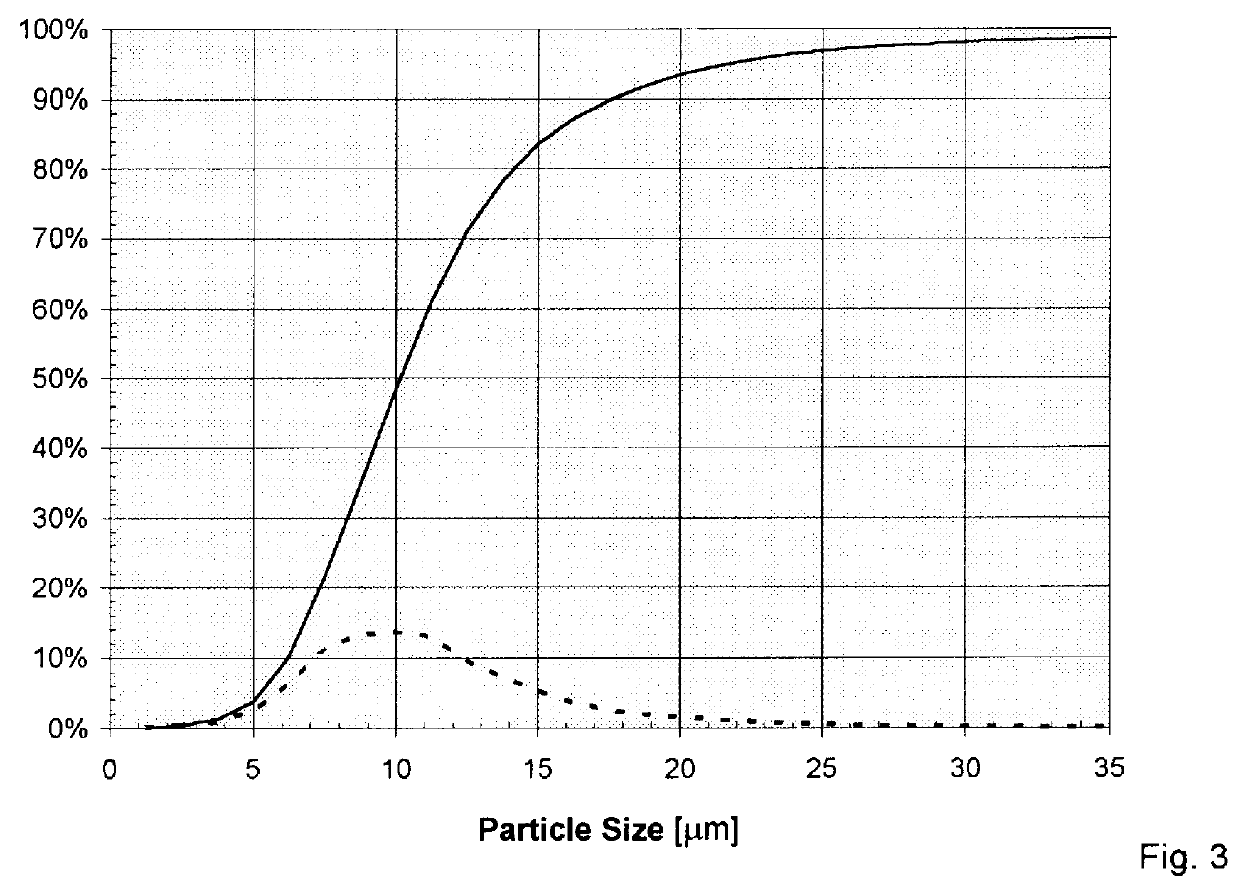

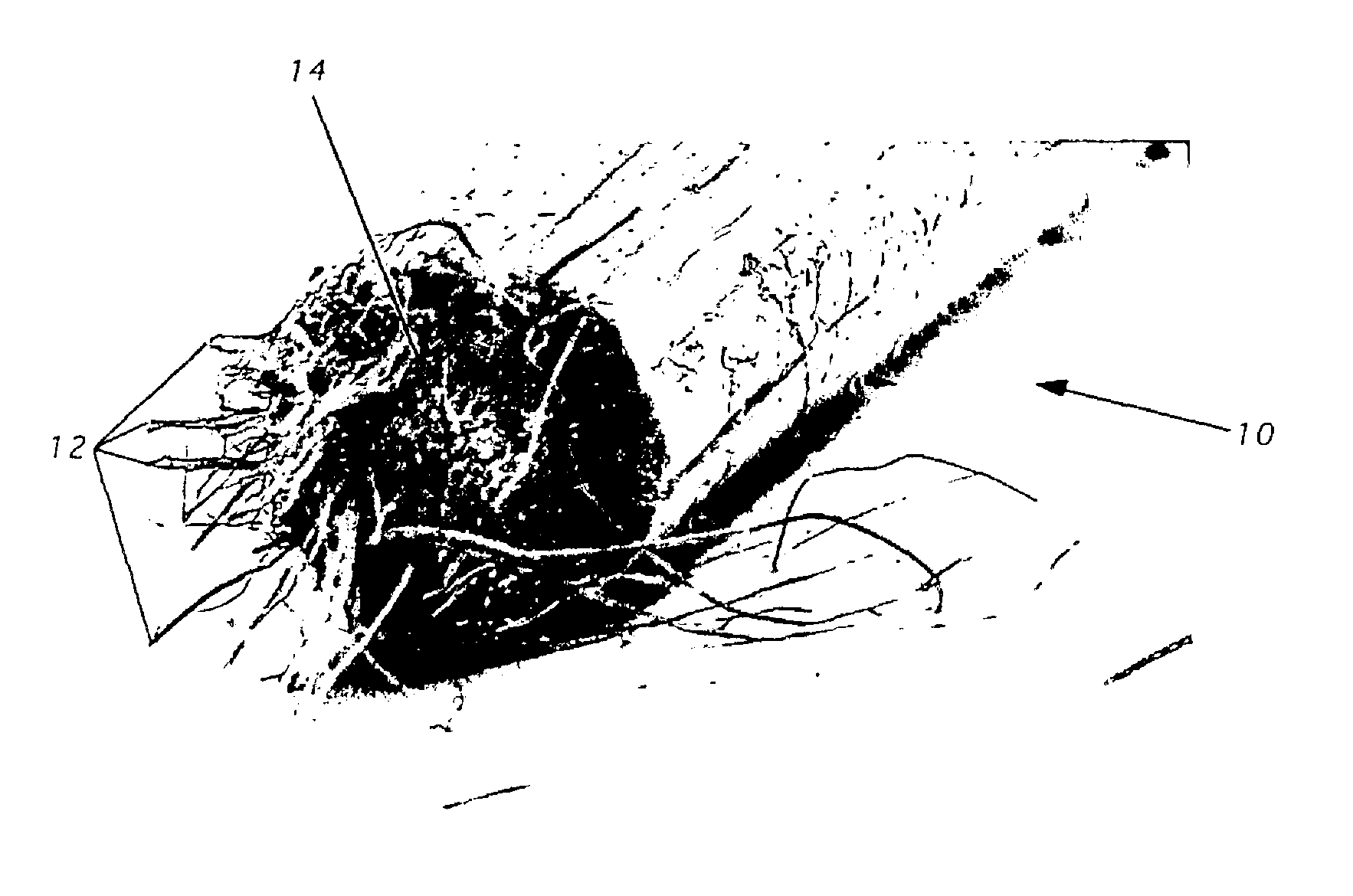

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

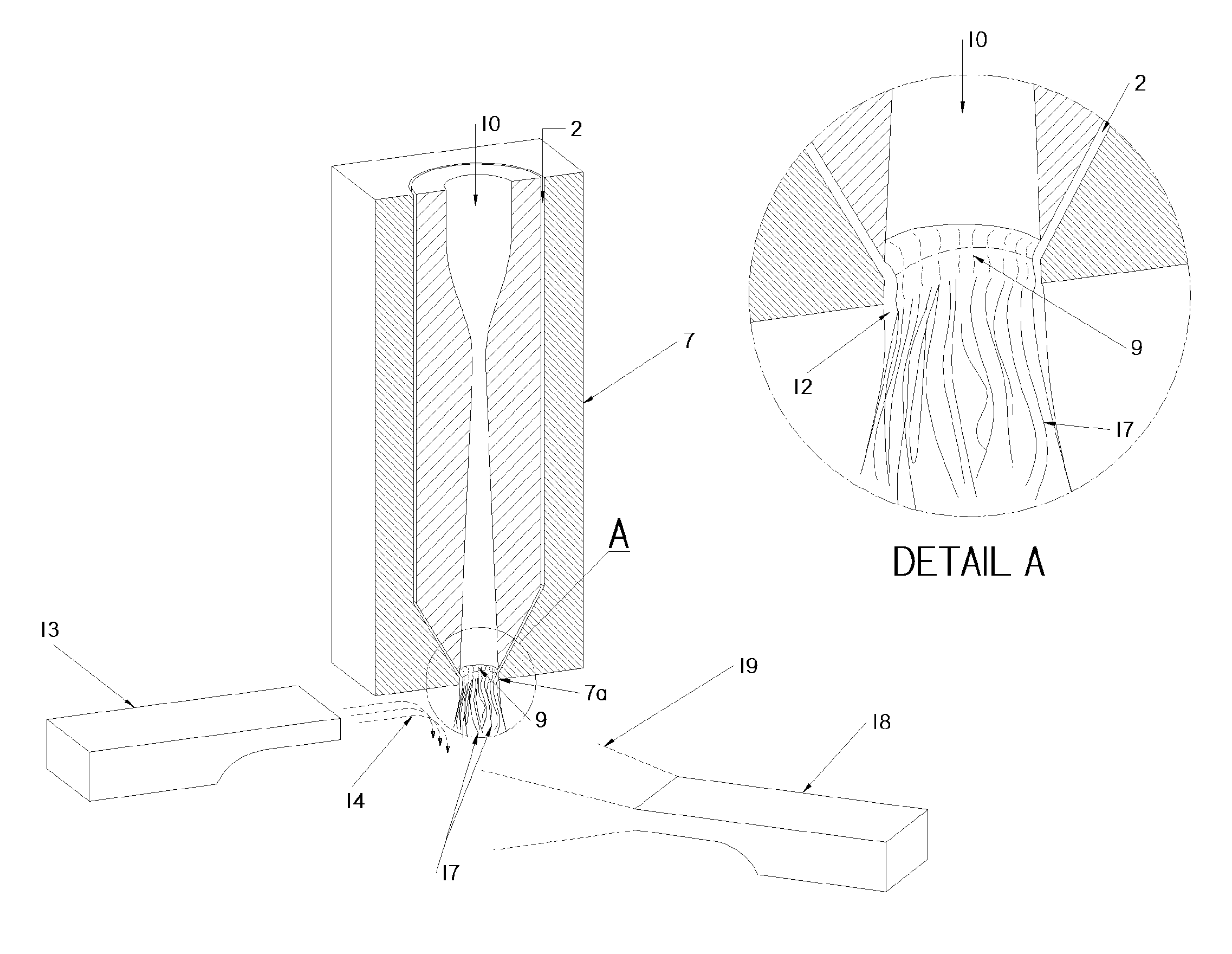

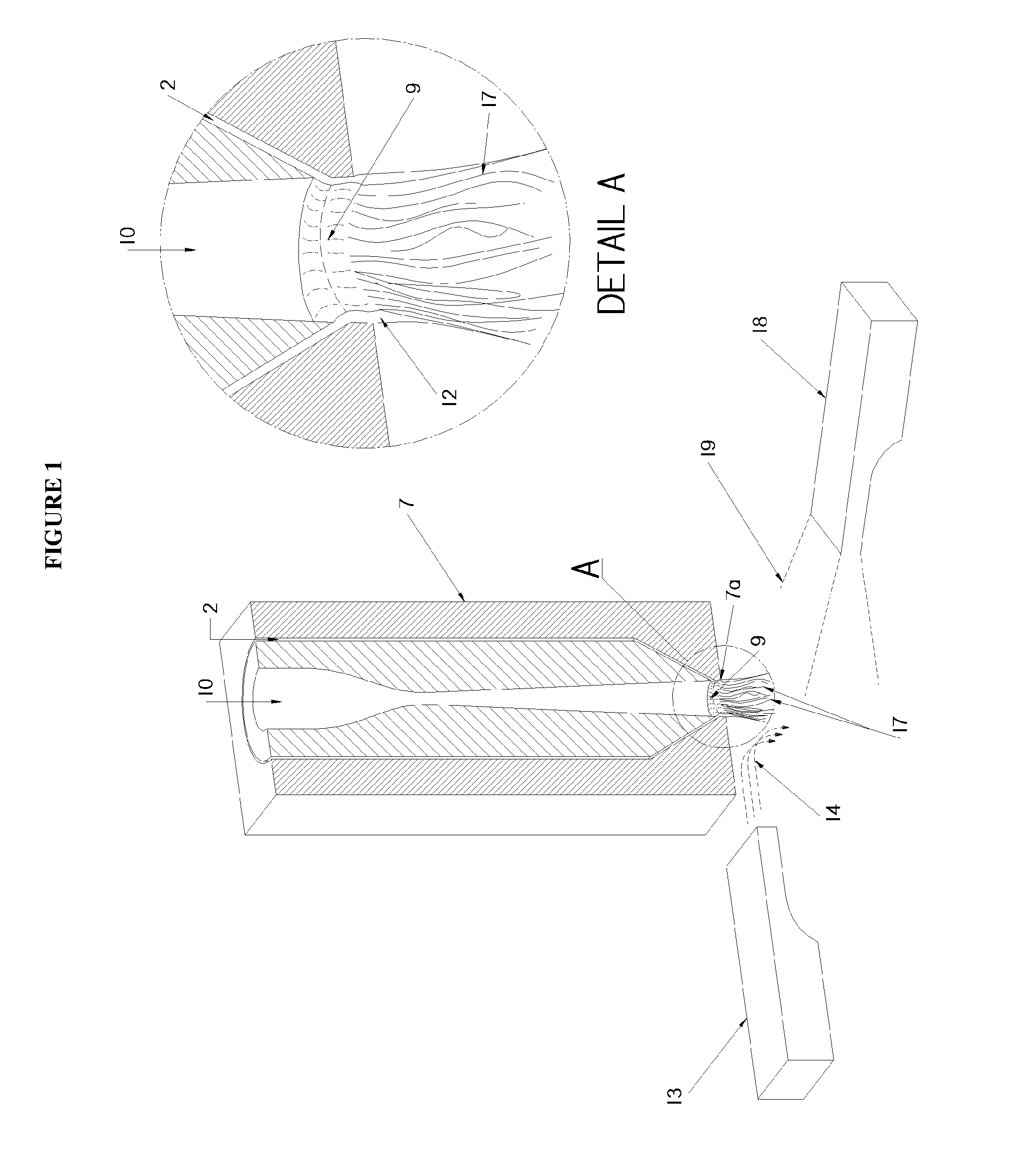

On-the fly coating of acid-releasing degradable material onto a particulate

ActiveUS20050034861A1Reduce molecular weightLiquid surface applicatorsFluid removalParticulatesPlasticizer

The present invention relates to methods and compositions for treating subterranean formations, and more specifically, to improved methods and compositions for degrading filter cake deposited on a subterranean formation. One embodiment of the present invention provides a method of creating particulates coated with acid-releasing degradable material on-the-fly comprising the step of: combining an acid-releasing degradable material with a solvent or a plasticizer to create a coating solution; and, coating the coating solution onto a particulate on-the-fly to create coated particulates. Another embodiment of the present invention provides a gravel pack comprising gravel particles coated on-the-fly with an acid-releasing degradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

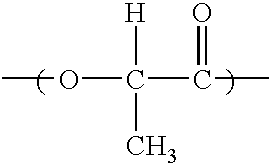

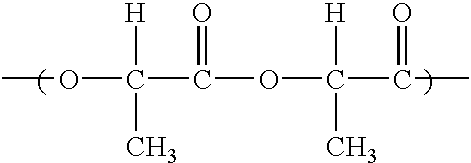

Fibers comprising starch and biodegradable polymers

Owner:PROCTER & GAMBLE CO

Gelatinous elastomer

An improved gelatinous elastomer is disclosed which uses an A-B-A triblock copolymer having a molecular weight in the range of 125,000 to 175,000, or about 150,000, and a plasticizer.

Owner:PURPLE INNOVATION LLC

Dissolvable Fibrous Web Structure Article Comprising Active Agents

The personal care compositions of the present invention are in the form of an Article comprising a dissolvable fibrous web structure. The fibers of the dissolvable fibrous web structure comprise a surfactant; a water soluble polymeric structurant; and a plasticizer. Additionally the ratio of the water soluble water soluble polymeric structurant to the active agent in the fiber is 3.5 or less.

Owner:THE PROCTER & GAMBLE COMPANY

High impact polymer interlayers

InactiveUS20080268270A1Improve the level ofSynthetic resin layered productsConstructions elementsPlasticizerEngineering

The present invention provides multiple poly(vinyl butyral) layer interlayers that can be used in multiple layer glass panel type applications that require a high level of impact protection, for example in hurricane protection applications or in bullet proof glass applications. This effect is achieved by forming a poly(vinyl butyral) interlayer that has a relatively stiff poly(vinyl butyral) inner layer disposed between two relatively soft outer poly(vinyl butyral) layers, where the stiffness difference is achieved by a plasticizer differential that is achieved at least in substantial part by a residual hydroxyl content difference among the poly(vinyl butyral) layers.

Owner:SOLUTIA INC

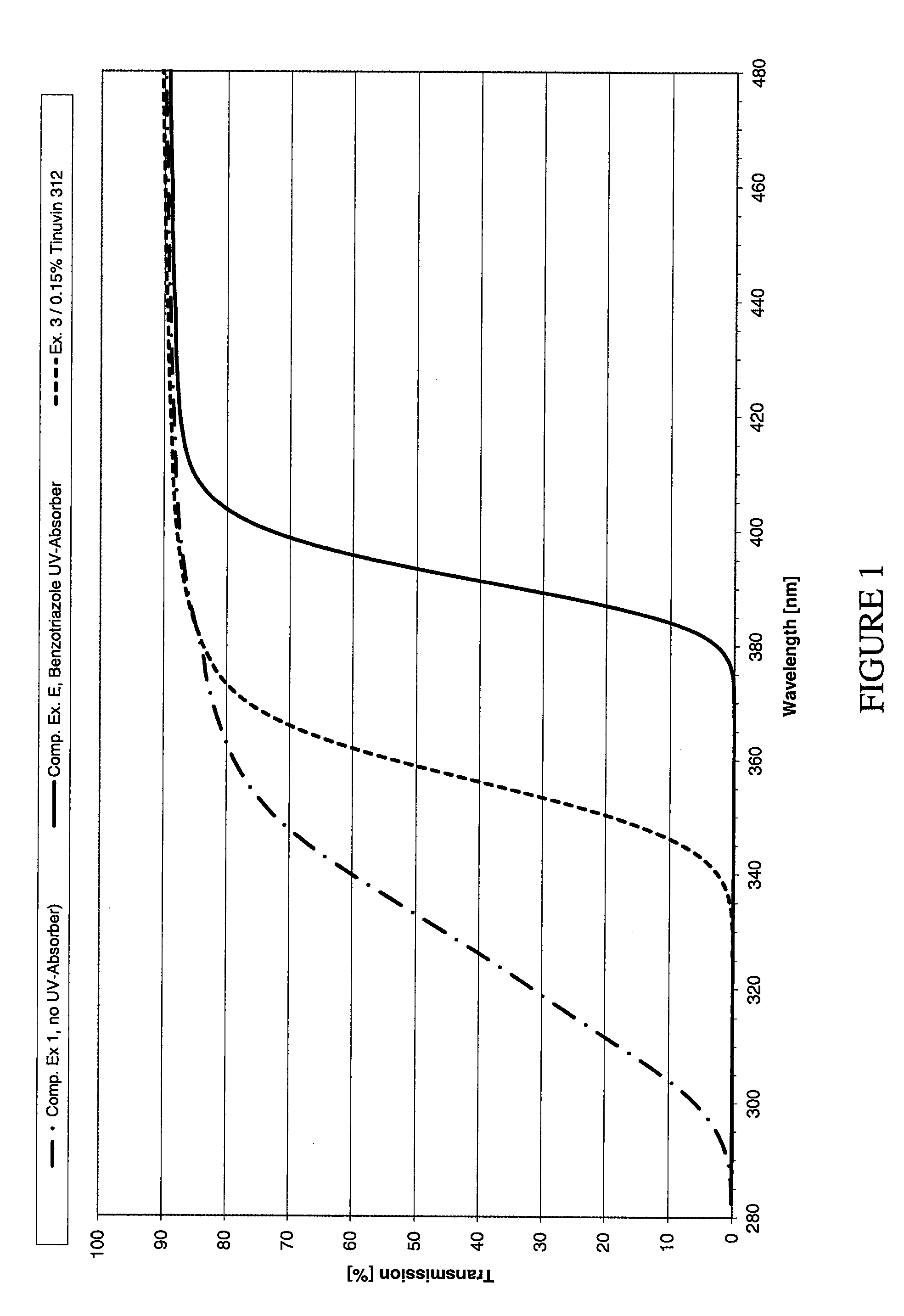

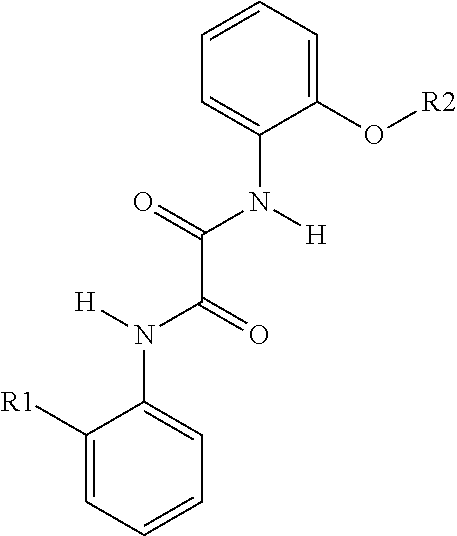

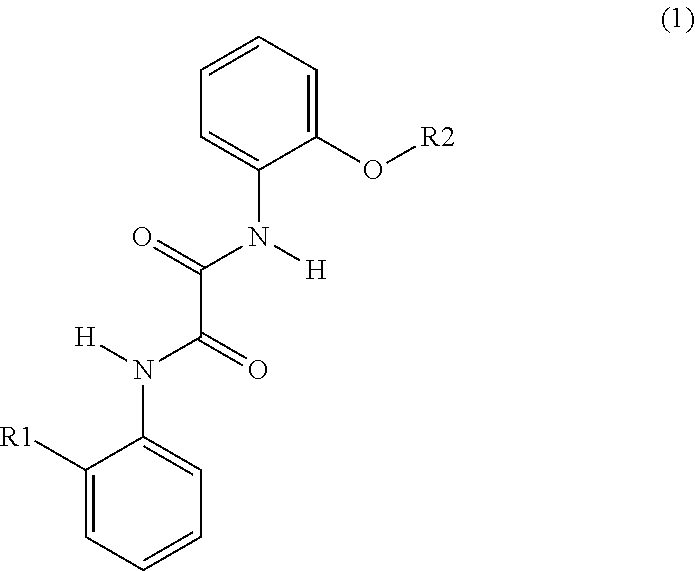

Plasticizer-Containing Films Based On Polyvinyl Acetal Having Selective Permeability For UV Radiation

InactiveUS20120052310A1Climate change adaptationSynthetic resin layered productsPlasticizerUltraviolet

Plasticizer-containing films based on polyvinyl acetal containing a UV absorbers of the oxanilide type of formula (1)exhibit high UVA transmission while also exhibiting low UVB transmission, with reduced tendency to yellow.

Owner:KURARAY EURO GMBH

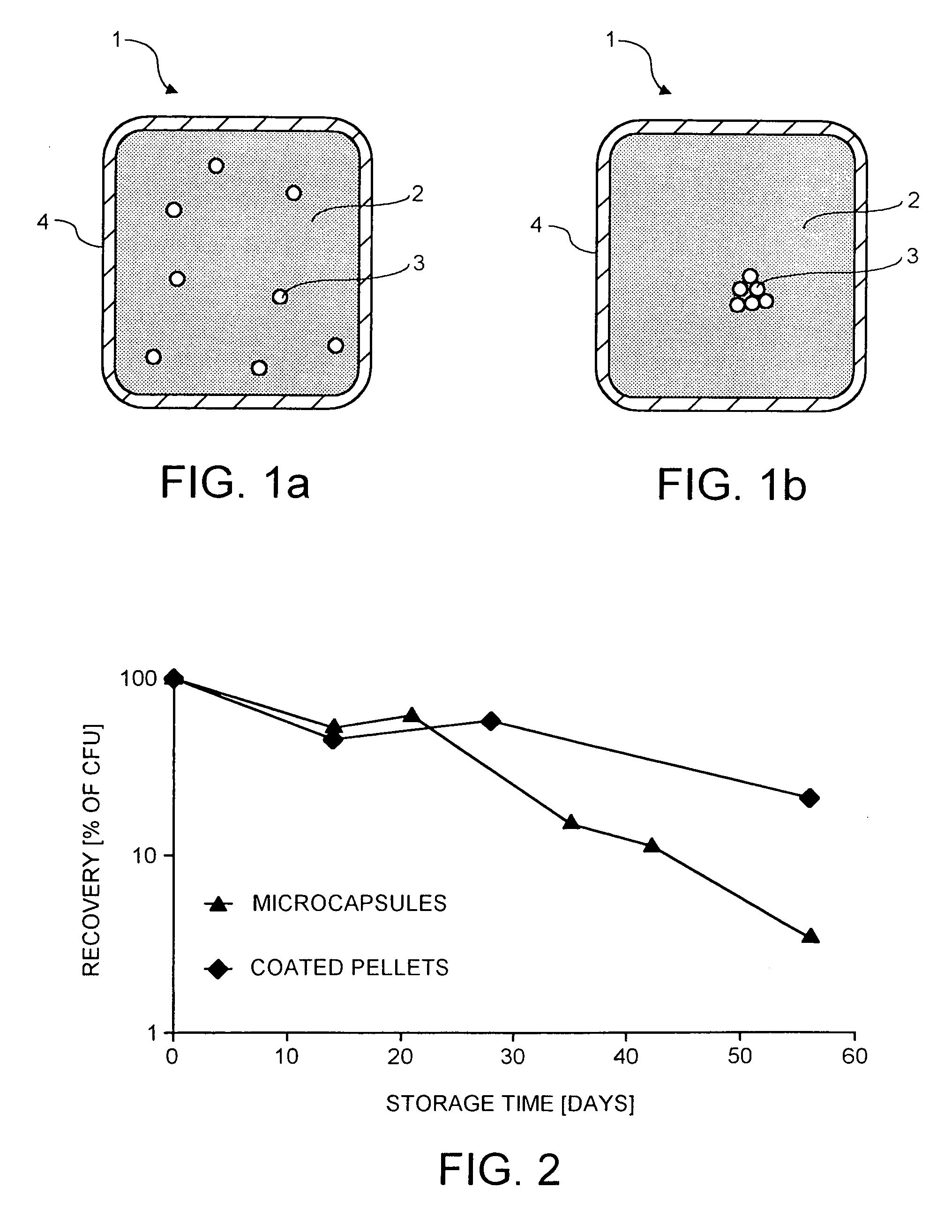

Probiotic delivery system

InactiveUS20050153018A1Improve stabilityProcessing is easy and straightforwardFood ingredient as barrier agentMicroorganism preservationMicroorganismBiotechnology

The present invention relates to a probiotic delivery system that is preferably added to a food product. In particular, the invention shows that compacted pellets having a volume of at least 0.02 cm3, that comprise, besides viable micro-organisms, arbitrary or eligible components, such as fillers, binder, plasticizer, other functional ingredients and a coating may be added to semi-moist, moist or semi-dry products. The micro-organisms remain viable for a longer time than commercially obtainable preparations of probiotics.

Owner:NESTEC SA

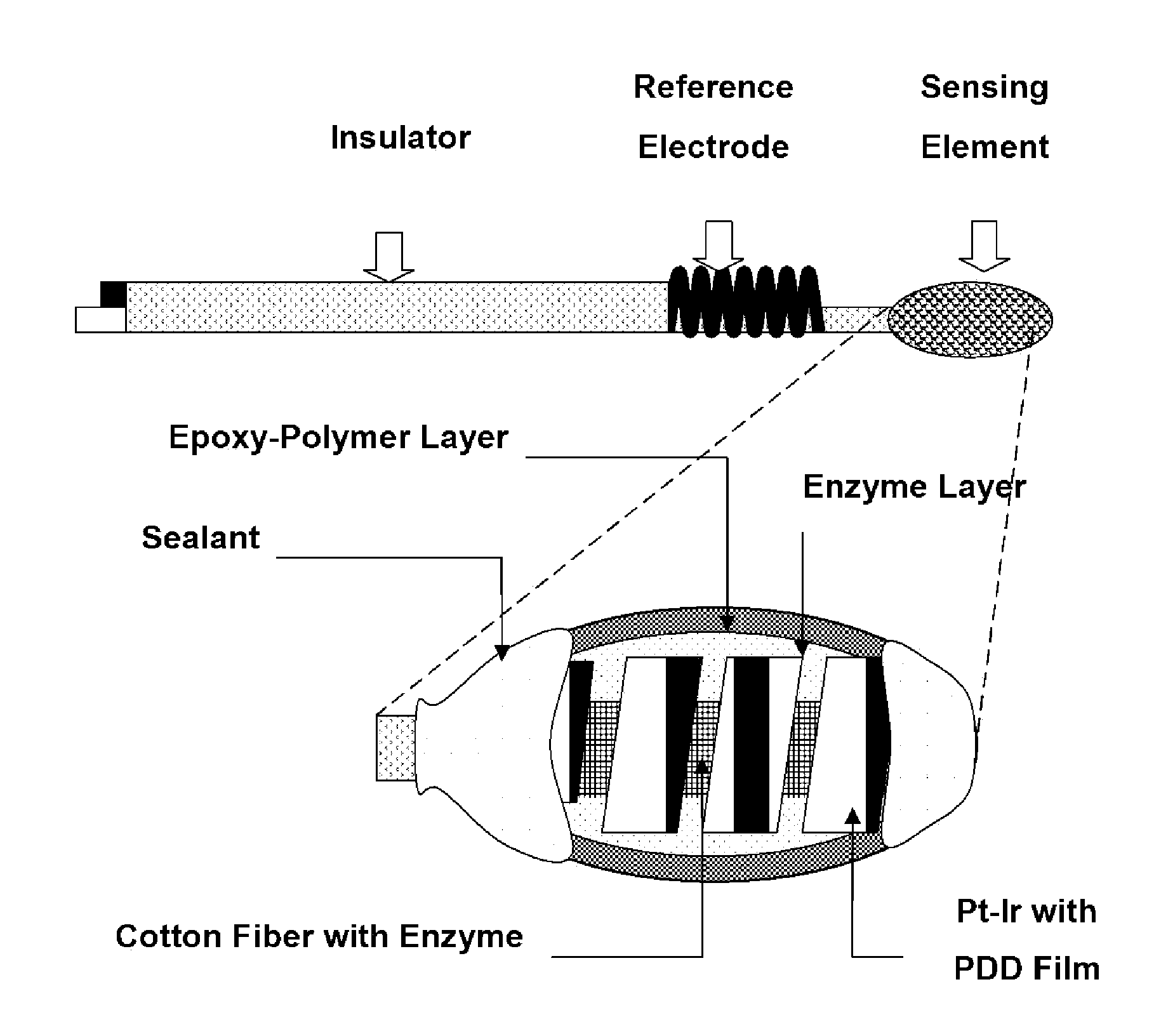

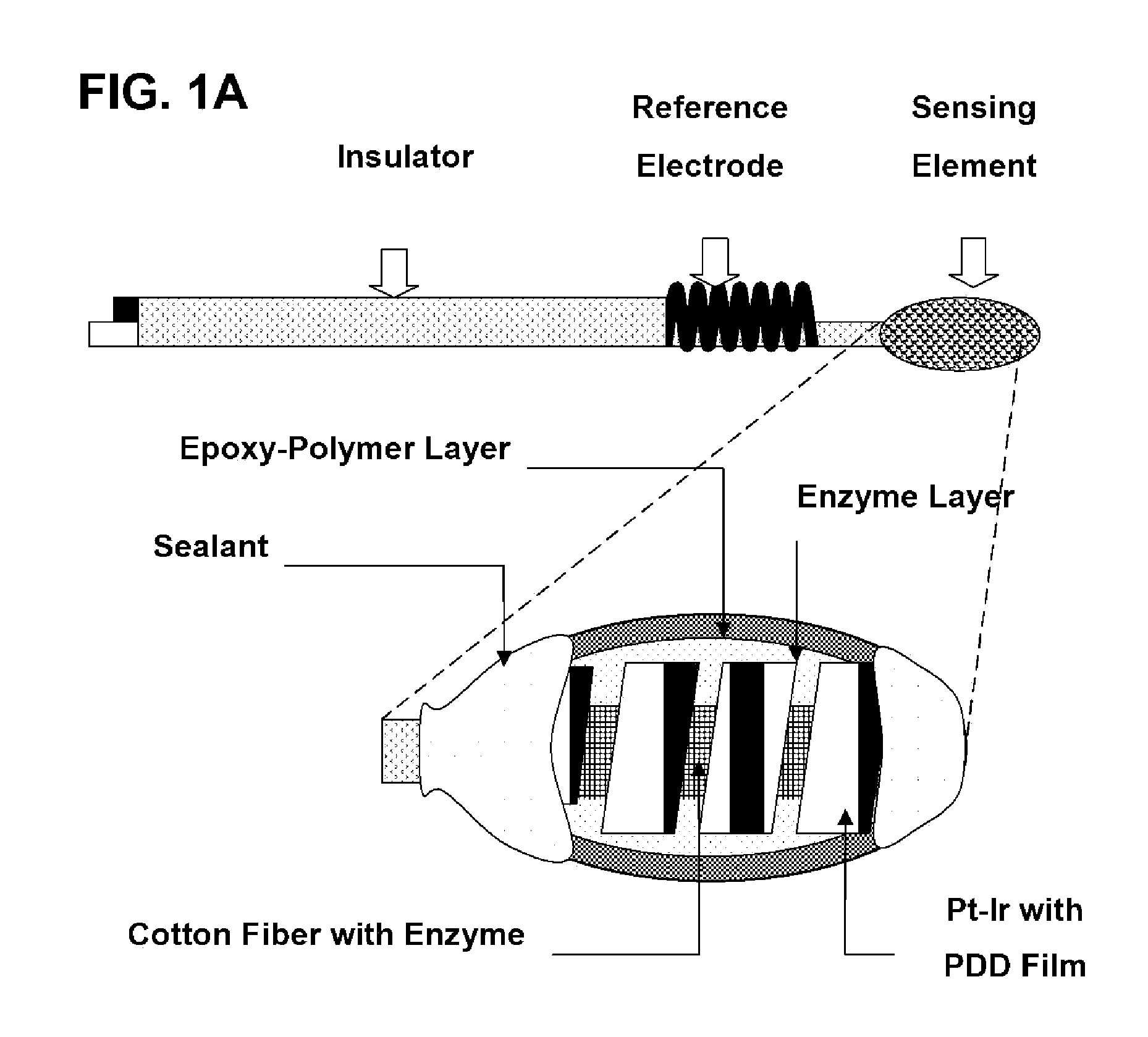

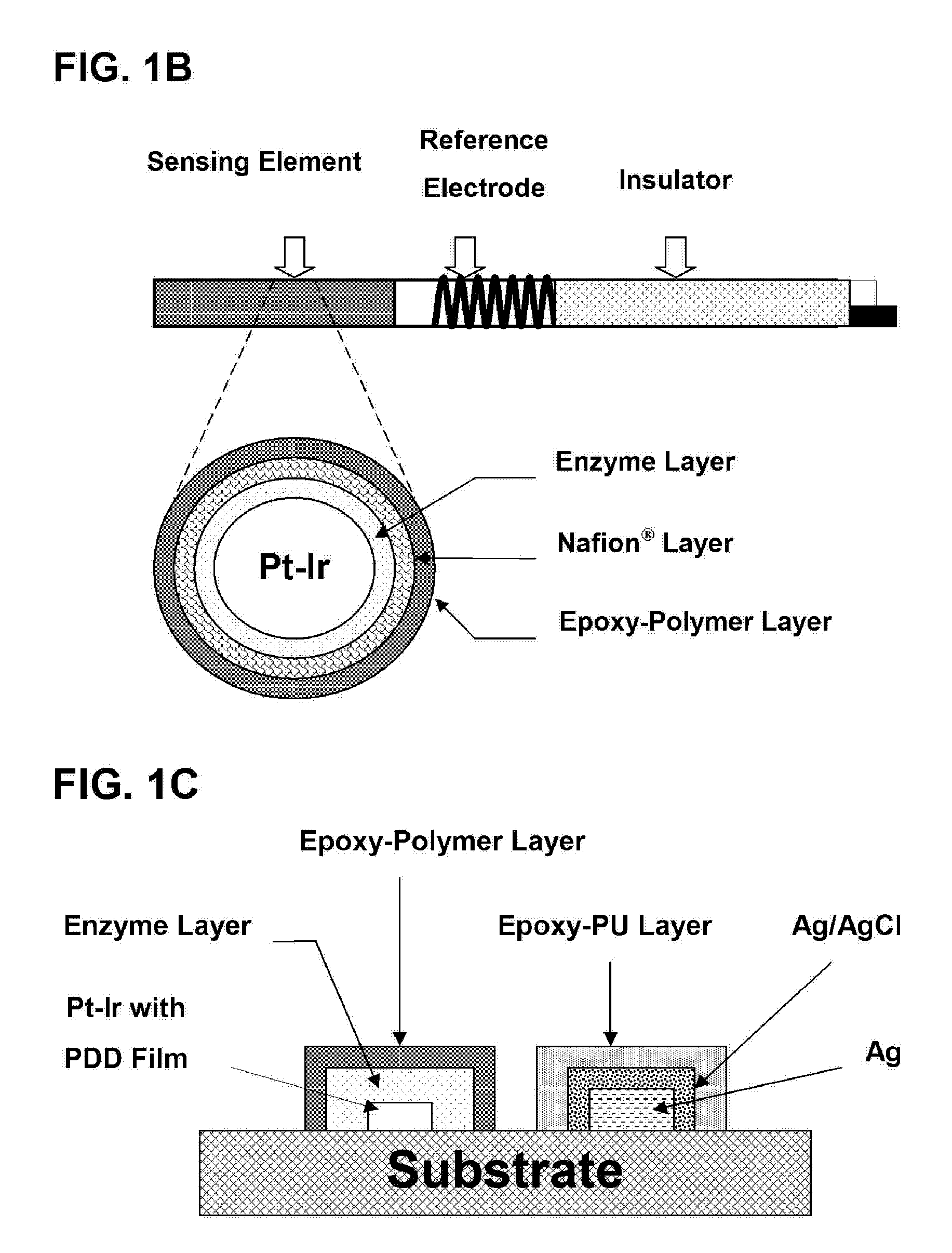

Epoxy Enhanced Polymer Membrane to Increase Durability of Biosensors

ActiveUS20060289307A1Increasing in vivo durabilityImprove long-term stabilityImmobilised enzymesBioreactor/fermenter combinationsEpoxyPolyethylene oxide

The present invention provides a polymer membrane enhanced with cured epoxy resin for use as the outer membrane of biosensors. The membrane includes approximately 30-80% epoxy resin adhesives, 10-60% polymer such as poly(vinyl chloride), polycarbonate and polyurethane and 0-30% plasticizers and 5-15% surface modifier reagent such as polyethylene oxide-containing block copolymers. Utilizing the polymer membrane of the present invention, a three-layered sensing element has been developed. This sensing element will be particularly useful for miniaturized biosensors used for in vitro blood measurements or for continuous in vivo monitoring such as implantable biosensors. This element includes an enzyme layer, an interference-eliminating layer and the novel polymer member of the present invention as the outer polymer layer. This novel sensing element shows excellent response characteristics in solutions and has an extremely long lifetime. This technology is particularly useful for improving the lifetime of implantable biosensors.

Owner:UNIV OF SOUTH FLORIDA

Topical spray compositions

InactiveUS6962691B1Reduce disadvantagesReduce decreaseBiocideOrganic active ingredientsPlasticizerTopical spray

A topical, medicinal spray composition is provided comprising a drug or combination of drugs in a carrier which, when sprayed on a surface, forms a film. The composition comprises at least one medicament, at least one film former and at least one vehicle. The composition of the invention may further comprise at least one permeation enhancer, at least one solubilizer, at least one plasticizer, and at least one water soluble additive. A metered dose of the composition can be sprayed on a topical site to form a stable, breathable film, preferably over a fixed surface area. A wide range of medicaments for human and veterinary use may be present that act locally or transdermally.

Owner:CIPLA LTD

Non-gelatin capsule shell formulation

A film-forming hydrocolloid composition comprising kappa carrageenan, iota carrageenan, a bulking agent, plasticizer and water is described. The ratio of bulking agent to total carrageenan is from about 1:1 to 20:1. Kappa carrageenan is present in an amount of less than or equal to 50% by weight of total carrageenan present. To form the composition, all dry materials are mixed and added to a heated mixture of all liquid materials. The final mixture is heated until a composition free of particulate materials is formed. The formed composition can be cast or extruded into ribbons, films, sheets, tubes or the like, for encapsulating wet or dry materials including medicinal dosage forms, nutritional supplements, cosmetics, bath oils and gels, and paint balls.

Owner:PATHEON SOFTGELS INC

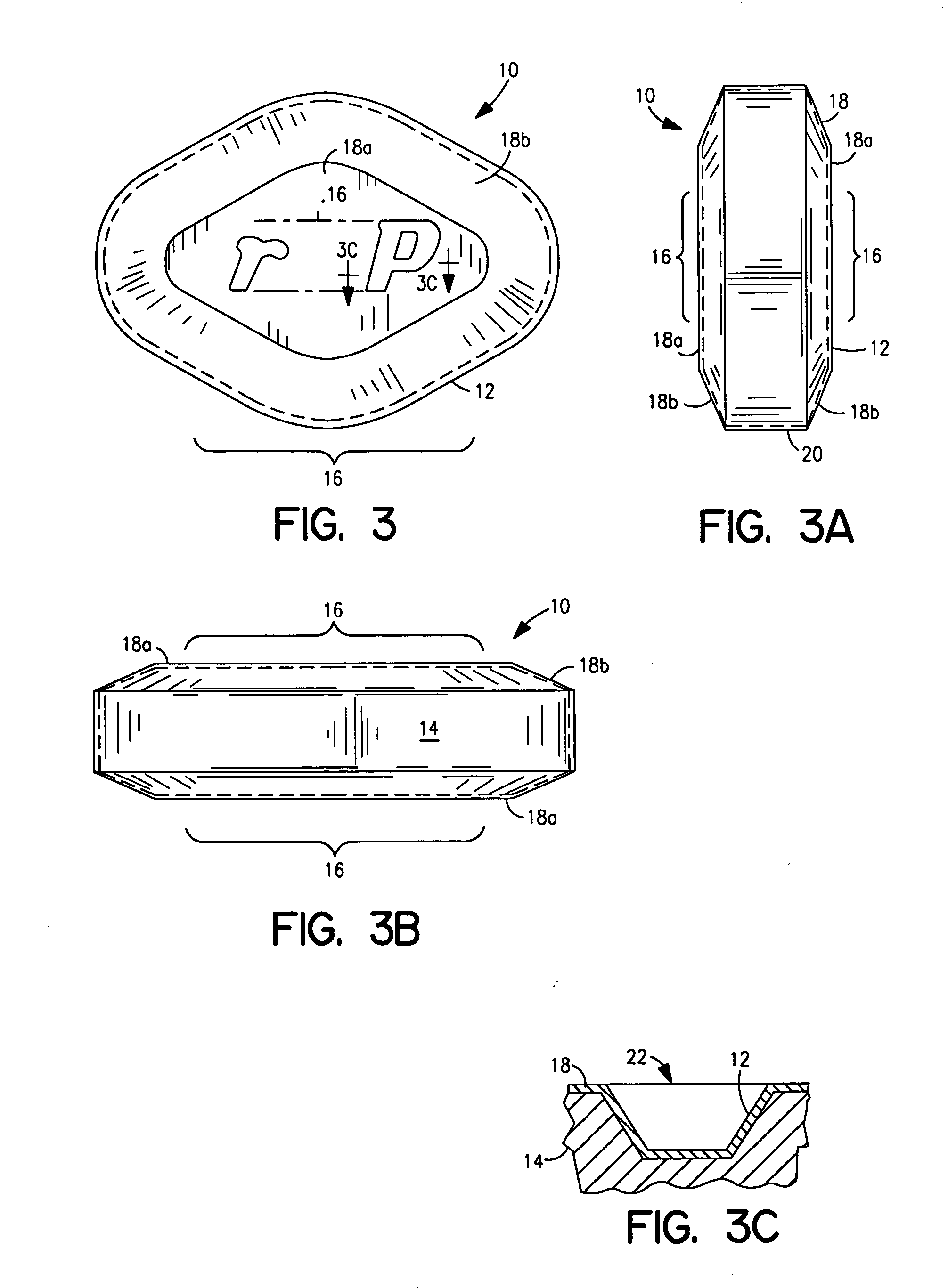

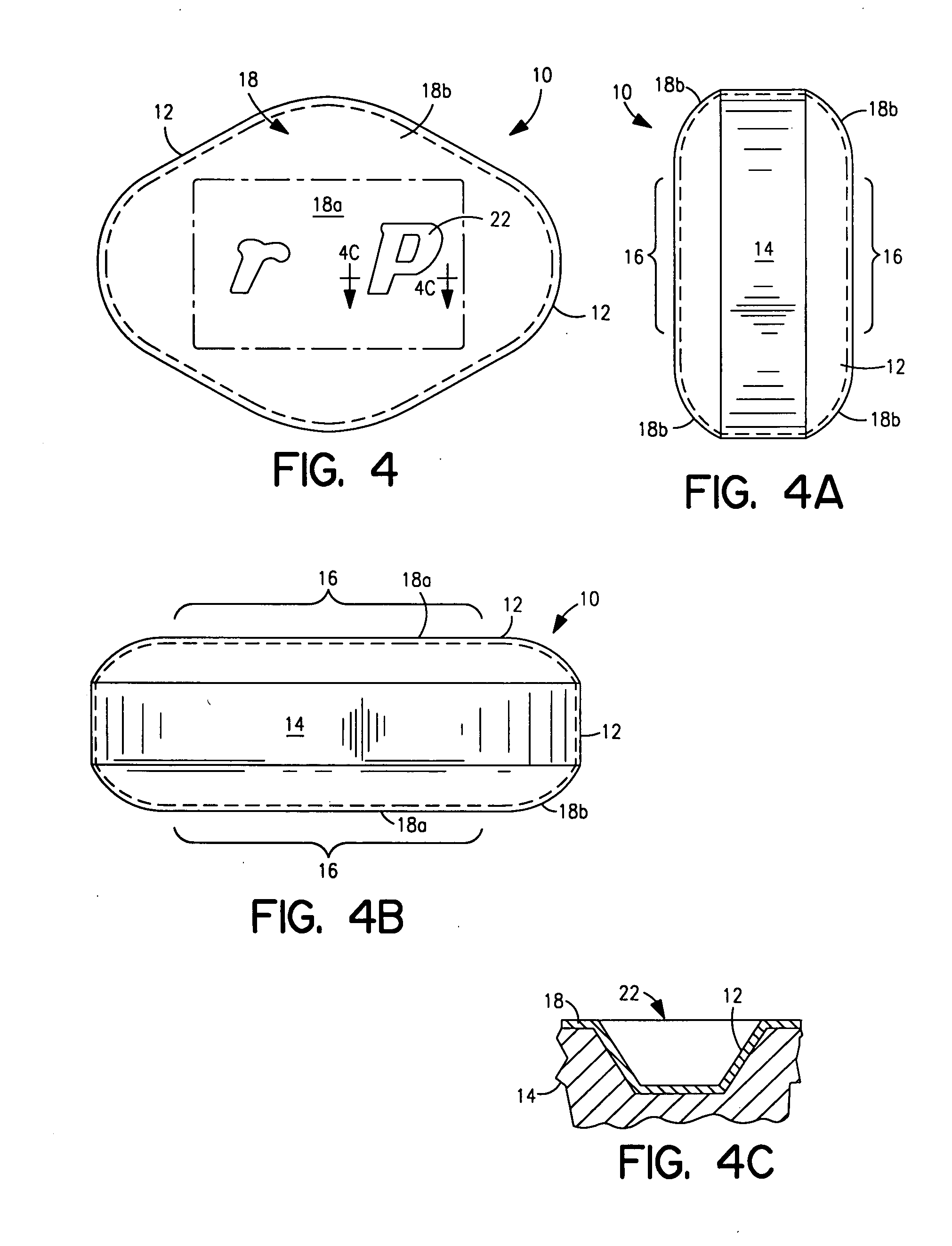

Edible holographic products, particularly pharmaceuticals and methods and apparatus for producing same

InactiveUS20060068006A1Preserve product integrityCheap productionPretreated surfacesDiffraction gratingsCoated tabletsPlasticizer

An edible product such as a unit dosage form of a pharmaceutically active substance includes a layer of a material that can receive and retain a high resolution microrelief that can convey information. The microrelief is themo-formable, preferably formed from an aqueous solution of HPMC and / or HPC plus a plasticizer and colorant. Other additives such as strengtheners, surfactants and adherents may be used depending on the application. The materials are selected and proportioned to control the fading or change in color of the visual image or effect produced by the relief to indicate exposure to an unacceptable degree of heat or humidity. The dosage form can be the relief-containing layer itself with the pharmaceutical carried therein. In a preferred form, the layer is an outer coating over a core containing the pharmaceutically active substance. Coated tablets are configured to resist twinning. To produce such dosage forms, the coated core is transported in unison with a flexible mold or transfer plate that can heat-replicate the microrelief on the outer layer of the dosage form, followed by a cooling and release of the transfer plate from the coating.

Owner:EDWARDS ANGELL PALMER & DODGE

Seamless capsule

InactiveUS20100119598A1Improve stabilityIncrease contentBiocideAnimal repellantsPolymer sciencePlasticizer

The present invention aims to provide a seamless capsule free of an interfacial tension modifier and a gelling agent. The present invention provides a shell formed by a shell composition containing gelatin and a plasticizer, but free of an interfacial tension modifier and a gelling agent, and a seamless capsule comprising a capsule content free of an interfacial tension modifier and a gelling agent.

Owner:TAKEDA PHARMA CO LTD

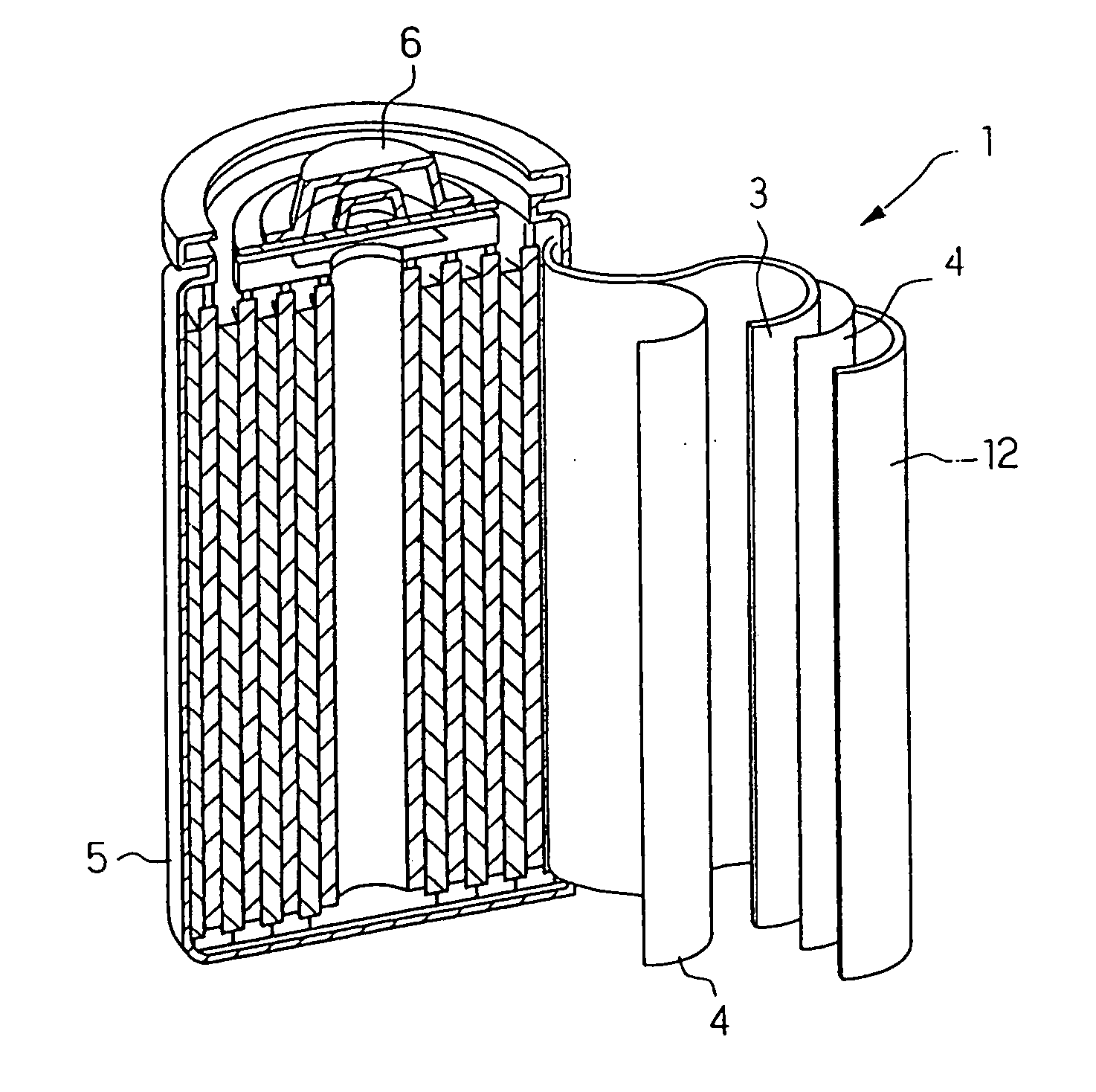

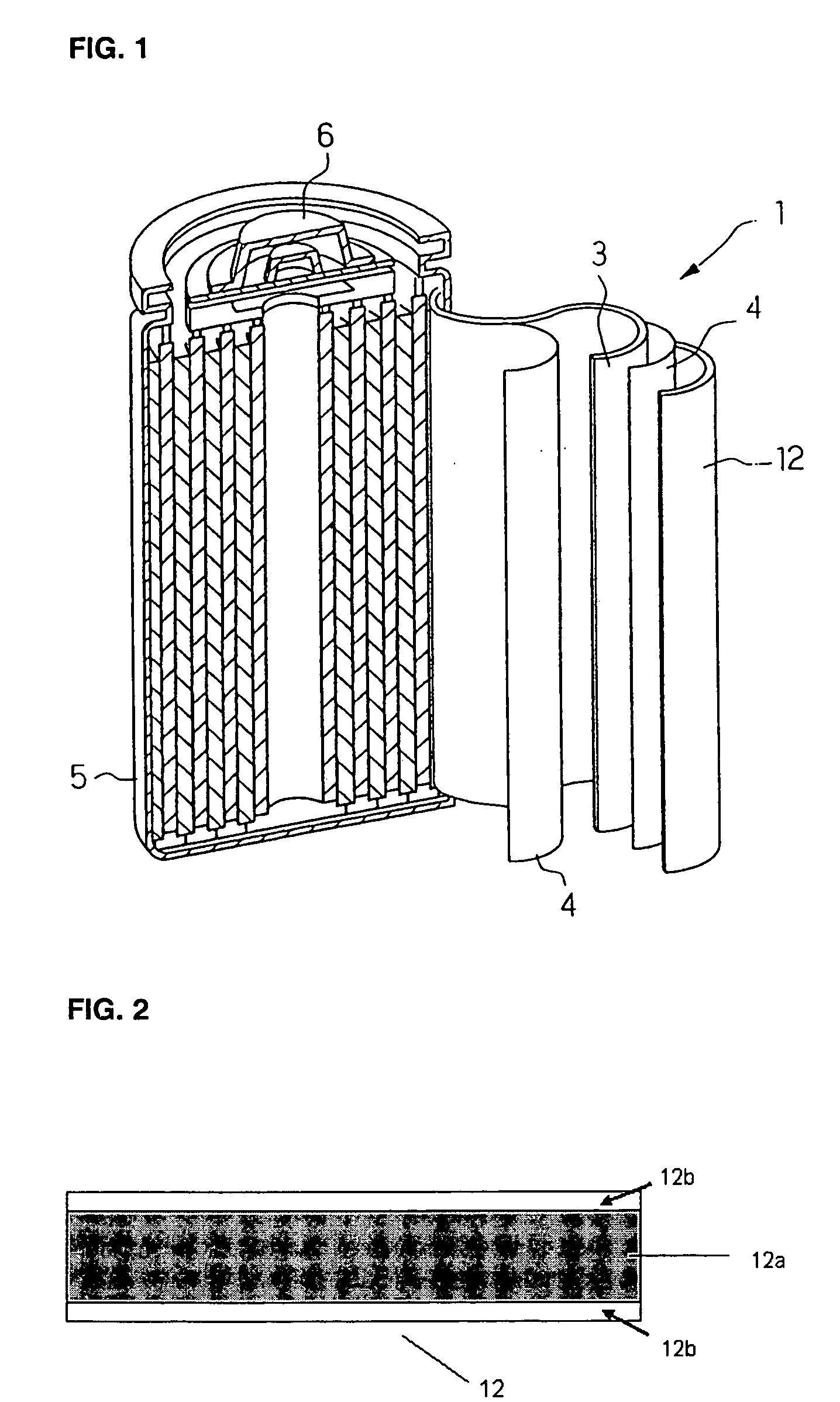

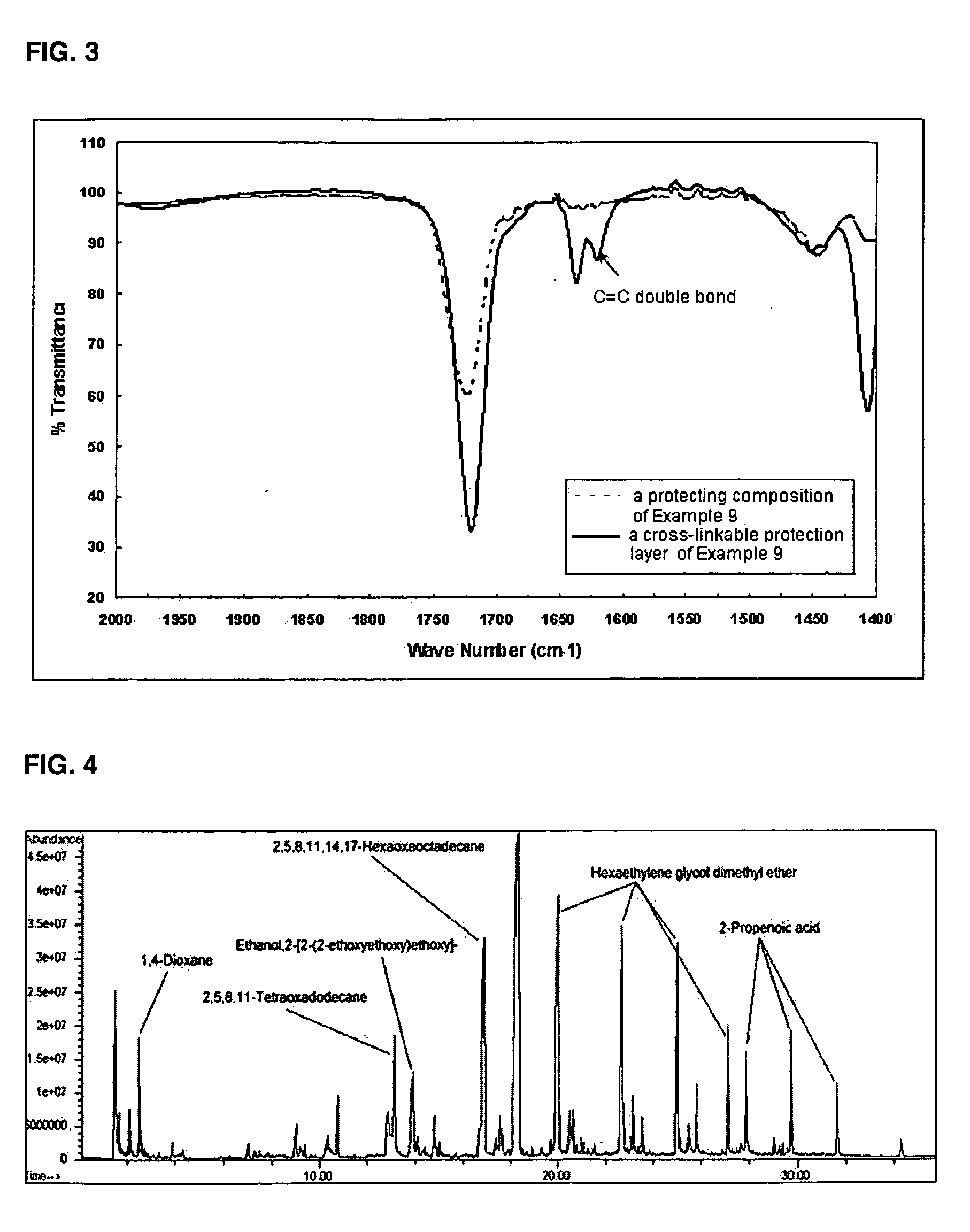

Composition for protecting negative electrode for lithium metal battery, and lithium metal battery fabricated using same

InactiveUS20050042515A1Improve cycle lifeInhibit side effectsFinal product manufactureNegative electrodesLithium metalPlasticizer

Disclosed is a composition for protecting a negative electrode for a lithium metal battery including a multifunctional monomer having at least two double bonds for facilitating cross-linking, a plasticizer, and at least one alkali metal salt.

Owner:SAMSUNG SDI CO LTD

Multilayer Films Or Plasticizer-Containing Polyvinyl Acetal With Sound-Absorbing Properties

ActiveUS20100028642A1Improve sound absorptionLow costSynthetic resin layered productsConstructions elementsPolyvinyl acetatePolyvinyl alcohol

An interlayer film for laminated glass with sound-absorbing properties contains at least two individual films, wherein the first individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of 0.1 to 11 mol % and a second individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of between 5 and 8 mol %.

Owner:KURARAY EURO GMBH

Polypropylene based fibers and nonwovens

InactiveUS20060008643A1Great contributionSynthetic resin layered productsWoven fabricsFiberPolyolefin

The present invention relates to fibers and nonwovens made from plasticized polyolefin compositions comprising a polyolefin, a non-functionalized hydrocarbon plasticizer and a slip agent.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com