Patents

Literature

6312results about "Constructions elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

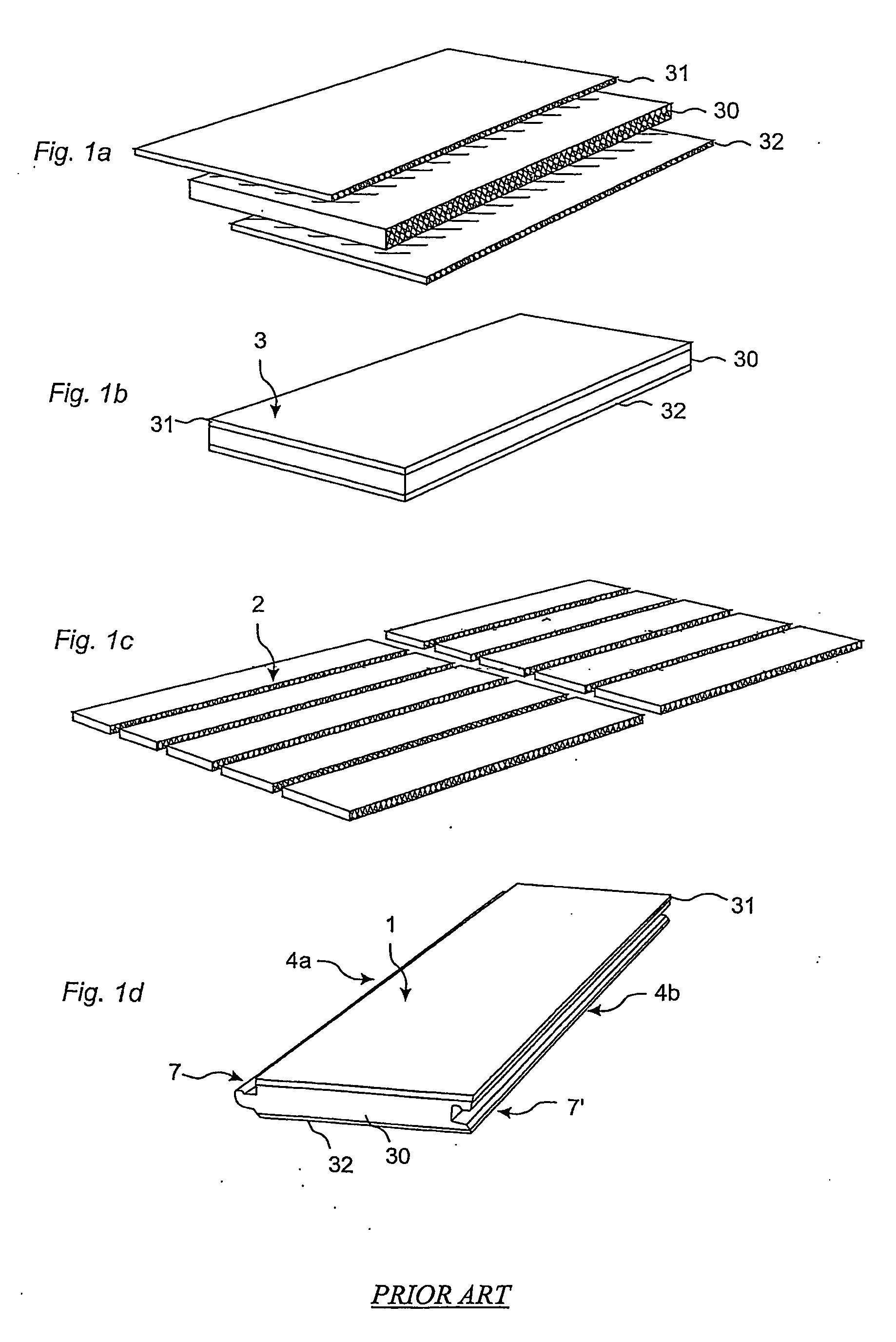

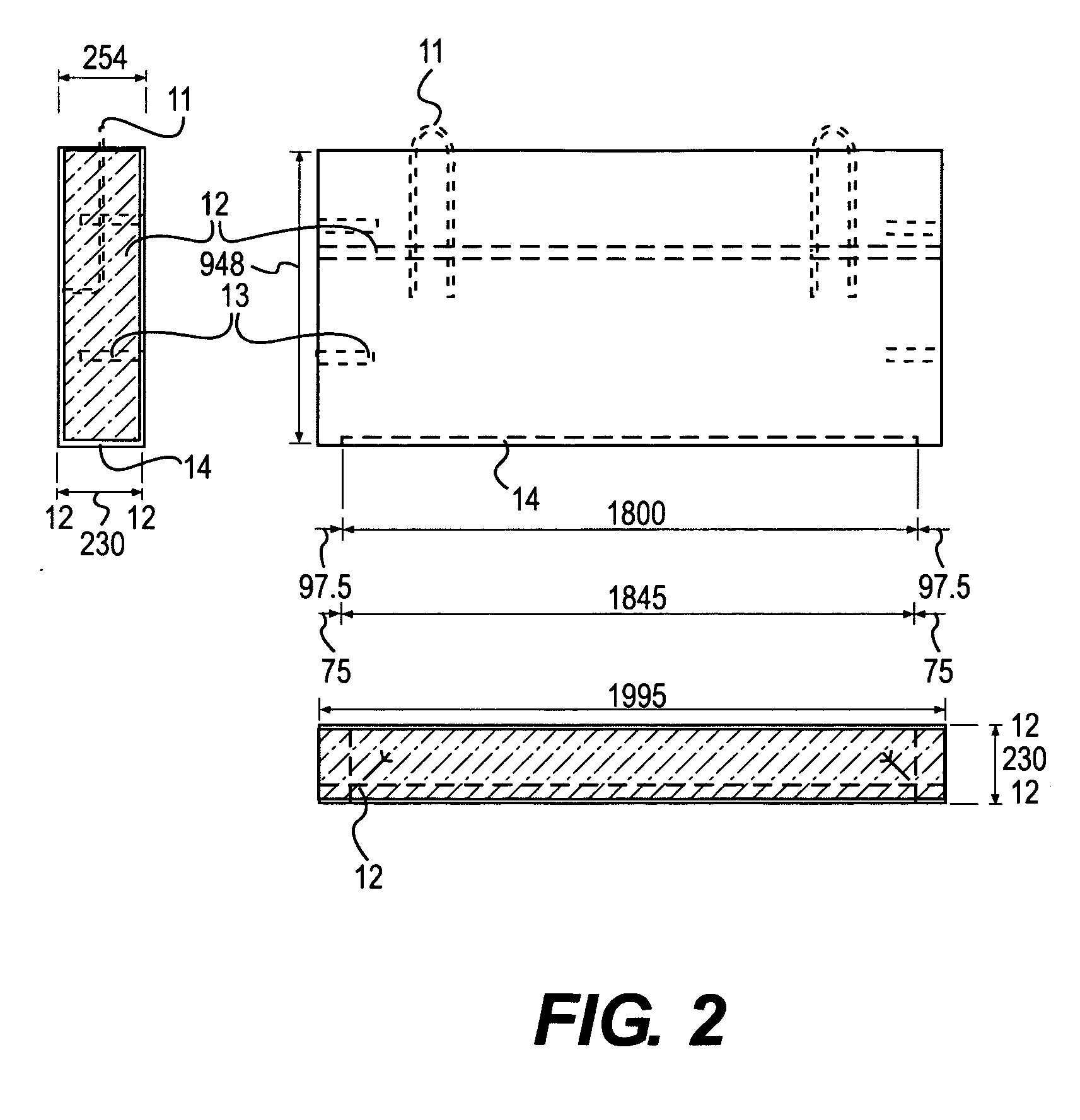

Flooring products and methods of making the same

InactiveUS20060032175A1Improve moisture resistanceStrutsSynthetic resin layered productsThick plateNatural fiber

A plank is described wherein the plank comprises a core, and optionally, a print layer, and optionally an overlay. The core includes from about 30 wt % to about 95 wt % at least one polymeric material, by weight of the core, and from about 5 wt % to about 70 wt % of least one natural fiber or flour, by weight of the core, wherein the core includes a top surface and a bottom surface, and opposing sides, wherein said plank is substantially moisture resistant, having a swelling property of from about 0.5% to about 5% by NALFA Thickness Test Section 3.2 LF 01-2003 standard, and wherein said plank includes a bow of from about 0.5% to about 4%. In addition, a method of making the plank is further described.

Owner:MANNINGTON MILLS

Floor Covering With Interlocking Design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

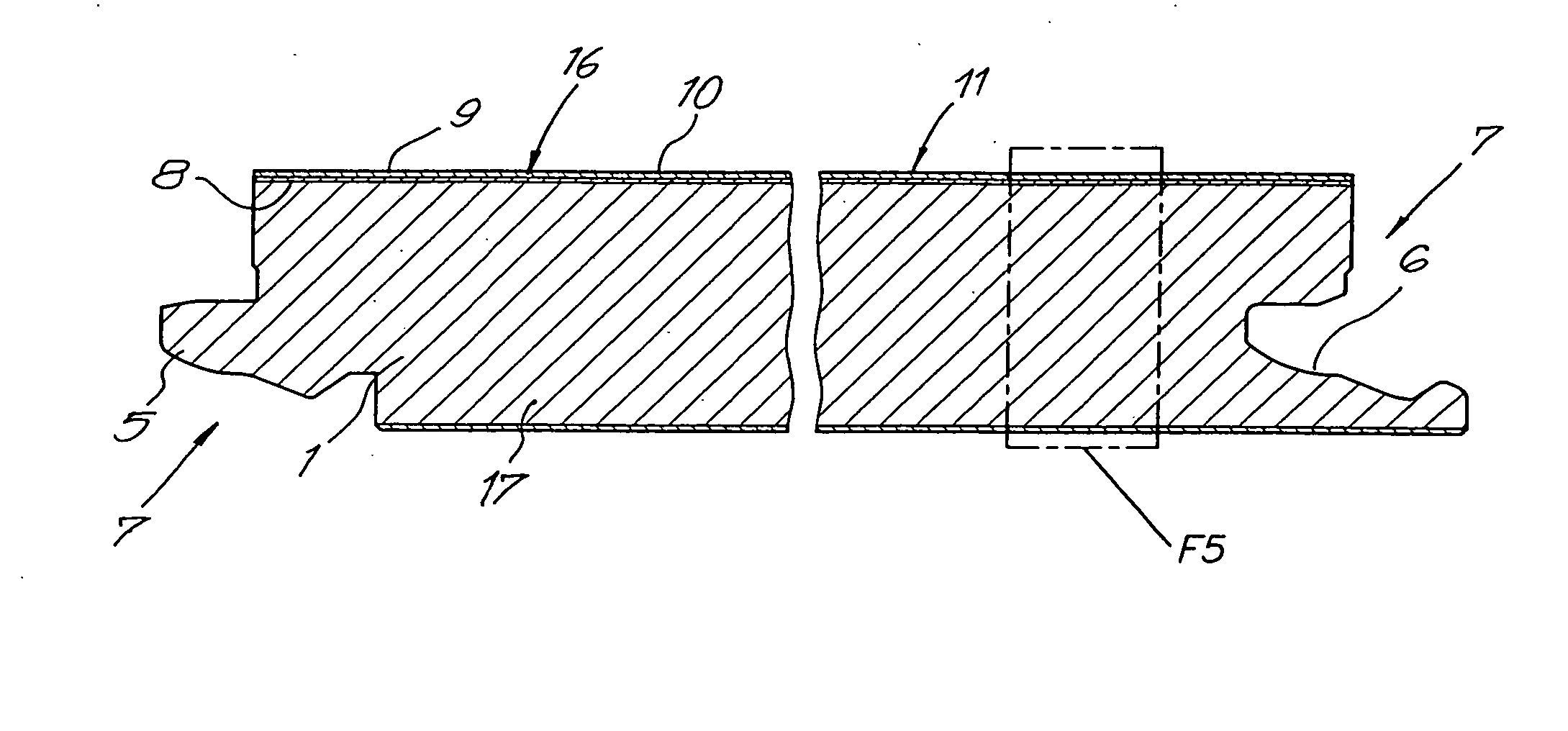

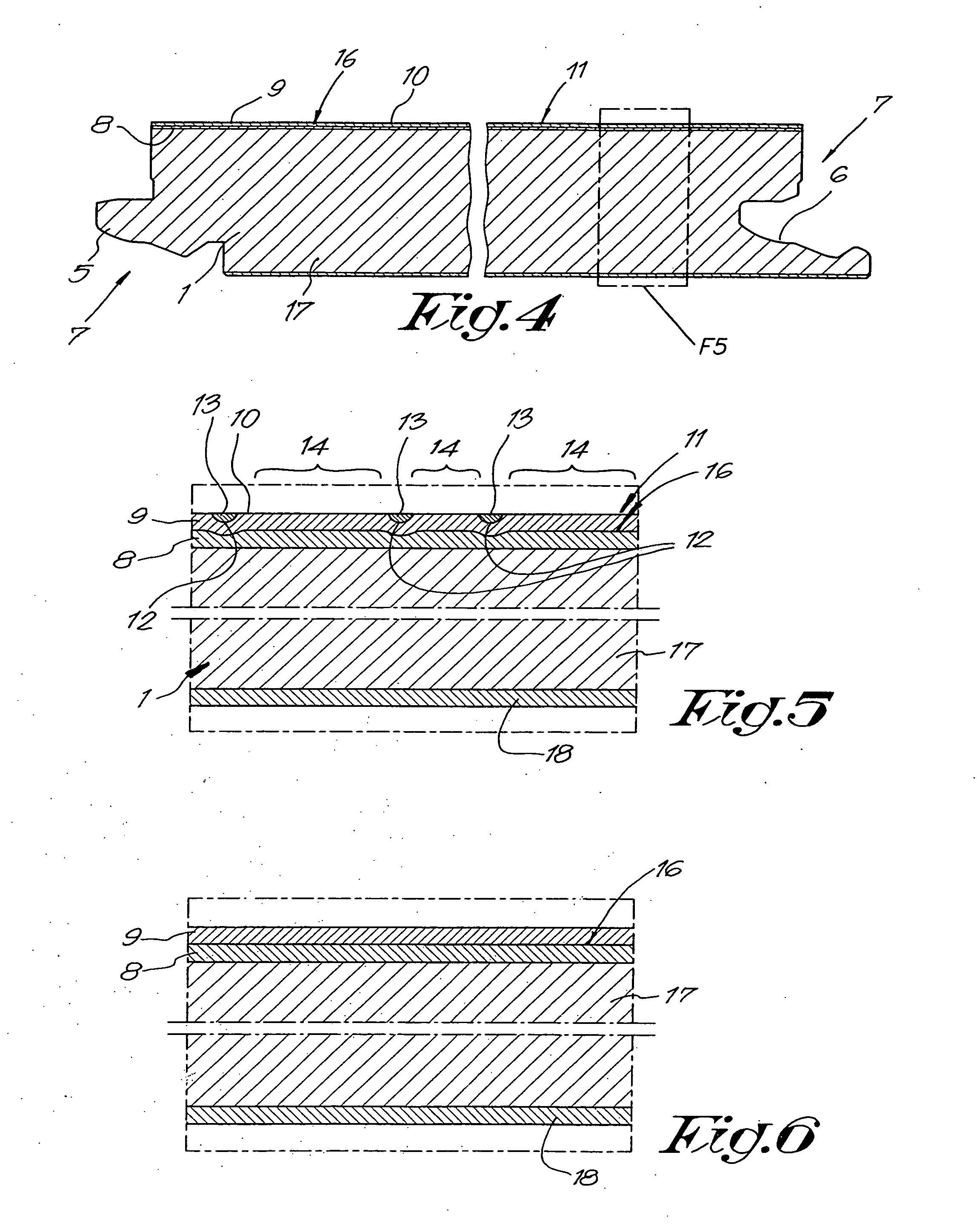

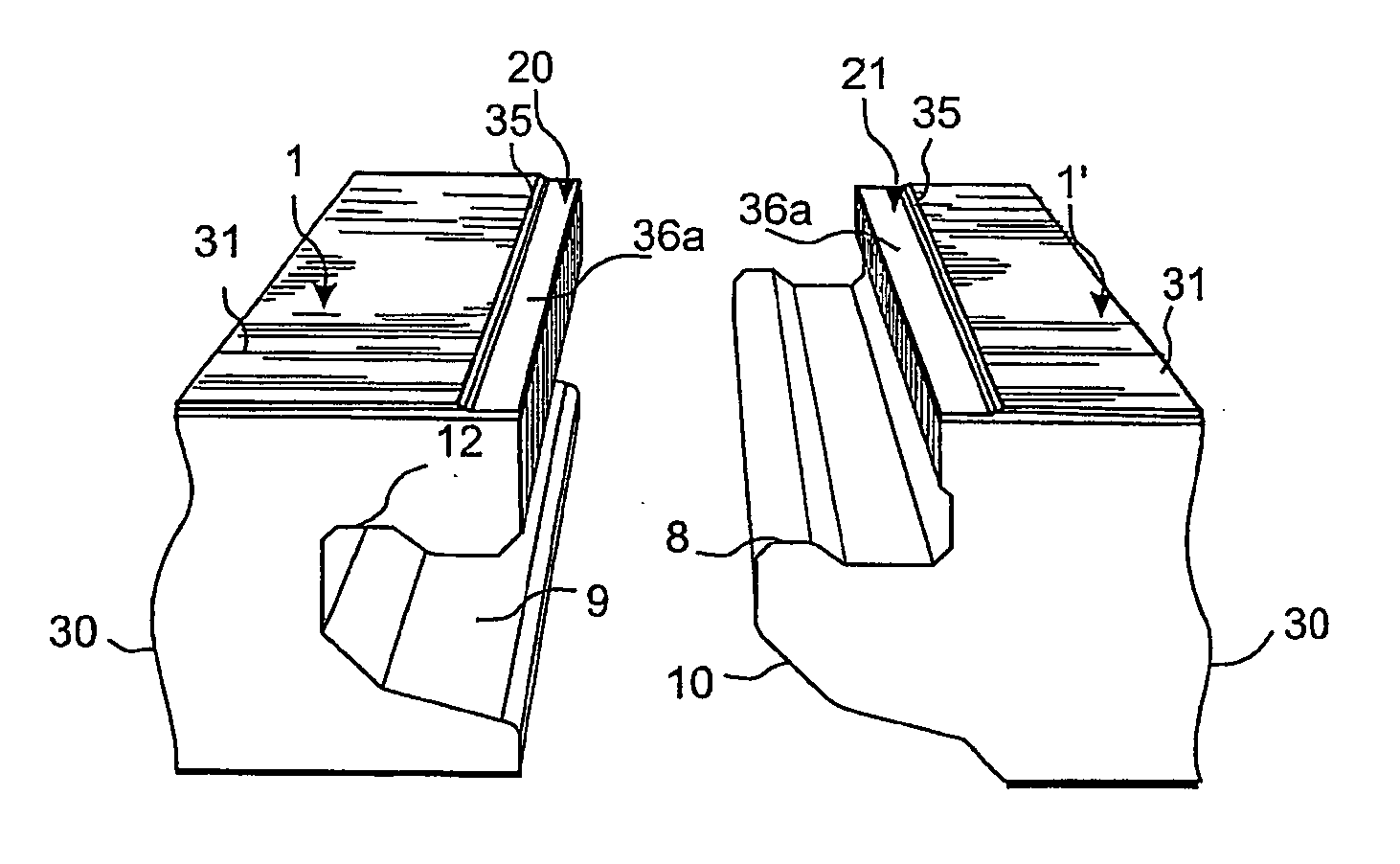

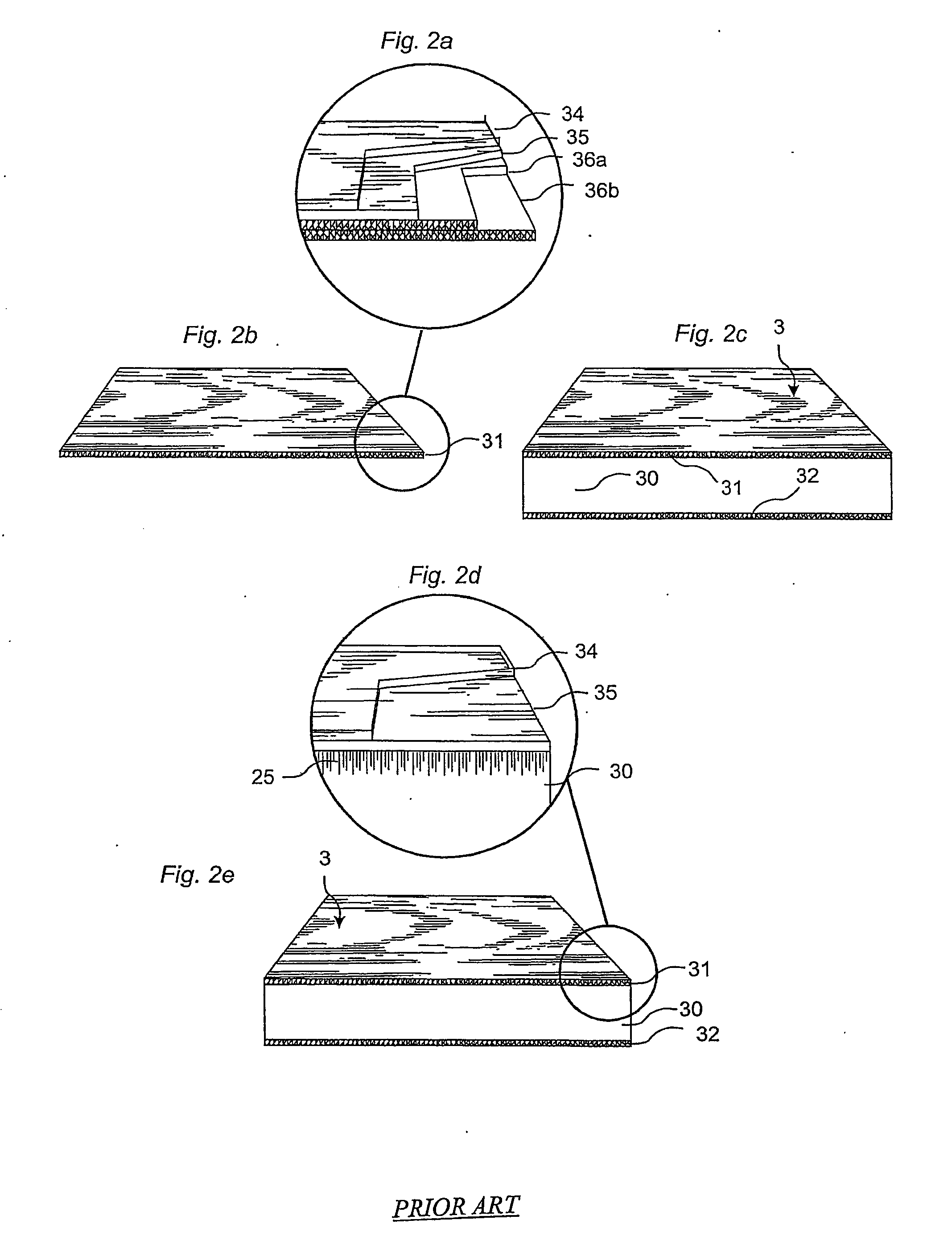

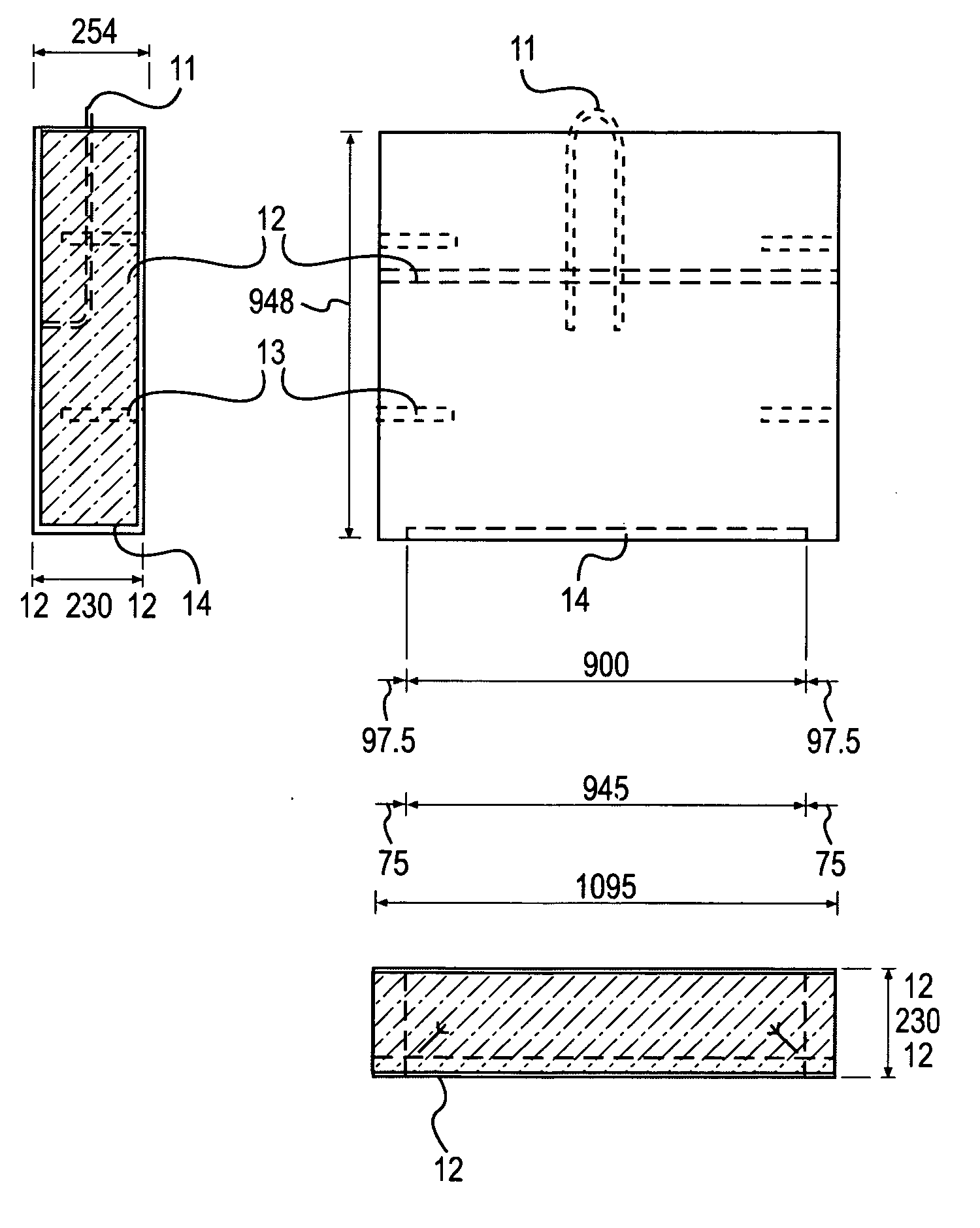

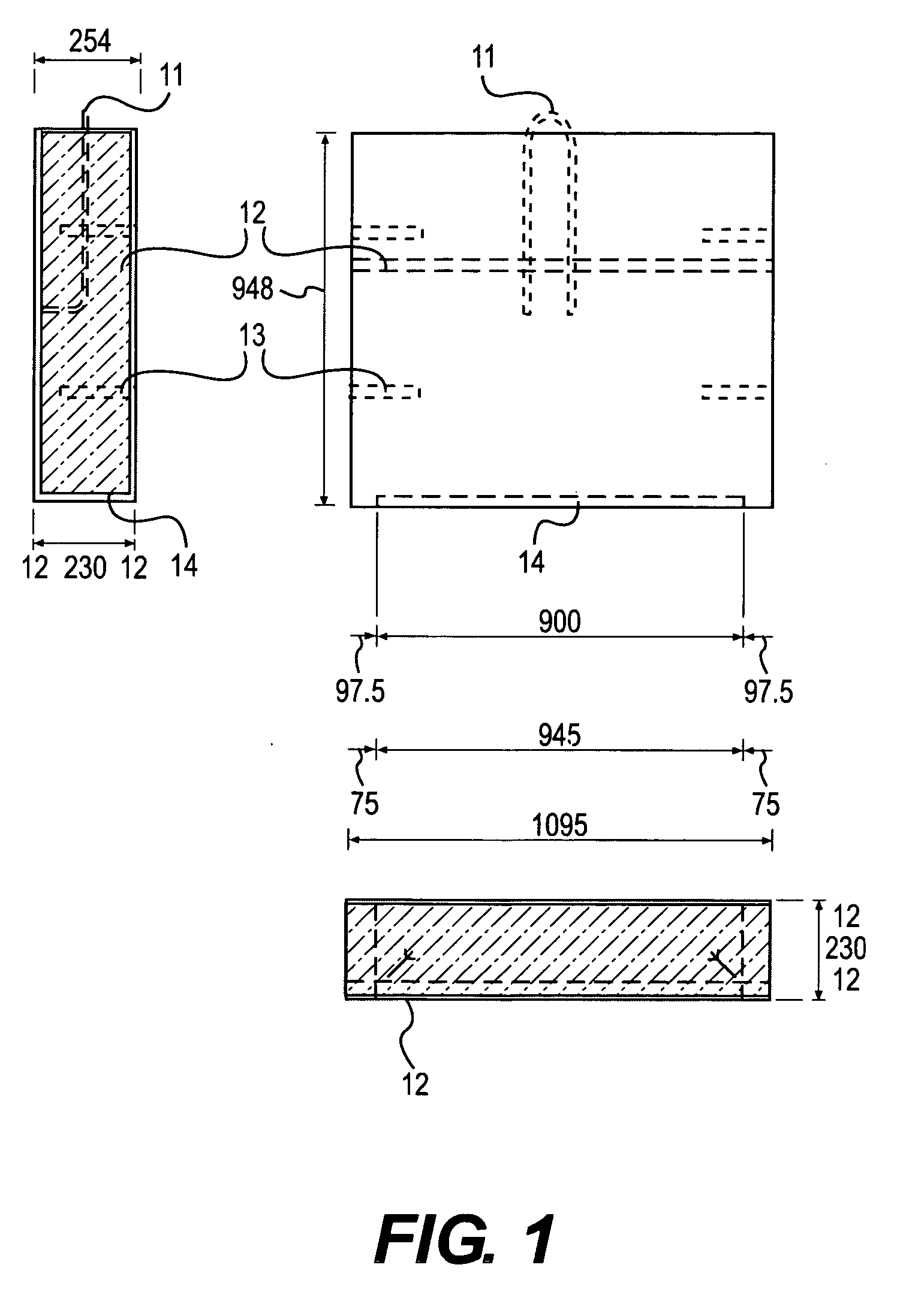

Floor panel and method for manufacturing such floor panels

Floor panel, of the type consisting of a laminate panel which comprises at least a printed decorative layer (8) and a top layer (9) forming the upper surface (10) of the floor panel (1), more particularly a so-called overlay, whereby this top layer (9), or, thus, overlay, is realized on the basis of a thermosetting resin, characterized in that in the upper side (11) of the floor panel (1), indentations (12) are formed and in that at last in a number of these indentations (12), a component (13) is provided, which is obtained in that it has been provided in those indentations (12) after the provision of the indentations (12).

Owner:FLOORING IND LTD

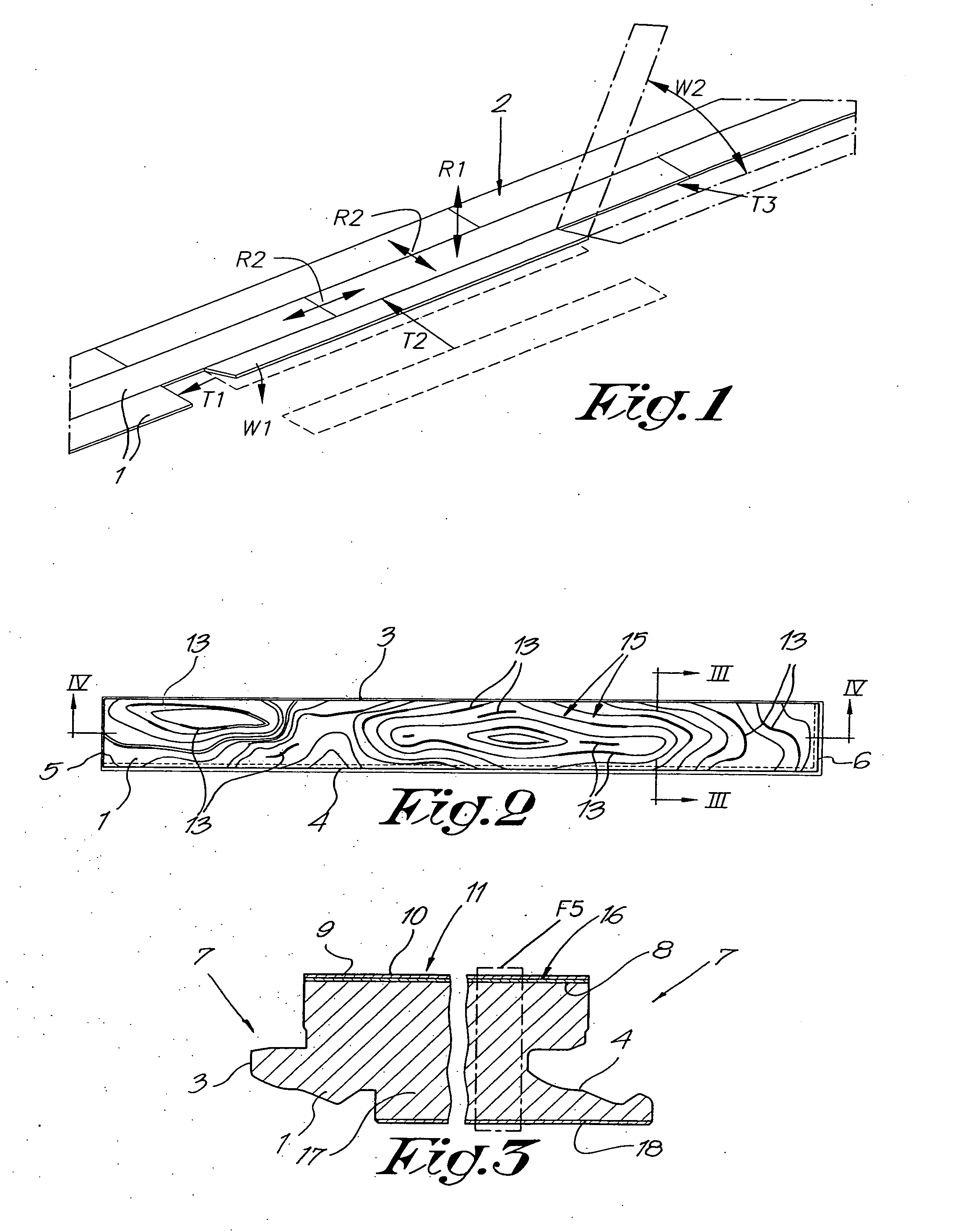

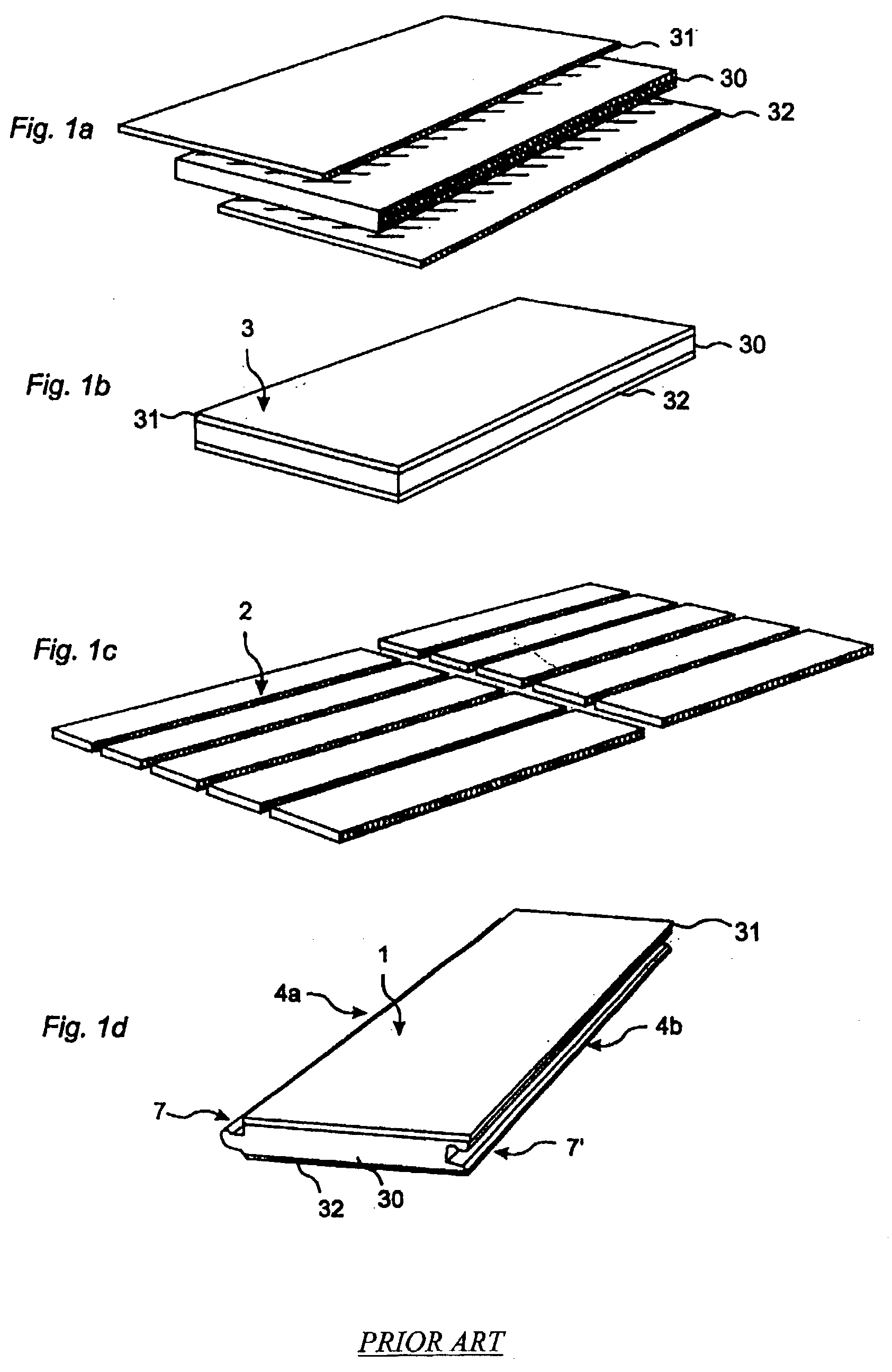

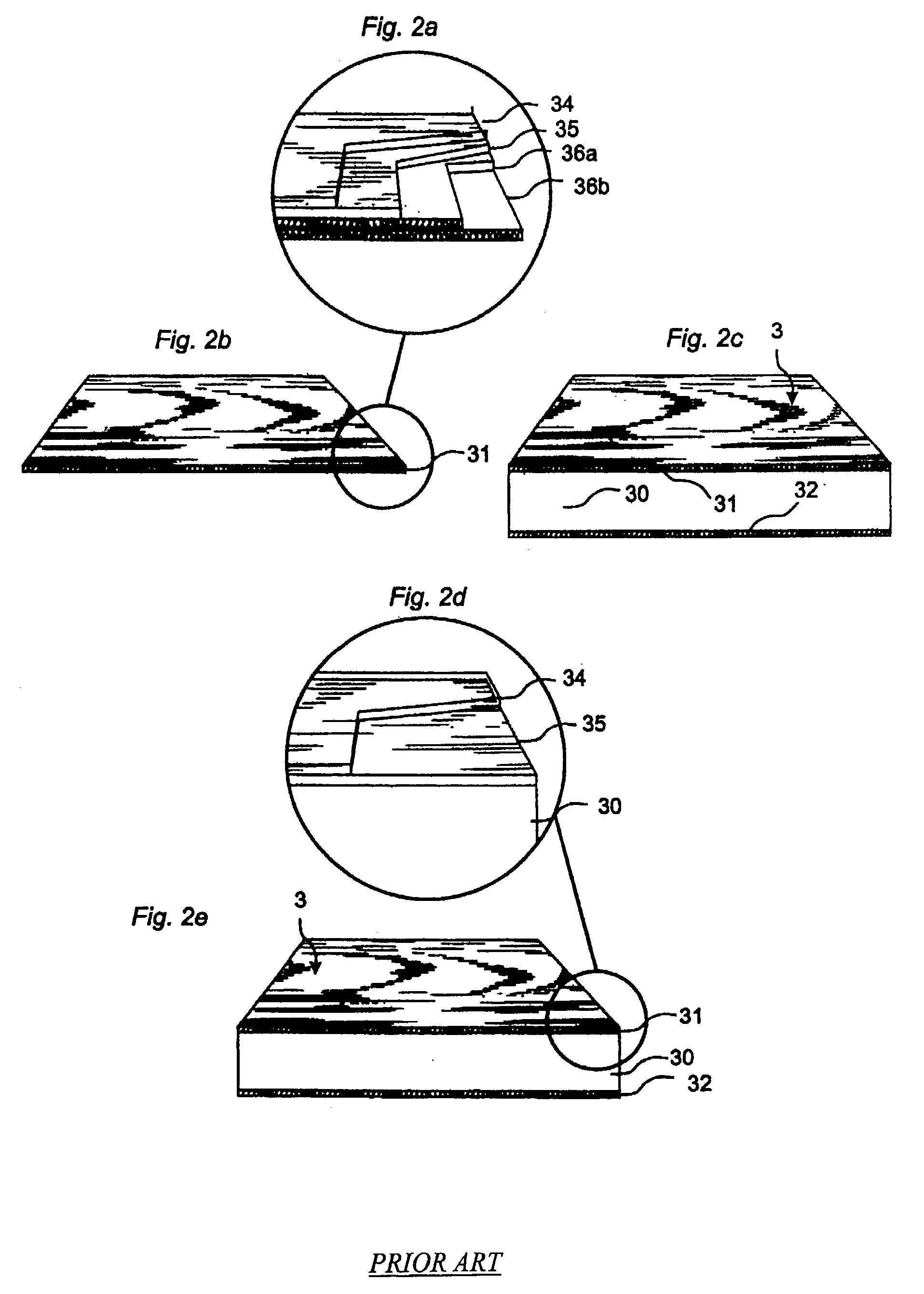

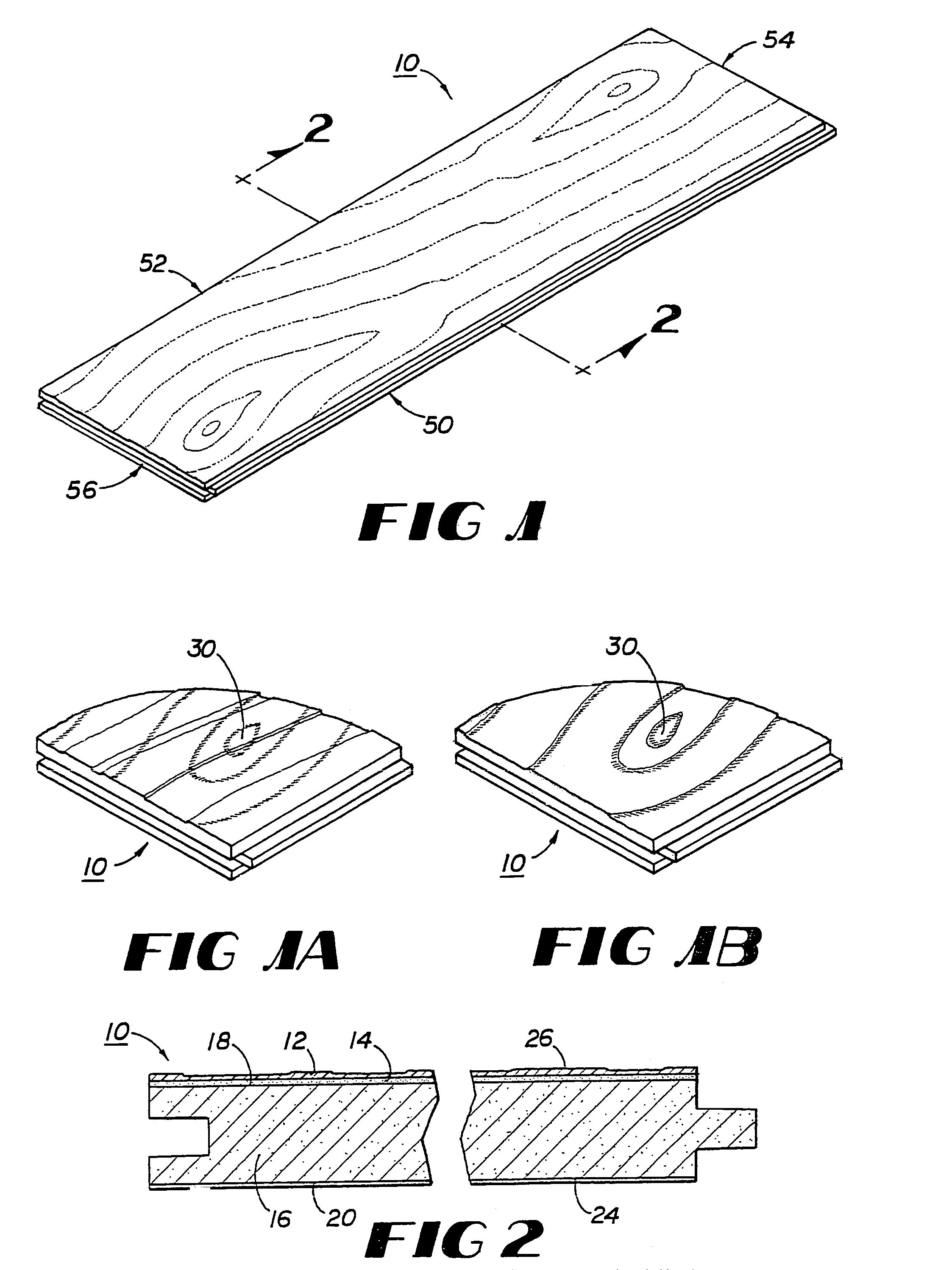

Floorboards with decorative grooves

InactiveUS20040035078A1Provides appearance and durabilityNatural appearanceCovering/liningsTongue/grooves making apparatusSurface layerEngineering

Floorboards consisting of a core and a surface layer with decorative joint edge portions which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

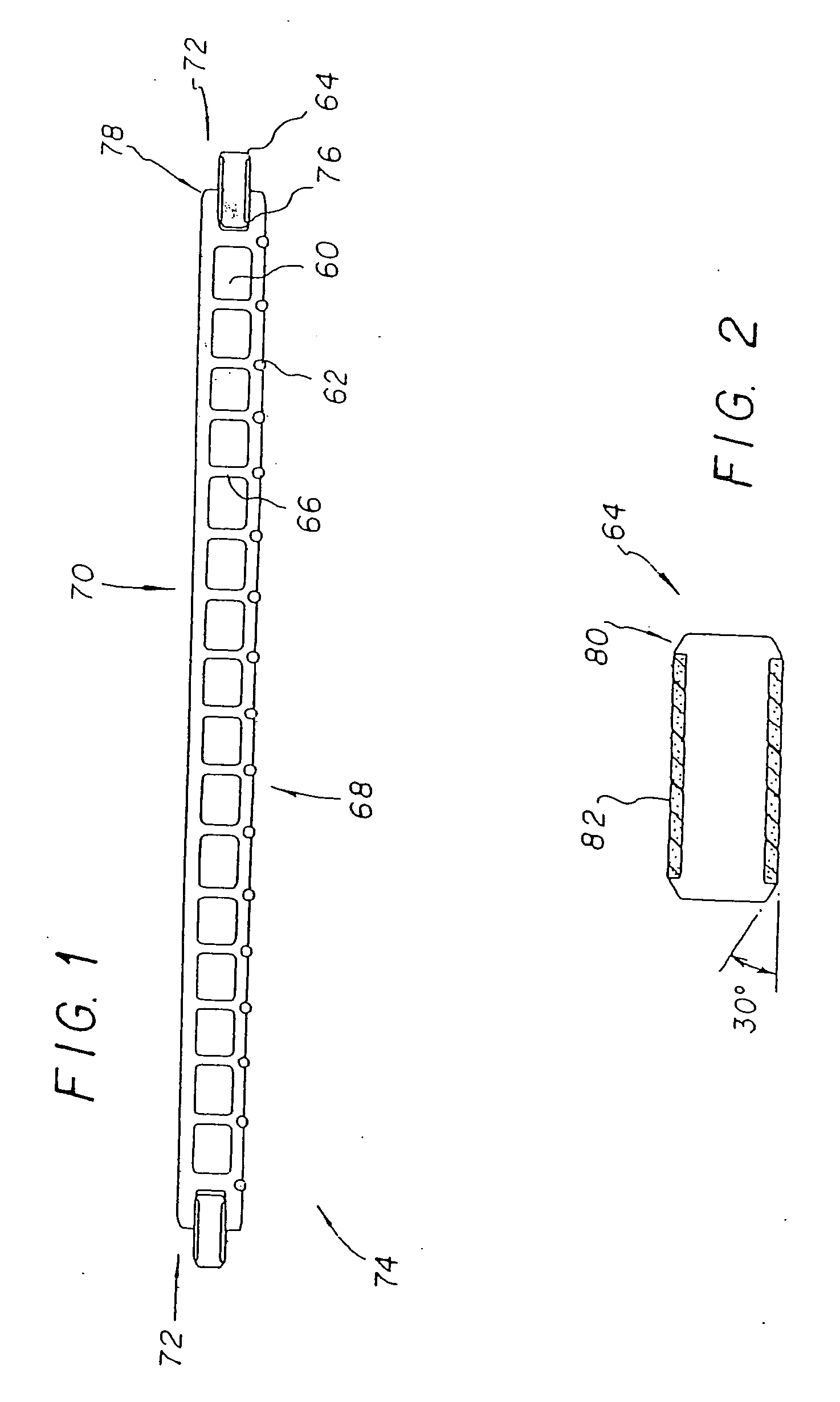

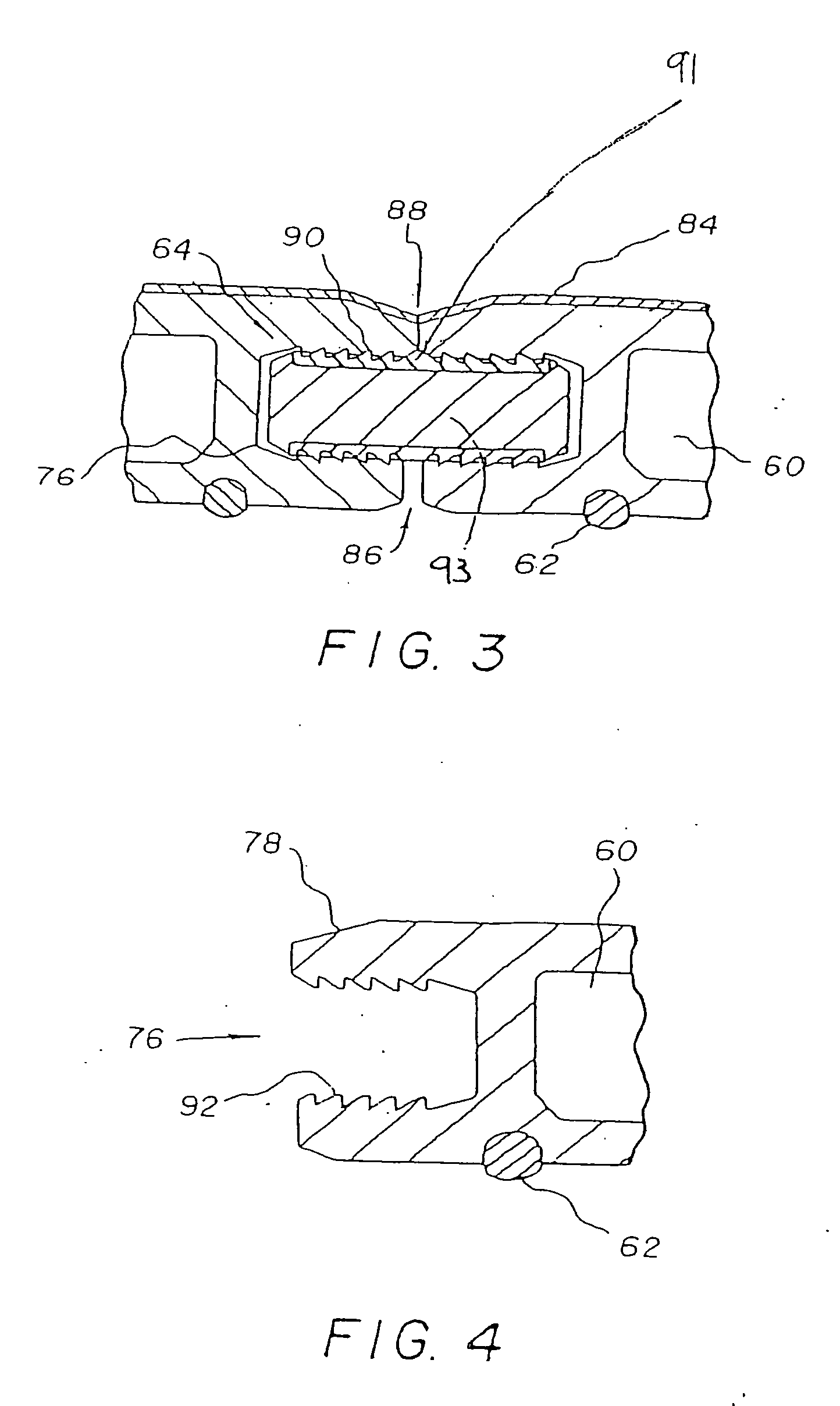

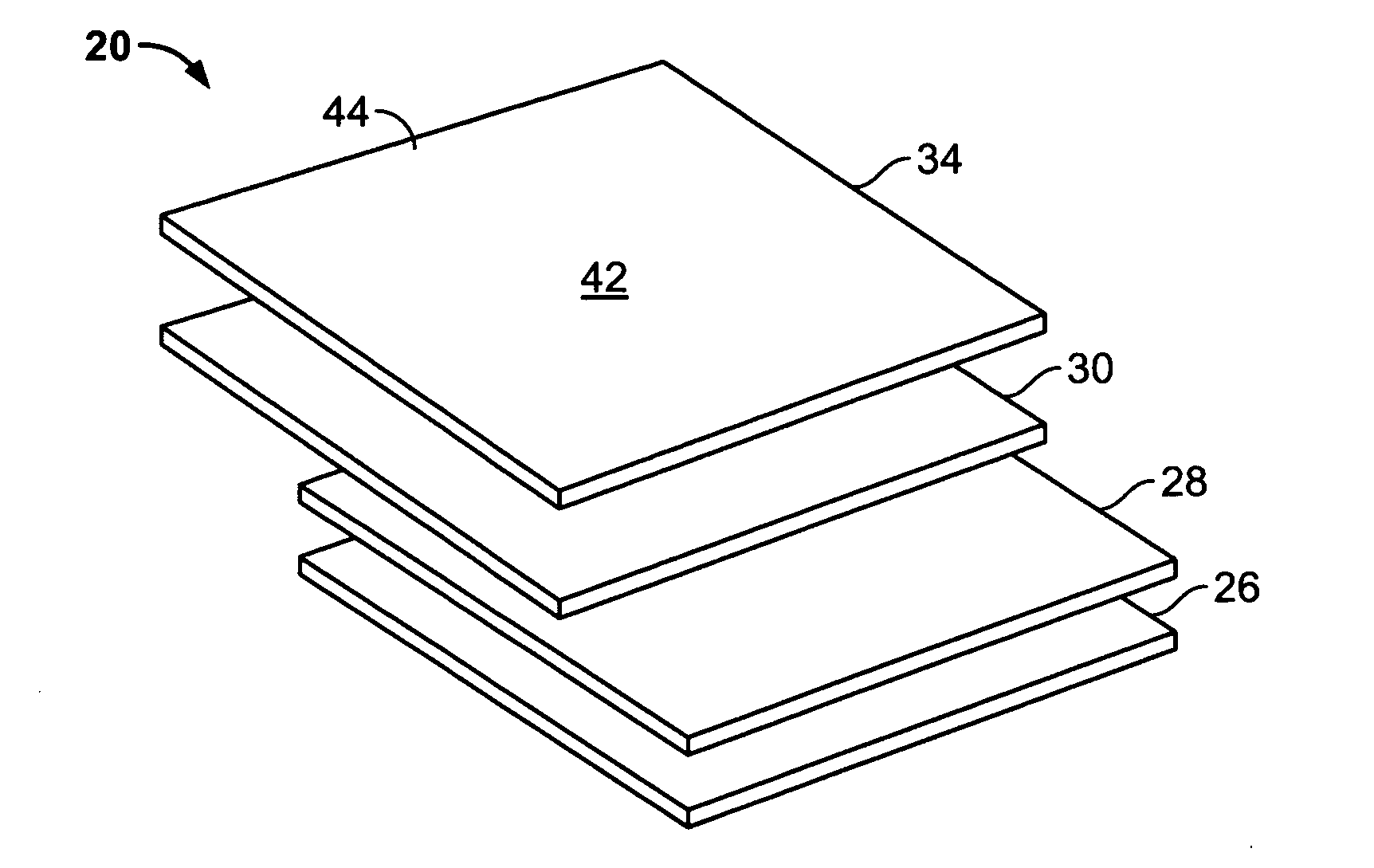

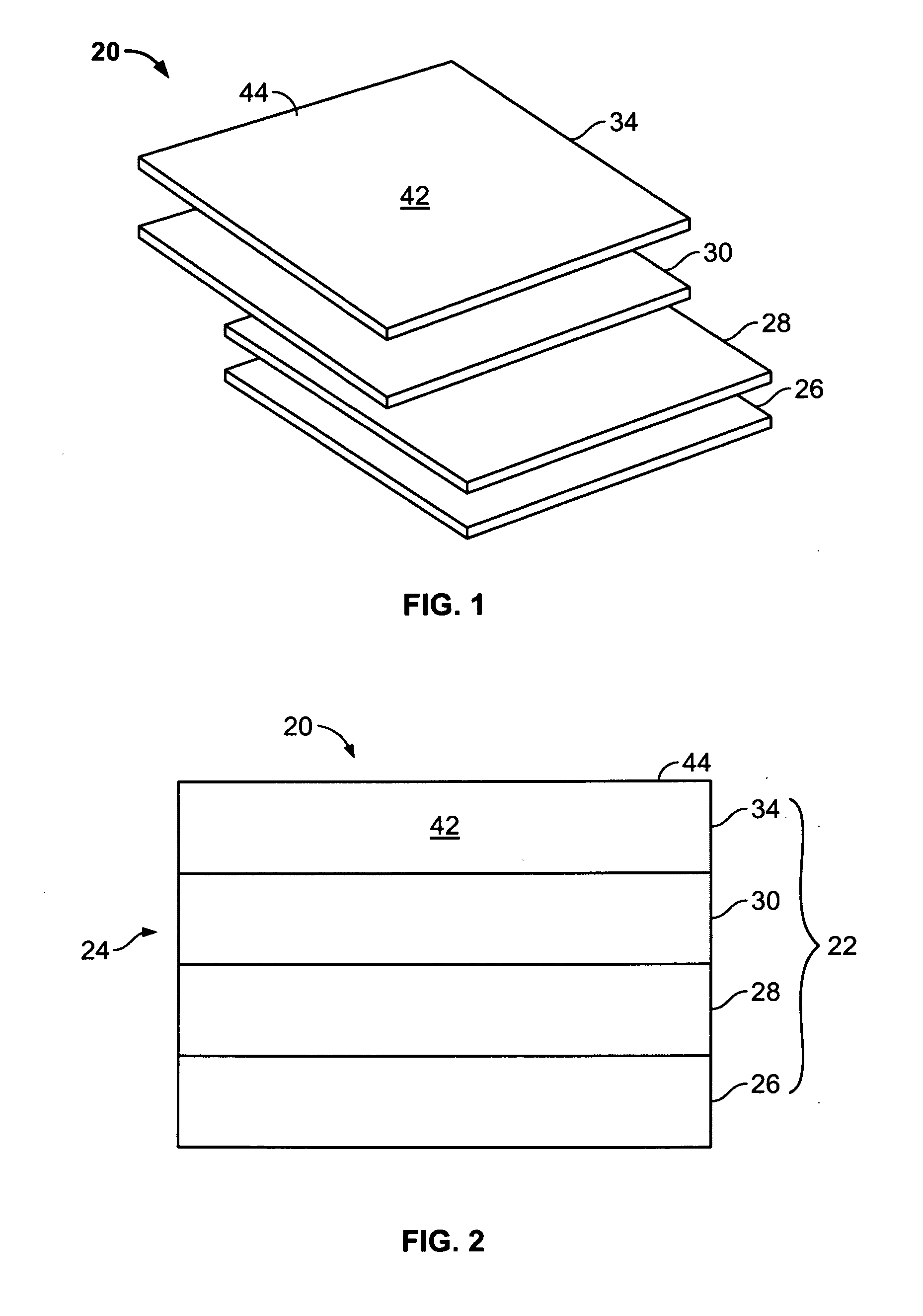

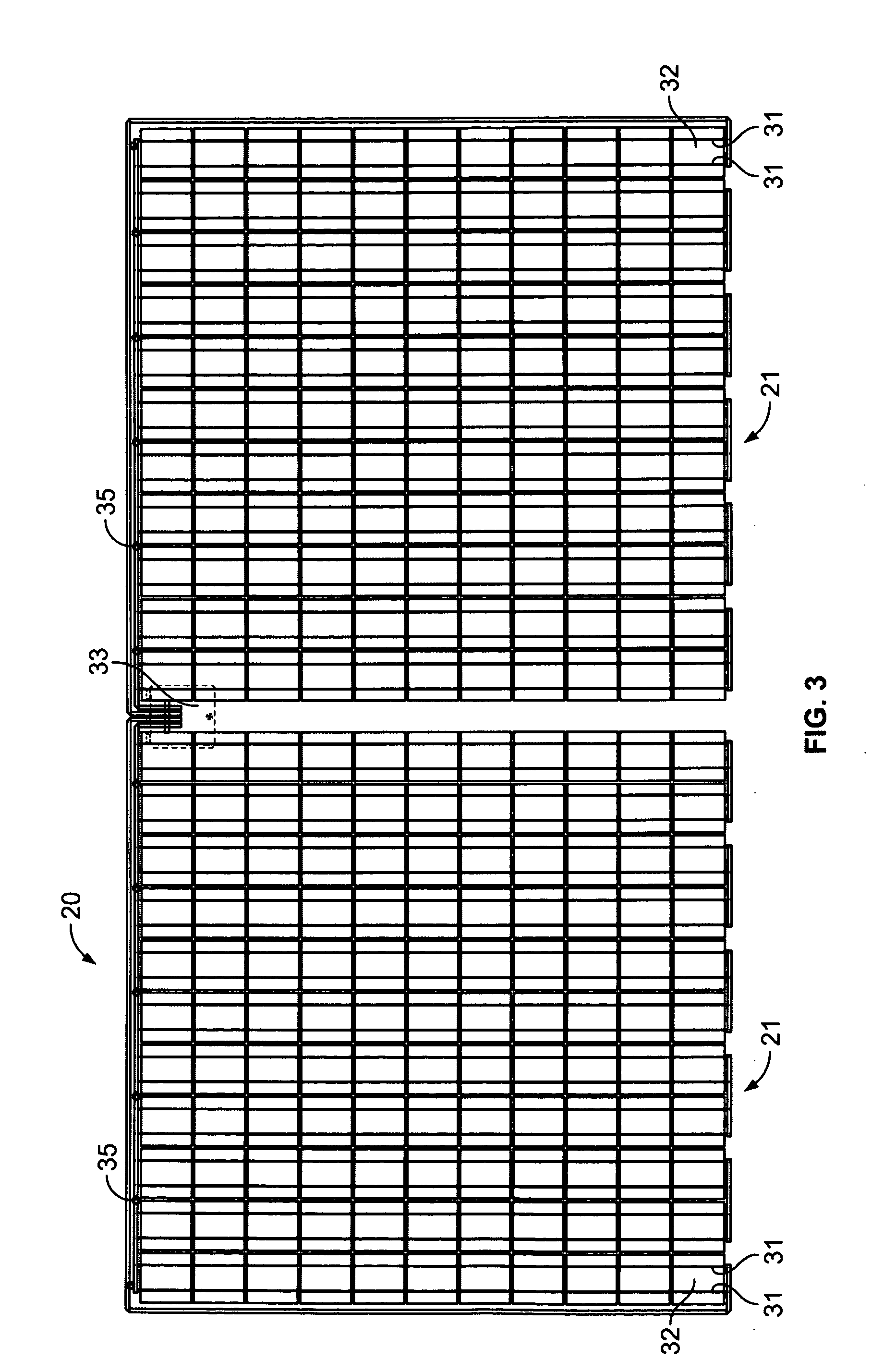

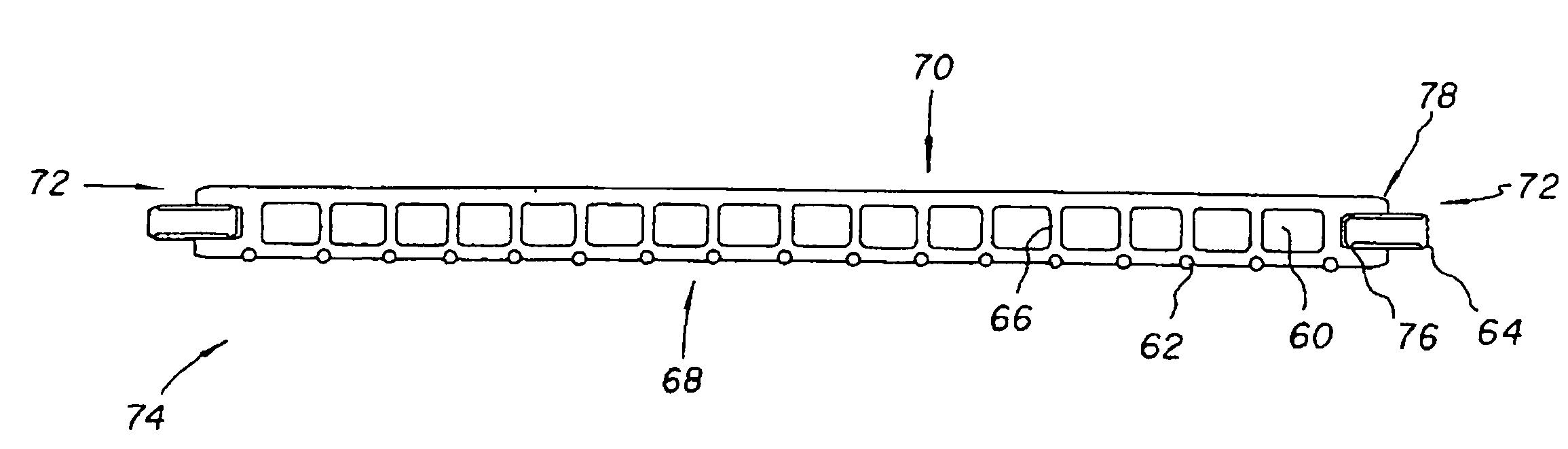

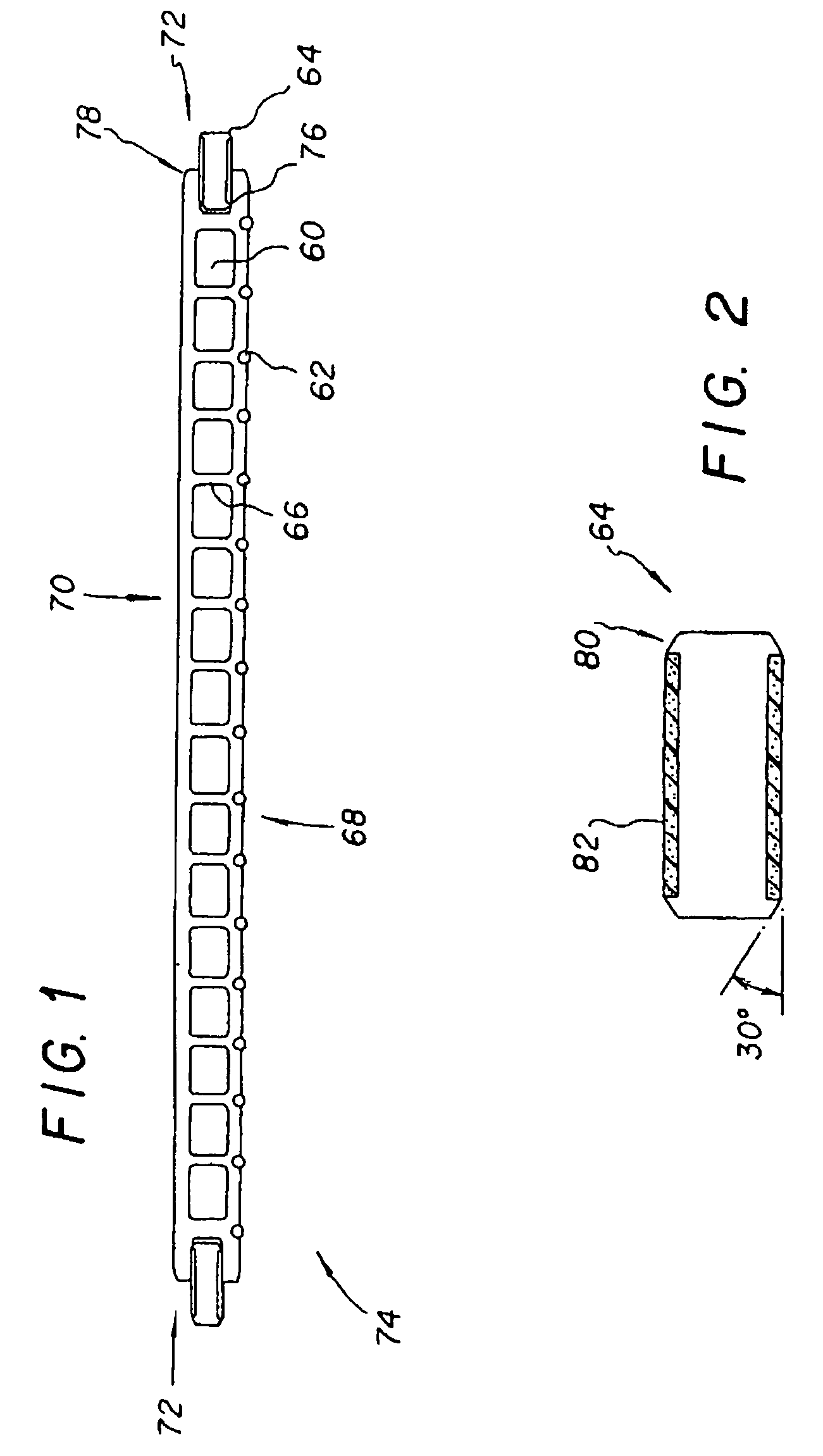

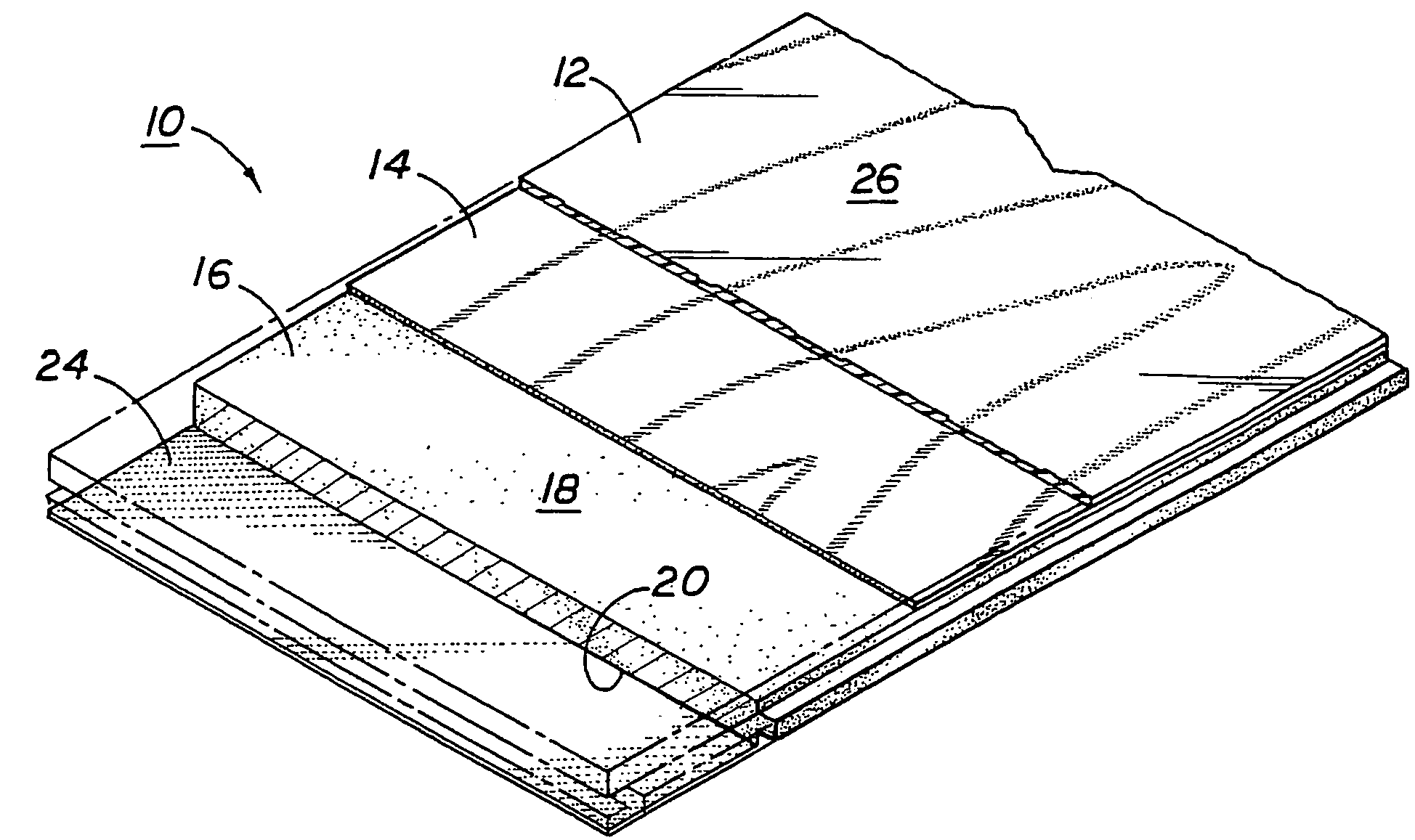

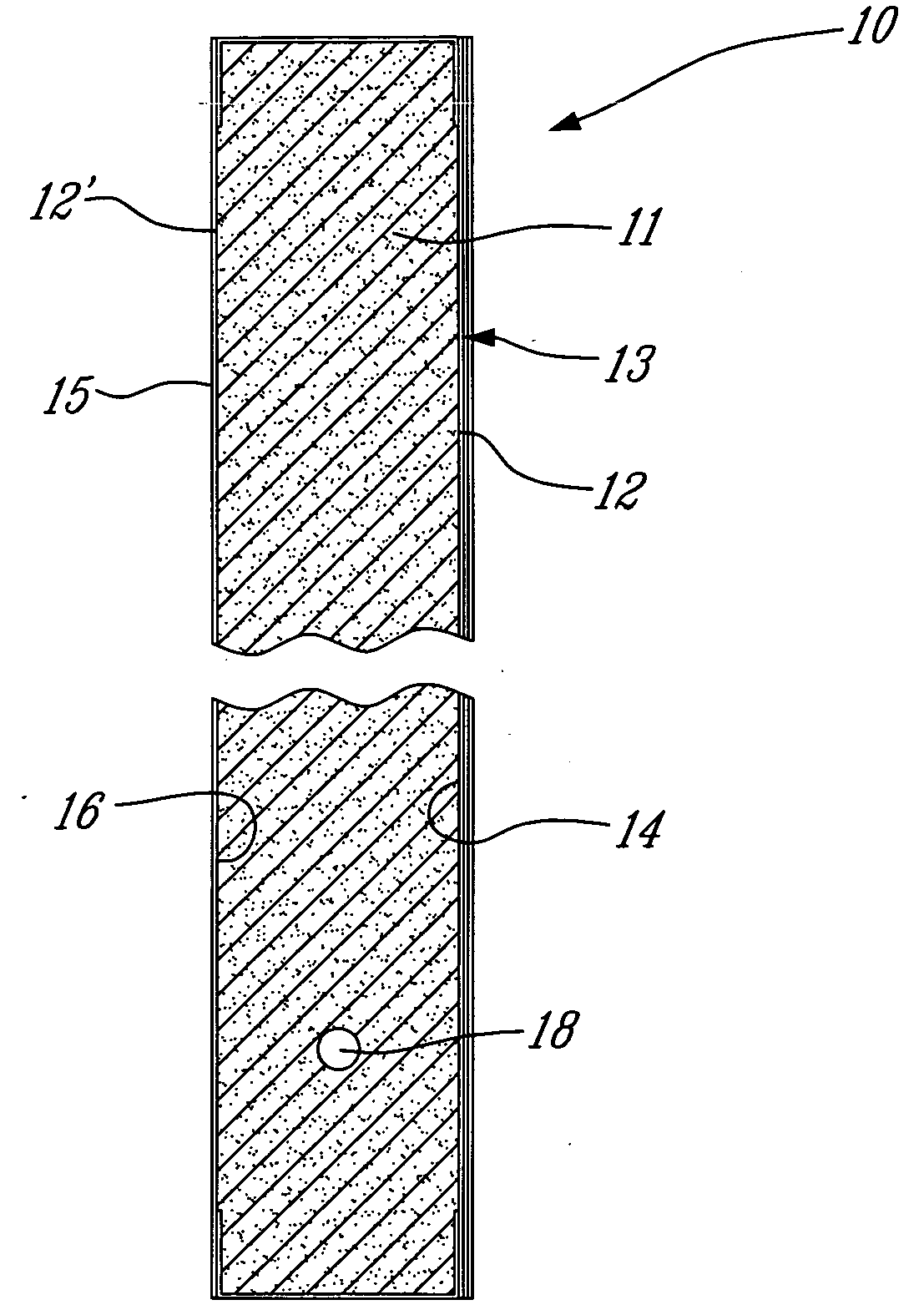

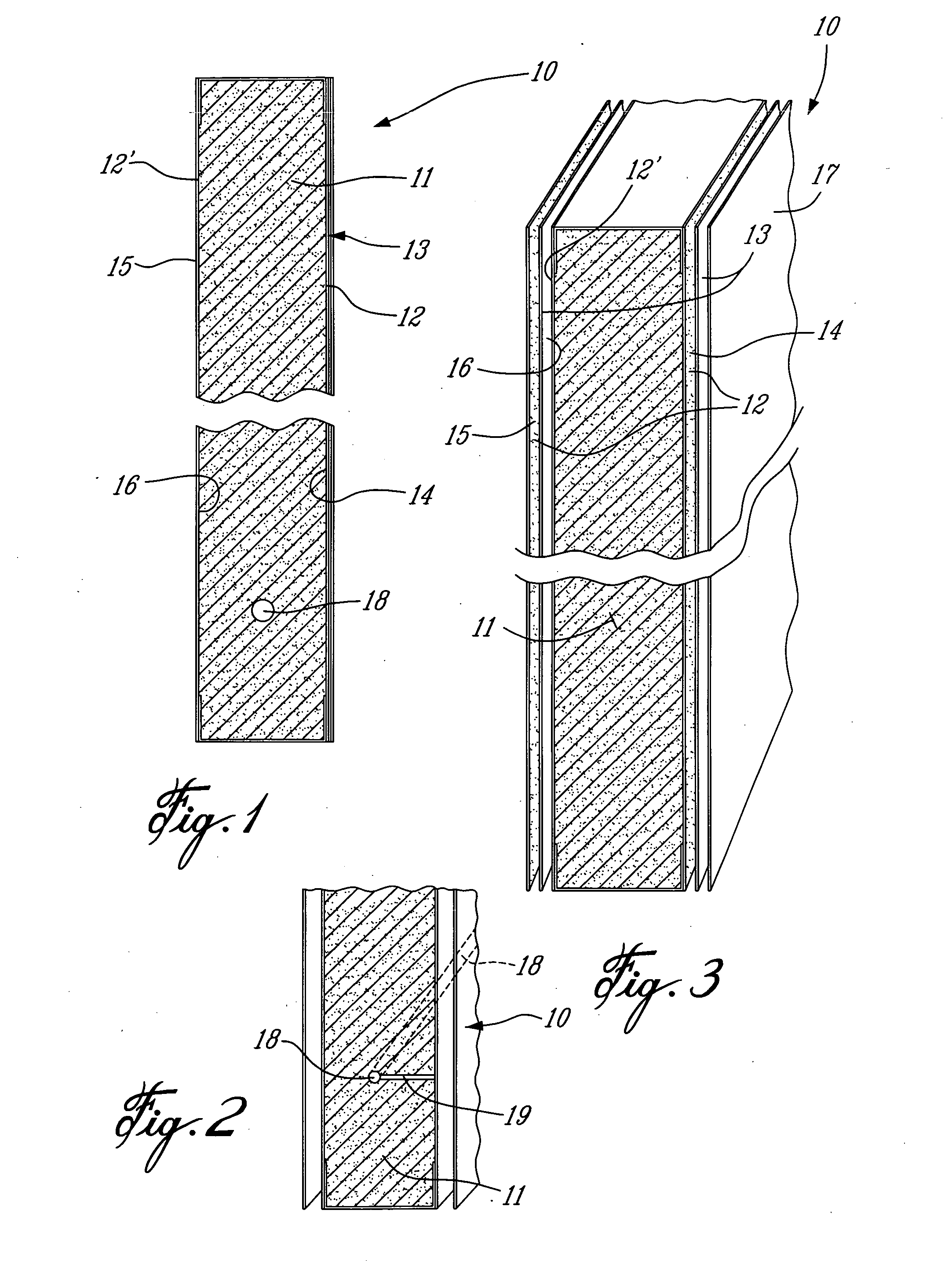

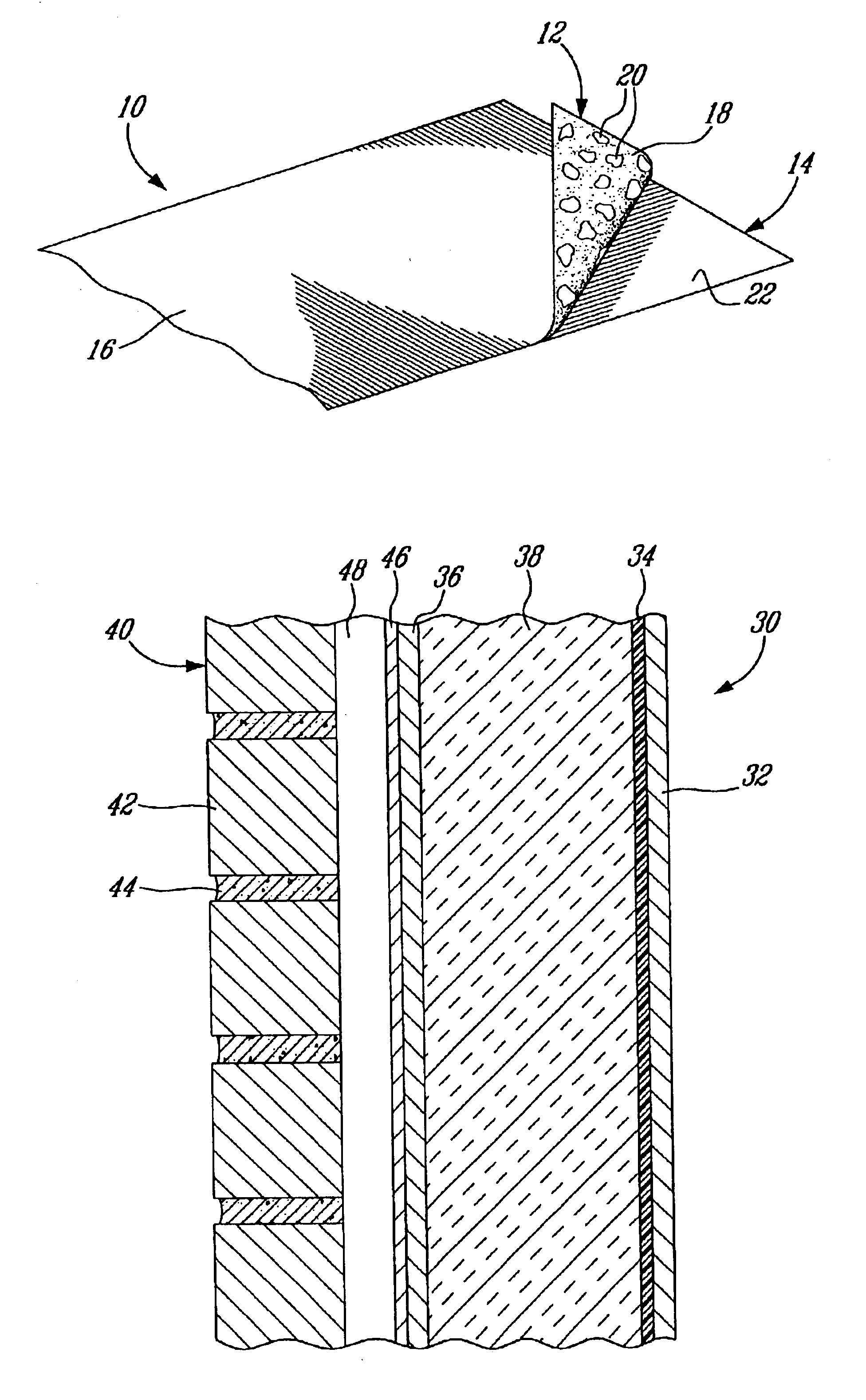

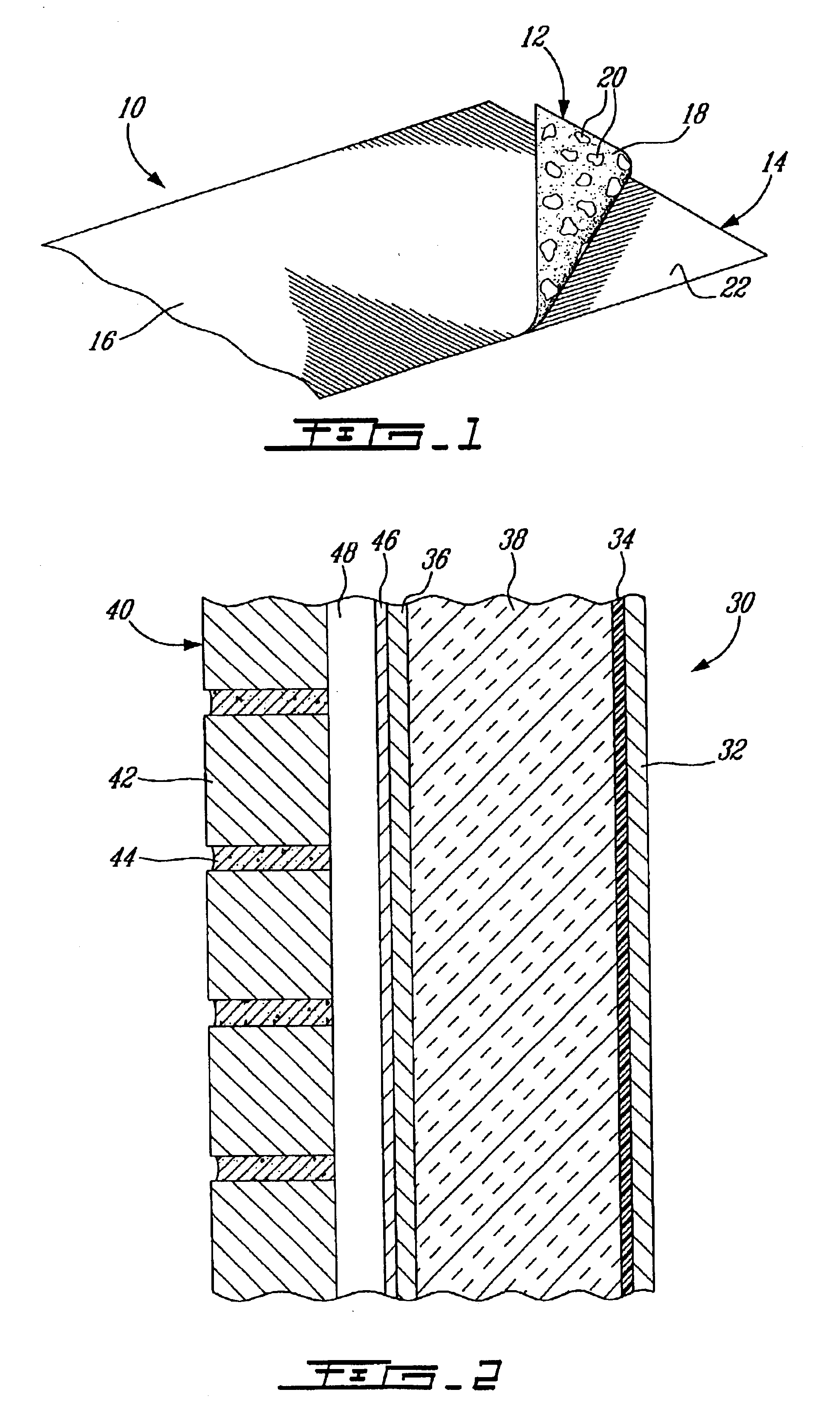

Photovoltaic system and method of making same

The present invention relates to a photovoltaic system and methods of making same. The photovoltaic system has a plurality of layers attached to each other to form a unitary structure. More specifically, the photovoltaic system includes: a base, flexible membrane layer; a photovoltaic layer having at least one photovoltaic cell associated therewith; a semi-rigid layer for supporting the photovoltaic layer and imparting rigidity thereto; and a top, transparent, protective layer for protecting the base, flexible membrane layer, the semi-rigid layer and the photovoltaic layer from exposure to the environment. The photovoltaic layer and the semi-rigid layer are disposed between the base, flexible membrane layer and the top, protective layer. Additional layers of adhesive may be disposed between the various layers to facilitate bonding thereof.

Owner:OPEN ENERGY CORP

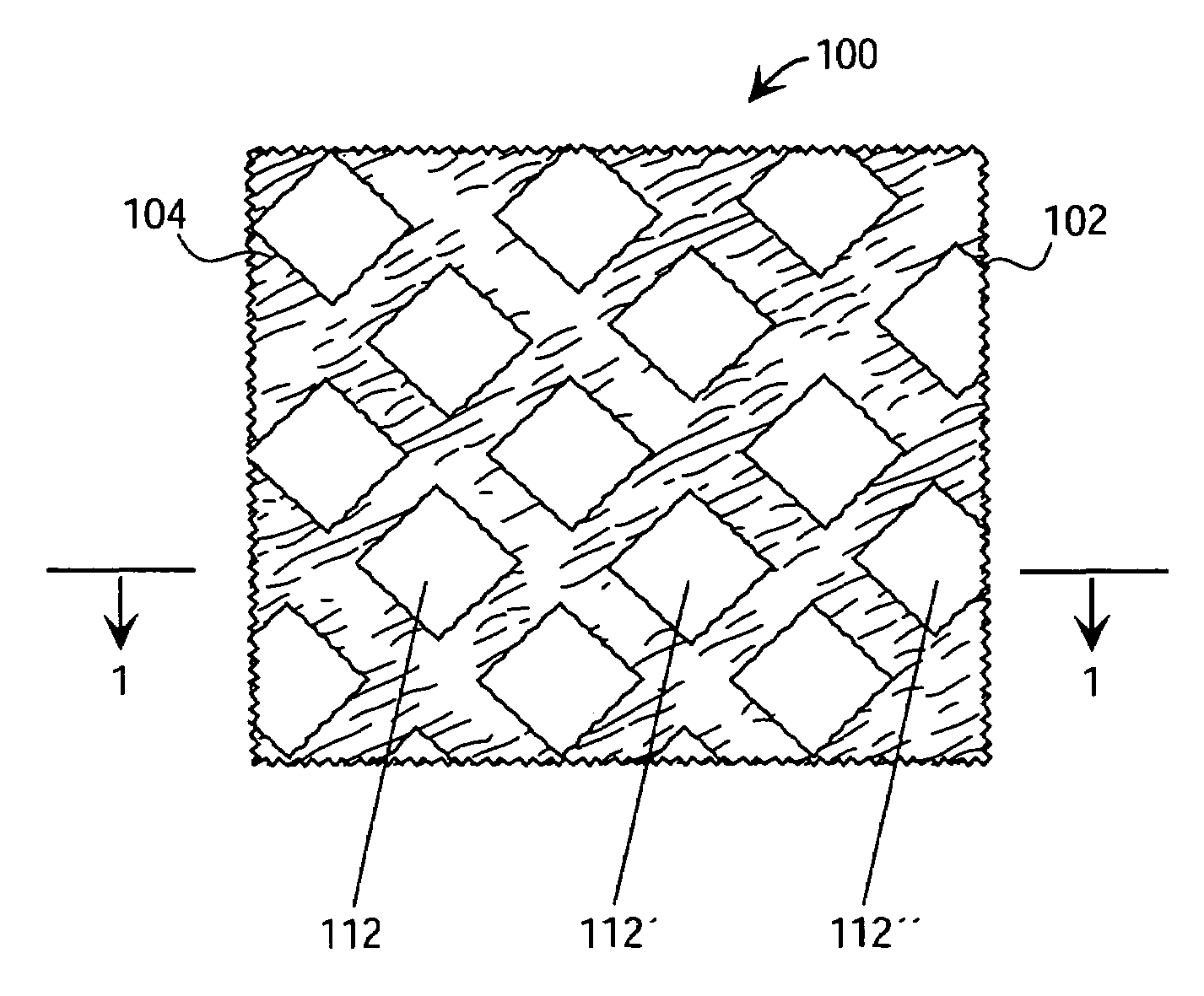

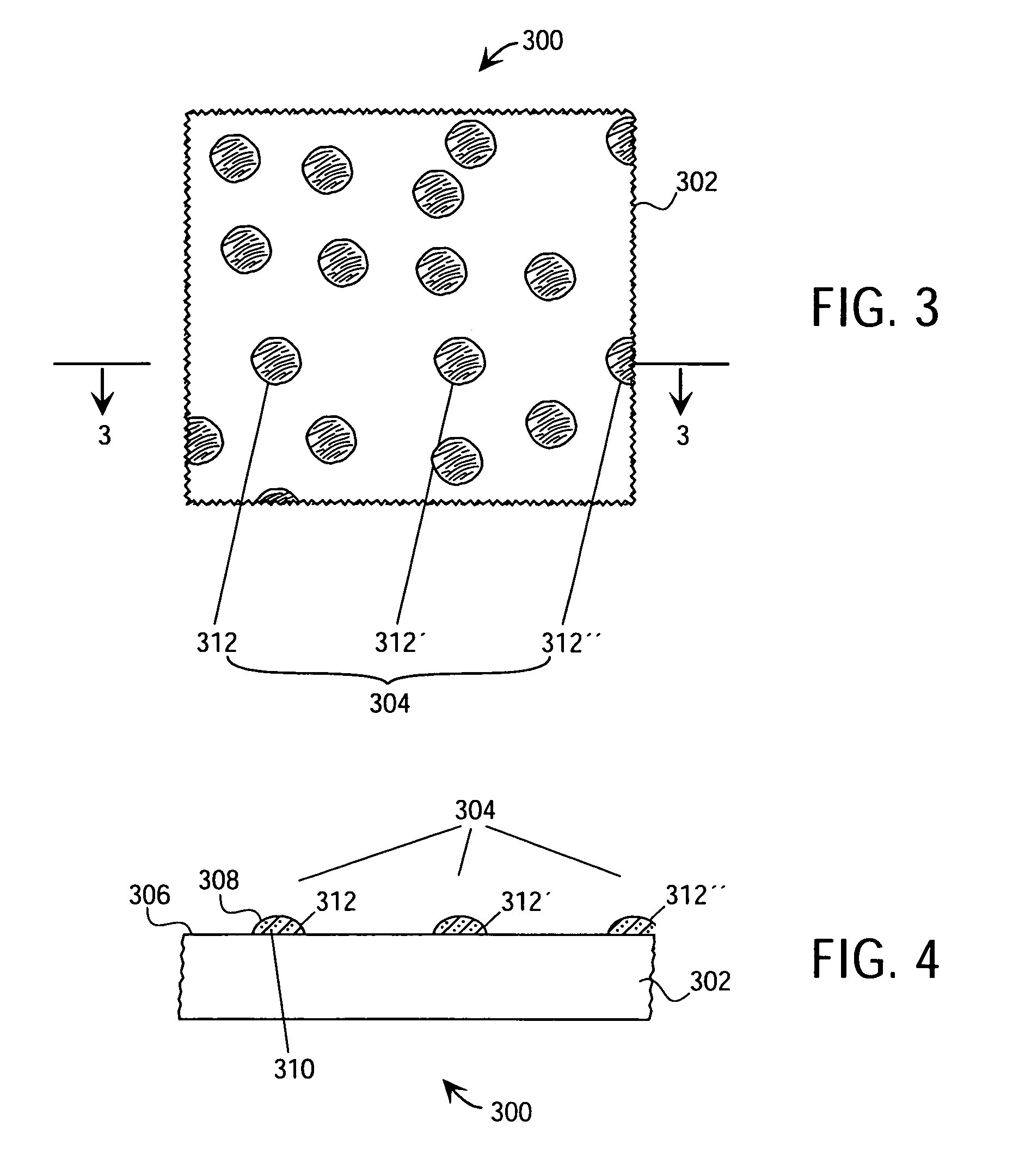

Coated articles having enhanced reversible thermal properties and exhibiting improved flexibility, softness, air permeability, or water vapor transport properties

InactiveUS7135424B2Enhanced reversible thermal propertyImprove breathabilityHeat storage plantsDecorative surface effectsWater vaporMedical product

The invention relates to a coated article having enhanced reversible thermal properties. The coated article comprises a substrate having a surface and a coating covering a portion of the surface and comprising a polymeric material and a temperature regulating material dispersed in the polymeric material. The coating is formed with a plurality of regions of discontinuity that are separated from one another and expose a remaining portion of the surface to provide improved flexibility, softness, air permeability, or water vapor transport properties. The coated article may be used in apparel, footwear, medical products, containers and packagings, building materials, appliances, and other products.

Owner:OUTLAST TECH LLC

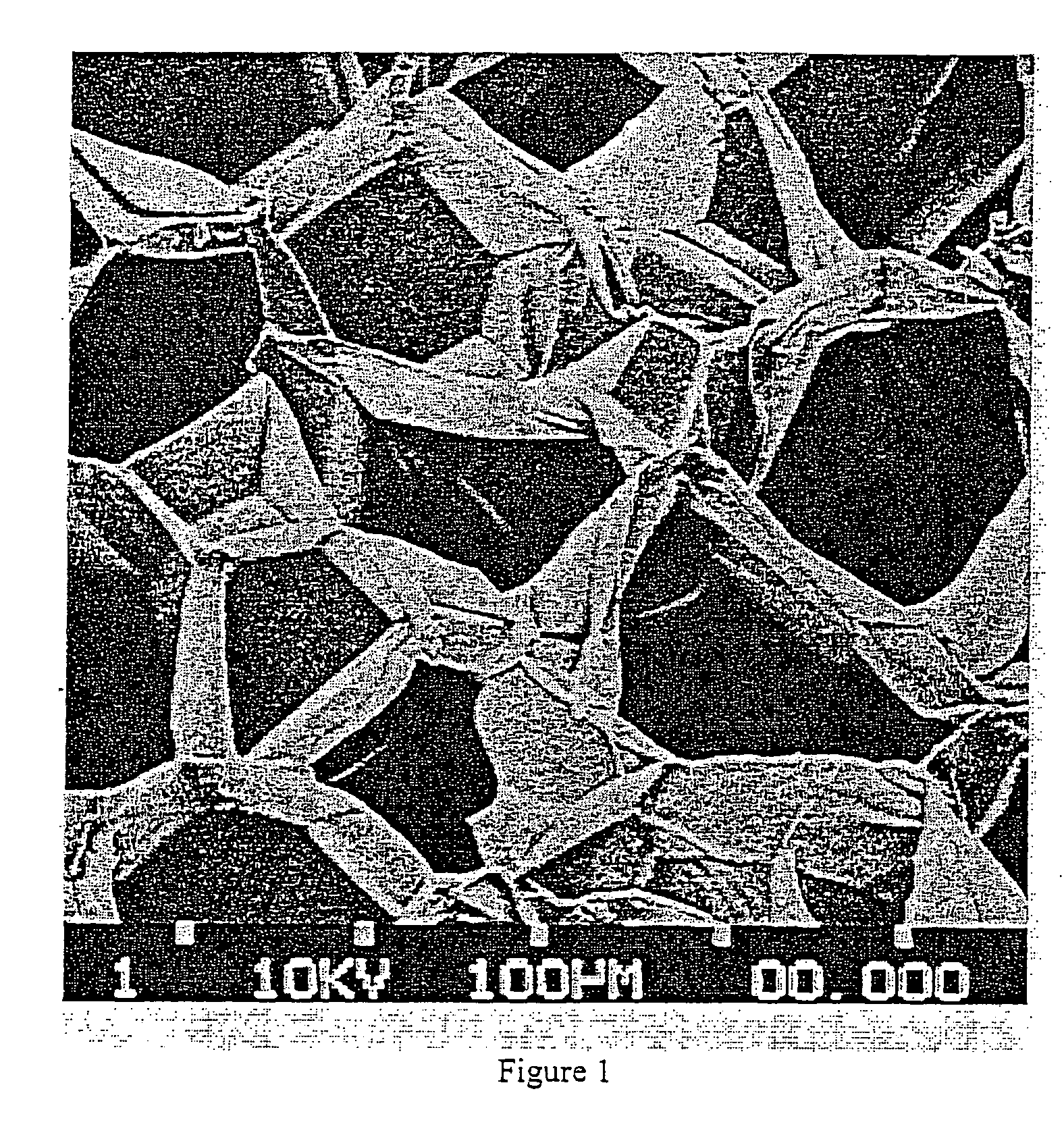

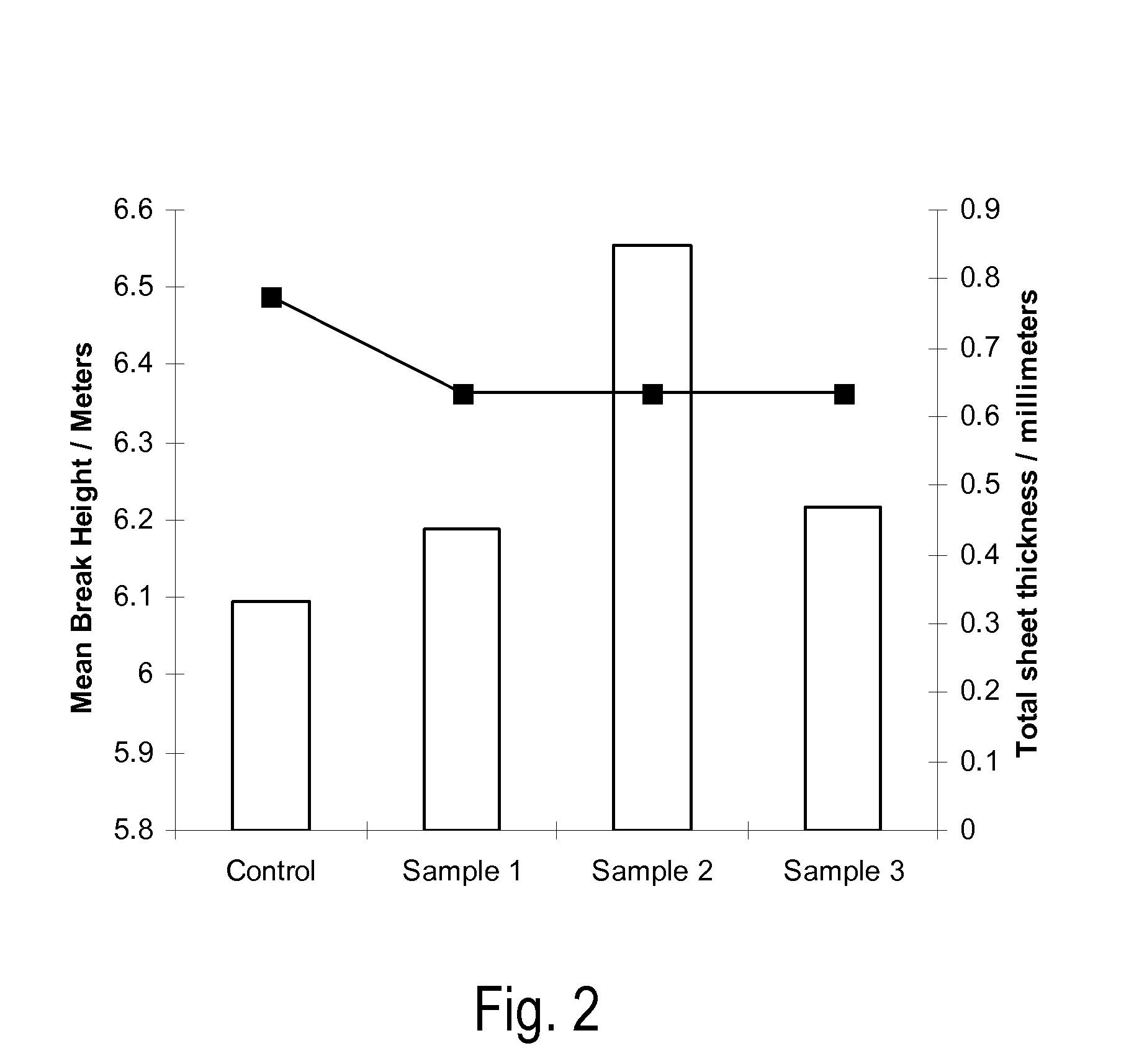

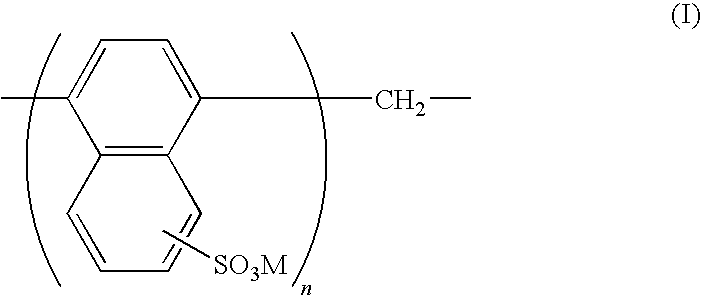

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

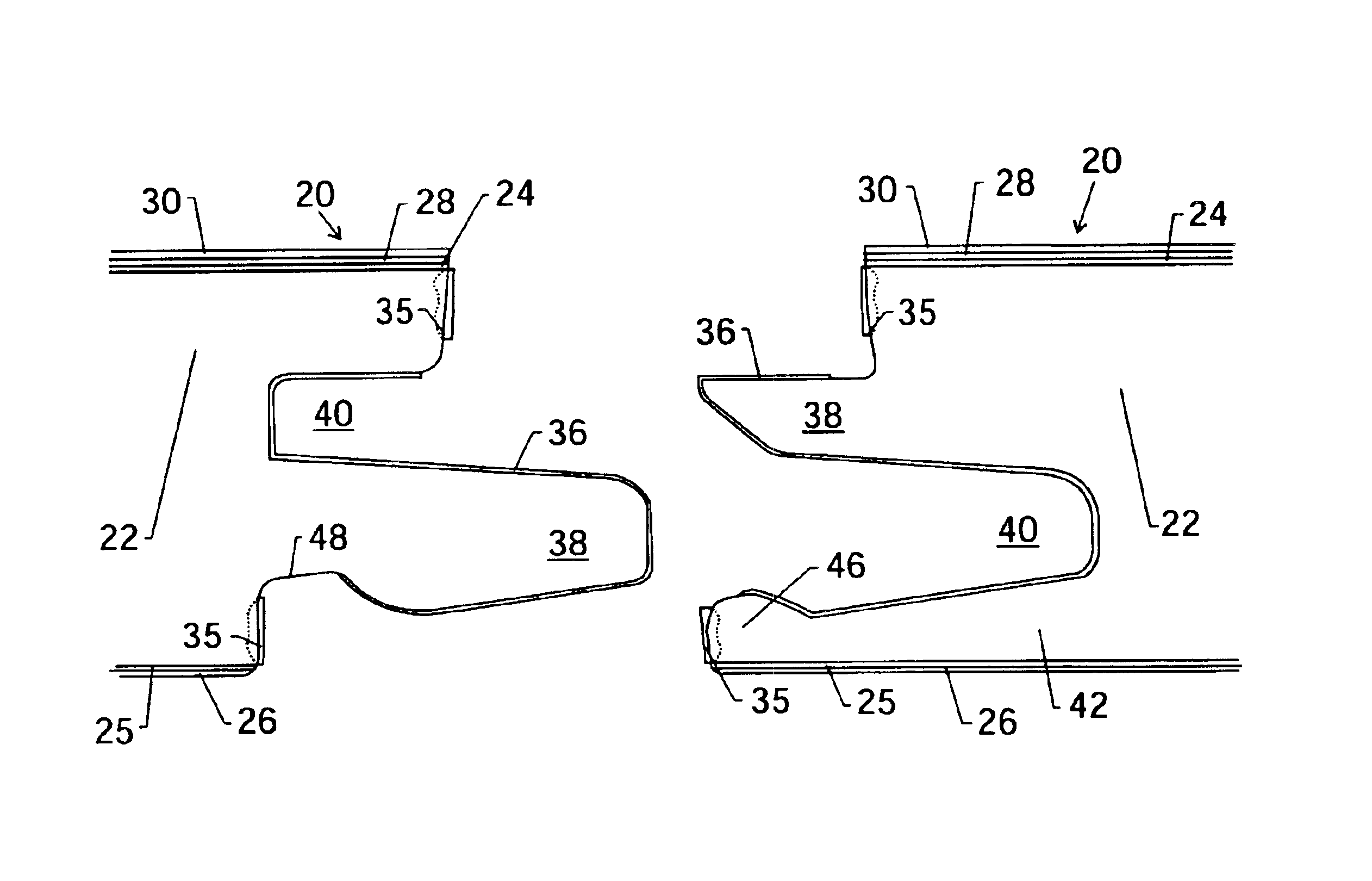

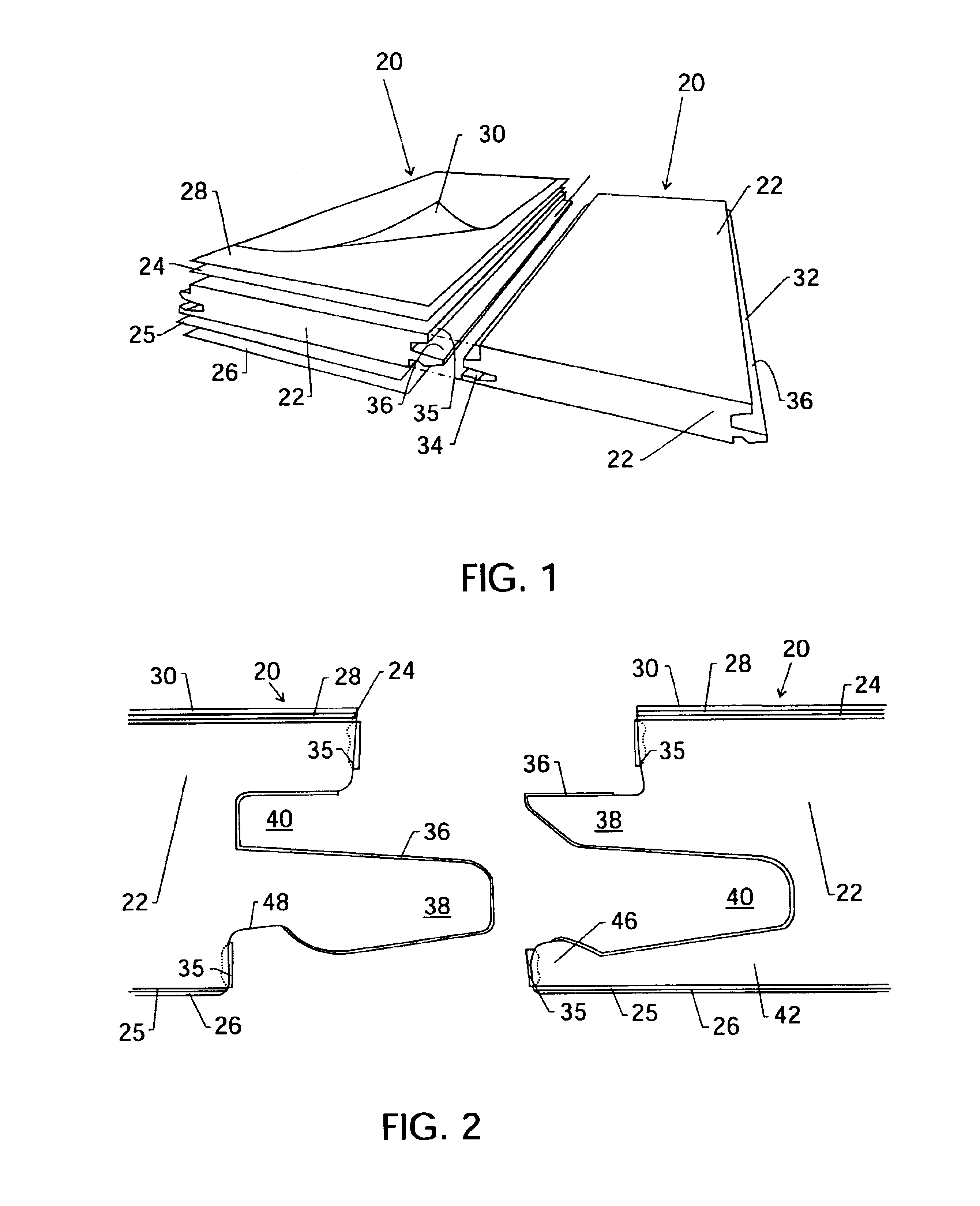

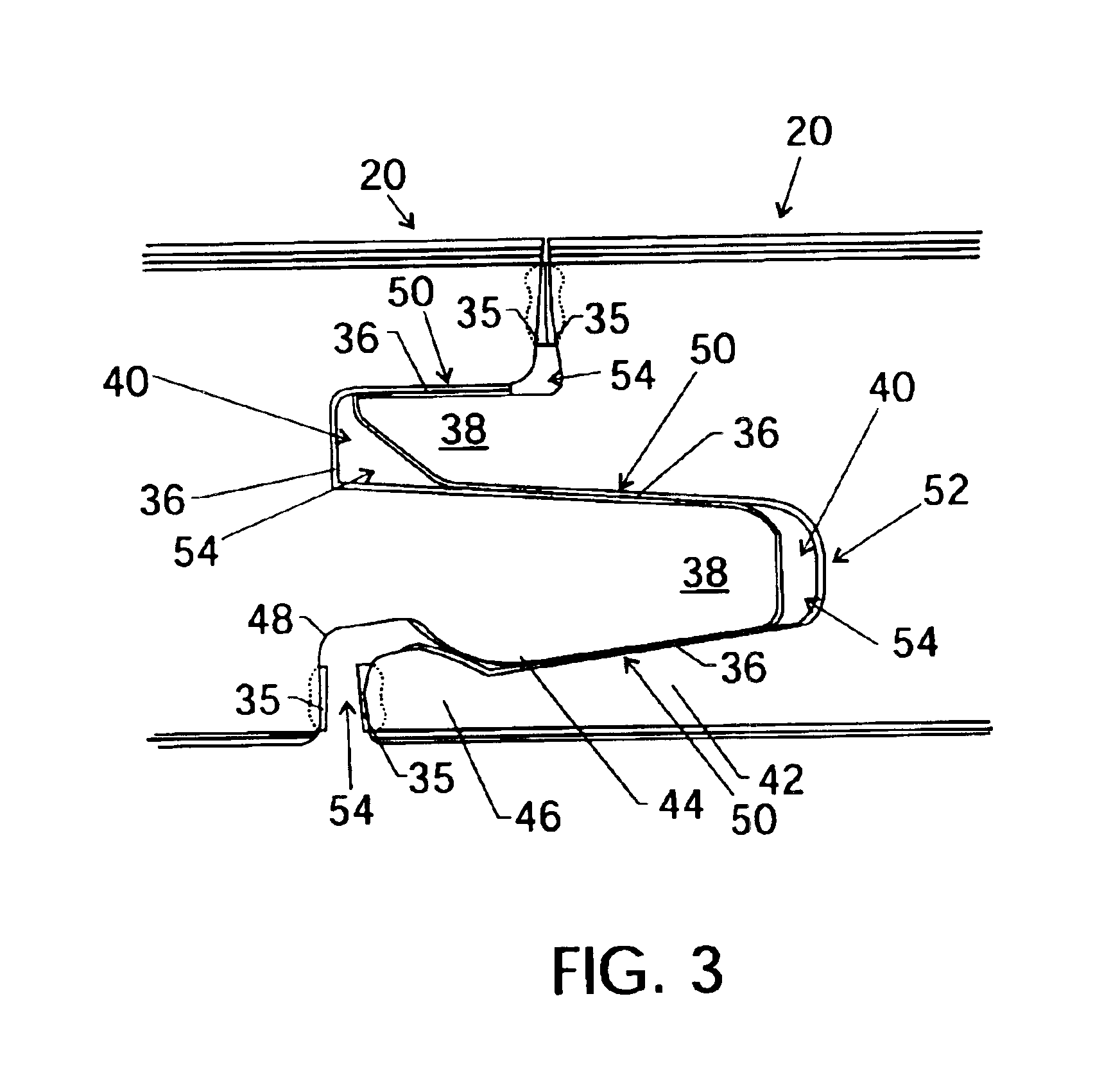

High impact polymer interlayers

InactiveUS20080268270A1Improve the level ofSynthetic resin layered productsConstructions elementsPlasticizerEngineering

The present invention provides multiple poly(vinyl butyral) layer interlayers that can be used in multiple layer glass panel type applications that require a high level of impact protection, for example in hurricane protection applications or in bullet proof glass applications. This effect is achieved by forming a poly(vinyl butyral) interlayer that has a relatively stiff poly(vinyl butyral) inner layer disposed between two relatively soft outer poly(vinyl butyral) layers, where the stiffness difference is achieved by a plasticizer differential that is achieved at least in substantial part by a residual hydroxyl content difference among the poly(vinyl butyral) layers.

Owner:SOLUTIA INC

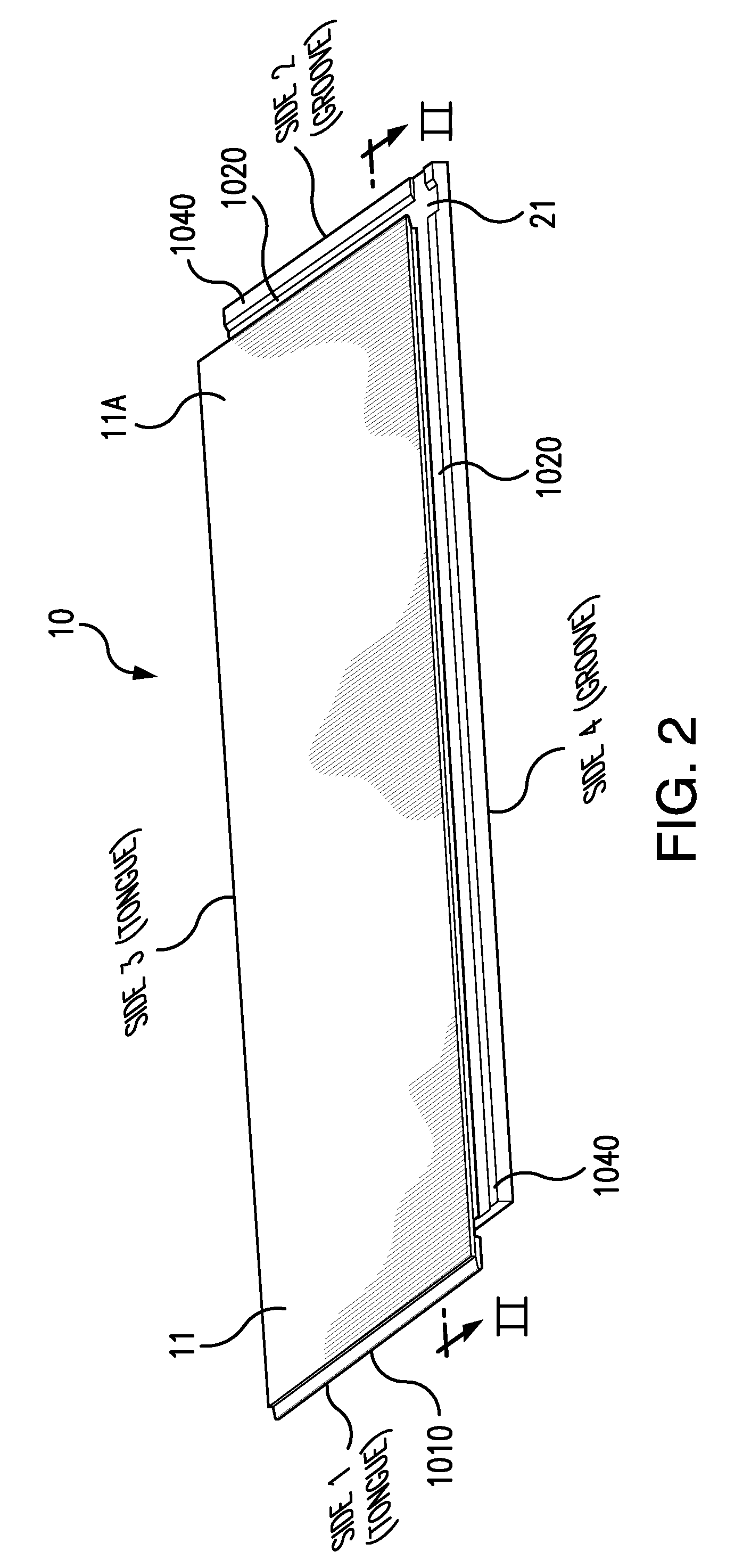

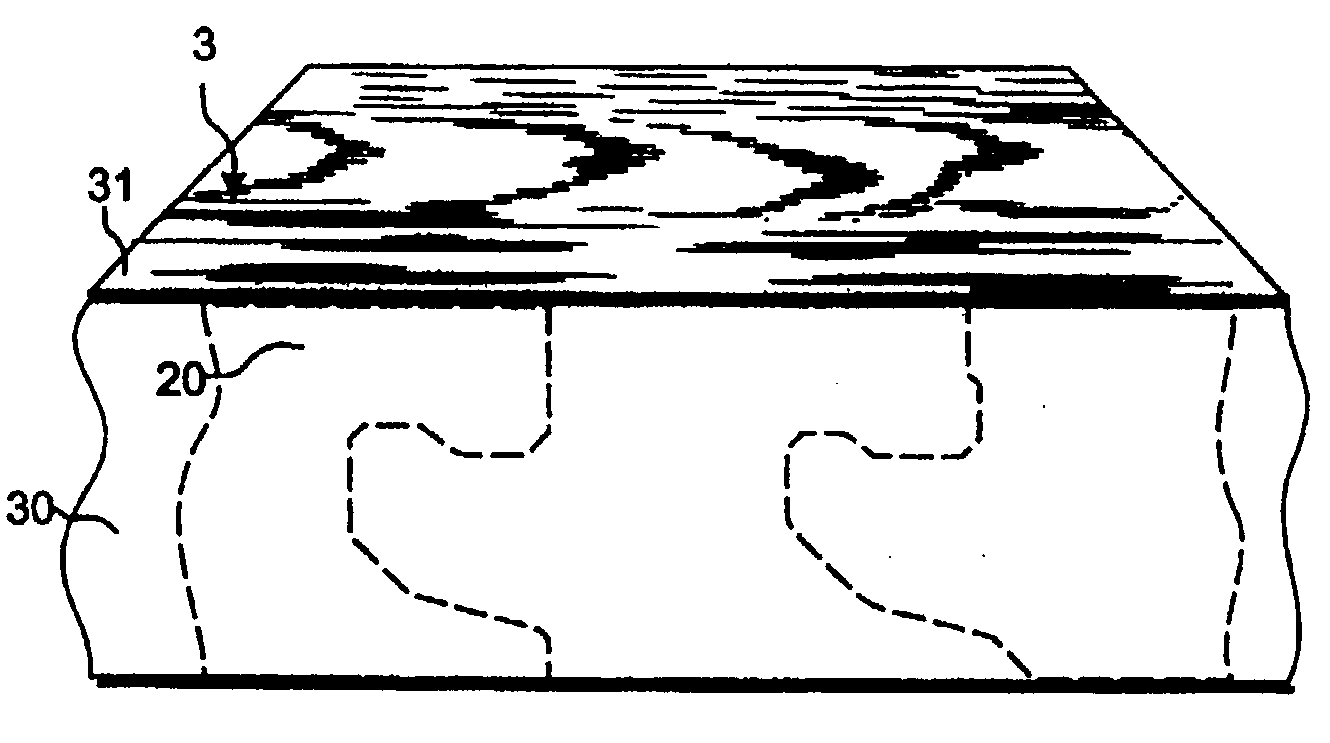

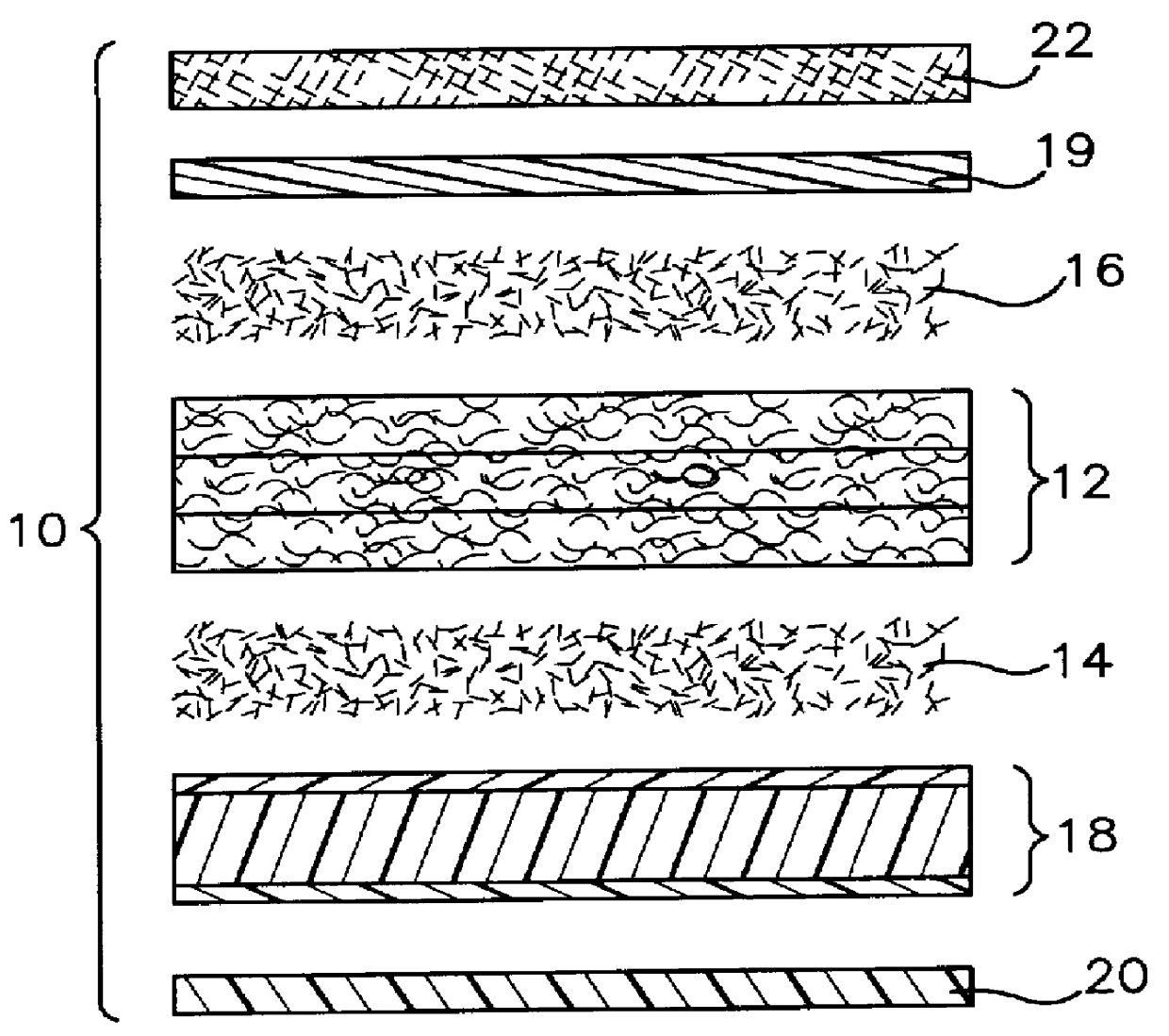

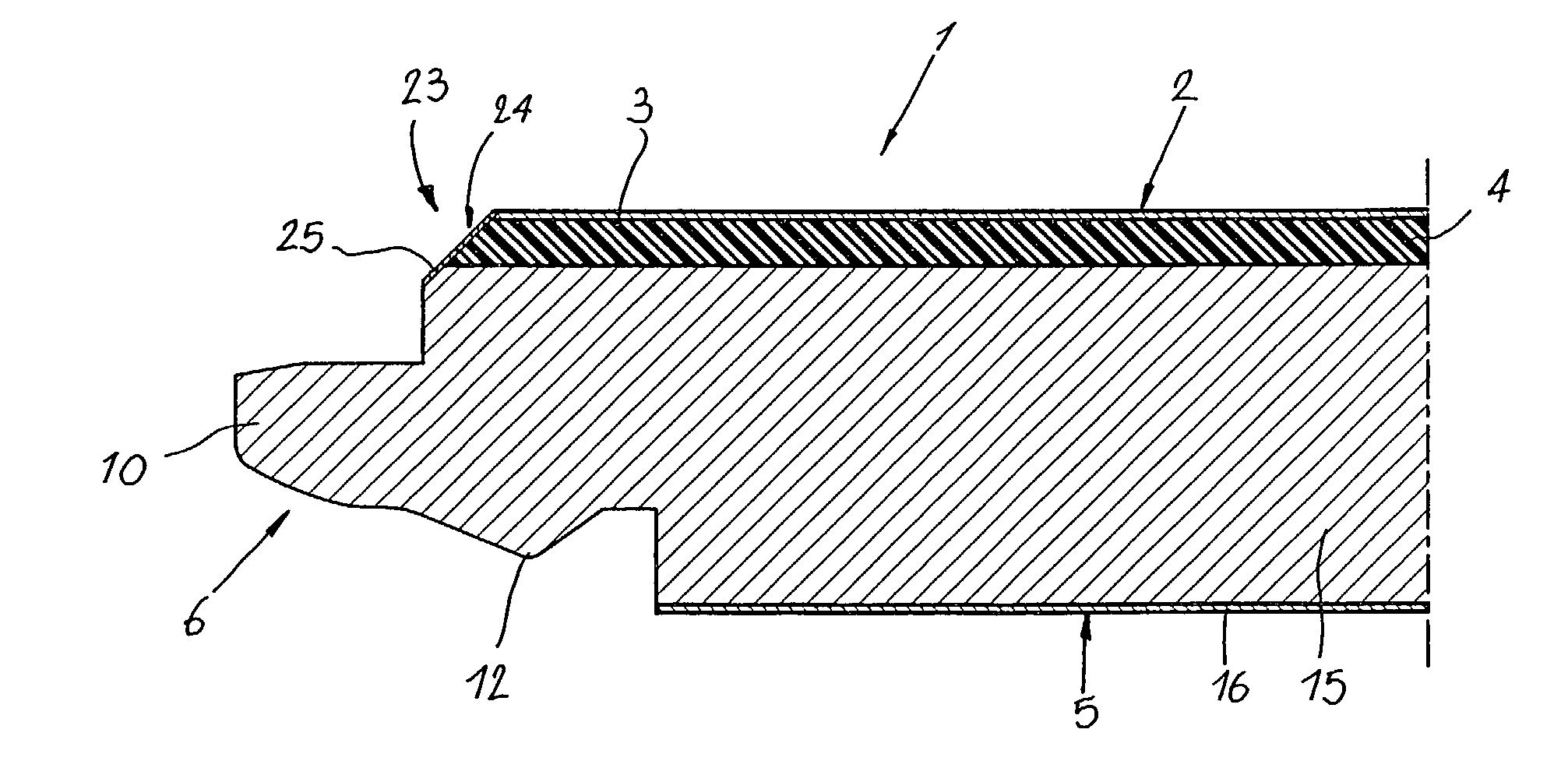

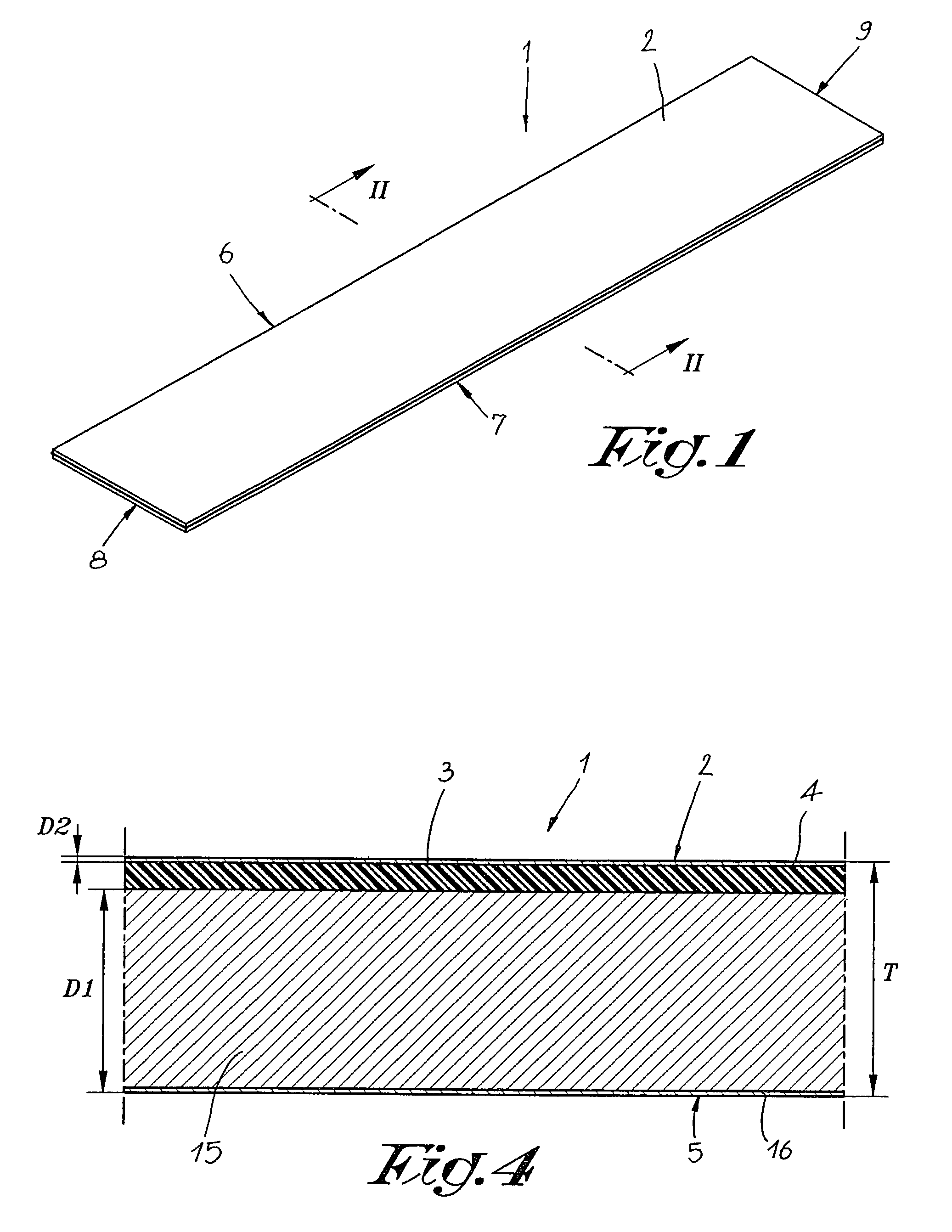

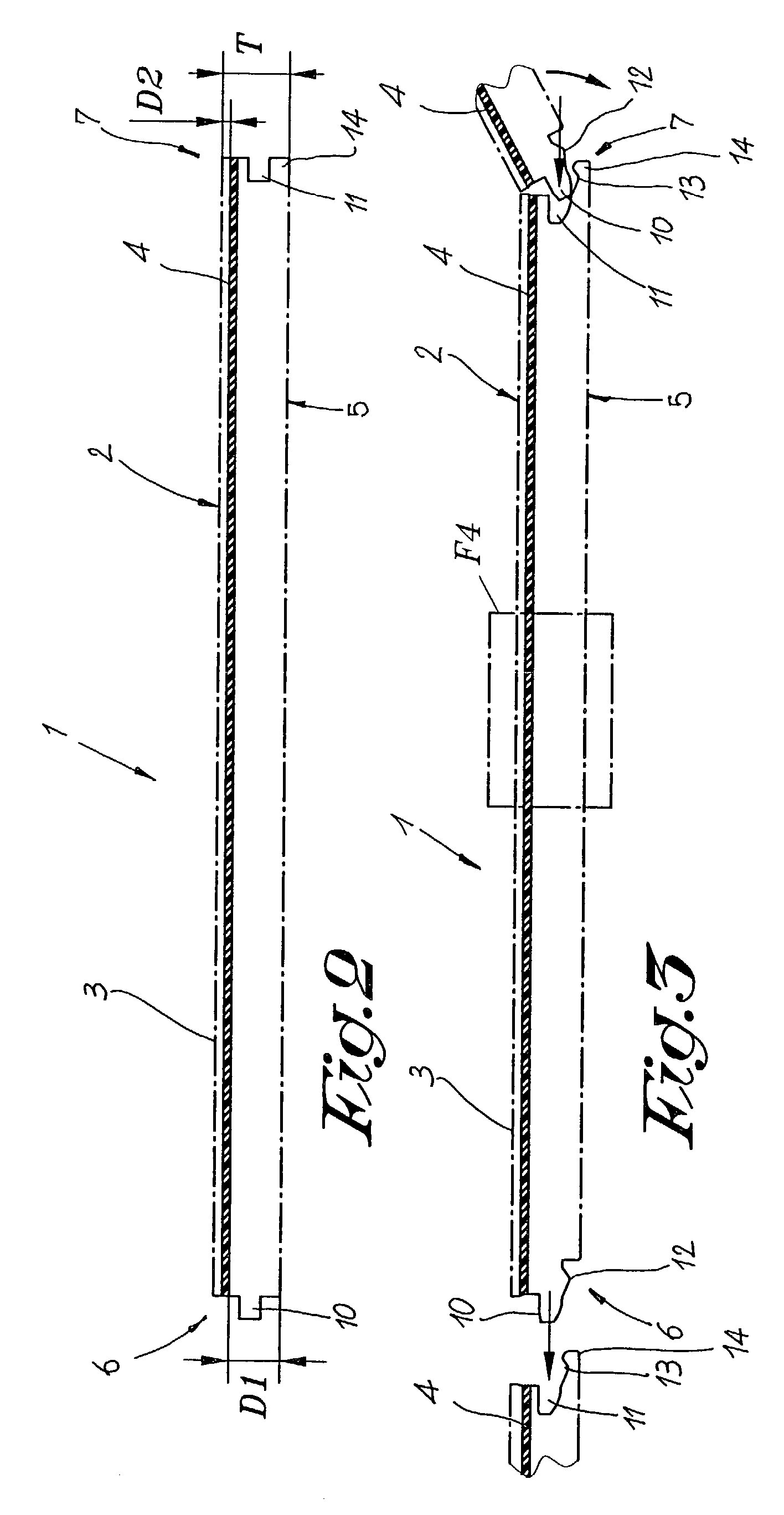

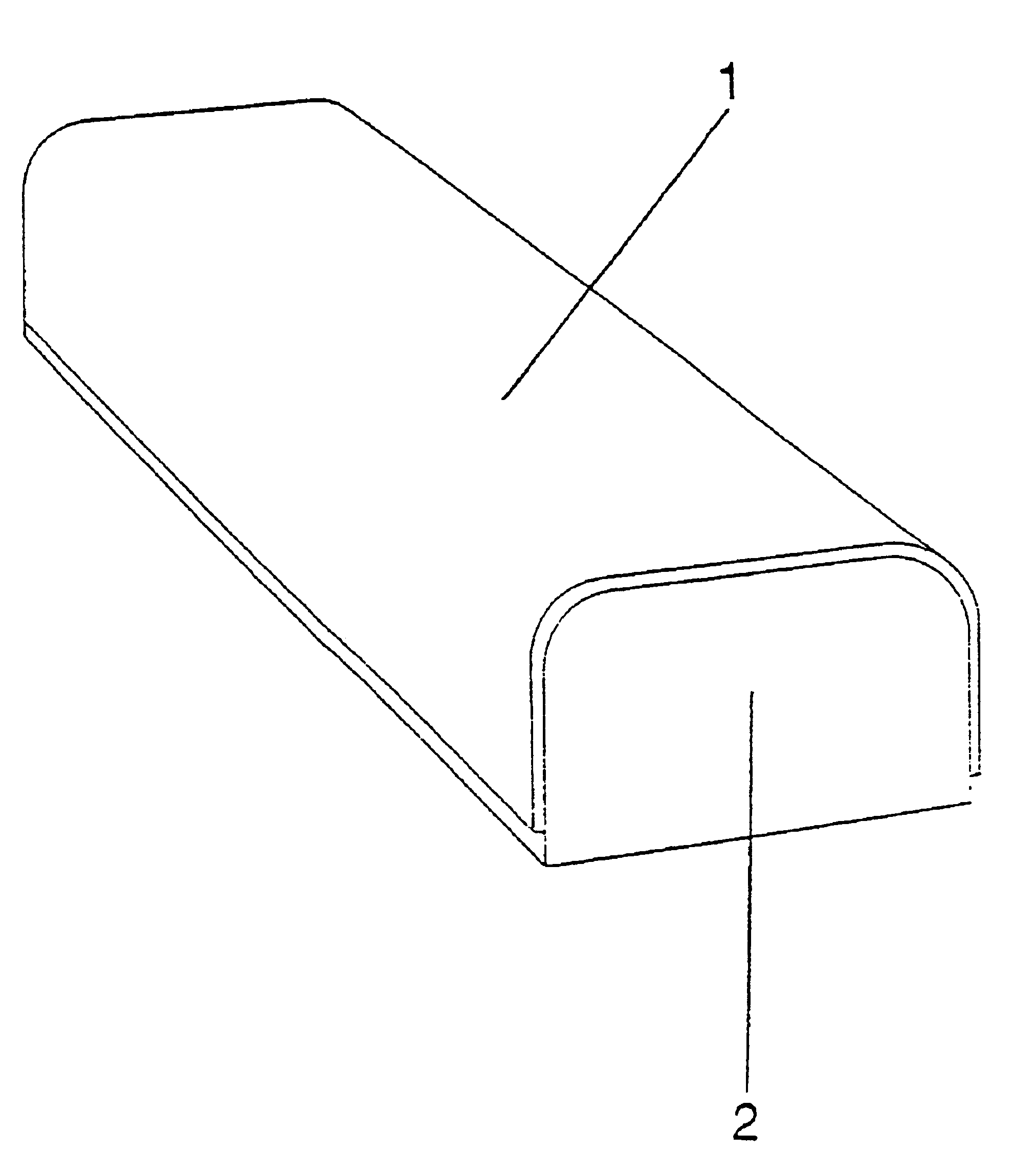

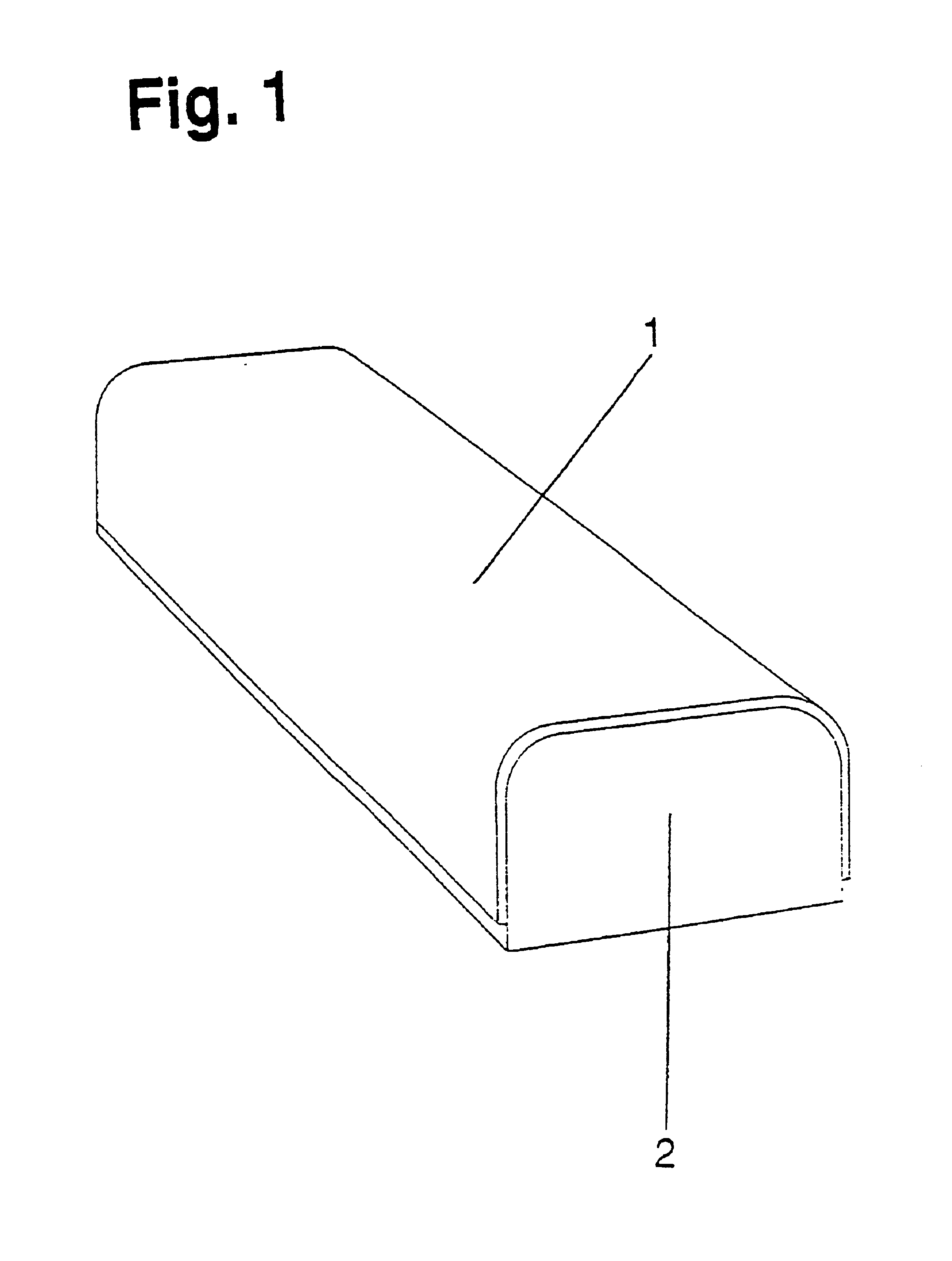

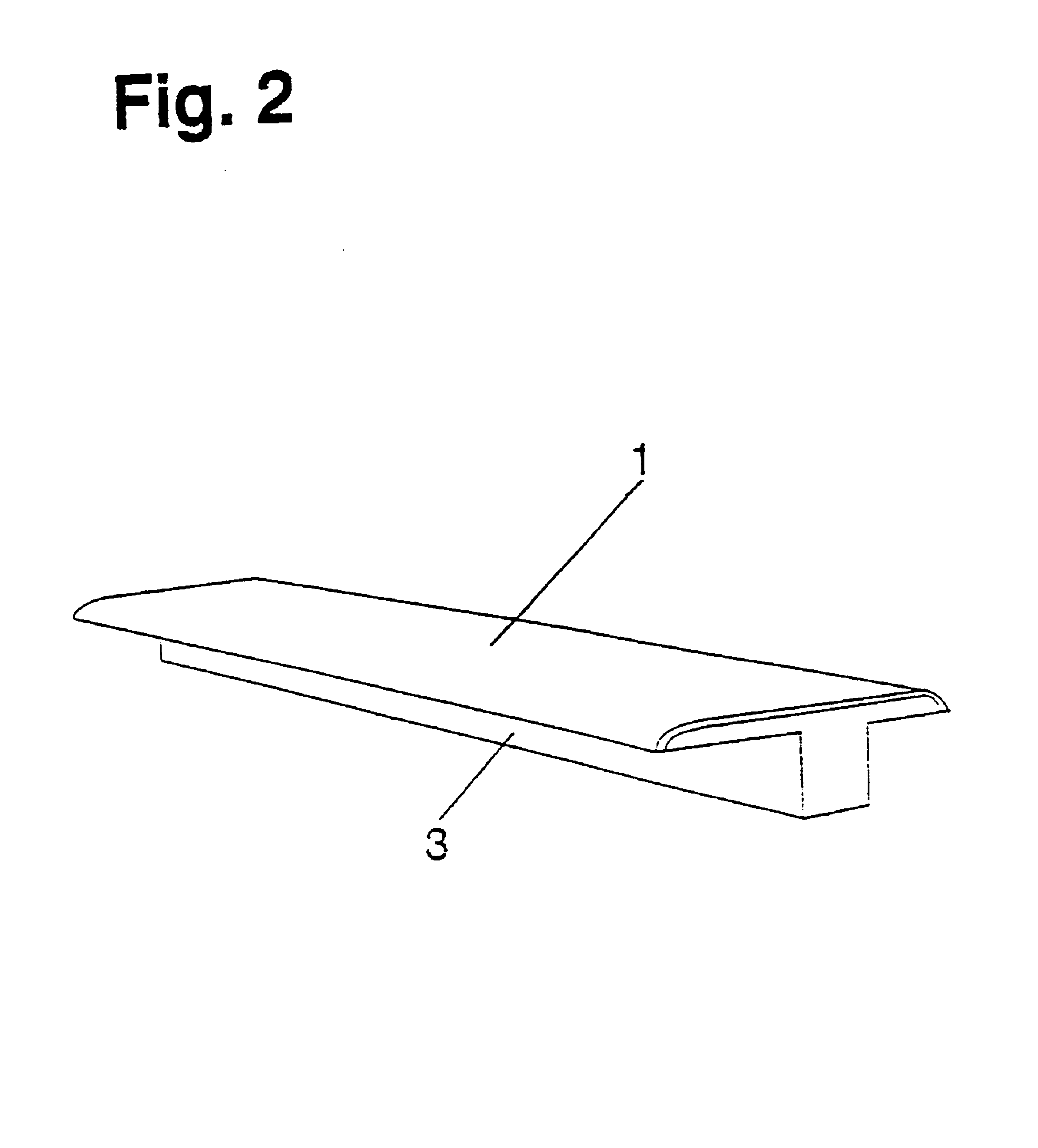

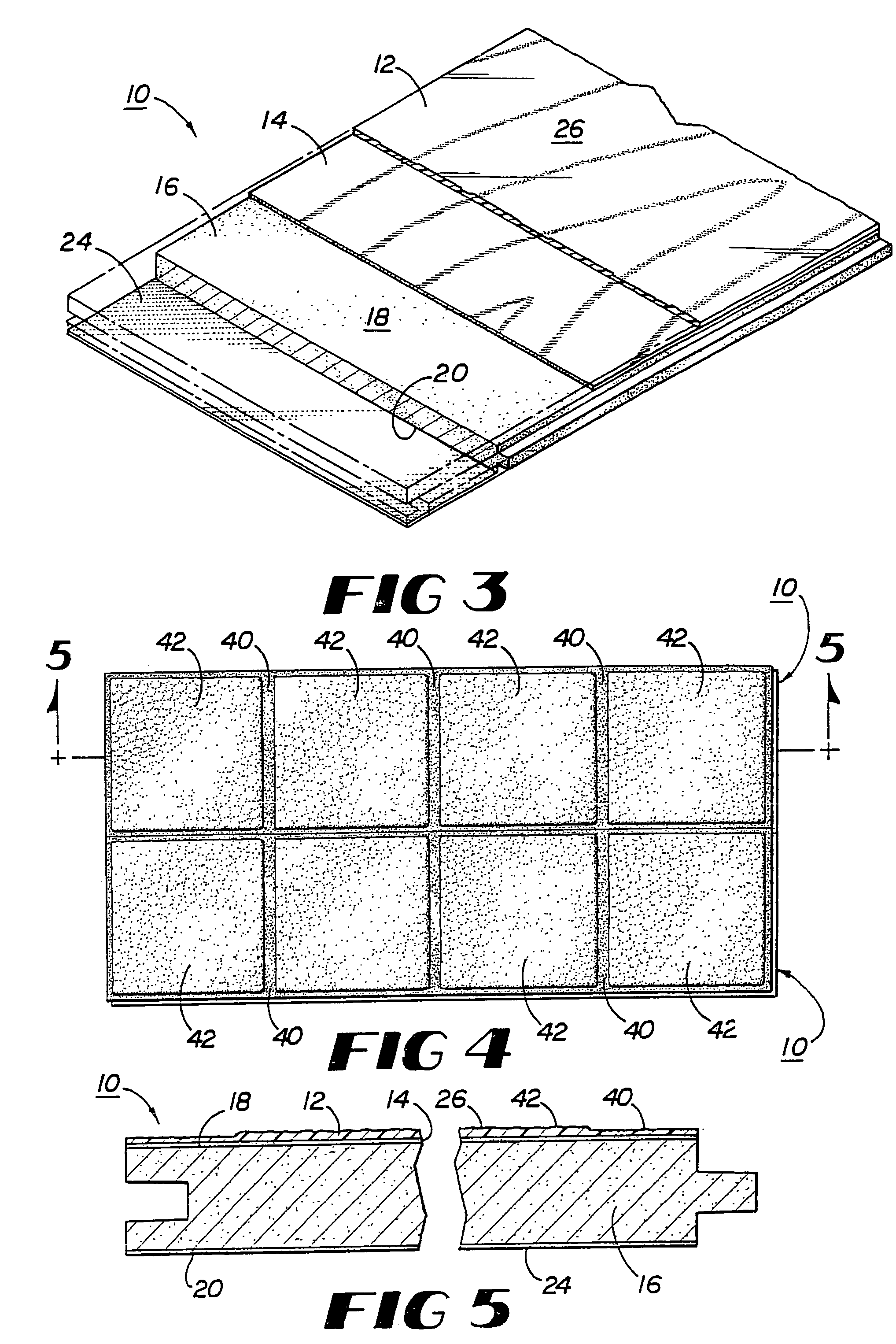

Thermoplastic planks and methods for making the same

InactiveUS7763345B2Improve moisture resistanceEasy flexibilityCovering/liningsDecorative surface effectsThick plateEngineering

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

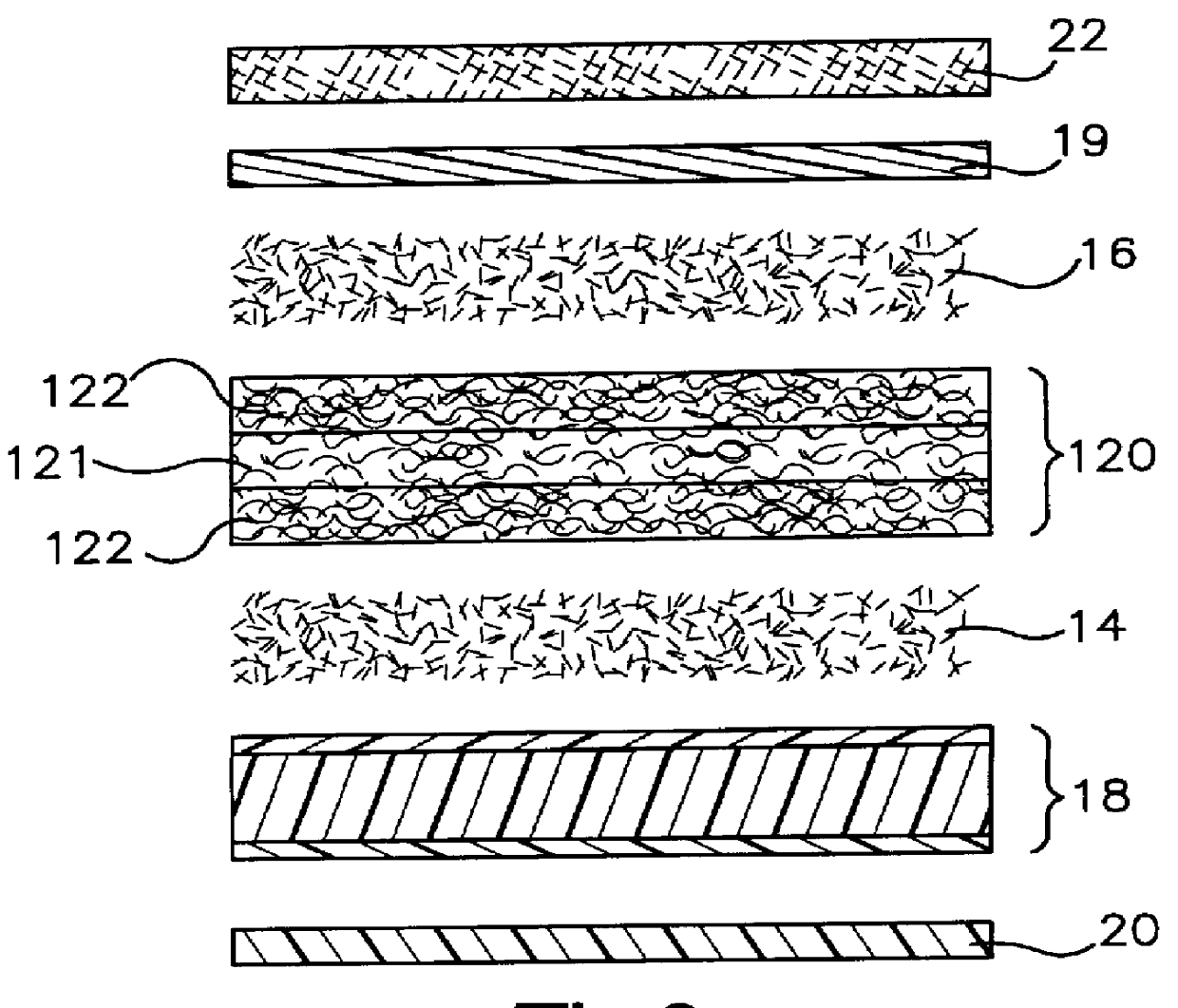

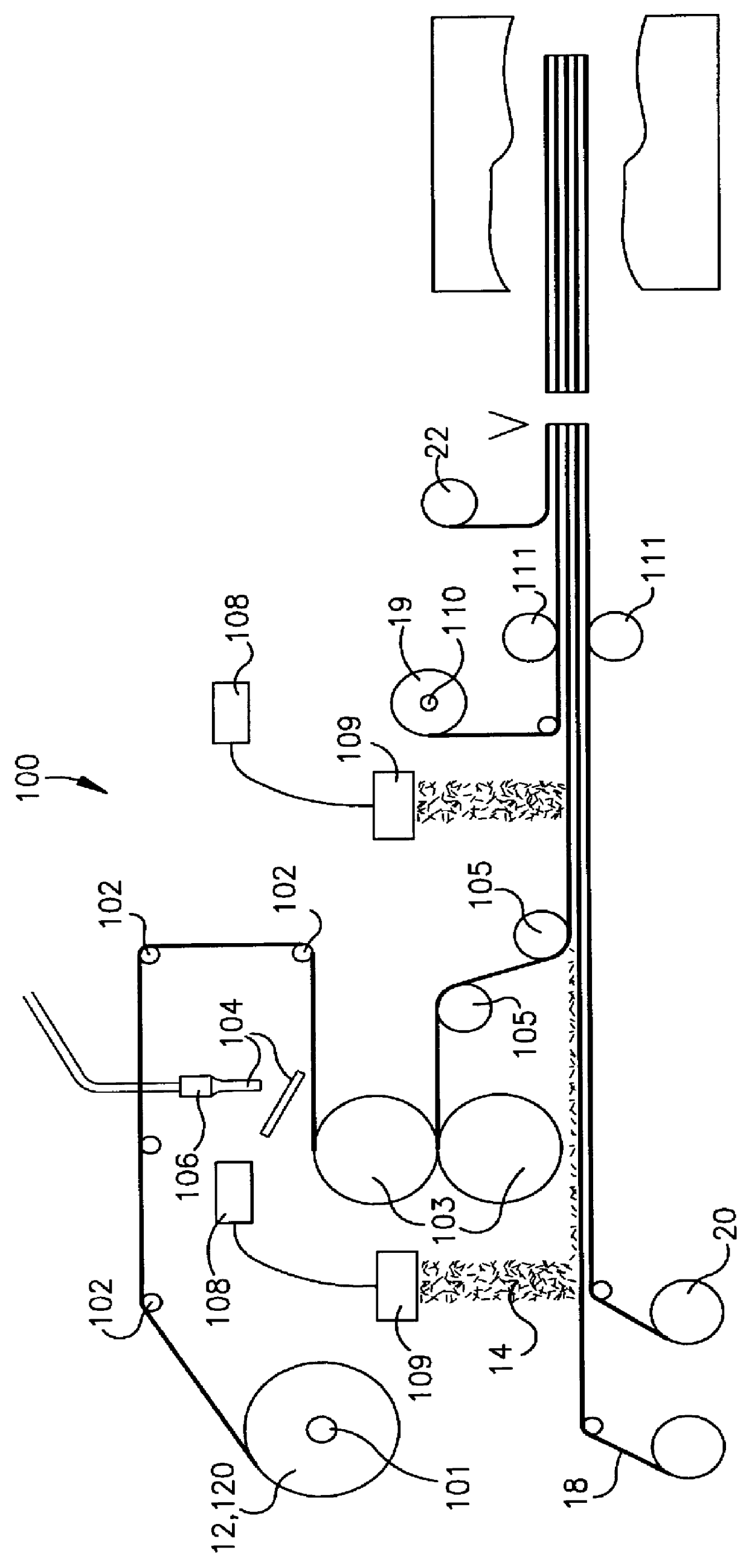

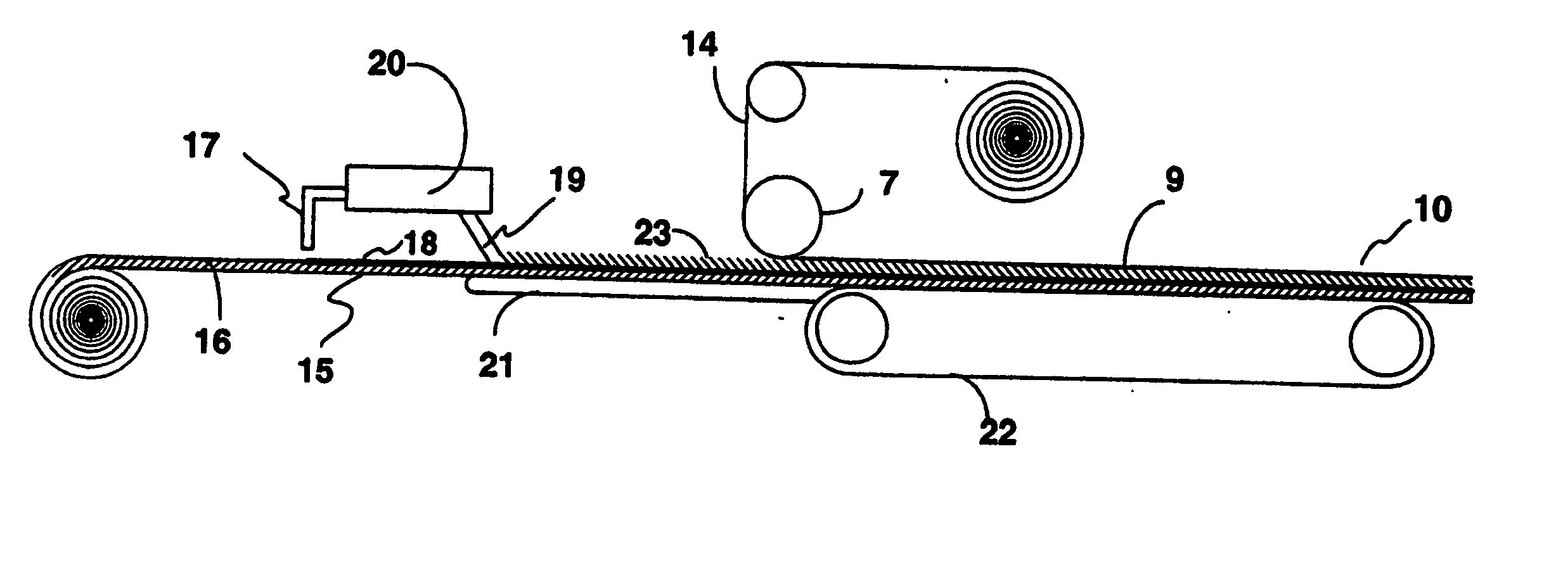

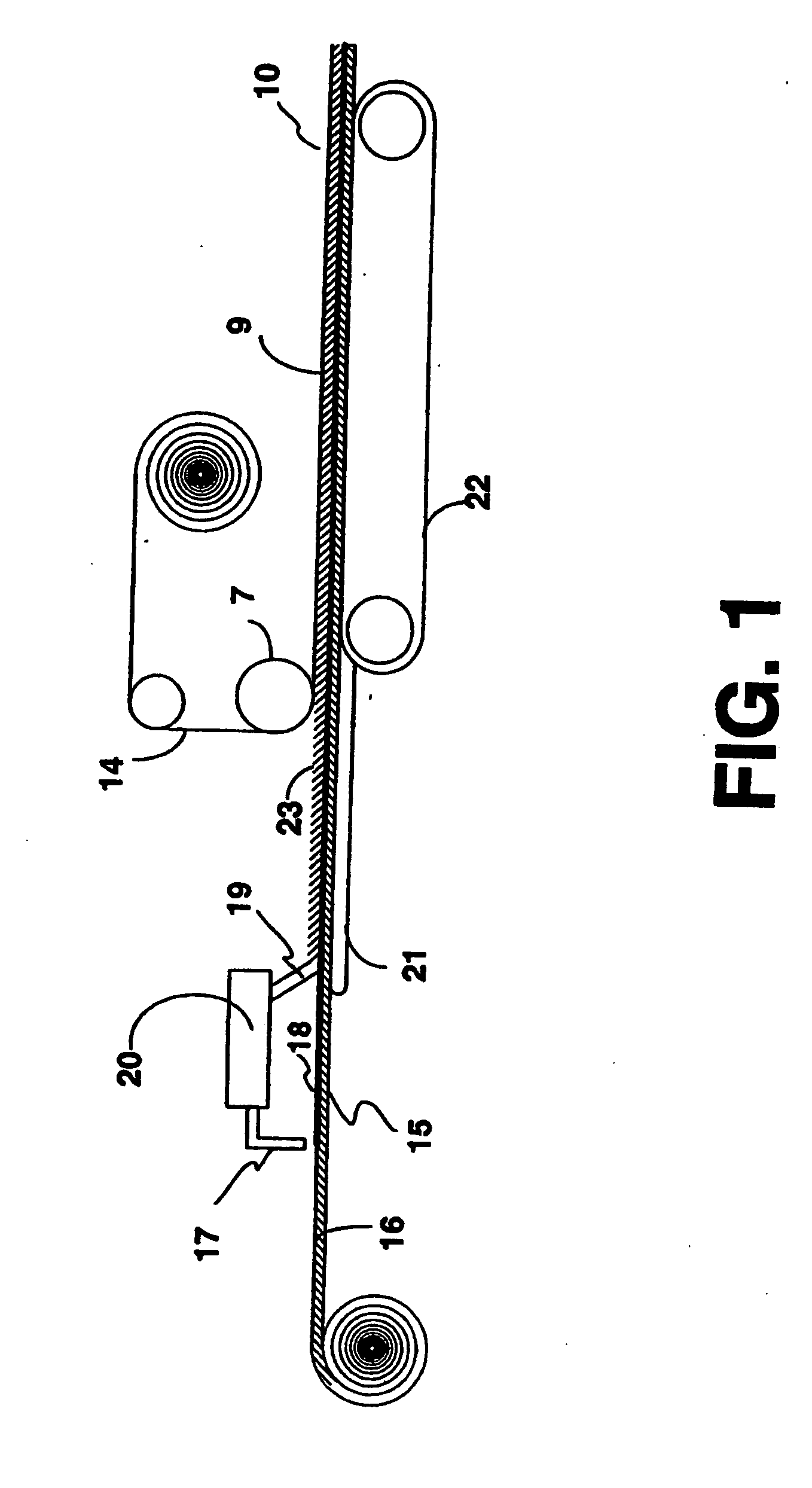

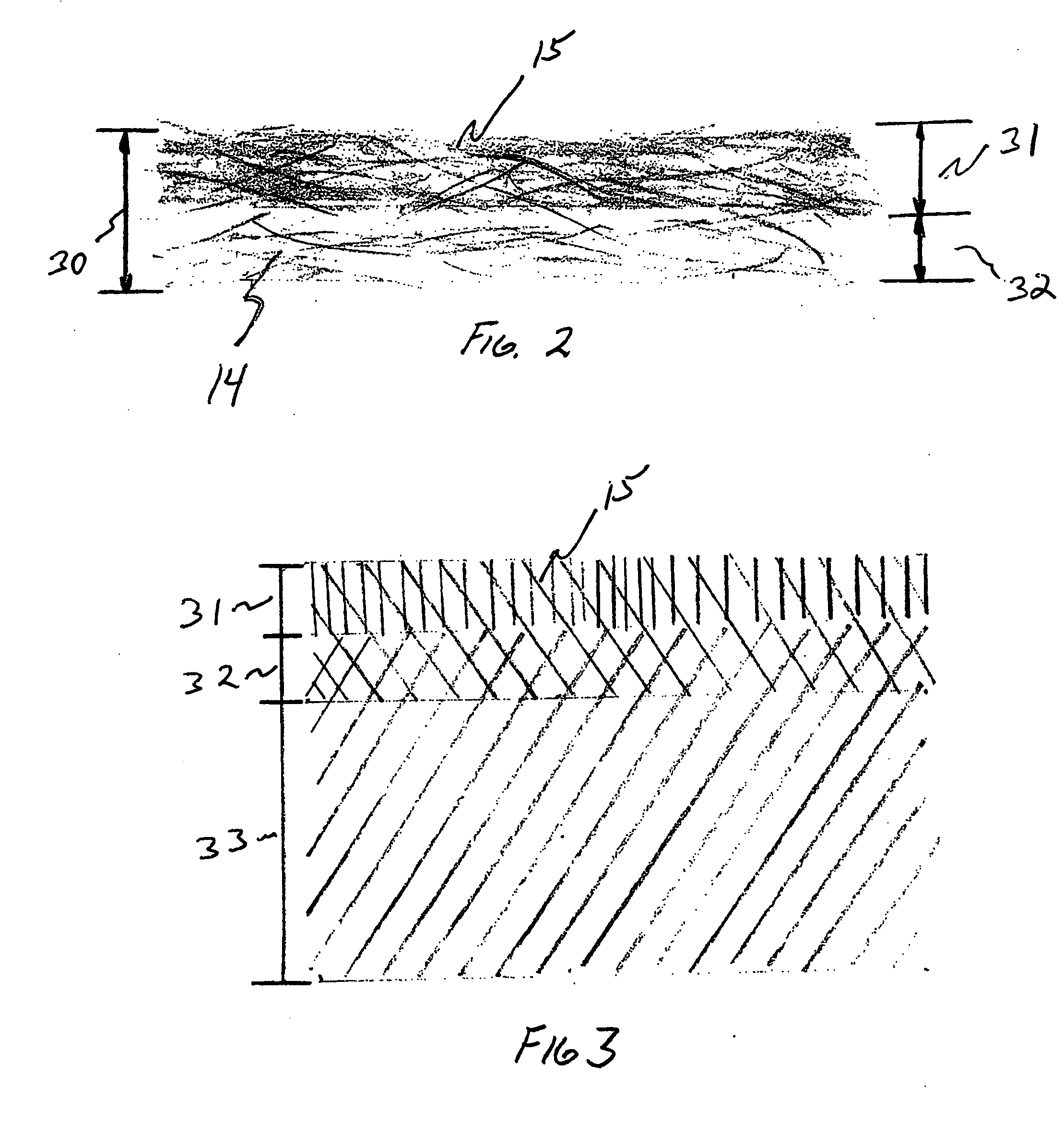

Laminated structures with multiple denier polyester core fibers, randomly oriented reinforcement fibers, and methods of manufacture

InactiveUS6156682AEnhanced sound absorption and structural propertySynthetic resin layered productsLaminationFiberPolyester

A laminated panel-type structure particularly suited for vehicle interior applications such as headliners and door panels has a multiple denier polyester fiber core and randomly oriented structural reinforcing fibers. The laminated structure has superior sound attenuation properties resulting from a core of intertwined polyester fibers of differing deniers, with preferably relatively larger denier fibers on exterior areas of the core and some bicomponent fibers, short non-woven reinforcing fiber strands which are randomly attached and intertwined with the core on opposing major sides of the core, an impervious polymer film with a low melt layer which retains the reinforcing fibers against one side of the core and is attached to a scrim layer, and a polymer web on an opposite side of the core which retains the reinforcing fiber strands on the opposing major side of the core and to which a cover stock is applied. The invention further includes a method of manufacturing the laminated structure wherein the various layers are sequentially unfurled from spools, passed through nip rollers at points of various subcombinations of materials and layers, the reinforcing fiber strands are randomly distributed on to the carrying layers from hoppers or directly from a fiber chopping device, and the completed laminated structure is cut and molded.

Owner:SK AUTOMOTIVE S DE R L DE

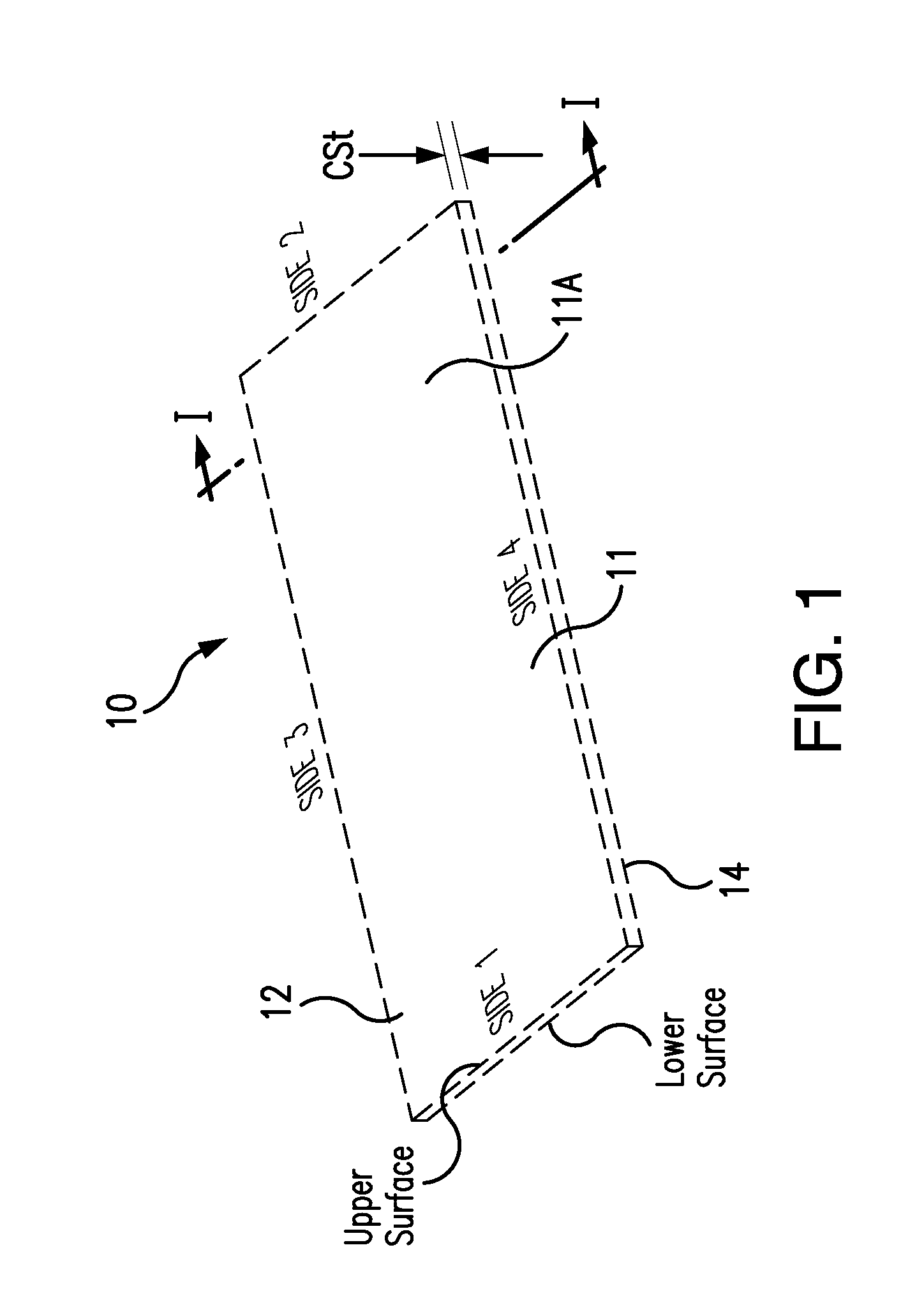

Floor panel and method for the manufacture thereof

ActiveUS8196366B2Global structure of such floor panel still can be kept relatively thick and stableReduce thicknessCovering/liningsWallsFloor covering

Owner:FLOORING IND LTD

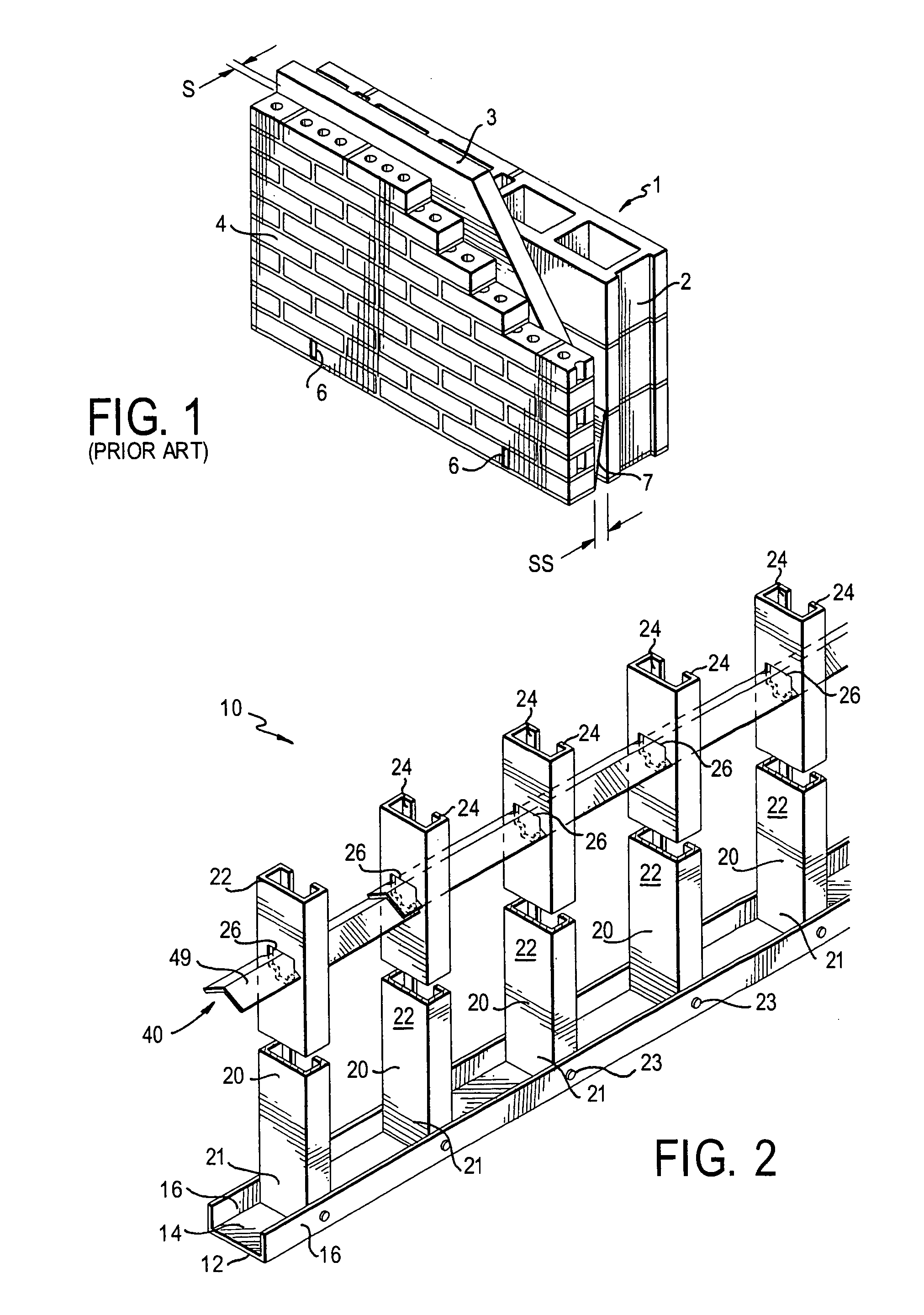

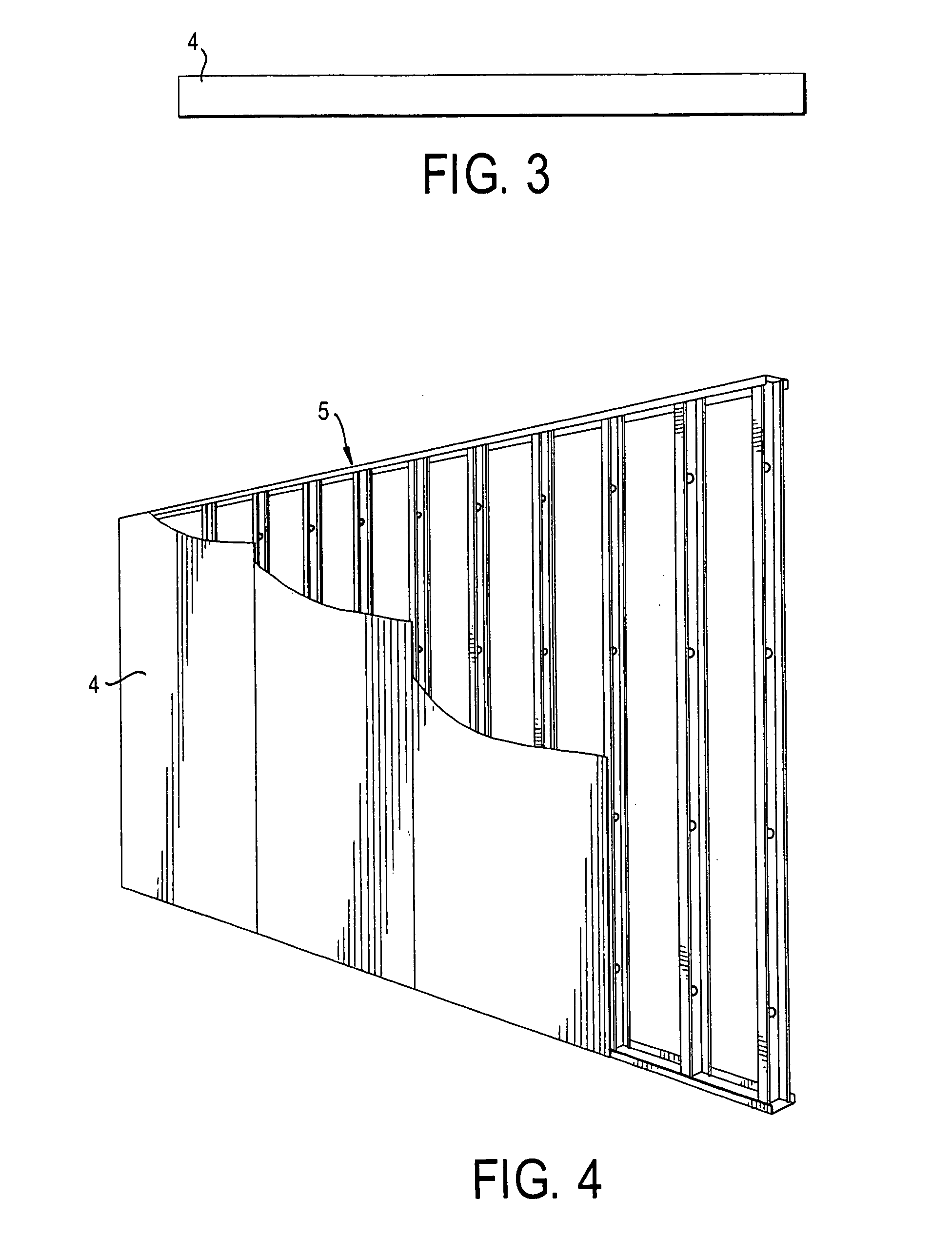

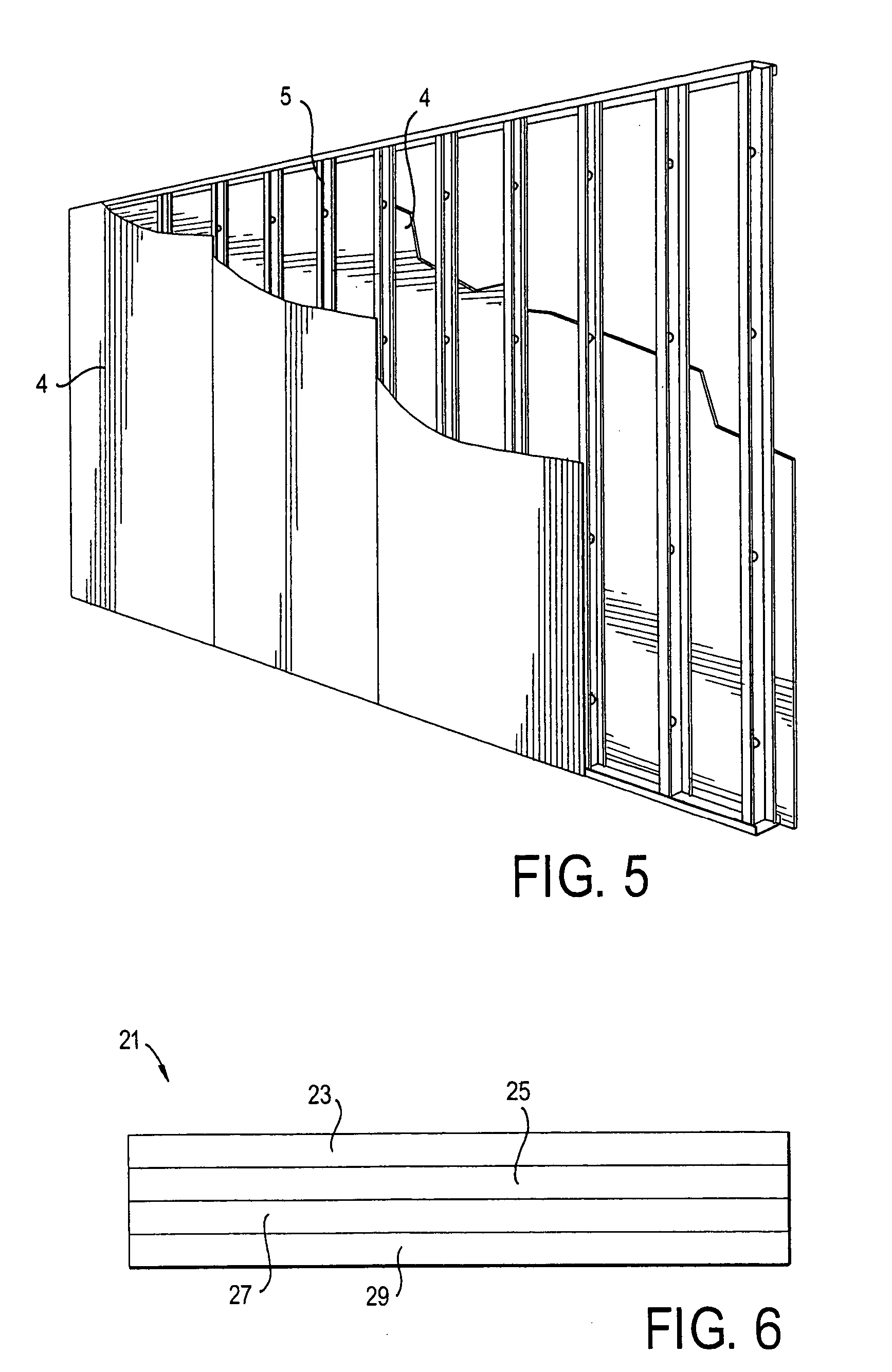

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Panel and methods for manufacturing panels

InactiveUS20130062006A1Realized more smoothly and/or economicallyAcceptable soundCovering/liningsDecorative surface effectsSynthetic materialsEngineering

Owner:FLOORING IND LTD

Multilayer Films Or Plasticizer-Containing Polyvinyl Acetal With Sound-Absorbing Properties

ActiveUS20100028642A1Improve sound absorptionLow costSynthetic resin layered productsConstructions elementsPolyvinyl acetatePolyvinyl alcohol

An interlayer film for laminated glass with sound-absorbing properties contains at least two individual films, wherein the first individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of 0.1 to 11 mol % and a second individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of between 5 and 8 mol %.

Owner:KURARAY EURO GMBH

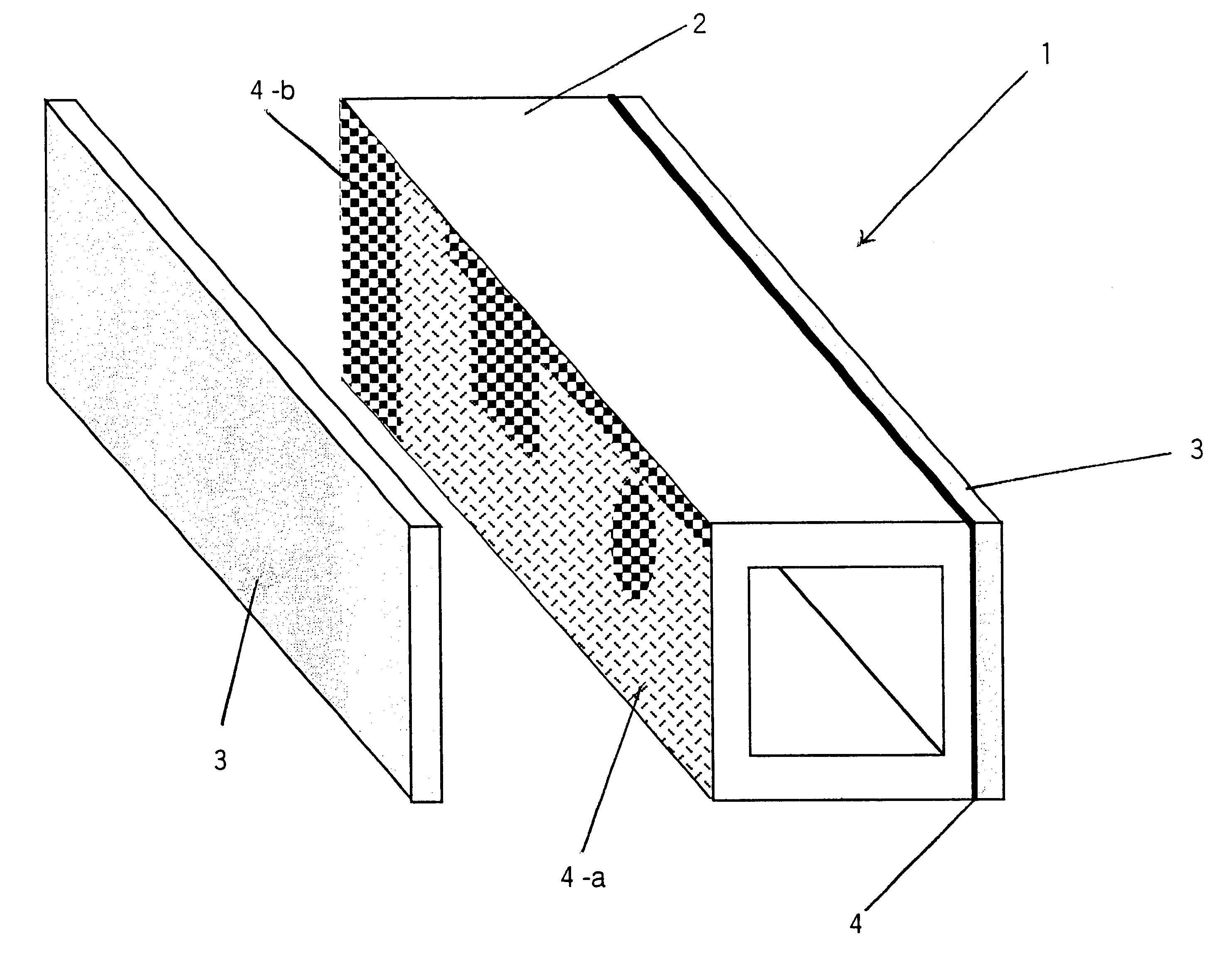

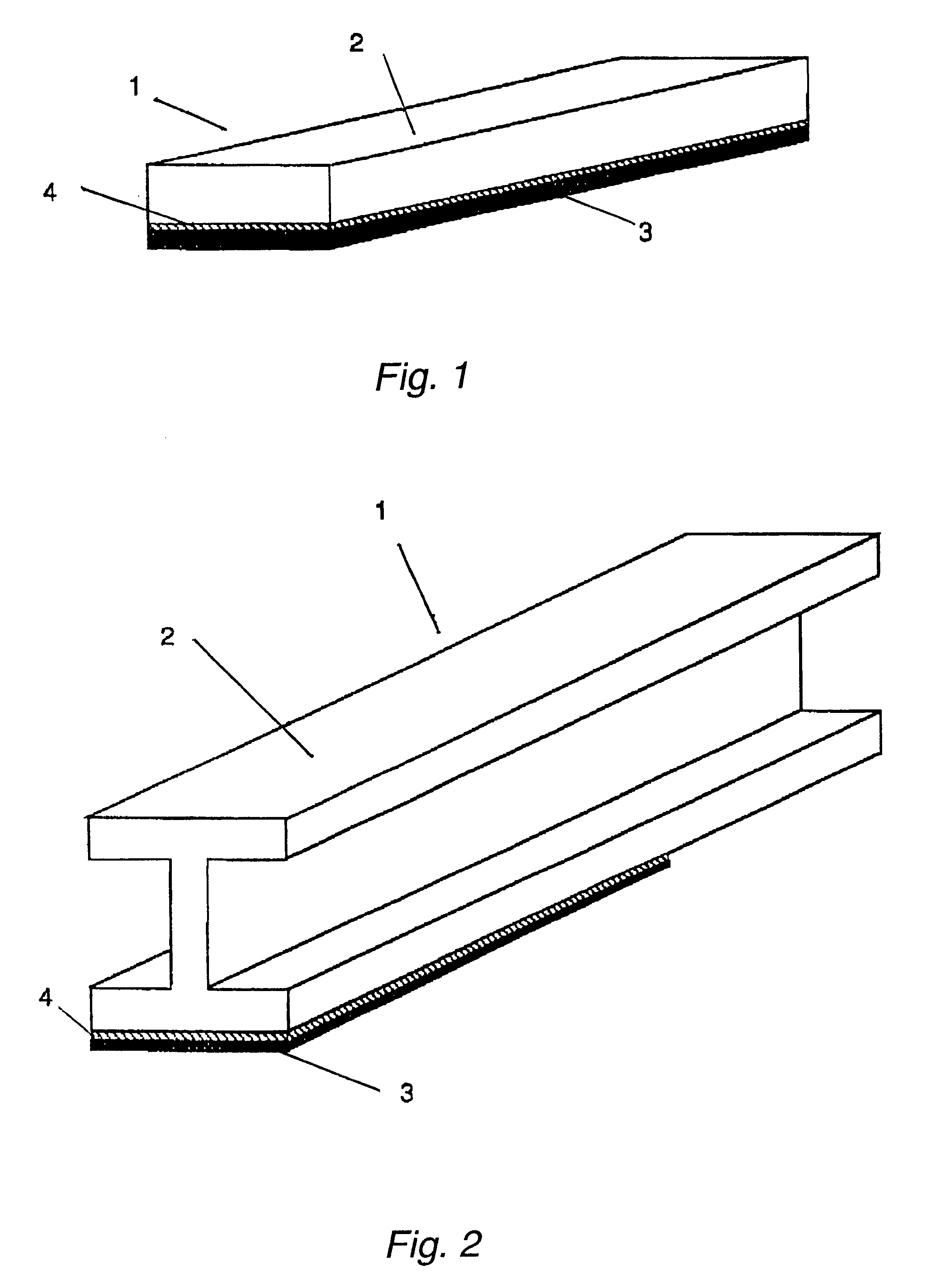

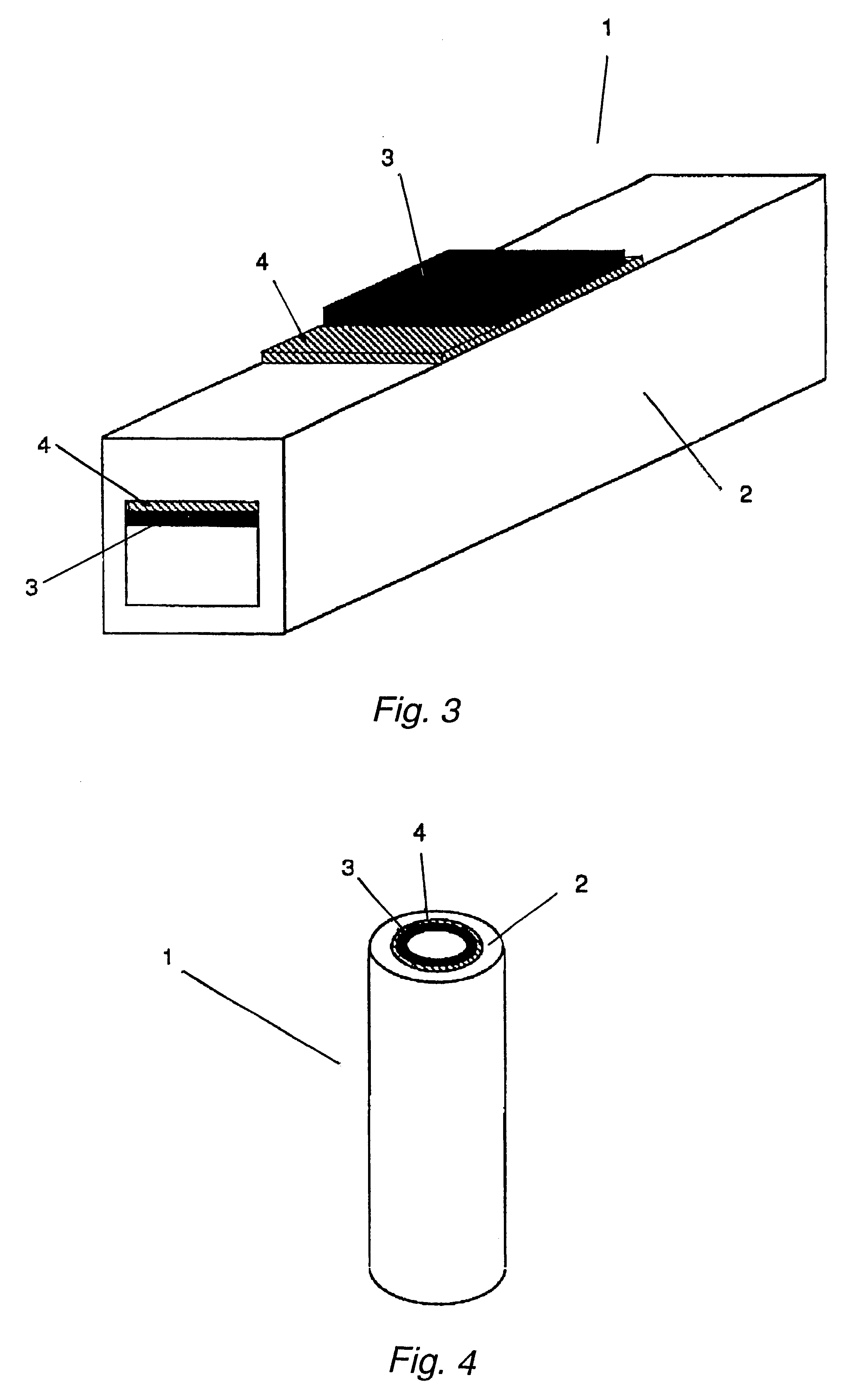

Light metal/CFRP structural member

InactiveUS6468613B1Prevent galvanic corrosionHigh structural reliabilitySynthetic resin layered productsCeramic shaping apparatusMetallic materialsRoom temperature

Light metal / CFRP-made structural members which are characterized in that they are structural materials in which a CFRP material is stuck to the surface of a light metal material via an adhesive agent layer of thickness at least 10 mum and up to 500 mum, and the volume resistivity of the adhesive agent layer between said metal material and said CFRP material is at least 1x1013 OMEGA.cm and, furthermore, the adhesive strength at room temperature is at least 15 MPa. In accordance with the present invention, since conventional light metal / CFRP structural materials can be made lighter and, furthermore, since the resistance to galvanic corrosion is outstanding and it is possible to markedly enhance the strength and the impact energy absorption performance, the development of applications and large-scale expansion into new fields becomes possible. Weight reduction and enhancing the durability and reliability of structures also makes a considerable contribution in terms of environmental protection.

Owner:TORAY IND INC

Use of pre-coated mat for preparing gypsum board

A gypsum board which comprises a set gypsum core sandwiched between and faced with fibrous mats, wherein a free surface of one of said mats is pre-coated with a combination of a mineral pigment, optionally an inorganic adhesive binder and an organic binder, preferably a hydrophobic, UV resistant polymer latex adhesive binder applied to said surface as an aqueous coating composition, said aqueous coating composition upon drying and setting providing a pre-coated mat satisfying certain morphology requirements.

Owner:GEORGIA PACIFIC GYPSUM LLC

Floor strip

InactiveUS6898911B2Increase resistanceSmooth transitionWood working apparatusPaper/cardboardReducerEngineering

Owner:PERGO

Floorboards with decorative grooves

ActiveUS20060048474A1Rational and cost-efficientEasy to cleanTongue/grooves making apparatusWallsSurface layerEngineering

Floorboards are shown, which consist of a core and a surface layer and are provided with decorative joint edges which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

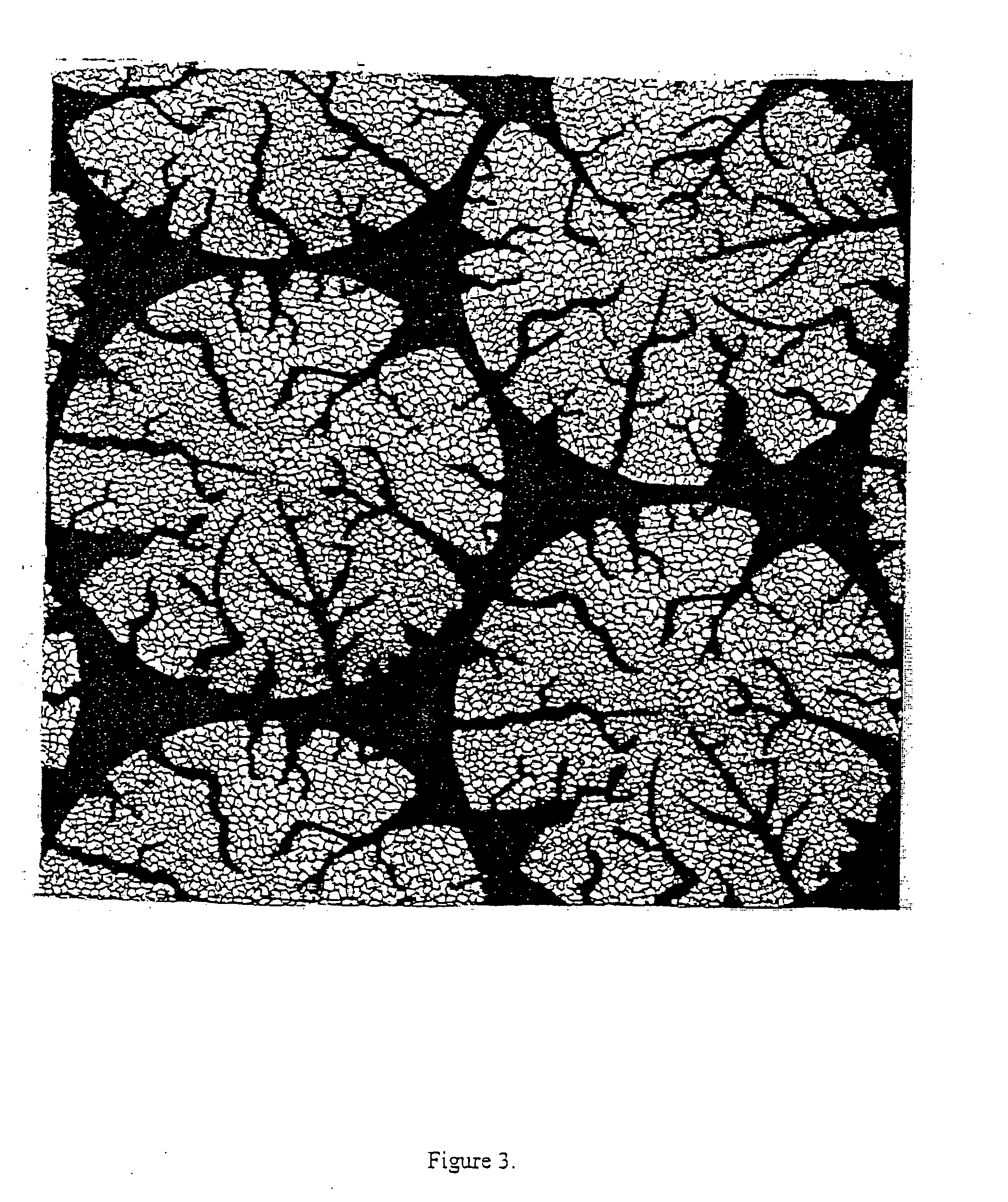

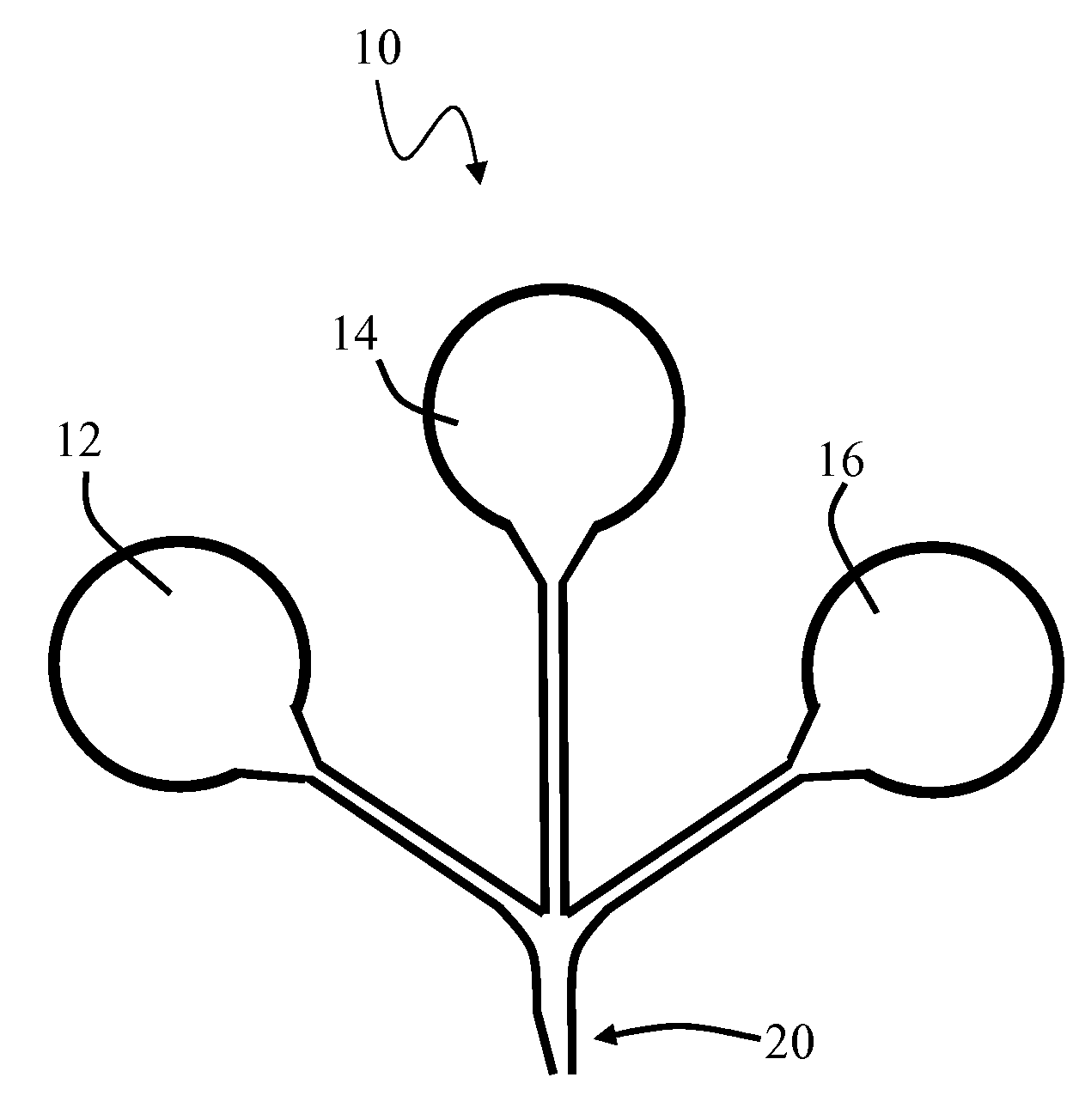

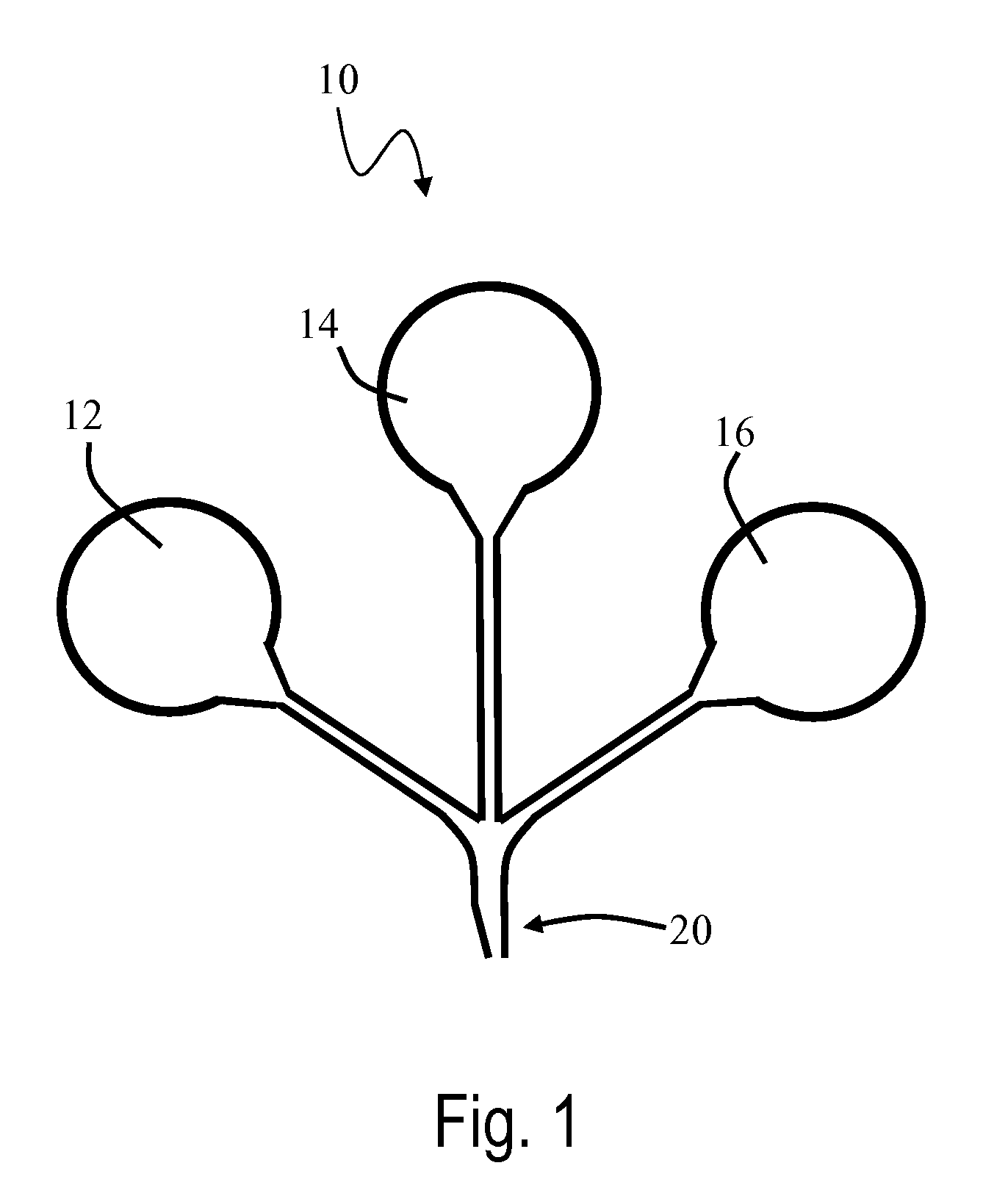

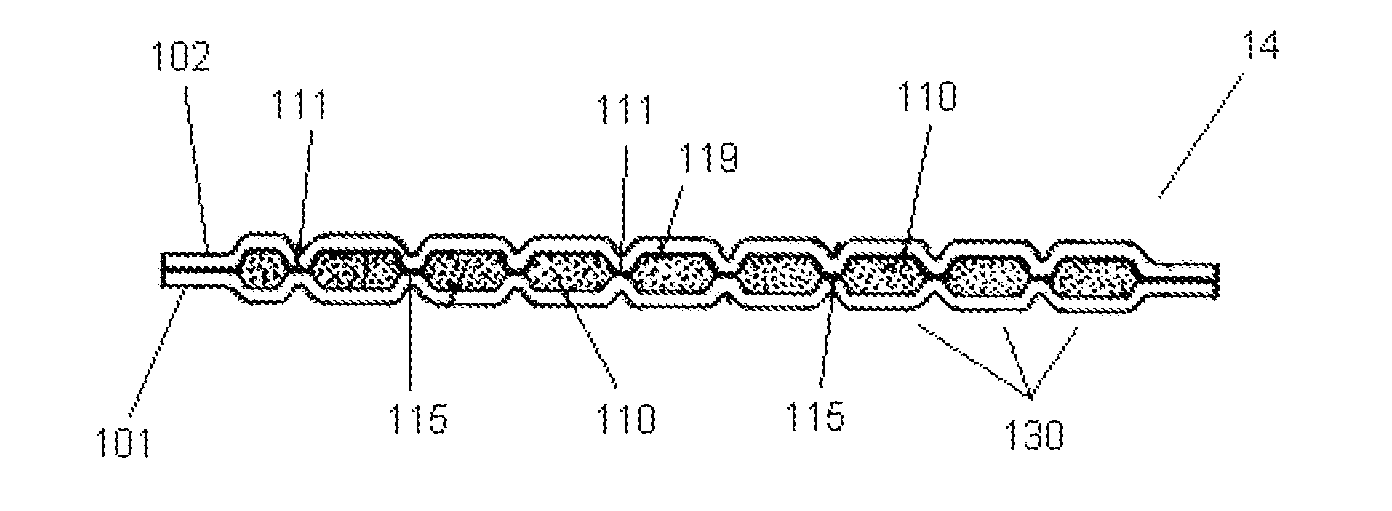

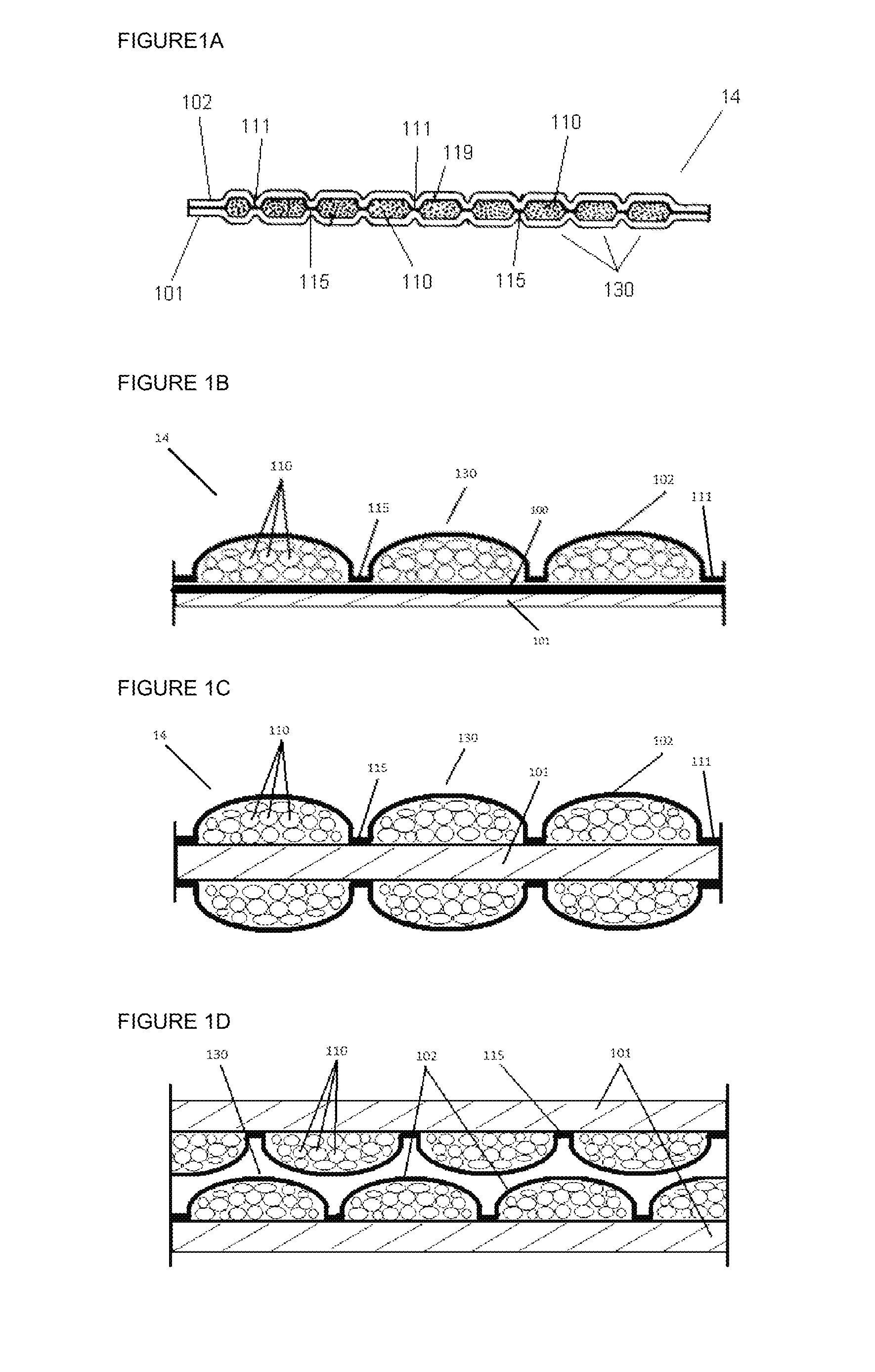

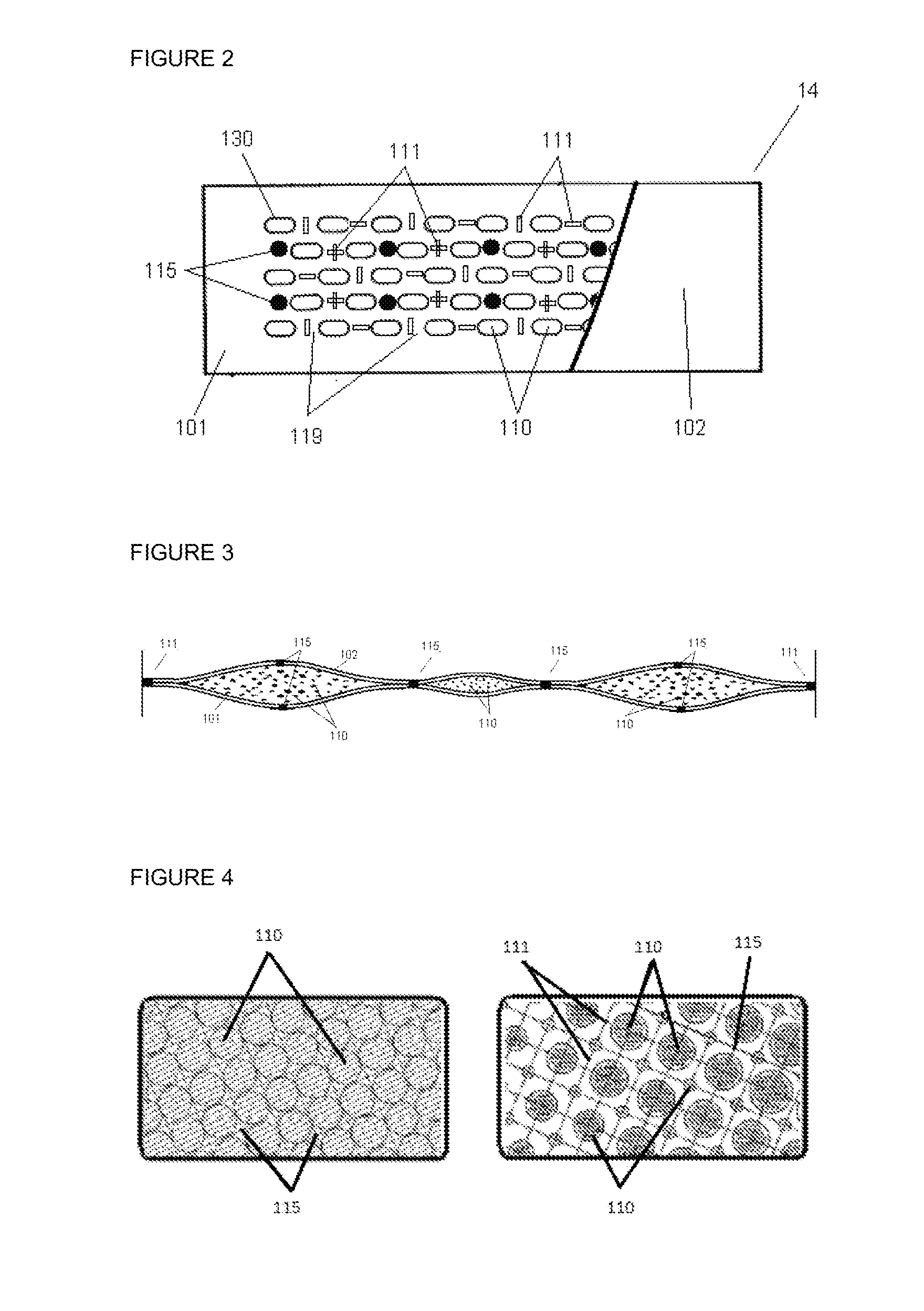

Absorbent structure

InactiveUS20130226120A1Excellent fluid managementInhibit migrationLiquid surface applicatorsPattern makingEngineeringFluid management

The present invention relates to an absorbent structure, preferably for use in absorbent products, such as used in the food, consumer, household, building and construction, beauty and medical industry, and as used in the personal hygiene industry. The substantially cellulose free absorbent structures continuously immobilise absorbent polymer material via initial smaller pockets and subsequently larger compartments allowing excellent fluid management of the absorbent polymer material in dry, partially and fully liquid loaded state. Preferably such absorbent structure volume increases are result of temporary secondary attachment patterns made in combination with substantially permanent primary attachment grids allowing the release of bigger volumes from the initial smaller volumes by detachment of the secondary attachments. Furthermore the absorbent structure according to an embodiment of the invention non-homogeneously swells to form a liquid-managing surface structure as a result of exposing the absorbent structure to liquid. The present invention foresees in the need for improved flexible, thin, lightweight absorbent structures which overcome the absorbency problems of the prior art during absorption, distribution and retention of liquids with optimal fit.

Owner:DRYLOCK TECHNILOGIES NV

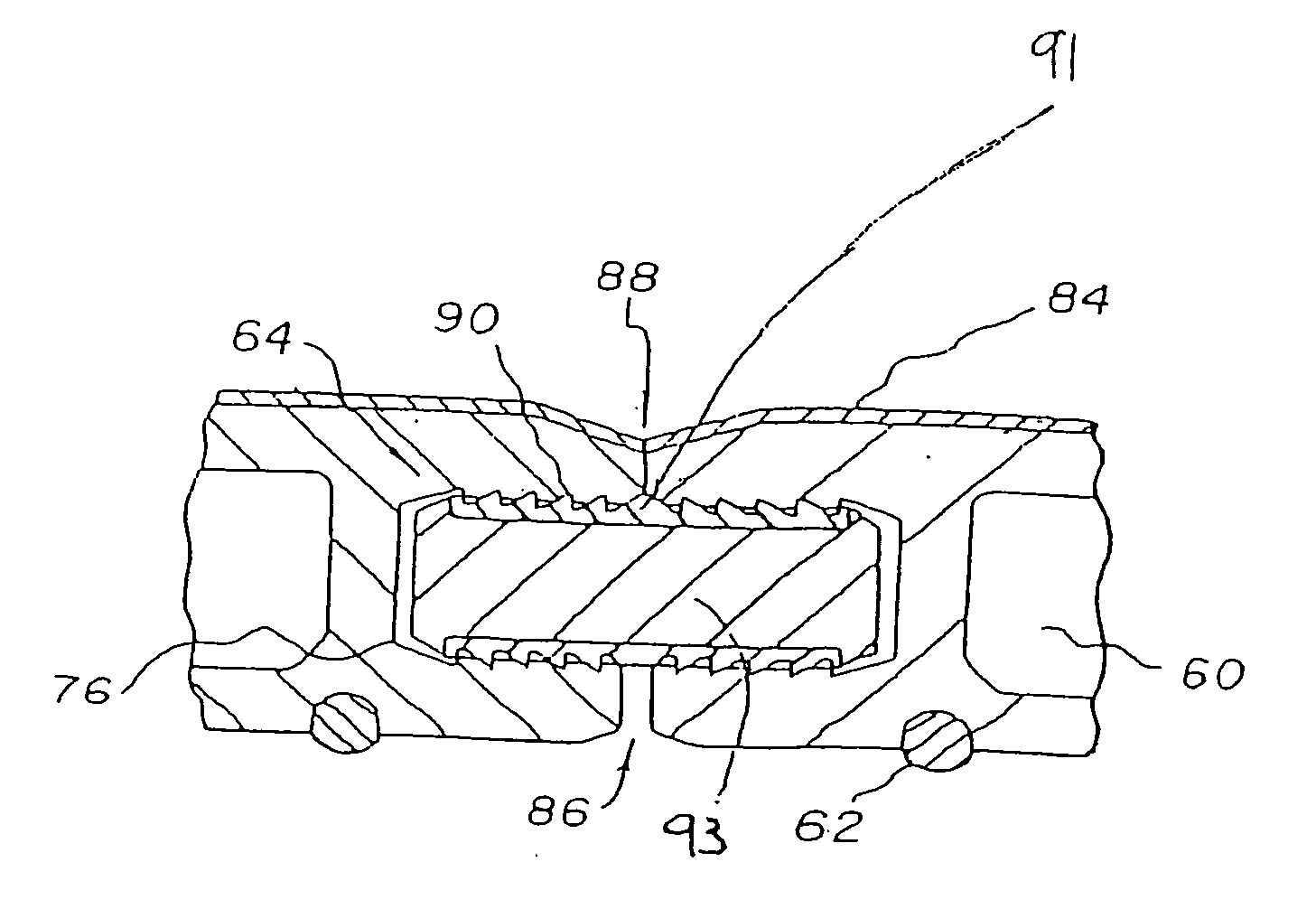

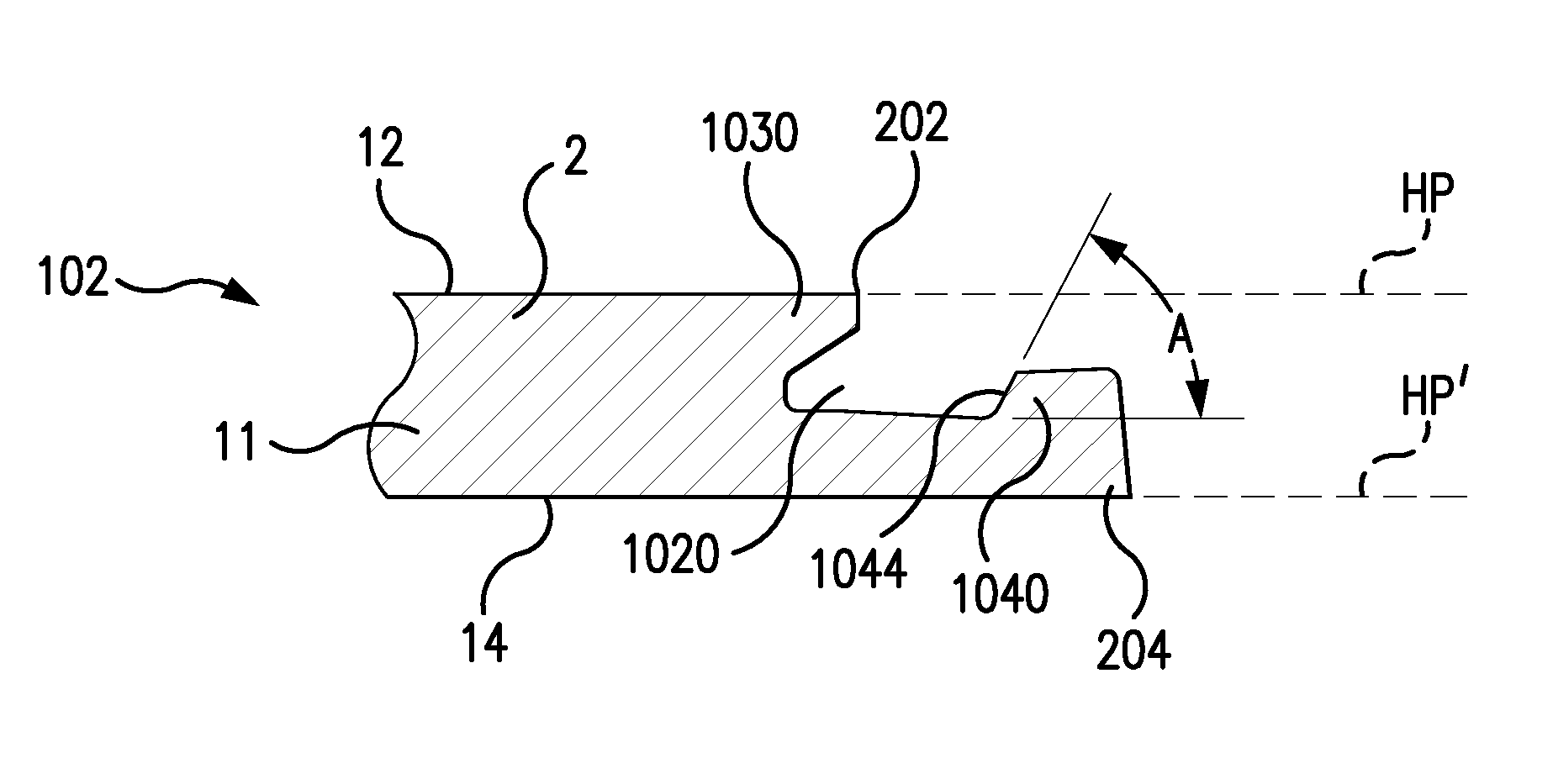

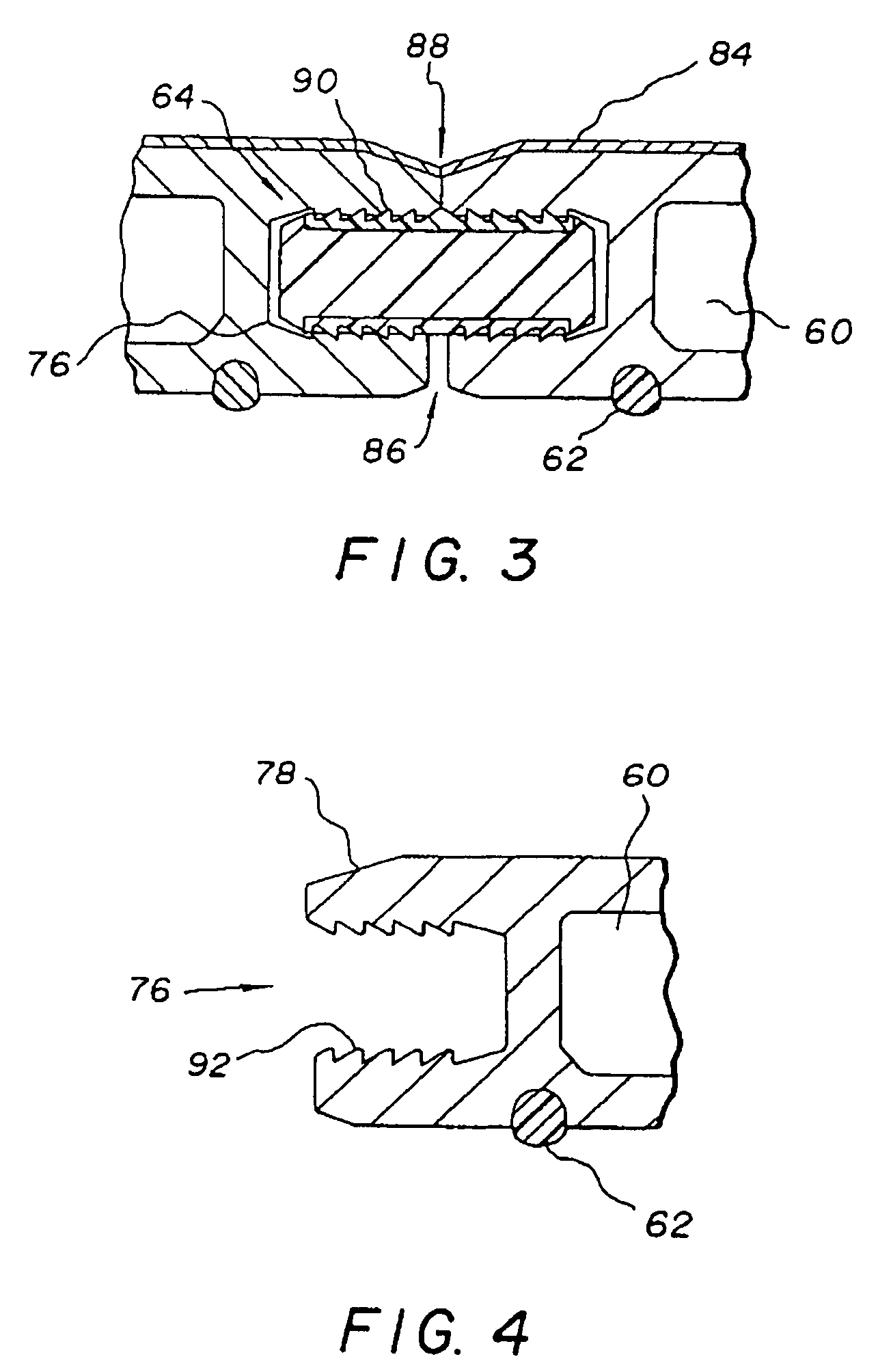

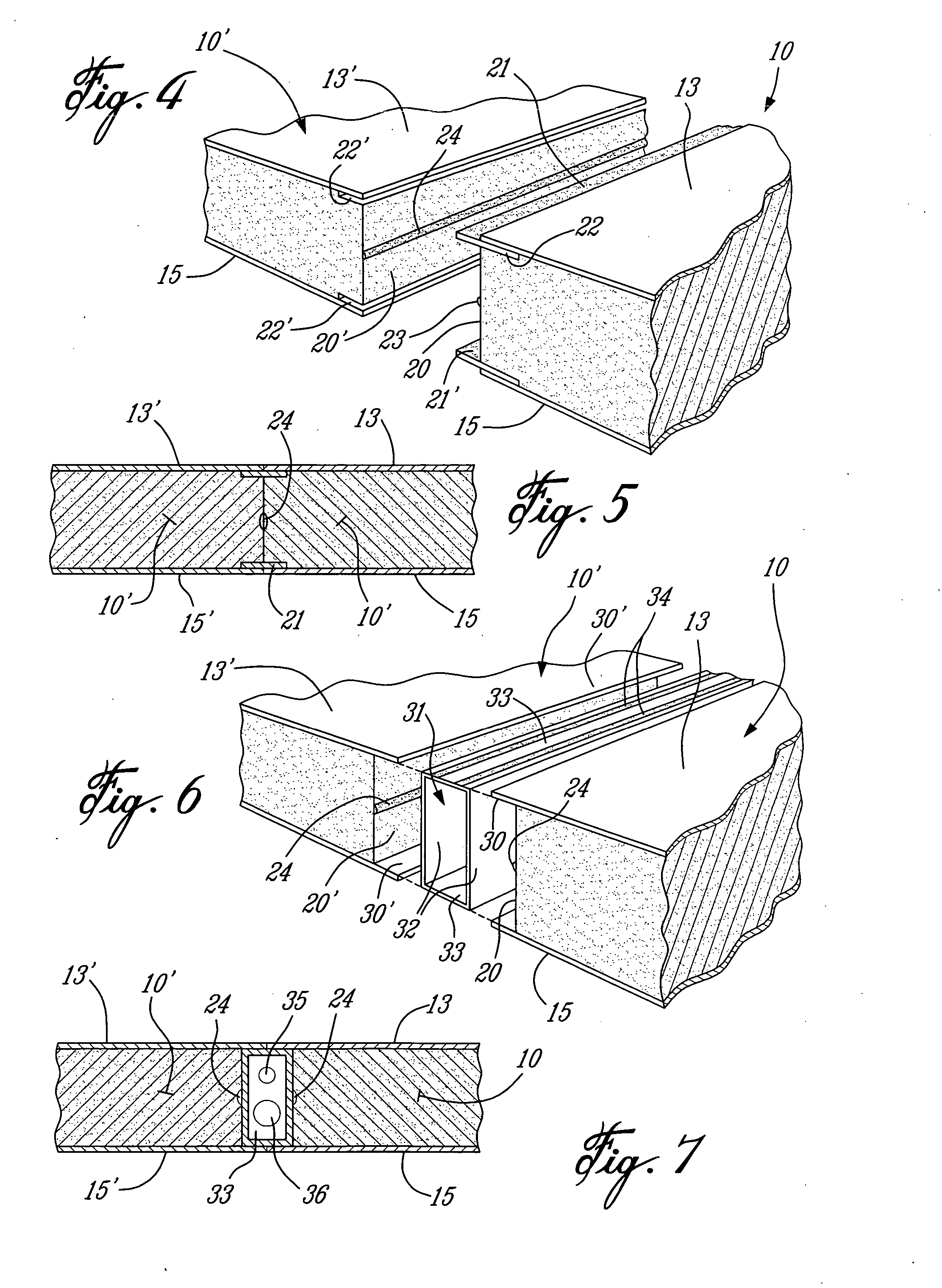

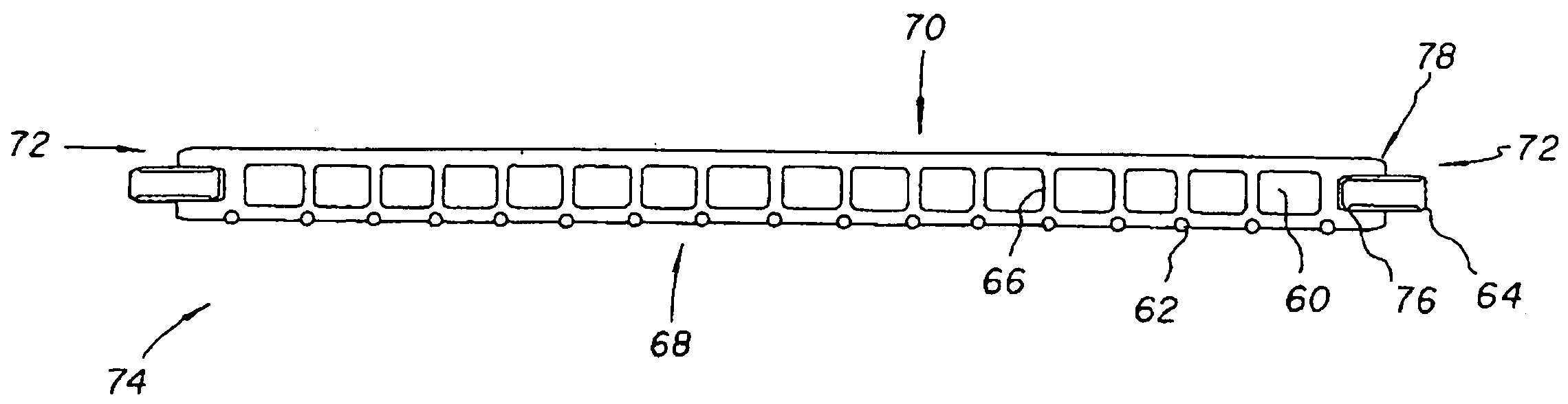

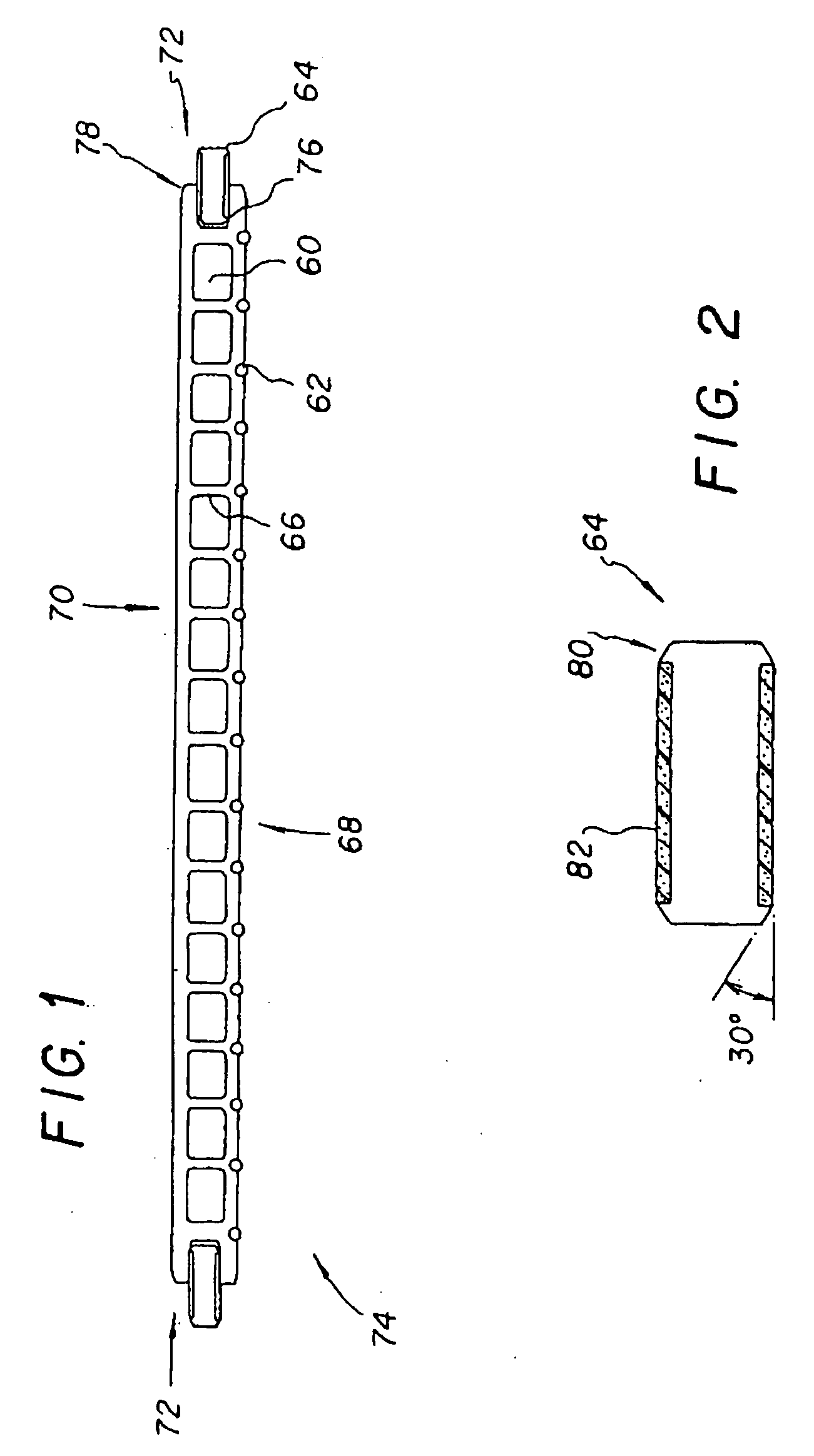

Bonded interlocking flooring

The present technique relates to a floor system that includes panels designed to be joined to one another, with an adhesive coating and a sealant at each joint to facilitate assembly. The panels include mechanically interlocking portions that mate when the system is installed. Disposed on the interlocking portions is a coating adapted to cohesively bond upon contact with itself under ambient conditions and without external activation. The sealant protects the joint and prevents the ingress of moisture following installation. Advantageously, the cohesive bonding of the coating is delayed such that the bonding does not obstruct the installation of the floor panel.

Owner:WILSONART

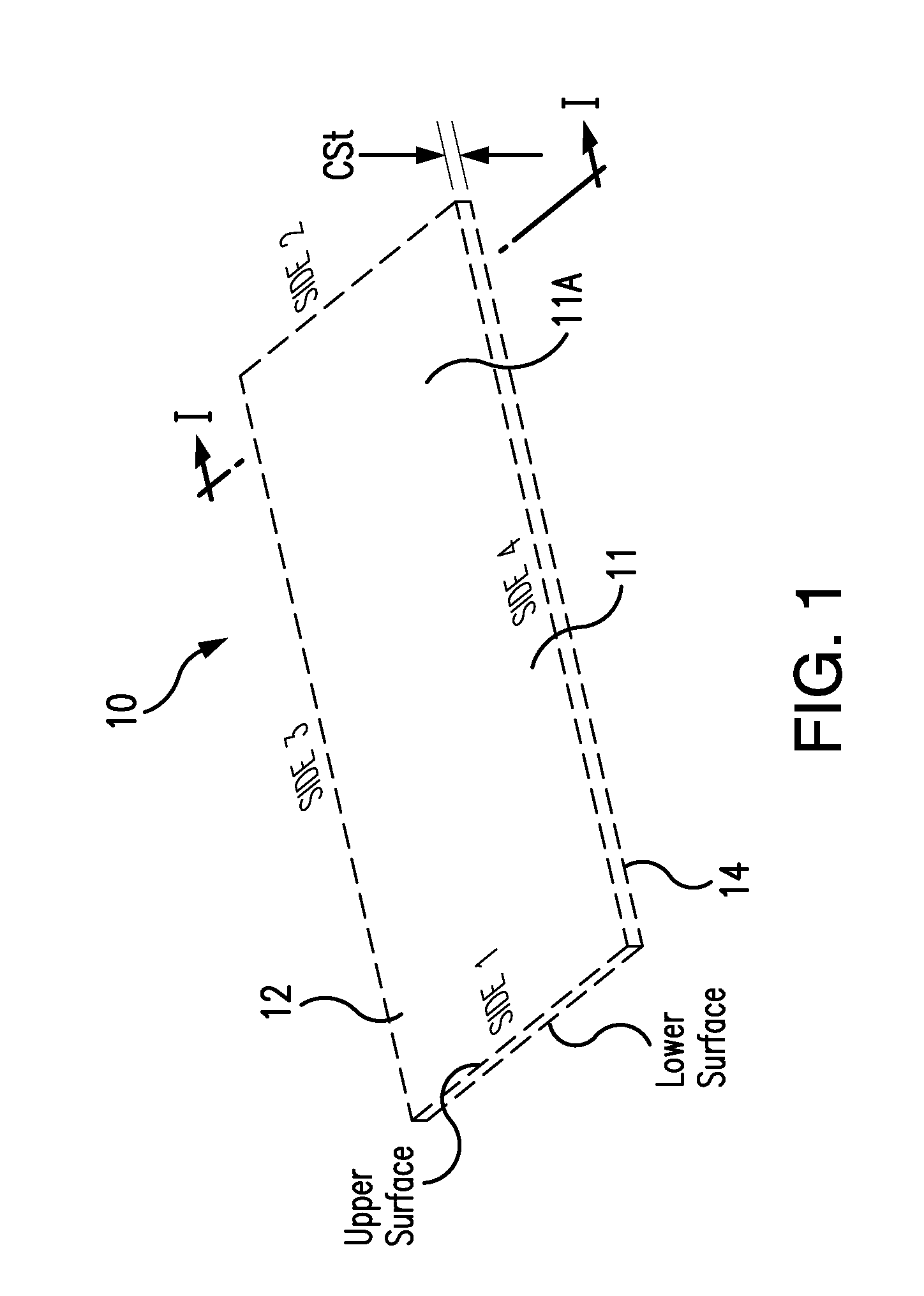

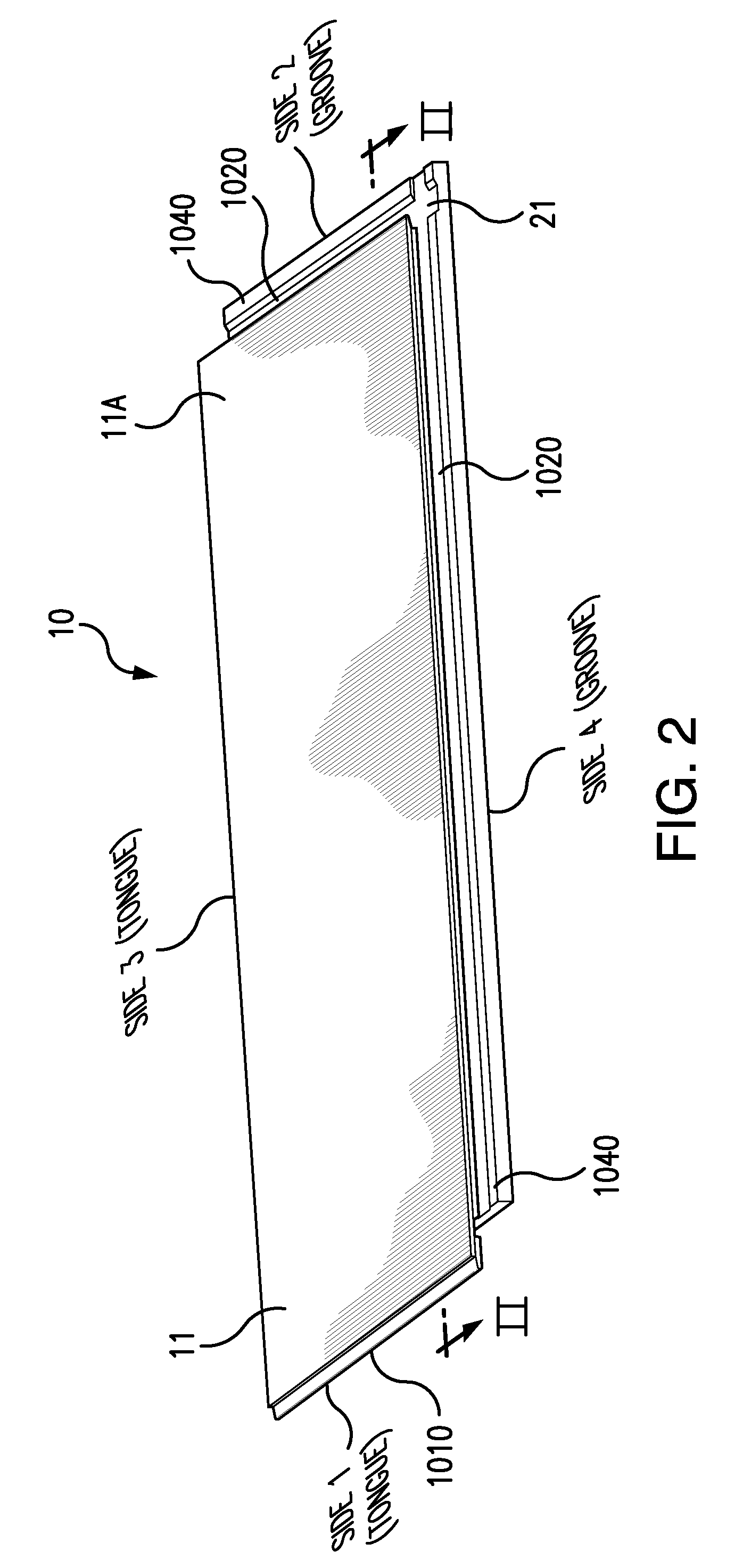

Floor covering with interlocking design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

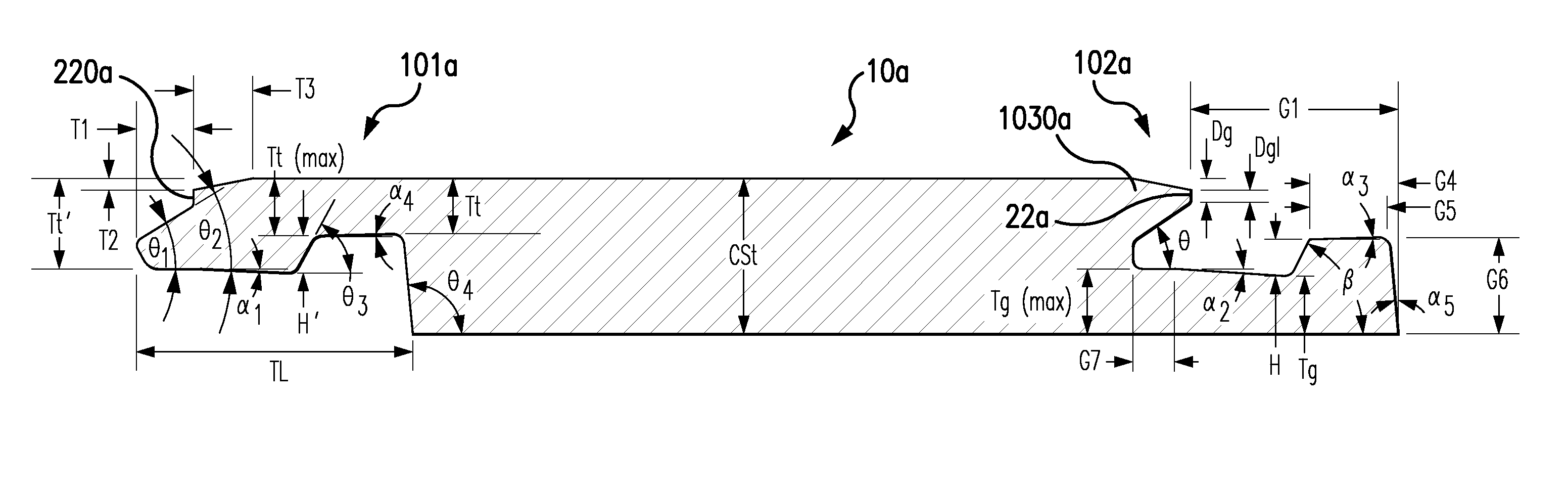

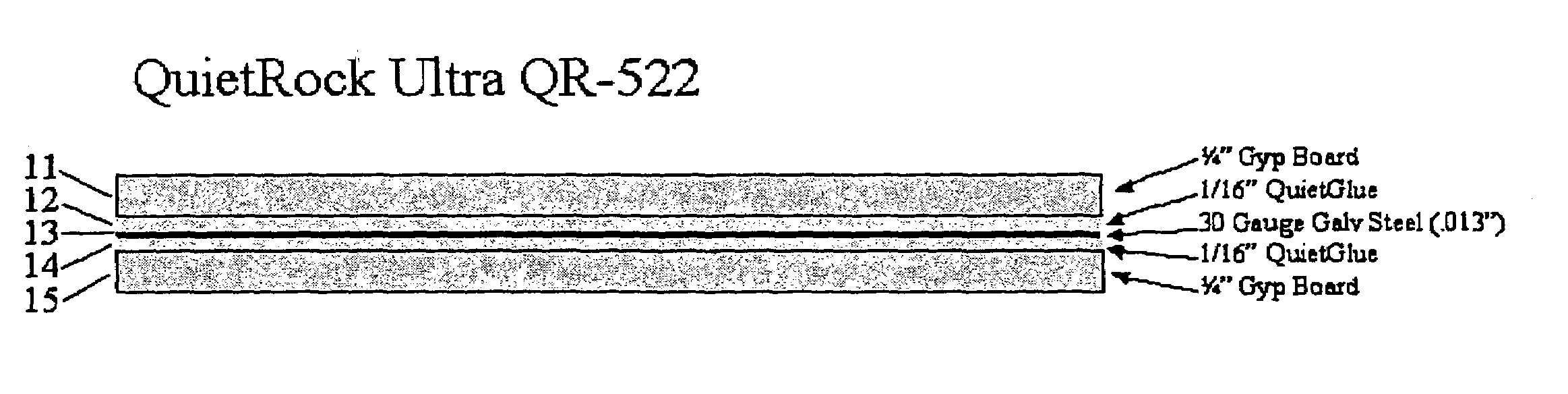

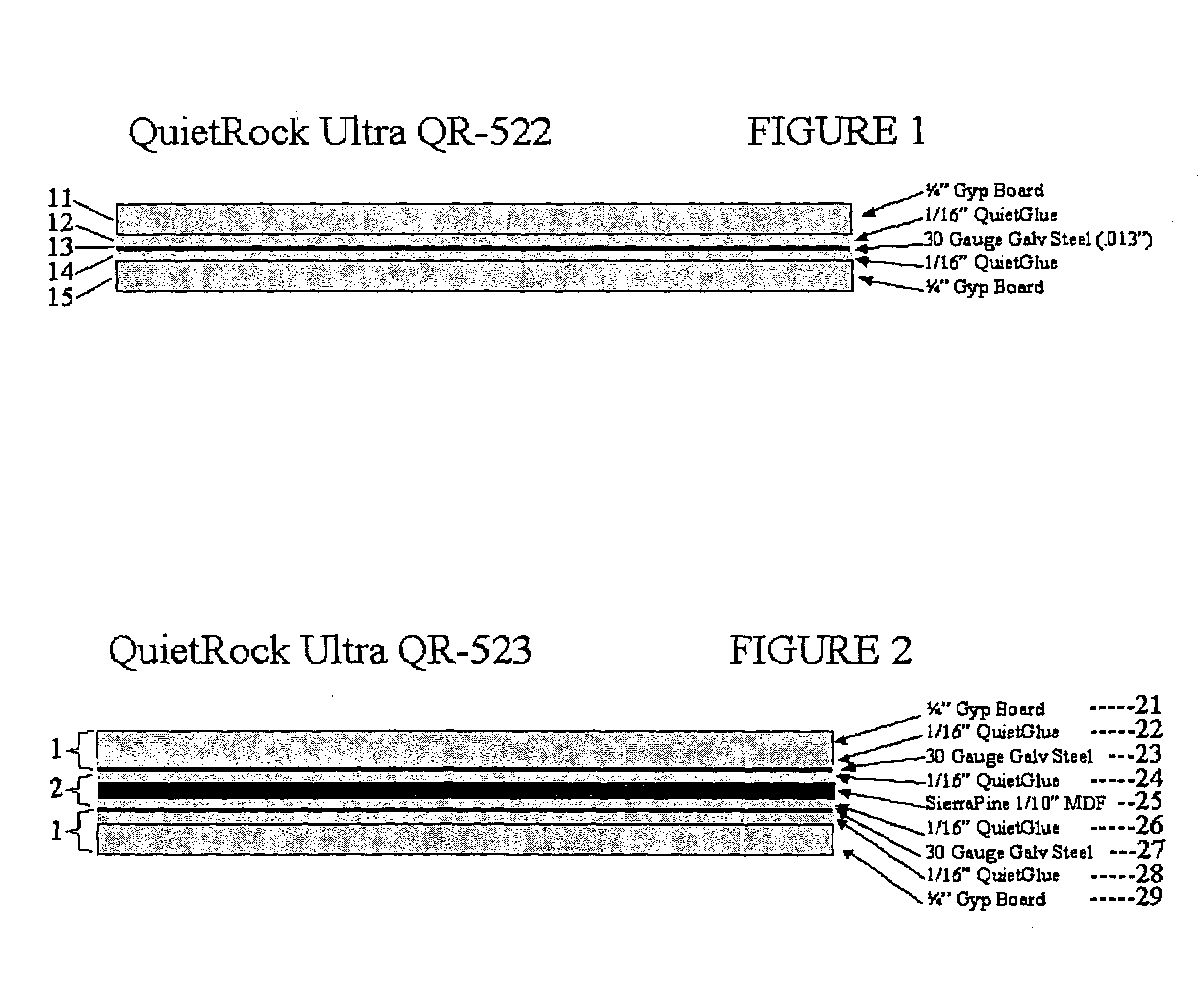

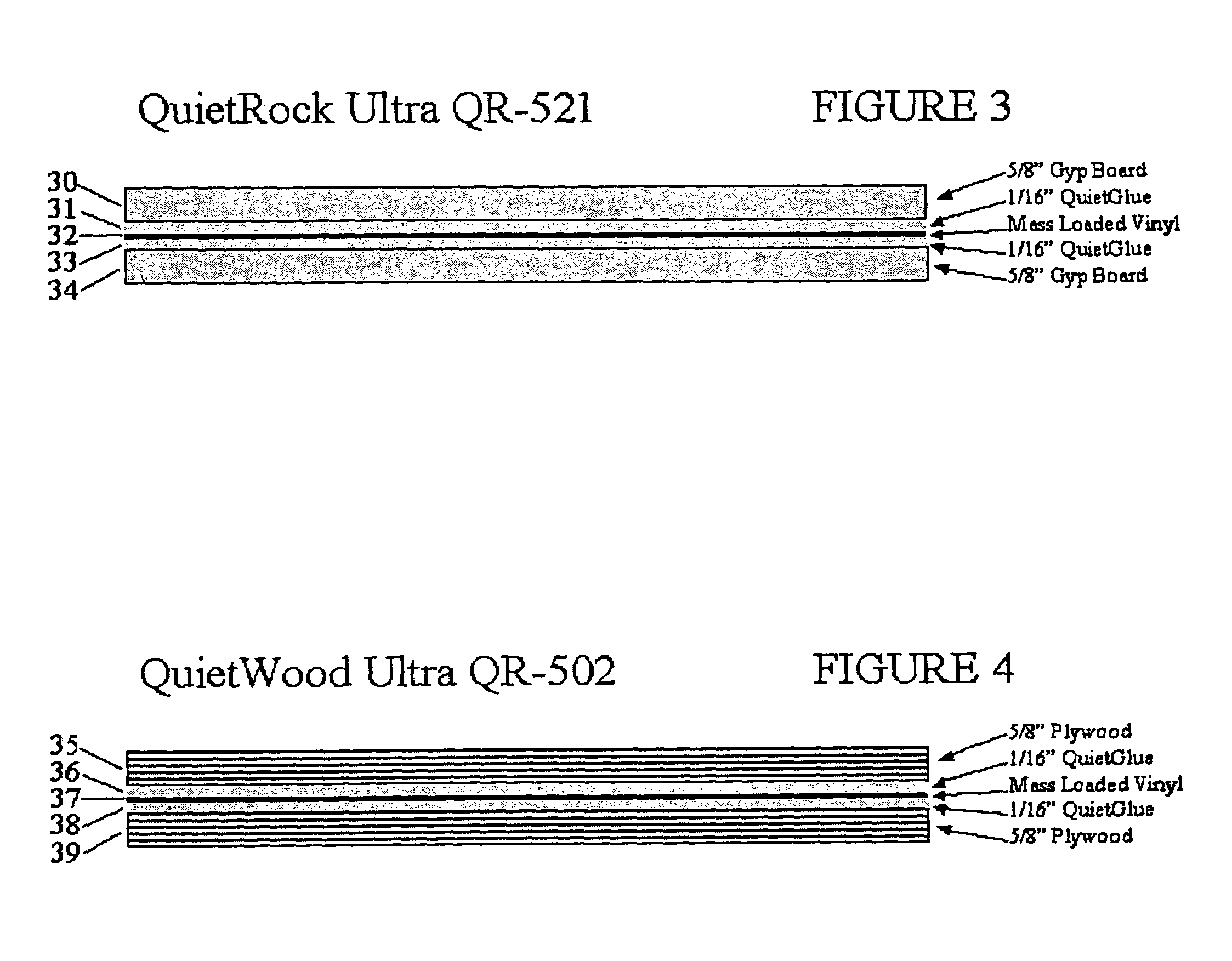

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

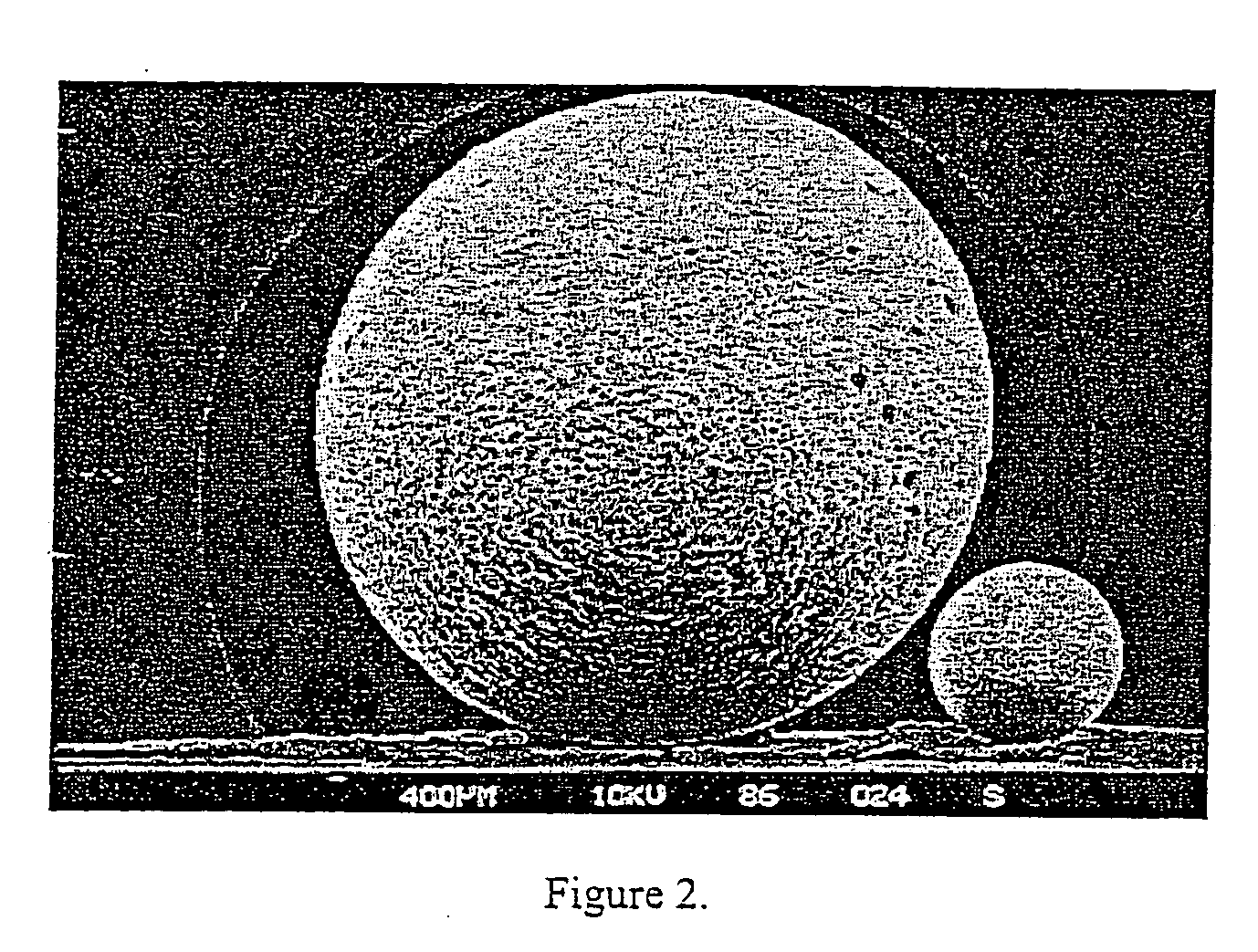

Composite light weight gypsum wallboard

The invention generally provides a light weight composite gypsum board including a foamed low density set gypsum core, a top non-foamed (or reduced-foamed) bonding high density layer and a bottom non-foamed (or reduced-foamed) bonding high density layer, a top cover sheet bonded to the foamed low density set gypsum core by the top non-foamed (or reduced-foamed) bonding high density layer, and a bottom cover sheet bonded to the foamed low density set gypsum core by the bottom non-foamed (or reduced-foamed) bonding high density layer. The foamed low density set gypsum core and the non-foamed (or reduced-foamed) bonding high density layers are made from a gypsum slurry including stucco, pregelatinized starch present in an amount of about 0.5-10% by weight based on the weight of stucco, preferably a naphthalenesulfonate disperant present in an amount of about 0.1-3.0% by weight based on the weight of stucco, and preferably sodium trimetaphosphate present in an amount of about 0.12-0.4% by weight based on the weight of stucco. Other slurry additives can include accelerators, binders, paper fiber, glass fiber, and other known ingredients. The foamed low density set gypsum core is prepared having a density of less than about 30 pcf using soap foam in the gypsum-containing slurry. The combination of components provide a composite gypsum board having light weight and high strength. A method of making the composite gypsum board is also provided.

Owner:UNITED STATES GYPSUM CO

Textured laminate flooring

InactiveUS7243469B2Provide protectionImprove aestheticsCovering/liningsSpecial paperSubject matterEngineering

A decorated floor panel having a core with a top surface and an opposite bottom surface; a decorative layer coupled to the top surface of the core, the decorative layer having a desired aesthetic appearance; and a wear layer coupled to and substantially covering the decorative layer for protecting the decorative layer. The wear layer has an exposed wear surface with depressions therein of a variable depth below the wear surface, the depressions being arranged to display a desired texture pattern. It is noted that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to ascertain quickly the subject matter of the technical disclosure. The abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims pursuant to 37 C.F.R. § 1.72(b).

Owner:COLUMBIA INSURANCE CO

Construction products and method of making same

InactiveUS20070062143A1Eliminate needShorten construction timeSolid waste managementWallsBuilding productCement board

A highly durable and easy to use prefabricated construction product is disclosed having a cellular concrete component sandwiched between two cement boards, wherein the cellular concrete component comprises cement, fly ash, an activating agent and water, and the cement boards comprise cement, fly ash, an activating agent, sand, silica fume, a water reducer agent, a reinforcing fiber, and water.

Owner:NOUSHAD RAFIE LOTFI

Structural insulated panel construction for building structures

InactiveUS20070125042A1High strengthEasy to assembleSynthetic resin layered productsBuilding componentsRigid coreExpanded polystyrene

A structural insulated laminated construction panel for building structures is described. The panel comprises a rigid core material layer of expanded polymeric material having opposed flat parallel surfaces. An outer skin is adhesively secured to one of the flat surfaces and an inner skin is adhesively secured to the other of the flat surfaces. The core material layer has a density of about 2 lbs / cubic foot. The core material is preferably an expanded polystyrene material. A building structure is constructed from such panels used as exterior and interior wall panels, floor panels and roof panels.

Owner:HUGHES JOHN +3

Thermoplastic Planks and Methods For Making The Same

InactiveUS20080311355A1Improve moisture resistanceEasy flexibilityCovering/liningsDecorative surface effectsEngineeringThermoplastic materials

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

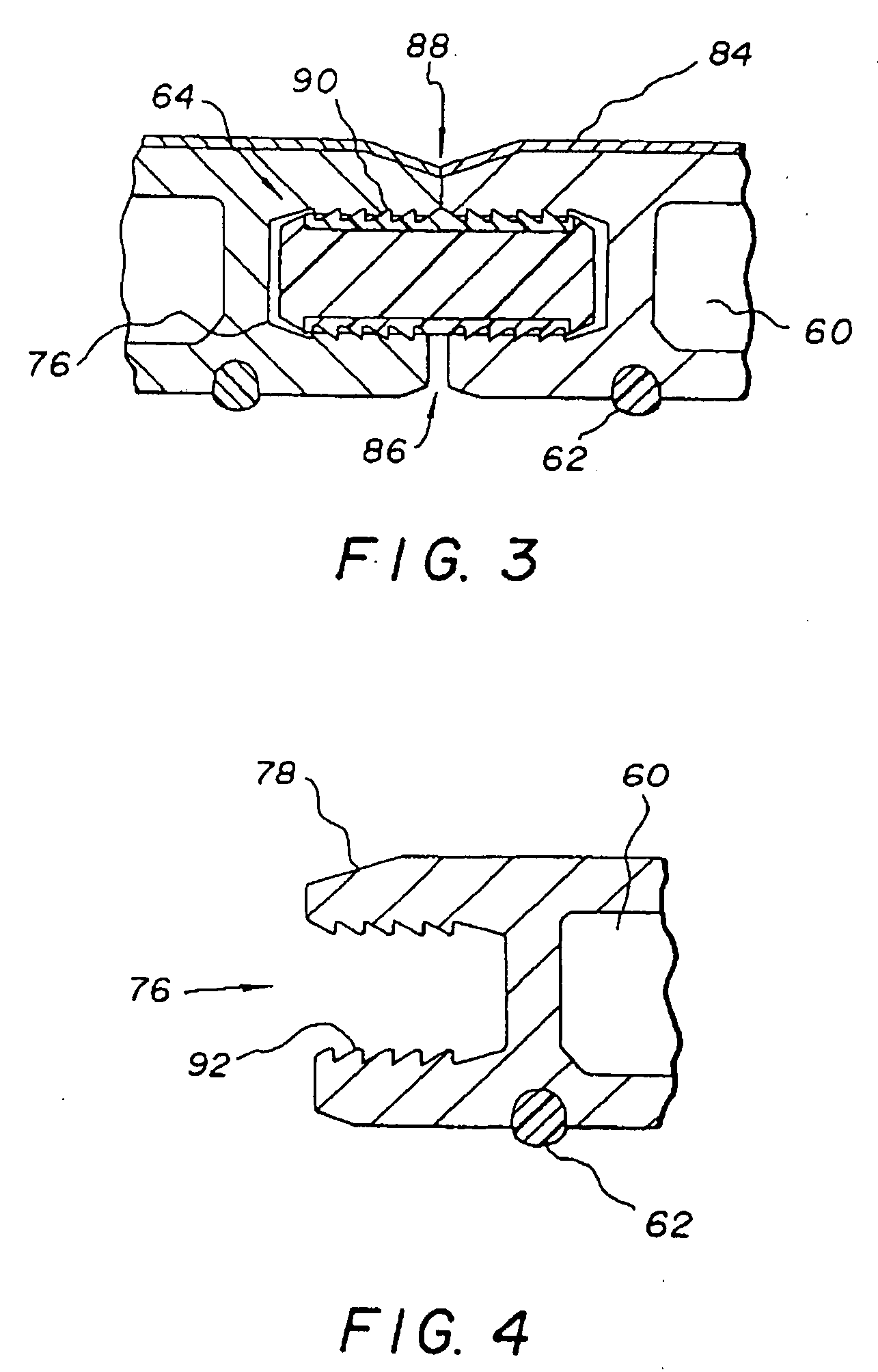

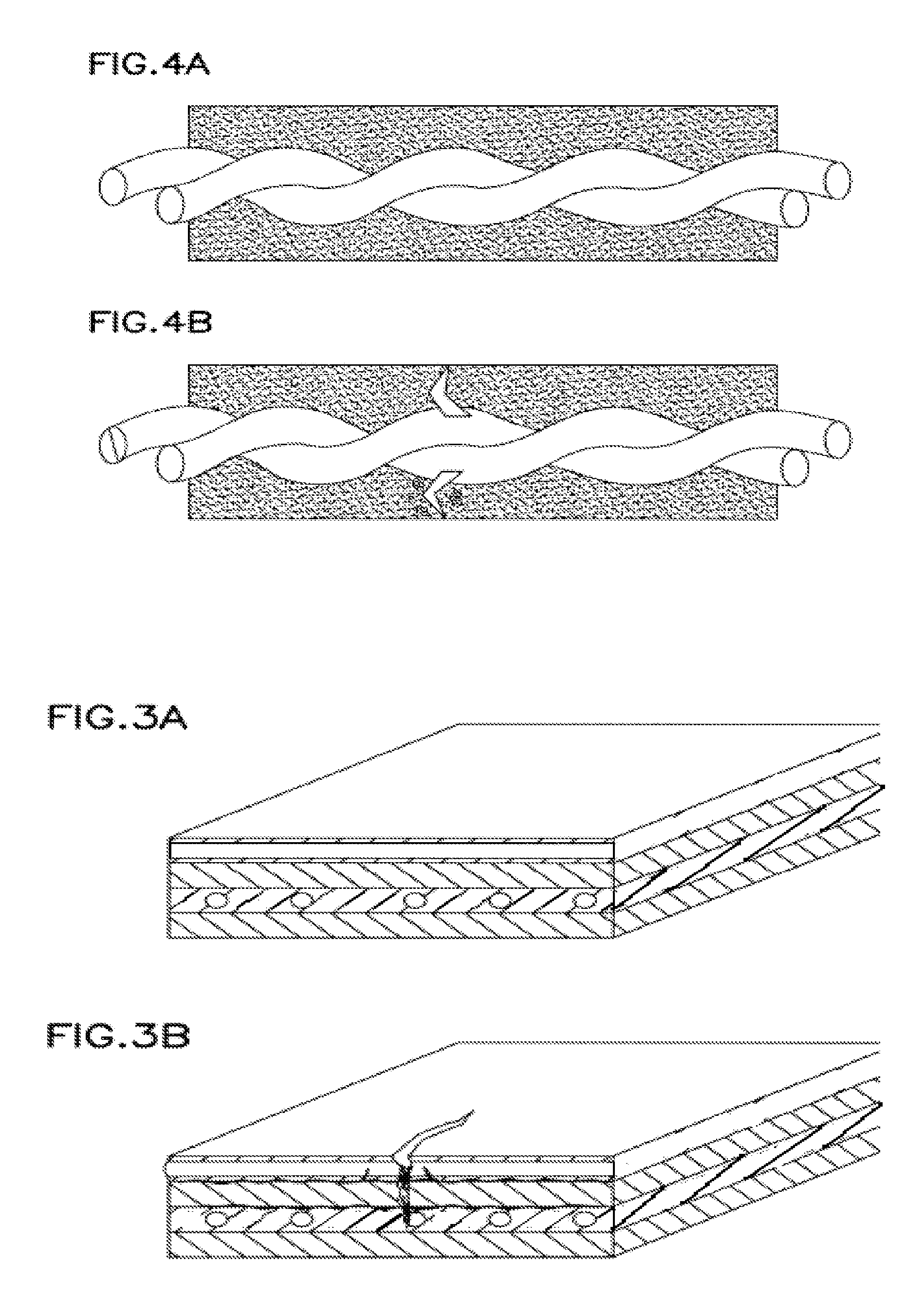

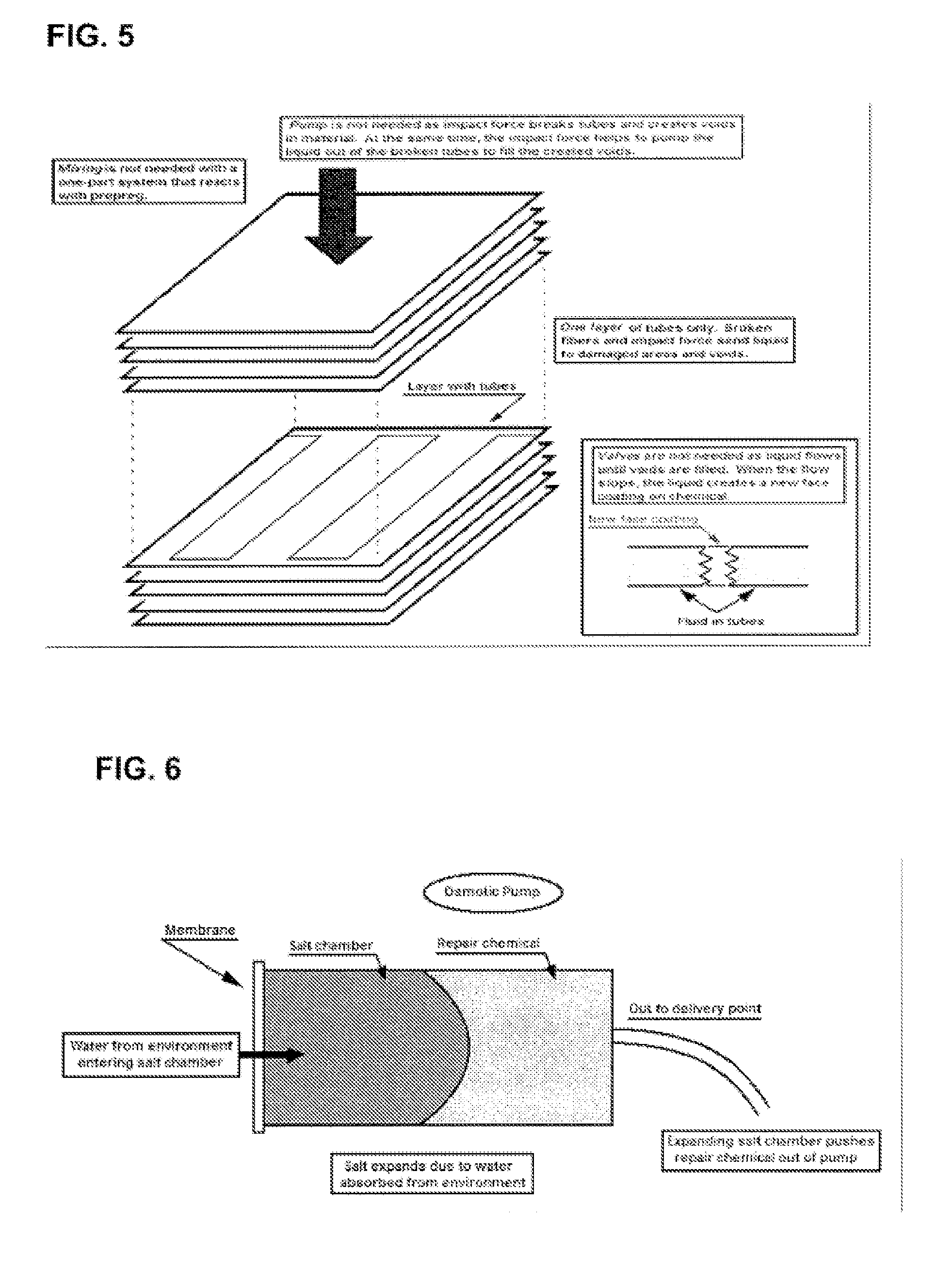

Multiple function, self-repairing composites with special adhesives

InactiveUS20070087198A1Fast chemical reactionExtended shelf lifeLayered productsConstructions elementsFiber matrixChemical substance

A system for self-repairing matrices such as concrete or cementitous matrices, polymeric matrices, and / or fibrous matrices, including laminates thereof. The system includes repair agents retained in and / or on vessels, such as hollow fibers, within the matrix. Upon impact, the vessel rupture, releasing the chemicals. For multi-layer laminates, the systems provides a total dynamic energetic circulation system that functions as an in situ fluidic system in at least one layer or area. The energy from the impact ruptures the vessels to release the chemical(s), and mixes the chemical(s) and pushes the chemical(s) and / or resulting compound through the matrix. The repair agents can withstand high temperatures, such as the heat of processing of many laminates, e.g., 250-350° F.

Owner:DRY CAROLYN

Self-adhering vapor permeable air and moisture barrier membrane

InactiveUS6901712B2Prevent lateral movementEliminate channelingCovering/liningsWallsAdhesiveWater vapor

Owner:HENRY COMPANY CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com