Patents

Literature

1243 results about "Cement board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

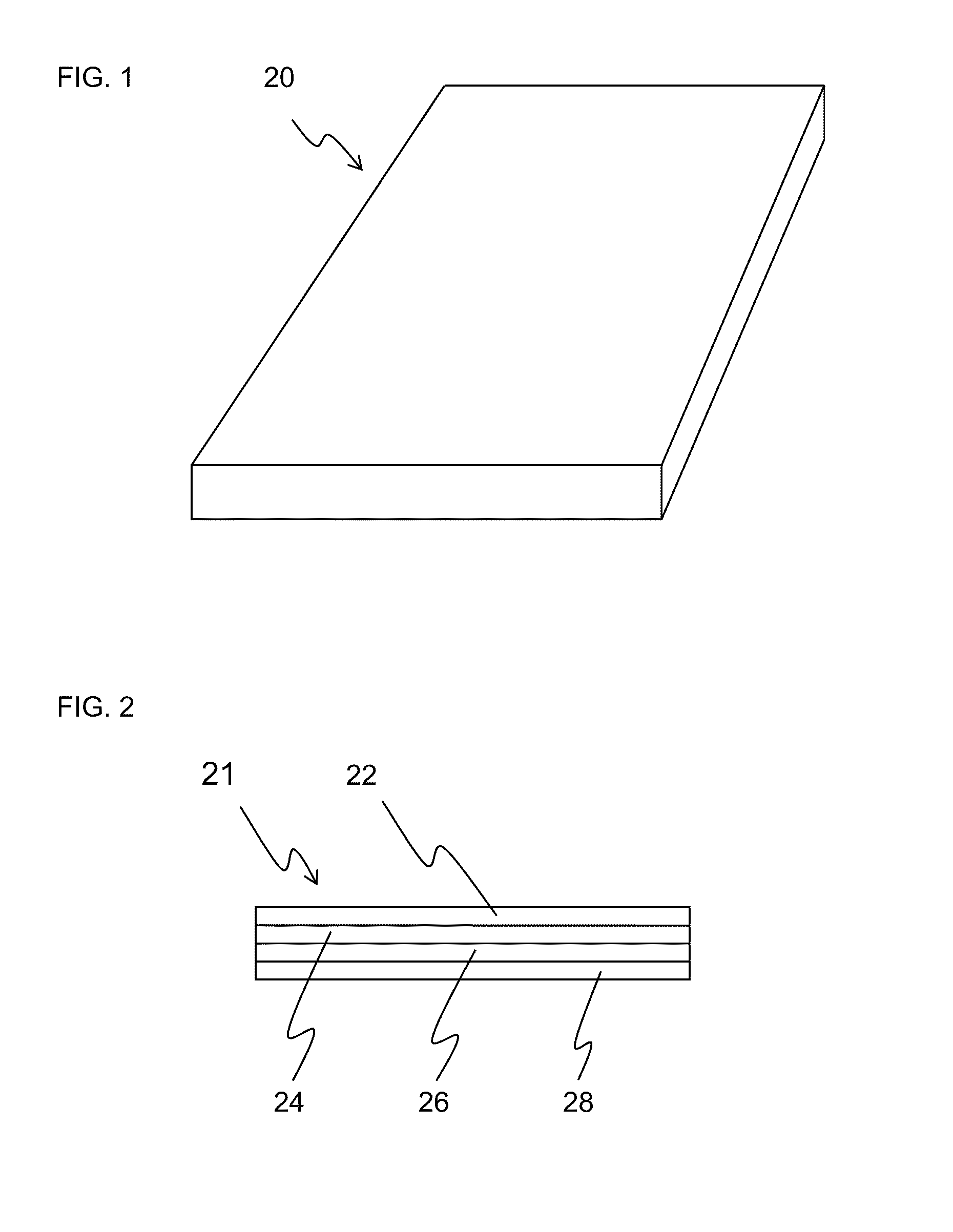

A cement board is a combination of cement and reinforcing fibers formed into 3 by 5 feet (91 by 152 cm) sheets, ¹⁄₄ to ¹⁄₂ inch (6.4 to 12.7 mm) thick that are typically used as a tile backing board. Cement board can be nailed or screwed to wood or steel studs to create a substrate for vertical tile and attached horizontally to plywood for tile floors, kitchen counters and backsplashes. It can be used on the exterior of buildings as a base for exterior plaster (stucco) systems and sometimes as the finish system itself.

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

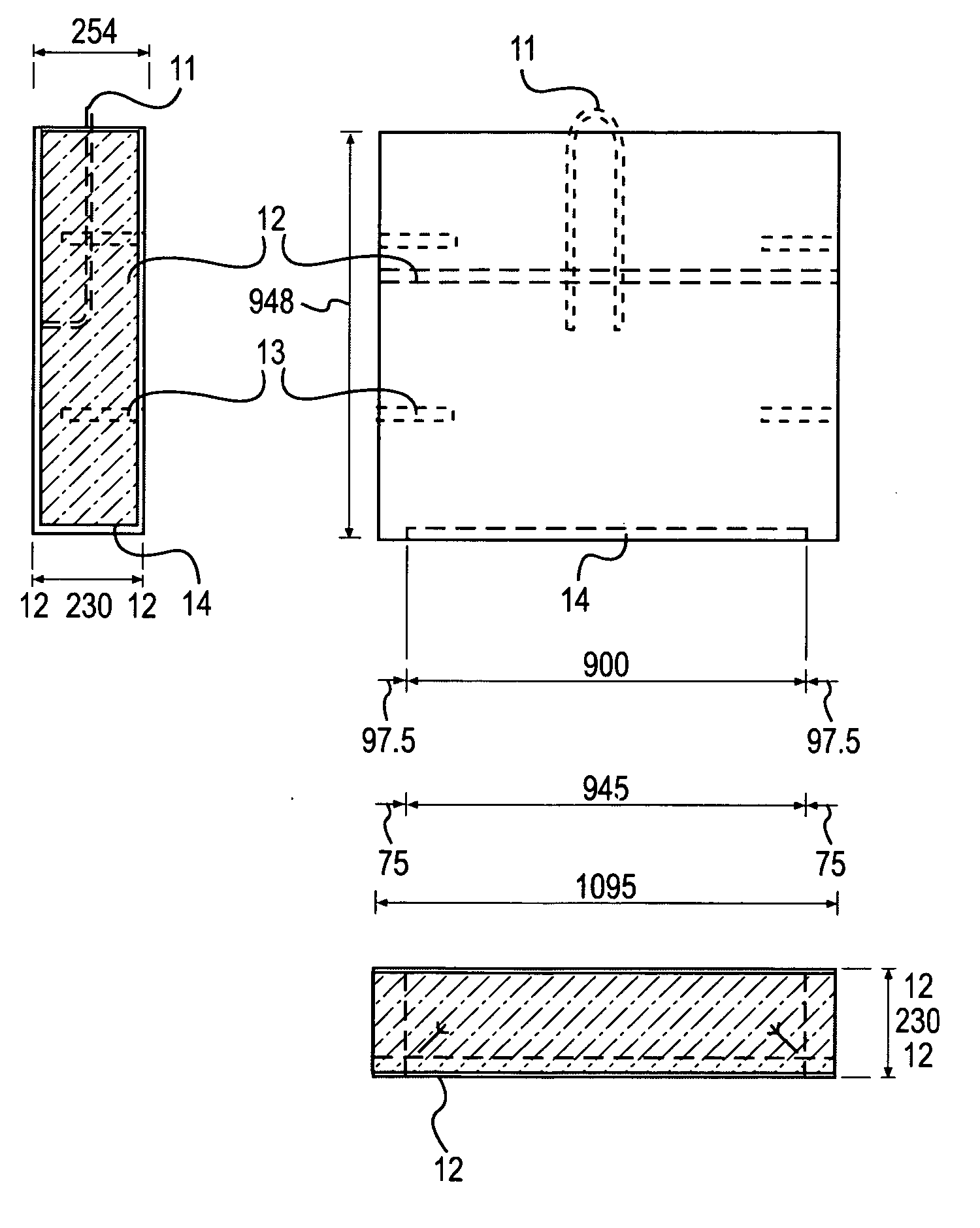

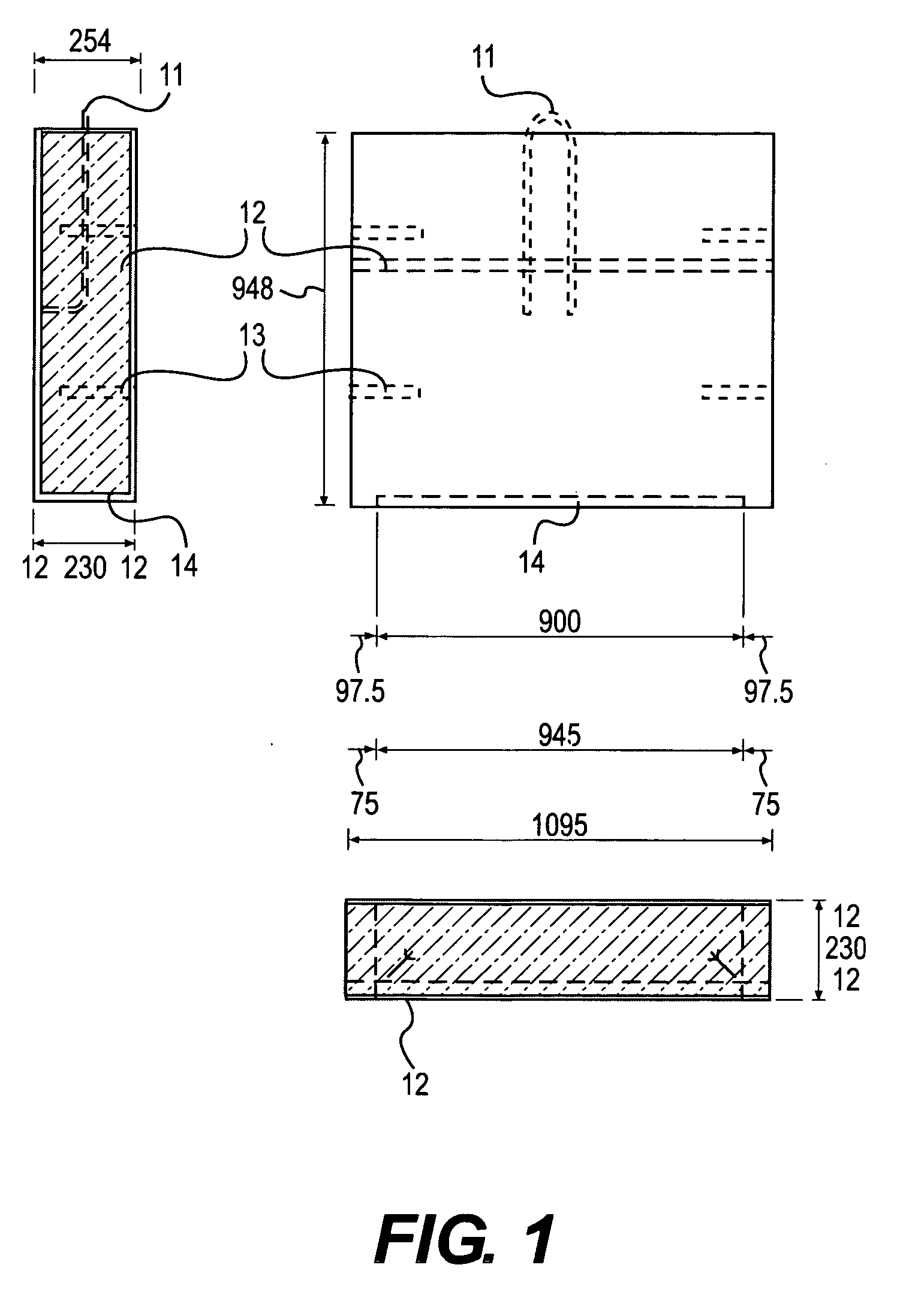

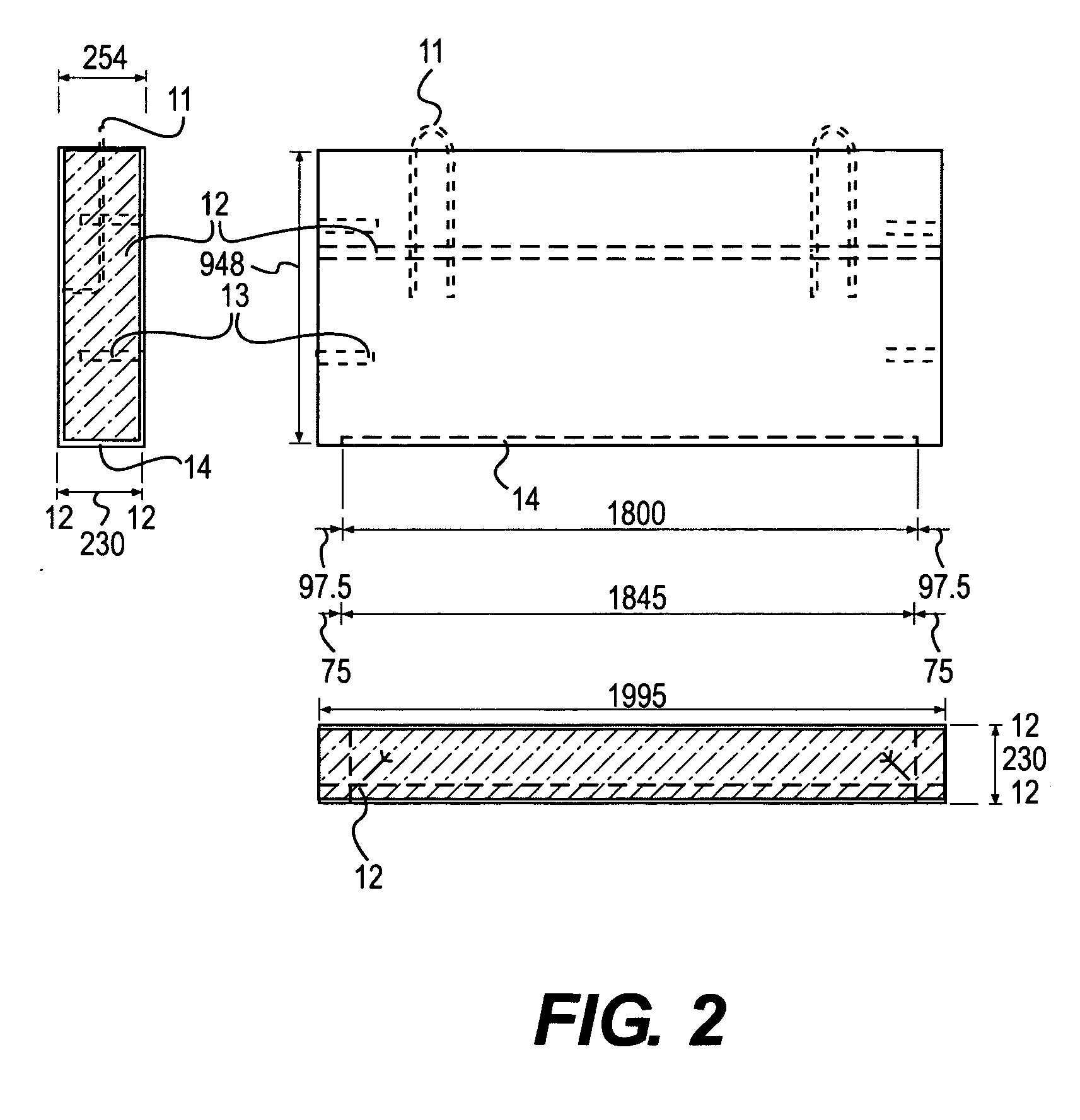

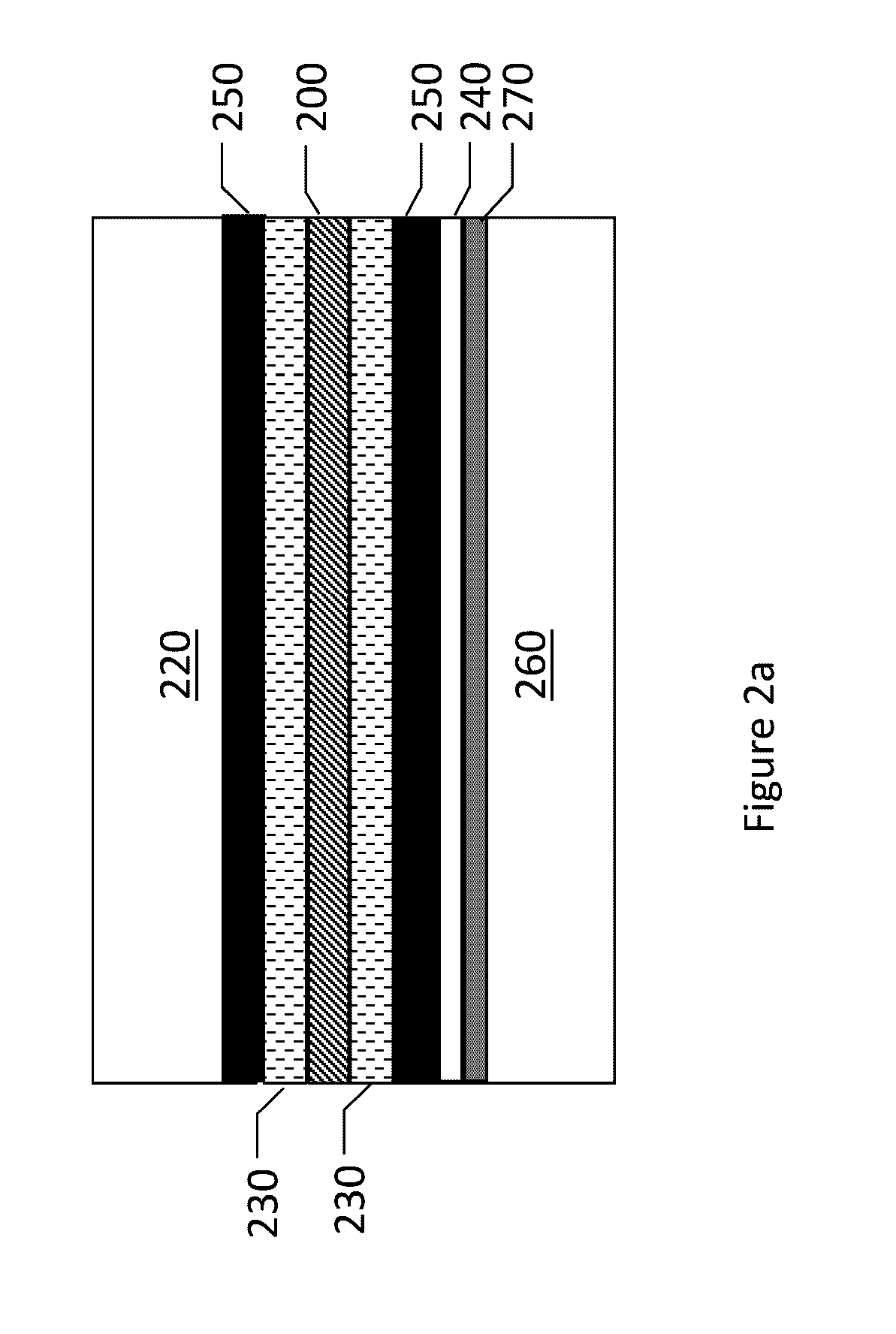

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

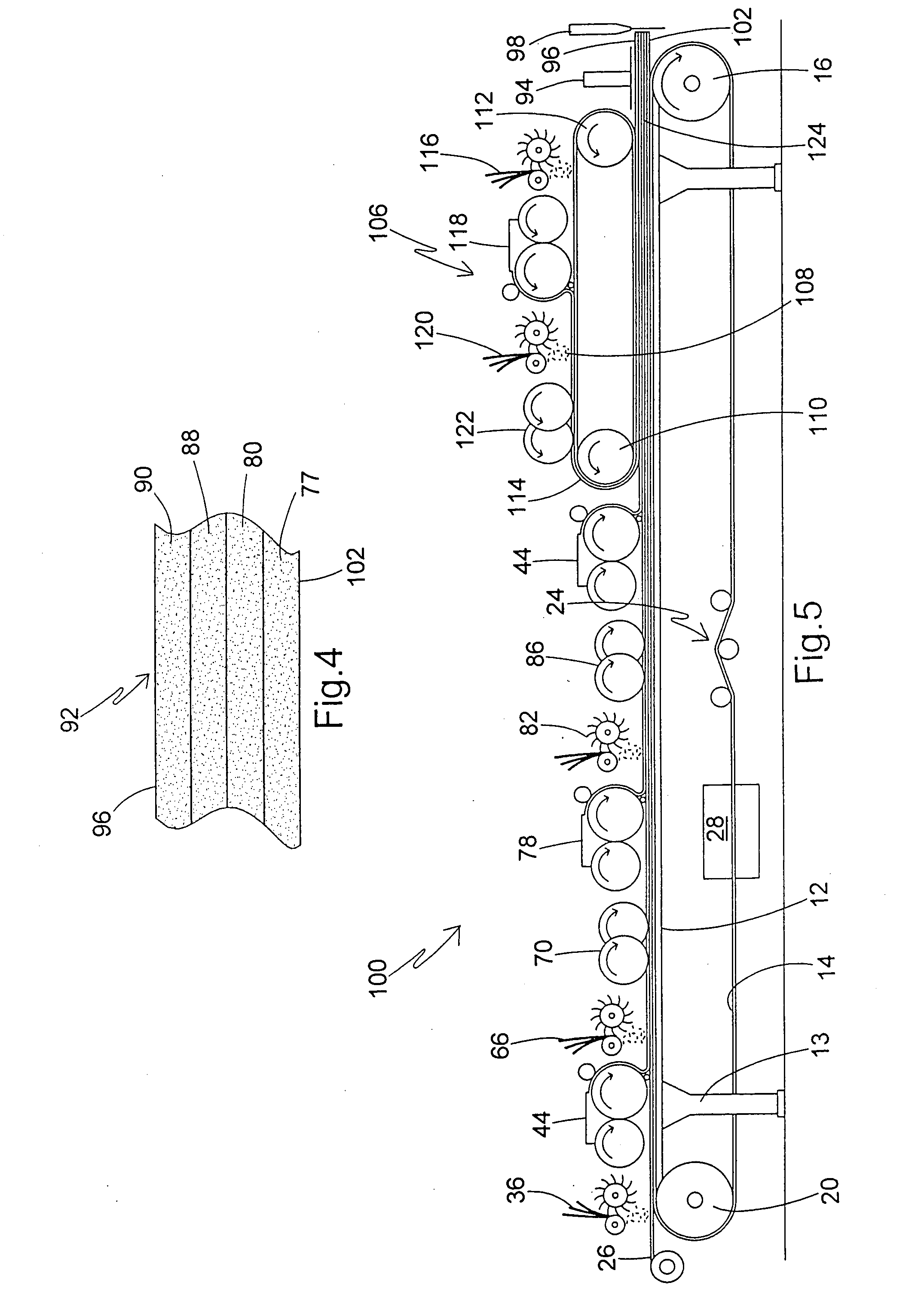

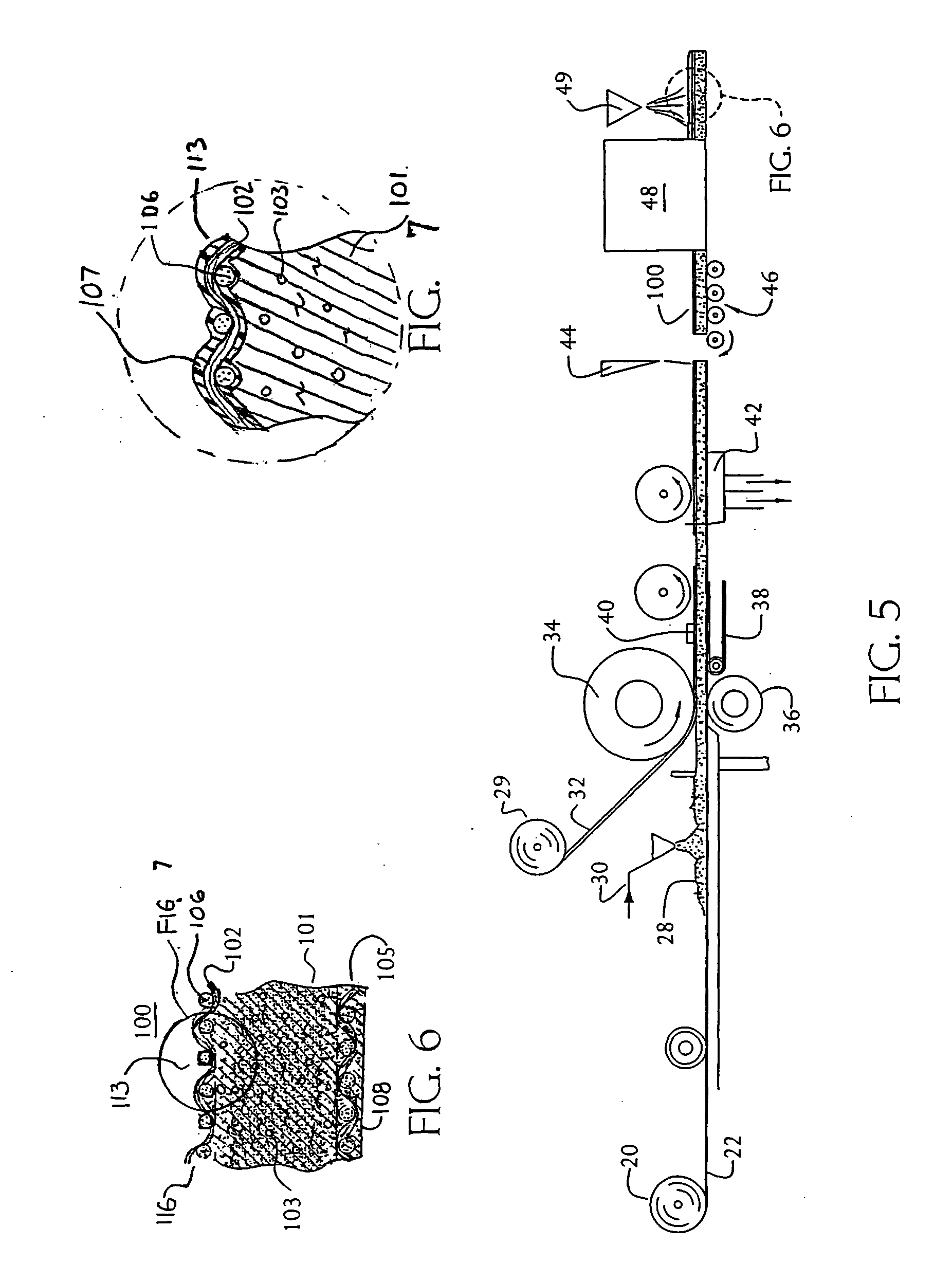

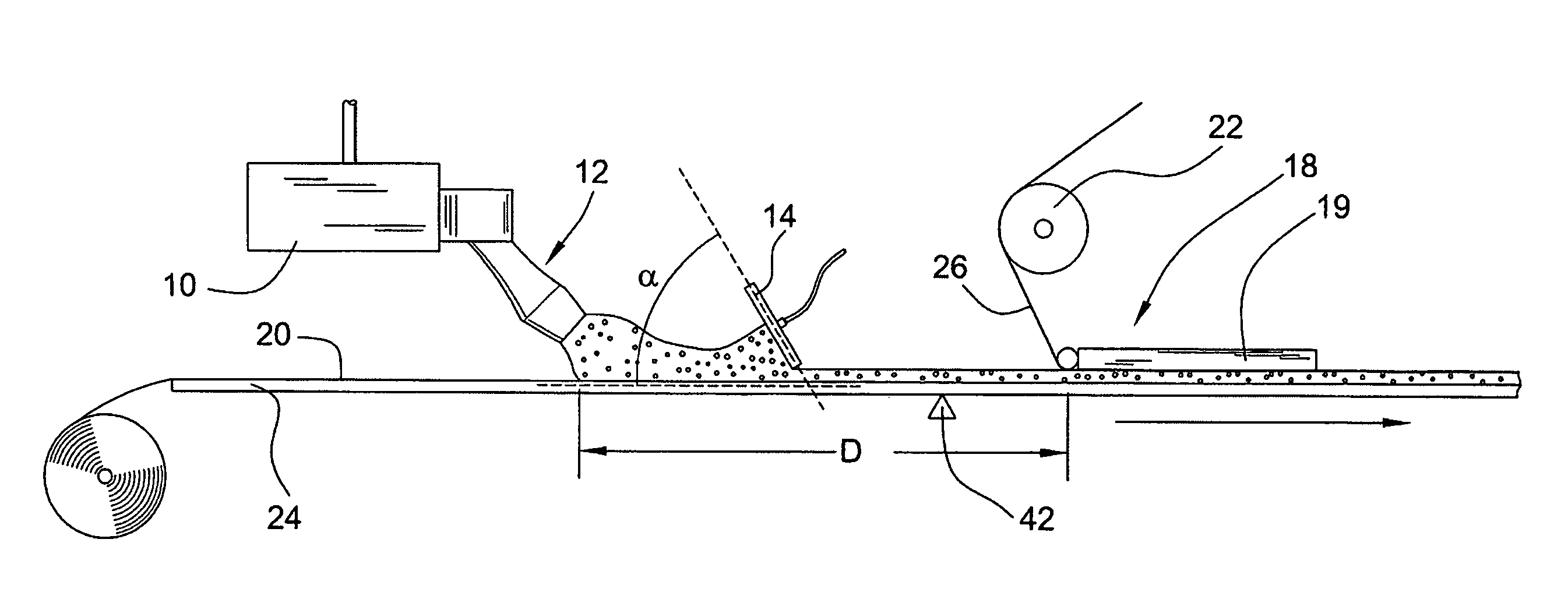

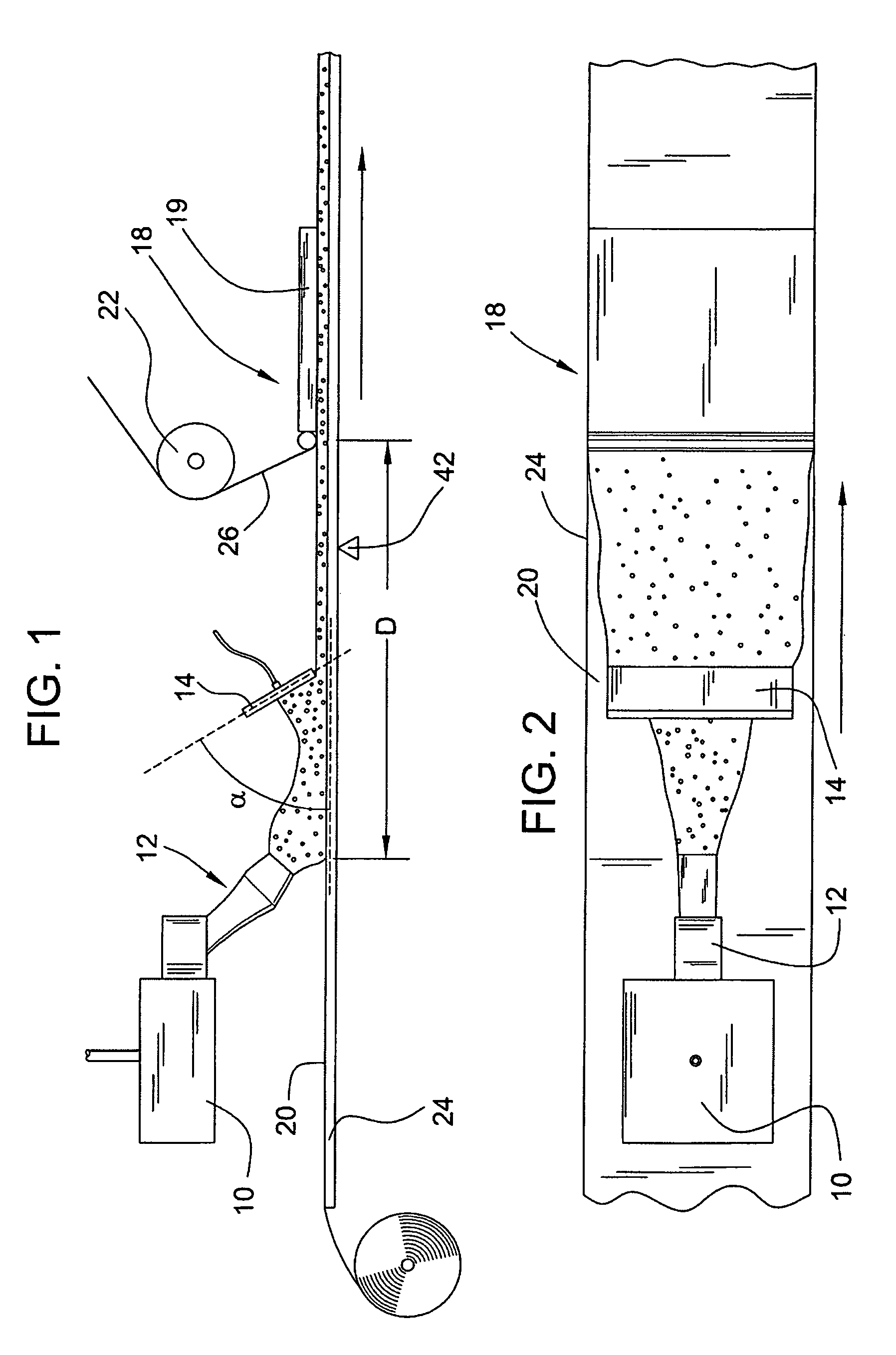

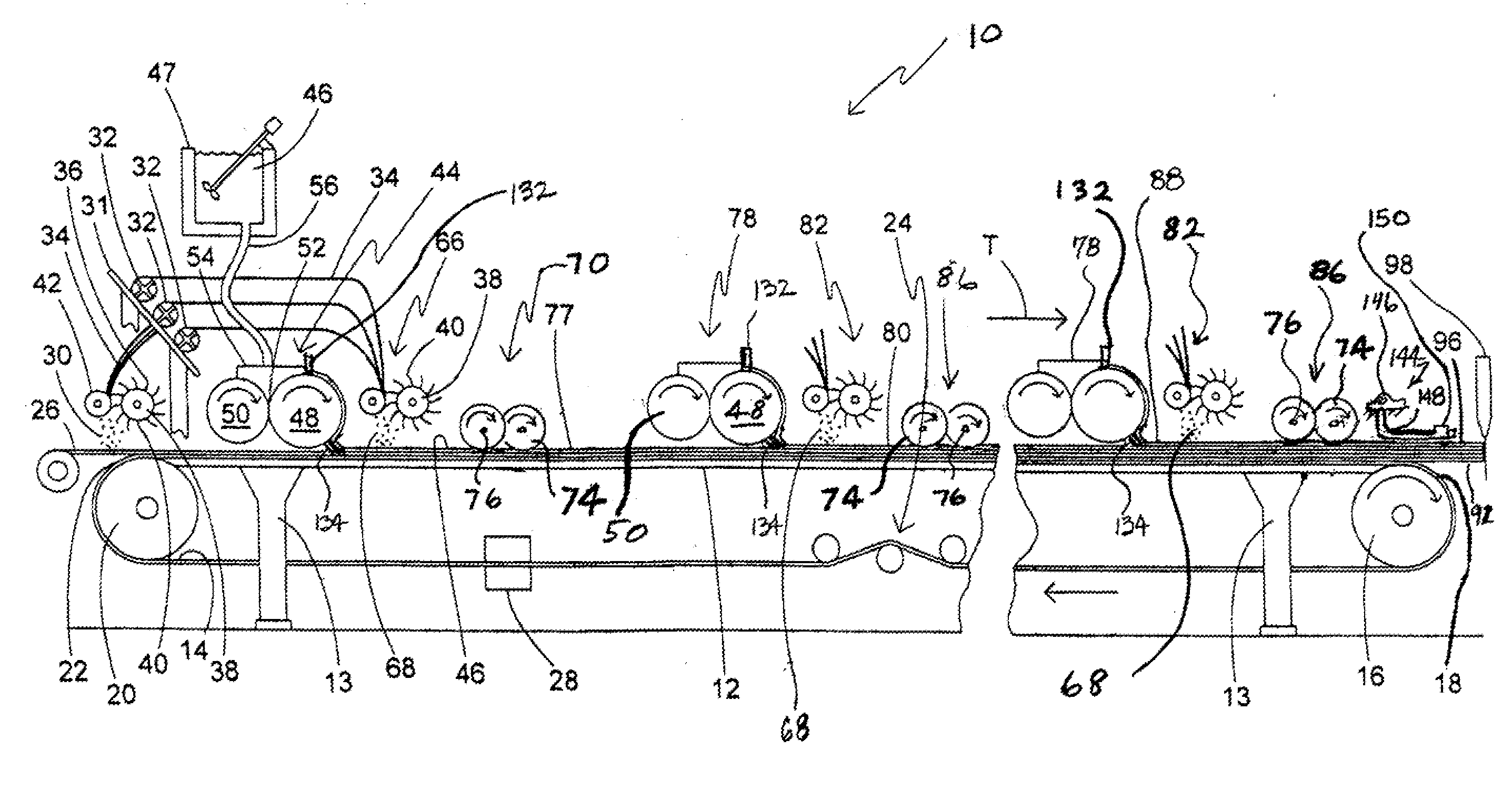

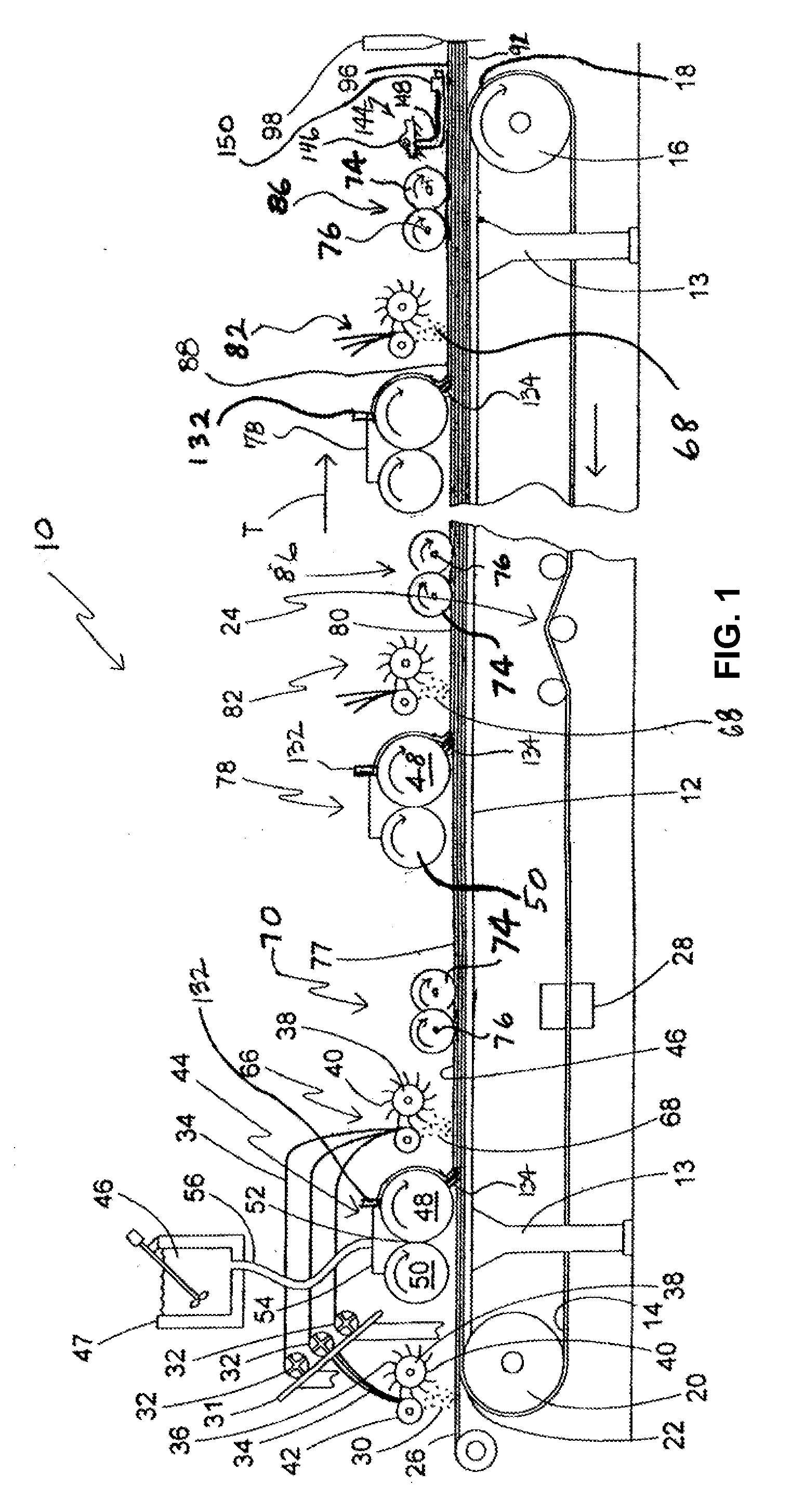

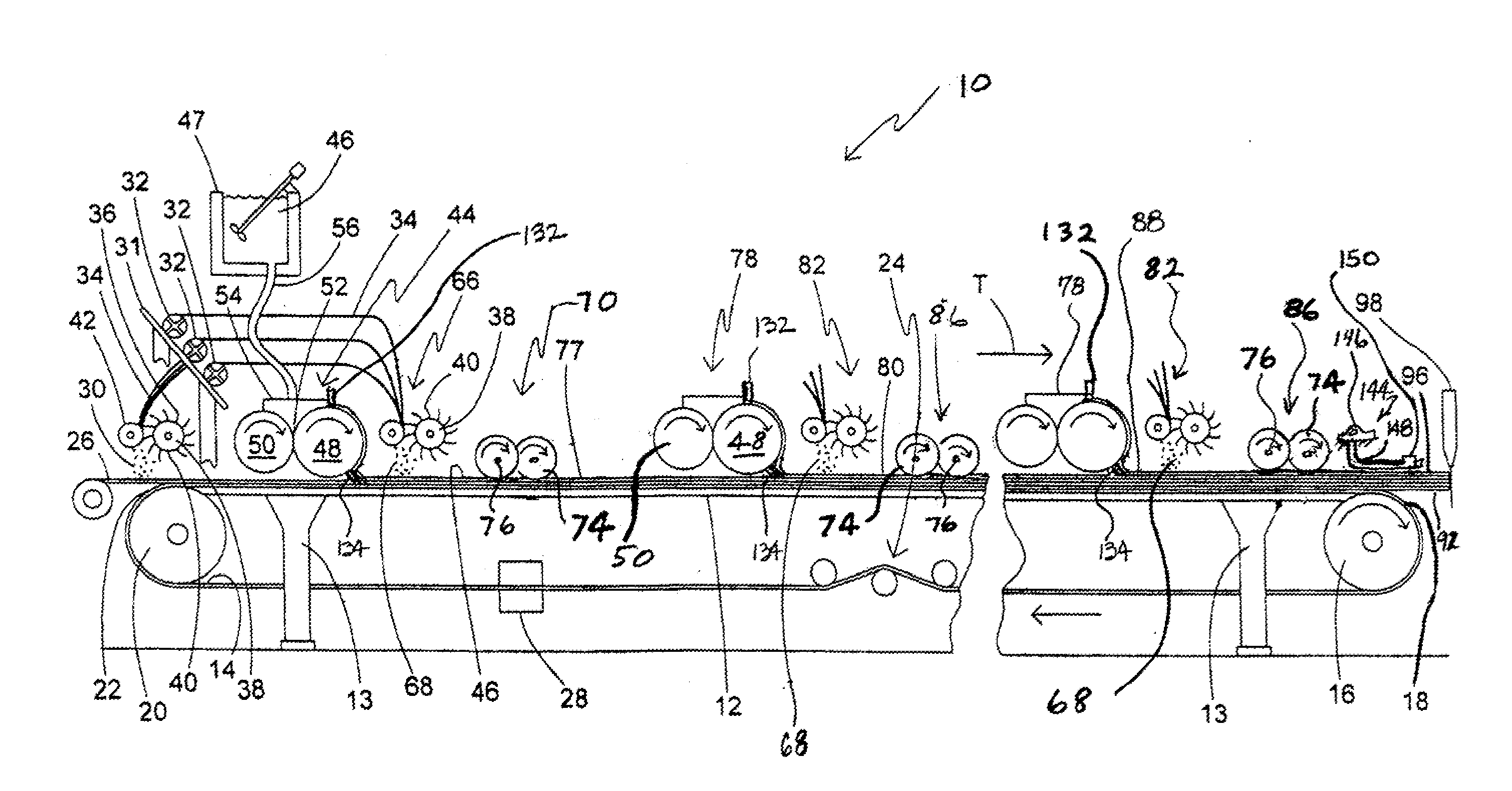

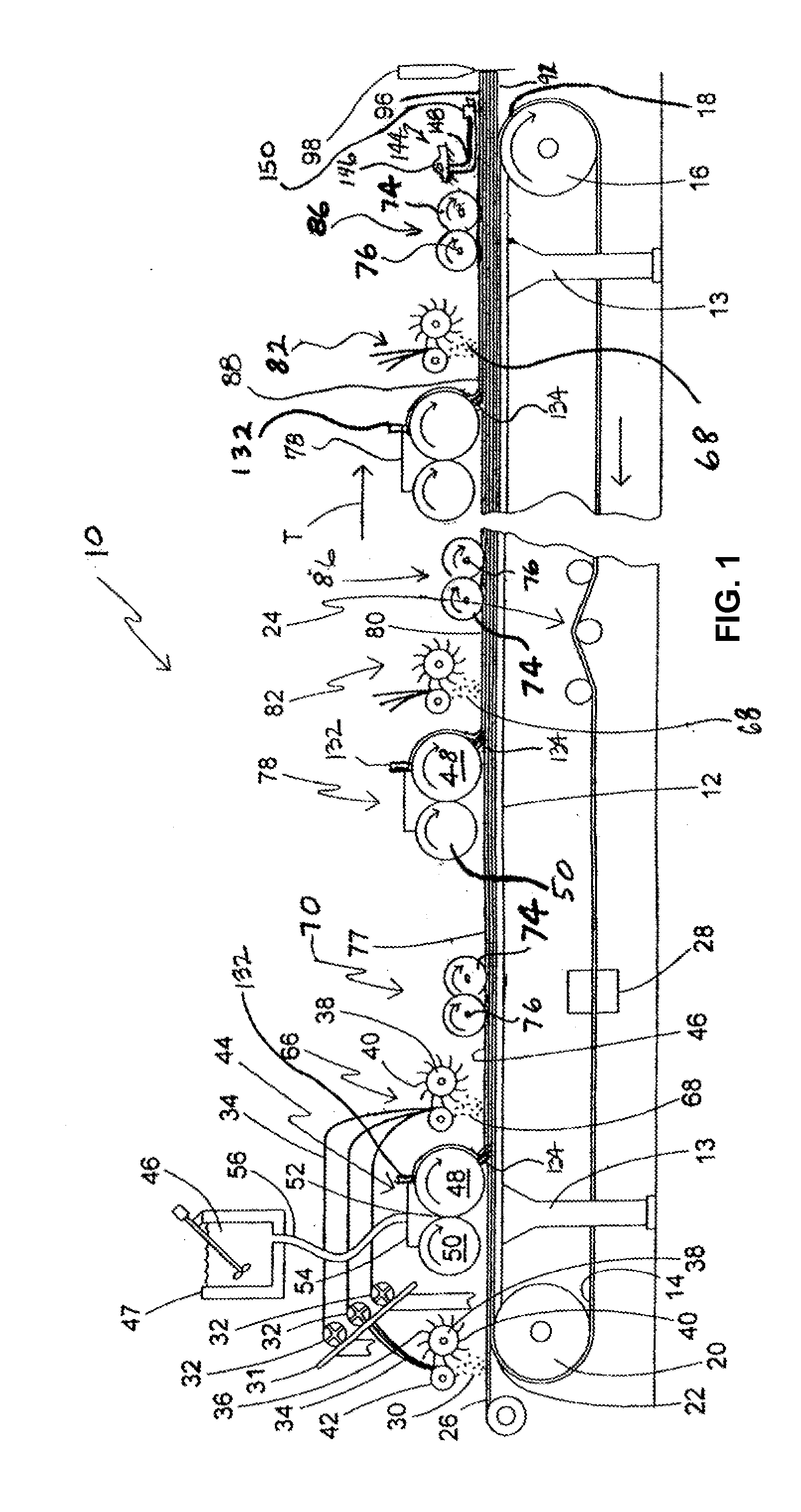

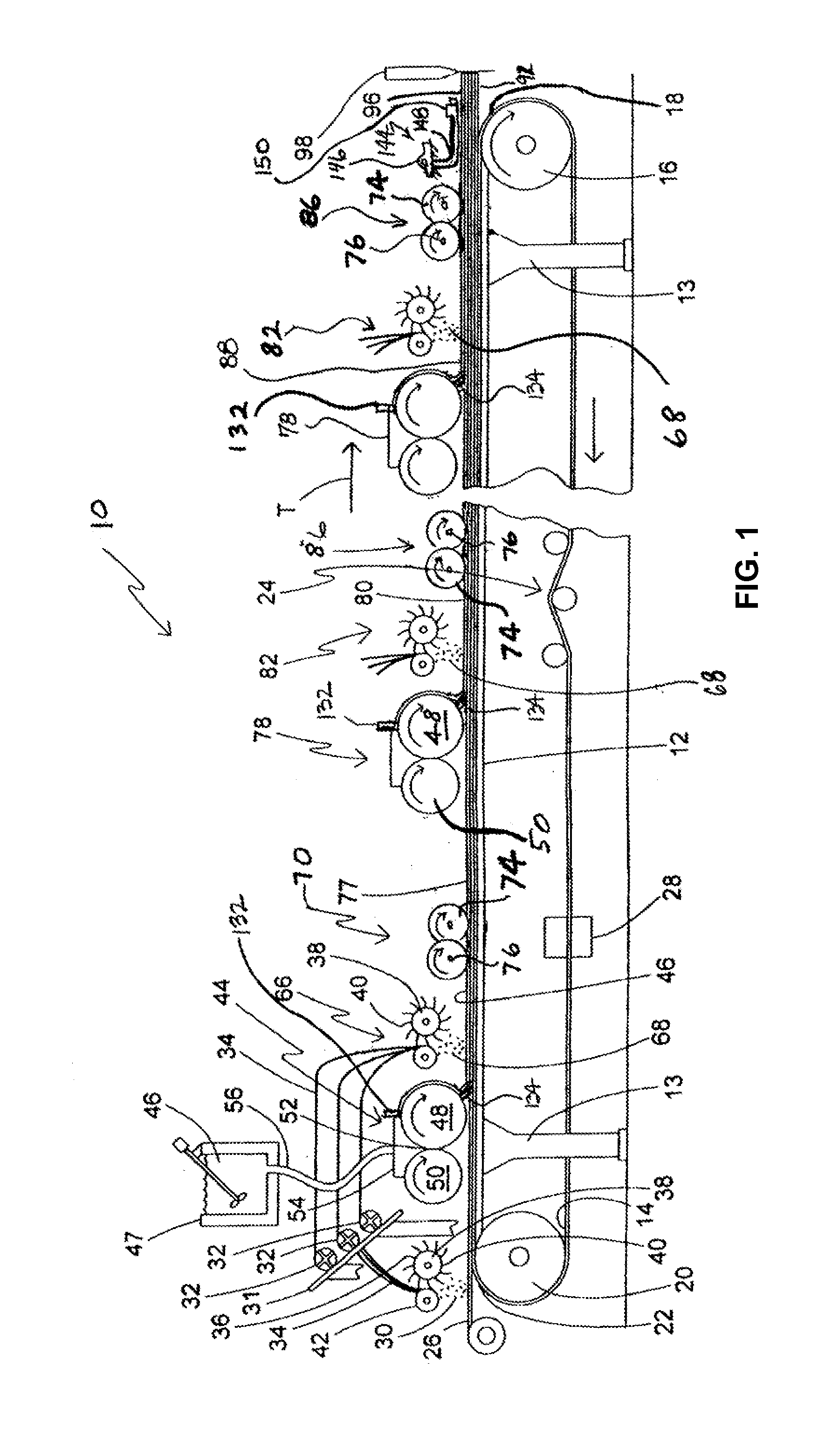

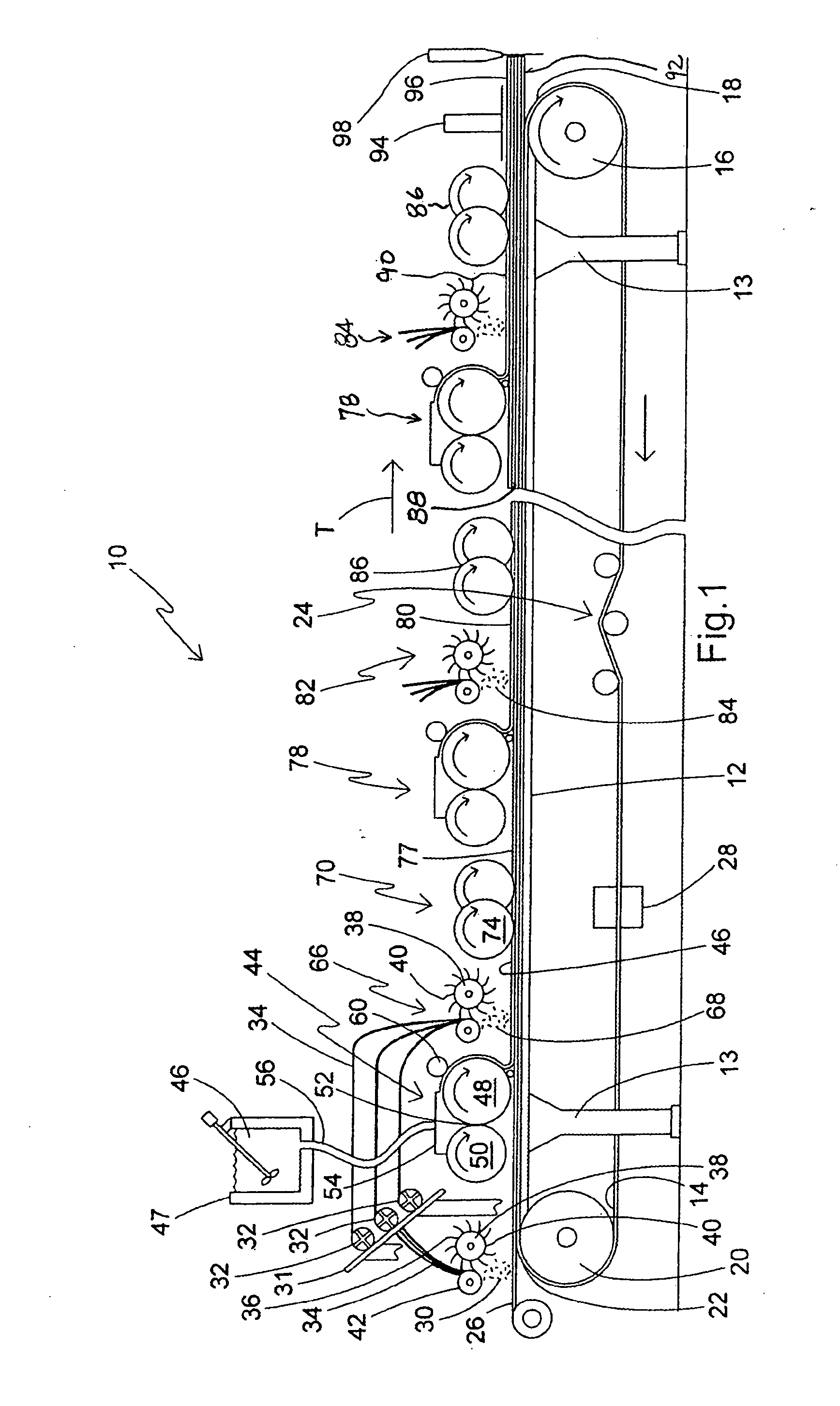

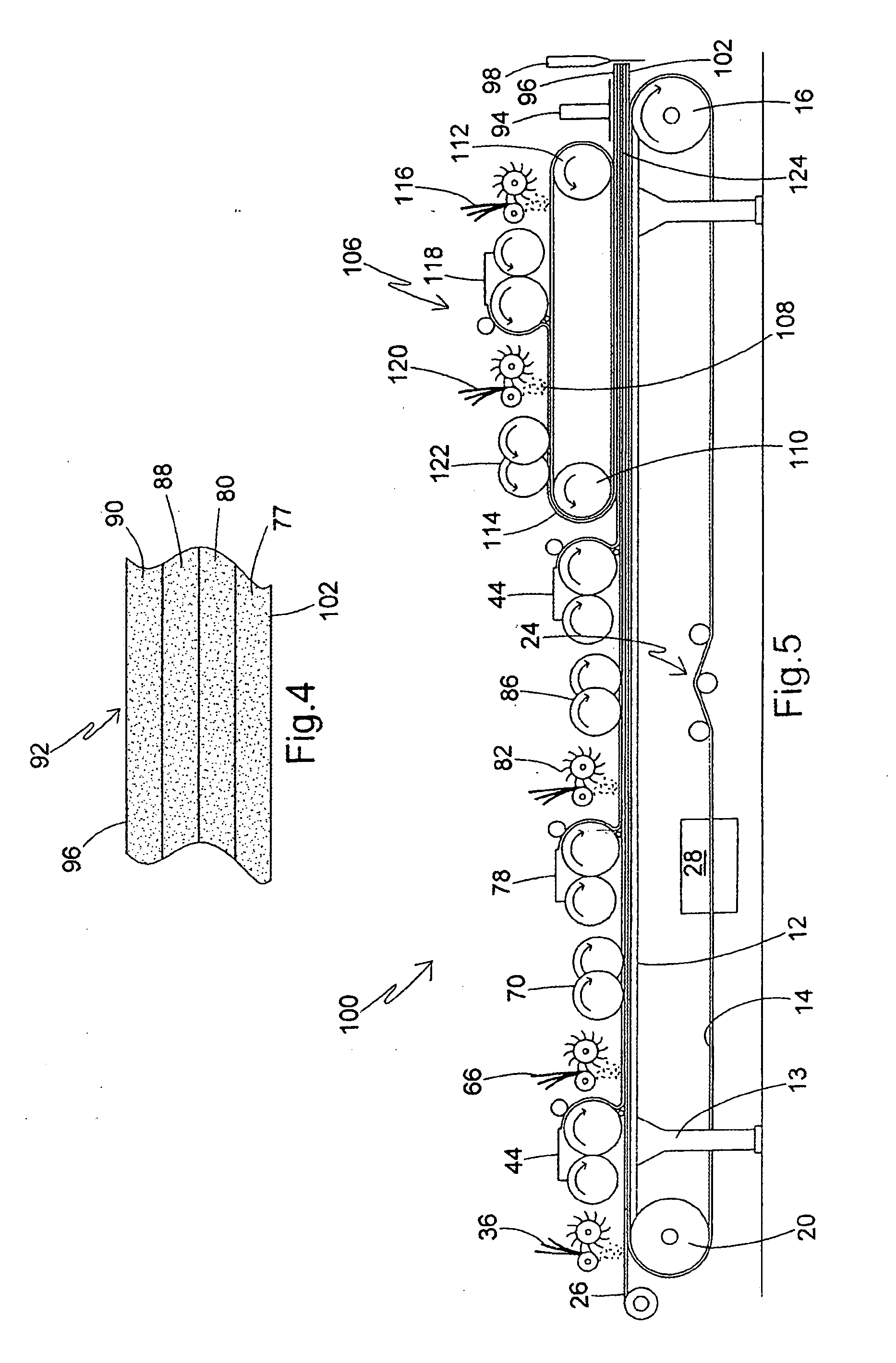

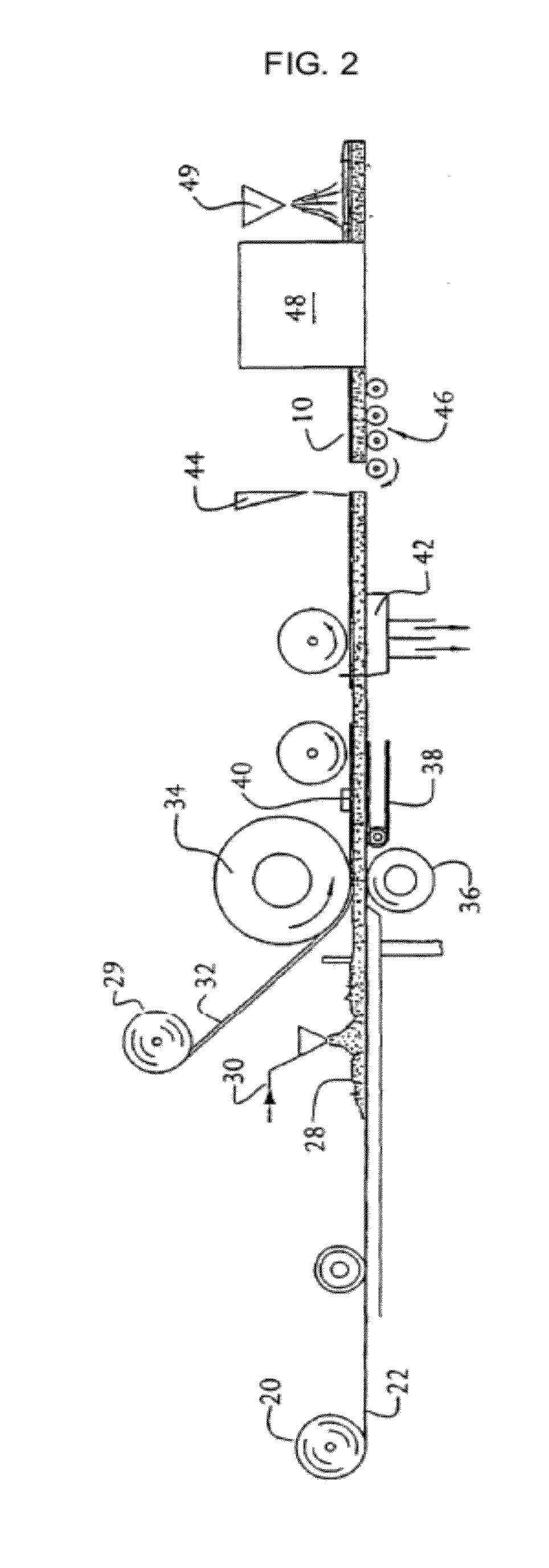

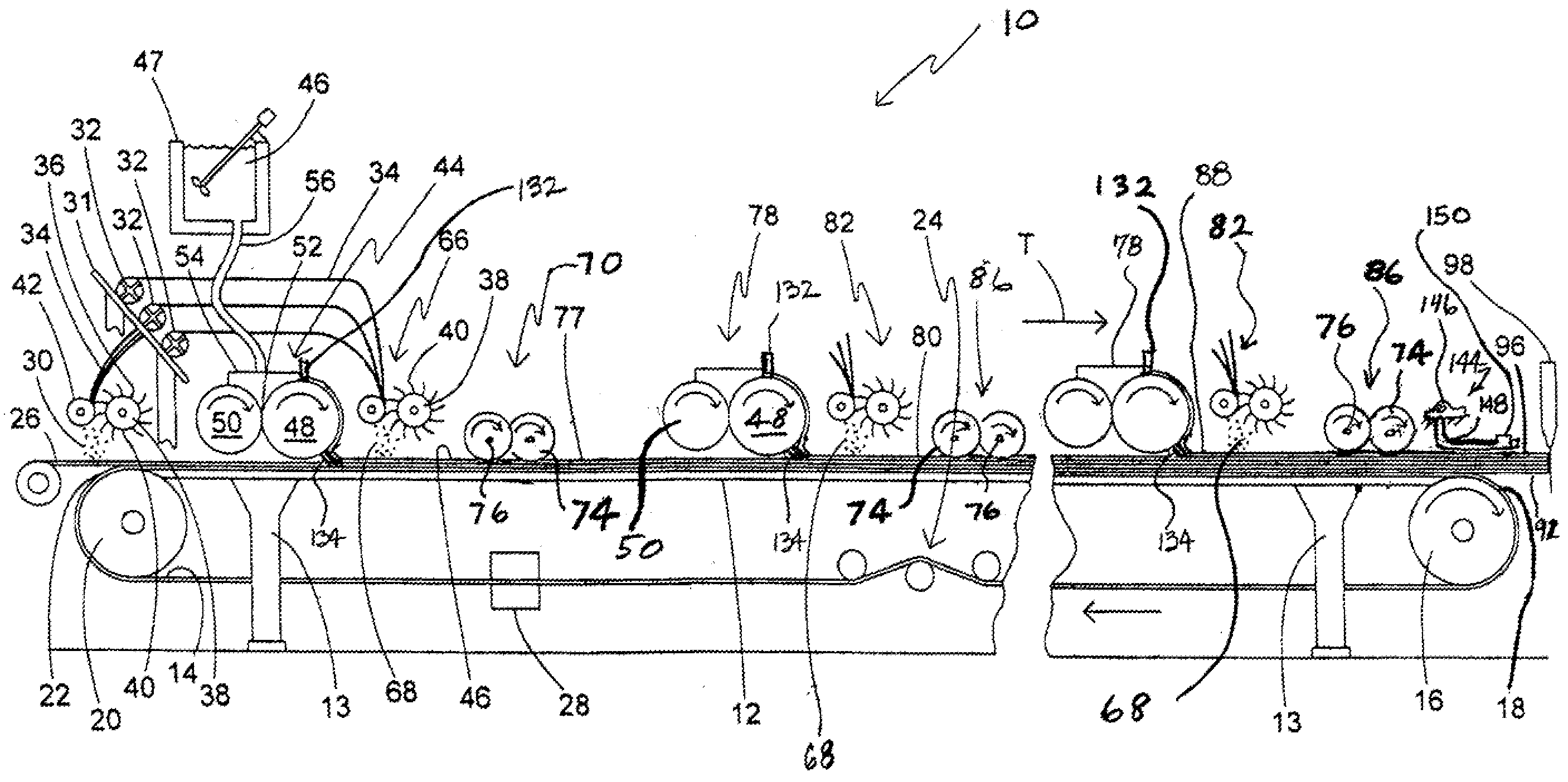

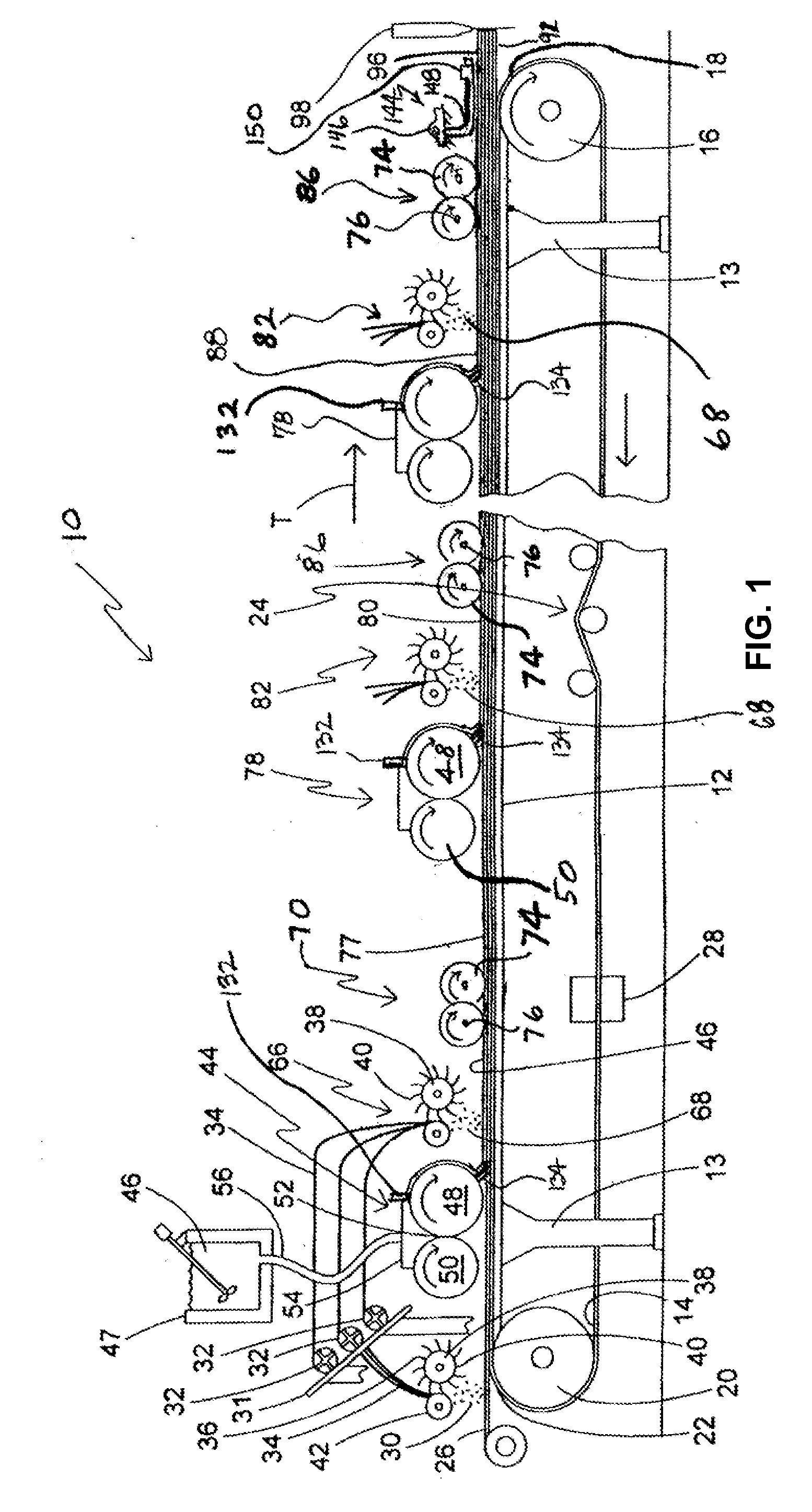

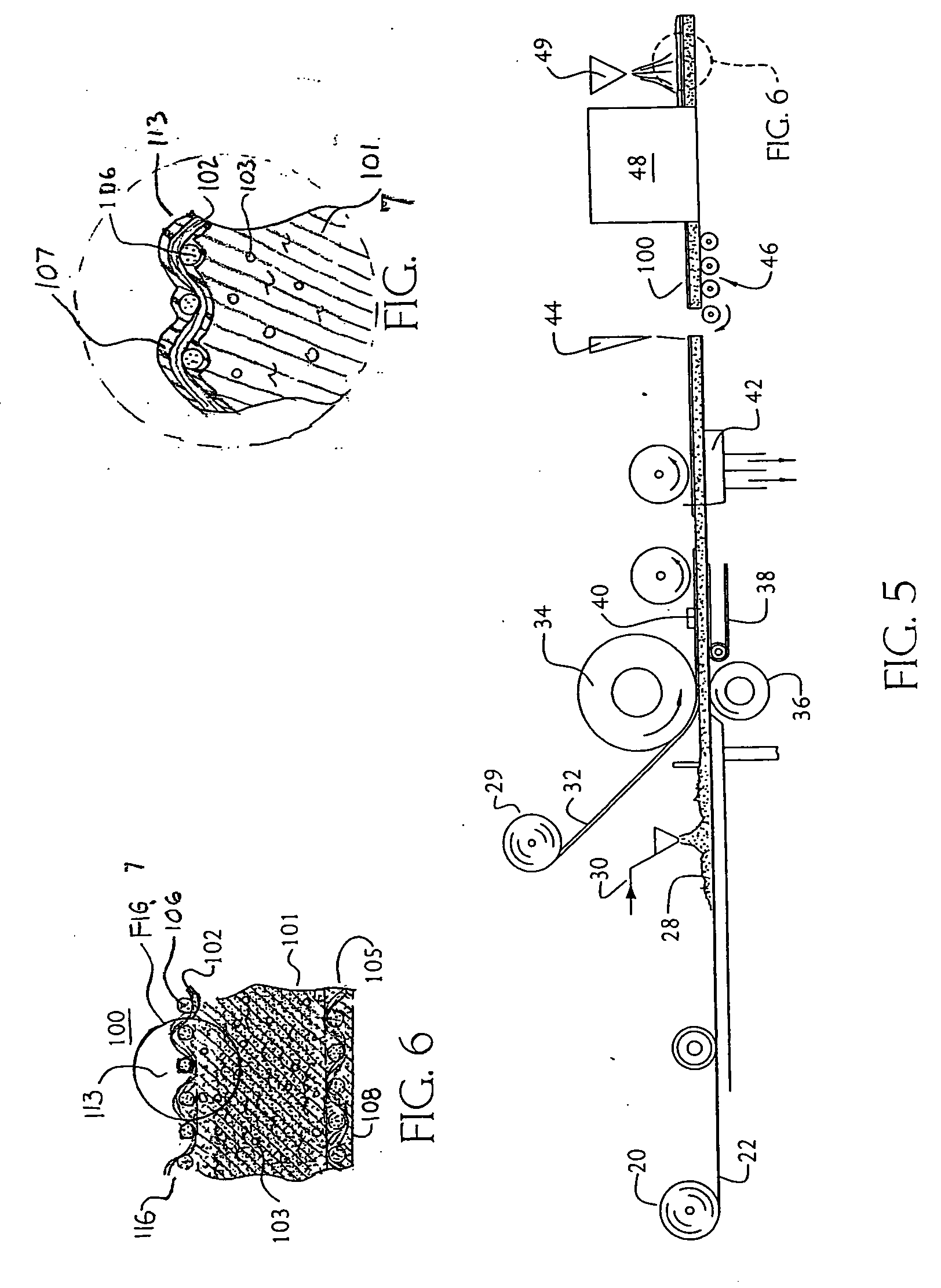

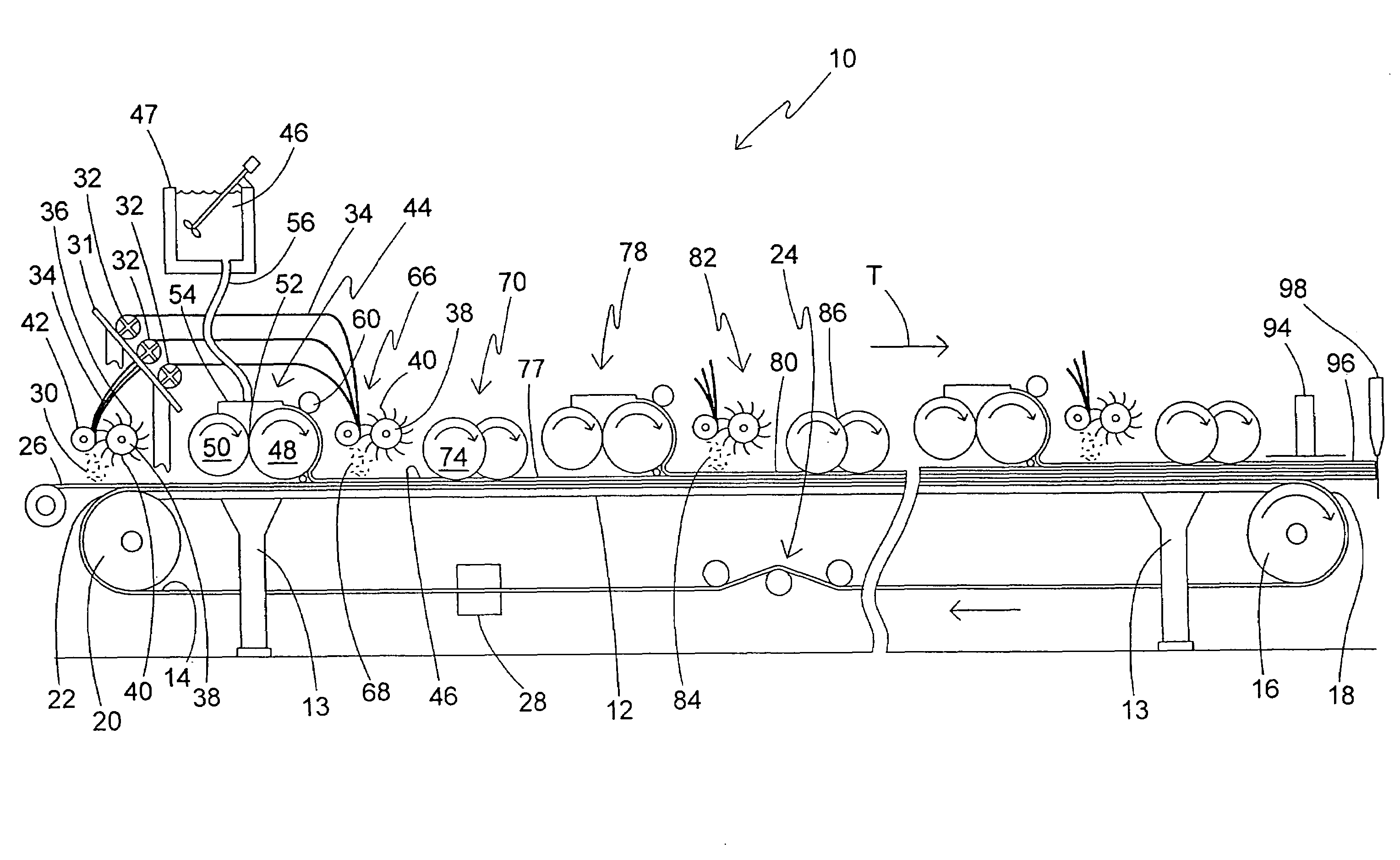

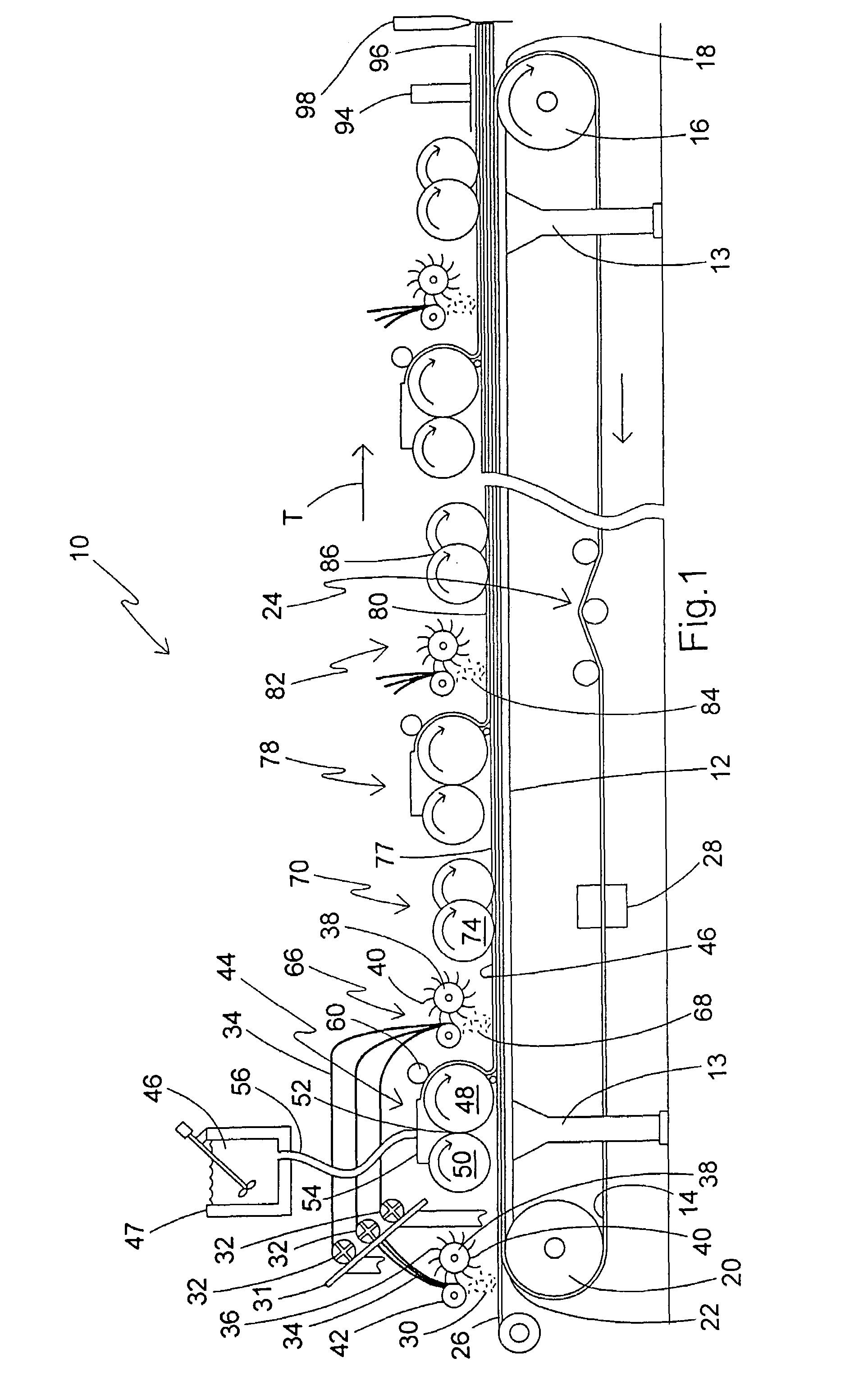

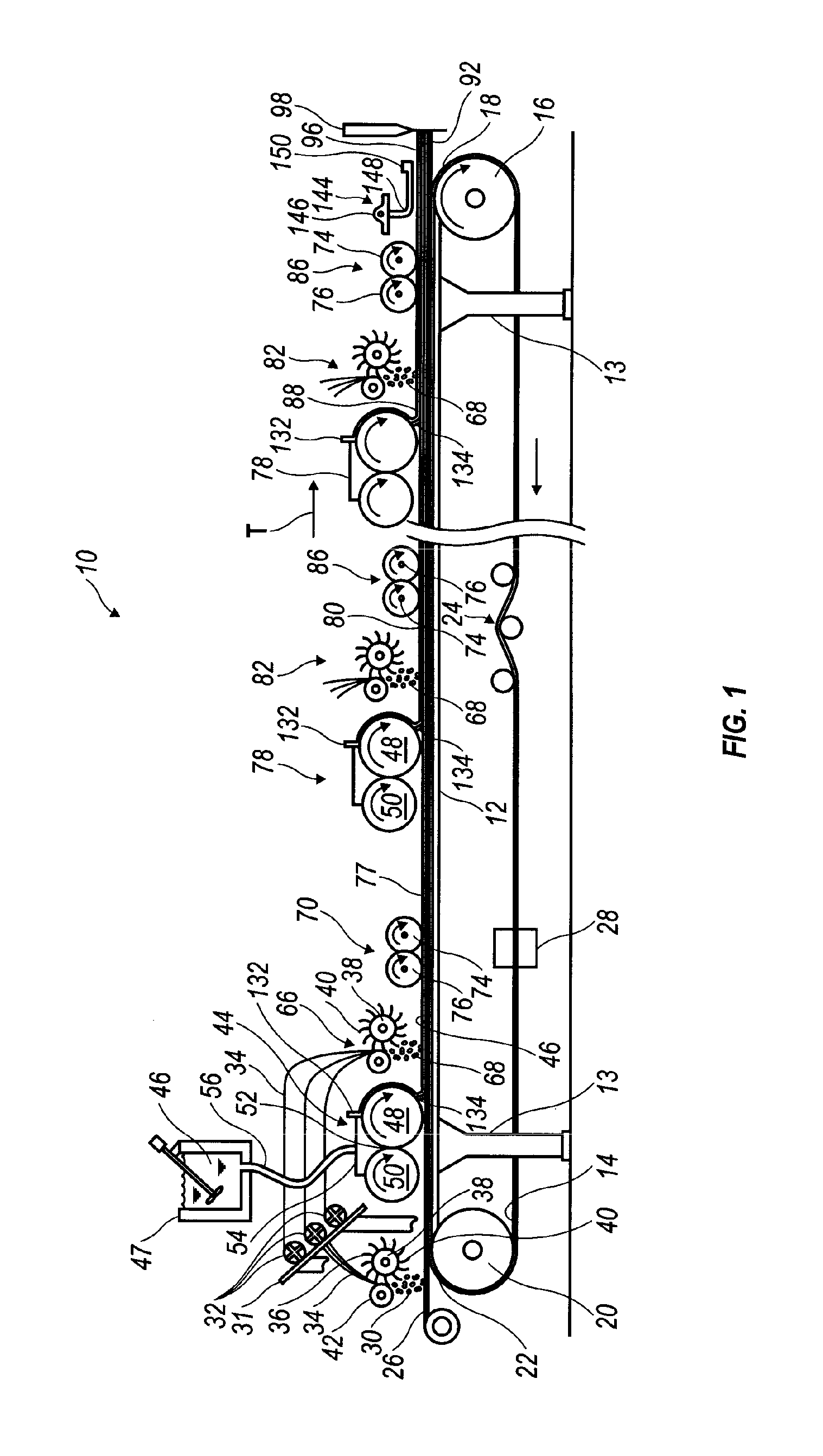

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels

ActiveUS20050064164A1Equally distributedStrong panelConstruction materialLaminationCement boardOptoelectronics

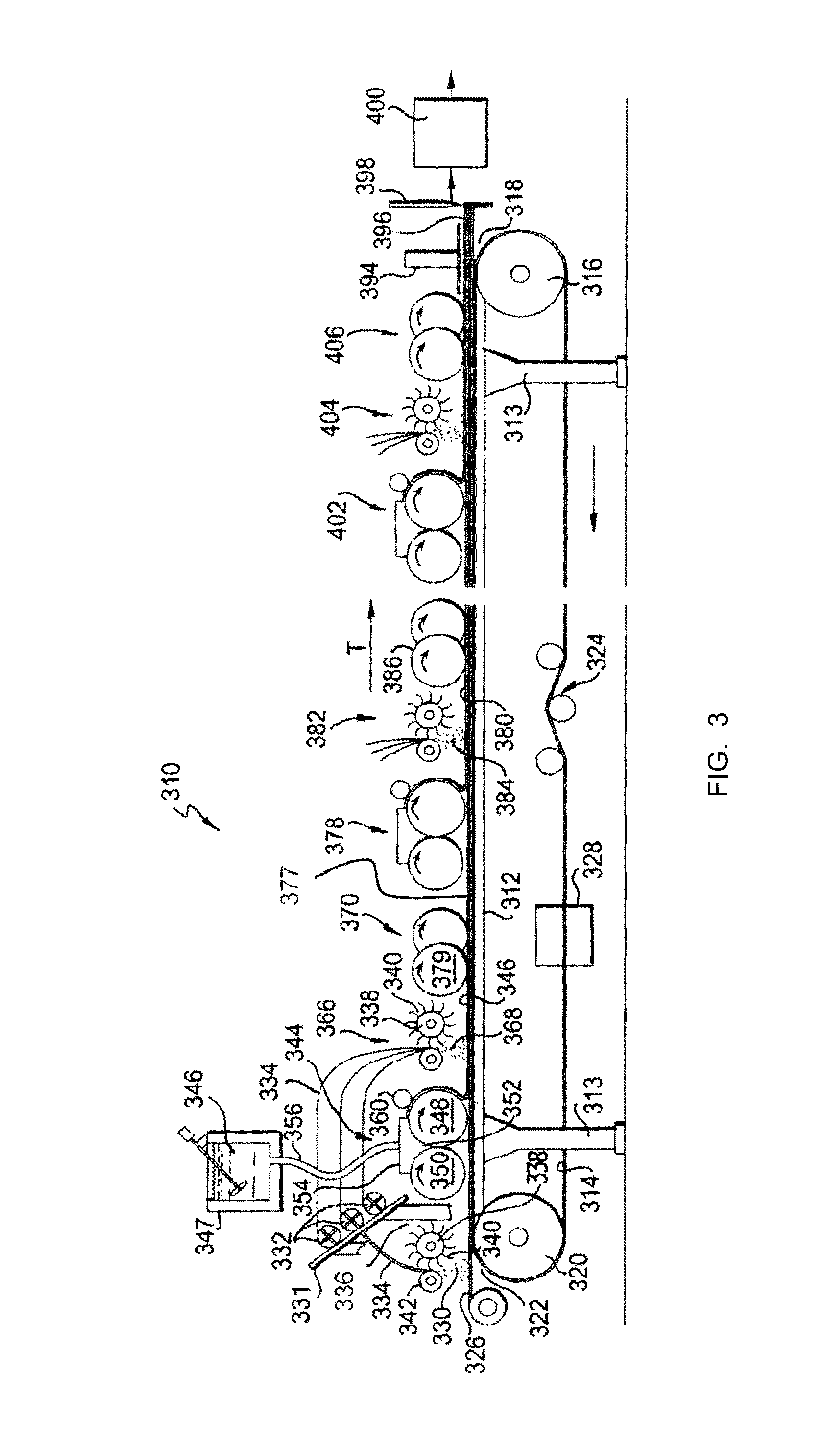

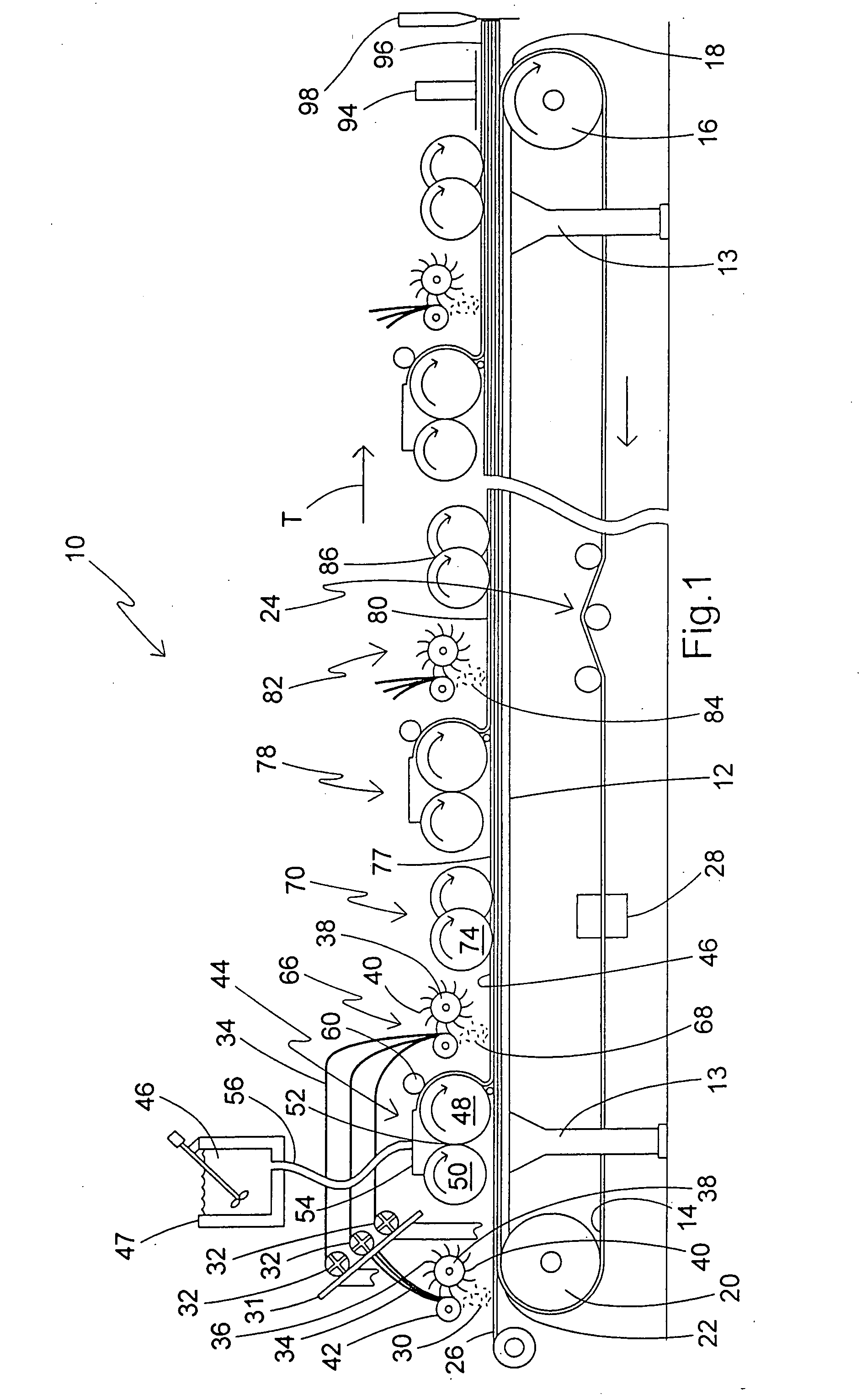

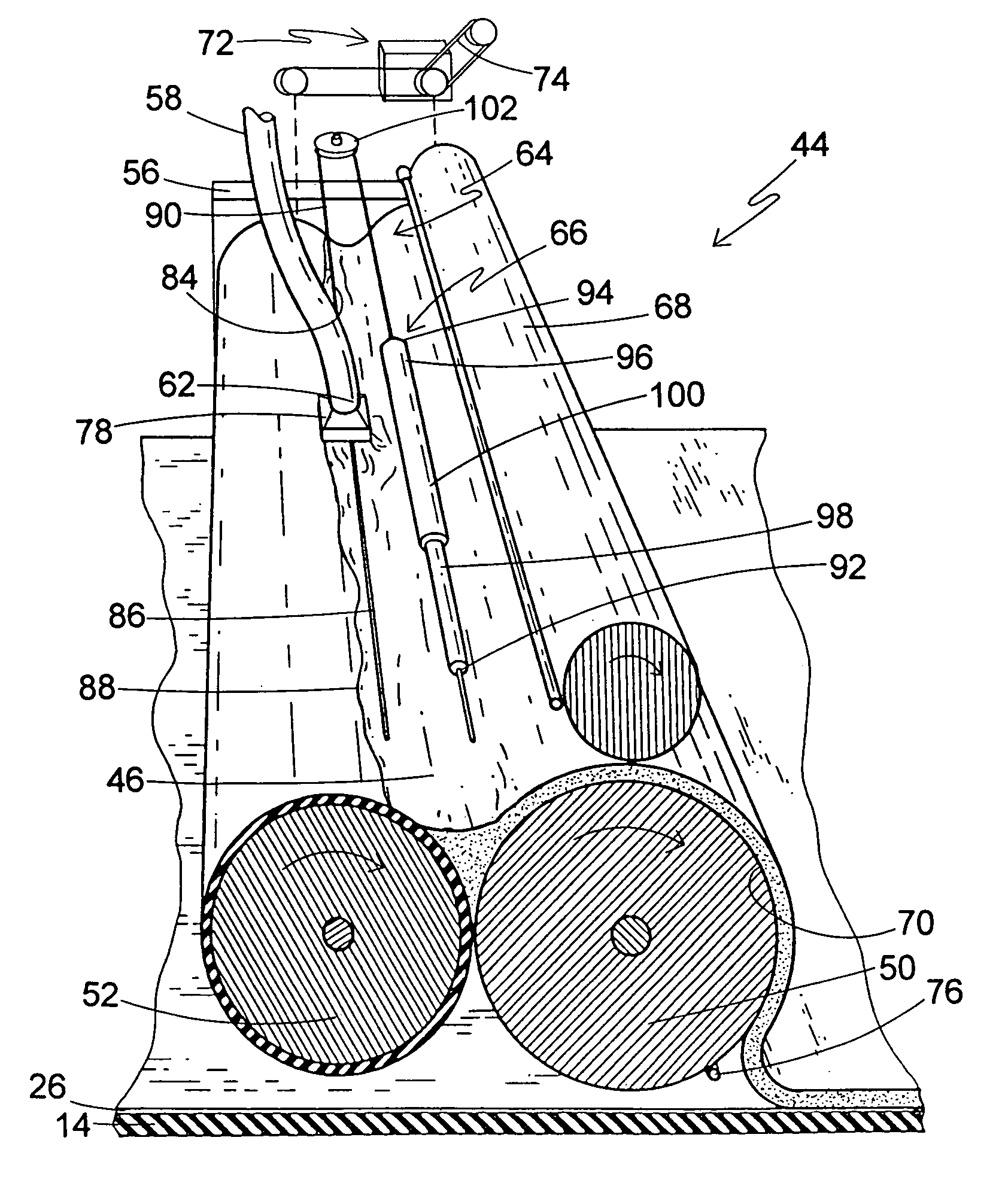

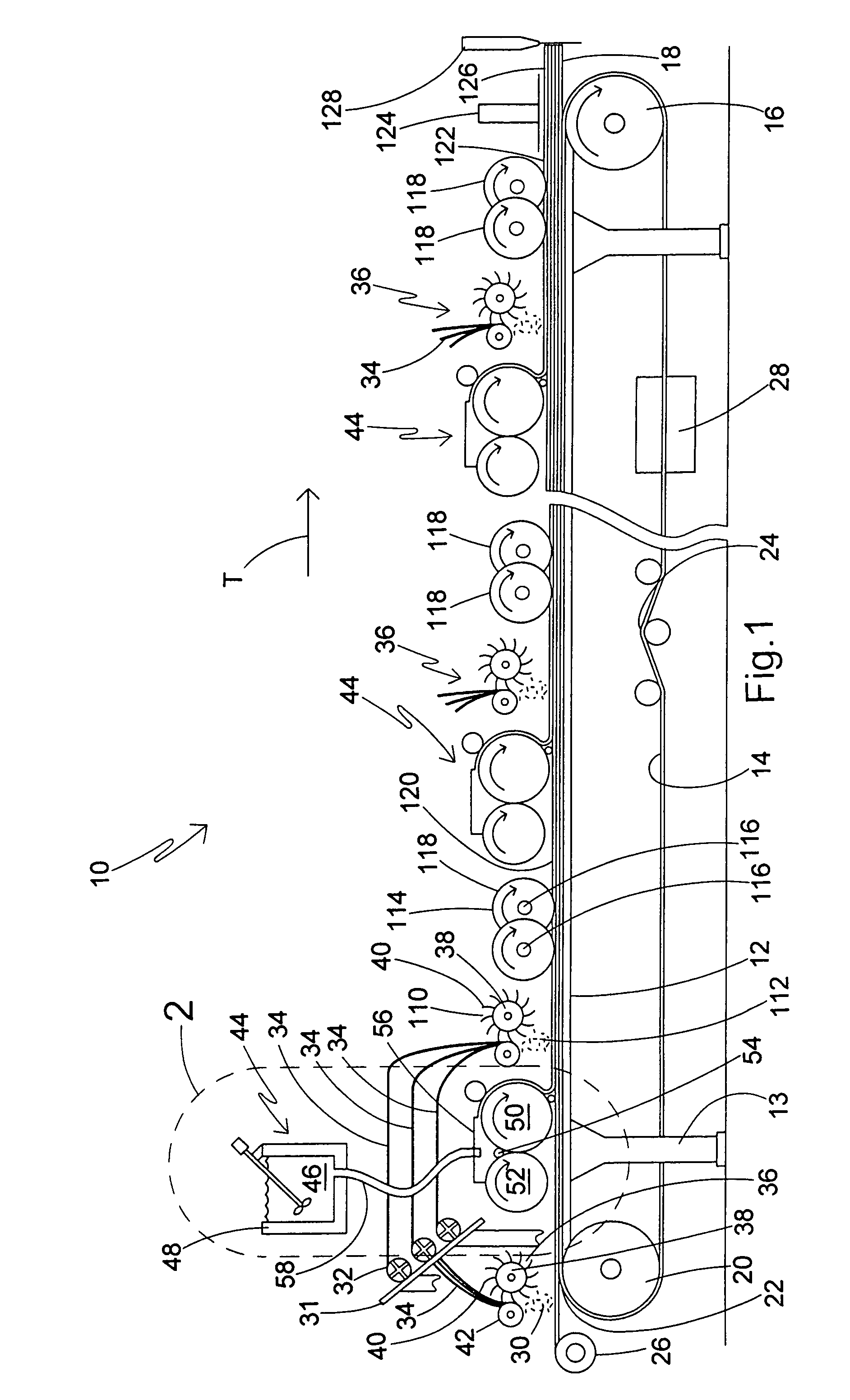

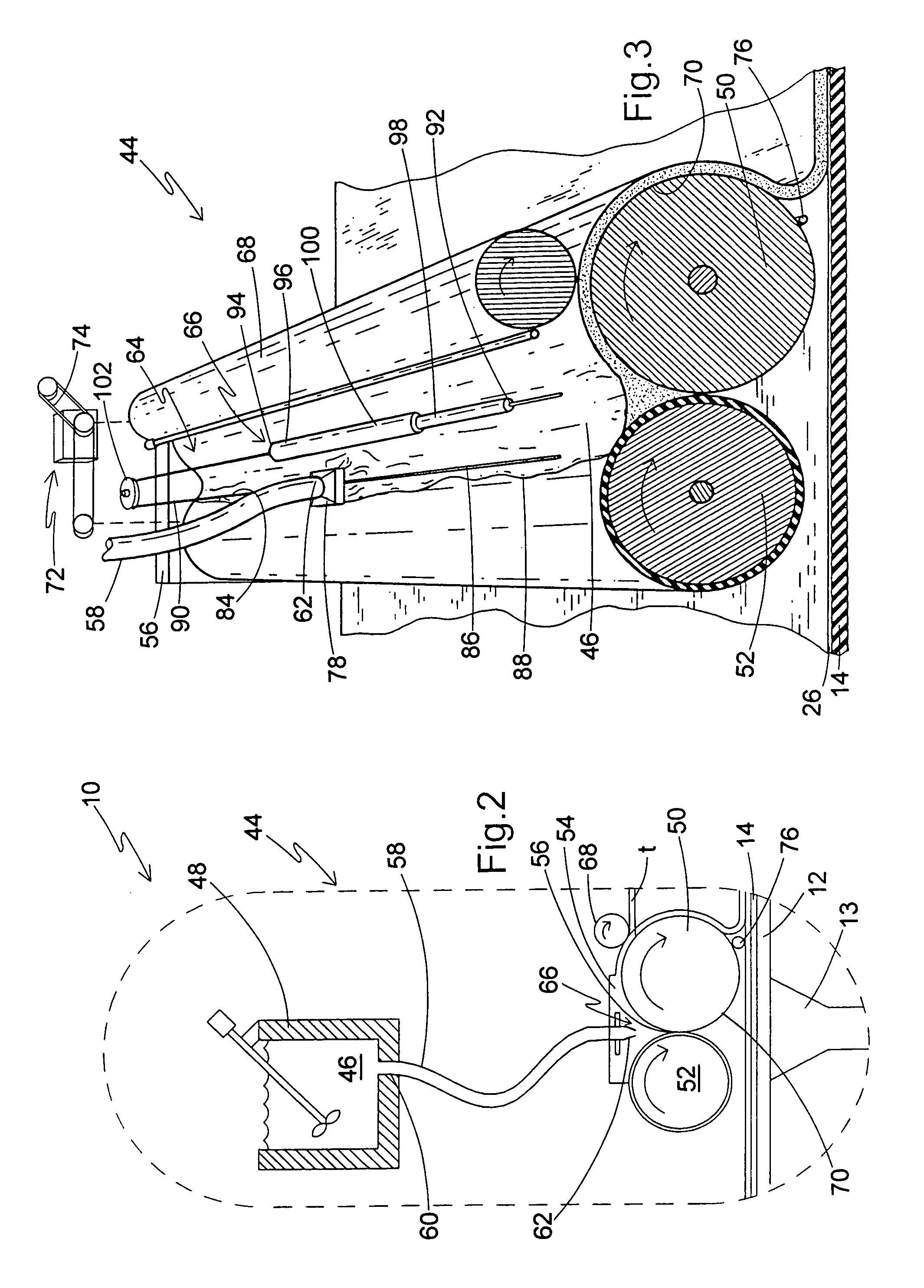

A multi-layer process for producing structural cementitious panels, includes, (a.) providing a moving web; (b.) one of depositing a first layer of loose fibers upon the web and (c.) depositing a layer of settable slurry upon the web; (d.) depositing a second layer of loose fibers upon the slurry; (e.) embedding said second layer of fibers into the slurry; and (f.) repeating steps (c.) through (e.) until the desired number of layers of settable fiber-enhanced slurry in the panel is obtained. Also provided are a structural panel produced by the present process, an apparatus suitable for producing structural cementitious panels according to the present process, and a structural cementitious panel having multiple layers, each layer created by depositing a layer of settable slurry upon a moving web, depositing fibers upon the slurry and embedding the fibers into the slurry such that each layer is integrally formed with the adjacent layers.

Owner:UNITED STATES GYPSUM CO

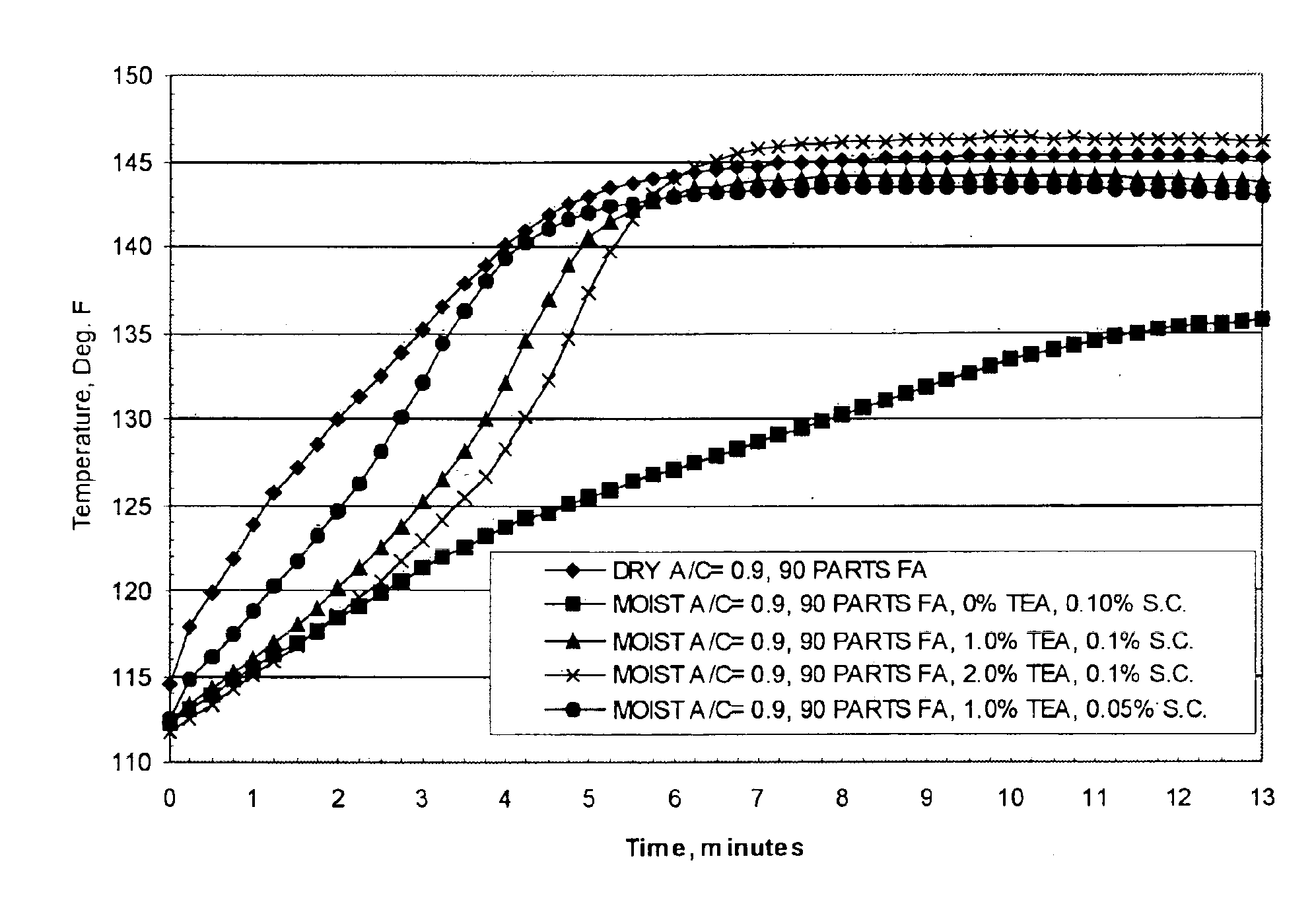

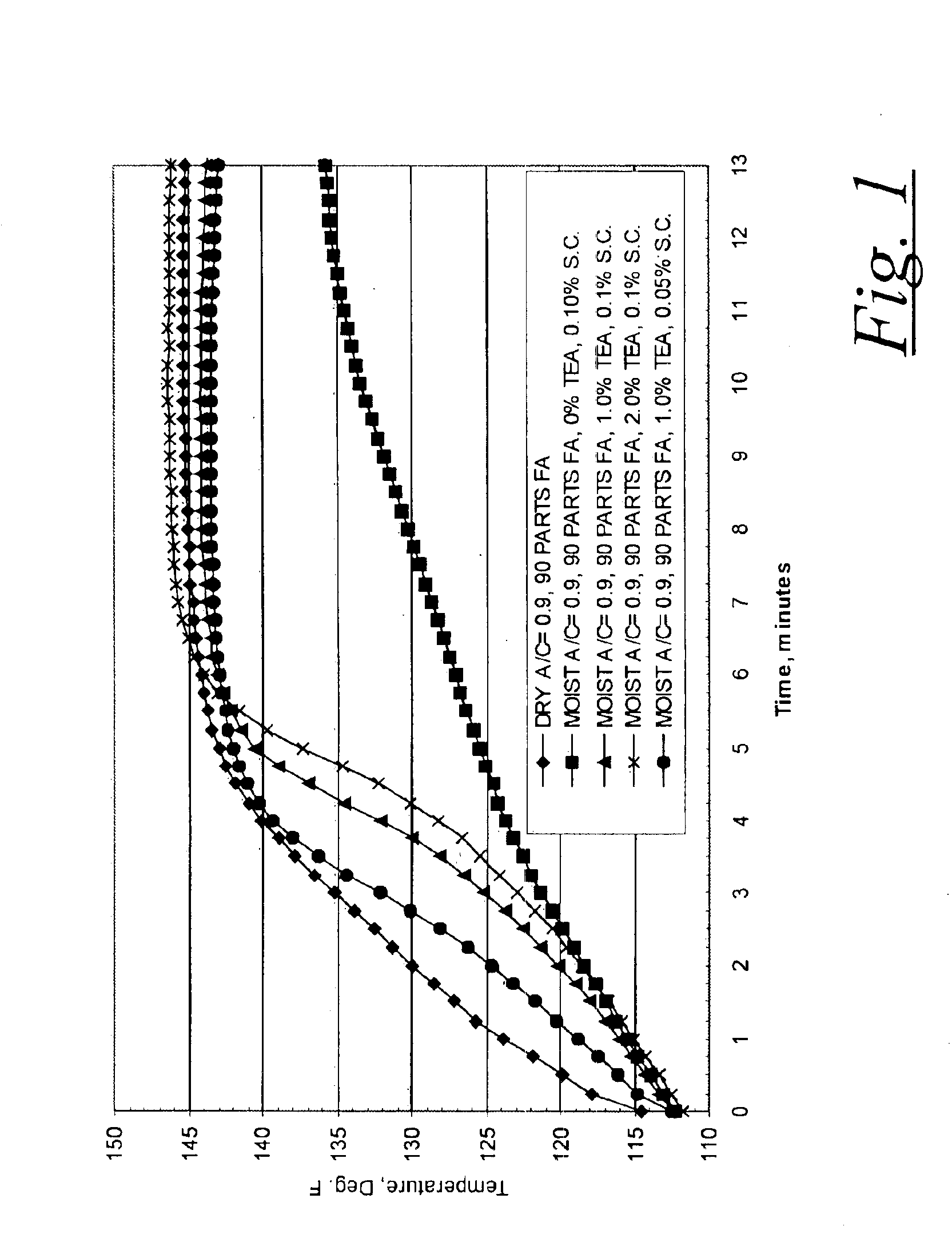

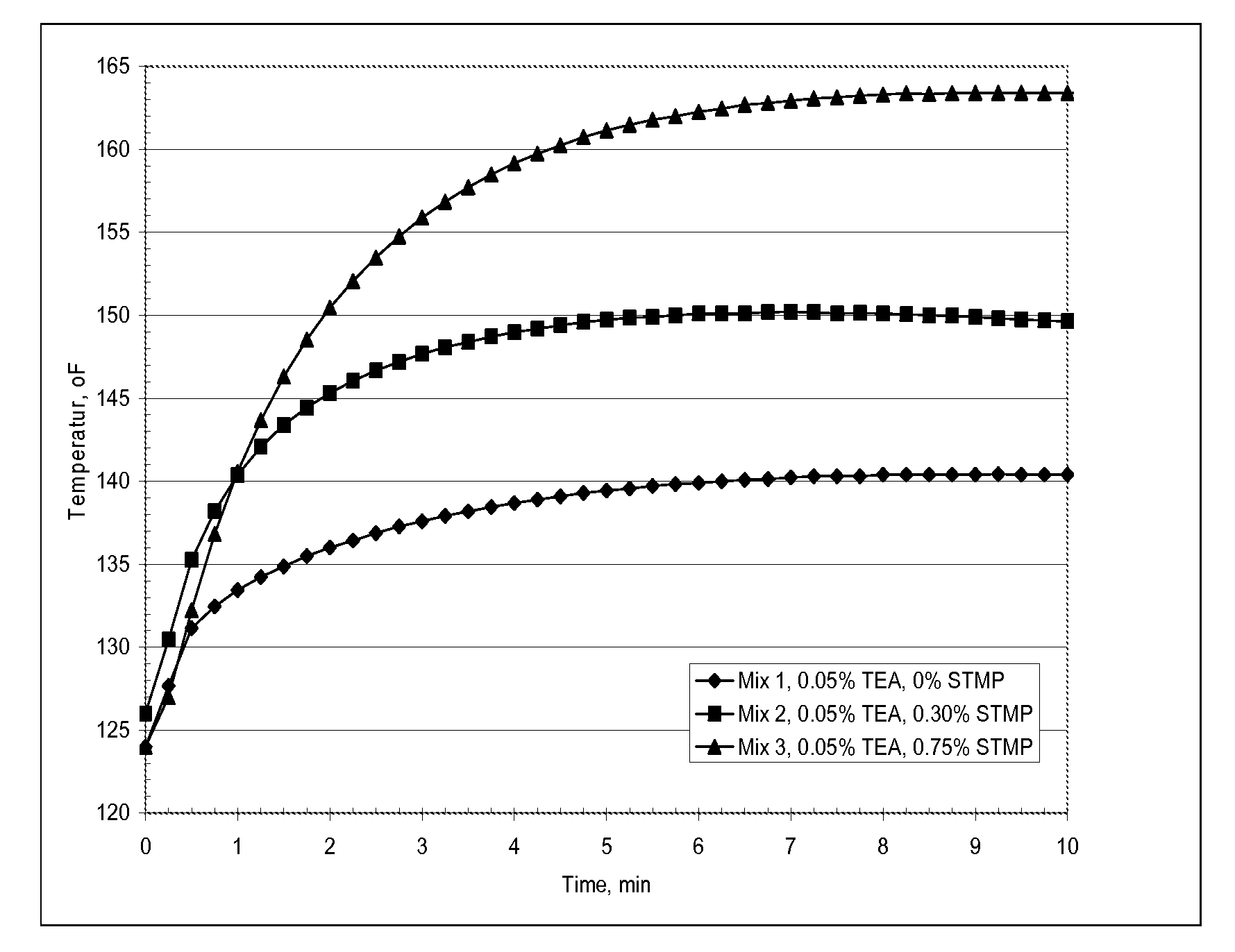

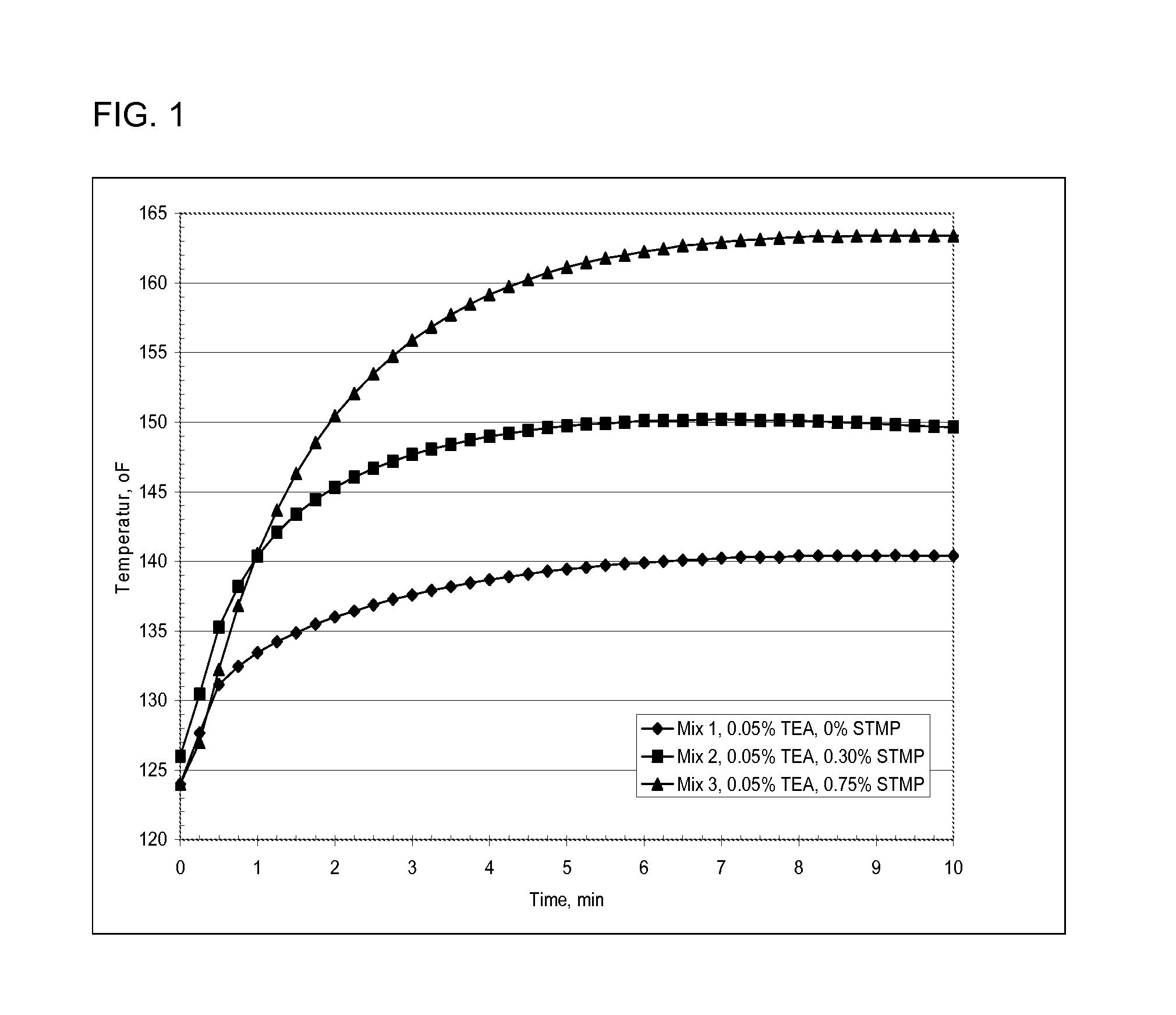

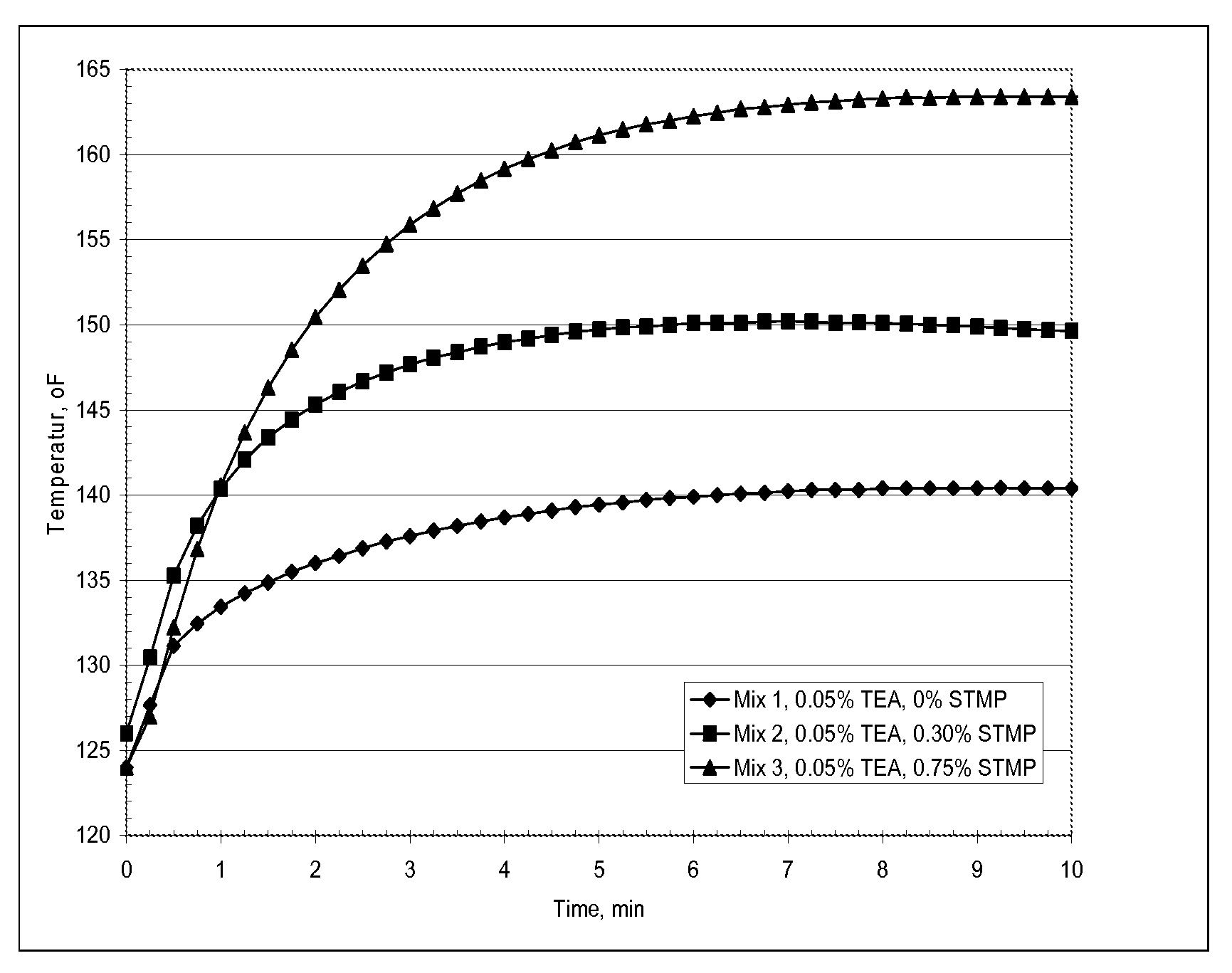

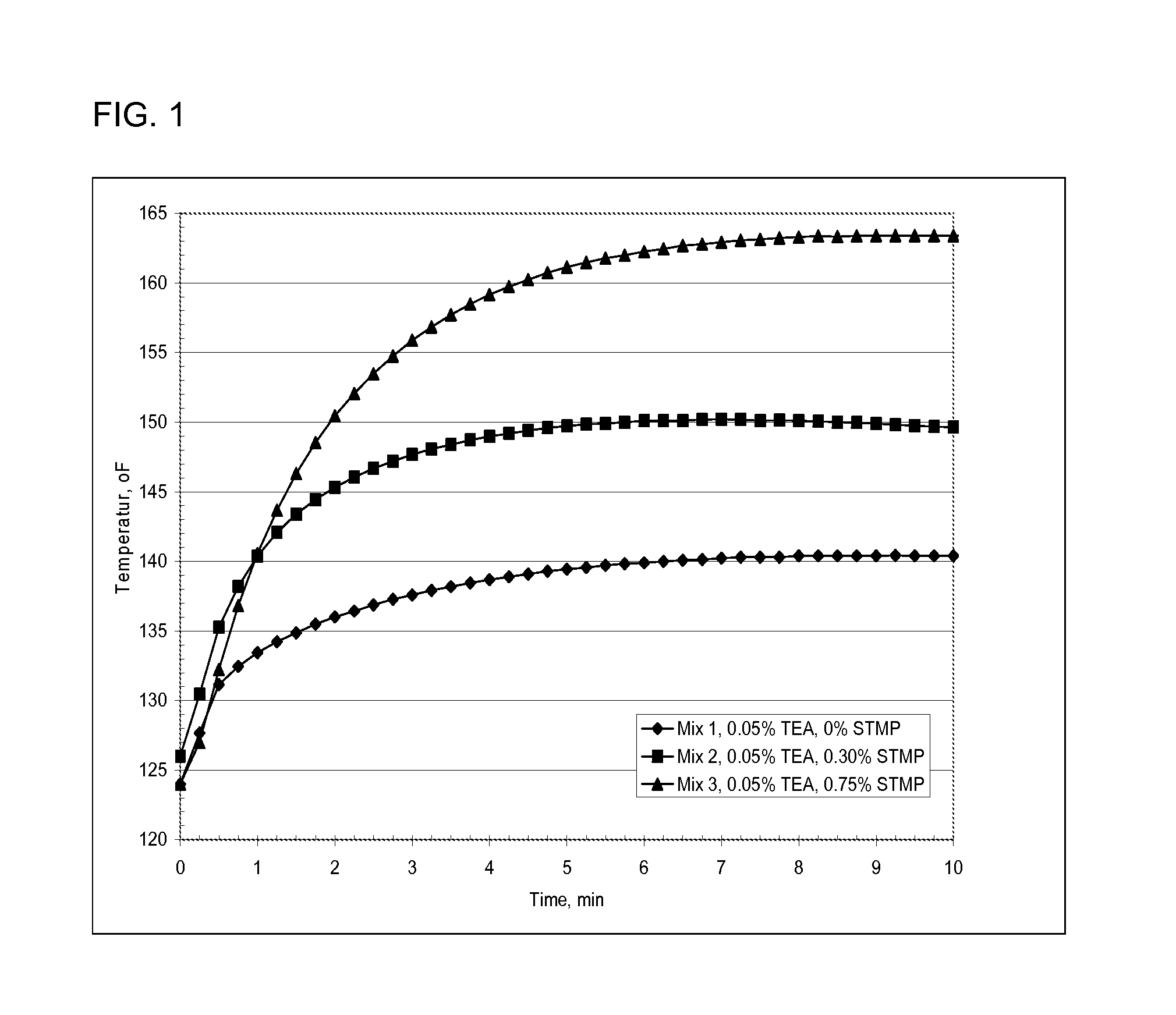

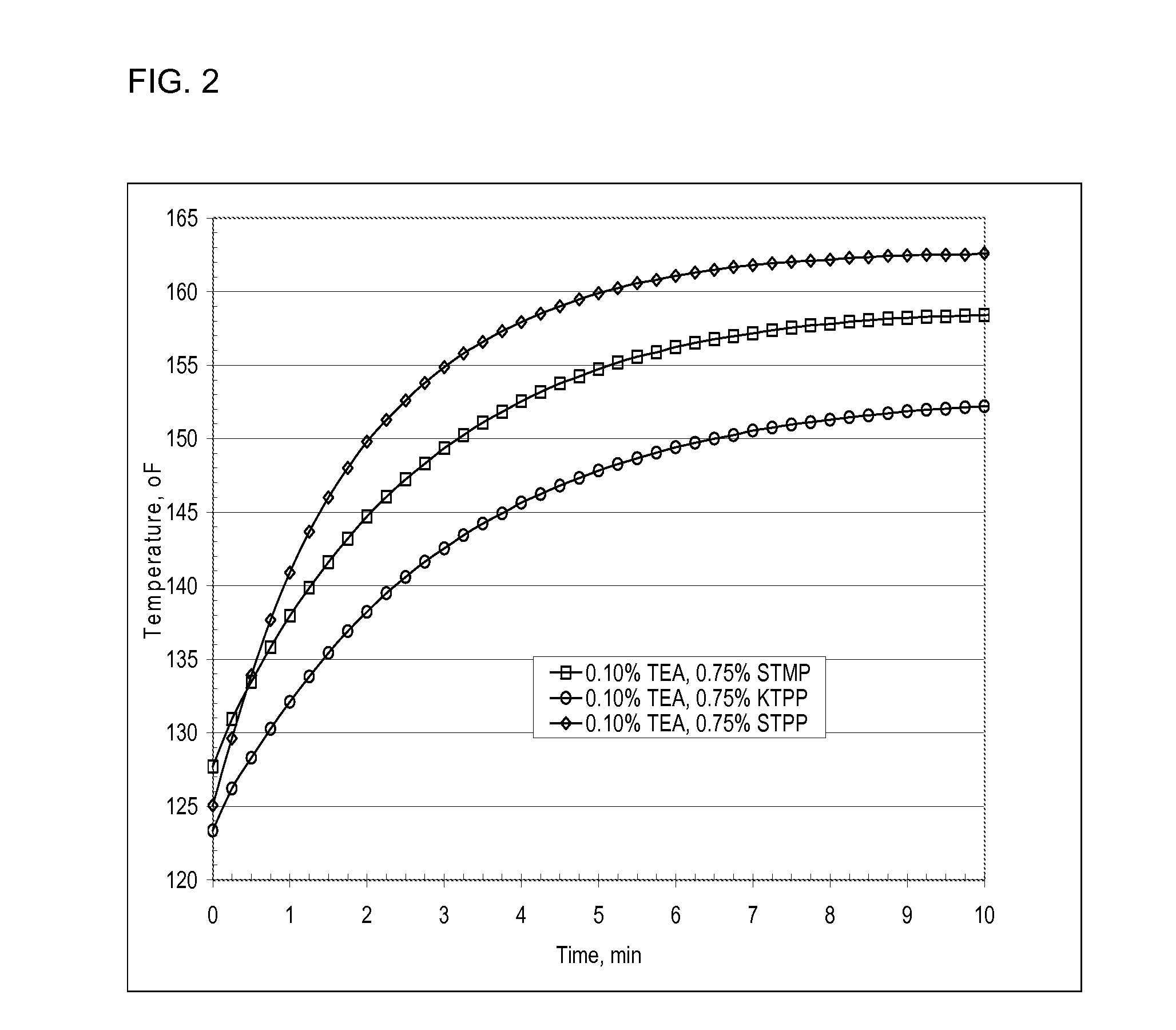

Very fast setting cementitious composition

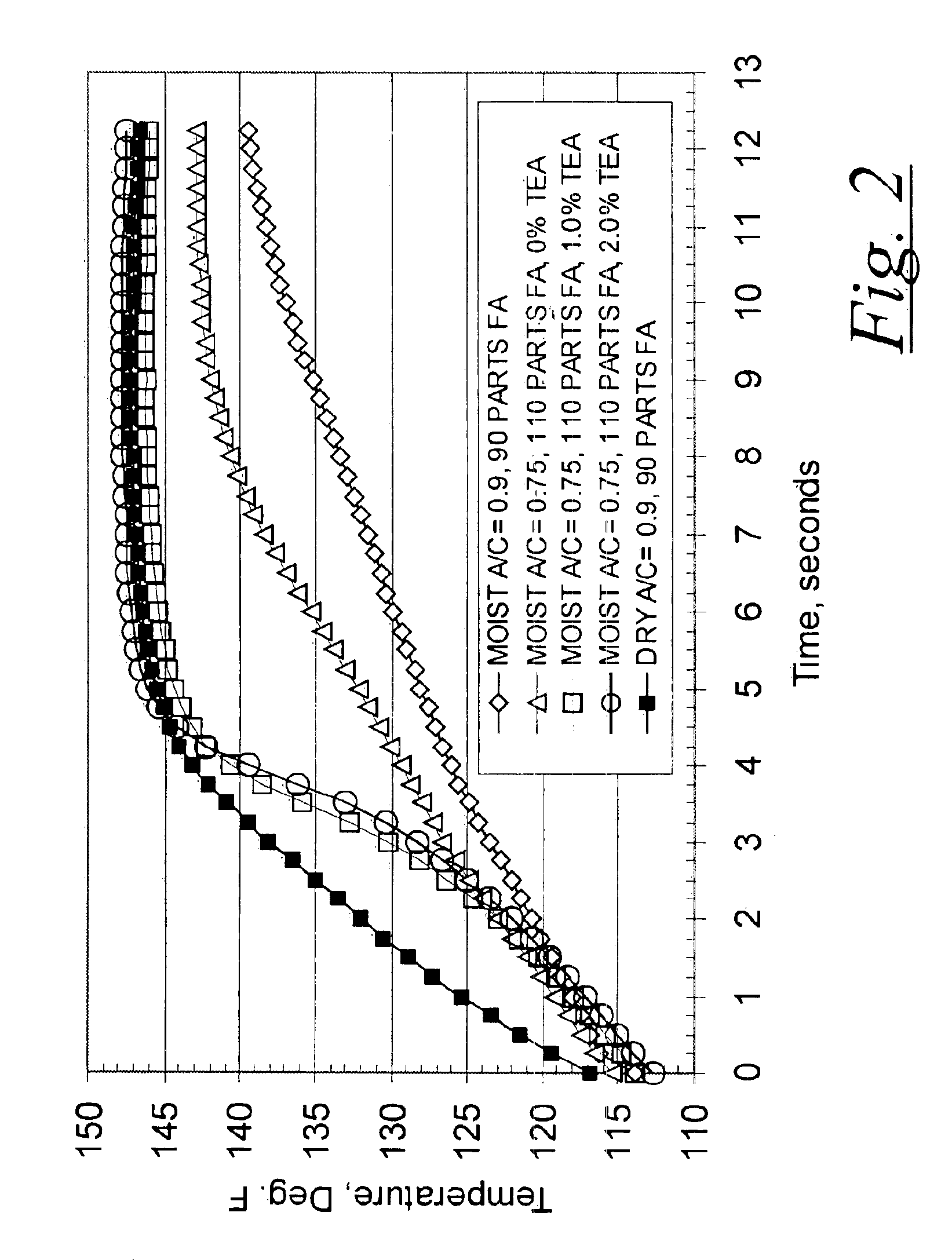

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

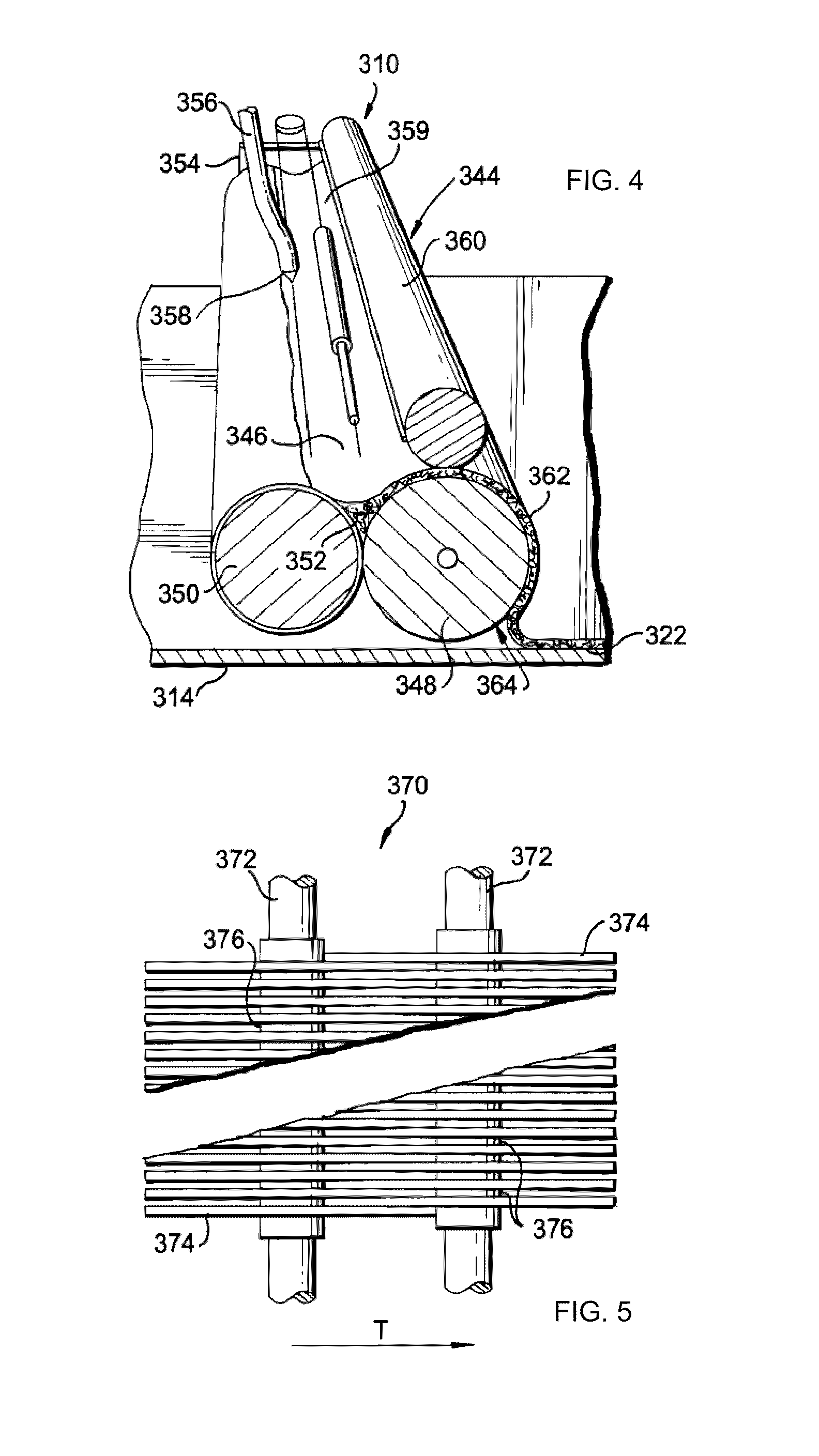

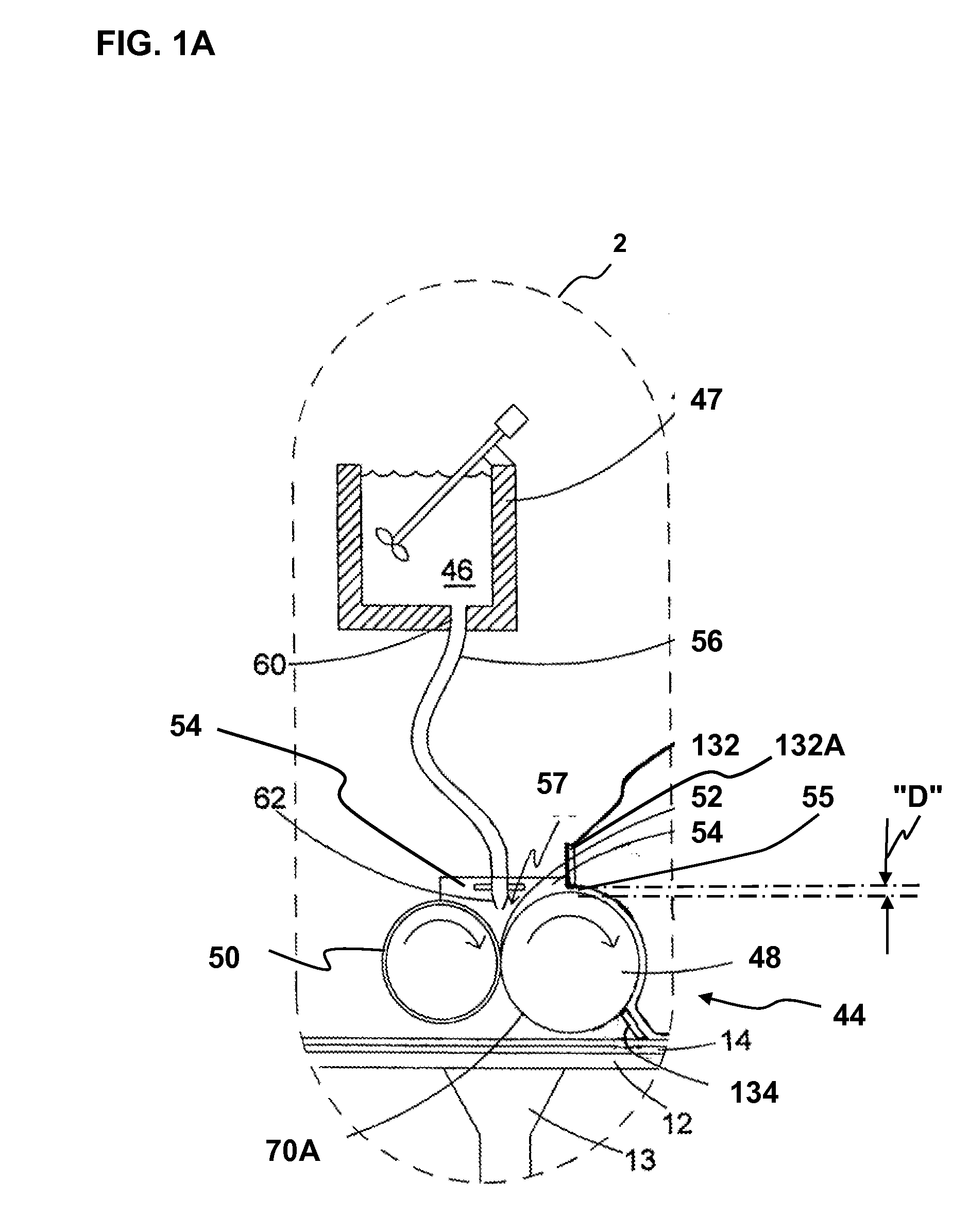

Slurry feed apparatus for fiber-reinforced structural cementitious panel production

Owner:UNITED STATES GYPSUM CO

Construction products and method of making same

InactiveUS20070062143A1Eliminate needShorten construction timeSolid waste managementWallsBuilding productCement board

A highly durable and easy to use prefabricated construction product is disclosed having a cellular concrete component sandwiched between two cement boards, wherein the cellular concrete component comprises cement, fly ash, an activating agent and water, and the cement boards comprise cement, fly ash, an activating agent, sand, silica fume, a water reducer agent, a reinforcing fiber, and water.

Owner:NOUSHAD RAFIE LOTFI

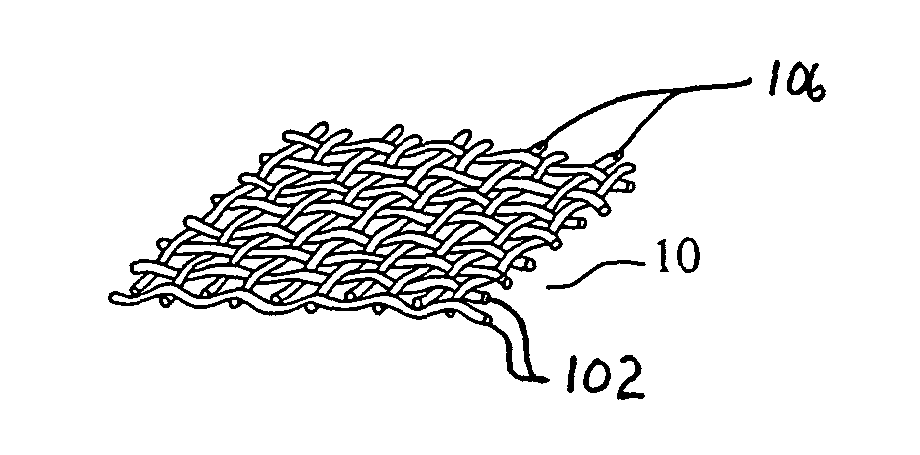

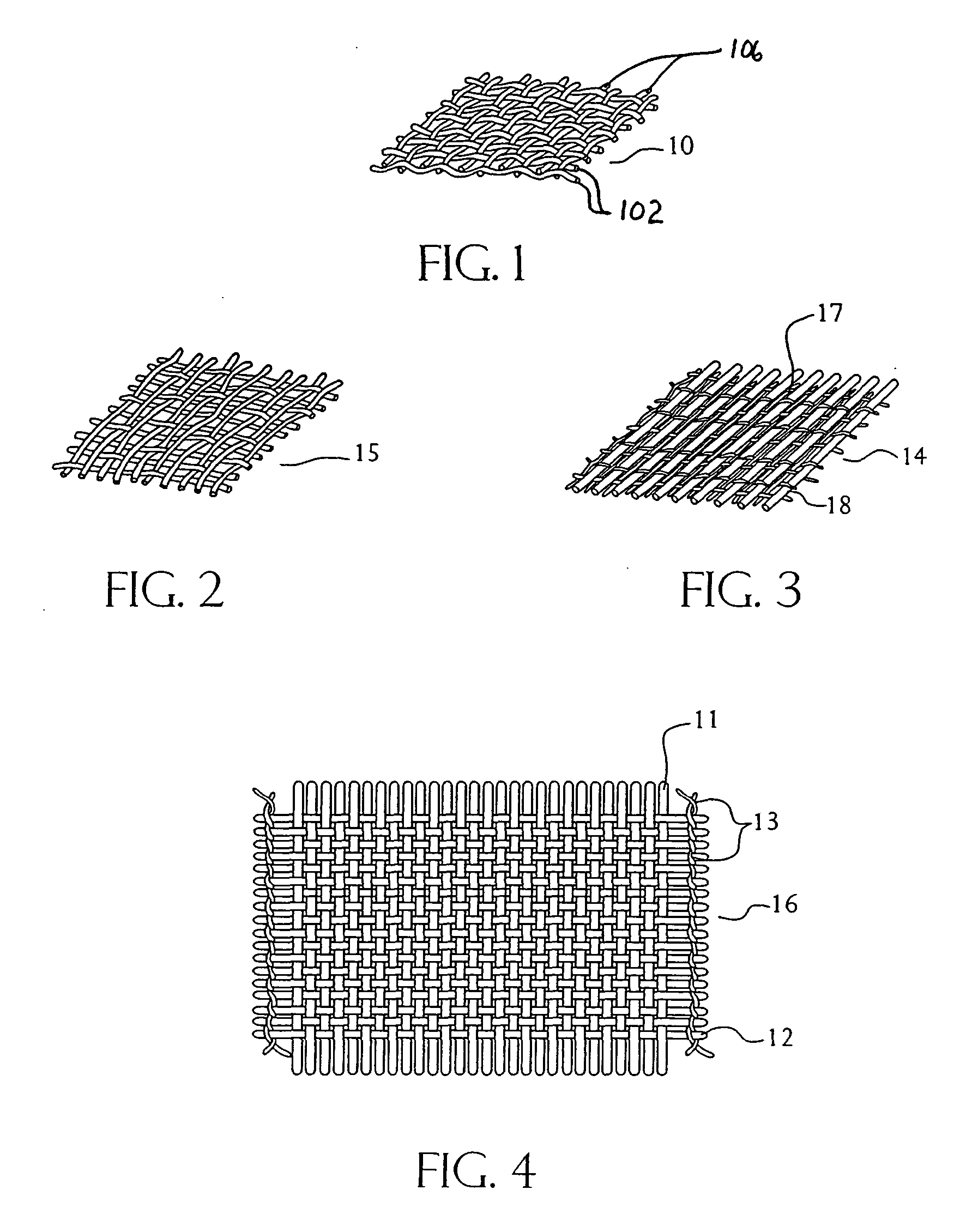

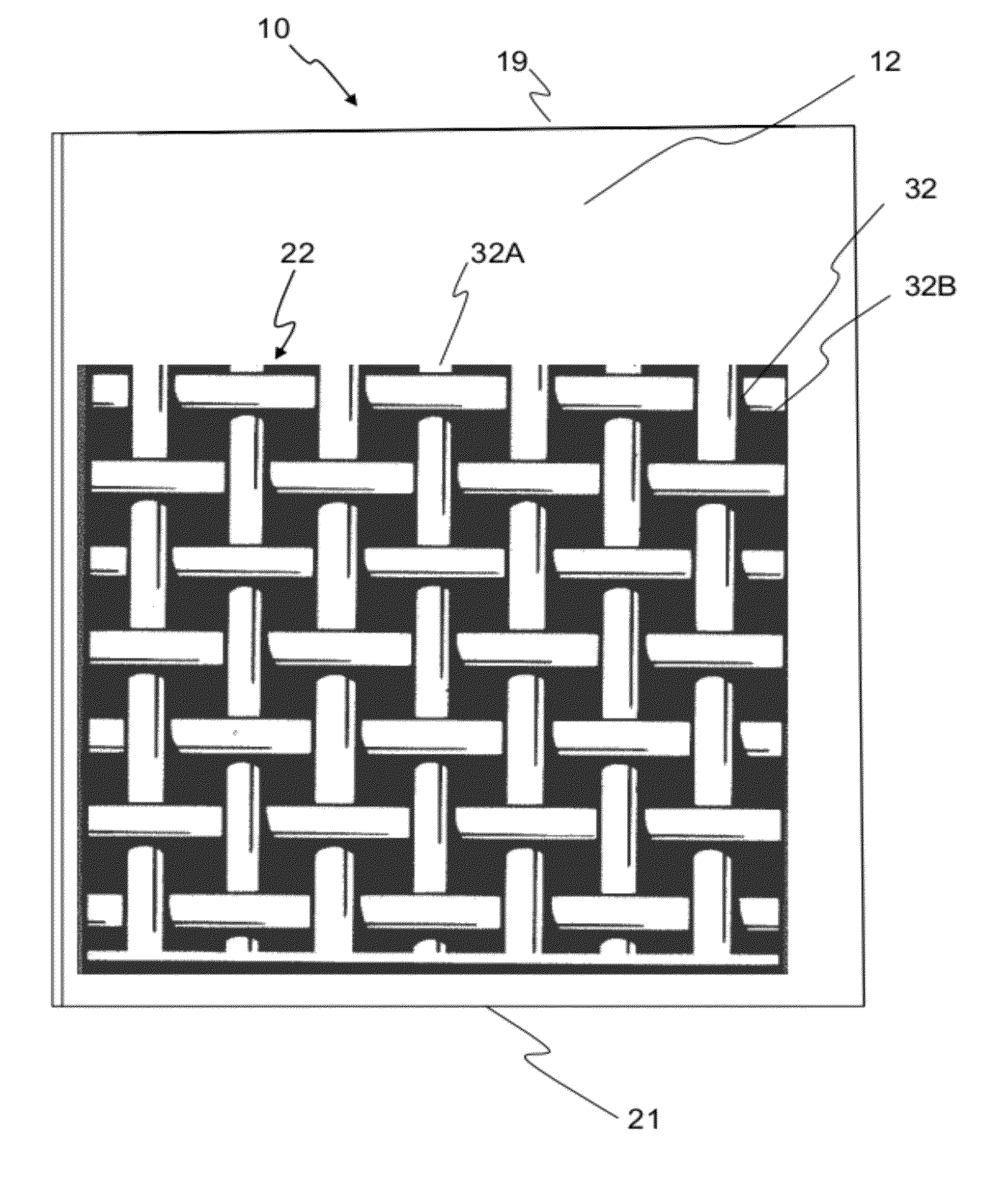

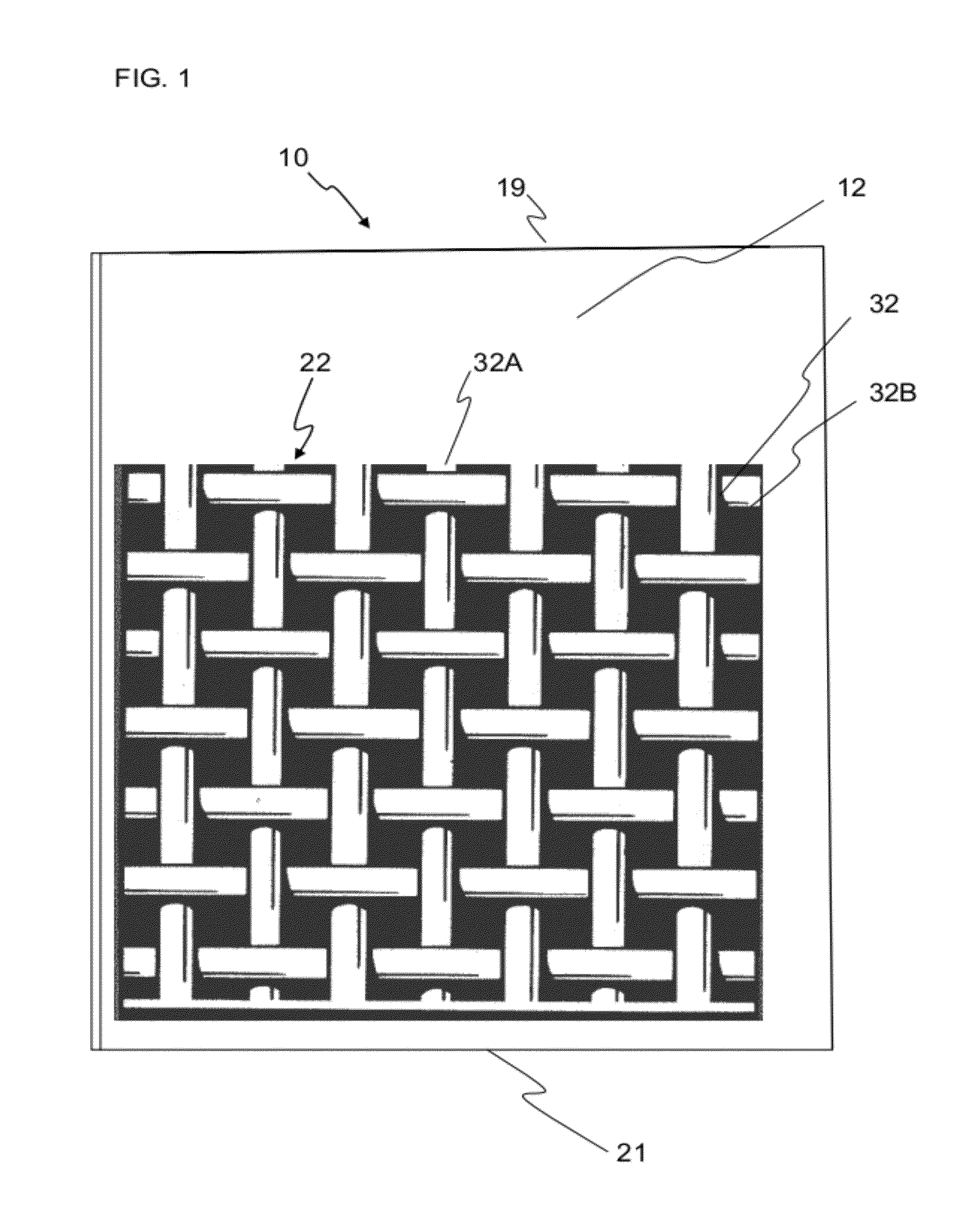

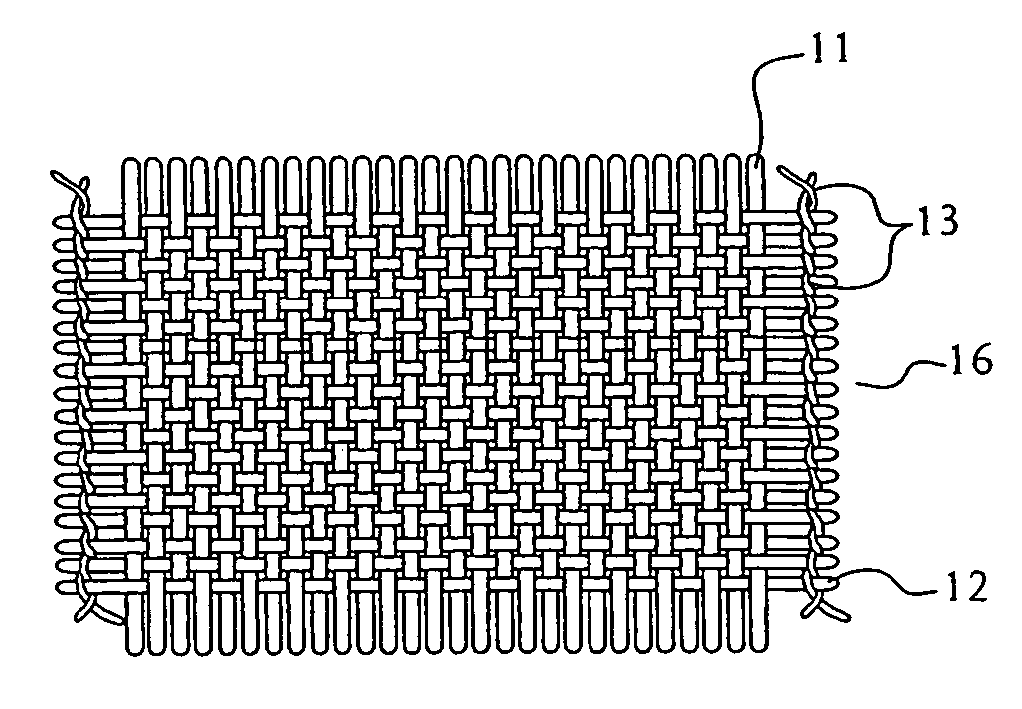

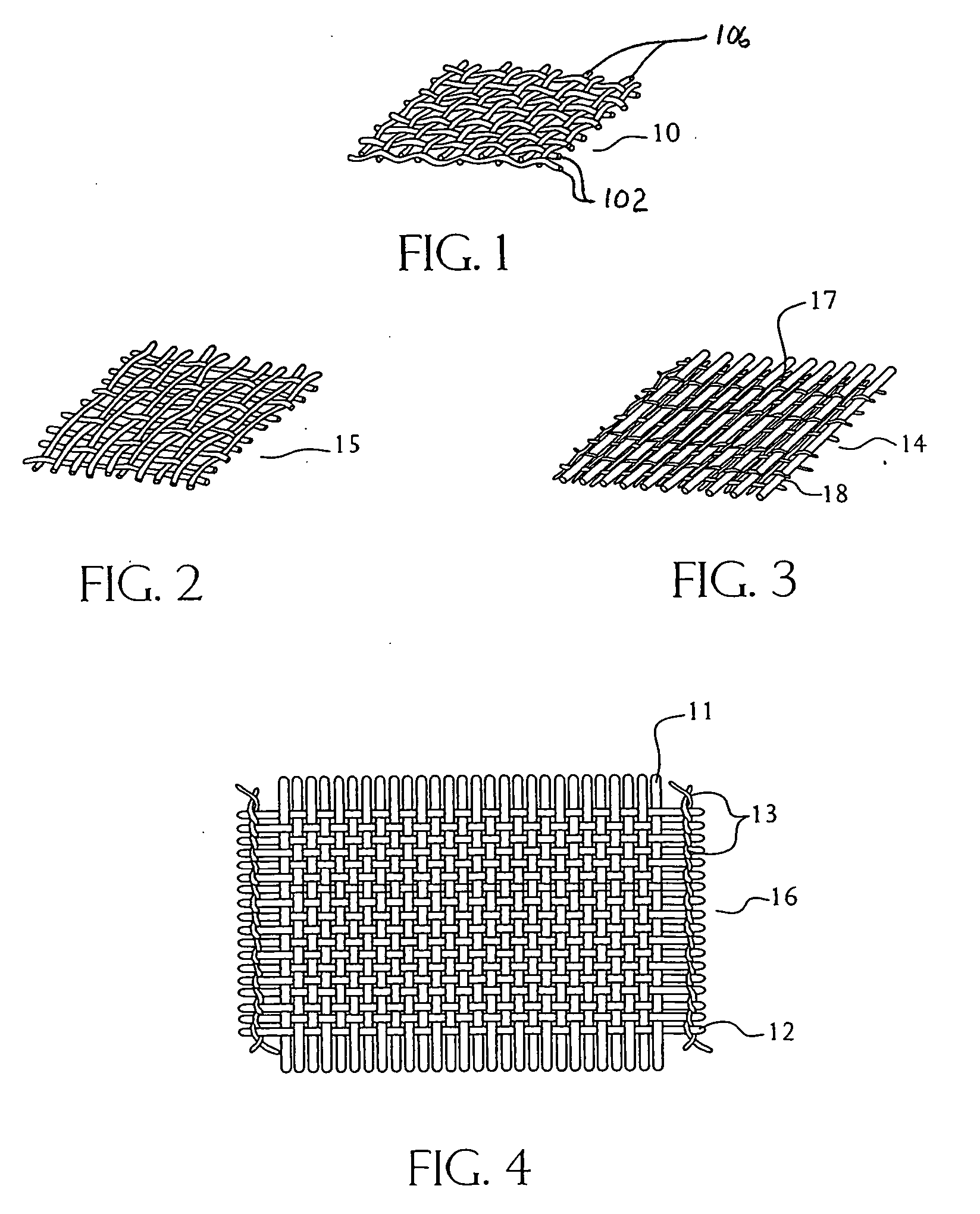

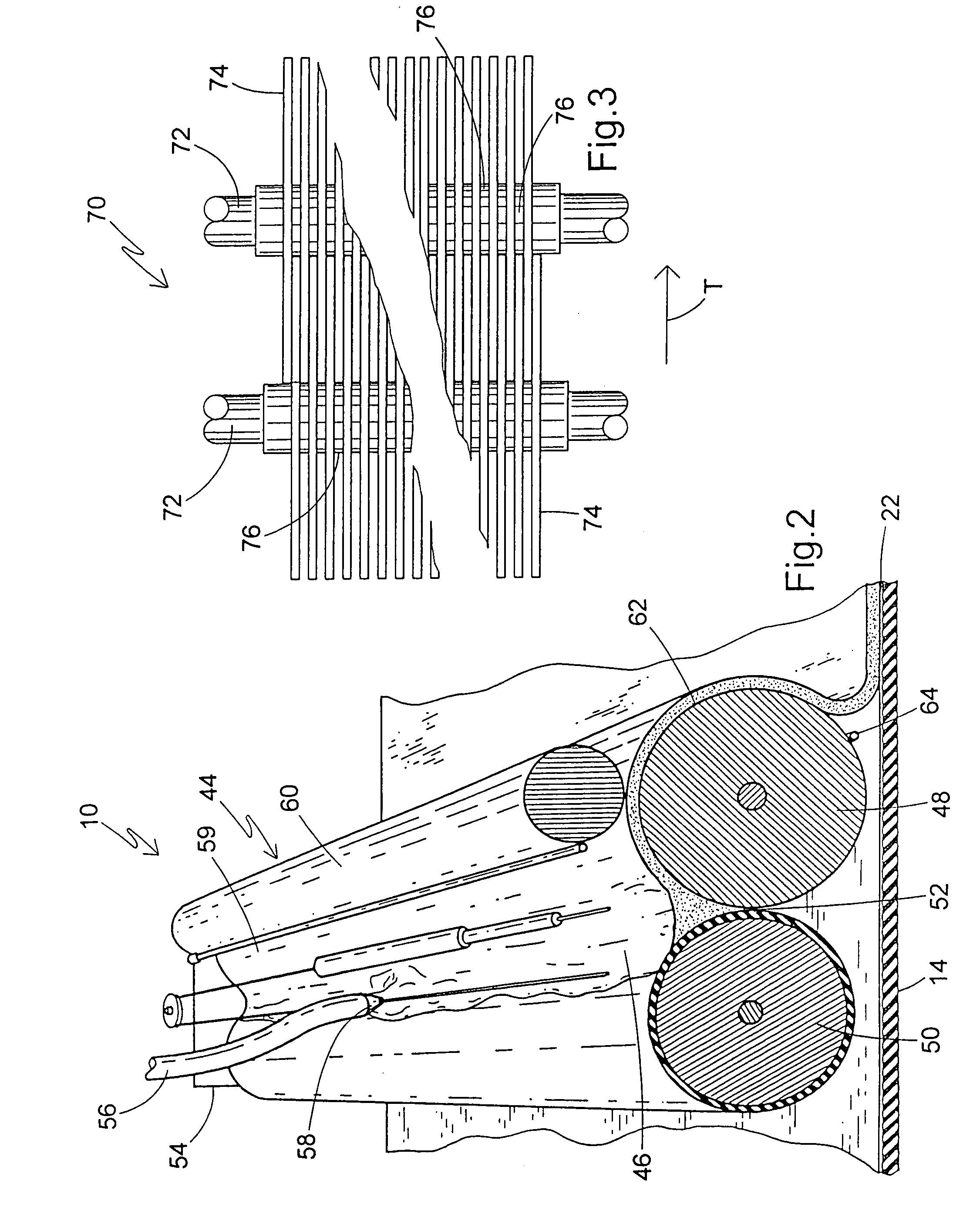

Fabric reinforcement and cementitious boards faced with same

ActiveUS20050009428A1Improve coating uniformityConvenient coatingDecorative surface effectsPretreated surfacesCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Lightweight, fiber-reinforced cementitious panels

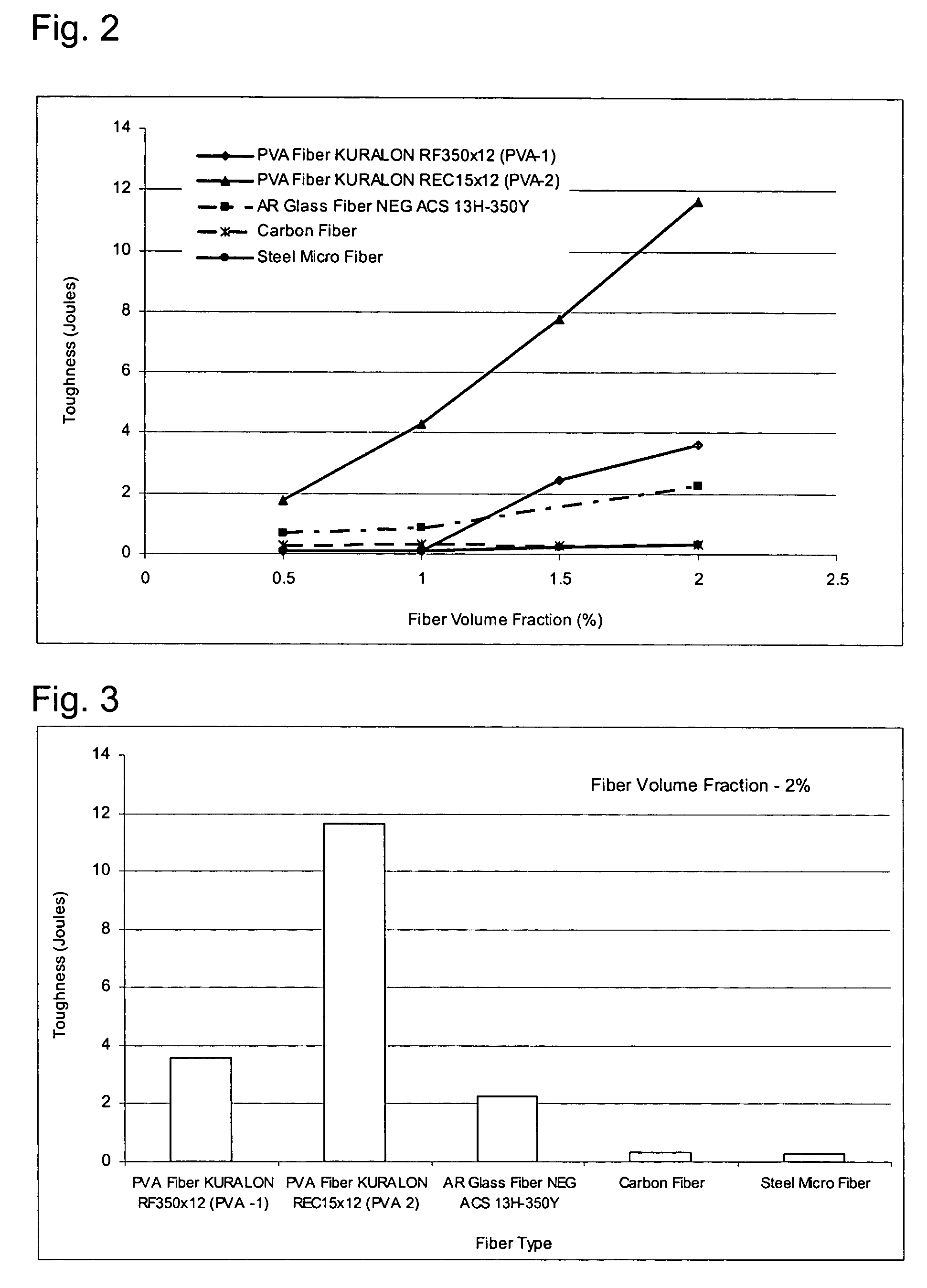

ActiveUS20060147681A1Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

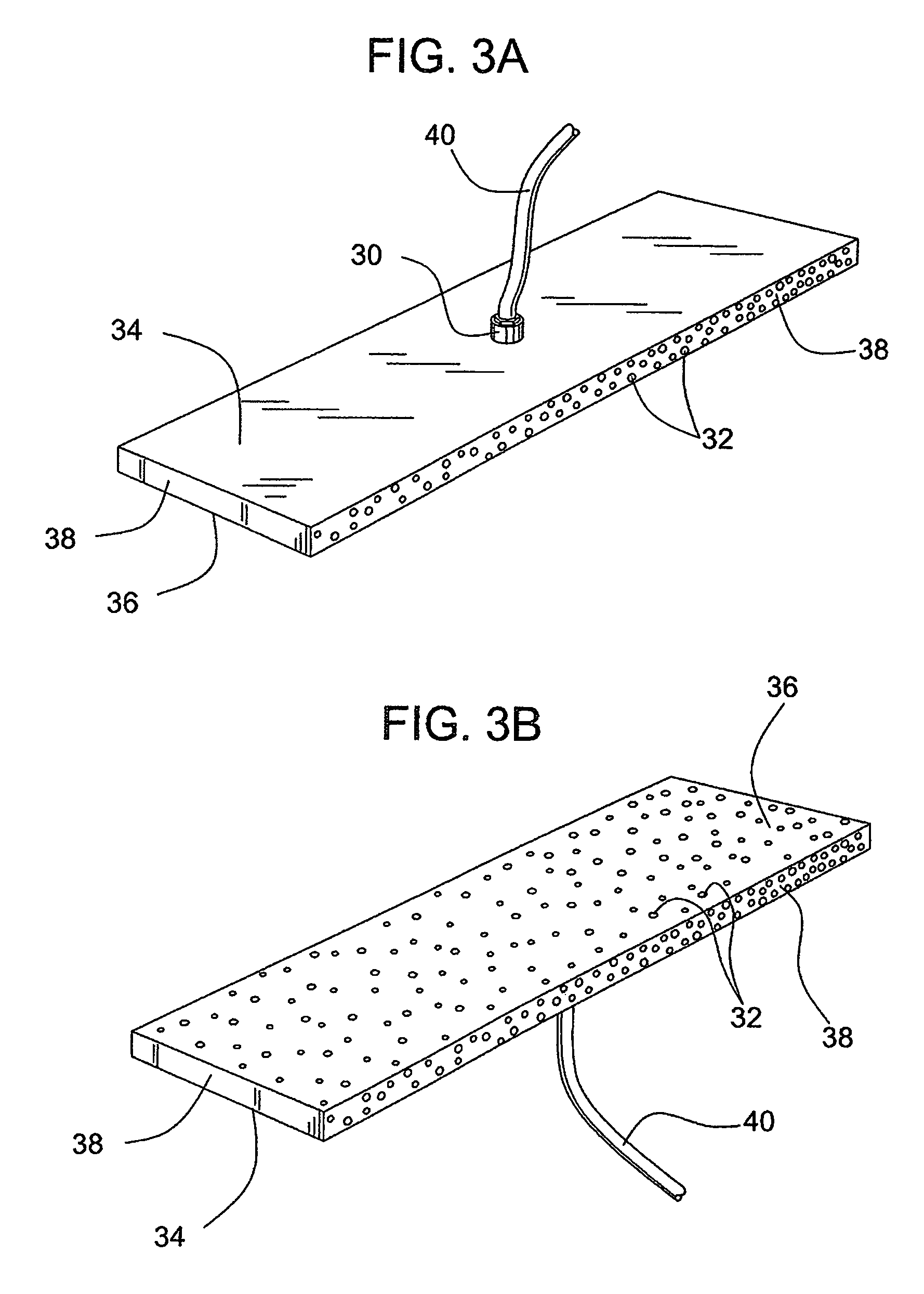

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

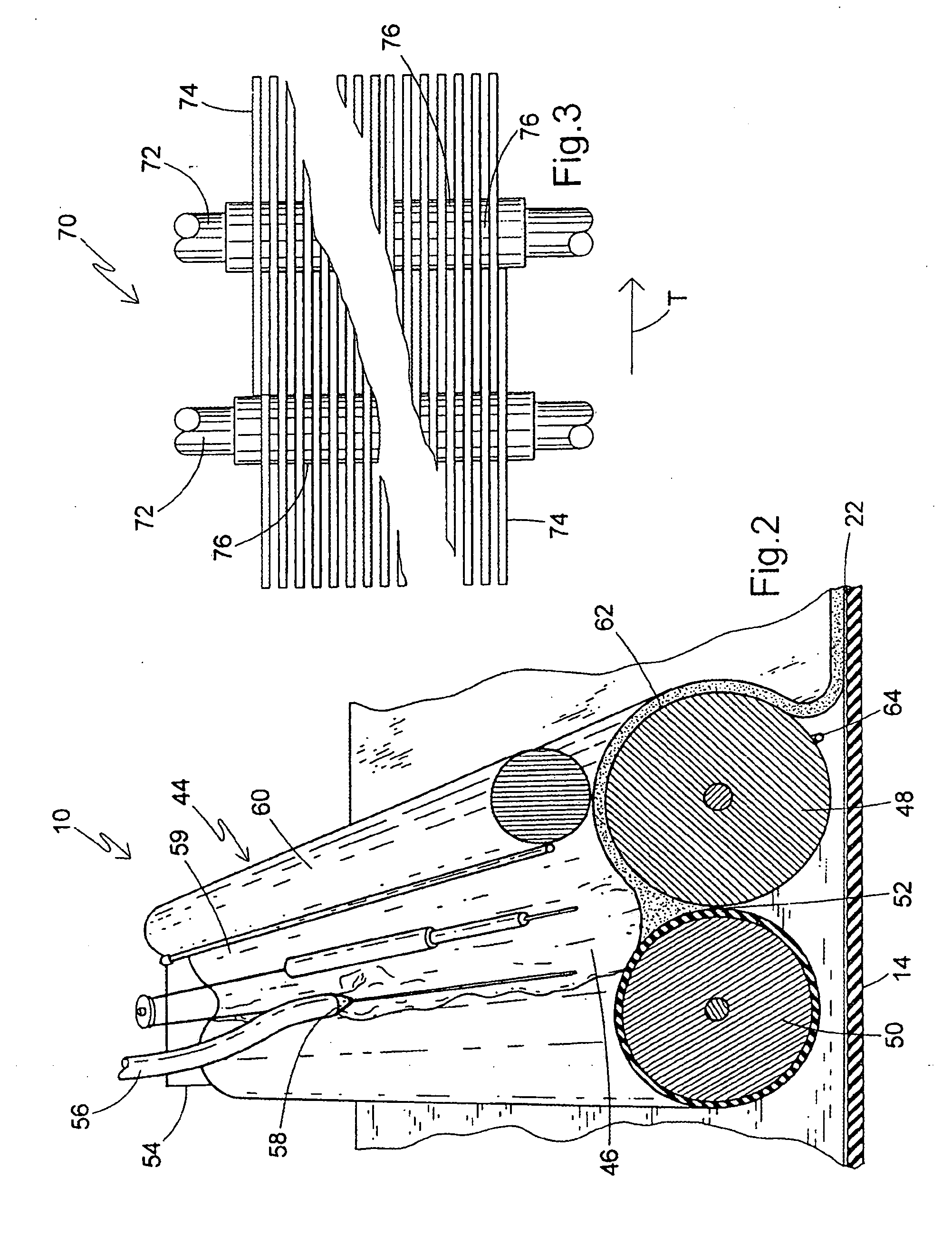

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

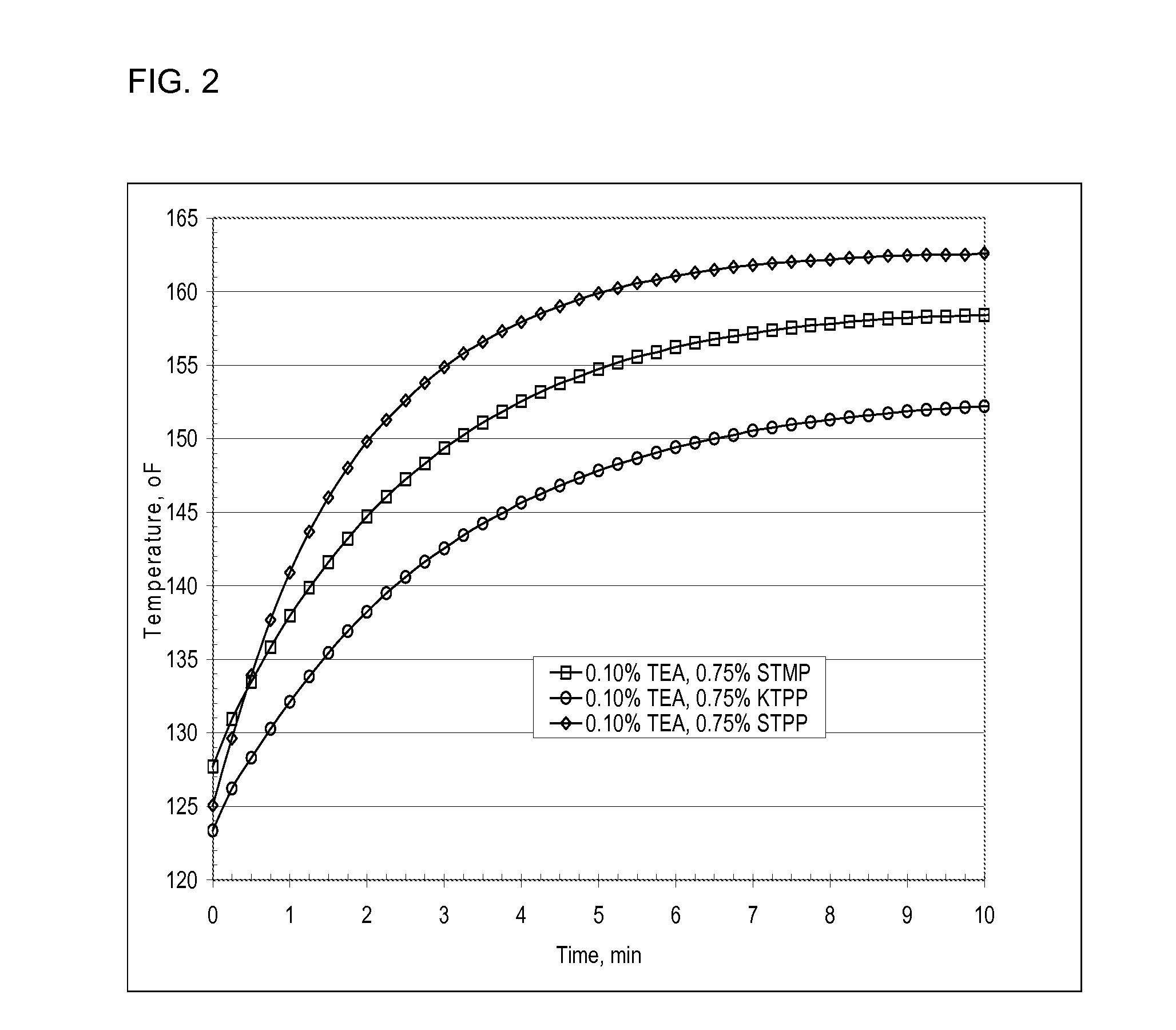

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

Panel smoothing process and apparatus for forming a smooth continuous surface on fiber-reinforced structural cement panels

InactiveUS20080099133A1Remove pock marks or groovesA large amountSolid waste managementTransportation and packagingProduction lineSurface layer

A vibrating flexible smoothing sheet or shroud disposed transversely of a direction of travel of a formed fiber panel including gypsum-cementitious slurry and embedded chopped fibers. The sheet is used to smooth the surface of the panel as it exits a fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to reduce the need for costly finishing after the panels are cured and cut to size. The flexible sheet is designed to float over the surface of the formed panel without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the panel. The vibrating sheet is pivotally mounted on the side dams of the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

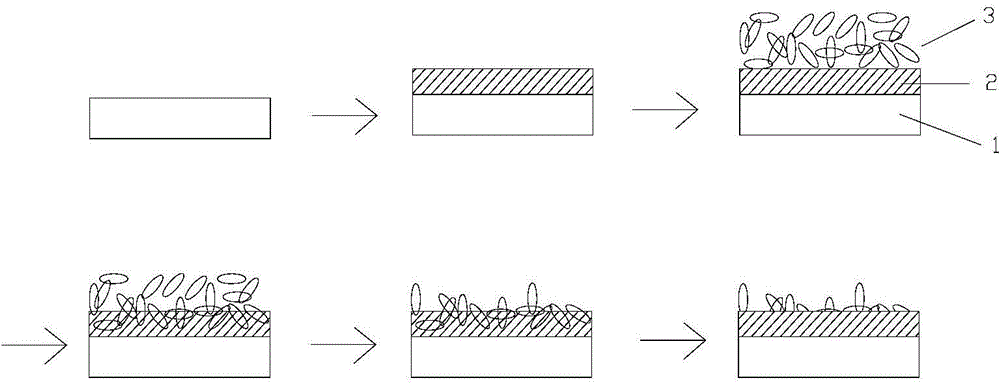

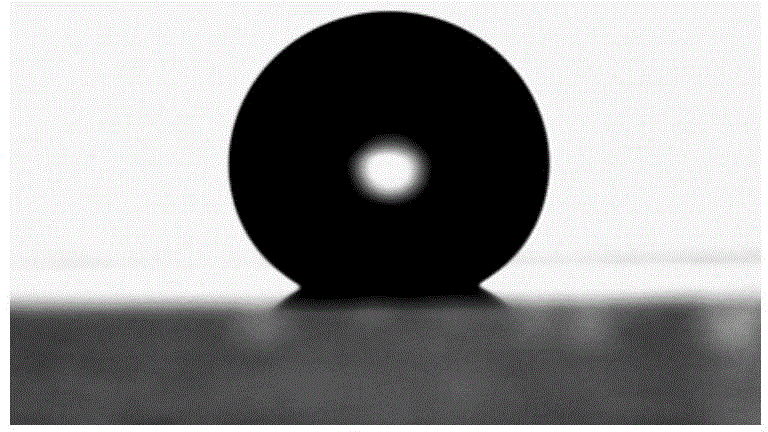

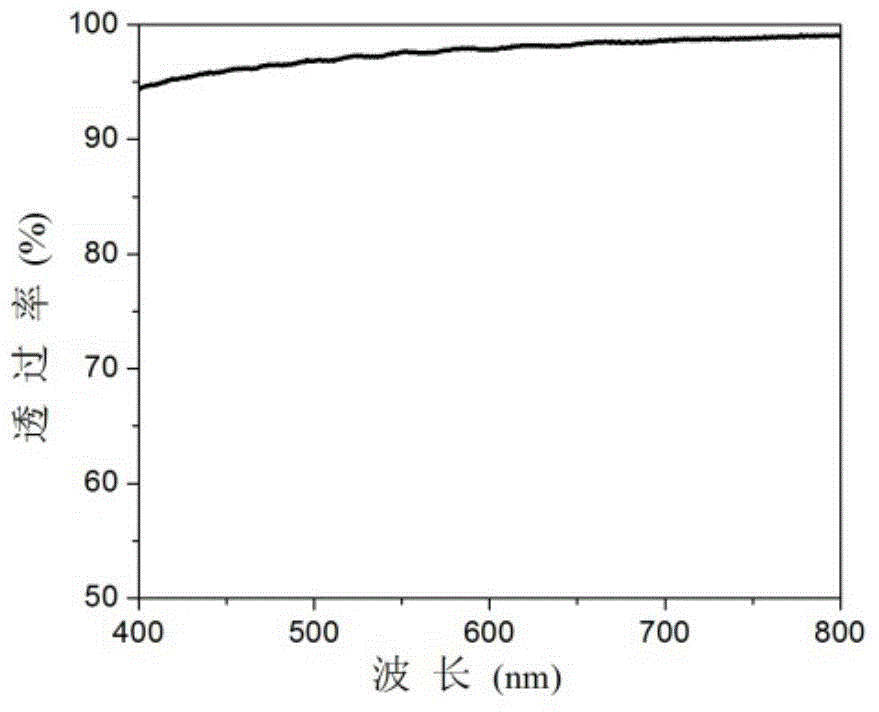

Transparent wear-resistant super-hydrophobic coating material, preparation method and coating process thereof

ActiveCN104910776ASuperhydrophobicHigh transparencyPretreated surfacesPolyurea/polyurethane coatingsWear resistantCement board

The present invention relates to a transparent wear-resistant super-hydrophobic coating material, a preparation method and a coating process thereof. The transparent wear-resistant super-hydrophobic coating material comprises a nanometer material dispersion liquid and an adhesion material dispersion liquid. According to the present invention, during the preparation, a nanometer material and a volatile solvent are mixed and dispersed to prepare the nanometer material dispersion liquid, and the adhesion material and the good solvent thereof are mixed and dispersed to prepare the adhesion material dispersion liquid; during the coating, the substrate surface is cleaned, the adhesion material dispersion liquid is coated to form the adhesion layer, the nanometer material dispersion liquid is coated after drying, the partial nanometer material is embedded into the adhesion layer through heating, pressurization and other ways, and finally the unstably-binding nanoparticles are removed by using scraping or adhesive tape adhesion to obtain the super-hydrophobic coating, wherein the coating has characteristics of good transparency, strong binding force, and wear resistance; and the super-hydrophobic coating material of the present invention can be used for the surfaces of a variety of materials such as metals, plastics, glass, cement boards and the like so as to achieve functions of water resistance, stain resistance, corrosion resistance, self-cleaning, dew resistance, icing resistance, and the like.

Owner:王舒

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS20080302276A1Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

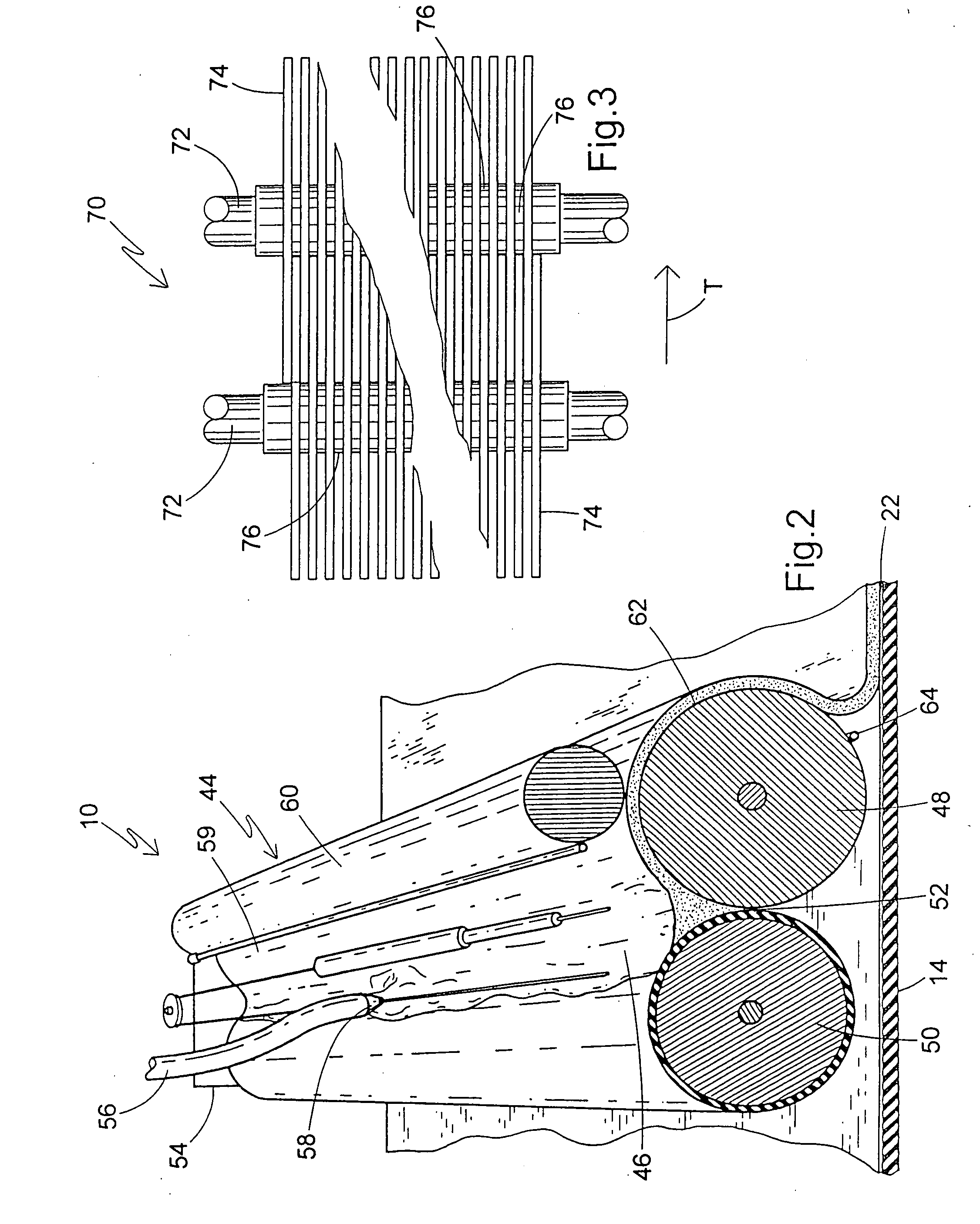

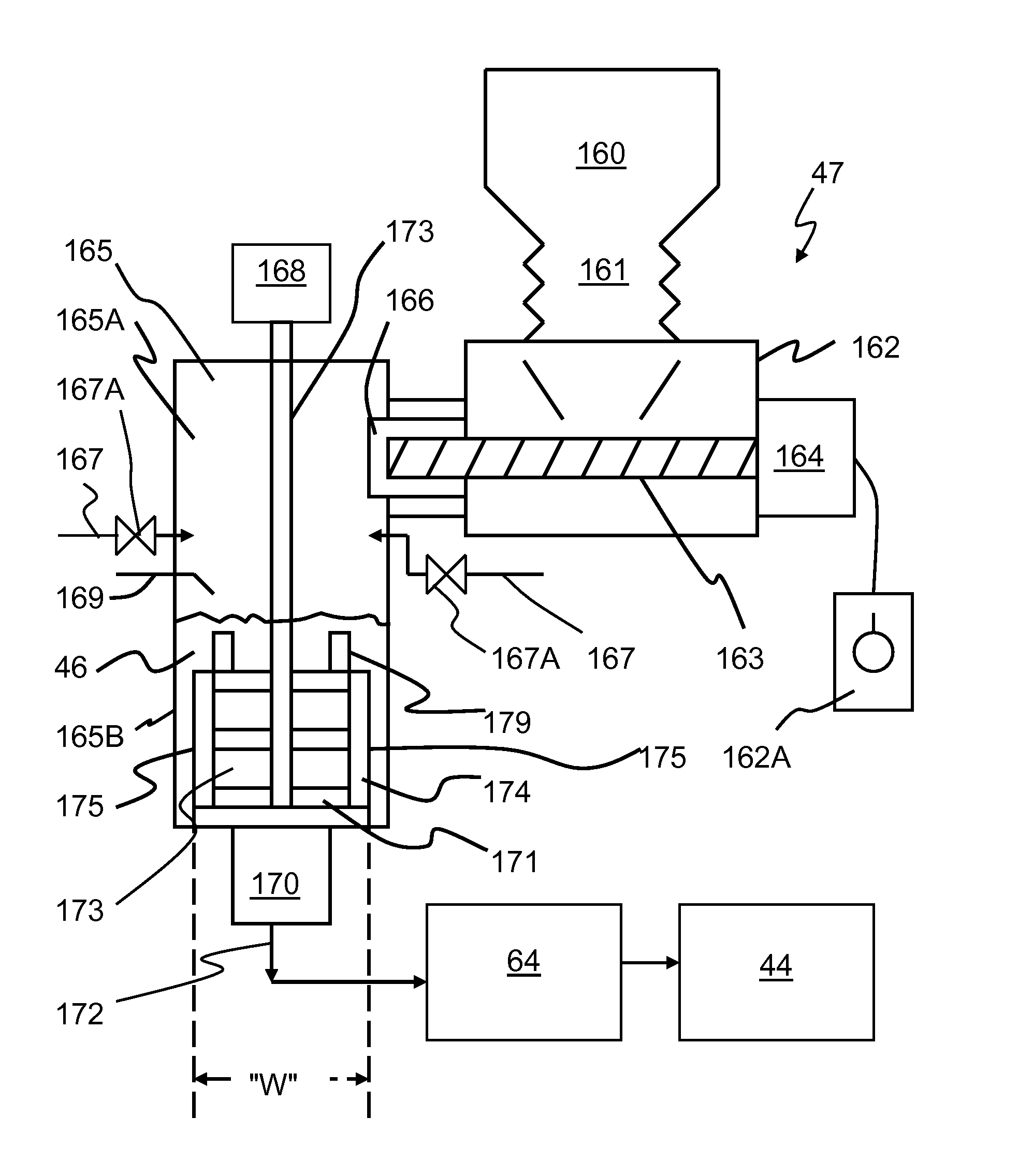

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS20080101150A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed means for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

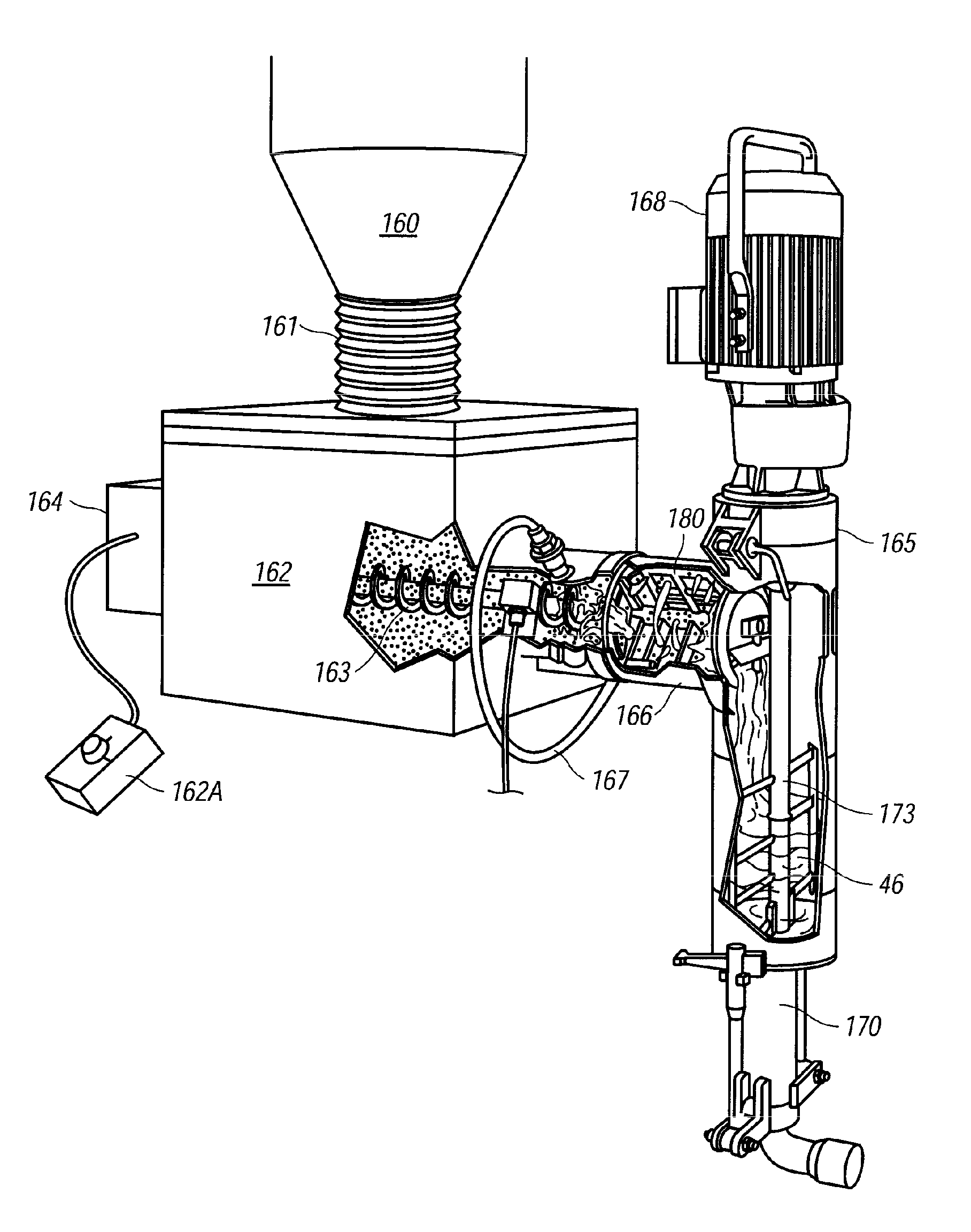

Apparatus and method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080101151A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels with enhanced fiber content

ActiveUS20070110970A1Good strength propertiesA large amountLiquid surface applicatorsConstruction materialCement boardSlurry

A process for producing fiber-reinforced structural cementitious panels made of at least one layer of fiber reinforced cementitious slurry, the process for each such layer of slurry including providing a moving web; depositing a first layer of individual, loose fibers upon the web; depositing a layer of settable slurry upon the deposited first layer of individual, loose fibers; depositing a second layer of individual, loose fibers upon the deposited layer of settable slurry; and actively embedding both layers of individual, loose fibers into the layer of slurry to distribute the fibers throughout the slurry.

Owner:UNITED STATES GYPSUM CO

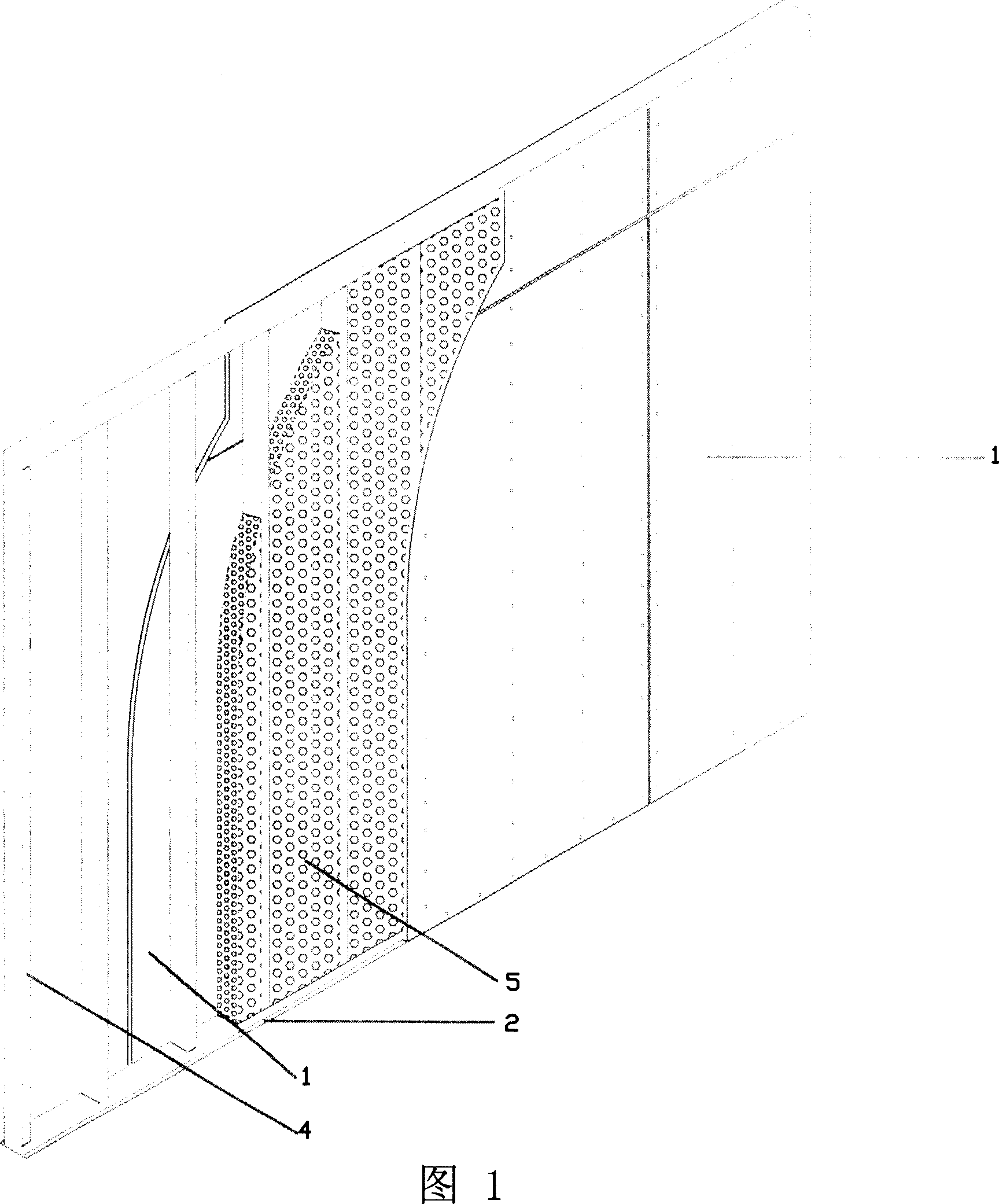

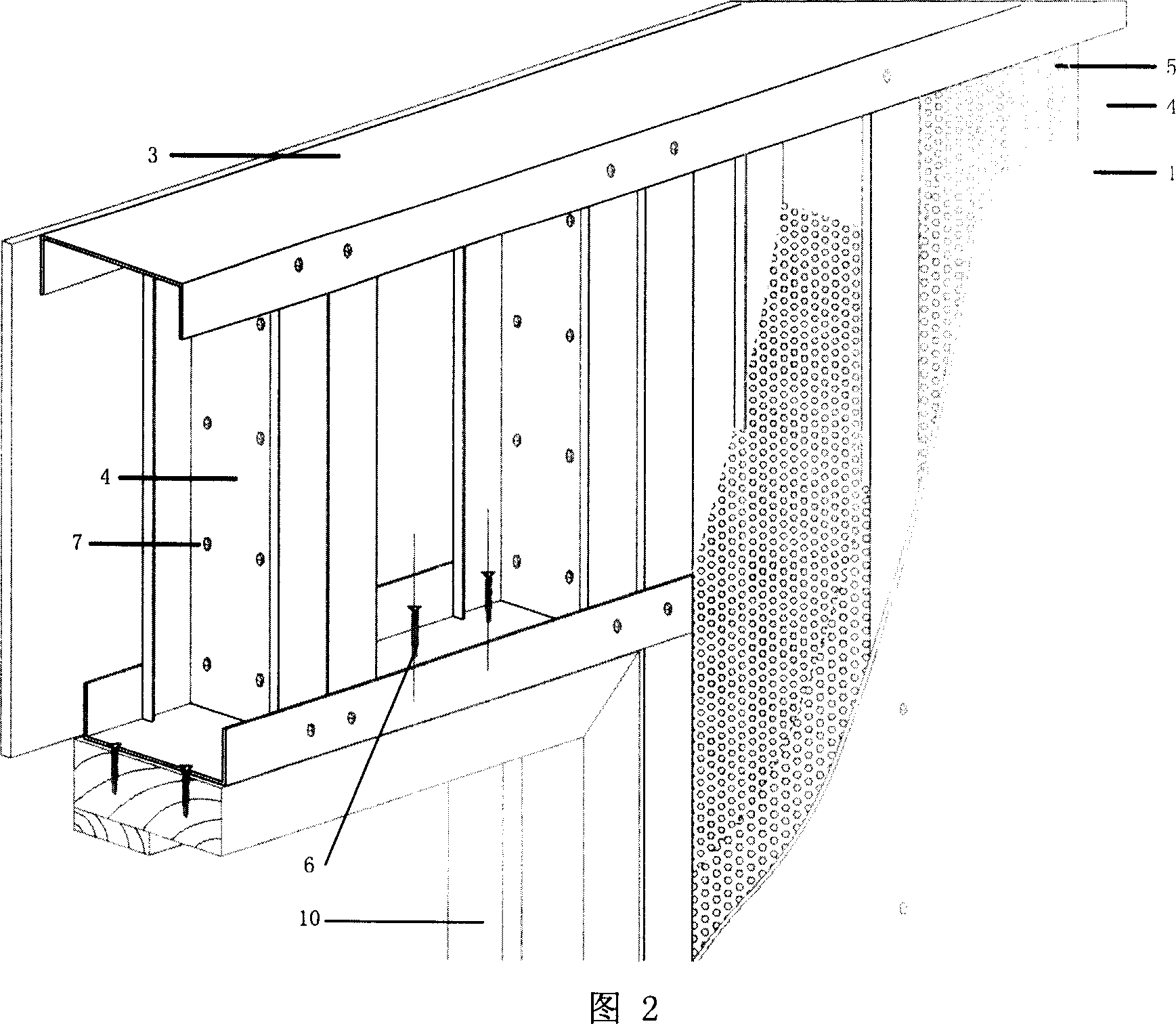

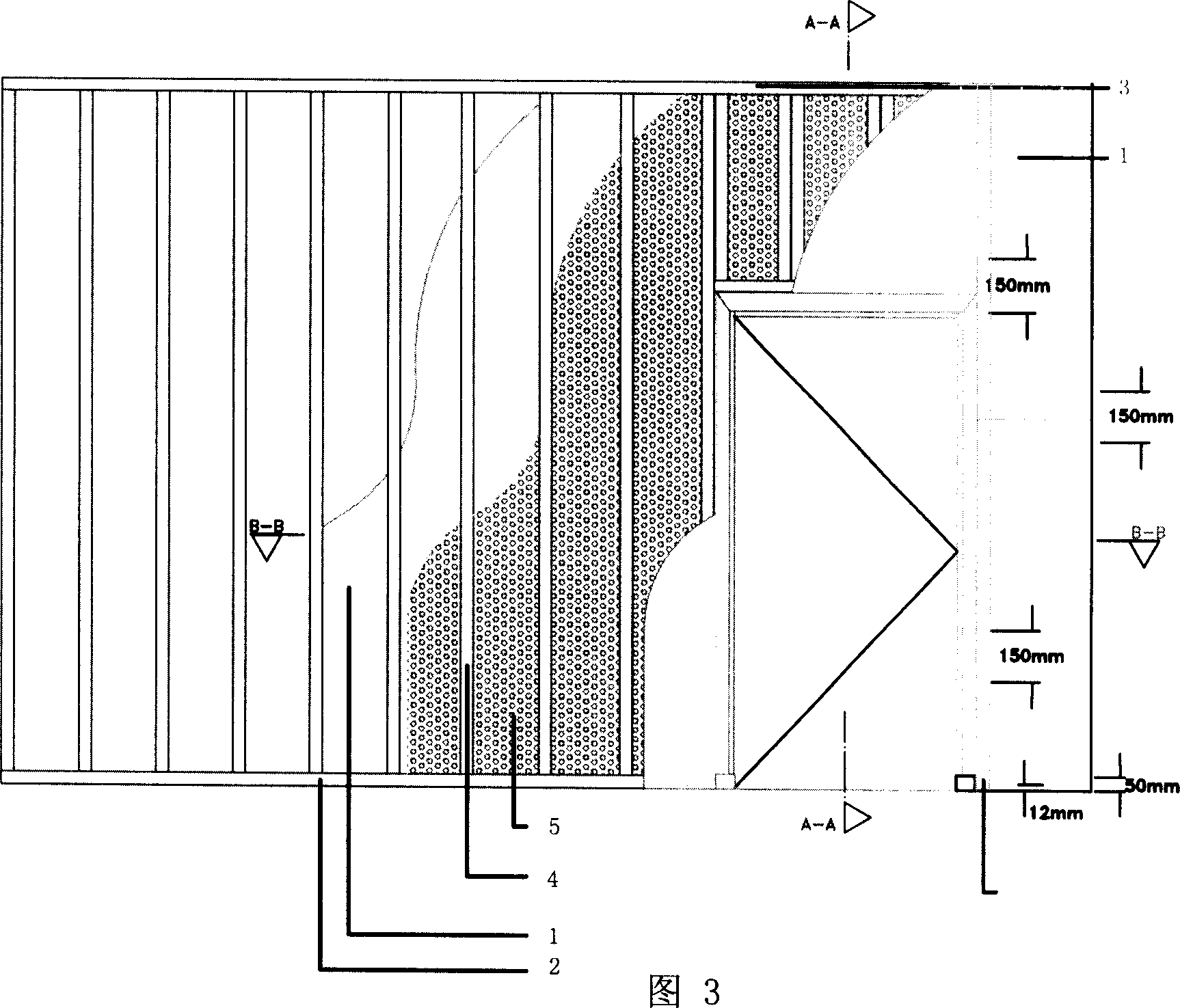

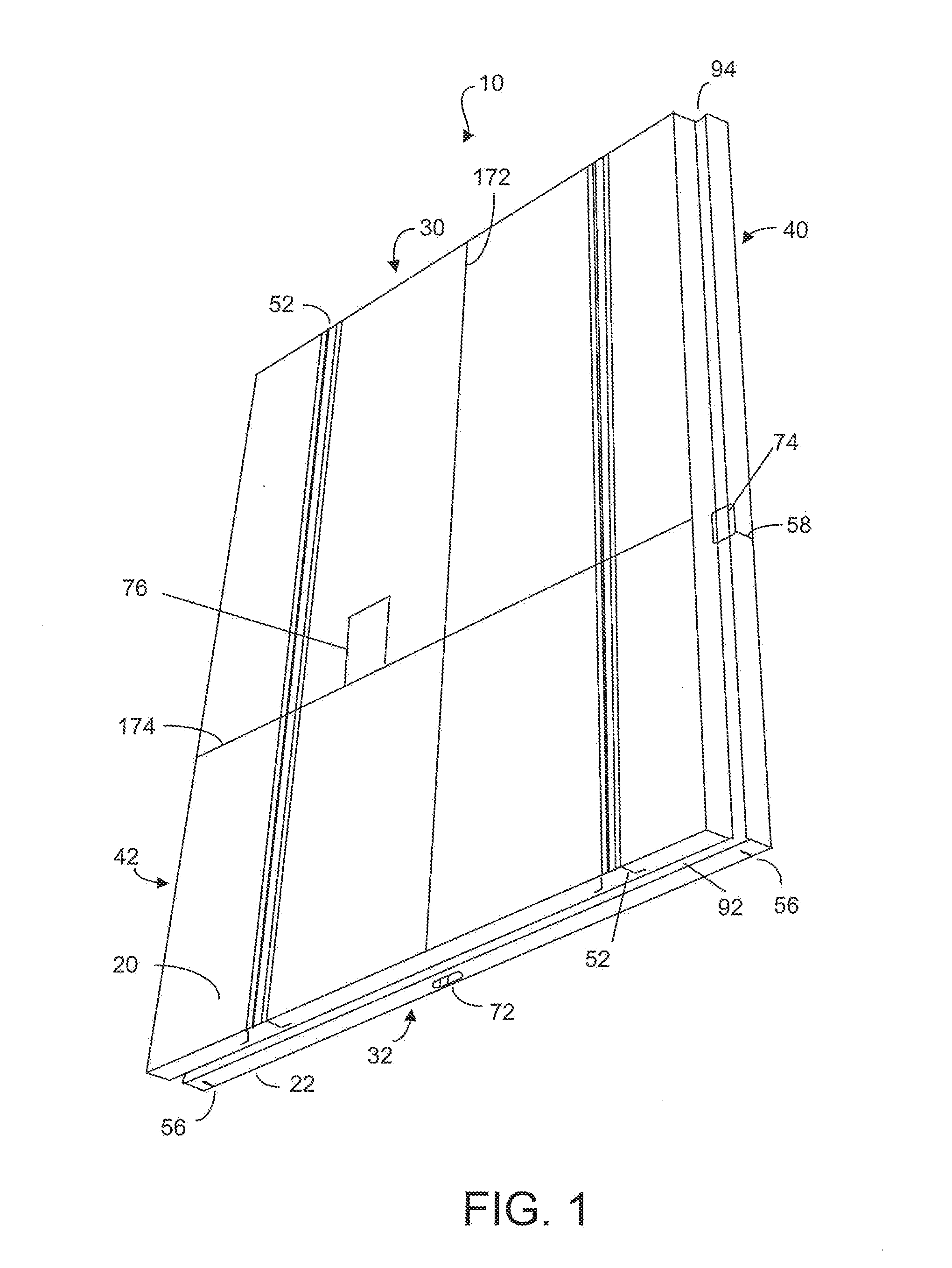

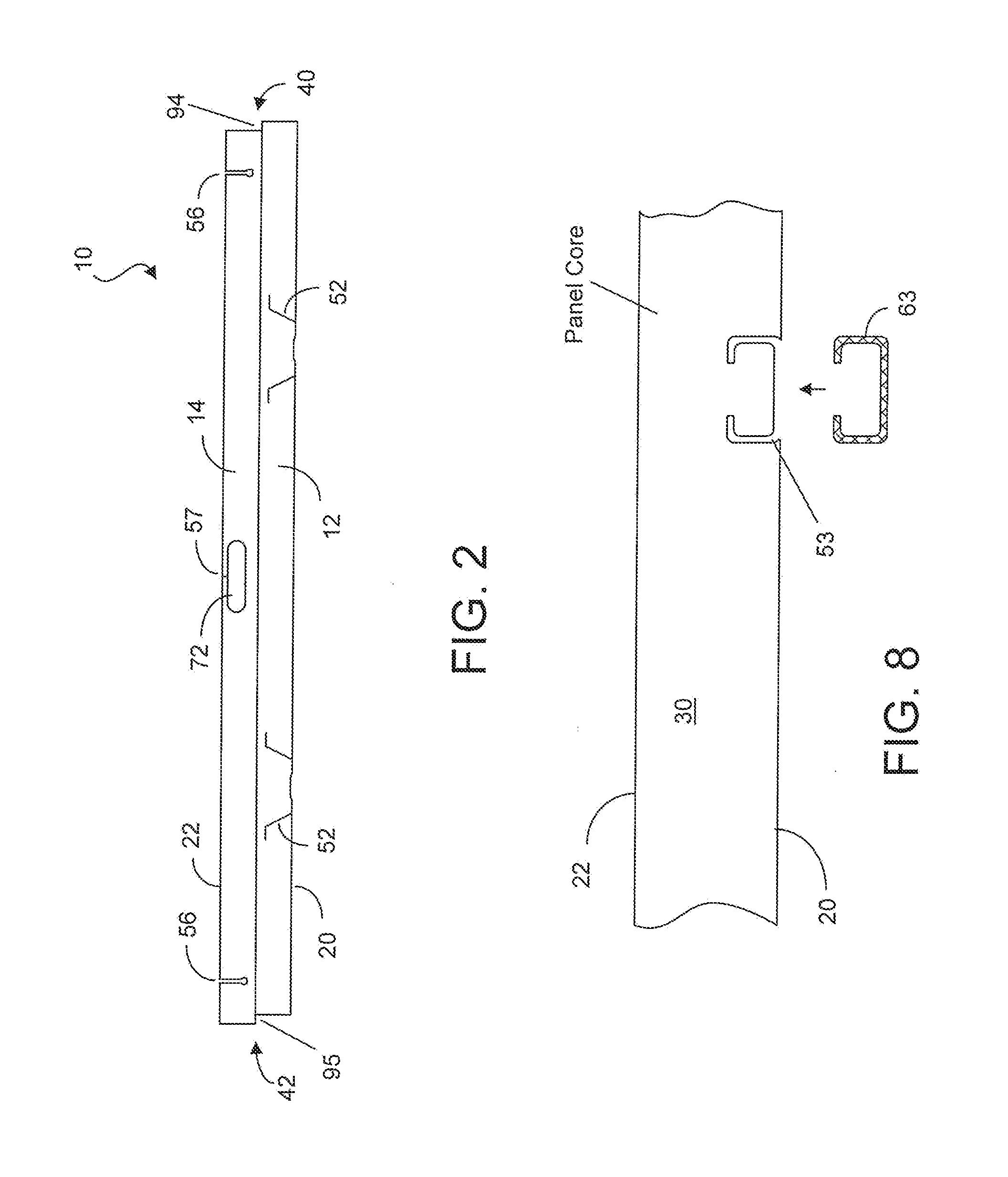

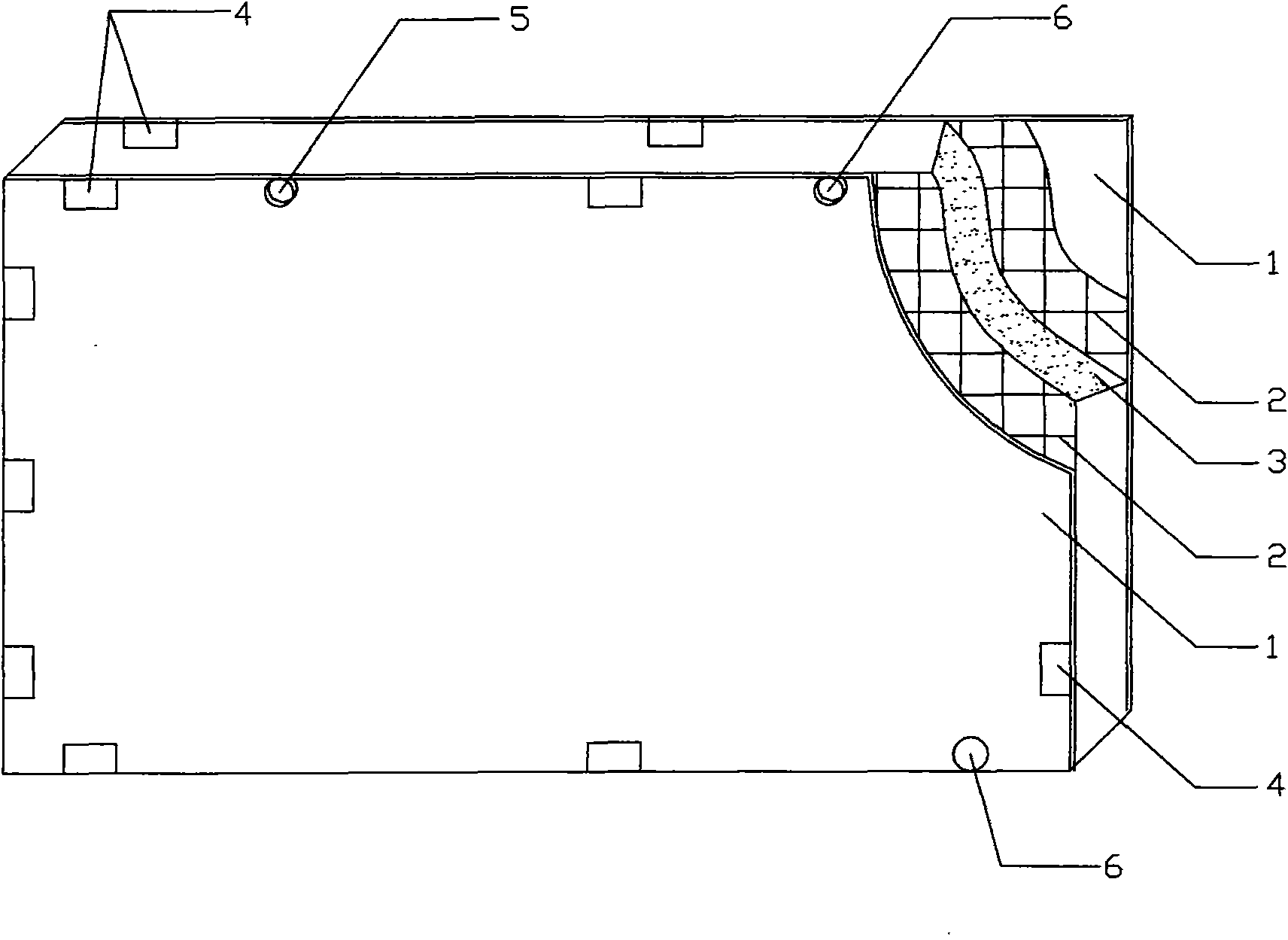

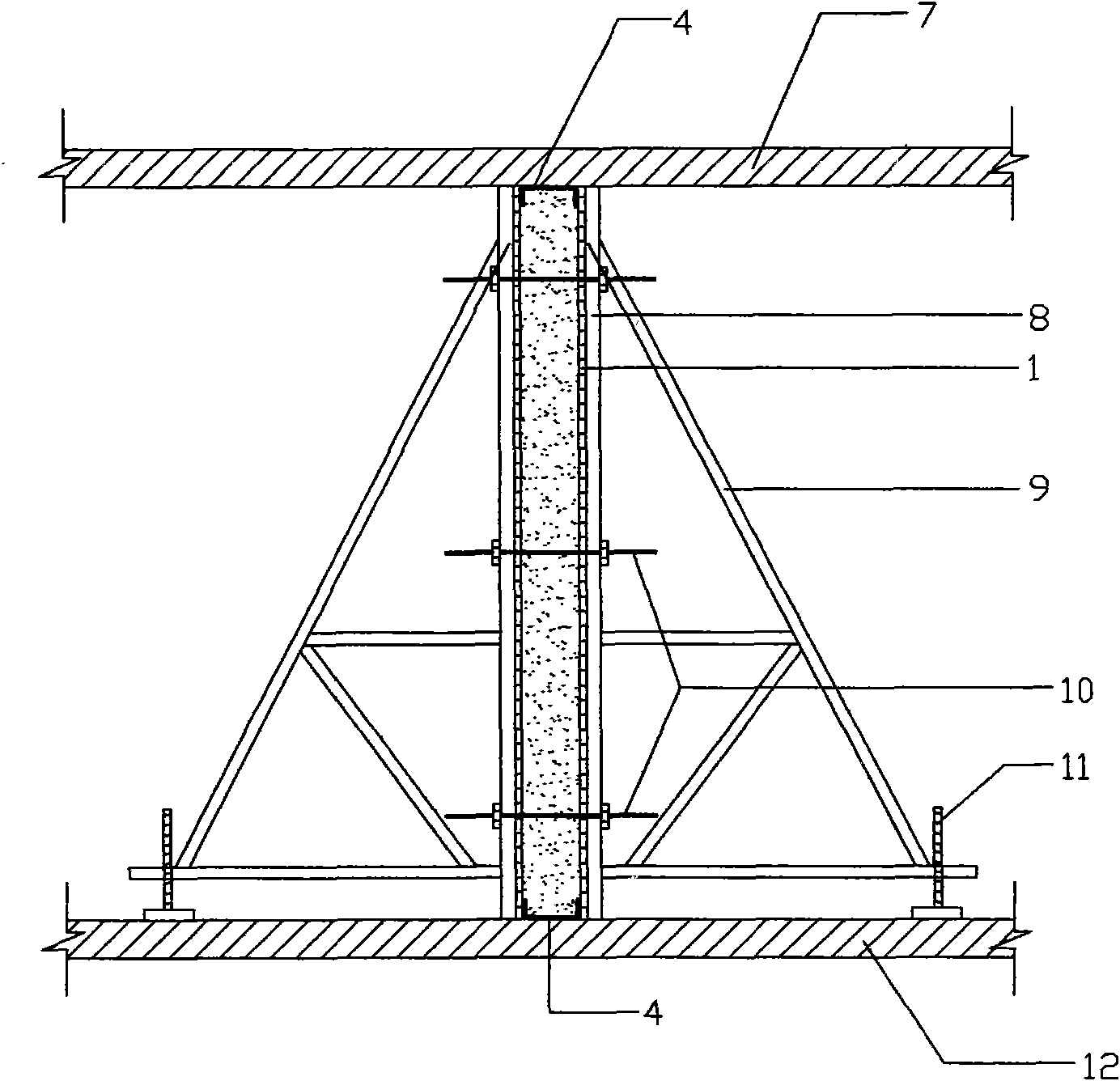

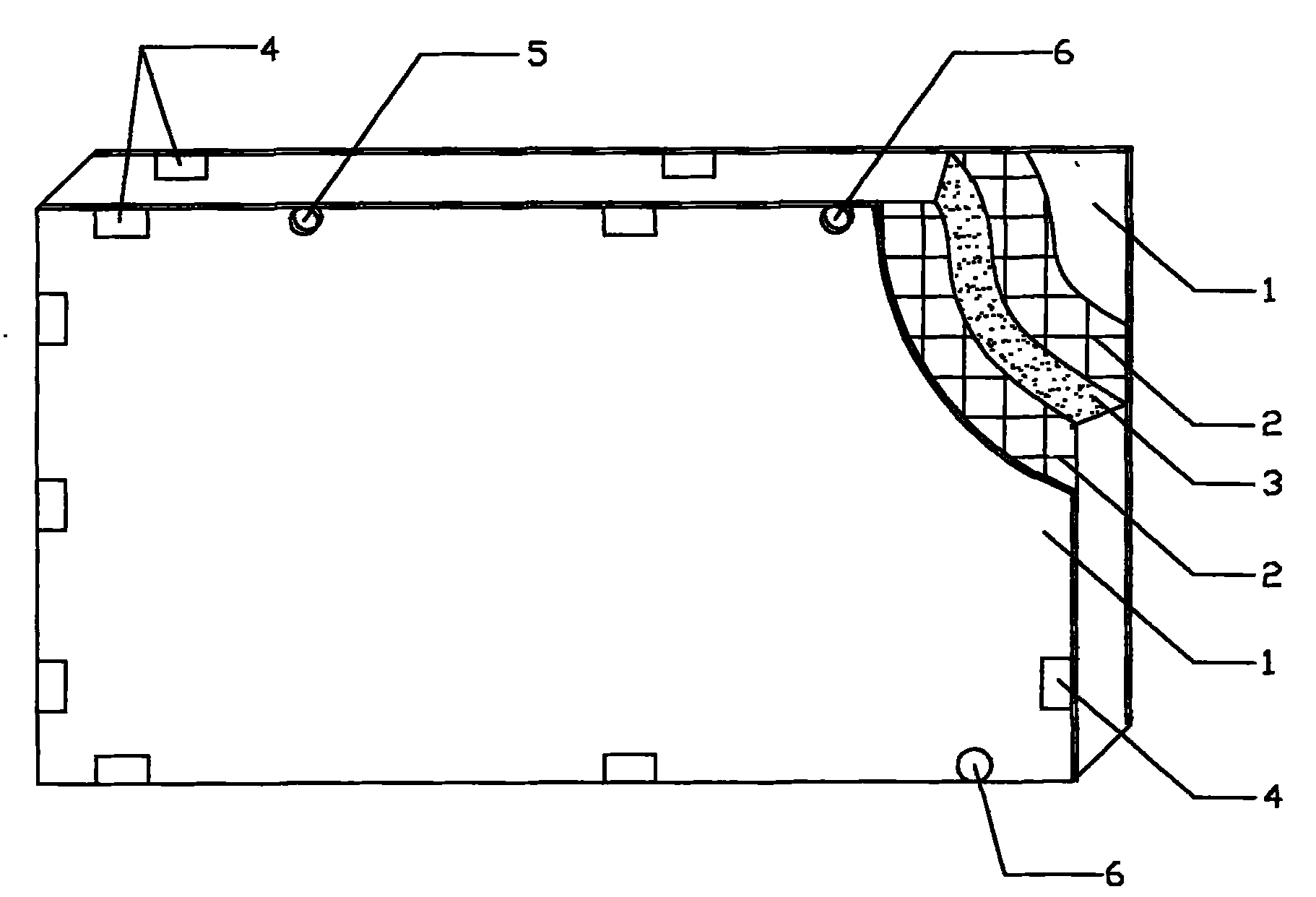

Fiver cement board grouting wall and construction method therefor

The invention discloses a lightweight nonbearing grouting wall and its construction method for inner walls of buildings, comprising a lightgage steel joist or C-shaped steel as a framework, two fiber cements covered on two sides, a hollow space within lightweight grouting materials by special equipment, and a skin layer decorated and dealt directly. The wall has a simple structure for easy construction and a light weight thereby reducing the cost of entire structure and improving the fireproof property up to 2.5 hours or more and the sound insulation property as 40dB, therefore the invention is an inner wall construction with higher utility and economic profit.

Owner:杨建平

Fiberglass mesh scrim reinforced cementitious board system

InactiveUS20120148806A1High densityGood field performanceSolid waste managementWarp knittingSpatial OrientationsYarn

A cementitious board system which is reinforced on its opposed surfaces by an improved glass fiber mesh scrim with thicker yarn and larger mesh openings to provide a cementitious board with improved handling properties while retaining tensile strength and long term durability. The fabric is constructed as a mesh of high modulus strands of bundled glass fibers encapsulated by alkali and water resistant material, e.g. a thermoplastic material. The composite fabric also has suitable physical characteristics for embedment within the cement matrix of the panels or boards closely adjacent the opposed faces thereof. The fabric provides a board system with long-lasting, high strength tensile reinforcement and improved handling properties regardless of their spatial orientation during handling. Included as part of the invention are methods for making the reinforced board.

Owner:UNITED STATES GYPSUM CO

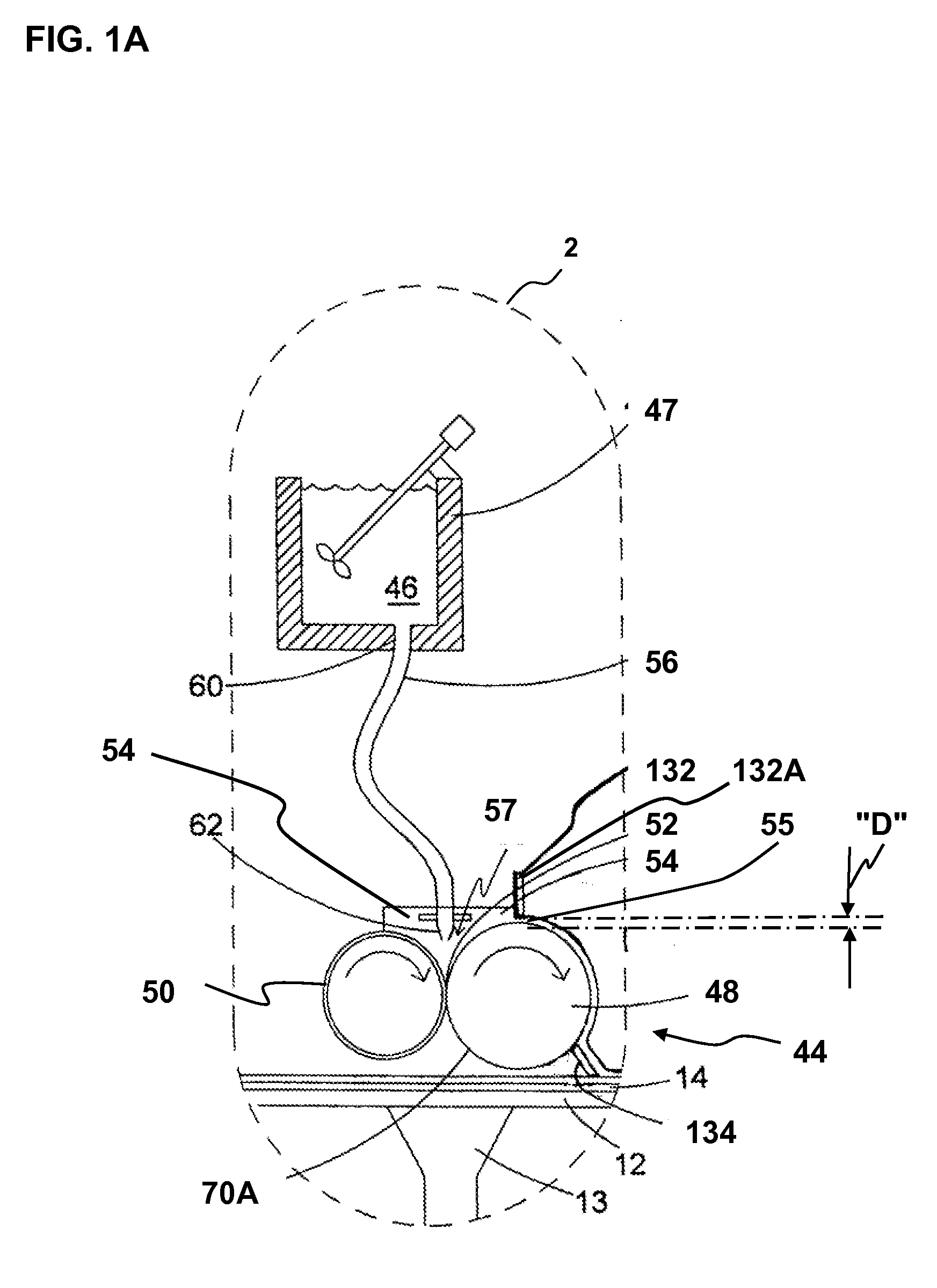

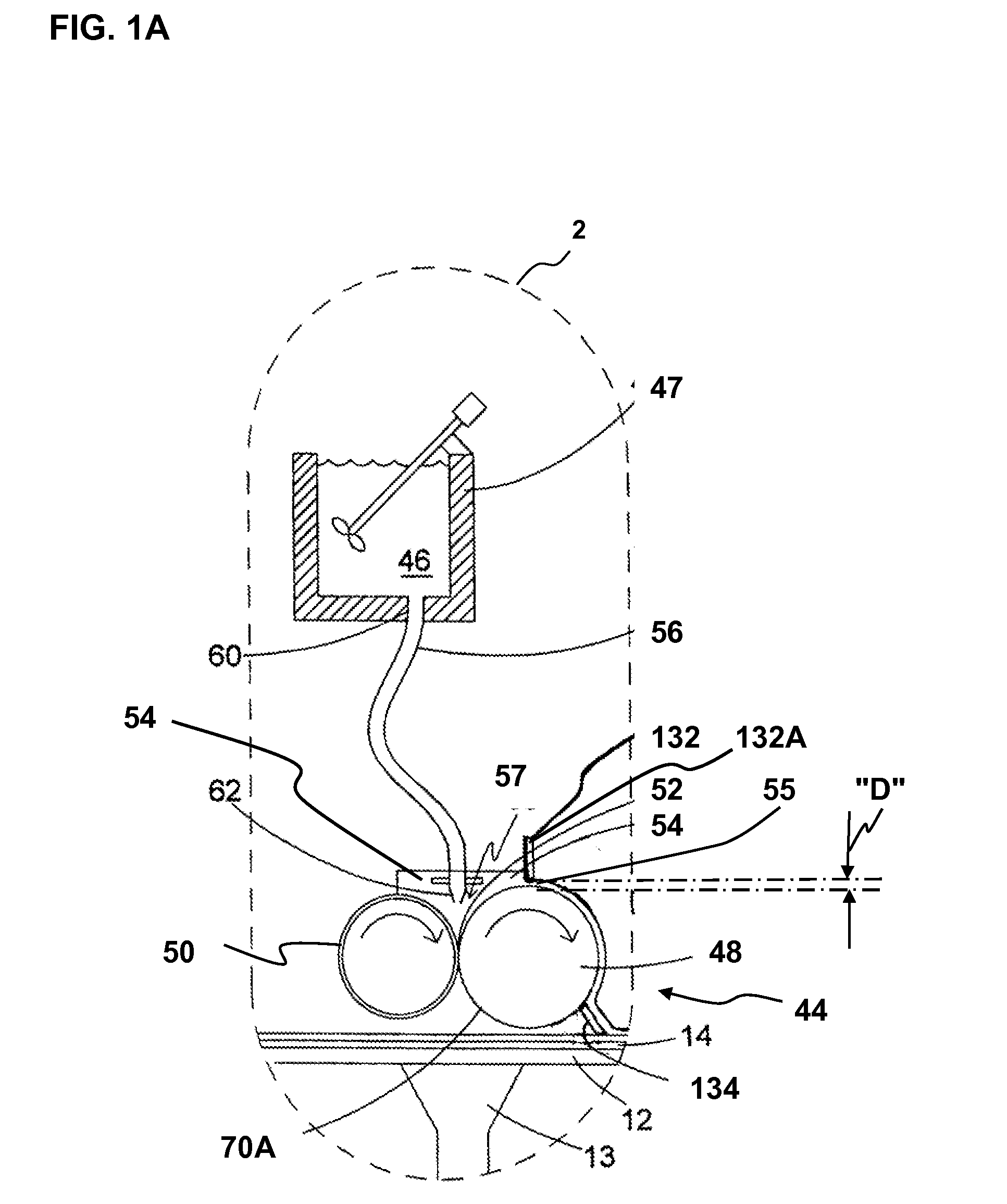

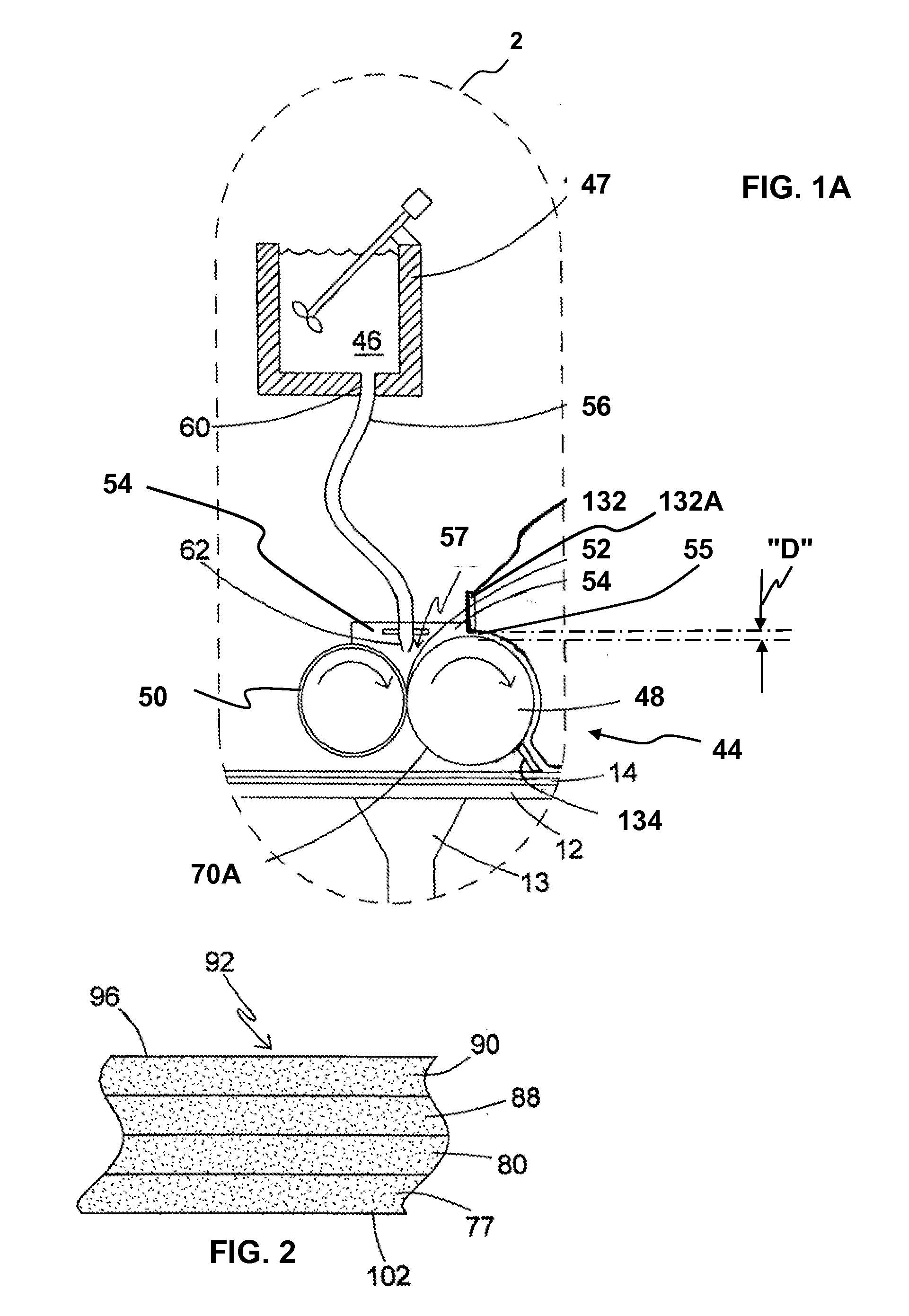

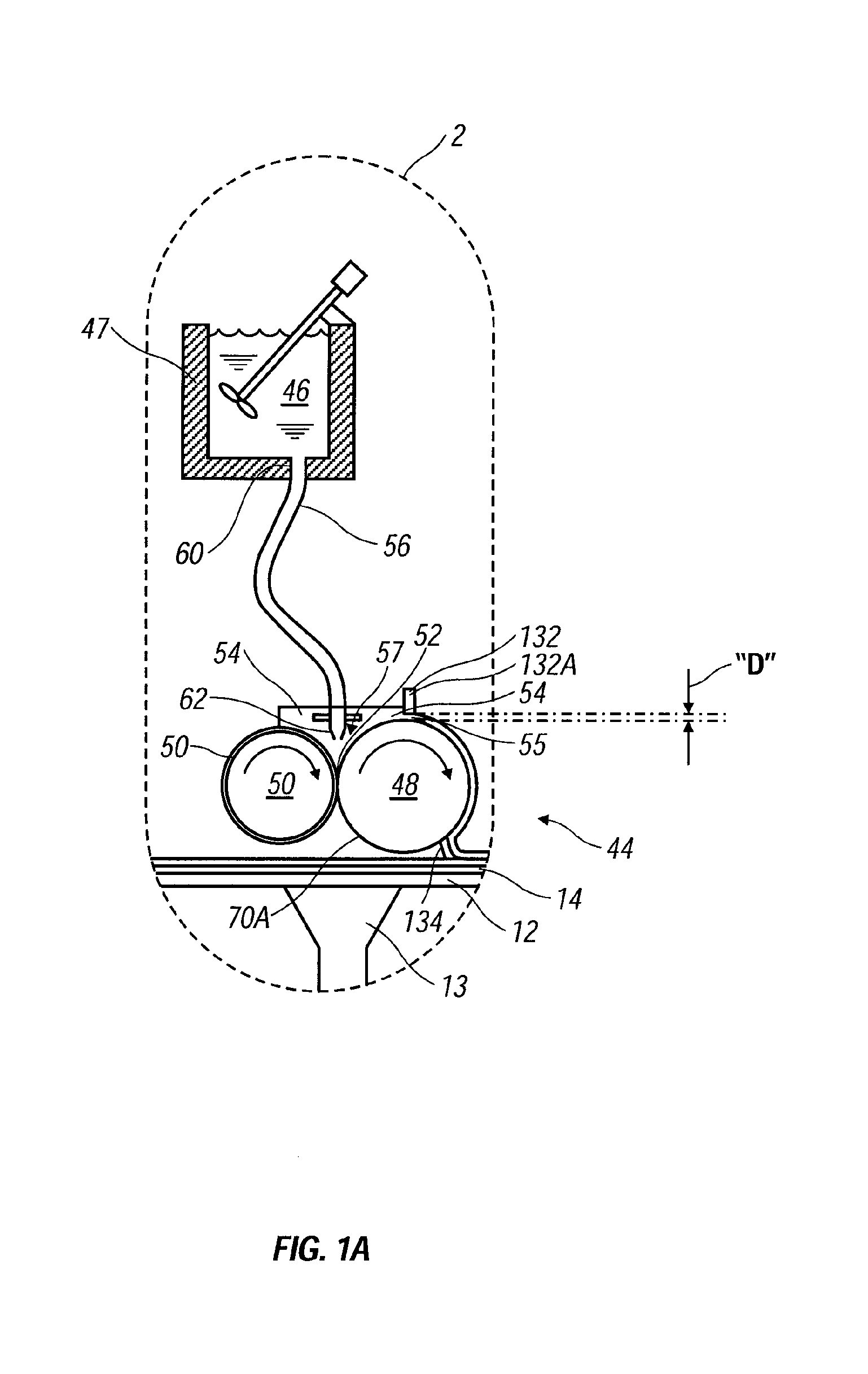

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080099171A1Good strength propertiesA large amountNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFibre reinforcement

A head-box for depositing slurry upon a moving web including a main metering roll, a companion roll disposed in closely spaced relation to the metering roll and a vibrating gate which forms a nip between the metering roller and the gate. The nip is arranged to retain a supply of the slurry, and the rolls are driven so slurry retained in the nip progresses over an upper outer peripheral surface of the metering roll to be deposited upon the web. Also, preferably included is a doctor blade disposed in operational relationship to the metering roll for directing the slurry downwardly from the outer metering roll surface to a point above the surface of a carrier for a fiberglass layer upon which the slurry layer is deposited. The vibrating gate and doctor blade may be pivotally mounted to either side of the surfaces of the head-box.

Owner:UNITED STATES GYPSUM CO

Fabric reinforcement and cementitious boards faced with same

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels

A multi-layer process for producing structural cementitious panels, includes, a. providing a moving web; b. one of depositing a first layer of loose fibers upon the web and c. depositing a layer of settable slurry upon the web; d. depositing a second layer of loose fibers upon the slurry; e. embedding said second layer of fibers into the slurry; and f. repeating steps c. through e. until the desired number of layers of settable fiber-enhanced slurry in the panel is obtained. Also provided are a structural panel produced by the present process, an apparatus suitable for producing structural cementitious panels according to the present process, and a structural cementitious panel having multiple layers, each layer created by depositing a layer of settable slurry upon a moving web, depositing fibers upon the slurry and embedding the fibers into the slurry such that each layer is integrally formed with the adjacent layers.

Owner:UNITED STATES GYPSUM CO

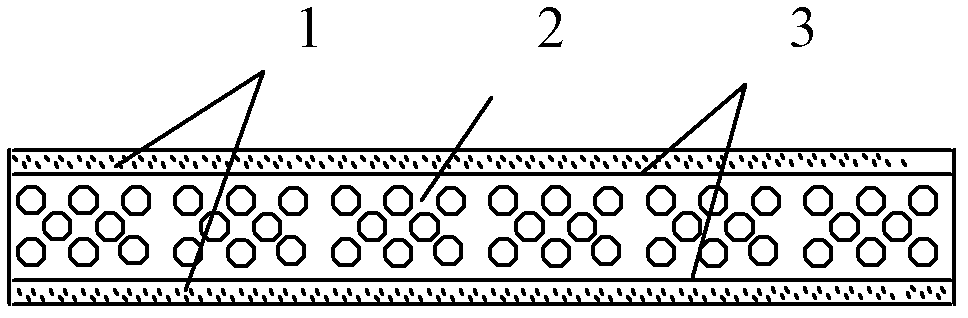

Magnesium oxysulfate cement board and method for preparing same by using semidry method

InactiveCN102493598AAnti-bendingLower pH valueCeramic shaping apparatusBuilding componentsPlant fibreCement board

The invention relates to a magnesium oxysulfate cement board and a method for preparing the same by using a semidry method. The magnesium oxysulfate cement board comprises a heat insulation core layer and strength structure layers respectively compounded on the two surfaces of the heat insulation core layer. The heat insulation core layer is a layer structure formed by stirring and pressing magnesium oxysulfate which is used as a gelatinizing agent and a light material which is used as a filler. Each strength structure layer is a layer structure formed by the magnesium oxysulfate which is used as the gelatinizing agent. The magnesium oxysulfate cement board disclosed by the invention has the outstanding substantive characteristics that a plate material with a multilayer composite structure is formed by mixing the magnesium oxysulfate utilized as the gelatinizing agent with the light material and / or a reinforcing fiber; the structure of the core layer has the characteristics of light weight and good heat preservation and heat insulation effects; the strength structure layers on the two surfaces of the core layer have the characteristics of bending resistance and high compression strength; and meanwhile, the magnesium oxysulfate cement board is low in PH value and has no chlorine content. Therefore, the occurrence of the moisture absorption and the halogenation are avoided; the corrosion on materials, such as plant fibers, metal pieces and the like, is avoided; and the application range is widened and the service life is prolonged.

Owner:NG TERASUN AIR DUCT

Fiber-reinforced composite material cement board and preparation method thereof

ActiveCN101508133ALow water absorptionReduce moisture contentConstruction materialSurface layering apparatusFiberglass meshGlass fiber

The invention discloses a method for preparing a fiber composite material concrete board, which comprises the following steps: laying a first layer of slurry in a mould; laying a first layer of glass fiber grid cloth on the laid first layer of the slurry; laying a second layer of slurry on the laid first layer of the glass grid cloth; laying a second layer of glass fiber grid cloth on the laid second layer of the slurry; laying a third layer of slurry on the laid second layer of the glass fiber grid cloth; vibrating the mould by a vibration device; putting the mould into a steam autoclave; and performing autoclave leaving, demoulding, airing and final treatment to form the concrete board made of the fiber composite material. The invention also discloses a concrete board made of a fiber composite material. The method has the advantages of simple manufacturing process, little capital and equipment input and low cost; and the concrete board made of the fiber composite material has the advantages of low water absorbing rate, high strength, good toughness, high durability, and the like.

Owner:广德衡峰新型建材有限公司

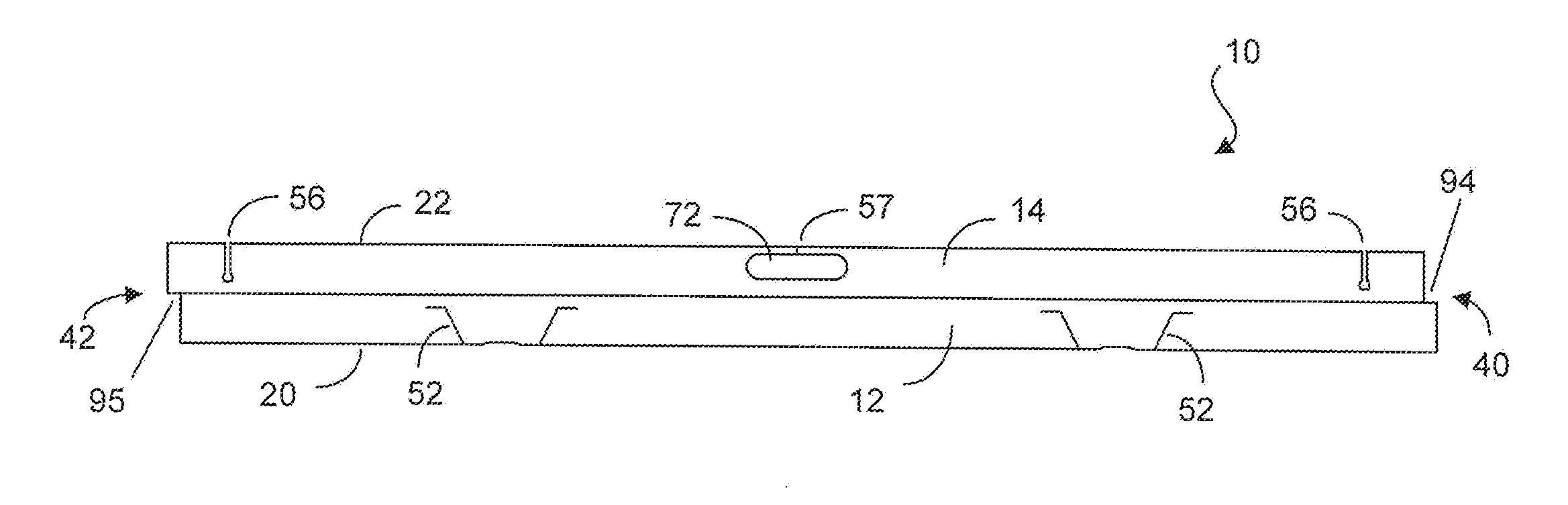

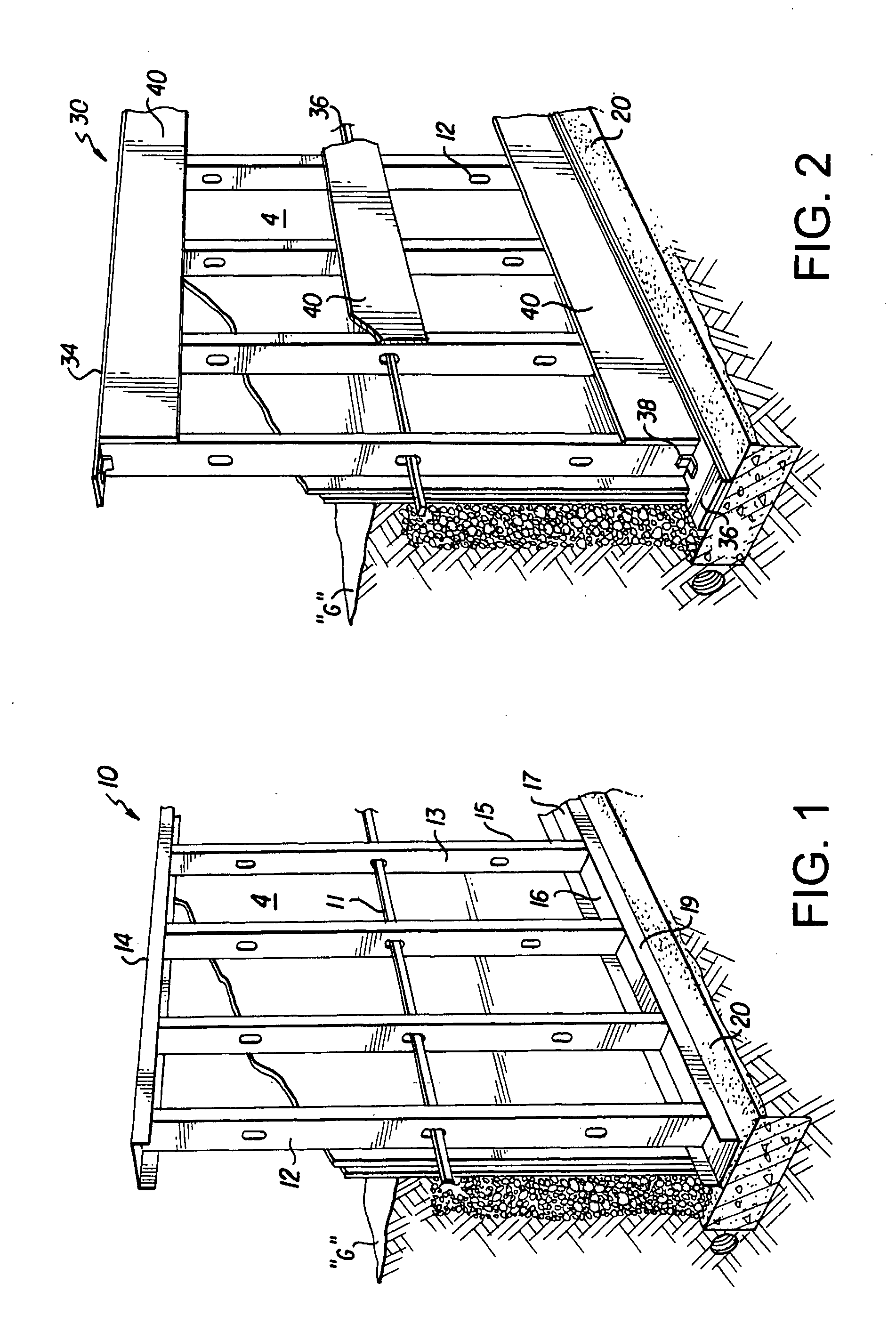

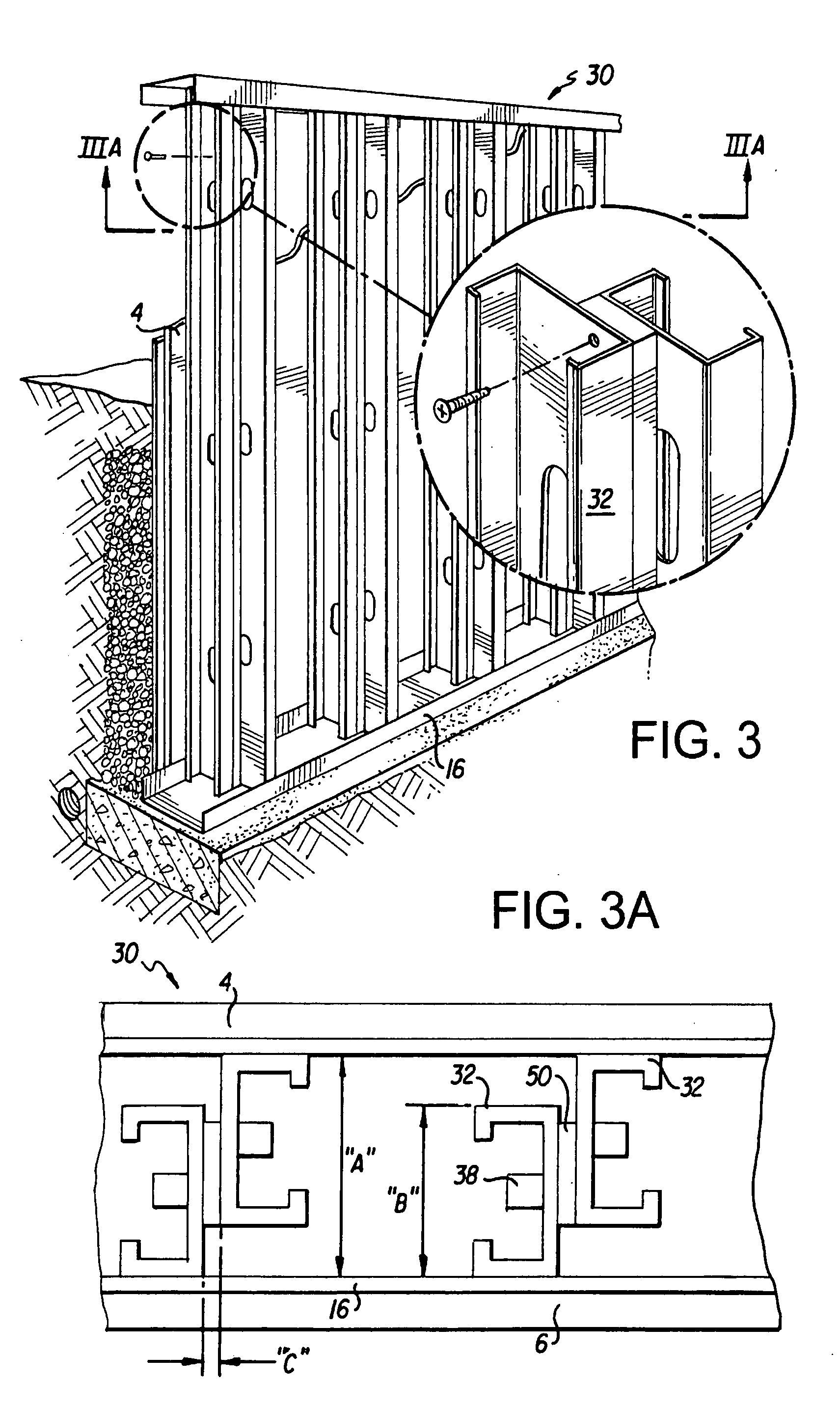

Insulating Wall Panel System

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

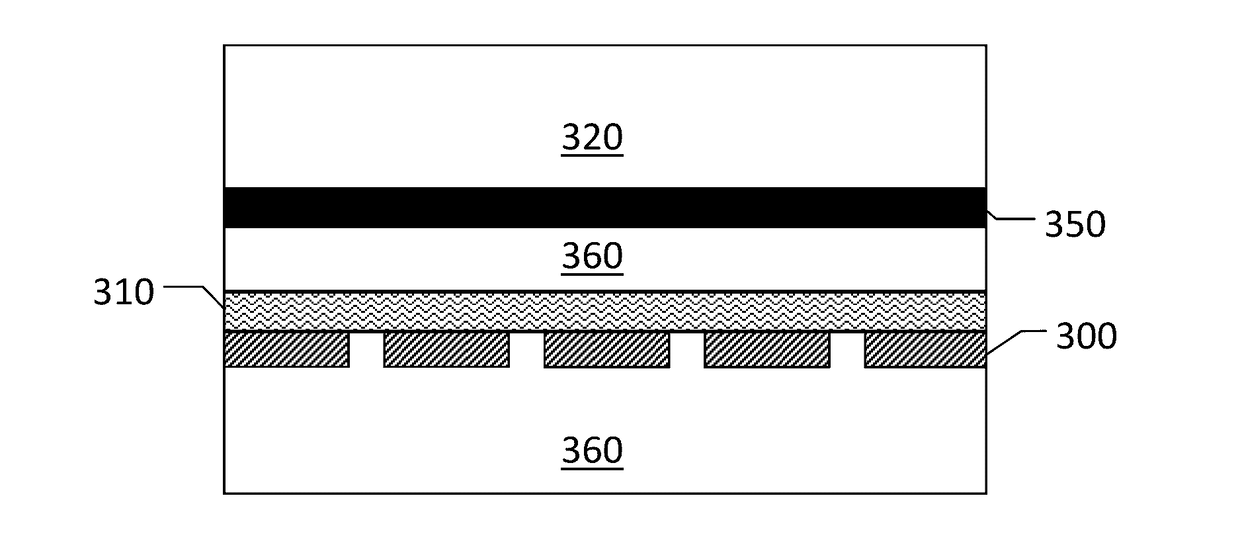

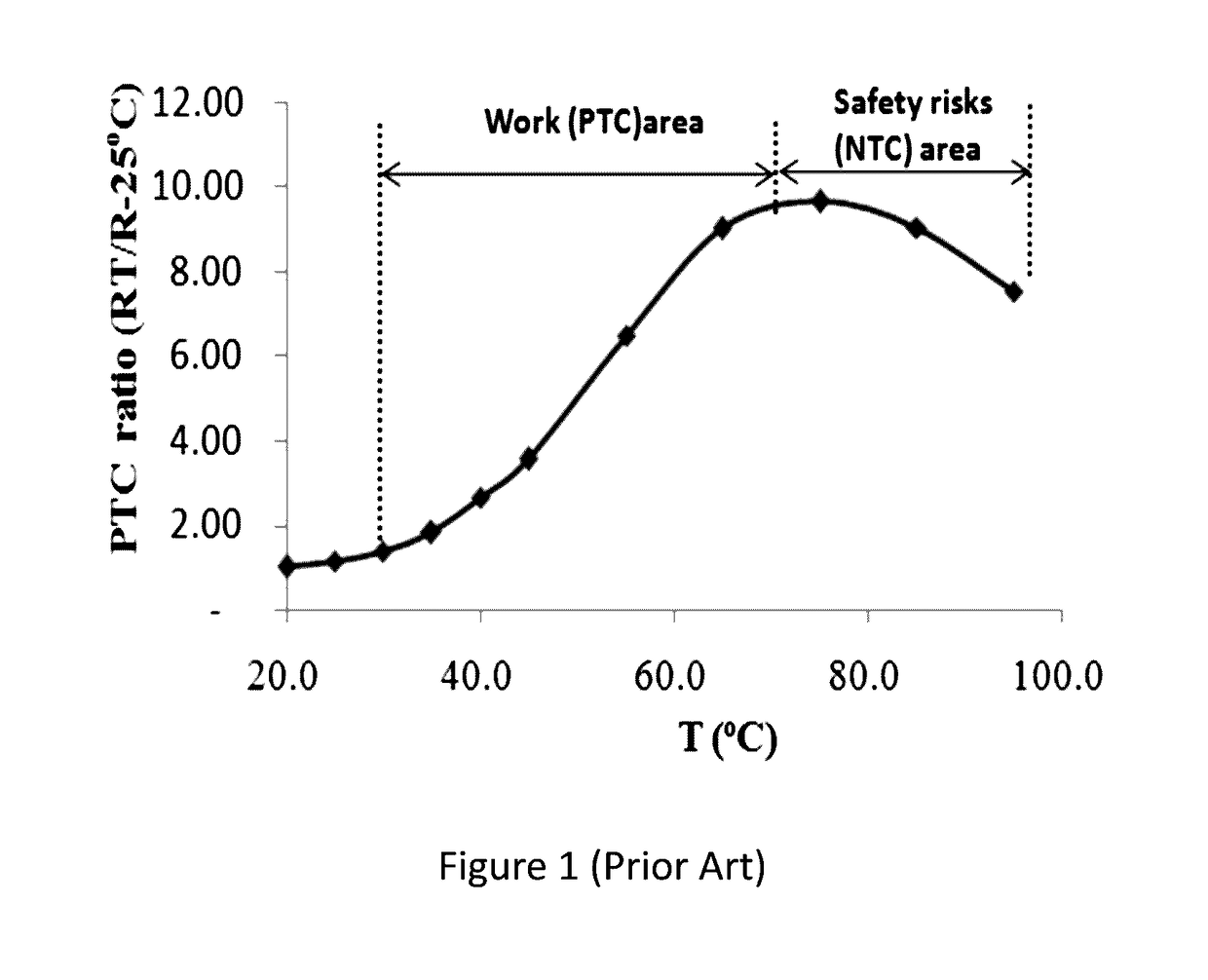

Electrically conductive PTC ink with double switching temperatures and applications thereof in flexible double-switching heaters

ActiveUS20170158898A1Eliminate the effects ofHigh PTC characteristicLighting and heating apparatusIce productionPolyesterCarbon composites

A double-switching heater includes a double-switching PTC ink deposited on a substrate to form one or more resistors. The double-switching PTC ink has a first resin that provides a first PTC effect at a first temperature range and a second resin that provides a second PTC effect at a second temperature range, where the second temperature range is higher than the first temperature range. The substrate may be a flexible substrate or a rigid substrate, and may bedeformable to generate a three-dimensional structure. The substrate may be: polyester, polyimide, polyamide, polypropylene, thermoplastic polyurethane, fiberglass, cement board, carbon composite materials, polyethylene terephthalate, polyethylene, aluminum, steel, glass composite, molded plastic, high-density polyethylene or styrene ethylene butylene styrene.

Owner:LMS CONSULTING GRP LLC

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

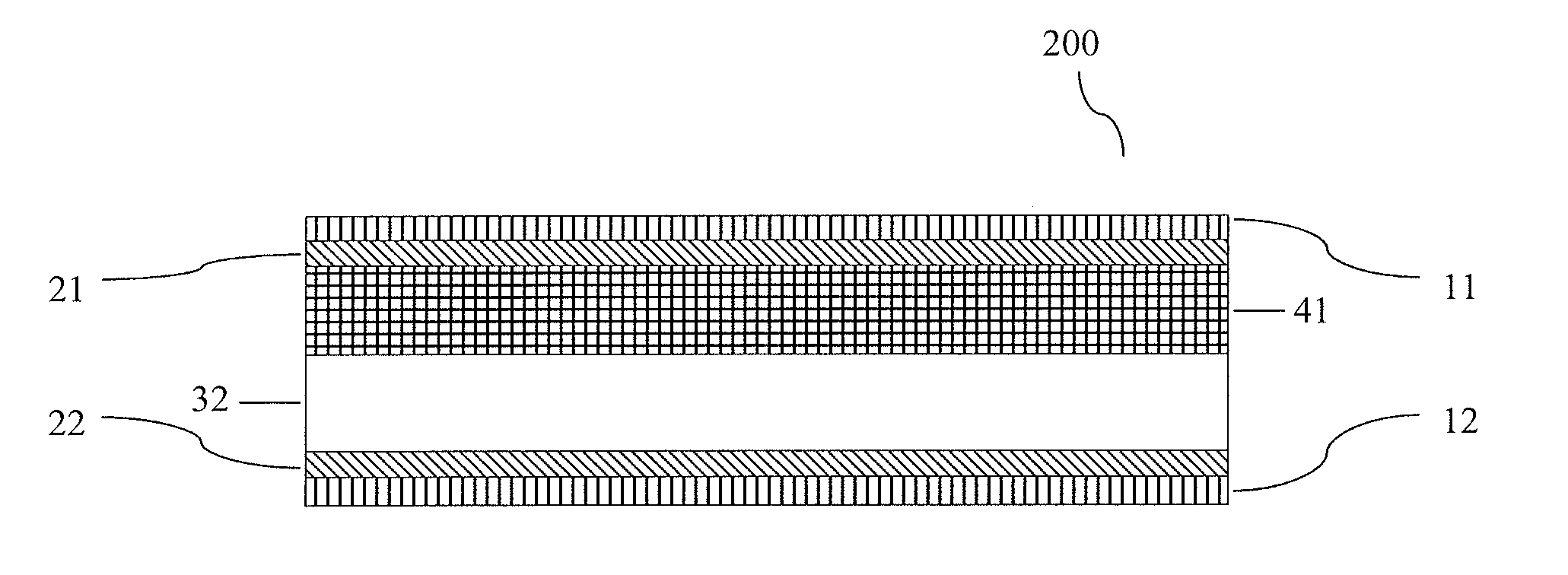

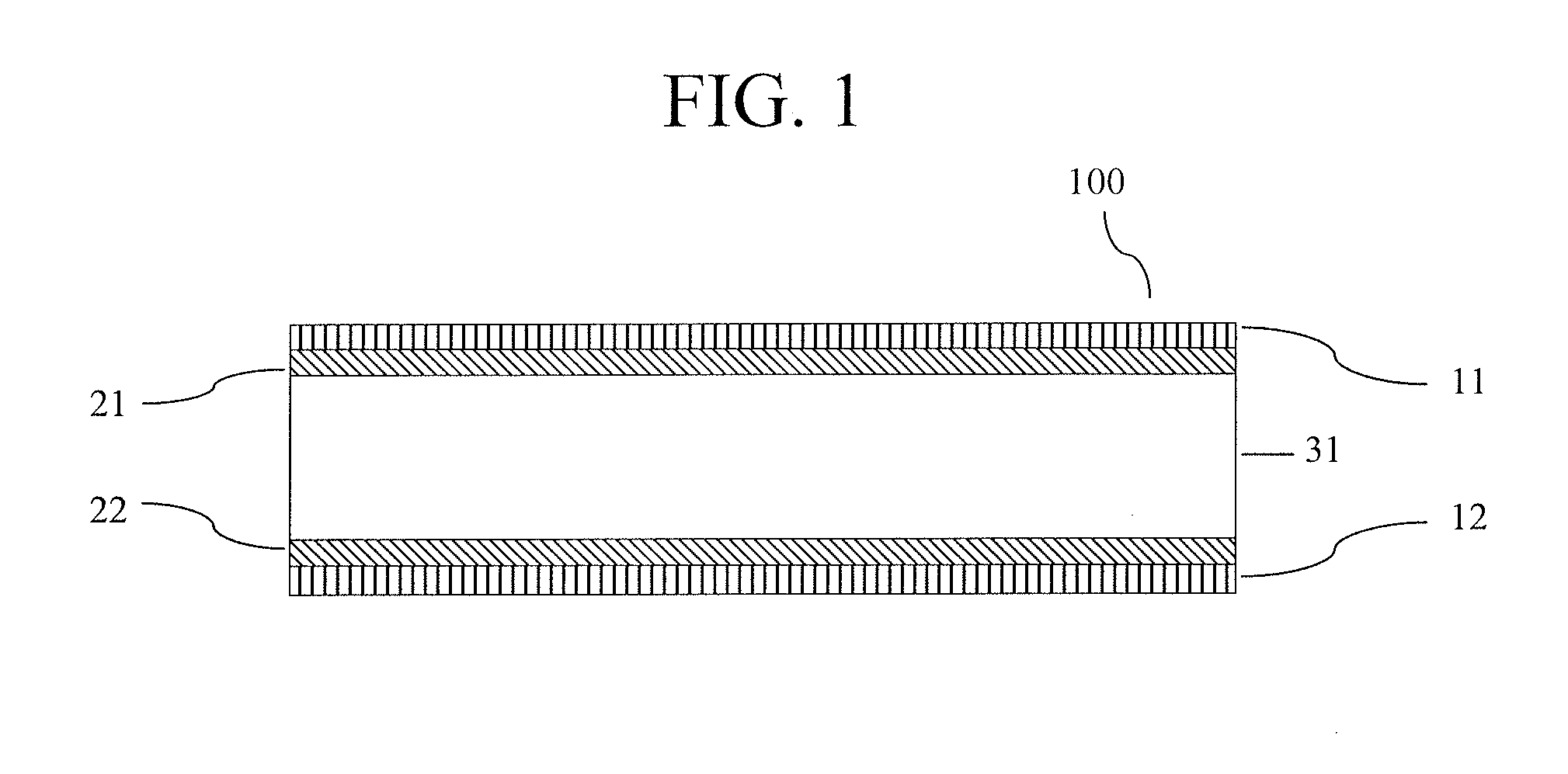

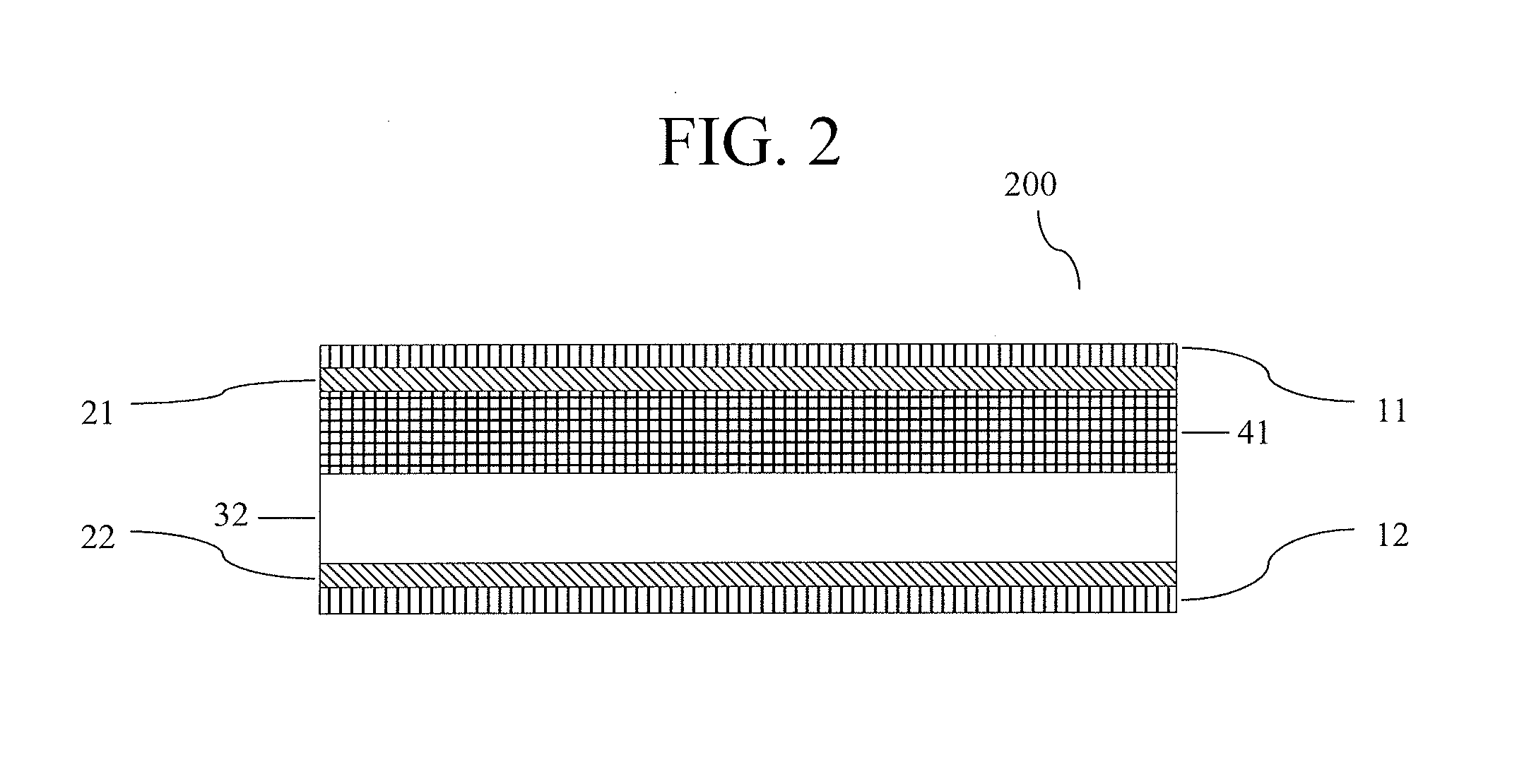

Cement based laminated armor panels

ActiveUS20100229714A1Ultra-high compressive strengthReduce intensityConstruction materialSolid waste managementSuperplasticizerCement board

A cementitious panel with ballistic and blast resistant properties having a core layer of ultra-high compressive strength composite and at least one skin layer. The panels can also be used in walls, ceiling and flooring panels which require high compressive strength for resistance to earthquakes and surfaces resistant to surface abuse such as in prison and other institutions. The panel core layer has a continuous cementitious phase resulting from the curing of an aqueous mixture, in the absence of silica flour, of inorganic cement binder, inorganic mineral filler having a particle size of about 150-450 microns, a pozzolanic mineral filler, polycarboxylate based superplasticizer, alkanolamine and acid or alkali metal acid salt; and water. The mixture may be uniformly reinforced with fiber added before curing. The cementitious core layer is then reinforced with the skin, such as fiber reinforced polymer, attached to at least one panel surface.

Owner:UNITED STATES GYPSUM CO +1

Non-combustible reinforced cementitious lightweight panels and metal frame system for building foundations

ActiveUS20070294974A1Alleviate bearing capacityStiffen and strengthen and toughen panelSolid waste managementWallsMicrosphereCement board

A foundation system includes metal framing members that support a reinforced, lightweight, dimensionally stable cementitious panel. The foundation system is non-combustible, water durable, mold and rot resistant, and termite resistant. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Multilayered core board with enhanced nail-pull strength

InactiveUS20120207989A1Avoid layeringWash-out can be preventedLamination ancillary operationsPretreated surfacesCement boardUltimate tensile strength

Disclosed herein are multilayered core cementitious boards with increased nail-pull resistance. The boards can comprise two or more layers of cementitious compositions, where each layer can be a different density. Methods of making the multilayered core boards are also disclosed. The methods include having a layer of cementitious composition partially set prior to applying the next layer.

Owner:UNITED STATES GYPSUM CO

Lightweight wall construction

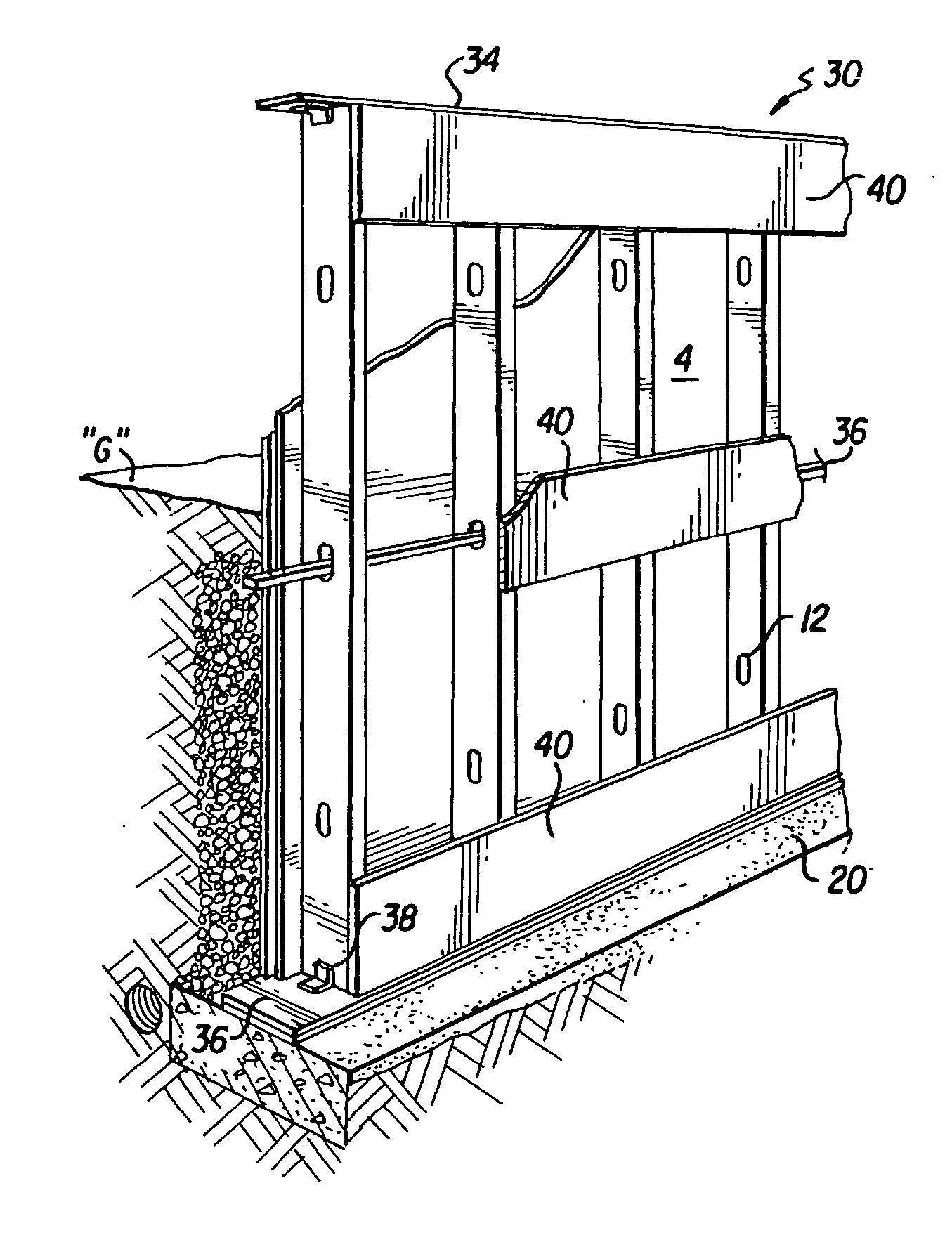

InactiveUS6907708B2High viscosityImprove suppression propertiesConstruction materialWallsCement boardLoose fill

A low or no fines lightweight concrete mixture. The mixture comprises one part by volume of a cementitious binder, 2-10 parts inert coarse aggregate, a cement additive in an amount of 0.05 to 0.3% by weight of the cementitious binder and an effective amount of water, the additive including 40-99% of a viscosity enhancing agent, which in water either dissolves or forms colloidal dispersions, and 1-60% of an air entrainment agent / surfactant adapted to entrain air when mixed with water and / or pumped. The mixture is particularly suitable for constructing a building panel where a frame is prepared, the front and rear faces being covered by fibre reinforced cementitious sheets and the cavity there between at least partially filled with the lightweight concrete mixture which flows in a manner similar to loose fill.

Owner:JAMES HARDIE TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com