Patents

Literature

1284 results about "Acid salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid salts are a class of salts that produce an acidic solution after being dissolved in a solvent. Its formation as a substance has a greater electrical conductivity than that of the pure solvent. An acidic solution formed by acid salt is made during partial neutralization of diprotic or polyprotic acids. A half-neutralization occurs due to the remaining of replaceable hydrogen atoms from the partial dissociation of weak acids that have not been reacted with hydroxide ions (OH⁻) to create water molecules. Acid salt is an ionic compound consisted of an anion, contributed from a weak parent acid, and a cation, contributed from a strong parent base.

Encapsulated unsaturated fatty acid substance and method for producing the same

InactiveUS6531150B1Improve product qualityInhibit oxygen-permeabilityPowder deliveryGranular deliveryWater solubleGelatin

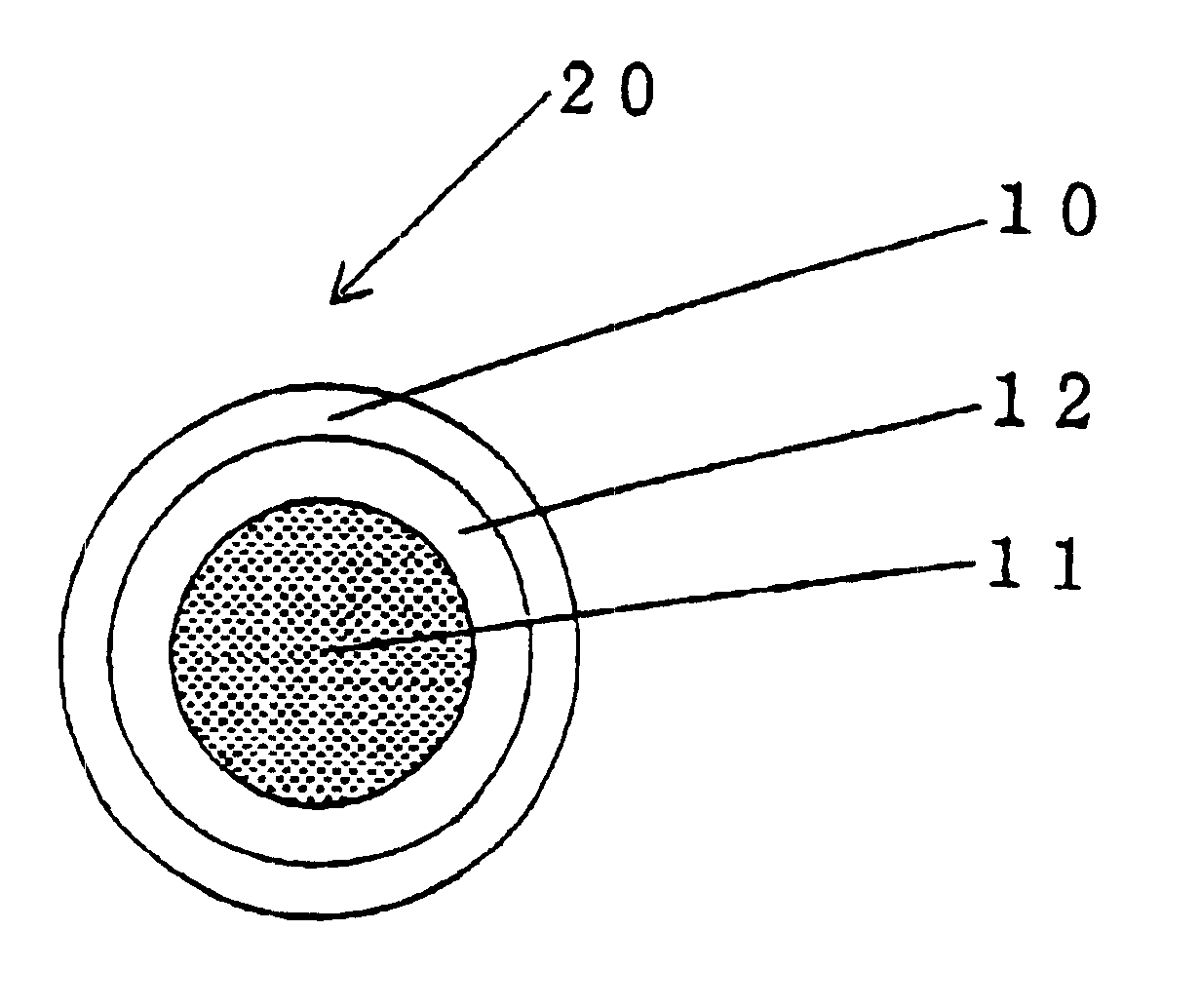

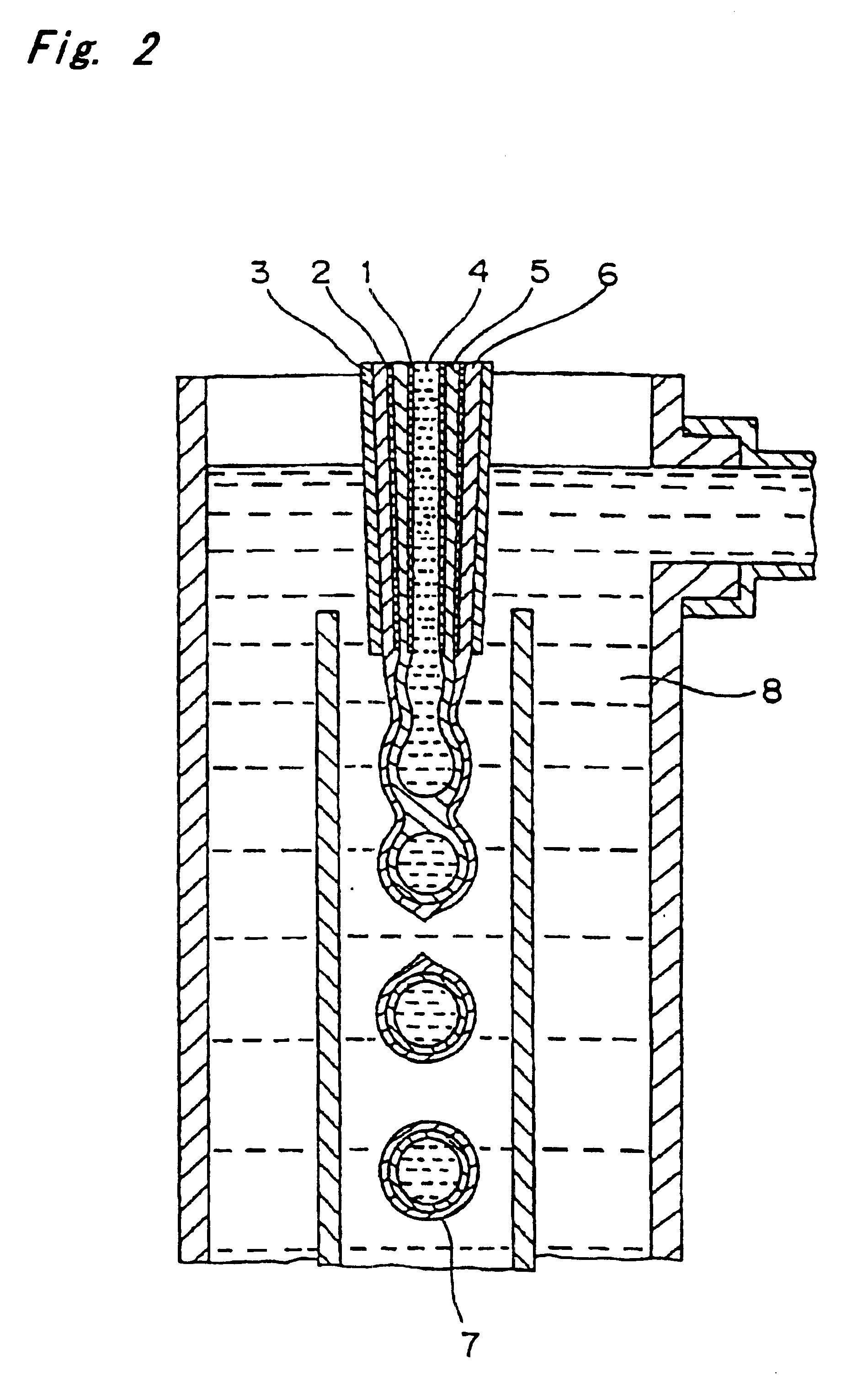

The present invention relates to an encapsulated unsaturated fatty acid substance in a form of a three-layered capsule, comprising an unsaturated fatty acid or a derivative thereof (11) as a content and a coating layer (10) mainly containing gelatin, encapsulating the content (11), wherein a water-soluble gel layer (12) containing an acid or an acid salt thereof is present between the coating layer (10) and the content (11). The encapsulated unsaturated fatty acid substance of the present invention is characterized by that it has neither insolubility nor deterioration with time, and that it is enteric.

Owner:MORISHITA JINTAN CO LTD

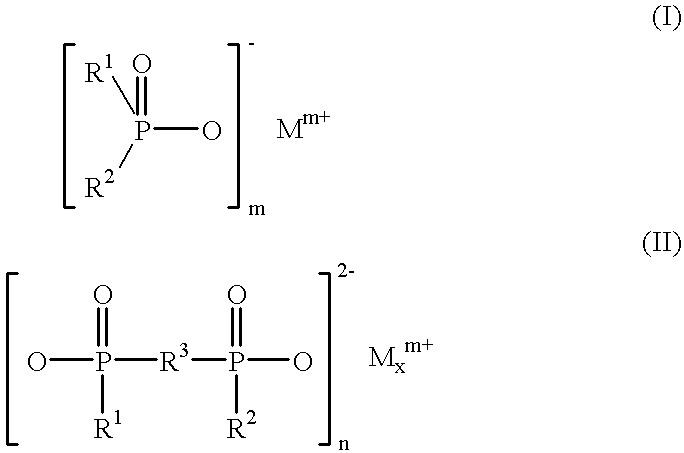

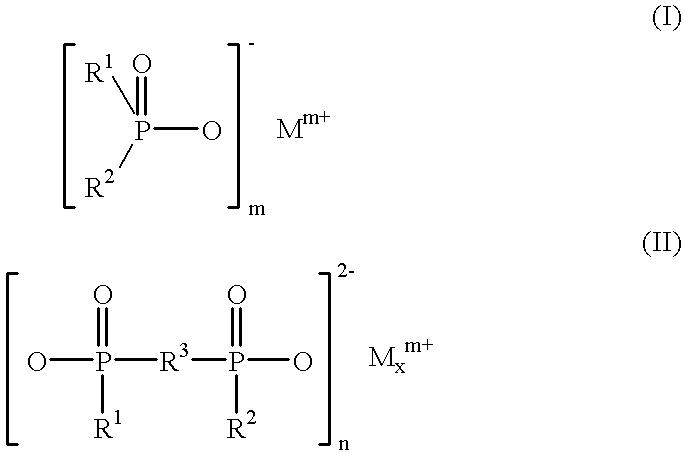

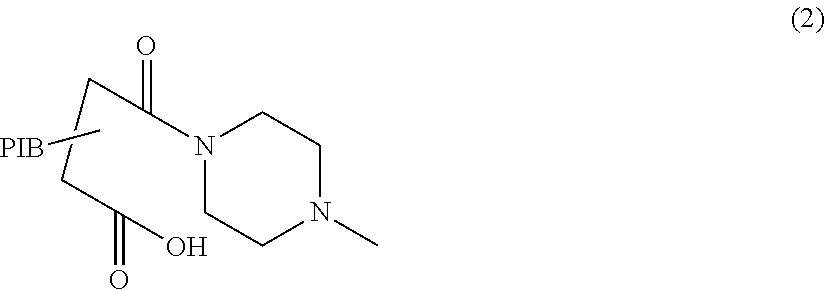

Synergistic flameproofing combination for polymers

The present invention relates to a synergistic flameproofing combination for polymers, in particular for ABS, which contains, as component A, a phosphinic acid salt of the formulae (I) defined in the description and / or a diphosphinic acid salt of the formula (II) and / or polymers thereof and which contains, as component B, a nitrogen-containing phosphate or a mixture of the compounds defined by the formulae.

Owner:CLARIANT PROD DEUT GMBH

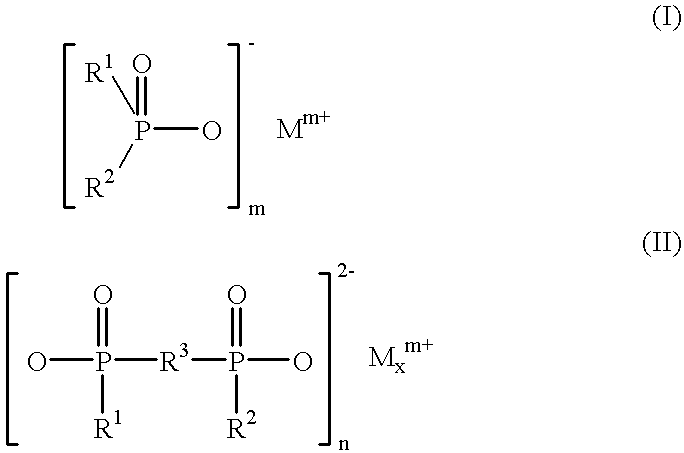

Method for preparing humic acid and salt thereof by oxidation and degradation of brown coal

The invention discloses a method for producing humic acid and salt thereof through the oxidative degradation of young lignite. The method comprises the following steps: carrying out the oxidation reaction of the lignite containing the humic acid and aqueous hydrogen peroxide solution; after the reaction, obtaining water soluble fulvic acid through centrifugal separation, supernatant filtration, concentration and drying; adding alkali into the fulvic acid to prepare a fulvic acid salt product; carrying out the alkaline extraction and centrifugal separation of the residue deposit of the production of the fulvic acid, adding acid into the supernatant till the pH value is 1 to 2, carrying out a reaction at an increased temperature or room temperature, carrying out centrifugal separation after the reaction is finished, and obtaining purified ulmic acid after precipitation and drying; and directly concentrating and drying the supernatant in the previous step to obtain the humate. The method can improve the yield of the fulvic acid and total humic acid in the young lignite, and simultaneously increase the active group in the humic acid. The method can be used for producing fulvic acid, fulvic acid salt, ulmic acid and ulmic acid salt products. In particular, the method puts an end to the environmental pollution caused by the nitric acid which is taken as an oxidation degradation agent. In addition, the method has a short technological line, low cost, simple requirements on equipment, and moderate conditions. The method which can be applied to the industrialized production has good application prospect.

Owner:KUNMING UNIV OF SCI & TECH +4

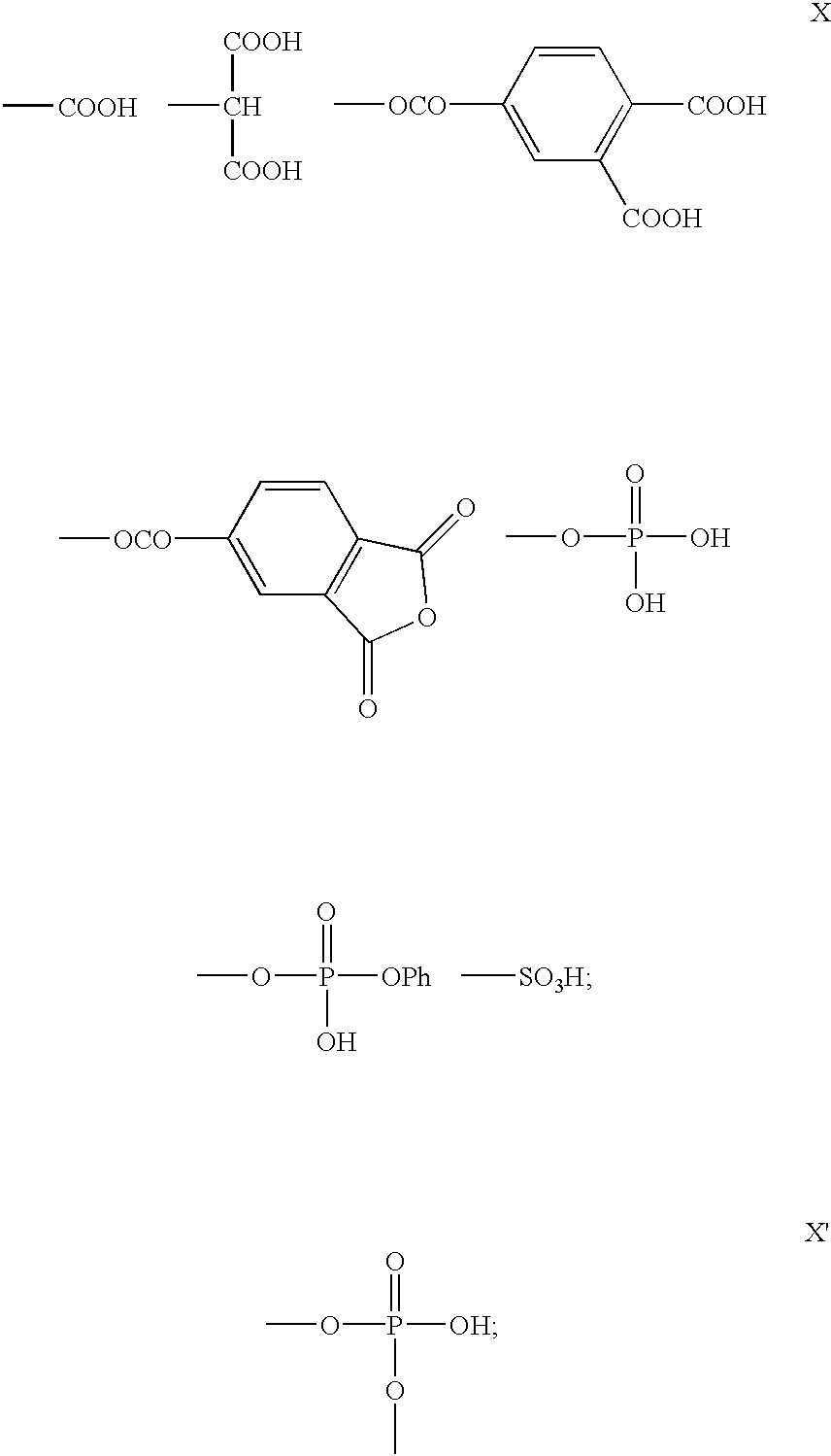

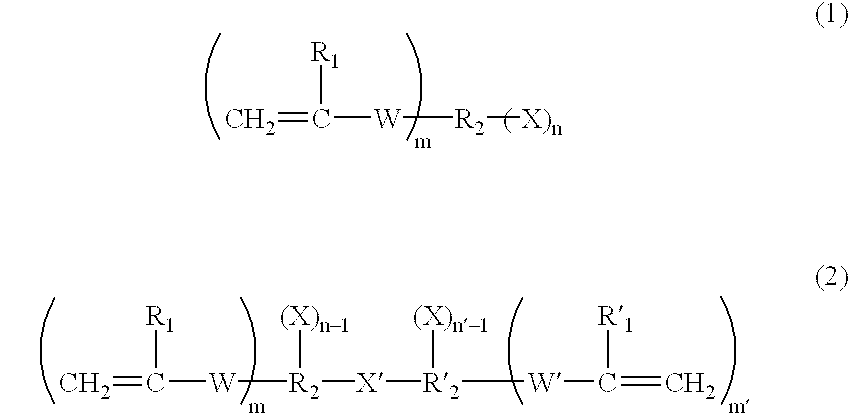

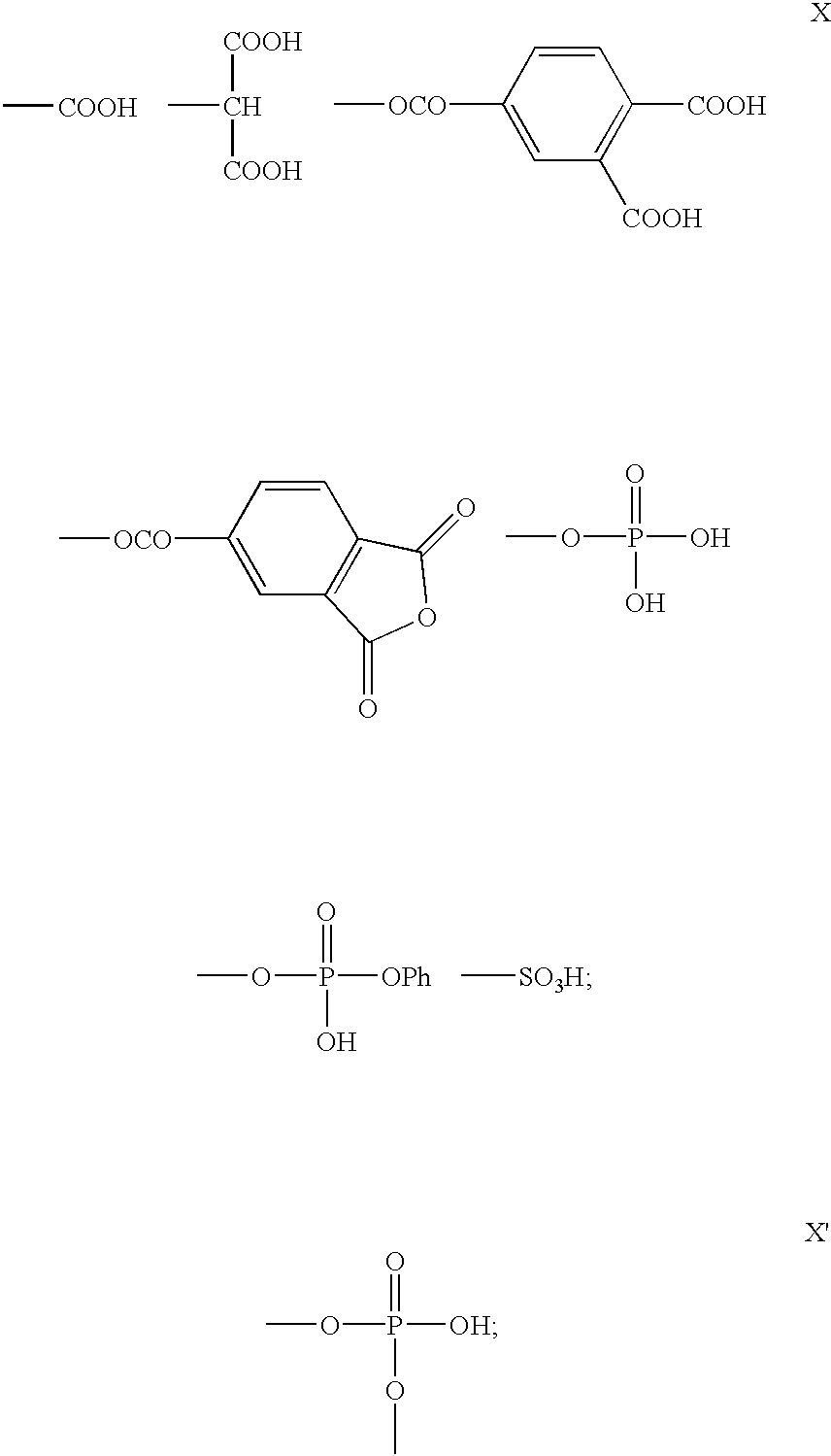

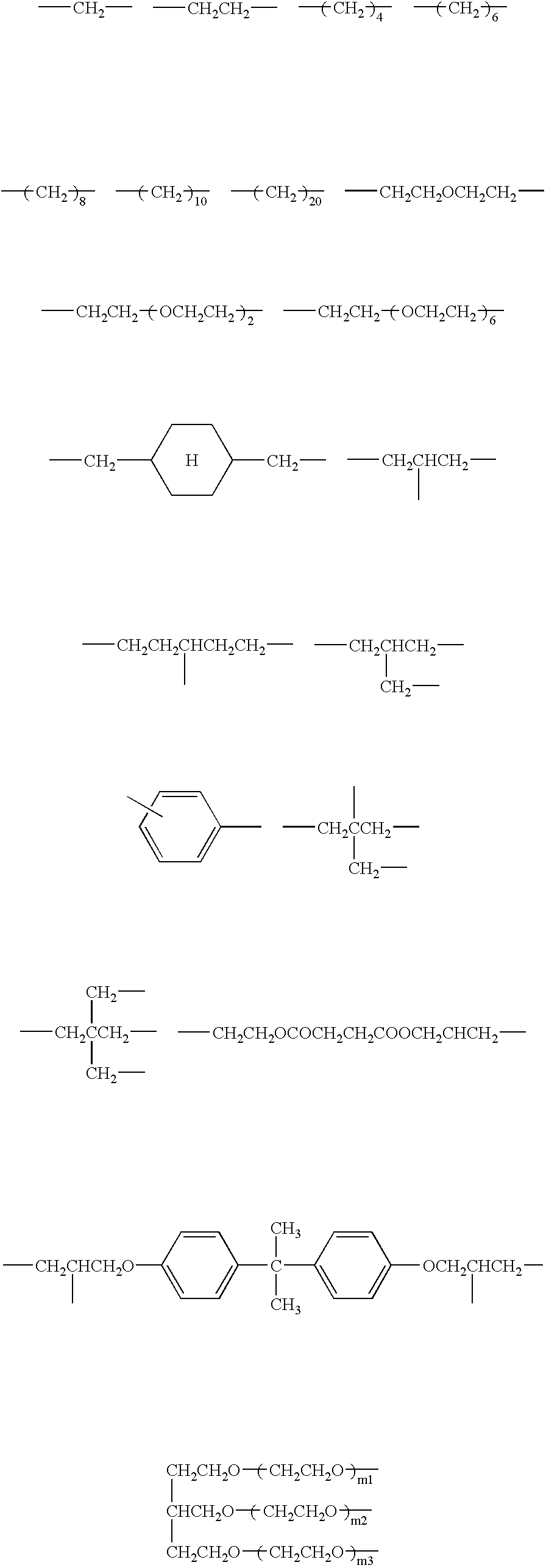

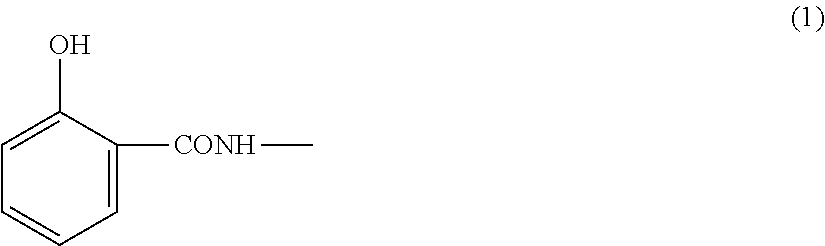

Dental adhesive composition

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

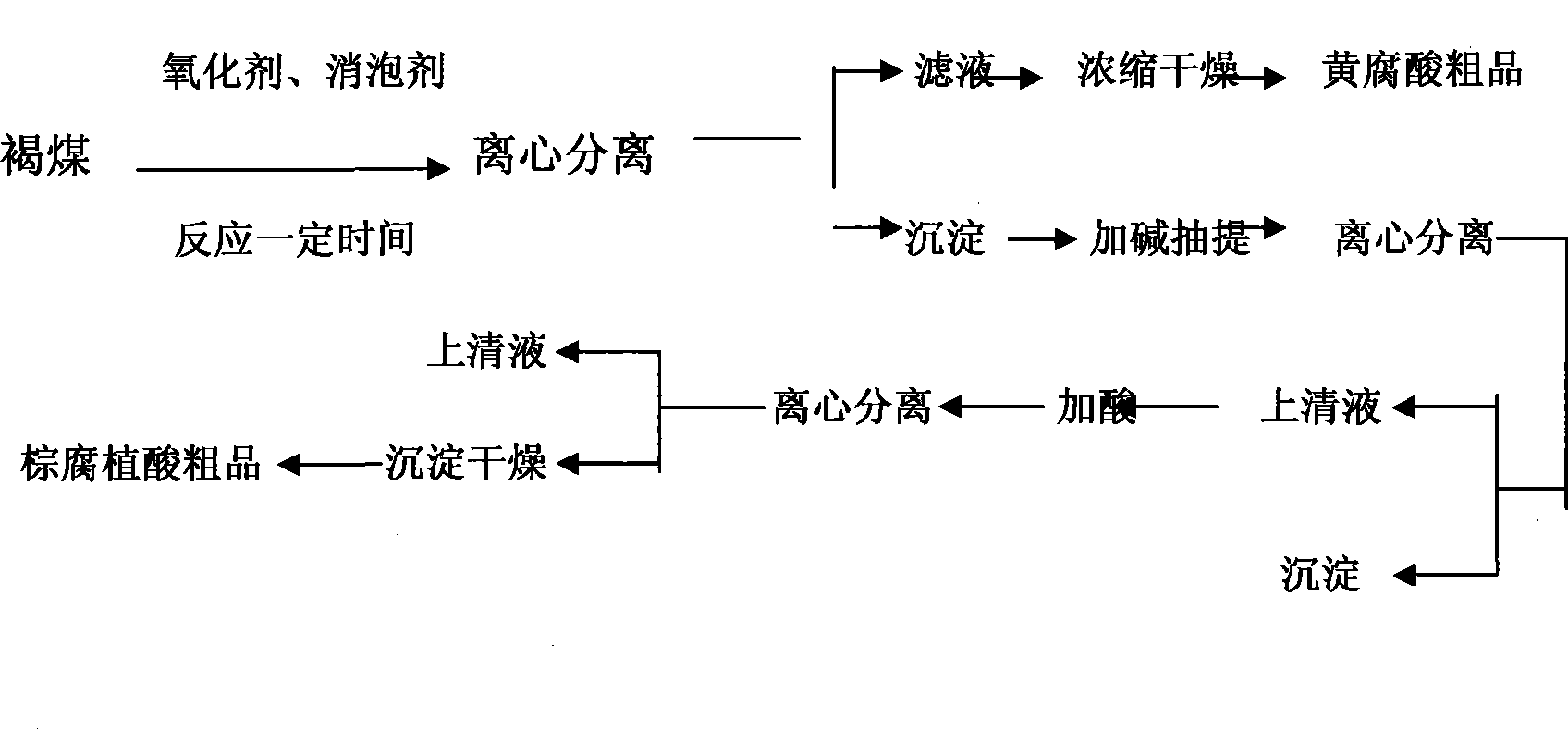

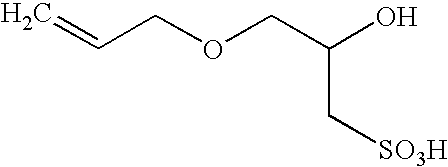

Polymerization of fluoromonomers using a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant

InactiveUS6869997B2Reduce the binding forceOrganic chemistryFibre treatmentFluoropolymerBuffering agent

Fluoropolymers are prepared by a process comprising polymerizing at least one fluoromonomer in an aqueous reaction medium containing monomer, a radical initiator and a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

Method for treating wood with a metal-containing treating agent and wood treated thereby

InactiveUS6541038B1Reduce leachingEasy to fixBiocideHeavy metal active ingredientsLignosulfonatesMetal

A method for treating wood, characterized by impregnating wood with a metal-containing treating agent containing lignin and / or lignin derivatives and a metal, a metal compound, and / or a metal ion and oxidizing and / or macromolecularizing of the lignin and / or lignin derivatives in the wood to fix the metal component in the wood, and wood and woody materials obtained by the treating method. According to the method of the present invention, while effectively utilizing lignins, lignosulfonic acids, or lignosulfonic acid salts, leaching of the metal component can be suppressed to a low level to thereby retain the effects due to the incorporation of the metal components for a prolonged period.

Owner:SDS BIOTECH CO LTD

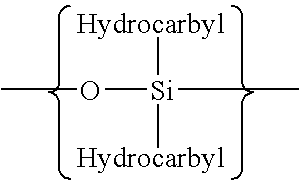

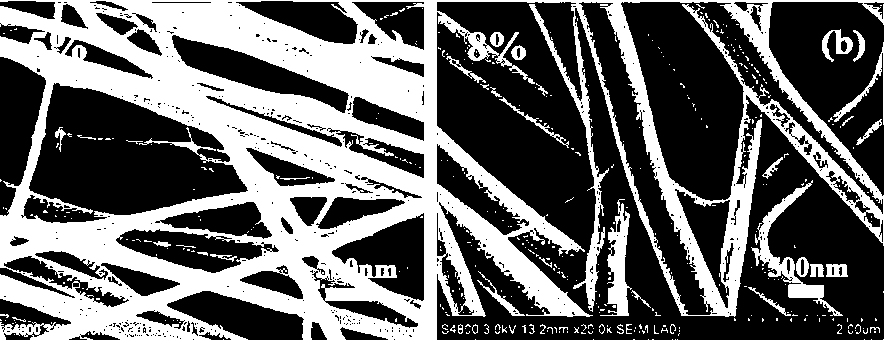

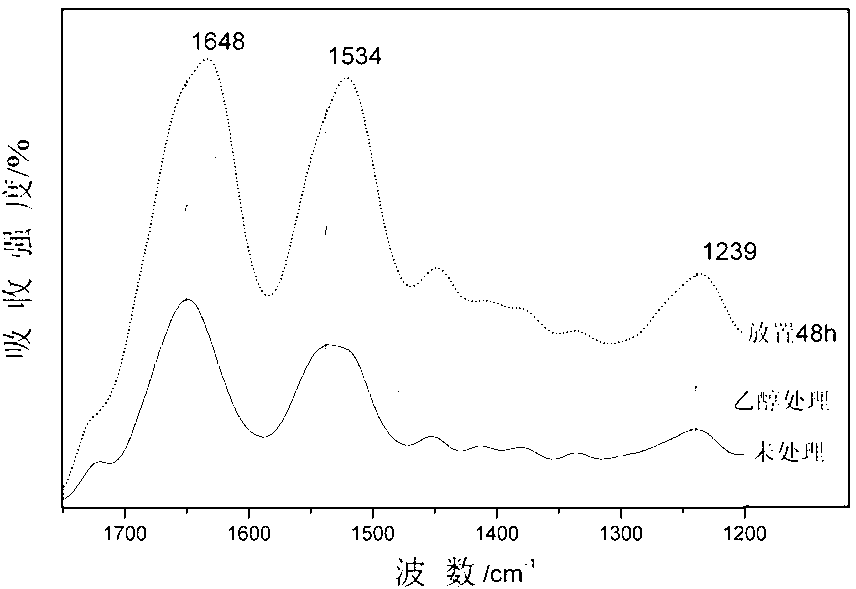

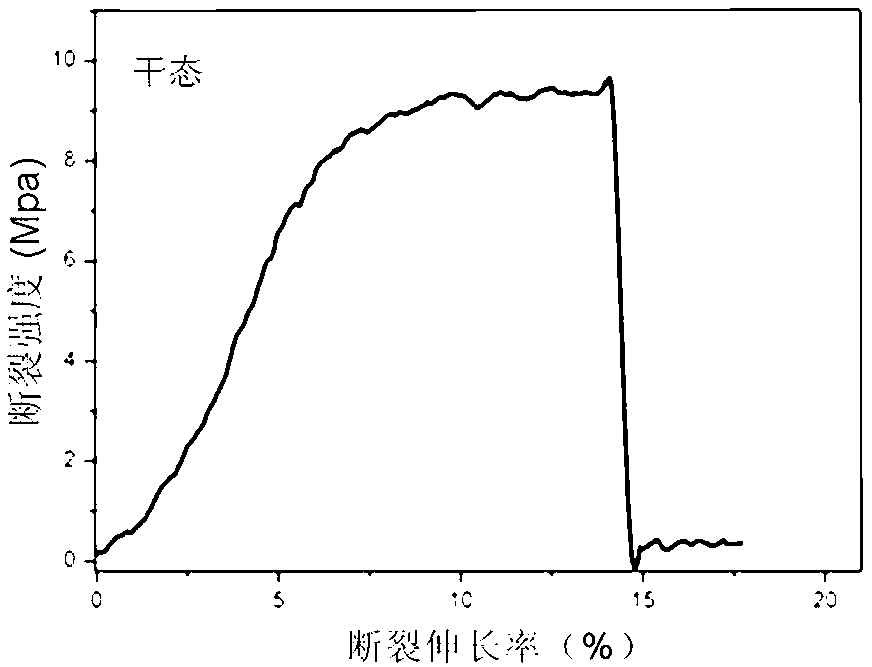

Silk fibroin nanofiber membrane and preparation method thereof

The invention discloses a silk fibroin nanofiber membrane and a preparation method of the silk fibroin nanofiber membrane. The preparation method comprises the following specific steps of: dissolving natural silk taken as a main raw material by an acid salt solution, forming a membrane, desalting the membrane, dissolving the membrane by methanoic acid and hexafluoroisopropanol to prepare a spinning solution, and carrying out electrostatic spinning to prepare the silk fibroin nanofiber membrane. The silk fibroin nanofiber membrane comprises fibers with the diameter of 10nm-10 microns and has the excellent mechanical property, the breaking strength of greater than 8Mpa at dry state, the breaking elongation of greater than 15% at dry state, the breaking strength of greater than 1Mpa at wet state and the breaking elongation of greater than 100% at wet state. In addition, the silk fibroin nanofiber membrane prepared by the method is stable and controllable in structure, has good biocompatibility and can serve as a medicinal biological material. The preparation method disclosed by the invention is simple and short in flow path, has high film formation and spinning efficiency and is suitable for industrialization large-scale production.

Owner:上海丝波敦生物科技有限公司

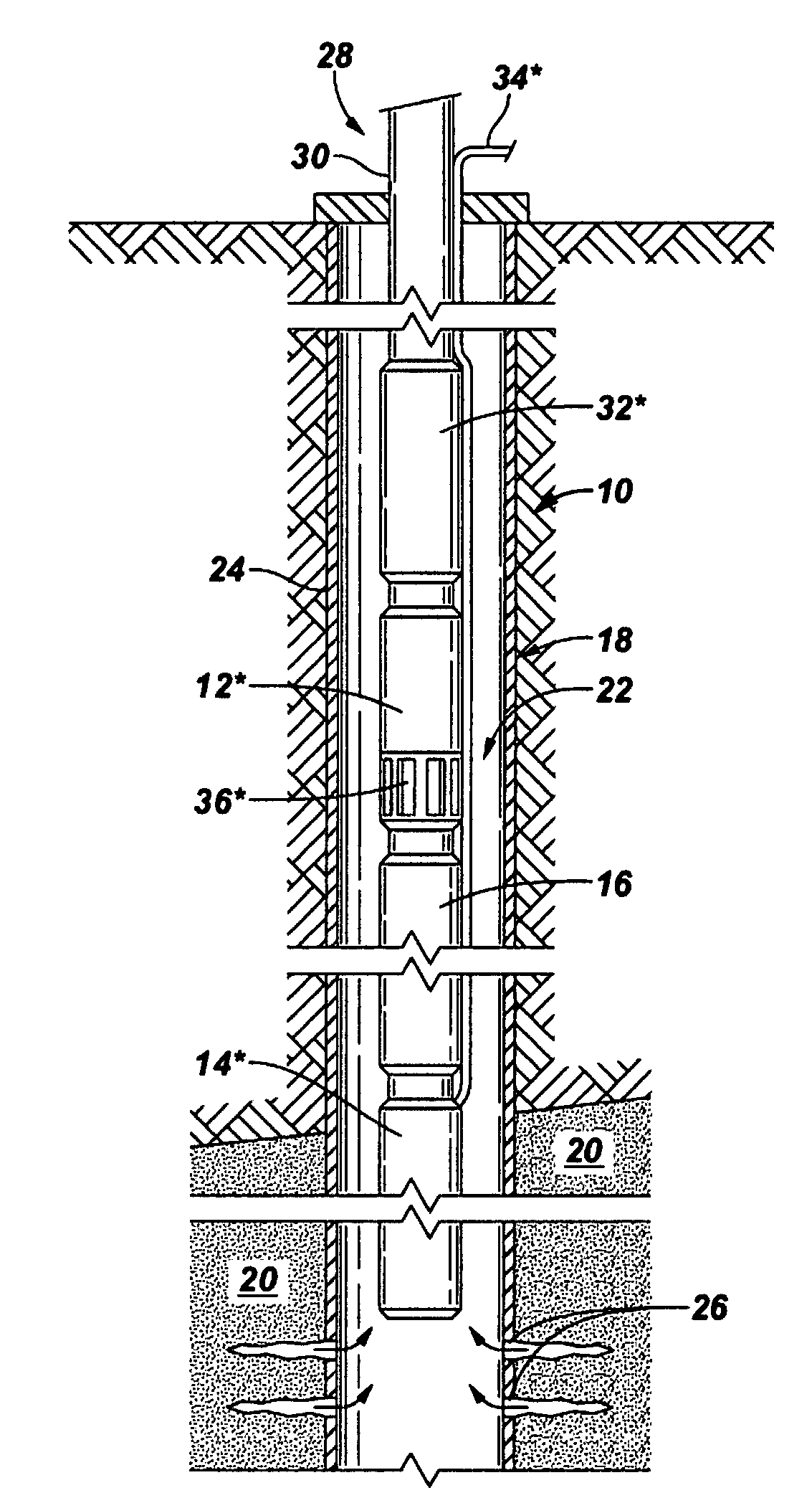

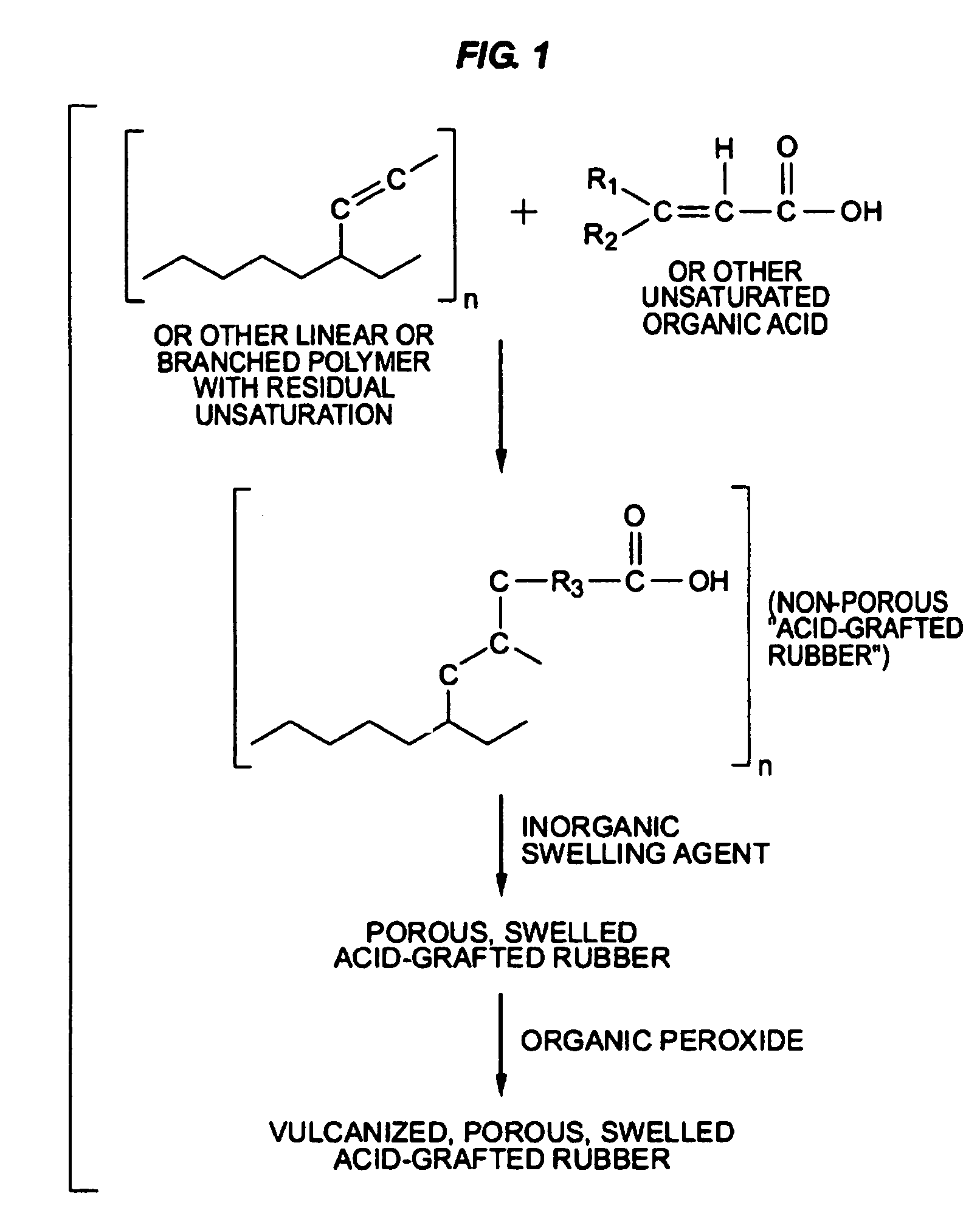

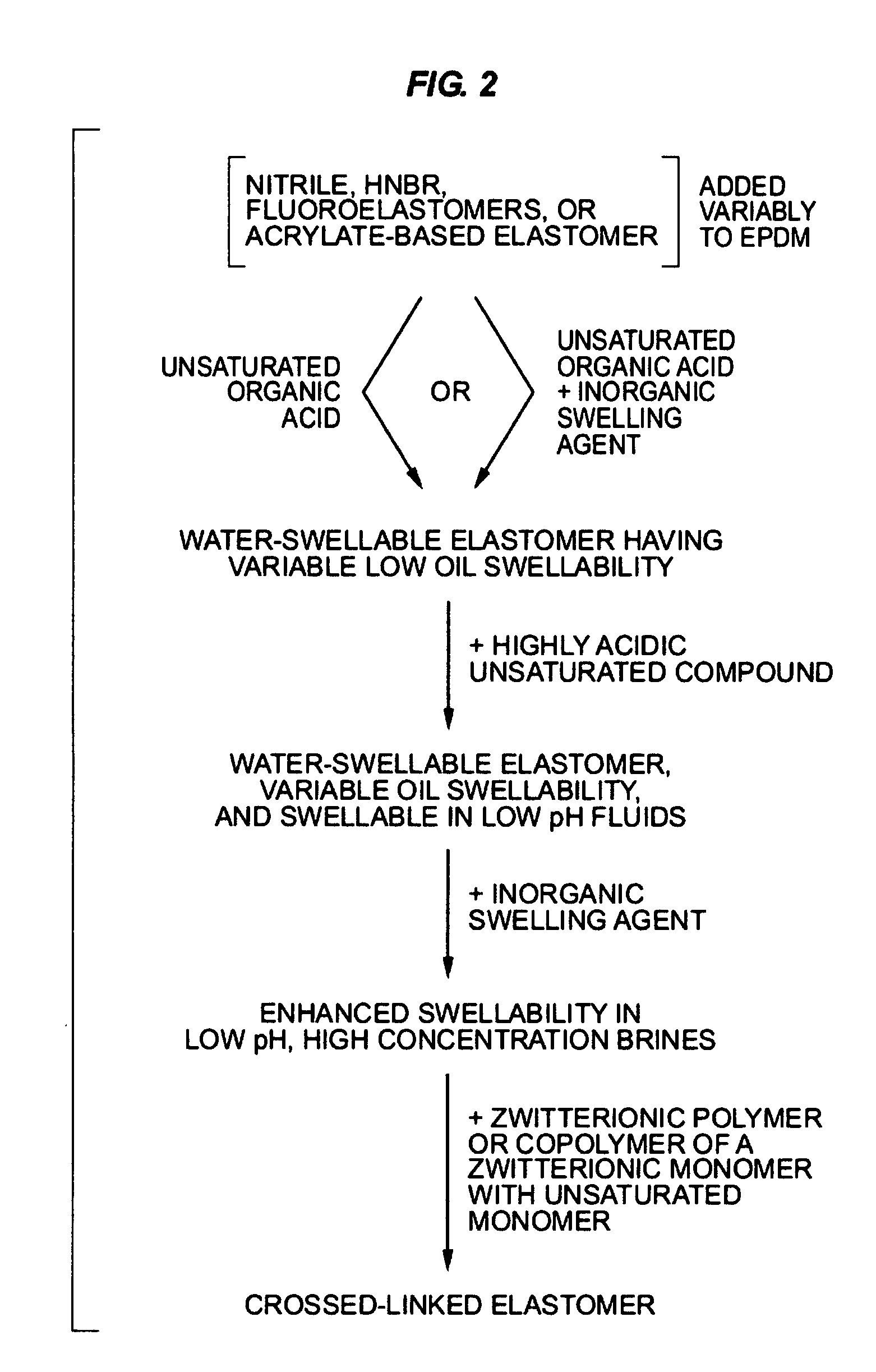

Swellable elastomer-based apparatus, oilfield elements comprising same, and methods of using same in oilfield applications

InactiveUS7373991B2Add waterIncrease oil-swellabilityFluid removalWell/borehole valve arrangementsElastomerAcid anhydride

Oilfield apparatus and methods of use, the apparatus comprising an elastomeric composition comprising the reaction product of a linear or branched polymer having residual ethylenic unsaturation with an ethylenically unsaturated organic monomer having at least one reactive moiety selected from the group consisting of acid, acid anhydride, and acid salt.

Owner:SCHLUMBERGER TECH CORP

Self-leveling cementitious composition with controlled rate of strength development and ultra-high compressive strength upon hardening and articles made from same

ActiveUS20090239977A1High strengthImprove the immunitySolid waste managementTriethanolamineFiber reinforcement

A self-leveling cementitious mixture with excellent flow properties and which hardens with a controlled rate of strength development to an ultra-high compressive strength composite composition for use in making articles such as cementitious armor panel with ballistic and blast resistant properties including: a continuous phase resulting from the curing of an aqueous mixture, in the absence of silica flour, of inorganic cement binder, inorganic mineral filler having a particle size of about 150-450 microns, pozzolanic mineral filler, polycarboxylate based self-leveling agent and water. The cementitious mixture may include alkanolamine, such as triethanolamine, and acid or acid salt, such as tartaric acid. The cementitious composition may be reinforced with reinforcing fibers, e.g. glass fibers, in an amount of about 0.5-6.0% by volume of the overall cementitious composition. The fibers are uniformly dispersed in the cementitious composition before it is cured to form a final cementitious armor panel.

Owner:UNITED STATES GYPSUM CO +1

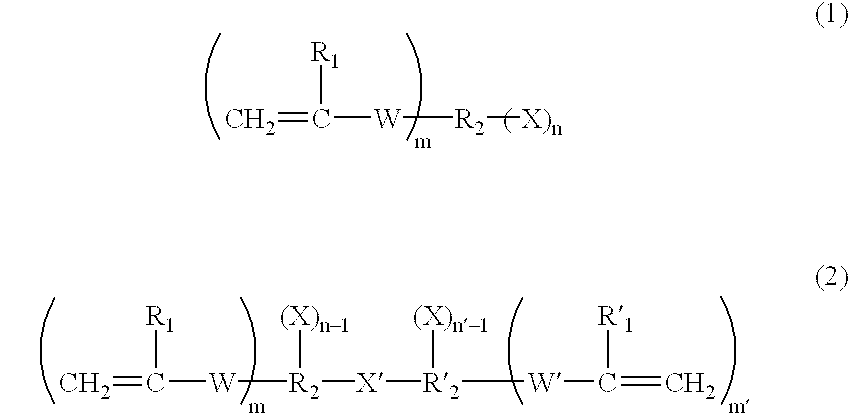

Process for Producing Self-Assembling Peptide Derivatives

ActiveUS20150175663A1Economical and efficientMass productionPeptide/protein ingredientsImmunoglobulinsTrifluoroacetic acidDisulfuric acid

An object of the present invention is to provide a process capable of producing a self-assembling peptide derivative that is useful in the fields of regenerative medicine and surgery in large quantities and in an economical and efficient manner. In particular, provided is a production process employing a combination of (i) a step of convergently constructing a sequence with use of a common repeating unit consisting of a specific amino acid sequence and (ii) a step of first isolating the peptide derivative as a disulfuric acid salt, a tetramethanesulfonic acid salt or a tetra(trifluoroacetic acid (TFA) salt), and then subjecting the peptide salt to a salt exchange reaction to yield a tetrahydrochloric acid salt.

Owner:MENICON CO LTD

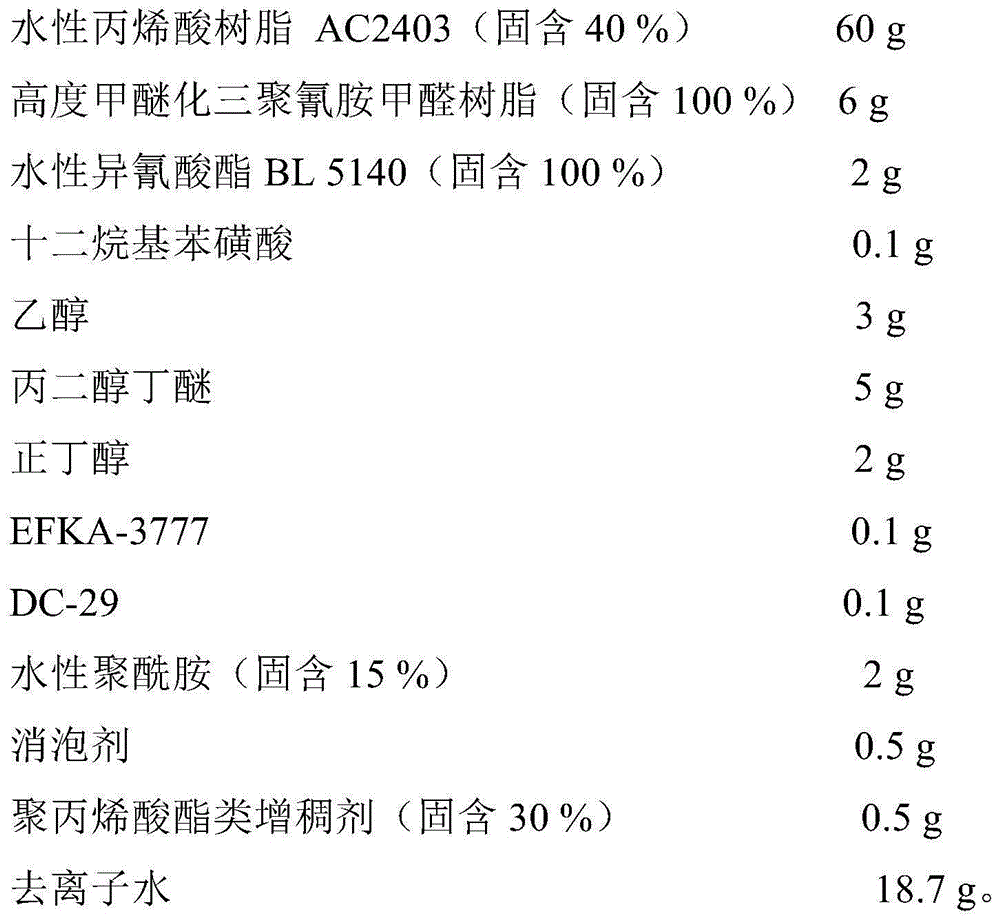

Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

ActiveCN105038464AEmission reductionReduce pollutionPretreated surfacesAnti-corrosive paintsWater basedMicrometer

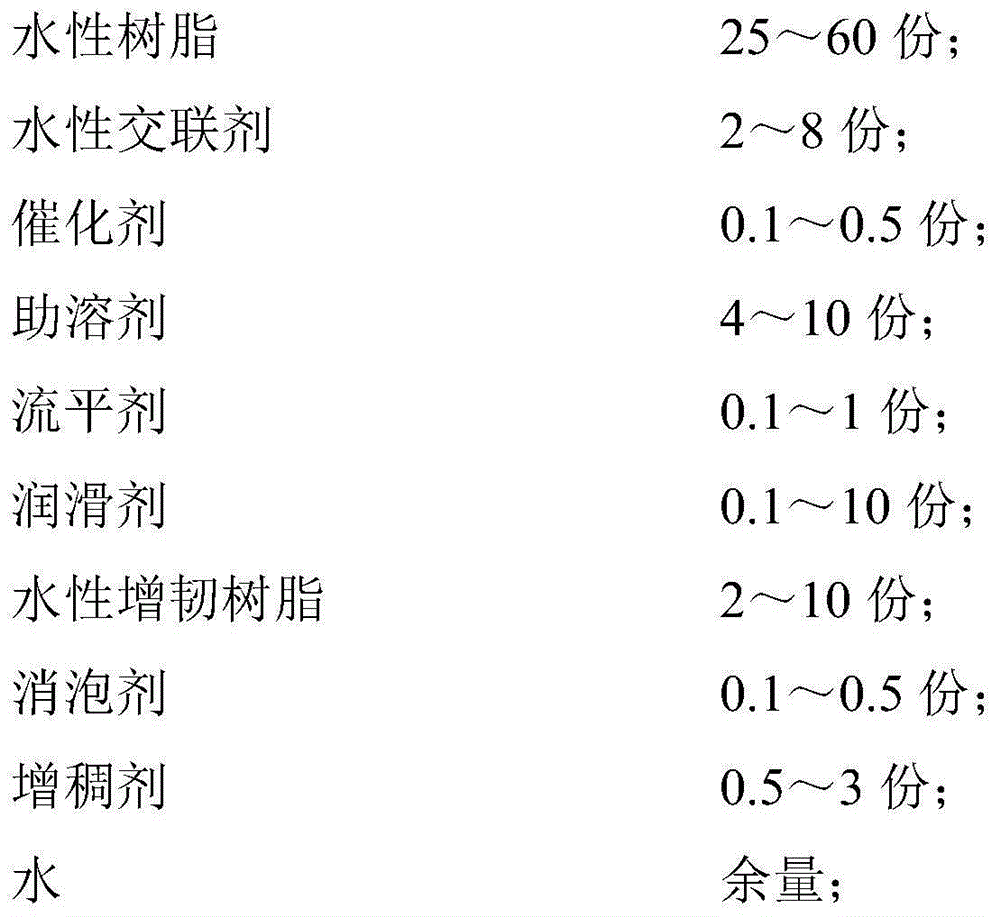

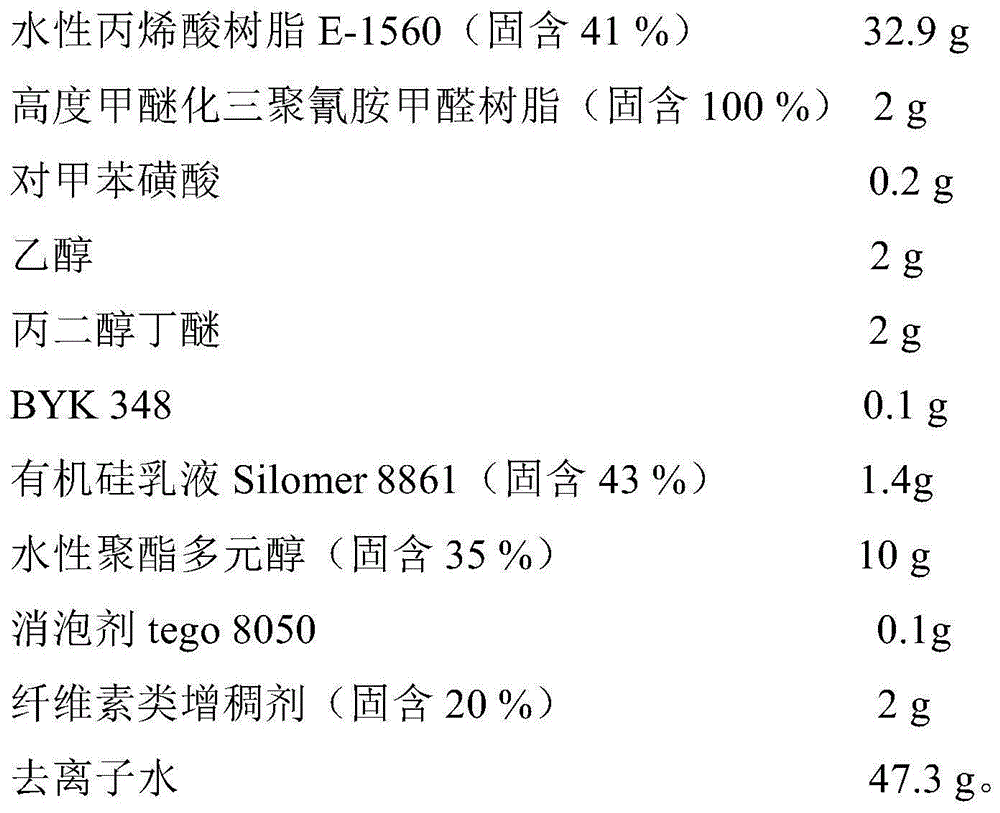

The invention belongs to the technical field of surface corrosion prevention and discloses a water-based high-corrosion-resistance coating with excellent stamping performance and a preparing method and application of the water-based high-corrosion-resistance coating. The coating comprises, by mass, 25-60 parts of water-based resin, 2-8 parts of water-based cross-linking agent, 0.1-0.5 part of catalyst, 4-10 parts of cosolvent, 0.1-1 part of flatting agent, 0.1-10 parts of lubricating agent, 2-10 parts of water-based toughening resin, 0.1-0.5 part of defoaming agent, 0.5-3 parts of thickening agent and the balance water, and the total mass parts of the components are 100 parts. According to the water-based high-corrosion-resistance coating, the water-base resin serves as film forming matter, so that good construction performance is achieved, curing is quick, super corrosion resistance can be obtained when the thickness of the coating is 2-5 micrometers, the performance of resisting neutral salt mist is longer than 2,000 hours, resistance to acid salt mist is longer than 500 h, the corrosion grade can reach 9.8 or higher, and the salt mist resisting performance of the coating is maintained unchanged after stamping or bending is carried out.

Owner:GUANGZHOU HUMAN CHEM

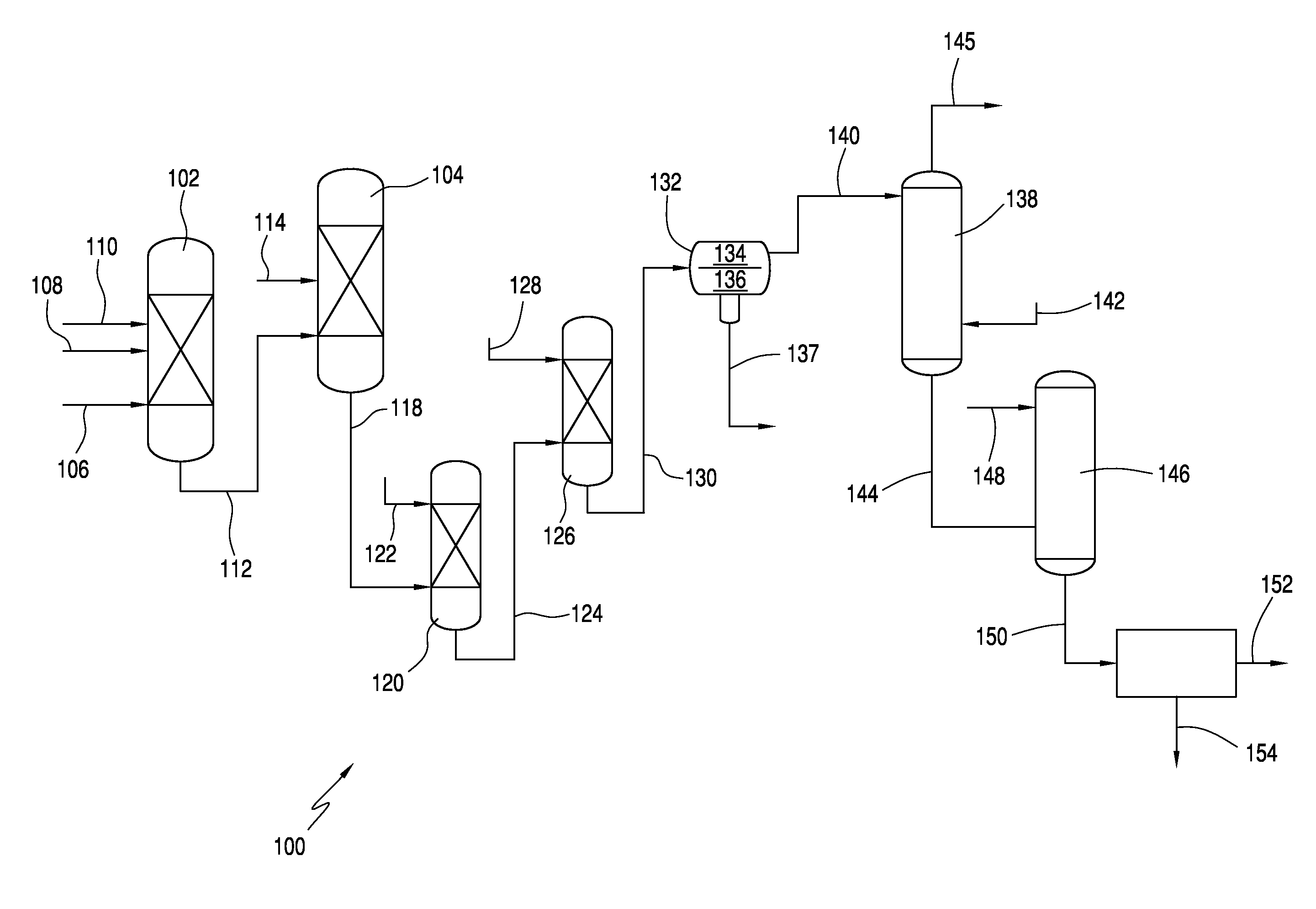

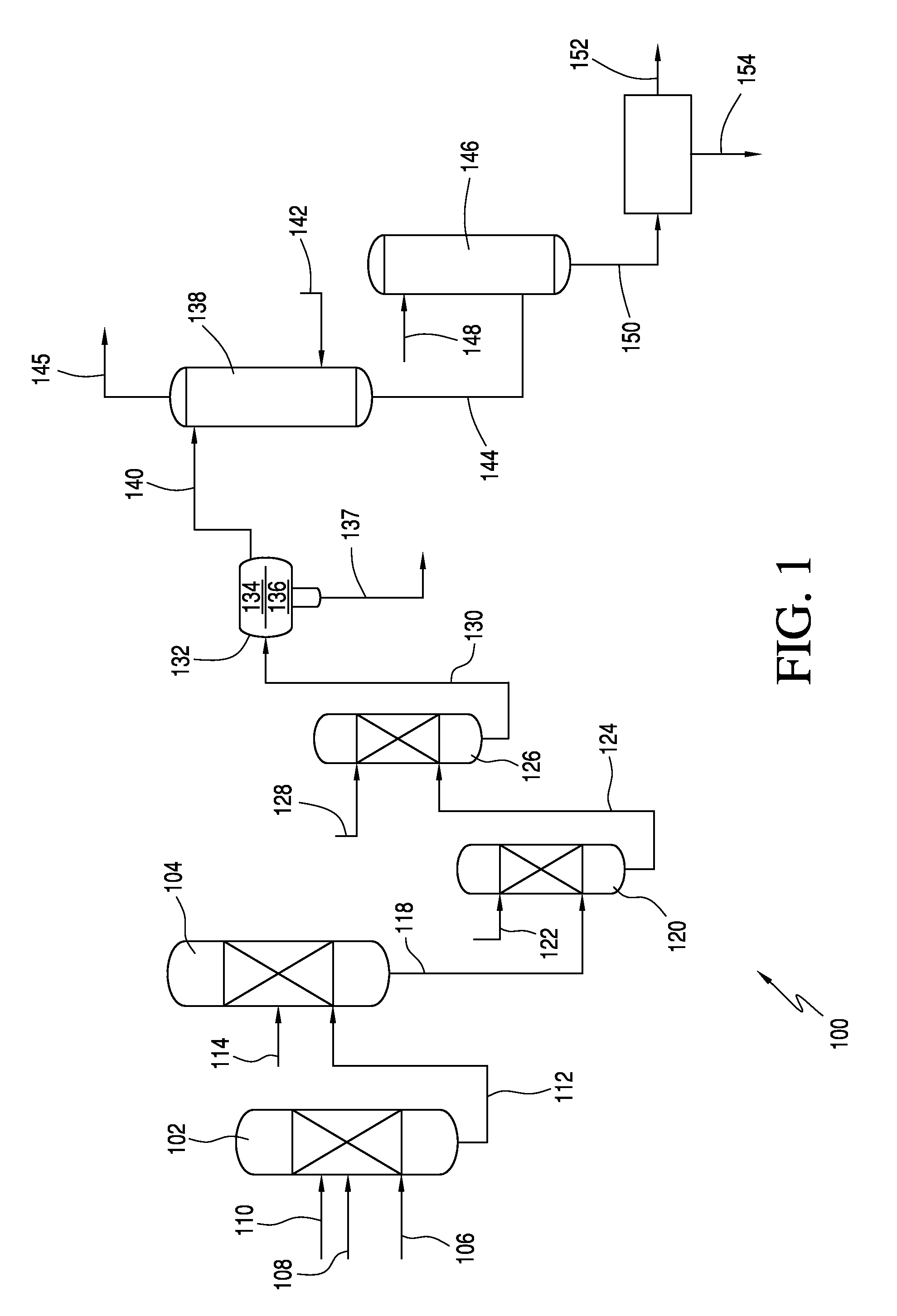

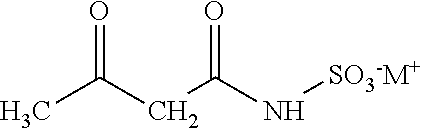

Process for Producing Acesulfame Potassium

ActiveUS20130331565A1Organic compound preparationSulfuric acid amide preparationAcetic acidSulfamic acid

In one embodiment, the invention relates to processes for producing acesulfame potassium. In one embodiment, the process comprises the step of reacting a first reaction mixture to form an amidosulfamic acid salt such as a trialkyl ammonium amidosulfamic acid salt. The first reaction mixture comprises sulfamic acid, an amine, and smaller amounts, if any, acetic acid, e.g., less than 1 wt % (10000 wppm). In terms of ranges, the first reaction mixture may comprise from 1 wppm to 1 wt % acetic acid. The process further comprises the step of reacting the amidosulfamic acid salt with diketene to form an acetoacetamide salt. In preferred embodiments, the amidosulfamic acid salt formation reaction is conducted at pH levels from 5.5 to 7.0. The process further comprises the step of deriving the acesulfame-K from the acetoacetamide salt.

Owner:CELANESE SALES GERMANY

Dental adhesive composition

InactiveUS20030050359A1Short working hoursOptimize working timeImpression capsTeeth fillingArylAdhesive

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

Flame-retardant thermoplastic resin composition and molded article

A flame-retardant thermoplastic resin composition that has a largely decreased corrosiveness to metals while maintaining a high degree of flame retardancy is provided, which is produced by adding a phosphinic acid salt and a compound having a specific structure to a thermoplastic resin, and molded articles with largely decreased corrosiveness to metals are also provided, so that useful molded articles can be provided as materials for mechanical machine parts, electric / electronic components, and automotive parts. The flame-retardant thermoplastic resin composition includes 65 to 99 wt % of (A) a thermoplastic resin, 1 to 35 wt % of (B) at least one phosphinic acid salt selected from the group of phosphinic acid salt, diphosphinic acid salt, polymer of phosphinic acid salts, and polymer of diphosphinic acid salts, and 0.001 to 0.70 wt % of (C) a compound having a specific, and molded articles produced therefrom.

Owner:TORAY IND INC

Normal temperature formaldehyde removal catalysis material

InactiveCN104741130ALow costEfficient enrichmentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCatalytic oxidation

The invention relates to a formula and a corresponding preparation technology of a normal temperature formaldehyde removal catalysis material, and belongs to the technical fields of normal temperature adsorption catalysis and air pollution treatment. The catalysis material is prepared by adopting a one-step co-precipitation process or a step-by-step dipping process to load active components with granular, cylindrical, spherical or honeycomb high-specific surface area shell activated carbon as a carrier, one or more non-noble metal salts as main active components, such as nitrate, sulfate or chloride of manganese, iron, cobalt, nickel, copper, zinc, lanthanum or cerium, one or more alkali metal / alkaline earth metal salts as an inorganic additive, such as oxalate, nitrate, sulfate, acetate, carbonate and bicarbonate of sodium, potassium, magnesium, calcium, and ethylenediamine tetracetic acid / ethylenediamine tetraacetic acid salt, basic amino acid, polyamide monomer and polyurethane monomer as a nitrogen-containing organic additive. The normal temperature formaldehyde removal catalysis material has the characteristics of rapid capture, high efficiency catalytic oxidation and long working cycle, and can meet requirements of long-time effective removal of formaldehyde in indoor real environment.

Owner:江苏瑞丰科技实业有限公司

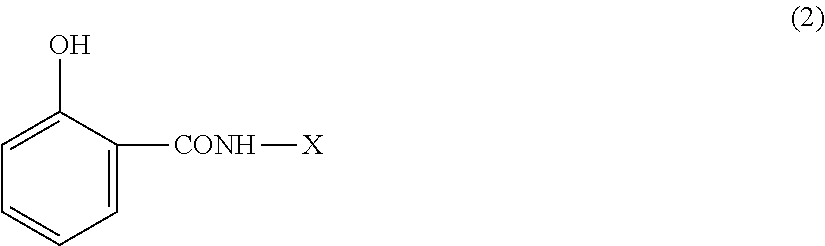

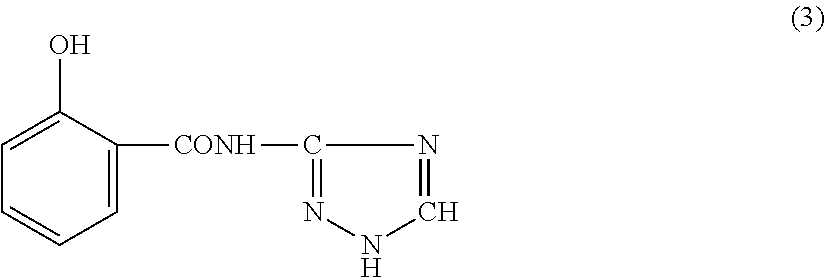

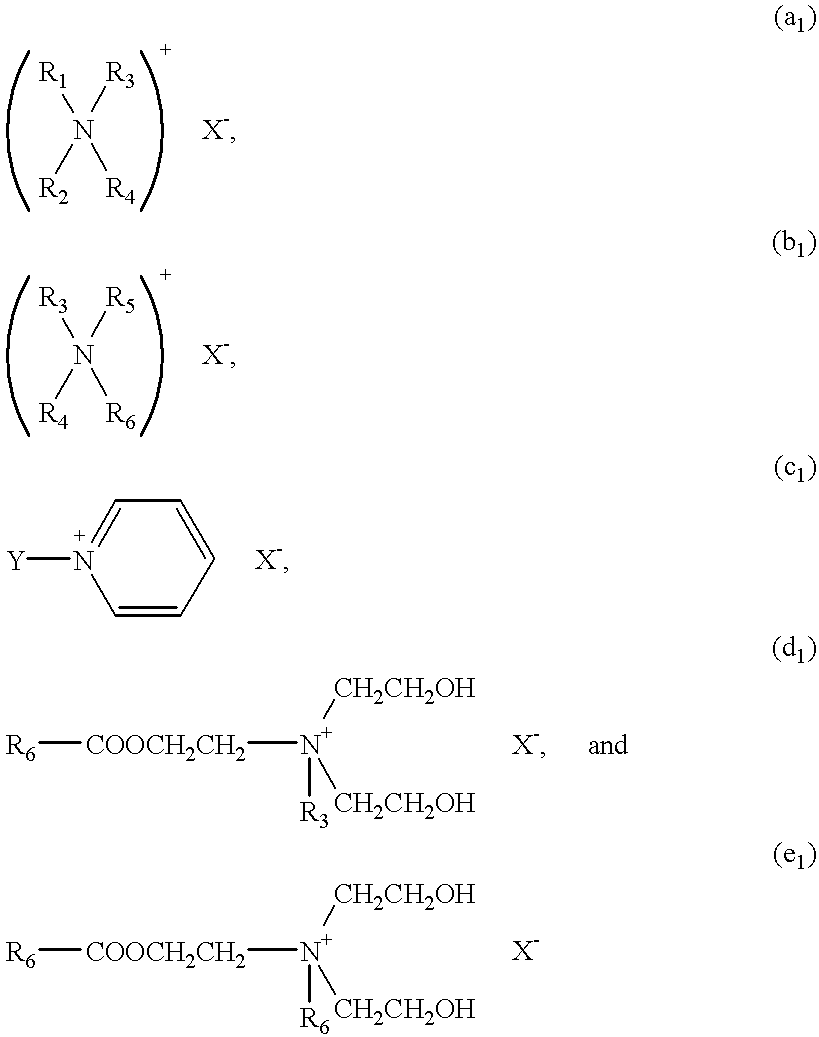

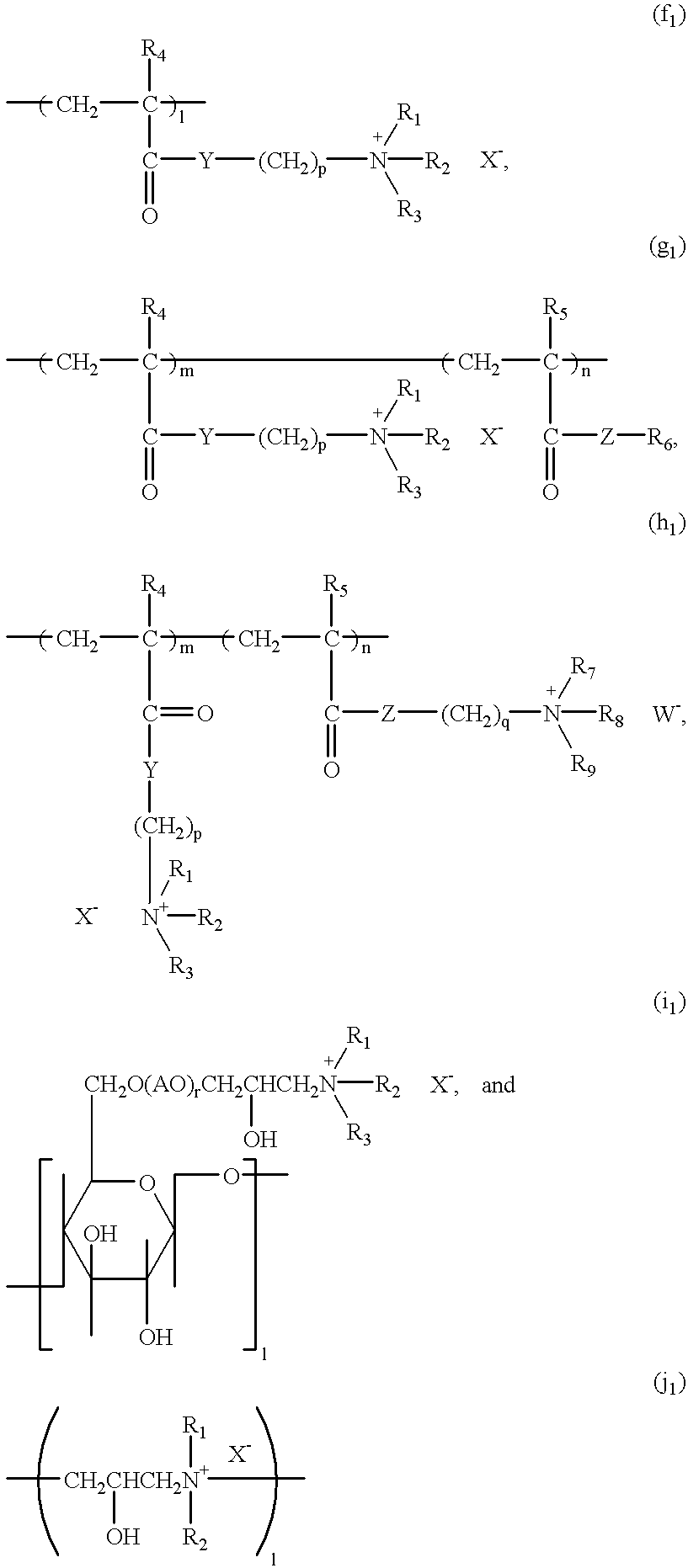

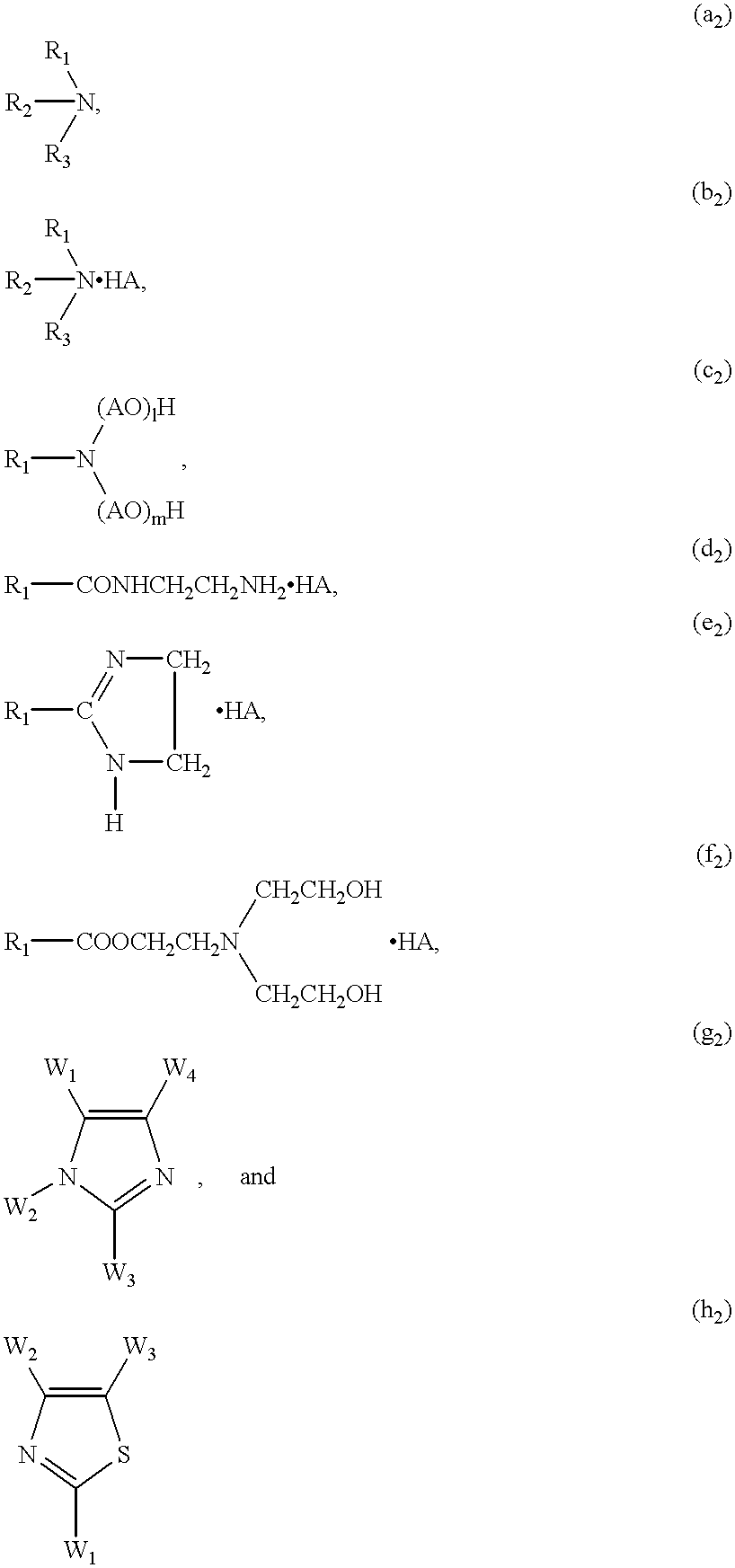

Wastepaper deinking method using amine or acid salt of amine in the flotation stage

InactiveUS6251220B1High whitenessLess residual ink spotPaper recyclingWaste paper working-upFatty acidAdduct

A deinking method comprising the steps of liberating ink from waste paper as a raw material and removing the liberated ink from a flotation system, wherein a nonionic surfactant, e.g., a reaction product obtained by adding an alkylene oxide to a mixture of an oil & fat and an alcohol, an alkylene oxide adduct of a fatty acid, or an alkylene oxide adduct of a higher alcohol, is used for the liberation of ink, and the flotation step is effected in the presence of a cationic compound, an amine, an acid salt of an amine or an amphoteric compound at a pH of from 4 to 9, provides a high quality deinked pulp having a high whiteness and a little residual ink spots.

Owner:KAO CORP

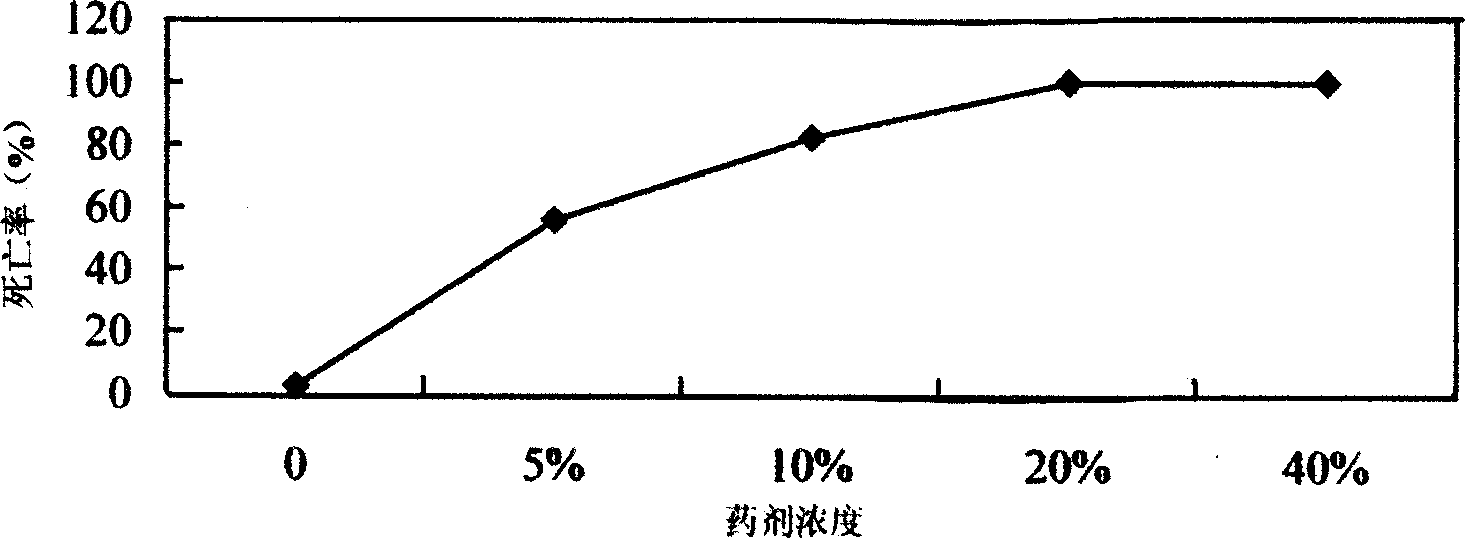

Double effective fatty acid preparation for improving plant growing and protecting plant

ActiveCN101167452APromote growthIncrease productionBiocidePlant growth regulatorsGrowth plantOrganic acid

Disclosed is a combined preparation with aliphatic acid as the core, the preparation formulation of which is combining aliphatic acid or aliphatic acid salt or derivant, inorganic acid or organic acid and inorganic salt or organic salt. The preparation can accelerate vegetation, increase plant output and control the harm of plant pests with very low aliphatic acid density, which realizes double effects of both increasing plant output and controlling the harm of plant pests with one preparation.

Owner:成都特普生物科技股份有限公司

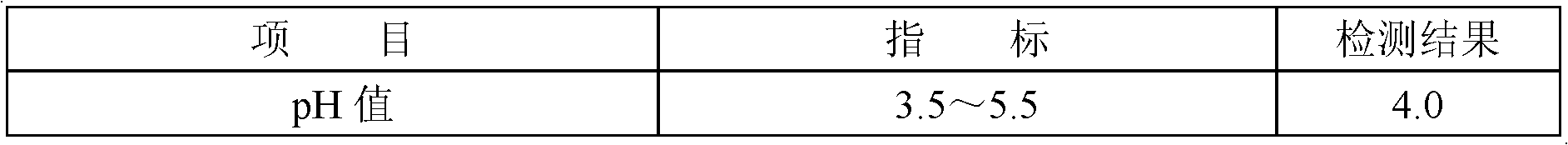

Cleaning antirust agent, preparation method and method for removing scale and preventing rust by using cleaning antirust agent

The invention discloses a cleaning antirust agent, a preparation method for the cleaning antirust agent and a method for removing scale and preventing rust by using the cleaning antirust agent. The cleaning antirust agent mainly comprises the following components in percentage by weight: 5 to 15 percent of citric acid, 3 to 12 percent of ethylene diamine tetraacetic acid salt, 1 to 5 percent of ammonium nitrate, 5 to 15 percent of dirt dispersion agent, 1 to 5 percent of penetrating agent, 0.5 to 3 percent of corrosion inhibitor, 1 to 6 percent of solubilizing agent and the balance of deionized water. Due to the adoption of the efficient penetrating agent and corrosion inhibitor in the cleaning antirust agent, scale deposit on the inner wall of a water tank of an automobile can be cleaned within a short time, so that matrix metal is protected in the cleaning process, a corrosion inhibition film clad layer is formed on the water tank, the corrosion resistance of the water tank is improved, and the cleaning antirust agent is convenient to use.

Owner:广东好顺欧迪斯科技股份有限公司

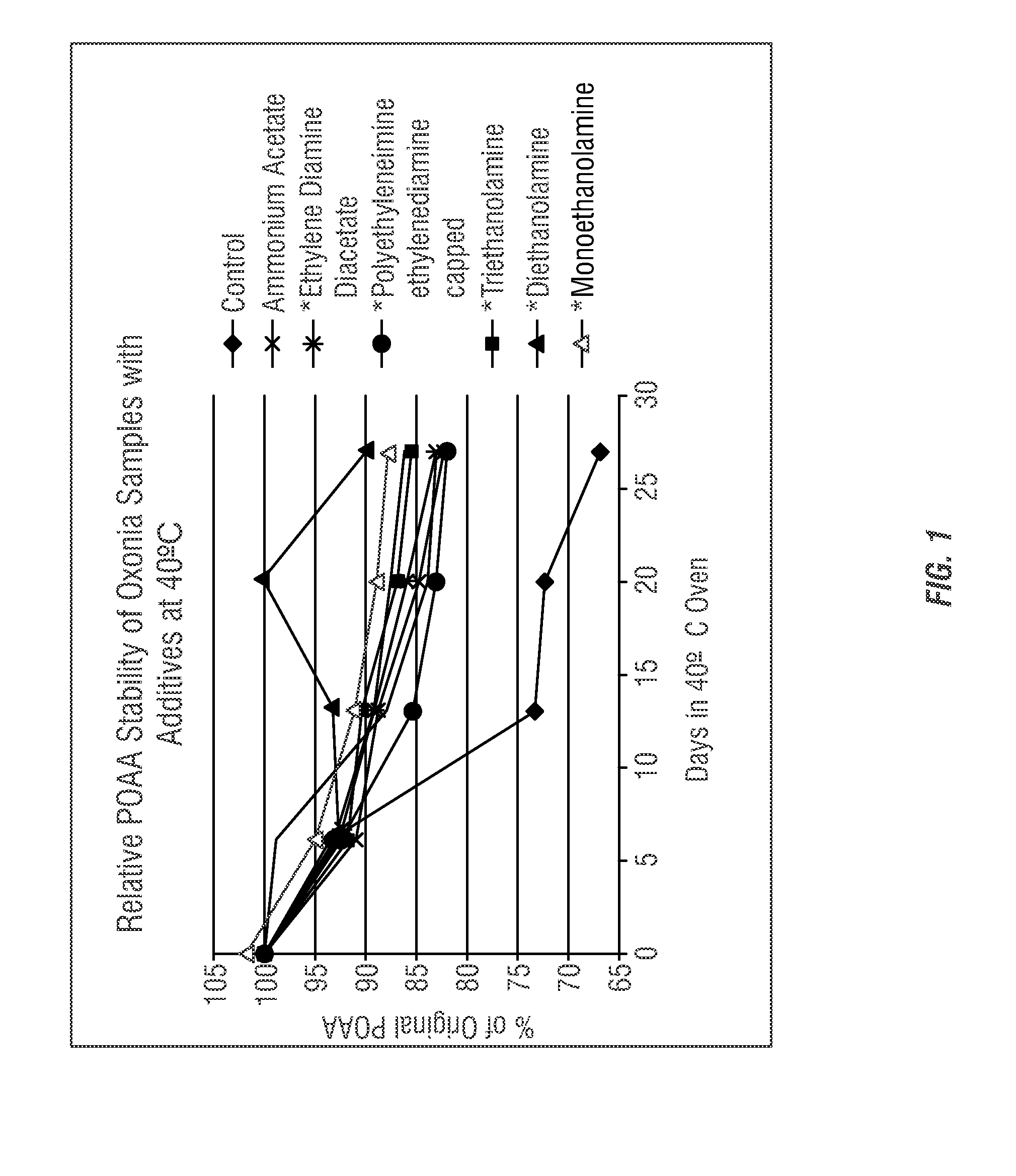

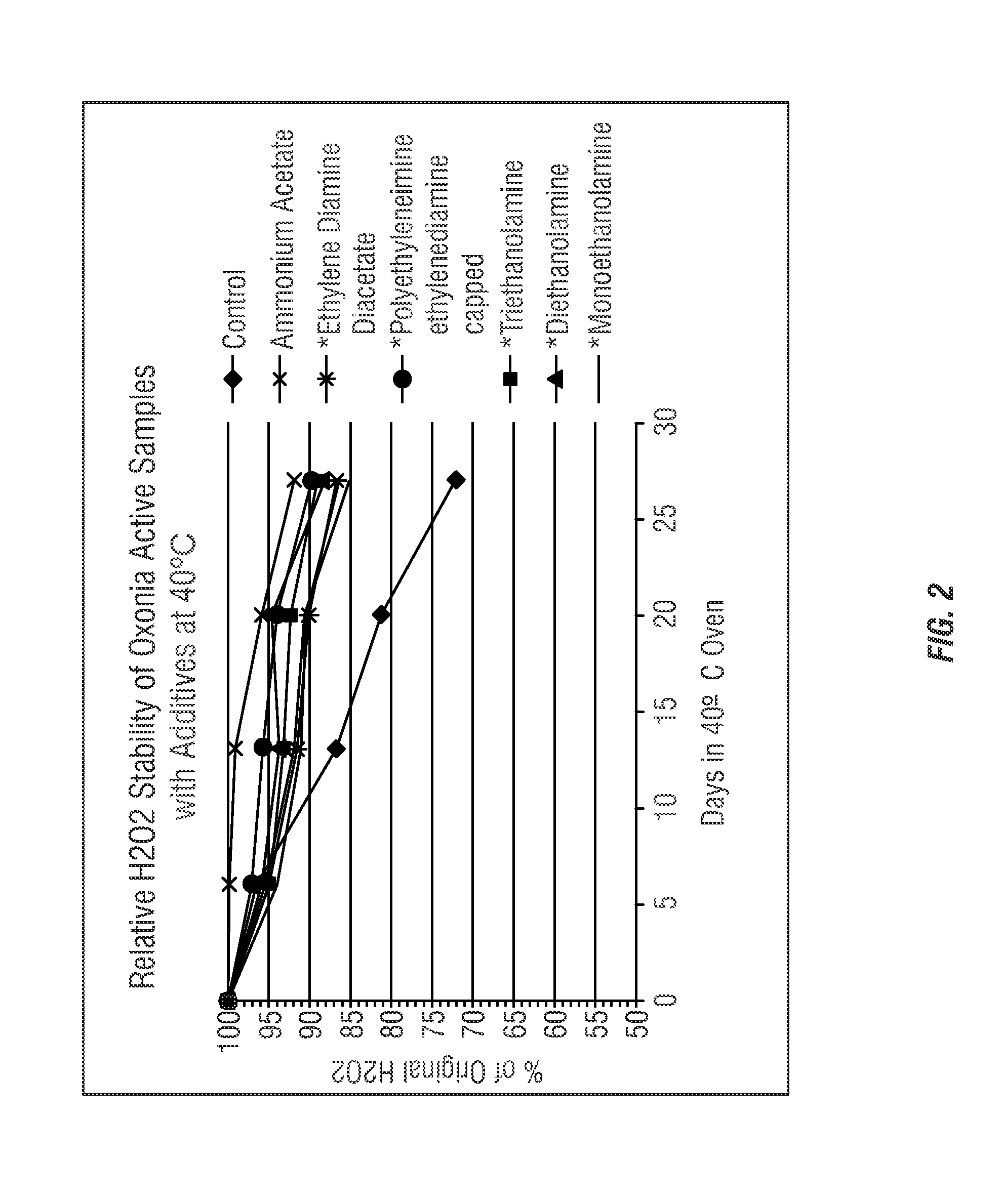

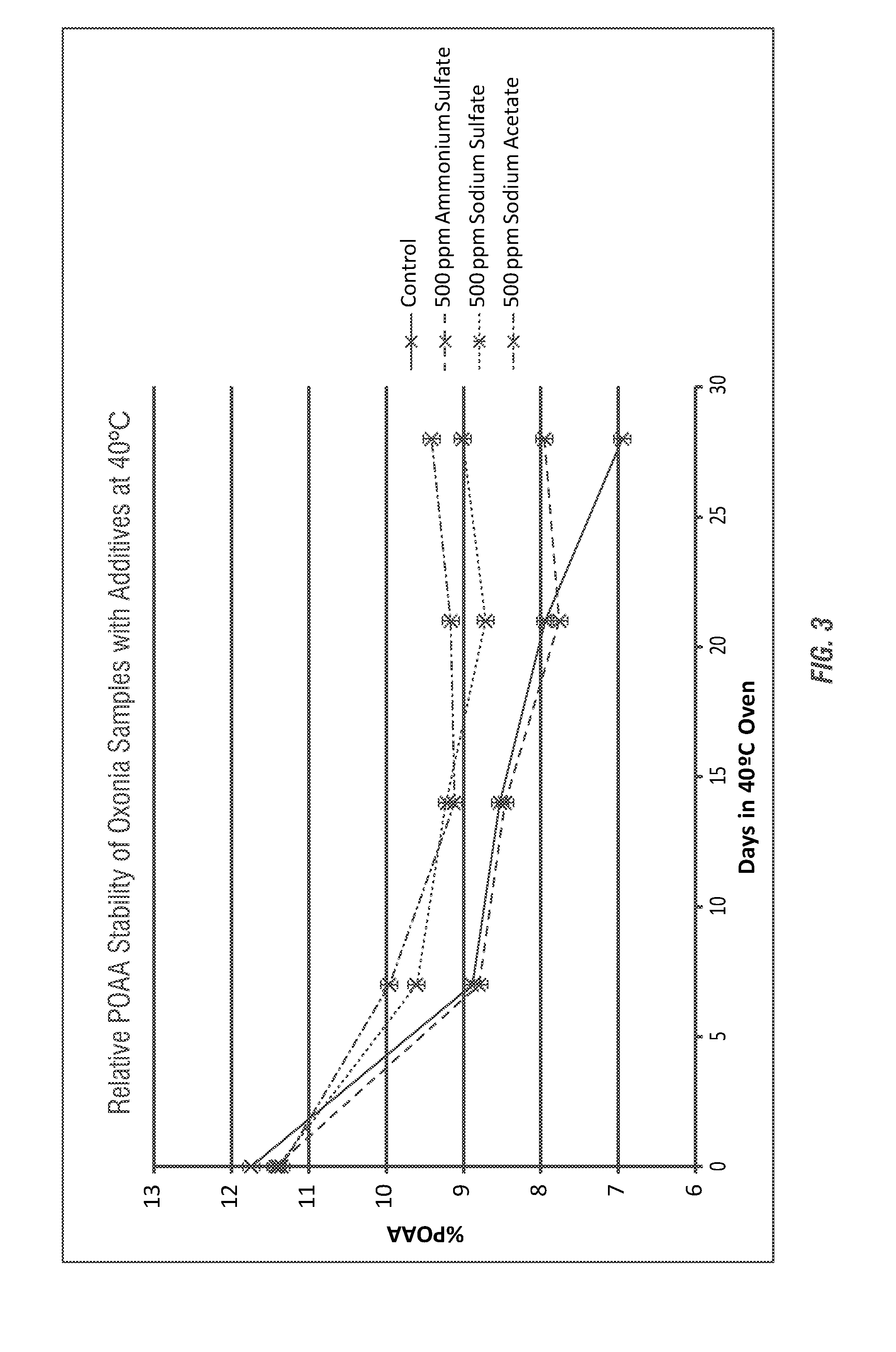

Stabilization of peroxycarboxylic acids using amine acid salts

InactiveUS20140120179A1Improve stabilityImprovement of shelf-stability for peroxycarboxylic acidBiocidePeroxide active ingredientsAcetic acidCarboxylic acid

Peroxycarboxylic acid compositions and methods of using the same are provided to enhance stability and increase shelf-life over conventional peracid compositions. Peroxycarboxylic acid compositions are formulated or treated with amine salts of acetic acid and / or sulfuric acid, ammonium salts, sodium salts of acetic acid and / or sulfuric acid, polymeric amines and / or other stabilizing agents according to the invention. The invention further relates to methods employing such compositions, and methods of making these compositions.

Owner:ECOLAB USA INC

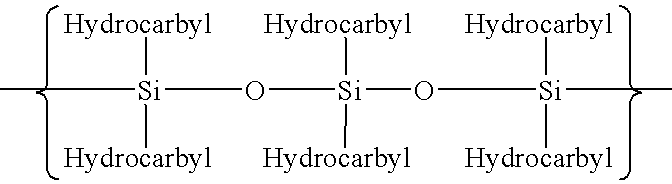

Laser (230NM) ablatable compositions of electrically conducting polymers made with a perfluoropolymeric acid applications thereof

InactiveUS20080213594A1Electroluminescent light sourcesSynthetic resin layered productsConductive polymerPolymer chemistry

An aqueous composition including (a) a dispersion of at least one electrically conductive polymer doped with at least one highly-fluorinated acid polymer and (b) a second material which can be a second polymeric acid, an acid salt of the second polymeric acid, or a combination thereof.

Owner:EI DU PONT DE NEMOURS & CO

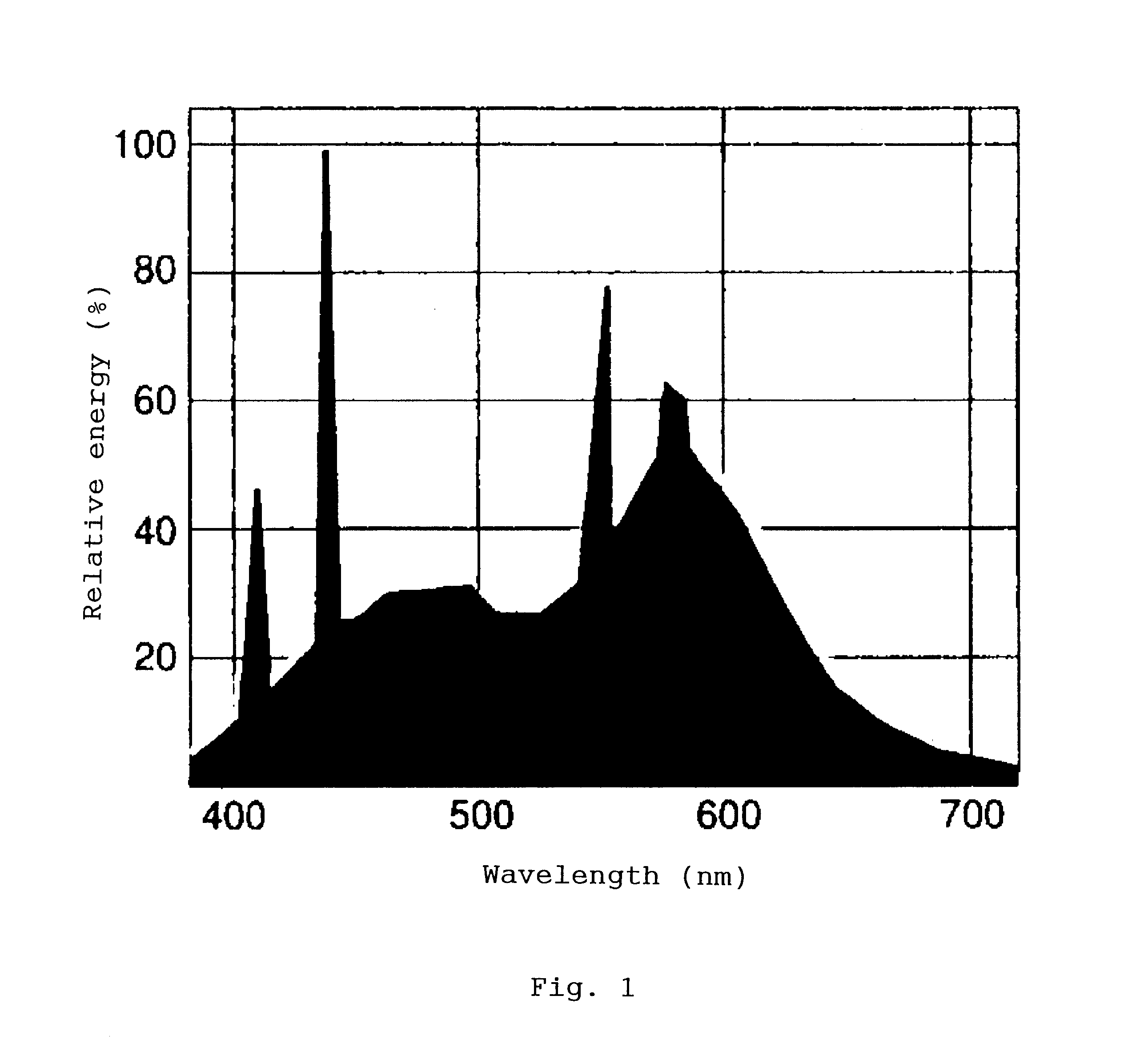

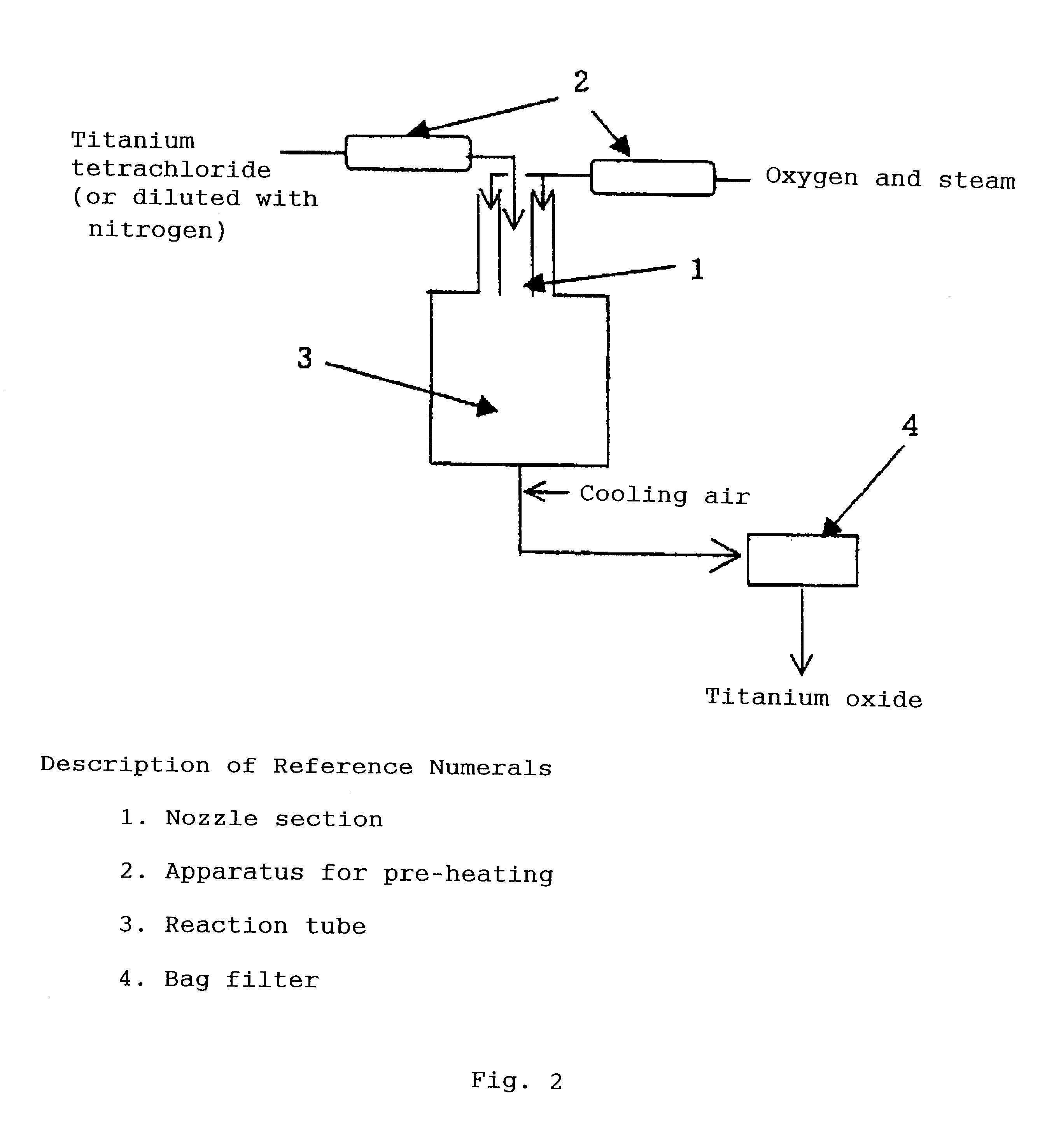

Photocatalyst

InactiveUS6887816B2Sufficient propertyMinimum level of coloringPigmenting treatmentPretreated surfacesAlkaline earth metalSlurry

When a polybasic acid salt containing at least one species selected from the group consisting of an alkaline earth metal, a transition metal, and Al is caused to be present on the surfaces of titanium dioxide fine particles, there are obtained photocatalytic particles and powder exhibiting sufficient photocatalytic properties when irradiated with light from a light source of low quantity of light. By use of the photo-functional particles and powder, an organic polymer composition, a slurry, a coating agent, and a product having a surface exhibiting photocatalytic property and hydrophilicity are obtained.

Owner:SHOWA DENKO KK

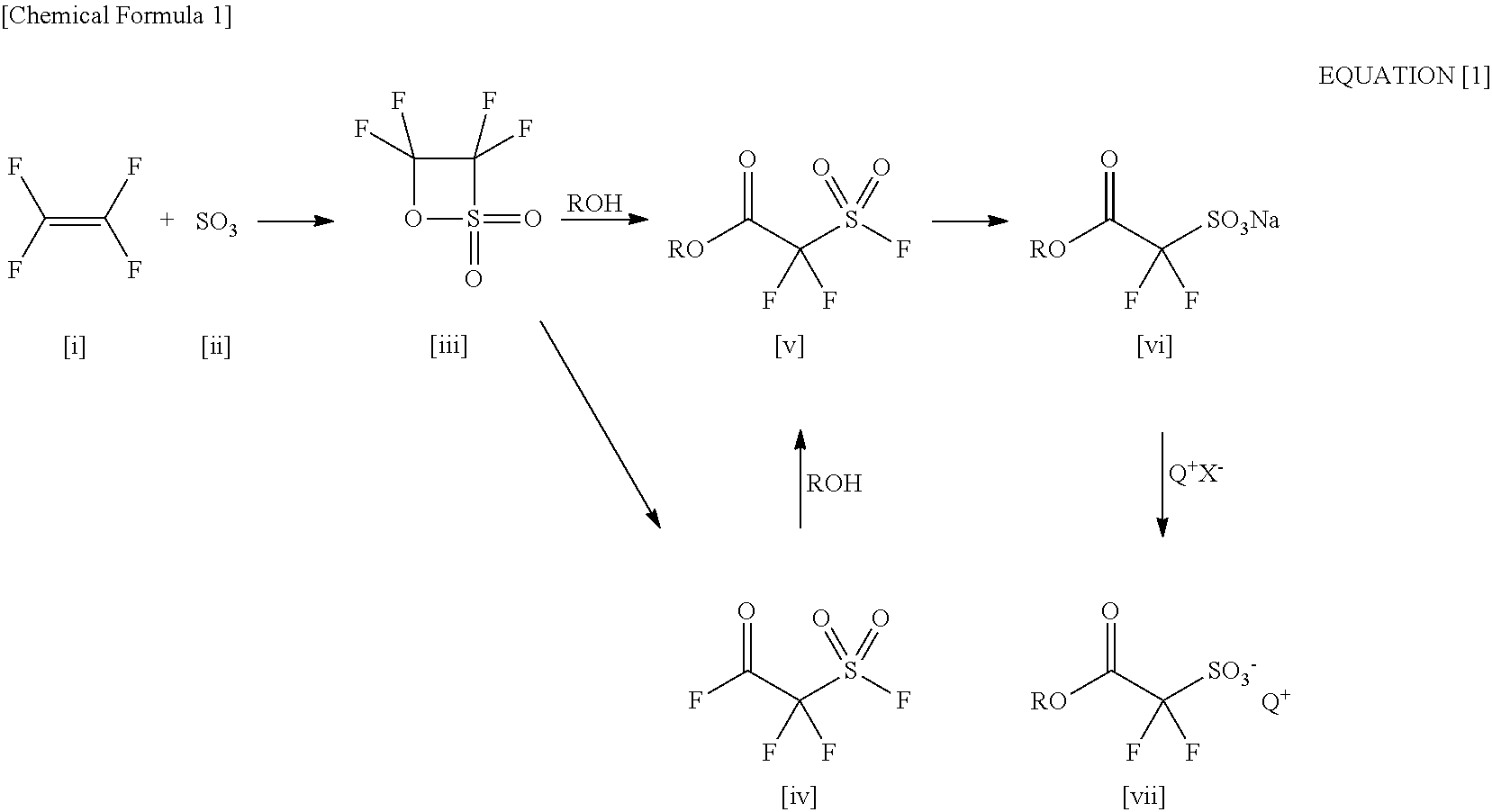

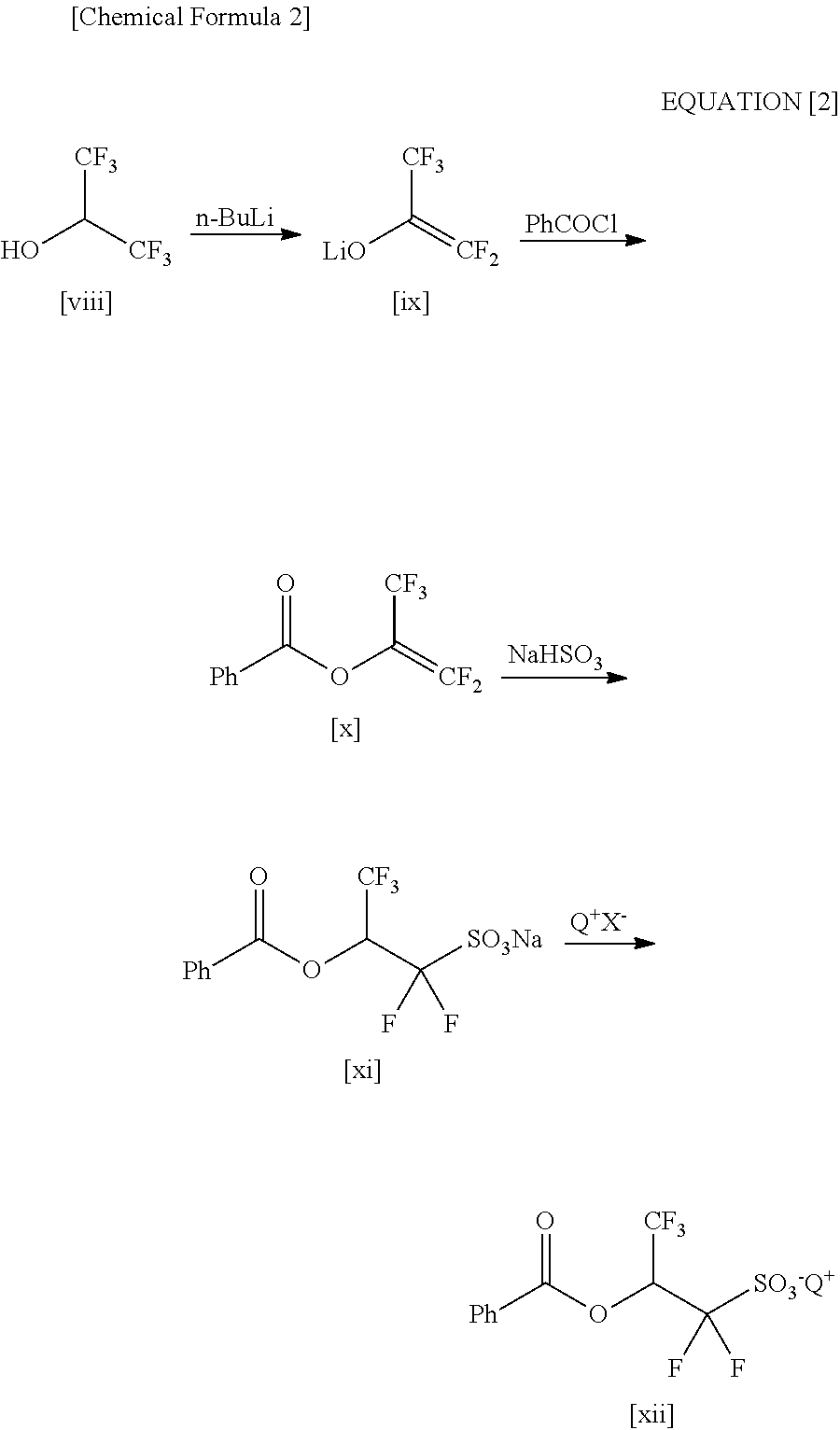

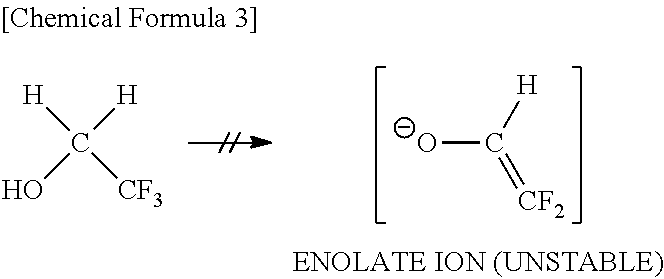

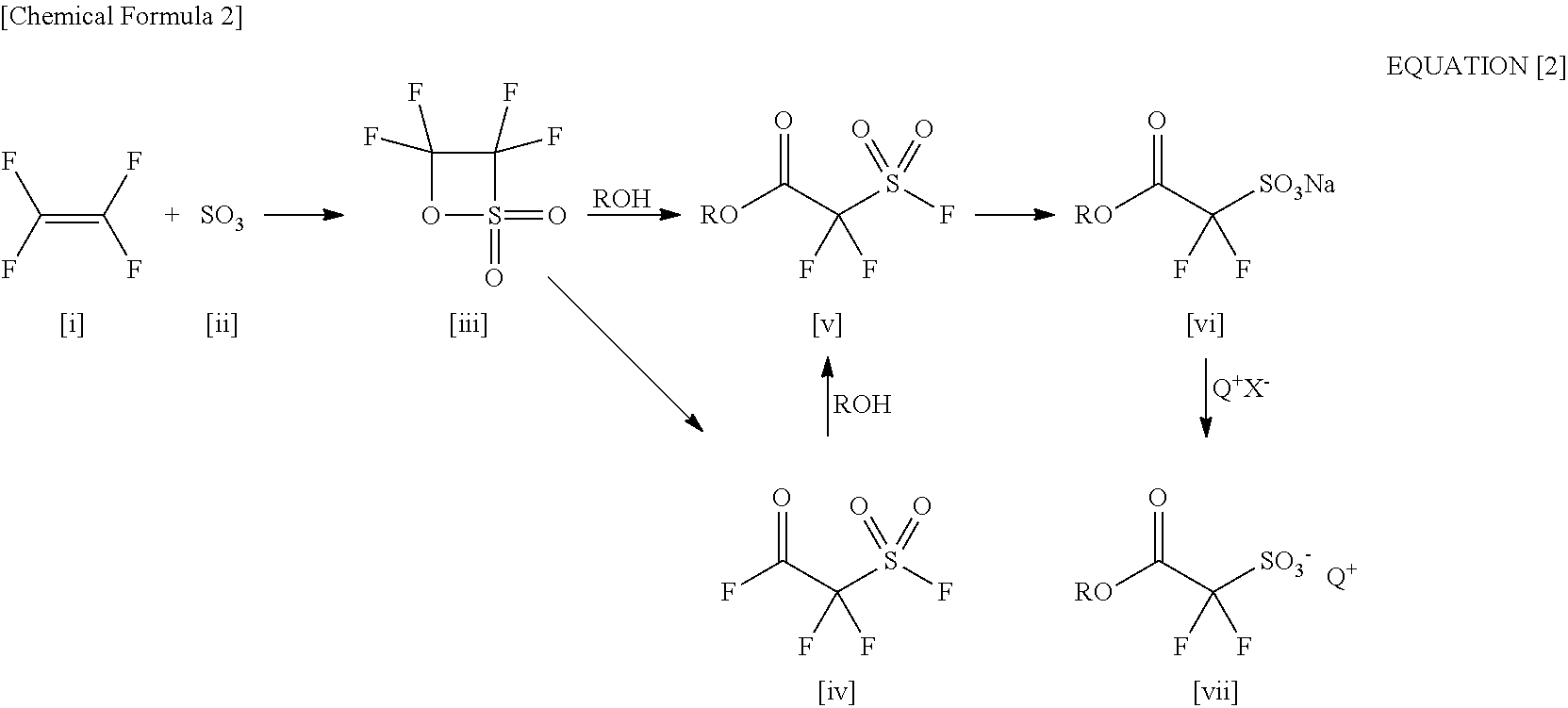

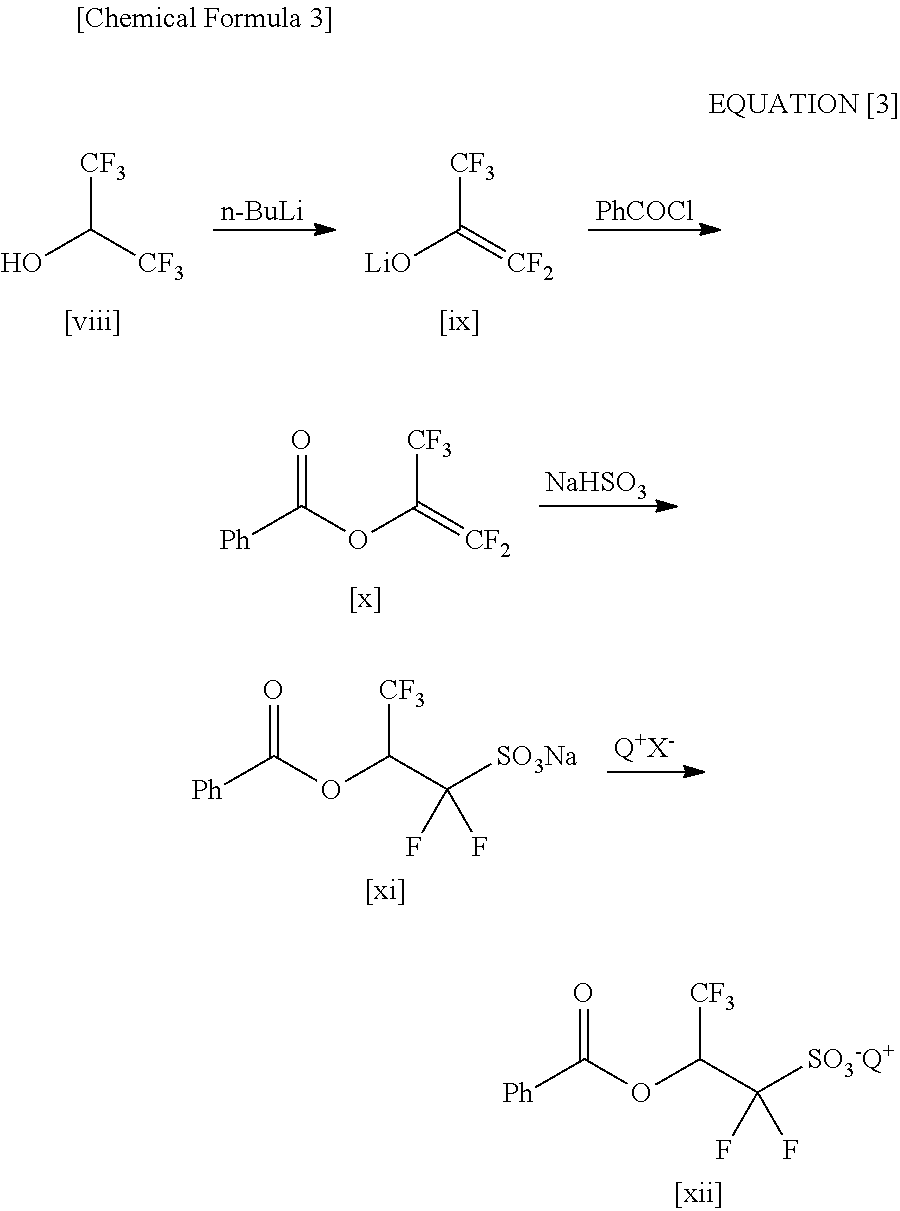

2-(Alkylcarbonyloxy)-1, 1-Difluoroethanesulfonic Acid Salt and Method for Producing the Same

ActiveUS20110034721A1Economically and readily producingPreparation from carboxylic acid halidesOrganic compound preparationSulfonateEthanesulfonic acid

By using an organic base when a carboxylic acid bromodifluoroethyl ester is sulfinated by using a sulfinating agent, there is obtained 2-(alkylcarbonyloxy)-1,1-difluoroethanesulfinic acid ammonium salt. By oxidizing the 2-(alkylcarbonyloxy)-1,1-difluoroethanesulfinic acid ammonium salt, there is obtained 2-(alkylcarbonyloxy)-1,1-difluoroethanesulfonic acid ammonium salt. By using the 2-(alkylcarbonyloxy)-1,1-difluoroethanesulfonic acid ammonium salt as a raw material and exchanging it into an onium salt directly or through saponification / esterification, there can be obtained a 2-alkylcarbonyloxy-1,1-difluoroethanesulfonic acid onium salt.

Owner:CENT GLASS CO LTD

Dechlorination agent and preparation method thereof

ActiveCN103386244AImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

Owner:康健科技(山东)有限公司

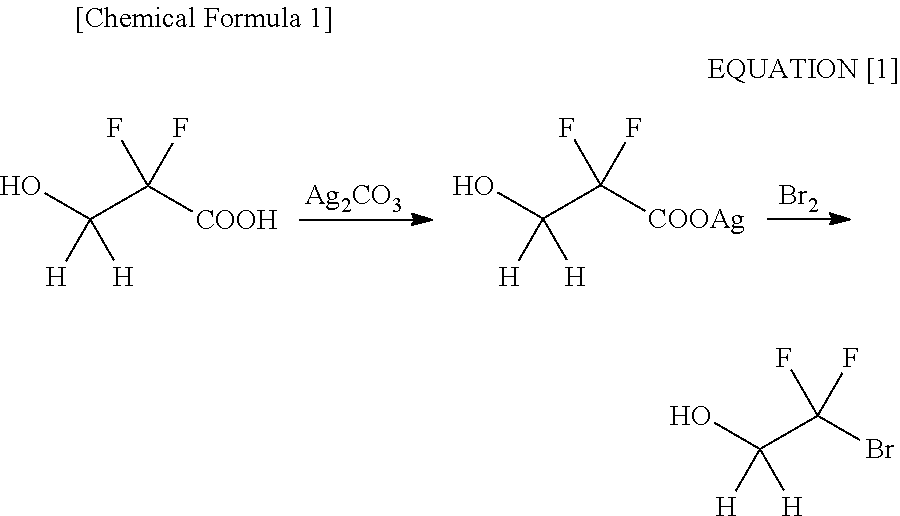

Processes for Production of 2-Bromo-2,2-Difluoroethanol and 2-(Alkylcarbonyloxy)-1,1-Difluoroethanesulfonic Acid Salt

ActiveUS20110015431A1Preparation from carboxylic acid halidesOrganic compound preparationHalogenAlkoxy group

Disclosed is a process for producing 2-bromo-2,2-difluoroethanol, which comprises reducing a bromodifluoroacetic acid derivative represented by the formula [1] by using an ate hydride complex as a reducing agent. 2-Bromo-2,2-difluoroethanol thus produced can be used as the starting material to carry out the esterification step, the sulfination step and the oxidation step in this order, thereby producing a 2-alkylcarbonyloxy-1,1-difluoroethanesulfonic acid salt, wherein A represents a substituted or unsubstituted linear, branched or cyclic alkoxy group having 1 to 20 carbon atoms, a substituted or unsubstituted aryloxy group having 6 to 15 carbon atoms, a heteroaryloxy group having 4 to 15 carbon atoms, or a halogen atom.

Owner:CENT GLASS CO LTD

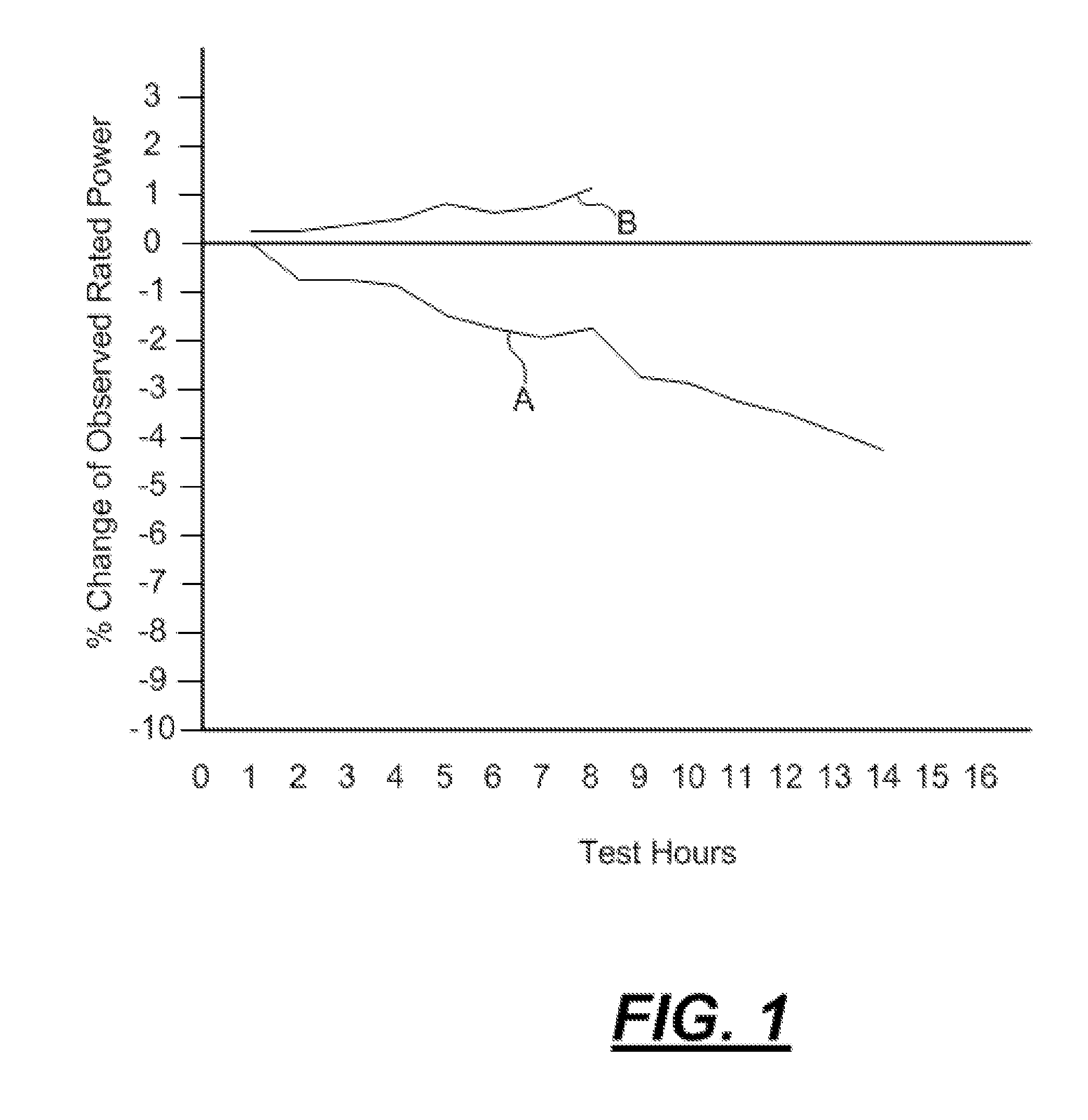

Diesel fuel additive

ActiveUS20120102826A1Improve engine performanceImprove performanceOrganic chemistryLiquid carbonaceous fuelsNitrogenEngineering

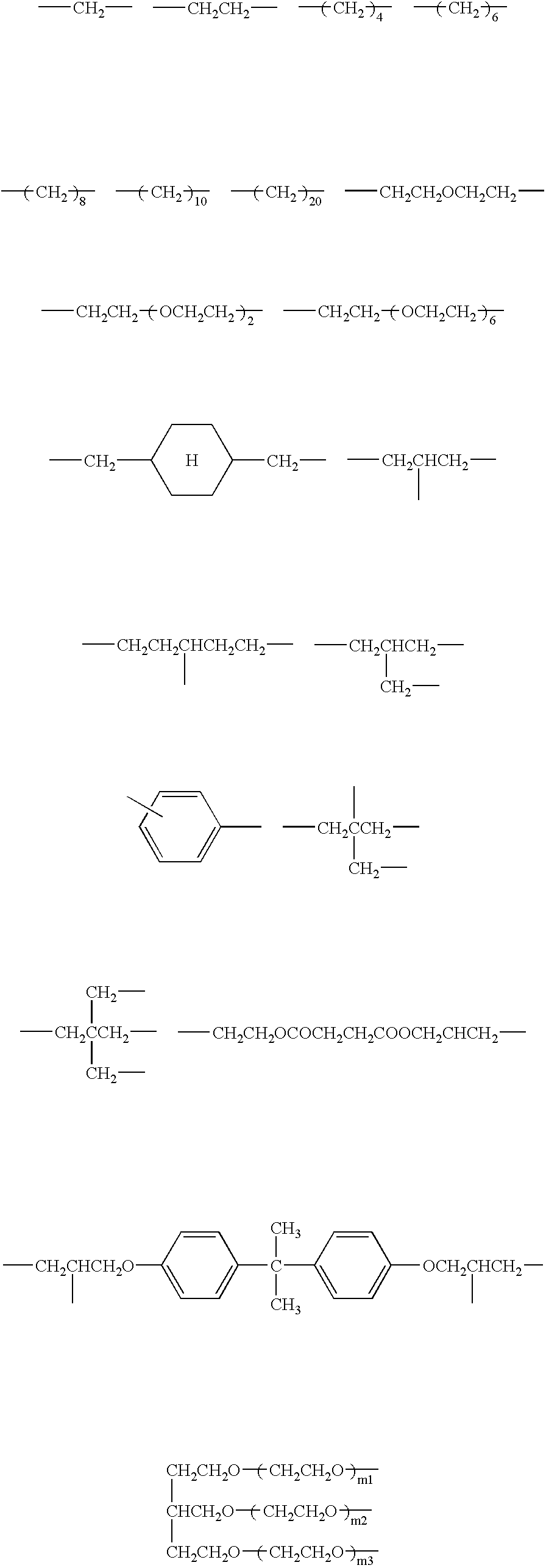

A diesel fuel additive composition, a fuel containing the fuel additive, a method for improving diesel engine performance using the additive. The diesel fuel additive includes a reaction product of (a) a hydrocarbyl-substituted acylating agent and (b) a reactant selected from the group consisting of a nitrogen-containing compound, a hydroxyl-containing compound, and water that provides a reaction product selected from the group consisting (1) a mono-amide / mono-acid or metal free mono-acid salt thereof, (2) a diacid or metal free diacid salt thereof, and (3) mono-ester / mono-acid or metal free mono-acid salt thereof. The reaction product includes at least about 10 molar percent acid groups based on total moles of the reaction product.

Owner:AFTON CHEMICAL

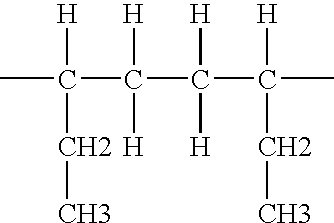

Catalyst Component For High Activity And High Stereoselectivity In Olefin Polymerization

ActiveUS20130244863A1Improve balanceMinimized solventOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

What is disclosed is a method for preparing a catalyst system and a catalyst system for polymerizing or copolymerizing an α-olefin. Catalyst component (A) is obtained by a process of reacting a magnesium complex (A-1) containing acid salts of group IB-VIIIB elements formed by contacting a magnesium halide with an acid salt solution of group IB-VIIIB metals or spherical particles adducts, an internal electron donor (A-2) of diester or diether or composite compounds, and a titanium compound (A-3). The catalyst compound (A) is contacted with a silicon compound (B) and an organoaluminium compound (C) to complete the catalyst system providing a good balance of catalyst performance in terms of activity and stereo-specificity.

Owner:FORMOSA PLASTICCS CORP

Heavy metal pollutant immobilized reagent composition and immobilization treatment method

InactiveCN102921142AReduce usageReduce active (migratable) heavy metal contentContaminated soil reclamationOrganic fertilisersPhosphatePhosphoric acid

The invention belongs to the technical field of soil environment treatment, and particularly relates to a heavy metal immobilization chemical reagent composition and a treatment method of heavy metal in immobilization polluted soil. The immobilized reagent composition comprises phosphate chemical compound of 5-70%, metal sulfide of 1-60%, metal oxide of 5-80%, strong alkali and weak acid salt of 5-65%, metal stabilizers of 0.1-15% and metal chelator of 0.1-10%. The invention further provides a method of restoring heavy metal polluted soil in an immobilization mode by immobilized reagents. The immobilized reagents can enable various heavy metal pollutants in the polluted soil to be immobilized, the content of activated state (transportable) heavy metal in soil is lowered, and restoration and treatment to the heavy metal polluted soil are achieved. The heavy metal pollutant immobilized reagent composition and the immobilization treatment method have the advantages of being good in immobilization effect, simple and easy in operating process, low in cost, and free of secondary pollution and the like.

Owner:LAIWO SAGACITY GREEN TECH BEIJING CO LTD

Salt of leonurine and its preparation

InactiveCN1415603ALess irritatingGuaranteed stabilityOrganic active ingredientsOrganic chemistryLeonurineOrganic acid

Owner:李晓祥

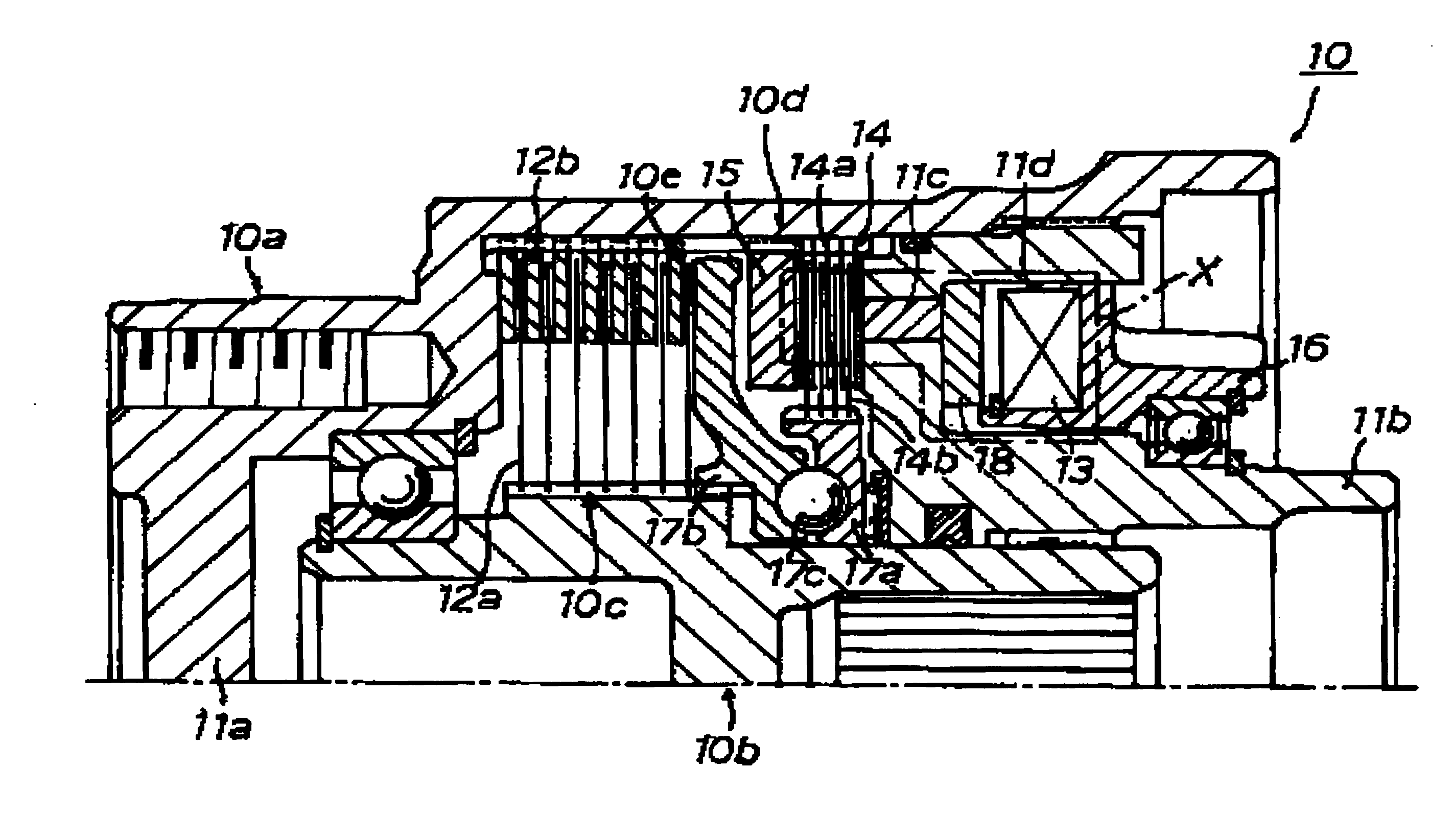

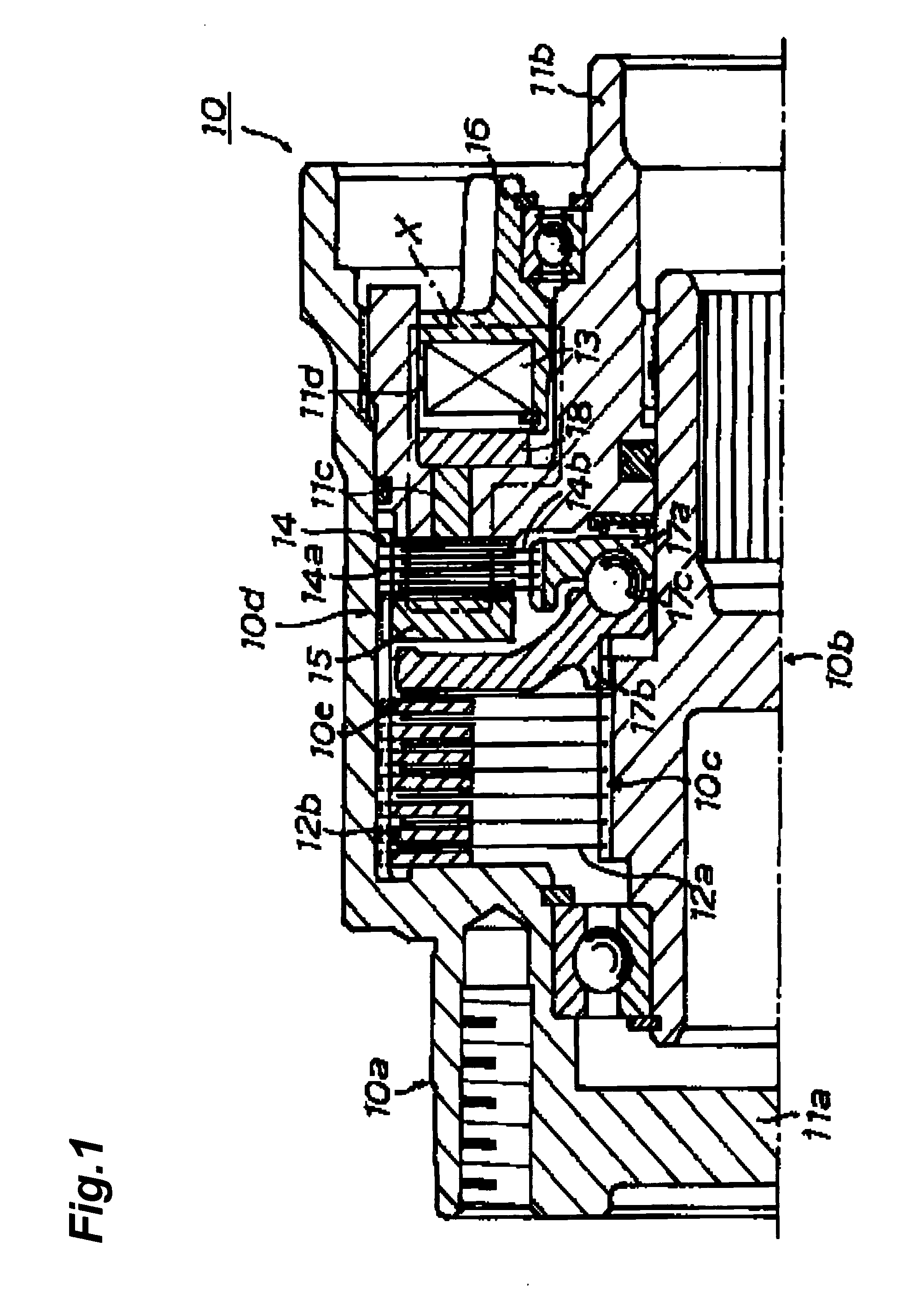

Lubricant Composition and Driving Force Transmitting System Using Same

InactiveUS20080146474A1Sufficient antiwear propertyImprove the level ofOrganic chemistryOrganic compound preparationOrganic acidSulfonate

The invention provides a lubricating oil composition comprising a lubricating base oil, a phosphorus compound and at least one organic acid salt selected from among alkaline earth metal sulfonates, alkaline earth metal phenates and alkaline earth metal salicylates, wherein the contents of the phosphorus compound and organic acid salt satisfy the conditions represented by the following formulas (1) to (3). In formulas (1)-(3), W(P) represents the content of phosphorus compound, in terms of phosphorus element, based on the total amount of the lubricating oil composition, and W(M) represents the content of organic acid salt content, in terms of alkaline earth metal elements, based on the total amount of the lubricating oil composition.0.01≦W(P)≦0.2 (1)0.01≦W(M)≦0.2 (2)0.1≦W(P) / W(M)≦10 (3)

Owner:NIPPON OIL CORP +1

Thermoplastic compositions and method of use thereof for molded articles

InactiveUS20060135679A1Reduce surface frictionImprove performanceDomestic articlesElastomerPolymer science

A polyolefin composition containing elastomers (plasticizers), crystalline polypropylene, modified by mixing with polybutene-1 and a coupling agent and a bicyclic dicarboxyl acid salt nucleating agent and / or a lubricant which comprises an unsaturated fatty acid ester which acts as a surface modifier in a molded article is described. The composition is adapted to be used with pigments to make finished molded articles which have an appearance of paint covered by a clear coat and which are scratch resistant and have good low temperature (−30° C.) impact properties.

Owner:ADVANTAGE POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com