Patents

Literature

3927 results about "Ammonium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium nitrate is a chemical compound, the nitrate salt of the ammonium cation. It has the chemical formula NH₄NO₃, simplified to N₂H₄O₃. It is a white crystal solid and is highly soluble in water. It is predominantly used in agriculture as a high-nitrogen fertilizer. Its other major use is as a component of explosive mixtures used in mining, quarrying, and civil construction. It is the major constituent of ANFO, a popular industrial explosive which accounts for 80% of explosives used in North America; similar formulations have been used in improvised explosive devices. Many countries are phasing out its use in consumer applications due to concerns over its potential for misuse.

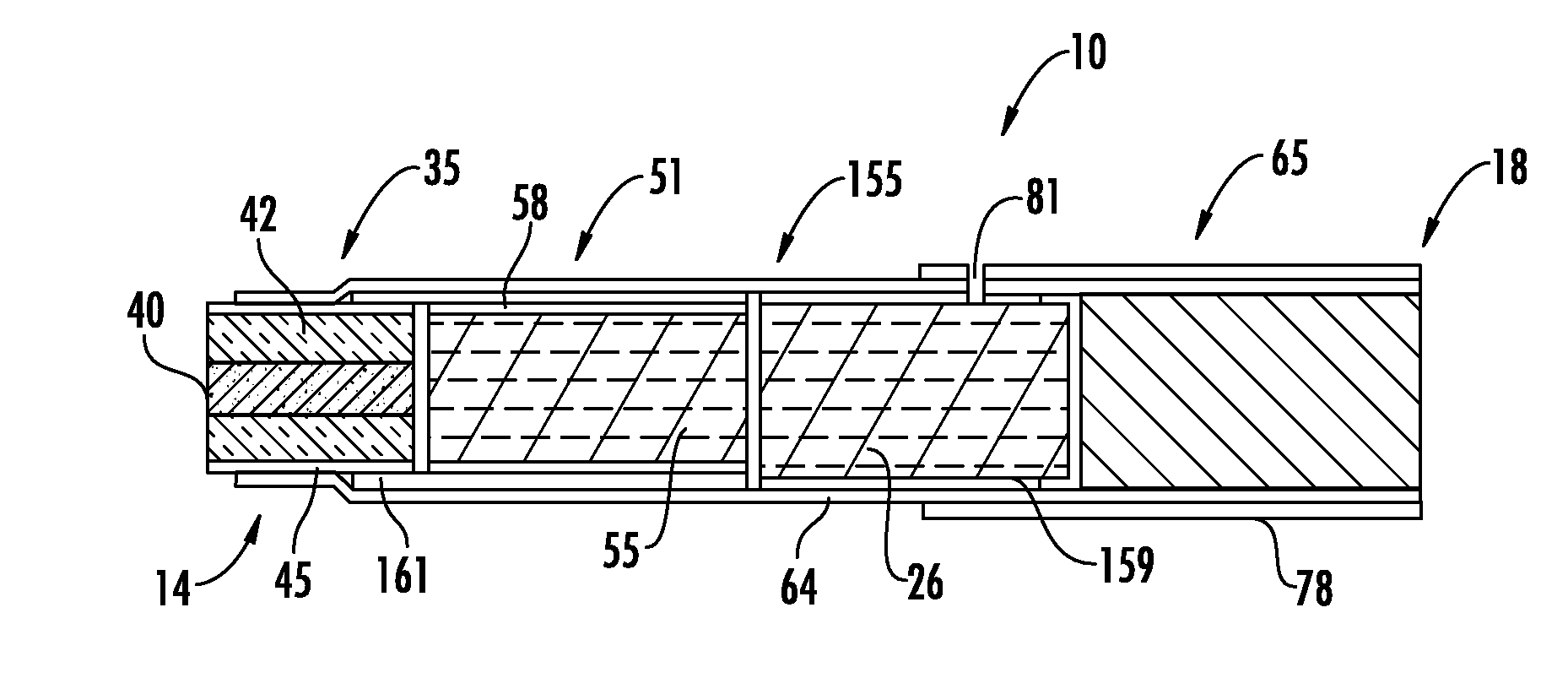

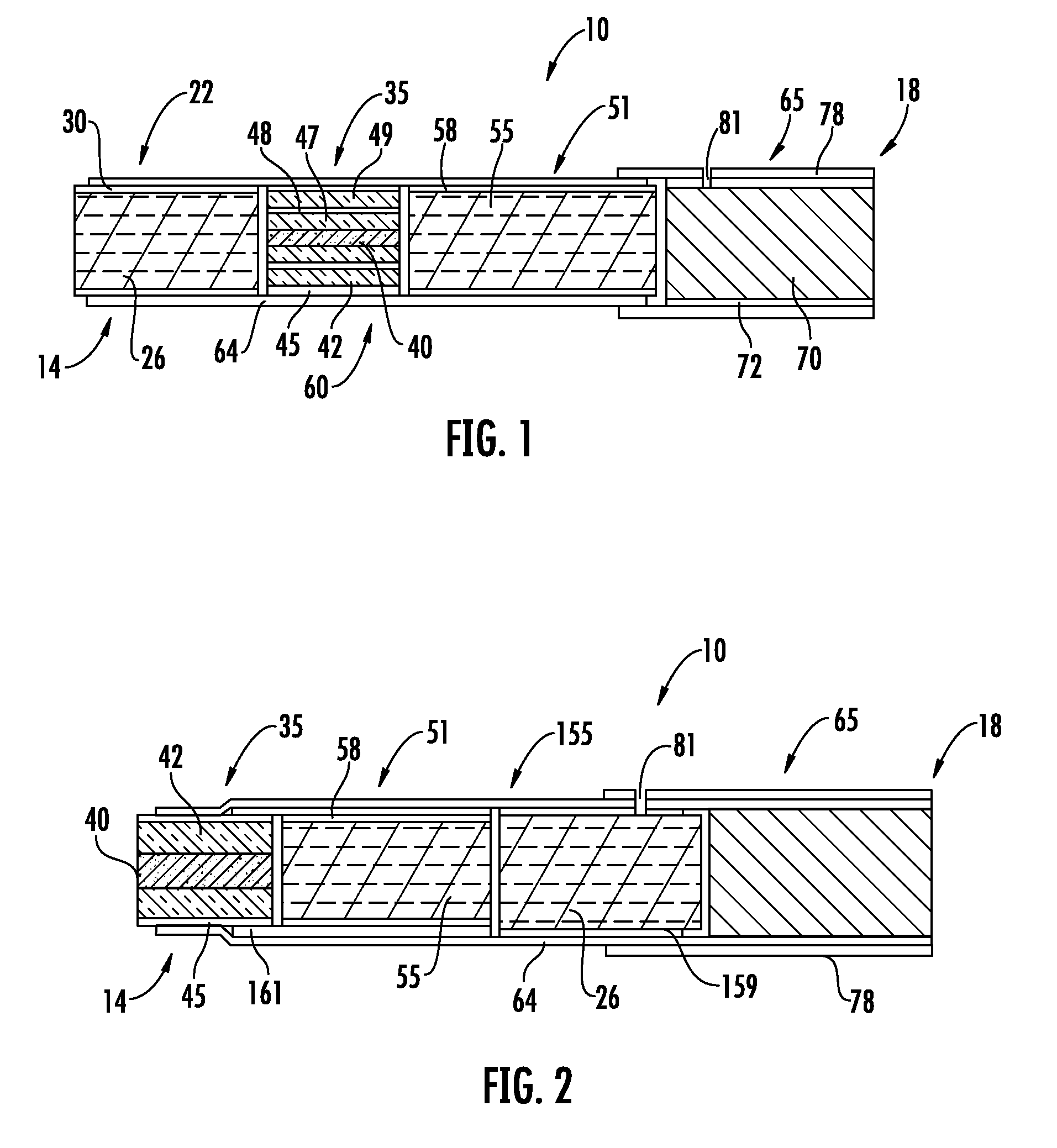

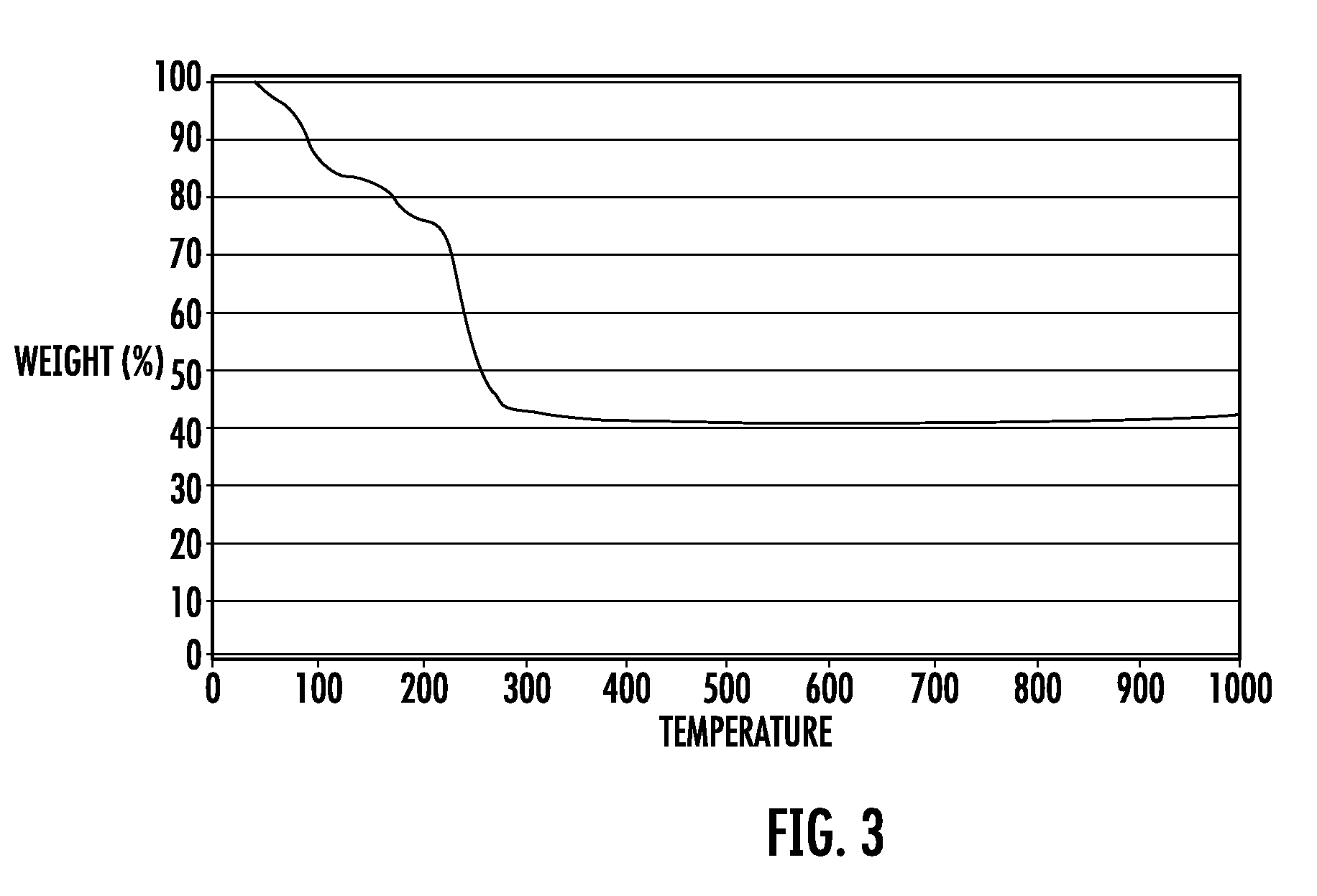

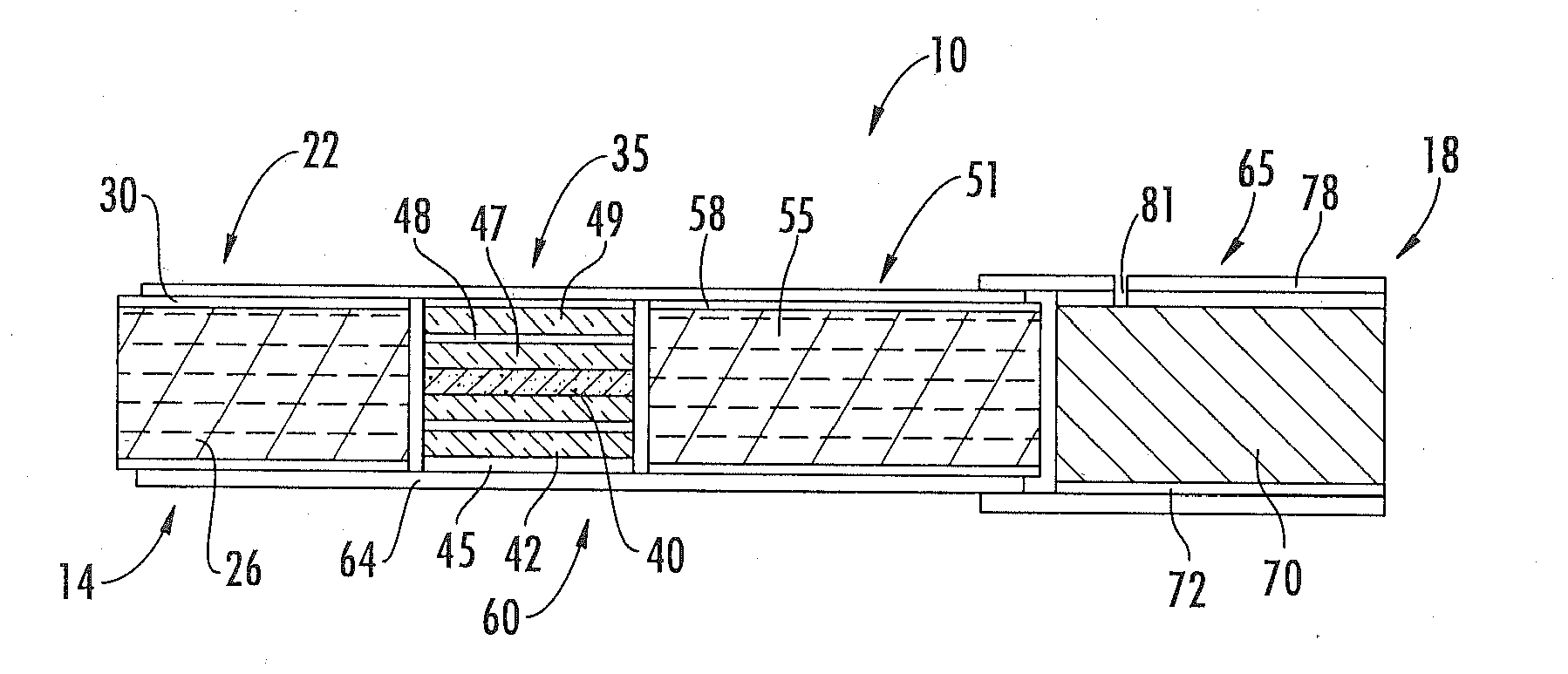

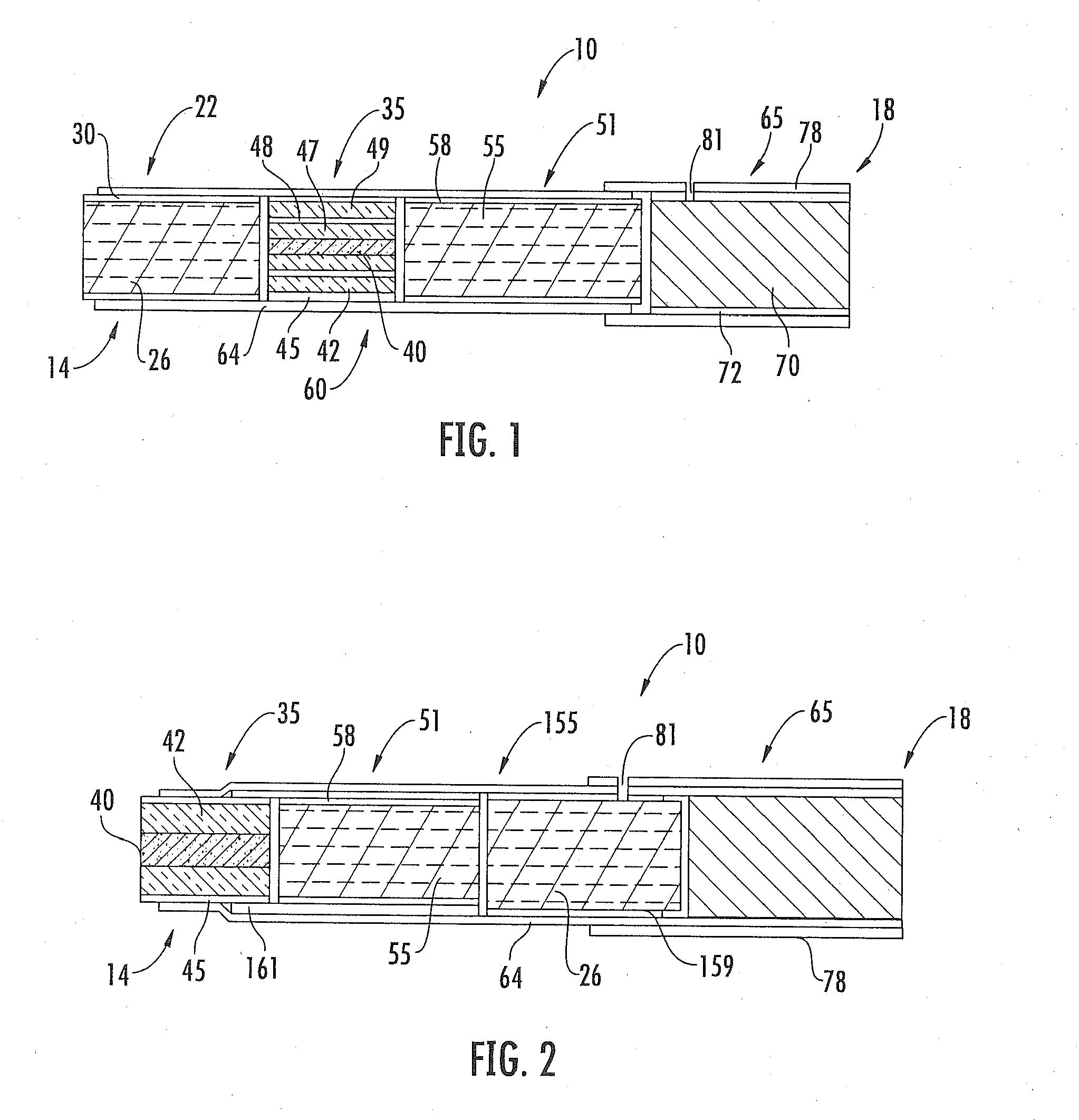

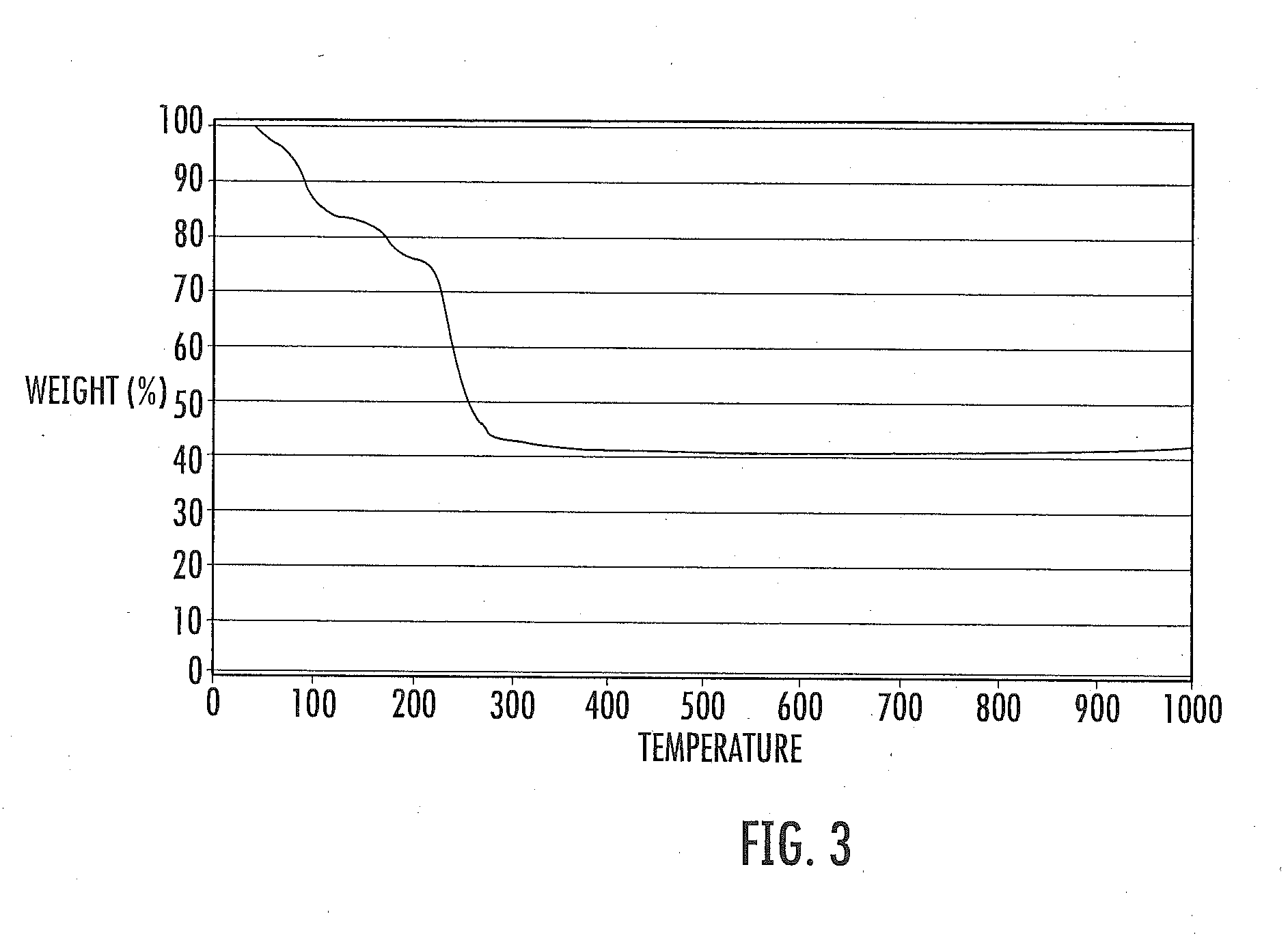

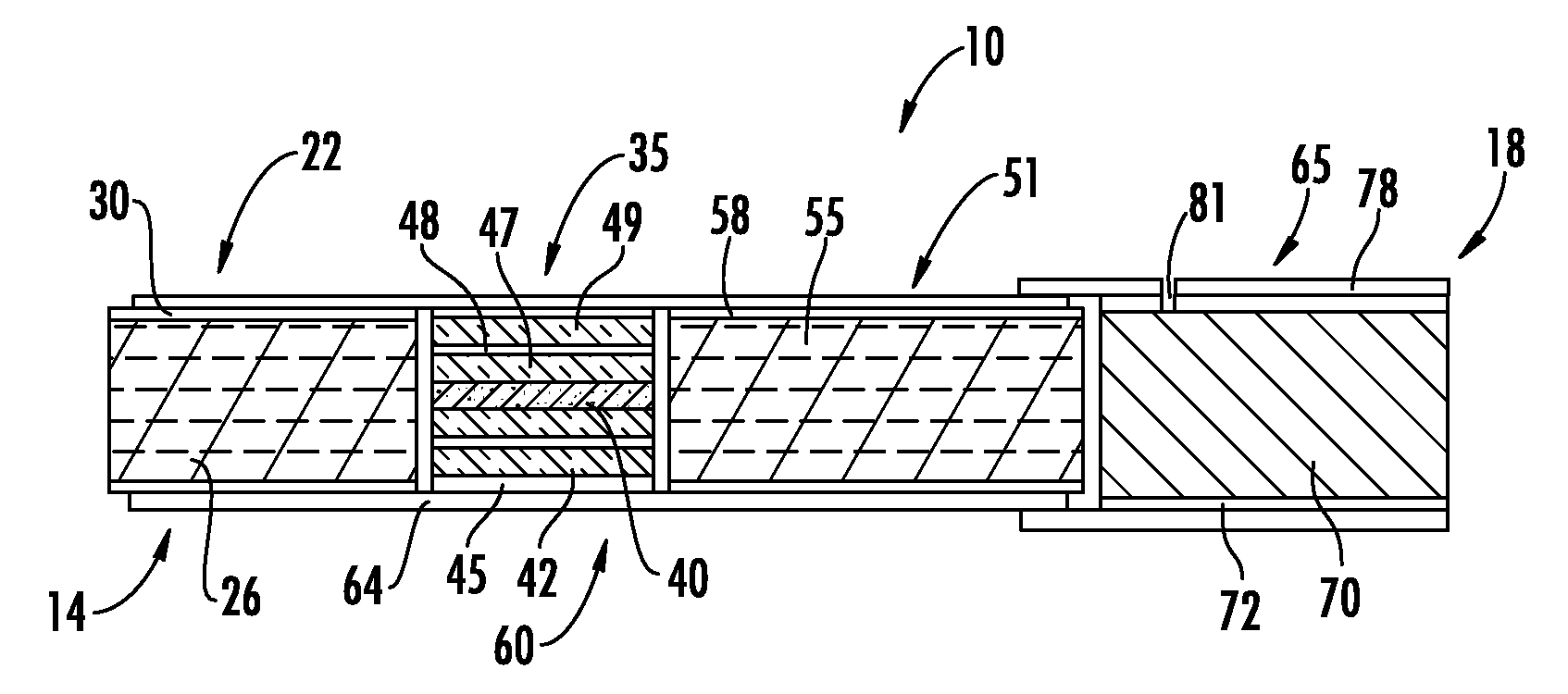

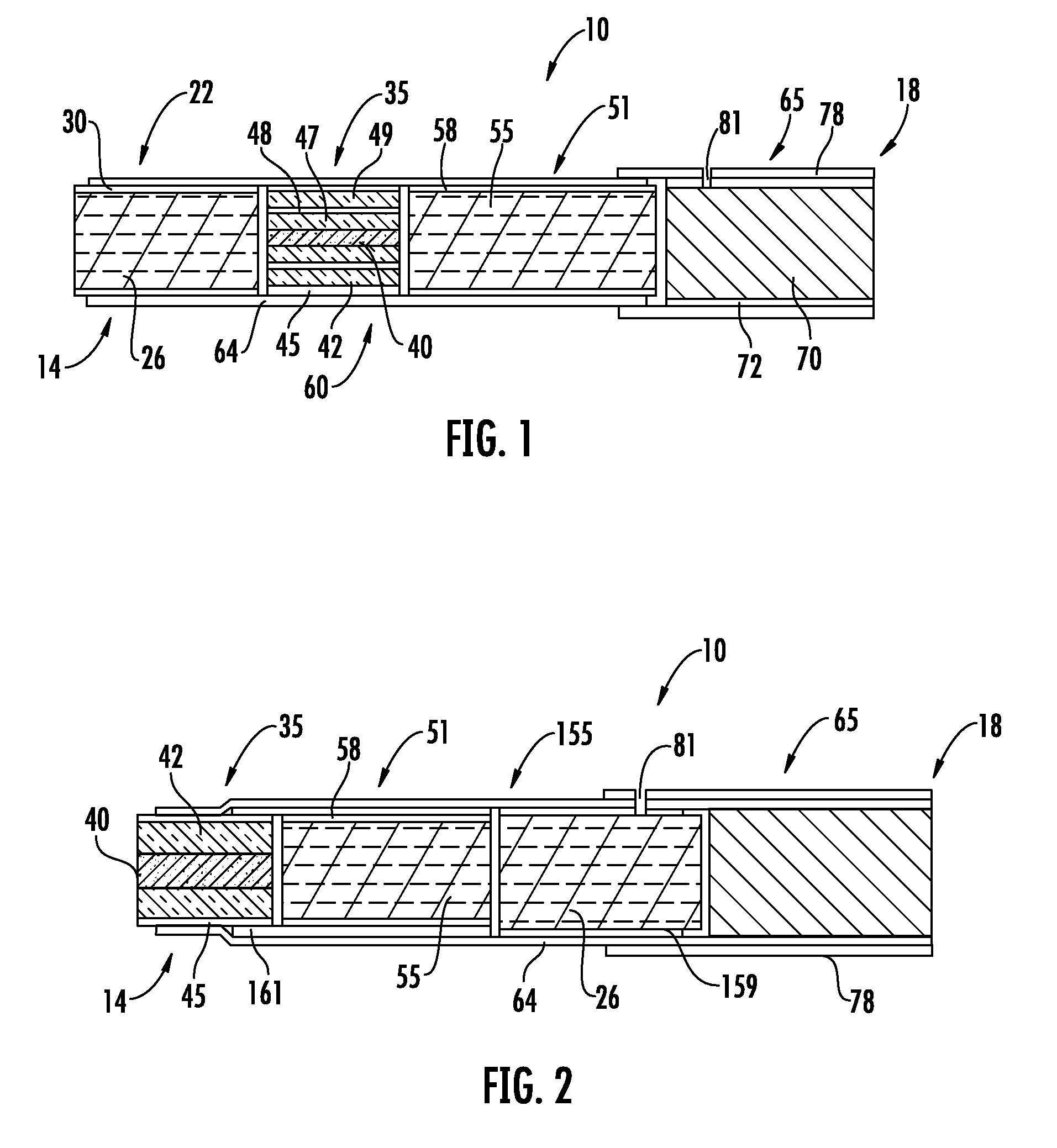

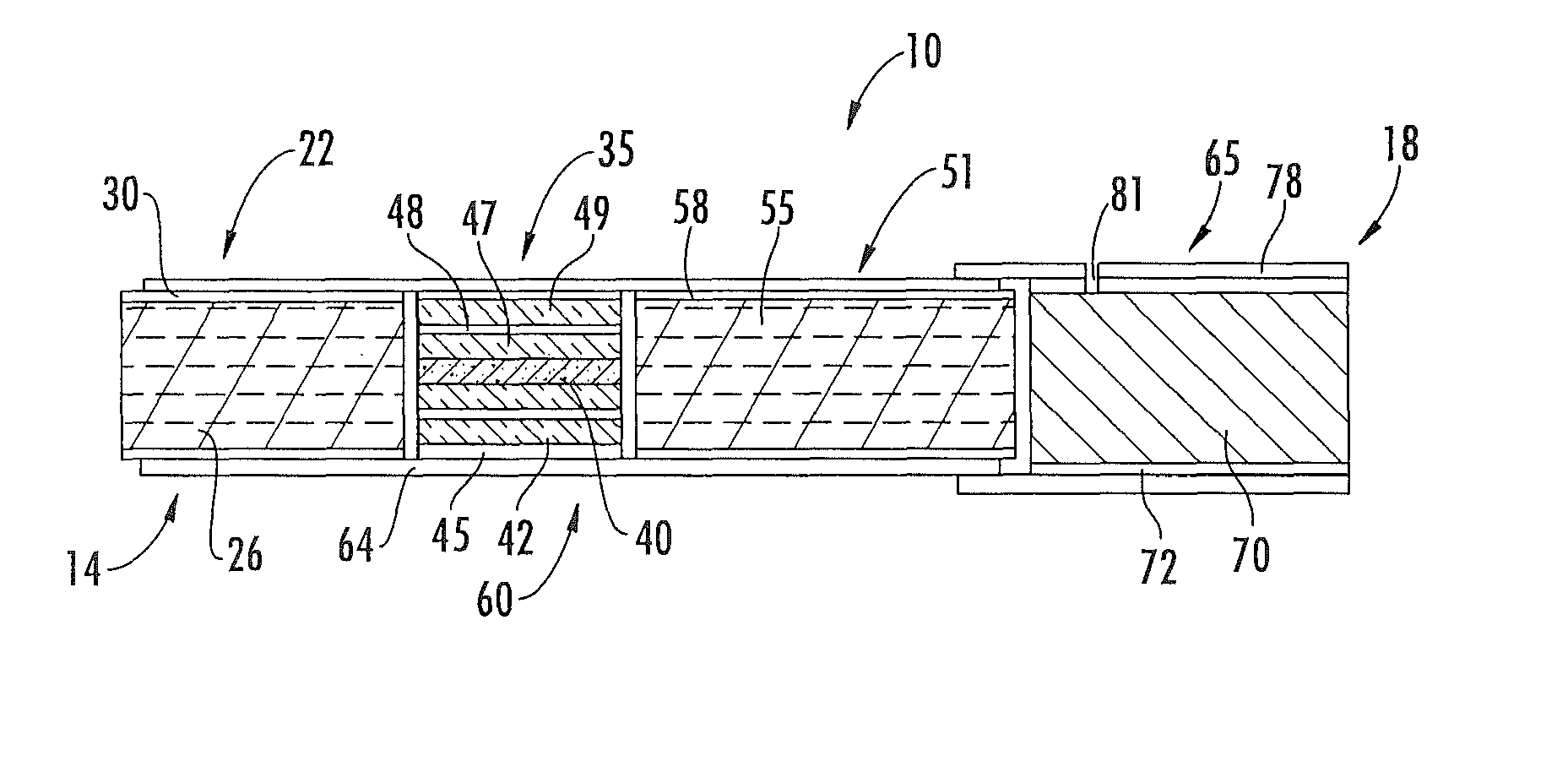

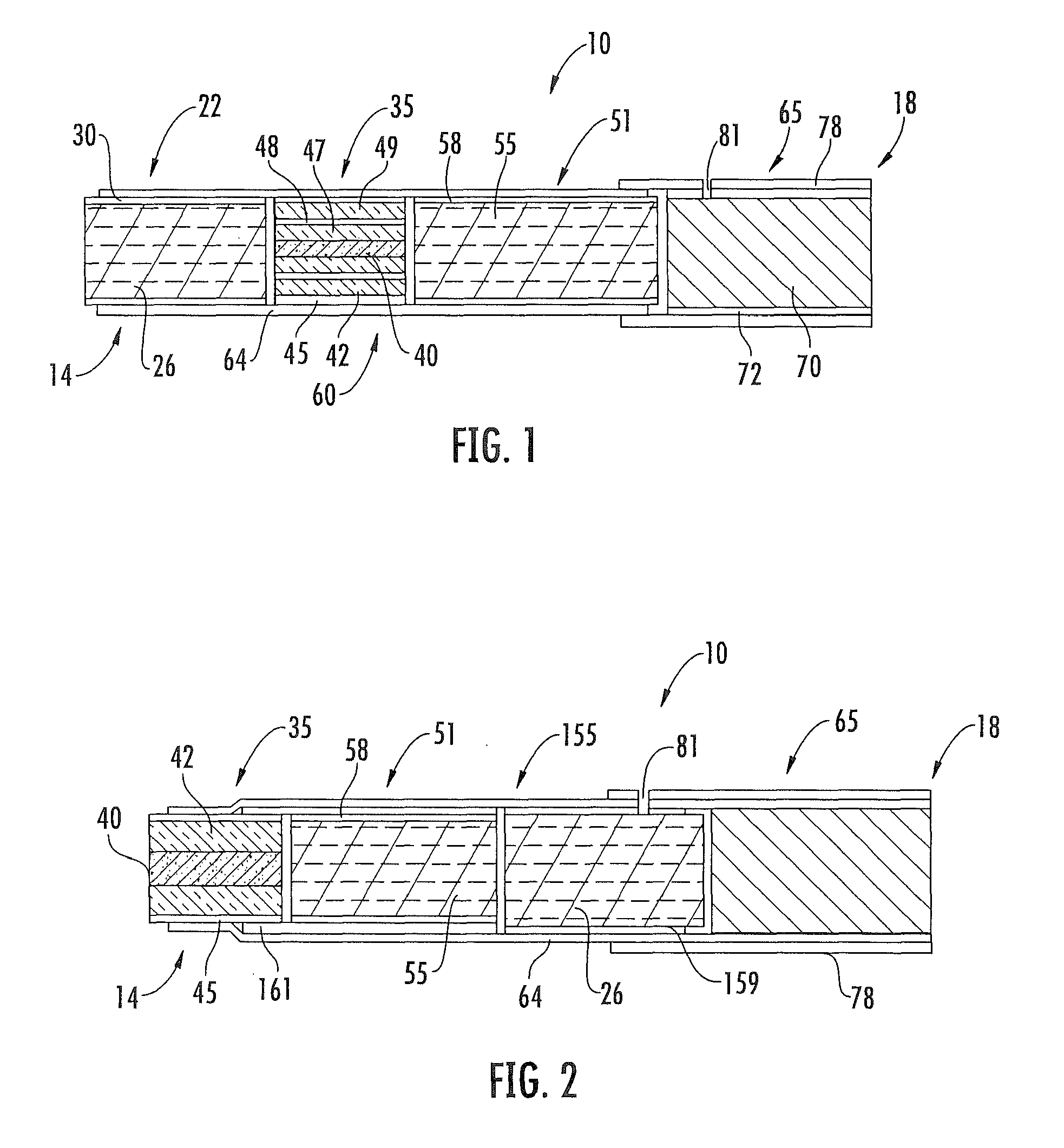

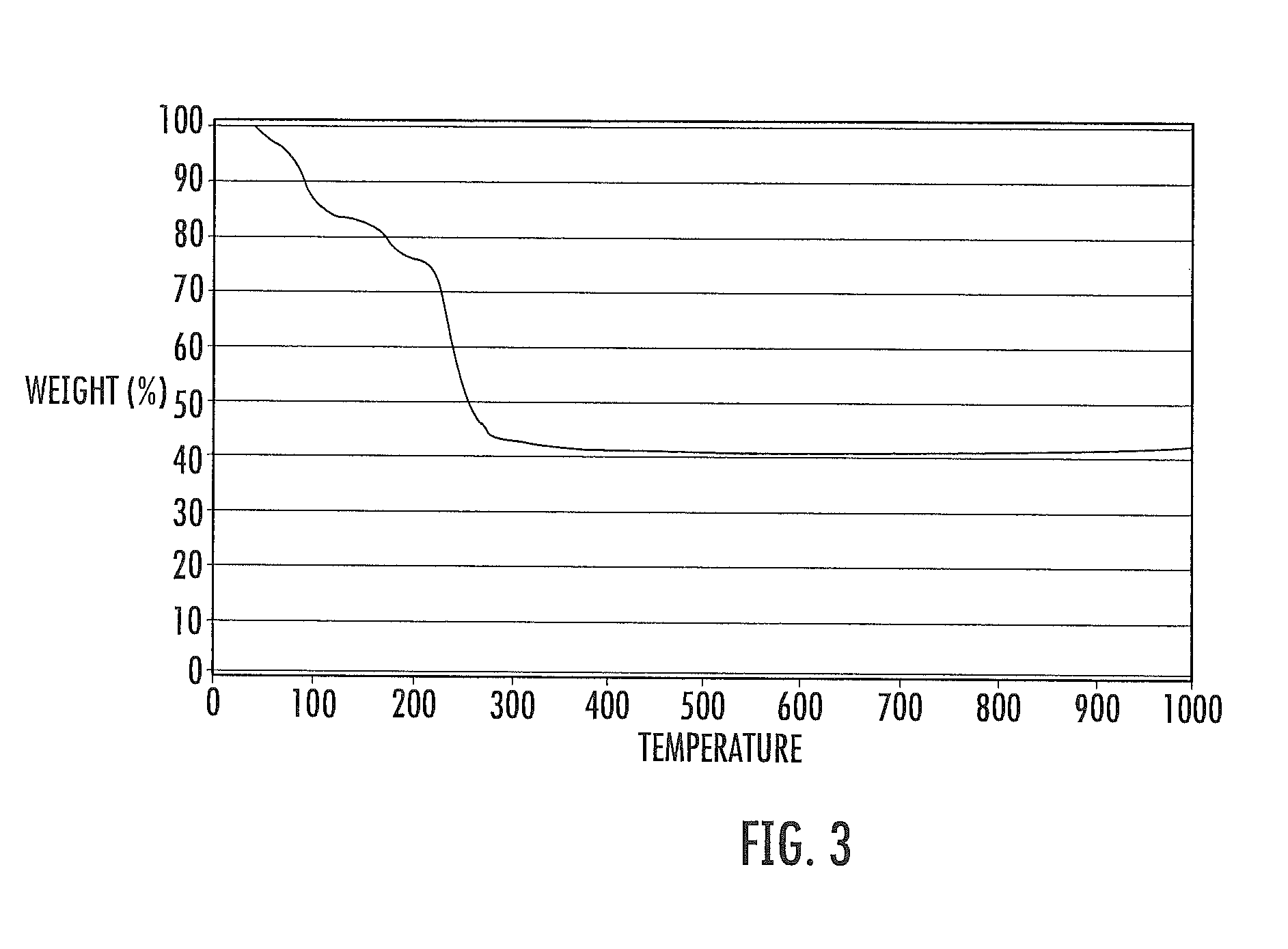

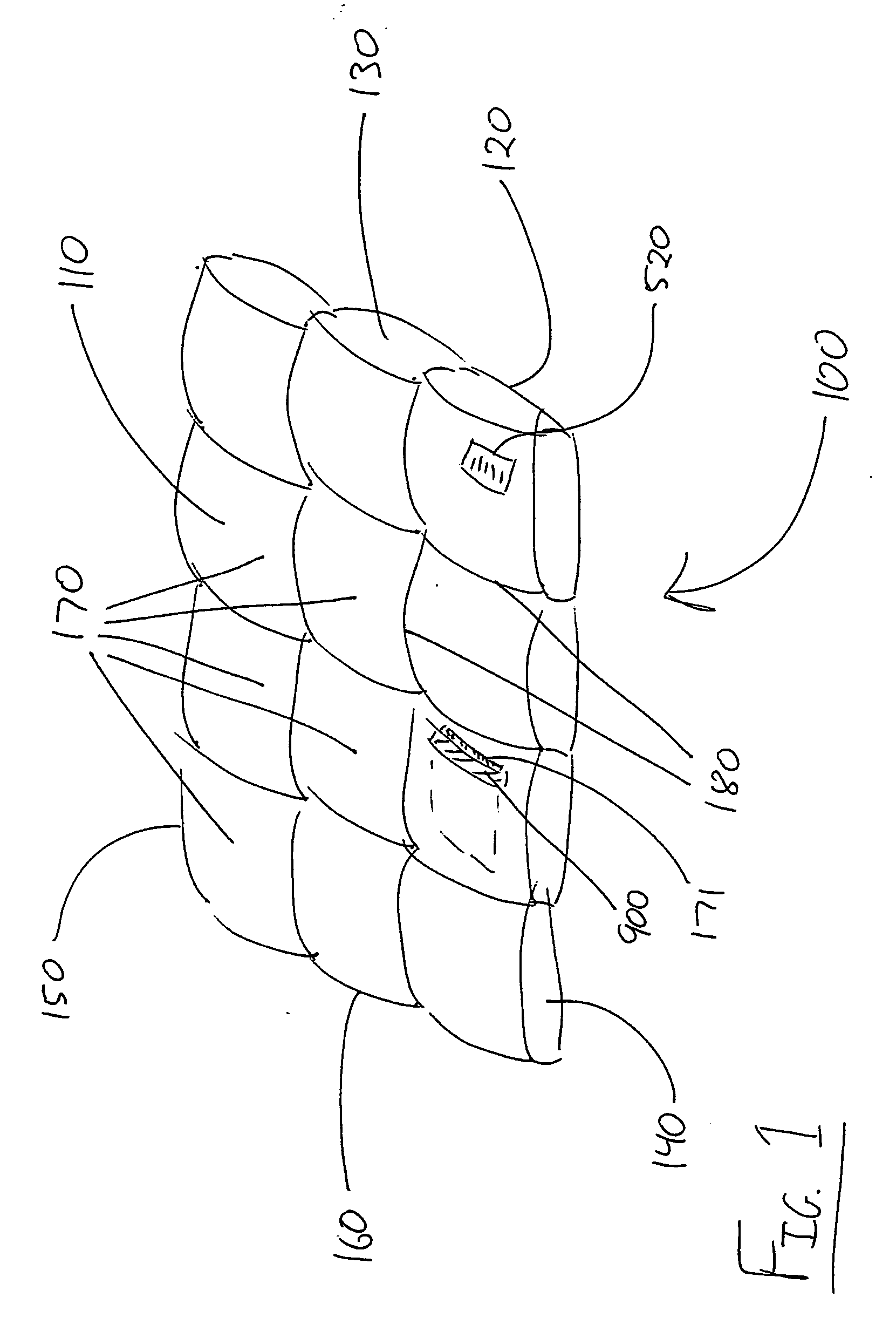

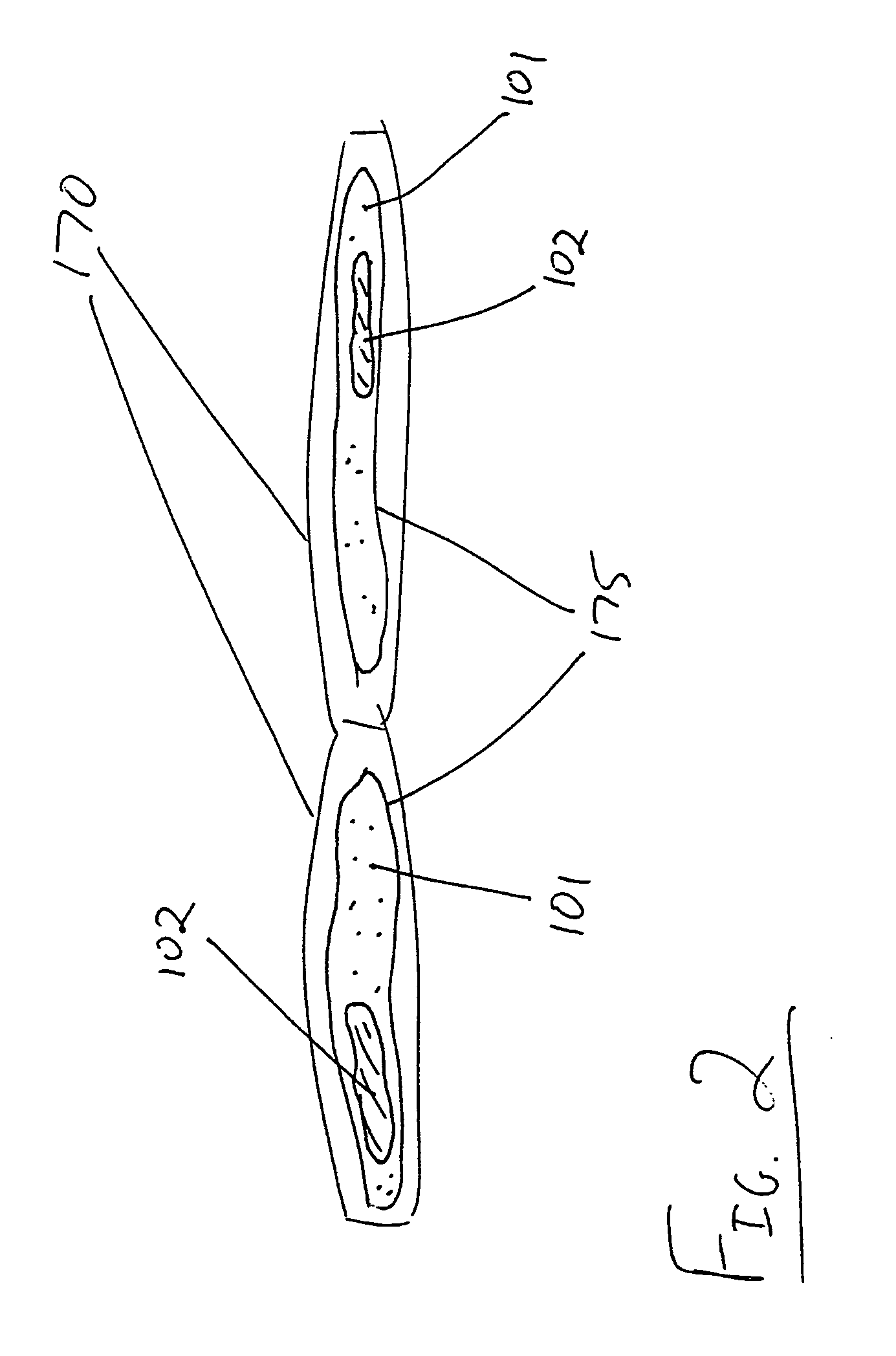

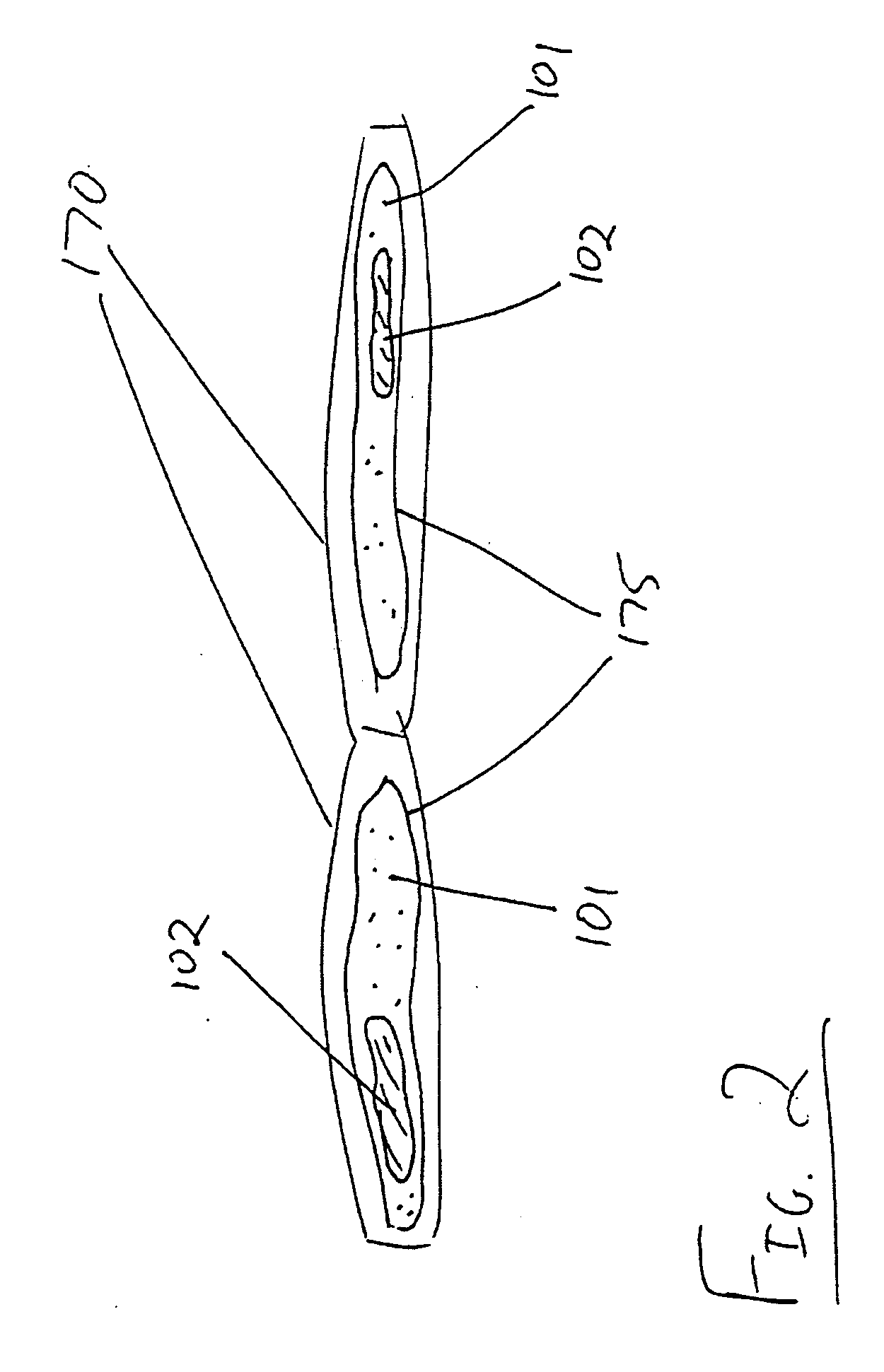

Method for Preparing Fuel Element For Smoking Article

ActiveUS20100065075A1Good water solubilityTobacco treatmentTobacco smoke filtersCerium nitrateCopper nitrate

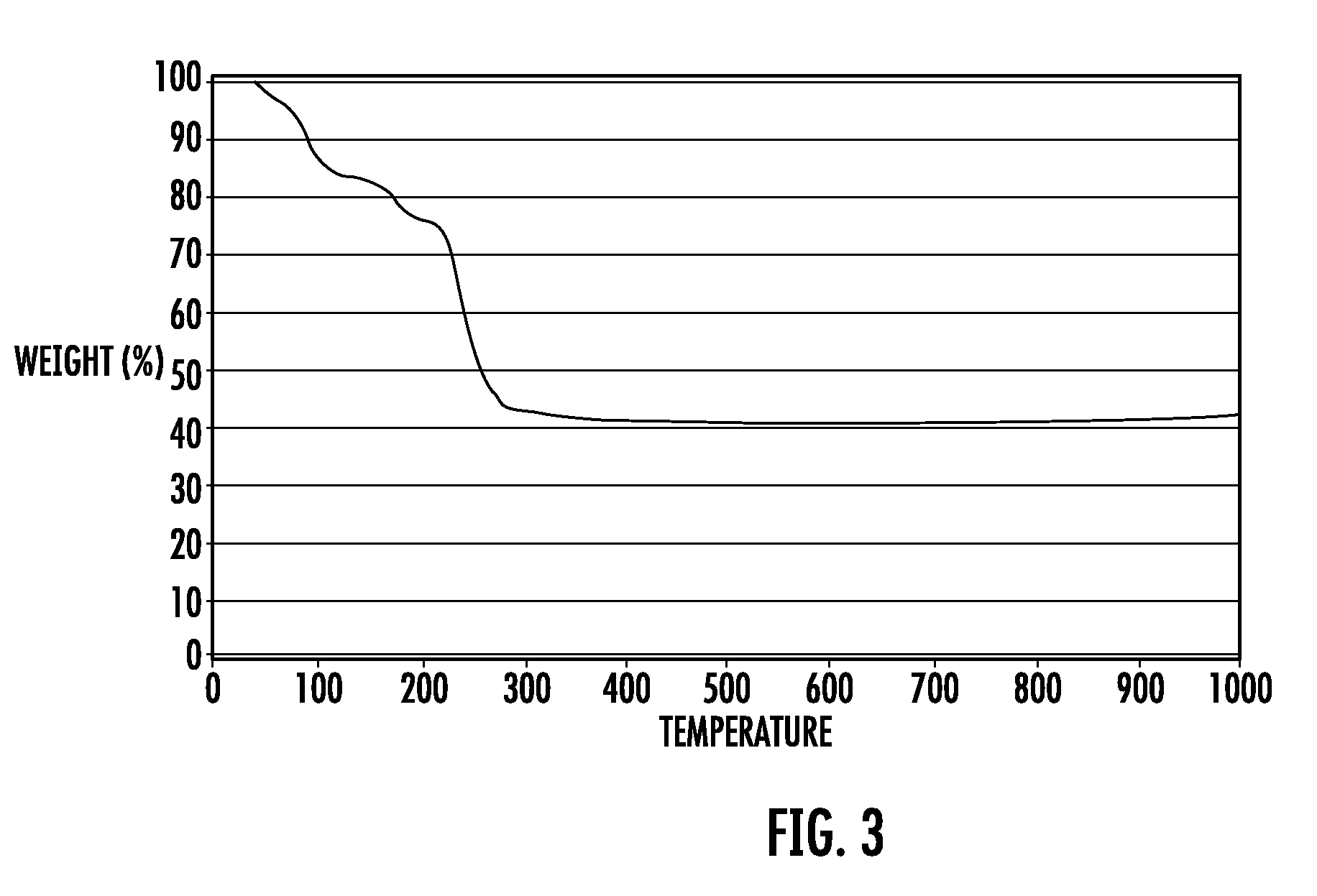

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

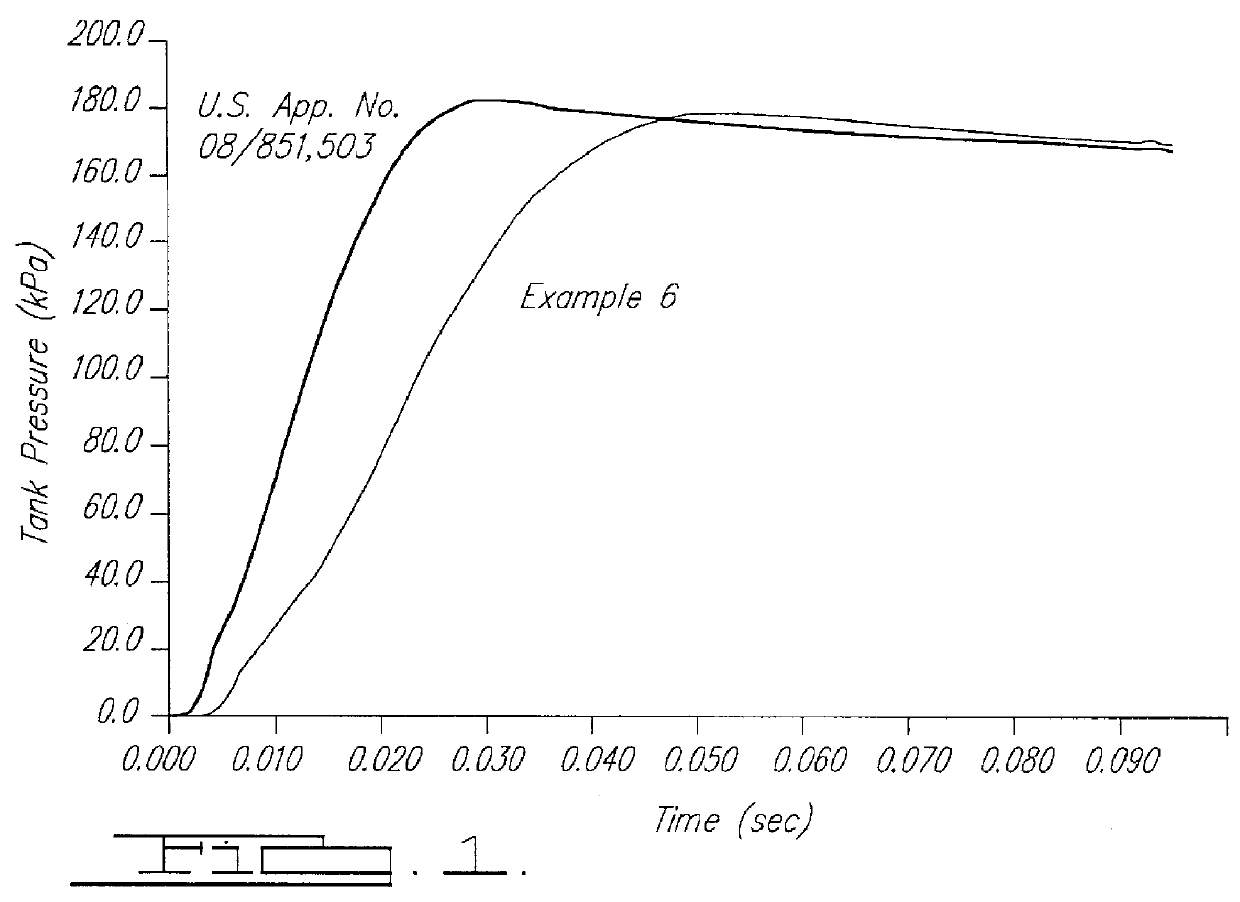

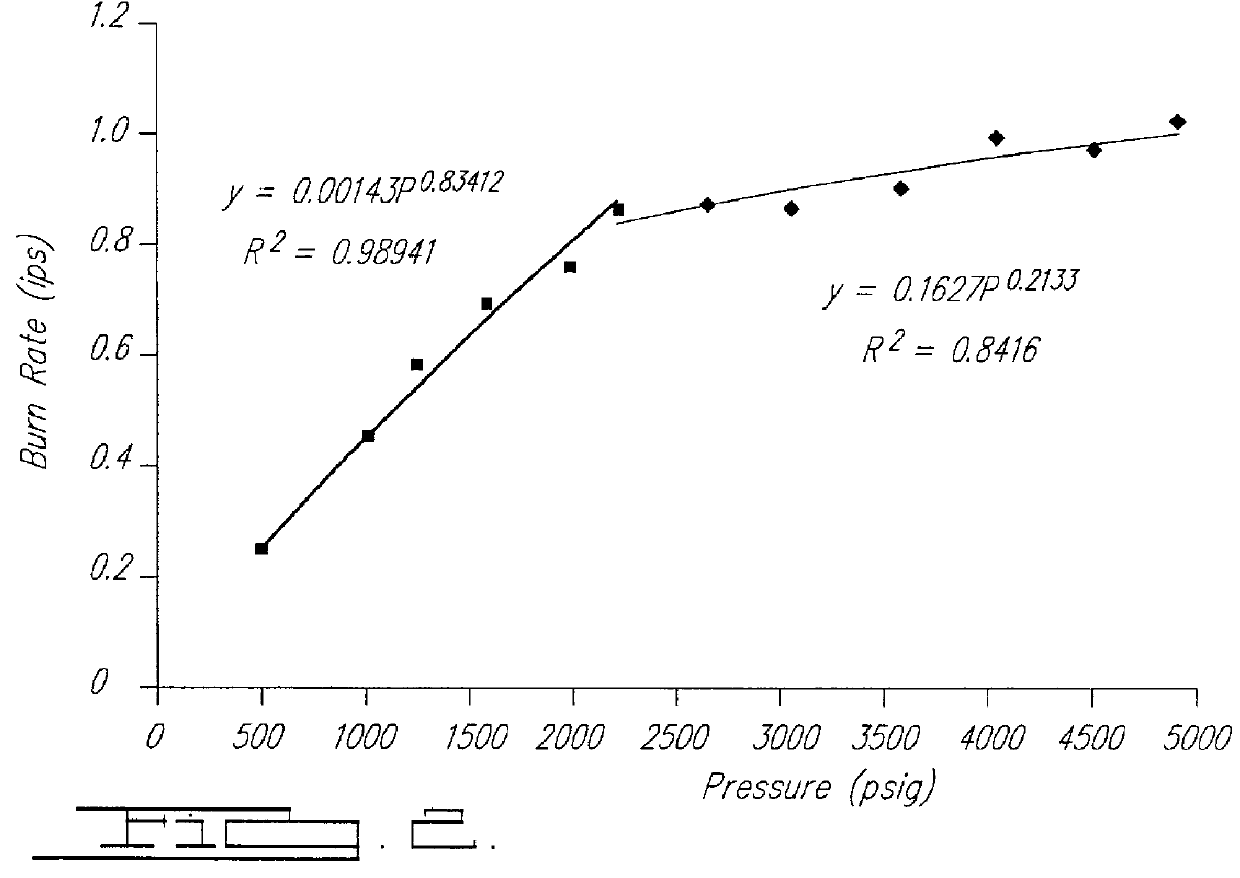

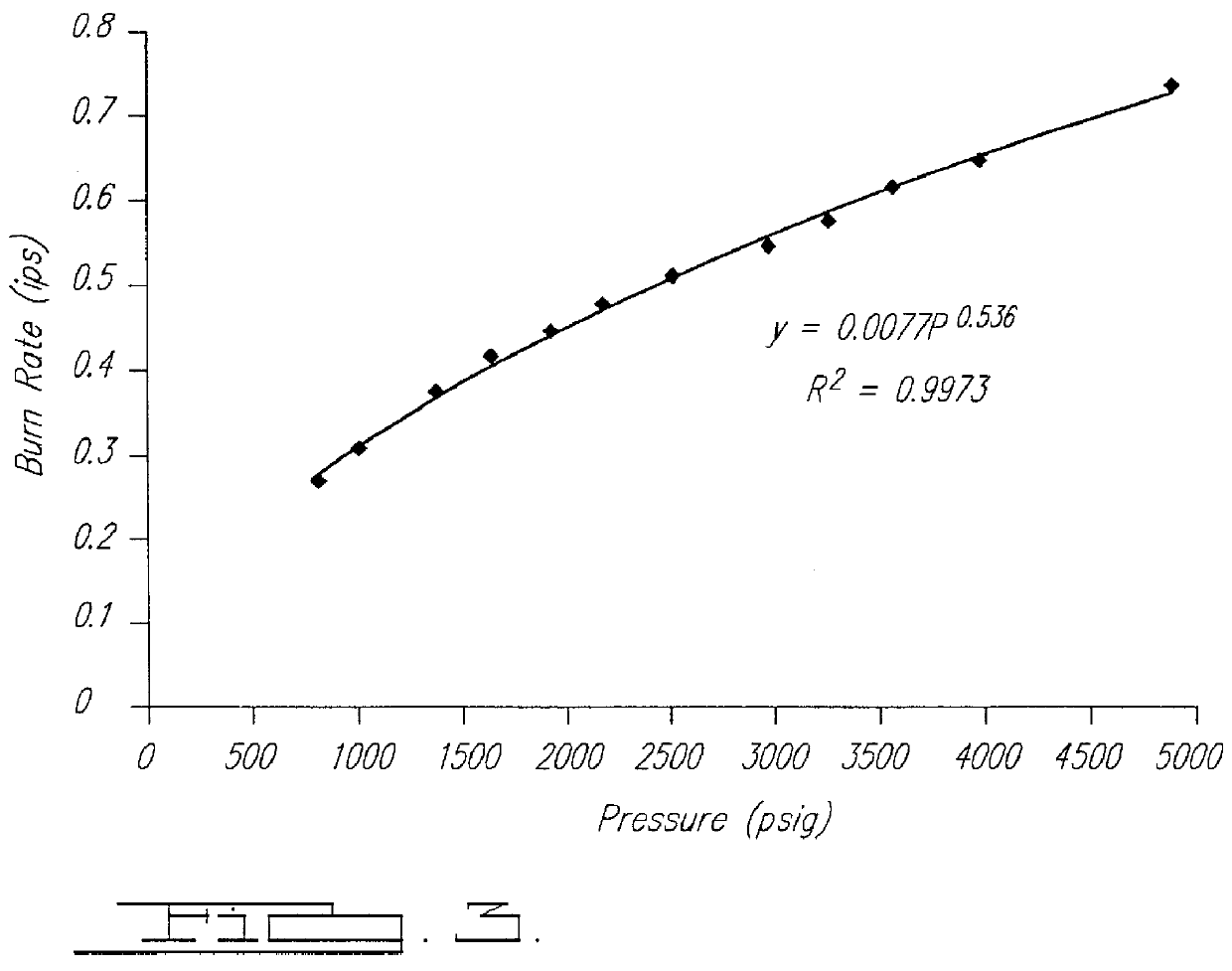

Smokeless gas generant compositions

Thermally stable gas generant compositions incorporate a combination of one or more primary nonazide high-nitrogen fuels selected from a group including tetrazoles, bitetrazoles, and triazoles, and salts thereof; and one or more secondary nonazide high nitrogen fuels selected from azodicarbonamide and hydrazodicarbonamide. The primary and secondary fuels are combined with phase-stabilized ammonium nitrate that when combusted, results in a greater yield of gaseous products per mass unit of gas generant, a reduced yield of solid combustion products, lower combustion temperatures, and acceptable burn rates, thermal stability, and ballistic properties. These compositions are especially suitable for inflating air bags in passenger-restraint devices.

Owner:AUTOMOTIVE SYST LAB

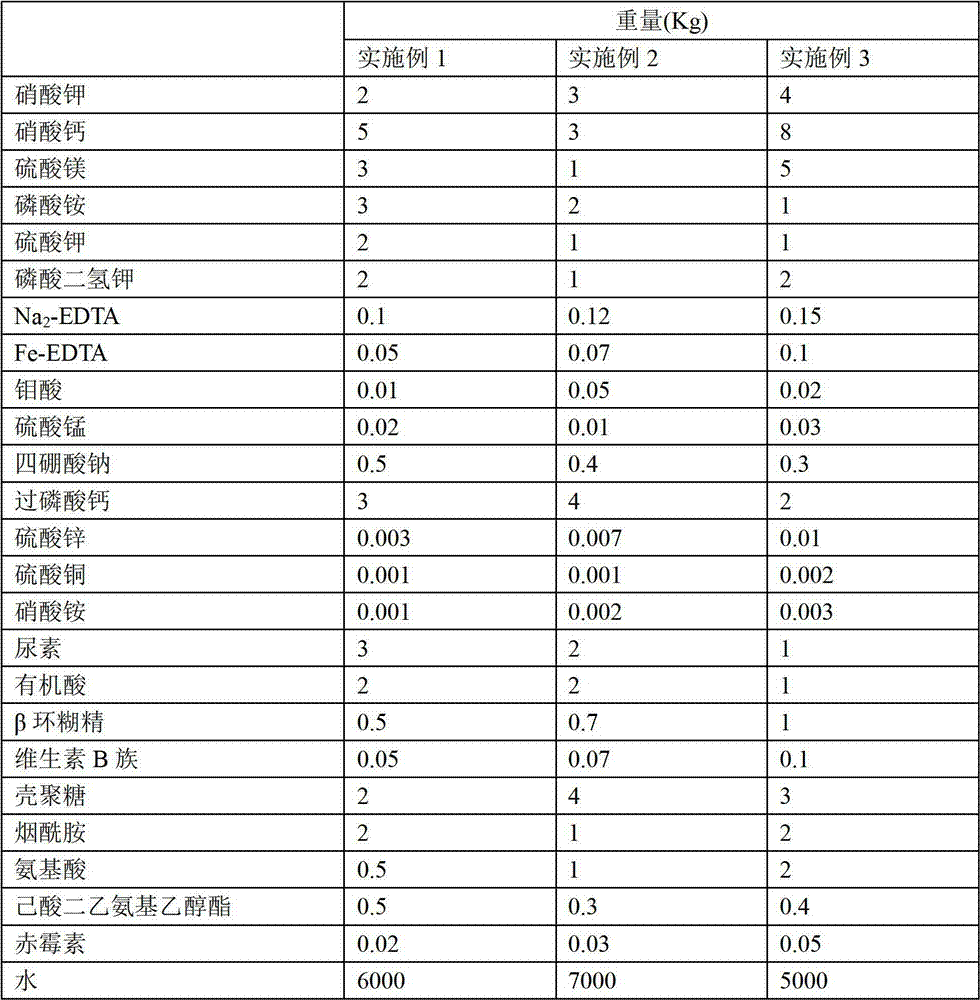

Plant nutrient solution for soilless culture of tomato

The invention provides a plant nutrient solution for soilless culture of tomato. The plant nutrient solution is prepared by the following raw materials in part by weight: 2 to 4 parts of potassium nitrate, 3 to 8 parts of calcium nitrate, 1 to 5 parts of magnesium sulfate, 1 to 3 parts of potassium phosphate, 1 to 2 parts of potassium sulphate, 1 to 2 parts of monopotassium phosphate, 0.1 to 0.15 part of Na2-EDTA, 0.05 to 0.1 part of Fe-EDTA, 0.01 to 0.05 part of molybdic acid, 0.01 to 0.03 part of manganese sulfate, 0.3 to 0.5 part of sodium tetraborate, 2 to 4 parts of superphosphate, 0.003 to 0.01 part of zinc sulfate, 0.001 to 0.002 part of copper sulfate, 0.001 to 0.003 part of ammonium nitrate, 1 to 3 parts of urea, 1 to 2 parts of organic acid, 0.5 to 1 part of beta cyclodextrin, 0.05 to 0.1 part of vitamin B, 2 to 4 parts of chitosan, 1 to 2 parts of nicotinamide, 0.5 to 2 parts of amino acid, 0.3 to 0.5 part of diethyl aminoethyl hexanoate, 0.02 to 0.5 part of gibberellin, and 5,000 to 7,000 parts of water. According to experiment, the plant nutrient solution provided by the invention can be used for carrying out soilless culture of tomato, and the tomato has high plant height, thick stem, high cluster and high output.

Owner:山西田森杜氏番茄科技有限公司

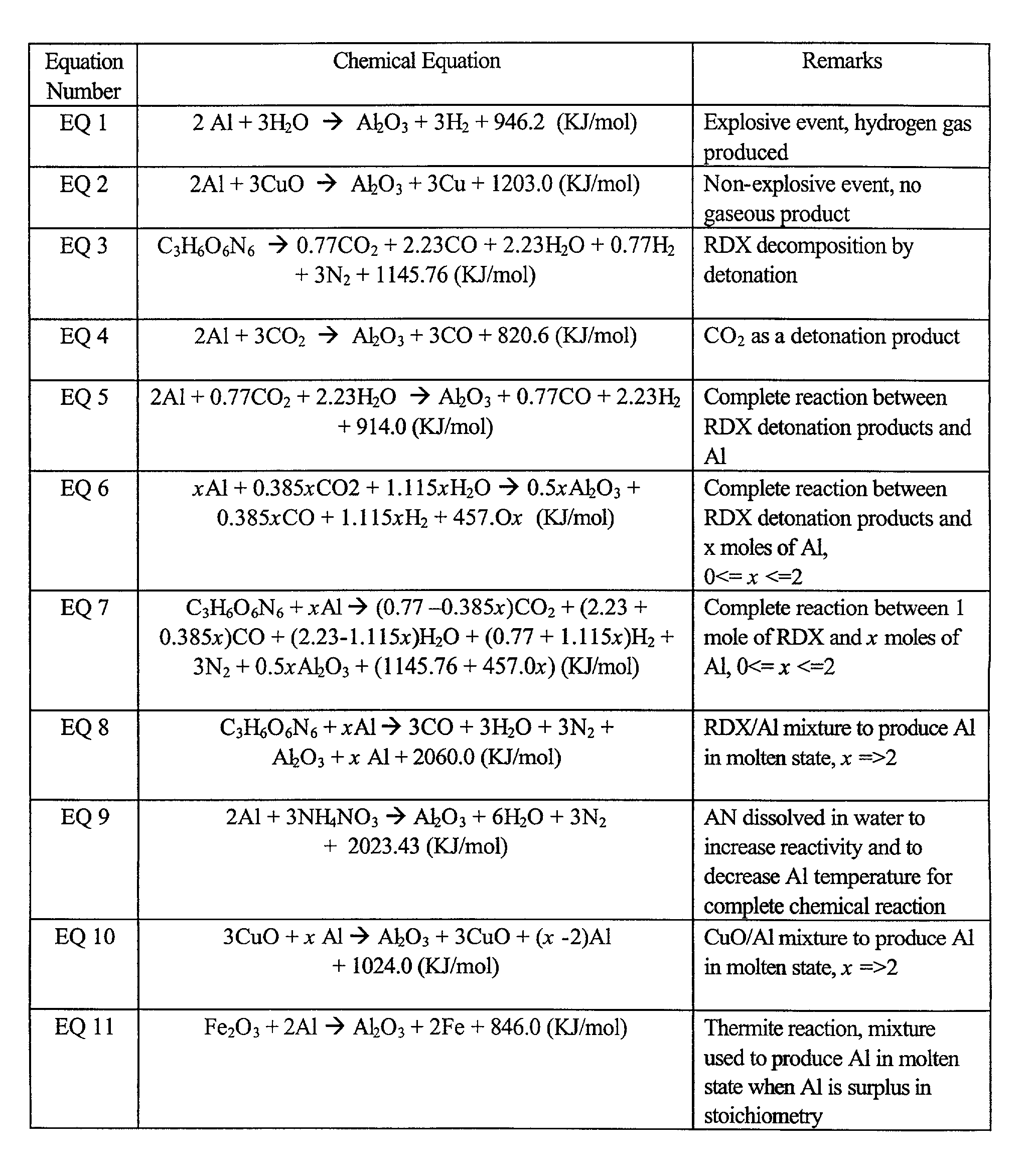

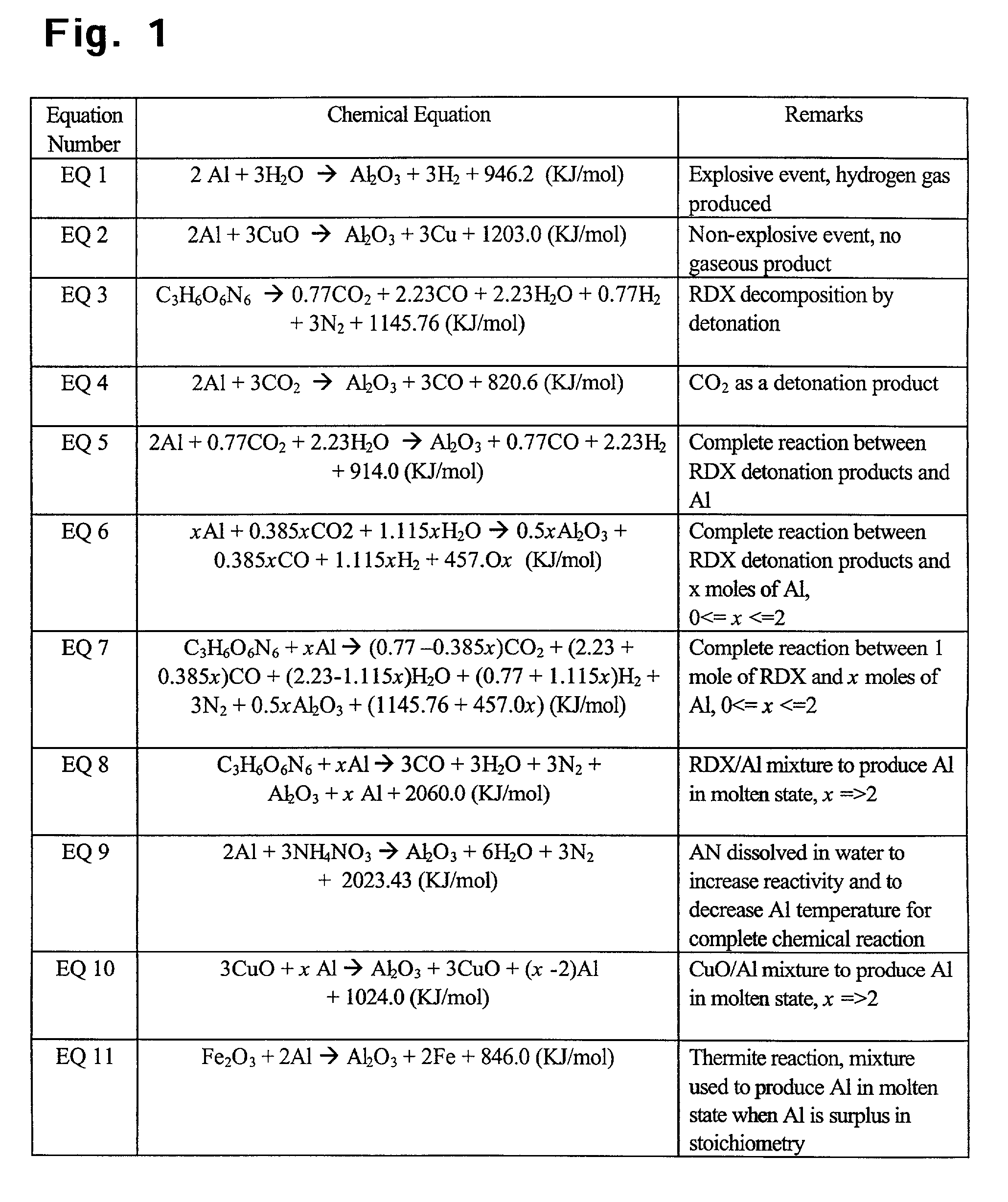

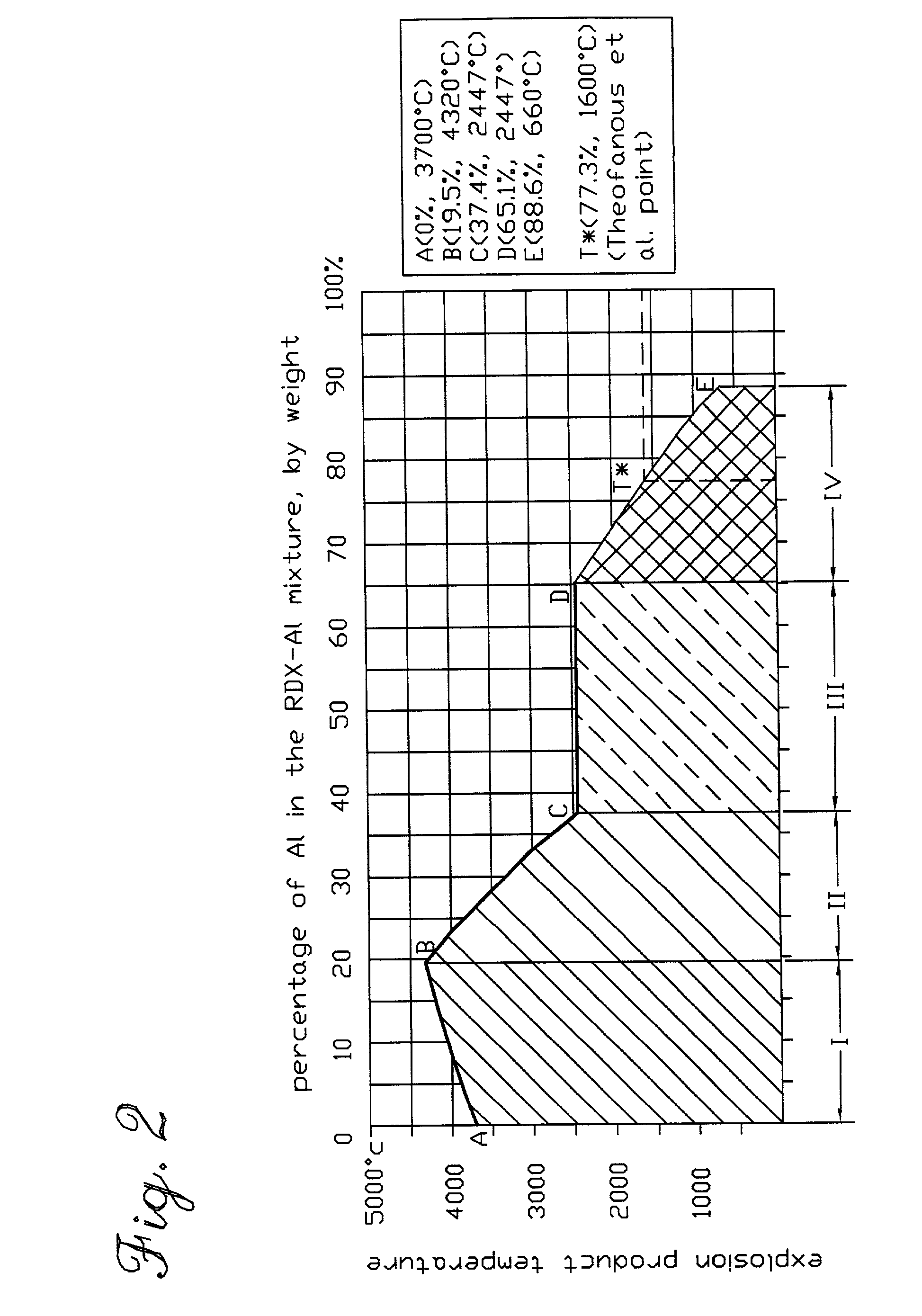

Use of aluminum in perforating and stimulating a subterranean formation and other engineering applications

InactiveUS7393423B2More energy outputImprove mechanical propertiesExplosive chargesBlasting cartridgesMolten stateThermal energy

A chemical reaction between molten aluminum and an oxygen carrier such as water to do useful work is disclosed, and in particular two chemical methods to obtain aluminum in its molten state. One is to detonate a HE / Al mixture with surplus Al in stoichiometry, and the other is to use an oxidizer / Al mixture with surplus Al in stoichiometry. Additionally, there is a physical method of shocking and heating Al using high temperature reaction products. The produced Al in its liquid form is forced to react with an oxygen carrying liquid (e.g. water), giving off heat and releasing hydrogen gas or other gaseous material. A water solution of some oxygen-rich chemicals (e.g. ammonium nitrate) can be advantageously used in place of water. A shaped charge is also disclosed having a liner that contains aluminum, propelled by a high explosive such as RDX or its mixture with aluminum powder. Some aluminum in its molten state is projected into the perforation and forced to react with water that also enters the perforation, creating another explosion, fracturing the crushed zone of the perforation and initializing cracks. Another shaped charge is shown having a liner of energetic material such as a mixture of aluminum powder and a metal oxide. Upon detonation, the collapsed liner carries kinetic and thermal energy. Also shown are methods to build and to detonate or fire explosive devices in an oxygen carrying liquid (e.g. water) to perforate and stimulate a hydrocarbon-bearing formation.

Owner:GEODYNAMICS

Glass and method for producing glass

Glass having a small number of bubbles even without containing As2O3 or Sb2O3 and further without containing SO3 and a method for producing glass without using either As2O3 or Sb2O3 as a refiner, are provided. Glass having a reduction degree such that Fe2+ / (Fe2++Fe3+) is at least 0.61, as the reduction degree of glass is represented by a ratio of Fe ions. A method for producing glass, which comprises melting raw material to produce glass comprising, as represented by mass percentage, at least 40% of Si as SiO2, characterized in that the raw material contains an ammonium salt (except for ammonium sulfate and ammonium nitrate).

Owner:ASAHI GLASS CO LTD

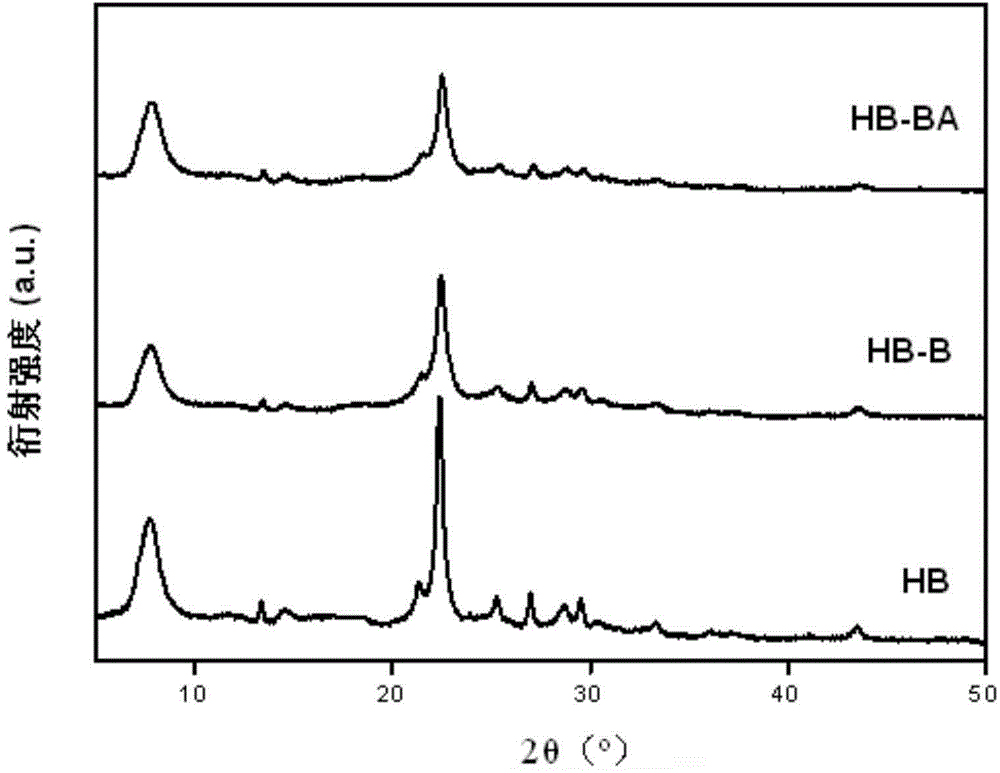

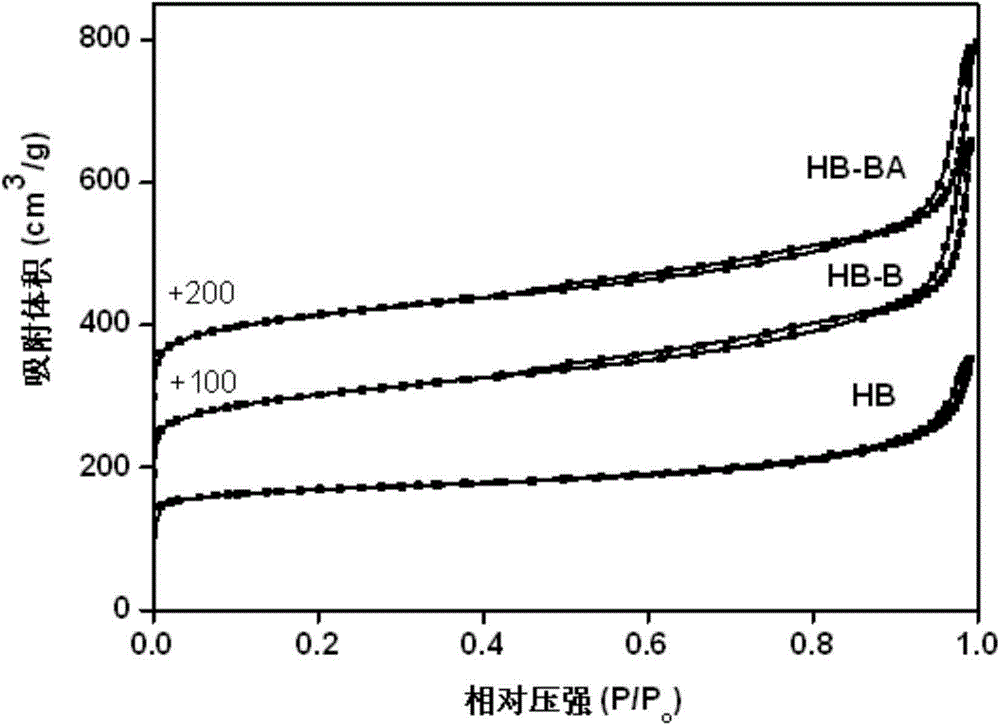

Preparation method of low-cost strong-acid hierarchical-pore Beta zeolite

The invention discloses a preparation method of low-cost strong-acid hierarchical-pore Beta zeolite, and relates to a preparation method of hierarchical-pore Beta zeolite. The problem that the acidity of an existing desilicication post-treatment hierarchical-pore Beta zeolite molecular sieve is weakened is solved. The preparation method comprises the steps of 1. calcining Beta zeolite to obtain microporous hydrogen type Beta zeolite; 2. adding the microporous hydrogen type Beta zeolite into an alkaline solution, stirring, and washing and drying to obtain sodium type desilicication hierarchical-pore Beta zeolite; 3. adding the sodium type desilicication hierarchical-pore Beta zeolite into an ammonium nitrate aqueous solution for exchange, and calcining to obtain hydrogen type desilicication hierarchical-pore Beta zeolite; and 4. adding the hydrogen type desilicication hierarchical-pore Beta zeolite into an acidic solution, stirring, washing and drying, and repeating the step 3 to obtain the strong-acid hierarchical-pore Beta zeolite.

Owner:HARBIN INST OF TECH

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

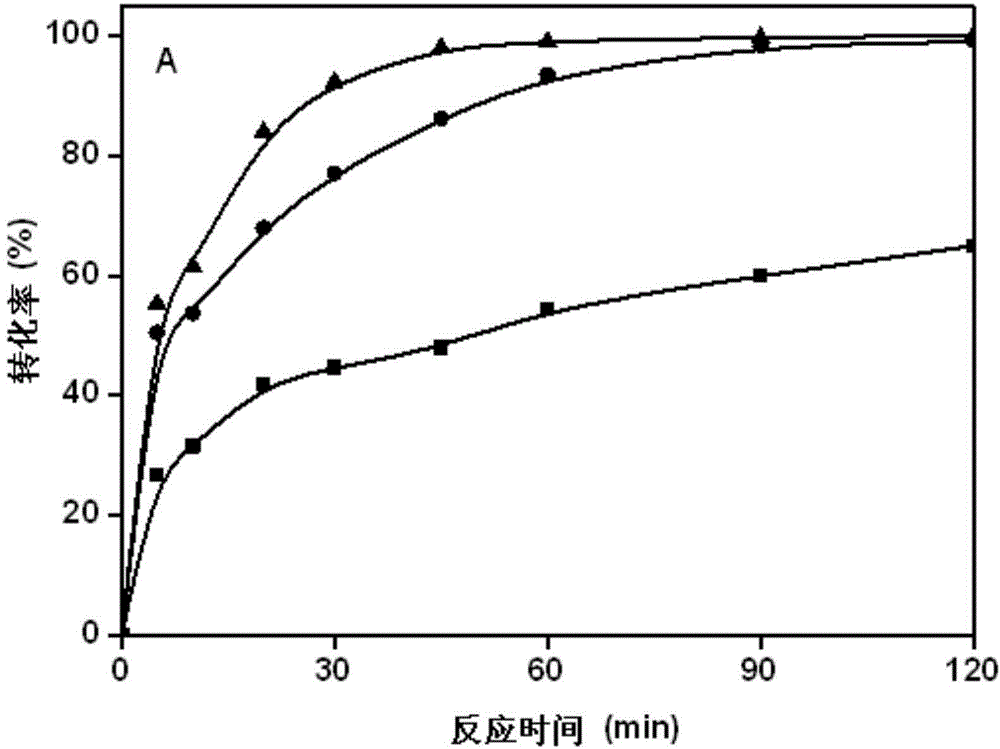

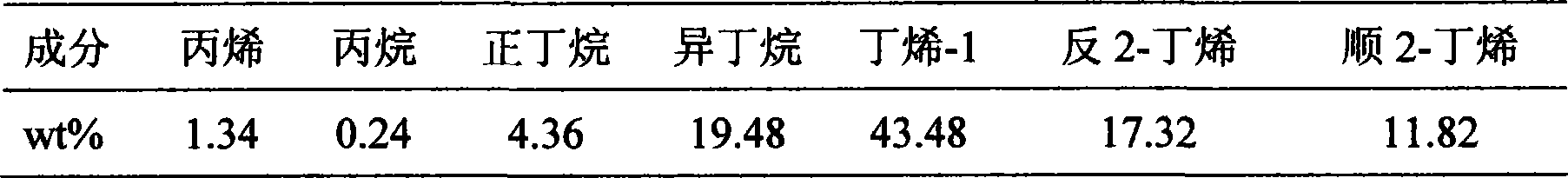

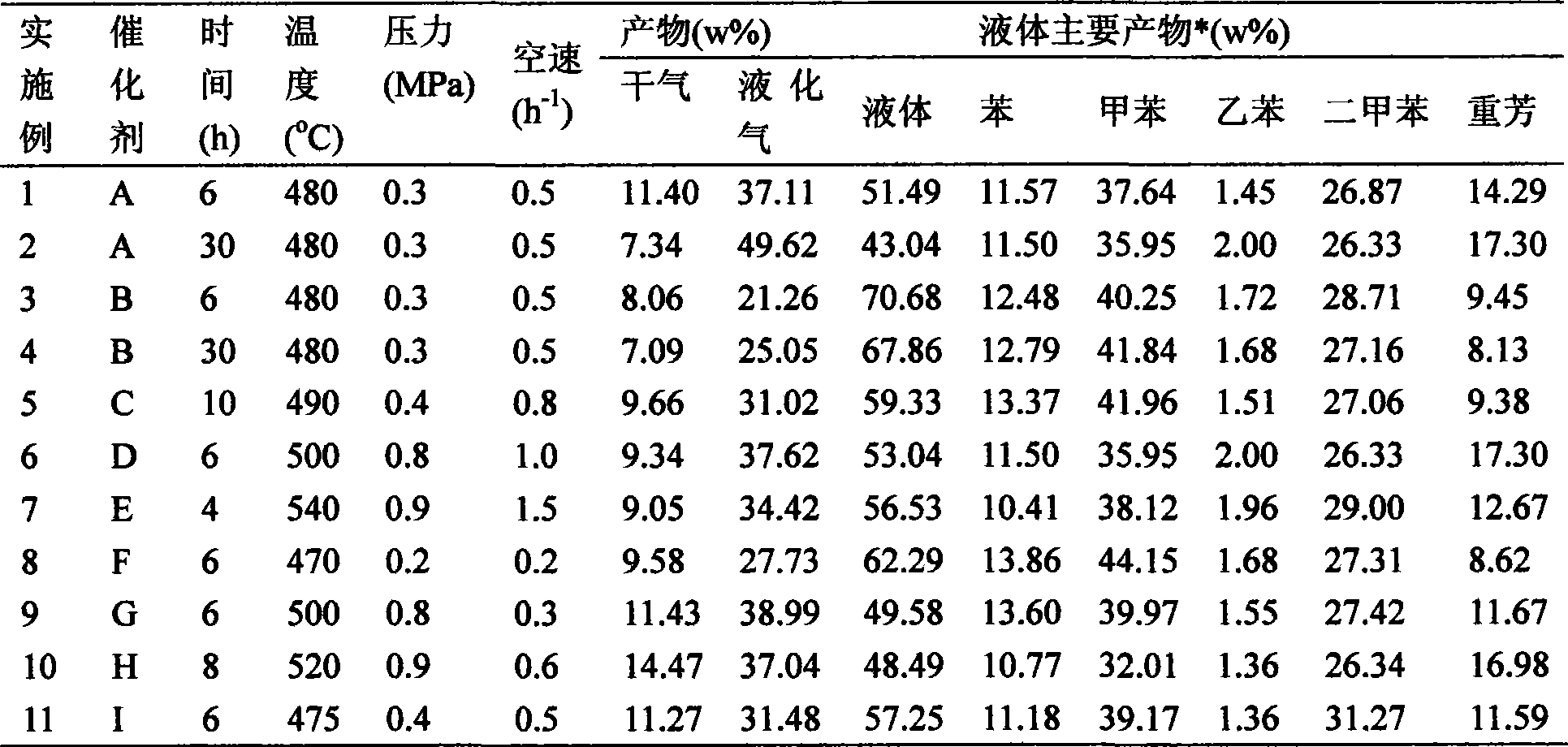

Method for preparing molecular sieve catalyst used in carbon 4 liquid gas aromatization reaction

InactiveCN101530813AHigh aromatization performanceMolecular sieve catalystsLiquid hydrocarbon mixtures productionMolecular sieveWater vapor

The invention relates to a method for preparing a molecular sieve catalyst used in carbon 4 liquid gas aromatization reaction. The concrete steps of the method are as follows: 1. the prepared rare earth-ZSM5 / ZSM11 co-crystallization molecular sieve, alumina and water are mixed uniformly, extruded and molded, dried and baked; 2. the above product is put in alkali solution with the concentration of 0.05 to 2.0M and air-bubble-stirred for 1 to 10 hours at 45 to 100 DEG C; 3. the product in step 2 is washed to neutrality, exchanged by ammonium nitrate solution, dried and baked into H-type molecular sieve; and 4. the product in step 3 is processed by high-temperature water vapor and loaded with metal zinc, thus obtaining the catalyst. The method has the advantages that the modified molecular sieve catalyst shows better carbon 4 liquid gas aromatization reaction performance compared with catalyst that is not alkali-treated.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

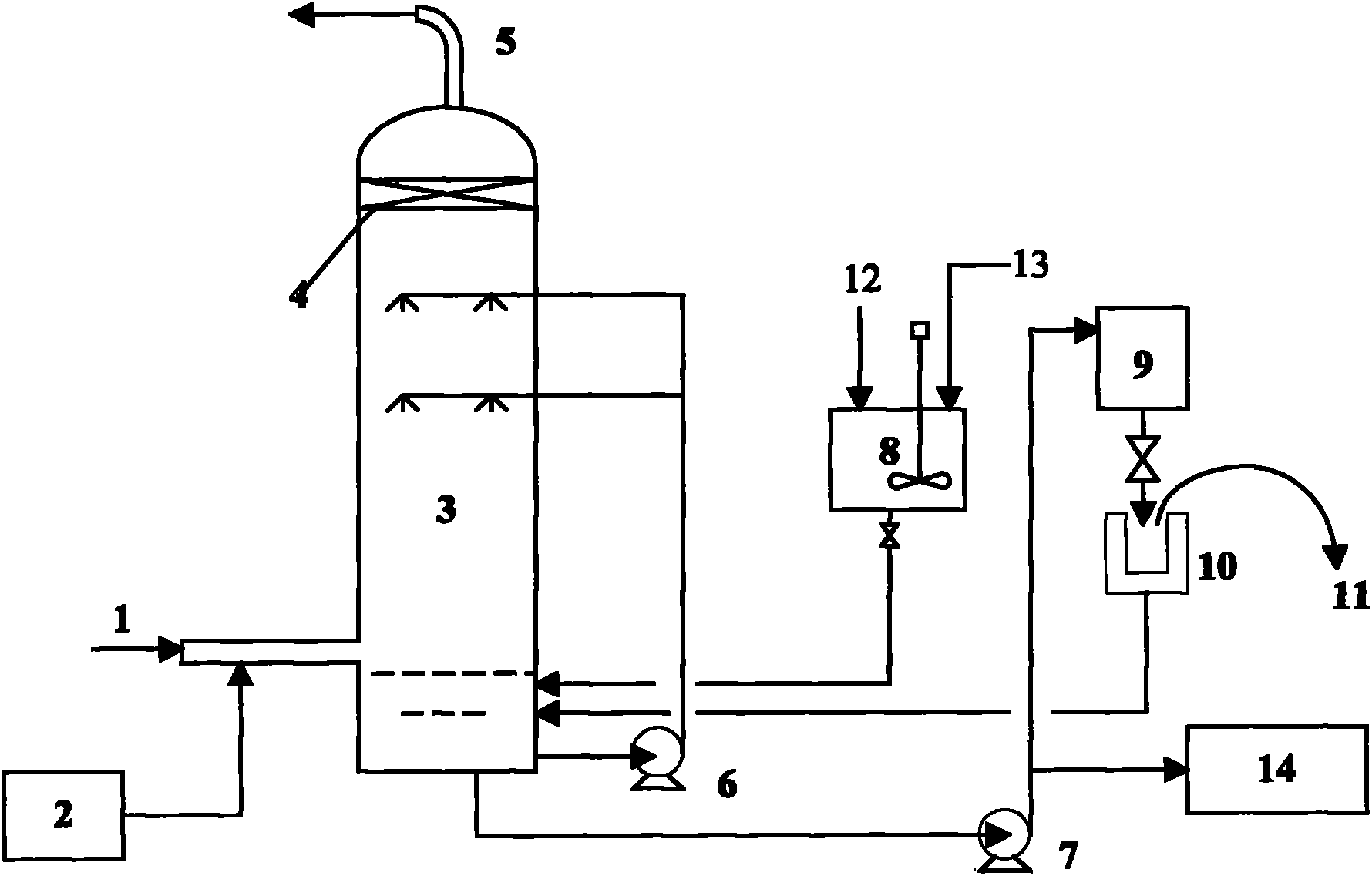

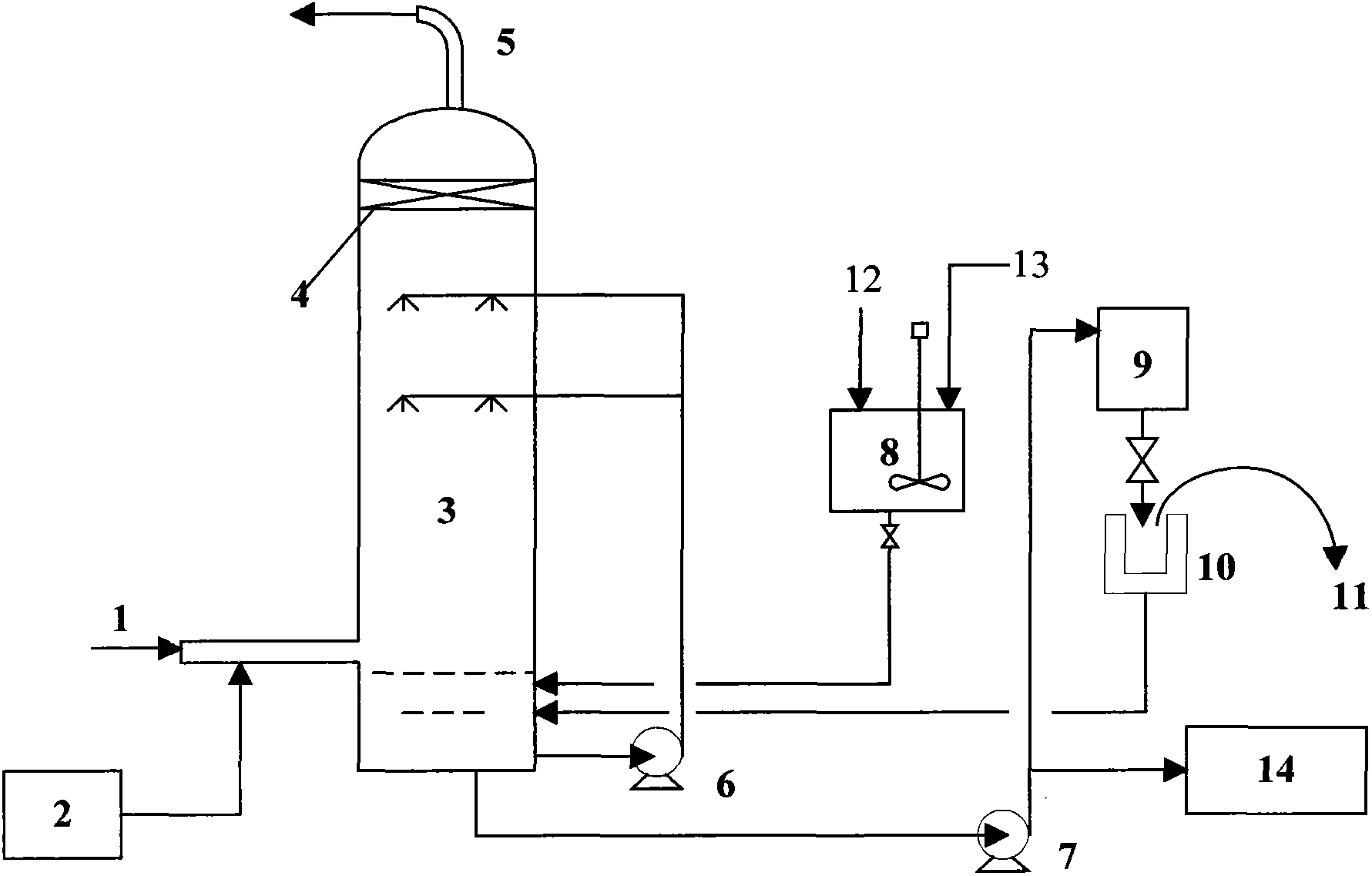

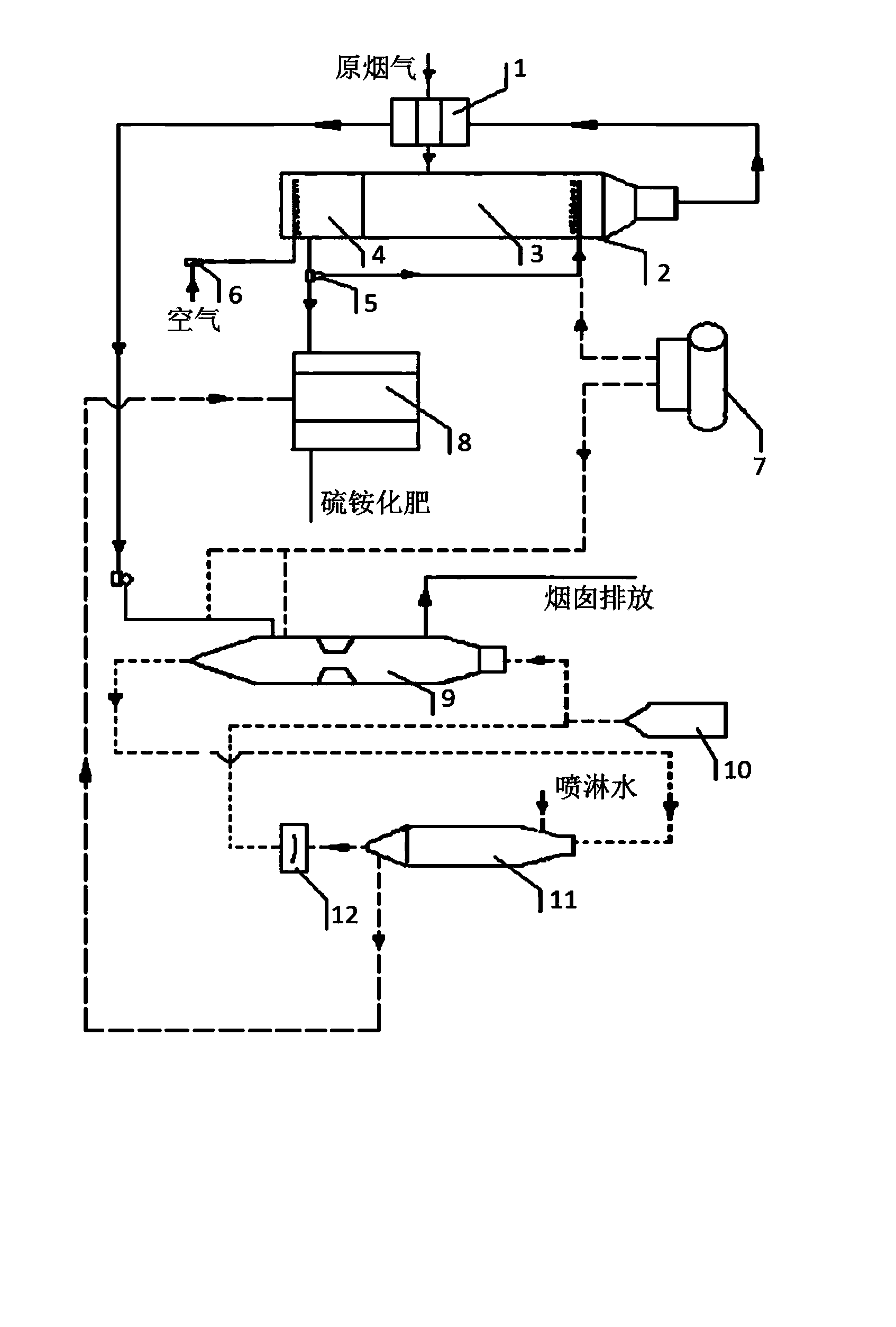

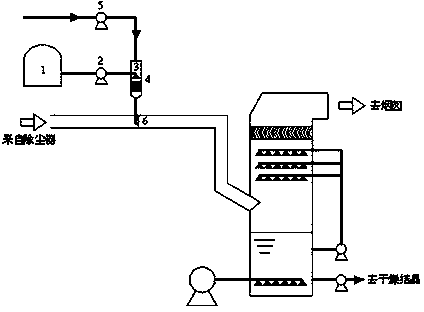

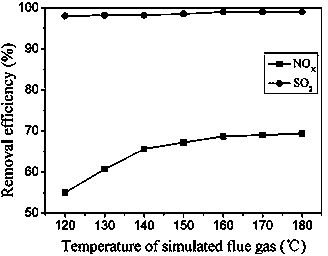

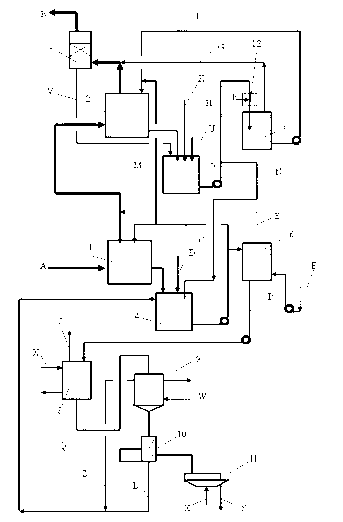

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

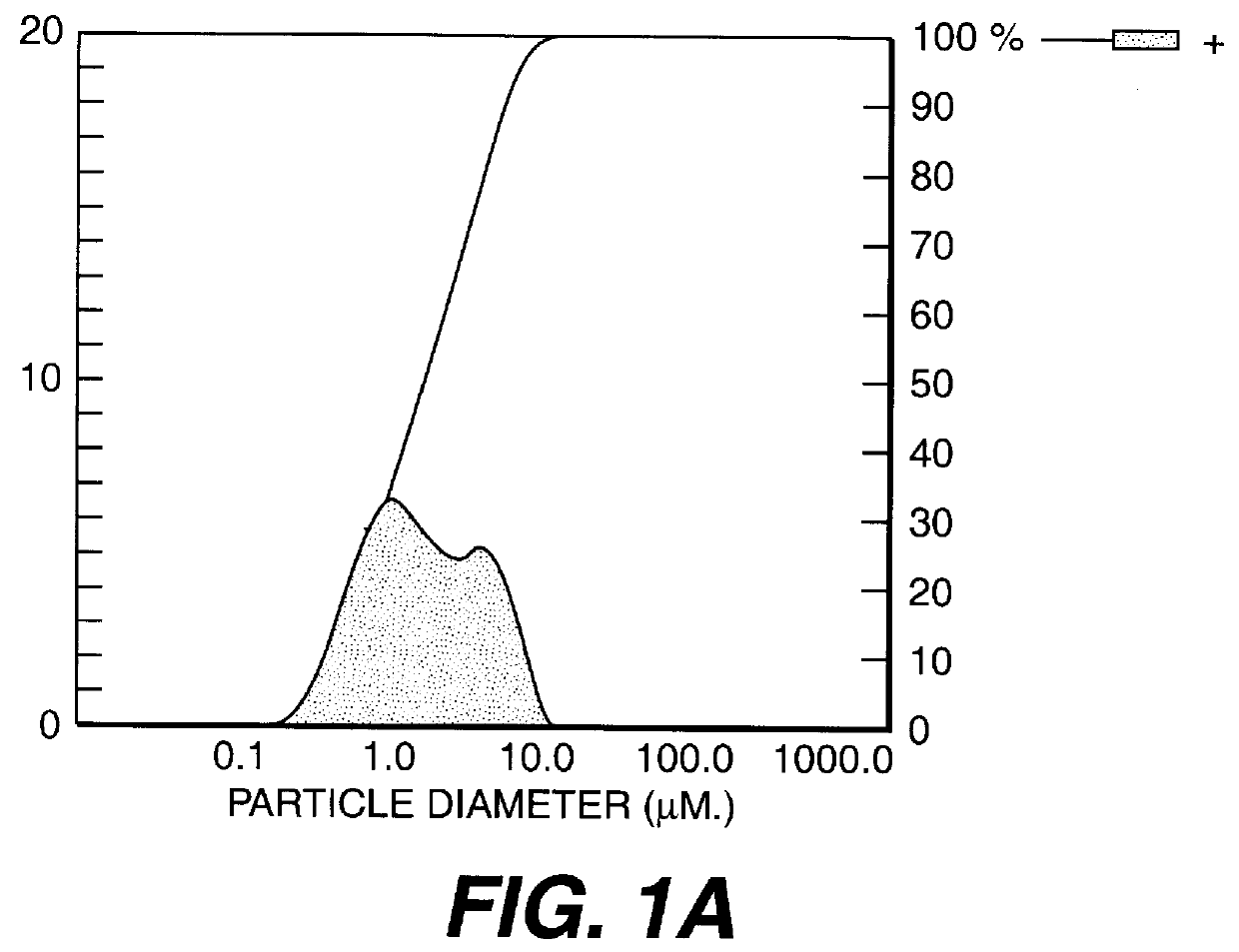

Calcium carbonate precipitation method

InactiveUS6036933ACalcium/strontium/barium carbonatesMagnesium carbonatesNitratePrecipitated calcium carbonate

PCT No. PCT / GB96 / 00488 Sec. 371 Date Oct. 22, 1997 Sec. 102(e) Date Oct. 22, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 26902 PCT Pub. Date Sep. 6, 1996A method for producing precipitated calcium carbonate by reacting an aqueous solution of calcium nitrate [Ca(NO3)2] with an aqueous solution of ammonium carbonate [(NH4)2CO3] and allowing calcium carbonate to precipitate from the resultant mixture containing nitrate [NH4NO3] in the mother liquor, the process being characterized in that: (i) the calcium nitrate [Ca(NO3)2)] solution utilized in the processes is prepared by slaking lime [CaO] in water in the presence of ammonium nitrate [NH4NO3] to form calcium nitrate [Ca(NO3)2] and ammonium hydroxide [NH4OH] in solution, filtering the solution to render it solids free, and heating the filtrate to dissociate the ammonium hydroxide [NH4OH] and to drive ammonia gas [NH3] from the solution; (ii) the ammonium carbonate (NH4)2CO3 solution utilized is prepared by absorbing ammonia gas [NH3] and carbon dioxide gas [CO2] in water, the ammonia gas preferably being derived from the step in (i) above in which the Ca(NO3)2 solution is heated; and (iii) the ammonium nitrate used is derived from the precipitation phase during which calcium carbonate is precipitated from the mother liquor containing ammonium nitrate.

Owner:PRETORIA PORTLAND CEMENT COMPANY +1

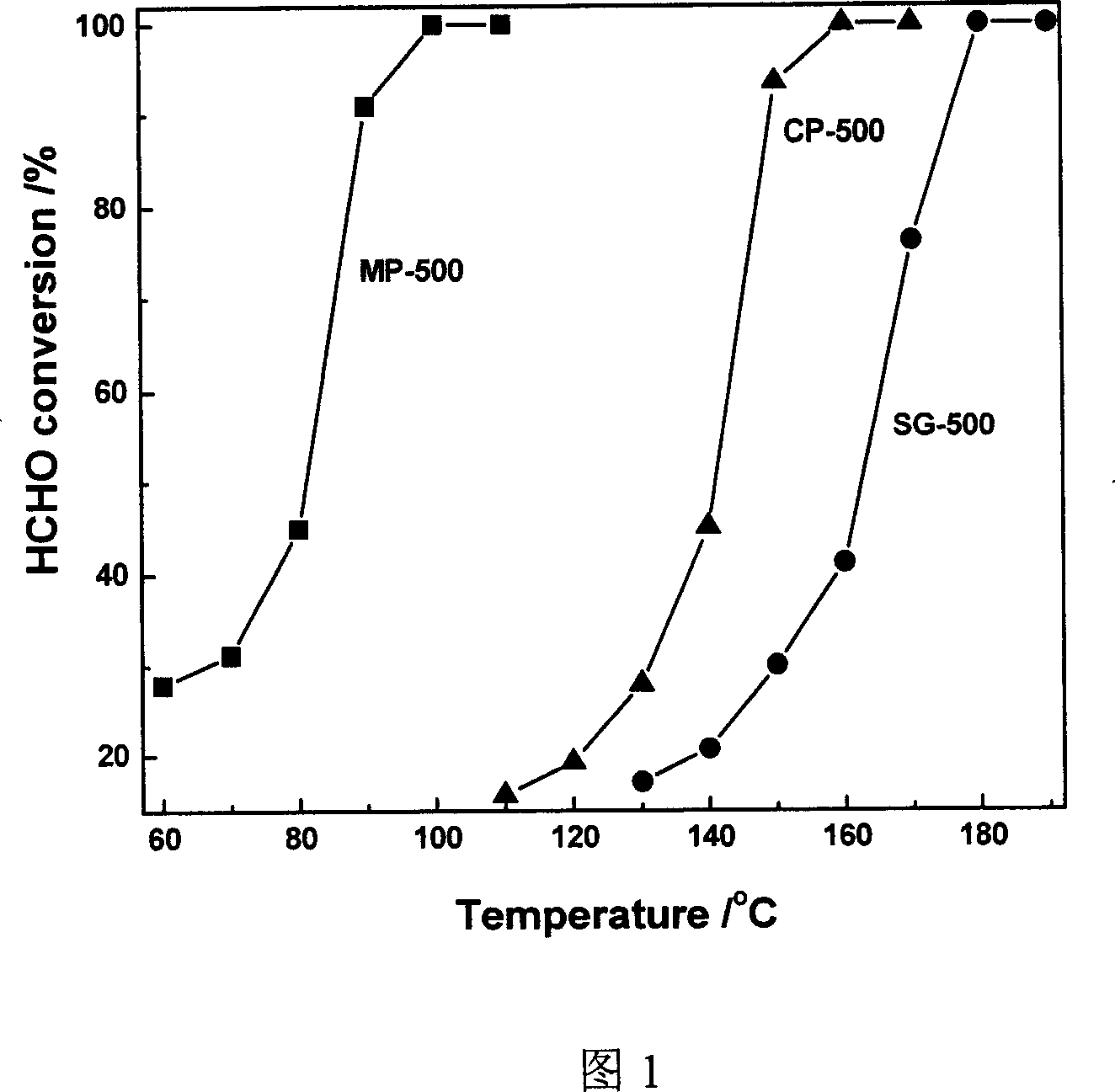

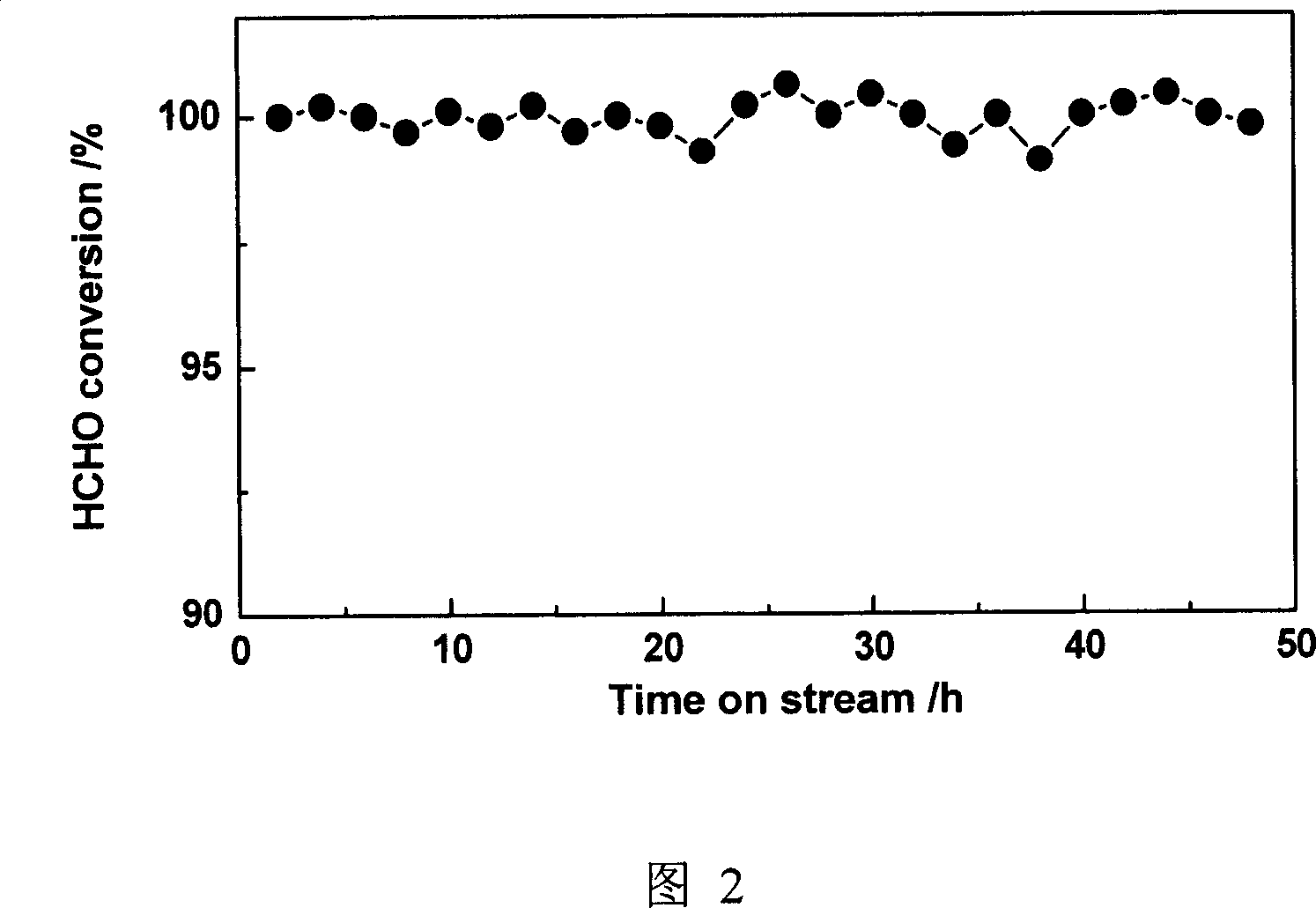

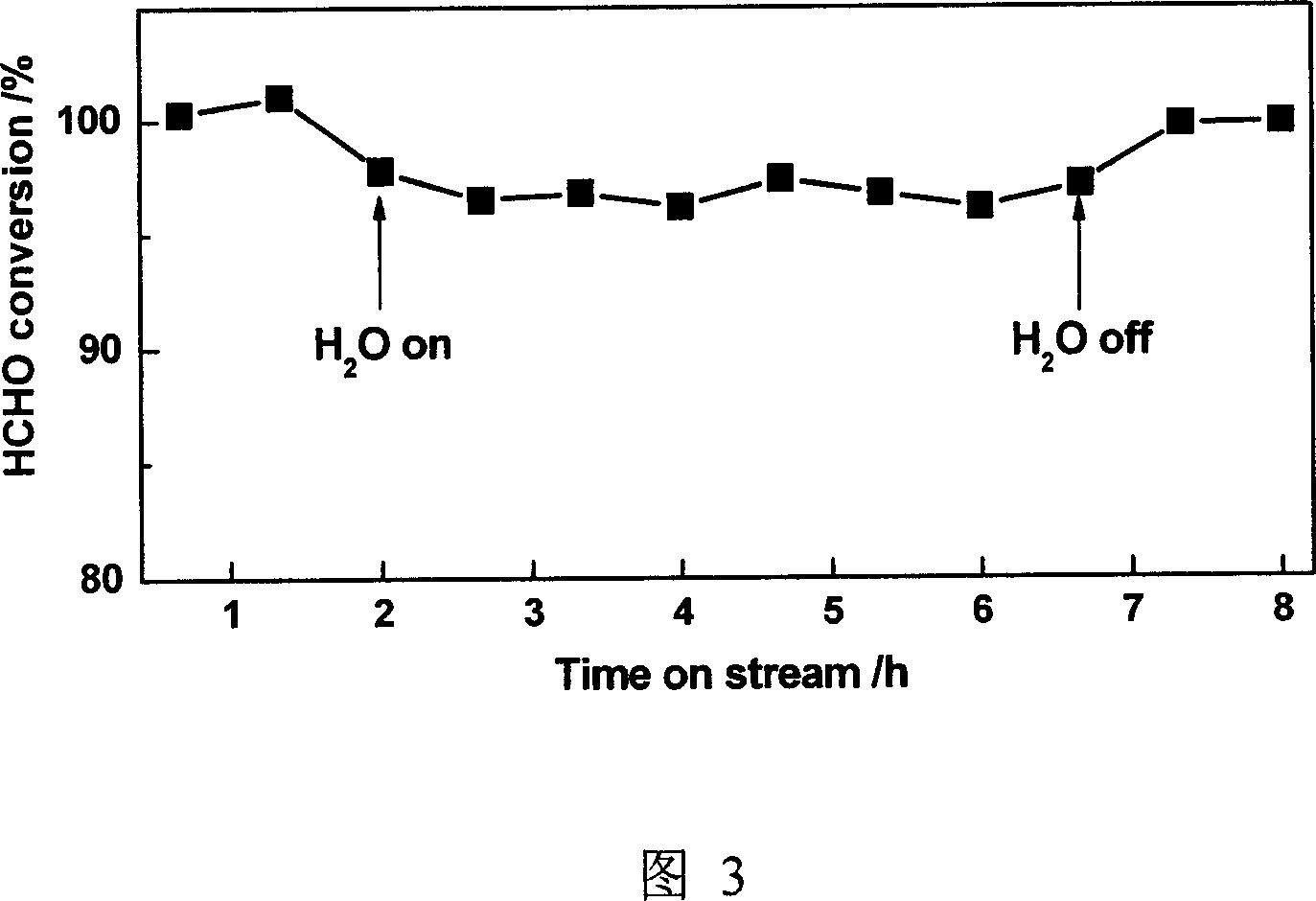

Manganese cerium composite oxide catalyst, its production and use

InactiveCN101028595AStrong interactionHigh activityDispersed particle separationCatalyst activation/preparationNitrateManganese

A composite Mn-Ce oxide catalyst for oxidizing the form-aldehyde into CO2 and H2O is prepared through adding soluble manganese nitrate in the solution of potassium permanganate and cerium ammonium nitrate while stirring, adding potassium hydroxide, stirring to obtain deposit, filtering, washing, drying at 80-120 deg.C and calcining.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

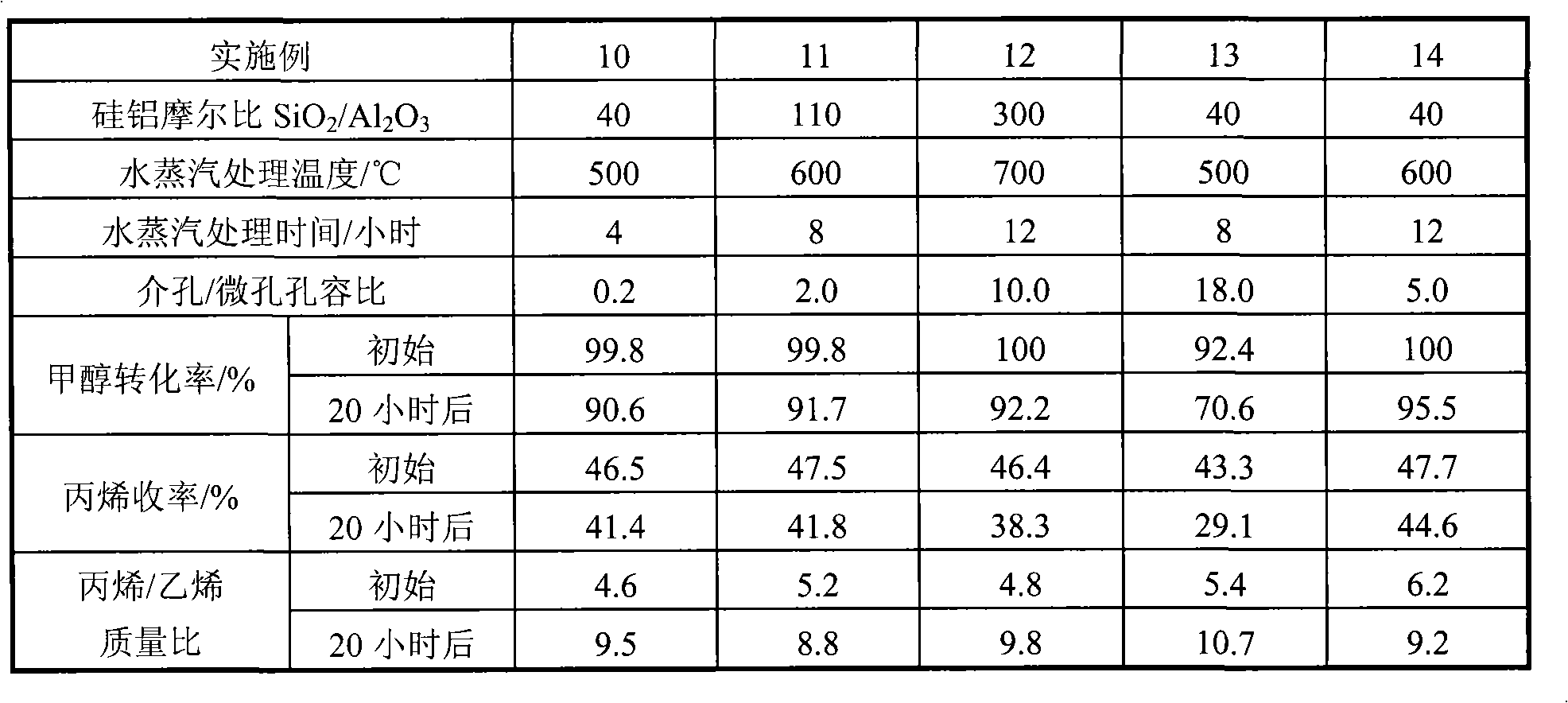

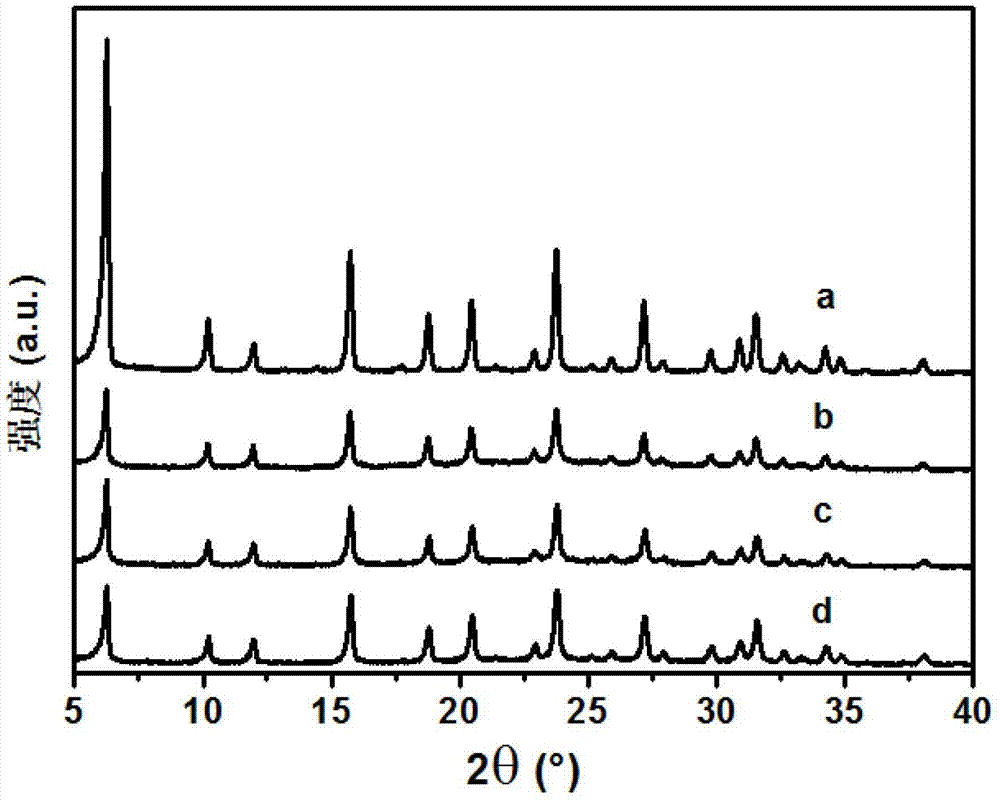

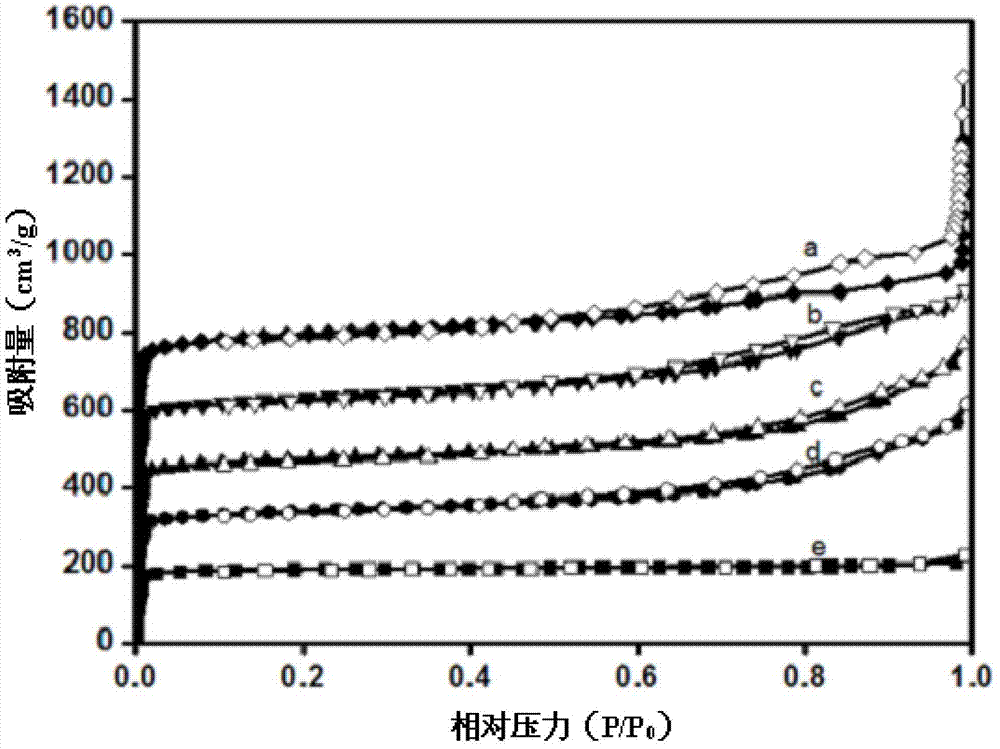

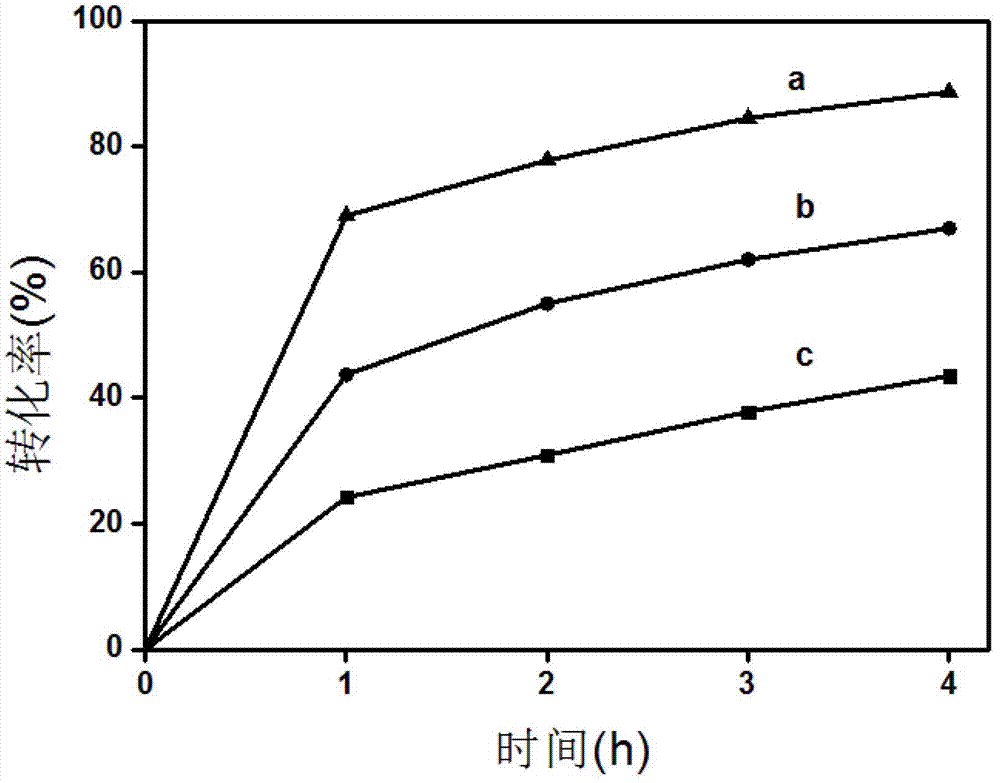

ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

ActiveCN101279282AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMaleopimaric acidAmmonium nitrate

The present invention relates to a ZSM-5 mesoporous molecular sieve catalyst used for manufacturing propylene by methanol and a preparation method thereof, which mainly solves the problems of low propylene selectivity, low propylene / ethylene mass ratio as well as poor thermal stability of molecular sieve and poor water thermal stability in the prior art. The present invention adopts the technical proposal of adopting ZSM-5 mesoporous molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 20 to 100 percent as well as at least one caking agent selected from SiO2, clay and Al2O3 to extrude, tablet or spray into shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid or maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of mesoporous-containing Y-shaped molecular sieve

ActiveCN103172082AMicroporosity unchangedGood hydrothermal stabilityFaujasite aluminosilicate zeoliteMolecular sieveOrganic acid

The invention relates to a preparation method of a mesoporous-containing Y-shaped molecular sieve, and relates to a preparation method of a Y-shaped molecular sieve. The preparation method aims to solve the problems of small pore diameter and pore volume of the Y-shaped molecular sieve prepared through the traditional method. The preparation method comprises the following steps of: 1, preparing a sodium type Y-shaped molecular sieve; 2, preparing an ammonium type Y-shaped molecular sieve; 3, processing through an organic acid water solution; 4, processing through NaOH; and 5, processing through an ammonium nitrate water solution so as to obtain the mesoporous-containing Y-shaped molecular sieve. The mesoporous-containing Y-shaped molecular sieve is synthesized through a simple and effective method under a moderate condition, contains abundant mesoporous, is unchanged in microporosity, achieves the volume of the mesoporous at 0.5-1.5 mL / g, greatly promotes the macromolecule to approach a catalytic active center and is favorable for reaction mass transfer through more concentrated pore diameter distribution, has the advantages of adjustable ratio of silicon and aluminum contained in a framework and good hydrothermal stability and can be used as a catalyst carrier or directly used as a catalyst. The preparation method disclosed by the invention can be used for preparing the mesoporous-containing Y-shaped molecular sieve.

Owner:HARBIN INST OF TECH

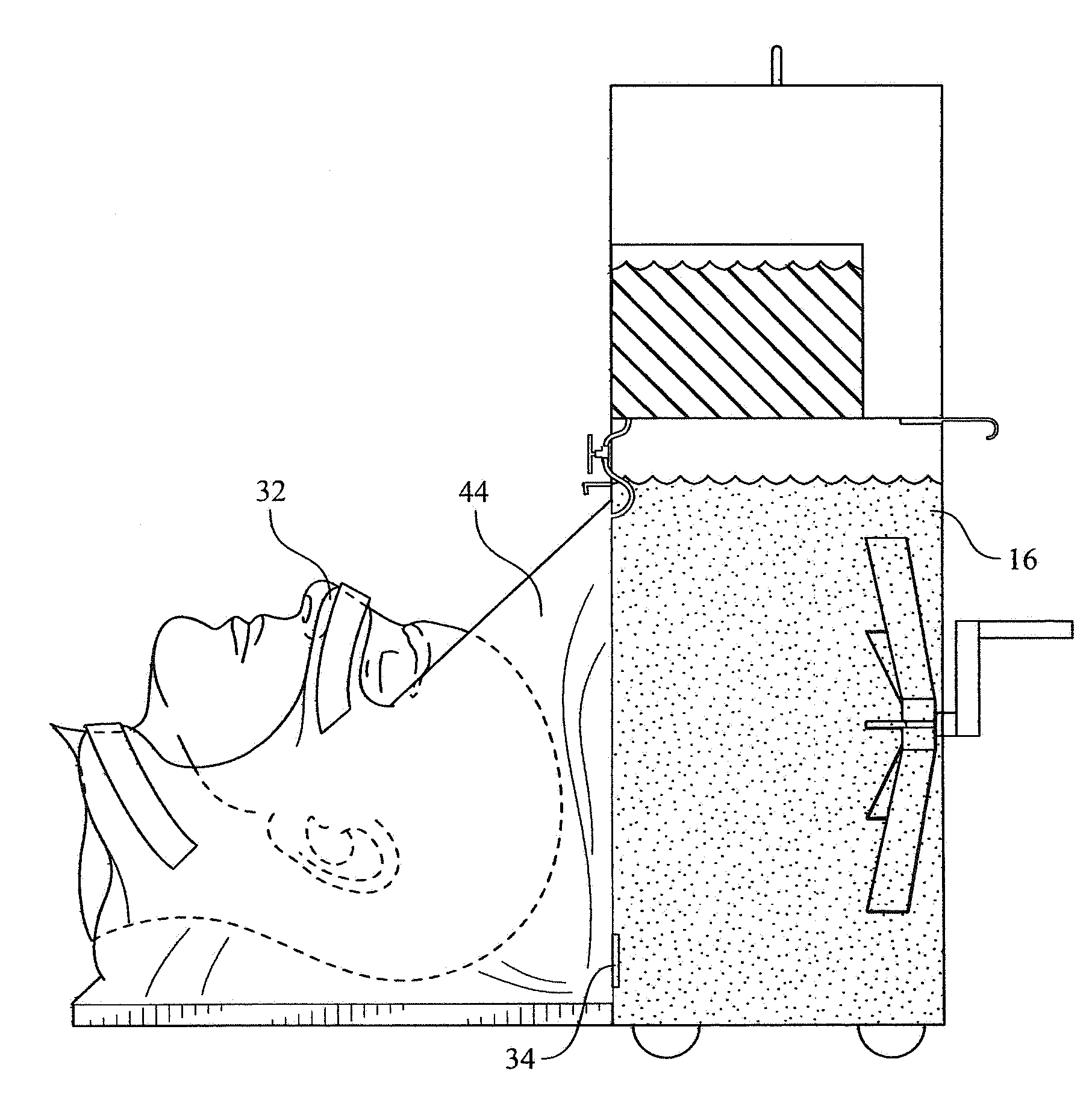

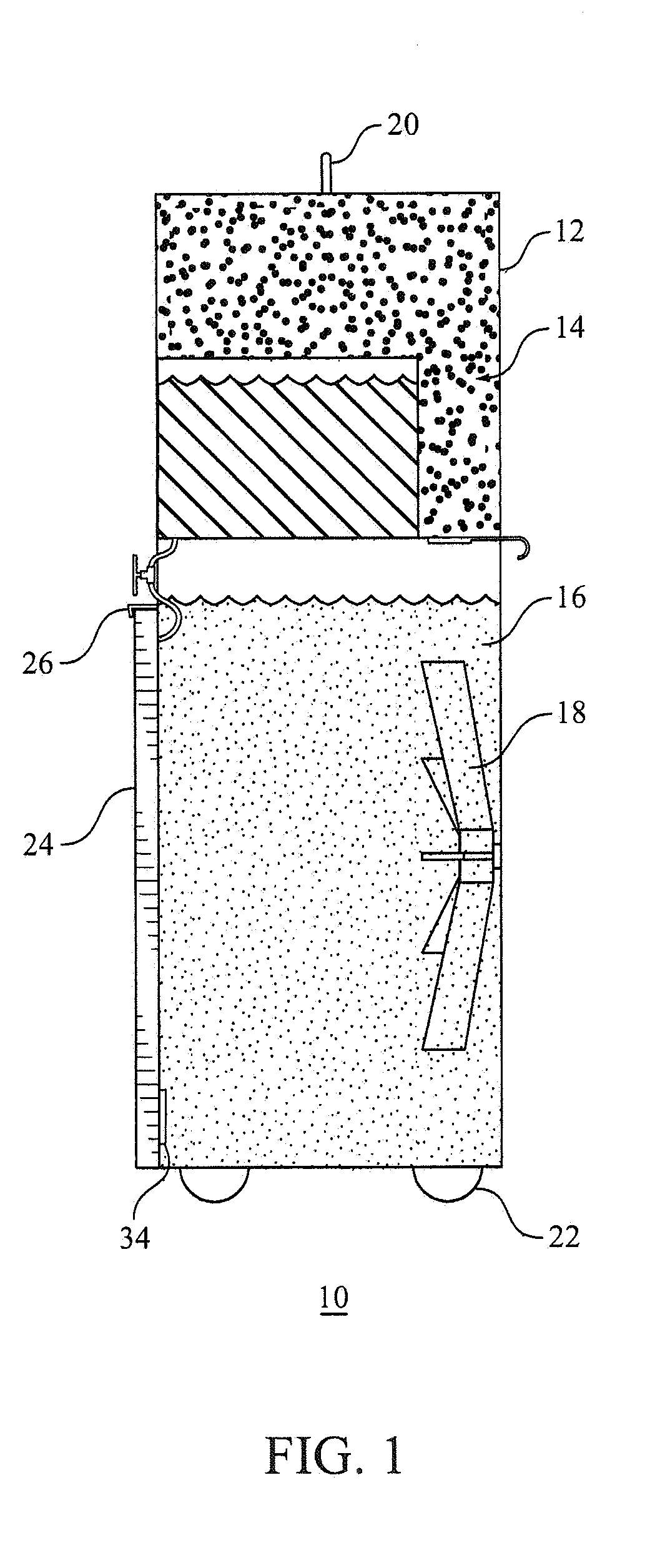

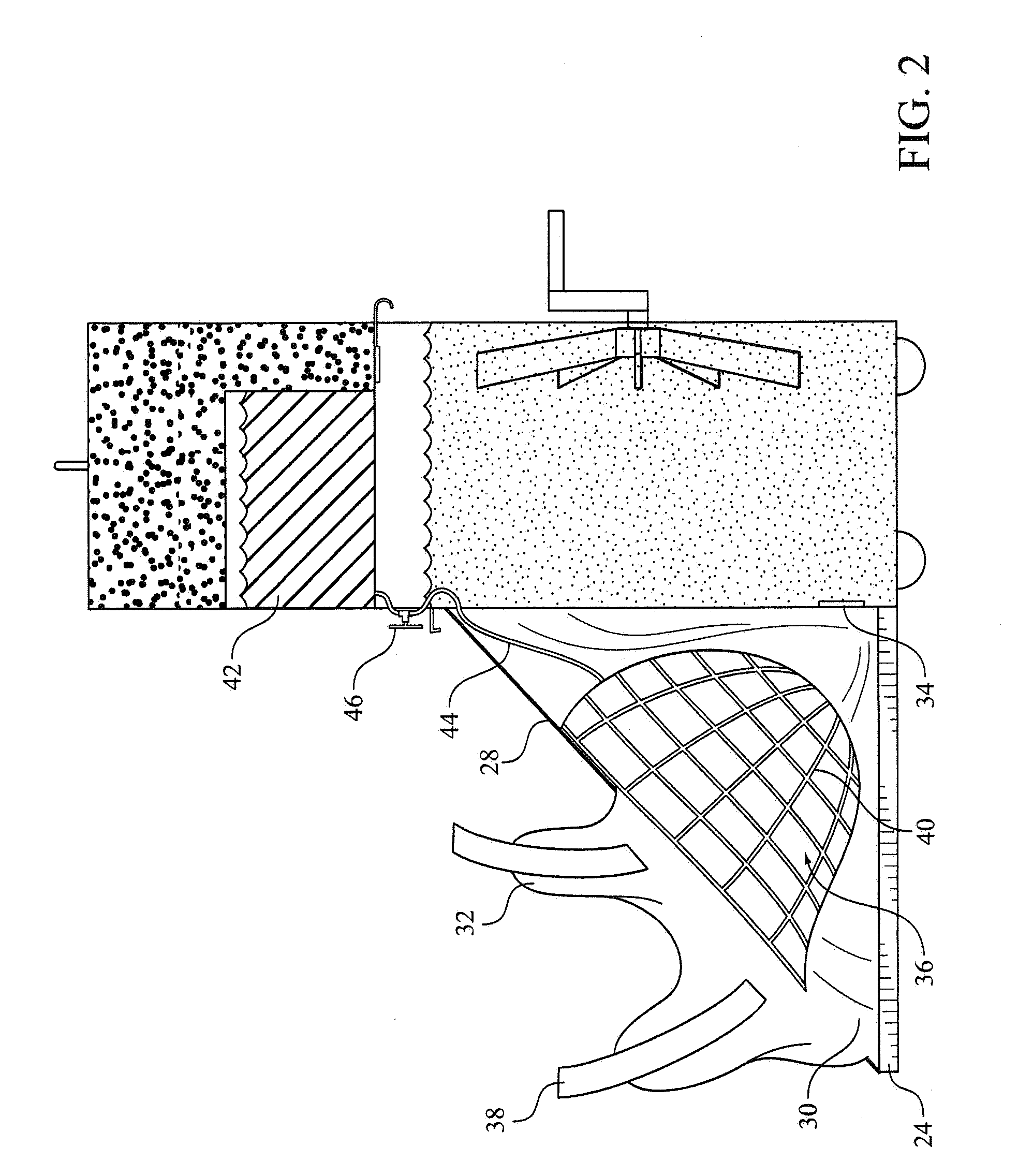

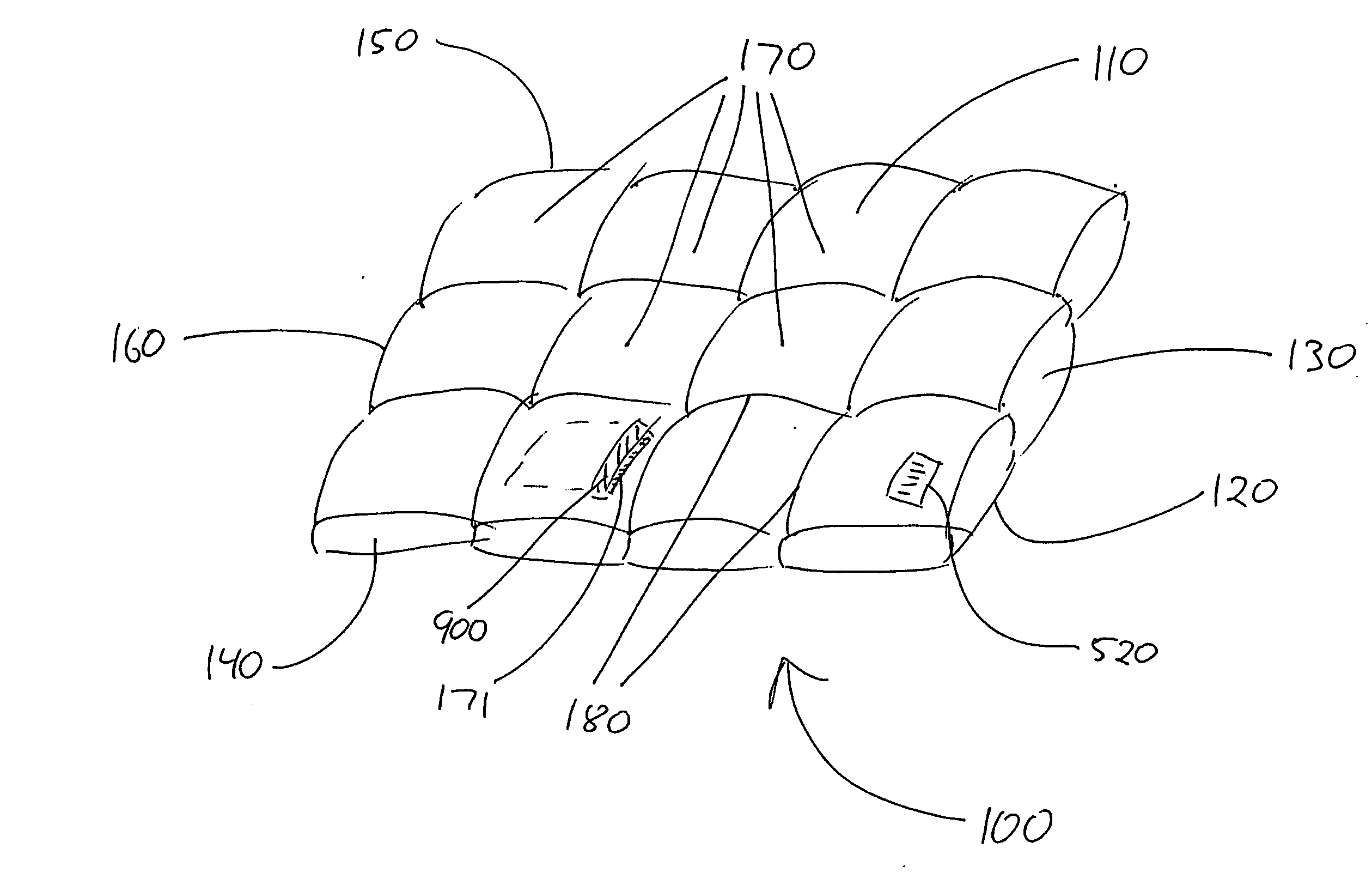

Apparatus and method for preventing brain damage during cardiac arrest, cpr, or severe shock

InactiveUS20090276018A1Rapid coolingImprove hypothermiaTherapeutic coolingTherapeutic heatingInjury brainCardiorespiratory arrest

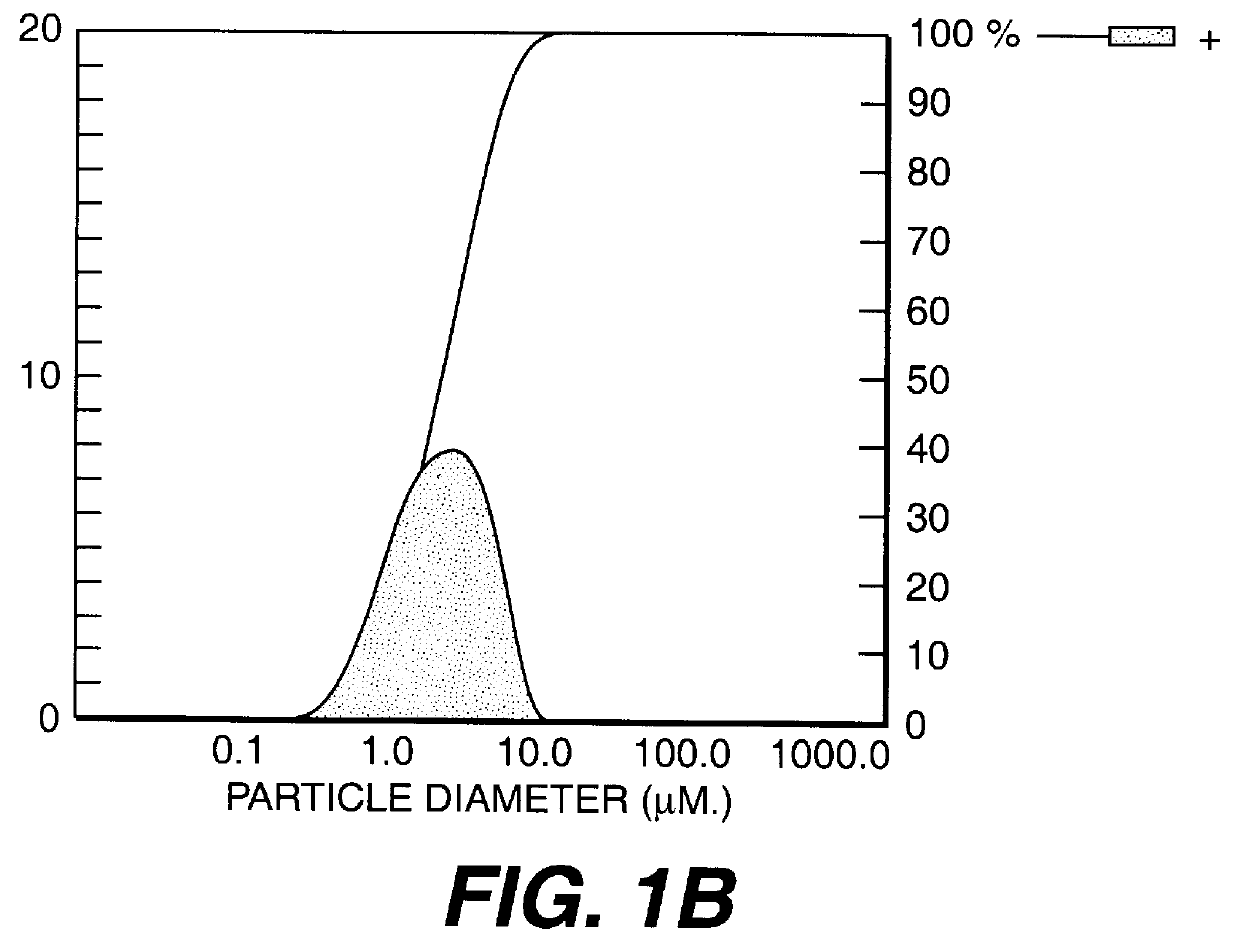

Apparatuses and methods for the cooling of the cranial and extracranial portions of a patient in need thereof. The apparatuses and methods of the present invention preferably employ a head cooling apparatus which includes a watertight shroud for the head and which needs no refrigeration. In certain preferred embodiments, the apparatuses of the present invention are collapsible and possess a reduced profile. In some presently preferred embodiments, the present invention includes a hammock that supports the head. In some embodiments, the present invention includes a shroud that lies behind the head with optional portions that may be drawn over the patient's neck and cranial area. The apparatuses and methods of the present invention also provide an improved mechanism for cooling the cranial and extracranial areas through the use of a novel distribution of endothermic solids (e.g. ammonium nitrate). The present invention provides a novel distribution of ammonium nitrate pellets that preferably includes multiple populations solid ammonium nitrate, preferably including small diameter (e.g., powdered) and larger diameter (e.g., 7 millimeter) ammonium nitrate to allow water initially to be cooled very quickly, thereby facilitating the rapid cooling of the cranial and extracranial areas, while at the same time producing extended hypothermia.

Owner:BRADER ERIC WILLIAM

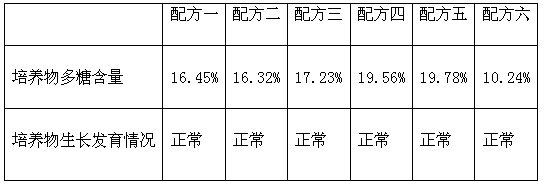

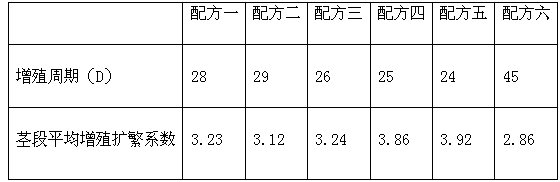

Dendrobium officinale culture solution

ActiveCN102976848AHigh in polysaccharidesHigh in amino acidsFertilizer mixturesEthylenediamineManganese

The invention discloses a Dendrobium officinale culture solution and belongs to the technical field of agricultural planting. The culture solution comprises the following ingredients: potassium nitrate, ammonium nitrate, magnesium sulfate, manganese sulfate, zinc sulfate, monopotassium phosphate, copper sulfate, potassium iodide, cobalt dichloride, boric acid, sodium molybdate, vitamin VB1, vitamin VB6, vitamin VB5, glycine, ferrous sulfate, disodium ethylenediamine tetraacetic acid, calcium chloride, naphthylacetic acid, mashed banana, mashed potato, white sugar, inositol, and powdered agar. The dendrobium officinale culture solution is reasonable in compatibility, can provide comprehensive nutrition for a Dendrobium officinale stem, fast promote the stem to grow out of a root, increase the polysaccharide content and the amino acid content in the Dendrobium officinale, shorten the time for culturing the Dendrobium officinale stem to a complete plant to about 25 days, and significantly improve the transplanting survival rate of the Dendrobium officinale.

Owner:杭州富阳文曲生态农业开发有限公司

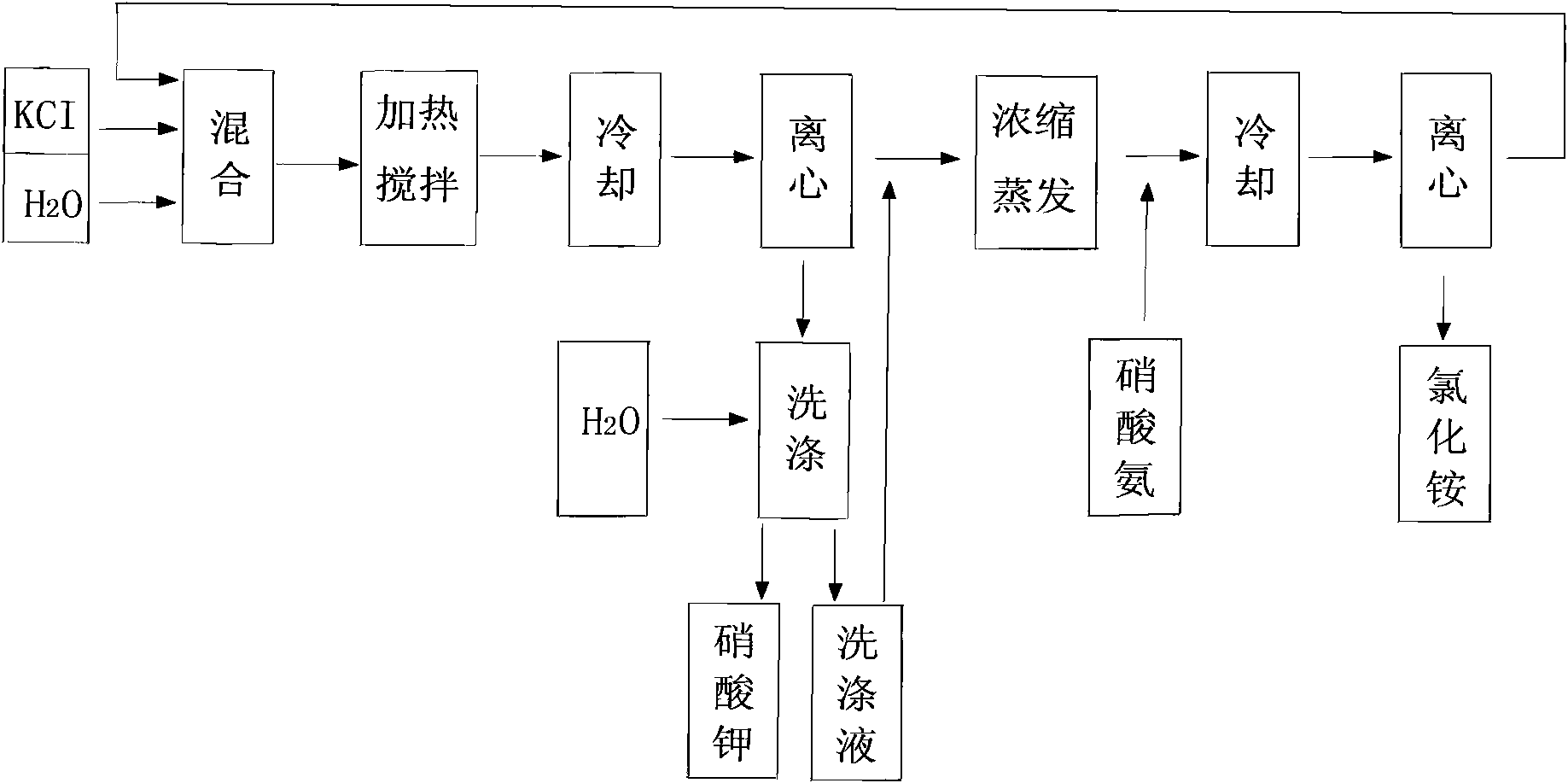

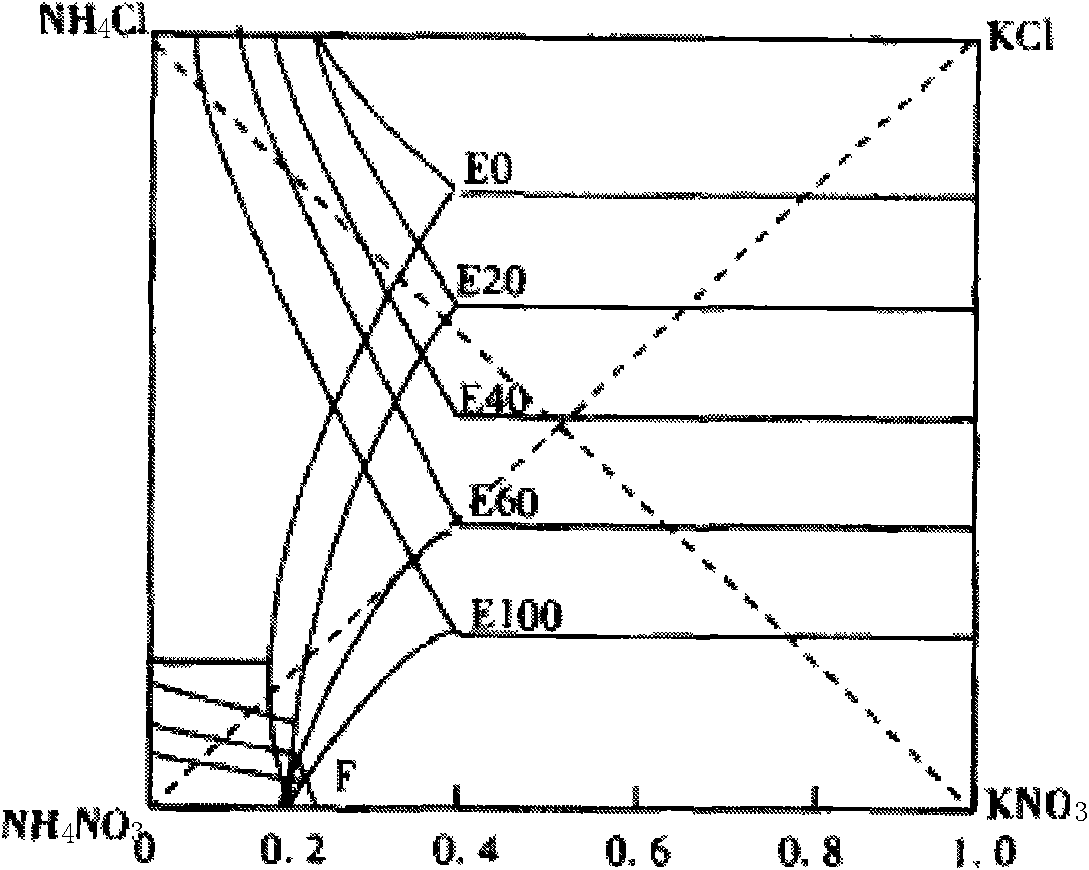

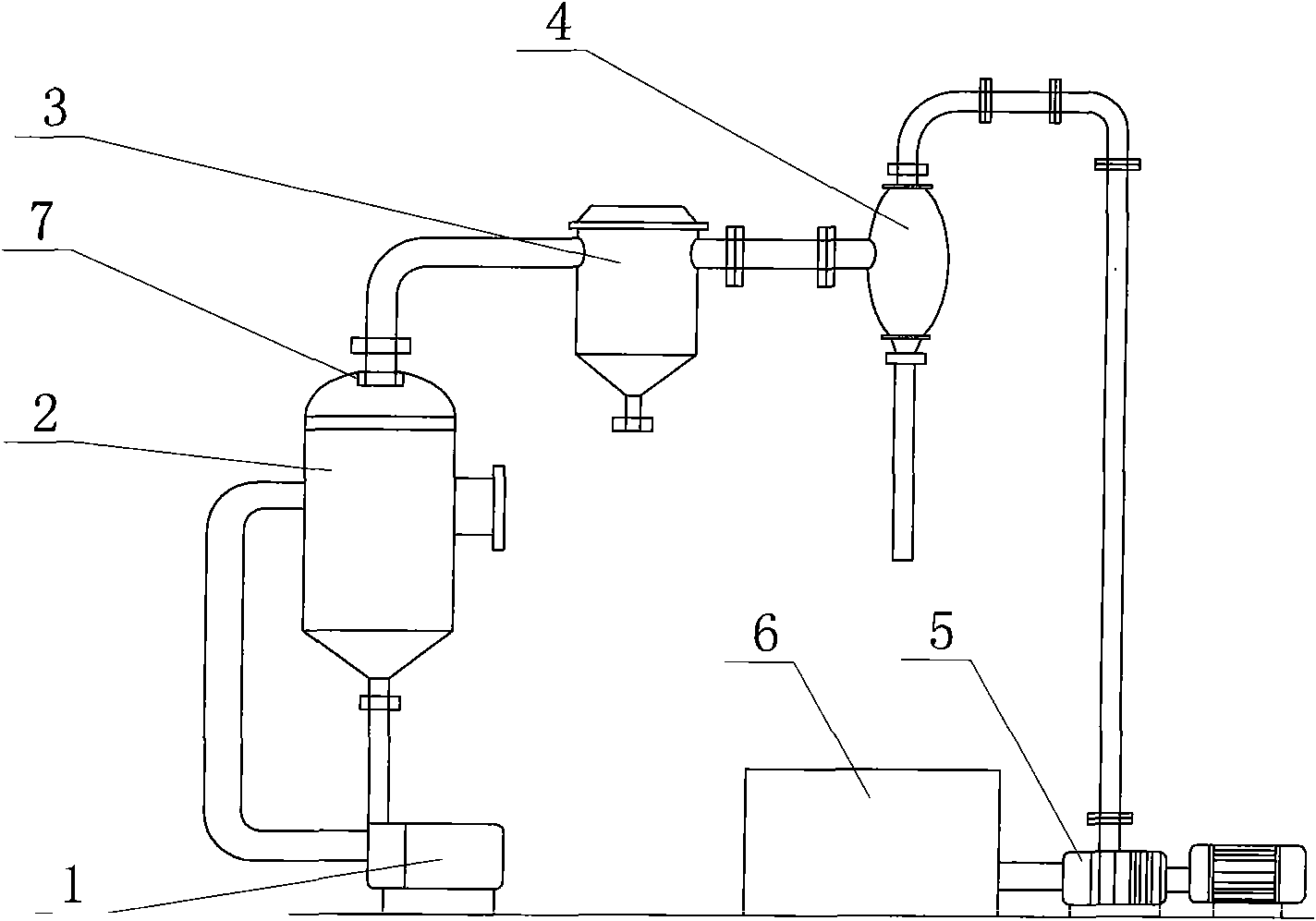

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

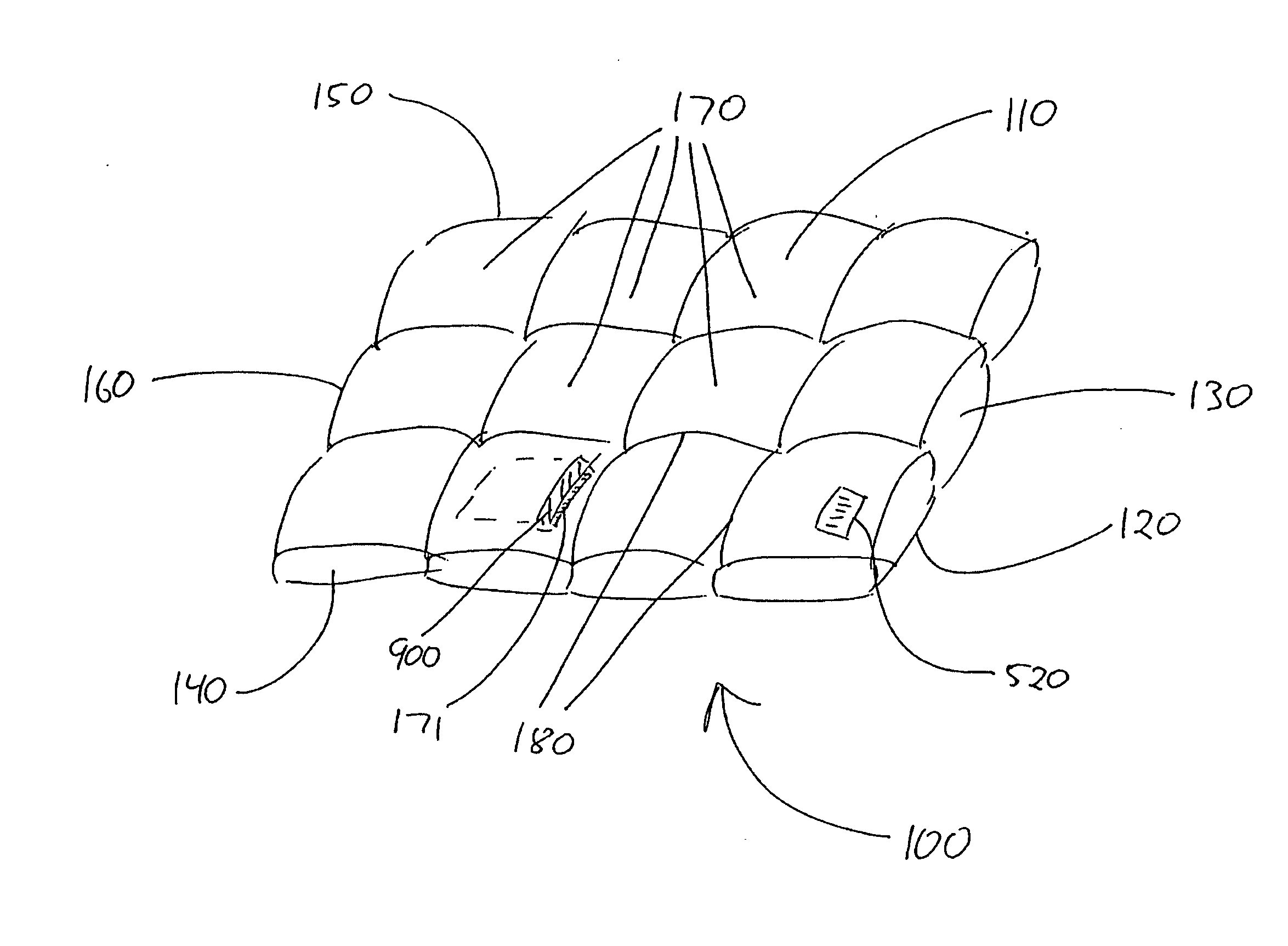

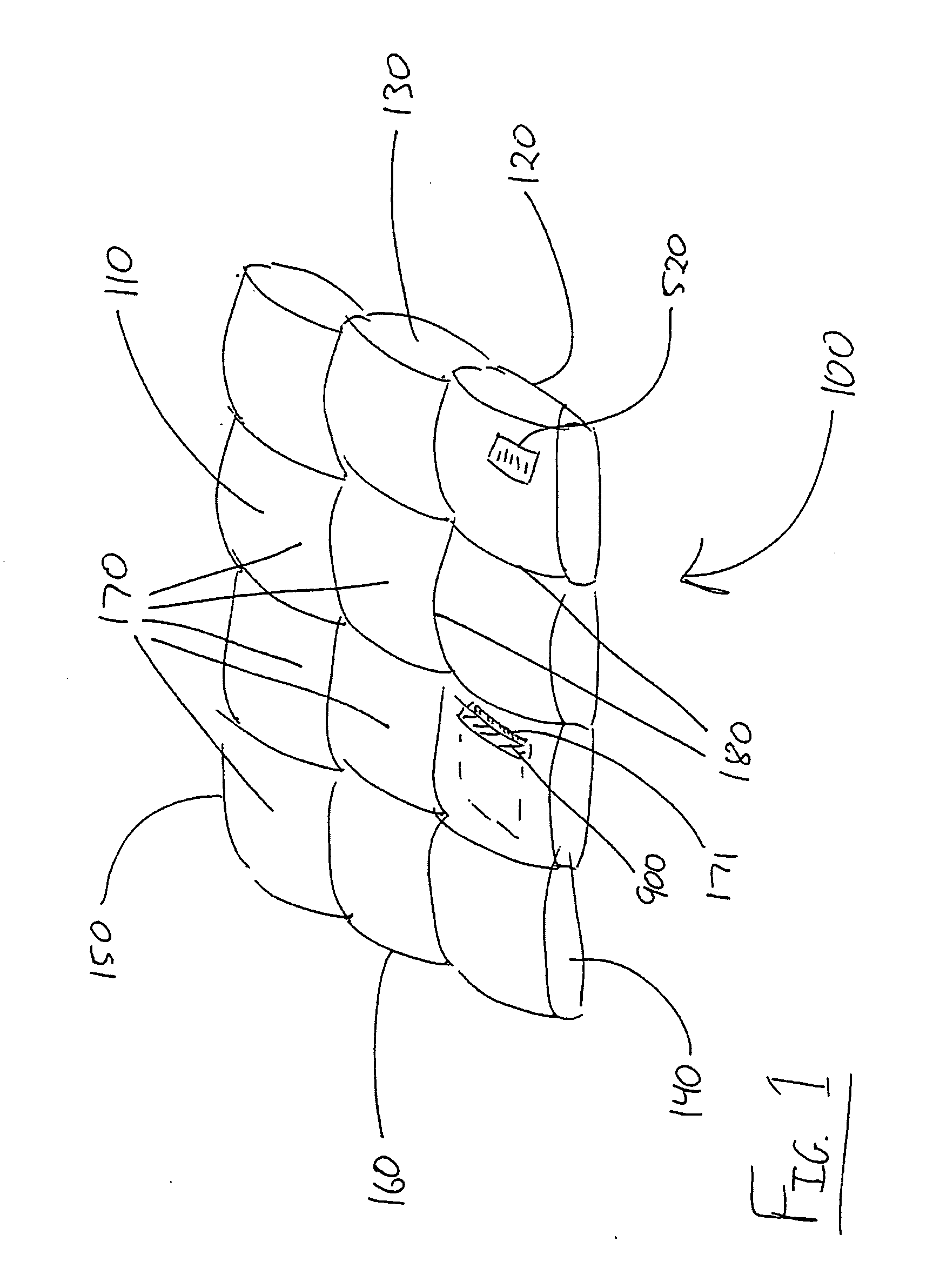

Cooling blanket

The invention provides a cooling blanket useful for lowering the body temperature of a mammal, such as a human. The cooling blanket may be particularly useful when used in connection with a deleterious cardiac event, such as myocardial infarction. The cooling blanket is activated when reagents, such as ammonium nitrate, urea, and / or water, are placed in contact with one another; thereby producing an endothermic reaction.

Owner:COOL MEDICAL INNOVATIONS

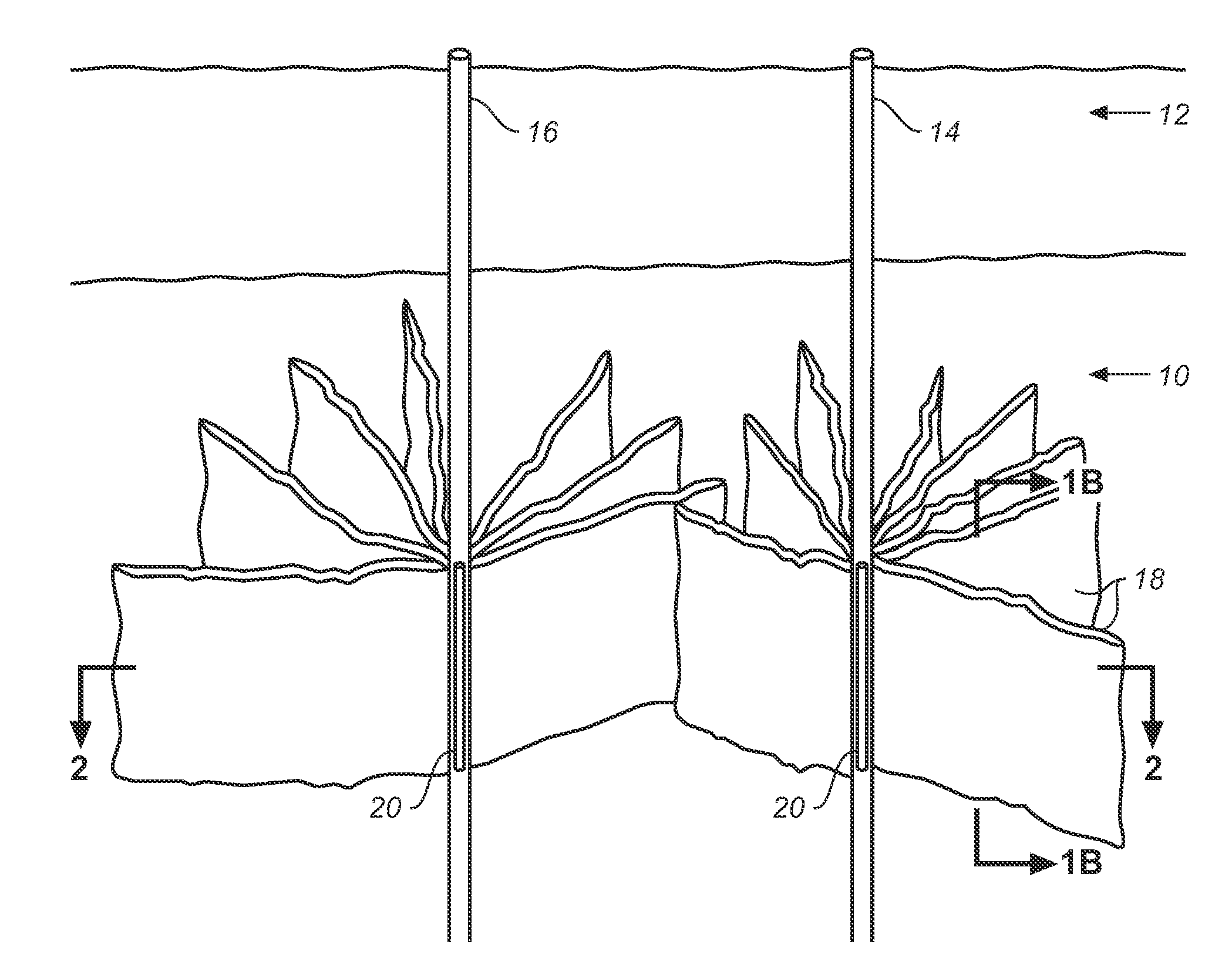

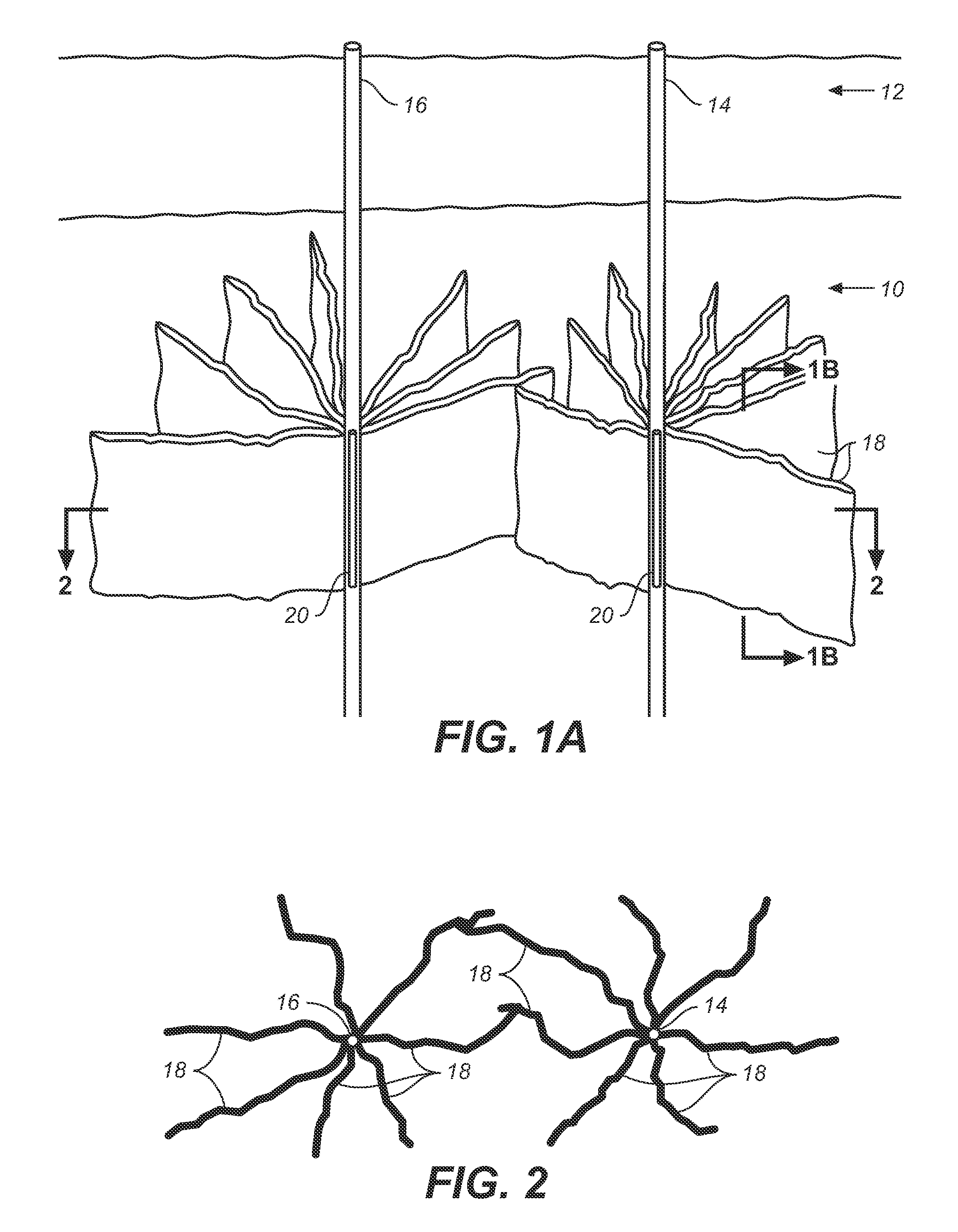

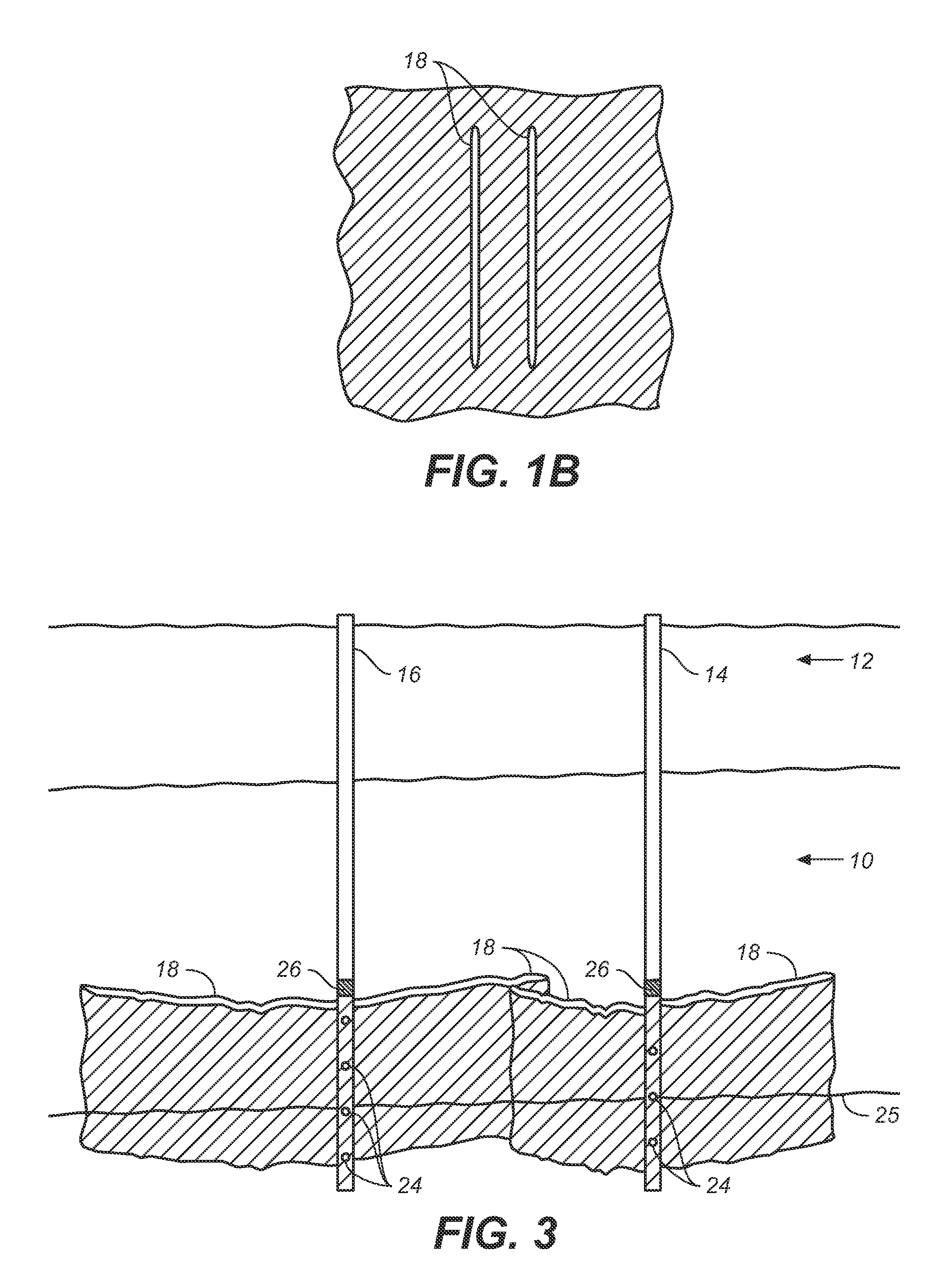

Process for two-step fracturing of oil shale formations for production of shale oil

A process for in situ production of shale oil comprises fracturing the target zone 10 of an shale oil formation using a two step approach. First, an initial set of fractures 18 is developed in the formation by using high pressure gas pulses. Second, a secondary set of fractures 28 extending and further fracturing the initial set of fractures 18 is created using a modified ANFO mix 22 wherein rubber particles acting as solid fuel are blended in with ammonium nitrate and fuel oil. The solid fuel enhances the fracturing characteristics of ANFO while minimizing its crushing and compacting tendencies. Hot high pour point oil is then injected into the formation and forced into the receptor well 16 where it is pumped to the surface. By circulating oil in the formation at carefully controlled temperatures, kerogen can be decomposed at the optimum rate to maximize the amount of oil recovered and yield high quality shale oil. High pour point oil reaching cooler extremities of the fractured formation will solidify creating an impermeable perimeter barrier 34 around the target zone 10.

Owner:YOUNG MICHAEL ROY

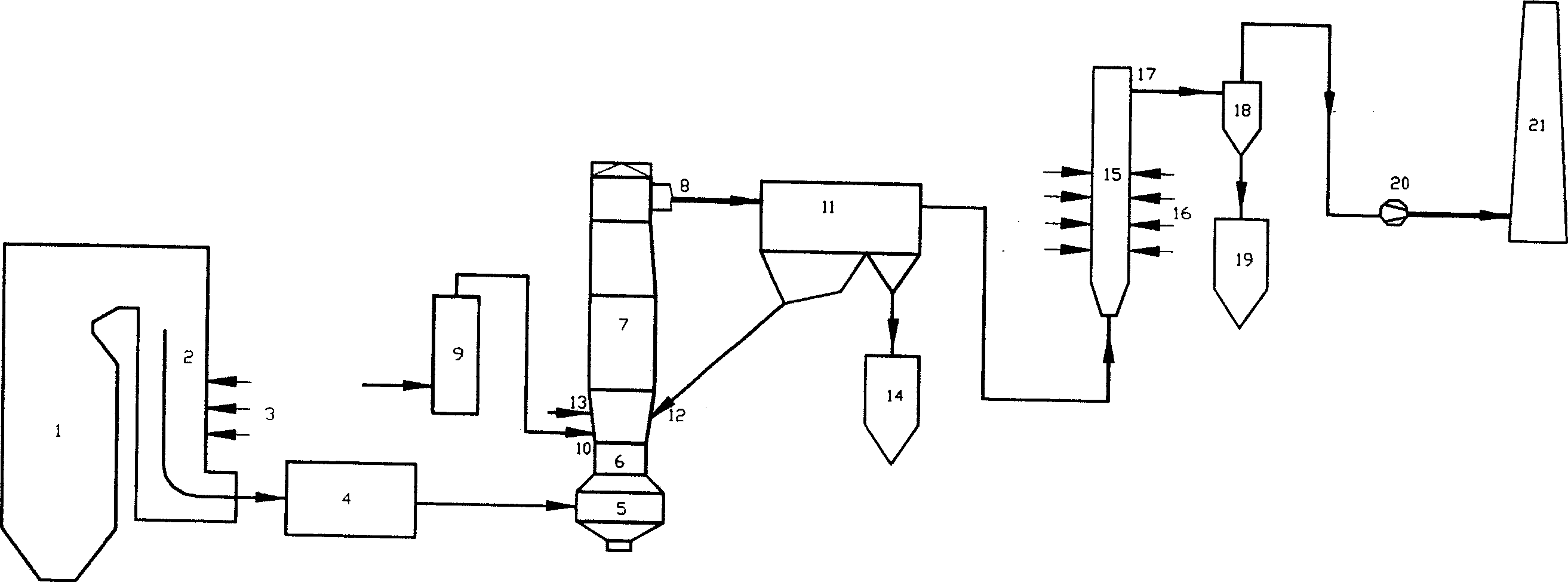

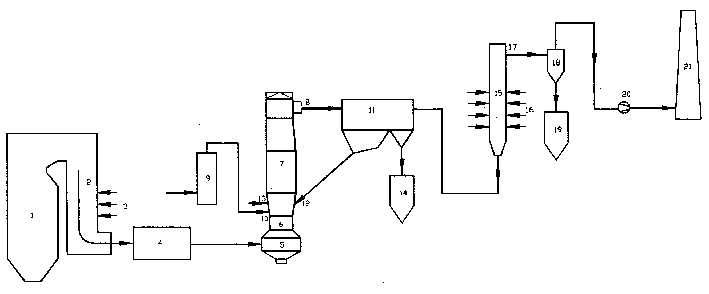

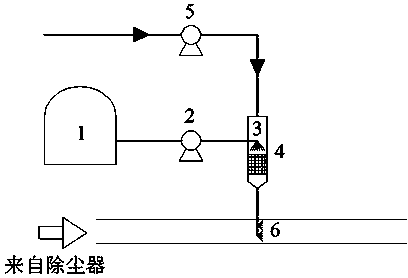

Dry smoke cleaning process for desulfurizing and denitrating simultaneously and its system

InactiveCN1589954ASimplify stand-alone removal systemsSimple processDispersed particle separationSprayerNitric oxide

A dry method for simultaneously desulfurizing and denitrating fume includes using H2O2 or methanol to convert the NO in fume to NO2, using Ca-base particles as desulfurizing agent to react with SO2 to obtain calcium sulfate, and using ammonia water or urea as denitrating agent to react with NO2 to obtain ammonium nitrate and clean fume. Its apparatus is composed of additive sprayer, desulfurizing system and denitrating system.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Method for simultaneously desulfurizing, denitrating and purifying flue gas

InactiveCN103861439ACompliance with emission standardsAdaptableAmmonium nitratesProductsFuranChemical industry

The invention discloses a method for simultaneously desulfurizing, denitrating and purifying flue gas and belongs to the field of flue gas purification. The method comprises the following steps: spraying the flue gas at the temperature of 50-90 DEG C by using ammonia absorption liquid to obtain a solution, and aerating and oxidizing the solution to obtain an ammonium sulfate solution; exchanging heat between the obtained flue gas and the original flue gas, heating to 120-350 DEG C, and supplementing ammonium hydroxide; converting NO and NO2 in the flue gas into N2 by addition or non-addition of an activated carbon material of a catalyst; performing reaction on the remaining SO2, ammonia and water vapor to generate ammonium sulfate; adsorbing mercury, dioxin, furan, a volatile organic compound, ammonia sol and other trace toxic substances by activated carbon; and regenerating the activated carbon after absorption and adsorption by using washing and heating methods. The method has the advantages that the process is simple and convenient, and the desulfurizing and denitrating efficiency is high; various toxic substances and fine particles in the flue gas can be adsorbed, a good prevention effect on PM2.5 pollution of industrial flue gas is achieved, ammonium sulfate and ammonium nitrate fertilizer byproducts are obtained, and resources can be recycled. The method can be applied to purification of sulfur-containing and nitrate-containing flue gas in the fields of boilers, metallurgy, chemical industry, thermoelectricity and garbage incineration power generation.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

Cooling blanket

The invention provides a cooling blanket useful for lowering the body temperature of a mammal, such as a human. The cooling blanket may be particularly useful when used in connection with a deleterious cardiac event, such as myocardial infarction. The cooling blanket is activated when reagents, such as ammonium nitrate, urea, and / or water, are placed in contact with one another; thereby producing an endothermic reaction.

Owner:COOL MEDICAL INNOVATIONS

Water culture nutrient solution prescription of lettuce and preparation method of water culture nutrient solution prescription

InactiveCN103172431ASmooth changeMeet the changeFertilizer mixturesPhosphoric acidMonopotassium phosphate

The invention discloses a water culture nutrient solution prescription of a lettuce and a preparation method of the water culture nutrient solution prescription, and belongs to the technical field of plant soilless culture of the agricultural science. The nutrient solution prescription of the lettuce comprises the following components: a fertilizer A composed of 584.23g / T of calcium nitrate, 421.34g / T of potassium nitrate and 47.8g / T of ammonium nitrate; a fertilizer B composed of 182.4g / T of monopotassium phosphate and, 256.23g / T of magnesium sulfate; a fertilizer C composed of 16.8g / T of FeEDTA (Ethylene Diamine Tetraacetic Acid), 3g / T of boric acid, 2g / T of manganese sulfate, 0.25g / T of zinc sulfate, 0.85g / T of copper sulfate, and 0.38g / T of ammonium molybdate; hormone composed of 0.1g / T indolebutyric acid of or 0.1g / T of naphthylacetic acid; a bactericide composed of 15g / T of carbendazim; and nutrient solution pH (Potential Of Hydrogen) adjusting acid composed of 200ml / T of phosphoric acid or 150g / T of citric acid. The prescription is nutritionally balanced, so that the demand of the lettuce to nutrition can be met, the amount of used nutrient elements is decreased at the same time, the output of the lettuce is increased, and the fertilizers are saved; and the prescription effectively decreases the contents of nitrates in the lettuce under the water culture, improves the quality of the lettuce, enables the simplification of the complicated processes in preparation based on the demand of the actual operation, and is suitable for being used for meeting the requirements of industrialization production.

Owner:NORTHWEST A & F UNIV

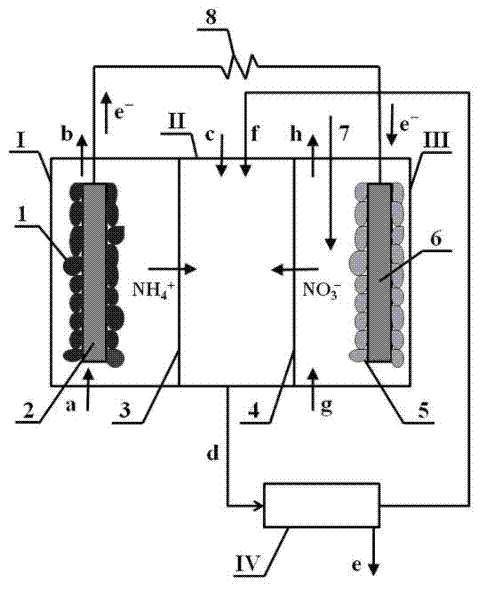

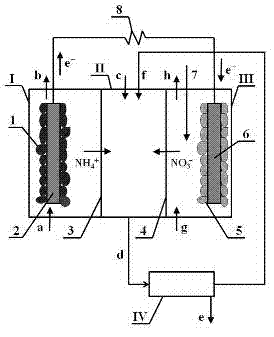

Nitrogen-containing sewage treatment process and device for synchronously producing electricity and recovering nitrogen element

InactiveCN102372398ARealize resource processingSimple structureFinal product manufactureBiochemical fuel cellsAnaerobic decompositionHigh concentration

The invention belongs to the technical field of water treatment, and in particular relates to a nitrogen-containing sewage treatment process and device for synchronously producing electricity and recovering a nitrogen element. The device comprises a bioelectrochemical system and a membrane distillation system, wherein the bioelectrochemical system comprises six parts, namely a positive electrode chamber, a positive membrane, a recovery chamber, a negative membrane, a negative electrode chamber, an outer circuit. The process comprises the following steps: entering nitrogen-containing sewage into the positive electrode chamber, carrying out microorganism anaerobic decomposition on pollutants and transferring electrons to a positive electrode, and further transferring the electrons to a negative electrode through the outer circuit so as to achieve electricity production; entering the nitrogen-containing sewage into the negative chamber for aerobic treatment, thus converting ammonia nitrogen into nitrate nitrogen; respectively entering ammonium radical in the positive electrode chamber and nitrate radical in the negative electrode chamber into the recovery chamber through the positivemembrane and the negative membrane under the driving of potential difference; and treating water in the recovery chamber with the membrane distillation system, and refluxing percolate to the recoverychamber, wherein a concentrated liquid is a solution containing high-concentration ammonium nitrate and the like, thereby achieving the recovery of the nitrogen element. The process provided by the invention is simple and has high efficiency and good economic benefits; and the treatment device is simple in structure, and is convenient for practical application.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Method for preparing organic fertilizer by using plant residues as raw material

InactiveCN104261911AAccelerates decay and degradationImprove decomposition abilityBio-organic fraction processingExcrement fertilisersMicrobial agentDecomposition

The invention relates to a method for preparing an organic fertilizer by using plant residues as a raw material. The method comprises the following steps: crushing the raw material to below 20mm, stirring and mixing the broken material with animal wastes or an inorganic fertilizer; controlling the C / N ratio of the mixed materials to be (15-35) to 1 and the pH to be 6-9; adding water, so that the moisture content in the mixed materials in the step (2) is 55-70wt%; adding a first composite microbial agent to ferment; after once fermentation, raising the temperature of windrows to above 50 DEG C; and spraying a water-dispersed second composite microbial agent to ferment for the second time. With plant residues heap corruption (composting) as a biological process for succession of a microbial community, through inoculation of exogenous complex microbial agents, efficient decomposition on agricultural wastes is facilitated; different composite microbial agents are respectively added at different composting stages; and a small amount of additives (animal wastes, urea, ammonium nitrate and the like) are added, so that the composting speed is increased, and the quality of the product organic fertilizer is really improved.

Owner:烟台中正新技术有限公司

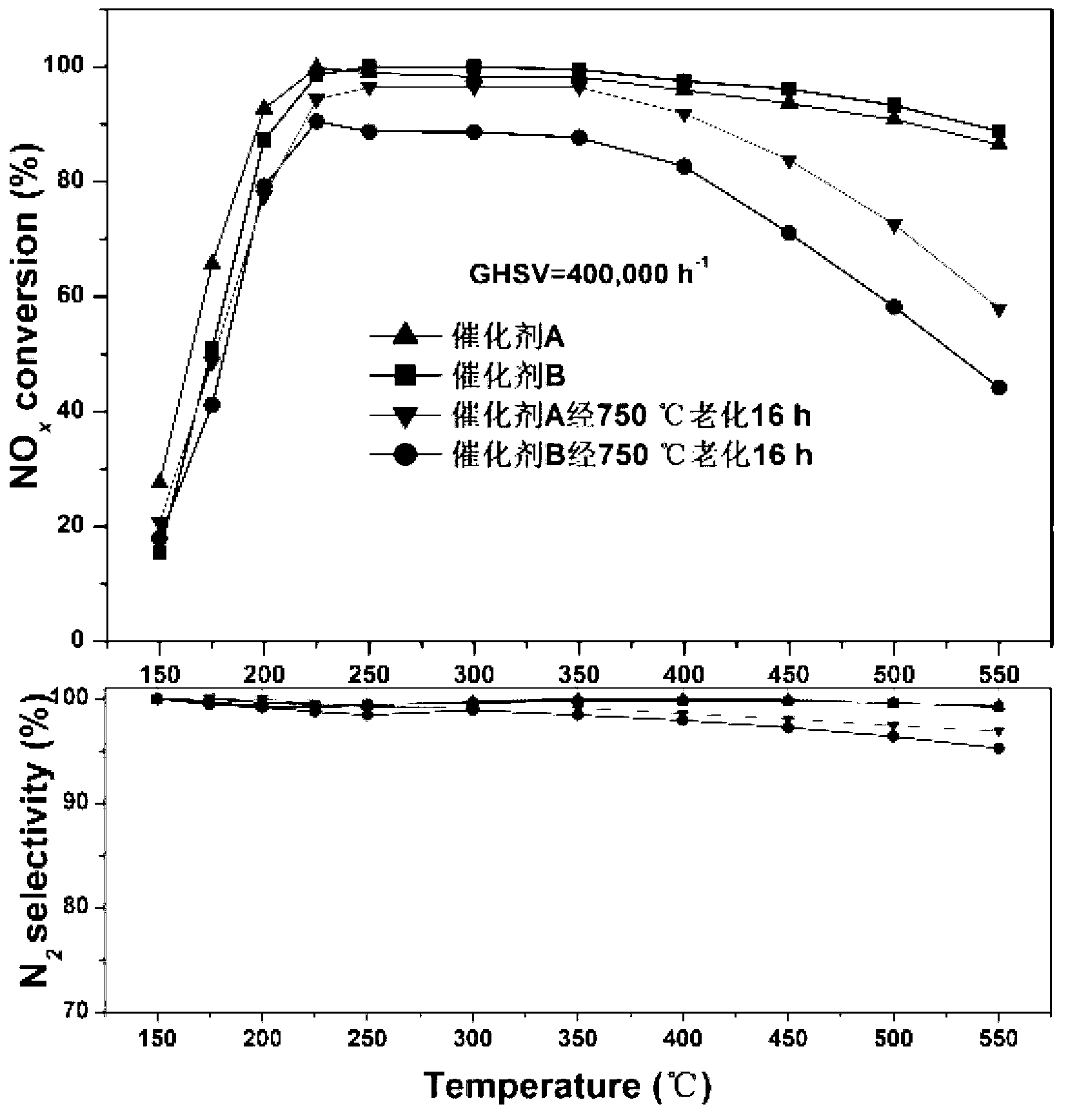

Cu-SSZ-13 catalyst, and preparation method and application thereof

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

Device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation

ActiveCN103463978AHigh removal rateImprove oxidation efficiencyDispersed particle separationAir quality improvementPtru catalystCatalytic decomposition

The invention provides a device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation (H2O2). The H2O2 is sprayed into an H2O2 catalytic decomposition device through an injection pump and reacts with catalysts, a large amount of active matter is generated, the active matter is injected into a smoke channel along with a bypass air flow from an air blower in a blowing mode and reacts with sulfur dioxide (SO2) and oxynitride (NOX) in smoke to generate sulfuric acid and nitric acid. The sulfuric acid, the nitric acid and pollutants left in the smoke enter an ammonia absorption tower, and finally two kinds of important chemical fertilizer, namely ammonium sulfate and ammonium nitrate are generated. The device and method are suitable for smoke simultaneous desulfurization and denitrification in large, medium and small size boiler and reconstruction application of built combustion equipment, and the NOX and SO2 can be removed at the same time.

Owner:NANJING UNIV OF SCI & TECH

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com