Patents

Literature

41091 results about "Methanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

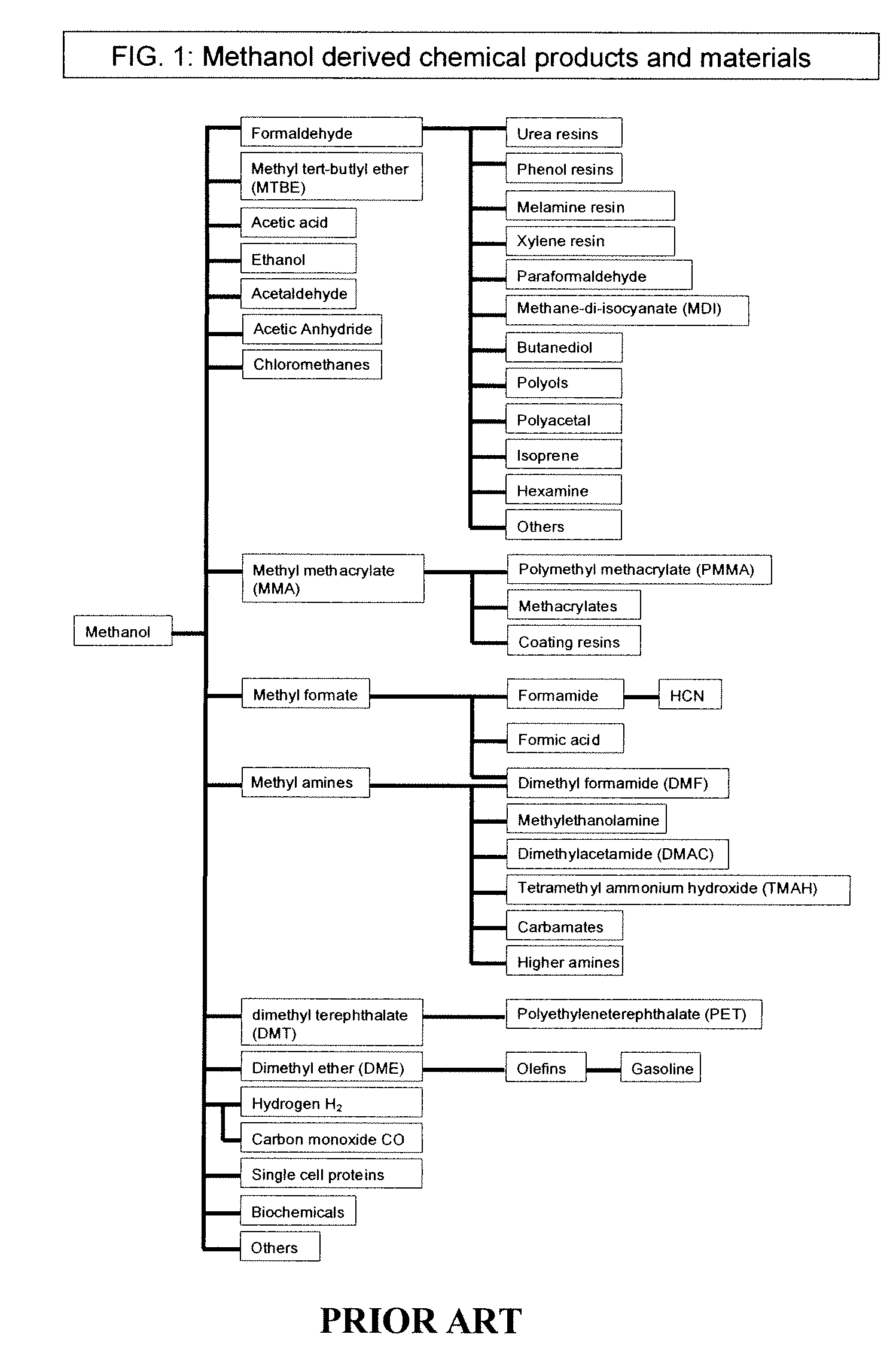

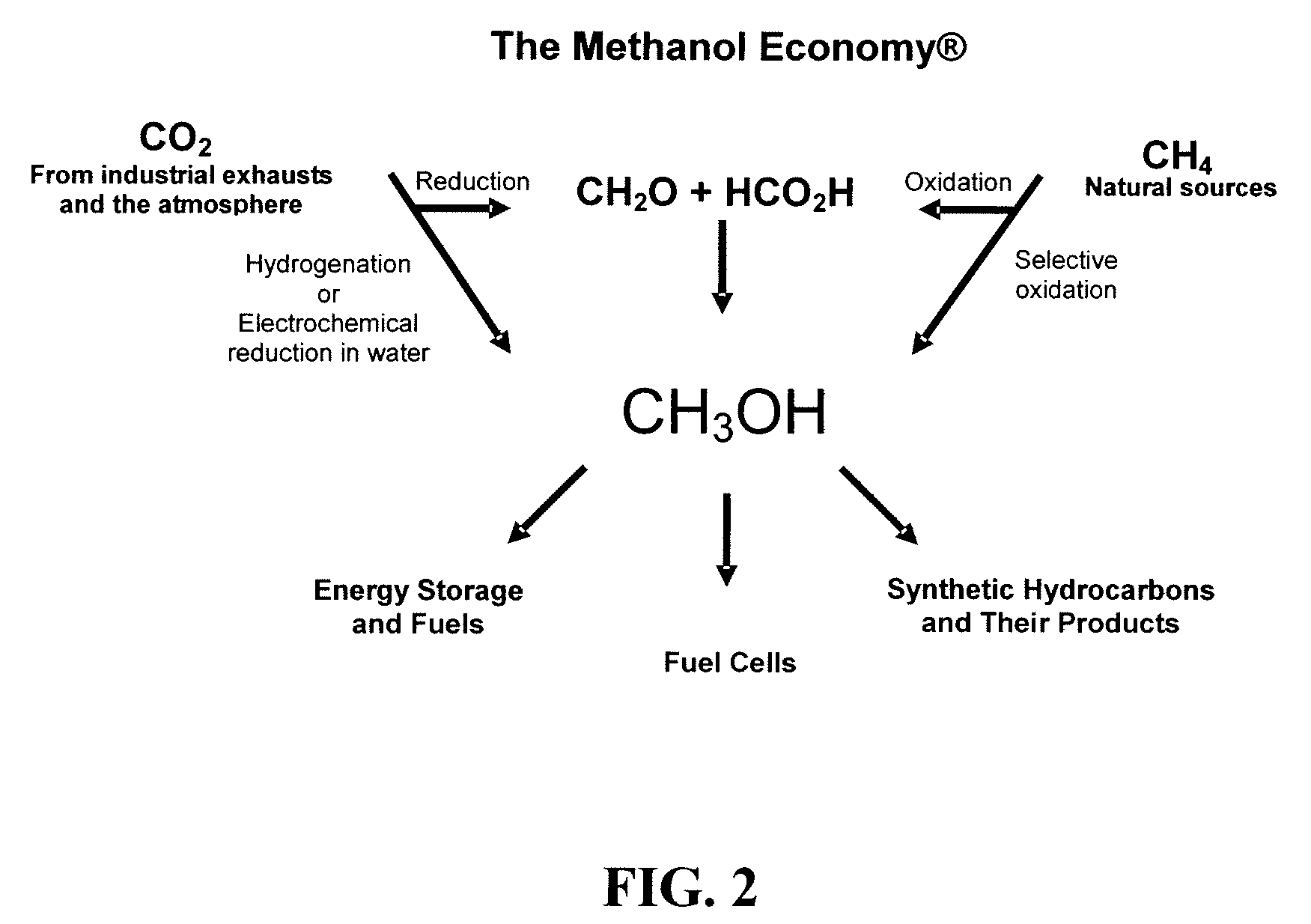

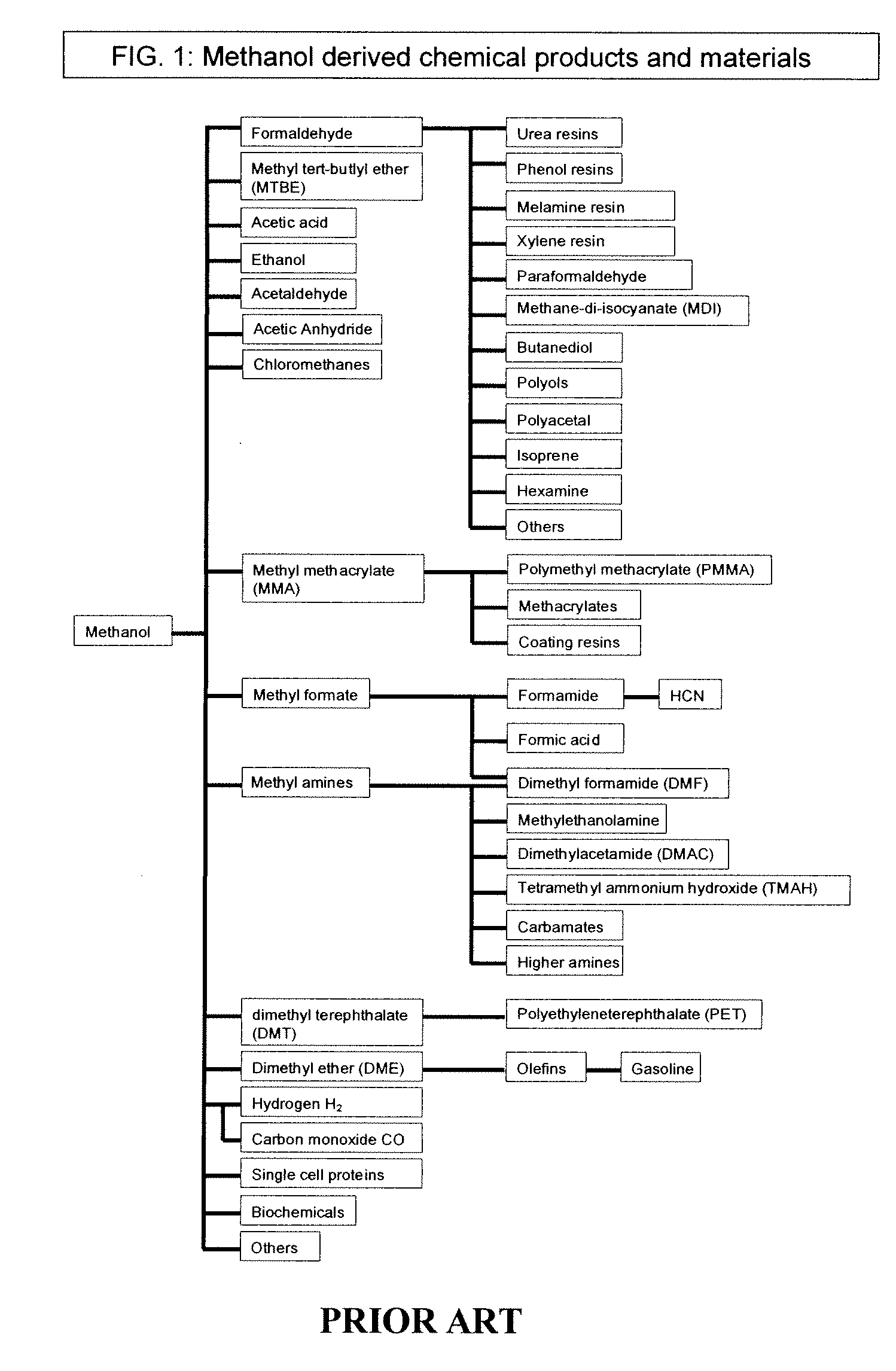

Methanol, also known as methyl alcohol amongst other names, is a chemical with the formula CH₃OH (a methyl group linked to a hydroxyl group, often abbreviated MeOH). Methanol acquired the name wood alcohol because it was once produced chiefly by the destructive distillation of wood. Today, methanol is mainly produced industrially by hydrogenation of carbon monoxide.

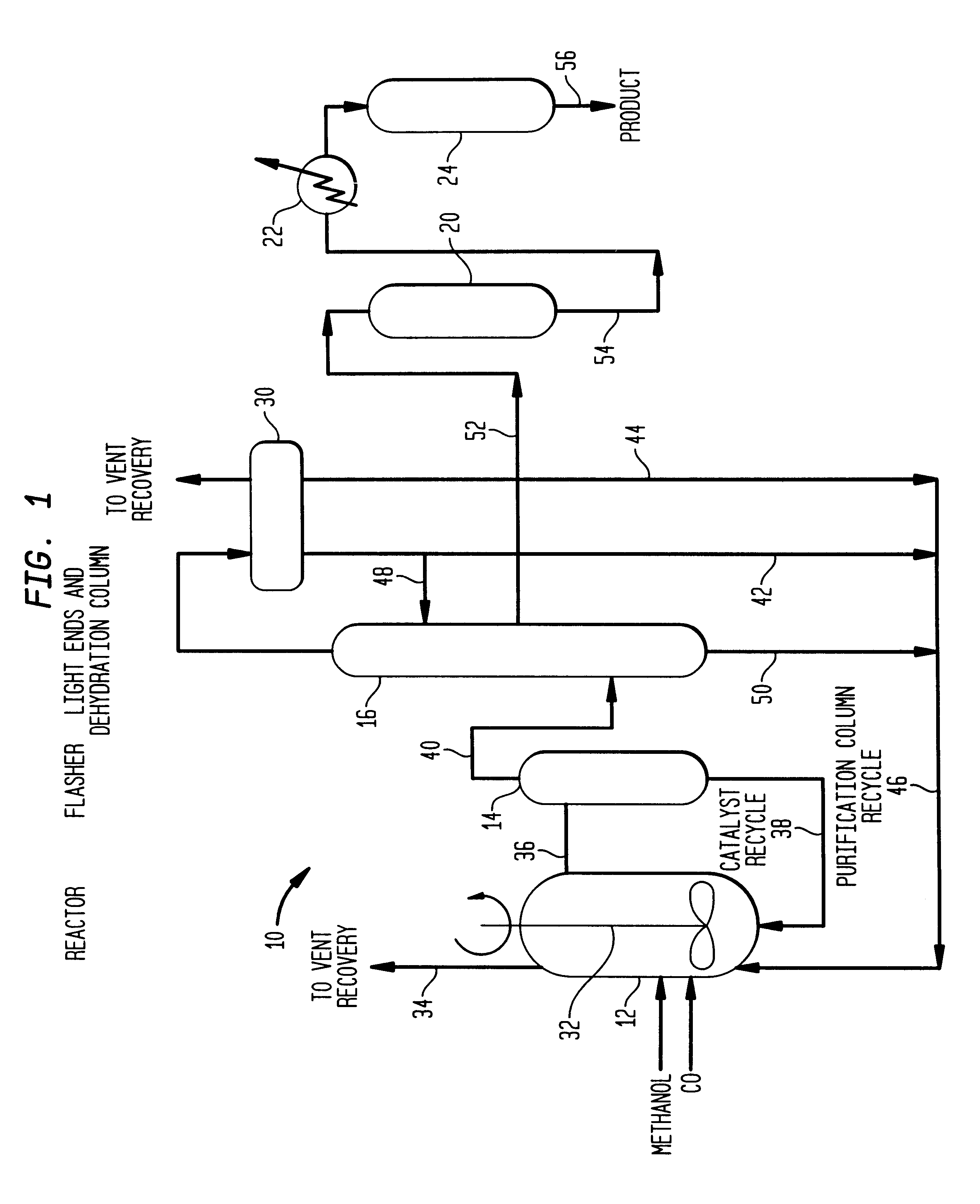

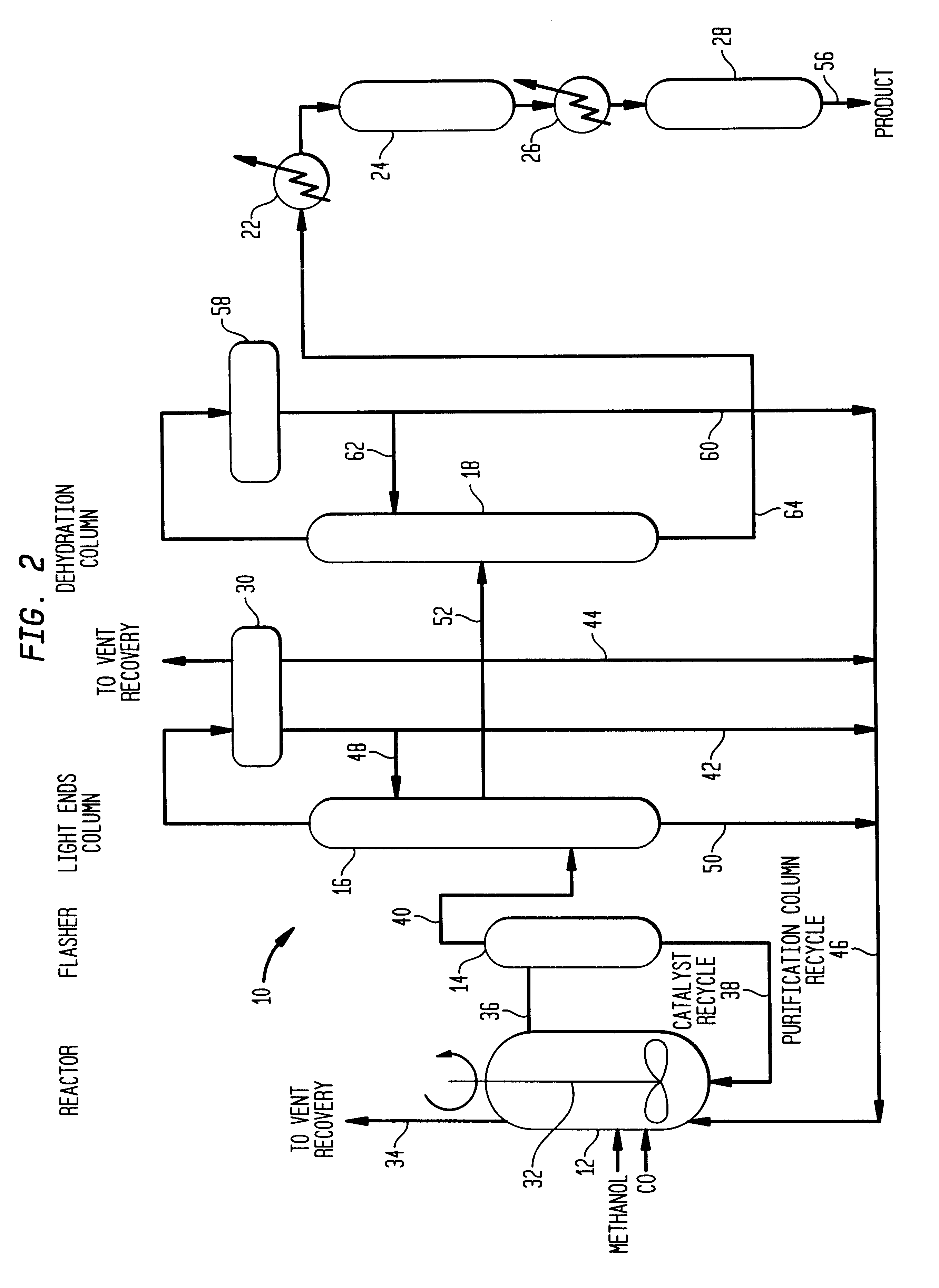

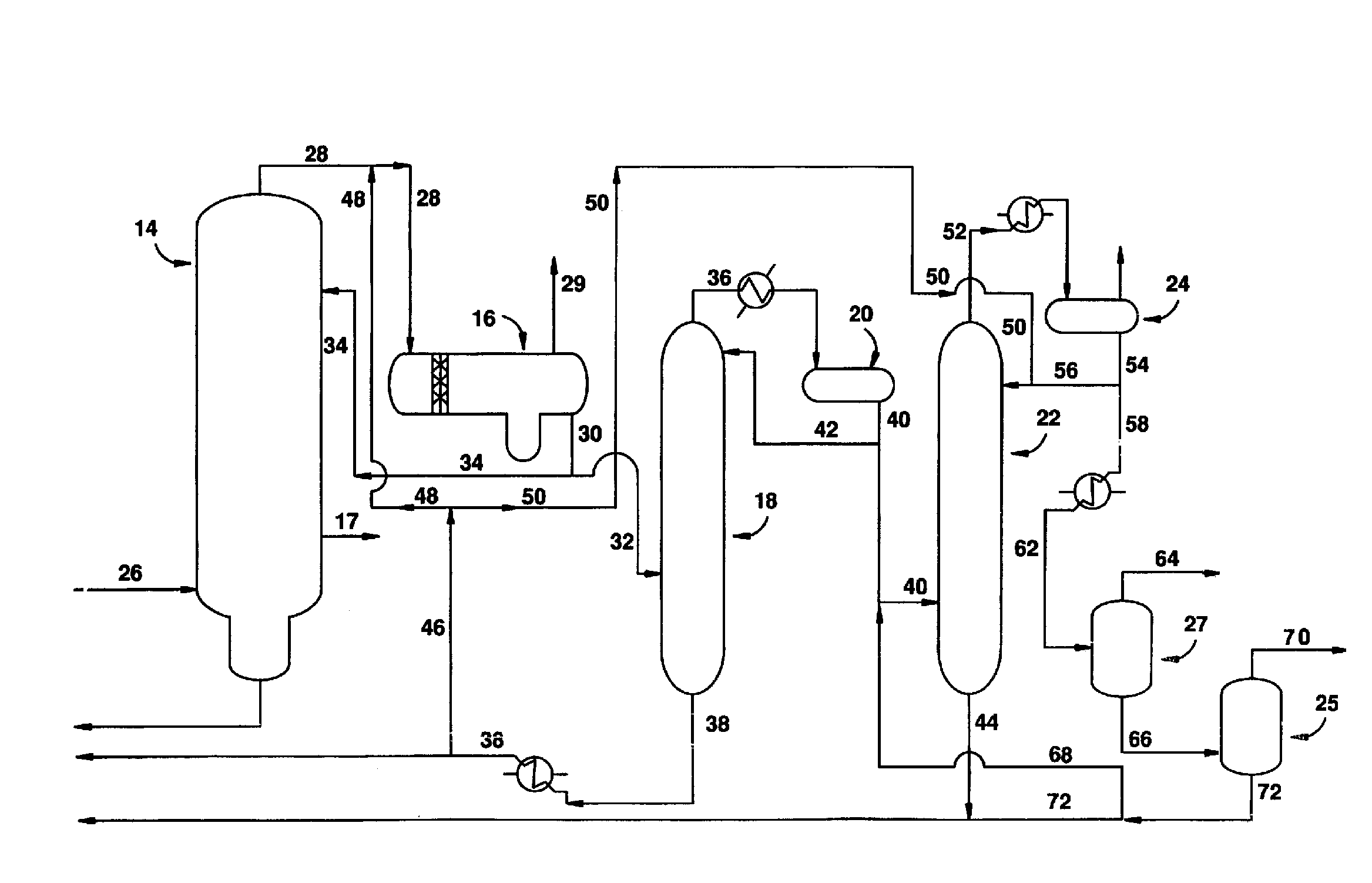

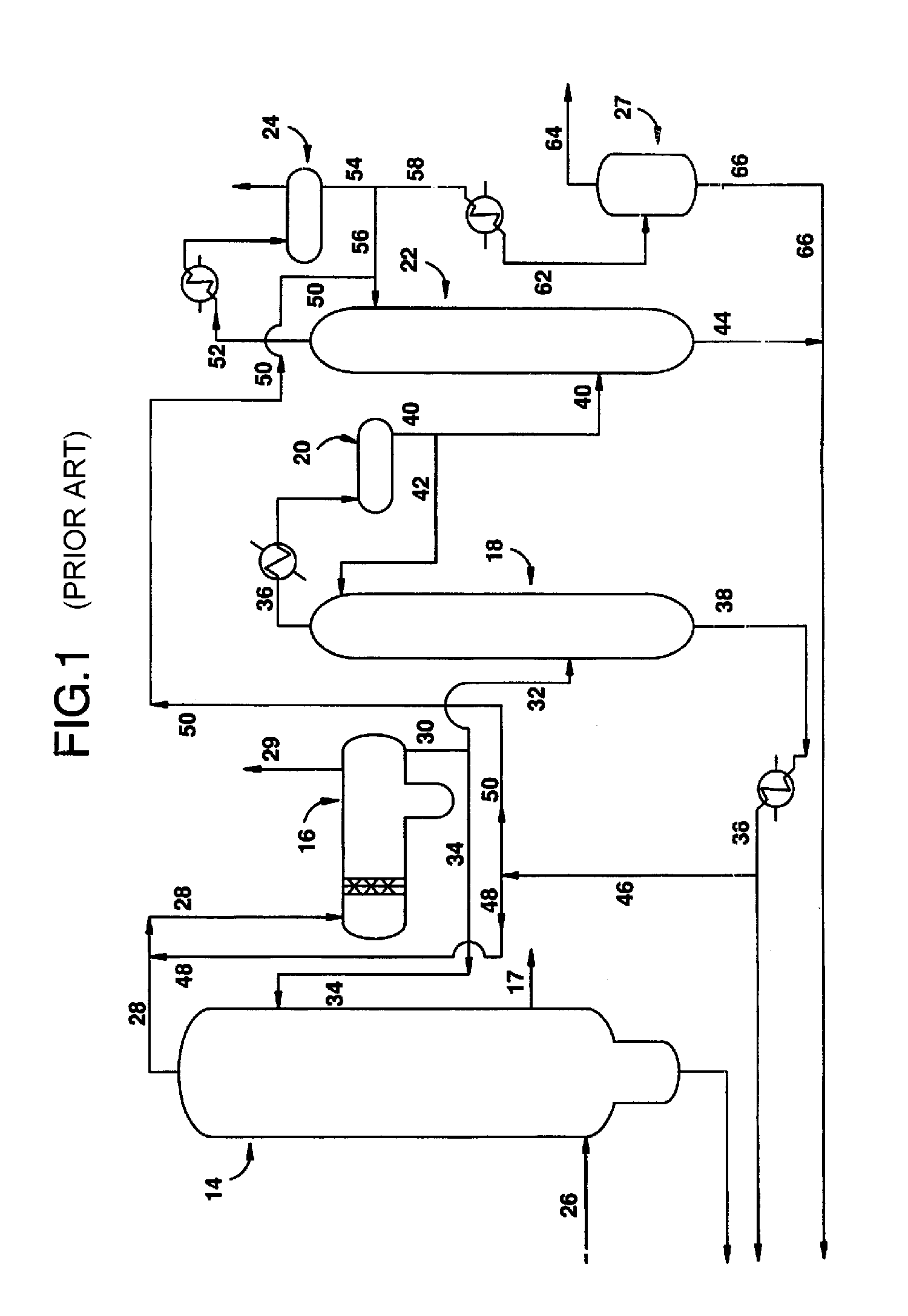

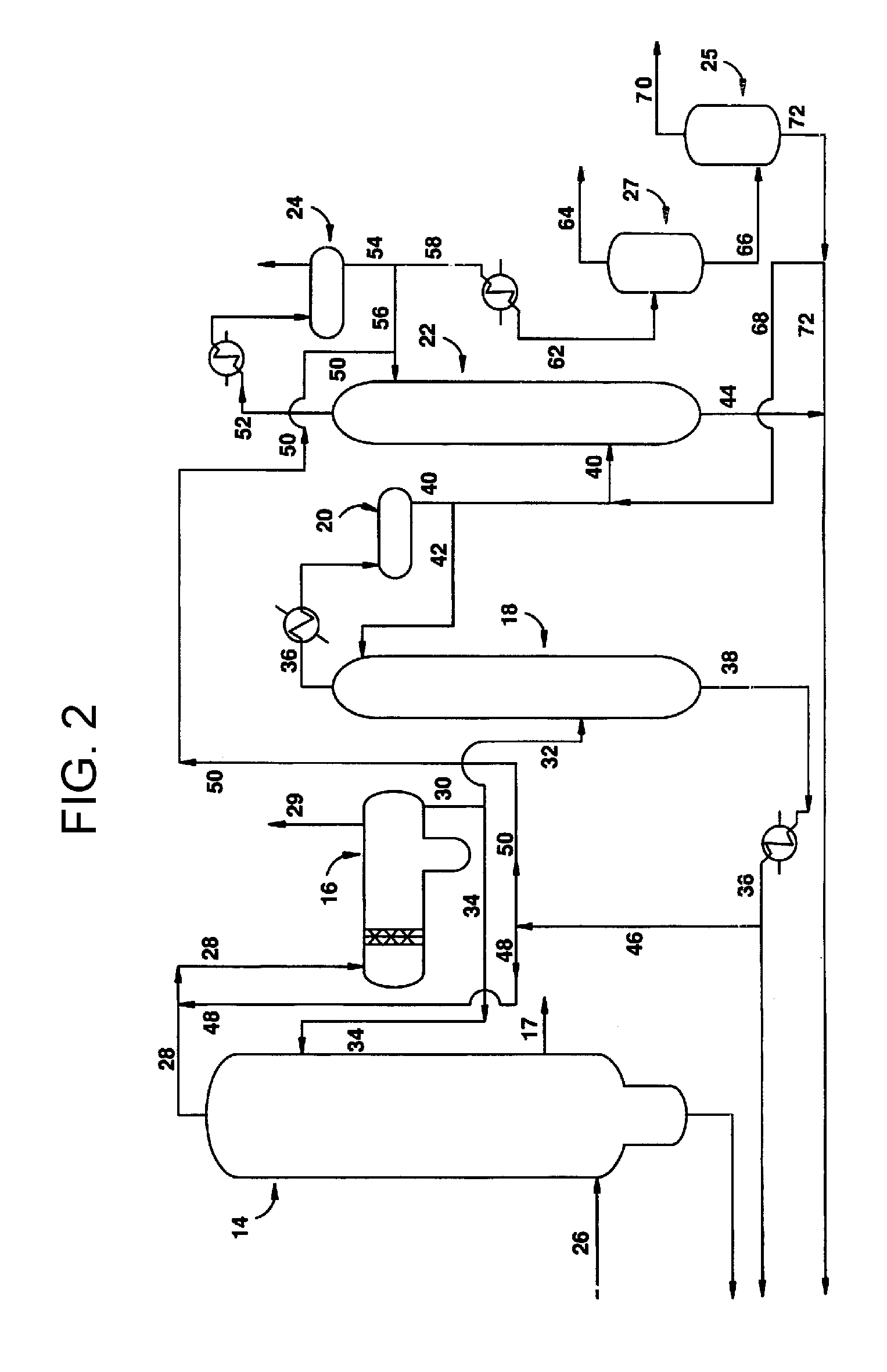

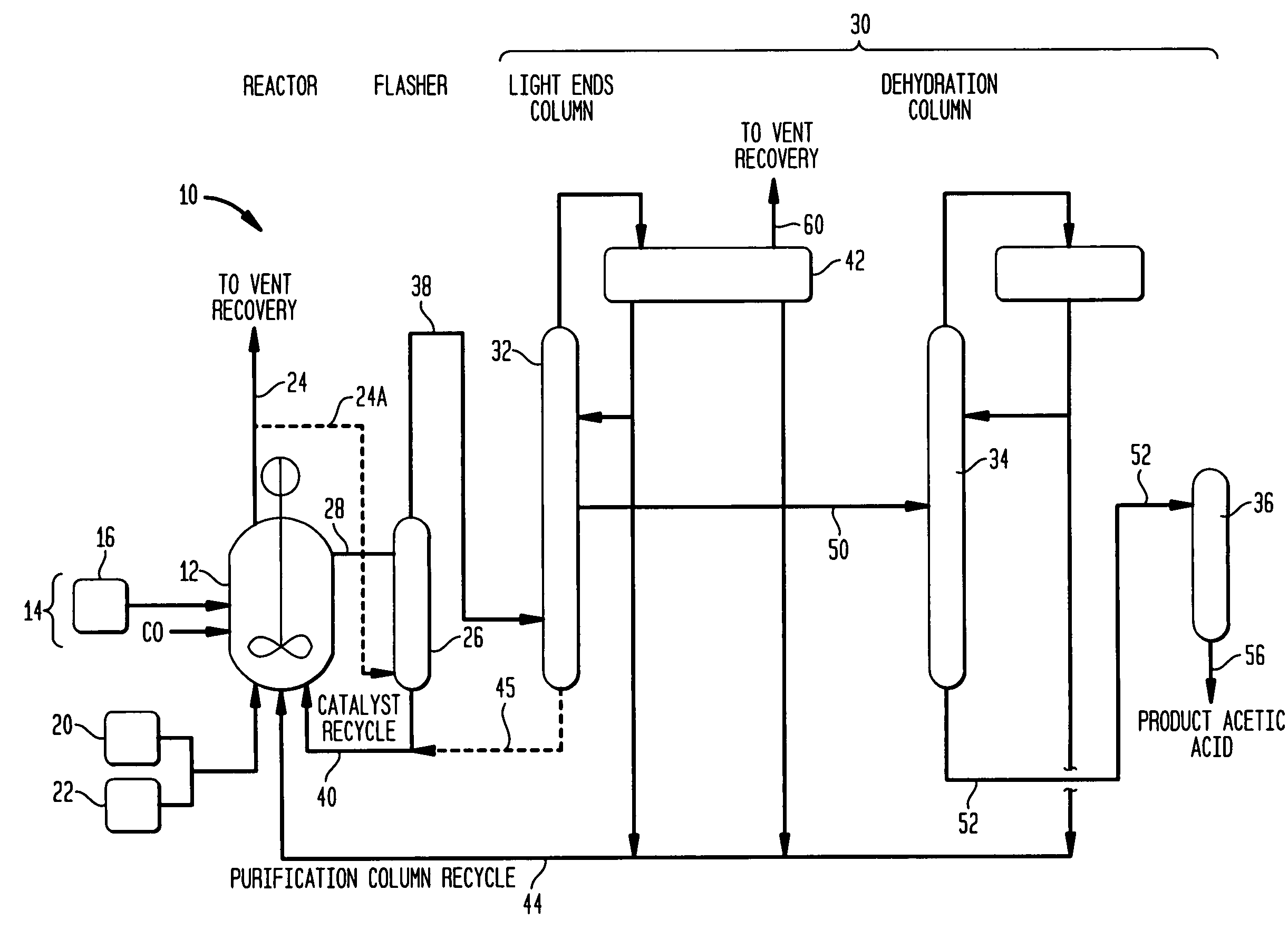

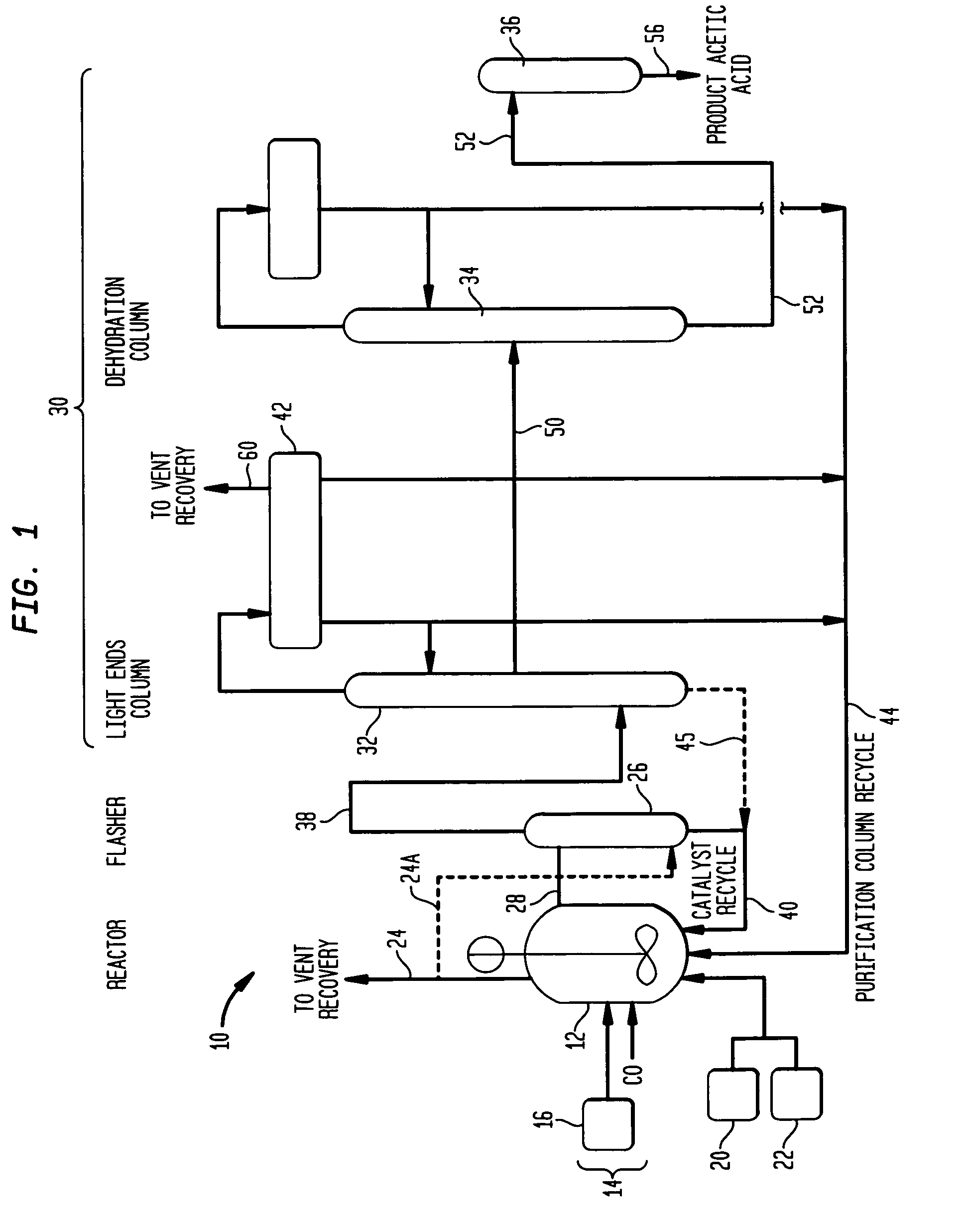

Low energy carbonylation process

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

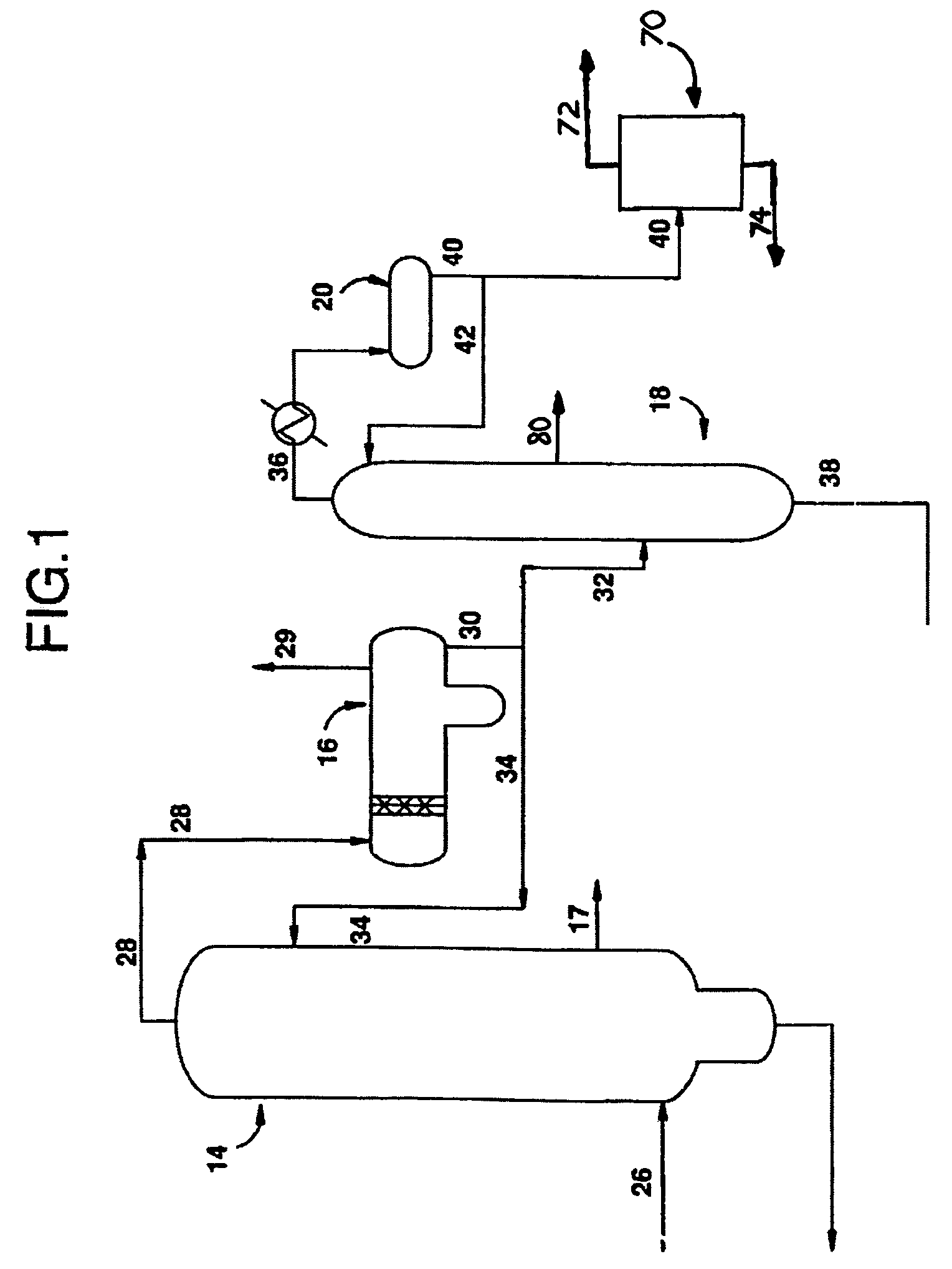

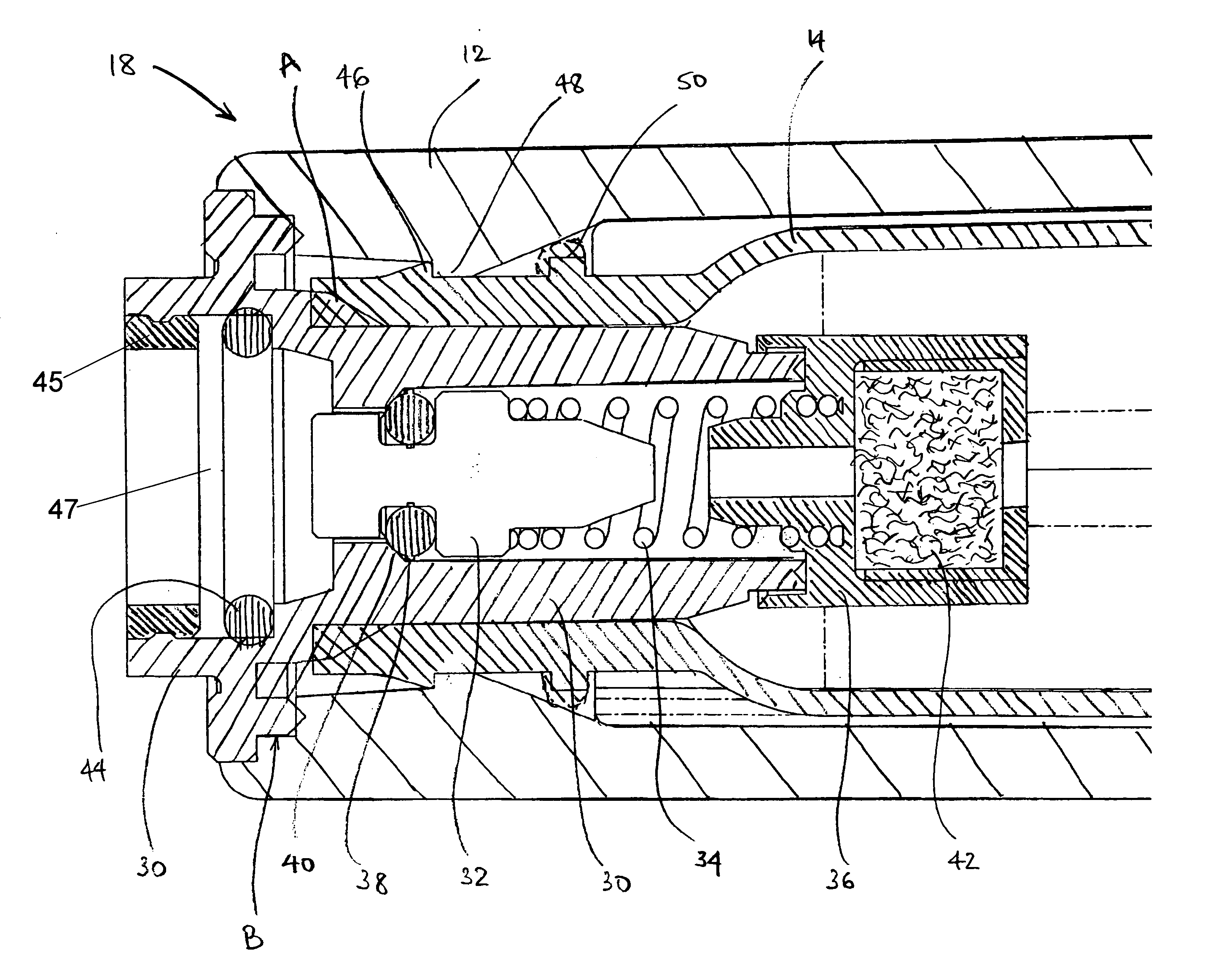

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

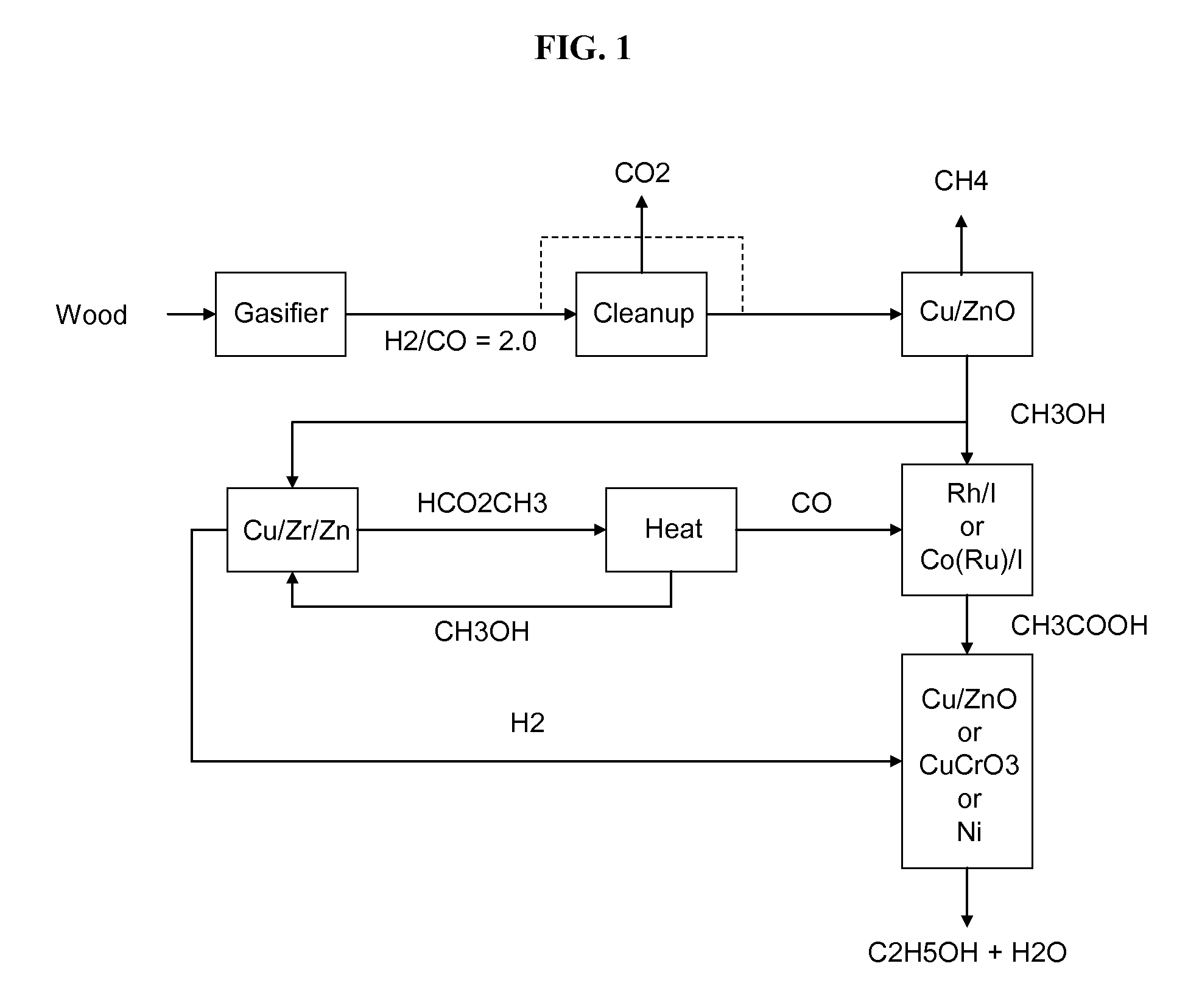

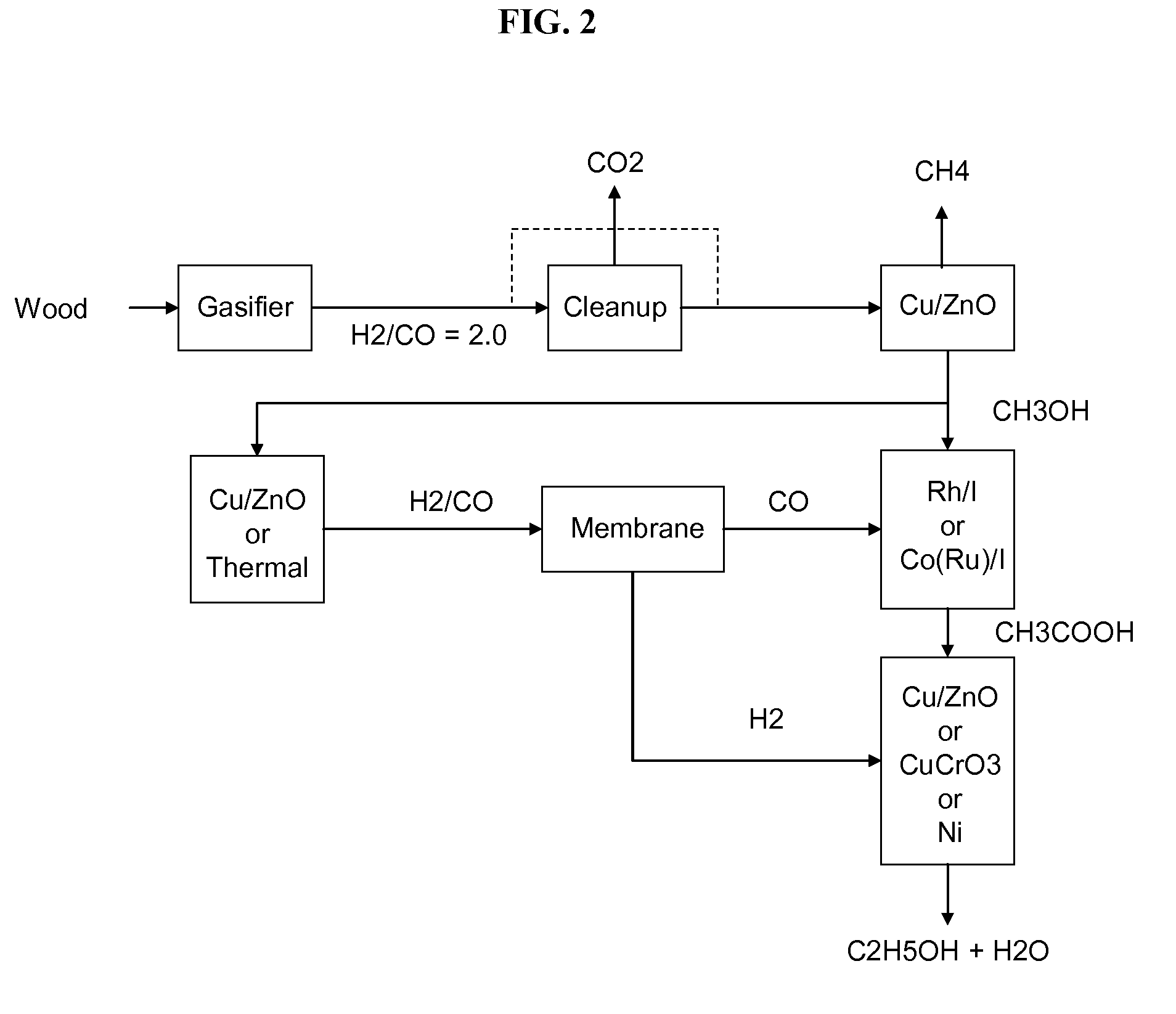

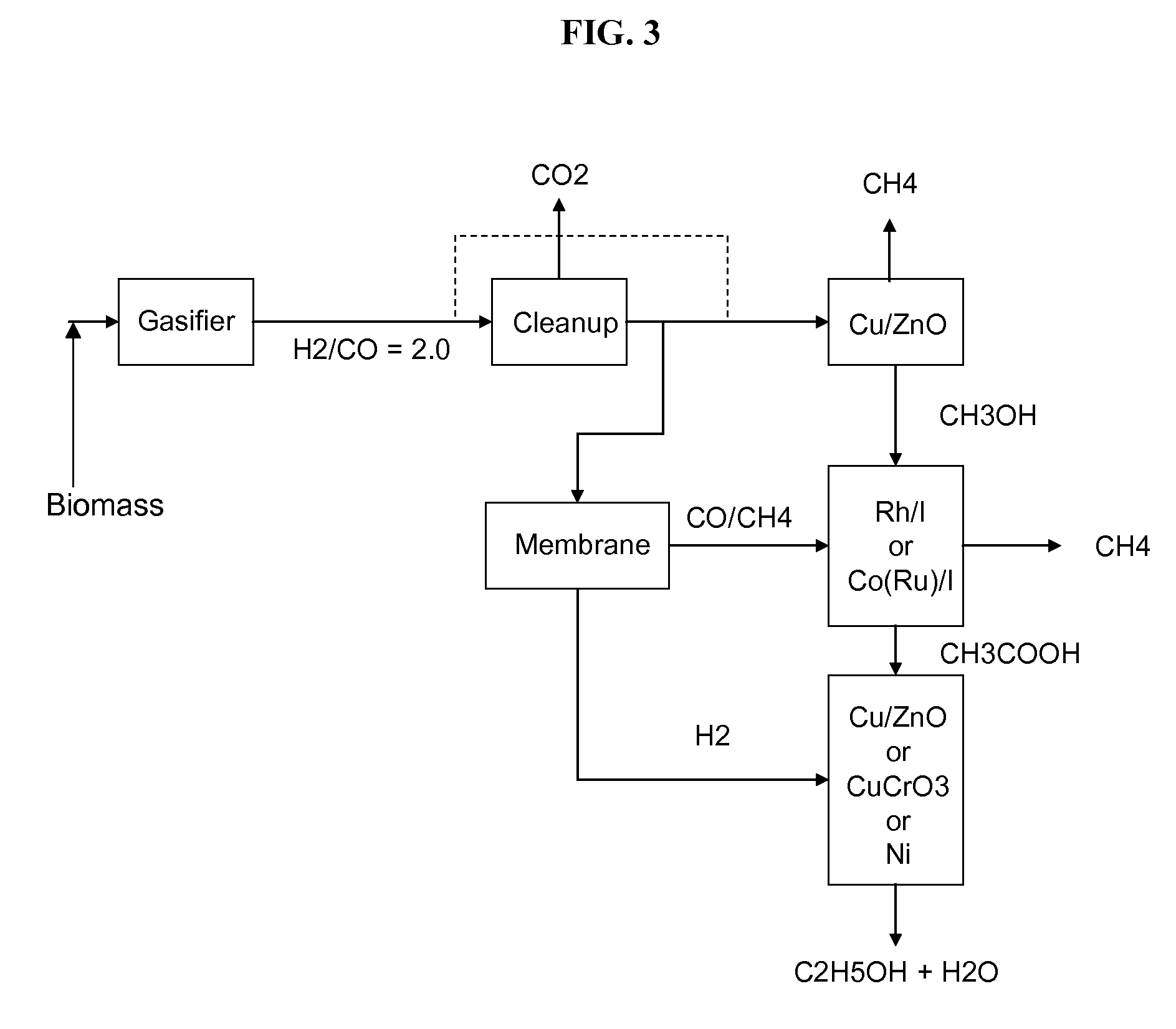

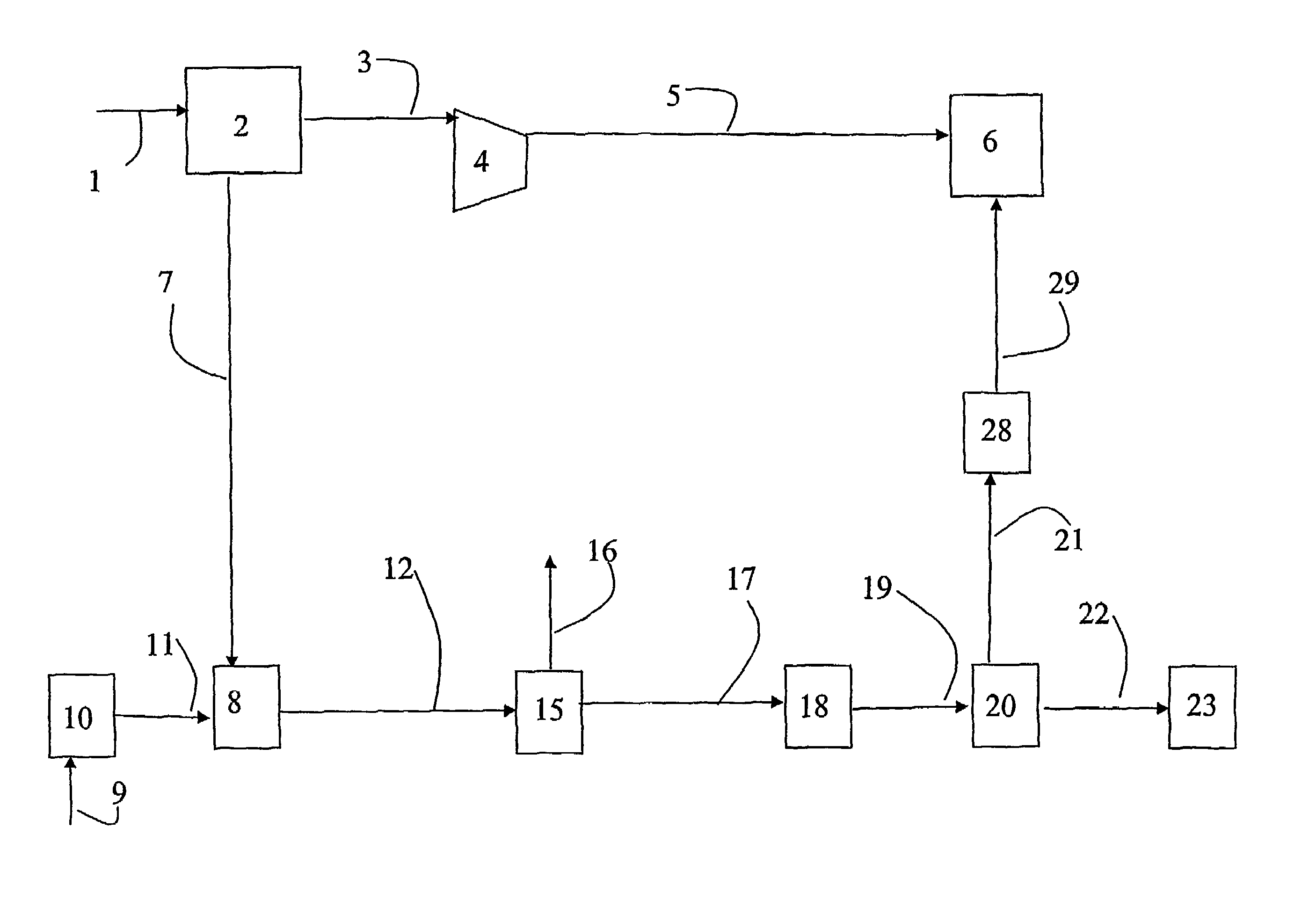

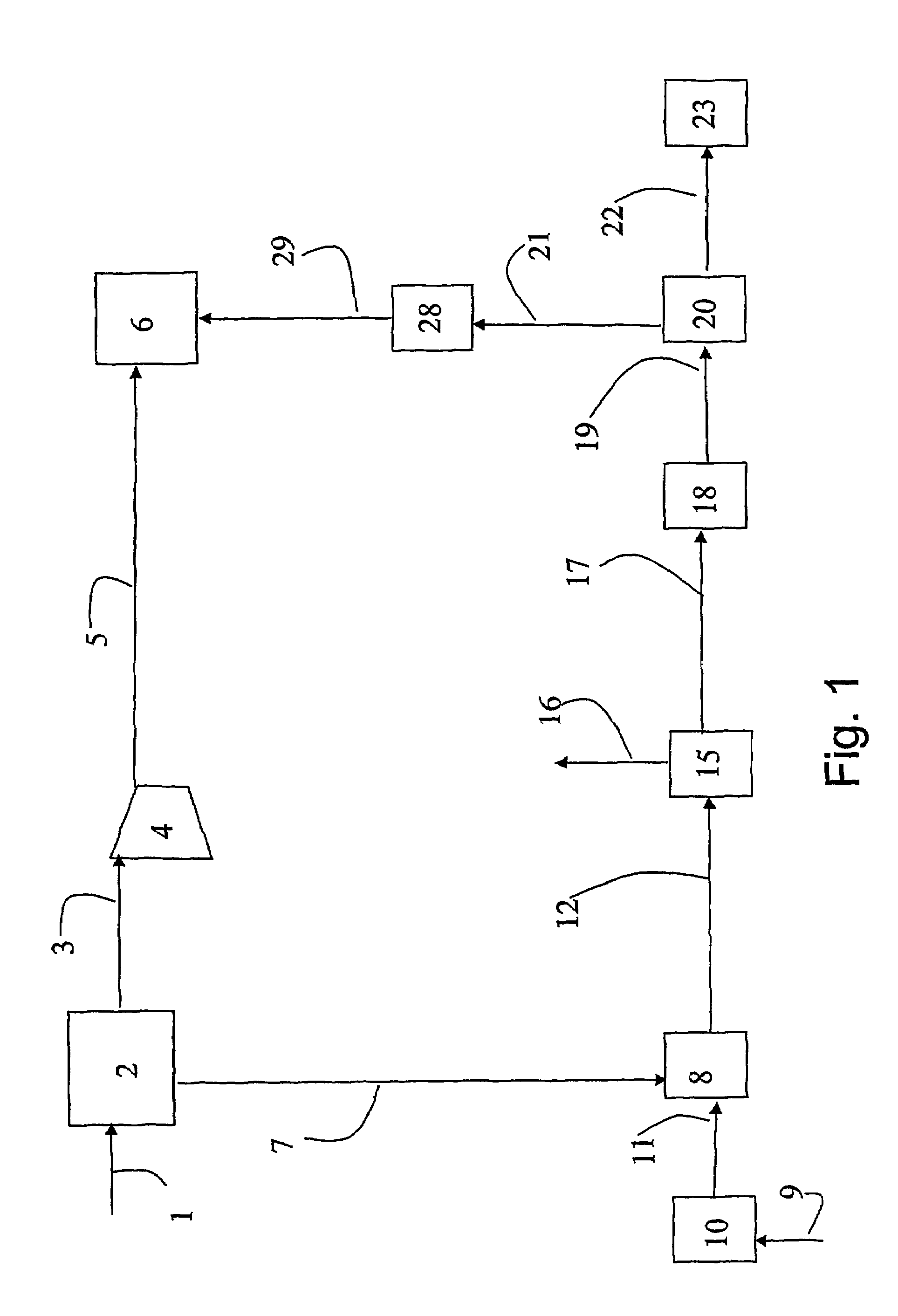

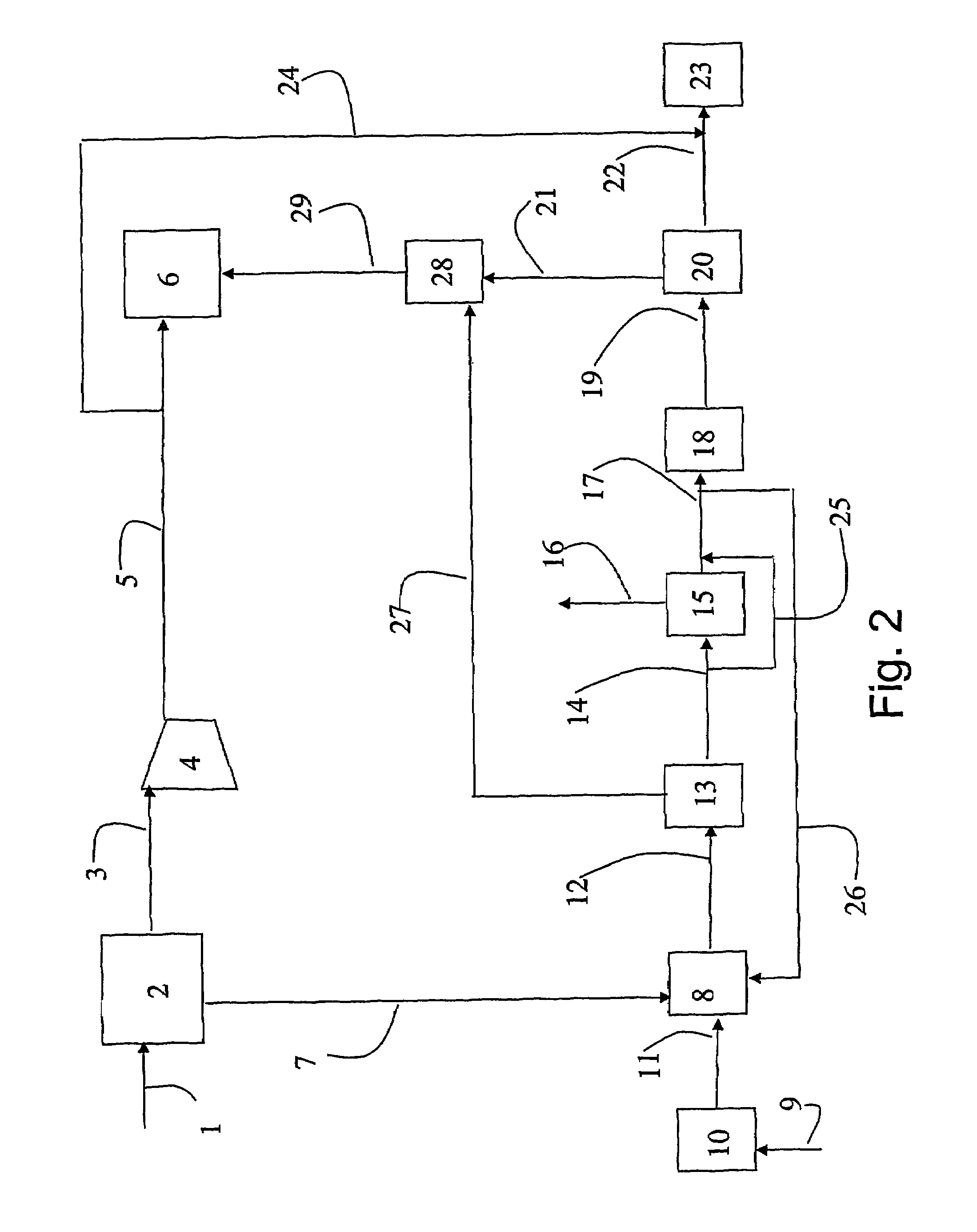

Methods and apparatus for selectively producing ethanol from synthesis gas

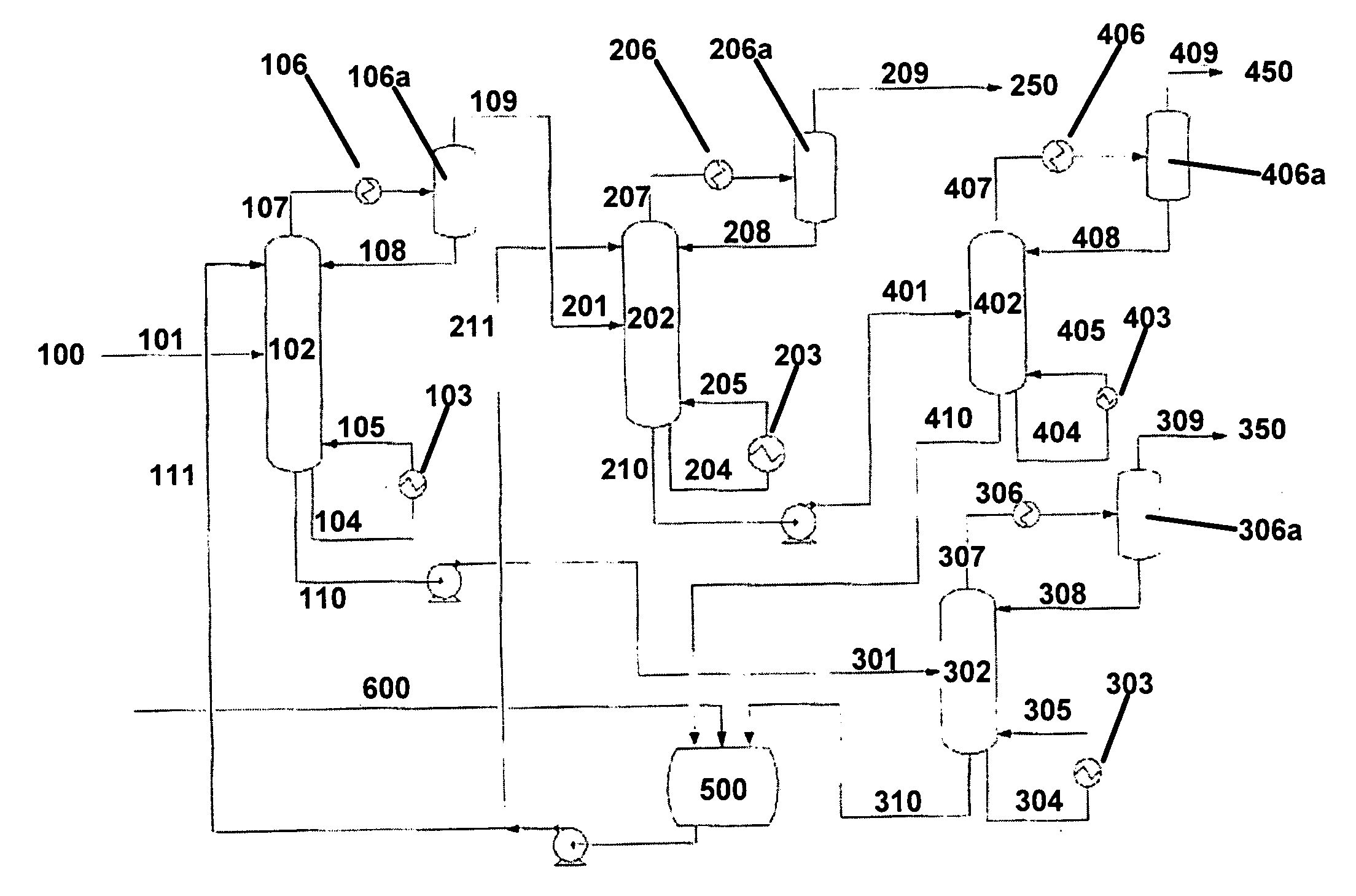

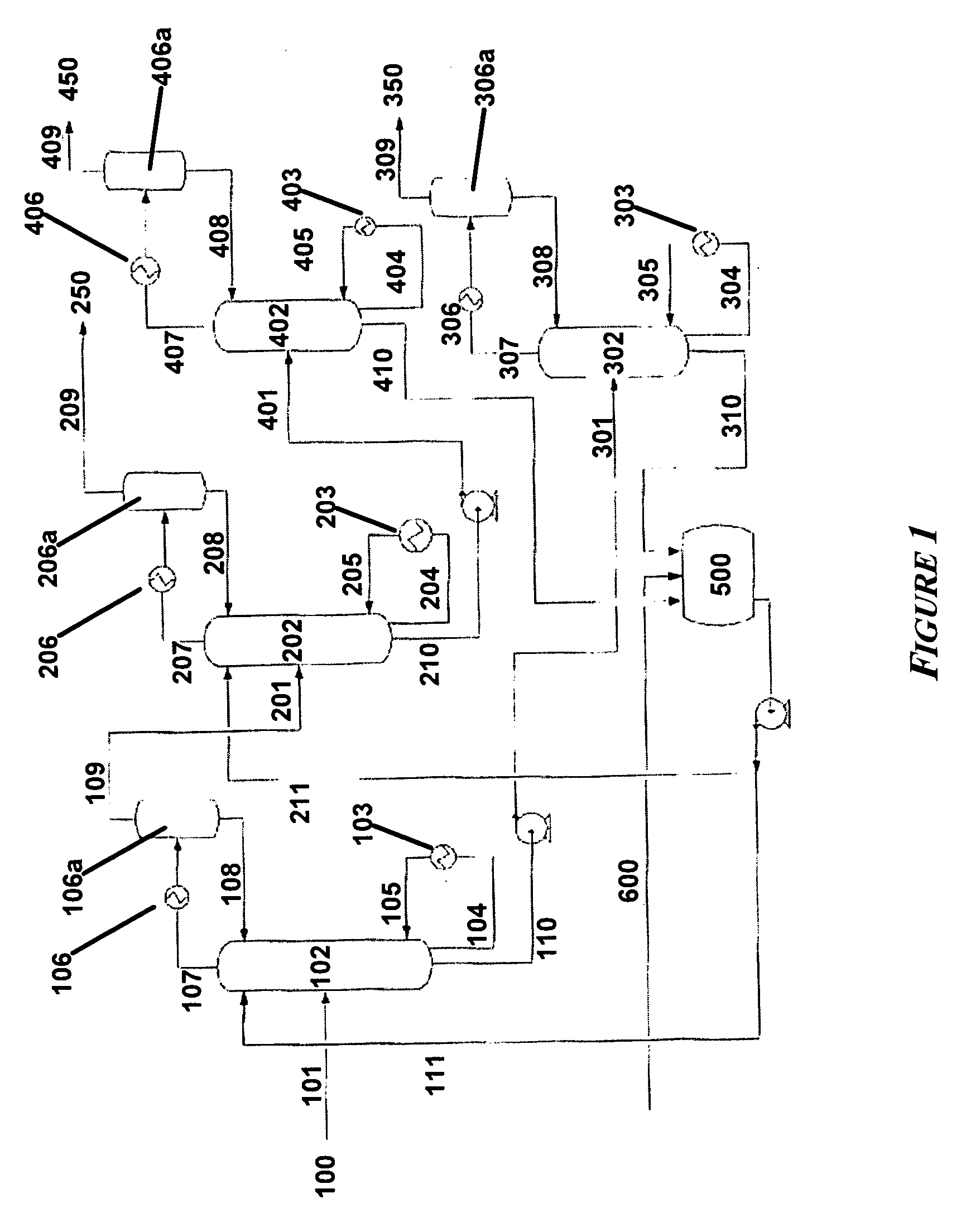

The invention provides methods and apparatus for selectively producing ethanol from syngas. As disclosed herein, syngas derived from cellulosic biomass (or other sources) can be catalytically converted into methanol, which in turn can be catalytically converted into acetic acid or acetates. Finally, the acetic acid or acetates can be reduced to ethanol according to several variations. In some embodiments, yields of ethanol from biomass can exceed 100 gallons per dry ton of biomass.

Owner:CELANESE INT CORP

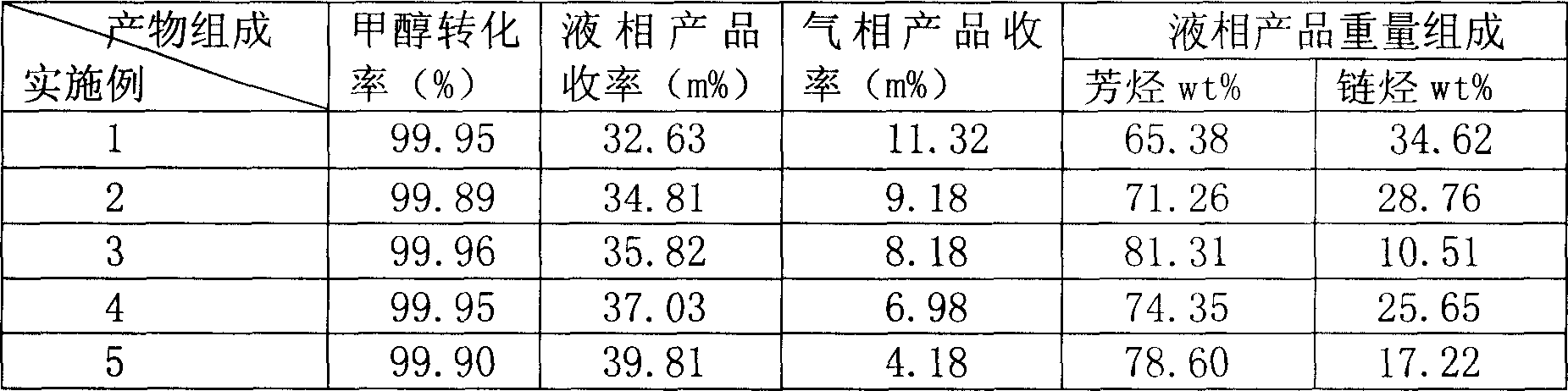

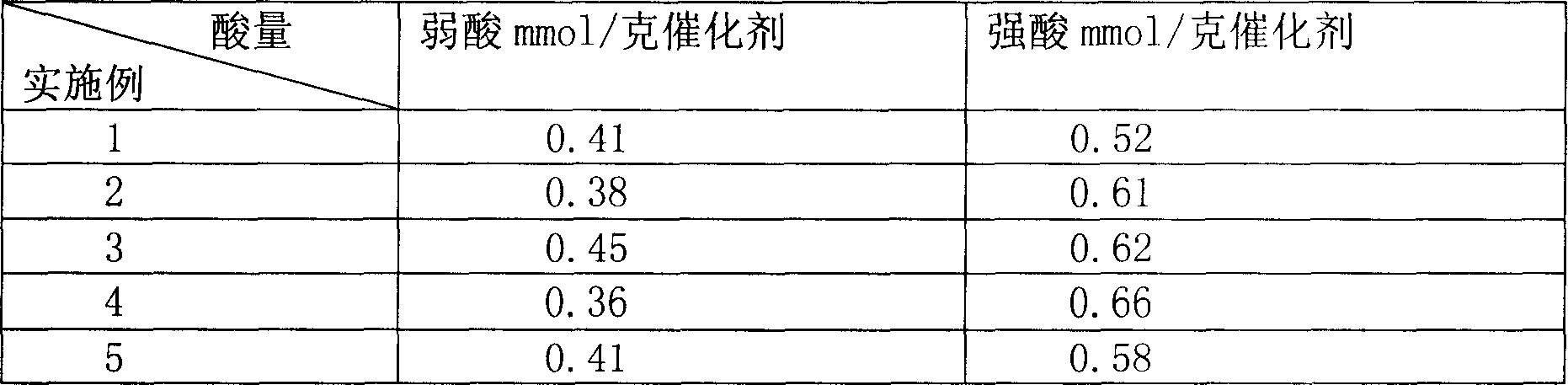

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

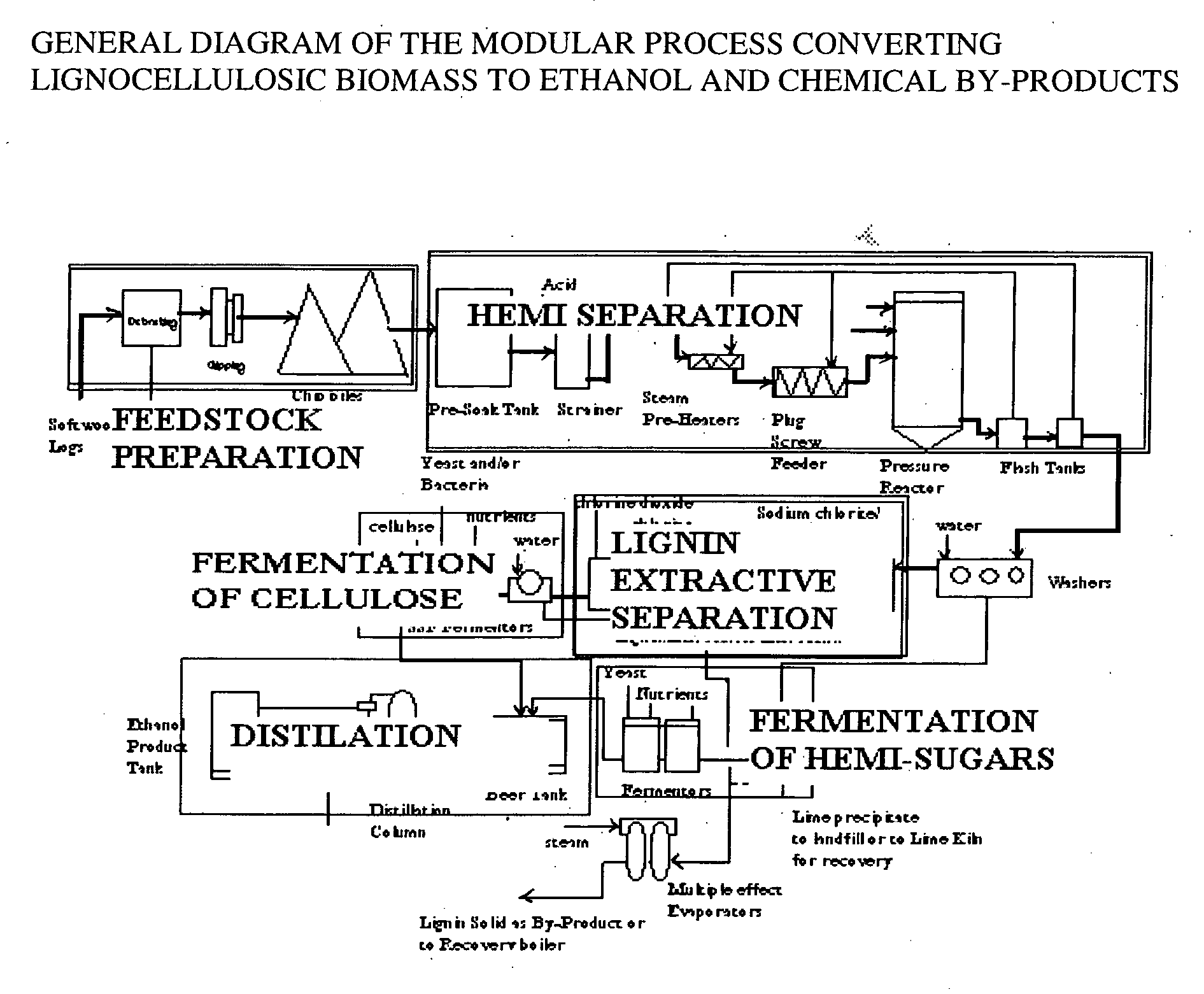

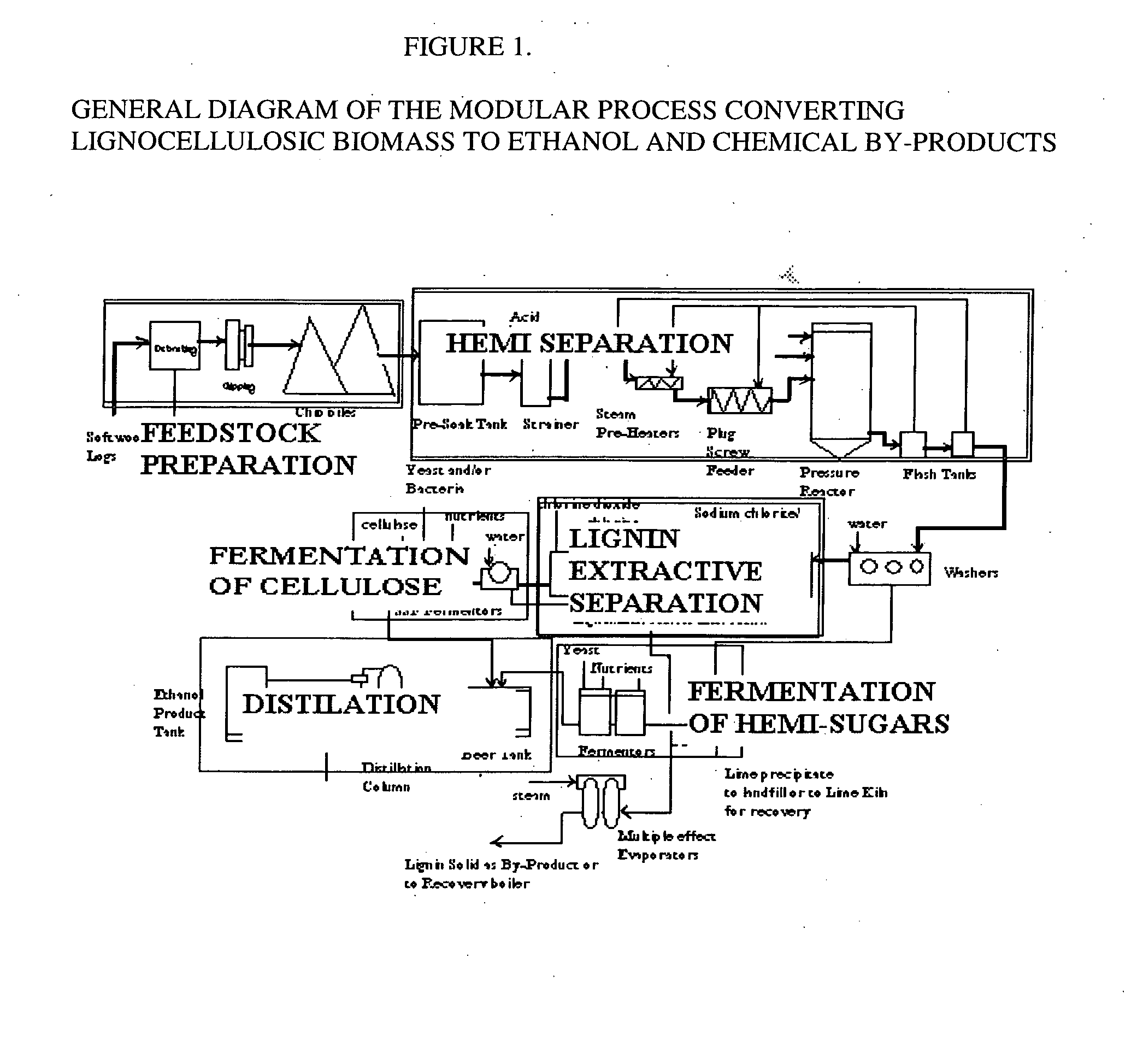

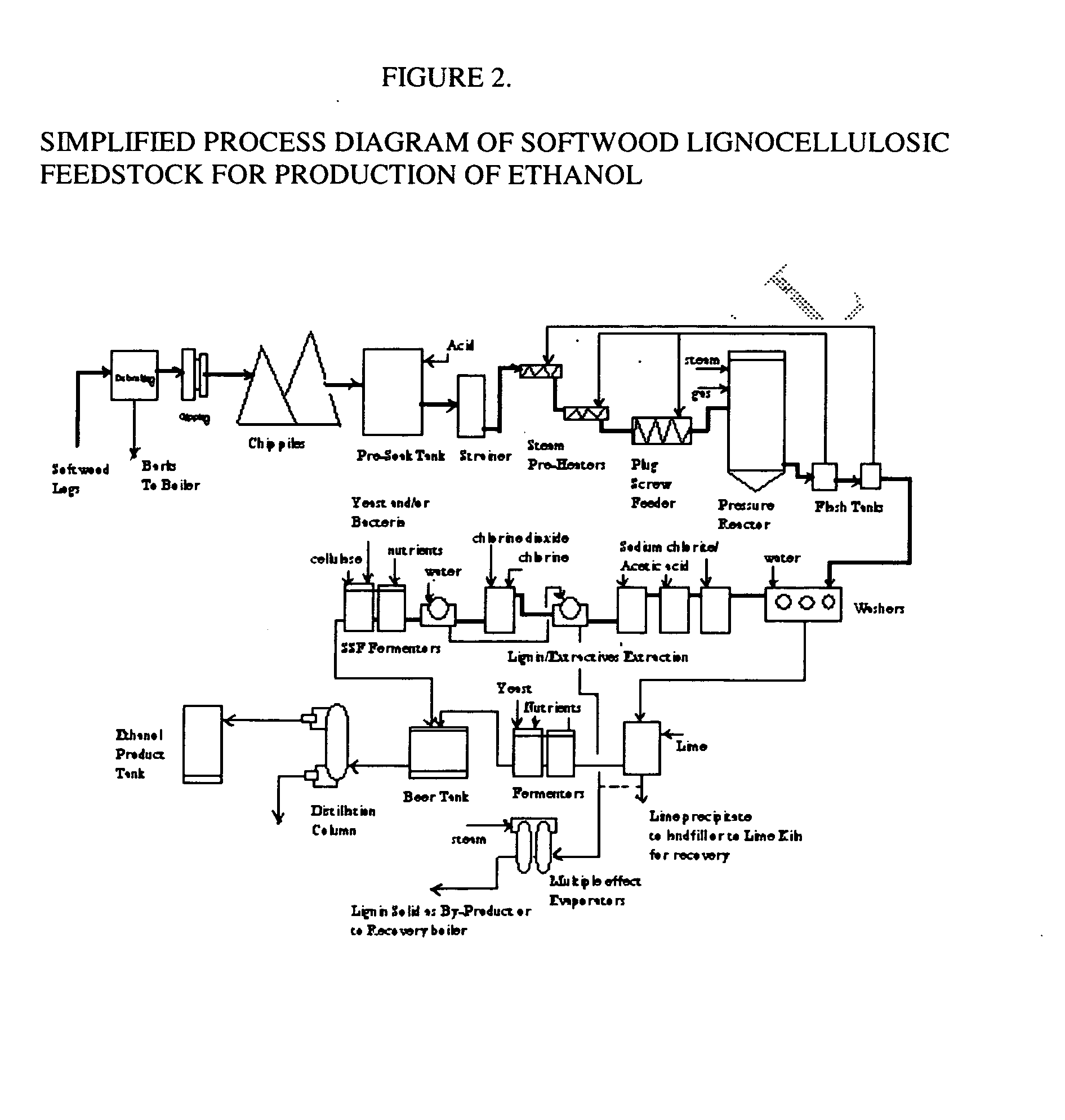

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

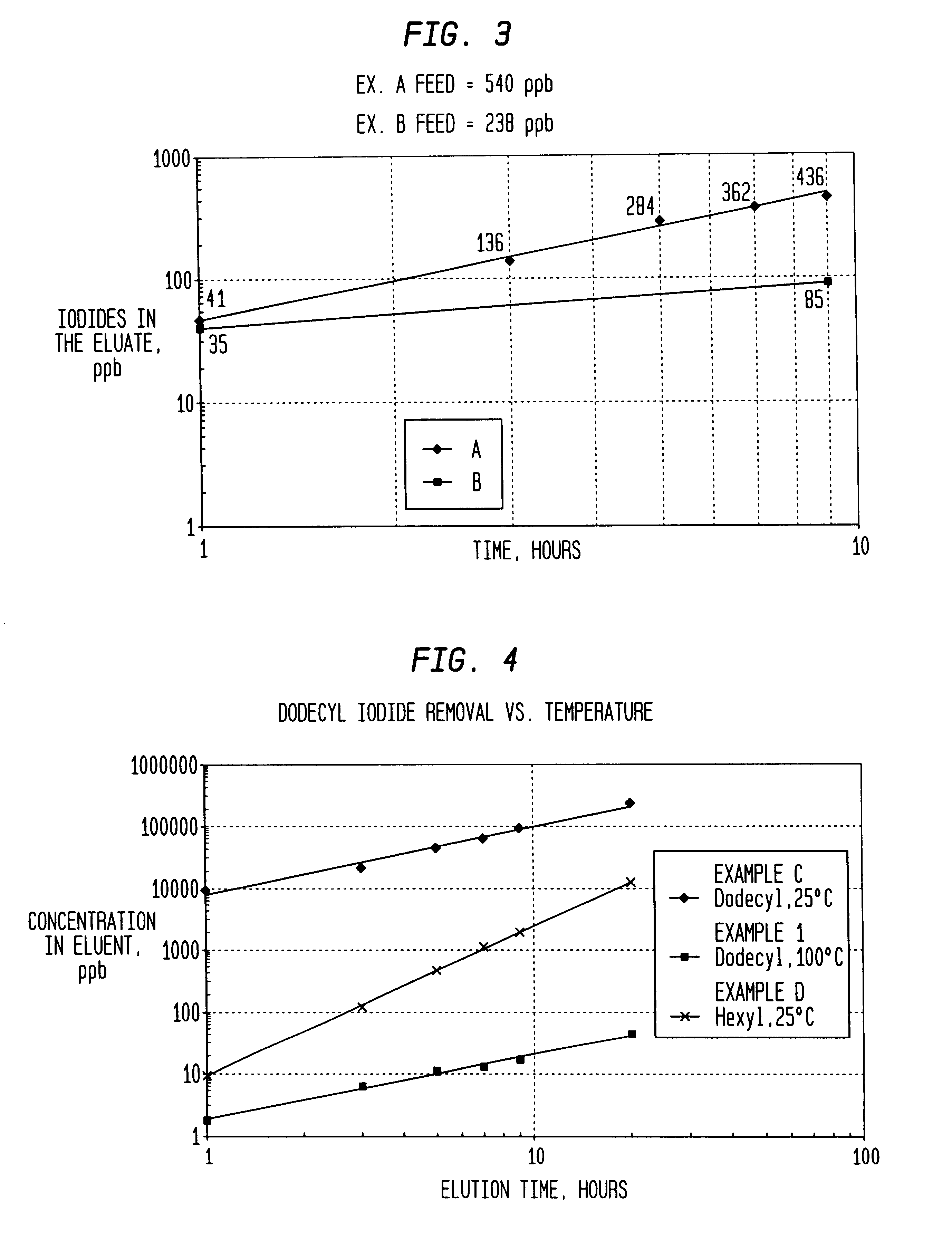

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223886B2Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

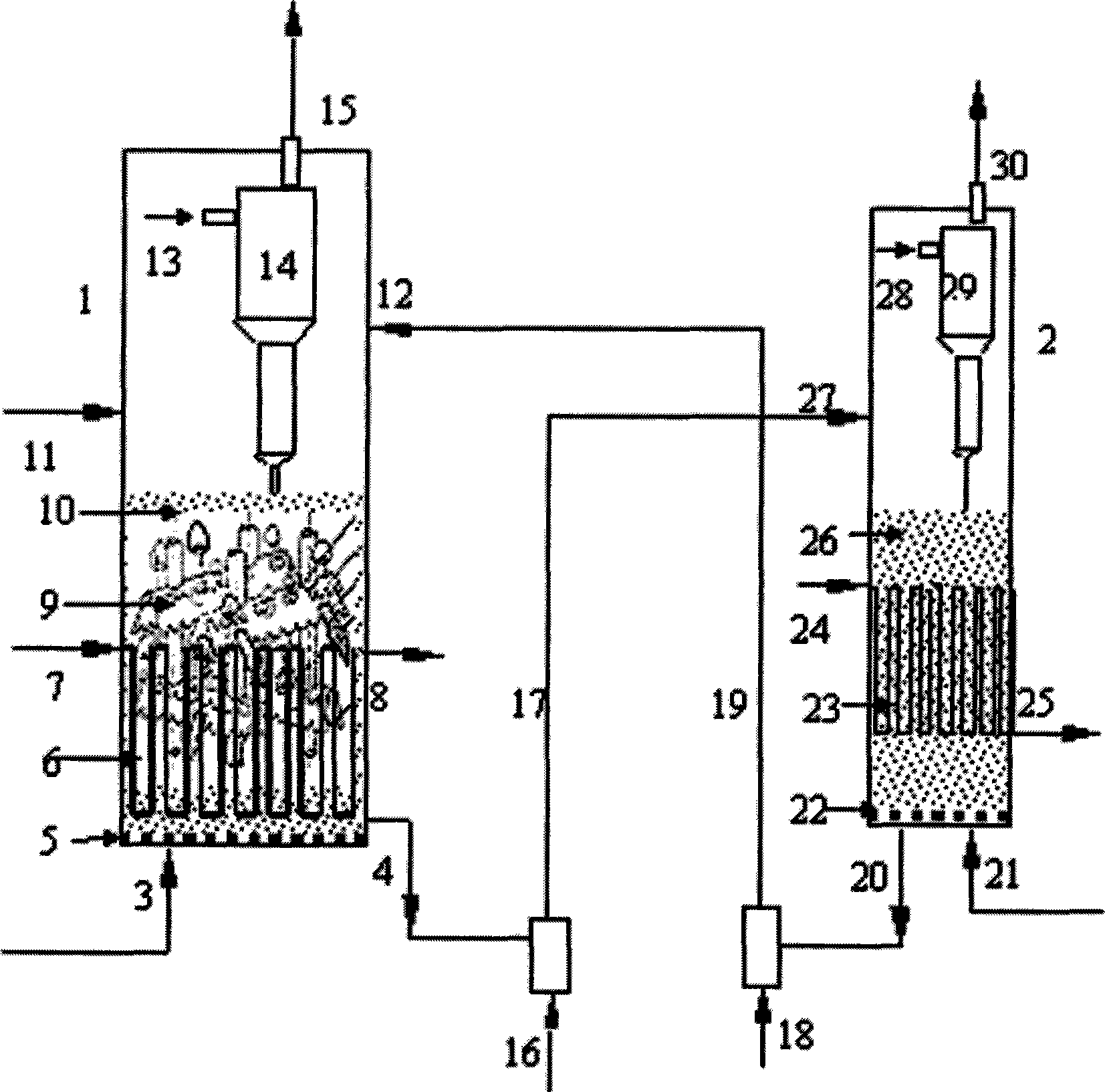

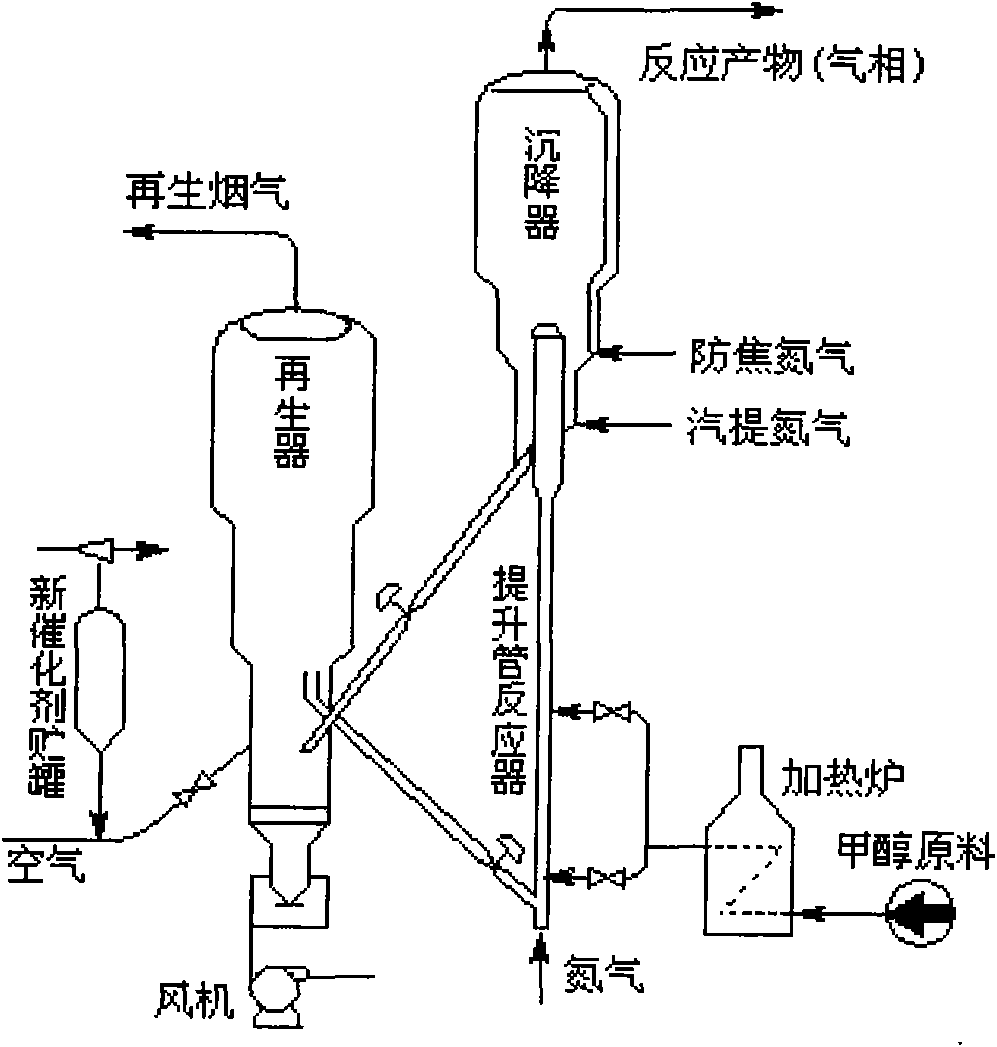

Continuous aromatization and catalyst regeneration device and method thereof

ActiveCN101244969ANo temperature fluctuationsDoes not affect aromatization reactionMolecular sieve catalystsCatalyst regeneration/reactivationFluidized bedAromatization

The invention discloses and belongs to the chemical equipment field, which more particularly relates to a C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device (comprising an aromatization fluidized bed, a catalyst continuous regeneration fluidized bed, a pipeline used for catalyst transportation and a solid transportation device which are arranged between the two fluidized beds), and an aromatization catalyst which is suitable for the fluidized bed operations and the operation methods of aromatization reaction, catalyst regeneration and the device. The device, the catalyst and the method are used for regulating the coking status of the catalyst in an aromatization reactor at any time, thus achieving the aim of transforming the C1-C2 hydrocarbon or the methanol continuously and efficiently and generating aromatics with high selectivity. The C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device of the invention with adjustable catalyst activity and selectivity can improve the purity and yield of the aromatics, can lead the aromatization reactor operates continuously without stopping at the same time, can improve the strength of aromatics production, and lower the operation cost of the catalyst regeneration when stopping and restarting the whole system.

Owner:TSINGHUA UNIV

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

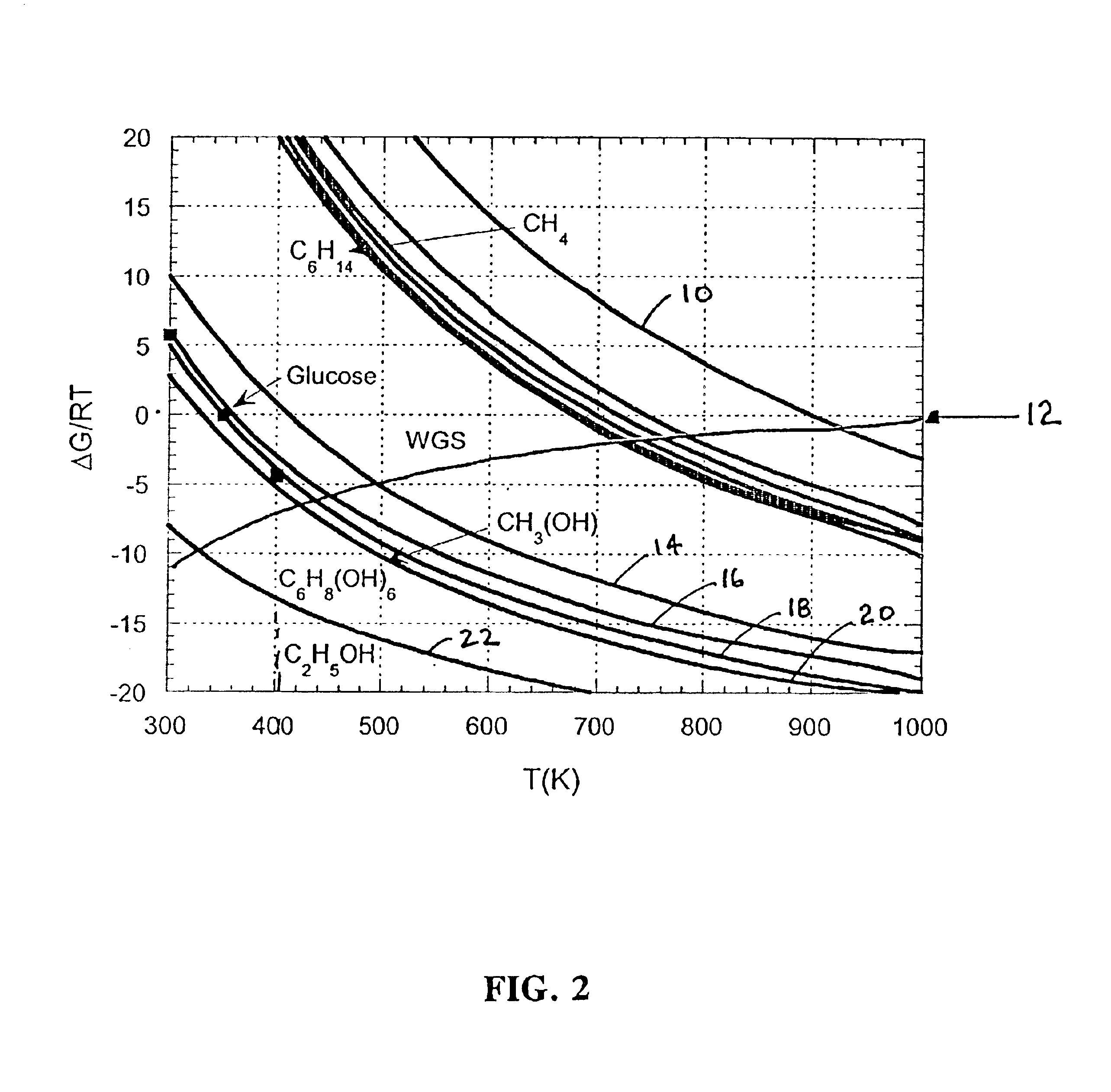

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

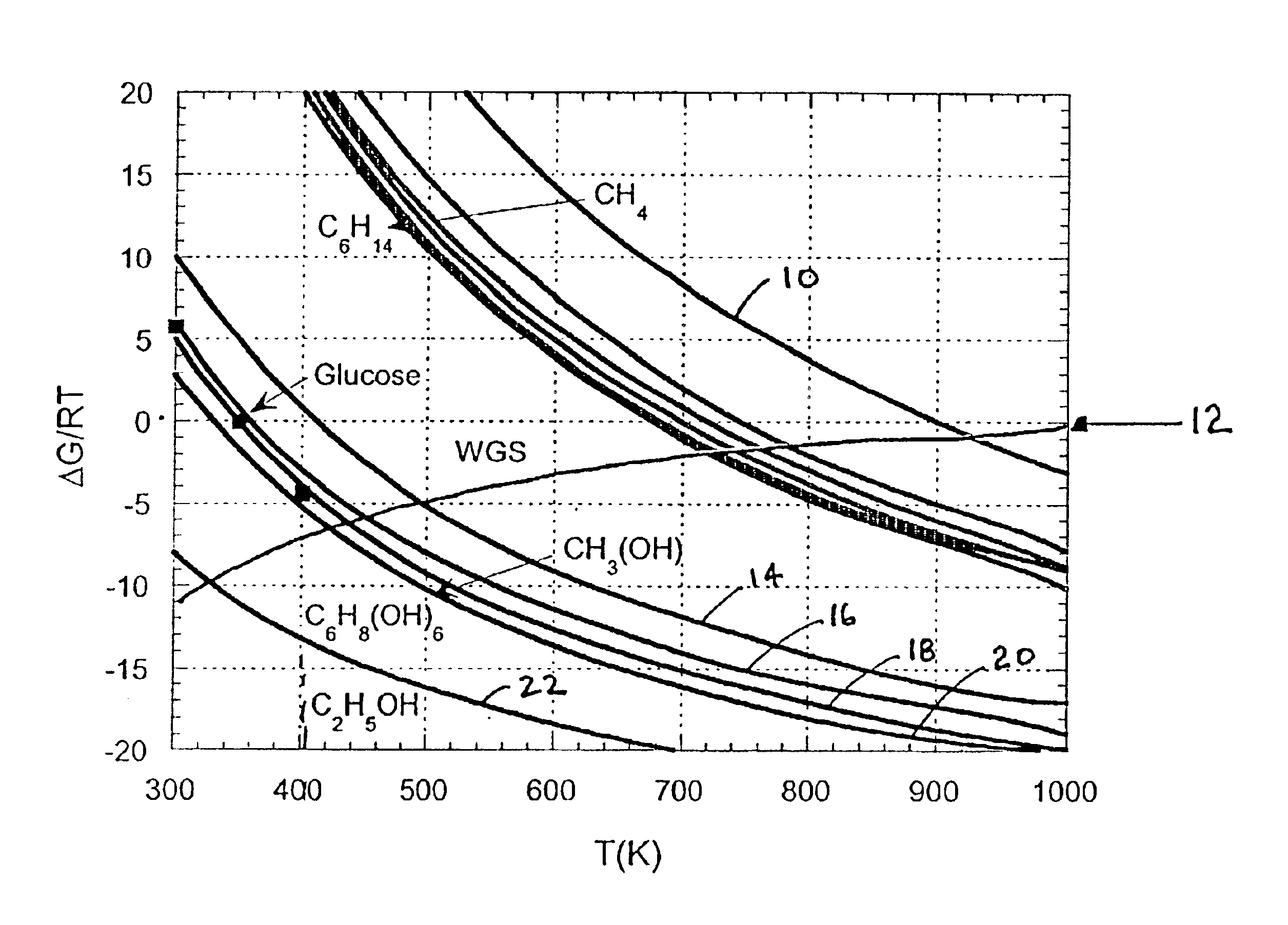

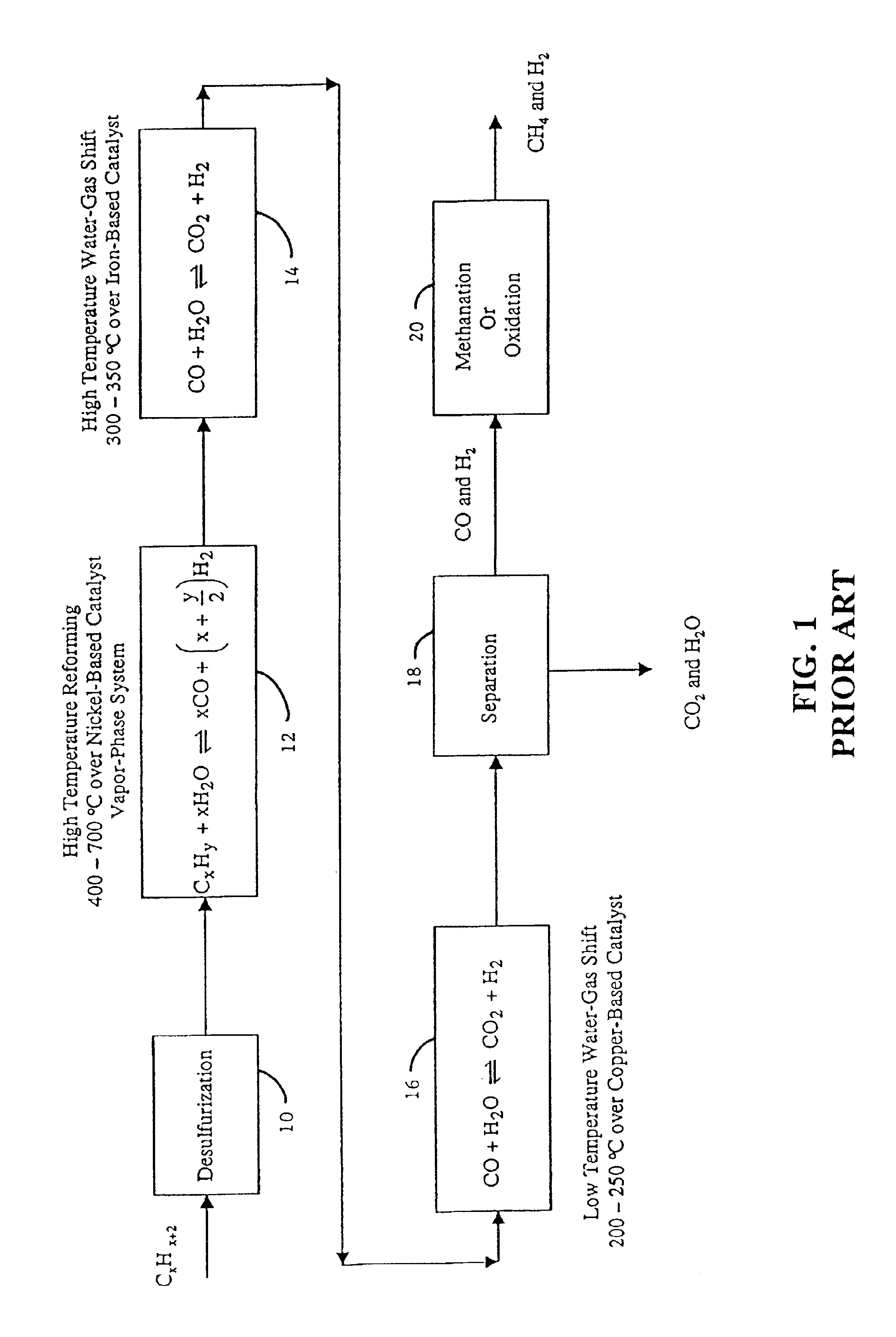

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Process for preparing dimethylbenzene by aromatization of methanol

ActiveCN101671226AHigh yieldExtend the life cycleHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

A process for preparing dimethylbenzene by aromatization of methanol relates to a process for preparing dimethylbenzene by conducting aromatization reaction in a methanol aromatization reactor with methanol and hydrocarbon as raw materials. The process uses a metal-modified molecular sieve composite material as catalyst and causes the mixture of methanol and one or a plurality of C1-C12 hydrocarbons to conduct aromatization reaction in the methanol aromatization reactor. By adjusting the ratio between methanol and hydrocarbons in the raw material, the process regulates and controls the coordination between aromatization and alkylation reaction and realizes the purposes of effectively improving the yield of the target product dimethylbenzene and prolonging the service cycle of catalyst.

Owner:TSINGHUA UNIV +1

Plant and a method for increased oil recovery

Owner:DEN NORSKE STATS OLJESELSKAP AS

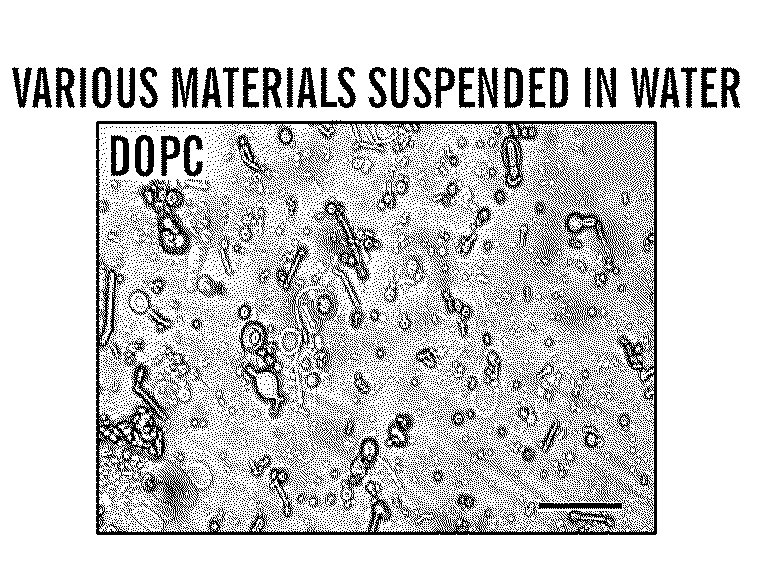

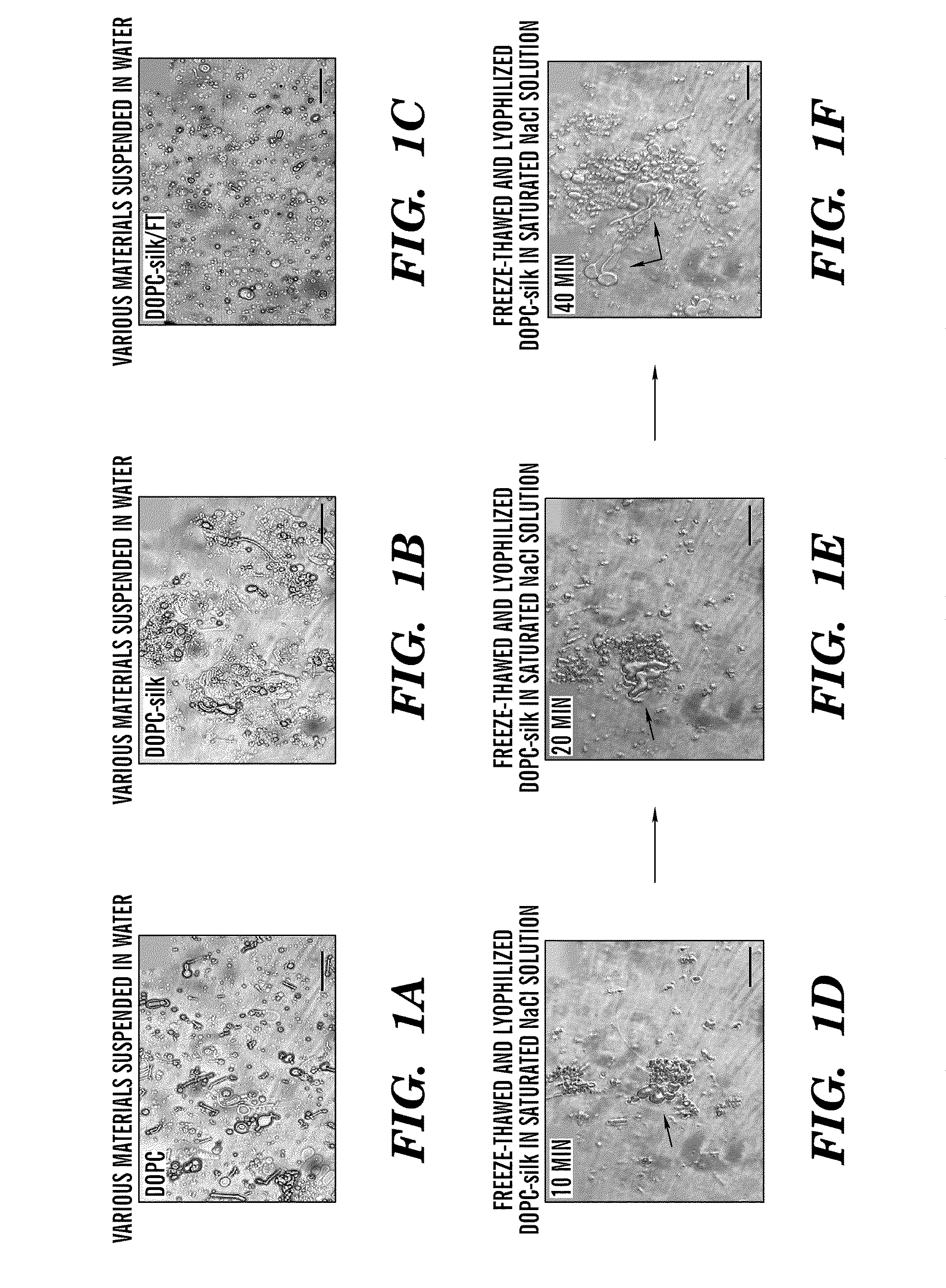

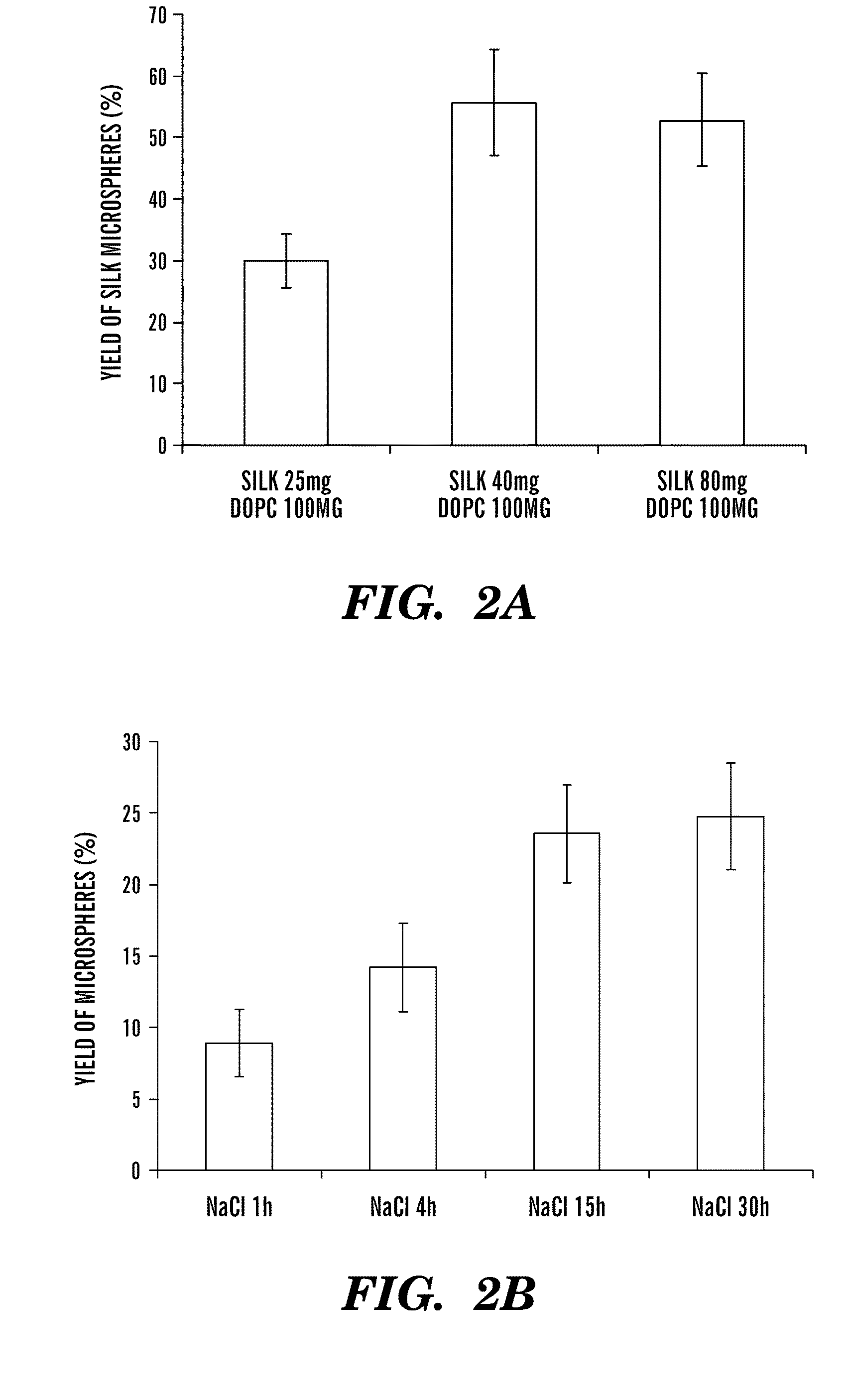

Silk microspheres for encapsulation and controlled release

A method was developed to prepare silk fibroin microspheres using lipid vesicles as templates to efficiently load therapeutic agents in active form for controlled release. The lipids are subsequently removed through the use of a dehydration agent, such as methanol or sodium chloride, resulting in β-sheet structure dominant silk microsphere structures having about 2 μm in diameter. The therapeutic agent can be entrapped in the silk microspheres and used in pharmaceutical formulations for controlled-release treatments.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

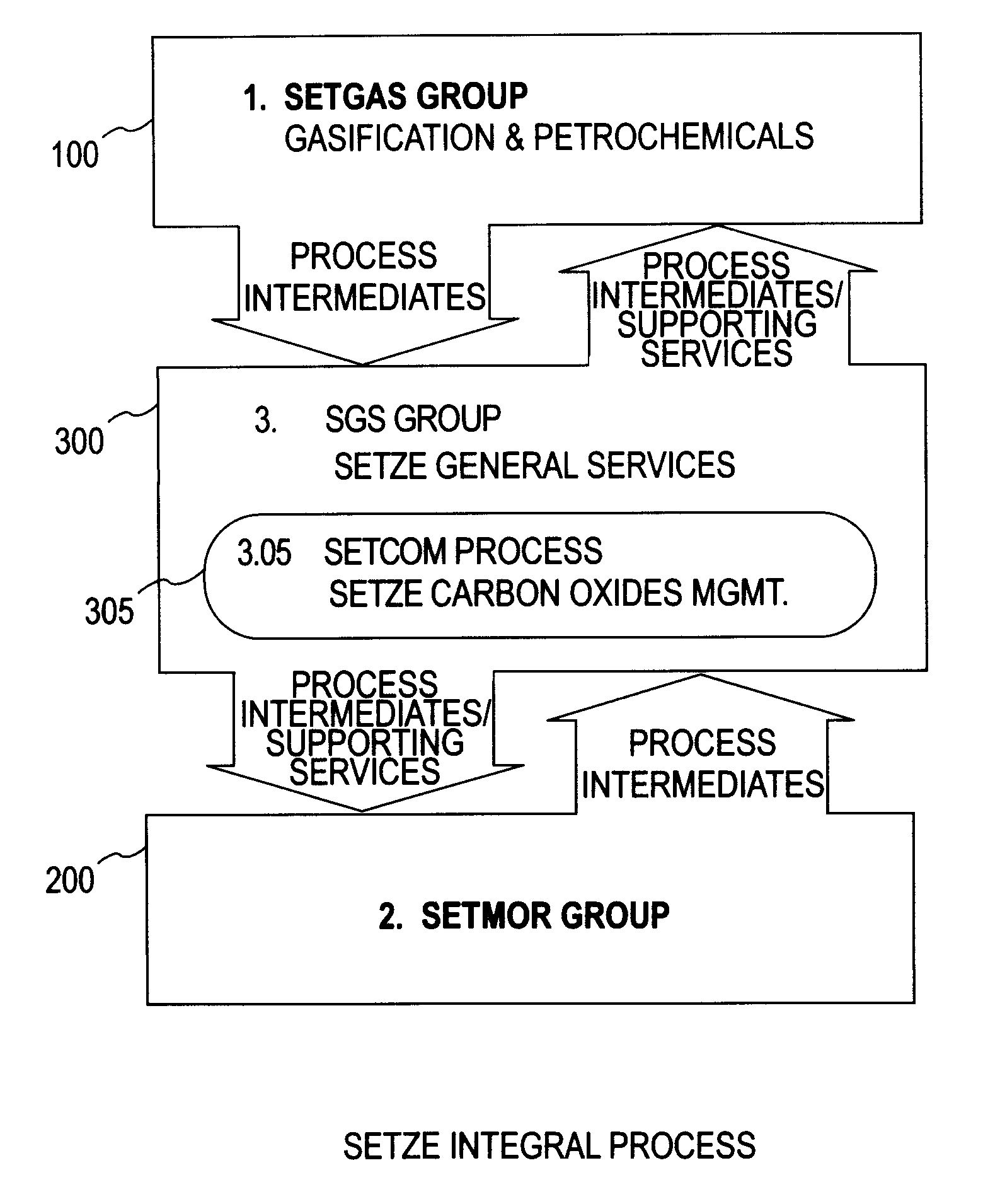

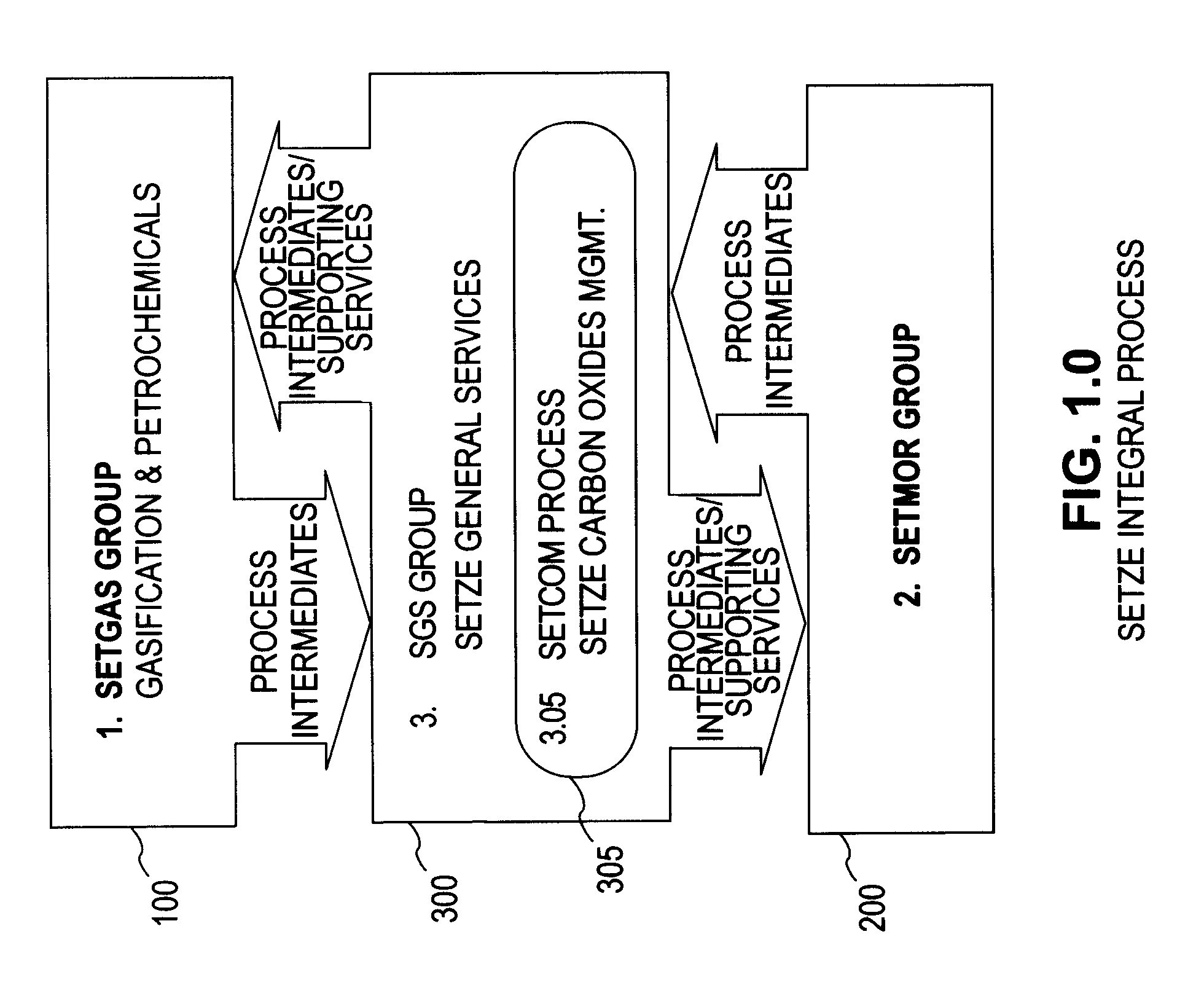

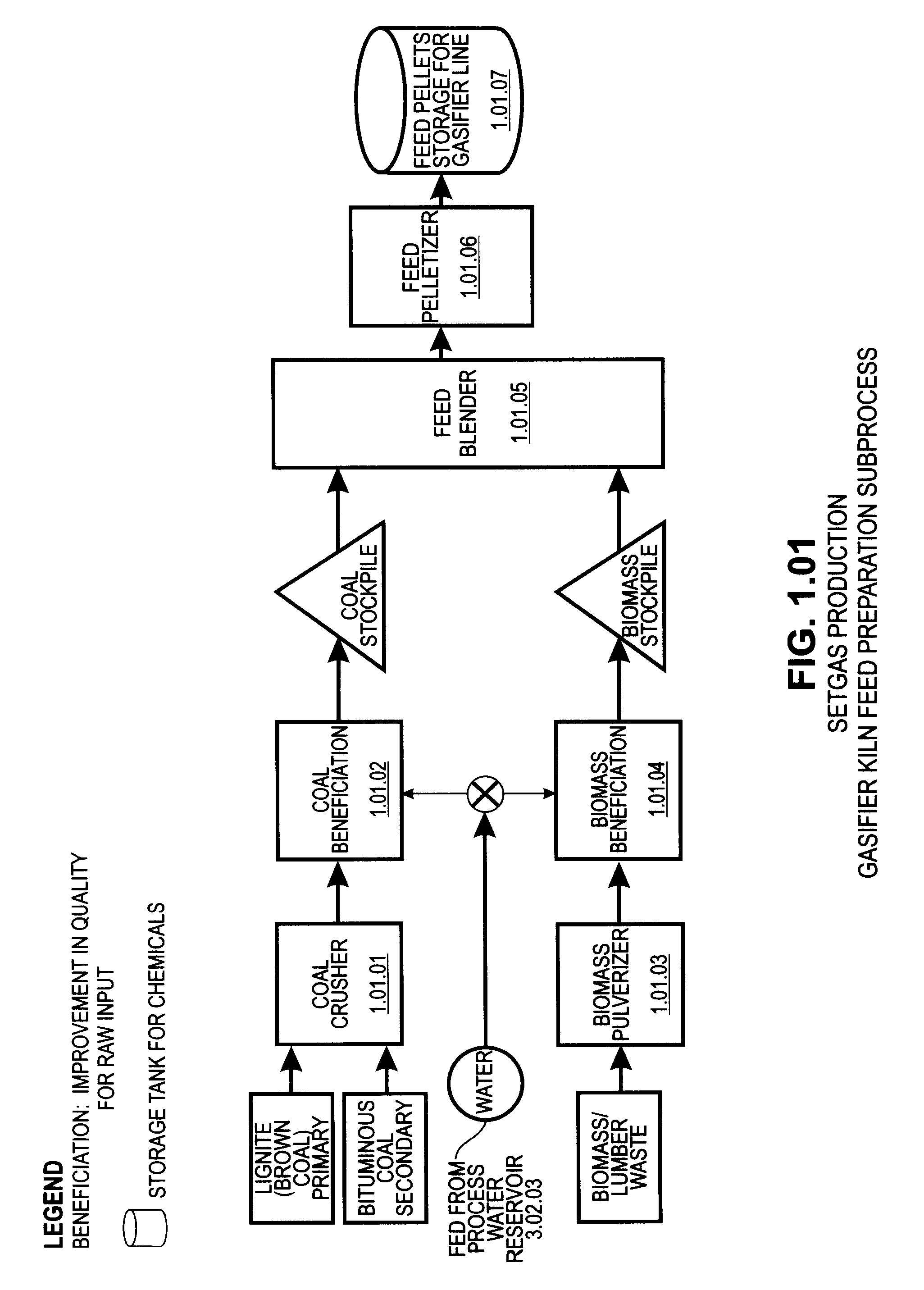

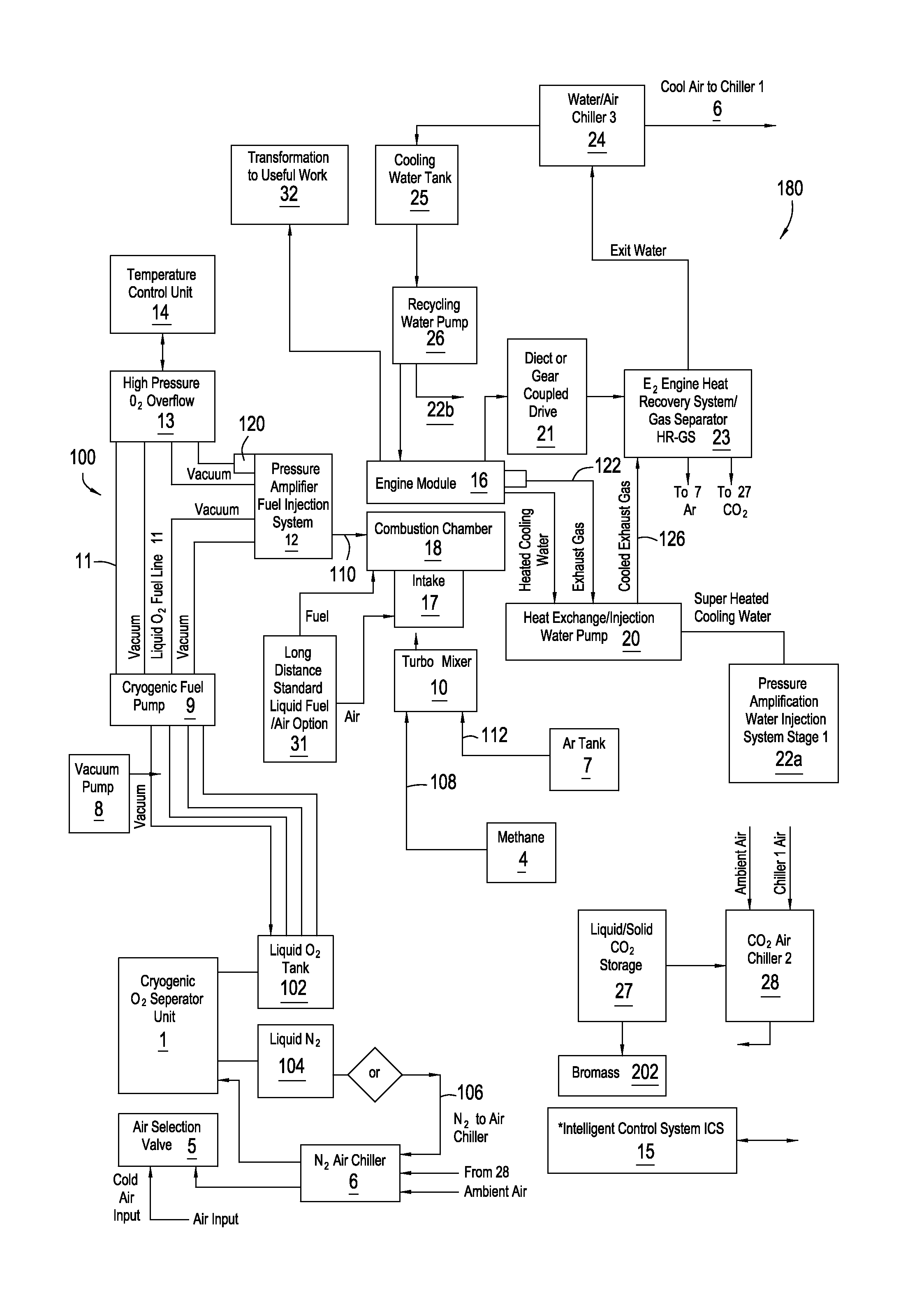

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

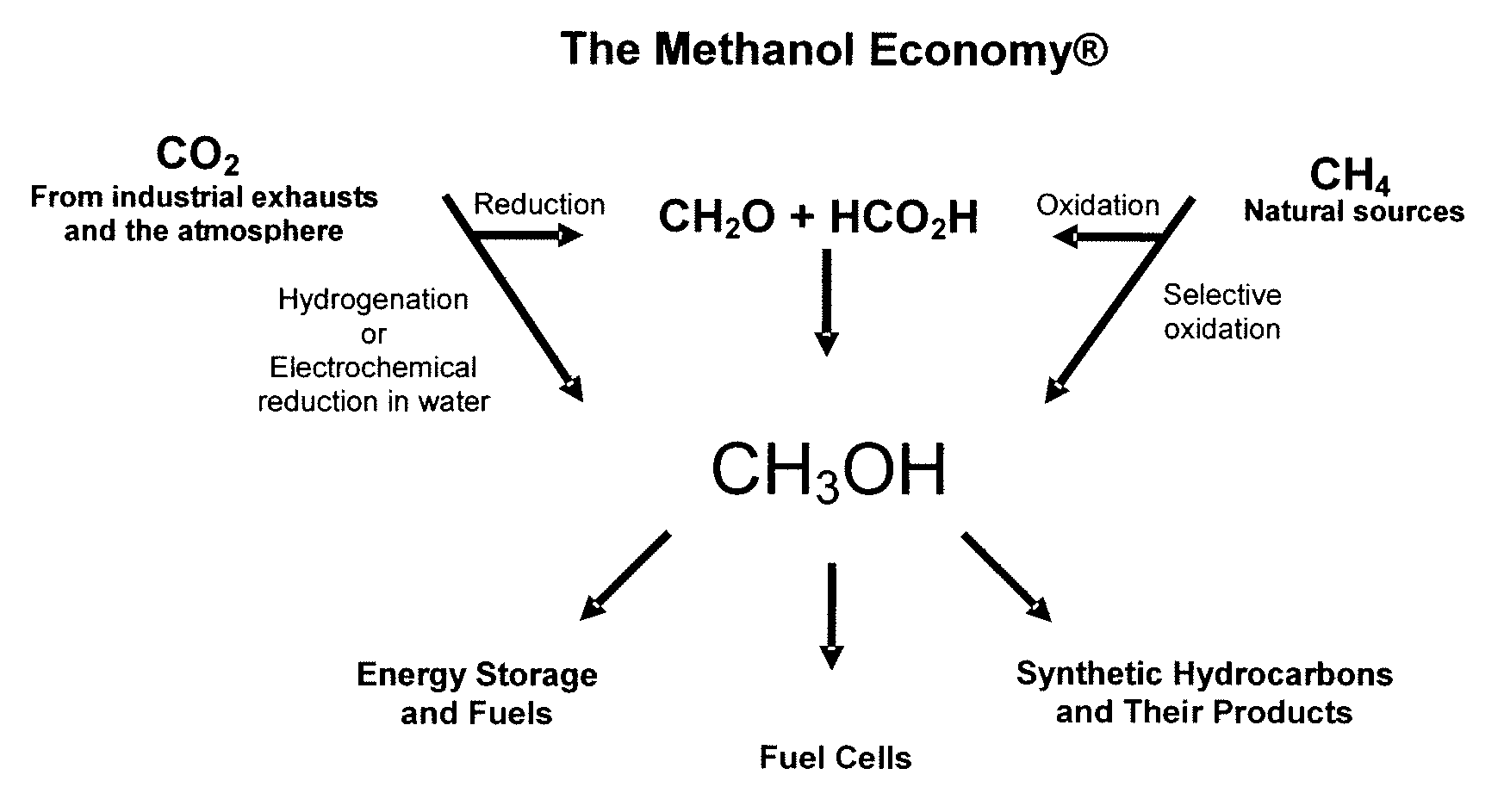

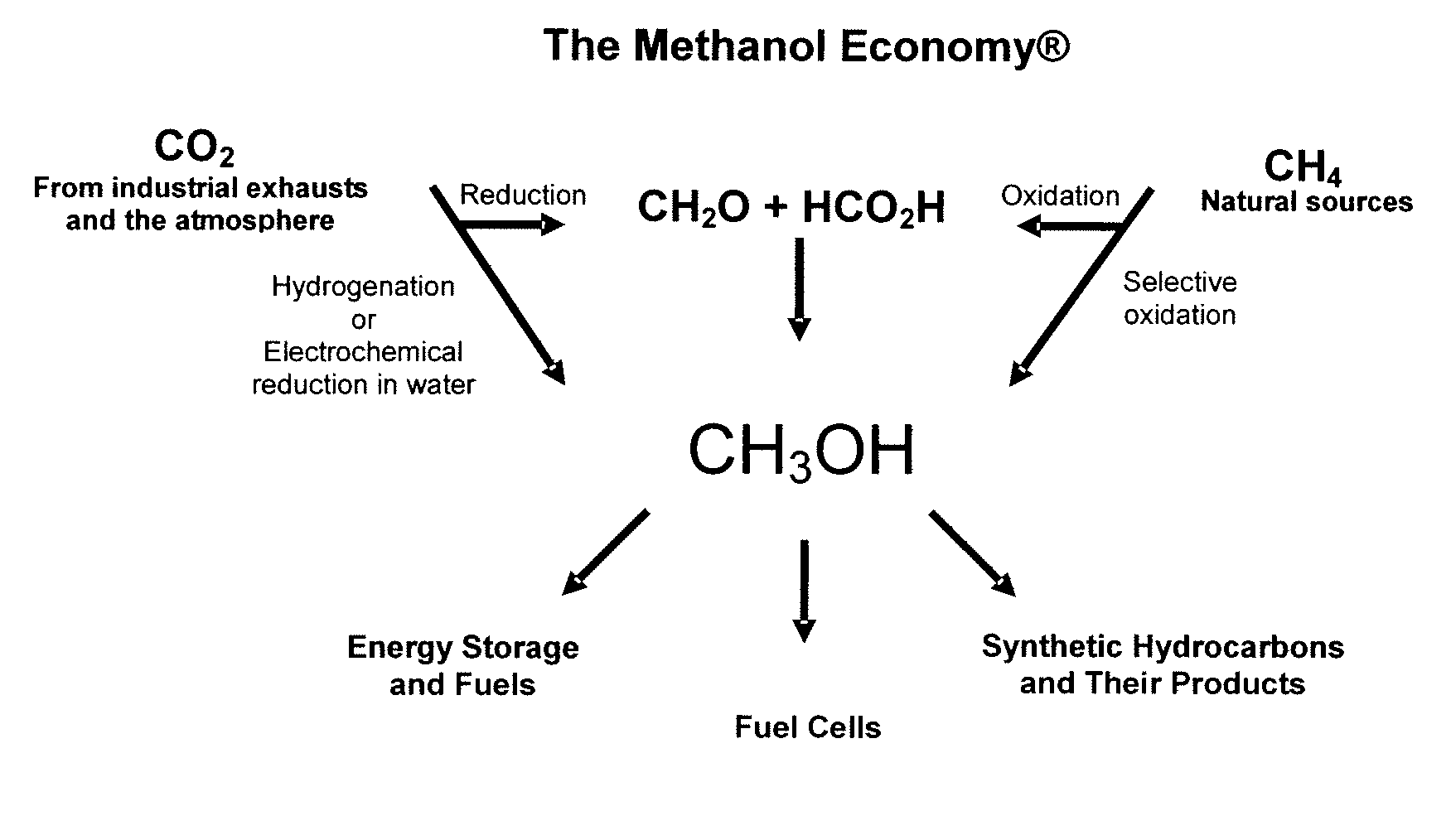

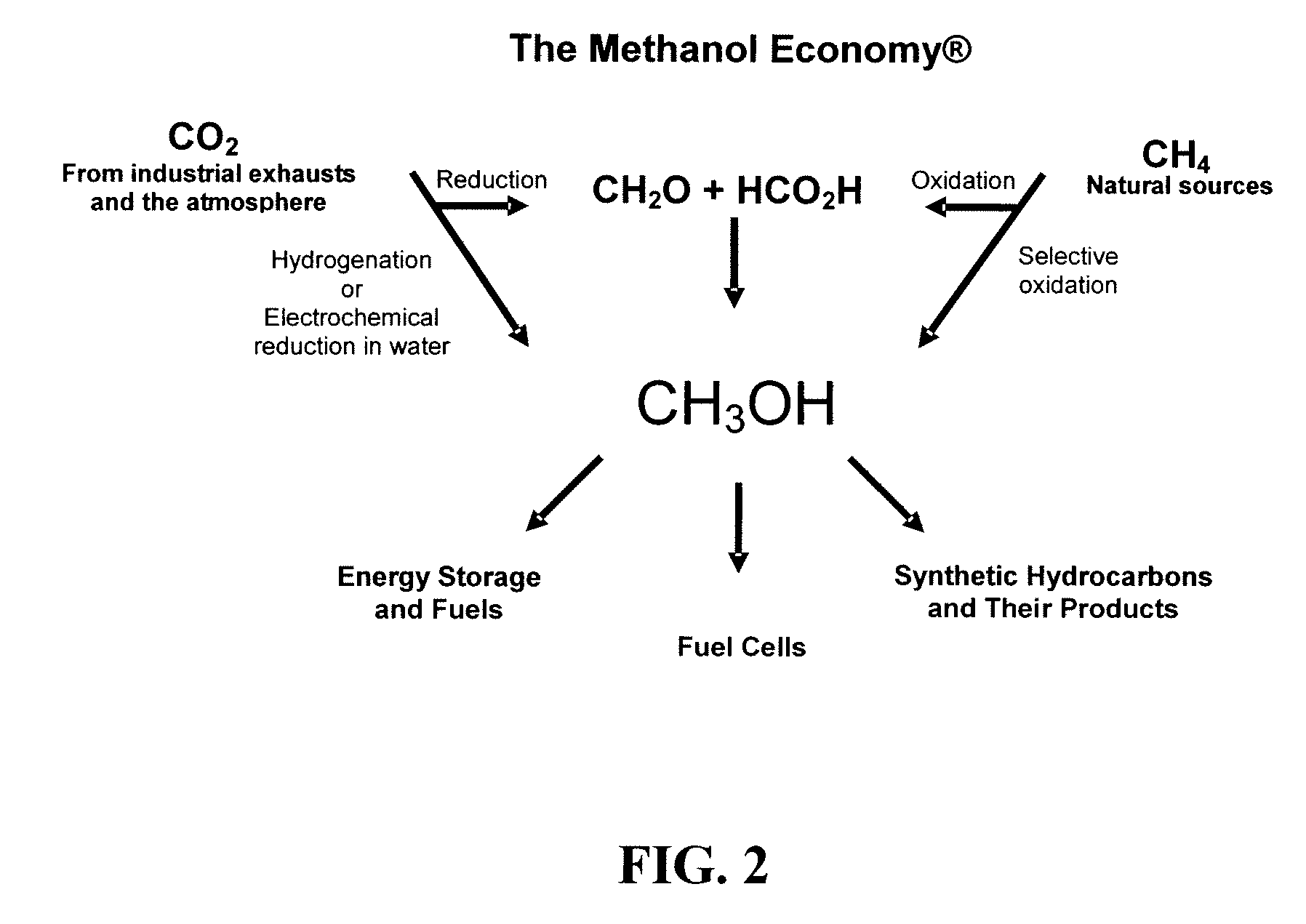

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

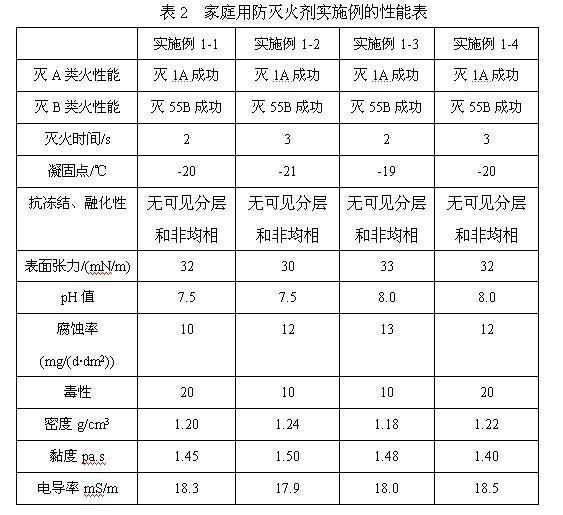

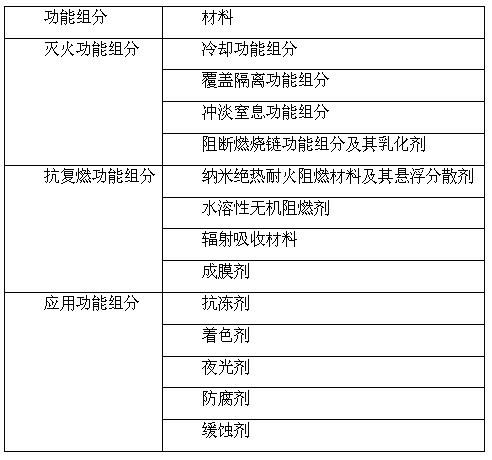

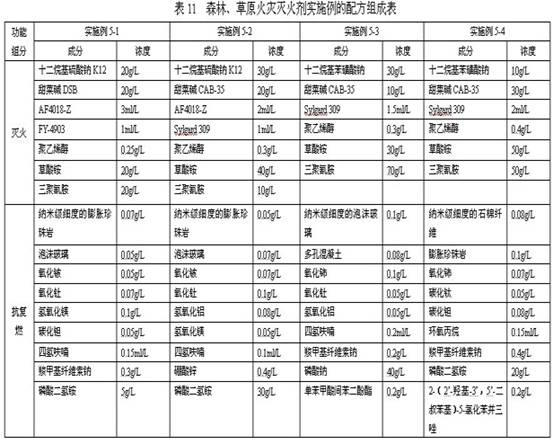

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

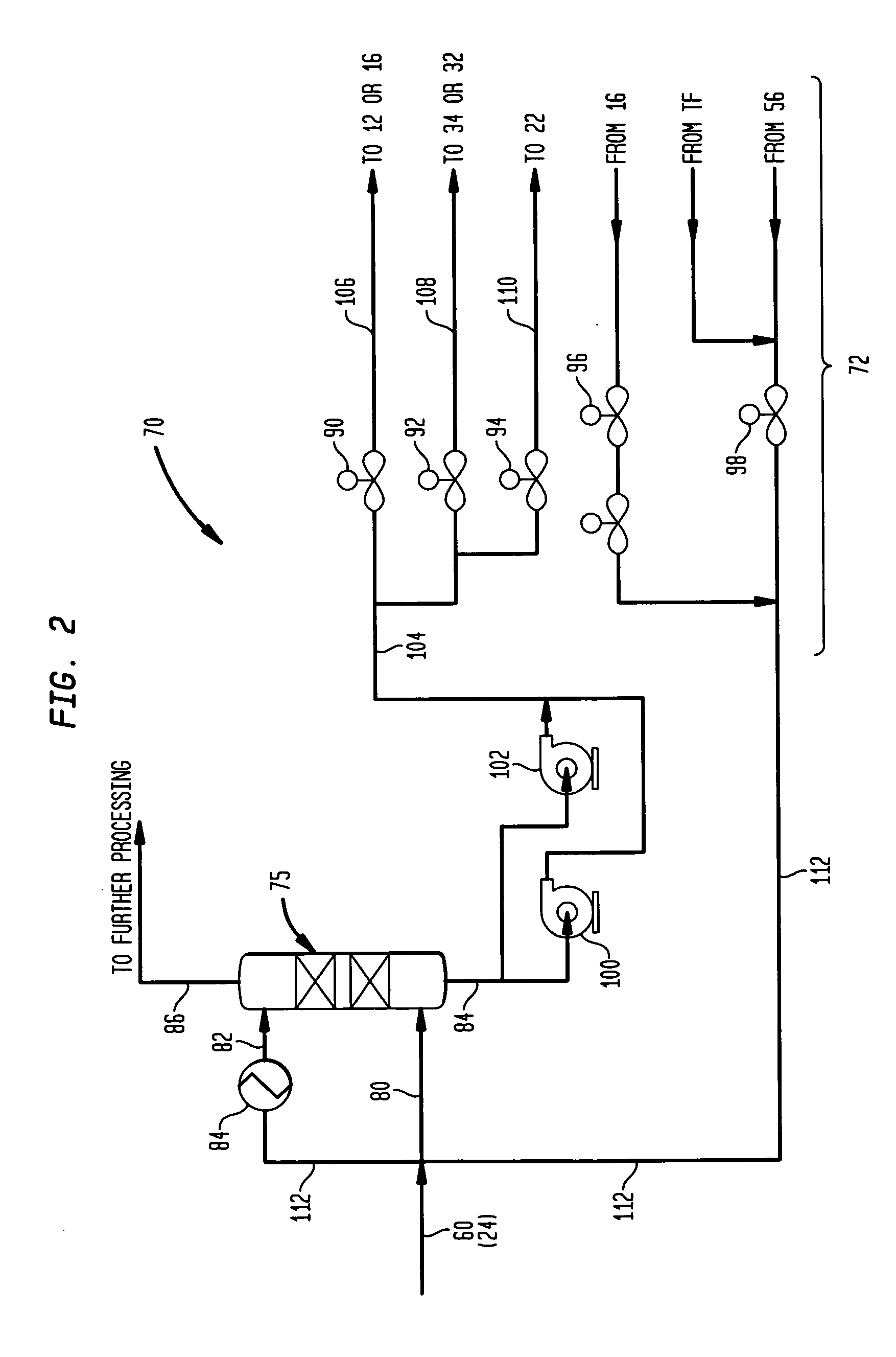

Methanol carbonylation system having absorber with multiple solvent options

A methanol carbonylation system 10 includes an absorber tower 75 adapted for receiving a vent gas stream and removing methyl iodide therefrom with a scrubber solvent, the absorber tower being coupled to first and second scrubber solvent sources 16, 56 which are capable of supplying different first and second scrubber solvents. A switching system including valves 90, 92, 94, 96, 98 alternatively provides first or second scrubber solvents to the absorber tower and returns the used solvent and sorbed material to the carbonylation system to accommodate different operating modes.

Owner:CELANESE INT CORP

Process for preparing arene selectivity by enhancing methanol aromatizatian and process for preparation of catalyst thereof

ActiveCN101550051AImprove methodHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveFixed bed

The invention relates to a process for preparing arene selectivity by enhancing methanol aromatizatian. The process uses methanol as raw material, compositely modifies HZSM-5 molecular sieve catalyst by active ions like Ga, Zn, Cu, Cr and Ag for catalyzing methanol aromatizatian, employs the fixed bed continuous process or the floating bed continuous process, wherein the reaction pressure is 0.1-3.5MPa; the reaction temperature is 380-500 DEG C; the space velocity of raw material liquid is 0.1-10.0 h; and N2 space velocity is 120-800 h. The advantages of the invention lie in collocation combination of mixing ion modification, and arene selectivity reaches to 70%.

Owner:TIANJI COAL CHEM IND GROUP +1

Process for the production of acetic acid

Owner:CELANESE INT CORP

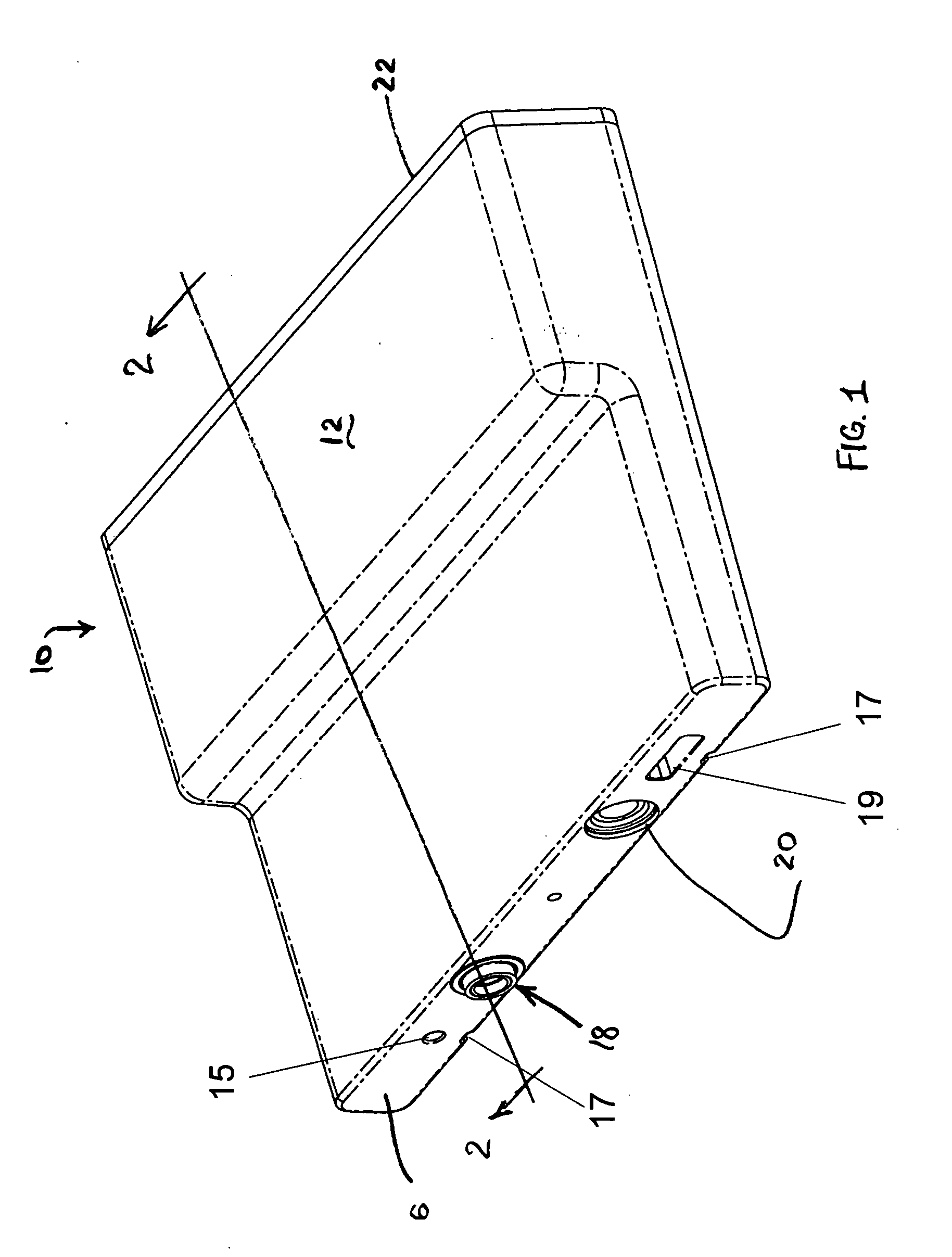

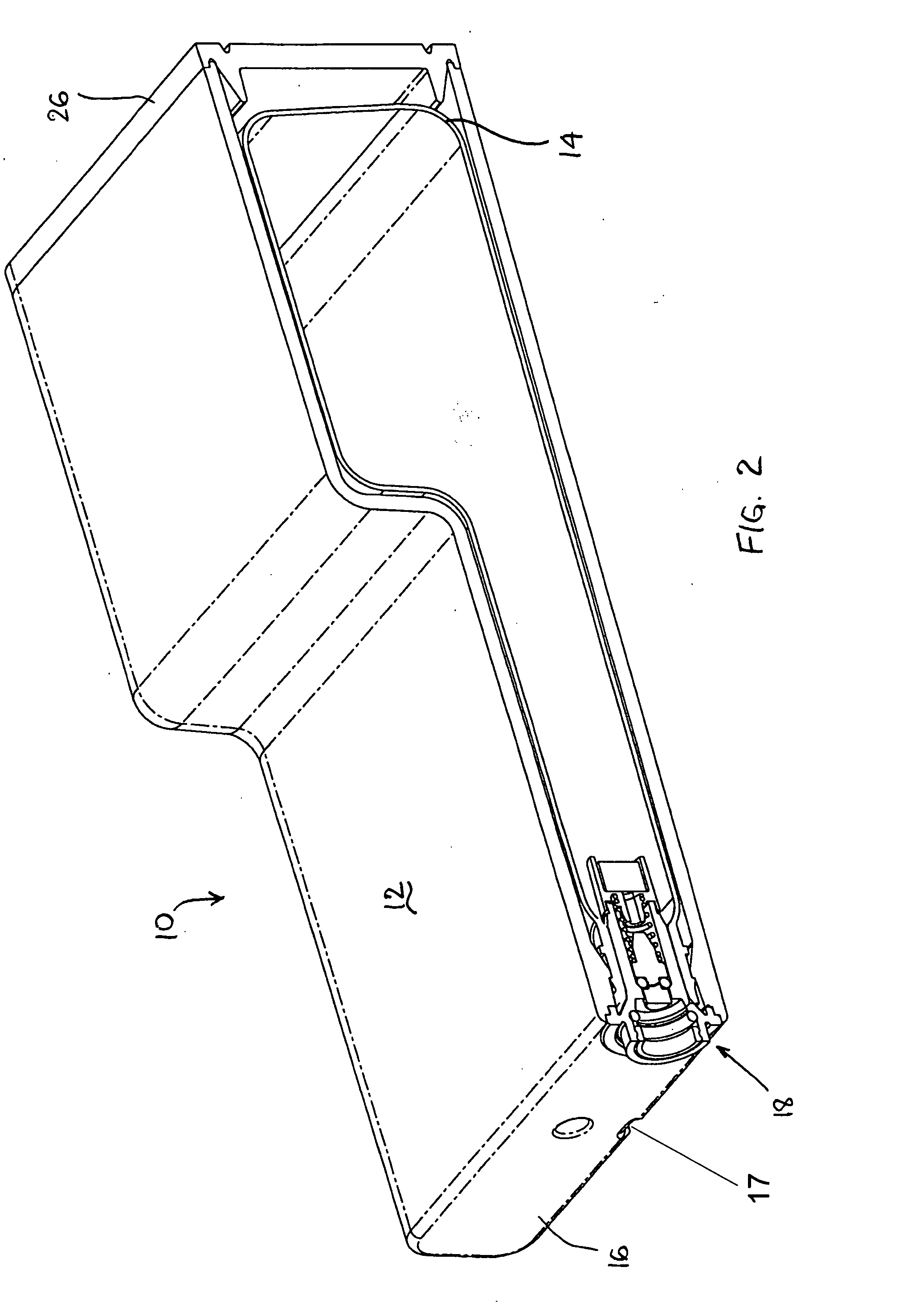

Fuel cell supply having fuel compatible materials

The present invention is directed to a fuel cell supply for a fuel cell having an outer casing, a liner member containing methanol, and a valve component comprising a valve body member and a slidable body member disposed inside the valve body member. The slidable body member is normally biased toward a valve seat surface to seal the valve component and the slidable body member can be moved away from the valve seat surface to open the valve component. The liner member, the valve body member and the slidable body member are made from at least two different materials and wherein at least one of the members compatible with methanol. Hence, each component can be selected from material(s) that is substantially optimal for its function in the fuel supply.

Owner:INTELLIGENT ENERGY LTD

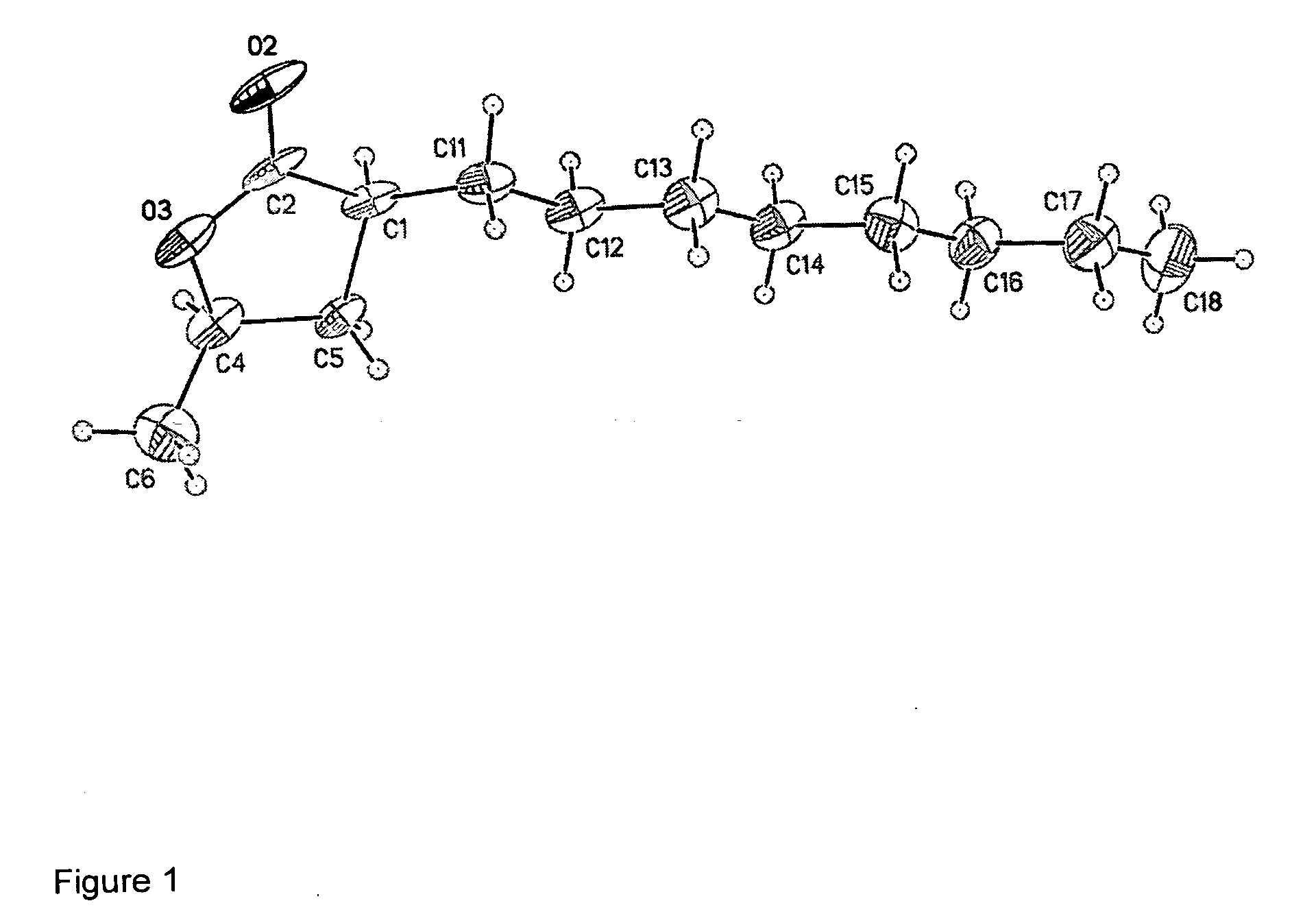

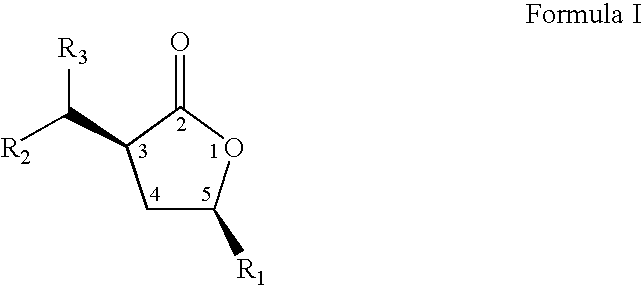

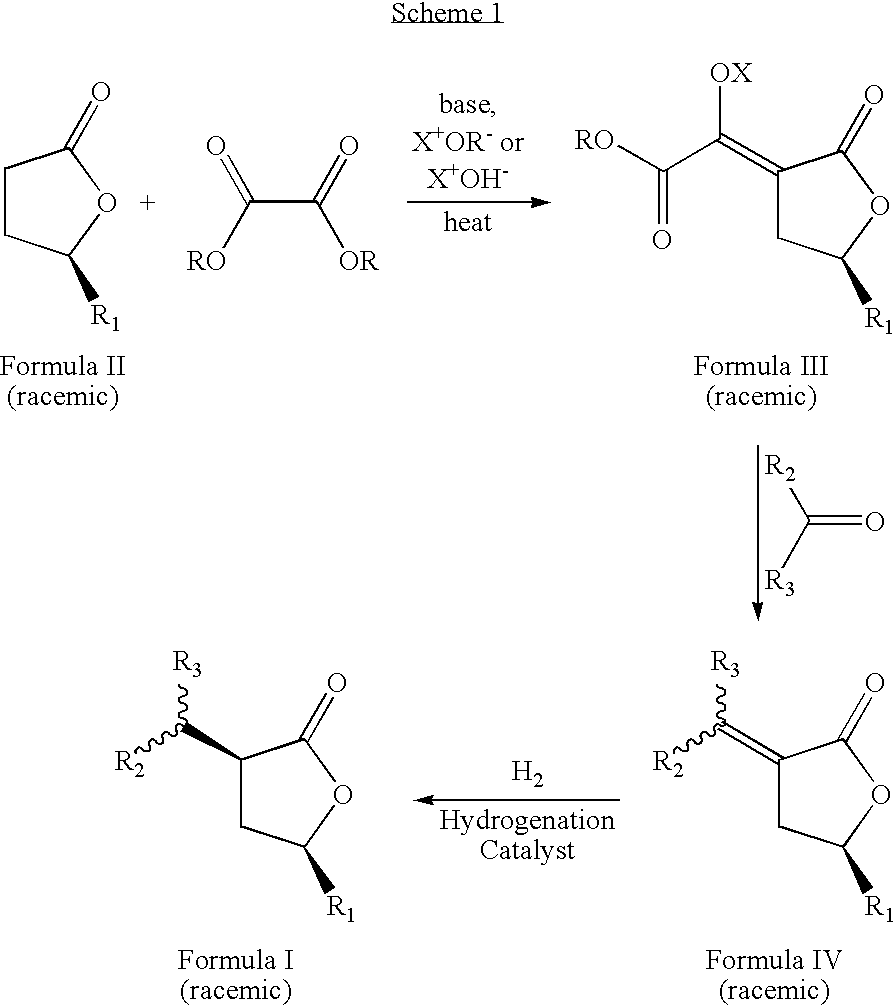

Cis-3,5-disubstituted-dihydro-furan-2-ones and the preparation and use thereof

The present invention relates to an improved process to prepare cis-3-dihydrocarbylmethano-5-hydrocarbyidihydro-furan-2-ones. The present invention also relates to novel compositions of matter comprising enantiomerically pure cis-3-dihydrocarbylmethano-5-hydrocarbyldihydro-furan-2-ones, being the (3S,5S), (3R,5R), (3S,5R), or (3R,5S) optically pure isomers, and a new, more cost efficient process to prepare said optically pure isomers.

Owner:EI DU PONT DE NEMOURS & CO

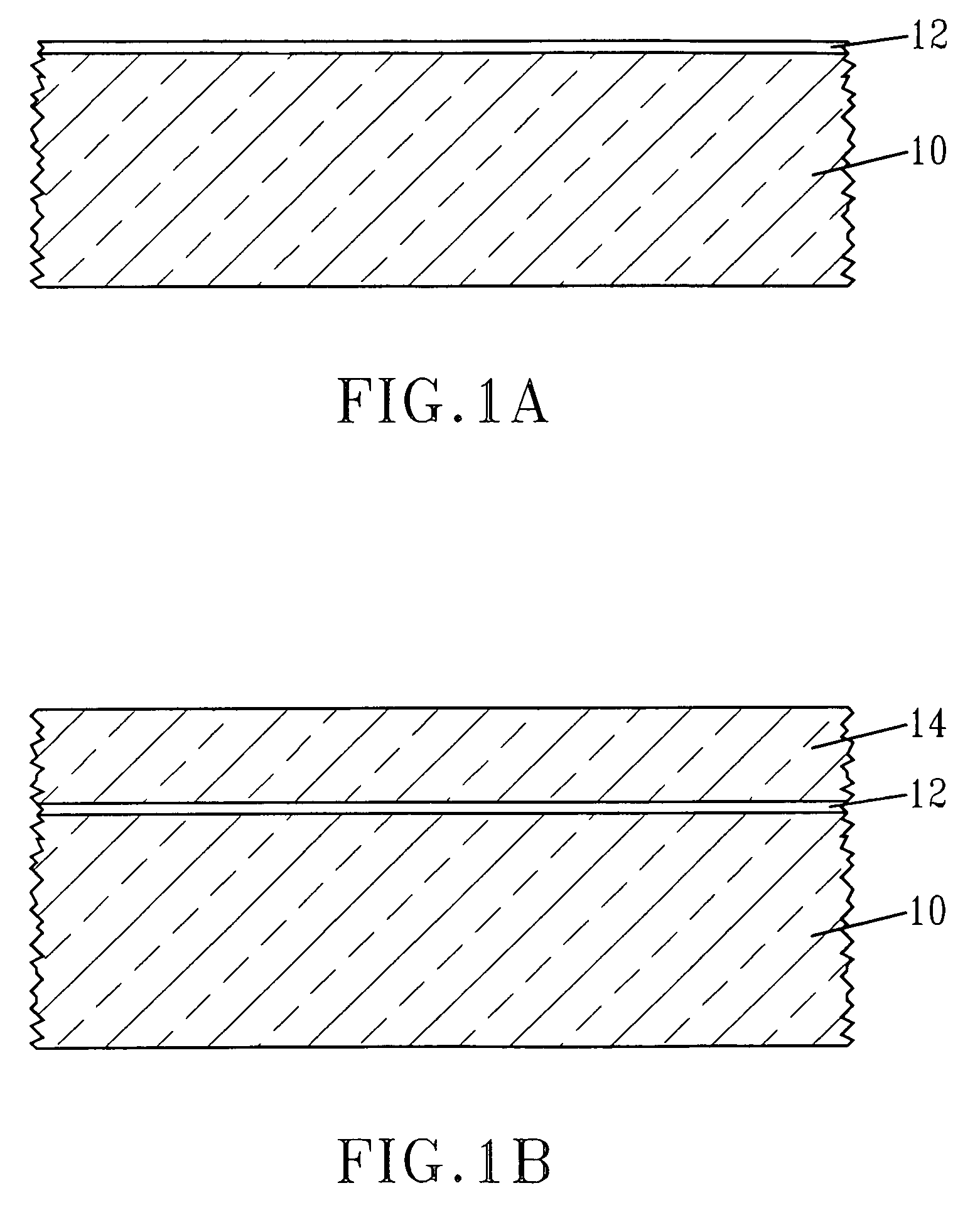

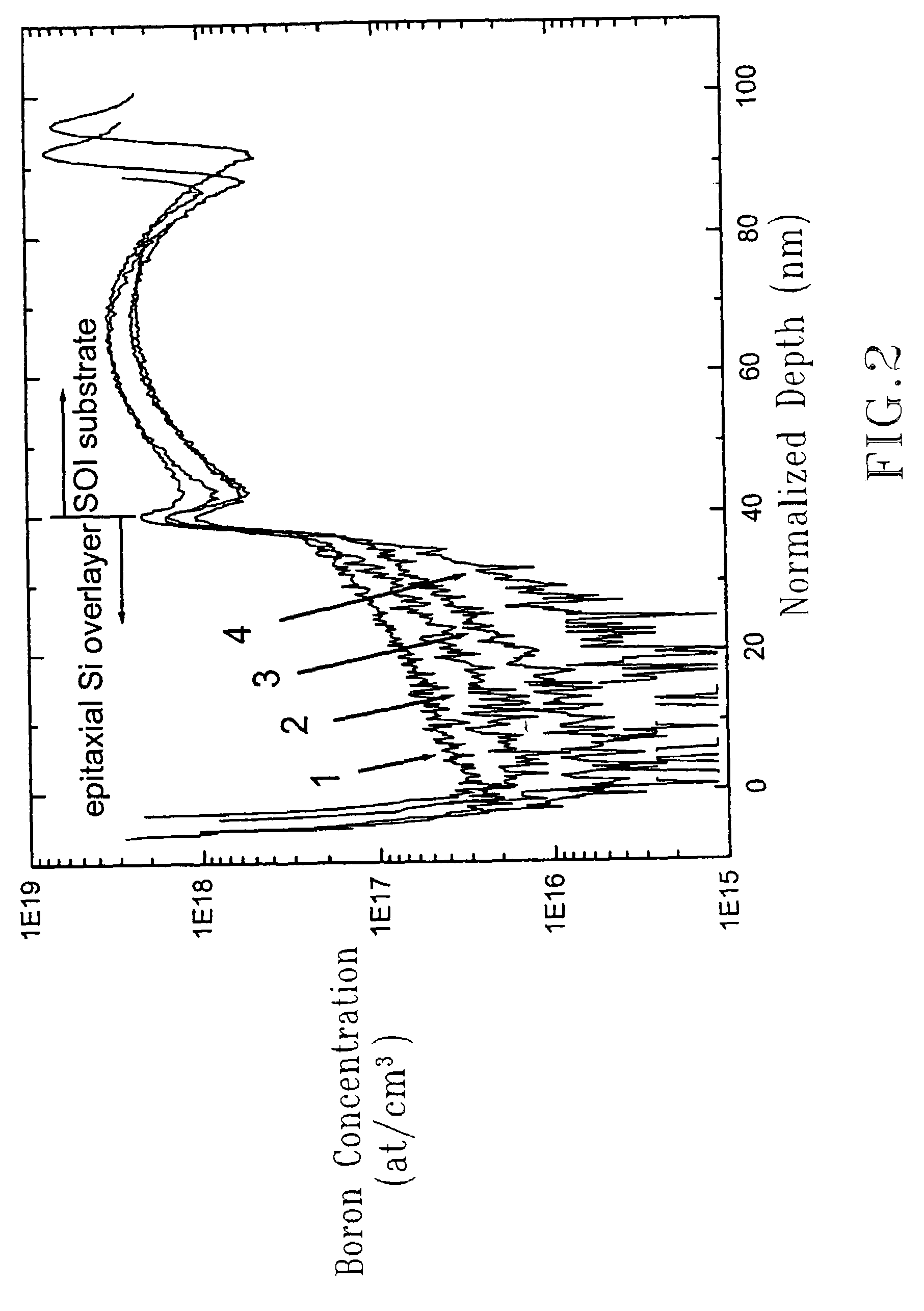

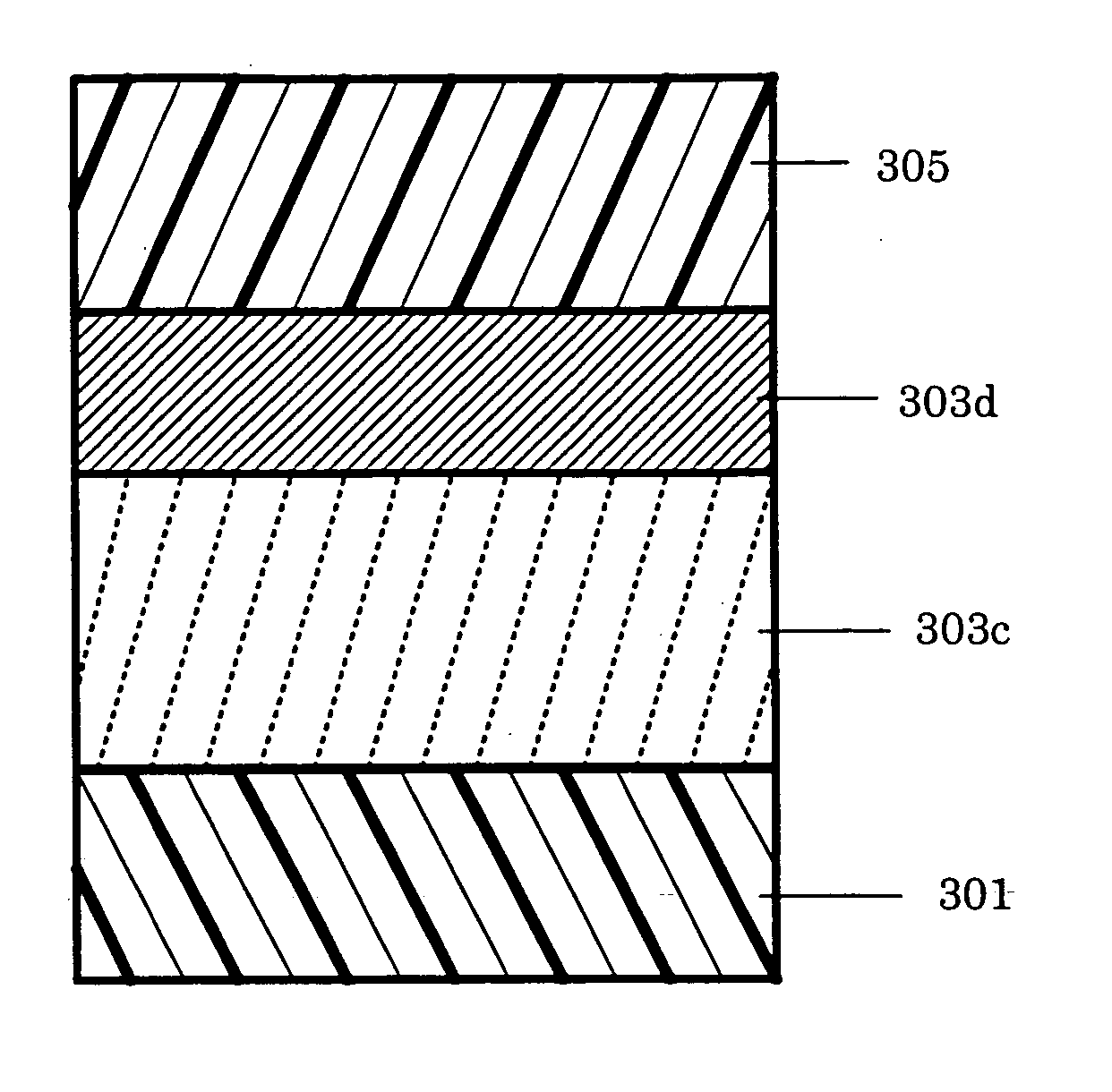

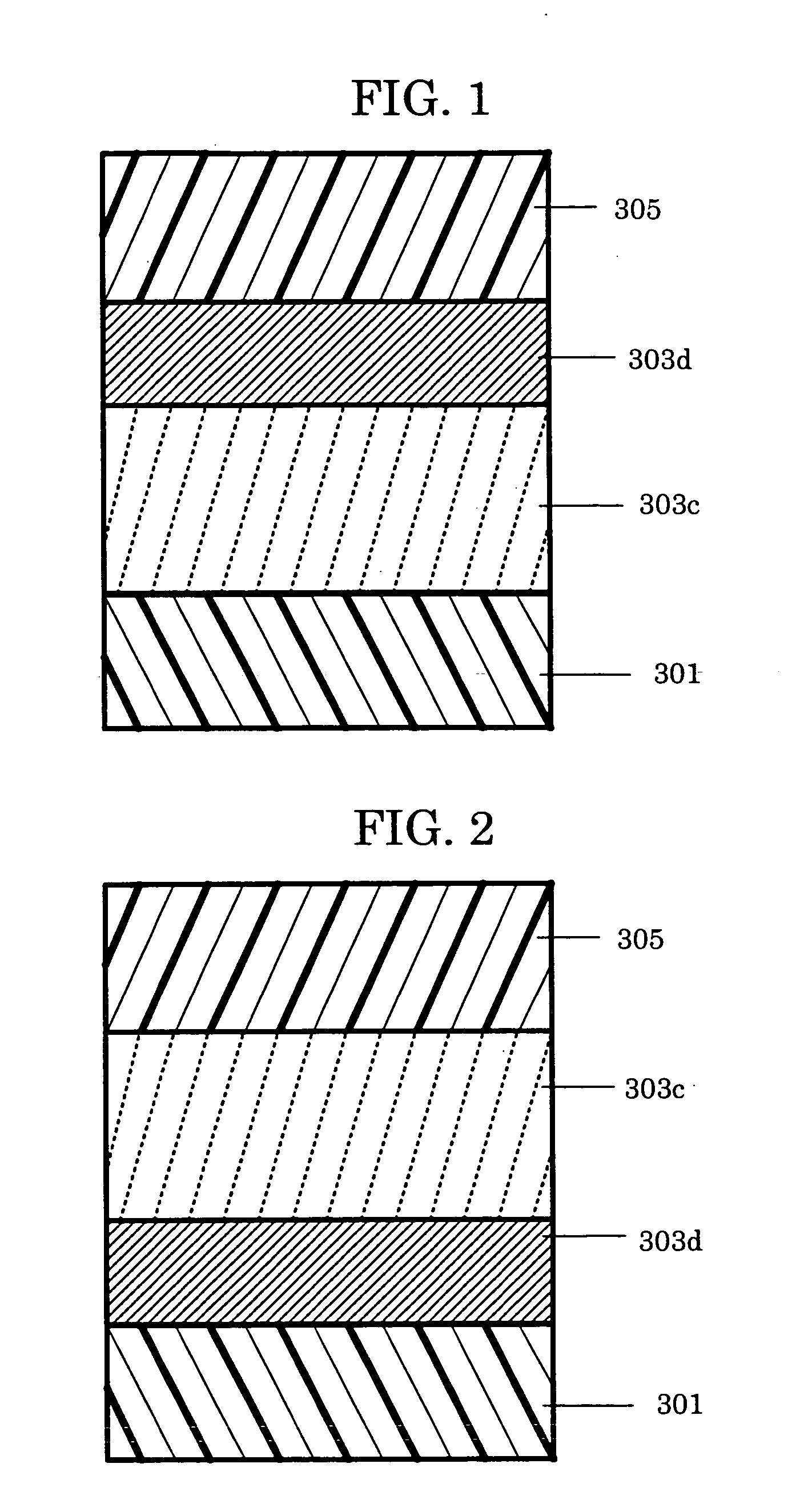

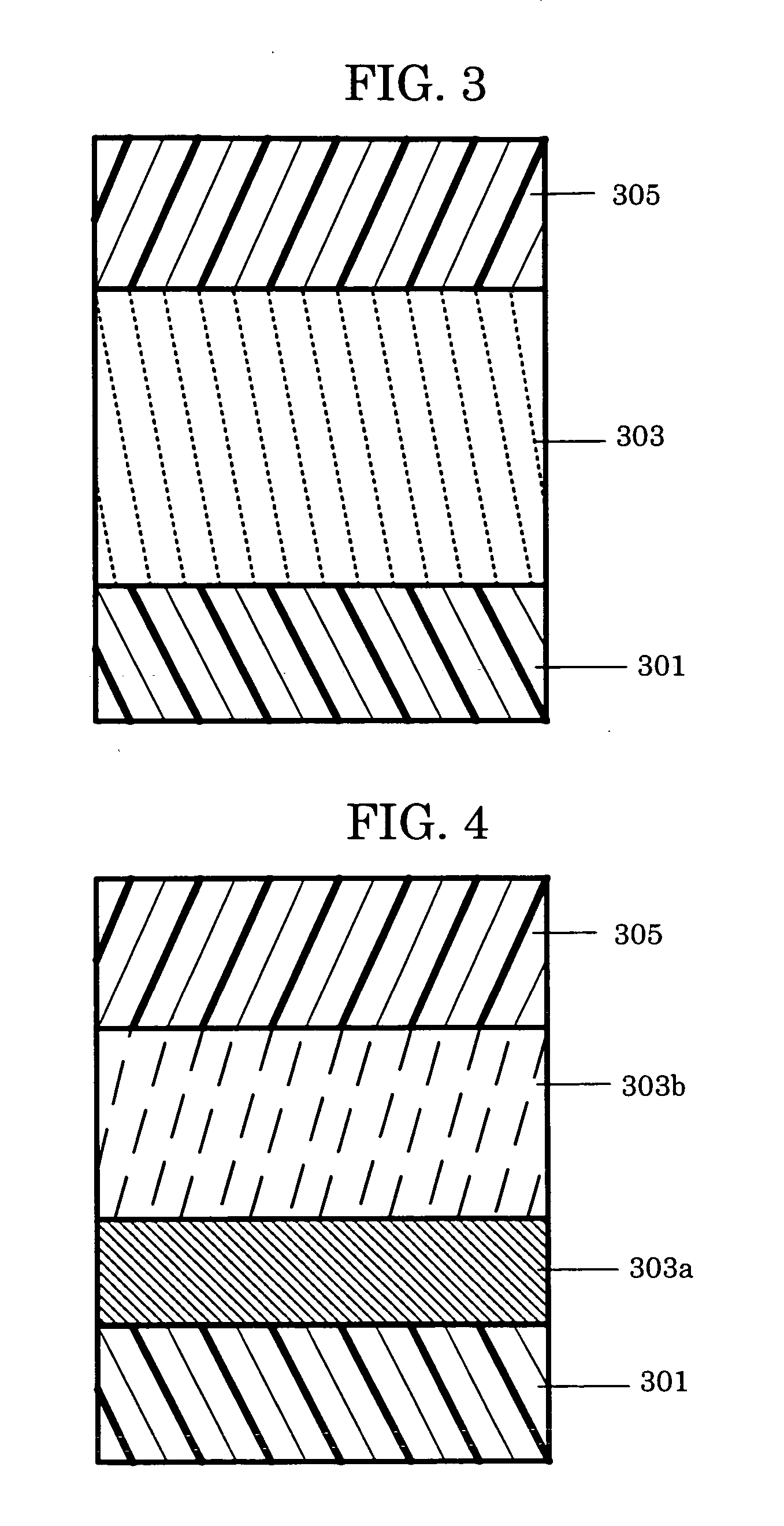

Chemical treatment to retard diffusion in a semiconductor overlayer

InactiveUS7071103B2Diffusion slowSimple technologySemiconductor/solid-state device manufacturingDopantChemical treatment

Owner:INT BUSINESS MASCH CORP

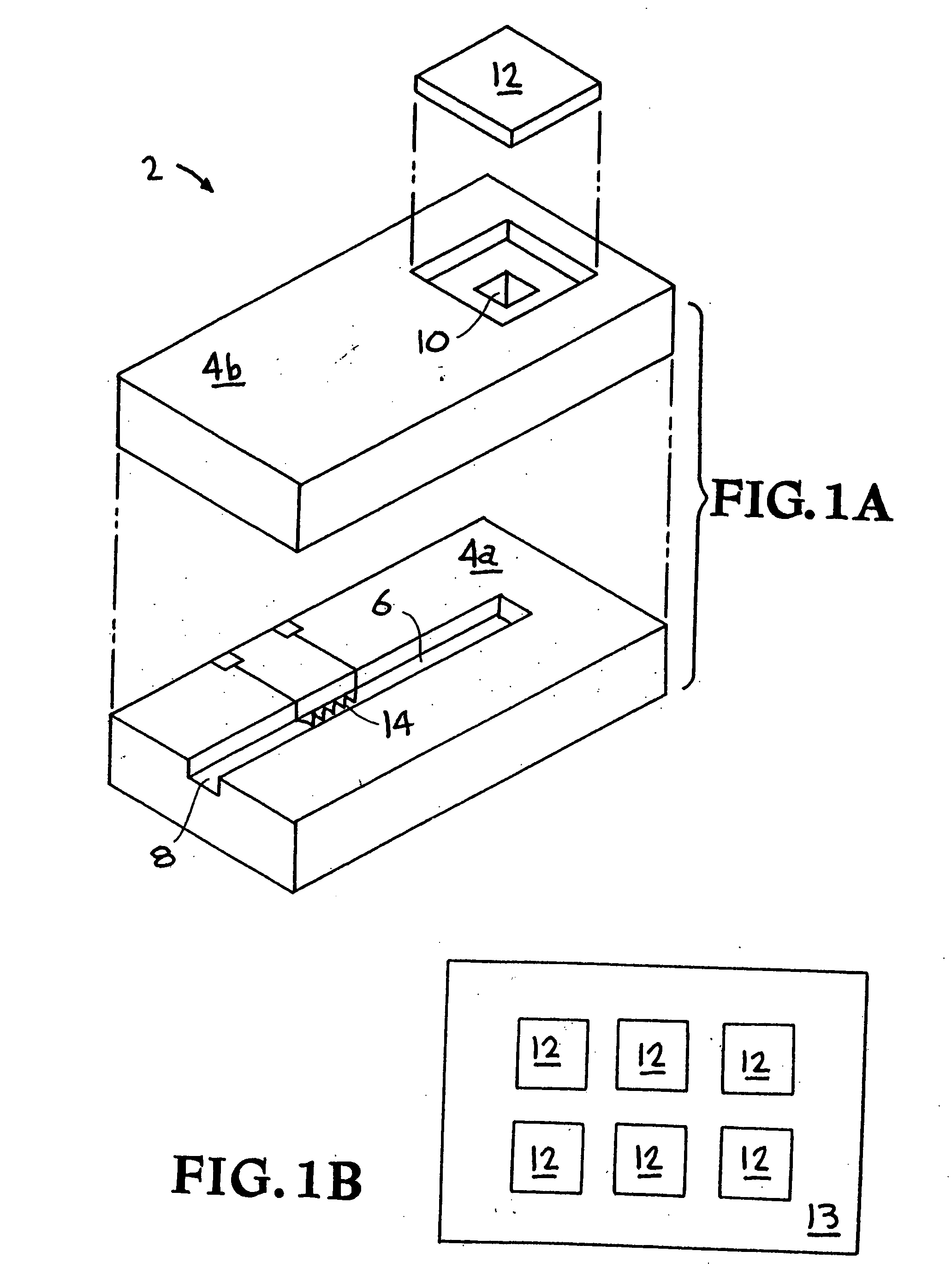

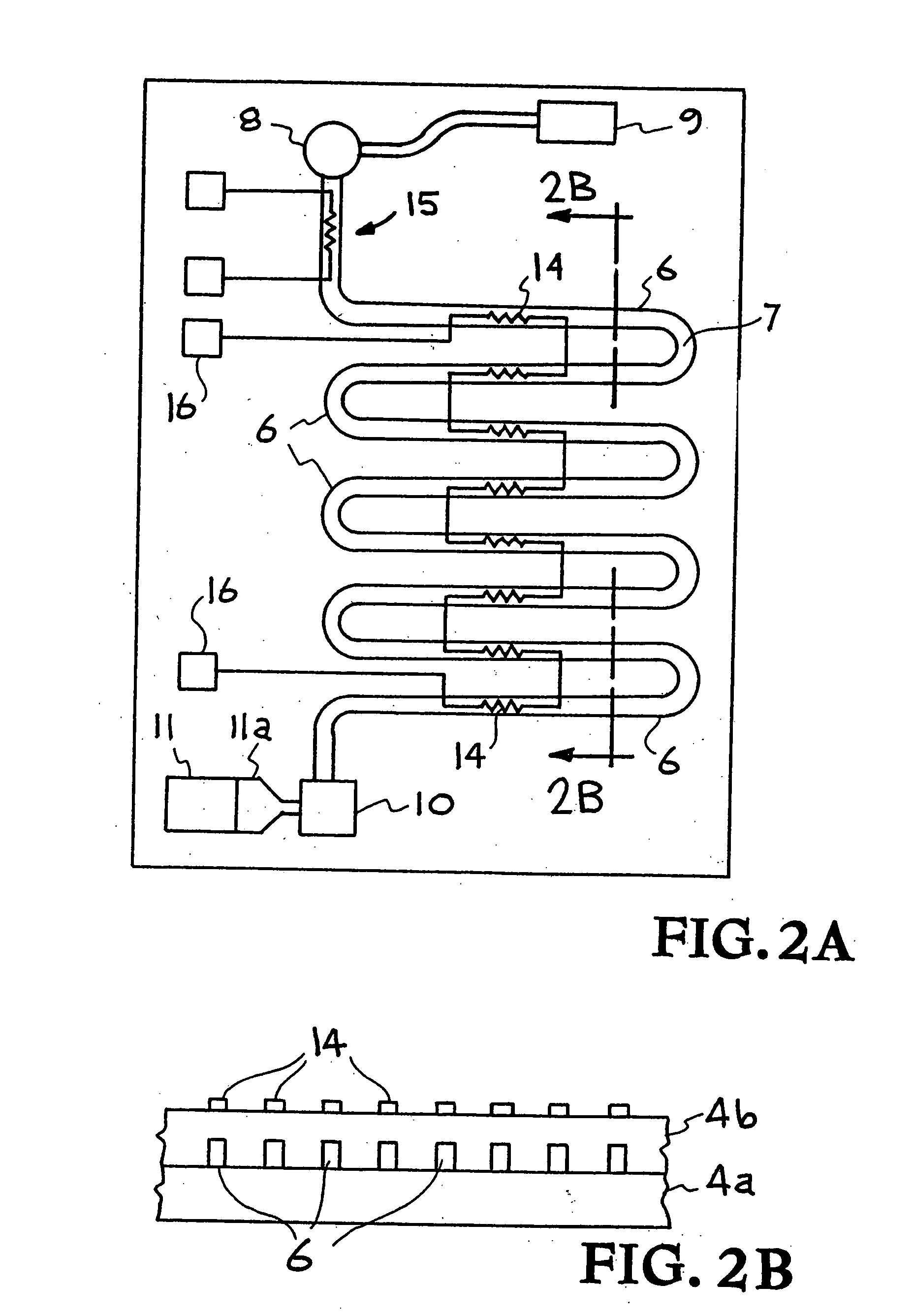

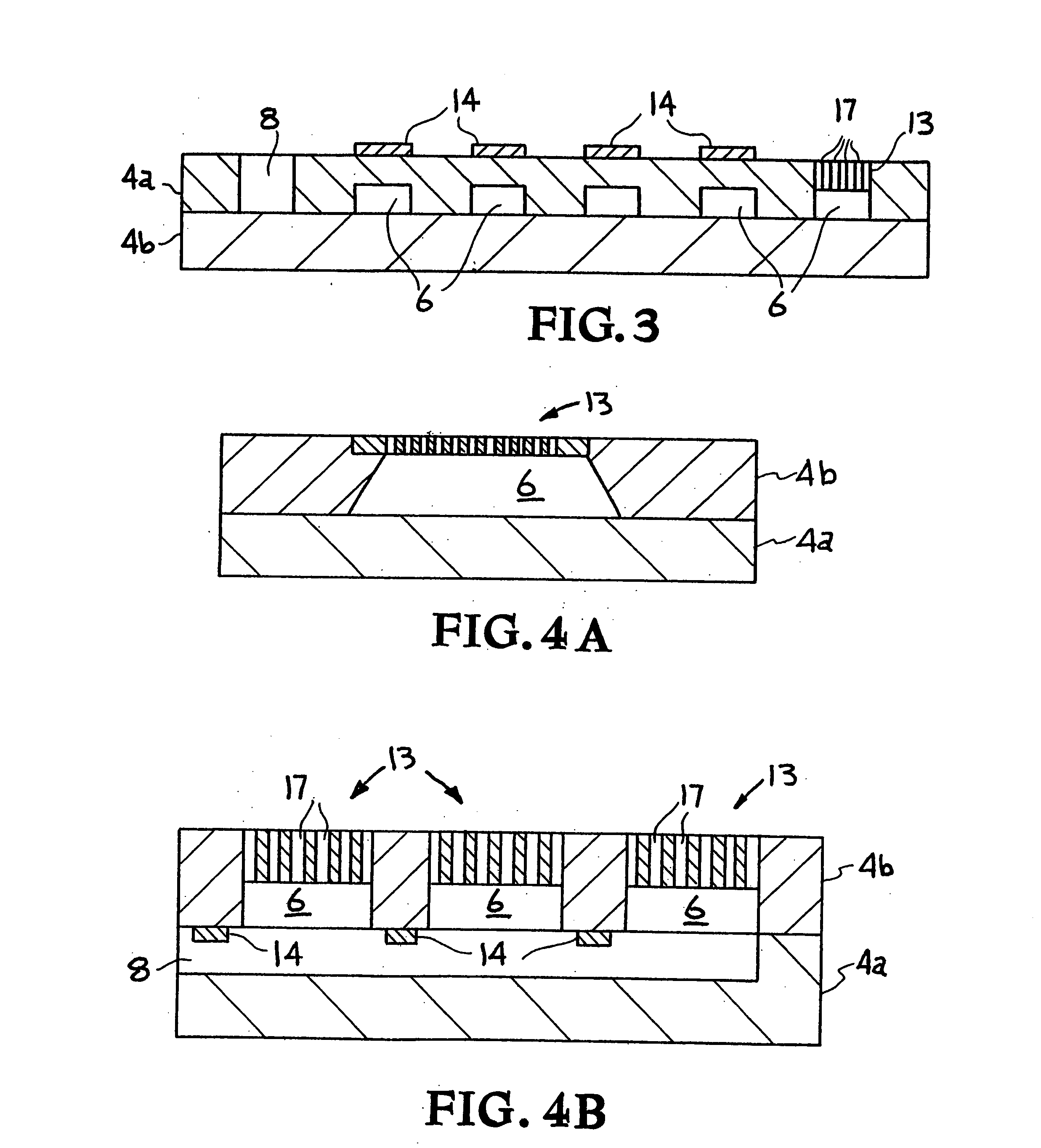

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Process for supercritical preparation of biologic diesel oil

InactiveCN1594504AReduce pollutionRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionBiodieselPhase splitting

The invention discloses a process for supercritical preparation of biologic diesel oil by using animal or plant oil, waste edible oil, oiling crop seeds as raw material through the steps of filtering, dewatering, esterification, ester interchange, filtering, steaming methanol and phase-splitting.

Owner:WUHAN CHEM COLLEGE

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

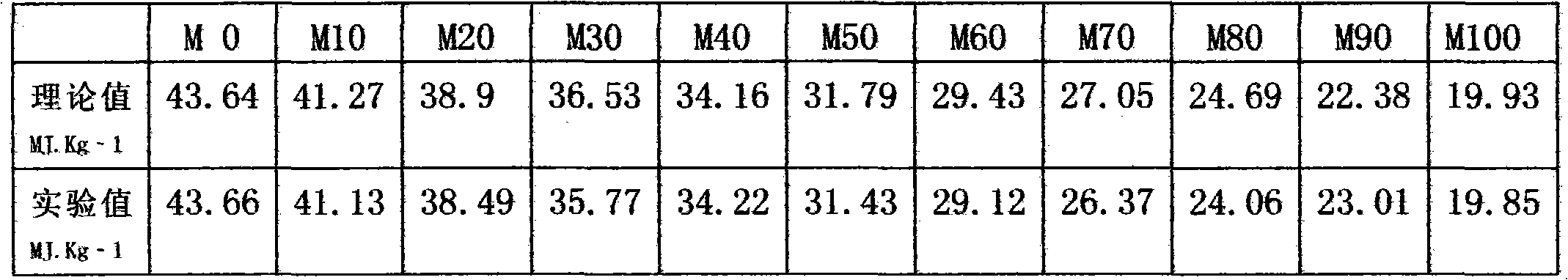

Methanol diesel oil manufacturing mode

The invention relates to a manufacturing mode of environment-friendly and energy-saving M15_M85 methanol diesel oil. The methanol diesel oil is composed of diesel oil, methanol, and additives. The methanol diesel oil is prepared with operations under normal temperatures and normal pressures. The invention discloses a plurality of common additives used for preparing methanol diesel oil in modern times. If explosives and aviation fuels are appropriately utilized, methanol defalcated heat value can be well compensated. The theory is tentatively considered as a gaseous detonation theory. The additives can be selected from nitric acid esters, nitrates, nitro compounds, non-aromatic compounds, peroxides, and the like.

Owner:陈若歆

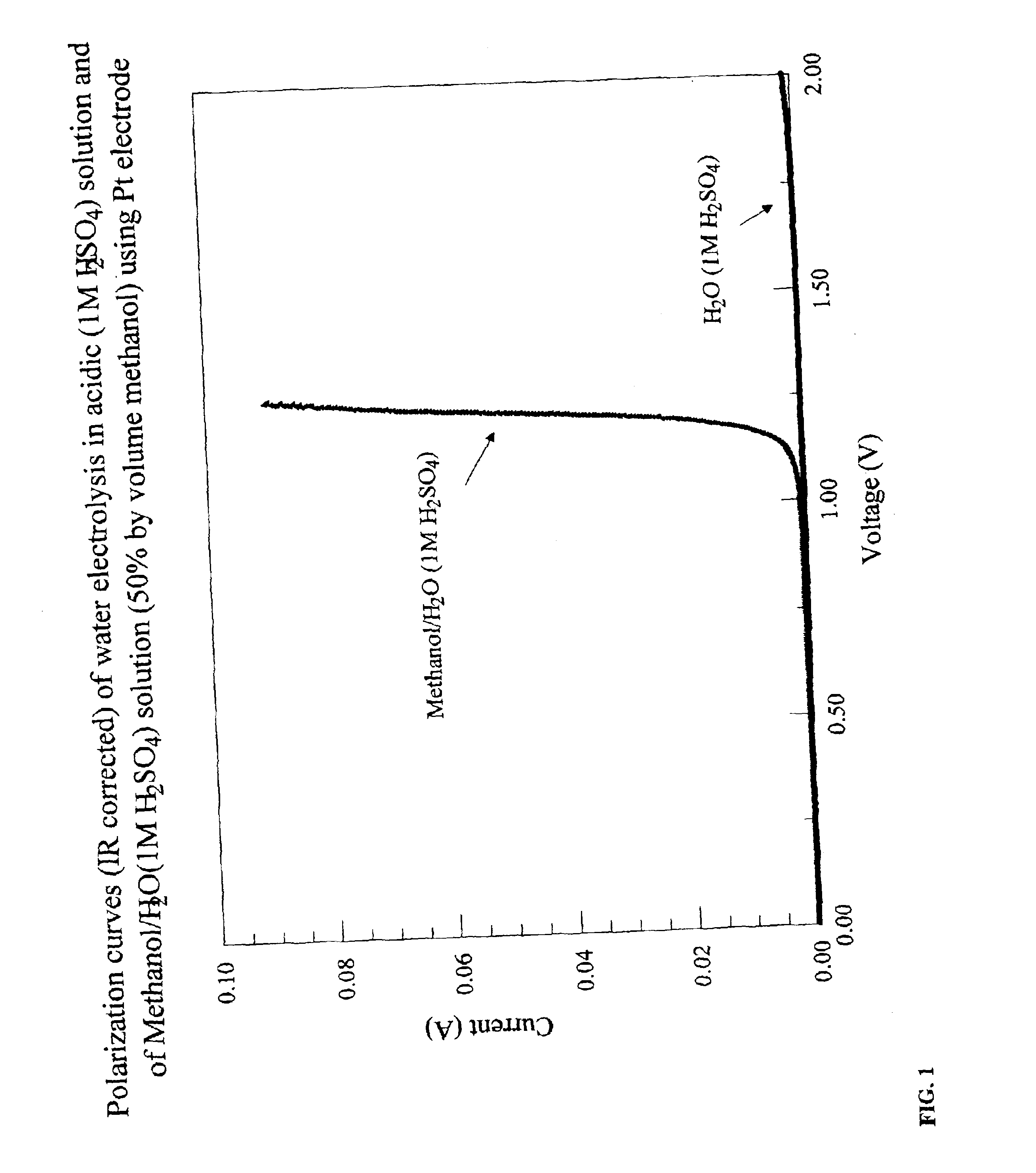

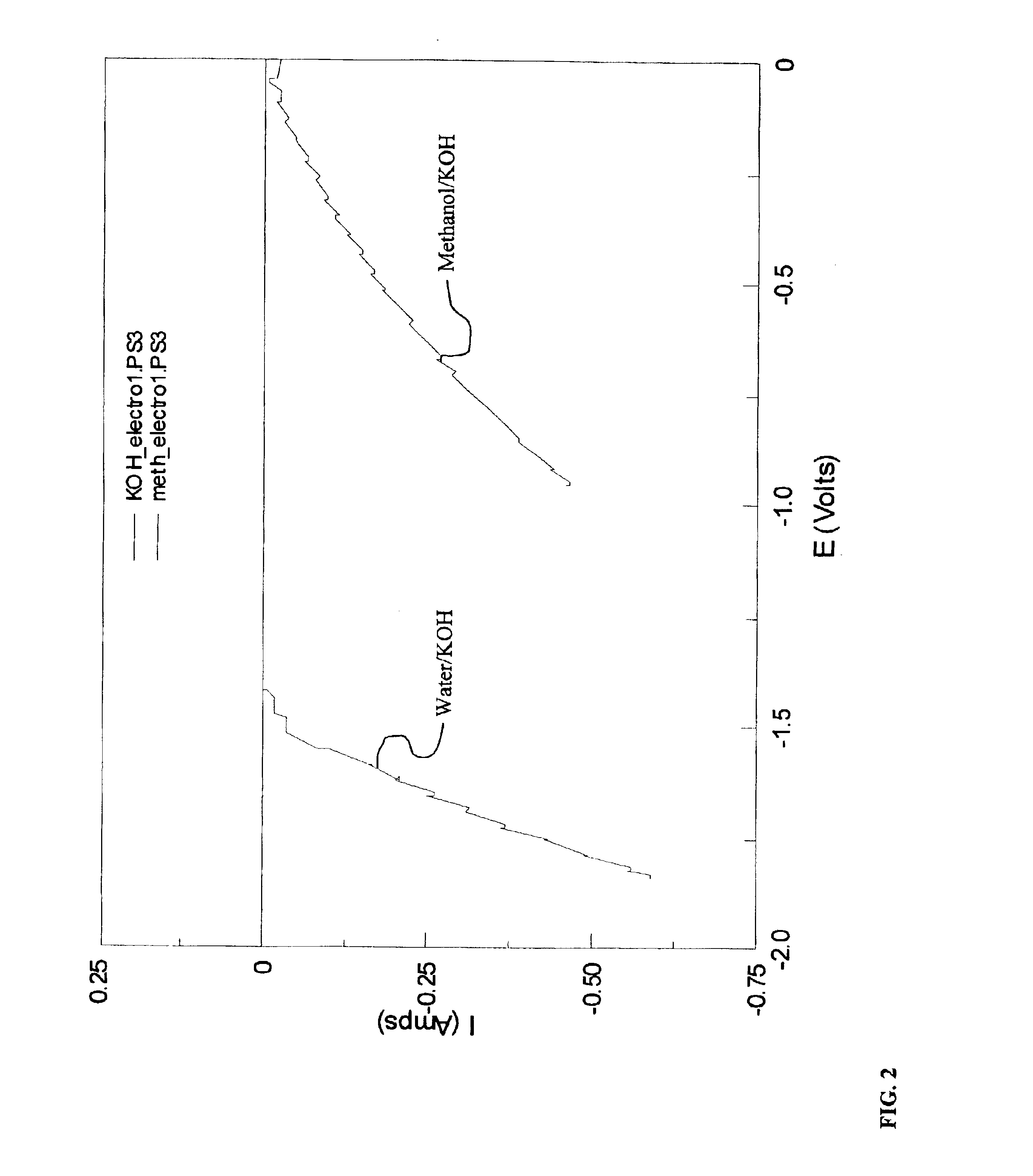

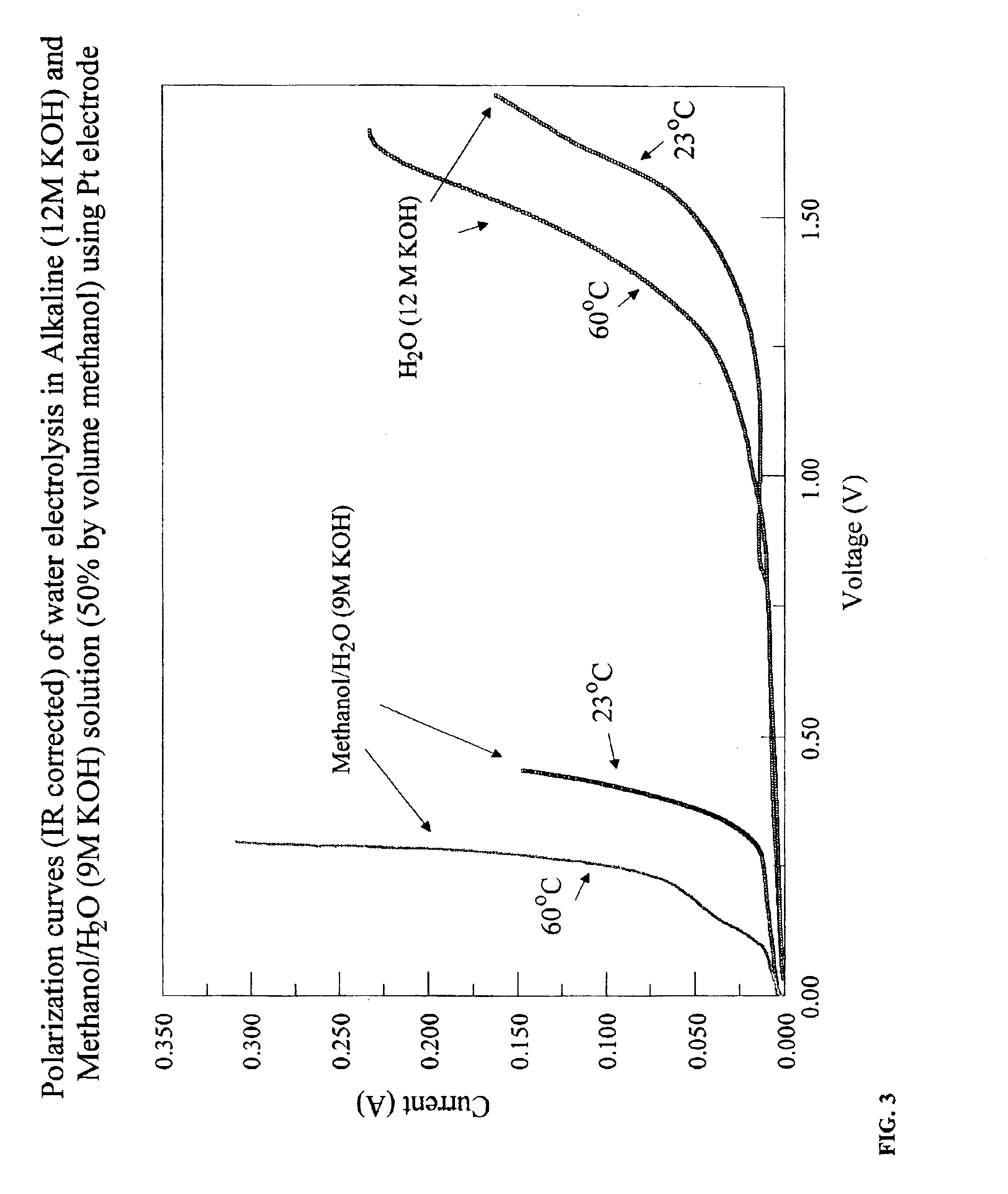

Electrolytic production of hydrogen

InactiveUS6890419B2Oxide/hydroxide preparationOrganic-compounds/hydrides/coordination-complexes catalystsElectrochemical responseElectrolysis

Methods for producing hydrogen gas from organic substances. According to the methods, hydrogen is produced from an electrochemical reaction of an organic substance with water or a base. The instant methods permit the production of hydrogen at lower operating voltages or lower operating temperatures relative to water electrolysis. Operable organic substances include alcohols, ethers, carboxylic acids, aldehydes, and ketones. In a preferred embodiment, hydrogen gas is produced from an electrochemical reaction of methanol in the presence of a base such as NaOH or KOH.

Owner:TACTICAL FUEL CELLS

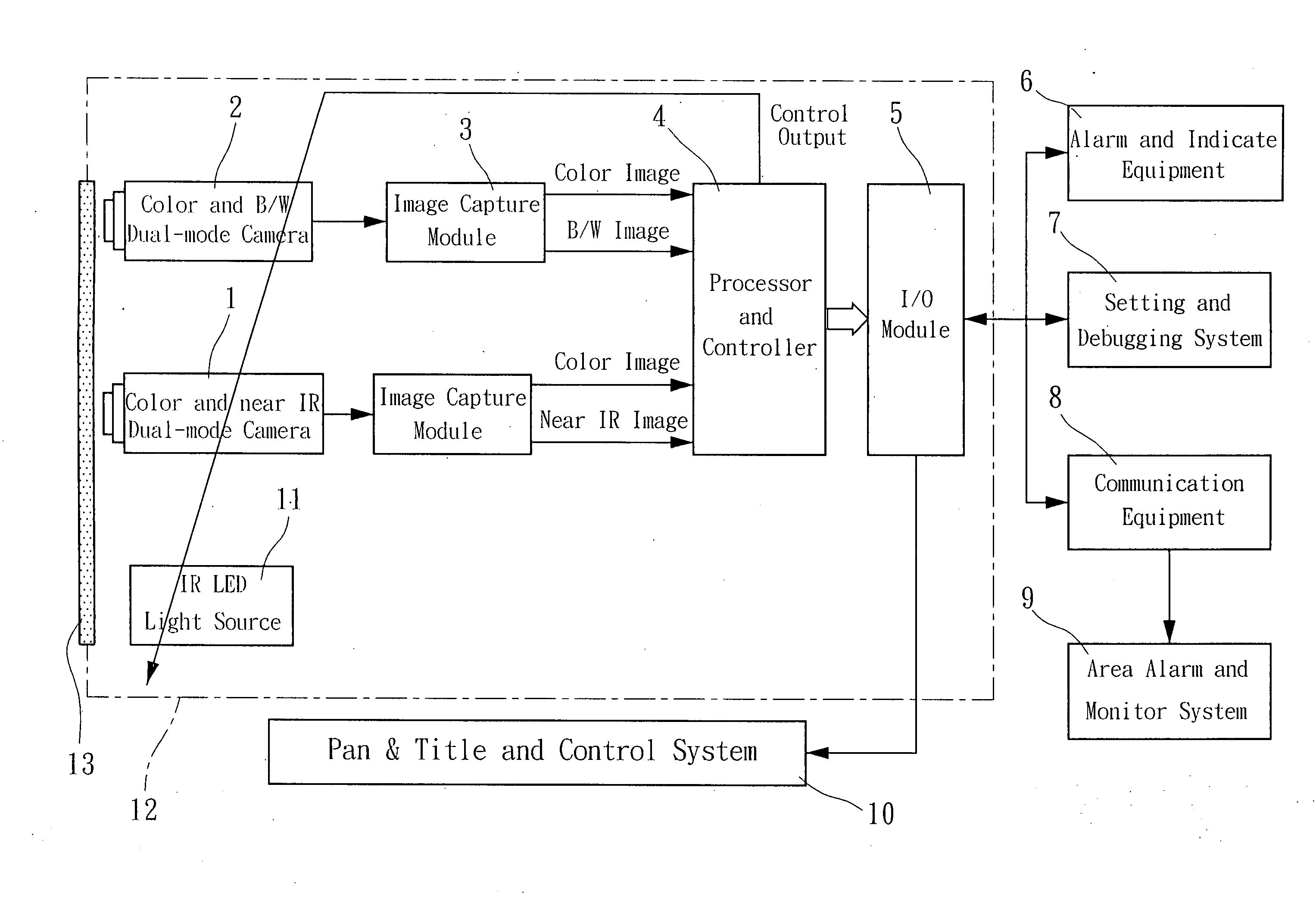

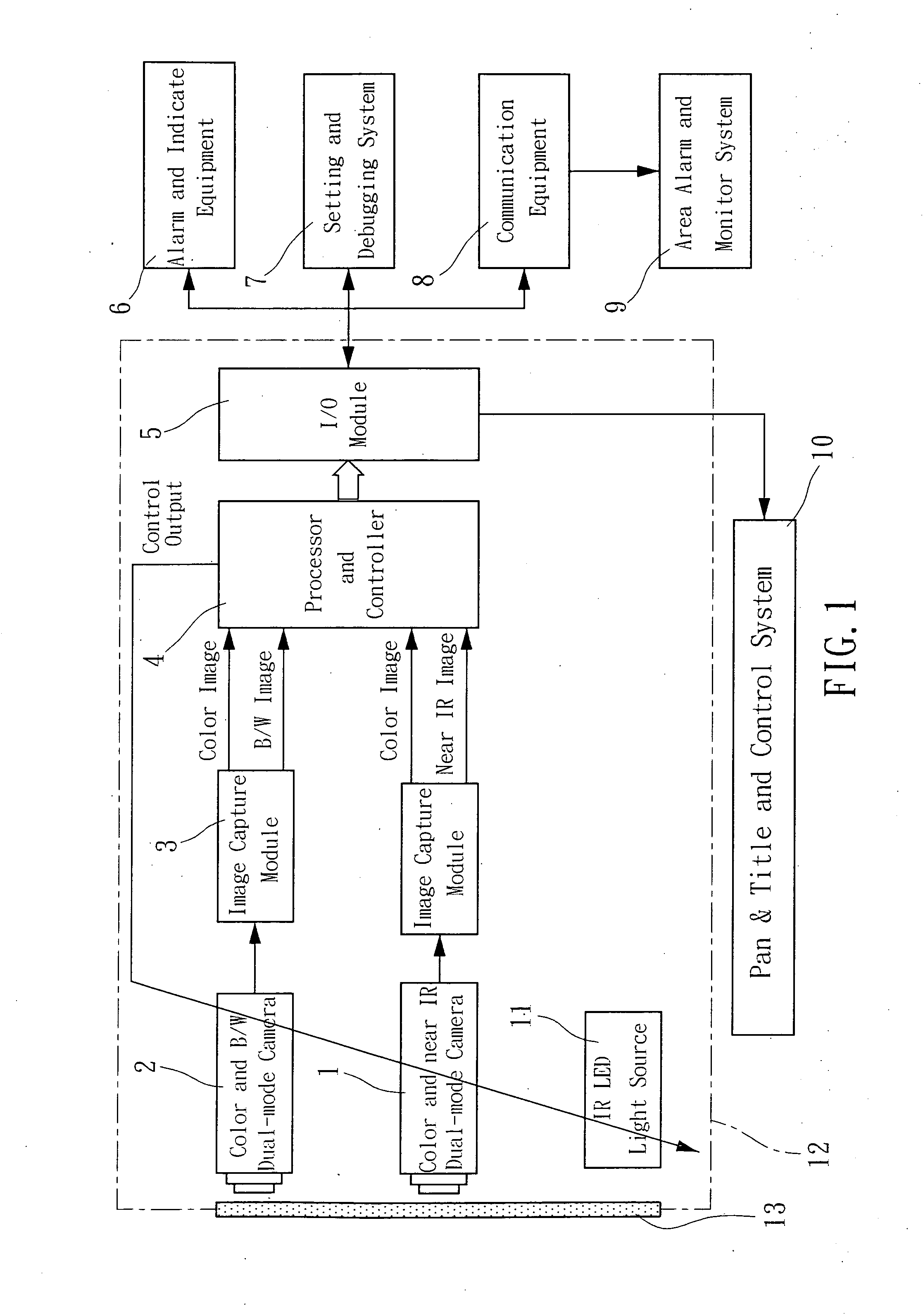

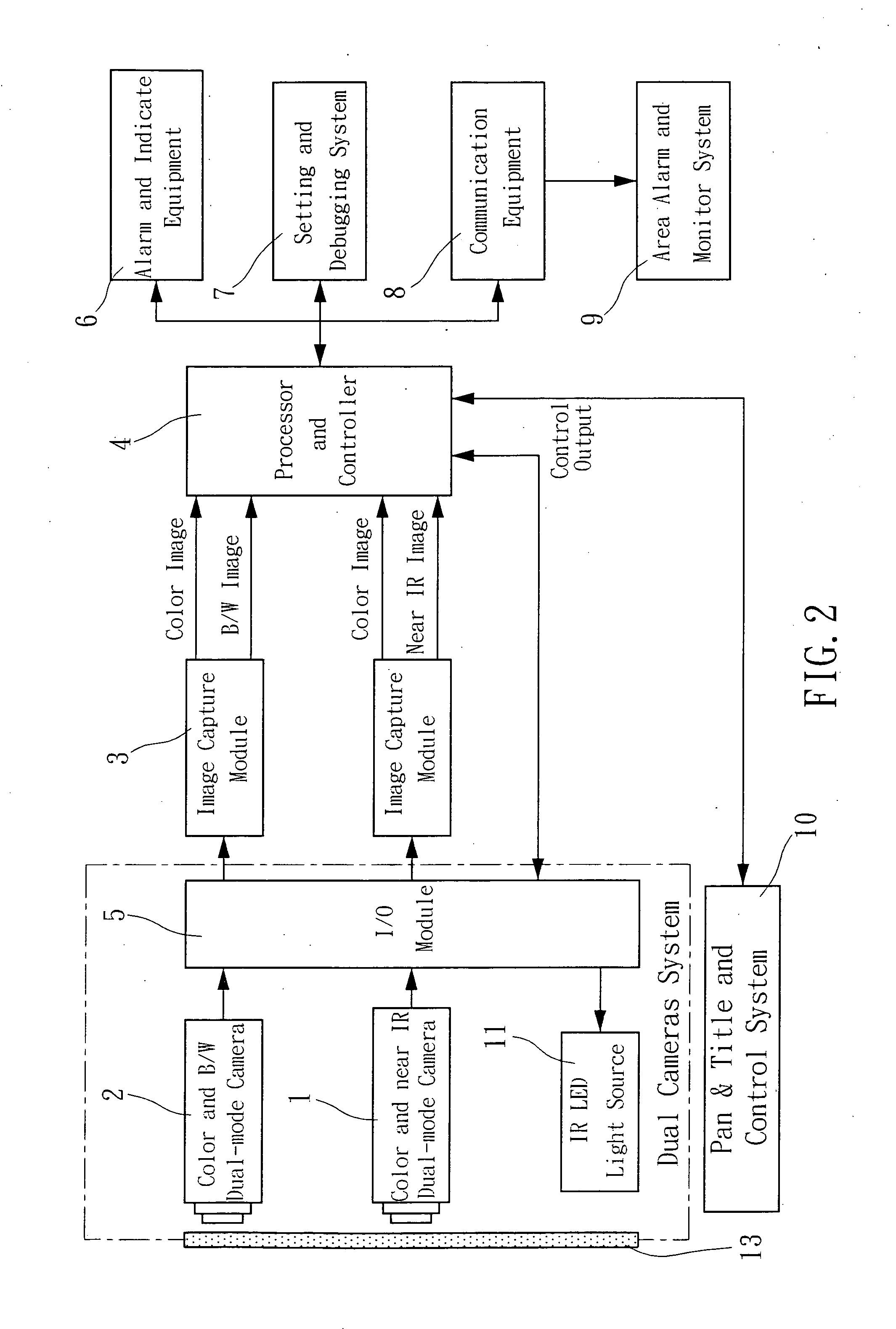

Multi-wavelength video image fire detecting system

InactiveUS20090315722A1Image information is clearReliable detectionSensing radiation from gases/flamesPyrometry for hot spots detectionDual modeAlarm Failure

To eliminate the drawbacks of false alarm problems due to mimic flame features of sunlight or moonlight reflecting on wave or mimic flame features of fabrics, animals or stage flames and alarm failures of methanol or ethanol burning flames or flames under a high illumination background condition, a multi-wavelength video image fire detecting system is disclosed consisting of a multi-wavelength video image fire detector, which is comprised of a color and near IR dual-mode camera, a color and B / W dual-mode camera, an image capture module, a processor and controller, an I / O module, a housing and a visible light and near IR view window, an alarm and indicate equipment, a setting and debugging system, a communication equipment, an area alarm and monitor system, and a pan & title and control system.

Owner:INNOSYS IND

Acid sensitive ARC and method of use

InactiveUS6110653APhotosensitive materialsSemiconductor/solid-state device manufacturingVinyl etherCross-link

A composition used to form an acid sensitive +E,uns a+EE nti+E,uns r+EE eflective +E,uns c+EE oating (ARC) includes a water soluble resin and a cross-linker. Radiation adsorptive components may be provided as part of the resin or, more preferably, as a separate dye. The composition may be applied on a substrate as a radiation adsorbing layer and additionally cross-linked to form an acid sensitive, water insoluble ARC on which a +E,uns p+EE hoto+E,uns p+EE atterning +E,uns r+EE esist (PPR) layer may be formed. Being acid sensitive, selected portions of an ARC formed from the composition may be removed by a suitable reversal of the cross-linking followed by a develop step, preferably with an aqueous developer, more preferably de-ionized water. The water soluble resin is preferably hydroxystyrene-sulfonated styrene copolymer, poly(2-isopropenyl-2-oxazoline), or poly(acrylic acid), the cross-linker is preferably an acetal diacid or a water soluble divinyl ether, and the dye is preferably 9-anthracene methanol or a squaric acid derivative. If a suitable +E,uns p+EE hoto+E,uns a+EE cid +E,uns g+EE enerator (PAG) is included then an ARC formed from such components may exhibit a photosensitivity similar to or even lower than that of the overlying PPR. The photosensitivity is preferably less than about 900 mJ / cm2, more preferably 100 mJ / cm2 or less.

Owner:IBM CORP

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

Coating liquid for intermediate layer in electrophotographic photoconductor, electrophotographic photoconductor utilizing the same, image forming apparatus and process cartridge for image forming apparatus

ActiveUS20060057479A1Prevent gelationAvoid viscosity increaseElectrographic process apparatusCoatingsNylon materialElectrical conductor

A coating liquid for an intermediate layer of an electrophotographic photoconductor comprises at least one of alcohol solvents; and N-methoxymethylated nylon, in which the N-methoxymethylated nylon has solution viscosity within a range from 43 mPa·s to 50 mPa·s when dissolving into methanol at 30° C. in a concentration of 20% by mass.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com